Patents

Literature

48542 results about "Polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In polymer chemistry, polymerization is a process of reacting monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are many forms of polymerization and different systems exist to categorize them.

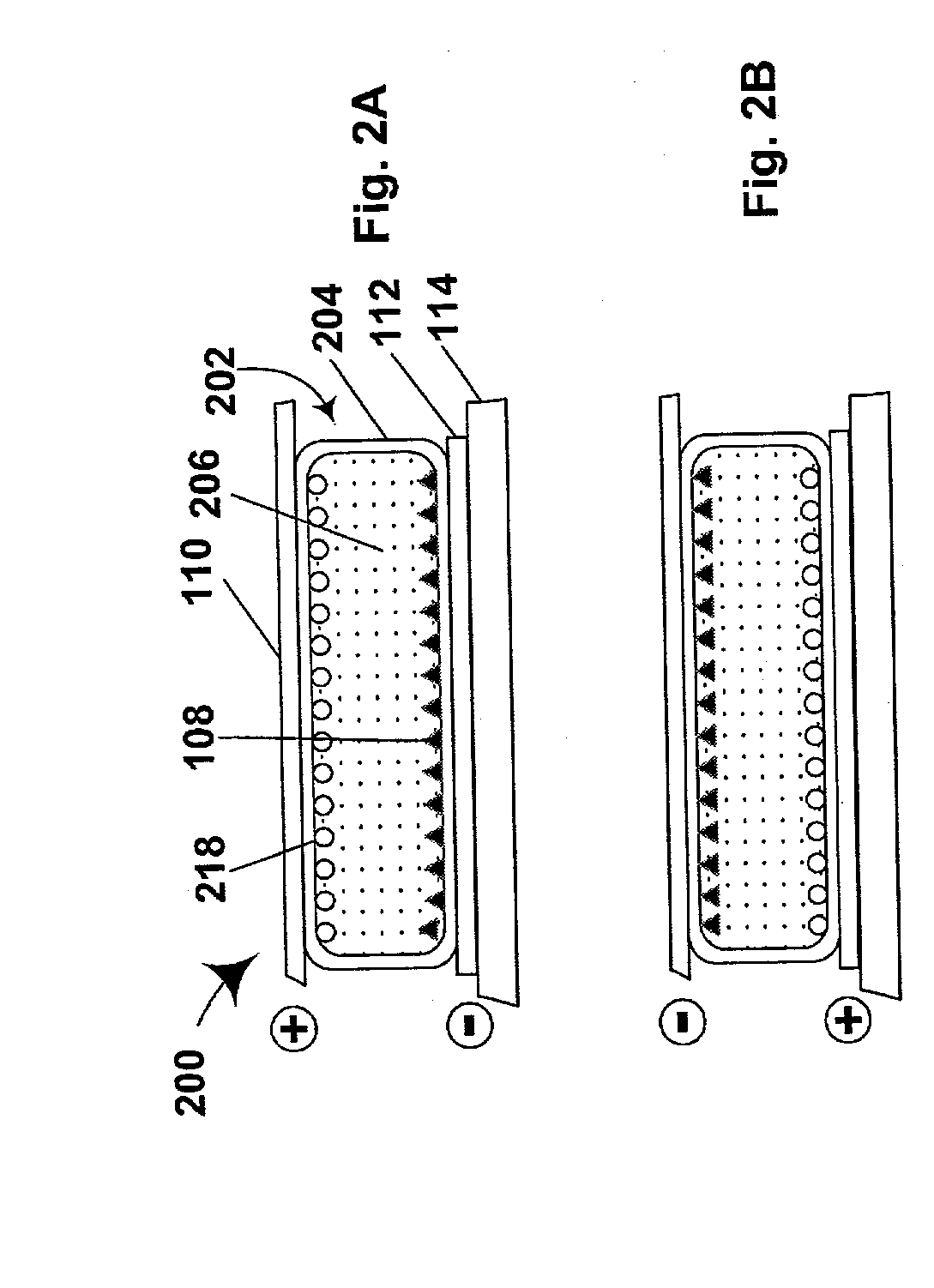

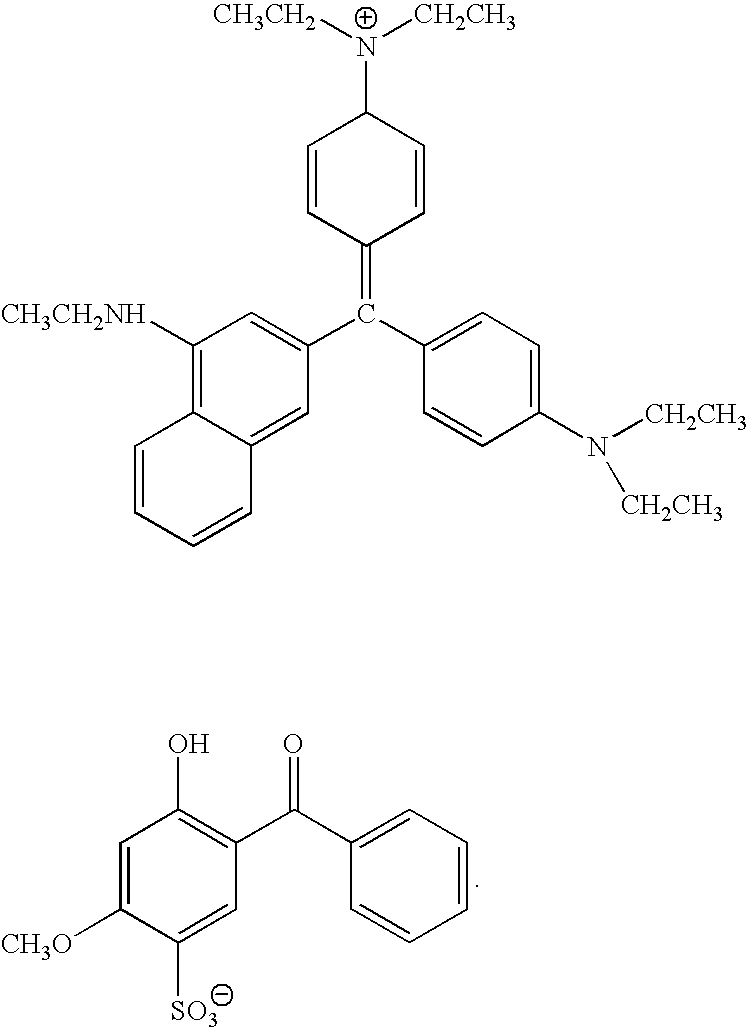

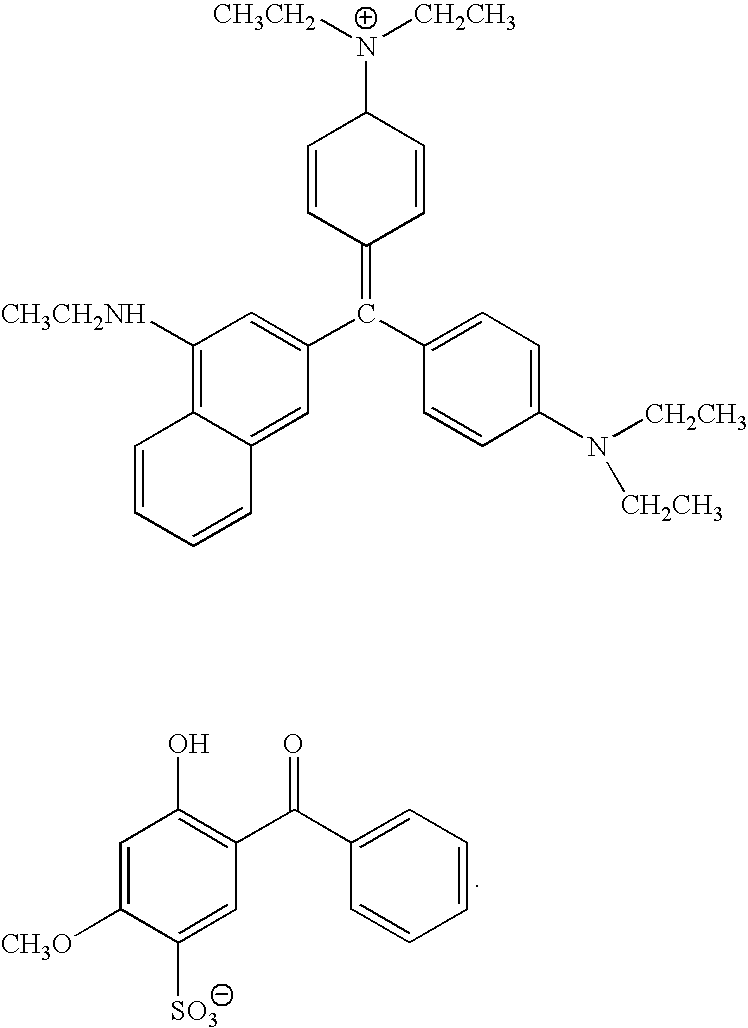

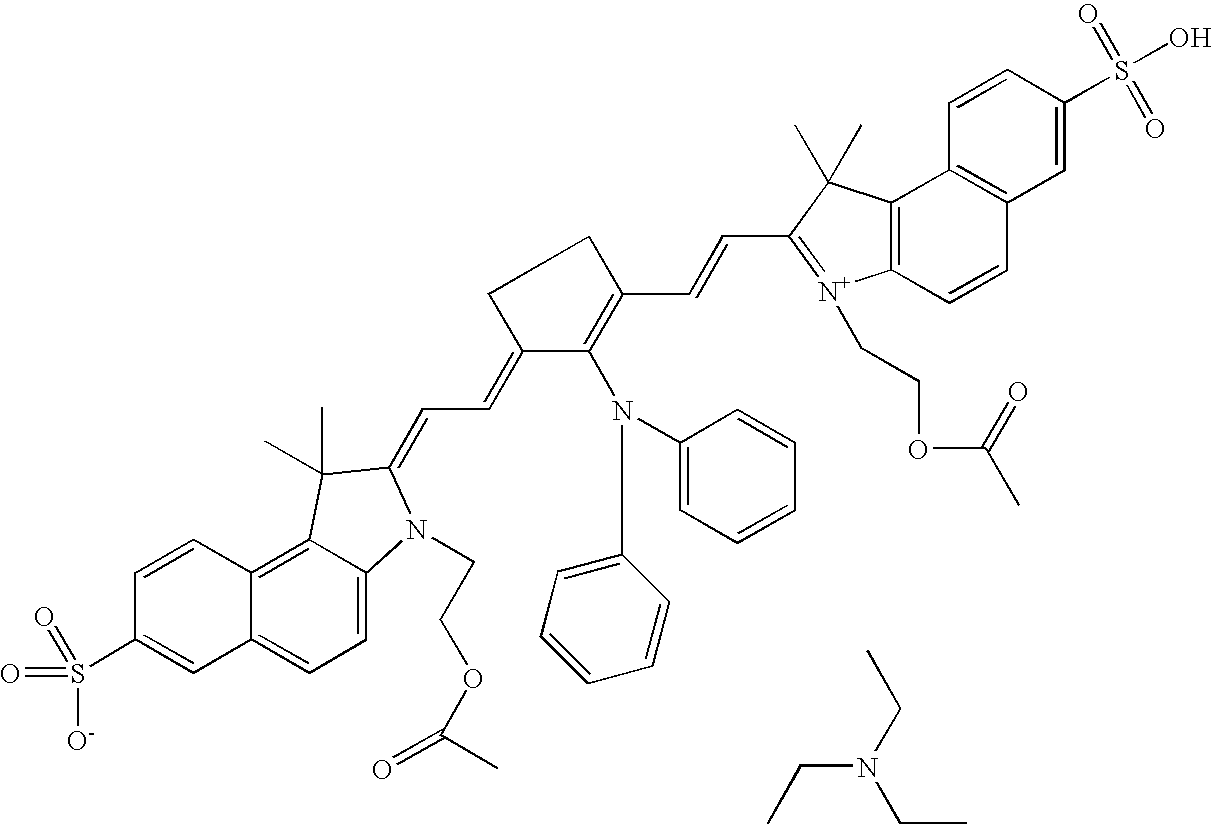

Electrophoretic particles and processes for the production thereof

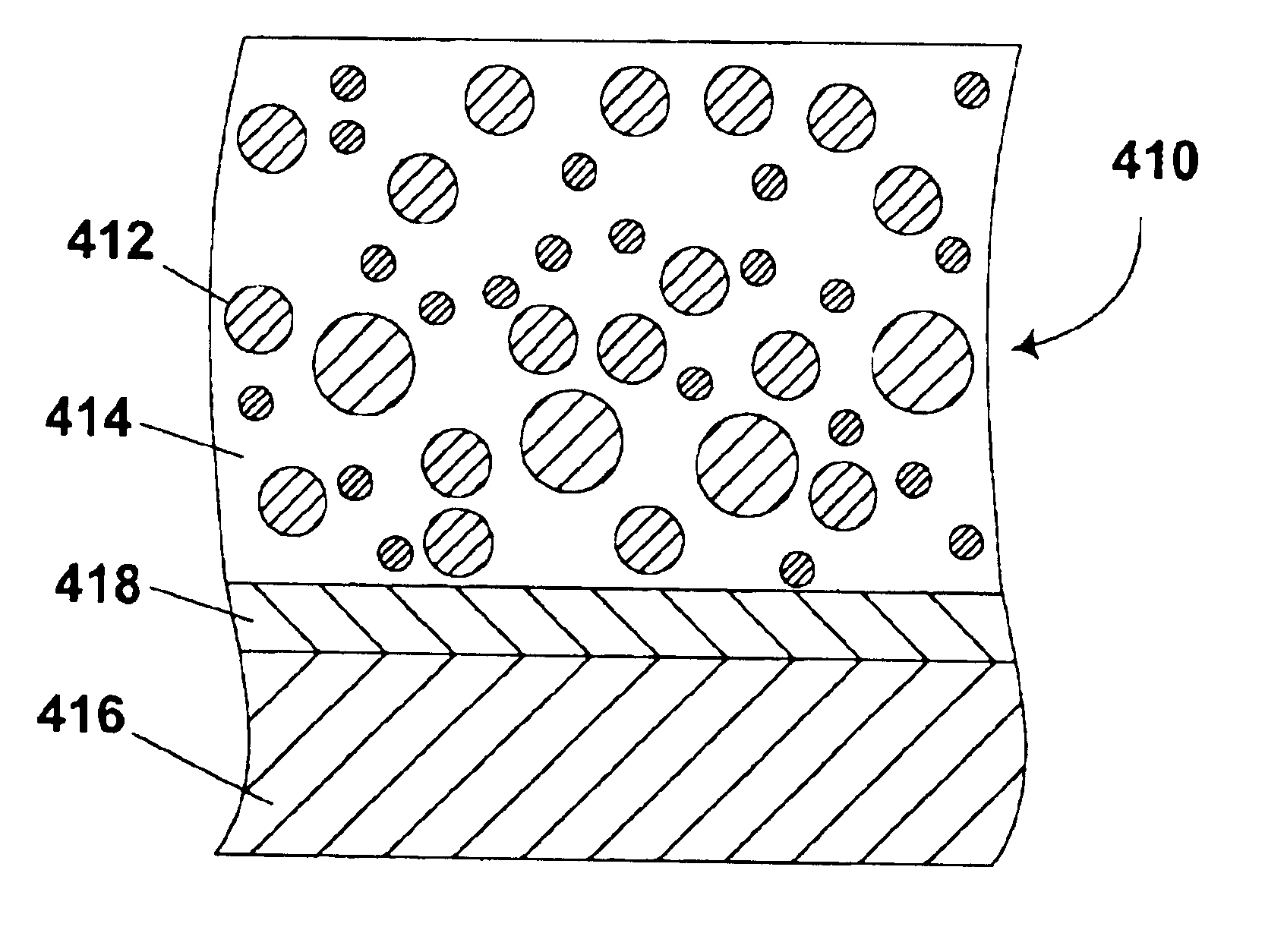

InactiveUS6822782B2Improve stabilityEasy to adaptMaterial nanotechnologyStatic indicating devicesCross-linkOligomer

In electrophoretic media, it is advantageous to use pigment particles having about 1 to 15 percent by weight of a polymer chemically bonded to, or cross-linked around, the pigment particles. The polymer desirably has a branched chain structure with side chains extending from a main chain. Charged or chargeable groups can be incorporated into the polymer or can be bonded to the particles separately from the polymer. The polymer-coated particles can be prepared by first attaching a polymerizable or polymerization-initiating group to the particle and then reacting the particle with one or more polymerizable monomers or oligomers.

Owner:E INK CORPORATION

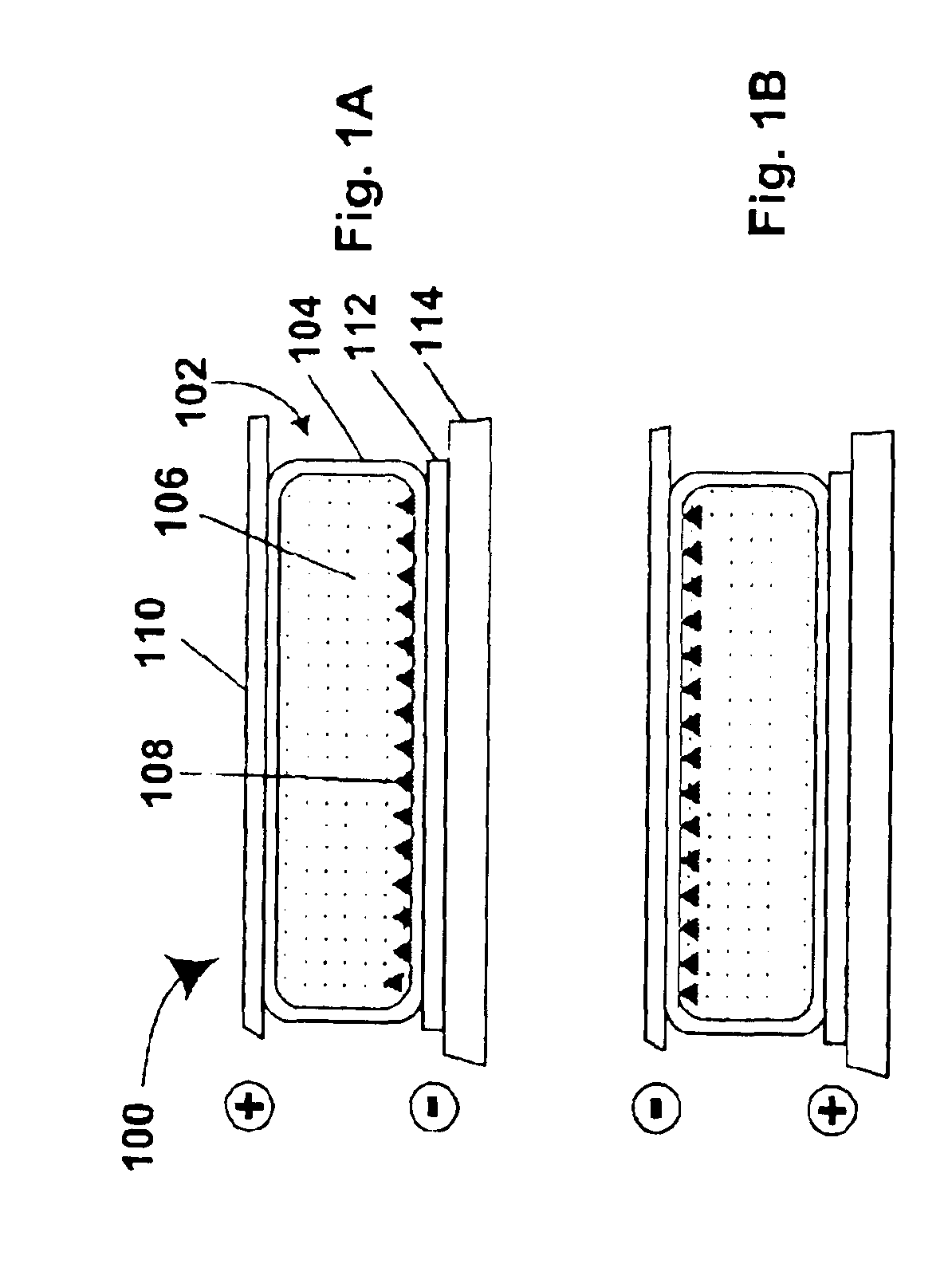

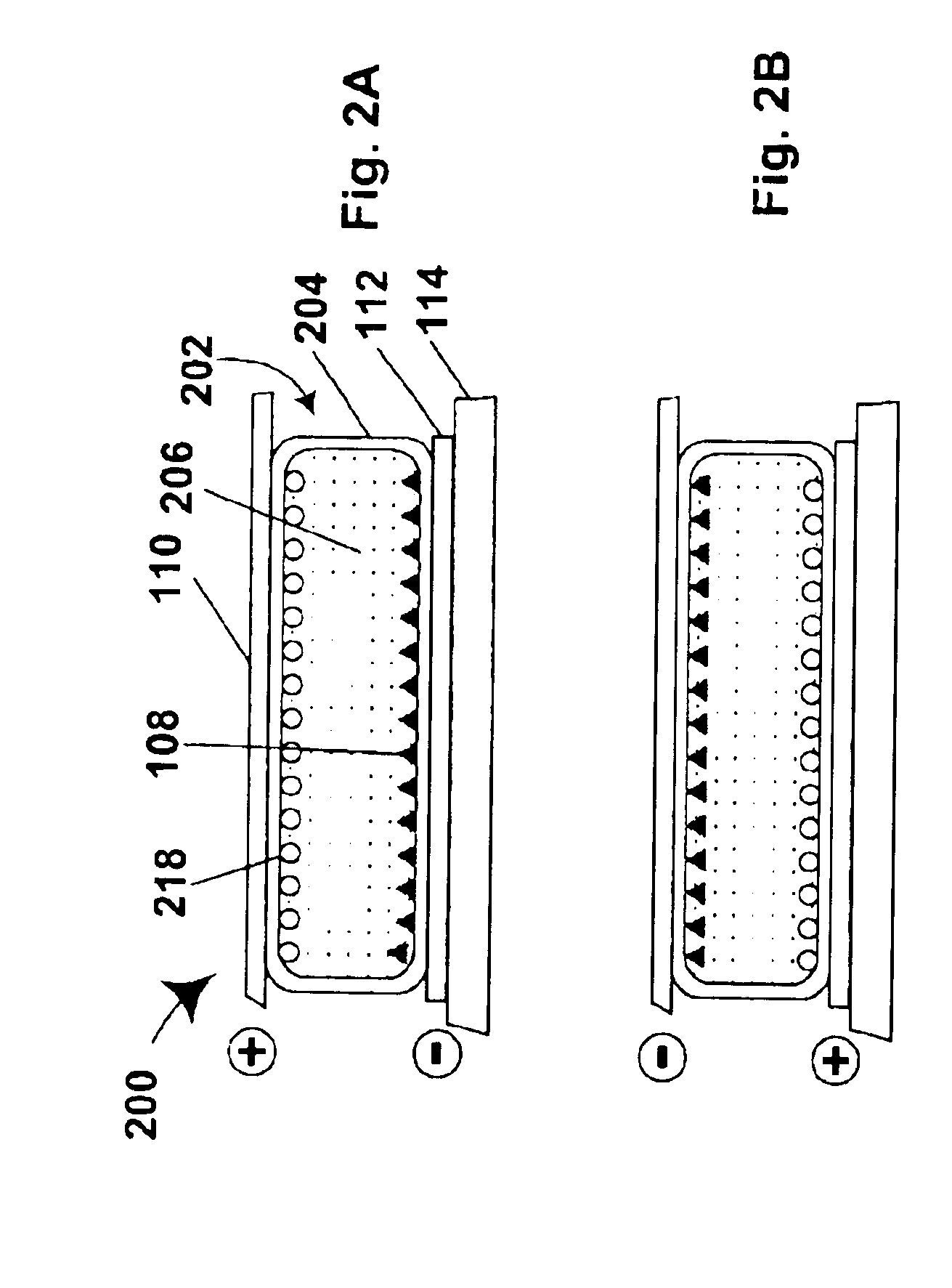

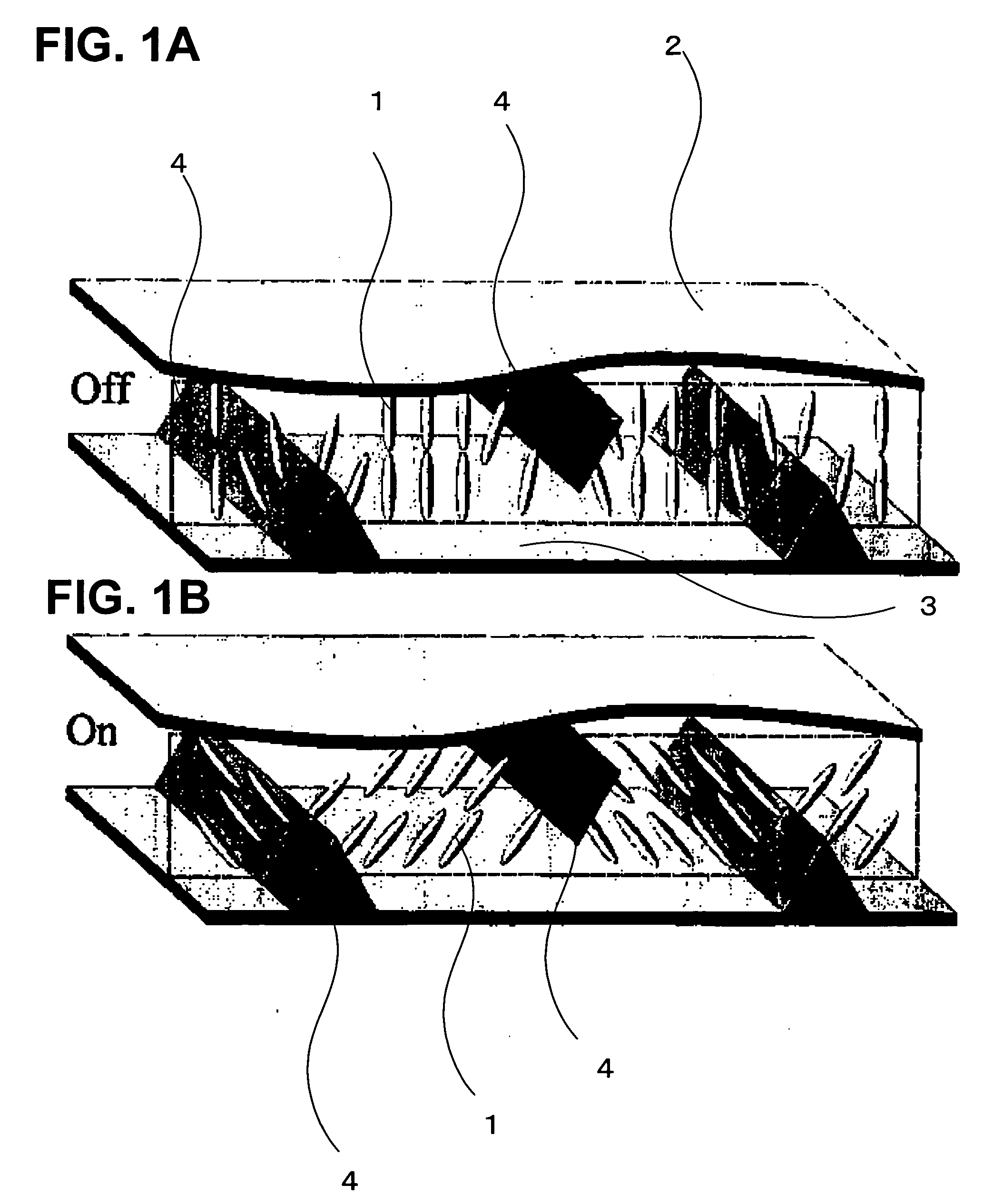

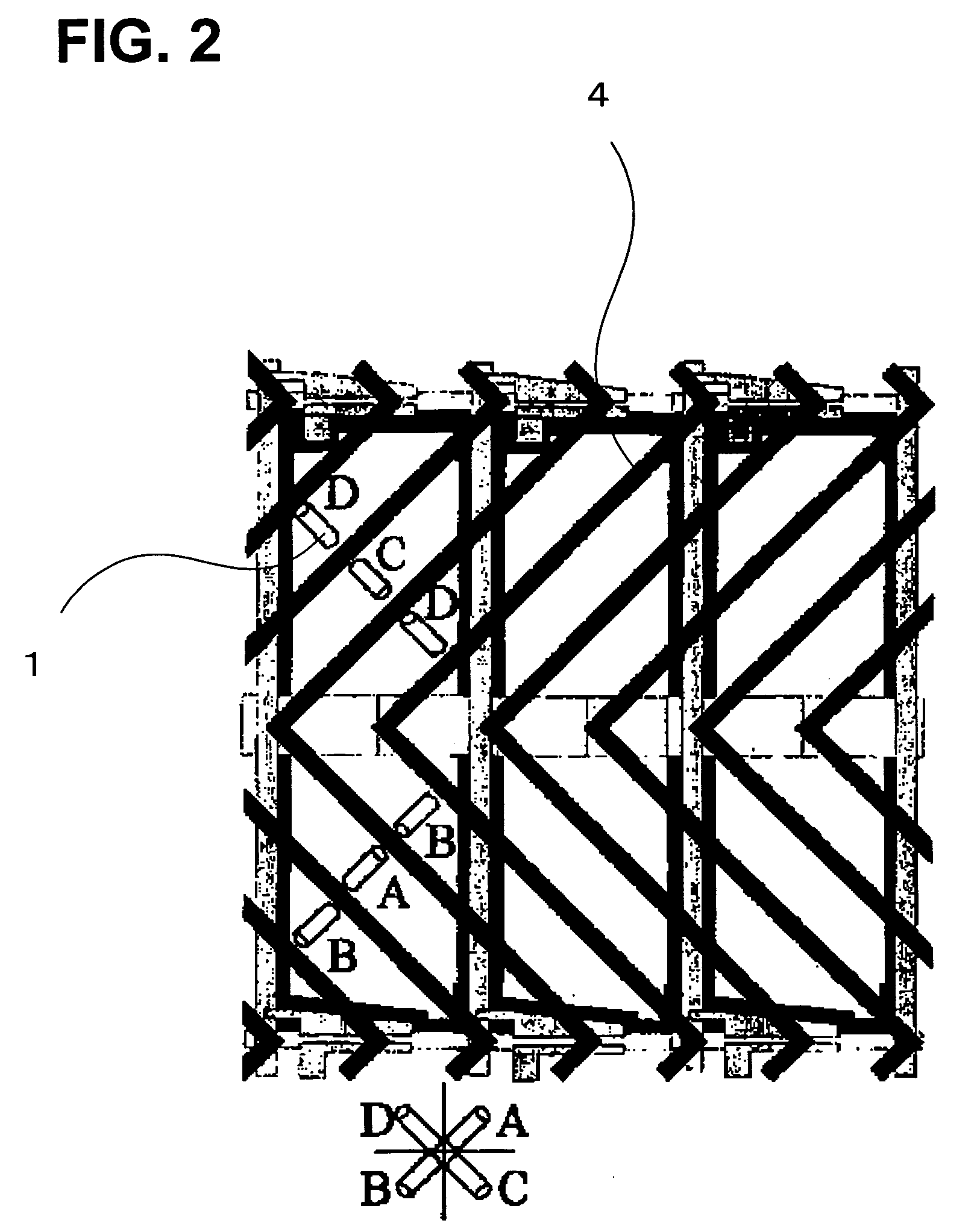

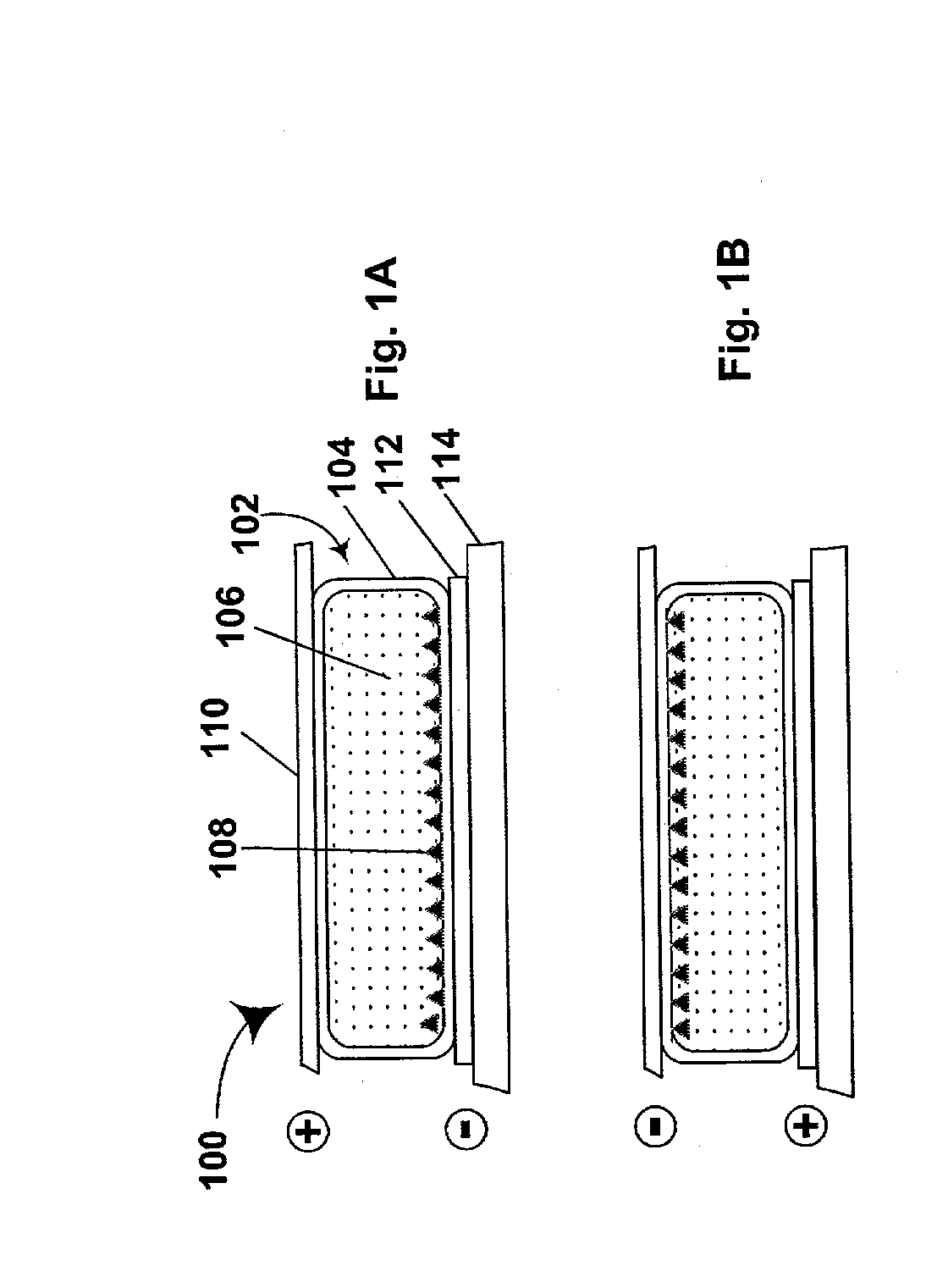

Liquid crystal display device and method of manufacture of the same

InactiveUS20060103804A1Improve reliabilityLittle and no tendency to exhibit white lineLiquid crystal compositionsNon-linear opticsLiquid-crystal displayReduced contrast volume

A liquid crystal composition, comprising a liquid crystal and a polymerizable compound capable of polymerization by means of light, heat, or a combination thereof, is placed in the gap between two parallel substrates on which are formed a pair of electrodes, and the polymerizable compound is polymerized to form a liquid crystal layer and a resin film. A liquid crystal display device is manufactured accordingly. The polymerizable compound comprises a monofunctional polymerizable compound, and the dipole moment of the monofunctional polymerizable compound is 4 debyes or lower. Thus, a liquid crystal display device, with high reliability, and of excellent quality with little or no contrast reduction due to white lines, is provided.

