Patents

Literature

181results about How to "Implement manual control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

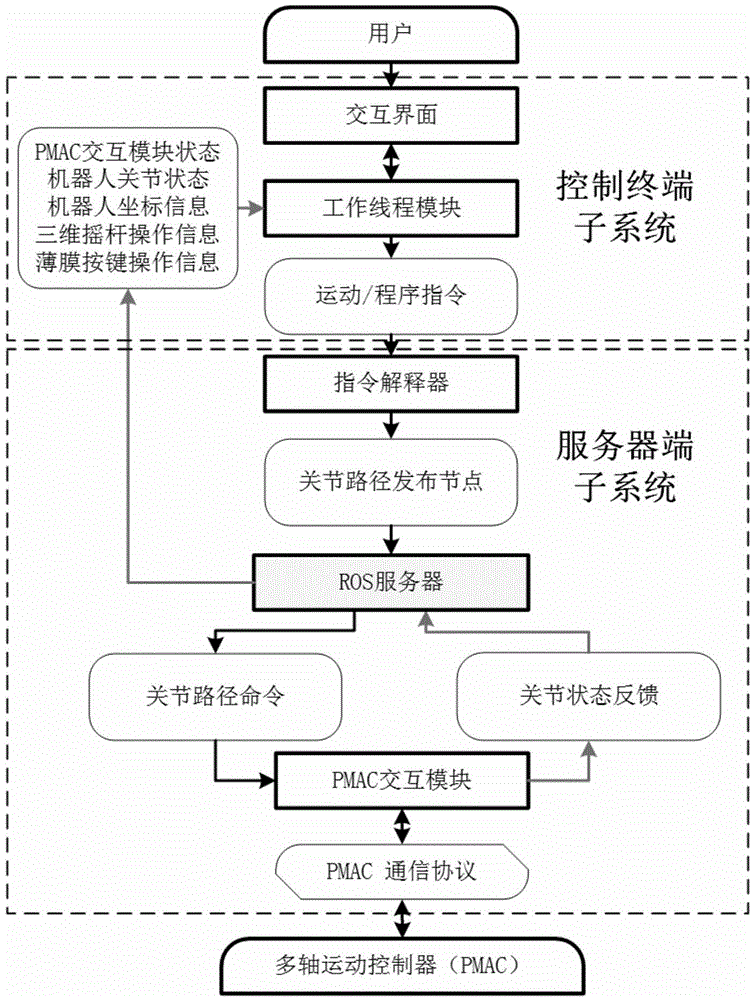

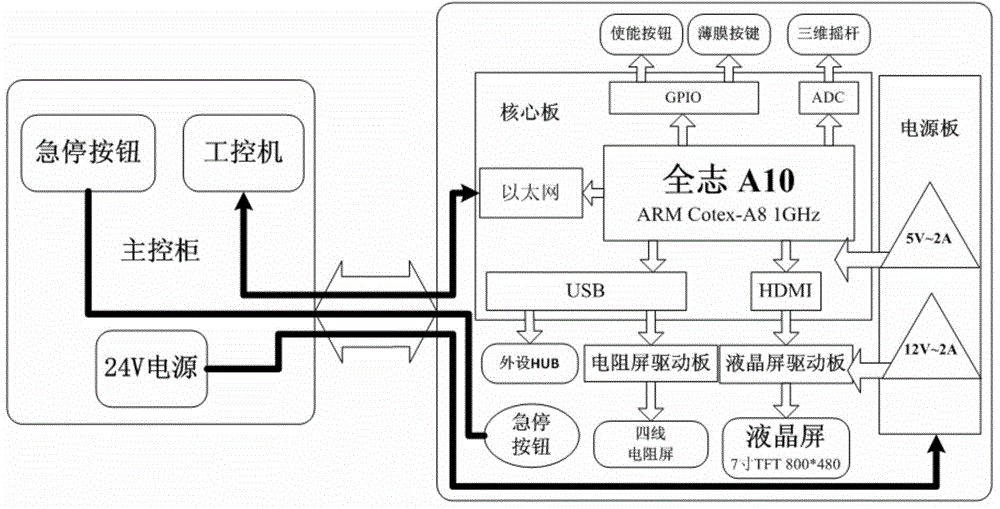

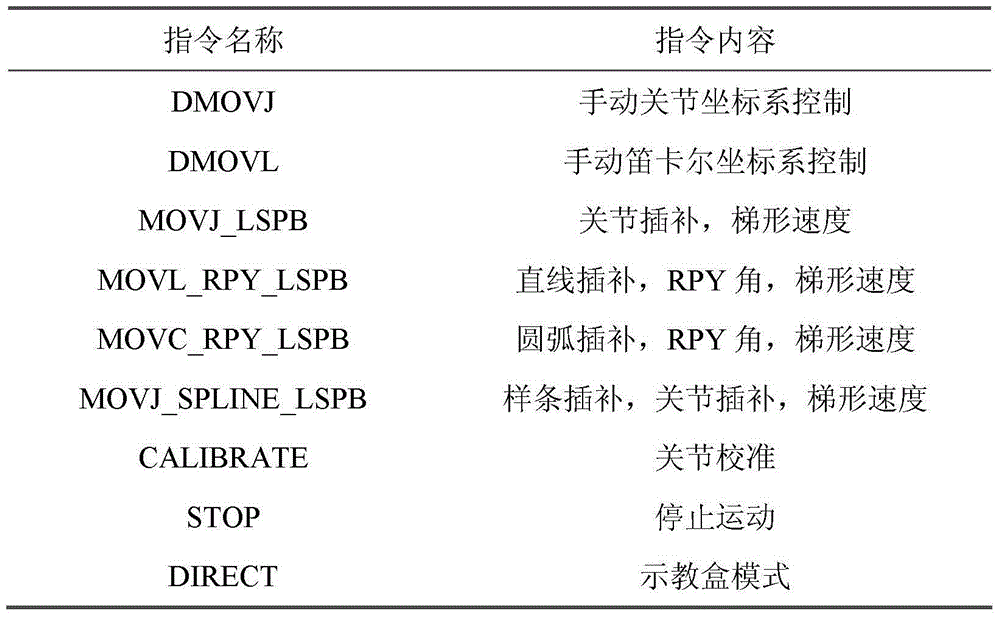

Robot motion control system

ActiveCN104699122AHigh degree of modularityImprove general performanceControl using feedbackNumerical controlExtensibilityInteraction interface

The invention discloses a robot motion control system, relates to the technical field of robot motion control, and aims to solve the problems of poor universality, poor extensibility and poor system openness existing in the existing robot motion control system. A control terminal subsystem comprises a human-computer interaction interface and a working thread module; a server terminal subsystem comprises an instruction interpreter, a server and an interaction module; a user transmits an operation instruction through the human-computer interaction interface; the operation instruction is converted into an instruction which can be recognized by the instruction interpreter by using the working thread module and is transferred to the instruction interpreter through network; the instruction interpreter is used for converting the received instruction into a joint path command by calling MoveIt ! and releasing on a node of an ROS (Read Only Storage) server; a PMAC (Programmable Multi Axis Controller) interconnection module receives the joint path command from the ROS server and converts into a motion control instruction through a PMAC communication protocol and transfers to PMAC through network. The system has higher modularization degree and extremely strong universality and can be compatible with various multi-degree-of-freedom series robots.

Owner:HARBIN INST OF TECH

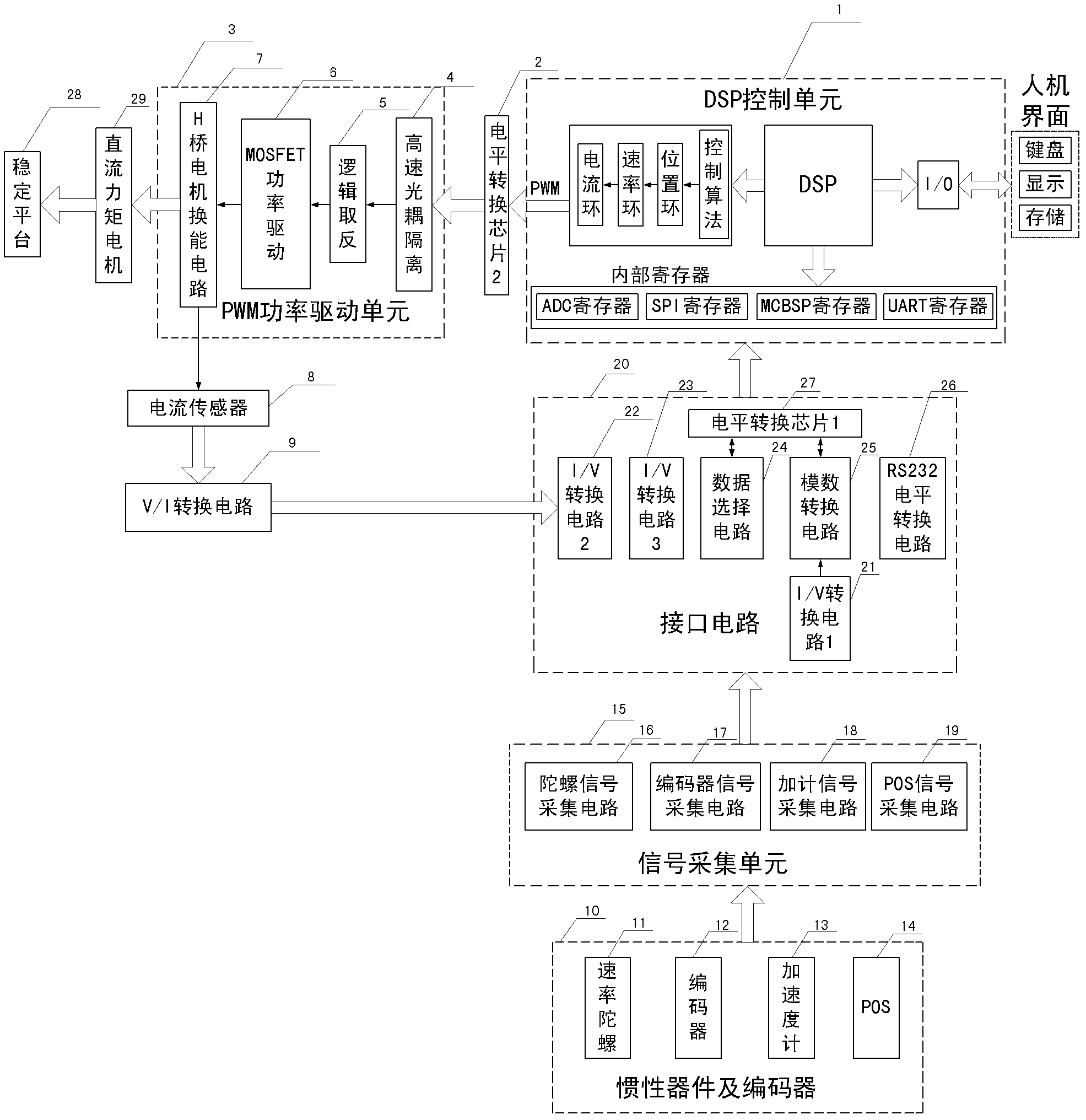

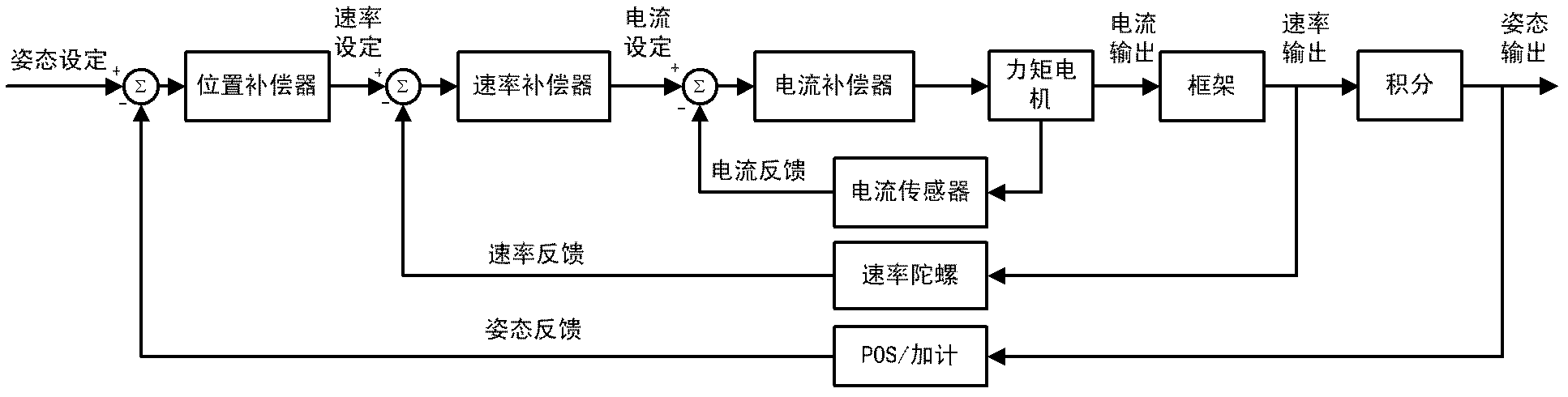

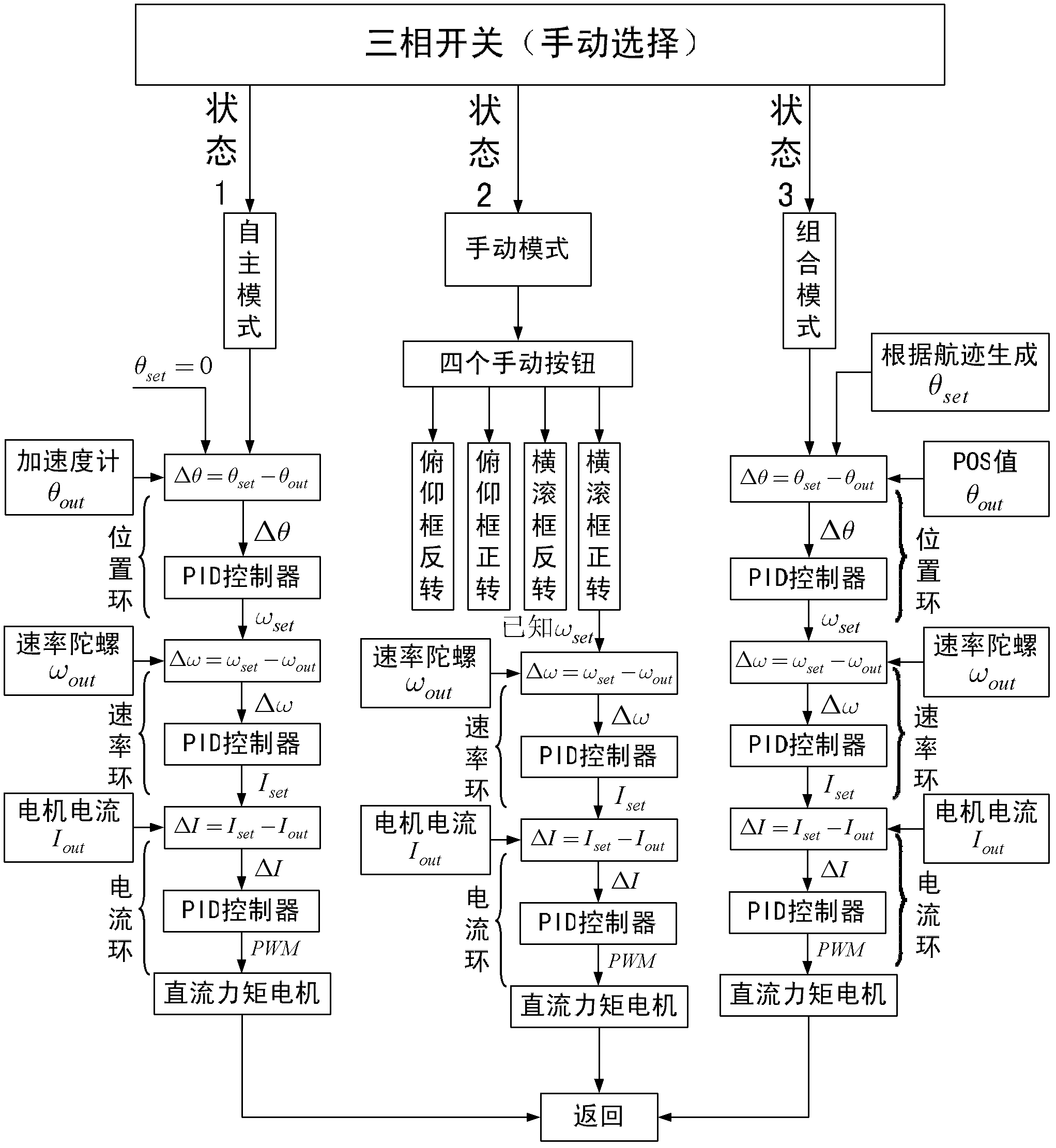

High-precision and large-load control system and method of three-axis inertially stabilized platform for airborne remote sensing

InactiveCN102436262AInhibition effectEnhanced inhibitory effectAttitude controlPosition/course control in three dimensionsDigital signal processingTorque motor

The invention provides a high-precision and large-load control system and method of a three-axis inertially stabilized platform for airborne remote sensing. The system comprises a DSP (digital signal processing) control unit, a PWM (pulse-width modulation) power drive unit, an interface circuit, a signal acquisition unit, an inertial device, an encoder and a direct current (DC) torque motor. The method comprises the following steps: acquiring data such as the attitude angle and angular speed of frameworks relative to an inertial space, coil current and relative corners among the frameworks through the signal acquisition unit; transferring the data into an internal register of the DSP control unit through the interface circuit so that the data is read by the DSP control unit; taking the data as signals to be input into the DSP control unit, and generating PWM controlled quantity by adopting a three-loop (a current loop, a speed loop and a position loop) compound control algorithm; and transferring PWM signals into an energy conversion circuit of an H-bridge DC motor through the power drive unit so as to drive the DC torque motor to change with reference instructions, and finally realizing active control of the inertially stabilized platform. The high-precision and large-load control system and method provided by the invention have the advantages that control precision and loading capability of the system are improved, the control algorithm is completed, and diversity and intellectualization of a platform operating mode are improved.

Owner:BEIHANG UNIV

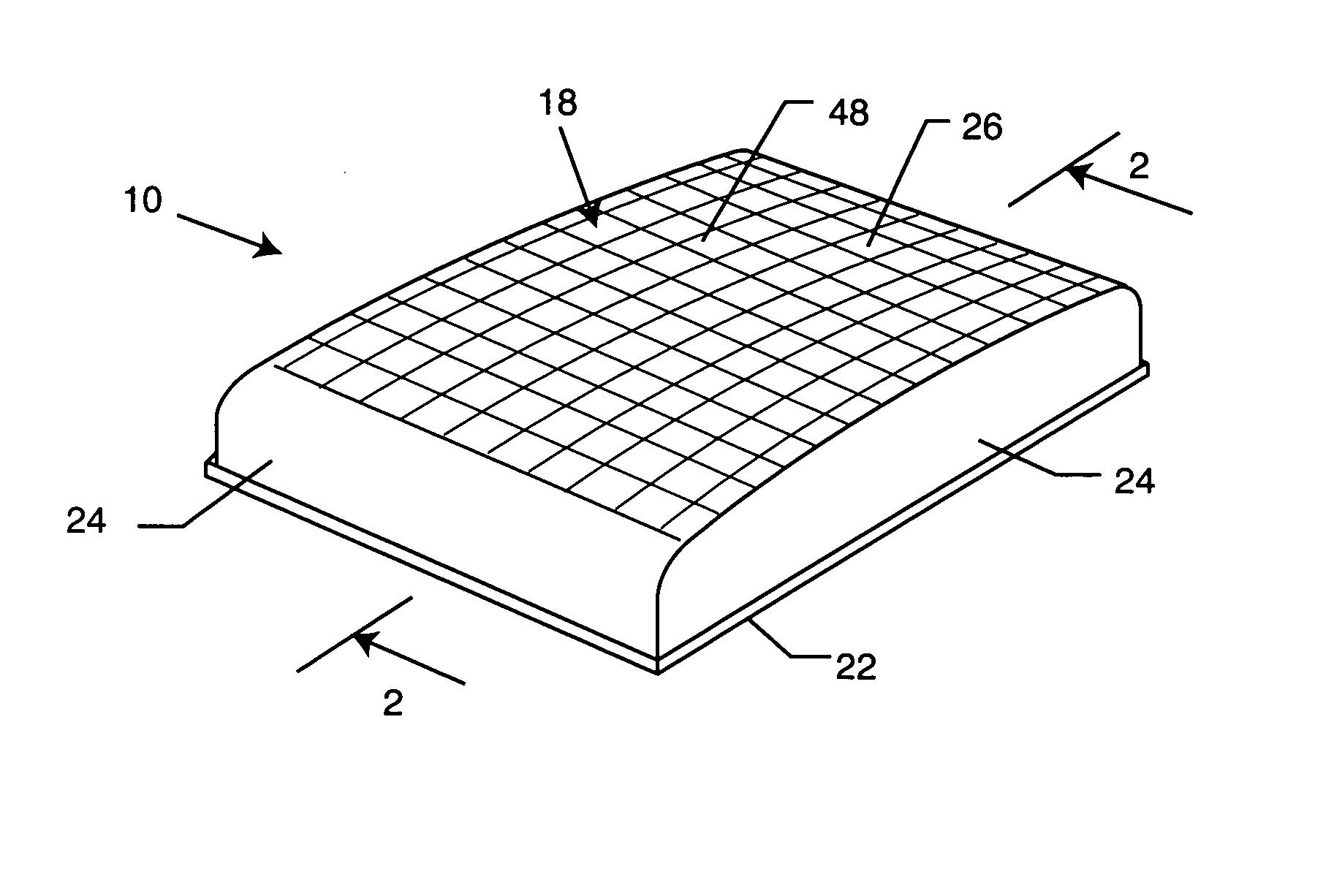

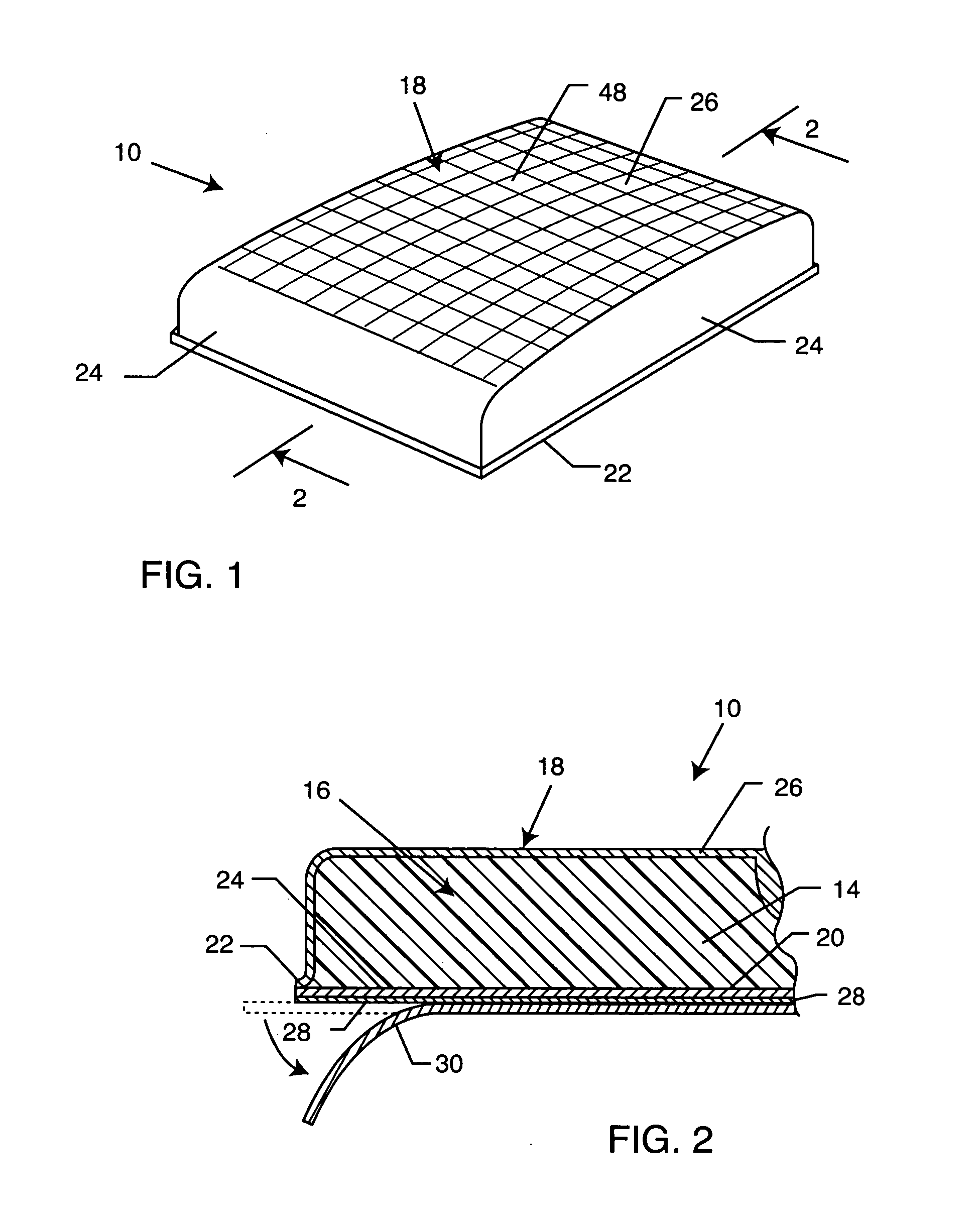

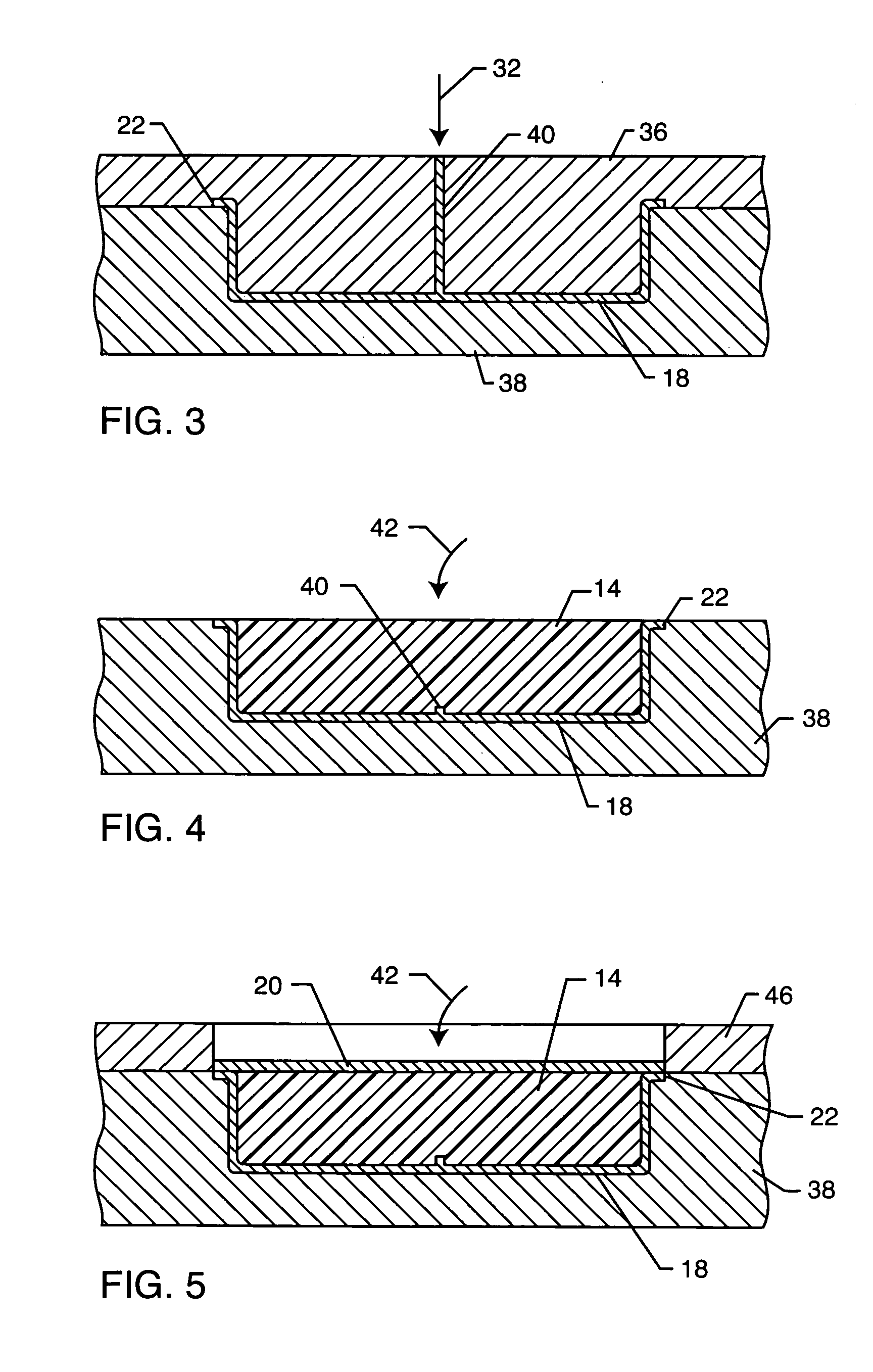

Conformable pod for a manual implement

InactiveUS20060031994A1Easy to transformMinimal resistanceCooking-vessel materialsSofasClosed chamberEngineering

A conformable pod and related method of production are provided, wherein the pod defines a soft structure adapted for deformation in response to minimal pressure applied manually, i.e., by contact with some portion of the body, and for retaining a deformed configuration substantially in the absence of continued application of manual pressure. The pod includes a viscous and tacky gel material encased within a closed chamber defined at least in part by a relatively thin and easily deformed outer skin providing minimal deformation resistance. In a preferred form, the encased gel material is a coagulated or partially coagulated gel such as a silicone-based gel material adapted for deformation in response to minimal applied manual pressure, and for substantially pressureless retention of the as-deformed shape, followed by relatively slow return (at least two seconds or more) to an initial nondeformed shape upon manual release of the pod.

