Patents

Literature

873 results about "Contact friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

When we try to slide one object over another, we find that there is a force which opposes the motion. This force is called friction. Whenever there is relative motion of two surfaces in contact, there is frictional resistance.

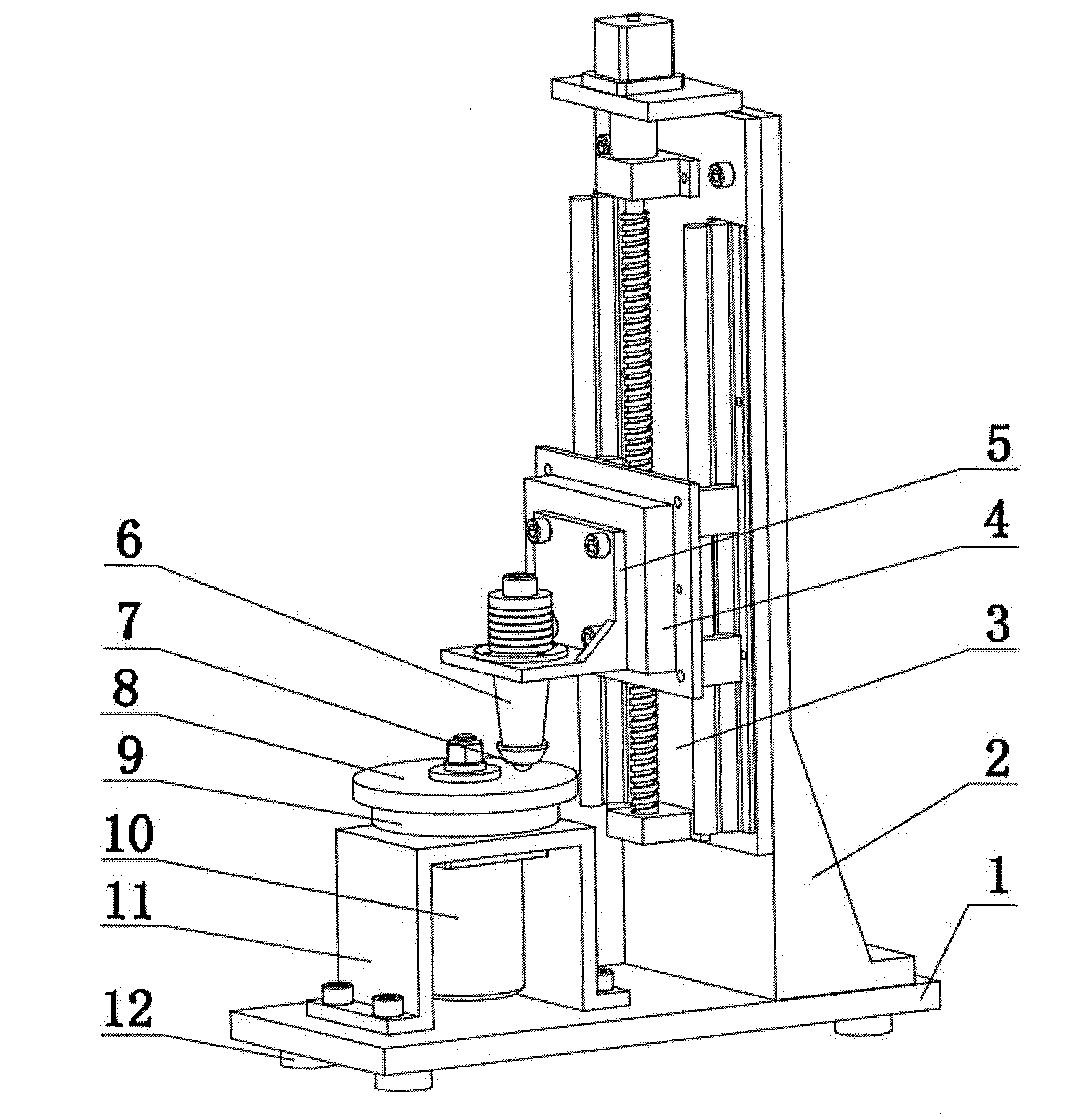

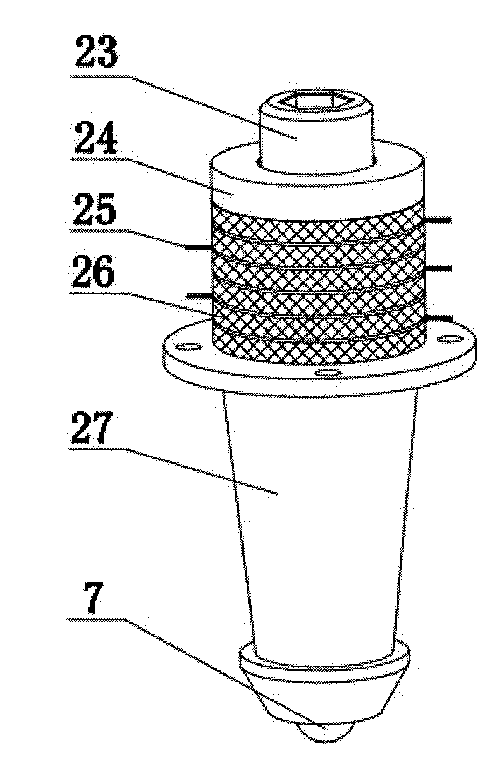

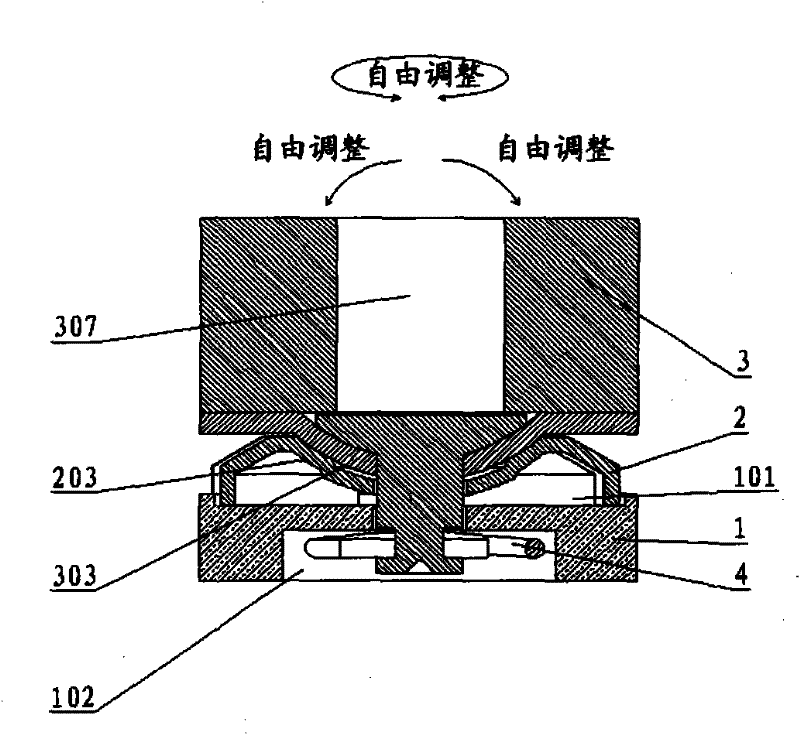

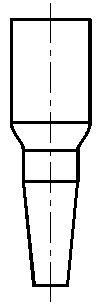

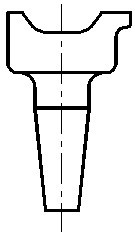

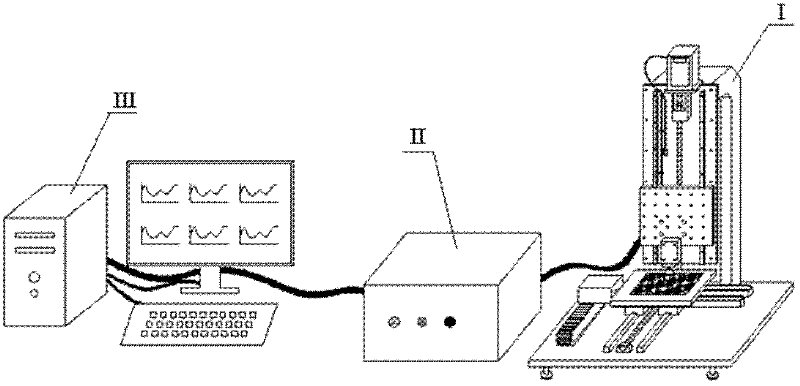

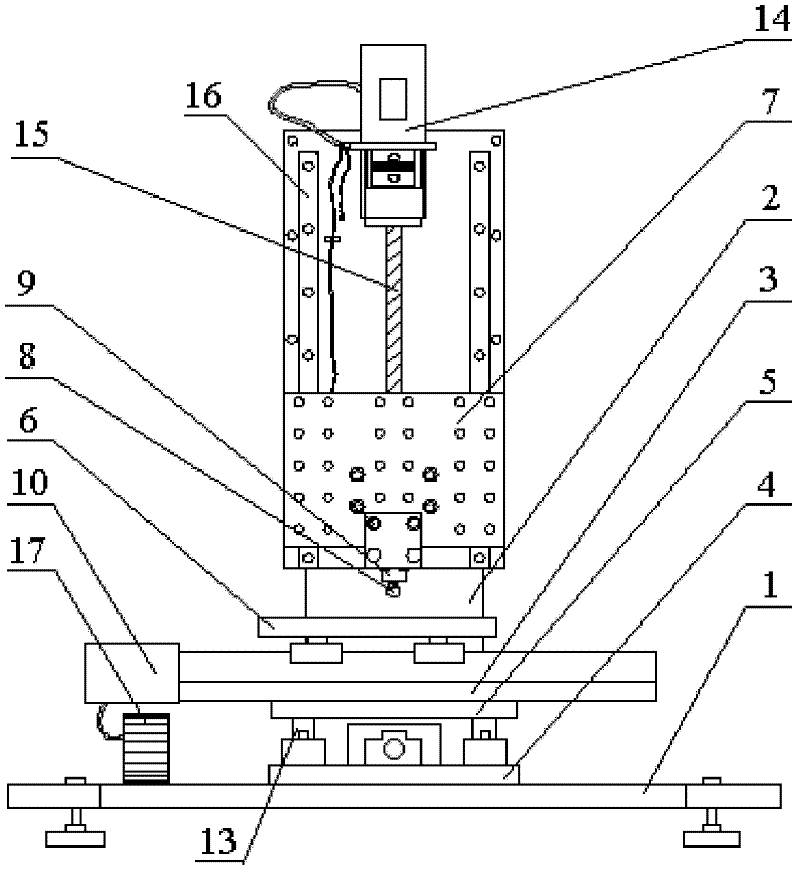

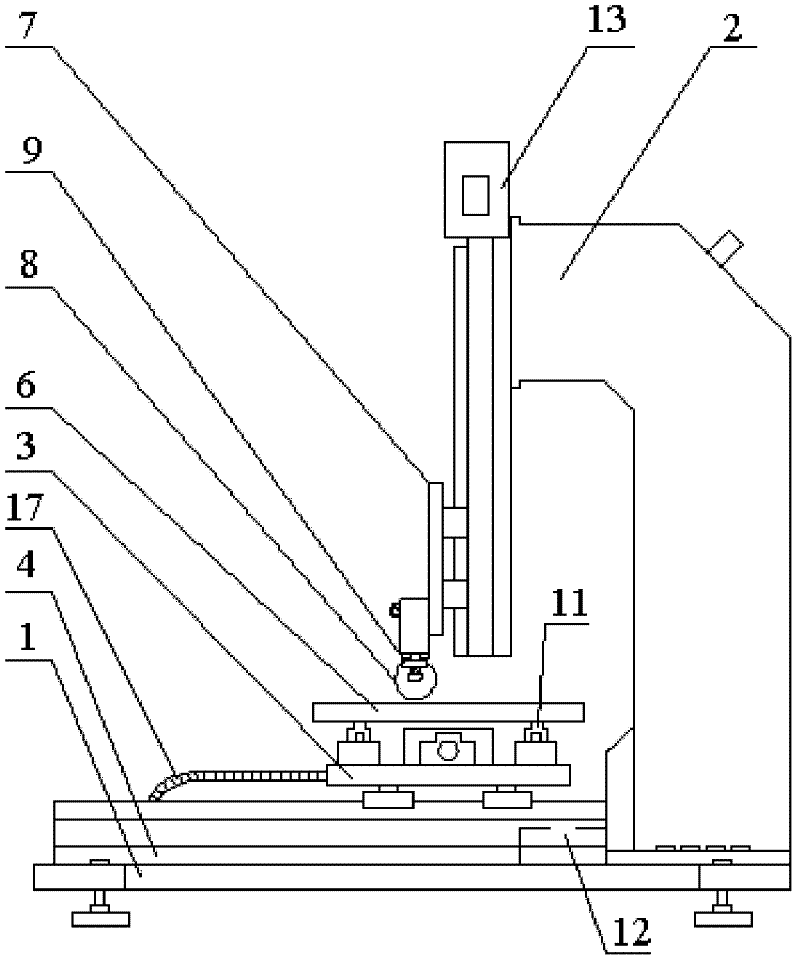

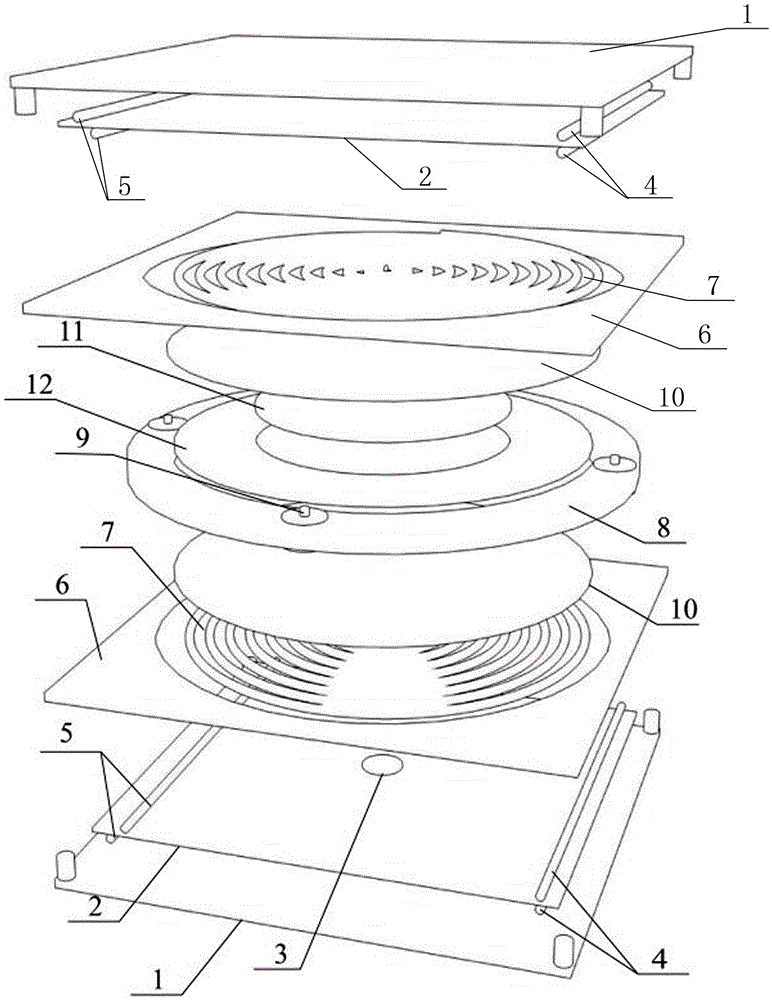

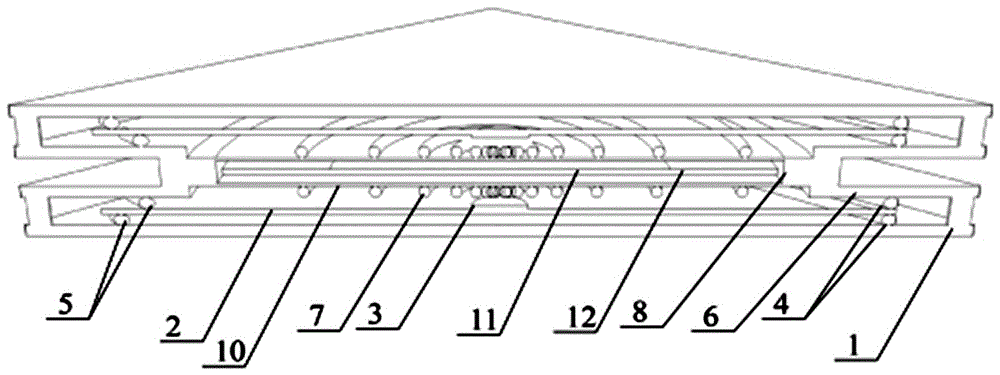

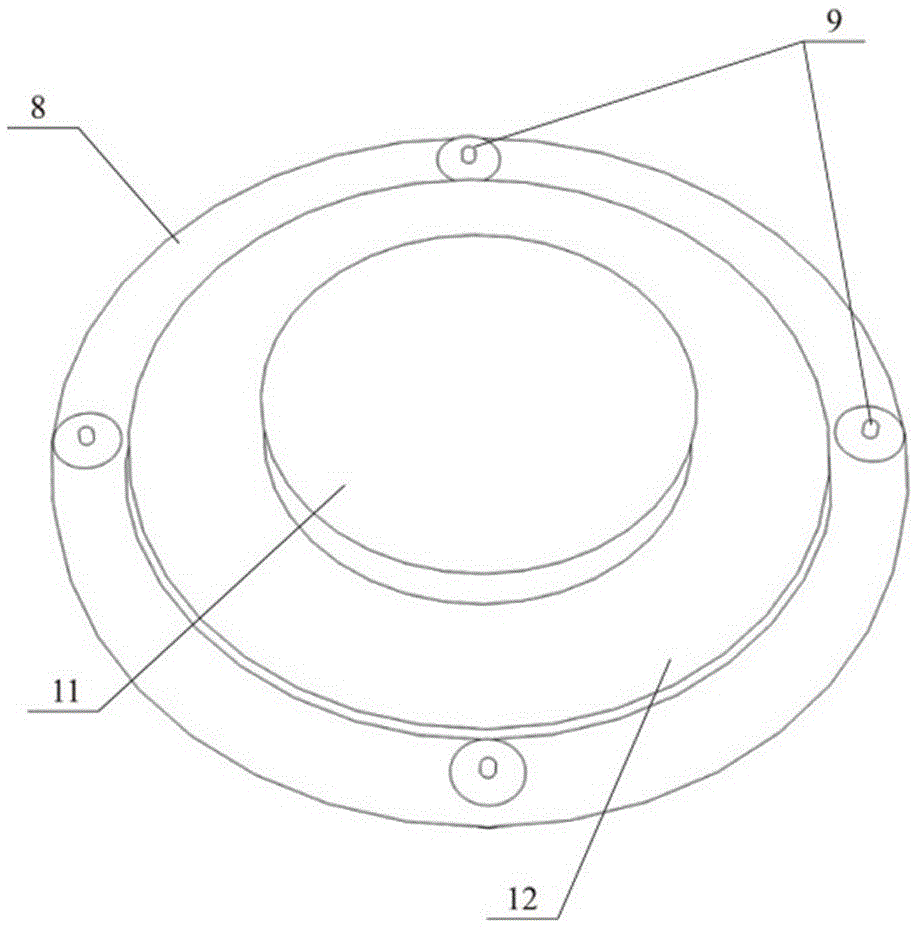

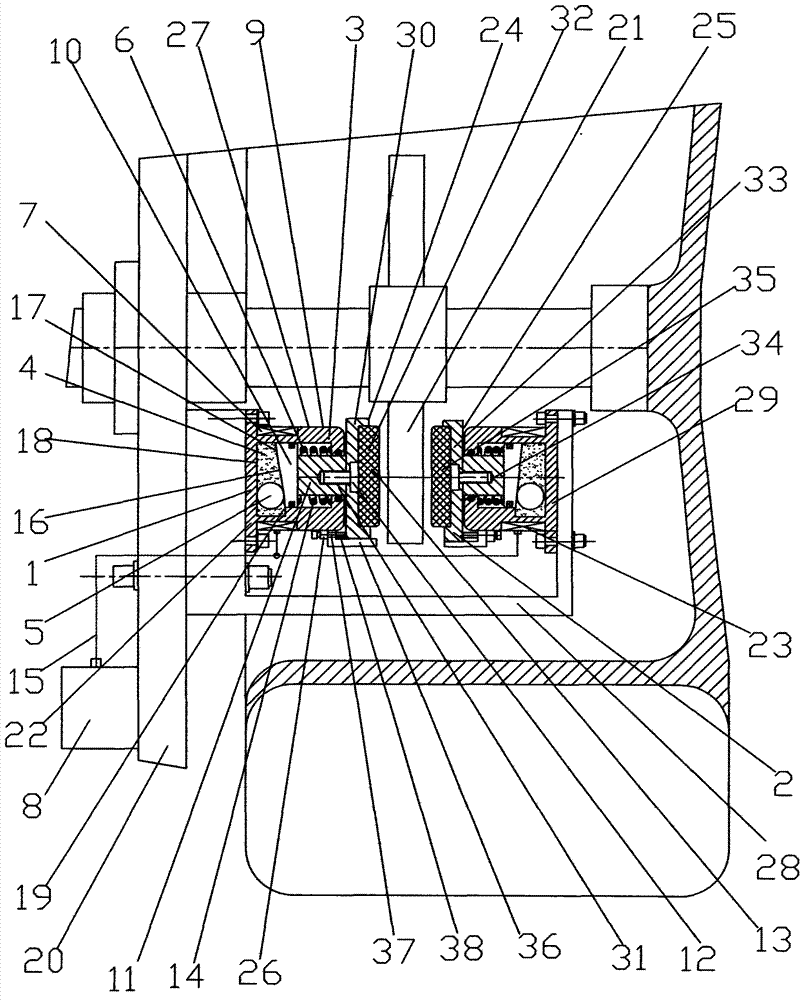

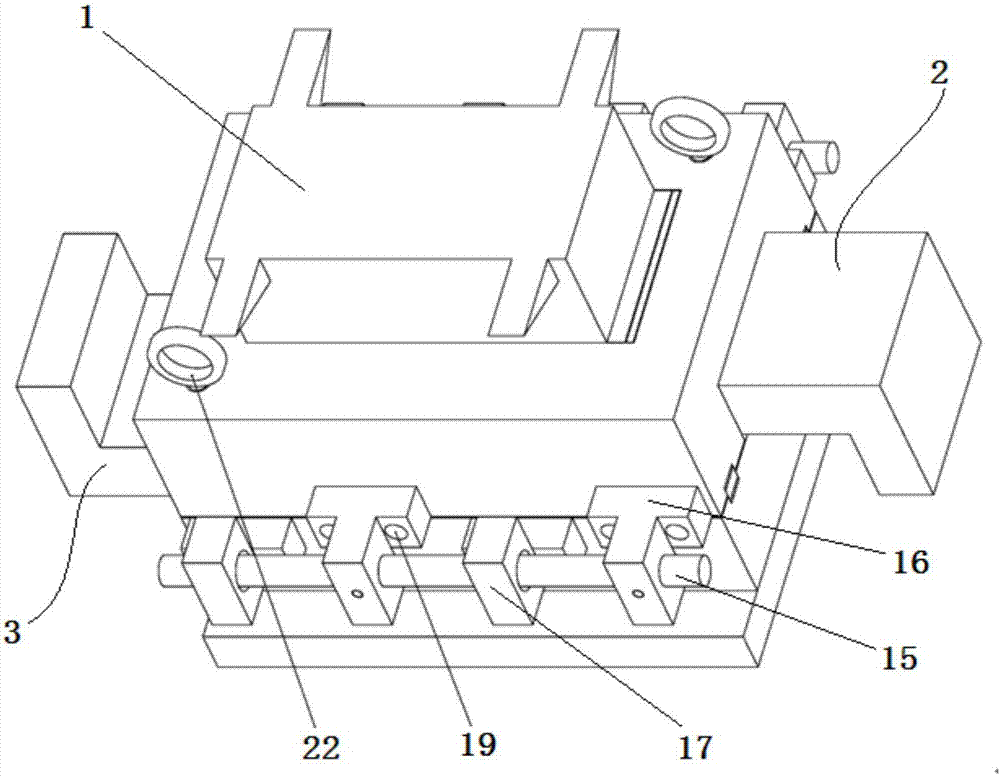

Spherical contact type friction characteristic testing device under ultrasonic vibration

InactiveCN103278411APrecise control of test parametersHigh degree of automationUsing mechanical meansInvestigating abrasion/wear resistanceRotary stageVibration amplitude

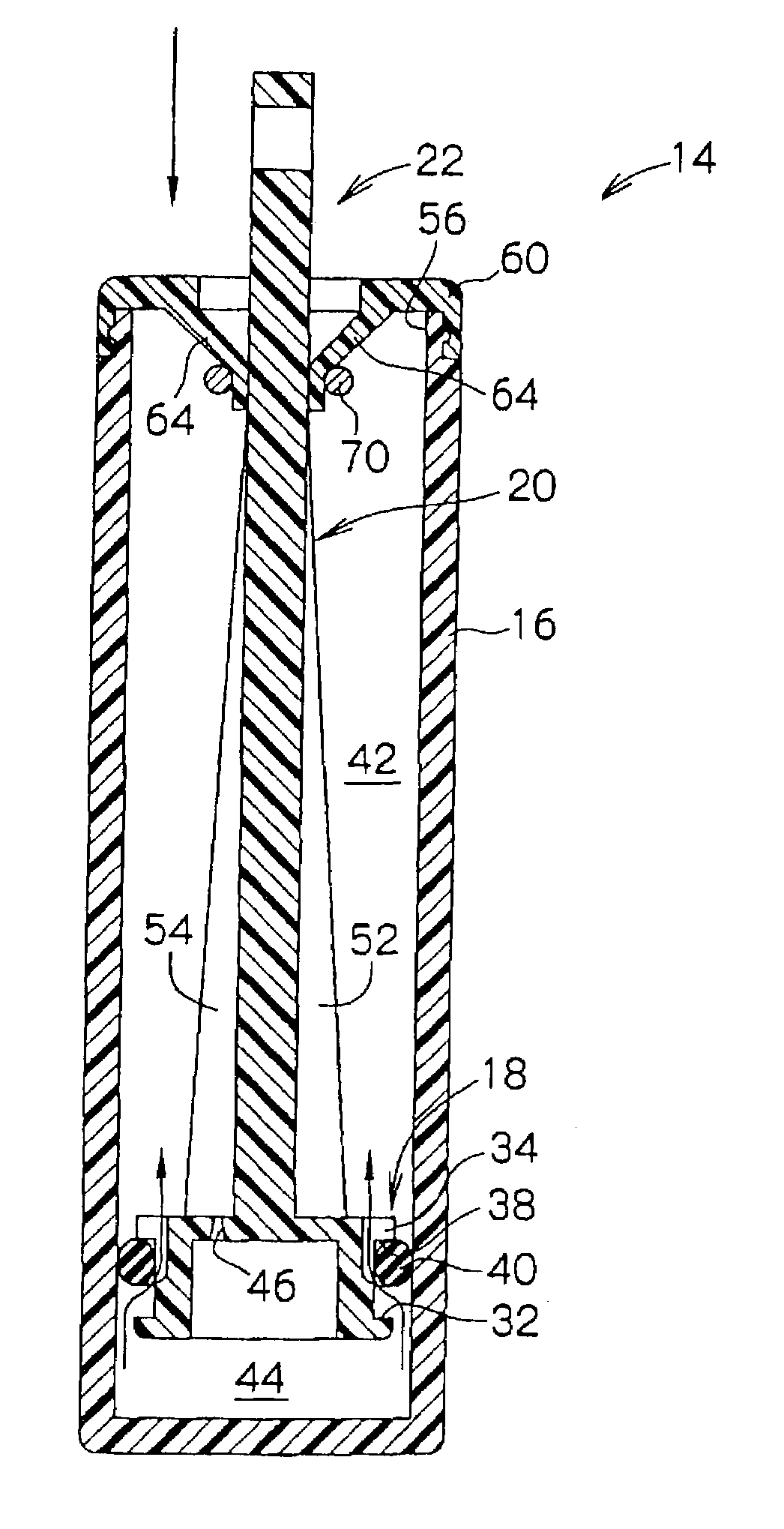

The invention discloses a spherical contact type friction characteristic testing device under ultrasonic vibration. The device consists of a main movement unit, a loading unit and a dynamometer unit, wherein the torque output by a step motor is converted into axial pressure of a sliding table through a lead screw nut pair of a trapezoidal screw, and an upper sample and a lower sample which are arranged at the bottom of a piezoelectric micromachined ultrasonic transducer are contacted with each other, and certain pressure is applied to the lower sample; when the piezoelectric micromachined ultrasonic transducer is connected with an ultrasonic power supply, the upper sample produces ultrasonic frequency vibration with micron-grade amplitude in the horizontal direction or the vertical direction, the lower sample rotates together with a rotating platform and forms a friction pair with the upper sample, so that the friction characteristic of the spherical contact under ultrasonic vibration can be tested. The device can be used for accurately controlling the testing parameters, is high in degree of automation, and can be used for performing spherical contact friction experiments of various types of friction materials under different ultrasonic vibration frequencies and vibration amplitudes.