Owner:SHARP KK

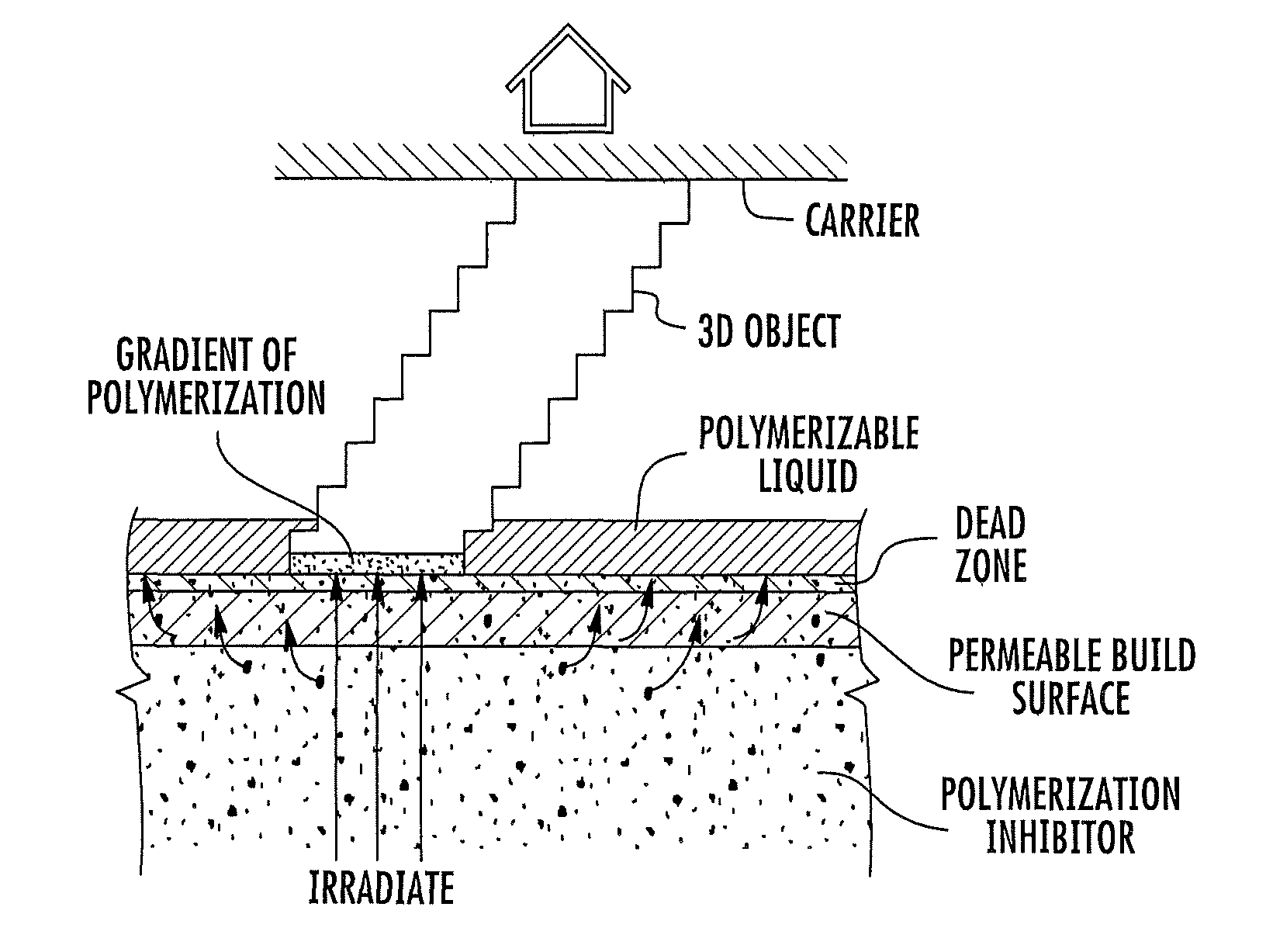

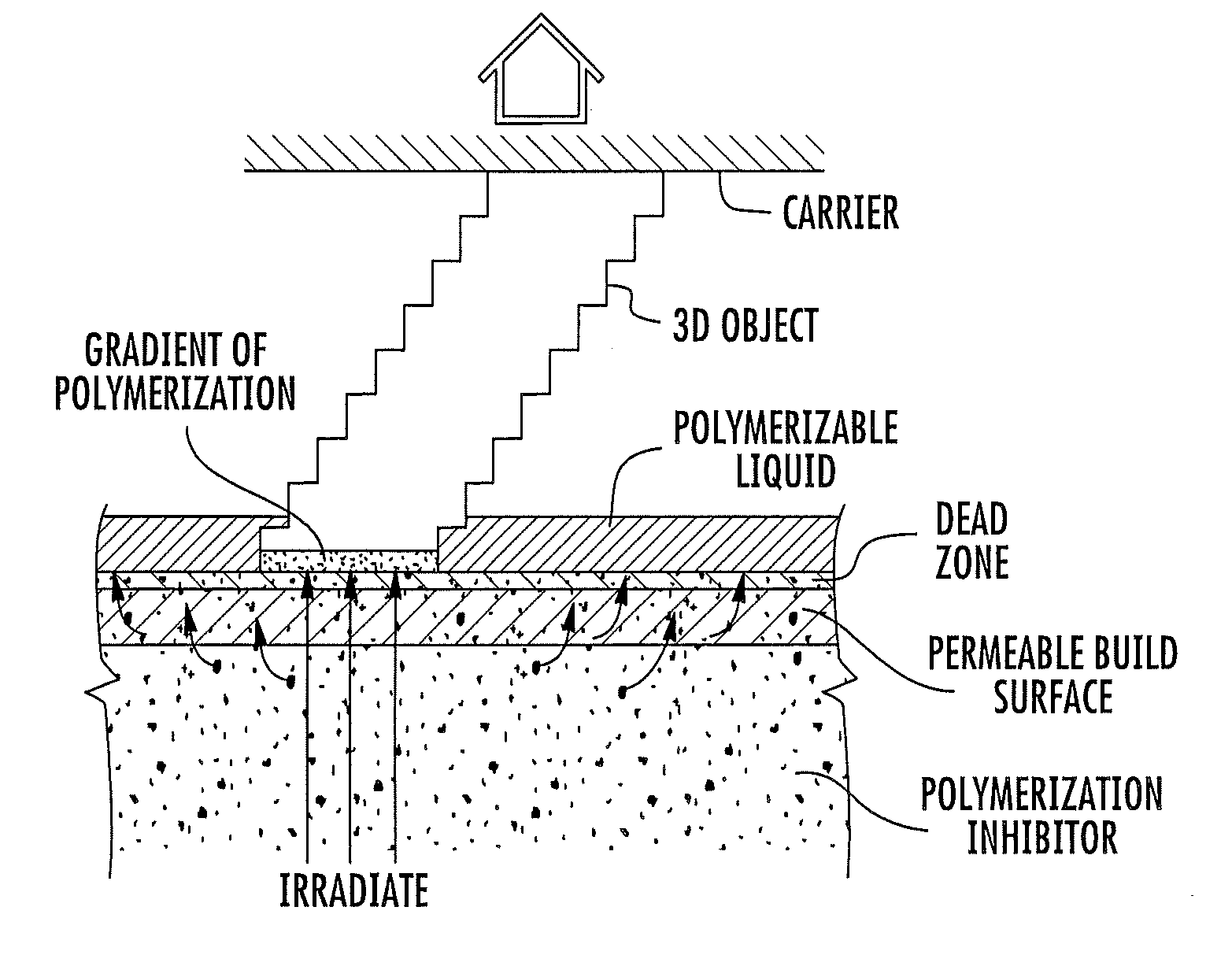

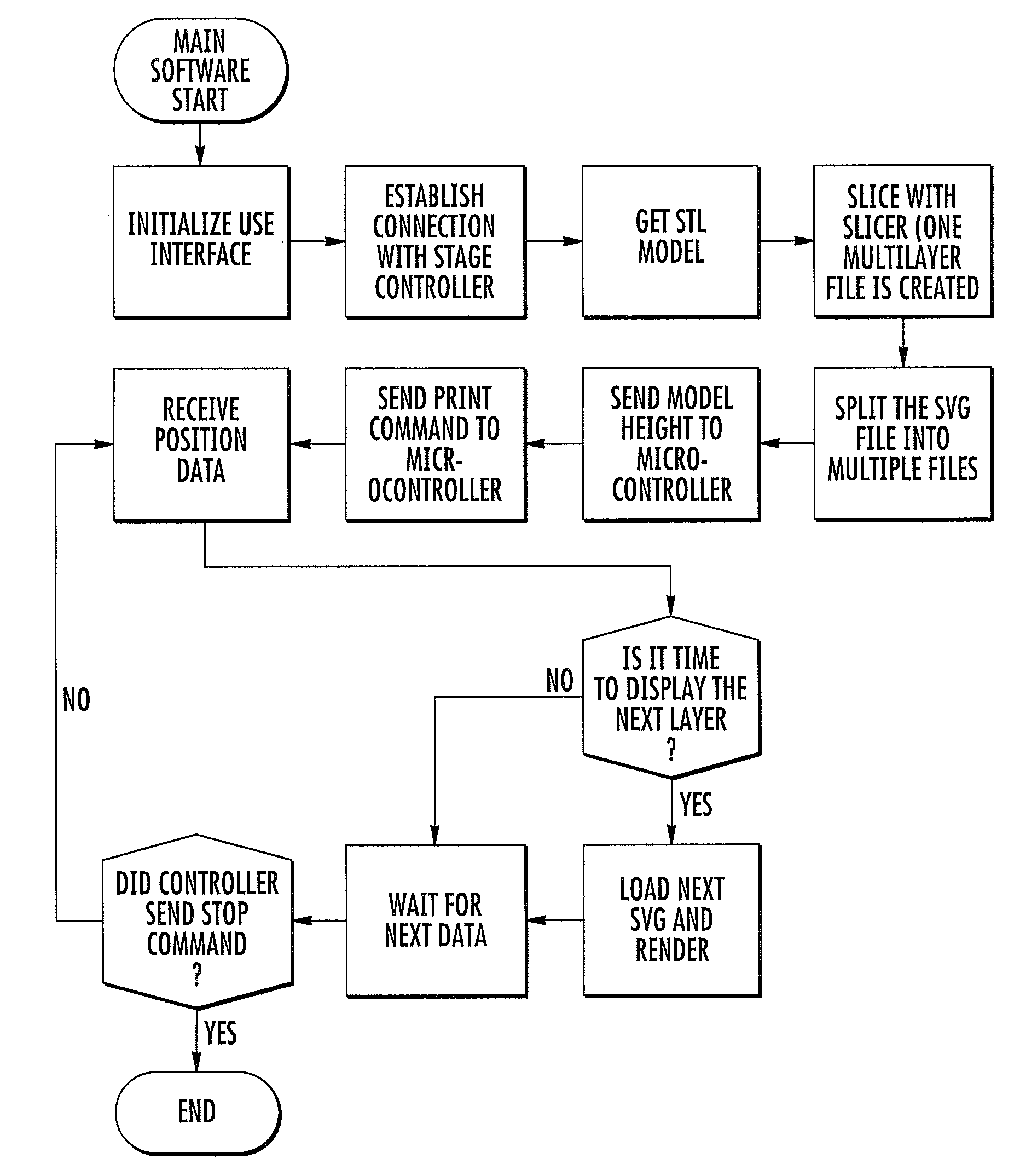

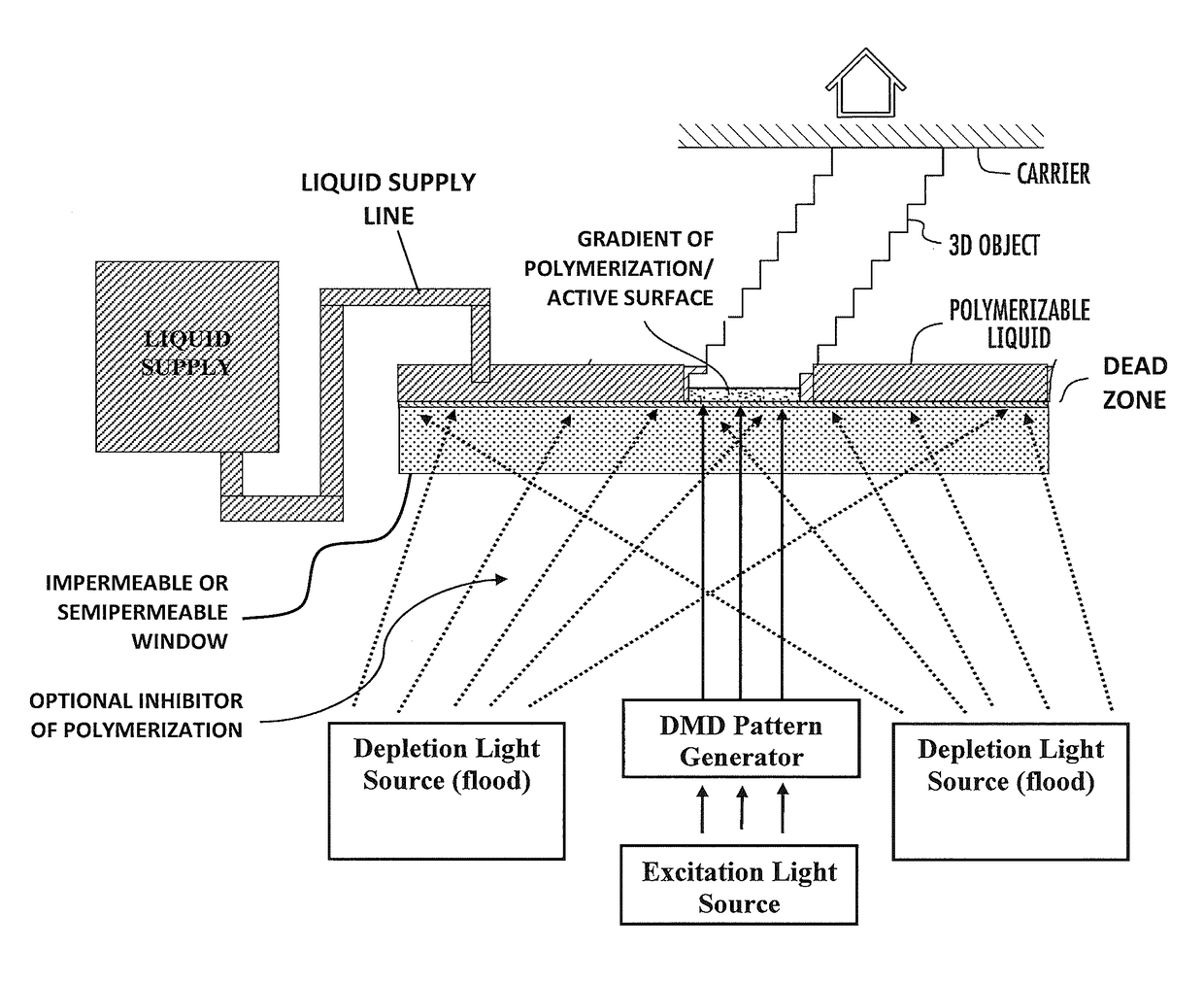

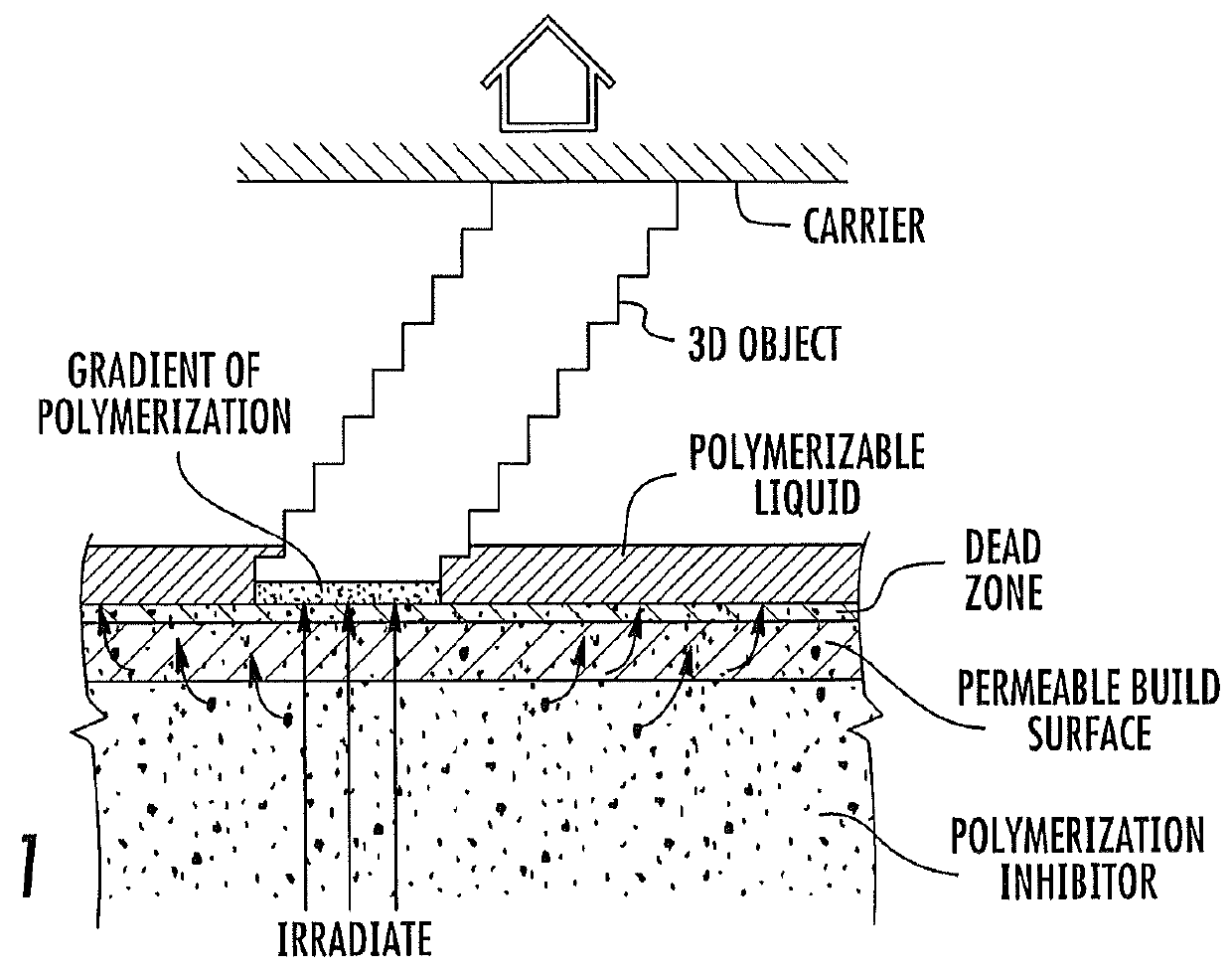

Continuous liquid interphase printing

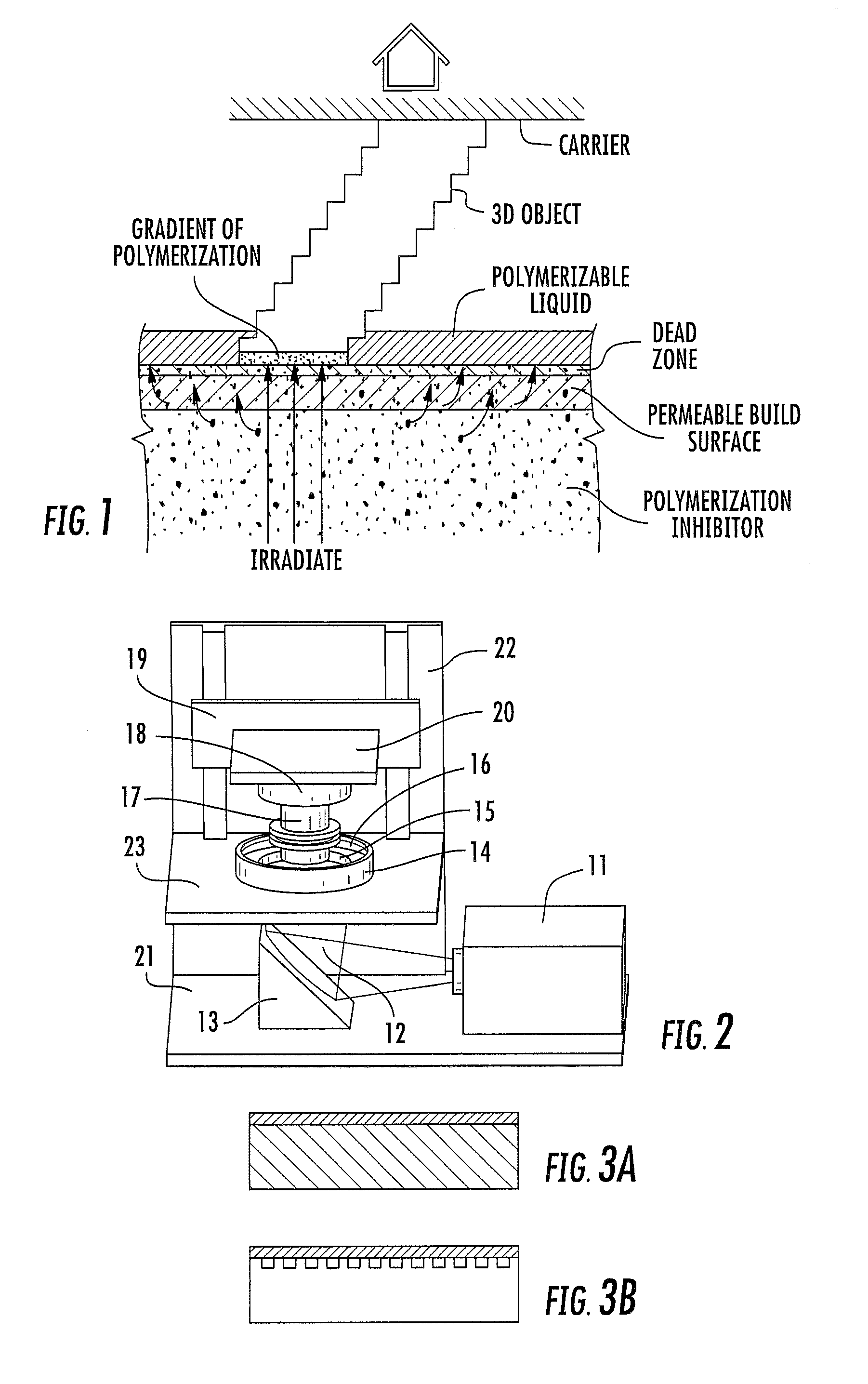

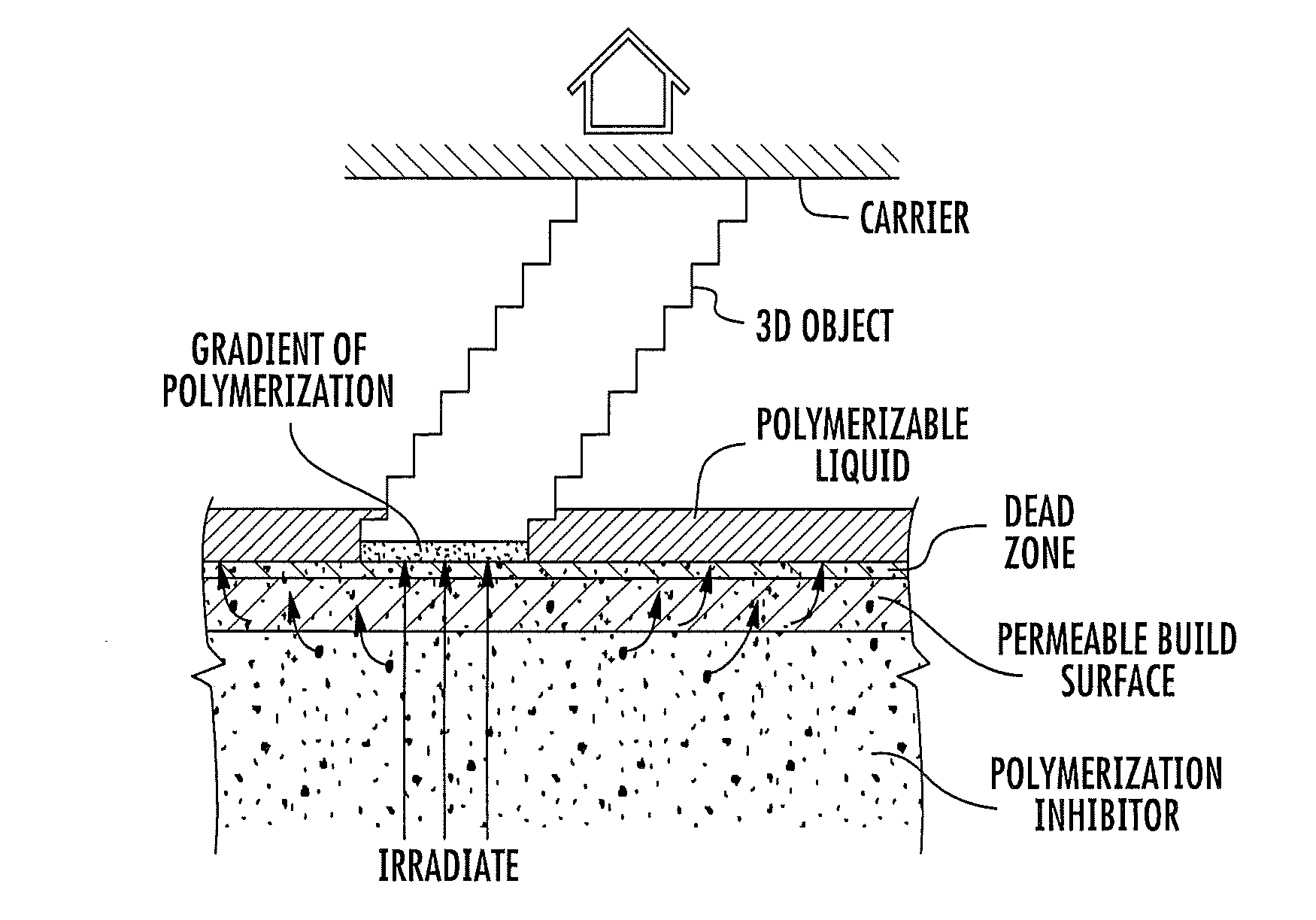

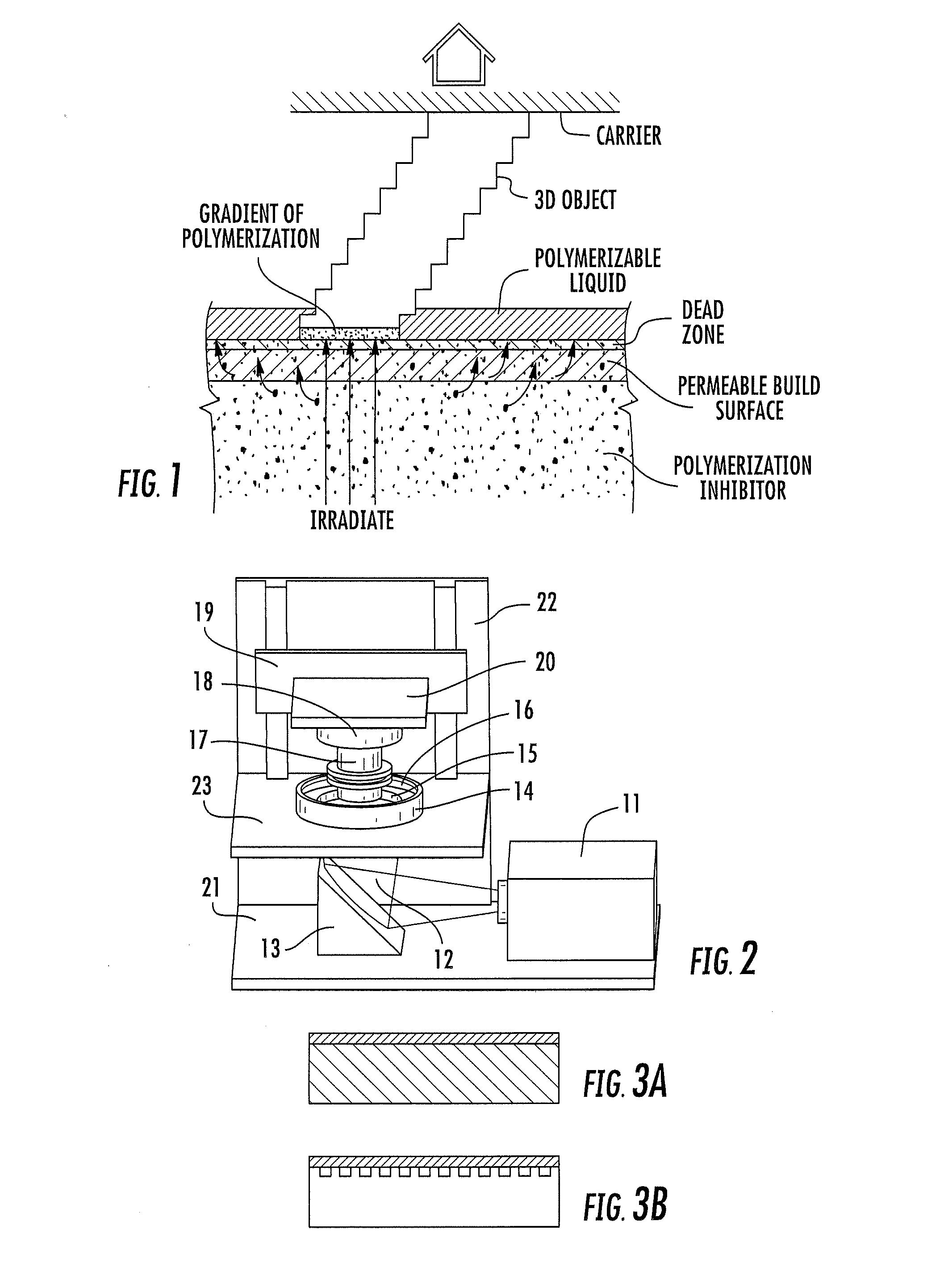

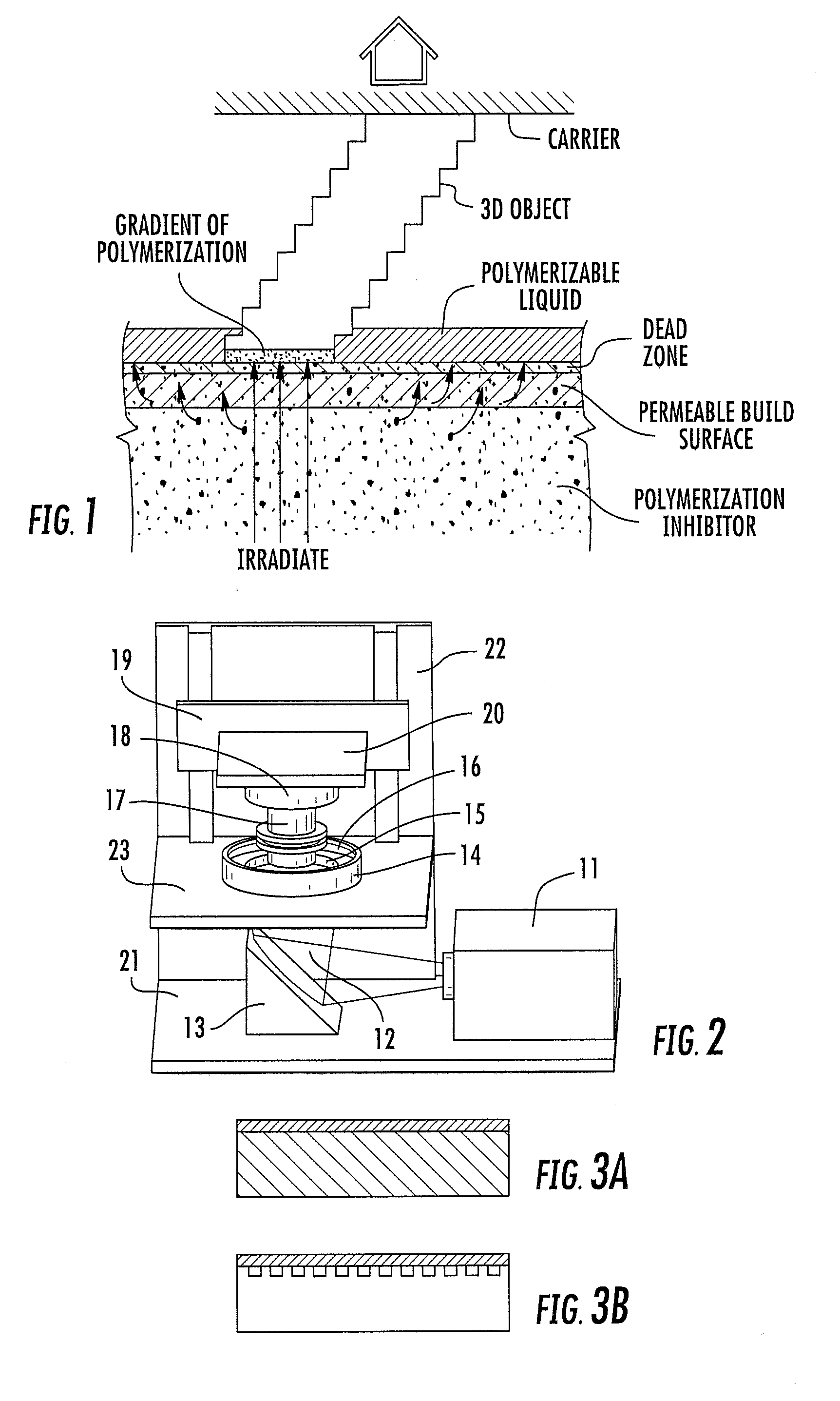

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

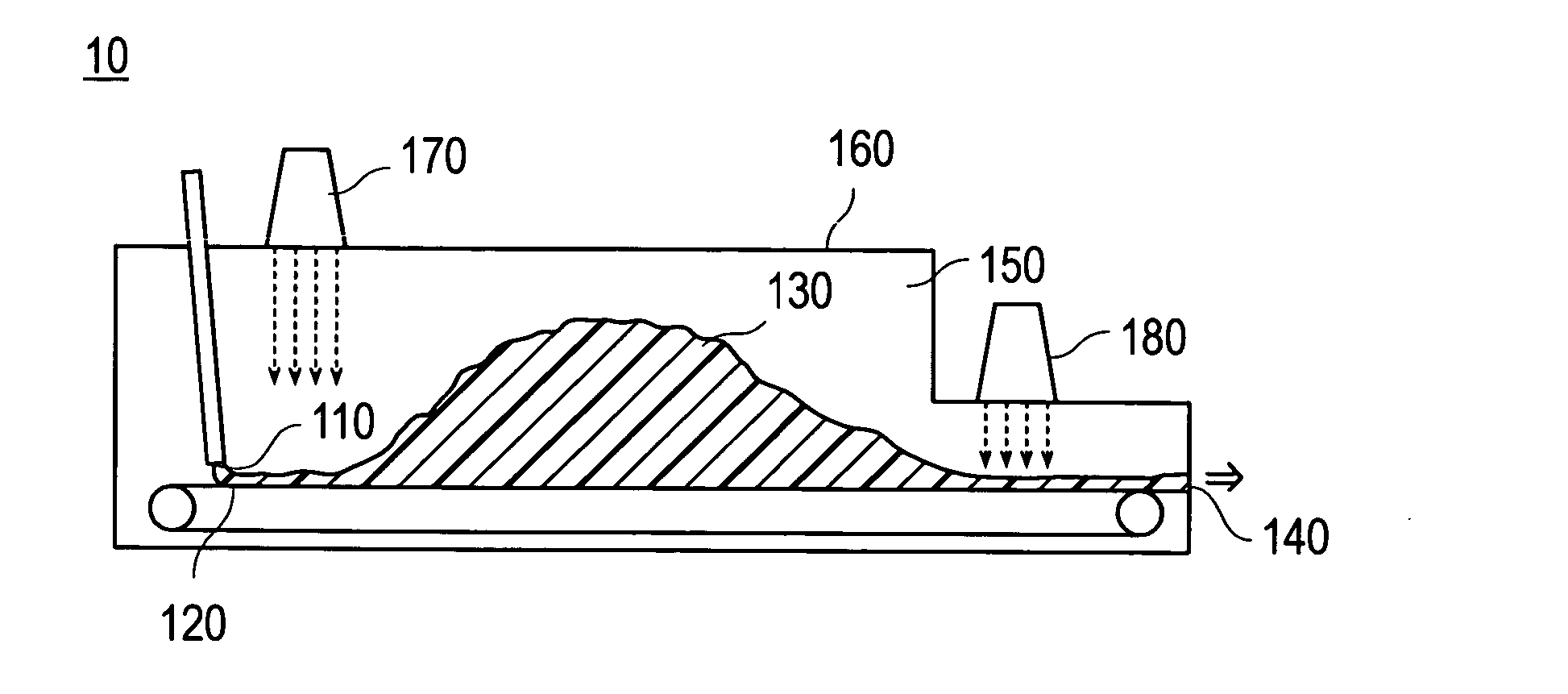

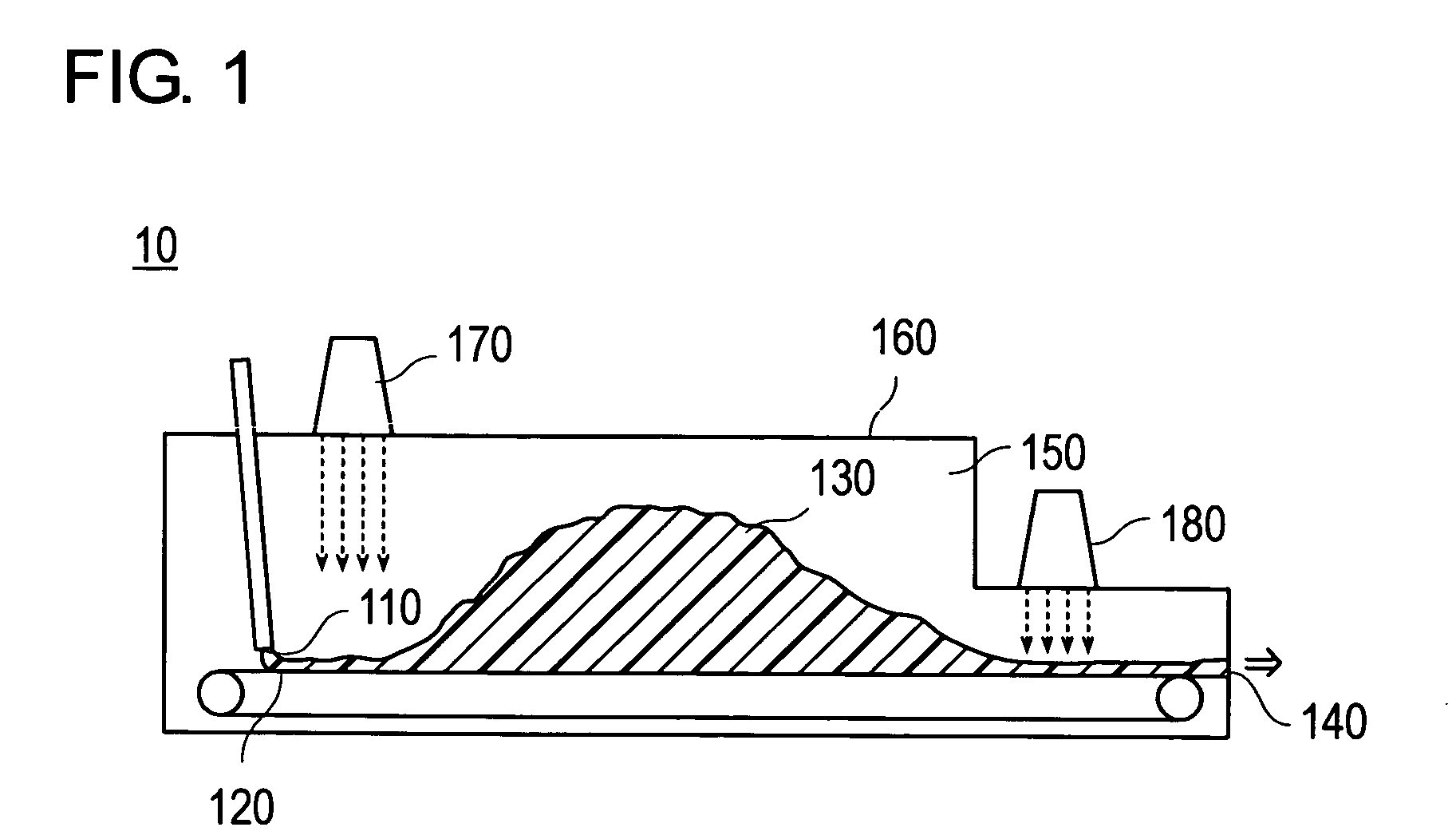

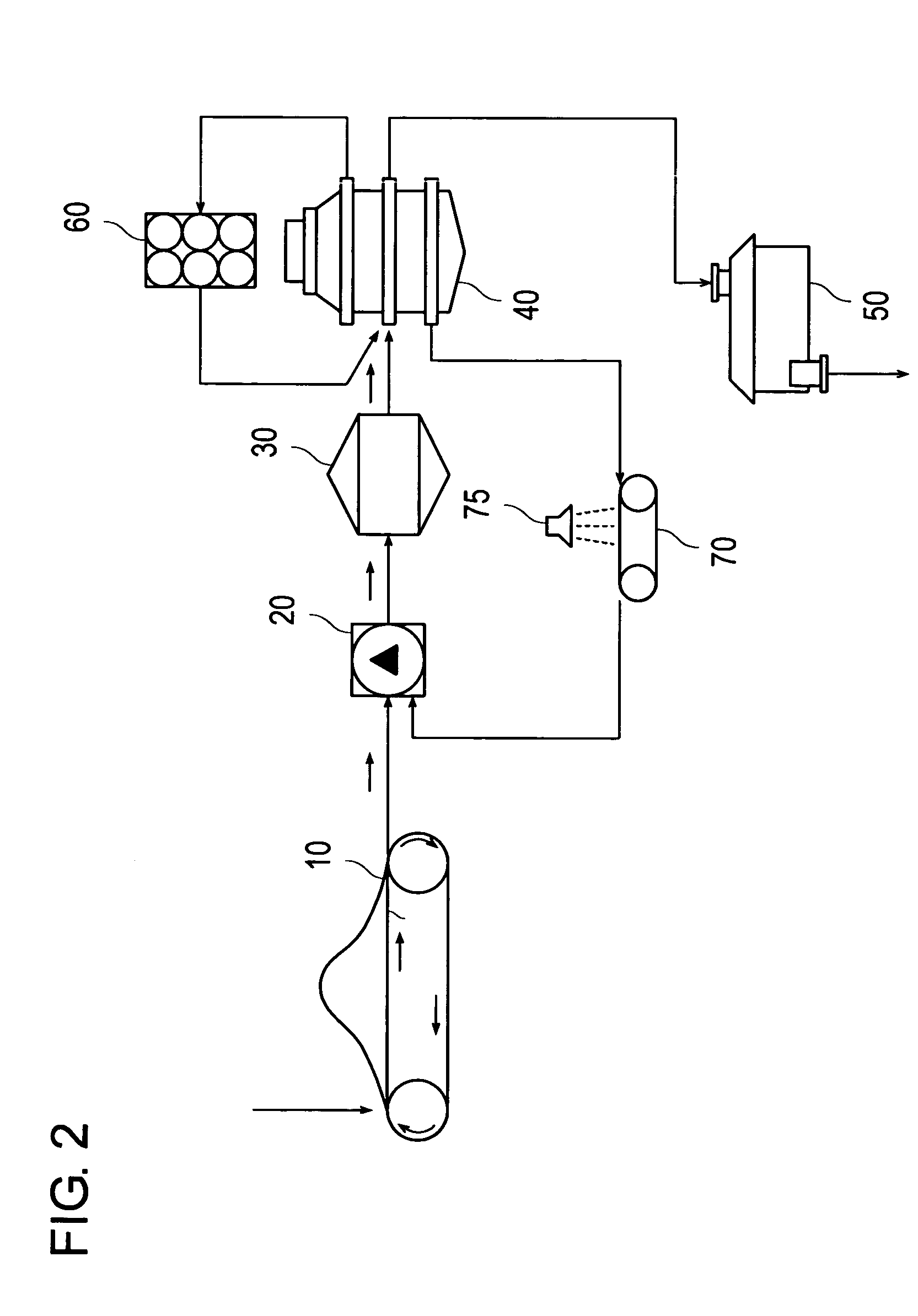

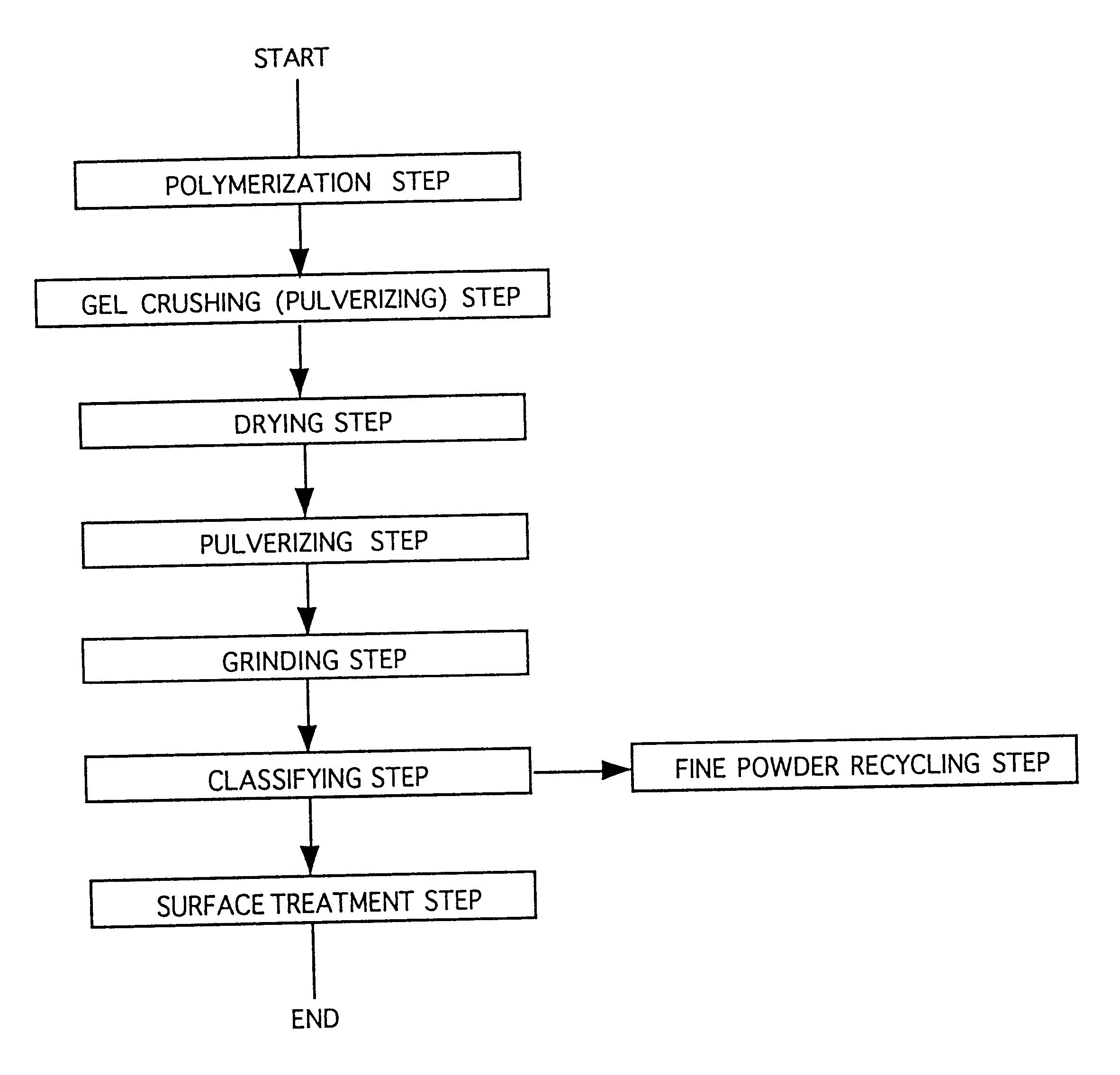

Method for continuous production of water-absorbent resin

The present invention relates to a method for continuous production of a water-absorbent resin by use of an continuous polymerization device having a charge part of a monomer aqueous solution; an endless belt on which the monomer and a hydropolymer formed are conveyed; and a discharge part of the hydropolymer, wherein the continuous polymerization device has side walls and a ceiling, and the space ratio in the device represented by the equation, “space ratio in the device=B / A”, is in the range of 1.2 to 20. In the equation, A is a maximum cross-sectional area (cm2) of the hydropolymer during the polymerization in the width direction of the endless belt, and B is a maximum cross-sectional area (cm2) of the space between the endless belt of the continuous polymerization device and the ceiling of the continuous polymerization device in the width direction of the endless belt.

Owner:NIPPON SHOKUBAI CO LTD

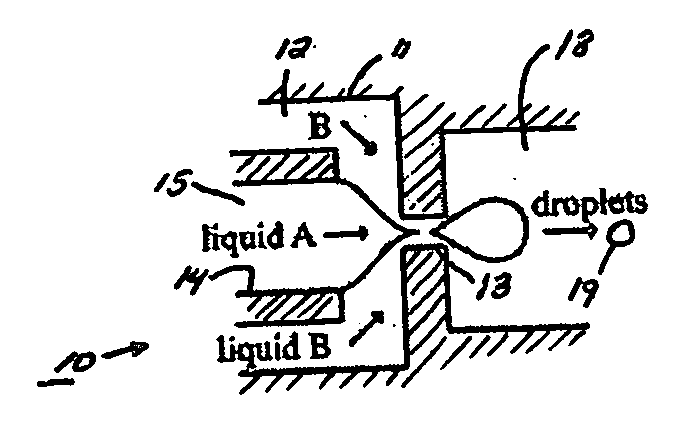

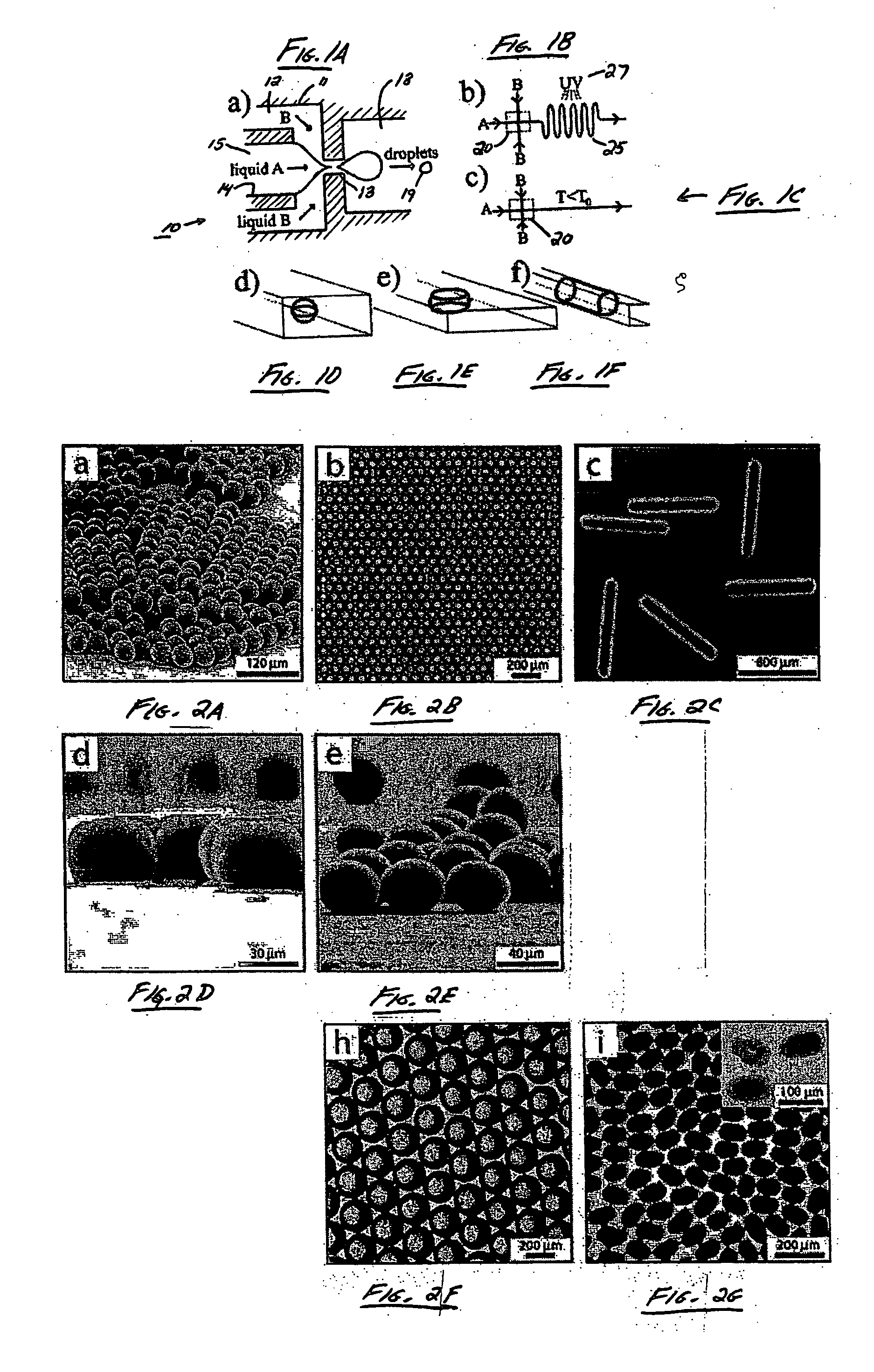

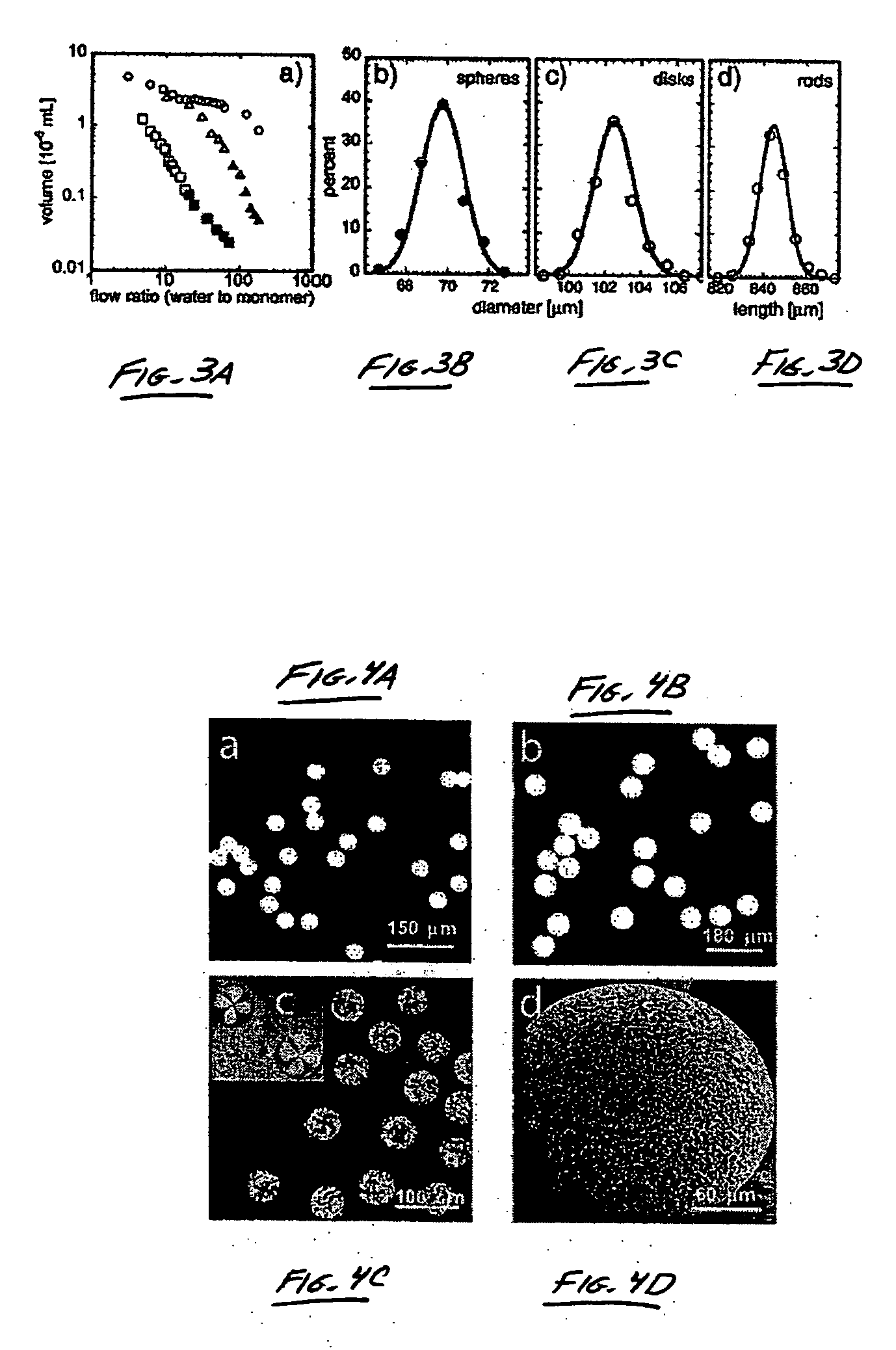

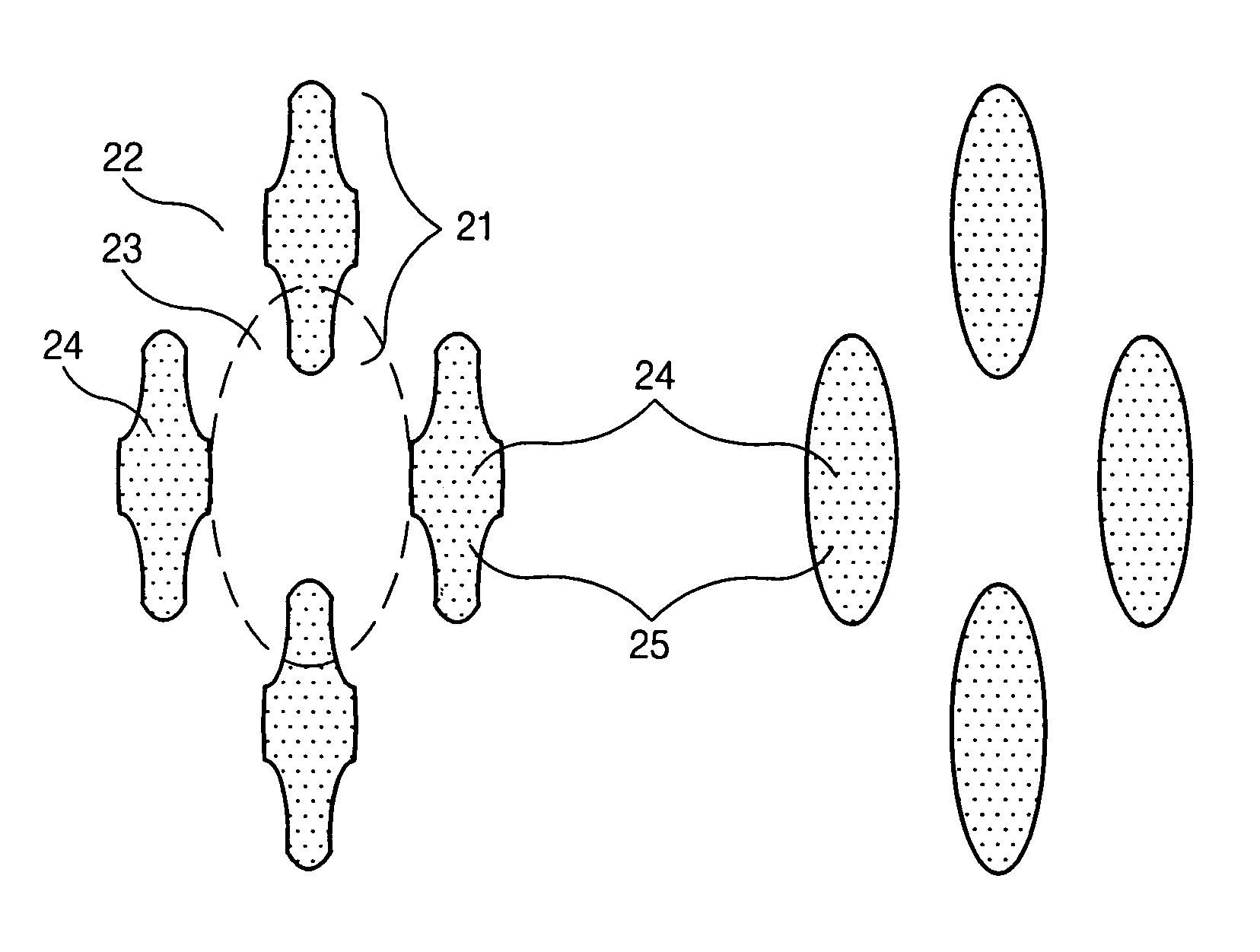

