Patents

Literature

941 results about "Composite surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

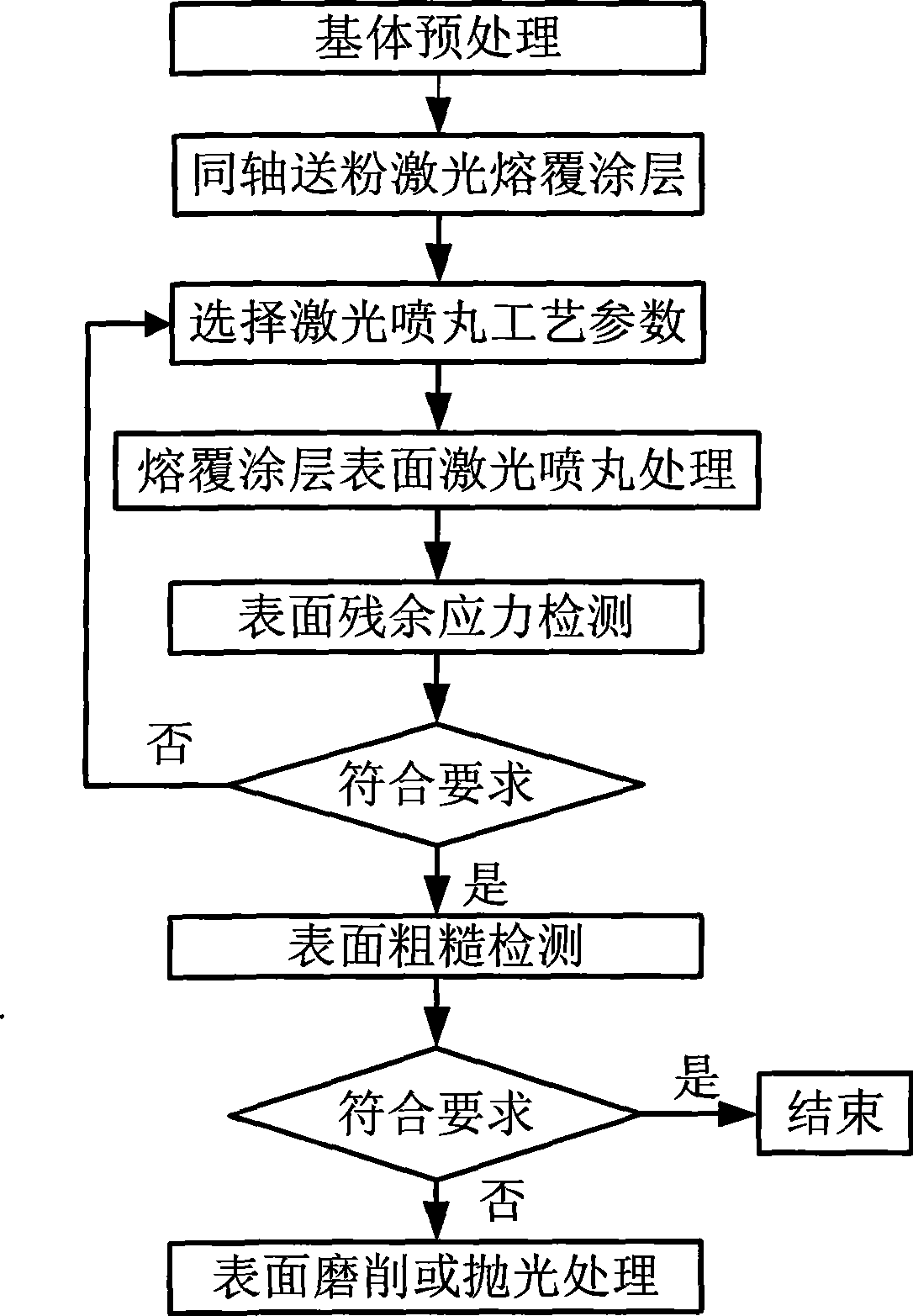

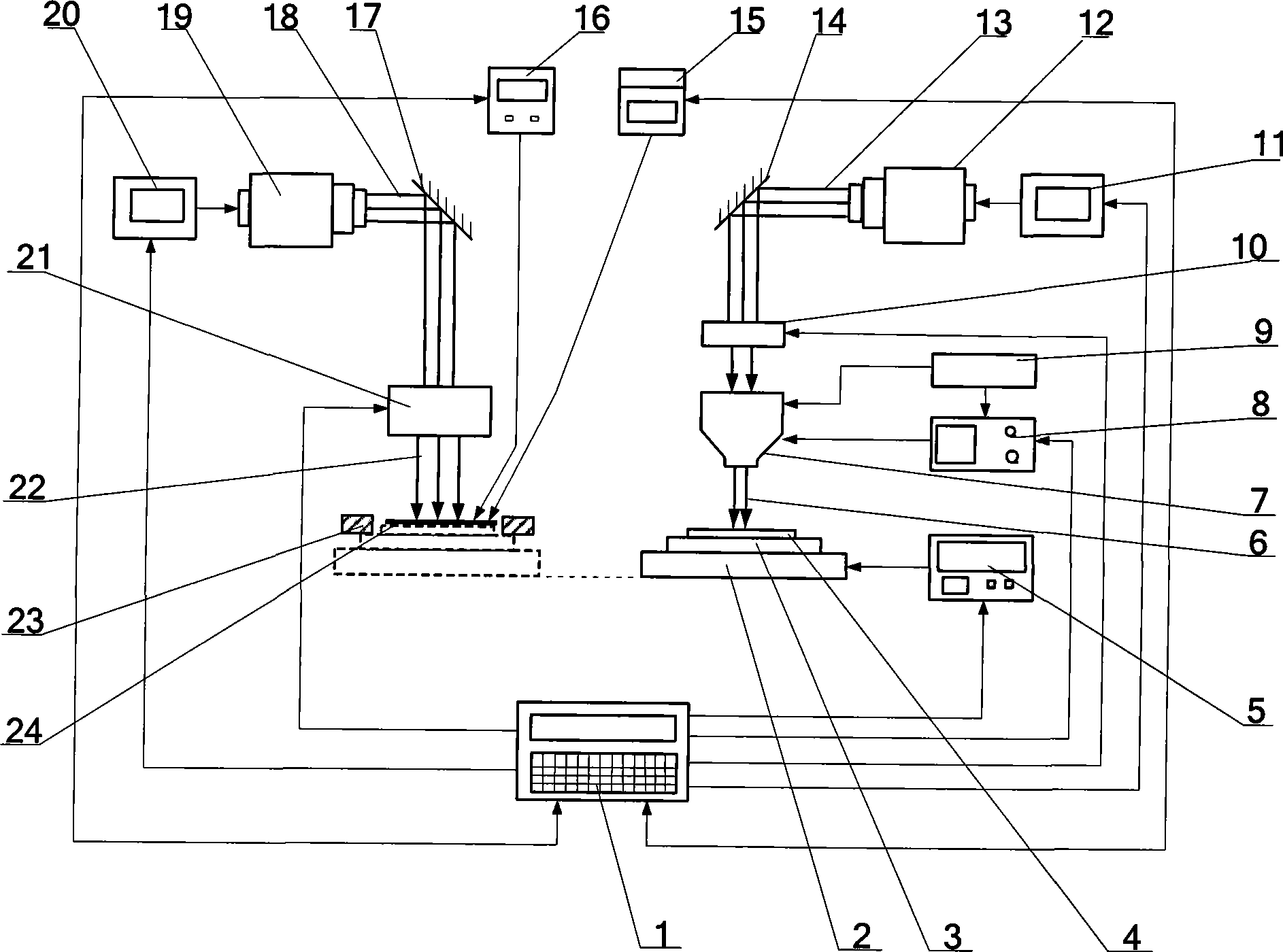

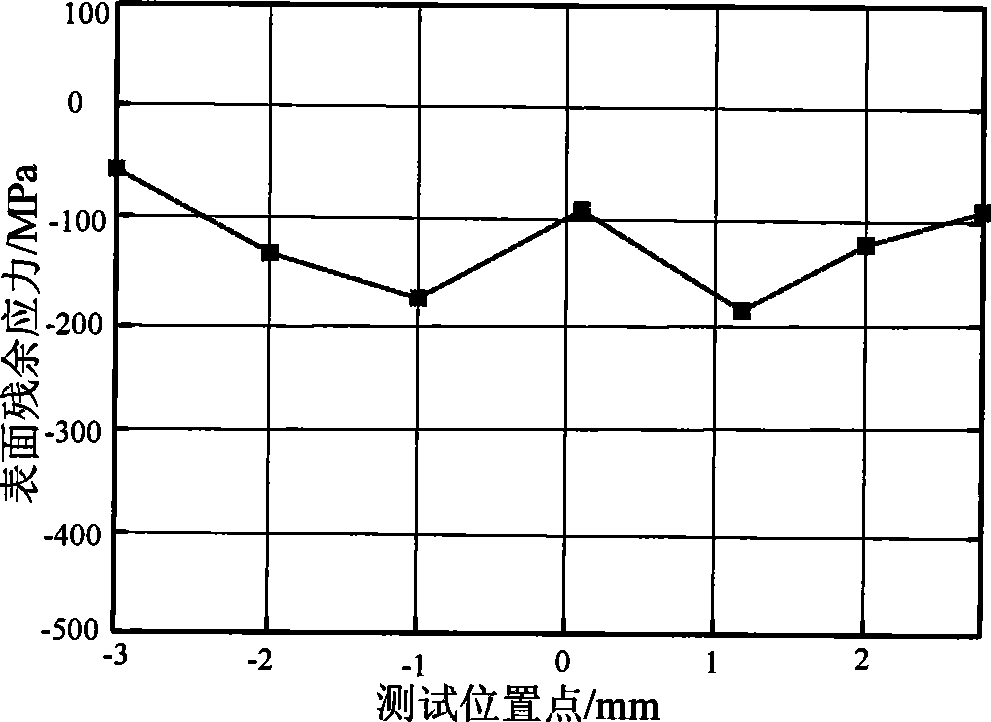

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

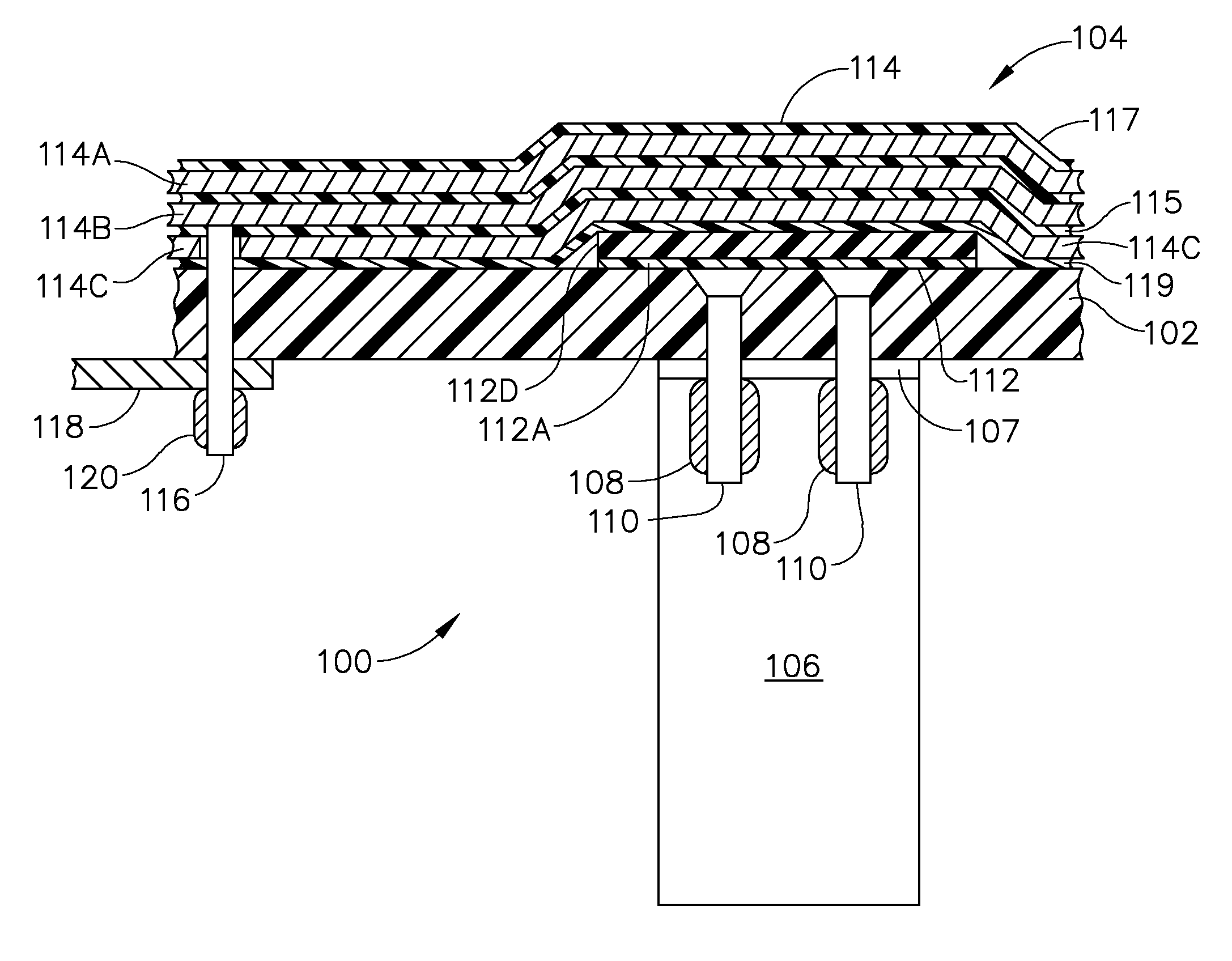

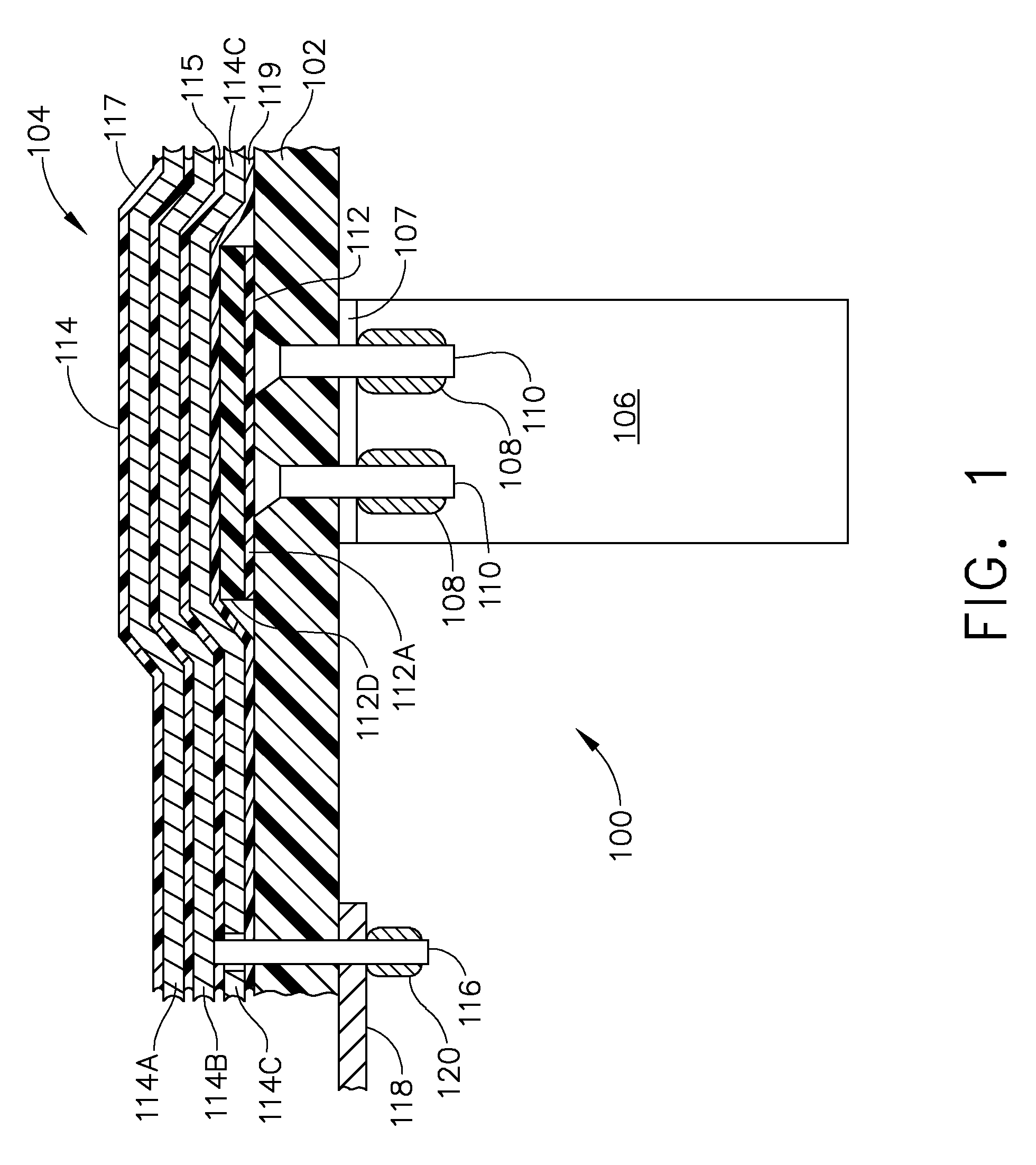

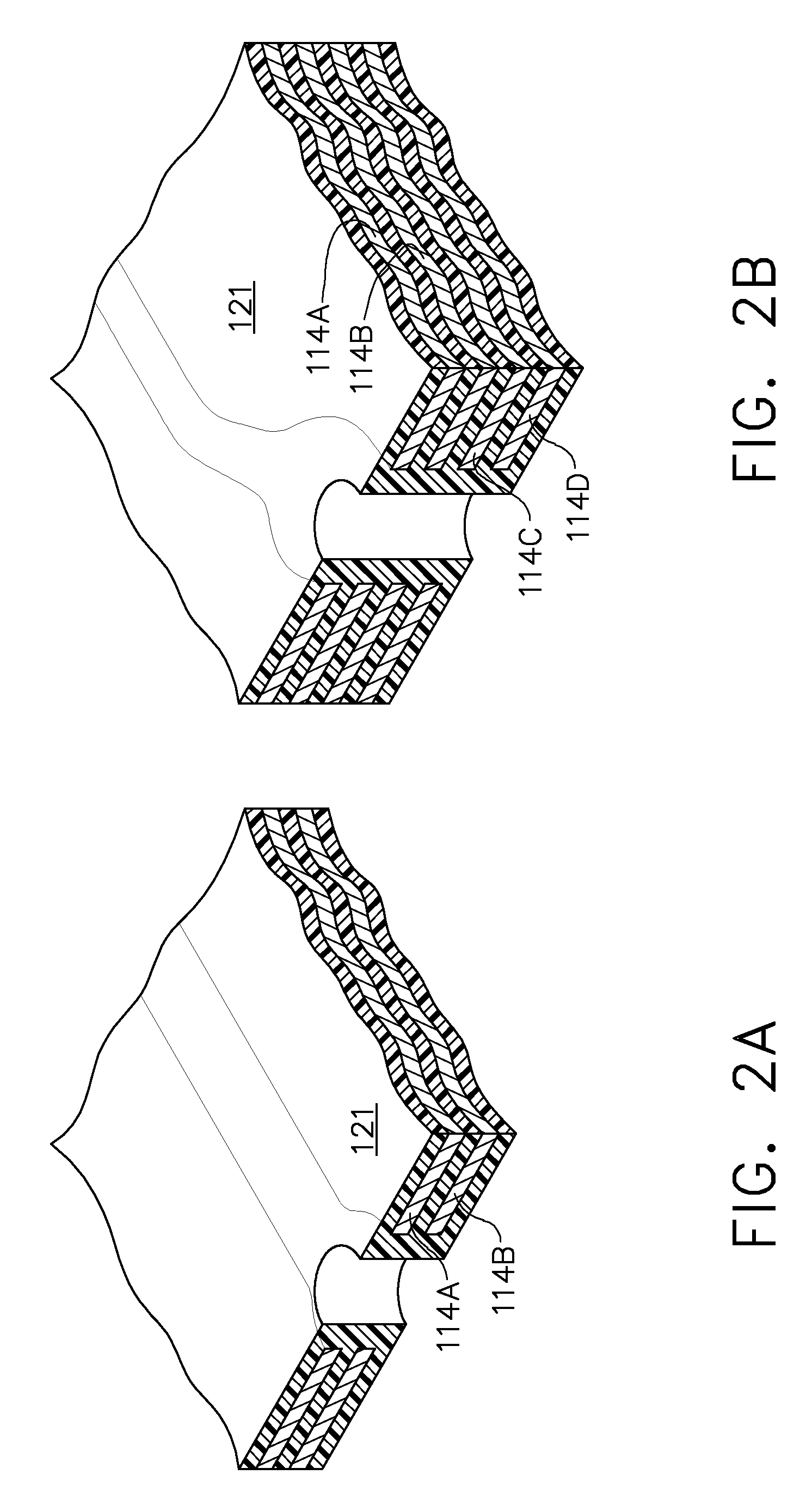

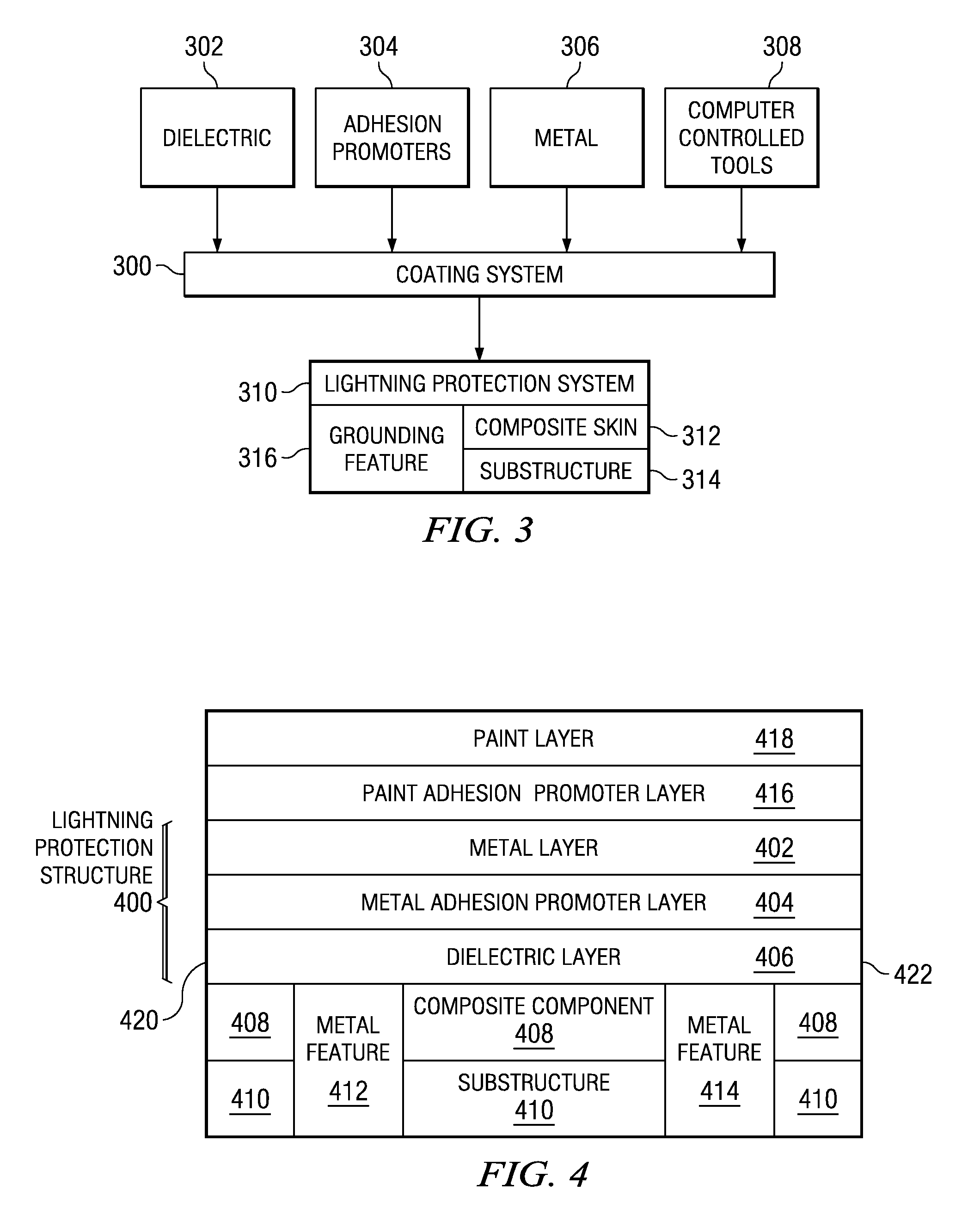

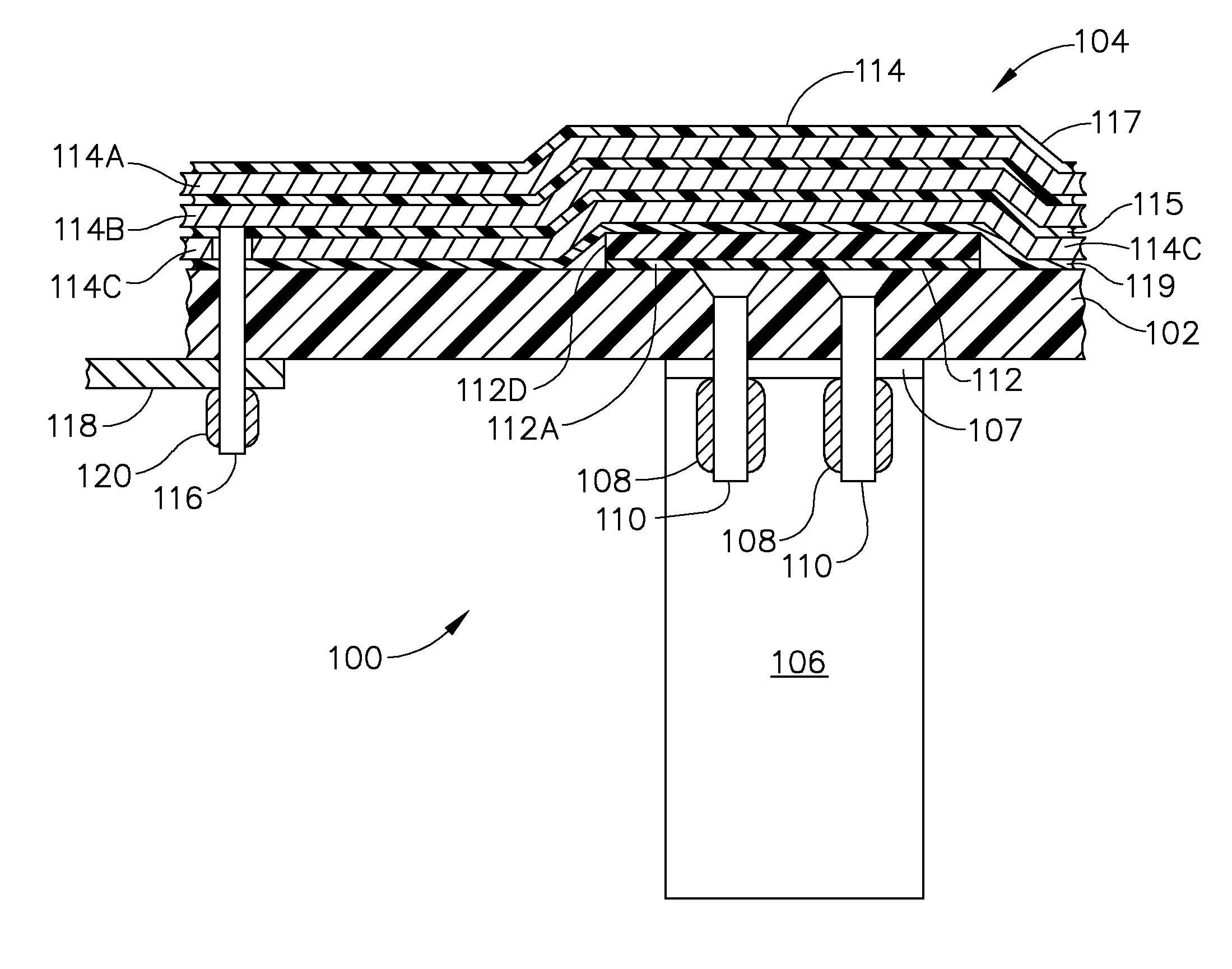

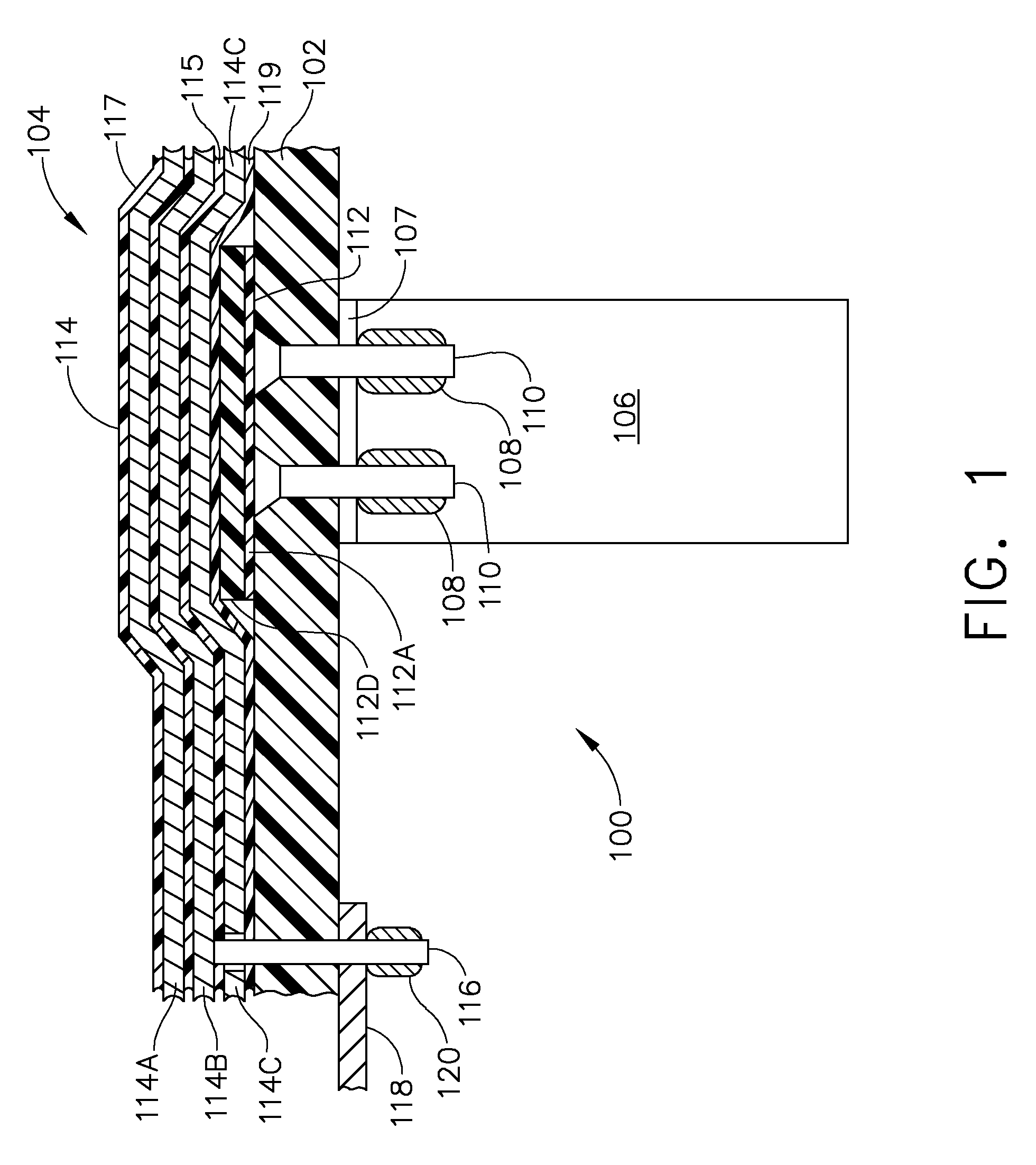

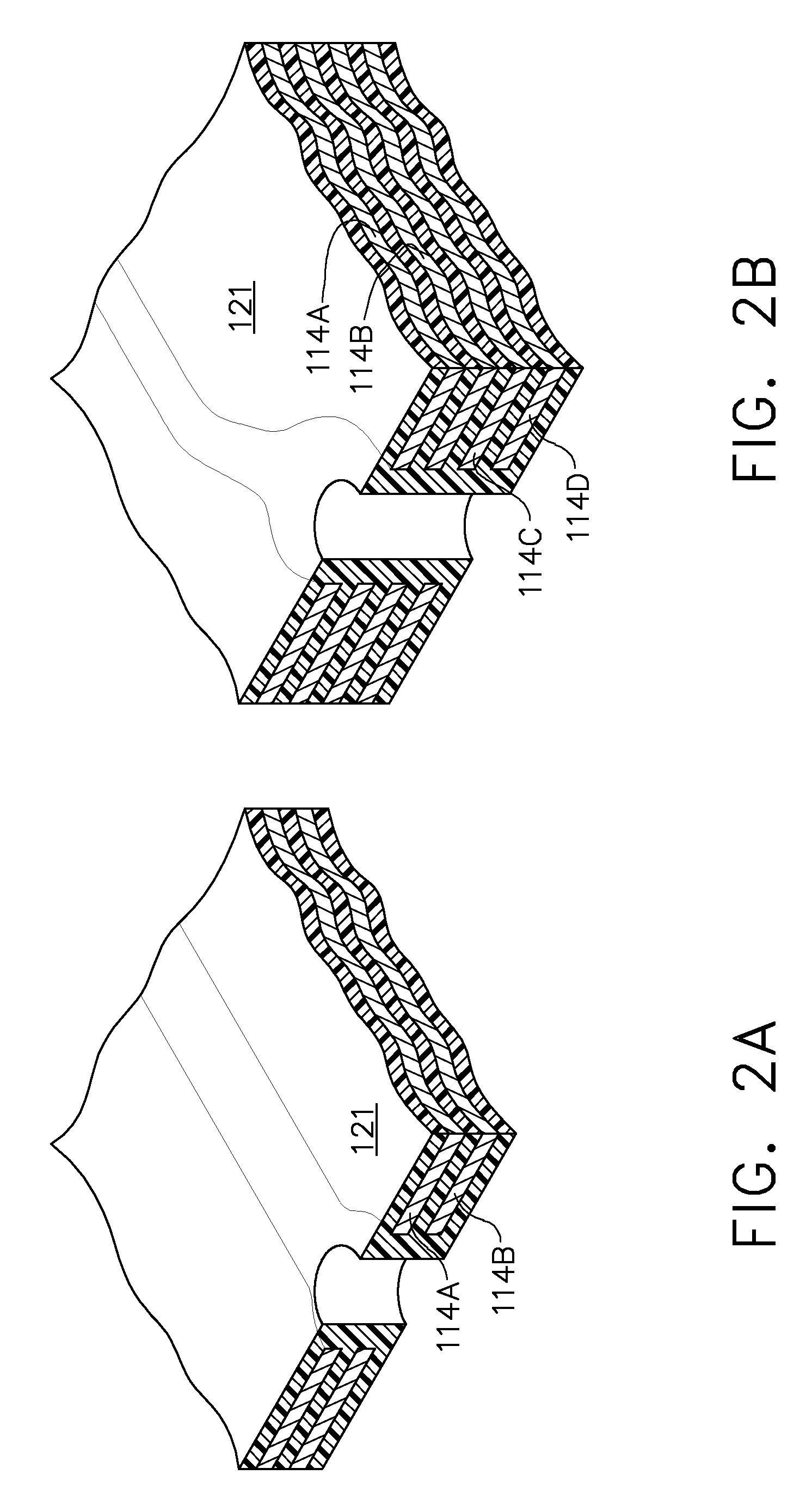

Flex circuit lightning protection applique system for skin fasteners in composite structures

A lightning protection appliqué incorporates a plurality of conductive plies adhesively affixed to a composite surface, at least a first one of the plies providing conductive characteristics sufficient to divert electrical energy from a lightning strike and at least a second one of the plies comprising operational circuitry. A dielectric ply is fixed to the composite surface over and completely covering at least one metal surface feature between the plurality of conductive plies and the composite surface.

Owner:THE BOEING CO

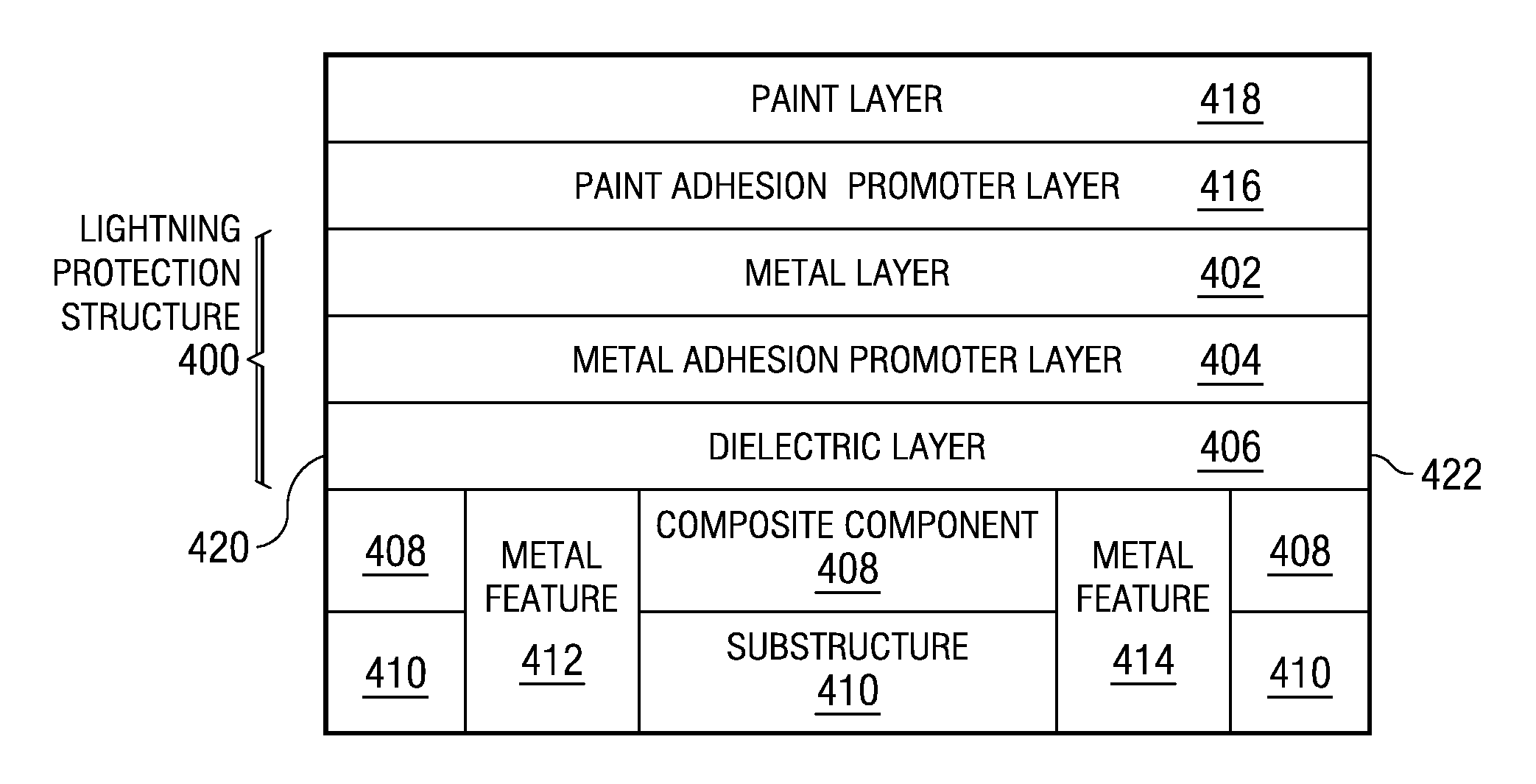

Method and apparatus for lightning protection of a composite structure

A method and apparatus for lighting protection. In one advantageous embodiment a method forms a lighting protection system on a composite surface of an aircraft. A dielectric coating is formed on the composite surface in which the dielectric coating covers a metal feature exposed on the composite surface. A metal adhesion promoter is applied in a pattern on the dielectric coating and over additional areas of the composite surface, including a grounding feature to form a metal adhesion promoter layer. A metal coating is formed on the metal adhesion promoter layer to create a path from an area including the metal feature to the grounding feature.

Owner:THE BOEING CO

Cold rolling manufacture method of copper and aluminum composite plate strips

InactiveCN102615102ADiffuse fullyFull responseAuxillary arrangementsMetal rolling arrangementsChemical reactionCopper

The invention discloses a cold rolling manufacture method of copper and aluminum composite plate strips. The cold rolling manufacture method comprises the following steps that: 1, a copper plate and an aluminum plate are subjected to homogenization annealing treatment; 2, surface treatment is carried out: firstly, the copper plate and the aluminum plate subjected to the homogenization annealing treatment are subjected to soaking degreasing, then, the copper plate and the aluminum plate subjected to the