Patents

Literature

2427 results about "Thin metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

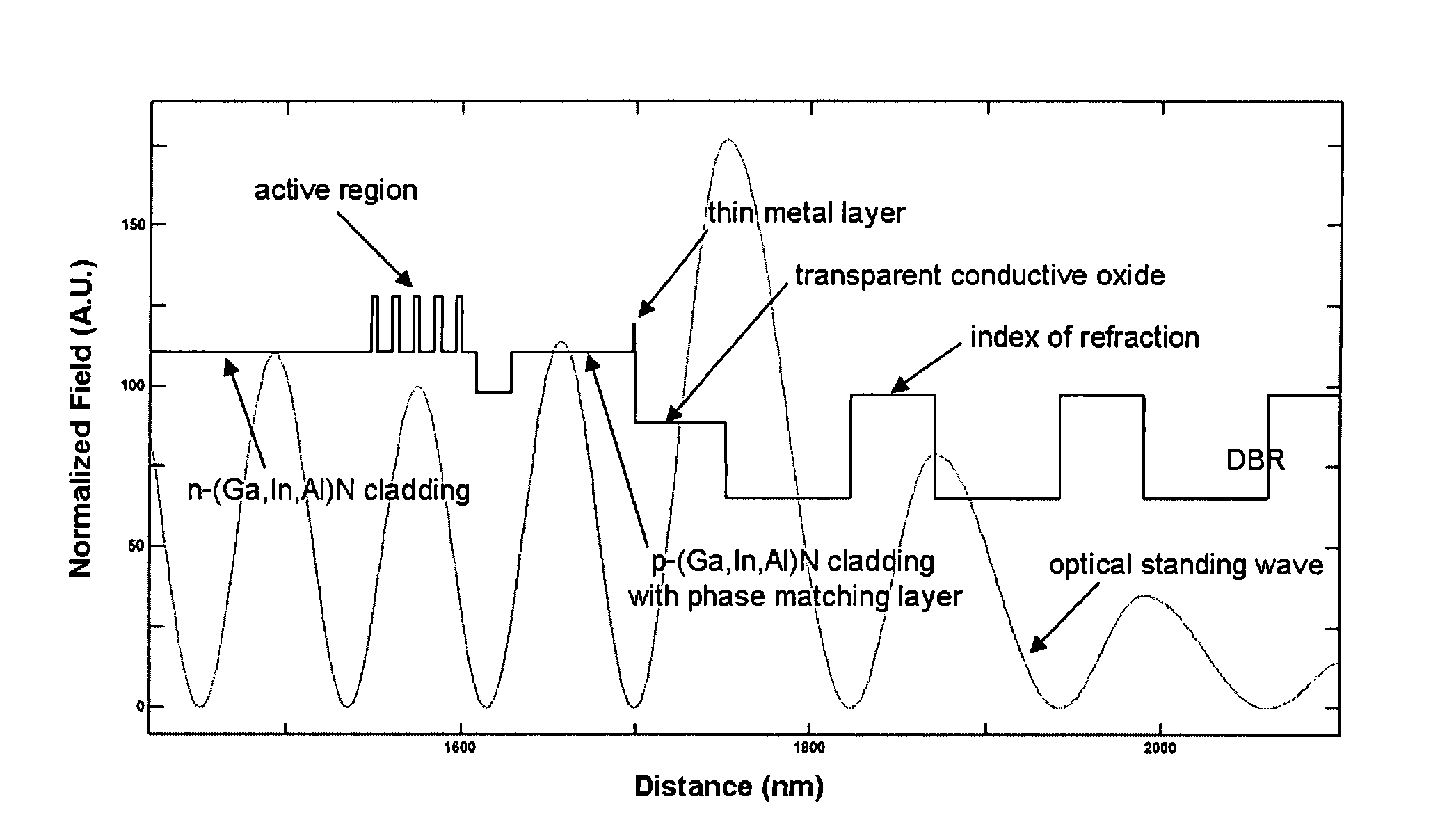

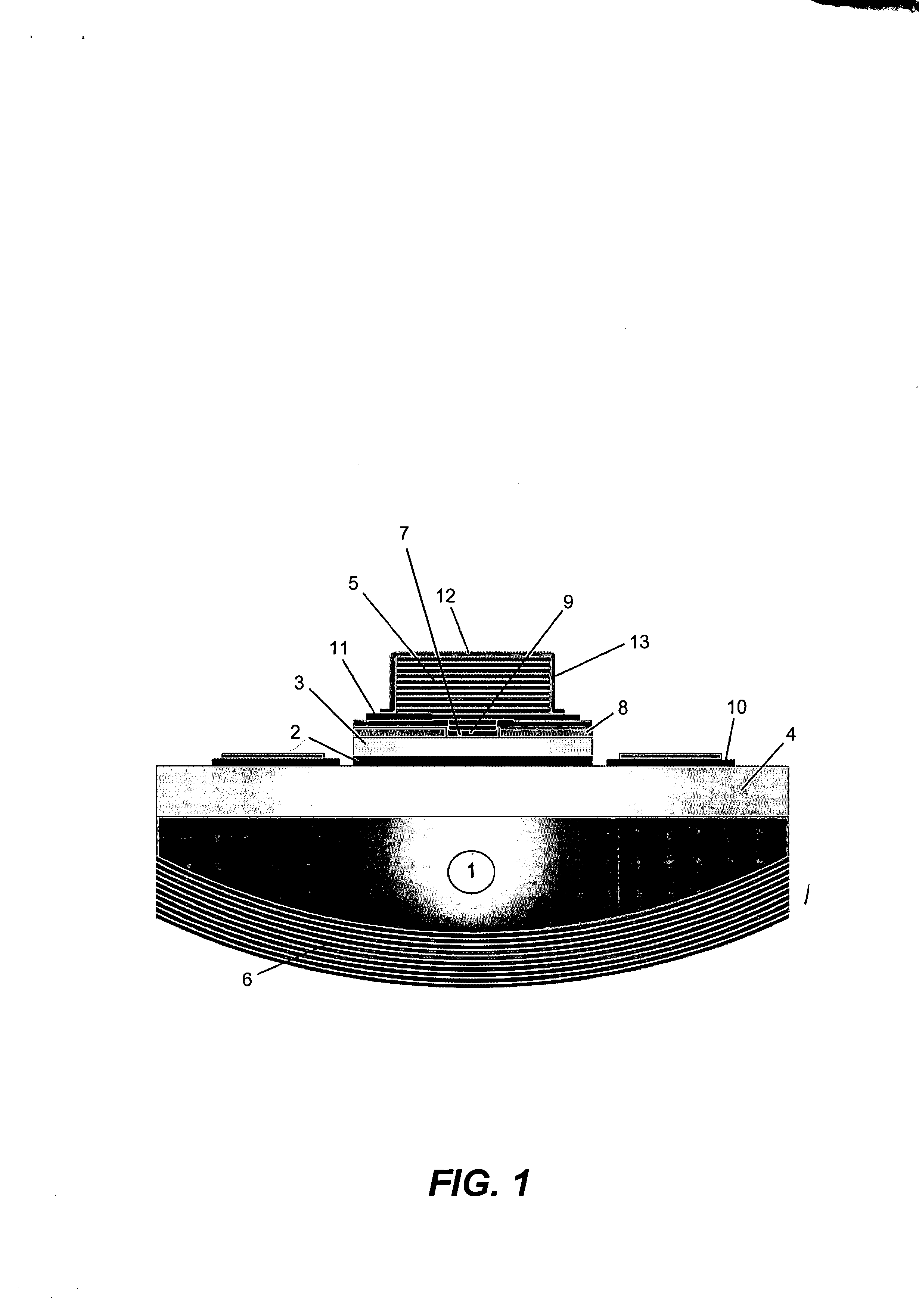

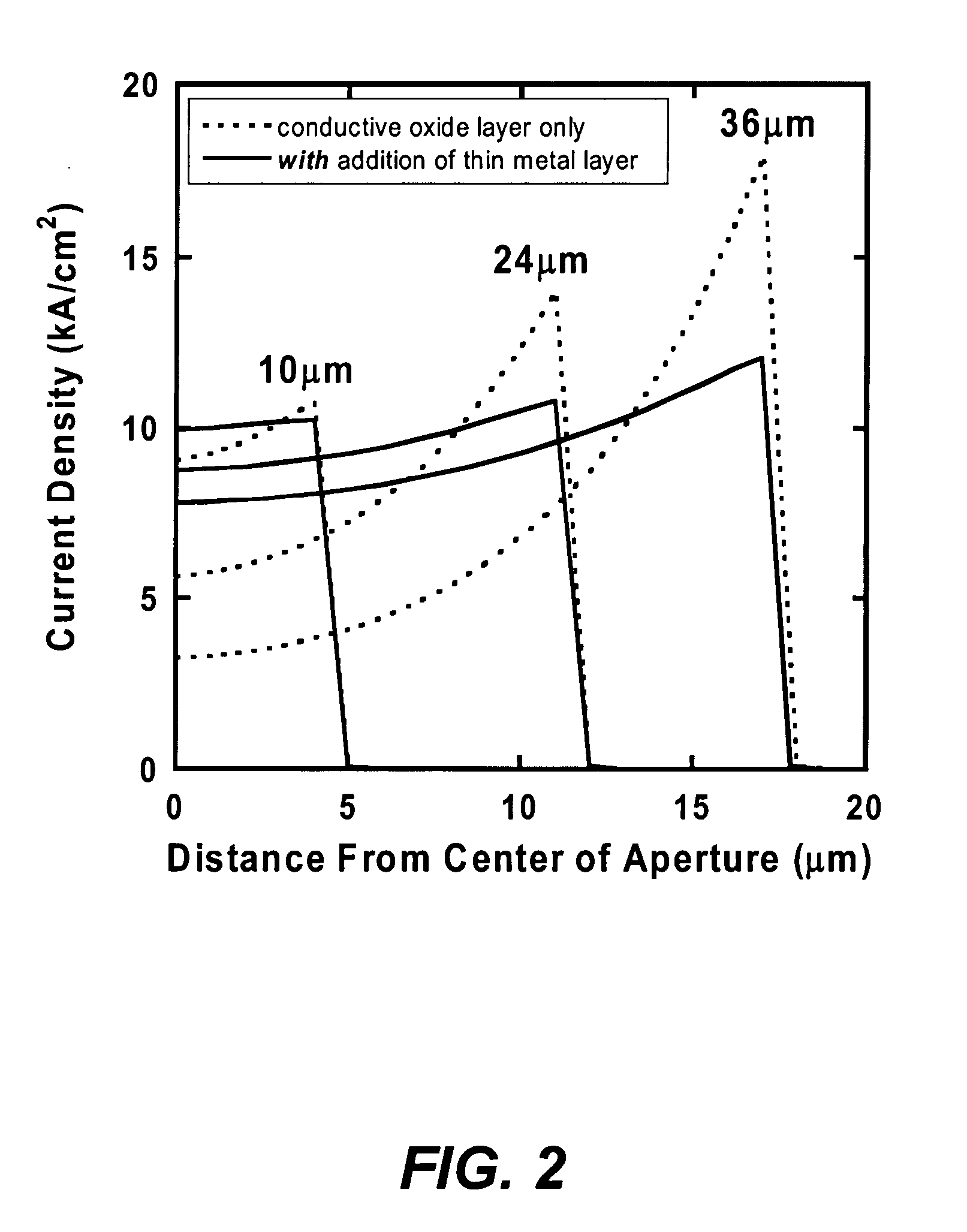

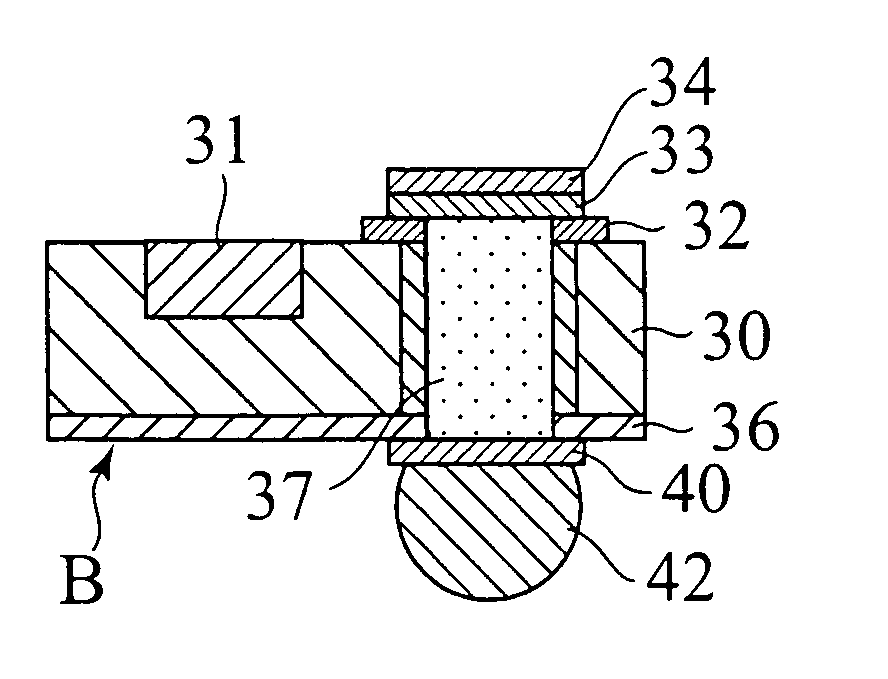

Electrically-pumped (Ga,In,Al)N vertical-cavity surface-emitting laser

InactiveUS20070280320A1Good ohmic contactOptical resonator shape and constructionSemiconductor lasersThin metalVertical-cavity surface-emitting laser

A vertical-cavity surface-emitting laser (VCSEL) comprising a low-loss thin metal contact and current spreading layer within the optical cavity that provides for improved ohmic contact and lateral current distribution, a substrate including a plano-concave optical cavity, a (Ga,In,Al)N multiple quantum well (MQW) active region contained within the optical cavity that generates light when injected by an electrical current, and an integrated micromirror fabricated onto the substrate that provides for optical mode control of the light generated by the active region. A relatively simple process is used to fabricate the VCSEL.

Owner:RGT UNIV OF CALIFORNIA

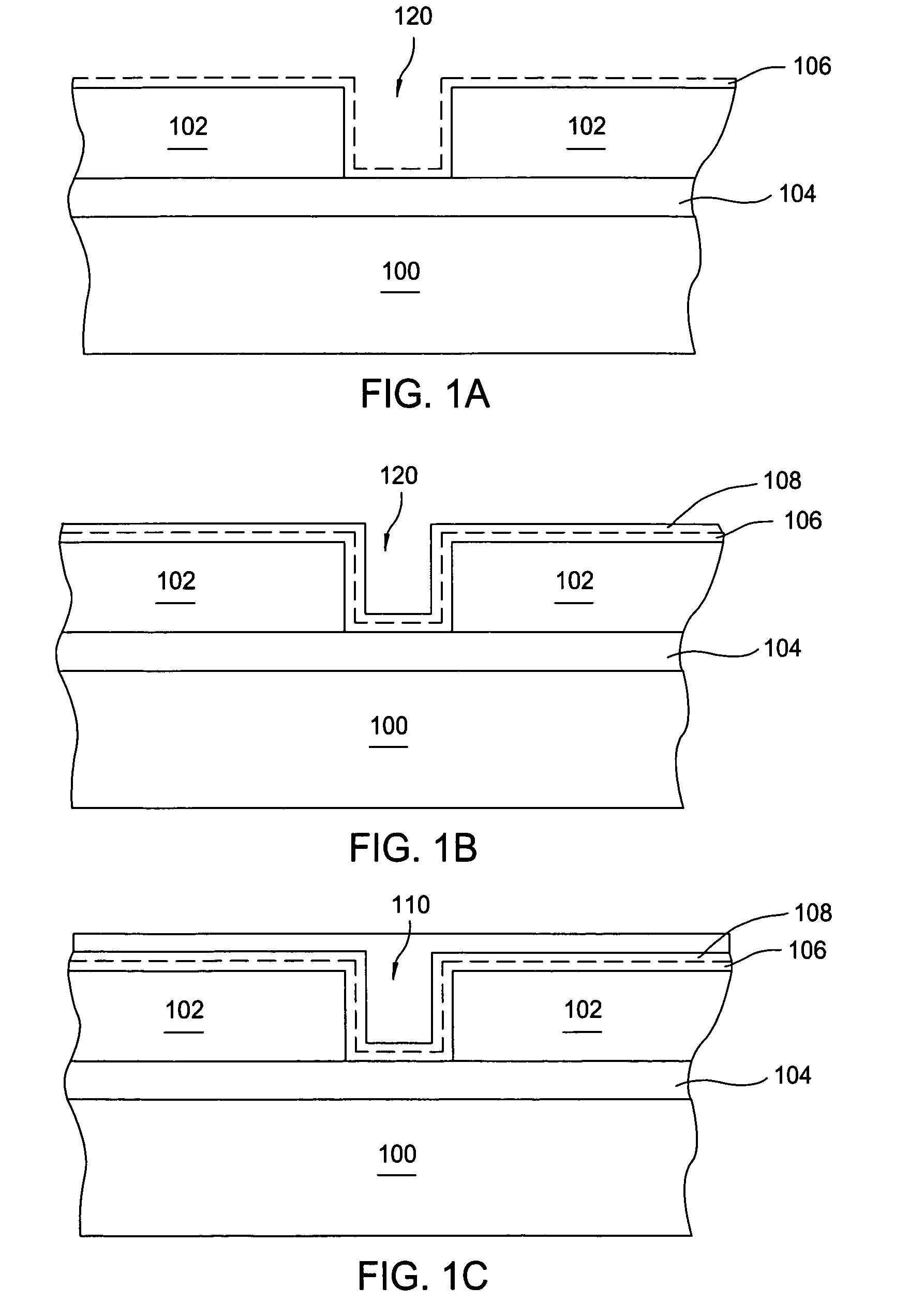

Apparatus and method for electrolytically depositing copper on a semiconductor workpiece

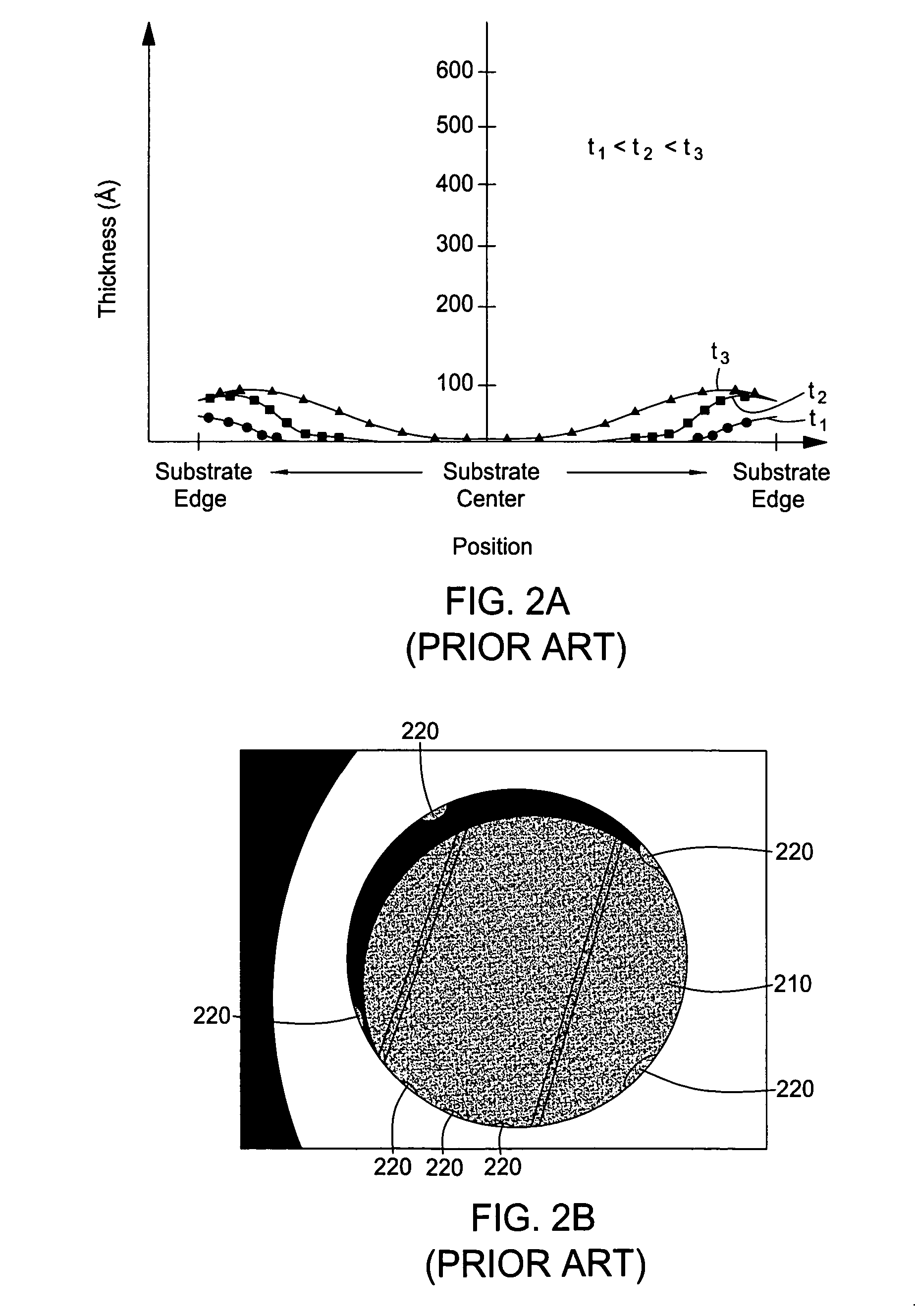

A process for applying a metallization interconnect as to a semiconductor workpiece having a barrier layer deposited on a surface thereof is set forth. The process includes the forming of an ultra-thin metal seed layer on the barrier layer. The ultra-thin seed layer having a thickness of less than or equal to about 500 Angstroms. The ultra-thin seed layer is then enhanced by depositing additional metal thereon to provide an enhanced sed layer. The enhanced seed layer has a thickness at all points on sidewalls of substantially all recessed features distributed within the workpiece that is equal to or greater than about 10% of the nominal seed layer thickness over an exteriorly disposed surface of the workpiece.

Owner:SEMITOOL INC

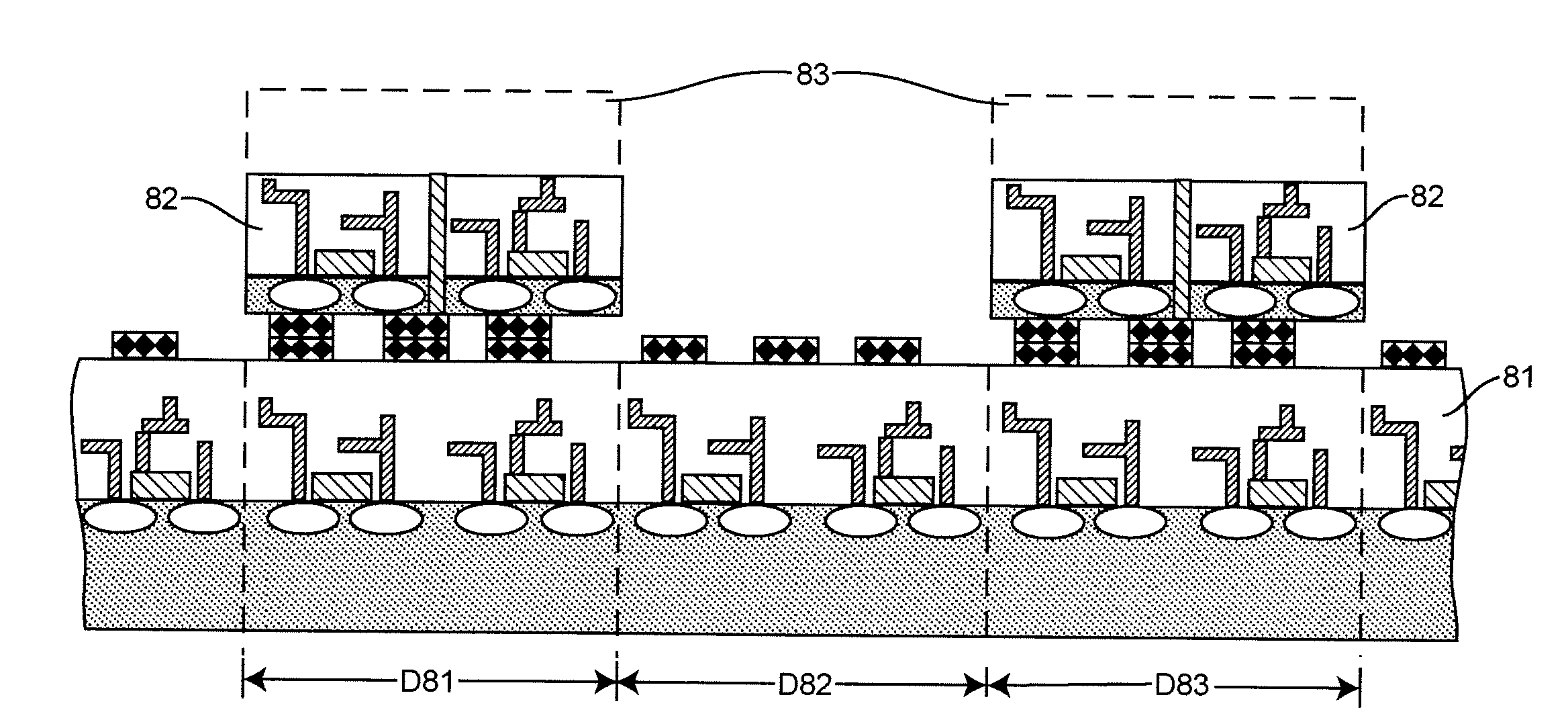

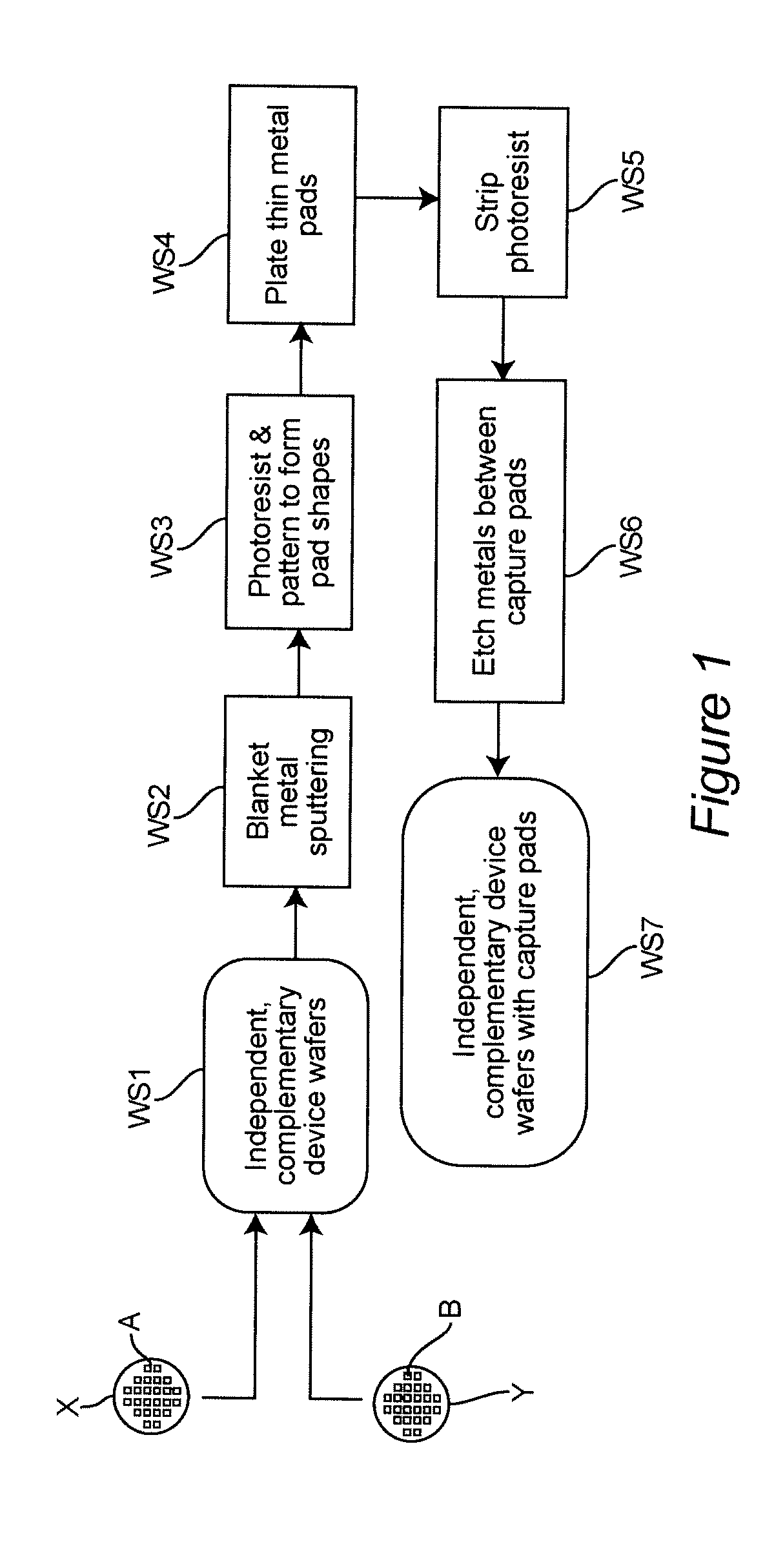

Method and Structure for Optimizing Yield of 3-D Chip Manufacture

ActiveUS20080142959A1Maximize frequencyLow costSemiconductor/solid-state device detailsSolid-state devicesThin metalEtching

The process begins with separate device wafers having complimentary chips. Thin metal capture pads, having a preferred thickness of about 10 microns so that substantial pressure may be applied during processing without damaging capture pads, are deposited on both device wafers, which are then tested and mapped for good chip sites. A handle wafer is attached to one device wafer, which can then be thinned to improve via etching and filling. Capture pads are removed and replaced after thinning. The device wafer with handle wafer is diced, and good chips with attached portions of the diced handle wafer are positioned and bonded to the good chip sites of the other device wafer, and the handle wafer portions are removed. The device wafer having known good 3-D chips then undergoes final processing.

Owner:INT BUSINESS MASCH CORP

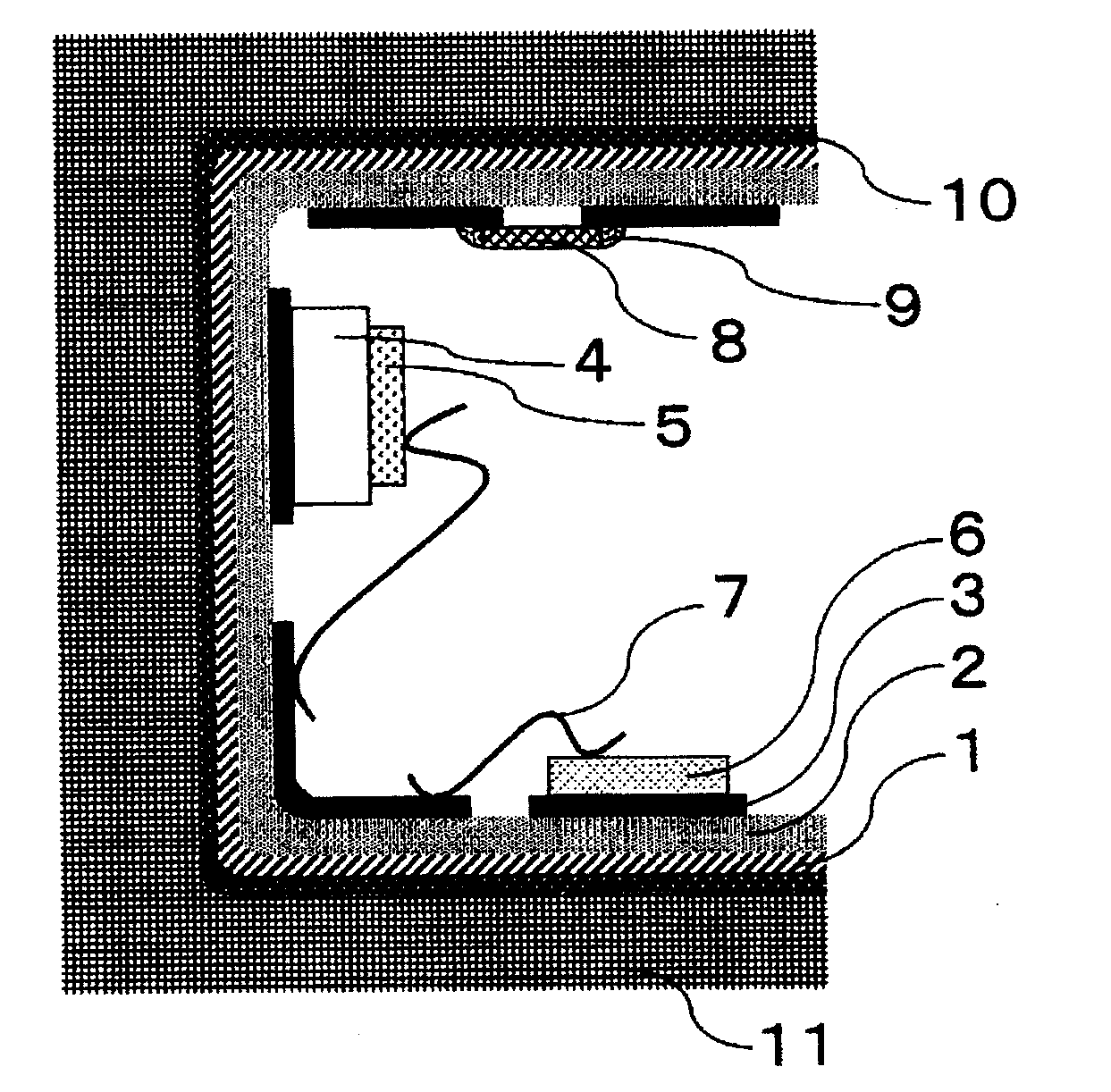

Organic EL device

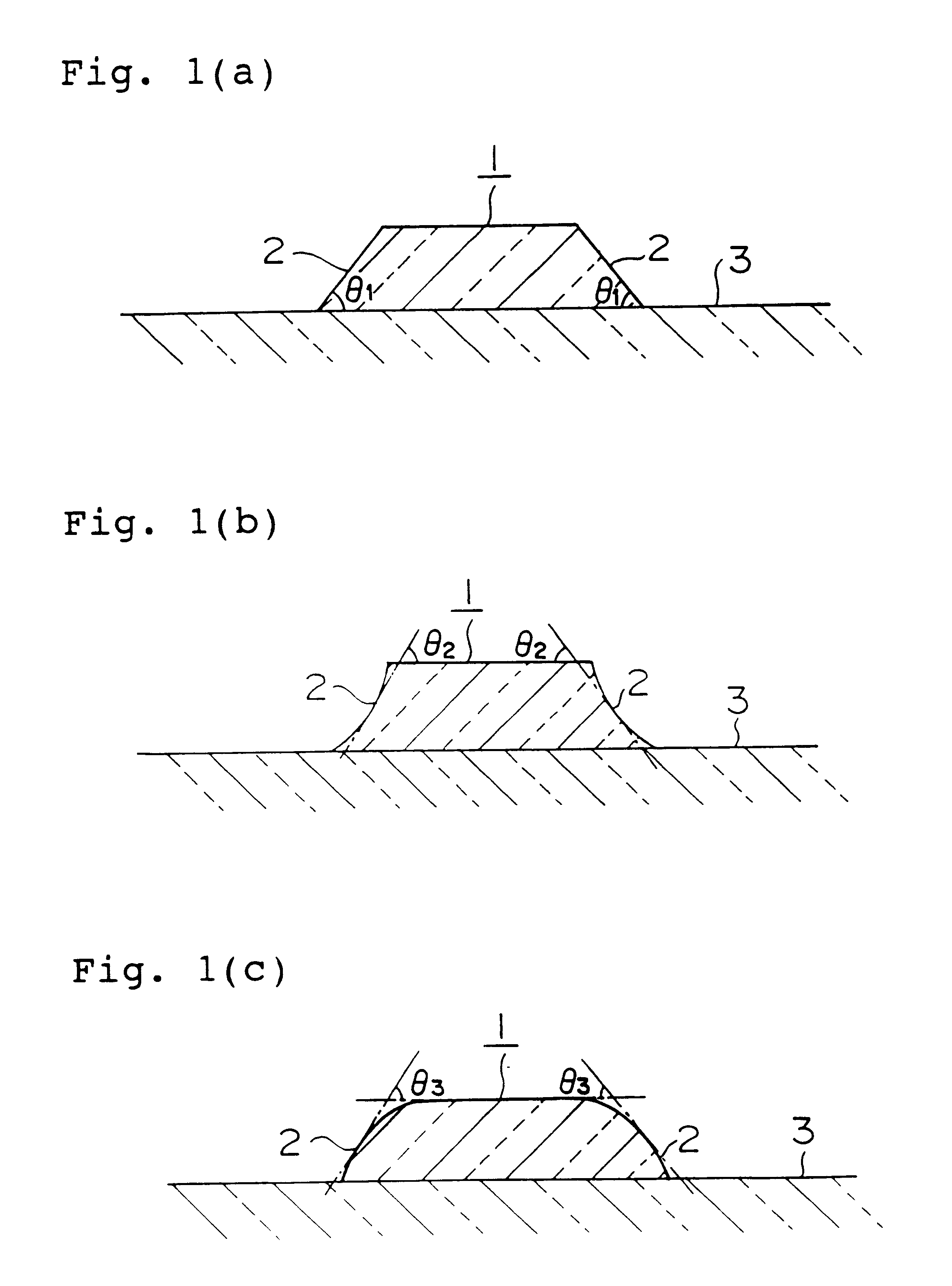

InactiveUS6280861B1Reduce displayEasy to produceDischarge tube luminescnet screensElectroluminescent light sourcesThin metalMono layer

An amorphous electrically conductive oxide such as In-Zn-O-containing amorphous oxide or amorphous ITO is used alone, or a laminate having a two- or three-layer structure constituted of the amorphous electrically conductive oxide and at least a thin metal layer is used, to form a transparent electrode whose side surface has a tapered form and whose top layer is formed of a layer of the above amorphous electrically conductive oxide, an organic single-layer portion or an organic multi-layer portion containing at least an organic light-emitting material is formed on the above transparent electrode, and further, an opposing electrode is formed on the above organic single-layer portion or the above organic multi-layer portion, whereby an organic EL device is obtained. A flattening layer is optionally provided so as to abut on the side surface of the transparent electrode for moderating a height-level difference between the above transparent electrode and the surface of the above substrate. Further, the above organic EL device is used to form an organic EL display panel.