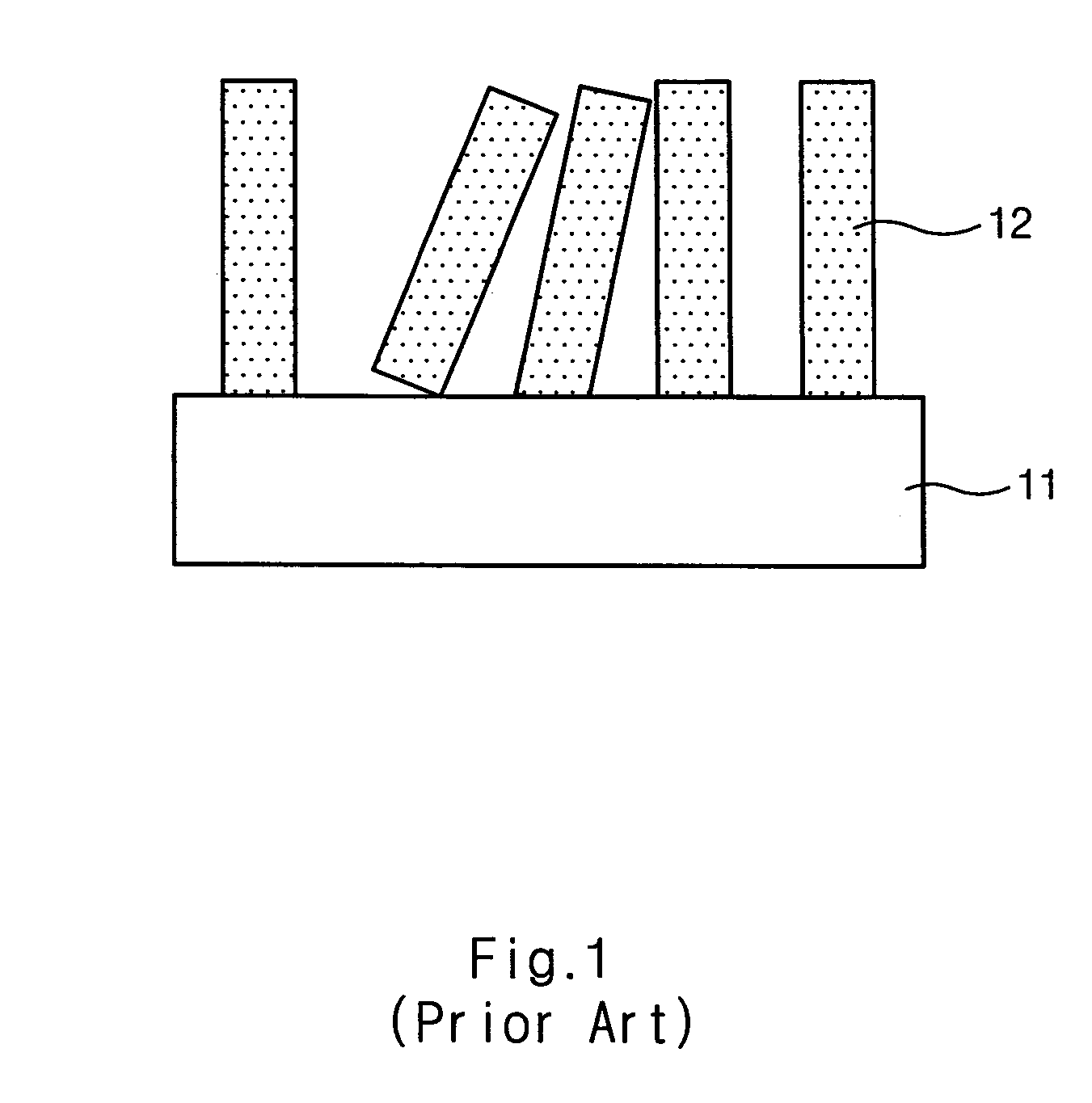

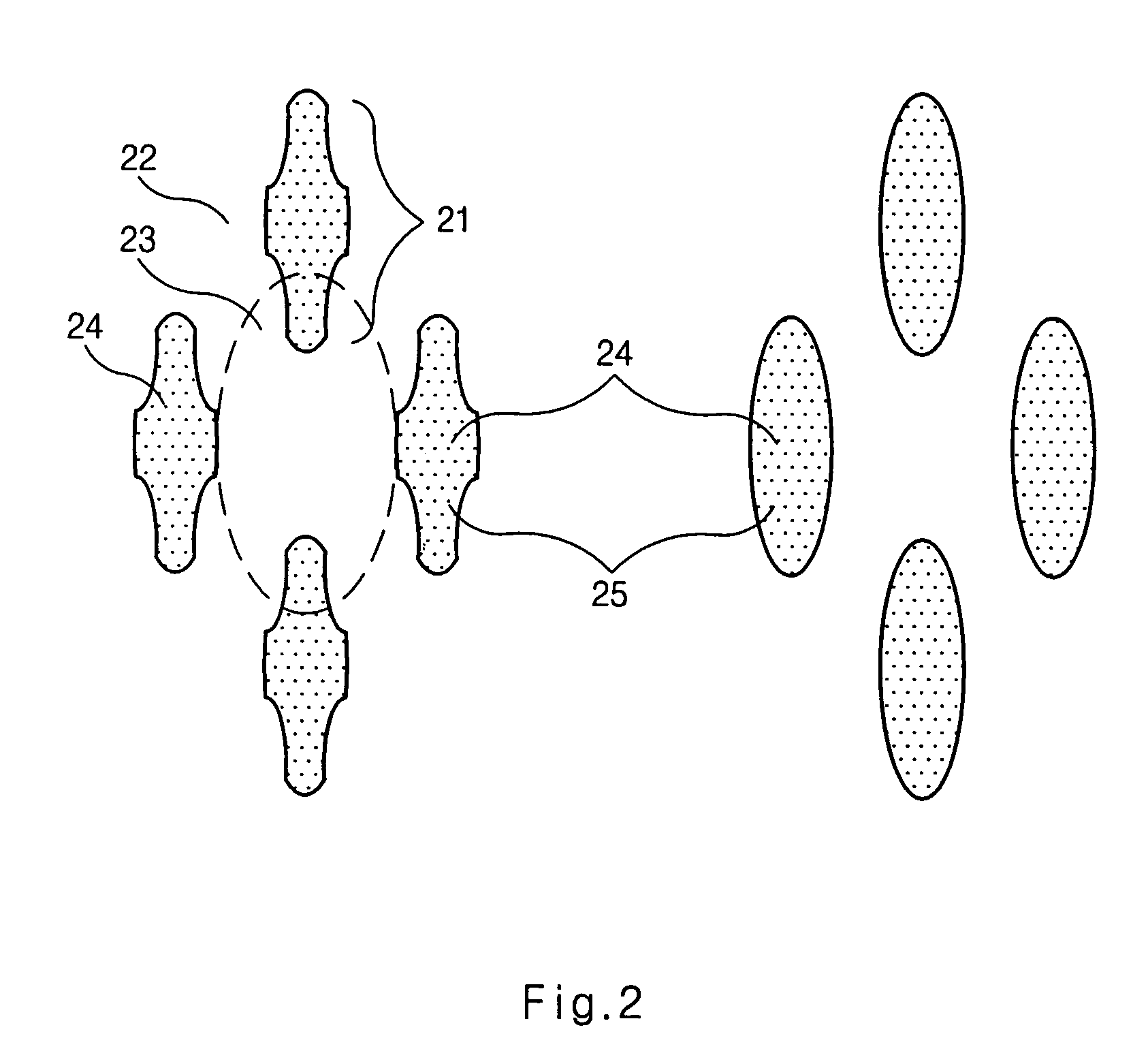

Systems and methods of forming particles

InactiveUS20070054119A1Synthetic resin layered productsChemical/physical/physico-chemical microreactorsChemical reactionMicrometer

The present invention generally relates to systems and methods of forming particles and, in certain aspects, to systems and methods of forming particles that are substantially monodisperse. Microfluidic systems and techniques for forming such particles are provided, for instance, particles may be formed using gellation, solidification, and / or chemical reactions such as cross-linking, polymerization, and / or interfacial polymerization reactions. In one aspect, the present invention is directed to a plurality of particles having an average dimension of less than about 500 micrometers and a distribution of dimensions such that no more than about 5% of the particles have a dimension greater than about 10% of the average dimension, which can be made via microfluidic systems. In one set of embodiments, at least some of the particles may comprise a metal, and in certain embodiments, at least some of the particles may comprise a magnetizable material. In another set of embodiments, at least some of the particles may be porous. In some embodiments, the invention includes non-spherical particles. Non-spherical particles may be formed, for example, by urging a fluidic droplet into a channel having a smallest dimension that is smaller than the diameter of a perfect mathematical sphere having a volume of the droplet, and solidifying the droplet, and / or by exposing at least a portion of a plurality of particles to an agent able to remove at least a portion of the particles.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