soaking degreasing are taken out for drying, and next, the composite surfaces to be rolled of the copper plate and the aluminum plate are ground by a stainless steel wire brush; 3, the copper plate and the aluminum plate are subjected to cold rolling compounding by a cold rolling mill, so copper and aluminum composite plate blanks are obtained; and 4, the copper and aluminum composite plate blanks subjected to the cold rolling are subjected to the diffusion annealing treatment. The cold rolling manufacture method has the advantages that through improving the cold rolling process operation and the process parameters, the copper plate and the aluminum plate are subjected to full diffusion and chemical reaction on the composite surfaces in the manufacture process, so the transition structure with excellent performance is obtained at the composite surfaces, and the bonding intensity of finished products is effectively improved.

Owner:HONGGUANG ELECTRIC GROUP CO LTD

Composite manufacturing method of ultra-thick steel plate

InactiveCN102240894AOvercome the problems existing in the production of extra-thick steel plates above 100mmThe internal quality of the product is goodSheet steelHydrogen

The invention relates to a composite manufacturing method of an ultra-thick steel plate, which adopts a method of high-temperature hydrogen reduction and hot rolling for producing an ultra-thick steel plate and belongs to the field of steel rolling in the metallurgical industry. The technical scheme is as follows: the composite manufacturing method sequentially comprises the following process steps: preparing a base material and a covering material; carrying out surface treatment on the base material and the covering material; carrying out welding and combined blanking on the side part of a composite surface; carrying out high-temperature hydrogen reduction; vacuumizing and sealing a composite cavity; heating and rolling; carrying out hot straightening; cooling and inspecting; and collecting and warehousing the finished product. The composite manufacturing method has the following benefits: the ultra-thick steel plate with the thickness of greater than 100mm can be manufactured by the composite manufacturing method, stratification and cracking can be avoided during shearing, drilling and other processing operations, the method overcomes the problems existing in the production of ultra-thick steel plates with the thickness of greater than 100mm in the background art, and the composite manufacturing method has the characteristics of good internal quality of the product, reasonable process steps, high efficiency, low investment, convenient operation process and the like.