Owner:JILIN UNIV

Composite power generator based on flowing liquid, power generation method and sensing method

ActiveCN105099260ASimple structureImprove convenienceSemi-permeable membranesFixed microstructural devicesPower sensorElectricity

Owner:BEIJING INST OF NANOENERGY & NANOSYST

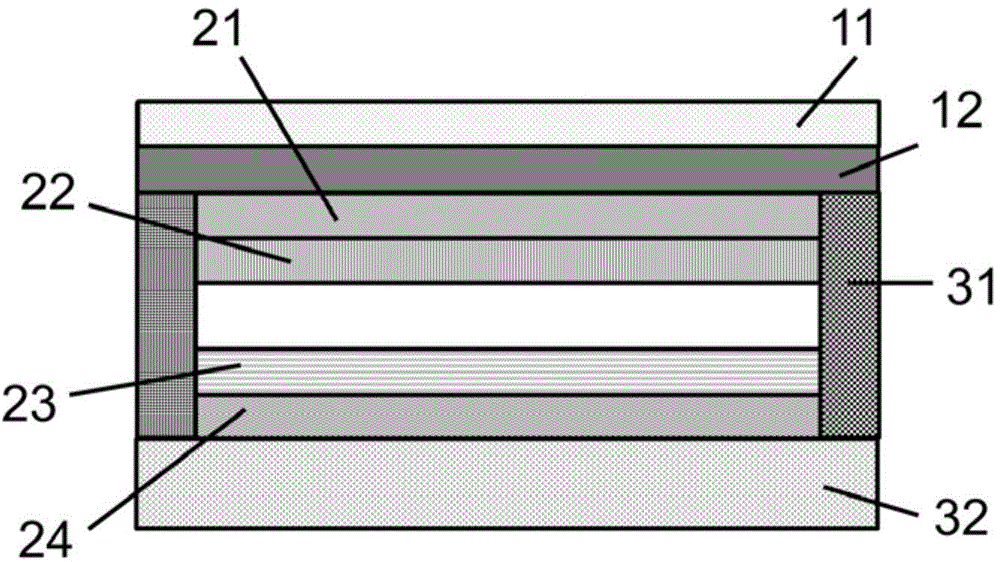

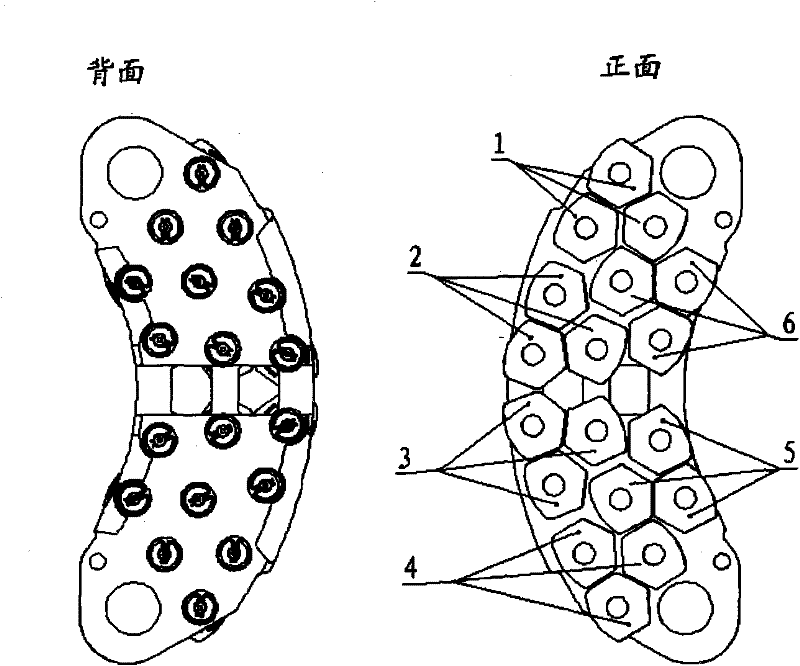

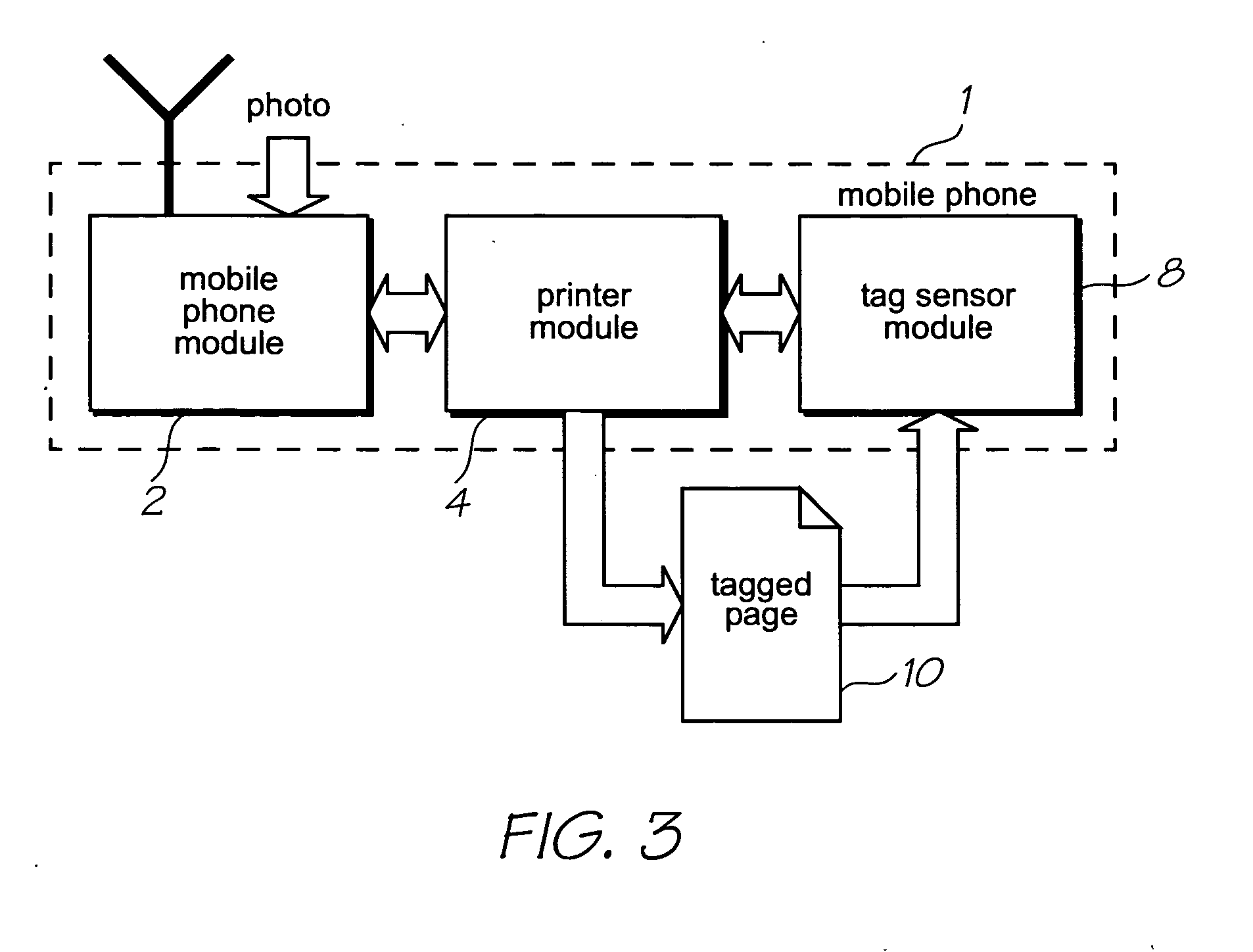

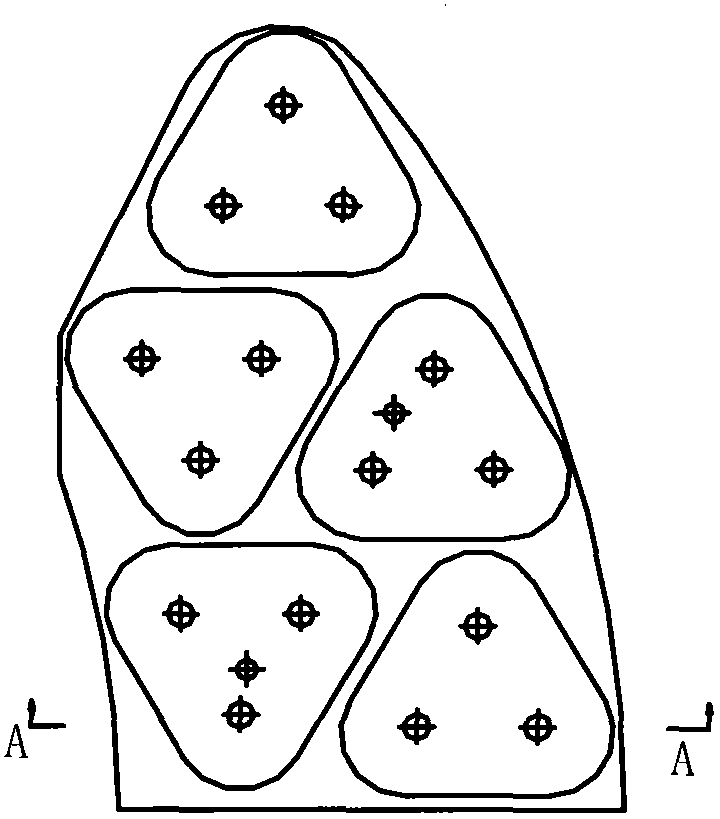

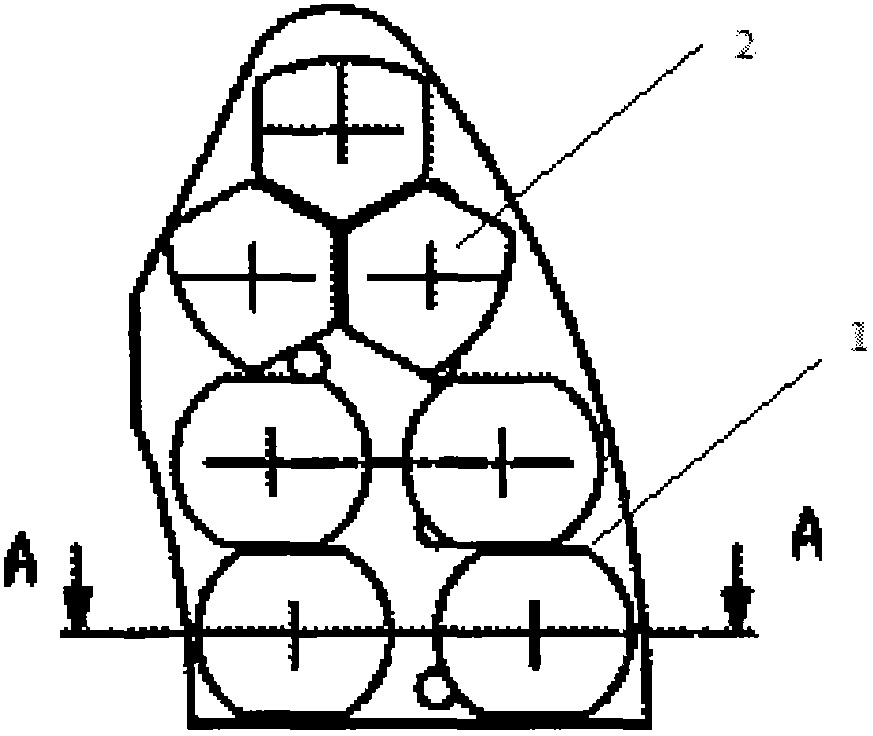

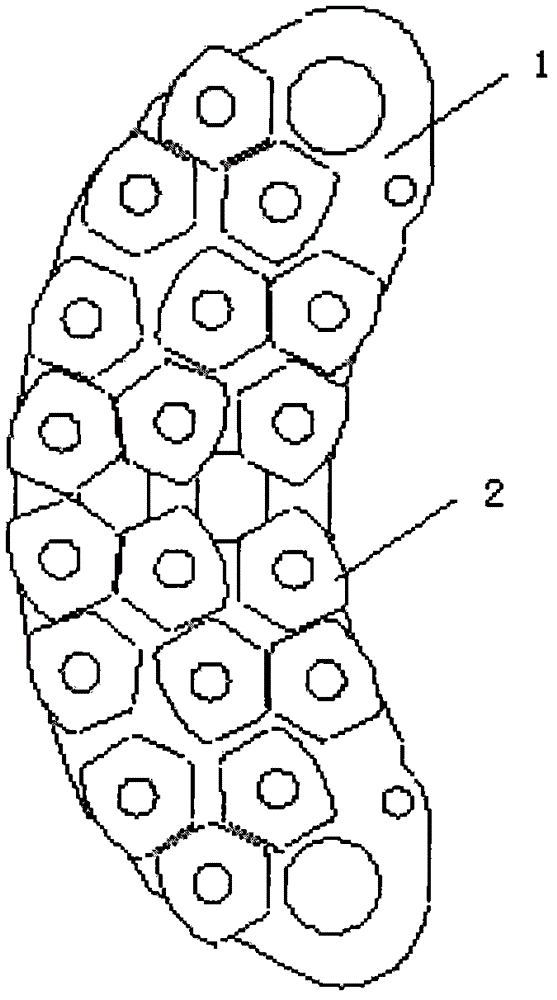

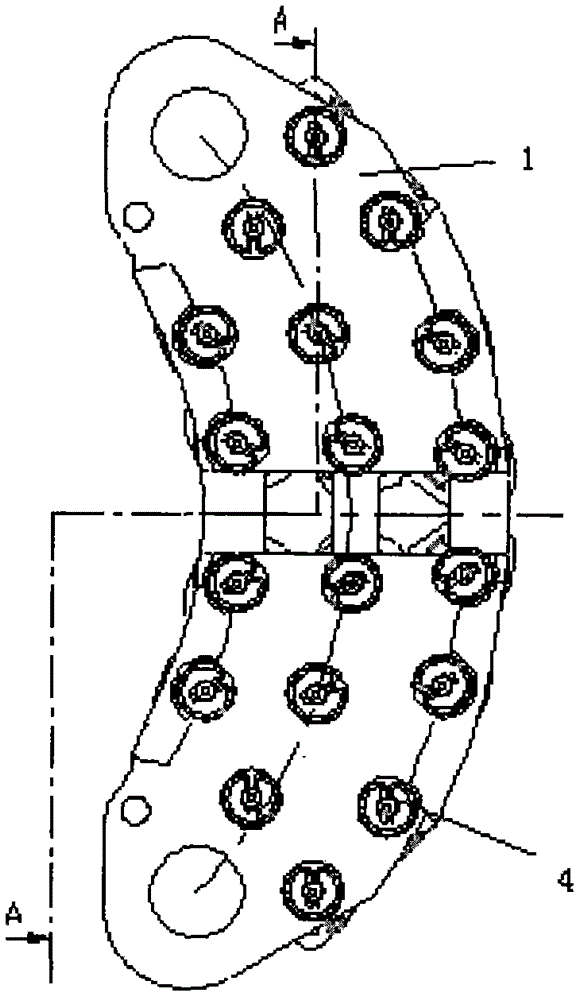

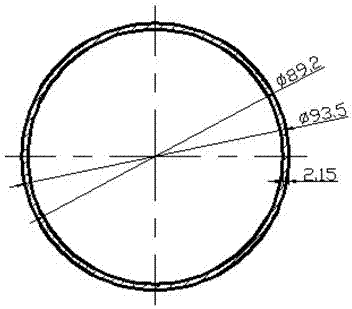

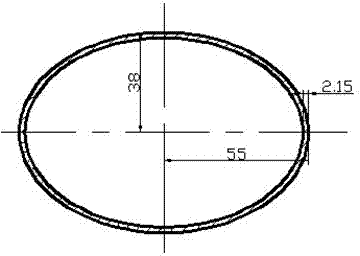

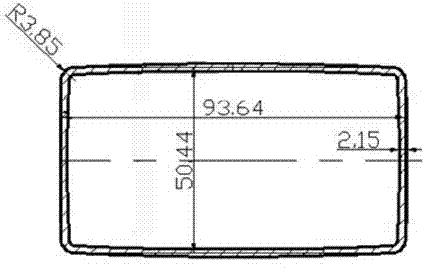

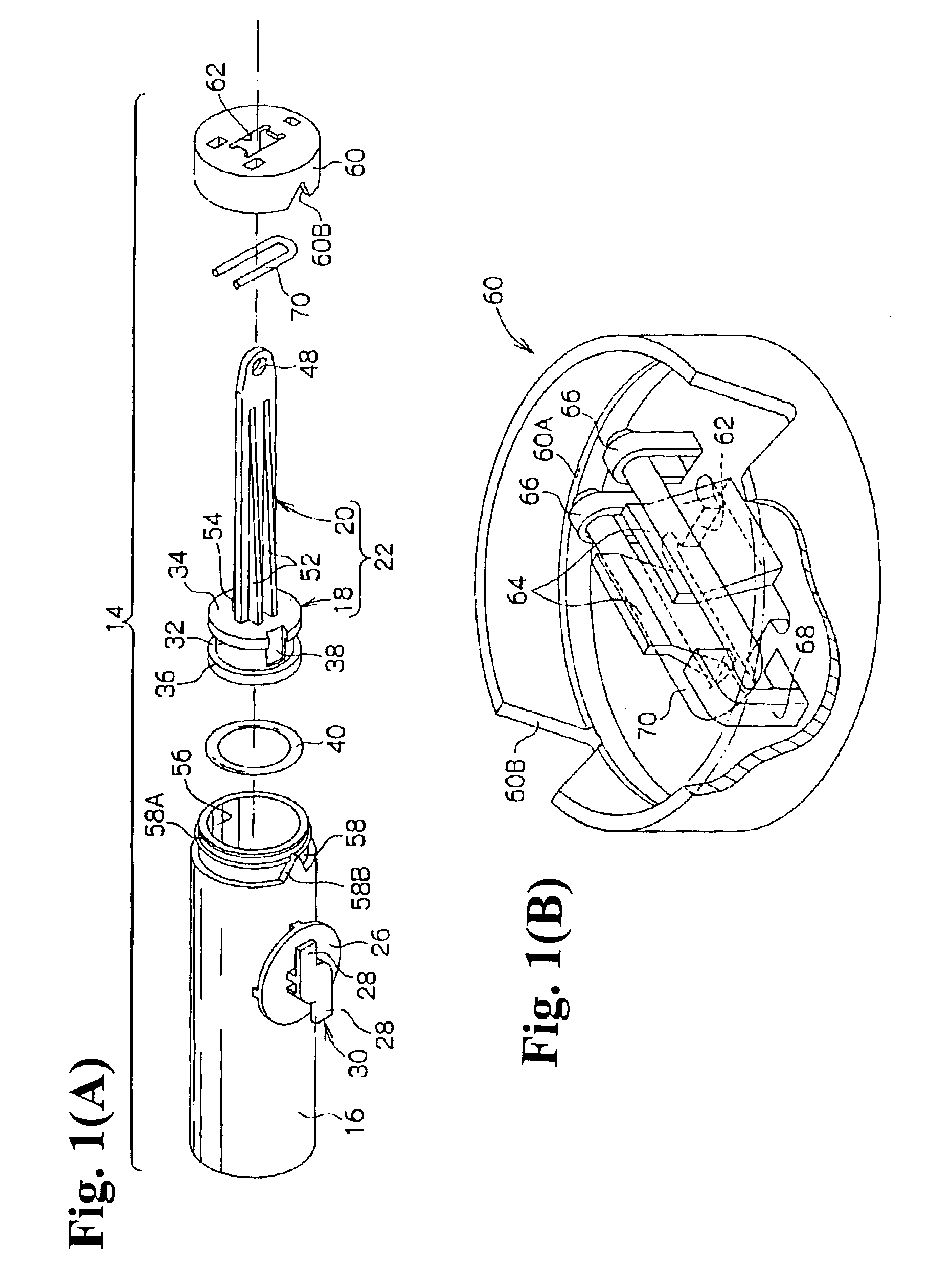

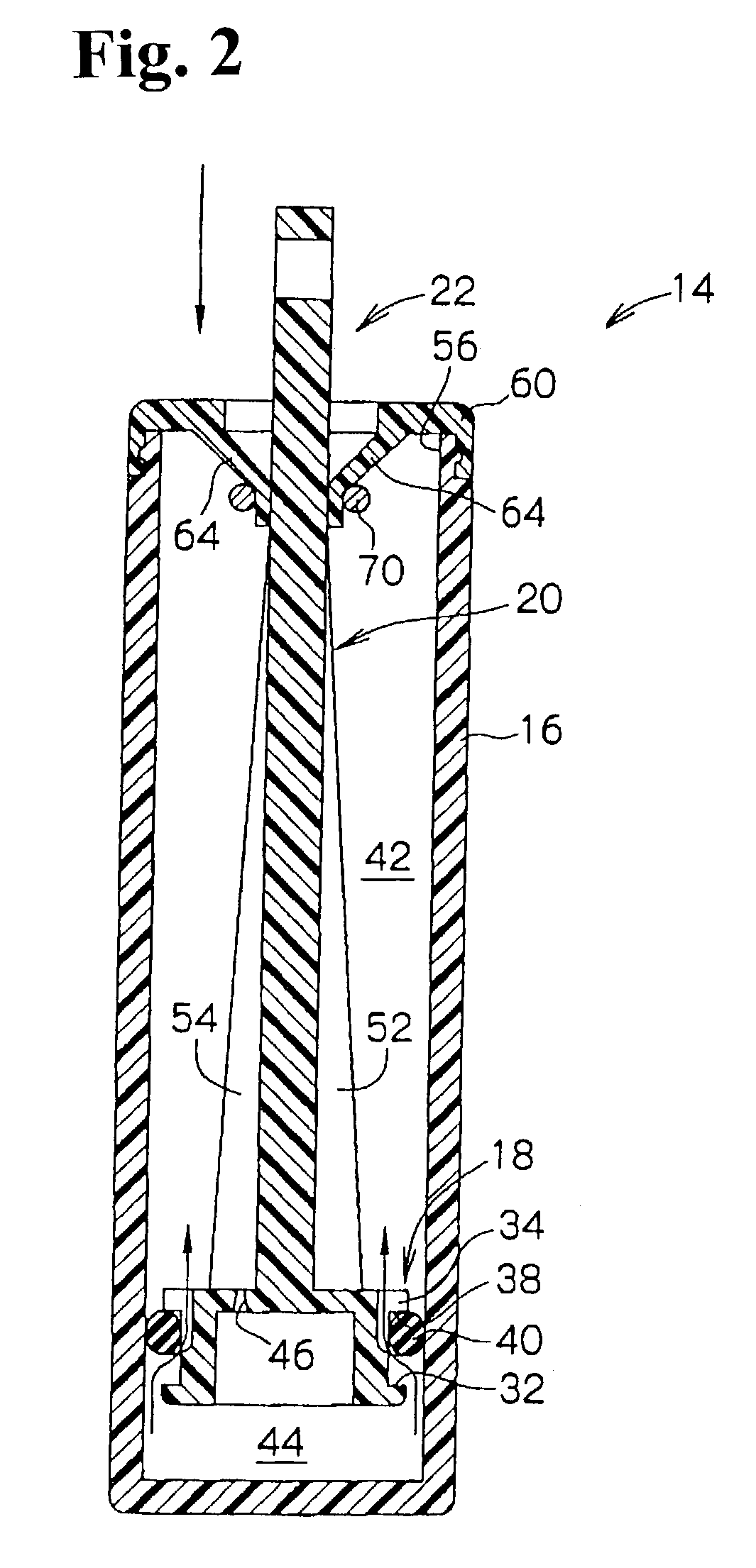

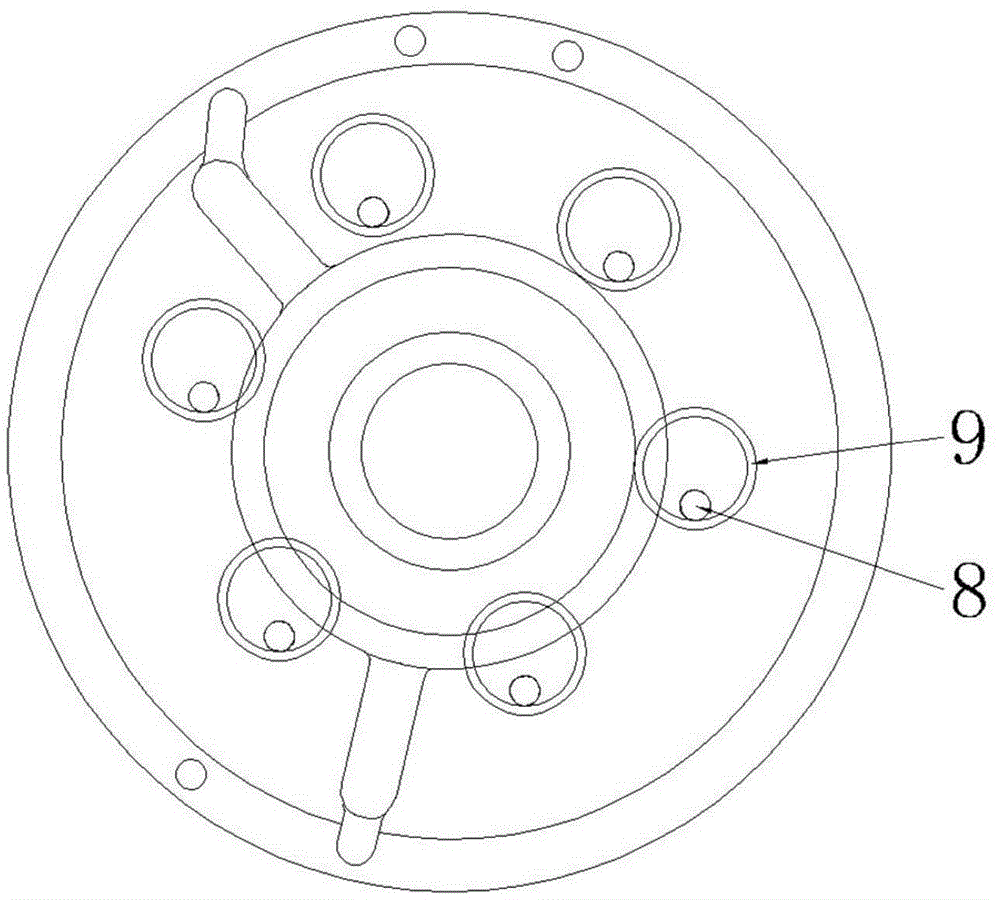

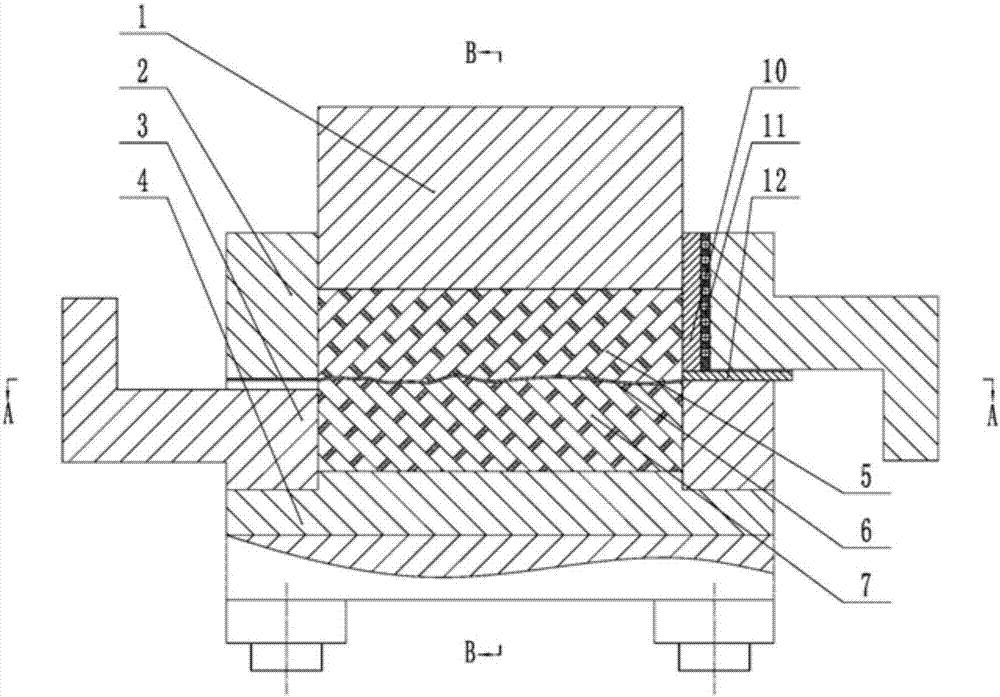

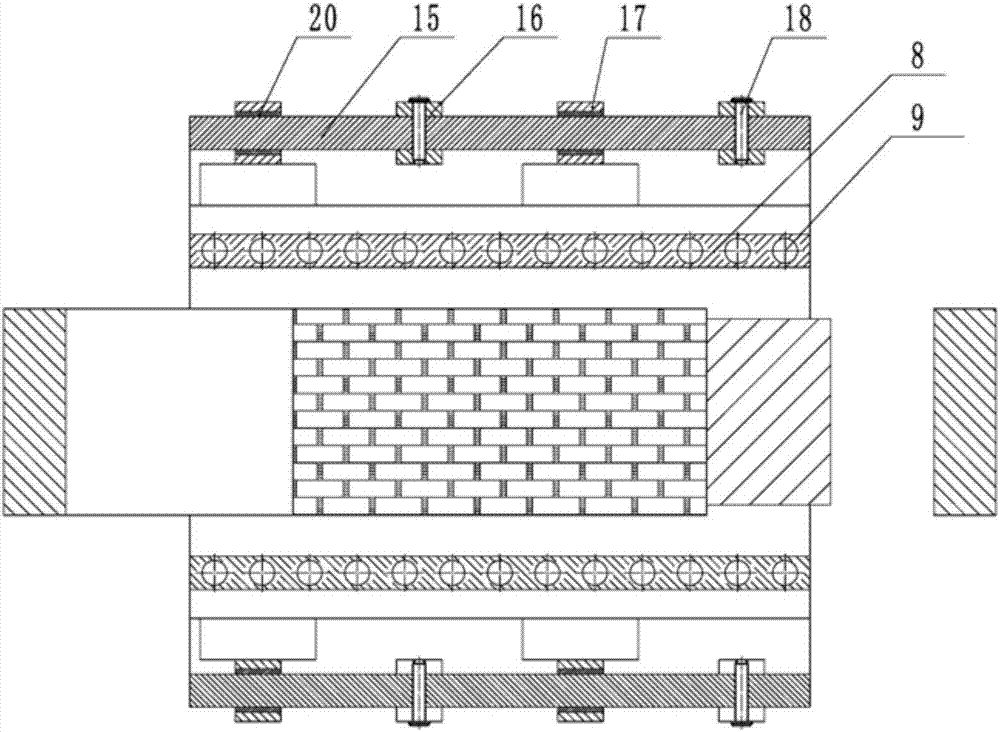

Floating type train brake pad capable of replacing friction block

InactiveCN102359523ASafe and reliable workIncrease contact friction areaBraking elementsFriction liningMetallic materialsEngineering

The invention discloses a brake pad which is applied to a disc type brake system of a high-speed train. A friction block constituted by the brake pad can be flexibly replaced. The brake pad comprises a brake pad back plate which is made of a metal material, an elastic supporting sheet, the friction block and a circular spring clamp, wherein the elastic supporting sheet is provided with a spherical supporting surface and a central guide hole; the lower part of the friction block is provided with a spherical supporting surface and a positioning and connecting shaft which is provided with a clamping groove; the connecting shaft can penetrate through the central guide hole and a back plate positioning hole of the elastic supporting sheet and is locked on the back plate by the circular spring clamp to realize floating connection; the friction block is provided with a polygonal block with a blind hole in the center; and every three friction blocks form an interlocking group, so that the rotation of the friction block during working of the brake pad is prevented. The brake pad can achieve the maximum contact friction area of the brake pad and a brake disc in a train braking process, so that the braking process is stable and the brake pad has the functions of damping, vibration reduction, noise reduction, heat dissipation and the like. The friction block is easy to replace, so that the train operation cost is lowered.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