Owner:IDEMITSU KOSAN CO LTD

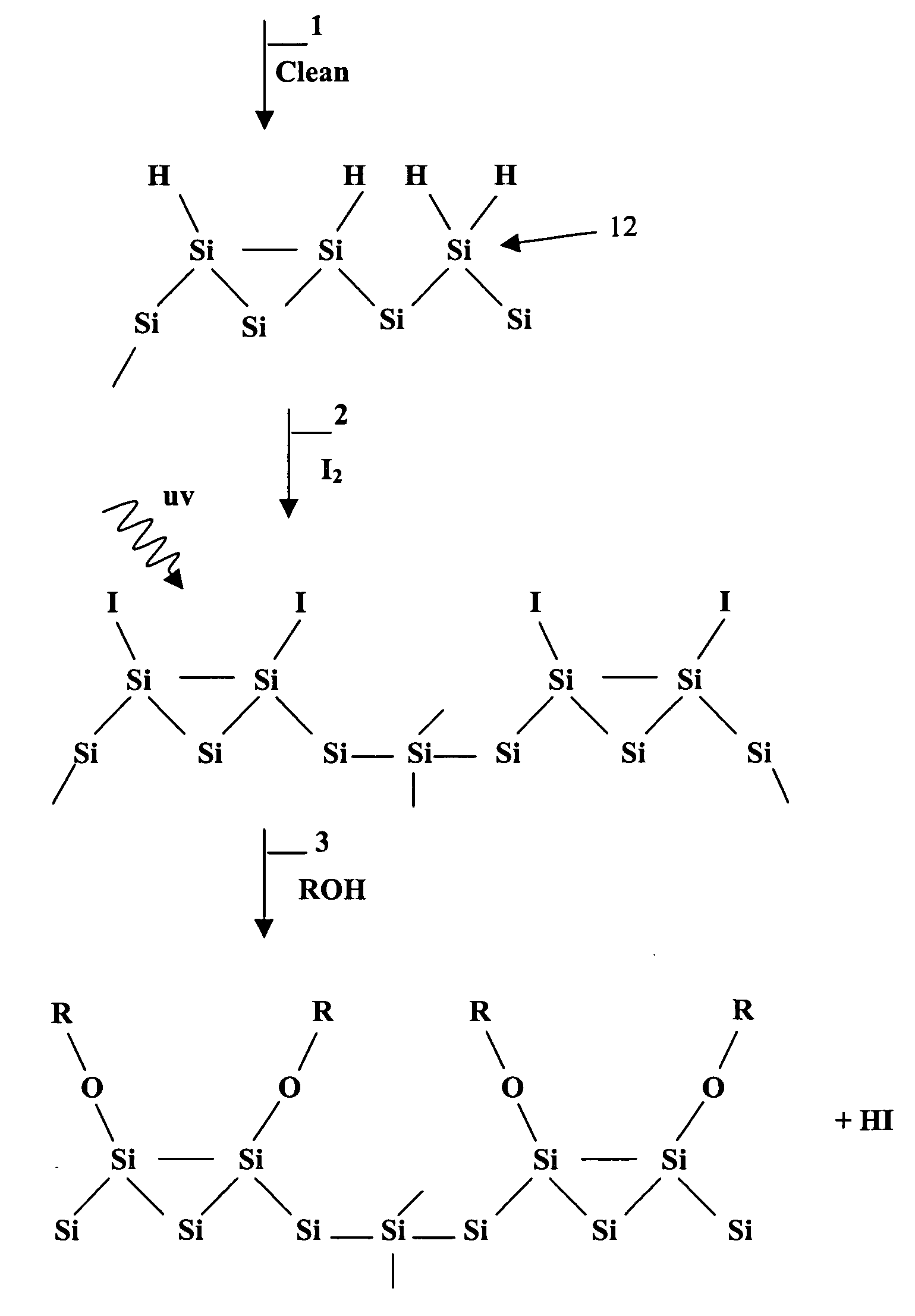

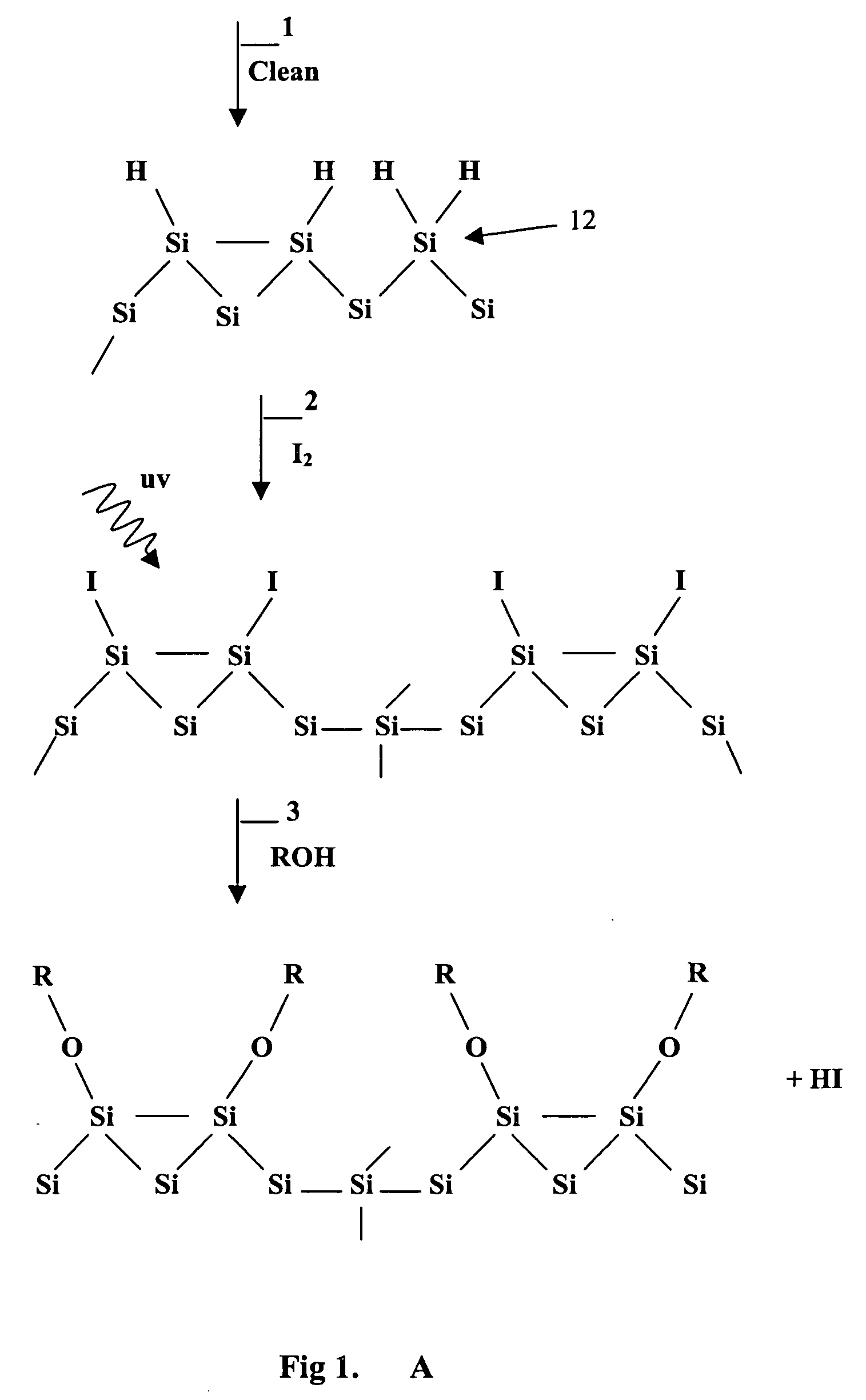

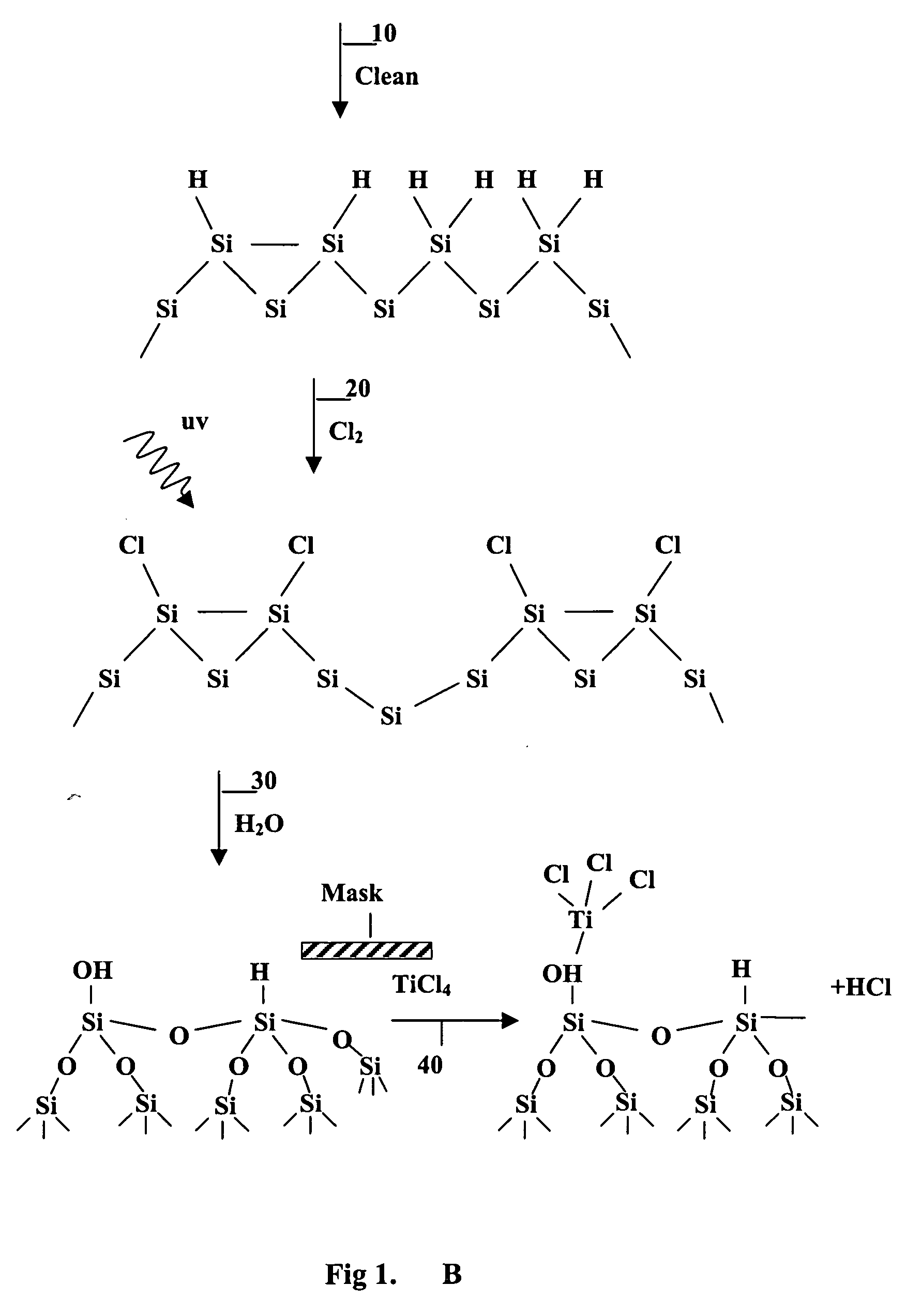

Surface manipulation and selective deposition processes using adsorbed halogen atoms

InactiveUS20060199399A1Saving process stepReduce environmental impactSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectrical conductorGas phase

The present invention provides a surface preparation process using adsorbed halogen. The halogen is applied in a gas phase with UV light. The adsorbed halogen is subsequently modified in another gas phase reaction. The halogen may be reacted with water to form a hydroxyl-bearing Si—O monolayer that forms a layer for subsequent metal deposition. In one aspect the halogen layer is reacted with an alkyl or alkoxy of the formula R-OH to form a passivation layer. By replacing hydrogen atom termination with alkoxy (e.g.methoxy termination, —OCH3). The selective deposition process can be used for passivating and depositing thin metal films on material surfaces composed of any combination of the group consisting of semiconductors, conductors, insulators, and the like.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

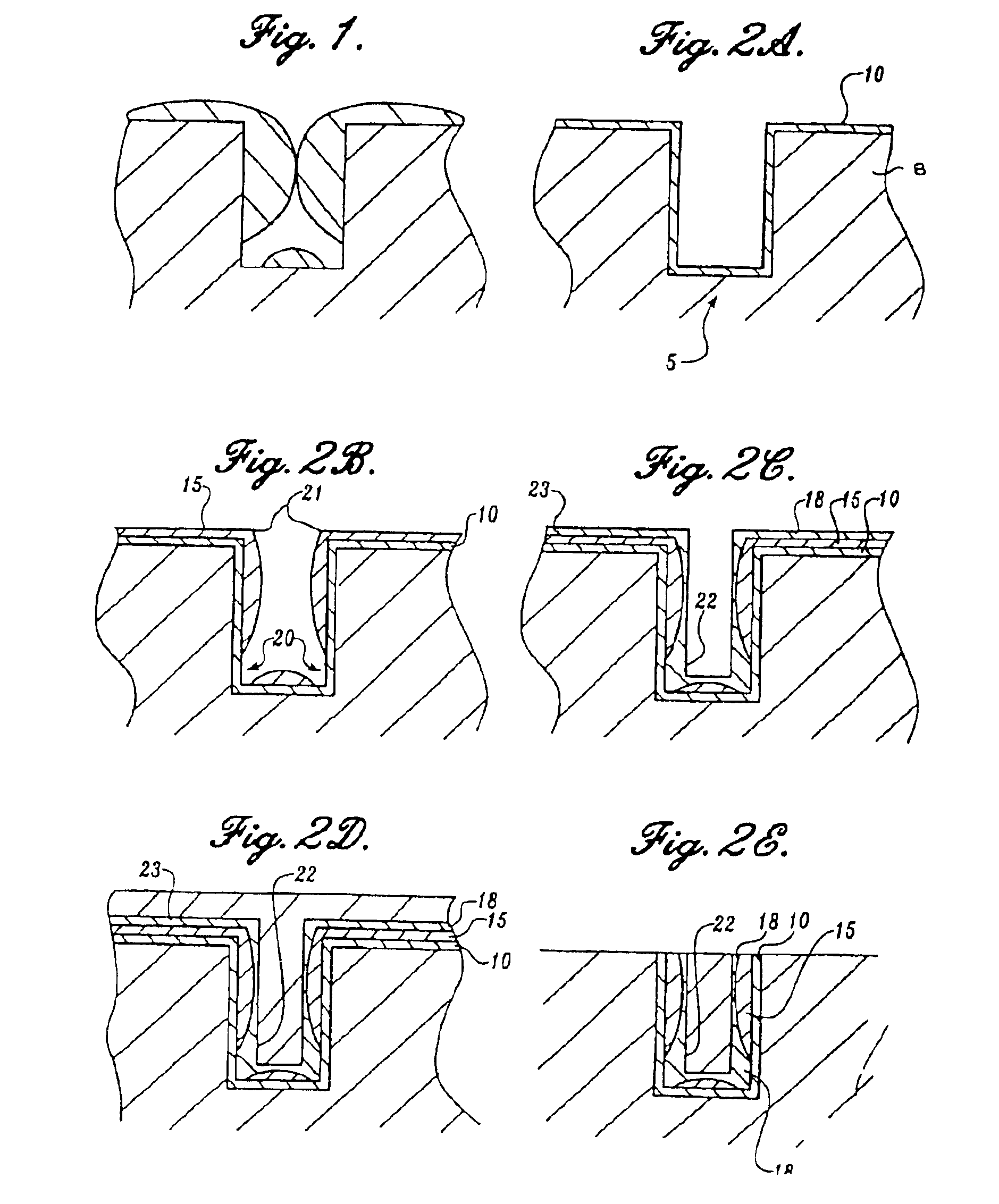

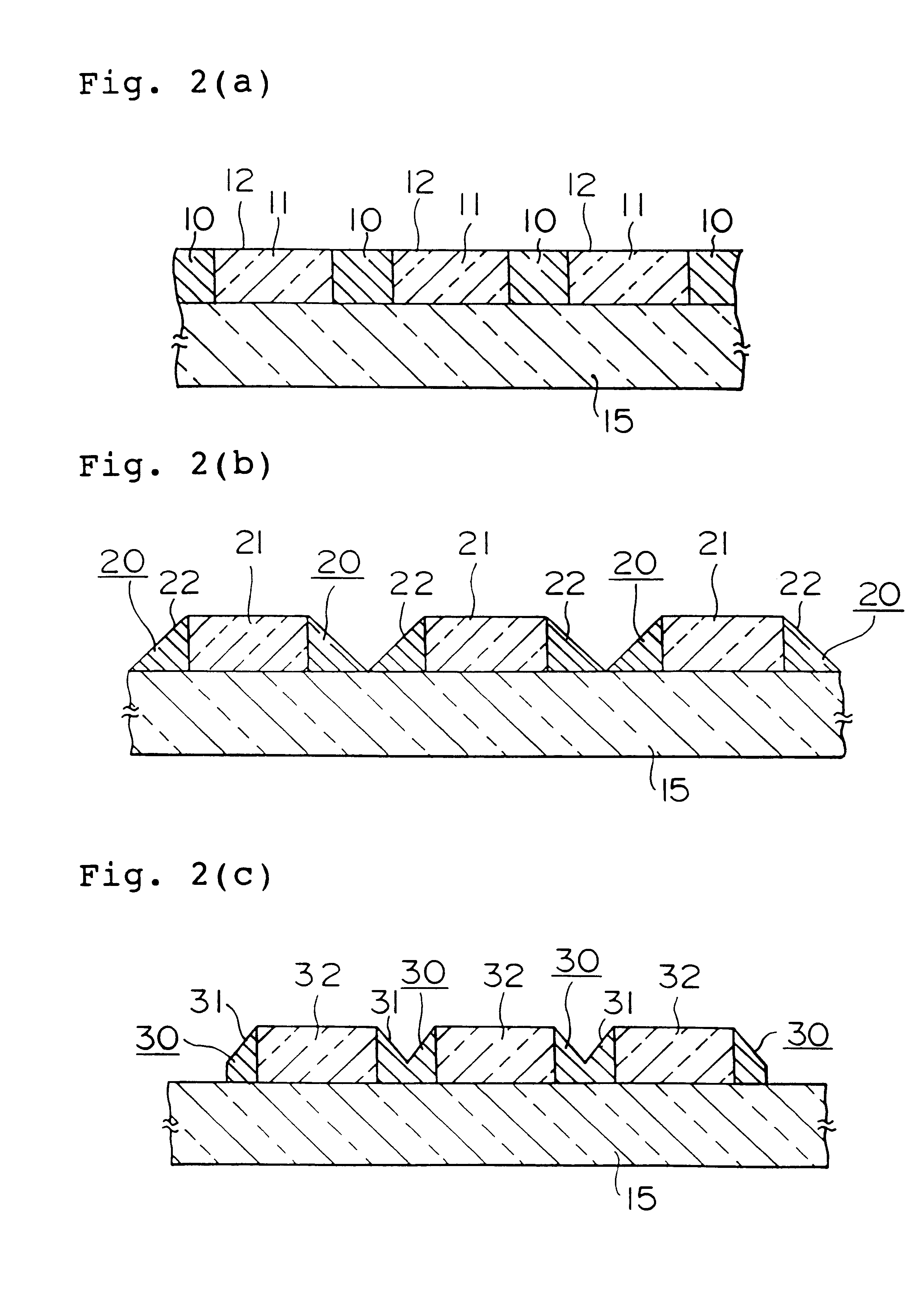

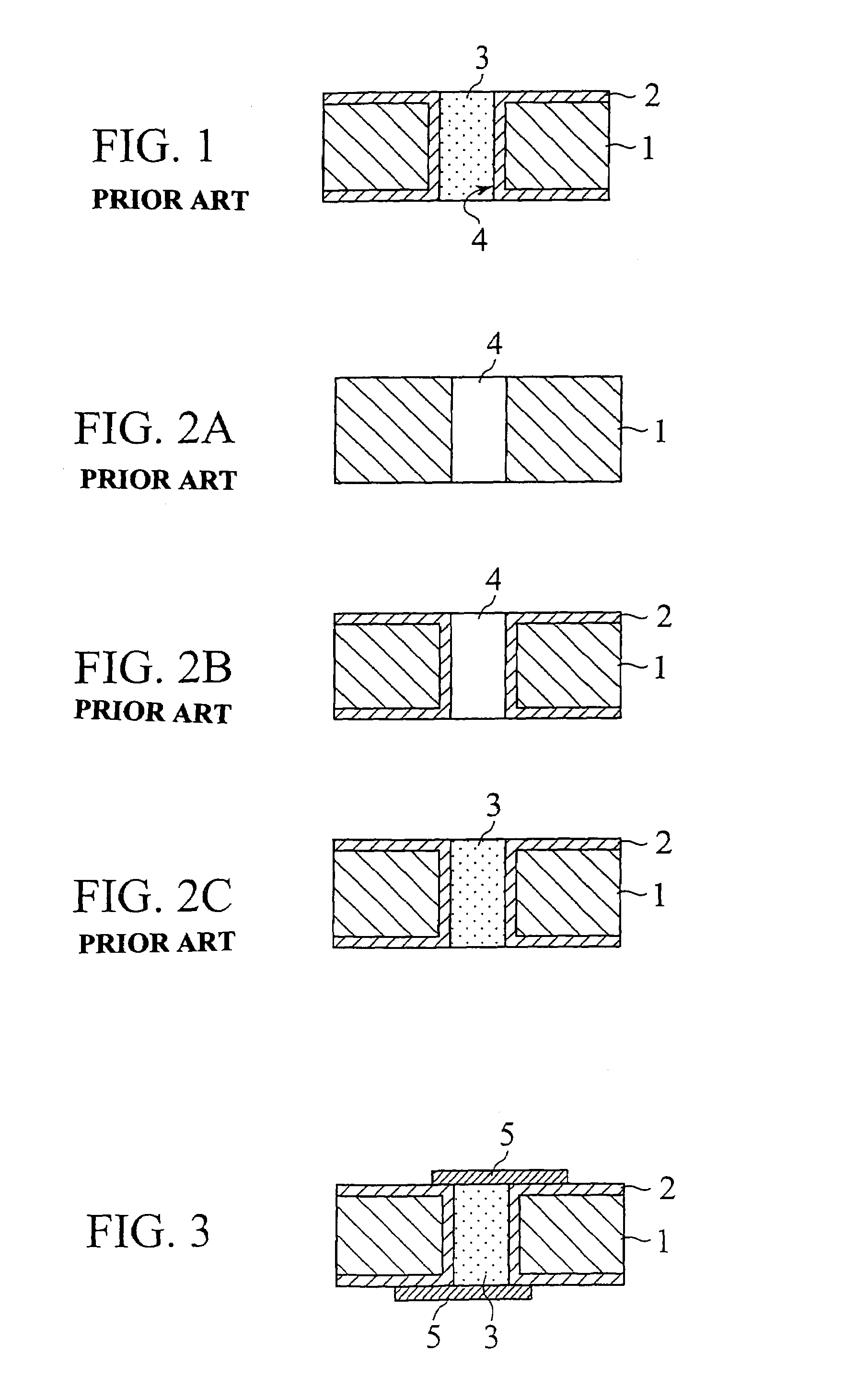

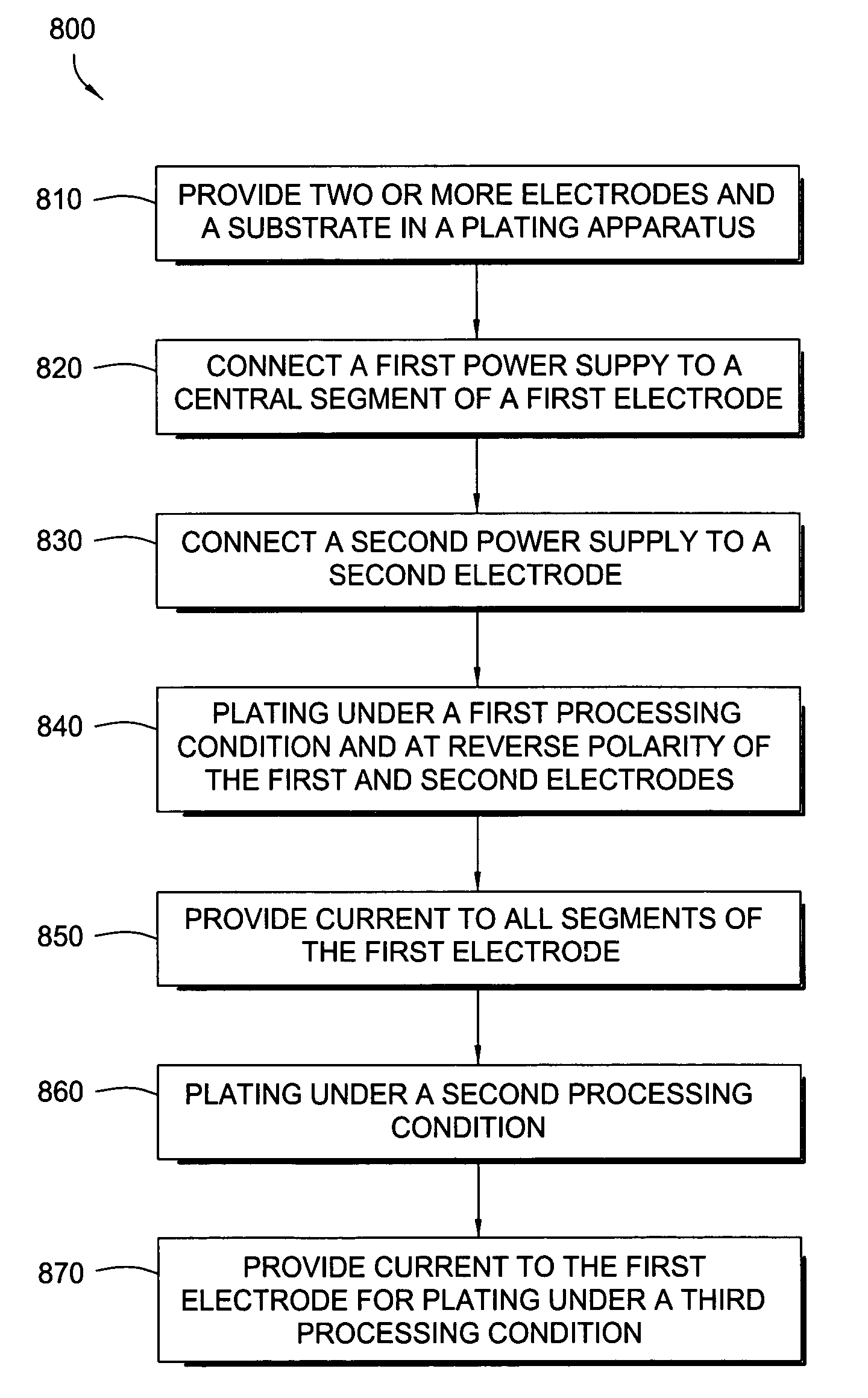

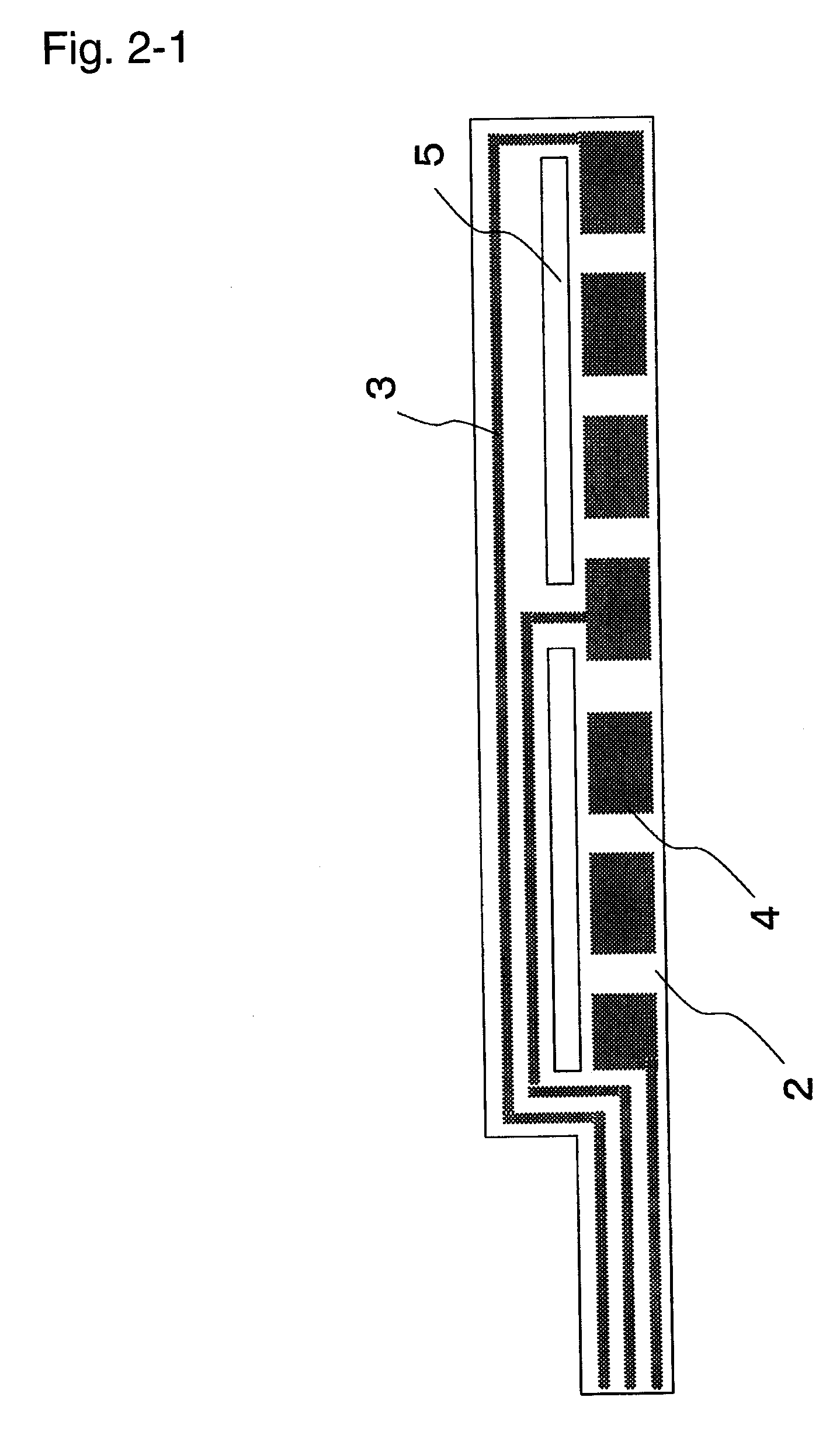

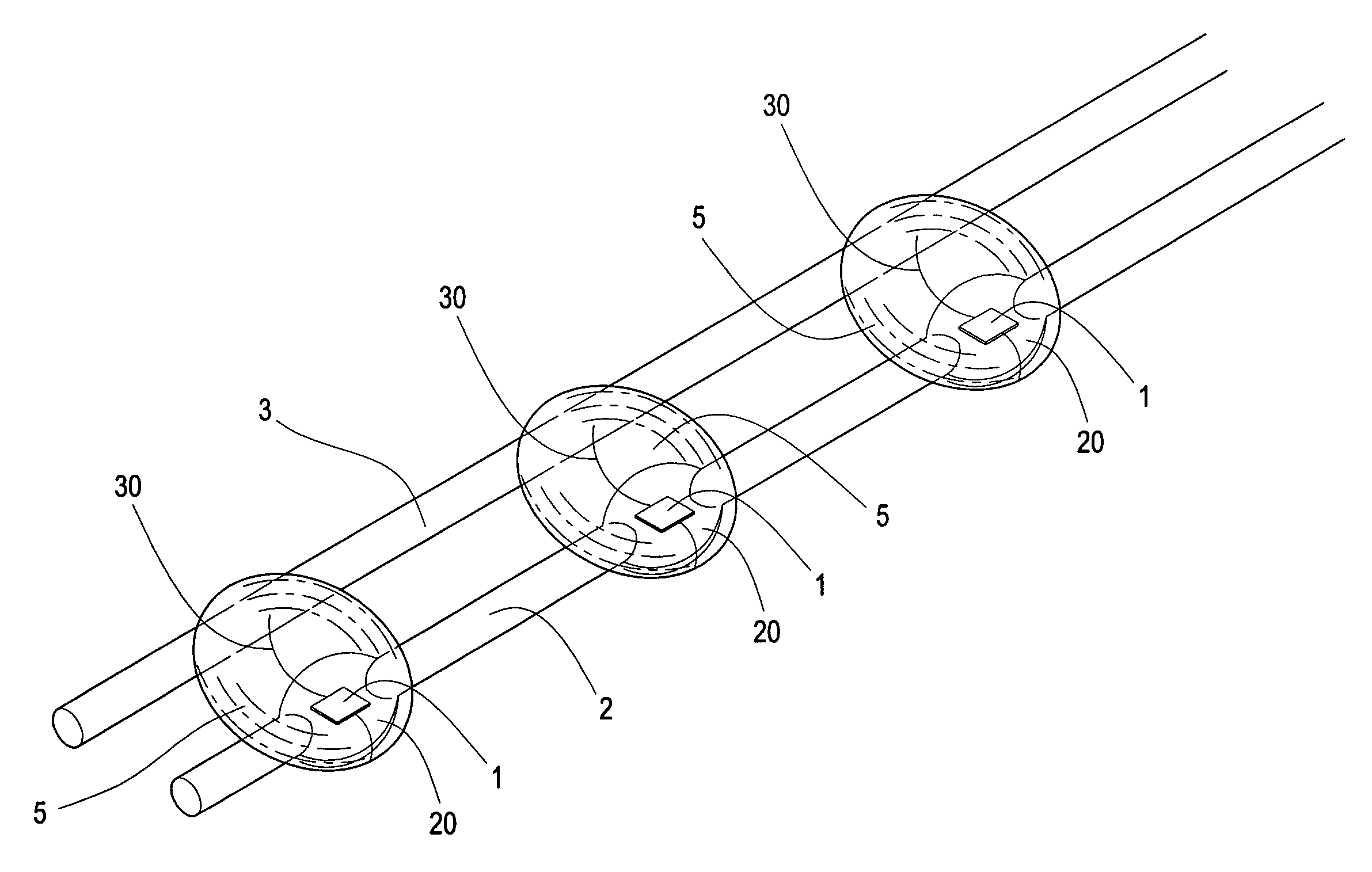

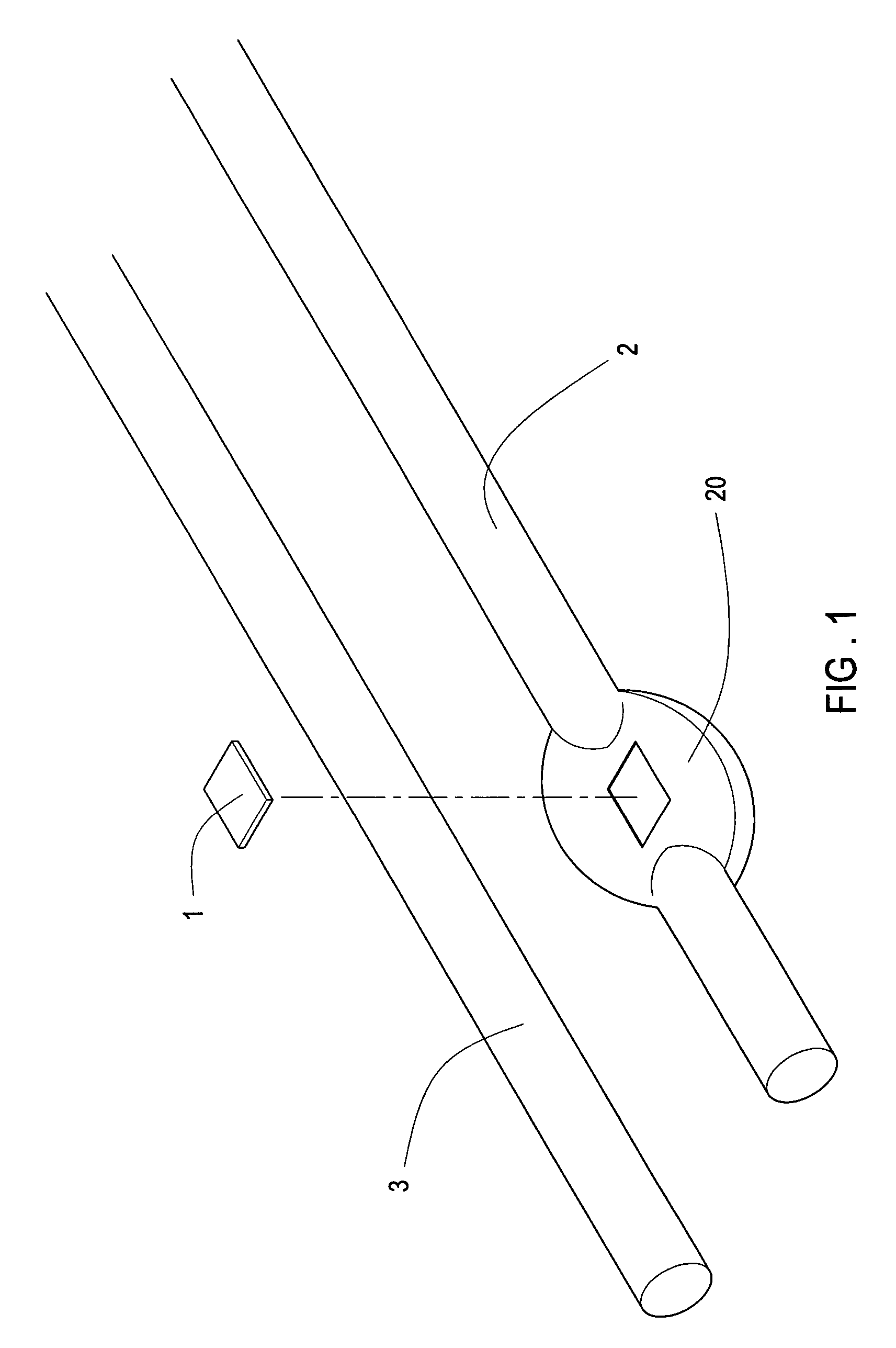

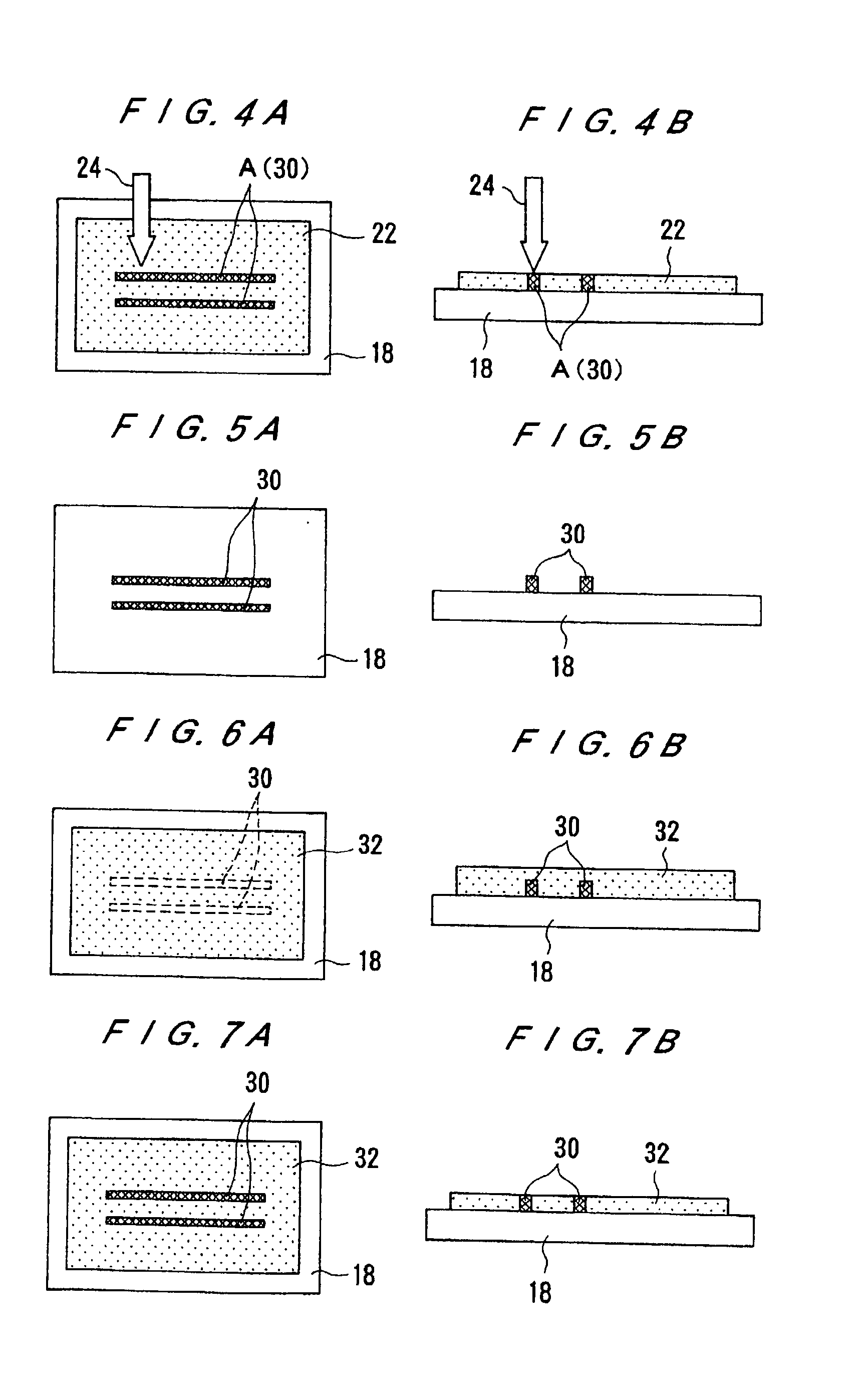

Manufacturing method of a semiconductor substrate provided with a through hole electrode

ActiveUS7022609B2Semiconductor/solid-state device detailsSolid-state devicesThin metalConductive materials

A manufacturing method of a semiconductor substrate provided with a through hole electrode is proposed. In accordance with the methods, it is possible to effectively form a through hole electrode in a semiconductor substrate in which a device and a wiring pattern have been already fabricated. This manufacturing method includes the steps of forming a first silicon oxide film 12 on a principal surface of the semiconductor substrate 11, forming a small hole 13 through the semiconductor substrate 11 from the opposite the step to reach to the first silicon oxide film 12, covering the inside of the small hole 13 with the second silicon oxide film 14, forming a first thin metal film 15 and a second thin metal film 16 on the first silicon oxide film 12, partially removing the first silicon oxide film 12 corresponding to the end of the small hole 13, and filling the small hole 13 with the conductive material to form a through hole electrode 17.