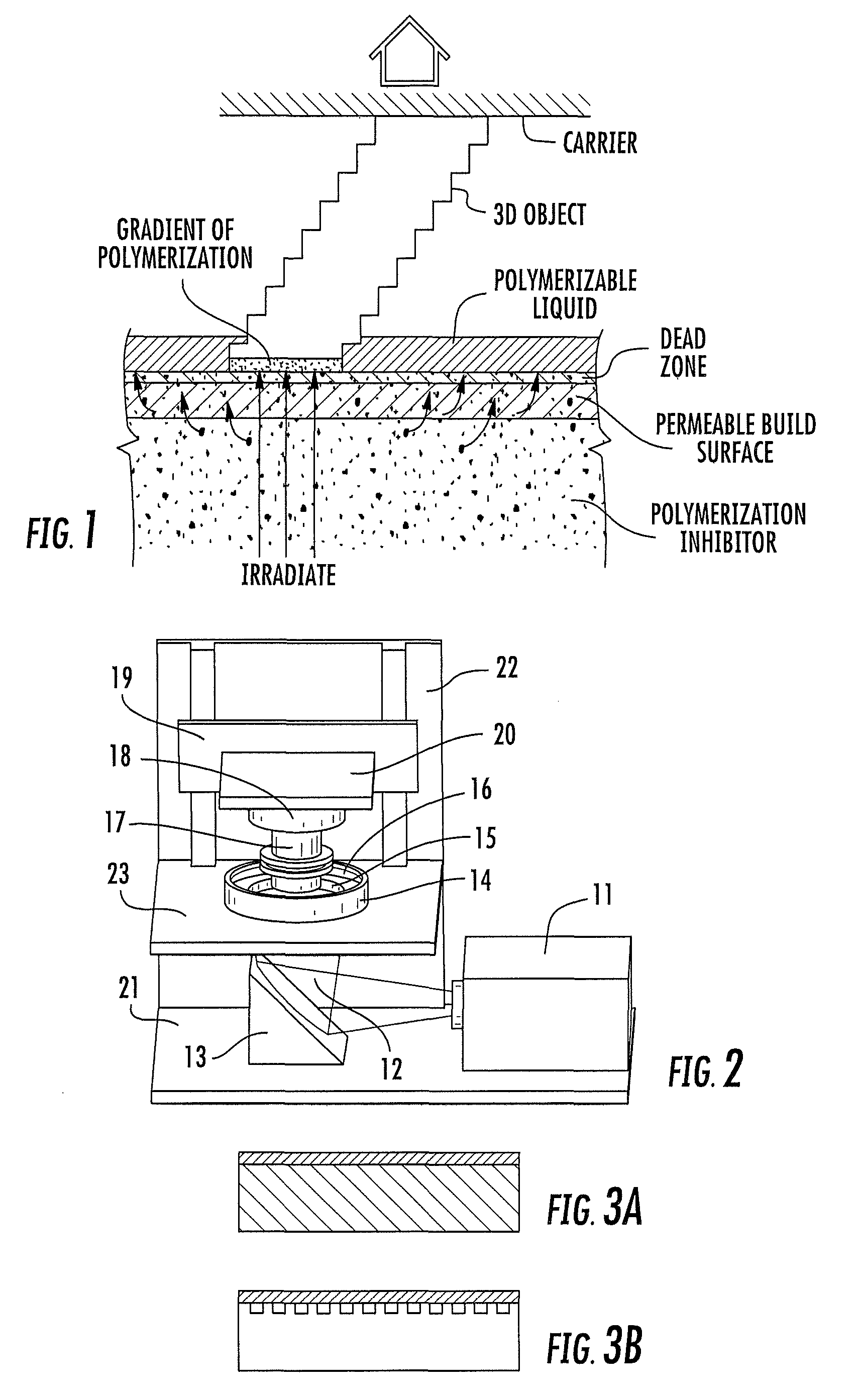

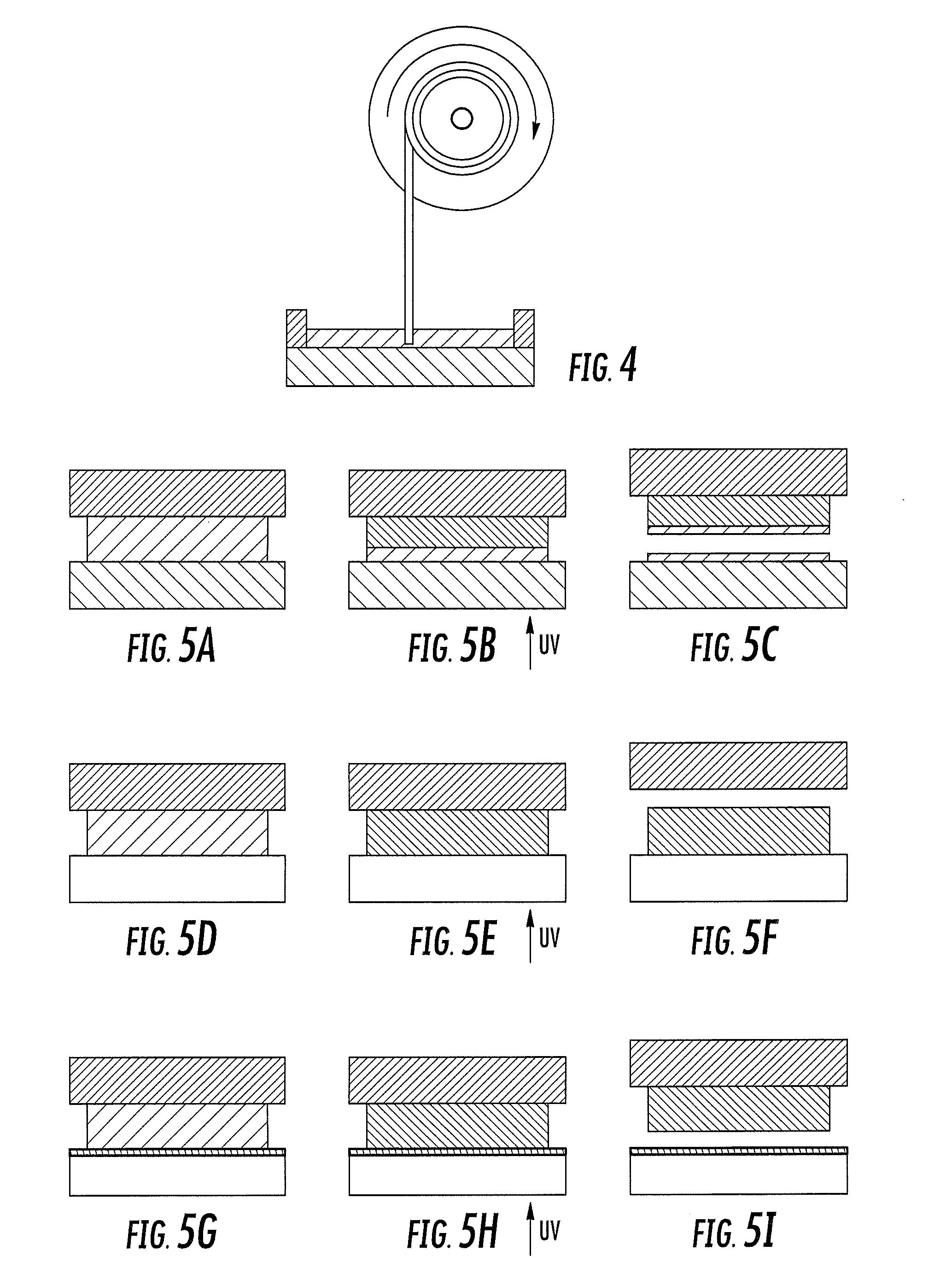

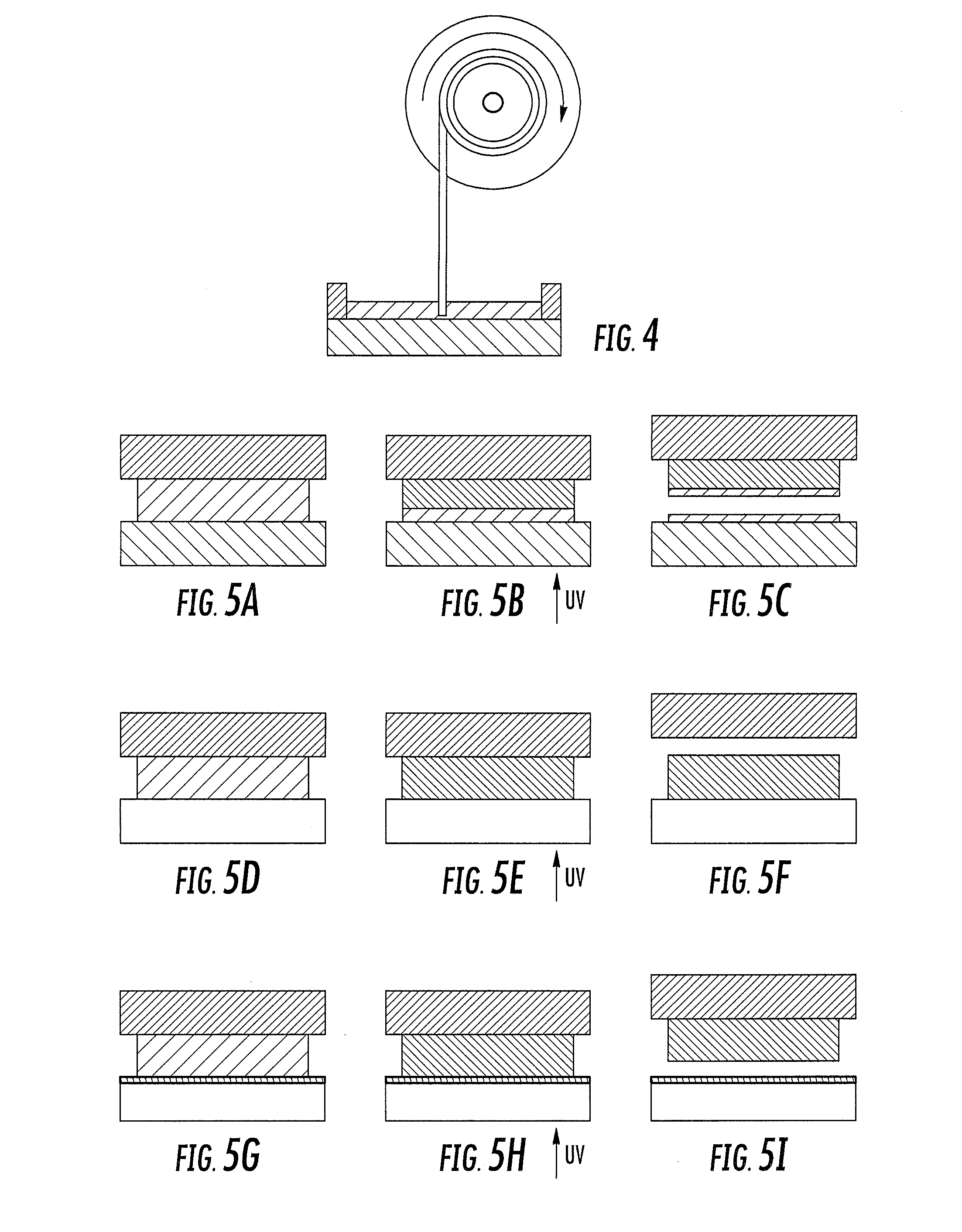

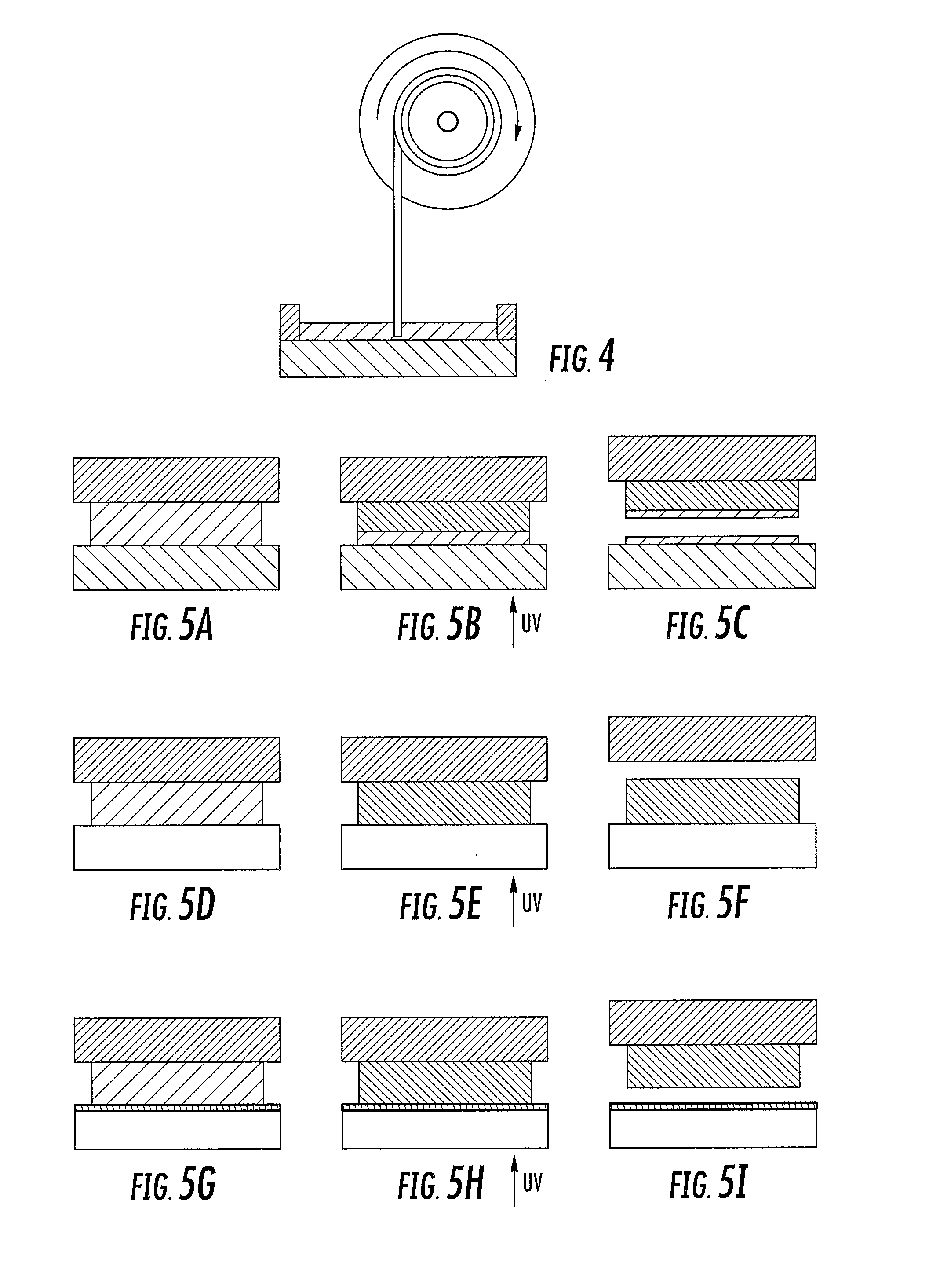

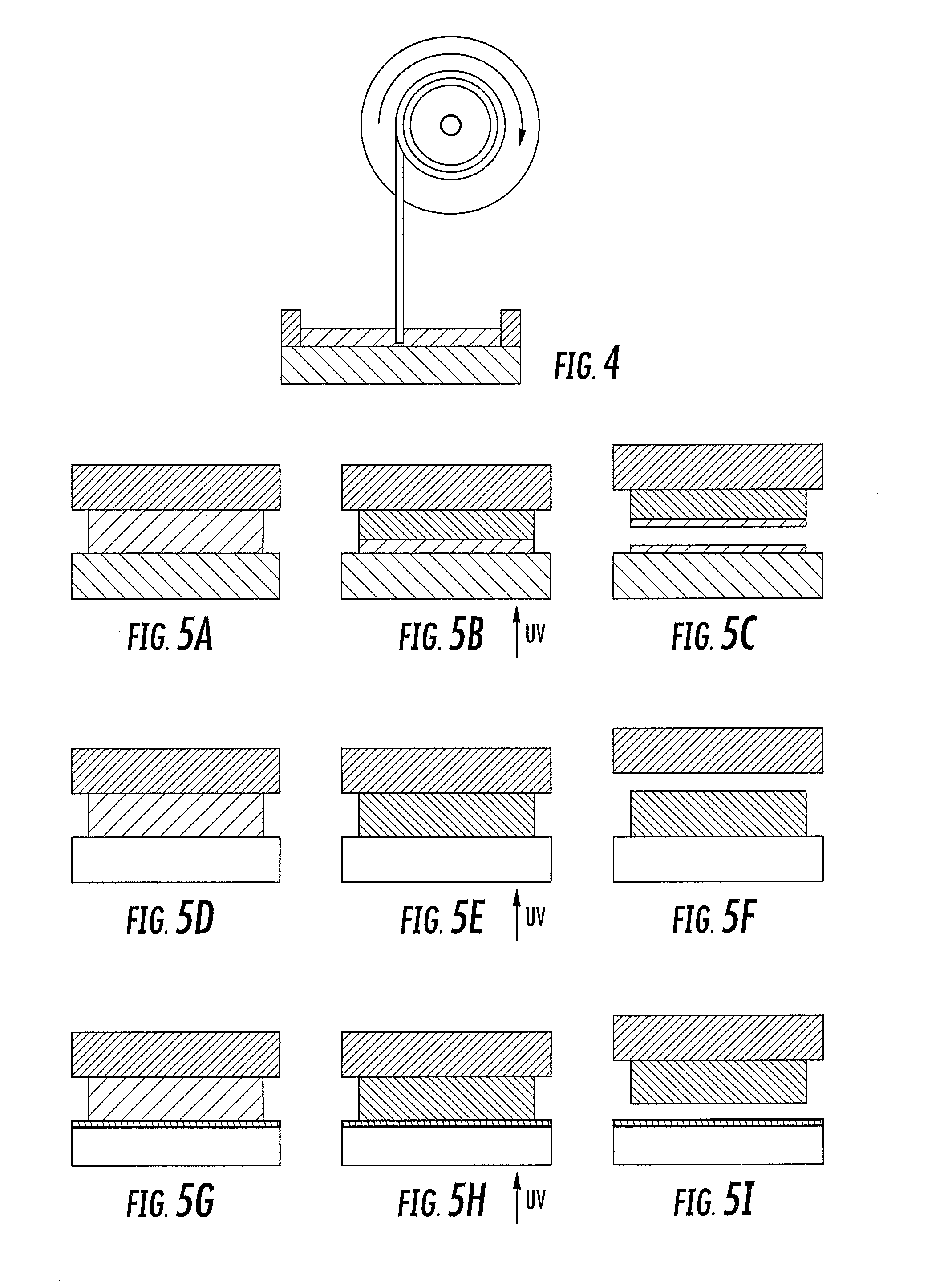

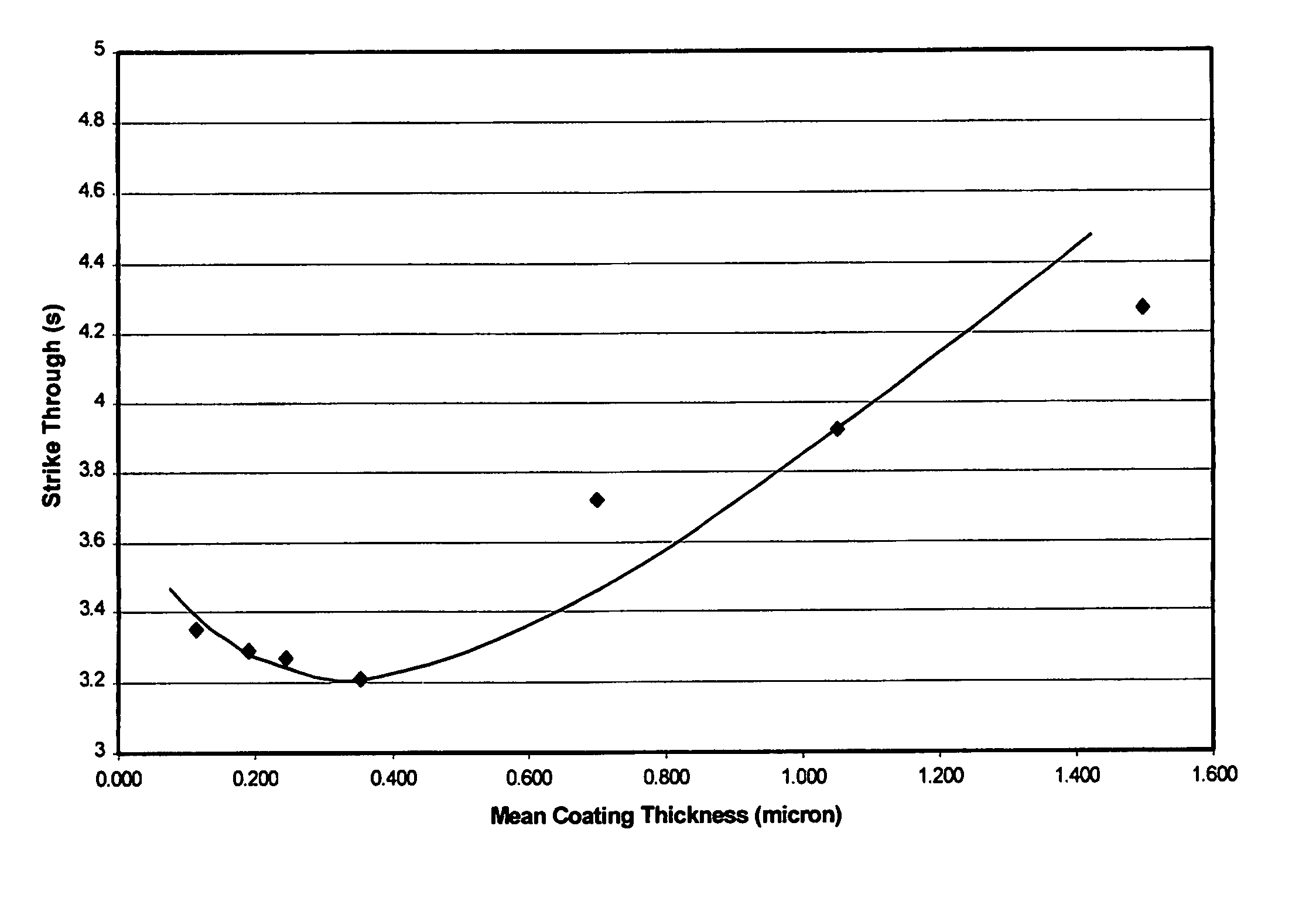

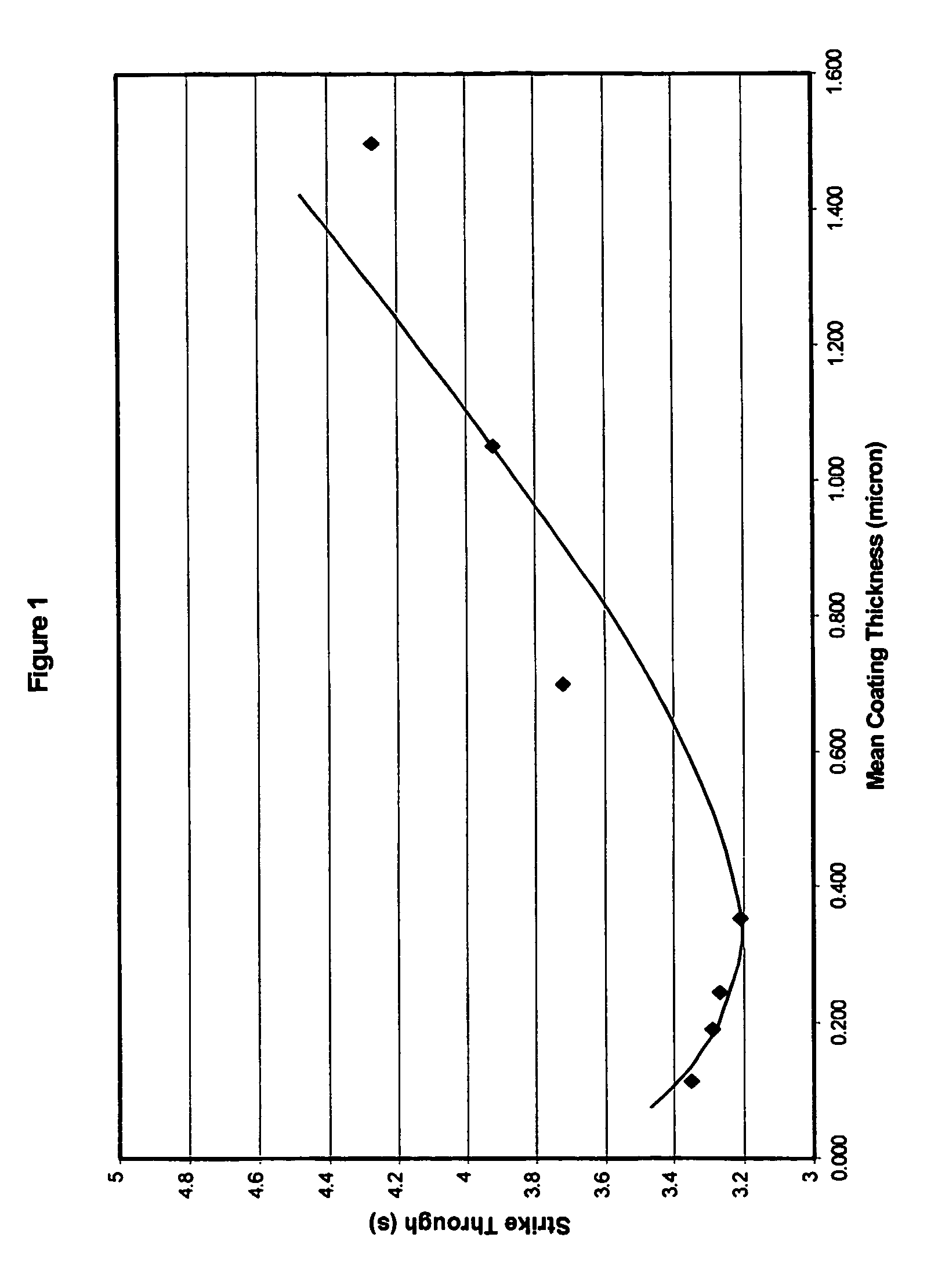

Method and apparatus for three-dimensional fabrication with feed through carrier

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

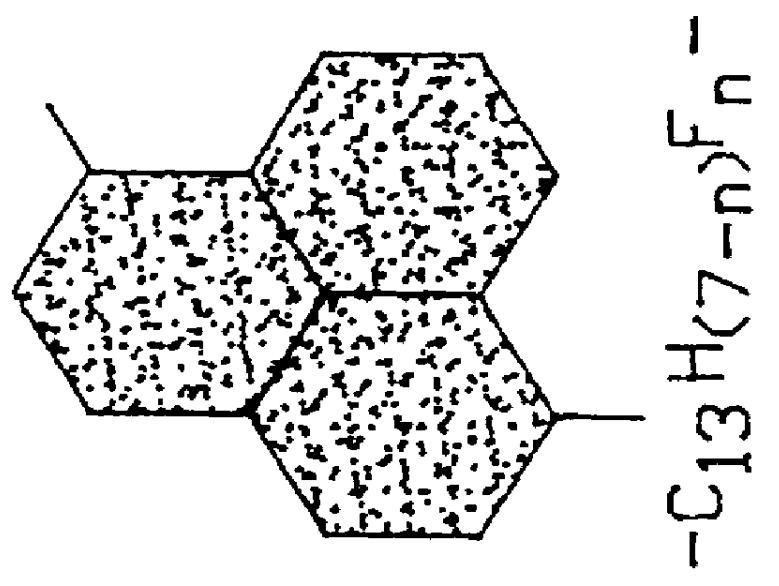

Photoresist polymer and photoresist composition containing the same

InactiveUS7361447B2Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersResistPolymer science

Photoresist polymers and photoresist compositions containing the same. Photoresist patterns of less than 50 nm are achieved with EUV (Extreme Ultraviolet) as an exposure light source with photoresist compositions comprising (i) a photoresist polymer comprising a polymerization repeating unit of Formula 2 or (ii) a photoresist polymer comprising a polymerization repeating unit of Formula 3 with polyvinylphenol. As a result, excellent etching resistance can be secured although the photoresist patterns have a very small thickness.wherein R1, R2, R3, R4, R5, R6, R7, R8, R9, R10, R11, R12, a, b, c, d, e, f and g are as defined in the specification.

Owner:SK HYNIX INC

Photoresist polymer and photoresist composition containing the same

InactiveUS7279256B2Enhance the imageImprove the immunityPhotosensitive materialsRadiation applicationsResistEnergy variation

Photoresist polymers and photoresist compositions are disclosed. A photoresist polymer comprising a polymerization repeating unit represented by Formula I is less sensitive to change in the amount of energy due to its higher active energy than that of a conventional photoresist polymer. As a result, a phenomenon where the portion of the pattern for the storage electrode contact region that receives relatively large amount of light becomes too thin is avoided when the device isolation film pattern is formed, and wherein pattern collapse caused by a high aspect ratio due to high etching resistance is prevented or avoided.whereinR1–R10, a, b, c and d are as defined in the description.

Owner:SK HYNIX INC

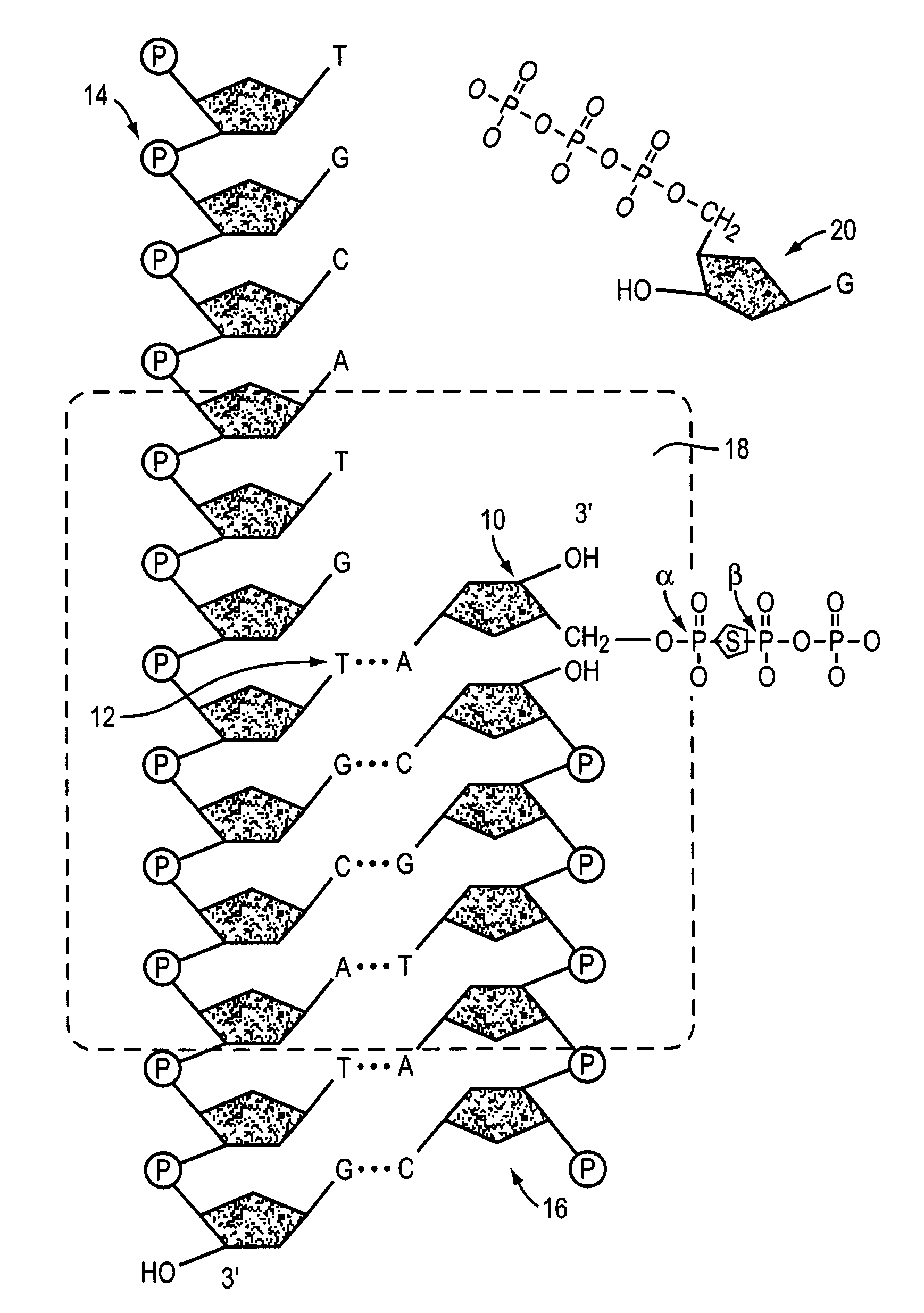

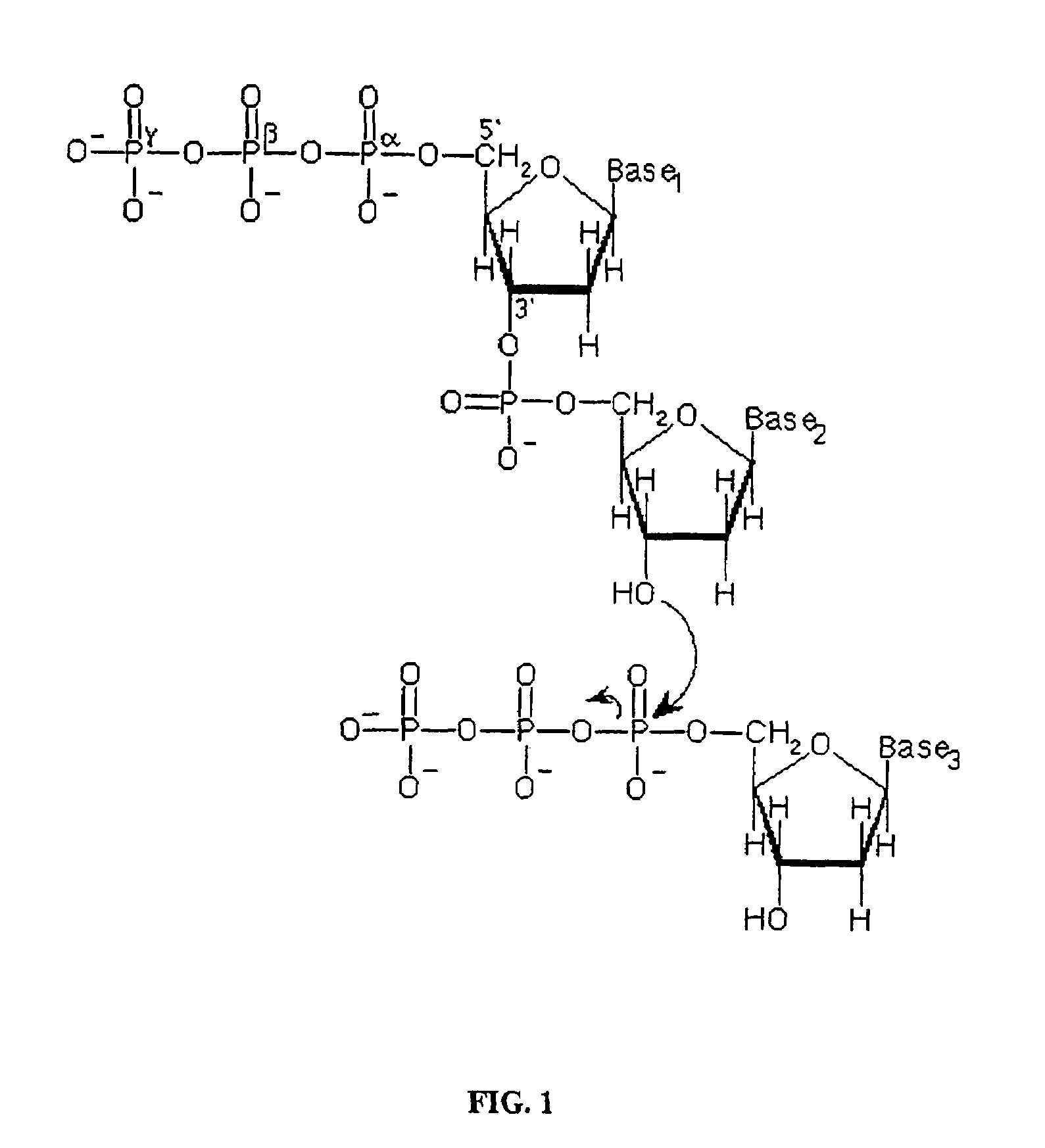

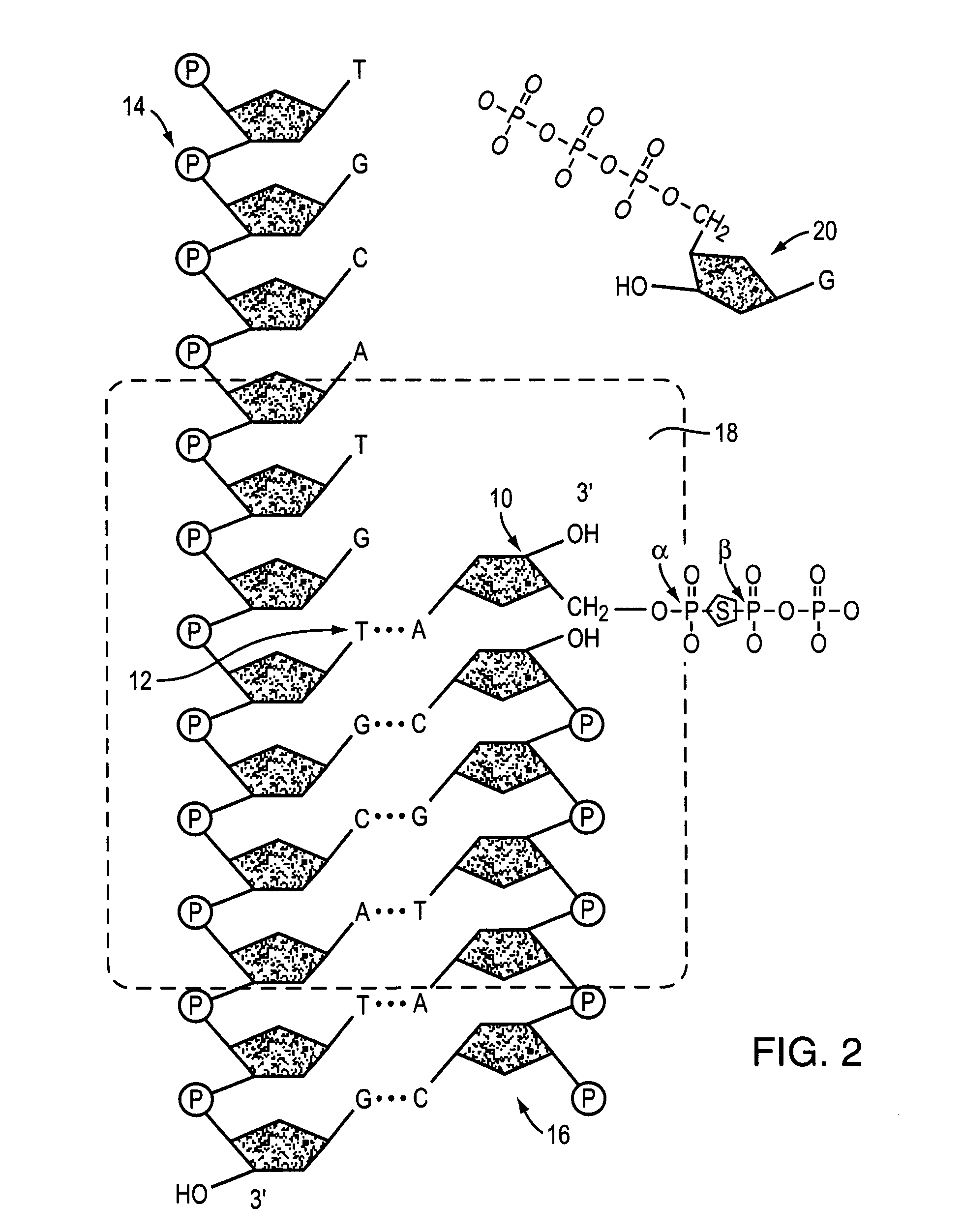

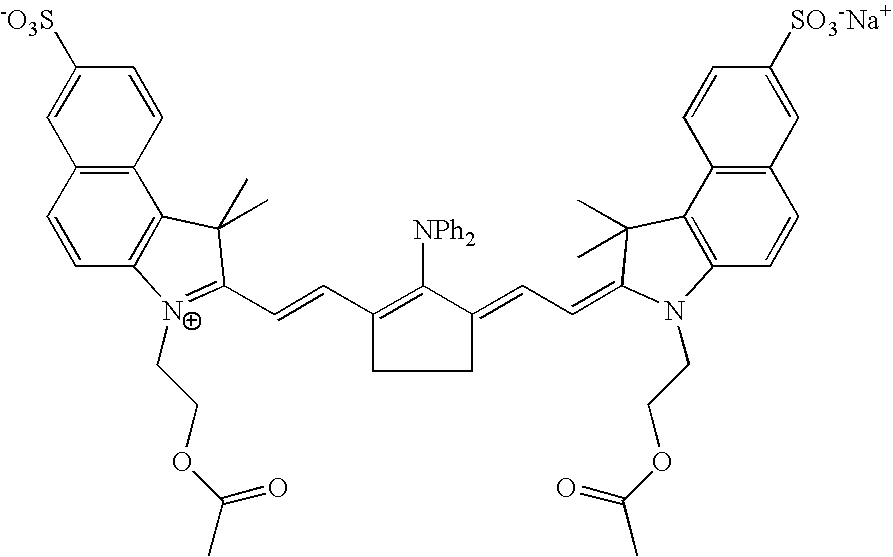

Methods and compositions for improving fidelity in a nucleic acid synthesis reaction

InactiveUS7482120B2Improve fidelityInhibition formationMicrobiological testing/measurementFermentationNucleotidePerylene derivatives

The invention provides methods and compositions for improving the fidelity of a sequencing-by-synthesis reaction by using a nucleotide derivative that forms a hydrogen bond with a complementary nucleotide on a template, but fails to form a phosphodiester bond with the 3′ hydroxyl group of a primer under conditions otherwise suitable for a polymerization reaction; thereby blocking incorporation of a mismatched nucleotide.

