Patents

Literature

939 results about "Solid substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A substrate is a solid substance or medium to which another substance is applied and to which that second substance adheres. In computing and electronics, the term refers to a slice of semiconductor material such as silicon , metal oxide or gallium arsenide ( GaAs ) that serves as the foundation for the construction of components such as transistor s and integrated circuits ( IC s).

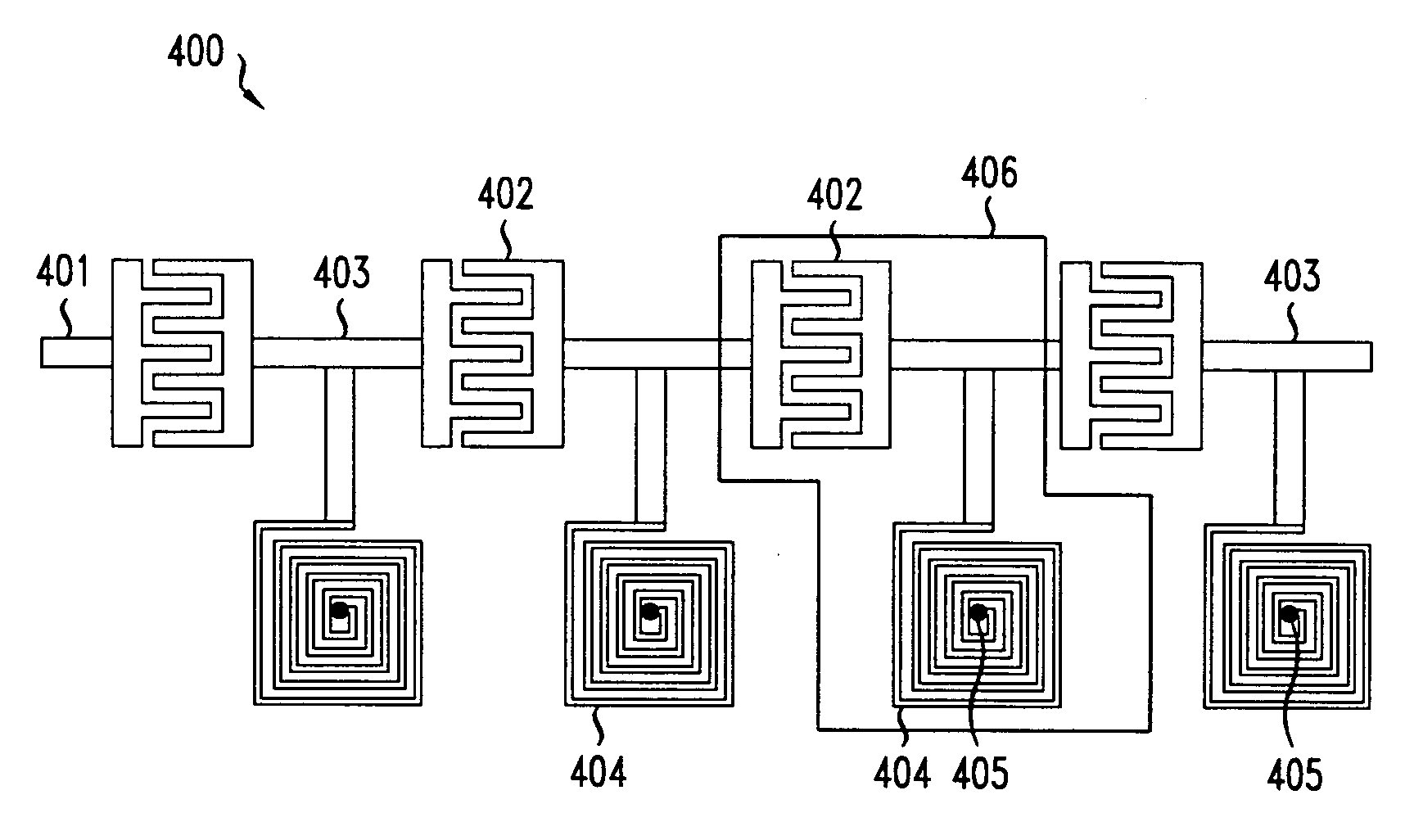

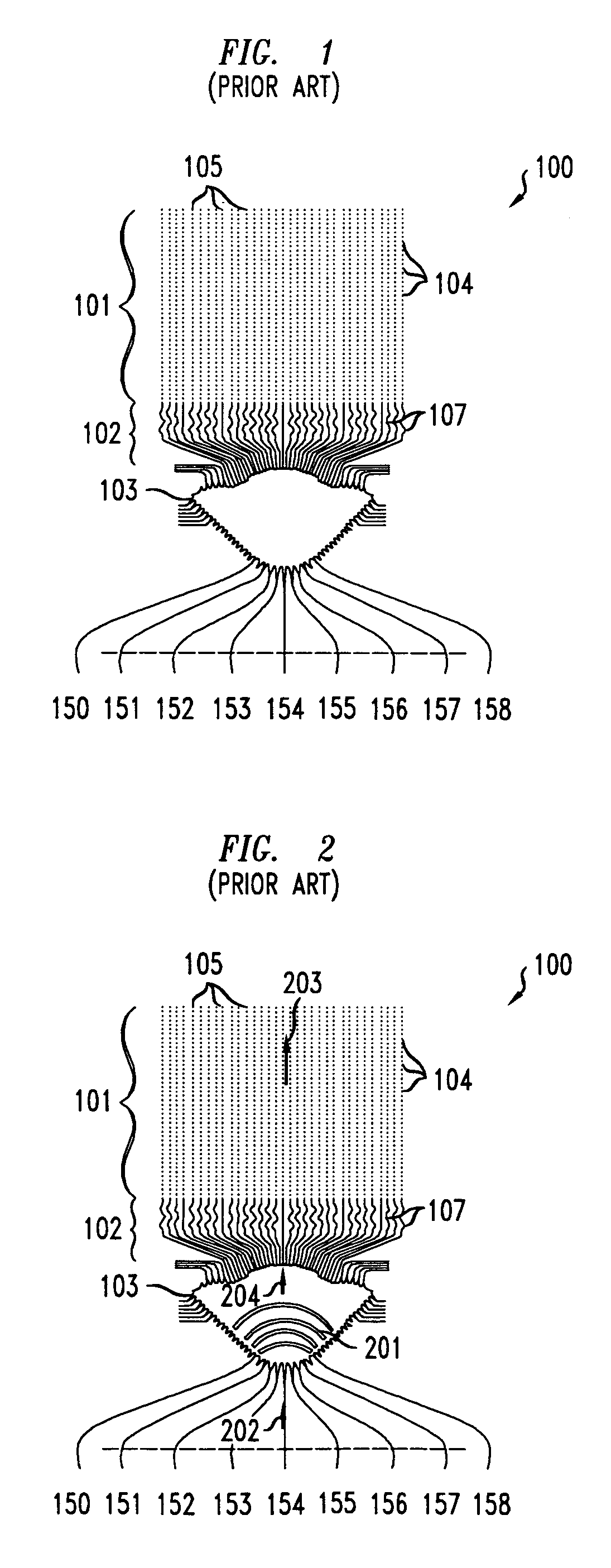

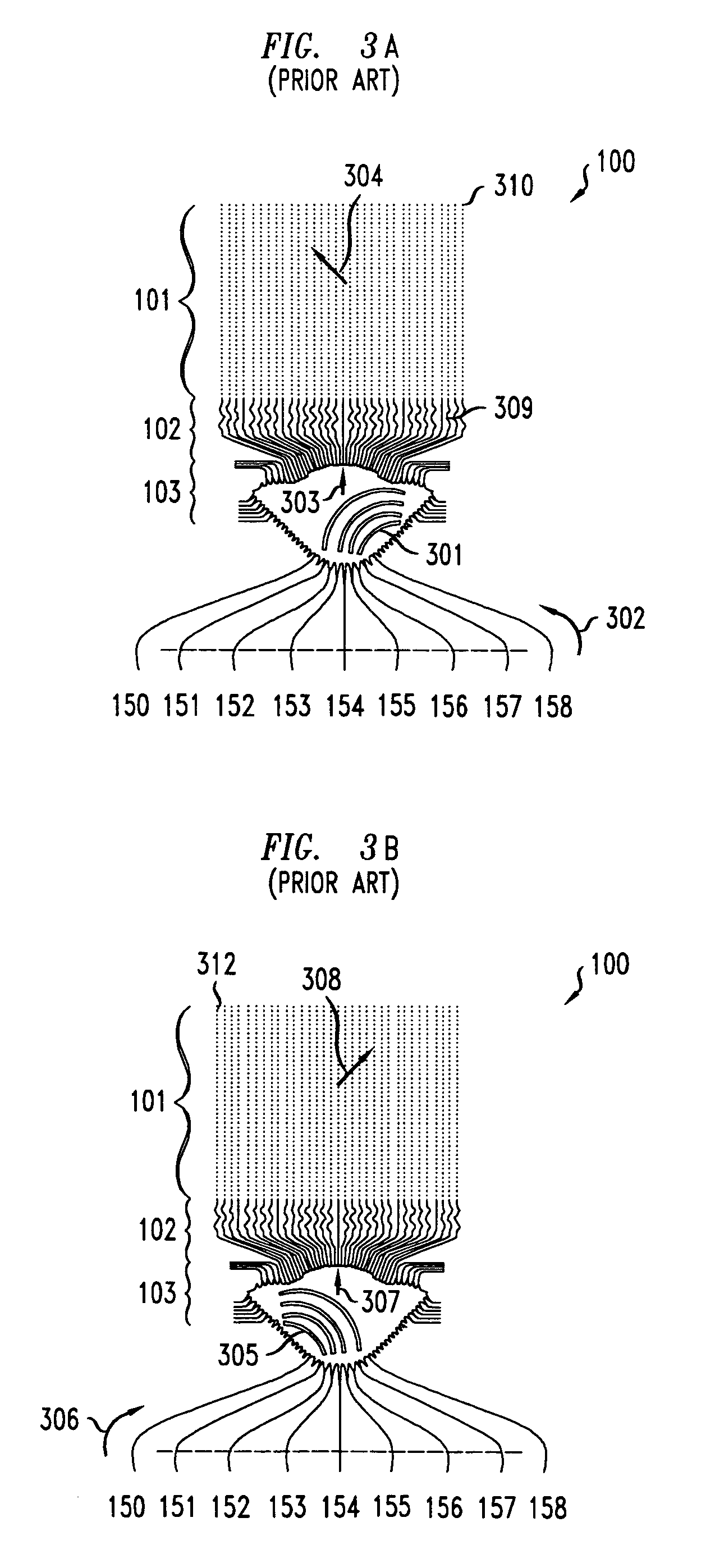

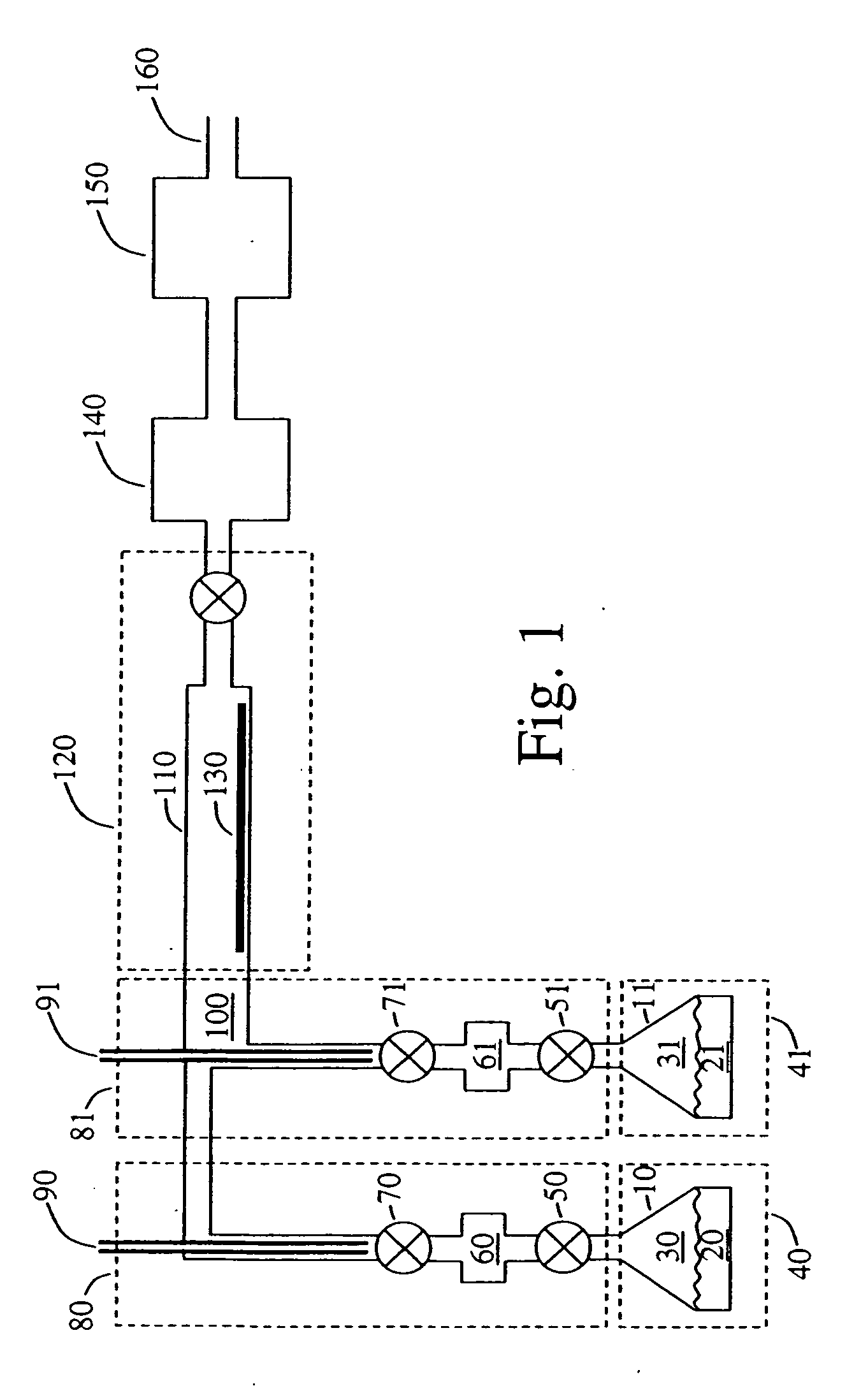

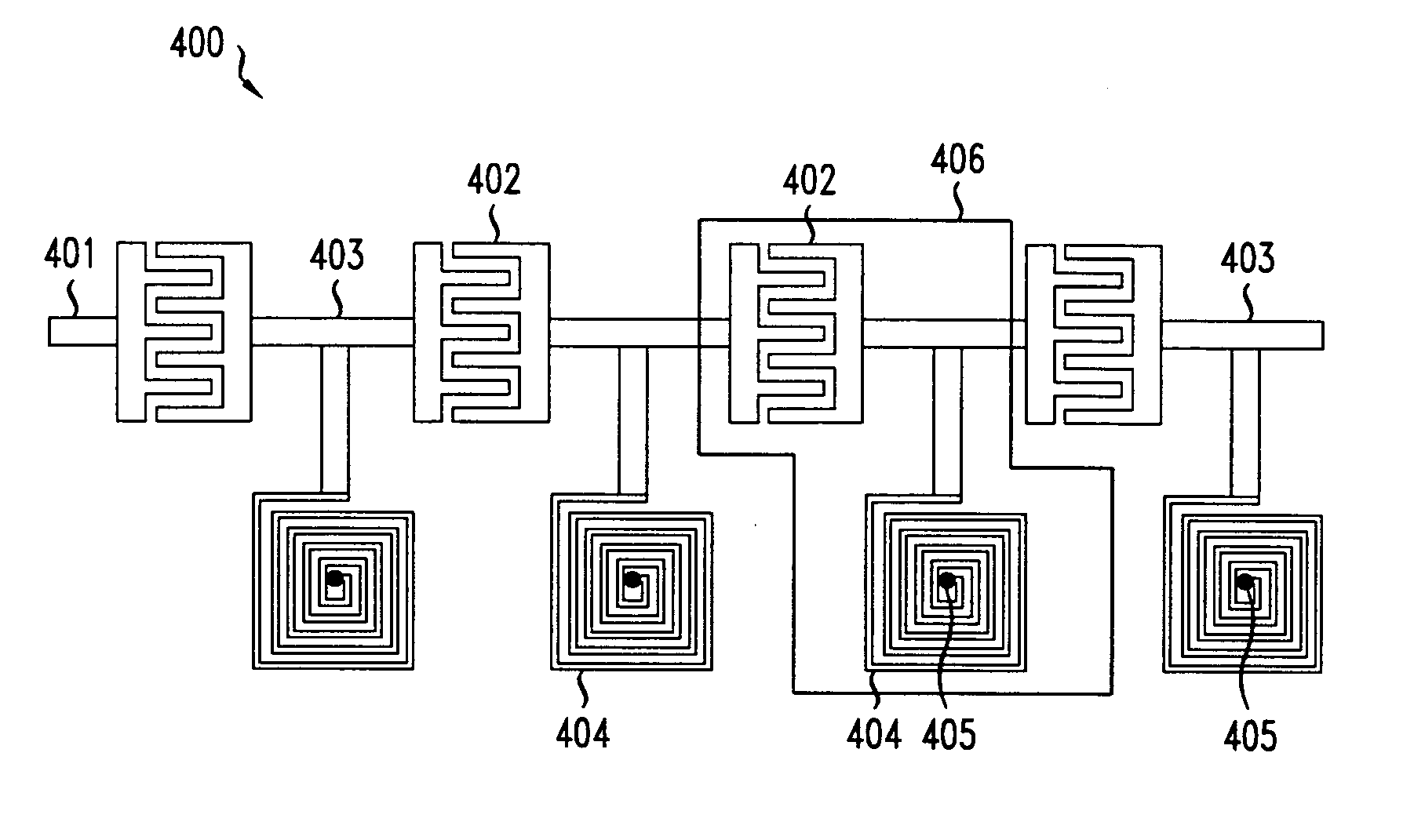

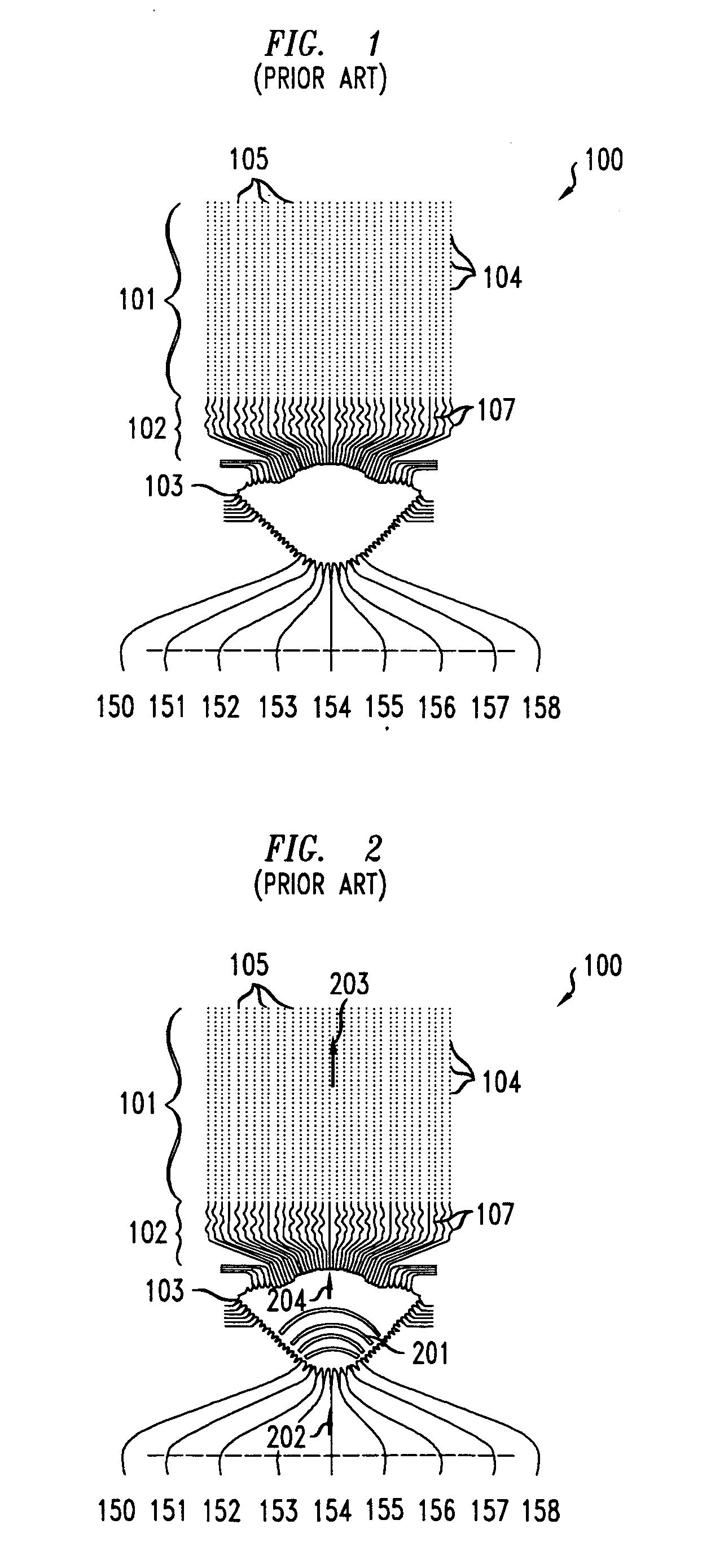

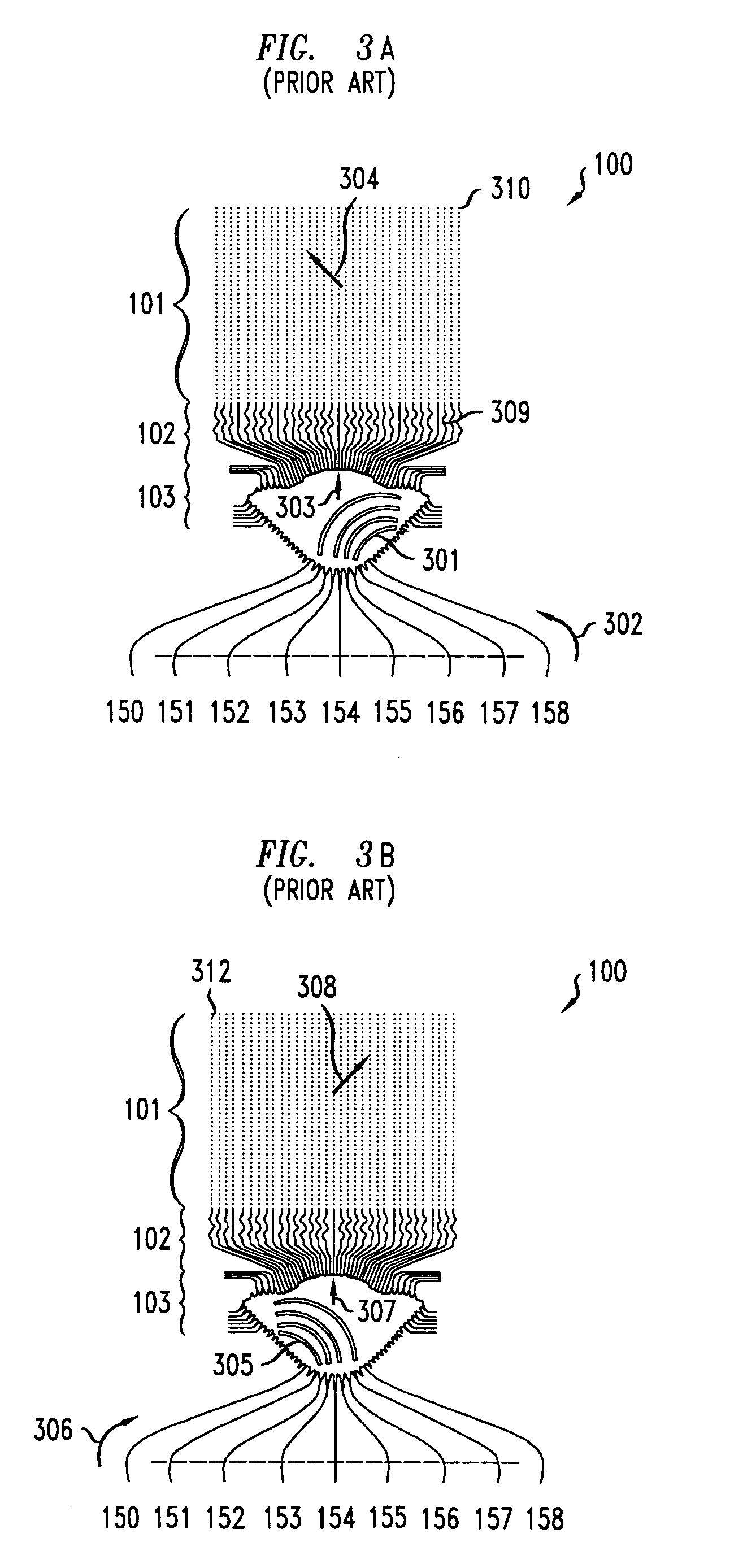

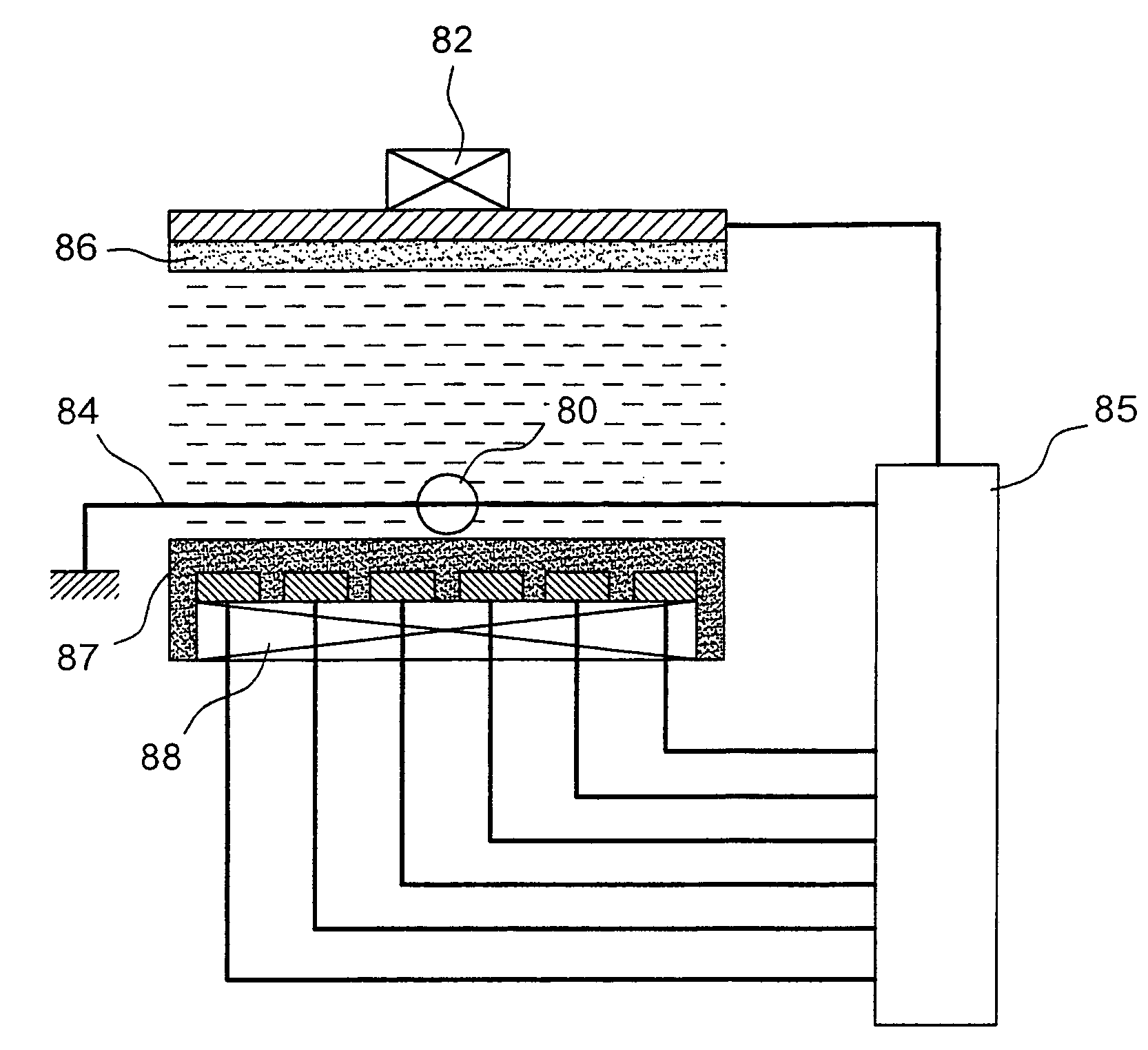

Phased array metamaterial antenna system

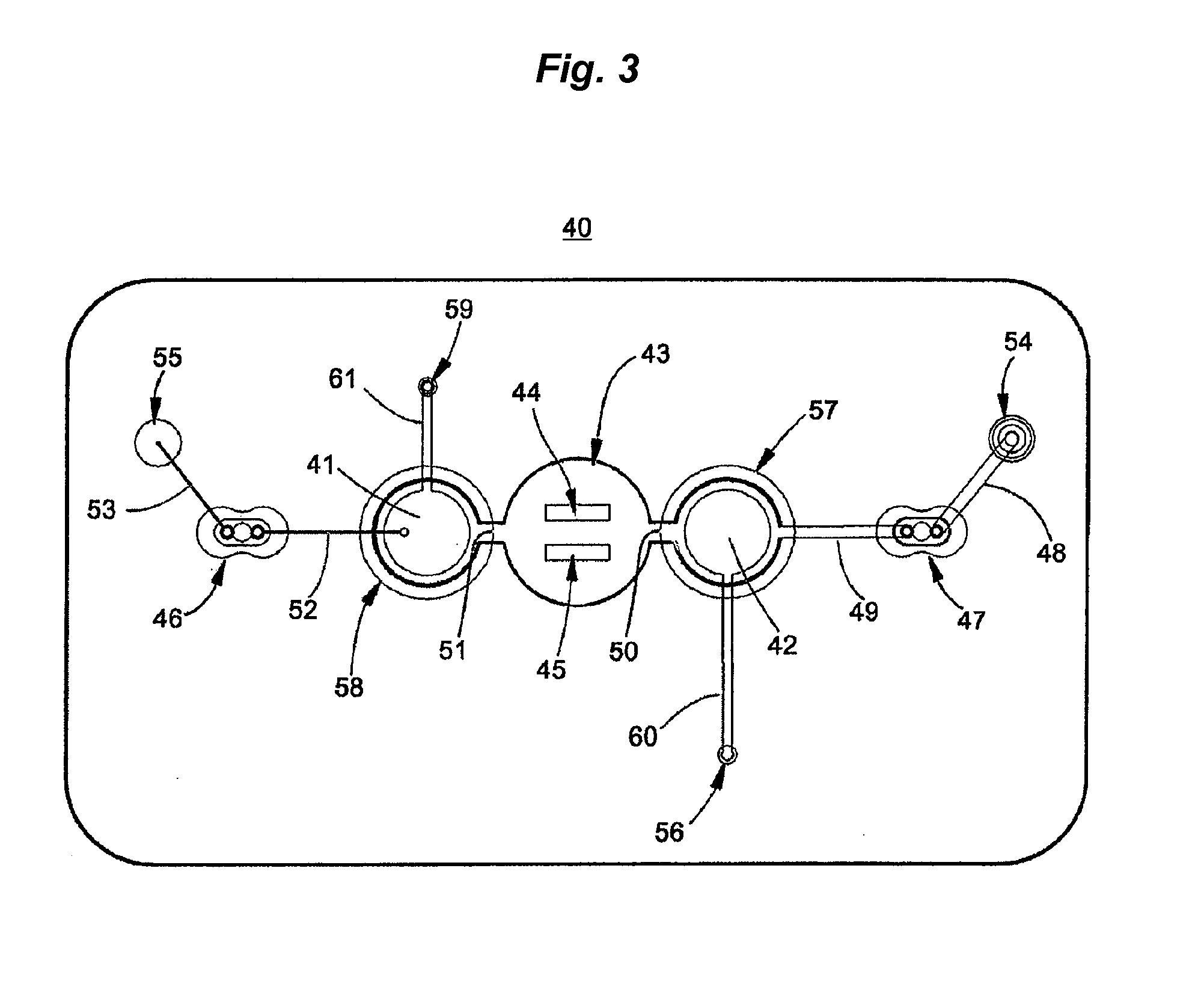

ActiveUS6958729B1Reduce sidelobeIncrease amplitude performanceSimultaneous aerial operationsRadiating elements structural formsSolid substratePhased array

An efficient, low-loss, low sidelobe, high dynamic range phased-array radar antenna system is disclosed that uses metamaterials, which are manmade composite materials having a negative index of refraction, to create a biconcave lens architecture (instead of the aforementioned biconvex lens) for focusing the microwaves transmitted by the antenna. Accordingly, the sidelobes of the antenna are reduced. Attenuation across microstrip transmission lines may be reduced by using low loss transmission lines that are suspended above a ground plane a predetermined distance in a way such they are not in contact with a solid substrate. By suspending the microstrip transmission lines in this manner, dielectric signal loss is reduced significantly, thus resulting in a less-attenuated signal at its destination.

