Patents

Literature

820results about "Fuel tank safety measures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

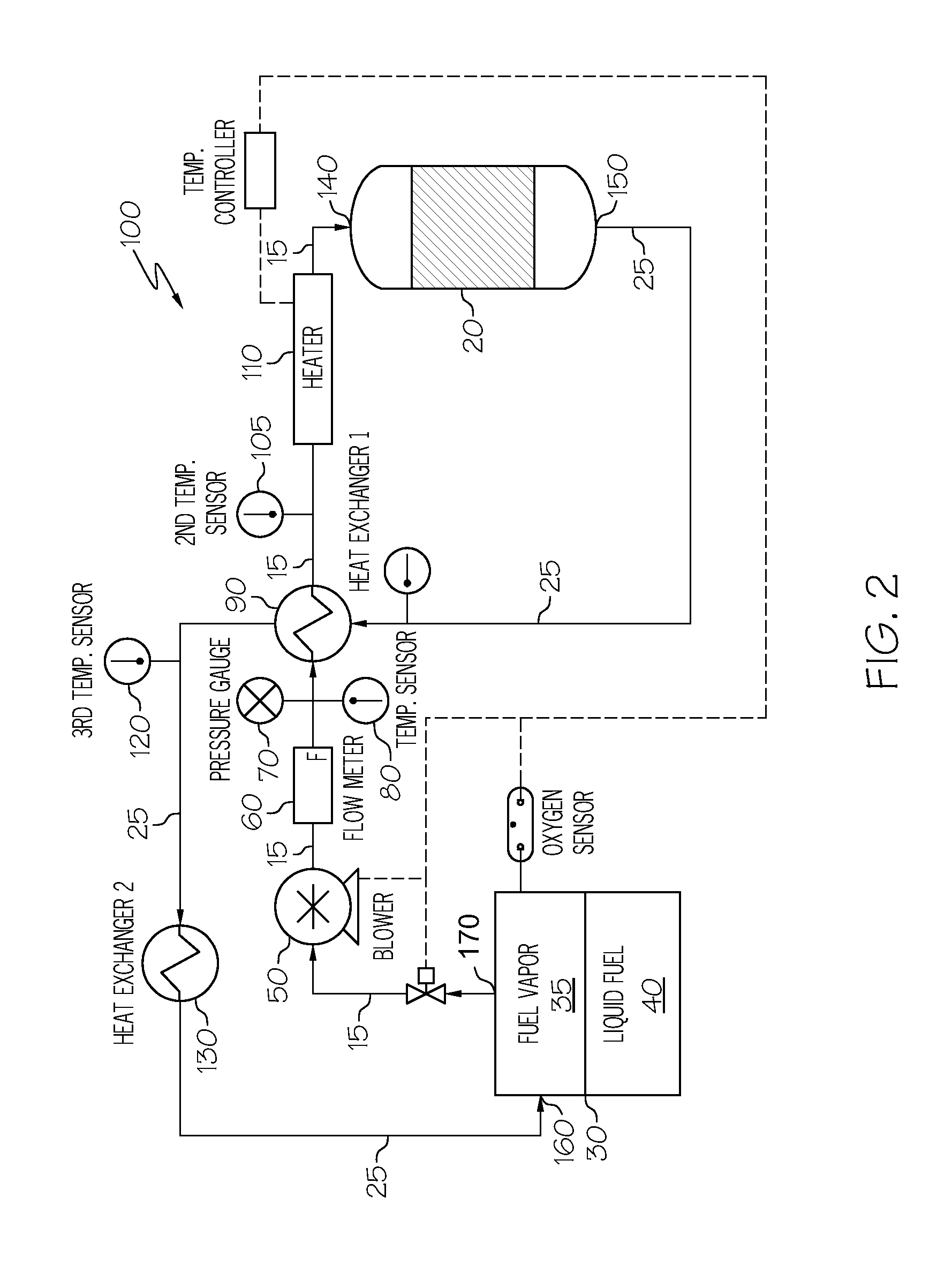

Advanced carbon dioxide fuel tank inerting system

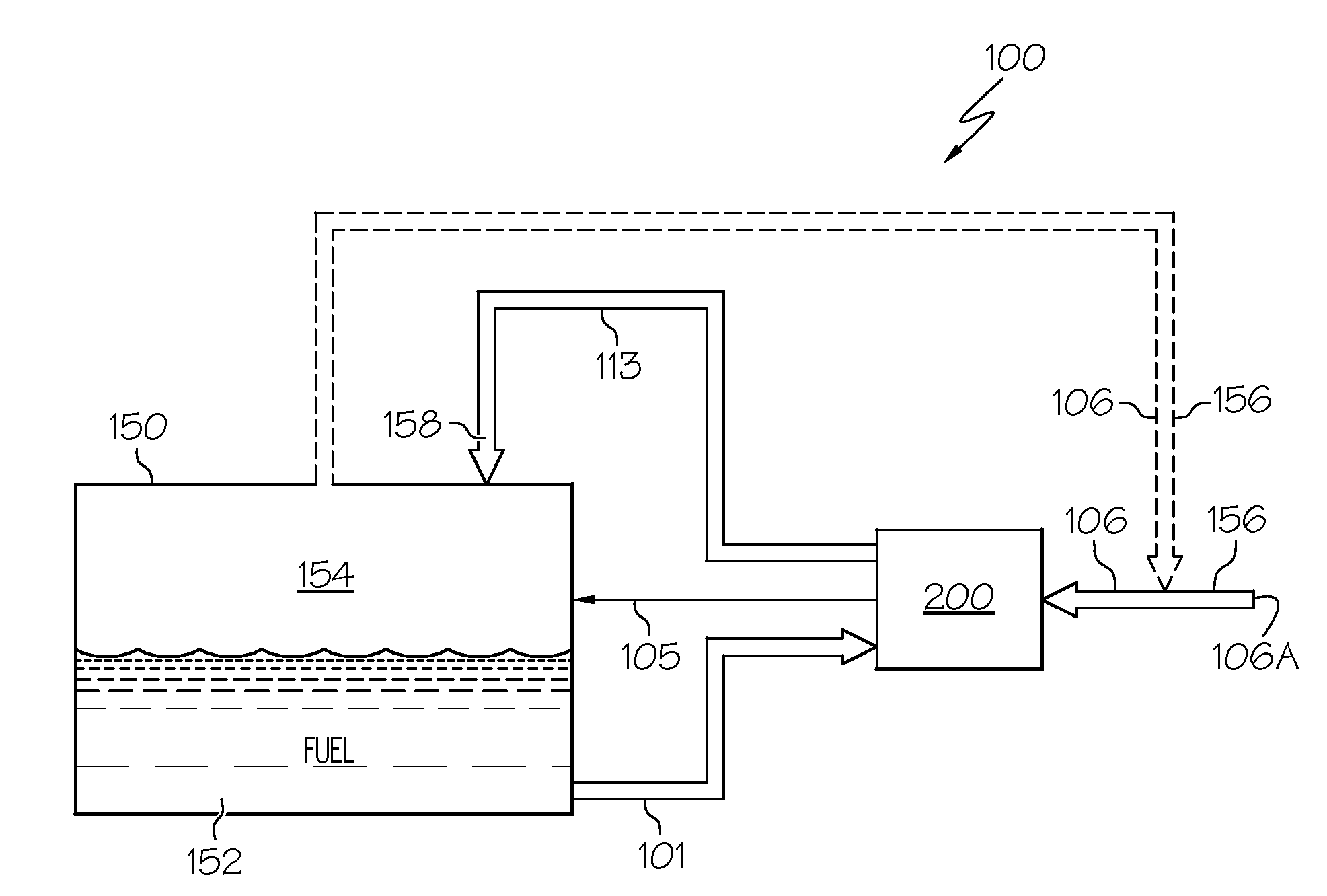

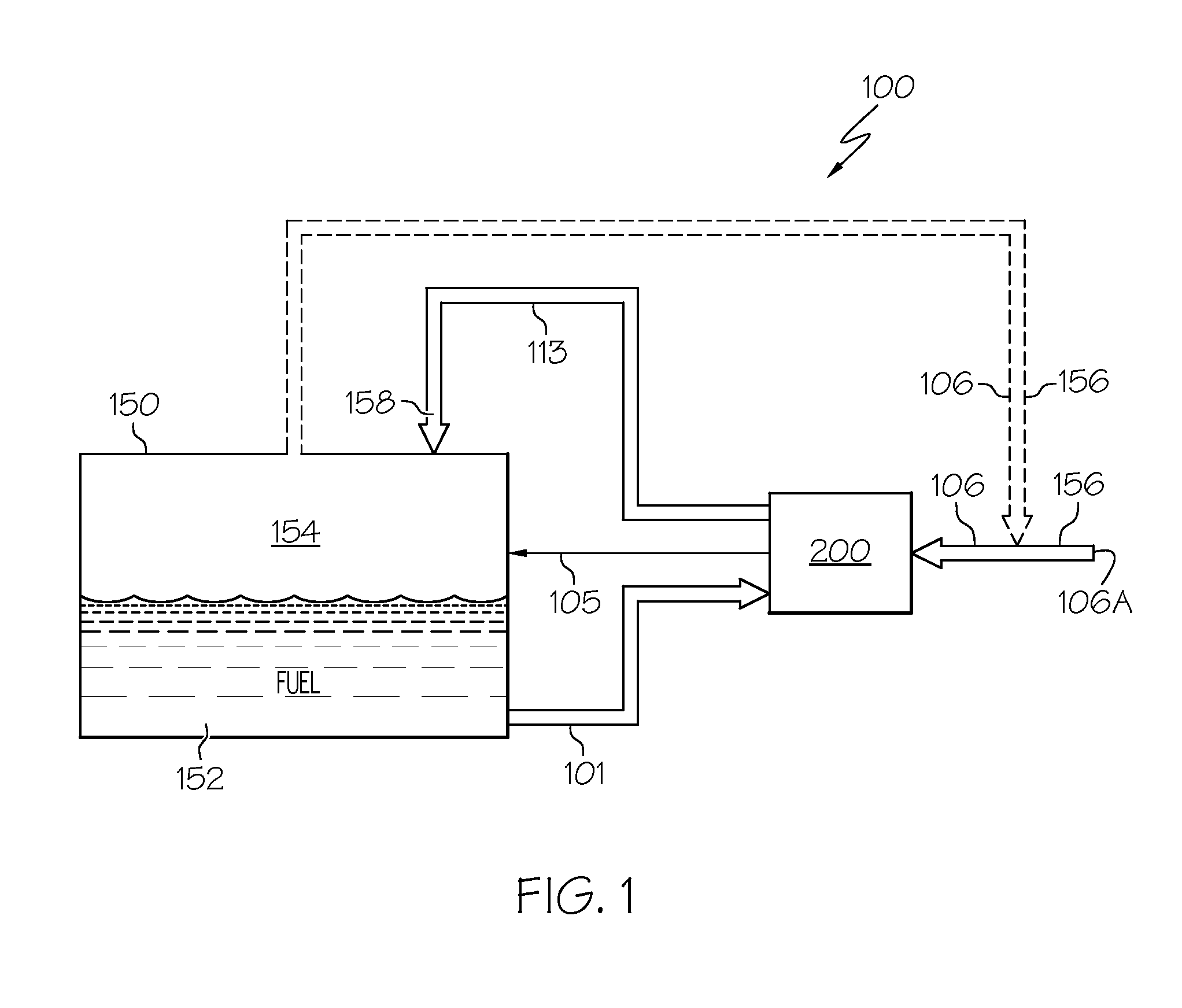

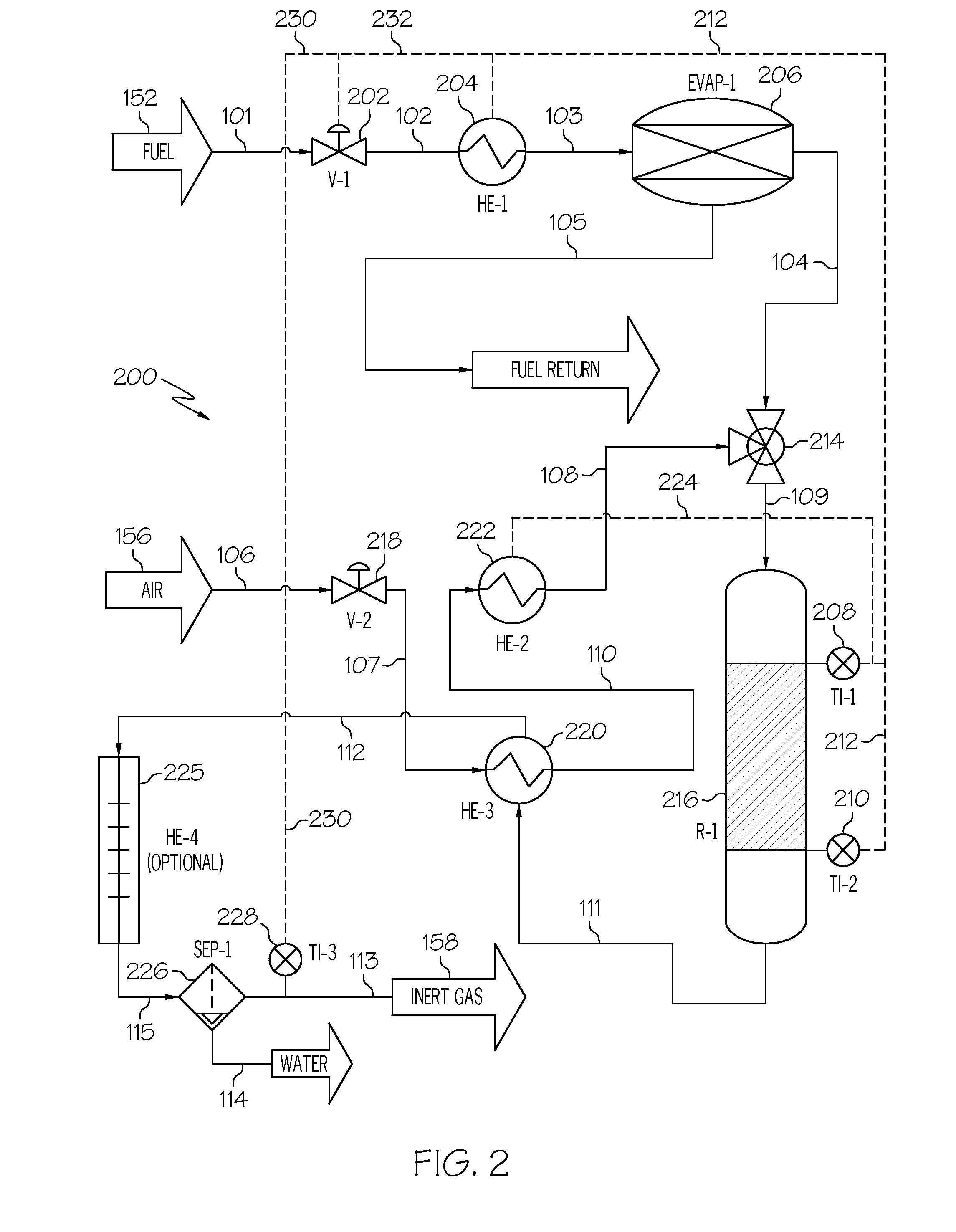

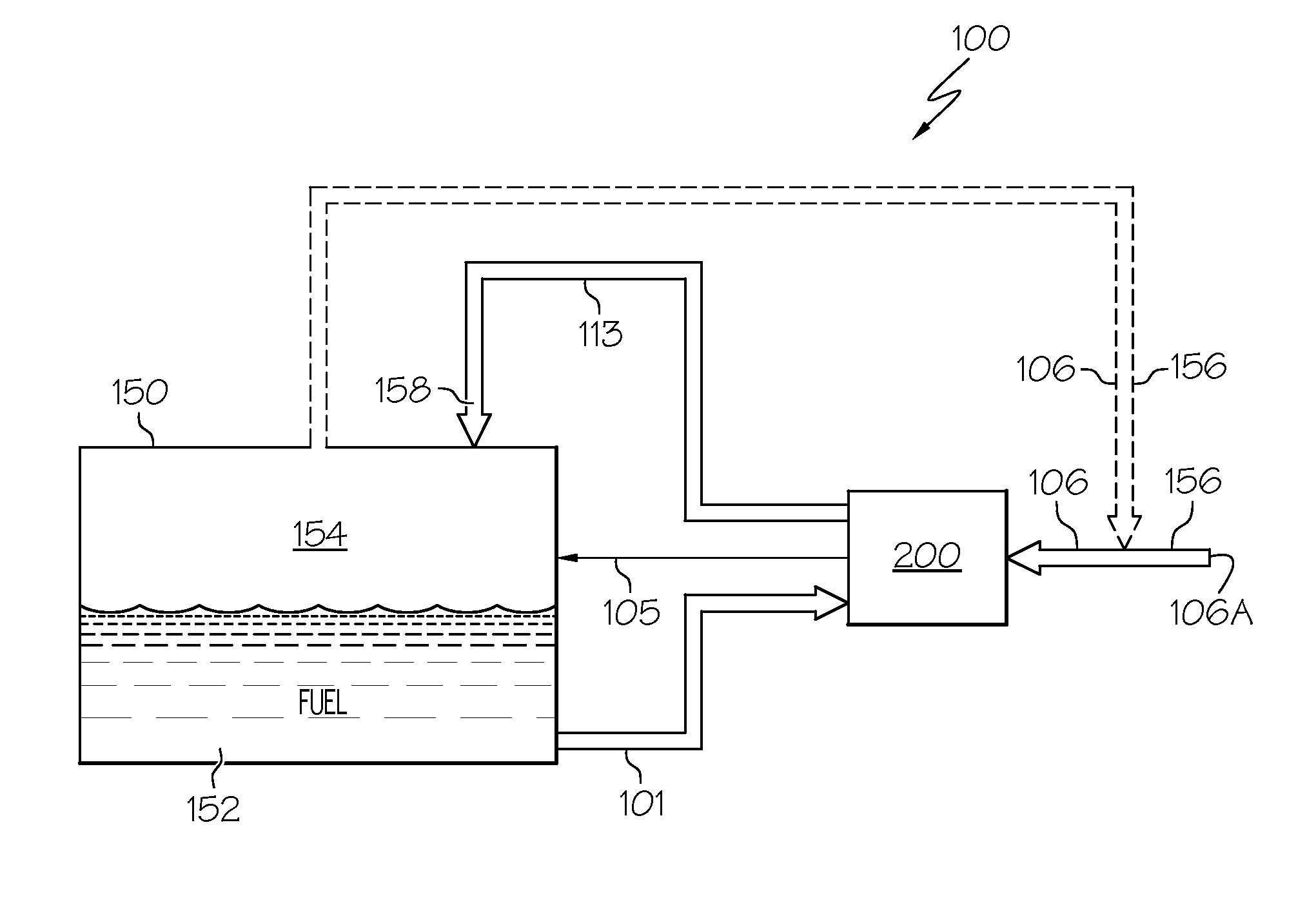

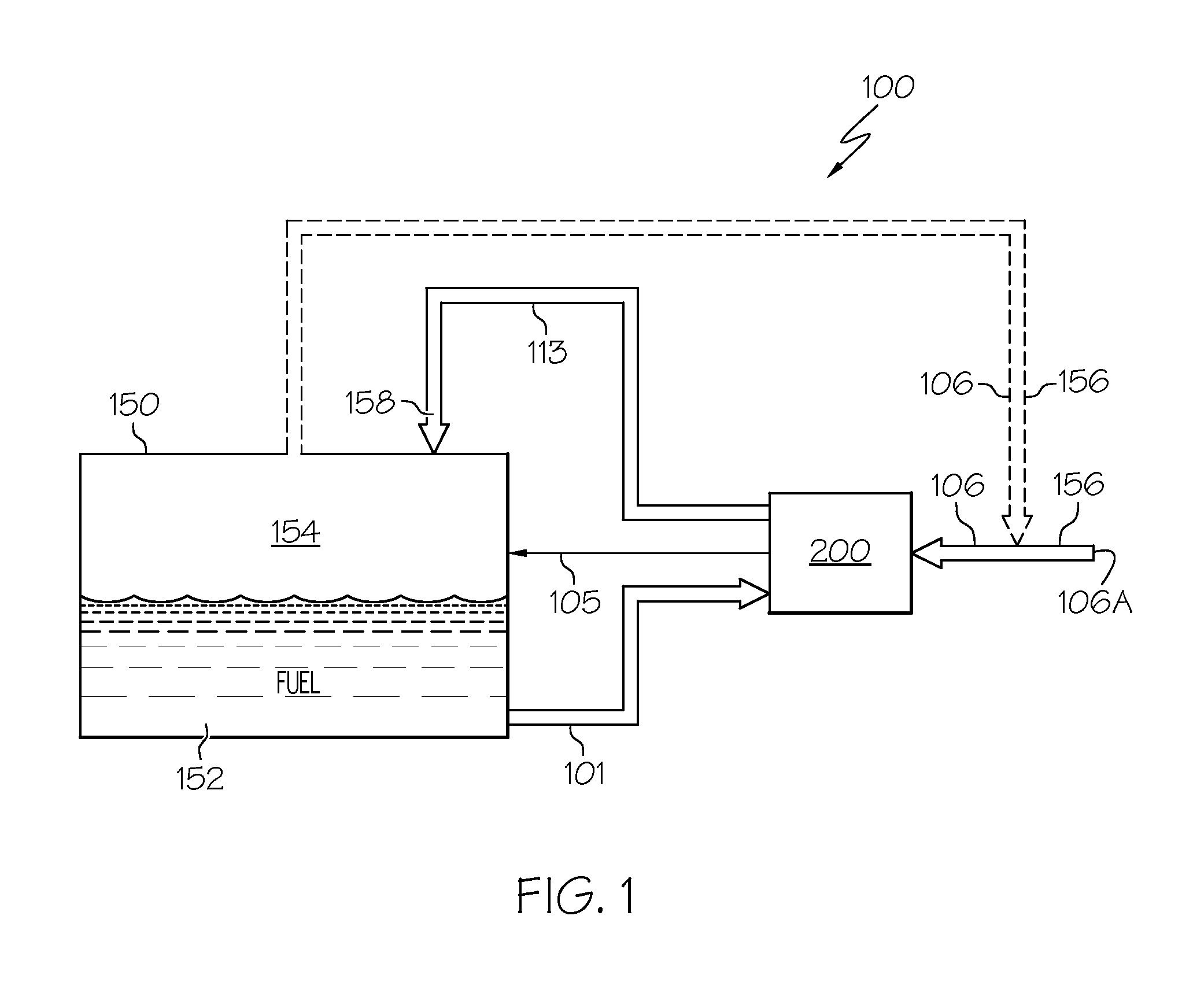

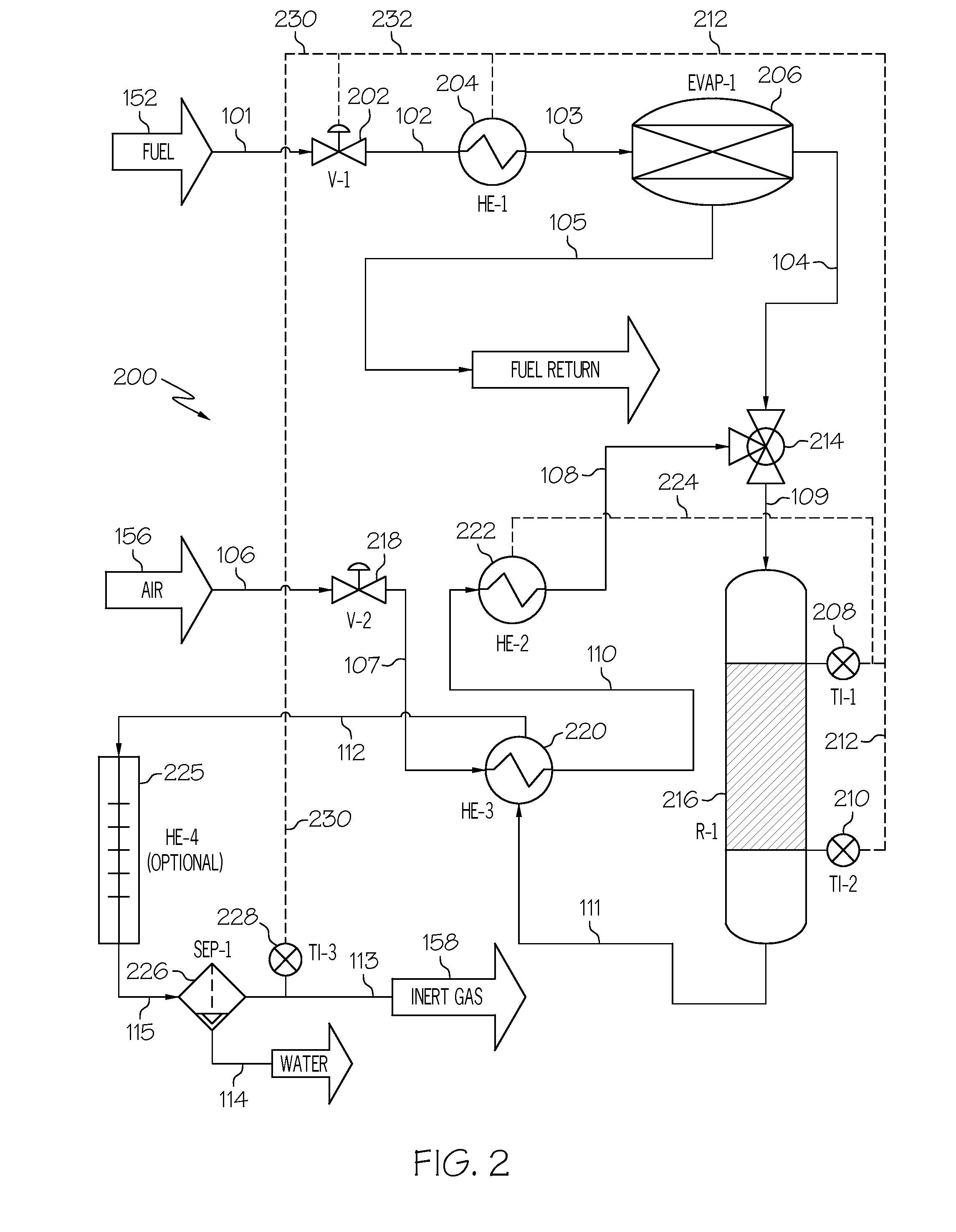

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

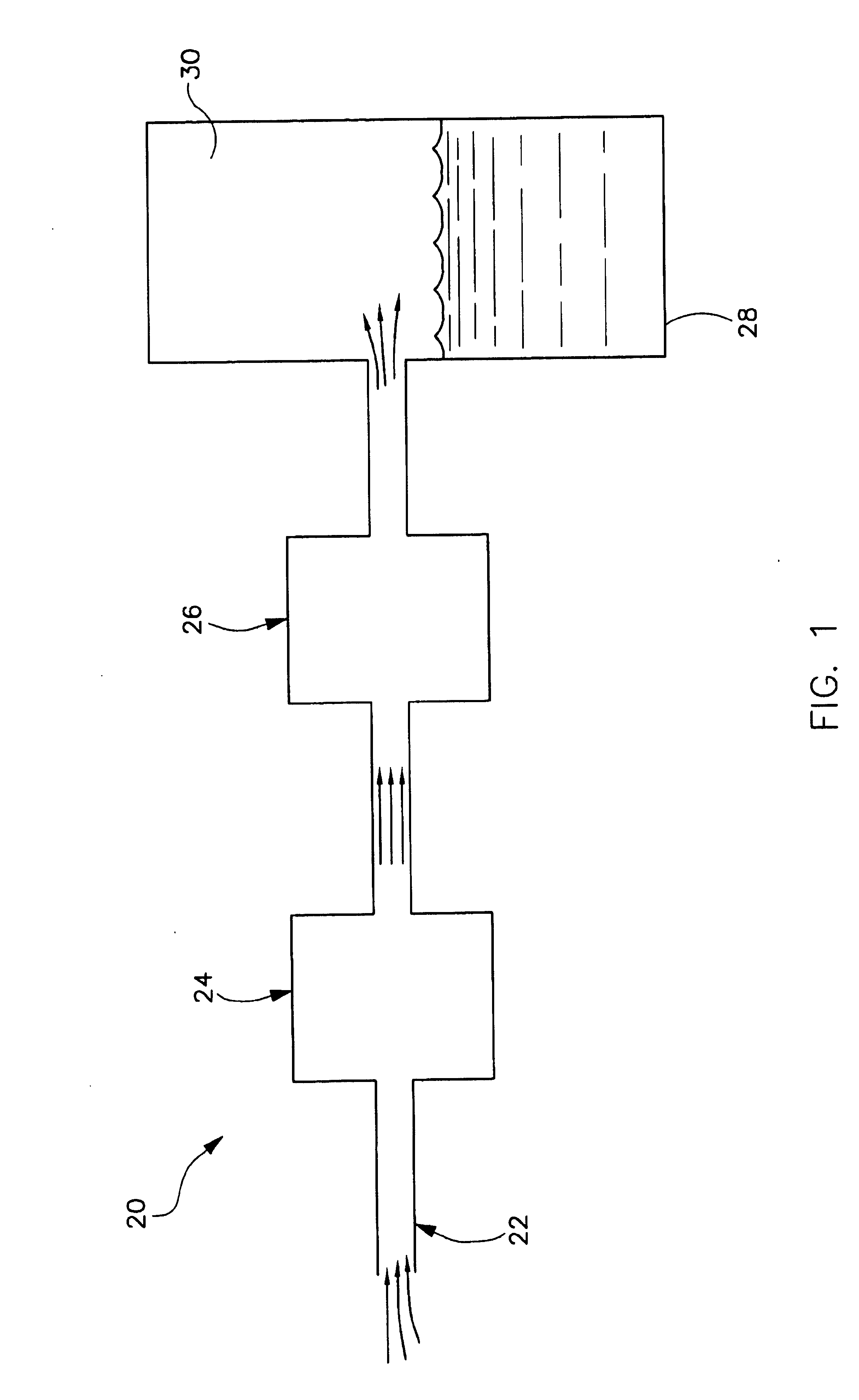

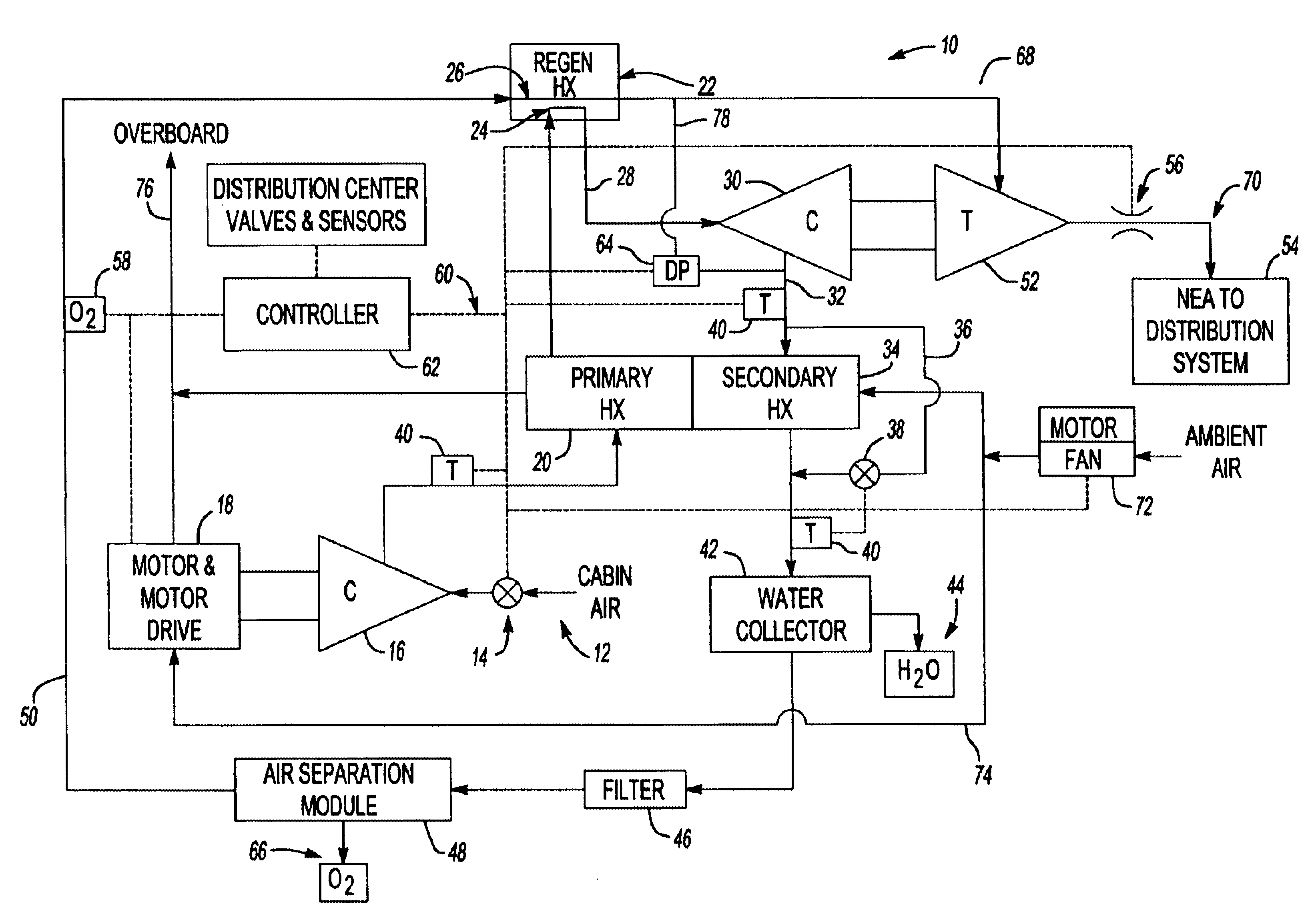

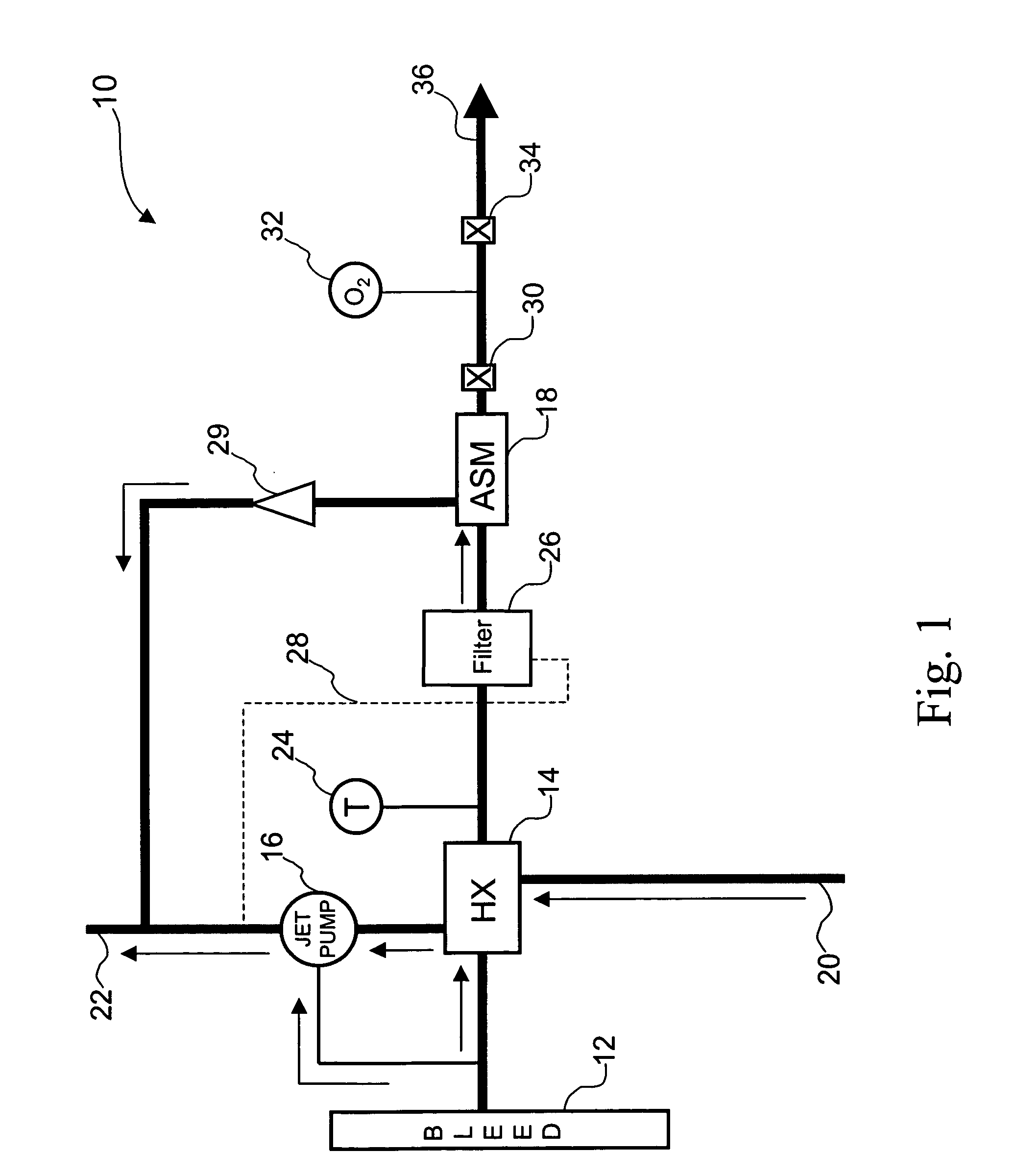

Method and apparatus for generating an inert gas on a vehicle

An inert gas generating system for generating inert gas on a vehicle having a fuel tank and a fuel tank vent. The system includes an inlet for receiving a flow of gas having a nitrogen component and an oxygen component from a gas source, a heat exchanger downstream from the inlet and in fluid communication with the inlet for cooling gas received from the inlet, and a gas separation module downstream from the heat exchanger and in fluid communication with the heat exchanger for separating gas received from the heat exchanger into a nitrogen-enriched gas flow and an oxygen-enriched gas flow. The gas separation module is adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank without delivering the nitrogen-enriched gas through the fuel tank vent. The gas separation module is also adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank vent.