Owner:WILLAT BOYD I

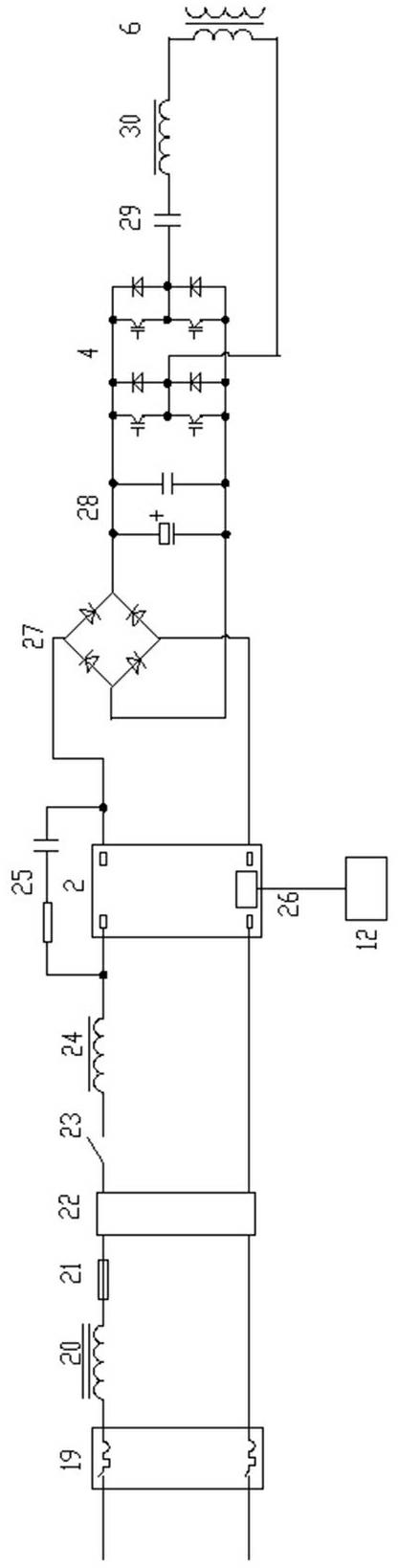

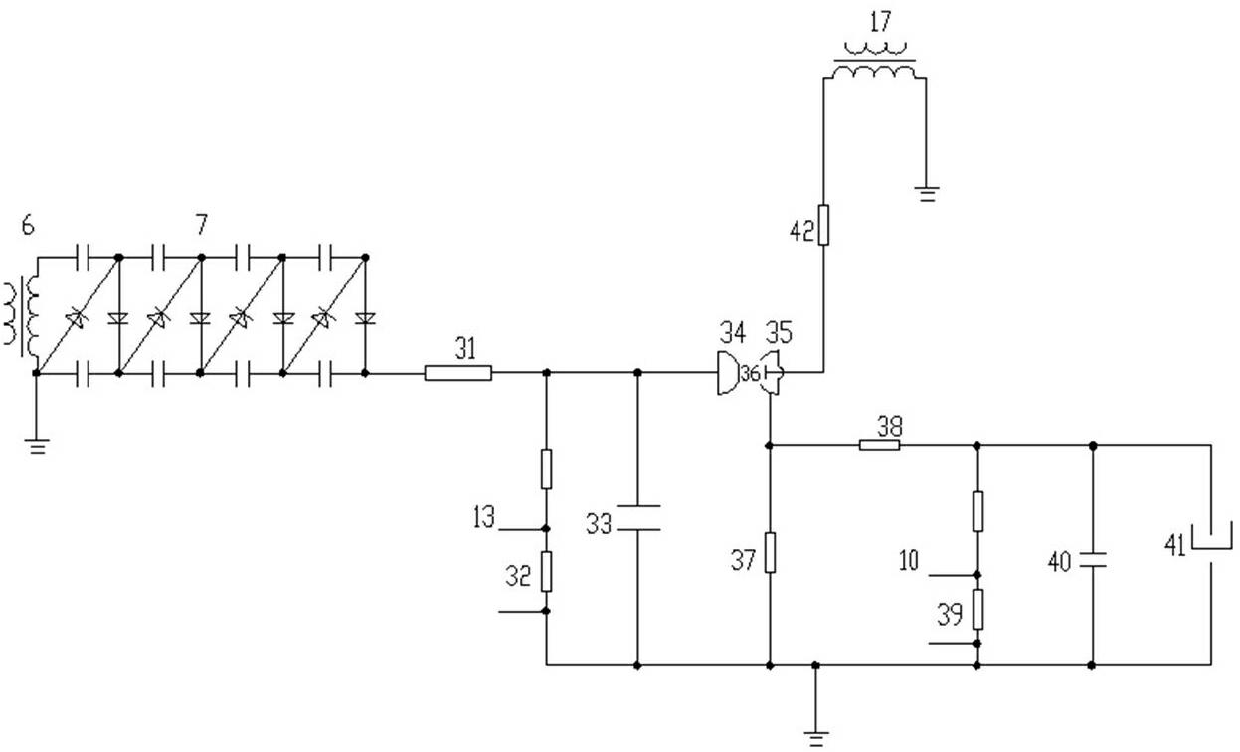

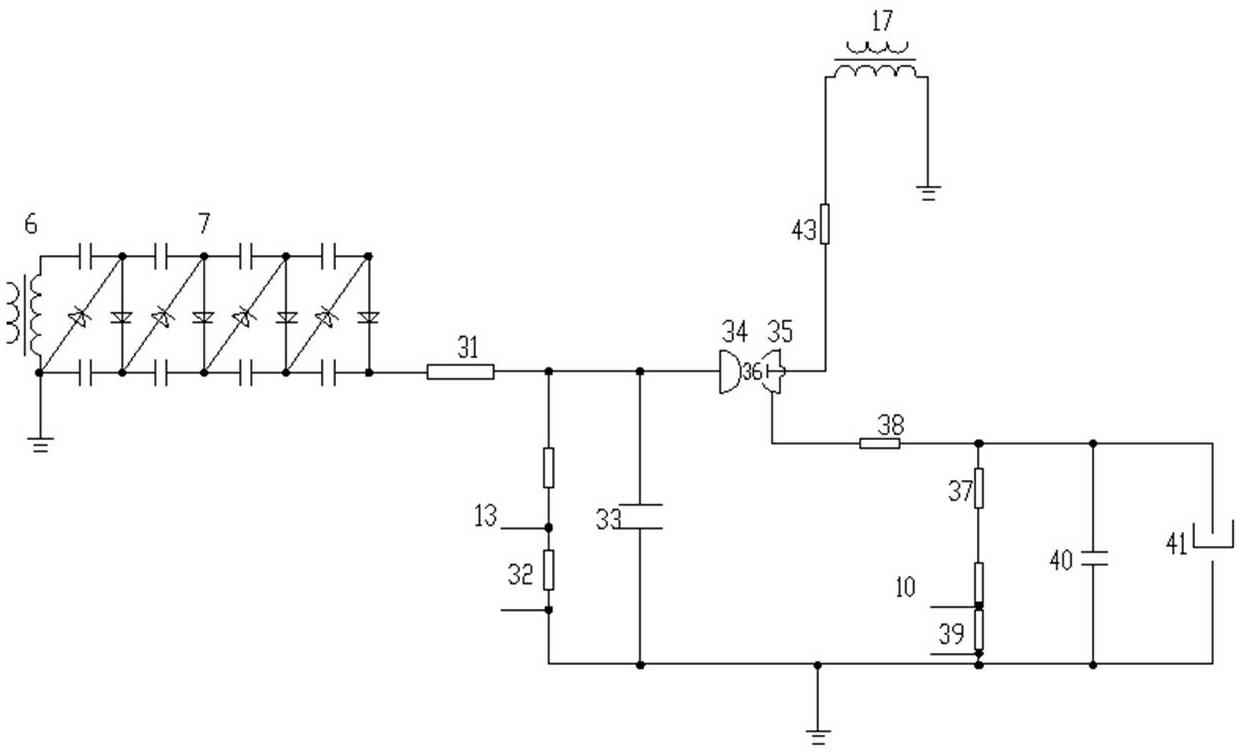

High-voltage pulse generator

InactiveCN102435800AEasy to operateHigh control precisionElectrical measurement instrument detailsElectrical testingLc resonant circuitHigh frequency

The invention provides a high-voltage pulse generator which comprises three parts such as a power supply cabinet, an operation board and a simulation lightning wave generator, wherein the power supply cabinet is used for controlling the operation of the generator and generating high-voltage pulse; the operation board is used for displaying and inputting a control instruction; the output end of an intelligent thyristor voltage regulating module is sequentially connected with a rectifier filter circuit, an H-bridge module and an LC (Liquid Crystal) resonance circuit; the LC resonance circuit is sequentially and electrically connected with a high-frequency and high-voltage charging transformer, a multiplier and an impulse voltage generator; and the impulse voltage generator is externally connected with an insulated testing system and is respectively and electrically connected with an external oscilloscope through a resistance voltage divider I as well as is electrically connected with an analog quantity input end of a programmable logic controller (PLC) in the cabinet through a resistance voltage divider II. According to the high-voltage pulse generator provided by the invention, the wave-front time can be regulated by regulating and converting a plurality of parameters in a grading way and the single triggering or automatic continuous triggering once each minute is realized; and the high-voltage pulse generator has the advantages of simpleness for operation, high control precision, safety and reliability.

Owner:四川中物海通特种电源有限责任公司

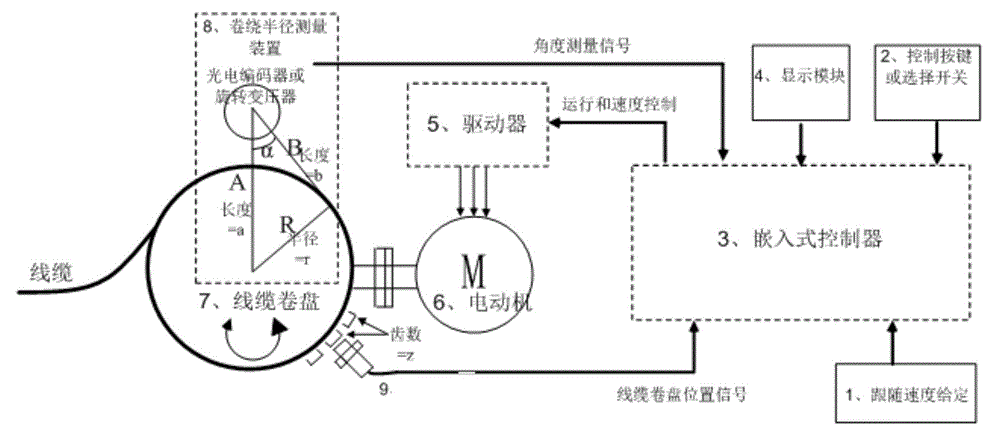

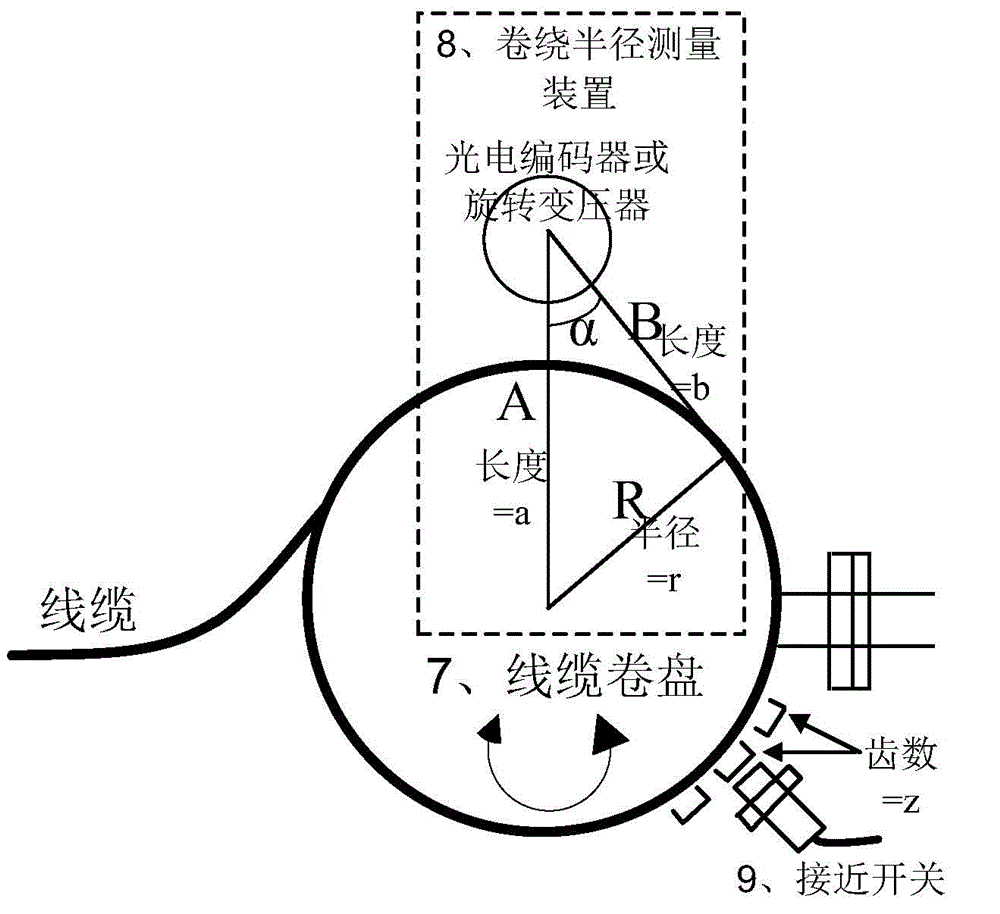

Method for accurately measuring cable winding and unwinding length and synchronous controller

ActiveCN104528463AAccurate measurementConsistent winding speedMeasurement devicesFilament handlingMeasurement deviceSynchronous motor

The invention discloses a method for accurately measuring the cable winding and unwinding length and a synchronous controller. Setting of external following speed is acquired by the controller in real time, automatic logic control, manual logic control and the like of a system are achieved according to a control button and a selective switch, and information of winding and unwinding speed, control states and the like is displayed on a display unit; a winding radius signal formed by a cable is acquired in real time through a designed winding radius measurement device; pre-designed counting teeth of a winding reel and a proximity switch form a winding turn number signal; the two signals form corresponding digital quantity signals through an embedded controller, and cable winding speed is calculated on the basis of the cosine law of a triangle and additional operation; the calculated cable winding speed and the external set following speed are subjected to PID operation, then, the controller controls the output of a driver through the digital quantity signals and an analog quantity signal interface, the driver controls the running speed of a motor, and the motor drags the cable winding reel to achieve consistency between the winding speed and the external given speed.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

Sanitary garbage disposal device

InactiveCN106985441AImplement manual controlAchieve normal workPressesWater dischargeArchitectural engineering

The invention discloses a sanitary garbage disposal device, which comprises a frame body, a compression groove is arranged inside the right side of the frame body, a variable chamber is arranged inside the frame body on the left side of the compression groove, and first The inner helical locking shaft and the second inner helical locking shaft, the left side of the variable chamber is provided with a first sliding joint groove, the bottom of the first sliding joint groove is provided with a concave groove, and the bottom of the concave groove and the top of the first sliding joint groove There is a first guide rod between them, the first guide rod is slidably connected with the first sliding block extended to the right side, the outer surface of the first guide rod at the bottom of the first sliding block is provided with a first coil, the first The extended part on the right side of the sliding block penetrates into the variable cavity and is in sliding contact with the right wall of the variable cavity. The first sliding block in the variable cavity is equipped with a motor, and the upper and lower ends of the motor are equipped with transmission shafts. The variable cavity There is a transmission cavity inside the upper frame body; the invention has simple structure, convenient operation, low manufacturing and maintenance costs, fast compression speed, high stability, good compression quality, reasonable discharge of sewage, clean and hygienic.