Owner:LUCENT TECH INC

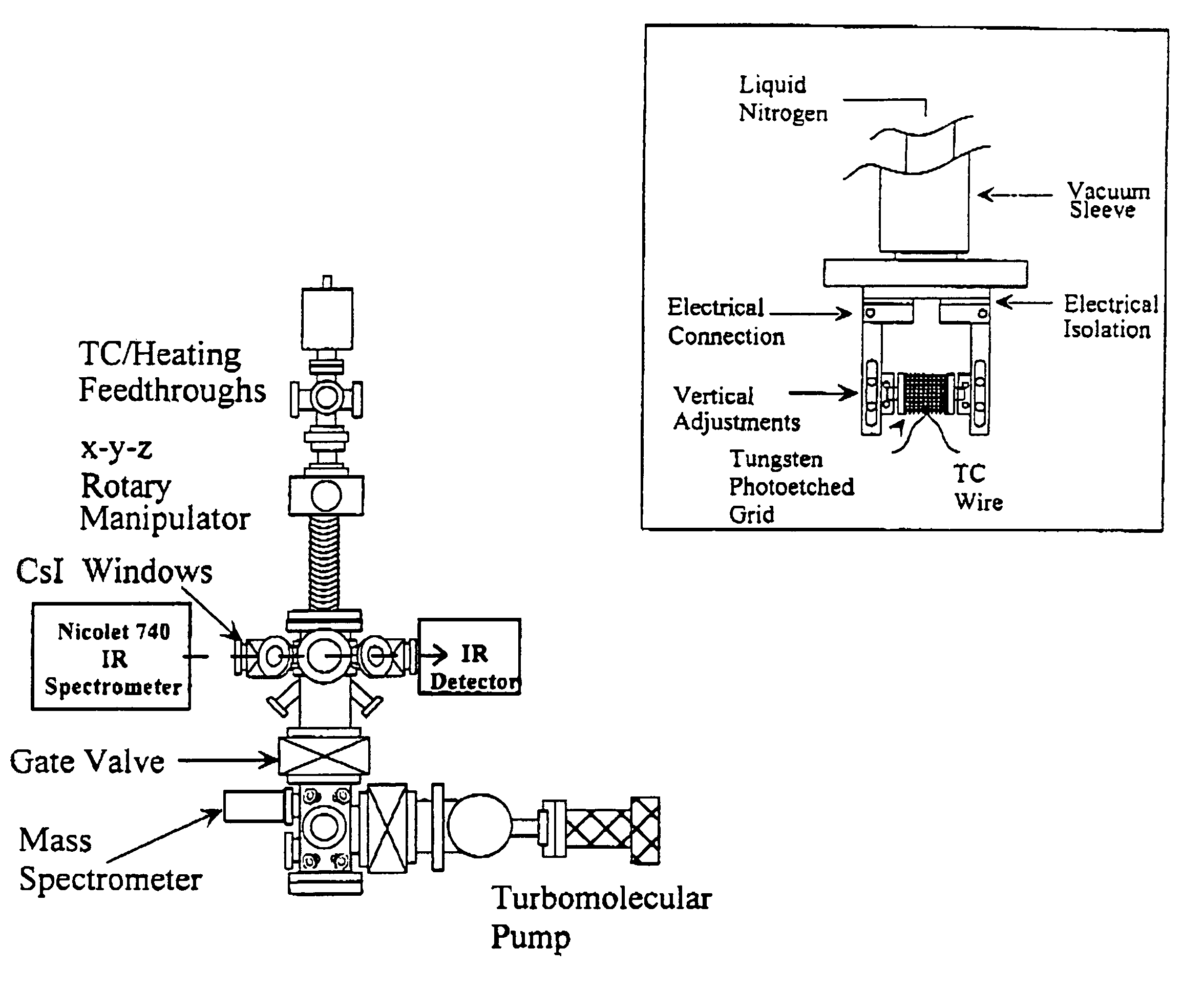

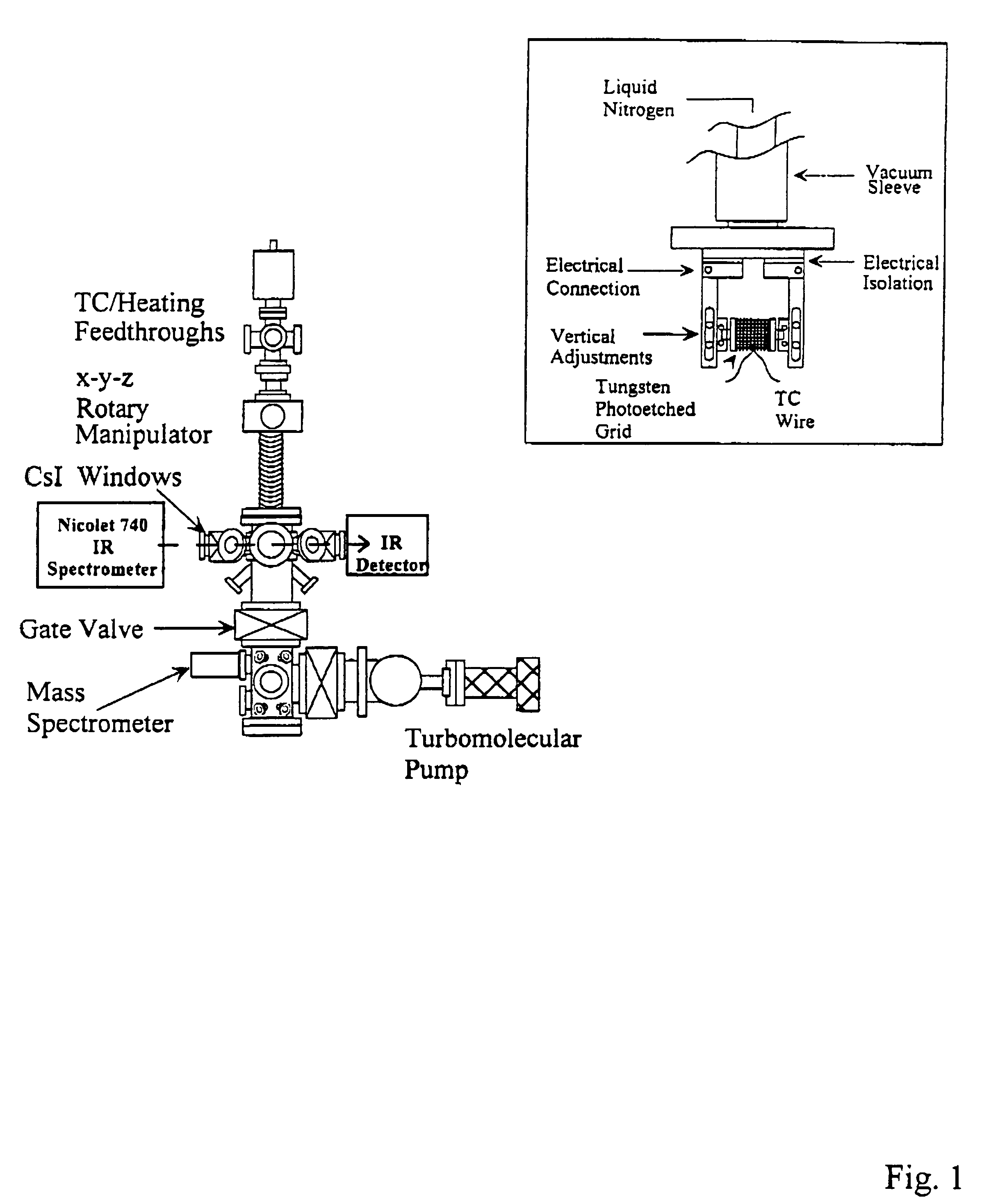

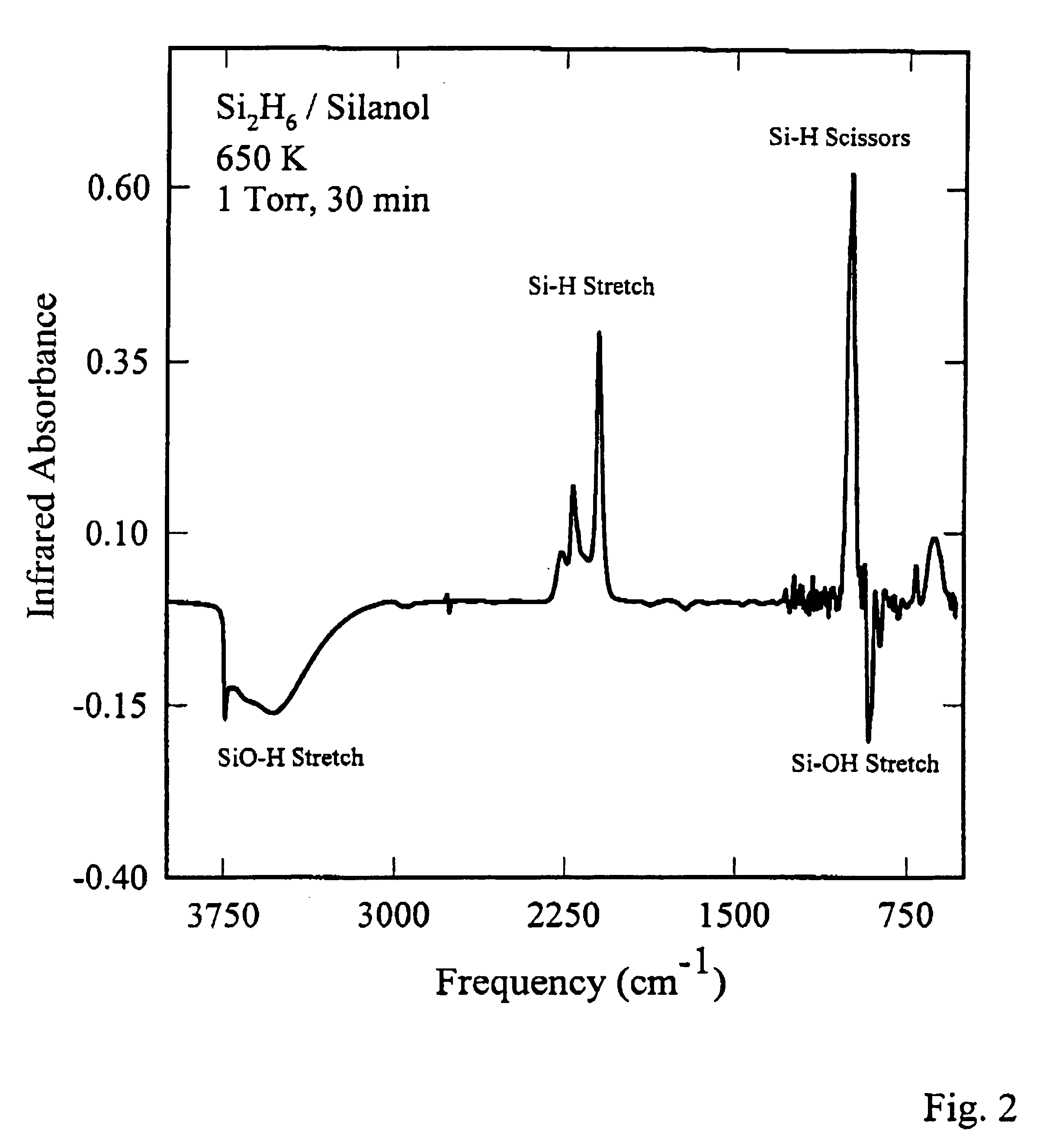

Vapor deposition of silicon dioxide nanolaminates

ActiveUS20050112282A1Easy to produceUniform thicknessMaterial nanotechnologySemiconductor/solid-state device manufacturingPorosityElectrical conductor

This invention relates to materials and processes for thin film deposition on solid substrates. Silica / alumina nanolaminates were deposited on heated substrates by the reaction of an aluminum-containing compound with a silanol. The nanolaminates have very uniform thickness and excellent step coverage in holes with aspect ratios over 40:1. The films are transparent and good electrical insulators. This invention also relates to materials and processes for producing improved porous dielectric materials used in the insulation of electrical conductors in microelectronic devices, particularly through materials and processes for producing semi-porous dielectric materials wherein surface porosity is significantly reduced or removed while internal porosity is preserved to maintain a desired low-k value for the overall dielectric material. The invention can also be used to selectively fill narrow trenches with low-k dielectric material while at the same time avoiding deposition of any dielectric on the surface area outside of the trenches.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

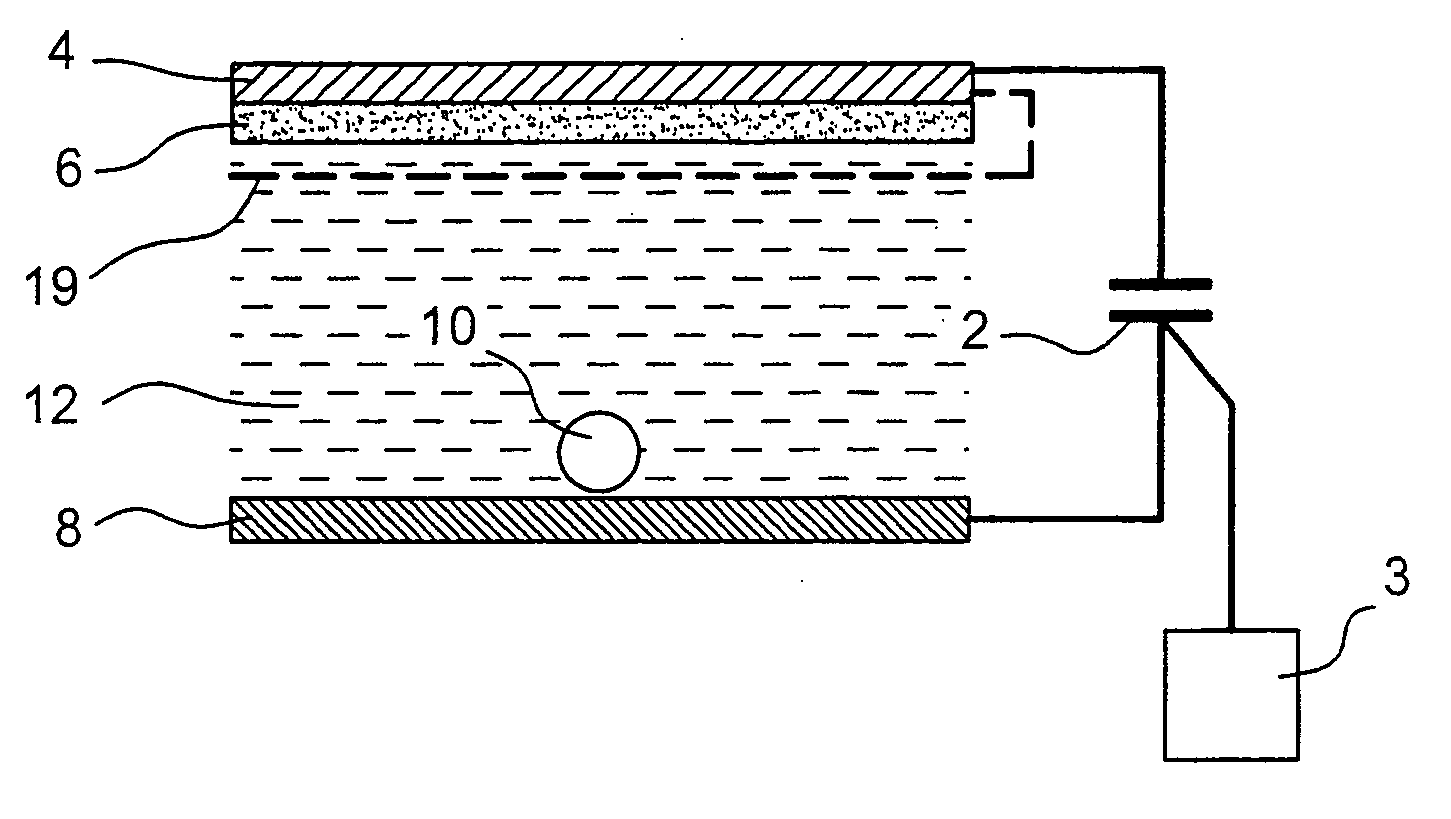

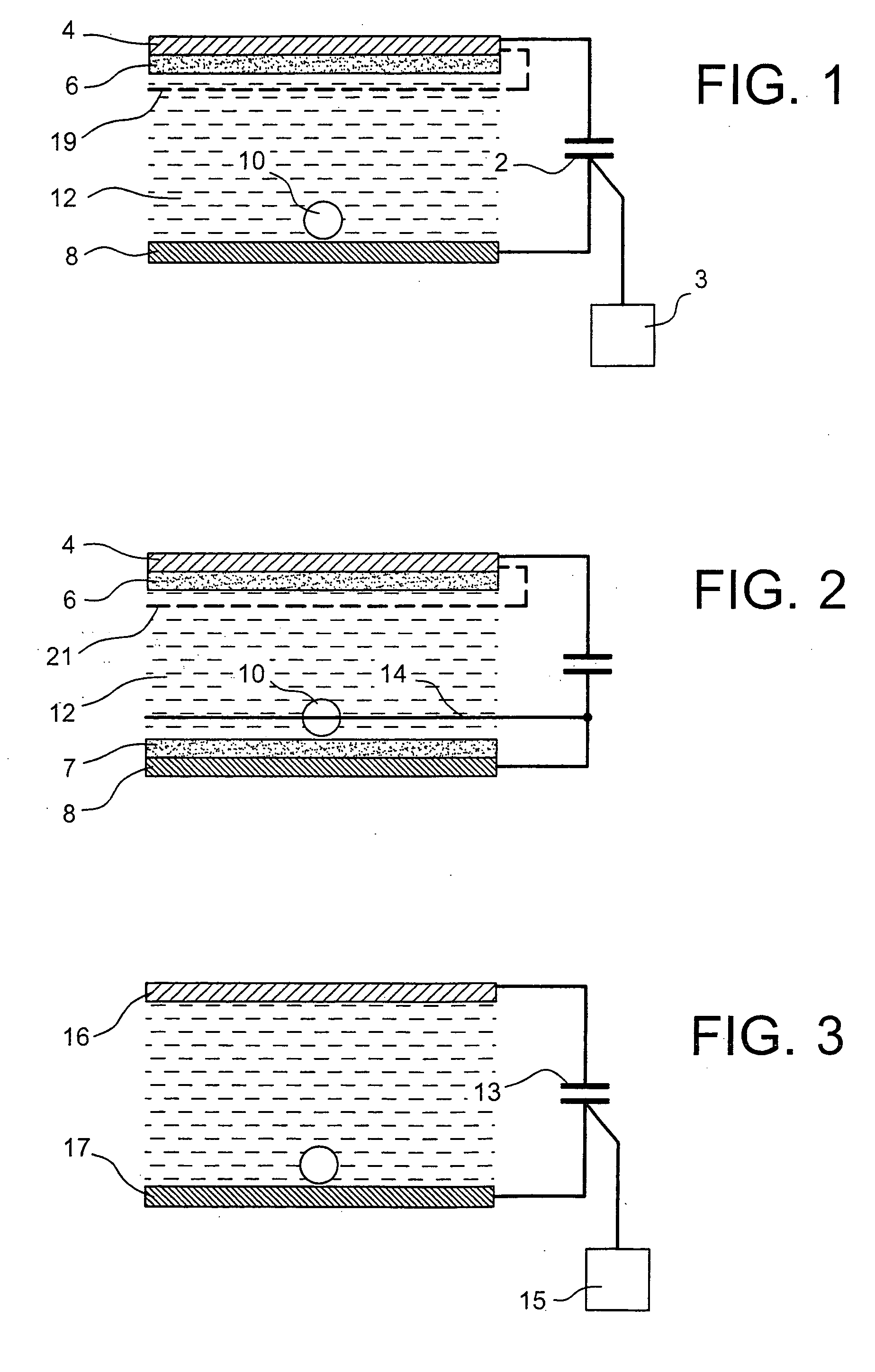

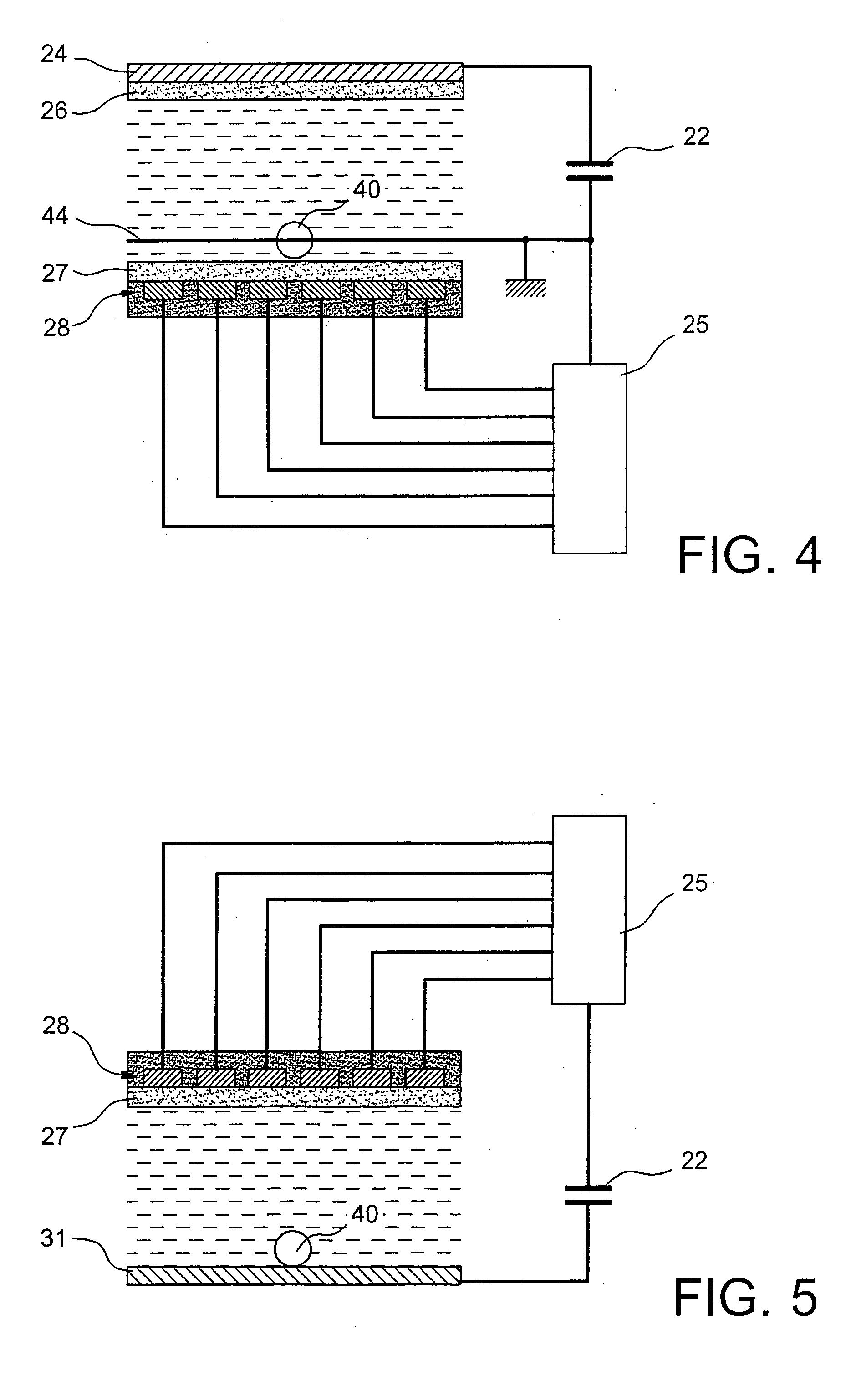

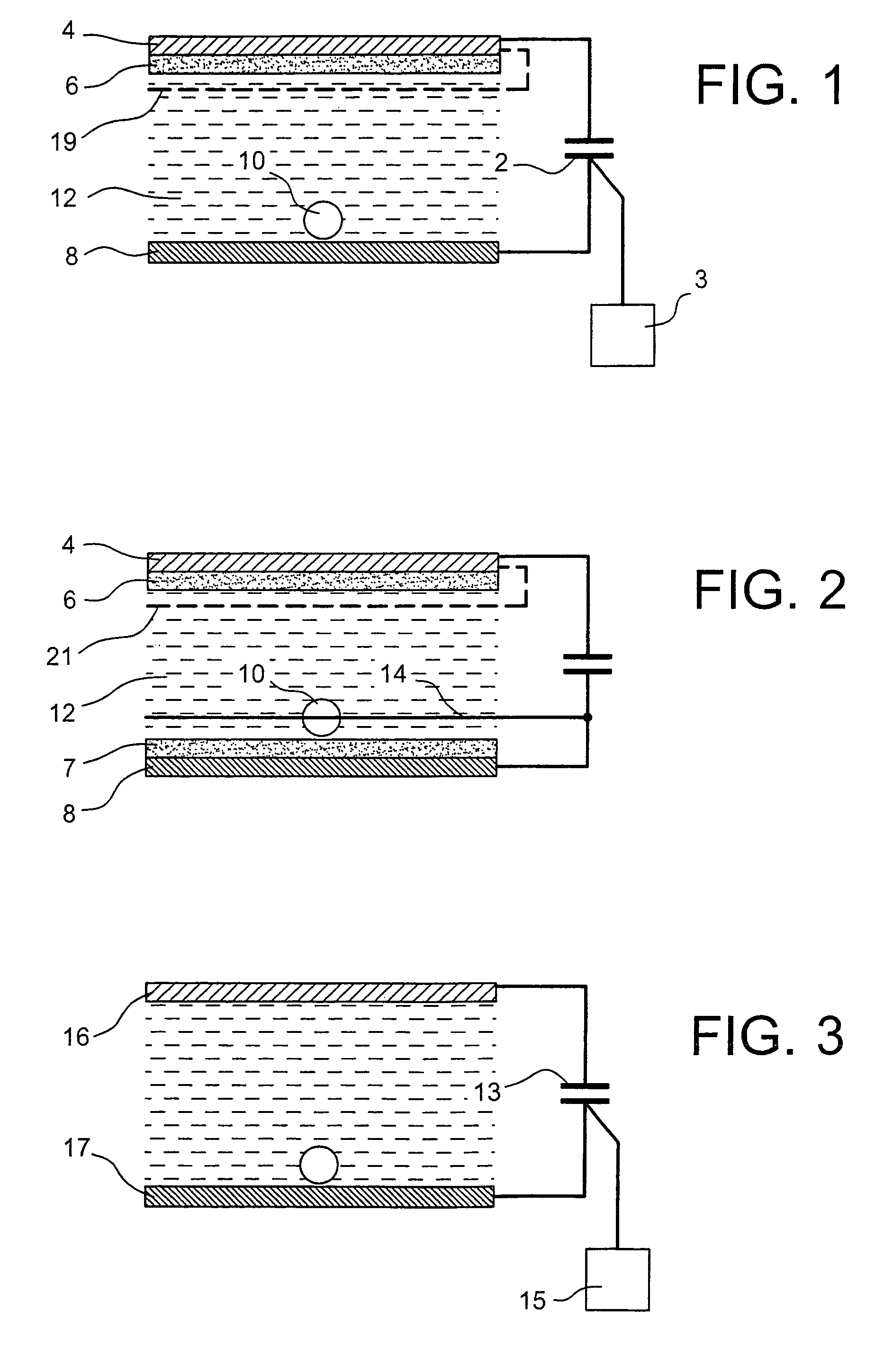

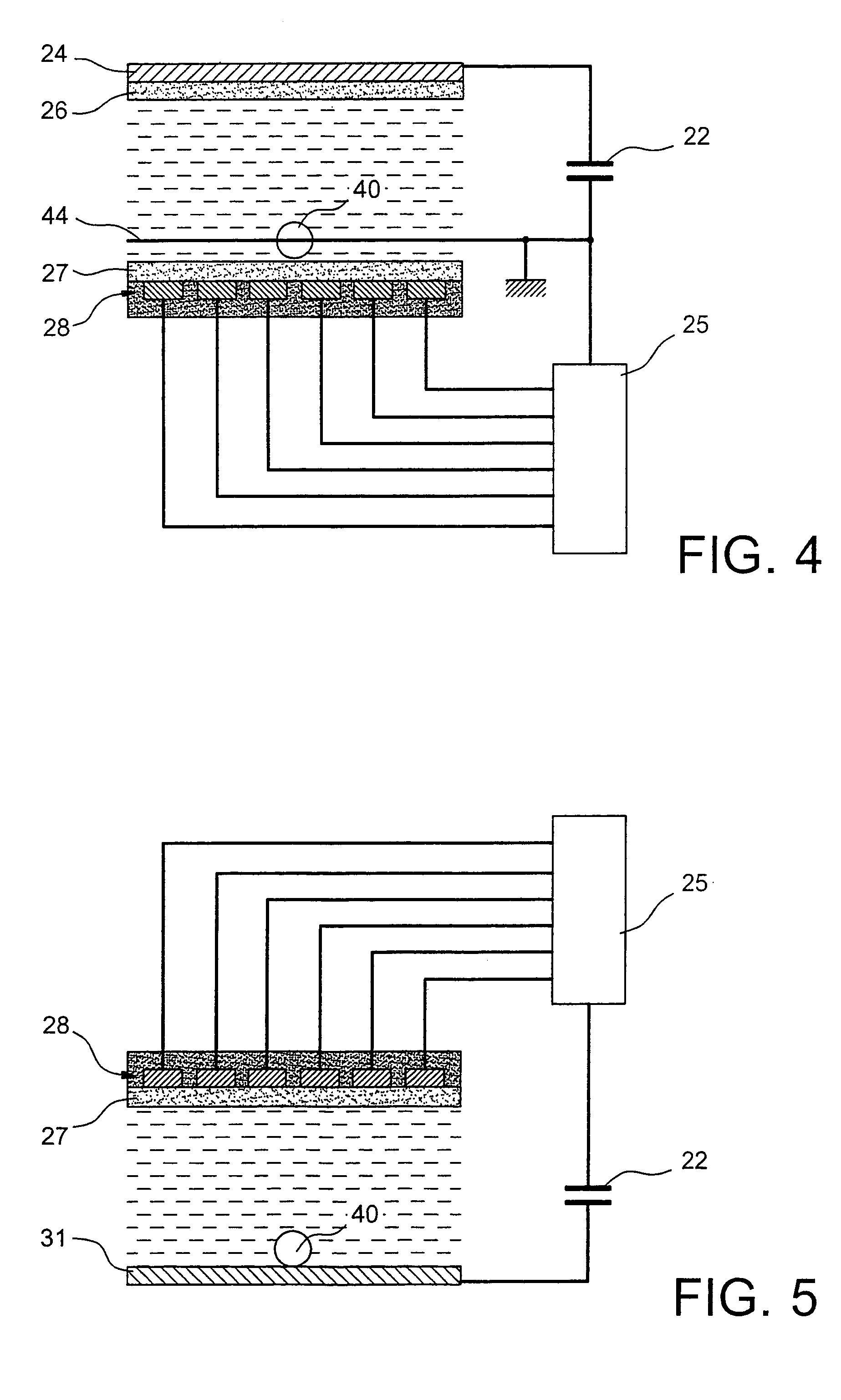

Device for controlling the displacement of a drop between two or several solid substrates

ActiveUS20050179746A1Fixed microstructural devicesVolume/mass flow measurementElectrical controlEngineering

The invention concerns a device for reversibly displacing at least one volume of liquid (10) under the effect of an electrical control, comprising first electrically conductive means (8), second electrically conductive means (4), and means for inducing a reversible displacement of a volume of liquid, from the first to the second electrically conductive means, without contact with said conductive means during the displacement.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