Owner:THE BOEING CO

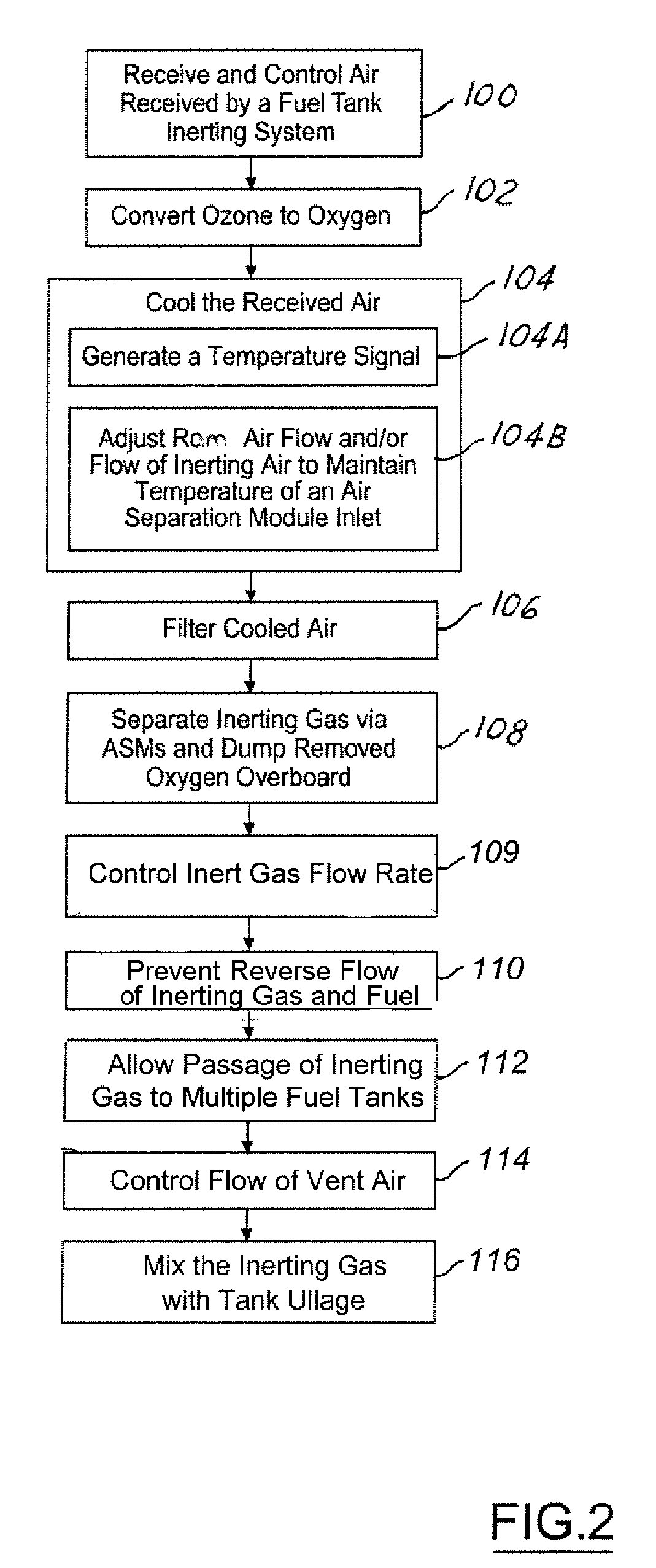

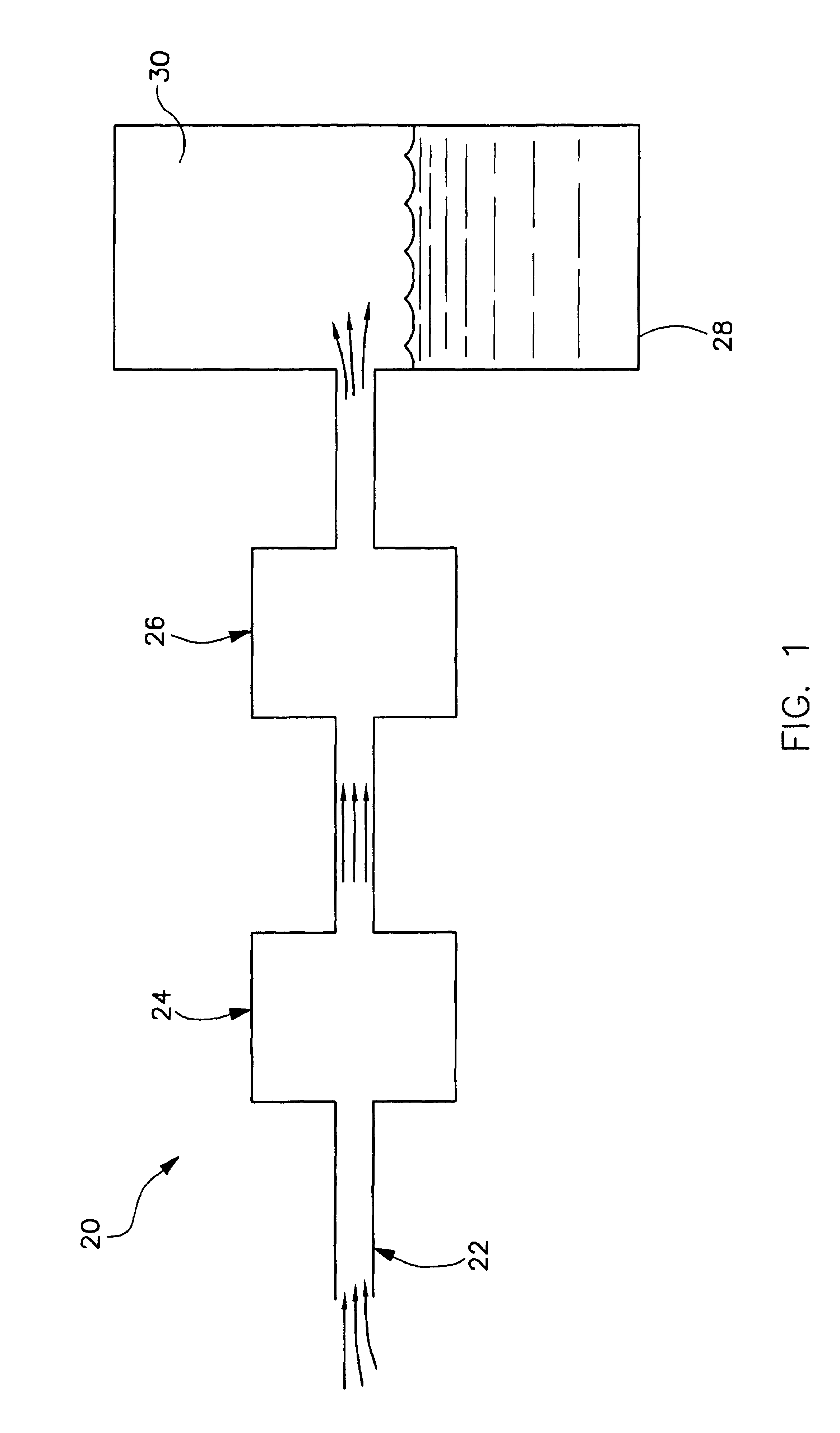

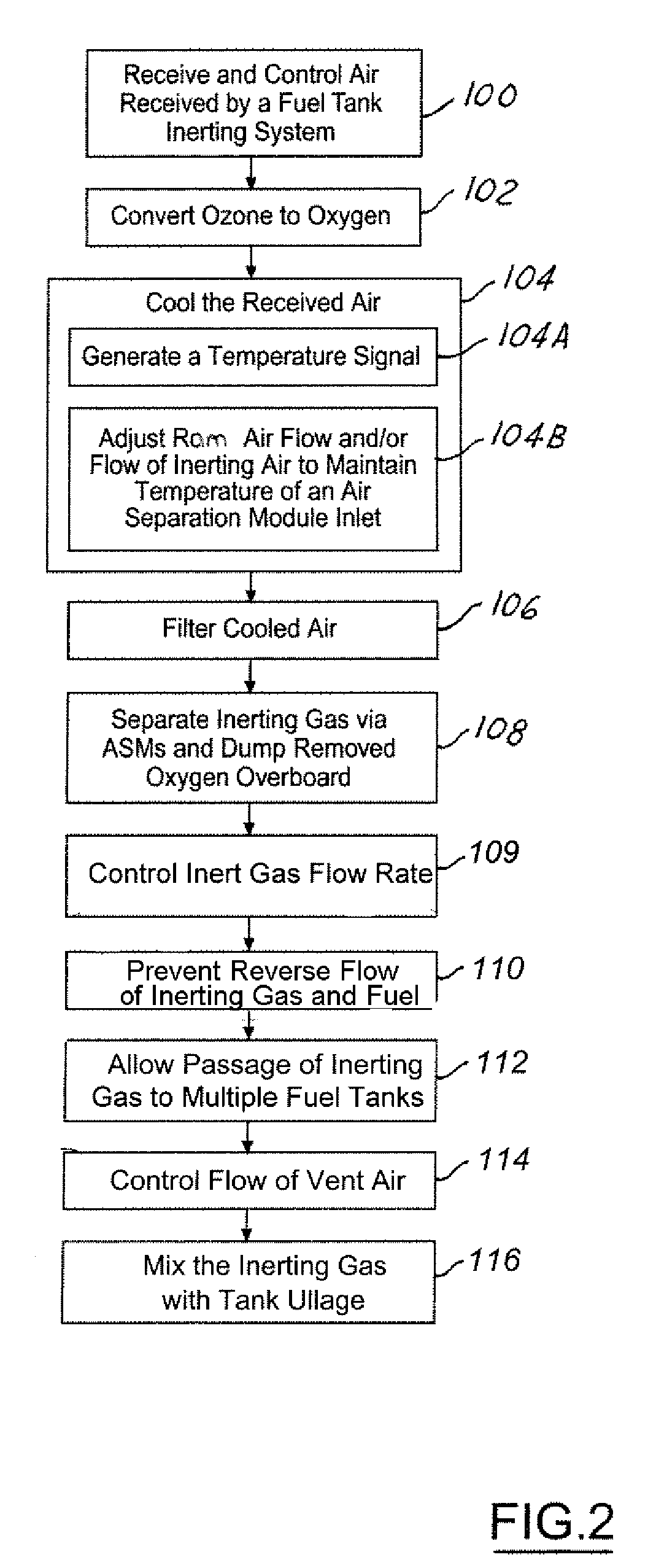

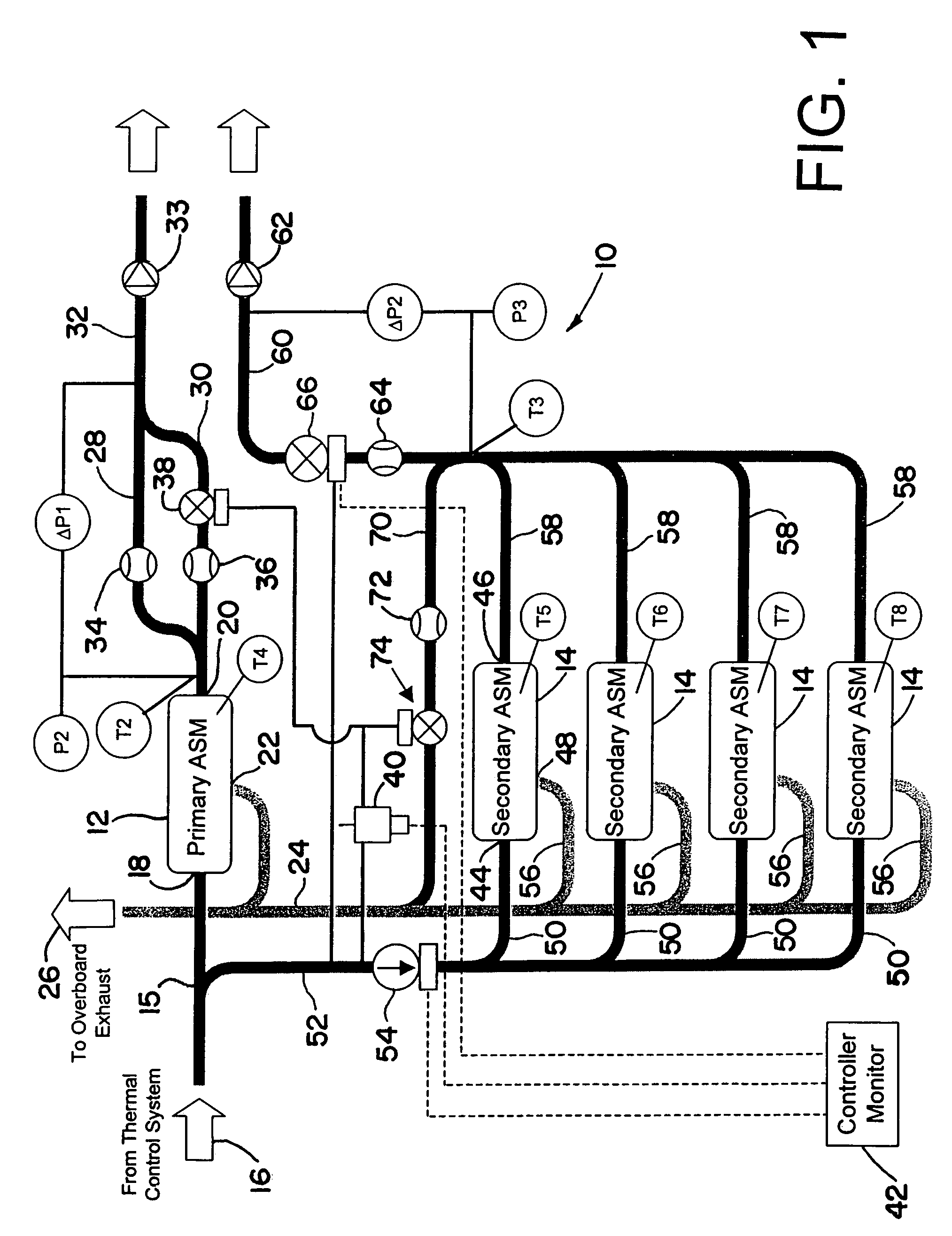

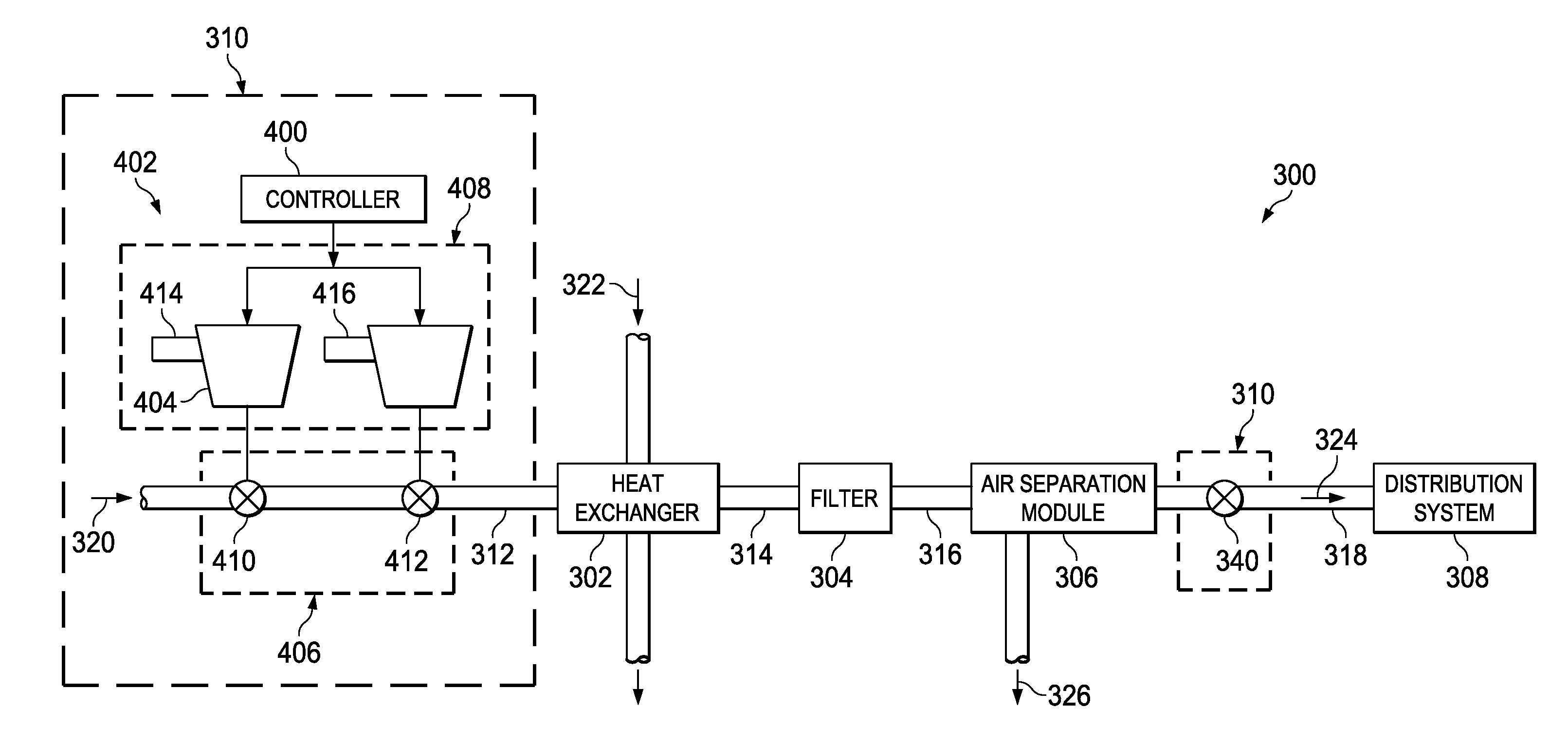

Gas generating system and method for inerting aircraft fuel tanks

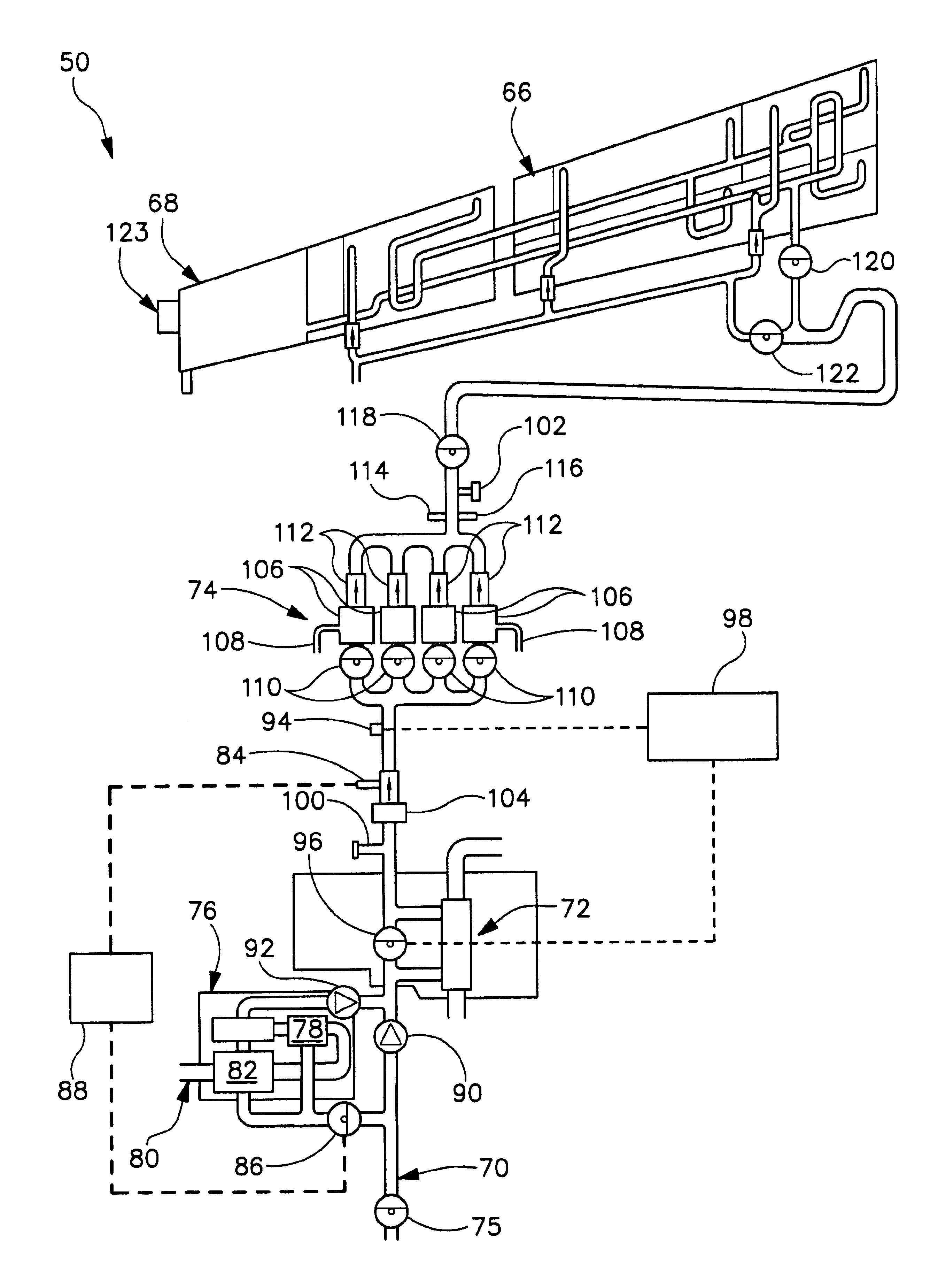

ActiveUS20050115404A1Avoid flowPrevent contamination from enteringGas treatmentDispersed particle filtrationOperational costsFuel tank

The present invention provides a system and method for generation of nitrogen enriched air for inerting aircraft fuels tanks. One embodiment of the present invention includes a duct assembly; a primary heat exchanger; a gas generating system heat exchanger; a first temperature sensor; a second temperature sensor; a controller monitor; a valve; an air separation module assembly having a primary module and a secondary module; at least one flow control orifice; and a pressure sensor. The present invention utilizes a minimal complement of components and streamlined processes, thus minimizing structural and operational costs while optimizing performance and safety features.

Owner:HONEYWELL INT INC

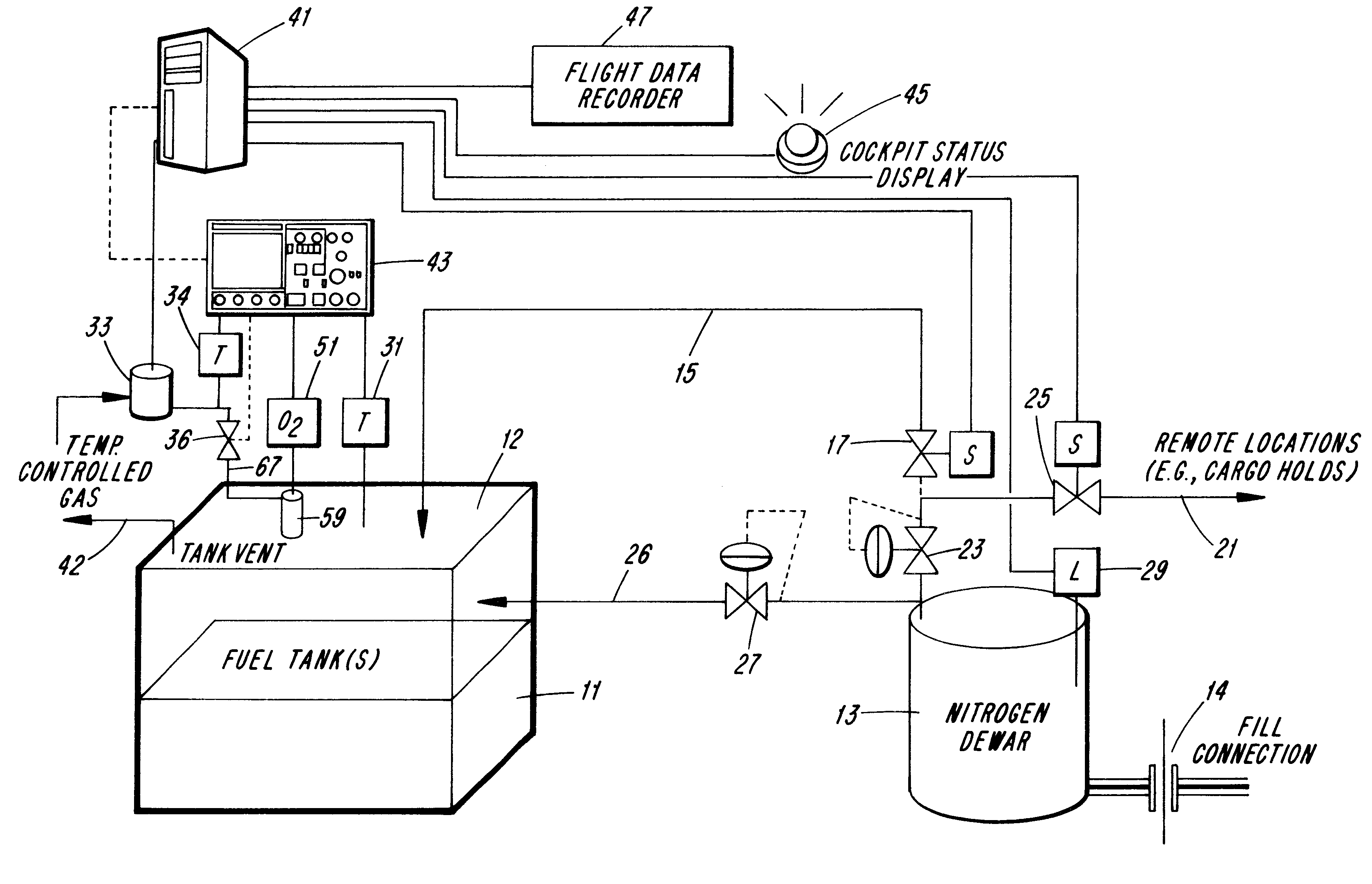

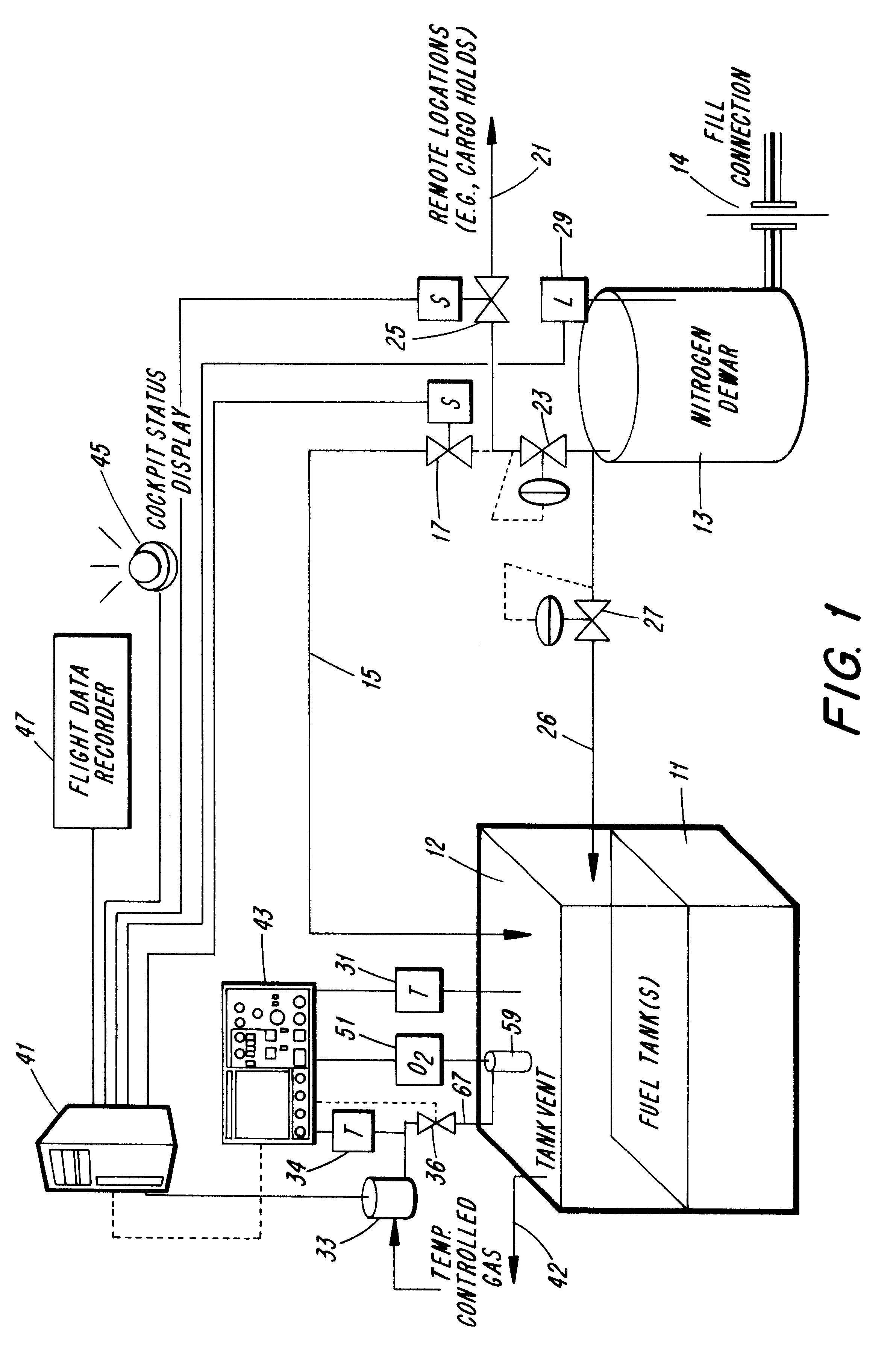

On-board fuel inerting system

InactiveUS6634598B2Effective monitoringExplosion is minimized and eliminatedPower plant fuel tanksFuel tank safety measuresUllageNitrogen gas

An inerting system is disclosed that is adaptable to inert the fuel tank of a vehicle, most typically an aircraft, that includes an oxygen detector to monitor the oxygen partial pressure of the vapors in the ullage (i.e., the overfuel) volume of the tank, a source of an inert gas (e.g., nitrogen) in valved communication with the ullage of the tank, and a detector for sensing the oxygen content in the ullage of the tank and controlling the flow of inert gas to the tillage to maintain that volume with a proportion oxygen that will not support combustion in the event of an ignition source or intrusion of another potentially explosive occurrence within said tank. A specific fiberoptic probe which enables monitoring oxygen content within the tank without introducing a source of electrical current within the tank is also disclosed.