Owner:袁兴芳

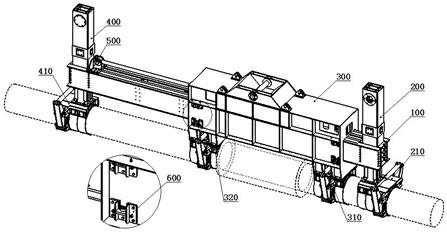

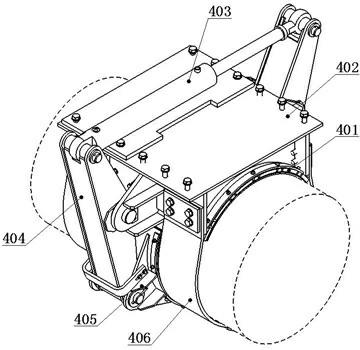

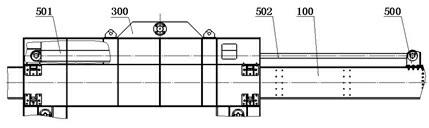

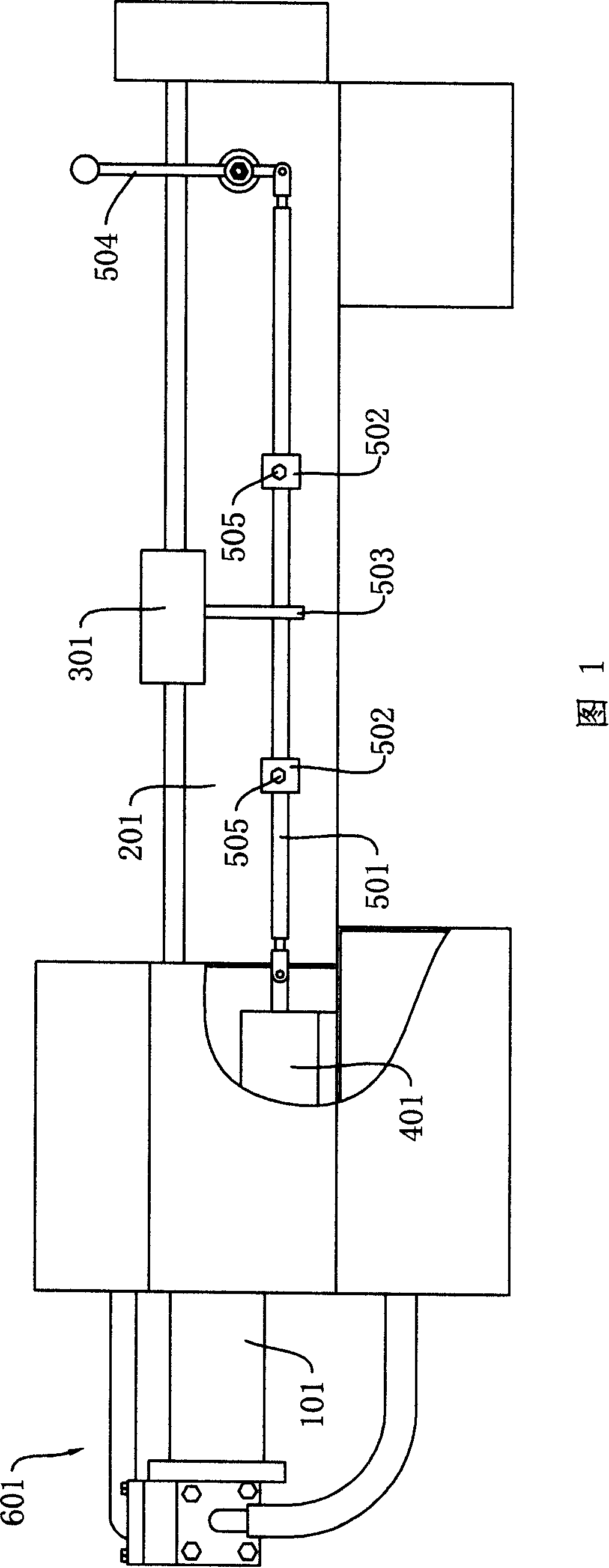

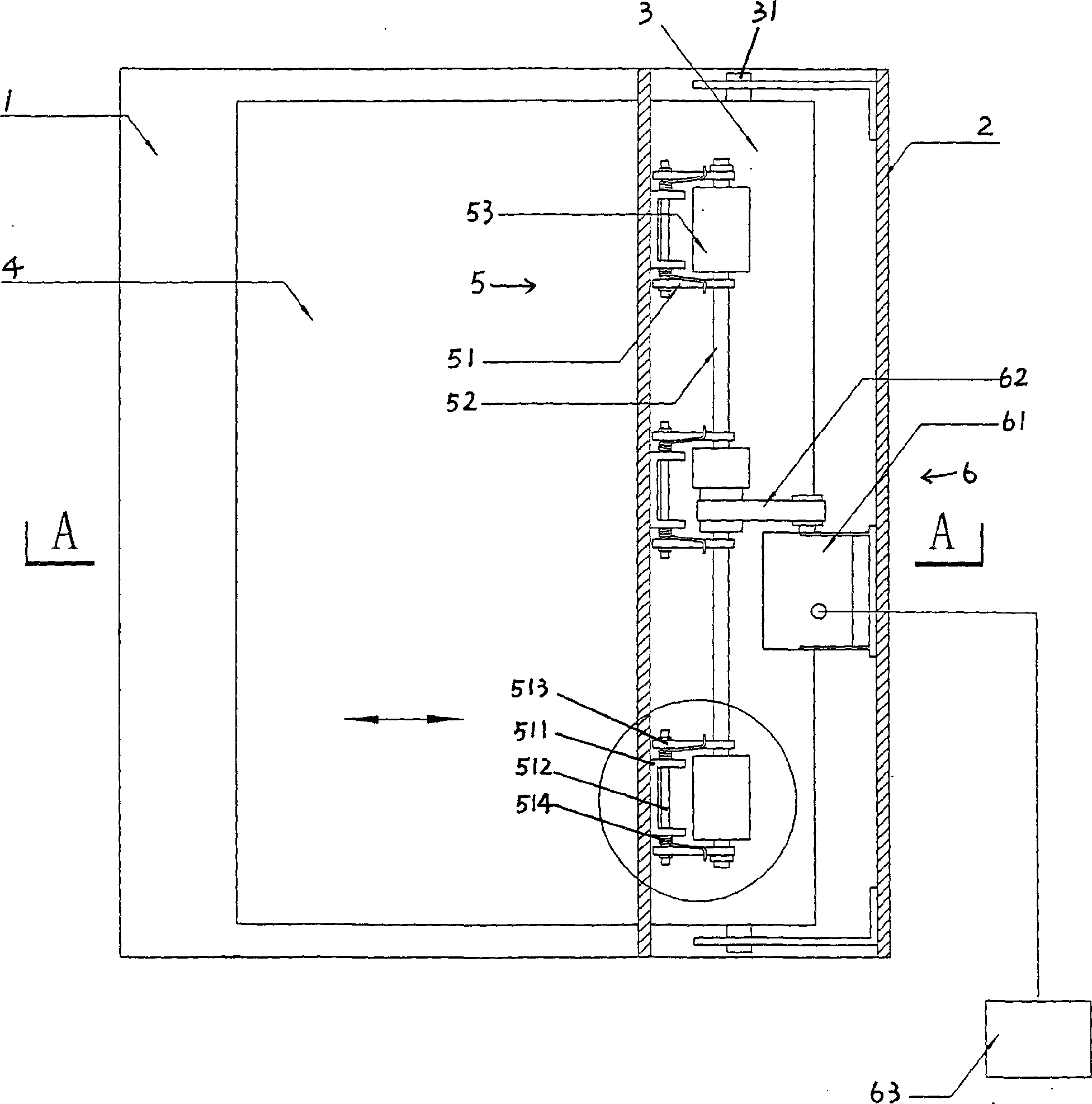

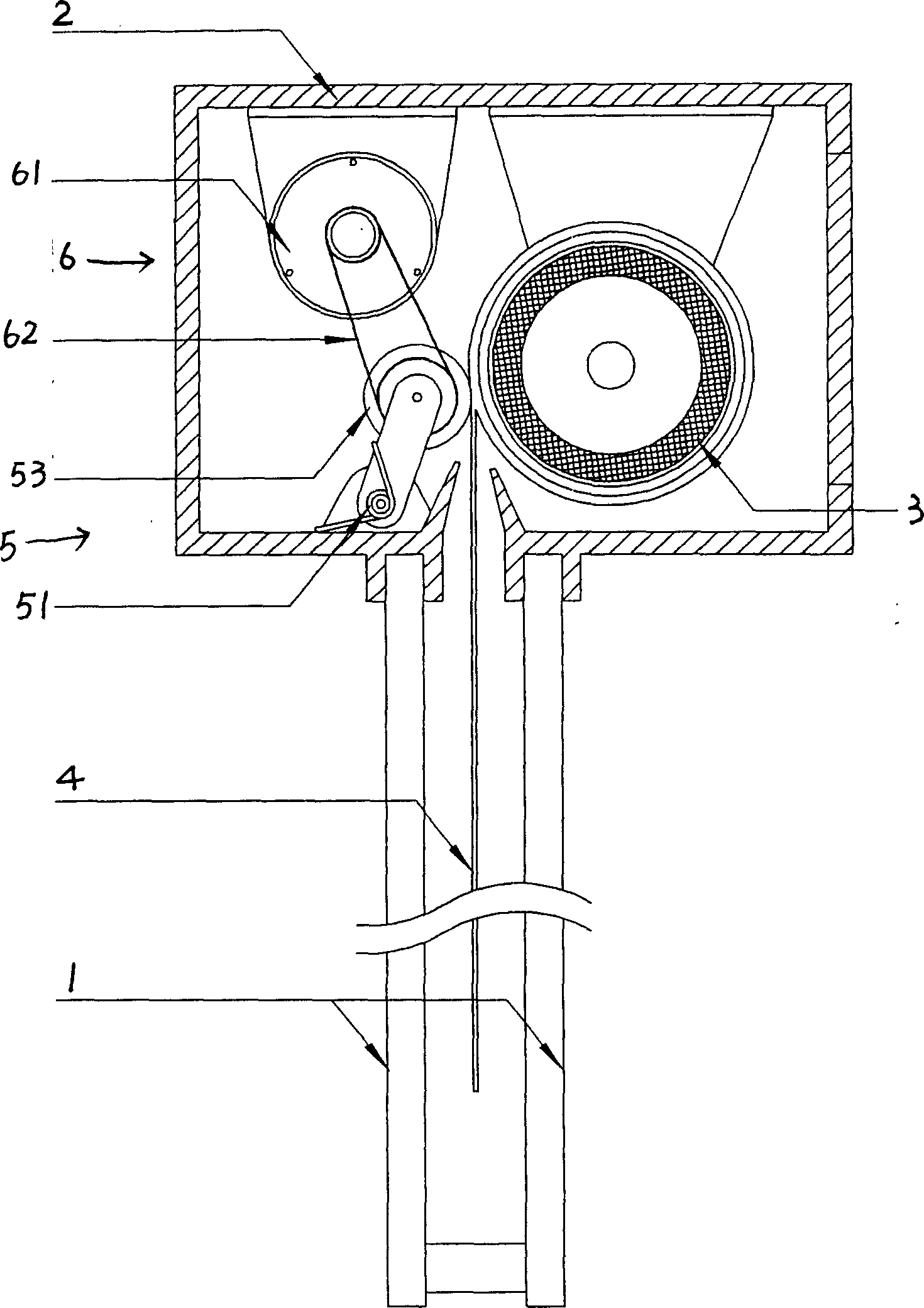

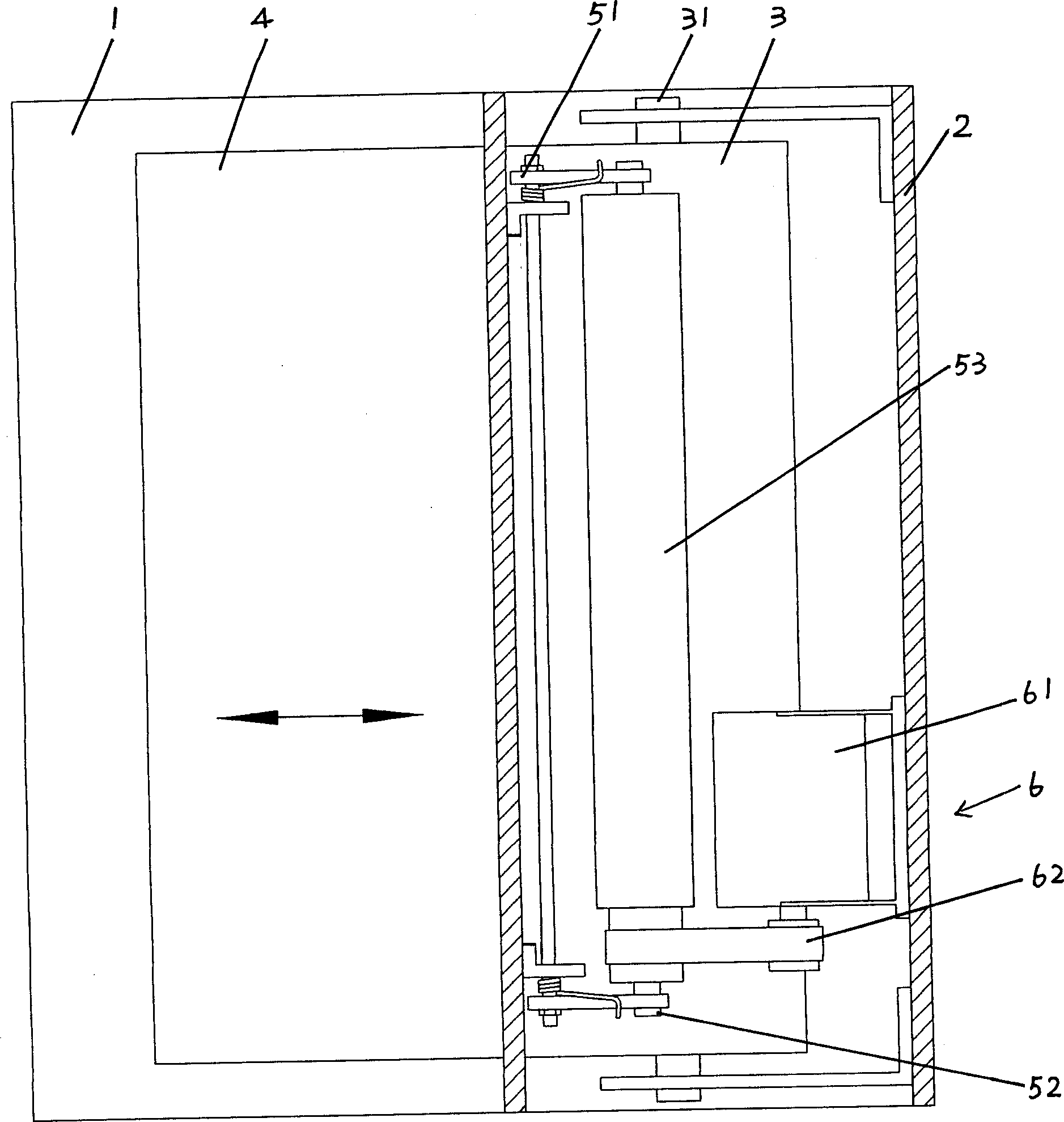

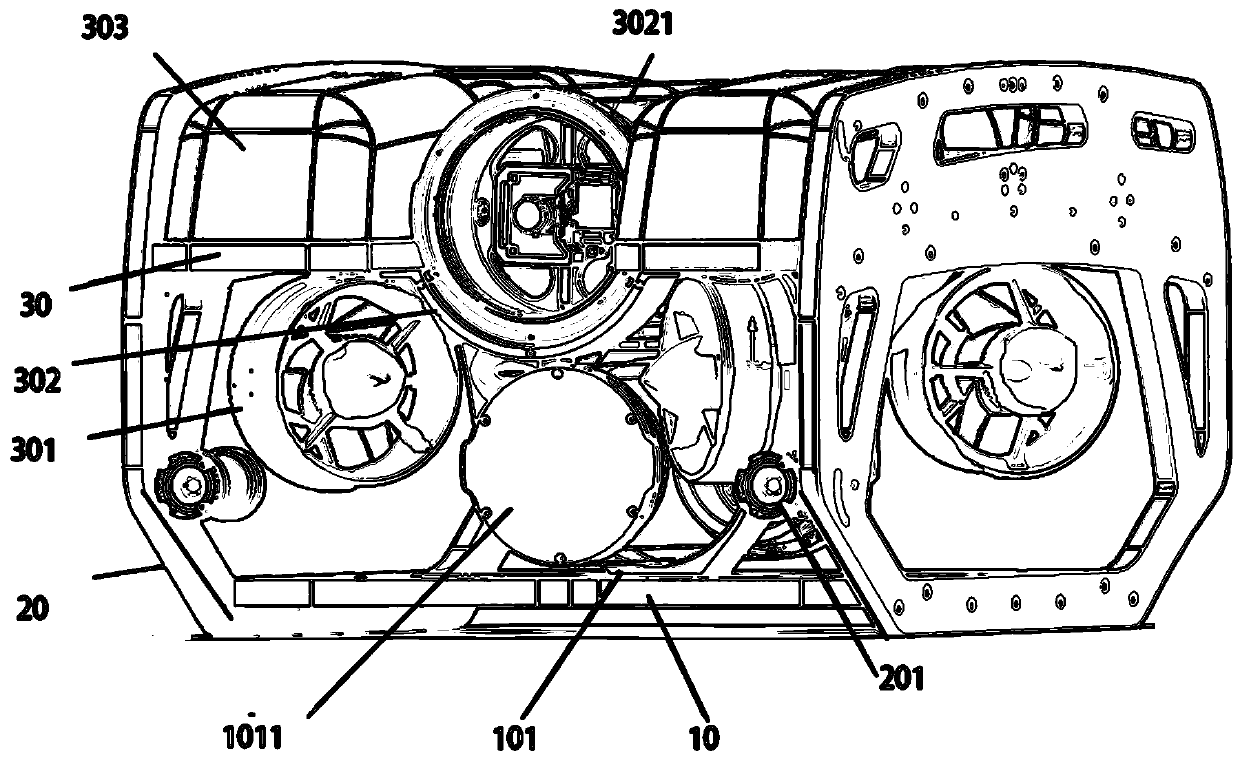

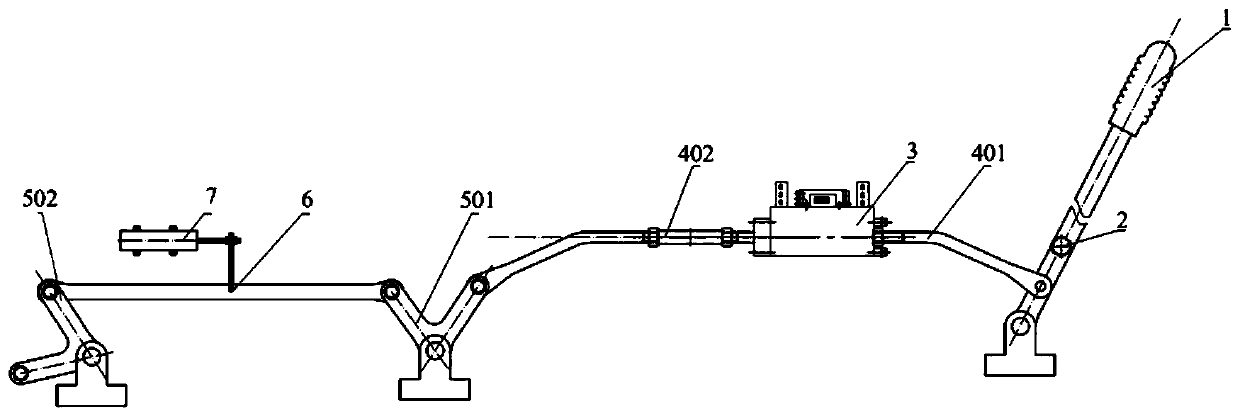

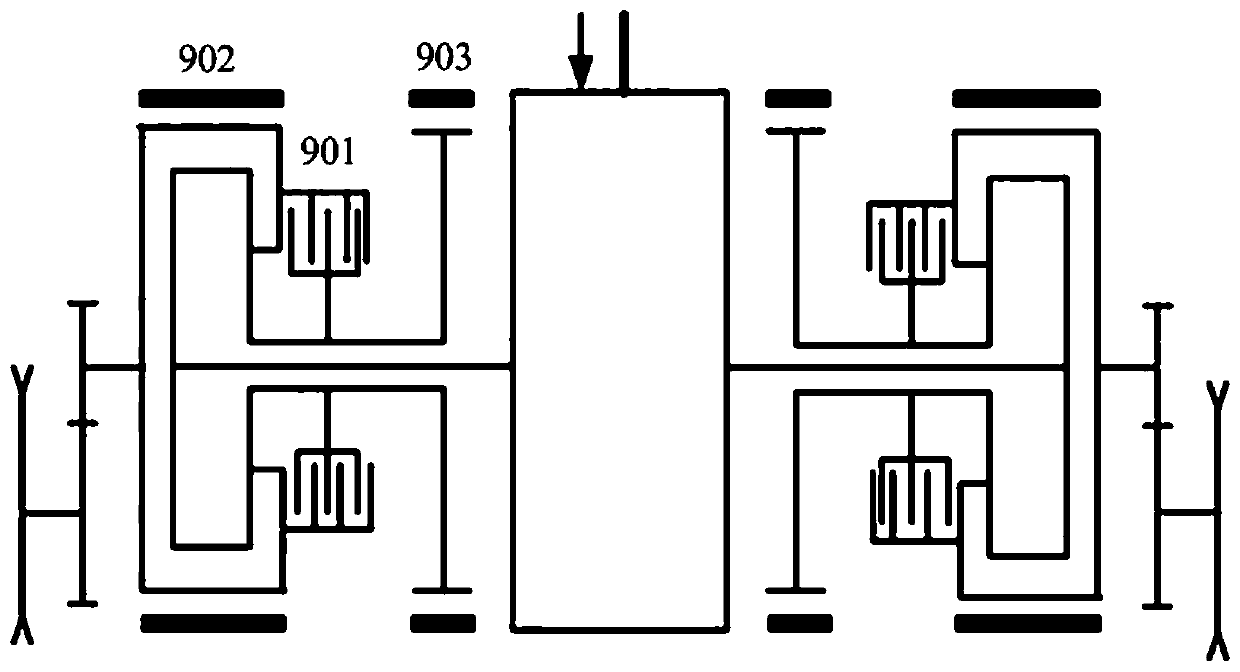

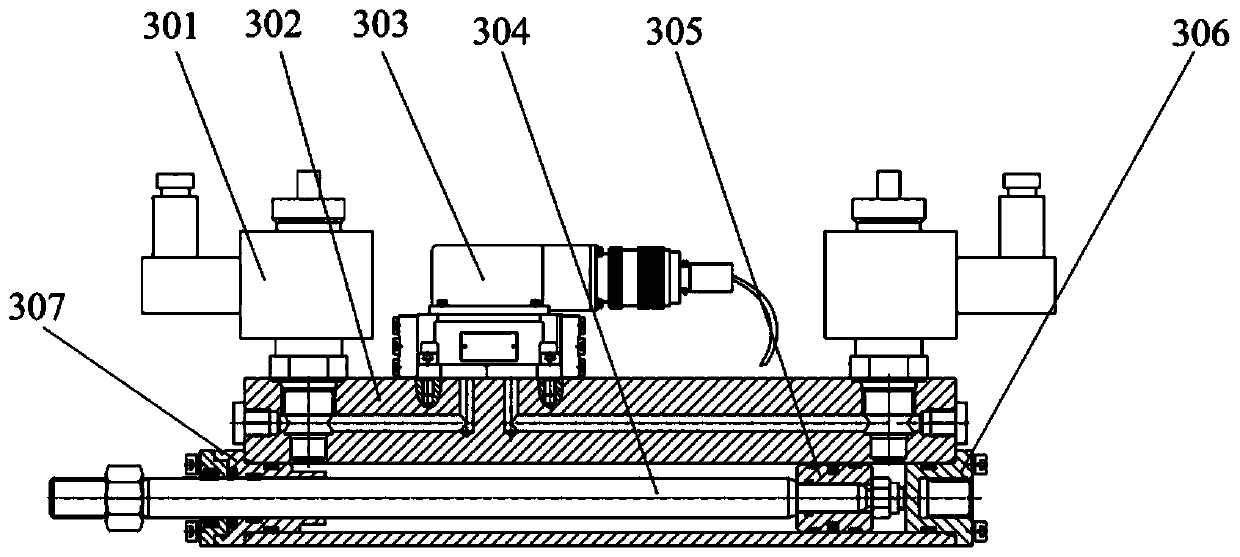

On-cable walking-type self-walking system

ActiveCN102154987AWalk to achieveAutomate the processBridge erection/assemblyEngineeringMechanical engineering

The invention discloses an on-cable walking-type self-walking system which comprises a guide beam (100), a walking frame (300) which is arranged on the guide beam and can move on the guide beam, two supporting legs (200 and 400) which are arranged on two ends of the guide beam, a walking cylinder (500), a hydraulic system, and the like, wherein the front side and the back side of the lower part of the walking frame are provided with two sets of automatic cable clamping devices (300 and 320) which can form the support on a cable, the supporting legs are respectively provided with a lifting cylinder (31) which is vertically arranged, one end of each lifting cylinder is connected with a supporting leg outer sleeve (201) for fixing the guide beam, the other ends of the lifting cylinders are connected with supporting leg inner sleeves (204) for fixing automatic cable clamping devices (210 and 410), one end of the walking cylinder (500) is connected with the guide beam, and the other end of the walking cylinder (500) is connected with the walking frame. The on-cable walking-type self-walking system disclosed by the invention does not need to be additionally provided with drawing equipment, and accessories for mutually high-altitude disassembling, assembling and carrying cable-clamping hoops, and the like, and has the advantages of self-walking, high automation degree, quick walking speed, and high safety.

Owner:SOUTHWEST JIAOTONG UNIV +1

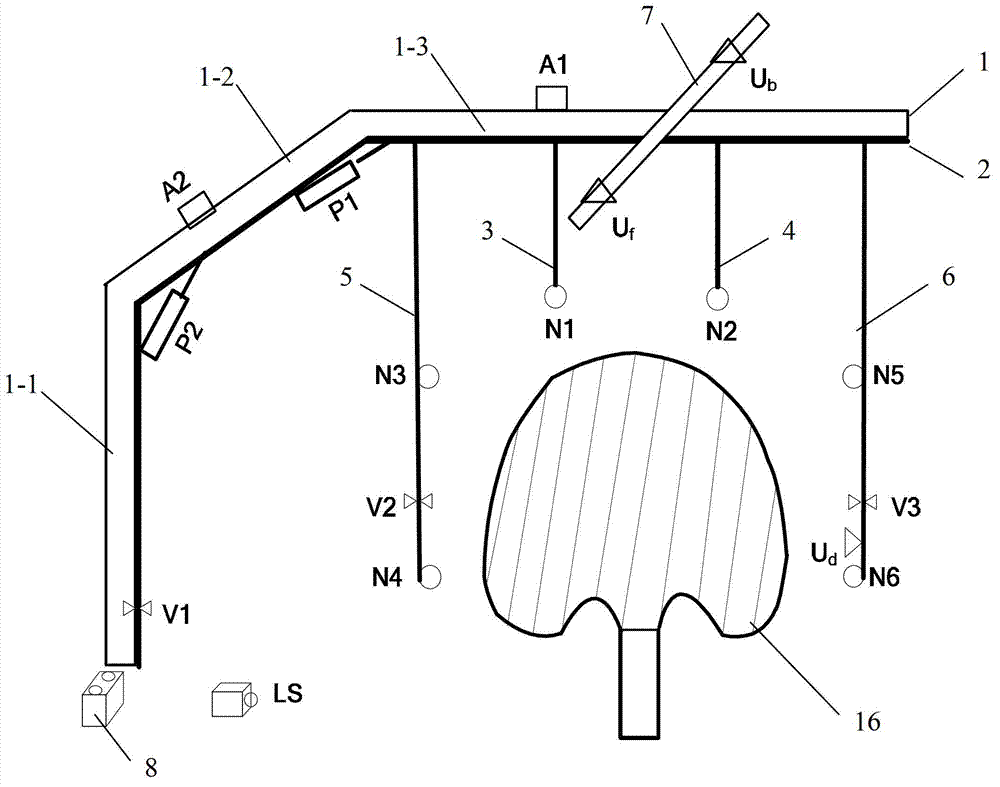

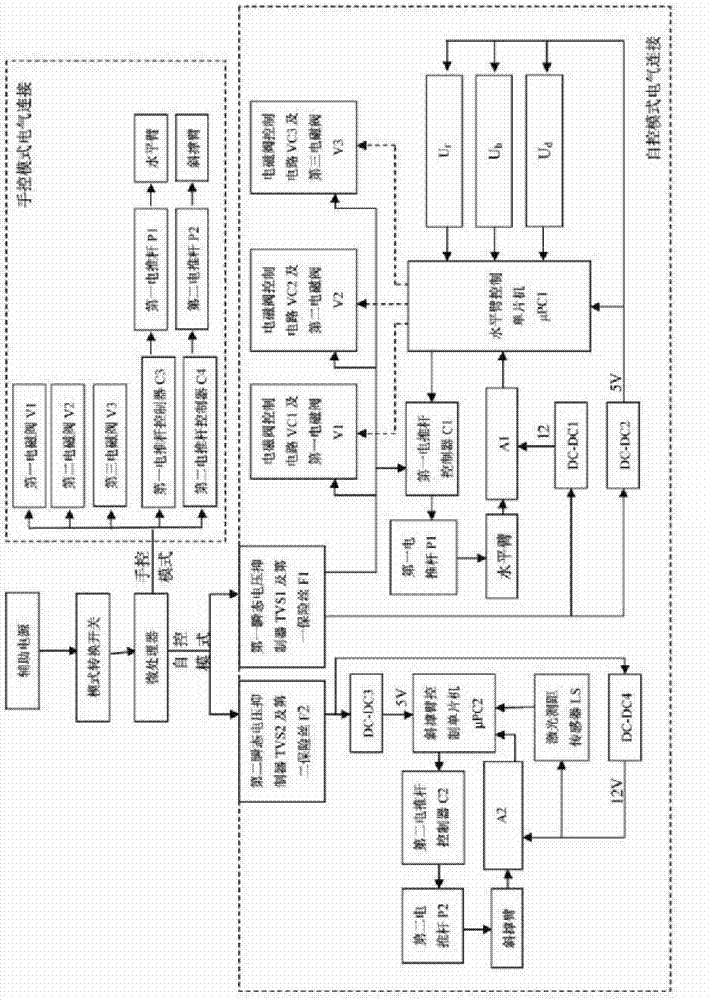

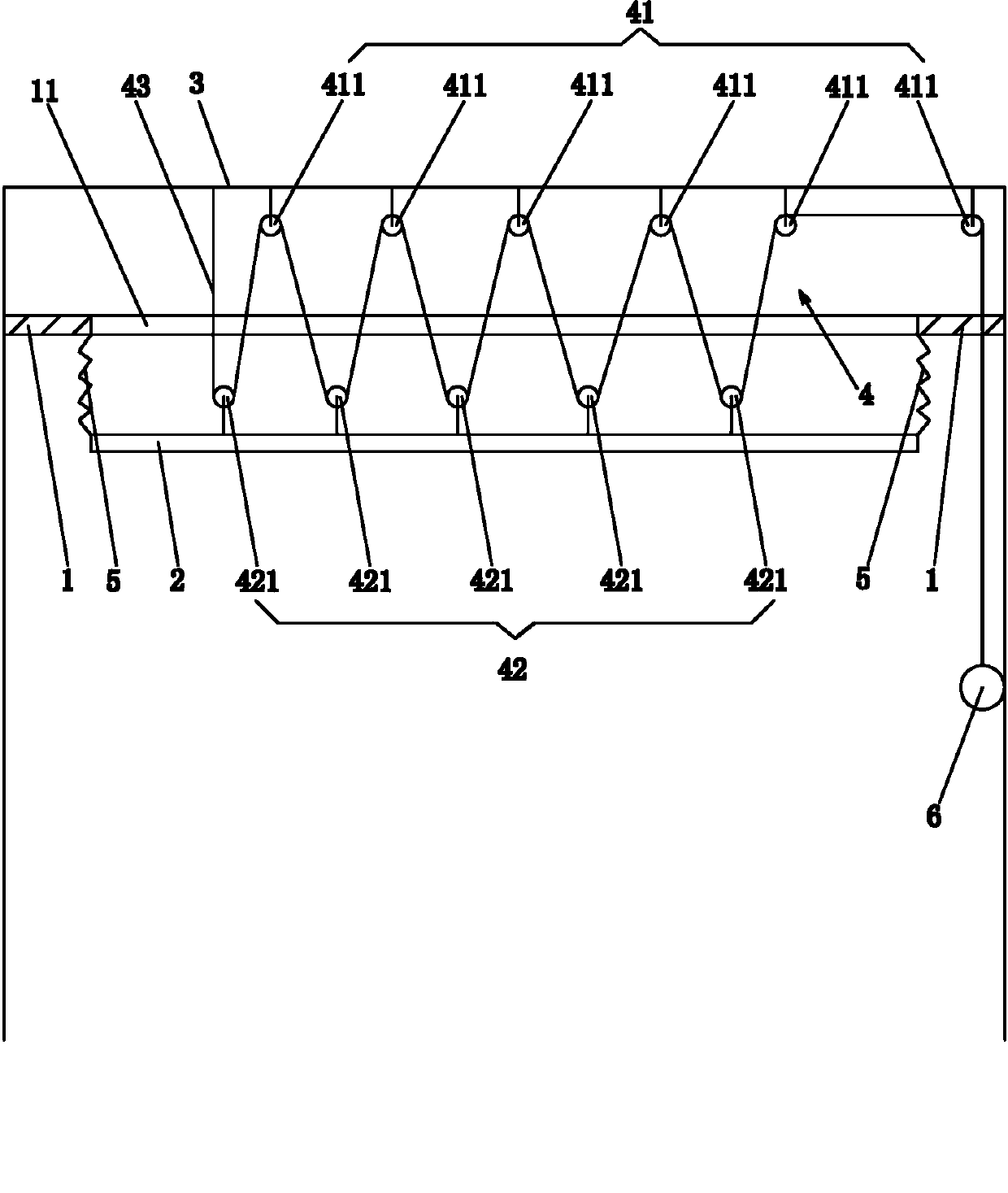

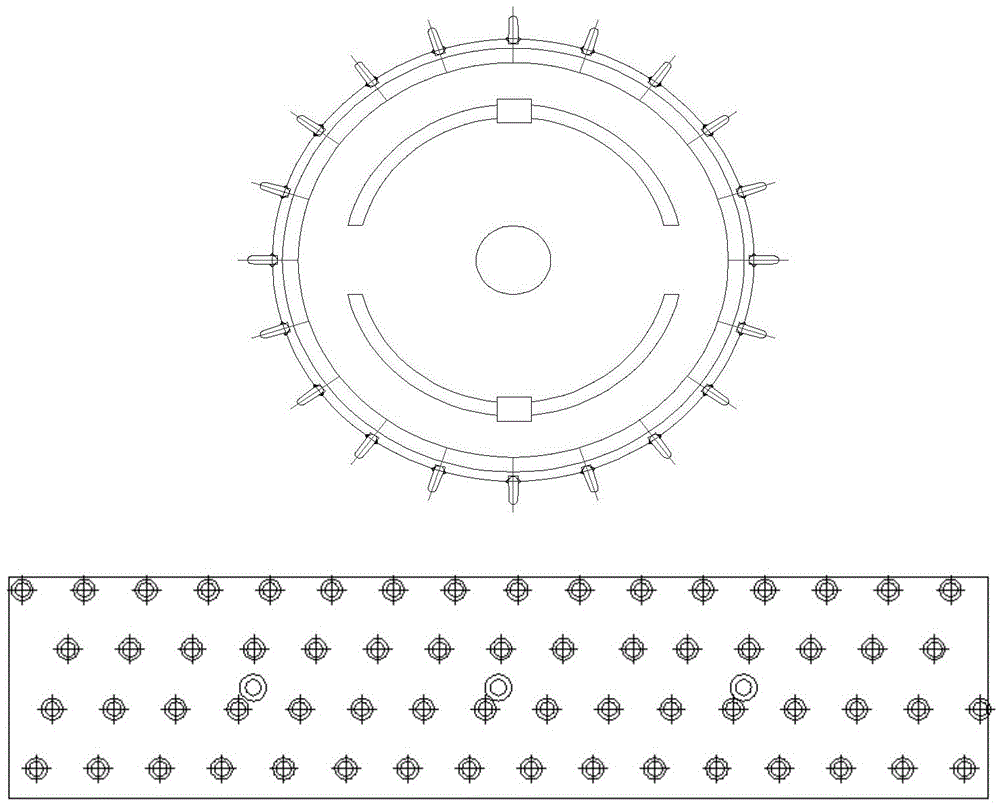

Flexible targeting spraying mechanism for orchards

ActiveCN103392684AImprove pesticide utilization and spray efficiencyReduce the waste of pesticidesInsect catchers and killersPesticideFruit tree

The invention discloses a flexible targeting spraying mechanism for orchards. The flexible targeting spraying mechanism comprises a spray support, a main spray pipe, a plurality of side spray pipes and a control device. The main spray pipe is disposed on the spray support which comprises a telescopic arm, a diagonal bracing arm and a horizontal arm, and the telescopic arm, the diagonal bracing arm and the horizontal arm are connected in sequence; the main spray pipe correspondingly comprises a vertical section, a diagonal section and a horizontal section; the side spray pipes are arranged on the horizontal section, and each side spray pipe is provided with a nozzle; a first solenoid valve is arranged on the main spray pipe, a first electric putter is arranged at the joint of the horizontal arm and the diagonal bracing arm on the spray support, a second electric putter is arranged at the joint of the diagonal bracing arm and the telescopic arm on the spray support, and the first solenoid valve, the first electric putter and the second electric putter are all respectively and electrically connected with the control device. By the flexible targeting spraying mechanism, shape of the spray support can be manually or automatically adjusted according to line spacing and row spacing of planted fruit trees and sizes thereof, so that targeting spraying effect can be guaranteed, pesticide utilization and spraying efficiency can be improved, waste of pesticides can be reduced, and further environmental pollution can be avoided.

Owner:SOUTH CHINA AGRI UNIV

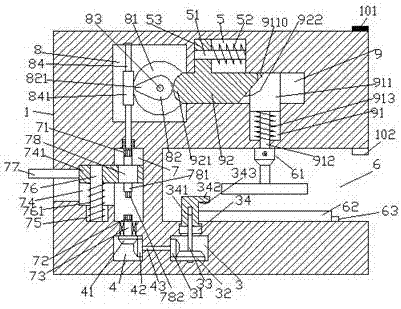

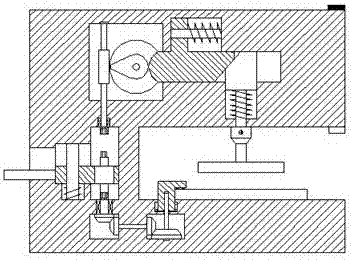

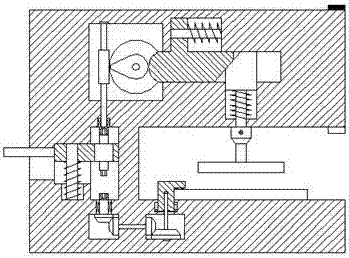

Horizontal broacher

ActiveCN101185979AMove fastImprove work efficiencyFluid-pressure actuatorsMetal working apparatusHydraulic cylinderDevice form

The invention discloses a horizontal broaching machine. The invention mainly has the following technical points: a speed-difference valve is arranged between a hydraulic cylinder and a reversing valve; the moving speed of a piston of the hydraulic cylinder can be raised by more than two times when a high-pressure oil is fed into a non-rod cavity of the hydraulic cylinder and then the return time of a broach can be largely shortened and the work efficiency of the broaching machine can be enhanced. One the other hand, a manual reversing valve is adopted, and a mechanical operation device is arranged between the manual reversing valve and a sliding seat. The operation device can drive a valve rod of the manual reversing valve to move when the sliding seat moves to a corresponding position so as to realize an automatic reversing of the hydraulic cylinder. Compared with a reversing device formed by a solenoid directional valve and a stroke switch, the invention has the advantages that the use is reliable; the regulation is convenient; the structure is simple and the manufacturing cost is low.

