Patents

Literature

1328results about How to "Reduce differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

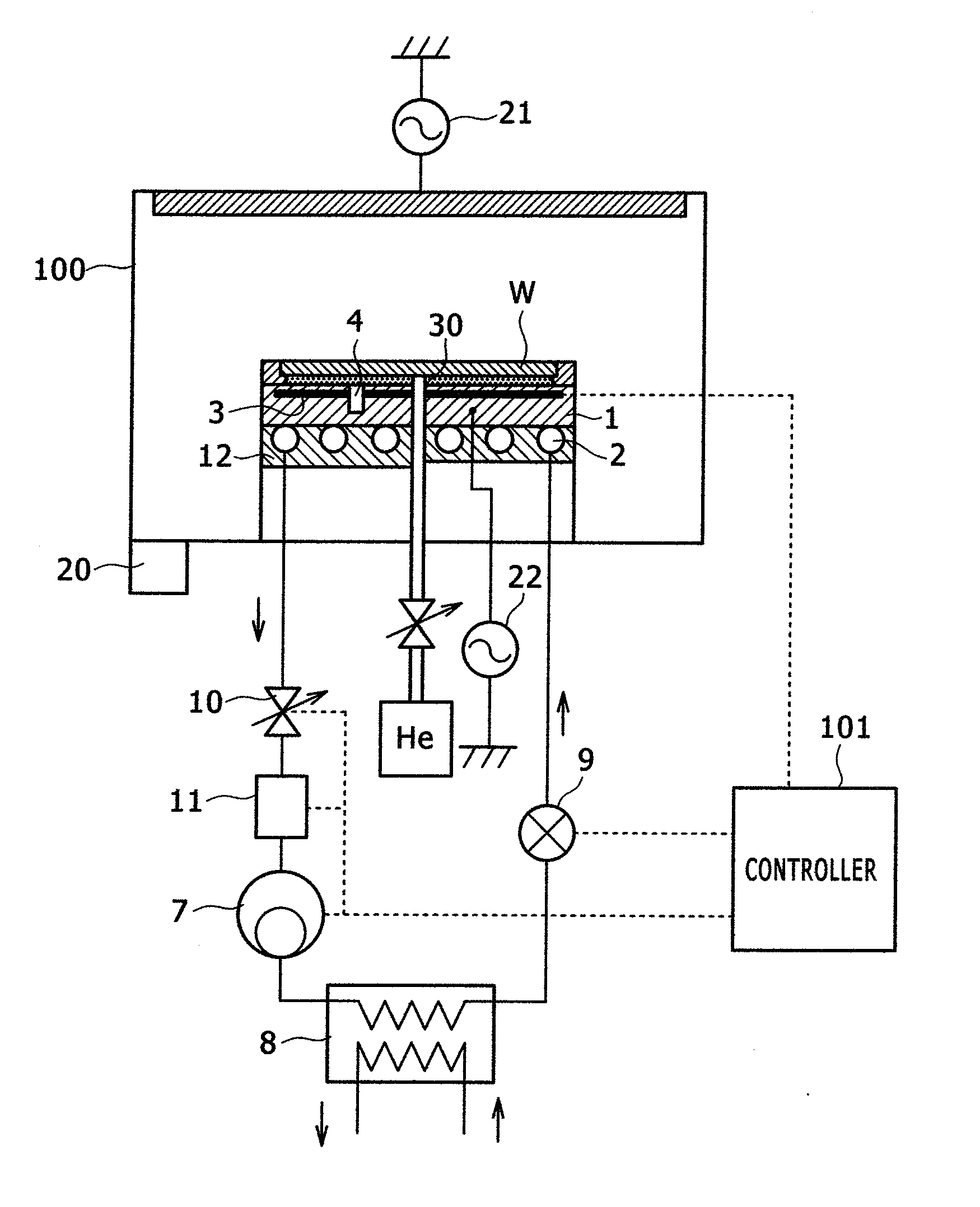

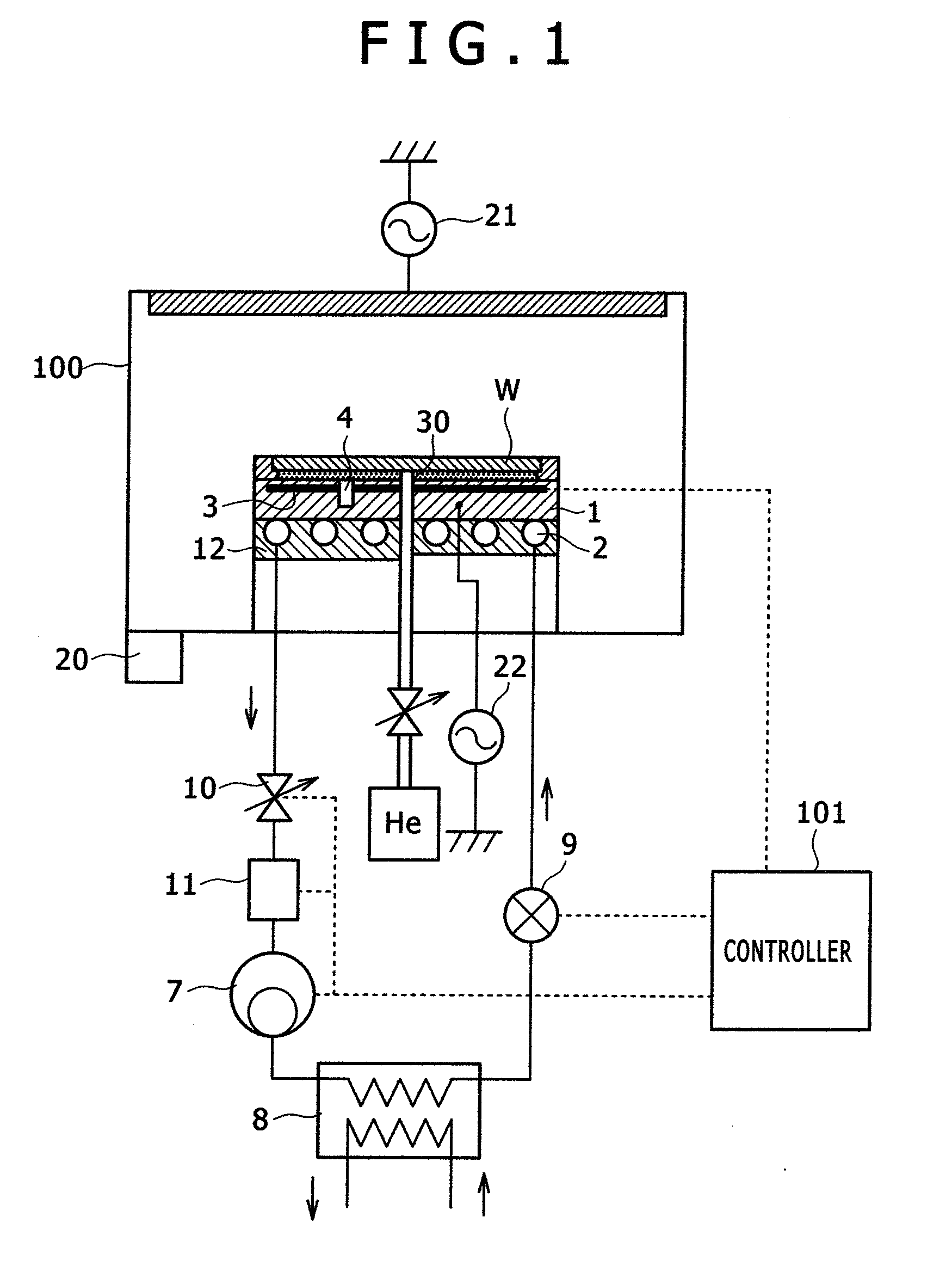

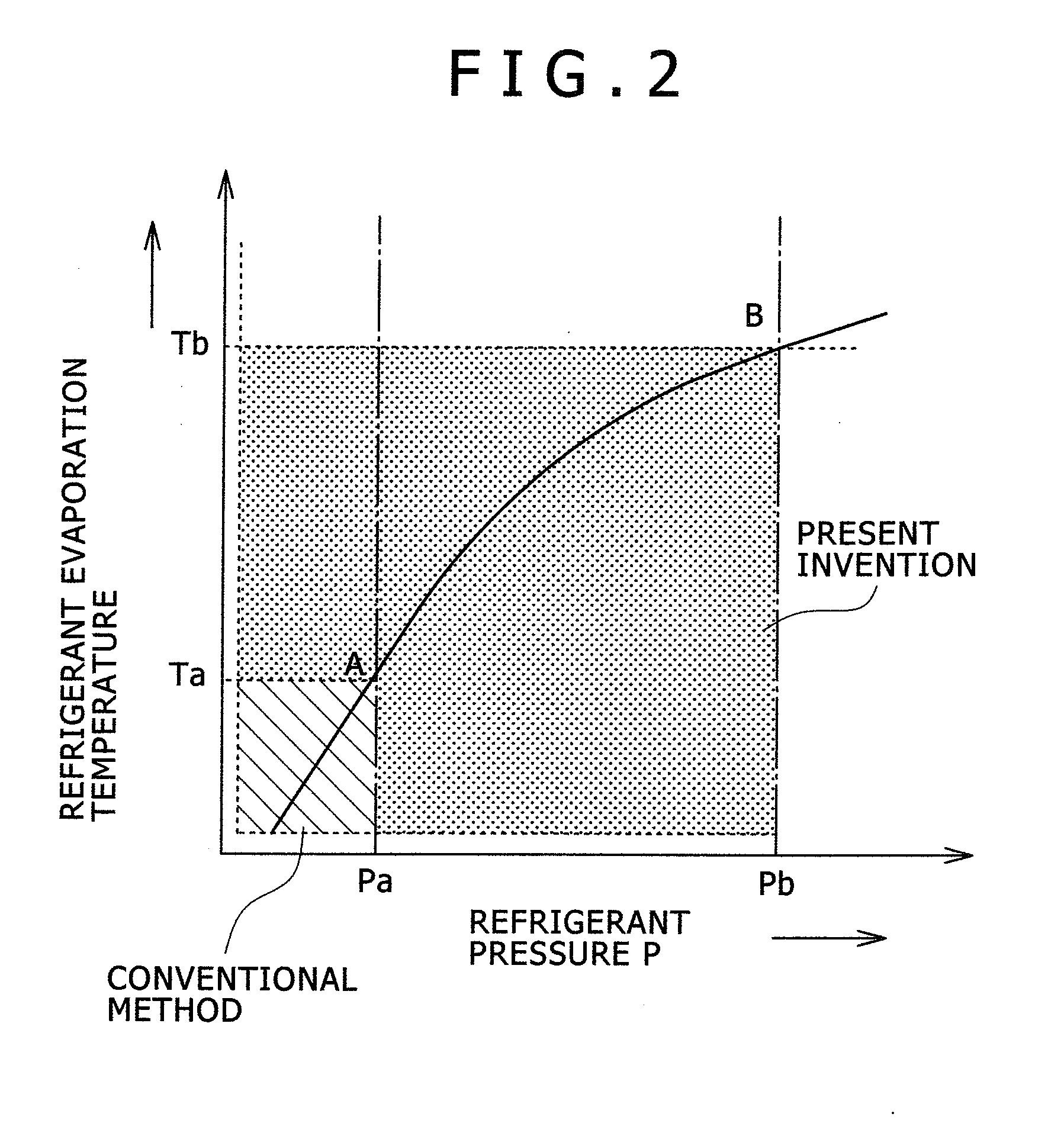

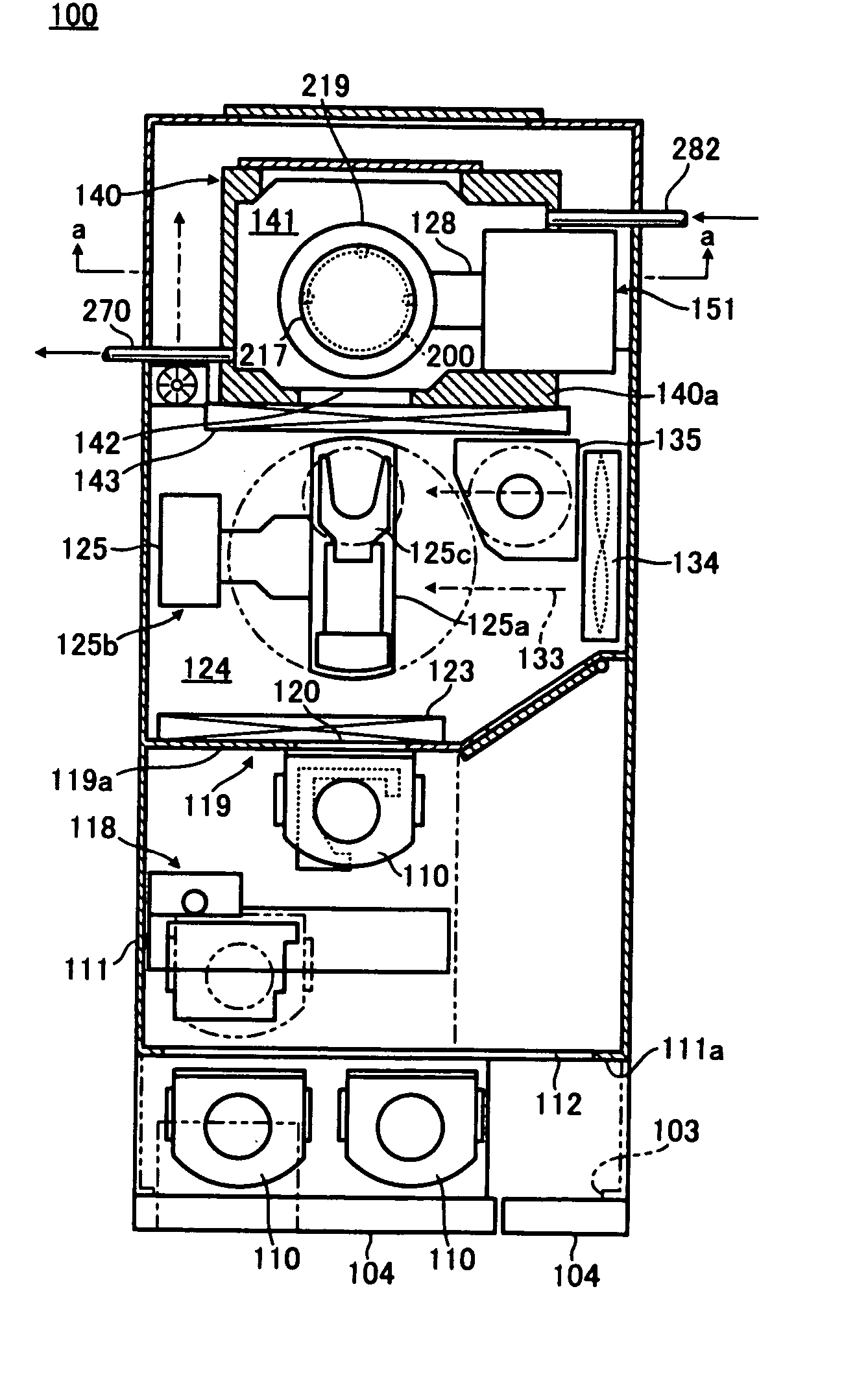

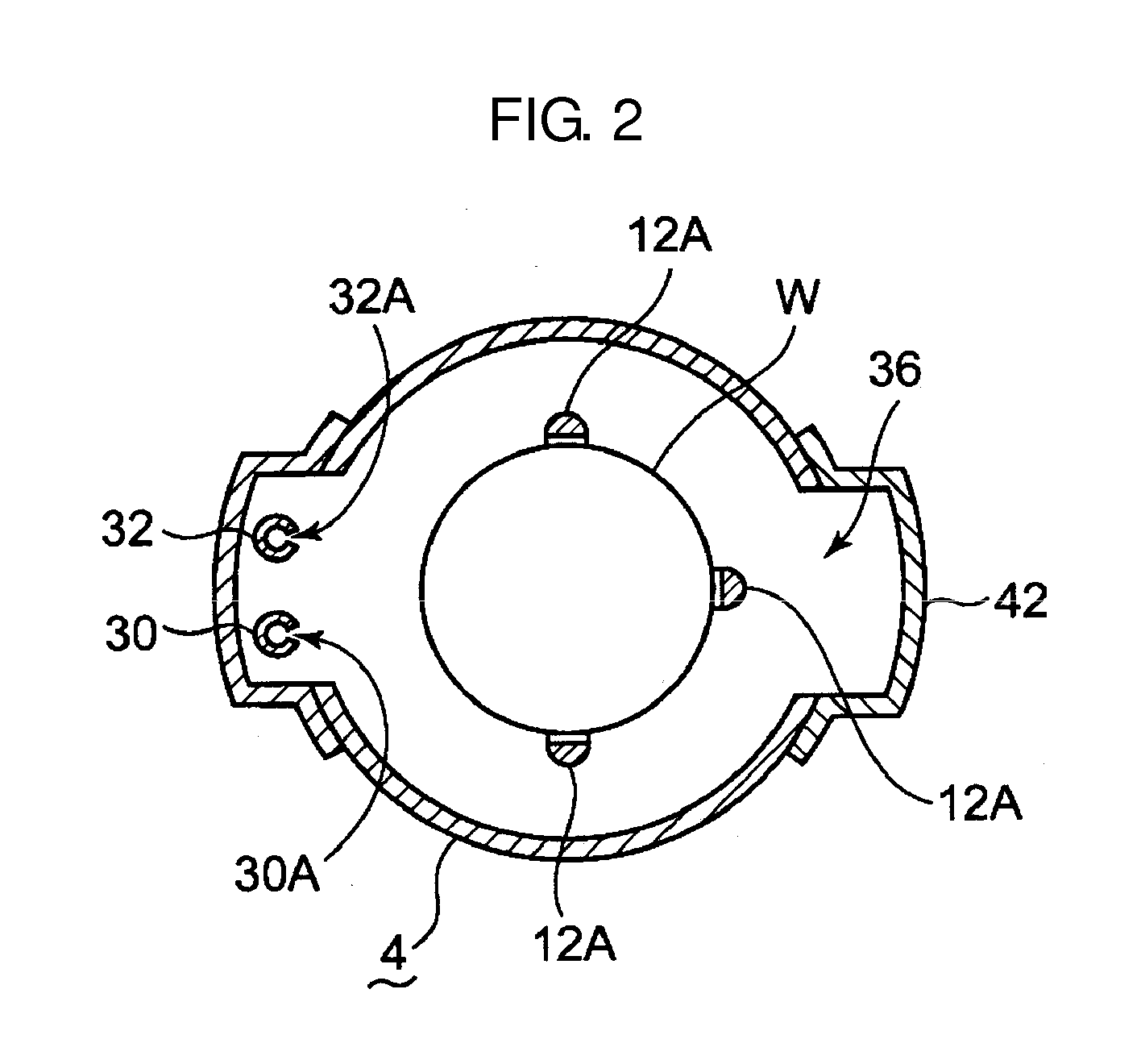

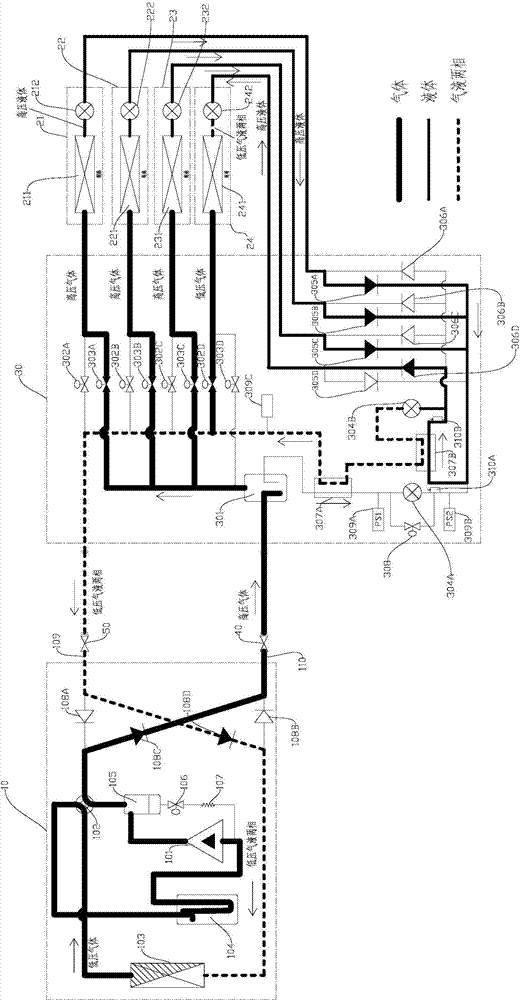

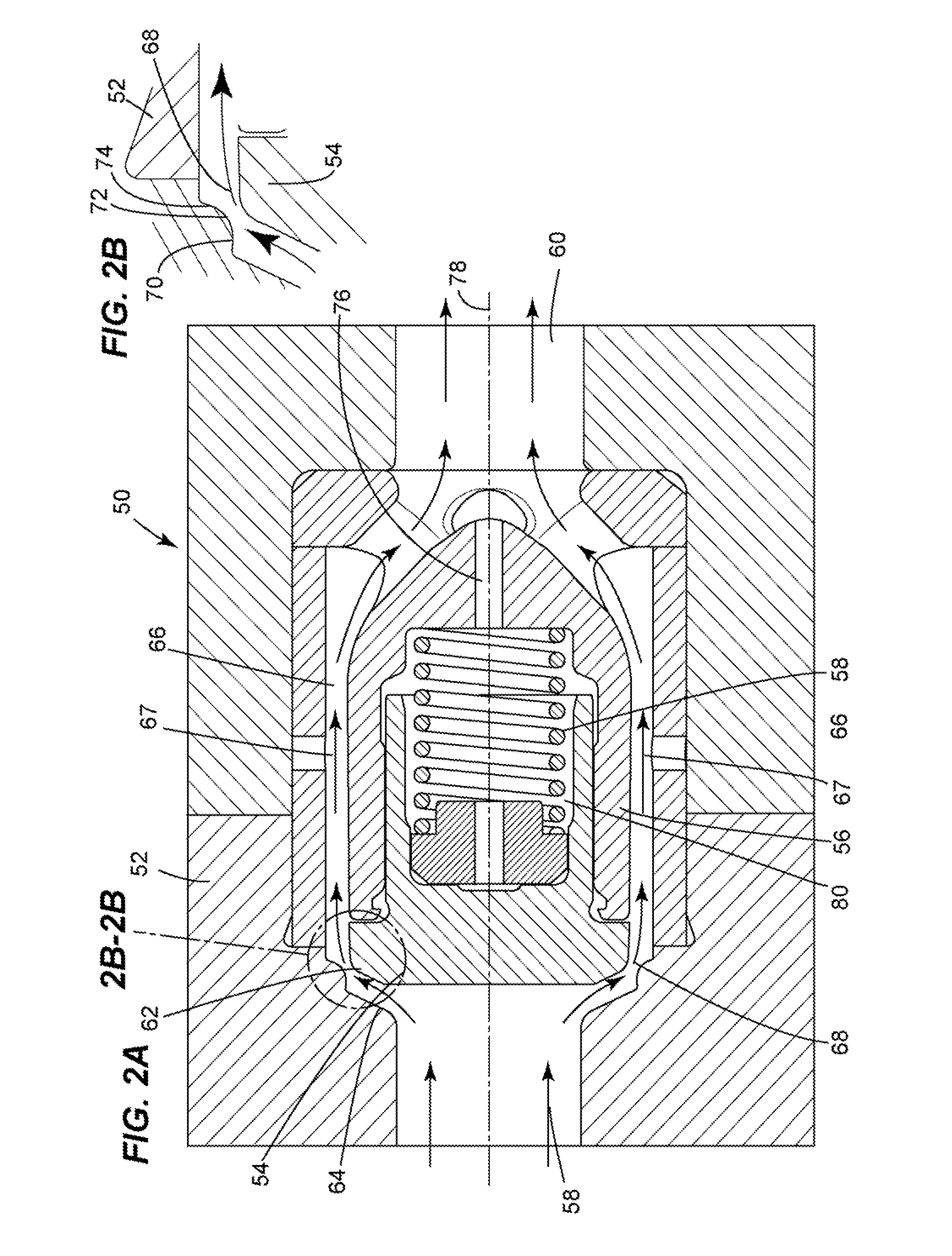

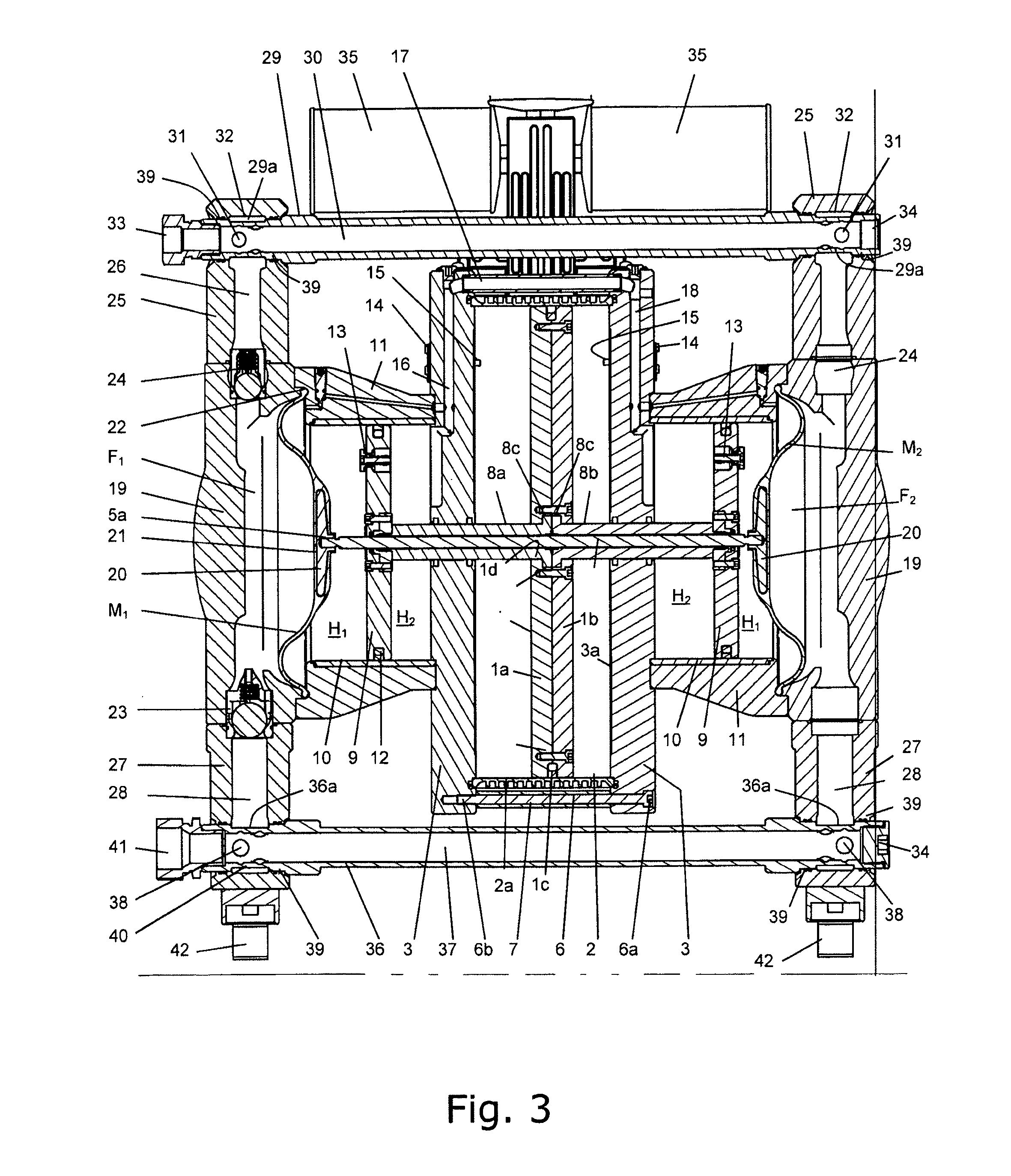

Plasma processing apparatus

ActiveUS20080289767A1High bias powerWide temperature rangeMechanical apparatusDomestic cooling apparatusIn planeEtching

The present invention provides a temperature control unit for an electrostatic adsorption electrode that is capable of controlling the wafer temperature rapidly over a wide temperature range without affecting in-plane uniformity while high heat input etching is conducted with high wafer bias power applied. A refrigerant flow path provided in the electrostatic adsorption electrode serves as an evaporator. The refrigerant flow path is connected to a compressor, a condenser, and a first expansion valve to form a direct expansion type refrigeration cycle. A second expansion valve is installed between the electrostatic adsorption electrode and the compressor to adjust the flow rate of a refrigerant. This makes it possible to compress the refrigerant in the refrigerant flow path of the electrostatic adsorption electrode and adjust the wafer temperature to a high level by raising the refrigerant evaporation temperature. Further, a thin-walled cylindrical refrigerant flow path is employed so that the thin-walled cylinder is deformed only slightly by the refrigerant pressure.

Owner:HITACHI HIGH-TECH CORP

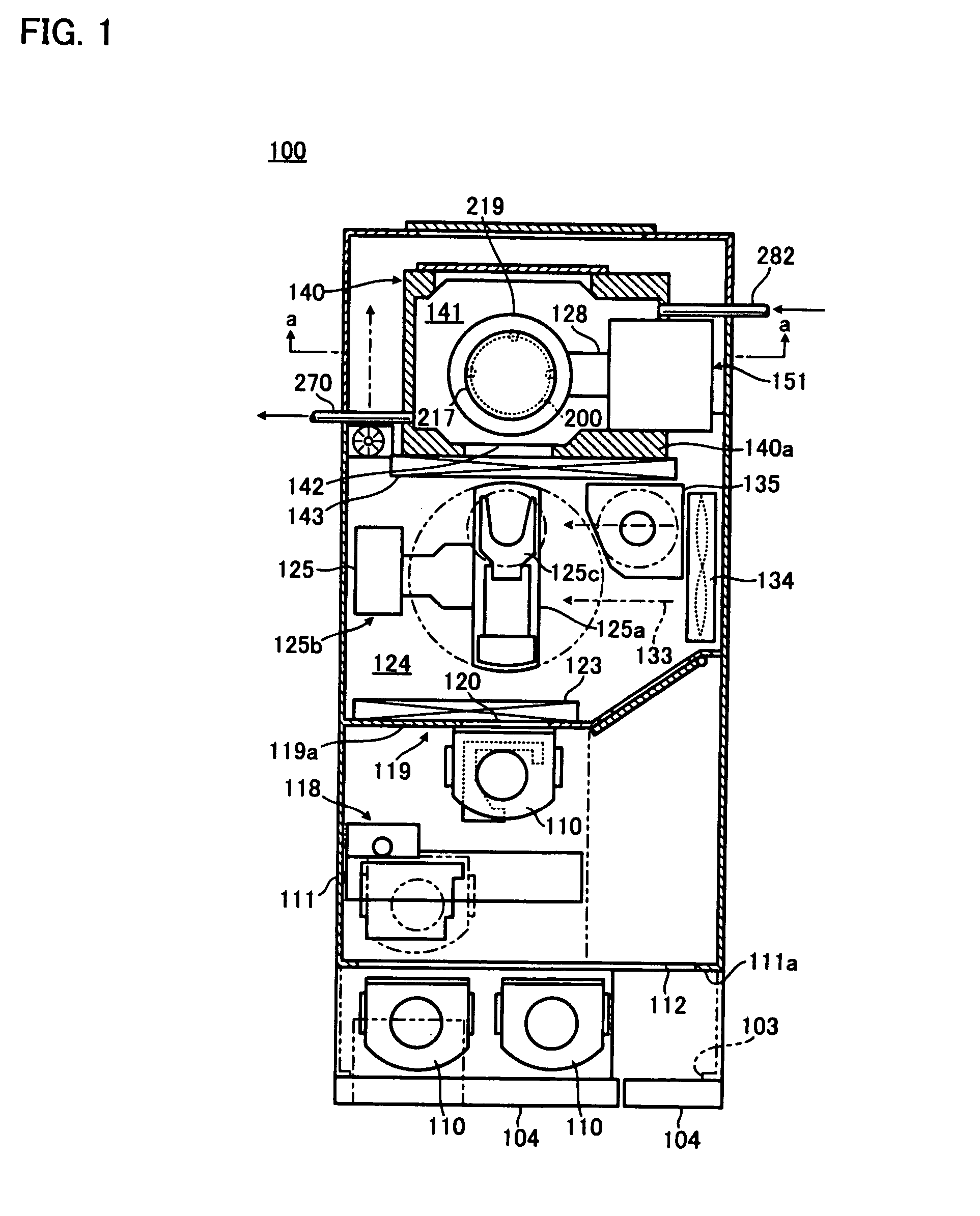

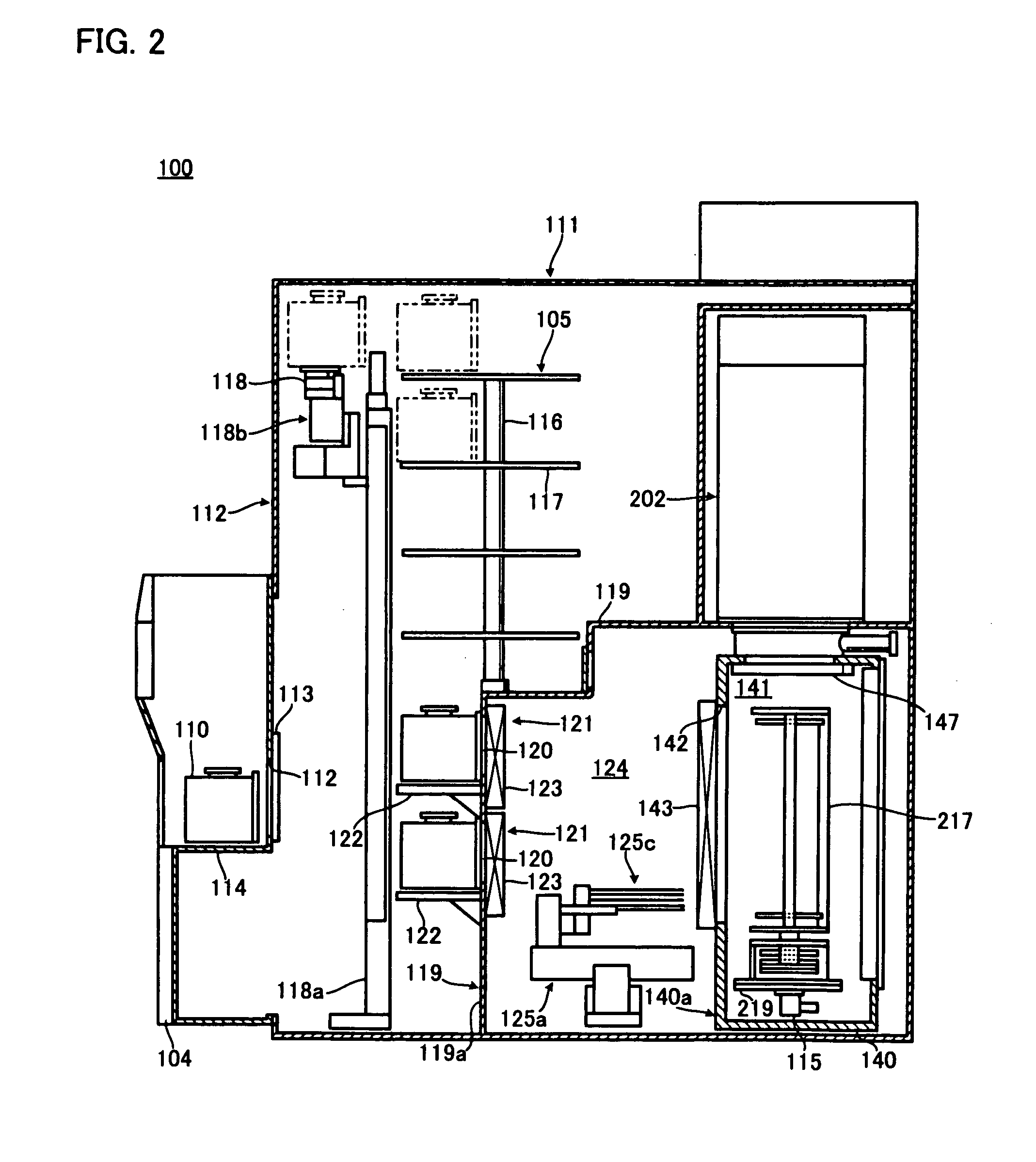

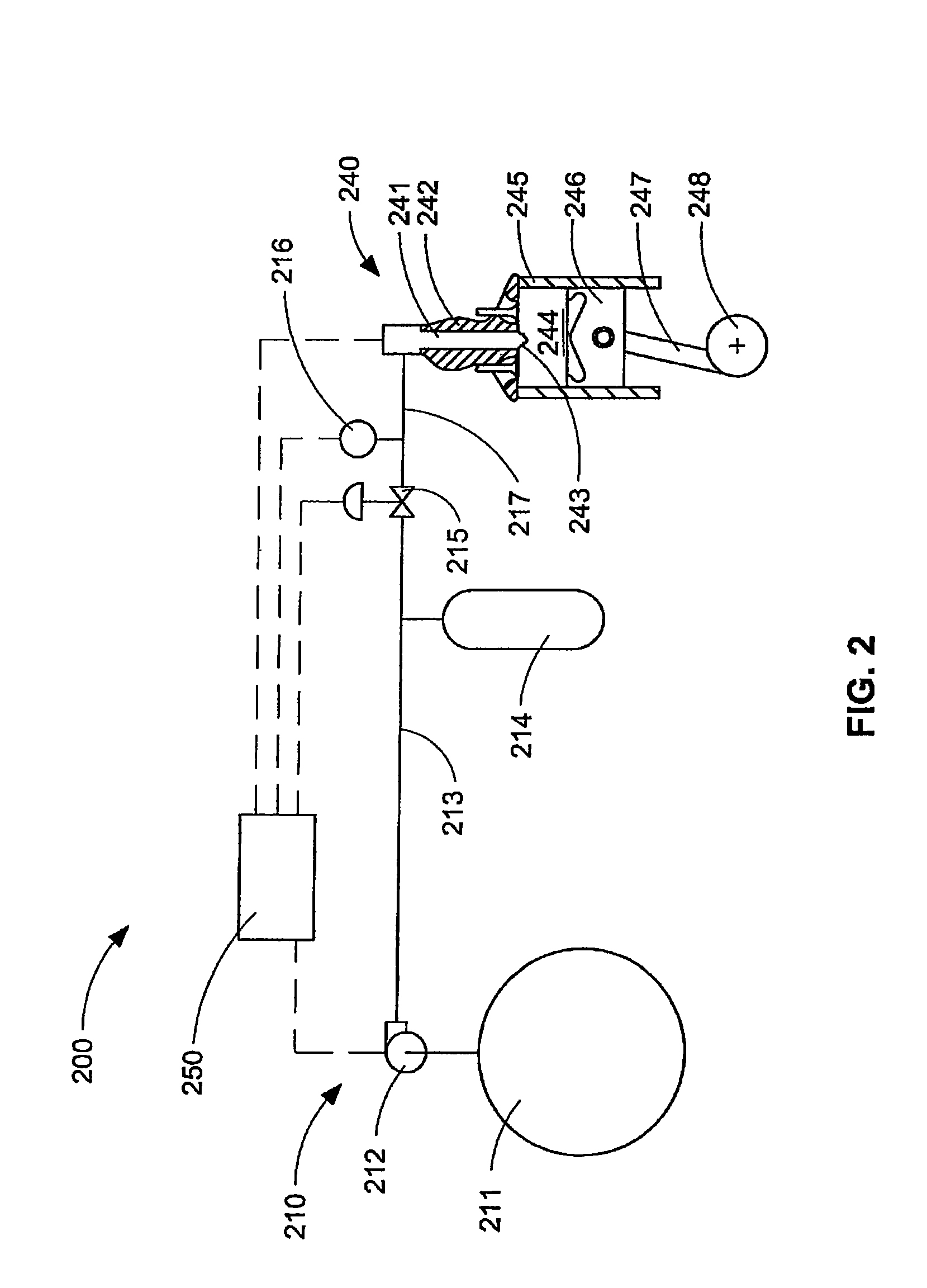

Board processing apparatus and method of fabricating semiconductor apparatus

InactiveUS20080087218A1Rapid gas flowReduce pressure differenceLiquid surface applicatorsSemiconductor/solid-state device manufacturingFast flowEngineering

A board processing apparatus and a method of fabricating a semiconductor apparatus for reducing a pressure difference between a preparing chamber and a processing chamber and restraining a rapid flow of a gas caused by the pressure difference to thereby prevent a board from being contaminated by a particle are disclosed.