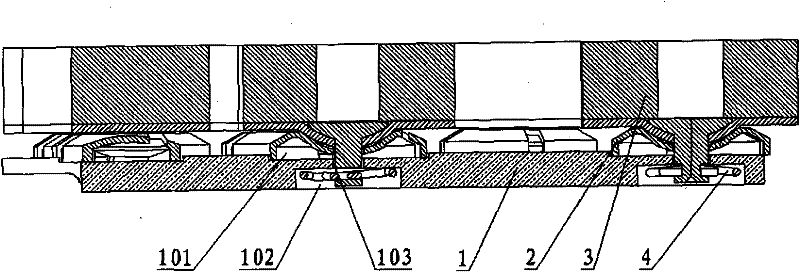

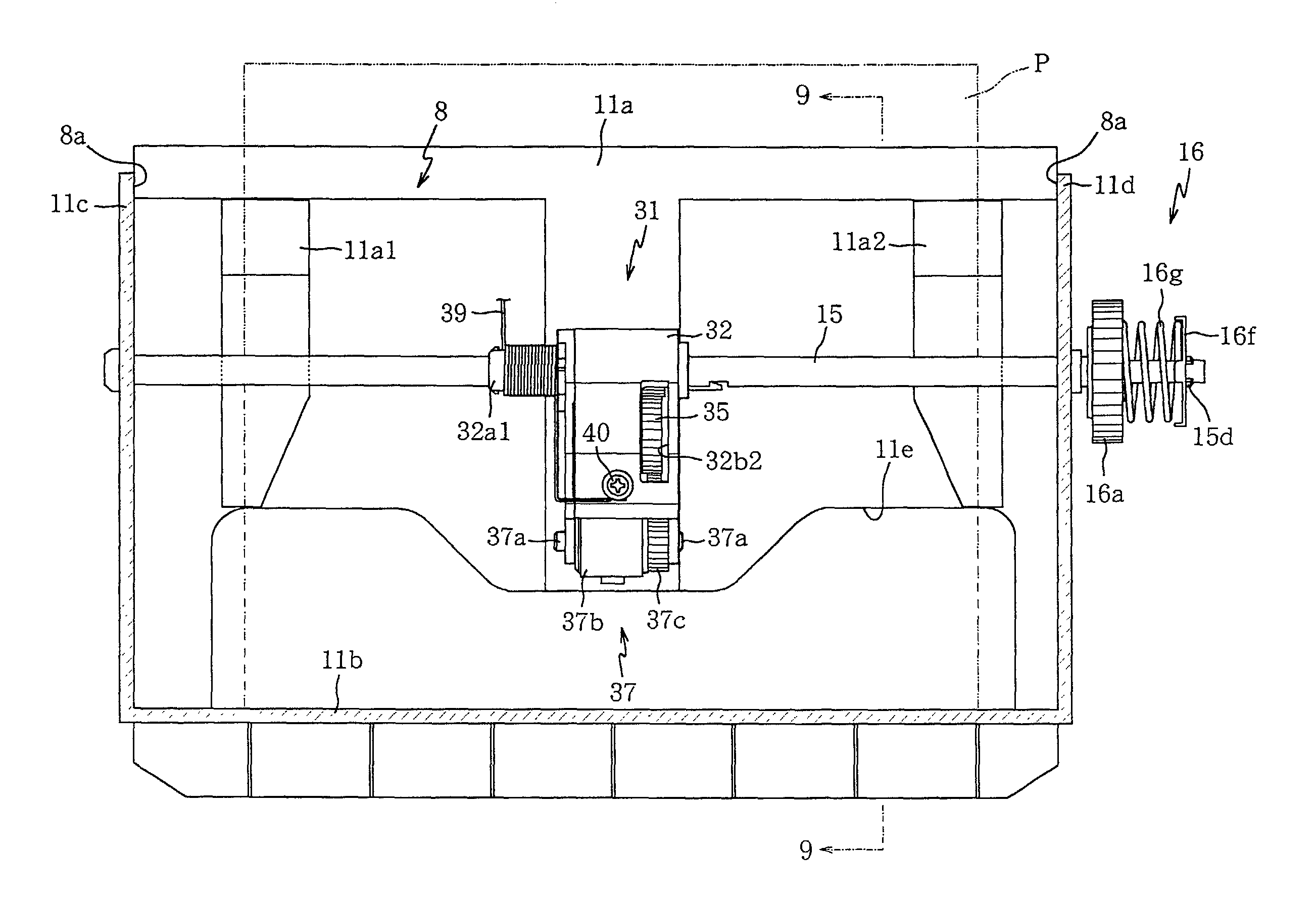

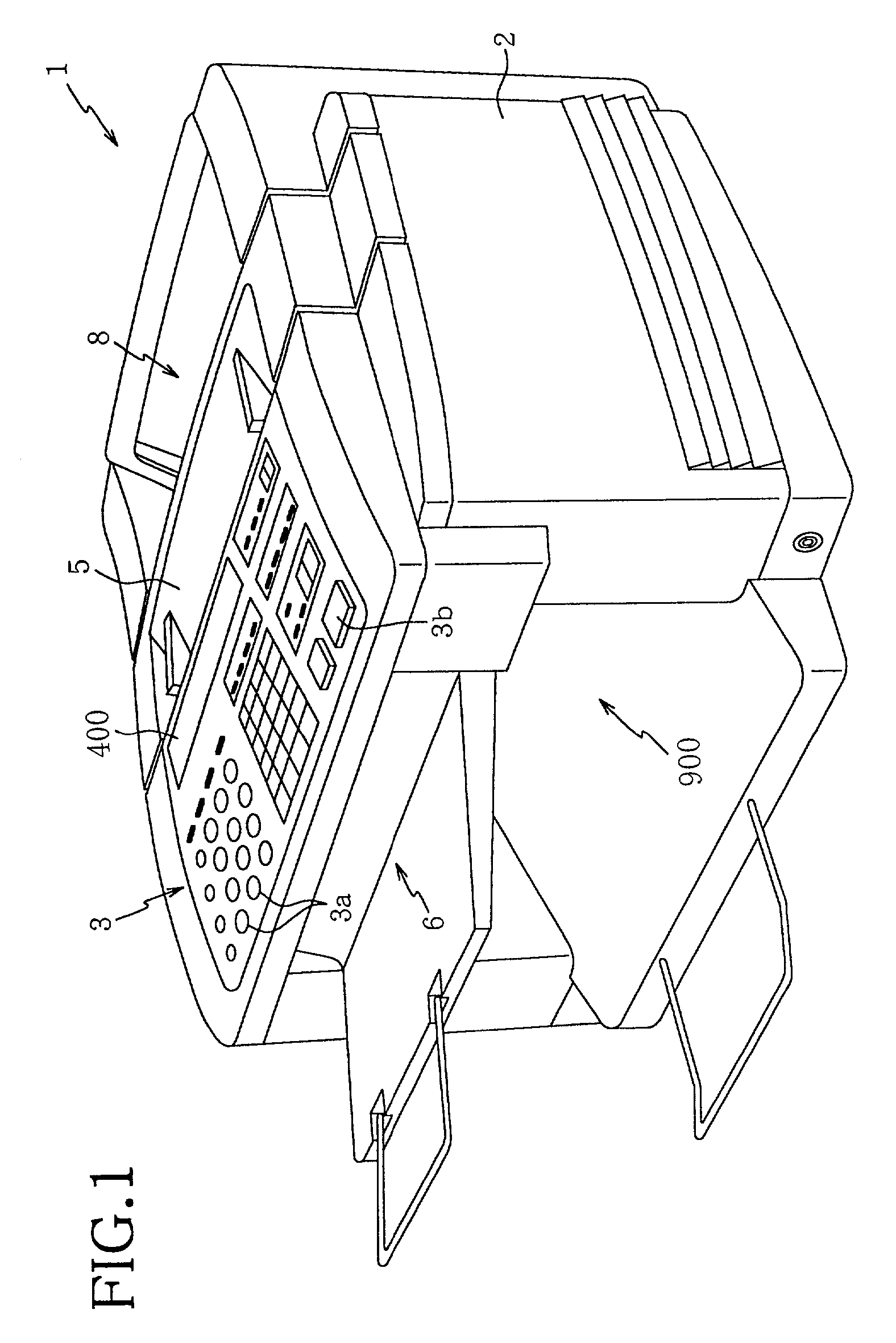

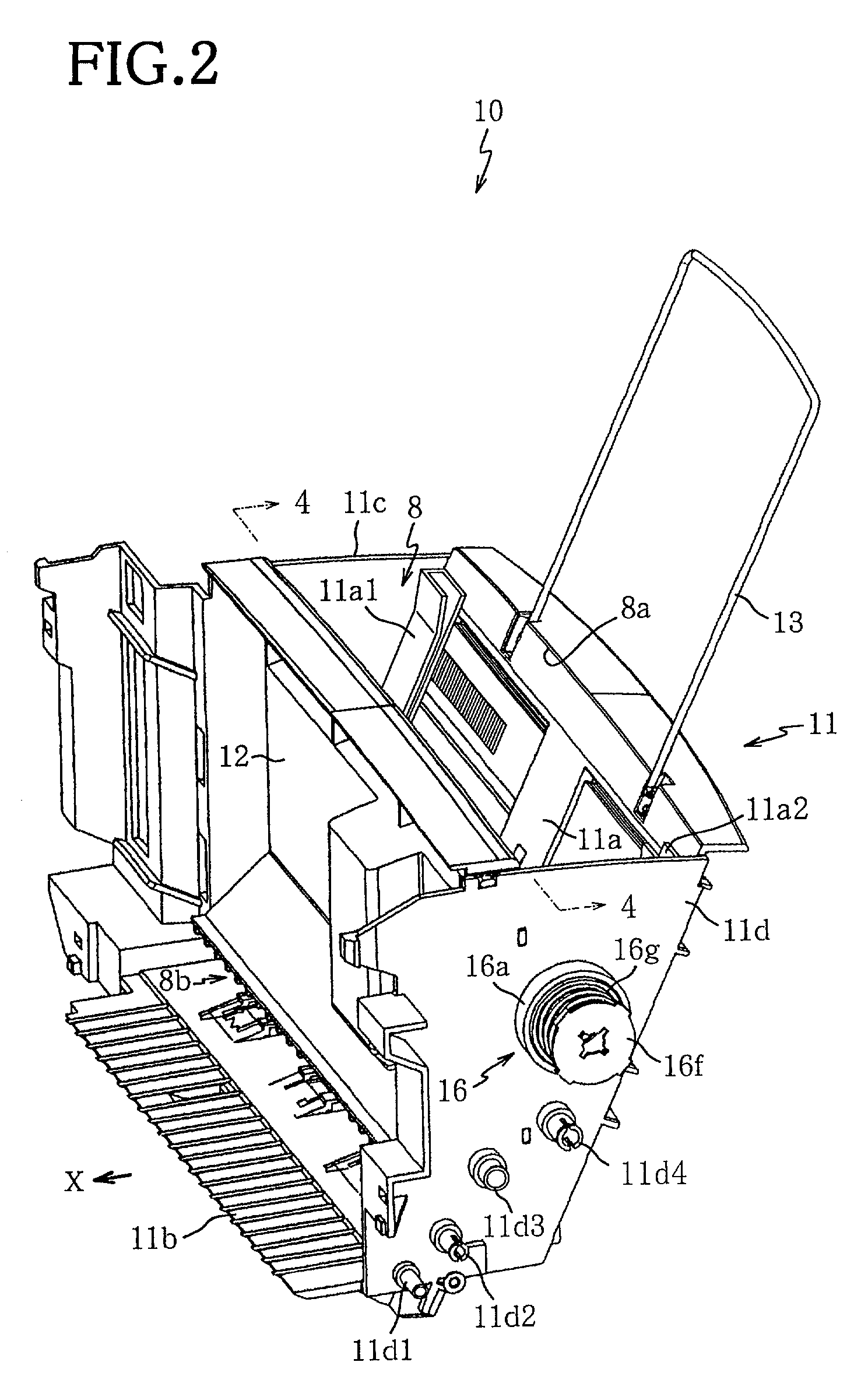

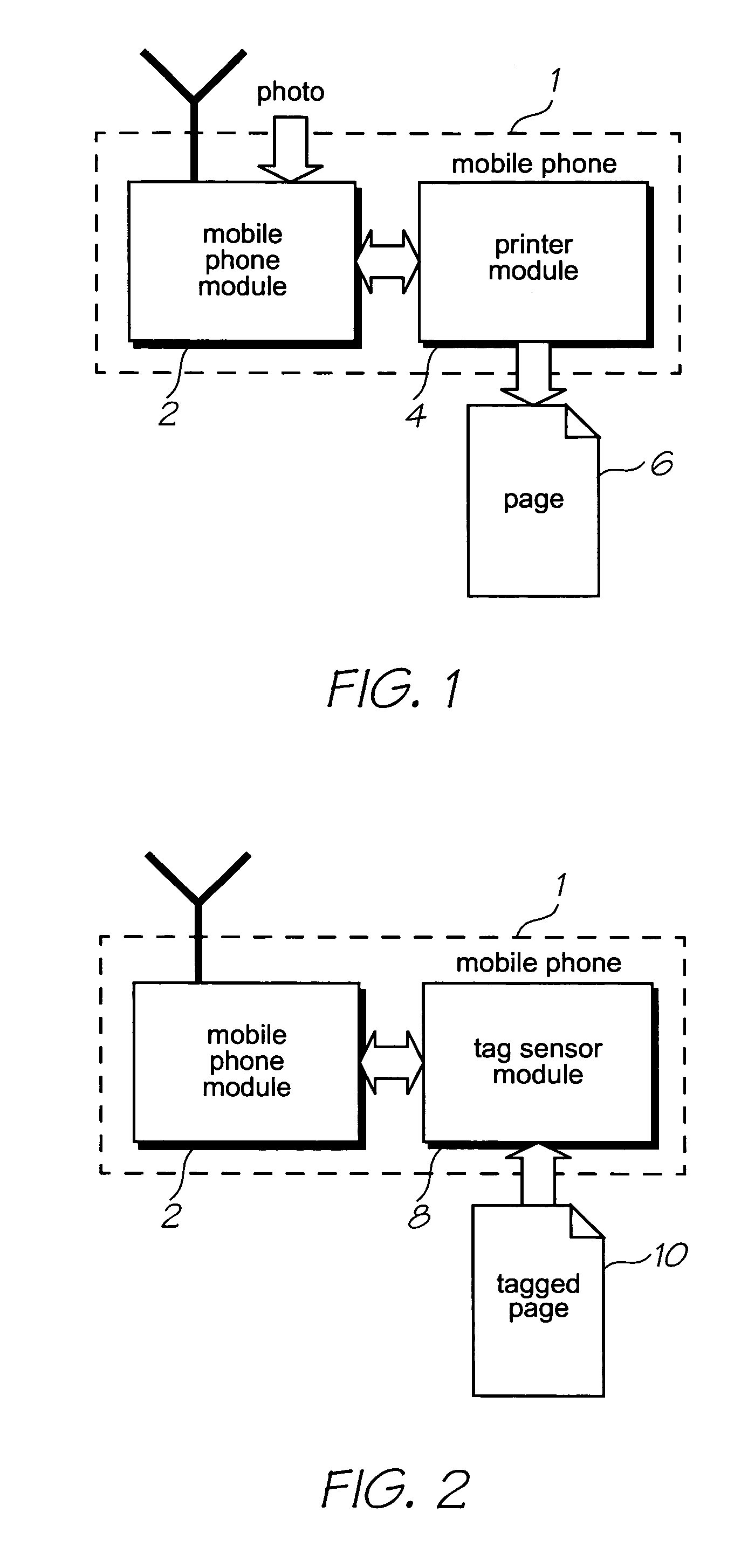

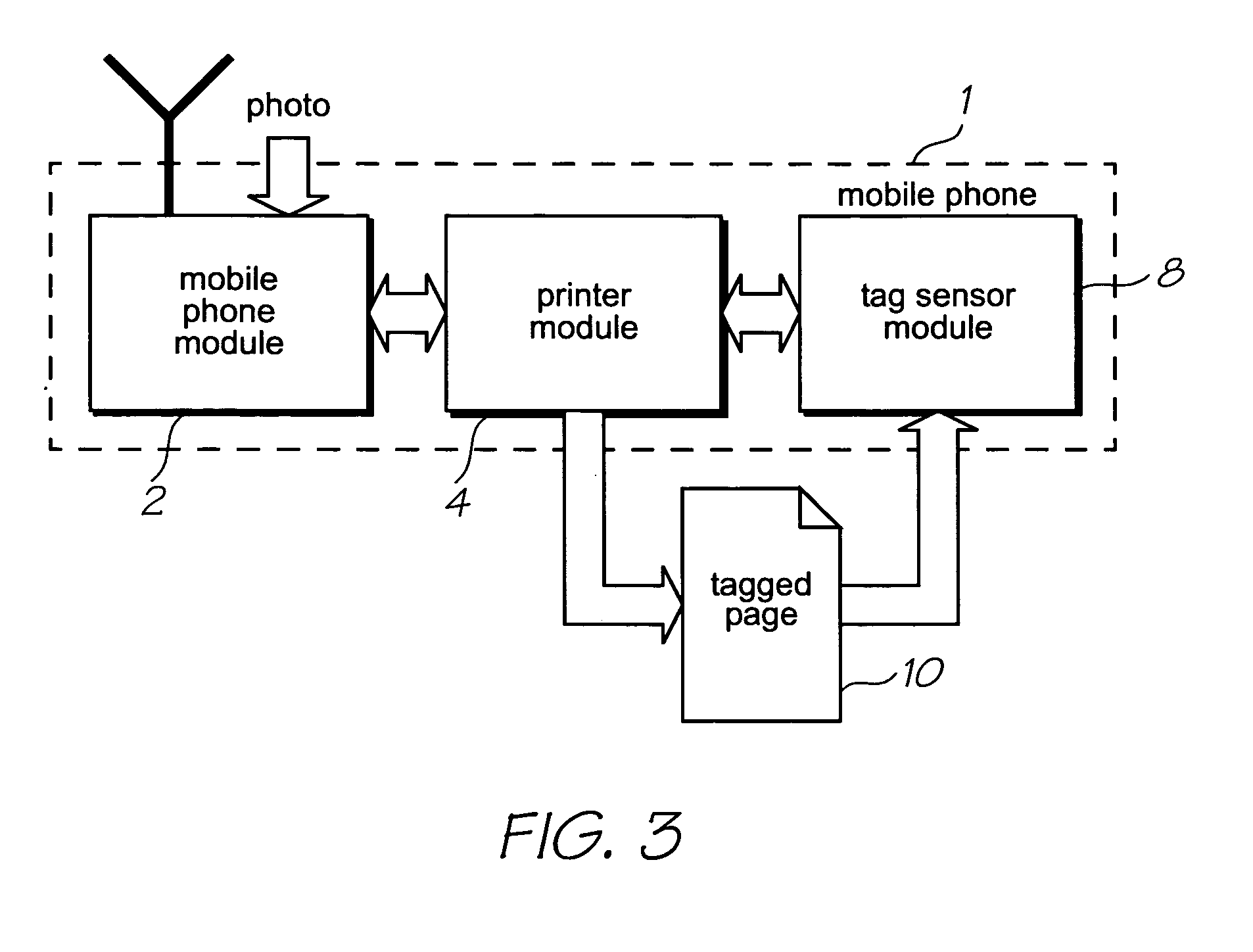

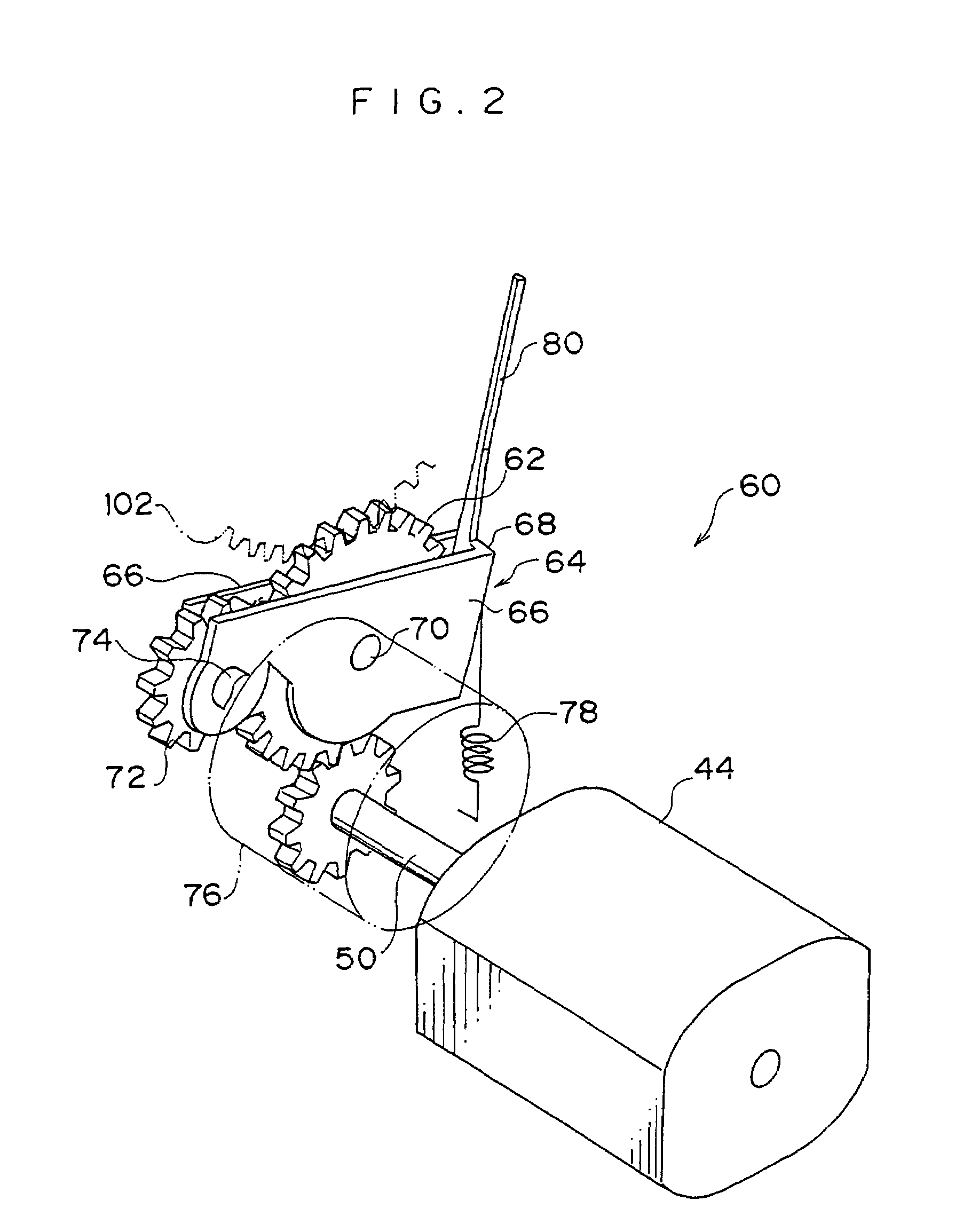

Sheet feeder

In a sheet feeder, when rotating force transmitted to a transmission gear is smaller than frictional force generated on a contact surface between a friction sheet and a transmission plate, the transmission plate is rotated together with the transmission gear, so that a drive shaft may rotate together with the transmission plate and the transmission gear. When the rotating force transmitted to the transmission gear is greater than the frictional force generated on the contact surface between the friction sheet and the transmission plate, each of surfaces of the friction sheet contacting the transmission plate and the transmission plate contacting the friction sheet slidably move, so that the transmission gear may rotate freely relative to the drive shaft. Thus, the sheet feeder restricts excessive rotating force being transmitted to a pick-up roller, so that damage or malfunction of the pick-up roller or a drive unit is prevented.

Owner:BROTHER KOGYO KK

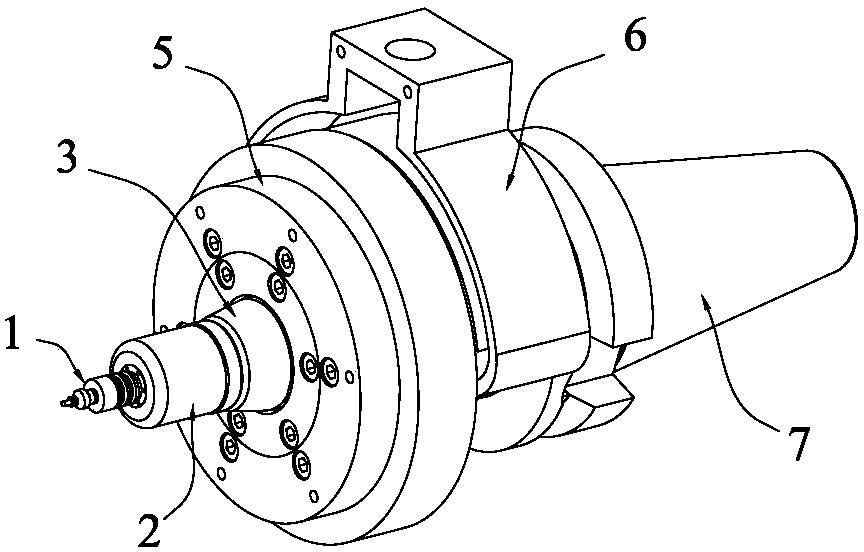

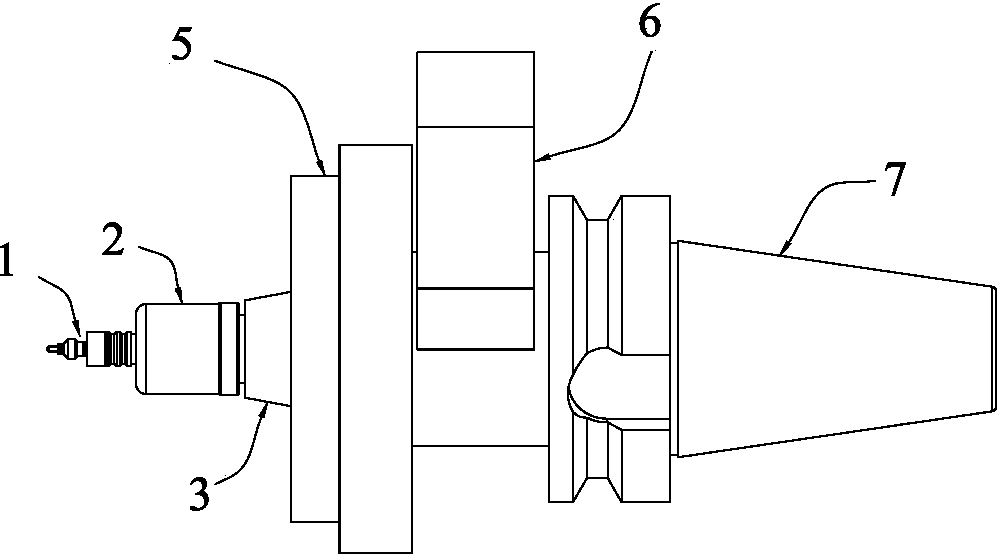

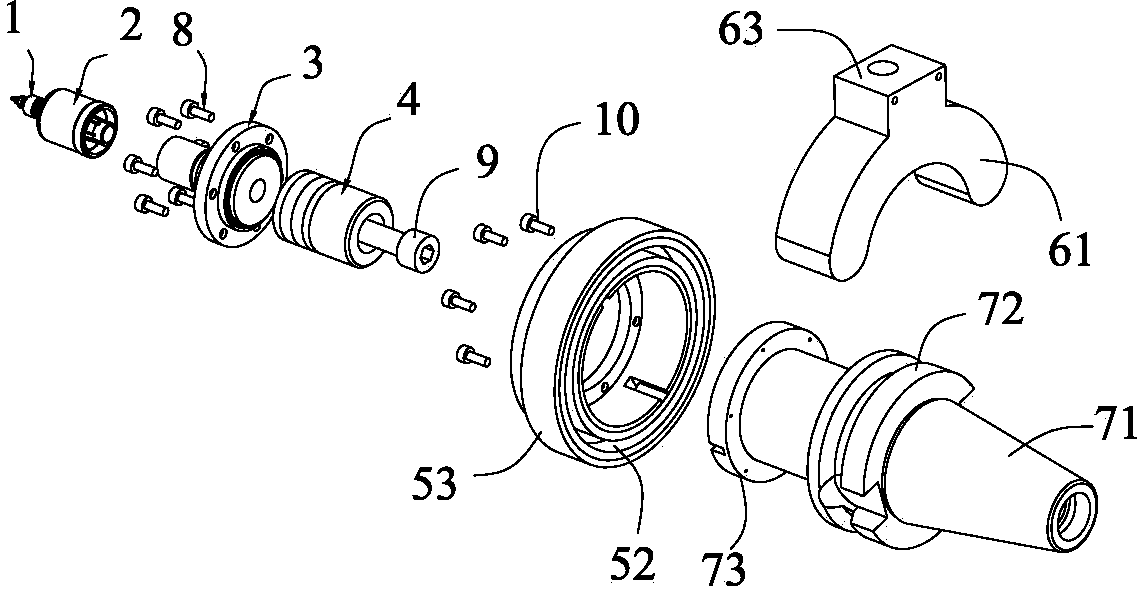

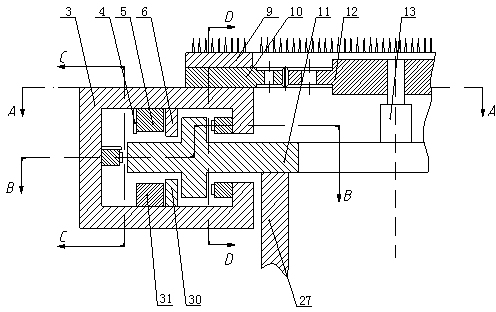

Non-contact energy transmission type ultrasonic machining device

The invention discloses a non-contact energy transmission type ultrasonic machining device. The non-contact energy transmission type ultrasonic machining device comprises a grinding head, an amplitude-change rod, a front cover plate, piezoelectric ceramic, secondary magnetic ring coil, a primary magnetic ring coil and a tool handle. The grinding head, the amplitude-change rod, the front cover plate and the tool handle are sequentially connected, the piezoelectric ceramic is arranged in a concave assembly position of the tool handle, the secondary magnetic ring coil is fixed to the front cover plate, the primary magnetic ring coil is arranged on a mechanical arm of an ultrasonic machine, and gap is formed between the secondary magnetic ring coil and the primary magnetic ring coil. The non-contact energy transmission type ultrasonic machining device is ingenious and reasonable in structural design; because of the non-contact energy transmission structure design, not only is non-contact high-efficiency transmission of electric energy achieved, but also the problem of traditional slip ring abrasion in ultrasonic machining is solved, the heat generation phenomenon caused by contact friction is avoided, the rotation speed of a spindle is increased without limitations, and meanwhile the automatic tool changing requirement of a machining center can be met; moreover, because no exposed conductors exist, electric energy transmission is not influenced by environments, and the non-contact energy transmission type ultrasonic machining device is good in working stability, safe, reliable, capable of keeping work for a long time and high in working efficiency.

Owner:张增英

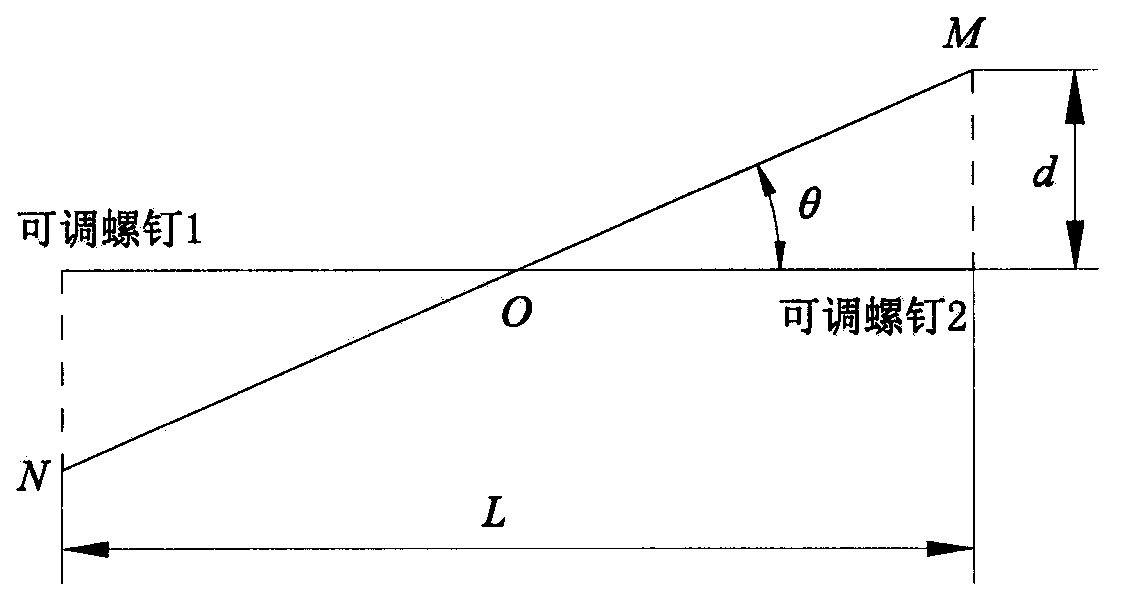

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

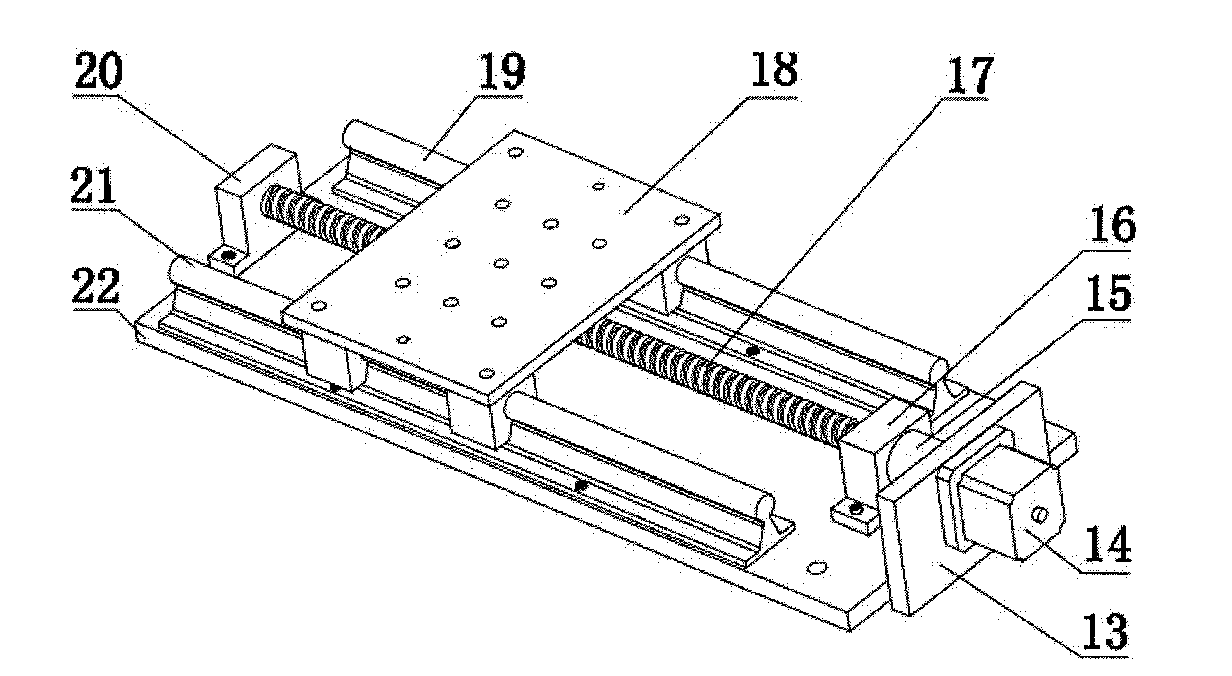

Skin/textile biologic friction dynamic measurement device

InactiveCN102590077AImprove test accuracySmall rangeUsing mechanical meansMaterial analysisData processing systemMeasurement device

The invention relates to a skin / textile biologic friction dynamic measurement device, which comprises a measurement base, wherein a vertical seat is fixed at the rear part of the measurement base; a first sliding way and a second sliding way are installed at the front part of the measurement base; the first sliding way is installed on a movable panel of the second sliding way; a measurement panel is also installed on the first sliding way; an installation panel which can move up and down is arranged at the front side of the vertical seat; a measurement contact is fixed on the installation panel and is positioned above the measurement panel; a multi-axial force / torque transducer is installed between the measurement contact and the installation panel; the multi-axial force / torque transducer is connected with a data processing system of a personal computer through a power supply box; the first sliding way can make the measurement panel move left and right; the second sliding way can make the movable panel move back and forth; and the installation panel can move up and down. The device not only can measure the frictional force, pressure and torque functions during the contact sliding process in real time, but also can truly reflect the skin / textile multidirectional contact friction movement process under different sliding speeds and initial pressures.