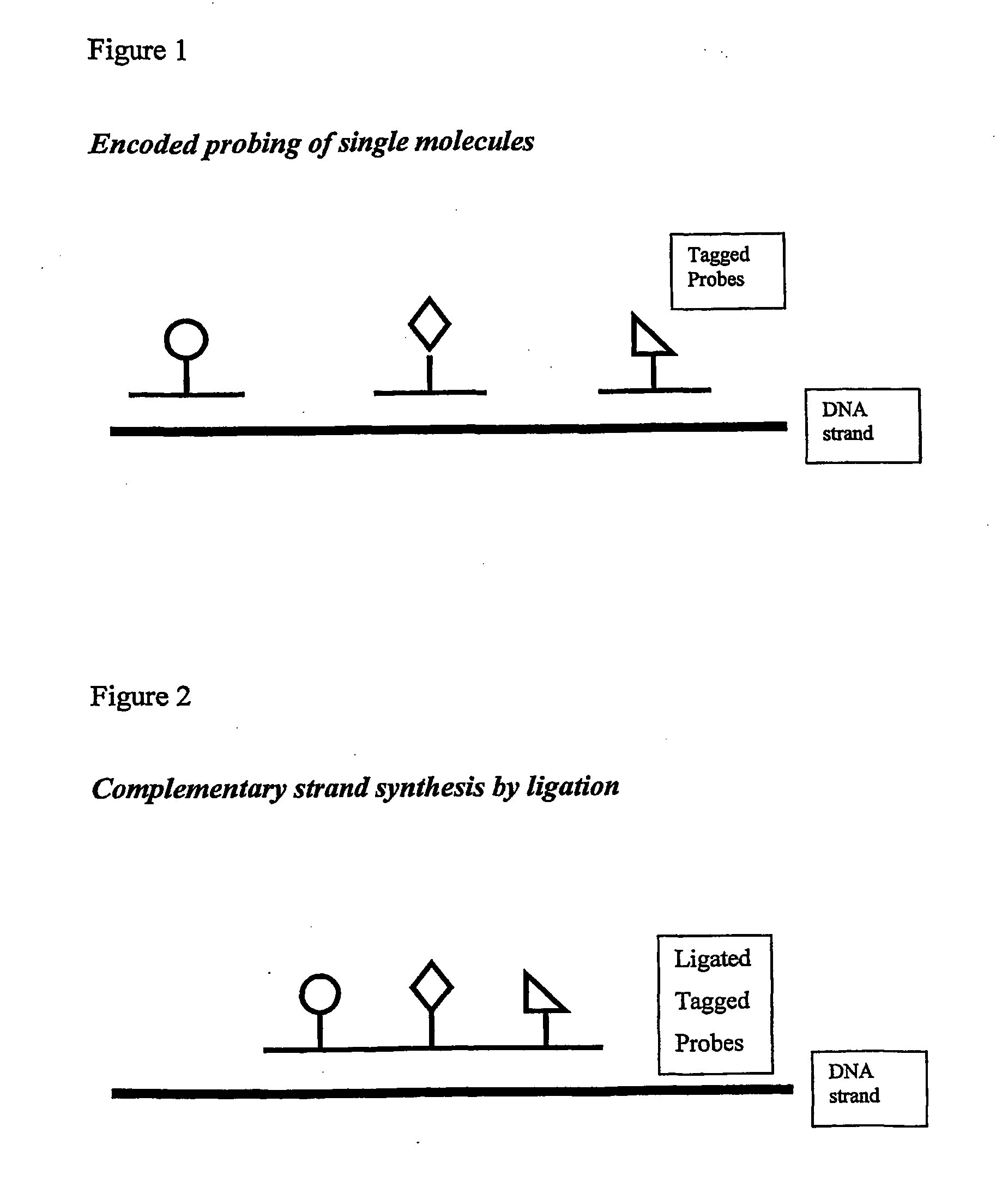

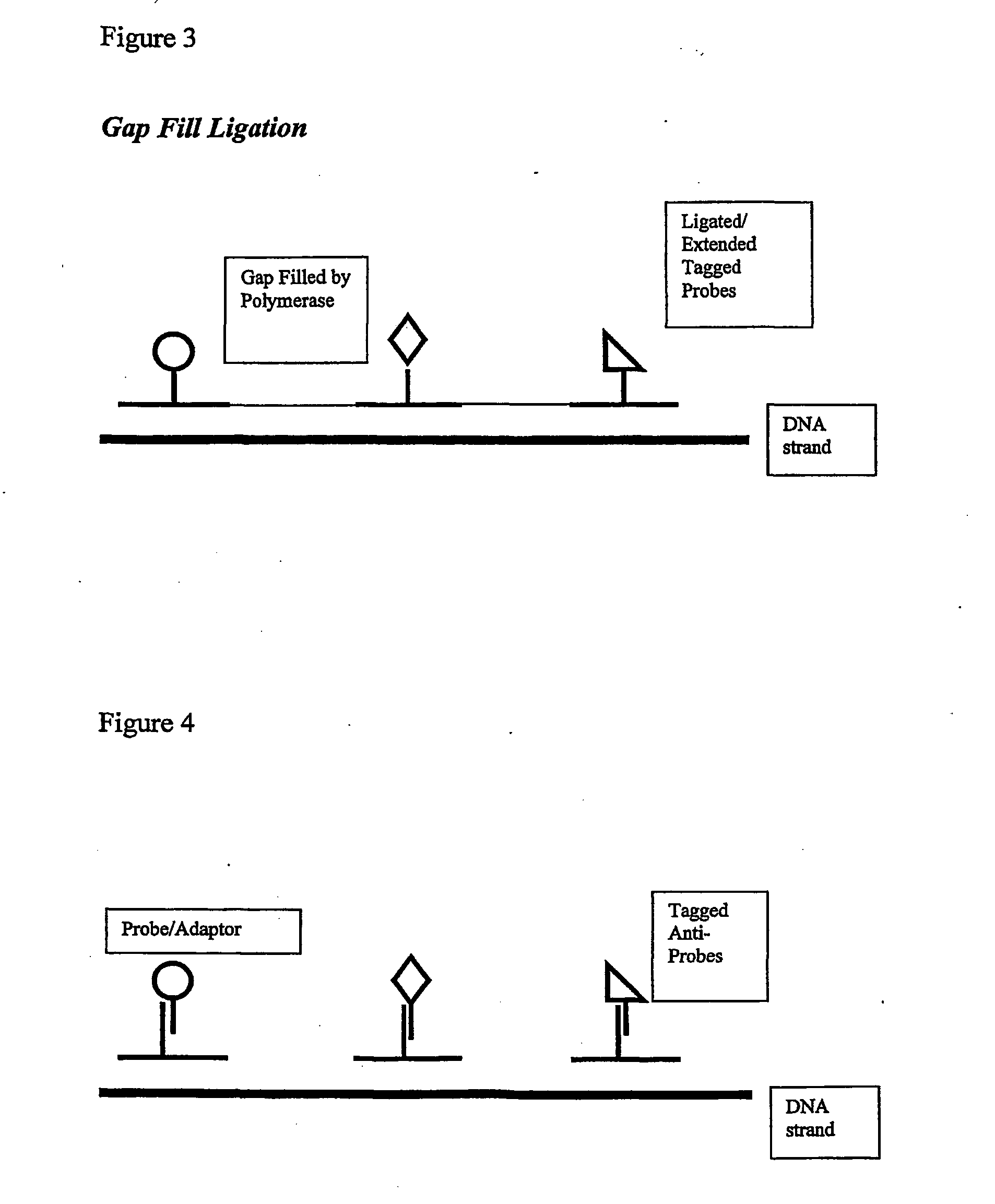

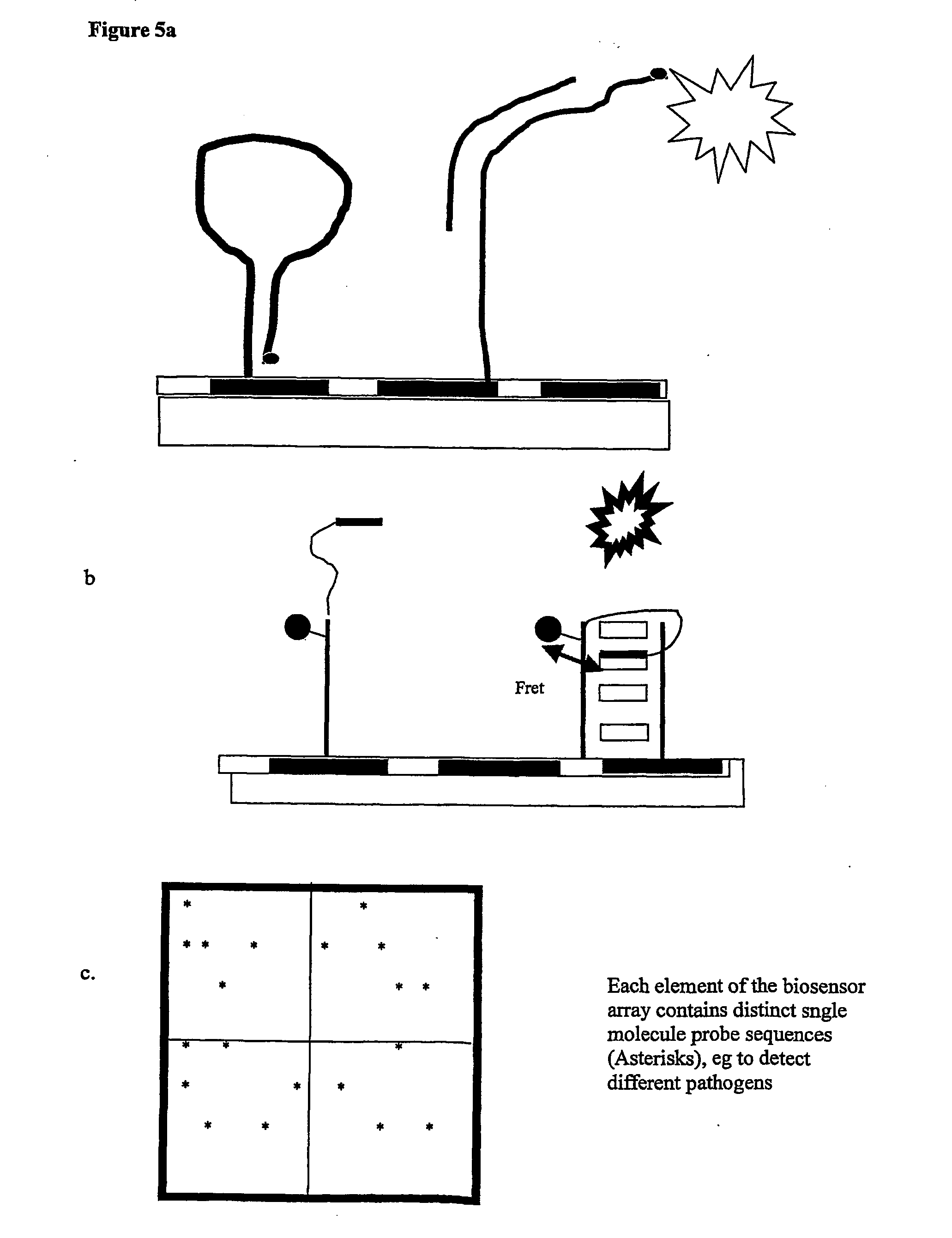

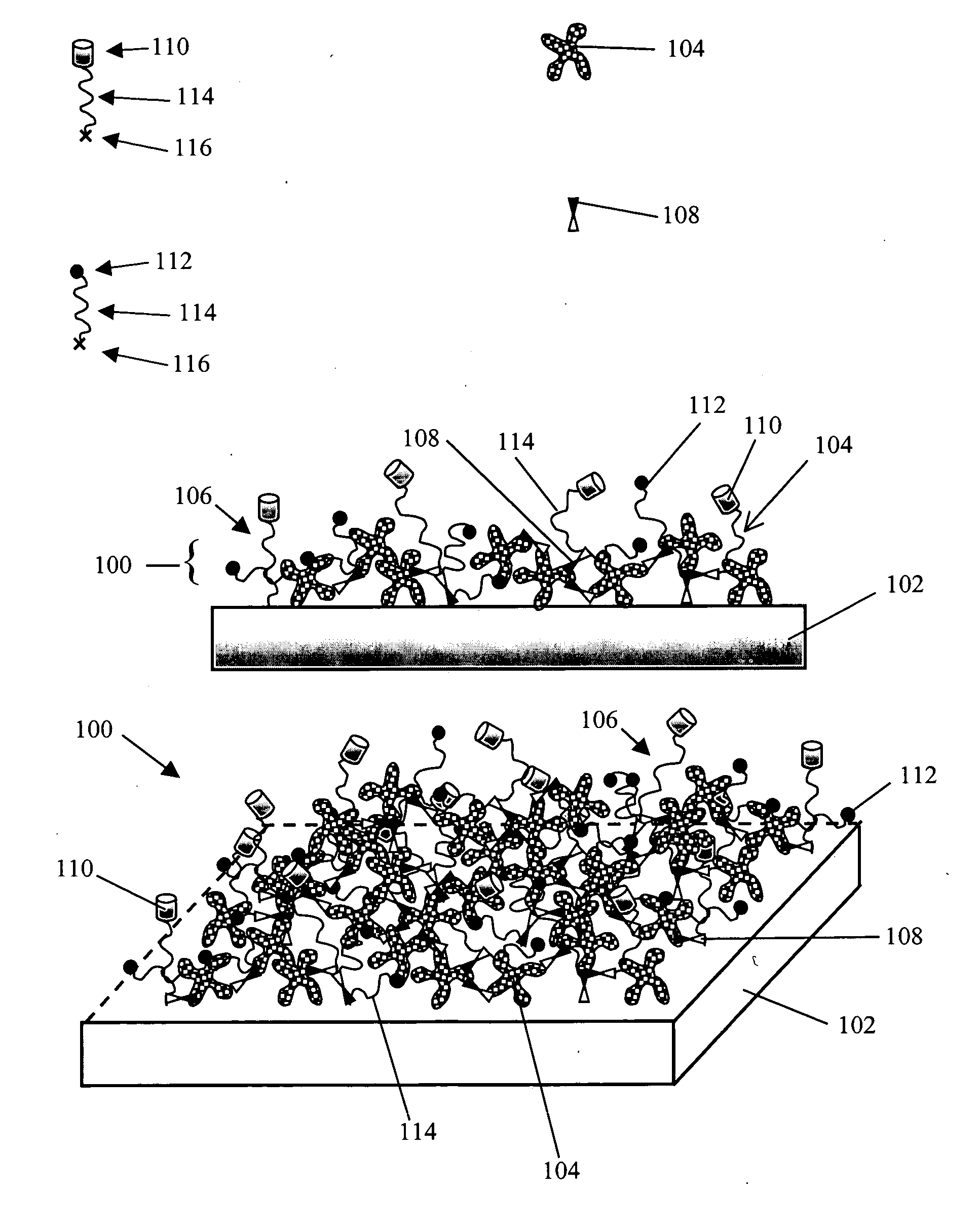

Arrays and methods of use

InactiveUS20040248144A1Minimise photobleachingMinimizing transferMaterial nanotechnologyBioreactor/fermenter combinationsMolecular arrayAssay

Methods are provided for producing a molecular array comprising a plurality of molecules immobilised to a solid substrate at a density which allows individual immobilised molecules to be individually resolved, wherein each individual molecule in the array is spatially addressable and the identity of each molecule is known or determined prior to immobilisation. The use of spatially addressable lowdensity molecular arrays in single molecule detection and analysis techniques is also provided. Novel assays and methods are also provided.

Owner:INVITAE CORP

Milled particles

InactiveUS6634576B2Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

A process for milling a solid substrate in the milling chamber of a dispersion or media mill in the presence of a two or more compositions of milling media bodies is disclosed wherein all milling media bodies contribute to the grinding of the solid substrate and wherein at least one composition of media bodies provides fragments of milling media bodies that are retained with the milled solid substrate particles in the form of a synergetic commixture produced in the milling process. More specifically, a process is disclosed for preparing a synergetic commixture comprising small particles of a solid substrate and small particulates of a first material of a desired size comprising the steps of (a) providing to the milling chamber of a media mill a contents comprising a pre-mix of a solid substrate, a fluid carrier, a plurality of milling bodies of a first material having a fracture toughness Kc1, and a plurality of milling bodies of a second material having a fracture toughness Kc2; (b) operating the media mill to grind the solid substrate and degrade at least a portion of the milling bodies of first material to produce a dispersion in the fluid carrier comprising a synergetic commixture of small particulates of the first material and small particles of the solid substrate having a desired size equal to or less than a size Sp; (c) separating the dispersion from any milling bodies and solid substrate particles having a size larger than Sp; and (d) optionally removing the fluid carrier from the dispersion to form a synergetic commixture free of fluid and comprising the particles and the small particulates, wherein KC2 is greater than KC1.

Owner:RTP PHARMA +1

Molecular arrays and single molecule detection

InactiveUS20050244863A1Precision and richness of informationPrecision and richness of and speedBioreactor/fermenter combinationsMaterial nanotechnologyChemical physicsMolecular array

Methods are provided for producing a molecular array comprising a plurality of molecules immobilized to a solid substrate at a density which allows individual immobilized molecules to be individually resolved, wherein each individual molecule in the array is spatially addressable and the identity of each molecule is known or determined prior to immobilisation. The use of spatially addressable low density molecular arrays in single molecule detection techniques is also provided.

Owner:KALIM MIR +2

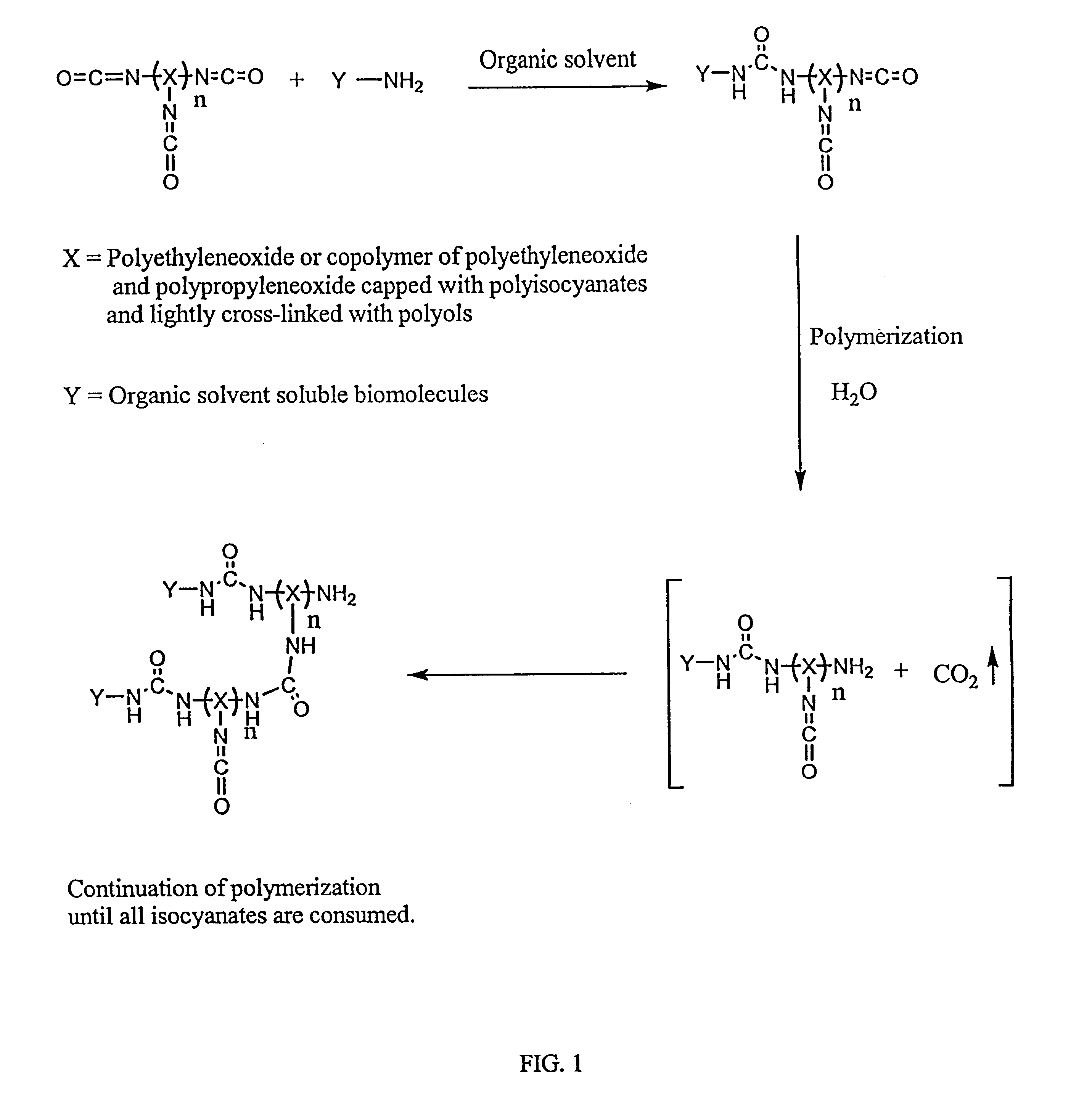

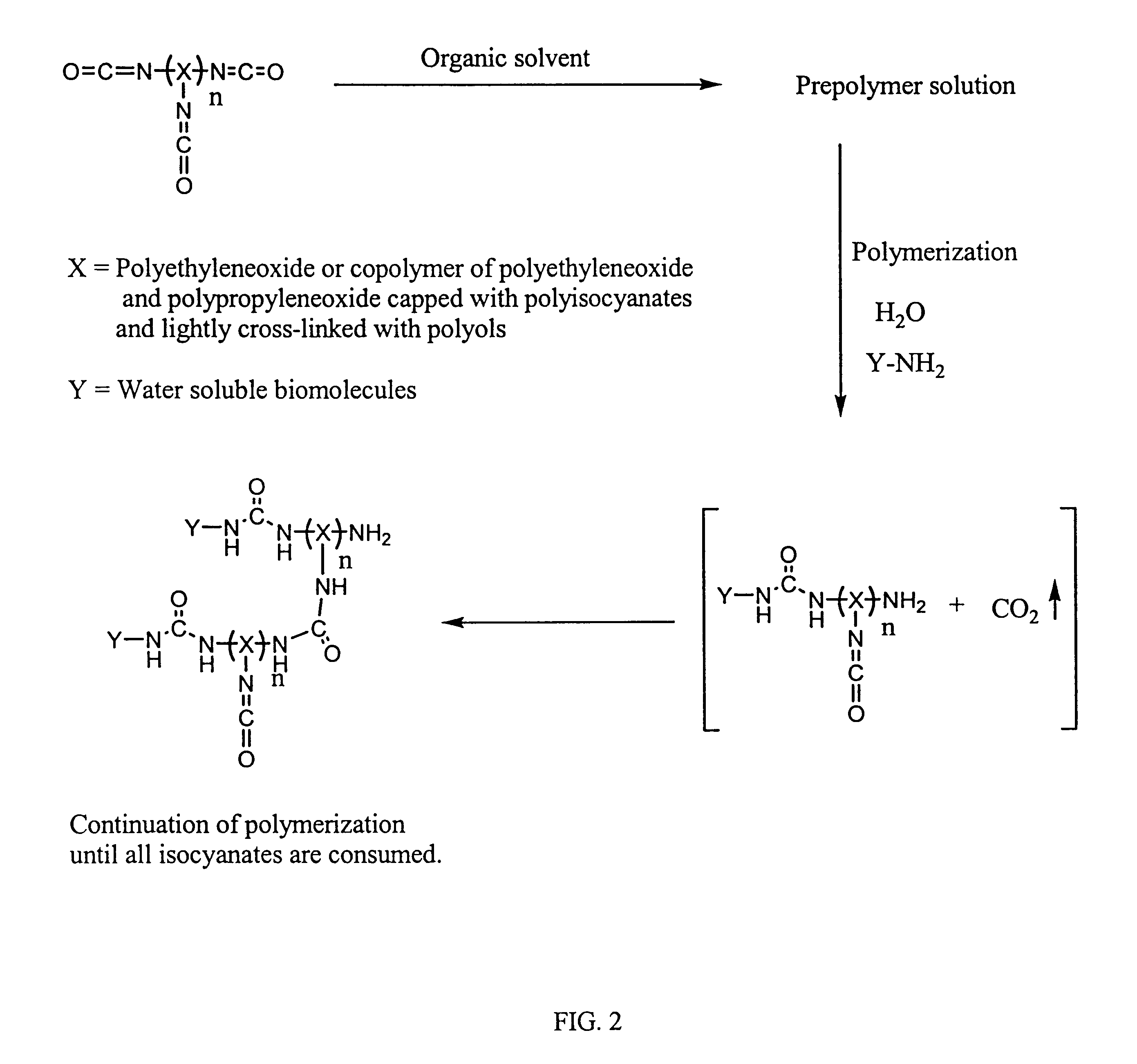

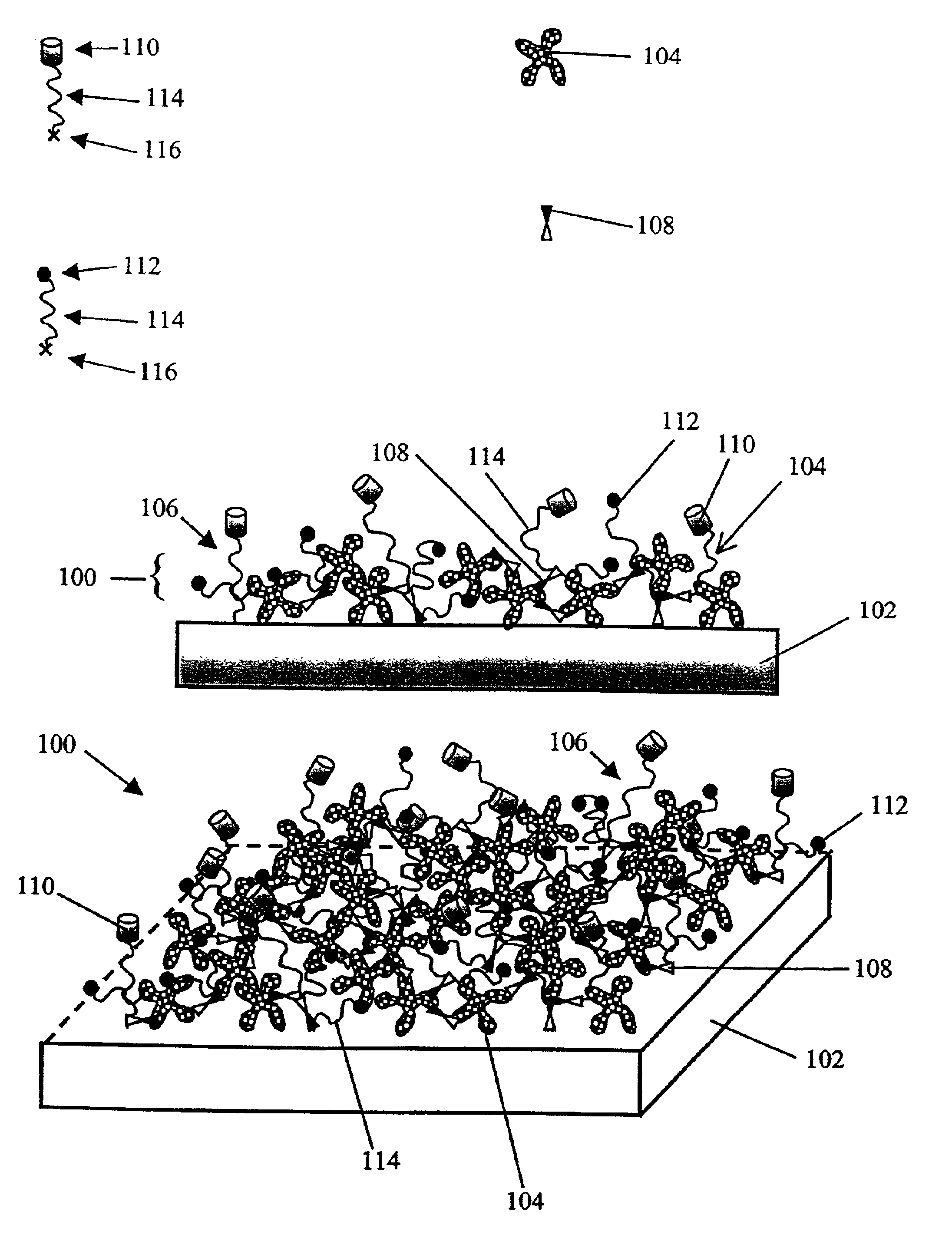

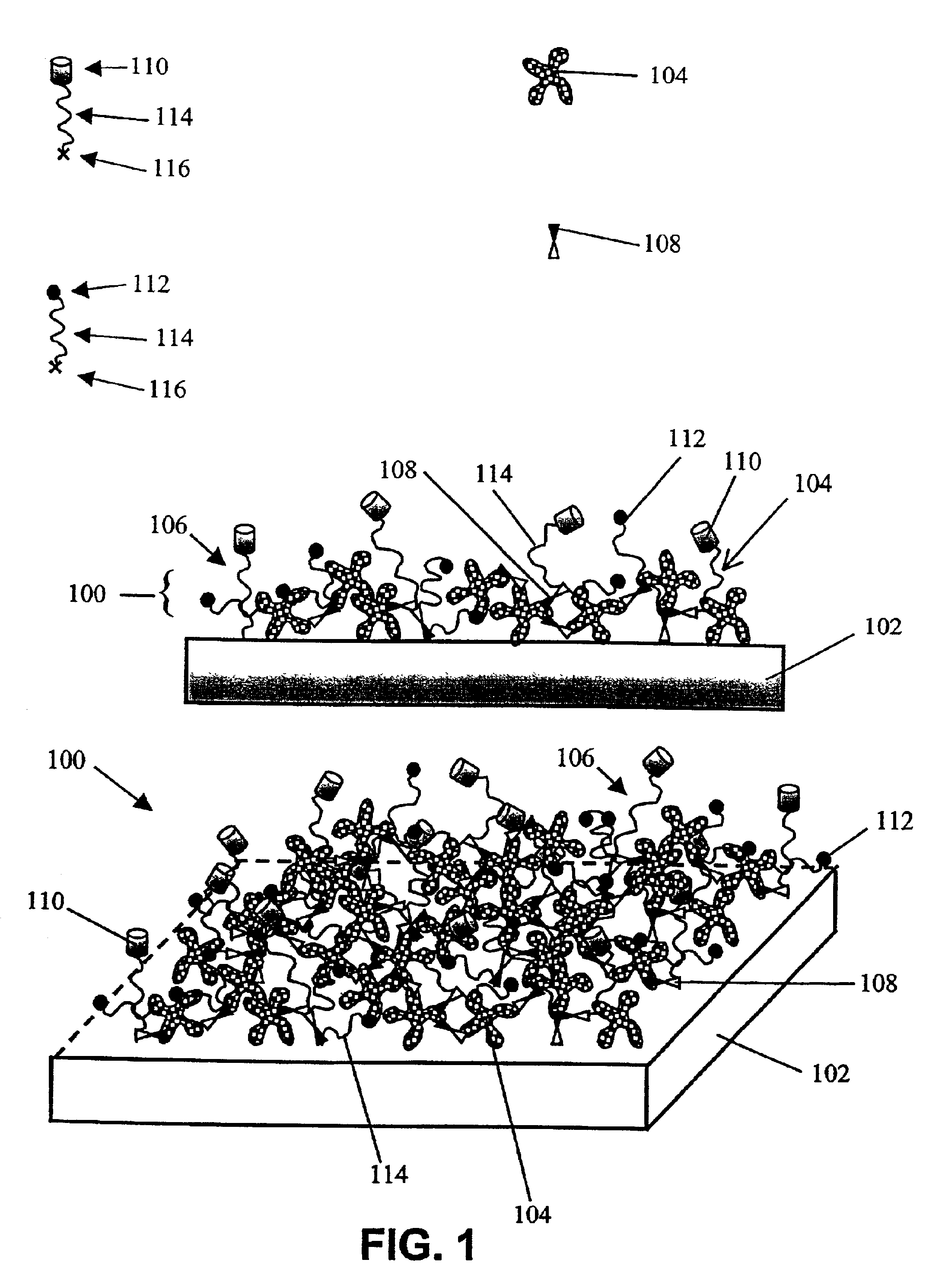

Method of making biochips and the biochips resulting therefrom

InactiveUS6174683B1Rapid and simple and cost-effective methodHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsSodium bicarbonateSolid substrate

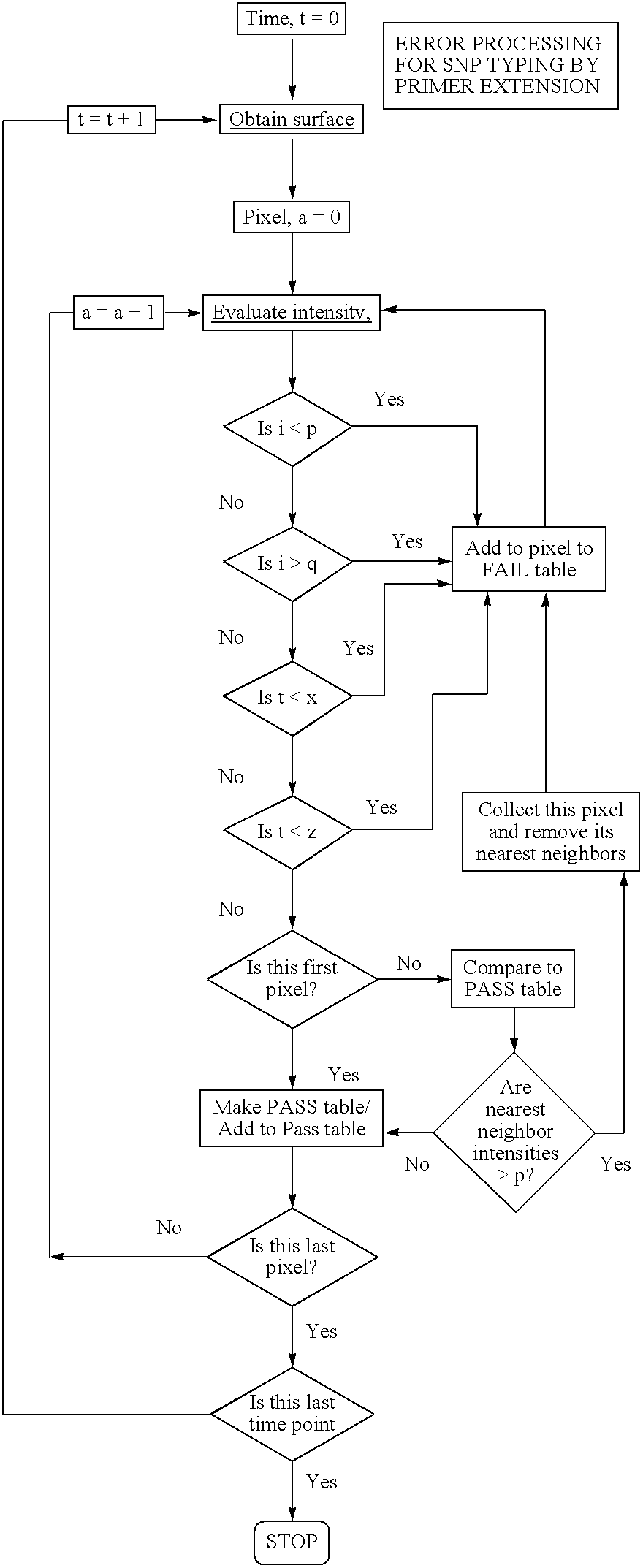

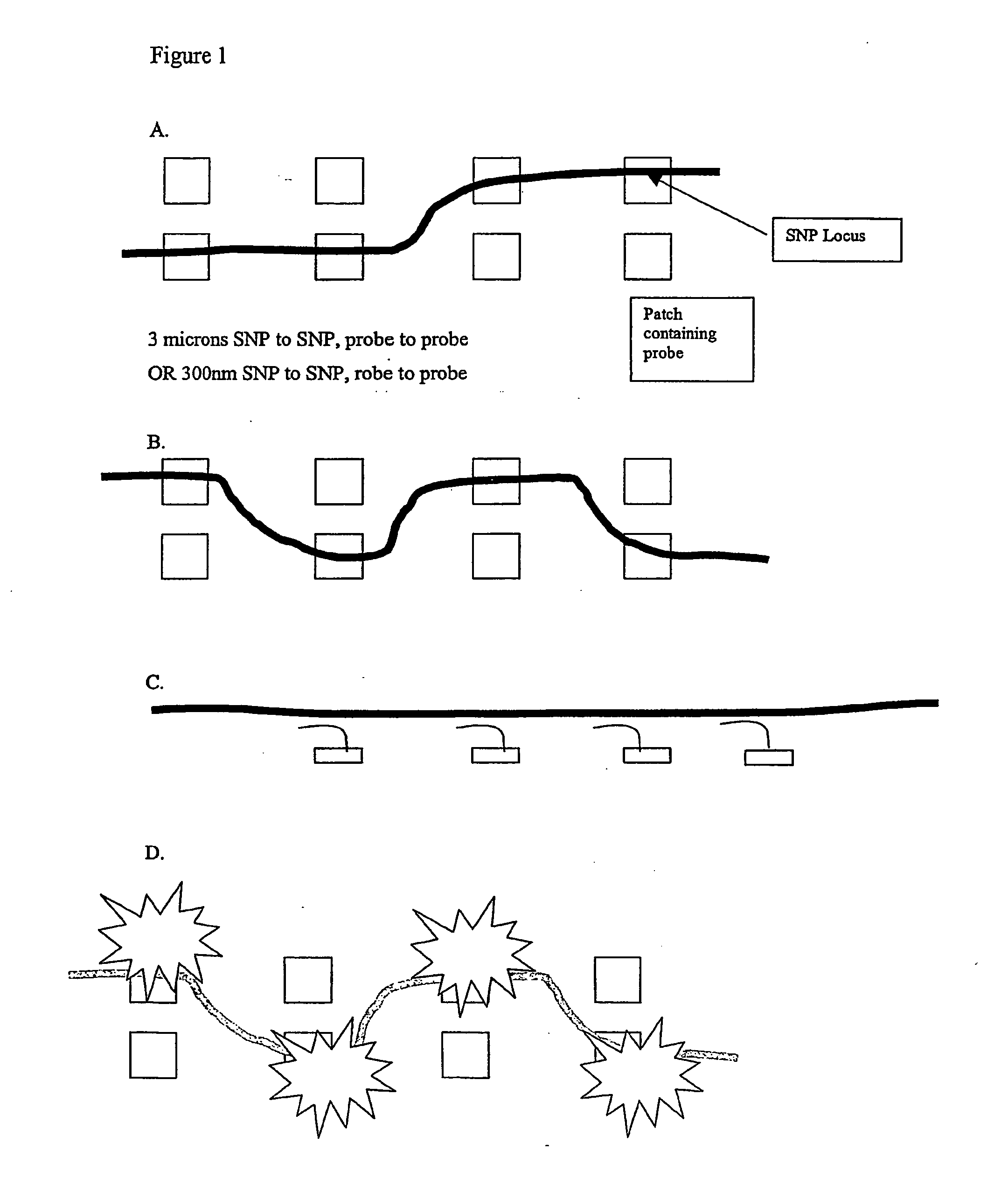

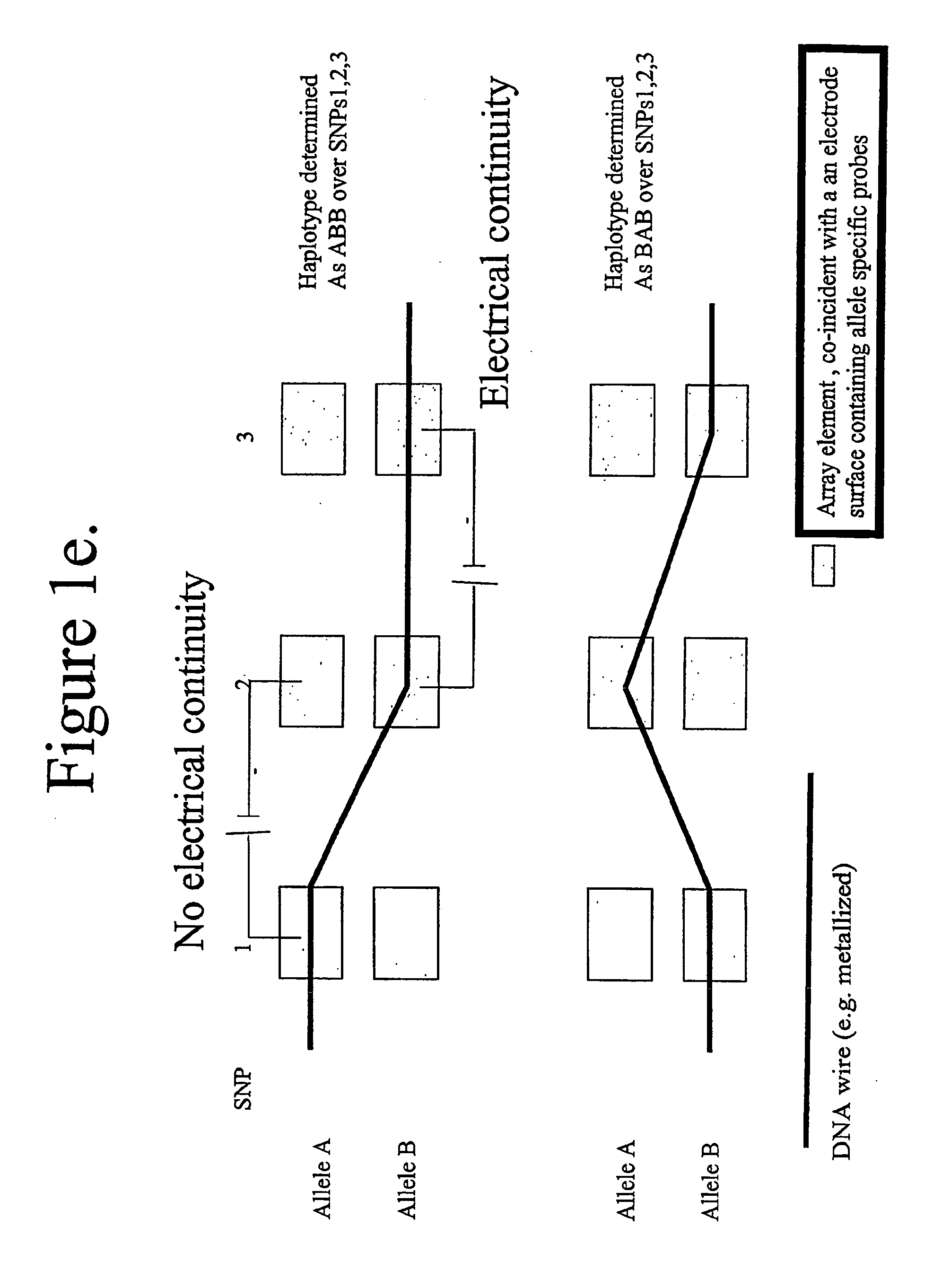

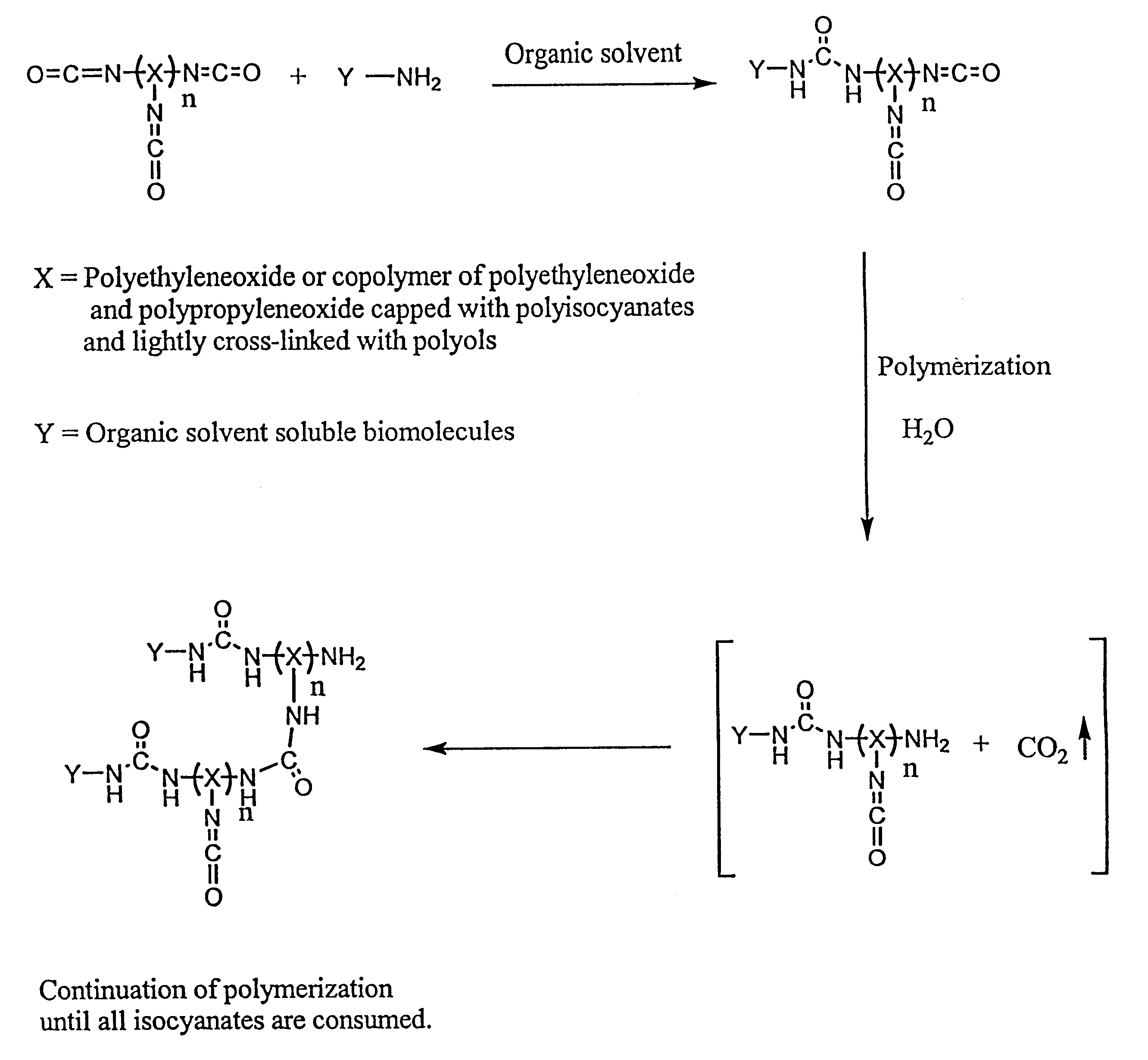

Methods for preparing a biochip are provided herein wherein the biomolecular probe to be used with the biochip is alternatively bound to a hydrogel prepolymer prior to or simultaneously with polymerization of the prepolymer. In particularly preferred embodiments, a polyurethane-based hydrogel prepolymer is derivatized with an organic solvent soluble biomolecule, such as a peptide nucleic acid probe in aprotic, organic solvent. Following derivatization of the prepolymer, an aqueous solution, for example sodium bicarbonate, preferably buffered to a pH of about 7.2 to about 9.5, is added to the derivatized prepolymer solution to initiate polymerization of the hydrogel. Alternatively, a water soluble biomolecule, such as DNA or other oligonucleotide, is prepared in an aqueous solution and added to the polyurethane-based hydrogel prepolymer such that derivatization and polymerization occur, essentially, simultaneously. While the hydrogel is polymerizing, it is microspotted onto a solid substrate, preferably a silanated glass substrate, to which the hydrogel microdroplet becomes covalently bound. Most preferably the hydrogel microdroplets are at least about 30 mum thick, for example about 50 mum to about 100 mum thick. The resulting biochips are particularly useful for gene discovery, gene characterization, functional gene analysis and related studies.