Owner:FLUIDIGM CORP

Imageable element with solvent-resistant polymeric binder

InactiveUS20050003285A1Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingSolventPendant group

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

Continuous liquid interphase printing

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

Room temperature-setting compositions

The present invention provides a room temperature-setting composition containing a polyoxyalkylene polymer (A), having a molecular weight of from 8000 to 50000 and having hydrolyzable silicon groups of the following formula (1), which comprises, as an essential component, the polyoxyalkylene polymer, having a molecular weight of from 8000 to 50000 and having hydrolyzable silicon groups of the formula (1), wherein a is 3 and a room temperature-setting composition containing a polyoxyalkylene polymer (A) having a molecular weight of from 8000 to 50000 and having hydrolyzable silicon groups of the formula (1), which comprises, as essential components, the polyoxyalkylene polymer having a molecular weight of from 8000 to 50000 and having hydrolyzable silicon groups of the formula (1) wherein a is 3, and a polymer (B) made by polymerization of a polymerizable unsaturated group-containing monomer (C):wherein R1 is a C1-20 substituted or unsubstituted monovalent organic group, X is a hydroxyl group or a hydrolyzable group, a is 1, 2 or 3, provided that when more than one R1 exist, the plurality of R1 may be the same or different, and when more than one X exist, the plurality of X may be the same or different.

Owner:ASAHI GLASS CO LTD

Absorbent hygiene product

InactiveUS20050159720A1Surface area can be easilyUniform and stableLayered productsFibre treatmentAbsorbent materialPolymer chemistry

Owner:FREUDENBERG NONWOVENS LTD

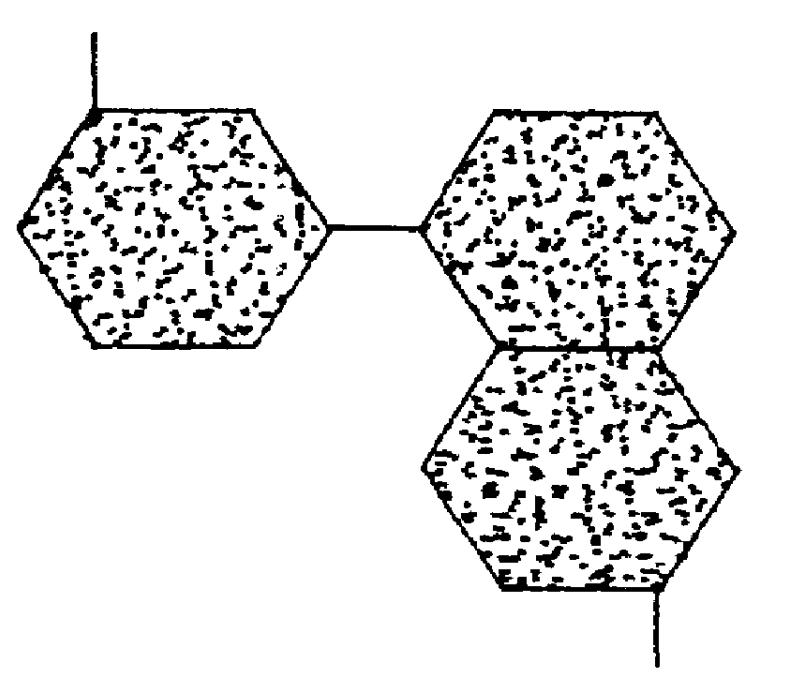

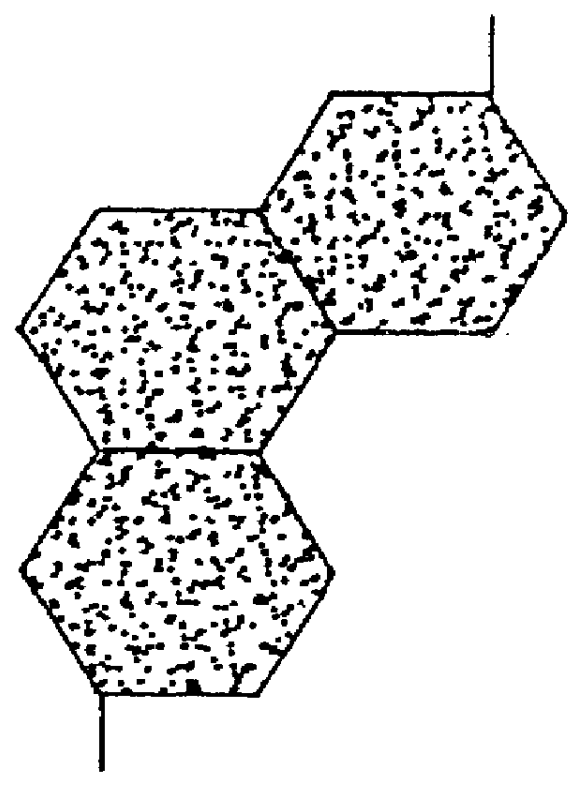

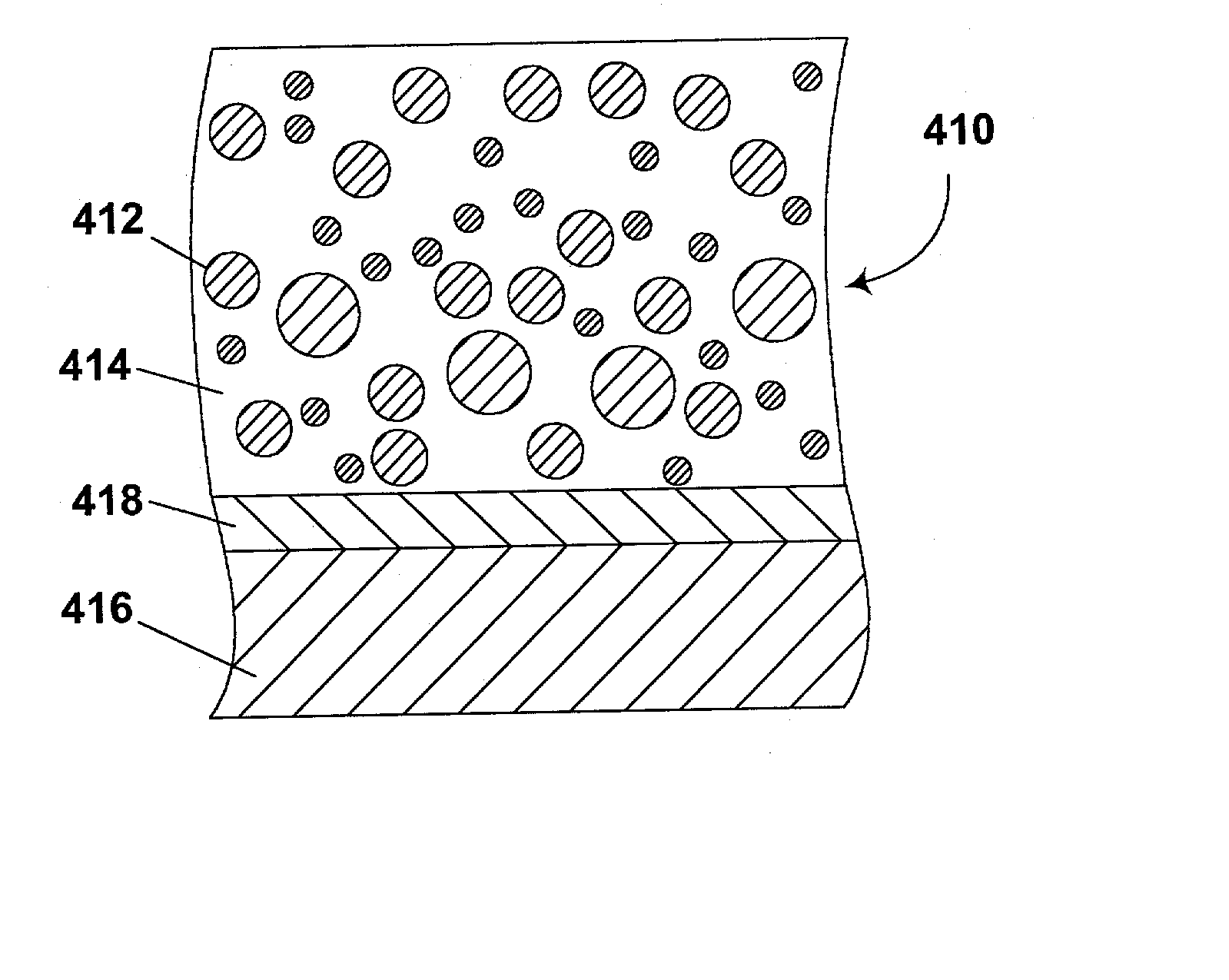

Poly(beta-amino alcohols), their preparation, and uses thereof

ActiveUS20130302401A1Organic active ingredientsPeptide/protein ingredientsChemical structureFibrosis

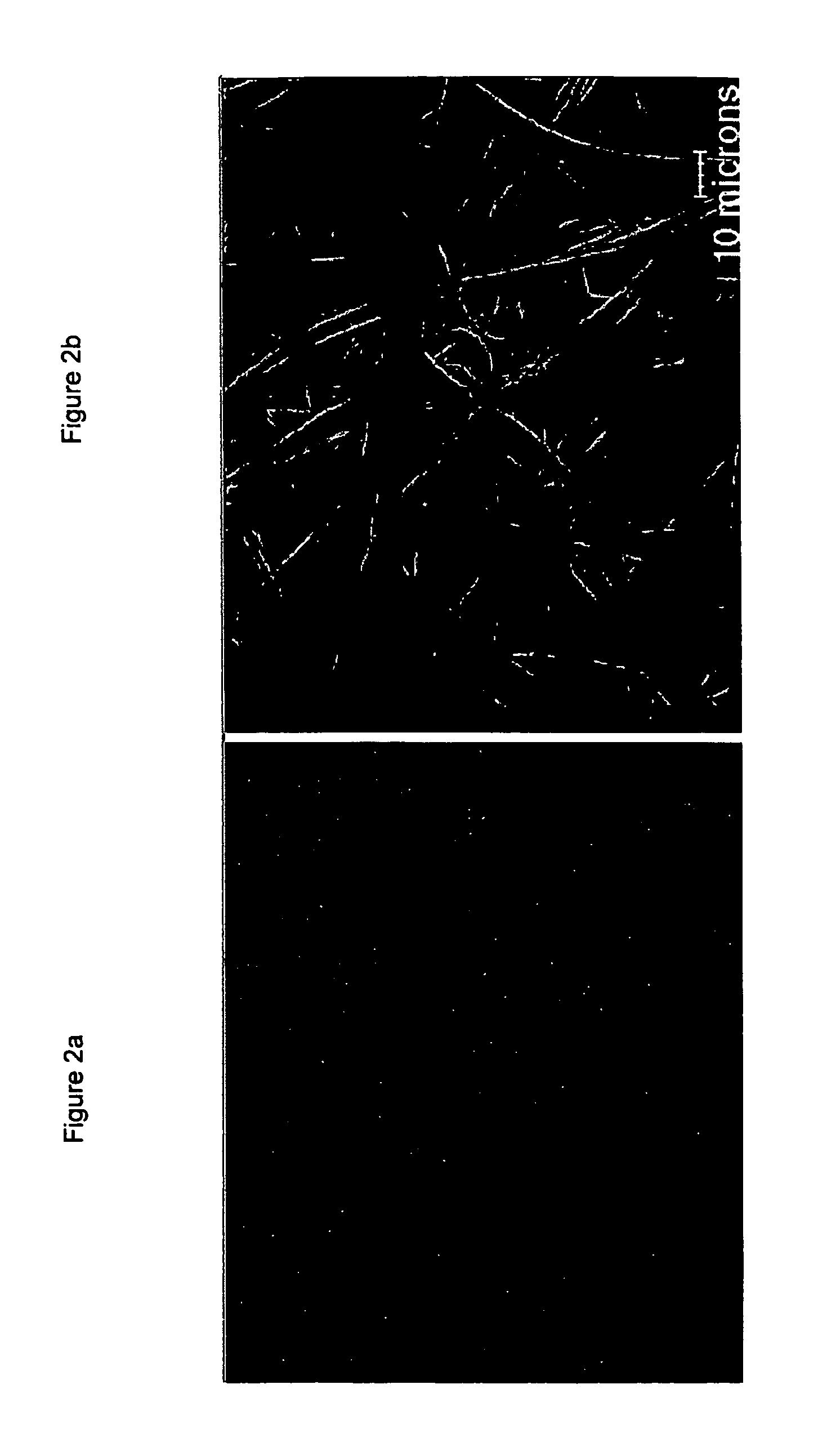

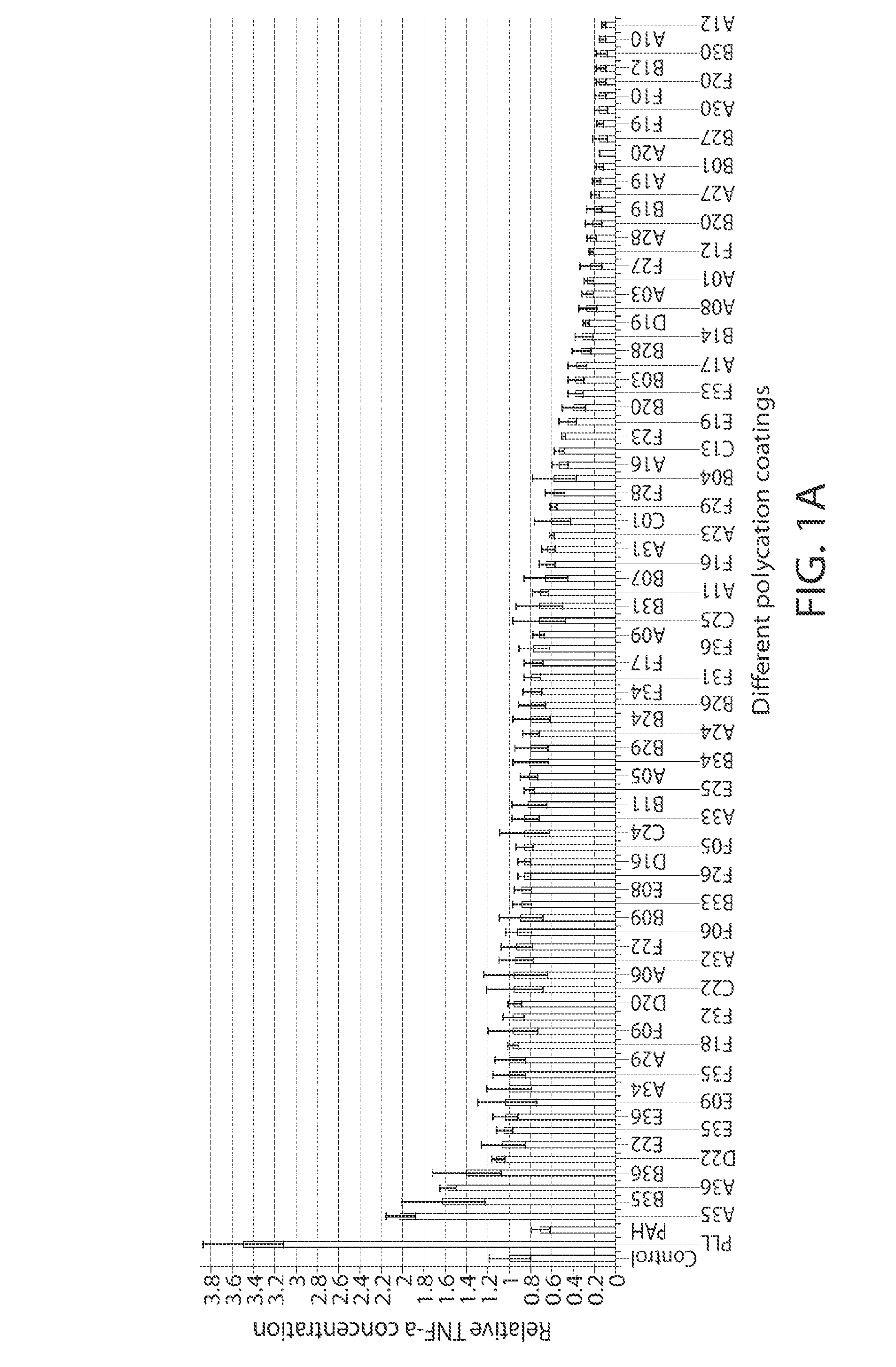

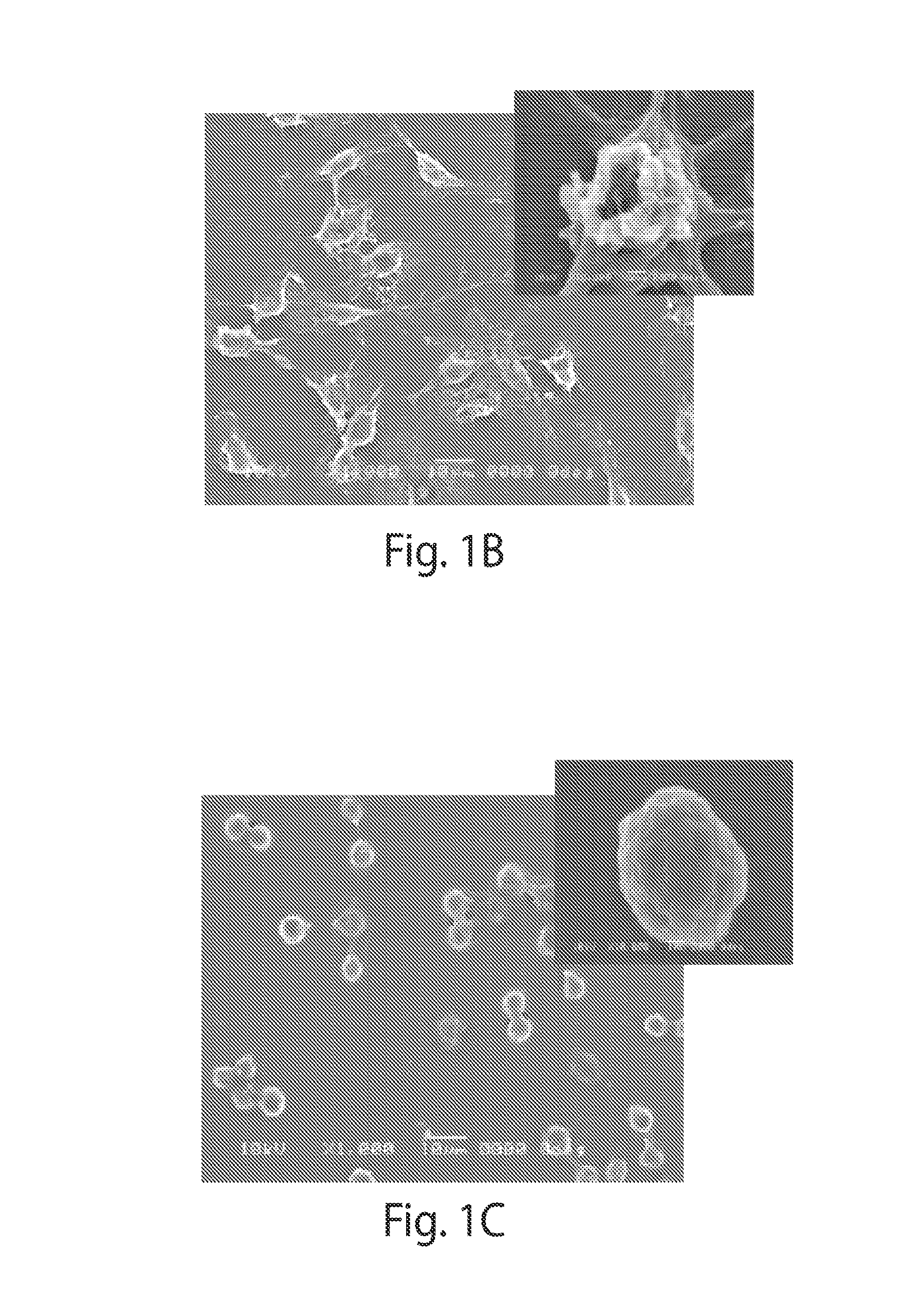

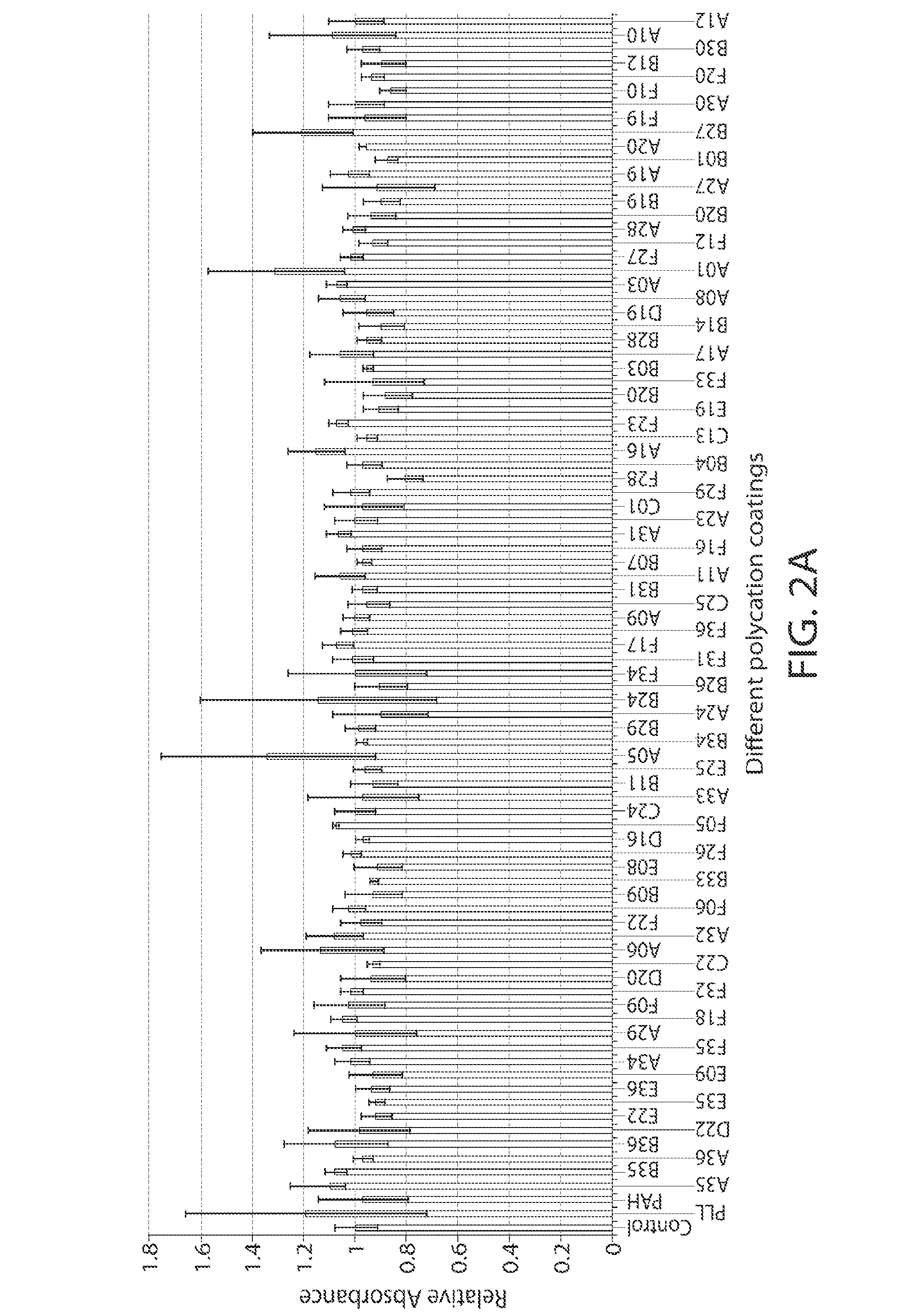

A new class of poly(beta-amino alcohols) (PBAAs) has been prepared using combinatorial polymerization. The inventive PBAAs may be used in biotechnology and biomedical applications as coatings (such as coatings of films or multilayer films for medical devices or implants), additives, materials, excipients, non-biofouling agents, micropatterning agents, and cellular encapsulation agents. When used as surface coatings, these PBAAs elicited different levels of inflammation, both in vitro and in vivo, depending on their chemical structures. The large chemical diversity of this class of materials allowed us to identify polymer coatings that inhibit macrophage activation in vitro. Furthermore, these coatings reduce the recruitment of inflammatory cells, and reduce fibrosis, following the subcutaneous implantation of carboxylated polystyrene microparticles. These polymers may be used to form polyelectrolyte complex capsules for cell encapsulation. The invention may also have many other biological applications such as antimicrobial coatings, DNA or siRNA delivery, and stem cell tissue engineering.

Owner:MASSACHUSETTS INST OF TECH

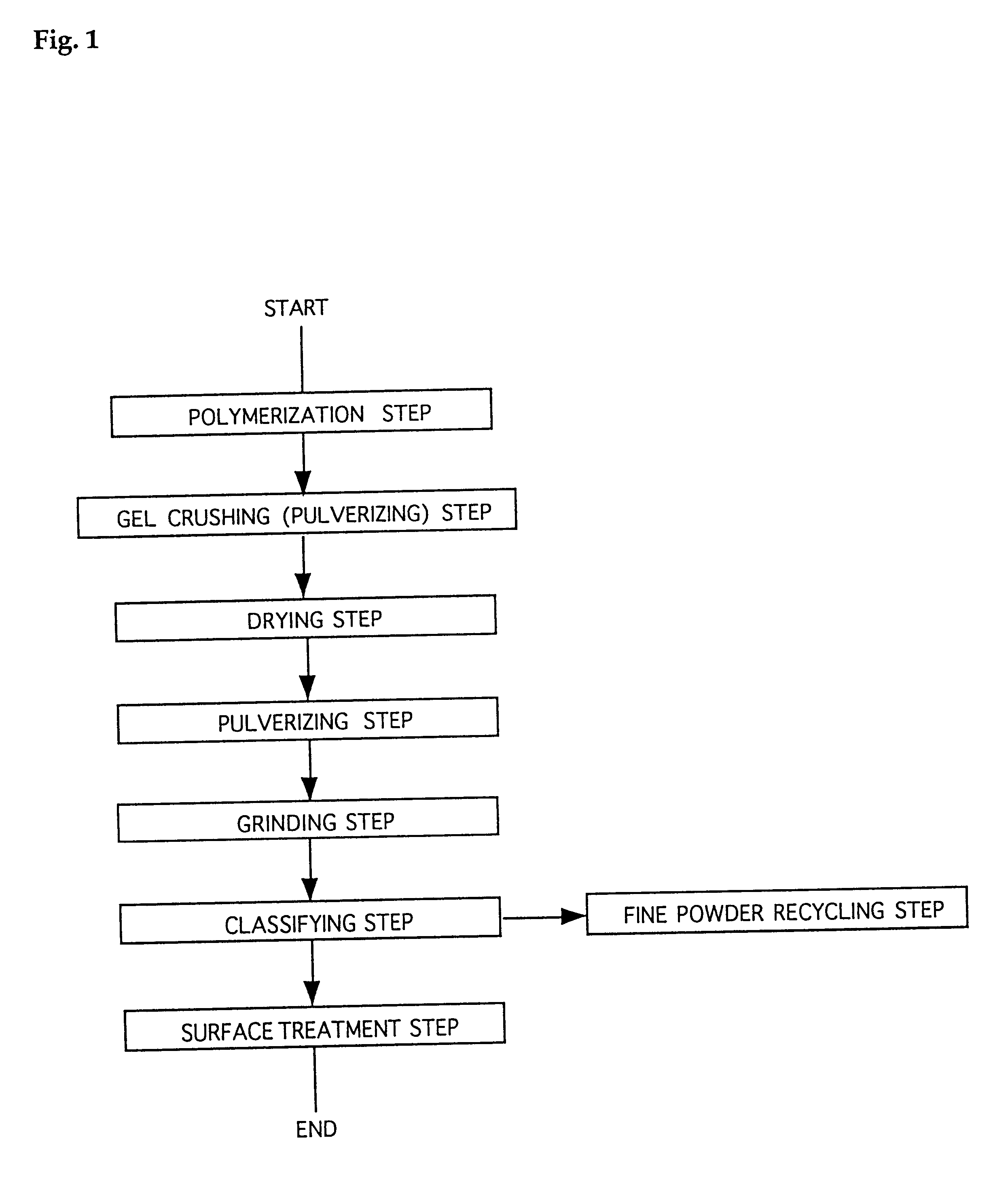

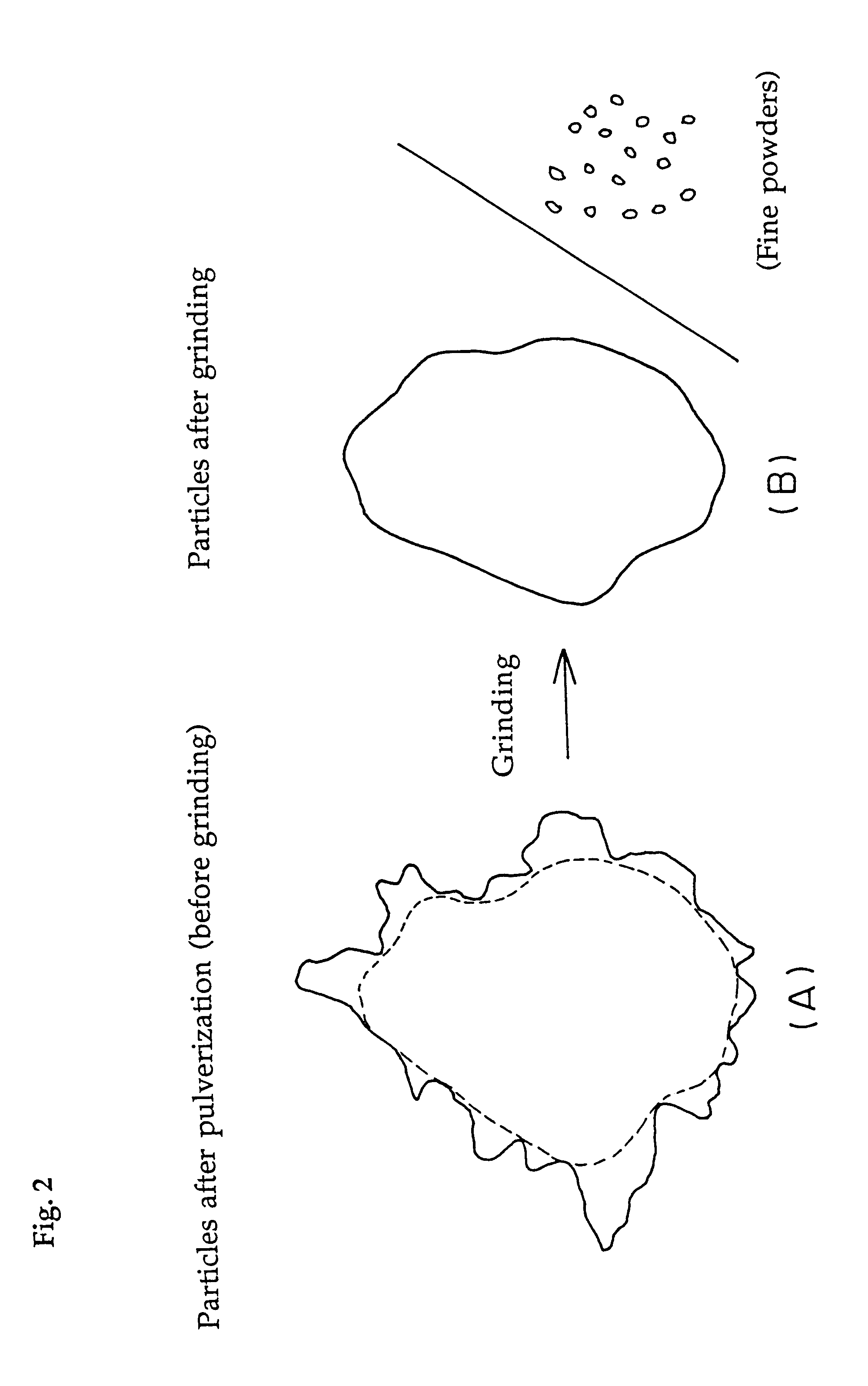

Water-absorbent resin powder and its production process and use

The present invention provides a water-absorbent resin powder and its production process and use, wherein the water-absorbent resin powder has high liquid permeability and high water absorbency. The production process for a water-absorbent resin powder, according to the present invention, comprises the step of obtaining water-absorbent crosslinked polymer particles by an aqueous solution polymerization step, and grinding the resultant crosslinked polymer particles until the bulk density thereof increases to not lower than 0.72 (g / ml). The water-absorbent resin powder is characterized by being arbitrarily pulverized and having a bulk density of not lower than 0.74 (g / ml) and a water absorption capacity of not lower than 20 (g / g) for 0.9 weight % physiological saline under a load of 0.7 psi (4.83 kPa). In addition, the absorbent structure comprises the above water-absorbent resin powder and a fibrous material. The absorbent article comprises an absorbent layer including the above absorbent structure.