Owner:FUJIKURA LTD +1

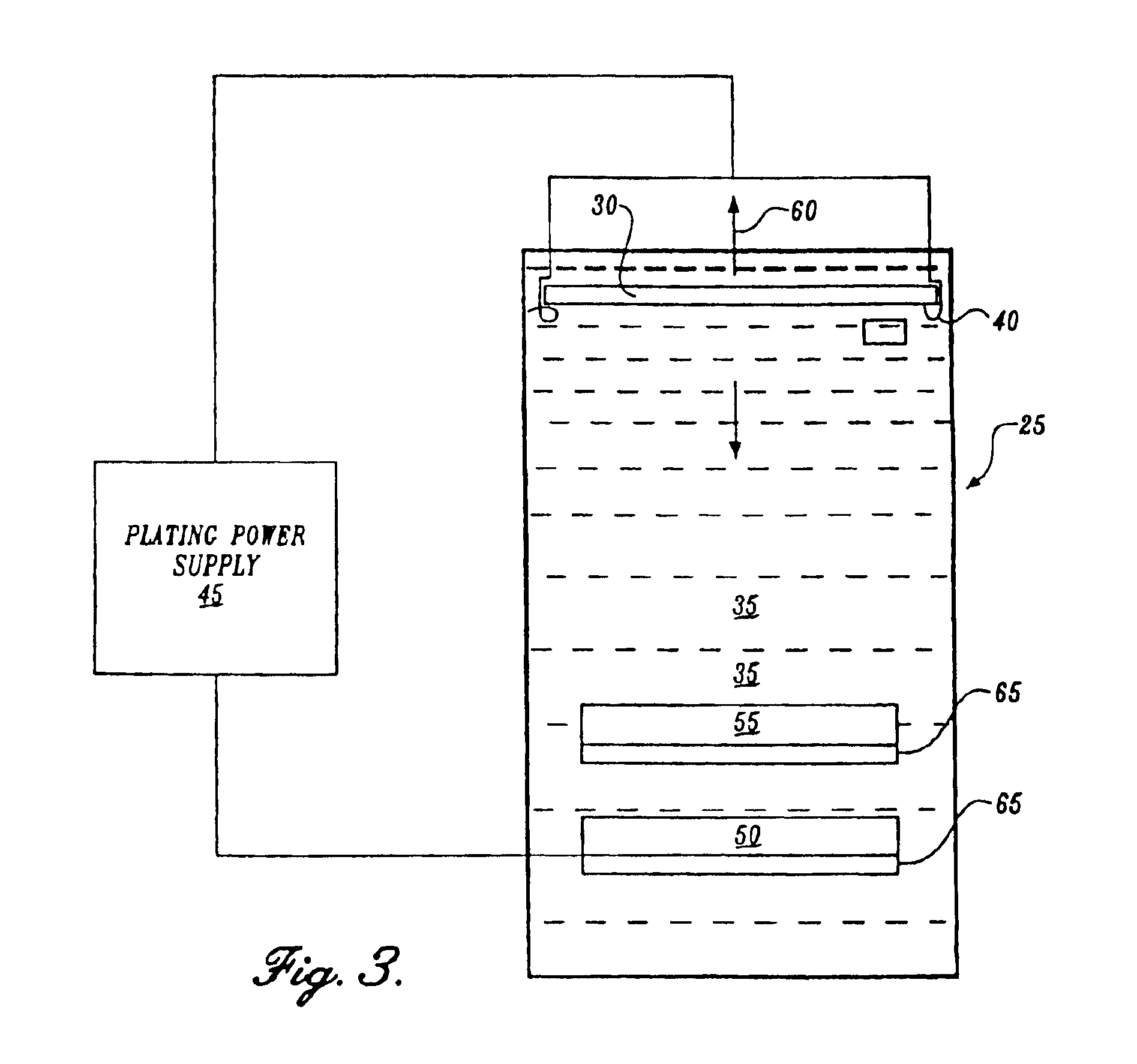

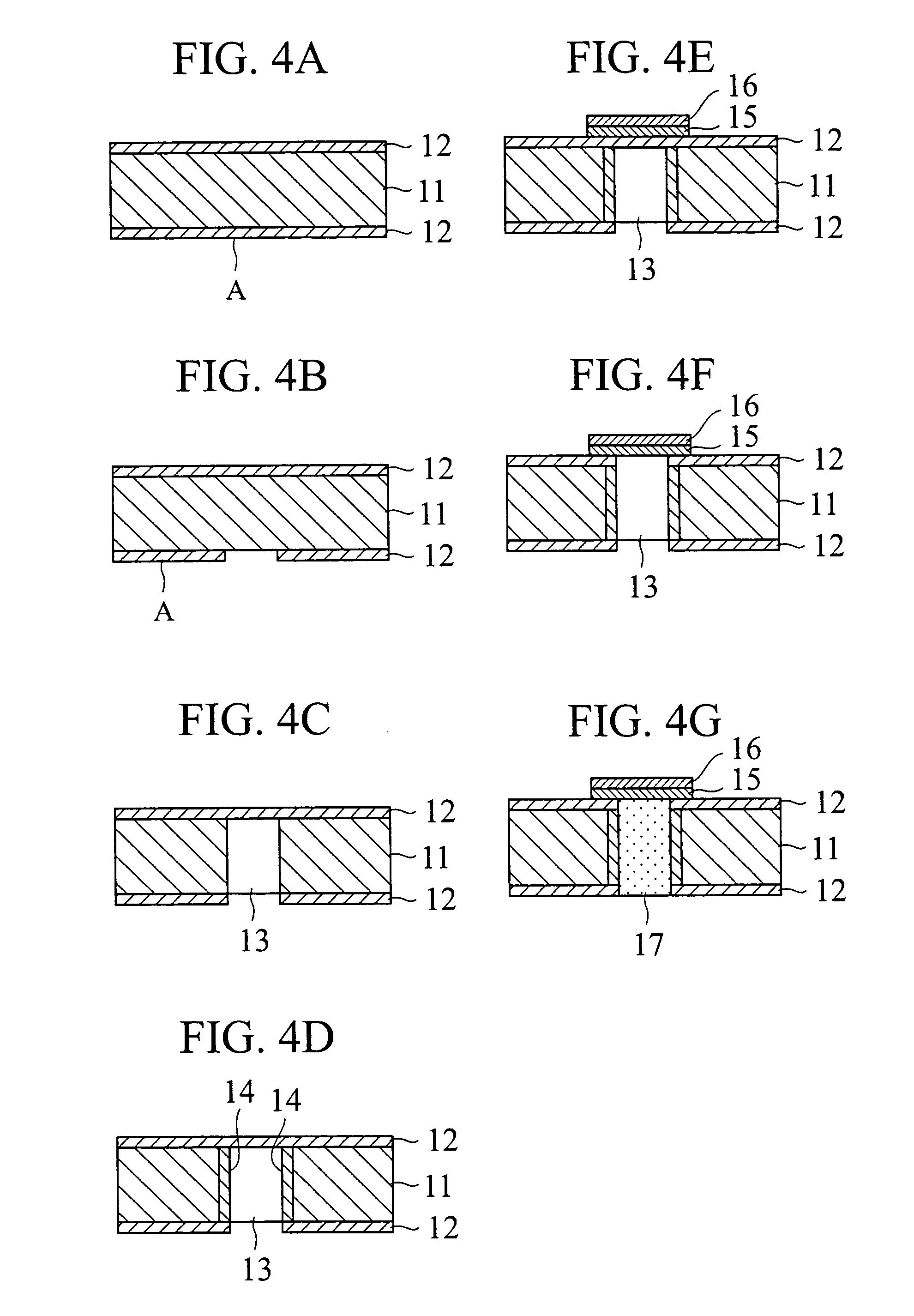

Plating of a thin metal seed layer

InactiveUS20050145499A1CellsSemiconductor/solid-state device manufacturingThin metalAuxiliary electrode

A method and apparatus for plating a metal layer onto a substrate is provided. The plating apparatus includes two or more segments of an anode and an auxiliary electrode. The plating method includes a first stage of plating a thin metal seed uniformly in the center of the substrate and near the edges of the substrate before metal gap filling and bulk metal plating are performed. The thin metal seed is plated on the substrate surface by applying a current pulse provided by a first power supply and a second power supply which are in electrical communication in reverse polarity with one segment of the anode and the auxiliary electrode. Thereafter, gap filling of features is performed by applying a second current pulse where current is provided to all segments of the anode.

Owner:APPLIED MATERIALS INC

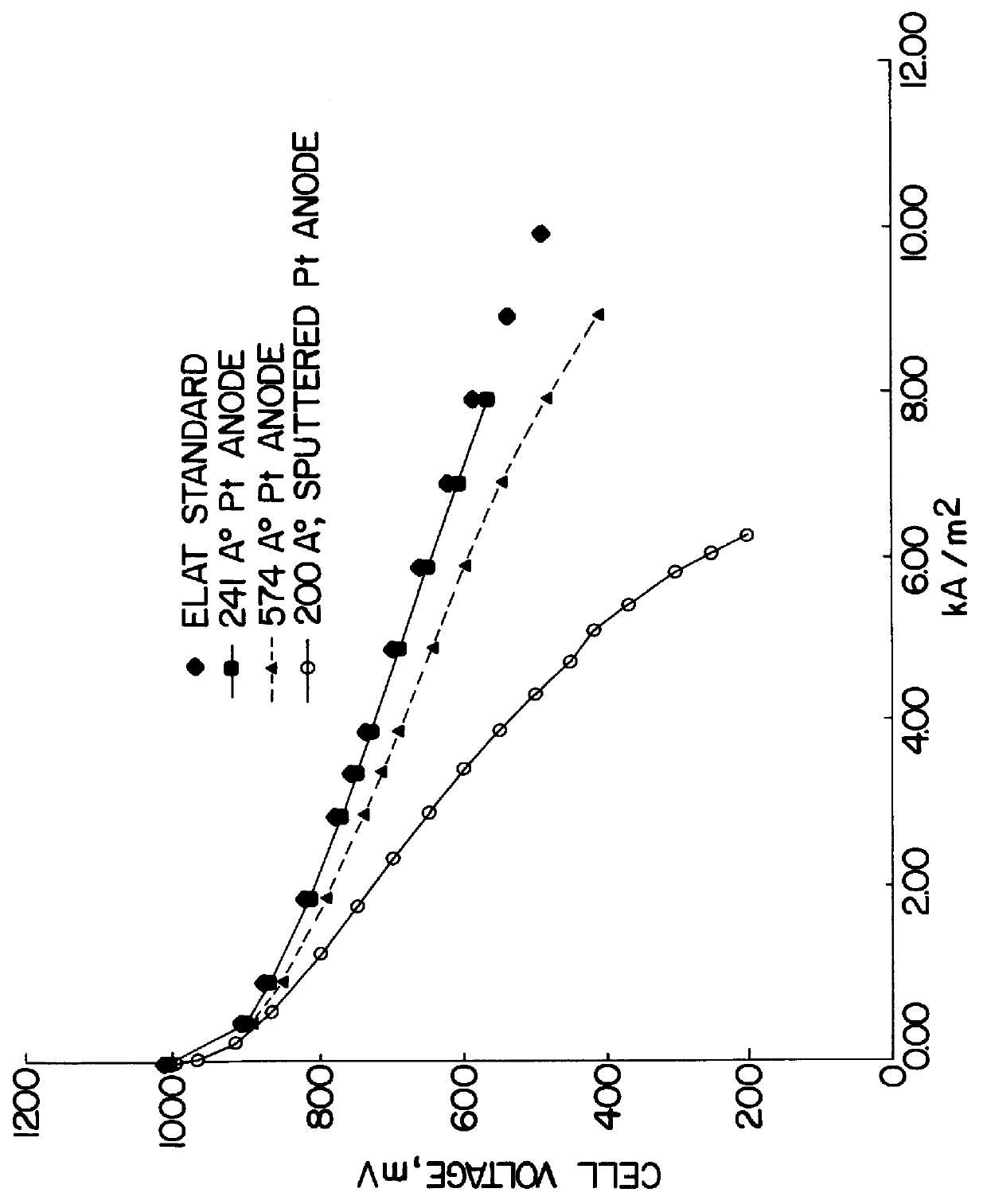

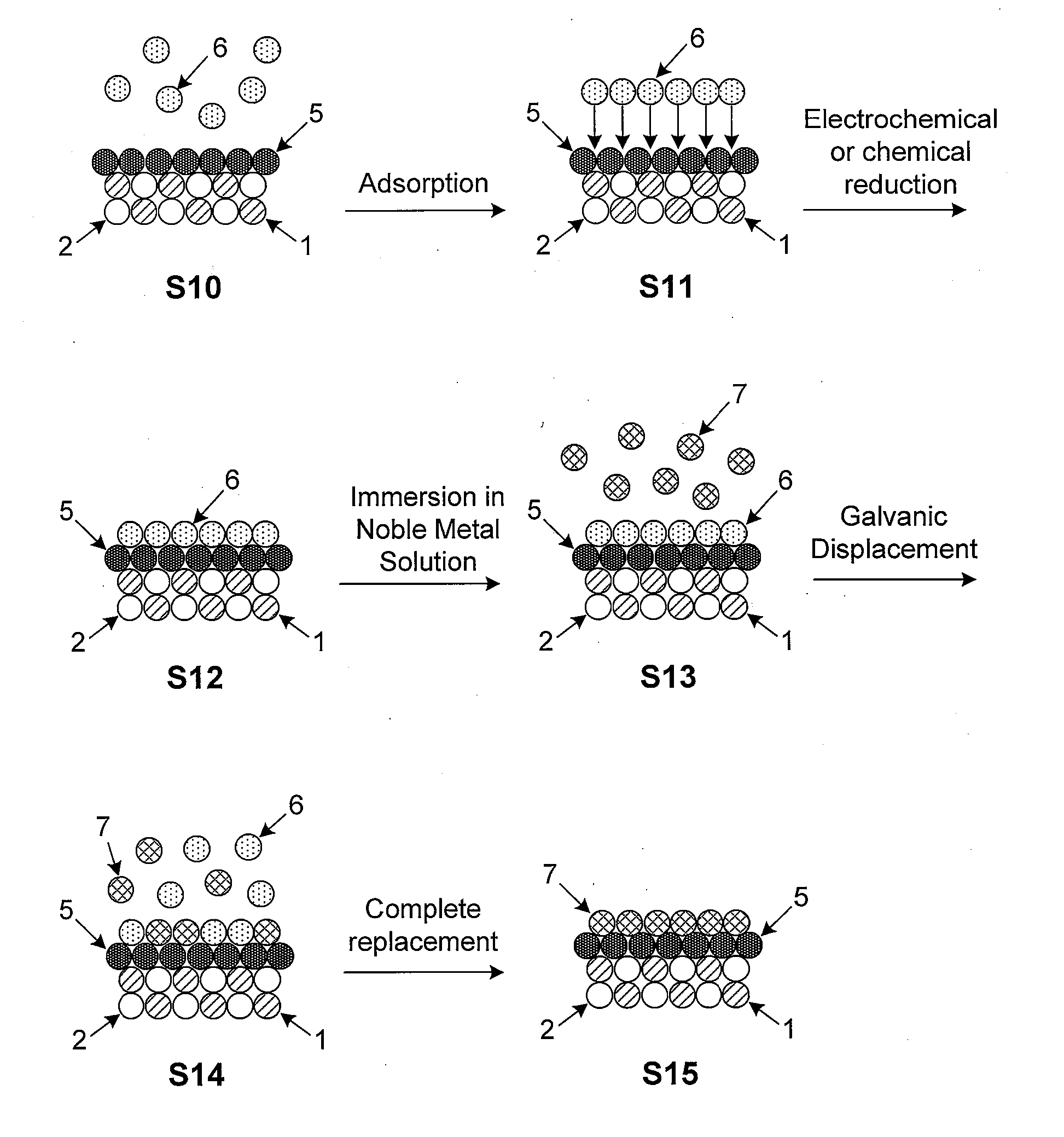

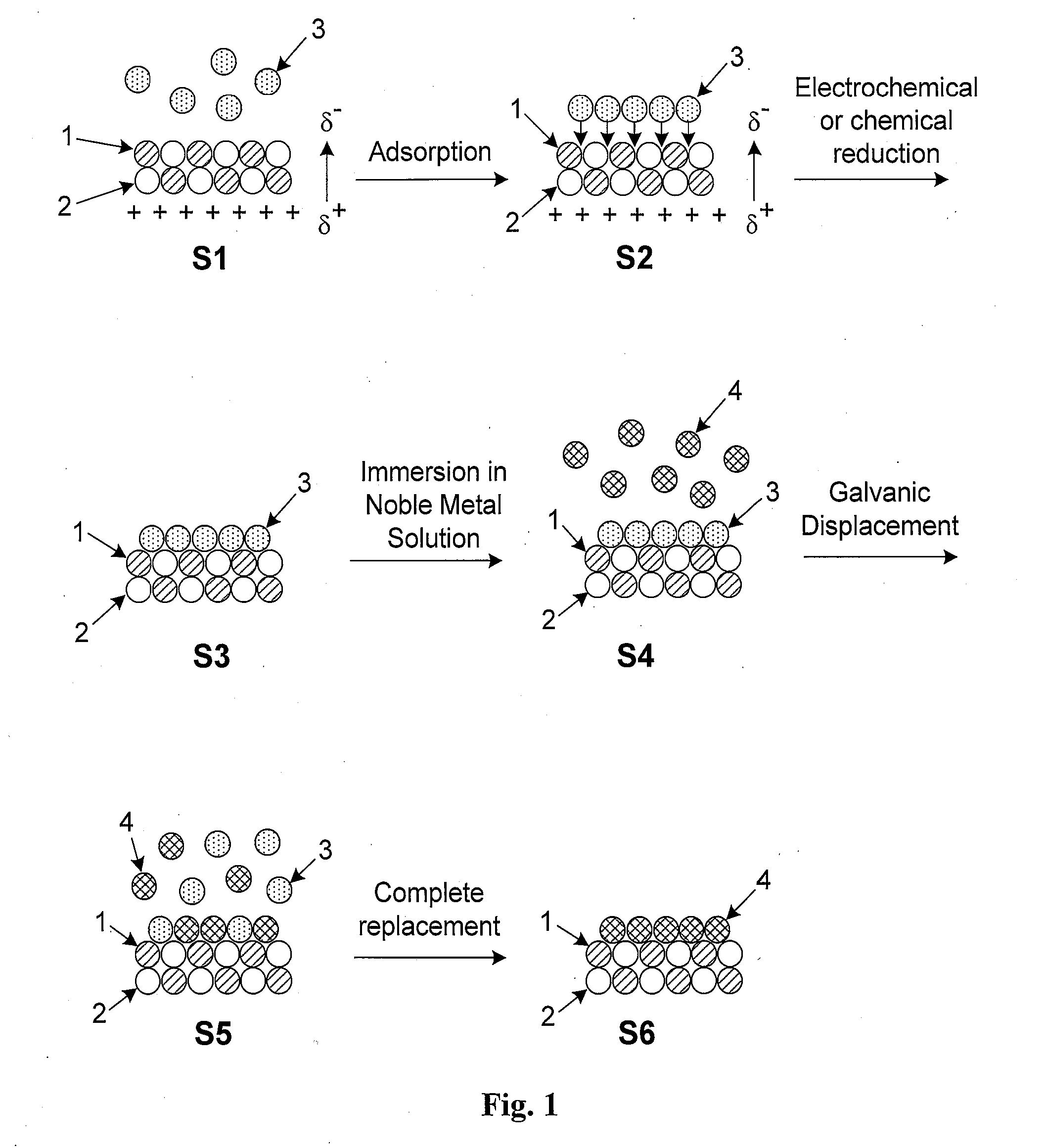

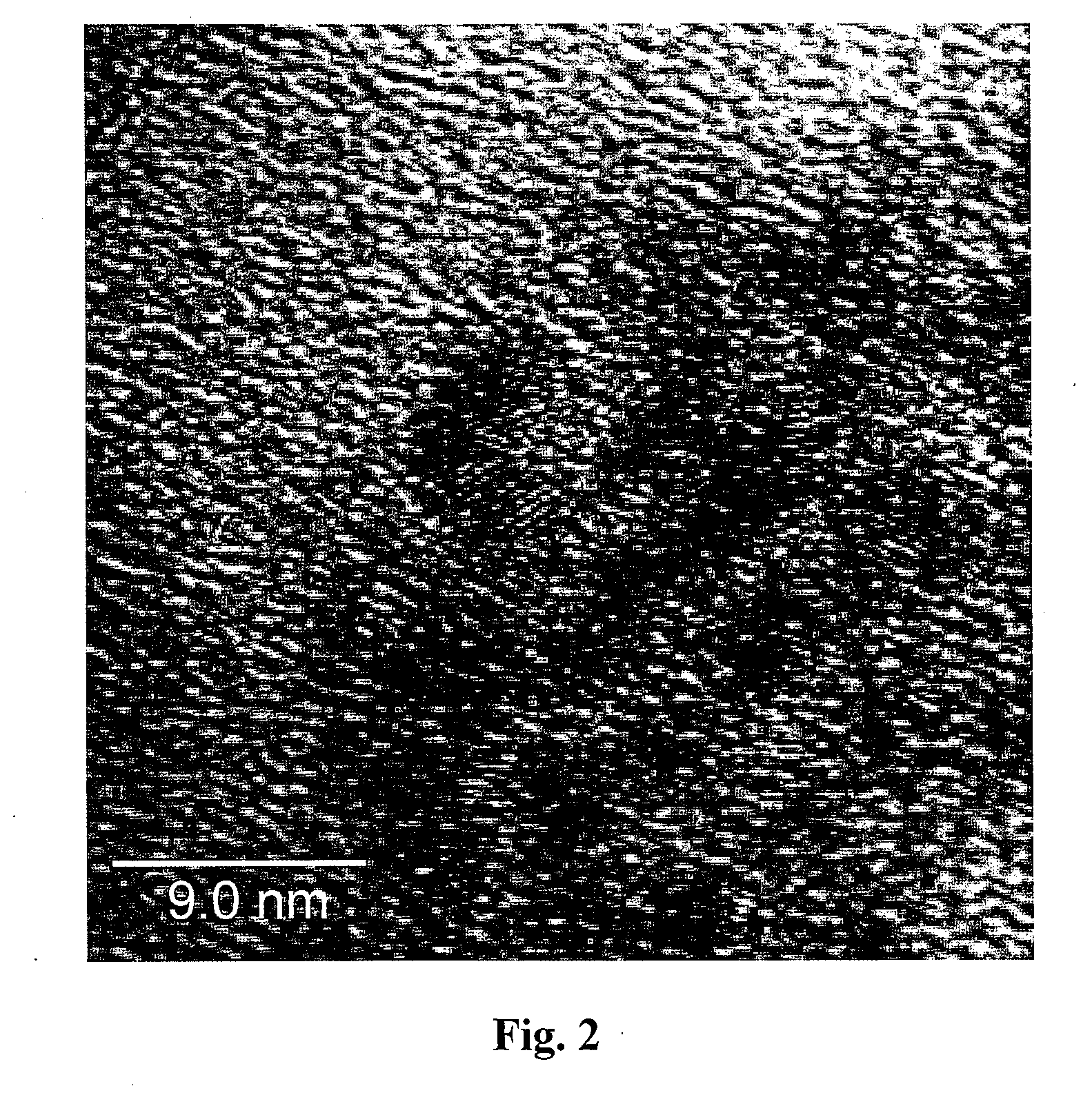

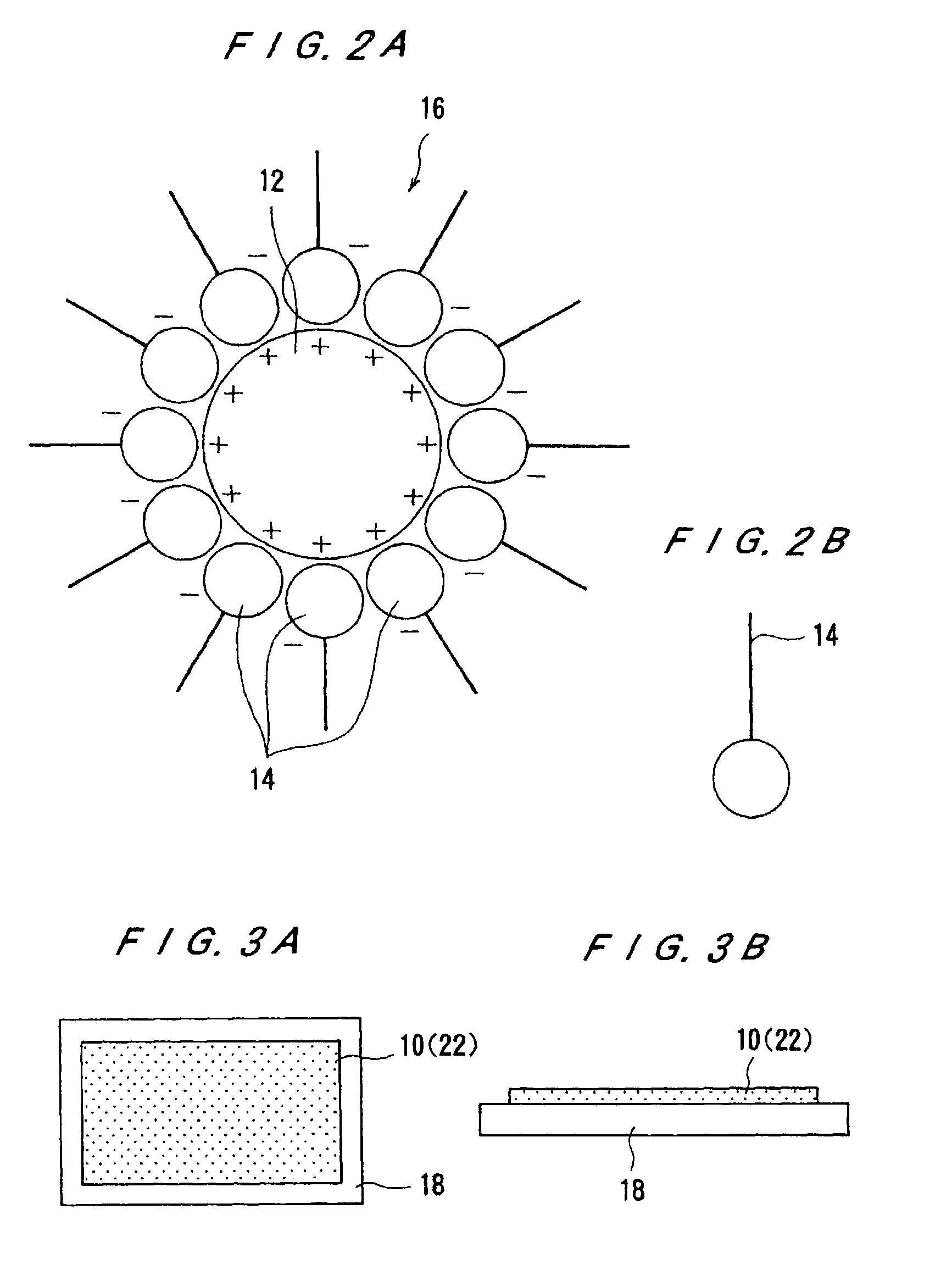

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

Metal base circuit board, LED, and LED light source unit

ActiveUS20090032295A1Easy to bendSmall sizePoint-like light sourcePrinted electric component incorporationThin metalMetal foil

To provide a thin metal base circuit board which can be not only installed on a flat portion but also closely attached to a side or bottom surface of a case or to a stepped or curved portion and which is excellent in heat dissipation performance, electrical insulating performance and flexibility; a process for its production; and a hybrid integrated circuit, an LED module and a bright, ultra-long-life LED light source employing it.A metal base circuit board having insulating layers and conductive circuits or metal foils alternately laminated, characterized in that the thickness of each conductive circuit or metal foil is from 5 μm to 450 μm, each insulating layer is made of a cured product of a resin composition comprising an inorganic filler and a thermosetting resin, and the thickness of each insulating layer is from 9 μm to 300 μm; and a hybrid circuit board employing it. The metal base circuit board wherein a coverlay is provided, and a layer having a magnetic loss or a layer having a dielectric loss is laminated on the surface of the coverlay. A LED light source unit having at least one light-emitting diode (LED) mounted on the conductive circuit.