Owner:CHAGYI LIHUI BROACHING MACHINE MAFACTURE

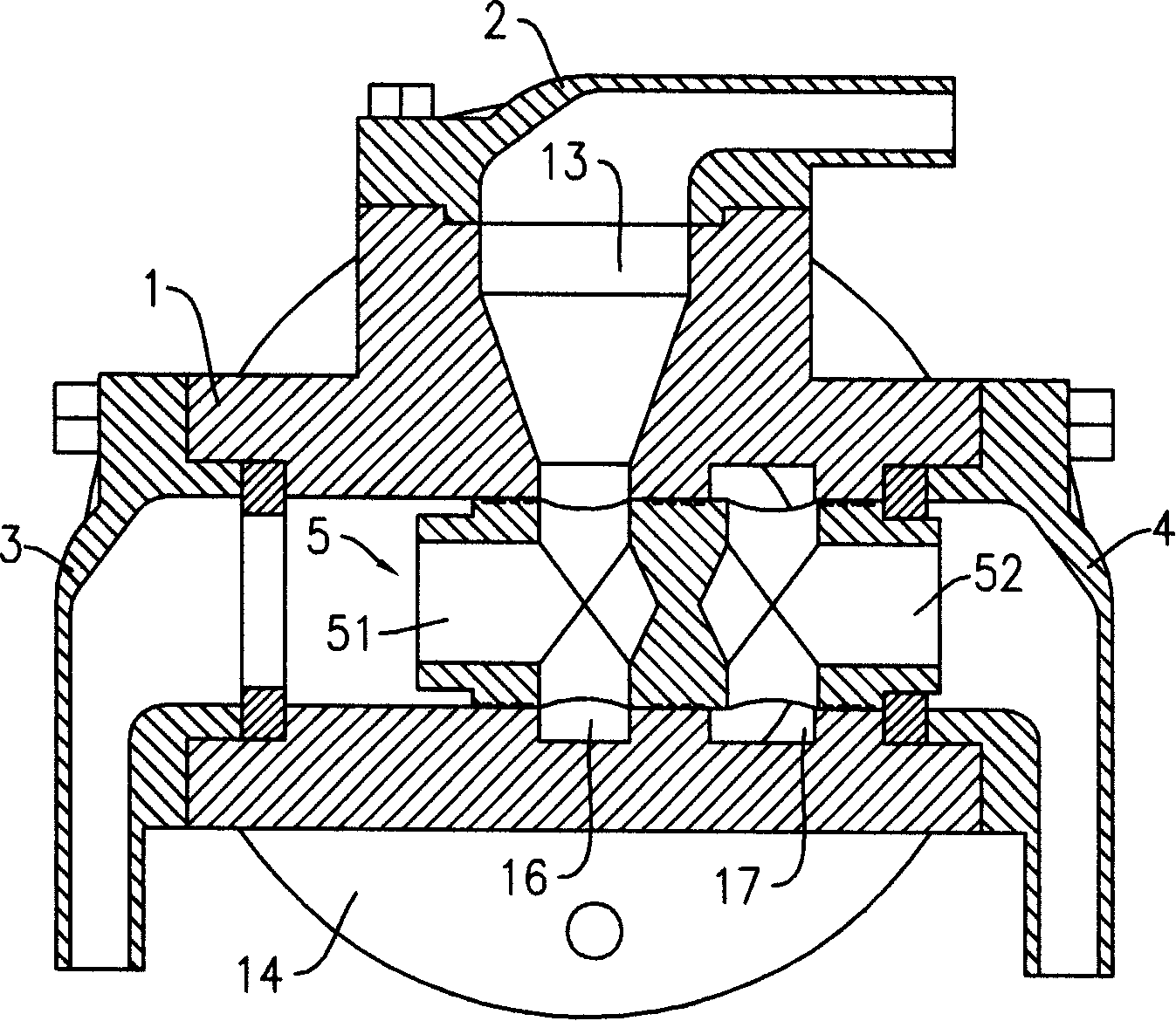

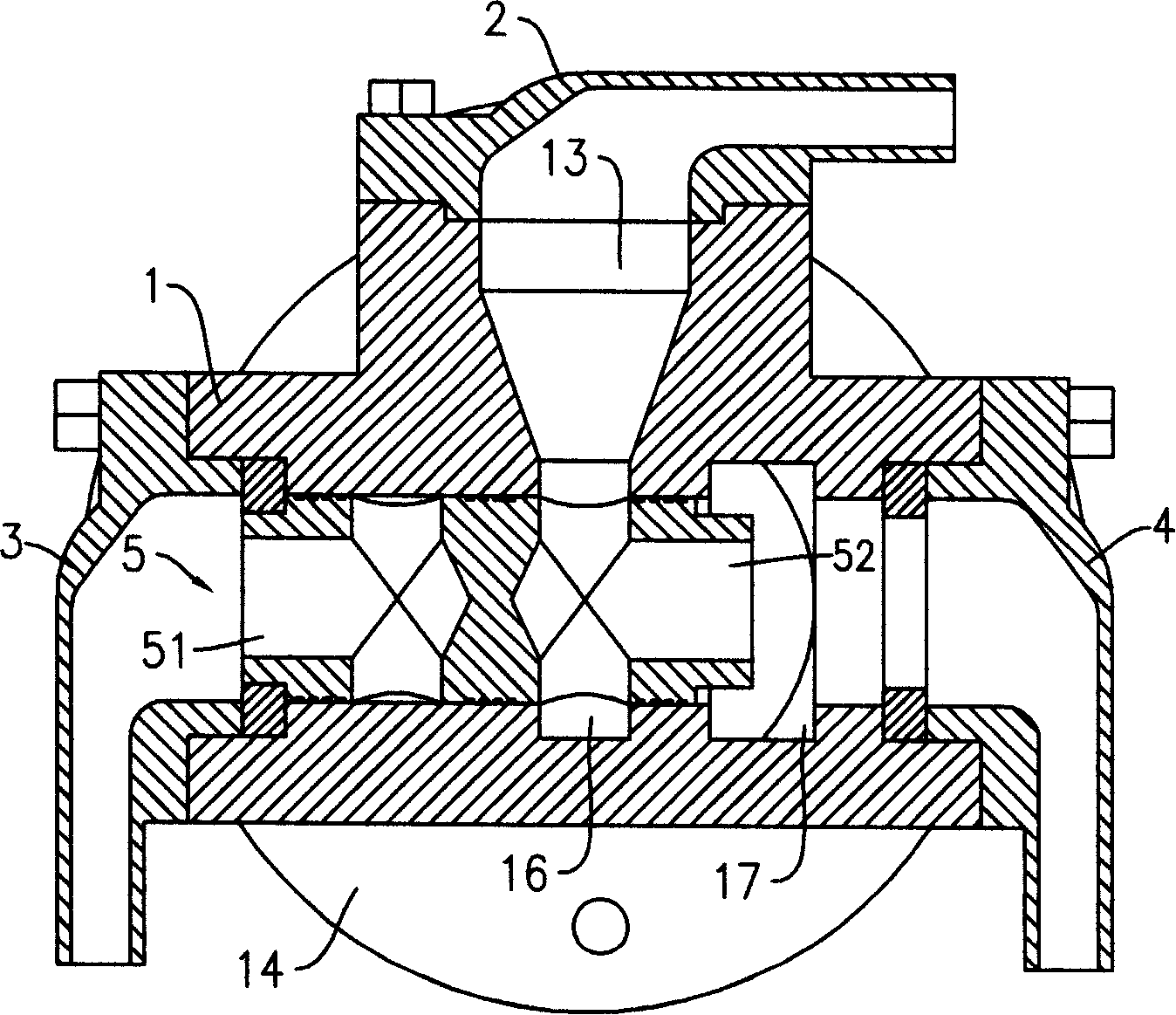

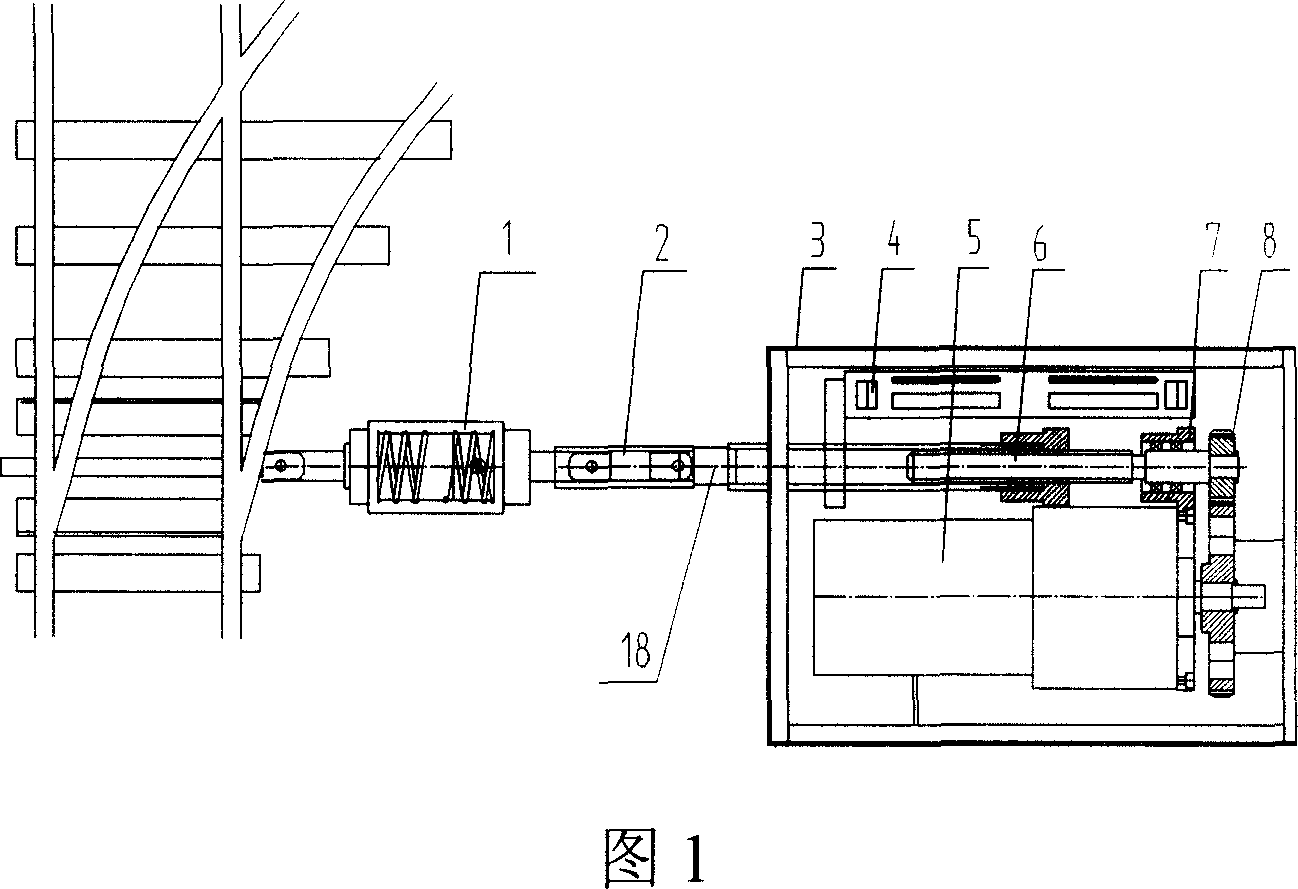

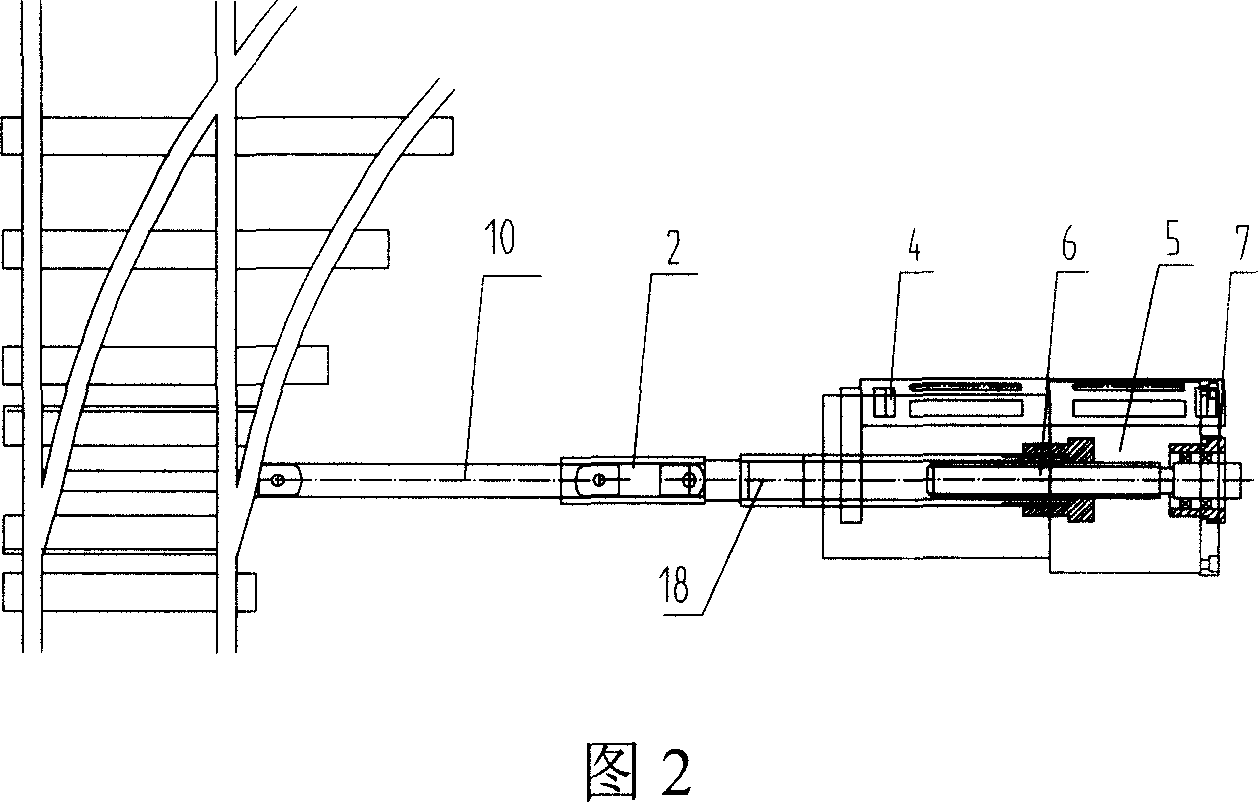

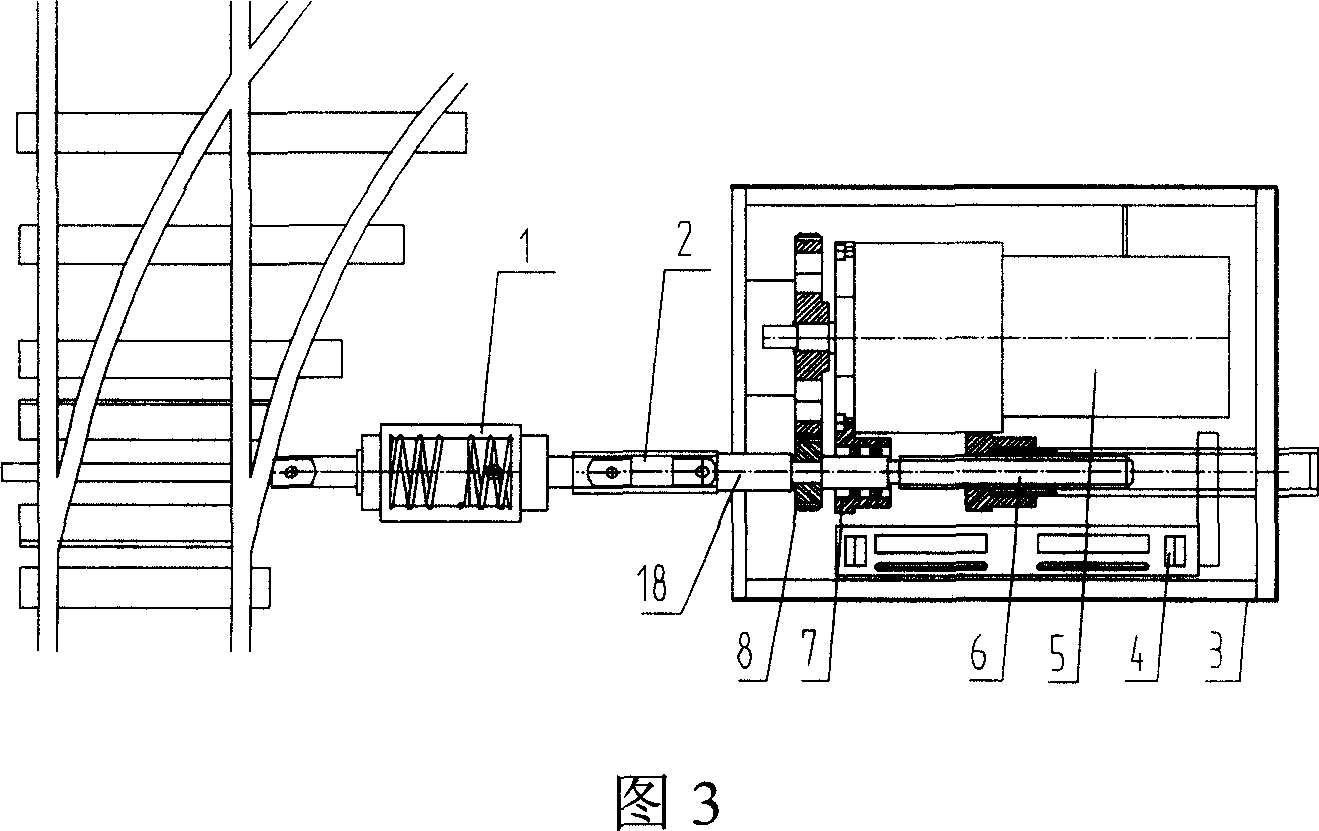

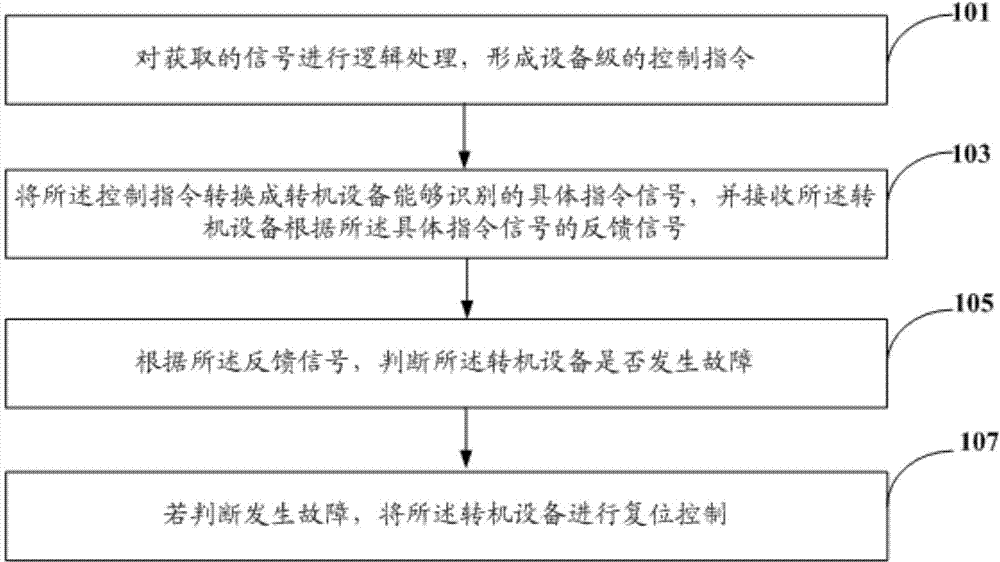

Rail switching device for electric control switch

InactiveCN1944145ASave spaceReduce volumeElectric devices for scotch-blocksAutomatic controlElectric machinery

The present invention relates to rail switching device, and is especially one kind of rail switching device for electrically controlled switch. The rail switching device includes an electric controller and a driver to connect the electric controller to the rail. The electric controller has a power machine and a push rod connected to the power machine. The switch controlling process includes the steps of changing voltage, converting the rotating force into linear force with the motor, changing drive moment mechanically and pushing or pulling the switch rail with the driver, and has great drive moment and small operating current. The rail switching device has also built-in lead screw, small DC permanent motor, inside micro reducer and contact-less stroke switch, and possesses reduced size, raised reliability and capacity of realizing automatic control.

Owner:史长春

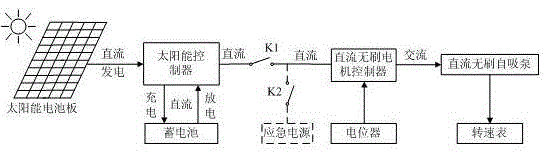

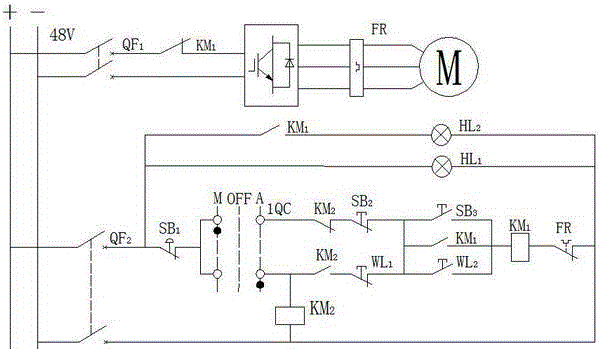

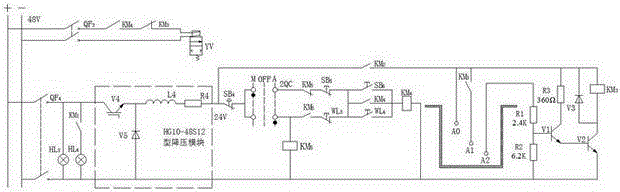

Water taking and pressurizing control system of solar sprinkler

InactiveCN104381098AEasy to operateOperational securityWatering devicesRenewable energy machinesBrushless motorsWireless control

The invention discloses a water taking and pressurizing control system of a solar sprinkler. The system comprises a solar photovoltaic power generating module, a direct-current brushless motor control circuit and a water source constant water level automatic water replenishing control circuit. The solar photovoltaic power generating module respectively powers the direct-current brushless motor control circuit and the water source constant water level automatic water replenishing control circuit. The direct-current brushless motor control circuit controls the power supply of a water pump. The control system has the advantages that the system uses clean solar energy to supply power, wireless control is used, convenient operation is achieved, remote on and off control of units is achieved, remote transmission indication and alarming of a system fault state unit can be achieved, a high-performance brushless direct-current motor is used to drive a self-priming pump, high system reliability and low energy loss are achieved, the water pump is started in a convenient and labor saving manner, automatic irrigation can be achieved conveniently, universality and flexibility of sprinkling irrigation units are increased effectively, and the irrigation requirements of farms, pastures, crops, economical crops and forage grass are satisfied.

Owner:NORTHWEST A & F UNIV

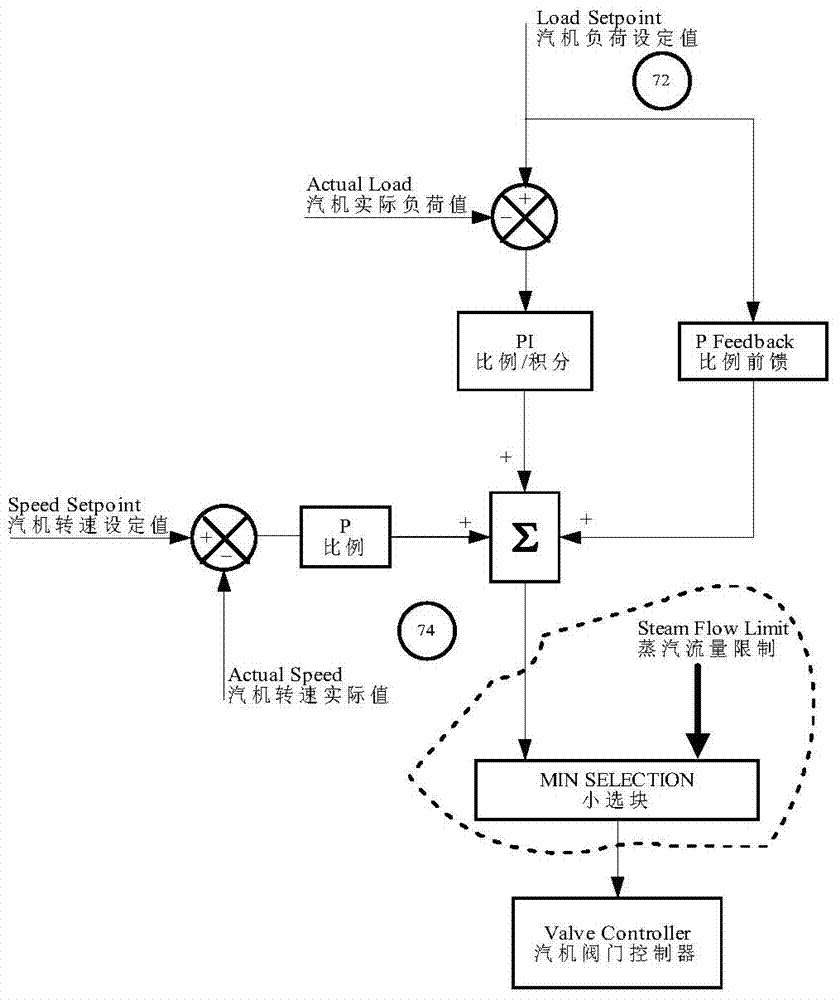

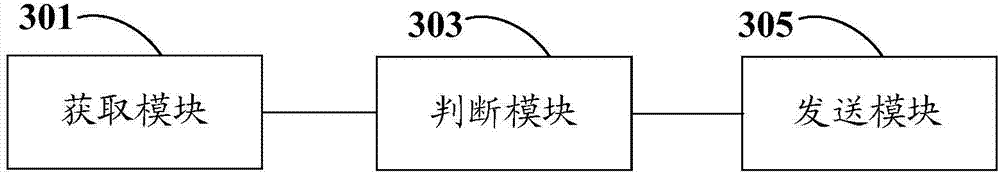

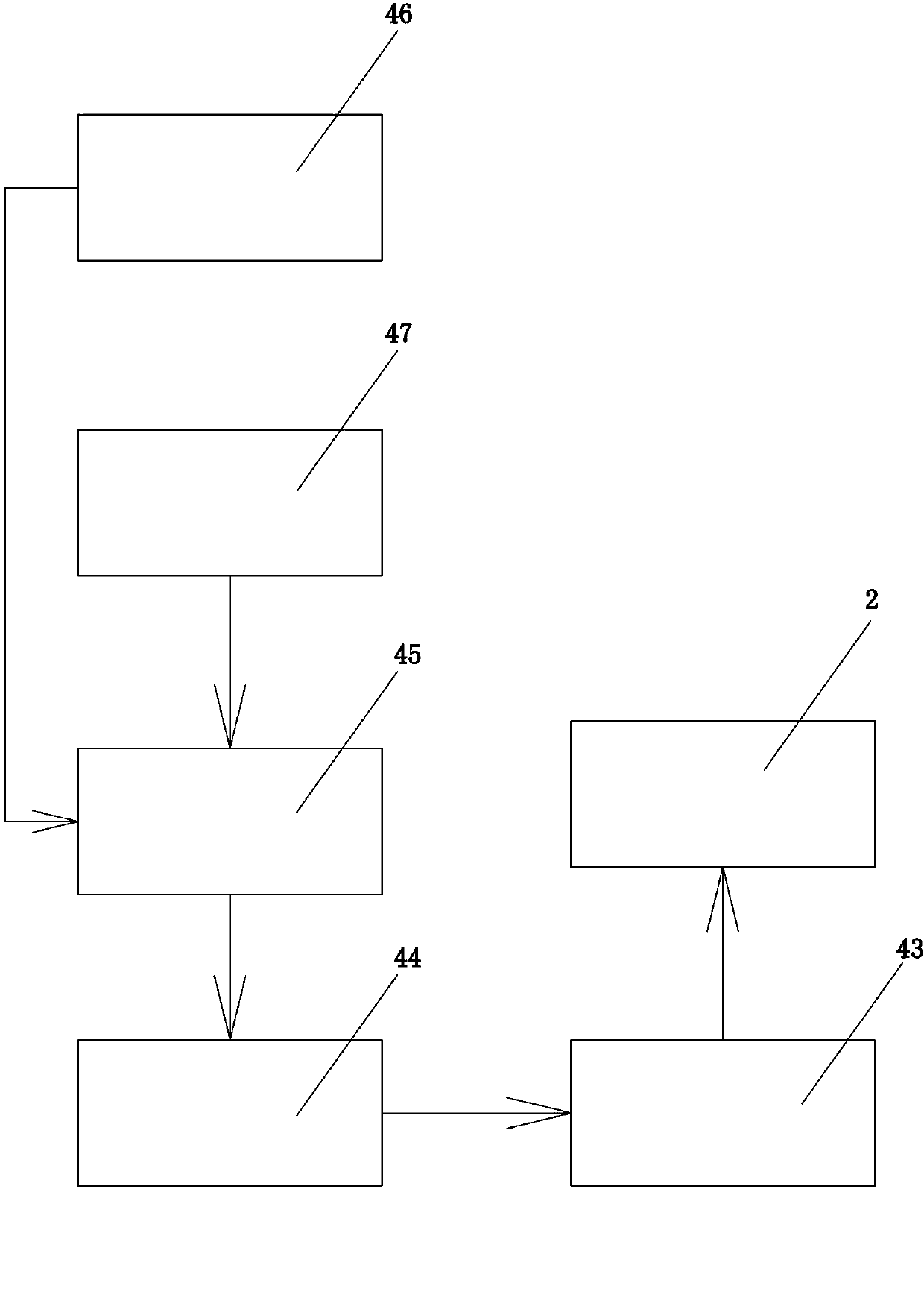

Load control method and system for adjustment of steam turbine of nuclear power station

ActiveCN104500151AMeet the requirements of load open-loop controlAvoid unnecessary perturbation problemsPlant parameters regulationNuclear energy generationNuclear engineeringControl system

The invention discloses a load control method for adjustment of a steam turbine of a nuclear power station. The method comprises the following steps: acquiring a set rotating speed value and an actual rotating speed value of the steam turbine of the nuclear power station; judging whether a difference value between an actual load value of the steam turbine for the nuclear power station and a set load value of the steam turbine of the nuclear power station exceeds a preset range or not according to the set rotating speed value and the actual rotating speed value; if the difference value between the actual load value of the steam turbine for the nuclear power station and the set load value of the steam turbine of the nuclear power station exceeds the preset range, sending a steam flow limiting signal to a main control chamber. The load control method for adjustment of the steam turbine of the nuclear power station is a reliable technology for controlling a load in the adjustment of the steam turbine of the nuclear power station, so that safe operation of a nuclear power unit can be guaranteed. Furthermore, the invention also discloses a load control system for adjustment of the steam turbine of the nuclear power station.