Owner:SUSKO KENNETH

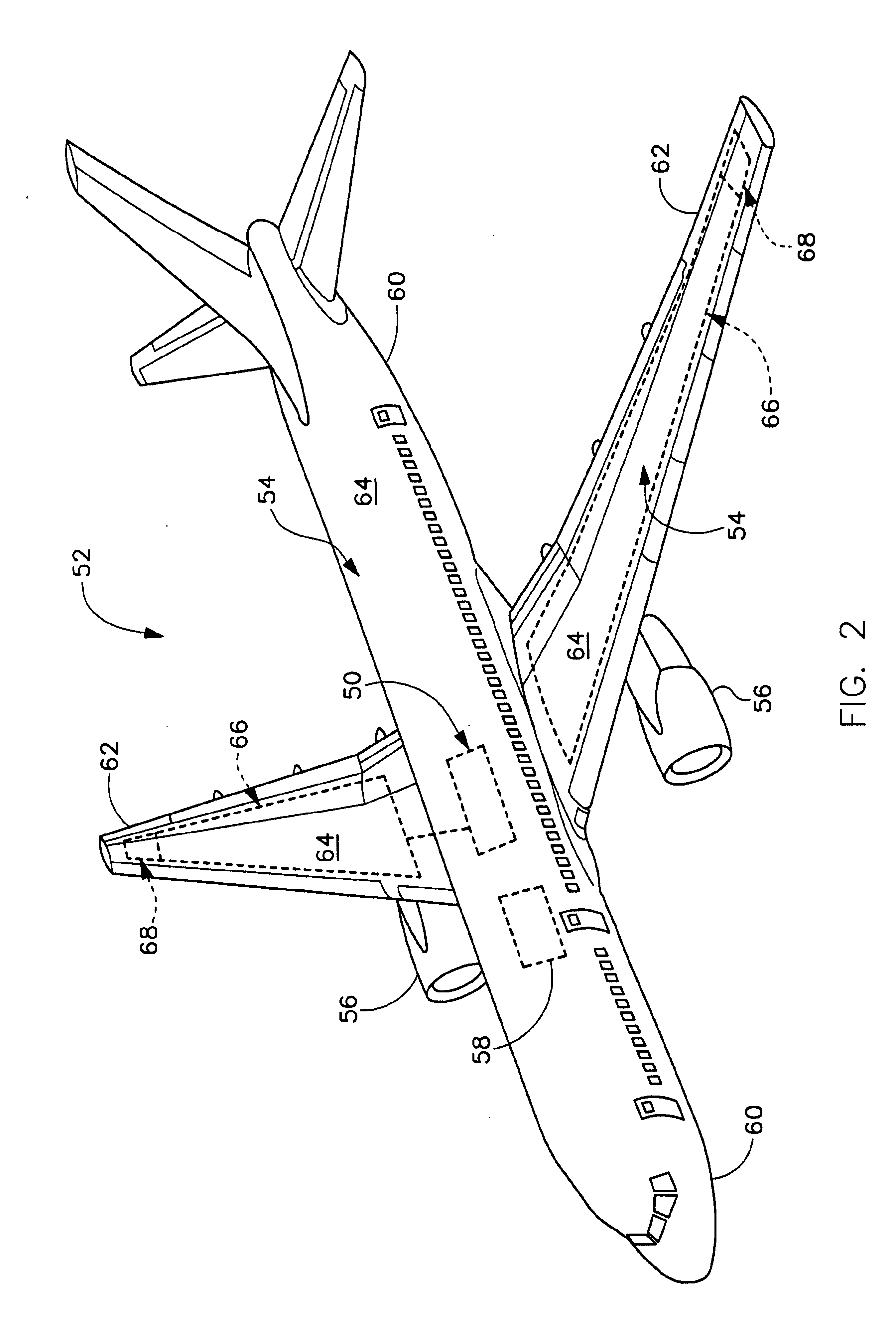

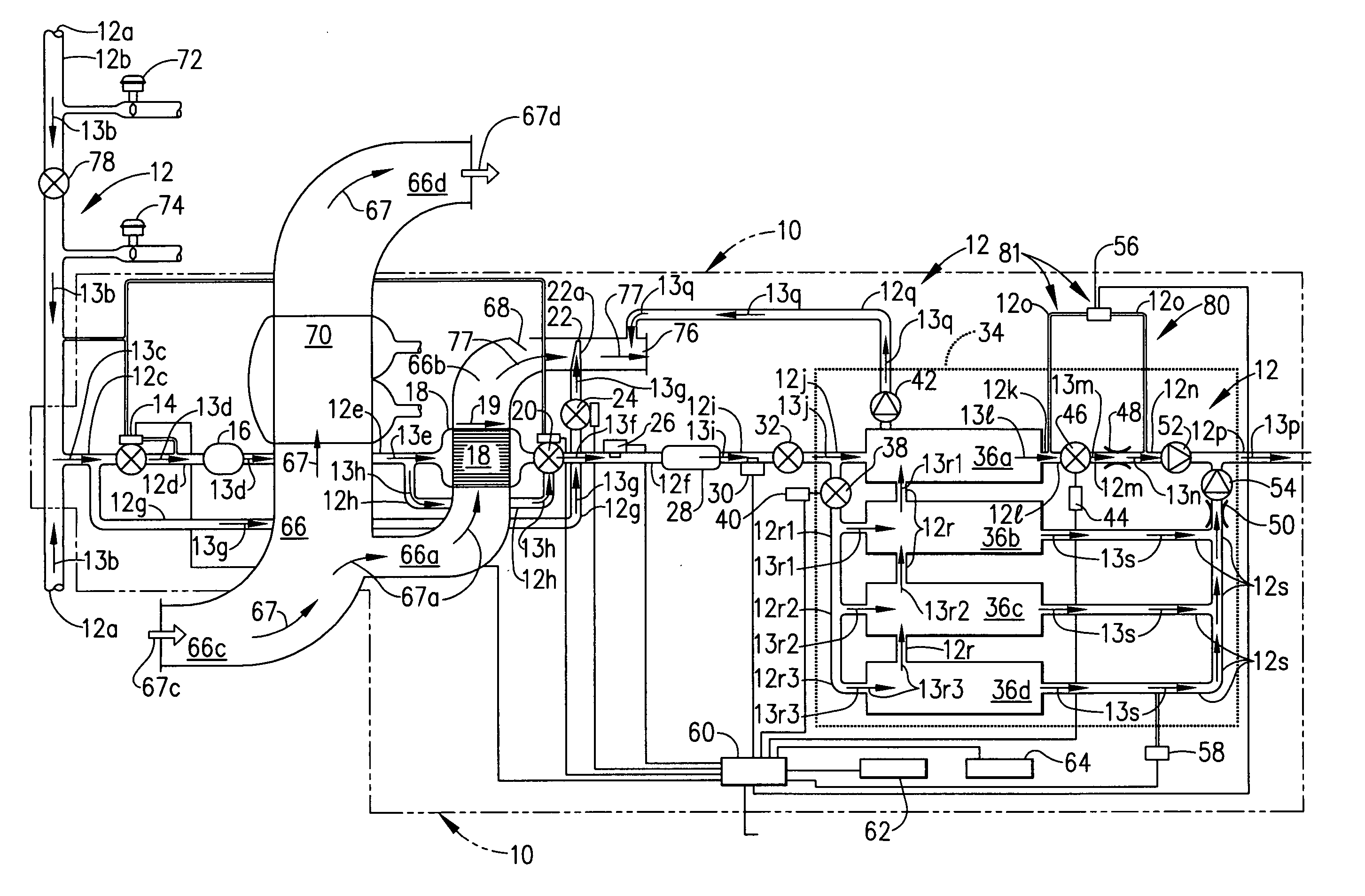

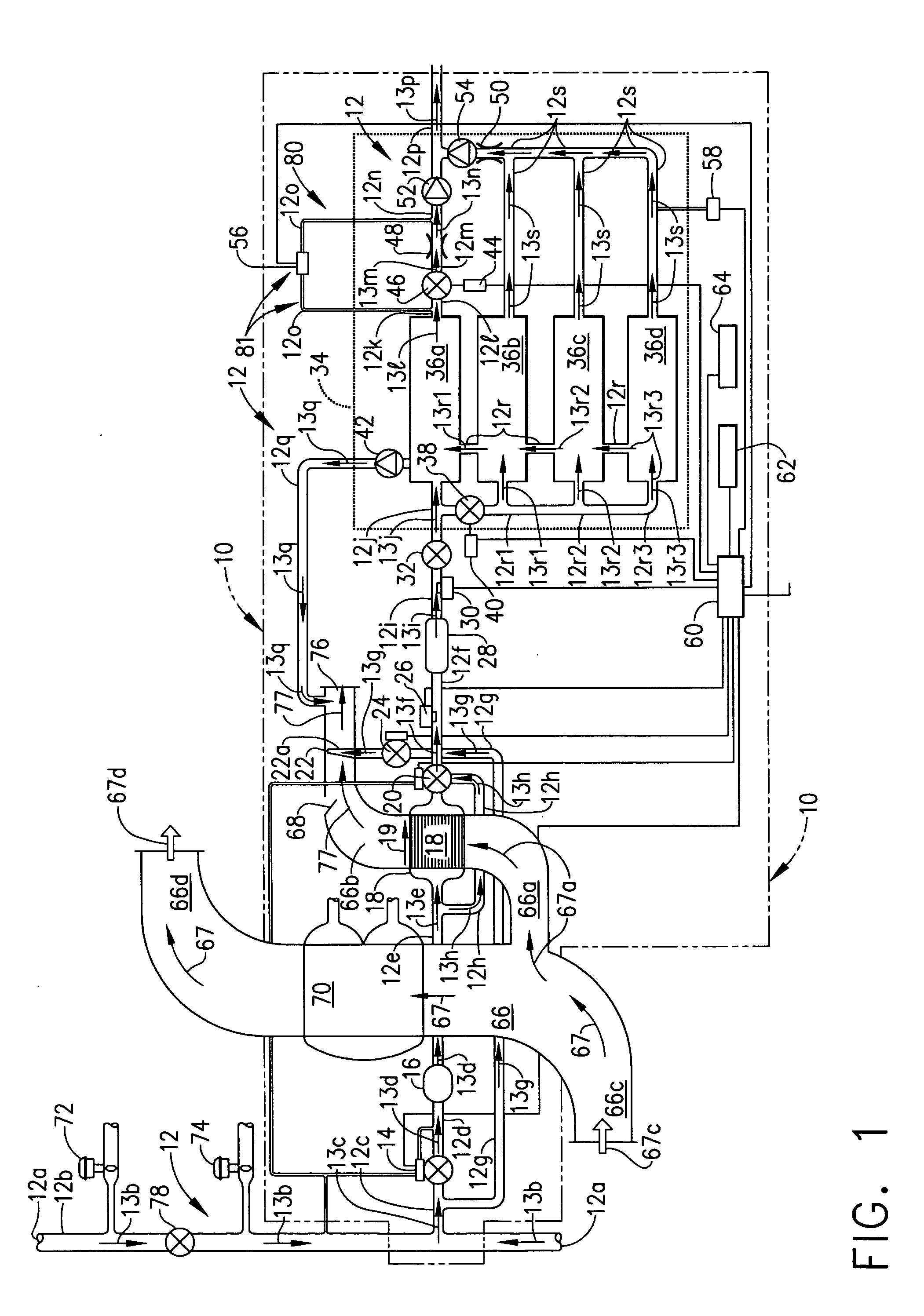

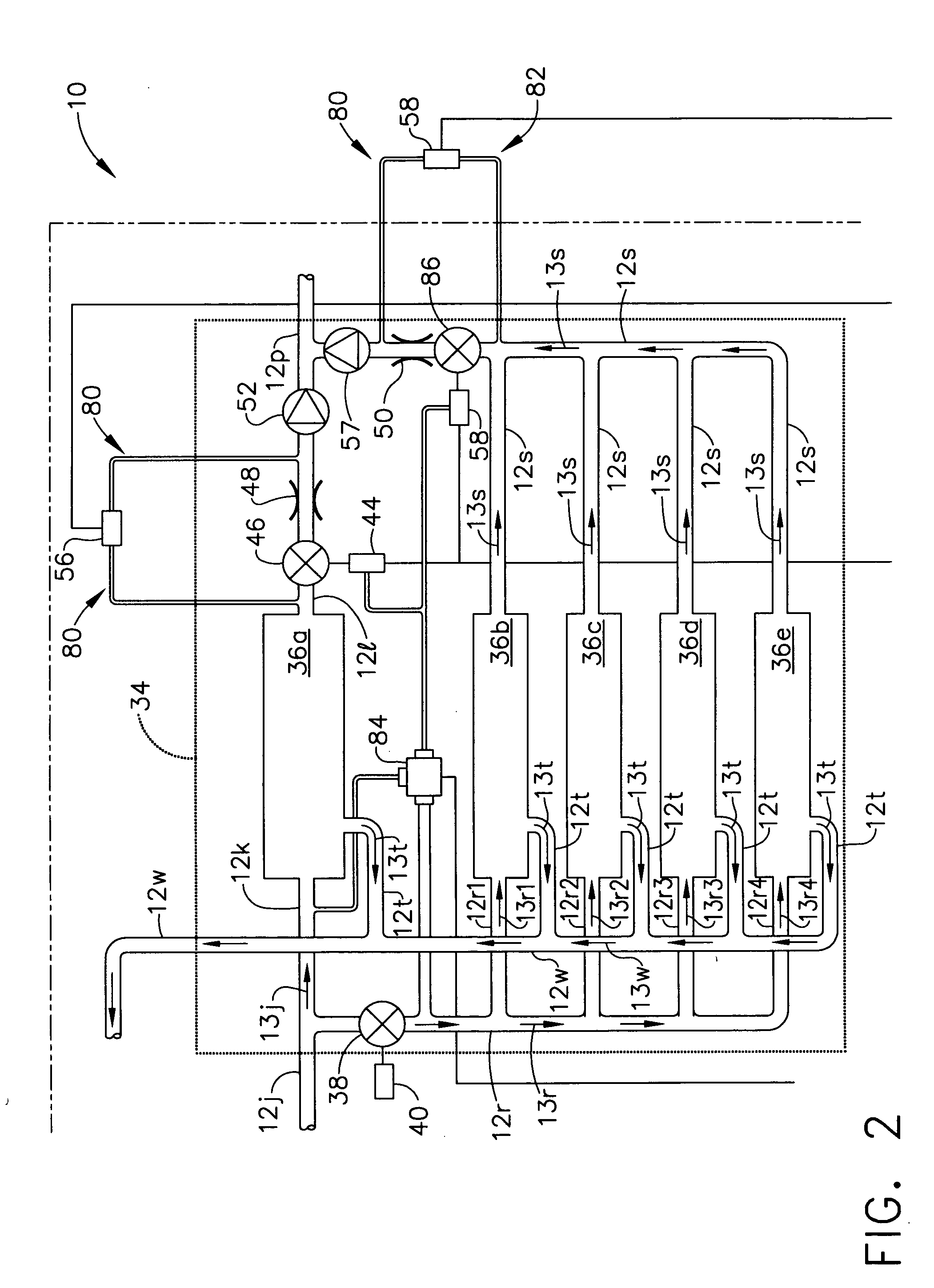

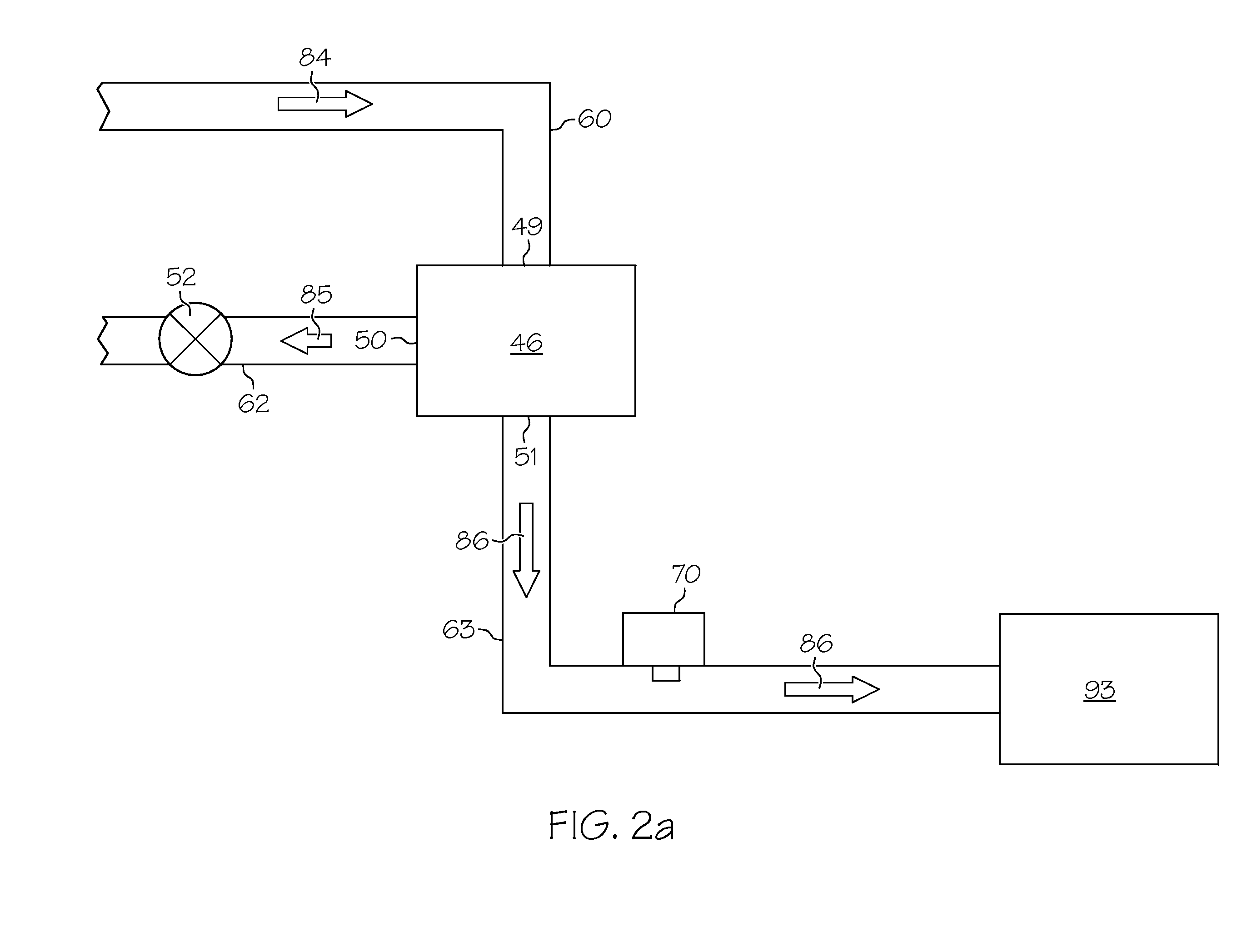

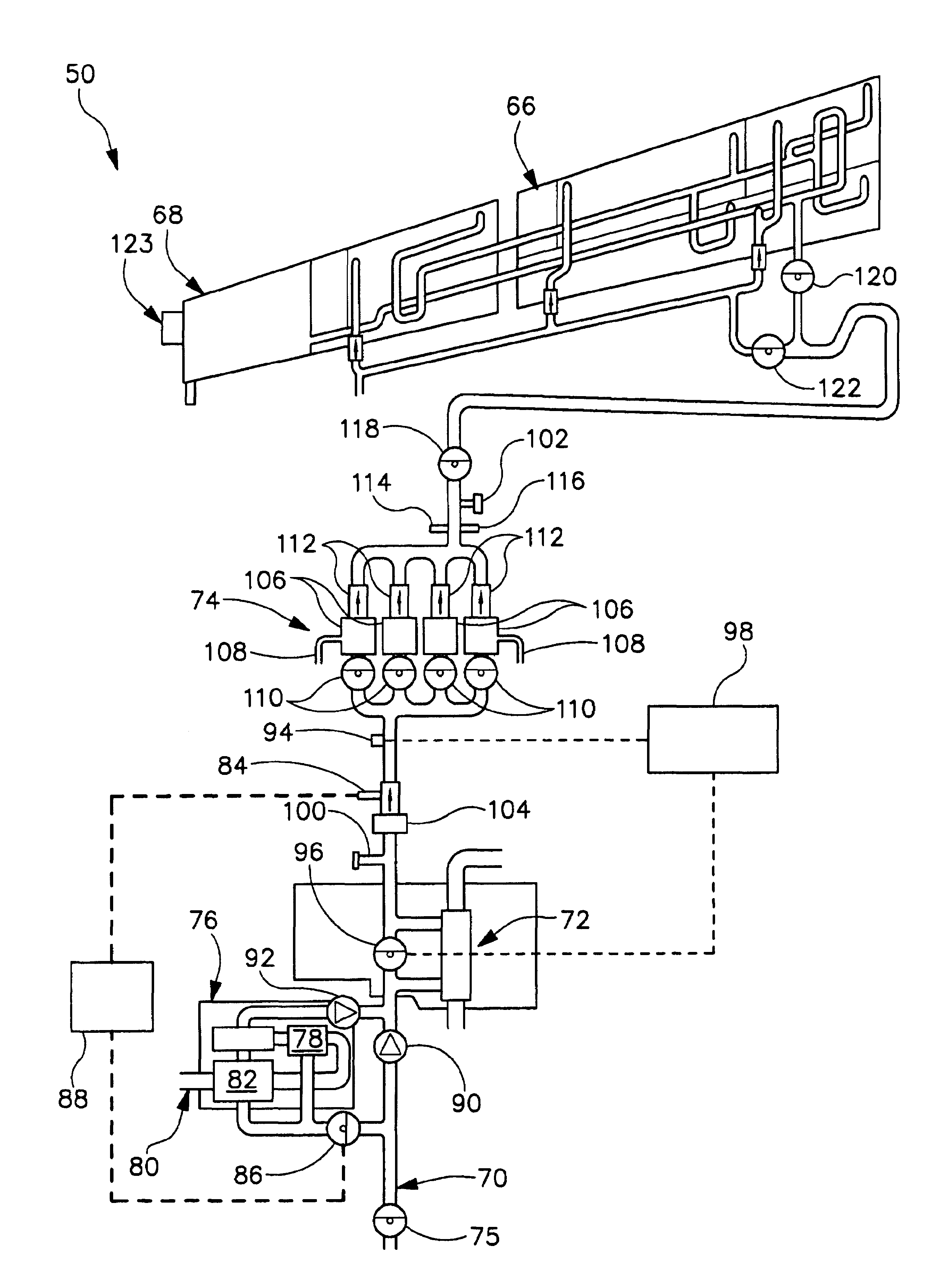

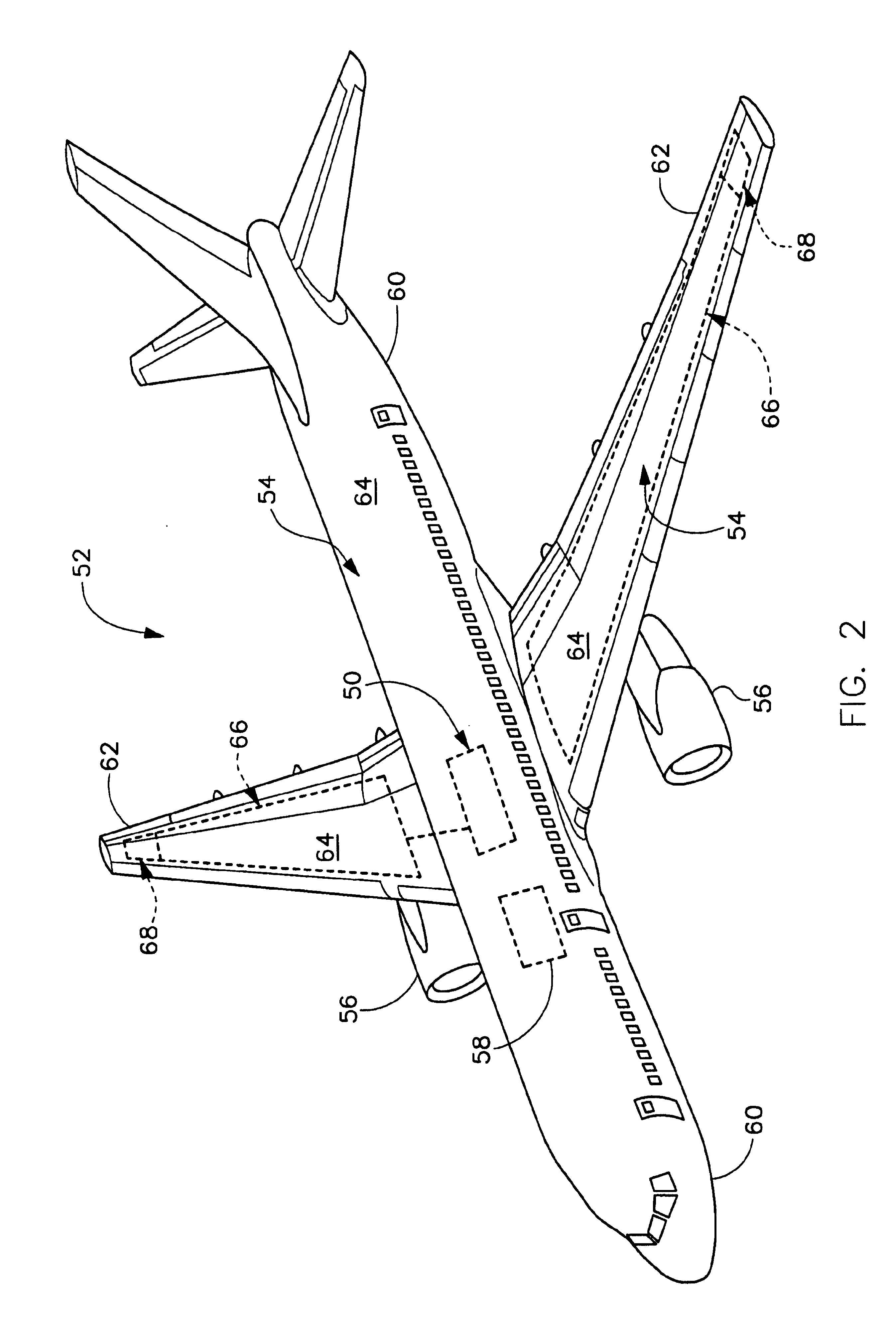

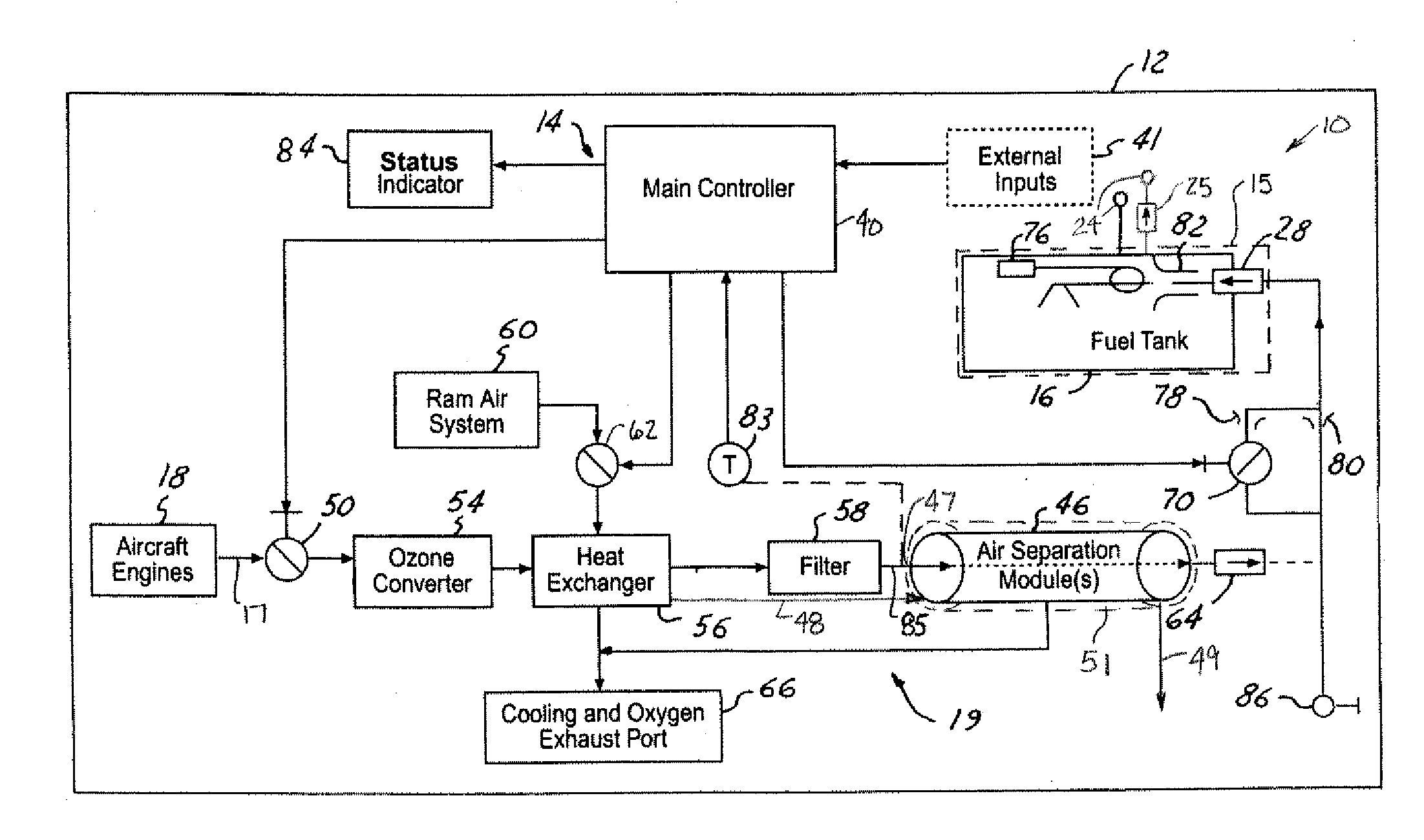

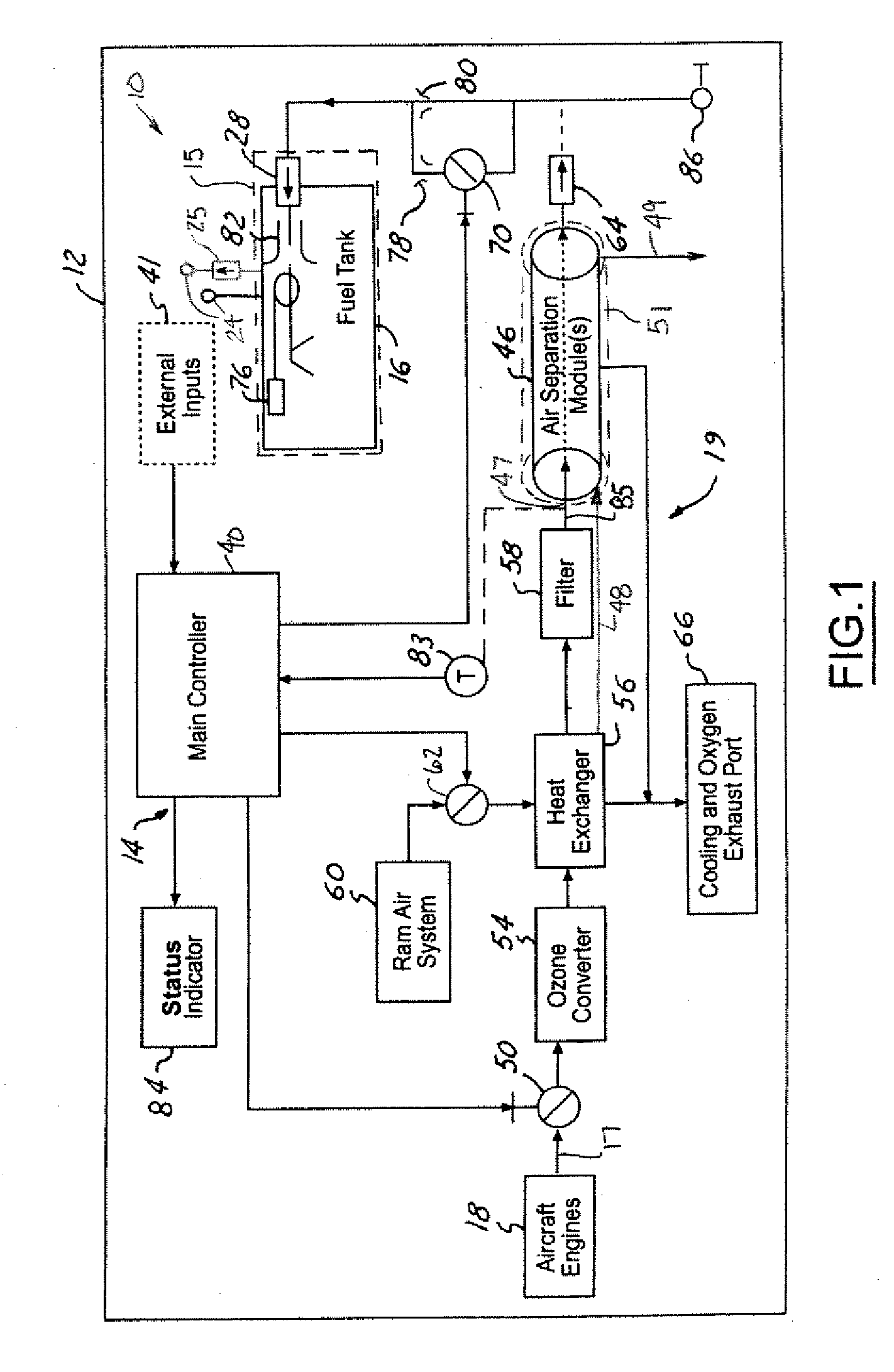

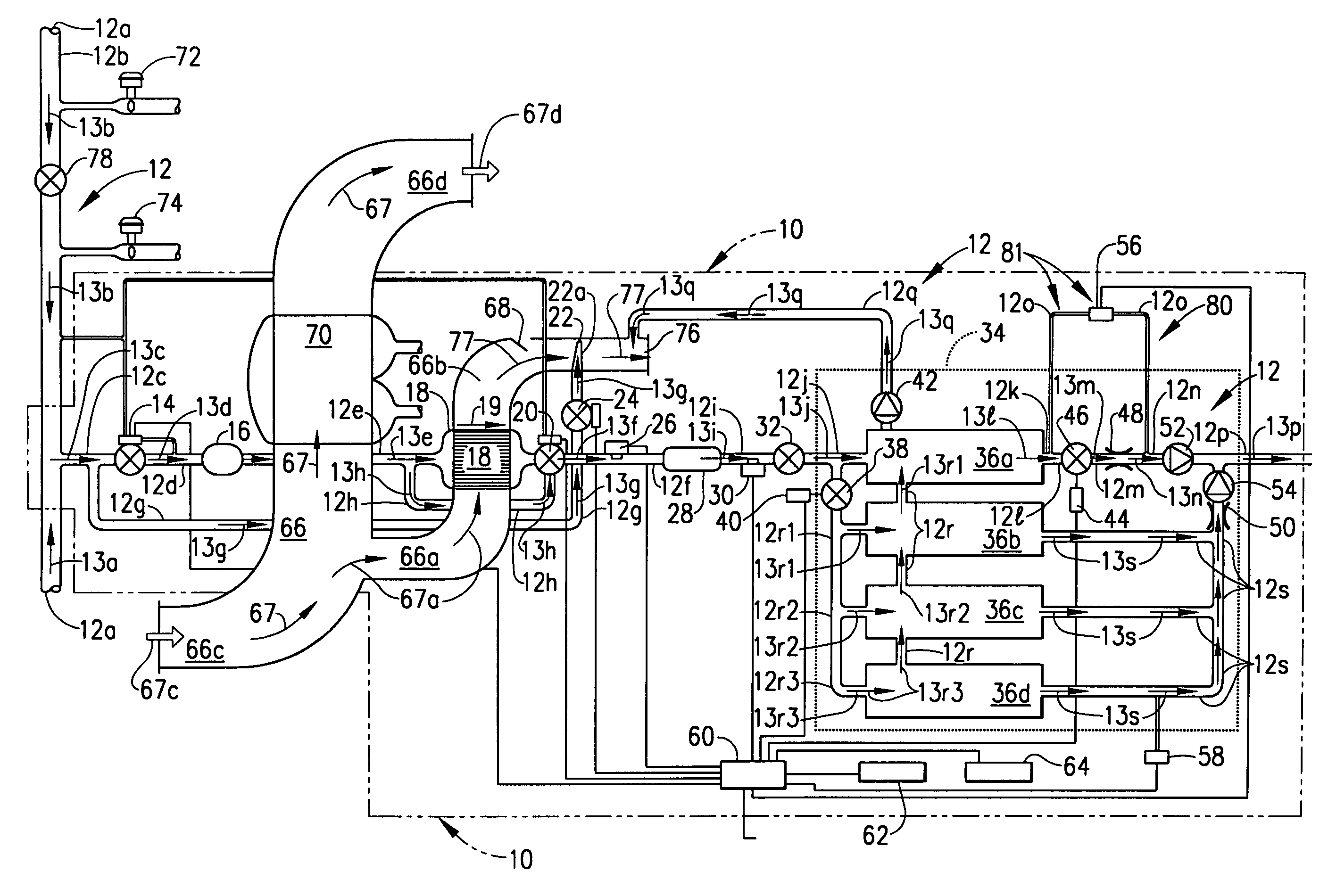

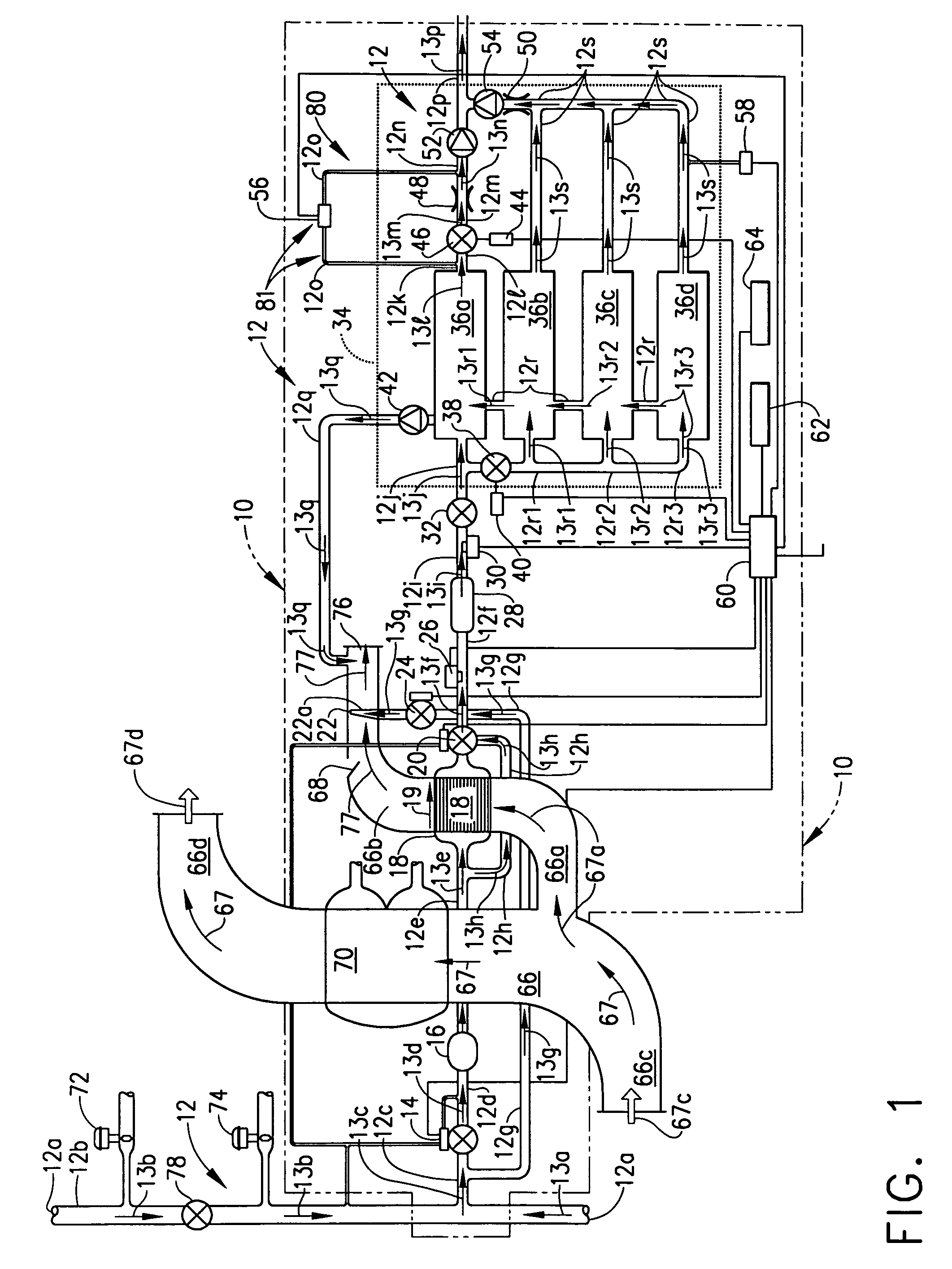

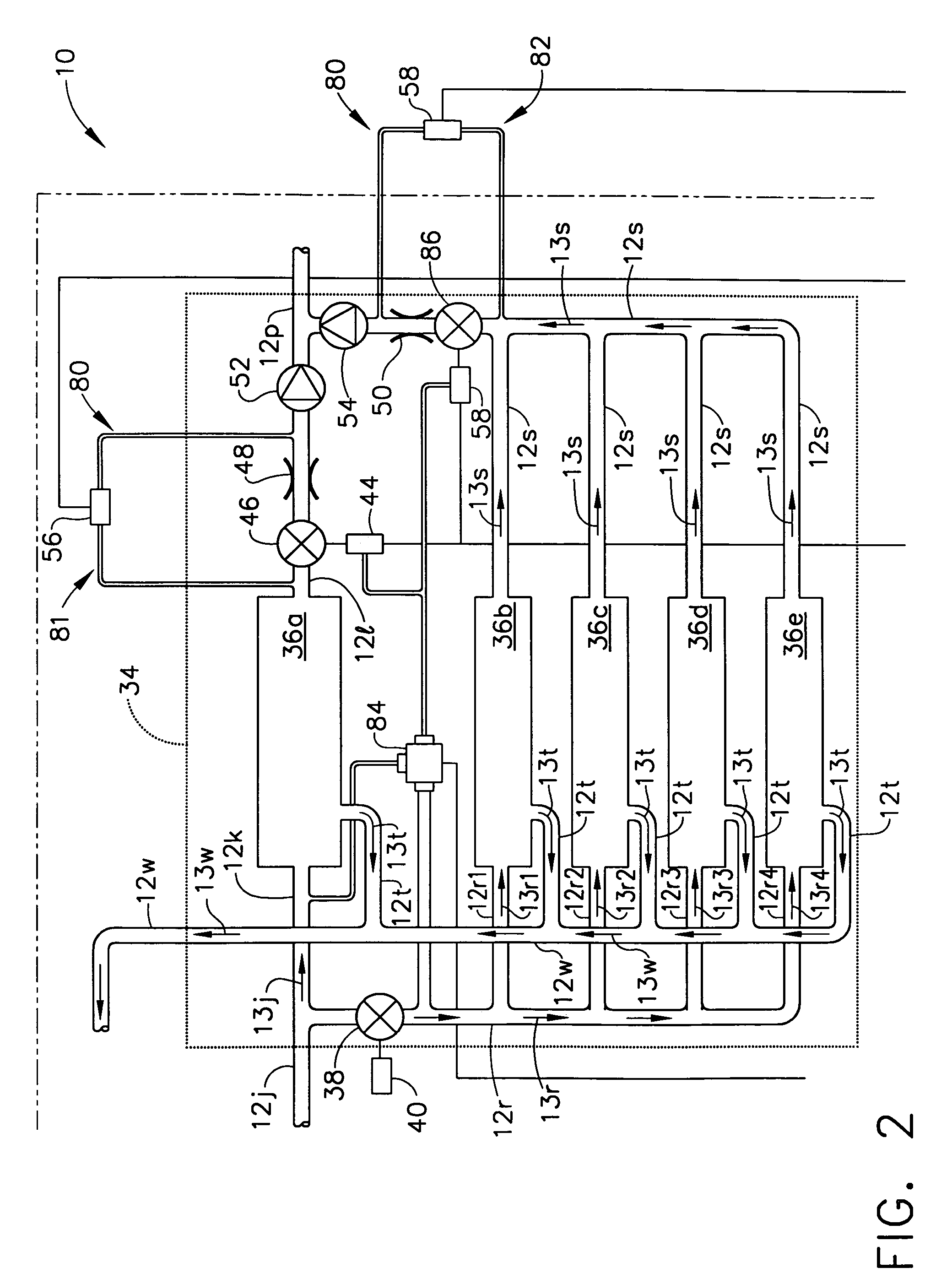

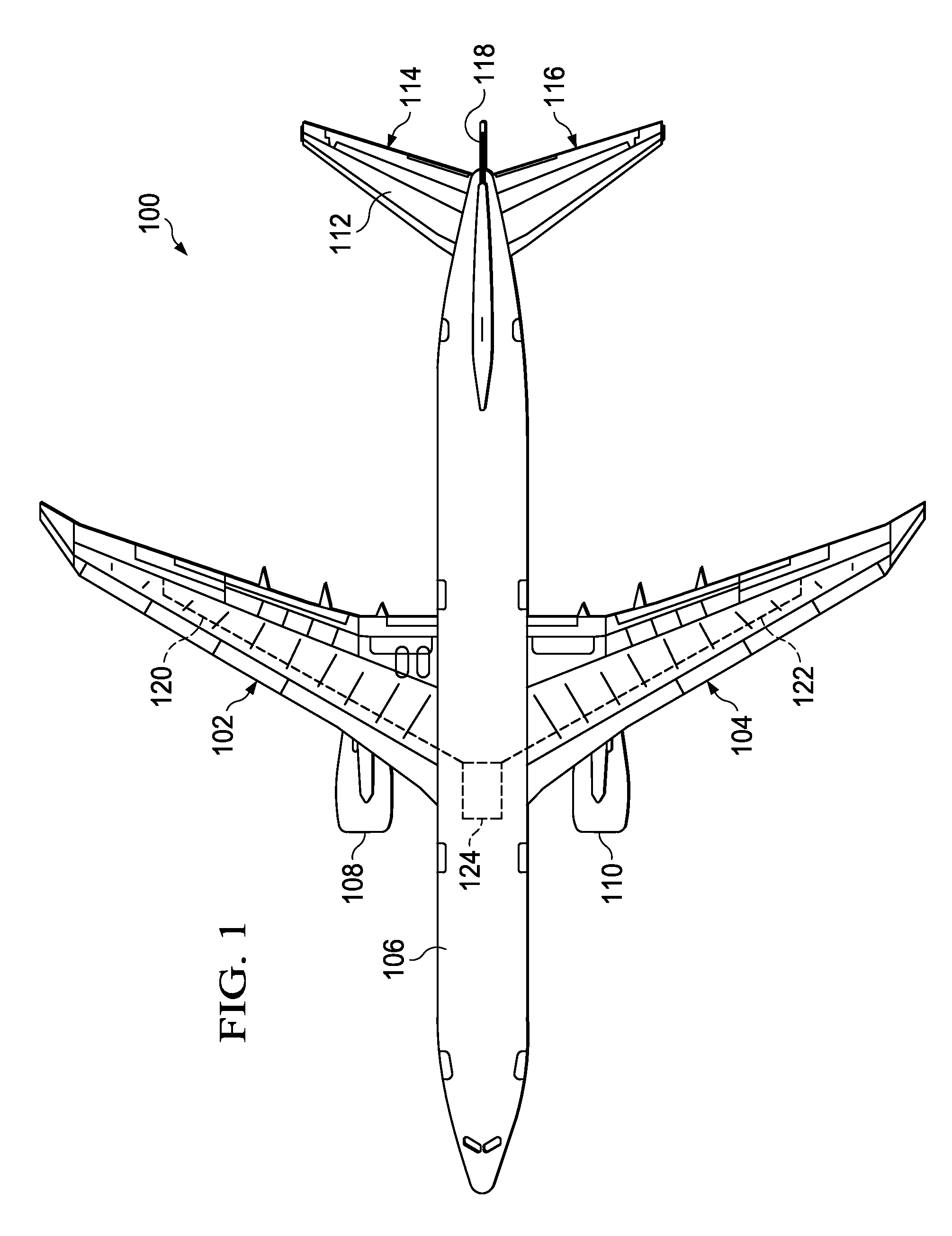

Commercial aircraft on-board inerting system

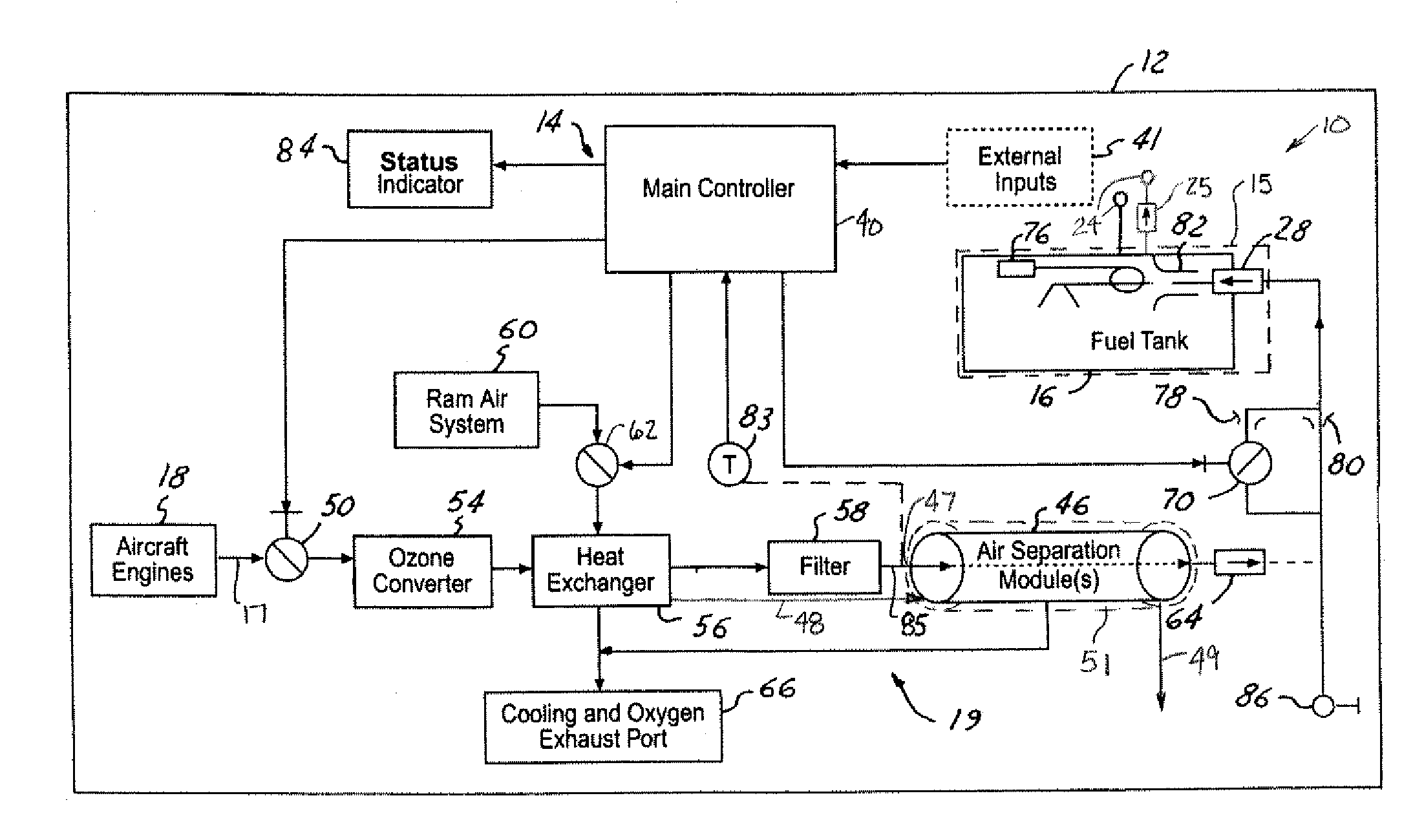

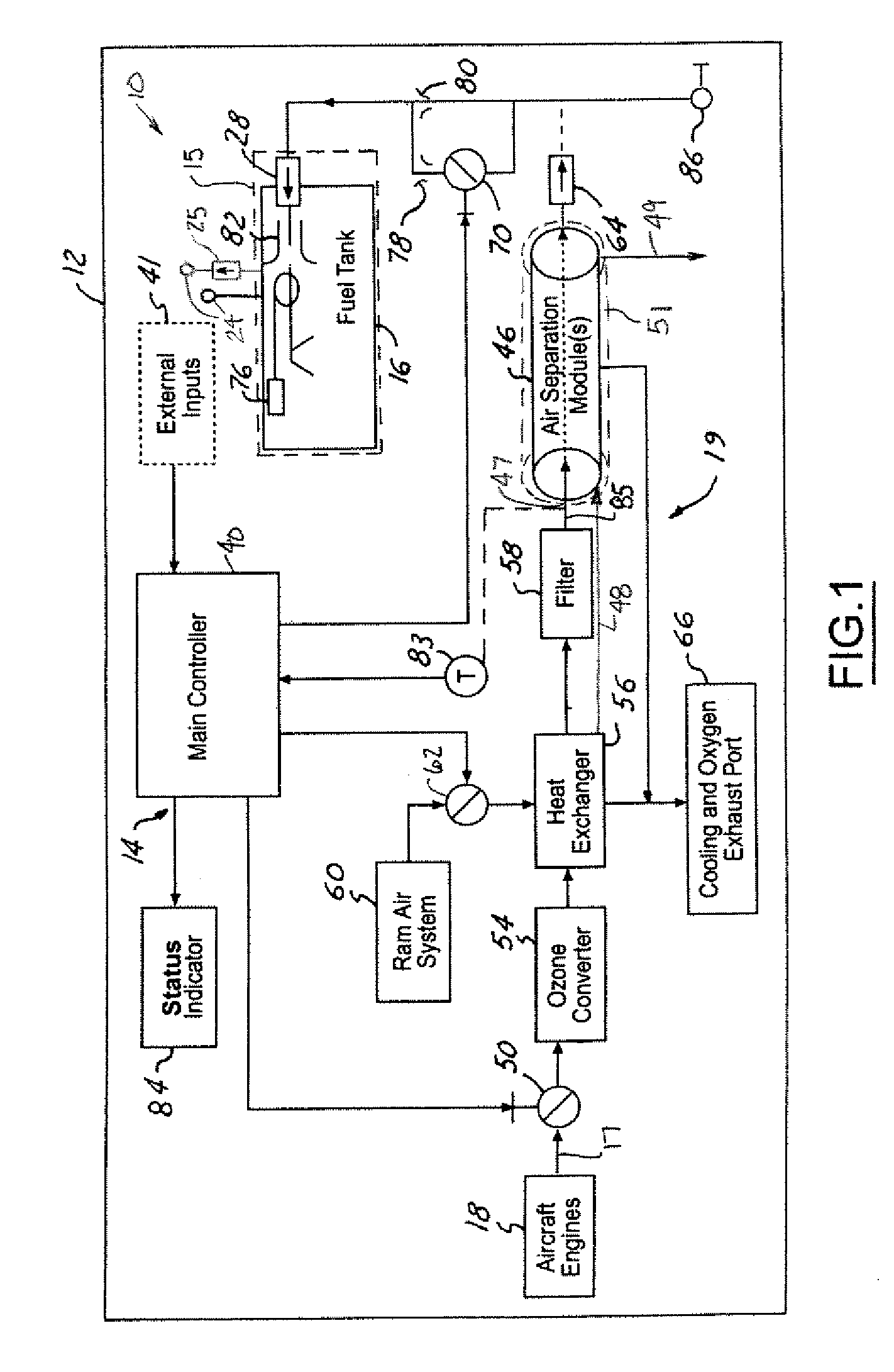

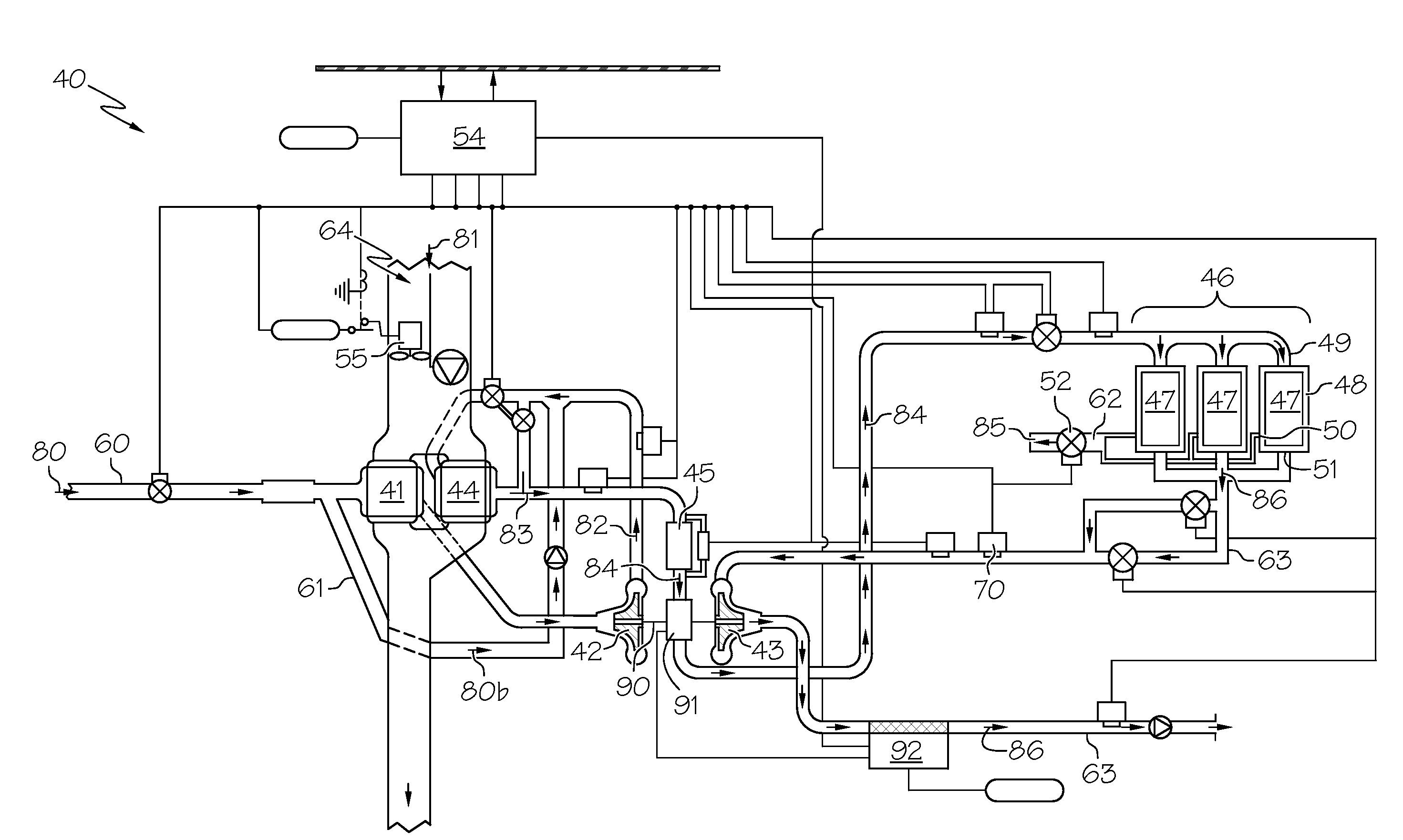

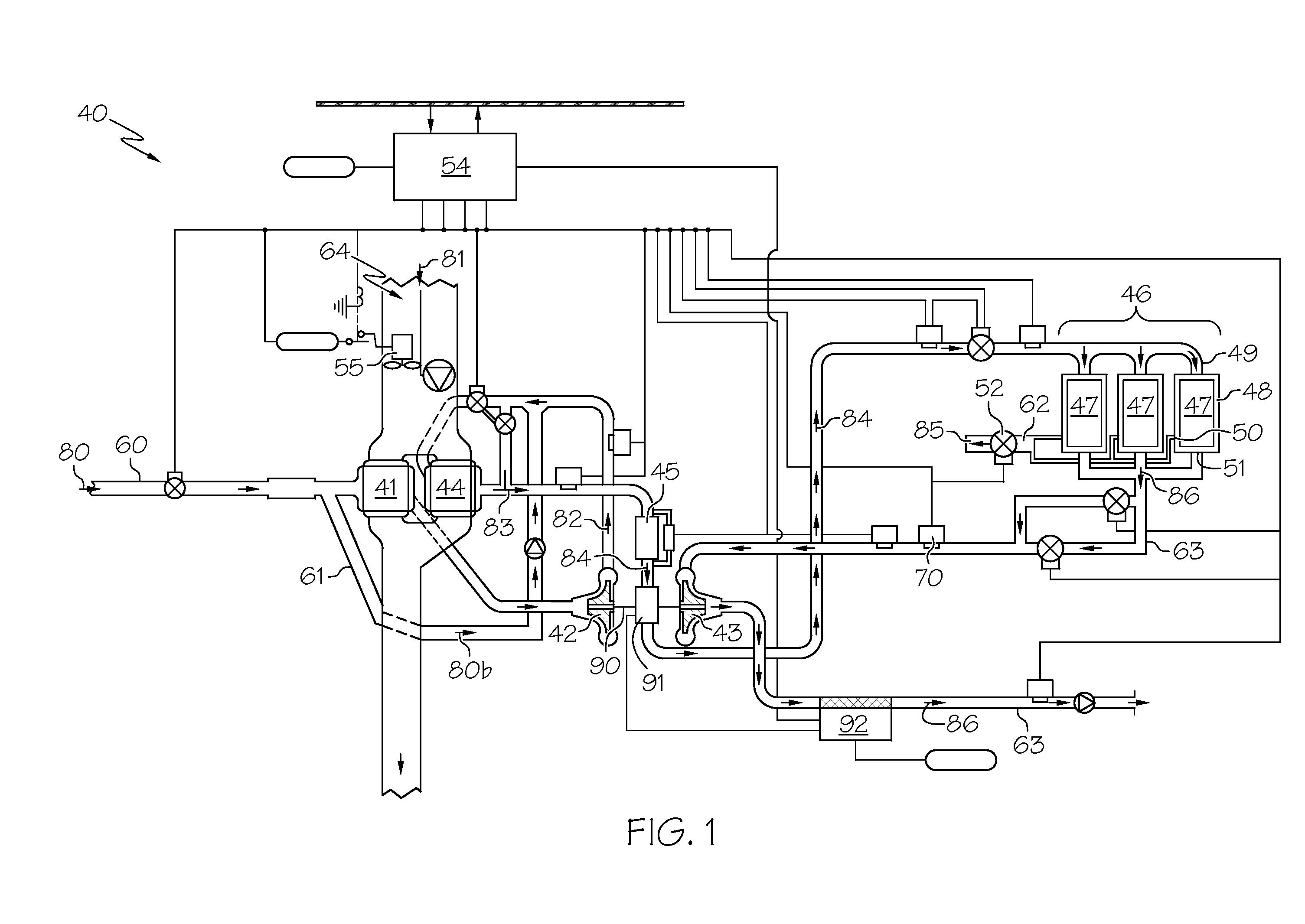

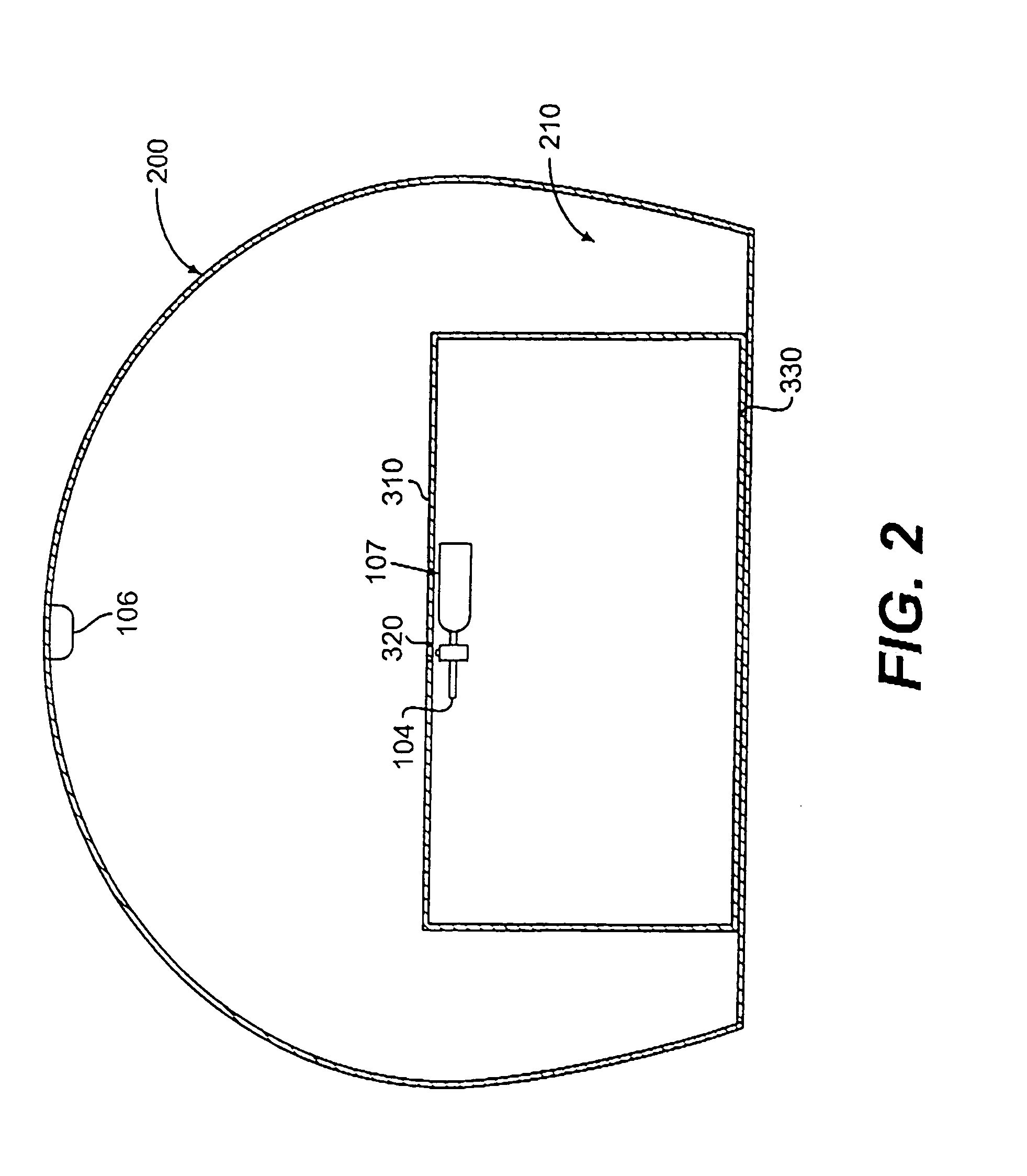

ActiveUS7152635B2Reduce flammabilityImprove flammabilityLiquid fillingPower plant fuel tanksInerting systemOn board

An inerting system (10) for an aircraft (12) includes one or more fuel tank circuits (15) associated with fuel tanks (16). An air source (17) supplies pressurized air. A heat exchanger (56) cools the pressurized air. An air separation module (46) is in fluid communication with the heat exchanger (56) and separates inerting gas from the pressurized air. A controller (40) controls flow of the inerting gas from the air separation module (46) to the fuel tanks (16).

Owner:THE BOEING CO

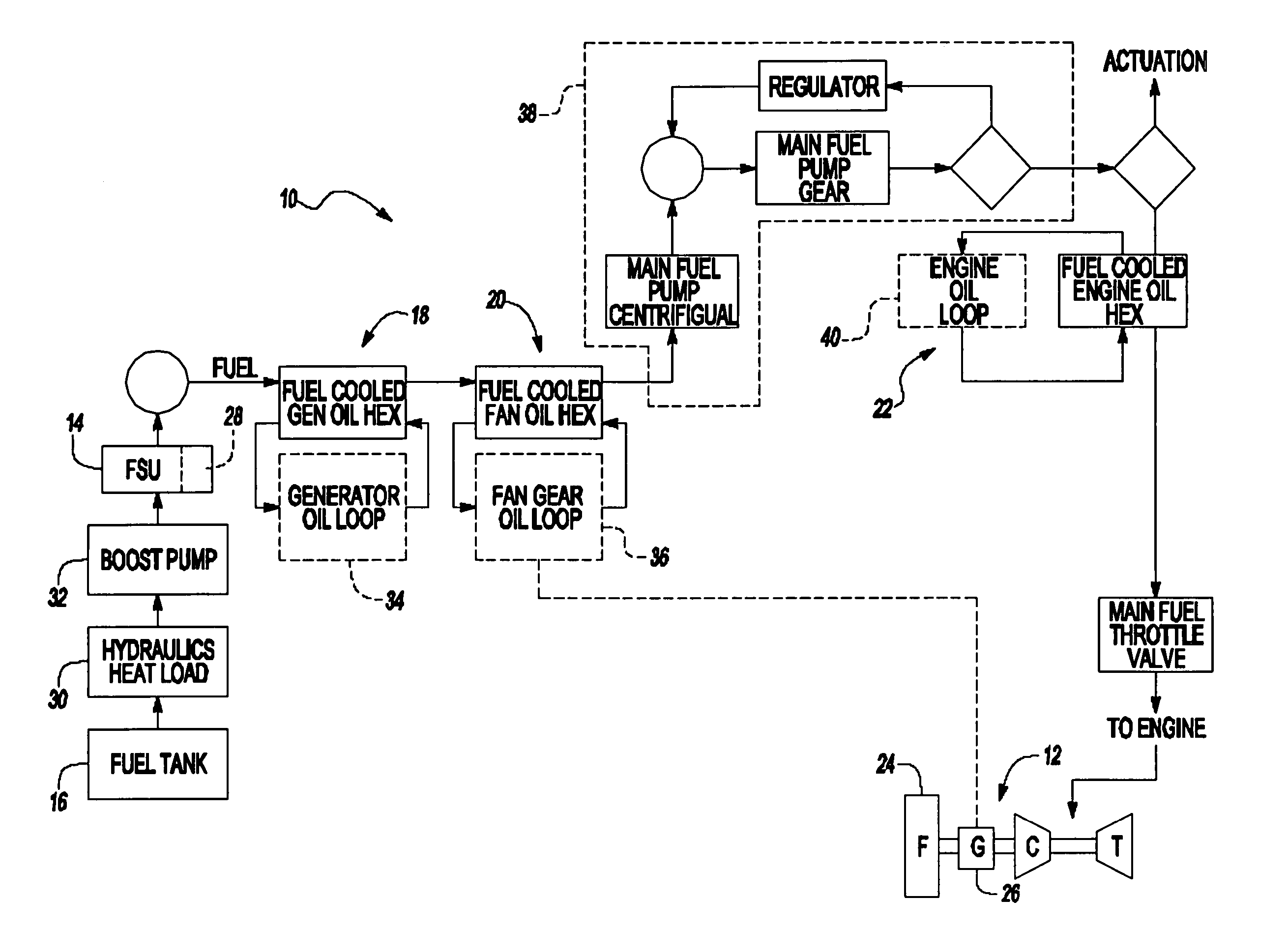

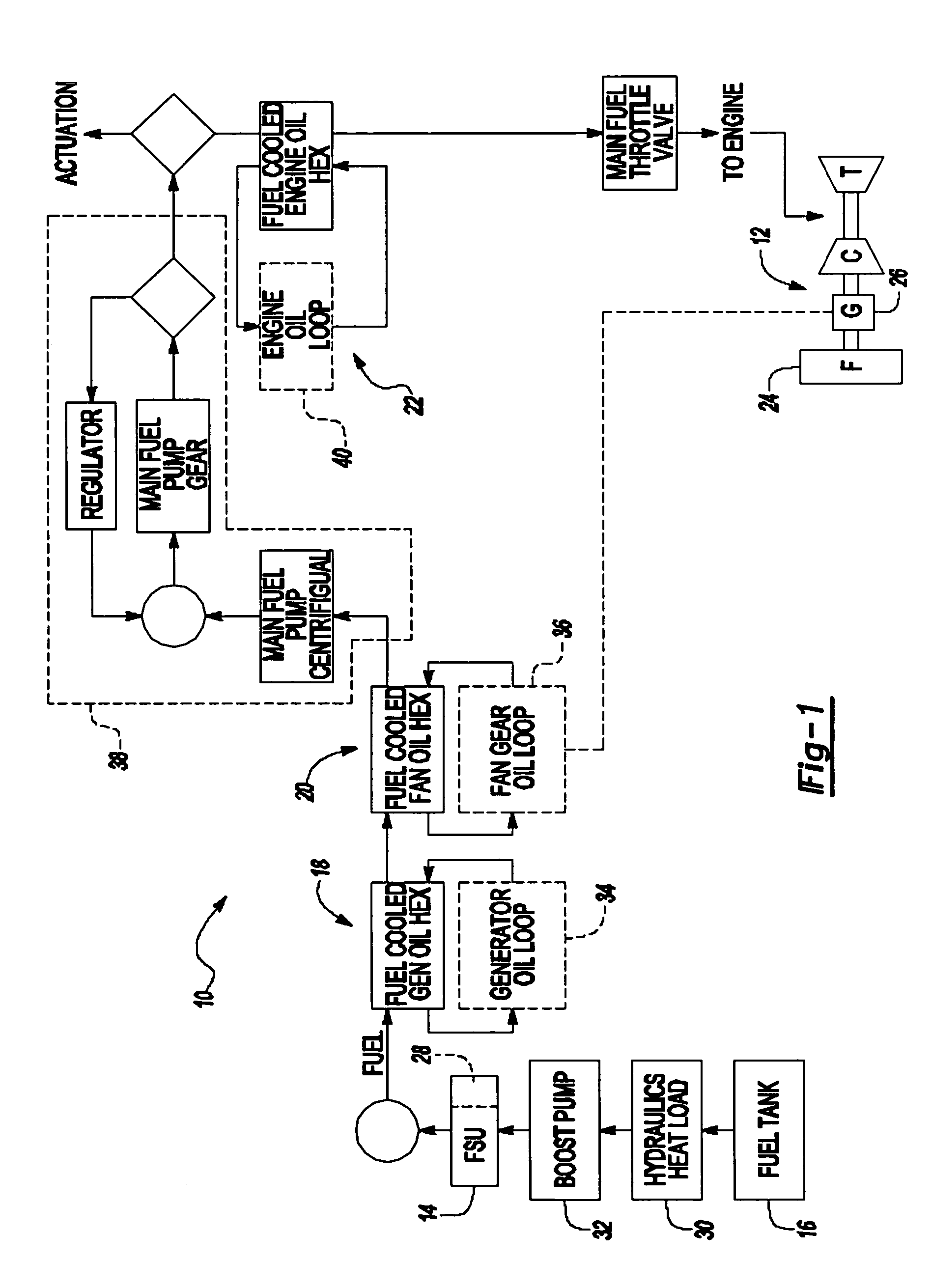

Thermal management system for an aircraft

ActiveUS7260926B2Minimizes air-to-liquid heat exchangersEngine fuctionsTurbine/propulsion fuel deliveryThermal management systemProcess engineering