Owner:DENKA CO LTD

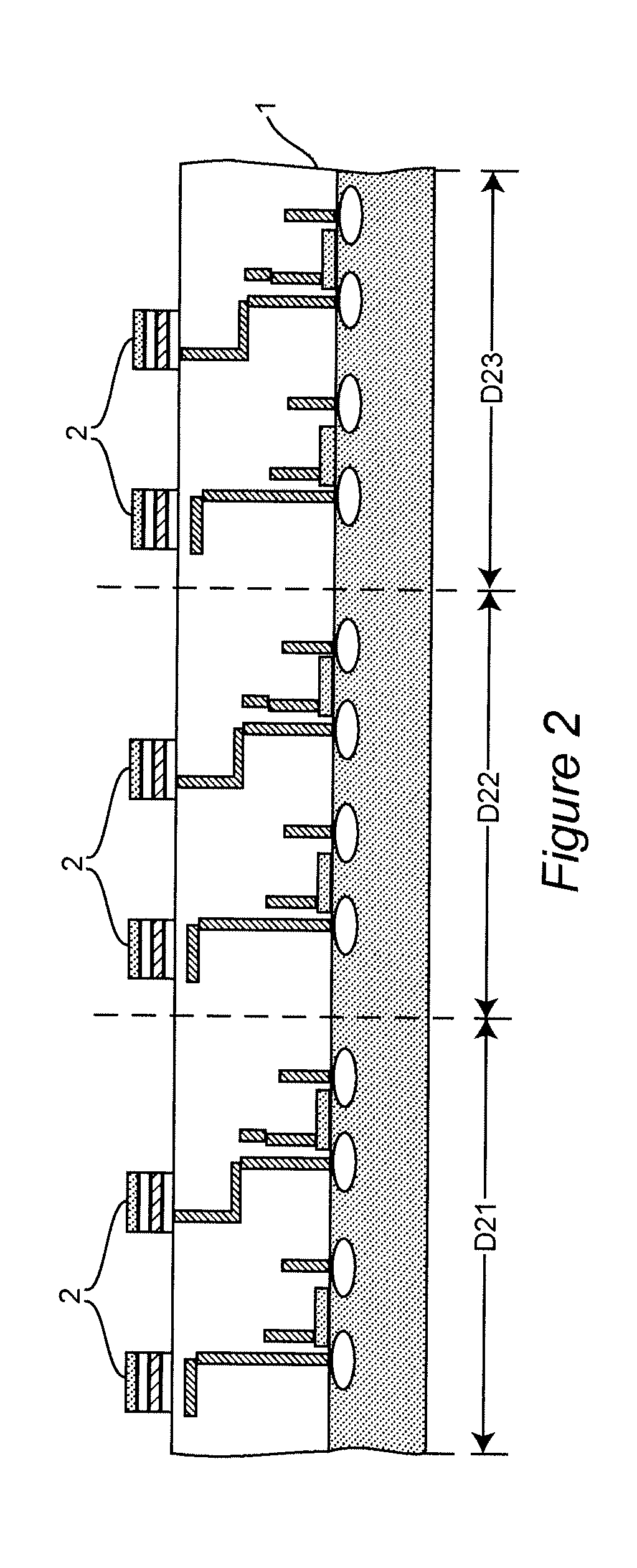

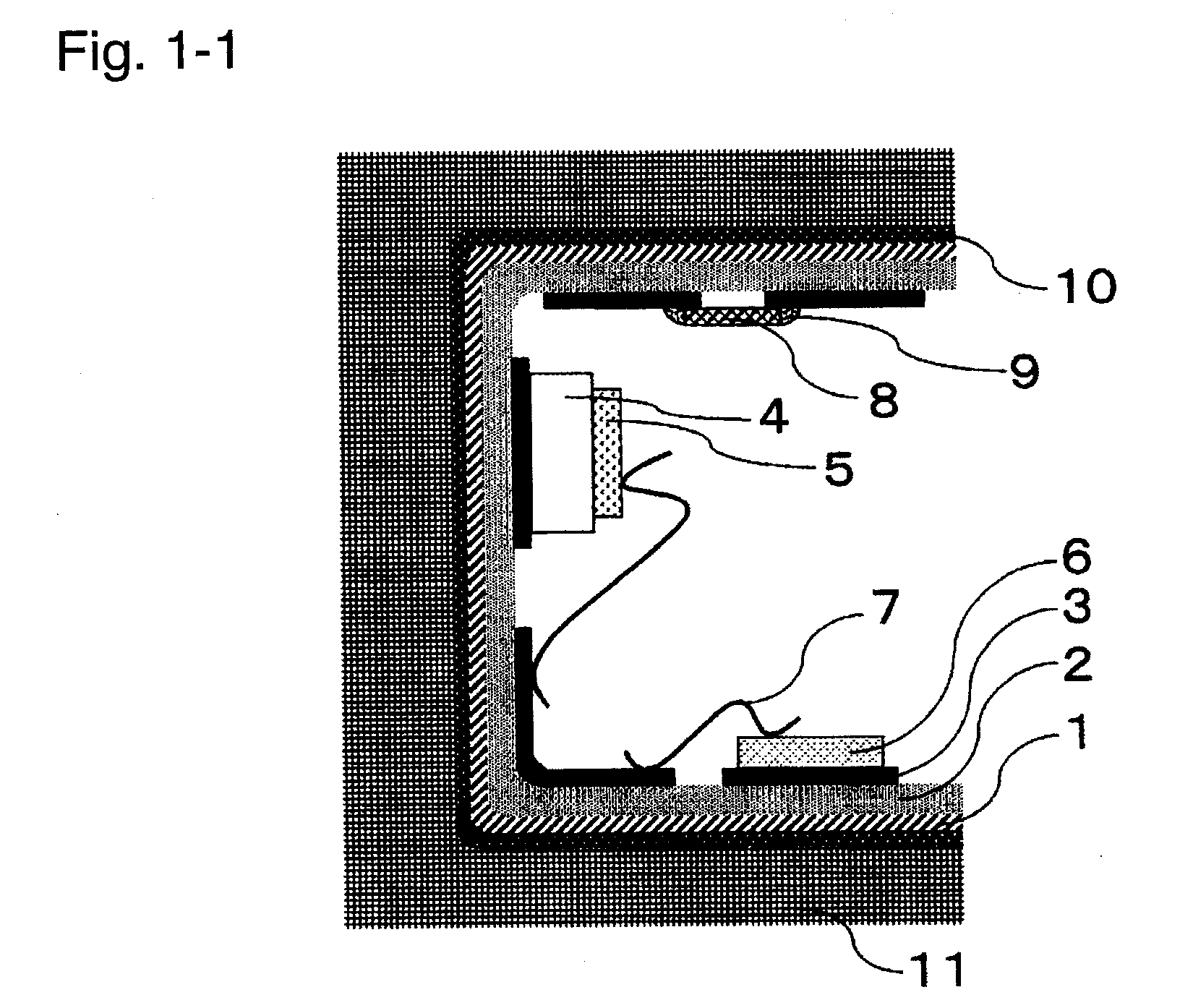

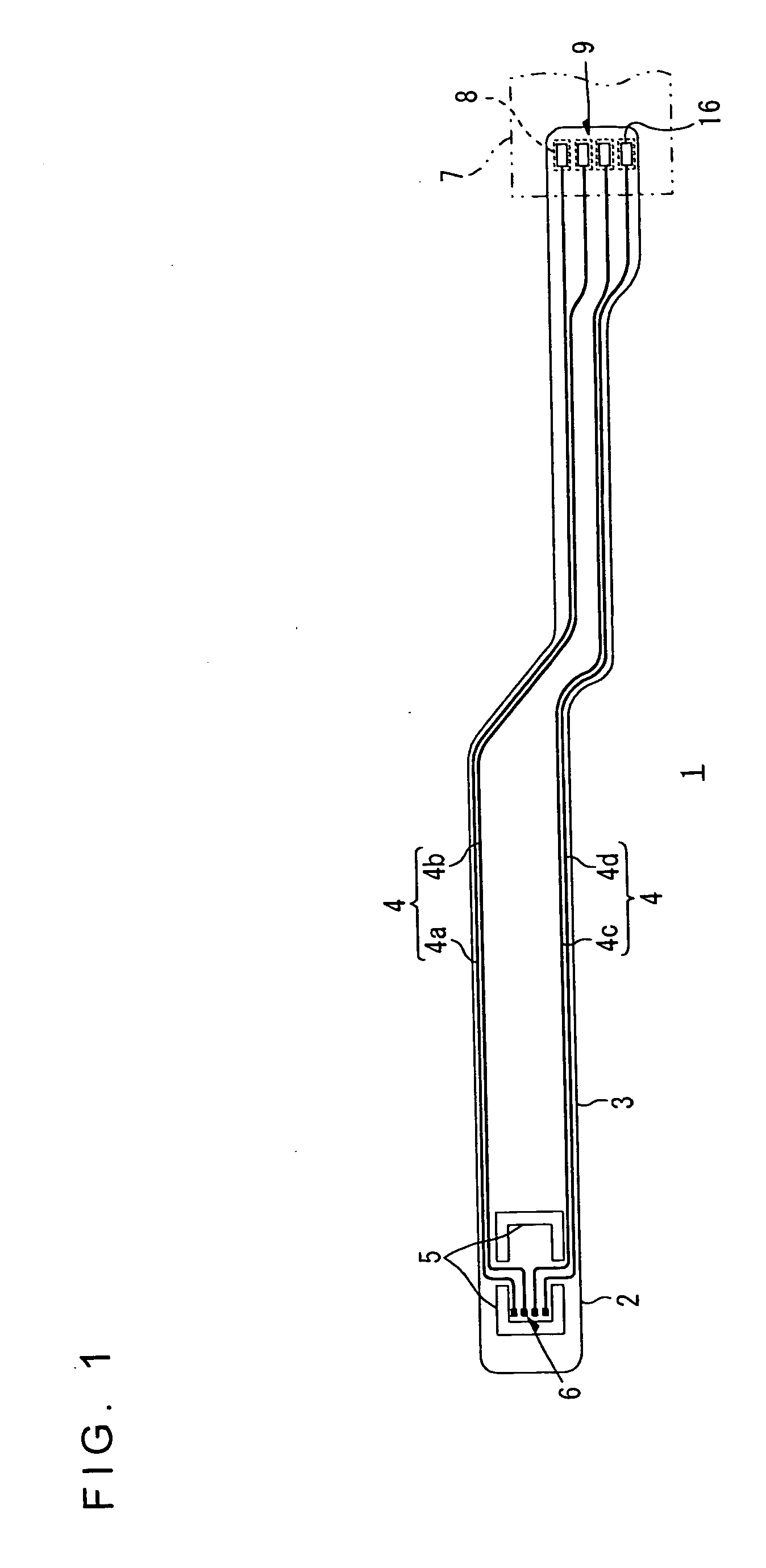

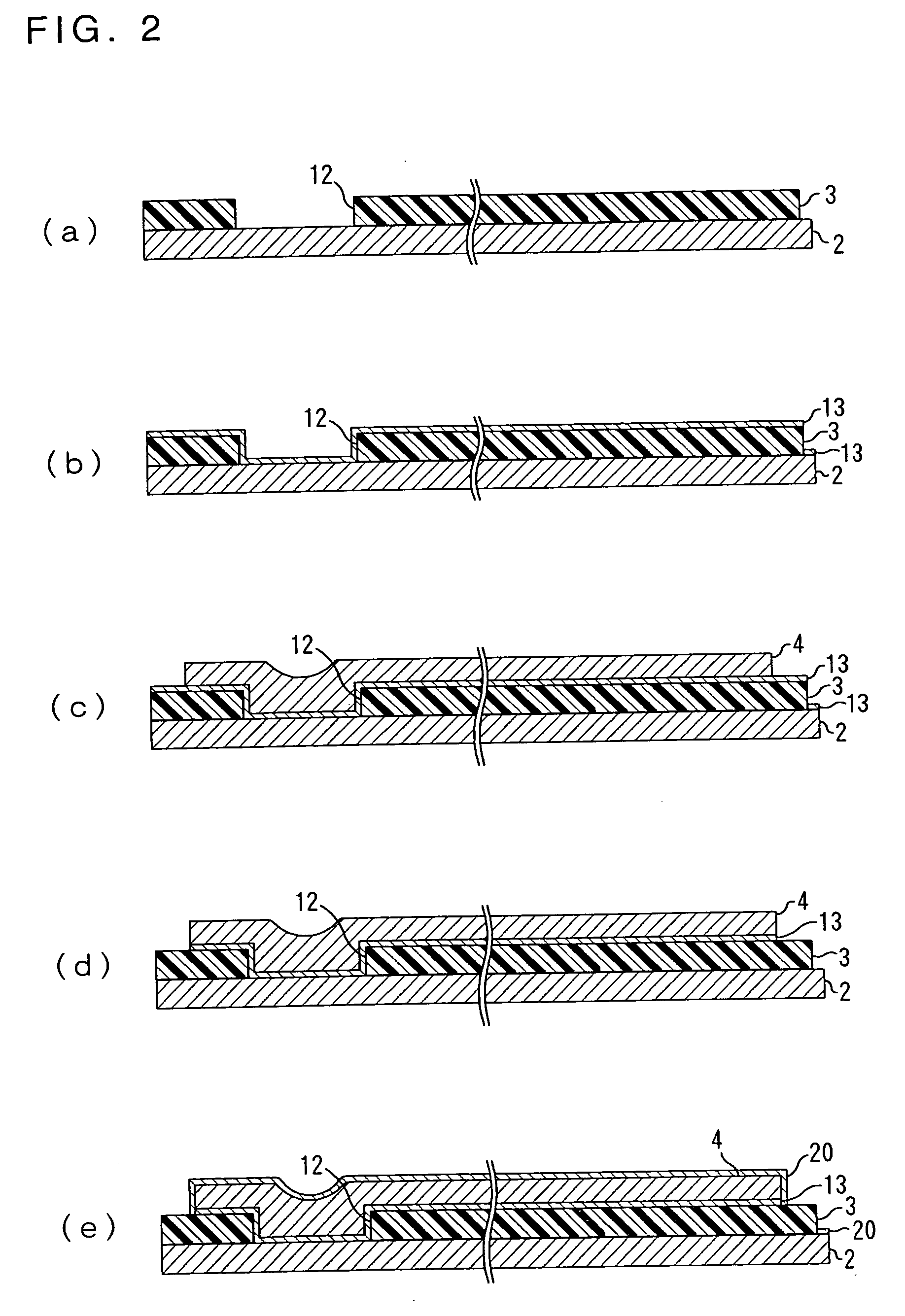

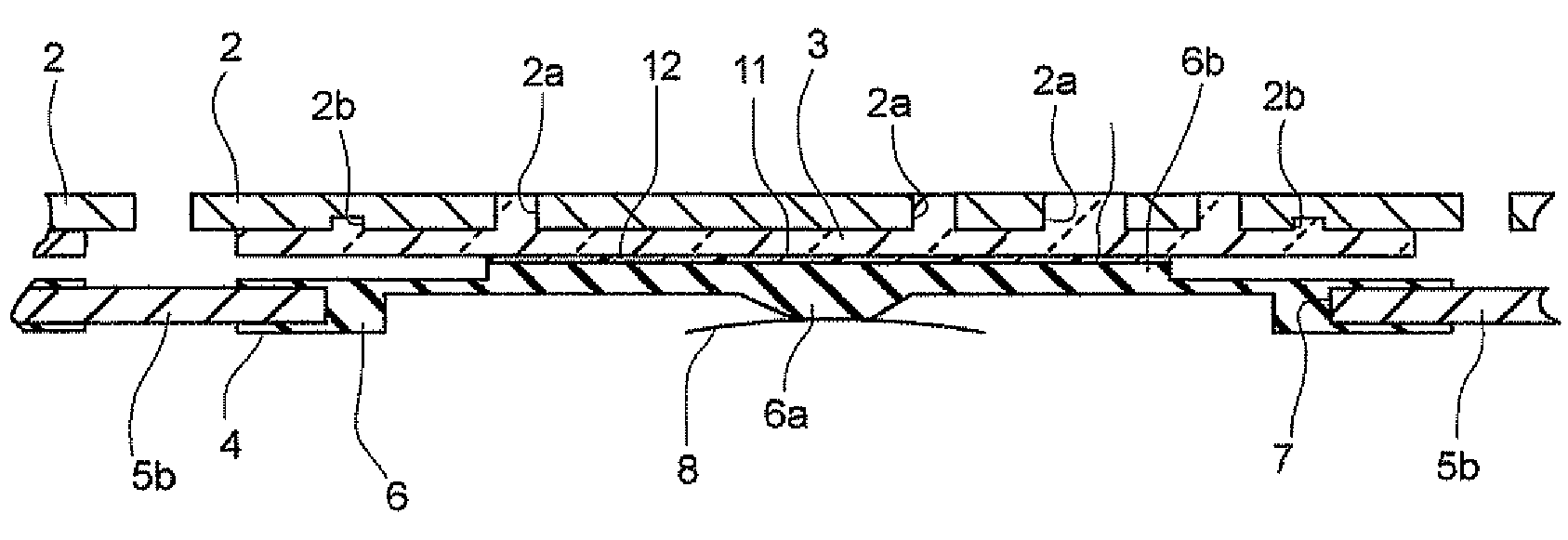

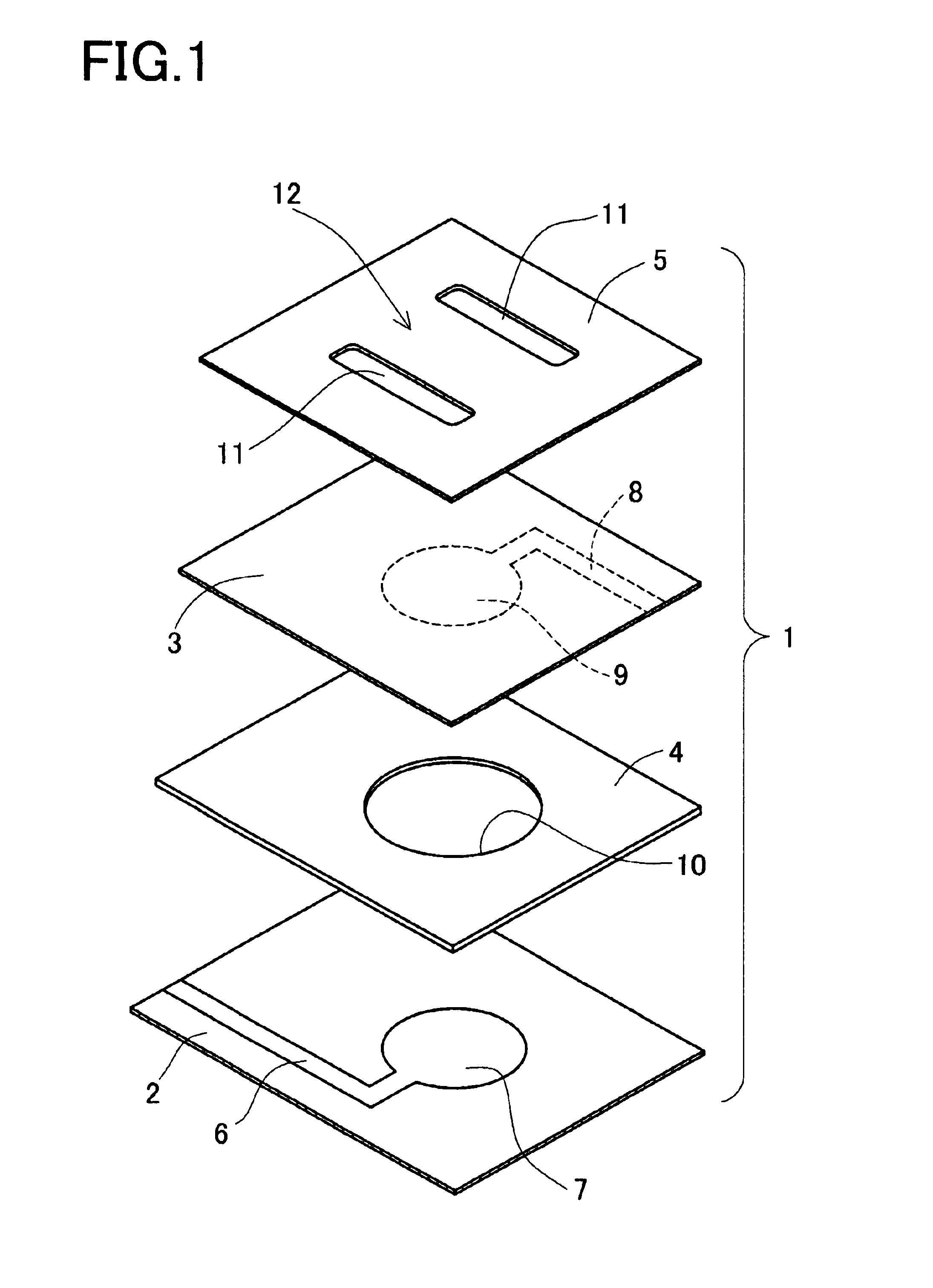

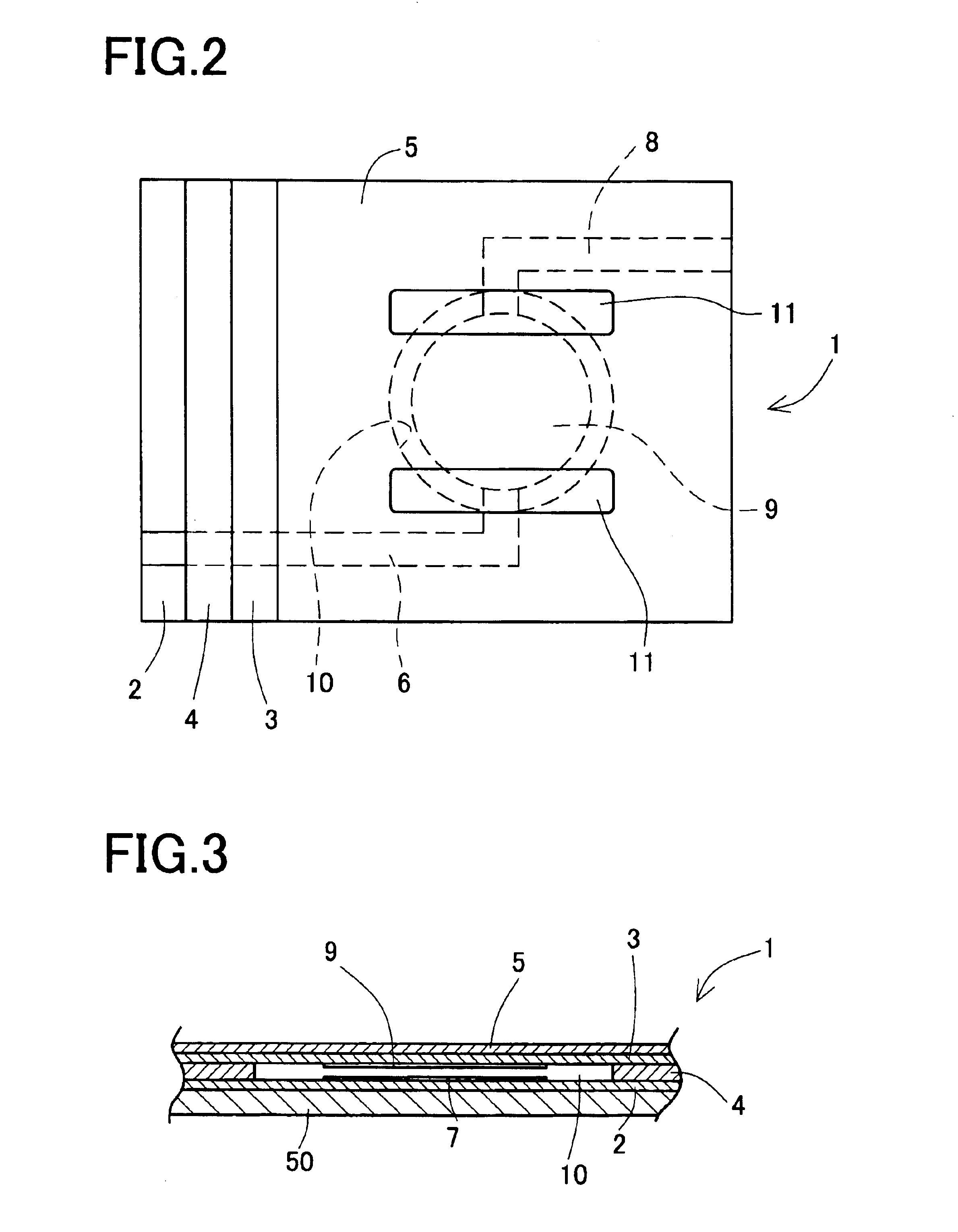

Suspension board with circuit and procuding method thereof

ActiveUS20050061542A1Increase productivityLow costInsulating substrate metal adhesion improvementCircuit arrangements on support structuresThin metalElectrical conductor

A producing method of a suspension board with circuit that can permit a terminal portion to be formed by electrolysis plating without exposing a conductor layer to outside and also can reduce the number of processes, and the suspension board with circuit produced by the same producing method. After an insulating base layer 3 is formed on a suspension board 2 in a specific pattern in which a second opening 12 is formed, a thin metal film 13 is formed on an entire surface of the insulating base layer 3 and on a surface of the suspension board 2 including the second opening 12 exposed from the insulating base layer 3.Then, a conductor layer 4 is formed in the form of a wired circuit pattern on the thin metal film 13. Thereafter, the insulating cover layer 10 is formed in such a manner that a pad opening 11 is formed in the insulating cover layer 10 and then a pad portion 16 is formed in the pad opening 11 using the suspension board 2 as a lead portion of the electrolysis plating. Thereafter, a first opening 25 larger than the second opening 12 is formed in the suspension board 2 at a portion thereof corresponding to the second opening 12.

Owner:NITTO DENKO CORP

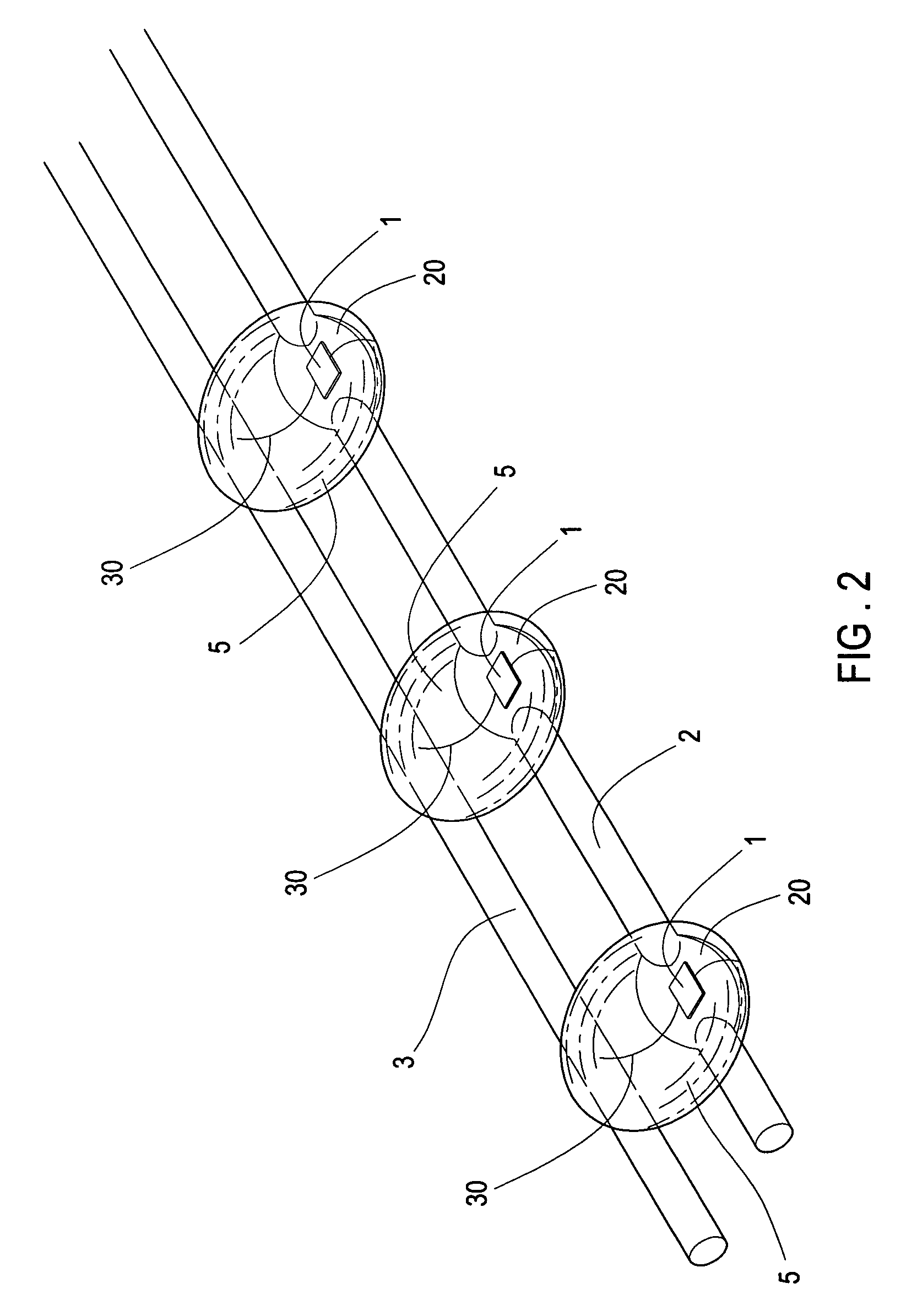

LED light set

InactiveUS7235815B2Small volumeEasy to manufacturePoint-like light sourceLighting support devicesThin metalEngineering

Owner:SHEN HSIEN TA

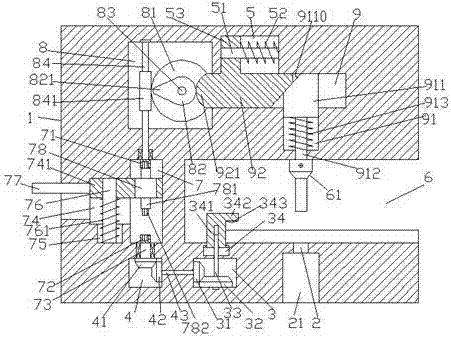

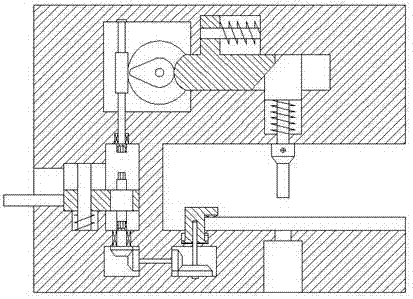

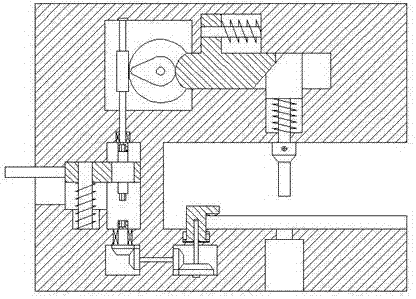

Simple and convenient thin metal sheet drilling machine device

InactiveCN106984698AImplement manual controlRealize manual control up and down switching mobile workMetal-working feeding devicesPositioning devicesThin metalDrive shaft

The invention discloses a simple and convenient thin metal sheet drilling machine device. The device comprises a device body. An operating groove is formed in the end face of the right side of the device body. A switching cavity is formed in the portion, on the left side of the operating groove, of the device body. A first inner spline shaft and a second inner spline shaft are arranged on the inner walls of the upper side and the lower side of the switching cavity correspondingly. A first sliding groove is formed in the inner wall of the left side of the switching cavity. A sediment groove is formed in the inner bottom wall of the first sliding groove. A first guide rod is arranged between the inner bottom wall of the sediment groove and the inner top wall of the first sliding groove. A first sliding block extending rightwards is slidably connected to the first guide rod in a matched mode. A first spring is arranged on the outer surface of the first guide rod located at the bottom of the first sliding block in a surrounding mode. A right extending section of the first sliding block extends into the switching cavity and abuts against the inner wall of the right side of the switching cavity in a sliding fit mode. A motor is arranged in the first sliding block in the switching cavity. Driving shafts are arranged at the ends of the upper side and the lower side of the motor. A transmission cavity is formed in the portion, above the switching cavity, in the device body. The device is simple in structure, convenient to operate, low in manufacturing and maintaining cost, high in drilling speed and stability and good in drilling quality.

Owner:衢州市洼帝尔数控设备有限公司

SPR sensor cell and immunoassay apparatus using the same

InactiveUS6432364B1Reduce intensityEasy maintenanceAnalysis by electrical excitationScattering properties measurementsThin metalEngineering

An SPR (surface plasmon resonance) sensor cell comprising: a light-transparent core; a clad covering the core and having a through hole at a predetermined position to communicate with the core; and a predetermined thin metal film formed on an exposed surface of the core corresponding to the through hole.

Owner:SUZUKI MOTOR CORP

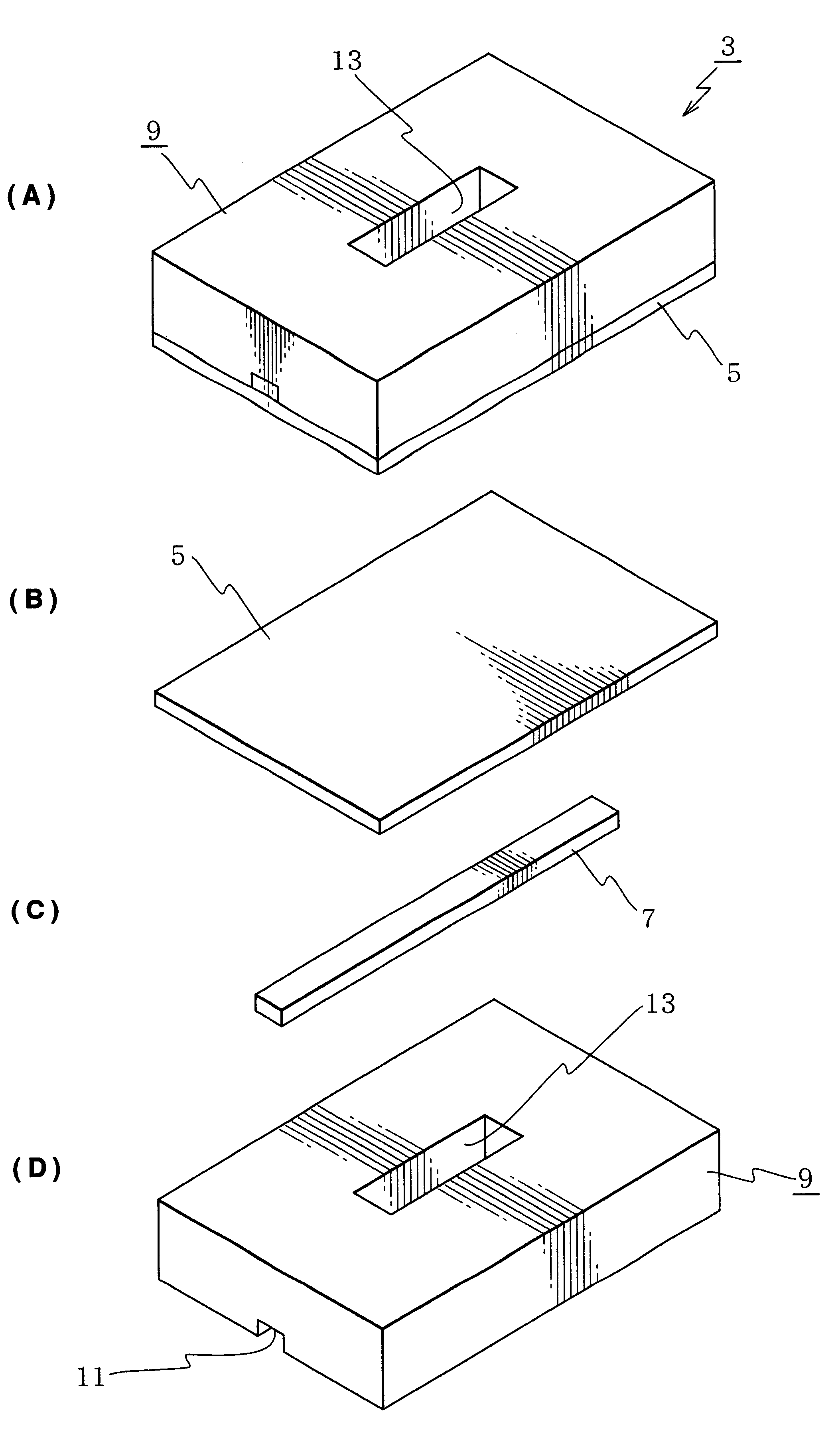

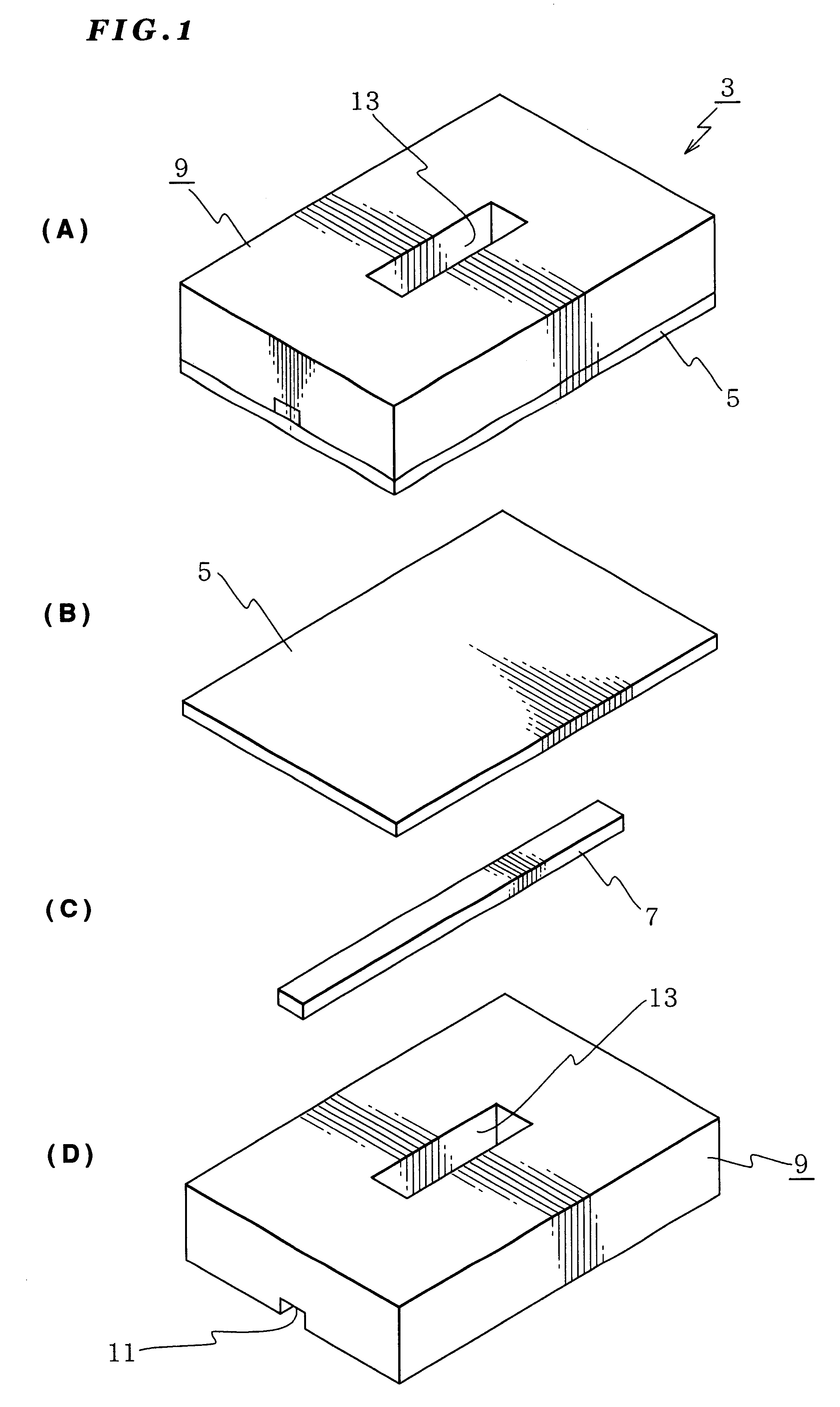

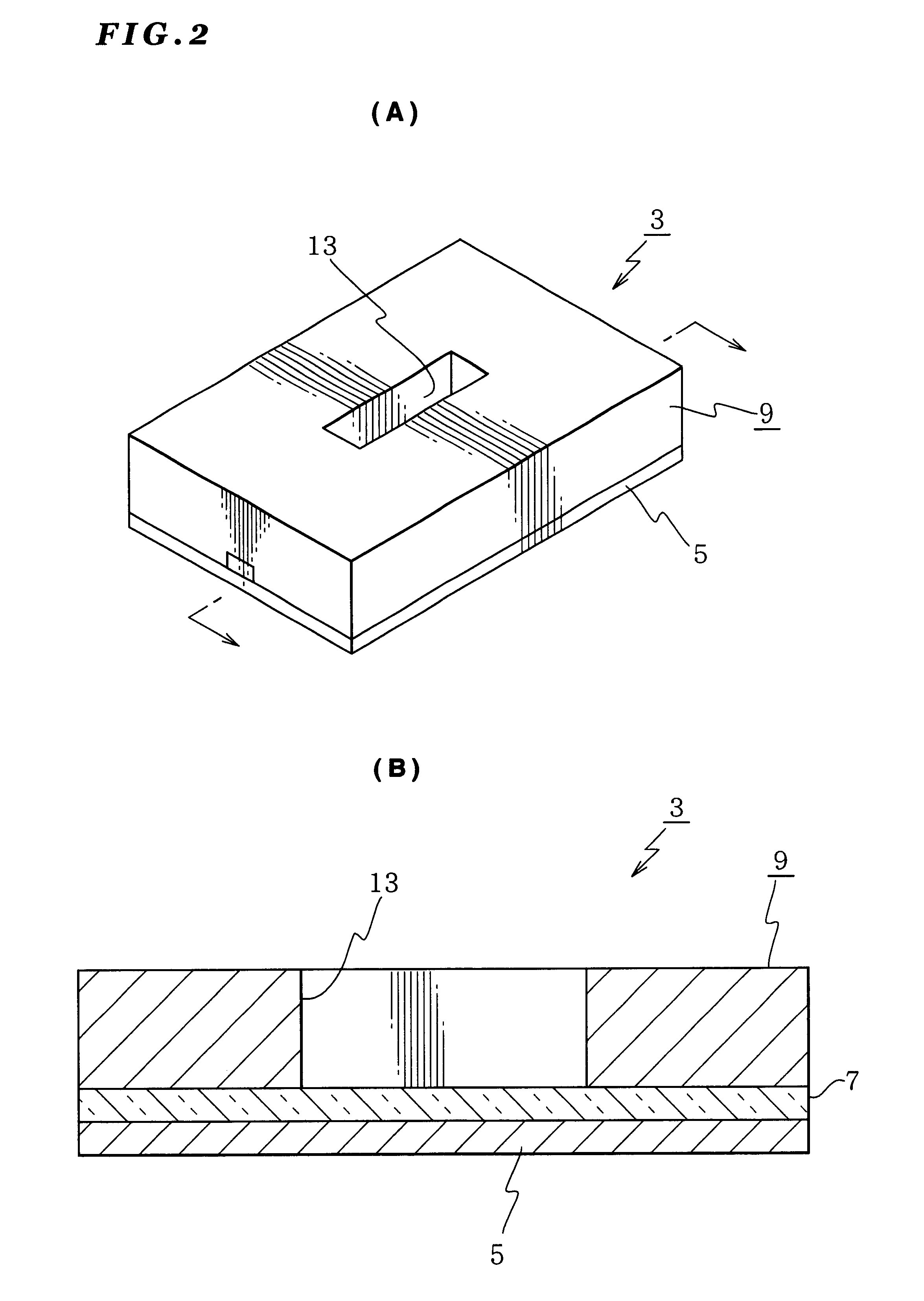

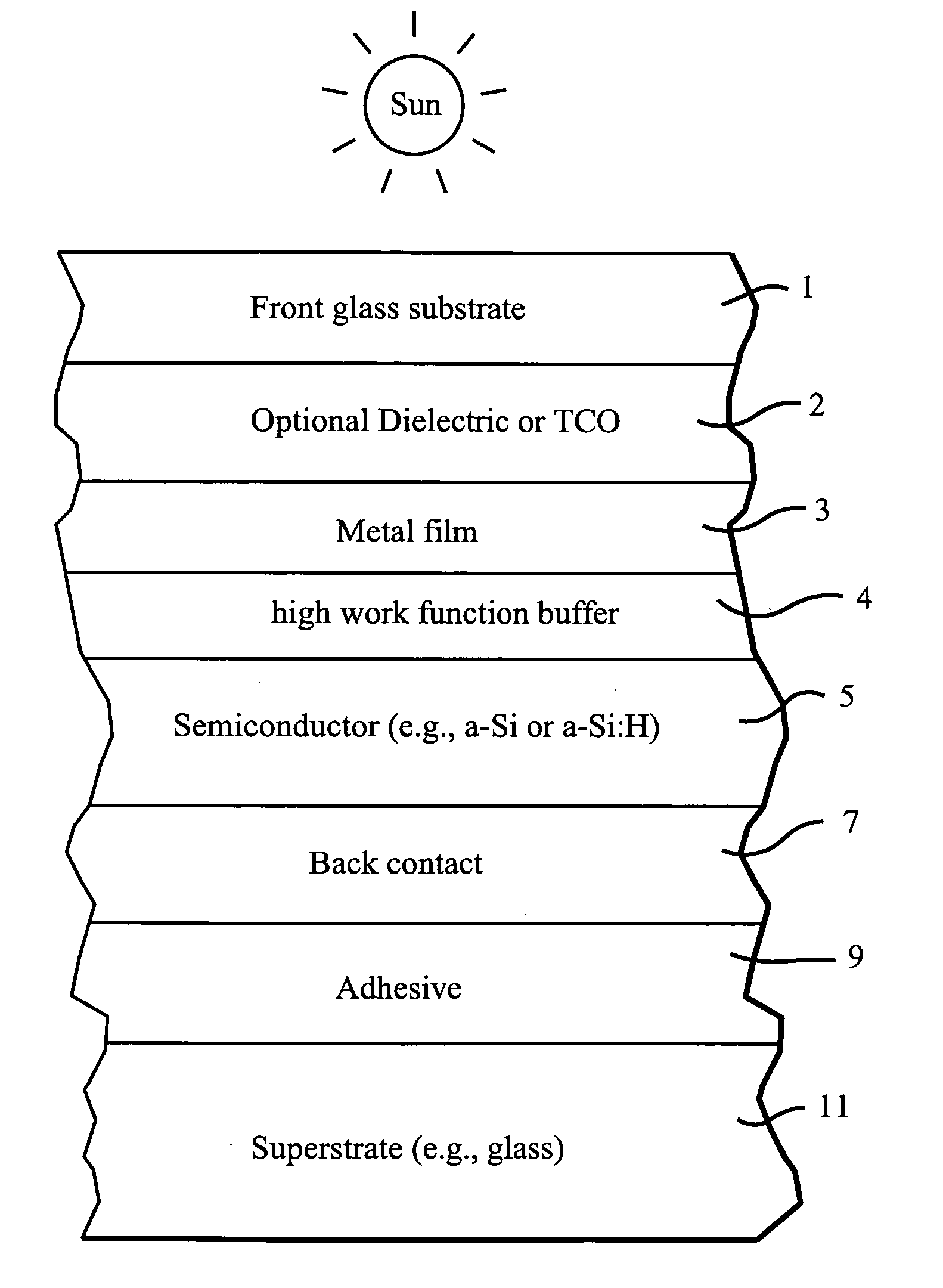

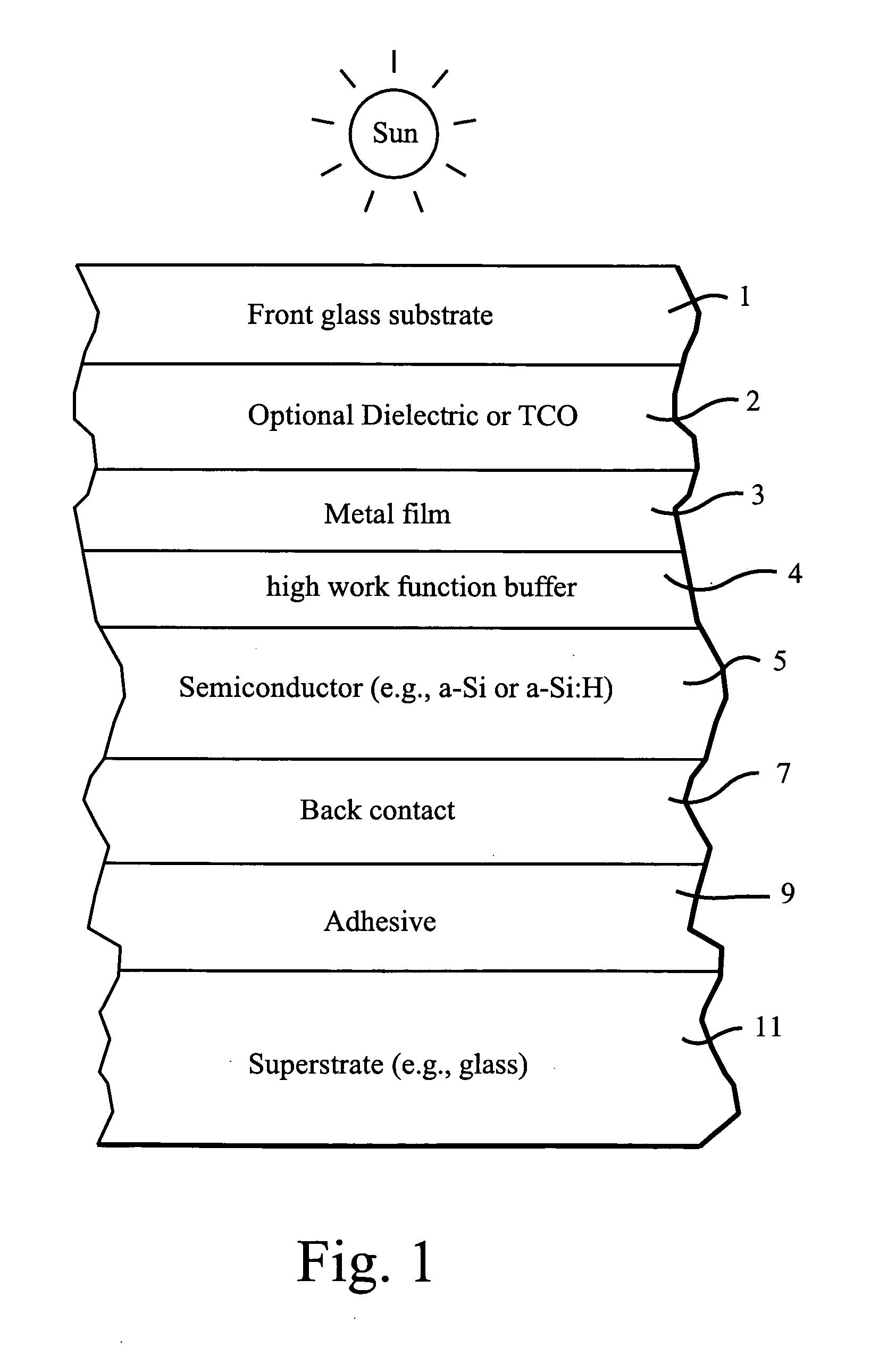

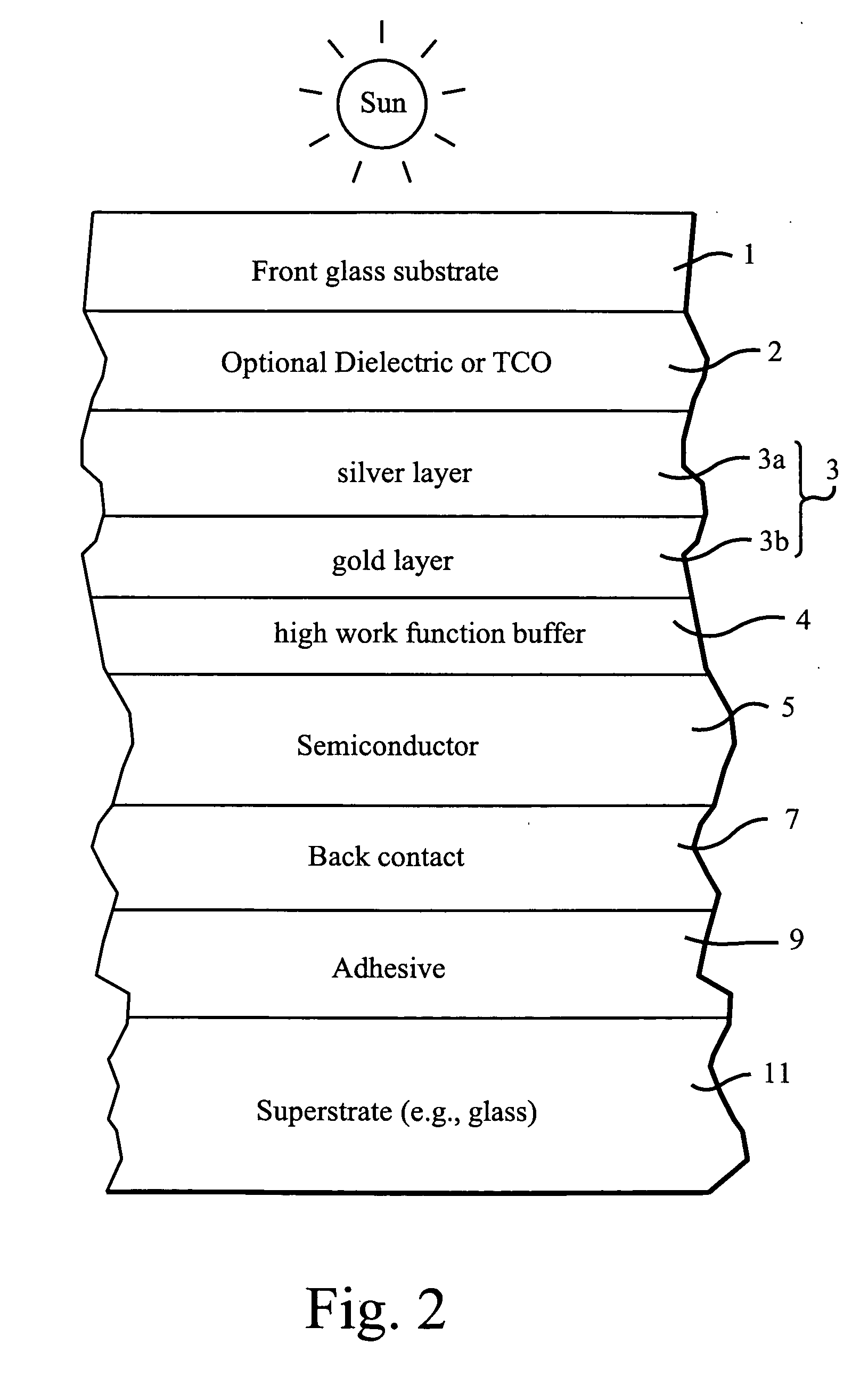

Front electrode with thin metal film layer and high work-function buffer layer for use in photovoltaic device and method of making same