Owner:BIOCEPT INC

Milled particles

InactiveUS20020047058A1Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

Owner:RTP PHARMA +1

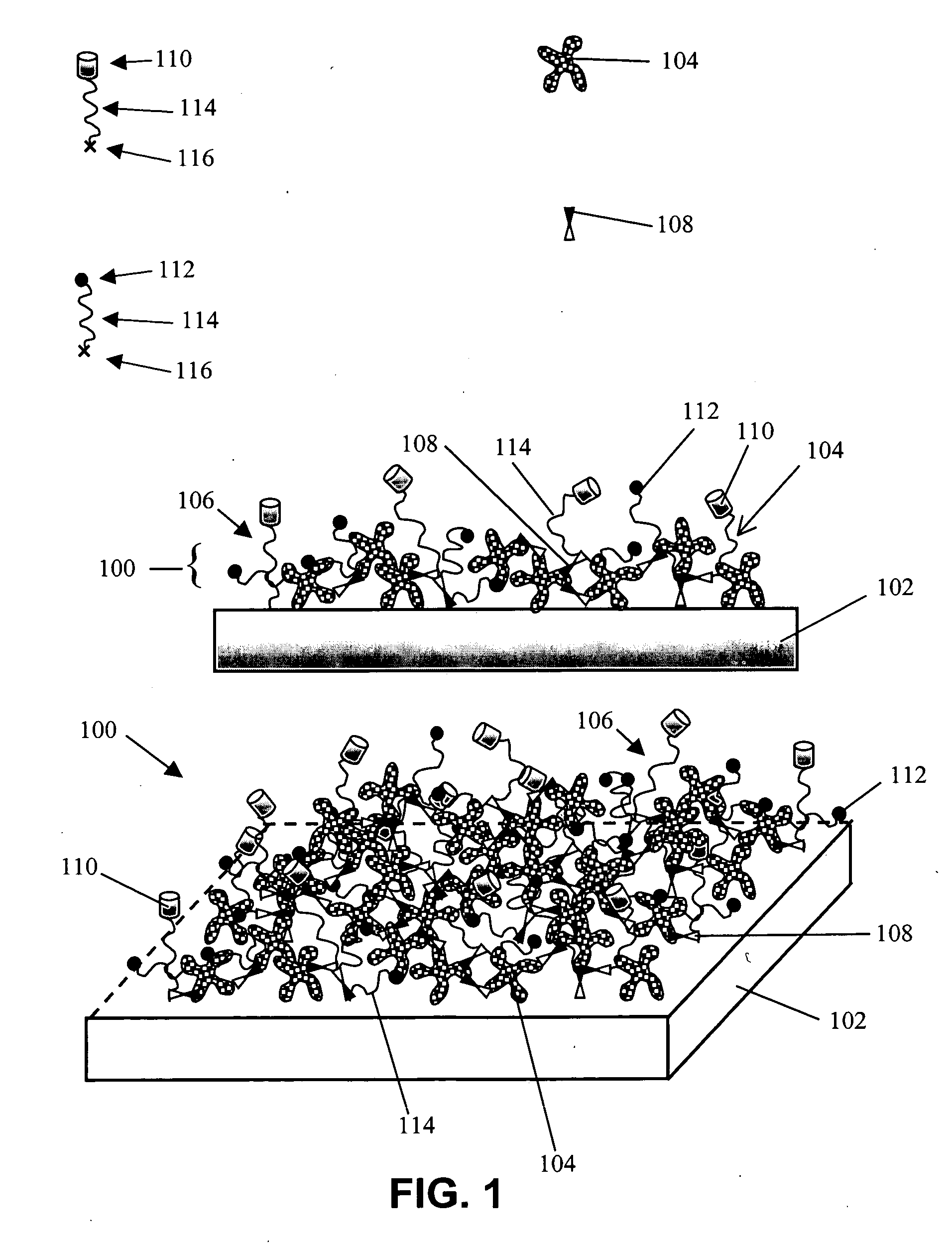

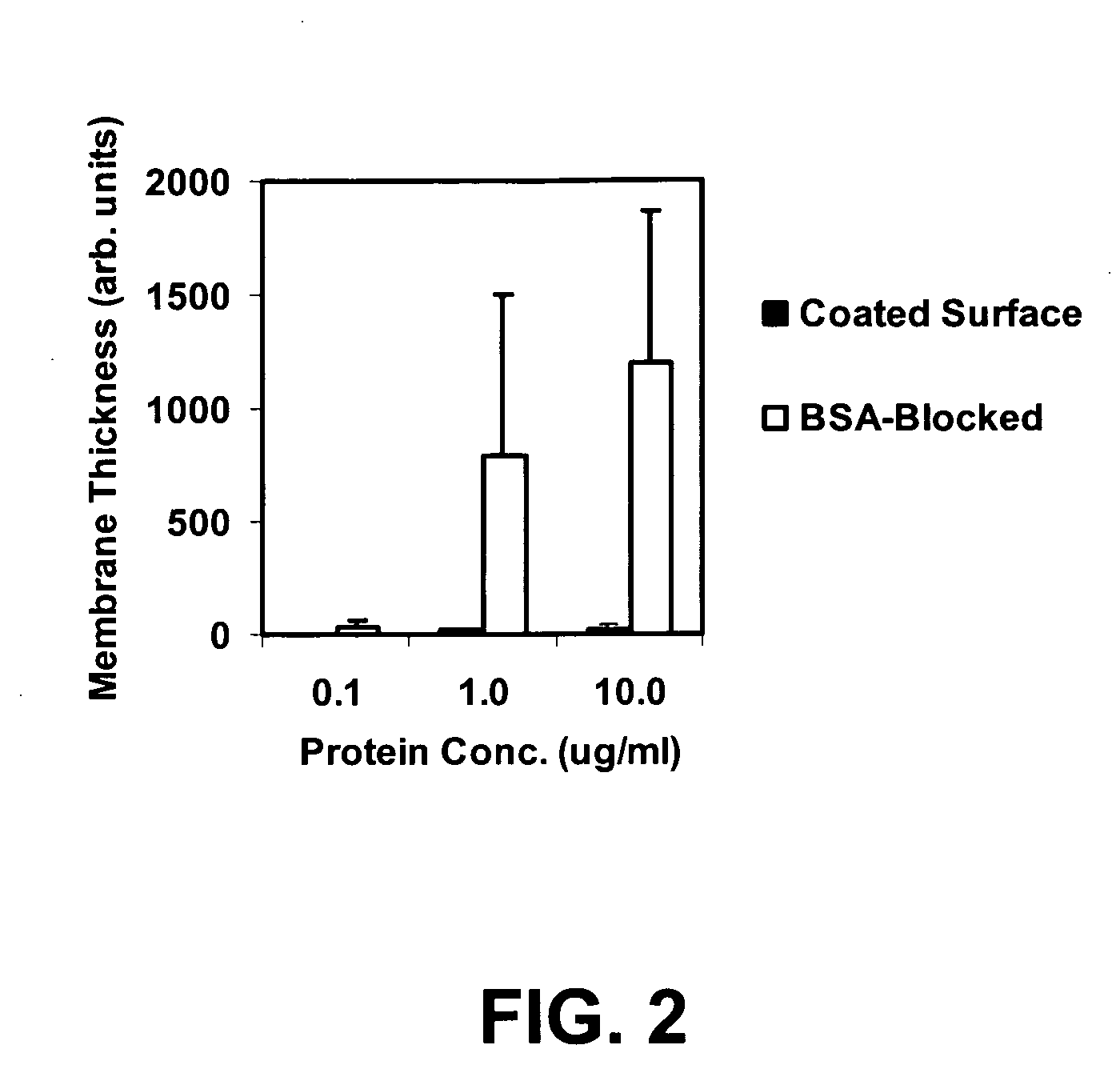

Functional surface coating

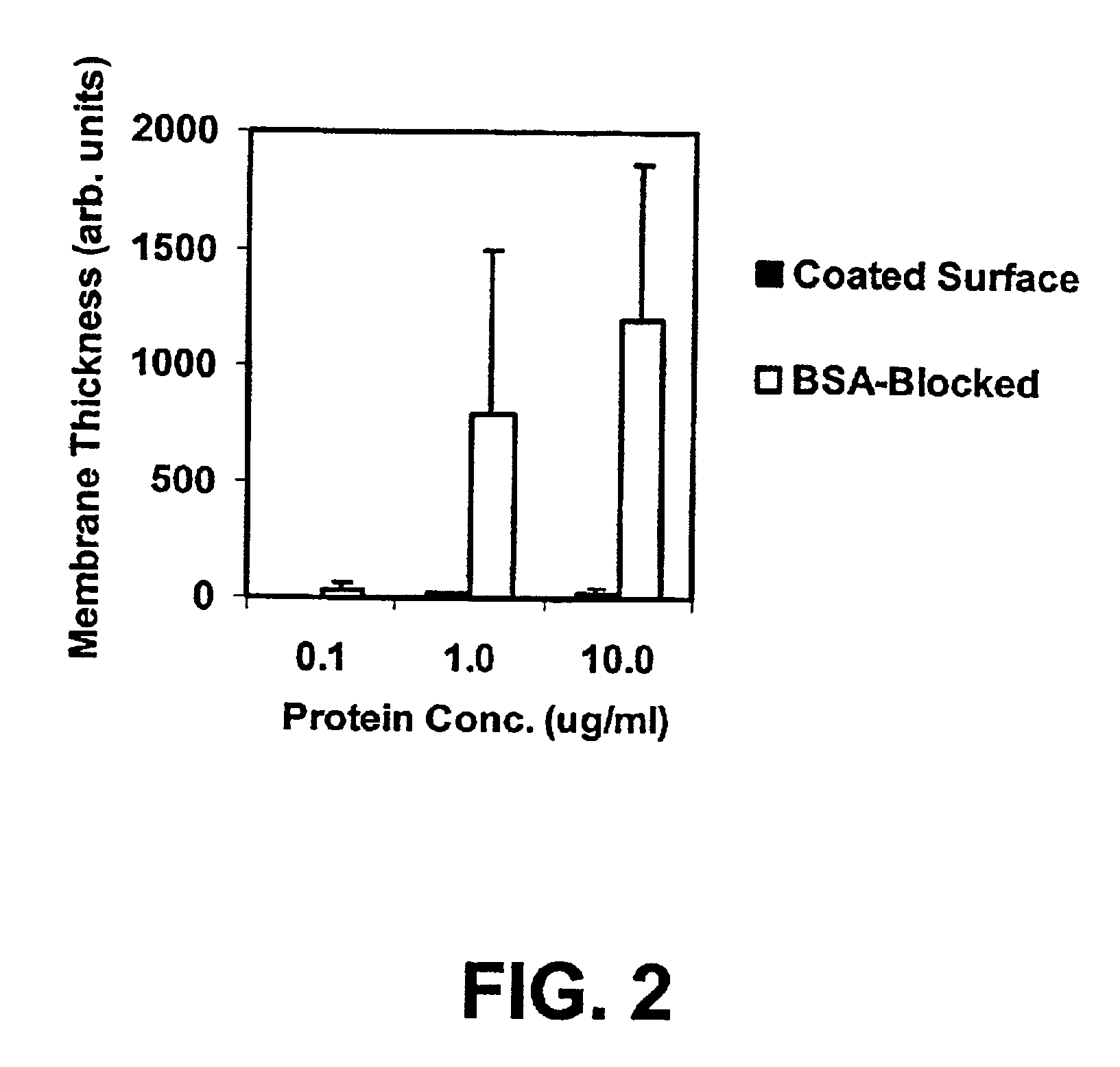

InactiveUS6844028B2Inhibit non-specific bindingImprove propertiesMicrobiological testing/measurementPreparing sample for investigationProtein targetBound property

Compositions and methods of preparing functional thin films or surface coatings with low non-specific binding are described. The thin films contain specified functional groups and non-specific binding repellant components. The thin films are either covalently bound to or passively adsorbed to various solid substrates. The specified functional group provides specified activity for the thin film modified solid surfaces and non-specific binding repellant components significantly reduce the non-specific binding to the thin film modified solid surfaces. Non-specific binding repellant components do not affect specified functional group's activity in the thin films. In these methods, specified functional groups are anchored to the solid substrates through a spacer. Surface coatings are also described having both non-specific protein binding properties combined with functional groups for specific binding activity thereby providing surface coating that specifically recognize target proteins but limit binding to non-specific protein.

Owner:ACCELERATED MEDICAL DIAGNOSTICS INC

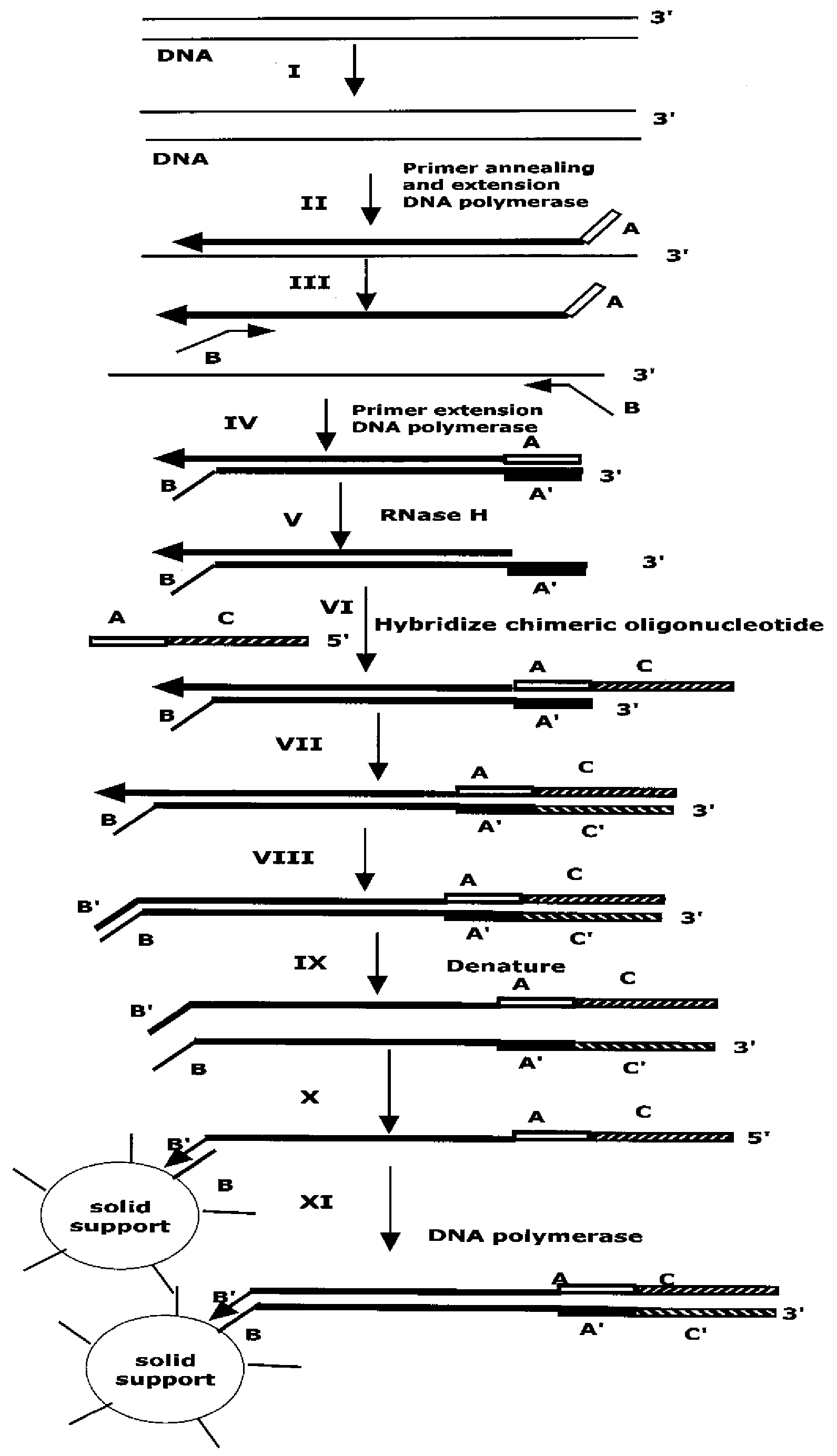

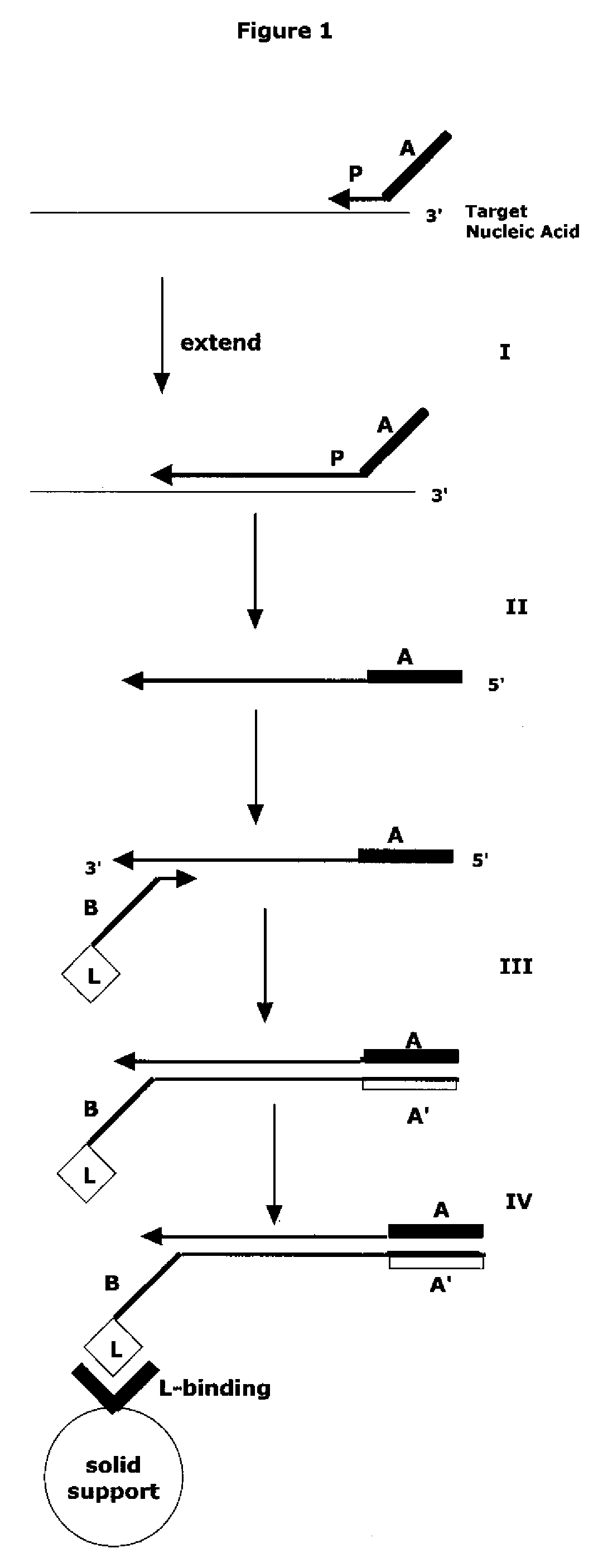

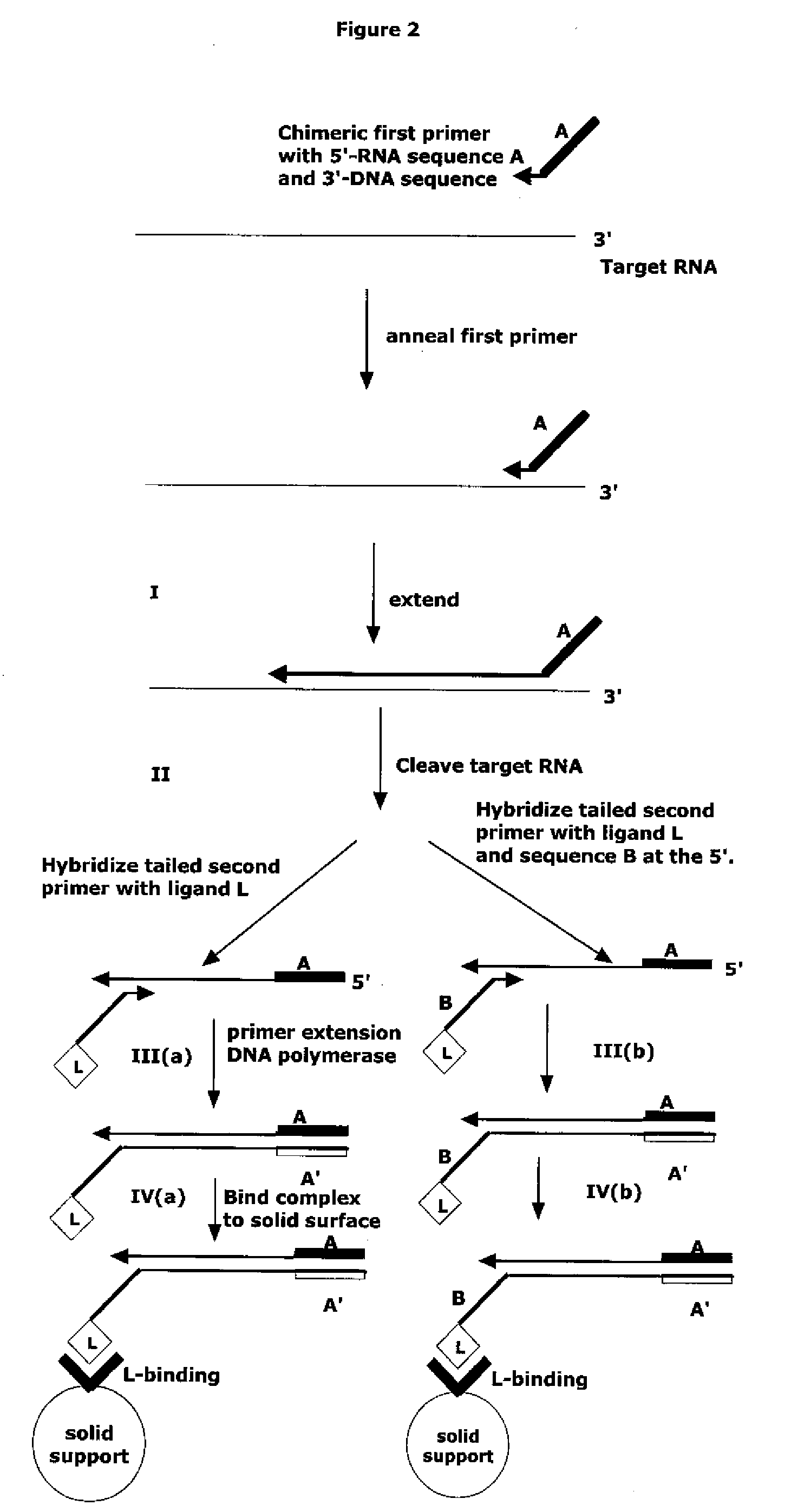

Method for Archiving and Clonal Expansion

InactiveUS20090203531A1Microbiological testing/measurementLibrary member identificationPresent methodTotal rna

The present method provides methods, libraries, and kits related to the archiving and clonal expansion of sequences related to target polynucleotide sequences. The method allow for the attachment of polynucleotides with defined 3′ and or 5′ sequences to solid surfaces. The polynucleotides attached to the solid substrates can be stored or archived as libraries and can subsequently be retrieved for analysis, for example by clonal expansion. In some embodiments, nucleotides attached to solid surfaces can be used for sequencing of nucleotide sequences related to target RNA or target RNA. The methods are applicable to total RNA and / or total DNA analysis.

Owner:NUGEN TECH

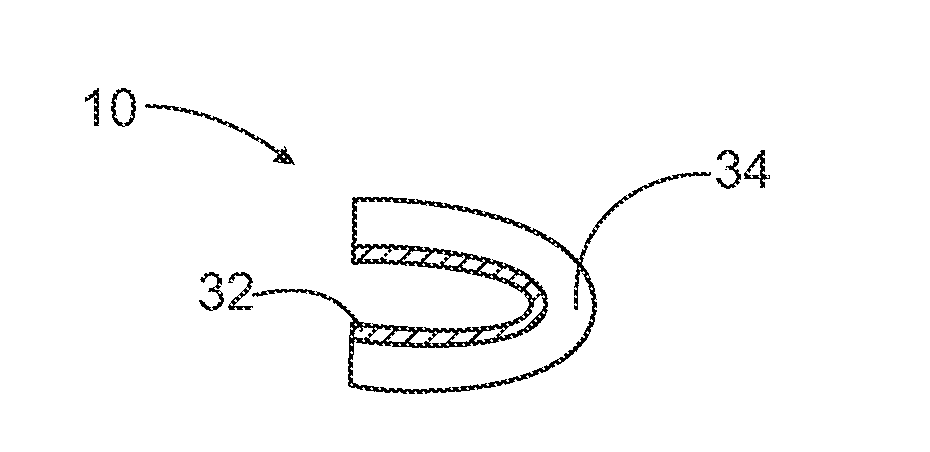

Phased array metamaterial antenna system

ActiveUS20050225492A1Low Sidelobe PerformanceReduce sidelobeRadiating elements structural formsWaveguidesSolid substratePhased array

An efficient, low-loss, low sidelobe, high dynamic range phased-array radar antenna system is disclosed that uses metamaterials, which are manmade composite materials having a negative index of refraction, to create a biconcave lens architecture (instead of the aforementioned biconvex lens) for focusing the microwaves transmitted by the antenna. Accordingly, the sidelobes of the antenna are reduced. Attenuation across microstrip transmission lines may be reduced by using low loss transmission lines that are suspended above a ground plane a predetermined distance in a way such they are not in contact with a solid substrate. By suspending the microstrip transmission lines in this manner, dielectric signal loss is reduced significantly, thus resulting in a less-attenuated signal at its destination.

Owner:LUCENT TECH INC

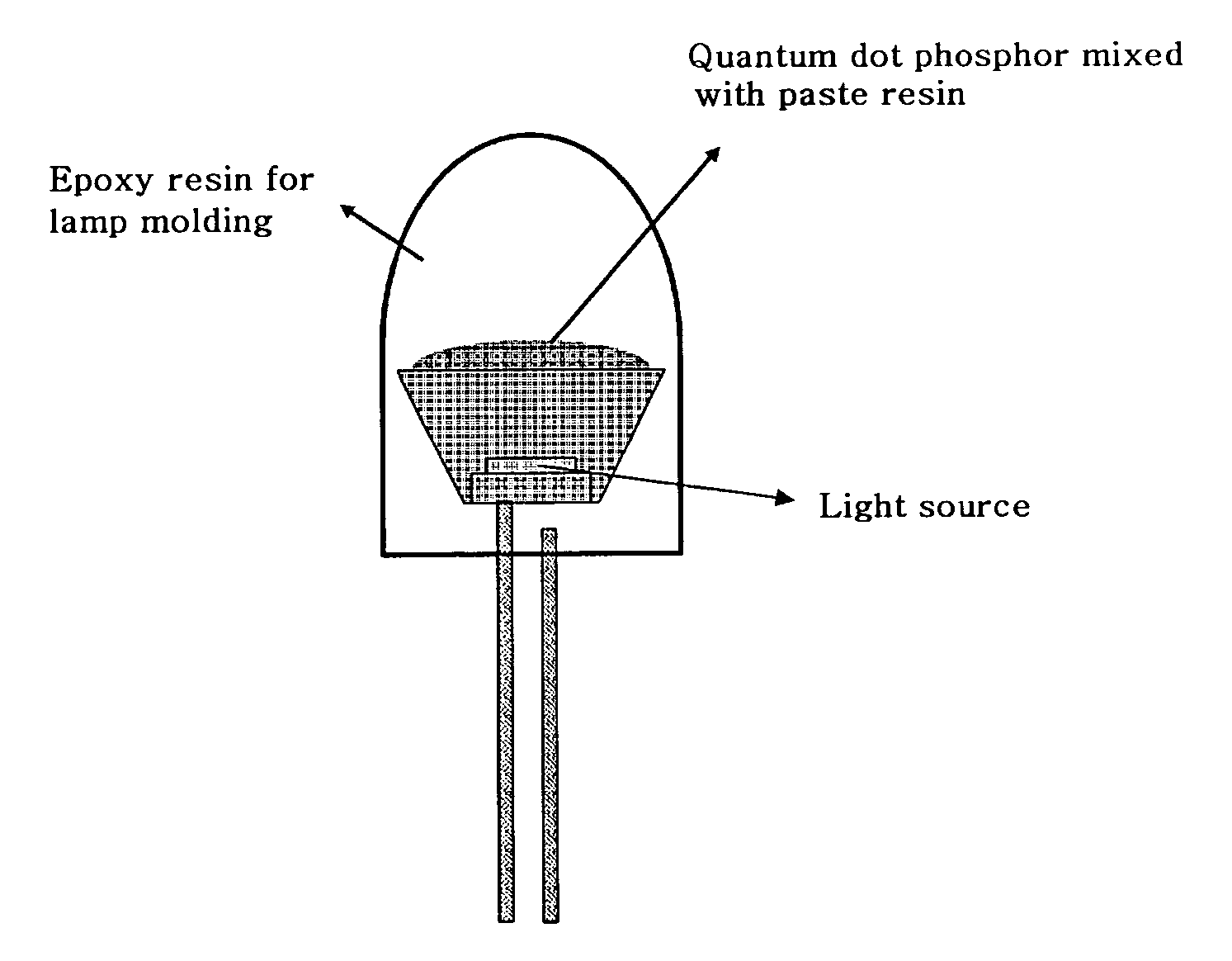

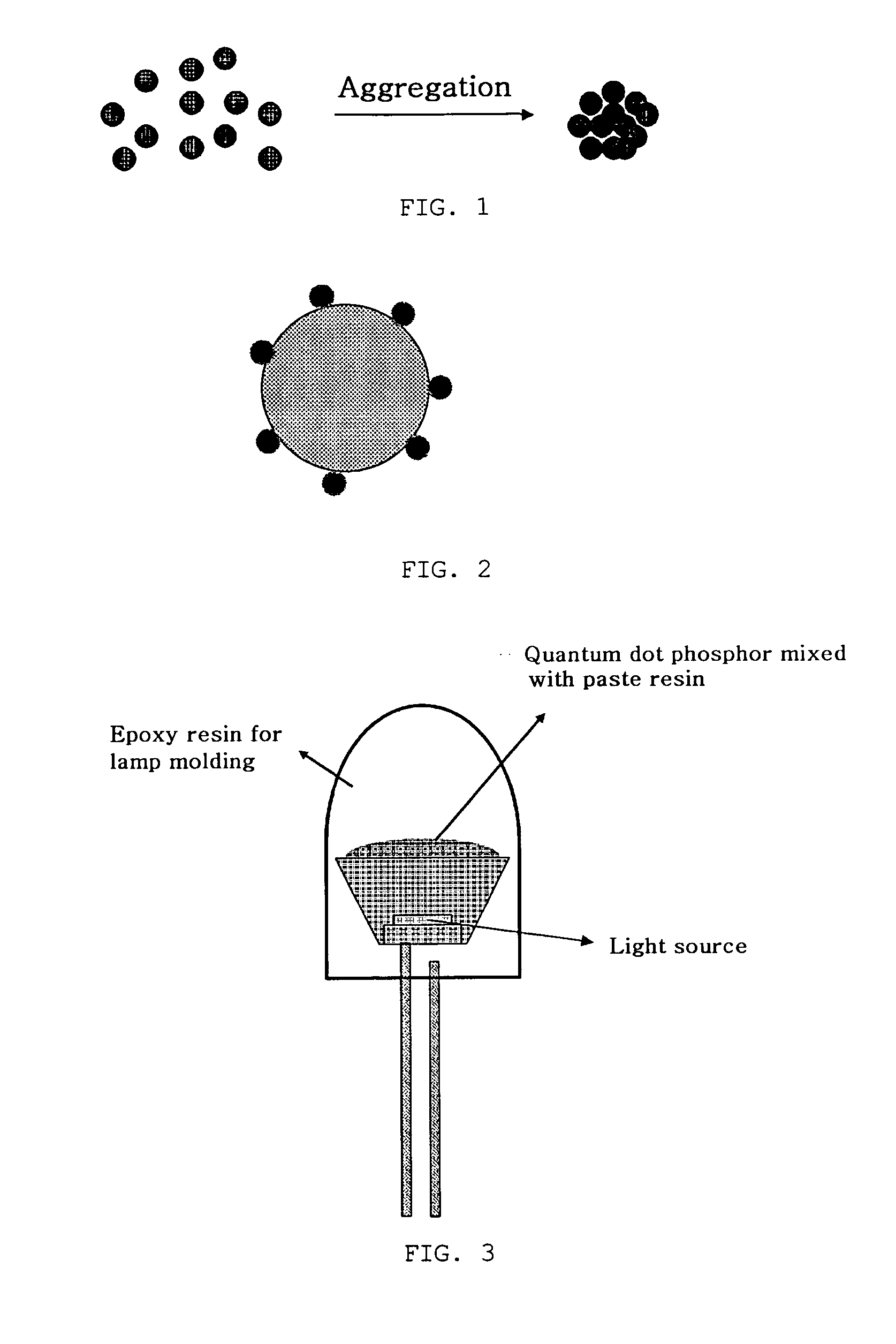

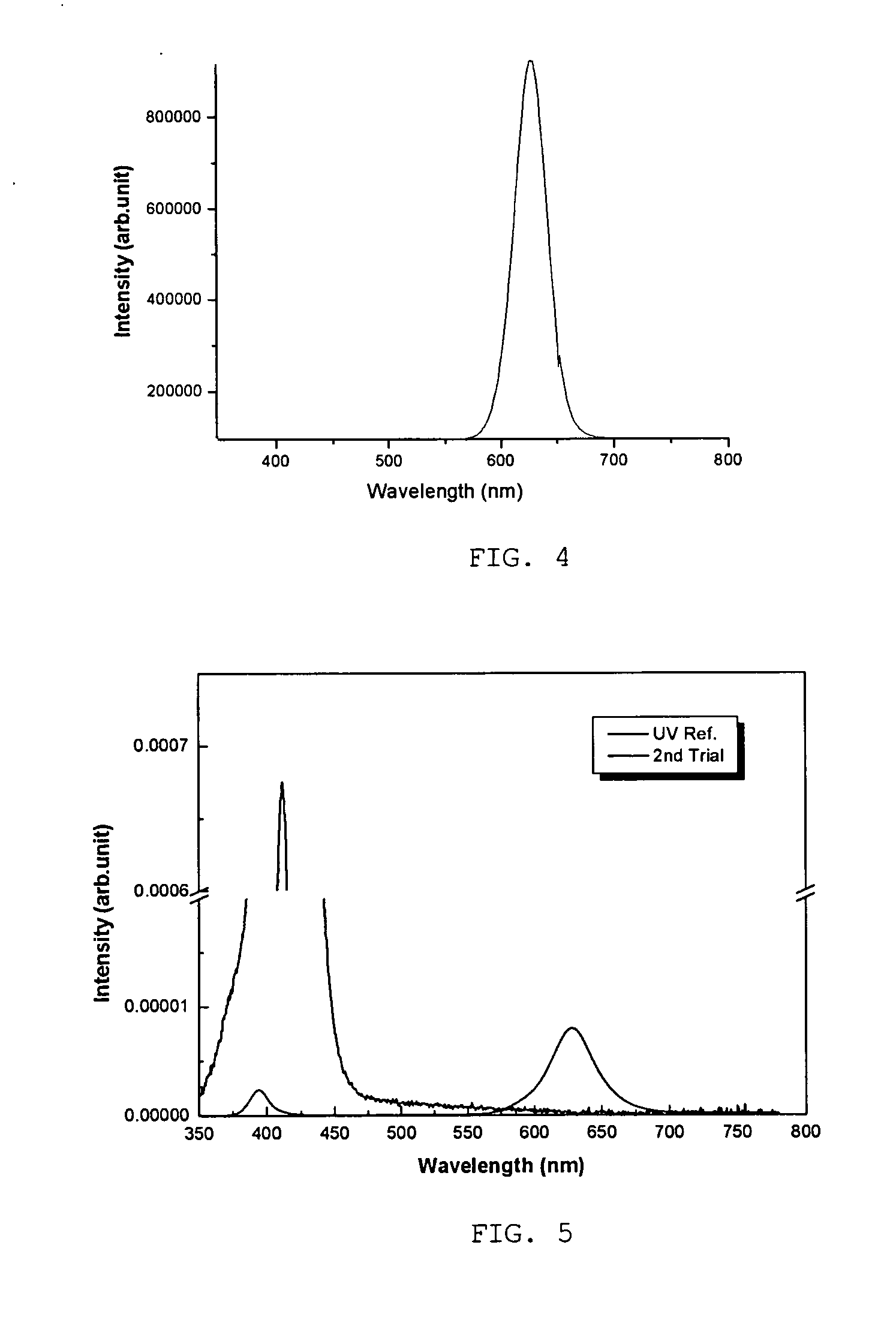

Quantum dot phosphor for light emitting diode and method of preparing the same

Disclosed herein is a quantum dot phosphor for light emitting diodes, which includes quantum dots and a solid substrate on which the quantum dots are supported. Also, a method of preparing the quantum dot phosphor is provided. Since the quantum dot phosphor of the current invention is composed of the quantum dots supported on the solid substrate, the quantum dots do not aggregate when dispensing a paste obtained by mixing the quantum dots with a paste resin for use in packaging of a light emitting diode. Thereby, a light emitting diode able to maintain excellent light emitting efficiency can be manufactured.