A fuel based thermal management system includes a fuel stabilization system which permits the fuel to exceed the traditional coking temperatures. High temperature components are arranged along the fuel flow path such that even at the higher operating temperatures the fuel operates as a heat sink to transfer heat from high temperature components to the fuel. An optimal high temperature ester-based oil permits an oil-loop to exceed current oil temperature limits and achieve a high temperature to permit efficient rejection of heat to the fuel late in the fuel flow path.

Owner:RTX CORP

Catalytic reactive component reduction system and methods for the use thereof

ActiveUS7694916B2Minimizes ventingReduce riskOrganic chemistryIndirect heat exchangersGas phaseEngineering

Owner:PHYRE TECH

Advanced carbon dioxide fuel tank inerting system

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

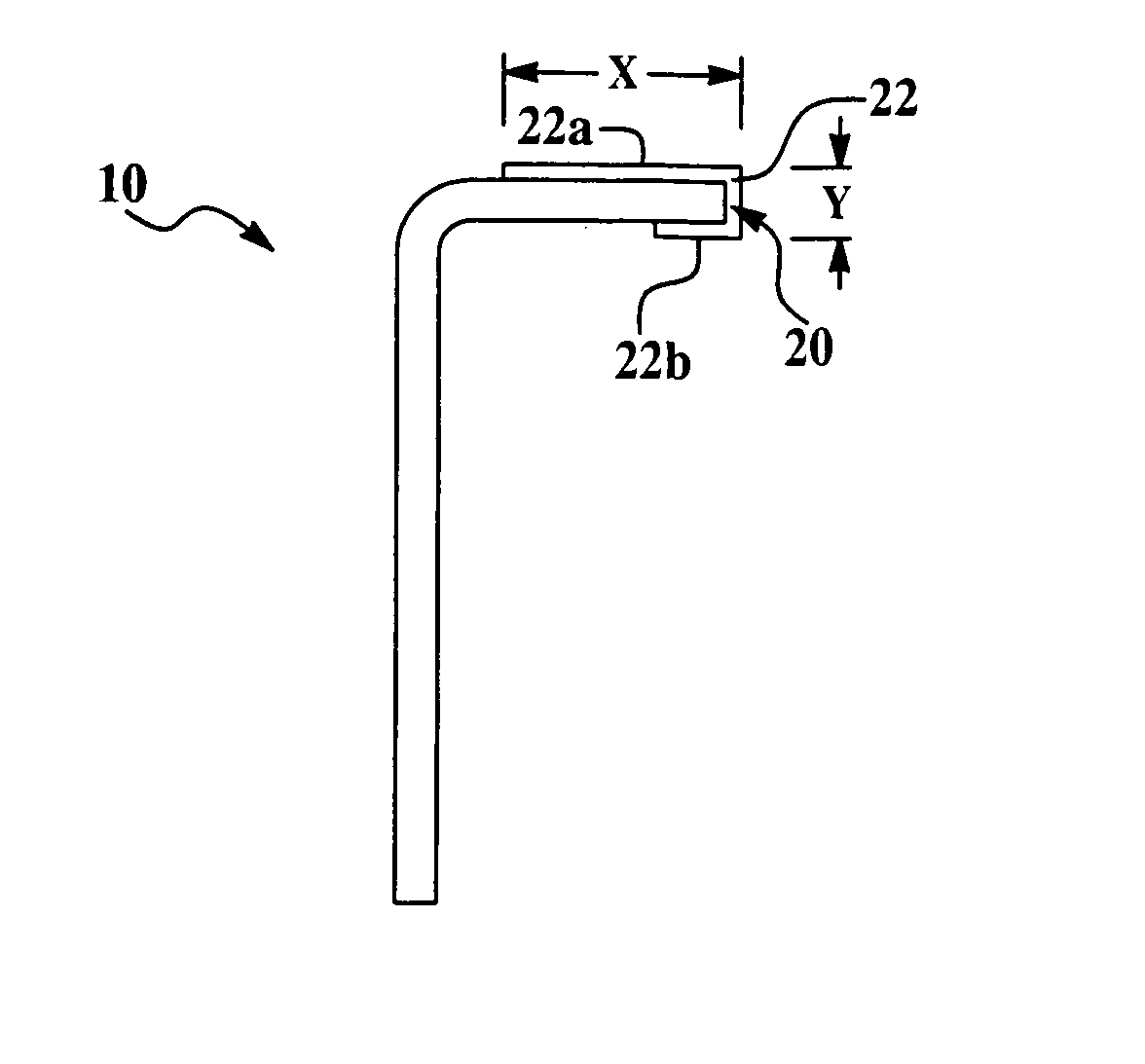

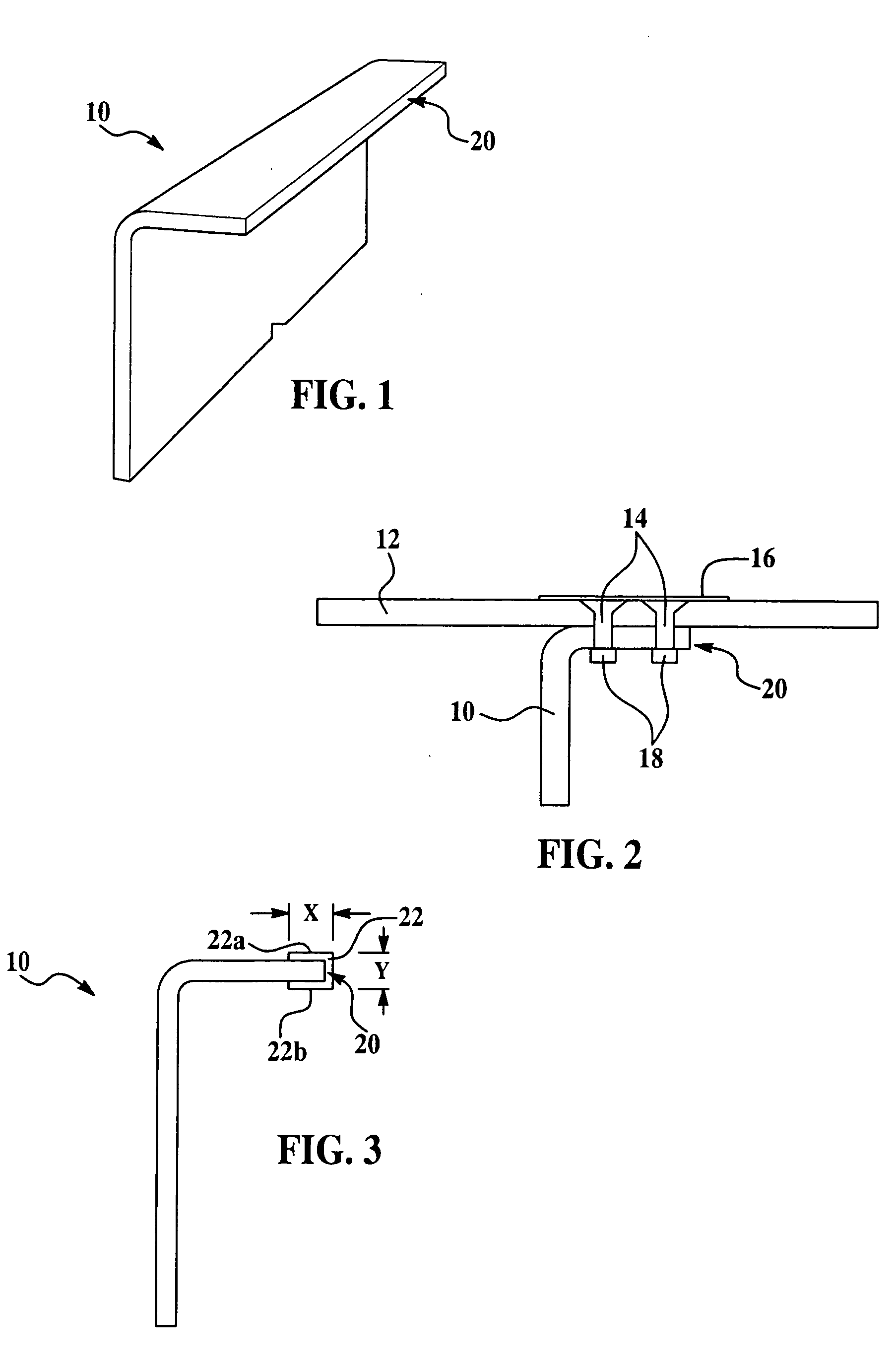

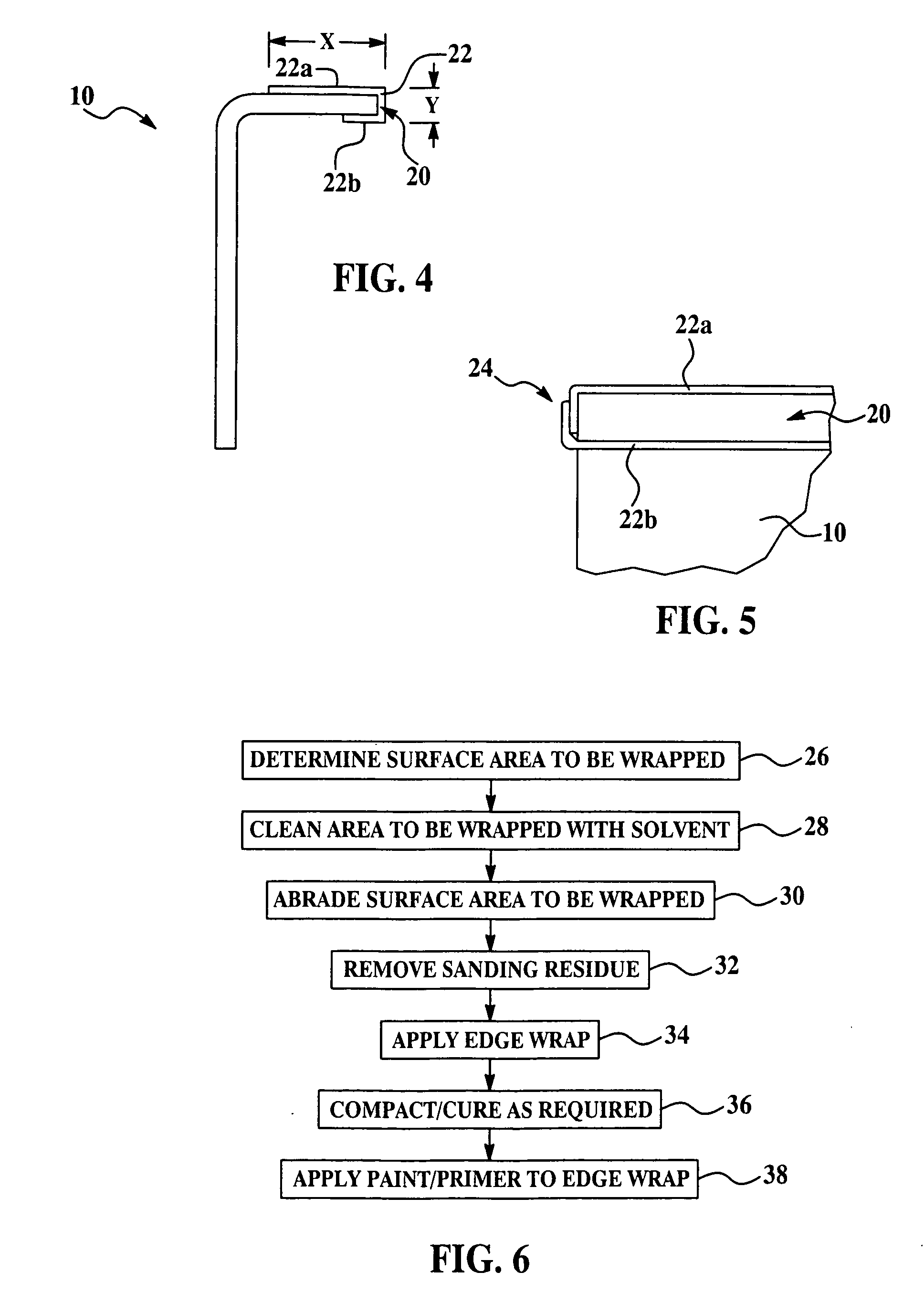

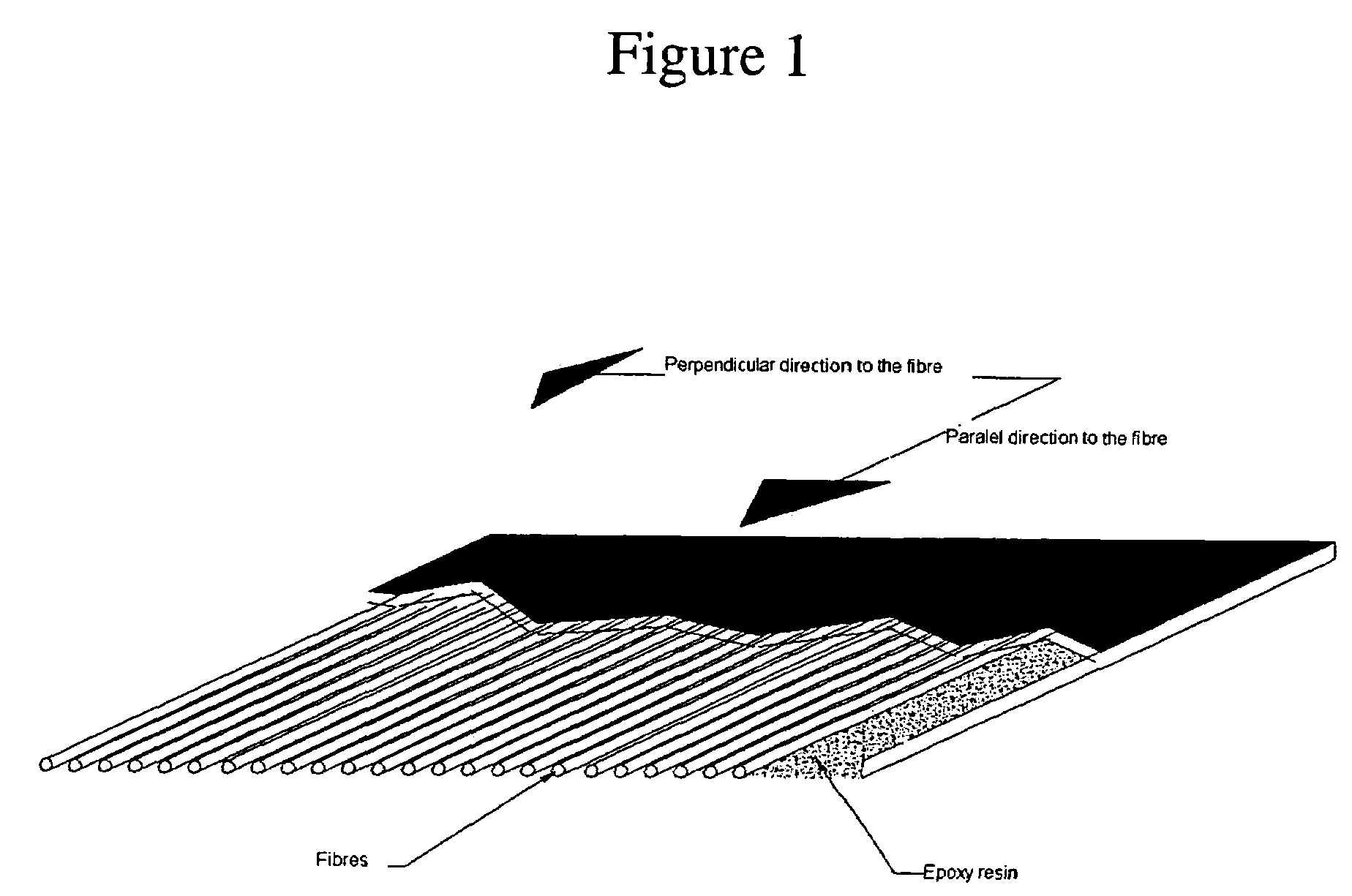

Edge seals for composite structure fuel tanks

ActiveUS20080128430A1Avoid contactPower plant fuel tanksFuel tank safety measuresFuel tankEngineering

The cut laminate edges of aircraft fuel tanks formed of carbon fiber reinforced polymers are sealed to prevent the exposure of carbon fibers to combustible fuel. The edge seal is produced from a prepreg form using a thermosetting resin matched to the characteristics of the resin used in the laminate. The prepreg form can be applied to the cut laminate edges either before or after the laminate is cured. The edge seal acts a dielectric layer that both electrically insulates the cut laminate edges from the fuel and mechanically contains energetic particles produced at the edges due to lighting strikes or other sources of electrical charges.