InactiveUS20080105299A1Reduce potential barrierMade cheaply and quicklyPhotovoltaic energy generationSemiconductor devicesDielectricThin metal

This invention relates to a front electrode or contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of the photovoltaic device includes a highly conductive metal film and a thin high work-function buffer layer. The high-work function buffer layer is located between the metal film and the uppermost semiconductor layer so as to provide for substantial work-function matching between the metal film and the high work-function uppermost semiconductor layer so as to reduce a potential barrier for holes extracted from the device by the front electrode / contact. Optionally, a layer such as a transparent conductive oxide (TCO) or a dielectric may be provided between a front glass substrate and the metal film.

Owner:GUARDIAN GLASS LLC

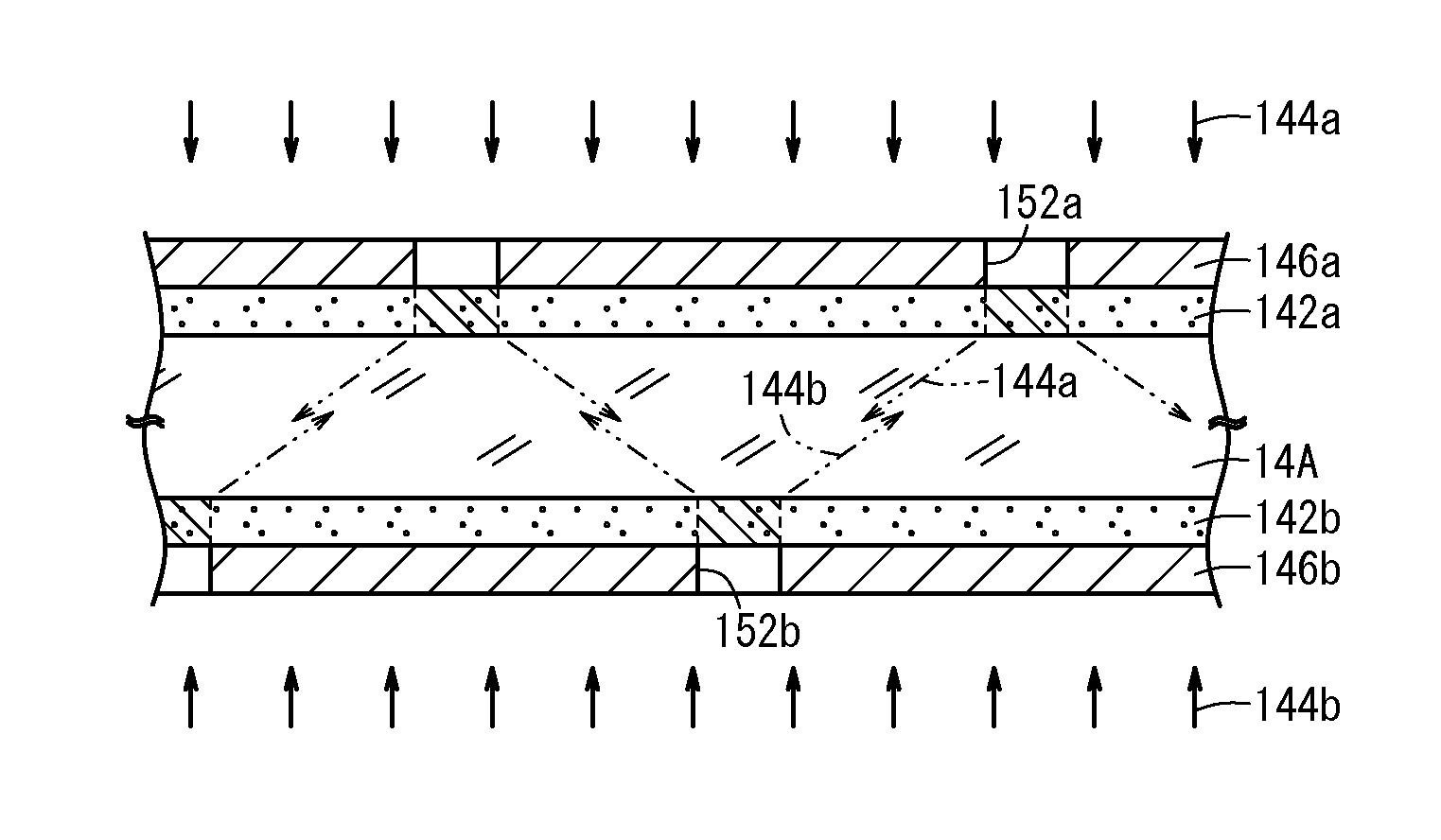

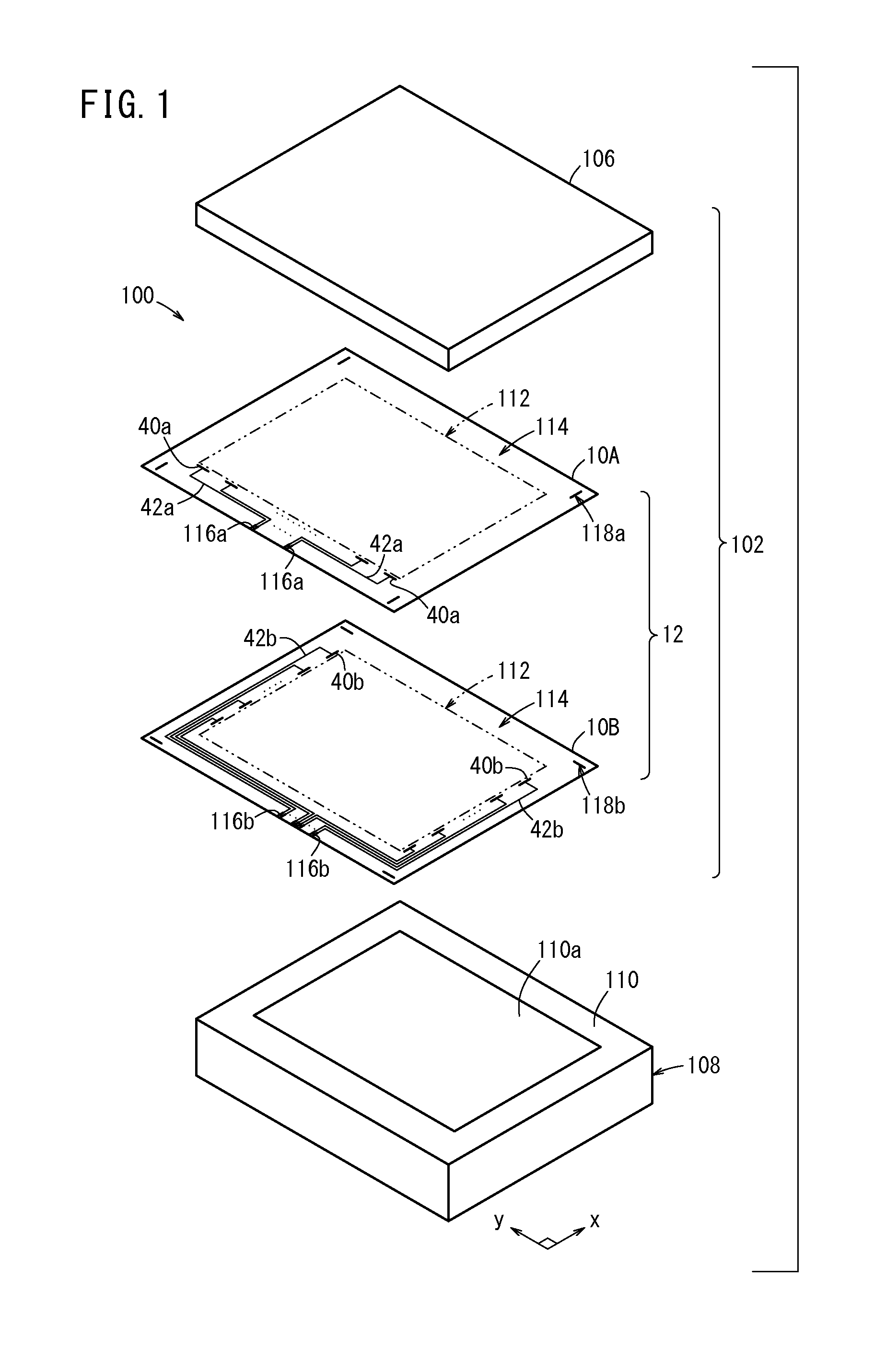

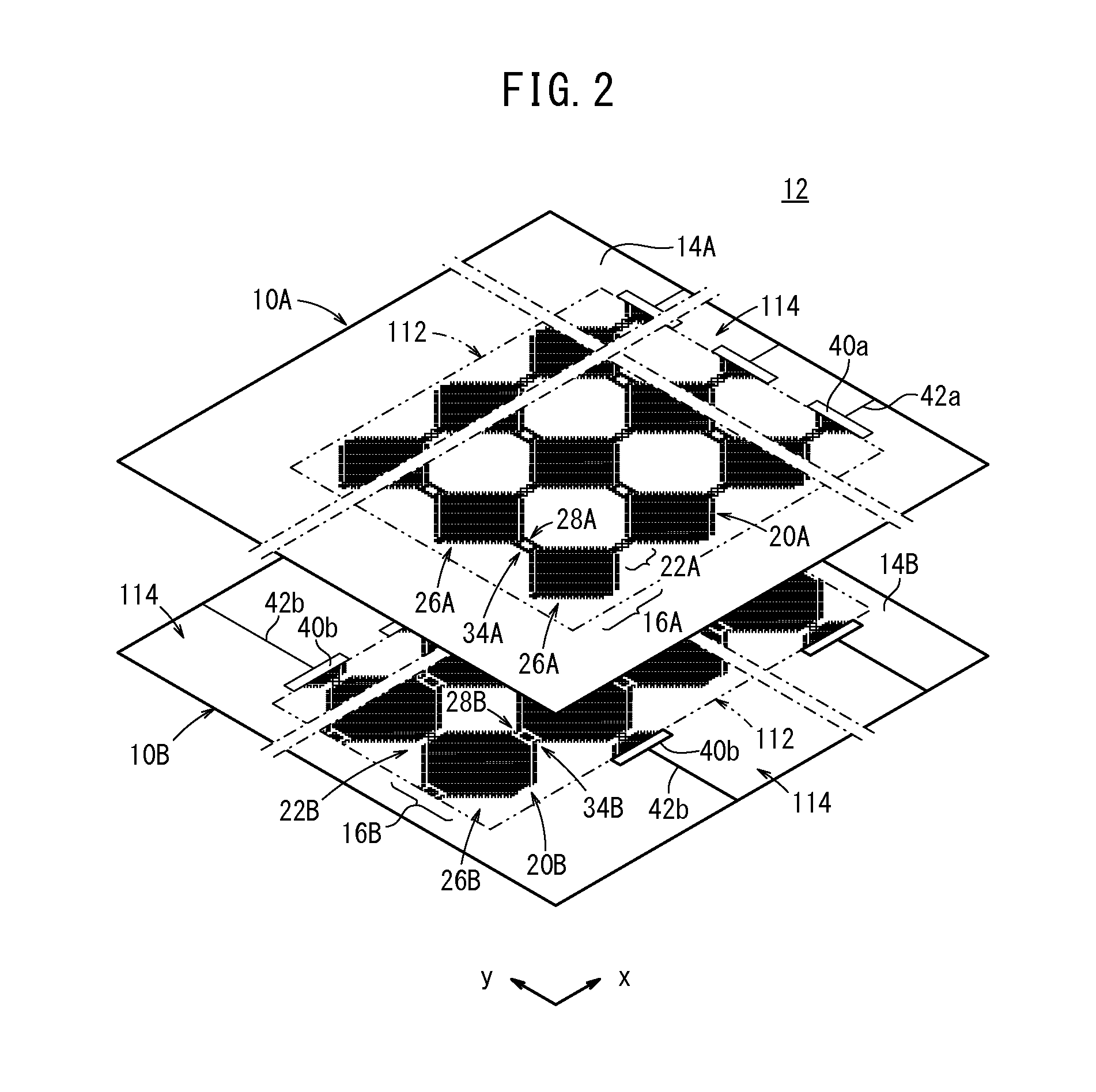

Electroconductive sheet and touch panel

ActiveUS20130327560A1High transparencyHigh detection sensitivityNon-insulated conductorsSuperimposed coating processThin metalEngineering

An electroconductive sheet and a touch panel having a first electroconductive section and a second electroconductive section, the second electroconductive section being disposed on the display-panel side. The first electroconductive section has a plurality of first electroconductive patterns arranged in the x-direction, a plurality of first large grids being respectively connected to the first electroconductive patterns. The second electroconductive section has a plurality of second electroconductive patterns arranged in the y-direction, a plurality of second large grids being respectively connected to the second electroconductive patterns. The area occupied by thin metal wires in the second electroconductive patterns is larger than the area occupied by thin metal wires in the first electroconductive patterns. The area occupied by thin metal wires in the second large grids is larger than the area occupied by thin metal wires in the first large grids.

Owner:FUJIFILM CORP

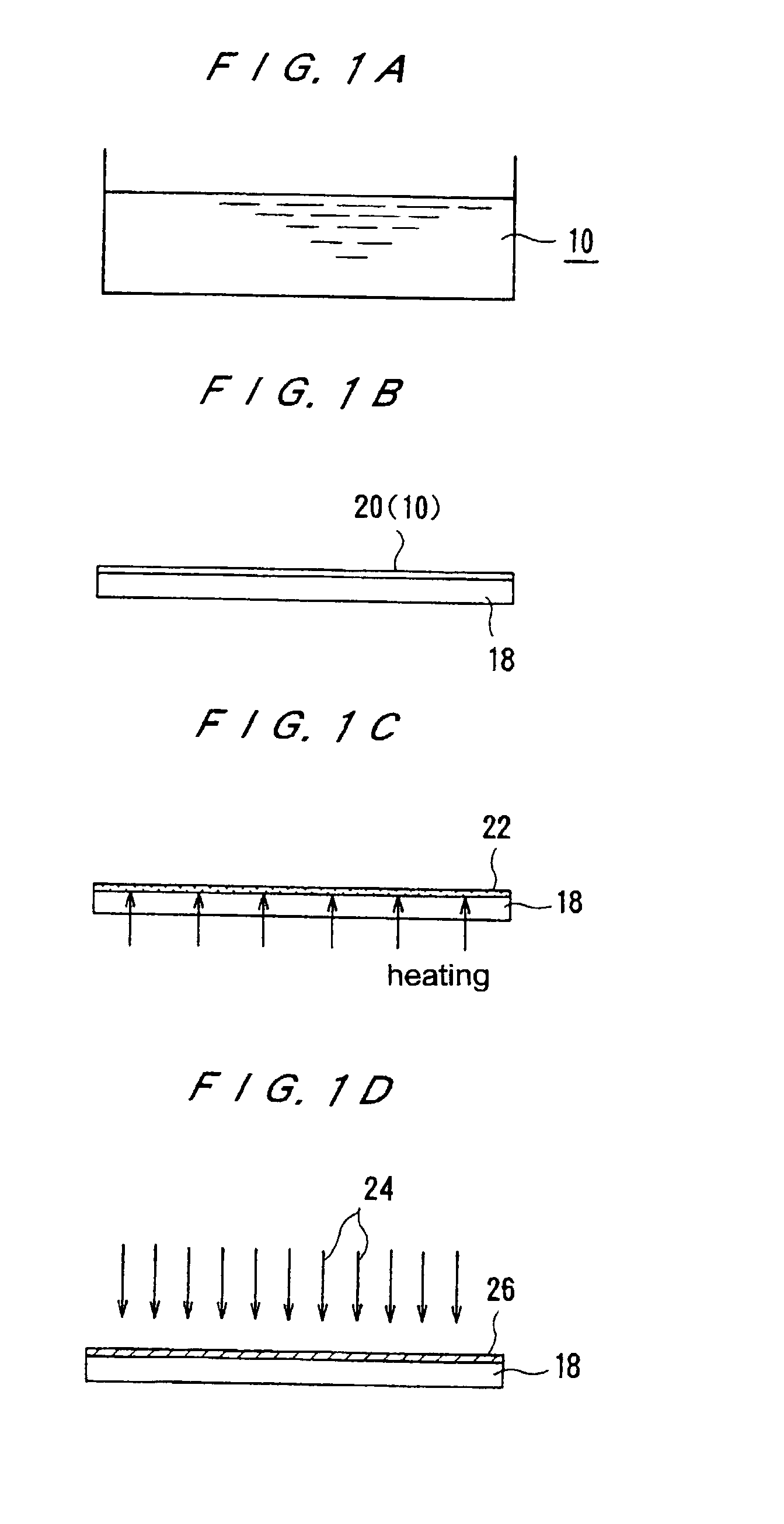

Method and apparatus for forming thin film of metal

InactiveUS20020160103A1Efficient qualityPretreated surfacesSemiconductor/solid-state device manufacturingSimple Organic CompoundsThin metal

The present invention relates to a method of and an apparatus for forming a thin metal film of copper, silver, or the like on a surface of a semiconductor or another substrate. A method of forming a thin metal film, comprises preparing a dispersed liquid having a metal-containing organic compound dispersed in a predetermined solvent, coating the dispersed liquid on a surface of a substrate and evaporating the solvent to form a coating layer, and applying an energy beam to the coating layer to decompose away an organic substance contained in the coating layer in an area irradiated with the energy beam and bond metal contained in the coating layer. According to the present invention, it is possible to form a thin metal film of good quality efficiently and stably. The thin metal film used as metal interconnects in highly integrated semiconductor circuits contributes to the progress of a process of fabricating semiconductor devices.

Owner:EBARA CORP

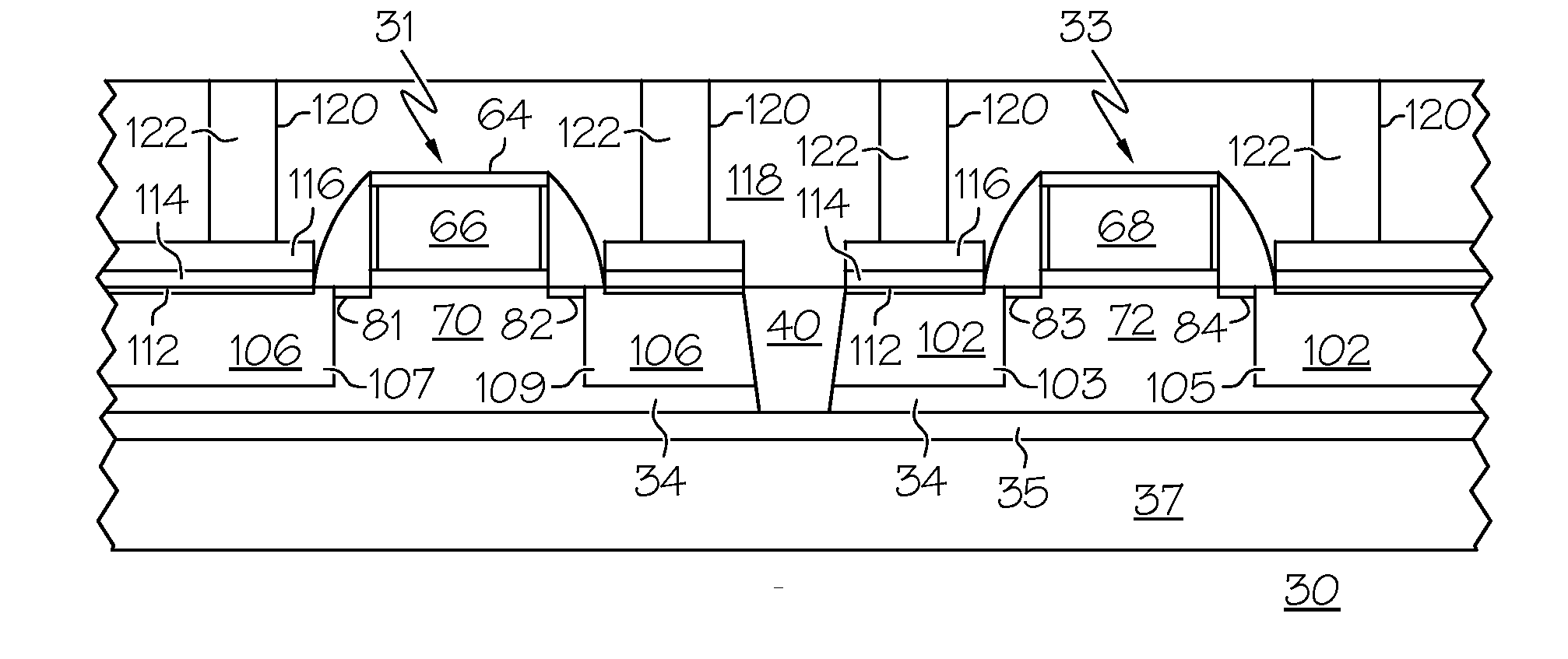

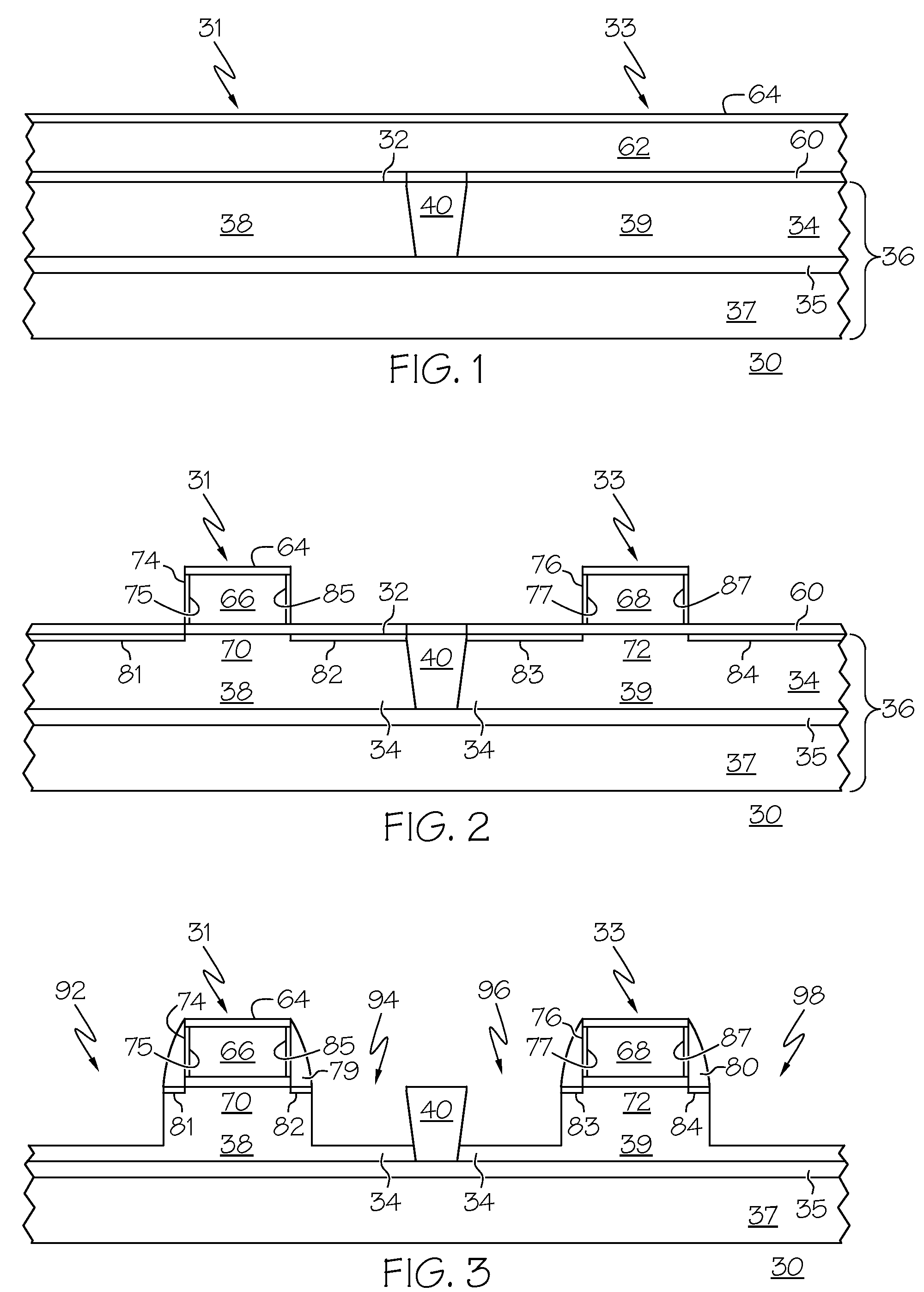

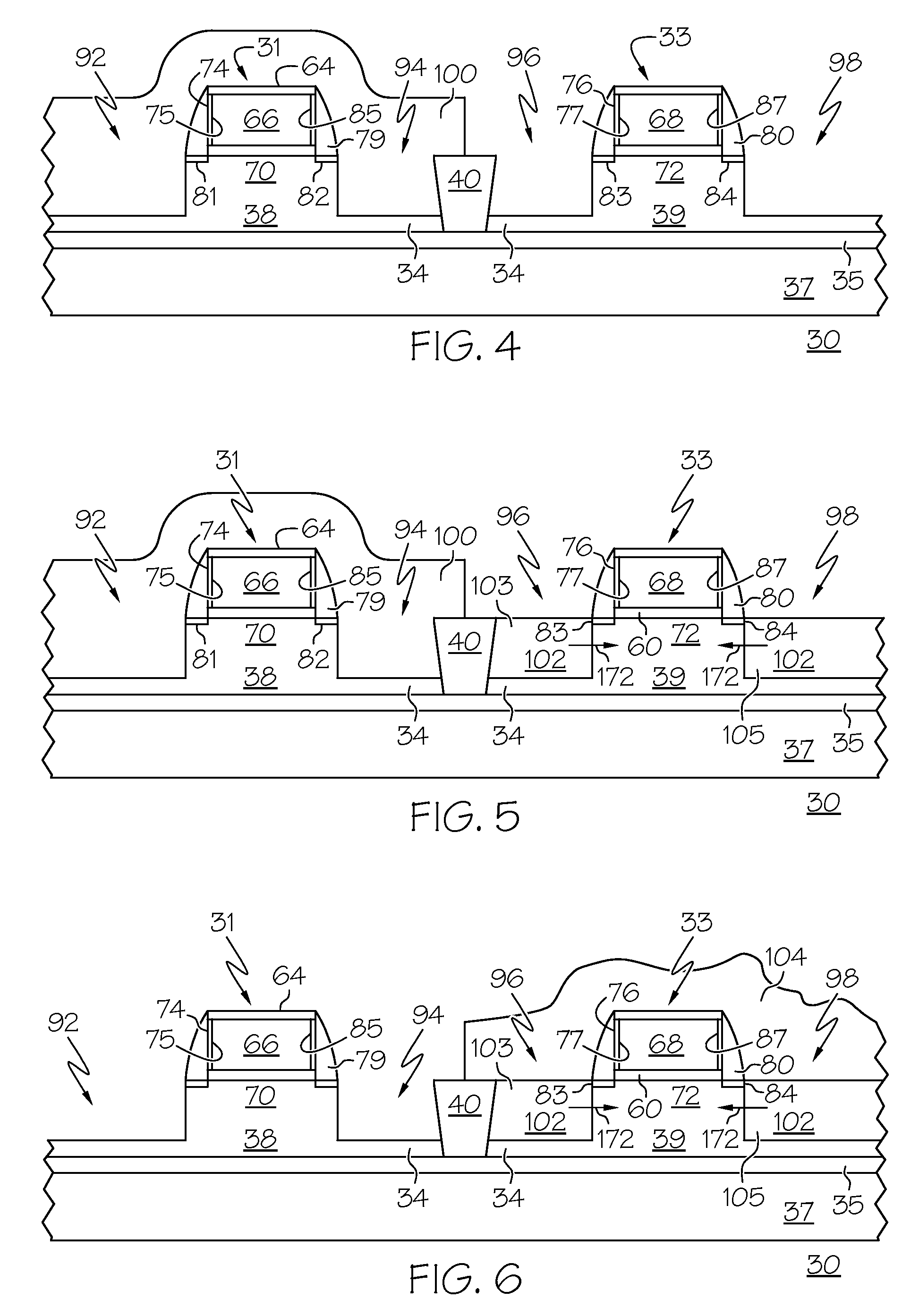

Strain enhanced semiconductor devices and methods for their fabrication

ActiveUS20080251851A1Not to relieve induced strainInduce strainSolid-state devicesSemiconductor/solid-state device manufacturingThin metalSalicide

A strain enhanced semiconductor device and methods for its fabrication are provided. One method comprises embedding a strain inducing semiconductor material in the source and drain regions of the device to induce a strain in the device channel. Thin metal silicide contacts are formed to the source and drain regions so as not to relieve the induced strain. A layer of conductive material is selectively deposited in contact with the thin metal silicide contacts, and metallized contacts are formed to the conductive material.