Owner:NIPPON SHOKUBAI CO LTD

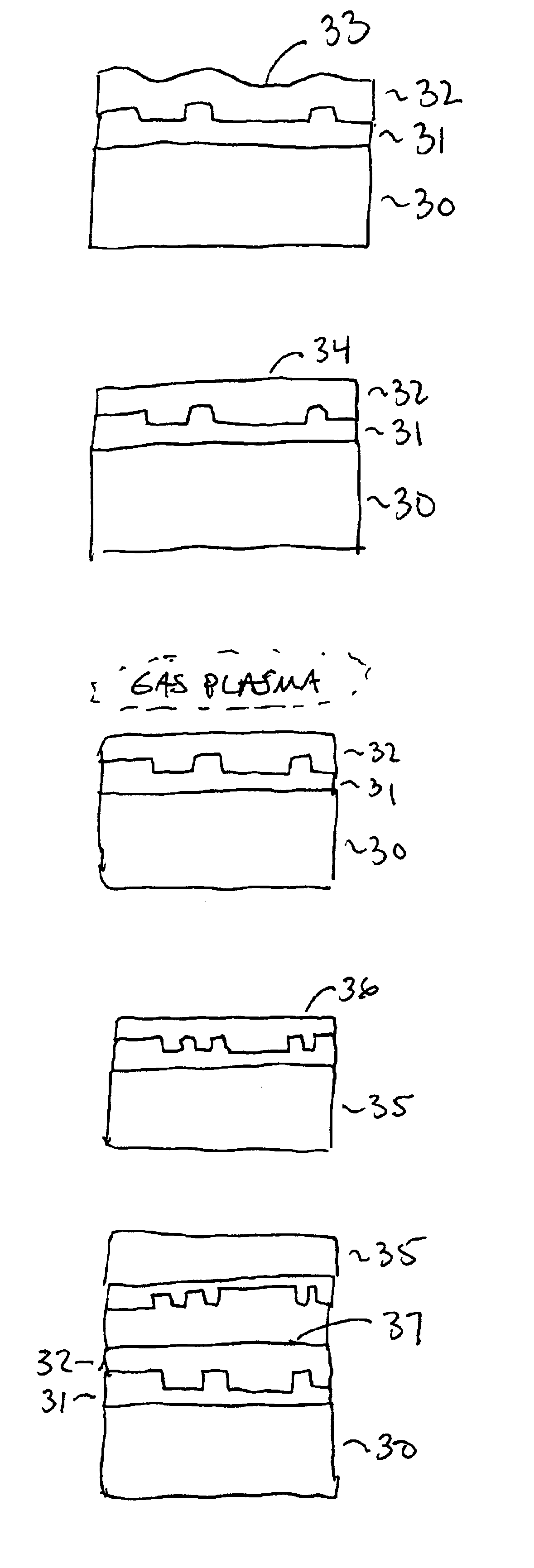

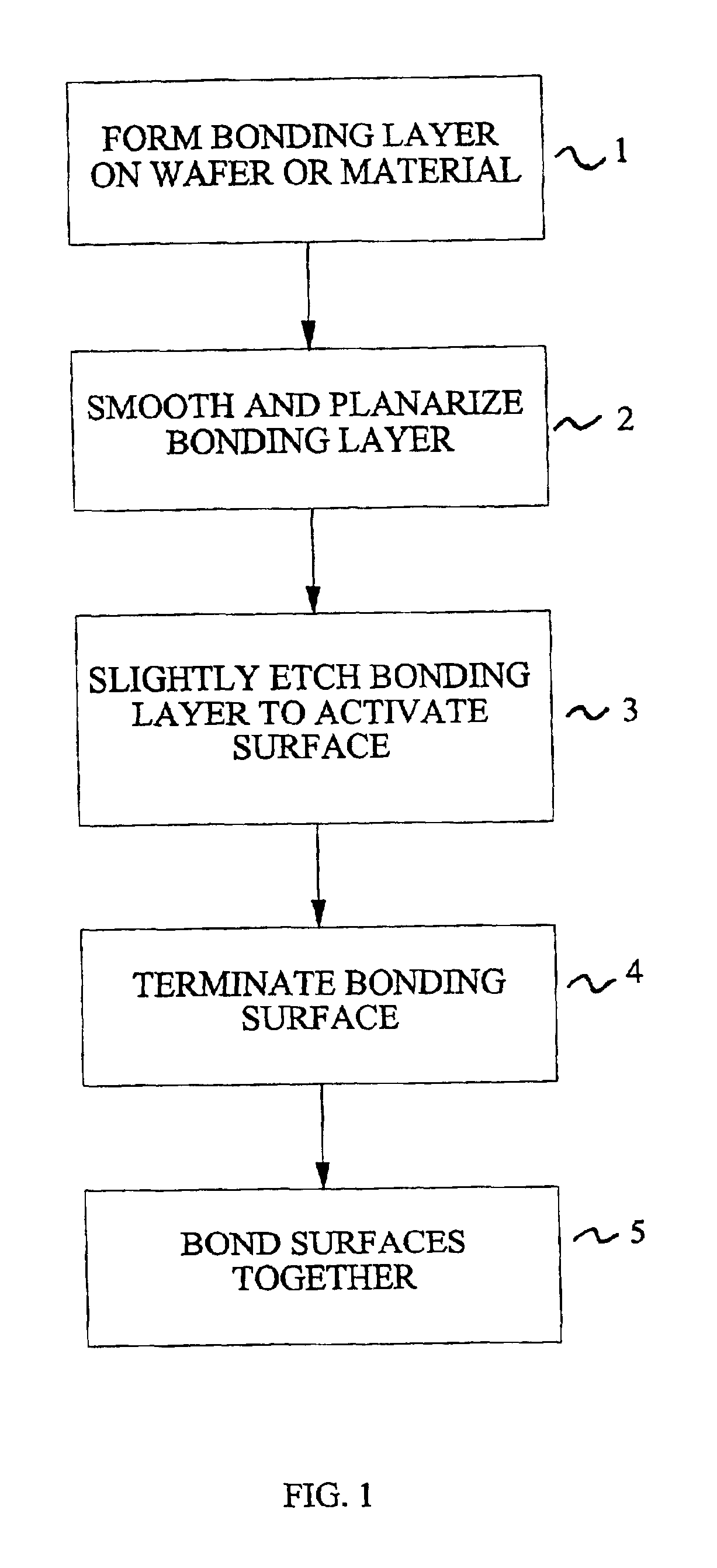

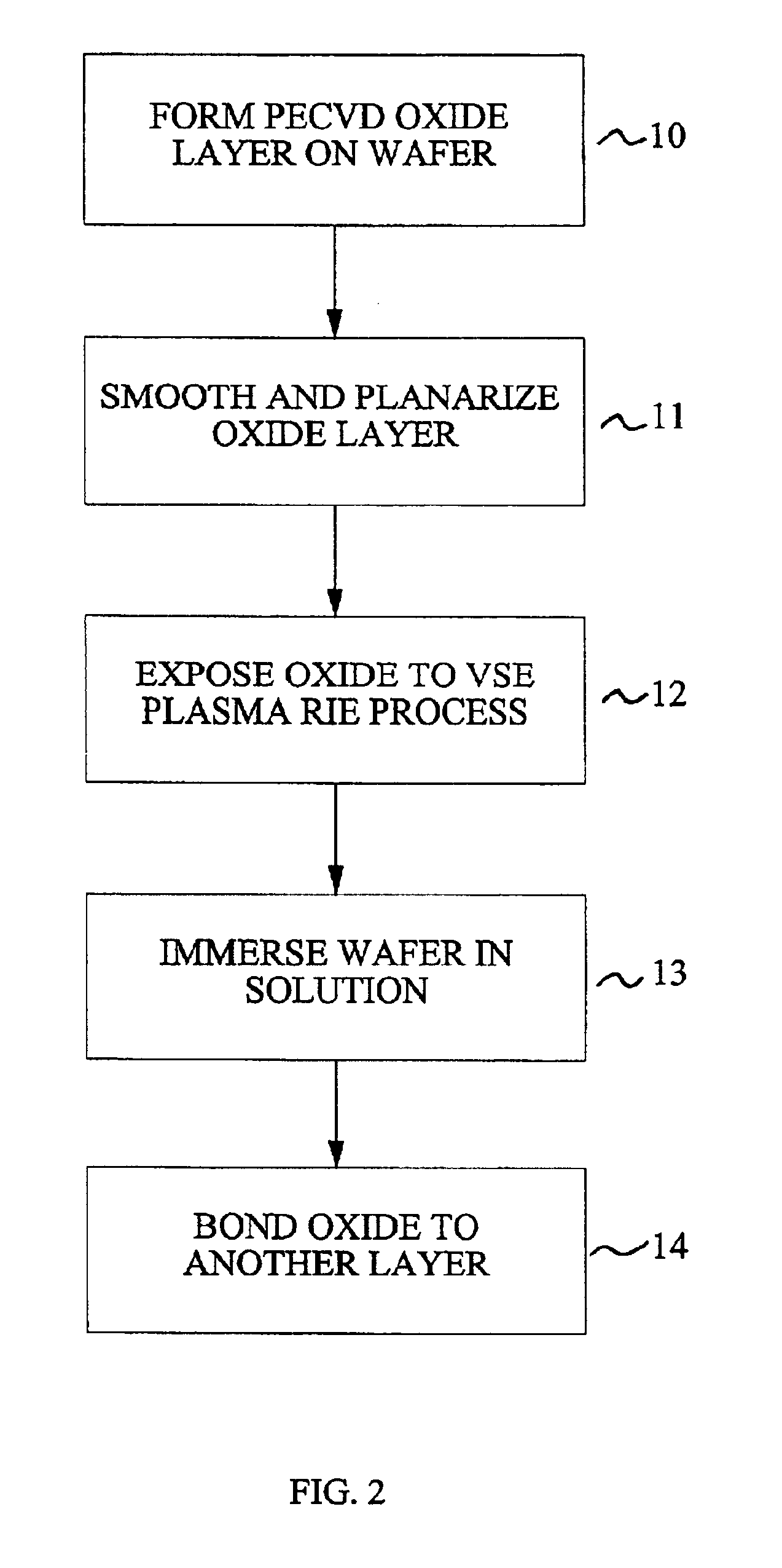

Method for low temperature bonding and bonded structure

InactiveUS6902987B1High bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSurface cleaningBiological activation

A method for bonding at low or room temperature includes steps of surface cleaning and activation by cleaning or etching. One etching process the method may also include removing by-products of interface polymerization to prevent a reverse polymerization reaction to allow room temperature chemical bonding of materials such as silicon, silicon nitride and SiO2. The surfaces to be bonded are polished to a high degree of smoothness and planarity. VSE may use reactive ion etching or wet etching to slightly etch the surfaces being bonded. The surface roughness and planarity are not degraded and may be enhanced by the VSE process. The etched surfaces may be rinsed in solutions such as ammonium hydroxide or ammonium fluoride to promote the formation of desired bonding species on the surfaces.

Owner:INVENSAS BONDING TECH INC

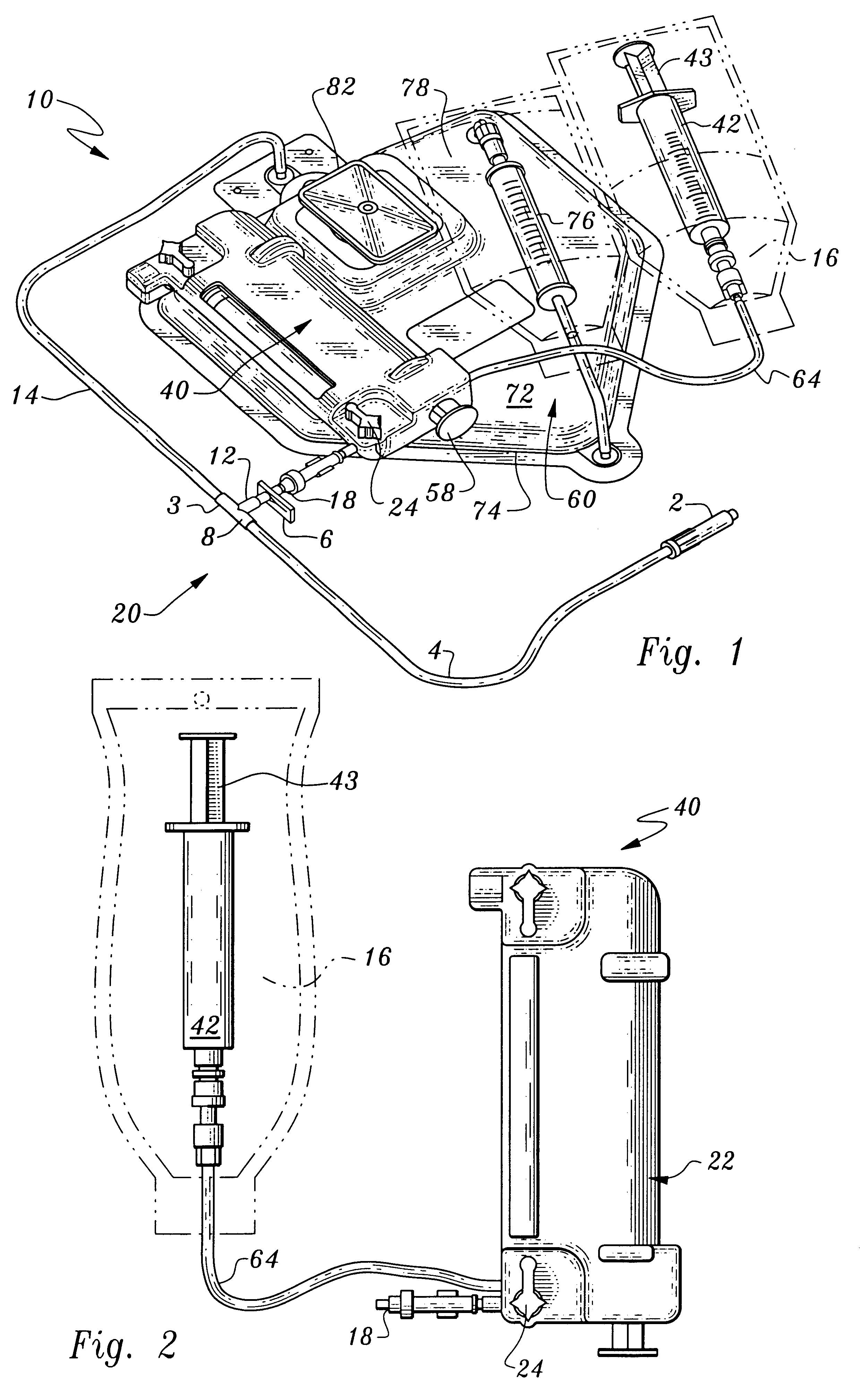

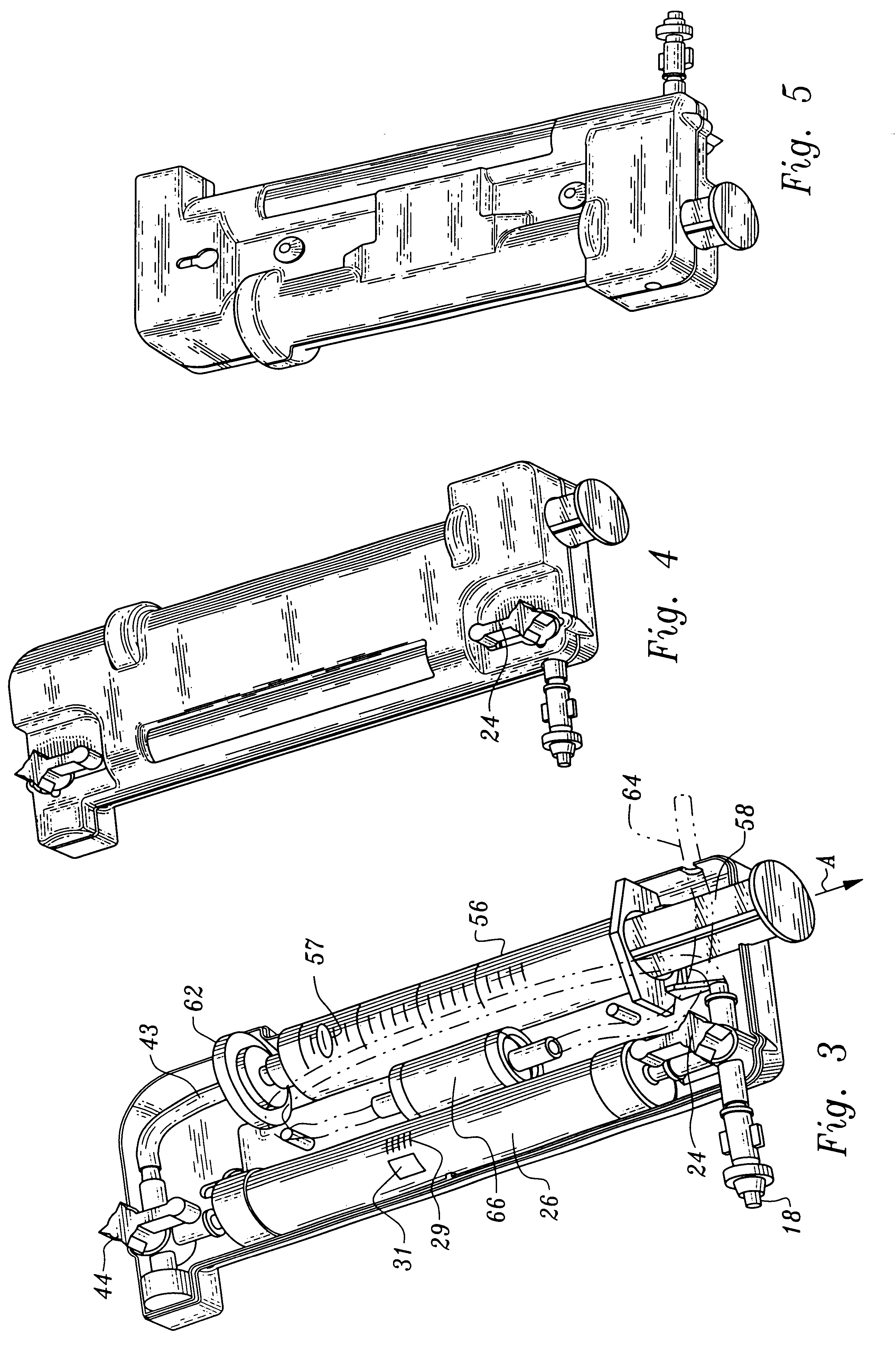

Method for preparing thrombin for use in a biological glue

InactiveUS6472162B1Derive fast acting, stable autologous thrombinSimple preparatory procedureBioreactor/fermenter combinationsBiological substance pretreatmentsTissue sealantDonors plasma

A sterile method for preparing stable thrombin component from a single donor's plasma in which the thrombin component and the clotting and adhesive proteins component are harvested simultaneously from the same donor plasma in less than one hour. The combined components provide an improved biological hemostatic agent and tissue sealant by virtue of its freedom from the risk of contaminating viruses or bacteria from allogenic human or bovine blood sources. The thrombin provides polymerization of the clotting and adhesive proteins in less than five seconds, and is sufficiently stable to provide that fast clotting over a six hour period. Further, the clotting times can be predictably lengthened by diluting the thrombin with saline.

Owner:ASAHI KASEI MEDICAL CO LTD

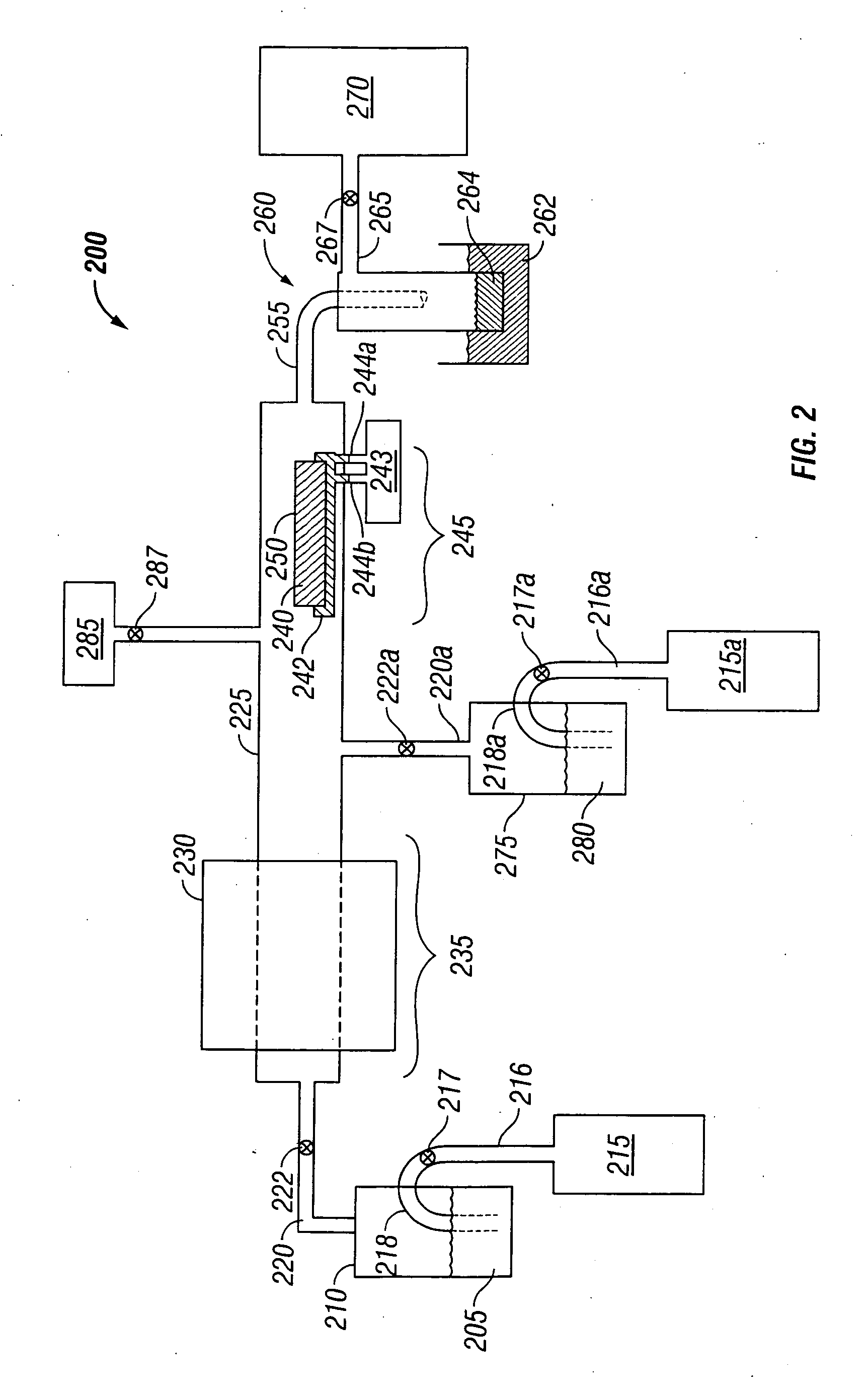

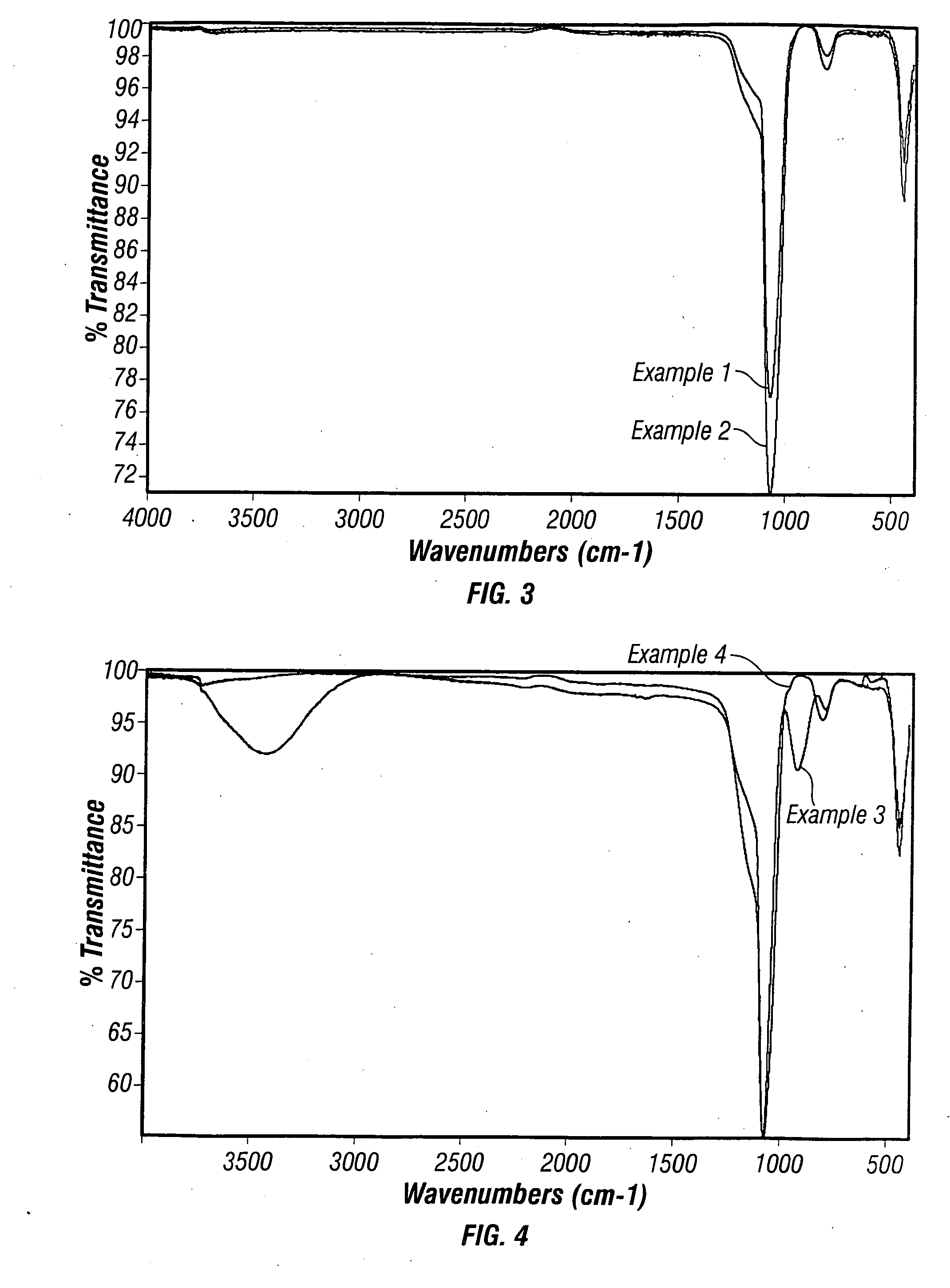

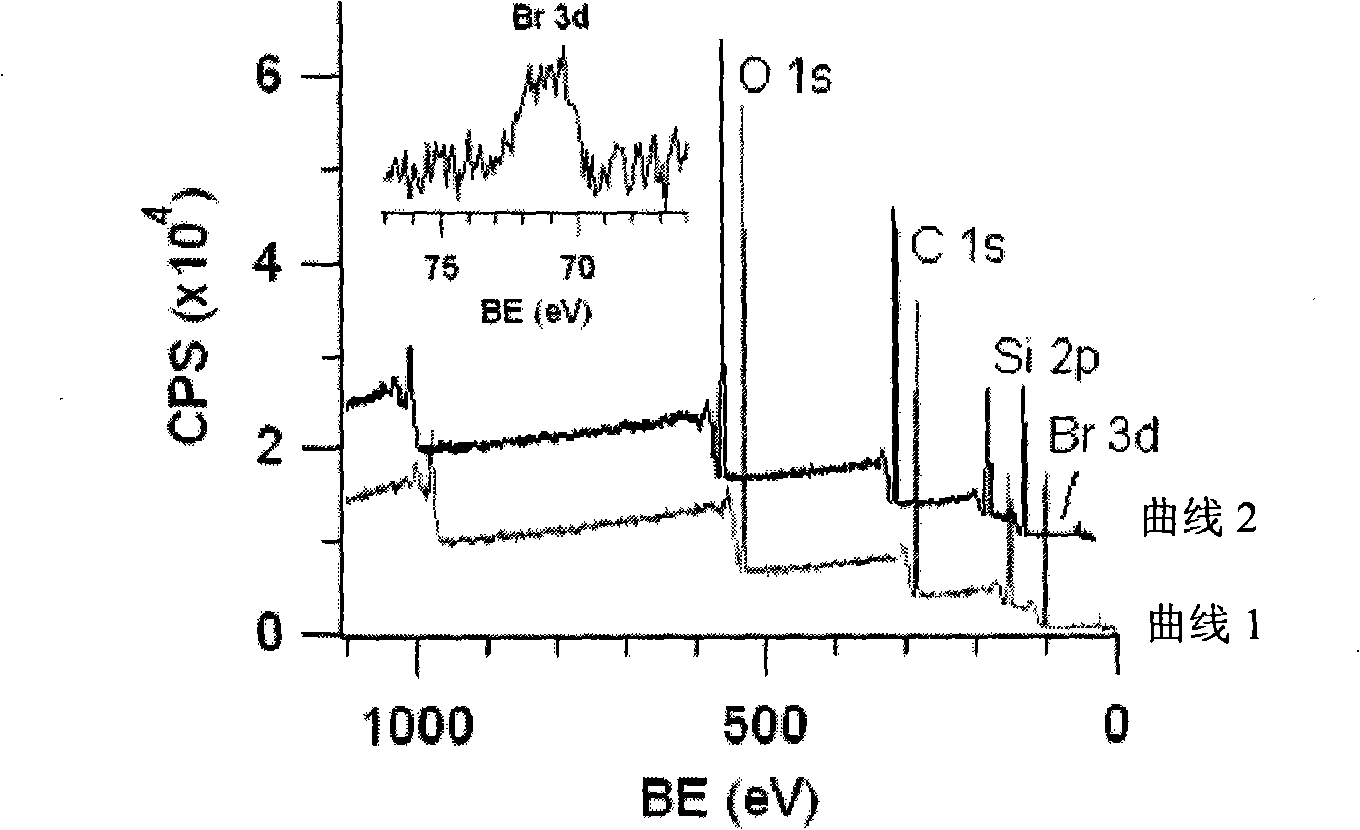

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

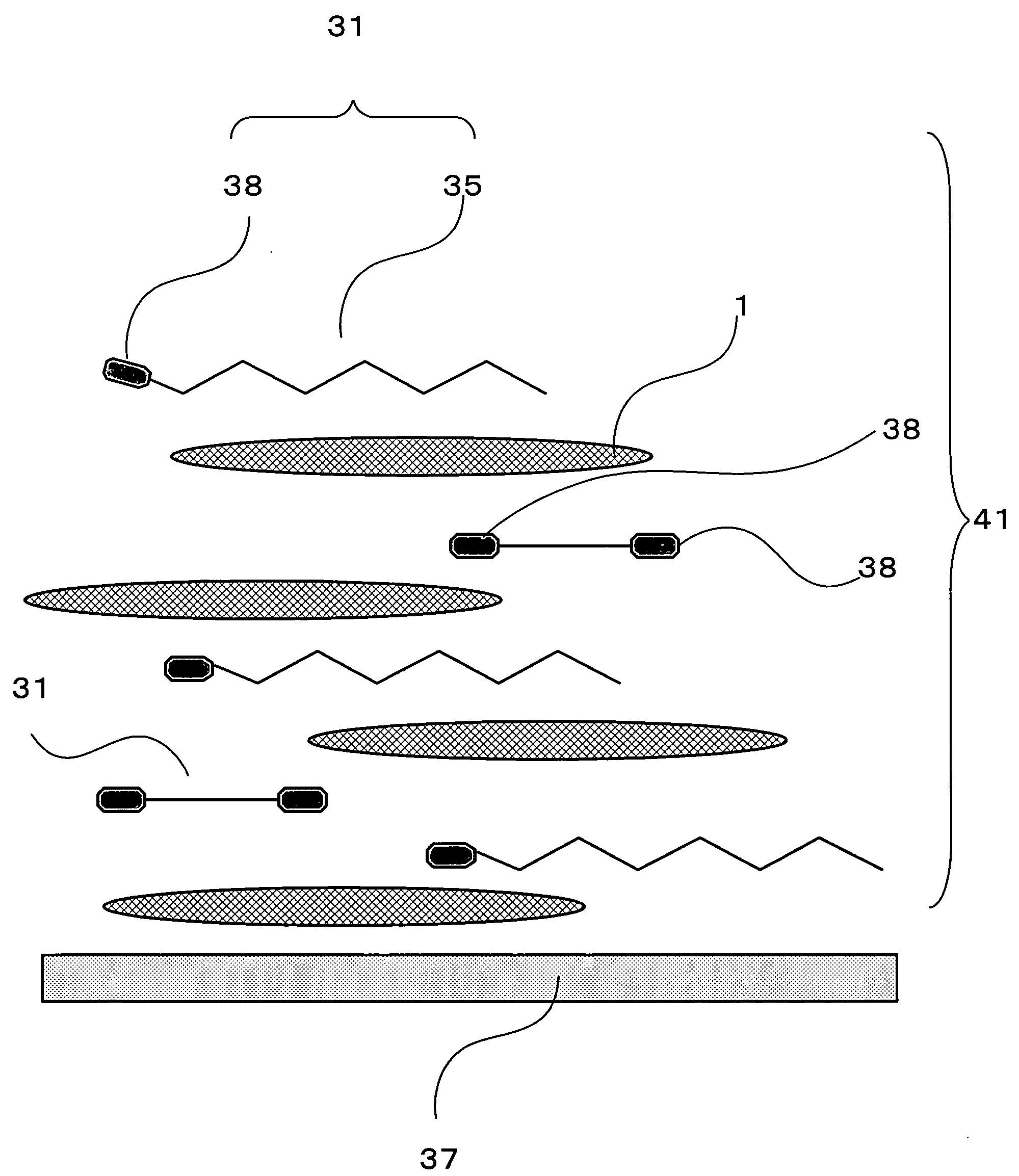

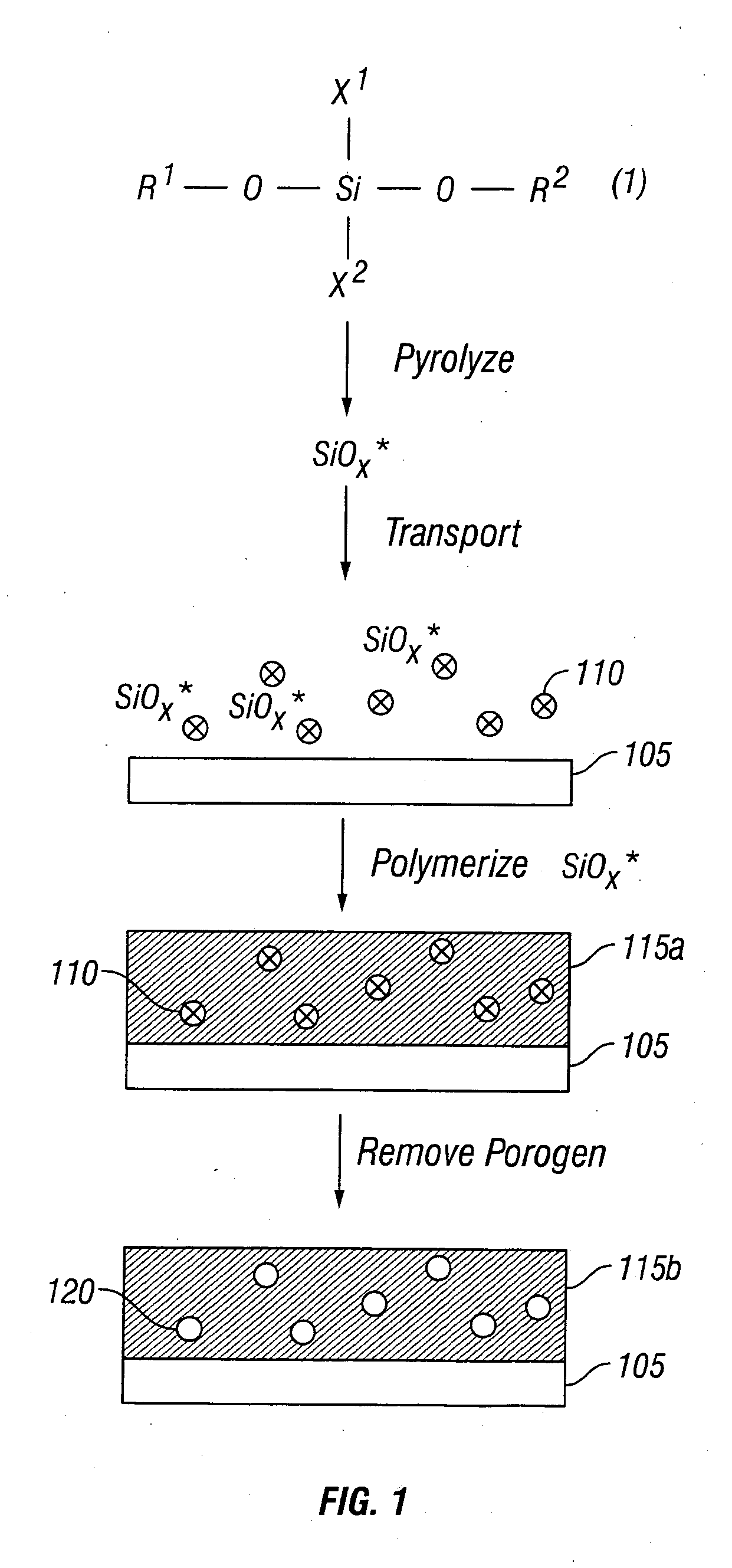

Apparatus, precursors and deposition methods for silicon-containing materials

A method for making a Si-containing material comprises transporting a pyrolyzed Si-precursor to a substrate and polymerizing the pyrolyzed Si-precursor on the substrate to form a Si-containing film. Polymerization of the pyrolyzed Si-precursor may be carried out in the presence of a porogen to thereby form a porogen-containing Si-containing film. The porogen may be removed from the porogen-containing Si-containing film to thereby form a porous Si-containing film. Preferred porous Si-containing films have low dielectric constants and thus are suitable for various low-k applications such as in microelectronics and microelectromechanical systems.

