Patents

Literature

821 results about "Cylindrical grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

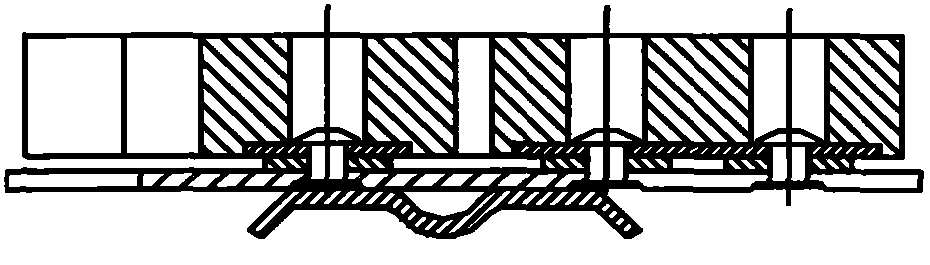

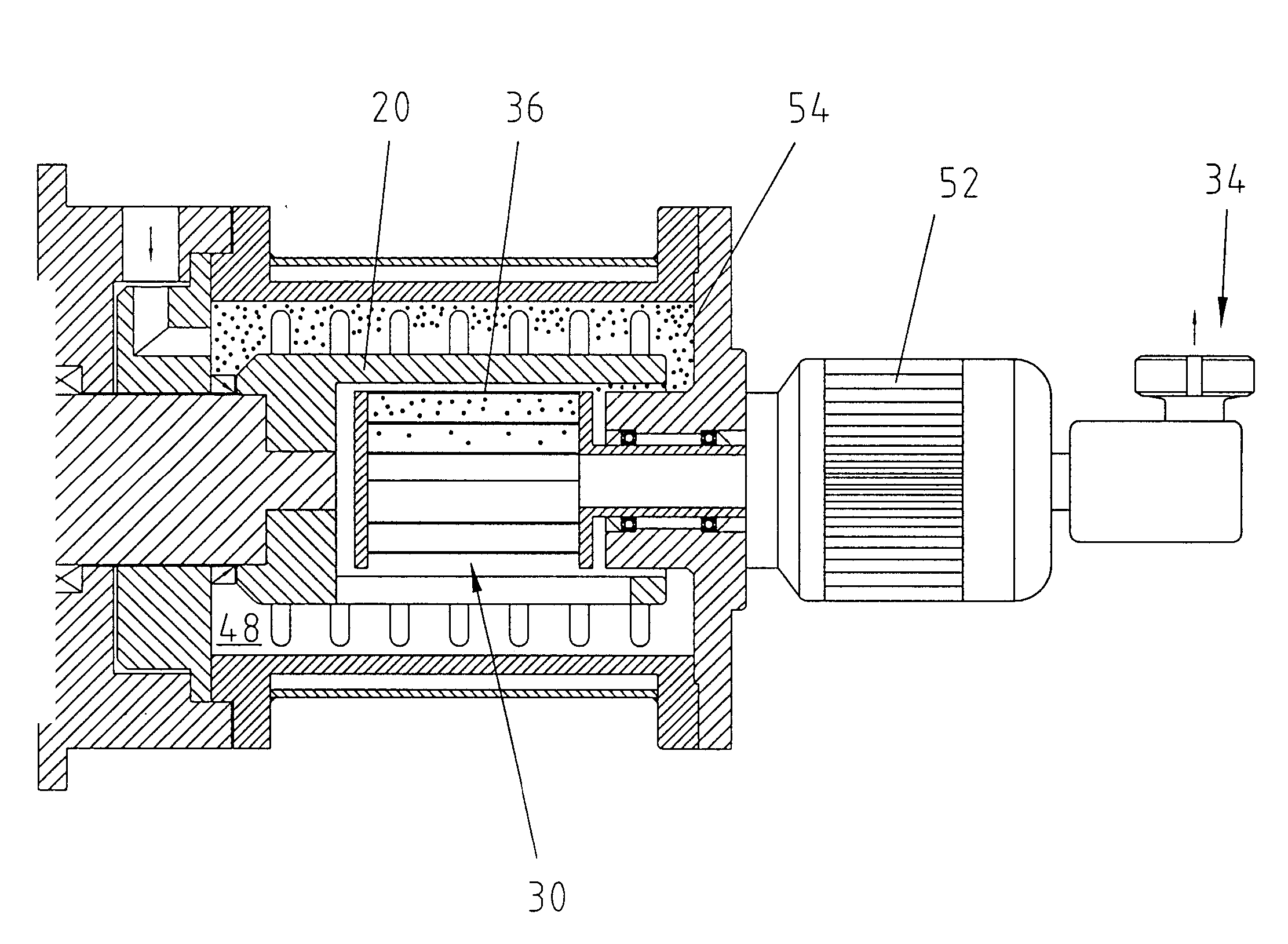

Stirring ball mill

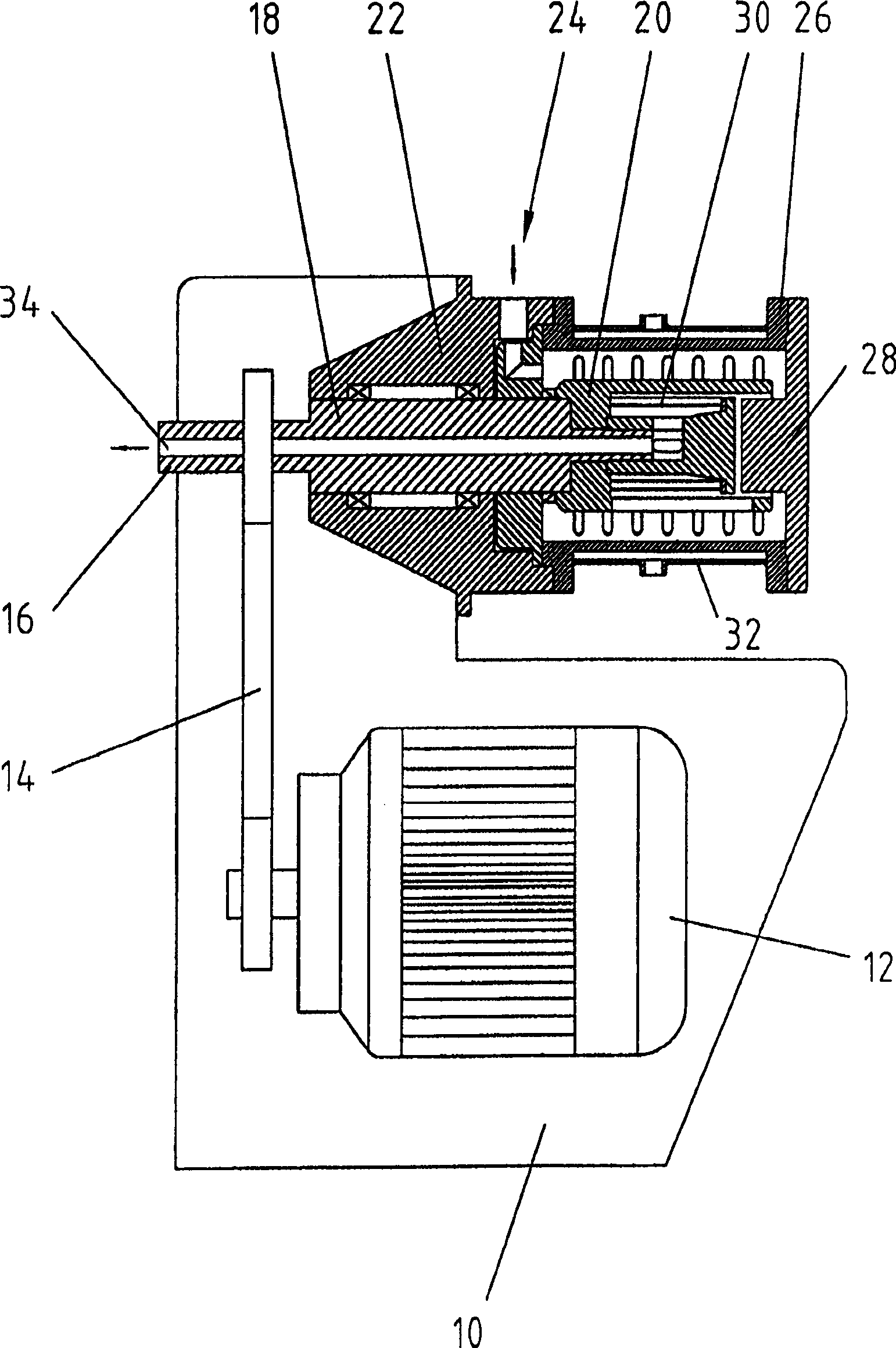

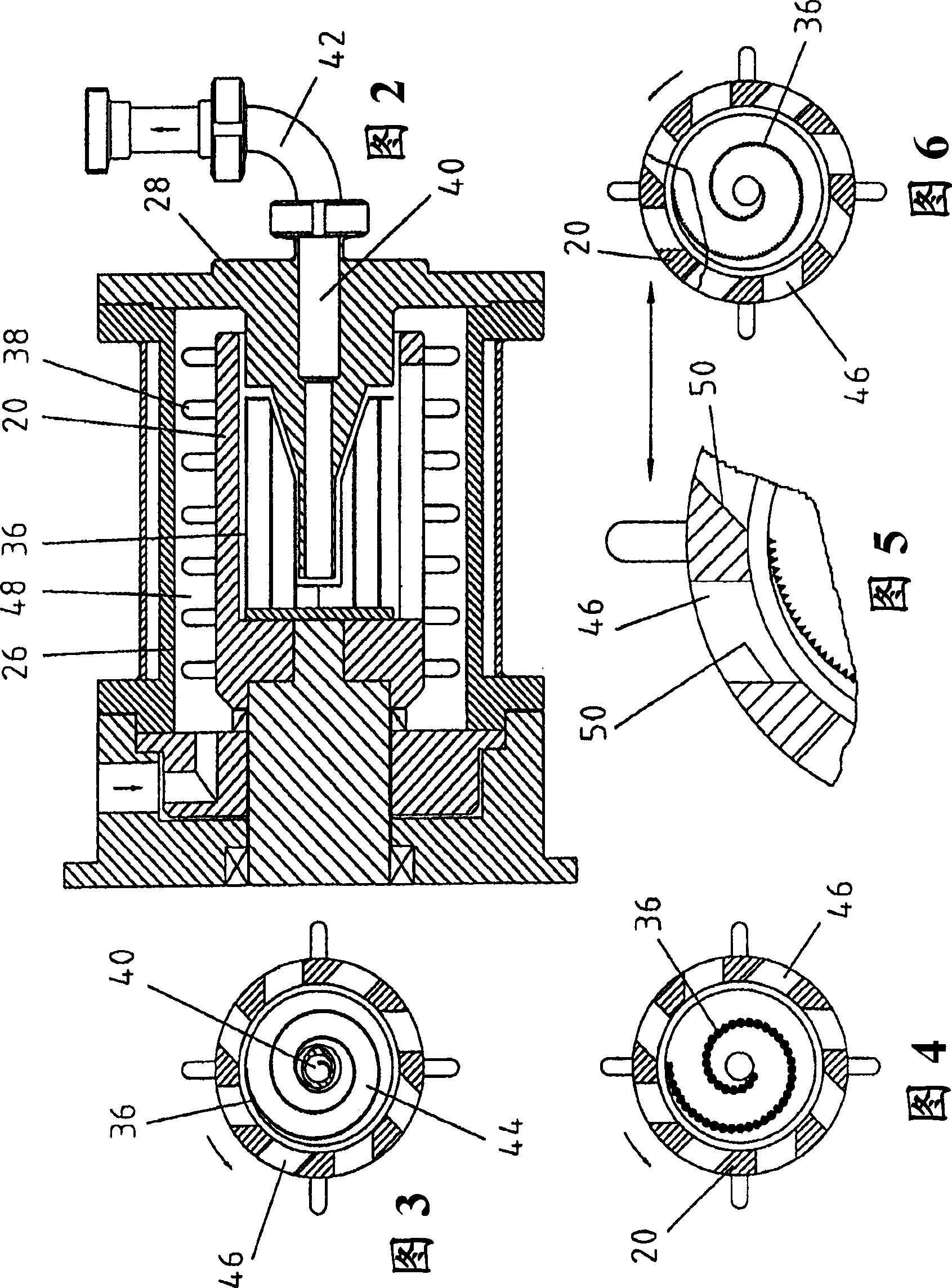

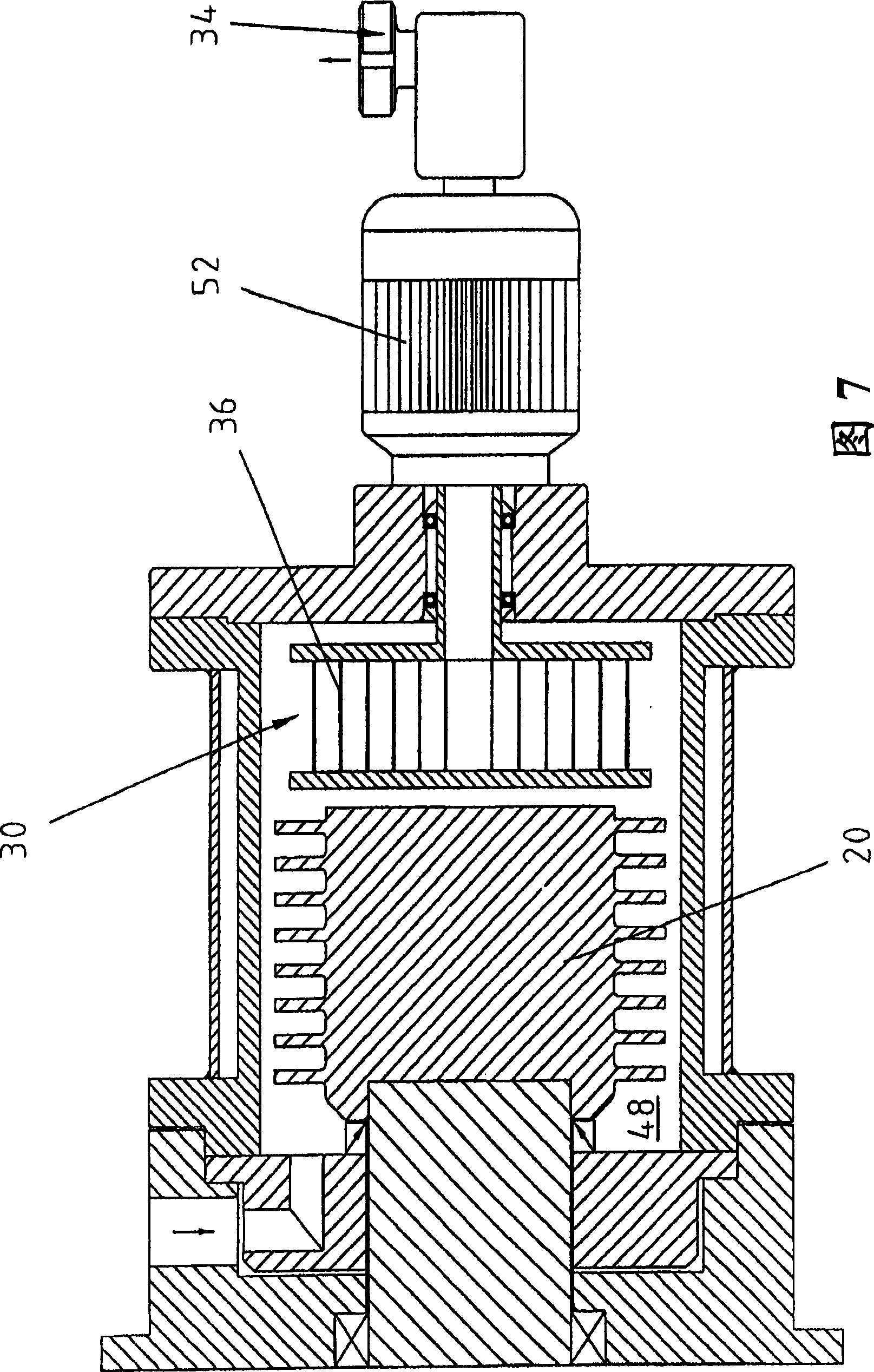

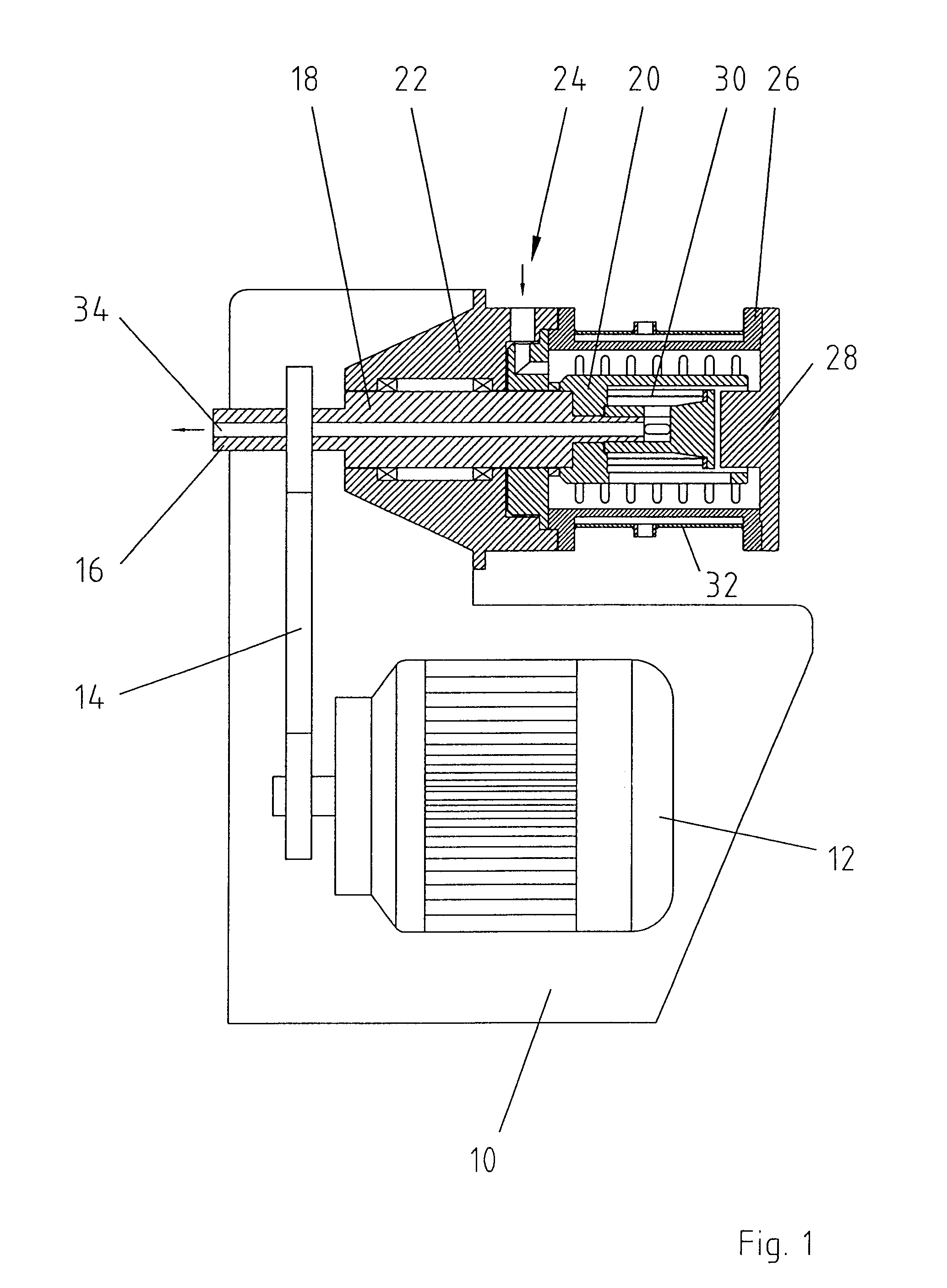

The invention discloses an agitating ball mill, spefically, the invention relates to an agitating ball mill with a cylindrical grinding vessel (26) comprising at least one grinding stock inlet (24) and at least one grinding stock outlet (34), wherein in the grinding vessel (26), an agitating shaft (20) connected with a drive (12) is arranged, which transmits a part of the drive energy to auxiliary grinding bodies (54) which are loosely arranged in the grinding vessel and a separating device (30) arranged in front of the grinding vessel outlet (34).

Owner:NETZSCH FEINMAHL TECH GMBH

Machining technology of elongated thin-wall C-shaped tubular parts

ActiveCN103846624AImprove processing qualityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringCylindrical grinding

The invention discloses a machining technology of elongated thin-wall C-shaped tubular parts and belongs to the technical field of machining precision parts. The machining technology comprises the steps of blanking, hot and cold processing, aging strengthening, rough machining, finish machining and through groove machining, wherein the blanking comprises bar material cutting, the rough machining comprises inner hole drilling and outer circle rough turning, the finish machining comprises outer circle finish turning, inner circle grinding and end surface cutting, the elongated thin-wall C-shaped tubular parts are machined by selecting a bar material, the machining quality and efficiency of the parts can be greatly increased through a concise and practical process route, and the technical difficulties of elongated shaft machining, thin-wall piece machining, deep hole machining, main guide rail groove machining and the like which relate to the elongated thin-wall C-shaped tubular parts can be solved.

Owner:GUIZHOU ZUNYI CHI YU PRECISION MACHINERY MFG

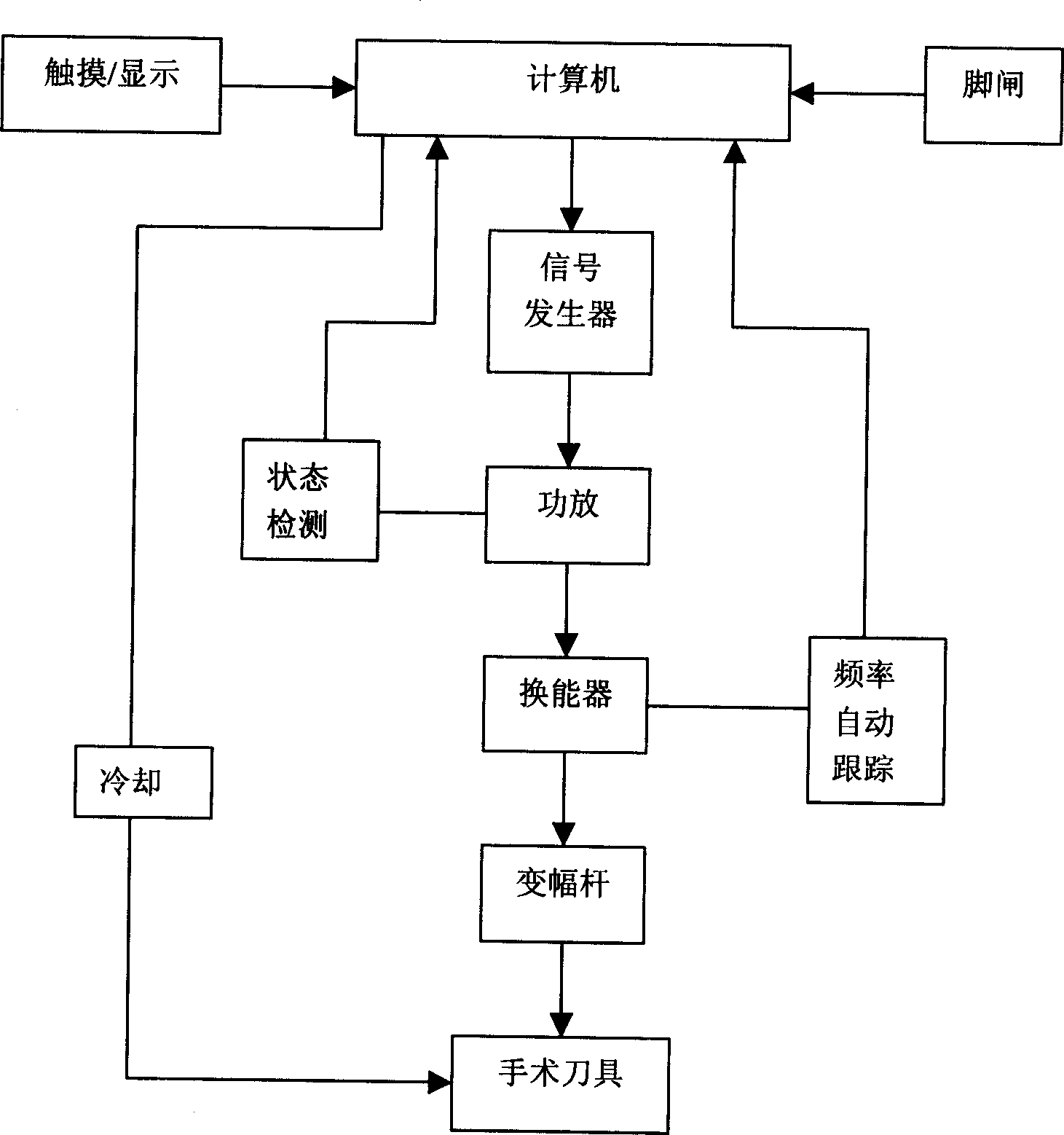

Bone-operating ultrasonic knife with expanding function

InactiveCN1745721AImprove securityClear visionSurgical instrument detailsEngineeringCylindrical grinding

An ultrasonic knife with extended function for the bone operation is composed of a group of handles (including ultrasonic handle, the ultrasonic handle with bite mechanism and the hollow ultrasonic handle), a group of cutting tools (including elongated ultrasonic cutting tool, the curved cutting tool and the spherical or cylindrical grinding head), and a main body. Its extended functions are micro-wound bone operation by use of endoscope, staltic function, longitudinal complex vibration for high cutting efficiency, biting bone for removing unnecessary bone, pouring liquid, and removing the residual bone bits.