Owner:ADVANCED MICRO DEVICES INC

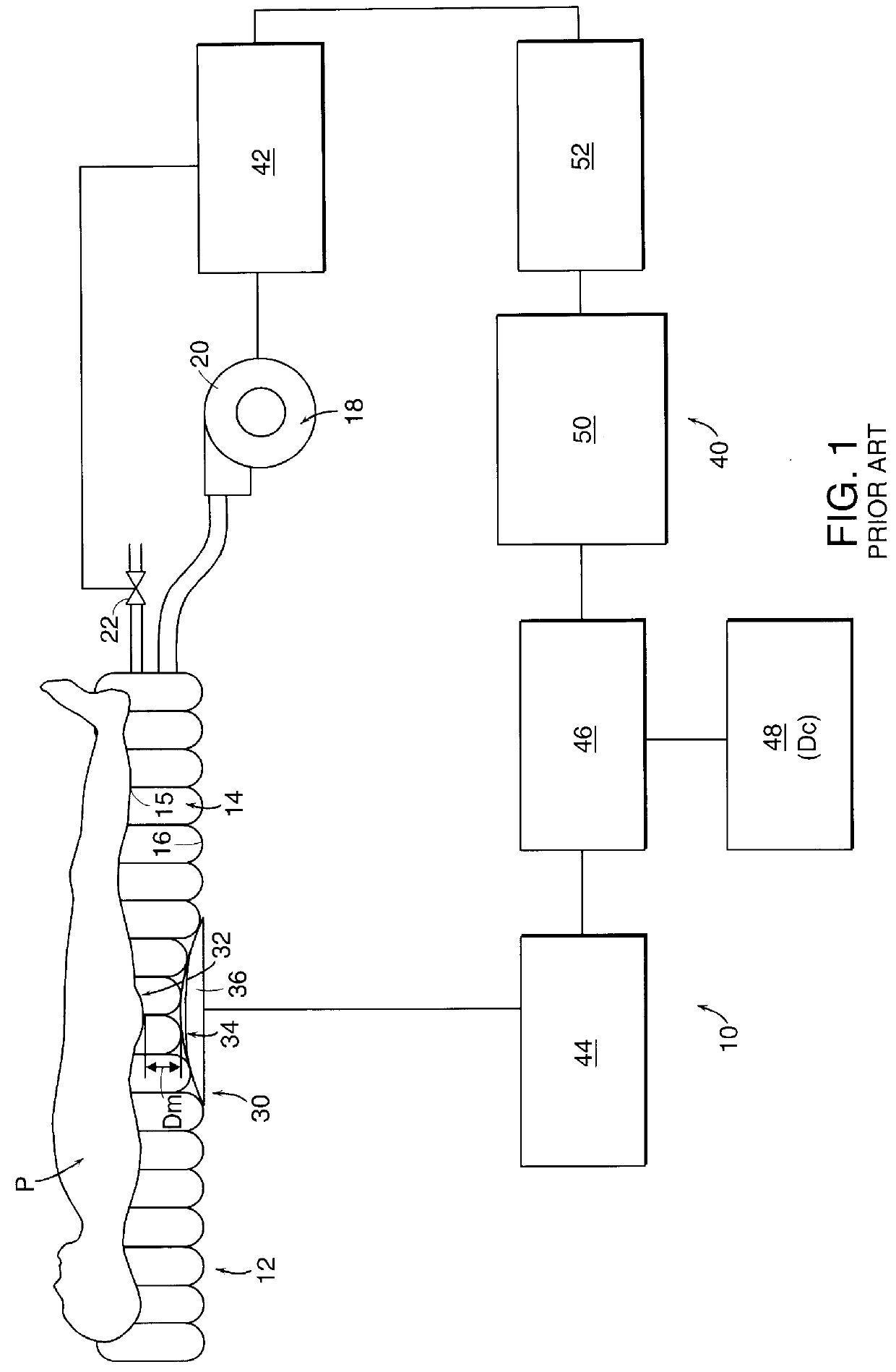

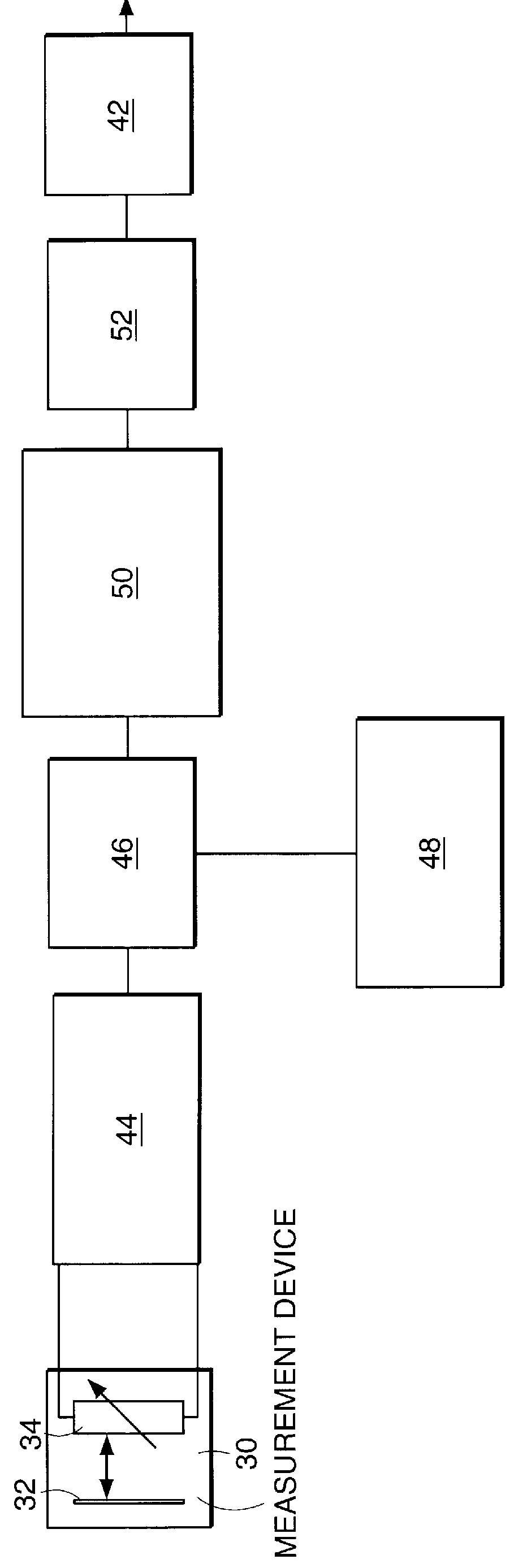

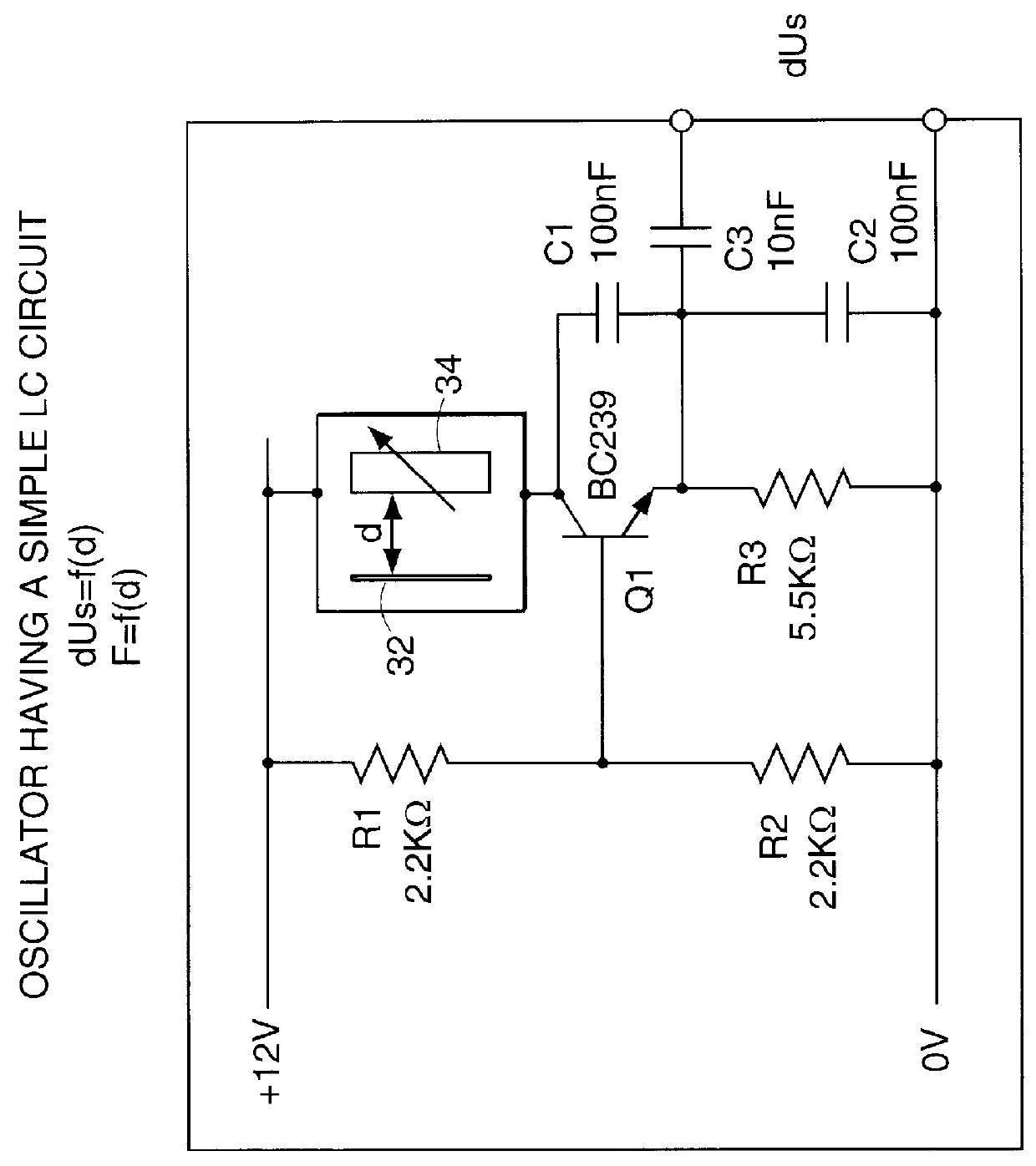

Apparatus for controlling the inflation pressure of a mattress in response to deformation of the mattress using impedance measurement

InactiveUS6034526AImprove electromagnetic compatibilityReduce riskStuffed mattressesOperating chairsControlled releaseThin metal

A method and apparatus for supporting a patient on a mattress. The apparatus includes a mattress which has at least one controlled release chamber with a top face and a bottom face. A flexible film of a thin metal foil is linked to the top face, while at least one impedance varying device is linked to the bottom face of the chamber. The impedance varying device is an integral part of a measuring electronic bridge. Changes in the impedance as a result of movement of the top face with respect to the bottom face activates a servo control which increases or decreases the inflation pressure within the chamber to make certain that the distance between the top face and the bottom face of the chamber is maintained at a predetermined distance. The method of this invention includes the steps of providing a mattress having at least one closed or controlled release chamber having a top face and a bottom face, providing a measurement device which includes a flexible film of a thin metal foil linked to the top face of the chamber and cooperating with at least one impedance varying element linked to the bottom face of the chamber, the impedance varying element being integral with a measuring electronic bridge, and measuring spacing between the top face and the bottom face to provide control of the supporting action of the mattress as a function of the patient's morphology and position on the mattress.

Owner:HILL ROM INDS

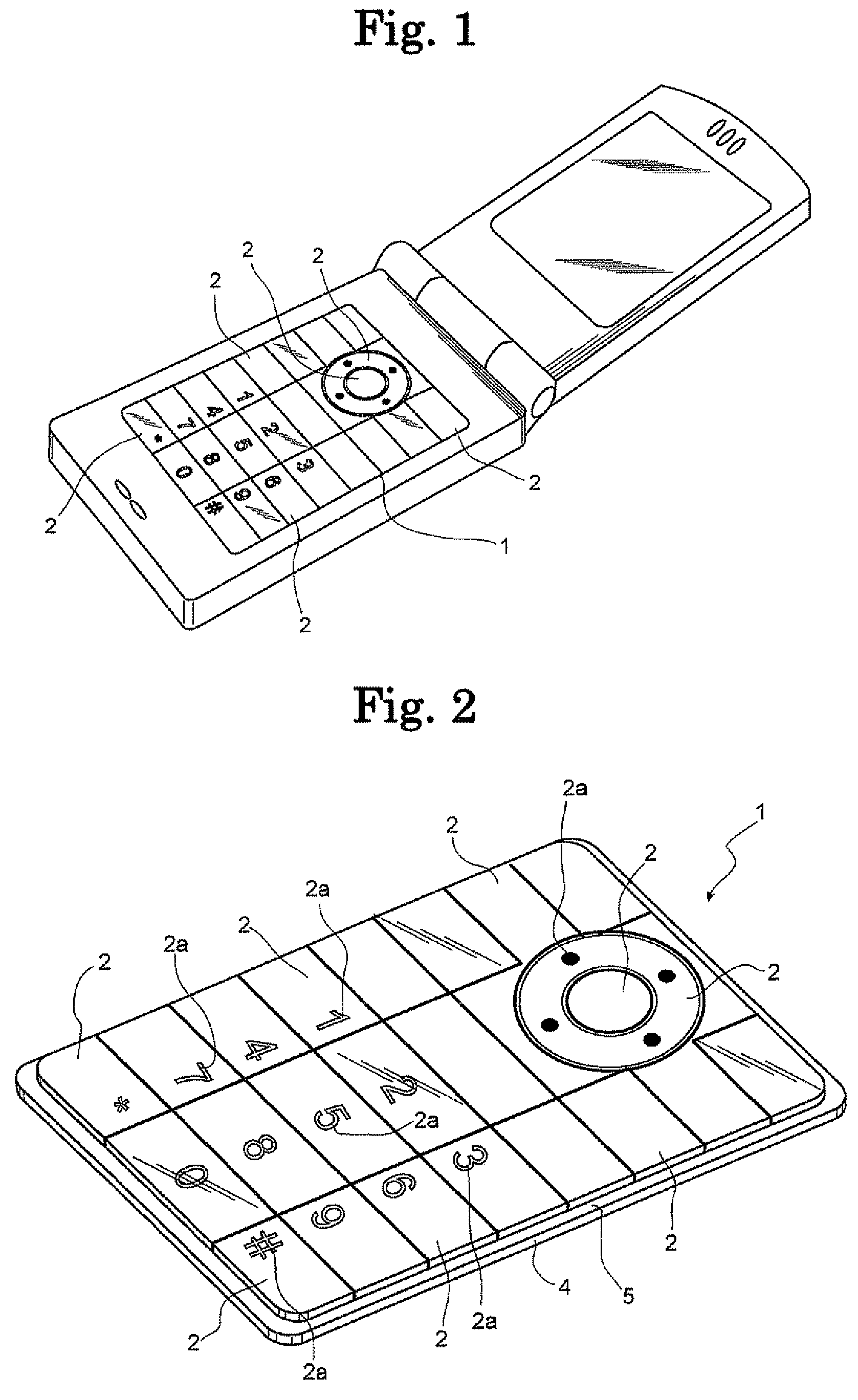

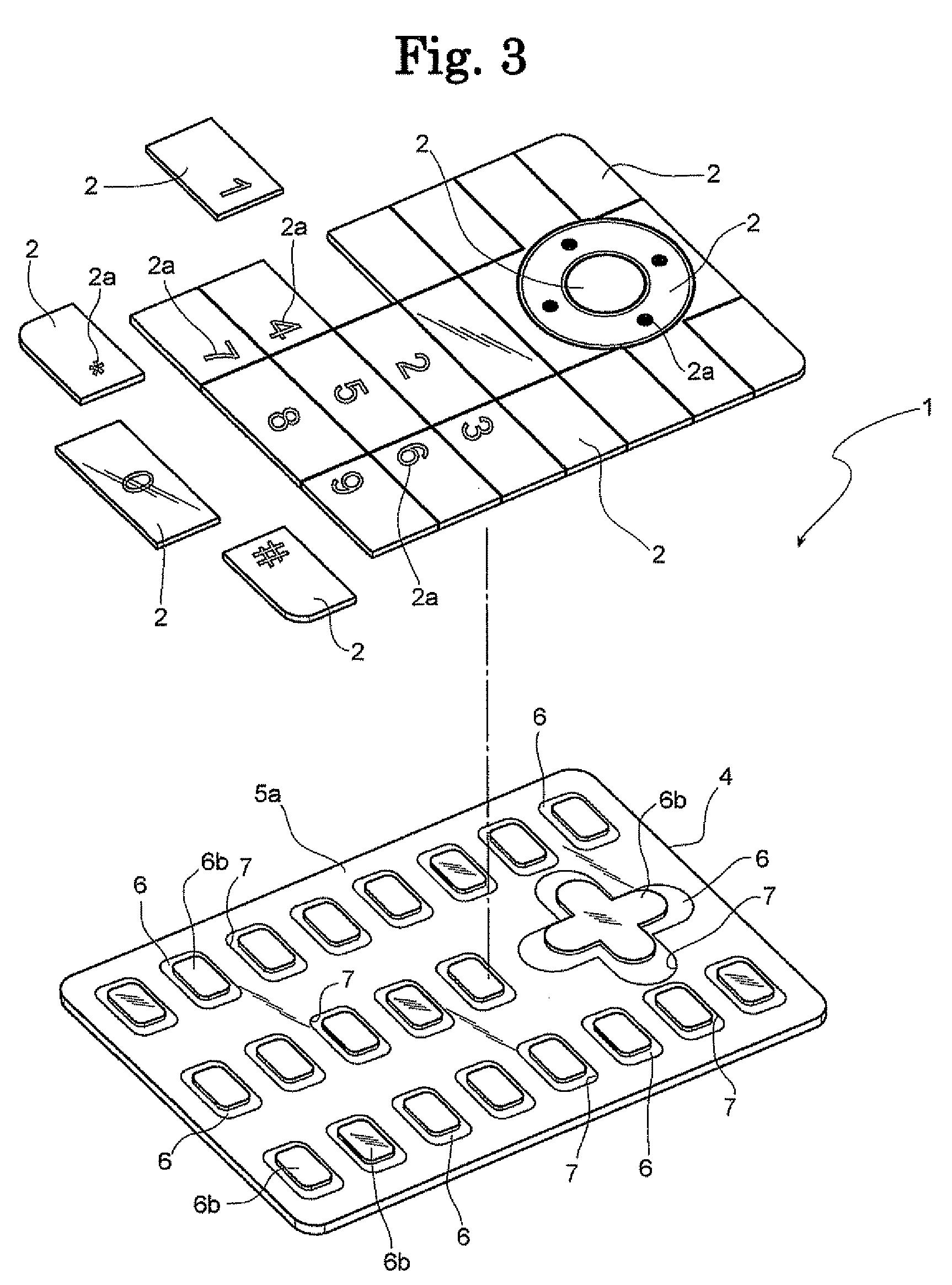

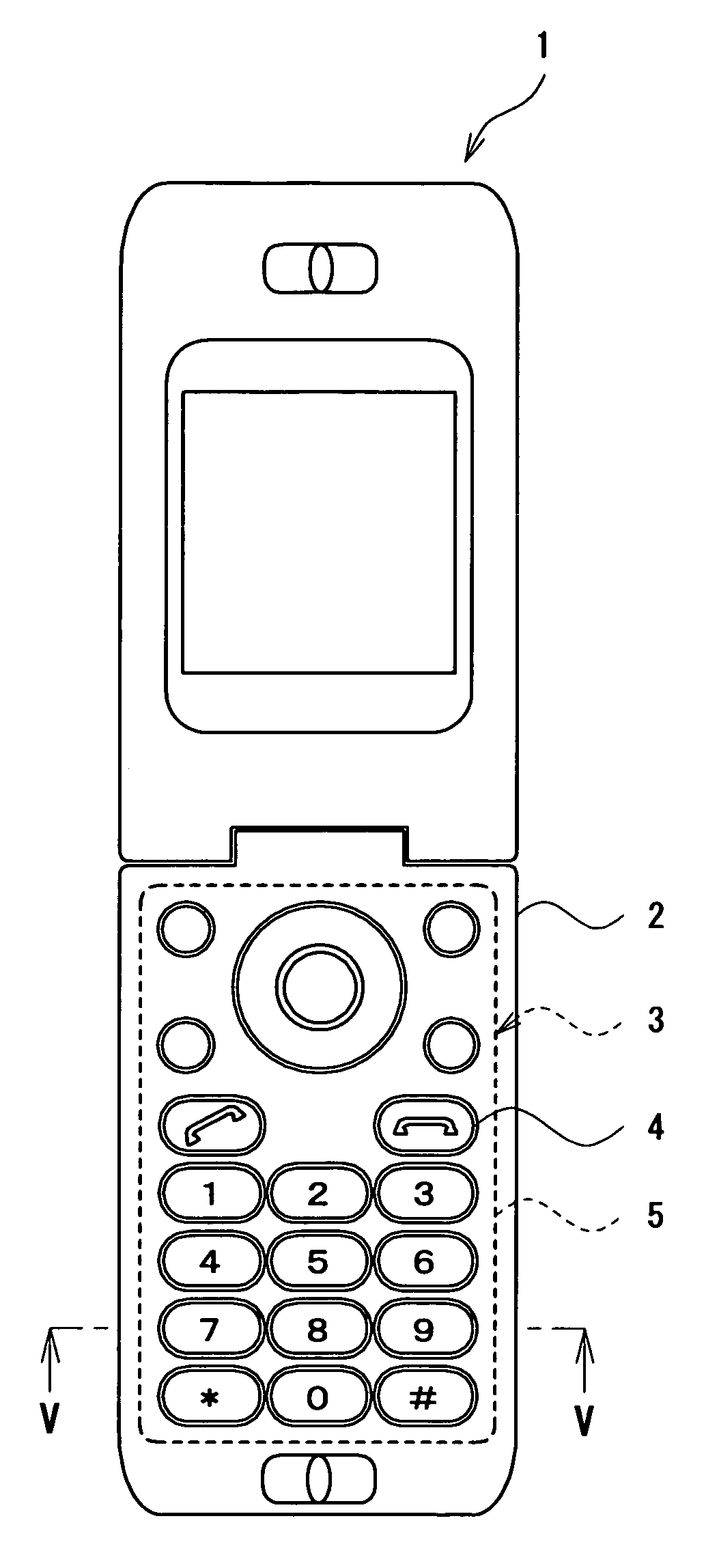

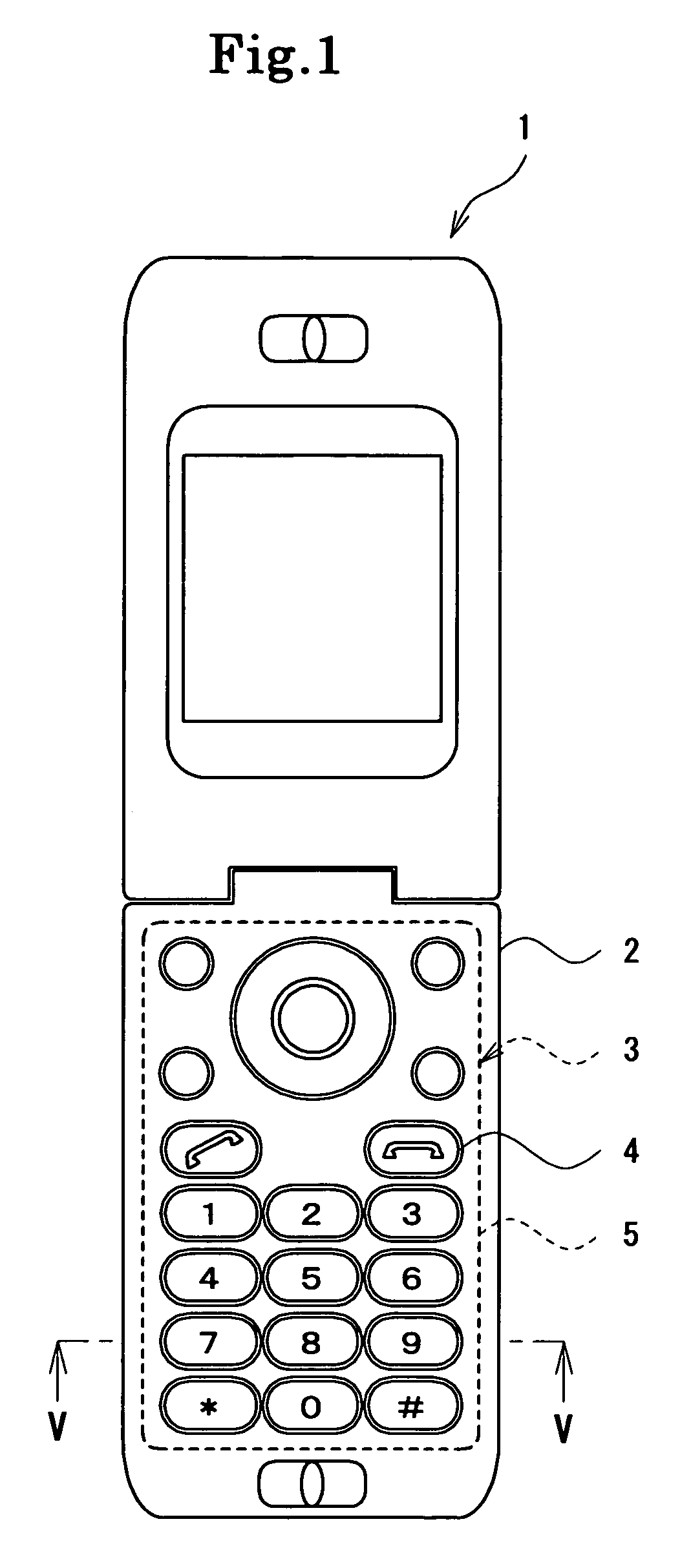

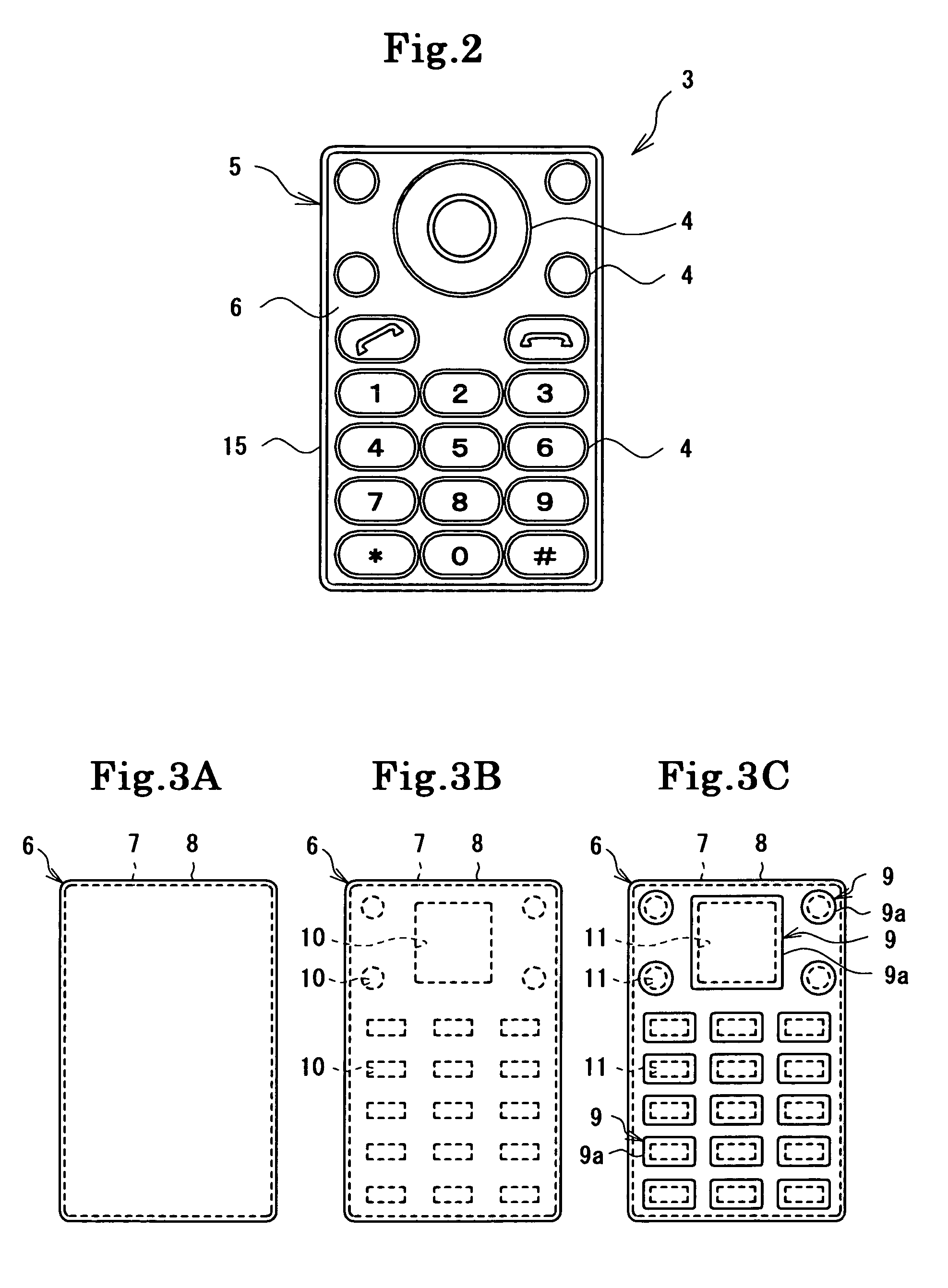

Key sheet and production method thereof

Portable phones are getting a trend that s design and thinner configuration becomes more important. Therefore, in order to meet this demand, the entire key top is made of a thin metal, and a thin resin layer is provided on the back surface of the key top and further letter holes are filled with a resin. According to those, the adhesiveness of the key top is improved as well as improvement of hand feeling. In addition, a printed layer for coloring the letters can be provided on the back surface of the key top.

Owner:SUNARROW CO LTD

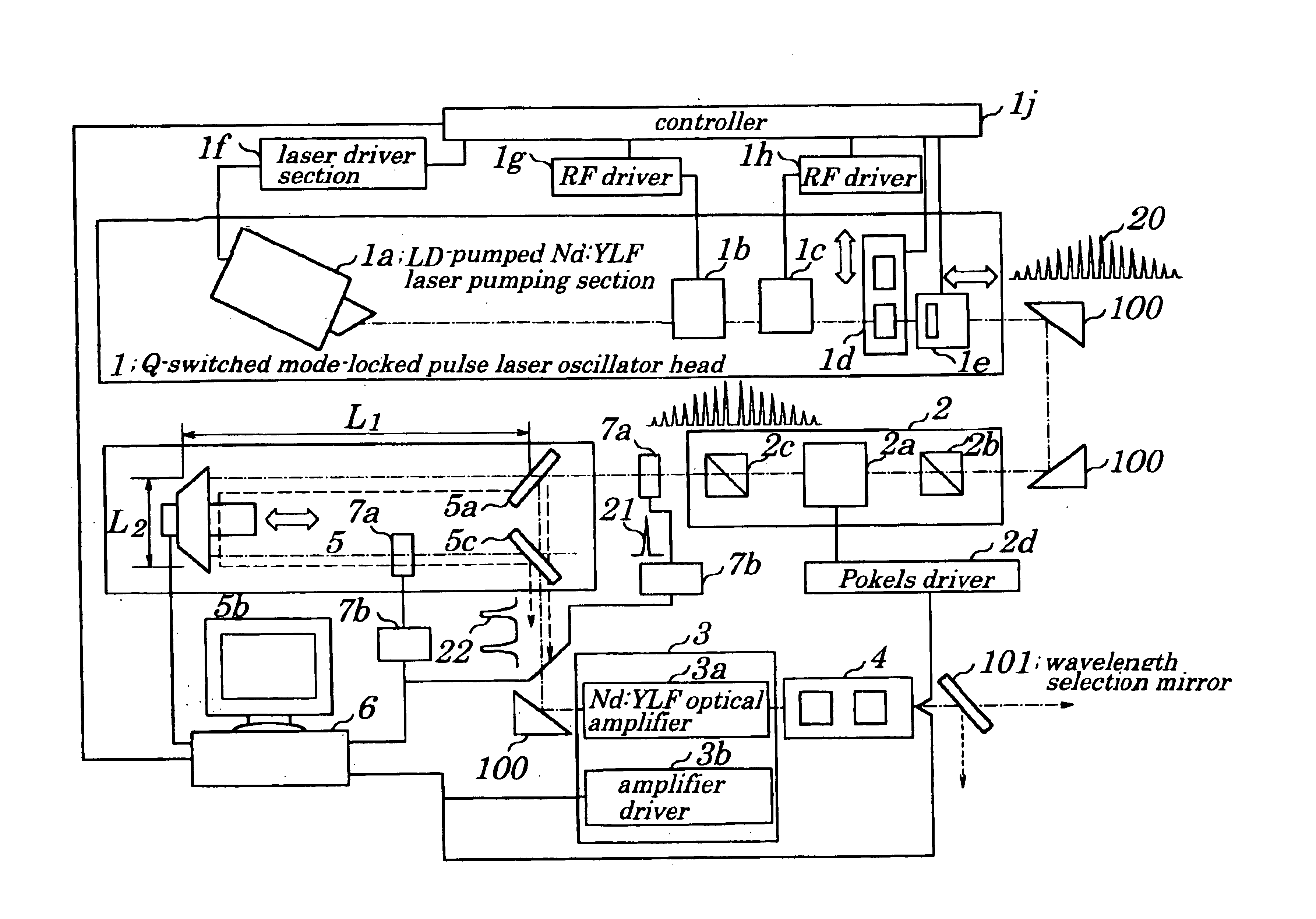

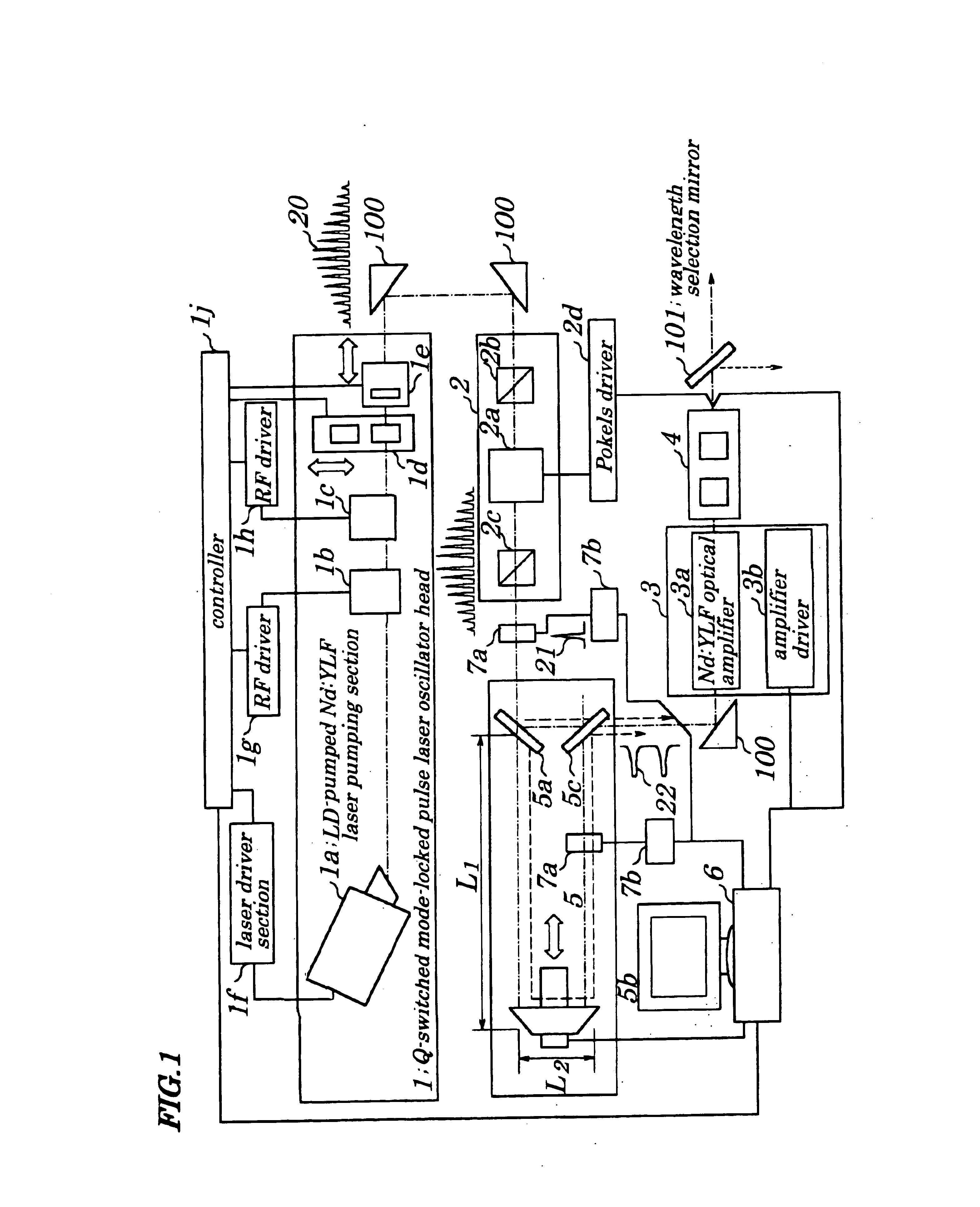

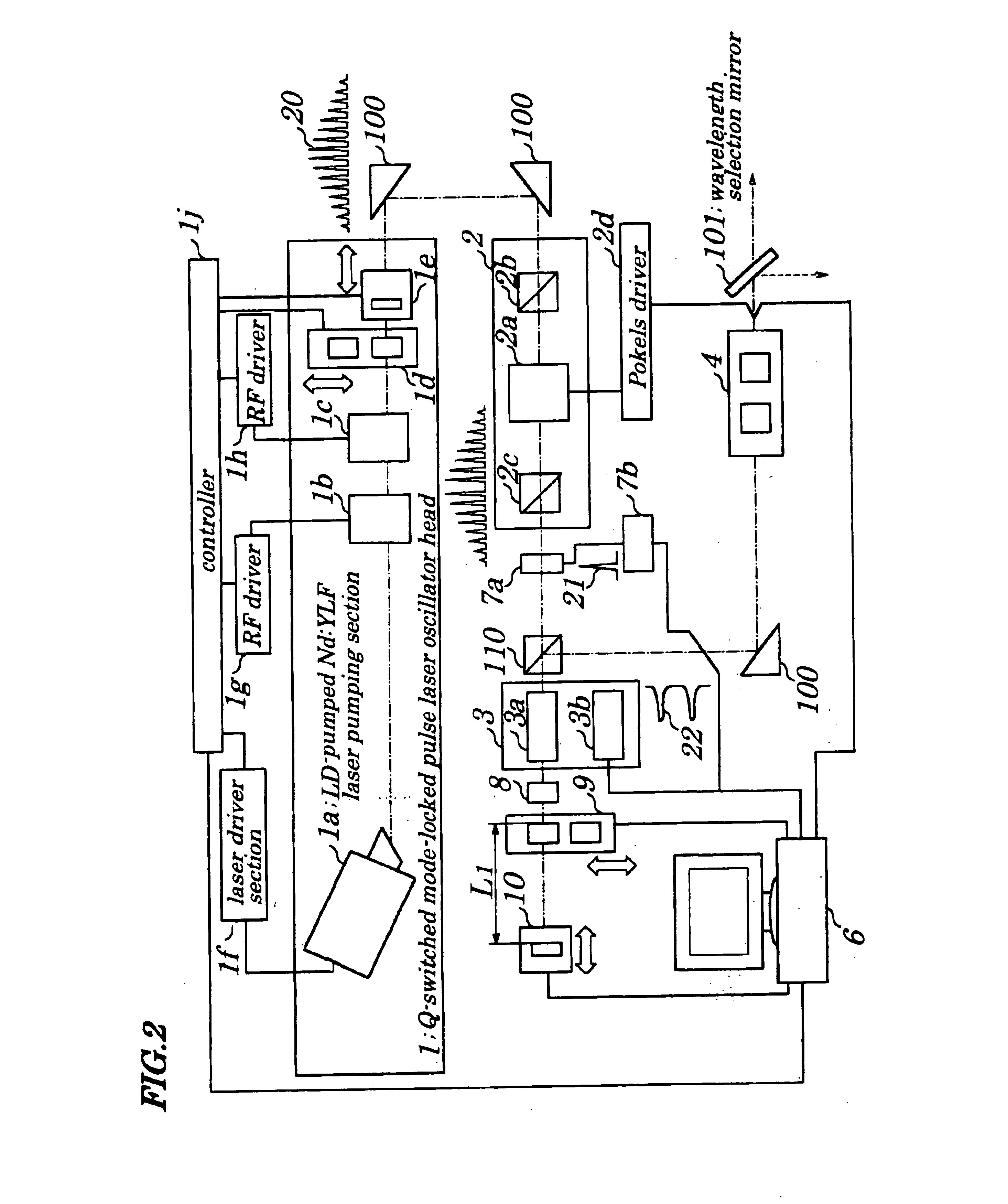

Method and apparatus for performing pattern defect repair using Q-switched mode-locked pulse laser

InactiveUS6879605B2Less heatPromote repairLaser detailsSemiconductor/solid-state device detailsThin metalOptoelectronics

A method for repairing a pattern by using a laser and a laser-based pattern repair apparatus are provided which are capable of reducing splashes, rolling-up, and damage to a glass substrate to a minimum in pattern defects repairing processing by removing a thin metal layer such as a chromium layer. A part of a string of pulses obtained by slicing, using an optical shutter, pulses from laser light having a pulse width of 10 ps to 300 ps emitted from a Q-switched mode-locked pulse laser is used to produce multi-pulses which are divided into two portions in terms of time base correction using an optical delaying unit.