Owner:SAMSUNG ELECTRONICS CO LTD

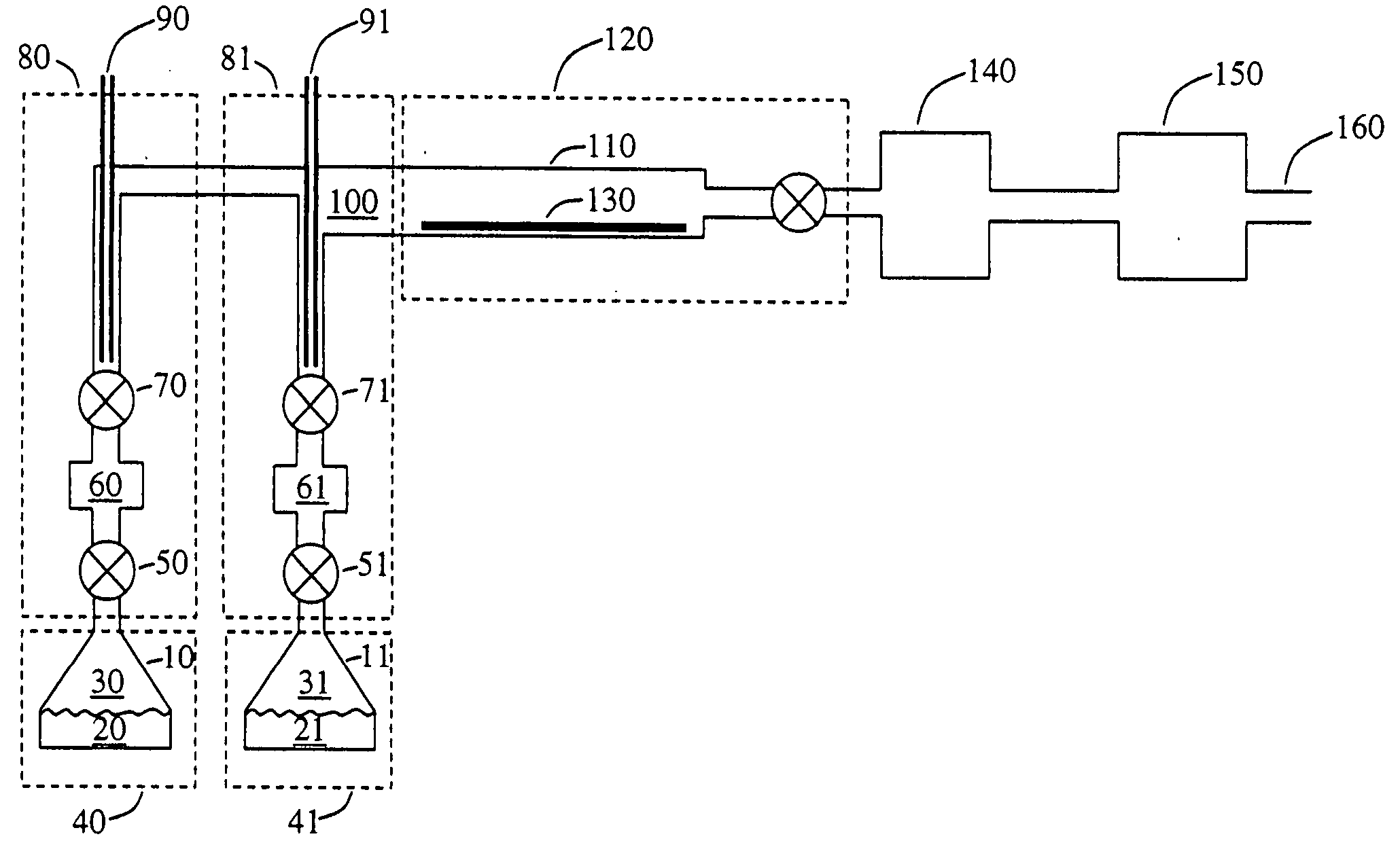

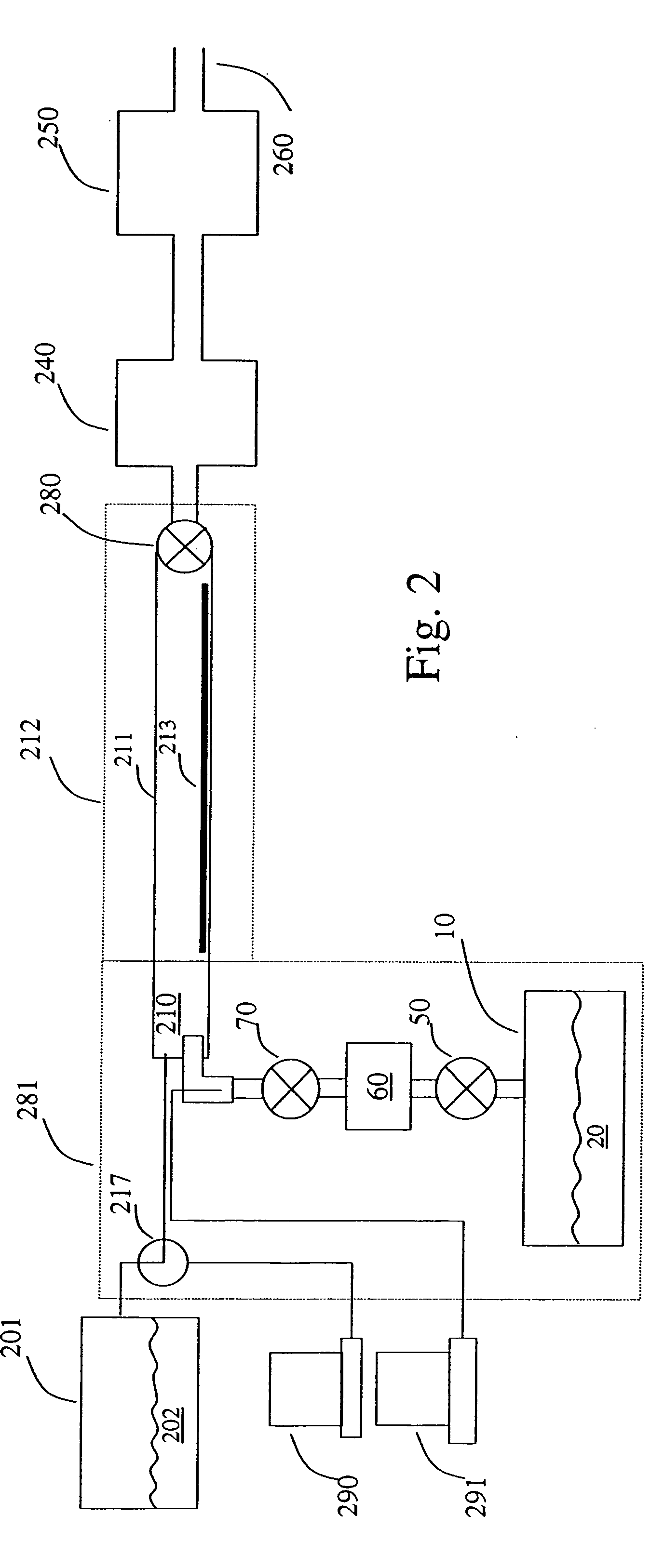

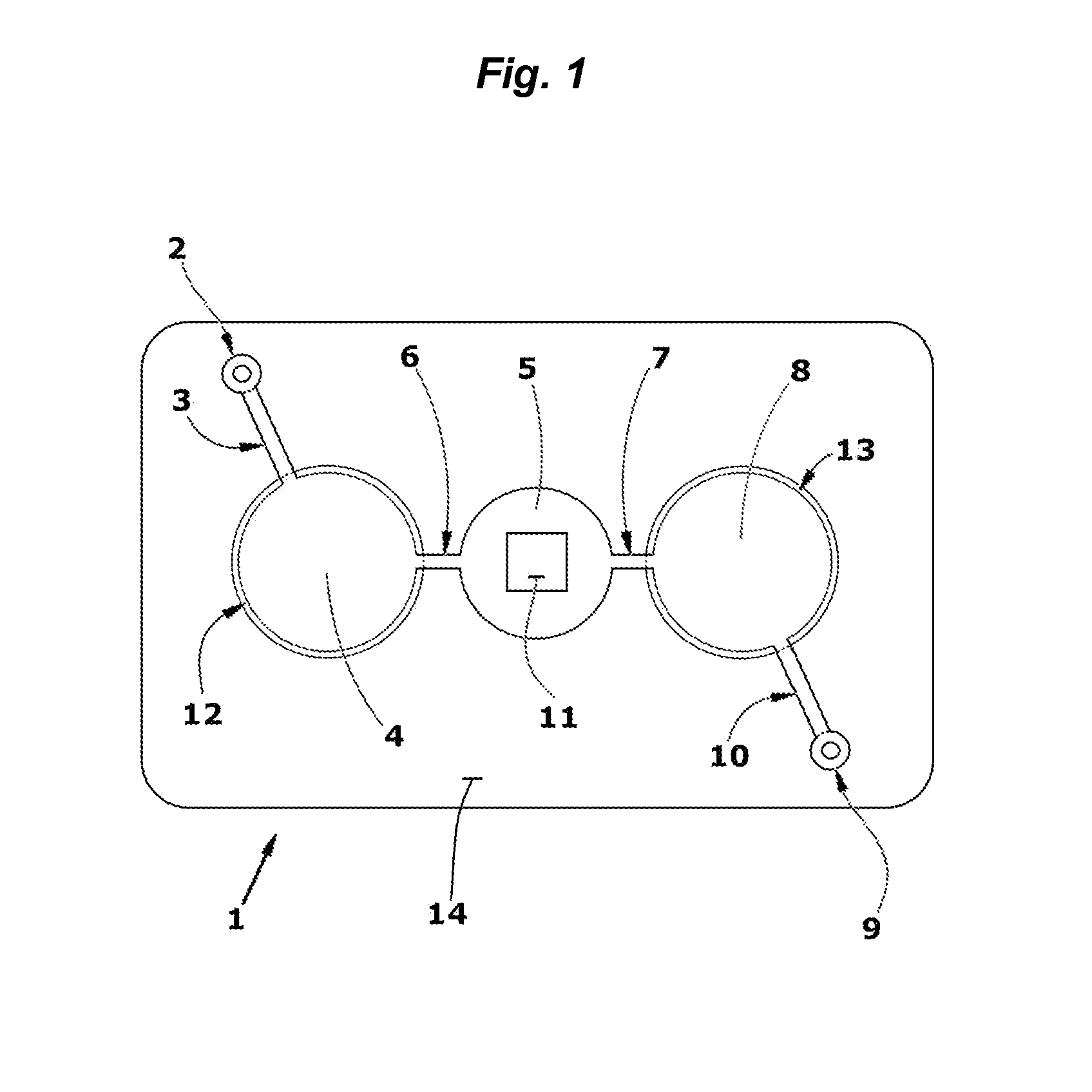

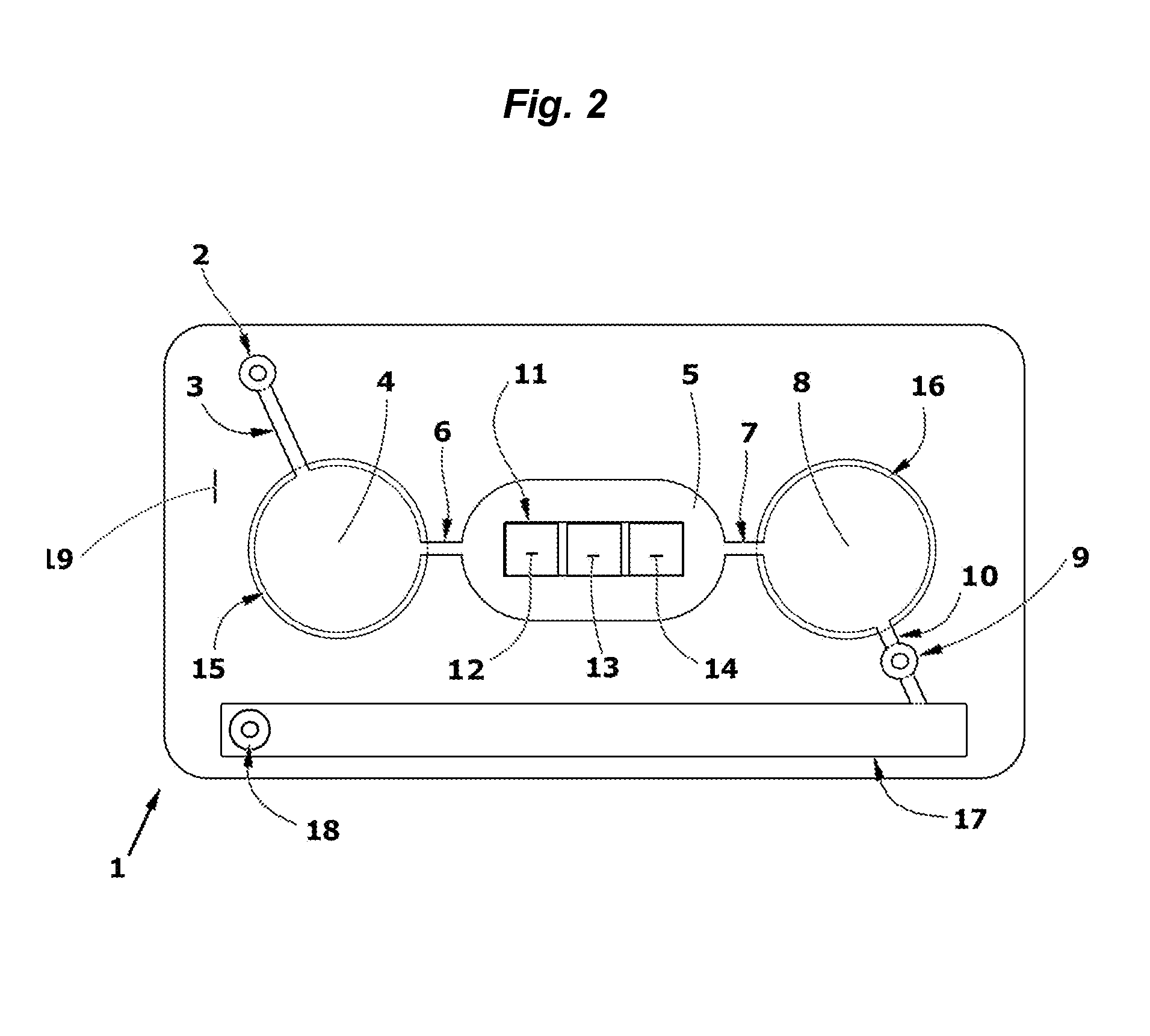

Microfluidic reactor system

ActiveUS20120177543A1Endpoint detectionReduce incubation timeShaking/oscillating/vibrating mixersTransportation and packagingDiaphragm pumpReactor system

A compact device for operatively coupling a solid planar substrate, for example a glass slide, to a microfluidic circuit and performing a reaction or reactions on organic matter bound to the face of the planar substrate. Typical reactions include binding, staining and / or labeling reactions. In use, a sealed reaction chamber is formed, the chamber enclosing the organic matter and at least a part of the solid substrate. Headspace in the sealed chamber between the solid substrate is generally of microfluidic dimensions, and diaphragm pump members are used to inject, exchange and / or mix the fluids in the chamber.

Owner:PERKINELMER HEALTH SCIENCES INC

Solid material comprising a thin metal film on its surface and methods for producing the same

InactiveUS6958174B1Reduce percentageVacuum evaporation coatingSputtering coatingSelf limitingMetallurgy

The present invention provides a solid material comprising a solid substrate having a thin metal film and methods for producing the same. The method generally involves using a plurality self-limiting reactions to control the thickness of the metal film.

Owner:UNIV TECH

Device for controlling the displacement of a drop between two or several solid substrates

ActiveUS7531072B2Fixed microstructural devicesVolume/mass flow measurementElectrical controlSolid substrate

A device for reversibly displacing at least one volume of liquid under the effect of an electrical control, including first electrically conductive device, second electrically conductive device, and a device for inducing a reversible displacement of a volume of liquid, from the first to the second electrically conductive devices, without contact with the conductive device during the displacement.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Functional surface coating

InactiveUS20050100675A1Inhibit non-specific bindingRobust attachmentPretreated surfacesBiological testingProtein targetCombinatorial chemistry

Compositions and methods of preparing functional thin films or surface coatings with low non-specific binding are described. The thin films contain specified functional groups and non-specific binding repellant components. The thin films are either covalently bound to or passively adsorbed to various solid substrates. The specified functional group provides specified activity for the thin film modified solid surfaces and non-specific binding repellant components significantly reduce the non-specific binding to the thin film modified solid surfaces. Non-specific binding repellant components do not affect specified functional group's activity in the thin films. In these methods, specified functional groups are anchored to the solid substrates through a spacer. Surface coatings are also described having both non-specific protein binding properties combined with functional groups for specific binding activity thereby providing surface coating that specifically recognize target proteins but limit binding to non-specific protein.

Owner:ACCELERATED MEDICAL DIAGNOSTICS INC

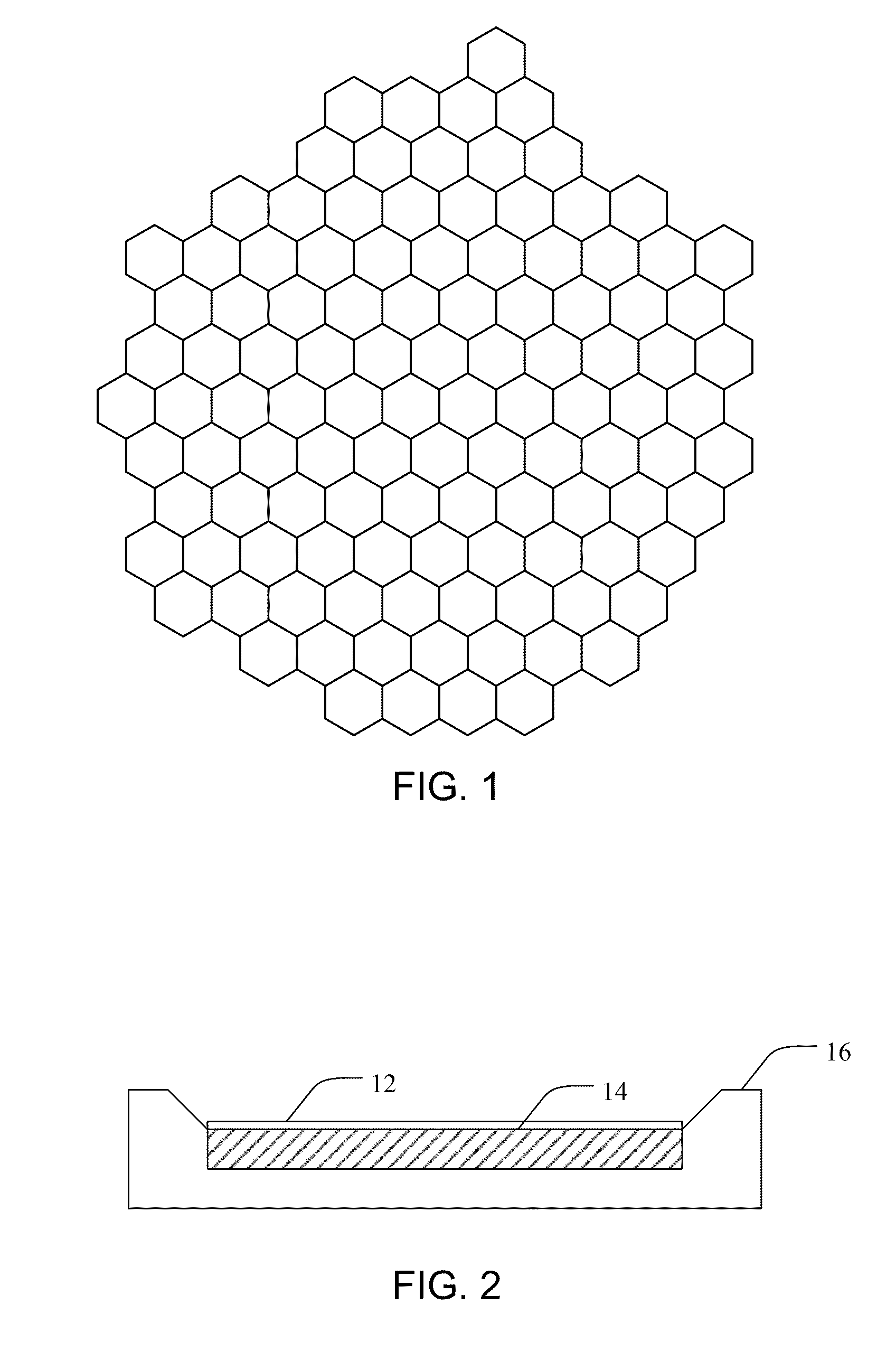

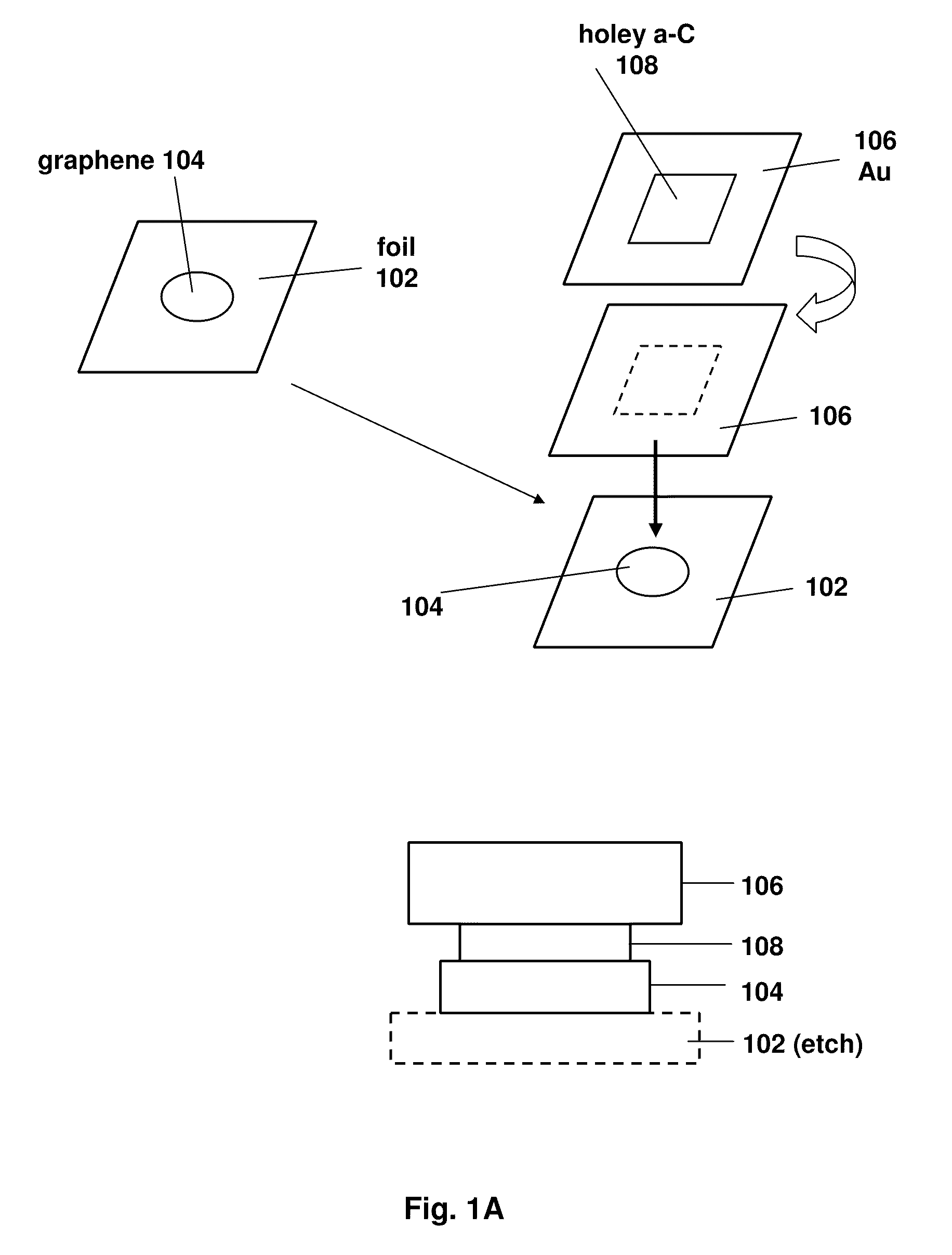

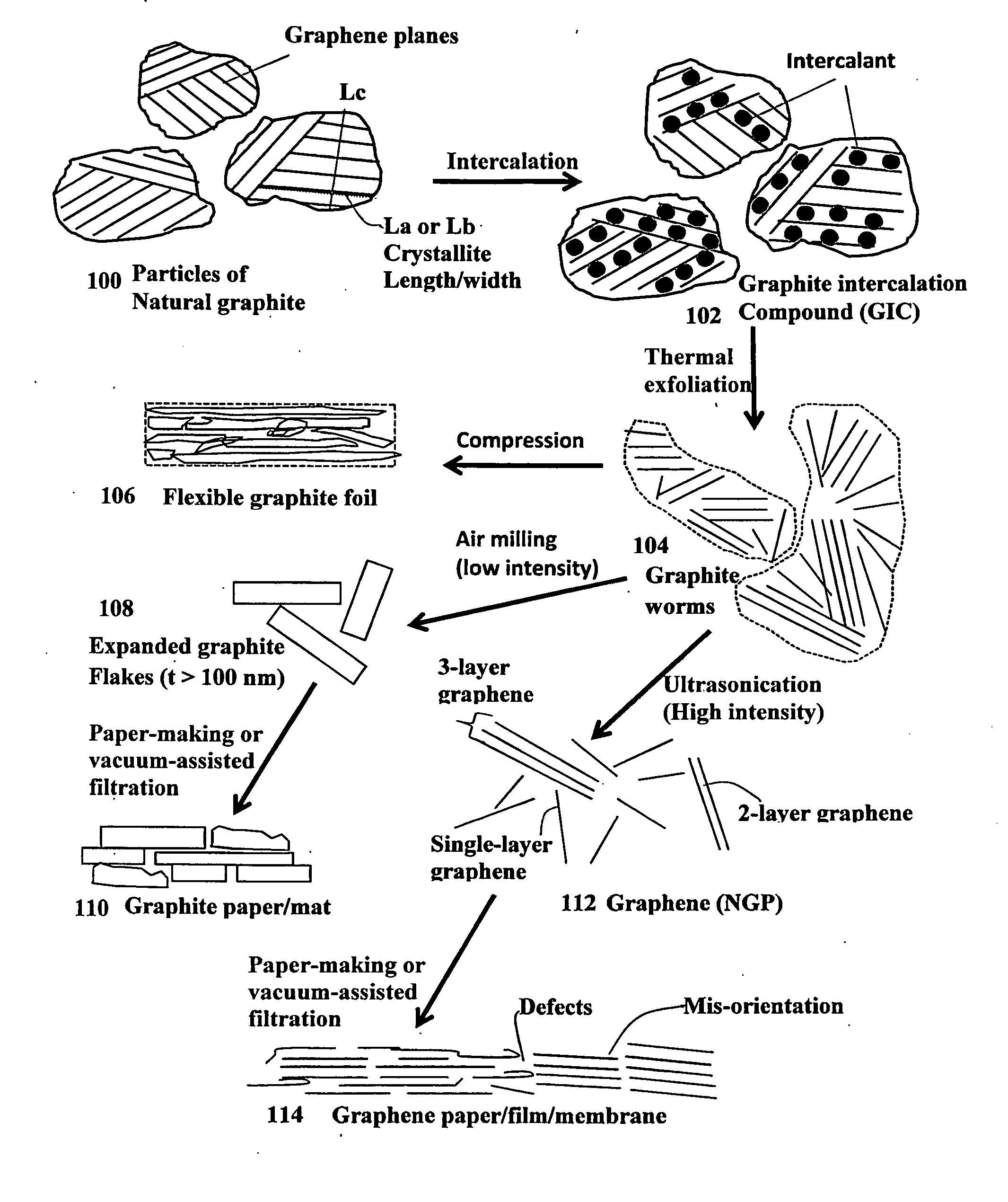

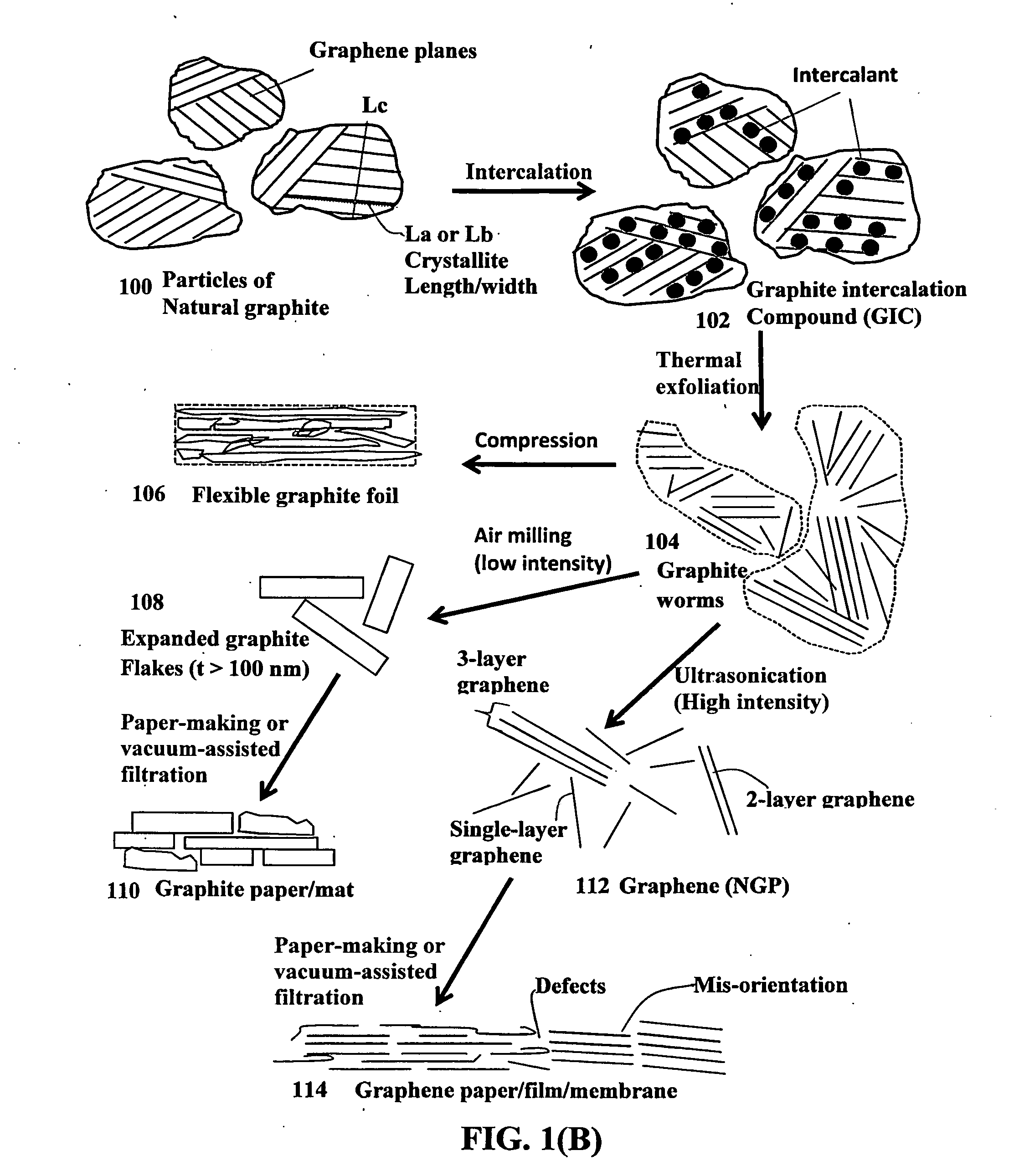

Graphene and Hexagonal Boron Nitride Planes and Associated Methods

Graphene layers made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, for example, a method of forming a graphite film can include heating a solid substrate under vacuum to a solubilizing temperature that is less than a melting point of the solid substrate, solubilizing carbon atoms from a graphite source into the heated solid substrate, and cooling the heated solid substrate at a rate sufficient to form a graphite film from the solubilized carbon atoms on at least one surface of the solid substrate. The graphite film is formed to be substantially free of lattice defects.

Owner:SUNG CHIEN MIN

Solid substrate used for sensors

InactiveUS20050181497A1Good solventPoor solventBioreactor/fermenter combinationsBiological substance pretreatmentsHydrophobic polymerSolid substrate

It is an object of the present invention to provide a solid substrate used for sensors that suppresses nonspecific adsorption and that is able to immobilize a physiologically active substance. The present invention provides A solid substrate used for sensors, wherein two or more different hydrophobic polymer layers are laminated on the solid substrate, and among the above hydrophobic polymer layers, the surface of a layer, which is farthest from the solid substrate, is modified.