Owner:NTT MOBILE COMM NETWORK INC

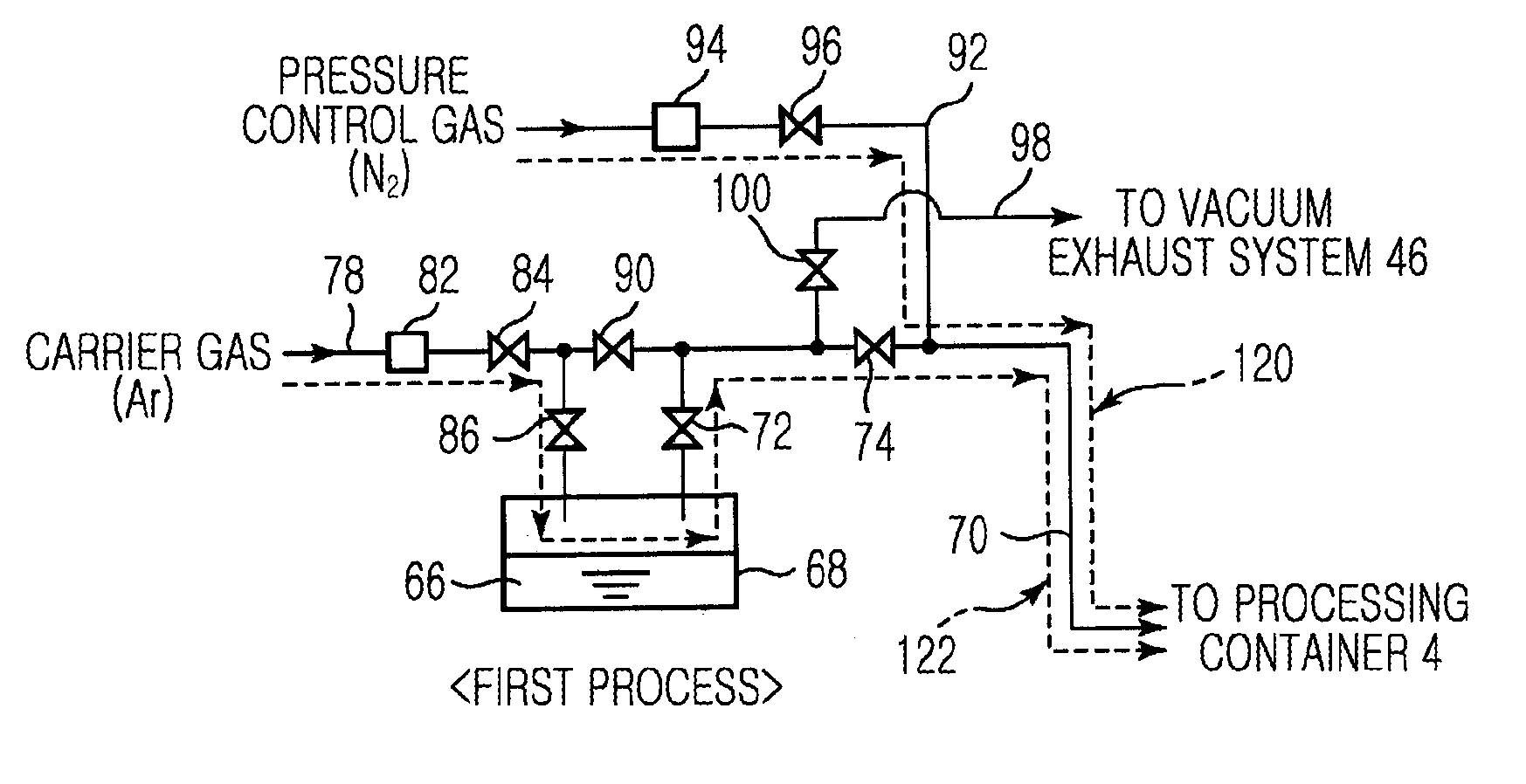

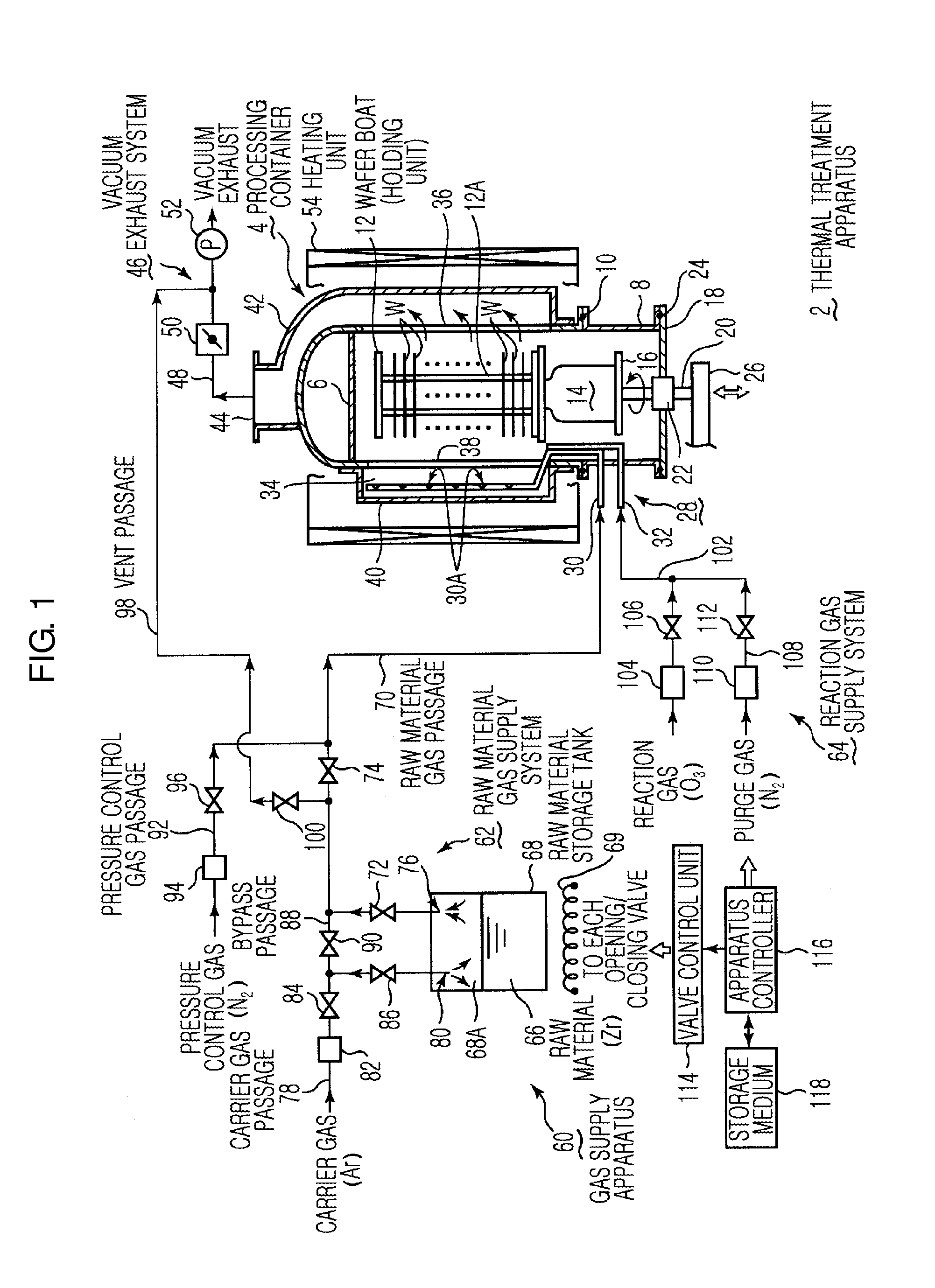

Gas supply apparatus, thermal treatment apparatus, gas supply method, and thermal treatment method

InactiveUS20120288625A1Avoid it happening againPressure differentialCheck valvesSemiconductor/solid-state device manufacturingProcess engineeringPressure controlled ventilation

A gas supply apparatus including a raw material gas supply system supplying a raw material gas inside a raw material storage tank into the processing container by the carrier gas, the gas supply apparatus includes: a carrier gas passage introducing the carrier gas into the raw material storage tank, a raw material gas passage connecting the raw material storage tank and the processing container to supply the carrier gas and the raw material gas; a pressure control gas passage being connected to the raw material gas passage to supply the pressure control gas; and a valve control unit controlling an opening / closing valve to perform for starting a supply of the pressure control gas into the processing container and simultaneously starting supply of the raw material gas into the processing container from the raw material storage tank, and stopping the supply of the pressure control gas.

Owner:TOKYO ELECTRON LTD

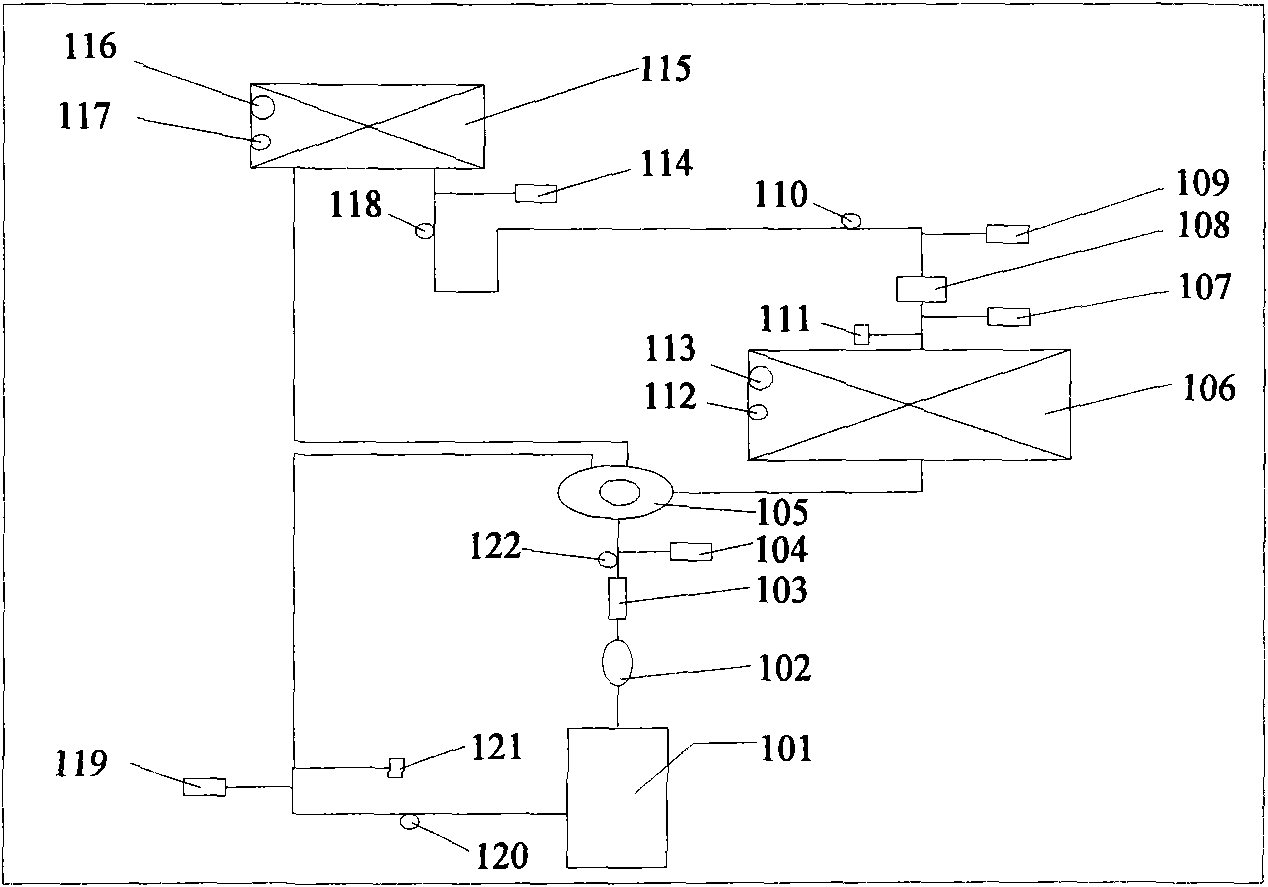

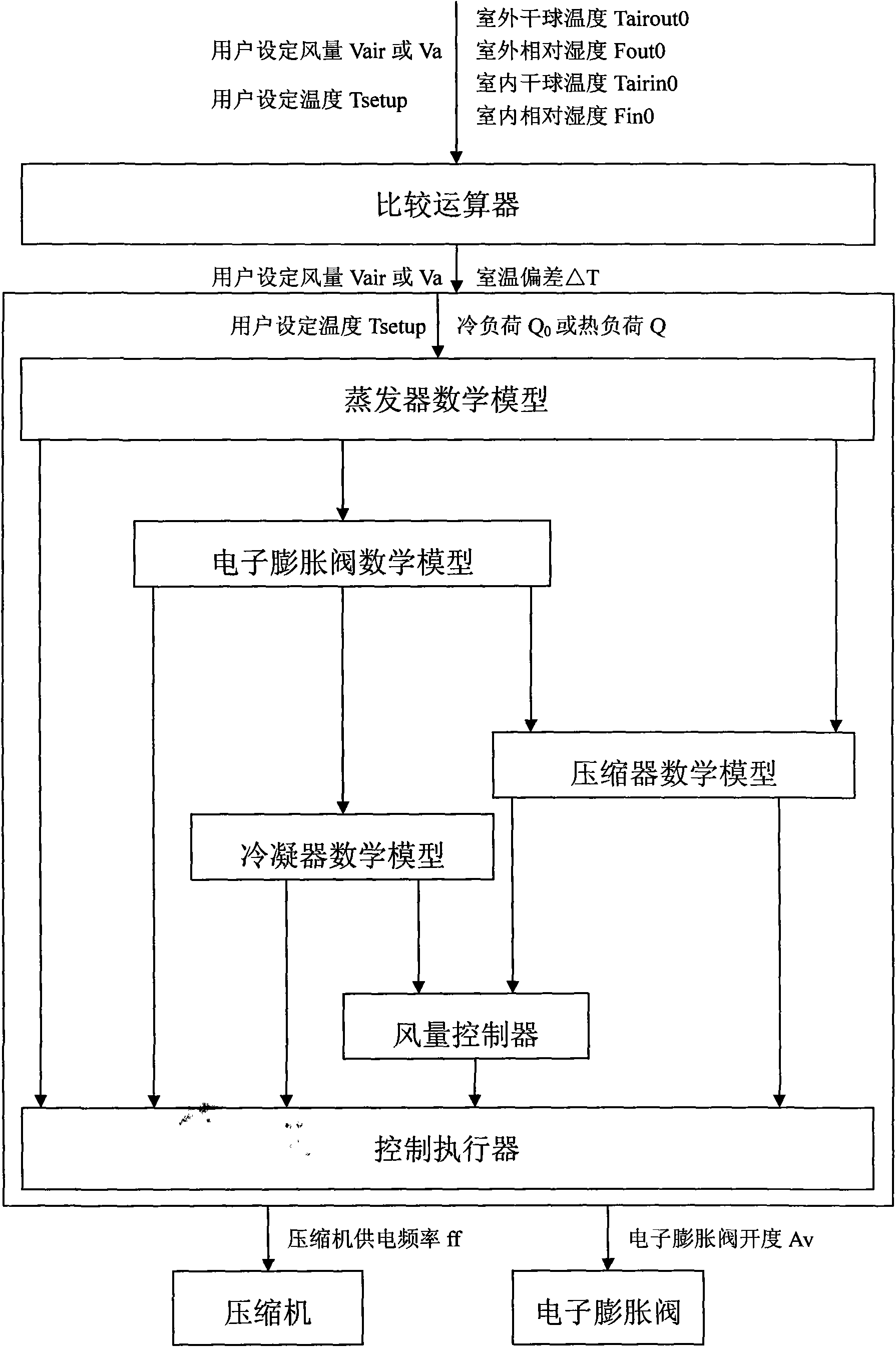

Variable frequency energy-saving control method for refrigeration system

ActiveCN101603751AGive full play to the heat exchange capacityReduce heat transfer temperature differenceSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAir volumeOperating point

The invention belongs to the technical field of energy conservation, and relates to a variable frequency energy-saving control method for a refrigeration system. The control method comprises the steps of: determining the mass flow of a refrigerant according to the change or change trend of cooling load, then determining consumed power of a compressor which satisfies the flow, predicting the minimum condensation pressure which ensures that the thermal load of a condenser satisfies the cooling load and the power change of the compressor through an established energy-saving control mathematical model, and gradually adjusting the power frequency of the compressor to ensure that the rotating speed of the compressor reaches a predicted value; and adjusting the opening degree of an expansion valve to ensure that the condensation pressure reaches to be lowest, realizing the minimum pressure difference operation between the condenser and an evaporator, and ensuring that the operation energy consumption of the refrigeration system is lowest. The method solves the optimizing control problem of the compressor, the expansion valve and a fan in the system, utilizes the energy-saving control mathematical model to perform joint regulation on controllable factors (such as the rotating speed of the compressor, the opening degree of the expansion valve, and the air volume of an outdoor unit) of the operation of the system, ensures that the refrigeration system operates at a best operating point, and realizes the further energy conservation of the refrigeration system based on the variable frequency regulation.

Owner:汉广中药科技(天津)有限公司

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

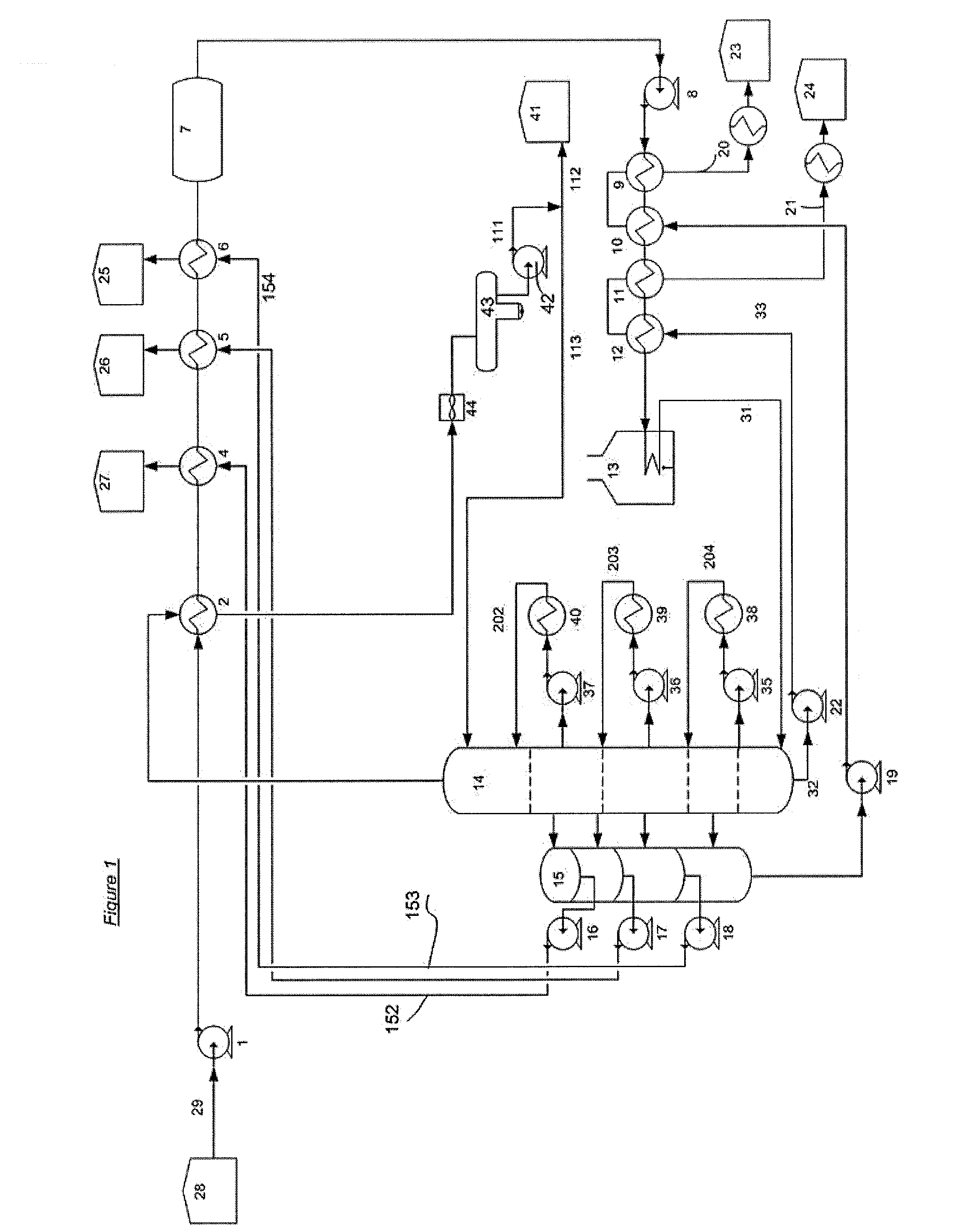

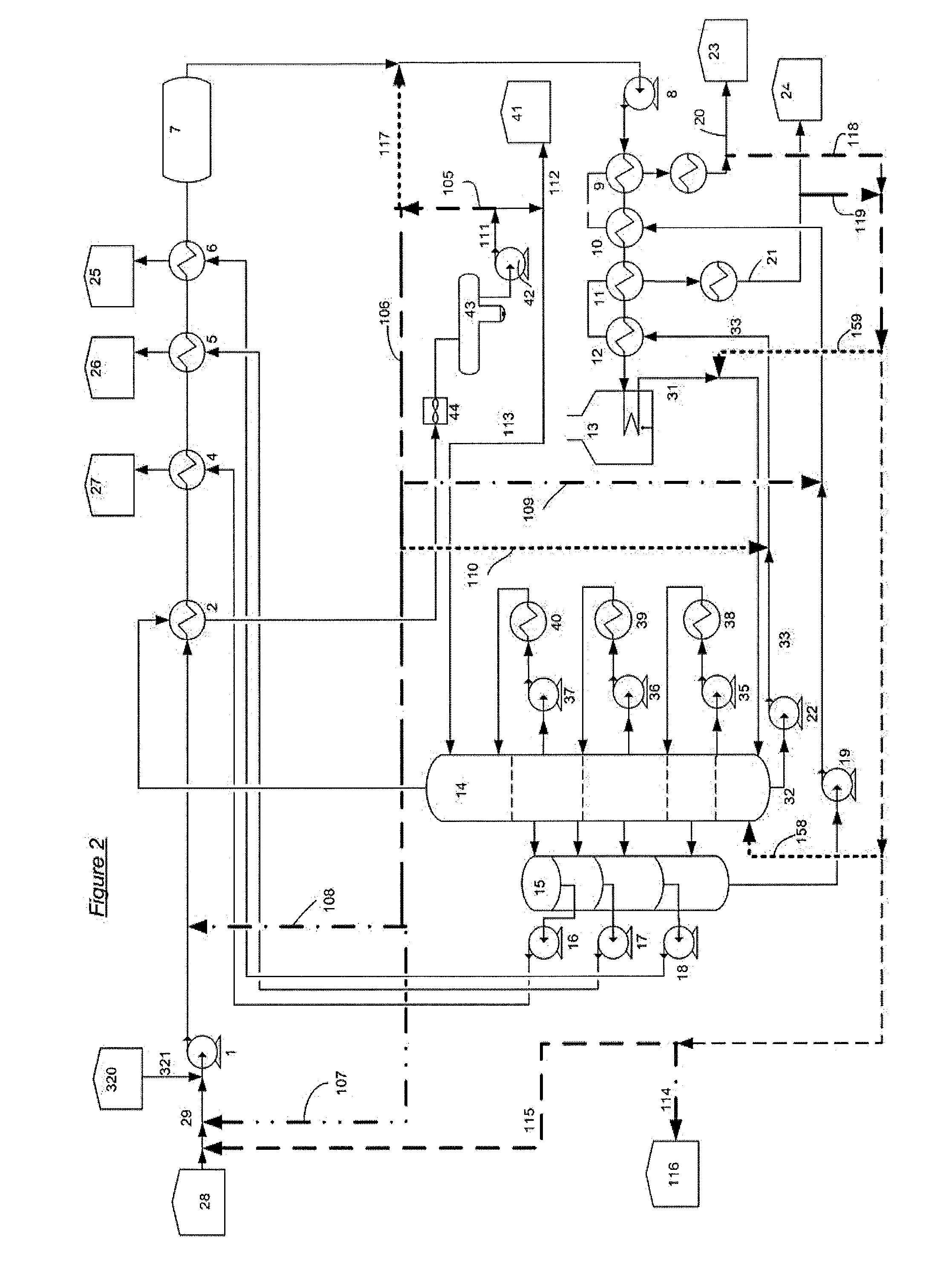

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

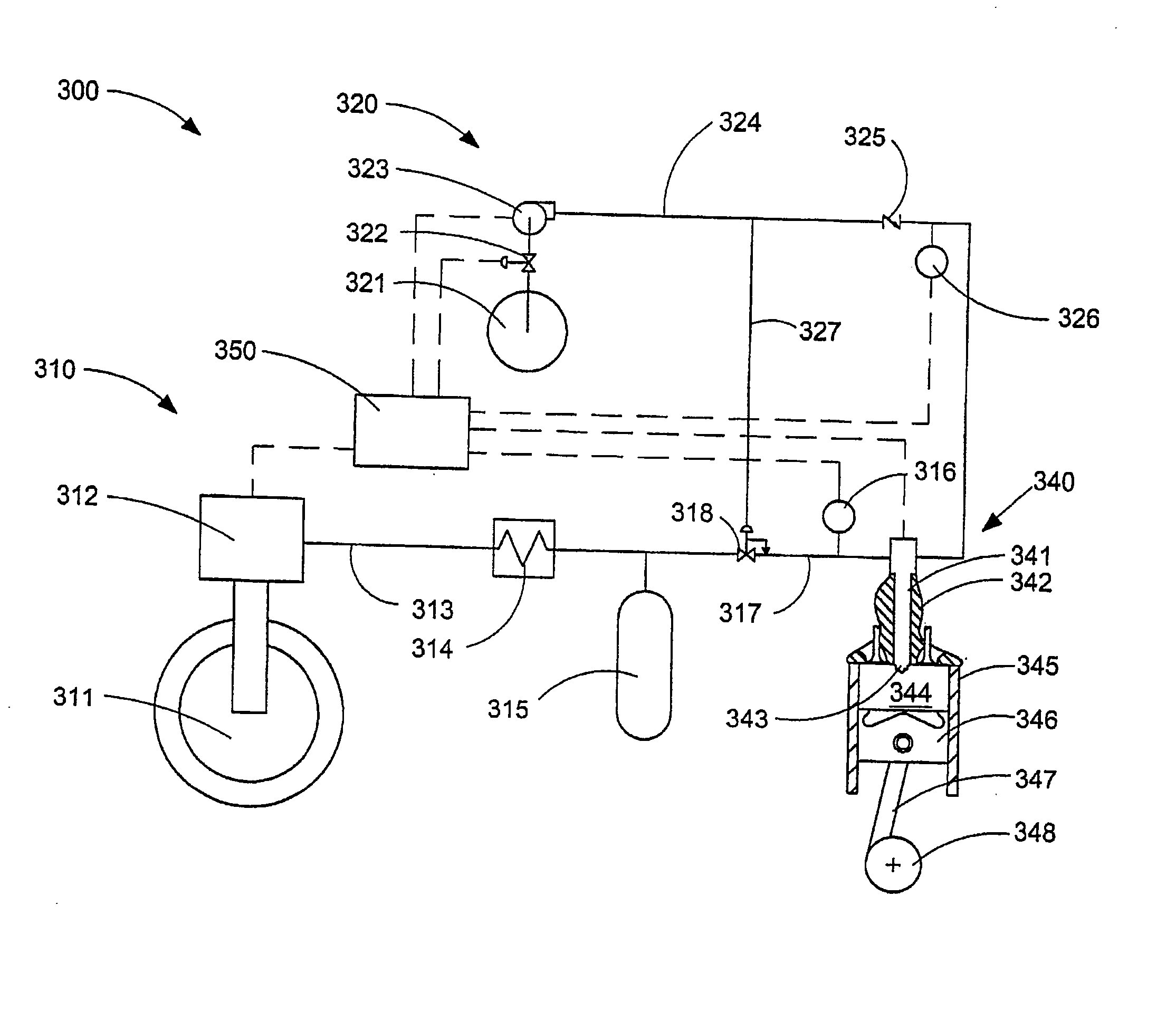

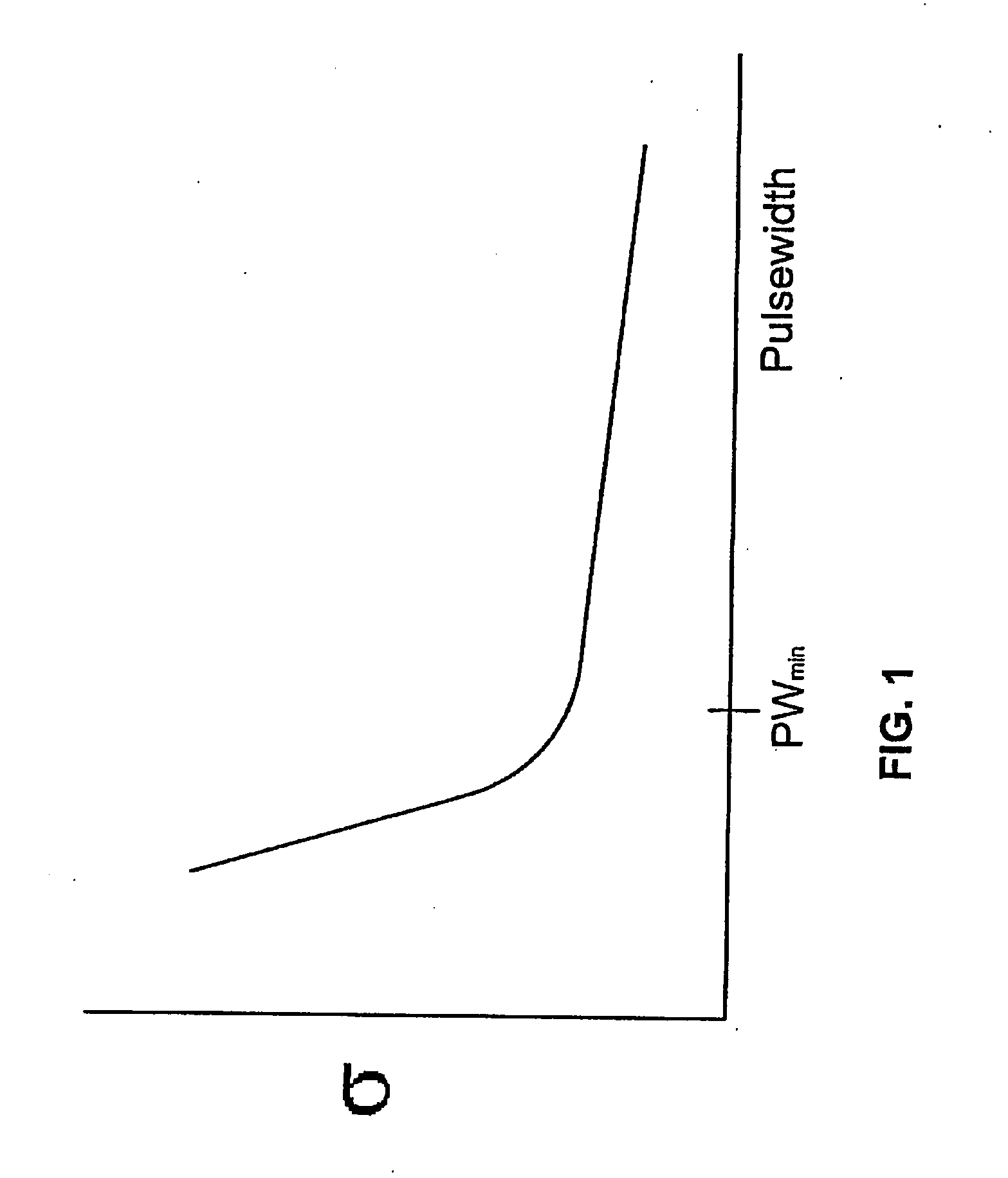

Direct injection gaseous-fuelled engine and method of controlling fuel injection pressure

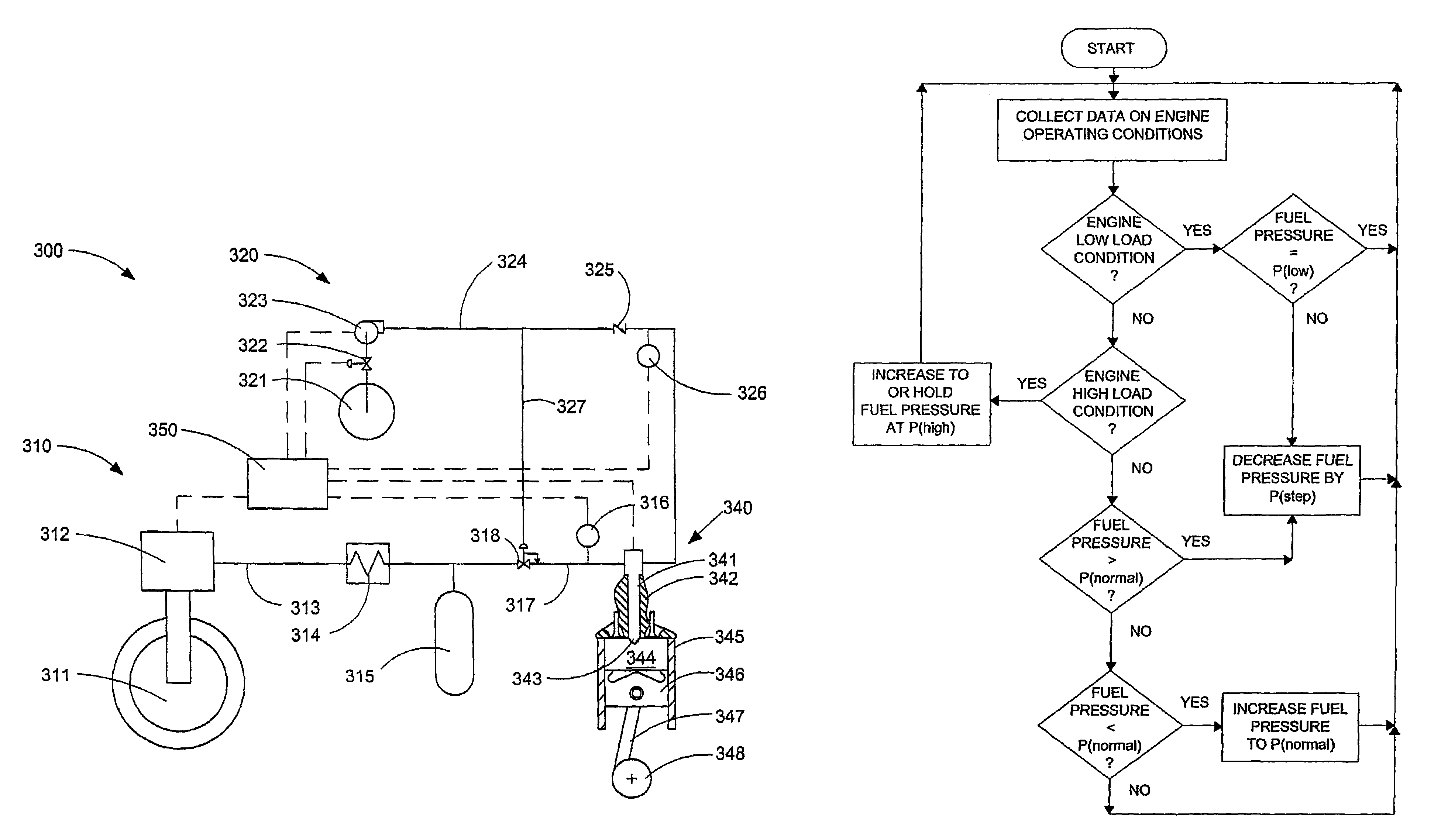

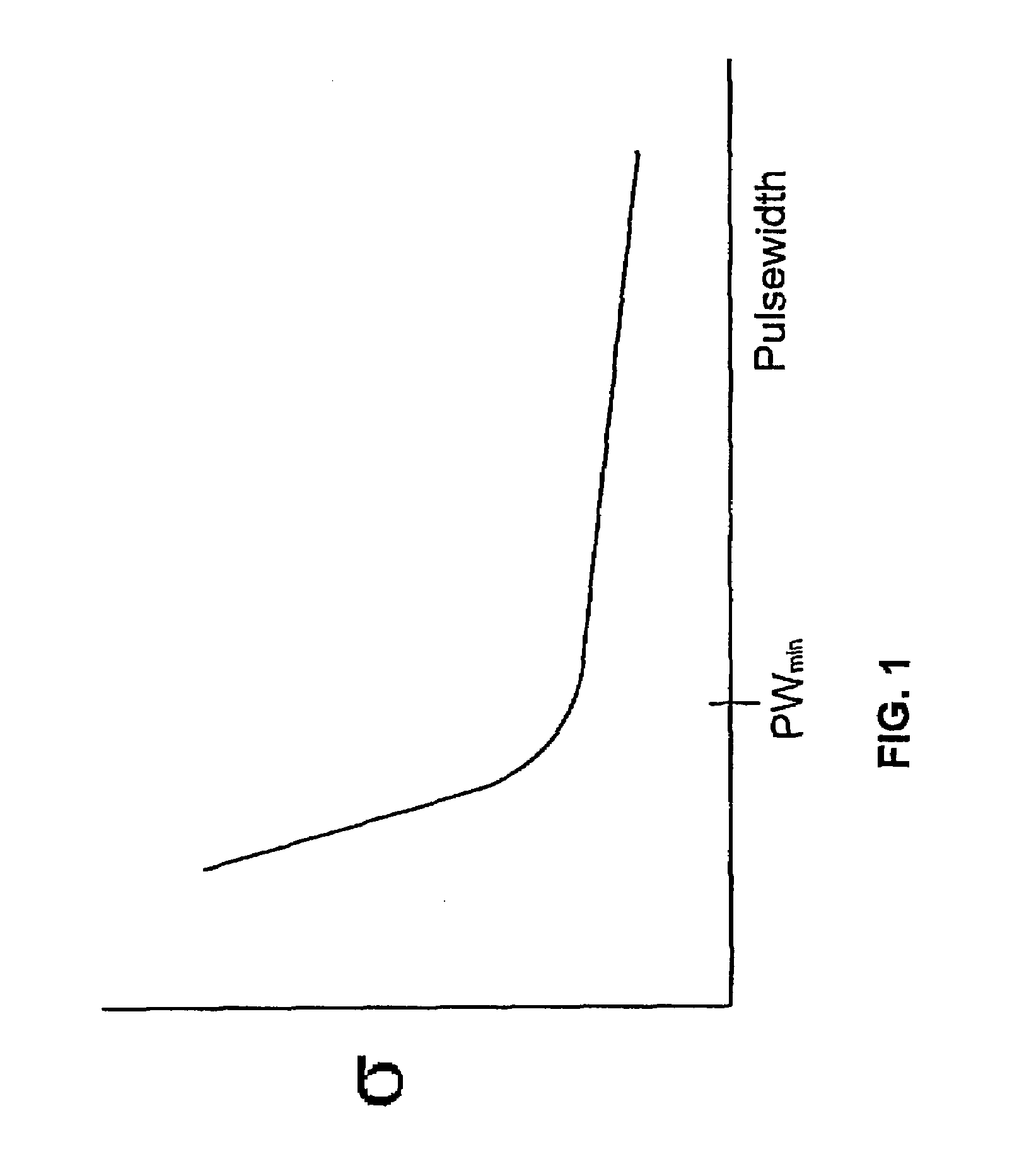

ActiveUS7463967B2Reduce modificationReduce differential pressureAnalogue computers for vehiclesInternal combustion piston enginesCombustion chamberFuel injection

An engine operating method and a direct injection gaseous fuelled system directly injects a gaseous fuel into a combustion chamber during a compression stroke, commands gaseous fuel injection pressure to a target value that is determined as a function of at least one pre-selected engine parameter, measures actual gaseous fuel injection pressure and adjusts fuel injection pulsewidth to correct for differences between the target value and the actual gaseous fuel injection pressure to thereby inject the desired mass quantity of gaseous fuel as determined from an engine map.