Owner:张毓笠 +2

Glass edging device

InactiveCN105252370ATurn fasterGrinding speed is fastEdge grinding machinesGrinding carriagesCylindrical grindingGrinding process

The invention discloses a glass edging device which comprises a base, a glass fixing mechanism and a glass grinding mechanism, wherein the glass fixing mechanism and the glass grinding mechanism are arranged on the base. The glass fixing mechanism comprises a servo motor, and a connecting shaft of the servo motor is fixedly connected with a vacuum chuck support. The glass grinding mechanism is located on the side face of the glass fixing mechanism and comprises a moving table in sliding connection with the base. A grinding frame is fixedly arranged on the moving table, a grinding motor is arranged on the grinding frame, and a rotating shaft is mounted on the lower portion of the grinding motor. Grinding heads rotating coaxially are arranged on the rotating shaft and comprise a cylindrical grinding head and two conical surface grinding heads arranged on the upper side and the lower side of the cylindrical grinding head, and the side, close to the cylindrical grinding head, of each conical surface grinding head is a small-diameter end. The glass edging device has the beneficial effects that three faces of a glass edge are ground at the same time through the two conical surface grinding heads and the cylindrical grinding head in the grinding process.

Owner:深圳市光华中空玻璃工程有限公司

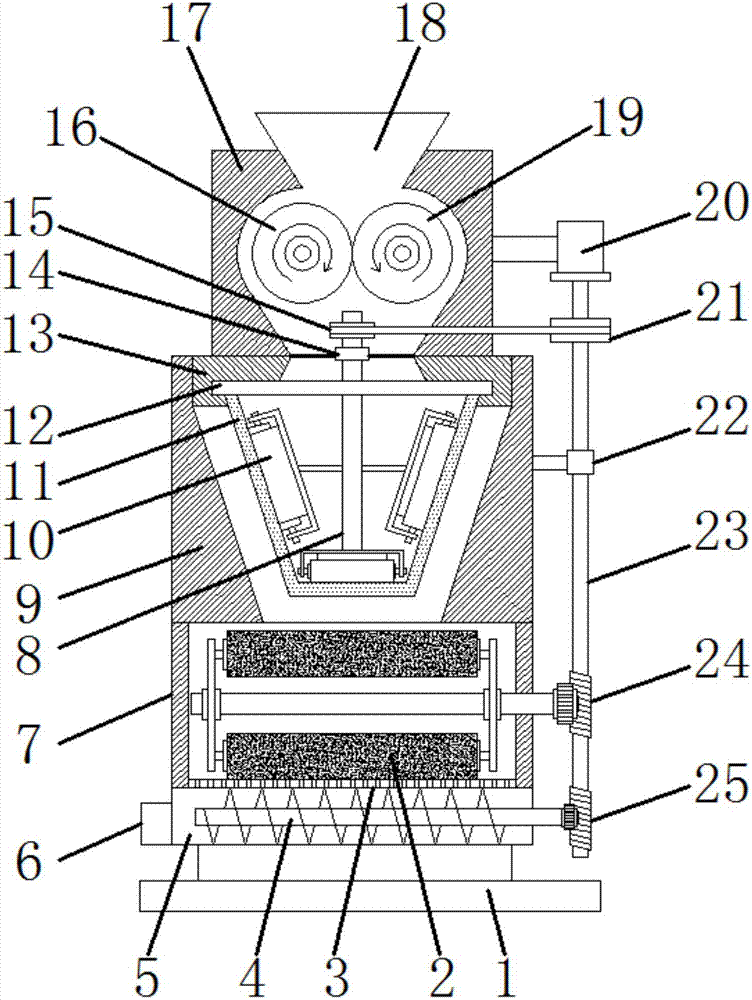

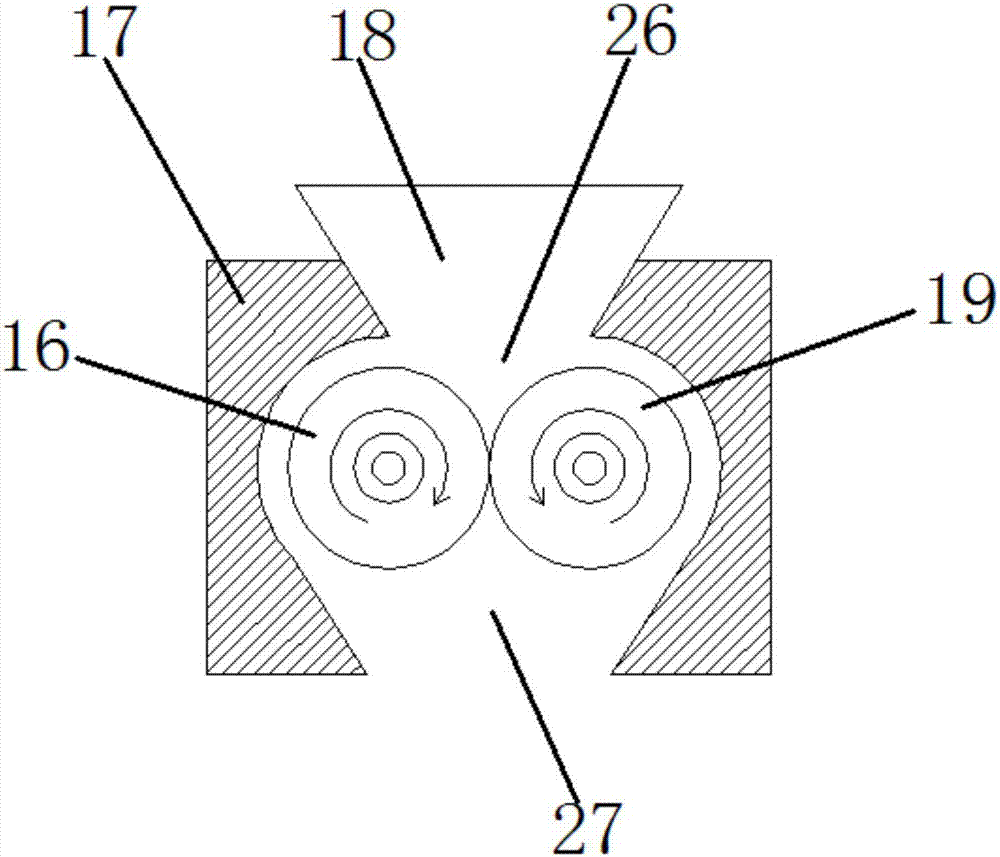

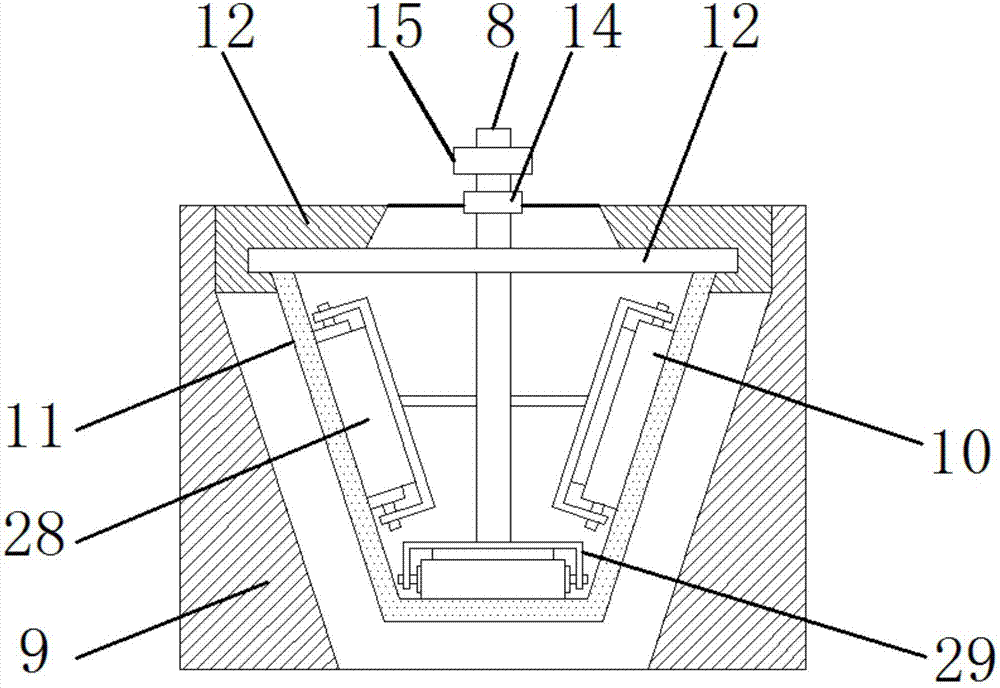

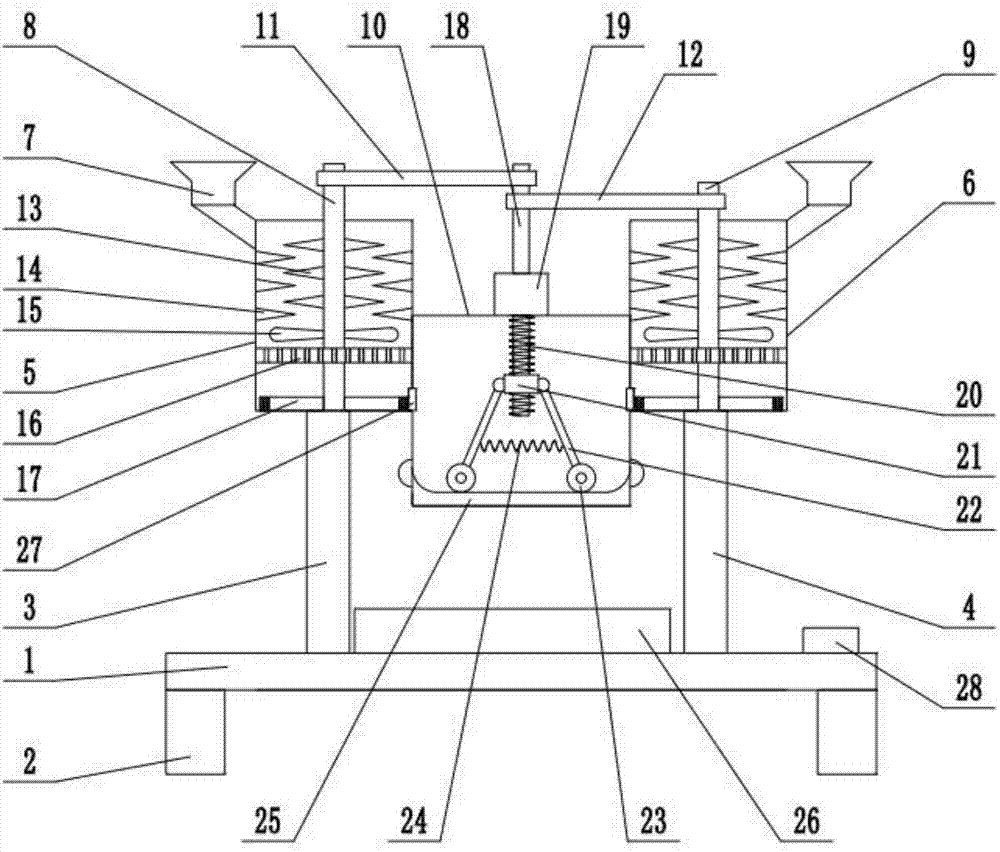

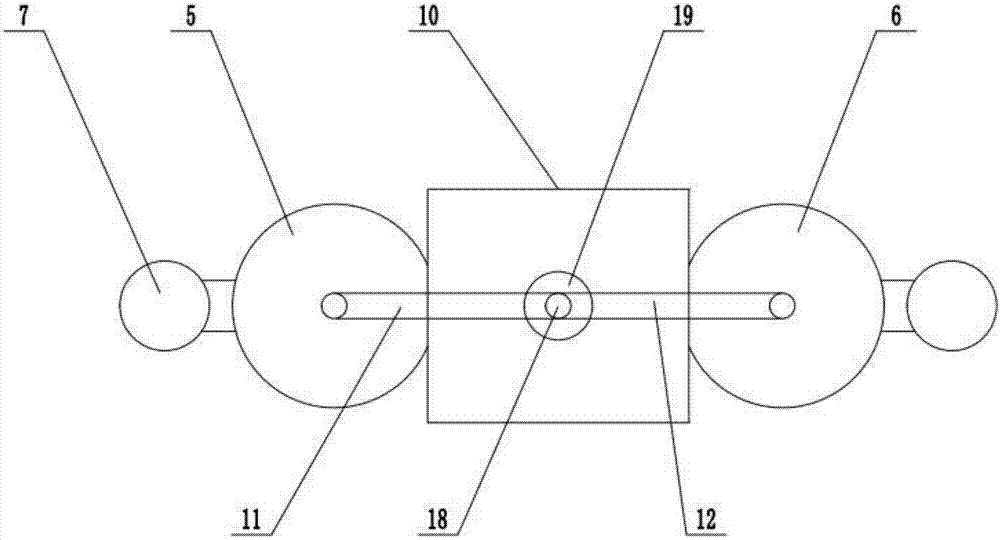

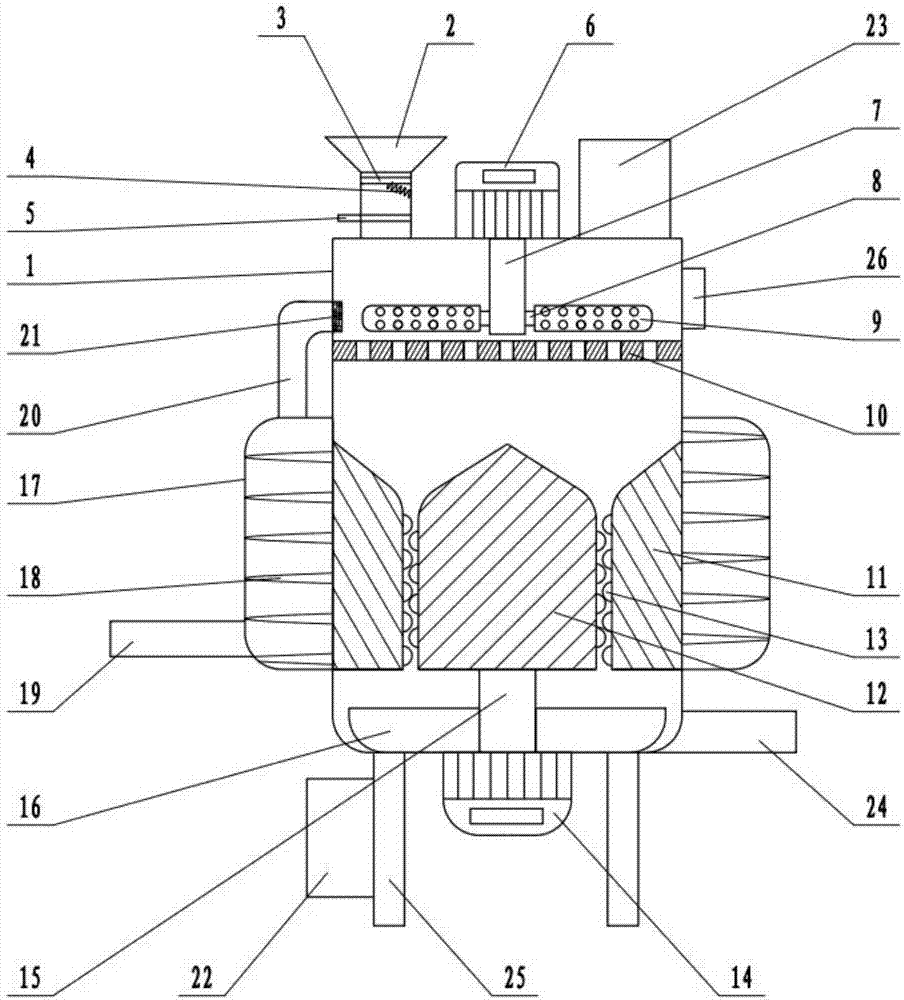

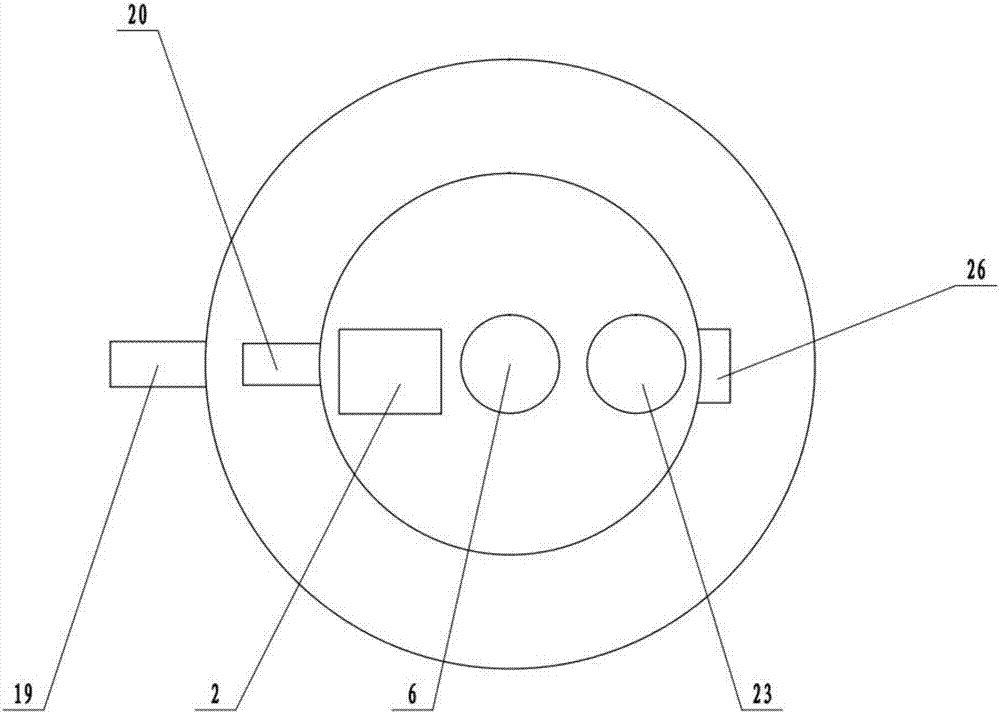

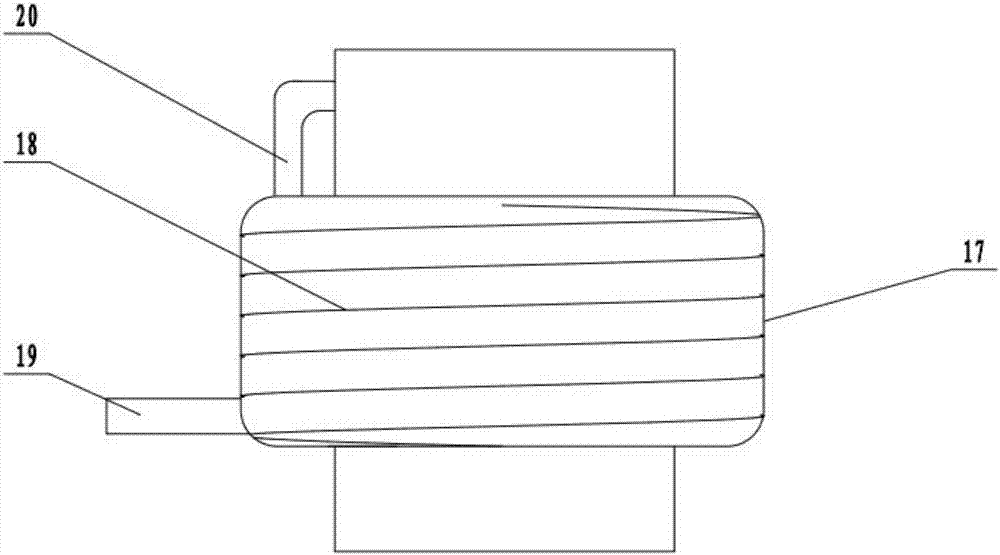

Multistage crushing, grinding and outputting device for construction aggregate

InactiveCN107029860AAchieve primary crushingSimple structureGrain treatmentsArchitectural engineeringCrusher

The invention discloses a multi-stage crushing and grinding output device for building aggregate, which comprises a base, a pushing material cylinder, a grinding cylinder, a secondary crushing cylinder and a primary crushing cylinder. The upper end of the base is fixed with a pushing material cylinder, and the pushing material The upper end of the cylinder is welded in sequence from bottom to top with a grinding cylinder, a secondary crushing cylinder, a primary crushing cylinder and a feeding hopper. The cavity is connected, and the left crushing roller and the right crushing roller are installed in the primary crushing cavity; the bottom of the primary crushing cylinder is provided with a primary crushing port, and the bottom of the primary crushing port is connected to the crushing and screening hopper, which has a simple structure and is convenient for feeding. , realize the primary crushing of building aggregates, and obtain evenly textured building aggregate crushed particles with good grinding effect, which are discharged from the discharge port under the push of the pusher screw, and realize the step-by-step crushing, grinding and output operations of building aggregates. Improve the efficiency and effect of building aggregate crushing and grinding.