Owner:ASM JAPAN

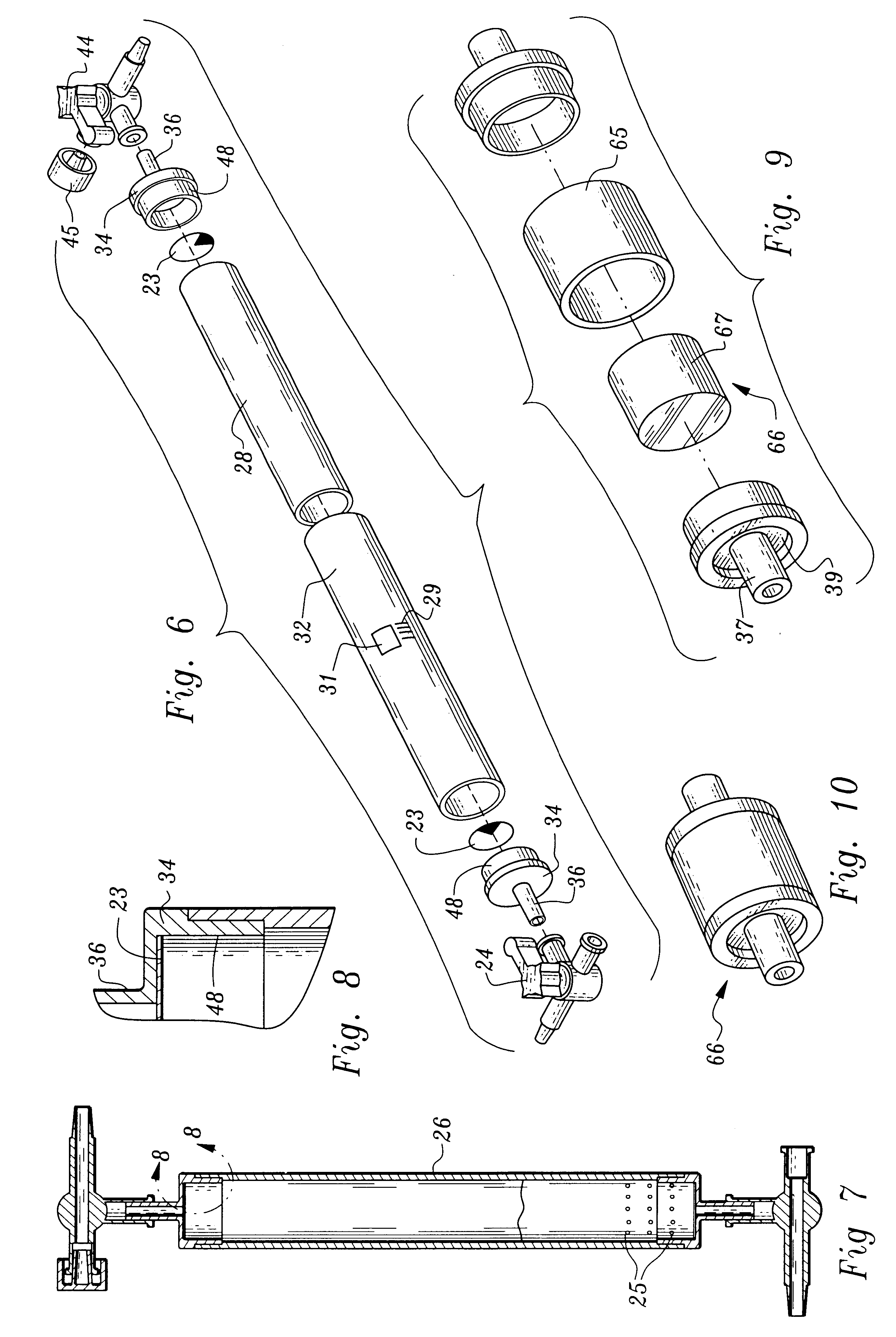

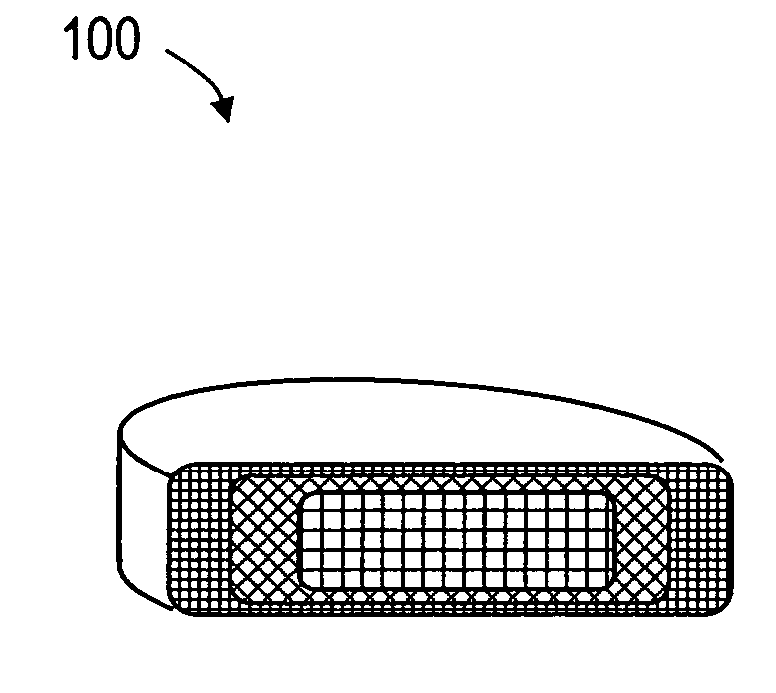

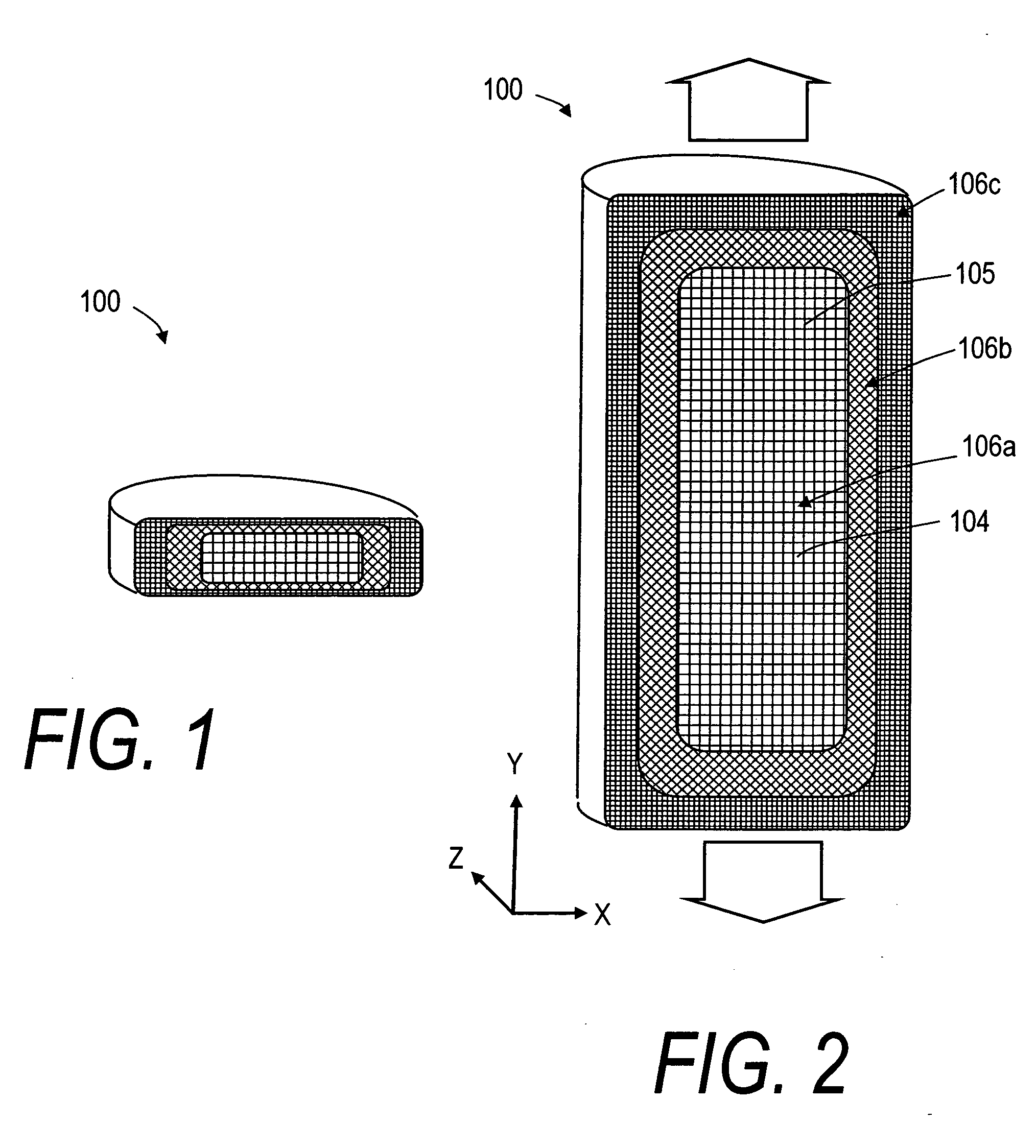

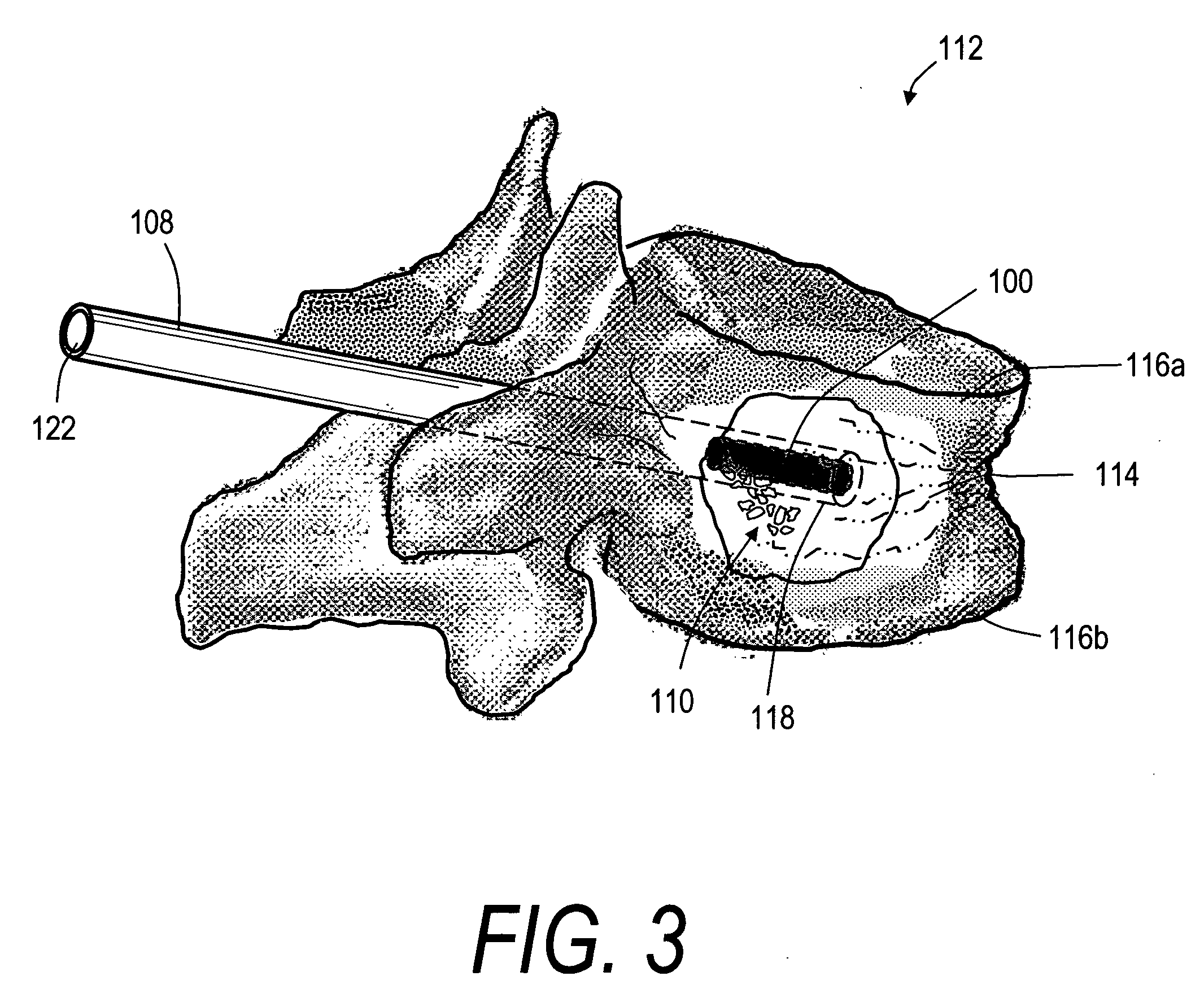

Bone treatment systems and methods

InactiveUS20060106459A1Reduces and eliminates possibilityAvoid thermal damageInternal osteosythesisSpinal implantsFracture reductionHigh pressure

A system for treating an abnormal vertebral body such as a compression fracture. In an exemplary embodiment, the system includes a biocompatible flow-through implant structure configured with a three-dimensional interior web that defines flow openings therein for cooperating with a two-part hardenable bone cement. The flow-through structure is capable of compacted and extended shapes and in one embodiment provides a gradient in flow openings for controlling flow parameters of a bone cement injected under high pressure into the interior thereof. The flow-through implant structure is configured for transducing cement injection forces into a selected direction for moving apart cortical endplates of a vertebra to reduce a fracture. In one embodiment, the flow-through implant structure is coupled to an Rf source for applying Rf energy to a two-part bone cement to accelerate curing of the cement to thereby allow on-demand alterations of cement viscosity. The Rf system allows for control of bone cement polymerization globally or regionally to prevent cement extravasion and to direct forces applied to a vertebra to reduce a fracture.

Owner:DFINE INC

Electrophoretic particles and processes for the production thereof

In electrophoretic media, it is advantageous to use pigment particles having about 1 to 15 percent by weight of a polymer chemically bonded to, or cross-linked around, the pigment particles. The polymer desirably has a branched chain structure with side chains extending from a main chain. Charged or chargeable groups can be incorporated into the polymer or can be bonded to the particles separately from the polymer. The polymer-coated particles can be prepared by first attaching a polymerizable or polymerization-initiating group to the particle and then reacting the particle with one or more polymerizable monomers or oligomers.

Owner:E INK CORPORATION

Water-developable infrared-sensitive printing plate

ActiveUS20050123853A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersPendant groupAqueous solution

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. The imageable element can be developed using an aqueous developer solution. Alternatively, the imageable element can be developed on-press by contact with ink and / or fountain solution.

Owner:KODAK POLYCHROME GRAPHICS

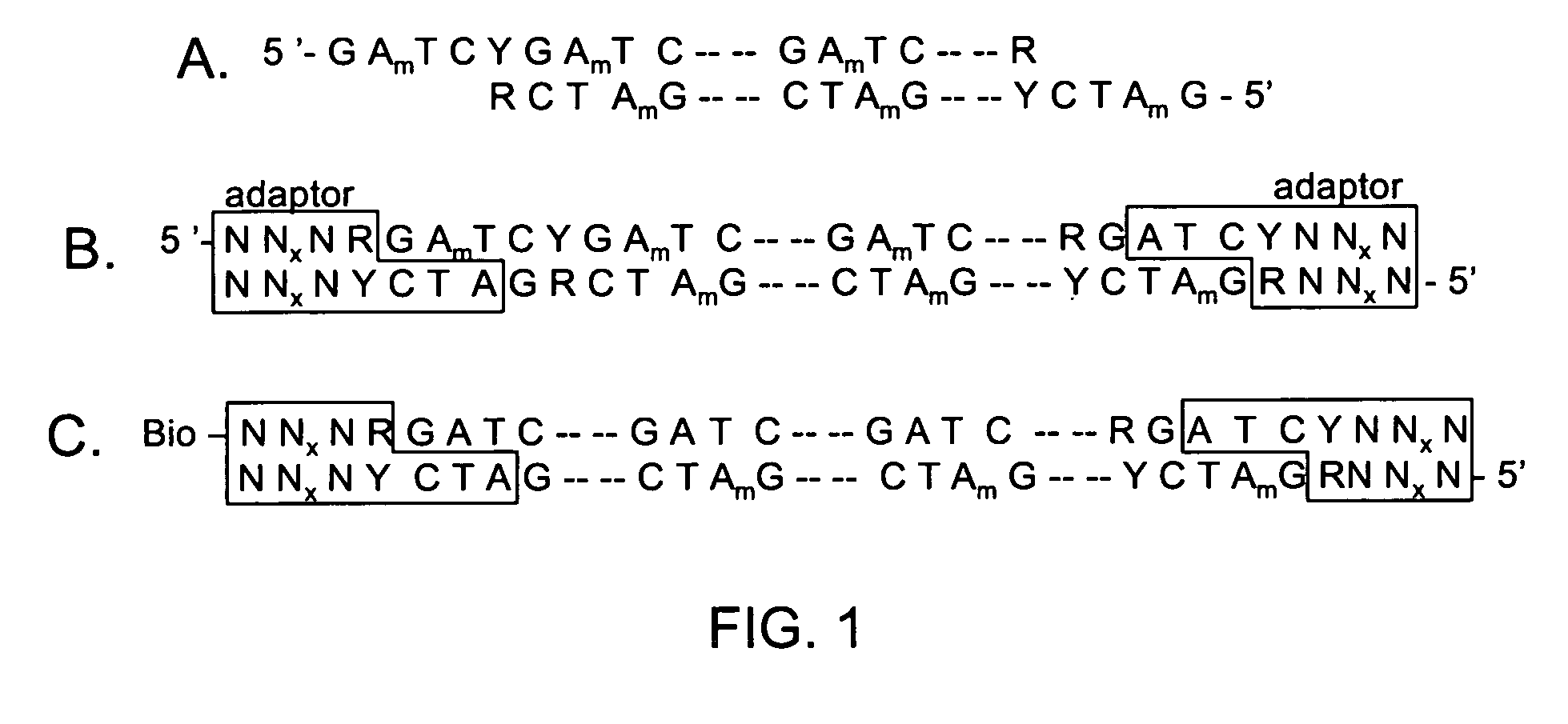

Method of making biochips and the biochips resulting therefrom

InactiveUS6174683B1Rapid and simple and cost-effective methodHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsSodium bicarbonateSolid substrate

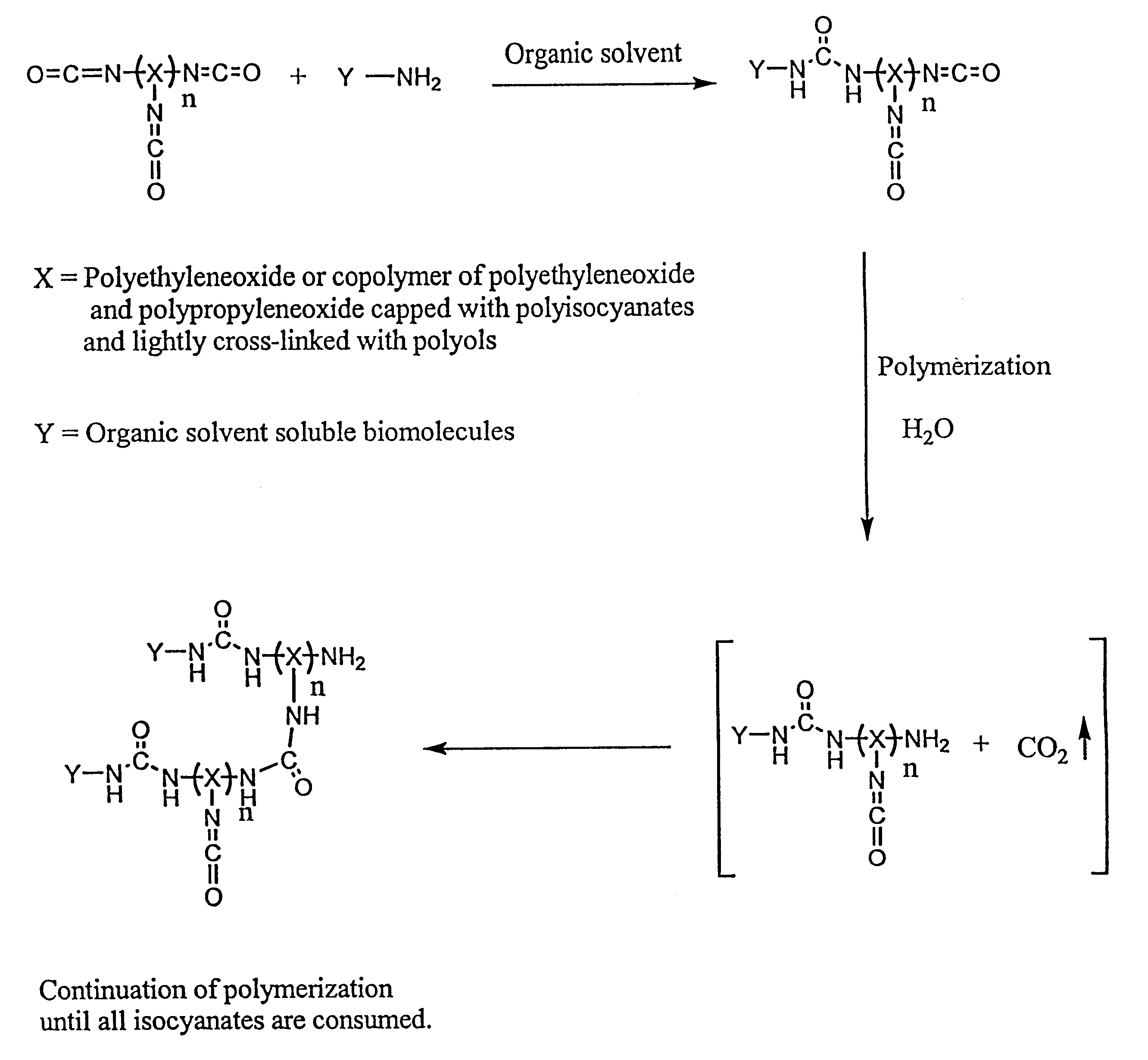

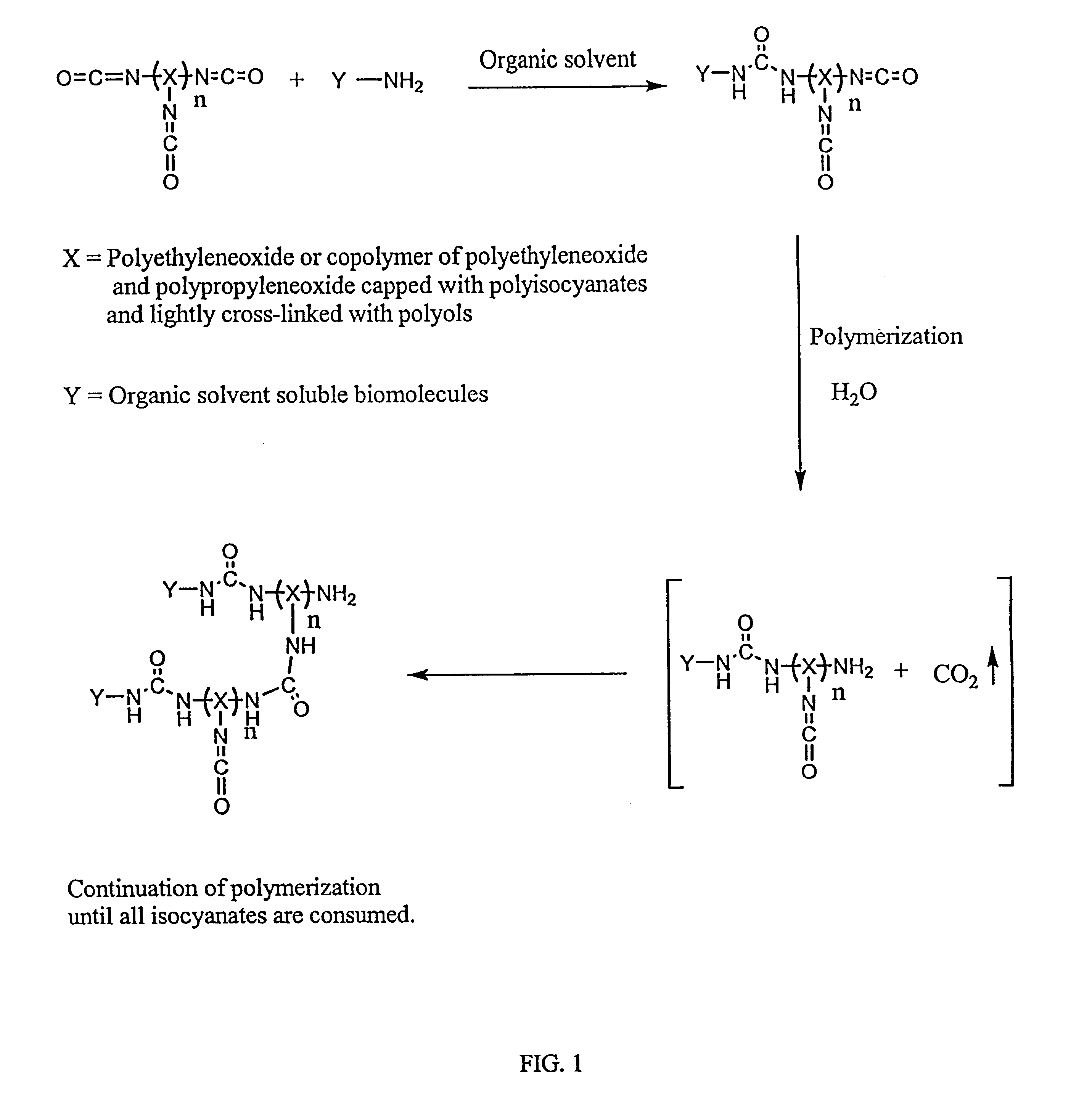

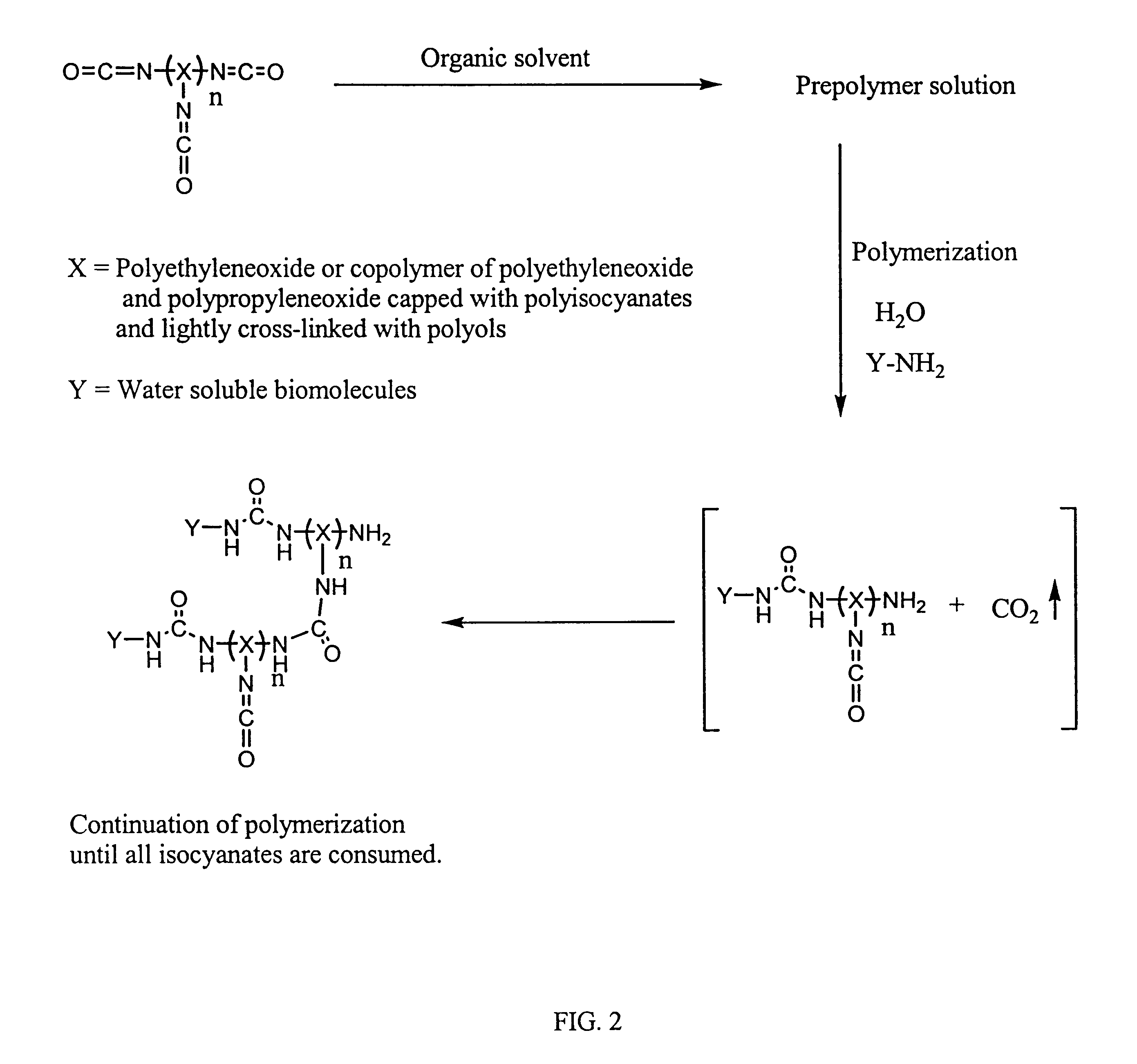

Methods for preparing a biochip are provided herein wherein the biomolecular probe to be used with the biochip is alternatively bound to a hydrogel prepolymer prior to or simultaneously with polymerization of the prepolymer. In particularly preferred embodiments, a polyurethane-based hydrogel prepolymer is derivatized with an organic solvent soluble biomolecule, such as a peptide nucleic acid probe in aprotic, organic solvent. Following derivatization of the prepolymer, an aqueous solution, for example sodium bicarbonate, preferably buffered to a pH of about 7.2 to about 9.5, is added to the derivatized prepolymer solution to initiate polymerization of the hydrogel. Alternatively, a water soluble biomolecule, such as DNA or other oligonucleotide, is prepared in an aqueous solution and added to the polyurethane-based hydrogel prepolymer such that derivatization and polymerization occur, essentially, simultaneously. While the hydrogel is polymerizing, it is microspotted onto a solid substrate, preferably a silanated glass substrate, to which the hydrogel microdroplet becomes covalently bound. Most preferably the hydrogel microdroplets are at least about 30 mum thick, for example about 50 mum to about 100 mum thick. The resulting biochips are particularly useful for gene discovery, gene characterization, functional gene analysis and related studies.