Owner:WESTPORT FUEL SYST CANADA INC

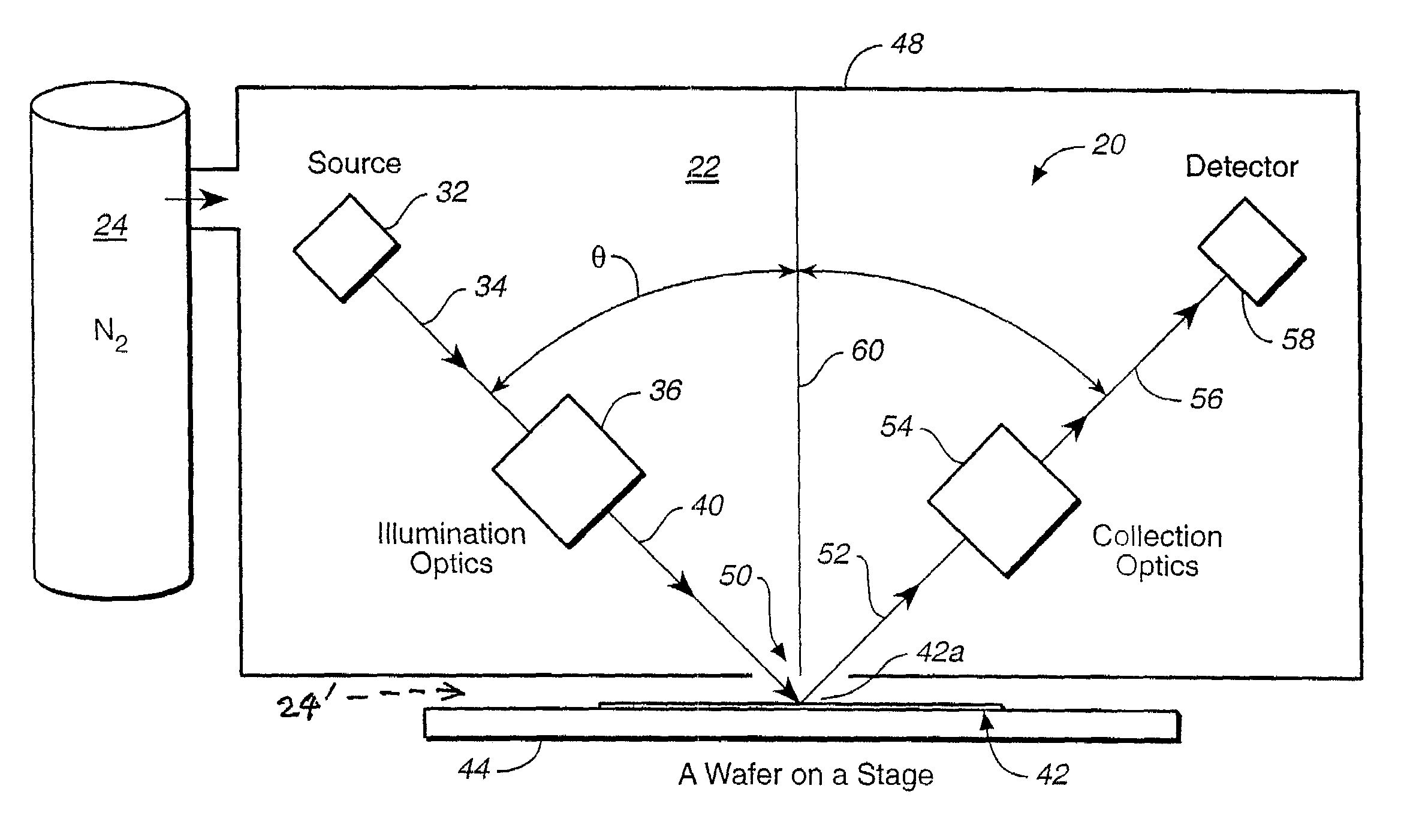

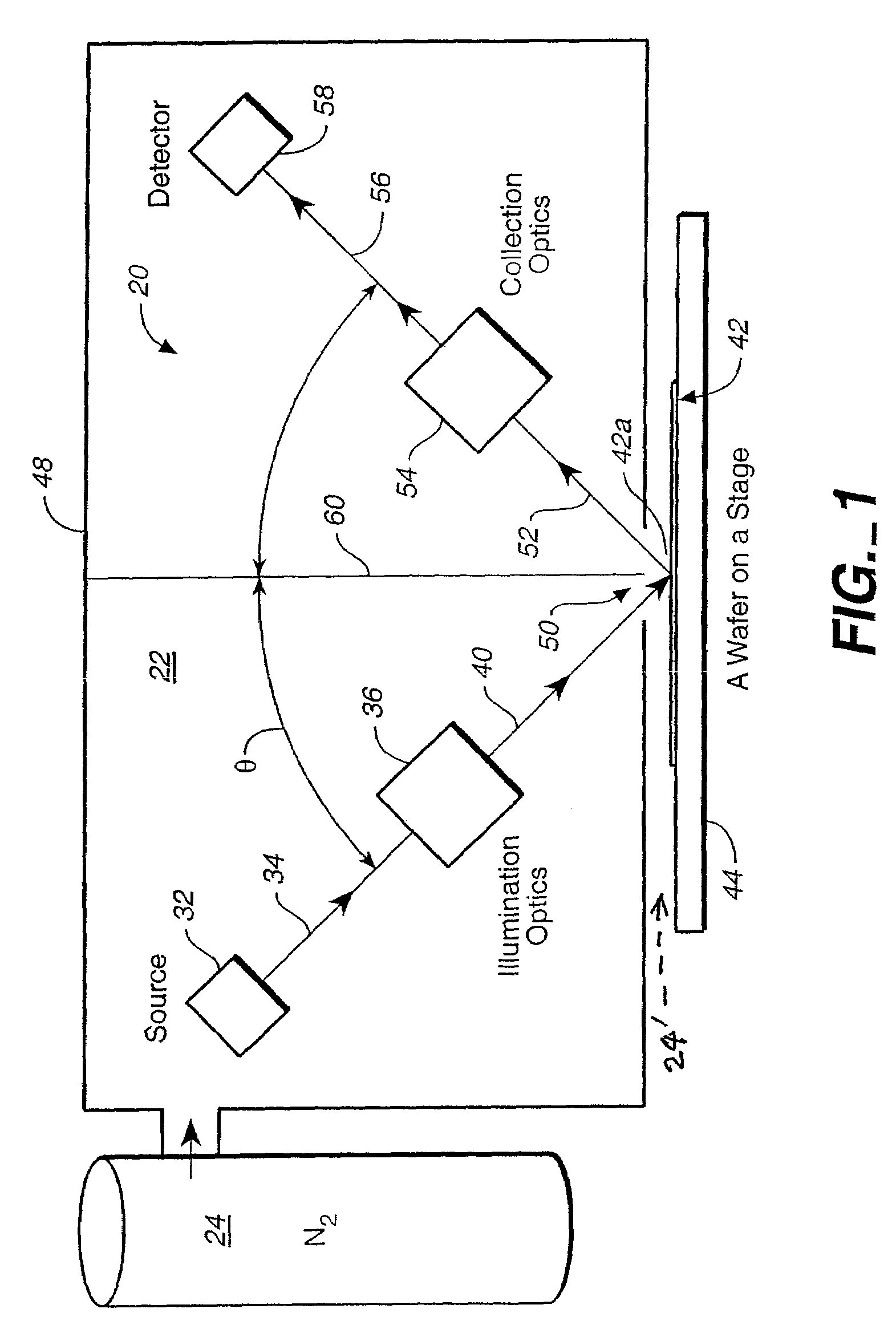

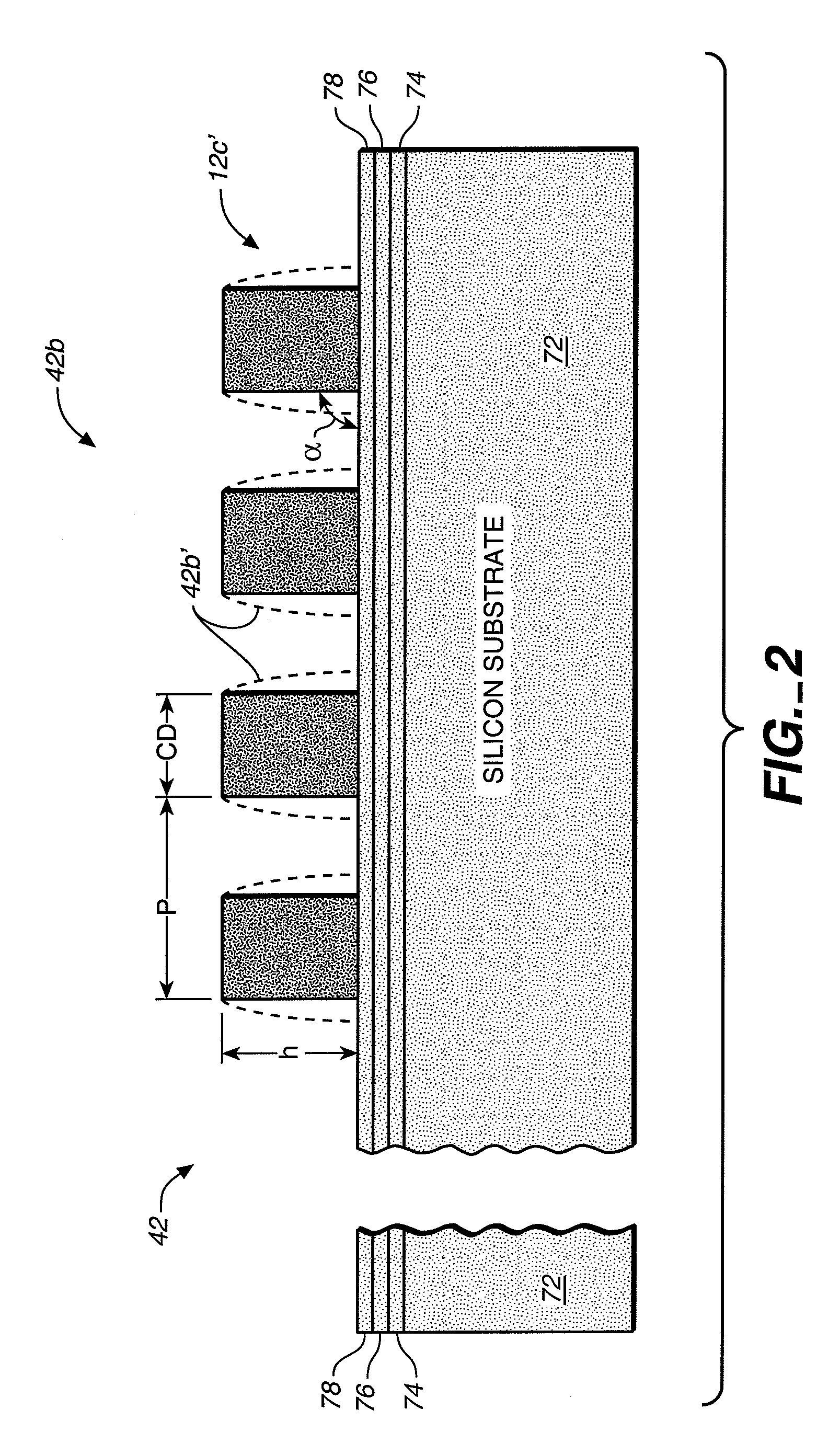

Optical system for measuring samples using short wavelength radiation

ActiveUS7369233B2Reduce decreaseImprove system throughputOptically investigating flaws/contaminationUsing optical meansUltrasound attenuationLength wave

In an optical system measuring sample characteristics, by reducing the amount of ambient absorbing gas or gases and moisture present in at least a portion of the illumination and detection paths experienced by vacuum ultraviolet (VUV) radiation used in the measurement process, the attenuation of such wavelength components can be reduced. Such reduction can be accomplished by a process without requiring the evacuation of all gases and moisture from the measurement system. In one embodiment, the reduction can be accomplished by displacing at least some of the absorbing gas(es) and moisture present in at least a portion of the measuring paths so as to reduce the attenuation of VUV radiation. In this manner, the sample does not need to be placed in a vacuum, thereby enhancing system throughput.

Owner:KLA TENCOR TECH CORP

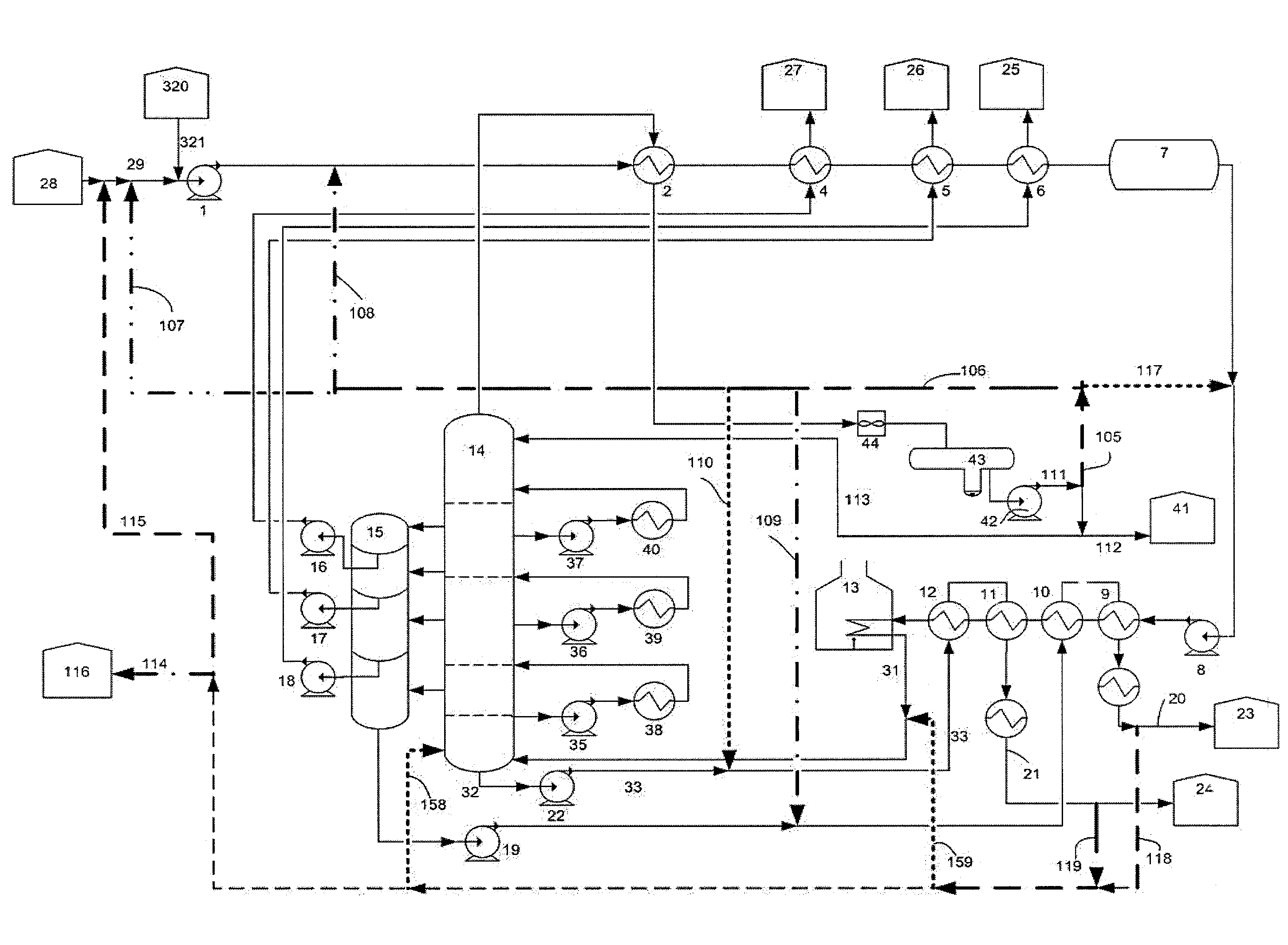

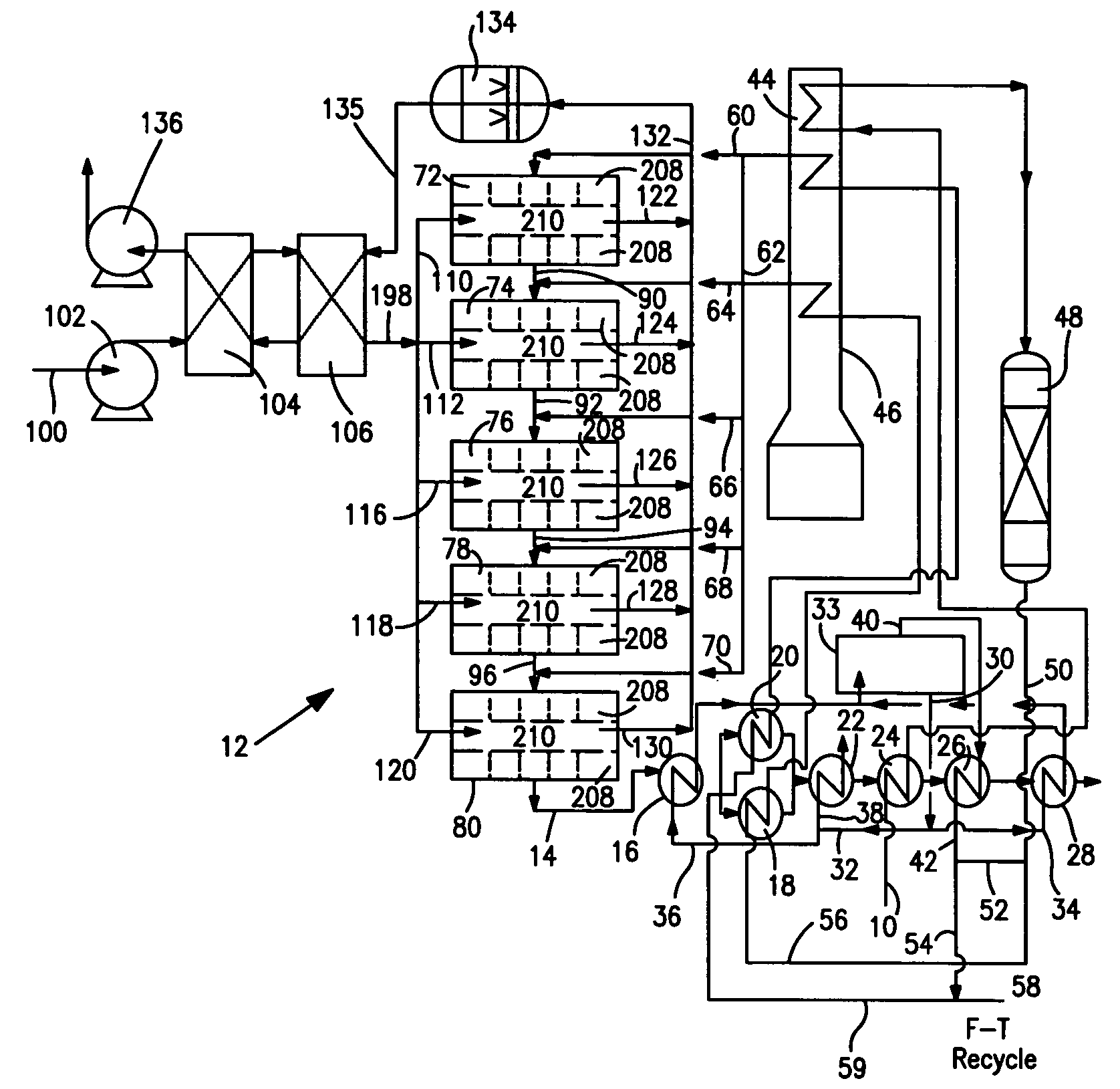

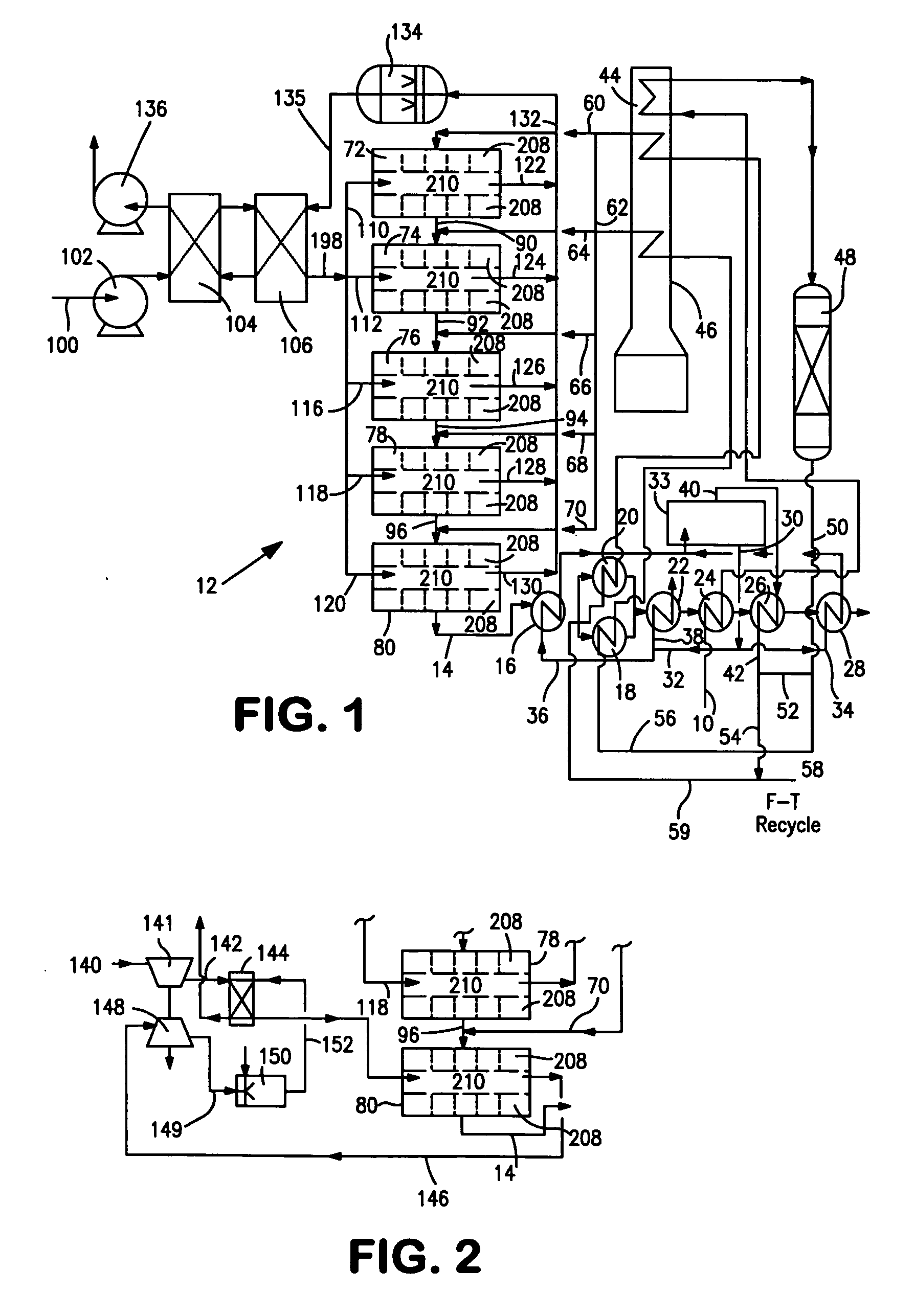

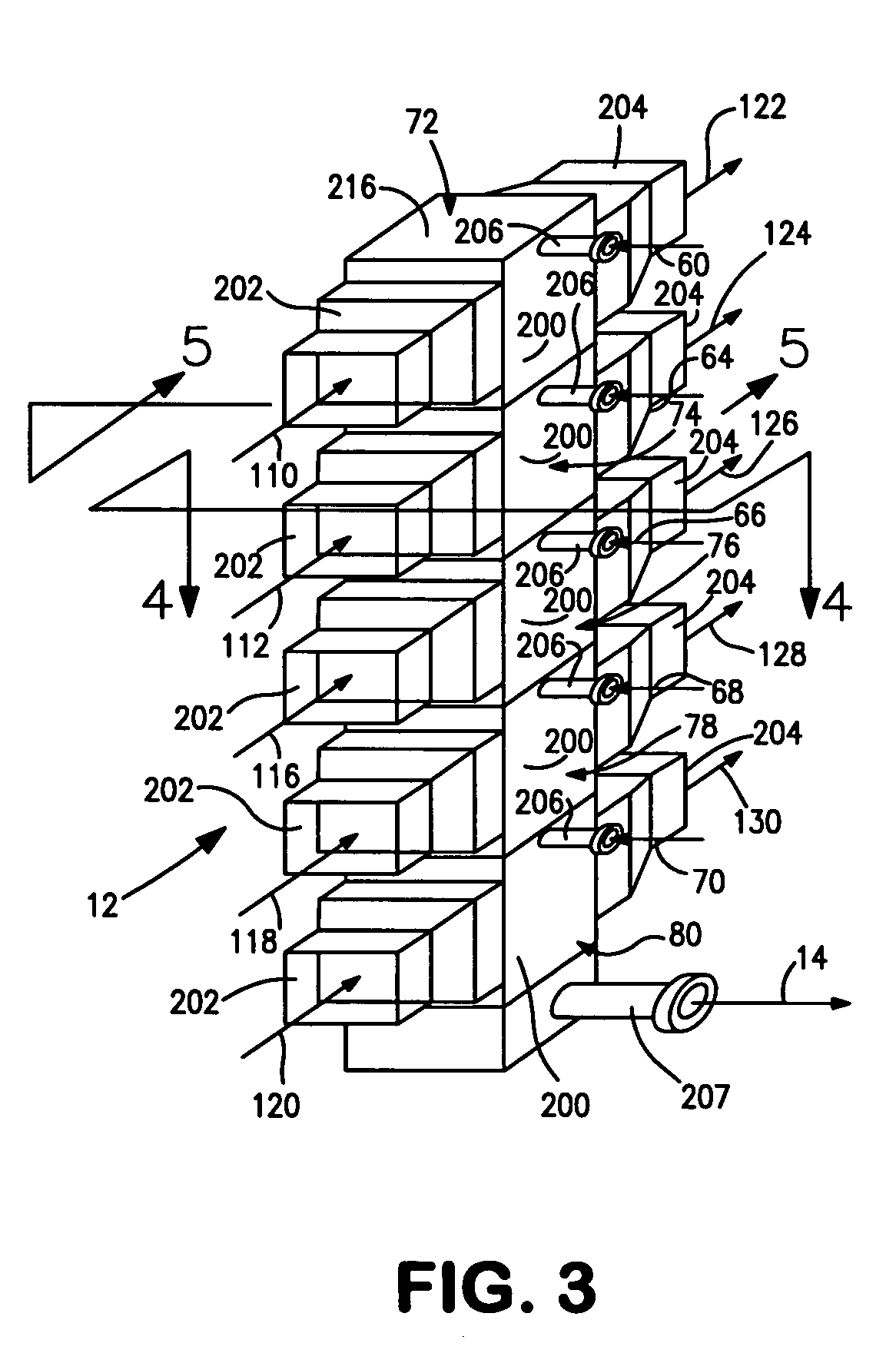

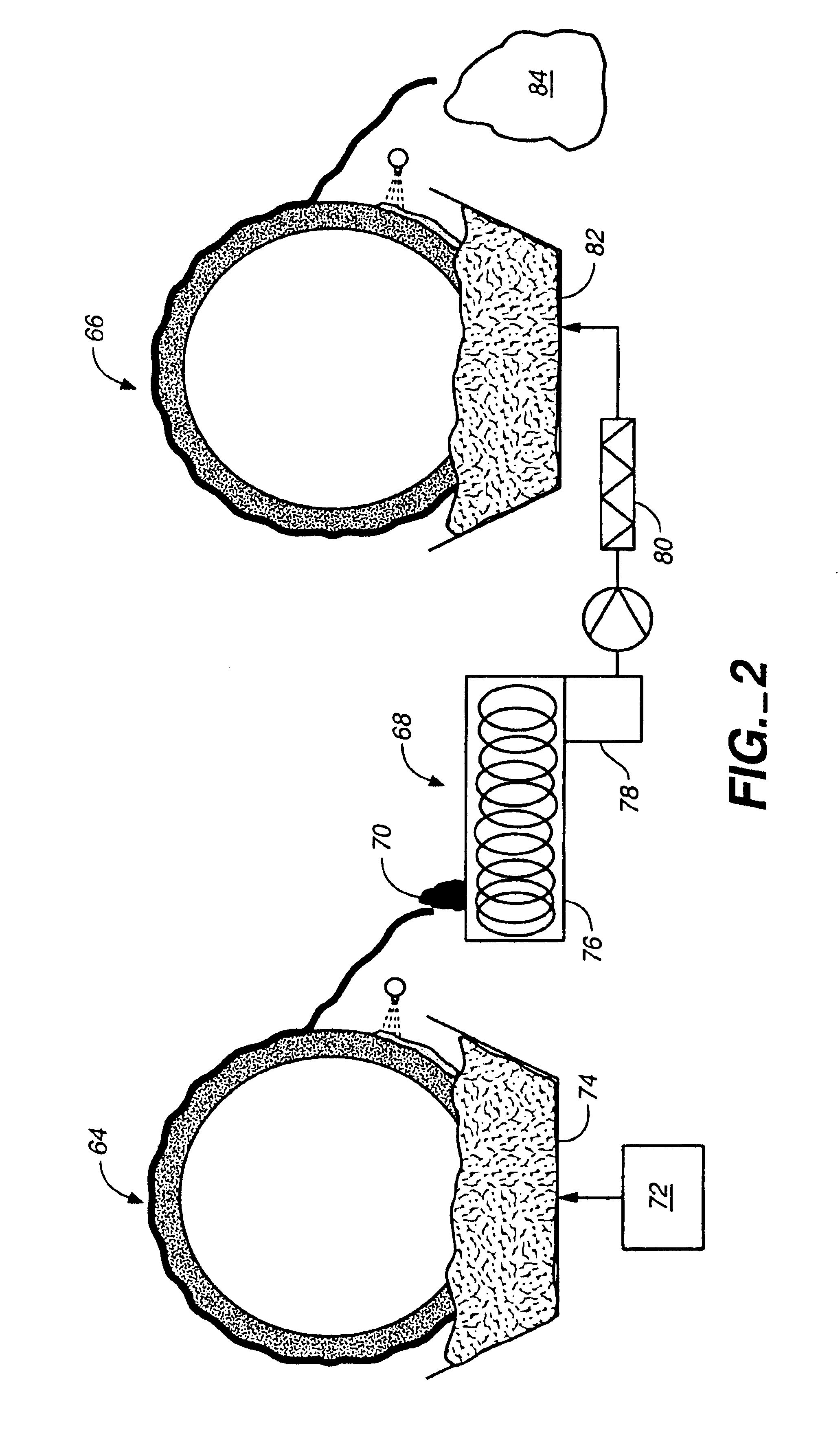

Synthesis gas production method and reactor

InactiveUS20070292342A1Mitigate carbon formationReduce possible catalyst poisoningCombination devicesHydrogenChemistryPartial oxidation

A method of producing a synthesis gas from a hydrocarbon containing gaseous feed in which the hydrocarbon containing gaseous feed is reacted in an autothermal reactor having separated reaction stages in which partial oxidation and steam methane reforming reactions occur. Each of the reaction stages has alternating separation zones and catalytic reaction zones. Oxygen separated by oxygen ion transport in the separation zone supports the partial oxidation reactions occurring in the catalytic reaction zones. Reactants are separately metered to the reaction stages to control temperatures within the reaction stages so that use of expensive high temperature materials is confined to one or more final reaction stages. Reaction stages can incorporate perforated planar members with regions of oxygen ion transport membrane material in registry with such perforated regions form the separation zones and the catalytic reaction zones.

Owner:STATOIL ASA PETRO SA (NO) +1

Direct Injection Gaseous-Fuelled Engine And Method Of Controlling Fuel Injection Pressure

ActiveUS20080103676A1Improve featuresReduce engine emissionsAnalogue computers for vehiclesElectrical controlCombustion chamberEngineering

An engine operating method and a direct injection gaseous fuelled system directly injects a gaseous fuel into a combustion chamber during a compression stroke, commands gaseous fuel injection pressure to a target value that is determined as a function of at least one pre-selected engine parameter, measures actual gaseous fuel injection pressure and adjusts fuel injection pulsewidth to correct for differences between the target value and the actual gaseous fuel injection pressure to thereby inject the desired mass quantity of gaseous fuel as determined from an engine map.

