Organic-inorganic composite emulsion water-and-oil-repellent finishing agent and application thereof

An inorganic composite, water- and oil-repellent technology, used in fiber treatment, textiles and papermaking, animal fibers, etc., can solve problems such as flammability, pollution, and complex preparation processes, and achieve pollution reduction, good dispersion stability, and good dispersion stability. Water and oil repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

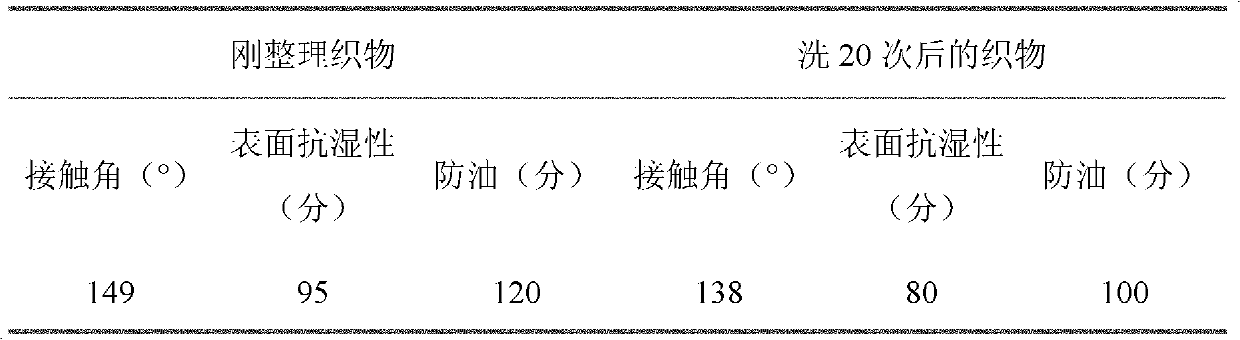

Embodiment 1

[0031] (1) Vinyl functionalized nano-SiO 2 Preparation: Add 100mL deionized water, 0.02g composite surfactant (AEO-9 to SDS mass ratio is 1:1) and 3g γ-methacryloyloxy Propyltrimethoxysilane, heated to 50°C, stirred at high speed for 1.5h to make it evenly dispersed, then added 3mL of ammonia water, continued to stir rapidly, and reacted for 3h to obtain functionalized nano-SiO 2 water dispersion;

[0032] (2) Preparation of organic-inorganic composite emulsion

[0033] Pre-emulsification: Add 0.4g emulsifier (the mass ratio of AEO-9 to SDS is 1:1), 6g methyl methacrylate, 4g butyl acrylate and 0.4g hydroxyethyl methacrylate into the container, and heat Stir for 50min and set aside.

[0034] Polymerization reaction: Add the above-mentioned 3.6g functionalized nano-SiO to a container equipped with a stirrer, a reflux condenser, and a thermometer 2 Water dispersion, 1 / 3 pre-emulsified monomer and 0.02g initiator, after heating up to 80°C, slowly add the remaining pre-emulsif...

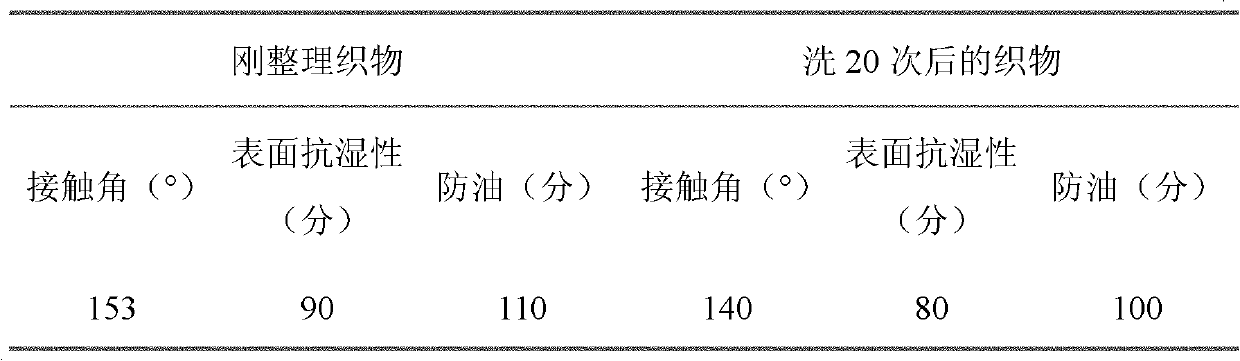

Embodiment 2

[0039] (1) Vinyl functionalized nano-SiO 2 Preparation: Add 100mL of deionized water, 0.04g of composite surfactant (the mass ratio of AEO-9 to SDS is 1:1) and 4g of vinyltrimethoxysilane in a container equipped with a stirrer, condenser tube and thermometer, Raise the temperature to 40°C, stir at high speed for 2 hours to make it evenly dispersed, then add 2 mL of ammonia water, continue to stir rapidly, and react for 4 hours to obtain functionalized nano-SiO 2 water dispersion;

[0040] (2) Preparation of organic-inorganic composite emulsion

[0041] Pre-emulsification: Add 0.6g emulsifier (the mass ratio of AEO-9 to SDS is 1:1), 6g methyl methacrylate, 4g butyl acrylate and 0.4g hydroxyethyl methacrylate into the container, and heat Stir for 50min and set aside.

[0042] Polymerization reaction: Add the above-mentioned 2.6g functionalized nano-SiO to a container equipped with a stirrer, a reflux condenser, and a thermometer 2 Water dispersion, 1 / 3 pre-emulsified monomer...

Embodiment 3

[0047] (1) Vinyl functionalized nano-SiO 2 Preparation: Add 100mL of deionized water, 0.03g of composite surfactant (the mass ratio of AEO-9 to SDS is 1:1) and 3g of vinyltrimethoxysilane in a container equipped with a stirrer, condenser tube and thermometer, Raise the temperature to 30°C, stir at high speed for 2 hours to make it evenly dispersed, then add 3 mL of ammonia water, continue to stir rapidly, and react for 4 hours to obtain functionalized nano-SiO 2 water dispersion;

[0048] (2) Preparation of organic-inorganic composite emulsion

[0049] Pre-emulsification: Add 0.8g emulsifier (the mass ratio of AEO-9 to SDS is 1:1) and 6.1g methyl methacrylate, 4.1g butyl acrylate and 0.4g hydroxyethyl methacrylate into the container, at 50 Stir at high speed for 50 min at ℃, set aside.

[0050] Polymerization reaction: Add the above-mentioned 3.4g functionalized nano-SiO to a container equipped with a stirrer, a reflux condenser, and a thermometer 2 Water dispersion, 1 / 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com