Owner:NEC CORP

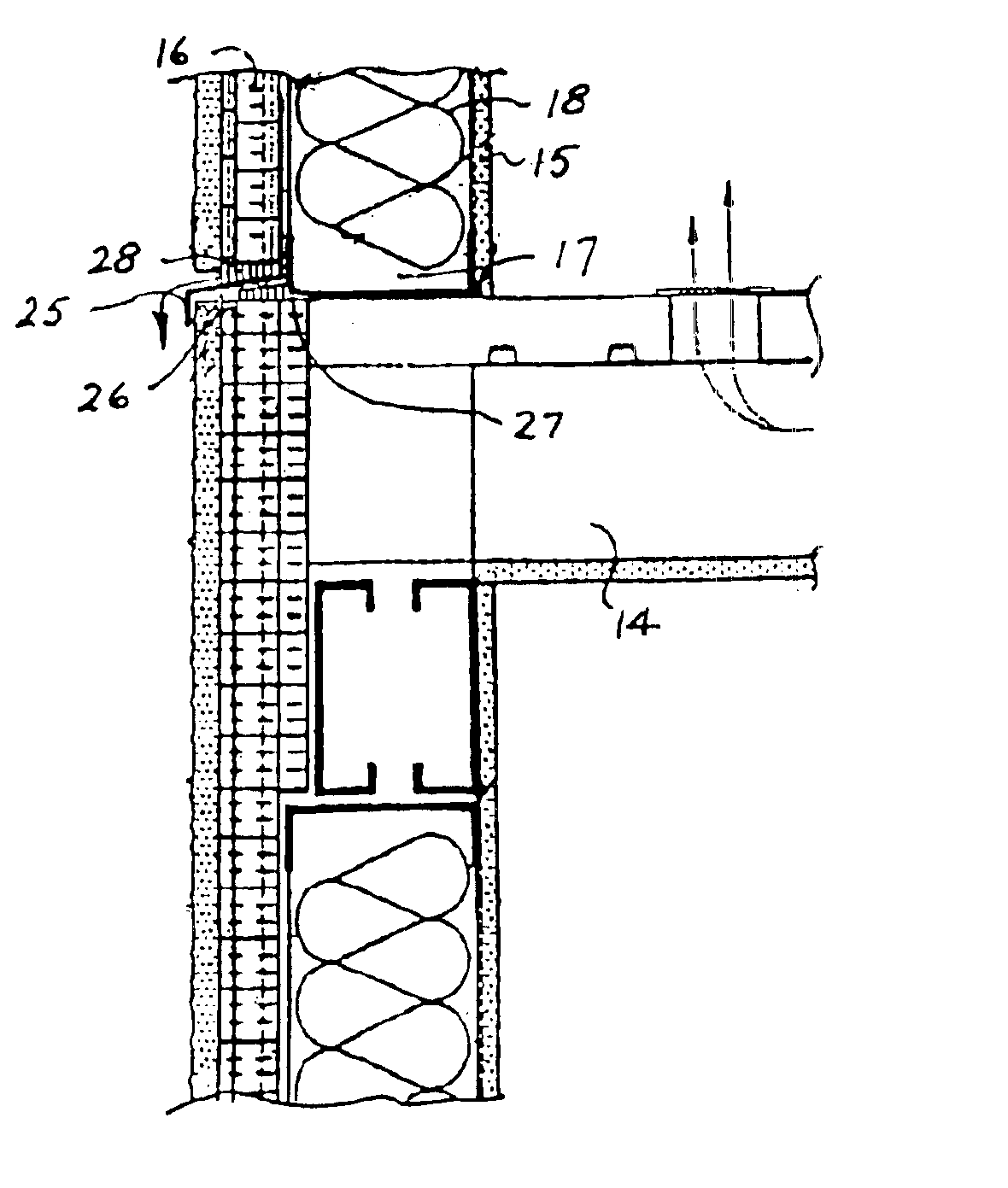

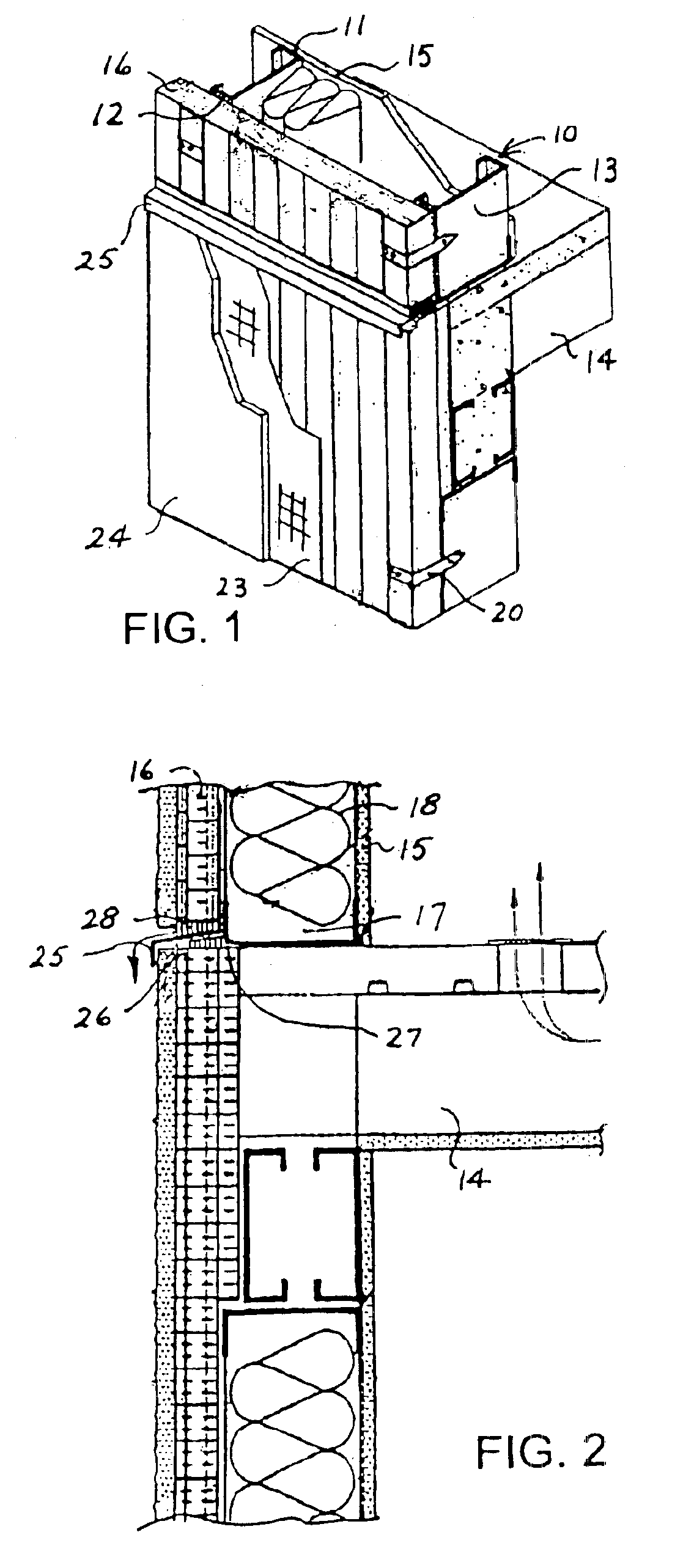

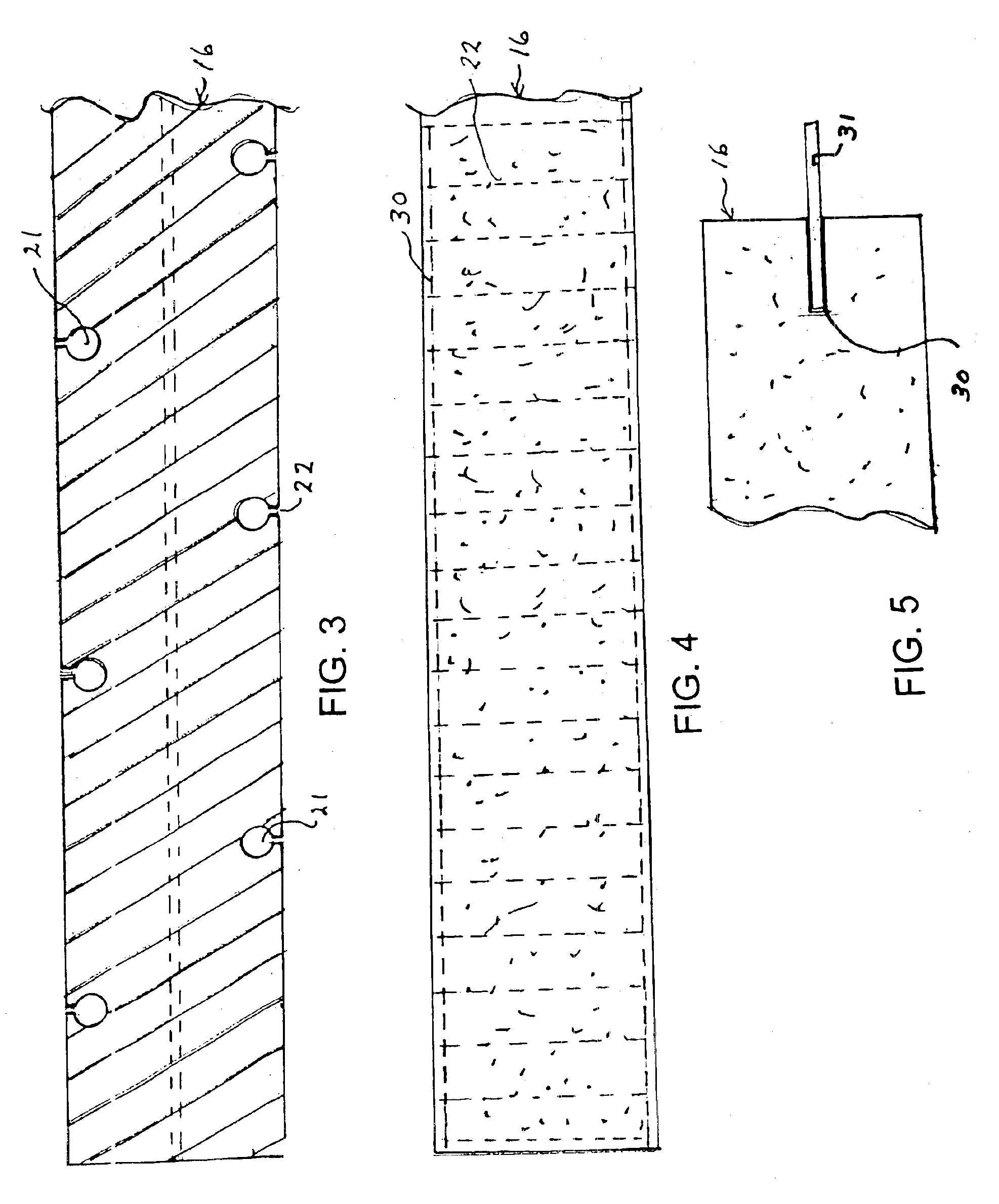

Exterior building cladding having rigid foam layer with drain channels

InactiveUS6886301B2Reduce conductivityStructural failureCeilingsConstruction materialInsulation layerSteel frame

A novel building construction is described for exterior building walls. The construction comprises an interior frame formed of a plurality of laterally spaced studs or beams, a layer of rigid insulation adjacent to the exterior side of this steel frame, exterior building cladding adjacent the exterior side of the rigid insulation and a plurality of low conductivity connectors, e.g. insulating plastic connectors or thin metal strips having an insulating plastic foam coating, extending through the layer of rigid insulation and connecting together the exterior cladding and the interior steel studs or beams. Vertical channels are formed adjacent both the inside and outside faces of the insulation layer to remove moisture. This provides the required structural strength with a minimum of thermal conductivity from the warm side to the cold side of the building envelope, while providing exterior drain channels and interior moisture removing channels.

Owner:SCHILGER HERBERT K

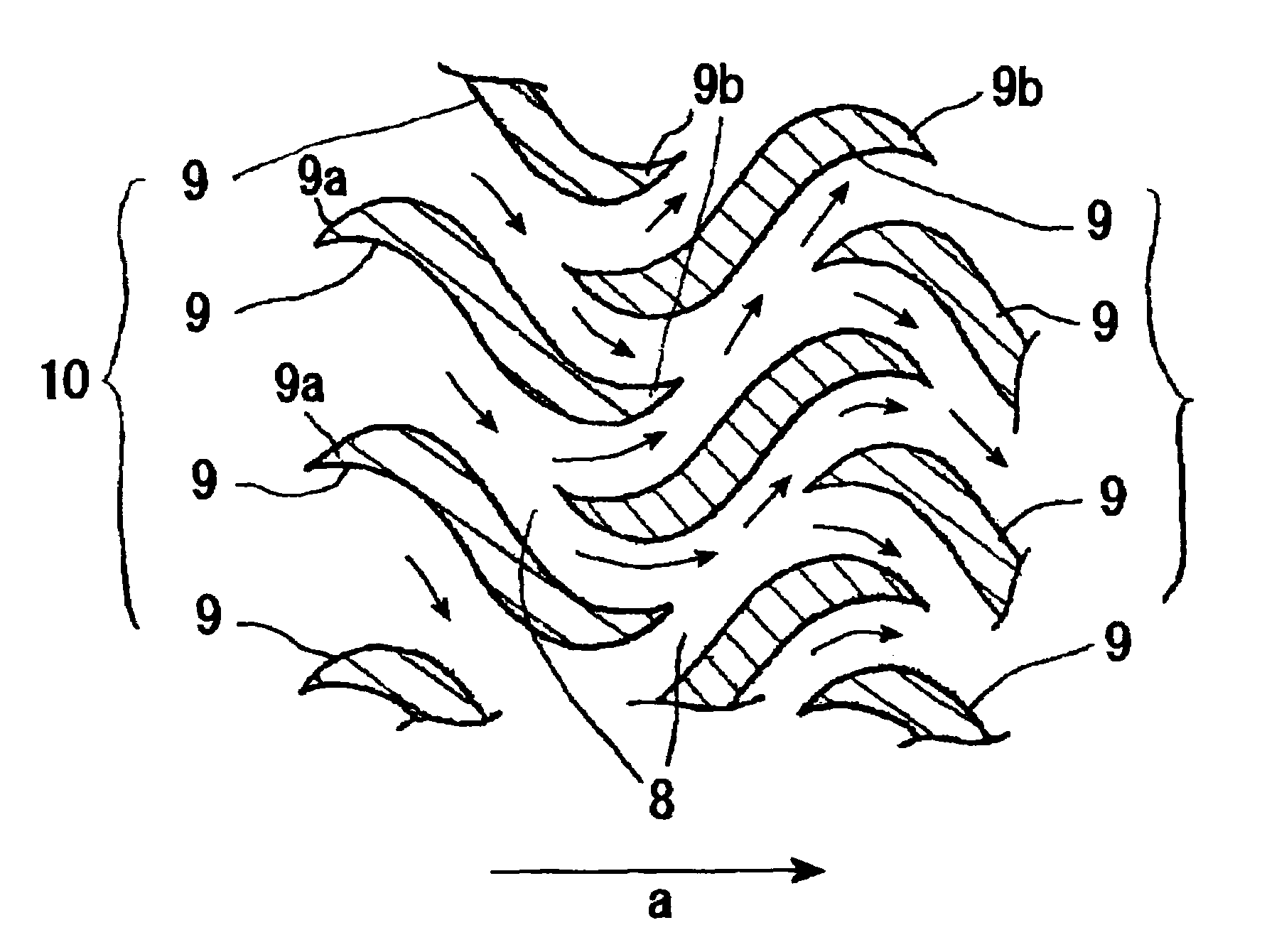

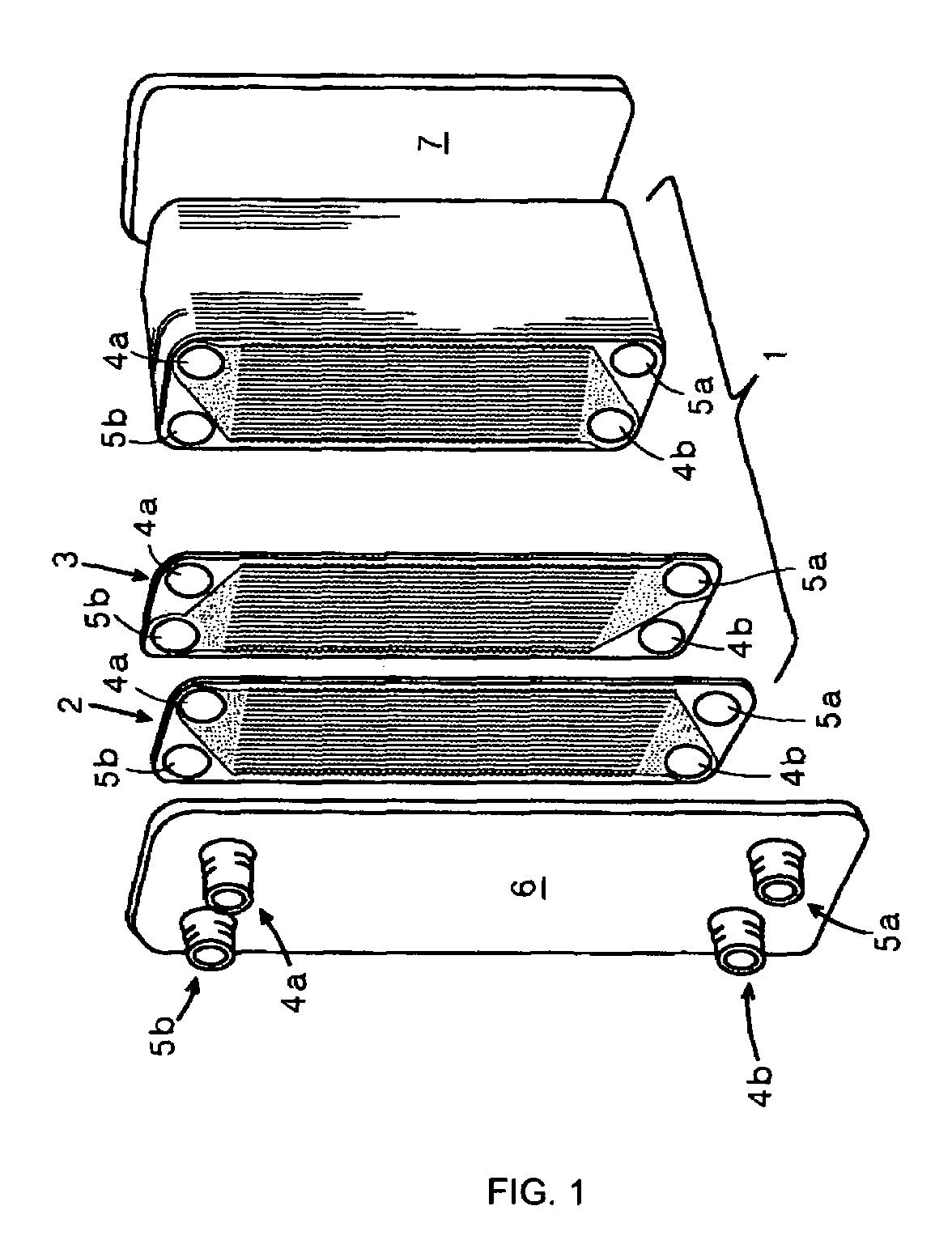

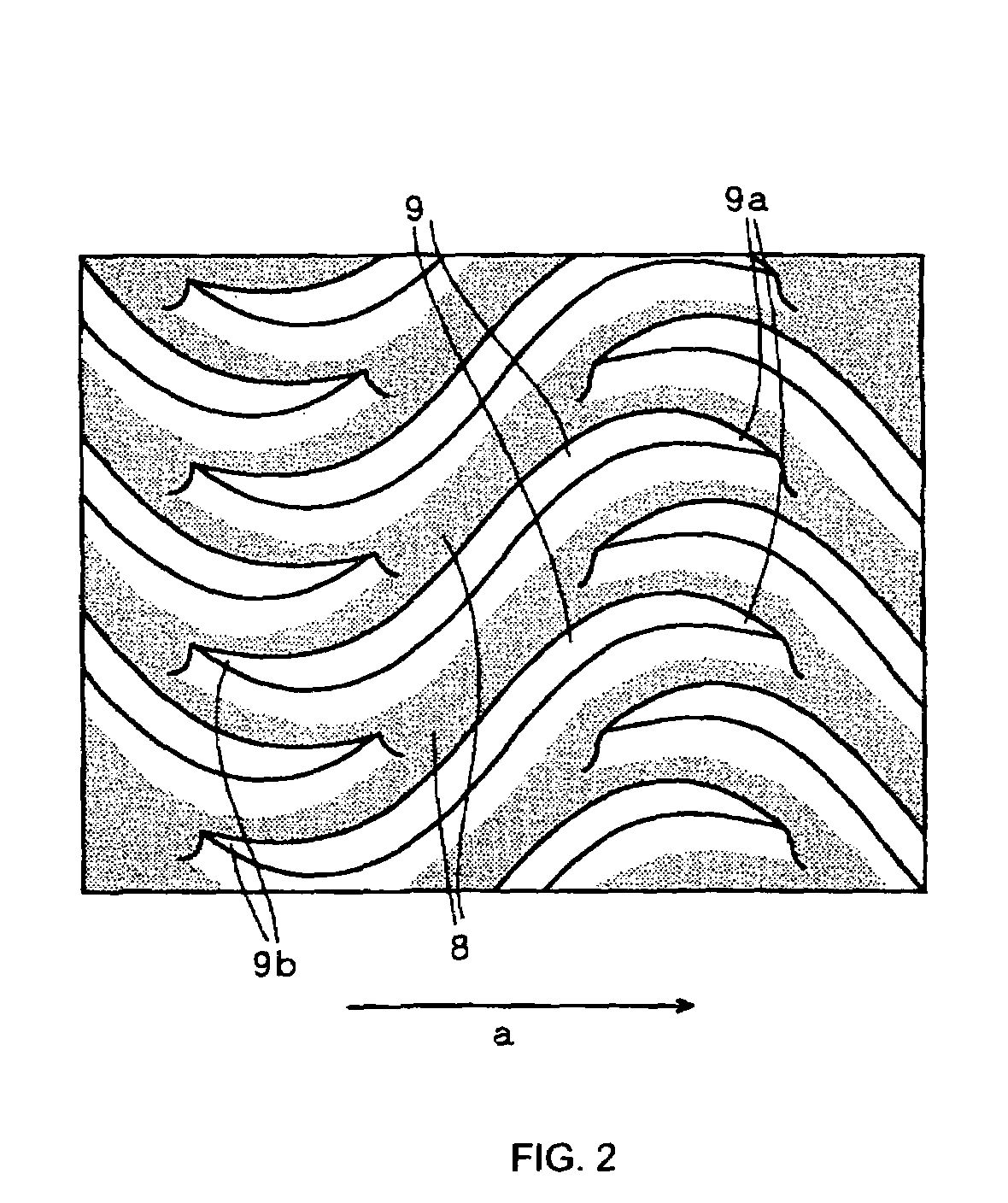

Heat exchanger

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

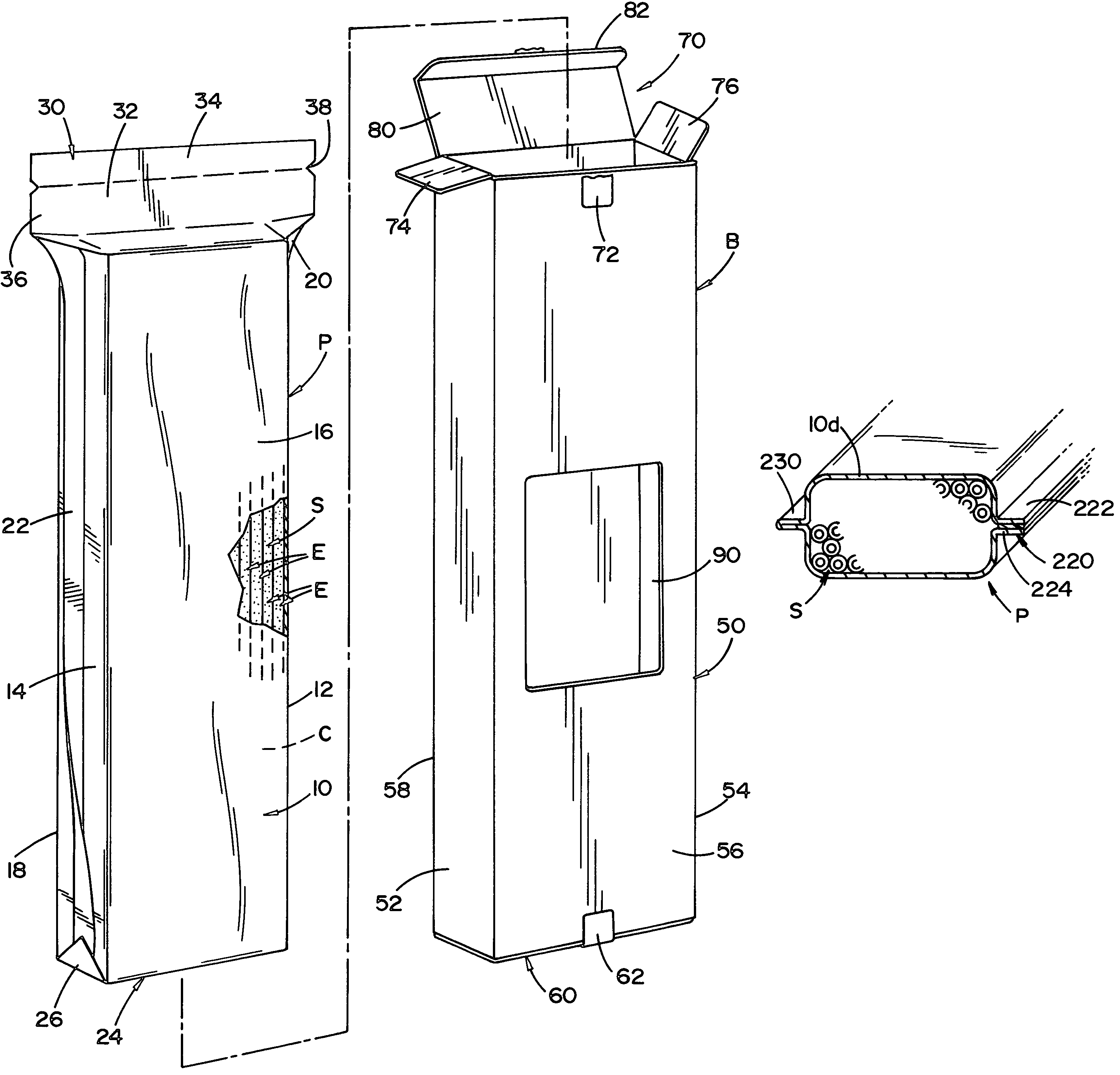

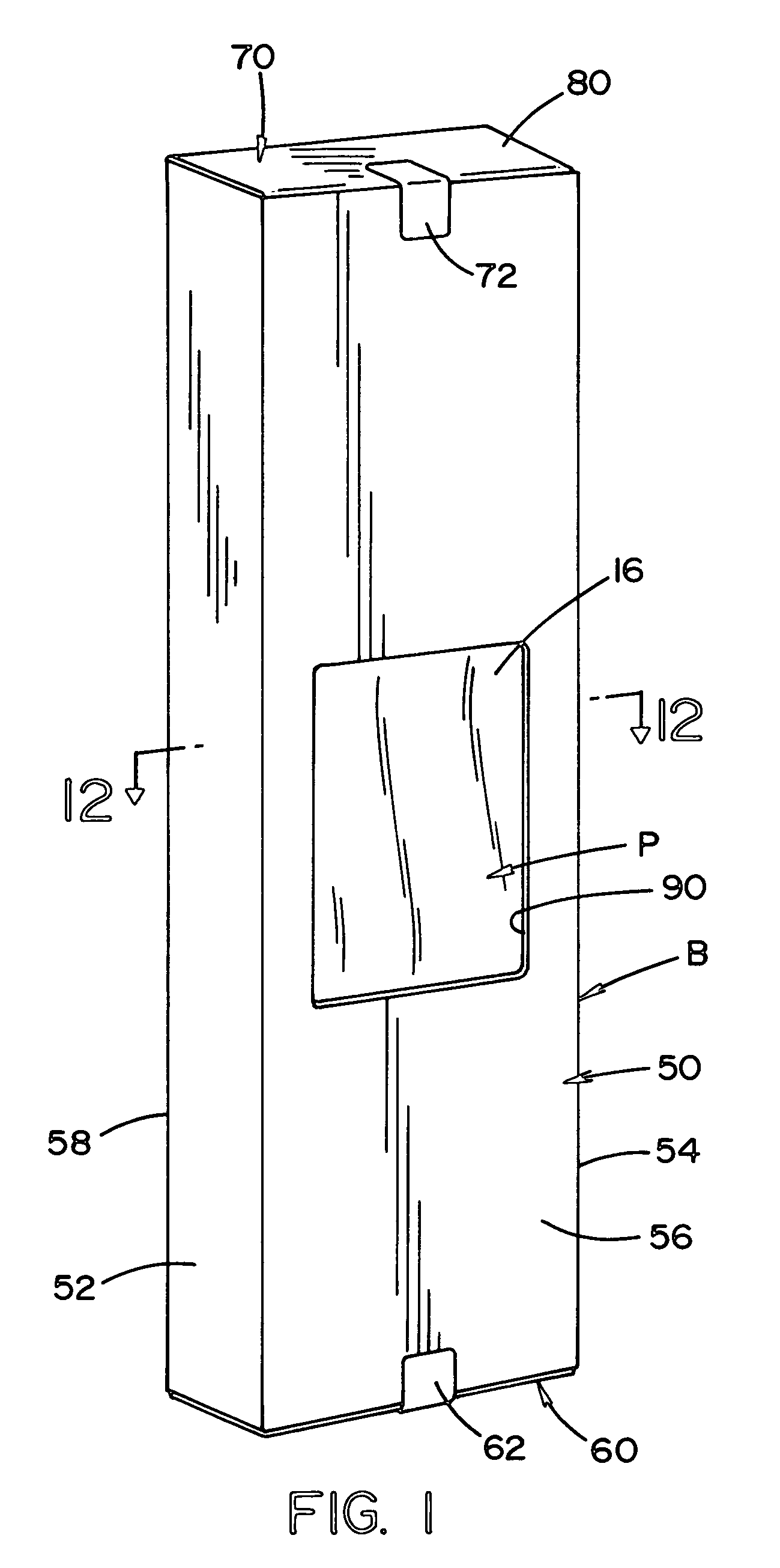

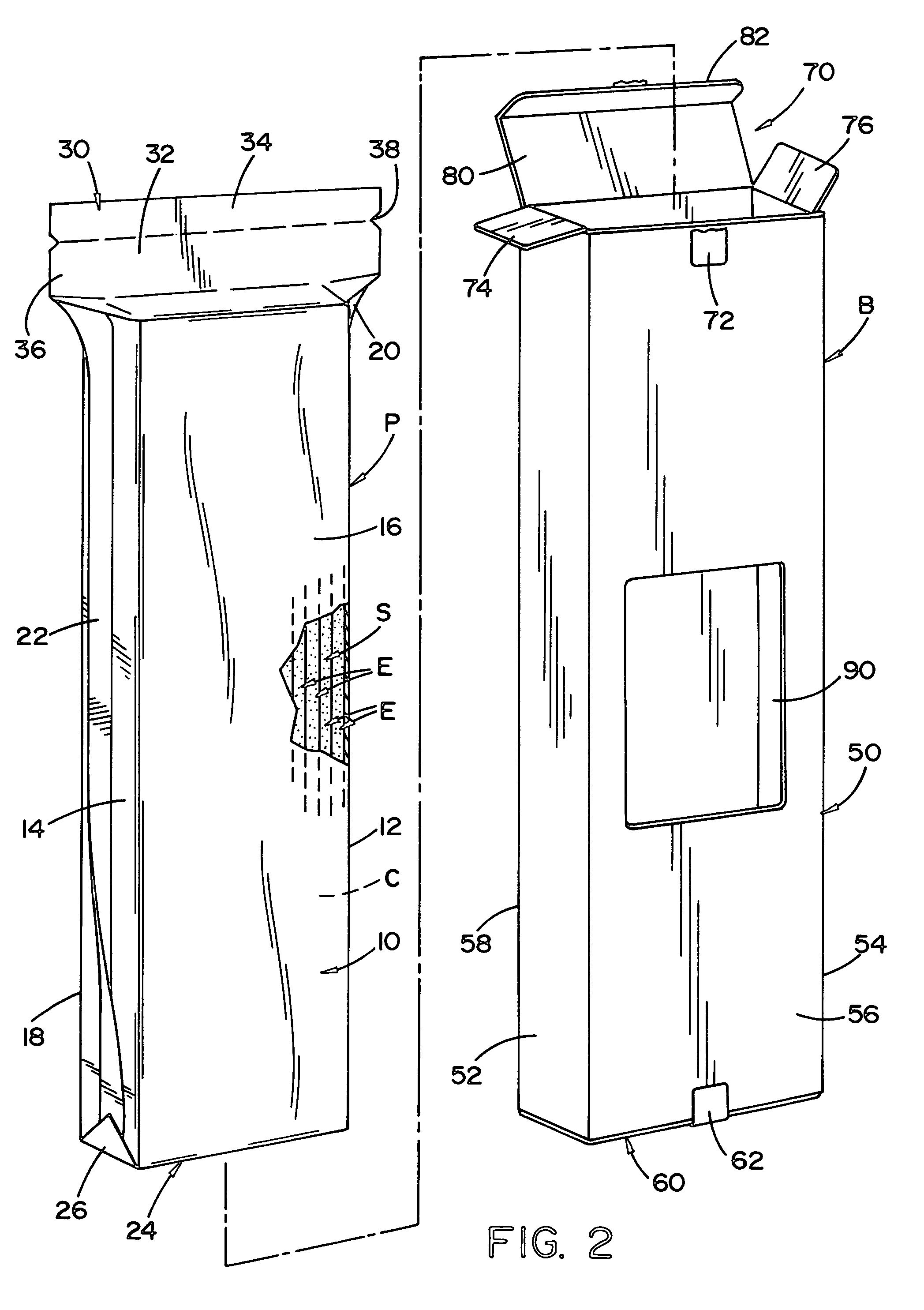

Package for stick electrodes

A package for a compacted stack of stick electrodes comprising a thin metal foil encapsulating the stack with at least one axial seam and two end closures. One end closure includes a generally flat end portion extending from the stack and terminating in a sealed section of the metal foil spaced outwardly from the stack. The flat end portion including a structure to open the package for access to the stack of electrodes. This package is used in combination with an elongated shipping carton with a vision opening exposing a package therein.

Owner:LINCOLN GLOBAL INC

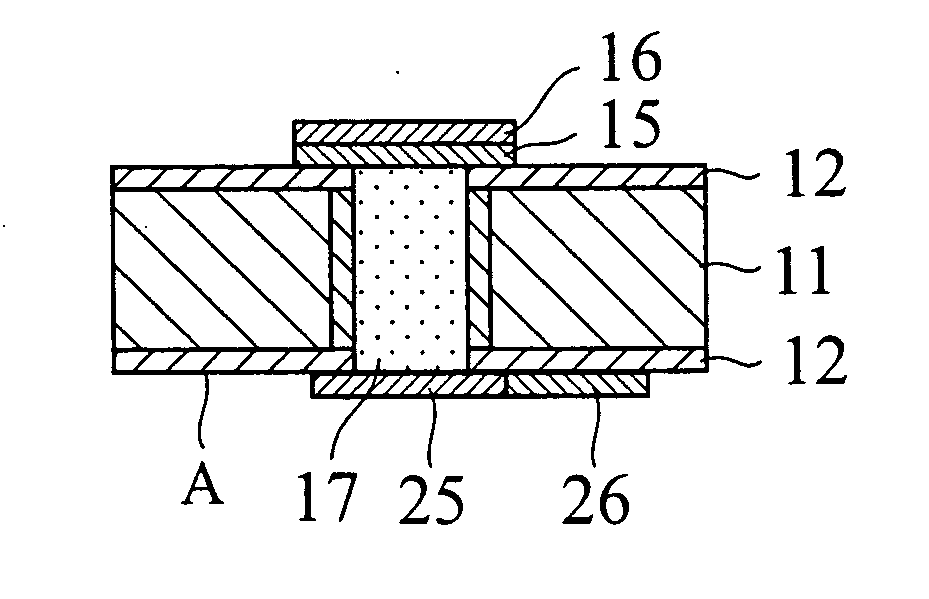

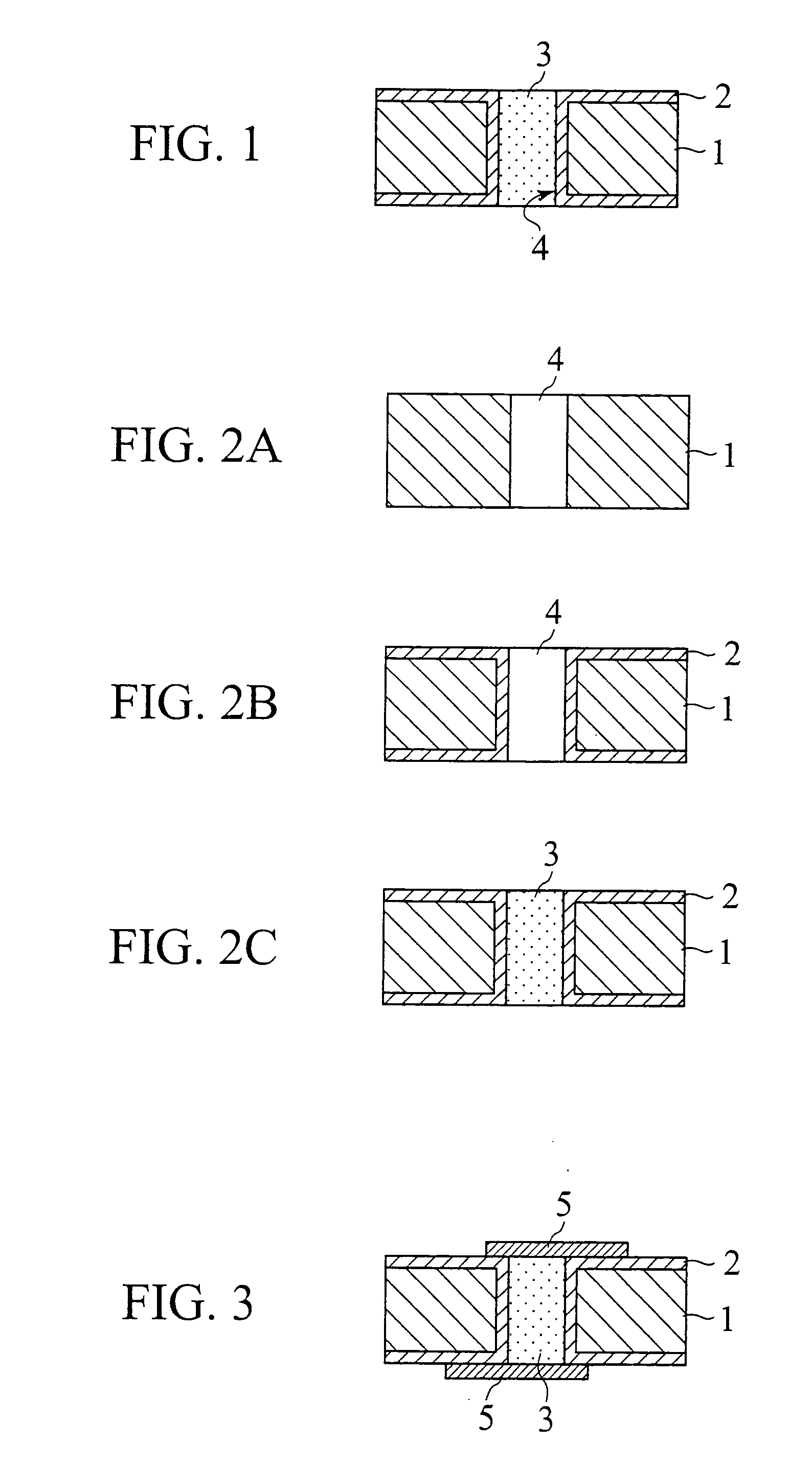

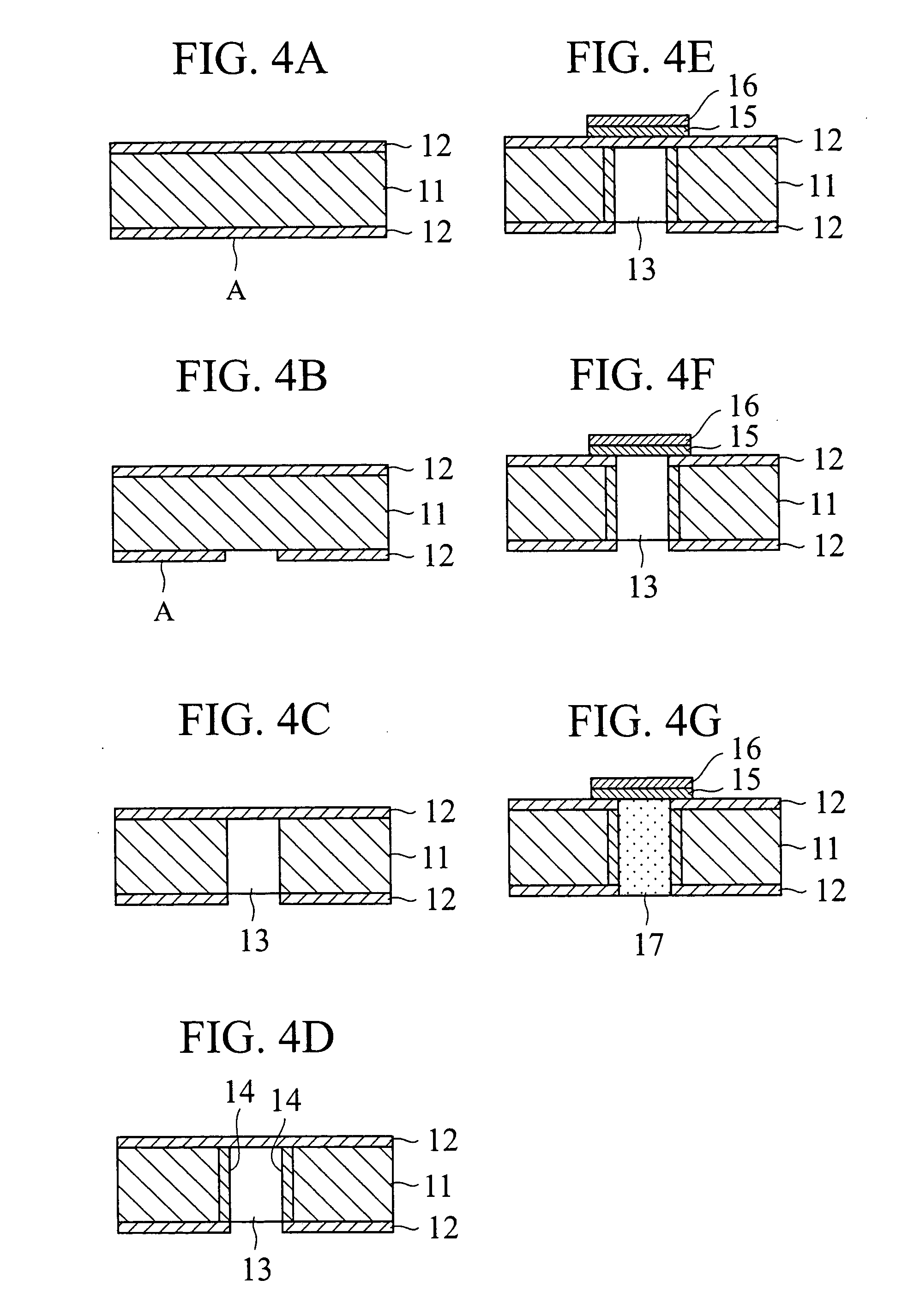

Manufacturing method of a semiconductor substrate provided with a through hole electrode

ActiveUS20040043615A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

A manufacturing method of a semiconductor substrate provided with a through hole electrode is proposed. In accordance with the methods, it is possible to effectively form a through hole electrode in a semiconductor substrate in which a device and a wiring pattern have been already fabricated. This manufacturing method includes the steps of forming a first silicon oxide film 12 on a principal surface of the semiconductor substrate 11, forming a small hole 13 through the semiconductor substrate 11 from the opposite the step to reach to the first silicon oxide film 12, covering the inside of the small hole 13 with the second silicon oxide film 14, forming a first thin metal film 15 and a second thin metal film 16 on the first silicon oxide film 12, partially removing the first silicon oxide film 12 corresponding to the end of the small hole 13, and filling the small hole 13 with the conductive material to form a through hole electrode 17.