Owner:WESTPORT FUEL SYST CANADA INC

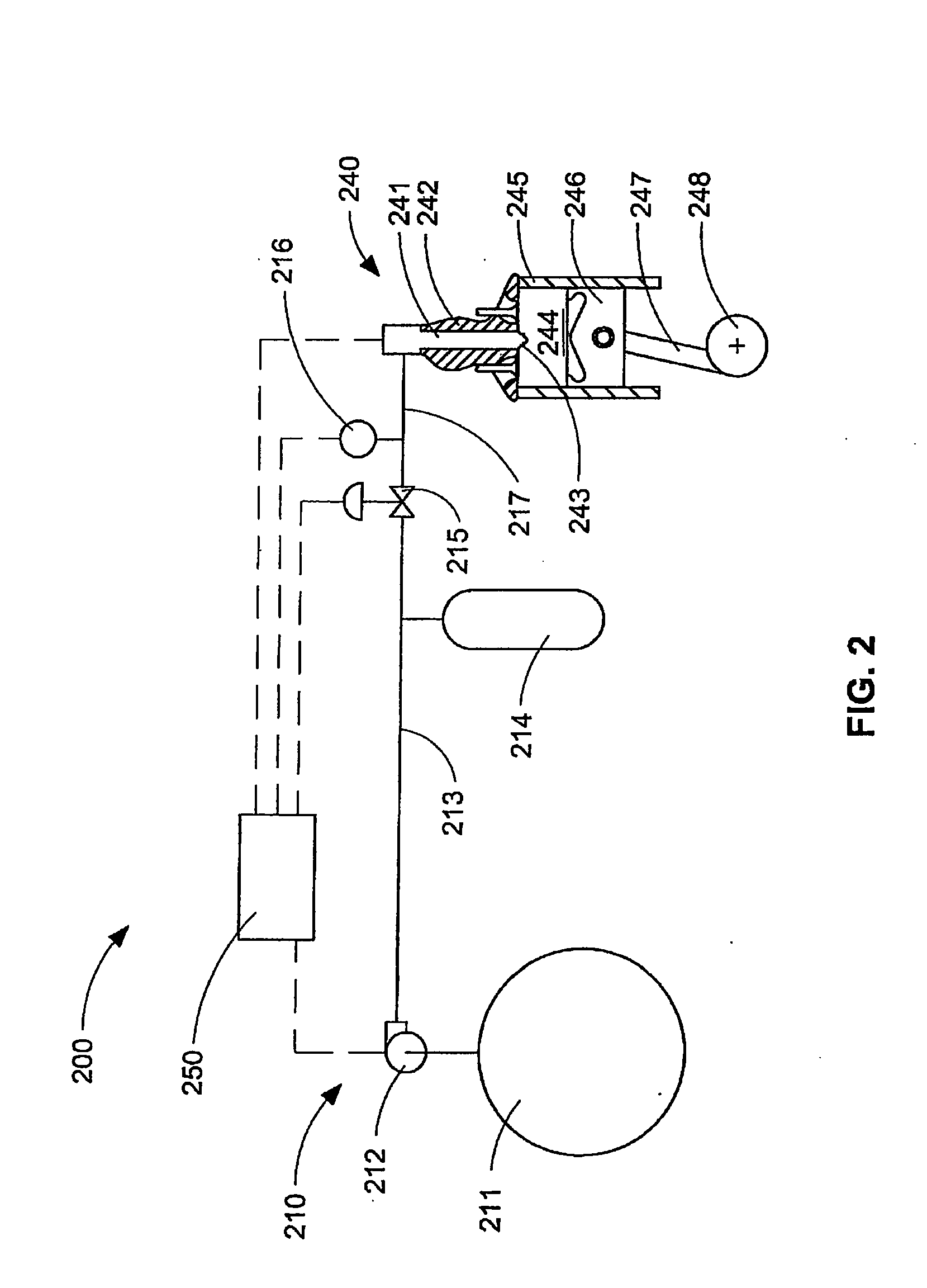

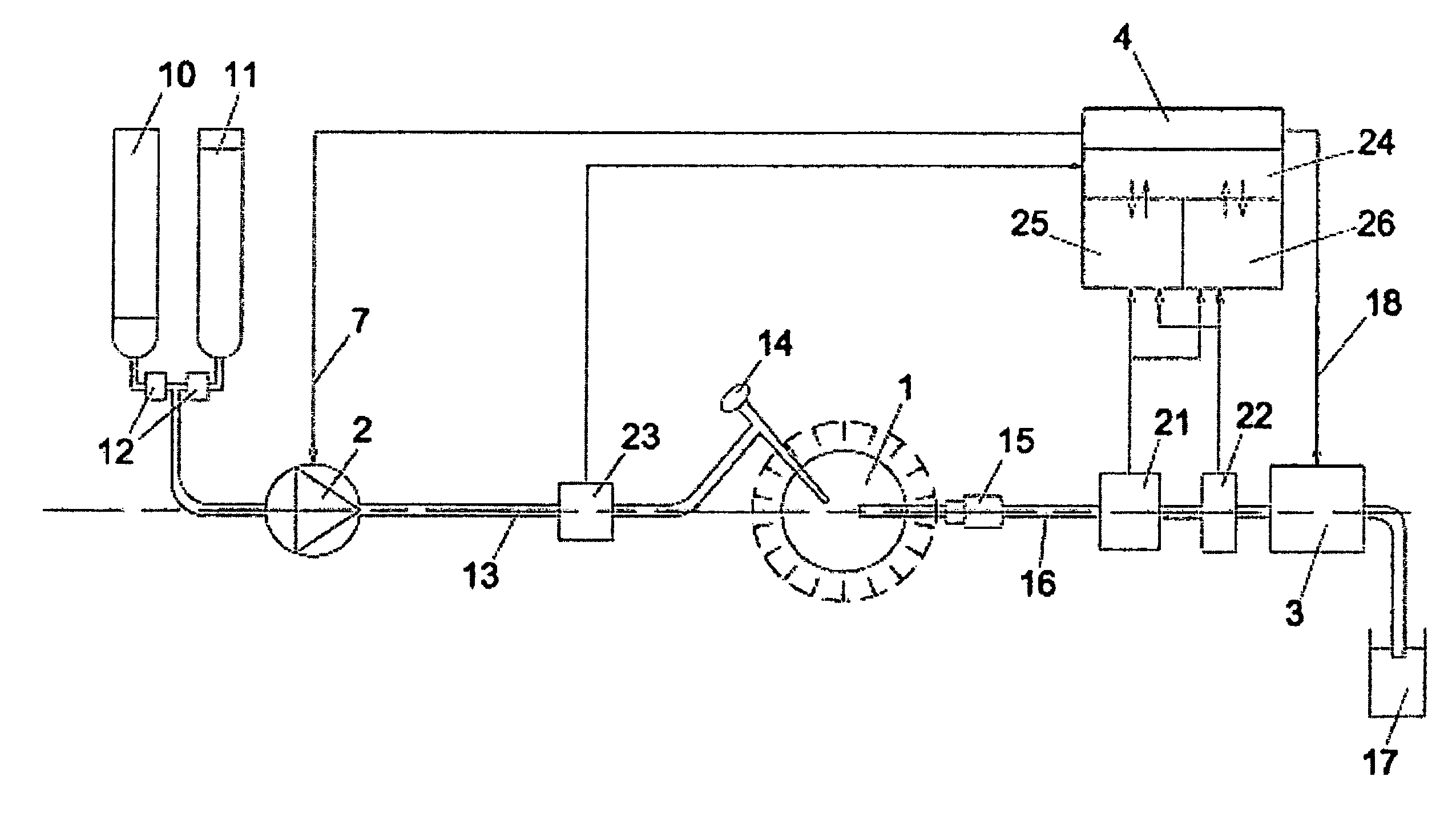

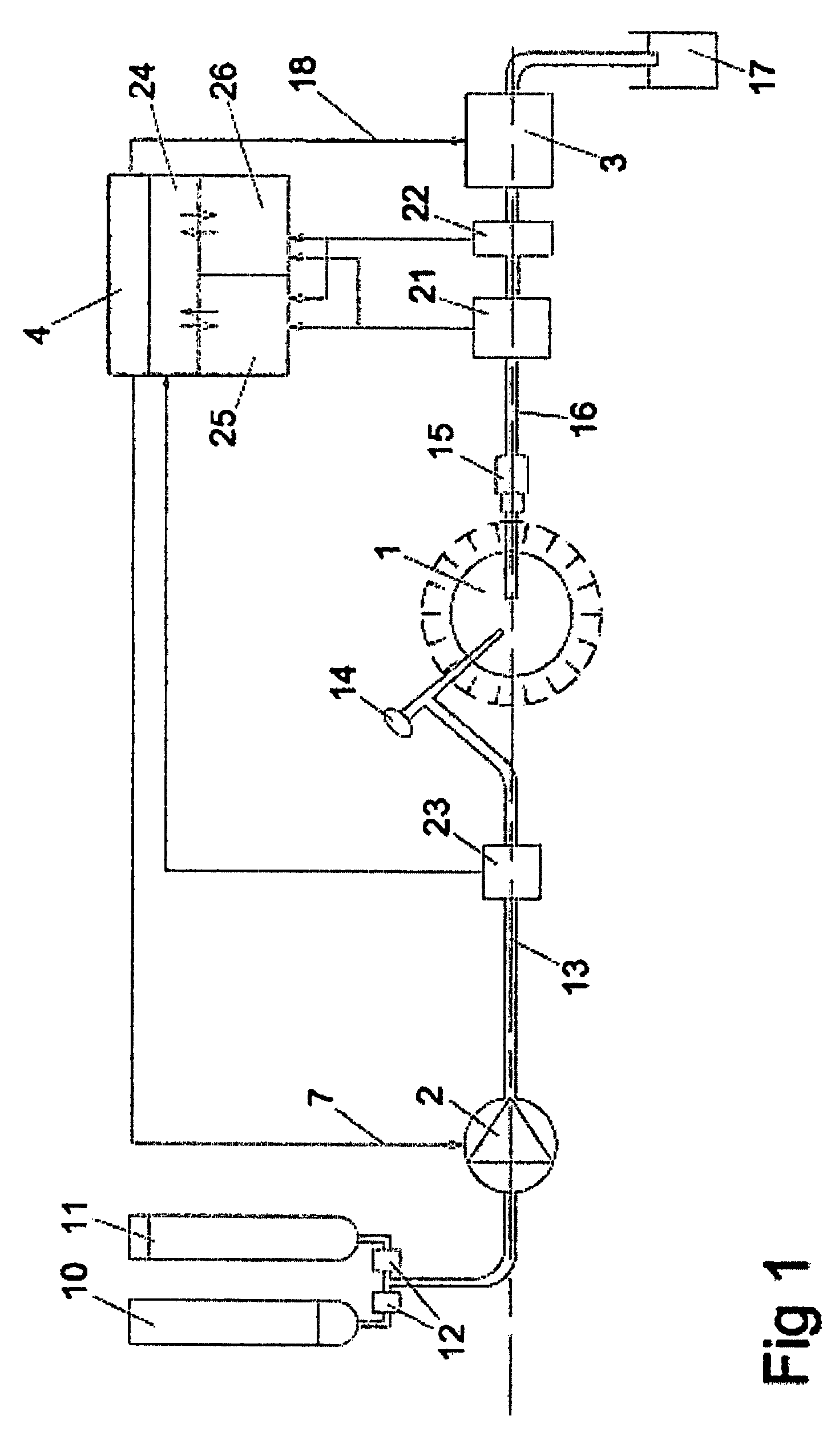

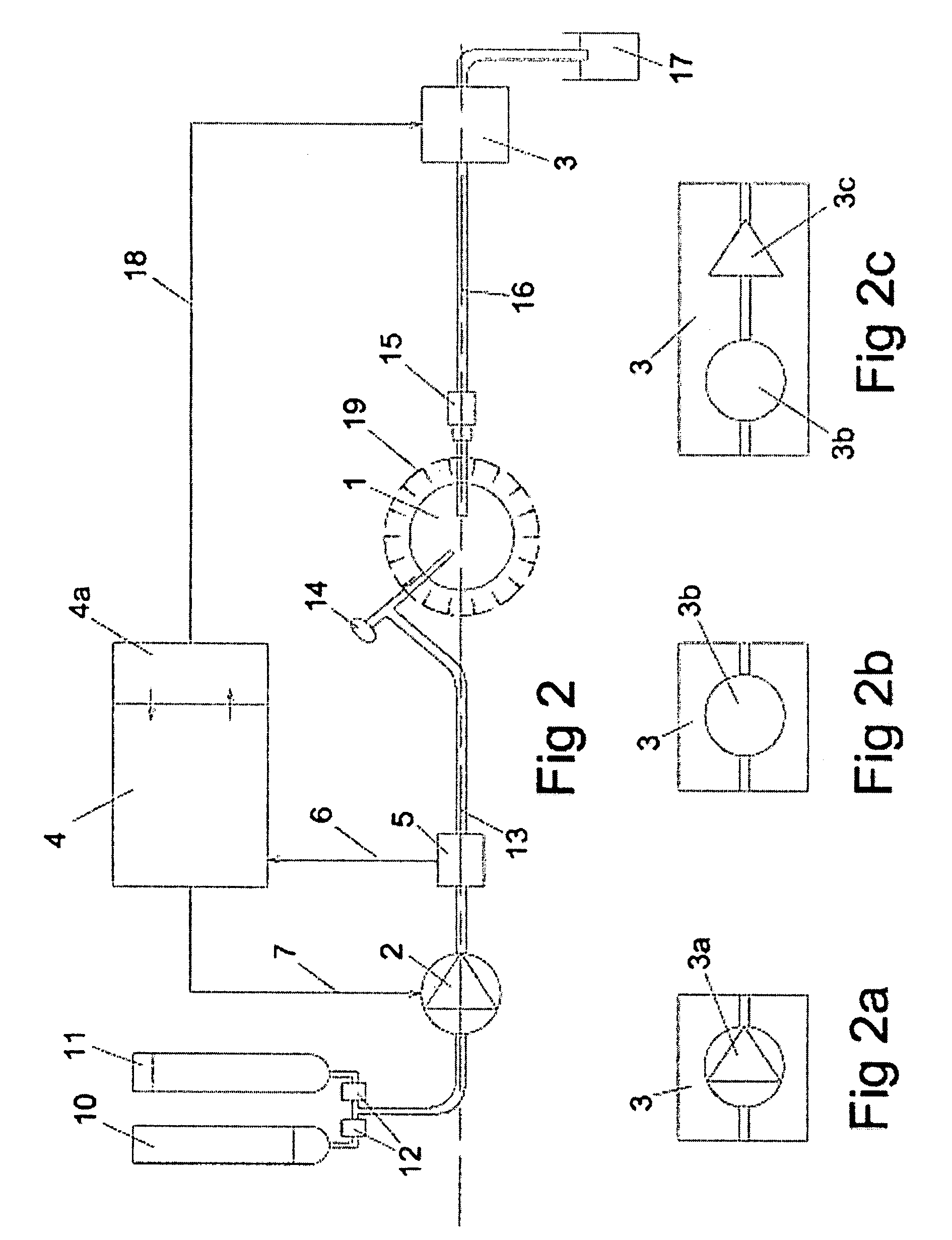

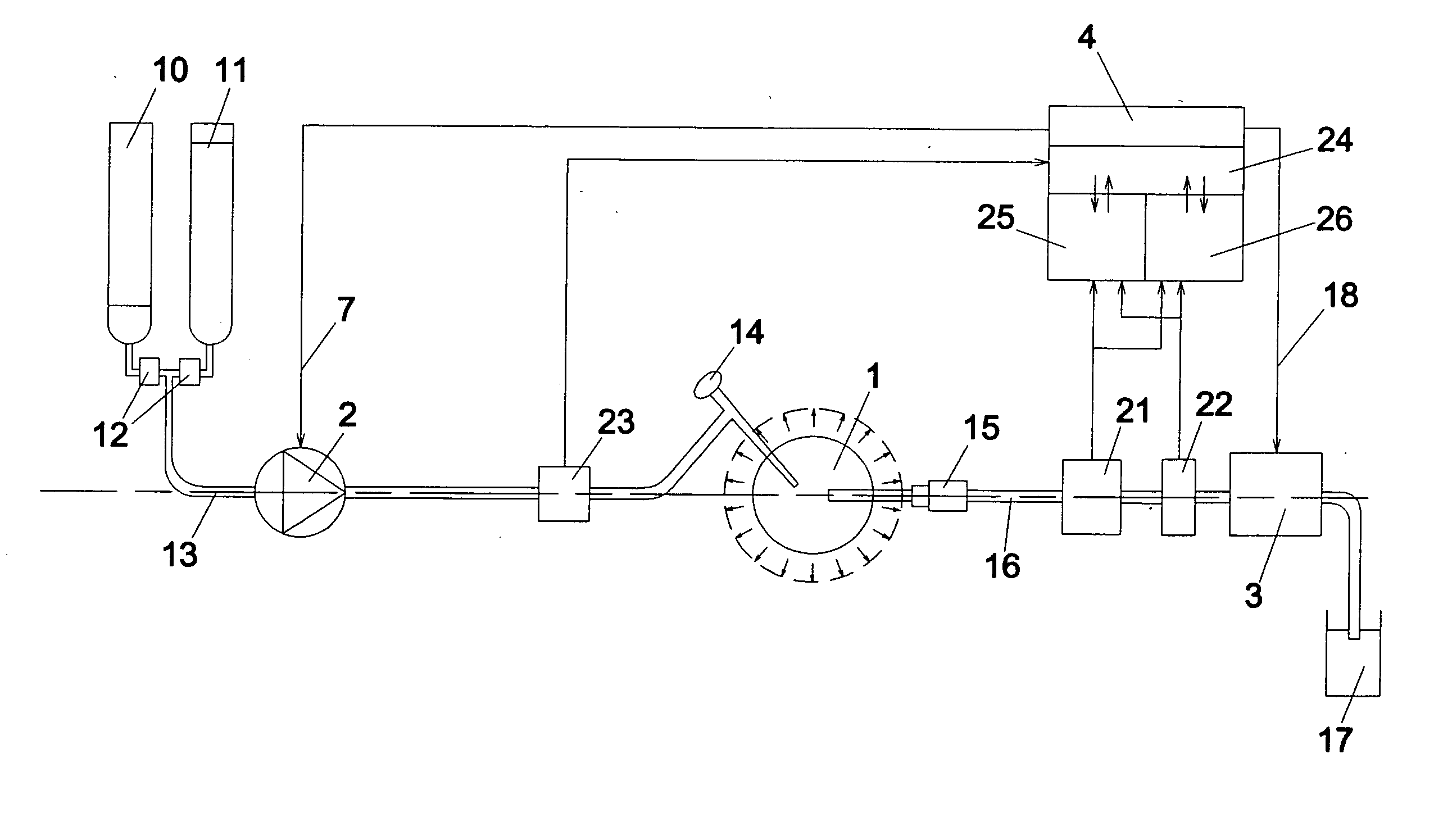

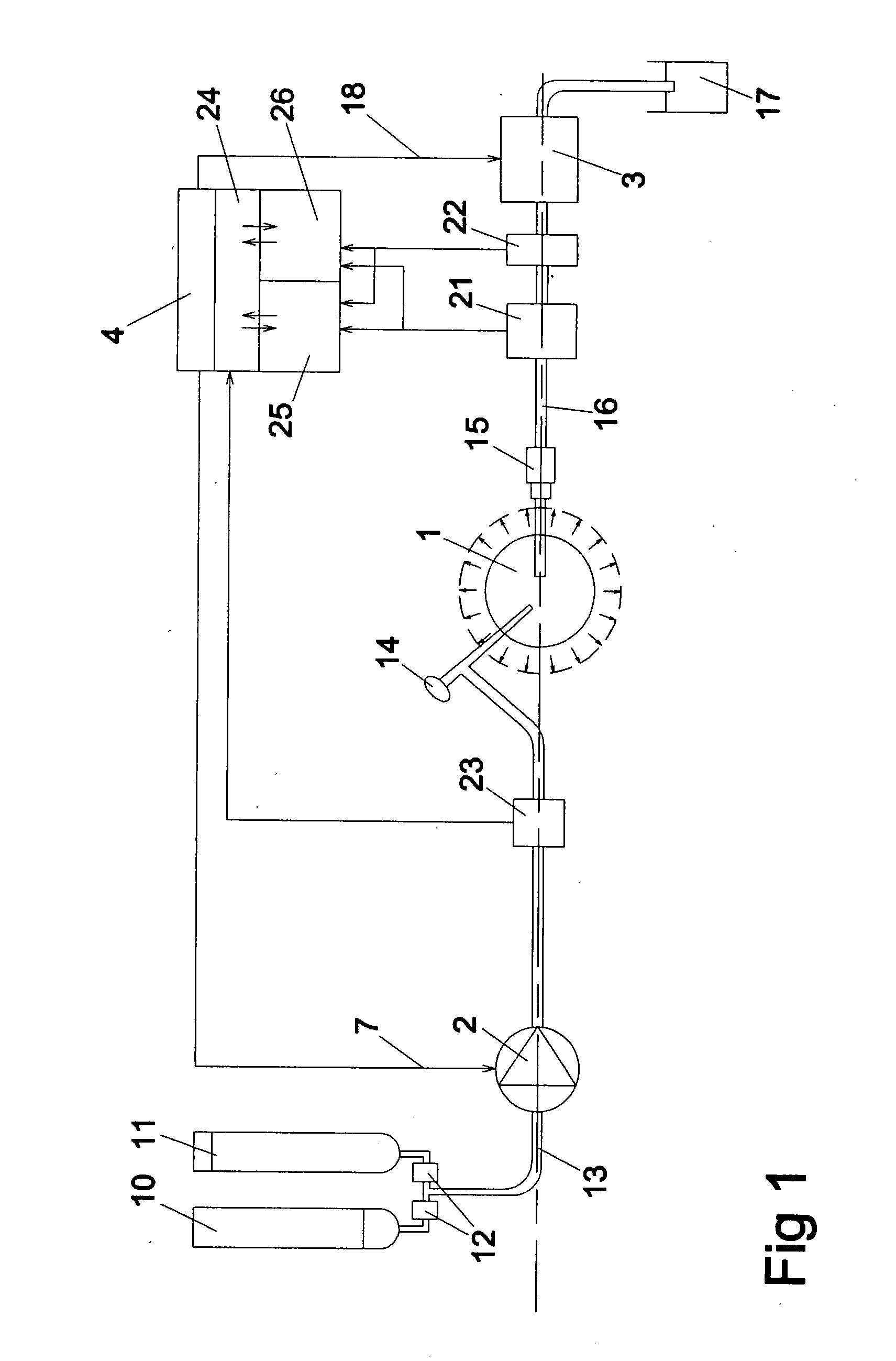

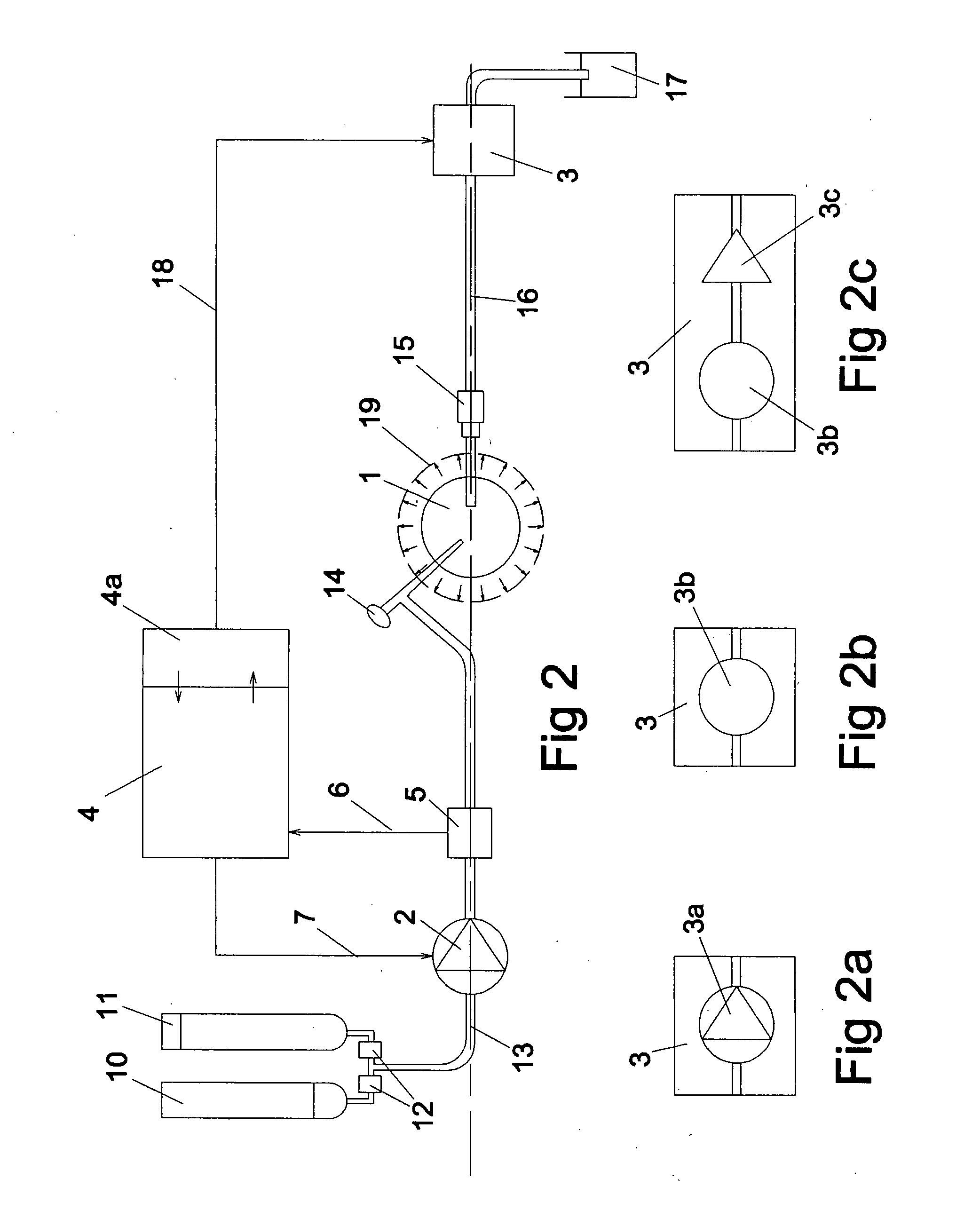

Method and device for irrigation of body cavities

ActiveUS7981073B2Minimize timeReduce differential pressureEndoscopesMedical devicesAutomatic controlRed blood cell

A pressure and a vision regulation method and device for irrigation of a body cavity (1), in which an inflow liquid pump (2) pressurizes the irrigation liquid in a feed line (13) and an outflow device (3) or an external suction source (20) drains the irrigation liquid from the body cavity (1) through a tubing (16) into a waste container (17). A control unit (4) controls either the inflow liquid pump (2) only or both the inflow liquid pump (2) and the outflow device (3) depending on an inflow irrigation liquid pressure from a pressure sensor (5). The method and the device are combined with a method for detecting blood cells, red blood cells, haemoglobin and / or debris in liquid coming from a surgical site to provide an automatic control and rinsing system with clear vision in the viewing area of the operational site.

Owner:TENNESSEE MEDICAL INNOVATIONS INC

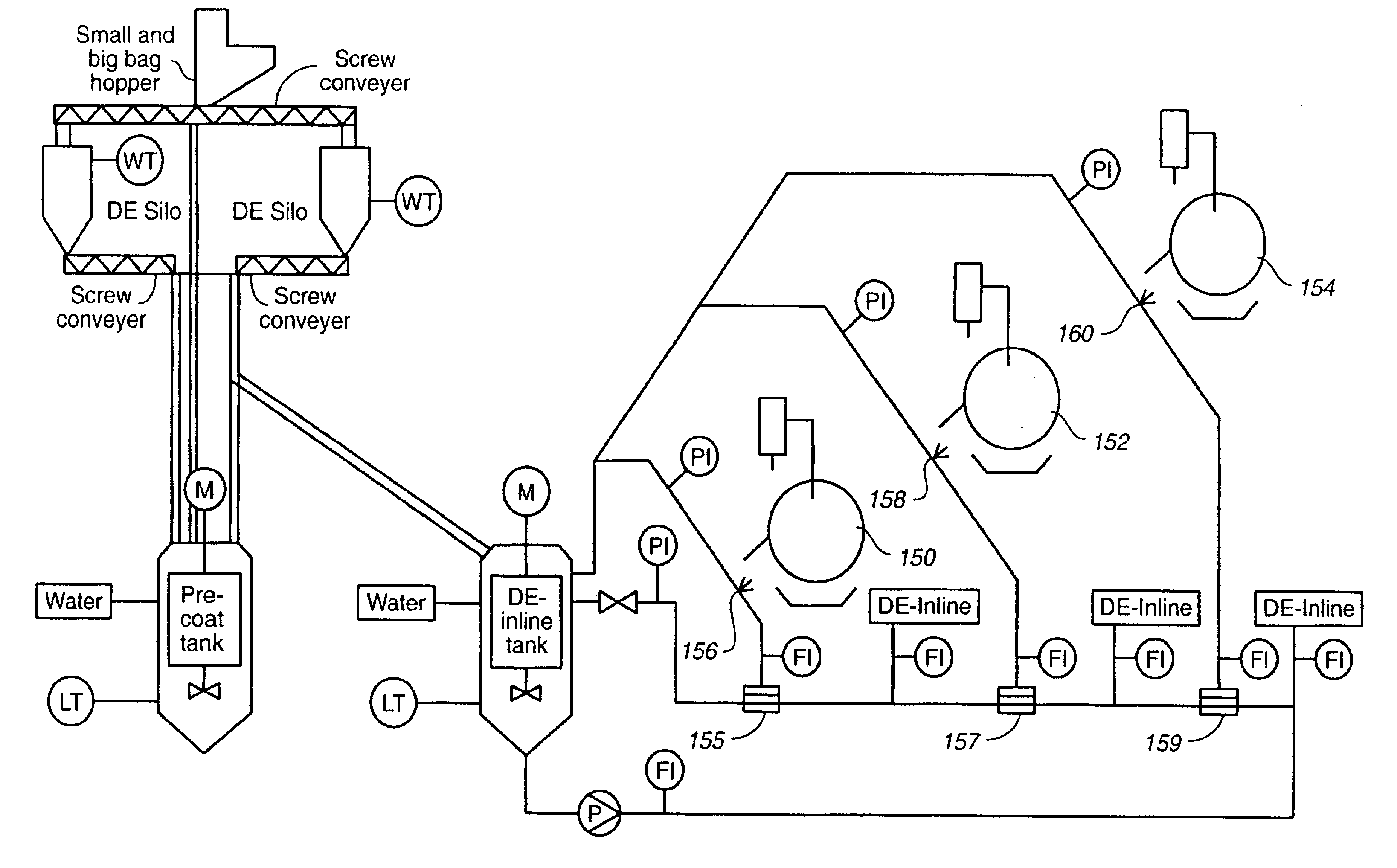

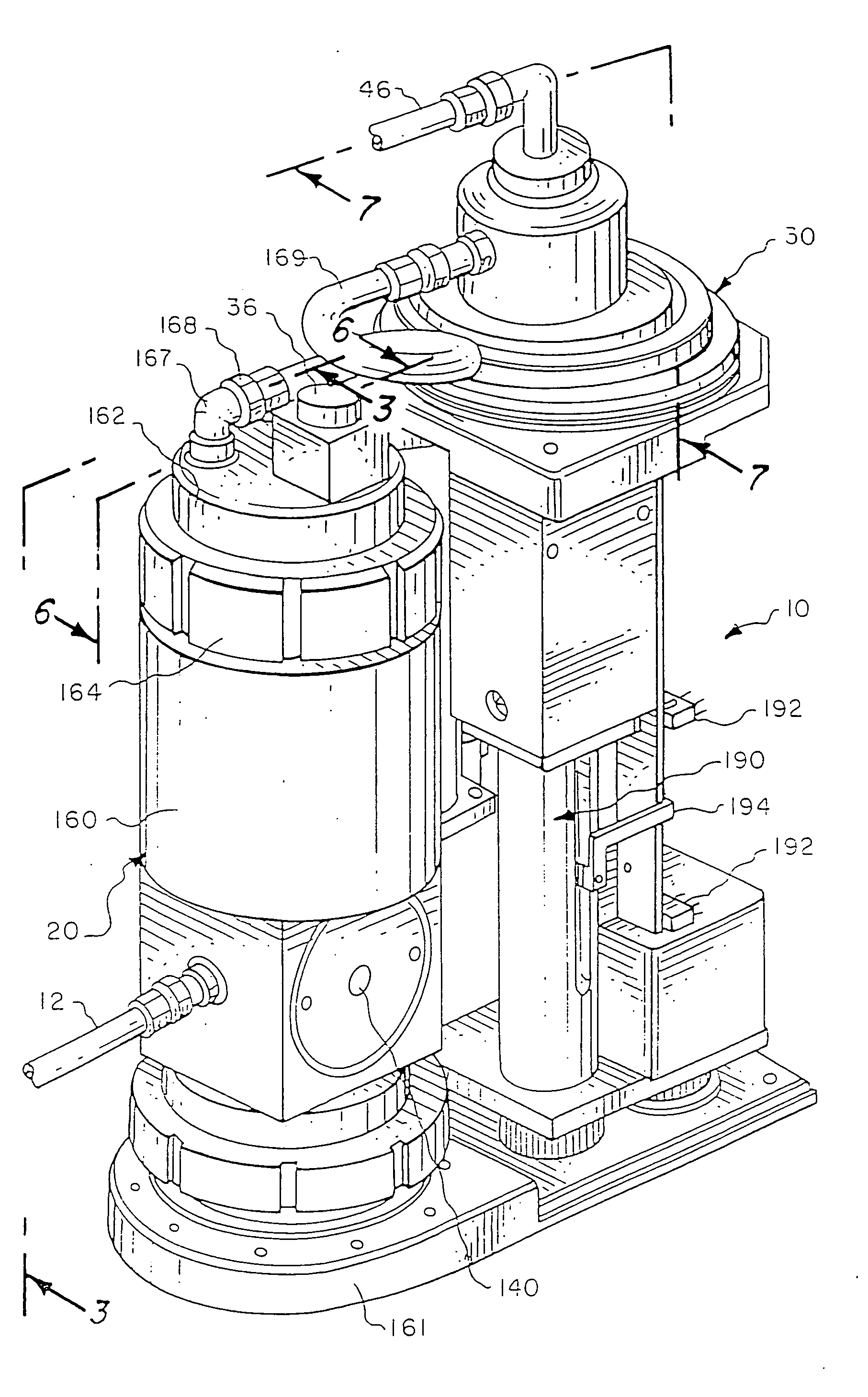

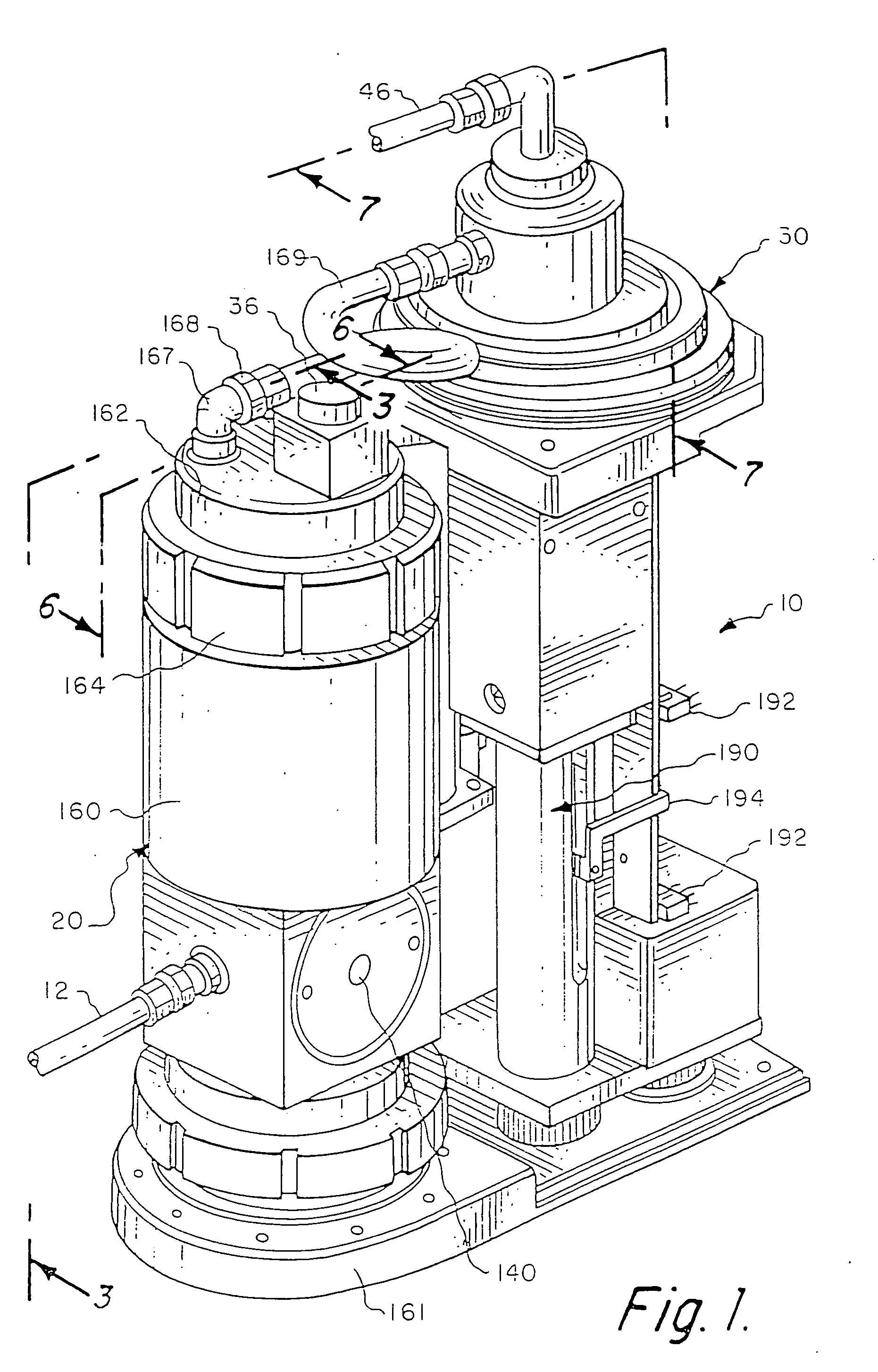

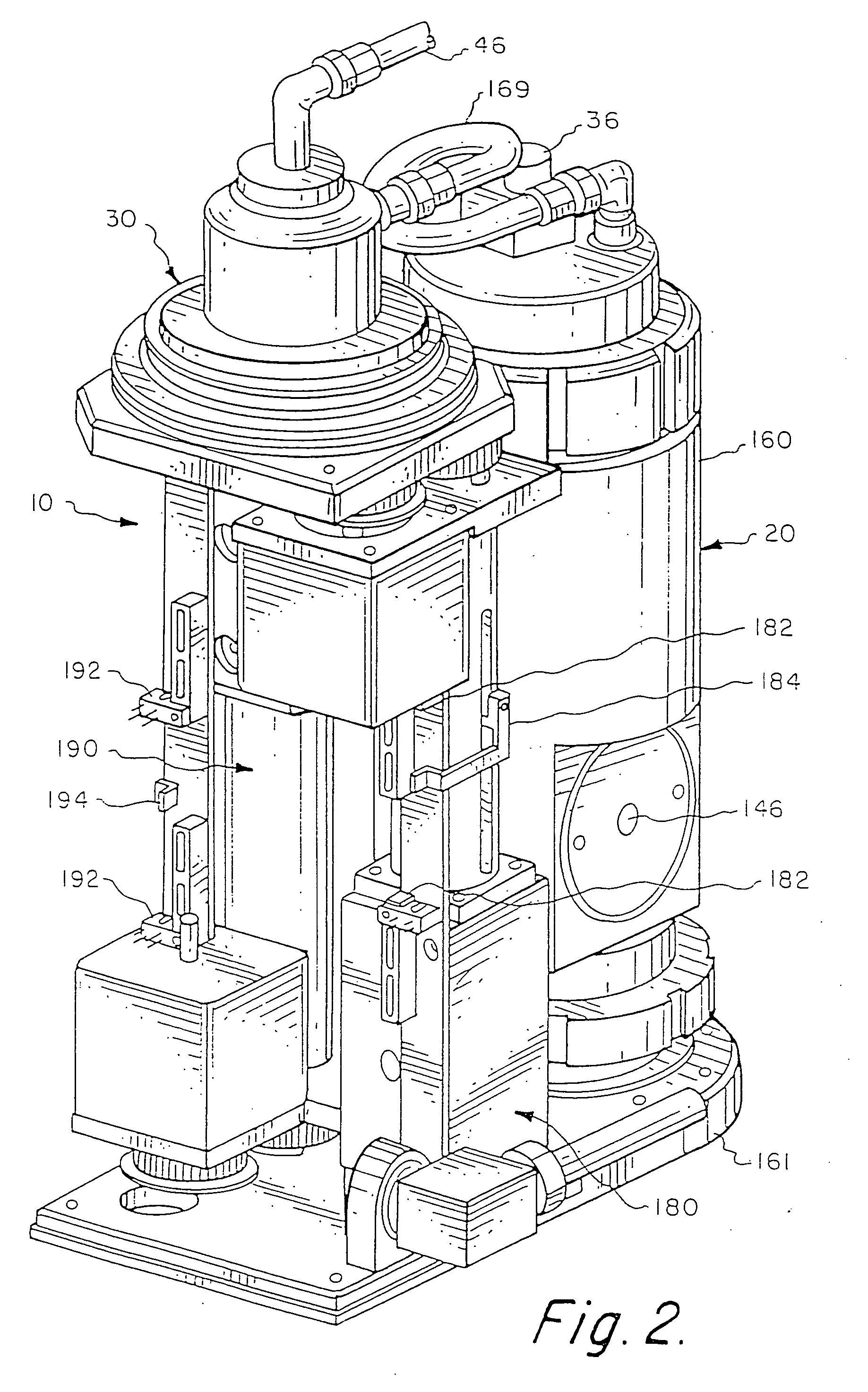

Continuously operable rotating drum pressure differential filter, method and systems

InactiveUS6800197B1Reduce downtimeImprove throughputWater/sewage treatmentMultistage water/sewage treatmentFilter mediaFilter system

A rotating drum pressure differential filter is provided whereby a layer of filter medium is continuously refreshed by a spray applicator device after the layer is utilized to filter components sample medium and a portion of the layer is subsequently scraped to remove sample medium waste from the layer. Methods of filtration using the device are also provided as are systems employing two or more such filters. A spray applicator device useful for refreshing a filter medium on the outer surface of a rotating drum pressure differential filter is also provided as is a retro fit kit useful in modifying existing rotating drum pressure differential filters to enable the continuous formation of a refreshed filter medium layer. The continuously refreshed filter and filter systems provide a minimized down time of the filter and system operations. Multiple-stage filtration processes are also provided and are particularly in the recovery of enzymes from fermentation broths.