Owner:刘月明

Chinese medicinal material crushing and grinding integrated machine

InactiveCN107233970AImprove crushing effectImprove processing efficiencyGrain treatmentsEngineeringCylindrical grinding

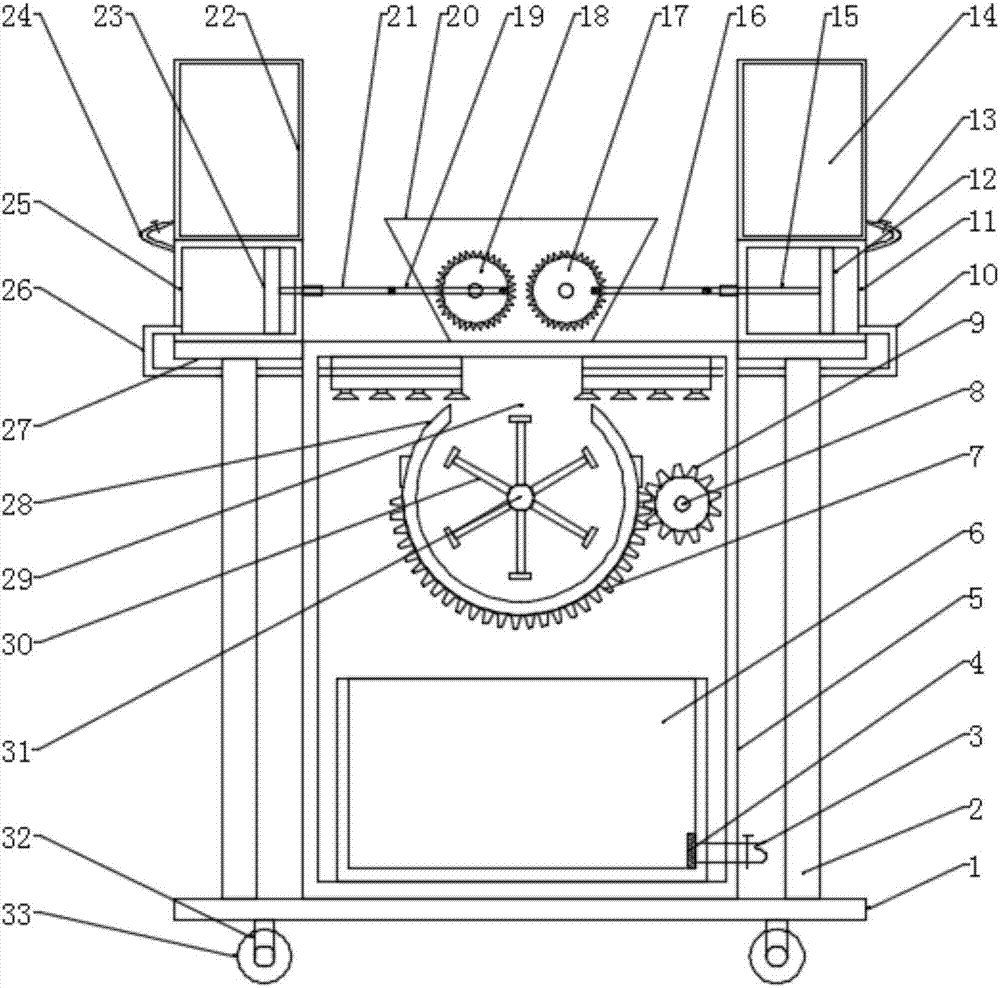

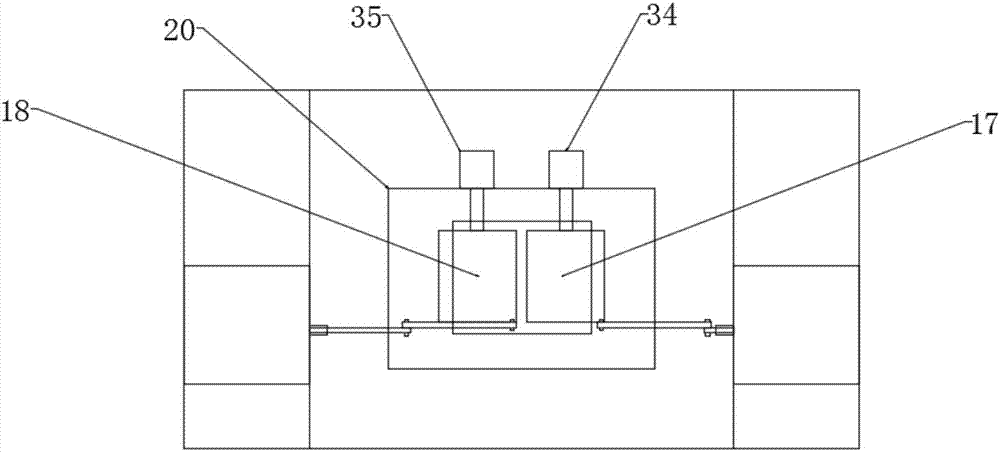

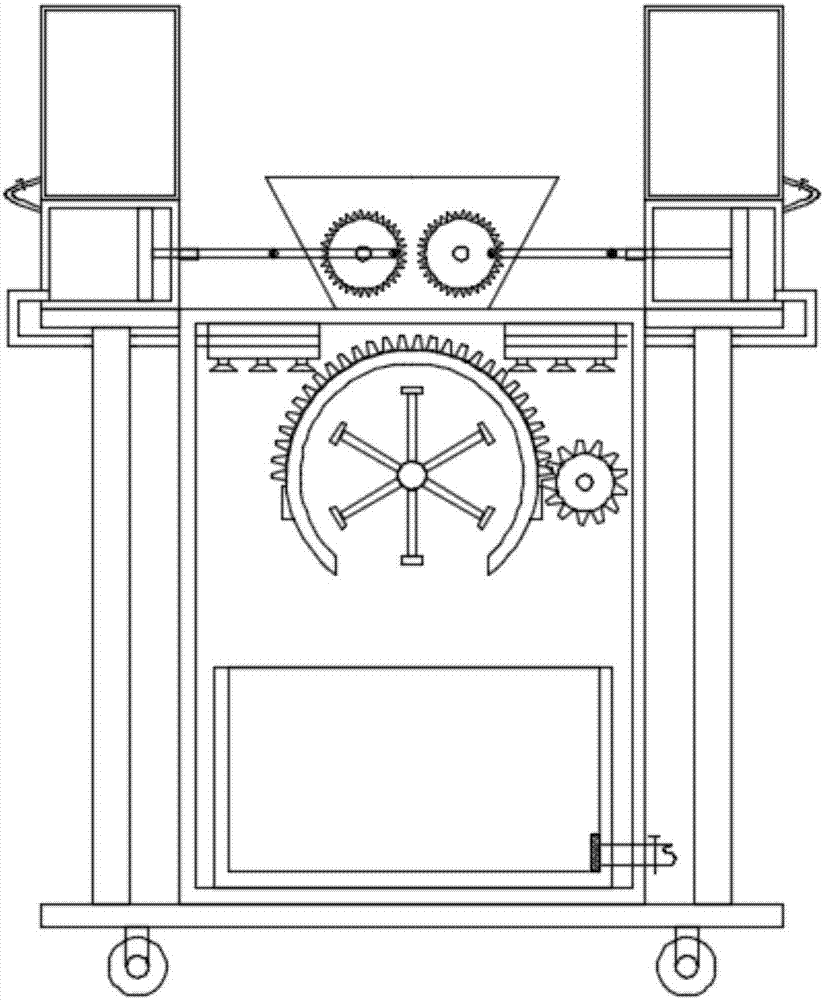

The invention discloses a Chinese medicinal material crushing and grinding integrated machine which comprises a base, supporting feet, a left supporting column, a right supporting column, a left crushing cylinder, a right crushing cylinder, feeding inlets, grinding rollers, a cover plate and a collecting box. The left supporting column and the right supporting column are fixedly connected to the upper surface of the base; the left crushing cylinder is fixedly connected to the top of the left supporting column; the right crushing cylinder is fixedly connected to the top of the right supporting column; a grinding bin is arranged between the left crushing cylinder and the right crushing cylinder; a double-axis motor is fixedly connected to the top of the grinding bin; and a screw rod is fixedly connected to the lower shaft-extension end of the double-axis motor and sleeved with a sliding block. According to the Chinese medicinal material crushing and grinding integrated machine, a variety of Chinese medicinal materials can be put into the left crushing cylinder and the right crushing cylinder according to actual needs; the crushing effect of the Chinese medicinal materials is improved through matching use of crushing edges and crushing blades; the Chinese medicinal materials are ground by means of the method that the grinding rollers roll on a bottom plate; and through the machine, the situation that the two different kinds of Chinese medicinal materials are ground and mixed simultaneously can be achieved, and the processing efficiency is greatly improved.

Owner:临泉县生产力促进中心

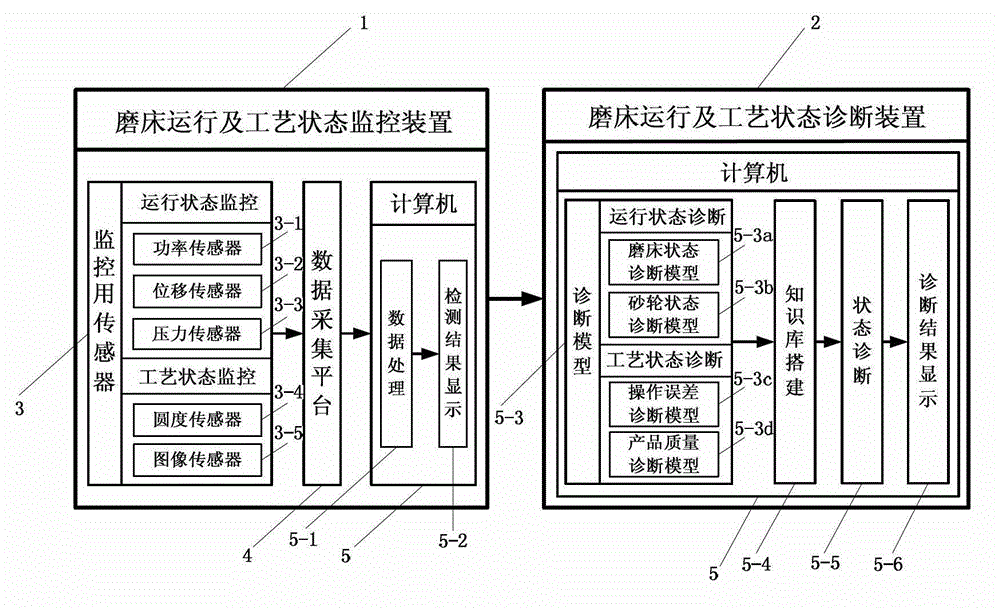

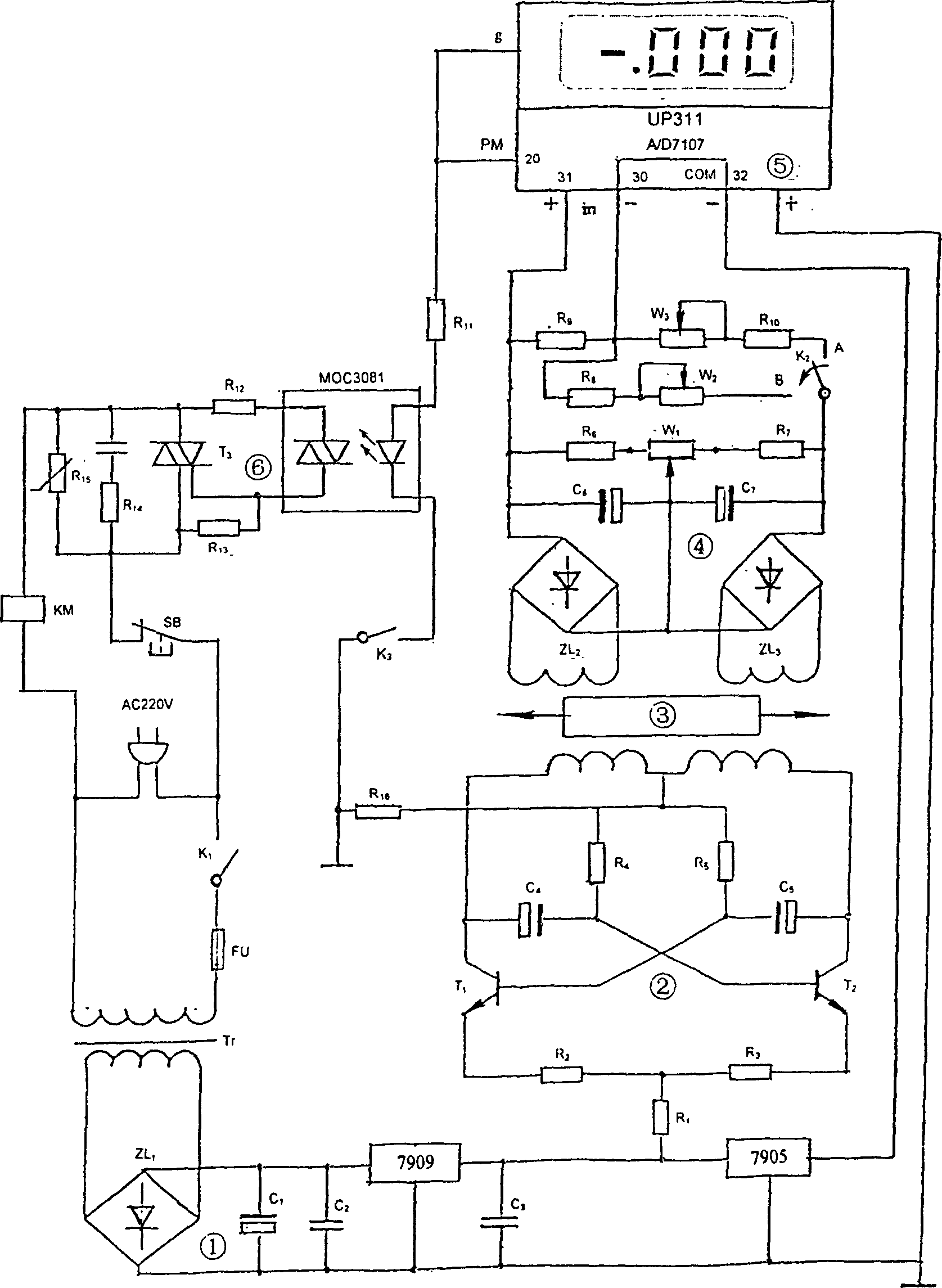

Monitoring and diagnosing system of operation and process state of numerically controlled cylindrical grinding machine

ActiveCN102975119AImprove operational efficiencyHigh precisionGrinding feed controlControl systemComputer module

A monitoring and diagnosing system of operation and a process state of a numerically controlled cylindrical grinding machine comprises a monitoring device of the operation and the process state of a grinding machine and a diagnosing device of the operation and the process state of the grinding machine. The monitoring device of the operation and the process state of the grinding machine comprises a monitoring sensor, a data collecting platform and a computer, the monitoring sensor is connected with the data collecting platform which is connected with the computer, and the monitoring device of the operation and the process state of the grinding machine is connected with the diagnosing device of the operation and the process state of the grinding machine. The functions of the diagnosing device of the operation and the process state of the grinding machine are achieved on the basis of the computer, the monitoring and diagnosing system of the operation and the process state of the numerically controlled cylindrical grinding machine carries out diagnosis according to measuring and analysis of the key signals in a grinding machine processing process, improves the quick response ability of a machine tool manufacturing enterprise to user malfunctions, and achieves the diagnosing of machine on-line faults by integrating an intelligent diagnosing module with the numerically controlled system part of an existing precision machine tool.

Owner:TSINGHUA UNIV

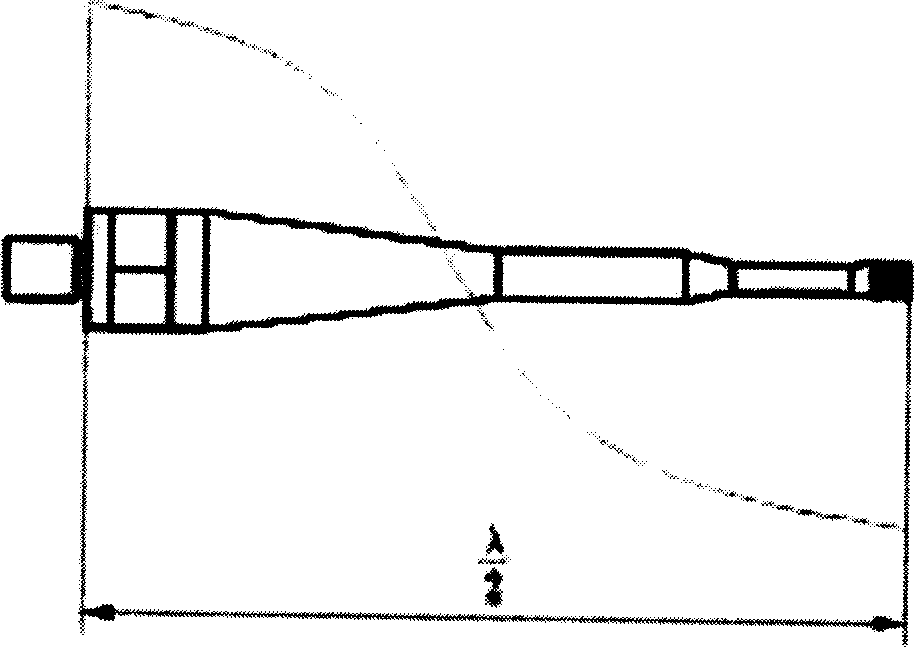

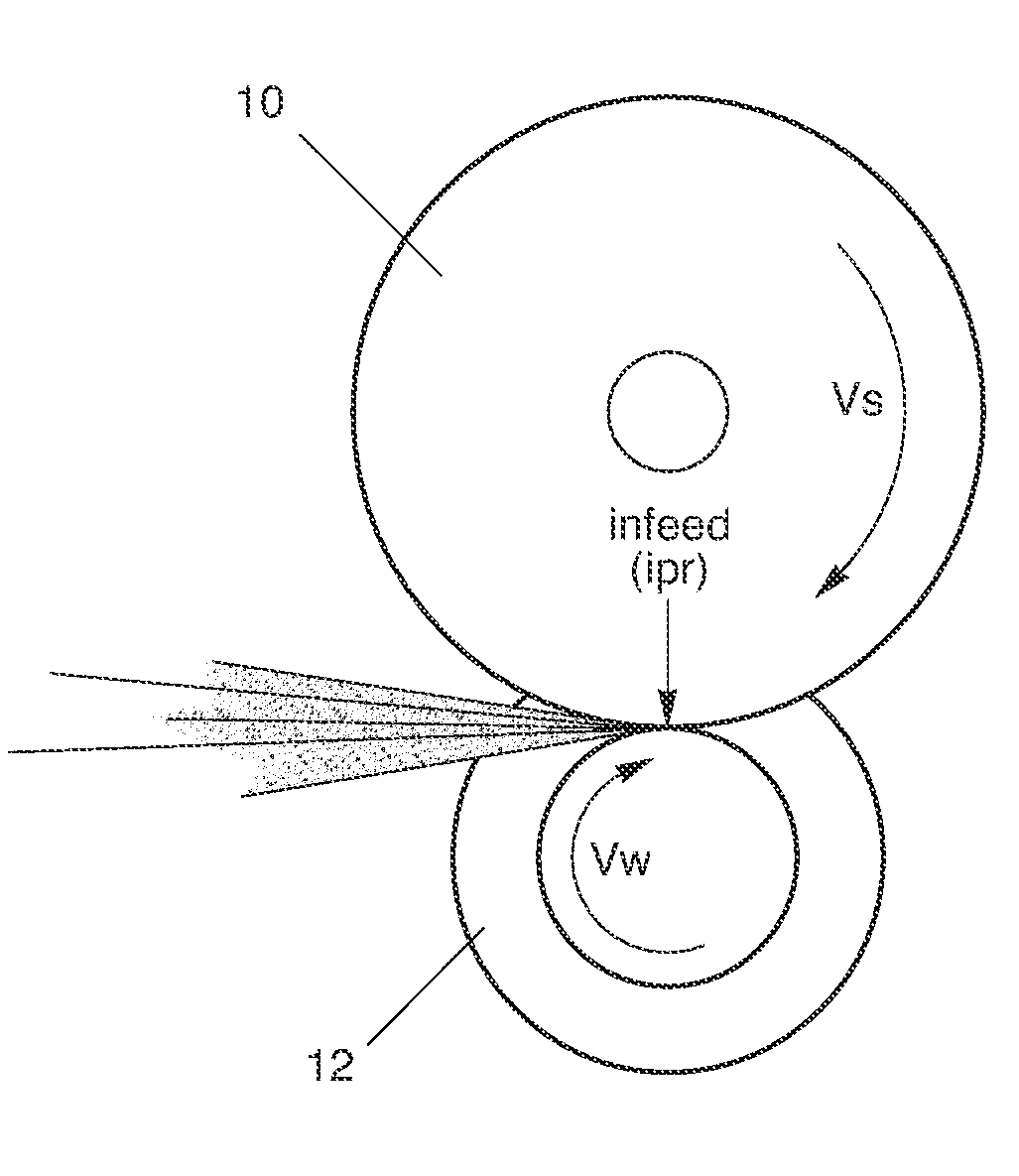

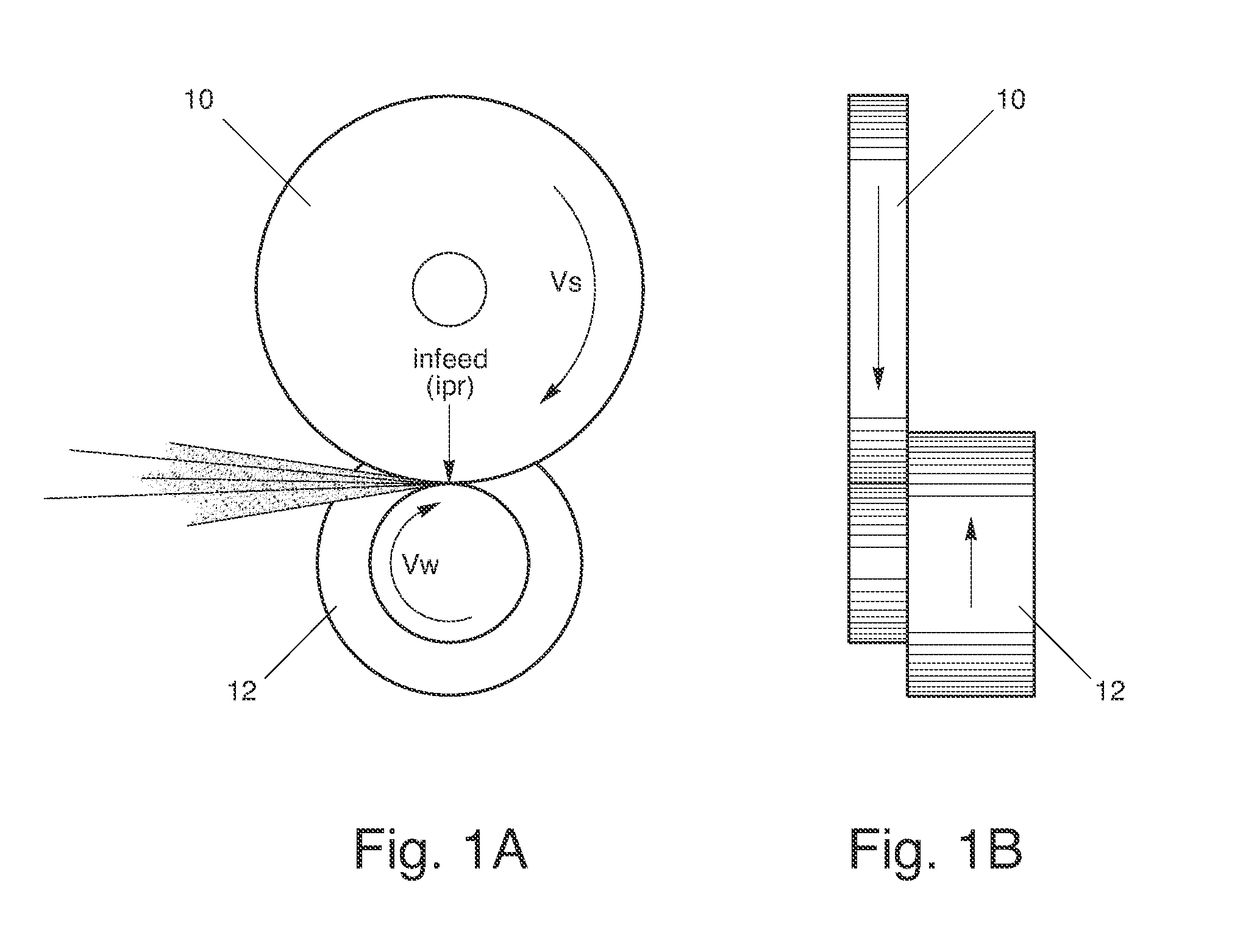

Techniques for cylindrical grinding

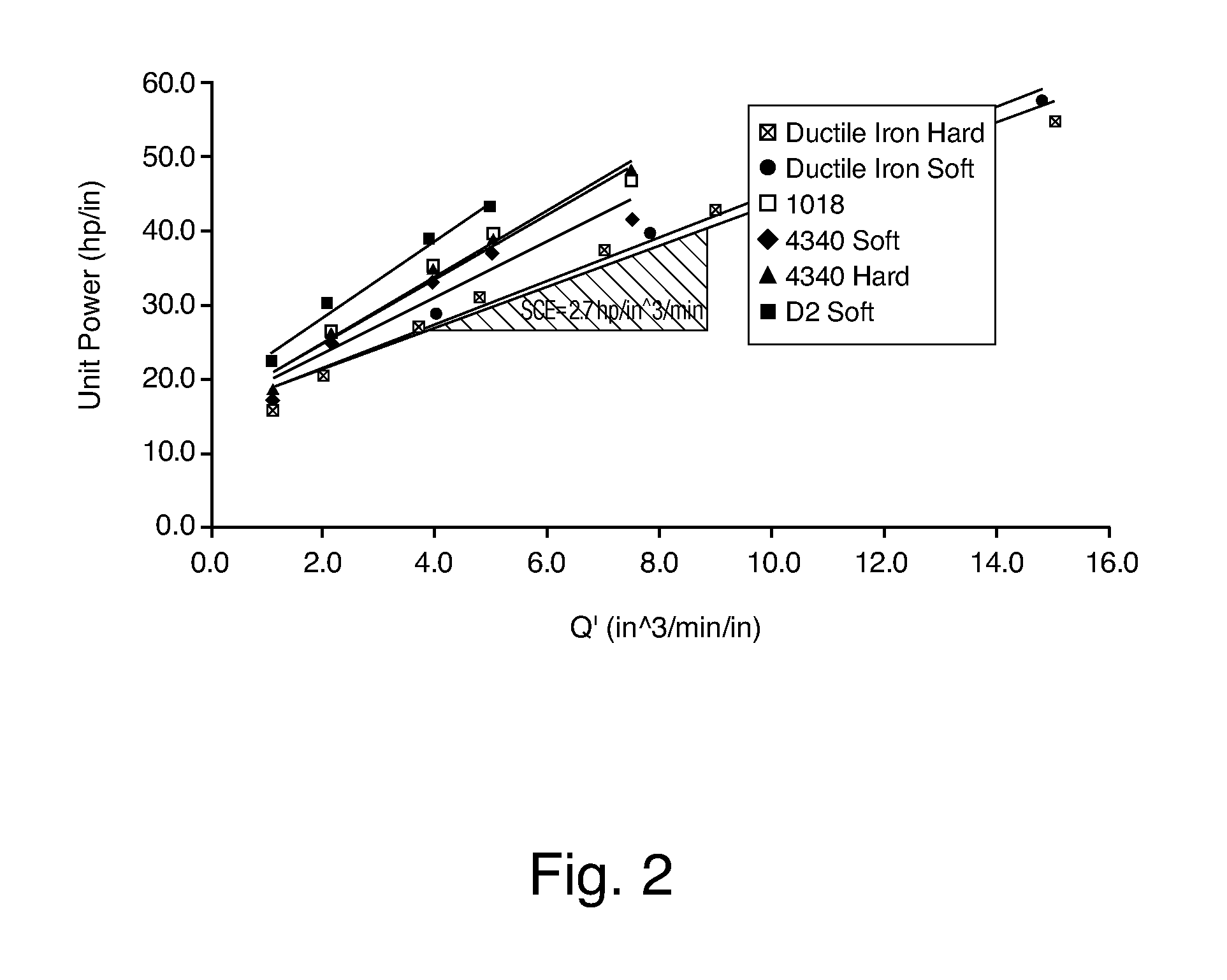

ActiveUS20090093198A1High surface finishShort processing timeRevolution surface grinding machinesAbrasion apparatusMaterial removalMetallurgy

Methods for cylindrical grinding a workpiece are disclosed. The method includes cylindrical grinding, with a bonded abrasive wheel having a permeable structure that includes interconnected porosity, a workpiece at a specific cutting energy of less than about 12 Hp / in3·min (29.7 J / mm3), and a material removal rate of at least about 1 in3 / min·in (10.8 mm3 / sec / mm)grinding. The bonded abrasive wheel may include at least about 3 volume percent of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1, or agglomerates thereof. In one embodiment, the workpiece is ground in the presence of a water soluble oil.