Owner:DONGHUA UNIV

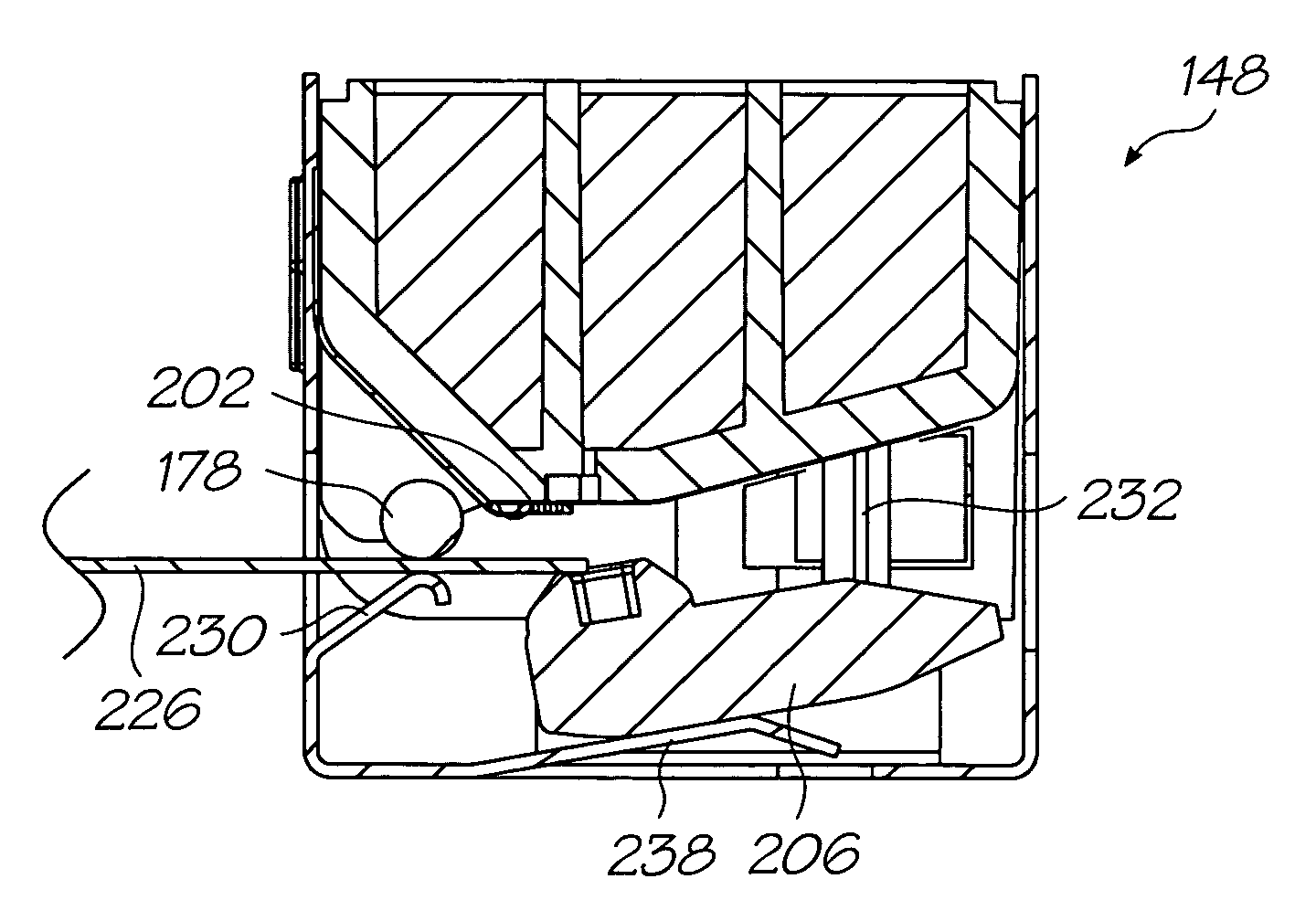

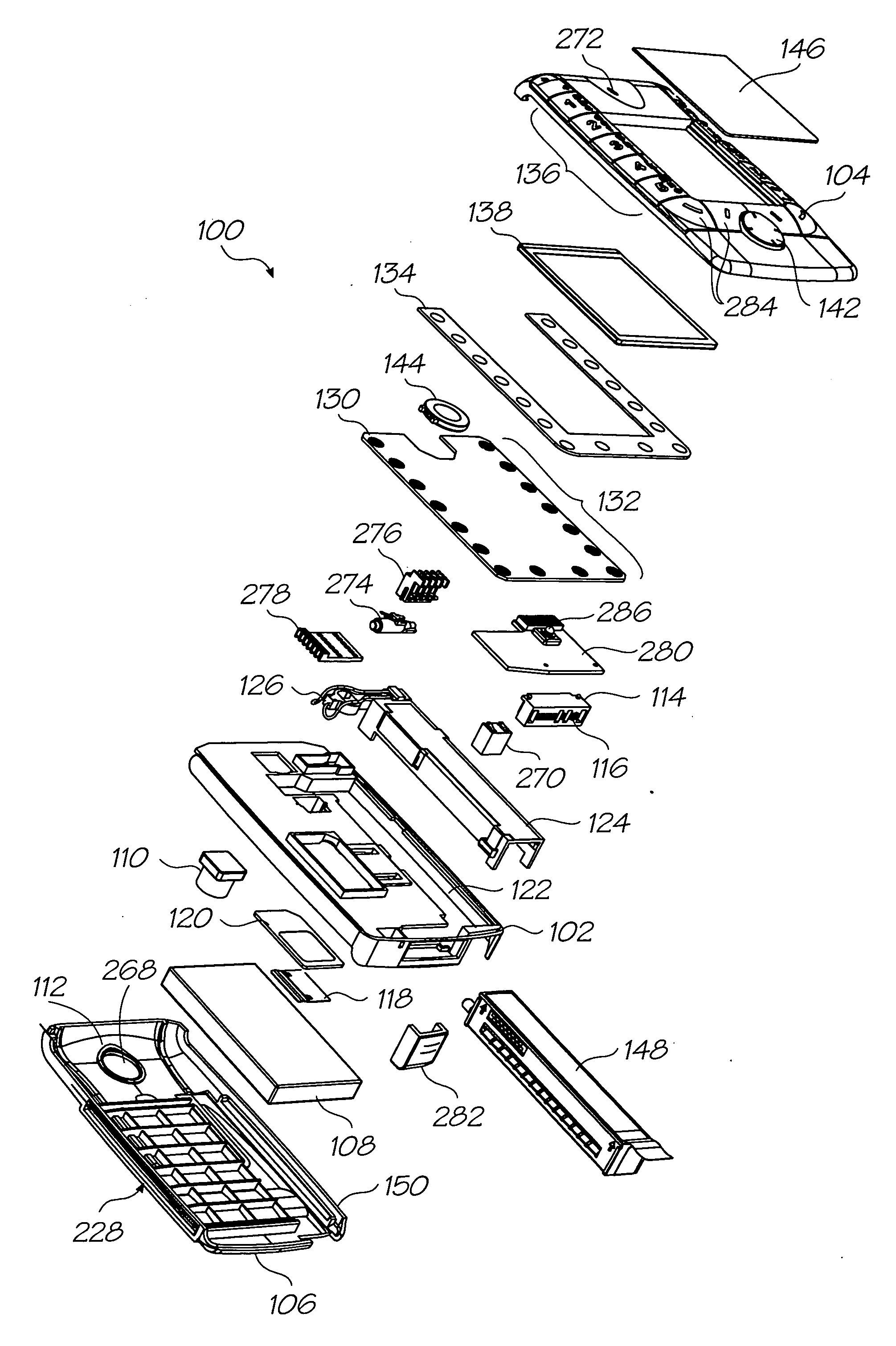

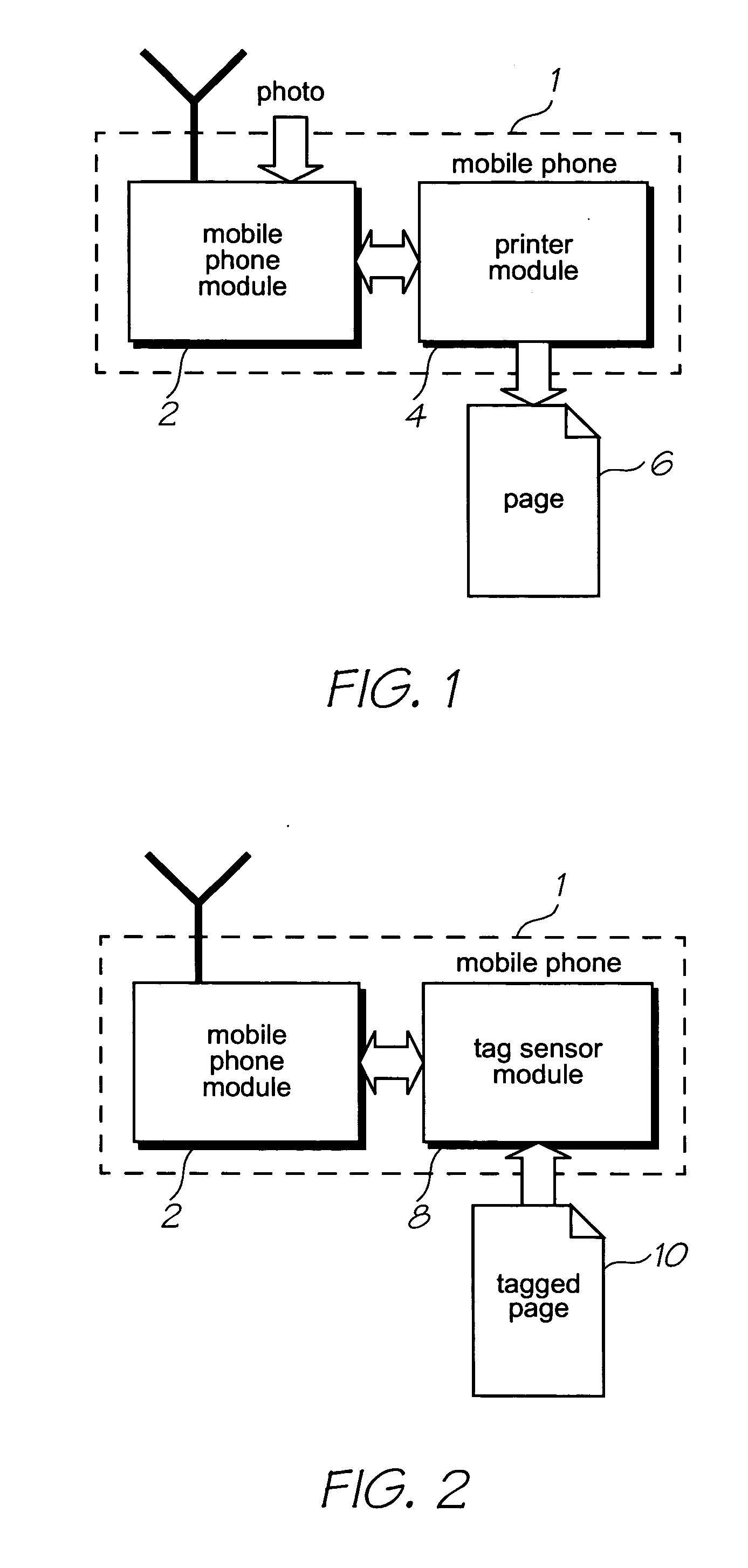

Print cartridge with friction driven media feed shaft

A print cartridge for an inkjet printer with a media drive assembly, the cartridge comprising: a drive shaft for feeding a media substrate past a printhead, the drive shaft positioned such that it engages the media drive assembly upon installation of the cartridge; wherein during use, the drive assembly transfer torque to the drive shaft by contact friction.

Owner:SILVERBROOK RES PTY LTD +1

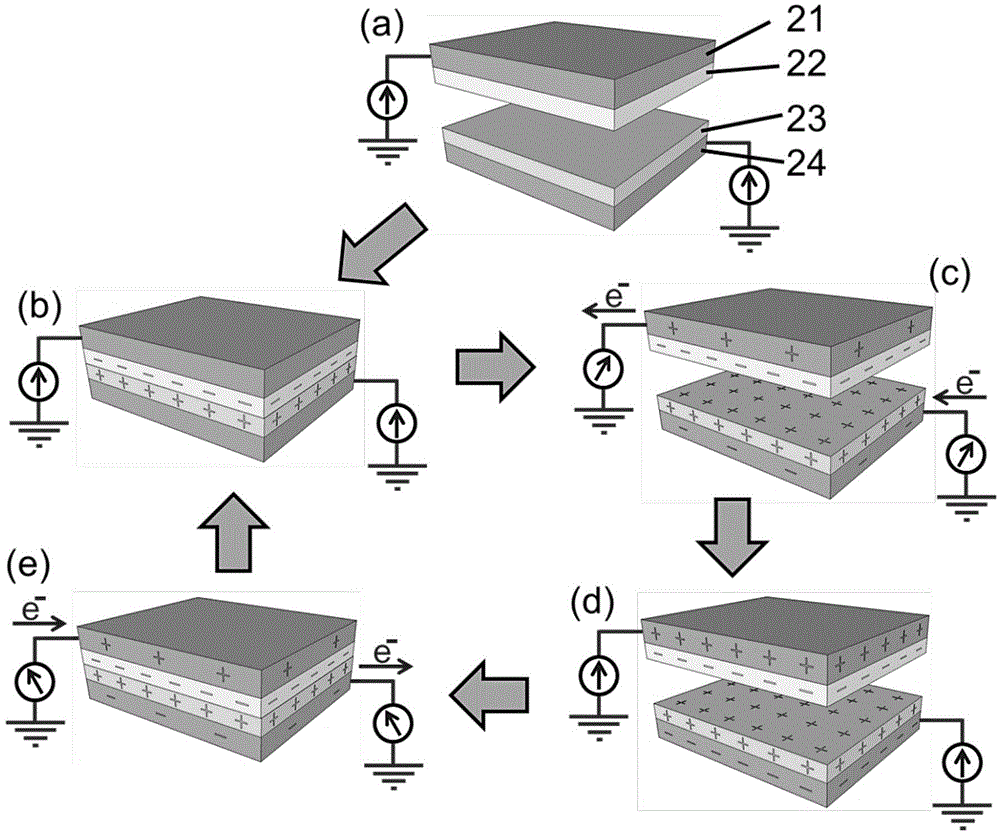

Friction-piezoelectricity-magnetoelectricity composite vibration miniature energy collector

ActiveCN105915117ASolve self-powering problemsReasonable designPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesElectricityMechanical energy

The invention discloses a friction-piezoelectricity-magnetoelectricity composite vibration micro-energy collector. A magnet is suspended to serve as a sensitive unit of the miniature energy collector, thereby improving the sensitivity of a sensitive part, and achieving the collection of mechanical energy. Meanwhile, three power generation units (piezoelectricity, magnetoelectricity and friction) with a complementary working mode are integrated, thereby achieving the high-efficiency collection of the mechanical energy. The collector sequentially comprises an electromagnet, frictional films, an electromagnetic induction coil, a piezoelectric layer and a structural substrate from the center to two sides. An electromagnetic layer employs the magnetic suspension design, thereby avoiding the mechanical connection on a sensitive element in a conventional structure. The controller can sense smaller mechanical vibration. One end of the piezoelectric layer is fixed and connected with an electrode, and the other end of the piezoelectric layer employs a staggered support structural design. Moreover, the controller employs the principle of homopolar repulsion of a magnetic field, senses the displacement change of a sensitive induction element, and enables a piezoelectric film to deform. A frictional layer employs a mode that two films are overlapped, and is contacted through the vibration of a suspended magnet. Charges are induced between two frictional films.

Owner:ZHONGBEI UNIV

Print cartridge with friction driven media feed shaft

A print cartridge for an inkjet printer with a media drive assembly, the cartridge comprising: a drive shaft for feeding a media substrate past a printhead, the drive shaft positoned such that it engages the media drive assembly upon installation of the cartridge; wherein during use, the drive assembly transfer torque to the drive shaft by contact friction.

Owner:SILVERBROOK RES PTY LTD +1

Floatation type brake pad for high speed train

InactiveCN102705405AAvoid bluePrevent thermal crackingBraking elementsVibration attenuationEngineering

The invention relates to a floatation type brake pad for a high speed train.. The floatation type brake pad is characterized by comprising a pad rear panel, a dovetail board, friction block bodies, an elastic supporting sheet and a round spring clip; the pad rear panel is in an arc half-sole structure; the elastic supporting sheet is provided with a spherical supporting surface and a center guide hole; the frication block is provided with a spherical supporting surface and a guide connection shaft with a clamping groove; the elastic supporting sheet, the round spring clip and the friction block bodies are in elastic floatation connection with the pad rear panel; the spherical supporting surface of the elastic supporting sheet and the spherical supporting surface at the root of a connection shaft of each friction block body are rotary, so that the balance of a braking force is realized; the three single-arc quadrilateral friction bodies in one group are mutually engaged and locked; and friction bodies of four cylindrical grinding column bodies are mutually engaged and locked in pairs. With the adoption of the floatation type brake pad provided by the invention, a maximum contact friction area can be obtained, so that a braking process is stable, and the functions of damping, vibration attenuation, noise reduction, heat radiation and the like can be achieved. The friction blocks are easy to replace; the operation cost is low; and the floatation type brake pad can be widely used for a braking system of the high speed train.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

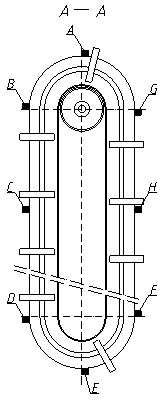

Tentering shaping conveying device for magnetic suspension functional fabric

The invention discloses a tentering shaping conveying device for a magnetic suspension functional fabric. The device comprises a supporting block, and is characterized in that a runway-type static rail is mounted on the supporting block; a magnetic suspension movable rail is sleeved on the static rail; a gear belt is mounted on the magnetic suspension movable rail; a plurality of needle felts are mounted on the gear belt; a rotary motor is mounted at an arc end of the static rail; a gear disc is mounted on the rotary motor; and the gear disc is engaged with the gear belt. The tentering shaping conveying device is reasonable in structure, applicable to various functional coated fabric production occasions, has the advantages of contactless friction, low energy consumption, high kinematic accuracy, low noise, and the like, and can effectively prolong the maintenance and repair period of a system.