Owner:GENENCOR INT INC

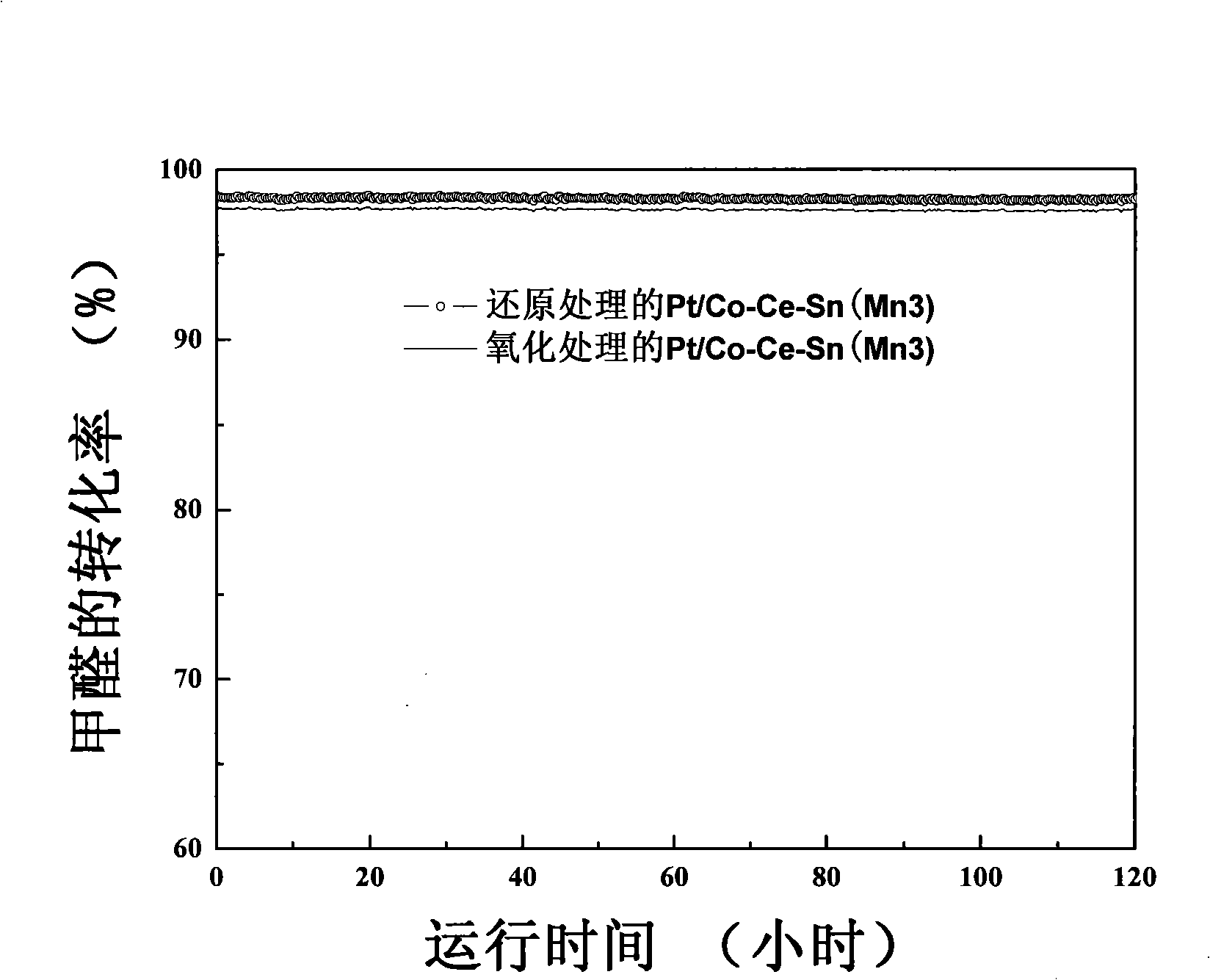

Room temperature catalyst for removing formaldehyde in air and method of preparing the same

ActiveCN101274281AReduce differential pressureCatalyst activation/preparationDeodrantsAir volumeAdditive ingredient

The invention discloses a high-efficiency oxidation catalyst which is used for oxidizing formaldehyde into H2O and CO2 below the room temperature and a preparation method thereof, and the invention is characterized in that the high-efficiency oxidation catalyst takes a honeycomb cordierite pottery and porcelain coated with poriferous Co-Ce-Sn composite oxides as a carrier, 0 to 10 percent of Pt as active components, and MoO3, CuOx, MnOx, TiO2 and so on as accessory ingredients, and the high-efficiency oxidation catalyst does not need energy resources such as light, heat and electricity, etc. and chemical agents to be additionally provided, has much higher removing efficiency of formaldehyde than the techniques of photochemical catalysis and plasma under the conditions of heavy blast volume and high humidity level, etc., does not have any byproduct, and is applicable to the highly-efficient removing of formaldehyde pollution of enclosed or semi-enclosed spaces such as production departments of man-made boards, living rooms and building material and furniture markets, etc.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

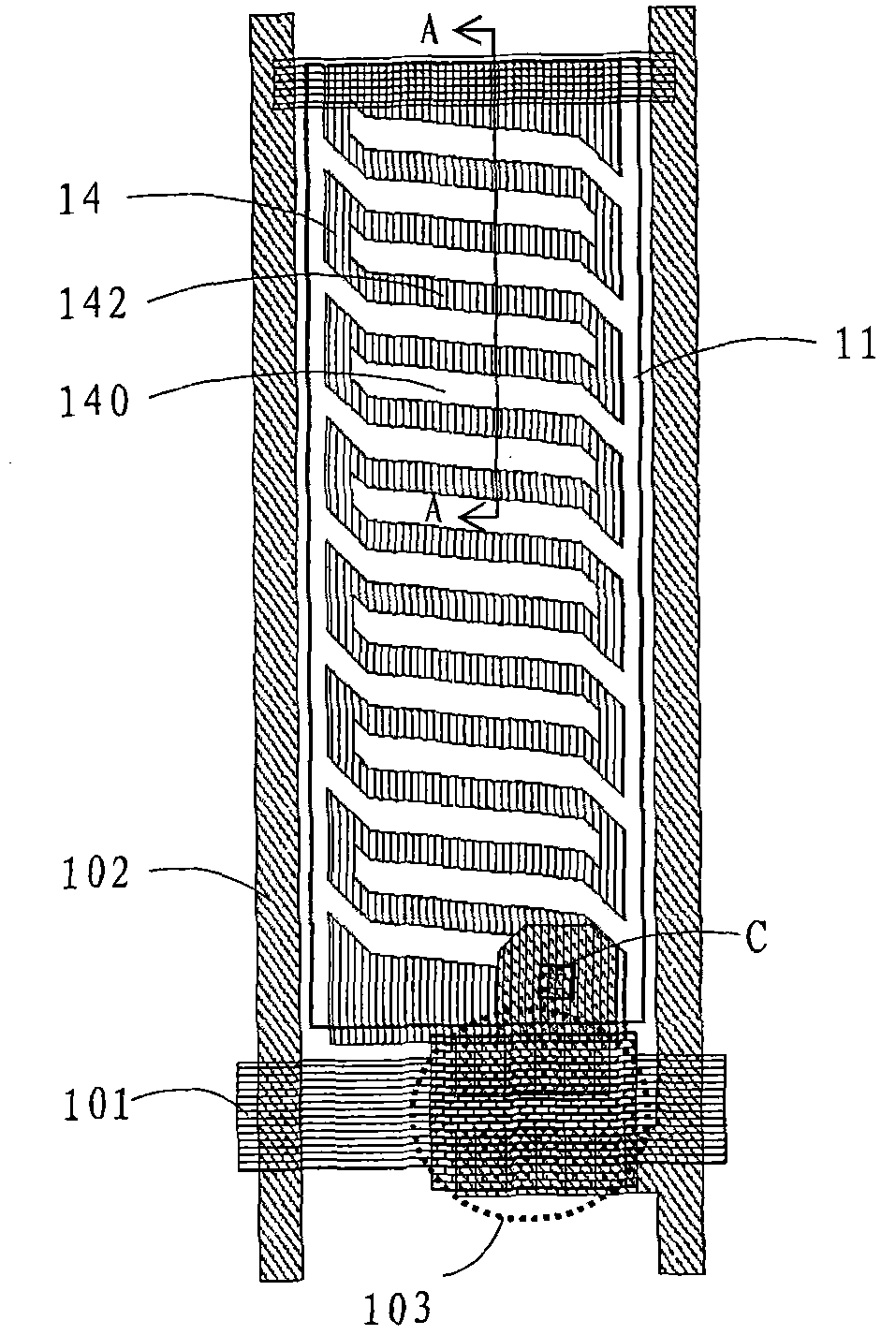

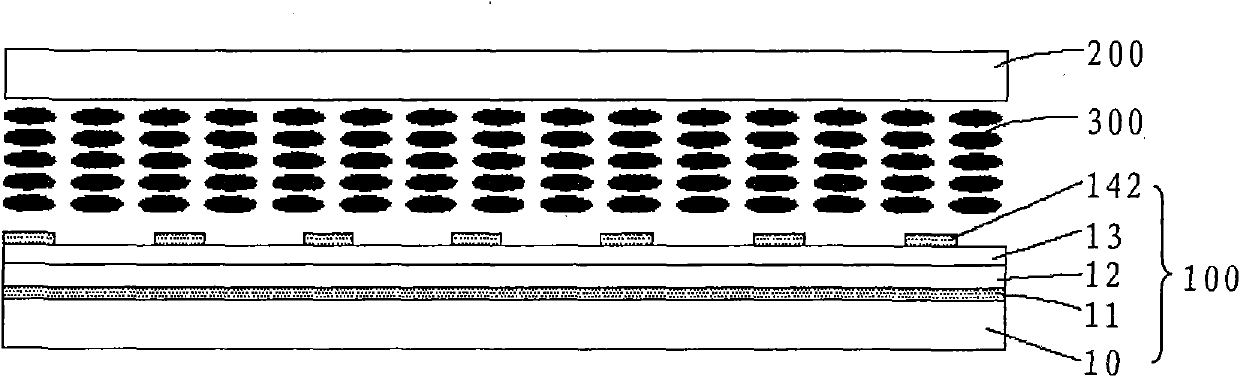

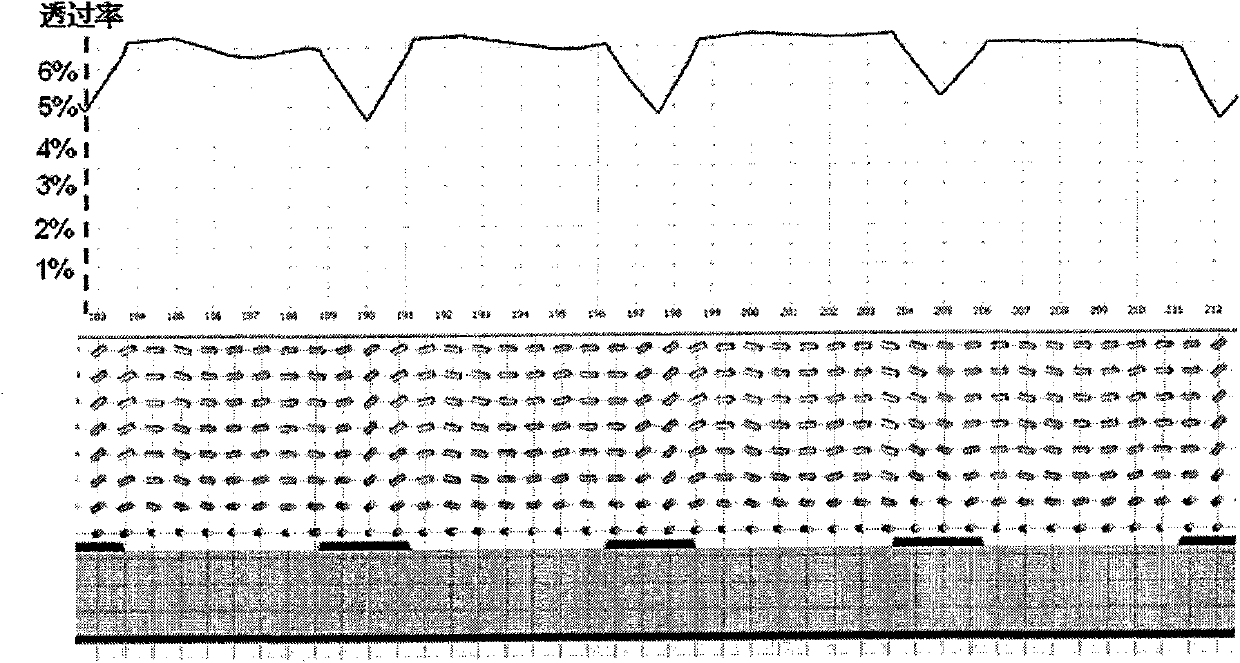

Fringe field switching (FFS) liquid crystal display (LCD) panel, manufacturing method thereof and LCD

ActiveCN101995707AReduce differential pressureReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingTransistor arrayLiquid-crystal display

The invention discloses a fringe field switching (FFS) liquid crystal display (LCD) panel, a manufacturing method thereof and an LCD. The LCD panel comprises a thin film transistor (TFT) array substrate, and the TFT array substrate comprises a transparent substrate as well as a plurality of scanning lines and a plurality of data lines which are formed on the transparent substrate, wherein, the plurality of scanning lines are crossed with the plurality of data lines to limit a plurality of pixel regions; each pixel region comprises a first transparent electrode, a second transparent electrode and a TFT; the first transparent electrode is equipped with a plurality of strip slots so that a plurality of first strip transparent electrode parts which are respectively spaced by the plurality of strip slots and electrically connected with each other are formed on the first transparent electrode; and each pixel region further comprises a plurality of strip projections which are positioned below the second transparent electrode and are corresponding to the positions of the plurality of slots of the first transparent electrode. The invention has the advantages that the driving voltage of theLCD panel can be lowered and the transmissivity can be improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

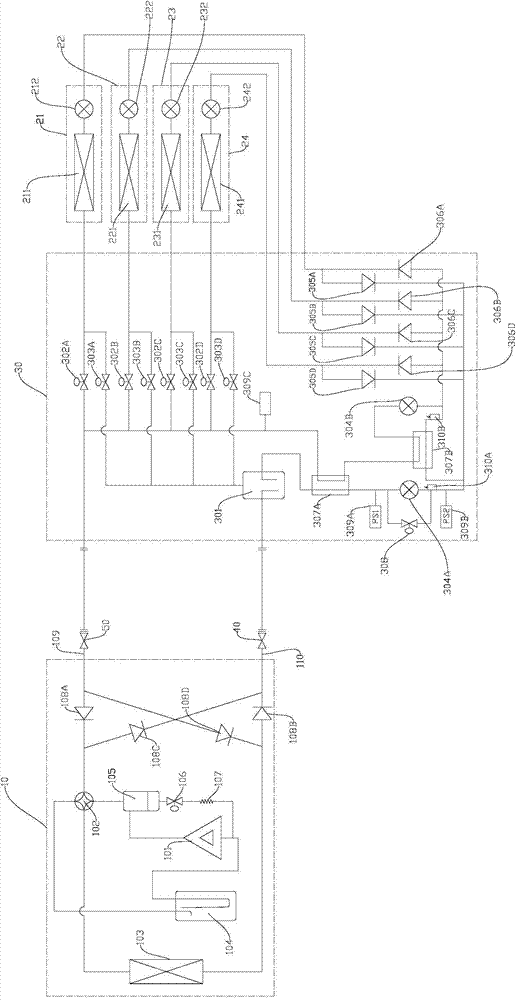

Multi-split system

ActiveCN104748239AImprove comfortReduce differential pressureMechanical apparatusSpace heating and ventilation safety systemsEmbedded systemUnit device

The invention discloses a multi-split system. The multi-split system comprises an outdoor unit device, a shunting device and multiple indoor unit devices; each indoor unit device comprises an indoor heat exchanger and a throttling element, and the shunting device comprises multiple first control valves and multiple second control valves corresponding to all the indoor unit devices; when any one of the indoor unit devices receives a mode switching instruction, the indoor unit device transmits the mode switching instruction to the shunting device, and the shunting device judges whether to open or close a first on-off valve and a second on-off valve corresponding to the indoor unit device according to the mode switching instruction. The multi-split system can effectively reduce noise generated in the mode switching process of the indoor unit devices, and improve the comfort of a user.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Apparatus and methods for pumping high viscosity fluids

InactiveUS20060070960A1Good benefitImprove performanceSpecific fluid pumpsPower operated devicesPump headViscosity

A system for dispensing and filtering fluid is disclosed, in which the fluid flow path is substantially vertical from the fluid inlet through fluid dispense. Substantially all wetted surfaces are Teflon® or some similar non-contaminating fluid, for applications such as cleanroom processes. A valve and a filter chamber are incorporated into a pump head to simplify the flow path and reduce potential contamination points. Preferred methods, and chips or other microelectronic devices fabricated from the apparatus or methods, are also disclosed.

Owner:ENTEGRIS INC

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS20100024891A1Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

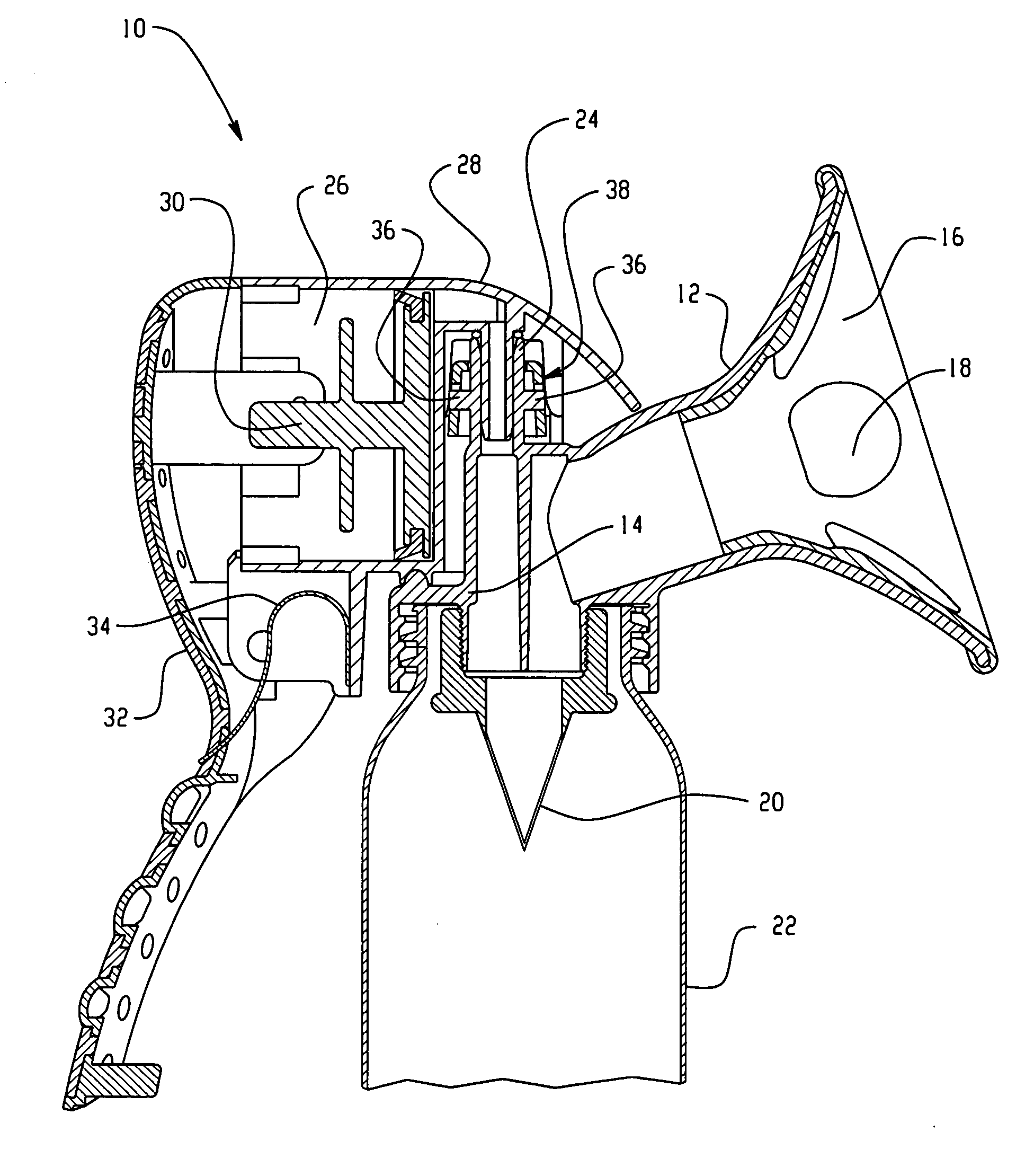

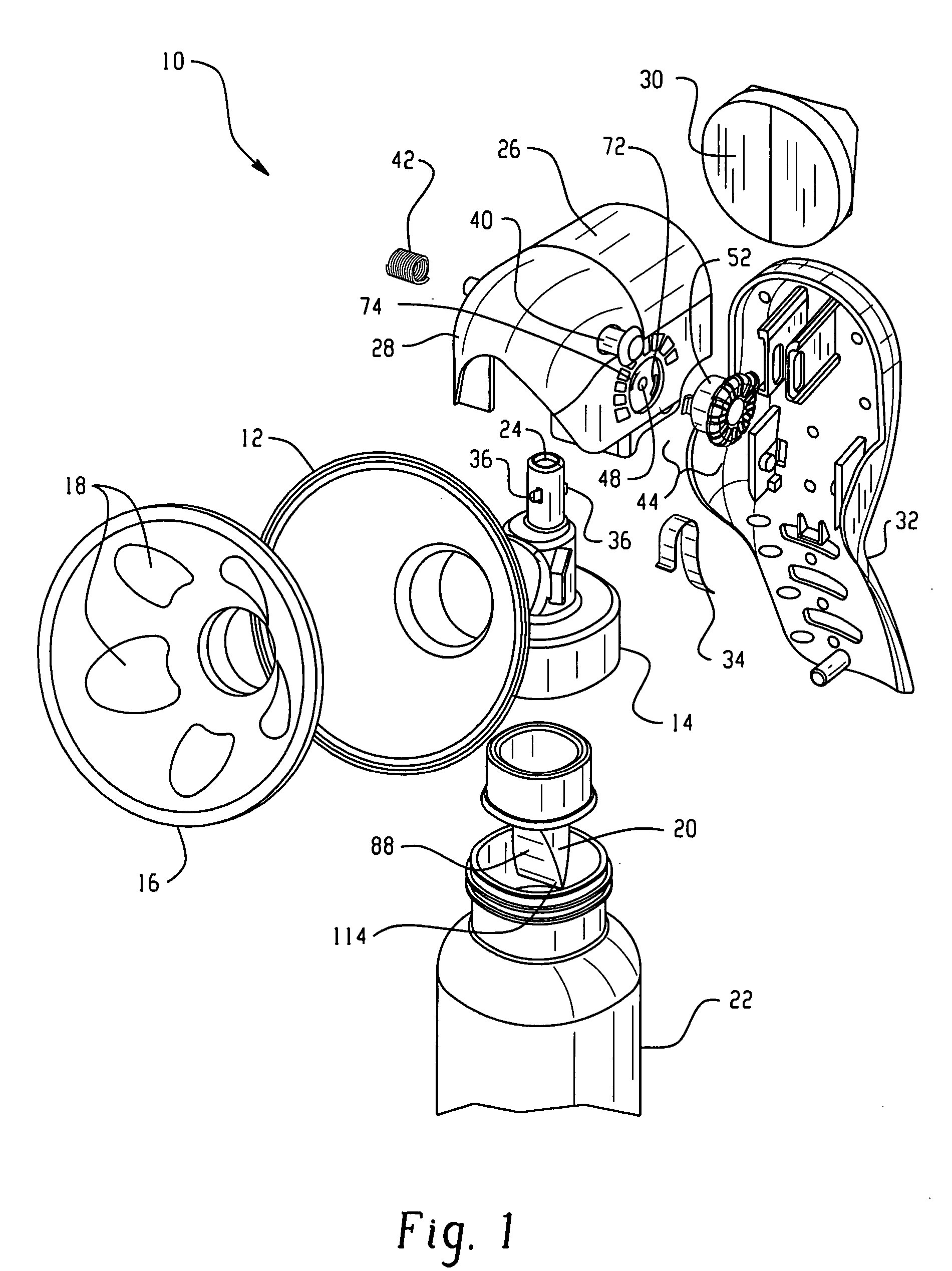

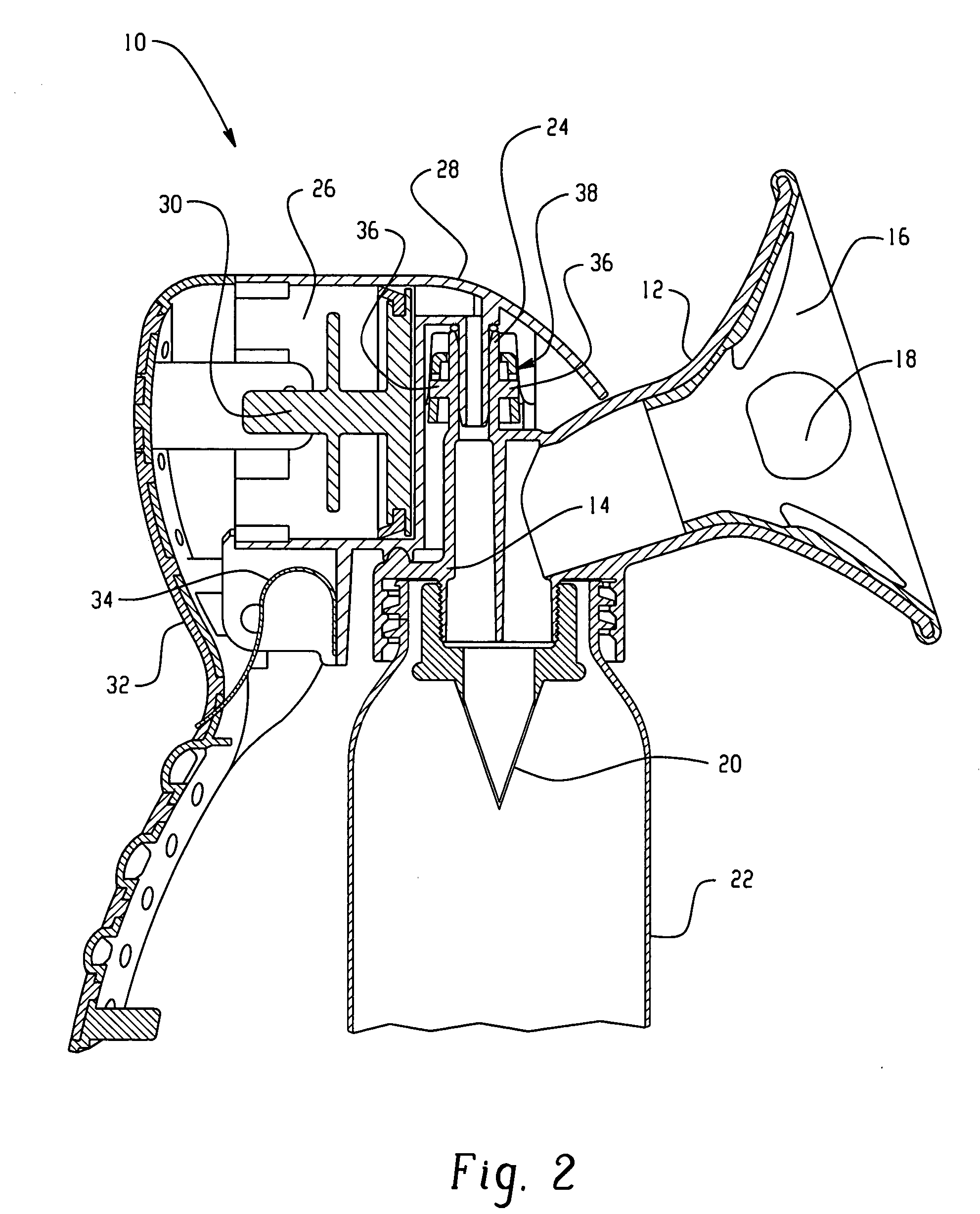

Breast pump pressure regulation valve

A pressure regulation device for selectively regulating the flow of a fluid between a lower pressure sink of a breast pump and a higher pressure source, the pressure regulation device comprising: (a) a valve body oriented with respect to a valve seat to selectively provide fluid communication between a lower pressure sink of a breast pump and a higher pressure source; and (b) an actuator operatively coupled to at least one of the valve body and the valve seat to manipulate the orientation of the valve seat with respect to the valve body, where the actuator is repositionable to selectively manipulate a volumetric flow of fluid between the higher pressure source and the lower pressure sink by varying the proximity of the valve seat with respect to the valve body.

Owner:EVENFLO CO INC

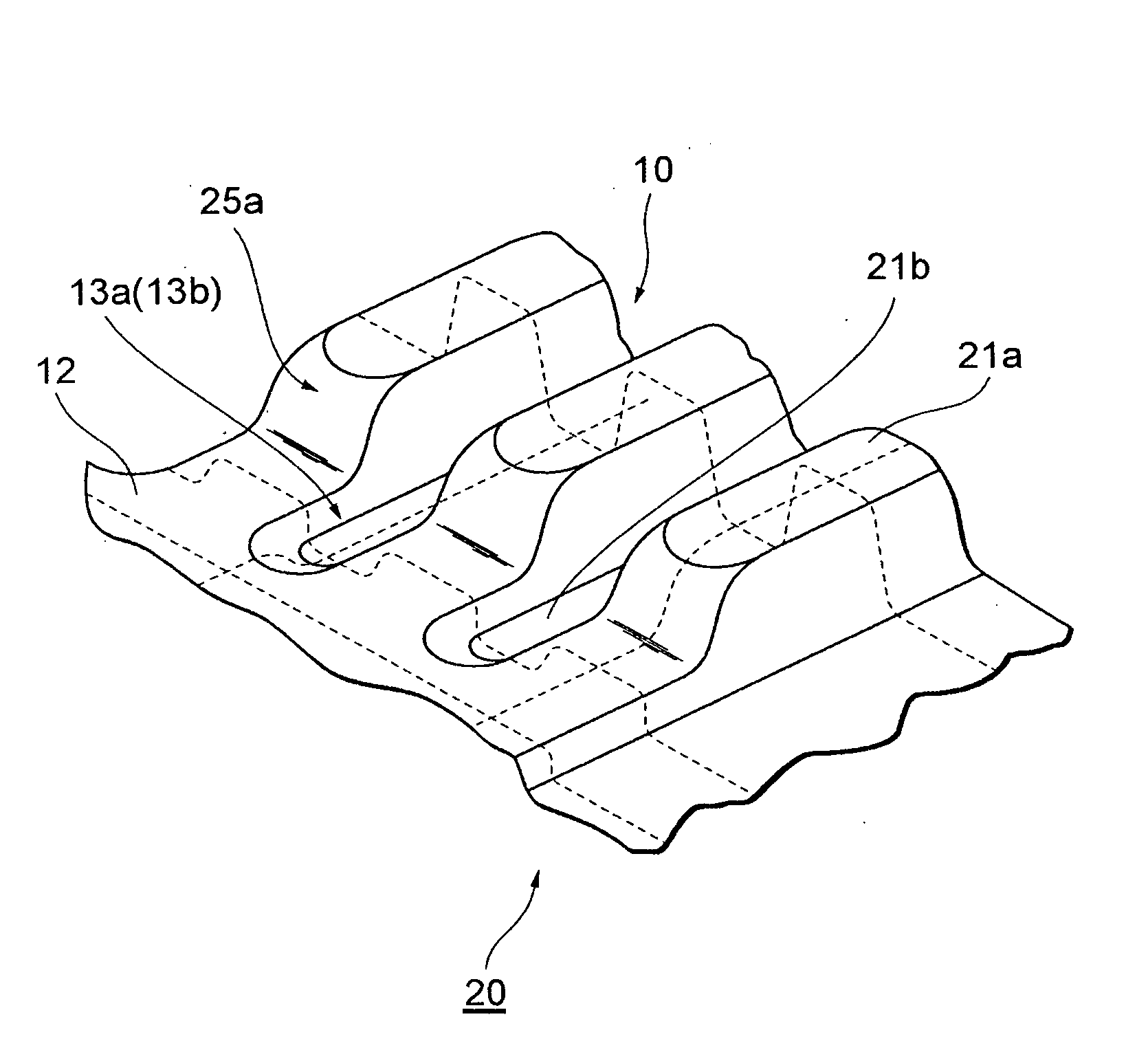

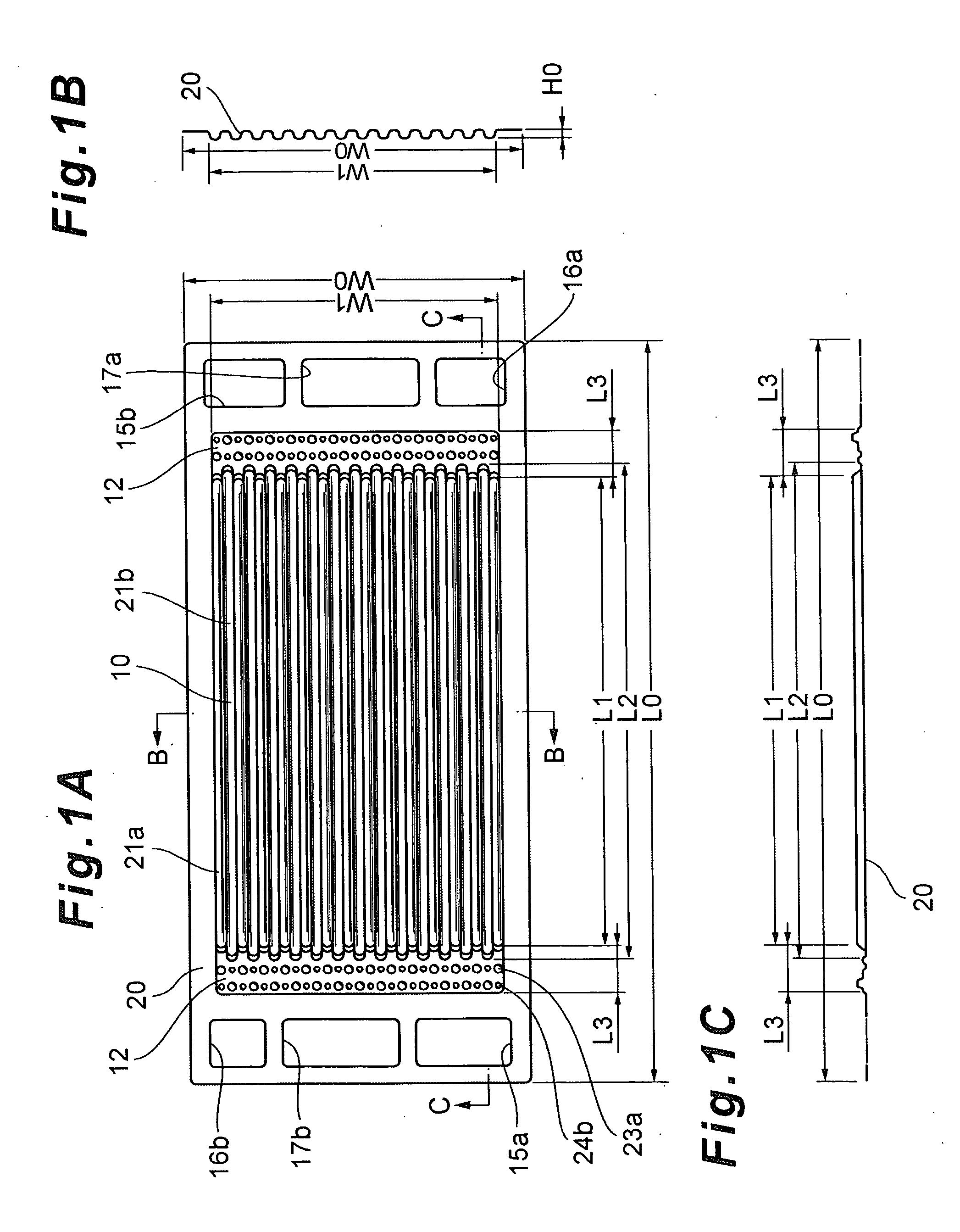

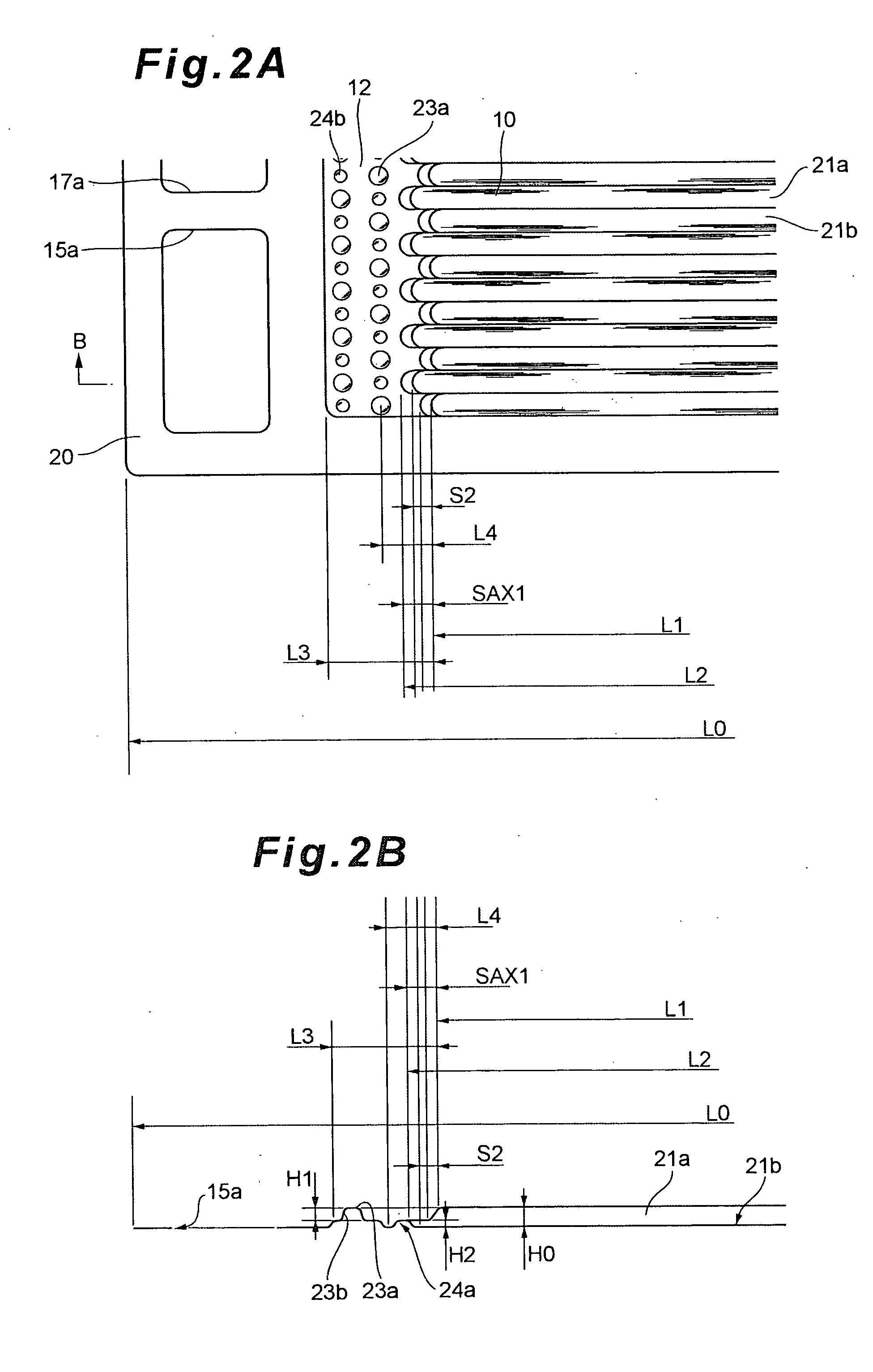

Separator of Fuel Cell

InactiveUS20090169964A1Easy to fixReduce differential pressureFuel cells groupingFuel cell auxillariesFuel cellsDifferential pressure

A differential pressure in a boundary portion between a streaked or linear fluid channel formed of a plurality of convex and concave portions disposed adjacent to one another in an undulated manner and a distribution channel for distributing a reactant gas or cooling water to be introduced into the plurality of fluid channels is reduced. In a structure of a separator of a fuel cell having a structure including streaked fluid channels formed of adjacent convex and concave portions formed on the surface of the separator, and a distribution channel which distributes, to these fluid channels, a fluid to be introduced into the fluid channels, in a boundary portion between the linear fluid channel and the distribution channel, a position of a terminal end of the convex portion constituting the fluid channel and a position of a terminal end of the concave portion are displaced in a streak direction of the fluid channel. It is preferable that the terminal end of the concave portion is positioned closer to the distribution channel than the terminal end of the convex portion. It is also preferable that the separator has a structure of such a type that front and back surfaces are integrated.