Owner:SAINT GOBAIN ABRASIVES INC +1

Processing technology of camshaft

InactiveCN103433709ASimple processing technologyFlexible processing technologyMachine partsMechanical components

The invention belongs to the field of machine part machining, and particularly relates to a processing technology of a camshaft. The processing technology of the camshaft comprises the step A of blanking according to the standard that two finished products are blanked from each work-blank; the step B of carrying out rough machining, rough turning and end face flattening on the work-blank and machining eccentric circles through a numerically controlled lathe; the step C of thermal refining and enabling the rigid to be 26-31 HRC; the step D of carrying out half finish turning on the work-blank through the numerically controlled lathe; the step E of carrying out accurate grinding on the work-blank through a cylindrical grinding machine; the step F of carrying out linear cutting on the work-blank for forming two same products; the step G of carrying out flat facing through the numerically controlled lathe; the step H of carrying out punching through a machining center and carrying out punching and chamfering on the two products; and the step I of thermal treating. The processing technology of the camshaft is simple, the two products can be machined at the same time, and therefore the producing and machining cost is saved greatly, the production efficiency is improved, the processing technology is flexible, and the universality is good.

Owner:宁波富莱茵汽车部件有限公司

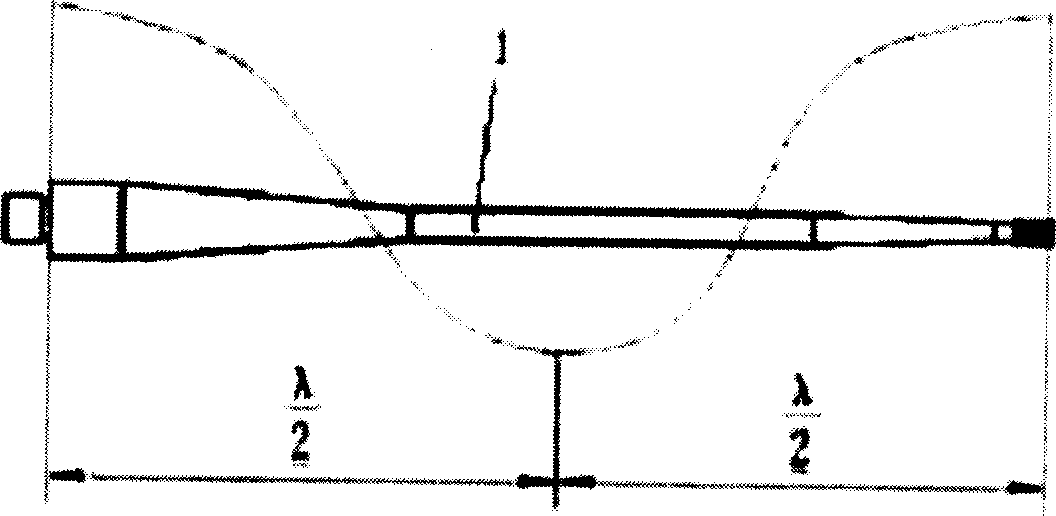

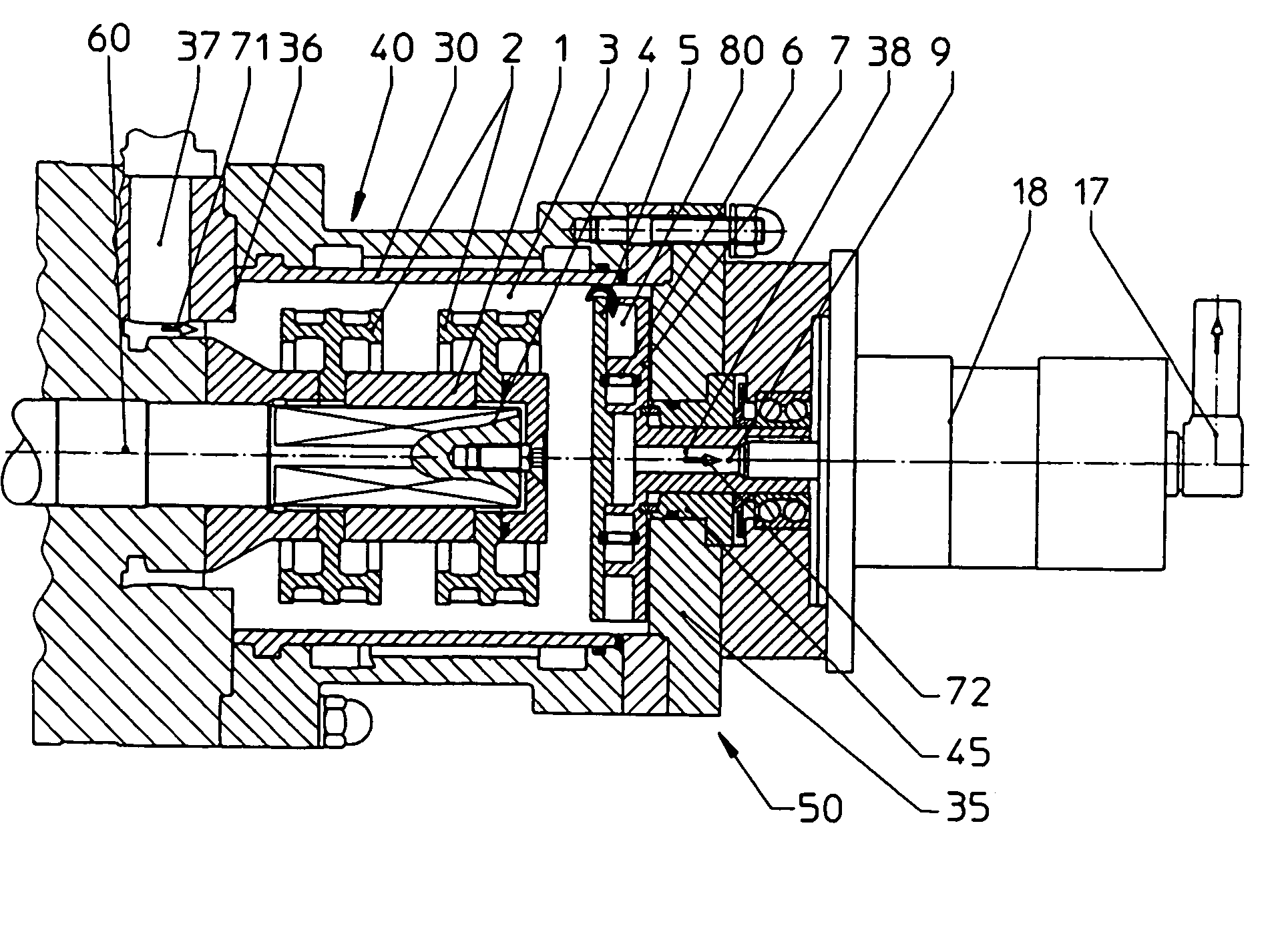

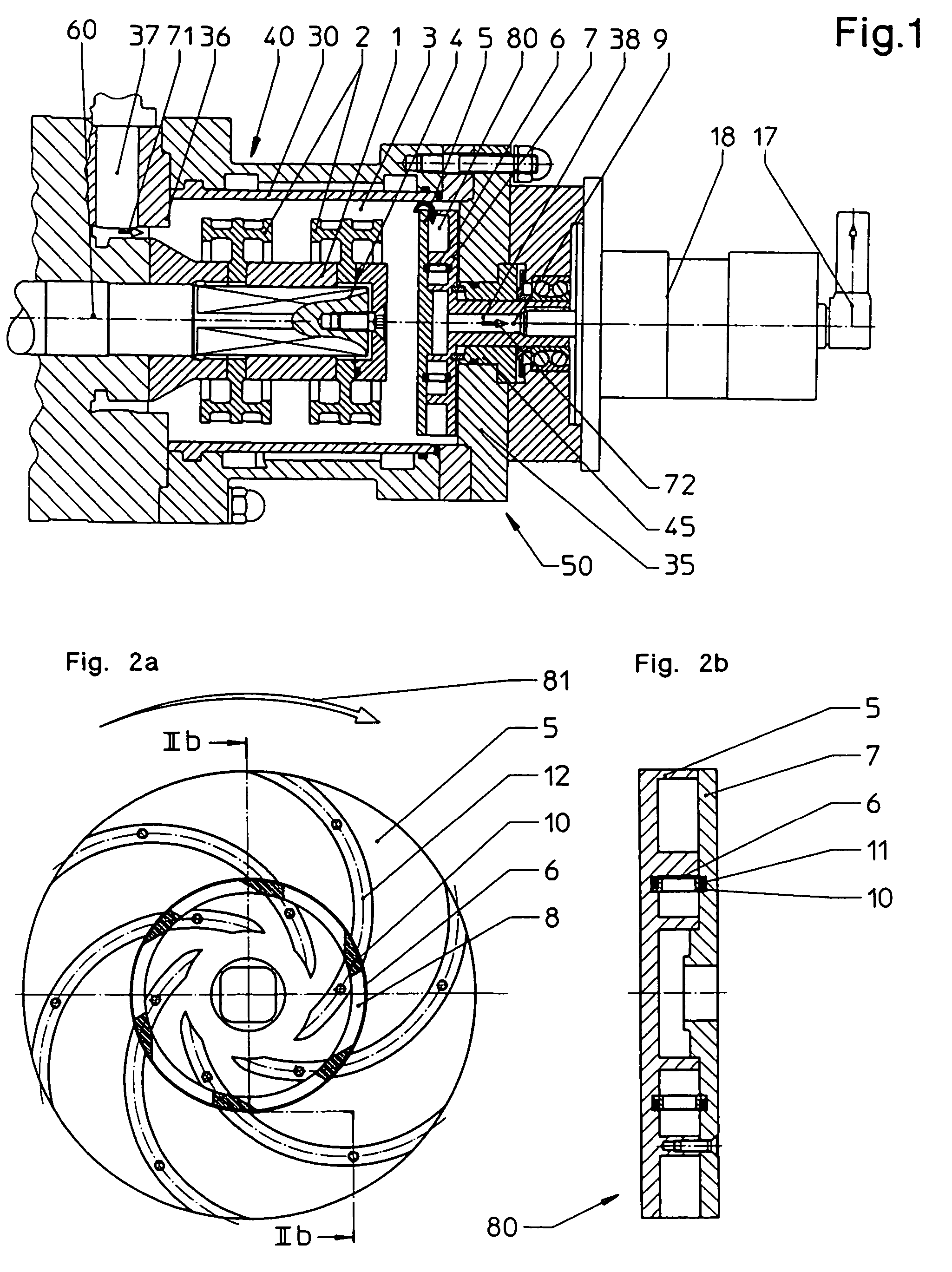

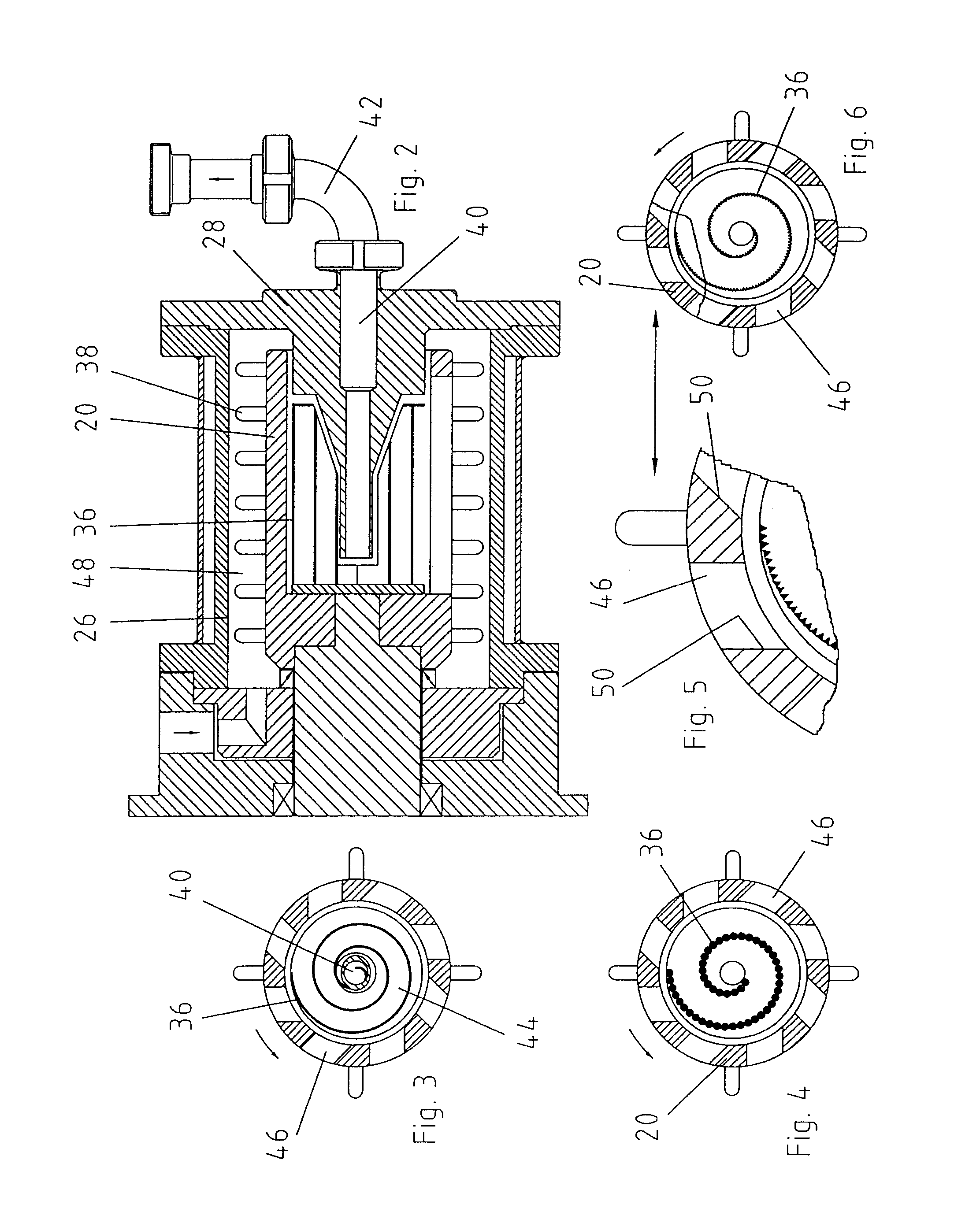

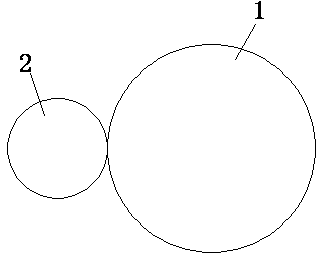

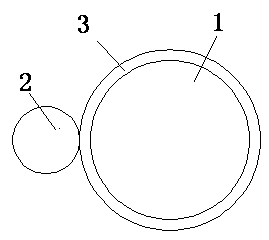

Stirred ball mill

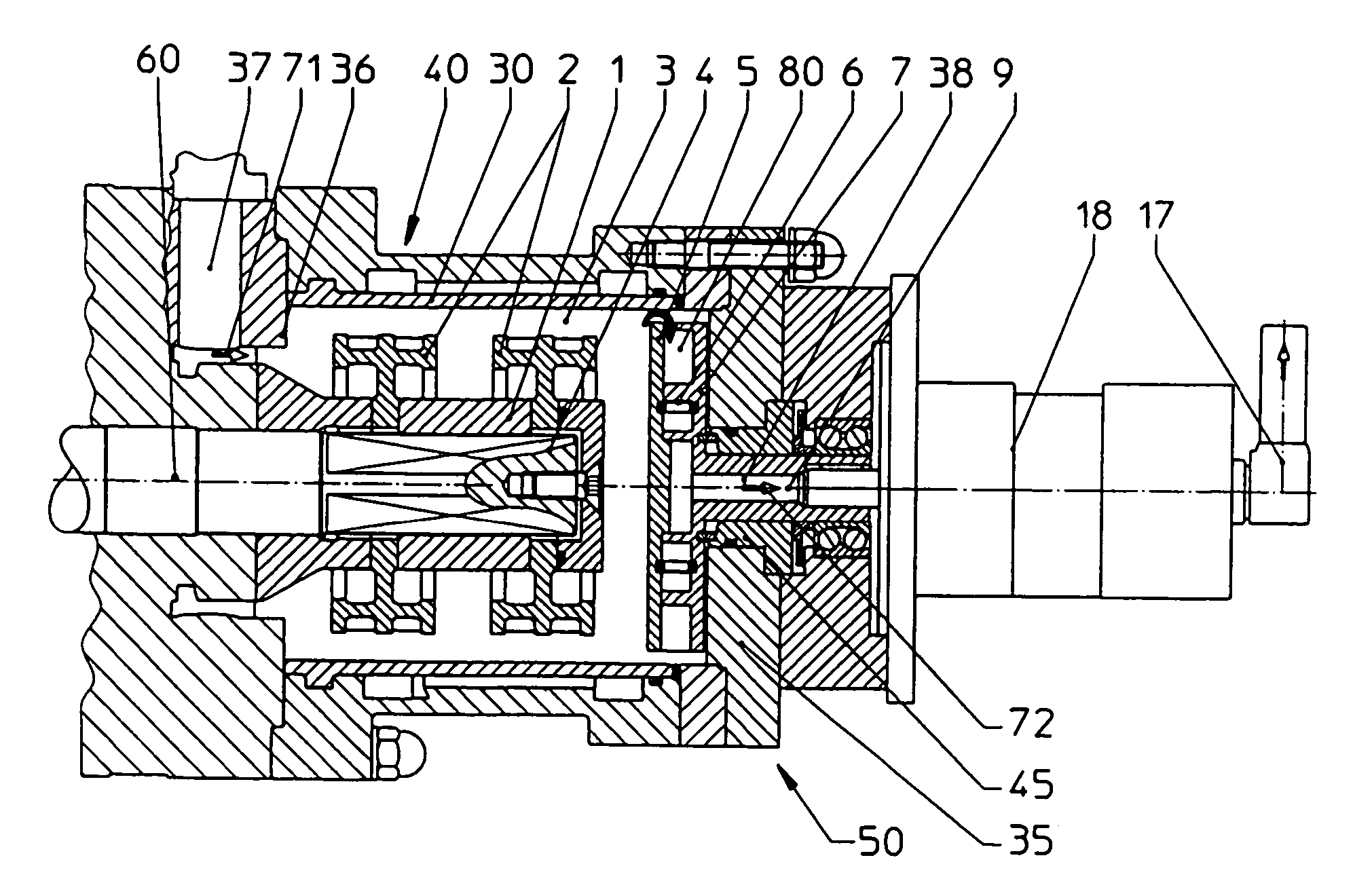

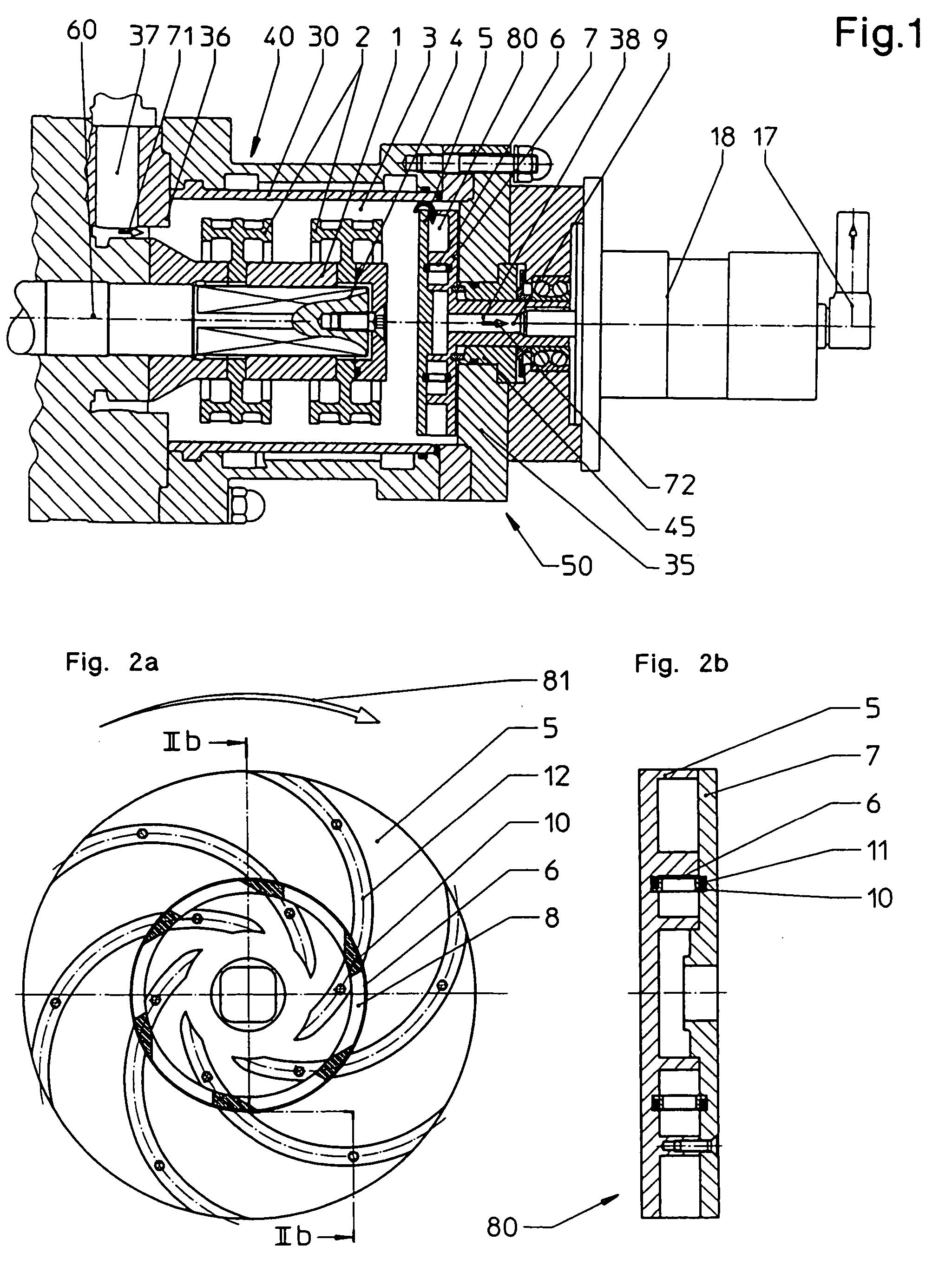

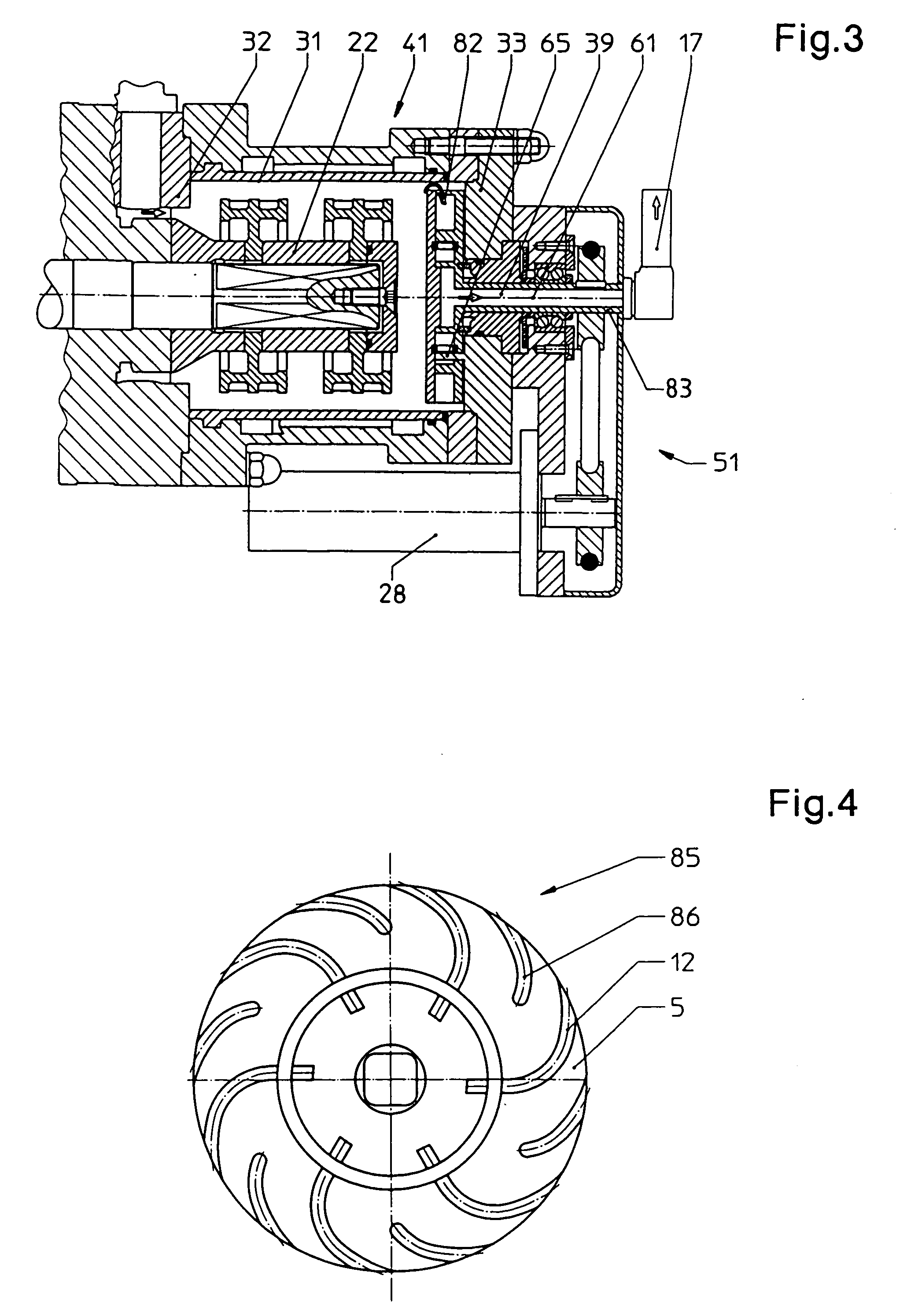

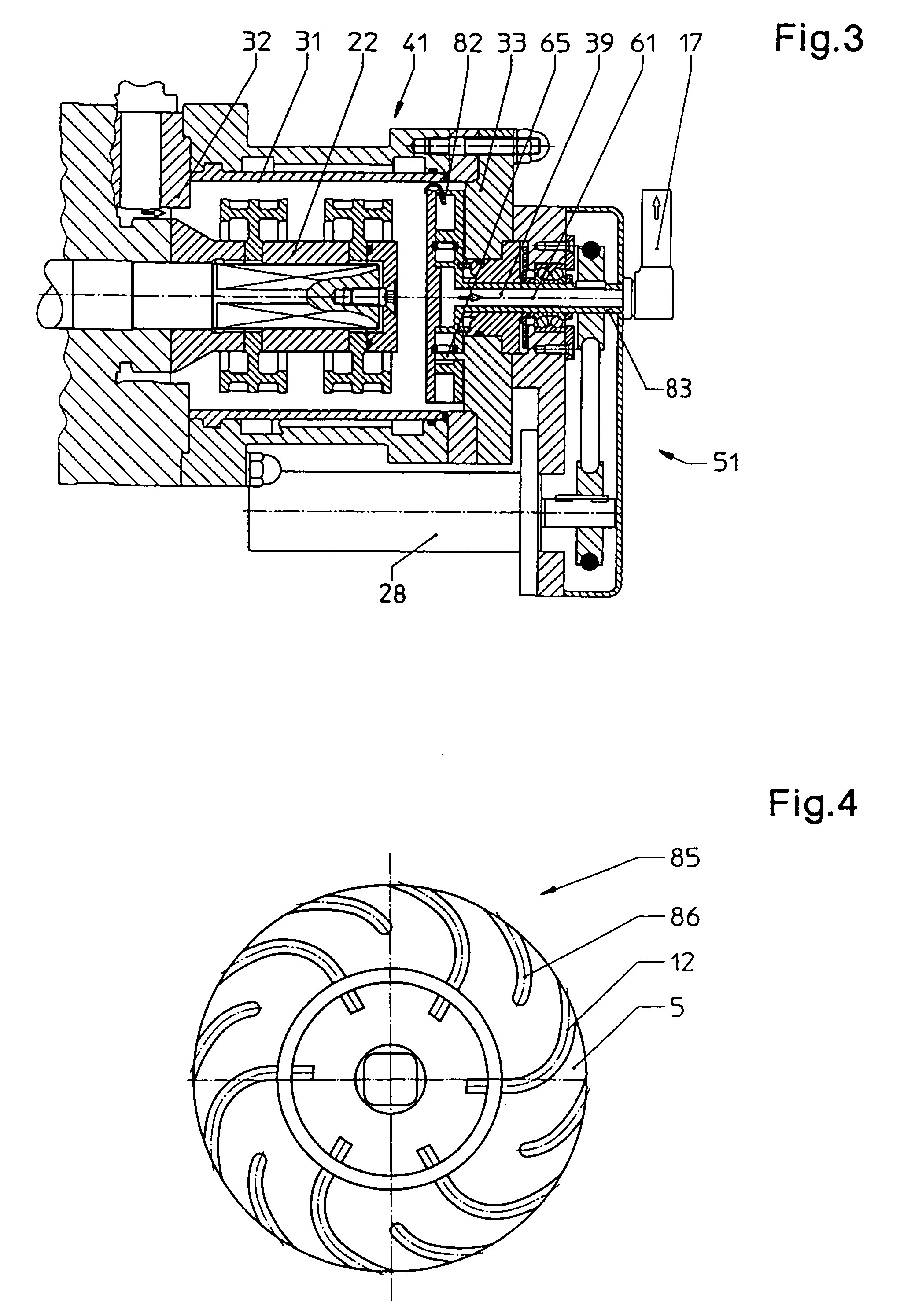

The horizontally operating stirred ball mill has a cylindrical grinding chamber (50) serving for receiving grinding media, a material inlet (37) arranged at the end of the grinding chamber (50) and opening into the interior (3) of the grinding chamber (50), a material outlet (38) arranged at the other end of the grinding chamber and leading out of the interior (3), a stirrer (1) having a plurality of stirrer members (2) and coaxial with the chamber axis (60), and a separation system present upstream of the material outlet (38) and consisting of a separation member (80) and a drive member which drives said separation member and which separates the grinding media from the ground material and transports them back into the interior (3) of the grinding chamber (50). The separation member (80) has two circular disks (5, 7) which are arranged coaxially with the chamber axis (61) and between which a plurality of conveying or blade elements (12) symmetrically distributed around the midpoint of the disk and leading inwards from the disk edge are arranged, which elements, during operation of the stirred ball mill, generate an opposing pressure on the mixture of material and grinding media, so that, owing to the centrifugal force and the different specific density, the grinding media are separated from the product and are transported back into the interior (3).

Owner:WILLY A BACHOFEN AG

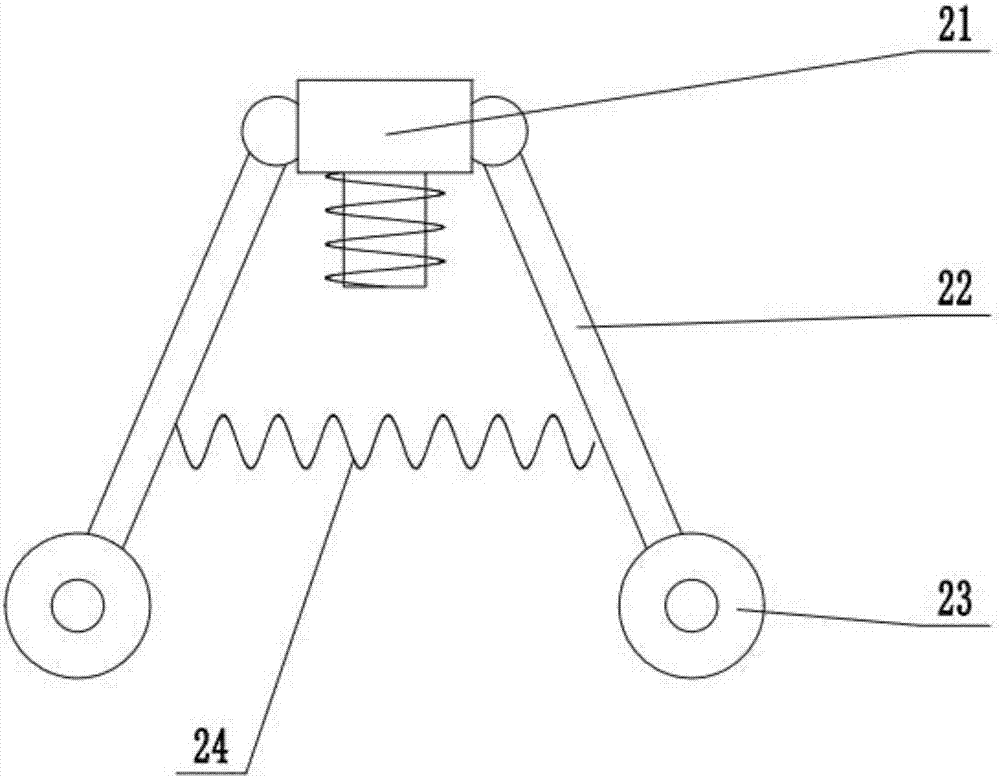

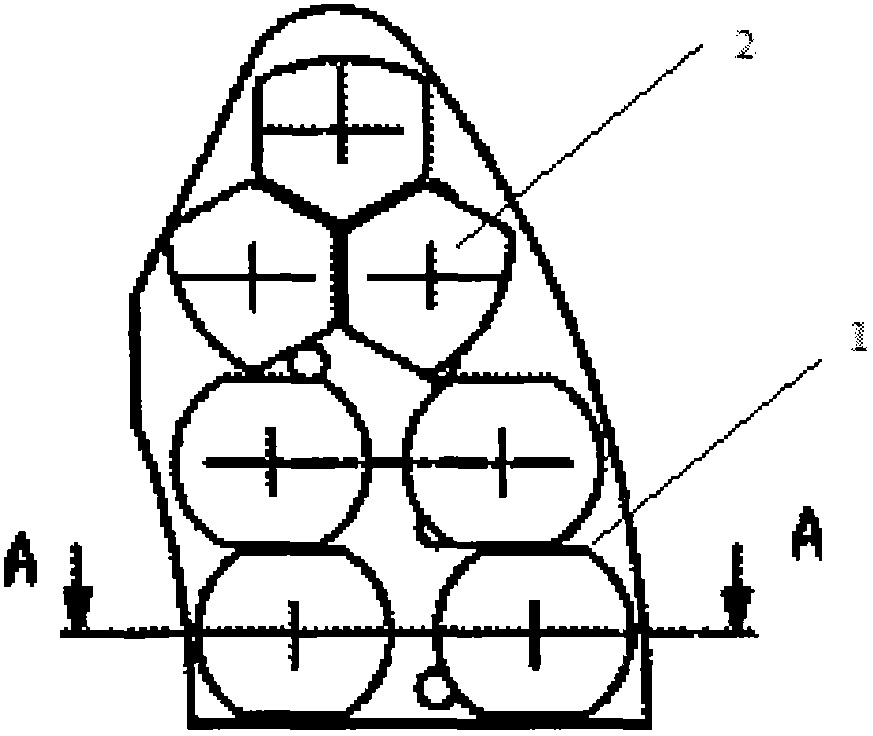

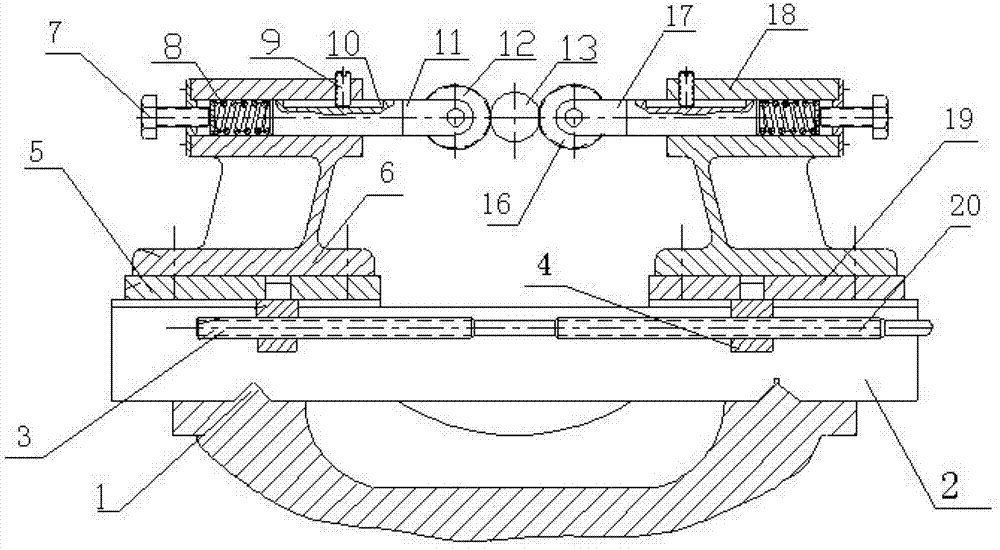

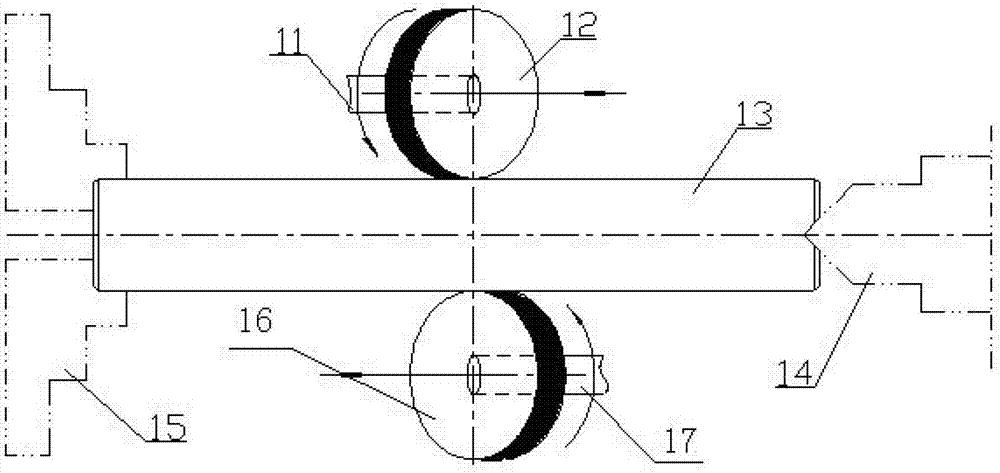

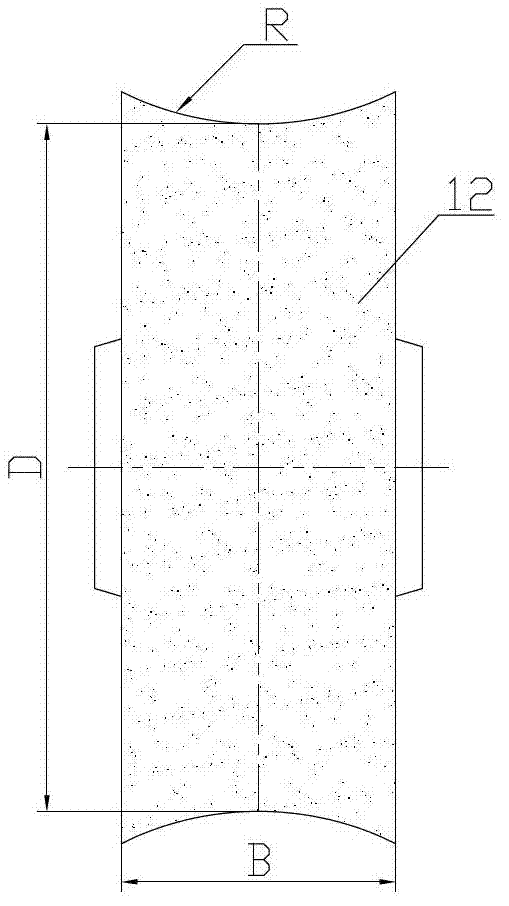

Floatation type brake pad for high speed train

InactiveCN102705405AAvoid bluePrevent thermal crackingBraking elementsVibration attenuationEngineering

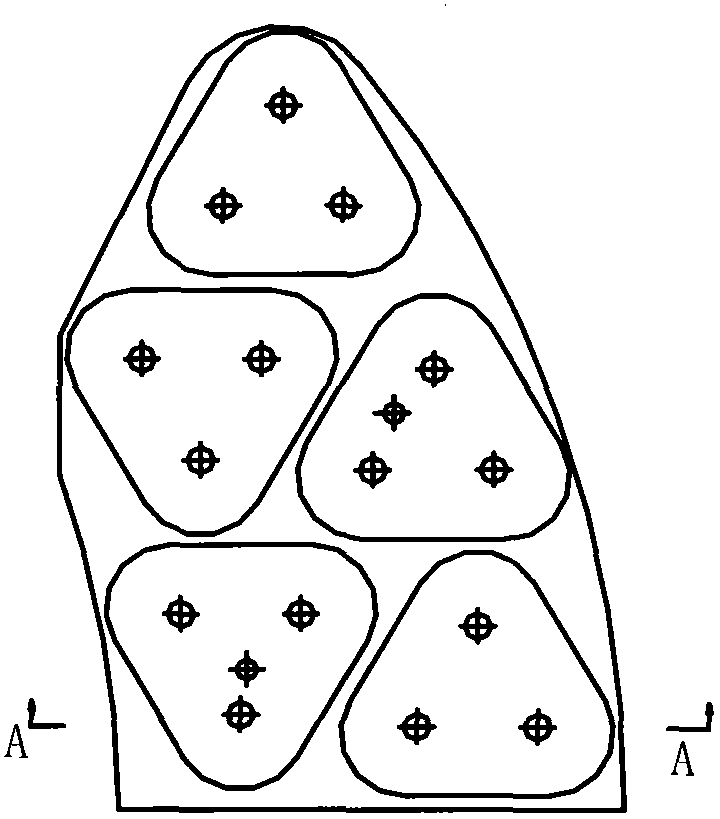