Owner:HEBEI IRON & STEEL GRP

Tuyeres of blast furnace surface recombination coating and method for preparing the same

ActiveCN101492749AImprove thermal shock resistanceReasonable distribution of temperature fieldMolten spray coatingArc welding apparatusAlloyThermal shock

Owner:BAOSHAN IRON & STEEL CO LTD +1

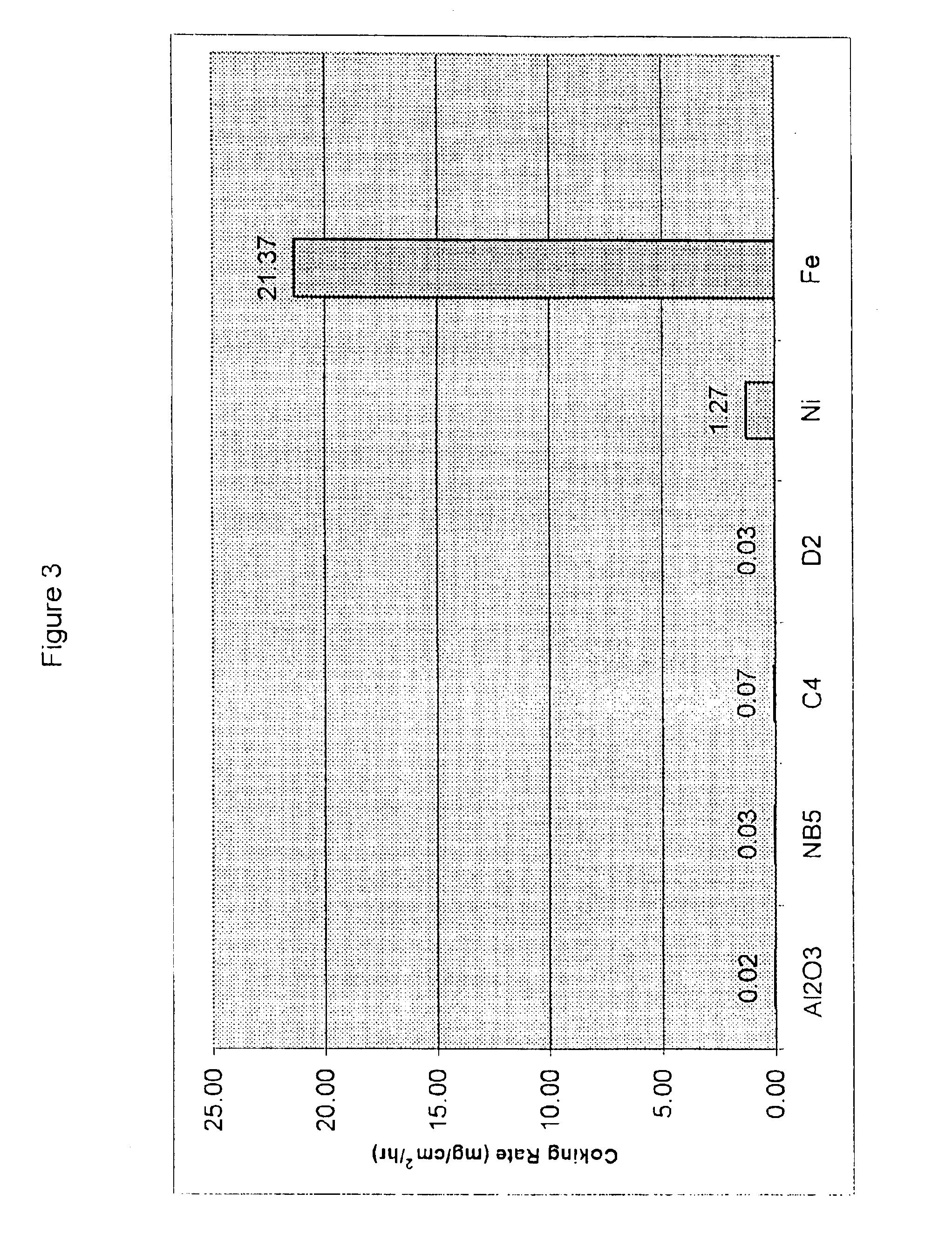

Composite surface on a stainless steel matrix

A composite surface having a thickness from 10 to 5,000 microns comprising a spinel of the formula MnxCr3−xO4 wherein x is from 0.5 to 2 and oxides of Mn, Si selected from the group consisting of MnO, MnSiO3, Mn2SiO4 and mixtures thereof which are not prone to coking and are suitable for hydrocarbyl reactions such as furnace tubes for cracking.

Owner:NOVA CHEM (INT) SA

Method of Lubricating an Aluminum Silicate Composite Surface with a Lubricant Comprising Ashless, Sulphur, Phosphorous Free Antiwear Agent

The present invention relates to a method of lubricating an aluminium-composite surface by supplying to the aluminium composite surface (typically an internal combustion engine aluminium surface) a lubricating composition comprising an oil of lubricating viscosity and an ashless antiwear agent.

Owner:THE LUBRIZOL CORP

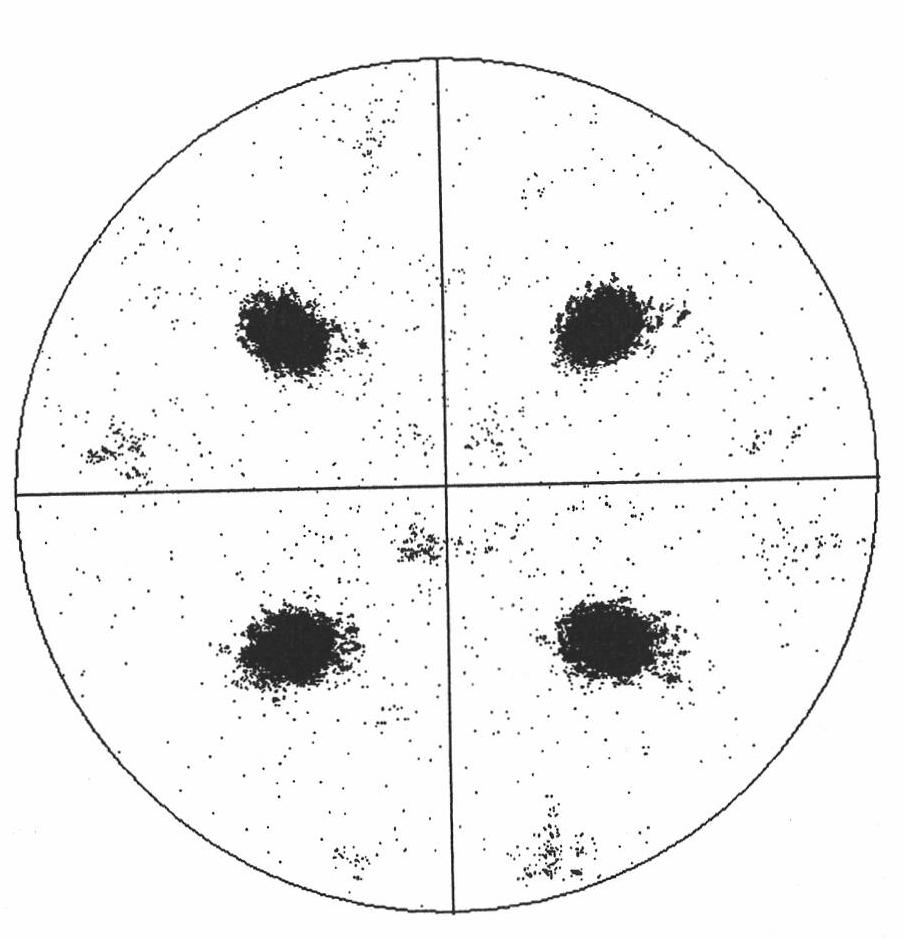

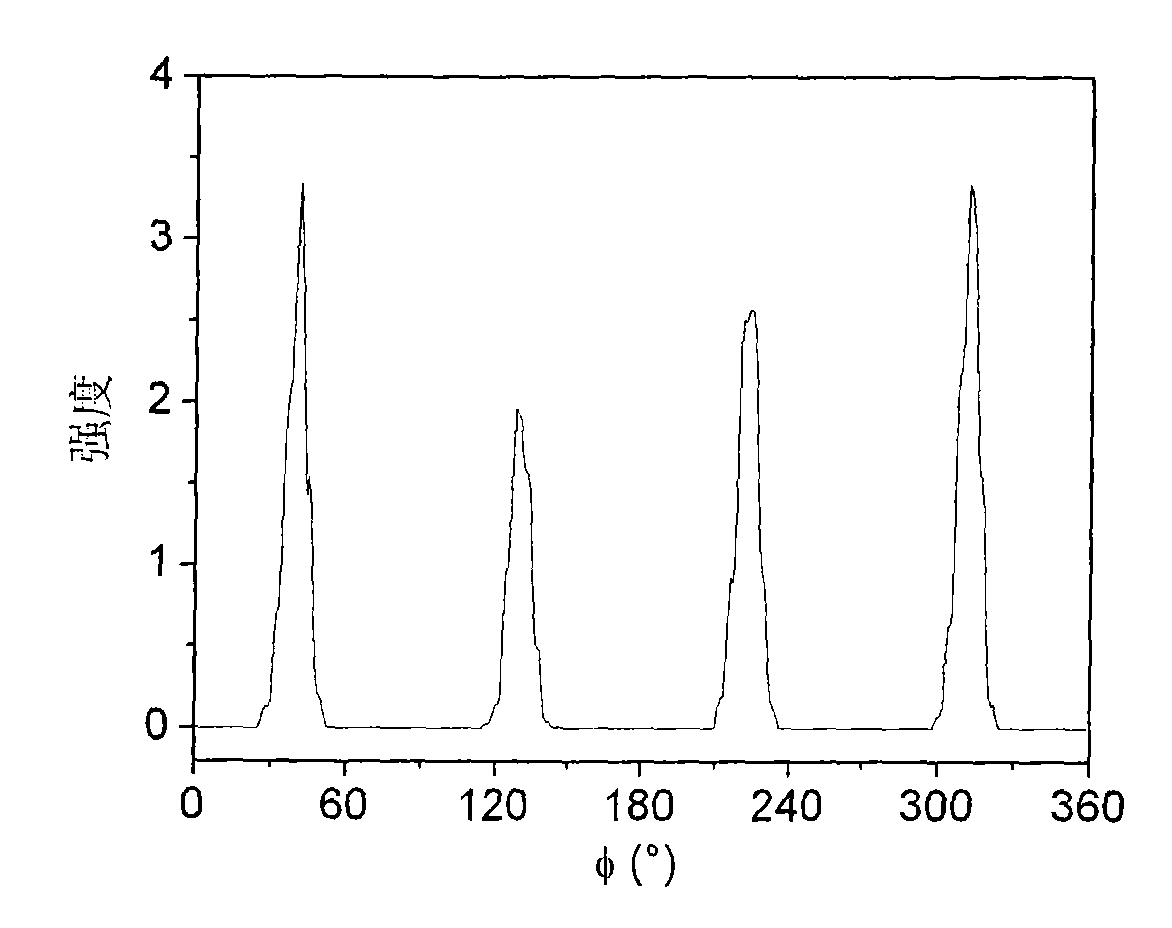

Non-magnetic cube texture Cu-based alloy composite base band and preparation method thereof

InactiveCN101786352AHigh mechanical strengthNo Magnetic GuaranteeMetal rolling arrangementsMetal layered productsSurface layerMold filling

The invention discloses a non-magnetic cube texture Cu-based alloy composite base band. The non-magnetic cube texture Cu-based alloy composite base band is prepared by compositing surface layers and a core layer and has the structure of surface layer, core layer and surface layer, wherein each surface layer is copper-nickel alloy in which the weight percentage of nickel is less than 50 percent; and the core layer is nickel-tungsten alloy in which the atomic percentage of tungsten is between 9 and 12 percent. A preparation method by using powder metallurgy comprises the following steps: (1) initial powder mixing and mold filling; (2) compressing and sintering of a composite green compact; (3) deforming and rolling of the sintered composite bullet; and (4) recrystallizing heat treatment for a cold rolling base band. The preparation method improves the mechanical strength of the whole base band and simultaneously ensures the non-magnetic performance of the whole base band; and the composite base band has high yield strength.

Owner:BEIJING UNIV OF TECH

Synthetic method of anti-compression and anti-bacterial super absorbent polymer for physiology

The invention relates to a super absorbent polymer for physiology, in particular to an anti-compression and anti-bacterial super absorbent polymer still with high water absorbency under compression and with natural anti-bacterial property. The super absorbent polymer adopts the following technical scheme: taking polyvinyl alcohol with the polymer long chain rich in hydroxy as the interpenetrating polymer network (IPN), carboxymethyl chitosan with bioactivity and natural antibacterial property as the graft polymer and acrylate as the main comonomer, being combined with a cross-linking agent with molecular chains different in length, adopting the three-stage complex initiation system and realizing interpenetrating of polyvinyl alcohol and grafting of carboxymethyl chitosan by way of aqueous solution radical copolymerization to prepare the super absorbent resins with regular granularity, uniform crosslinking and less residual monomers. The invention develops multi-component composite surface treatment solution to carry out surface treatment on the super absorbent resins, thus further reducing the residual monomers, forming gradient crosslinking on the surfaces of the super absorbent resins and finally preparing the anti-compression and anti-bacterial super absorbent polymer for physiology. The super absorbent polymer is white without yellow spots, has regular granularity, inadherent surface, good liquidity, high absorption rate and absorption, excellent filtration property and less residual monomers and is against compression and tolerant to salt and free of gel plugging.