Owner:TOYOTA JIDOSHA KK

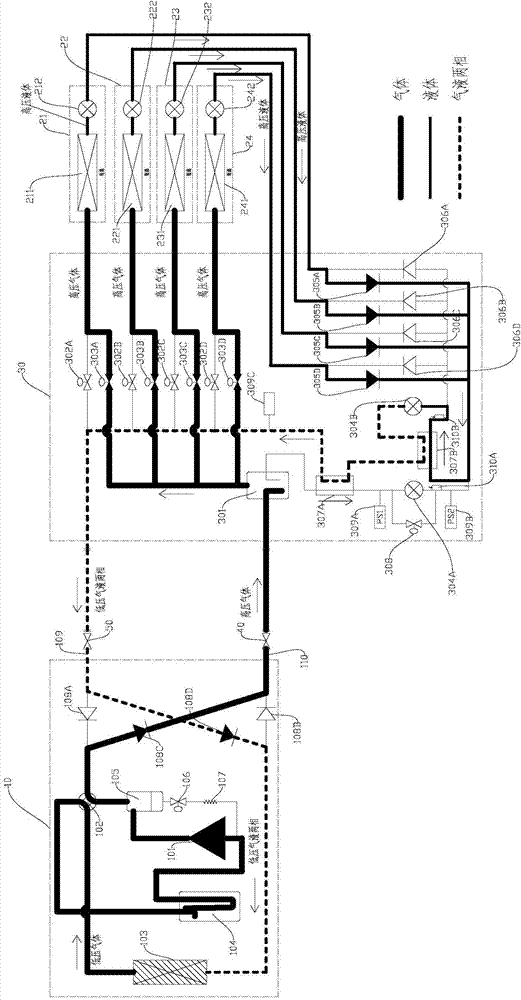

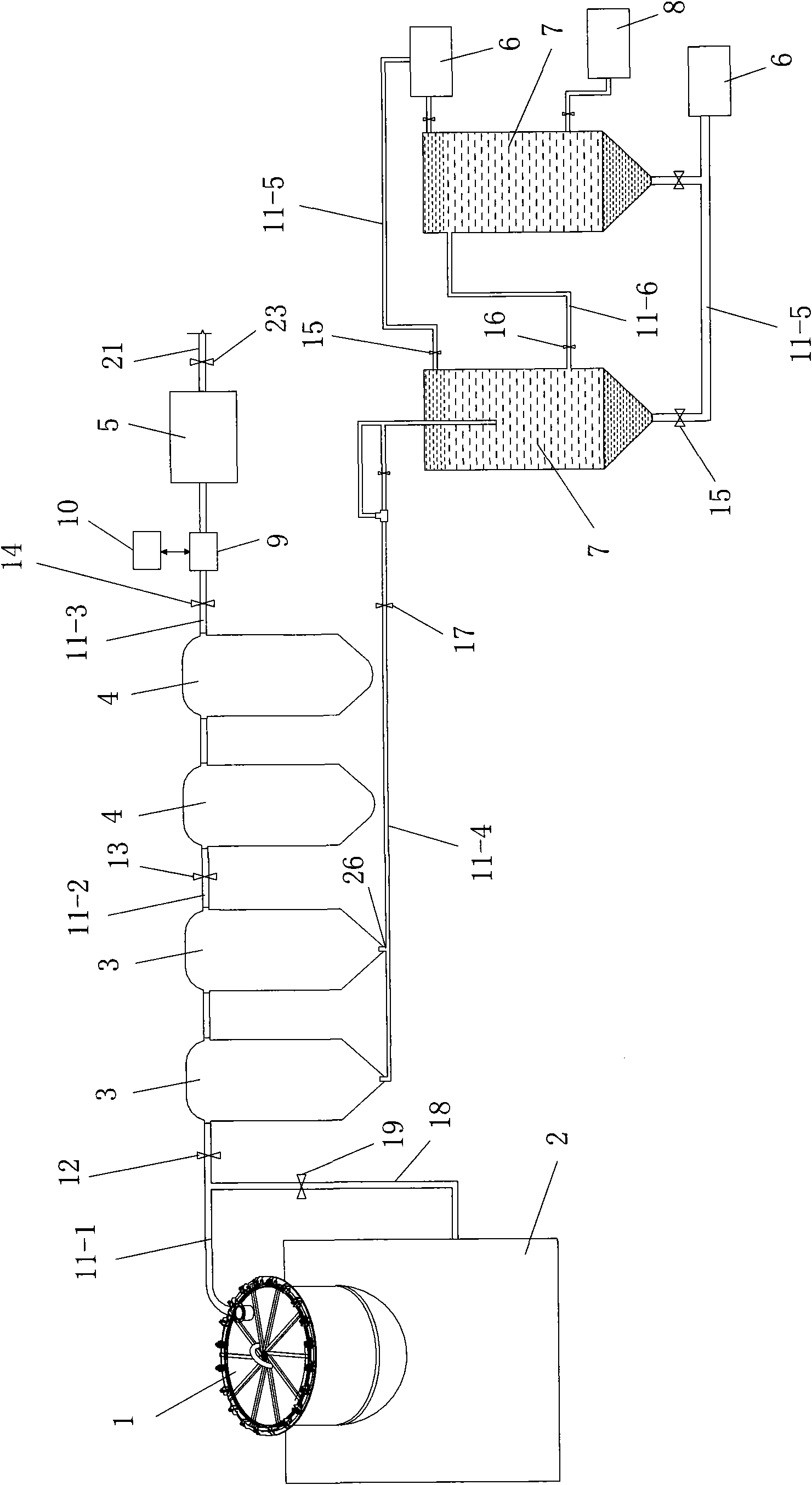

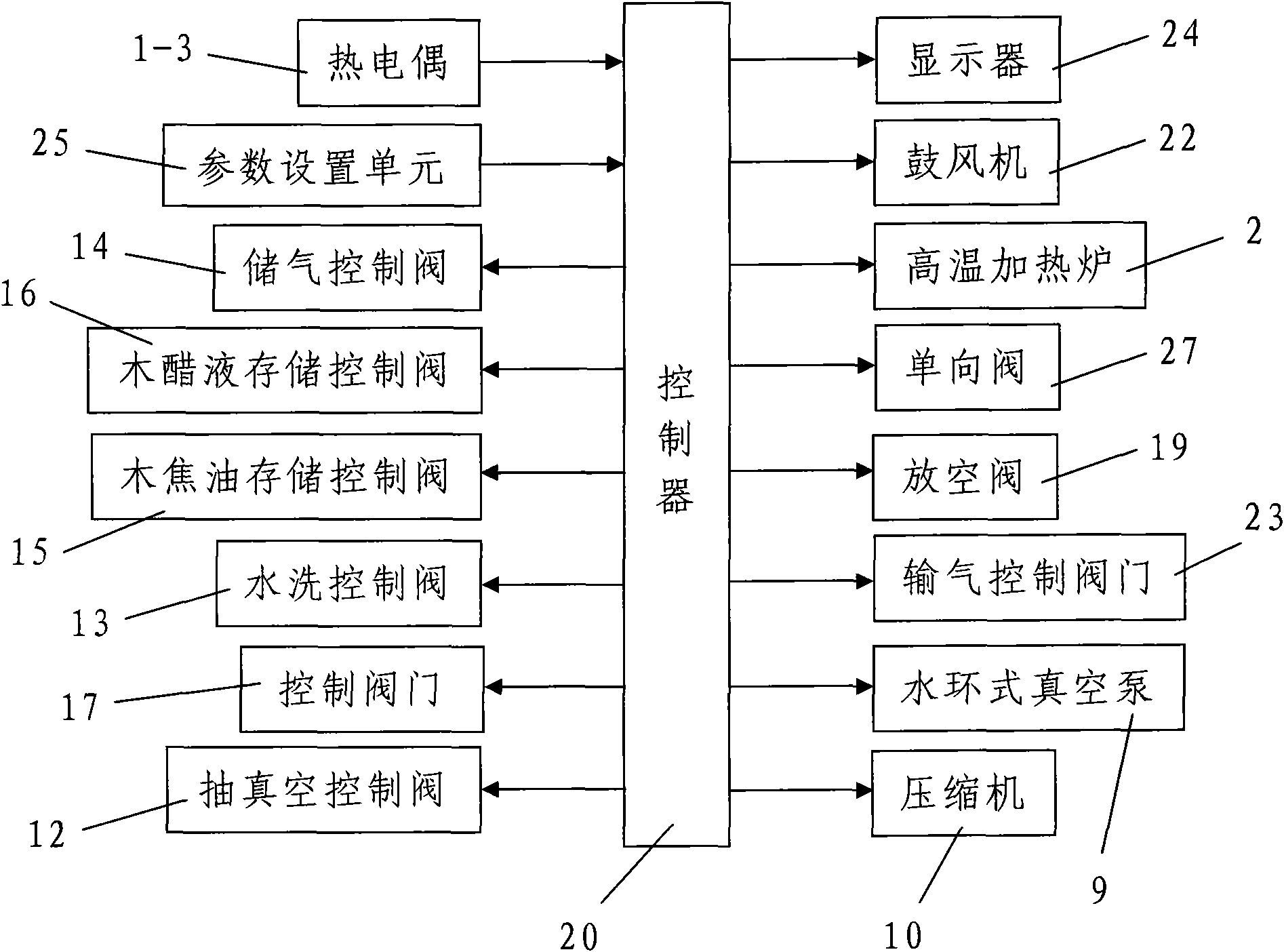

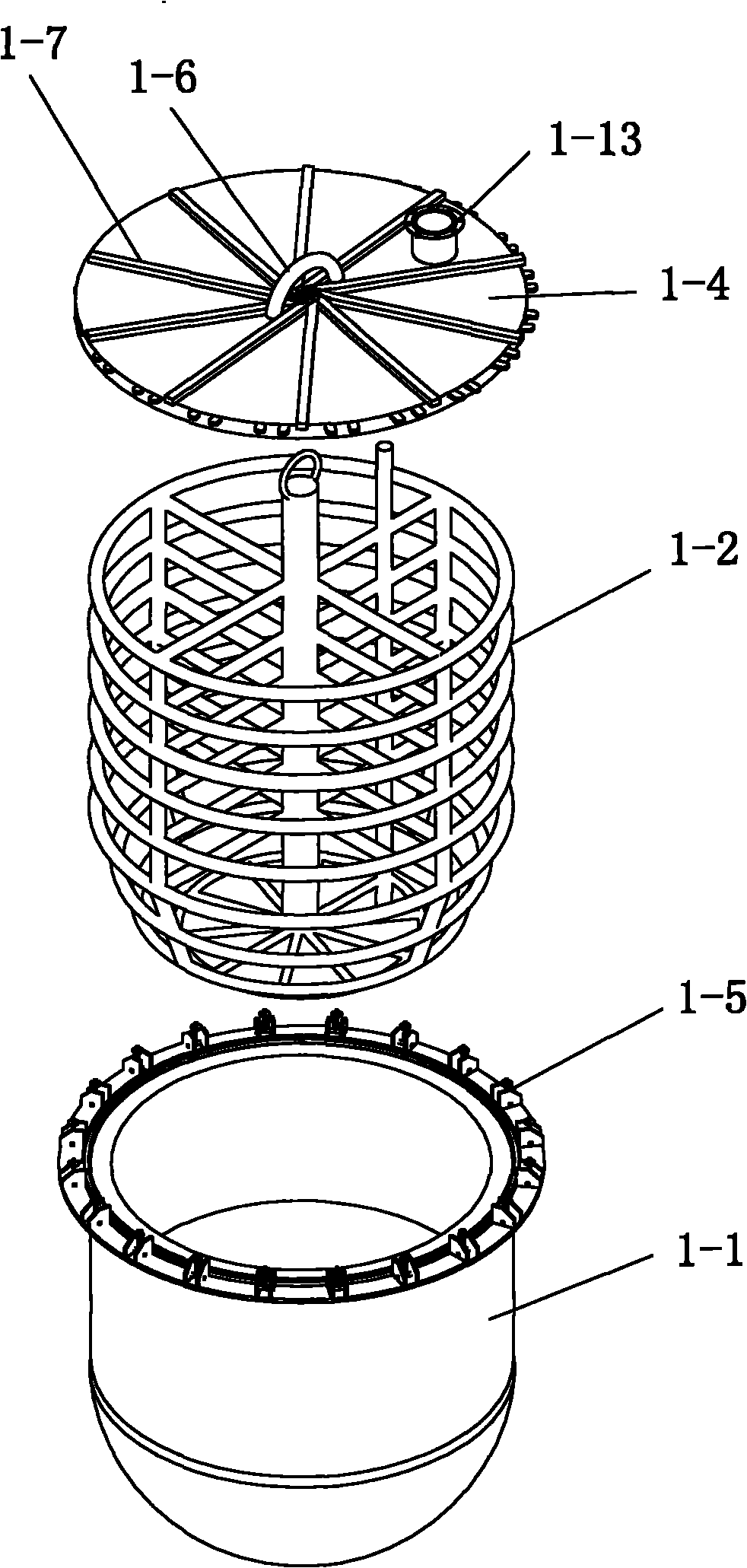

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

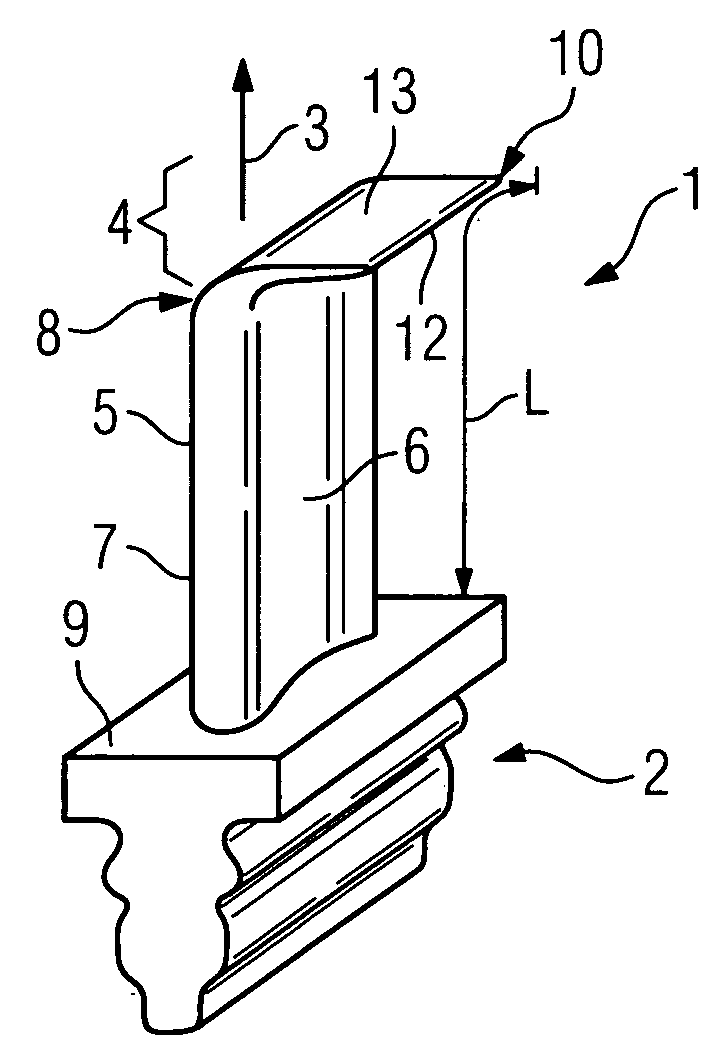

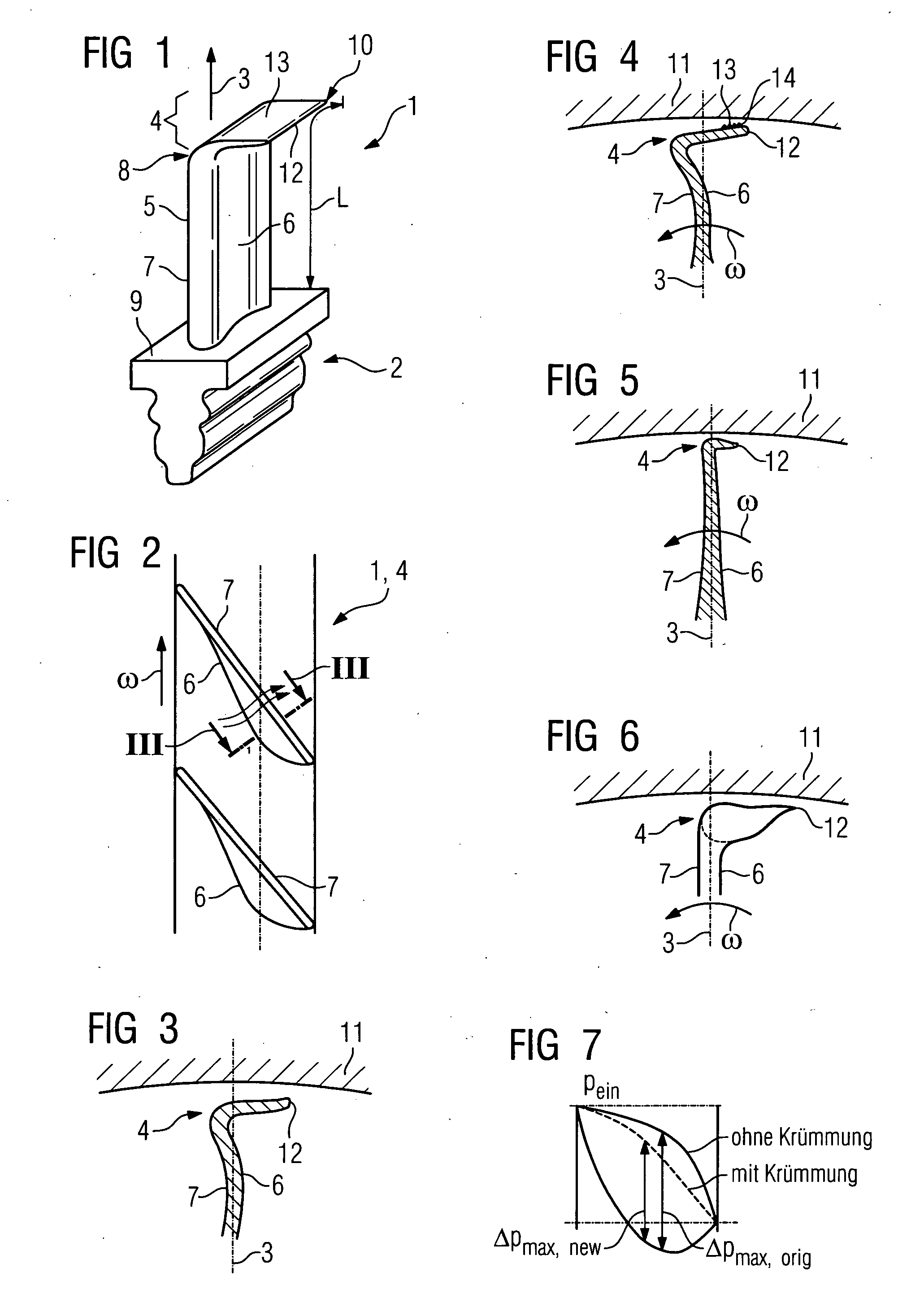

Free-standing turbine blade

InactiveUS20080213098A1Low gap lossReduce differential pressurePropellersPump componentsTurbine bladeAirplane

There is described a blade for a turbomachine, such as a steam turbine. The blade has a blade tip, which is curved in relation to the blade airfoil profile. The curvature has the shape of a winglet, which is known from aircraft construction.

Owner:SIEMENS AG

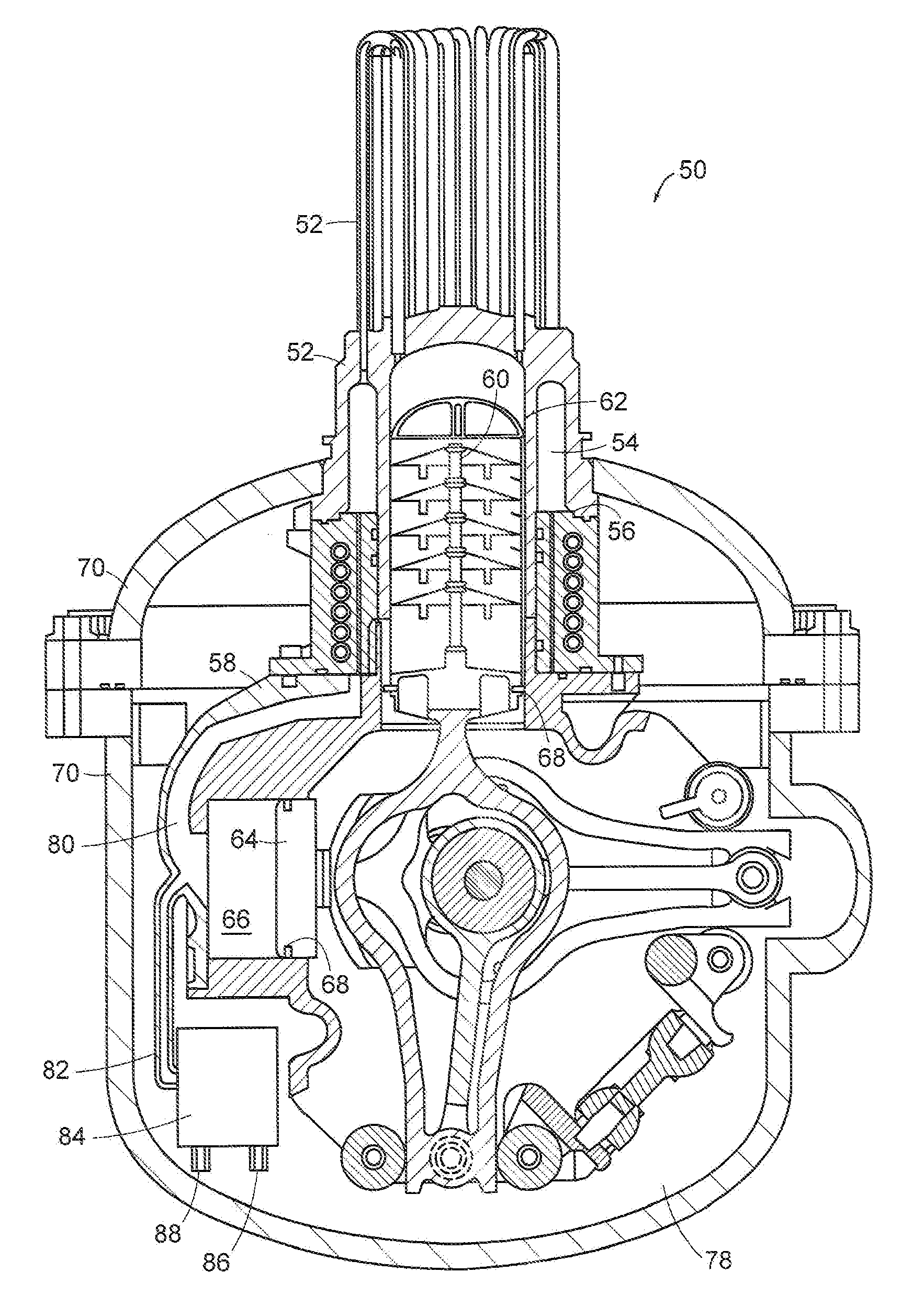

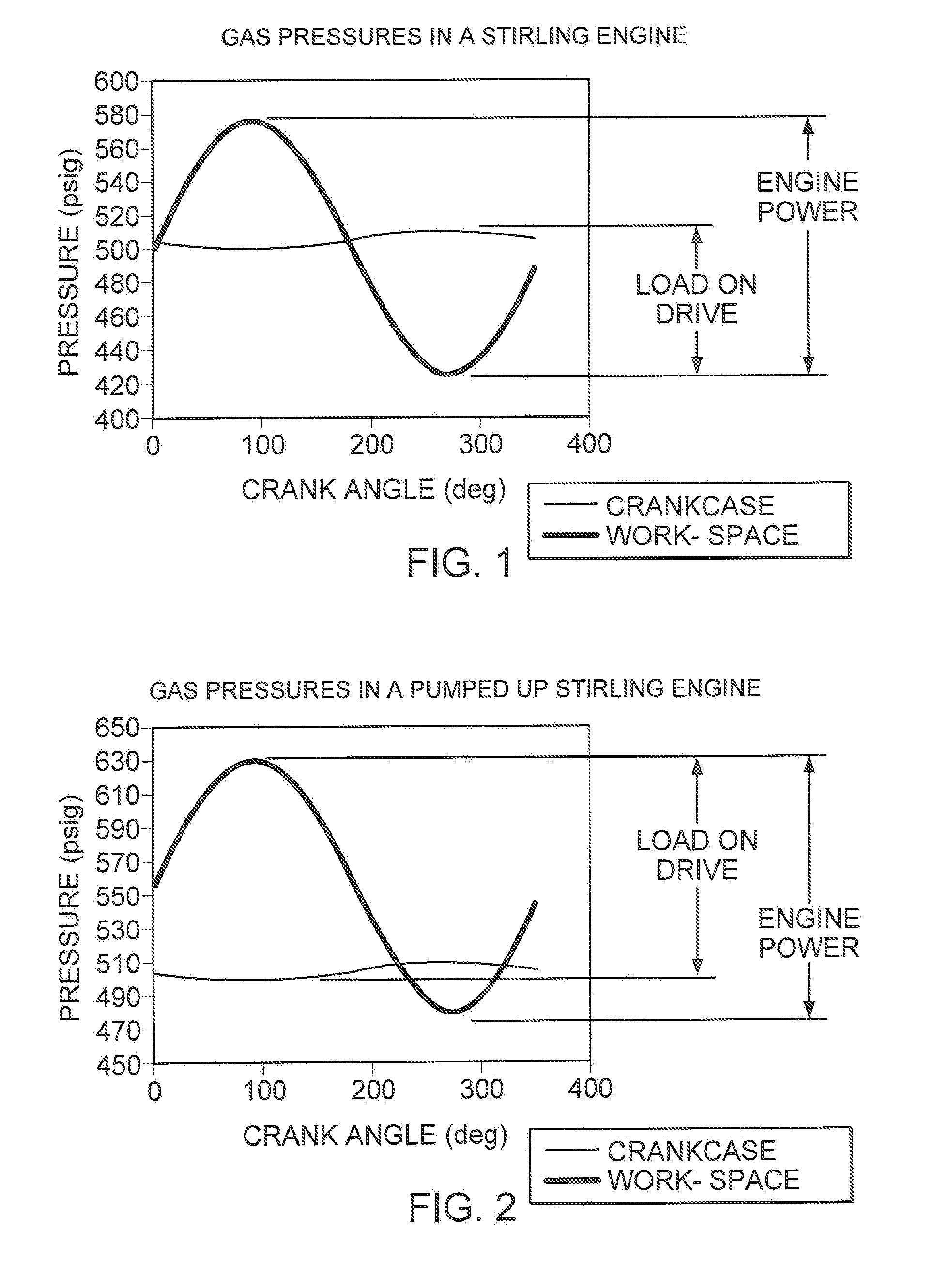

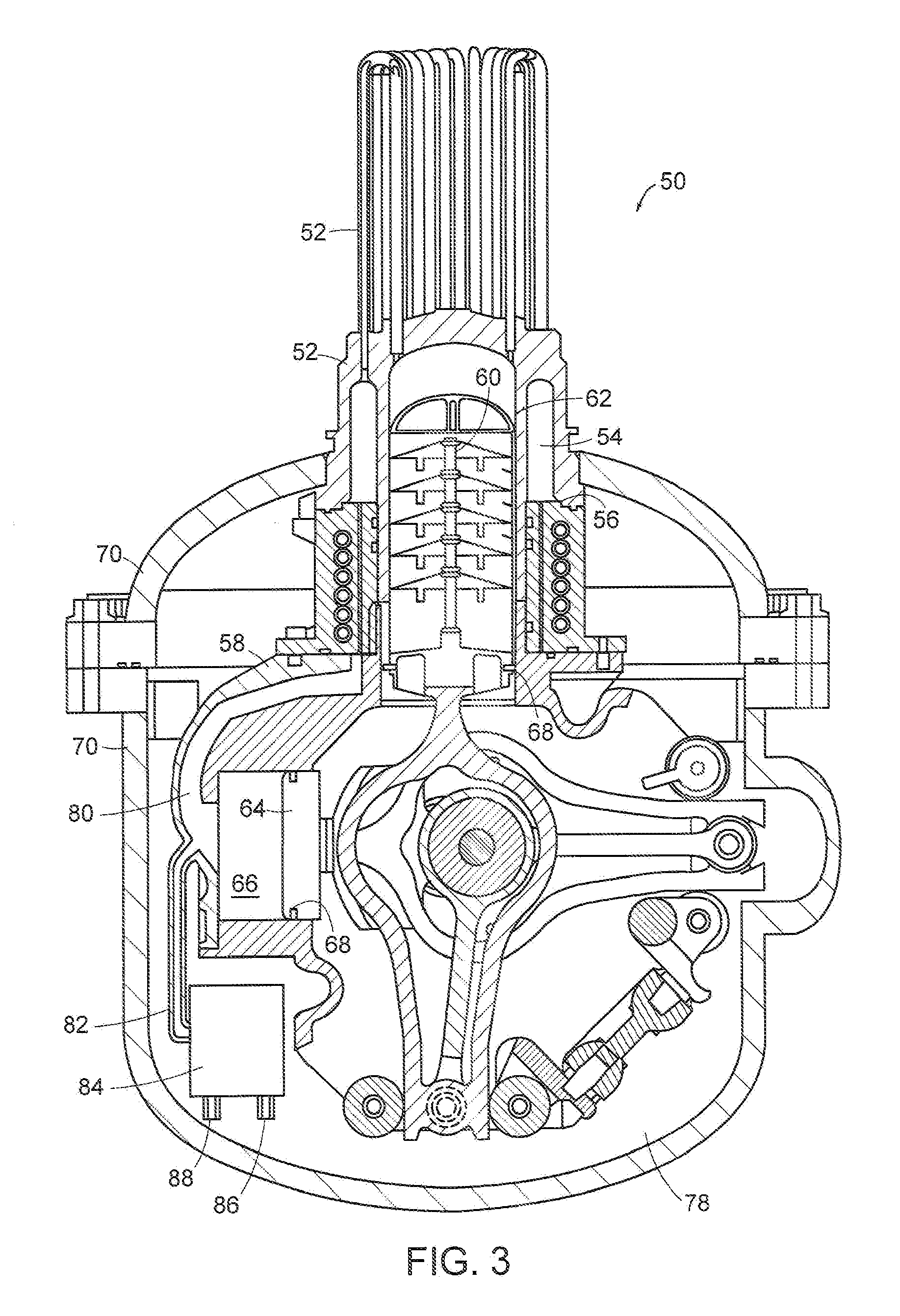

Work-space pressure regulator

ActiveUS7310945B2Reduces mean pressure differenceReduce differential pressurePump controlPositive-displacement liquid enginesEngineeringCrankcase

Owner:NEW POWER CONCEPTS

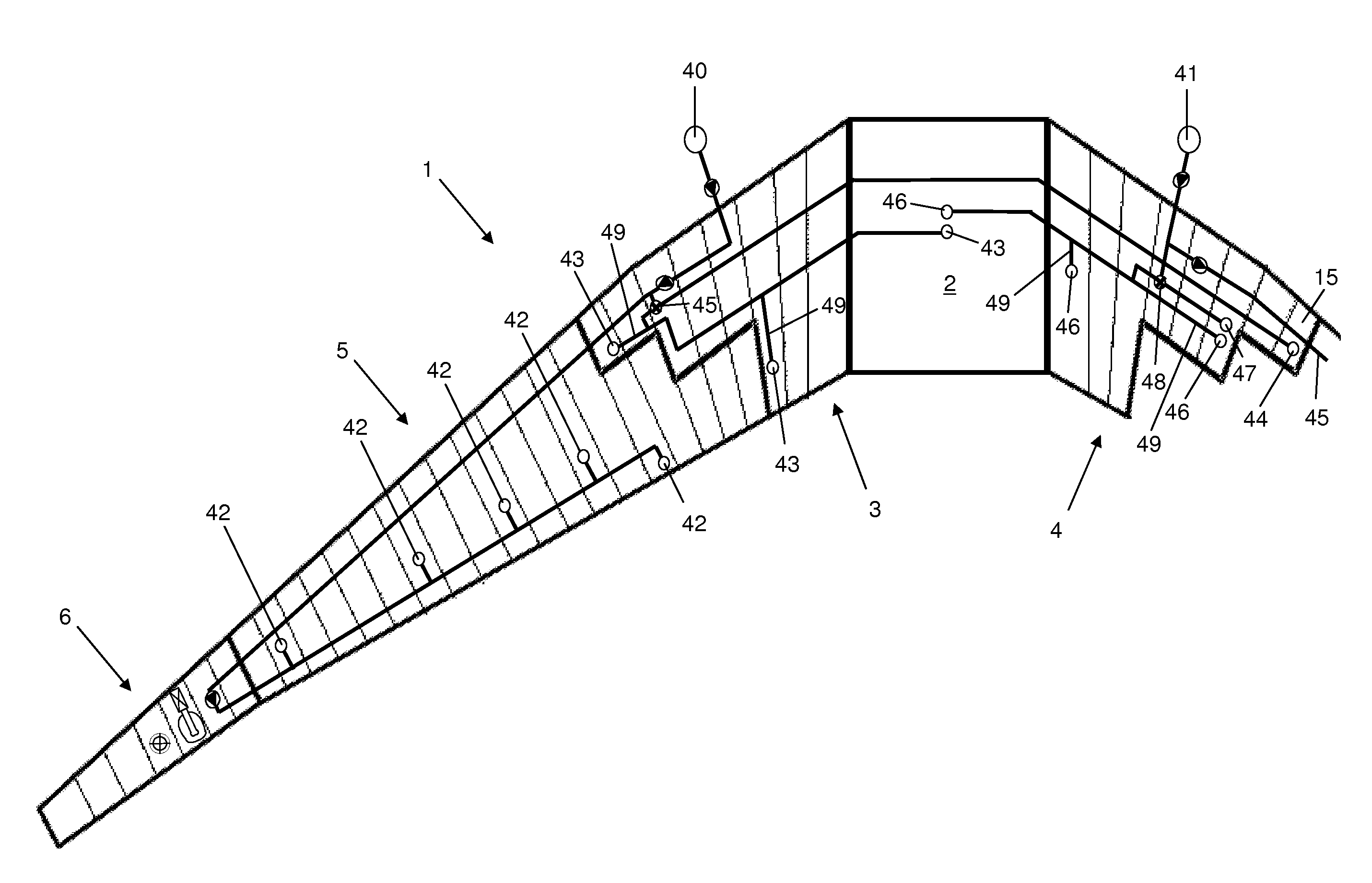

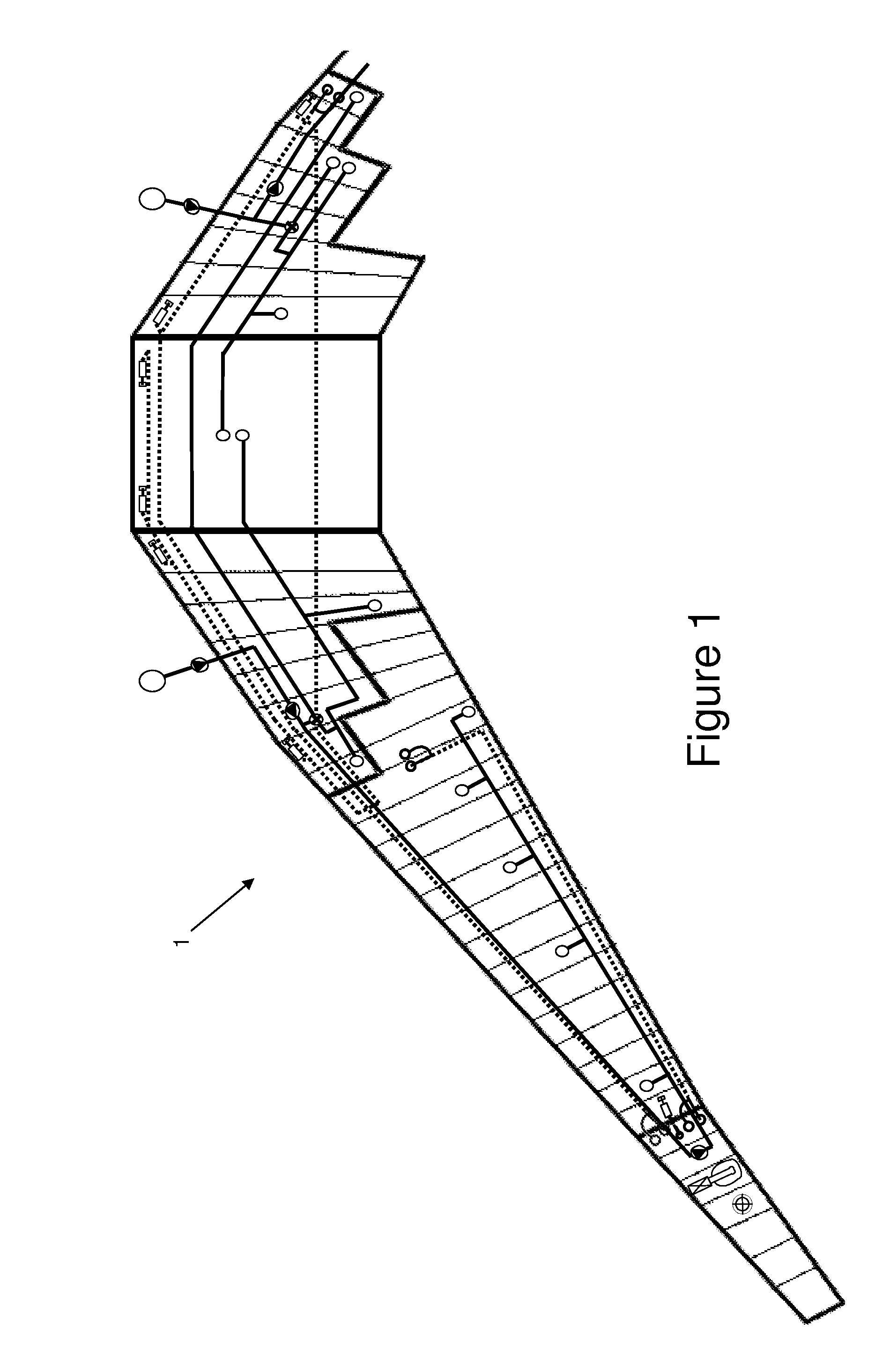

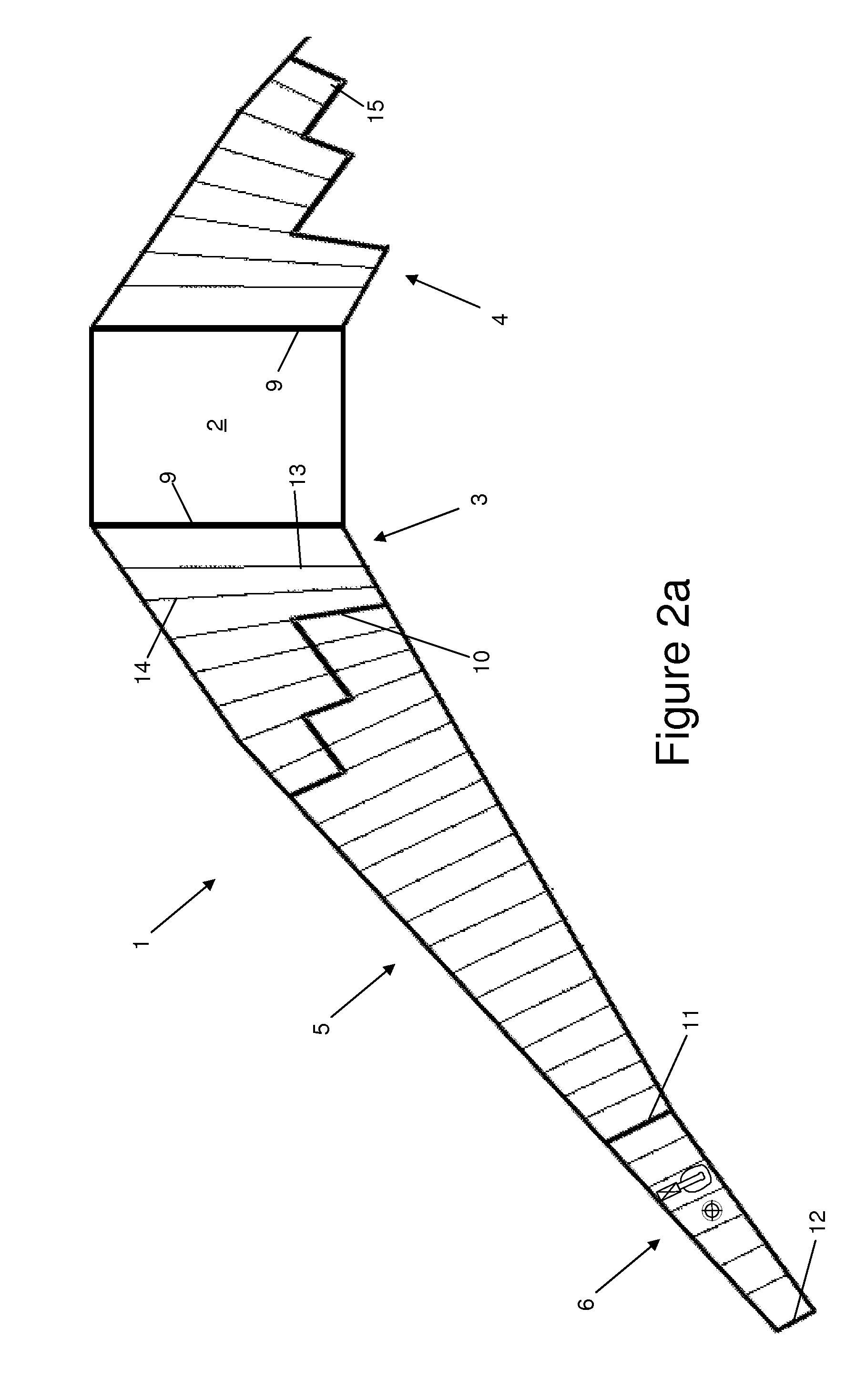

Aircraft fuel system

InactiveUS20120193479A1Reduce differenceReduce differential pressurePower plant fuel tanksFuel tank safety measuresAirplaneAutomotive engineering

An aircraft fuel system has a fuel tank with first and second cells separated by one or more baffles. A venting system reduces pressure difference between the interior and exterior of the fuel tank, and an inerting system supplies oxygen-depleted gas to the fuel tank. The baffles permit the flow of fluid between the cells. The venting system has one or more vent nozzles within the fuel tank and in fluid communication with one or more vent ports. The inerting system has one or more inerting nozzles for injecting oxygen-depleted gas into the first and second cells. A control device varies the ratio between the total flow rates of the oxygen-depleted gas into the first and second cells.