Owner:FUJIFILM HLDG CORP +1

Methods of placing treatment chemicals

Among the methods provided are methods of treating a subterranean formation comprising placing a solid treatment chemical and a tacky polymer onto a solid substrate to create a coated solid substrate; placing the coated solid substrate into a portion of a subterranean formation; and, allowing the tacky polymer to degrade and allowing the solid treatment chemical to be released into the portion of the subterranean formation. Also provided are methods of creating a particulate pack comprising a treatment chemical in a subterranean formation comprising placing a solid treatment chemical and a tacky polymer onto a particulate to create a coated particulate; creating a slurry comprising the coated particulates slurried into a treatment fluid; placing the slurry into a portion of a subterranean formation so as to create a particulate pack; and, allowing the tacky polymer to degrade and allowing the solid treatment chemical to be released into the portion of the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

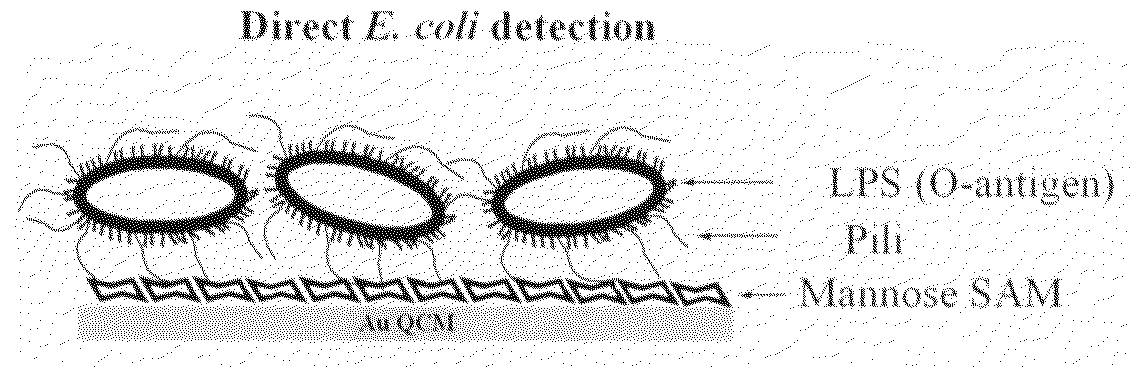

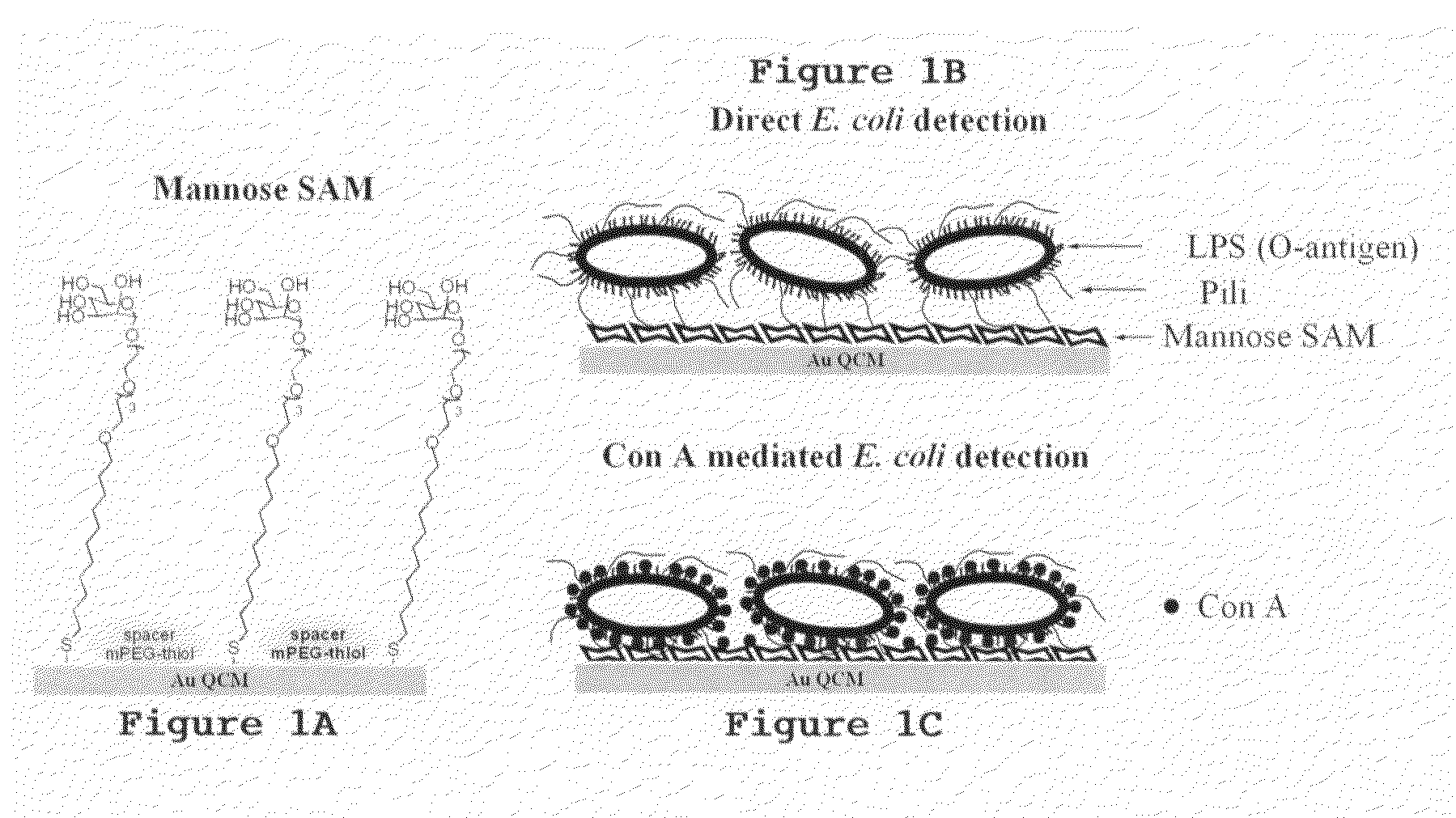

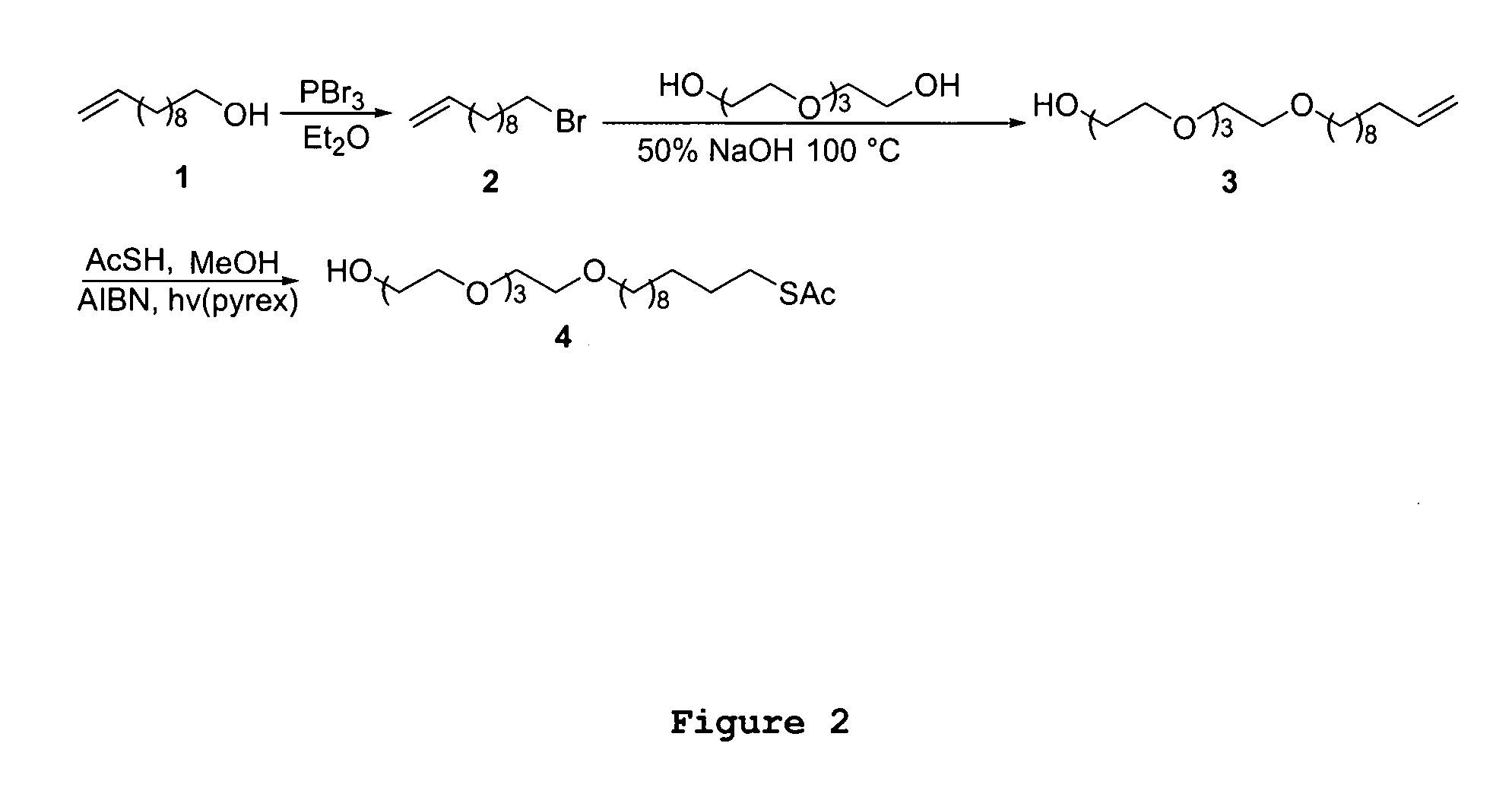

Microorganism detection and analysis using carbohydrate and lectin recognition

ActiveUS20080193965A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismQuartz crystal microbalance

Methods of binding and detecting a microorganism on a solid substrate. The microorganism is bound on a solid substrate covalently bound to a capture agent having a saccharide moiety. A lectin capable of binding to the microorganism and the saccharide moiety of the capture agent is added to the sample to bind the microorganism on the solid substrate. Further provided are biosensor devices, such as a quartz crystal microbalance (QCM) device or a surface plasmon resonance (SPR) device, that incorporate the solid substrate for the detection of microorganisms.

Owner:OAKLAND UNIVESITY

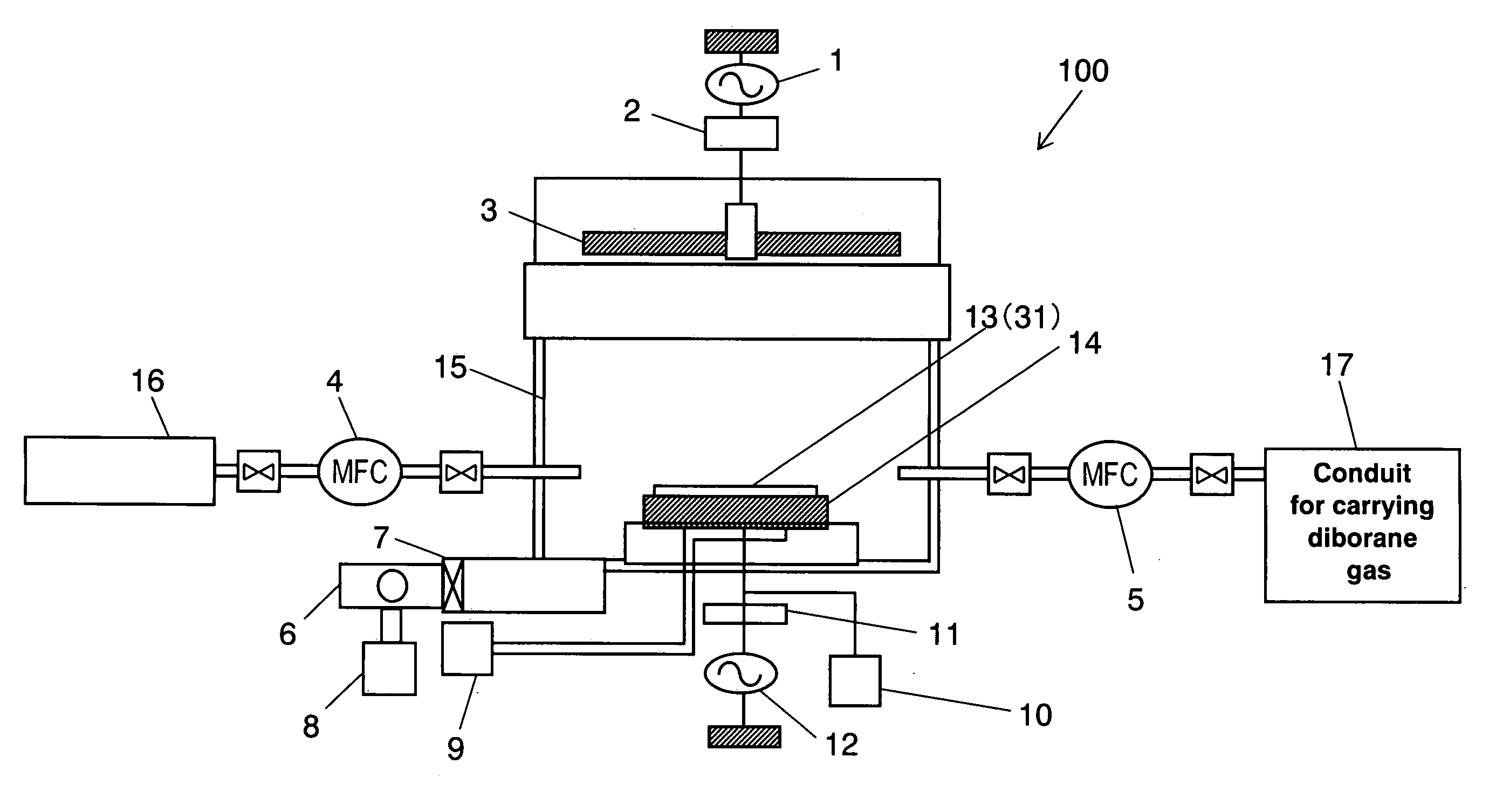

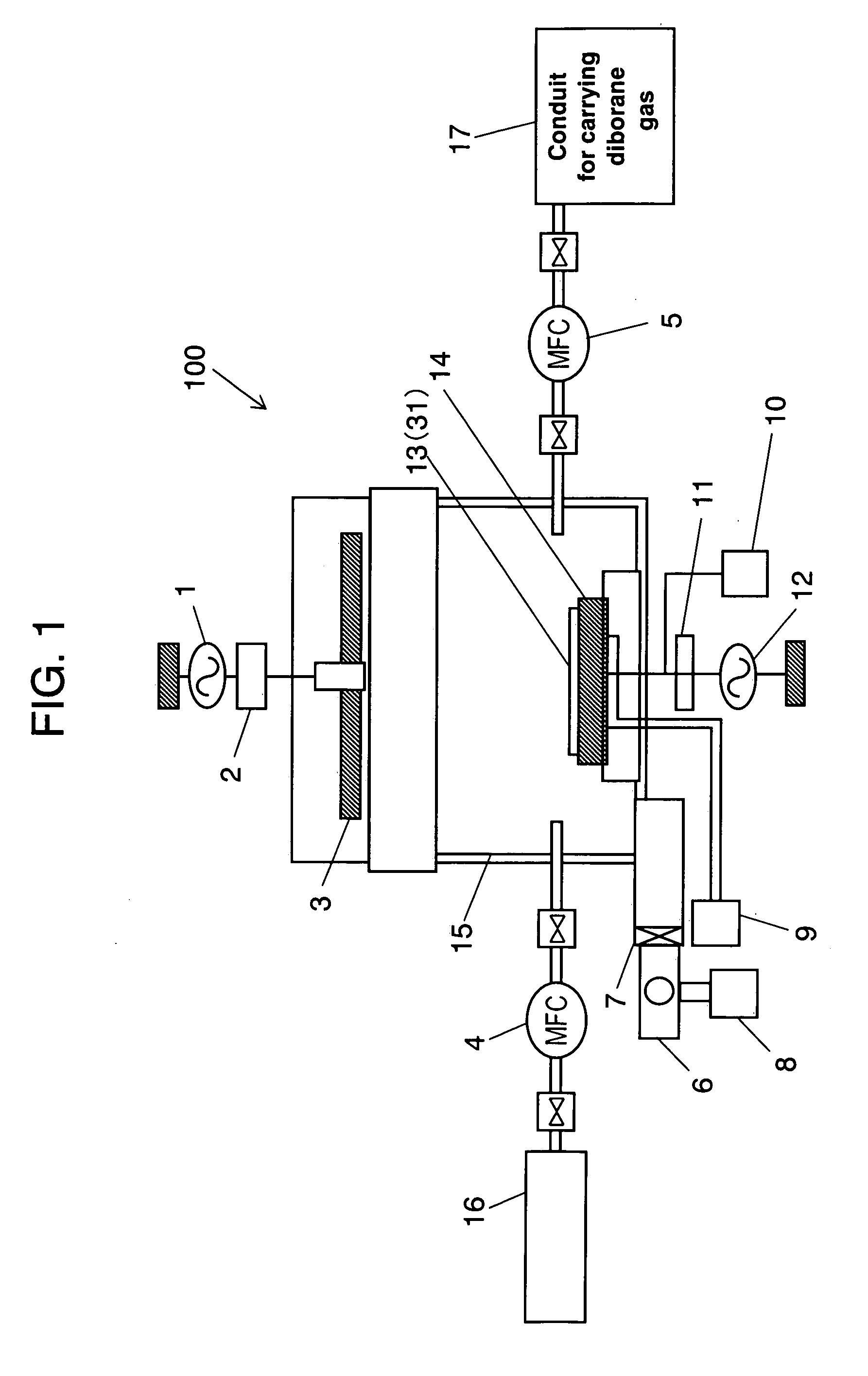

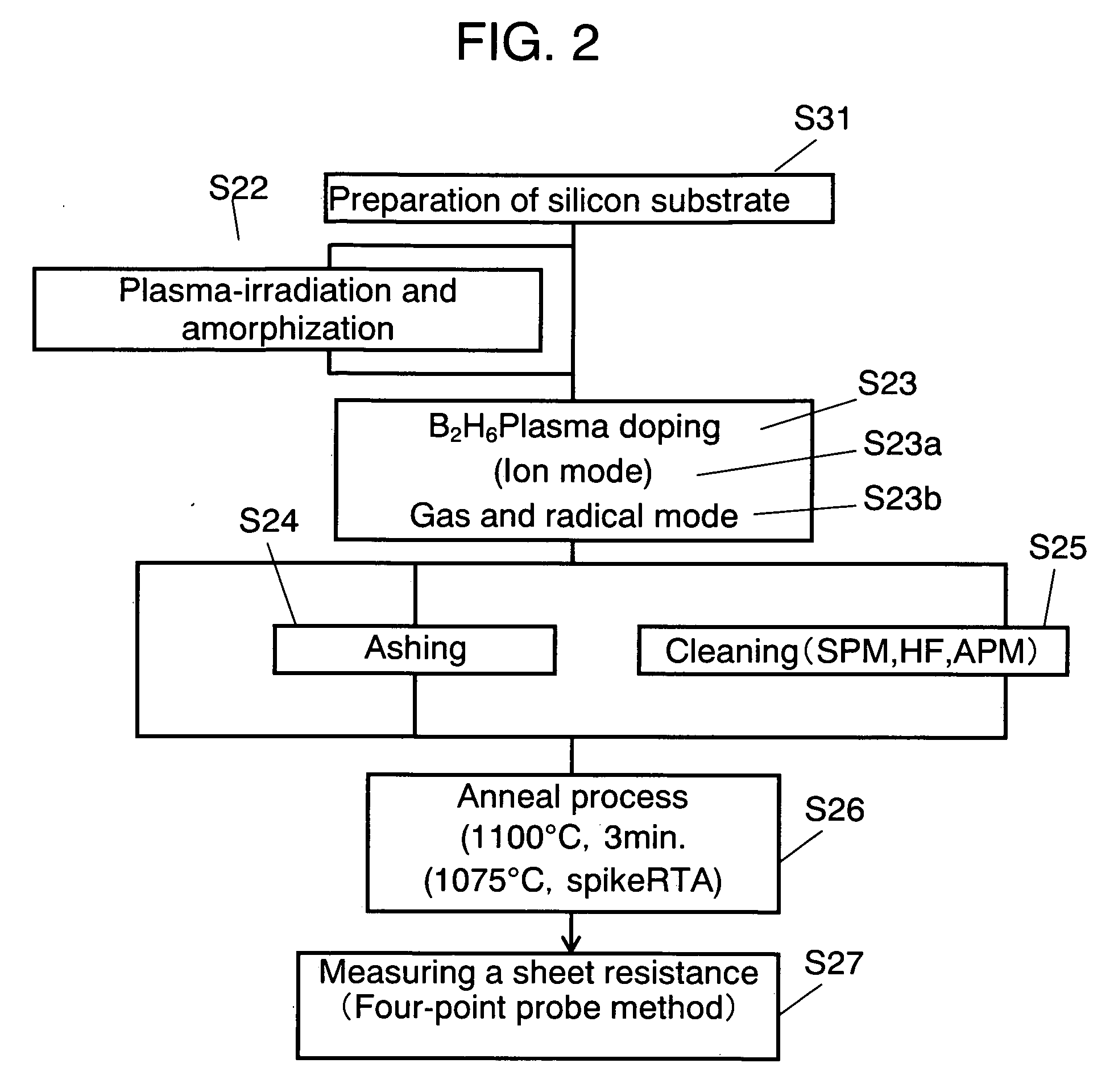

Method for formng impurity-introduced layer, method for cleaning object to be processed apparatus for introducing impurity and method for producing device

A method of forming an impurity-introduced layer is disclosed. The method includes at least a step of forming a resist pattern on a principal face of a solid substrate such as a silicon substrate (S27); a step of introducing impurity into the solid substrate through plasma-doping in ion mode (S23), a step of removing a resist (S28), a step of cleaning metal contamination and particles attached to a surface of the solid substrate (S25a); a step of anneal (S26). The step of removing a resist (S28) irradiates the resist with oxygen-plasma or brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the resist. The step of cleaning (S25a) brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate. The step of removing a resist (S28) and the step of cleaning (S25a) can be conducted simultaneously by bringing mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