Owner:NANTONG KEYI CHEM

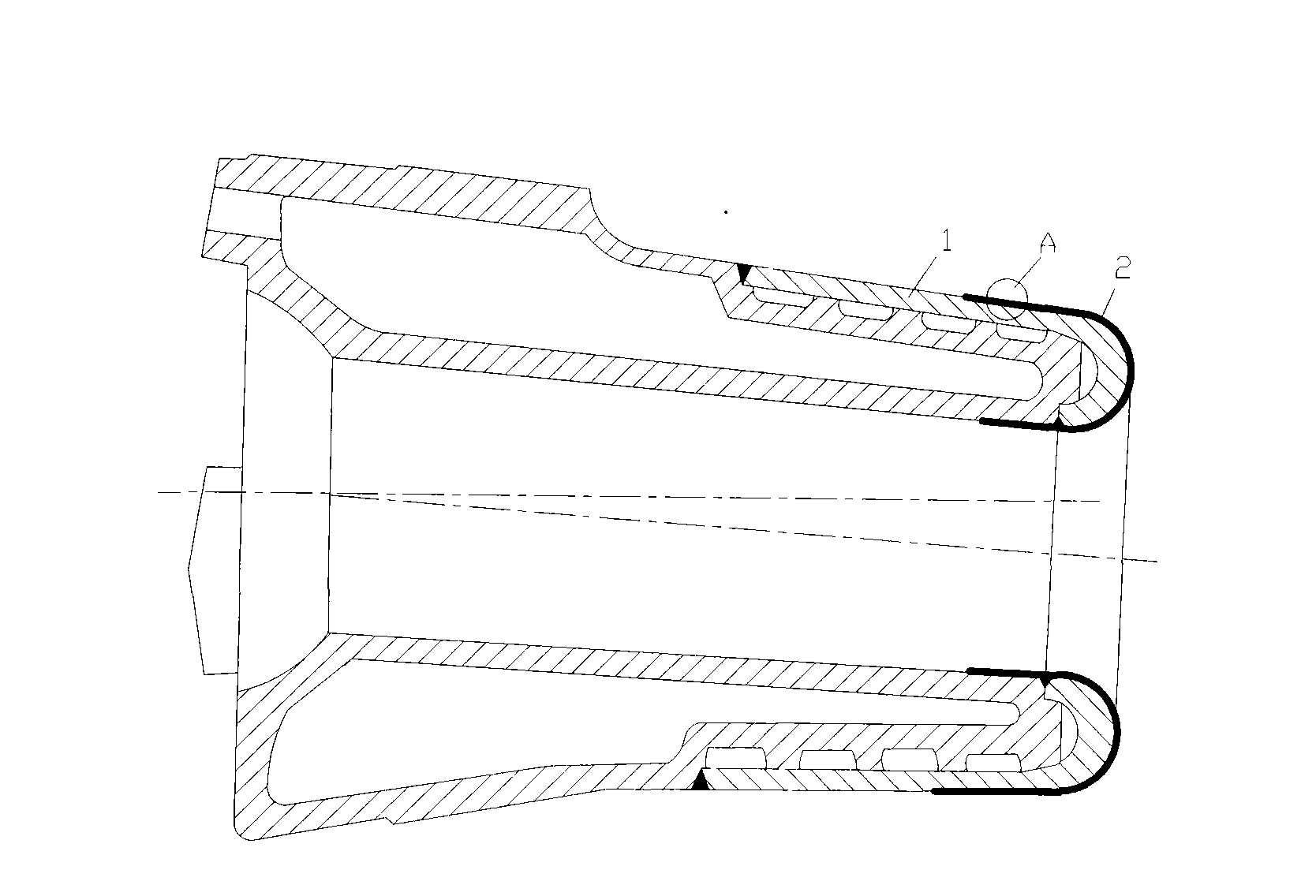

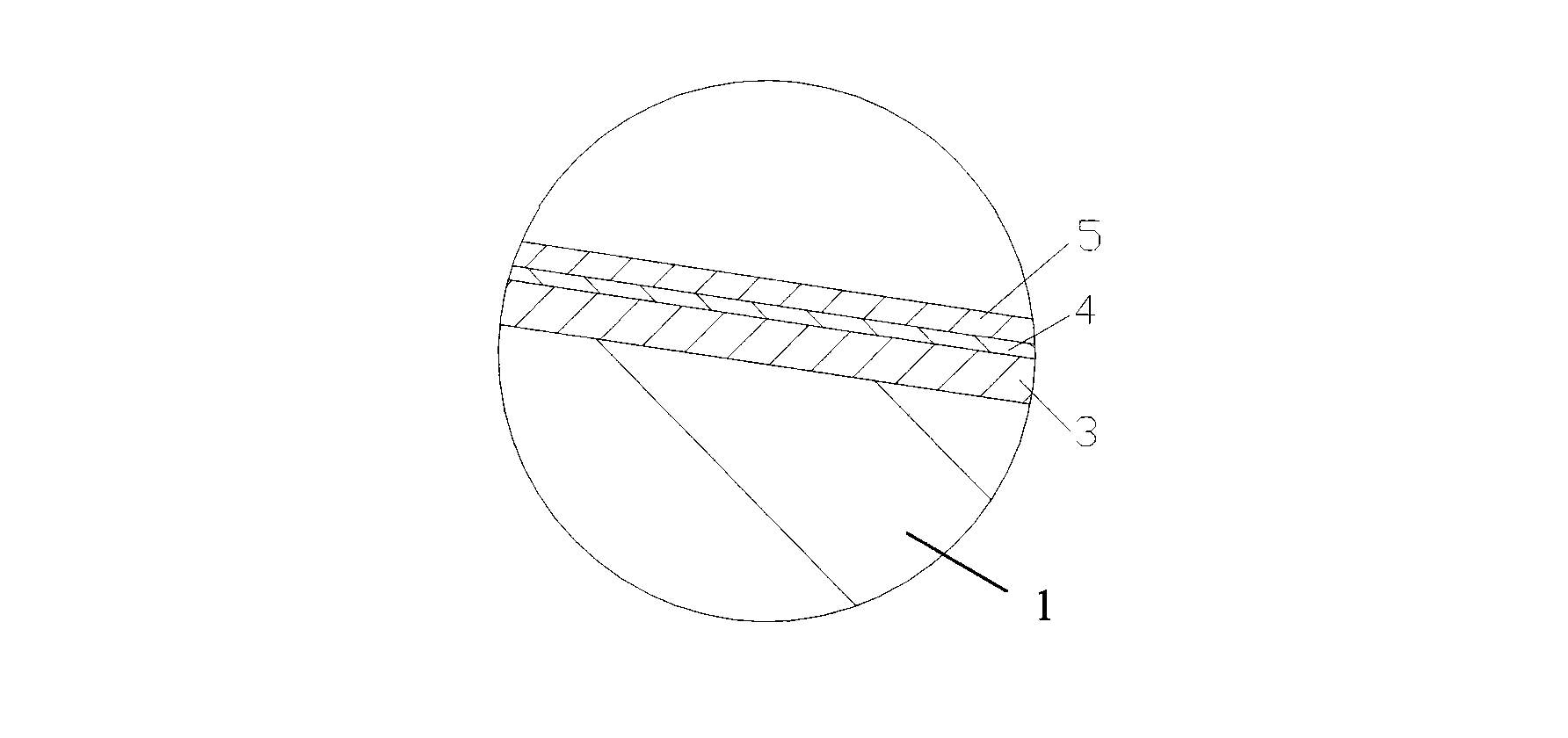

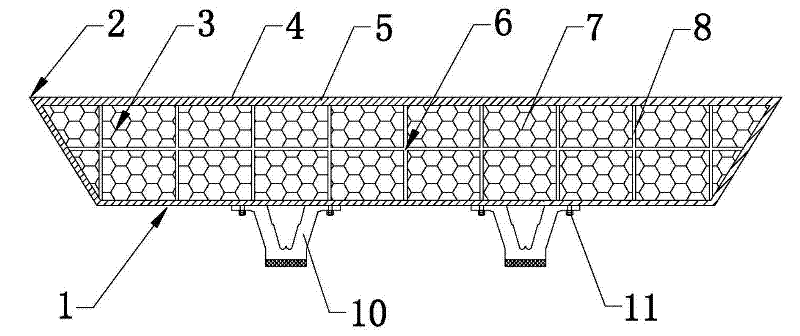

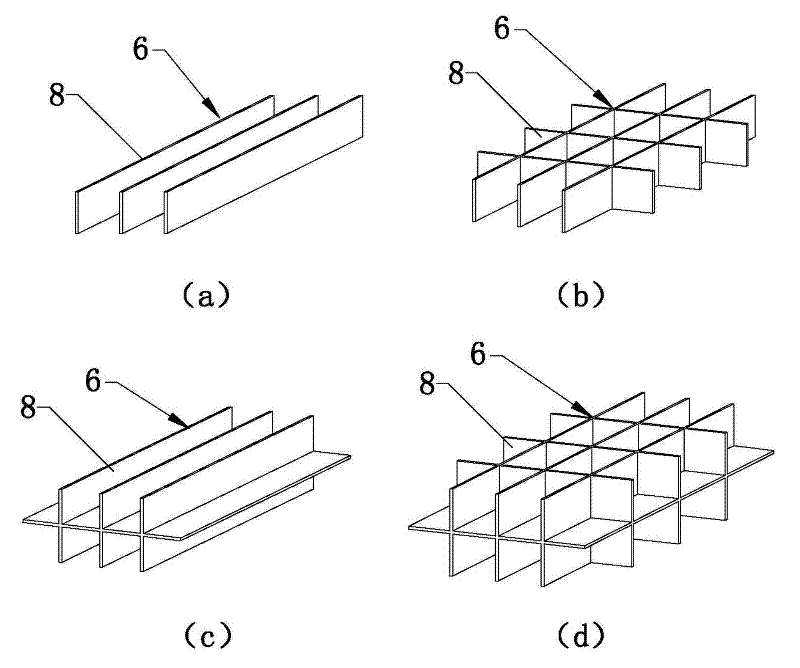

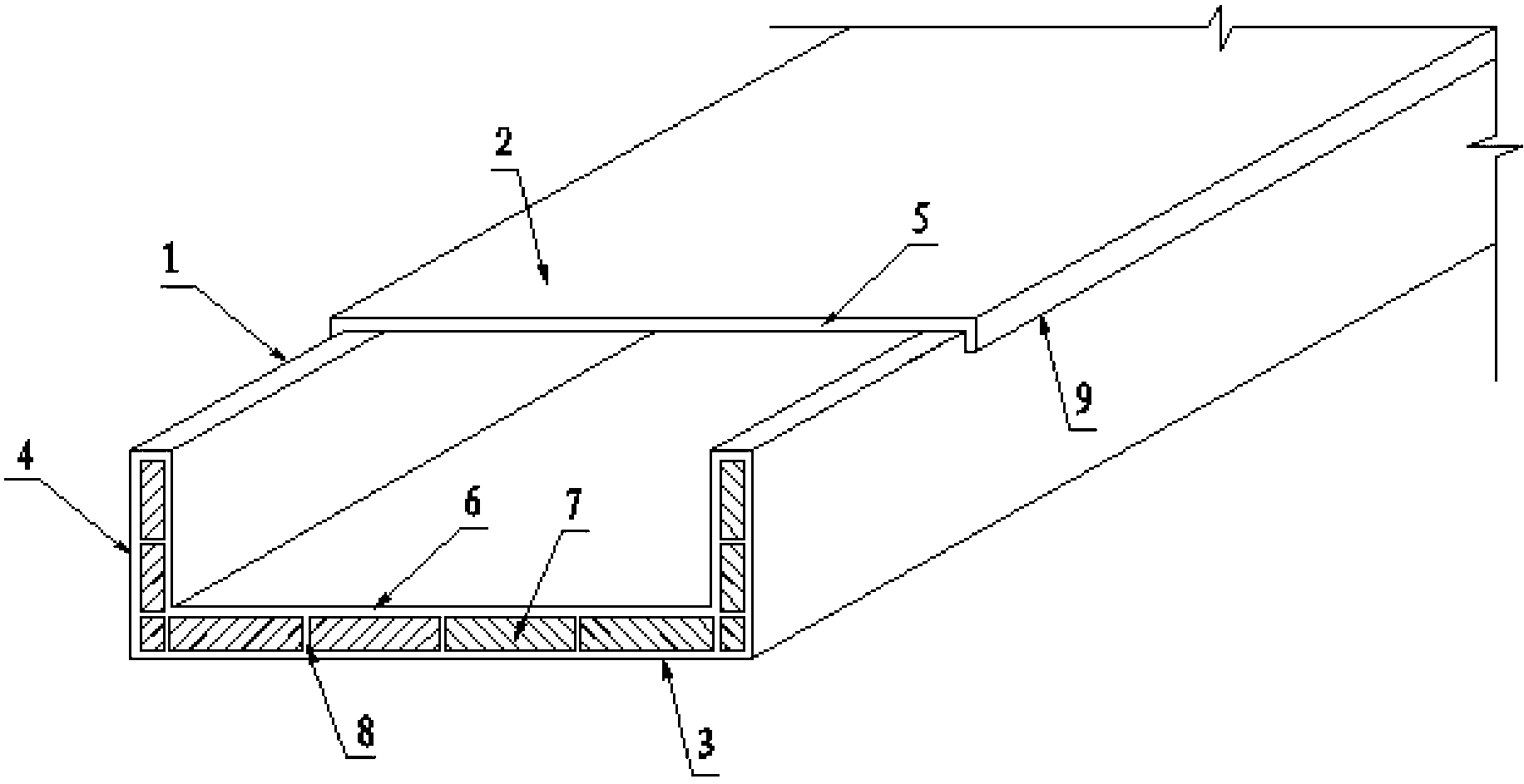

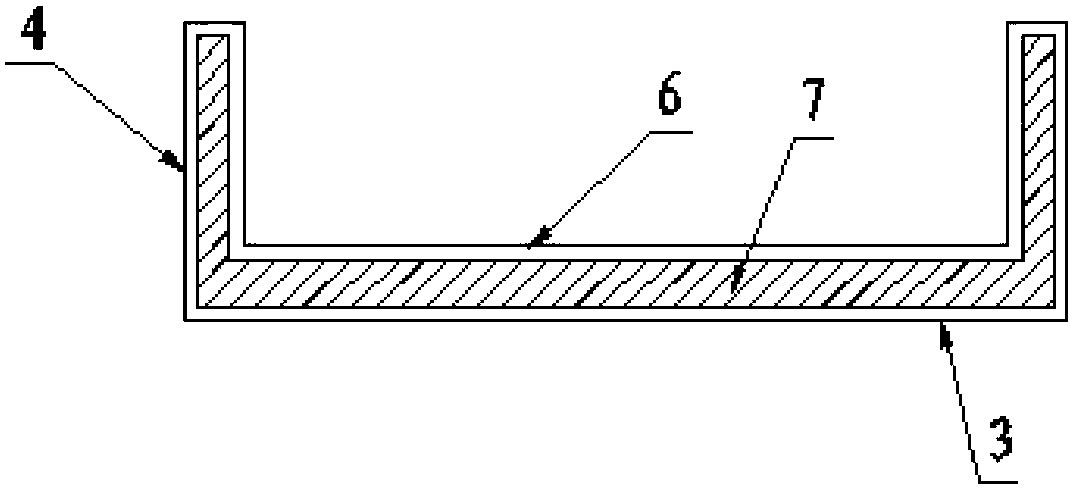

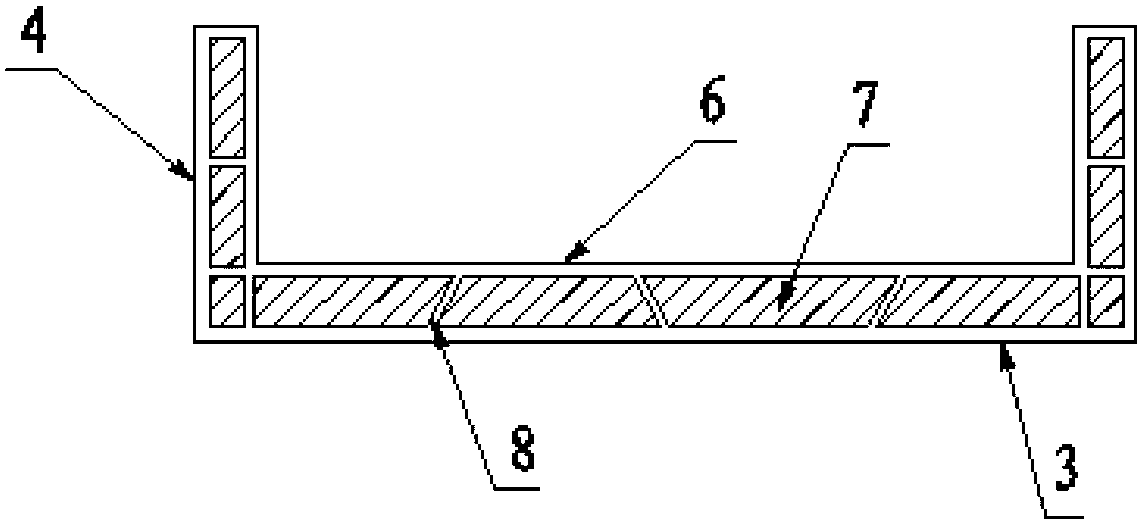

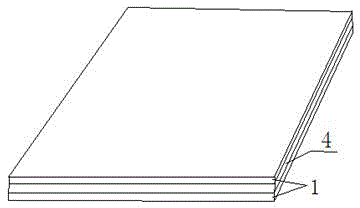

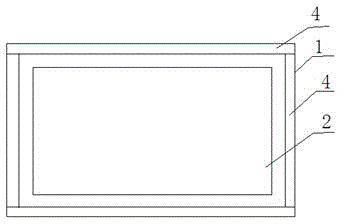

Buffering energy-absorbing web reinforced composite anti-collision device

InactiveCN102561230AEasy to replace if damagedIncreased shear strengthClimate change adaptationShipping equipmentFiberFilling materials

The invention discloses a buffering energy-absorbing web reinforced composite anti-collision device. The device comprises an anti-collision unit (1); the anti-collision unit (1) comprises a shell (2) and a filling material body (3) positioned in the shell (2); the shell (2) is a solid shell consisting of a composite surface layer (4) or a sandwiched shell consisting of a composite surface layer (4) in which a sandwich material (5) is filled and the sandwich material (5); and the filling material body (3) comprises a spatial lattice body (6) and a dissipative material (7), the spatial lattice body (6) is formed by arranging fiber webs (8) in the shell (2) in a single-layer unidirectional, single-layer bidirectional, multi-layer unidirectional or multi-layer multi-directional mode, and the dissipative material (7) is positioned between the fiber webs (8) and / or the fiber webs (8) and the inner wall of the shell (2). The anti-collision device has the characteristics of low cost, strong anti-collision property and long service life, and is easy to assemble and replace and suitable for popularization and use.

Owner:NANJING UNIV OF TECH +1

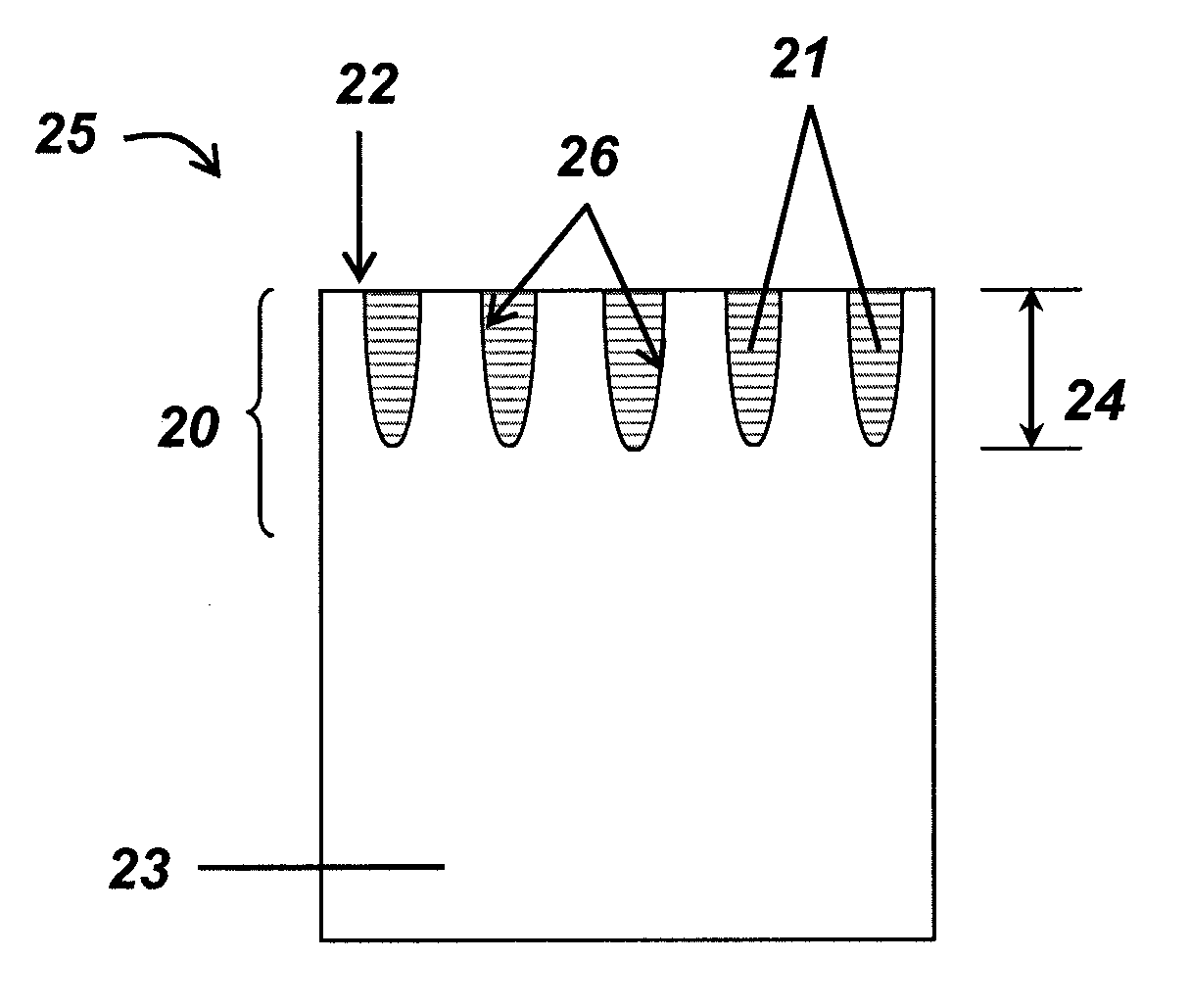

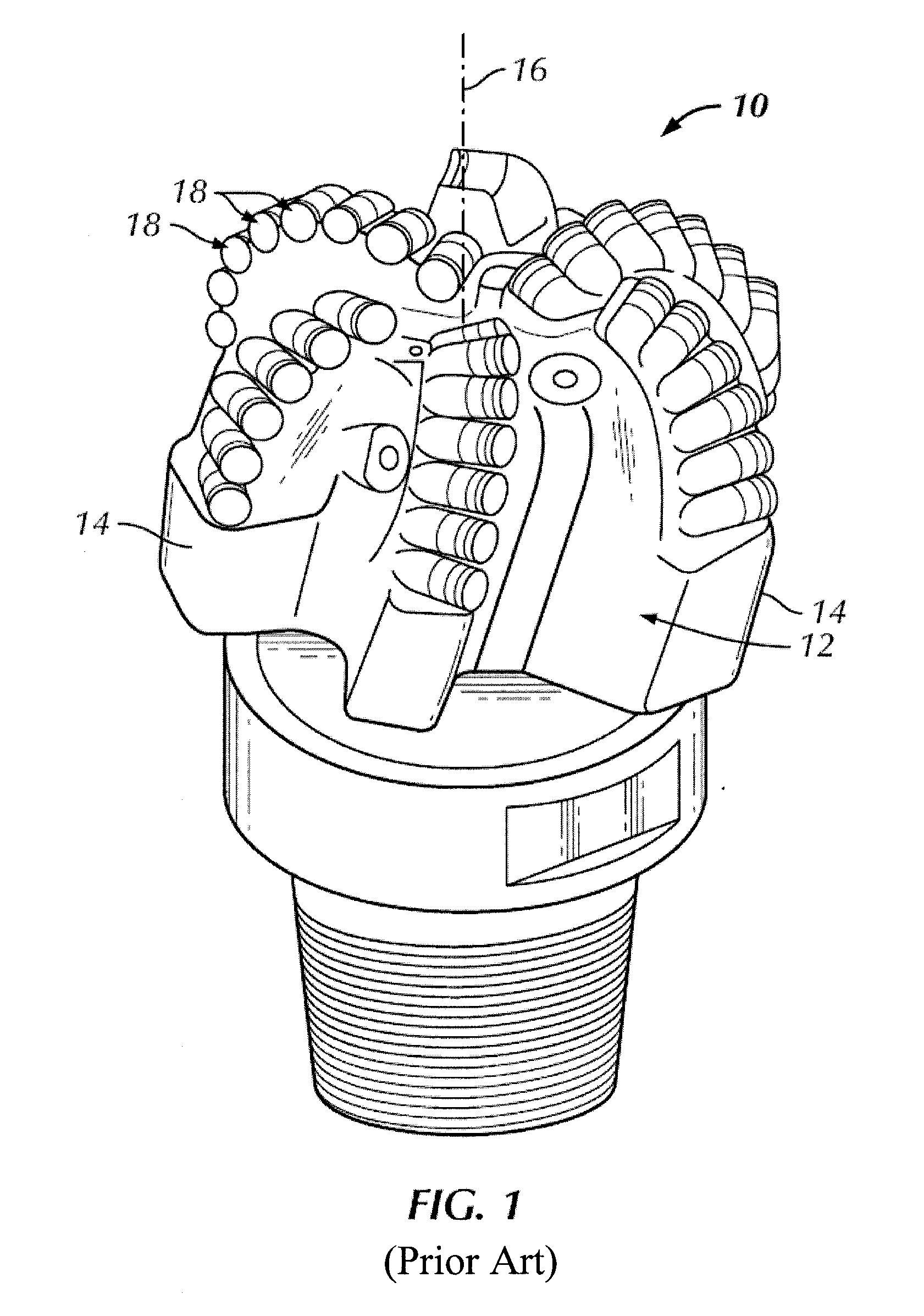

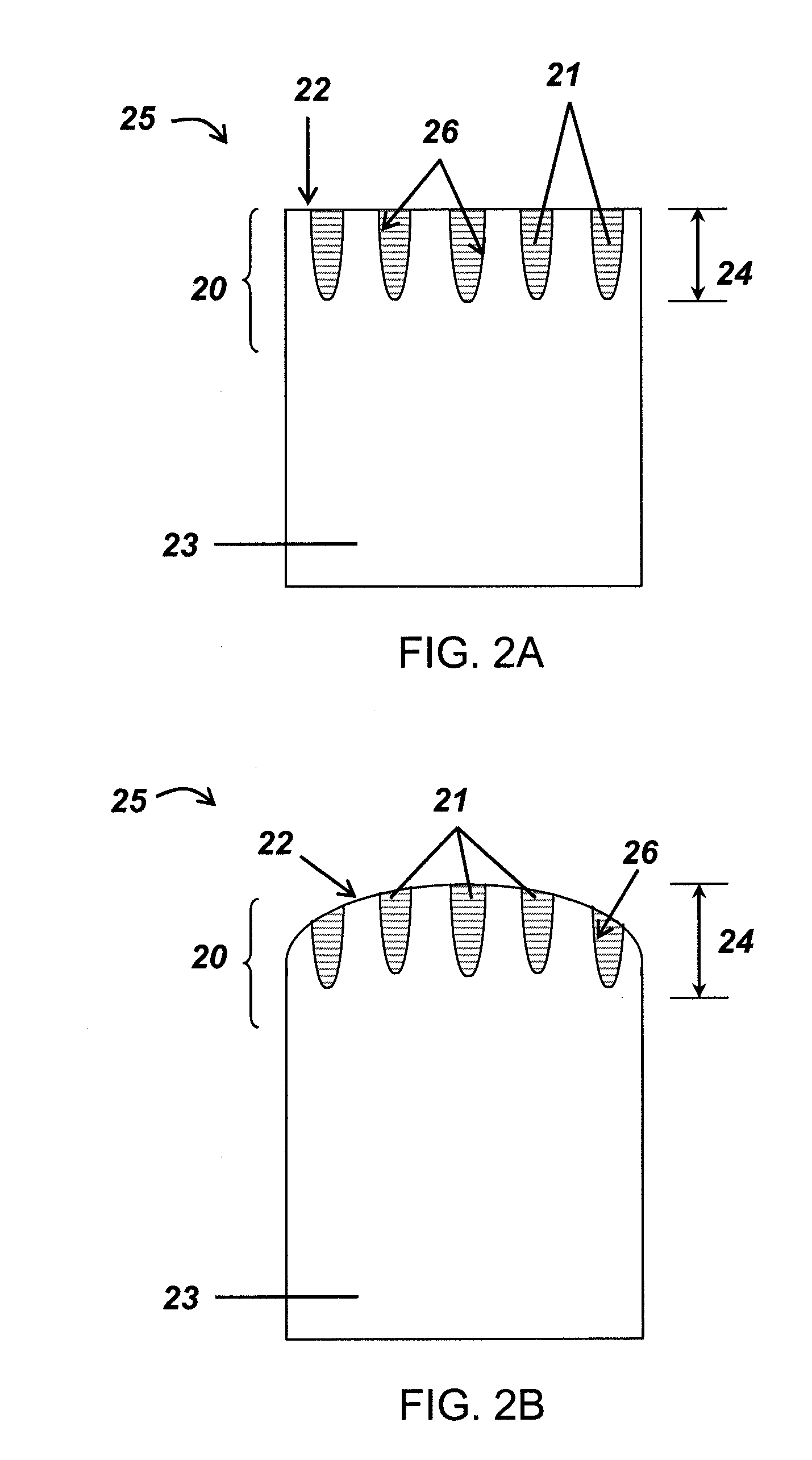

Composite cutter substrate to mitigate residual stress

A method of forming a cutting element that includes filling at least one non-planar region on an upper surface of a carbide substrate with a diamond mixture, subjecting the substrate and the diamond mixture to high pressure high temperature sintering conditions to form a reduced-CTE substrate having polycrystalline diamond that extends a depth into the reduced-CTE substrate in an interface region, and an upper surface made of a composite surface of diamond and carbide, and attaching a polycrystalline diamond body to the composite surface of the reduced-CTE substrate is disclosed.