Owner:THE BOEING CO

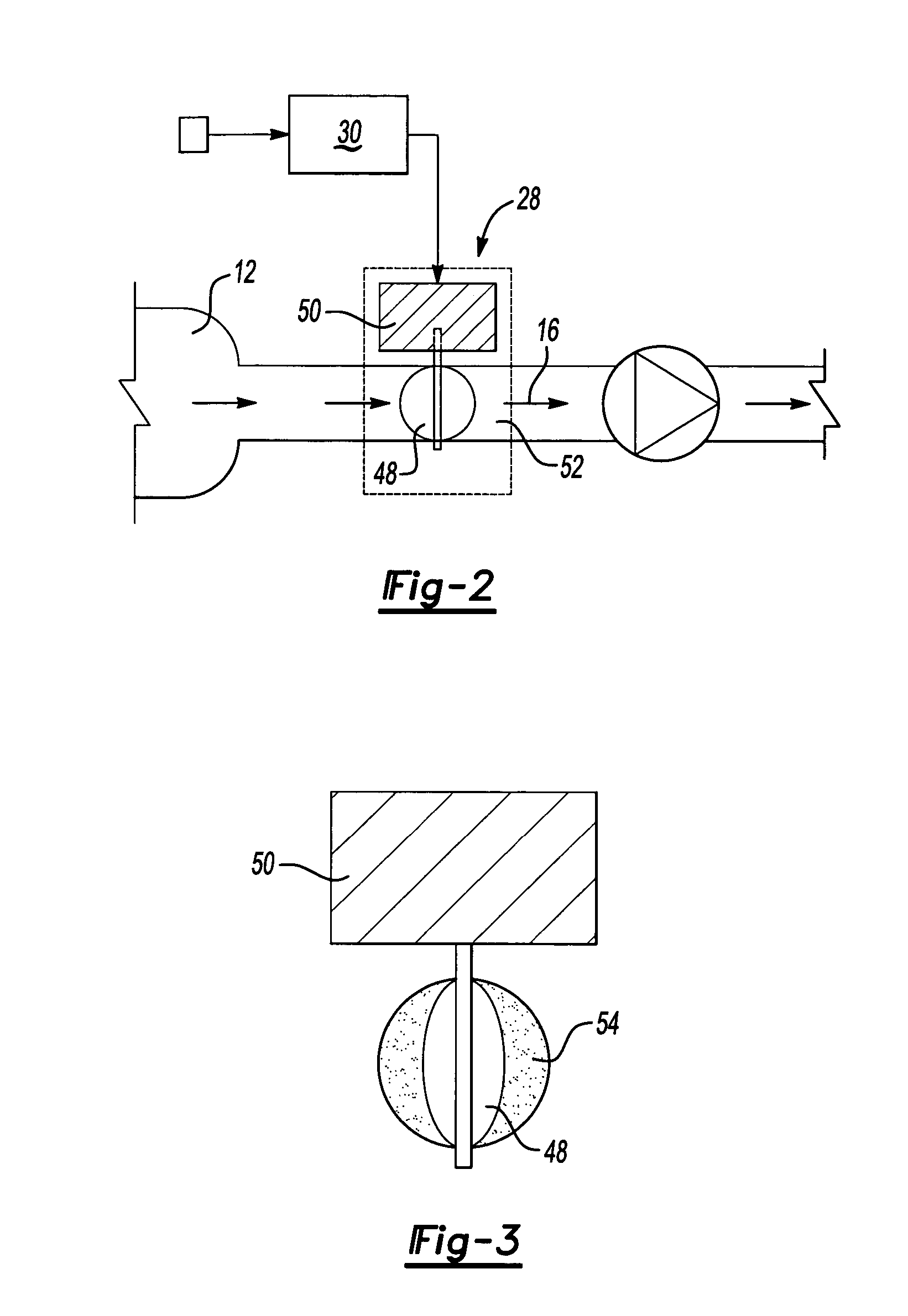

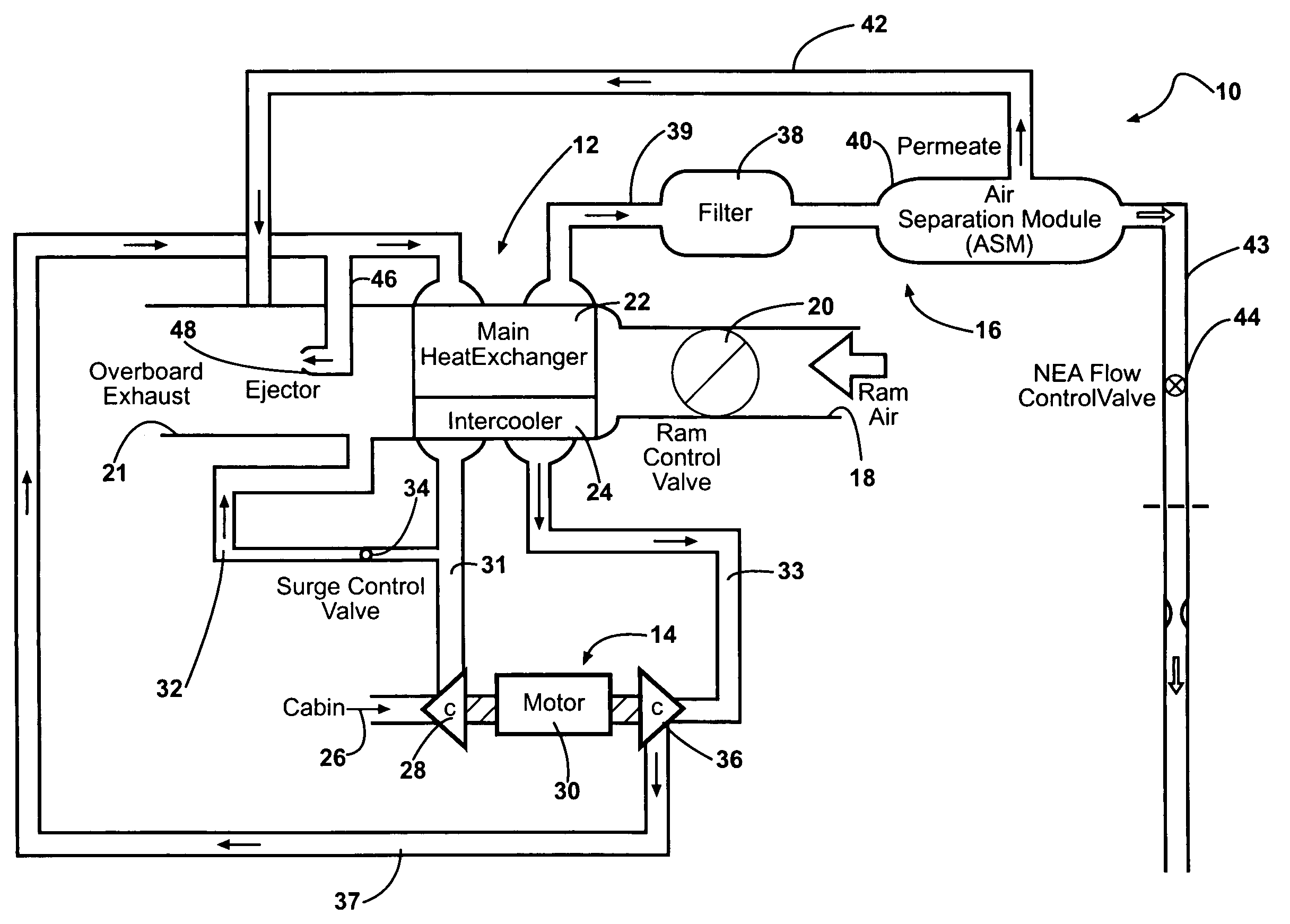

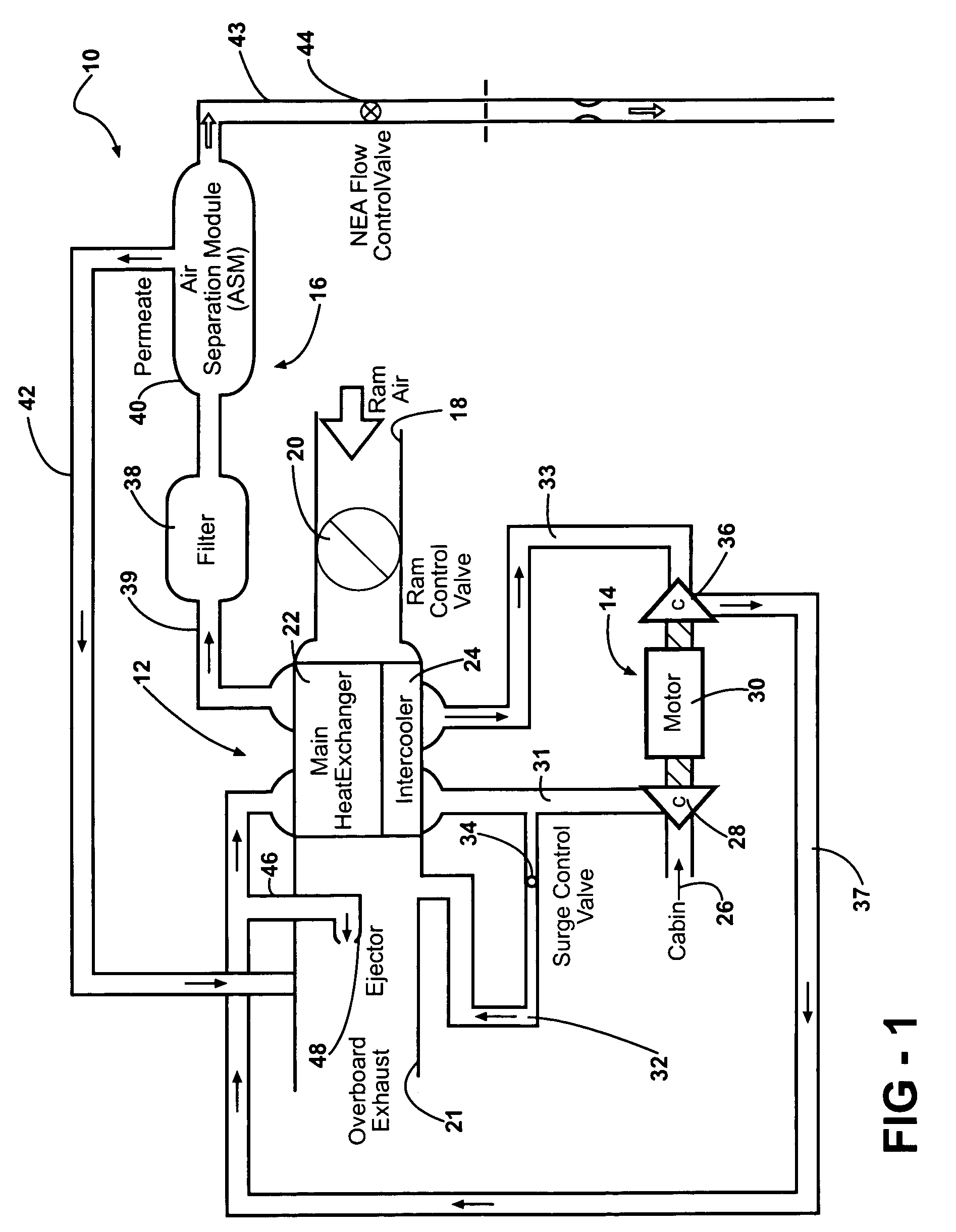

Enhanced obiggs

A gas generating system comprises an air separation module (ASM) in fluid communication with a nitrogen enriched air (NEA) line and an oxygen enriched air (OEA) line. A valve is positioned in the OEA line and an oxygen sensor is positioned in the NEA line. The valve can be modulated in response to the oxygen sensor to create a backpressure forcing more airflow into the NEA line. The OEA line can be backpressured until a predetermined NEA oxygen concentration is reached.

Owner:HONEYWELL INT INC

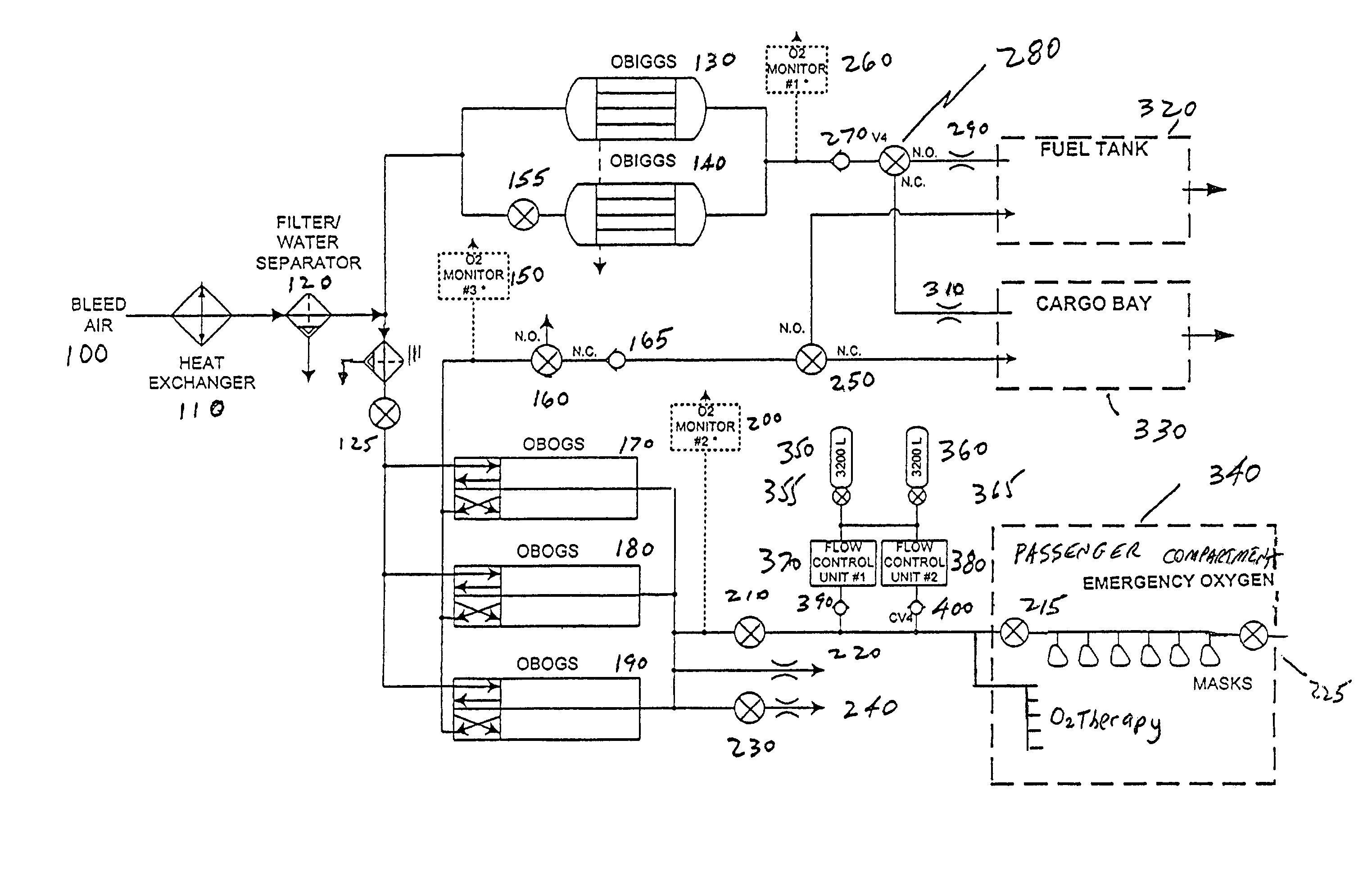

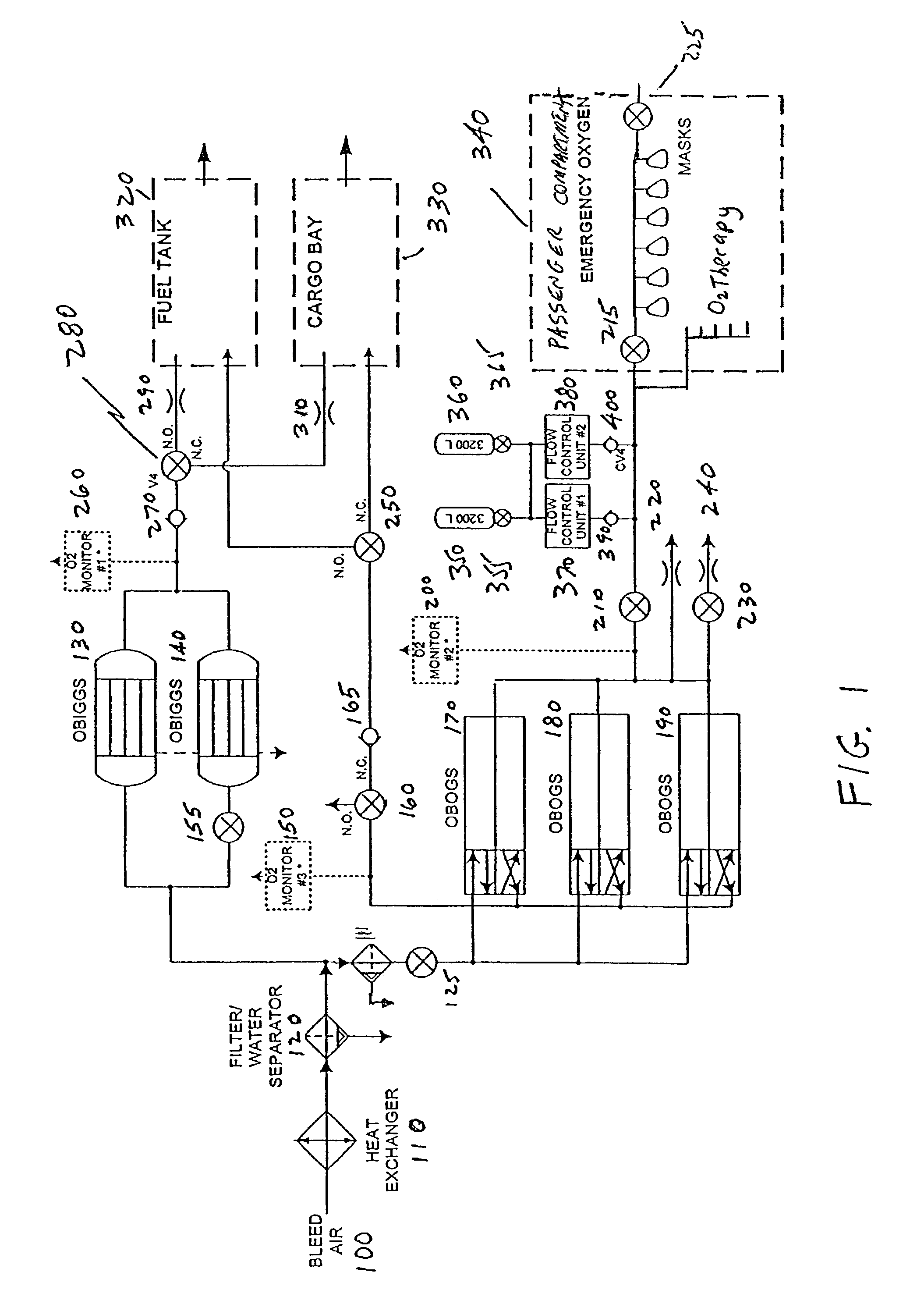

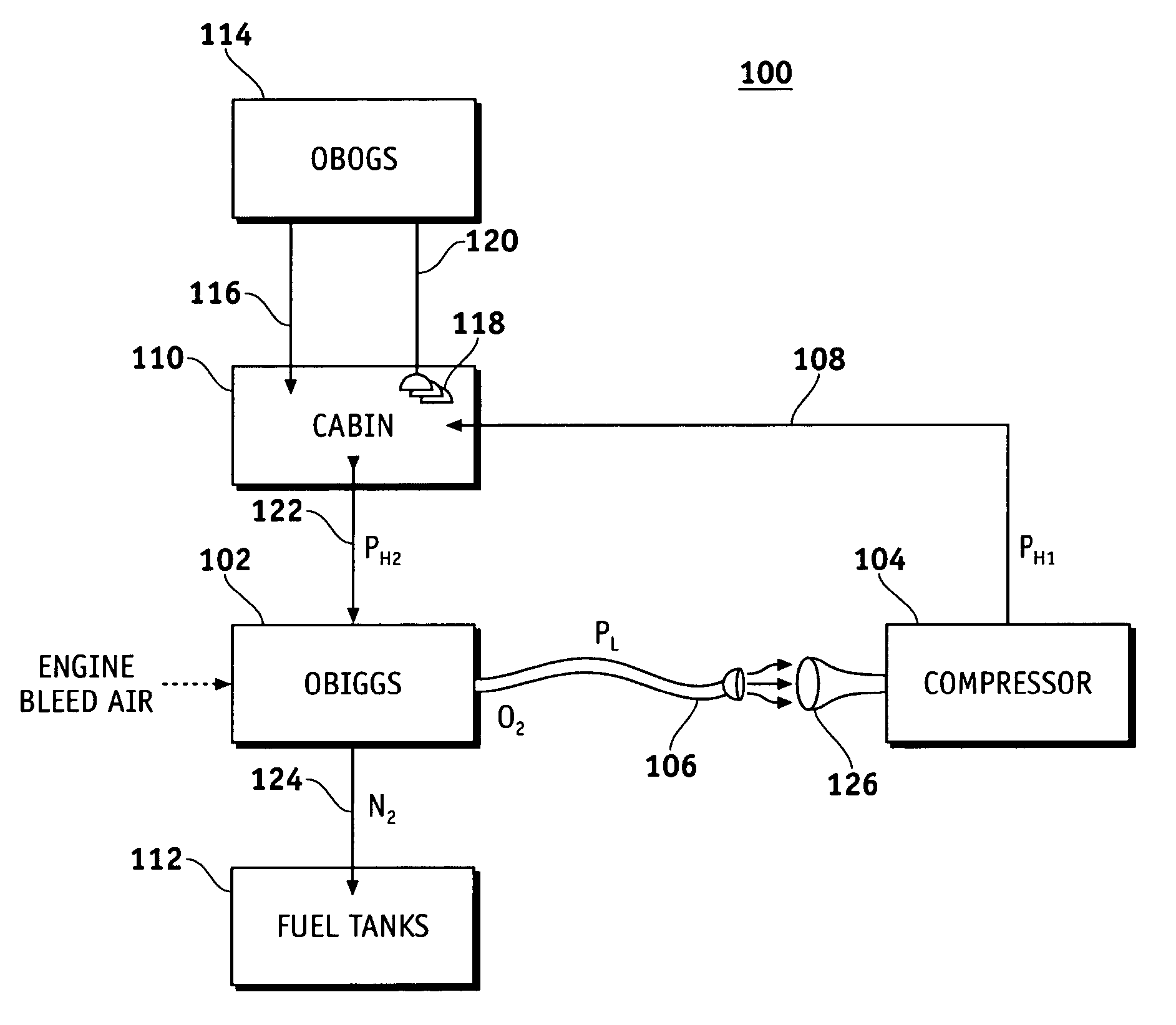

Oxygen/inert gas generator

InactiveUS6997970B2Capable be useDispersed particle filtrationAir-treatment apparatus arrangementsAtmospheric airOn board

A gas generation method and apparatus, capable of use in an aircraft, generates oxygen with at least one On Board Oxygen Generating System (OBOGS) and generates an inert gas with at least one On Board Inert Gas Generating System (OBIGGS) and selectively supplies an auxiliary supply of inert gas utilizing a waste gas output of the at least one OBOGS. The inert gas can include nitrogen. An auxiliary source of oxygen can also be provided. Control valves can be used to selectively supply the waste gas output of the at least one OBOGS to the atmosphere or to either of two locations. The oxygen can be used in a passenger compartment of the aircraft and the inert gas used in either a fuel tank or cargo bay of the aircraft.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

Low power nitrogen enriched air generation system

InactiveUS6913636B2Reduce capacityReduce weightDispersed particle filtrationAir-treatment apparatus arrangementsNacelleInerting system

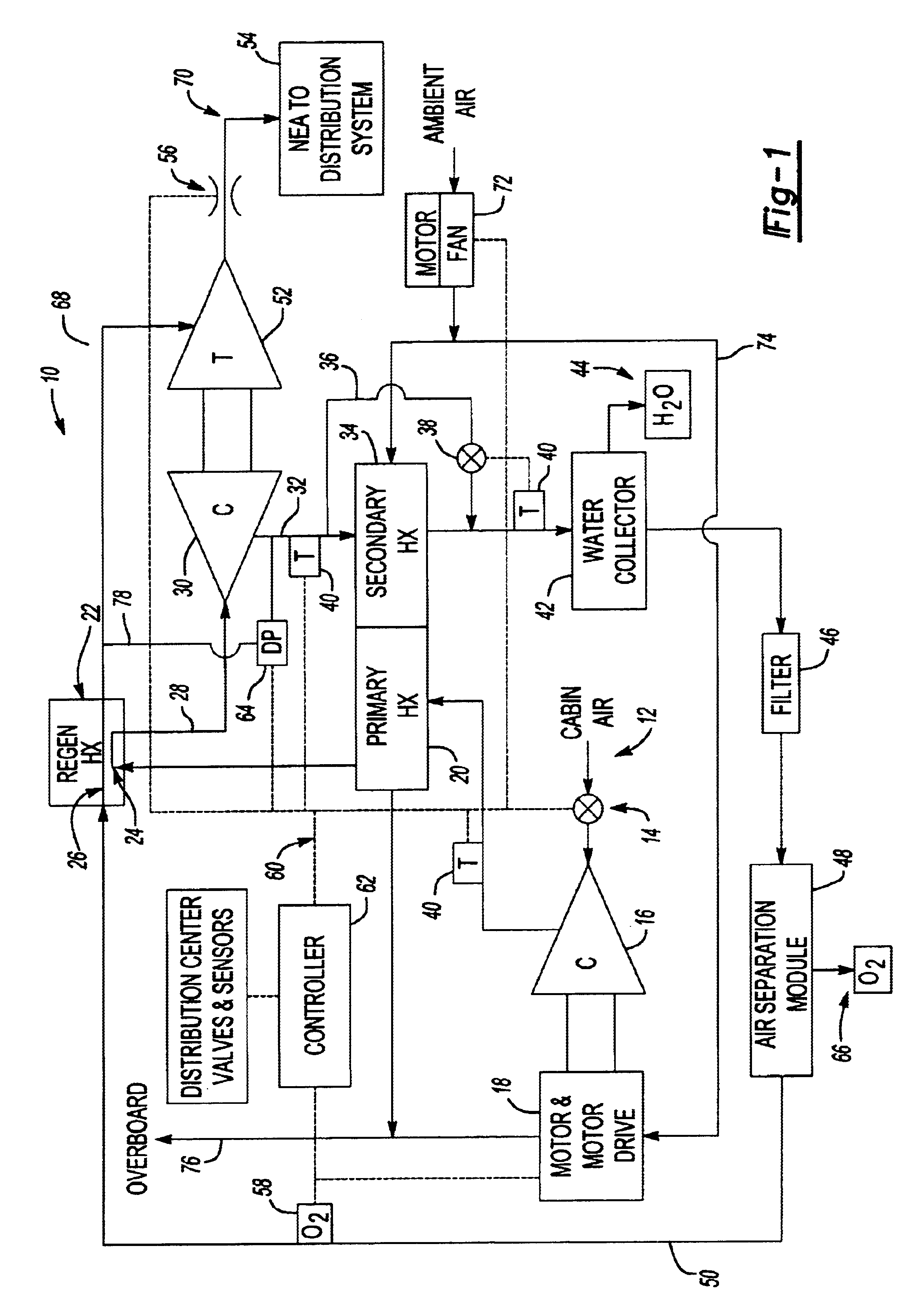

An inerting system provides air with reduced oxygen content by flowing and directing air through an air separation module. Optimal working pressure for the air separation module is obtained with two compressors. A first compressor elevates air from the aircraft cabin to a second pressure. The second pressure is at an intermediate level below the working pressure of the air separation module. A second compressor elevates air from the second pressure to the working pressure. The second compressor is driven by air that is exhausted through a turbine. The pressure difference between air at the working pressure and air required by the fuel distribution system is used to power the turbine and drive the second compressor.

Owner:HAMILTON SUNDSTRAND CORP

Flow control for on-board inert gas generation system

An on-board inert gas generating system includes a flow control valve modulated according to changes in ambient conditions to minimize changes to oxygen content within a fuel tank. The quality of the nitrogen-enriched air stream that is provided by the air separation module varies in response to flow. Higher flow rates through the air separation module removes less oxygen relative to lower flow rates. The amount of flow through the air separation module that produces the least amount of oxygen within the fuel tank is determined for an ambient pressure and provided by modulating the flow control valve.

Owner:HAMILTON SUNDSTRAND CORP

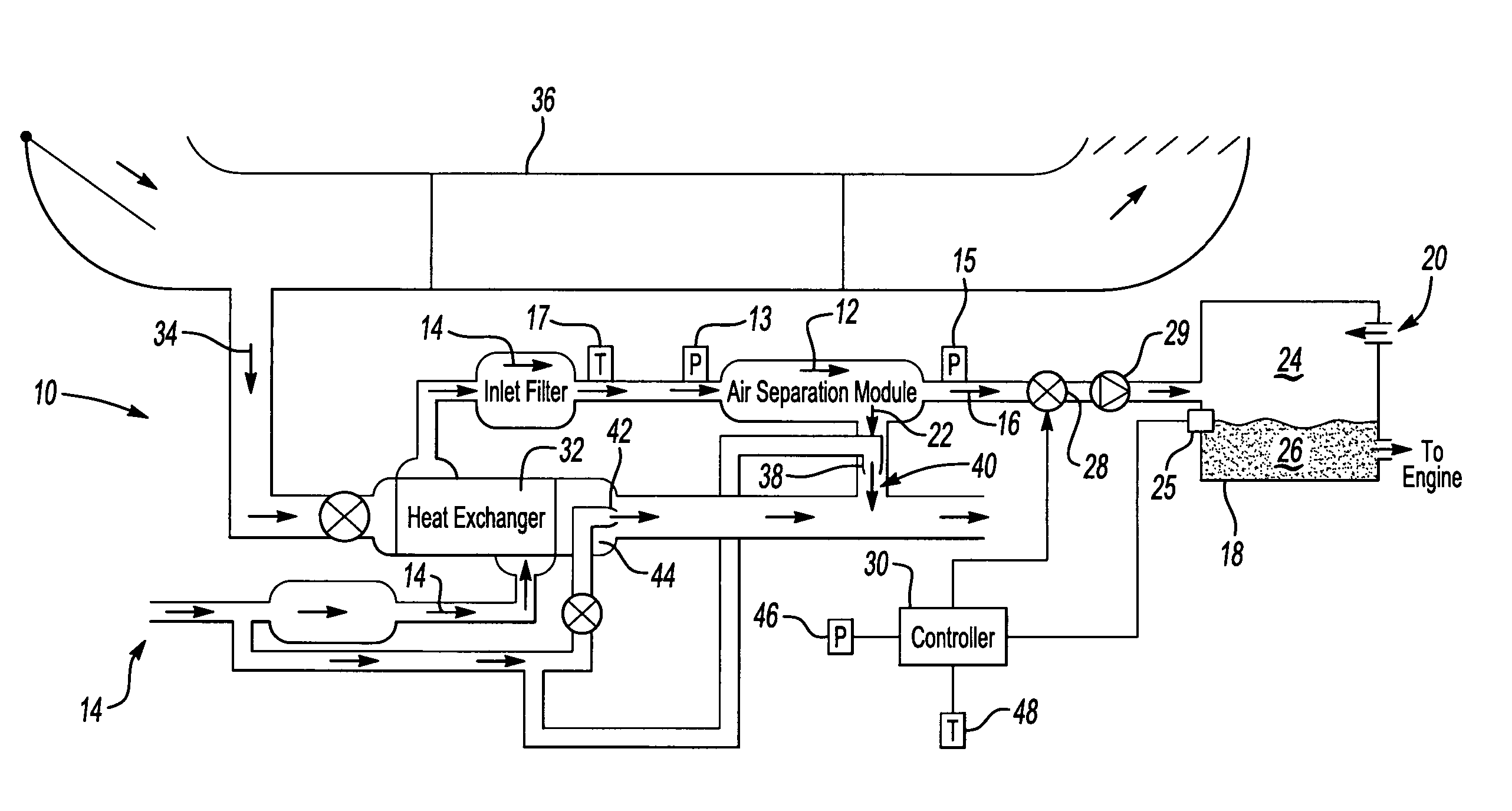

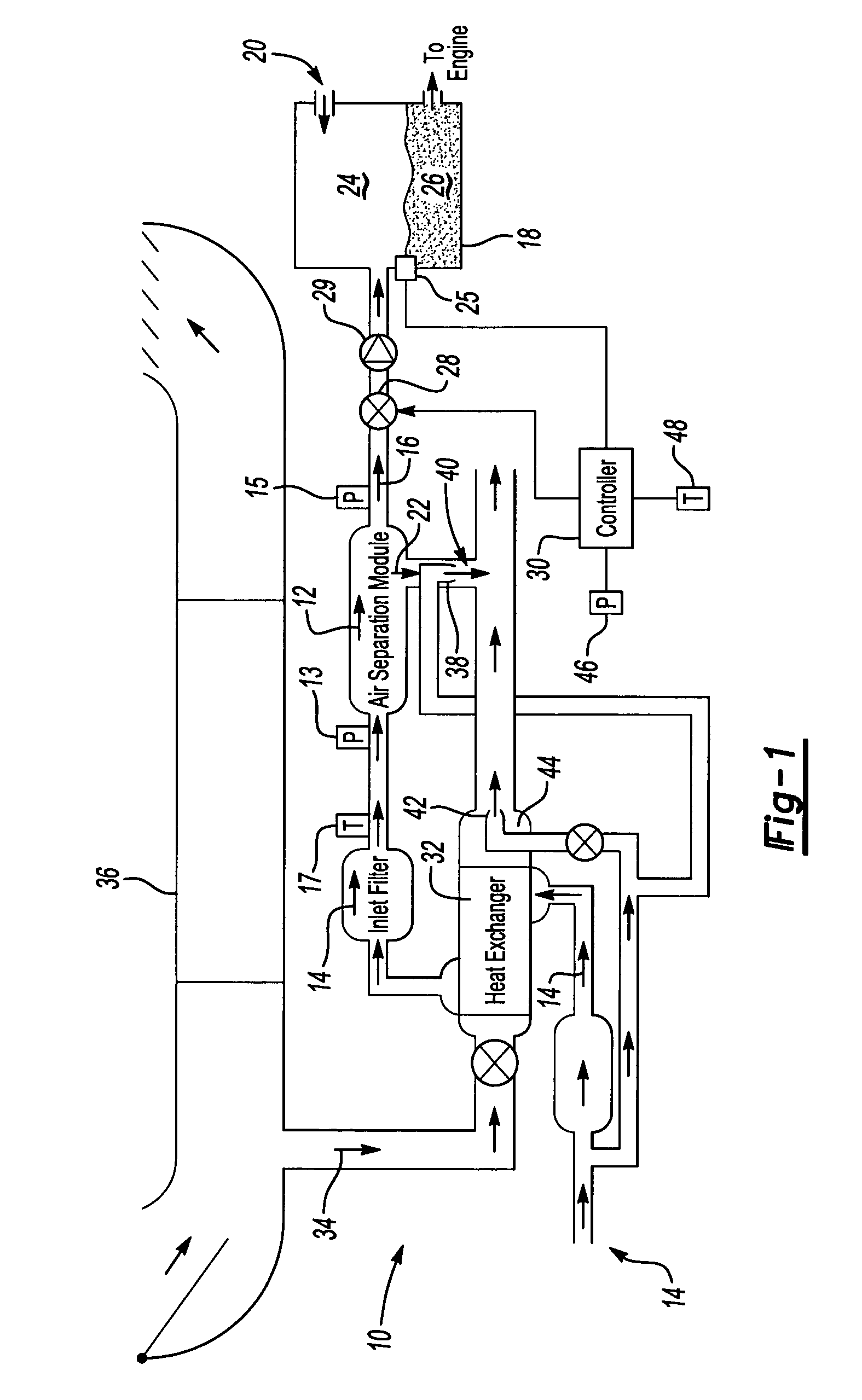

Method and apparatus for generating an inert gas on a vehicle

An inert gas generating system for generating inert gas on a vehicle having a fuel tank and a fuel tank vent. The system includes an inlet for receiving a flow of gas having a nitrogen component and an oxygen component from a gas source, a heat exchanger downstream from the inlet and in fluid communication with the inlet for cooling gas received from the inlet, and a gas separation module downstream from the heat exchanger and in fluid communication with the heat exchanger for separating gas received from the heat exchanger into a nitrogen-enriched gas flow and an oxygen-enriched gas flow. The gas separation module is adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank without delivering the nitrogen-enriched gas through the fuel tank vent. The gas separation module is also adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank vent.

Owner:THE BOEING CO

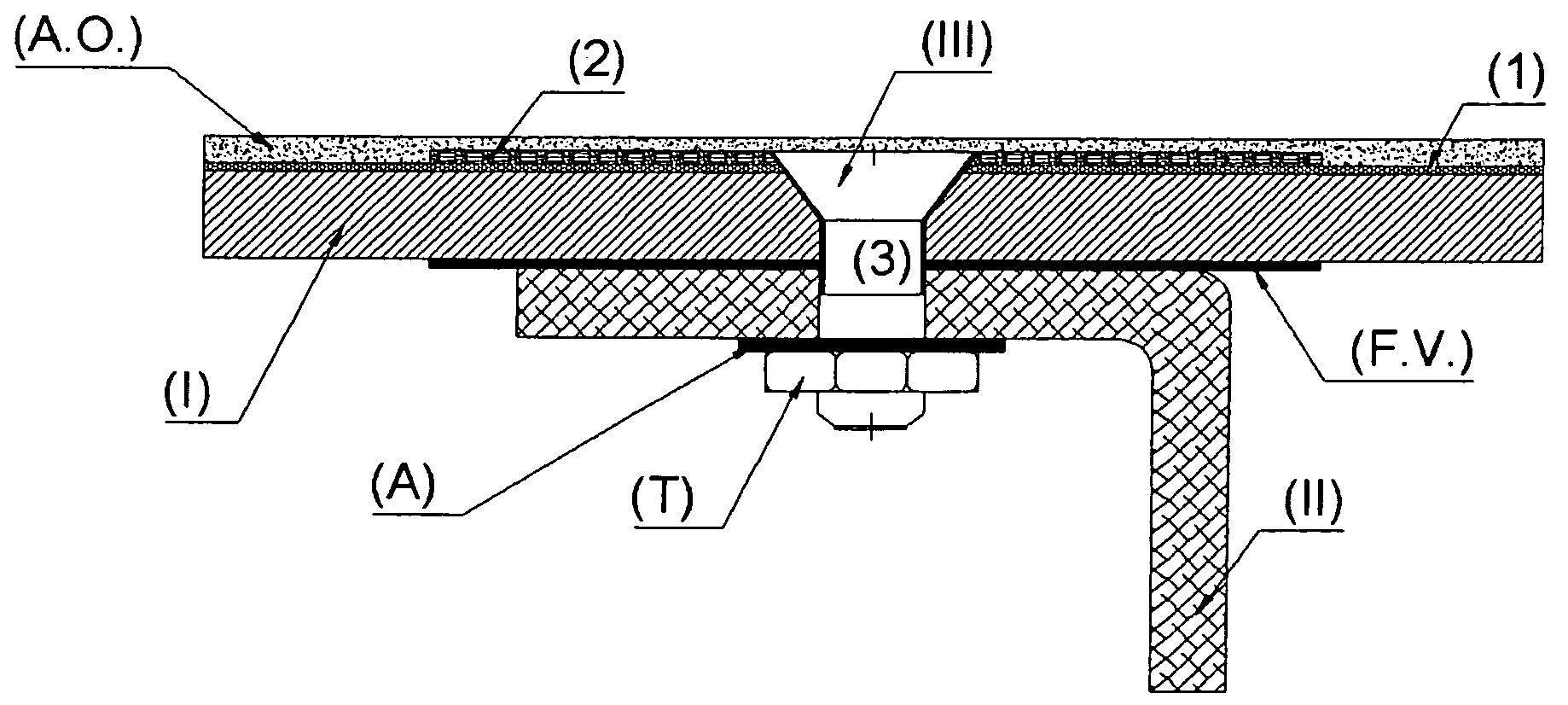

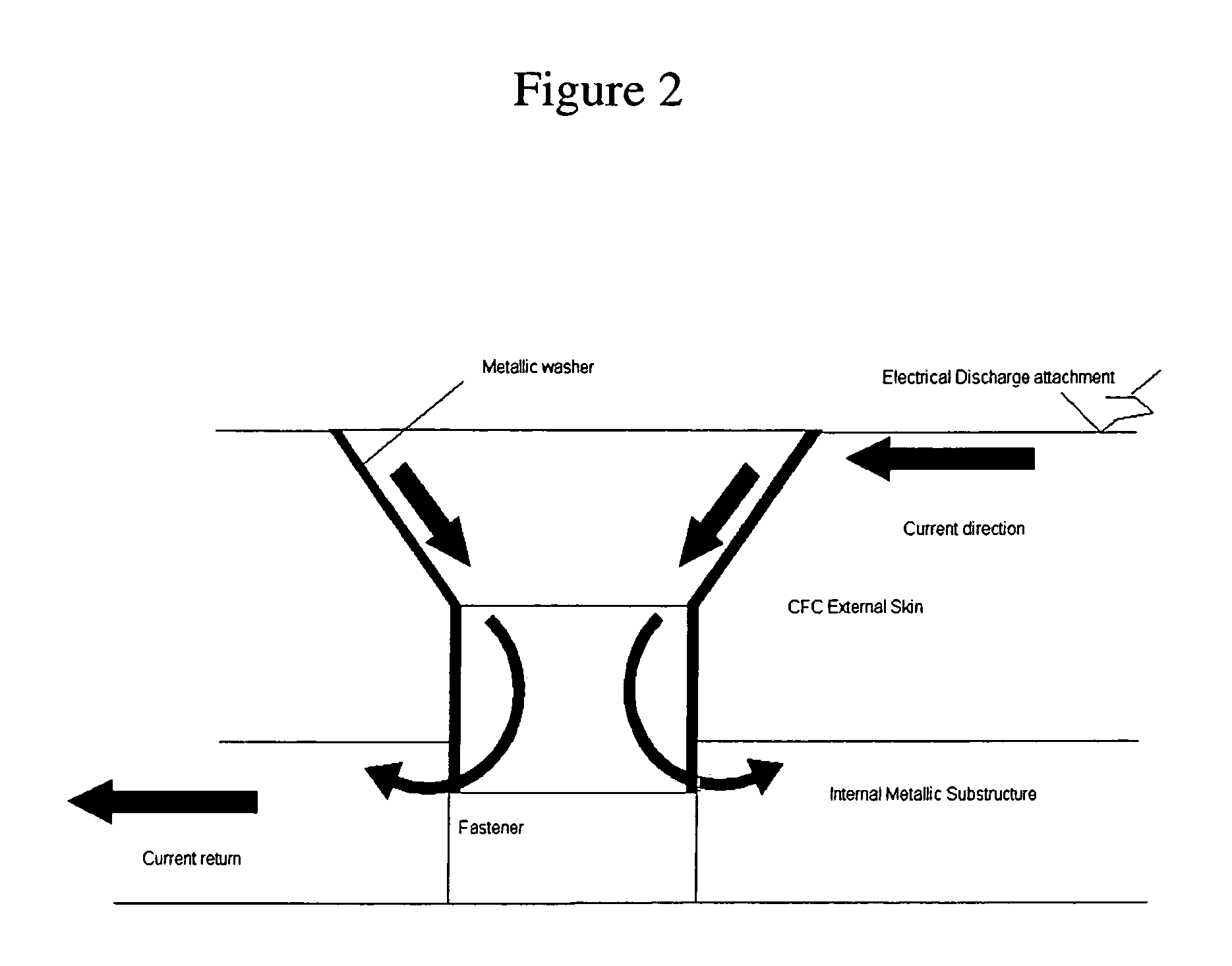

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material

ActiveUS7307825B2Severe structural damage can be avoidedMinimize damageFuel tank safety measuresAircraft lighting protectorsLightning strikeFuel tank

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material. The system comprises an electrical conductive thin wire mesh (1) that covers the whole external surface of the tank outer skin (I) made of composite and a thick wire metallic mesh (2) overlapping the mesh (1) at a minimum distance of 50 mm to both sides of a row of fasteners (III) joining the said outer skin (I) to one internal part (II) of either composite or metallic material. Both metallic meshes (1, 2) maintain electrical contact by their installation / assembly and by means of metallic countersunk head washers (3) connected to bonding points and set to the gap existing between the fastener (III) and the outer skin (I). The corresponding fabrication process is also described.