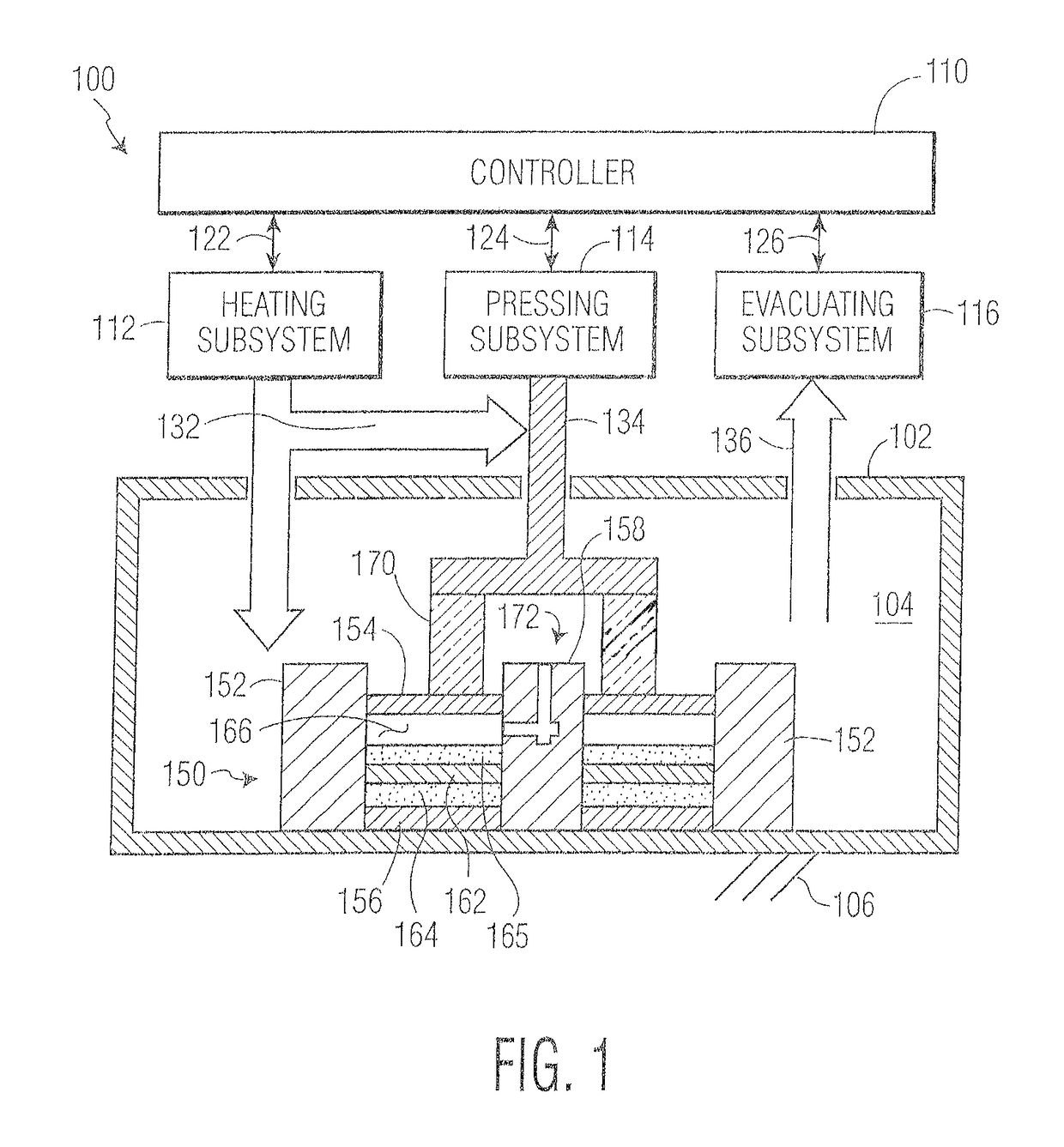

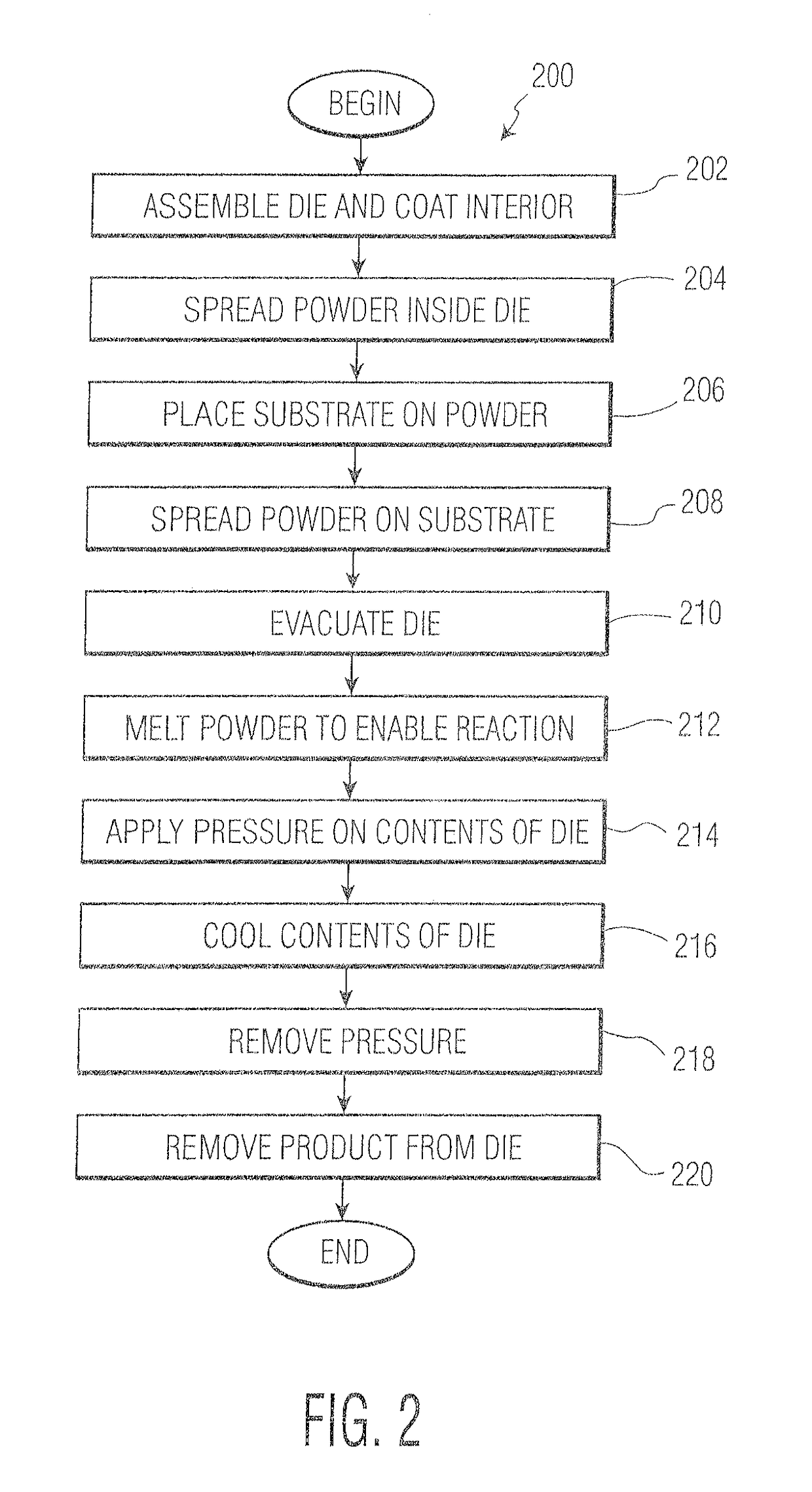

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

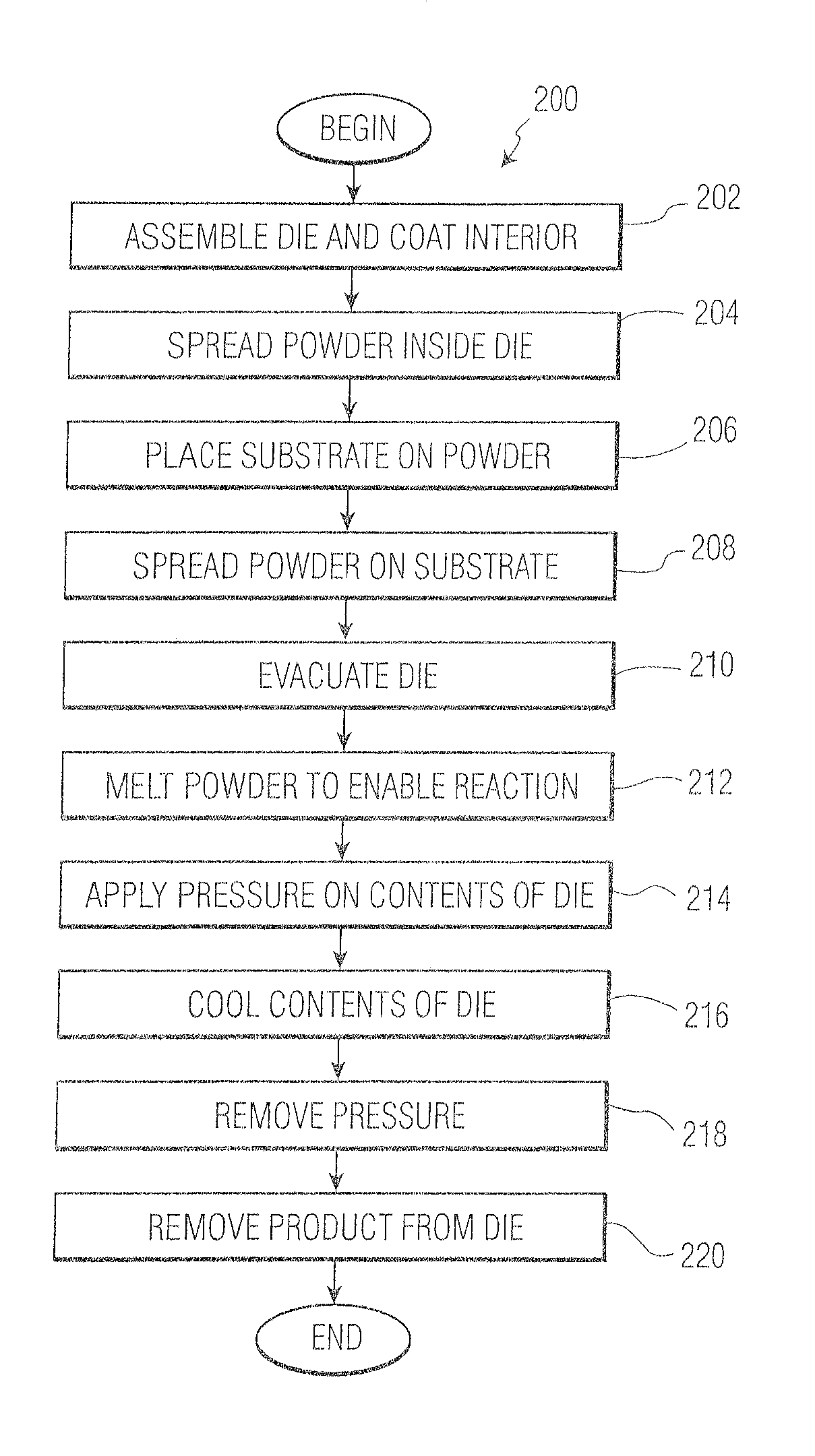

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

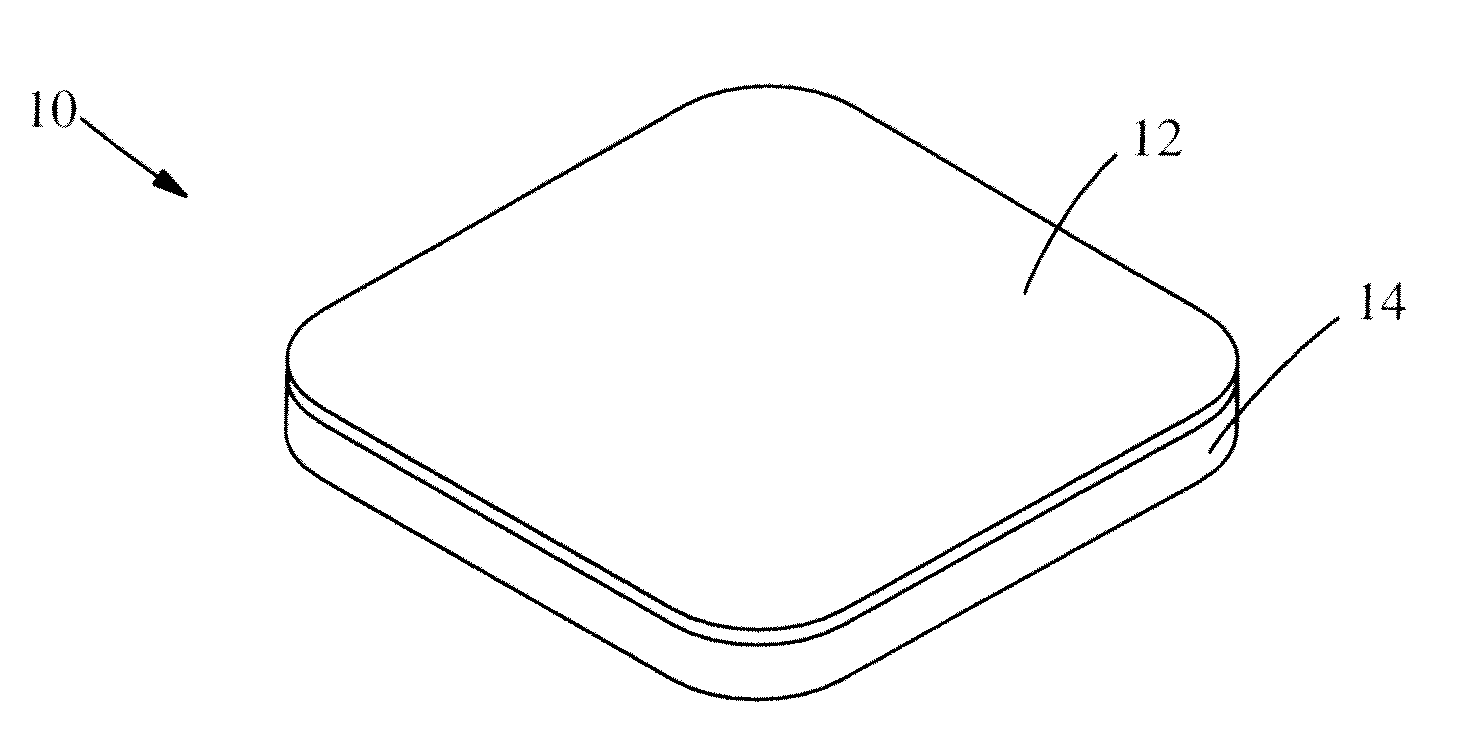

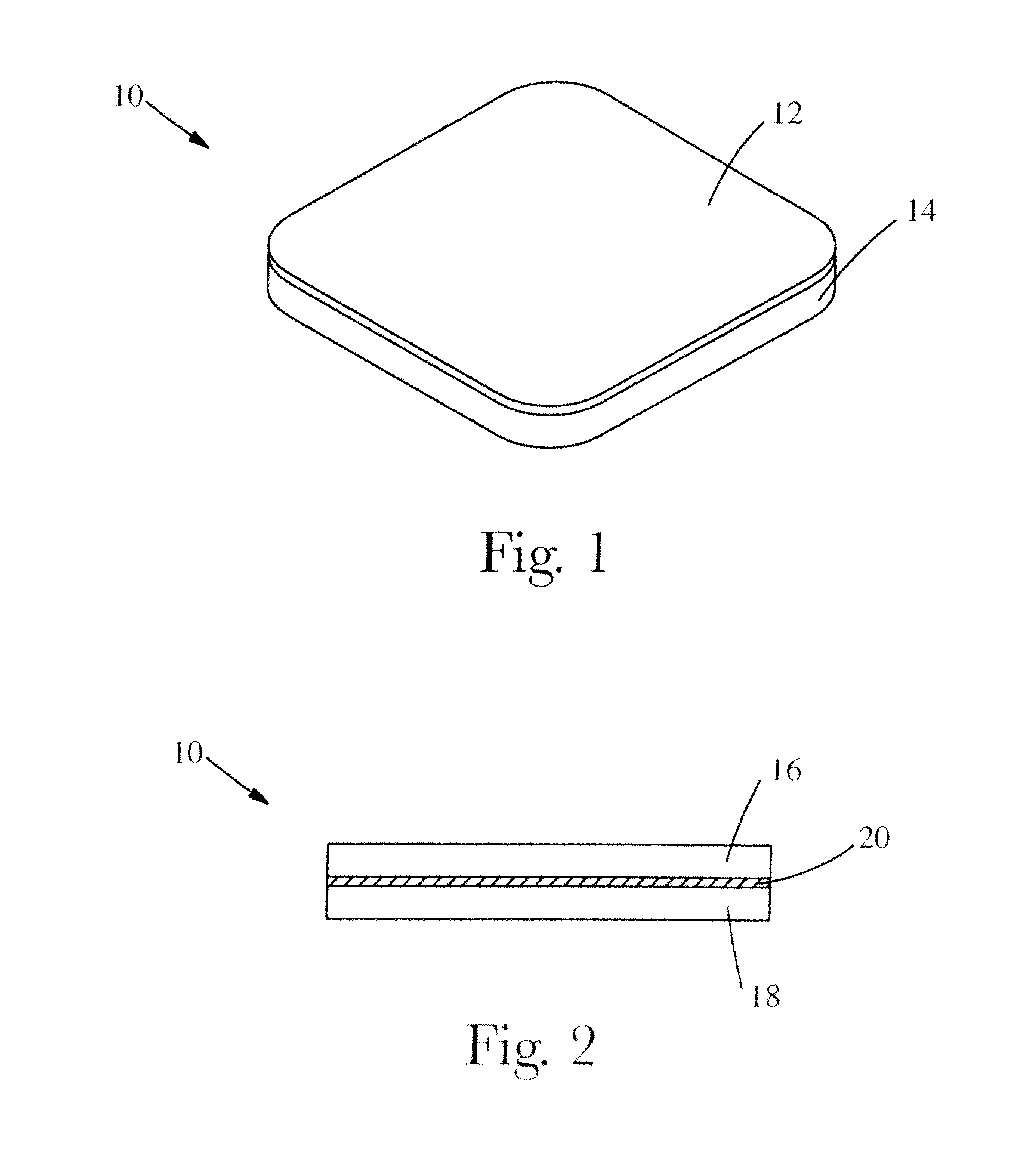

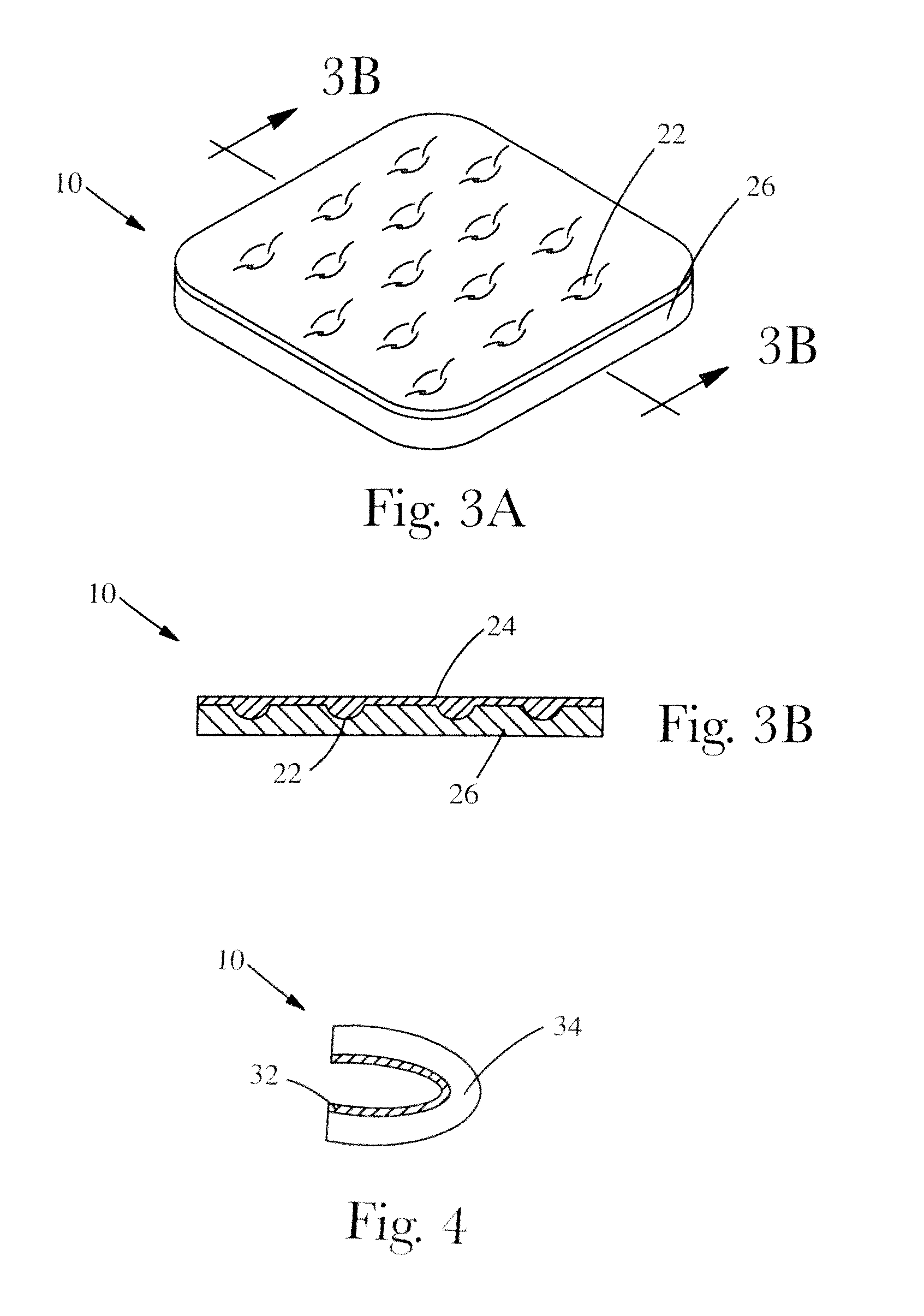

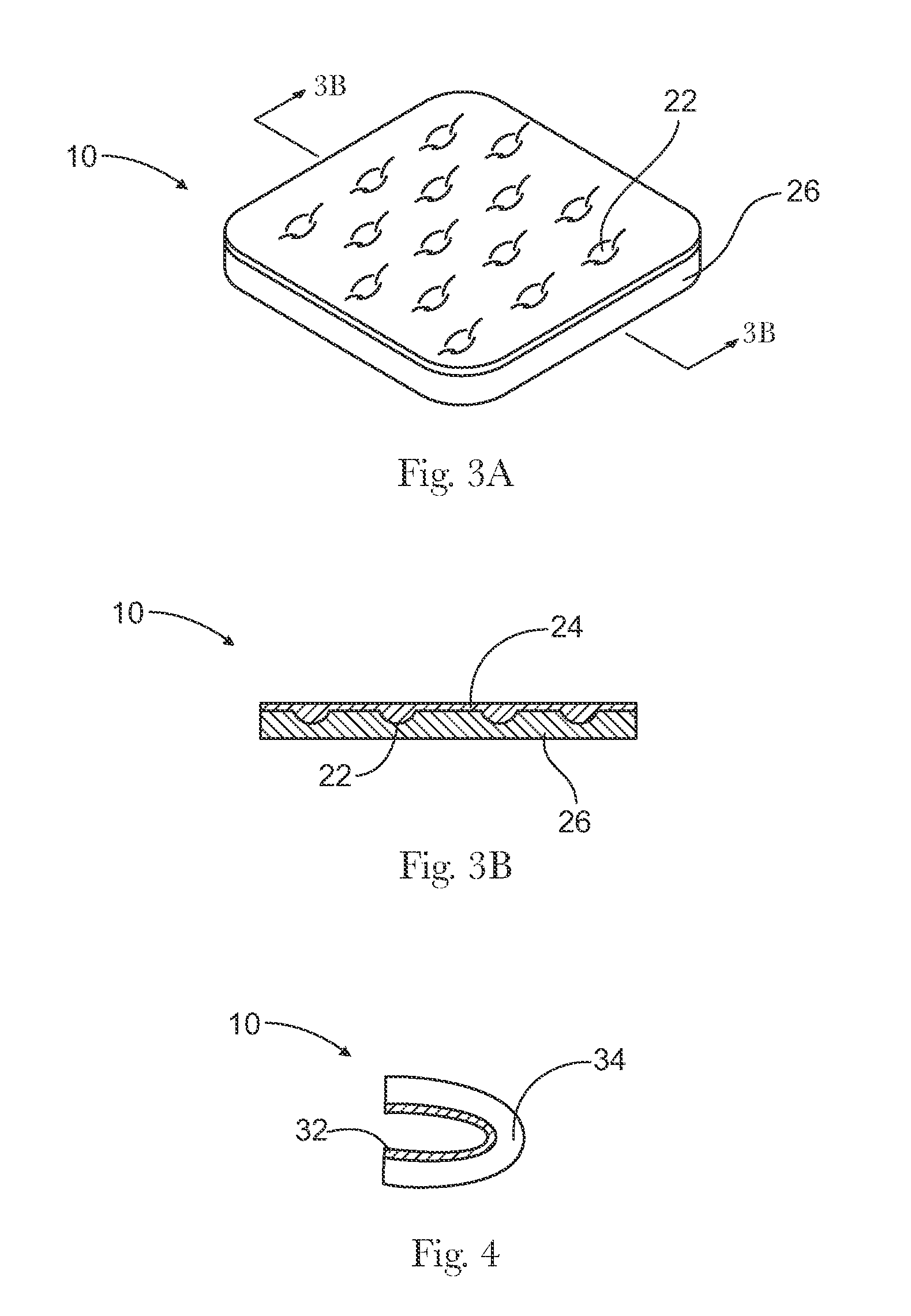

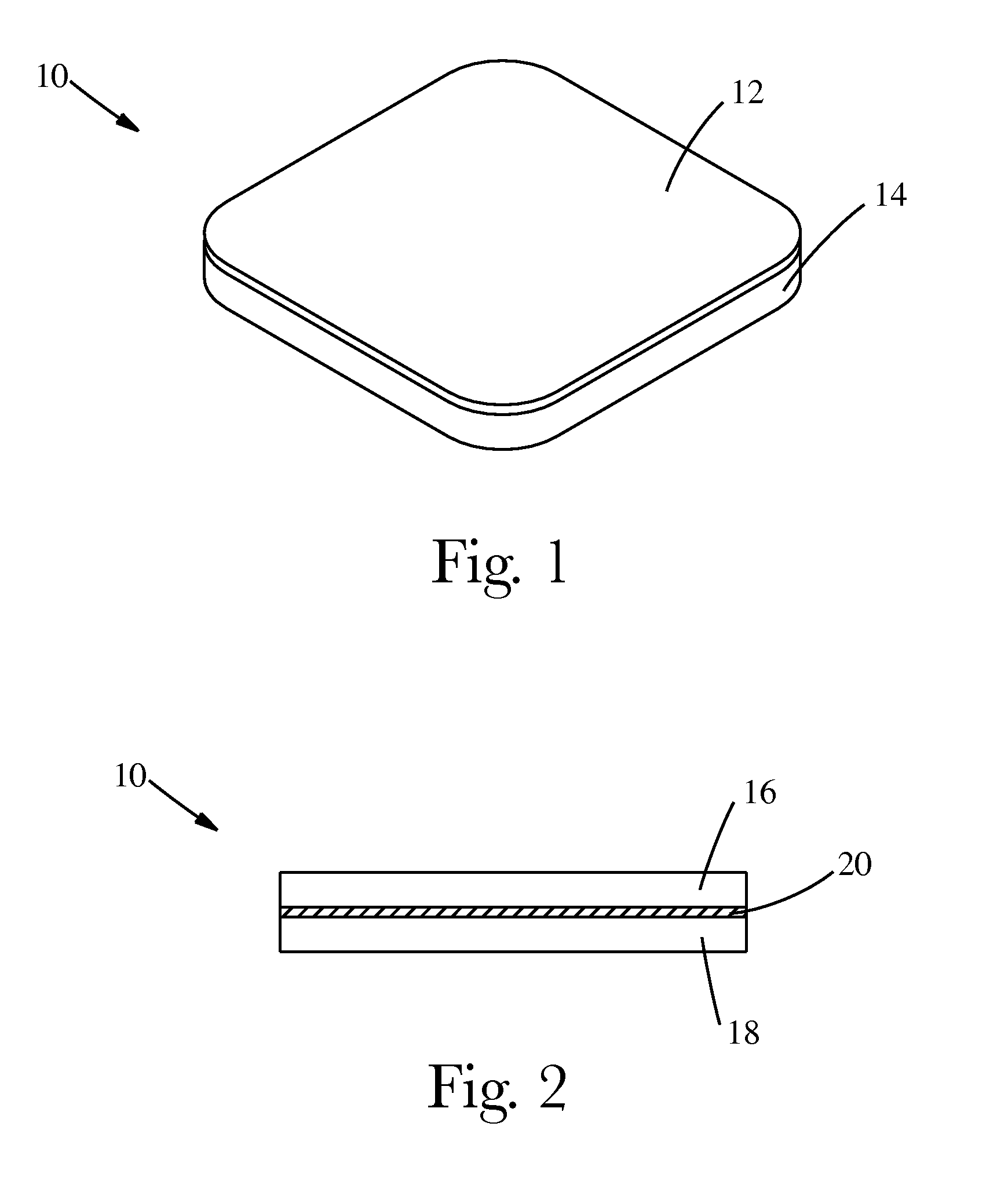

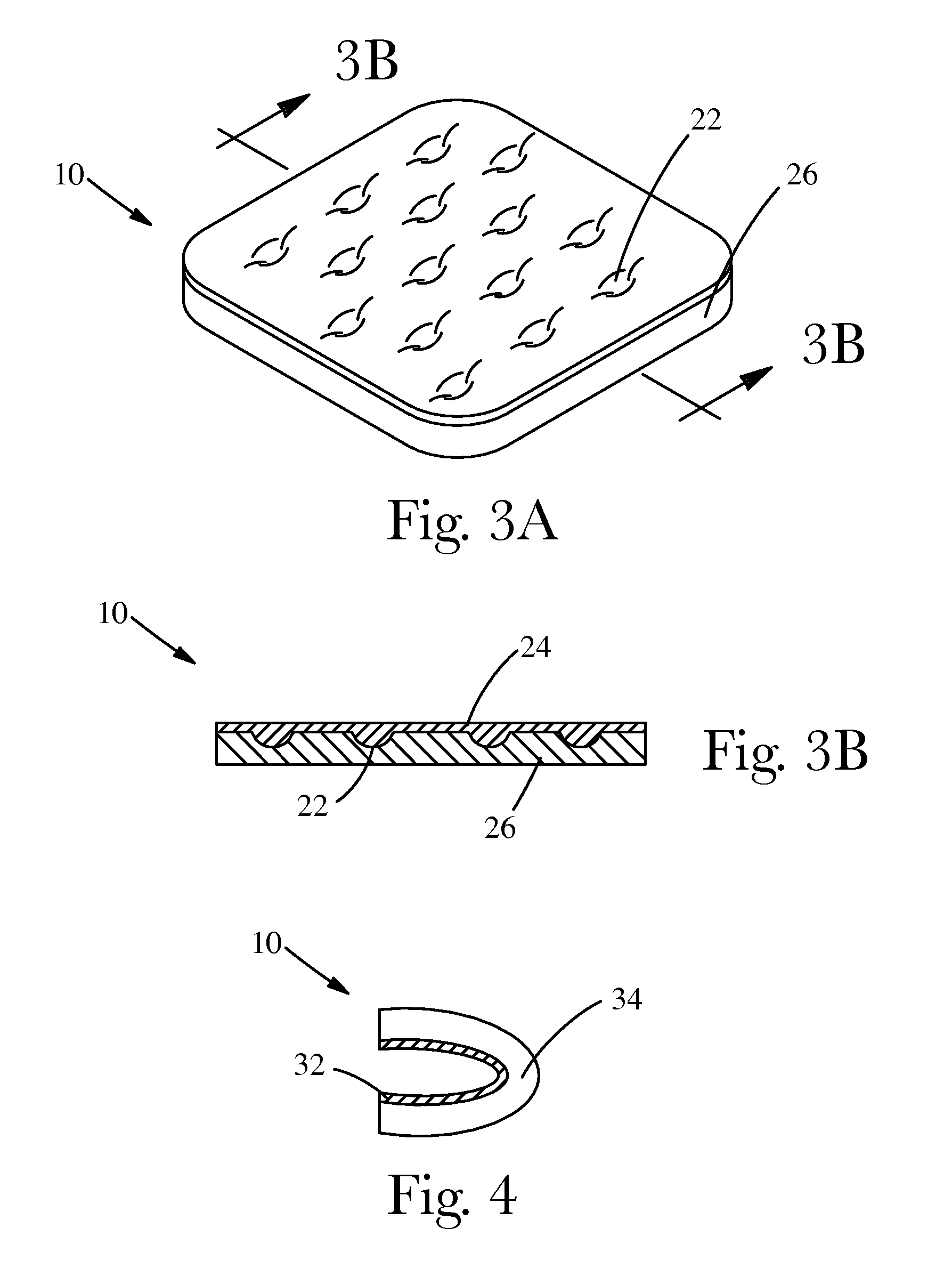

Porous, Dissolvable Solid Substrate and Surface Resident Coating Comprising Matrix Microspheres

ActiveUS20110182956A1Conveniently and quickly dissolvedEfficient use ofCosmetic preparationsCationic surface-active compoundsPersonal careMicrosphere

The present invention relates to personal care compositions, especially those personal care compositions in the form of a personal care article that is a porous dissolvable solid substrate. The porous dissolvable solid substrate has a surface resident coating comprising a surface resident coating comprising from about 25% to about 70% of a starch derived material, from about 5% to about 60% of a cationic surfactant conditioner, and from about 5% to about 60% of a perfume, that can provide a consumer benefit.

Owner:THE PROCTER & GAMBLE COMPANY

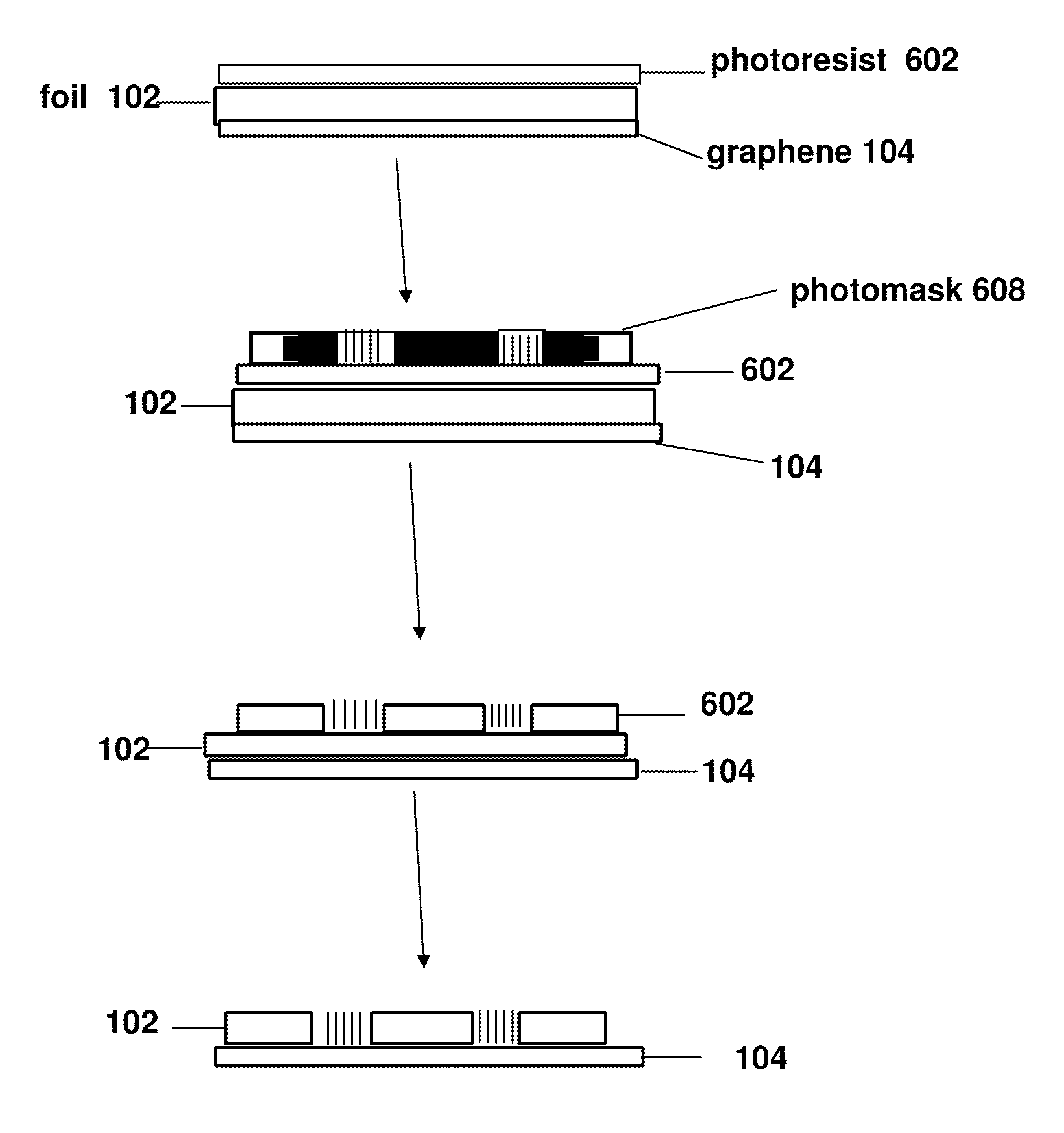

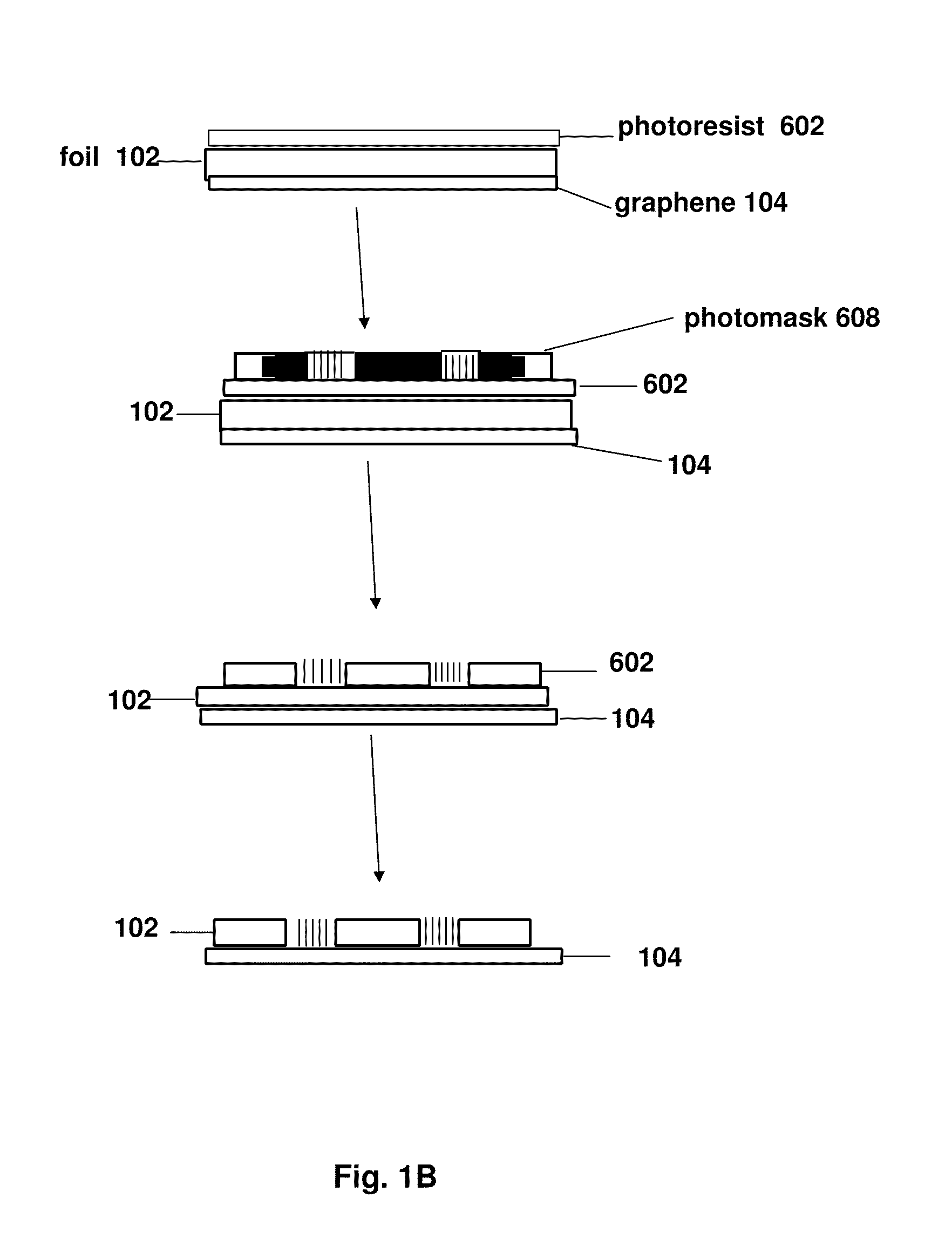

Suspended Thin Film Structures

InactiveUS20110200787A1Improve bindingMaterial nanotechnologyLamination ancillary operationsLithographic artistPresent method

Disclosed is a method of preparing a support structure suitable for use, e.g., in microscopic studies, comprising a free standing atomically thin film (e.g. graphene) suspended across an opening in the support structure. The method in one aspect comprises the steps of preparing a thin film which is an atomically thin film (e.g., graphene) on a surface of a solid substrate to form a graphene-layered substrate; attaching the graphene layer to a hole-containing support mesh; removing the solid support, thereby transferring the graphene layer from the substrate to the carbonaceous hole-containing layer on the support mesh; and then removing contaminants to obtain said structure. In another aspect, the present method does not involve a transfer, but comprises a lithography and etching process in which the atomically thin layer is applied to a support which is marked with a lithographic pattern and selectively etched, leaving the free standing film.