Owner:SMITH INT INC

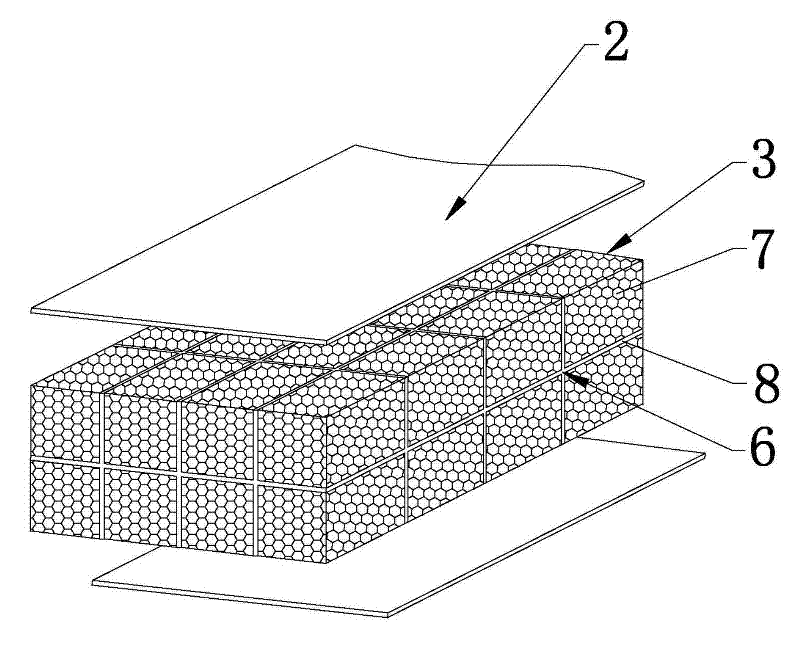

Composite sandwich structure cable bridge

InactiveCN103244753AIncrease stiffnessImprove bearing capacityPipe supportsElectrical apparatusEngineeringHigh load

The invention discloses a composite sandwich structure cable bridge which is convenient to popularize and simple and convenient to construct, can effectively improve rigidity and can realize high load bearing capacity and large span. The composite sandwich structure cable bridge comprises a trough type unit and a cover plate unit, the trough type unit comprises side plates and a bottom plate, the side plate and bottom plate structure comprises one or combination of a solid shell comprising a composite surface layer, a sandwich solid body comprising a composite surface layer and sandwich materials, a sandwich solid body comprising a composite surface layer and a lattice web plate and a sandwich solid body comprising a composite surface layer, sandwich materials and a lattice web plate, and each of the side plates and the bottom plate is provided with at most one solid shell structure comprising the composite surface layer. The composite sandwich structure cable bridge can be arranged on large communication and power transmission lines of subways, bridges and the like.

Owner:NANJING UNIV OF TECH

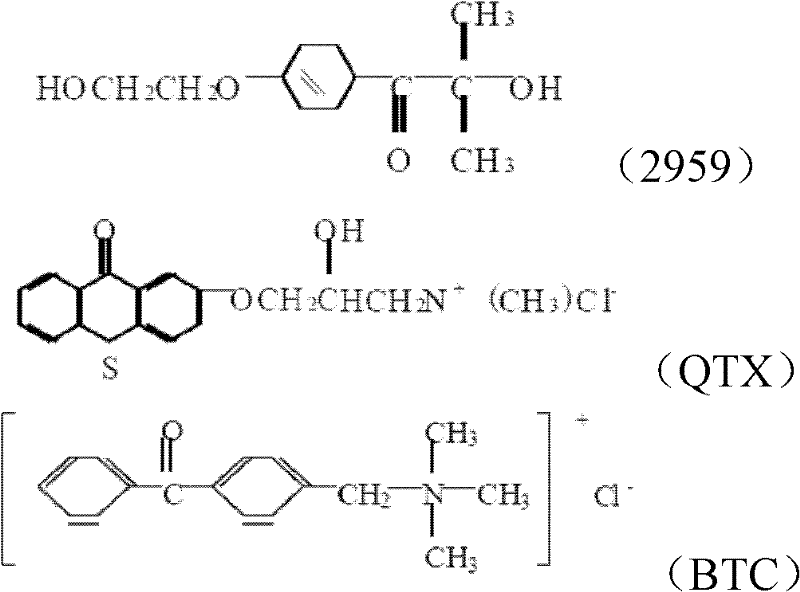

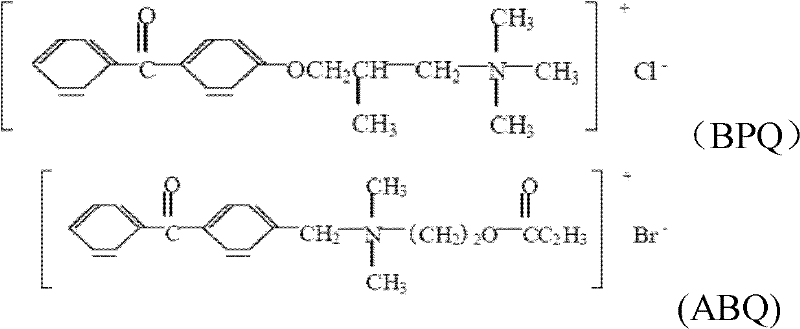

Aqueous UV (ultraviolet) printing ink dispersed by utilizing vermiculate micelle system and preparation method thereof

The invention relates to an aqueous UV (ultraviolet) printing ink dispersed by utilizing a vermiculate micelle system and a preparation method thereof. According to the preparation method, a vermiculate micelle phase is formed in an aqueous solution by using a composite surfactant composed of a polymerizable type cationic surfactant and organic acids / organic salts, and various printing ink components (solid pigment, an aqueous ultraviolet light initiator, and various functional additives and a small amount of monomers) are encapsulated in the vermiculate micelle phase; and the aqueous UV printing ink with viscoelasticity is prepared by the steps of ultrasonic dispersion, centrifugal filtration and the like. According to the invention, an organic solvent is prevented from being used, so that the aqueous printing ink is environmentally-friendly; the aqueous printing ink has UV initiating activity, can be rapidly crosslinked and solidified on the surface of a printing stock, and embodiesgood water tolerance and abrasive resistance; and the vermiculate micelle in the system endows the printing ink with changeable fluid properties at different temperatures, and enables the printing ink to have better leveling property at high temperature and higher adhesion at low temperature, thus the aqueous printing ink is suitable for high-speed printing on various printing stocks such as plastic, metal and the like and has excellent gloss and color reproducibility.

Owner:中国印刷科学技术研究所 +1

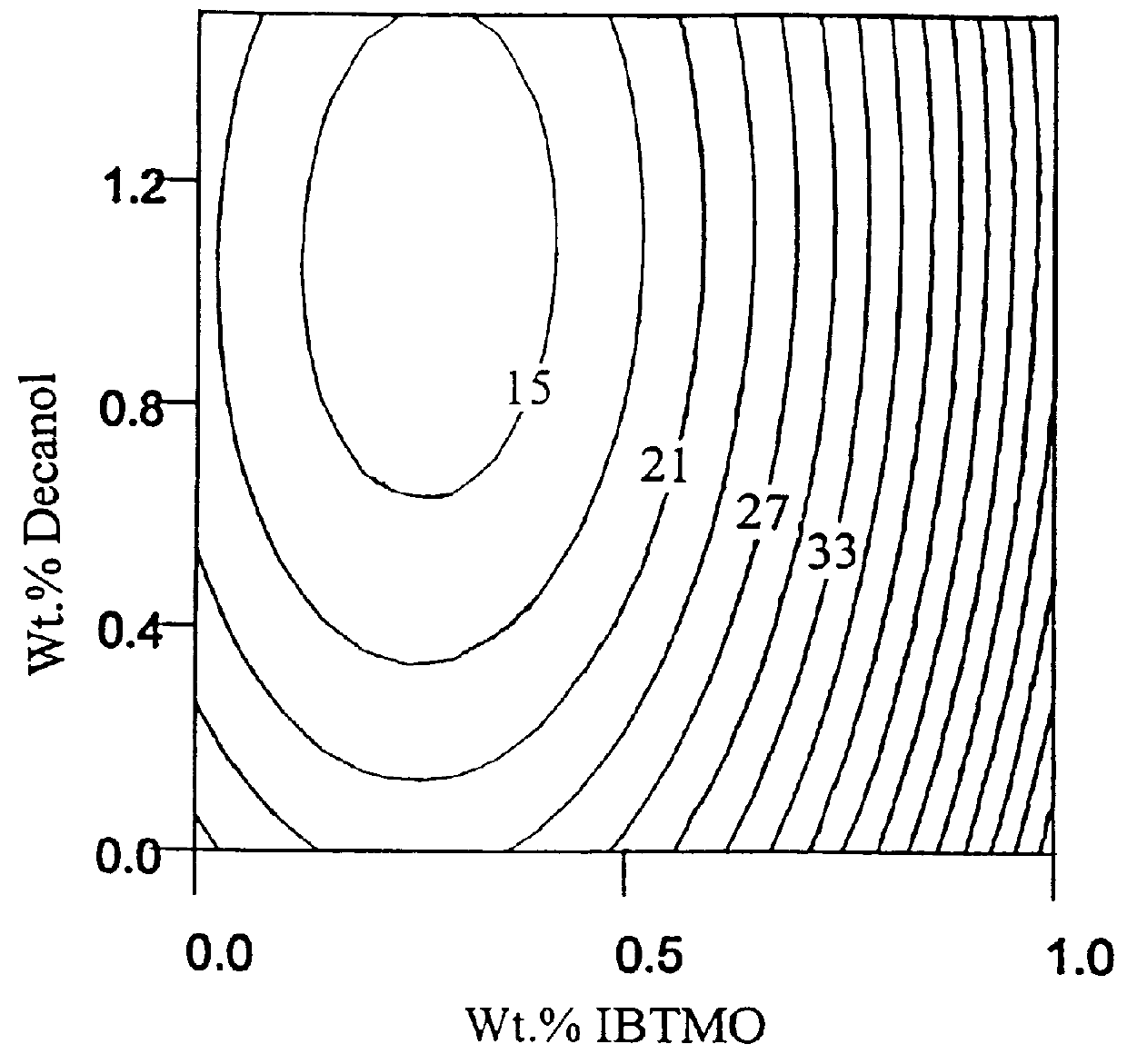

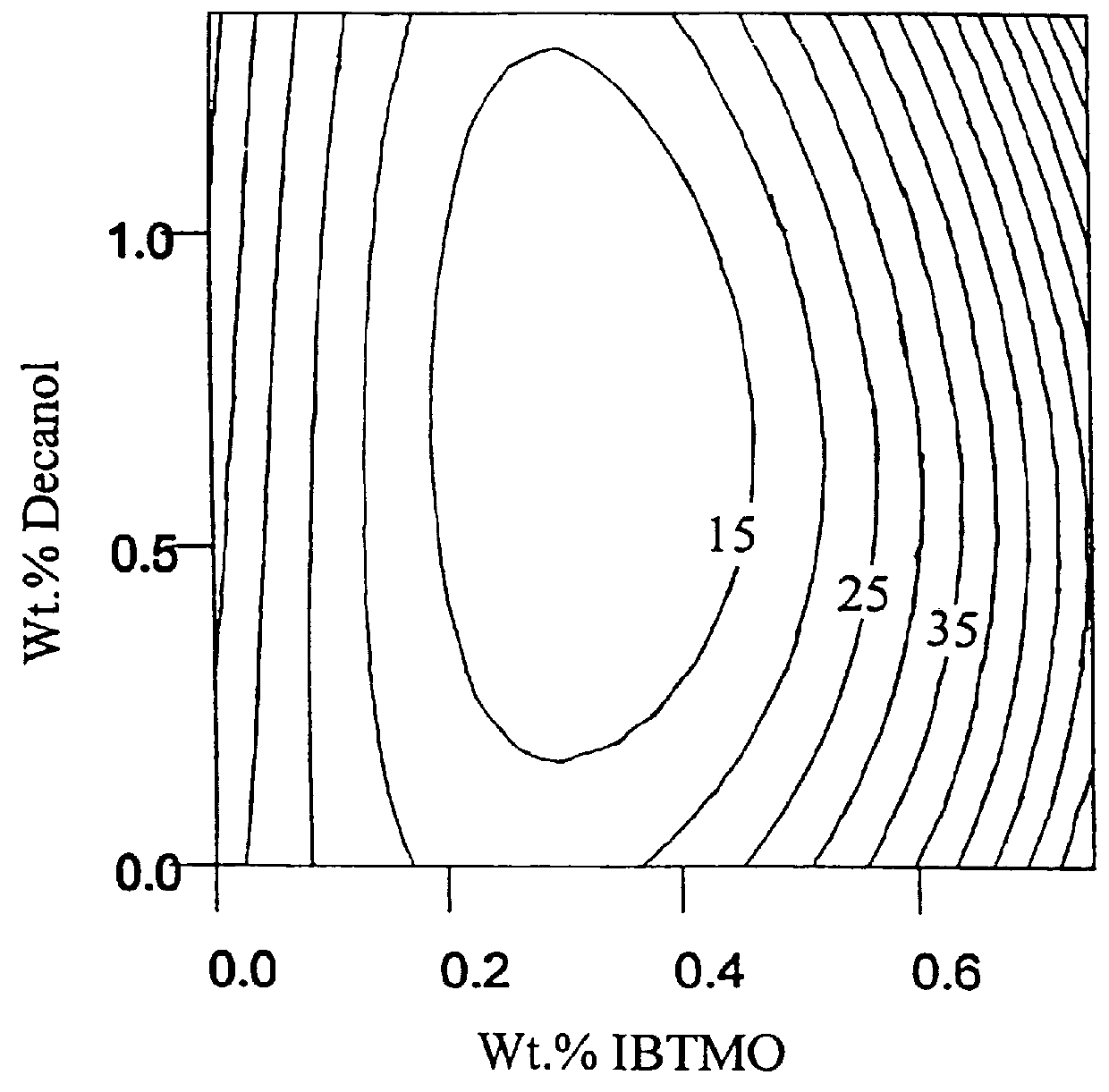

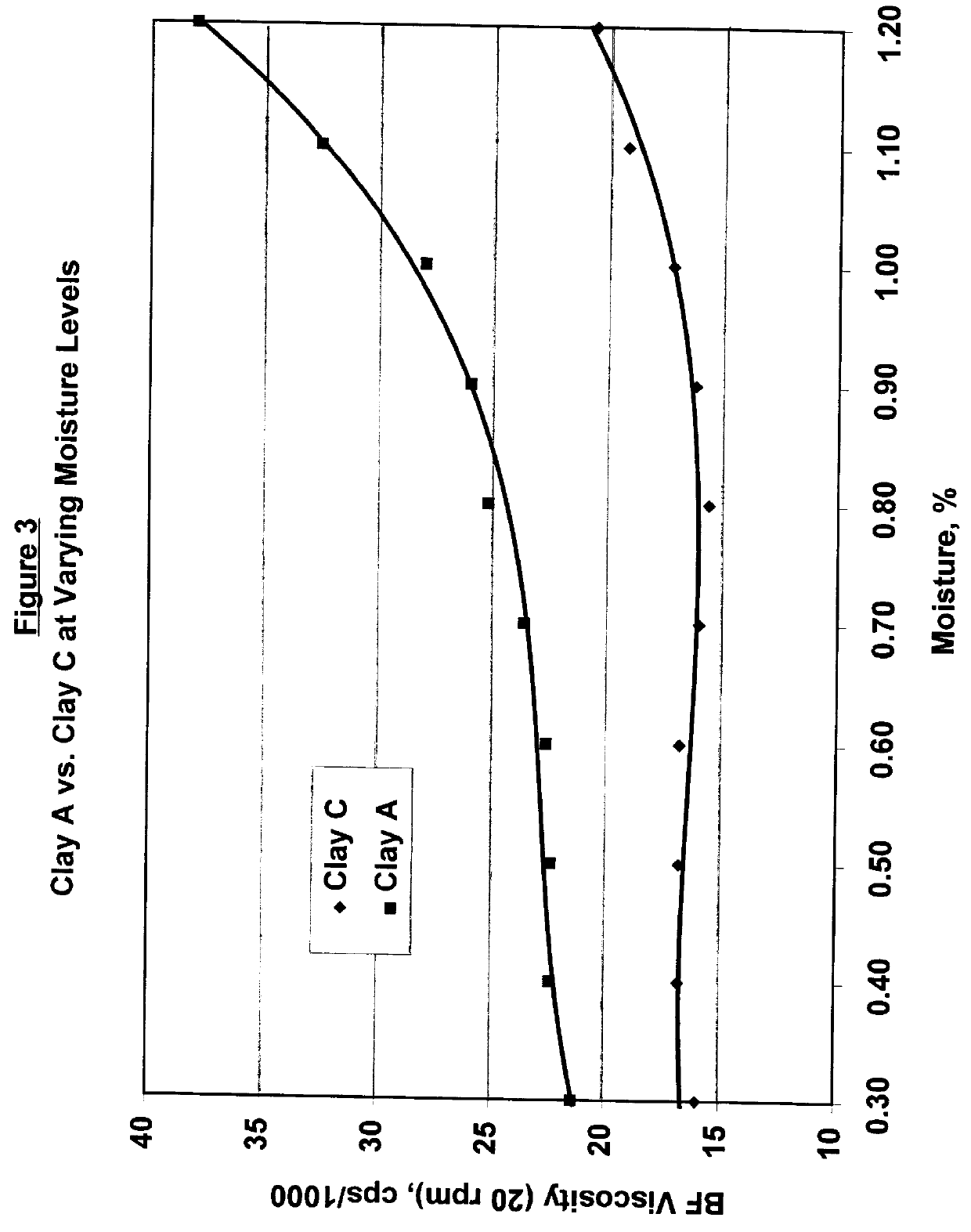

Modified mineral filler for thermosets

InactiveUS6011087APaste viscosityReduction in paste viscosityOther chemical processesMicaSilanesKaolin clay

Modified mineral fillers, derived from either a coarse particle kaolin clay or a coarse particle ATH, having excellent utility in thermoset polymers as low paste viscosity fillers are disclosed. The method of treatment involves the use of specific weight ratio combinations of a silane and a long chain aliphatic alcohol. The treatment of clay can also involve the auxiliary use of a surfactant in small amounts, which is utilized to emulsify the silane and aliphatic alcohol treatment components in water either individually or as a co-emulsion blend prior to their addition to the clay. The surfactant, which is preferably a nonionic surfactant having a HLB value of 12-18, aides in uniformly treating all the clay particle surfaces with the silane / alcohol treatment combination. Coarse particle clays having general utility in the invention are those having an average Stokes equivalent particle diameter of at least 3.0 microns, while the coarse particle ATH fillers having general utility in the invention are those having a BET surface area value less than 5.0 m2 / g. Clays or ATH so treated with the inventive silane / alcohol treatment provide unique viscosity reduction benefits in thermoset polymers unattainable by using either treatment additive alone in any amount. This low viscosity characteristic allows the treated mineral products to be used at high loadings in various thermoset compounds, as fillers or extenders, which is advantageous in terms of reducing cost and / or gaining certain performance properties, such as physical reinforcement, composite surface smoothness or flame retardancy.