The invention relates to a floatation type brake pad for a high speed train.. The floatation type brake pad is characterized by comprising a pad rear panel, a dovetail board, friction block bodies, an elastic supporting sheet and a round spring clip; the pad rear panel is in an arc half-sole structure; the elastic supporting sheet is provided with a spherical supporting surface and a center guide hole; the frication block is provided with a spherical supporting surface and a guide connection shaft with a clamping groove; the elastic supporting sheet, the round spring clip and the friction block bodies are in elastic floatation connection with the pad rear panel; the spherical supporting surface of the elastic supporting sheet and the spherical supporting surface at the root of a connection shaft of each friction block body are rotary, so that the balance of a braking force is realized; the three single-arc quadrilateral friction bodies in one group are mutually engaged and locked; and friction bodies of four cylindrical grinding column bodies are mutually engaged and locked in pairs. With the adoption of the floatation type brake pad provided by the invention, a maximum contact friction area can be obtained, so that a braking process is stable, and the functions of damping, vibration attenuation, noise reduction, heat radiation and the like can be achieved. The friction blocks are easy to replace; the operation cost is low; and the floatation type brake pad can be widely used for a braking system of the high speed train.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Stirred ball mill

The horizontally operating stirred ball mill has a cylindrical grinding chamber (50) serving for receiving grinding media, a material inlet (37) arranged at the end of the grinding chamber (50) and opening into the interior (3) of the grinding chamber (50), a material outlet (38) arranged at the other end of the grinding chamber and leading out of the interior (3), a stirrer (1) having a plurality of stirrer members (2) and coaxial with the chamber axis (60), and a separation system present upstream of the material outlet (38) and consisting of a separation member (80) and a drive member which drives said separation member and which separates the grinding media from the ground material and transports them back into the interior (3) of the grinding chamber (50). The separation member (80) has two circular disks (5, 7) which are arranged coaxially with the chamber axis (61) and between which a plurality of conveying or blade elements (12) symmetrically distributed around the midpoint of the disk and leading inwards from the disk edge are arranged, which elements, during operation of the stirred ball mill, generate an opposing pressure on the mixture of material and grinding media, so that, owing to the centrifugal force and the different specific density, the grinding media are separated from the product and are transported back into the interior (3).

Owner:WILLY A BACHOFEN AG

Architectural efficient pulverizing device for coagulated cement blocks and facilitating material discharging

InactiveCN107233986AProtect healthAchieve rotationUsing liquid separation agentHollow article cleaningGear wheelEngineering

The invention discloses a high-efficiency crushing device for congealed cement blocks for construction which is convenient for discharging, which comprises a bottom plate, a box body, a feeding hopper, a first motor, a second motor, a first crushing roller, a second crushing roller, a first continuous Rod, first piston rod, first piston, first cylinder, first water tank, second connecting rod, second piston rod, second piston, second cylinder, second water tank, crushing cylinder, semicircle outer Racks, rotating shafts, crushing hammers, gears and collection frames. The present invention is provided with a first crushing roller and a second crushing roller for pre-crushing to ensure the thoroughness of crushing. It is provided with a first connecting rod, a second connecting rod, The first piston rod and the second piston rod continuously spray water to reduce dust, protect the environment while ensuring the health of the staff, and can also clean the device. There are crushing cylinders, crushing hammers, semicircular external racks and gears, and The cement block is crushed for the second time, and the crushing cylinder is rotated through the cooperation of the gear and the semi-circular outer rack, which makes the unloading more convenient.