Owner:AIRBUS OPERATIONS SL

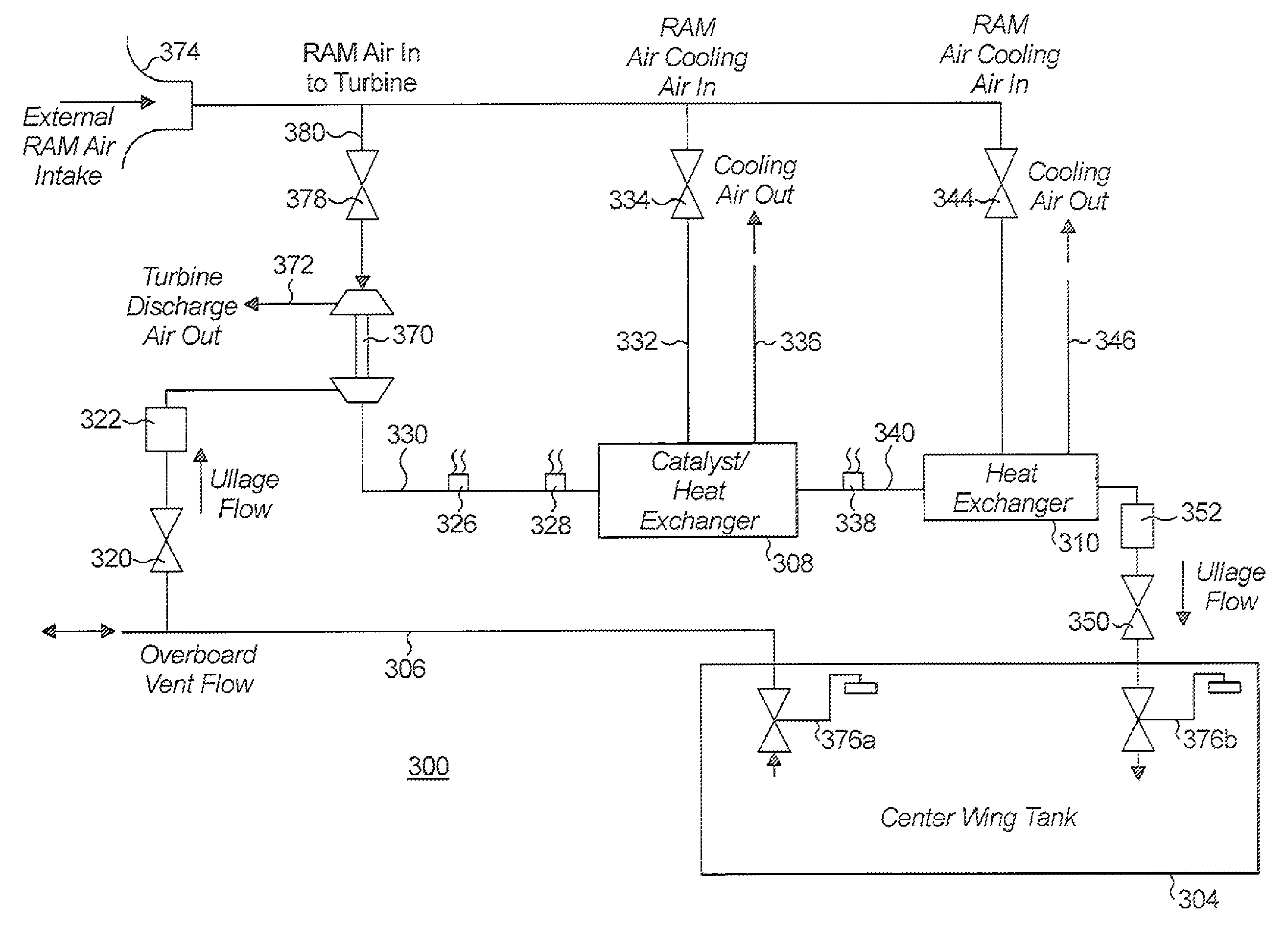

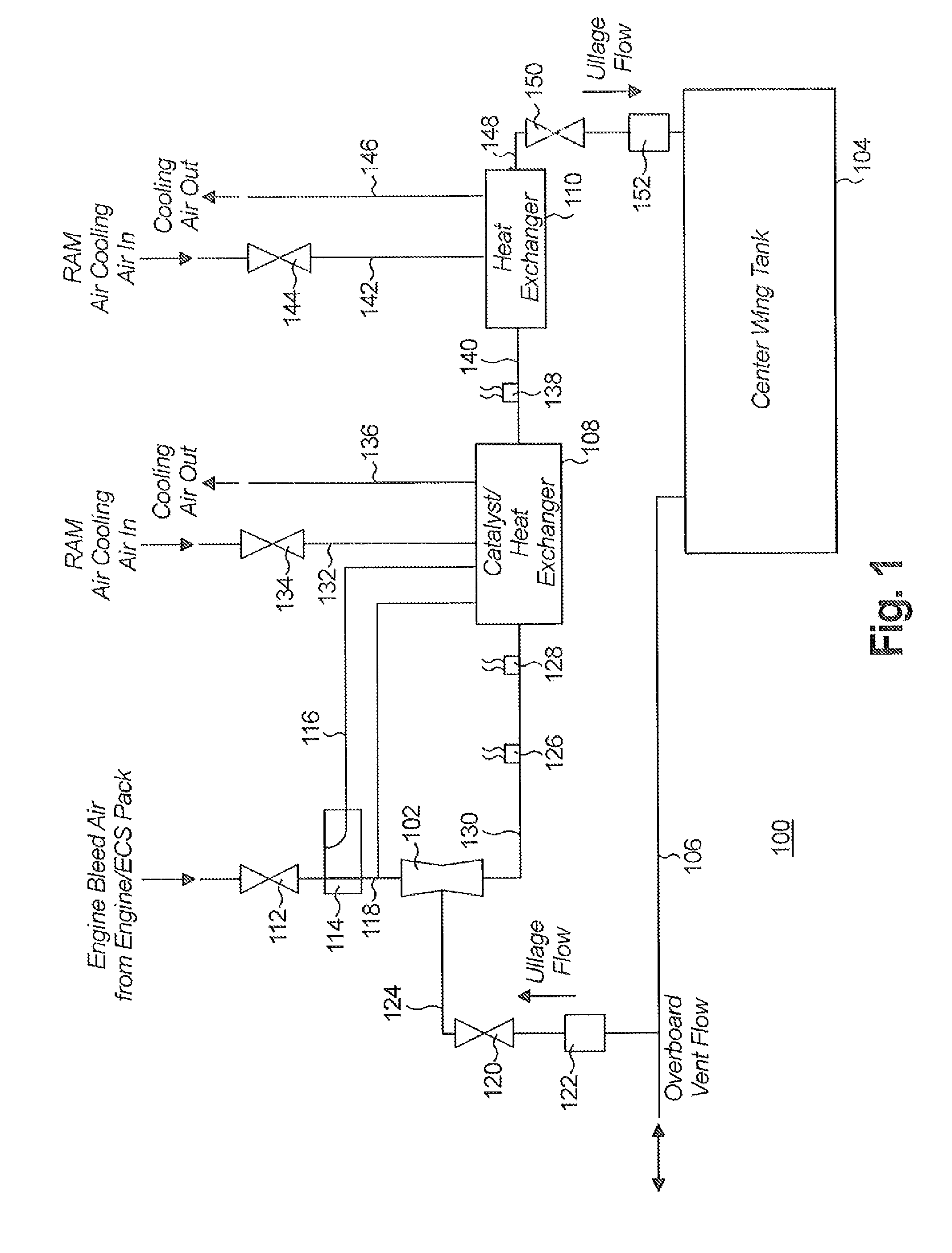

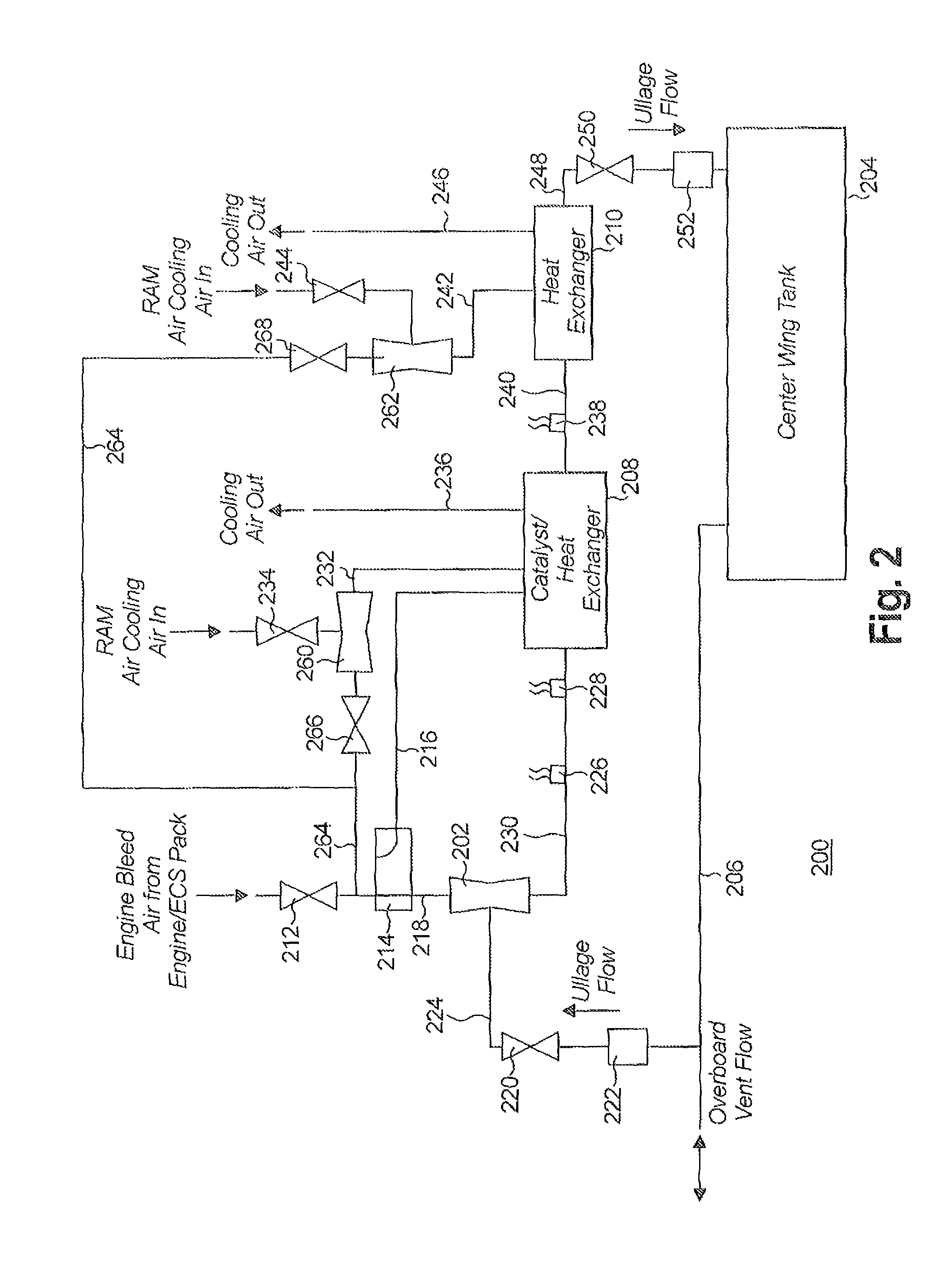

System and method for scavenging ullage from center wing tanks in an airplane

InactiveUS8602362B2Increase power consumptionImprove reliabilityPower plant fuel tanksFuel tank safety measuresJet aeroplaneFuel tank

Owner:SIMMONDS PRECISION PRODS

Commercial Aircraft On-Board Inerting System

ActiveUS20050173017A1Reduce flammabilityMinimizing system sizeLiquid fillingAir-treatment apparatus arrangementsInerting systemOn board

An inerting system (10) for an aircraft (12) includes one or more fuel tank circuits (15) associated with fuel tanks (16). An air source (17) supplies pressurized air. A heat exchanger (56) cools the pressurized air. An air separation module (46) is in fluid communication with the heat exchanger (56) and separates inerting gas from the pressurized air. A controller (40) controls flow of the inerting gas from the air separation module (46) to the fuel tanks (16).

Owner:THE BOEING CO

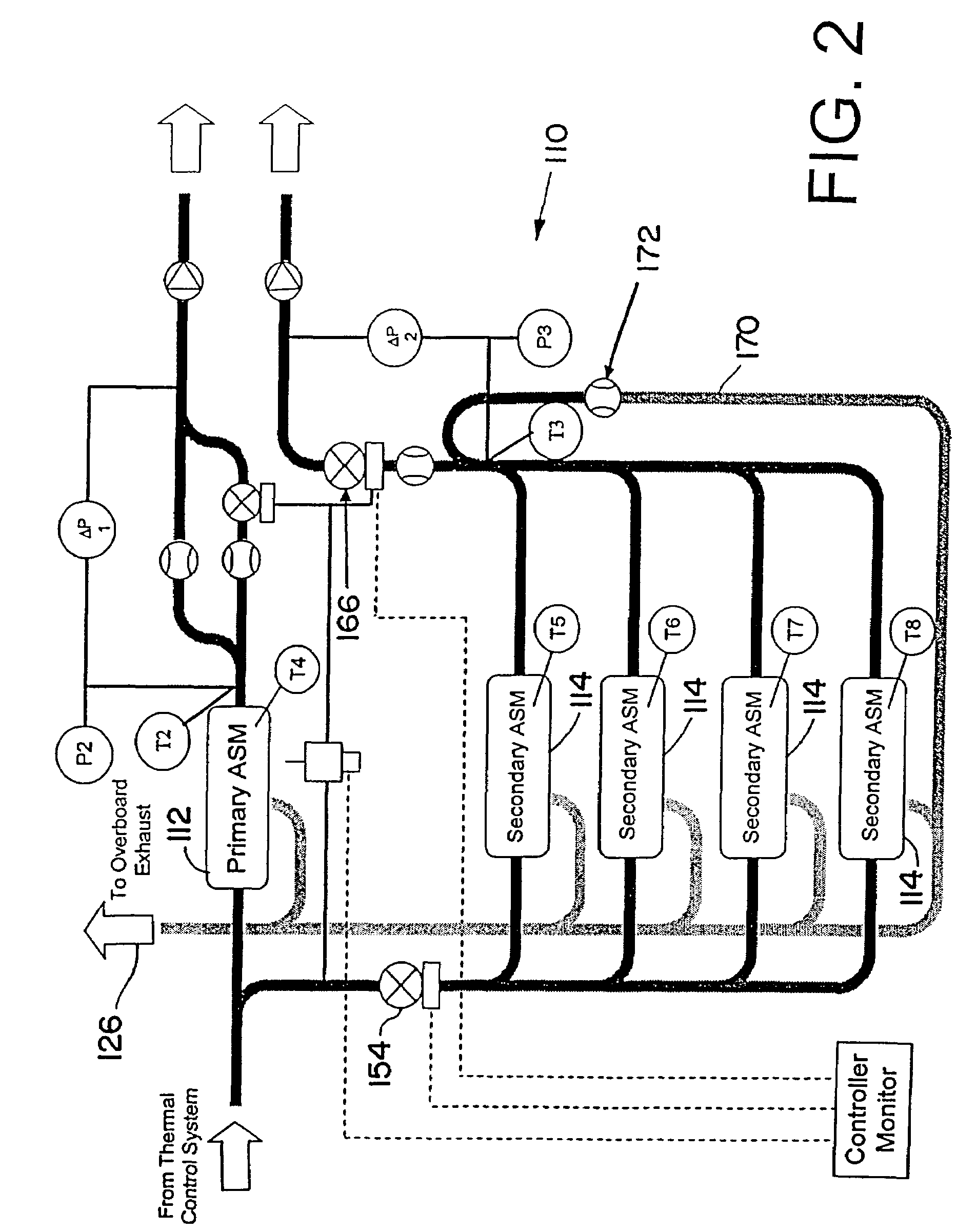

Gas generating system and method for inerting aircraft fuel tanks

ActiveUS7081153B2Avoid flowPrevent contamination from enteringGas treatmentDispersed particle filtrationOperational costsFuel tank

The present invention provides a system and method for generation of nitrogen enriched air for inerting aircraft fuel tanks. One embodiment of the present invention includes a duct assembly; a primary heat exchanger; a gas generating system heat exchanger; a first temperature sensor; a second temperature sensor; a controller monitor; a valve; an air separation module assembly having a primary module and a secondary module; at least one flow control orifice; and a pressure sensor. The present invention utilizes a minimal complement of components and streamlined processes, thus minimizing structural and operational costs while optimizing performance and safety features.

Owner:HONEYWELL INT INC

Air separation system and method with modulated warning flow

An inerting system and method characterized by a primary air separation module configured to communicate with an upstream source of pressurized air at elevated temperature for production of a primary downstream flow of nitrogen-enriched air to be delivered to a space to be inerted; a secondary air separation module configured to communicate with the upstream source of pressurized air at elevated temperature for production of a supplemental downstream flow of nitrogen-enriched air to be delivered to a space to be inerted when high nitrogen-enriched airflow is desired during a high flow period; and a flow controller configured to provide a warming flow through the secondary air separation module to heat the secondary air separation module to above ambient temperature during a warming period other than the high flow period.

Owner:PARKER INTANGIBLES LLC

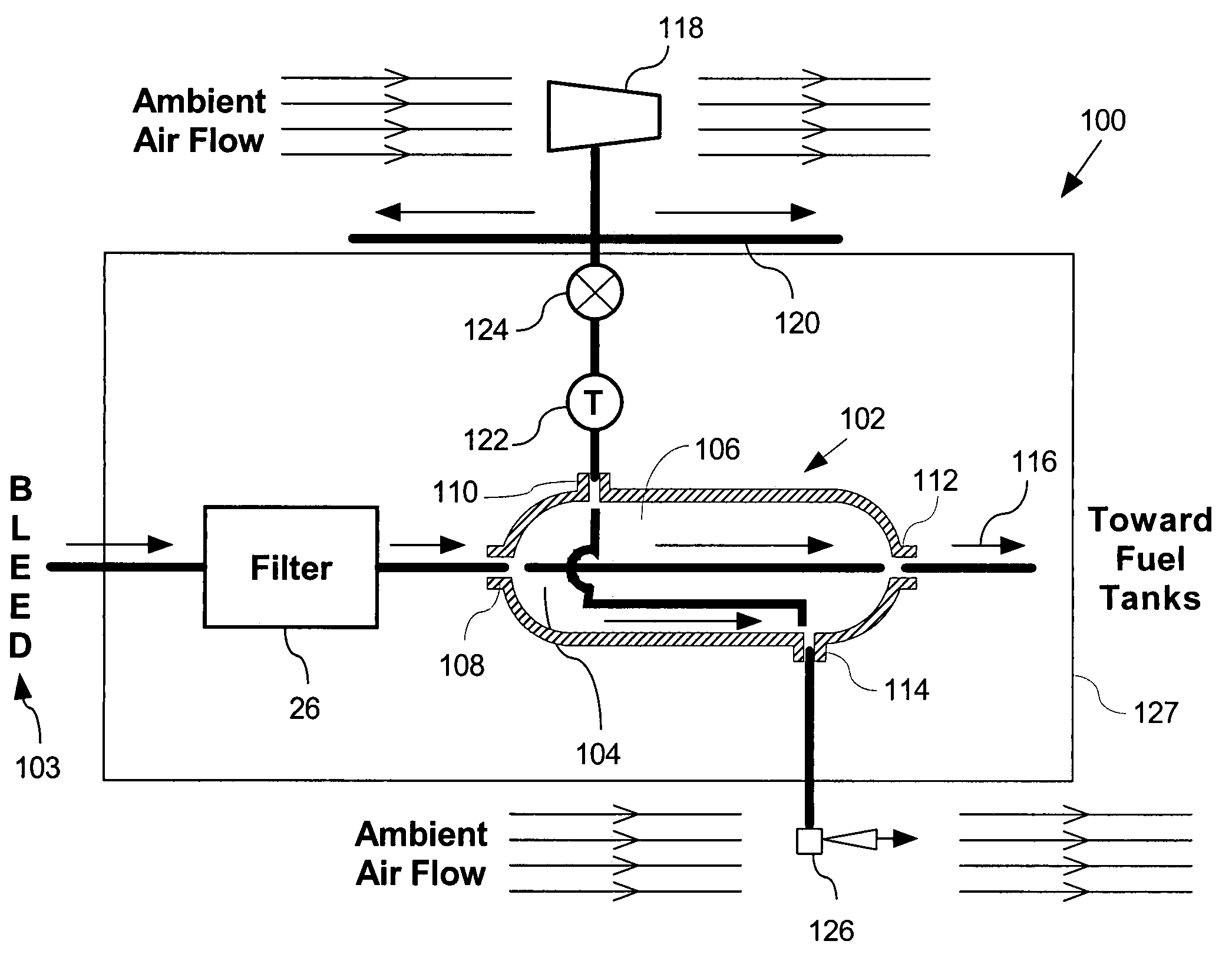

Cooling system for an on-board inert gas generating system

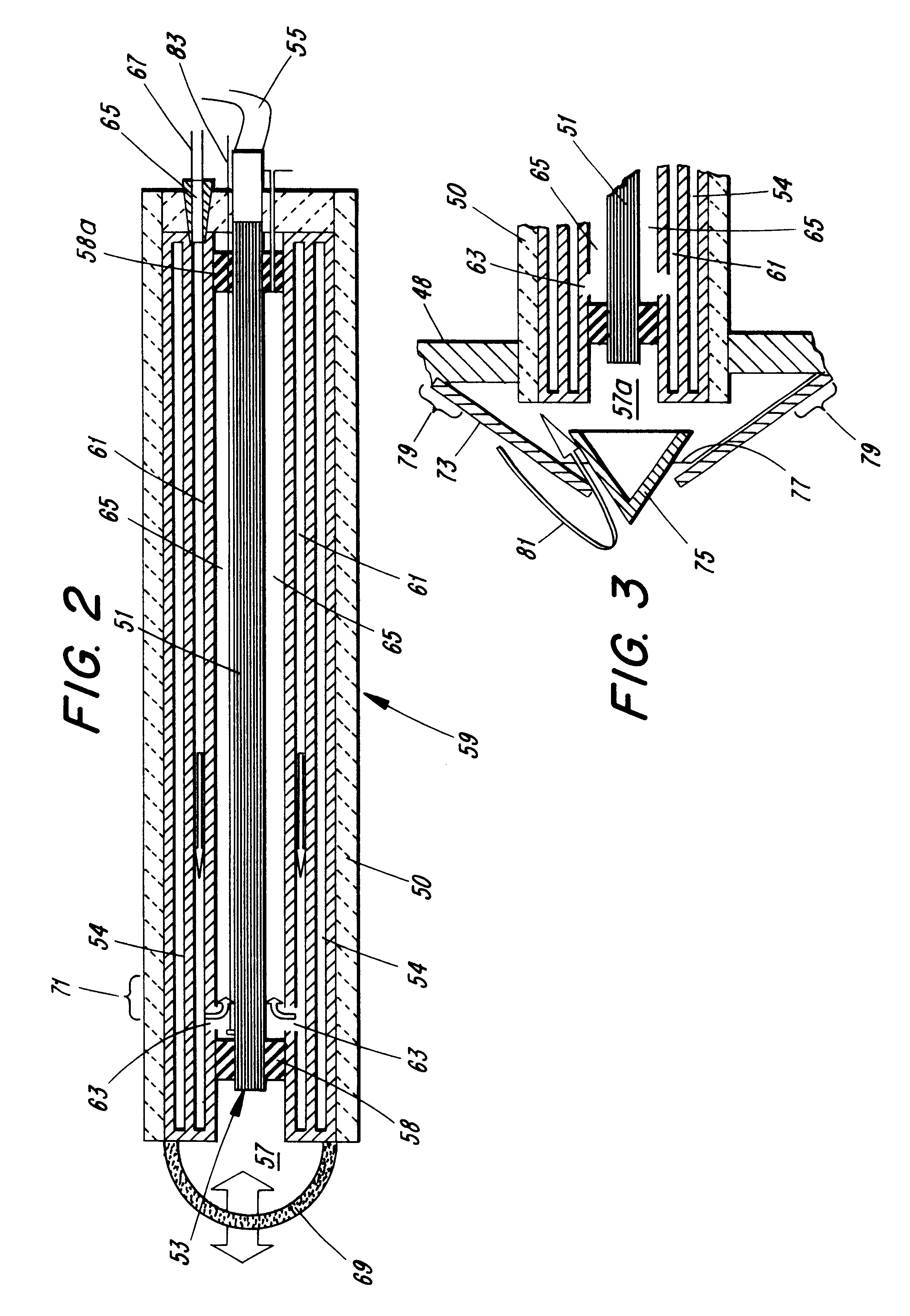

ActiveUS6997013B2Reduce the likelihood of burningImprove system performanceSolidificationLiquefactionHollow fibre membraneFiber

The inert gas generating system includes a compressed air source, a cooling air source, and a separation module. The separation module includes first and second inlets and outlets. The first inlet is coupled to the compressed air source. The first outlet is coupled to the first inlet via a bundle of hollow fiber membranes. The second inlet is coupled to the cooling air source, and the second outlet is coupled to the second inlet via a space surrounding the bundle of hollow fiber membranes.

Owner:PARKER INTANGIBLES LLC

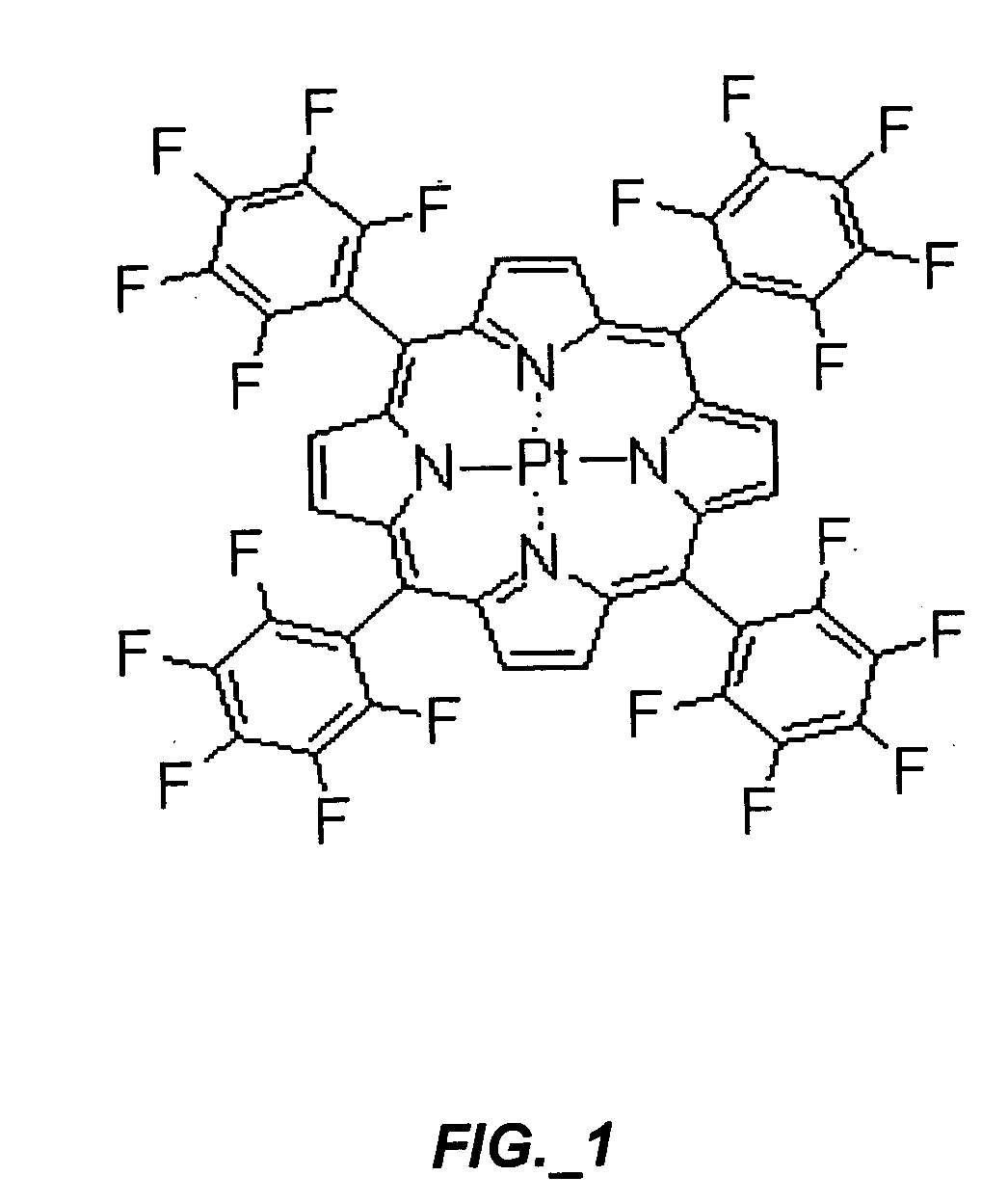

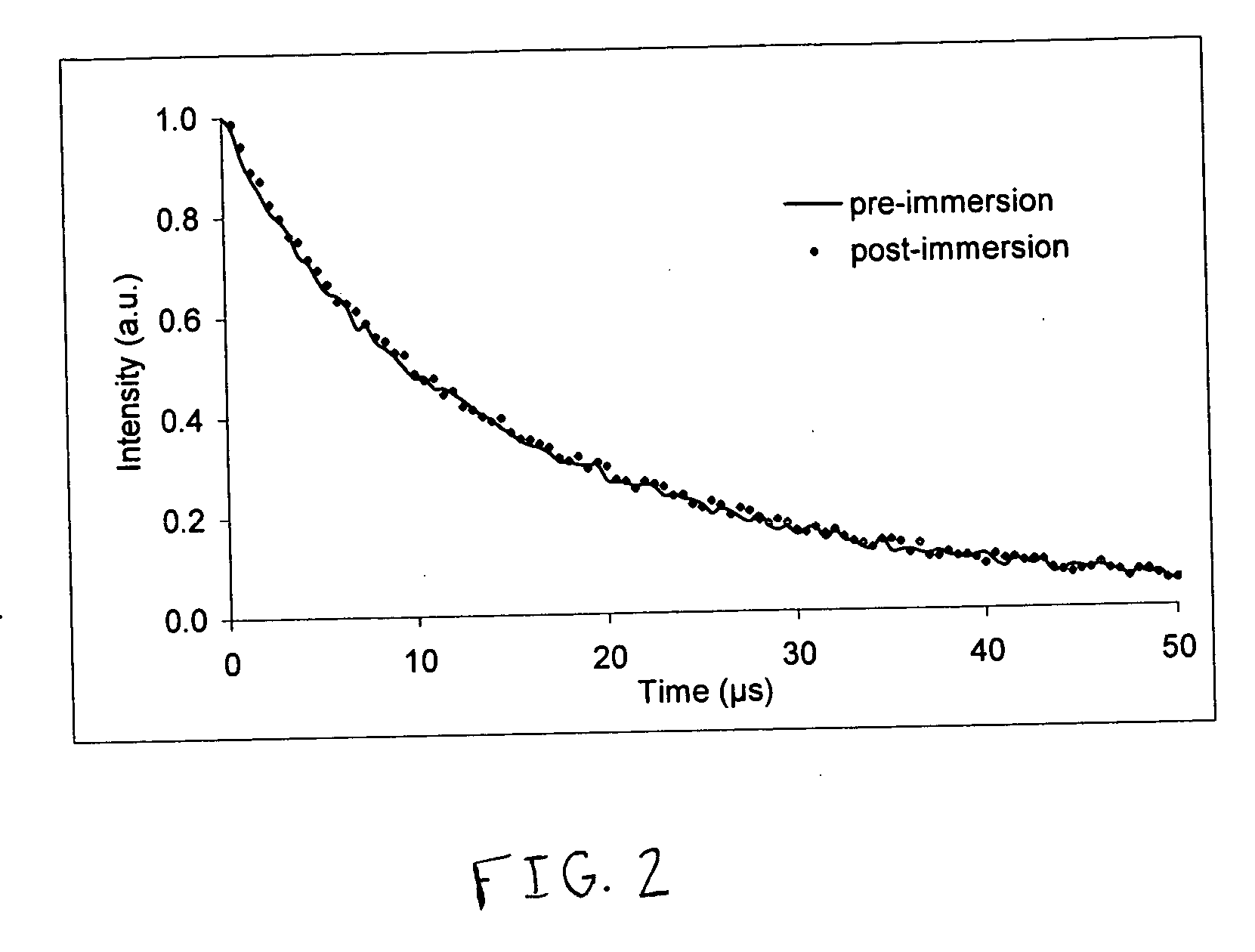

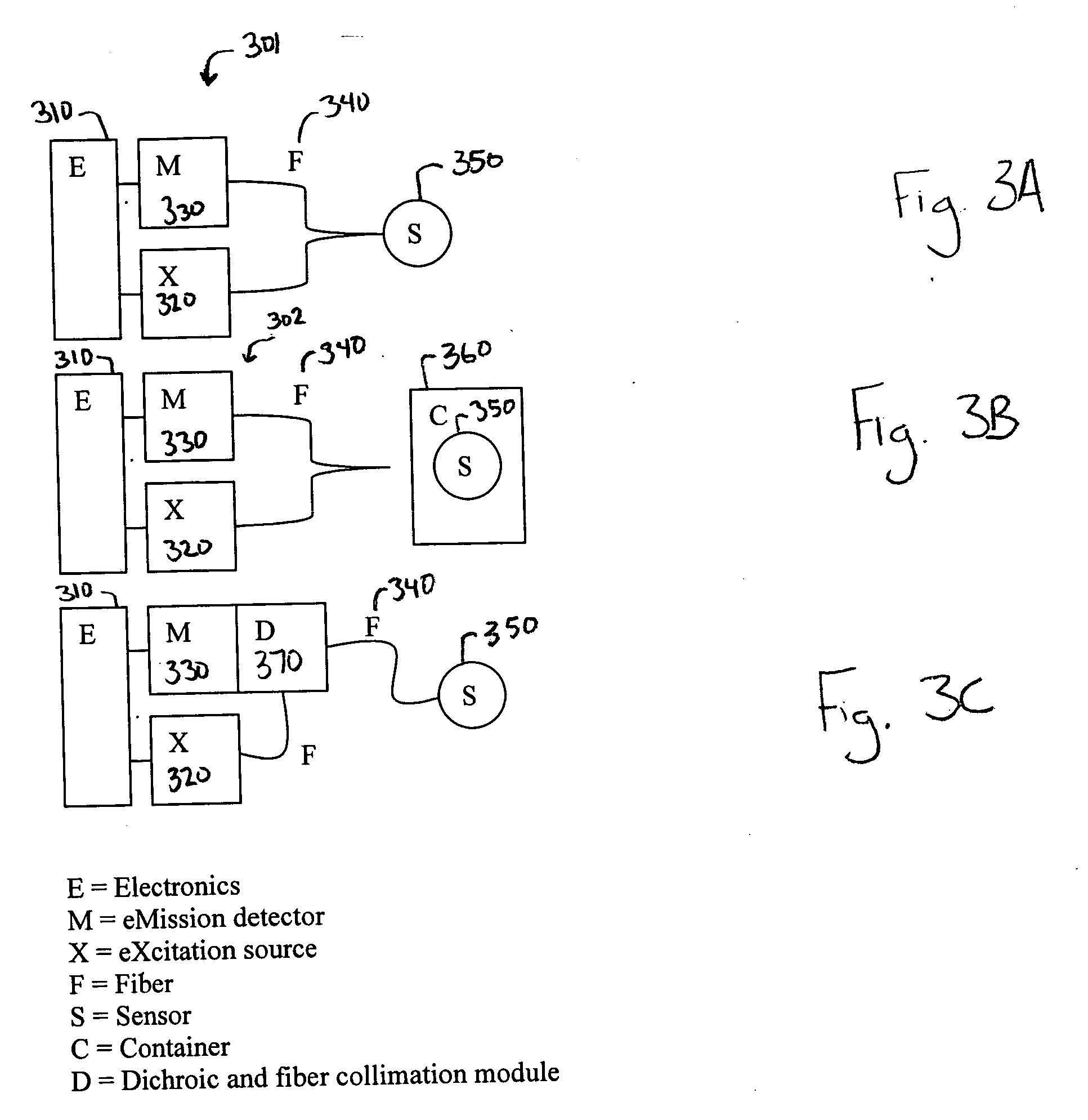

Sensors for measuring analytes

InactiveUS20060171845A1Low costImprove solubilityFuel tank safety measuresFluorescence/phosphorescenceAnalyteOrganic solvent

A sensor and system using the sensor for detecting an analyte, where the sensor includes an amorphous fluorinated polymer and a luminescent metal-ligand complex is provided. Sensor systems for monitoring oxygen in environments containing volatile organic solvents are also provided.

Owner:DAKOTA TECH

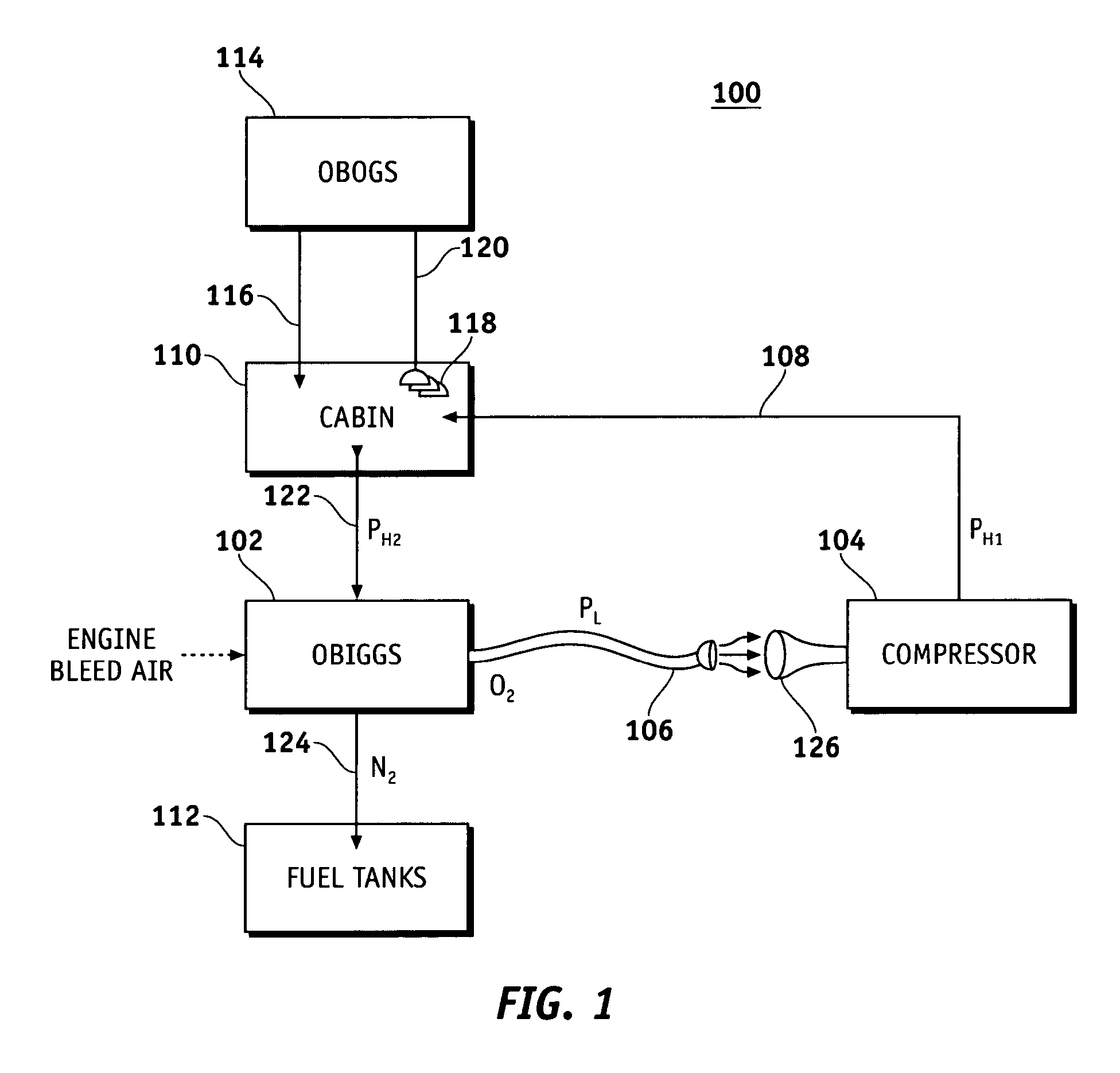

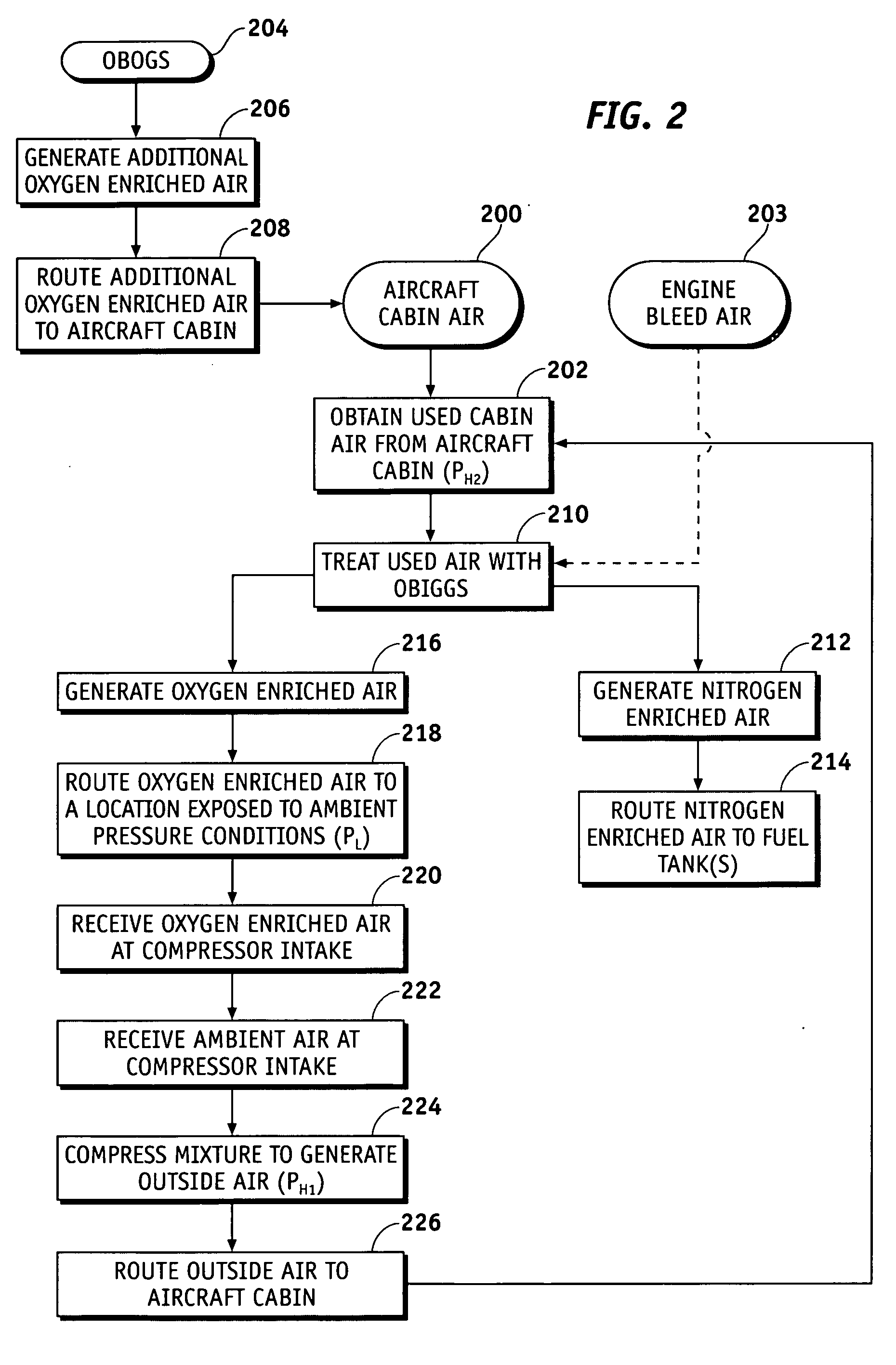

System and method for enriching aircraft cabin air with oxygen from a nitrogen generation system

InactiveUS20070062371A1Increasing oxygen pressureIncrease pressureRespiratorsBreathing masksNacelleNitrogen

An aircraft cabin air treatment system configured in accordance with the invention utilizes oxygen enriched air, which is produced as a byproduct of an onboard inert gas generation system. The oxygen enriched air is released into an environment under ambient pressure conditions, i.e., at a relatively low absolute pressure compared to the cabin pressure. The low pressure oxygen enriched air is compressed with a cabin air compressor, and the outside air is routed back into the cabin. The cabin air compressor functions to generate oxygen enriched outside air and to maintain the desired pressurization of the cabin.