Owner:苏州盛泽科技创业园发展有限公司

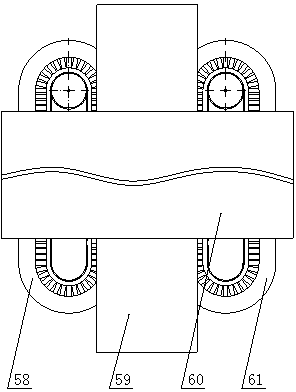

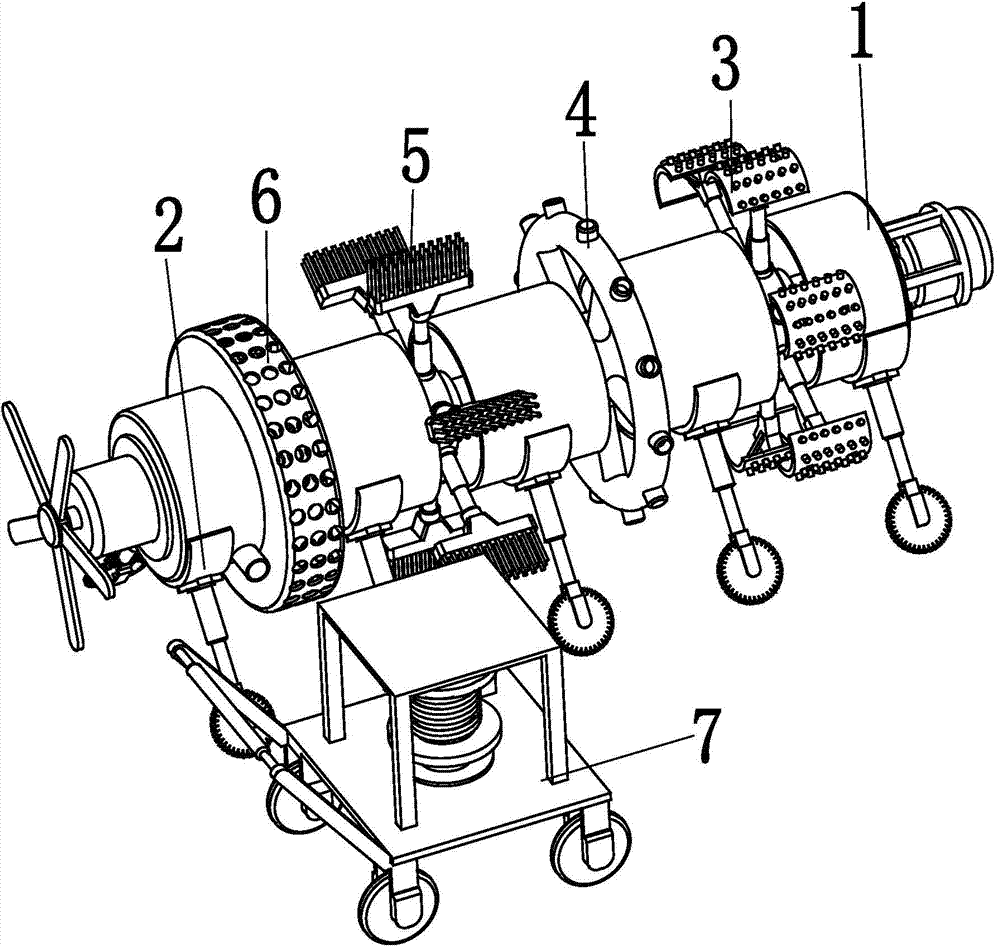

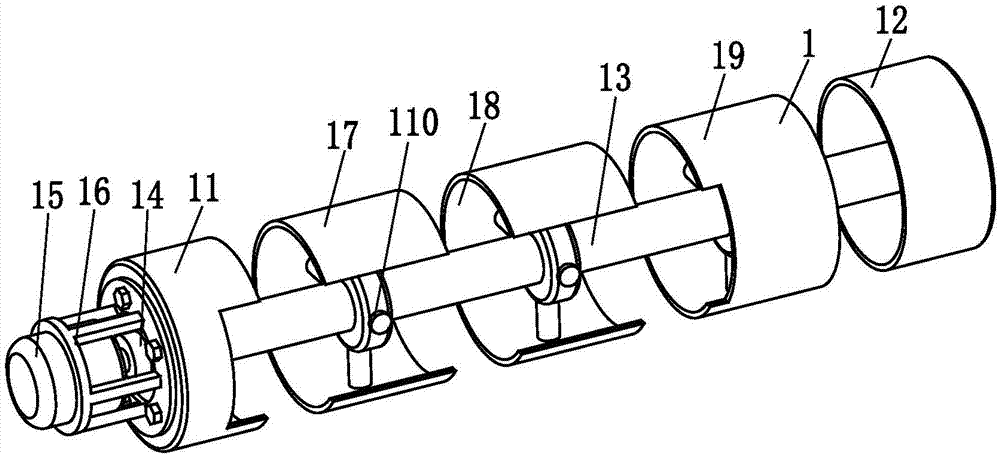

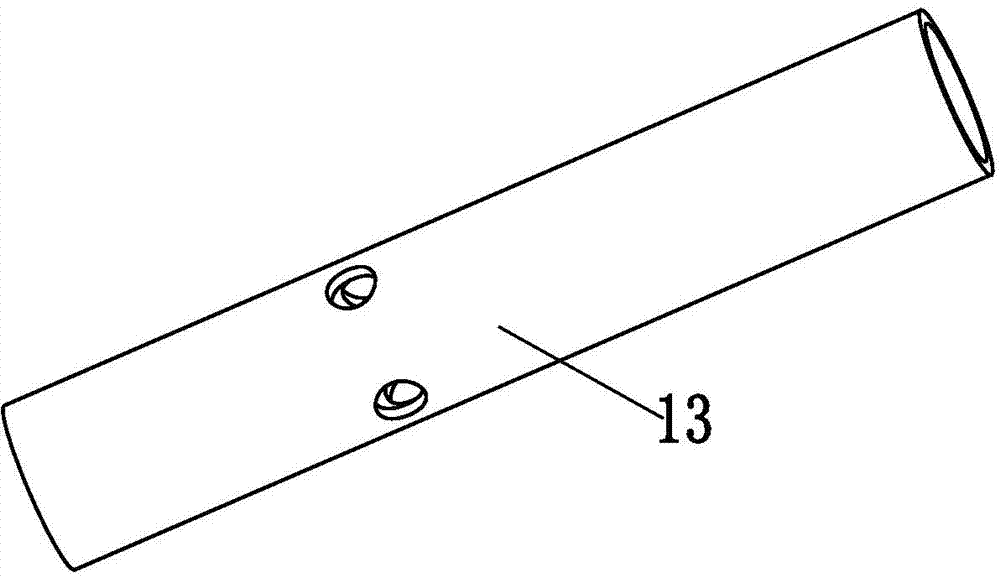

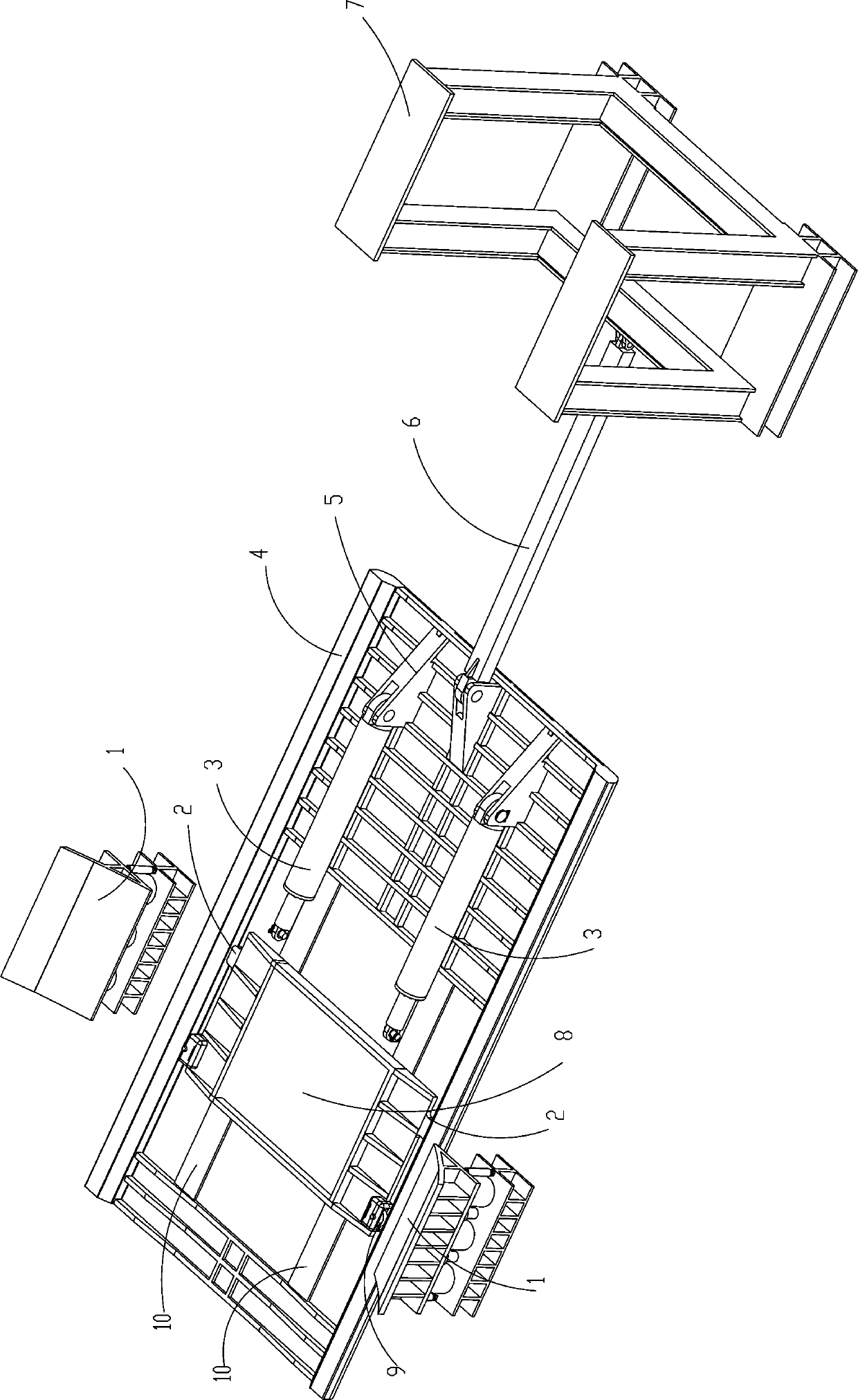

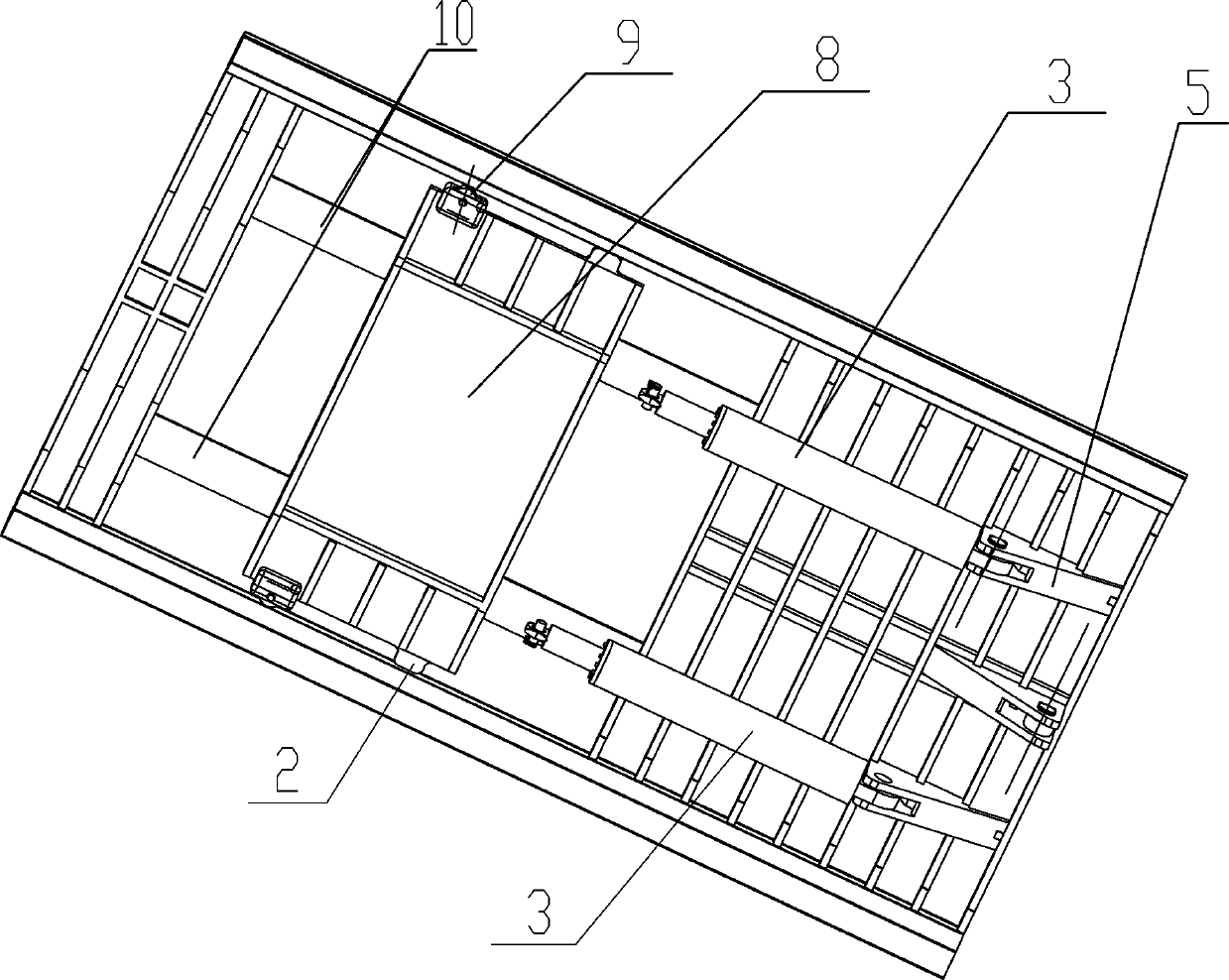

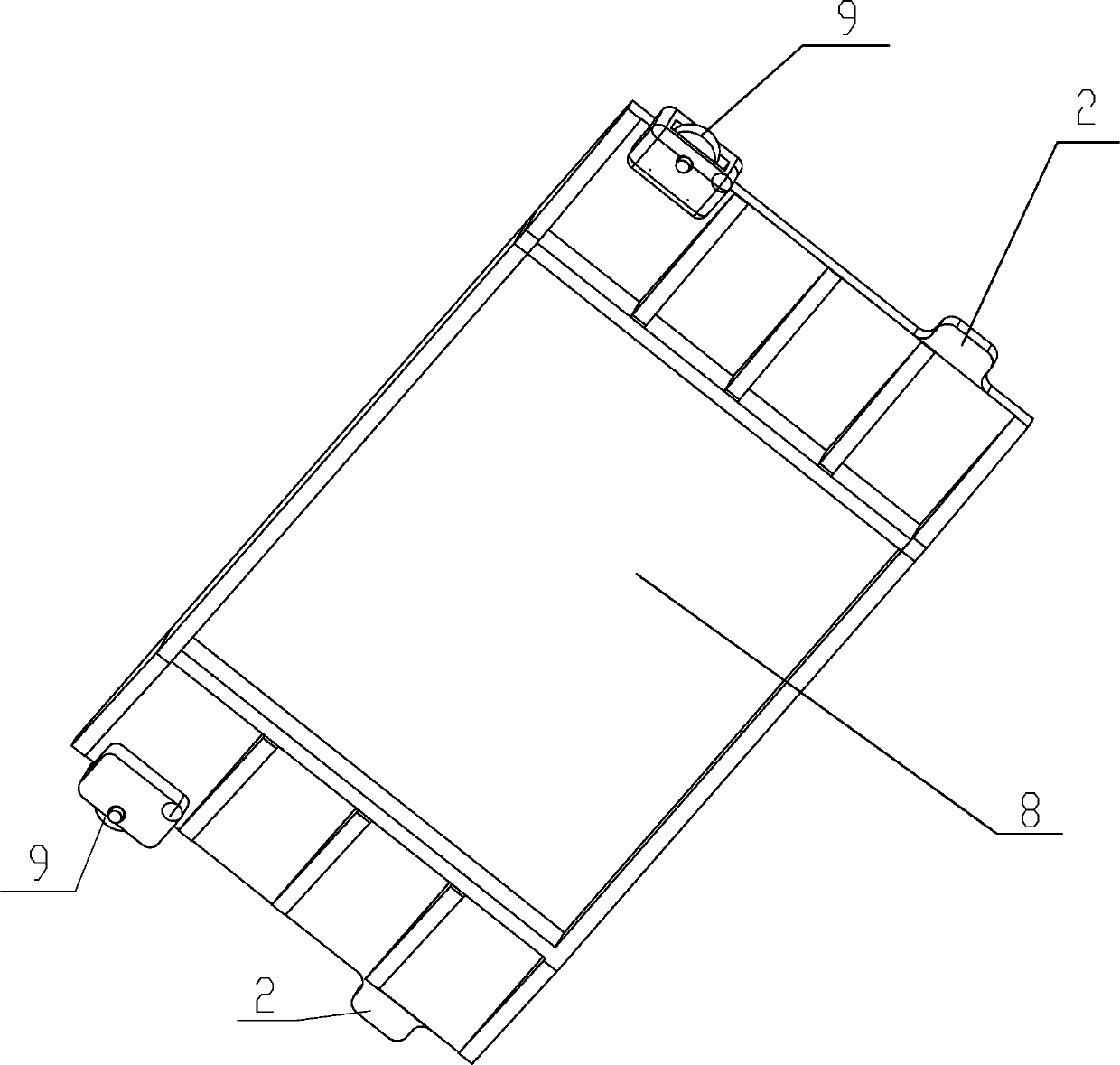

Internal surface cleaning machine

ActiveCN104289483AImprove working abilityIncrease contact frictionHollow article cleaningSurface cleaningEngineering

The invention relates to an internal surface cleaning machine. The internal surface cleaning machine comprises a machine body, a walking device, a dirt removing device, a cleaning device, a brushing and sweeping device, an air drying device and a collecting and releasing device. The walking device is located below the machine body and is fixedly connected with the machine body. The dirt removing device is located at the front end of the machine body, the cleaning device is located between the dirt removing device and the brushing and sweeping device, and the cleaning device is fixedly connected with the machine body. The air drying device is located behind the brushing and sweeping device. The collecting and releasing device is located on the left side of the machine body. The internal surface cleaning machine can finish dirt removing, cleaning, brushing, sweeping and air drying procedures, the cleaning time is shortened, the cleaning efficiency is improved, the integral rotating and cleaning function is achieved, the integral operability is high, the internal surface cleaning machine can be suitable for cleaning the inner surfaces of oil tank truck cylinders with different diameters, and the application range is wide; the contact friction force with the inner surfaces of the oil tank truck cylinders is large in the walking process, walking is stable and reliable, and the anti-skidding effect is achieved.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

Floating type train brake lining with replaceable friction blocks

The invention relates to a floating type train brake lining with replaceable friction blocks. The train brake lining is characterized in that the train brake lining comprises a brake lining back plate, a plurality of brake lining friction block bodies, a plurality of elastic supporting pieces and a plurality of round spring clips; installation holes are arranged on the brake lining back plate; elastic supporting pieces are provided with spherical supporting surfaces and central guide holes; lower portions of friction block bodies are provided with spherical supporting surfaces and positioning connection shafts with clamping grooves, and connection shafts can penetrate through central guide holes of elastic supporting pieces and positioning holes of the back plate and are locked on the back plate by round spring clips to achieve floating connection; and friction block bodies are polygonal block bodies with blind holes in centers, and every three friction block bodies form an interlocking group, so that rotation of friction block bodies during operation of the brake lining is prevented. By the aid of the brake lining, the maximum contact friction area between the brake lining and a braking disk can be obtained during braking of a train, so that the braking process is stable, functions such as damping, vibration absorption, noise reduction and heat dissipation are provided, friction block bodies are easy to replace, the operation cost of the train is reduced, and the brake lining can be widely used in braking systems of high-speed trains.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Method for processing rectangular aluminum alloy waveguide by multi-pass rolling drawing