Owner:殷志成

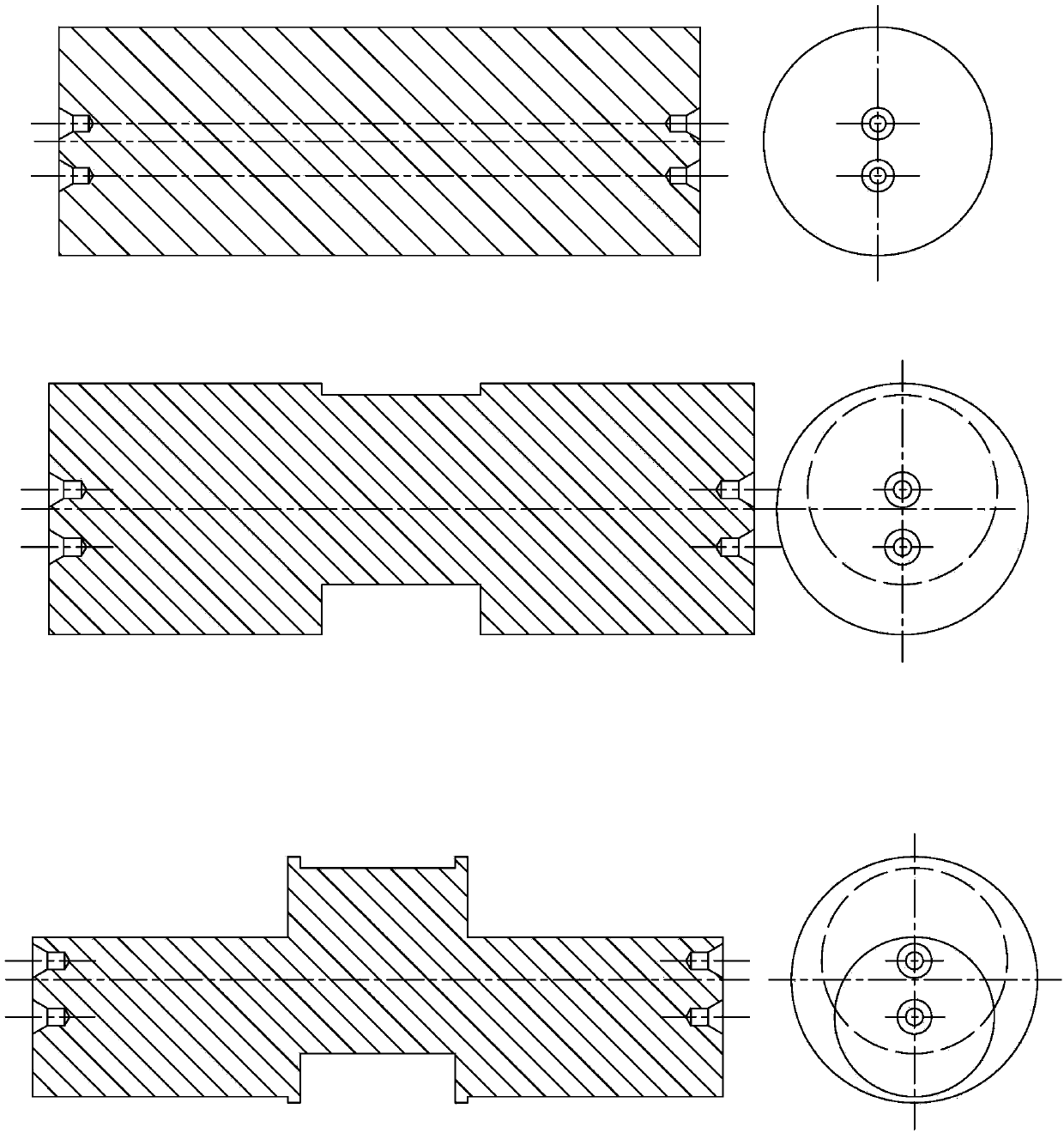

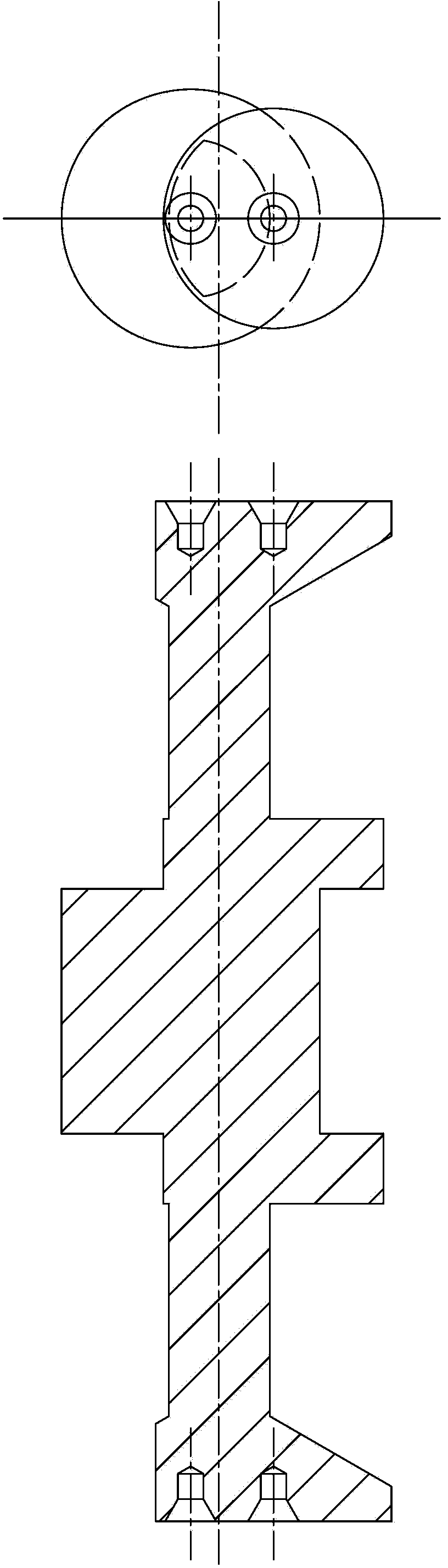

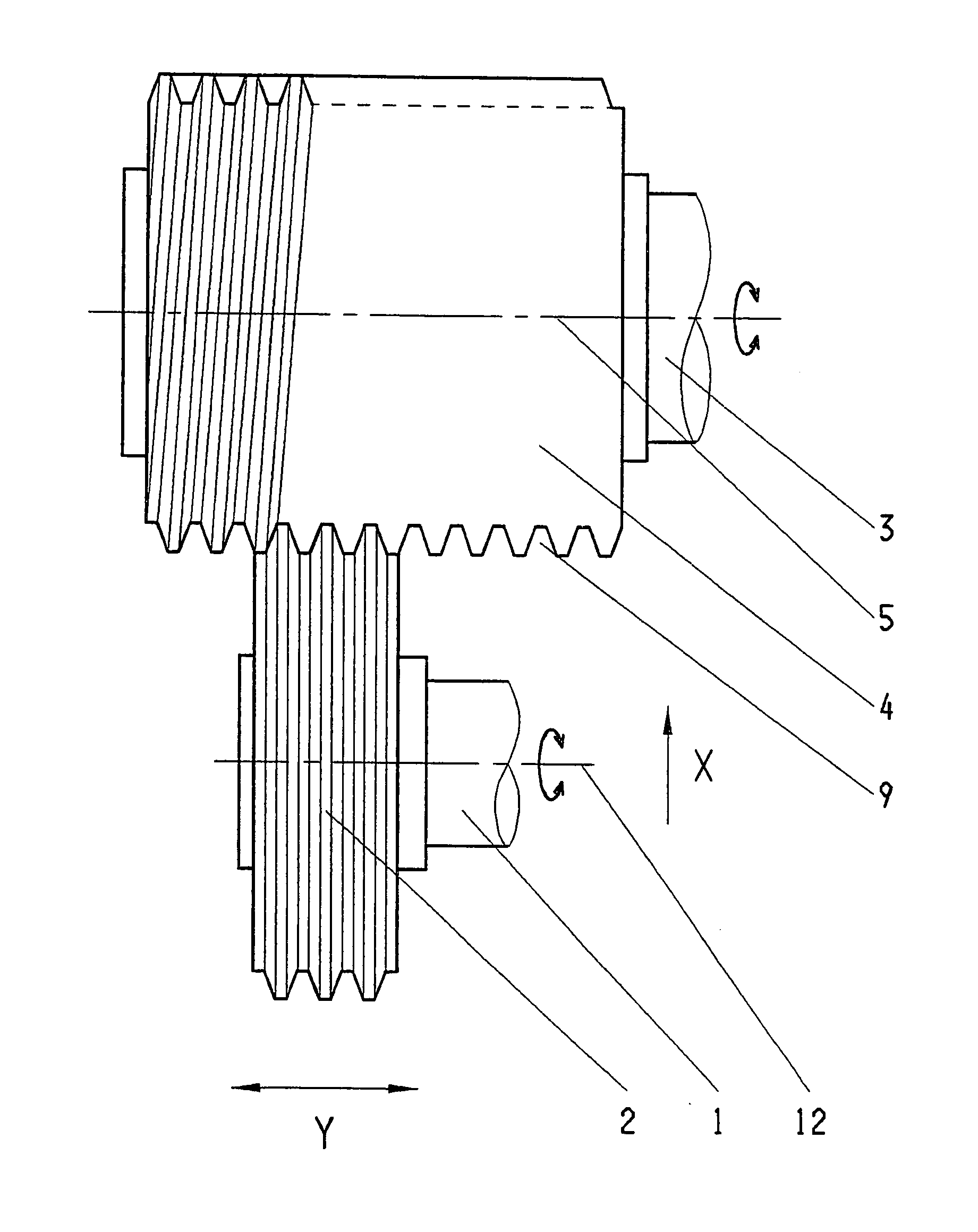

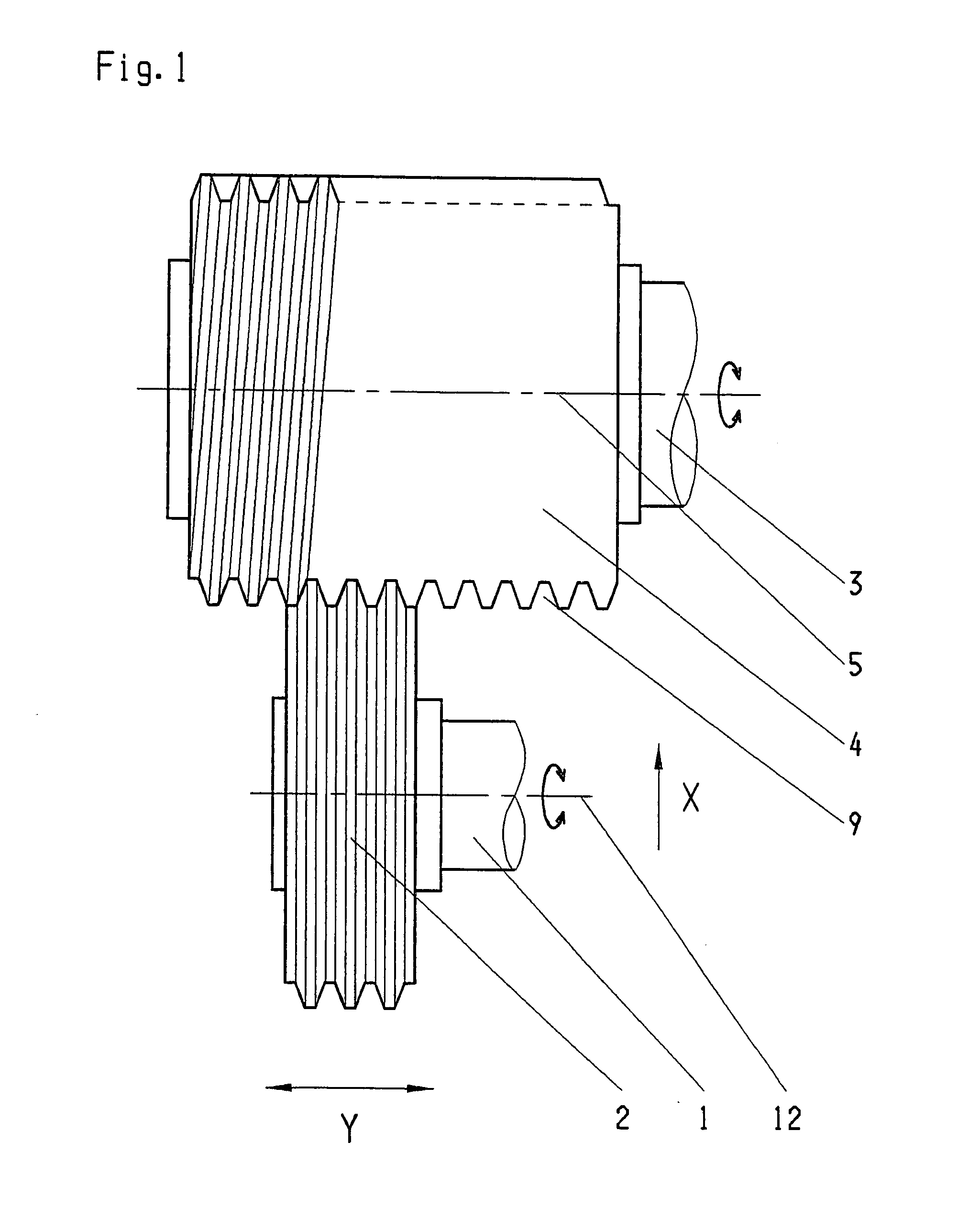

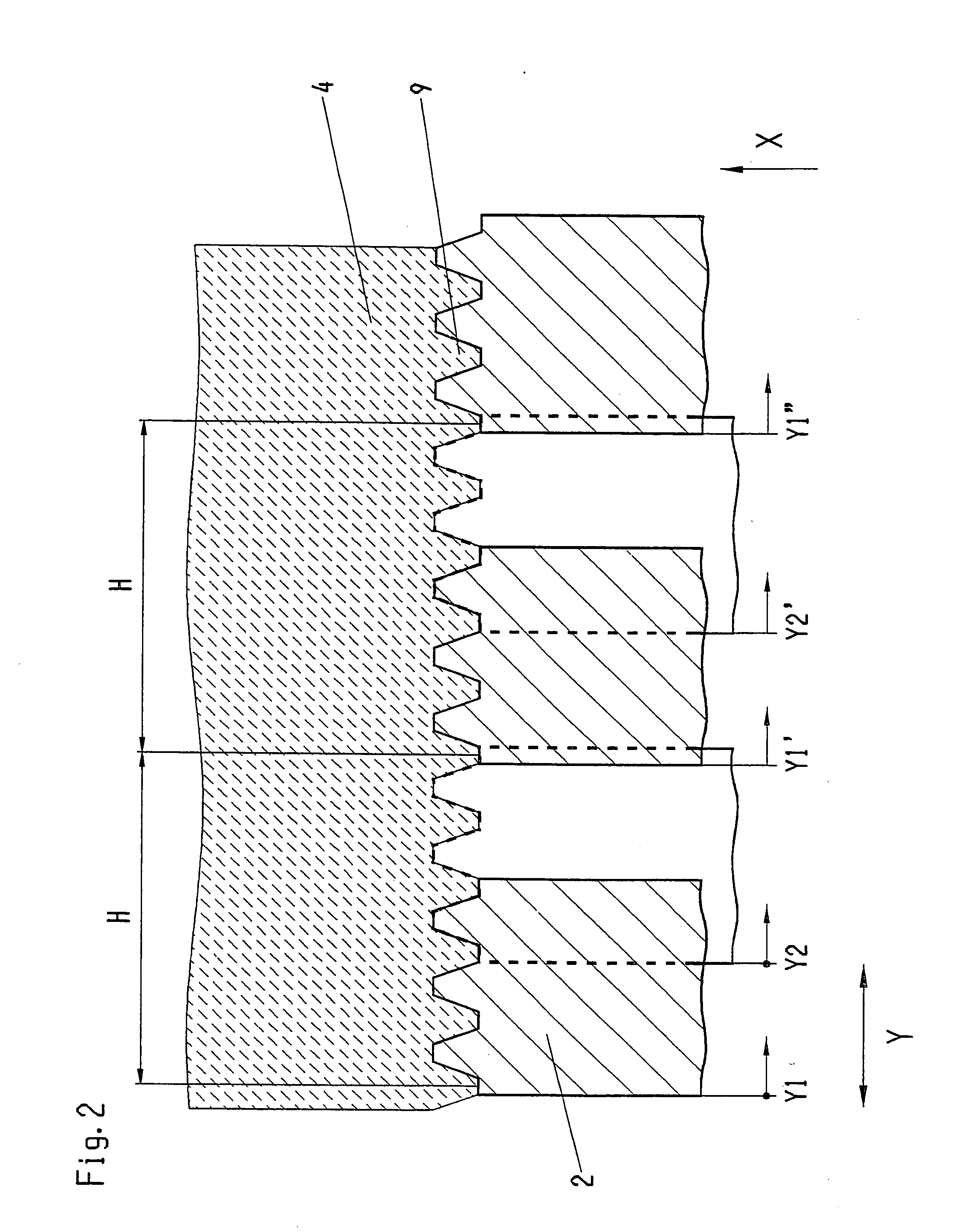

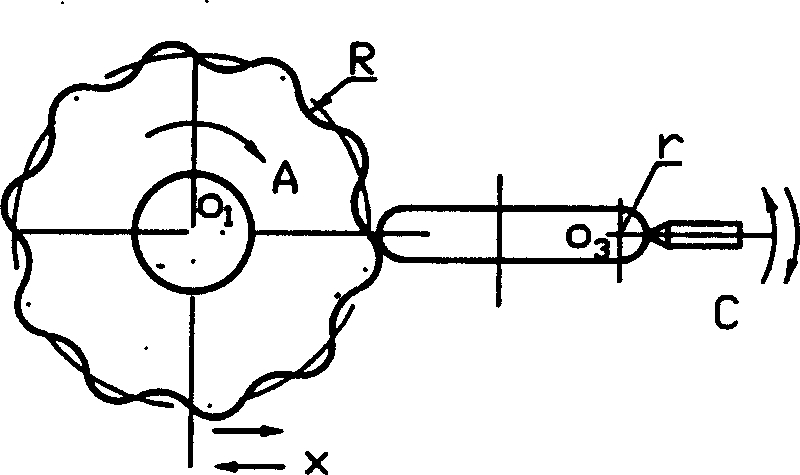

Process and dressing tool for the dressing of cylindrical grinding worms for the continuous generation grinding of gears

ActiveUS20050245176A1Improve accuracyGrinding feed controlAbrasive surface conditioning devicesCylindrical grindingGear tooth

A rotating dressing tool (2) coated with abrasive grains for profiling a multi-start grinding worm (4) for the continuous generation grinding of preferably small moduled gear teeth is provided with a stripping zone (6), a pre-profiling zone (7) and a finish profiling zone (8). After being swivelled into their dressing position about a swivel axis (F) at right angles to the axis of rotation of the dressing tool, the profiling zones are brought one after the other into engagement with the grinding worm (4). The number of profile ribs in the pre-profiling zone and finish profiling zone is equal to or greater than the number of thread starts on the grinding worm.

Owner:REISHAUER

Agitating Ball Mill

Agitating ball mill with a cylindrical grinding vessel comprising at least one grinding stock inlet and at least one grinding stock outlet wherein in the grinding vessel an agitating shaft connected with a drive is arranged which transmits a part of the drive energy to auxiliary grinding bodies which are loosely arranged in the grinding vessel and a separating device arranged in front of the grinding vessel outlet.

Owner:NETZSCH FEINMAHL TECH GMBH

Manufacturing method of milling cutter

The invention discloses a manufacturing method of a milling cutter. The manufacturing method of the milling cutter comprises the following steps: 1) performing cylindrical grinding on coarse steel; 2) performing heat treatment on blanks: performing low-temperature preheating at 555 to 565 DEG C and preserving heat for 2 hours, performing medium-temperature preheating at 855 to 865 DEG C and preserving heat for 20 minutes to 25 minutes, performing high-temperature heating at 1,295 to 1,305 DEG C and preserving heat for 110 seconds to 125 seconds, tempering for the first time at 560 to 575 DEG C for 2 to 3 hours, preserving heat for 2 to 3 hours and performing air cooling to room temperature, tempering for the second time at 560 to 575 DEG C for 2 to 3 hours and performing air cooling to room temperature, and tempering for the third time at 560 to 575 DEG C for 2 to 3 hours and performing air cooling to room temperature; 3) performing acid-washing treatment; 4) rolling a groove; 5) grinding cylindrical burrs; 6) annealing; 7) performing coarse cylindrical grinding; 8) edging; 9) performing fine cylindrical grinding; 10) performing surface treatment; 11) placing into engine oil, cooking for 6 hours and performing air cooling to room temperature; and 12) coating anti-rust oil to manufacture the finished product milling cutter. The milling cutter manufactured by the method is sharp and can be applied to fine machining.

Owner:SUZHOU SAN JUN TOOLS TECH CO LTD

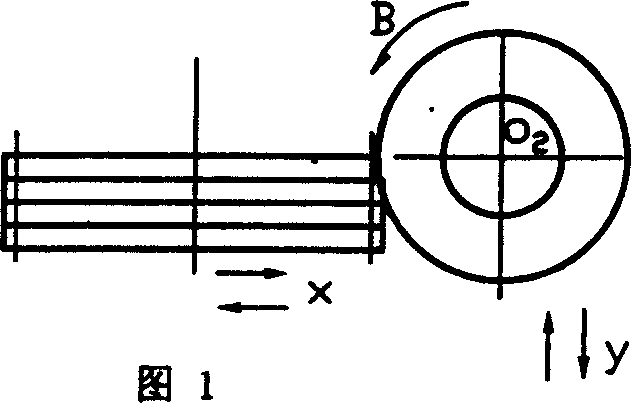

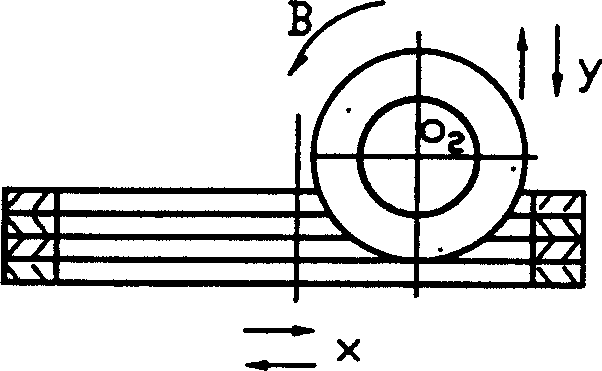

Digital controlled method for grinding teeth of cycloidal gear, and its appts.

A numerally controlled tooth grinding method for cycloid gear features that an abrasive disk is driven by a cranker-connecting rod mechanism to linearly reciprocate for forming an equivalent cylindrical grinding surface and the cycloid gear to be machined is driven by a dual-coordinate numerally controlling system controlled by microcomputer to shift and rotate, so enveloping whole tooth profile of cycloid gear.

Owner:CHONGQING UNIV

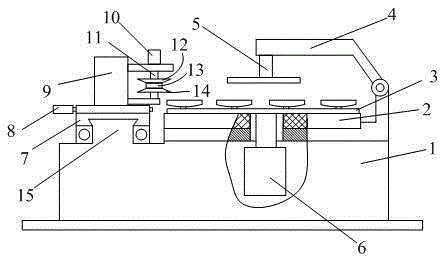

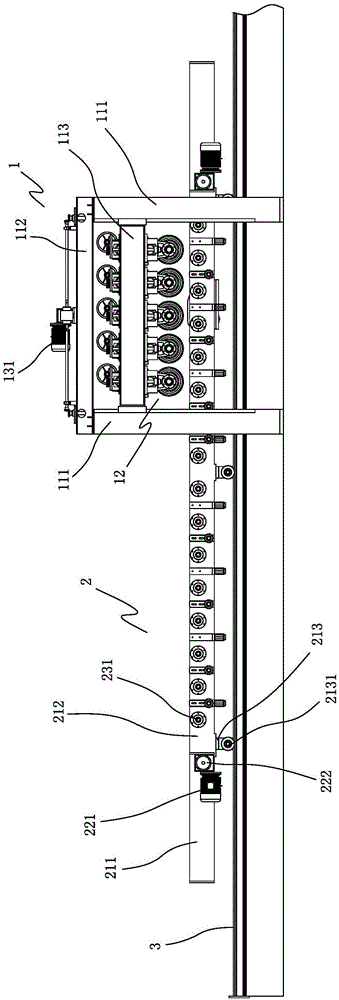

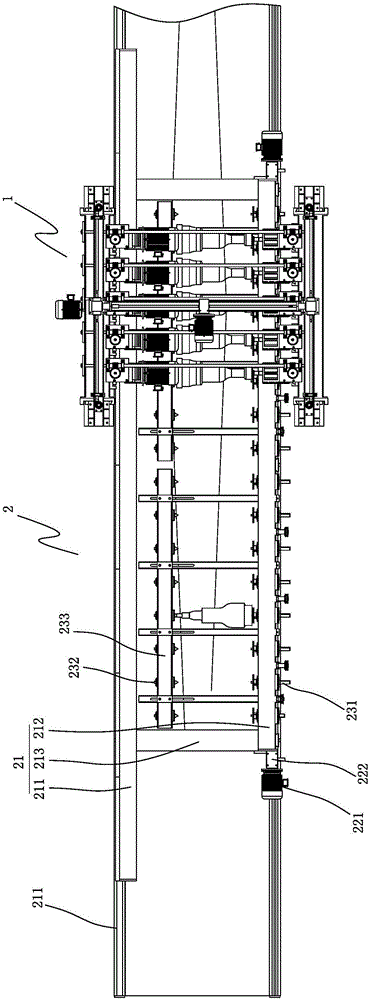

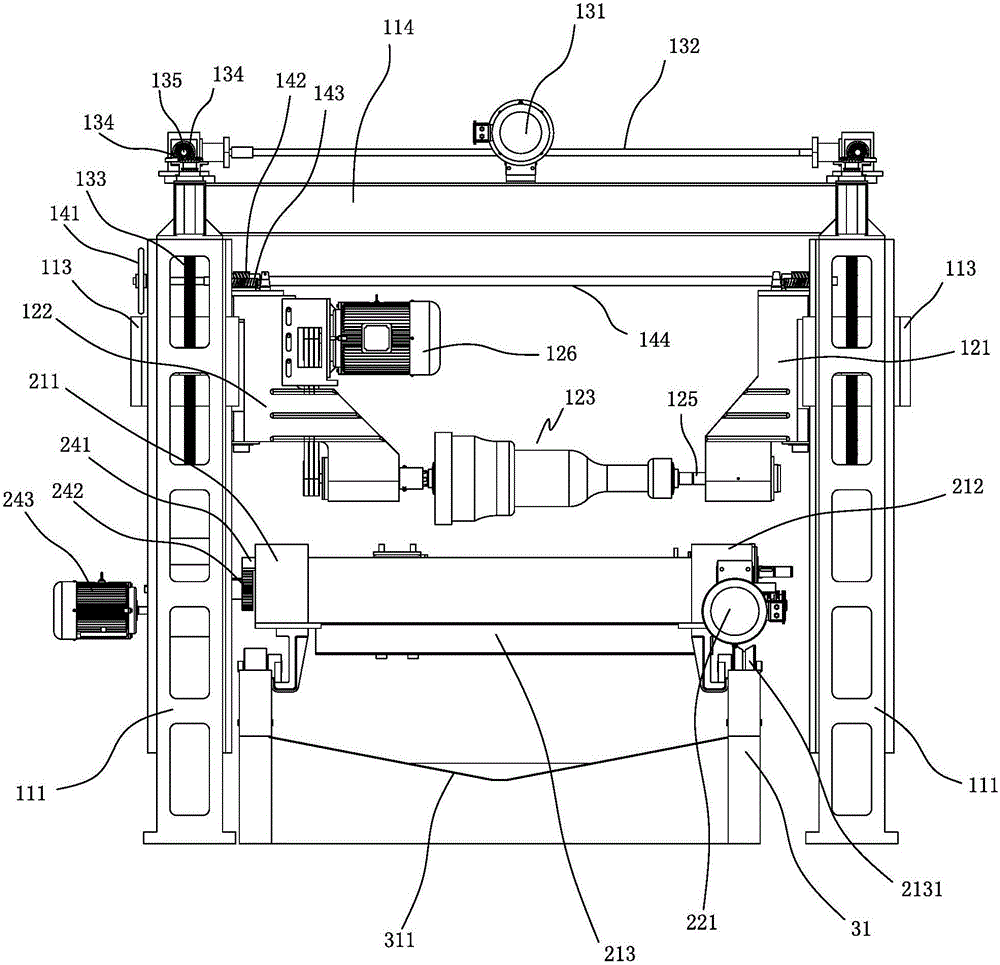

Grinding and polishing device and grinding and polishing machine

InactiveCN105081913AImprove grinding and polishing efficiencyIncrease productivityGrinding carriagesGrinding drivesDrive shaftEngineering

The invention discloses a grinding and polishing device and a grinding and polishing machine. The grinding and polishing device and the grinding and polishing machine are used for grinding and polishing the peripheral face of a cylindrical workpiece rotating around the axis of the workpiece. The grinding and polishing device comprises a knife rest, a driving shaft, a driven shaft, a main motor and a grinding tool. The driving shaft and the driven shaft are coaxially and oppositely arranged on the knife rest, and the main motor drives the driving shaft to rotate. The grinding tool comprises a knife shaft installed between the driving shaft and the driven shaft and a cylindrical grinding wheel fixedly arranged on the knife shaft. The outline of the peripheral face of the cylindrical grinding wheel is meshed with the outline of the peripheral face of the cylindrical workpiece. When the grinding and polishing device works, the knife shaft and the cylindrical workpiece are arranged in parallel, and the grinding wheel can be attached to the peripheral face of the cylindrical workpiece in a seamless manner to carry out grinding and polishing.