Owner:AIRBUS OPERATIONS LTD

Method and device for irrigation of body cavities

ActiveUS20070249993A1Accelerate liquid flowGood blood pressureEndoscopesMedical devicesAutomatic controlRed blood cell

A pressure and a vision regulation method and device for irrigation of a body cavity (1), in which method an inflow liquid pump (2) pressurizes the irrigation liquid in a feed line (13) and in which an outflow device (3) or an external suction source (20) drains the irrigation liquid from the body cavity (1) through a tubing (16) into a waste container (17) and in which a control unit (4) controls either the inflow liquid pump (2) only or both the inflow liquid pump (2) and the outflow device (3) depending on an inflow irrigation liquid pressure from a pressure sensor (5), where the first control unit (4) compares the inflow irrigation liquid pressure and flow with pressures calculated to correspond to pressure in the body cavity for the respective flow for a nominal surgical site and that a matching between the calculated values and the inflow irrigation liquid pressures is made by altering the effect of either the inflow liquid pump (2) only or the inflow liquid pump (2) and / or the outflow device (3) and / or the shut off valve. The above-mentioned pressure registration method and the device for irrigation of a body cavity is combined with an method for detecting blood cells, red blood cells, haemoglobin and / or debris in liquid coming from a surgical site so an automatically control and rinsing system is achieved keeping a clear vision in the viewing area of the operational site.

Owner:TENNESSEE MEDICAL INNOVATIONS INC

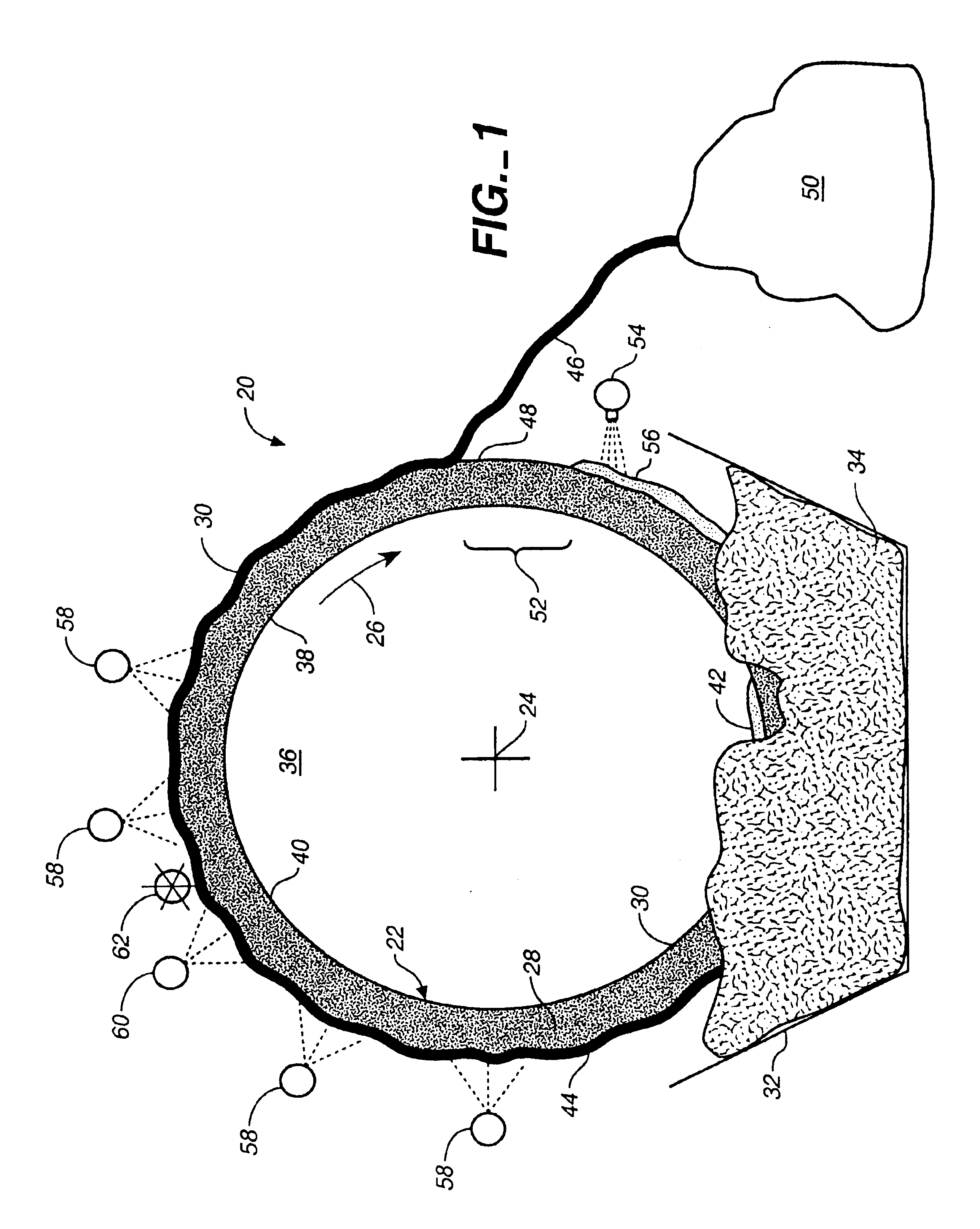

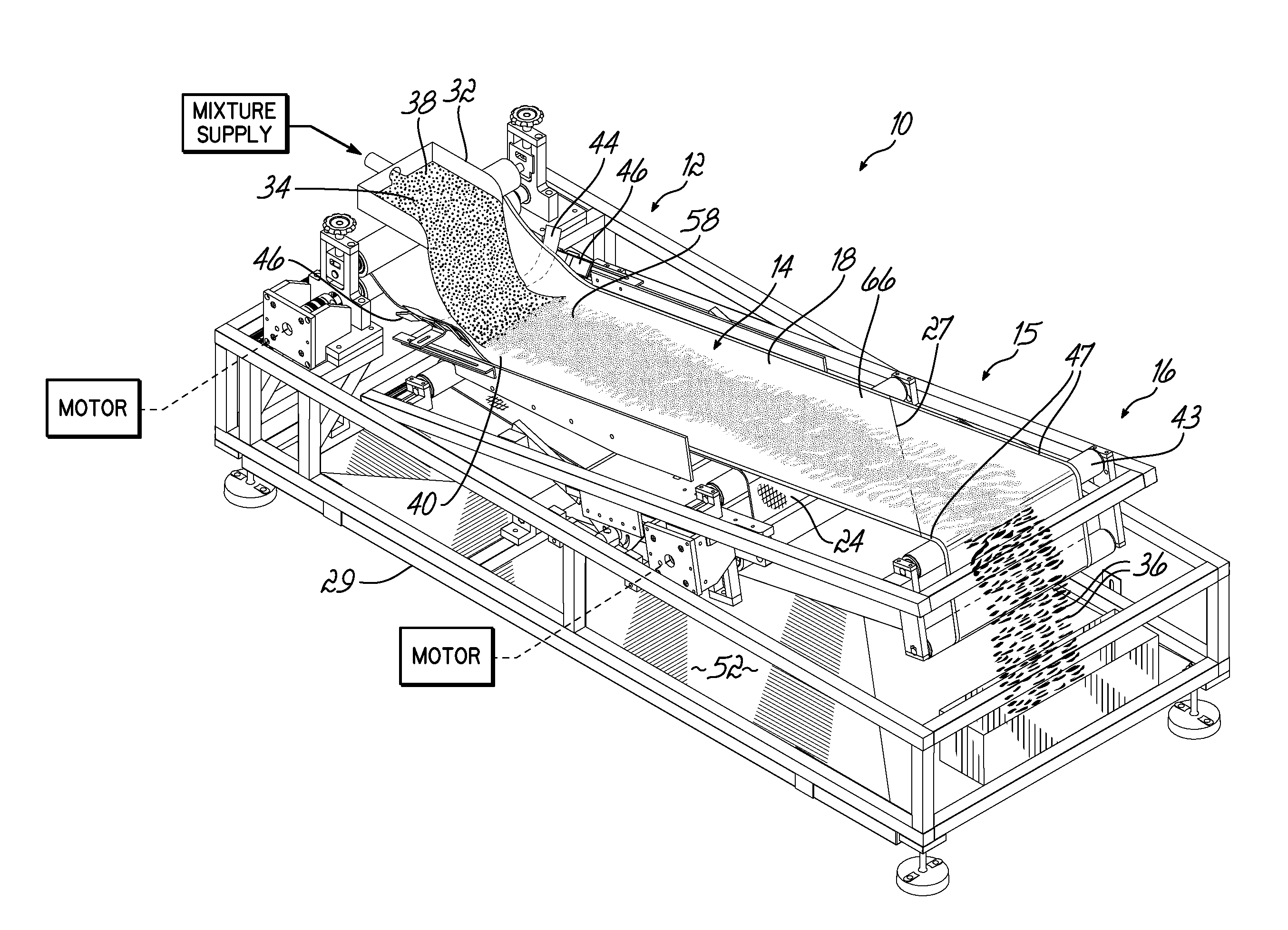

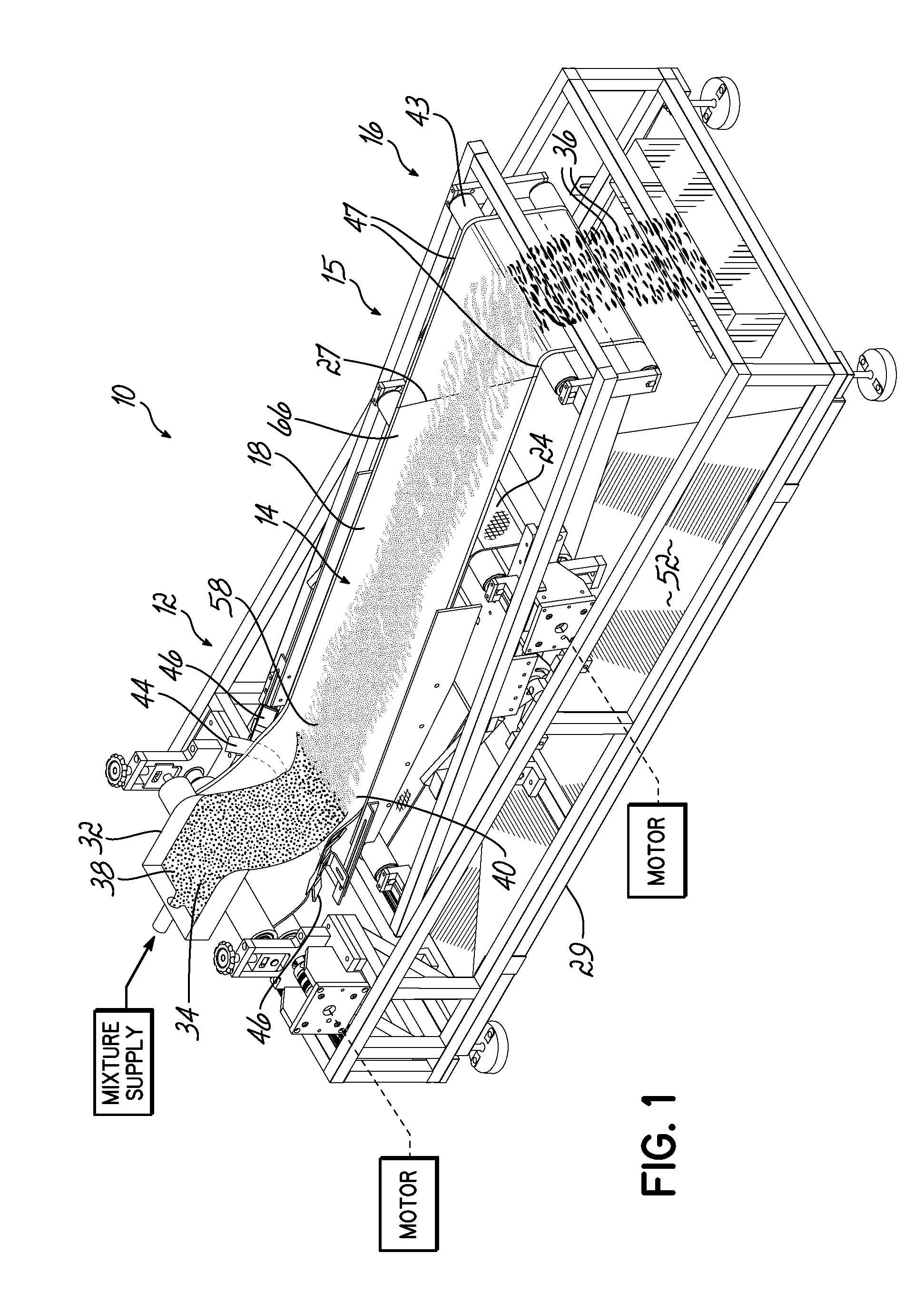

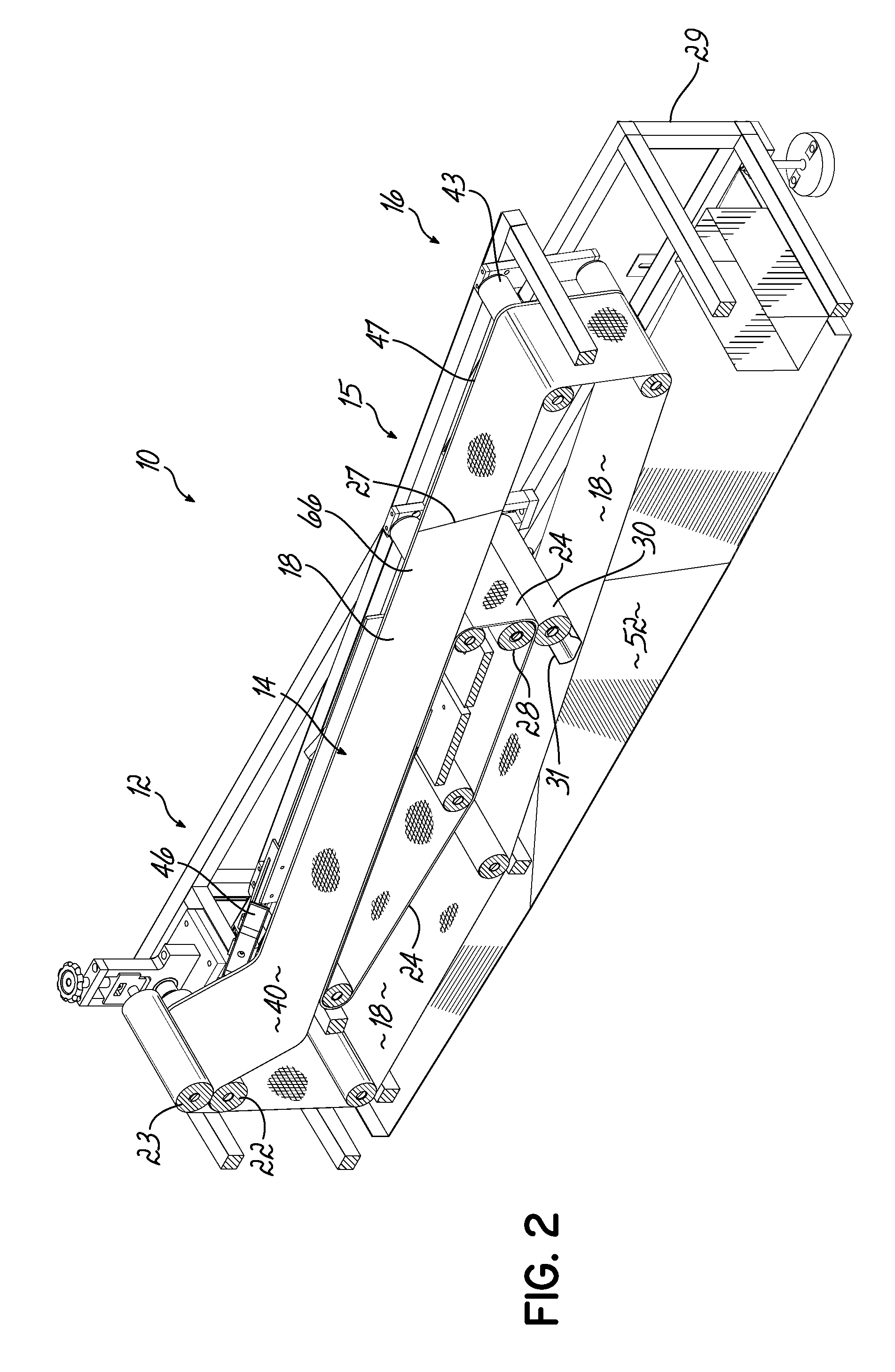

Method and apparatus for separating particles from a liquid

ActiveUS20100224574A1Easy to separateReduce differential pressureUnicellular algaeSolid sorbent liquid separationEngineering

Owner:UNIVENTURE

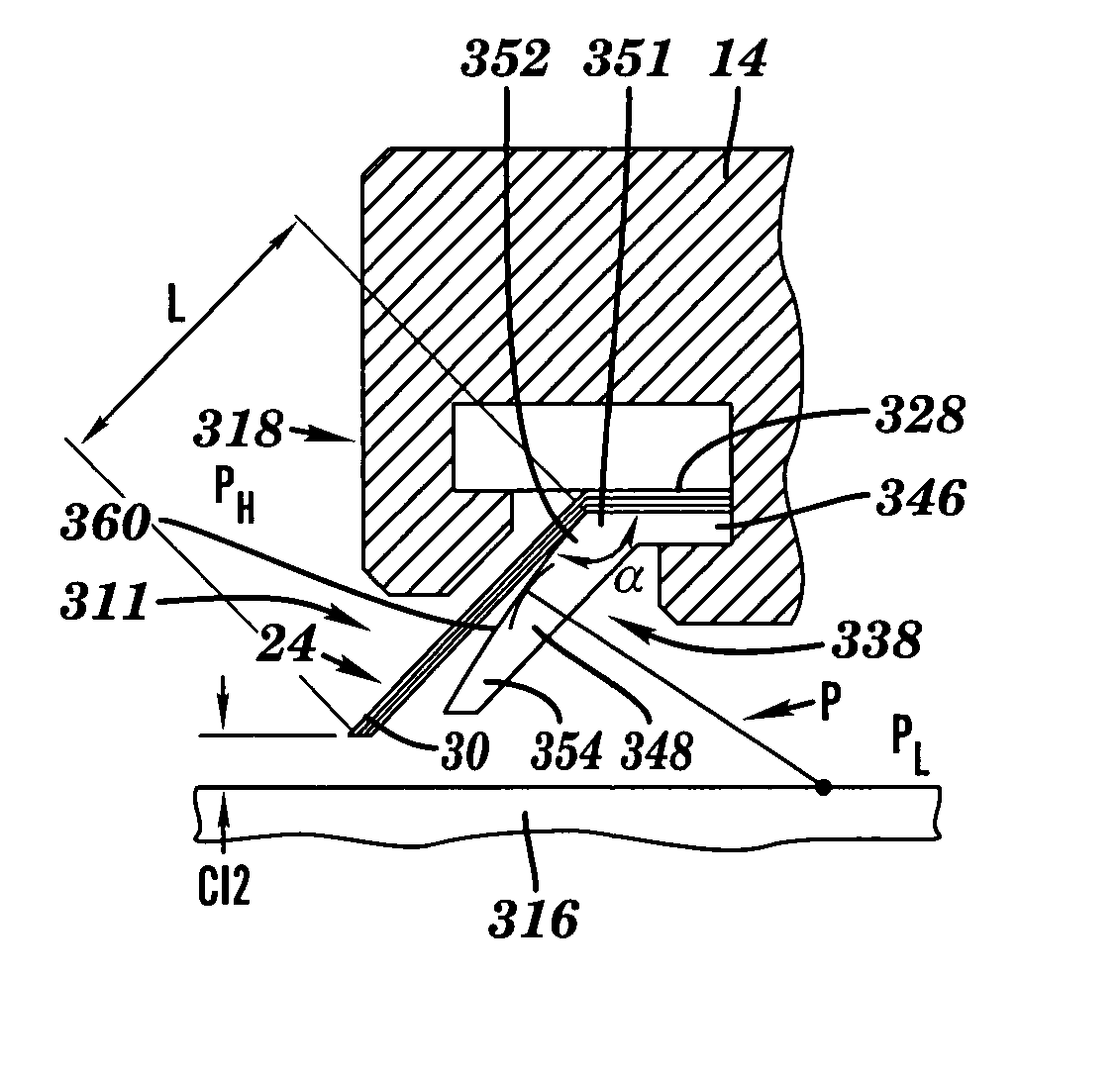

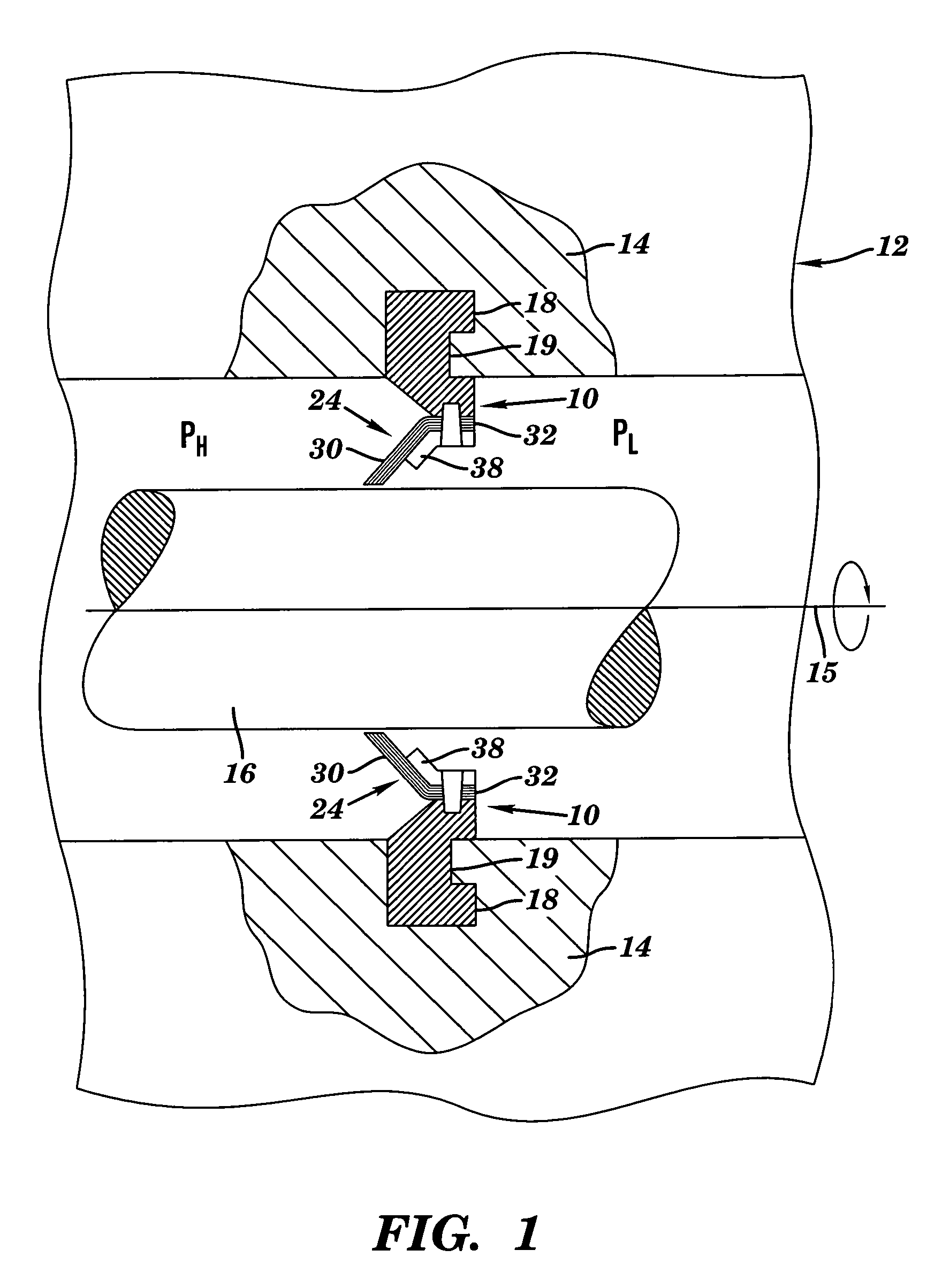

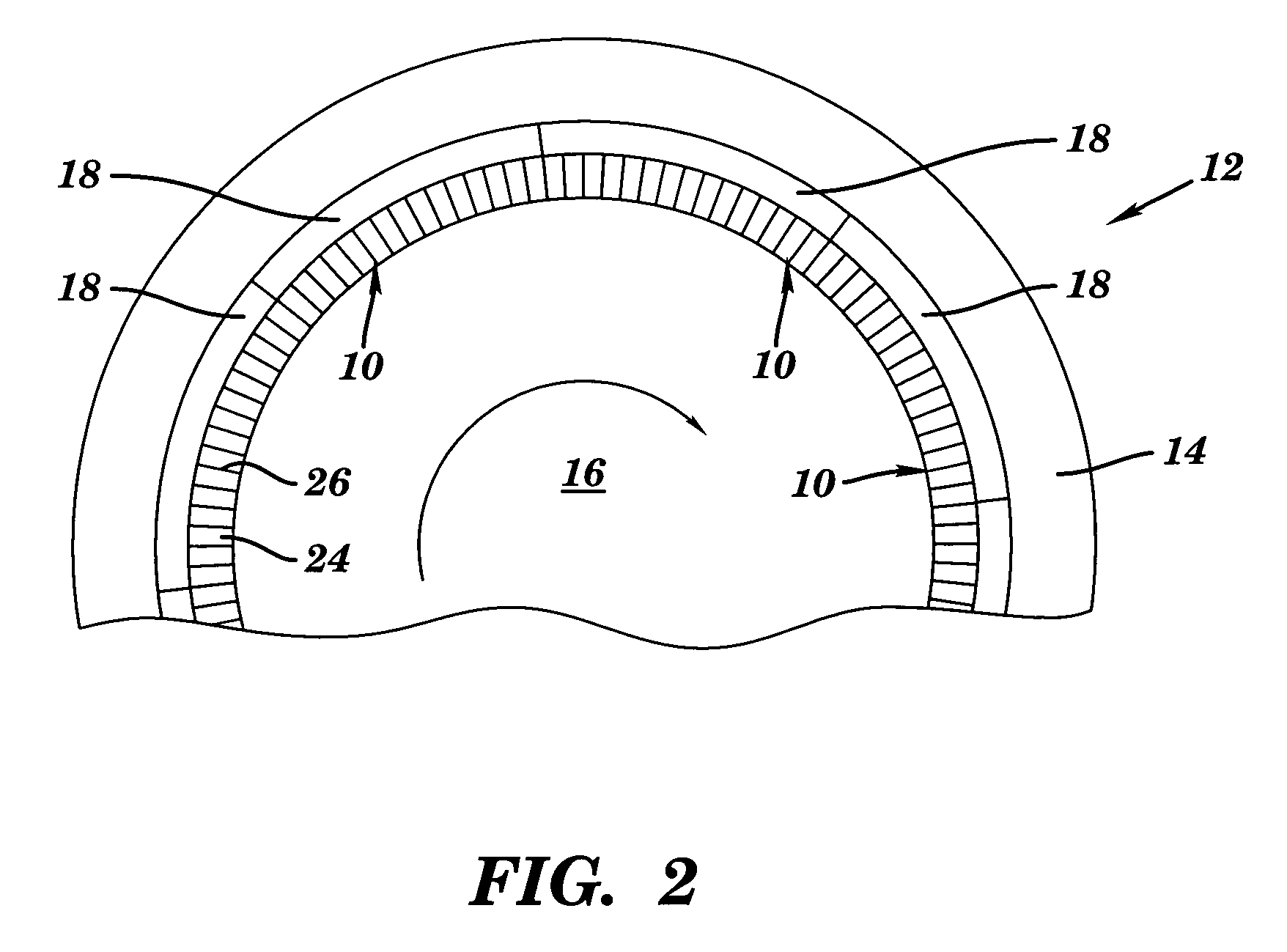

Seal assembly and rotary machine containing such seal

A seal assembly which, among other applications, may be used for sealing fluid leakage between a steam or combustion (gas) turbine rotor and a turbine stator body. The seal assembly includes elements having a plurality of spaced leaf seal members with slots therebetween. Each leaf seal member is angled out-of-plane between a fixed end and a free end thereof, and the free ends slidably engage the rotatable component. In one embodiment, the fixed ends of each leaf seal member are positioned substantially perpendicular to a longitudinal axis of the rotating component. A support may be provided supporting the free end such that it contacts a distal end of the support in an operative state and is out of contact with the distal end in an inoperative state. Seal members may include two different materials having different coefficients of thermal expansion.