Owner:THE BOEING CO

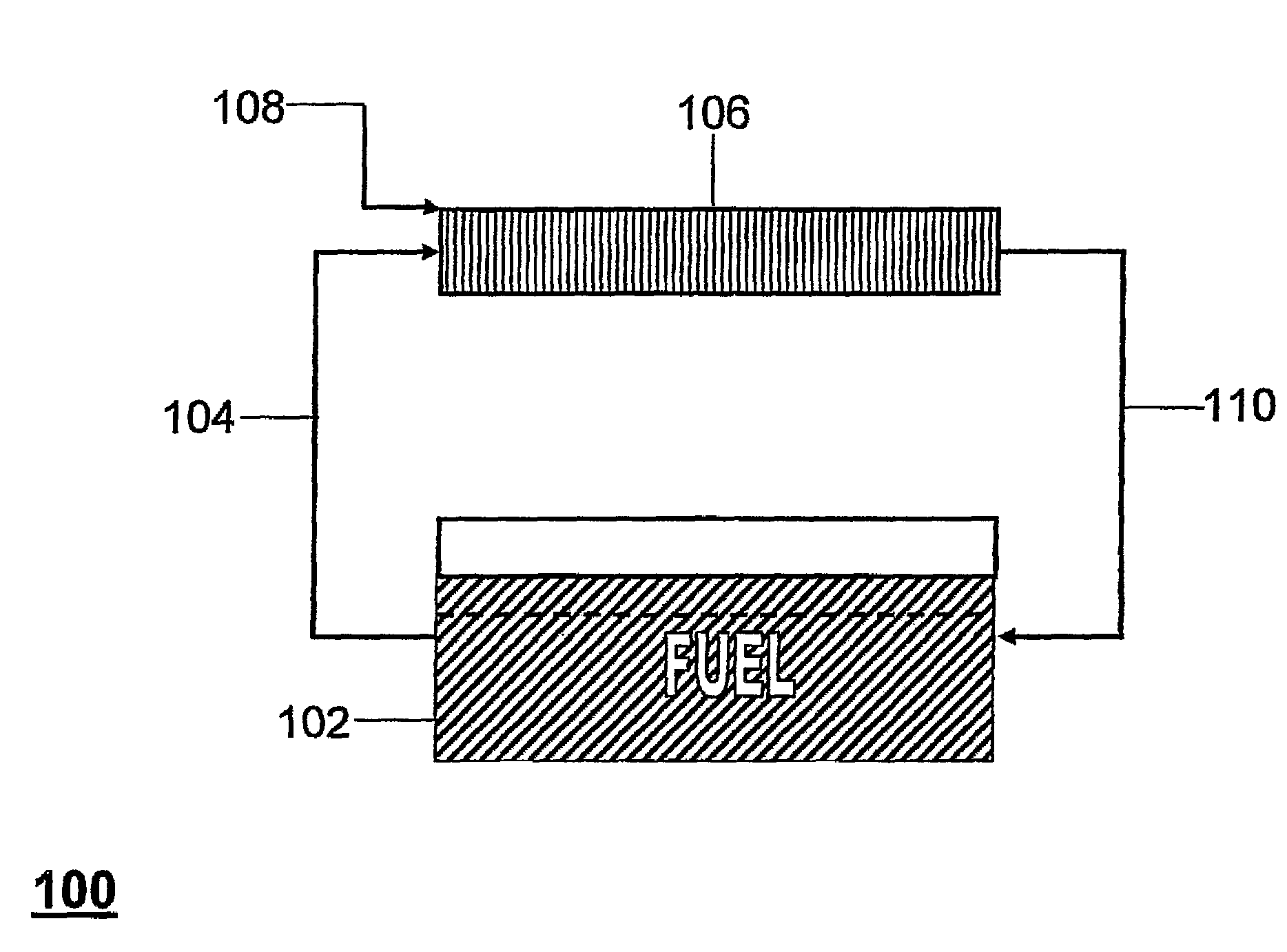

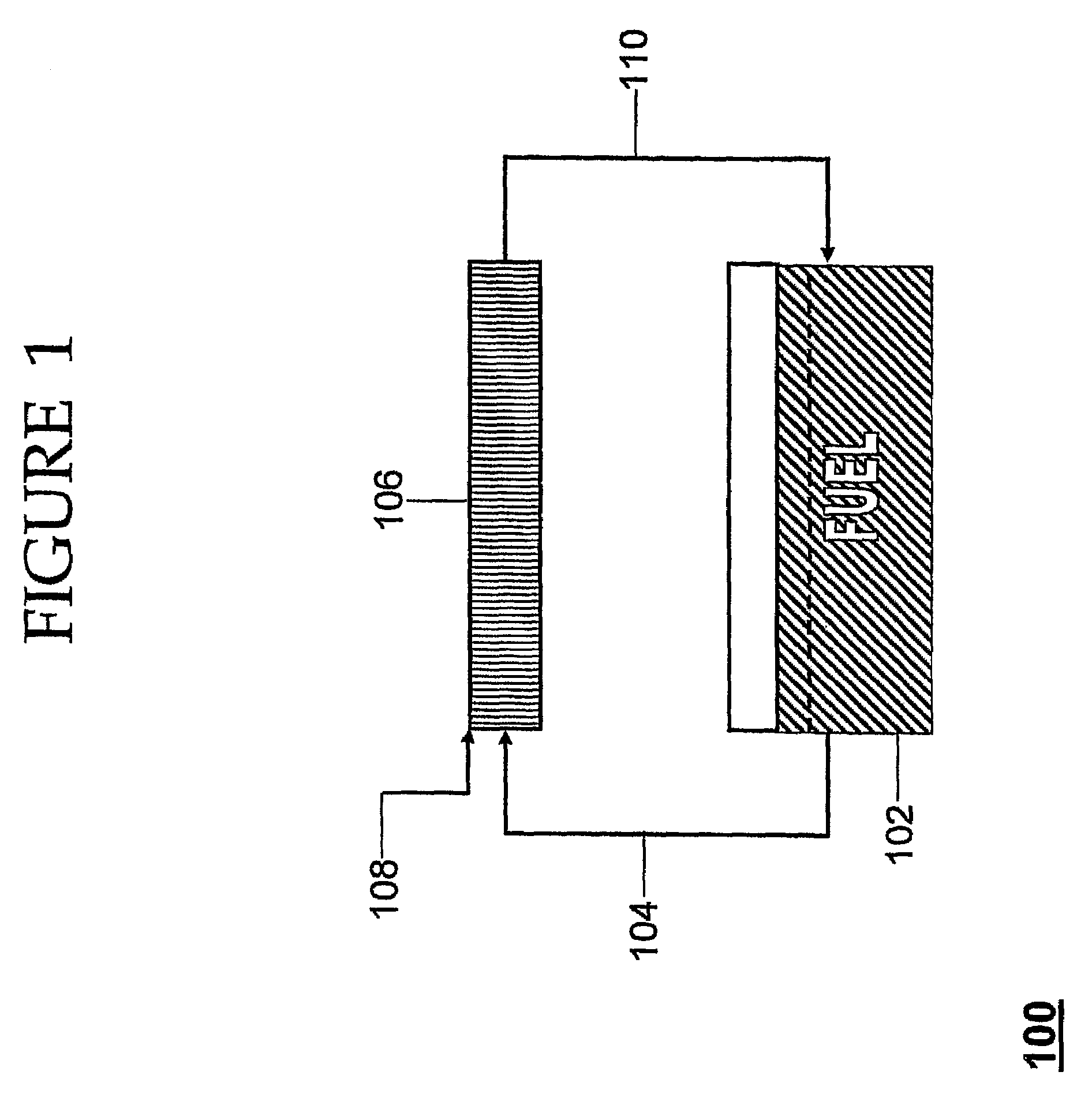

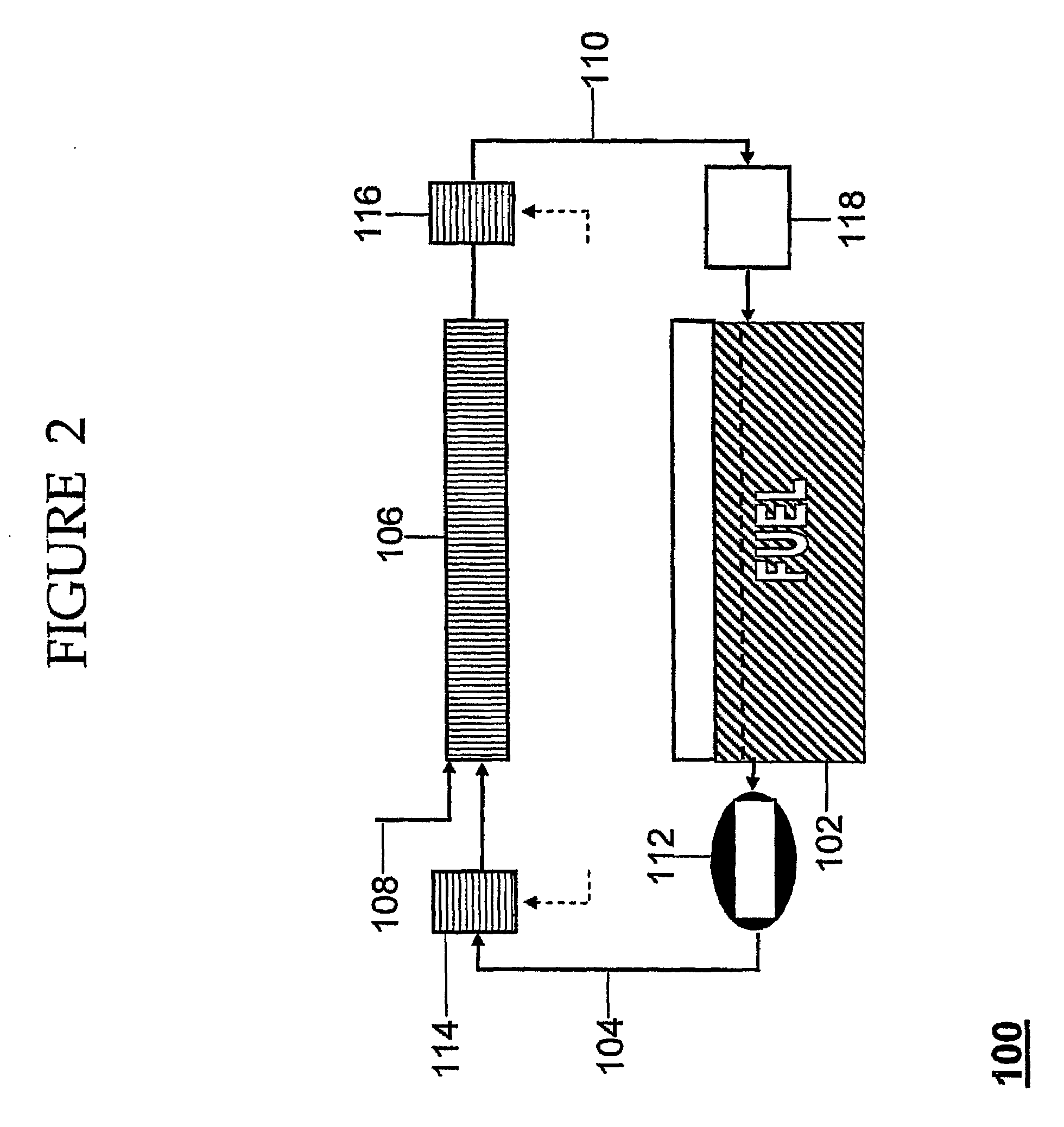

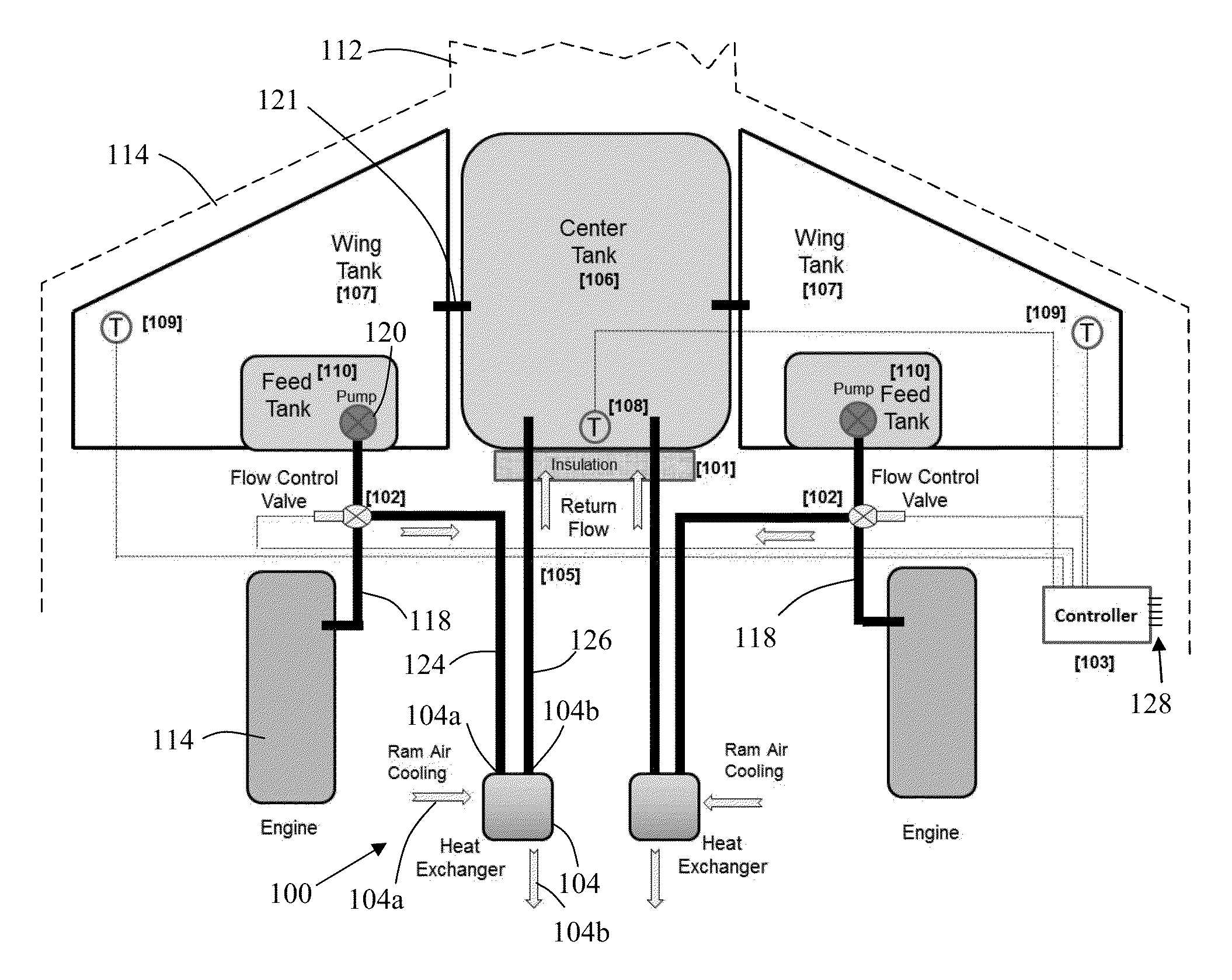

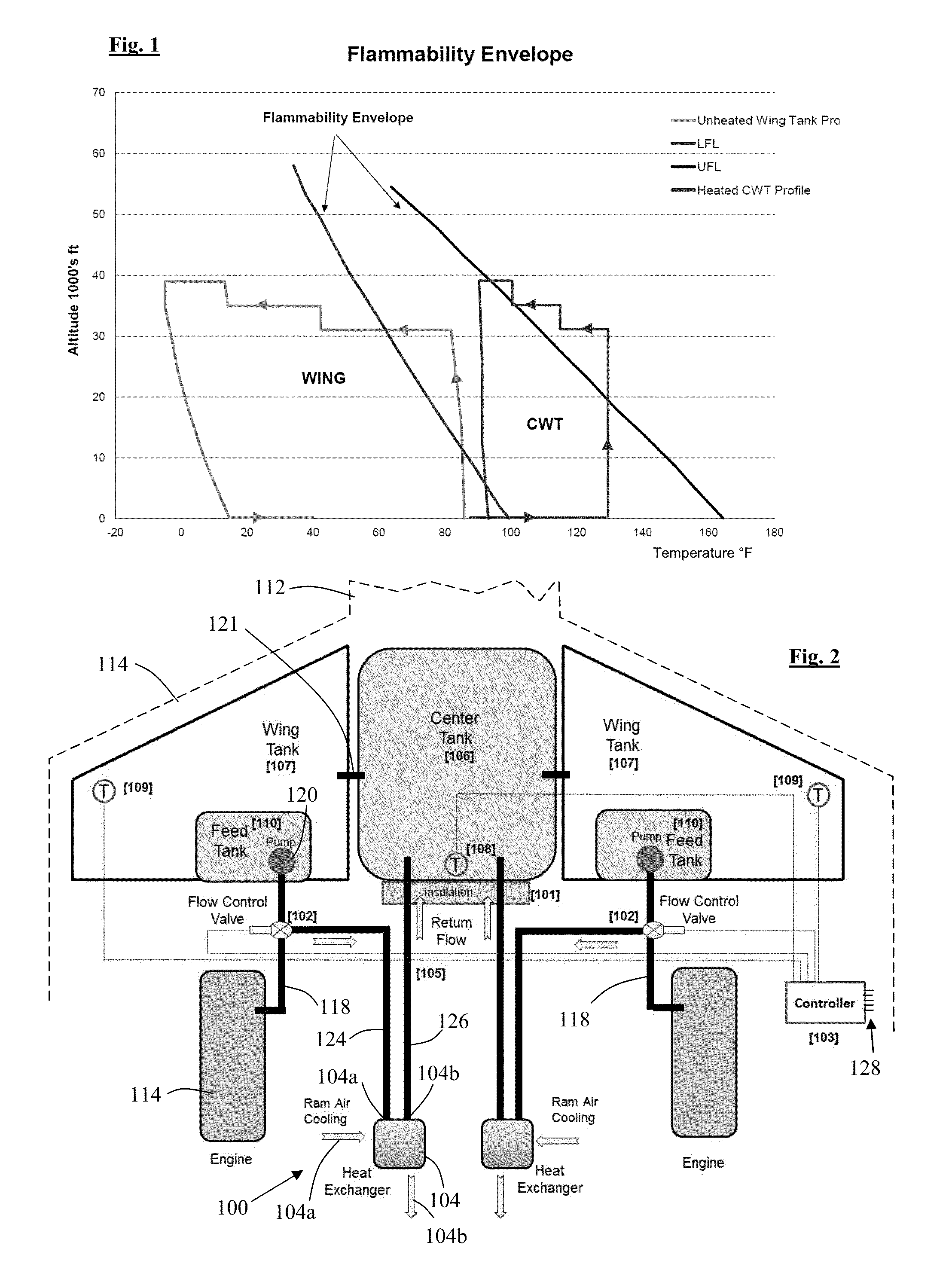

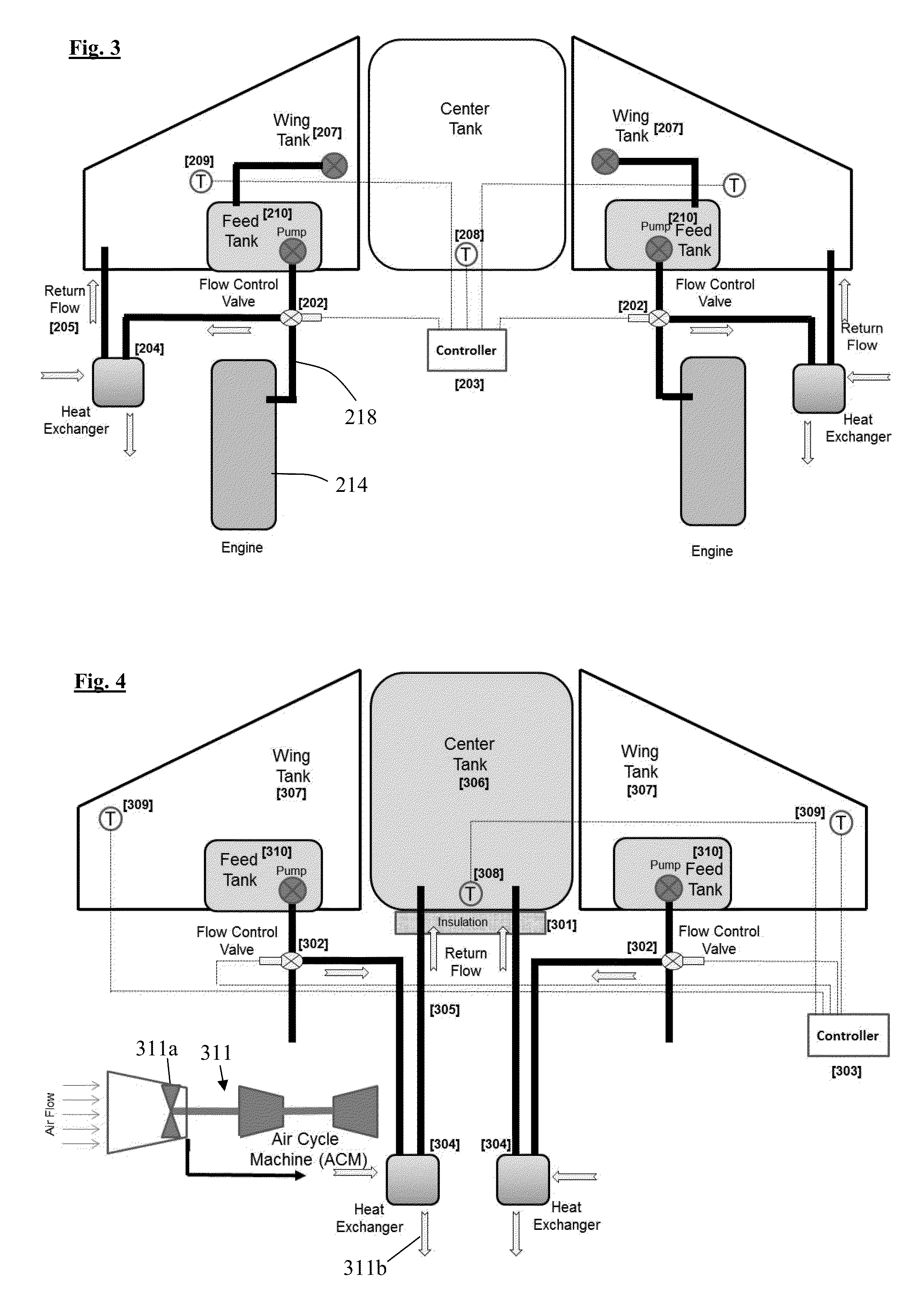

Aircraft fuel systems

ActiveUS20150217153A1Reduce flammabilityPower plant fuel tanksAir-treatment apparatus arrangementsAircraft fuel systemHeat flow

An aircraft fuel system architecture which reduces the fleet-wide flammability exposure of the fuel tanks. In one embodiment, the aircraft center fuel tank fuel is cooled at certain times in a flight to reduce its flammability exposure to be similar to that of an unheated conventional metal wing fuel tank. Aircraft fuel tanks that have adjacent heat sources are also insulated to minimize heat flow into the fuel. Fuel tanks that have lower cooling properties, such as composite wing tanks are cooled at certain times during flight such that their temperatures are reduced to be similar to metal wing tanks when the fuel is flammable. A fuel tank that is pressurized relative to outside pressure at altitude having a lower flammability exposure than unpressurized tanks is combined with the cooling of fuel in the tank to reduce the fleet-wide flammability exposure of the fuel tank to be similar to that of an unpressurized metal wing tank. Fuel is cooled by recirculating flow from a tank, passing through a heat exchanger and returning to the tank to be cooled. The heat exchanger is optionally cooled by flow of air from the outside of the aircraft, or by conditioned air from the aircraft environmental control system. The system is controlled by start and stop of fuel flow to the various tanks by means of a system controller. The controller uses sensors in the fuel tanks to command flow only when required to reduce the flammability exposure of the fuel tanks.

Owner:AERO SYST CONSULTANTS

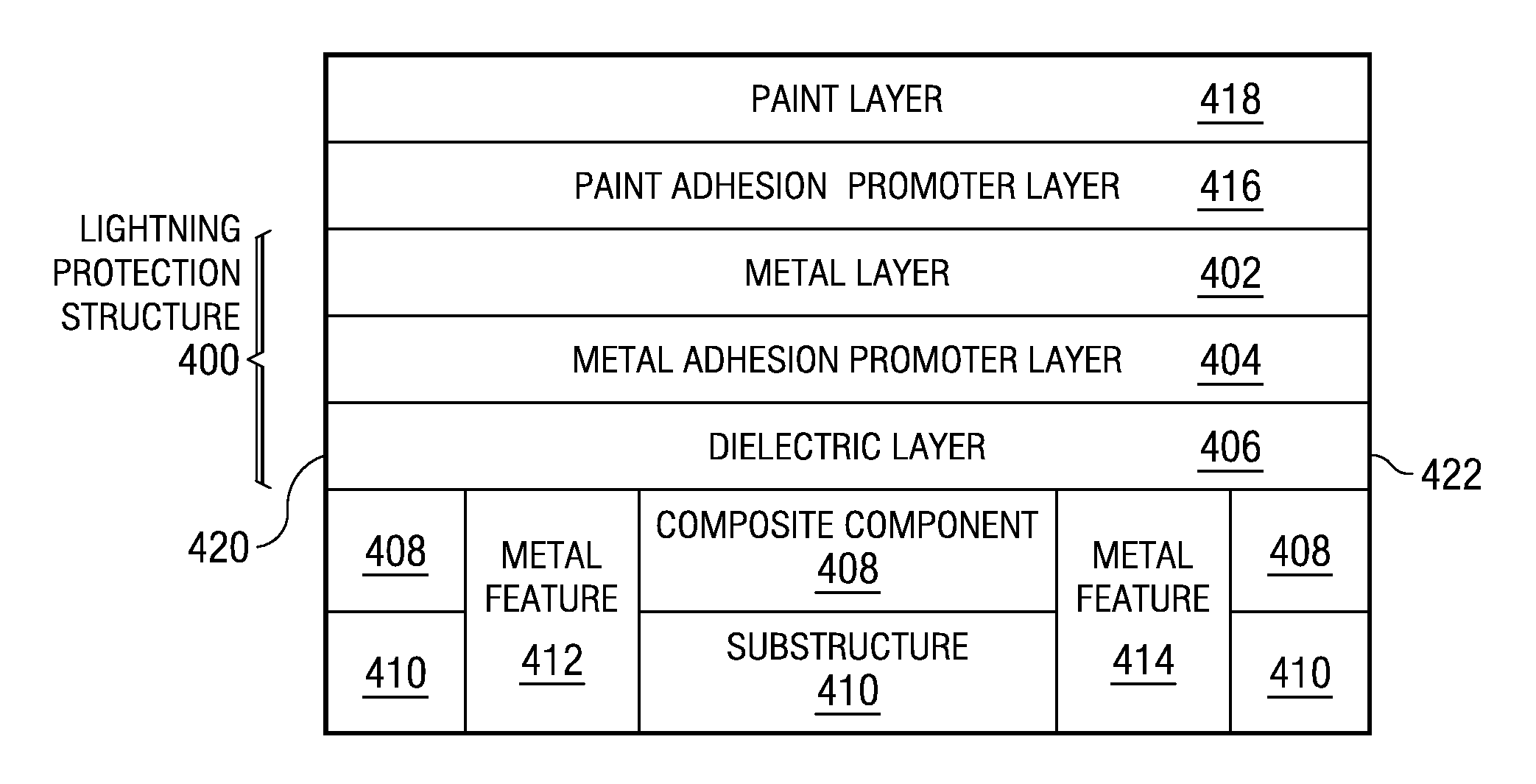

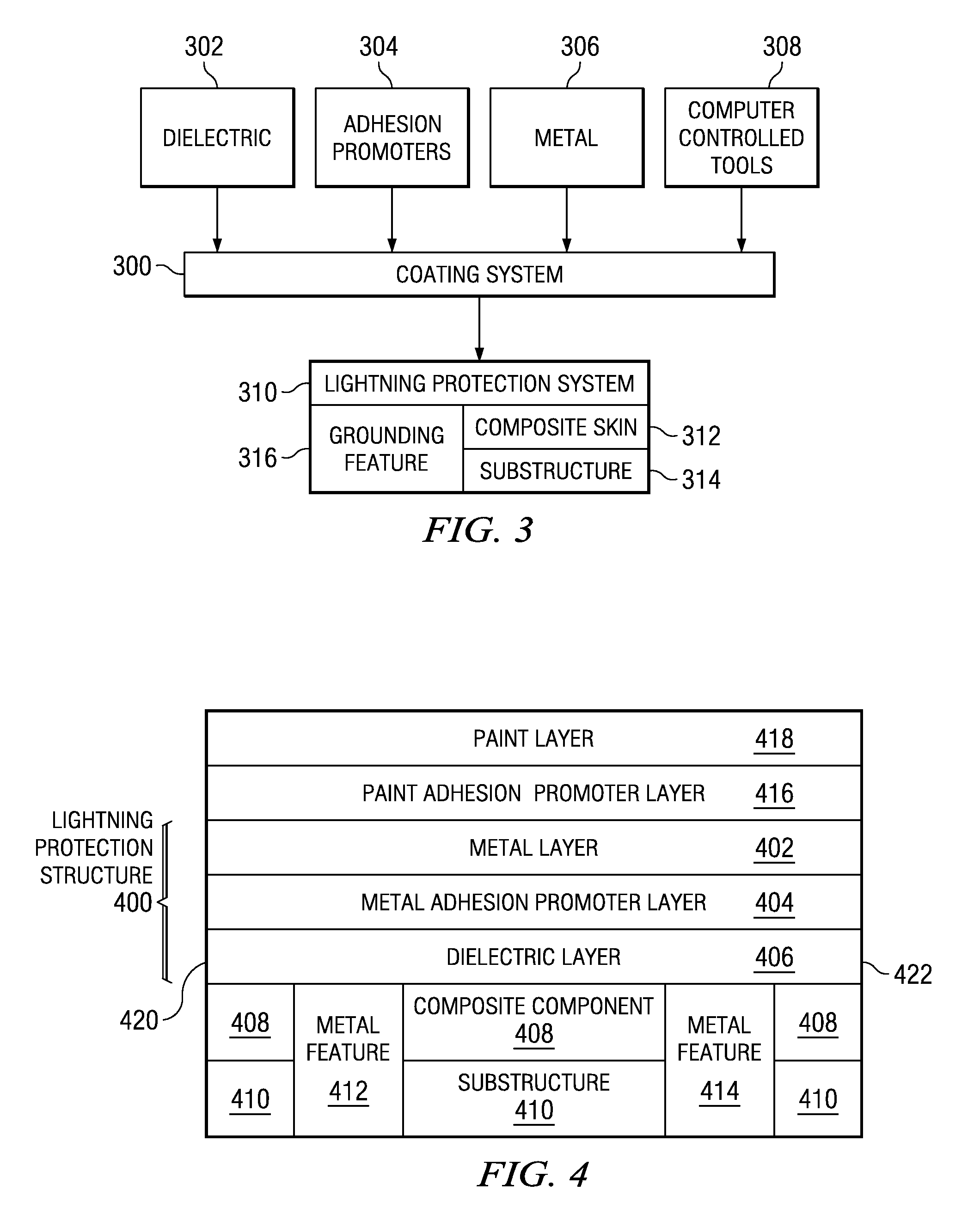

Method and apparatus for lightning protection of a composite structure

A method and apparatus for lighting protection. In one advantageous embodiment a method forms a lighting protection system on a composite surface of an aircraft. A dielectric coating is formed on the composite surface in which the dielectric coating covers a metal feature exposed on the composite surface. A metal adhesion promoter is applied in a pattern on the dielectric coating and over additional areas of the composite surface, including a grounding feature to form a metal adhesion promoter layer. A metal coating is formed on the metal adhesion promoter layer to create a path from an area including the metal feature to the grounding feature.

Owner:THE BOEING CO

On-board inert gas generation system

ActiveUS7273507B2Increase inlet pressureIncrease airflowCombination devicesAuxillary pretreatmentOn boardInlet pressure

An on-board inert gas generation system provides first and second compressors in fluid communication with one another. The second compressor includes an inlet and an outlet. The inlet is in fluid communication with the first compressor. The second compressor is the final compressor stage of the system. An air separation module is fluidly connected to the outlet of the second compressor by a passageway. A vent passage is arranged between the outlet and the air separation module for venting fluid between the outlet and air separation module. The vent passage enables the flow from the second compressor to be increased thereby increasing compressor efficiency and increasing the inlet pressure to the air separation module, which enables use of a smaller air separation module.