Owner:QUANZHOU JIANENG MACHINERY MFG

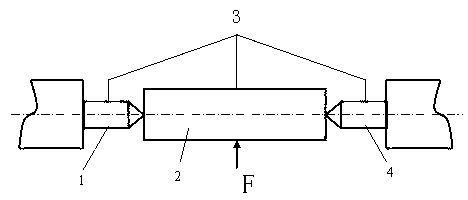

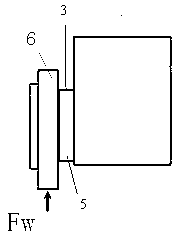

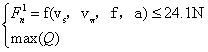

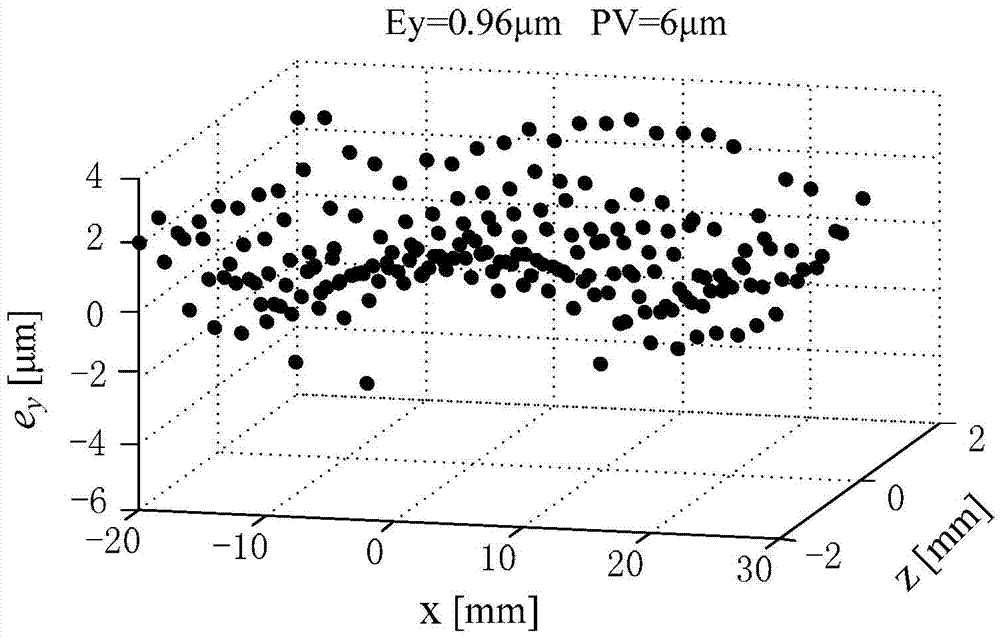

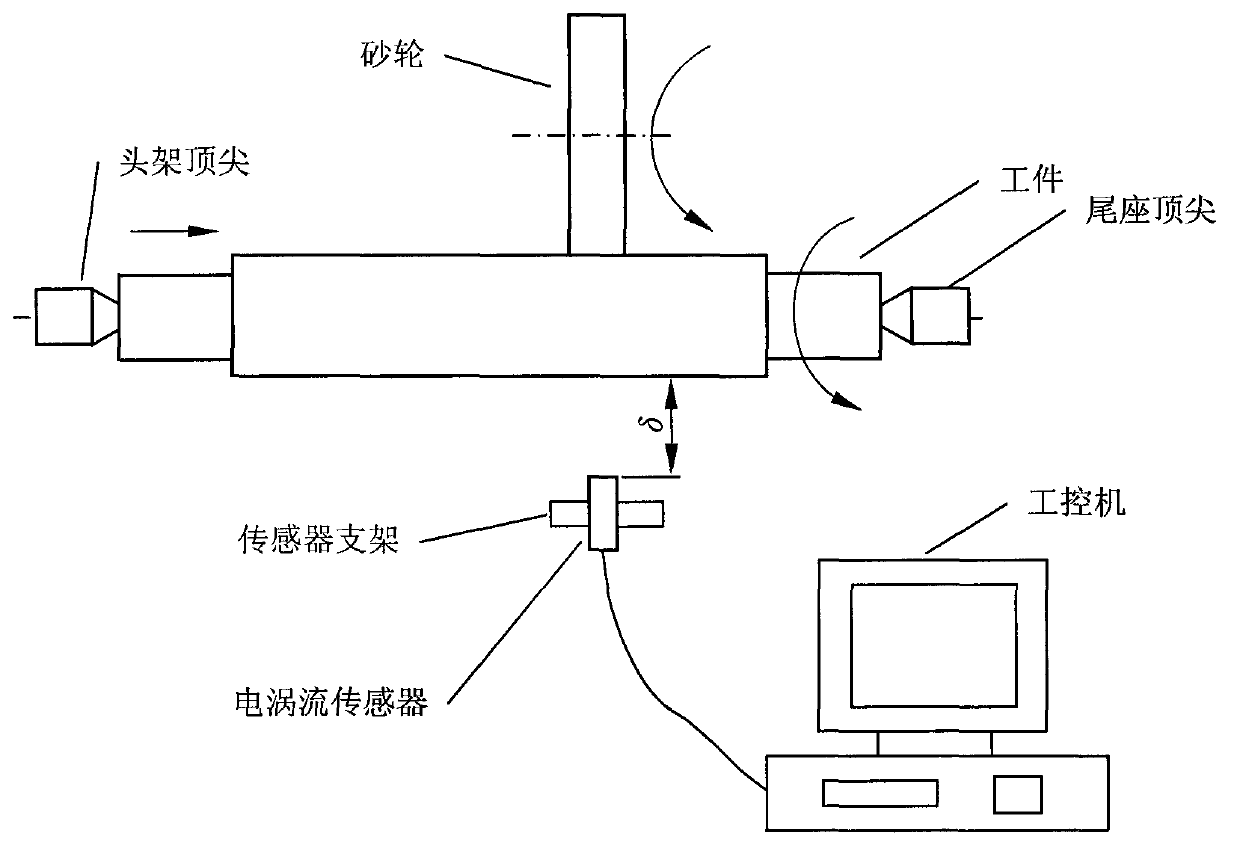

Stiffness-measurement-based optimization method for cylindrical grinding process parameters

InactiveCN103273387AGood grinding precisionGrinding Process Parameter OptimizationRevolution surface grinding machinesMaterial strength using tensile/compressive forcesEngineeringCylindrical grinder

The invention relates to a stiffness-measurement-based optimization method for cylindrical grinding process parameters. The method includes: 1, measuring machine tool static stiffness; 2, measuring grinding wheel spindle stiffness to optimize grinding process parameters. The method has the advantages that whether stiffness of a cylindrical grinder headstock, a tailstock center and a grinding wheel carriage system is satisfactory to the given grinding process parameters or not is analyzed; precision of ground workpieces is analyzed under certain grinding process parameters by measuring machine tool static stiffness and grinding wheel spindle stiffness according to a grinding force calculation formula so as to provide basis for the optimization of grinding process parameters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

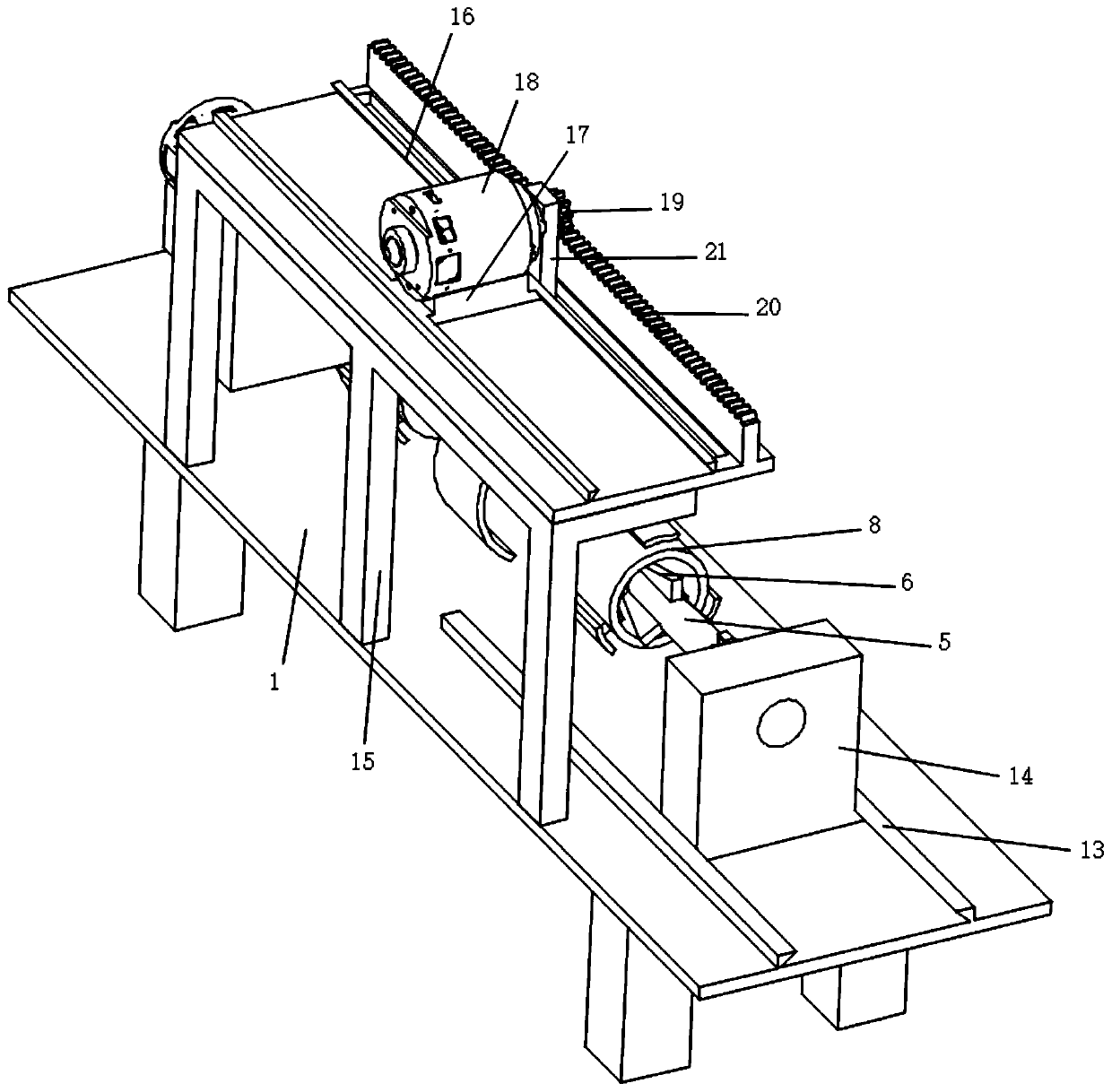

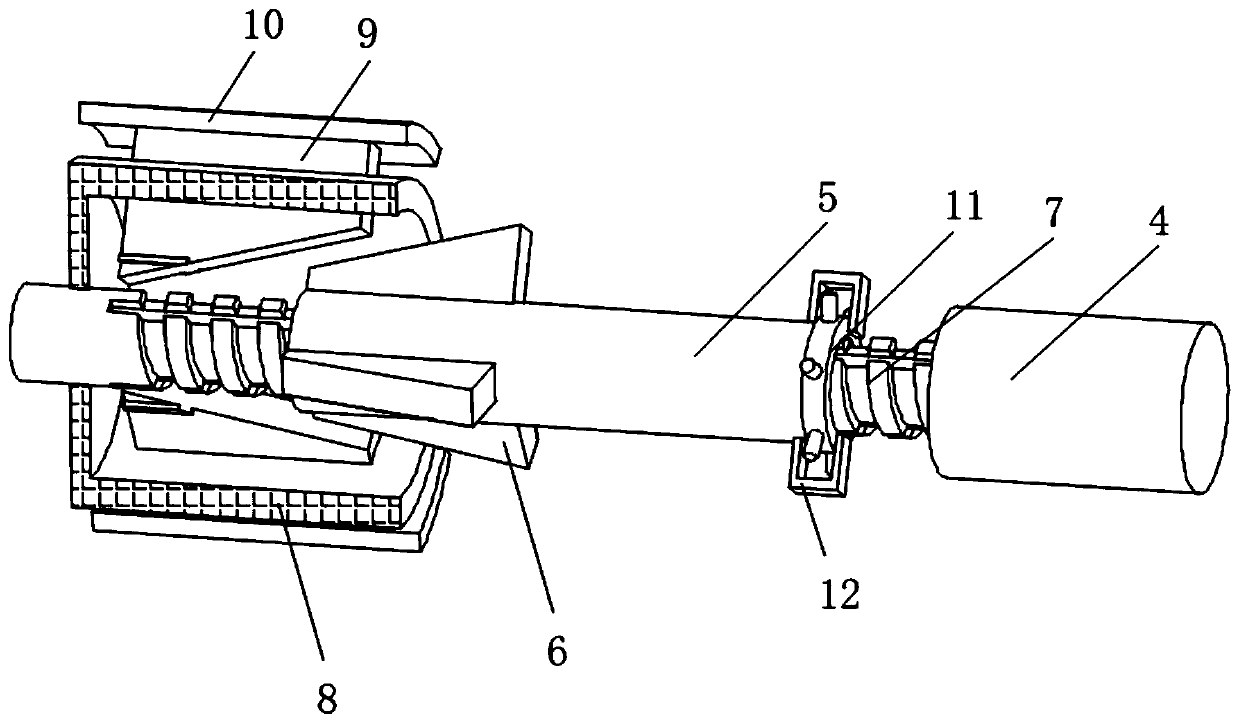

Cylindrical grinding device for hardware pipe fittings

InactiveCN110625452AEase of workImprove work efficiencyGrinding carriagesRevolution surface grinding machinesFixed bearingPipe fitting

The invention discloses a cylindrical grinding device for hardware pipe fittings, and relates to the technical field of grinding equipment. The cylindrical grinding device includes a supporting platform, a fixing block is fixedly installed on the right side of the top of the supporting platform, and a motor base is fixedly mounted on the right side of the fixing block; and a driving motor is fixedly mounted at the top of the motor base, a fixing bearing is fixedly mounted in the middle of the fixing block, and the fixing bearing movably sleeves an output shaft of the driving motor. According to the cylindrical grinding device for the hardware pipe fittings, an adjustment sleeve is driven to move left and right by rotating an adjustment lantern ring, so that an adjustment top plate outsidethe adjustment sleeve is driven to move left and right, because the top end of the adjustment top plate and the bottom end of a variable pitch top plate are inclined, when the adjustment top plate moves left and right, the adjustment top plate push the variable pitch top plate to move up and down in a pressing mode, the distance that the variable pitch top plate extends out is changed, the diameters of three locking plates are changed, and a round pipe sleeving the outside of the locking plates is clamped.

Owner:江门市中健金属制品有限公司

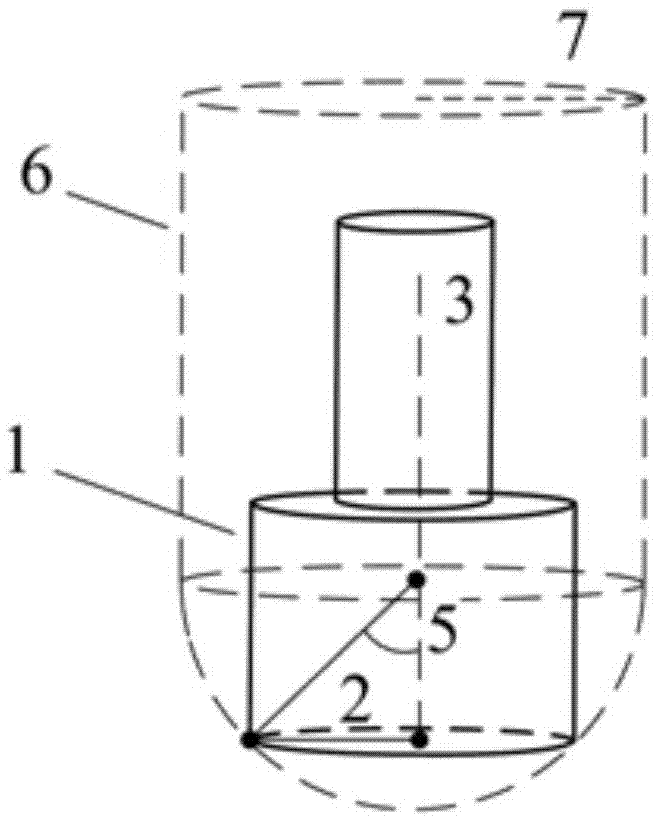

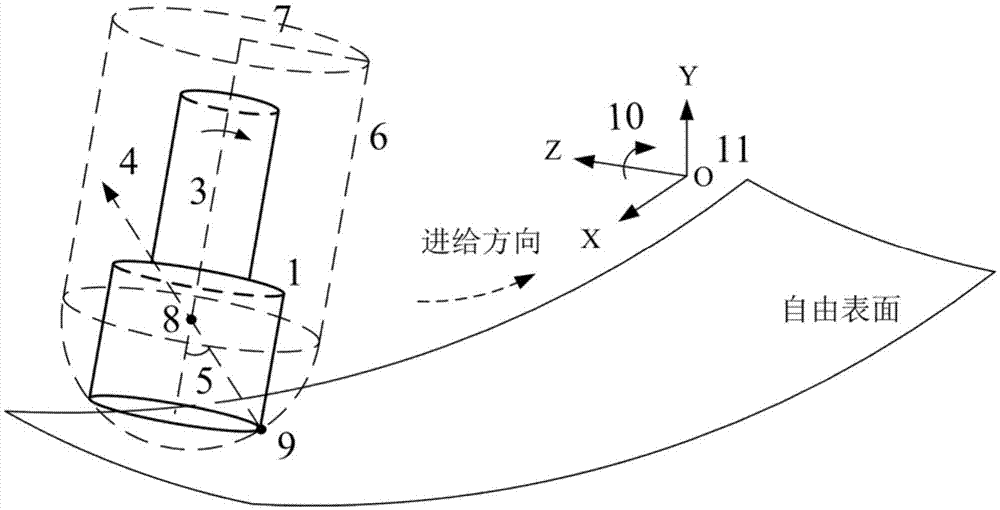

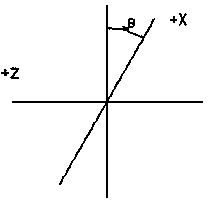

Method for curve surface grinding with cylindrical grinding wheel at virtual ball cutter radius

ActiveCN106853598AInterference handling is simpleImprove processing precisionGeometric CADOther manufacturing equipments/toolsRotational axisSurface roughness

The invention discloses a method for curve surface grinding with a cylindrical grinding wheel at a virtual ball cutter radius. The method includes the steps that 1, the attitude angle of the cylindrical grinding wheel is designed, and the inclination angle of the axis of the cylindrical grinding wheel on a curve surface tangency point normal vector is designed through a virtual ball cutter model; 2, a cutter path is planned and determined according to the curved surface tangency point normal vector and the virtual ball cutter model, and the set inclination angle in the step 1 is guaranteed through a rotating shaft of a machine tool; 3, by the adoption of an axial feeding mode, a workpiece is subjected to grinding machining according to the cutter path. The cylindrical or quasi-cylindrical grinding wheel can be used for four-axis machining of a free curved surface, and the method has the advantages that planning of the cutter path is simple and flexible, the precision of a machining shape is high, and surface roughness is low, and is suitable for machining free curve surfaces of optical glass and other hard brittle materials.

Owner:SOUTH CHINA UNIV OF TECH

Method for polishing circular stainless-steel accurate parts on old machine tool

InactiveCN101367191AImprove polishing effectChange sizePolishing machinesAcute angleCylindrical grinding

The invention provides a method for polishing an annular stainless steel precise part in an old machine tool, which is applied to the mechanical manufacturing industry. On the premise of not influencing the precision of the dimension of the prior part, the method can ensure that the surface of the part achieves higher luminance brightness and keeps a necessary acute angle. The method is characterized in that a specially-made polishing rod is used; one end of the polishing rod is clamped on a three-claw chuck of a mainshaft of an old cylindrical grinding machine or a common lathe; after spacer rings and a plurality of polished parts are sleeved on the polishing rod, and limit sleeves are mounted; a loose clamp arranged on a tail rack of the machine tool tightly clamps the other end of the polishing rod; a soft cloth polishing wheel is arranged on a grinding wheel machine and is positioned between the three-claw chuck and the loose clamp; after the startup, the soft cloth polishing wheel and the polishing rod clamped on the three-claw chuck rotate along clockwise direction; and the position of the soft cloth polishing wheel rotating at high-speed and the acting force between the soft cloth polishing wheel and the polished part are adjusted so as to implement the inner, the outer and the bilateral soft polishing to the polished part between the three-claw chuck and the loose clamp, thereby achieving the aim of polishing.

Owner:江苏星河集团有限公司 +1

High-precision rectangular spline shaft manufacturing process

The invention relates to the technical field of spline shafts, in particular to a high-precision rectangular spline shaft manufacturing process. According to the high-precision spline shaft manufacturing process, first, materials are selected, namely, 40Cr materials (selected according to the requirement) are adopted; second, rough turning machining is conducted on the spline workblank; third, thermal refining is conducted, wherein the rigidity HB is 250-280, and spline shaft core strength is improved; fourth, digital controlled lathe semi-finish turning is conducted, wherein a reserved bearing block margin is 0.3-0.5mm; fifth, spline rolling is conducted, namely, a spline milling machine for a grinding hob is used for machining the spline width and the bottom diameter, the margin of 0.3-0.4mm is reserved; sixth, quenching (heating processing) is conducted, namely, high-frequency quenching is adopted at the spline position, the rigidity HR is 48-53, and the rigidity of the spline position is improved; seventh, external diameter grinding of a cylindrical grinding machine is conducted (drawing technical requirements are met as needed); eighth, spline grinding is conducted, namely, a molding gear grinding machine is adopted, and a grinding wheel is corrected; ninth, the spline size is detected. The high-precision rectangular spline shaft manufacturing process improves the precision of the spline shaft, and improves working efficiency.

Owner:常州市格里森前进齿轮有限公司

Air-cooling type grain husking grinder

InactiveCN107175151ABlowout preventionAvoid damageGrain huskingGrain polishingElectric machineArchitectural engineering

The invention discloses an air-cooled grain husking grinder, which comprises a machine case, a material inlet, a first motor, a second motor, a material outlet and a pillar; the upper surface of the machine case is fixedly connected with a first motor, the first motor The shaft extension end is fixedly connected with the rotating shaft, the rotating shaft is fixedly connected with the fixed rod, the fixed rod is covered with a roller, the lower part of the roller is provided with a sieve plate, the lower part of the sieve plate is provided with an outer grinding cylinder, and the inside of the outer grinding cylinder is provided with a Inner grinding cylinder, the lower surface of the case is fixedly connected with the second motor, the shaft extension end of the second motor is fixedly connected with the grinding shaft, the outer wall of the case is covered with a cooling box, the inner wall of the cooling box is fixedly connected with a spiral plate, the side of the pillar The wall is fixedly connected with a blower, which uses the roller to crush and shell the grain on the sieve plate. The inner grinding cylinder cooperates with the outer grinding cylinder to grind the grain. The grinding contact area is large and the grinding effect is good; the blower blows air into the cooling box , to cool the chassis.