The invention relates to a method for processing a pipe with a rectangular section through multi-pass rolling drawing. The method is a novel plastic forming process formed by combining the advantages of two conventional deformation processes, namely rolling and drawing. In the method, metal is rolled by a plurality of groups of rollers with hole patterns, and an aluminum alloy waveguide with highshape and size accuracy and internal quality is manufactured at low cost. A flexible roller group replaces the conventional die to form the rectangular aluminum alloy waveguide, and a flow function is introduced to smooth a three-dimensional cavity formed by the rollers, so that contact friction force in the process of deforming a blank is reduced, and stability in the process of deforming the blank is improved; and by the novel processing method, the metal has larger deformation than that drawn by a fixed die, drawing force is small, processes can be reduced, energy consumption is reduced, and metal which is difficult to deform is easy to process.

Owner:CHONGQING UNIV

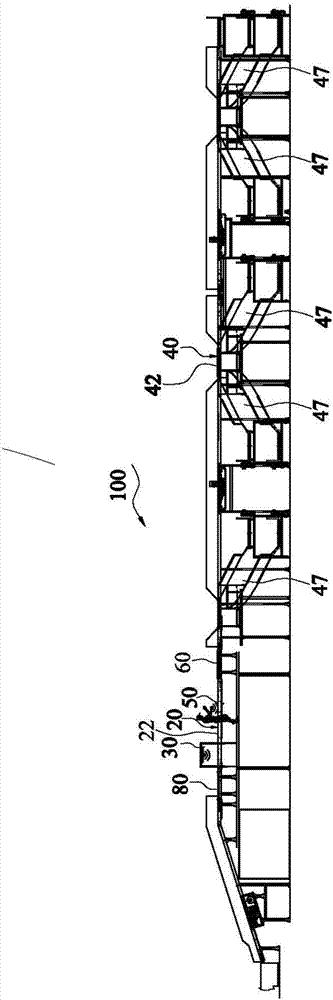

Open type TBM plane sliding stepping device and method

The invention discloses an open type TBM plane sliding stepping device and method. The device comprises a base board, lifting mechanisms and a rear support used for supporting a saddle and supporting boots of a TBM. The lifting mechanisms are arranged on the two sides of the front portion of the base board. The rear support is connected to the rear portion of the base board through a pull rod. The two ends of the pull rod are hinged to the base board and the rear support respectively. A sliding board used for supporting the front portion of the TBM is arranged on the base board. A pushing hydraulic cylinder is arranged behind the sliding board and the other end of the pushing hydraulic cylinder is hinged to a lug board on the base board. Upper supporting boards of the lifting mechanisms are connected with a left shield and a right shield of the TBM. According to the method, the friction difference principle that intermetallic contact friction between the sliding board and the base board is small and friction between the base board and a concrete bottom board is large is used, the sliding board and the TBM are jointly pushed by the pushing hydraulic cylinder to slide forwards along the base board, forward movement is achieved through multiple stepping pushing circulations, a pushing bearing reaction device does not need to be independently arranged, bearing reaction supplied through welding is not needed, the structure is simple, and cost is low.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

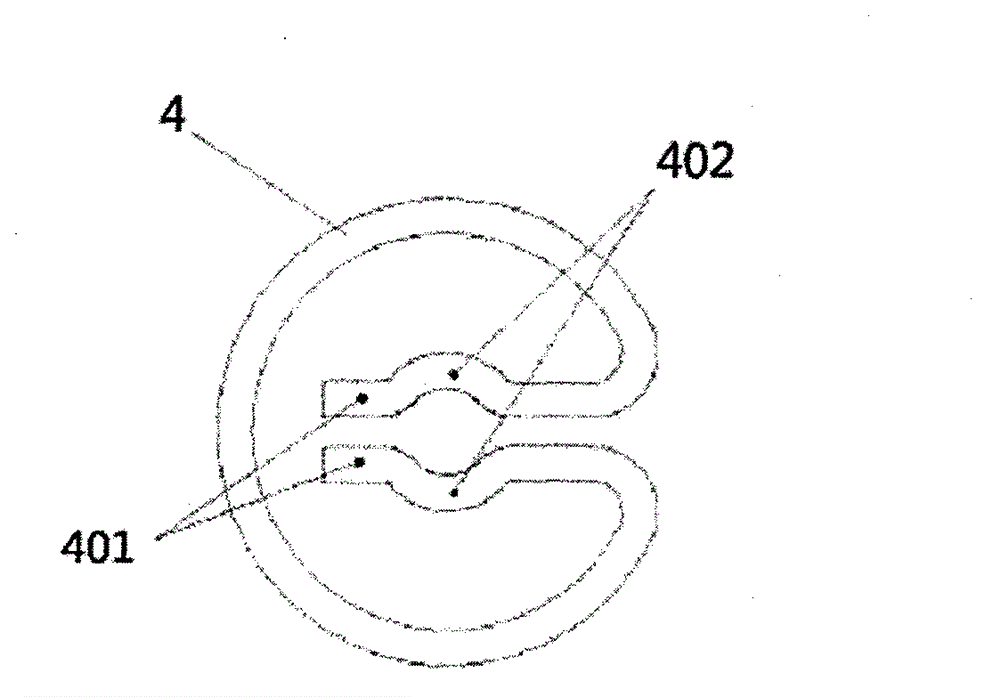

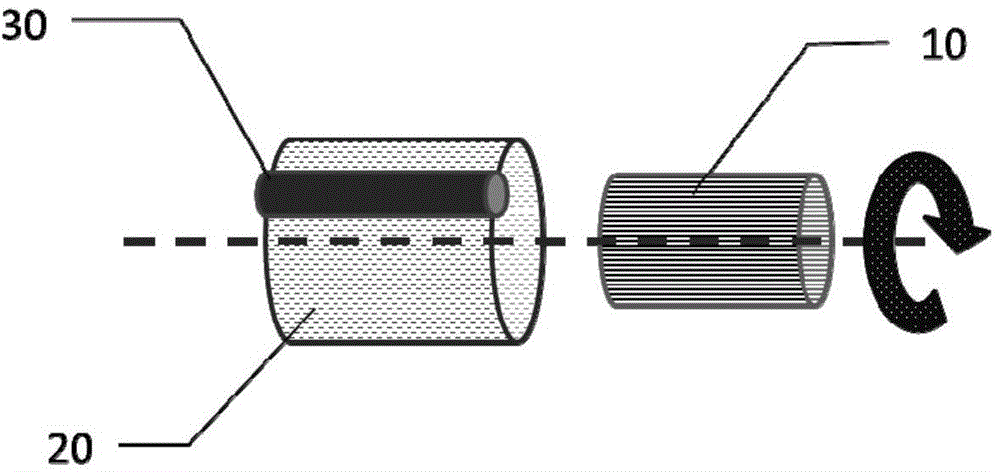

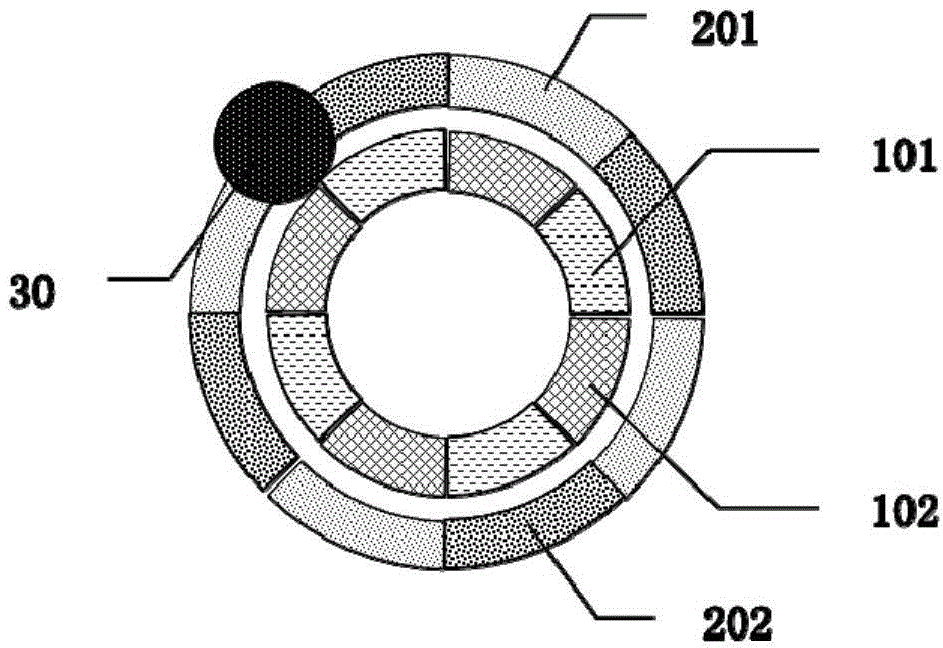

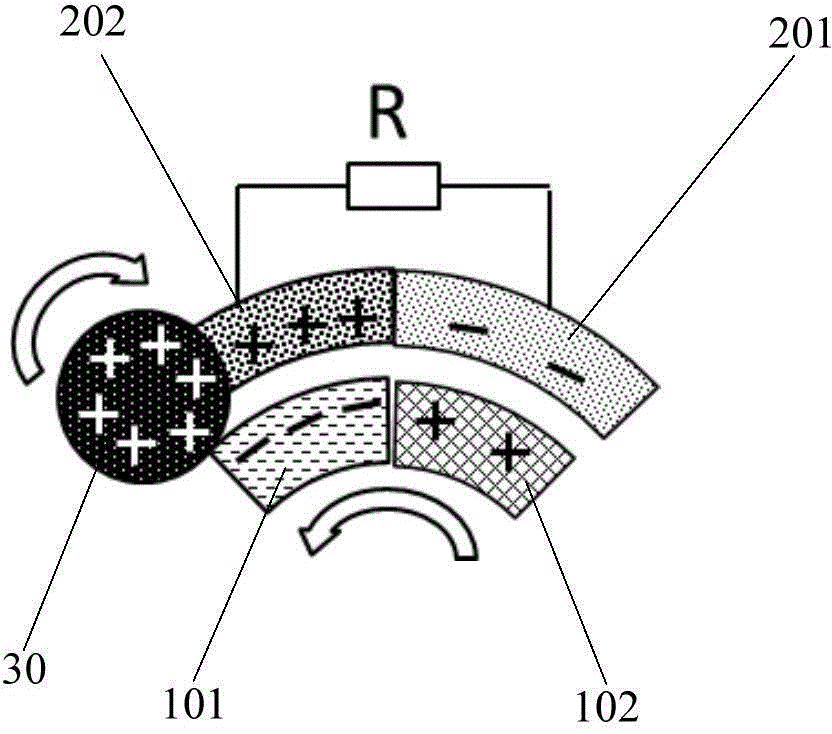

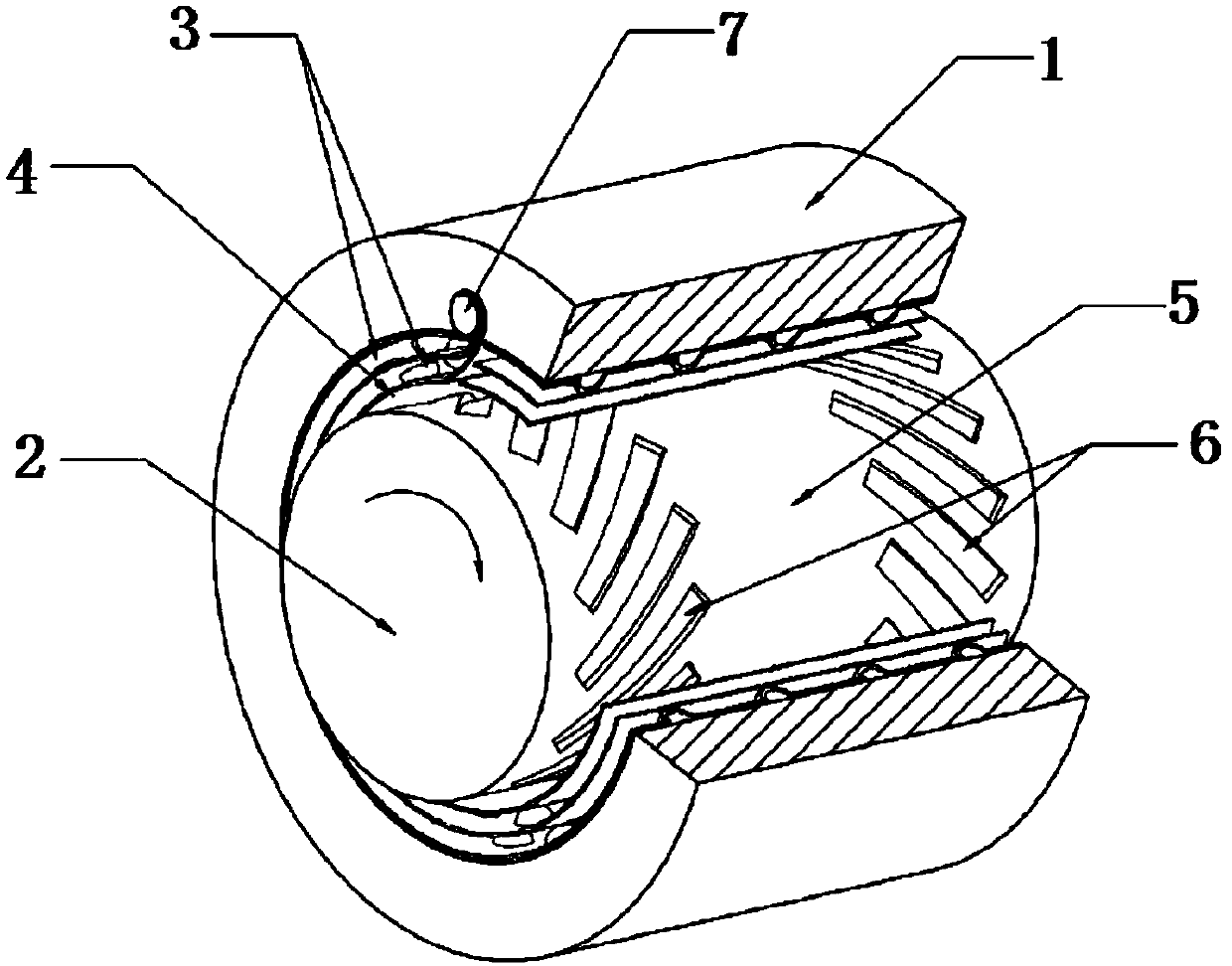

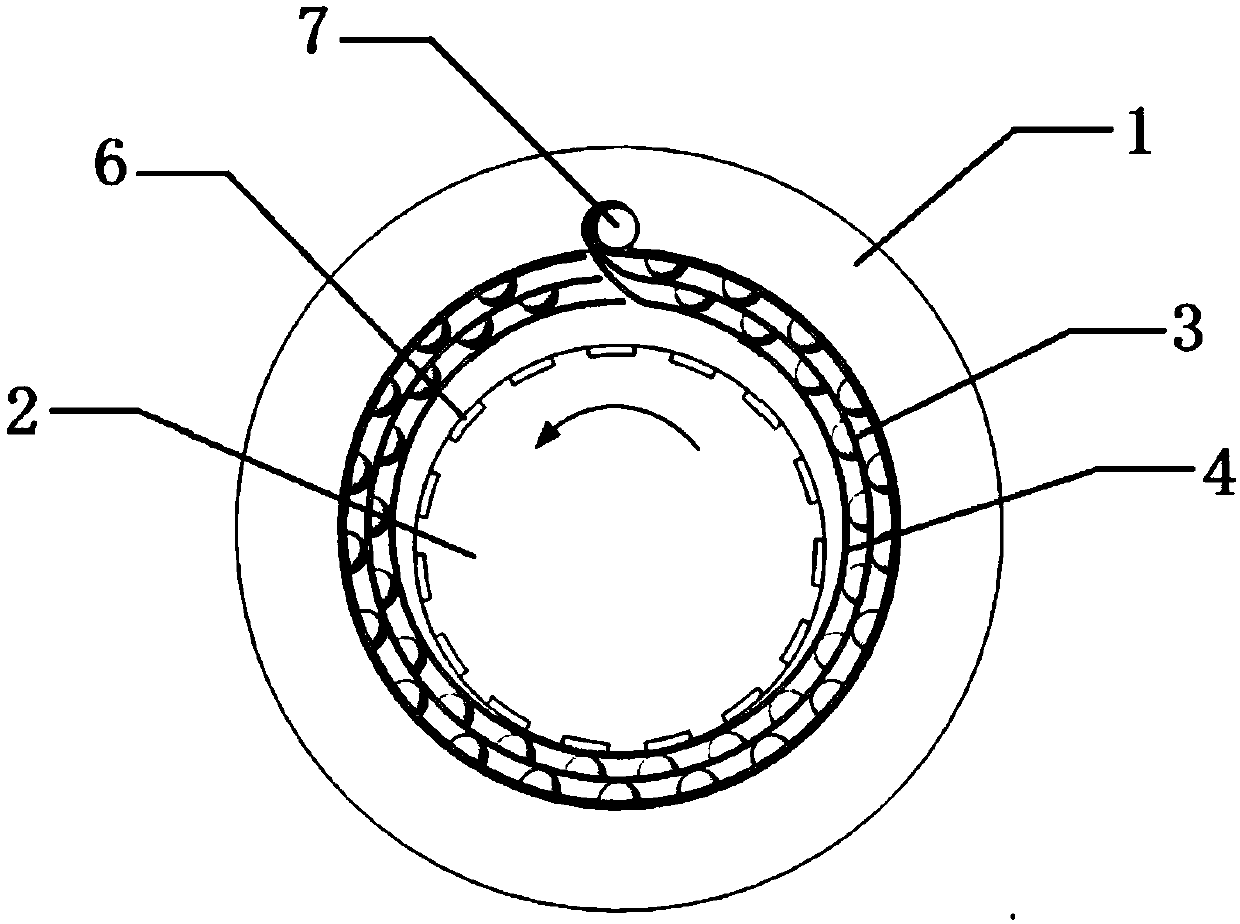

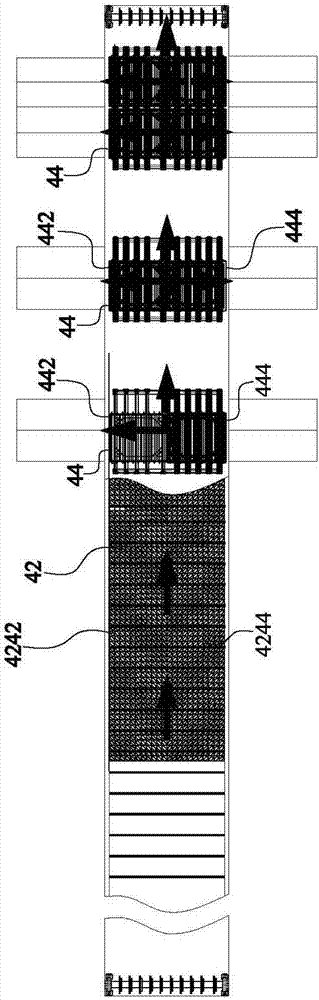

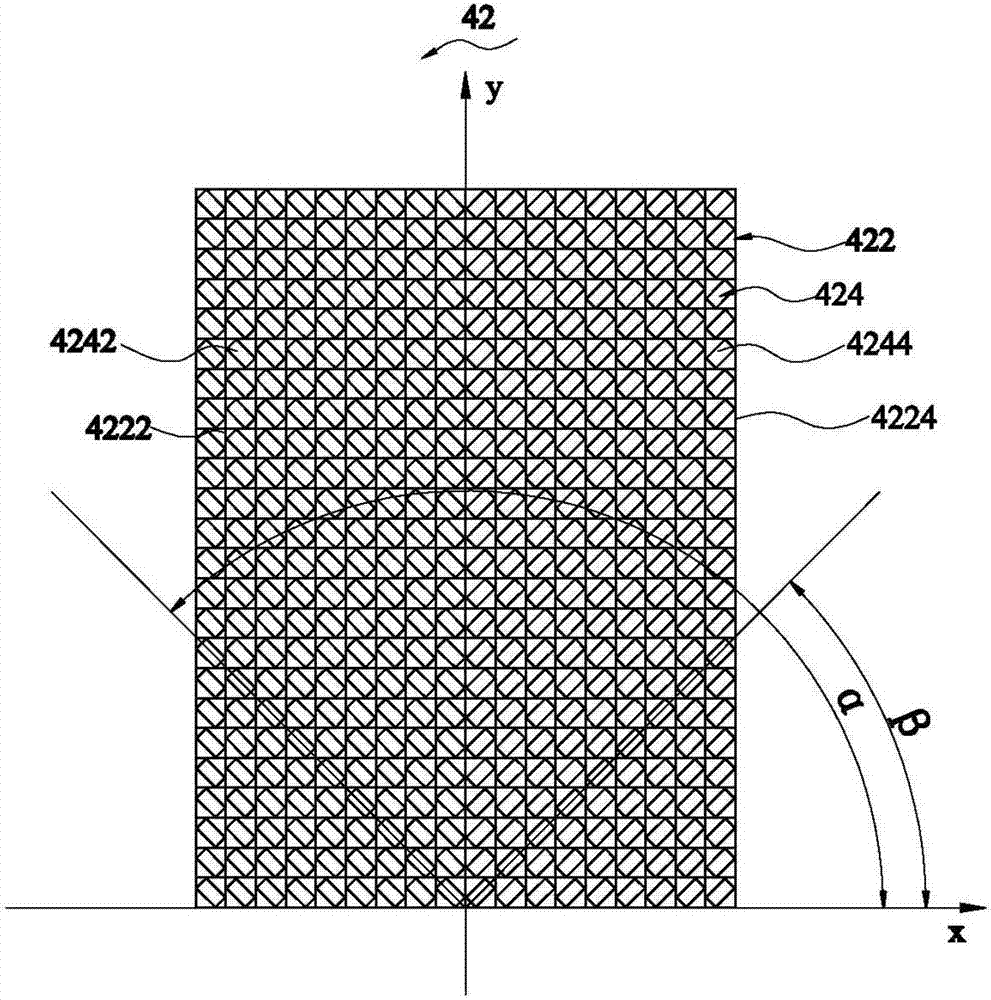

Rotary type friction nanometer electric generator

The invention relates to the technical field of electric generators and discloses a rotary type friction nanometer electric generator. The rotary type friction nanometer electric generator comprises a first part (10) which comprises at least one group of a first friction unit (101) and a second friction unit (102), a second part (20) and a third part (30), wherein the second part (20) and the first part (10) which arranged at an interval in a coaxial manner can move relative to each other, and the third part (30) is connected with the second part (20); during relative movement processes, the third part (30) is in a contact friction relation with the first friction unit (101) and the second friction unit (102), and triboelectric charges are respectively generated on the first friction unit (101) and the second friction unit (102). Via use of the rotary type friction nanometer electric generator, output performance of devices can be improved.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Damper