Owner:HAMILTON SUNDSTRAND CORP

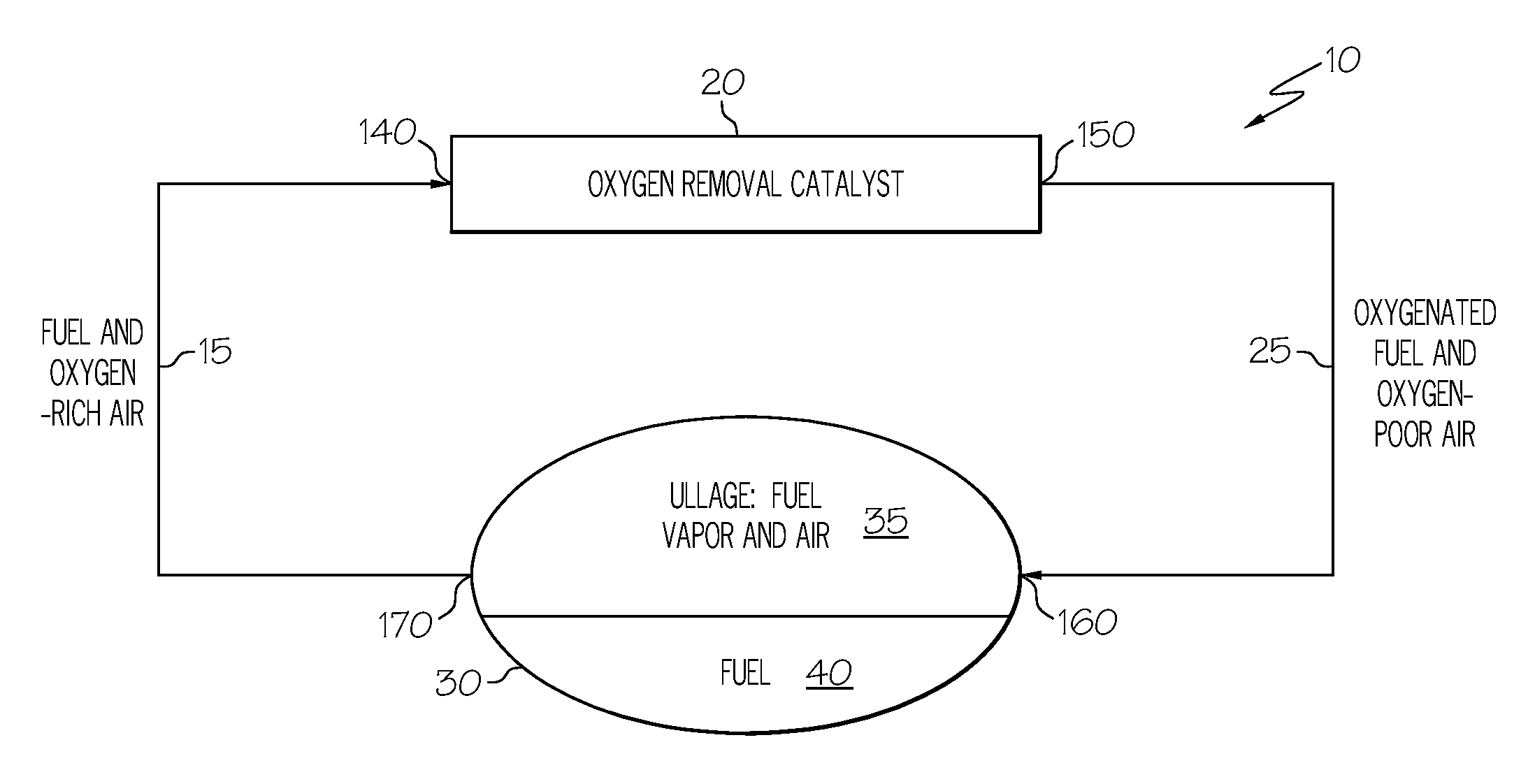

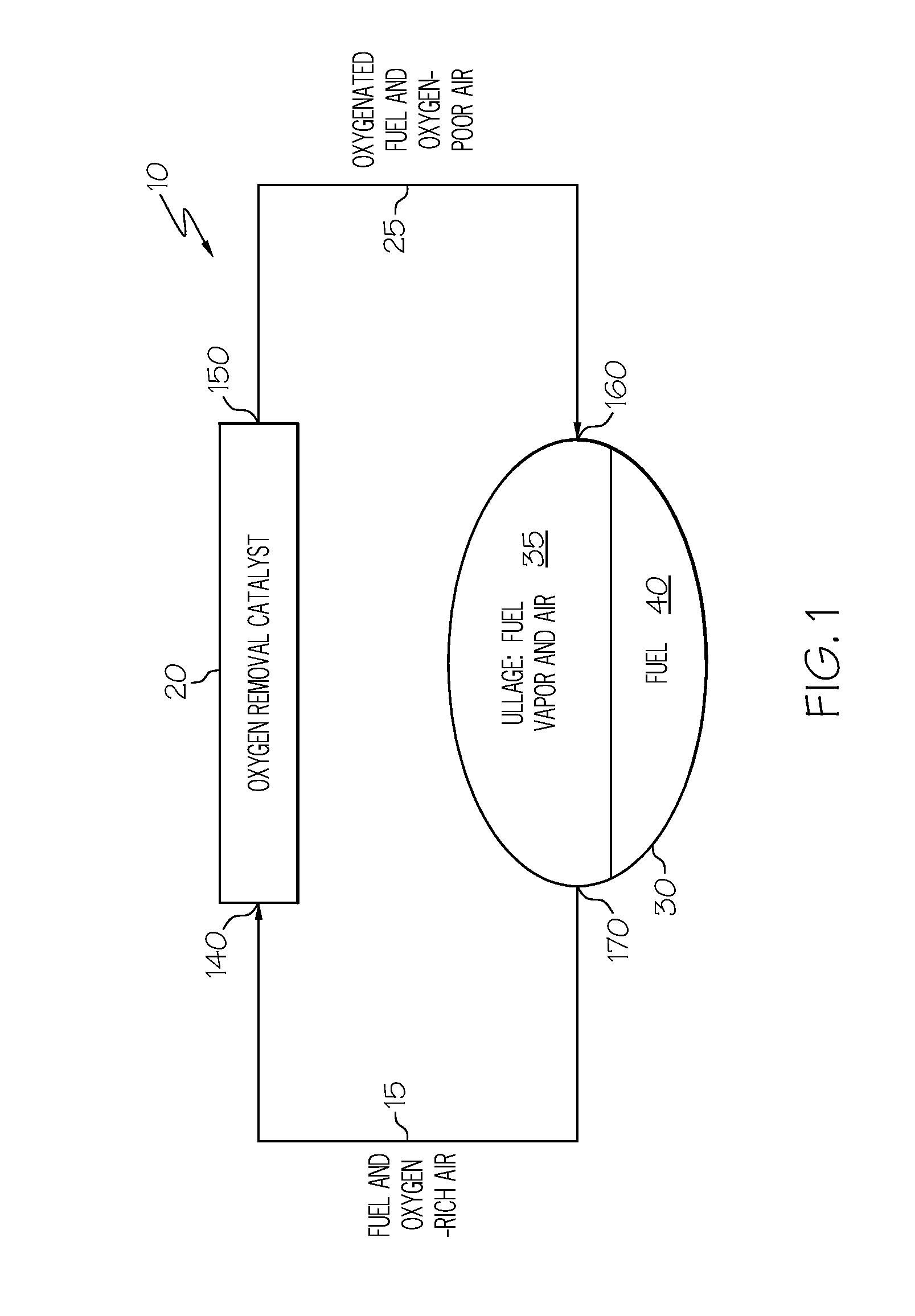

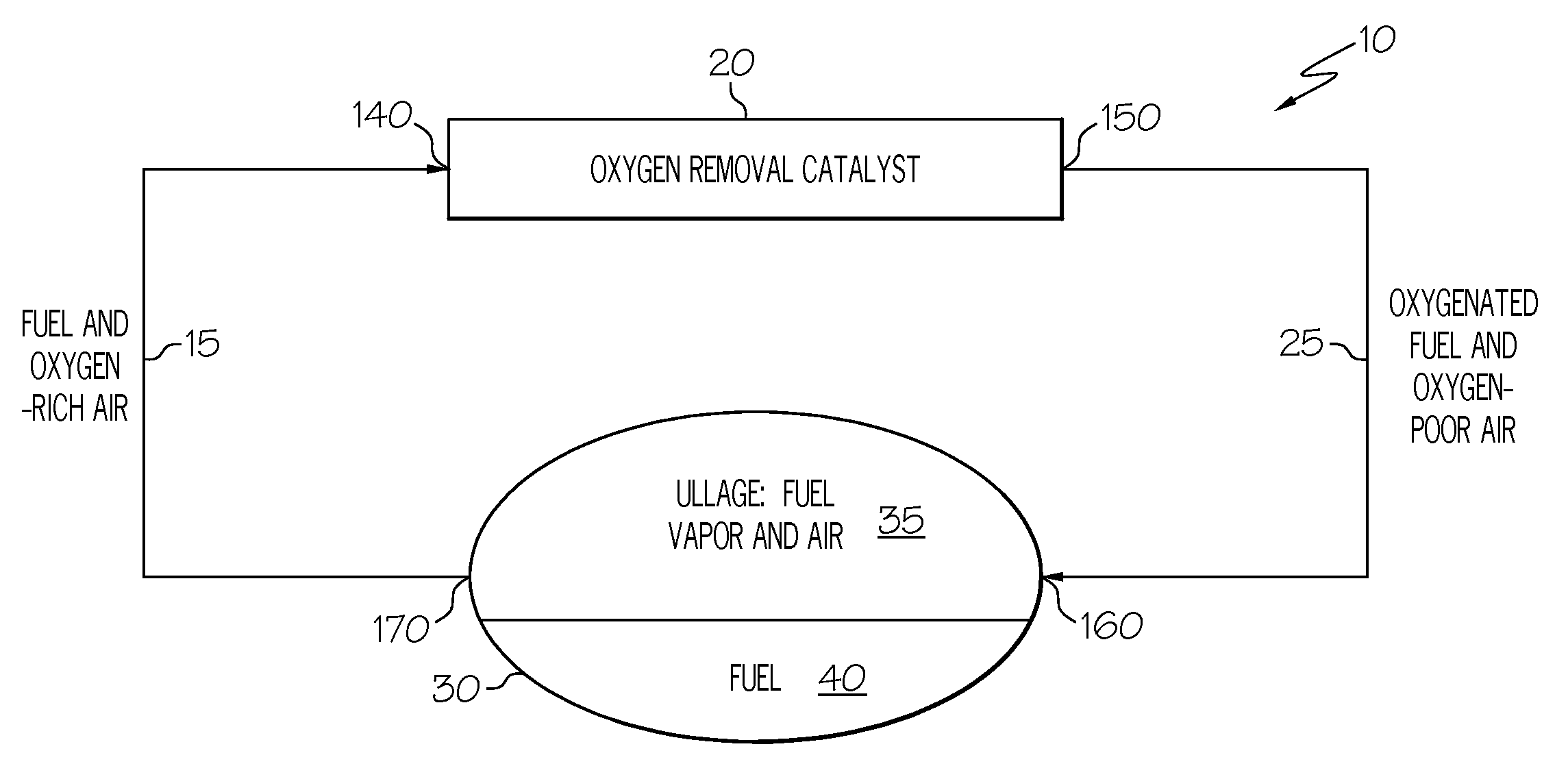

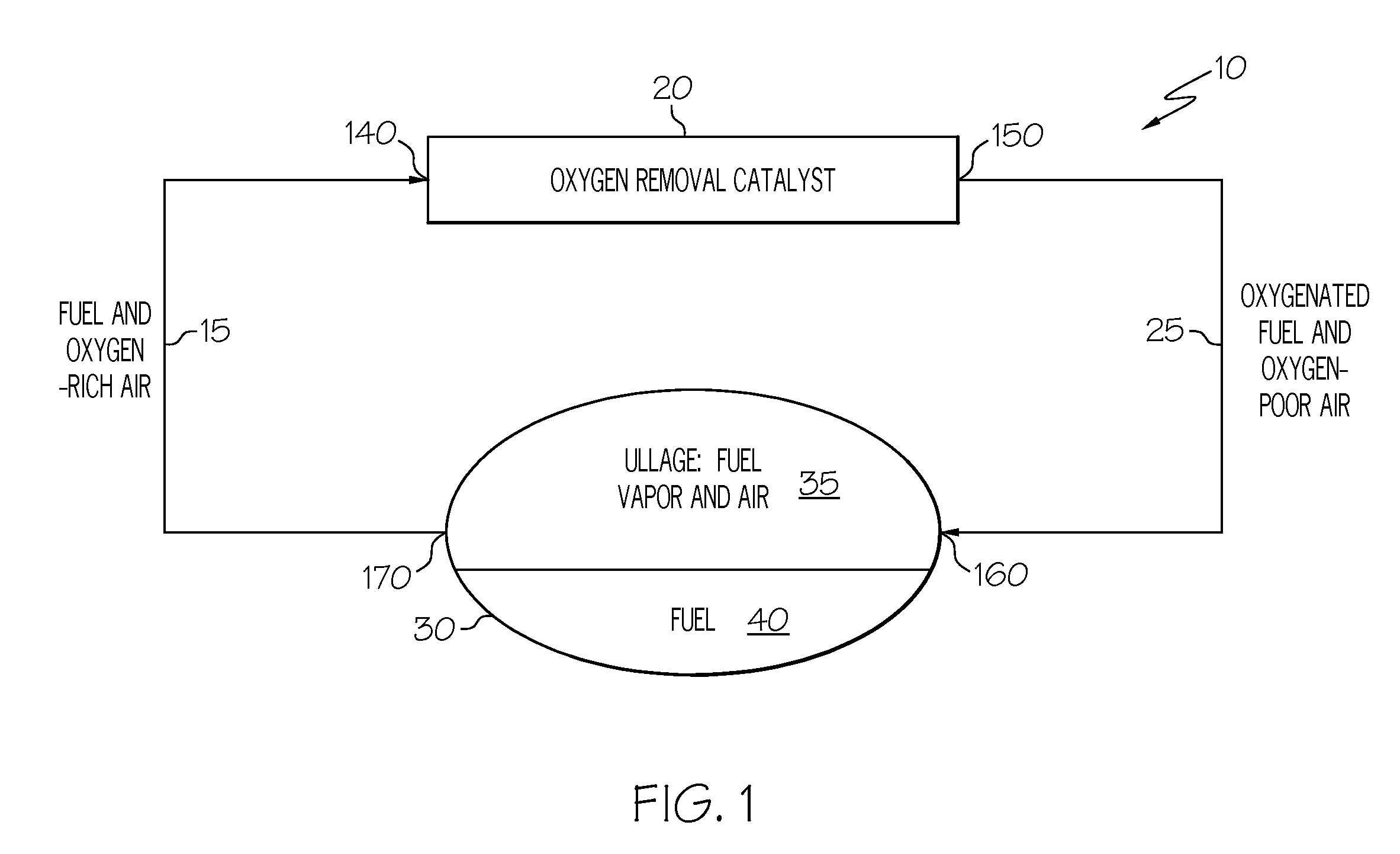

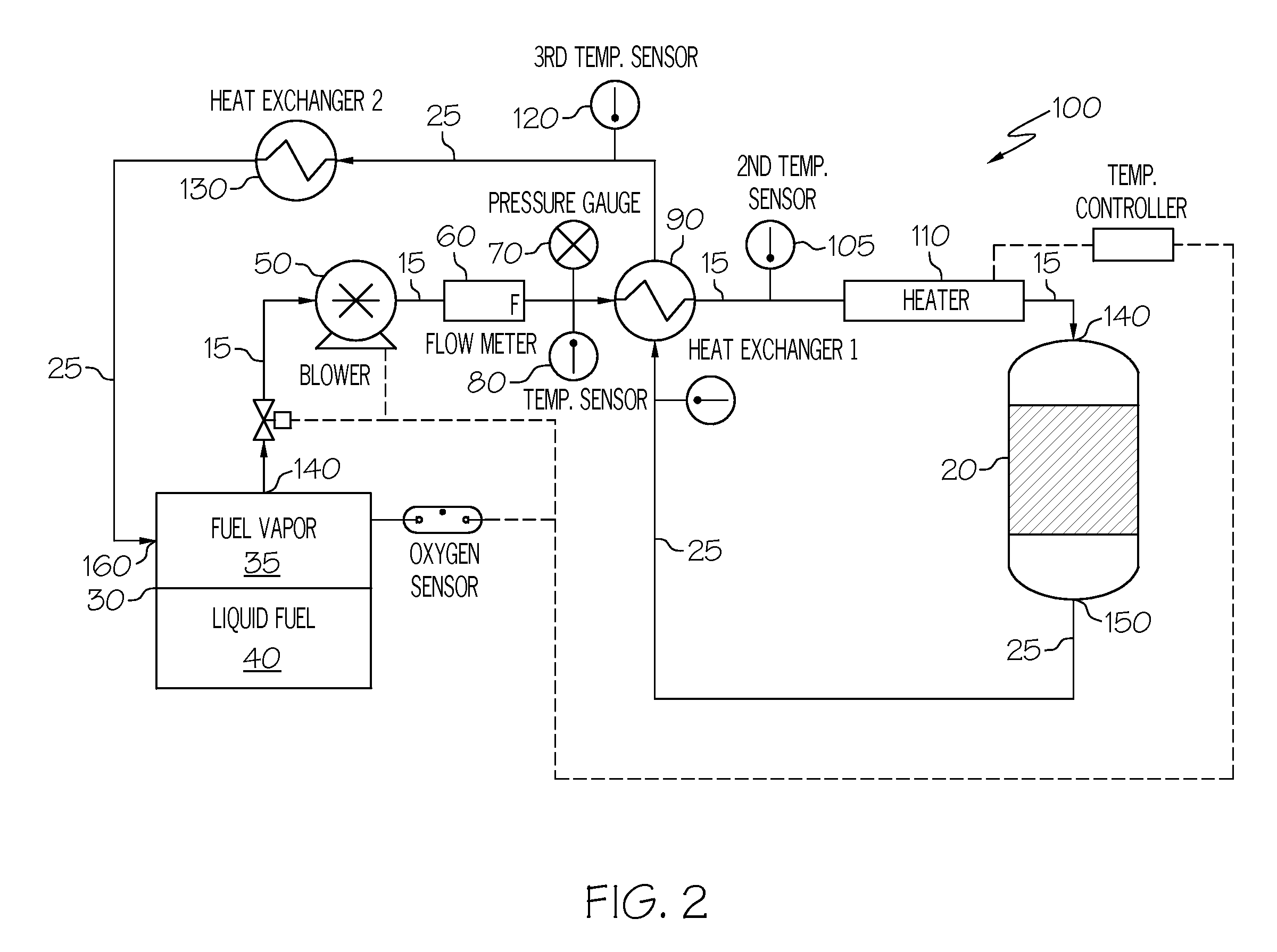

Oxygen removal system

A system and process to deplete or remove oxygen in the ullage of a fuel tank to reduce the oxygen / fuel vapor ratio below a lower explosion limit by exposing the ullage compounds to an oxygen removal catalyst active at a relatively low temperature. The oxygen removal catalyst may be a non-precious metal catalyst. A selective reaction of the oxygen by the catalyst forms primarily alcohols, aldehydes, and / or ketones and produces less than about 5% water by volume. The selective reaction, occurring at the relatively low temperature, reduces the risk of flammability of the fuel.

Owner:HONEYWELL INT INC

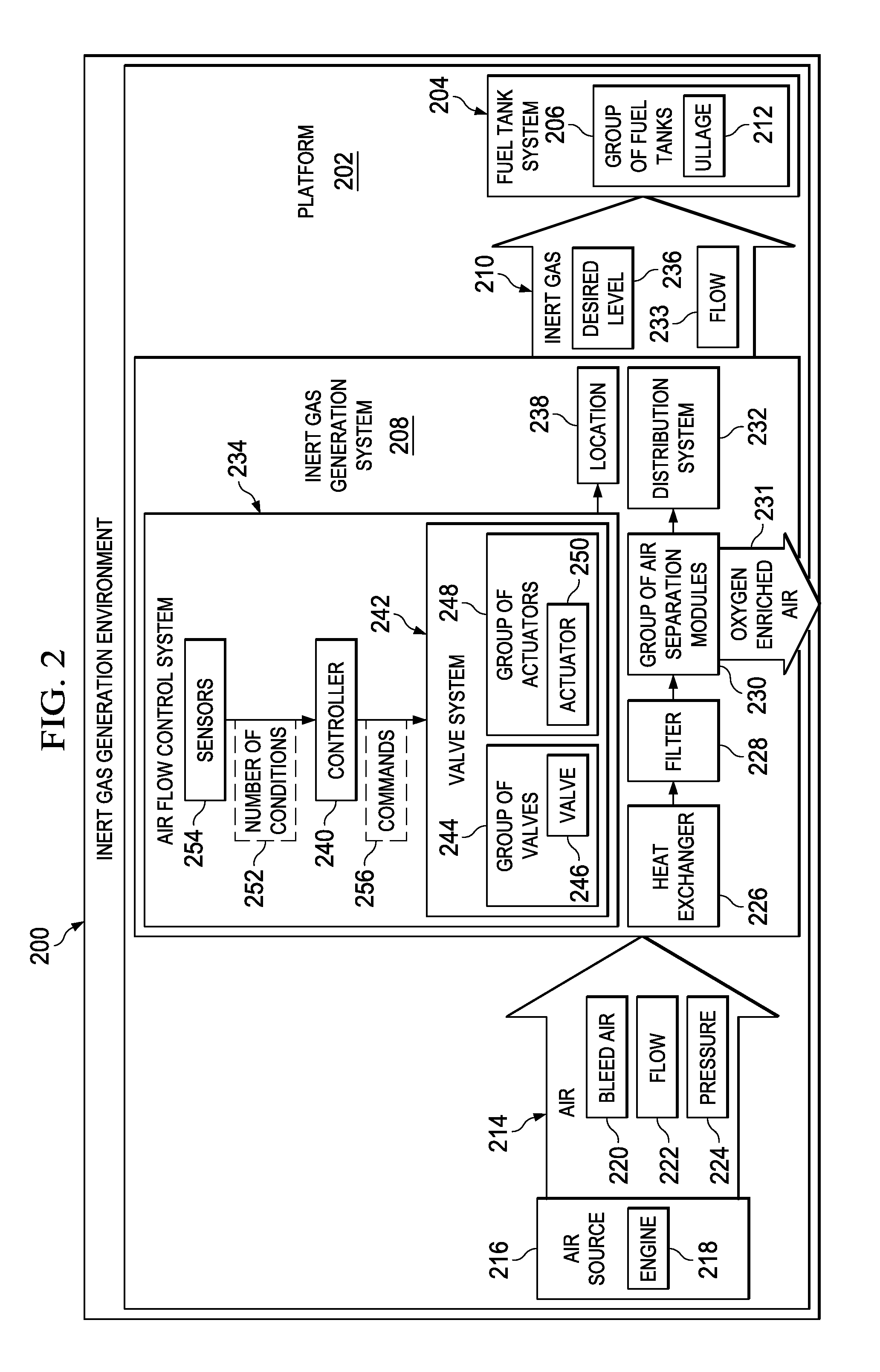

Fuel saving inert gas generation system

A method and apparatus for controlling inert gas generation. An apparatus comprises an air separation module and an air flow control system. The air separation module is configured to separate an inert gas from air input into the air separation module. The air flow control system is configured to control the flow of the air into the air separation module.

Owner:THE BOEING CO

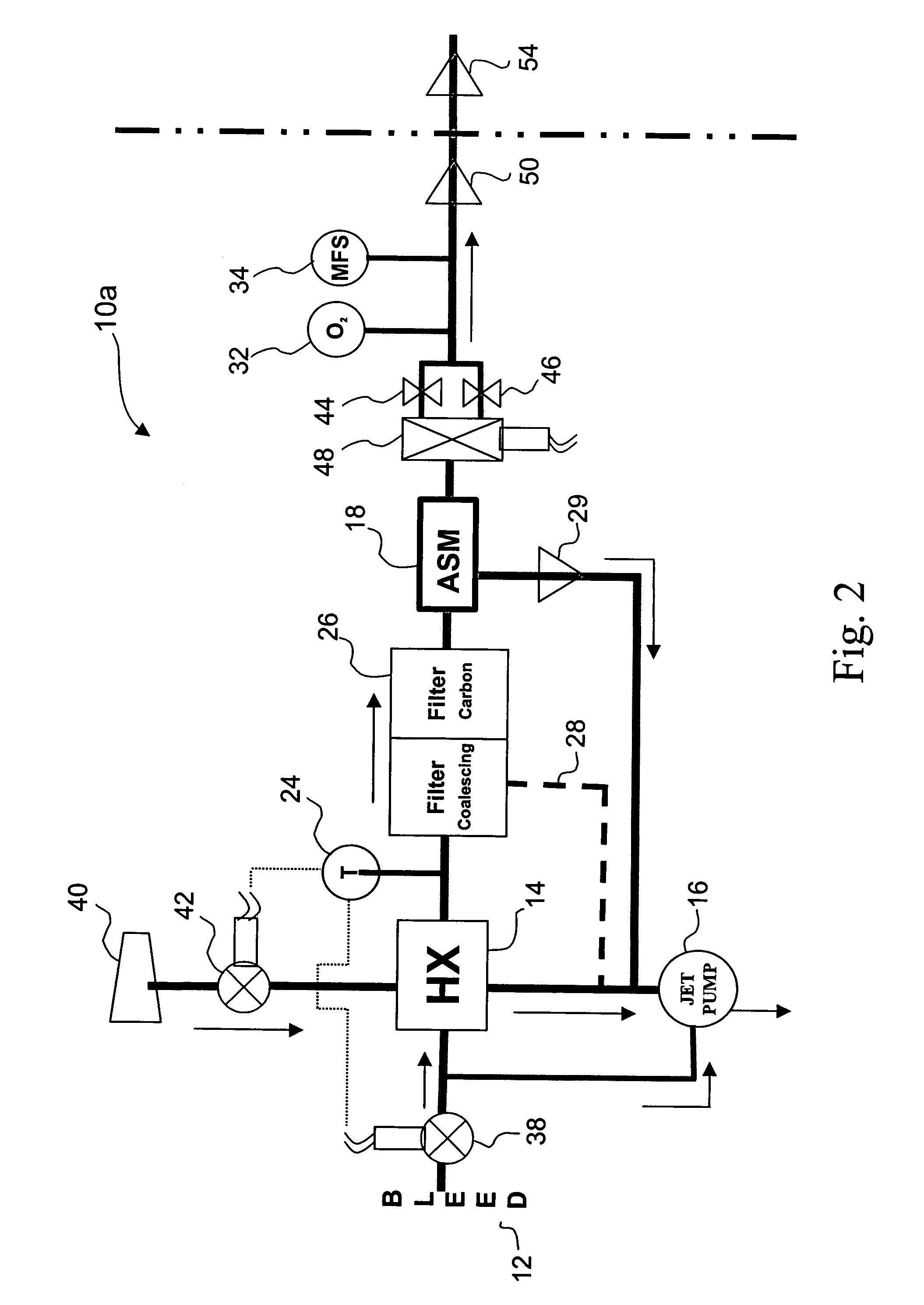

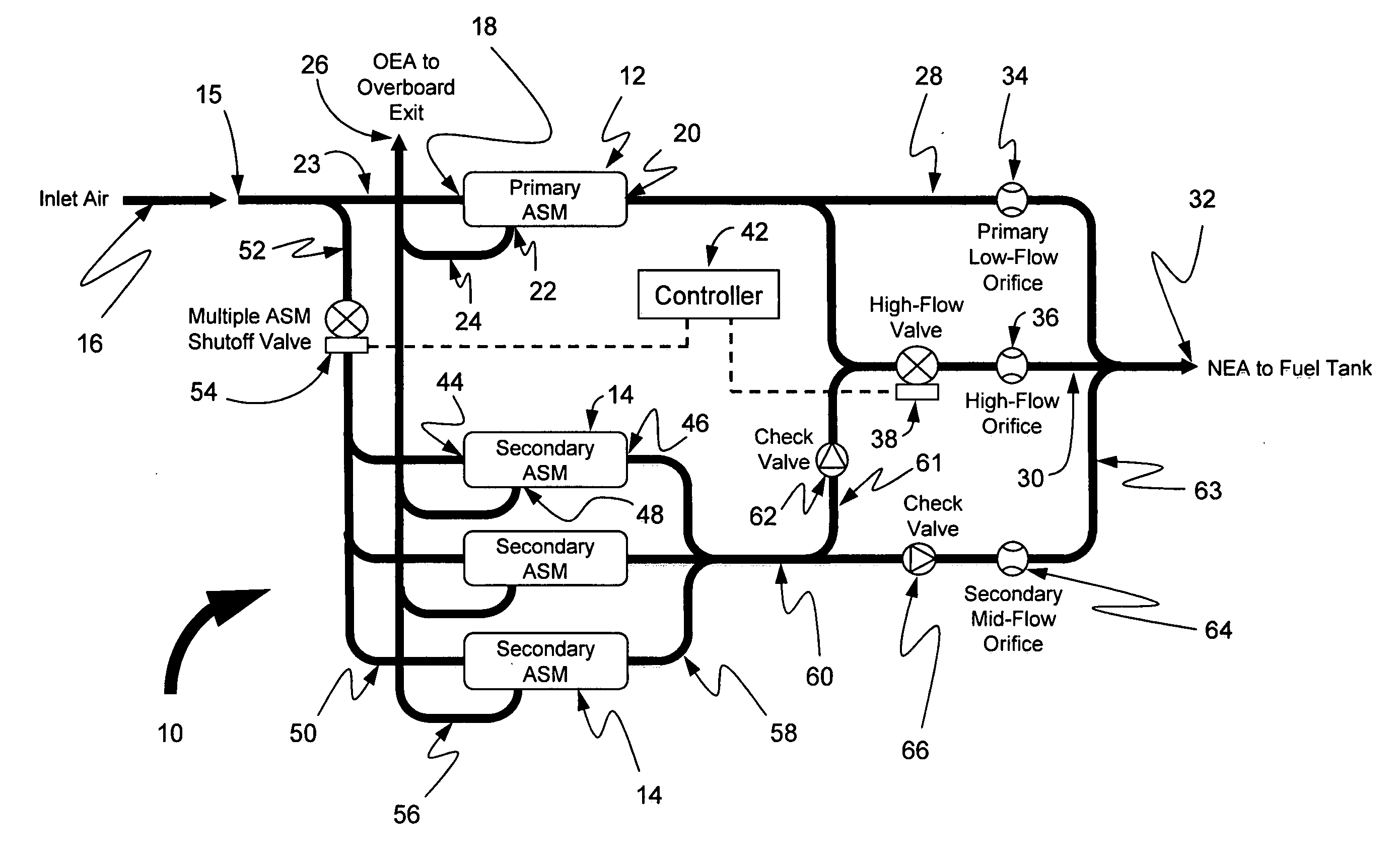

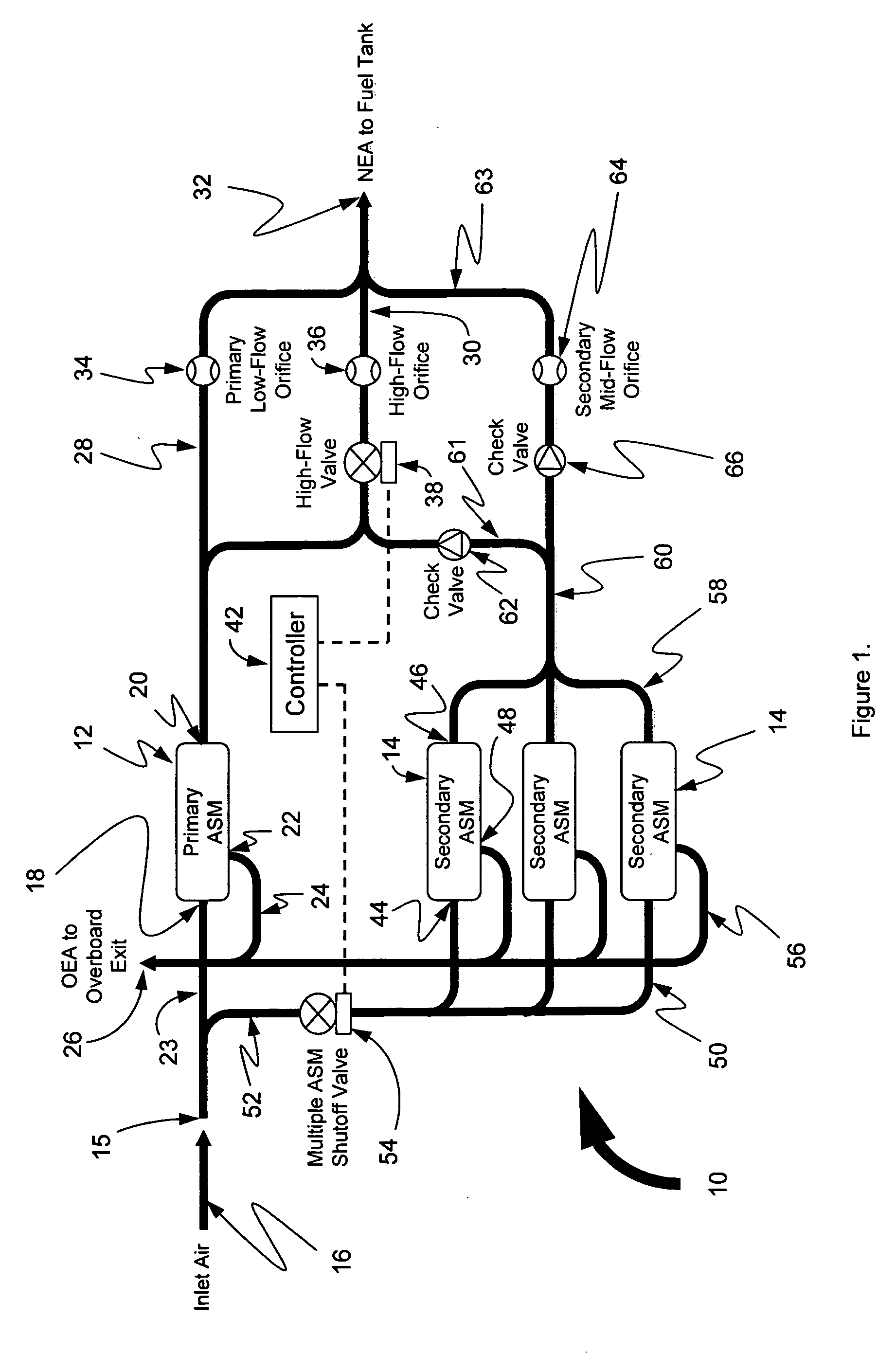

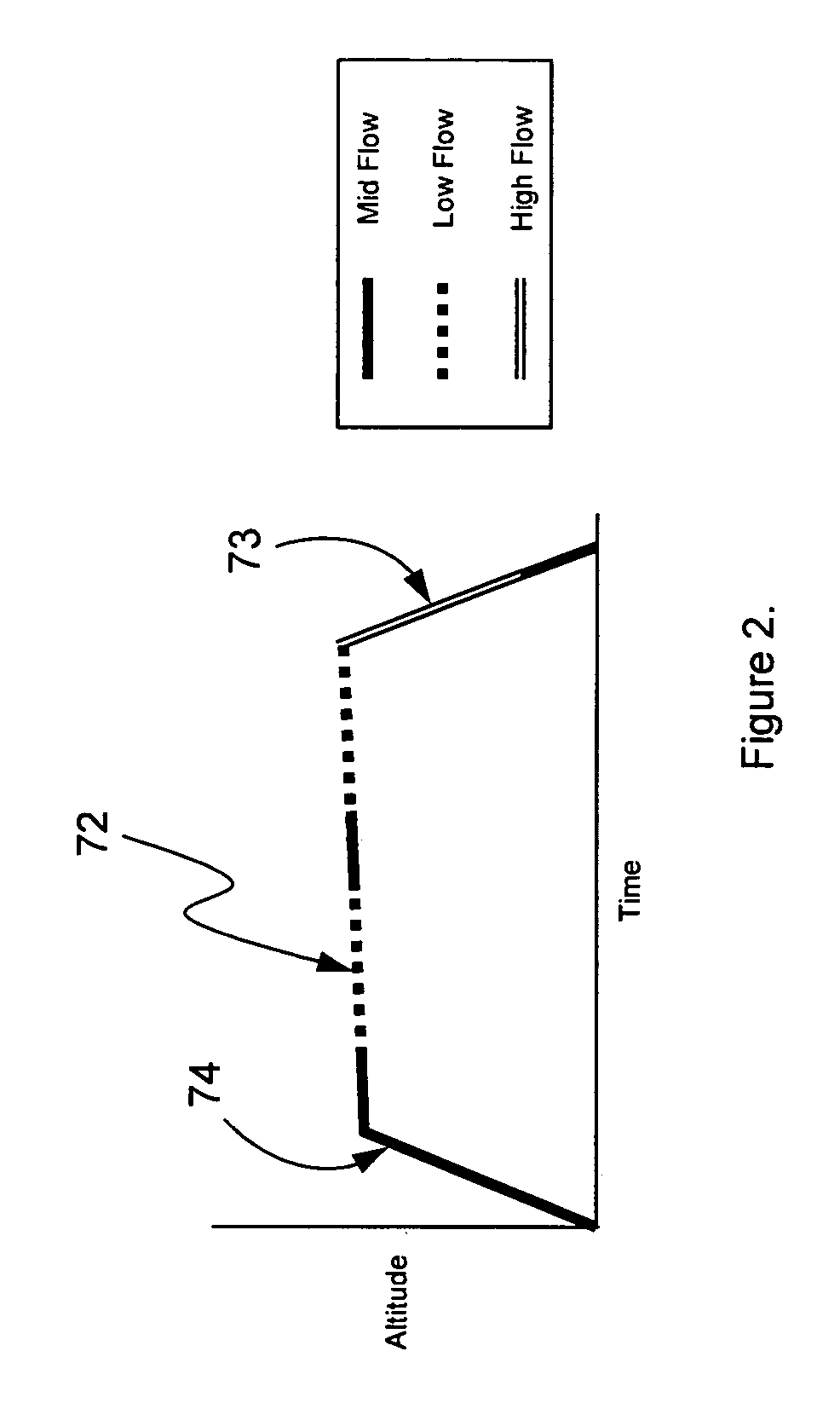

Three flow architecture and method for aircraft OBIGGS

ActiveUS20070054610A1Rapid inertingReduce oxygen concentrationDispersed particle filtrationAir-treatment apparatus arrangementsFiberEngineering

An air separation system and method wherein the outlet of a primary air separation module (one or more modules or bundles of fiber membranes) is split into two flow paths, a low flow path and a high flow path. The outlet of a secondary air separation module (one or more modules or bundles of fiber membranes) is split into two flow paths, a mid flow path and a high flow path, the latter being joined with the high flow of the primary air separation module. Flow along the primary low flow passes through a low-flow orifice, flow along the secondary mid-flow path passes through a mid-flow orifice, and flow along the high flow paths of both the primary and secondary air separation modules is joined together for passage through a shutoff valve and a high flow orifice. This configuration allows for three different flow modes of operation.

Owner:PARKER INTANGIBLES LLC

Oxygen removal system

ActiveUS20080099618A1Reduce riskReduce oxygen concentrationLiquid degasificationPower plant fuel tanksAlcoholKetone

A system and process is provided to deplete or remove oxygen in the ullage of a fuel tank to reduce the oxygen / fuel vapor ratio below a lower explosion limit by exposing the ullage compounds to an oxygen removal catalyst active at a relatively low temperature. The oxygen removal catalyst may be a non-precious metal catalyst. A selective reaction of the oxygen by the catalyst forms primarily alcohols, aldehydes, and / or ketones and produces less than about 5% water by volume. The selective reaction, occurring at the relatively low temperature, reduces the risk of flammability of the fuel.

Owner:HONEYWELL INT INC

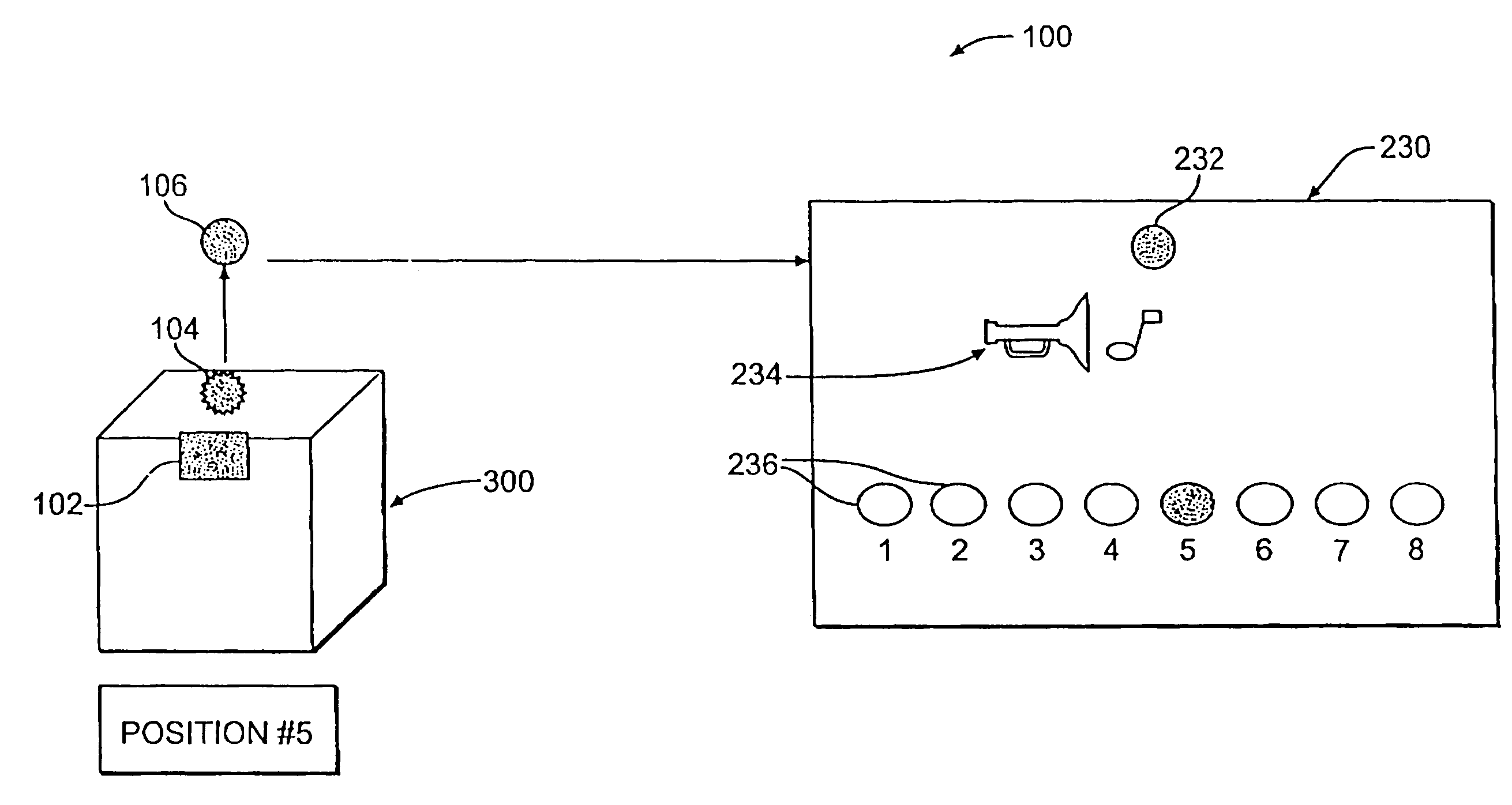

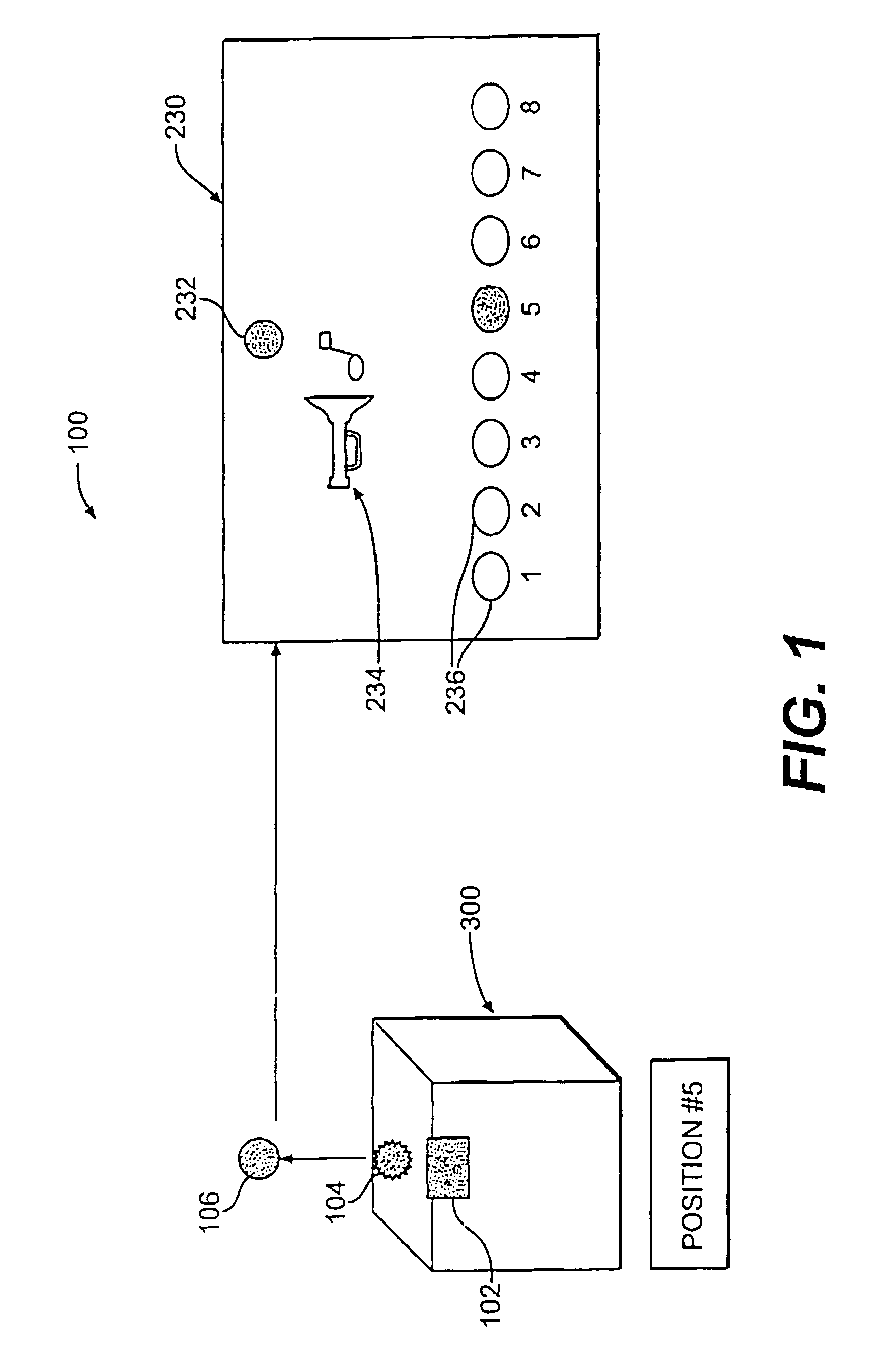

Fire suppression and indicator system and fire detection device

InactiveUS7456750B2Frequency-division multiplex detailsFuel tank safety measuresFire detectionEmbedded system

A system for detecting and suppressing a fire condition in a storage unit. The system comprises a transmitter associated with the storage unit and configured to transmit a first signal upon detection of the fire condition, at least one receiver configured to detect the first signal and configured to provide a second signal indicating detection of the fire condition, and a fire suppression device configured to discharge a fire suppressant material into the storage unit upon detection of the fire condition. There may also be a plurality of storage units, a plurality of transmitters, and a plurality of receivers. An individual transmitter and an individual receiver may be associated with each of the plurality of storage units. Each of the storage units may be located at a predetermined position relative to the individual receiver associated with the storage unit. The second signal from a receiver may be provided to a control panel that in response to the second signal identifies the storage unit experiencing the fire condition. The present invention is also directed at a fire suppression and indication system for use in an aircraft. The aircraft includes a cockpit, a control panel in the cockpit, and a storage area. The system includes a plurality of storage units located at predetermined positions in the storage area. a transmitter associated with each storage unit and configured to transmit a first signal upon detection of the fire condition, at least one receiver configured to detect the first signal and configured to provide a second signal indication detection of the fire condition, and a fire suppression device configured to discharge a fire suppressant material into the storage unit upon detection of the fire condition.

Owner:FEDERAL EXPRESS CORP US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com