Owner:宋衡星

Machining method of flange

InactiveCN105563029AGuaranteed machining accuracyEasy to processFlanged jointsEngineeringCylindrical grinding

The invention relates to the field of flange machining, in particular to a machining method of a flange. Firstly, one end face and one outer circle of a workpiece are roughly turned, after a center hole is drilled, broached and reamed, the other end of the flange is clamped, operation is turned around, and the other end face and the other outer circle of the workpiece are roughly turned; one end face and one outer circle of the workpiece are turned in a semi-finish manner and are chamfered, operation is turned around, and then the other end face and the other outer circle of the workpiece are turned in a semi-finish manner and are chamfered; grooving is performed on the workpiece, and the two side faces of the large end of the workpiece are turned in a finish manner; six through hole contour lines are drawn, and holes are drilled; the outer cylindrical face of the small end of the workpiece is positioned, and the outer cylindrical face of the other side of the workpiece is ground through an M1420A outer cylindrical grinding machine; operation is turned around, the outer cylindrical face of the other small end of the workpiece is positioned, and the outer cylindrical face of the small end of the workpiece is ground through the M1420A outer cylindrical grinding machine; key grooves are slotted though a slotting machine; and after machining ends, flange parts are blued, and then the parts are inspected and put in storage. By means of the machining method of the flange, the machining process is simple, the machining precision of the workpiece can be guaranteed, and production efficiency is improved.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

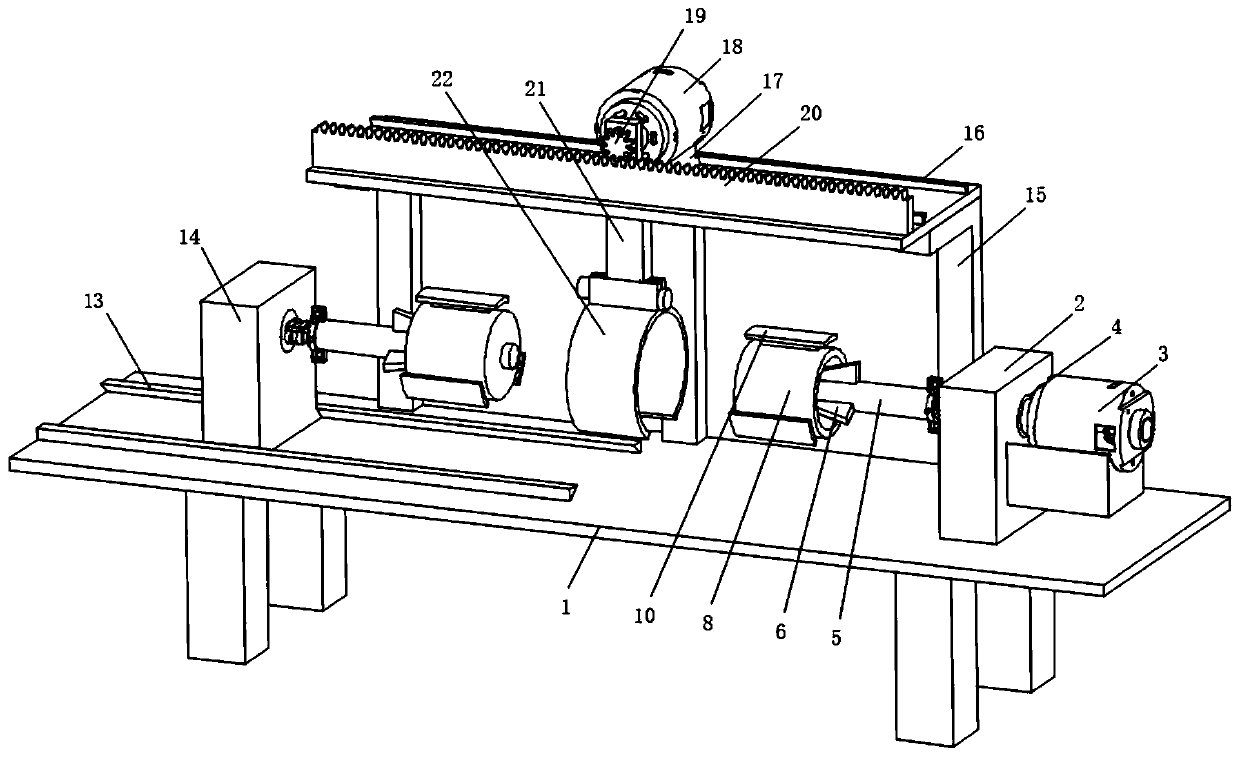

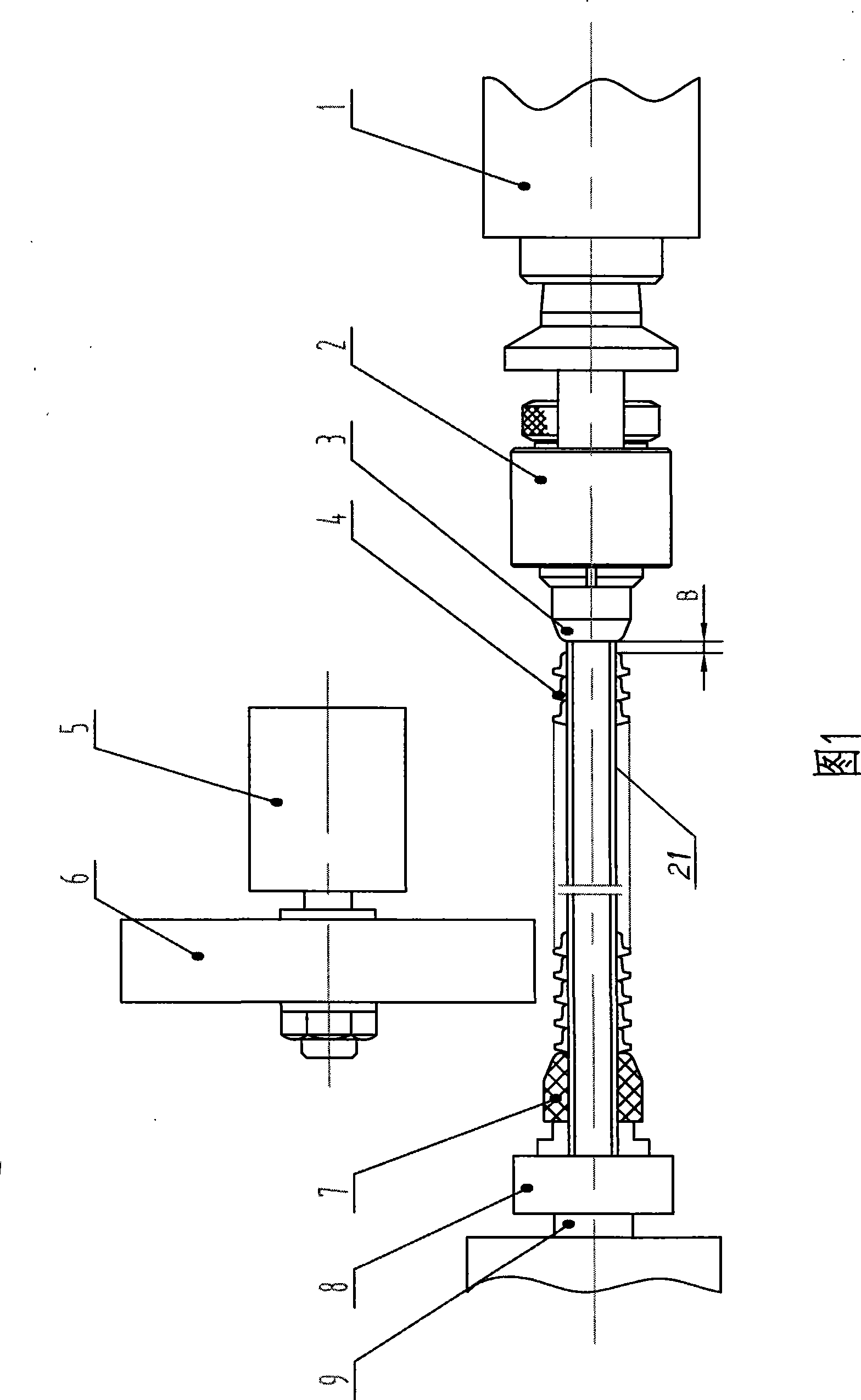

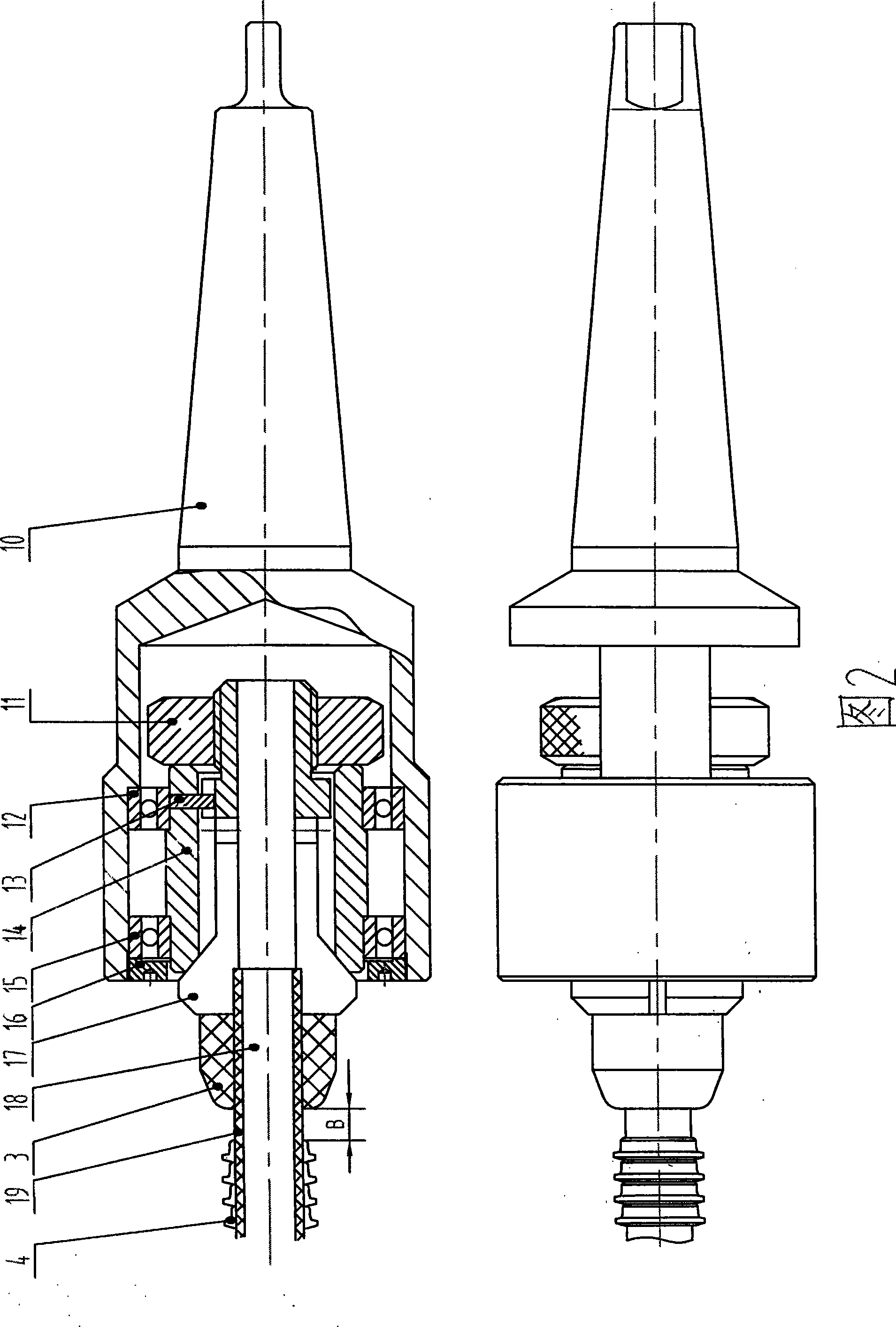

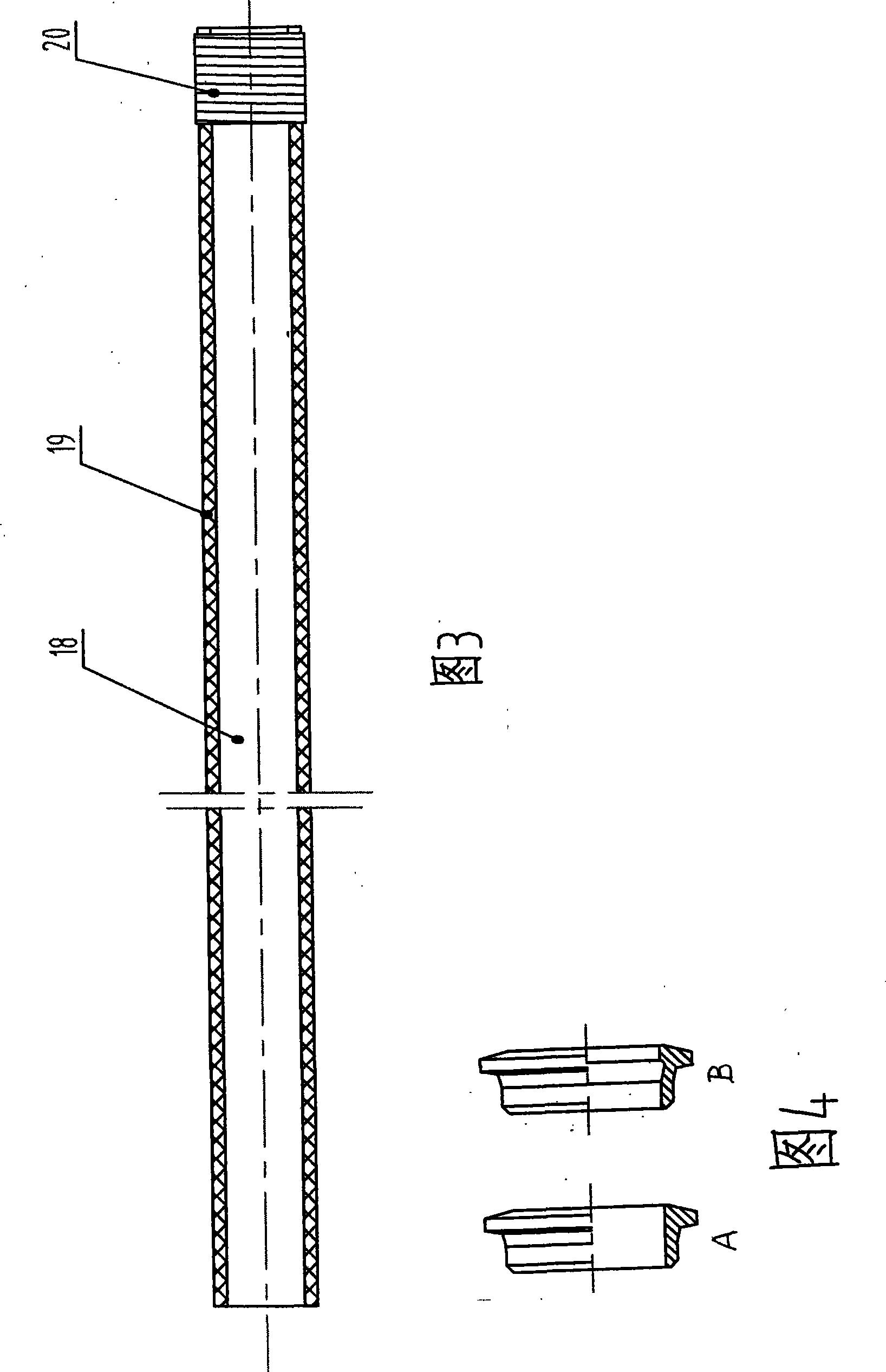

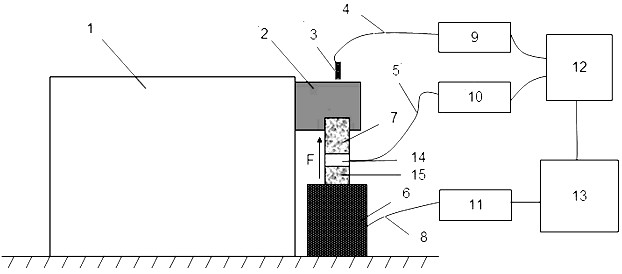

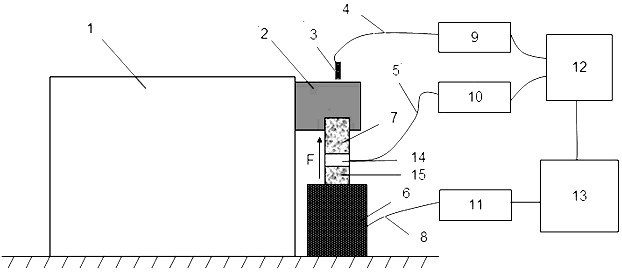

Rigidity measuring device for grinding carriage spindle of cylindrical grinding machine

InactiveCN102692321AEffective measurement of stiffnessImprove quality and efficiencyMachine part testingHydraulic cylinderEngineering

The invention relates to a rigidity measuring device for a grinding carriage spindle of a cylindrical grinding machine. The rigidity measuring device comprises an eddy current displacement sensor, a hydraulic cylinder driver, a force application rod, a hydraulic cylinder controller, a force sensor, a propelling rod and the like. The force application rod is arranged under the grinding carriage spindle, the propelling rod and the hydraulic cylinder driver are connected under the force application rod, the hydraulic driver is connected with a computer signal output end by the hydraulic cylinder controller; and the force sensor is arranged between the force application rod and the propelling rod, the eddy current displacement sensor is arranged on the grinding carriage spindle, the eddy current displacement sensor and the force sensor are respectively connected with an A / D collection card signal input end by an eddy current sensor signal processor and a force sensor signal processor, and an A / D collection card signal output end is connected with a computer signal input end. The device can conveniently measure the rigidity of different grinding carriage spindles, analyze dynamic characteristics of different grinding carriage spindles through comparison of experiment test results, and effectively provide grinding efficiency and grinding quality of a grinding workpiece.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method and device for detecting cylindrical grinding surface roughness through data fusion technology

InactiveCN103659602AImprove completenessImprove efficiencyGrinding feed controlUsing electrical meansProcess systemsGrinding test

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

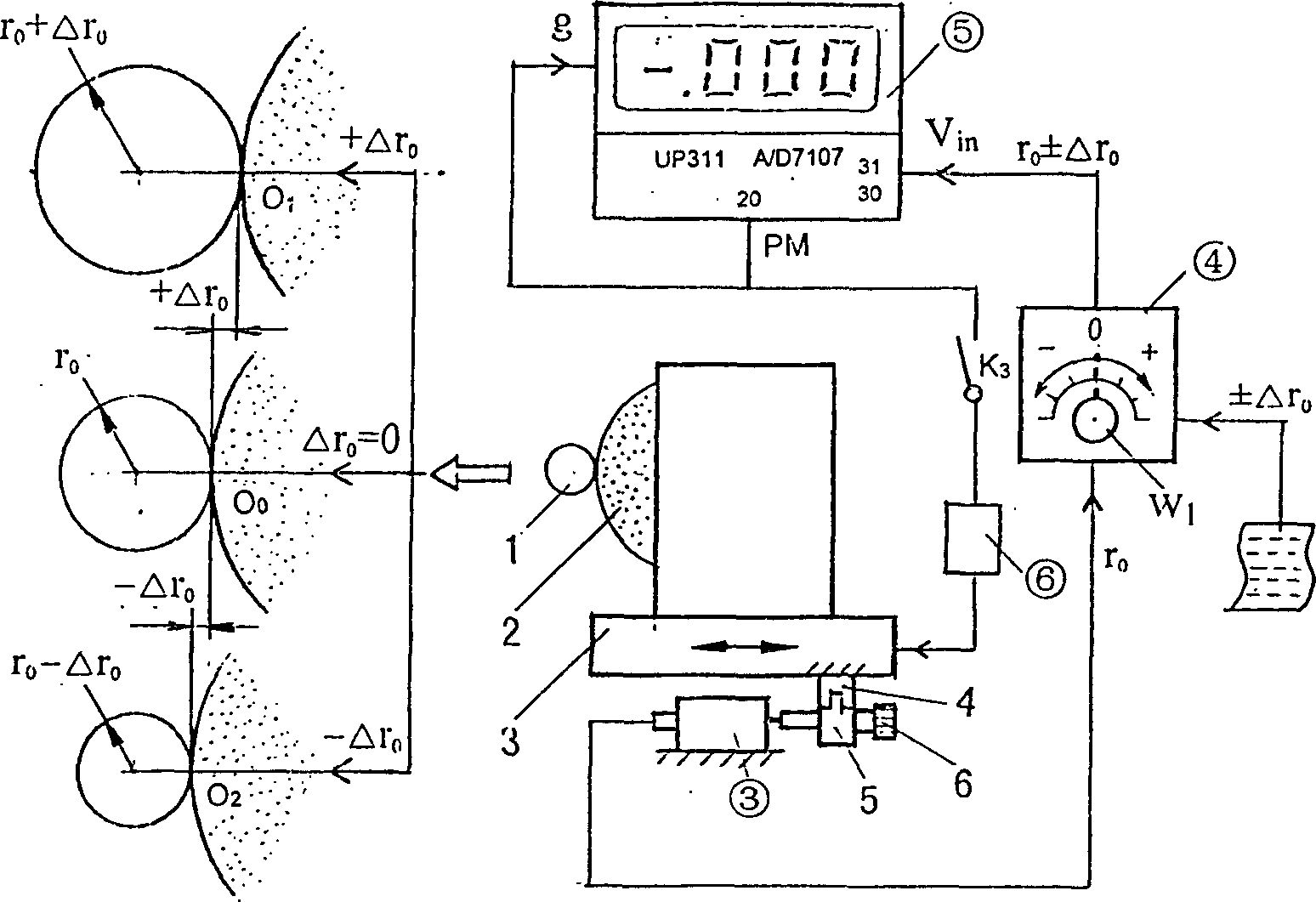

Automatic locating and grinding method for general cylindrical grinding machine

InactiveCN1857863AAvoid mutual interferenceGuaranteed flexibilityRevolution surface grinding machinesGrinding feed controlCylindrical grindingAutomatic testing

The automatic locating and grinding method in general cylindrical grinding machine includes the following steps: fixing the mandrel through rotating arm and rack onto the wheel slide for shifting, fixing the sensor to machine bed and connecting electrically to the differential rectifier circuit, connecting the power interface electrically to the electric executor of the grinding machine and the digital panel meter through a switch; cutting off the switch via setting the potentiometer to 0 position, trial grinding one axial diameter to determine the basic paired grinding radius and the escape point; and regulating the potentiometer to increase or decrease the machined radius. The said method can grind ideal paired ground parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

In-grinding coordinate automatic compensation method based on end face cylindrical grinder

The invention relates to an in-grinding coordinate automatic compensation method based on an end face cylindrical grinder. The method comprises the steps that when a coordinate system is established each time, difference values of target coordinates and mechanical coordinates are stored in a macro-variable, digital-controlled macro-variable memory coordinates are used for compensation amount and grinding wheel conditioning compensation amount, programs are called for computing coordinate values again each time a machine is started, and workpiece coordinates are automatically compensated; when coordinates are set manually, difference values before and after coordinate compensation are stored in the macro-variable, adding with grinding wheel diamond coordinates is carried out, and new diamond coordinates and grinding wheel frame safe position coordinates are computed; a measuring instrument is used for sending a signal to a CNC in a first gear for grinding multi-gear workpieces, a jumping-switching instruction is used in a program, accumulating is carried out on the measuring instrument compensation value each time, and the measuring instrument compensation values are stored in the macro-variable and are marked as measuring instrument accumulating compensation values; and before next grinding, the measuring instrument accumulating compensation values are subtracted from the first-time-established coordinate values. According to the method, errors caused by lathe repeated locating accuracy and grinding wheel loss can be automatically compensated during a grinding process.

Owner:SHANGHAI MACHINE TOOL WORK

Shaft part double-wheel symmetrical grinding device and process

The invention relates to a shaft part double-wheel symmetrical grinding device and process. The process includes: machining a workpiece on an excircle grinder to Ra0.40, leaving a machining allowance of 0.008-0.12mm, fixing a fixing piece during grinding, screwing a pressure-adjusting bolt compression spring, enabling grinding wheels to contact a workpiece surface to be ground, winding a lead screw, and enabling two grinding wheels to generate transverse feed; when the pressure of the spring on the workpiece is 2-3kg, stopping the transverse feed, starting a lathe, enabling the workpiece to rotate at the speed of 80-150 turns / minute, driving the two grinding wheels to rotate, starting a large carriage, enabling the large carriage to move vertically along a lathe track and drive the grinding wheels to move vertically together, controlling the moving quantity in the way that the grinding wheels move 2-3 mm vertically when the workpiece rotates a circle, washing through aviation gasoline till the workpiece surface roughness parameter meets the technical requirement, detaching the workpiece, and finishing grinding. The shaft part double-wheel symmetrical grinding device and process has the advantage that the process is simple, the roughness can be lower than Ra0.012, and efficiency is high.

Owner:江西铜业集团(德兴)铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com