InactiveUS6968930B2Good effectImprove staminaMultiple spring combinationsLiquid springsEngineeringContact friction

A damper includes a cylinder, and a piston rod inserted into the cylinder through an opening portion of the cylinder. The piston rod includes front and base ends, and a frictional engaging member provided on an outer surface along a longitudinal direction thereof extending from a front end side toward the base end. A resistance device is disposed at the opening portion of the cylinder. The resistance device contacts the frictional engaging member and deforms elastically to provide frictional resistance to the piston rod as the piston rod is withdrawn from the cylinder.

Owner:NIFCO INC

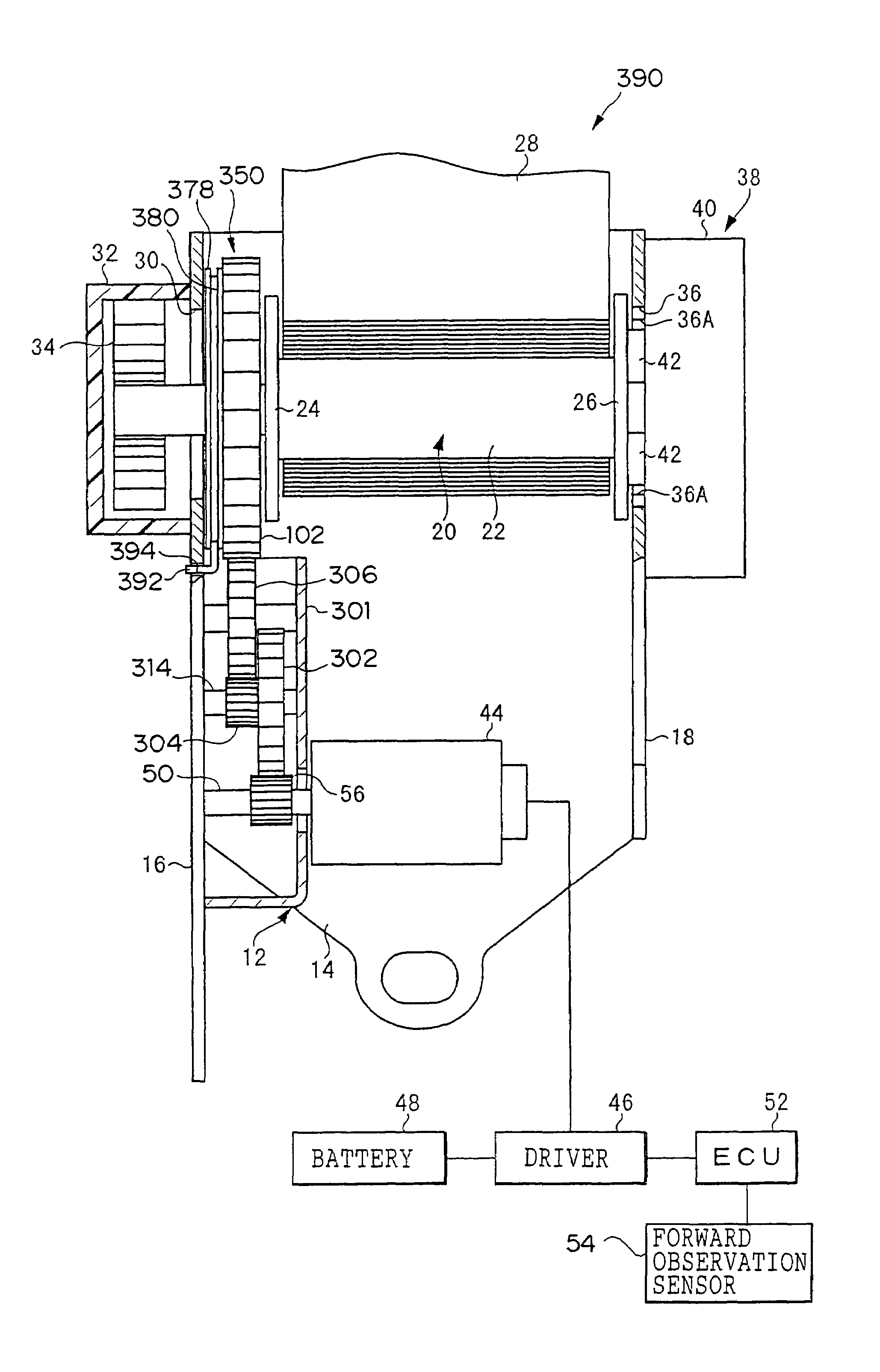

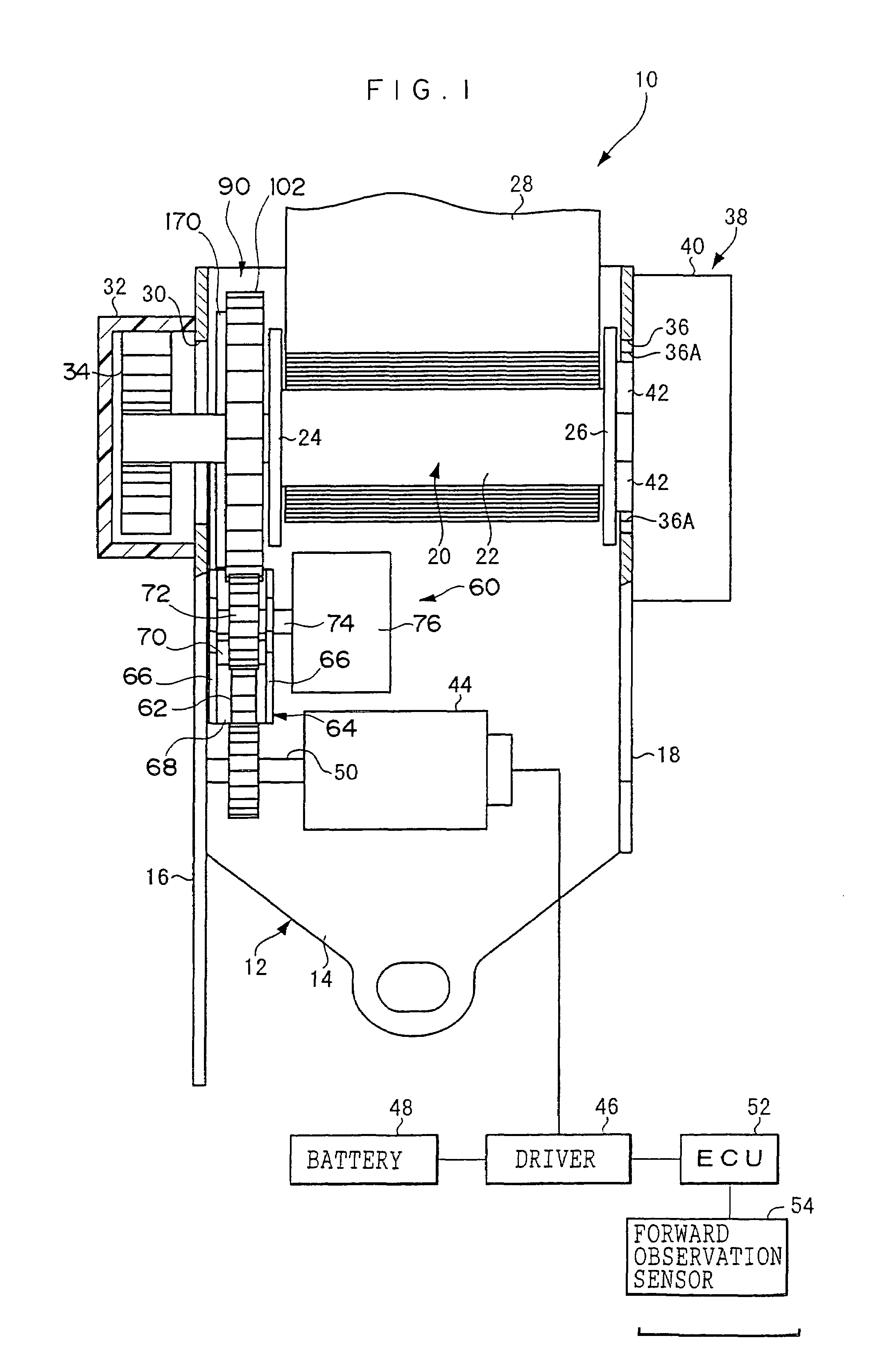

Webbing retractor

A webbing retractor which, by causing relative rotation between a prime mover rotating body and a rotating disc, connects the prime mover rotating body and a driven shaft which is connected to a take-up shaft of a webbing belt. A planet gear is pivotally supported at a plate having a braking piece and meshes with a sun gear. The plate is supported so as to be swingable around the sun gear. When the sun gear is driven to rotate at greater than a predetermined speed, the planet gear begins to circle around the sun gear against urging force of a spring attached to the plate, and makes the plate rotate such that the braking piece slidingly contacts the friction ring. Due to this braking, the rotating disc connected to the friction ring rotates relative to the prime mover rotating body.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

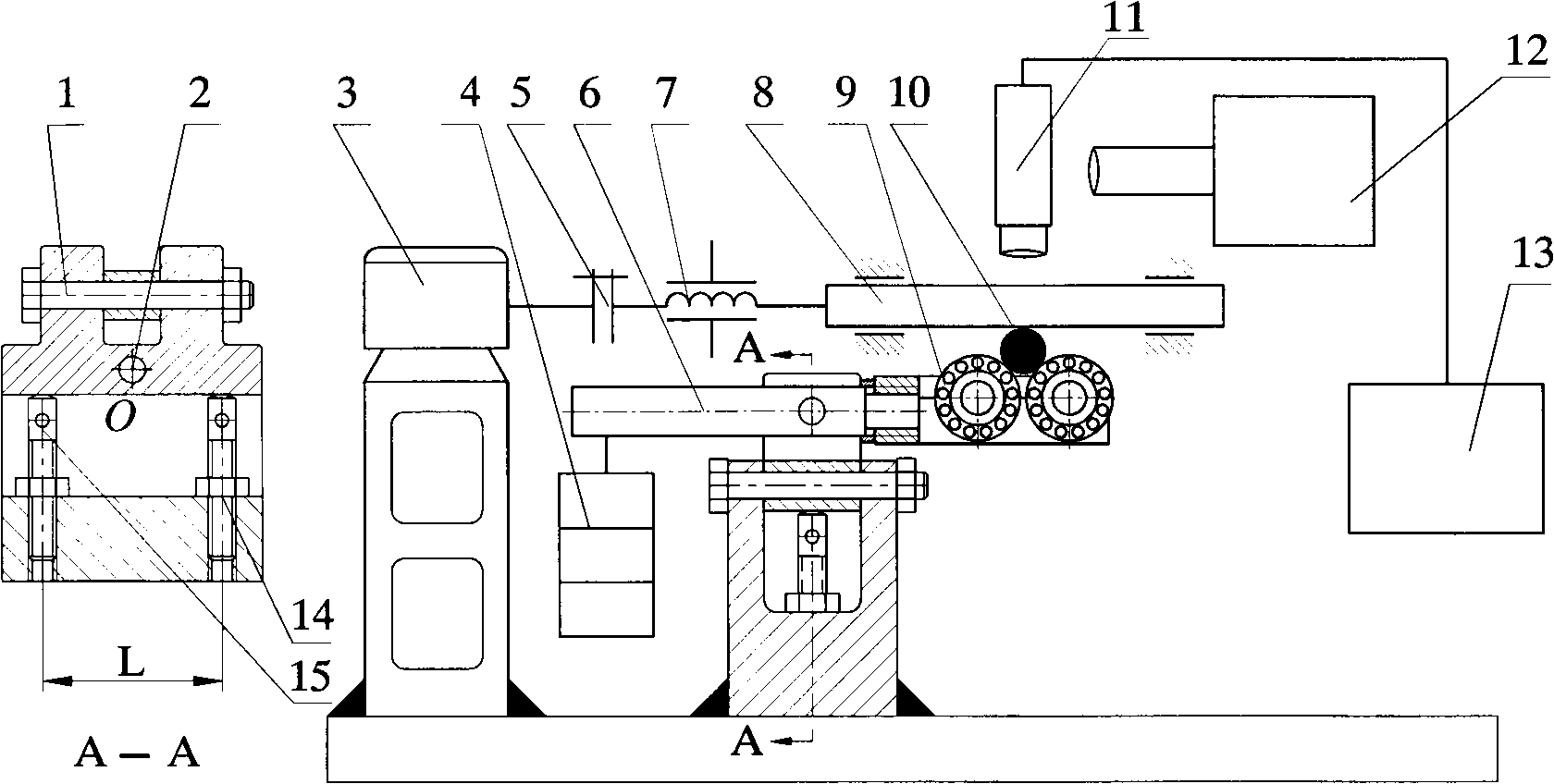

Deflective roller friction pair lubricating oil film measurement experiment table

InactiveCN103852016AAdjust Skew AngleSimple structureUsing optical meansRolling resistanceEngineering

The invention provides a deflective roller friction pair lubricating oil film measurement experiment table used for measuring pure rolling friction. According to the light interference principle, when a roller is in a deflective elastohydrodynamic working state, the thickness and shape of a line contact friction pair lubricating oil film are measured. The deflective roller friction pair lubricating oil film measurement experiment table has the following four advantages that a test piece is a cylindrical roller, and the deflection angle of a line contact pair in the axial direction of the roller can be accurately adjusted according to demands when the cylindrical roller makes contact with transparent materials; contact stress between the test roller and the transparent materials is in an elastohydrodynamic state, and the total load capacity is larger than or equal to 3000 N; the largest circular section of the cylindrical roller is stressed, and under the action of the force, elastic deformation of the roller exceeds deflection amount of the roller; the test roller is supported by a bearing idler wheel, and rolls purely along the largest circular section of the test roller. The deflective roller friction pair lubricating oil film measurement experiment table is simple in structure, high in practicability and reliable in measurement of the thickness and shape of the deflective cylindrical roller friction pair lubricating oil film in rolling friction, and axial deflection amount of the line contact friction pair can be determined accurately and easily.

Owner:CHANGZHOU UNIV

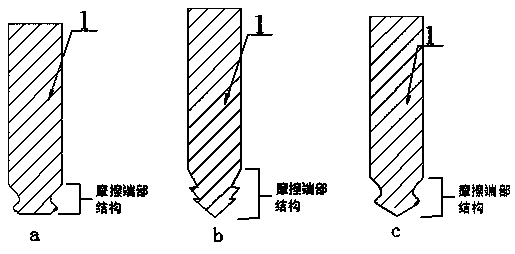

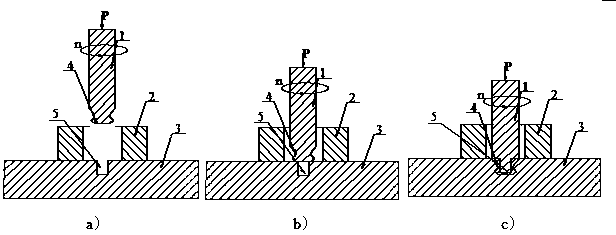

Steel stud and thick aluminum plate frictional stud welding method

ActiveCN103846545AReduce the impactGuaranteed flatnessWelding/soldering/cutting articlesNon-electric welding apparatusStud weldingWeld strength

The invention discloses a steel stud and thick aluminum plate frictional stud welding method, which is characterized in that the welding end part of a steel stud is subjected to certain structural design, the steel stud is rotated, is applied with frictional acting force, and is contacted and rubbed with an aluminum plate, and the steel stud is slowly embedded into the thick aluminum plate. Double characteristics of frictional stud welding and threaded connection are realized, so that a welded joint with good performance is manufactured. By the method, steel studs with middle and small diameters are welded with thick aluminum plates. According to the method, the welding strength of the stud welding can be obviously improved, the influence of defects in common welding on the joint quality is reduced, and the service life is greatly prolonged.

Owner:NANJING UNIV OF SCI & TECH +1

Elastic support foil hydrodynamic gas bearing with inherent structure pre-wedge space

PendingCN107725593AReduce shakingWhirl suppressionGas cushion bearingsSliding contact bearingsContact timeEngineering

The invention discloses an elastic support foil hydrodynamic gas bearing with inherent structure pre-wedge space. The elastic support foil hydrodynamic gas bearing comprises a bearing body and a rotary shaft located in the bearing body. An elastic support element is arranged on the inner side of the bearing body. Top-layer flat foil is arranged between the elastic support element and the rotary shaft. A smooth shaft segment is arranged on the axial middle area of the surface of the rotary shaft. The positions, located on the two sides of the smooth shaft segment, of the surface of the rotary shaft are each provided with a line of inclined grooves. The inner side of the top-layer flat foil surrounds and wraps the rotary shaft, a pre-clearance is formed between the top-layer flat foil and the rotary shaft, meanwhile, the elastic support element and one end of the top-layer flat foil are fixed to the same position of the bearing body, and the other end of the top-layer flat foil is free.The elastic support foil hydrodynamic gas bearing has the beneficial effects that a hydrodynamic gas film can be formed at the relatively-low rotating speed with small foil deformation, the rotary shaft and the bearing body are in contact uniformly in the start stage and the stop stage, the contact friction time between the rotary shaft and the bearing body is shortened, wear between the rotary shaft and the bearing body is reduced, and the operation stability and reliability of a system are improved.

Owner:XI AN JIAOTONG UNIV +1

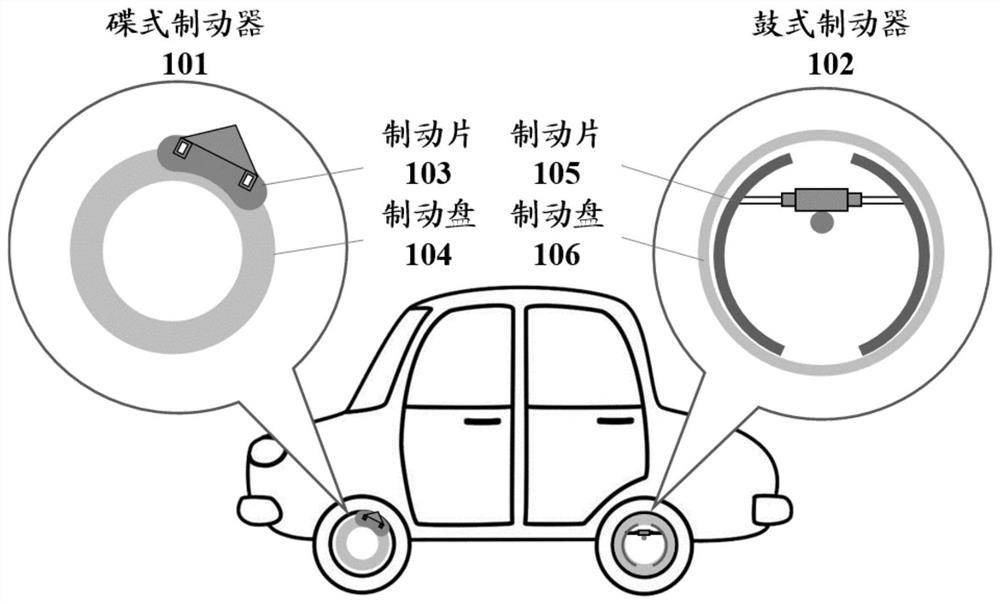

Magnetofluid disc brake

InactiveCN102817939ASave resourcesConserve limited resourcesLiquid resistance brakesContact frictionPiston rod

A magnetofluid disc brake comprises a magnetofluid brake drive mechanism and brake units, and the magnetofluid brake drive mechanism comprises brake cylinders, magnetofluids, floating parts, elastic elements, electromagnetic coils and a controller. A brake pedal and a brake switch are utilized to transmit a brake signal to the controller, the controller and the electromagnetic coils are utilized to control the magnetic fields of the magnetofluids in the brake cylinders, the change of the magnetic fields of the magnetofluids is utilized to control the floatage of the floating parts in the magnetofluids, the floatage of the floating parts is utilized to drive pistons and piston rods to move, the piston rods are utilized to drive brake bases and brake pads to be in frictional contact with a brake disc for braking, and thereby the purpose of utilizing the controller to control braking is implemented.