Owner:中广核工程有限公司 +1

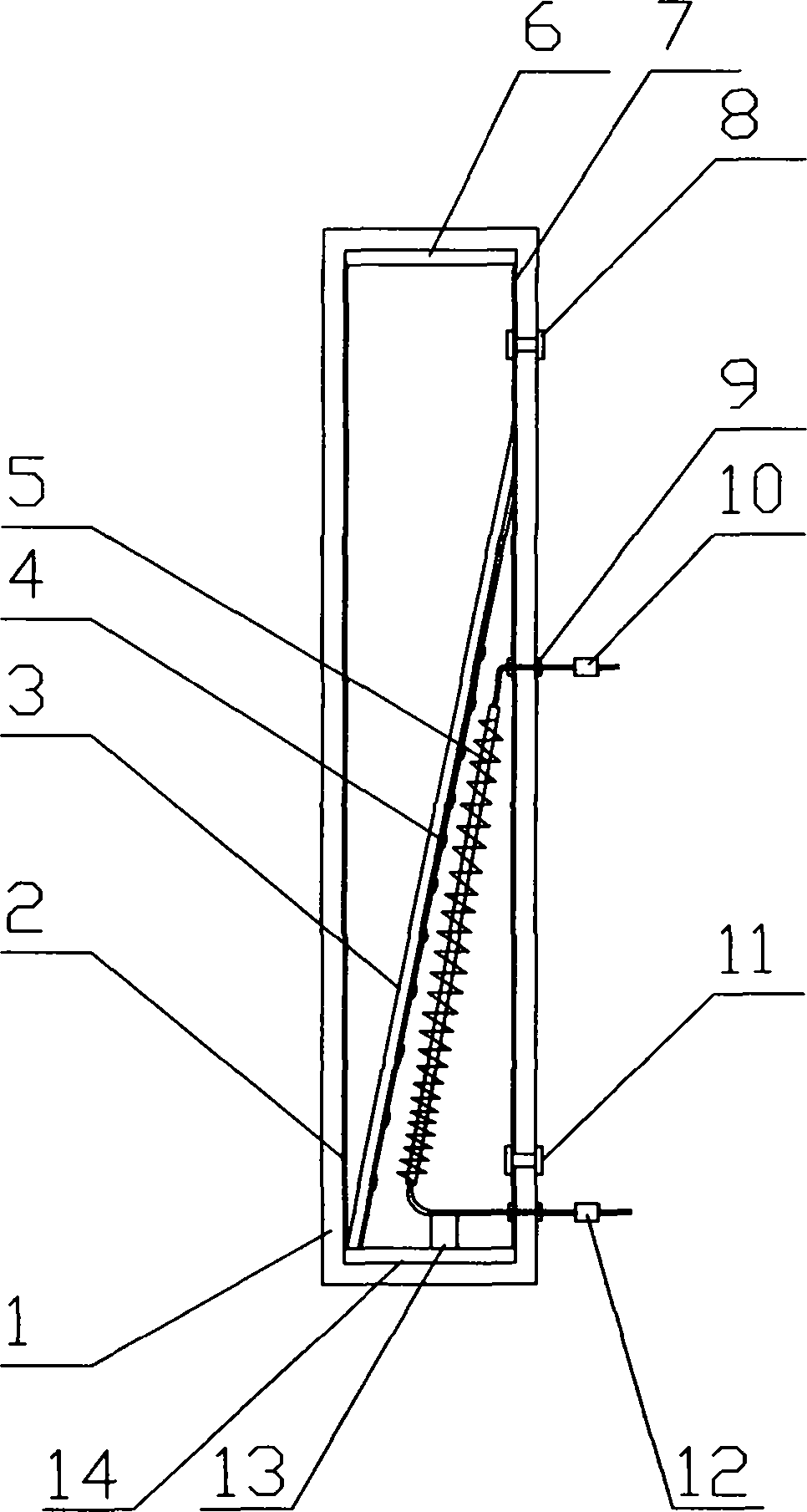

Solar energy wall body heat utilization system

InactiveCN101781915ANo power cycleImprove heat transfer efficiencyWallsSolar heat devicesMetal frameworkEngineering

The invention relates to a solar energy wall body heat utilization system. A heat storage wall body, which consists of light transmitting glass, a metal framework, a light-gathering glass mirror, a metal fin heat-absorbing tube, a sealing part, a heat insulation wall body, and a heat preservation material, is matched with a thermal heater, a water heater, and a hot air exchanger, wherein a phase change medium in the heat-absorbing tube absorbs heat and outputs hot air by gathering light and storing heat from the sun; and exchanged fluid is refluxed, so heat is exchanged. The temperature of the surface can be up to 120 DEG C in winter, and the heat energy can be stored in an indoor water heater, and also can be synchronously used for domestic heat supply, such as heating, hot air exchange, hot water and the like. The solar energy wall body heat utilization system can be produced in standardization, universalization and industrialization, is widely used in construction and reconstruction of the wall body and a domestic heat supply source, and has an obvious energy saving effect.

Owner:TIANJIN CITY CENTSTAGE TECH INCUBATOR COMPANY +2

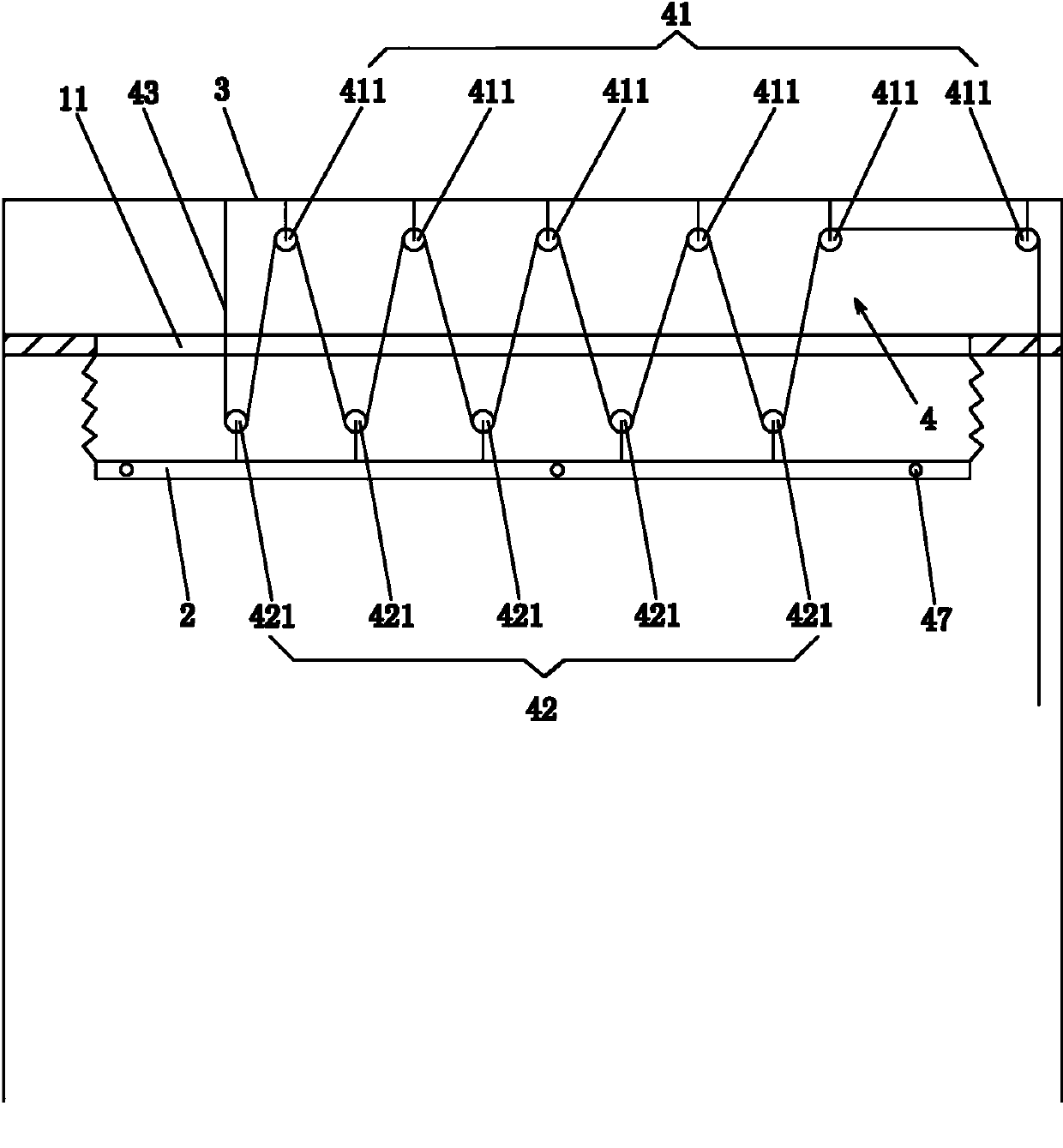

Adjustable suspended ceiling

An adjustable suspended ceiling comprises an adjustable suspended ceiling body and a driving device. The adjustable suspended ceiling body is arranged below the ceiling, and the driving device is arranged between the ceiling and the adjustable suspended ceiling body and can drive the adjustable suspended ceiling body to move up and down. Since the driving device can drive the adjustable suspended ceiling body to move up and down, height of the adjustable suspended ceiling body can be adjusted according to different using requirements of users so as to change the size of the interior space. Adjusting methods of the adjustable suspended ceiling body can be selected according to different locations, sizes of the adjustable suspended ceiling body and the like, both manual control and automatic control can be realized and different using requirements of users can be met.

Owner:洪思滨

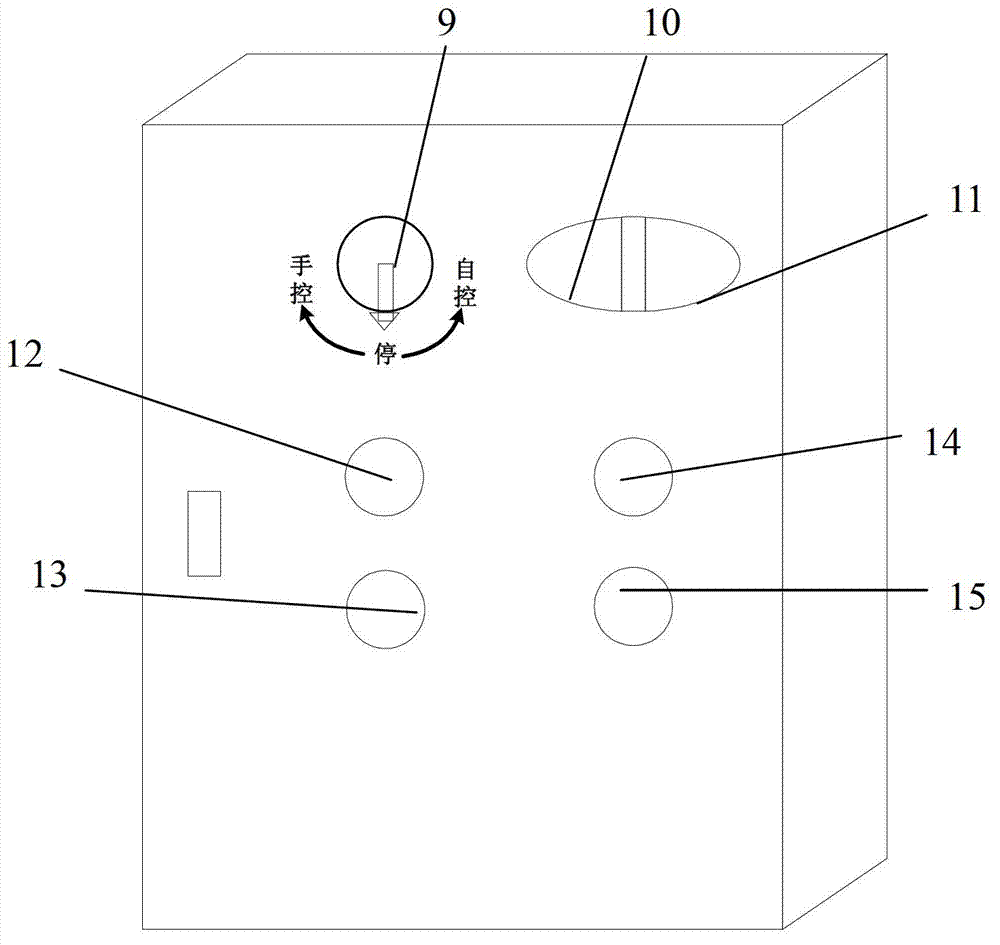

Automatic ridge walking device of tobacco harvester

ActiveCN104793617AImplement manual controlPosition/course control in two dimensionsAutomatic steeringMotor drive

The invention relates to an automatic ridge walking device of a tobacco harvester. The automatic ridge walking device comprises a machine frame, a walking system, a tobacco leaf collection box, a seat and a detection control system. The walking system comprises a hub motor and a motor drive system. The detection control system comprises infrared ranging sensors, a single-chip microcomputer and a D / A conversion module. The two infrared ranging sensors are movably fixed to the two sides of a sensor support and connected to the A / D collection port of the single-chip microcomputer. The I / O port of the single-chip microcomputer is connected with the D / A conversion module. The output port of the D / A conversion module is connected with the signal control end of the motor drive system. An output shaft of the motor hub is fixed to a hub fixing base below the machine frame. The distances between wheels on the two sides and a tobacco ridge can be accurately detected through the infrared ranging sensors, data obtained through the sensors are transmitted to the single-chip microcomputer, and the automatic steering is achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

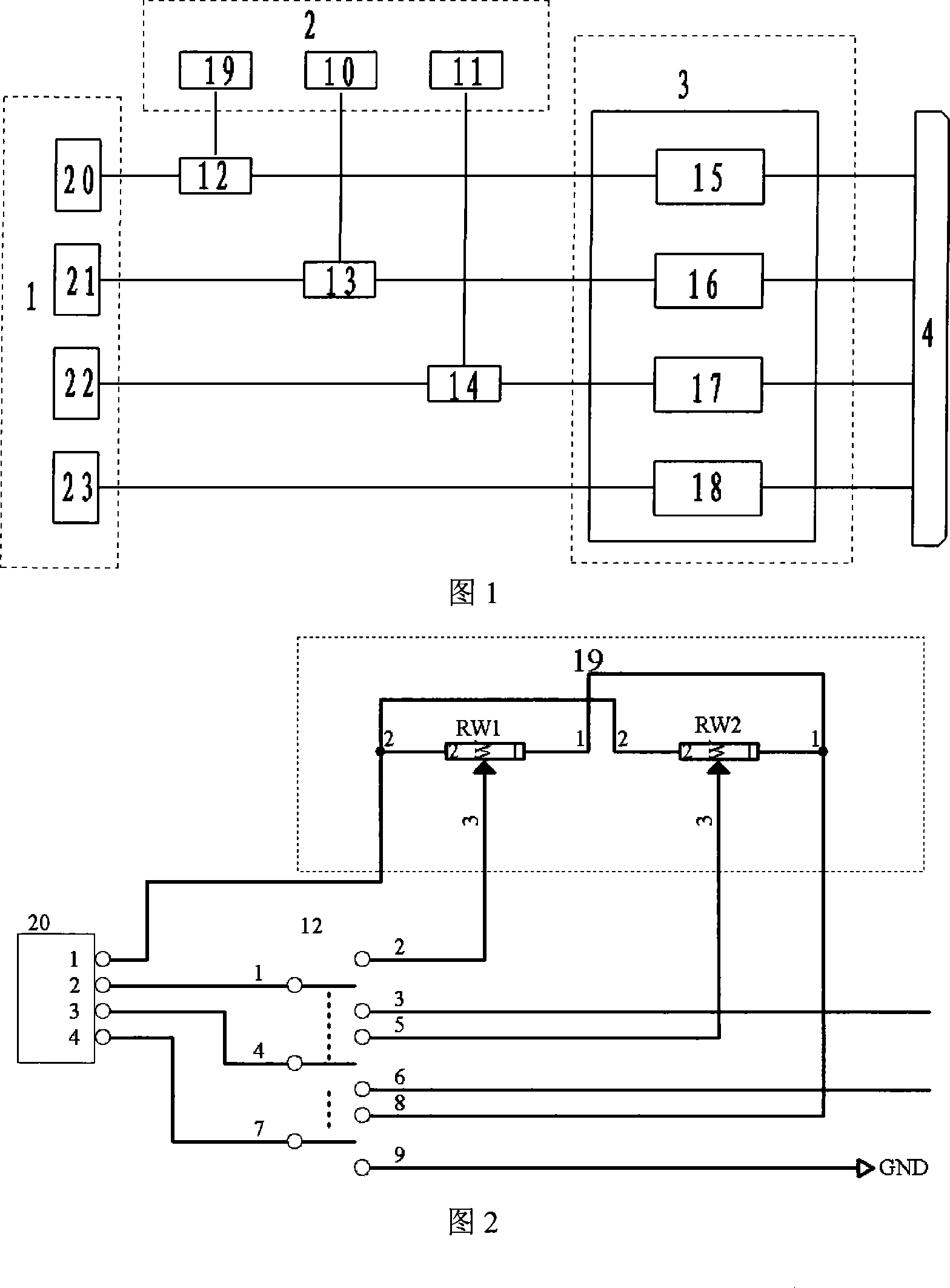

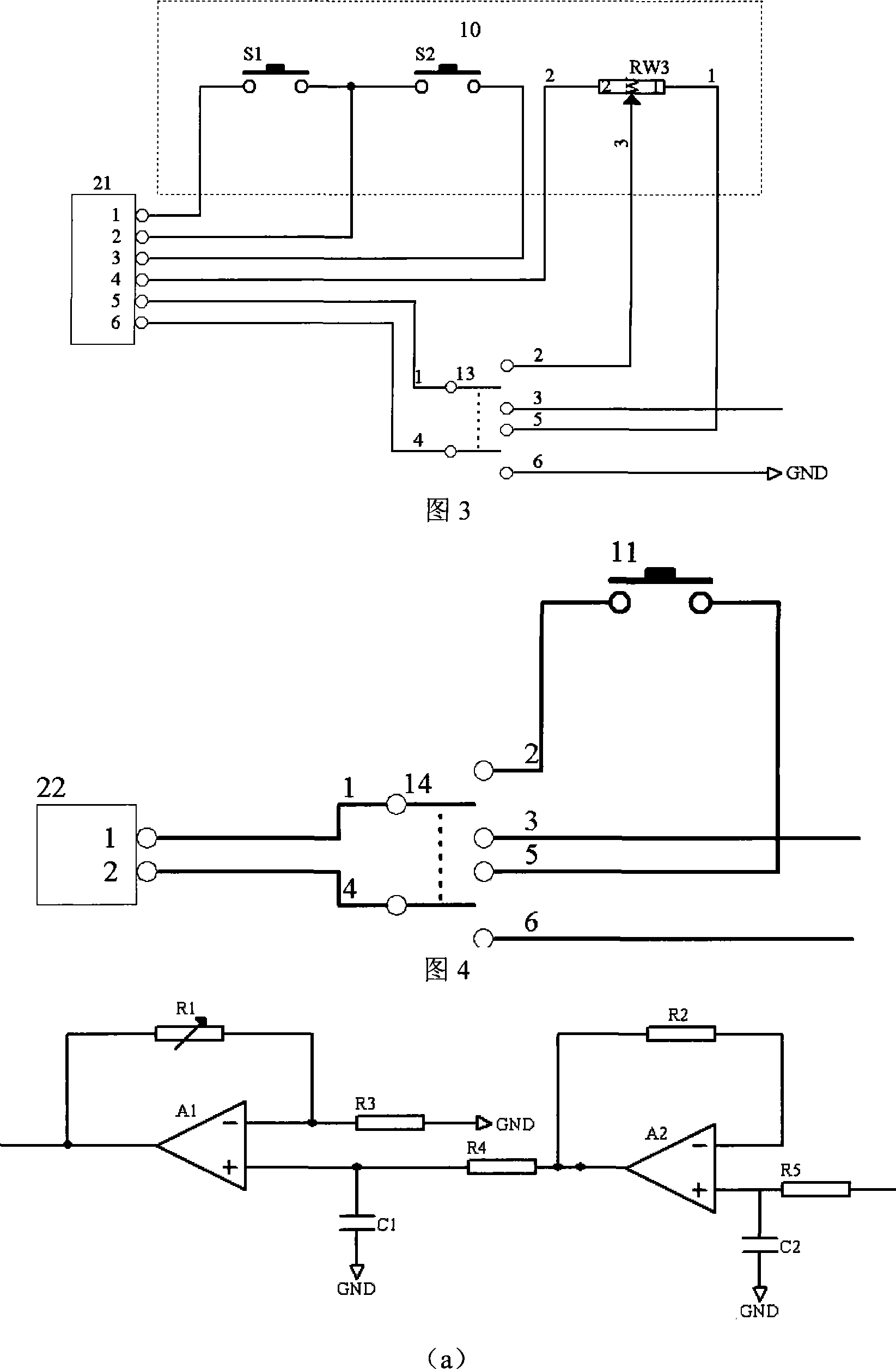

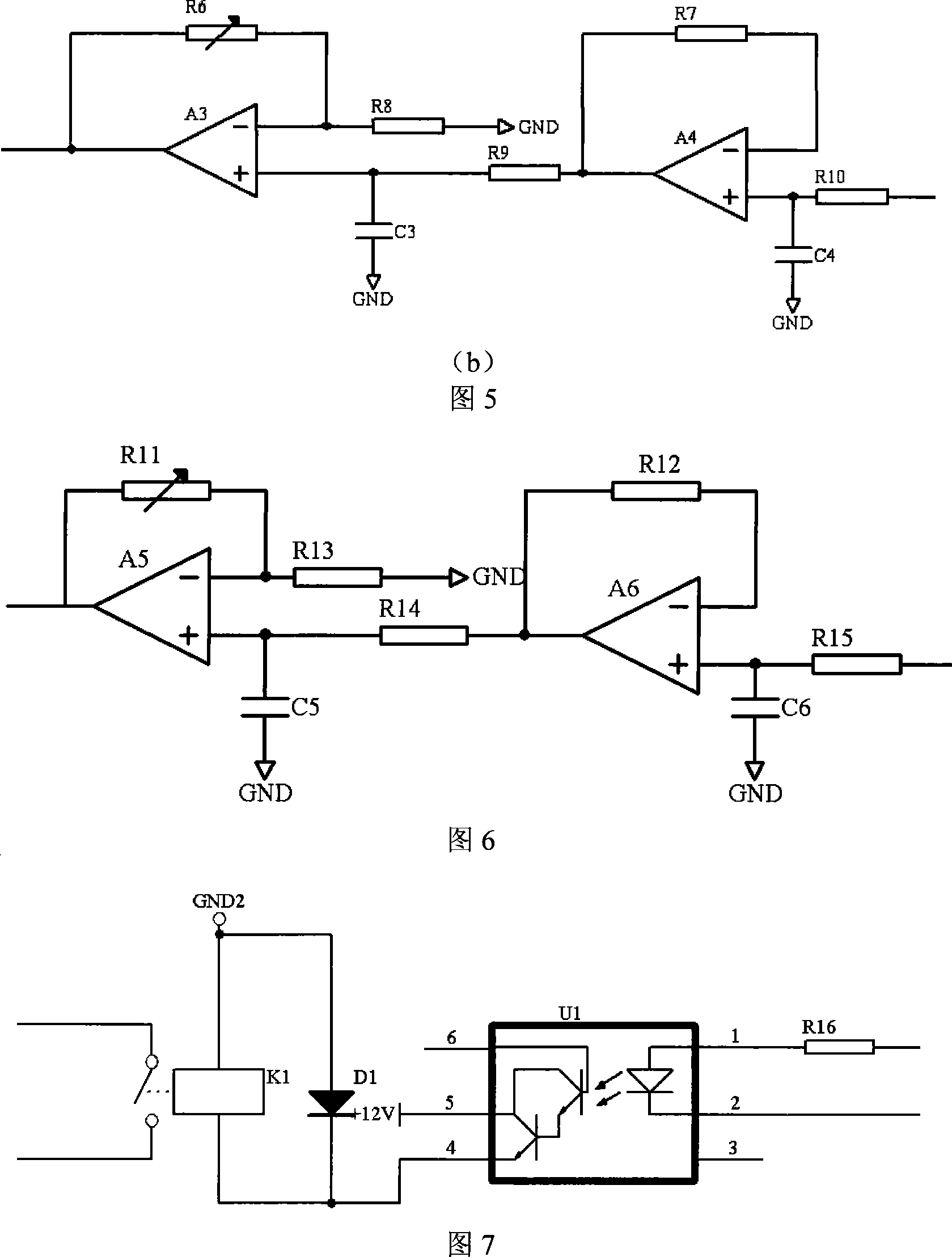

Gas protected tungsten pole argon arc welding automatic controlled system adapter

InactiveCN101204754AMeet the needs of automatic controlEffective automatic controlArc welding apparatusAutomatic controlWelding power supply

An automatic control system commutator for an air protection argon tungsten-arc welding in the technical field of welding includes a welding power interface circuit, a manual control circuit, an automatic control circuit, a computer interface circuit, a first shift switch, a second shift switch and a third shift switch used for connecting a welding power and a computer during the welding process of the air protection argon tungsten-arc welding and realizing the automatic control and manual control of the computer to the welding process. The invention adjusts a welding current and the size of a wire feeding speed in real time through the computer during the welding process and gets the welding process state information like arc starting, arc failure and pulse coming, etc., in the air protection argon tungsten-arc welding process in real time and realizes the effectively automatic control on the welding process.