Owner:J M HUBER CORP

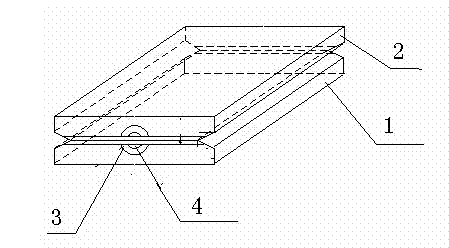

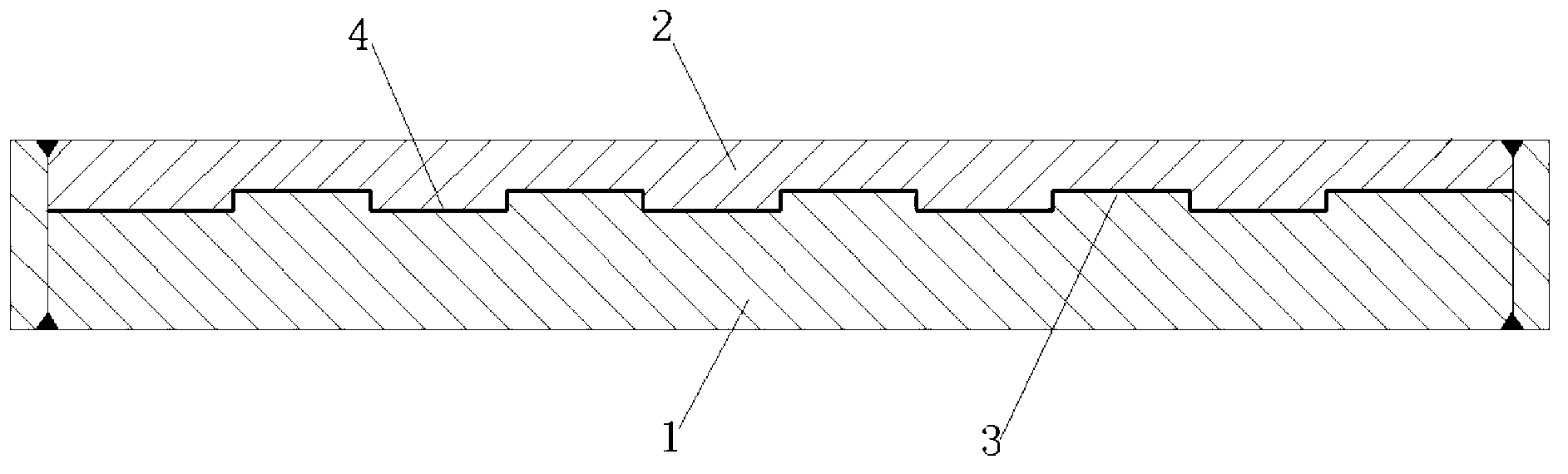

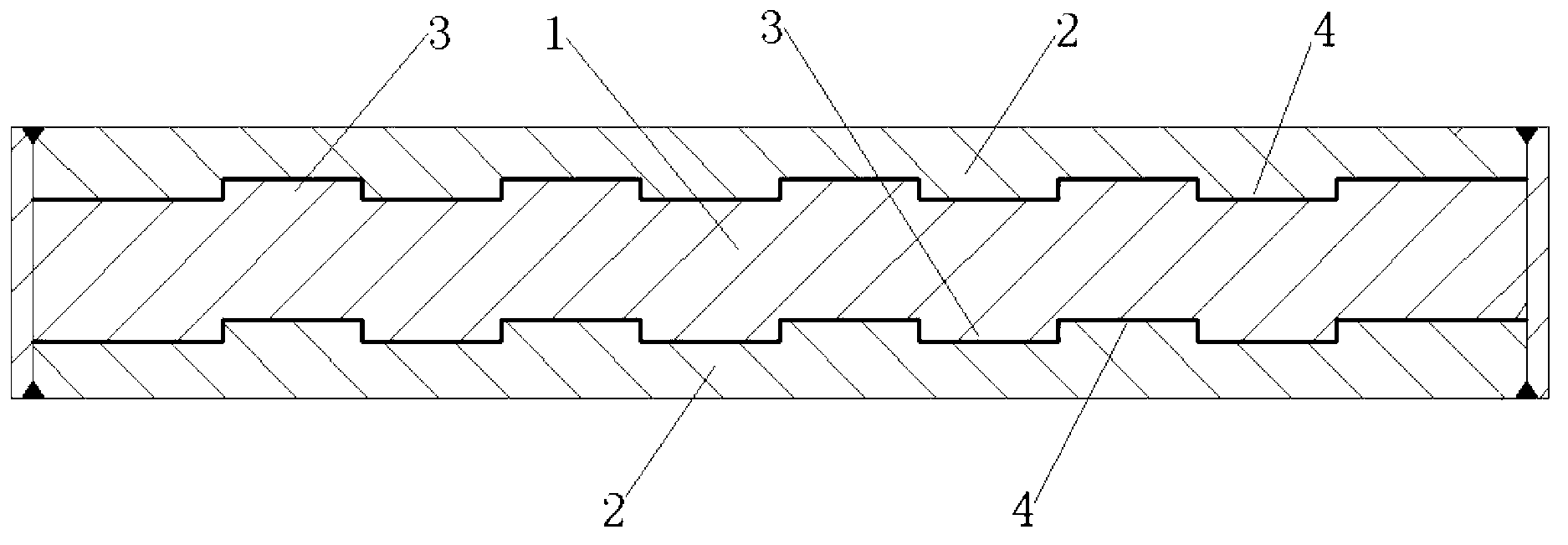

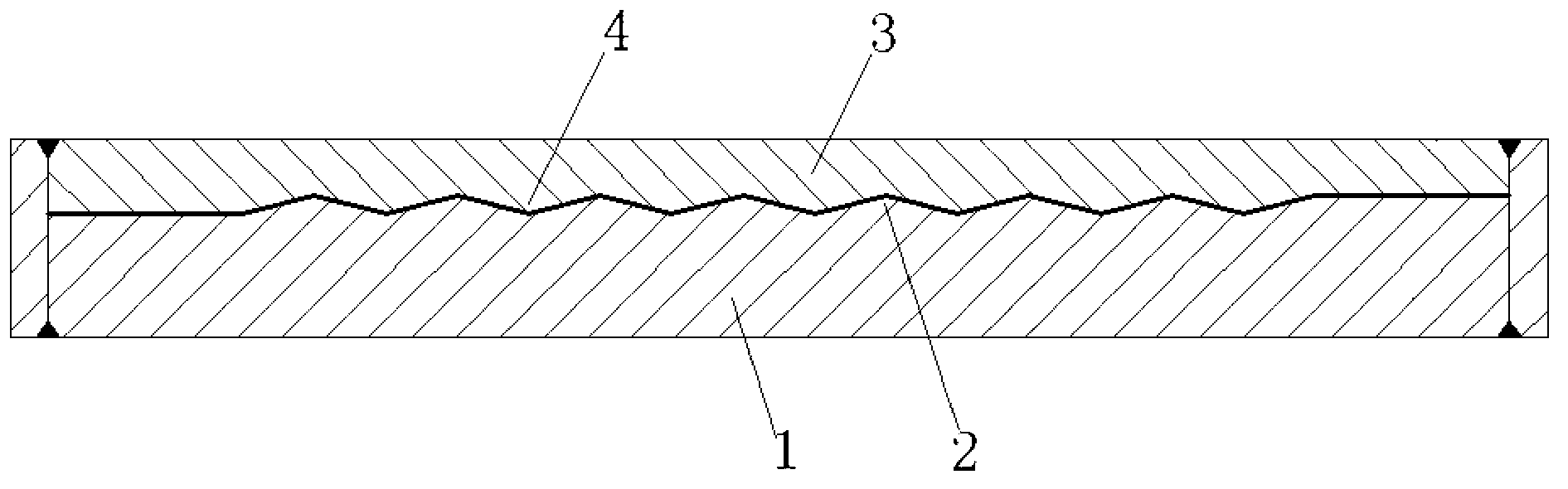

Meshing type composite plate vacuum rolling preparation method

InactiveCN103272842AImprove fitAvoid separationAuxillary arrangementsMetal rolling arrangementsComposite strengthComposite filter

The invention discloses a meshing type composite plate vacuum rolling preparation method. The meshing type composite plate vacuum rolling preparation method includes the steps: processing base plate protrusions and covering plate protrusions, which are matched mutually, on compositing surfaces of a base plate and a covering plate respectively; cleaning the compositing surfaces of the base plate and the covering plate; overlaying the base plate and the covering plate, and enabling the base plate protrusions on the base plate and the covering plate protrusions on the covering plate to be meshed mutually; obtaining a composite plate blank by means of blank assembly; and performing hot rolling so that a composite plate is obtained. The meshing type composite plate vacuum rolling preparation method has the advantages that the base plate protrusions and the covering plate protrusions which are matched mutually are processed on the compositing surfaces of the base plate and the covering plate respectively, so that fitting force between the base plate and the covering plate is increased by the aid of meshing force among the base plate protrusions and the covering plate protrusions, separation of the base plate from the covering plate during rolling is avoided, and rolling quality is improved while process is simple; meanwhile, contact area between the base plate and the covering plate is enlarged (namely, the area of a compositing interface is enlarged), so that compositing strength of the composite plate is enhanced; and the meshing type composite plate vacuum rolling preparation method is applicable to preparation of composite plates.

Owner:武钢集团有限公司

Preparation method of wear-resistant coating for high-accuracy roller piece

The invention relates to a preparation method of a wear-resistant coating for a high-accuracy roller piece. In the invention, a nickel-based (or cobalt-based) prefabricated layer is prepared by using a supersonic flame spraying process, and the prefabricated layer is treated by adopting an induction heating method, so that the bonding intensity between the coating and a substrate is enhanced. Thewear-resistant coating is prepared by adopting a composite surface treatment technology, so that a workpiece is prevented from being deformed in the machining process, the prepared coating is dense and crackless and has uniform hardness and high binding intensity, and the surface wear resistance and impact resistance of the workpiece are enhanced; and moreover, a preparation technology has the advantages of simple process, high cladding efficiency, low machining cost and the like. After machining, the binding intensity between the coating and the substrate is more than or equal to 70 MPa, andthe hardness of the coating can be up to HRB 55-70 by adjusting the adding amount of solid-phase wolfram carbide (WC) in spraying powder. The preparation method can be widely applied to the preparation of surface reinforced layers for industrial components with severe working conditions, such as high-frequency friction pairs, papermaking rollers, pumping rods, loops and the like.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

Flex circuit lightning protection applique system for skin fasteners in composite structures

A lightning protection appliqué incorporates a plurality of conductive plies adhesively affixed to a composite surface, at least a first one of the plies providing conductive characteristics sufficient to divert electrical energy from a lightning strike and at least a second one of the plies comprising operational circuitry. A dielectric ply is fixed to the composite surface over and completely covering at least one metal surface feature between the plurality of conductive plies and the composite surface.

Owner:THE BOEING CO

Flexible tapestry brick of external wall outer insulation system and production method thereof

The invention discloses a flexible decorated brick for exterior wall insulation system, mainly comprising main-body bricks or a composite surface coating of main-body bricks. The main-body brick formula contains major components of soil and acrylic emulsion, and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to different product performance requirements. The surface coating formula contains the main components of metal powder or a compound powder of more than two kinds of non-metallic powder or metal powder and acrylic emulsion and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to the needs of different product performances. The product of the invention is light-weighted, freeze-thaw resistance, anti-aging, high in bond strength, flexible and good in water-repellent and permeability, the pollution resistance of which is equivalent to that of polished tiles and the color of which is as rich as the paint and the appearance of which can be made into a decorative texture of metal curtain walls, stone walls, ceramic, wood, leather or cloth. Particularly, the inventive product has an excellent compatibility with the exterior insulation system, suitable for the decorated layer of the exterior insulation system. In addition, the inventive product avoids using the clay resource which is in shortage as the main production raw material and is a low-cost, environment-friendly flexible decorated material with high performance for exterior wall insulation system.

Owner:石磊

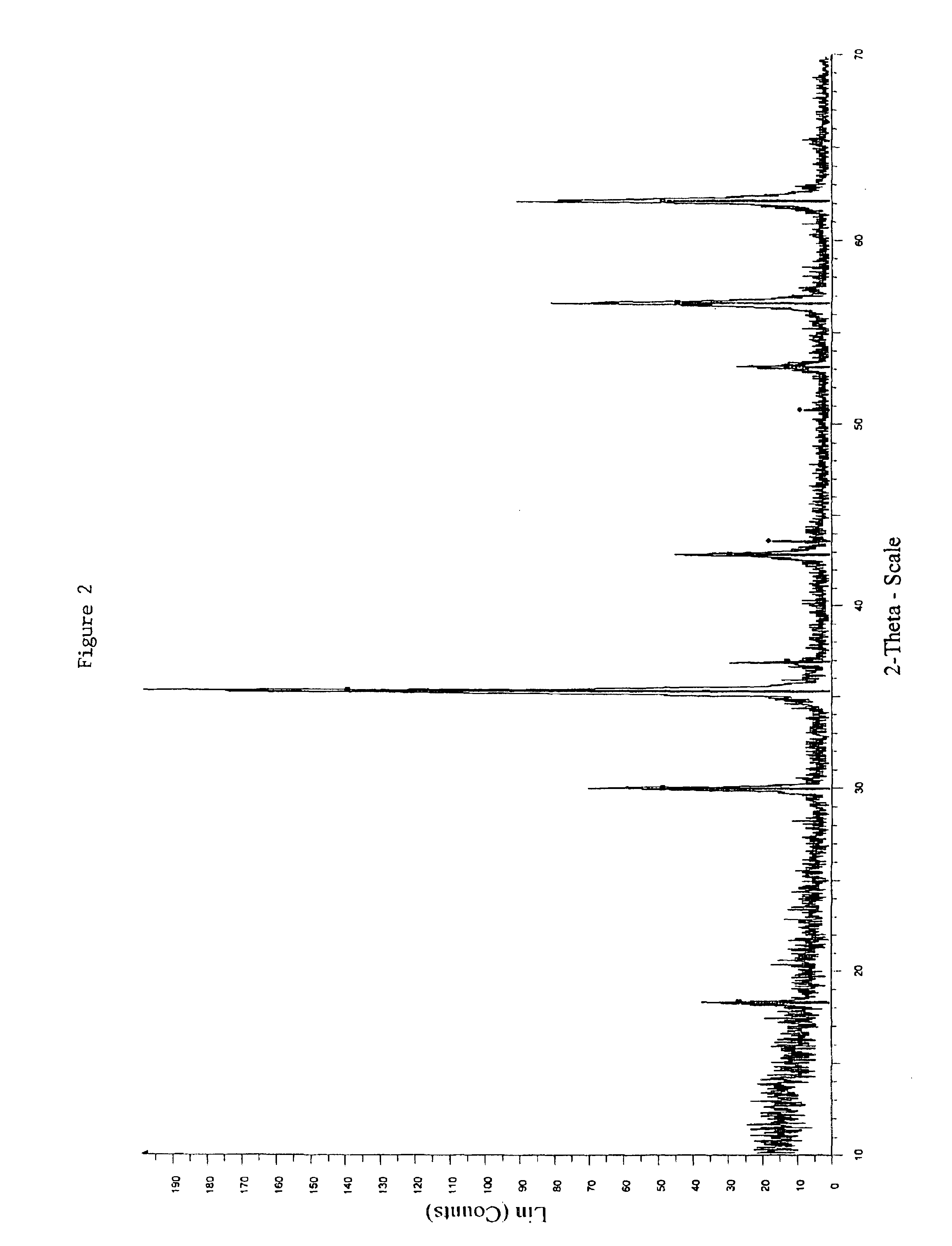

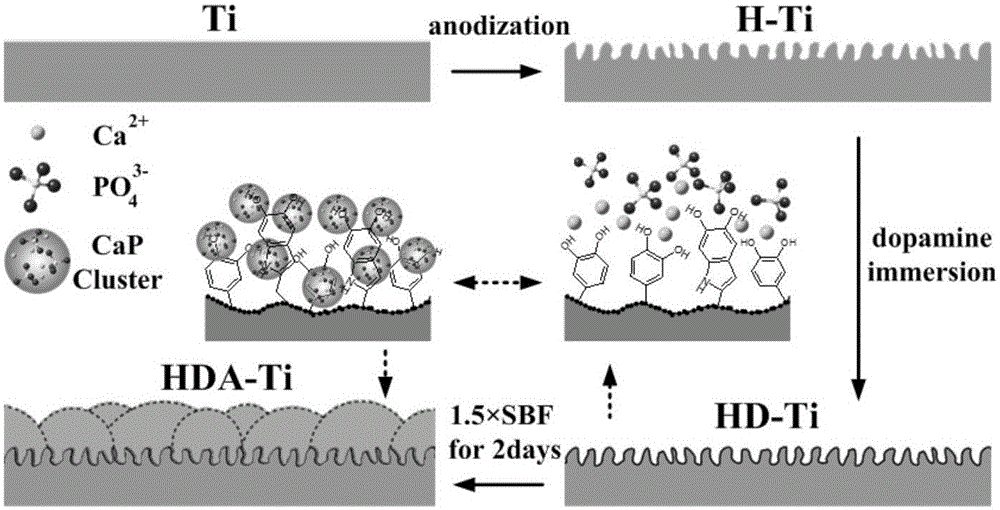

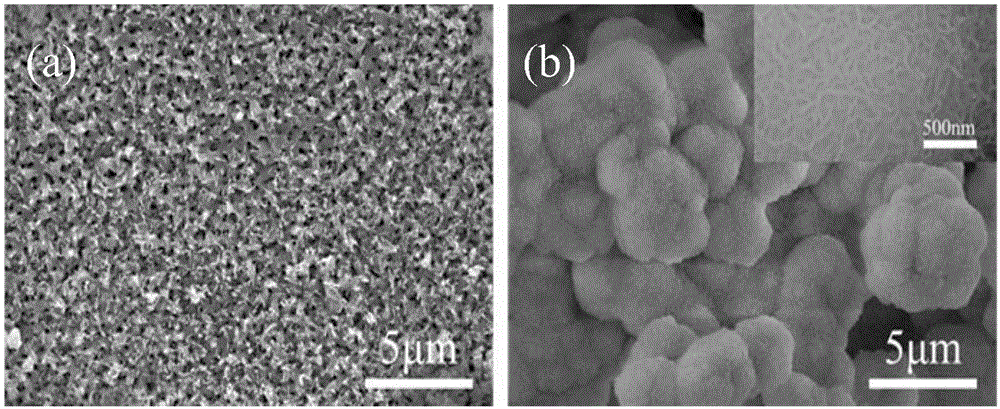

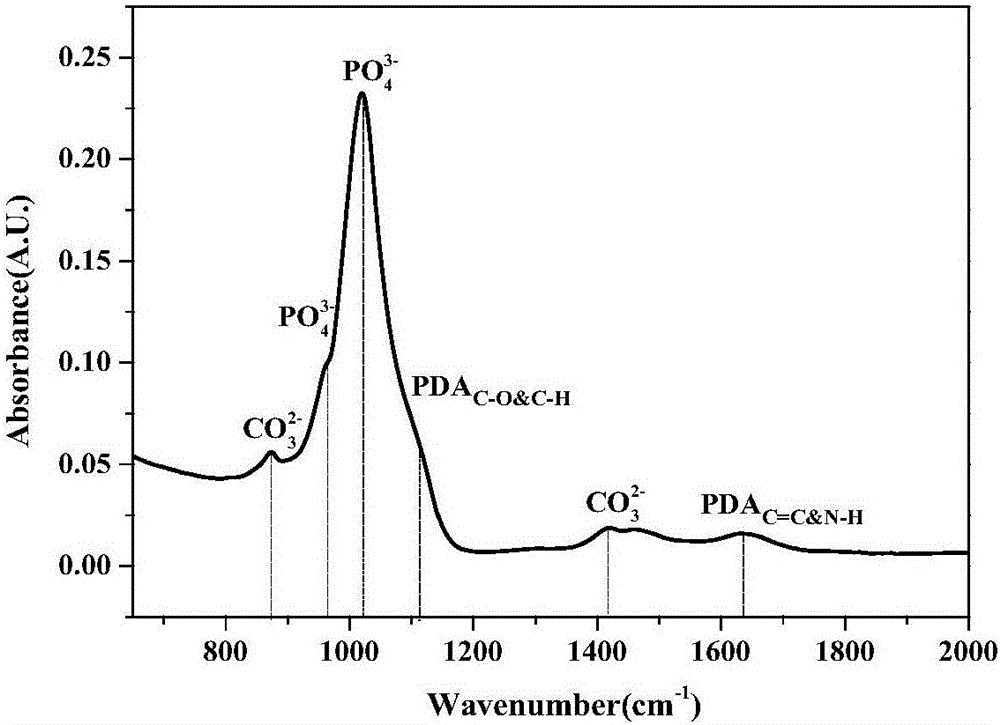

Preparation method of dental implant and composite surface thereof

InactiveCN105903076AImprove corrosion resistanceImprove surface hydrophilicityPharmaceutical delivery mechanismTissue regenerationOsteoblastNa k atpase activity

The invention relates to a preparation method of a dental implant and a composite surface thereof. In the dental implant, medical titanium or titanium alloy is used as a substrate, and porous morphology is prepared on the surface while polydopamine and hydroxyapatite are deposited to obtain a dental implant composite surface with good bioactivity. In the invention, a uniform multi-layer pore oxidation film is quickly formed on the surface of the titanium substrate to obtain nano porous morphology; and by enabling a thin layer of protein analogue (polydopamine) to tightly adhere to the surface, the surface hydrophilicity and the corrosion resistance of the dental implant can be improved. Finally, the hydroxyapatite deposition is induced on the surface to obtain a three-layer composite surface; moreover, the nano porous composite surface can effectively reinforce the adhesion and spreading of osteoblast on the implant surface as well as the alkaline phosphatase activity, early bone integration of the implant is accelerated, and firm combination of the material and the organism interface is realized so as to improve the stability and success rate of the implant.