Owner:BIOCEPT INC

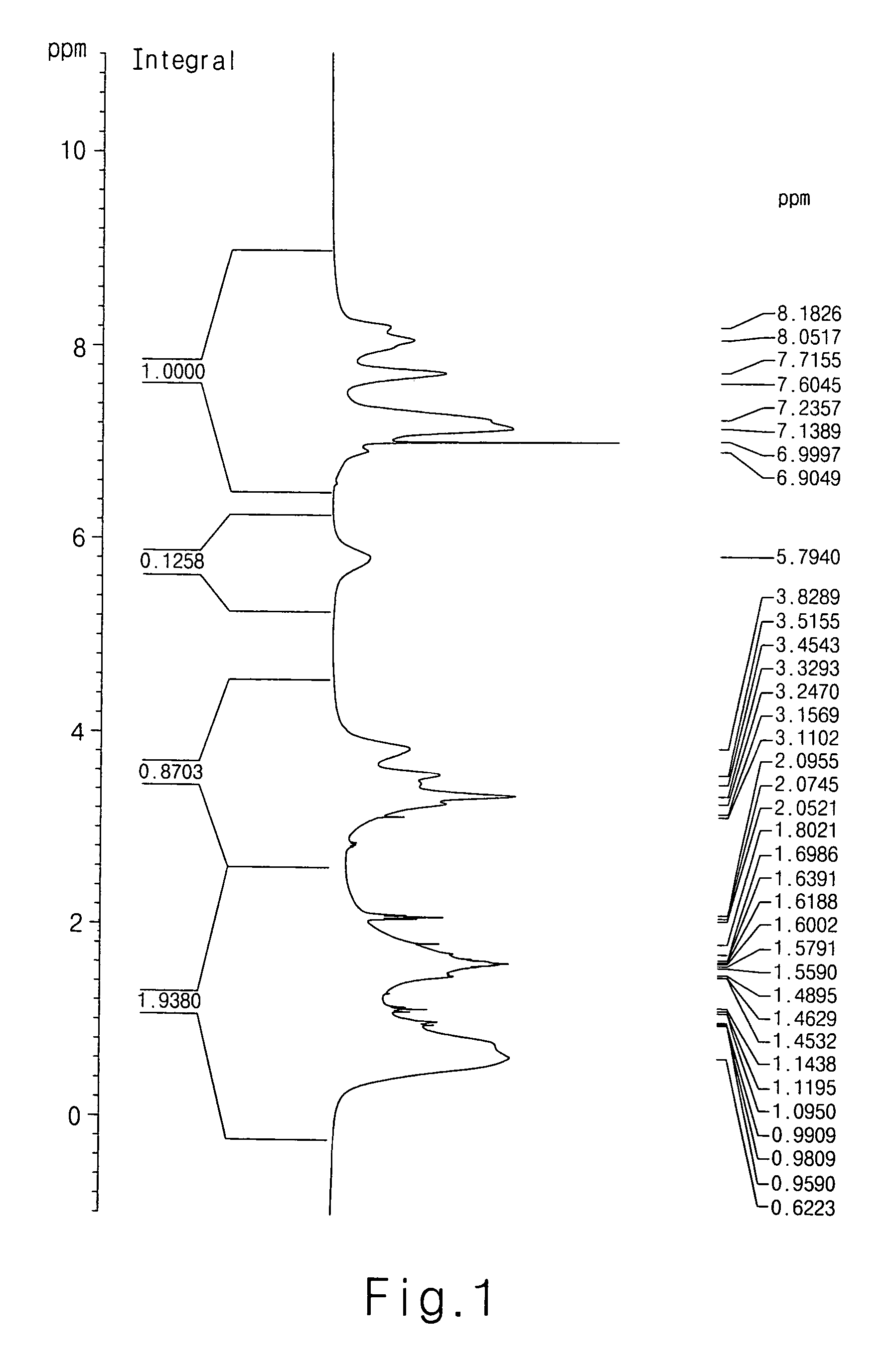

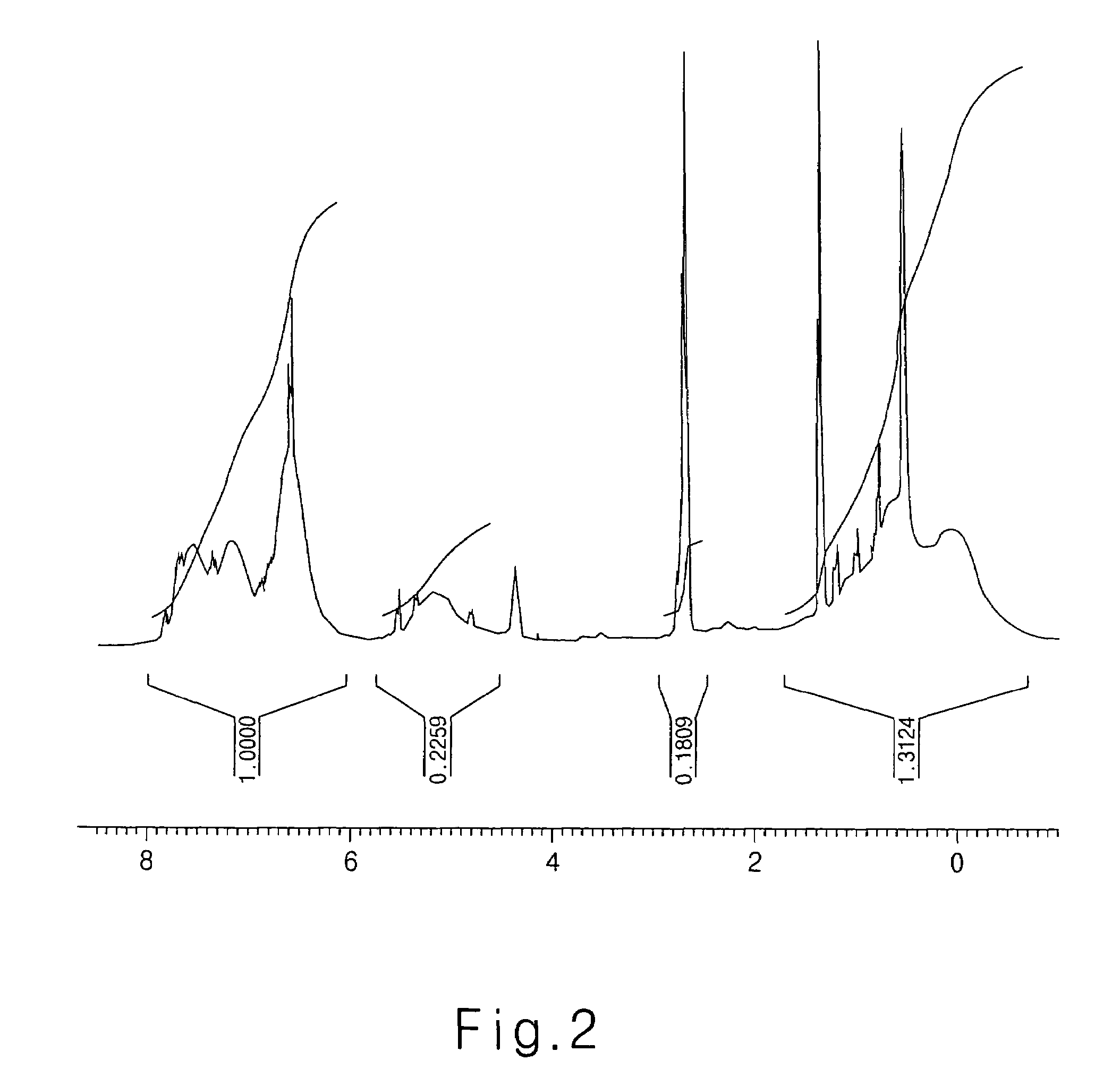

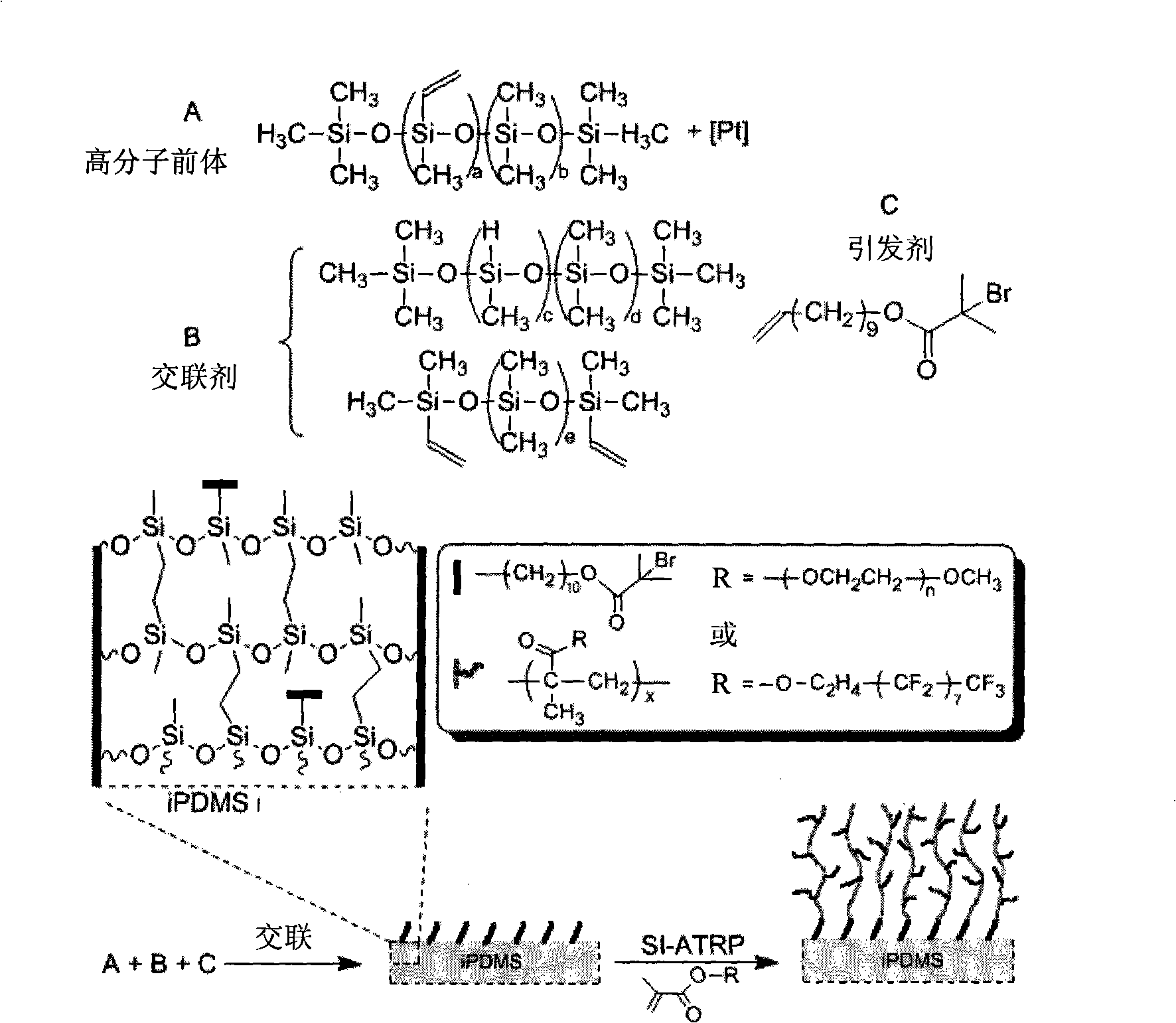

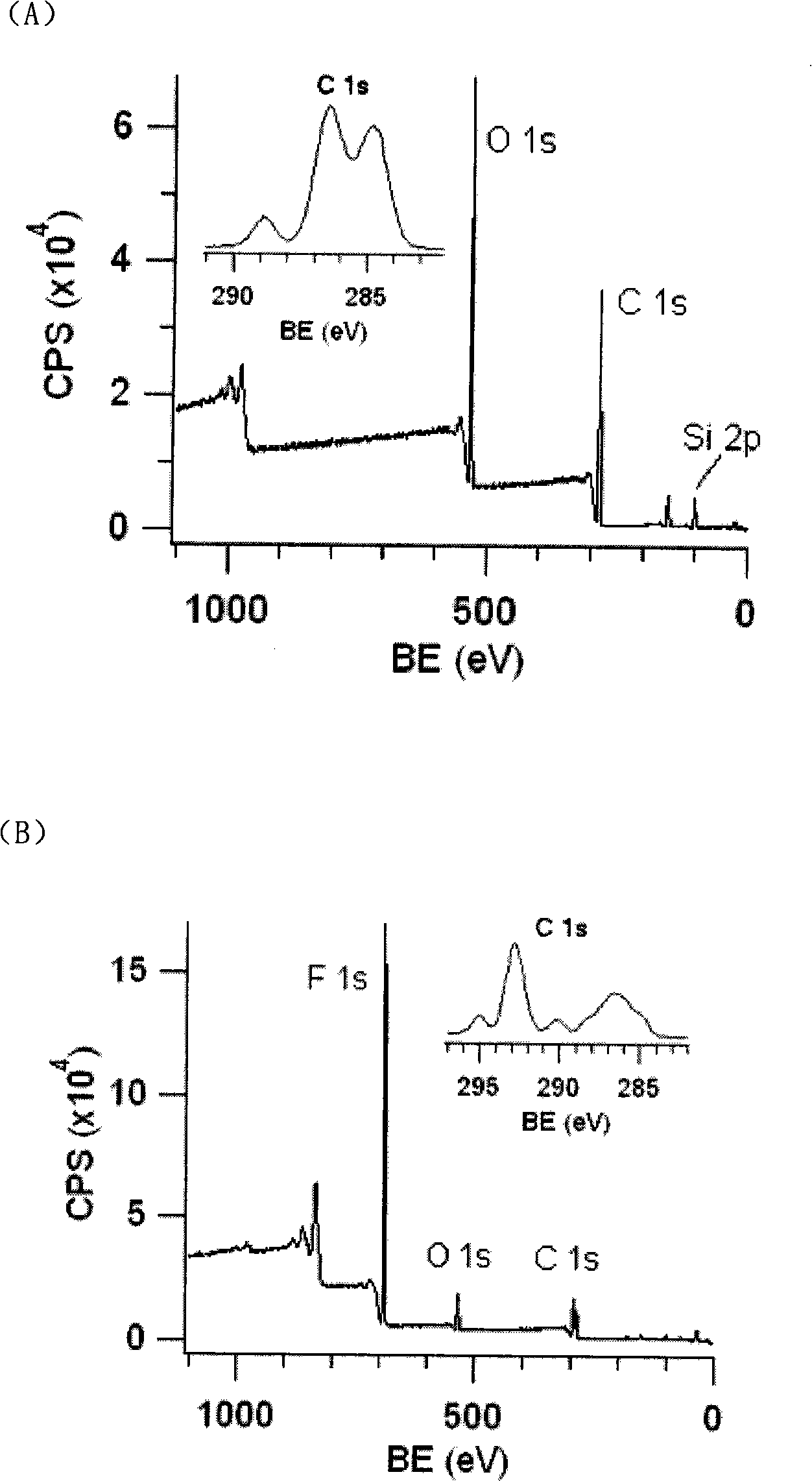

Polydimethylsiloxane with initiator on surface and its preparation method and use

The invention relates to polydimethylsiloxane which is provided with an initiator at the surface, and is the silicon-hydrogen bonding cross-linked polydimethylsiloxane, of which the surface contains 0.01 to 1At percent 2-bromine-2-methyl propioric acid 10-undecene ester. The material is formed by mixing a polymer precursor, a cross-liner and the initiator with olefinic end in the weight ratio of 10: 1: 4-0.01 and placing for 6 to 24 hours. The polydimethylsiloxane with the initiator at the surface which is provided by the invention further modifies a function layer on the surface by triggering the polymerization reaction on the surface, so the polydimethylsiloxane can be applied on biocompatible, organic solvent compatible and thermal sensitive materials. The invention uses the simple and convenient method to realize the universal, permanent, diverse and functional surface modified polydimethylsiloxane.

Owner:SUZHOU SIJU BIOMATERIALS

Surface-functionalized mesoporous carbon materials

ActiveUS9249241B2Effectively and efficiently functionalizedPractical and cost-effective for large scale productionProcess efficiency improvementPolyvinyl polymerSolvent

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

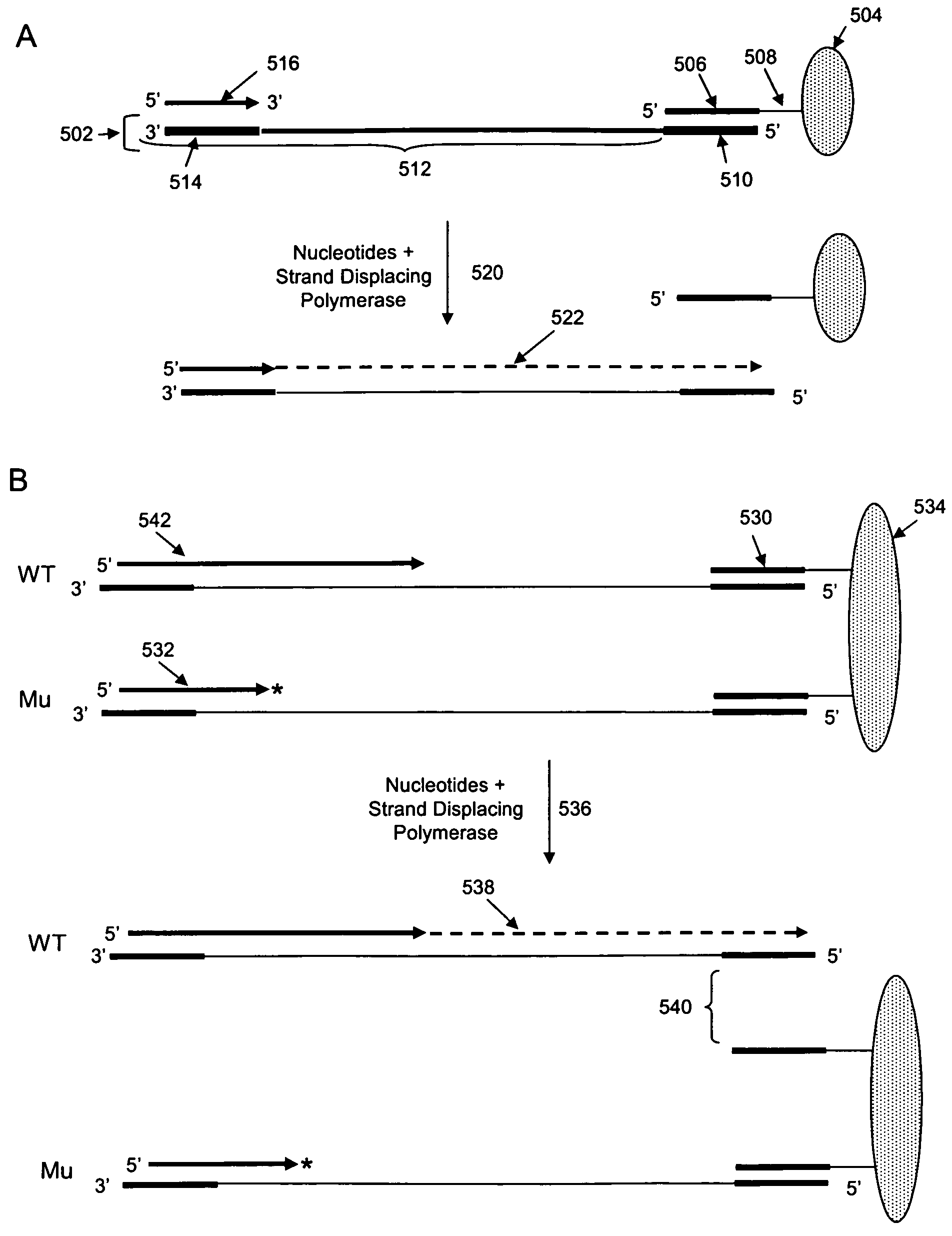

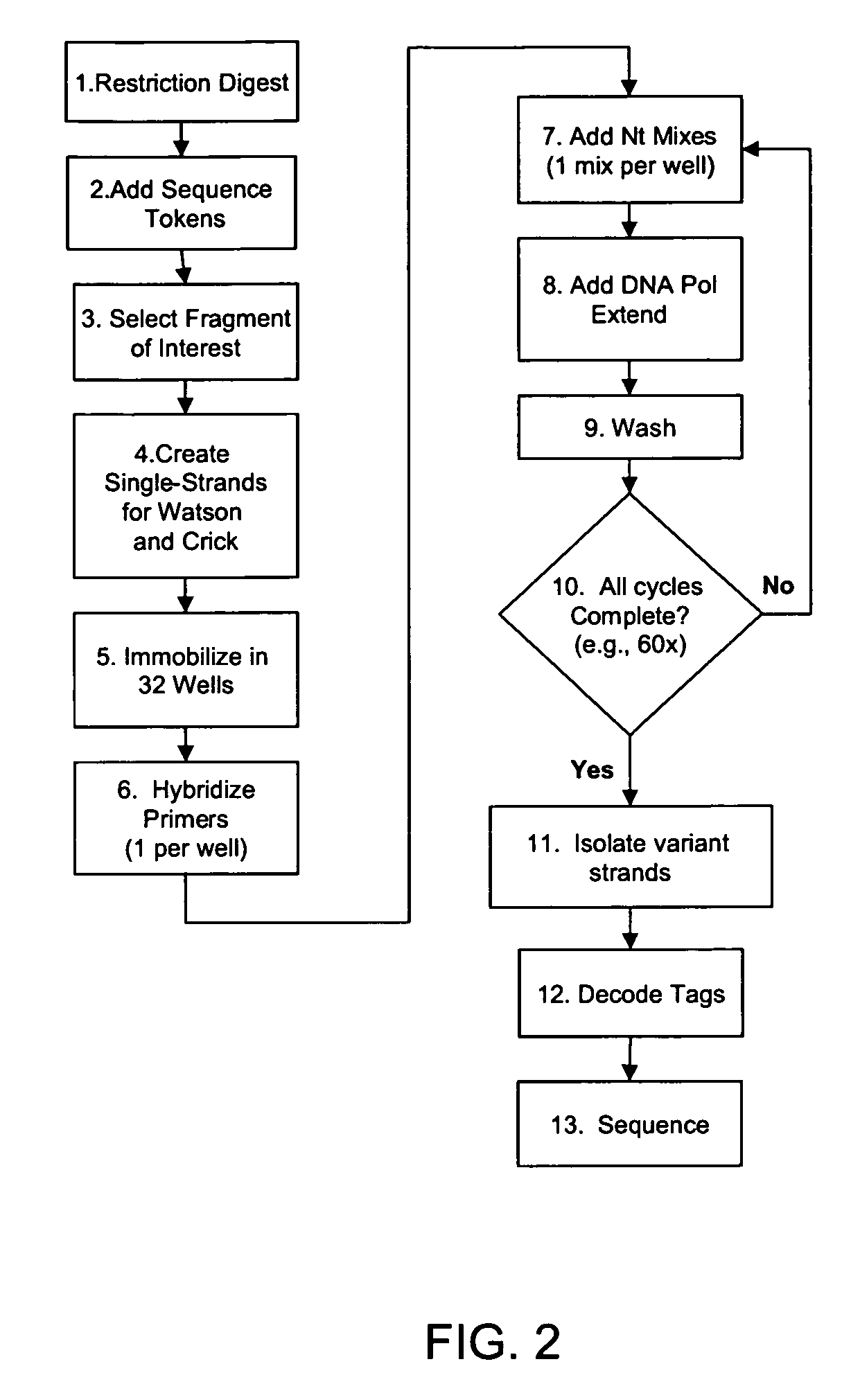

Methods and compositions for isolating nucleic acid sequence variants

The invention is drawn to isolating sequence variants of a genetic locus of interest using a modified iterative primer extension method. The nucleic acids analyzed are generally single stranded and have a reference sequence which is used as a basis for performing iterative single nucleotide extension reactions from a hybridized polymerization primer. The iterative polymerization reactions are configured such that polymerization of the strand will continue if the sequence of the nucleic acid being analyzed matches the reference sequence, whereas polymerization will be terminated if the nucleic acid being analyzed does not match the reference sequence. Nucleic acid strands that have mutations can be isolated using a variety of methods and sequenced to determine the precise identity of the mutation / polymorphism. By performing the method on both strands of the nucleic acid being analyzed, virtually all possible mutations can be identified.

Owner:AGENCY FOR SCI TECH & RES

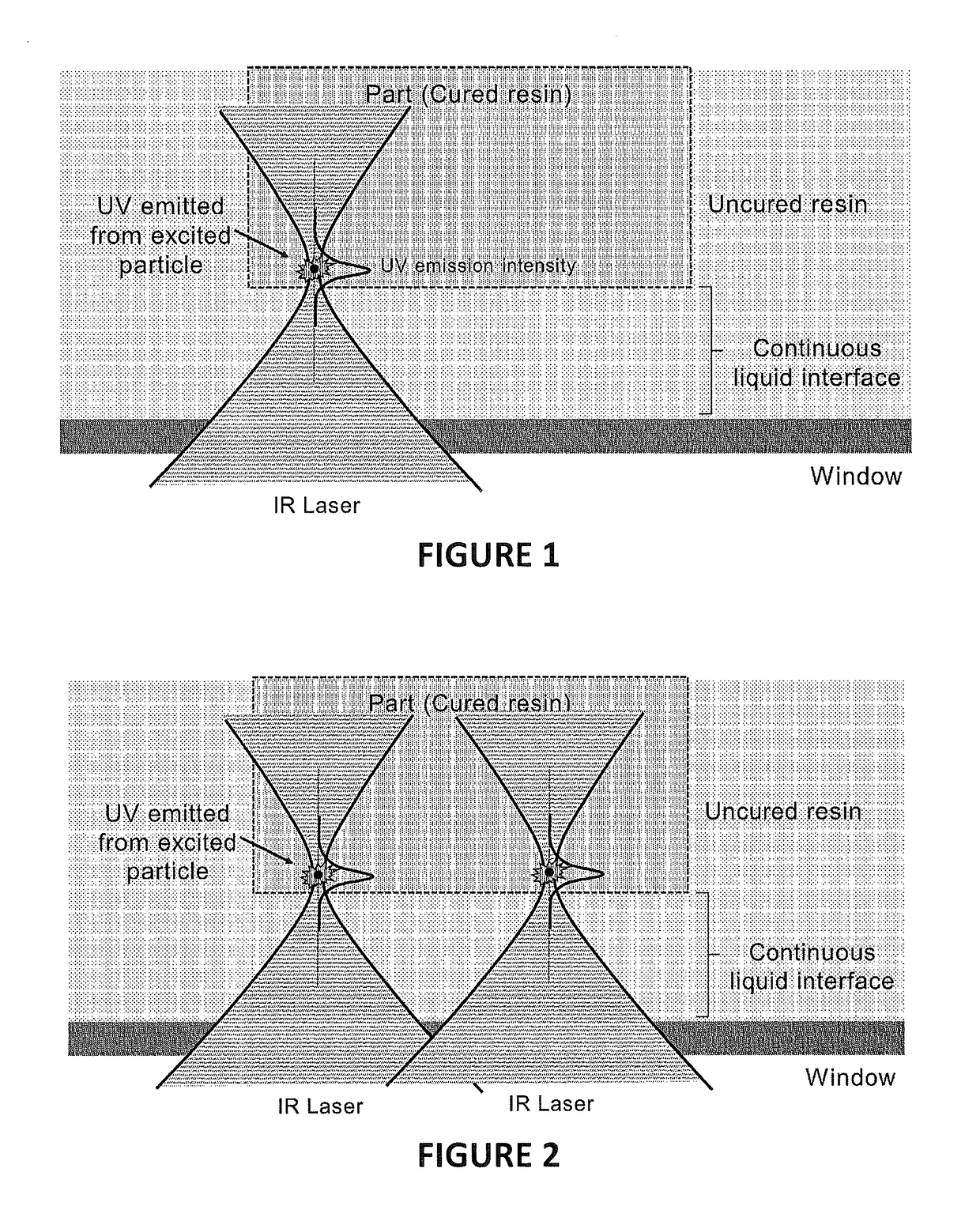

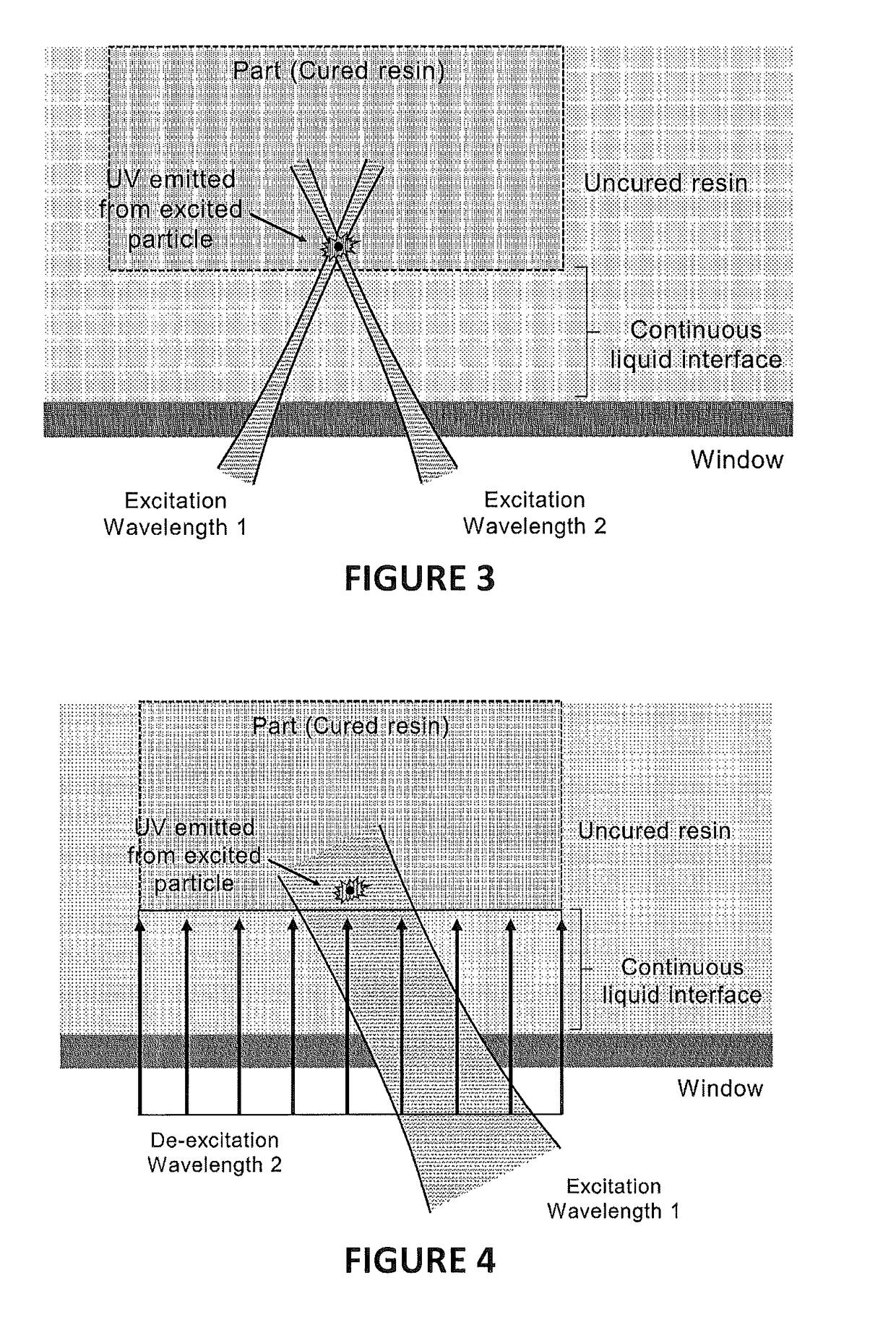

Continuous liquid interface production with upconversion photopolymerization

ActiveUS20180126630A1Additive manufacturing apparatus3D object support structuresLight excitationPolymeric liquid

A method of forming a three-dimensional object can be carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid comprising: (i) a polymerizable component; (ii) upconverting particles that are excited by light at a first wavelength and upon excitation emit light at a second wavelength that is shorter than the first wavelength; and (iii) a photoiniator that catalyzes polymerization of the polymerizable component upon excitation by light at the second wavelength; (c) irradiating the build region through the optically transparent member with an excitation light at the first wavelength, and optionally but in some embodiments preferably also advancing the carrier away from the build surface, wherein the excitation light is temporally and / or spatially modulated, to thereby form the three-dimensional object from the polymerizable liquid.

Owner:CARBON INC

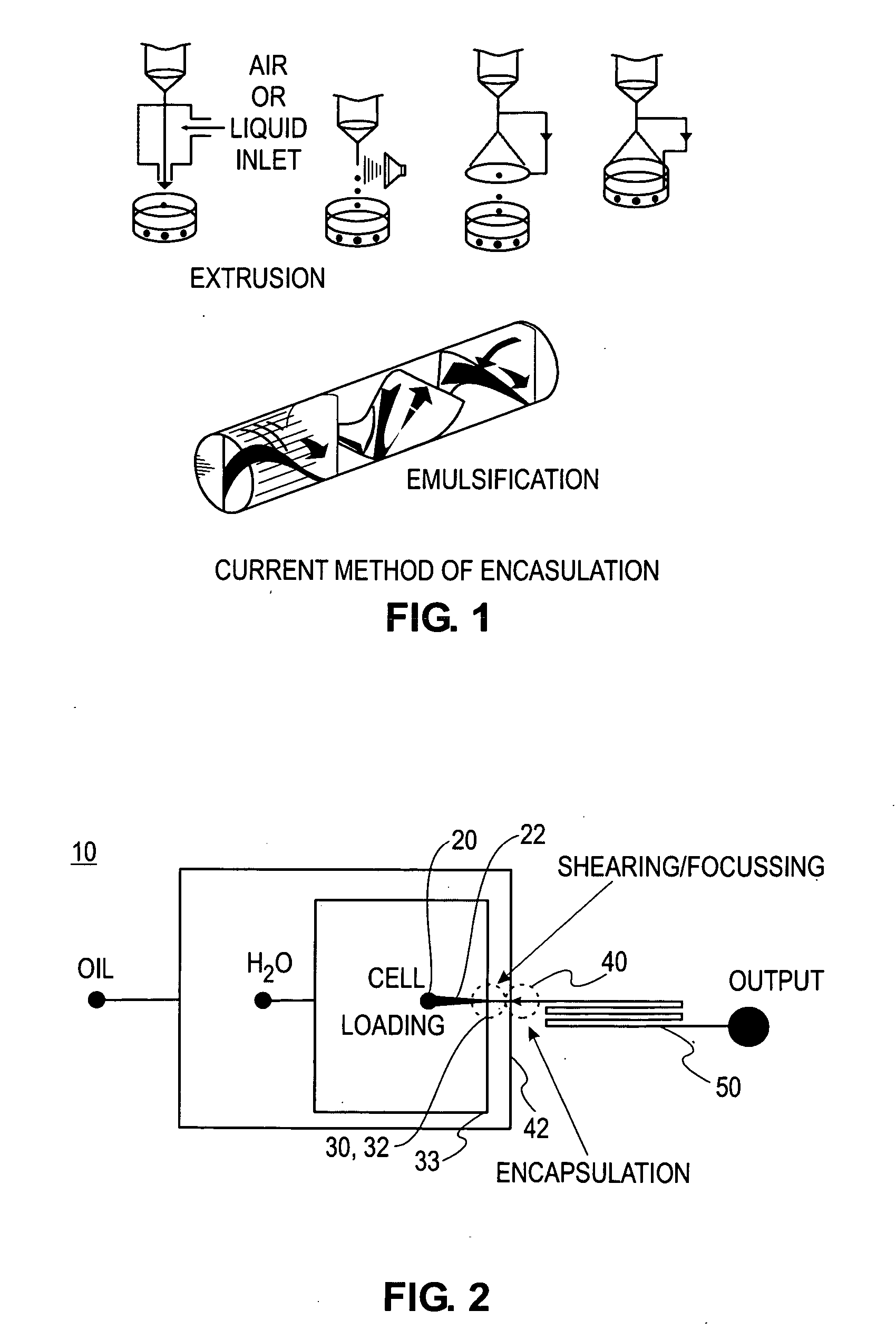

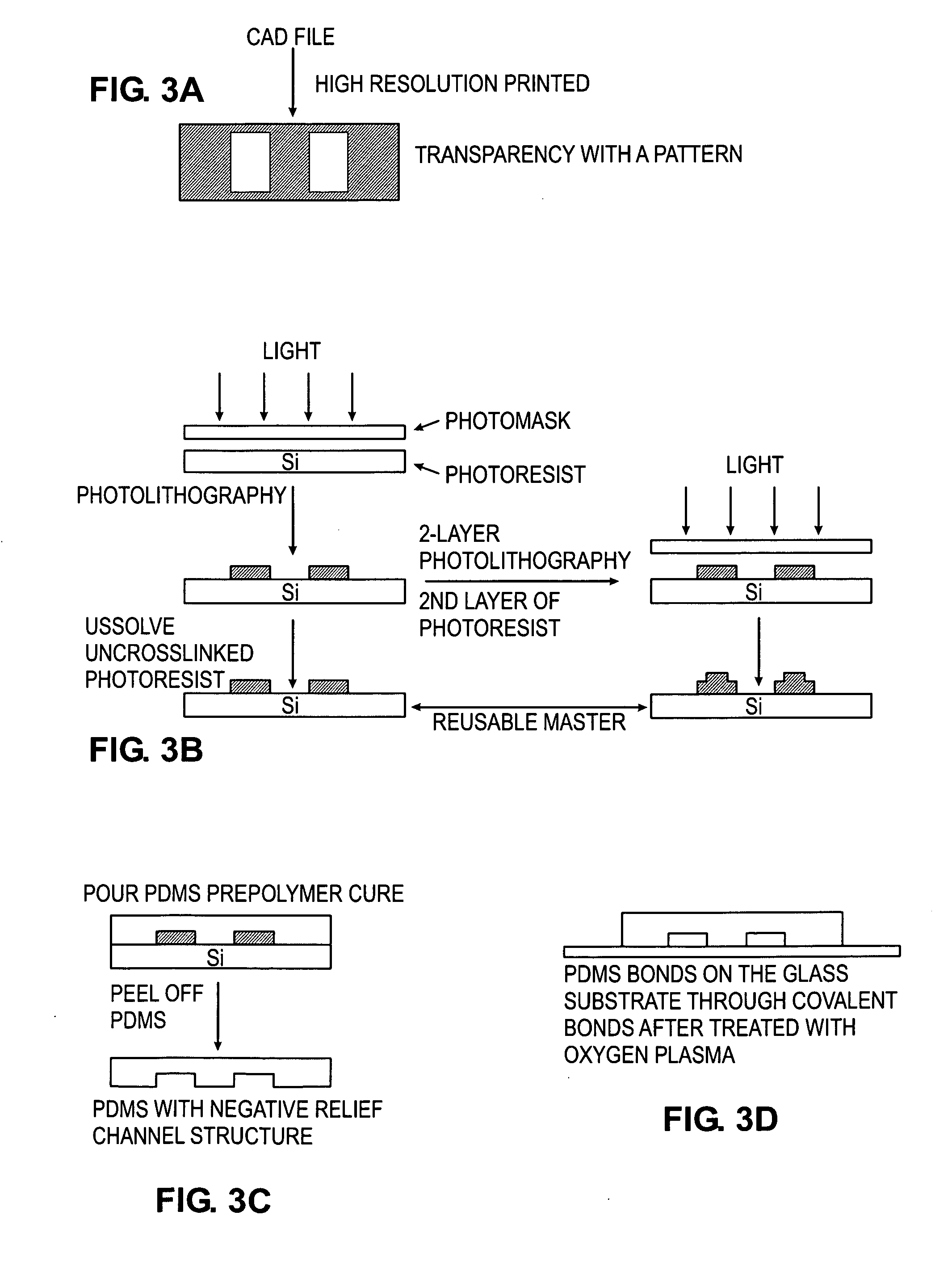

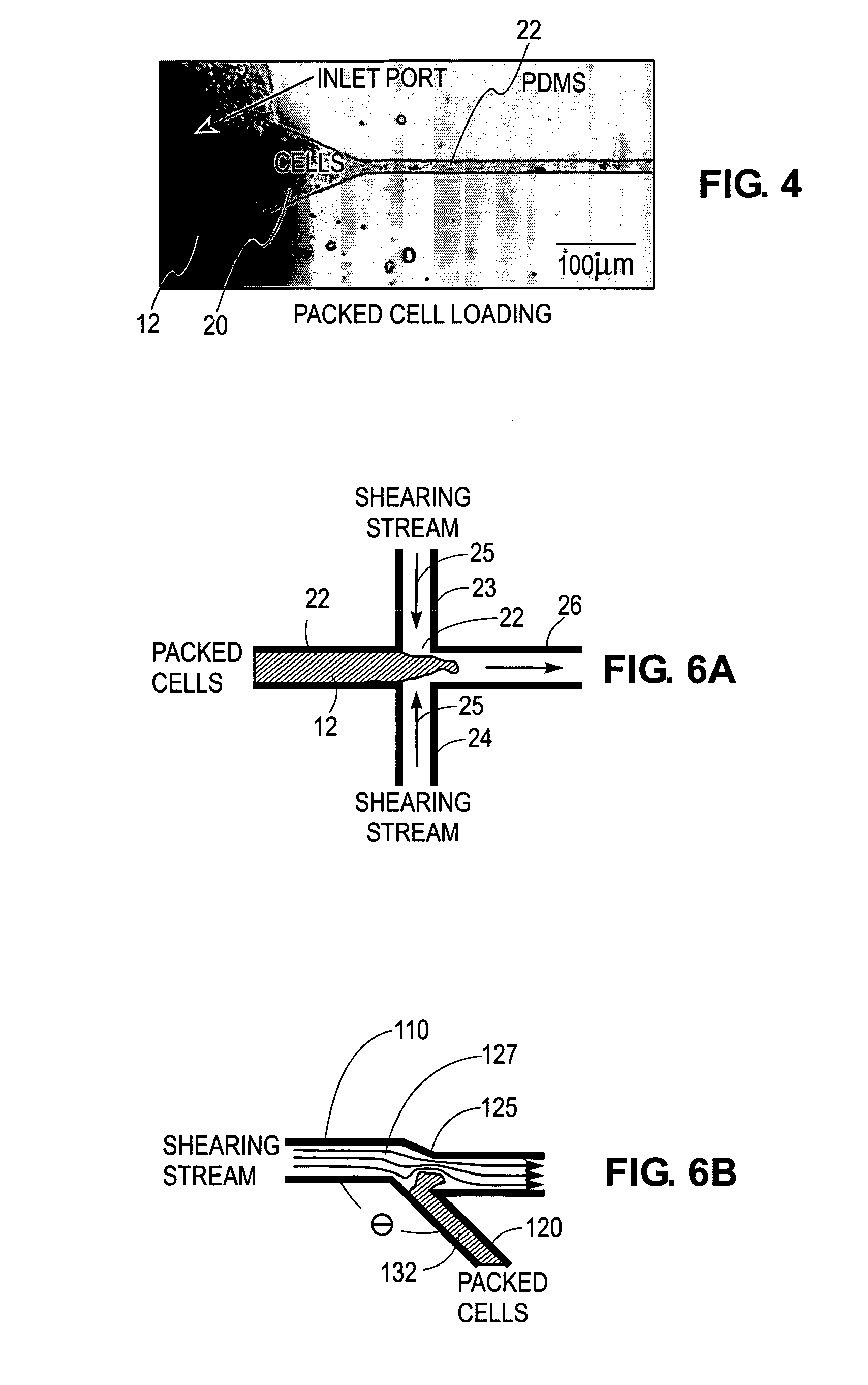

Microfluidic device for the encapsulation of cells with low and high cell densities

ActiveUS20060051329A1Small minimum droplet sizeUniform polymerization timeBioreactor/fermenter combinationsBiocideHigh cellEngineering

Devices and methods for the encapsulation of cells on microfluidic platforms are disclosed. The microfluidic device generally includes a plurality of functional regions to shear, focus, and encapsulate a desired cell or group of cells into a droplet. The microfluidic device can further comprise a polymerization zone to form a polymer bead around the droplet.

Owner:RGT UNIV OF CALIFORNIA

Continuous liquid interphase printing

ActiveUS9360757B2Low viscosityFacilitate re-fillingManufacturing platforms/substratesManufacturing heating elementsEngineeringMechanical engineering

A method of forming a three-dimensional object is carried out by providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid and advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently with the irradiating and / or advancing steps: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof. The gradient of polymerization zone comprises the polymerizable liquid in partially cured form (e.g., so that the formation of fault or cleavage lines between layers of solid polymer in the three-dimensional object is reduced). Apparatus for carrying out the method is also described.

Owner:CARBON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com