Owner:SHANGHAI JIAO TONG UNIV

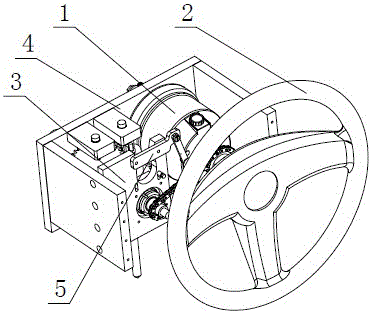

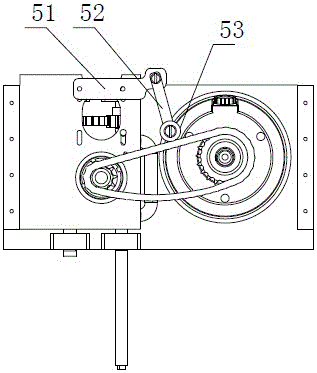

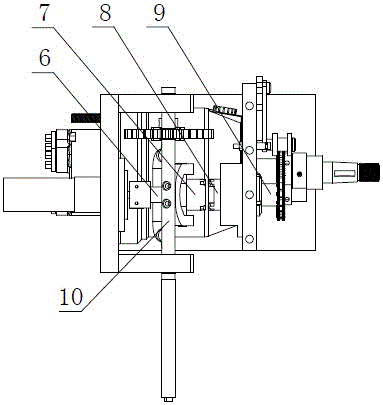

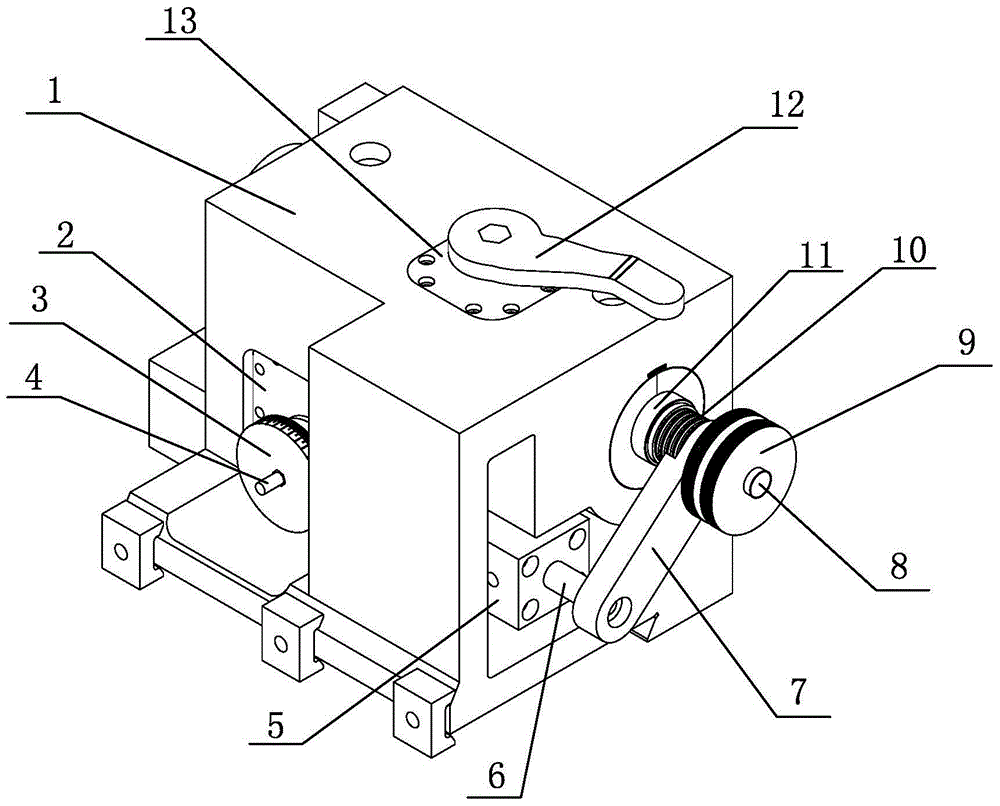

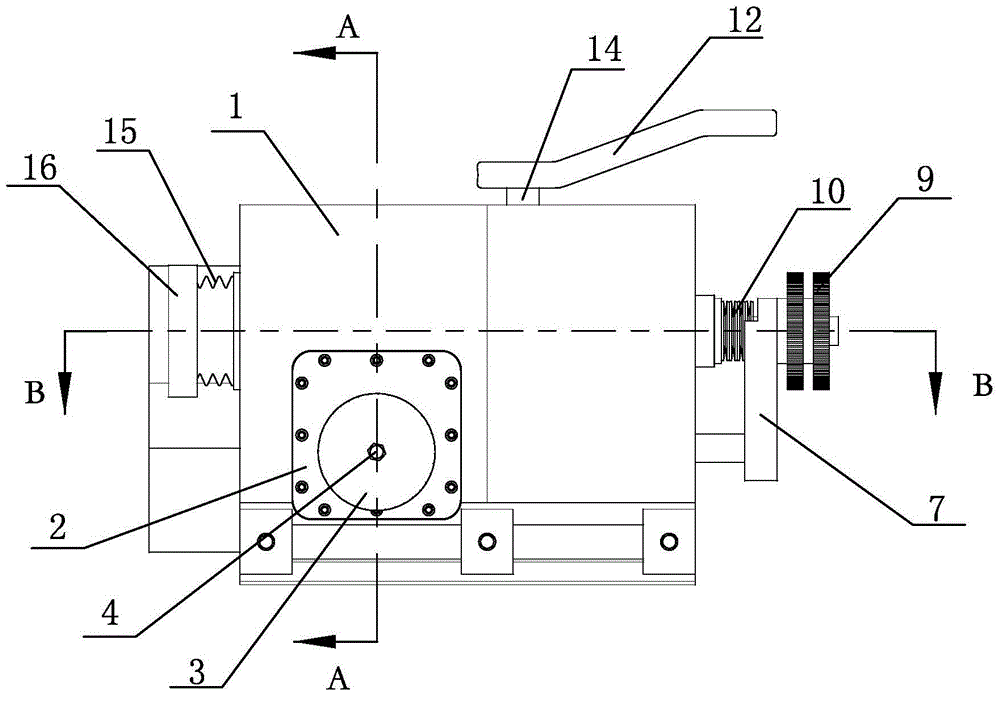

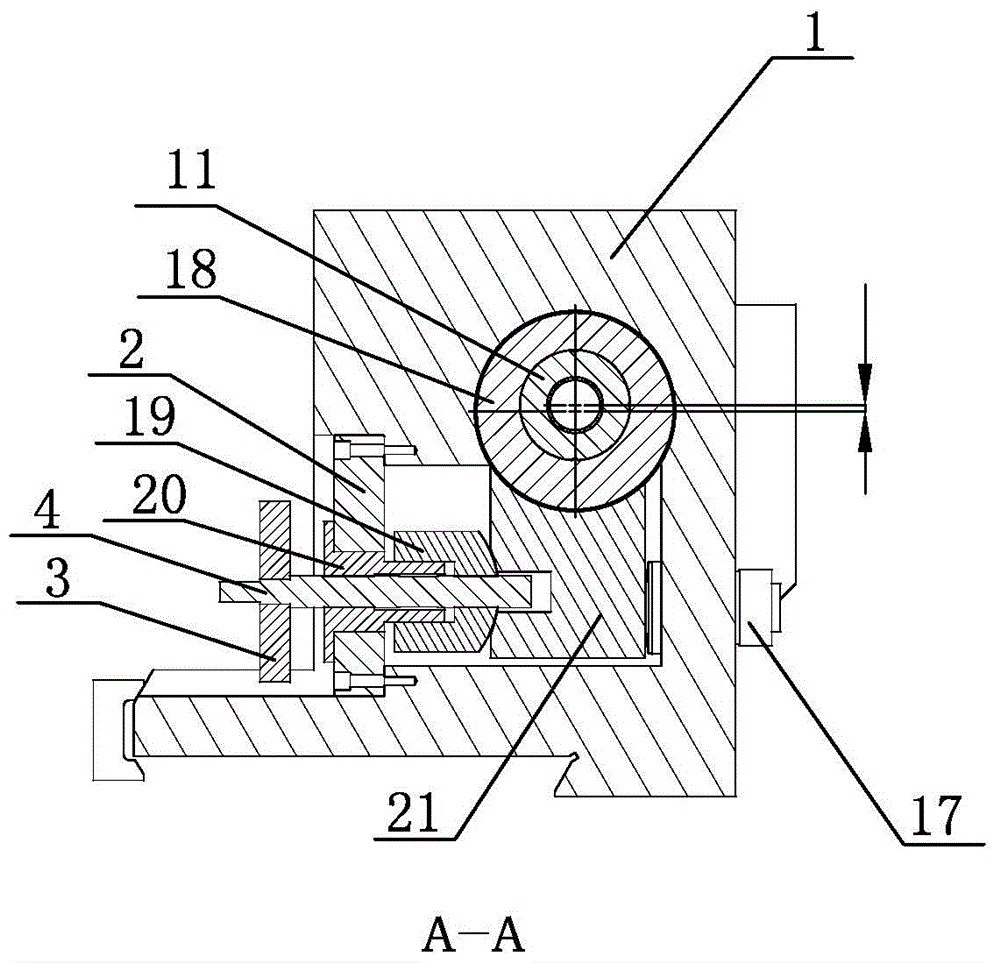

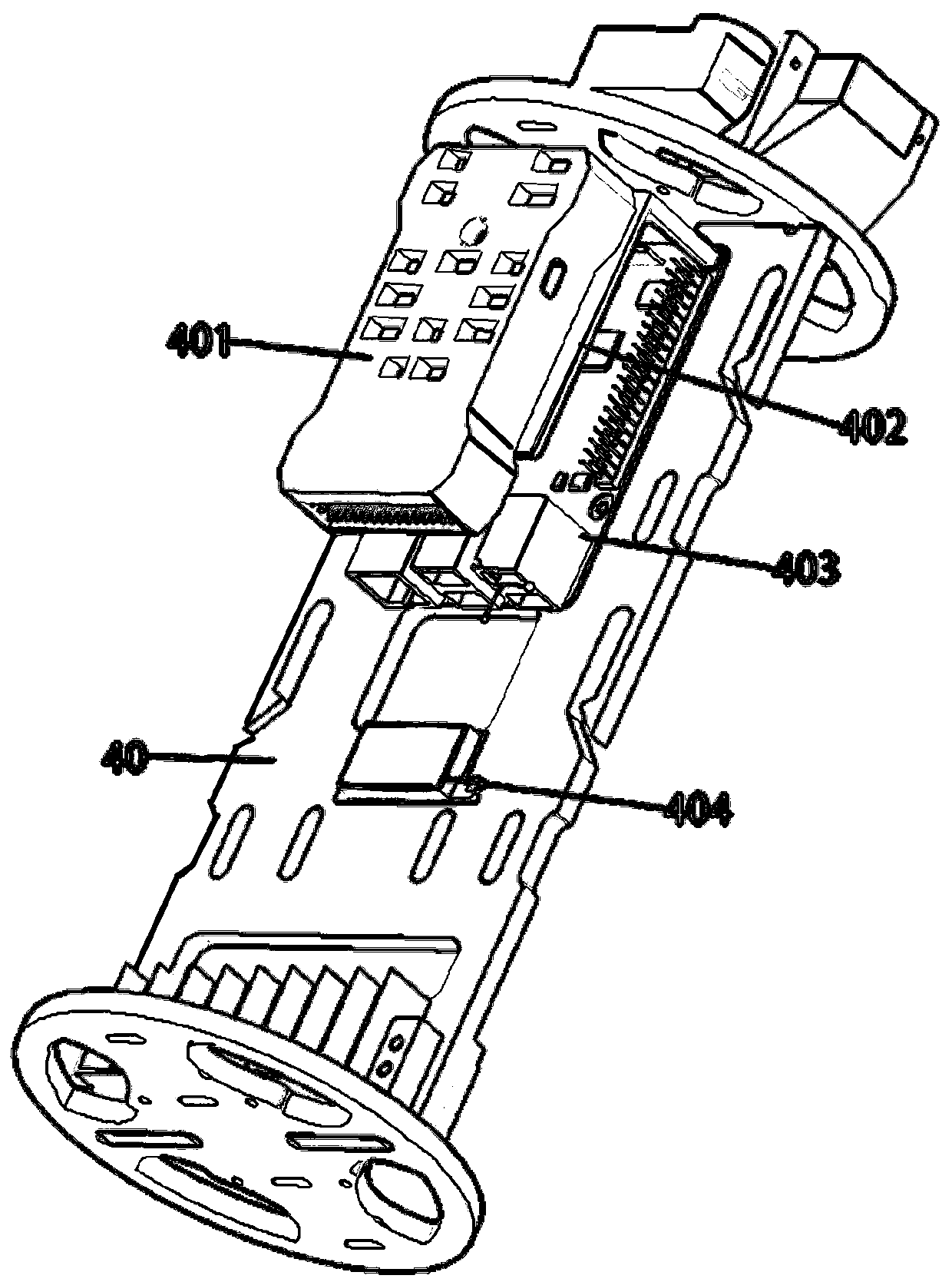

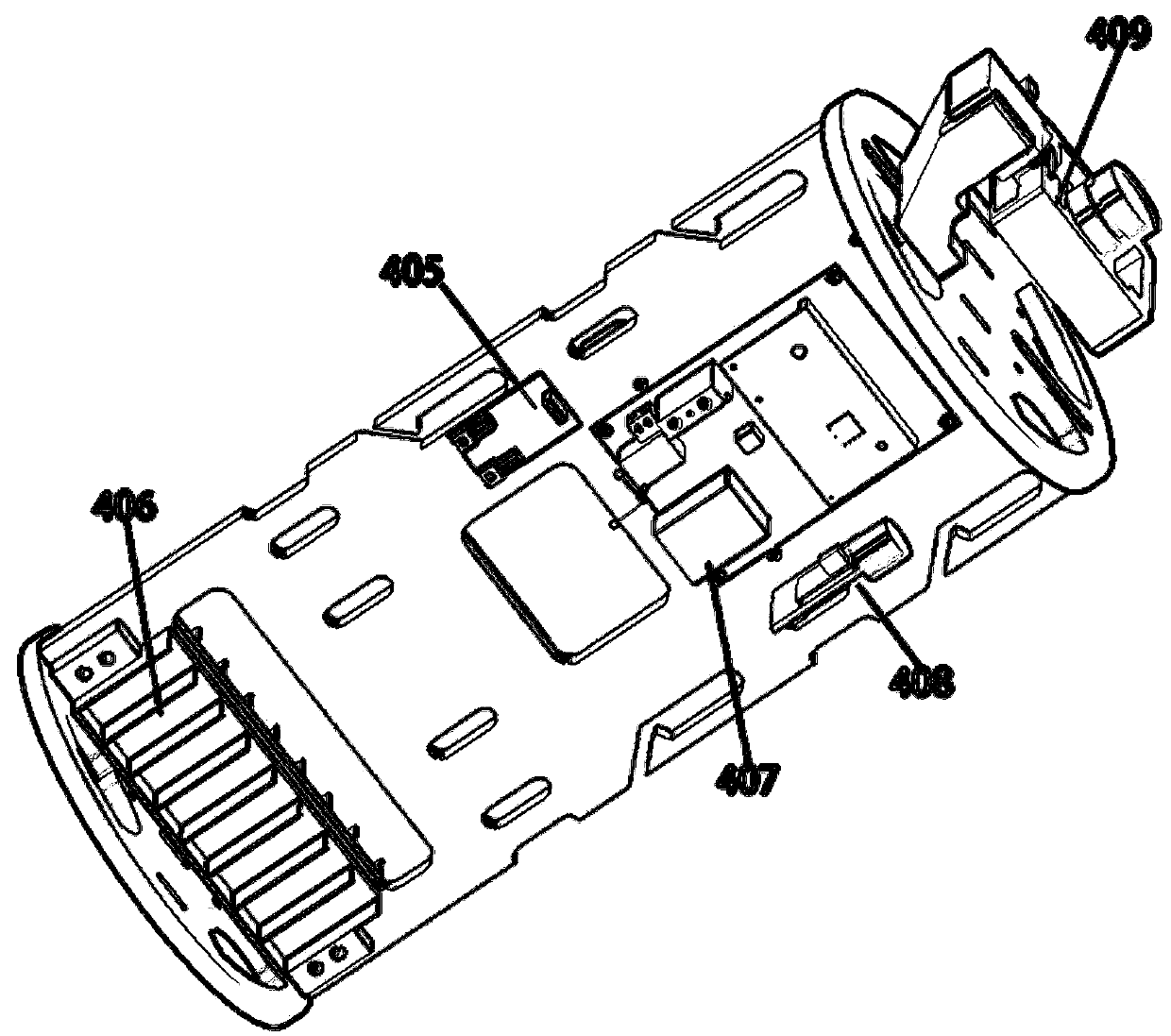

Manual and automatic dual-mode steering wheel

ActiveCN106628093AImplement manual controlRealize automatic controlSteering initiationsSteering wheelAutomatic control

The invention provides a manual and automatic dual-mode steering wheel which comprises a mounting base. A manual actuator is arranged on one side of the mounting base and is in linkage fit with the steering wheel, and an automatic actuator is arranged on the other side of the mounting base and comprises a motor transmission shaft linked with a motor and a linkage shaft in linkage fit with a transmission shaft of the steering wheel. A clutch mechanism is arranged between the linkage shaft and the motor transmission shaft. The mounting base is further provided with a control mechanism which is provided with the clutch mechanism. The clutch state of the clutch mechanism is changed through the control mechanism, accordingly switch between manual control and automatic control over the steering wheel is achieved, manual control and automatic control over a ship is achieved, and multiple purposes are achieved through one ship.

Owner:浙江嘉蓝海洋电子有限公司

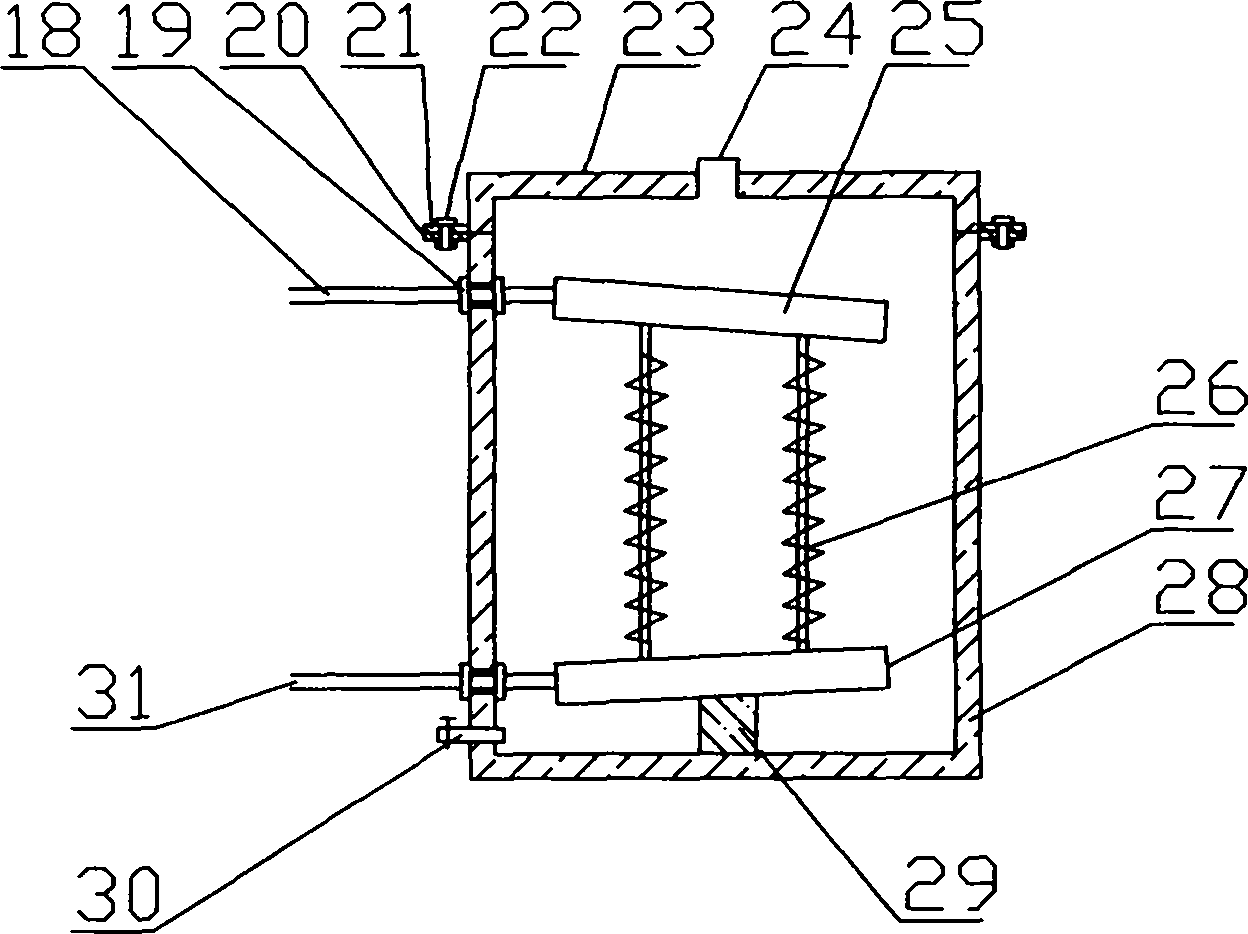

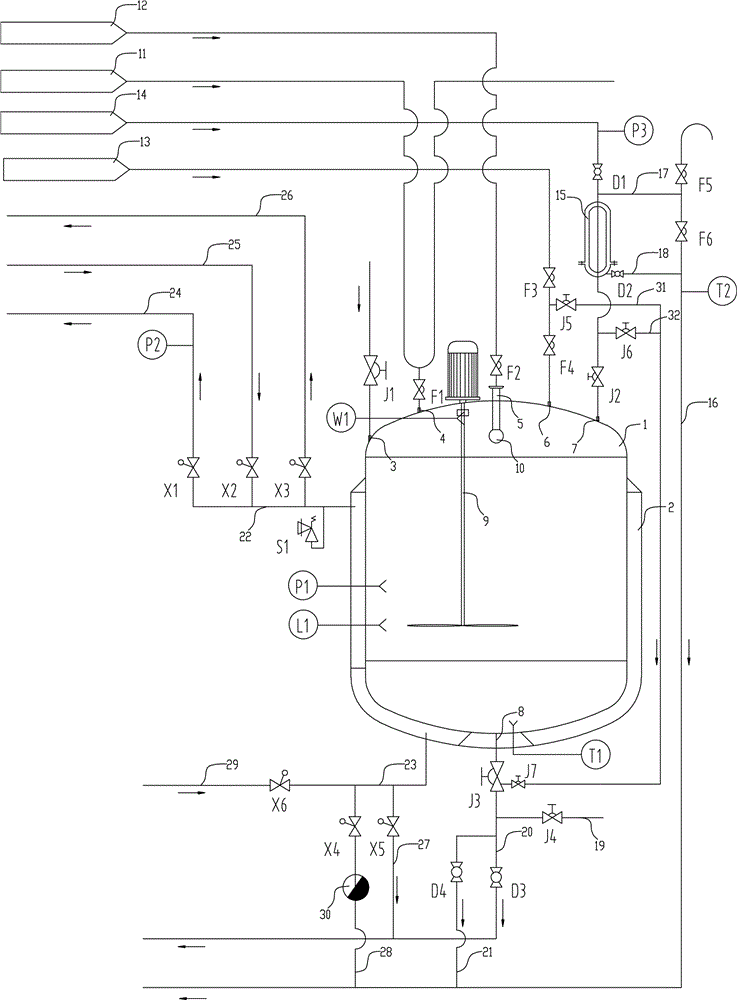

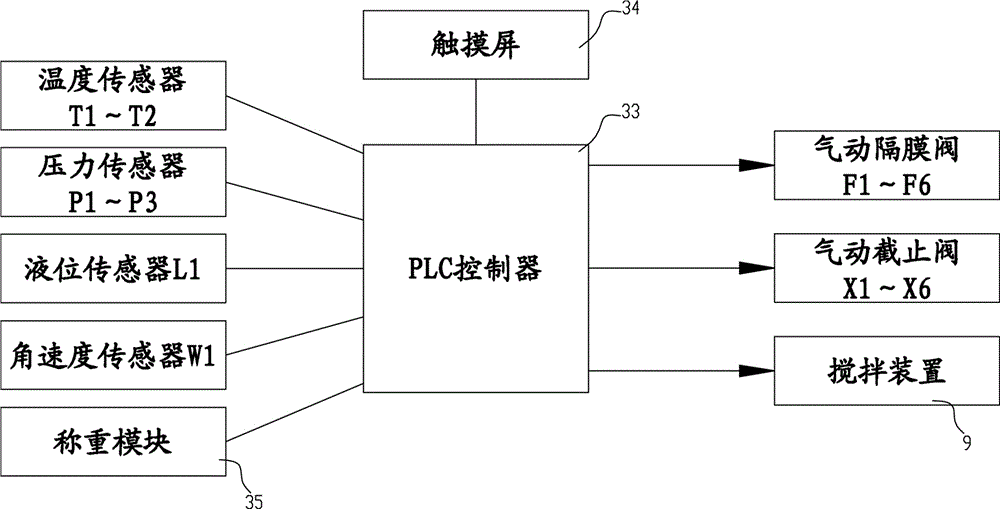

Dosing system

InactiveCN107519790ASimple structureIngenious designRotary stirring mixersTransportation and packagingAutomatic controlAir filter

The invention provides a dosing system. The dosing system comprises a dosing tank, wherein a jacket is arranged on the outer wall of the dosing tank; the dosing tank is provided with a feed inlet, a dosing port, a cleaning port, a pure steam inlet, a pure air inlet and a discharging outlet; a stirring device and a cleaning device are arranged in the dosing tank; the dosing port is externally connected with a dosing device; the cleaning port is internally connected with the cleaning device and externally connected with a cleaning fluid device; the pure steam inlet is externally connected with a pure steam generating device; the pure air inlet is externally connected with a pure air generating device; a ball valve D1, an air filter and a hand-operated diaphragm valve J2 are connected with a pipeline in series; an exhaust pipe A is arranged on the air filter; pneumatic diaphragm valves F5 and F6 are connected with the exhaust pipe A in series; a branch pipe A is arranged on the pipeline of the air inlet end of the air filter and is connected with the part, located between the pneumatic diaphragm valves F5 and F6, of the exhaust pipe Al; and the water draining outlet of the air filter is connected with the part, located at the other end of the pneumatic diaphragm valve F6, of exhaust pipe via a ball valve D2 and a branch pipe B. The dosing system provided by the invention is simple in operation, low in equipment cost and good in disinfection effect, and realizes manual / automatic control.

Owner:HUBEI HENGFENG MEDICAL PHARMA EQUIP CO LTD

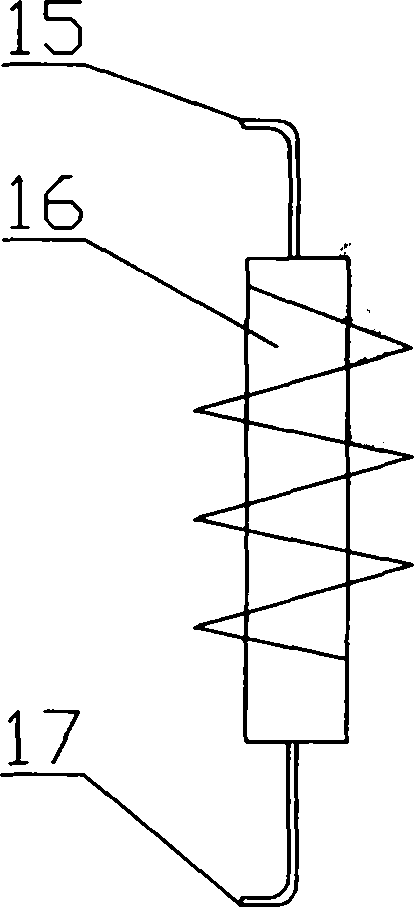

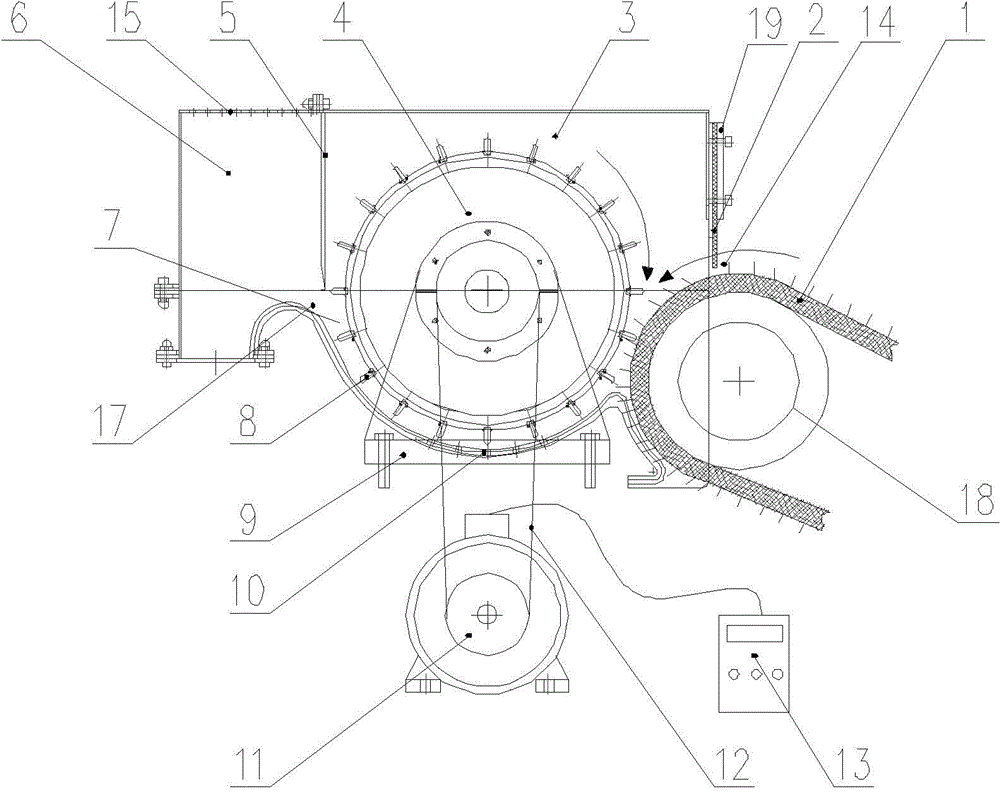

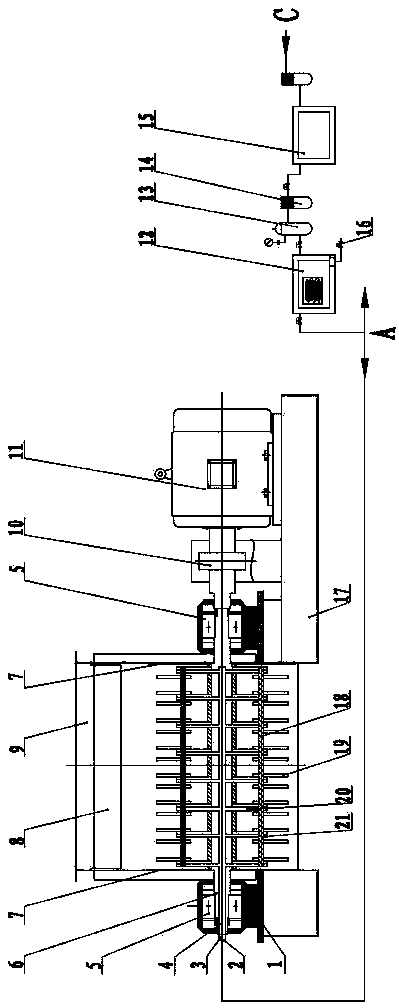

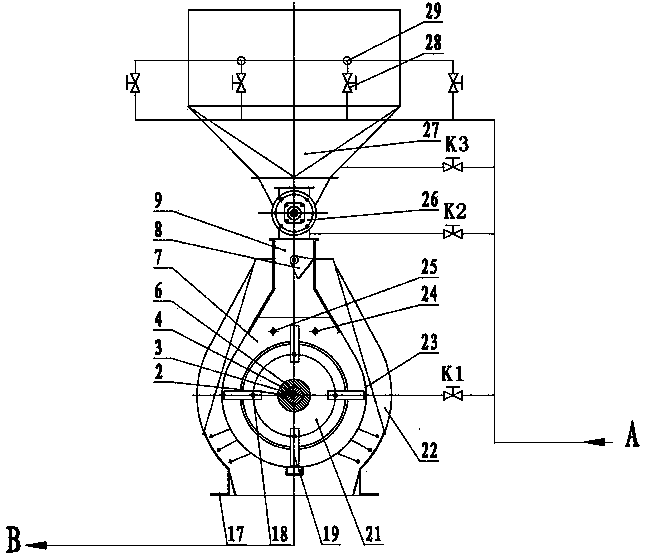

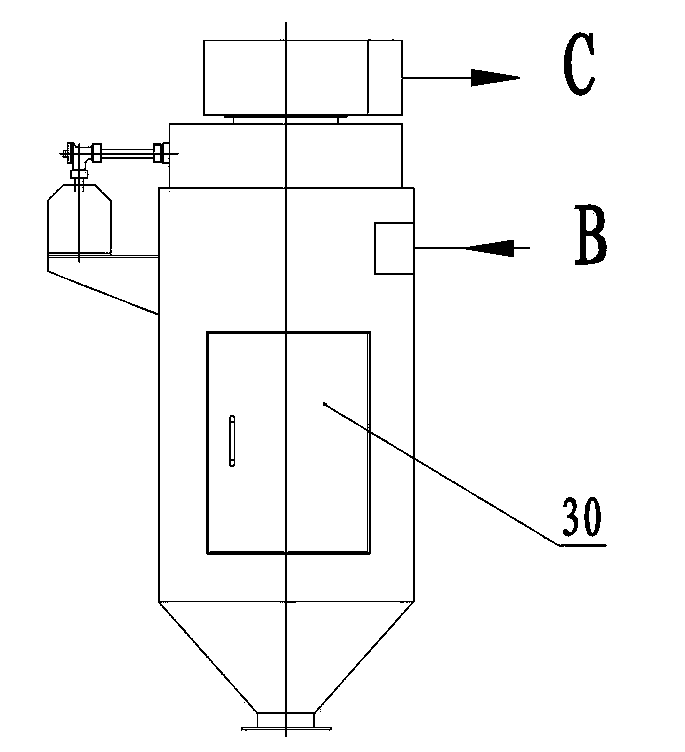

Internal circulating air-cooled pulverizer

The invention relates to an internal circulating air-cooled pulverizer, comprising an enclosure, a base and a motor, wherein a pulverizing cavity is formed in the enclosure, and a hammer rotor in the pulverizing cavity is driven by a motor through a main shaft to rotate and closed by a sieve plate; a circulating cooling air supply system formed by sequentially connecting a freeze dryer, a gas tank, a filter tank and an air compressor respectively supplies cooled gas A into the main shaft, the pulverizing cavity and a feeding hole through control valves, wherein the cooling gas A entering the main shaft cools the main shaft and a bearing through a first control valve K1 and is supplied to the sieve plate through the main shaft to cool the material in the pulverizing cavity and destroy a material gas-solid circulation layer; and gas B discharged from a discharge hole along with the material enters a dust separator, and separated gas C is returned to the air compressor, so that the cooling gas is circulated in the circulating cooling air supply system. The loss of energy is prevented, and the utilization rate of cold air is improved. The pulverizing efficiency is improved by over 10% compared with the existing pulverizer.