Owner:RGT UNIV OF CALIFORNIA

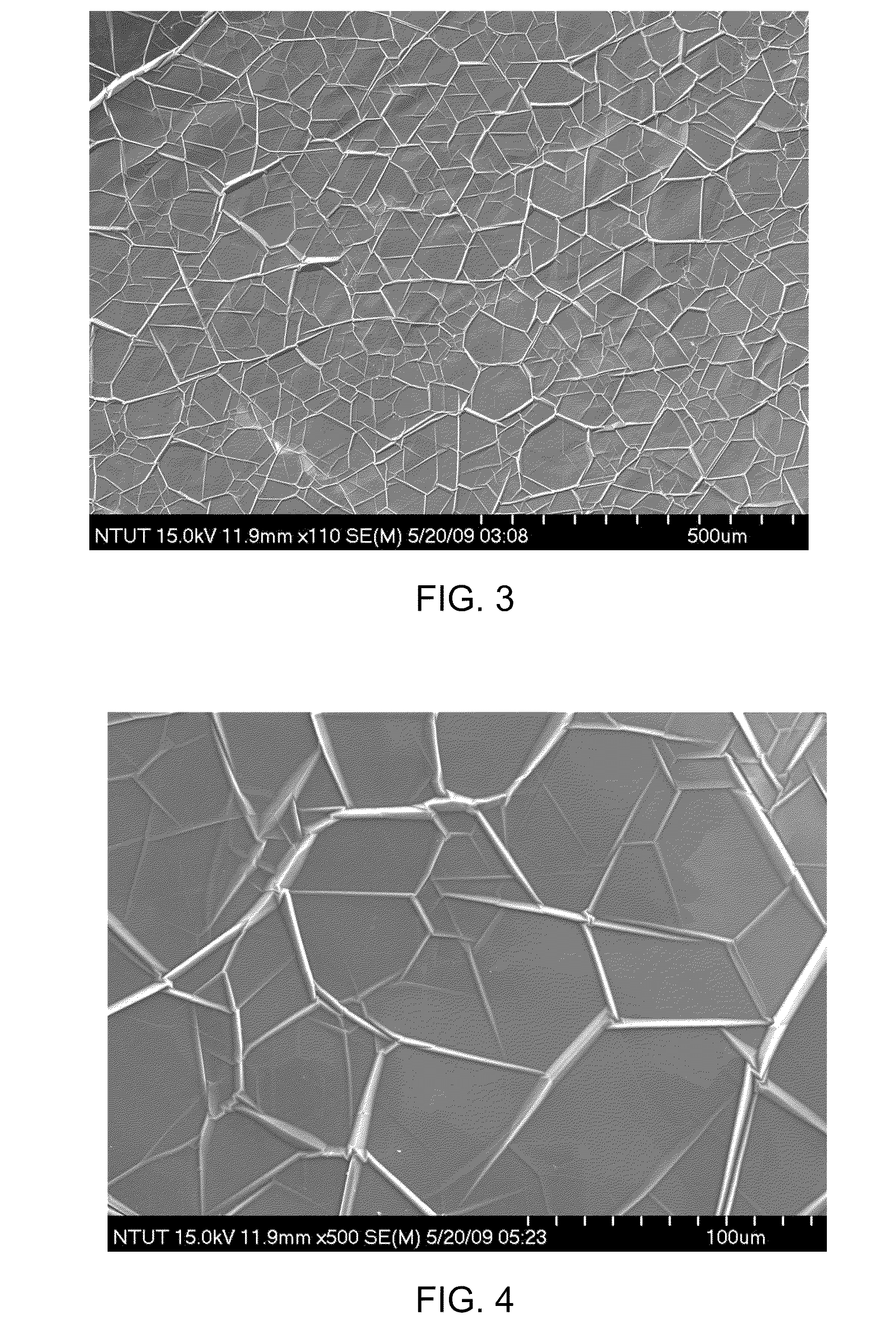

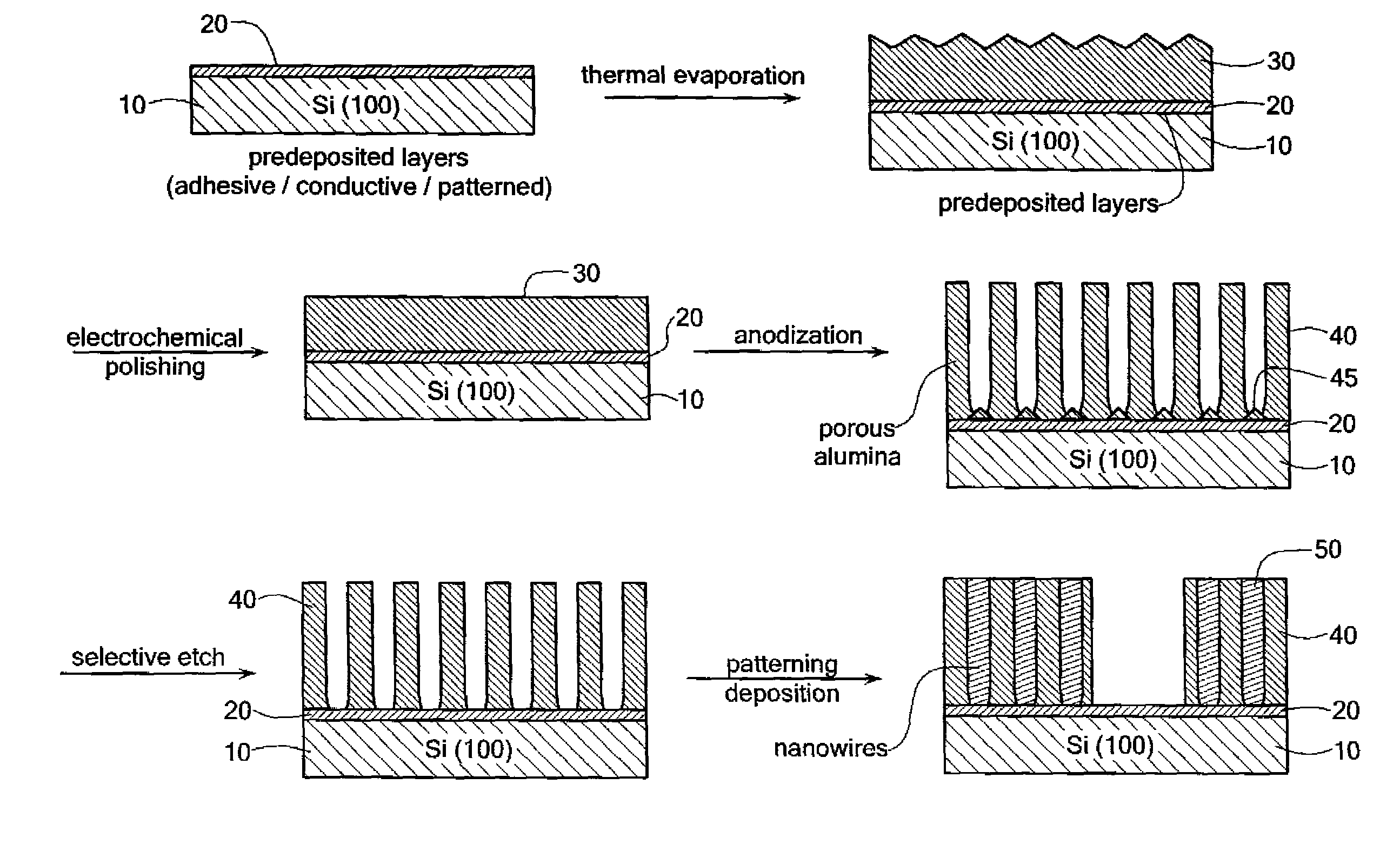

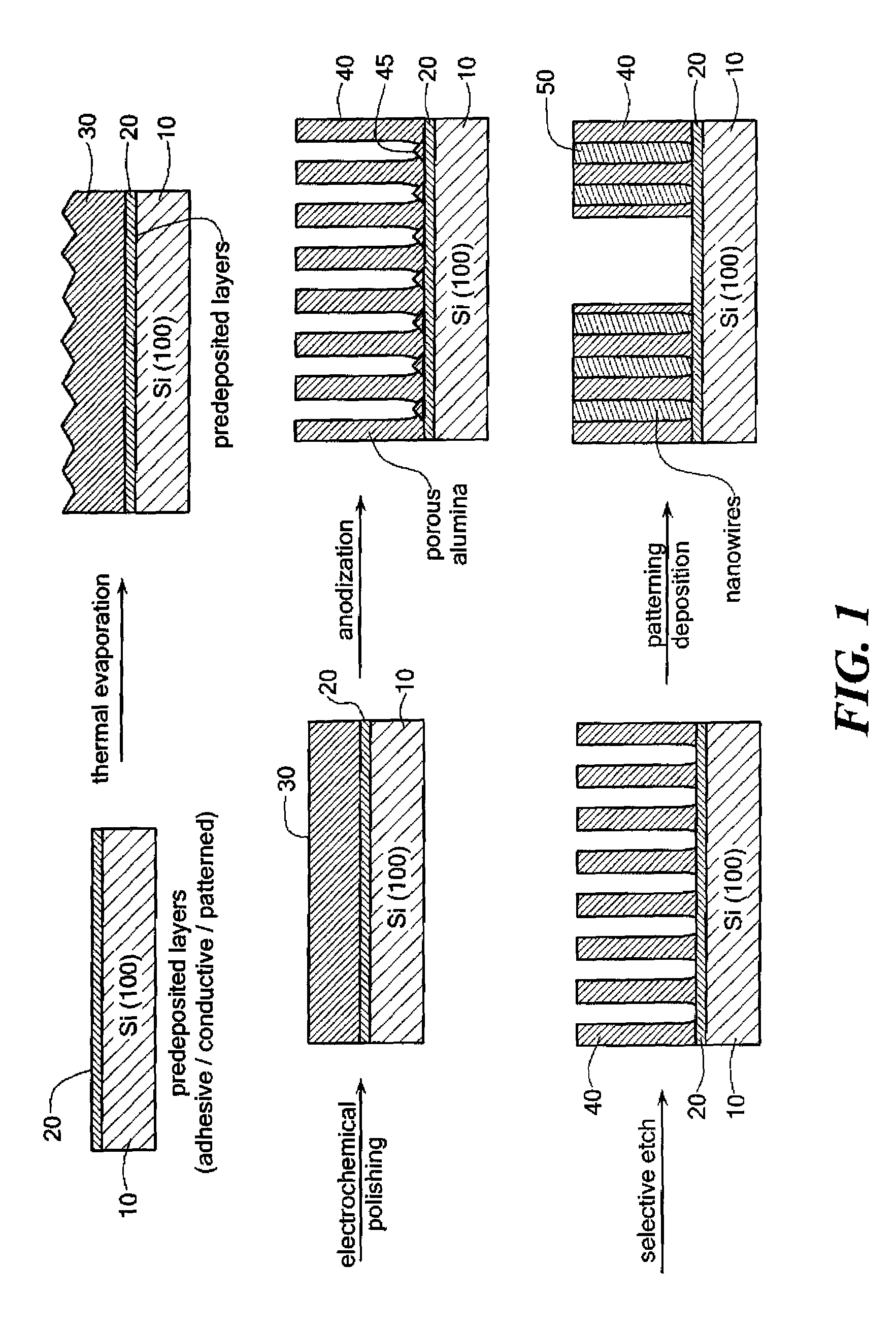

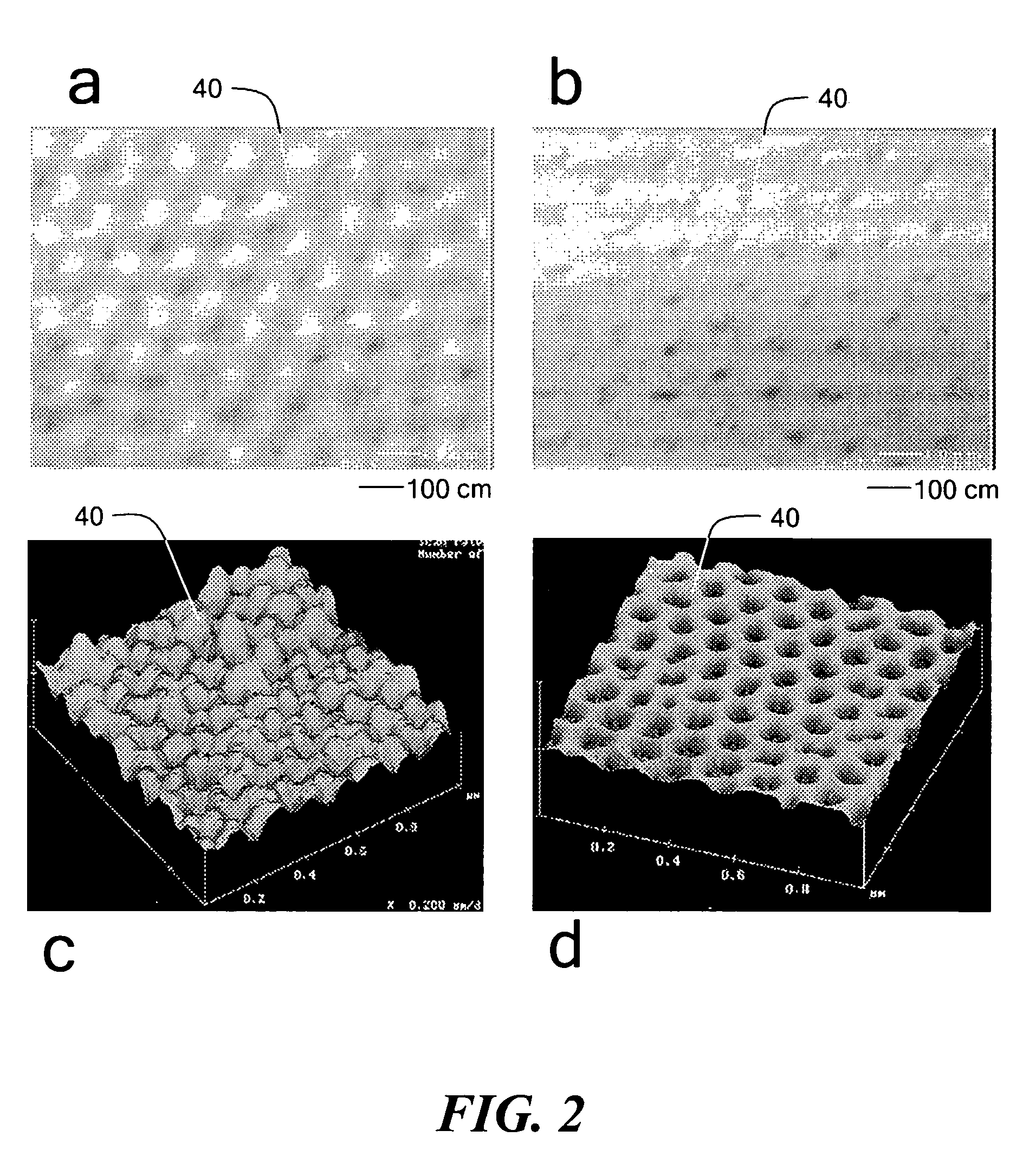

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS7267859B1Promote growthMore tractableMaterial nanotechnologyAnodisationSingle stageElectrochemistry

The presently disclosed invention provides for the fabrication of porous anodic alumina (PAA) films on a wide variety of substrates. The substrate comprises a wafer layer and may further include an adhesion layer deposited on the wafer layer. An anodic alumina template is formed on the substrate. When a rigid substrate such as Si is used, the resulting anodic alumina film is more tractable, easily grown on extensive areas in a uniform manner, and manipulated without danger of cracking. The substrate can be manipulated to obtain free-standing alumina templates of high optical quality and substantially flat surfaces PAA films can also be grown this way on patterned and non-planar surfaces. Furthermore, under certain conditions the resulting PAA is missing the barrier layer (partially or completely) and the bottom of the pores can be readily accessed electrically. The resultant film can be used as a template for forming an array of nanowires wherein the nanowires are deposited electrochemically into the pores of the template. By patterning the electrically conducting adhesion layer, pores in different areas of the template can be addressed independently, and can be filled electrochemically by different materials. Single-stage and multi-stage nanowire-based thermoelectric devices, consisting of both n-type and p-type nanowires, can be assembled on a silicon substrate by this method.

Owner:MASSACHUSETTS INST OF TECH

Porous, dissolvable solid substrate and surface resident inorganic particulate perfume complexes

ActiveUS20100167971A1Improve the level ofConveniently and quickly dissolvedCosmetic preparationsHair cosmeticsPersonal careParticulates

The present invention relates to personal care compositions, especially those personal care compositions in the form of a personal care article that is a porous dissolvable solid substrate. The porous dissolvable solid substrate has a surface resident coating comprising an inorganic particulate perfume complex that can provide a consumer benefit.

Owner:THE PROCTER & GAMBLE COMPANY

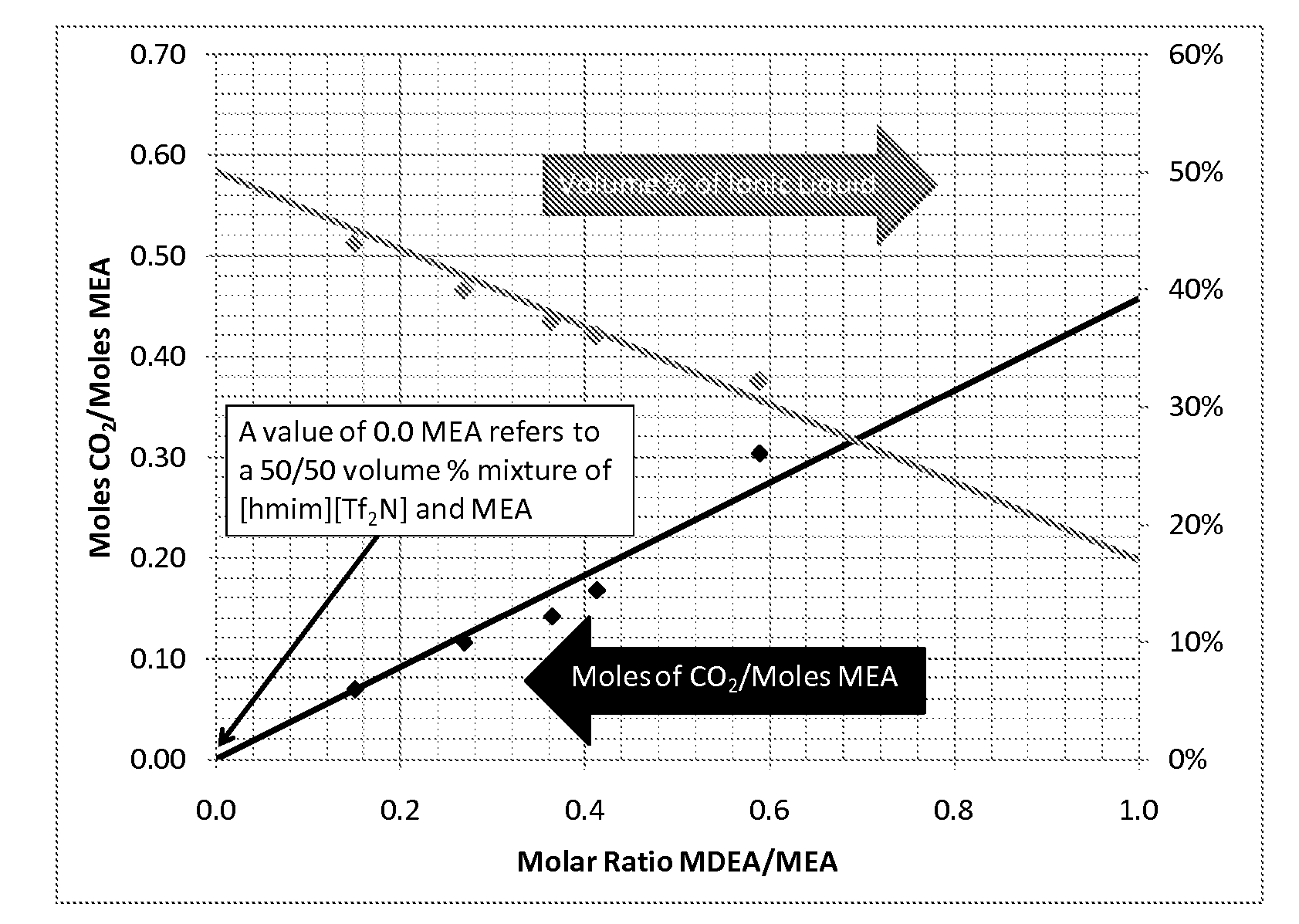

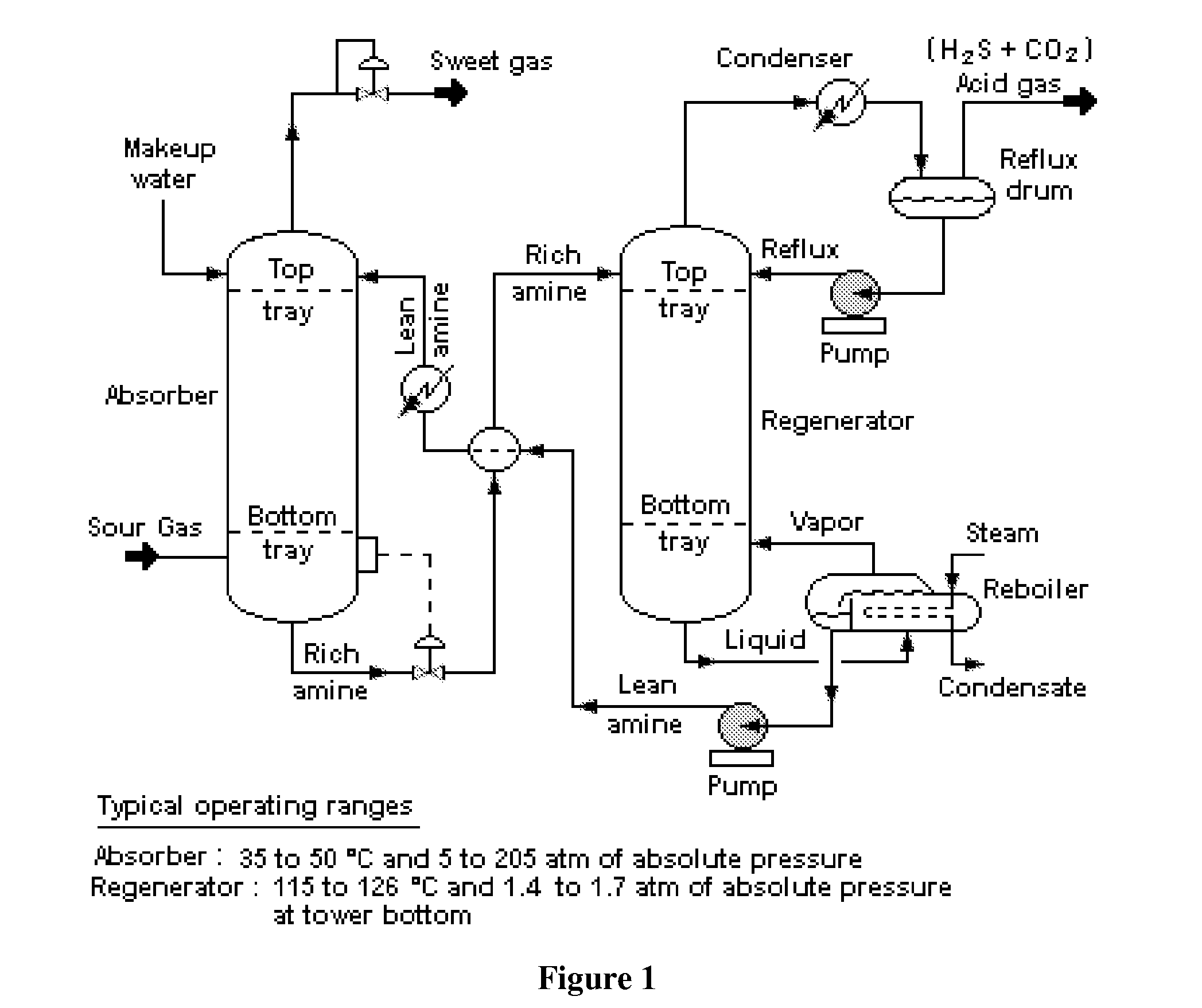

Ionic Liquids and Methods For Using the Same

InactiveUS20090291872A1Reducing and removing impurityReducing and removing and materialOrganic detergent compounding agentsLiquid degasification with auxillary substancesSolid substrateIonic liquid

The present invention provides compositions comprising ionic liquids and an amine compound, and methods for using and producing the same. In some embodiments, the compositions of the invention are useful in reducing the amount of impurities in a fluid medium or a solid substrate.

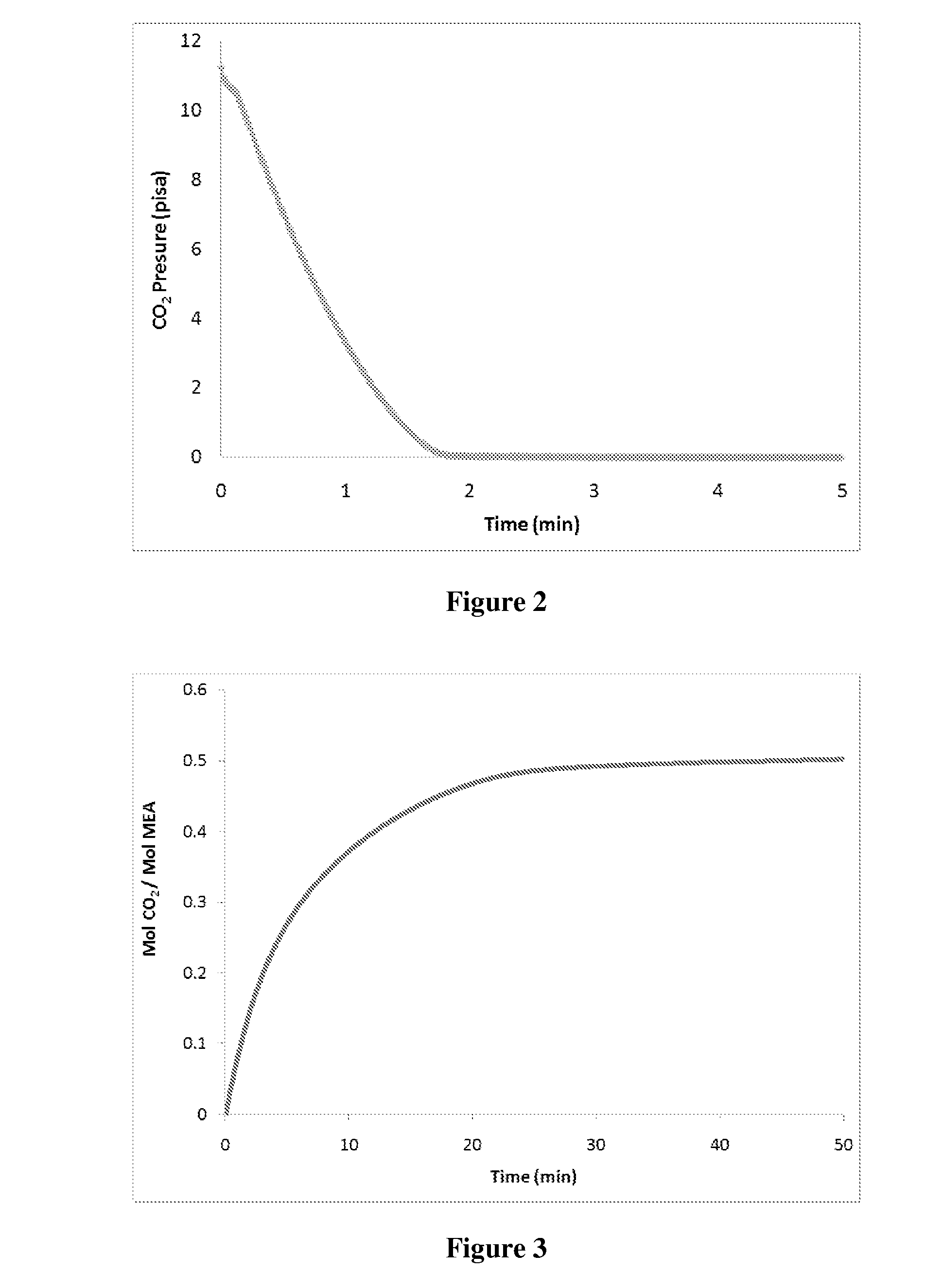

Owner:UNIV OF COLORADO THE REGENTS OF

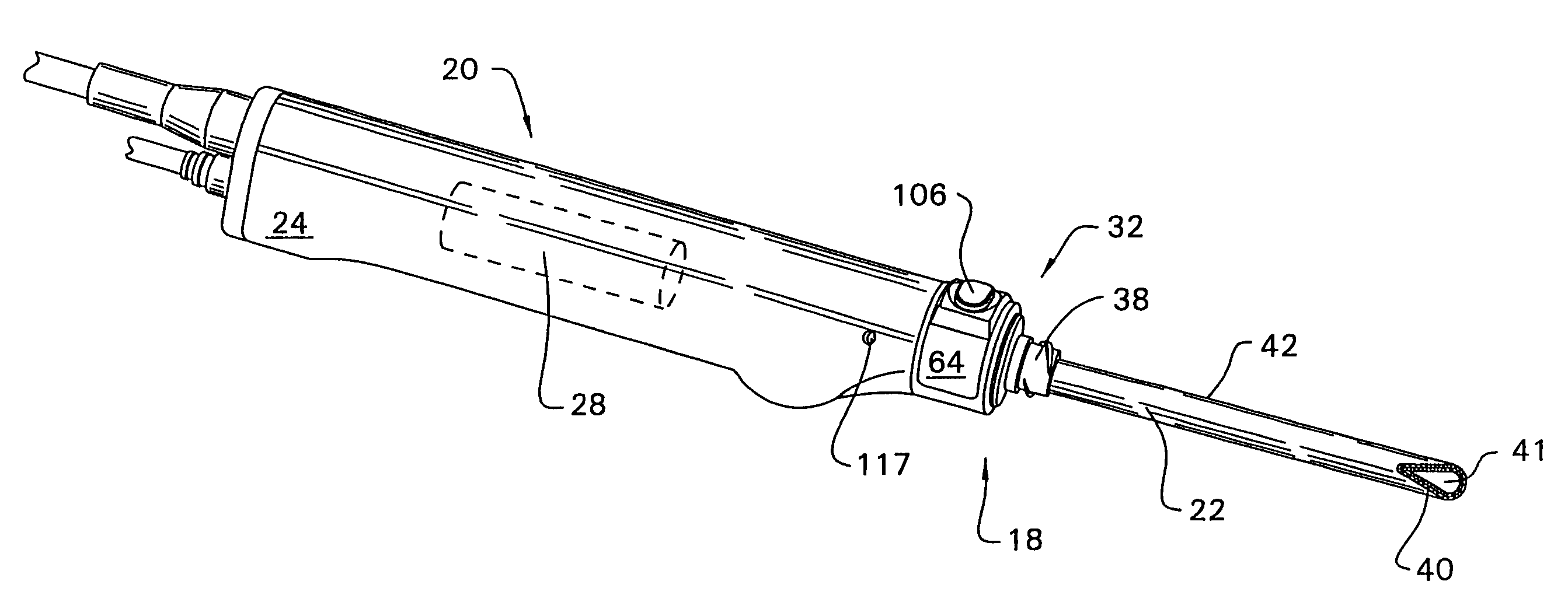

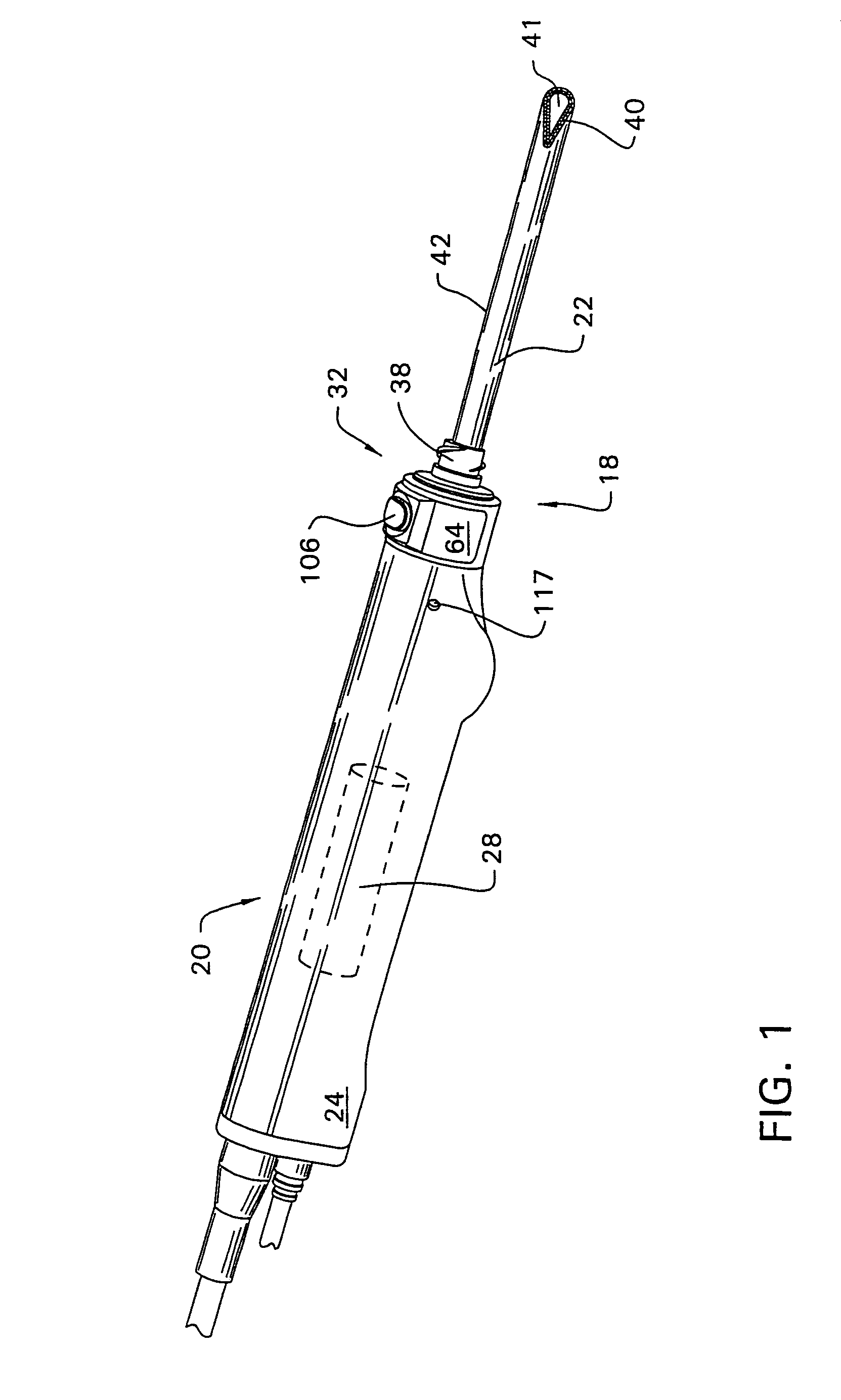

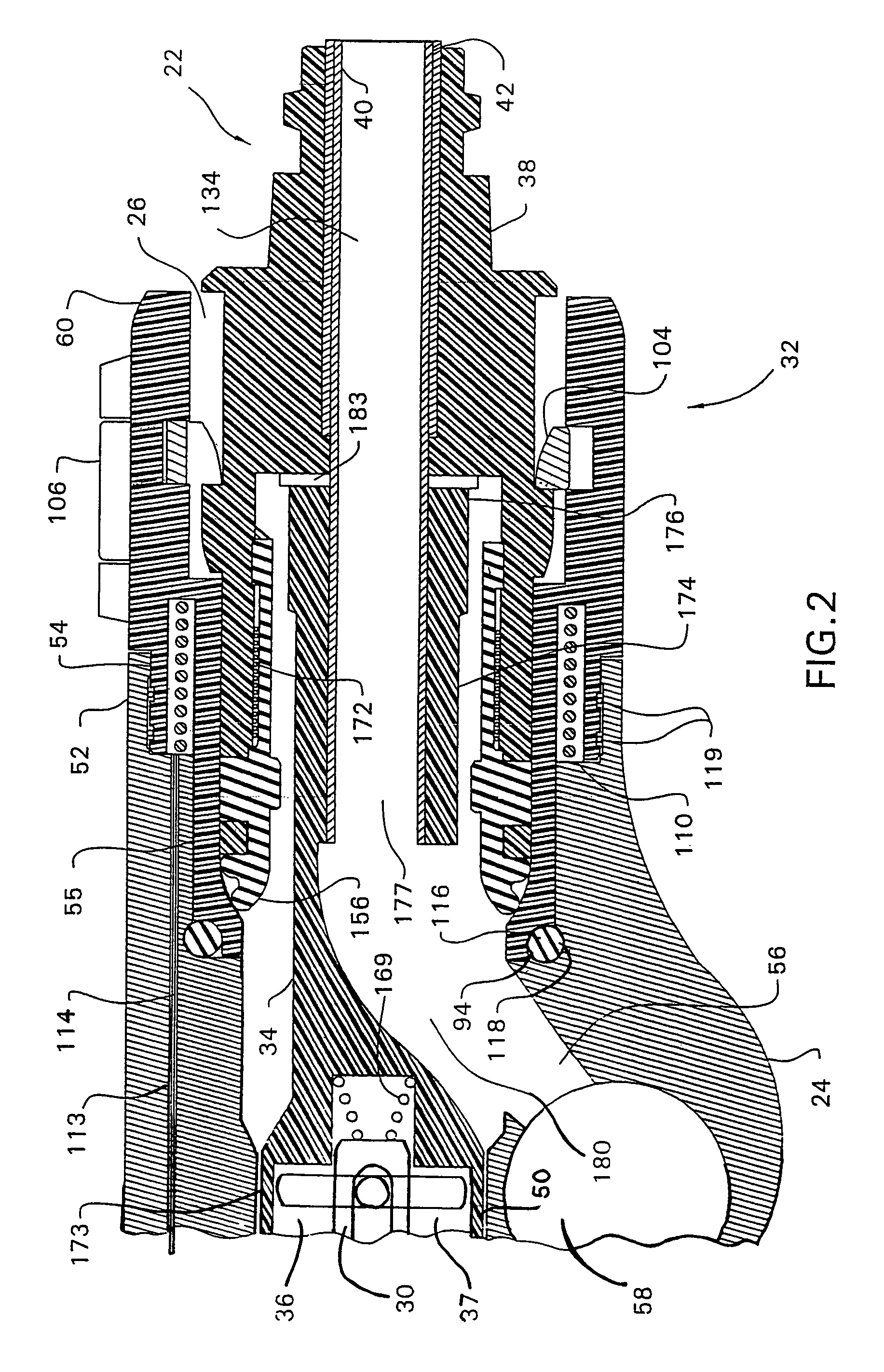

Surgical cutting accessory with encapsulated RFID chip

A cutting accessory for use with a powered surgical tool. The accessory includes a drive shaft to which an outer hub is attached. Internal to the outer hub is a self-contained transponder formed from an RFID chip and a coil of electrical conductor embedded within a solid substrate or encapsulated within a plastic enclosure. The transponder wirelessly communicates one or more pieces of information concerning the identity and operation of the accessory to the surgical tool when the accessory is attached to the surgical tool.

Owner:STRYKER CORP

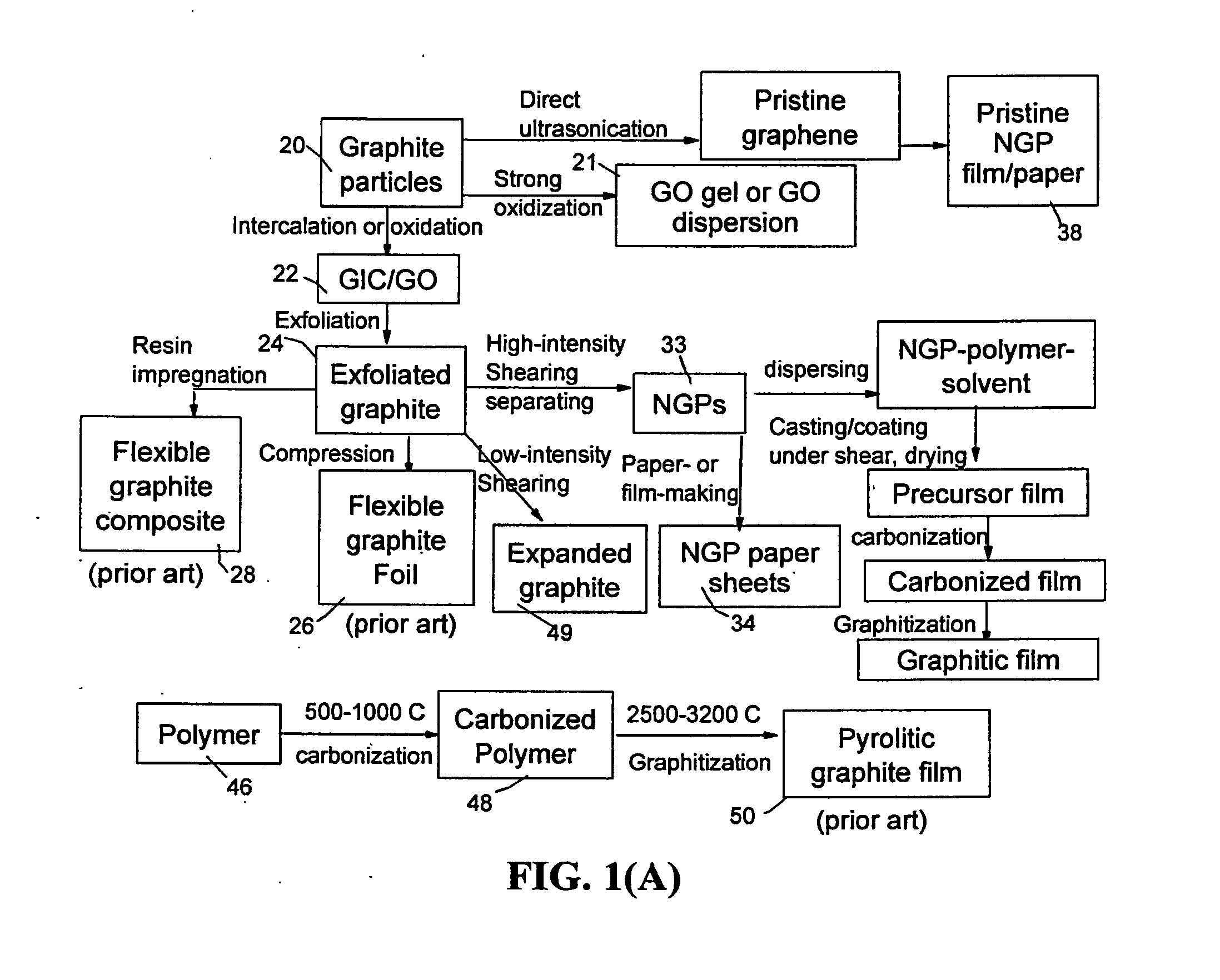

Production process for highly conductive graphitic films

ActiveUS20150266739A1Reduce thicknessImprove in-plane property of filmShielding materialsGraphiteComposite filmCarbonization

A process for producing a graphitic film comprising the steps of (a) mixing graphene platelets with a carbon precursor polymer and a liquid to form a slurry and forming the slurry into a wet film under the influence of an orientation-inducing stress field to align the graphene platelets on a solid substrate; (b) removing the liquid to form a precursor polymer composite film wherein the graphene platelets occupy a weight fraction of 1% to 99%; (c) carbonizing the precursor polymer composite film at a carbonization temperature of at least 300° C. to obtain a carbonized composite film; and (d) thermally treating the carbonized composite film at a final graphitization temperature higher than 1,500° C. to obtain the graphitic film. Preferably, the carbon precursor polymer is selected from the group consisting of polyimide, polyamide, polyoxadiazole, polybenzoxazole, polybenzobisoxazole, polythiazole, polybenzothiazole, polybenzobisthiazole, poly(p-phenylene vinylene), polybenzimidazole, polybenzobisimidazole, and combinations thereof.

Owner:GLOBAL GRAPHENE GRP INC

Porous, Dissolvable Solid Substrate and Surface Resident Coating Comprising Water Sensitive Actives

ActiveUS20110195098A1Conveniently and quickly dissolvedEfficient use ofCosmetic preparationsHair cosmeticsPersonal careSolid substrate

The present invention relates to personal care compositions, especially those personal care compositions in the form of a personal care article that is a porous dissolvable solid substrate. The porous dissolvable solid substrate has a surface resident coating comprising a water sensitive active that can deliver a consumer benefit.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com