Owner:UNIV OF SCI & TECH BEIJING

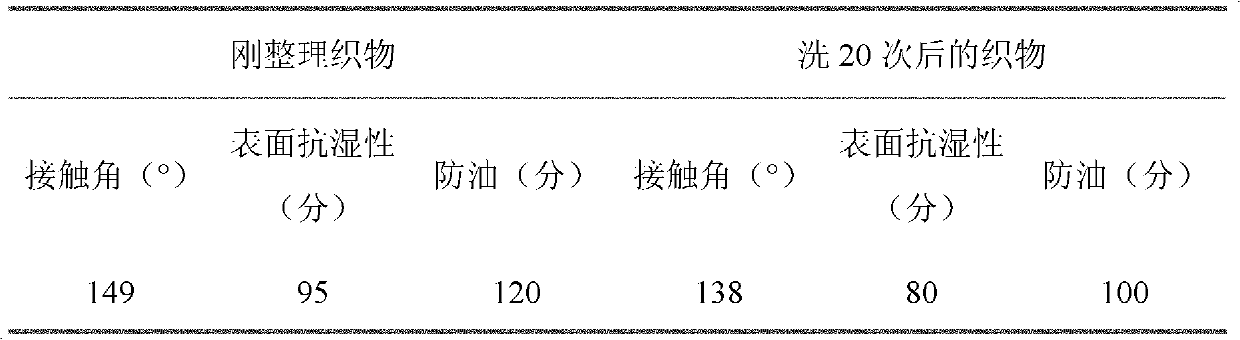

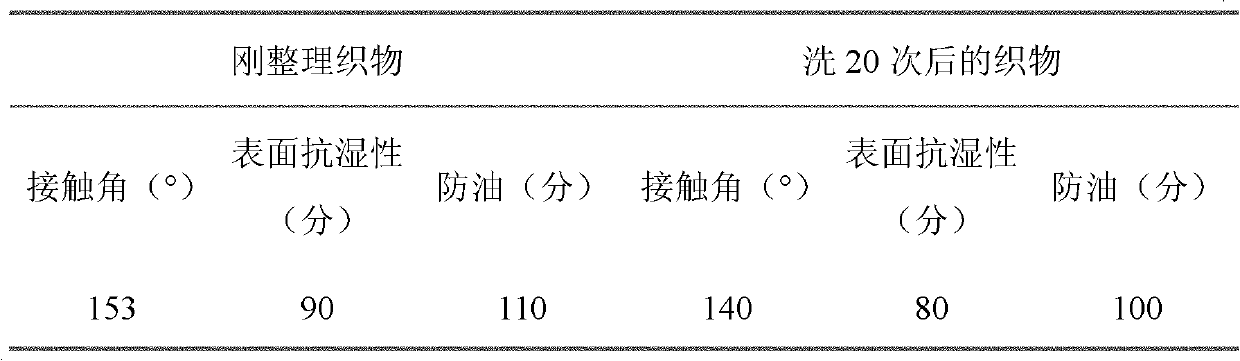

Organic-inorganic composite emulsion water-and-oil-repellent finishing agent and application thereof

ActiveCN102002128AReduce usageReduce pollutionVegetal fibresAnimal fibresDispersion stabilityActive agent

The invention relates to an organic-inorganic composite emulsion water-and-oil-repellent finishing agent and the application thereof. The preparation method of the finishing agent comprises the following steps of: (1) adding deionized water, composite surface active agent and an ethylene-contained silane coupling agent to a container provided with a stirrer, a reflux condensing tube and a thermometer, stirring at a high speed, adding ammonia, continuously and rapidly stirring and making the material react to obtain a functionalized nano SiO2 aqueous dispersion; and (2) adding the functionalized nano SiO2 aqueous dispersion and parts of monomer emulsified in advance and an initiator to the container provided with the stirrer, the reflux condensing tube and the thermometer, increasing the temperature, slowly dipping the rest monomer emulsified in advance and a fluorinated acrylate monomer, simultaneously dipping the rest initiator, cooling and adjusting the pH value to be 7-8. The finishing agent of the invention has favorable dispersion stability as well as favorable water and oil repellence when applied to textiles, and the preparation method is simple and suitable for industrial production.

Owner:DONGHUA UNIV +1

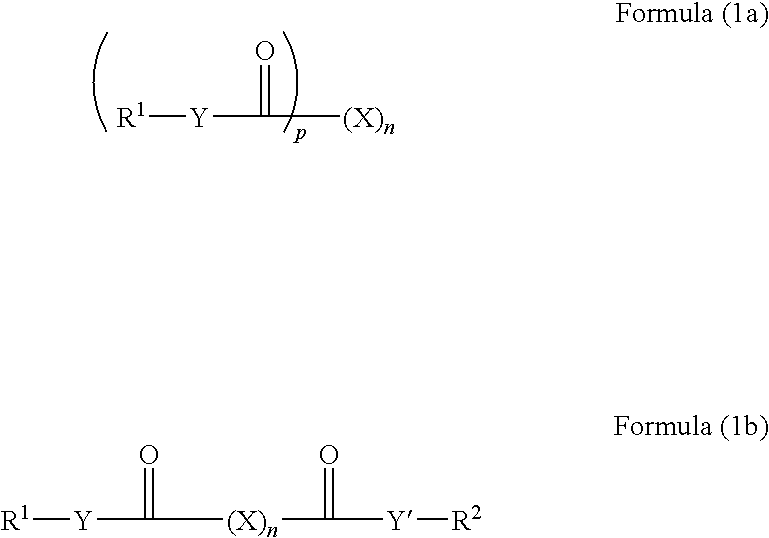

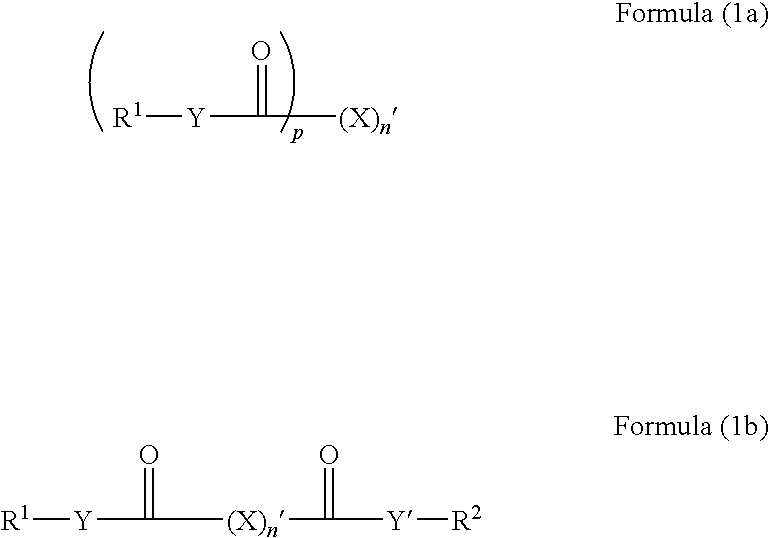

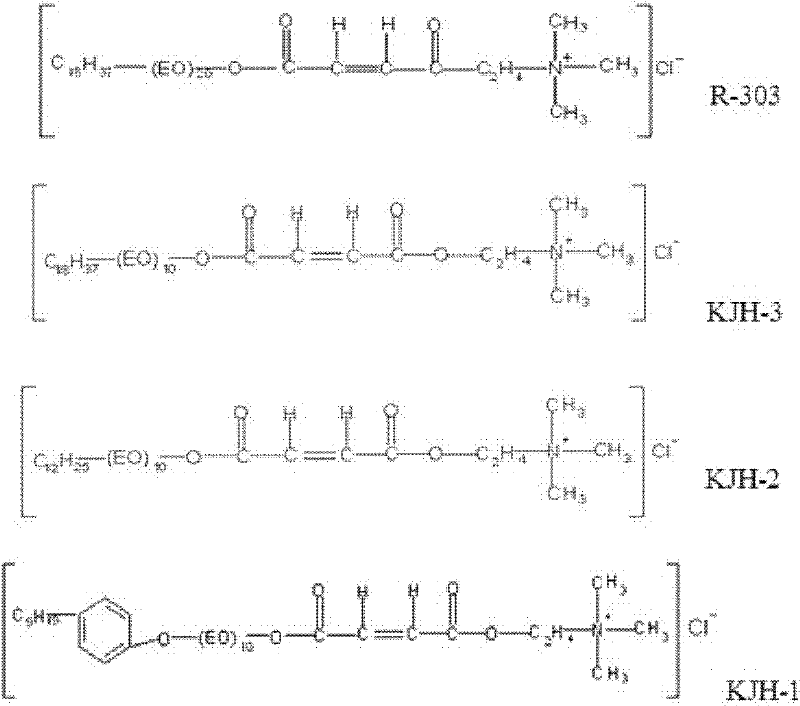

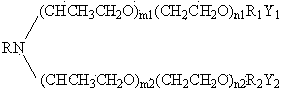

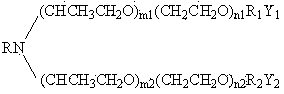

Composite surface active agent composition for tertiary oil recovery and preparation method and application thereof

ActiveCN104232044AImprove surface activityLarge adsorption capacityOrganic compound preparationSulfonic acids salts preparationAlkaline earth metalQuaternary ammonium cation

The invention relates to a surface active agent composition for tertiary oil recovery, and a preparation method and application thereof, and mainly solves the problems of poor displacement efficiency, and harm to the stratum and the oil field, corrosion of equipment and pipeline and difficult demulsification due to oil inorganic alkali contained in displacement system. The composition includes a cationic surface active agent and an anionic-non-ionic surface active agent; the cationic surface active agent is at least one selected from the group consisting of quaternary ammonium salt and quaternary ammonium alkali; the anionic-non-ionic surface active agent has the following general formula; and R represents C1-C30 alkyl or acyl, a m1+m2=0-100, n1+n2=0-100, R1 and R2 are independently selected from the group consisting of C1-C10 alkylene and substituted alkylene, Y1 and Y2 are independently selected from the group consisting of -SO3 (M) r and -COO (N) s, M and N are independently selected from the group consisting of H, alkali metal, ammonium or alkali-earth metal. The technical scheme well solves the problem, and can be used in intensified oil production of oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

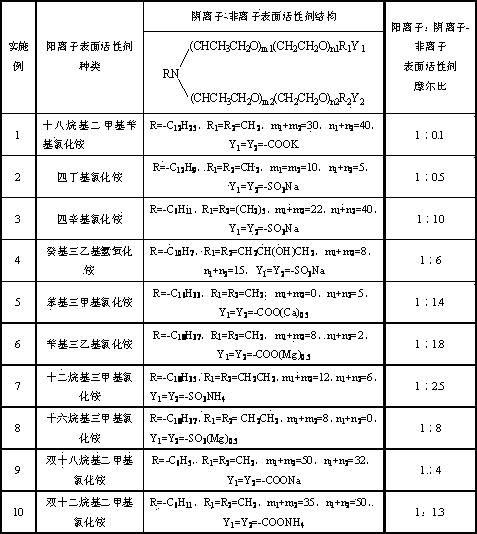

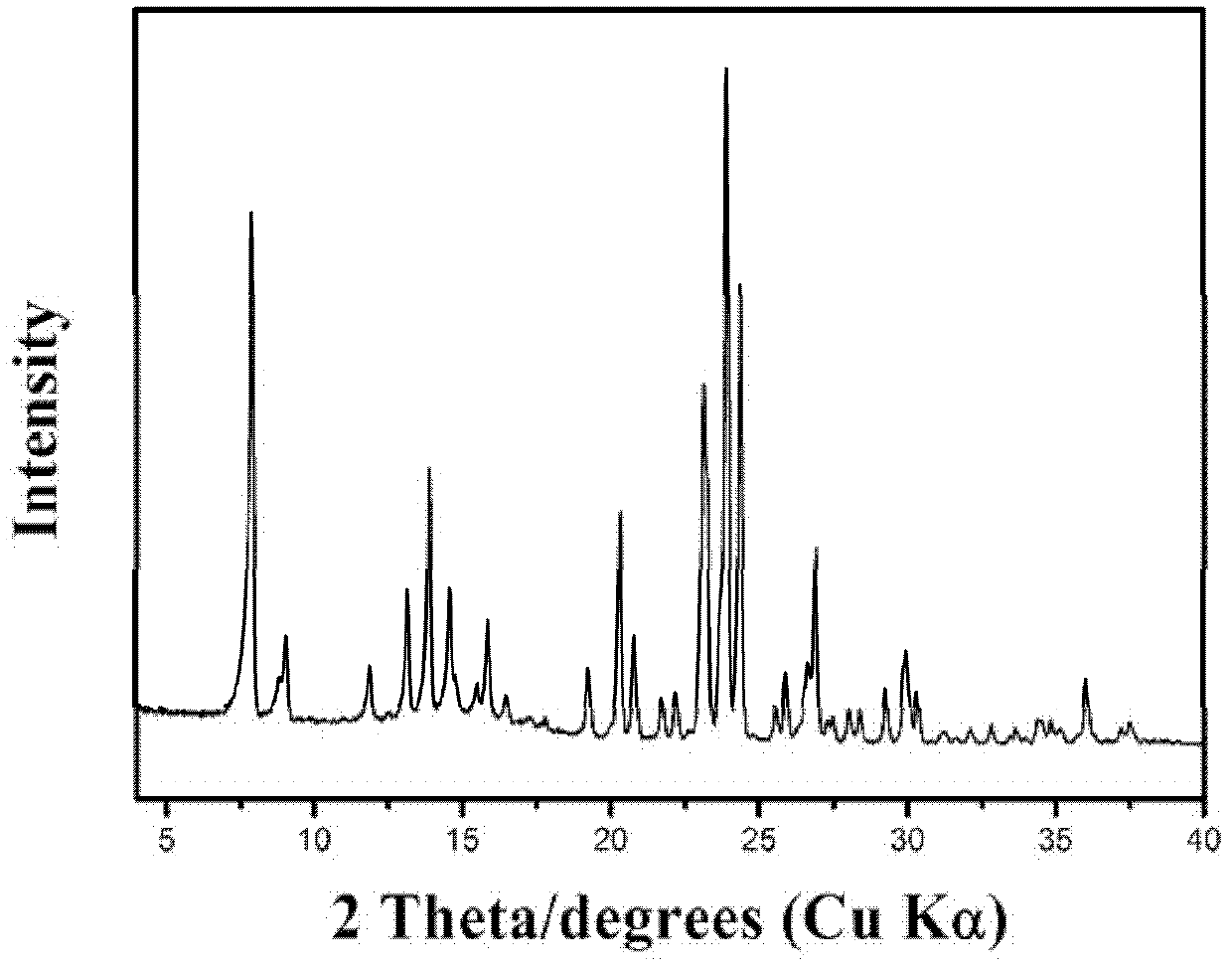

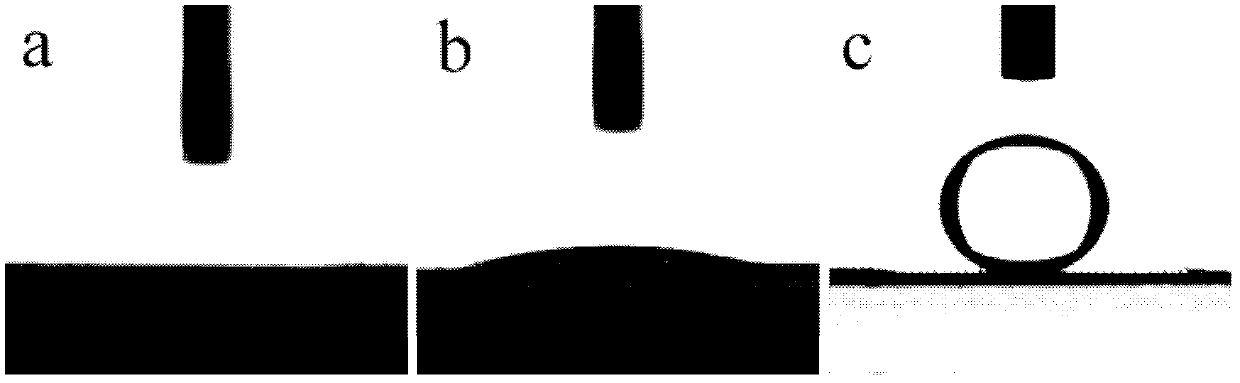

Inorganic phase separation membrane and application of thereof to oil-water separation

The invention discloses an inorganic phase separation membrane and application of thereof to oil-water separation, belongs to a functional material technology and relates to the superhydrophilic and underwater super hydrophobic oil inorganic phase separation membrane which grows a molecular sieve coating on a porous base, and thus micro and nanometer scale, a composite surface and a mesh structure are formed. The membrane material can be used for separating various greases at high efficiency and high speed and low energy consumption under various serious water body environments; and the membrane can be used for a long time and is easy to regenerate. The inorganic phase separation membrane consists of the porous base and the molecular sieve coating grown on the porous base; the aperture size of the porous base is 20-200 micrometers; the thickness range of the molecular sieve coating is 3-50 micrometers; the mass ratio of the porous base to the molecular sieve coating is (100:1)-(5:1); the porous base is made of a stainless steel wire mesh, a copper mesh, an aluminum mesh or porous ceramic; and framework types of the molecular sieve are LTA, SOD, FAU, MEL, CHA, MFI , DDR, AFI, BEA or PHI.

Owner:JILIN UNIV

Low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and preparing method thereof

The invention relates to low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and a preparing method thereof. The material is prepared by the steps of stirring and mixing 90-98 parts of high-temperature-resistant nylon, 1-5 parts of a hydrophobic high-temperature-resistant odor-adsorption masterbatch, 1-5 parts of surface treated nano silicon carbide, 0.1-0.5 part of a solid lubricant, 0.2-1.0 part of a lubricant and 0.1-1 part of an antioxidant and then carrying out melting extrusion granulation through a twin-screw extruder. Tetraethoxysilane and a coupling agent are used for composite surface treatment of the nano silicon carbide, the dispersity of the nano silicon carbide as a wear-resisting agent in matrix resin is increased, and thus the cohesive property of the wear-resisting agent and the high-temperature-resistant nylon matrix is improved, the prepared high-temperature-resistant nylon has significant improvement in wear resistance; at the same time, with use of the hydrophobic high-temperature-resistant odor-adsorption masterbatch, the product is kept a low-odor characteristic in processing and application processes.

Owner:HEFEI GENIUS NEW MATERIALS

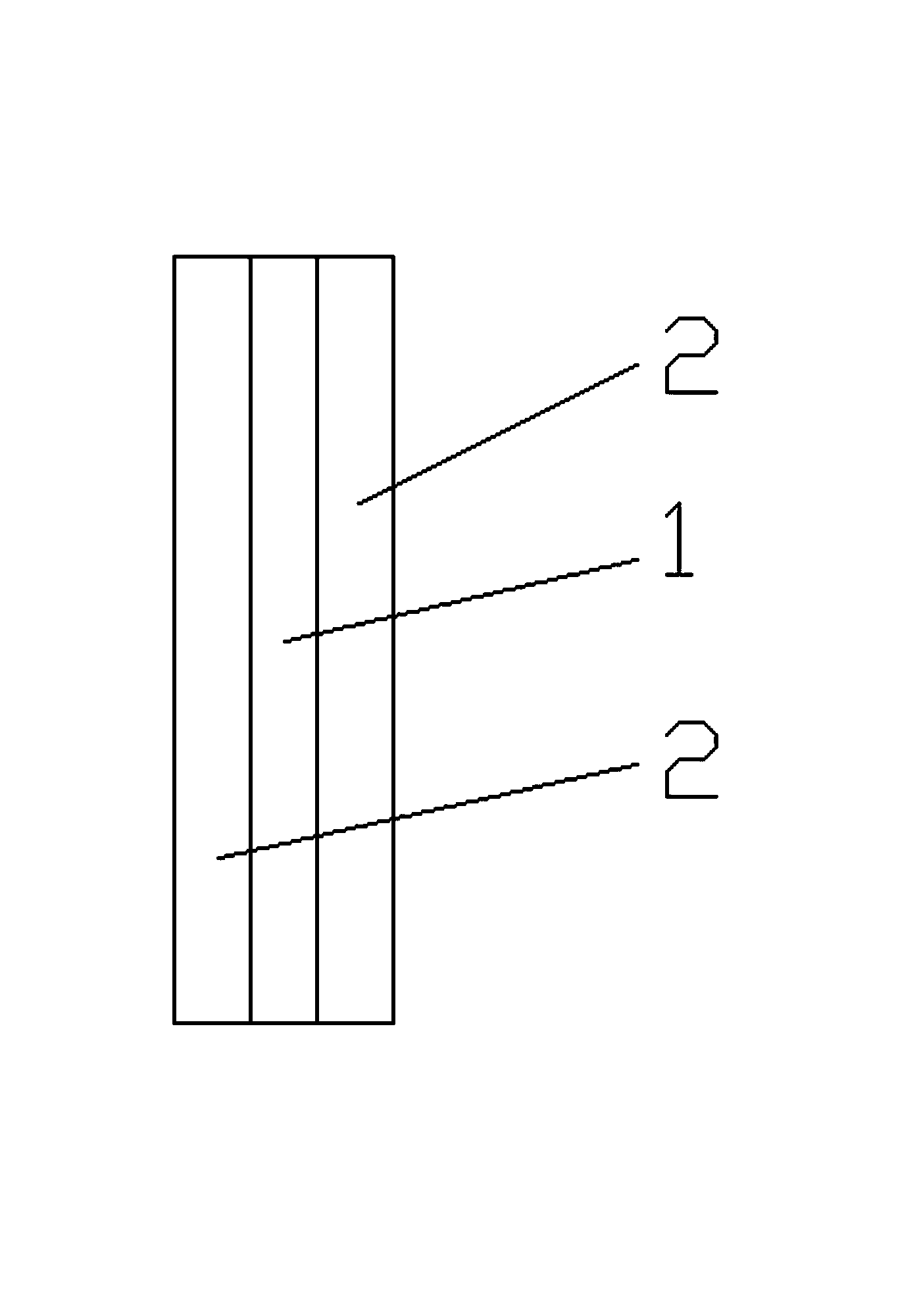

Composite insulating energy-saving light concrete wallboard as well as preparation method thereof

ActiveCN103526872AImprove sound insulationImprove flexural strengthConstruction materialCalcium silicateBreaking strength

The invention relates to a composite insulating energy-saving light concrete wallboard as well as a preparation method thereof. The wallboard comprises an aerated concrete core plate, wherein wallboard composite surface layers are spliced on two surfaces with the maximum area of the aerated concrete core plate. The preparation method comprises the following steps: preparing slurry; preparing a framework of steel reinforcement; preparing the aerated concrete core plate; and finally preparing the wallboard. The wallboard has good building energy efficiency and meets the demand of circular economy. The wallboard prepared is internally provided with the framework of steel reinforcement, so that the wallboard has good sound insulating performance, high breaking strength and good nailing and hanging performance. The calcium silicate board veneering light wallboard fully meets the demand of wall function and creates advantages for environment-friendliness, energy saving, waste utilization and circular economy, so that the wallboard is the optimum product for revolution of current wall materials. Therefore, the wallboard has a good development prospect.