Owner:SHANGHAI TIANYI GAODE ELECTROMECHANICAL

Cylindrical grinding machine tailstock

InactiveCN104440535APlay a buffer roleAchieving concentricity adjustmentRevolution surface grinding machinesGrinding work supportsAutomatic controlGear wheel

The invention relates to a cylindrical grinding machine tailstock, and belongs to the technical field of machine tool accessories. An existing tailstock has the shortcomings that impact force of a center shaft to the end face of a workpiece is large, and a certain tiny deviation exists between the axial line of the center shaft and the axial line of a main shaft of the workpiece. The cylindrical grinding machine tailstock comprises a tailstock body, the center shaft, a center shaft sleeve, a manual control mechanism, a buffer spring, an automatic control mechanism, a middle eccentric sleeve and a concentricity adjusting mechanism. The end, facing the workpiece, of the center shaft sleeve is sleeved with the buffer spring, so that the impact force is reduced, and the buffer effect is achieved; an oil cylinder drives the center shaft sleeve to move in the axial direction and provide ejection force, so that the ejection force is stable; in addition, the oil cylinder and the manual control mechanism of a gear and rack pair structure exist at the same time; the center shaft sleeve is sleeved with the middle eccentric sleeve and the concentricity adjusting mechanism composed of a swing rod, a left push rod mechanism and a right push rod mechanism, the tiny displacement deviation between a center part of the center shaft and the axel line of the main shaft of the workpiece can be adjusted, adjustment is convenient, and the machining accuracy of the workpiece is improved.

Owner:XINCHANG COUNTY HAILIPU SEIKO TECH

Multifunctional micro power dust collector

InactiveCN102716623AImplement manual controlRealize automatic controlDispersed particle filtrationEngineeringAerodynamics

Owner:DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

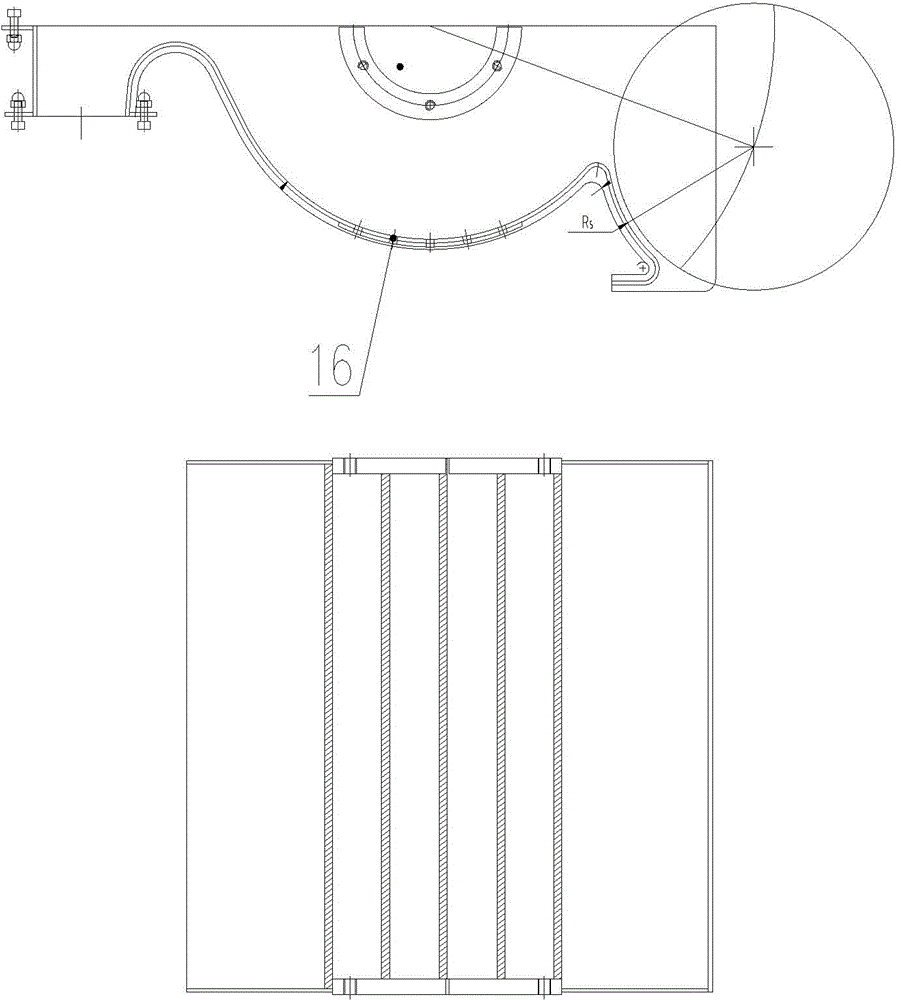

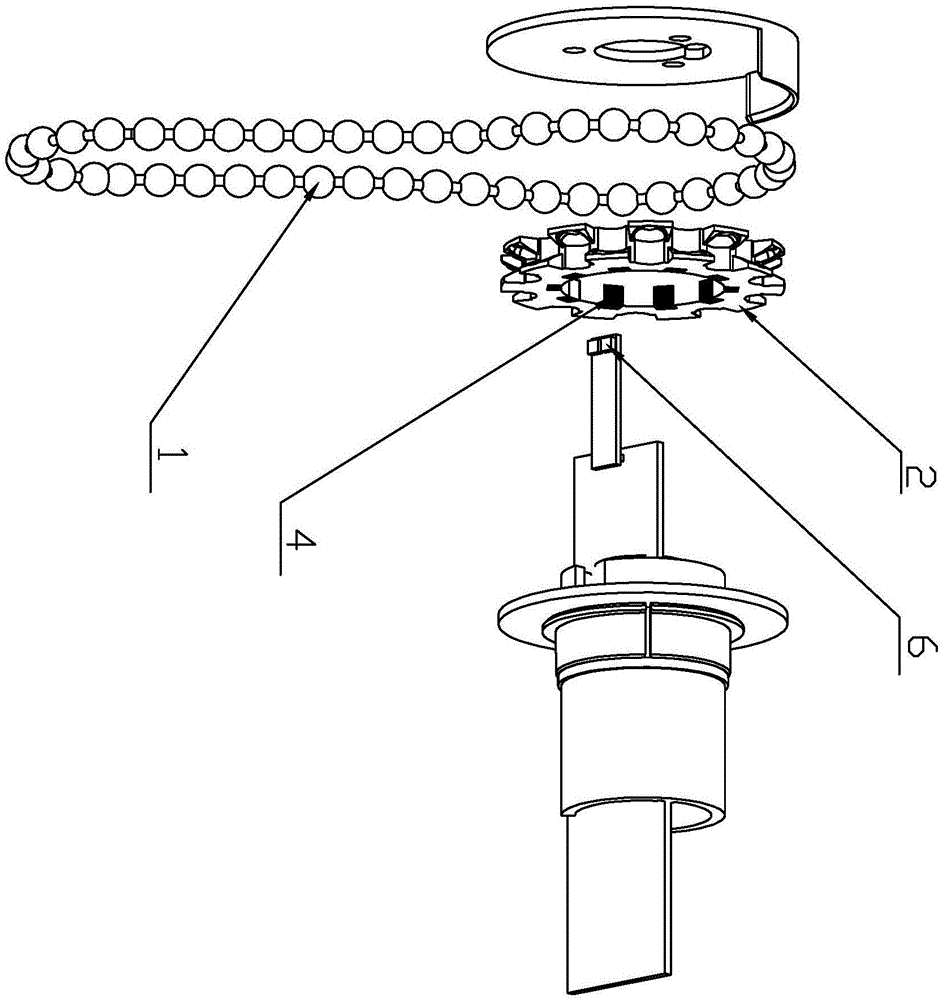

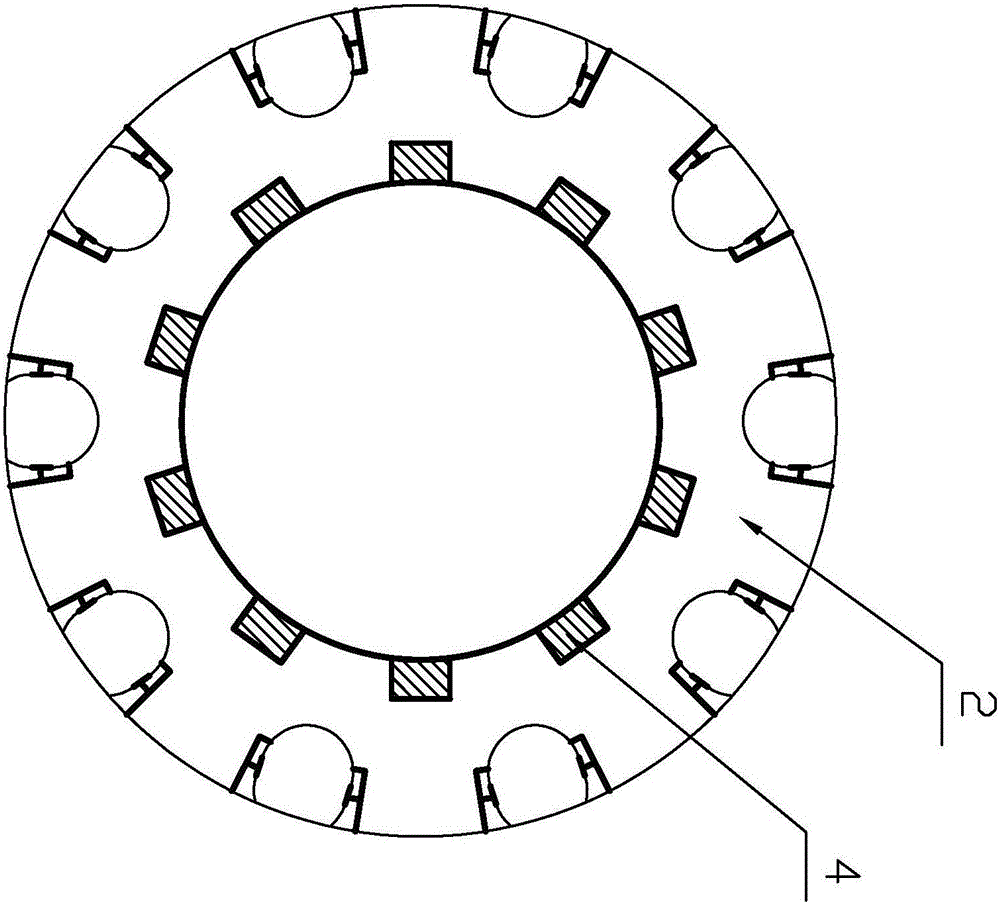

Tubular motor provided with hand-operated starter and used for curtain opening-closing system

InactiveCN105816000AImplement manual controlSimple and safe operationDoor/window protective devicesCurtain accessoriesReducerEngineering

The invention discloses a tubular motor provided with a hand-operated starter and used for a curtain opening-closing system. The tubular motor comprises a tubular motor barrel, a motor, a speed reducer, a control circuit board and a magneto-dependent sensor. The tail end of the motor barrel is provided with a rotating wheel. The rotating wheel is provided with a plurality of permanent magnetic components. The rotating wheel is provided with a pull rope. The rotating wheel rotates, so that a magnetic field produced by the permanent magnetic components is changed to trigger the magneto-dependent sensor to produce a working signal to drive the motor to rotate. According to the tubular motor, when a pull rope is pulled to drive the rotating wheel to rotate, the magnetic field sensed by the magneto-dependent sensor is changed, and the magneto-dependent sensor is triggered to send an instruction to the control circuit board so as to trigger the motor to rotate; the control circuit board has the remote intelligent control function, so that when a controller carries out remote intelligent control, a special curtain motor can be manually controlled like pulling a manual curtain, and the control effect that operation is simple, safe, convenient and efficient is achieved. The tubular motor is used in the field of curtain control devices.

Owner:GUANGDONG RAEX INTELLIGENT TECH CO LTD

Sandwiched door/window

InactiveCN1828004AOpen flexibleClose flexibleLight protection screensUnits with parallel planesEngineeringGlass sheet

The invention relates to an interlayer door / window, which comprises a door / window frame, at least two layers of glass plates inside the frame or outer transparent interlayer material, and a blind device. Wherein, said blind device comprises a blind frame, a drum, a blind curtain, a compress roller, and at least one driver. The blind frame is at one end of door / window frame and connect the inner chamber between layers; the drum via its rotational axle is rotationally mounted inside the blind frame; one end of blind curtain is fixed on the drum, while another end is free; the compress roller is inside the blind frame to compress the blind curtain or connect the drum via blind curtain; at least one driver is connected to the compress roller or connected to the drum and the compress roller. The invention arranges the blind curtain inside interlayer, without affecting view and occupying indoor room, with wider application.

Owner:吕孟龙

Multifunctional common remote control unmanned submersible platform and application method thereof

PendingCN109941412AImprove general performanceImplement manual controlUnderwater vesselsUnderwater equipmentRemote controlMarine engineering

The invention provides a multifunctional common remote control unmanned submersible platform. The submersible platform comprises a control cabin, a thruster module and a power cabin; the control cabinis connected with an external ground station system through a cable; the control cabin acquires a remote control instruction through the ground station system for controlling the submersible platformto work and transmits data back to a ground station platform through a cable. The submersible platform can be in butt joint with an upper computer of the ground station system, secondary developmentcan be conducted, and the universality is high.

Owner:FUZHOU UNIV

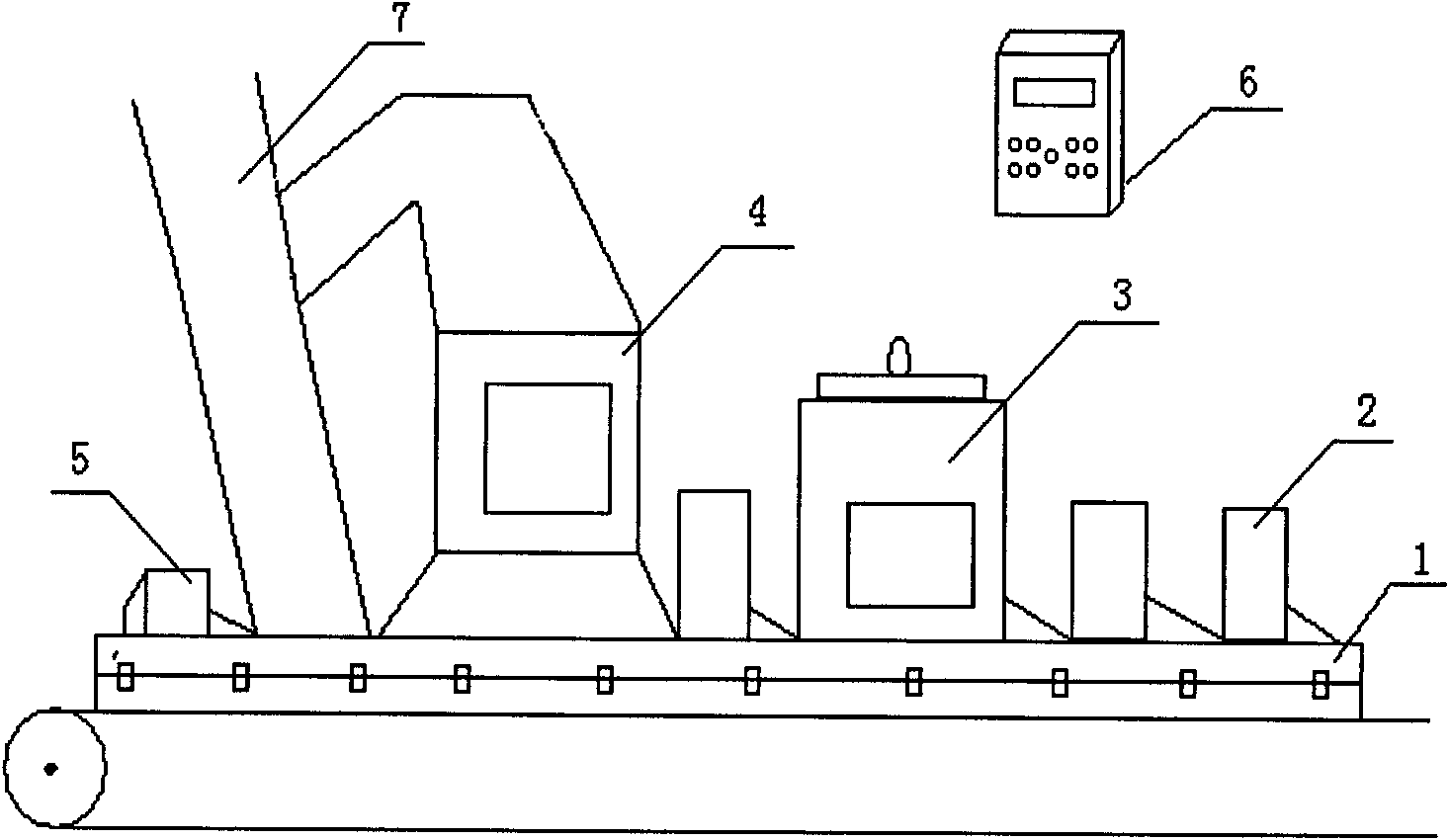

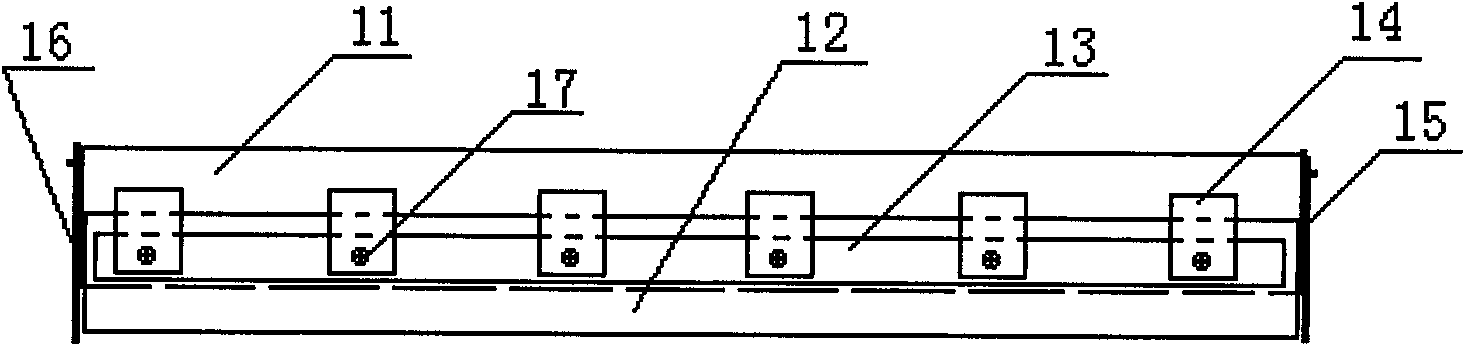

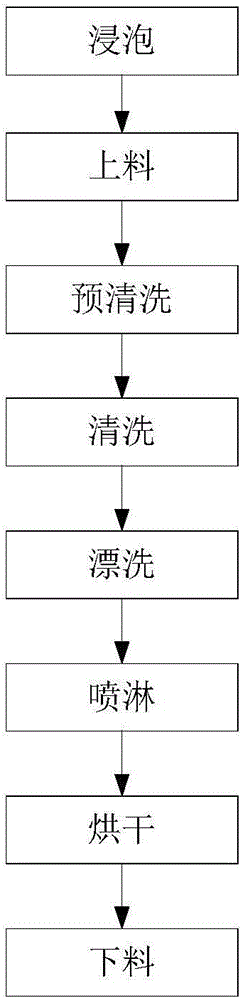

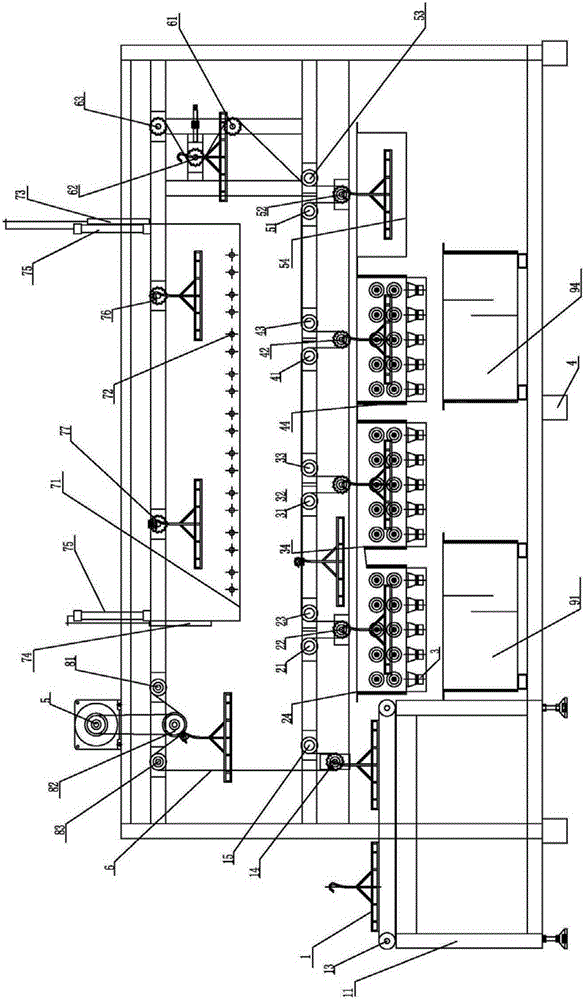

Automatic cleaning method for numbering machine

InactiveCN105903721AFully automaticAchieve cleaningCleaning using liquidsMegasonic cleaningPurchasing

The invention relates to an automatic cleaning method for a numbering machine. The method includes the following steps that (1) ultrasonic soaking is carried out, i.e., a bucket containing the numbering machine is soaked in a soaking tank, and a plurality of ultrasonic generators are arranged at the bottom of the soaking tank; (2) ultrasonic pre-cleaning is carried out, i.e., ultrasonic generators are arranged in a pre-cleaning tank; (3) ultrasonic cleaning is carried out, i.e., ultrasonic generators are arranged in a cleaning tank; (4) ultrasonic rinsing is carried out, i.e., ultrasonic generators are arranged in a rinsing tank; (5) spraying is carried out; and (6) drying is conducted. The technical problems that an existing numbering machine cleaning method is low in automation degree and long in cleaning time are solved. Automatic feeding, discharging and transporting of the numbering machine can be achieved, a whole set of automatic cleaning actions of ultrasonic cleaning, ultrasonic rinsing, spraying cleaning and drying are completed, finally full-automatic cleaning of the numbering machine is achieved, and the effect that the numbering machine is directly used is achieved. The numbering machine cleaning efficiency is improved, time for changing the line of production is indirectly shortened, and the numbering machine purchasing fund is lowered.