Owner:THE FUJIKURA CABLE WORKS LTD +1

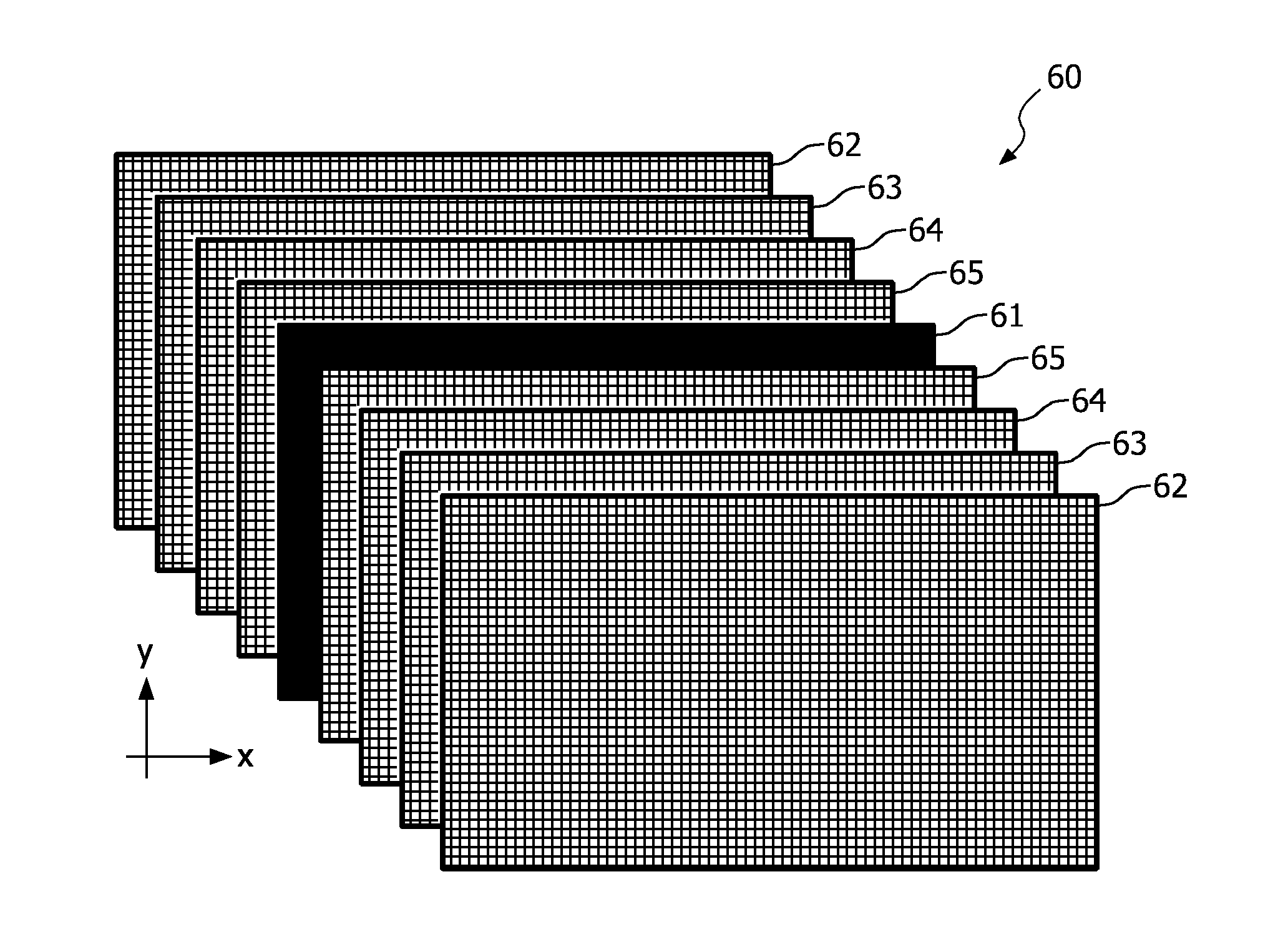

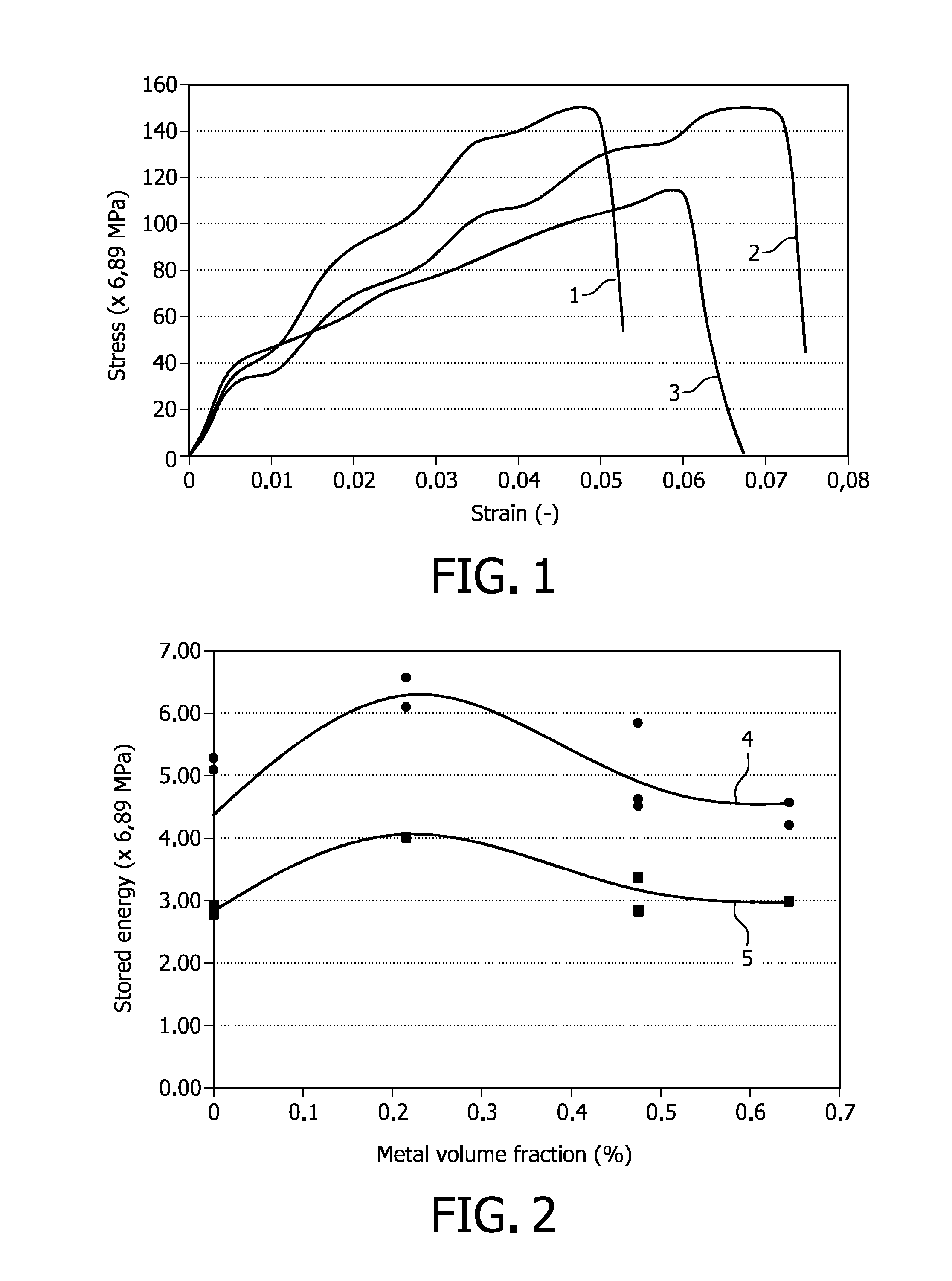

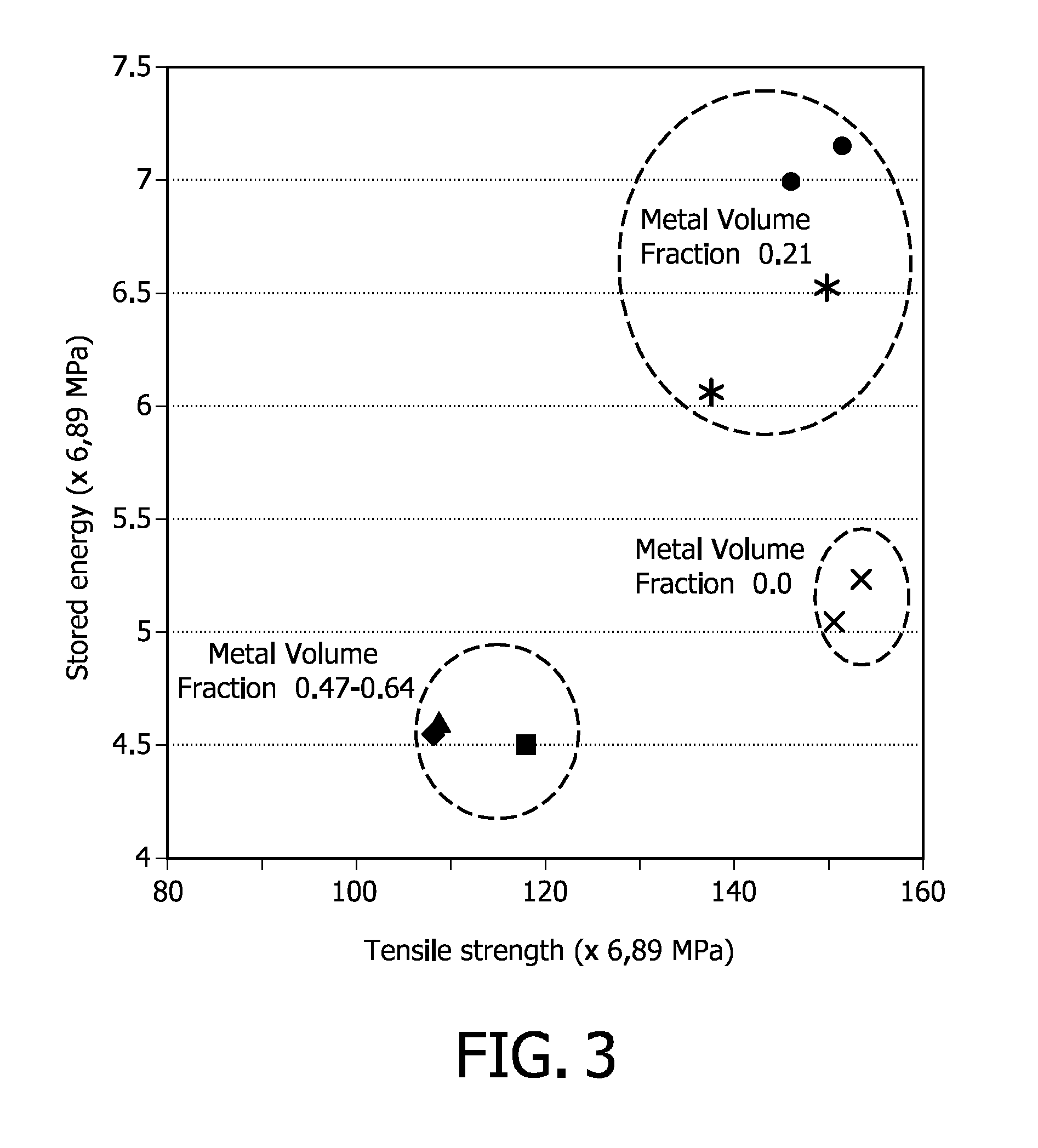

High toughness fiber-metal laminate

InactiveUS20110052910A1Good explosion resistanceReduce weightFilm/foil adhesivesAnimal housingThin metalLeading edge

The invention relates to a fiber-metallaminate comprising fiber-reinforced composite layers and thin metal sheets, wherein the total metal volume fraction of the laminate is between 0 vol. % and 47 vol. %. The fiber-metal laminate according to the invention shows an unprecedented combination of toughness and tensile strength. The laminate is advantageously used in constructing impact resistant objects, such as explosion resistant aircraft luggage containers and wing leading edges.

Owner:GTM HLDG +1

Key sheet

InactiveUS7378607B2Improve conductivityReduce thicknessContact operating partsEmergency protective devicesThin metalGraphite

Owner:POLYMATECH CO LTD

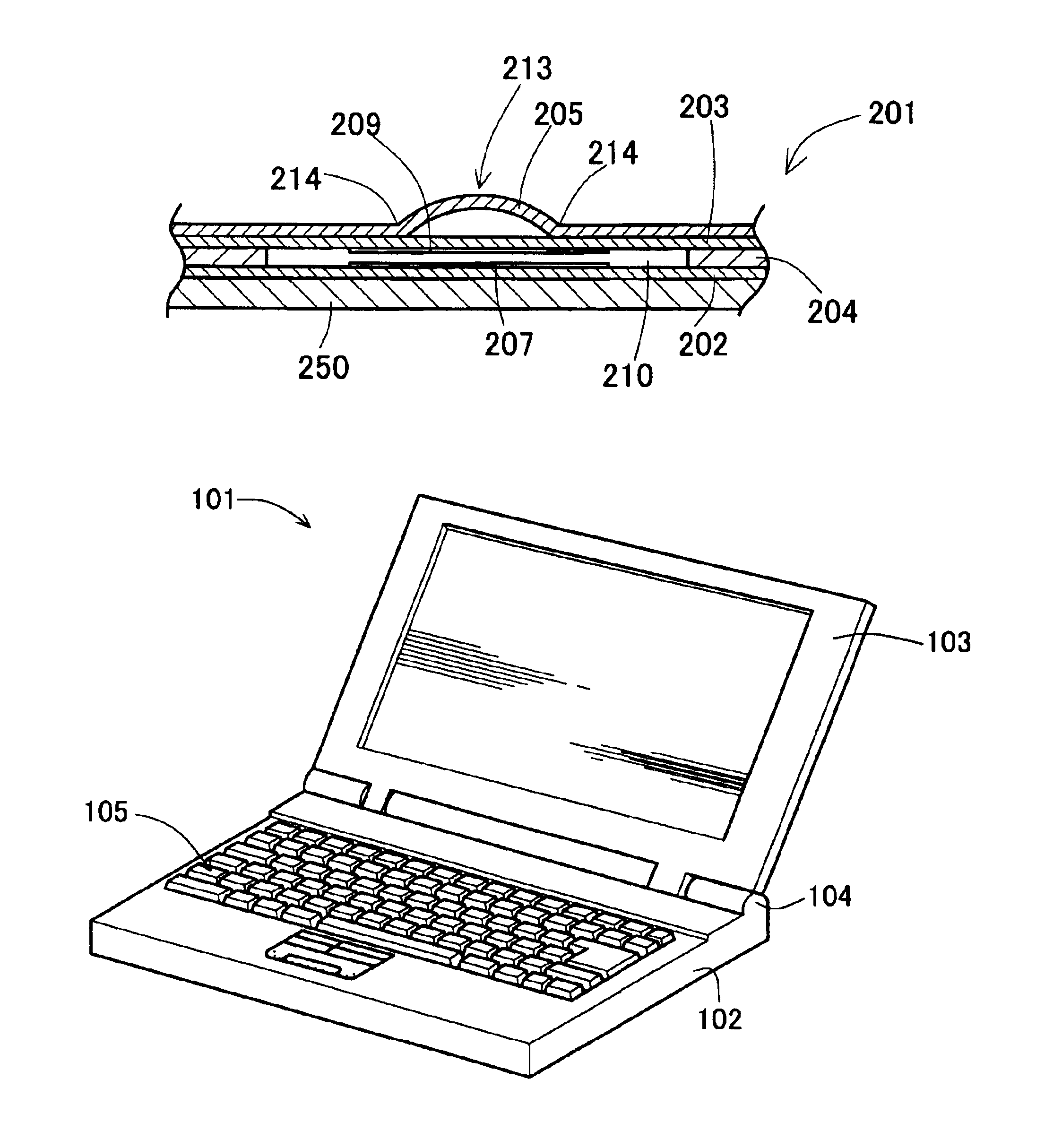

Membrane switch, key switch using membrane switch, keyboard having key switches, and personal computer having keyboard

InactiveUS6797906B2Guaranteed uptimeContact surface shape/structureDigital data processing detailsThin metalMembrane switch

A membrane switch is constituted of a lower membrane sheet, an upper membrane sheet and a spacer sheet which is inserted between both sheets, and a spring sheet which is formed of a thin metal plate arranged over the upper membrane sheet. A pair of slits formed in the spring sheet at positions corresponding to both sides of an upper electrode of the upper membrane sheet defines a switch portion in the spring sheet. When a key top is pushed down, the switch portion of the spring sheet is pushed down by a pushdown projection of the membrane switch to bring the upper electrode into contact with a lower electrode.

Owner:BROTHER KOGYO KK

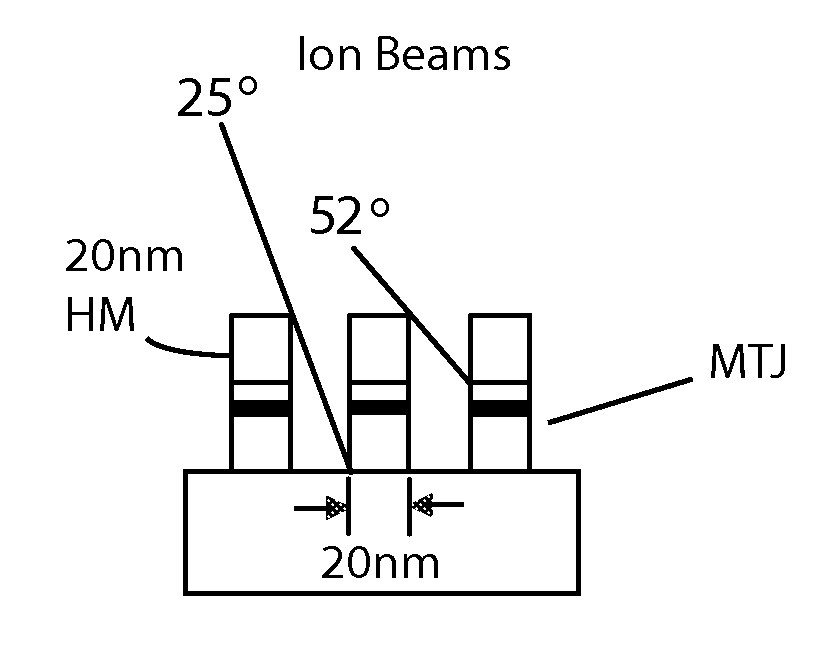

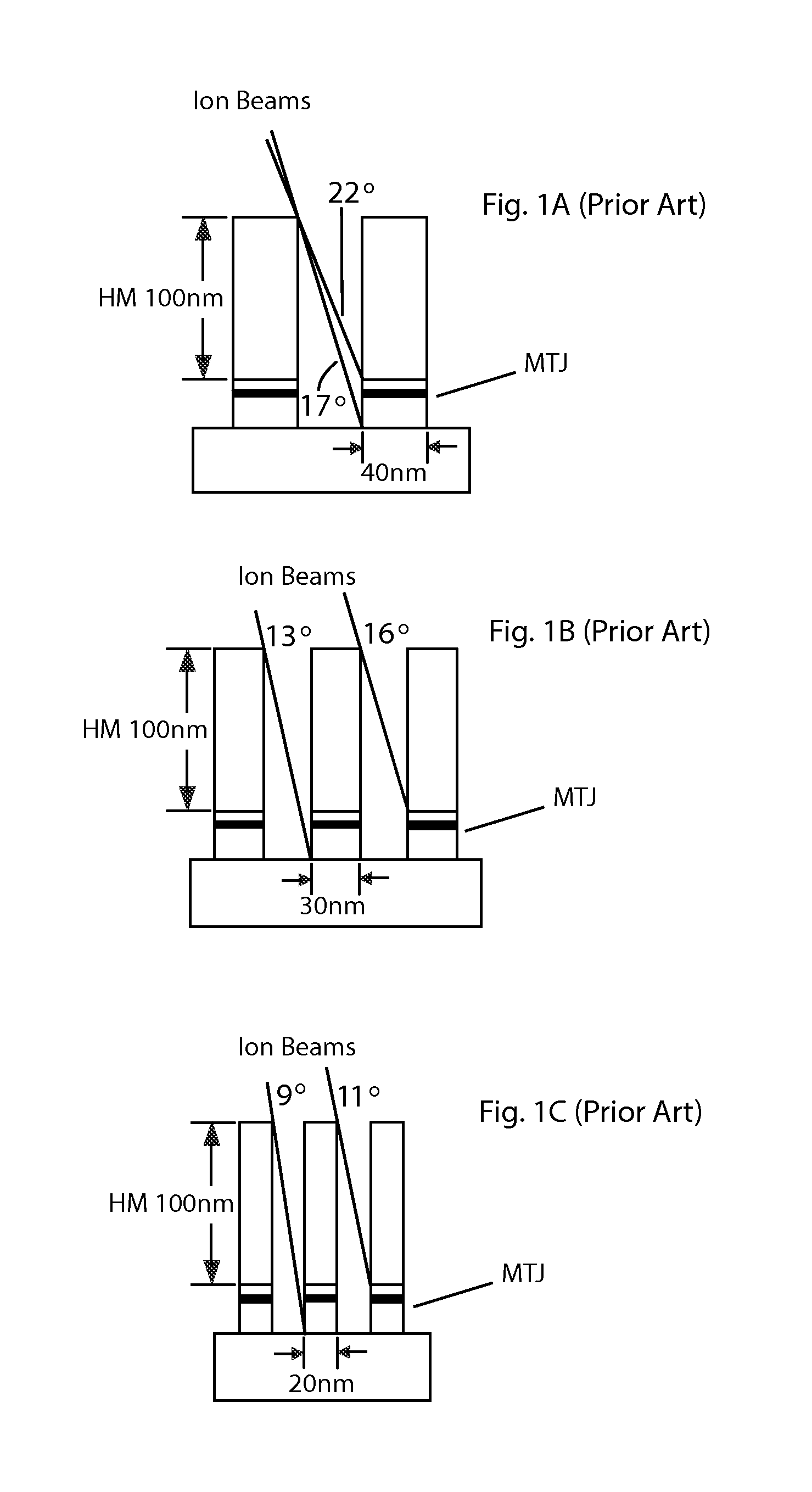

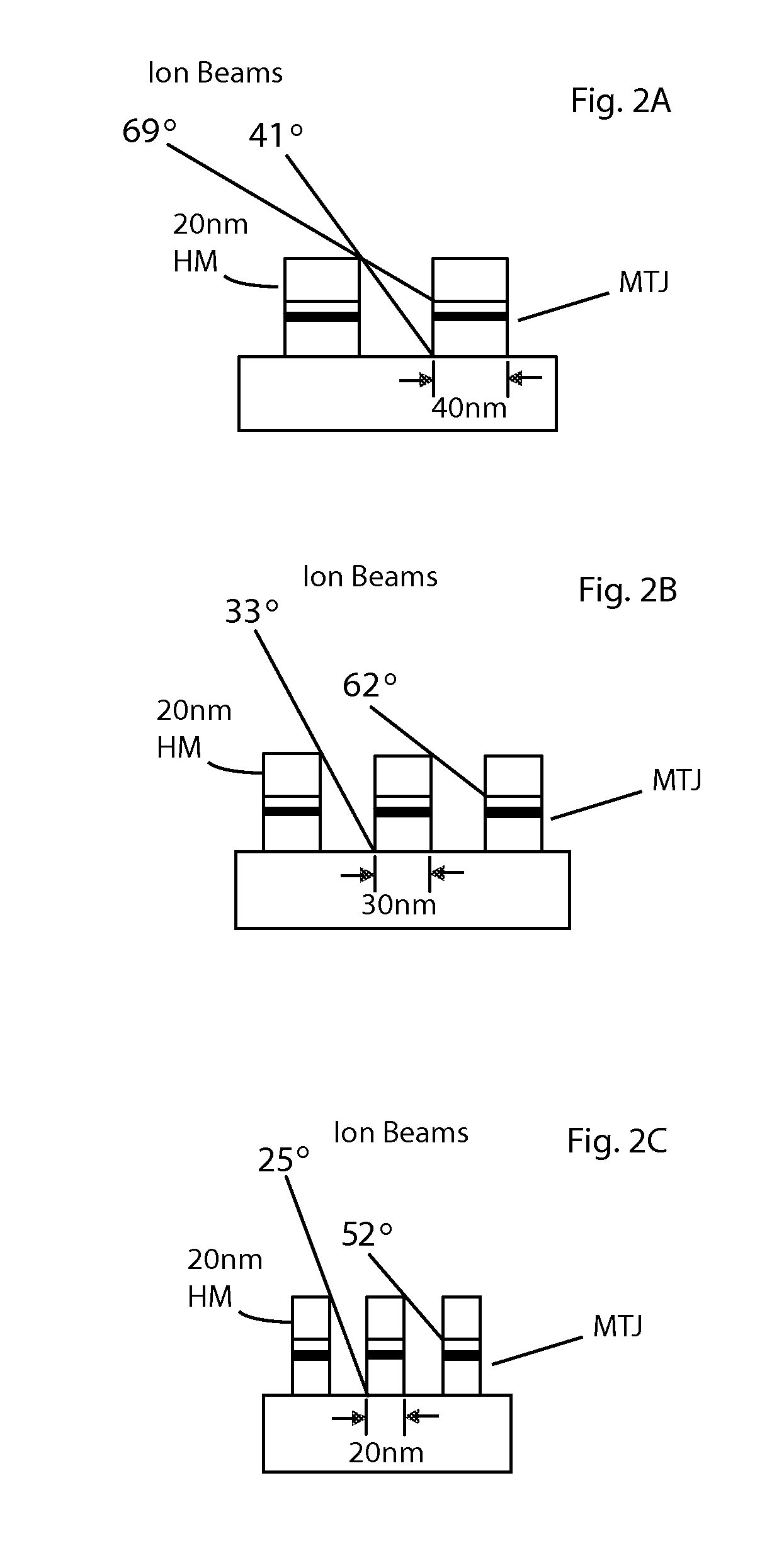

Fabrication method for high-density MRAM using thin hard mask

ActiveUS20150104882A1Increase incident IBE angleMaximum incidence angleSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentEtchingEngineering

Embodiments of the invention are described that use a thin metallic hard mask, which can be a bi-layer film, to increase the incident IBE angle for MTJ sidewall cleaning without losing the process margin for the subsequent interconnection process. The patterned metallic hard mask pads also serve as the top electrode for the MTJ cells. Using a thin metallic hard mask is possible when the hard mask material acts as a CMP stopper without substantial loss of thickness. In the first embodiment, the single layer hard mask is preferably ruthenium. In the second embodiment, the lower layer of the bi-layer hard mask is preferably ruthenium. The wafer is preferably rotated during the IBE process for uniform etching. A capping layer under the hard mask is preferably used as the etch stopper during hard mask etch process in order not to damage or etch through the upper magnetic layer.

Owner:AVALANCHE TECH

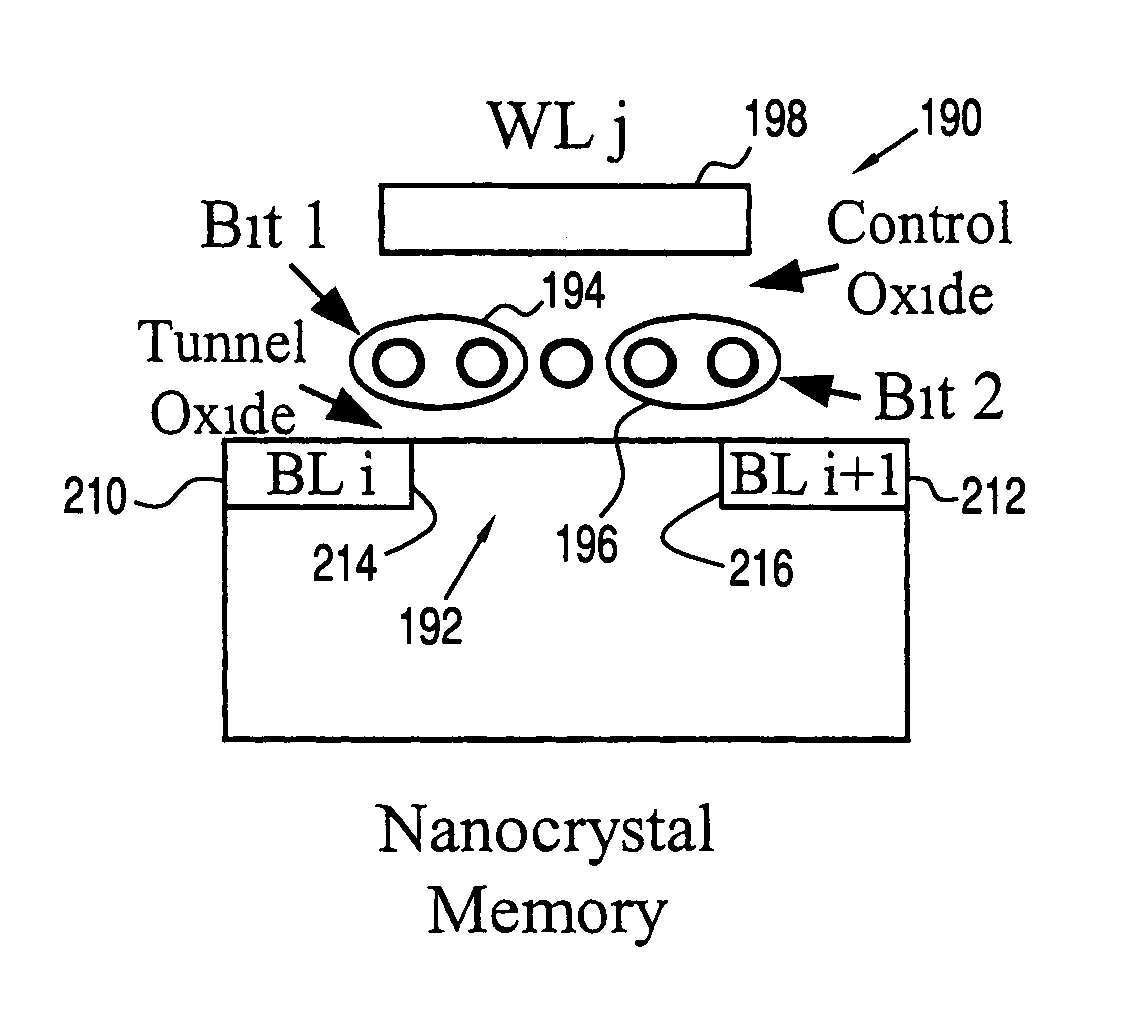

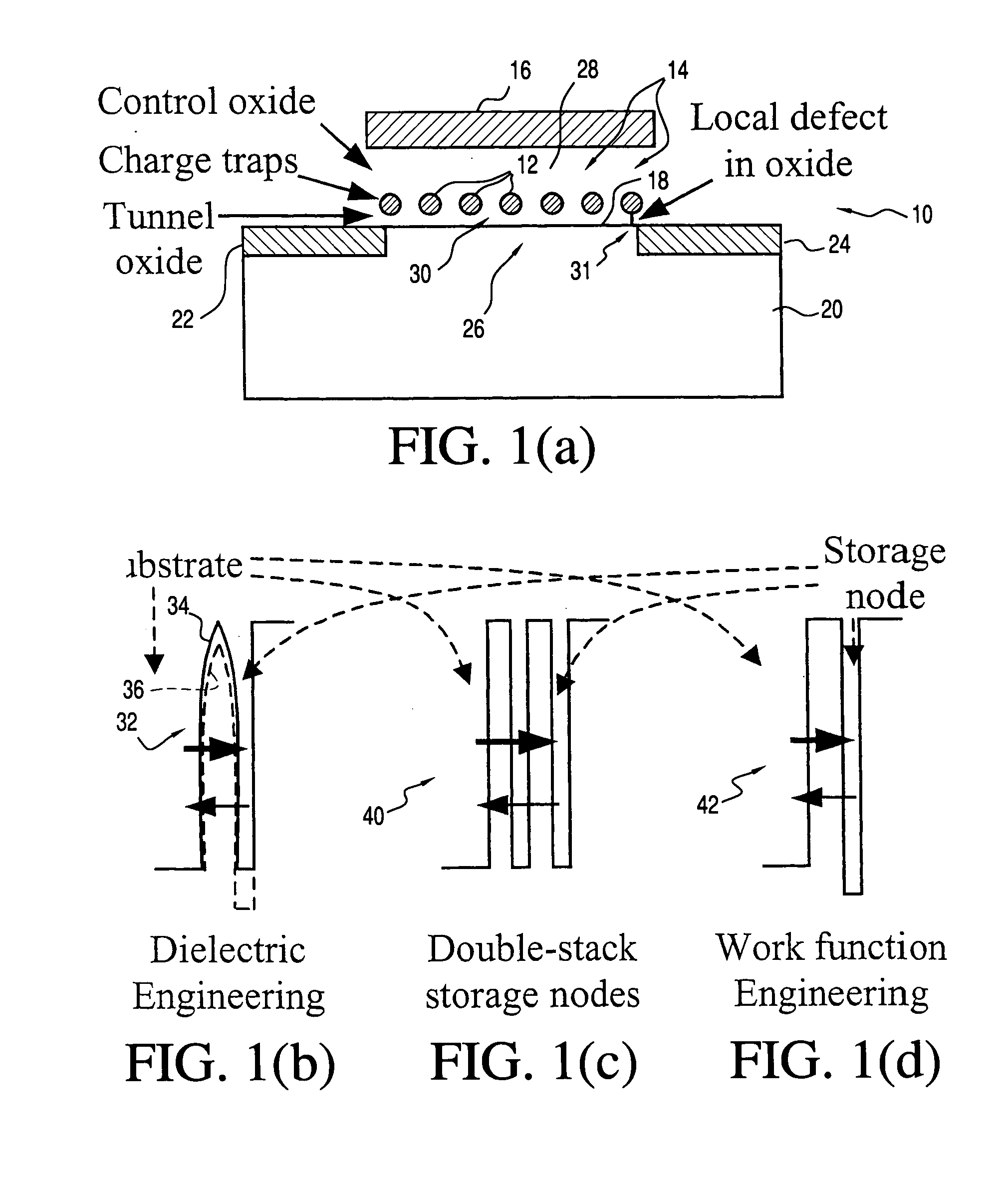

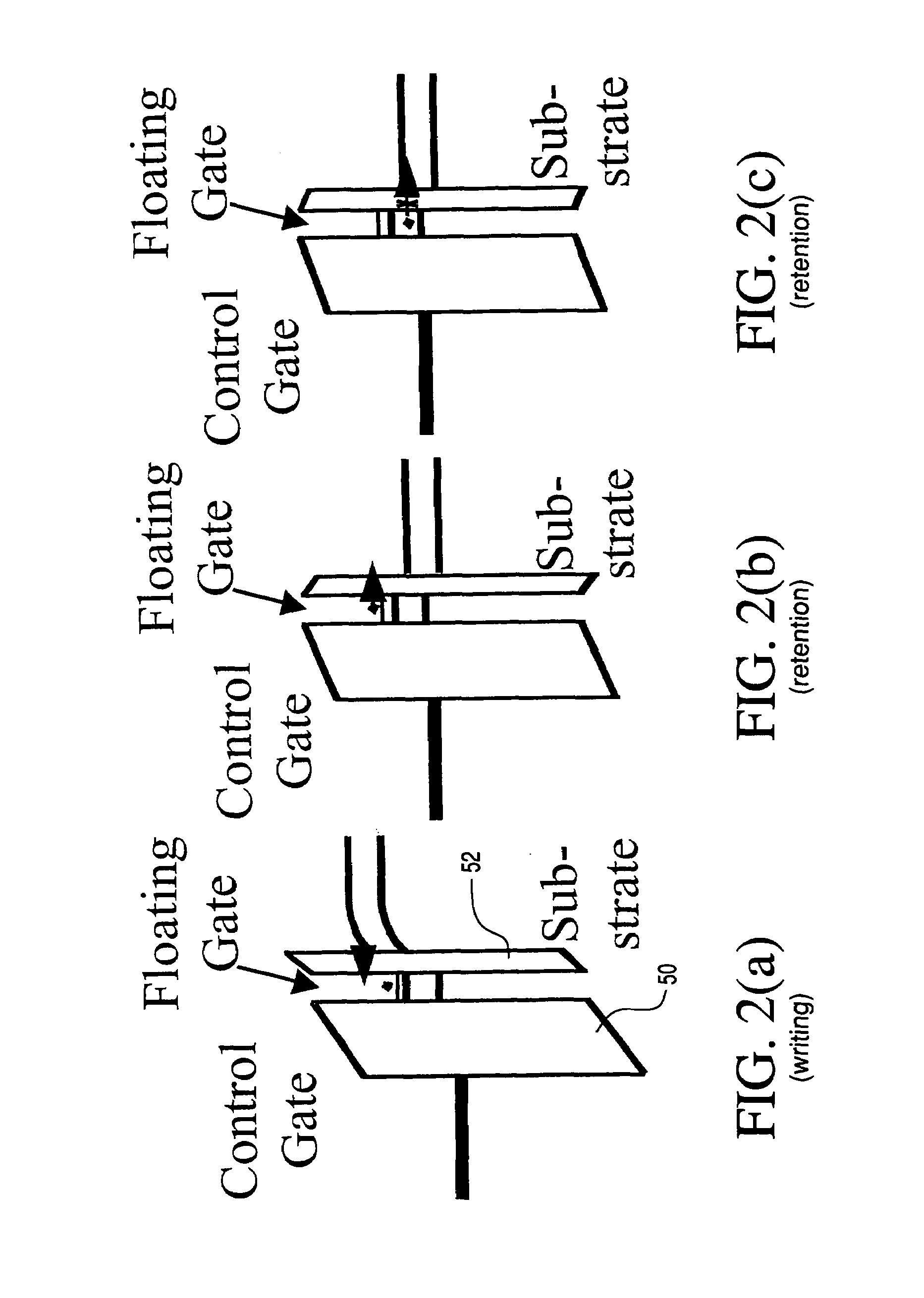

Multibit metal nanocrystal memories and fabrication

ActiveUS7259984B2Improve performanceImprove charge retentionNanoinformaticsRead-only memoriesRetention timeSemiconductor nanocrystals

Metal nanocrystal memories are fabricated to include higher density states, stronger coupling with the channel, and better size scalability, than has been available with semiconductor nanocrystal devices. A self-assembled nanocrystal formation process by rapid thermal annealing of ultra thin metal film deposited on top of gate oxide is integrated with NMOSFET to fabricate such devices. Devices with Au, Ag, and Pt nanocrystals working in the F-N tunneling regime, with hot-carrier injection as the programming mechanism, demonstrate retention times up to 106s, and provide 2-bit-per-cell storage capability.

Owner:CORNELL RES FOUNDATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com