Owner:SHAOGUAN QUANCHENG IND TECH CO LTD

Multifunctional plating assistant agent used for hot dipping

InactiveCN101575691AImprove the plating effectQuality improvementHot-dipping/immersion processesActive agentPotassium

The invention provides a multifunctional plating assistant agent used for hot dip plating, belonging to the technical field of the surface plating technique of steel and iron materials. The technical proposal is as follows: the aqueous solution of the plating assistant agent has the following components of zinc chloride, sodium chloride, potassium chloride, sodium fluoride and a composite surface active agent synthesized by fluorocarbon and hydrocarbon surface active agents with the respective proportion in sequence of 40 to 200g / L, 20 to 50g / L, 20 to 60g / L, 0 to 50g / L, 5 to 30g / L, 0.5 to 5g / L, and the balance of water. The plating assistant agent can improve the plating assistant effect of the plating assistant on the surface of the steel and iron part, prevent the steel and iron part after plating assistance from being oxidized secondarily in air, improve the quality of the surface plating layer of the steel and iron, does not generate zinc burst when in hot dip plating, reduces the dust amount generated by zinc bath surface when in hot dip plating, not only is suitable for hot dip plating, but also is suitable for hot dip aluminium plating.

Owner:KUNMING UNIV OF SCI & TECH

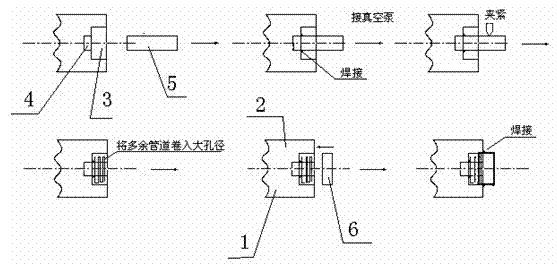

Production process for hot-rolled composite blank

InactiveCN104550233AGuaranteed vacuumImprove bindingElectron beam welding apparatusMetal rolling arrangementsThick plateHeating furnace

The invention relates to a production process of a hot-rolled composite blank. The production process comprises the following steps of: (1), cleaning base metal plates and clad metal plates, and cleaning the surface of a to-be-composited surface by use of a milling machine so that the surface is clean; (2), putting a high-temperature antisticking agent between the two clad metal plates, and putting the two superposed clad metal pates between the two base metal plates; (3), putting base plate metal strips at the parts, which are adjacent to the edges, of a gap between the two base metal plates, and performing spot welding on the base metal plates and the base plate metal strips so that the metal plates are fixed to form a blank; (4), sealing the peripheral edges of the blank by virtue of welding the blank via vacuum electron beam welding so as to form a dual-metal composite steel plate blank; and (5) heating the dual-metal composite steel plate blank in a heating furnace, discharging the blank out of the heating furnace, rolling the blank by virtue of a high-power medium and heavy plate mill, straightening after rolling, and trimming to obtain the hot-rolled composite blank. The production process is simple, good in combination quality, high in efficiency, relatively low in production cost, short in period, easy for production organization and low in loss.

Owner:SHANDONG IRON & STEEL CO LTD

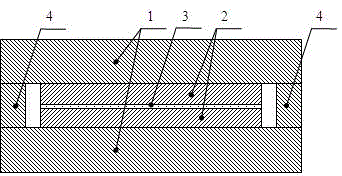

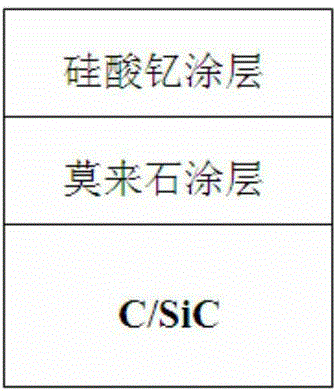

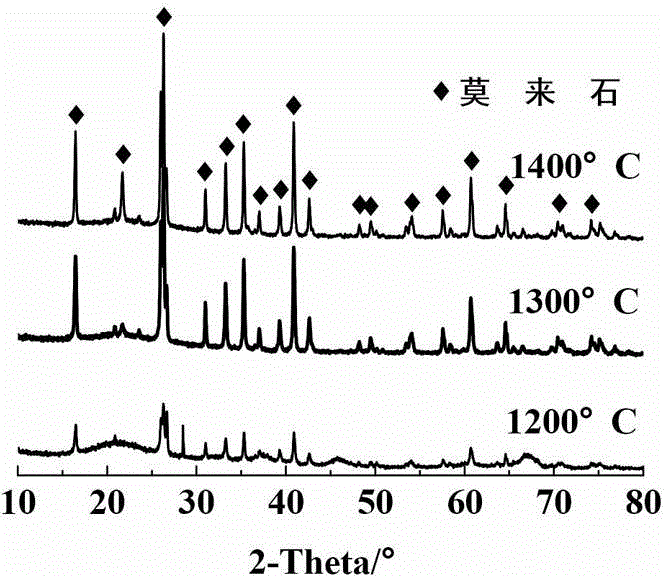

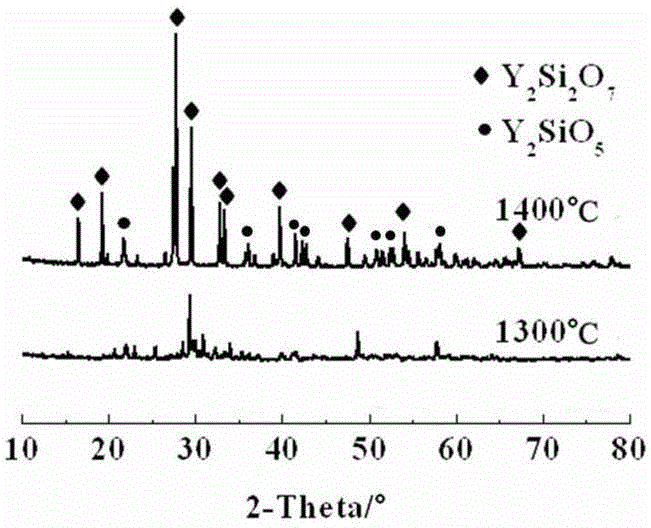

C/SiC composite surface coating system and preparation method thereof

The invention discloses a C / SiC composite surface coating system and a preparation method thereof. The surface coating system is arranged on the surface of a substrate of a C / SiC composite and comprises a mullite coating and an yttrium silicate coating which are sequentially distributed from bottom to top. The preparation method comprises steps as follows: (1), preparing Al2O3-SiO2 composite sol; (2), preparing raw mud materials of the yttrium silicate coating; (3), preparing the mullite coating; and (4), preparing the single-layer yttrium silicate coating or the multi-layered yttrium silicate coating. The C / SiC composite surface coating system has the characteristics of high densification and high temperature resistance, and the preparation method of the C / SiC composite surface coating system has engineering application universality.

Owner:NAT UNIV OF DEFENSE TECH

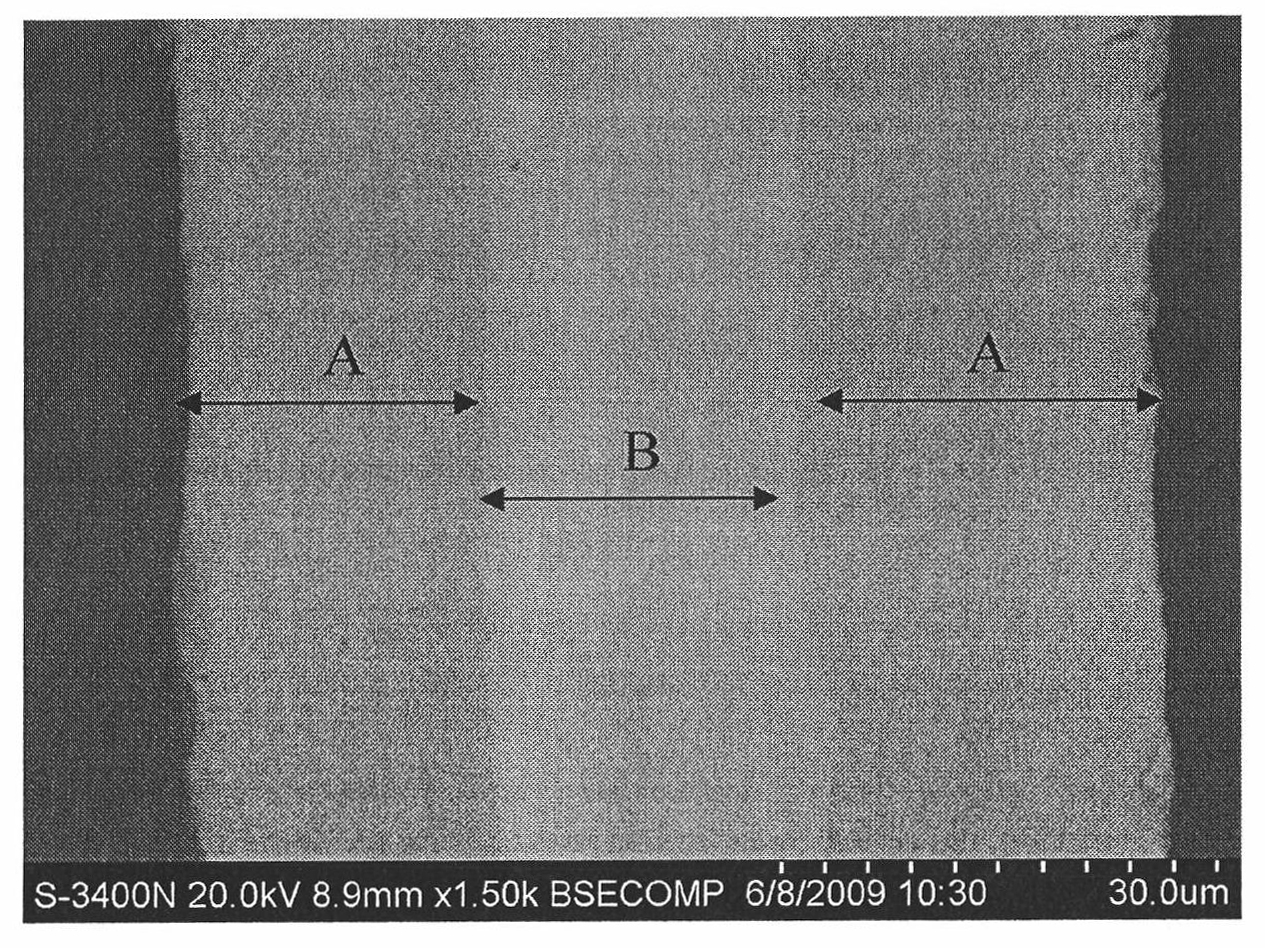

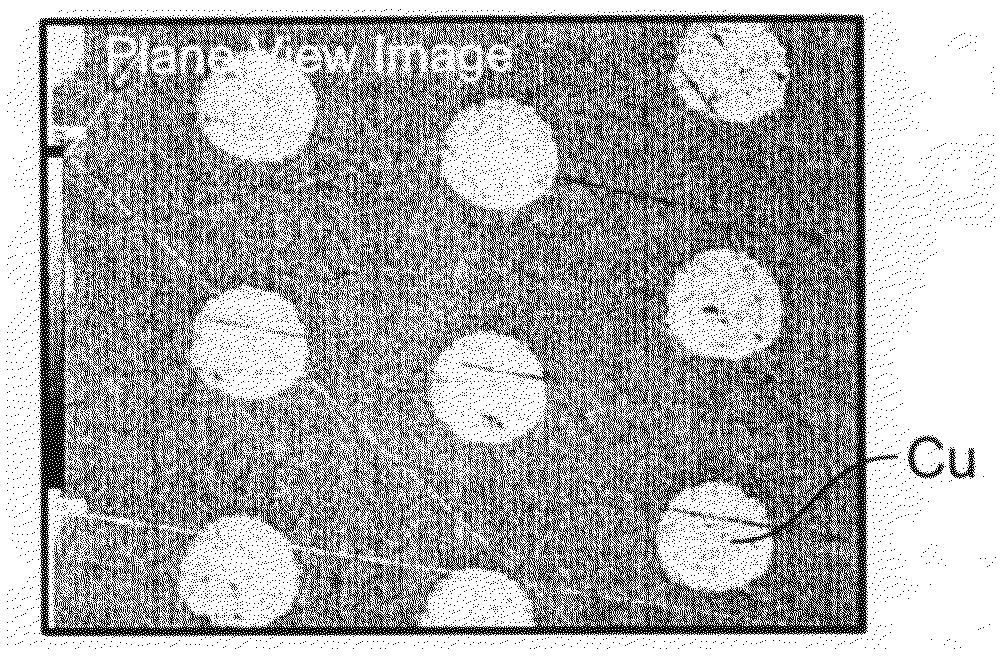

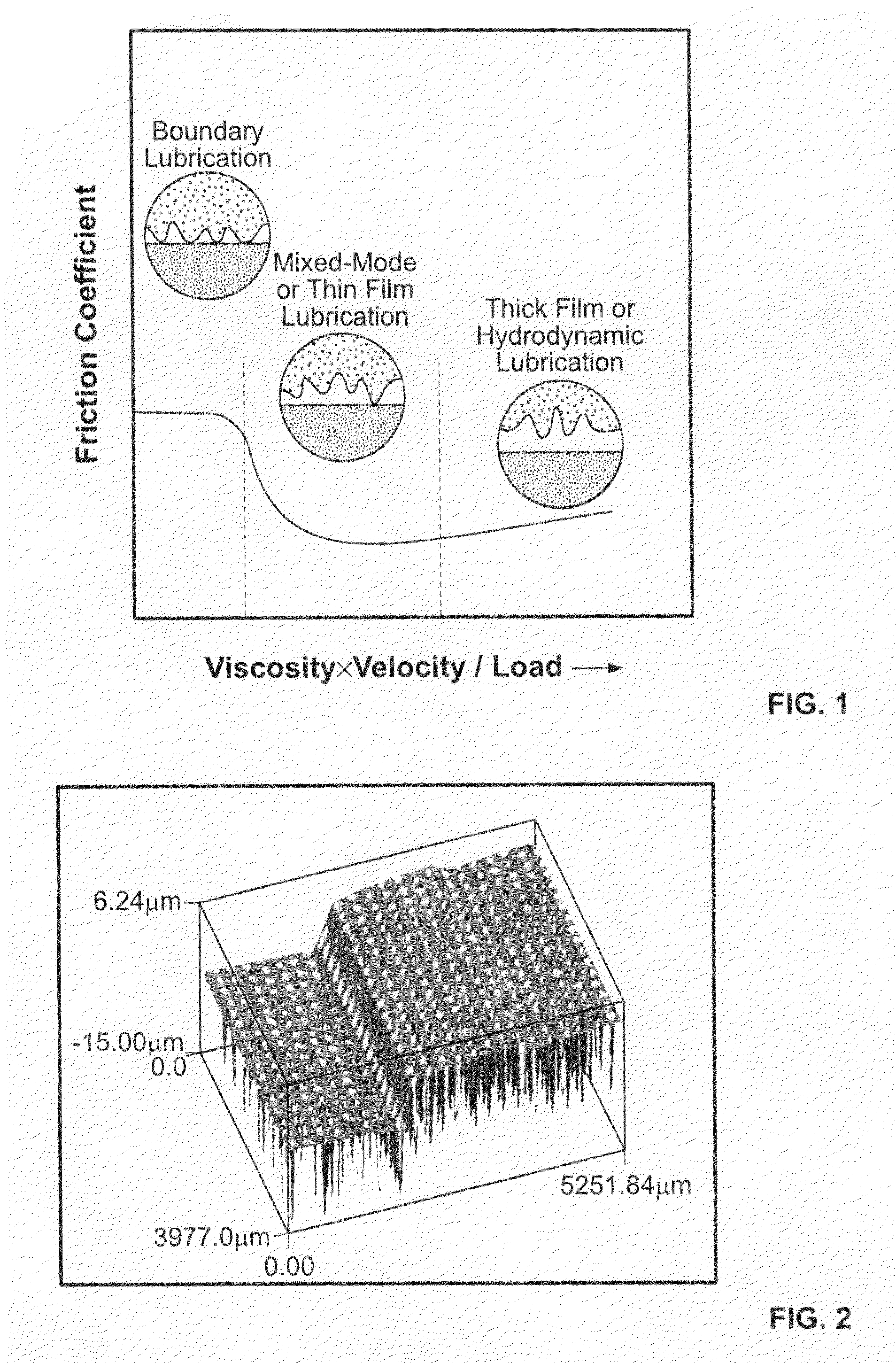

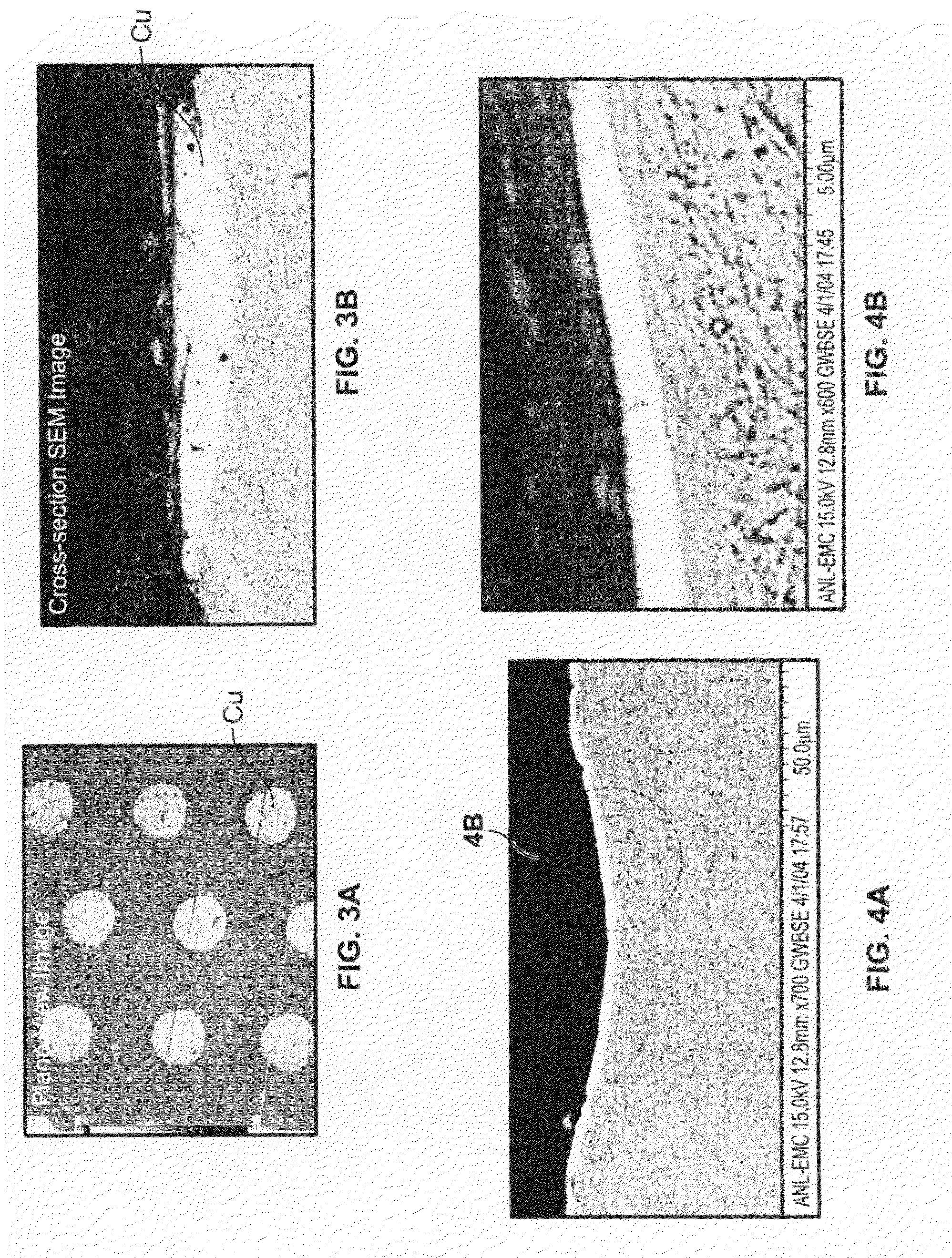

Modulated composite surfaces

InactiveUS7846556B2Improve the immunityReduce frictionMaterial nanotechnologyDecorative surface effectsWear resistanceNanometre

Methods and compositions relating to the preparation of structurally and compositionally modulated composite surfaces that can potentially reduce friction and increase resistance to wear and scuffing in rolling, rotating and sliding bearing applications. Preparation of nano-to-micro size pores, holes, or dimples on a given solid surface and filling them with soft or hard coatings at desired thickness to achieve such properties.

Owner:UCHICAGO ARGONNE LLC

Production method of copper-steel composite plate

ActiveCN102671943AGood direct connectionHigh strengthWork treatment devicesCleaning using liquidsSurface cleaningSpray coating

The invention relates to a production method of a copper-steel composite plate. The production method comprises the following steps of: performing surface cleaning, performing texturing treatment, spraying a binding layer, rolling and annealing, wherein before rolling, alloy plating layers are respectively plated on the surfaces of a steel plate and a copper plate, which need to be compounded through an immersion plating or spray coating way, the thickness of each plating layer is 4-8 mu m, and each alloy plating layer contains the following components: 6-8 parts by weight of Zr, 25-50 parts by weight of Zn, 5-30 parts by weight of Al, 10-40 parts by weight of Fe, 0.5-1 part by weight of Si and 0.4-0.6 part by weight of Mo. The production method disclosed by the invention has the beneficial effects that as the bonding layers with the mixture ratio are adopted, the direct bonding property between the steel plate and the copper plate is good; in addition, the compounding temperature is lower, the rolling reduction is smaller and the working cost is saved; and the composite copper-steel material prepared by the method disclosed by the invention has the advantages of high strength, high plasticity and toughness and excellent stress and corrosion resistance.

Owner:RUGAO OUTONG MACHINERY FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com