Owner:XIAN BANKNOTE PRINTING

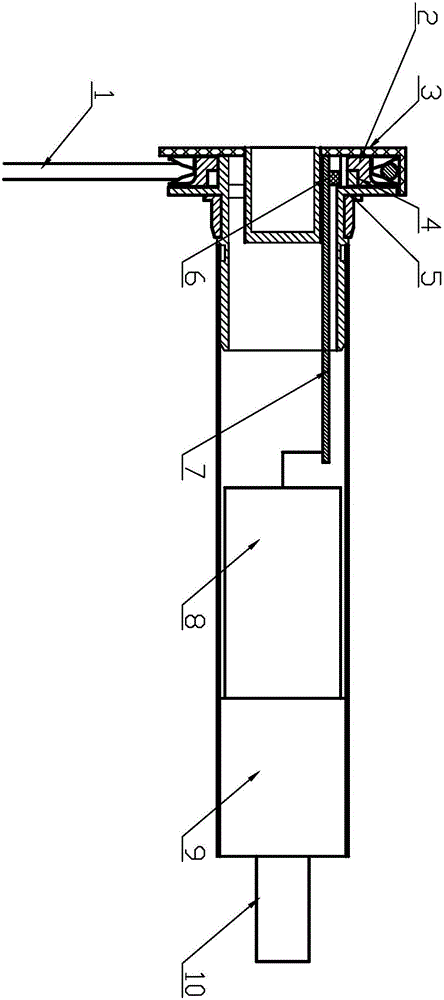

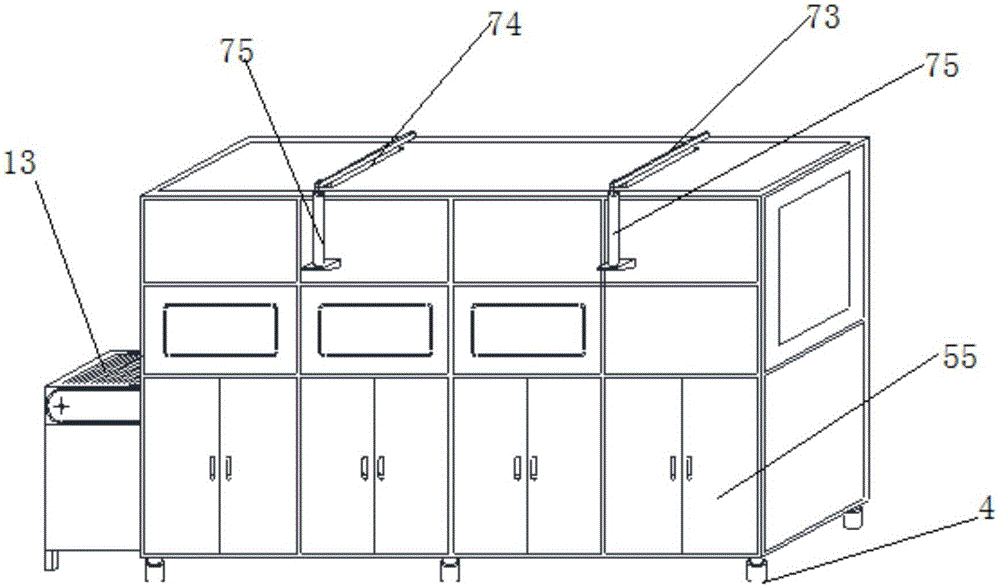

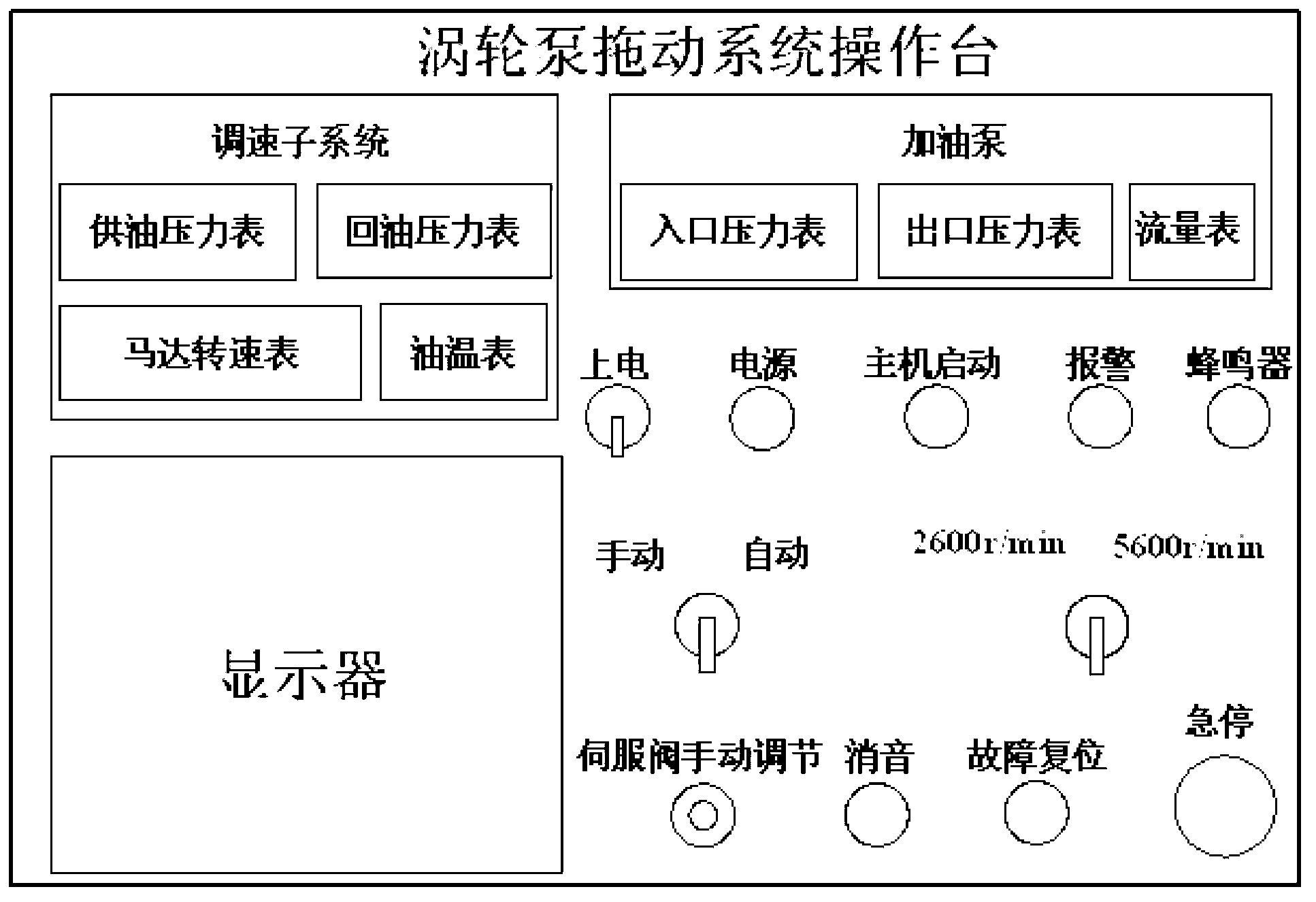

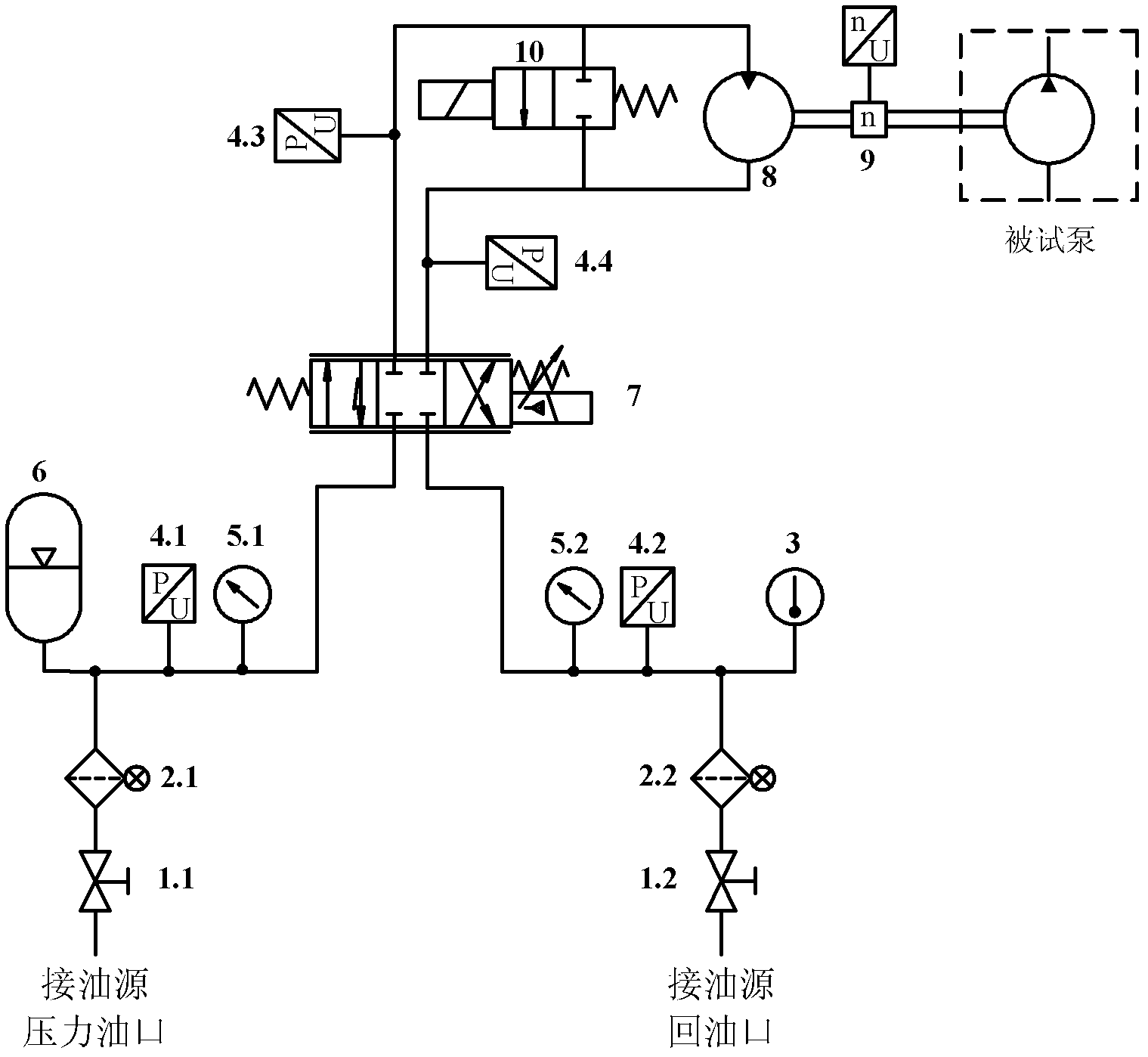

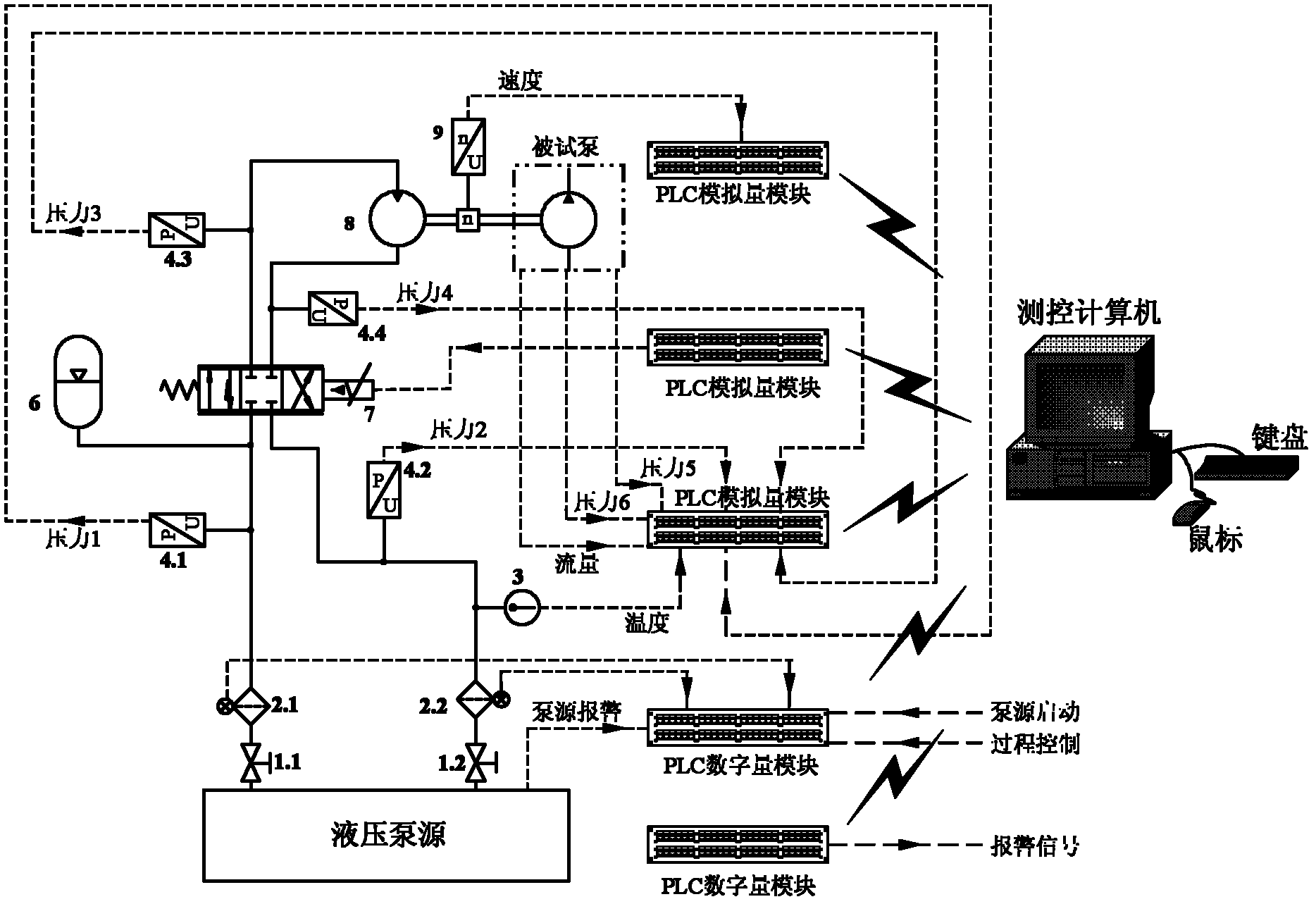

Hydraulic motor dragging system used for load of high-power and wide speed adjusting range

ActiveCN103174692AConvenient and neat wiringEasy to operateServomotorsFluid-pressure actuator componentsHydraulic motorHydraulic pump

The invention discloses a hydraulic motor dragging system used for a load of high-power and a wide speed adjusting range. The hydraulic motor dragging system is arranged on a hydraulic pump and is characterized by being mainly composed of a hydraulic system and an electrical system. The hydraulic system is composed of a high-pressure ball valve (1.1), a low-pressure ball valve ball valve (1.2), a high-pressure oil-pressing oil filter (2.1) with an alarming function, a low-pressure oil-pressing oil filter (2.2) with an alarming function, a temperature sensor (3), a pressure sensor, a pressure gage, an energy accumulator (6), a servo valve (7), a hydraulic motor (8), a speed sensor (9) and a bypass valve (10). The hydraulic motor dragging system used for the load of high-power and the wide speed adjusting range has the advantages of being high in automation degree, good in maintenance performance, high in reliability, optimized in layout, capable of being conveniently operated by testers, and capable of ensuring reliability and safety of the testing process.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

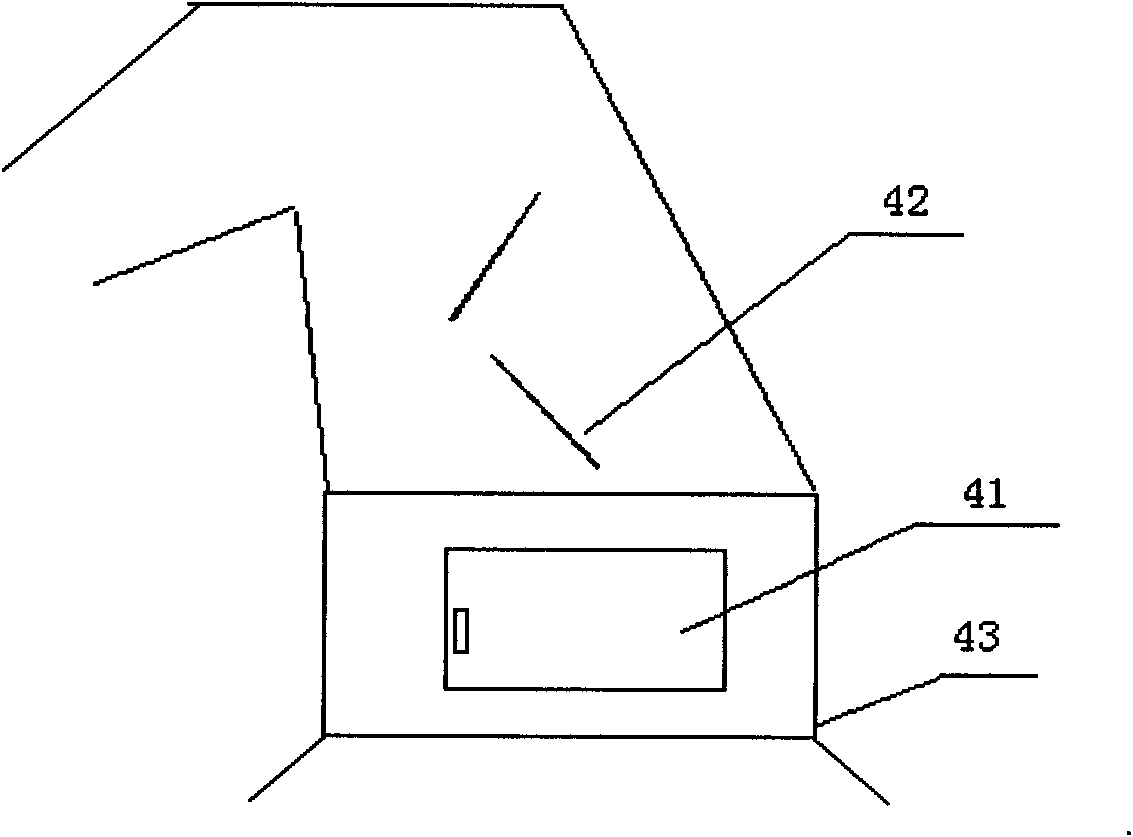

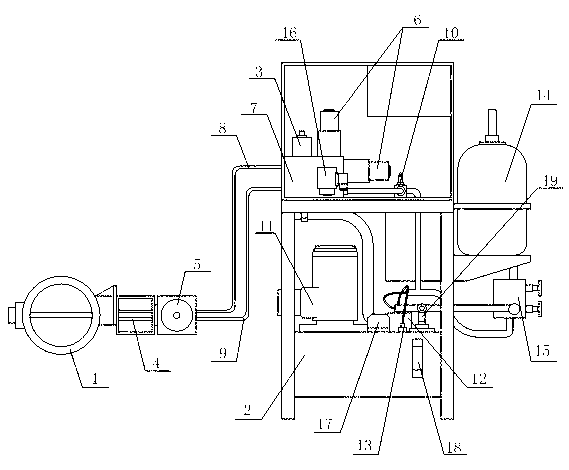

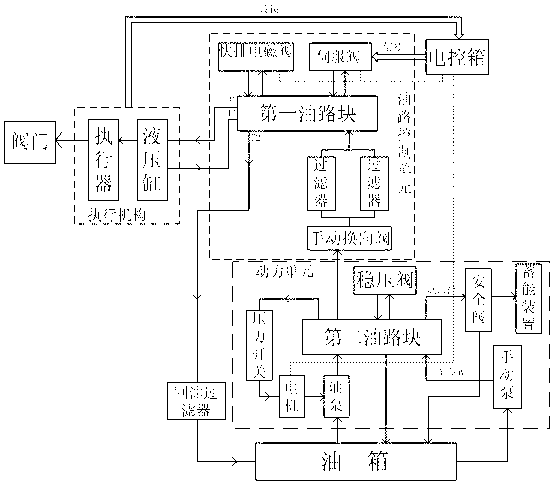

Electro-hydraulic integrated control device applied to valve control

ActiveCN103062484AAvoid damageOvercome defects such as poor heat dissipationOperating means/releasing devices for valvesElectro hydraulicActuator

The invention discloses an electro-hydraulic integrated control device applied to valve control. The electro-hydraulic integrated control device applied to valve control comprises an actuator connected with the valve (1) and adjusting the valve location. The actuator is connected to a control assembly controlling the operation of the actuator. The control assembly is a hydraulic control mechanism packaged in a cabinet structure. The control assembly is provided with a pipeline connecting with the actuator. The electro-hydraulic integrated control device applied to valve control is reasonable in design. The control assembly is designed into a control cabinet mode, and the control assembly of a filter, a manual pump and the like is arranged reasonably in the control cabinet structurally. The electro-hydraulic integrated control device applied to valve control is simple in operation, can avoid damages to the control assembly from the valve vibration effectively, can increase cleanliness capacity on site and is suitable for the regulation control and the on-off control of devices with any lineal travel movement and angular travel movement.

Owner:成都赛来科技有限公司

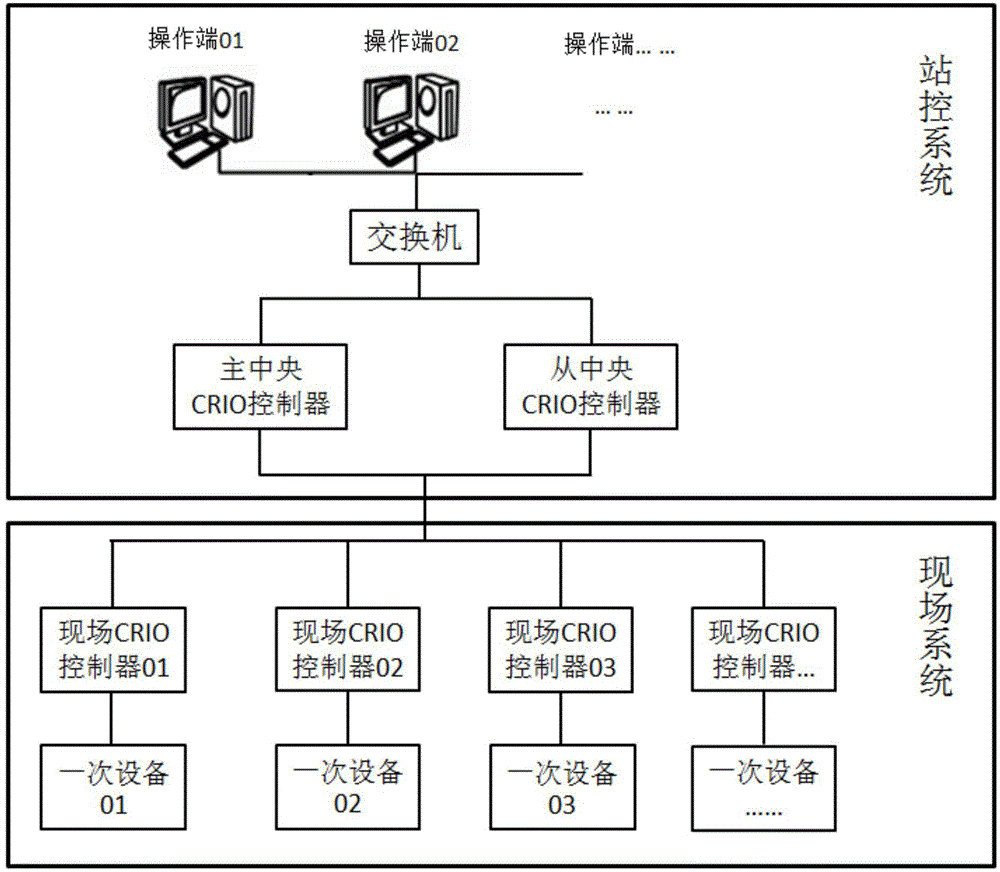

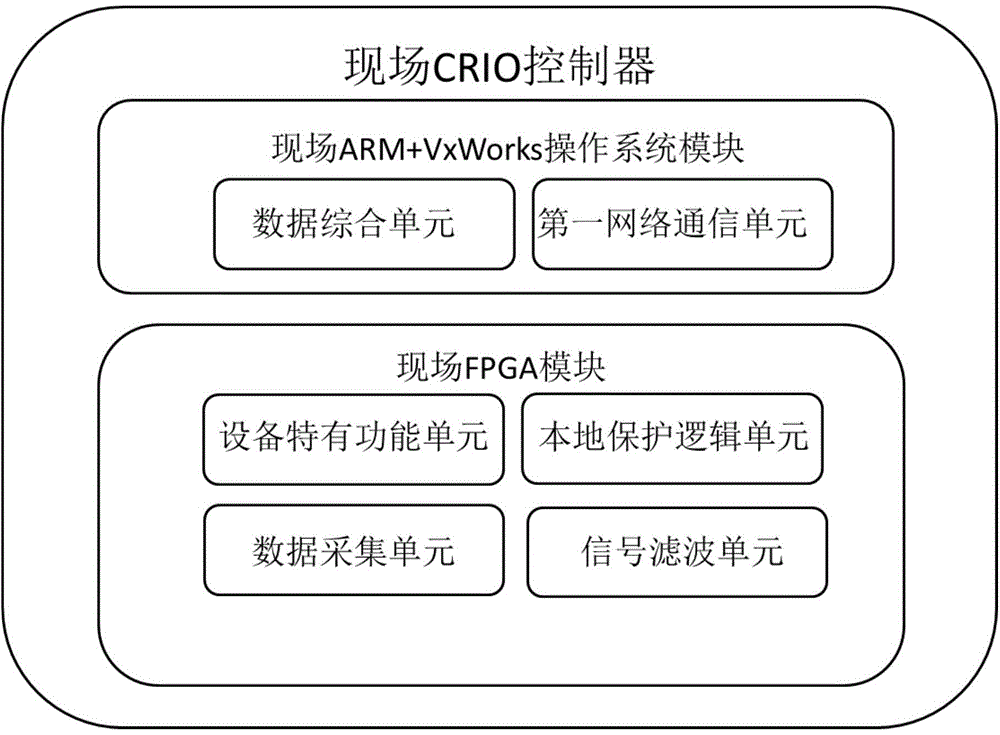

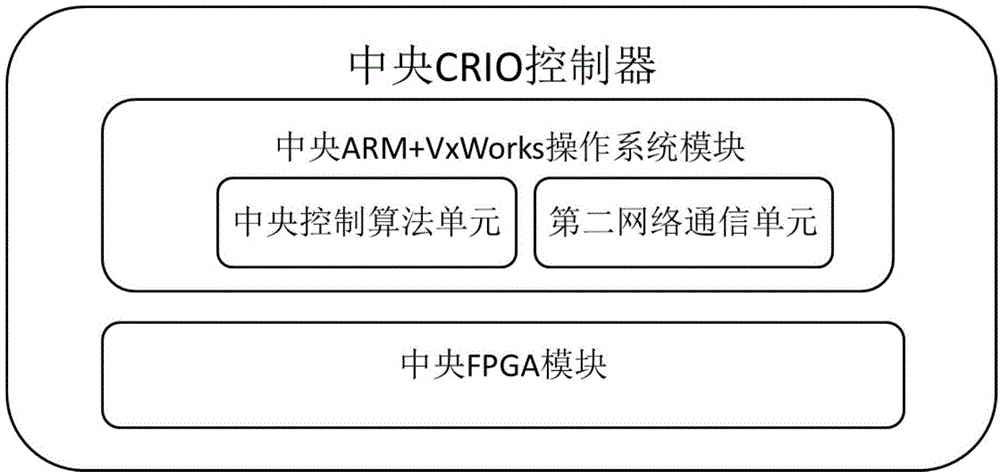

Method and system for controlling intelligent substation based on CRIO controllers

InactiveCN104317265AImprove reliabilityIncrease flexibilityTotal factory controlProgramme total factory controlSmart substationControl system

The invention relates to a system and a method for controlling an intelligent substation based on CRIO controllers. The system comprises a station control system and a field system; the station control system comprises an operating terminal, a switch and a main central CRIO controller; the field system comprises a field CRIO controller and a primary device. The field CRIO controller is used for obtaining the data of the operating condition of the primary device, processing the data and transmitting the data to the main central CRIO controller via a network; the main central CRIO controller receives the data transmitted by the field CRIO controller and sends a control instruction to the field CRIO controller according to a preset program, and then the field CRIO controller controls the primary device; a substation operator can manually modify the control algorithmic logic of the main central CRIO controller at the operating terminal and manually send instructions to the main central CRIO controller. The method for controlling the intelligent substation based on the CRIO controllers is capable of realizing centralized management on the substation control algorithms and centralized monitoring on all devices and signals, and therefore, the reliability, flexibility and extendability of the intelligent substation can be improved.

Owner:YUNNAN POWER GRID

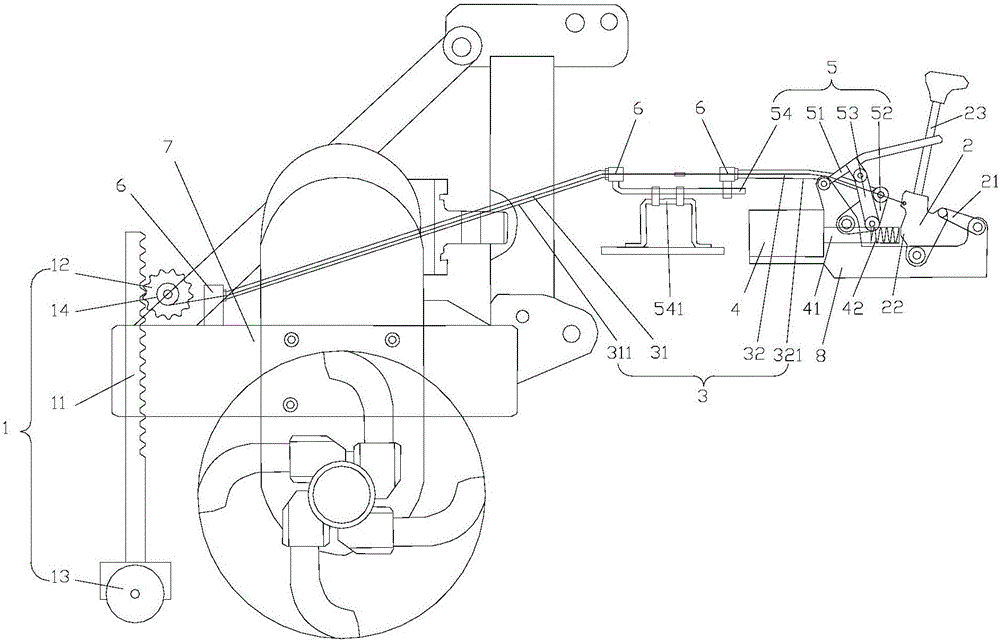

Automatic tilling depth control device applied to tillage machine tool

InactiveCN106508153ARealize automatic controlRealize automatic liftingAgricultural machinesAdjusting devicesAutomatic controlEngineering

The invention provides an automatic tilling depth control device applied to a tillage machine tool. The device comprises a tilling depth feedback mechanism, a control block, a pull line and a hydraulic valve. The tilling depth feedback mechanism comprises a rack and a gear engaged with the rack. The rack is vertically arranged and connected to a machine frame in a vertically-moving mode, a land wheel is arranged at the lower end of the rack, the gear is installed on a shaft seat on the machine frame through an axle, and a reel is arranged on the axle. The lower portion of the control block is installed on an installing seat through a pin shaft, the upper portion of the front side of the control block is connected with the portion, located on the front side of the control block, of the installing seat through a reset spring, a convex body is arranged in the middle of the rear side of the control block, a valve element of the hydraulic valve is connected with an outwards-stretching rod making contact with the rear end of the convex body, and the outwards-stretching rod is sleeved with a valve element spring. One end of the pull line is connected to the reel, and the other end of the pull line is connected to the upper portion of the rear side of the control block. The change of the tilling depth state can be precisely fed back in good time, a hydraulic suspension lifting device is automatically controlled, and therefore consistent tilling depth can be kept when the machine tool works.

Owner:HUNAN CHUNYAN MACHINERY MFG

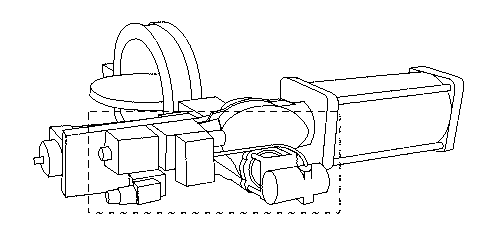

Unmanned vehicle steering system and method based on secondary planetary steering gear

ActiveCN110217290AAutomatic swingControl clutch stateSteering linkagesHand leversHydraulic cylinderReciprocating motion

The invention relates to an unmanned vehicle steering system and method based on a secondary planetary steering gear, belongs to the technical field of unmanned vehicle steering, and solves the problems of low control accuracy and low response speed of an executing mechanism in traditional vehicle unmanned control are solved. According to the unmanned vehicle steering system based on the secondaryplanetary steering gear, reciprocating motions of a hydraulic cylinder and a steering operating lever are controlled by using an electro-hydraulic servo valve so that a vehicle is driven to steer; and meanwhile, switching between manual operation and electric control operation can be realized; the mechanism is simple and feasible; the machining and mounting are convenient; and the unmanned vehicle steering system based on the secondary planetary steering gear is suitable for severe working environments of tracked vehicles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com