Owner:CMG TECH

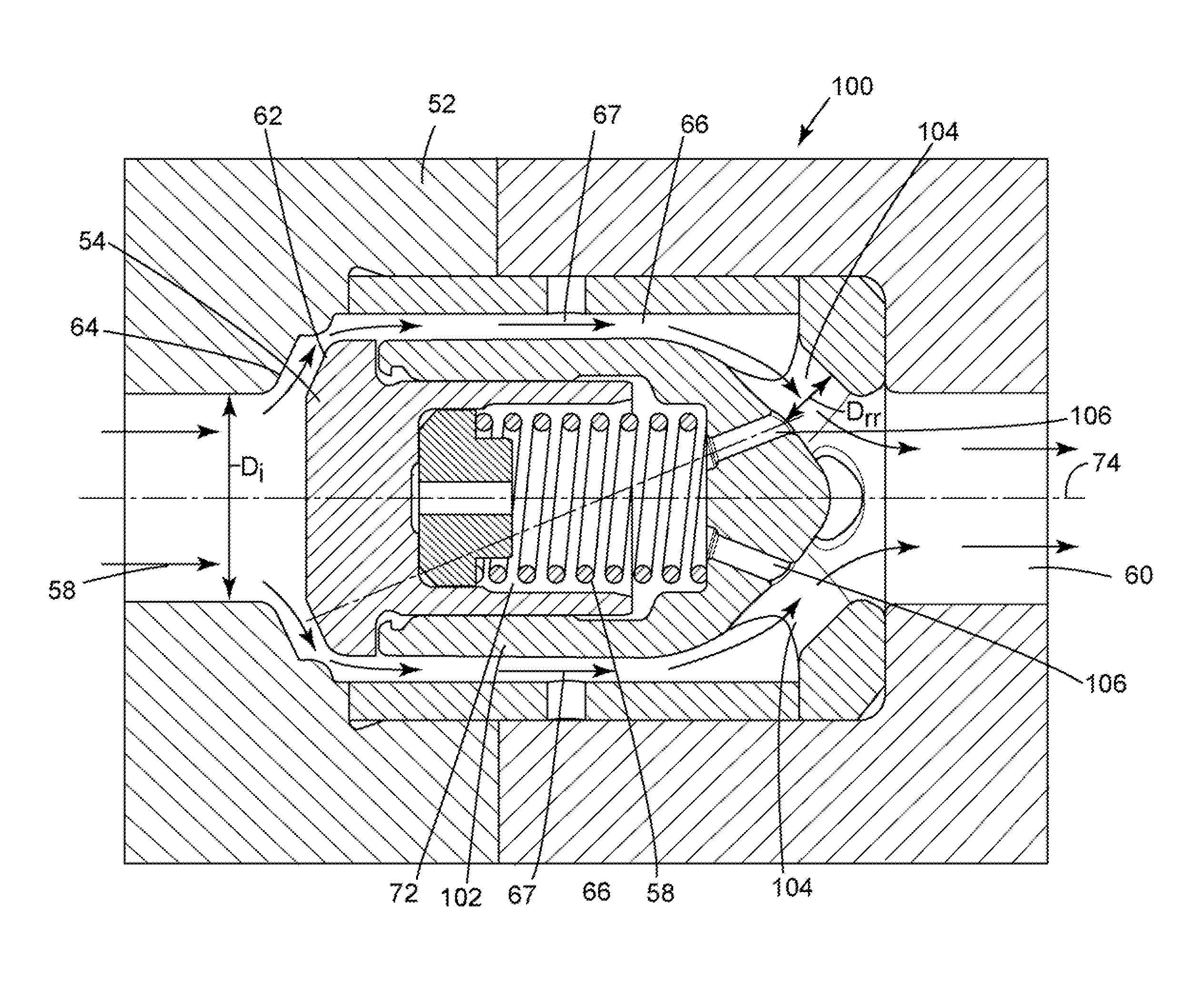

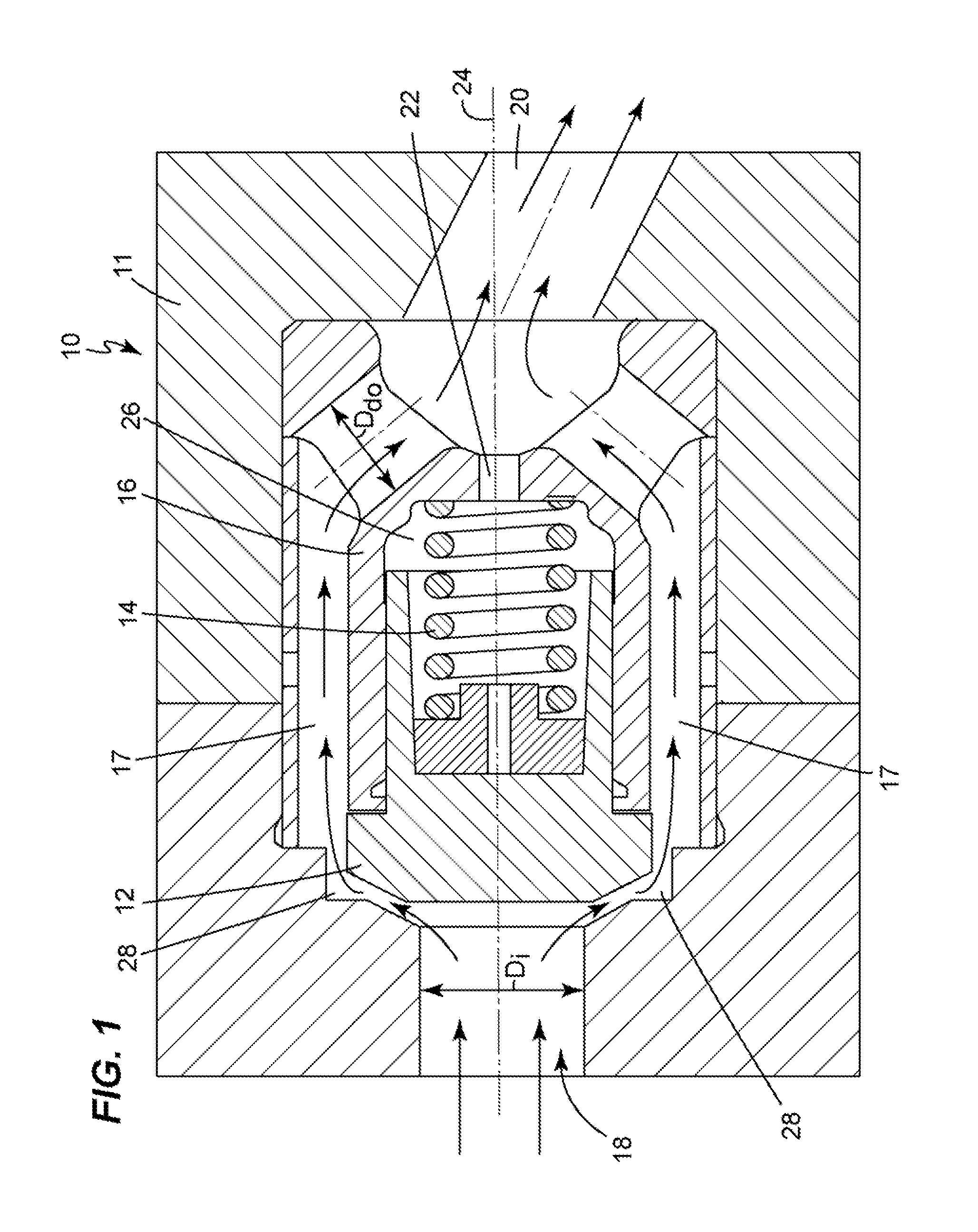

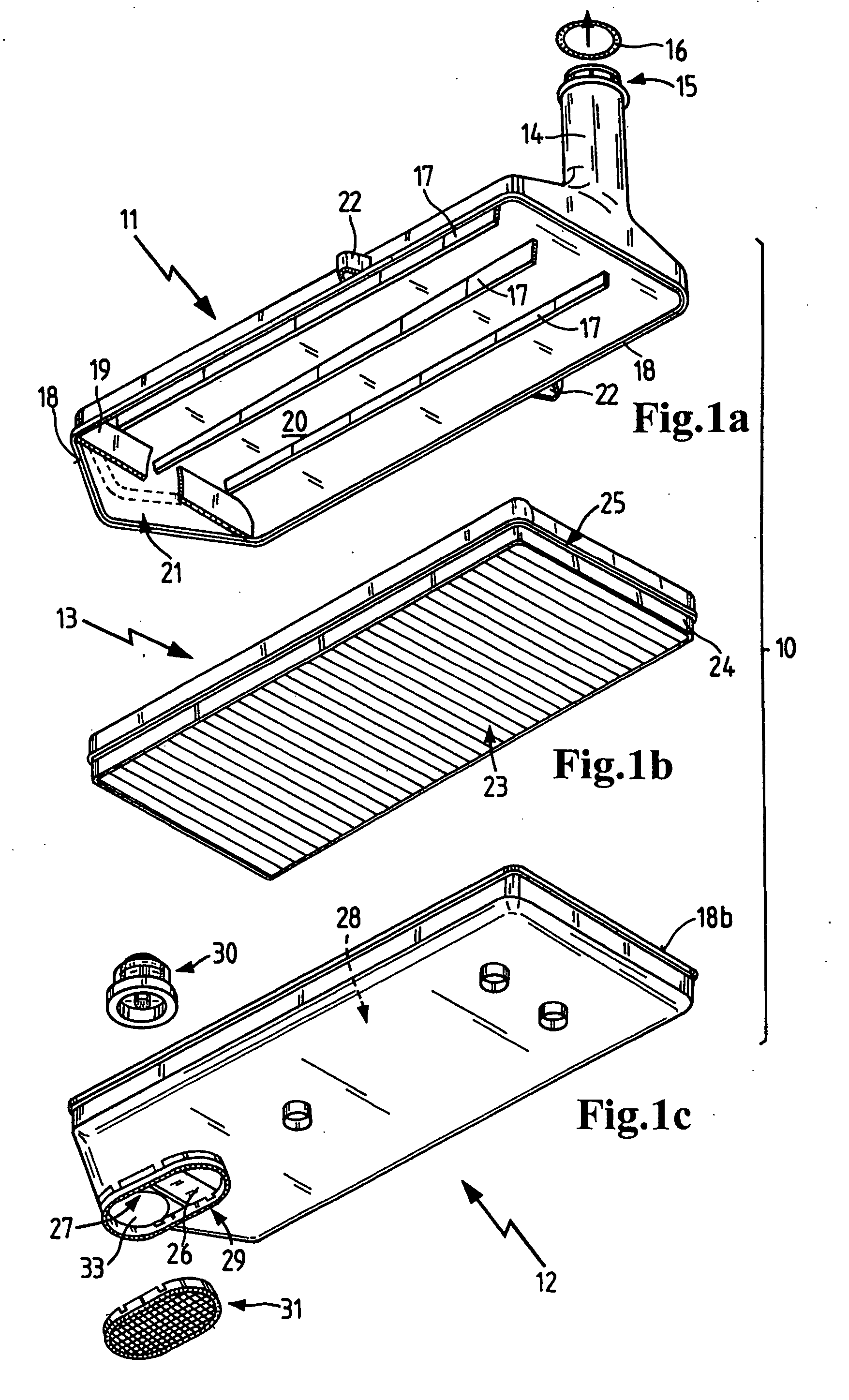

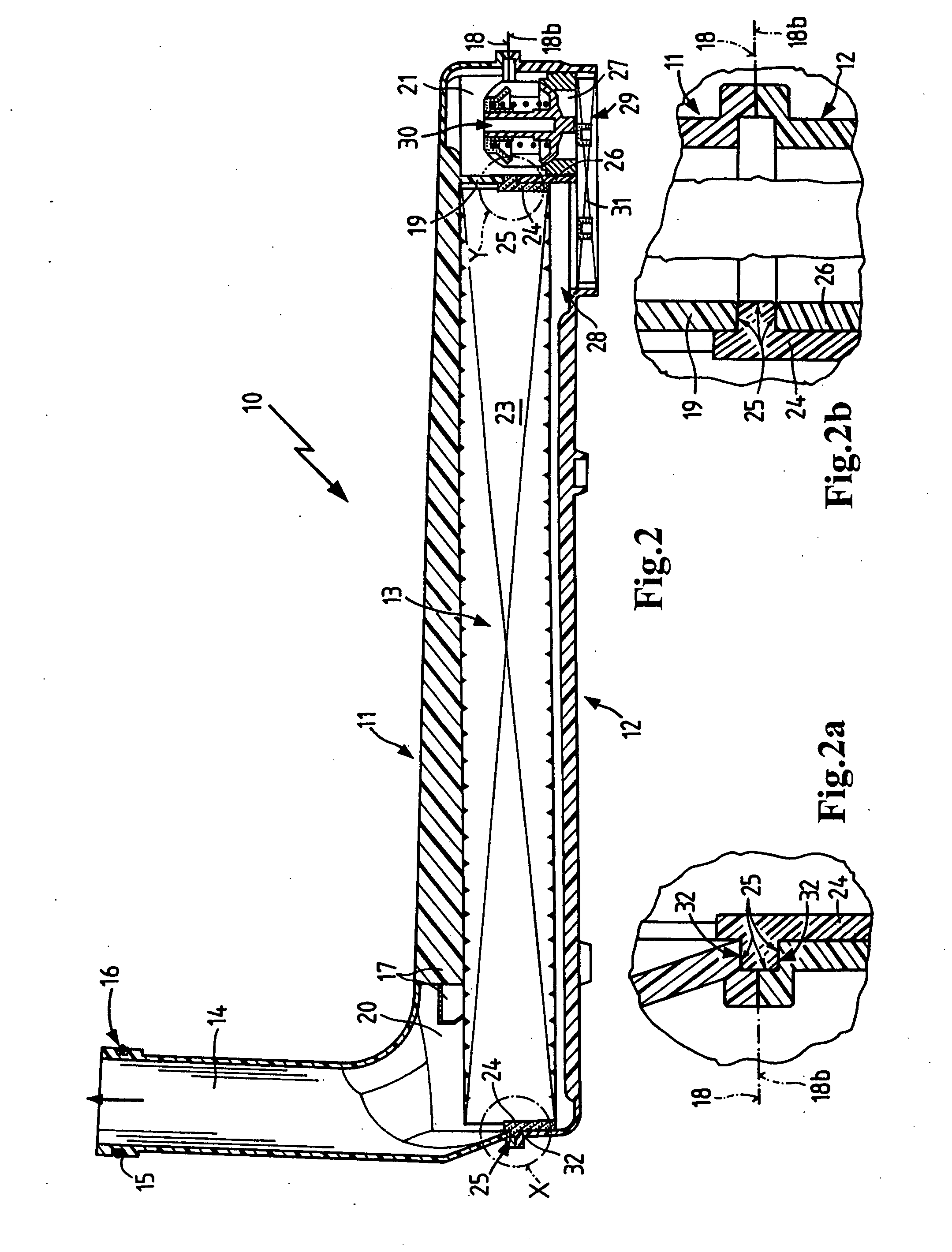

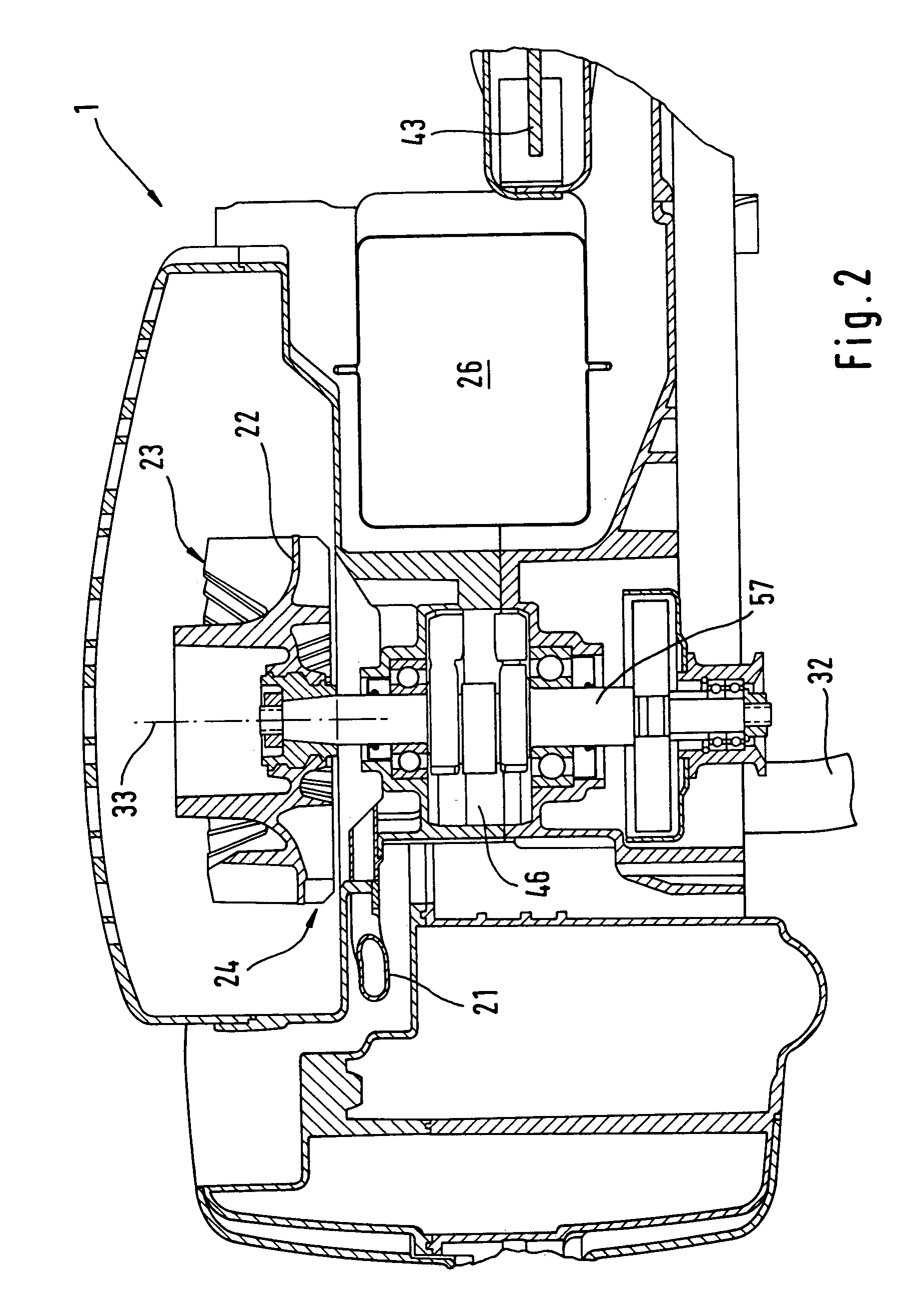

Oil filter unit

ActiveUS20060180541A1Reduce differential pressureImprove dirt holding capacityLoose filtering material filtersCartridge filtersAutomatic transmissionFilter media

An oil filter unit for arrangement in the oil sump of an oil circuit, particularly in an automatic transmission. The oil filter unit has a multi-part filter housing with a filter chamber disposed therein such that an oil inlet and an oil outlet communicate with the filter chamber. A filter element is sealingly mounted in the housing between the oil inlet and the oil outlet. The filter element has a pleated filter medium, which is sealingly enclosed by a frame, and the frame has seal contours designed to cooperate with the contours of the filter housing.

Owner:MANN HUMMEL GMBH

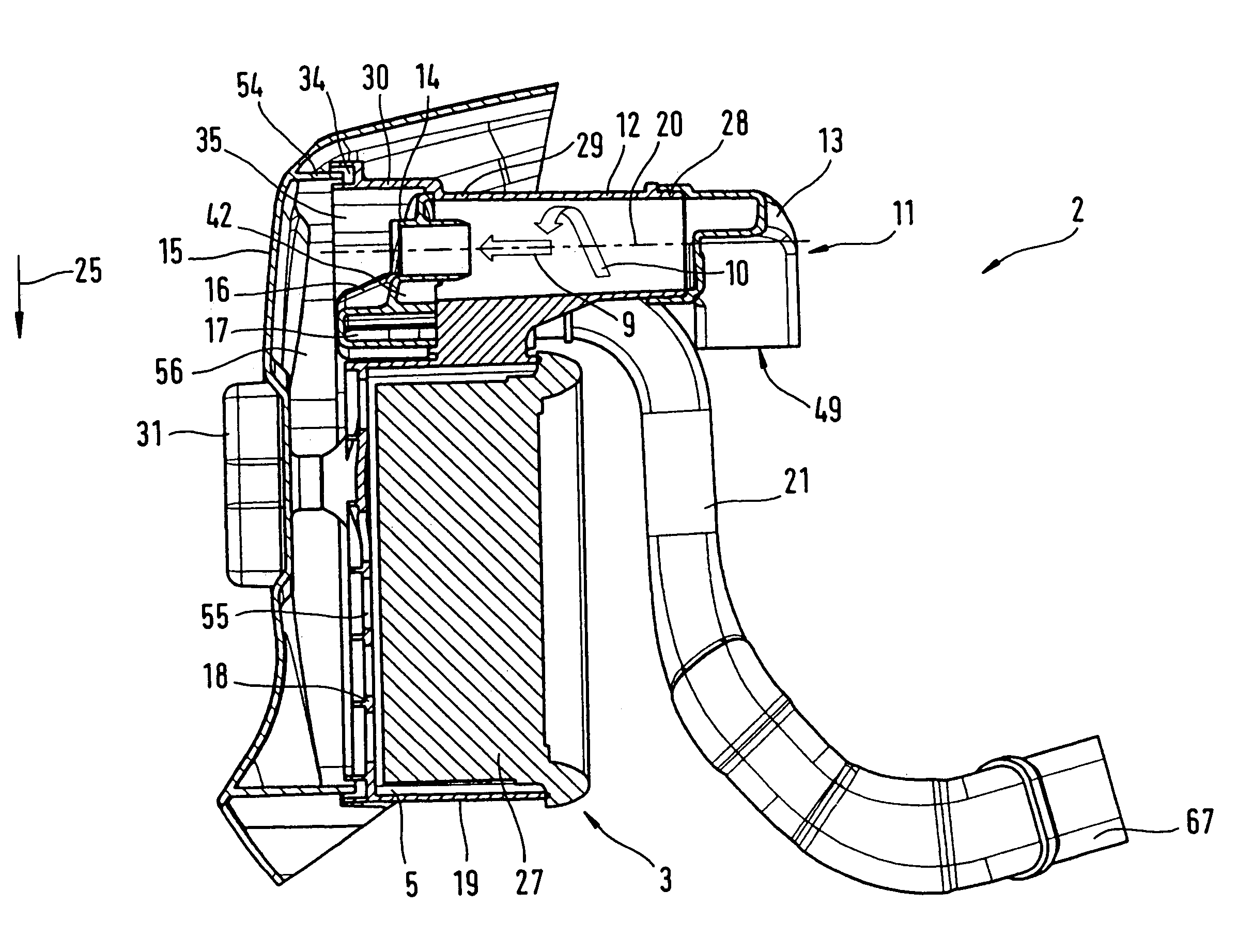

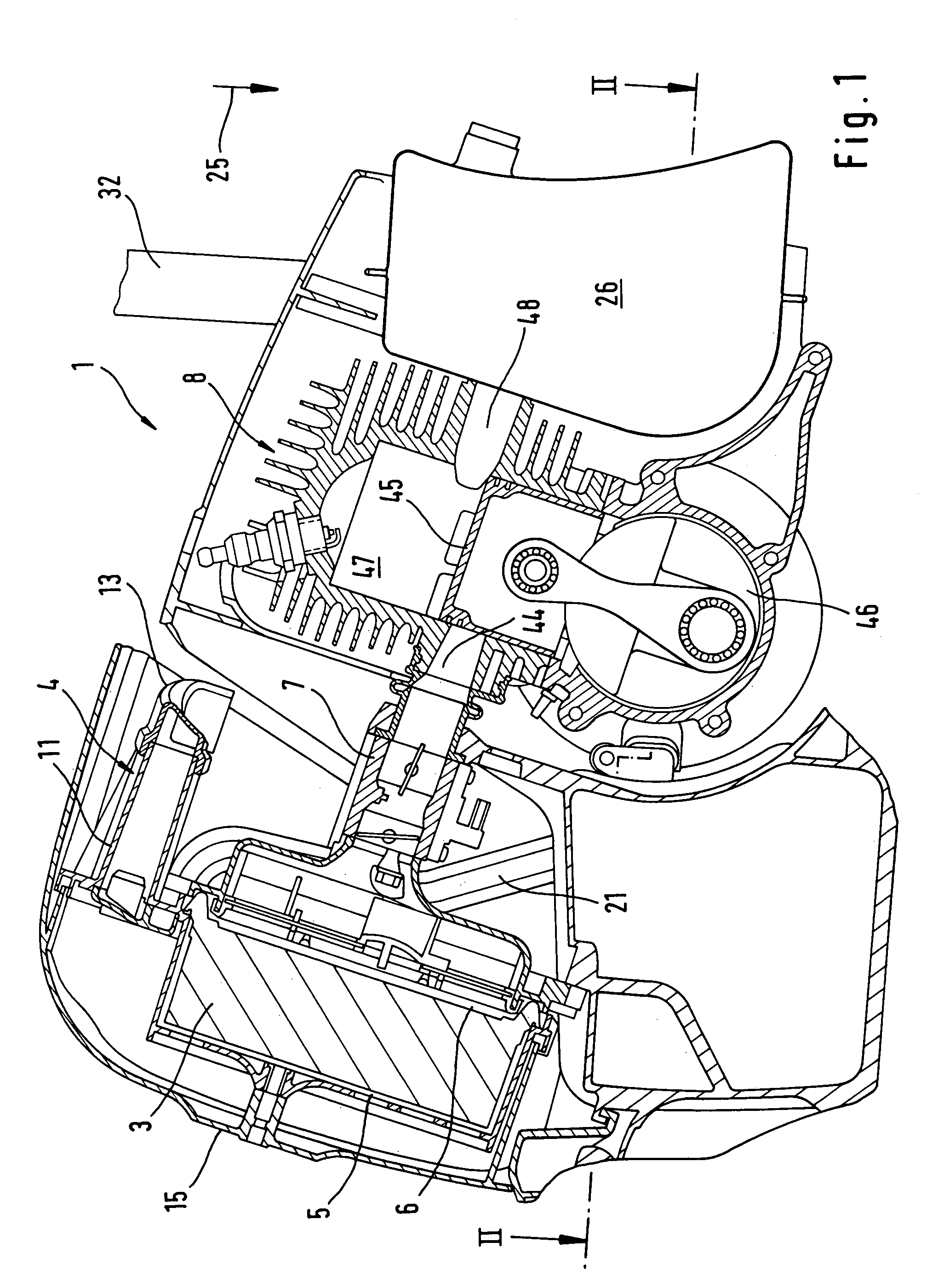

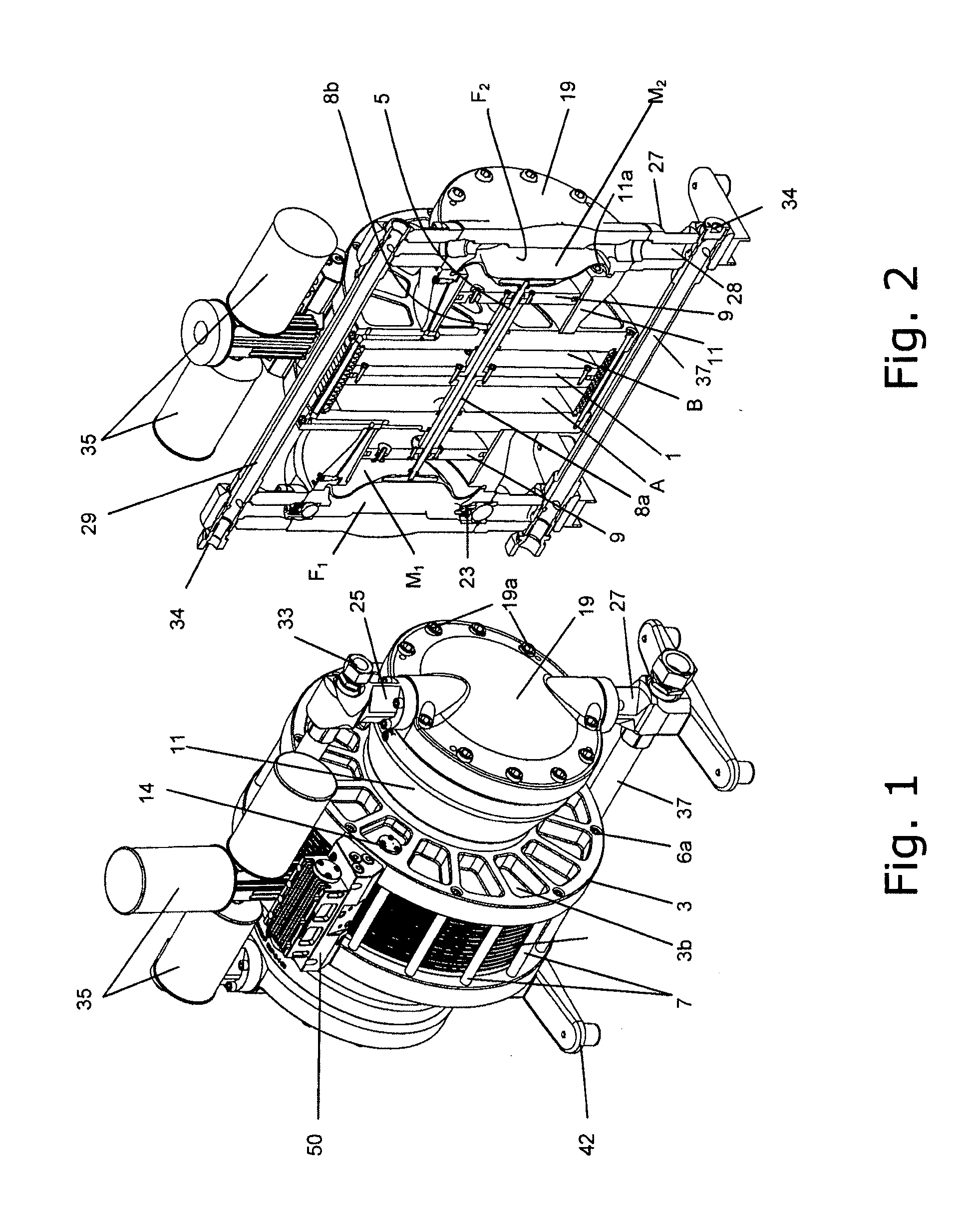

Intake system

An intake system for the combustion air of a motor of a hand held implement is provided. The system includes an air filter and a centrifugal separator. The air filter has a dirt chamber and a clean chamber that is separated therefrom by a filter medium. The clean chamber is fluidically connected with a carburetor of the motor to convey combustion air to the motor. The centrifugal separator splits the air stream into a core flow having low particle density and a peripheral flow having high particle density. The centrifugal separator includes at least two cyclones, wherein the discharged flows from the cyclones are respectively combined in pairs and open out into a common suction tube.

Owner:ANDREAS STIHL AG & CO KG

Magnetic tape having characterized backcoat layer and method of manufacturing the same

ActiveUS10475481B2Good electromagnetic propertiesReduce differential pressureBase layers for recording layersTape carriersMagnetic tapeMagnetic layer

The magnetic tape has a magnetic layer and a backcoat layer. The Ra on the magnetic layer side surface is less than or equal to 1.8 nm, the coefficient of friction measured on the base portion of the magnetic layer side surface is less than or equal to 0.35, and the Ra measured on the backcoat layer side surface is less than or equal to 5.0 nm. The backcoat layer contains a fatty acid ester. In addition, the FWHMbefore measured on the backcoat layer side surface before vacuum heating is greater than 0 nm but less than or equal to 10.0 nm, the FWHMafter after vacuum heating is greater than 0 nm but less than or equal to 10.0 nm, and the difference between the spacing measured on the backcoat layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm.

Owner:FUJIFILM CORP

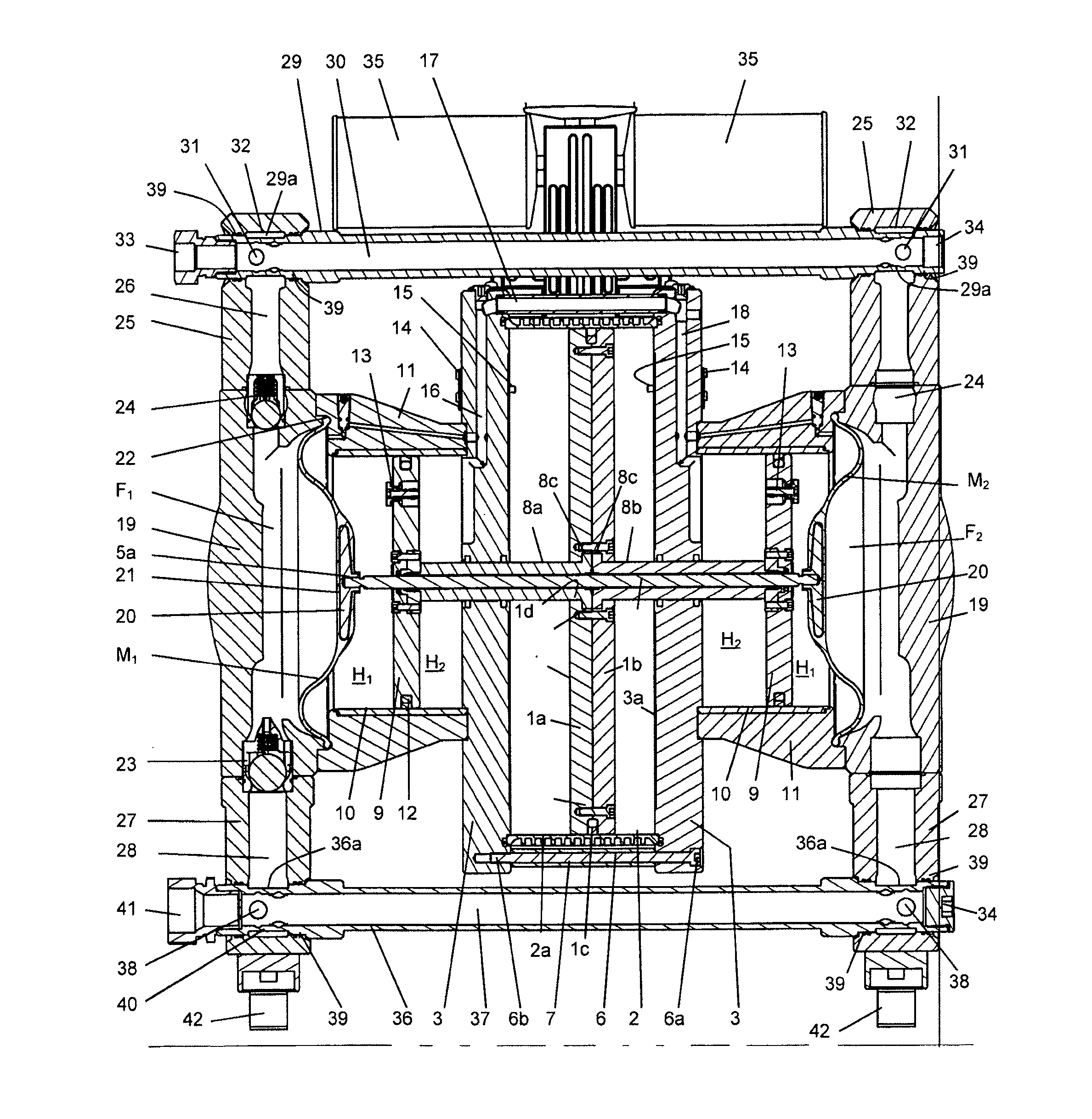

Double diaphragm pump

InactiveUS20130101445A1Easy to useReduce differential pressureFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpMechanical engineering

A diaphragm pump, in which a fluid moves at least a first piston of a first piston / cylinder system back and forth, the first piston being mechanically connected to at least one other hydraulic piston and the hydraulic piston driving at least one diaphragm by a hydraulic medium.

Owner:PROMERA

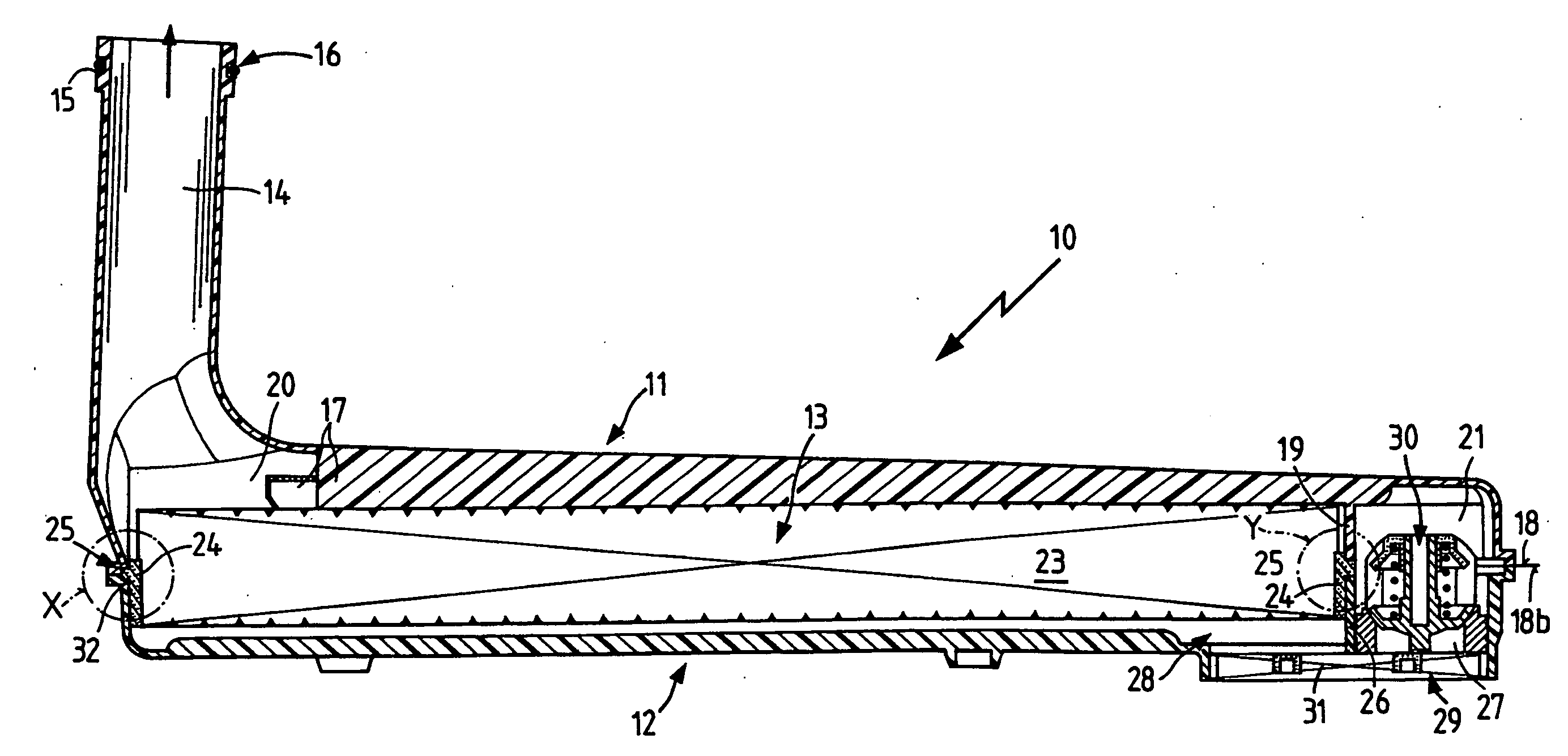

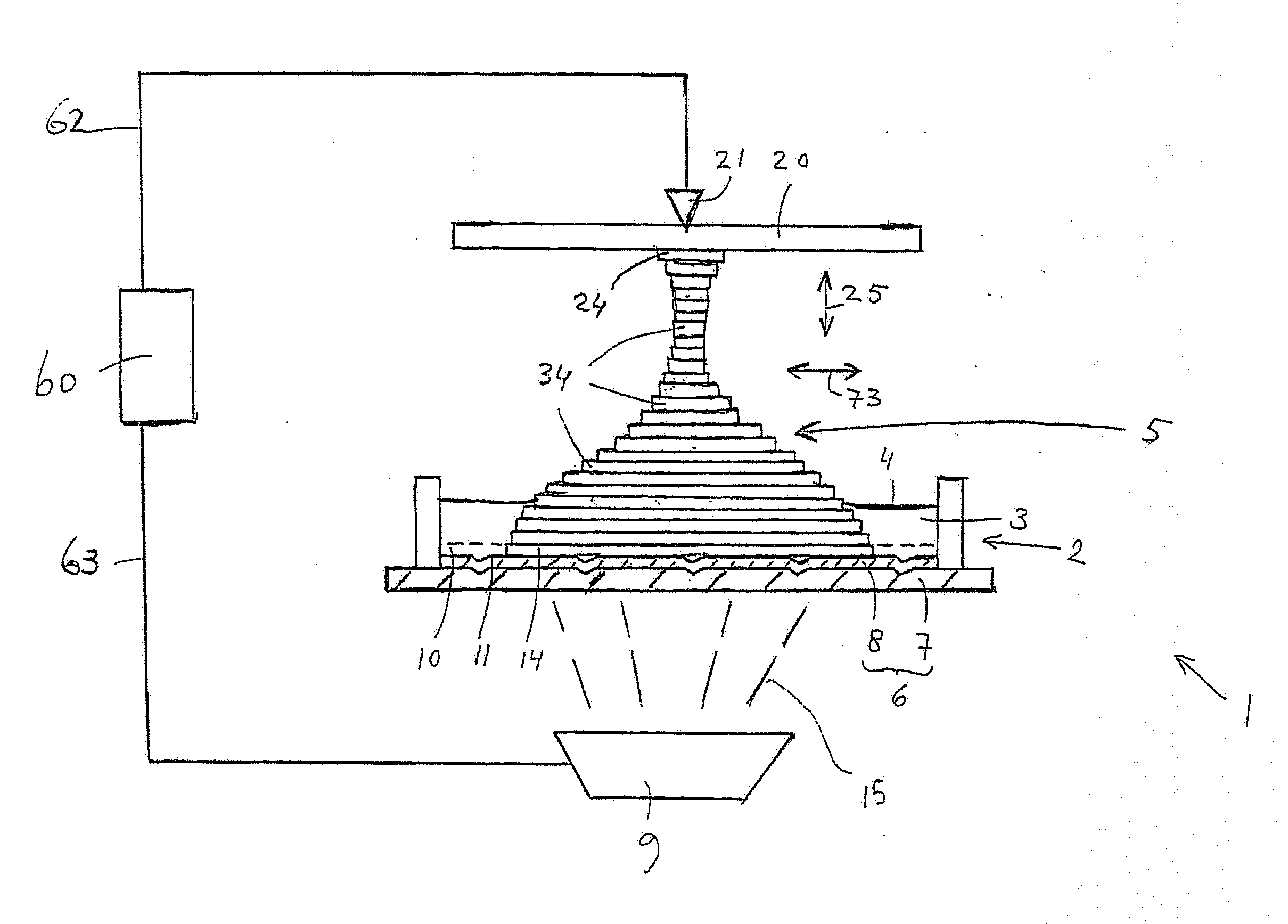

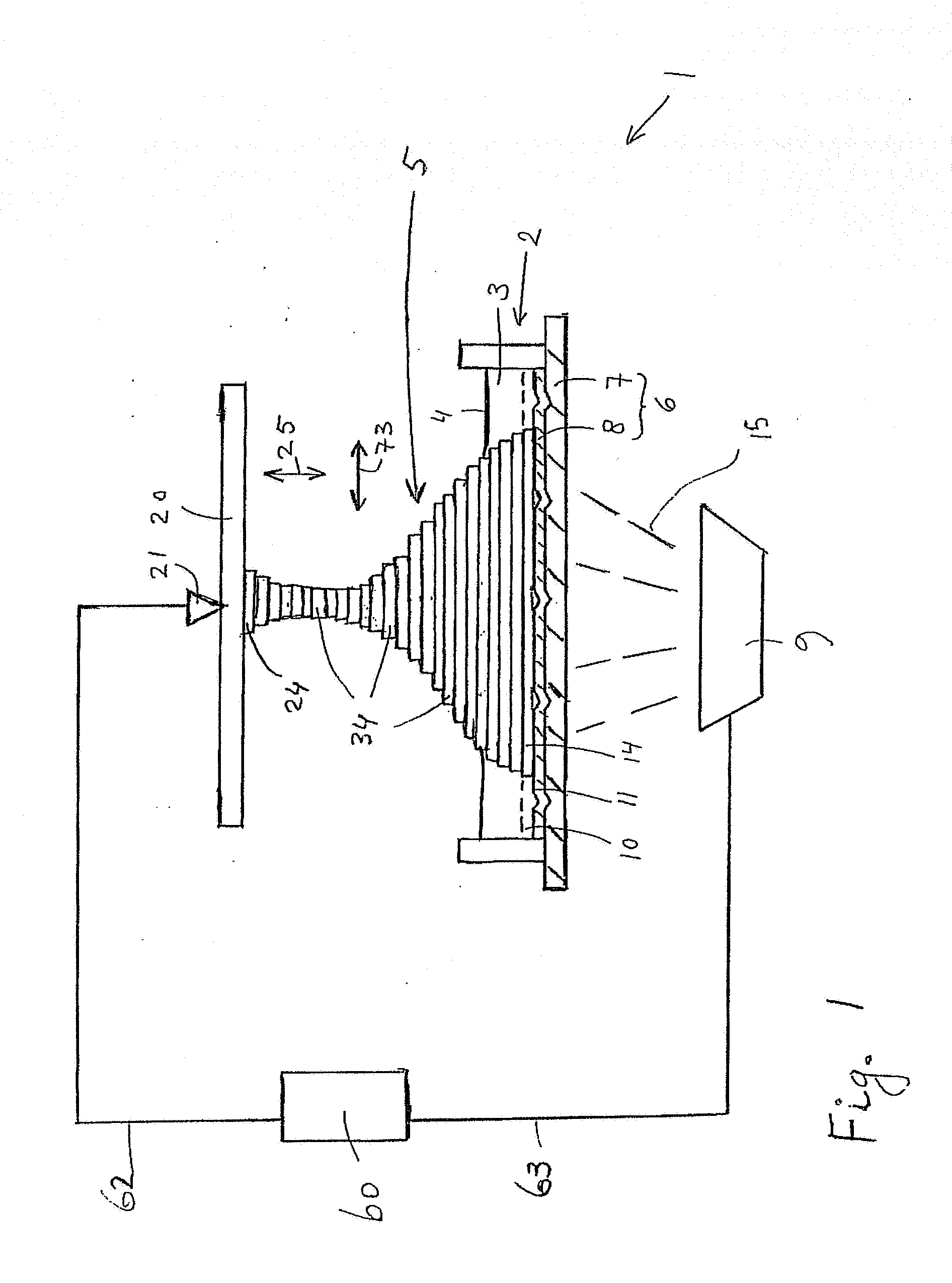

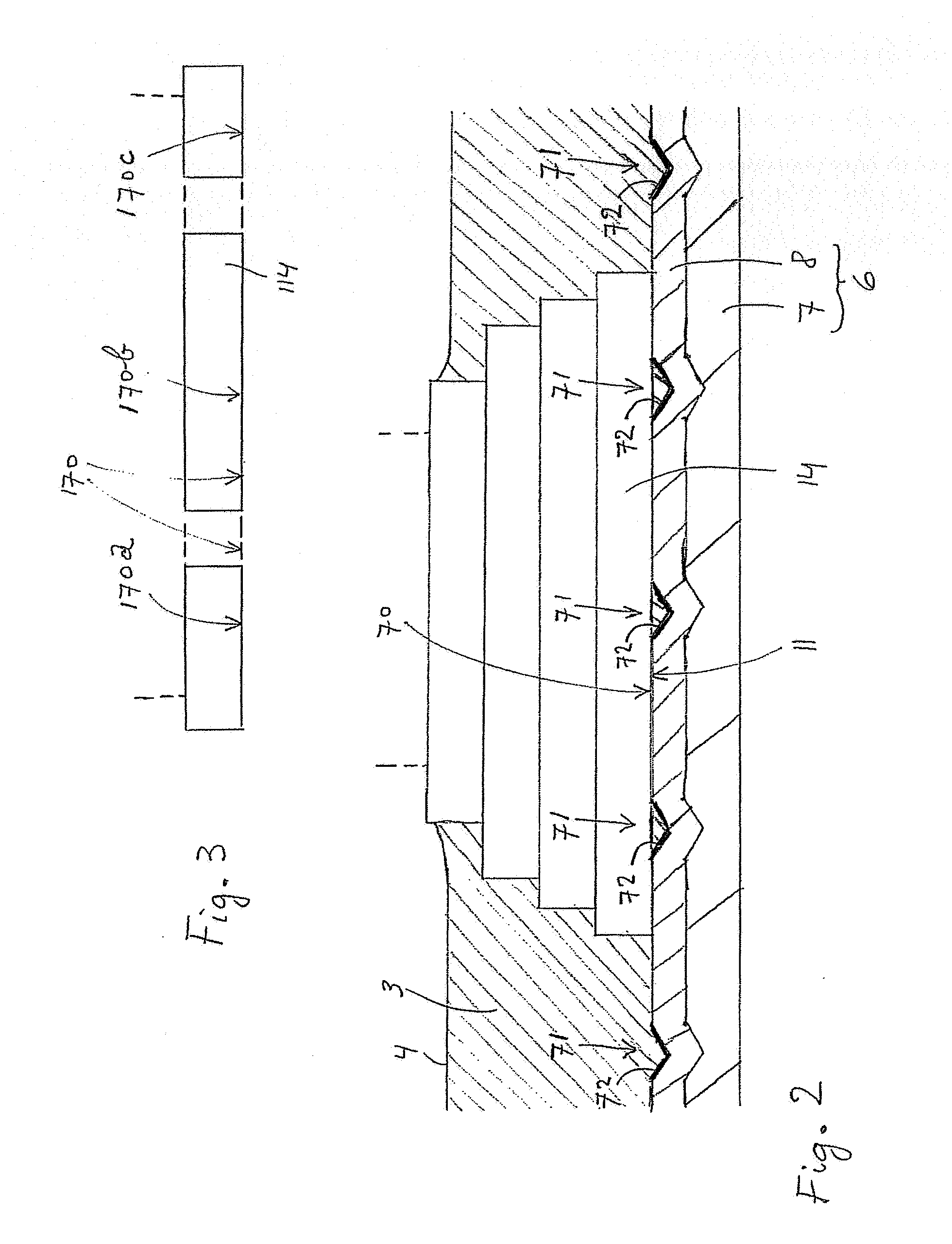

Method and system for layerwise production of a tangible object

ActiveUS20090309267A1Reduce differential pressureEasy to separateAdditive manufacturing apparatusTailstocks/centresTangible objectMechanical engineering

A method cycle of a method for layerwise production of a tangible object (5) comprises the successive steps of: solidifying predetermined parts of a liquid so as to obtain a solid layer (14) having a predetermined shape; separating said solid layer from a construction shape (6); and moving, relative to one another, the separated solid layer and the construction shape to a predetermined position relative to one another. Solidifying is carried out such that the solid layer and the construction shape have nonmatching shapes in the sense that all surface portions of a solid layer side (70) that are or have been in contact with a liquid contacting side (11) of the construction shape can not simultaneously be brought in full contacting engagement with the liquid contacting side.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com