Owner:林智勇

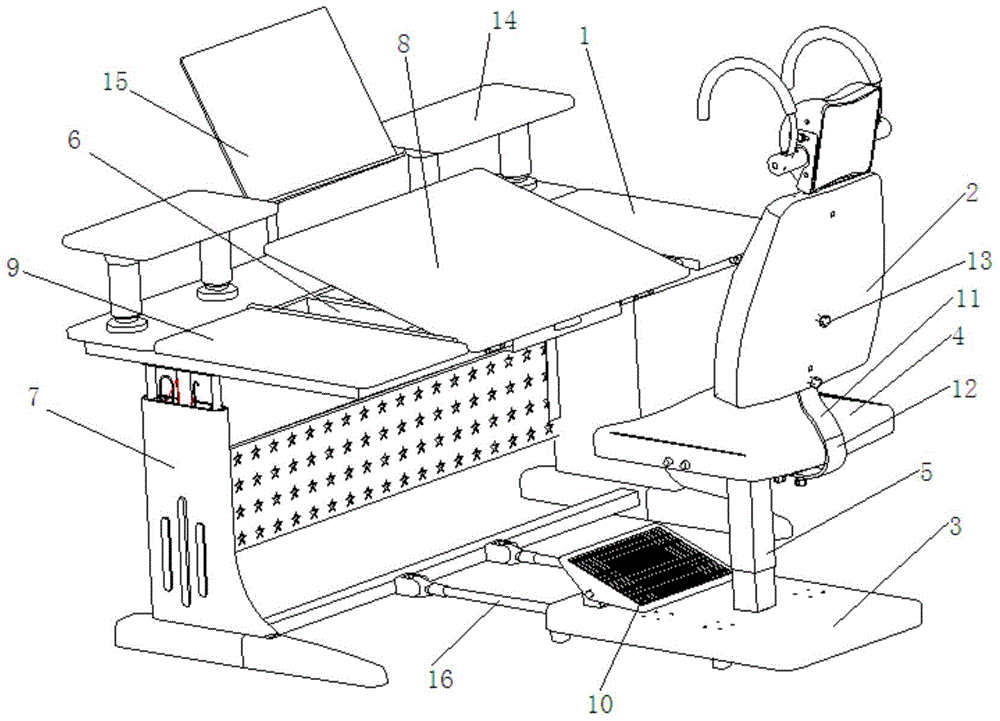

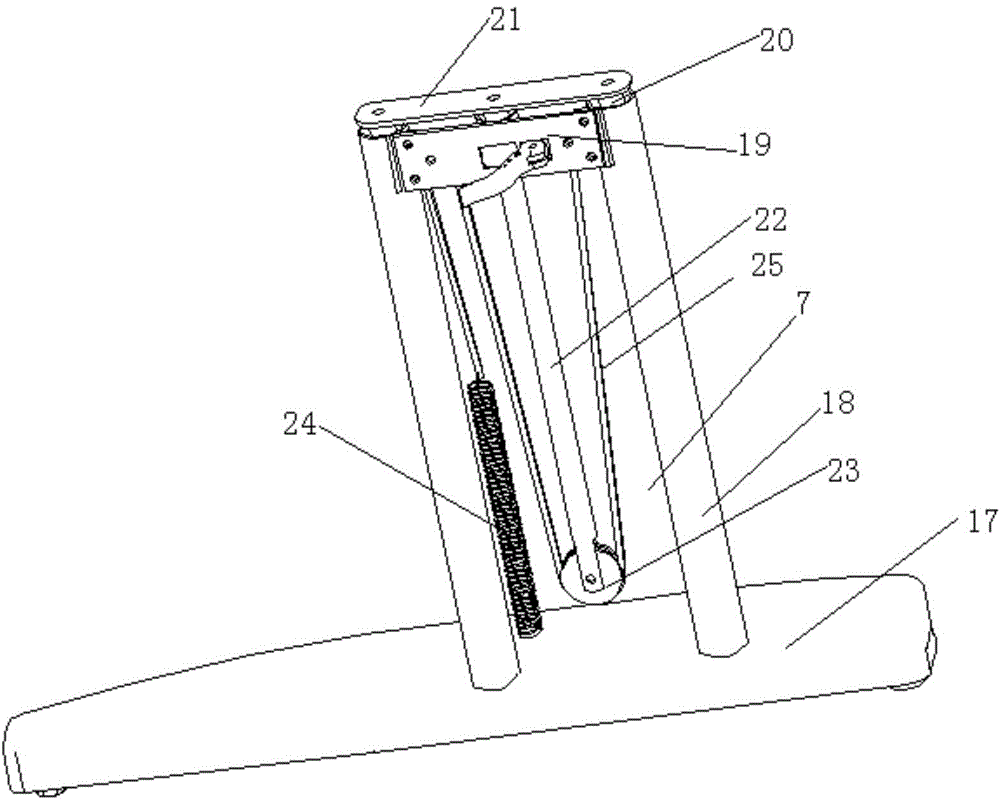

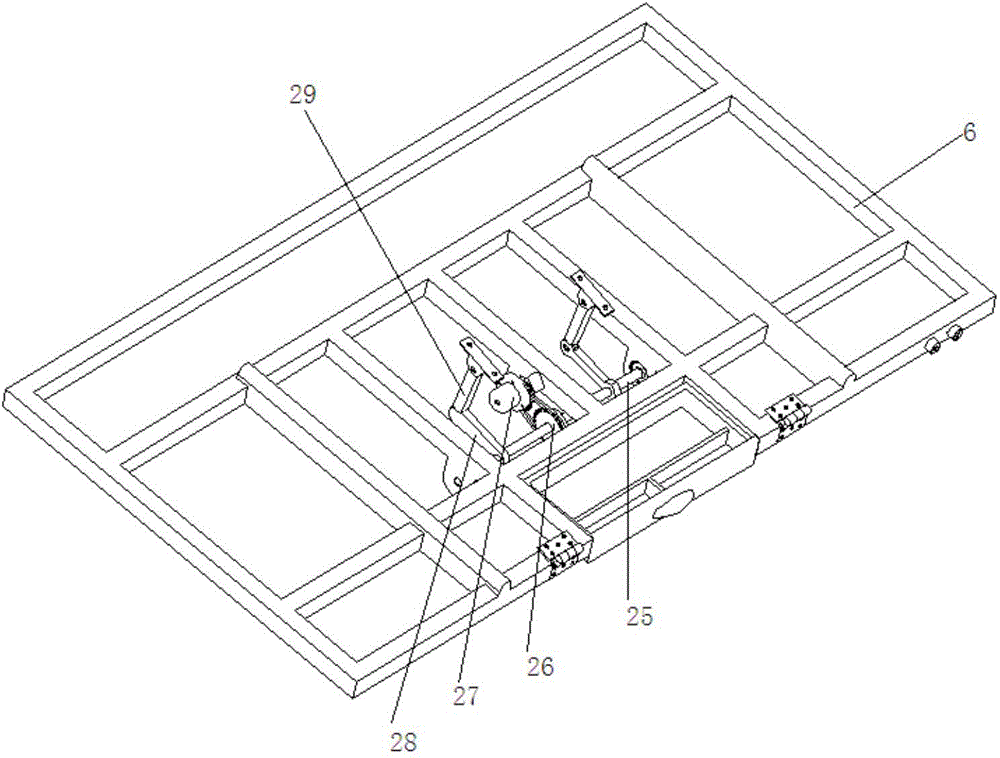

Household type myopia prevention learning desk and chair combination

The invention discloses a household type myopia prevention learning desk and chair combination which comprises a learning desk and a learning chair, wherein the learning chair comprises a chair base; the chair base is mounted on two parallel guide rods in a sliding manner; linear bearings which are in sliding linear fit with the guide rods are fixedly arranged on the chair base; the front ends of the guide rods are fixedly connected to a learning desk stander; the middle parts and the rear ends of the guide rods are fixedly provided with a front support and a rear support which are in contact with the ground respectively; a front chain wheel is mounted on the front support, and a speed reduction motor is mounted on the rear support; the speed reduction motor is connected with a rear chain wheel in a driving manner. The household type myopia prevention learning desk and chair combination is suitable for being used by a student at home; a desktop and a chair do not generate contact friction with a blanket or a floor when moving relative to each other; the overall height of the desktop is convenient to adjust; the front-and-back position and the height of the chair can be freely adjusted, and the chair cannot rotate freely; the use comfortableness of the student is improved, and myopia is prevented.

Owner:安徽堉帝智能科技有限公司

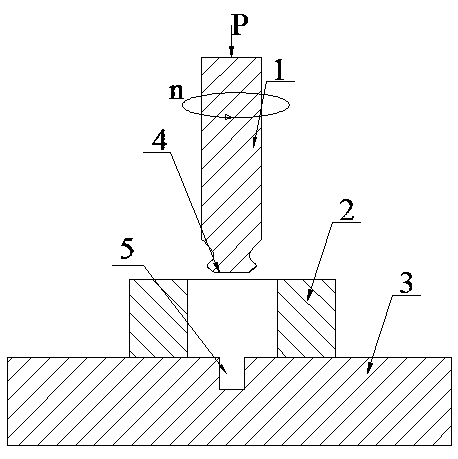

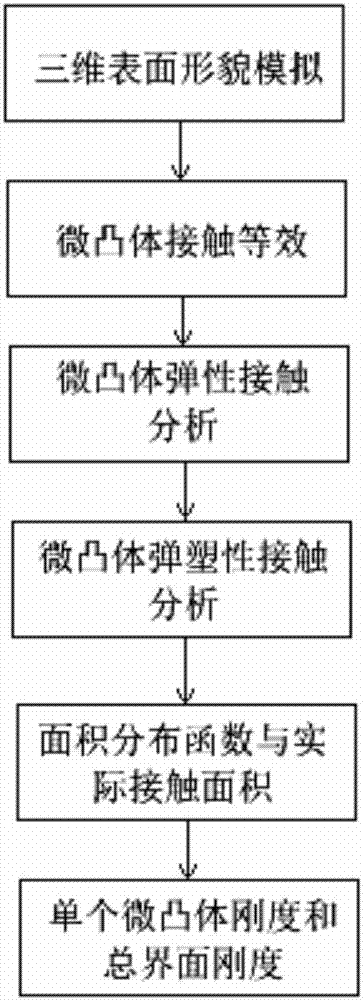

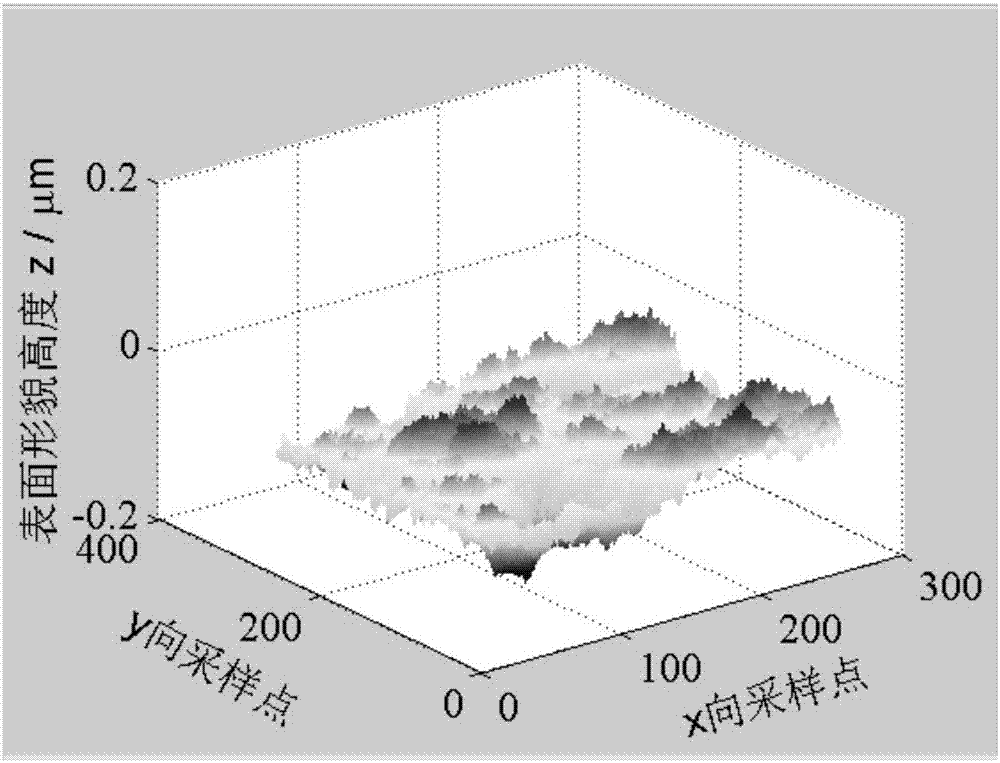

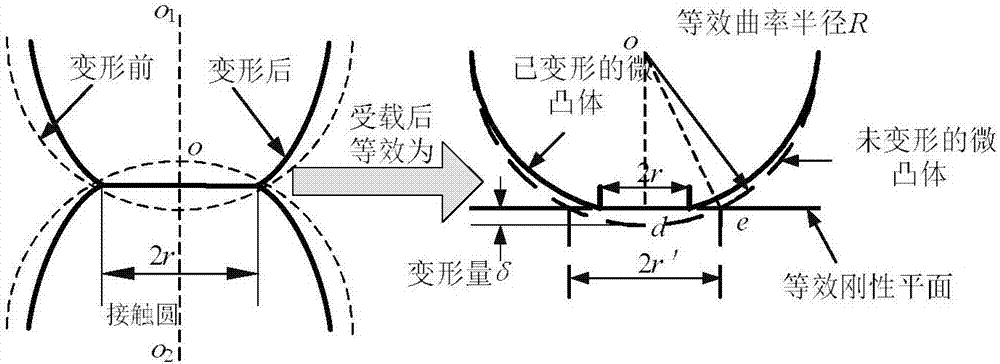

A normal interface rigidity prediction method considering three-dimensional fractal

InactiveCN106991219AControl Surface DynamicsGeometric CADDesign optimisation/simulationComputer scienceTopography

The invention relates to a normal interface rigidity prediction method considering three-dimensional fractal, the method comprising the steps of: improving a curvilinear function describing two-dimensional fractal into a correction function simulating three-dimensional fractal topography and expressing amplitudes of peaks and troughs described by the function as contact deformation quantities; making contact between two rough micro-bulges equivalent to contact between a rigid plane and an equivalent micro-bulge, wherein the actual contact area between the equivalent micro-bulge and the rigid plane meets a=pi R delta; separately calculating the deformation quantities of an elastic deformation stage and an elastoplastic deformation stage; calculating an area distribution function and the actual contact area; calculating the rigidity of a single micro-bulge and total interface rigidity; calculating the rigidity kn1 of the elastic stage, the rigidity kn2 of the elastoplastic stage and the total interface rigidity. The prediction method for acquiring the between-interface rigidity of precision machinery is simple and easy to implement. The method takes into consideration elastoplastic deformation of micro-bulges, contact friction factors and three-dimensional fractal distribution and obtained results can provide technical reference for prediction and control of dynamic characteristics of interfaces.

Owner:NORTHEASTERN UNIV

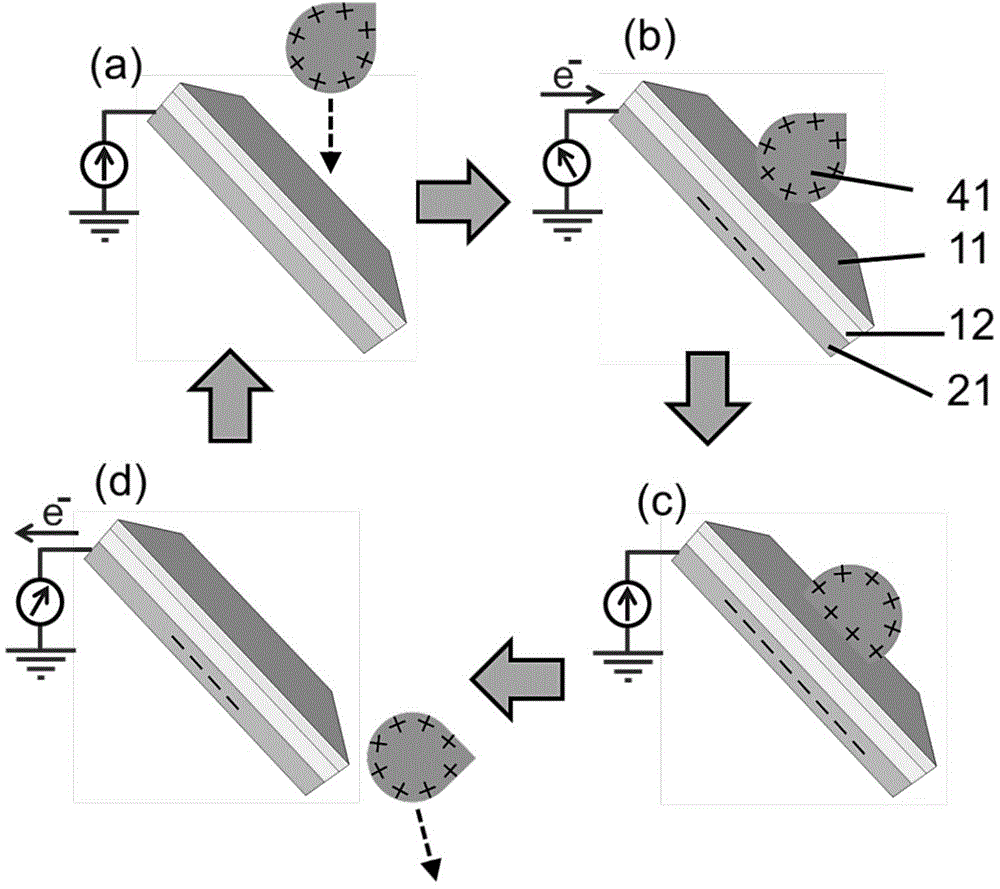

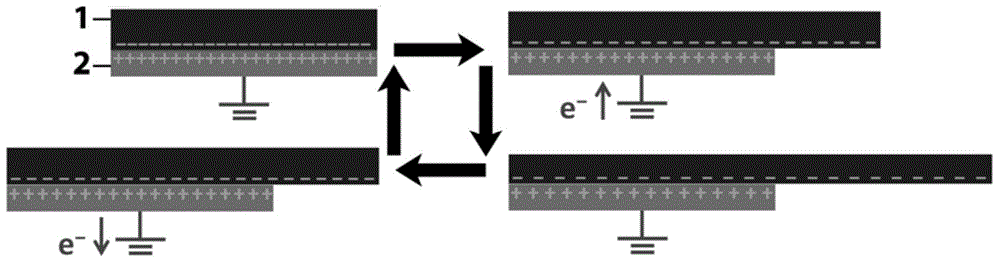

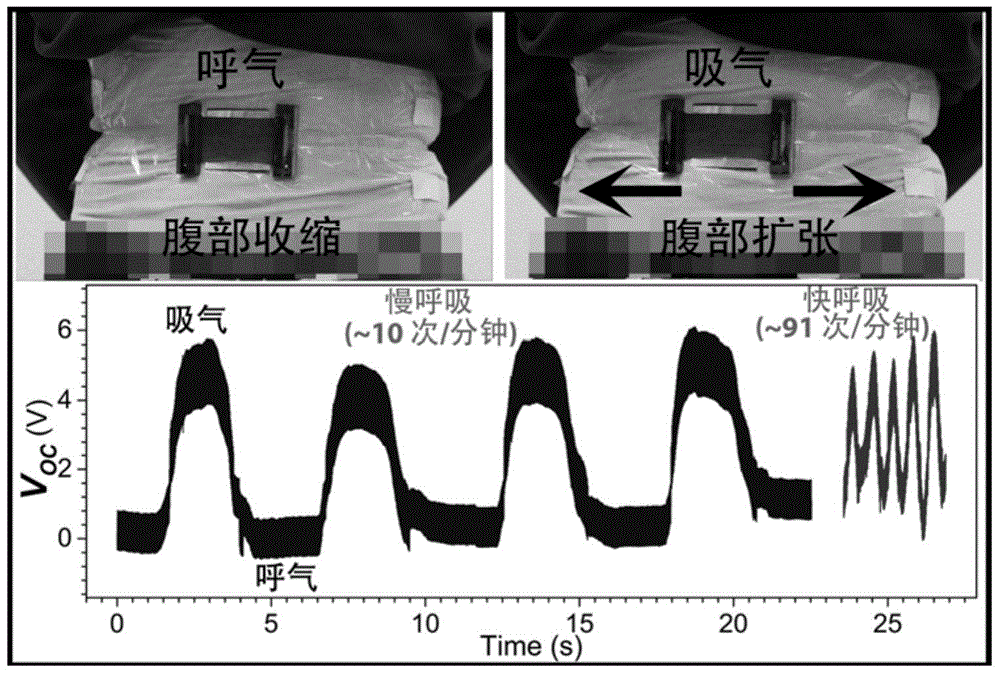

Flexible sensor for detecting human body motion and production method of flexible sensor

InactiveCN104873200AEasy to prepareLow costDiagnostic recording/measuringSensorsHuman bodyElectrical polarity

The invention relates to a flexible sensor for detecting human body motion and a production method of the flexible sensor. The flexible sensor comprises an electrode layer and a flexible polymer layer disposed on the electrode layer. The flexible polymer layer and the electrode layer have triboelectric charges same in electric charge quantity but opposite in polarity, and electric potential of the electrode layer is changed by means of stretching and retracting of the flexible polymer layer so as to drive electrons to flow between the electrode layer and a ground electrode in a reciprocating manner to generate electric signals. The flexible sensor can be used for detecting the human body motion, is simple in production method, low in cost, optionally adjustable in size, portable, high in detecting precision and the like, can be used for monitoring the human body motion in real time and has promising application prospect in the fields of medical treatment, sports, safety protection and the like.

Owner:UNIV OF SCI & TECH BEIJING

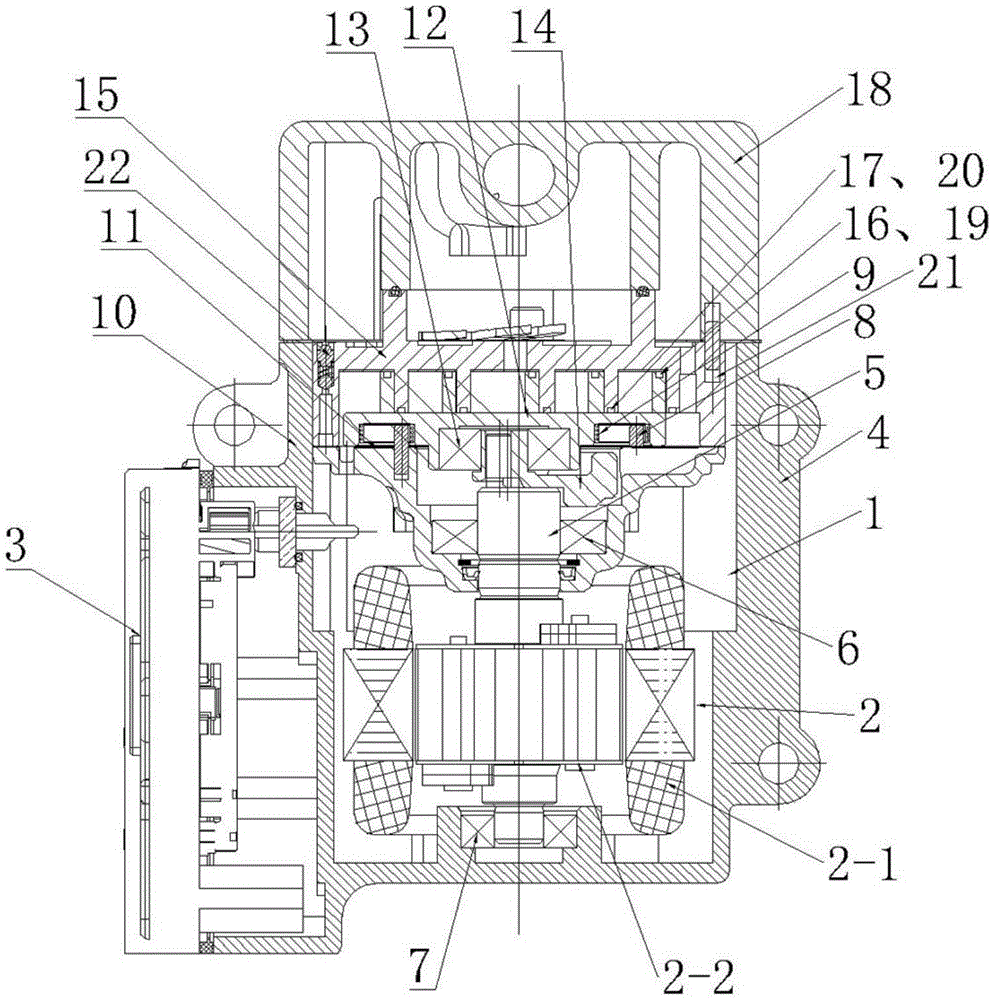

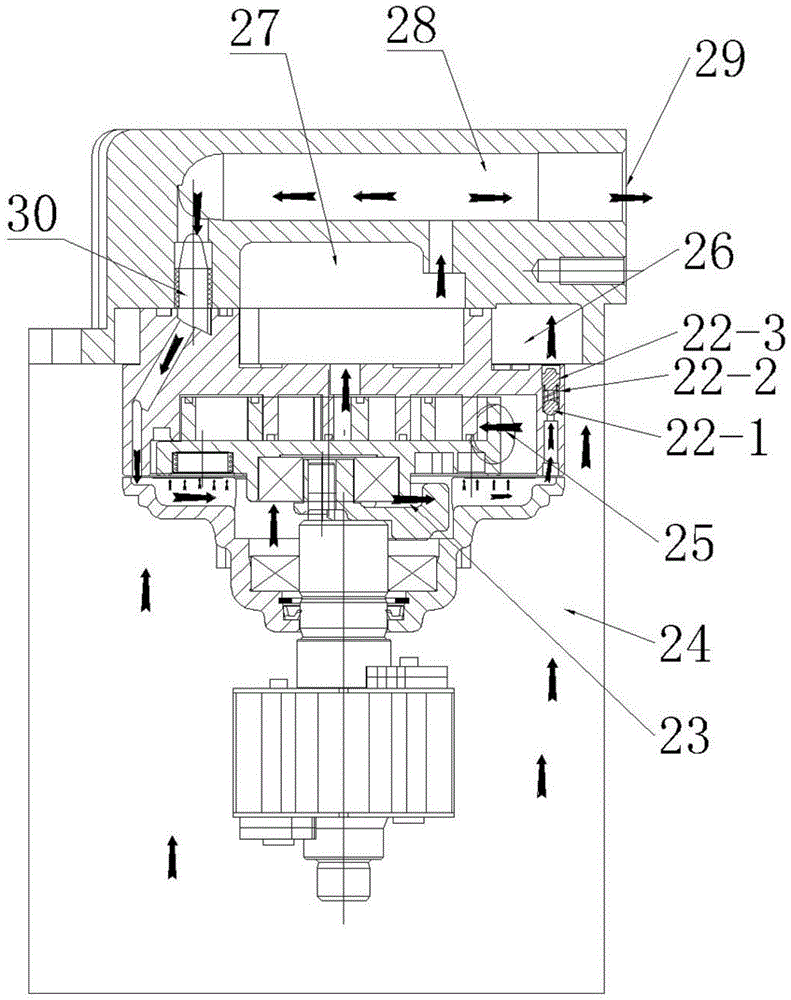

Automobile vortex type electric air conditioning compressor assembly

ActiveCN104088786AImprove sealingSimple structureRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsBrushless motorsWear resistant

The invention discloses an automobile vortex type electric air conditioning compressor assembly. The automobile vortex type electric air conditioning compressor assembly is an integrated semi-closed structure composed of a vortex type compression device, a motor and a controller, wherein the vortex type compression device comprises a shell, an end cover, a support, a direct current brushless motor, and a pair of circle involute equation type mobile plate and fixed plate. A stator of the motor is fixed in the shell; a rotor of the motor is installed on a main eccentric shaft; the main eccentric shaft is fixed in the support and the shell through a main shaft upper bearing and a main shaft lower bearing; the mobile plate is fixed on a wear-resistant pad on the support through anti-rotating pins and anti-rotating rings on the back surface; the fixed plate is fixed on the support; the end cover is fixed on the shell and the fixed plate; the stator of the motor is connected to the controller installed in an external groove of the shell through a binding post. The automobile vortex type electric air conditioning compressor assembly is simple in structure, prevents mechanical contact friction because the mobile plate and the fixed plate work sealingly in a back press manner, increases gas sealing property, and is high in efficiency, low in power consumption and convenient for maintenance.

Owner:GUANGDONG GUANGSHUN NEW ENERGY POWER TECH CO LTD +2

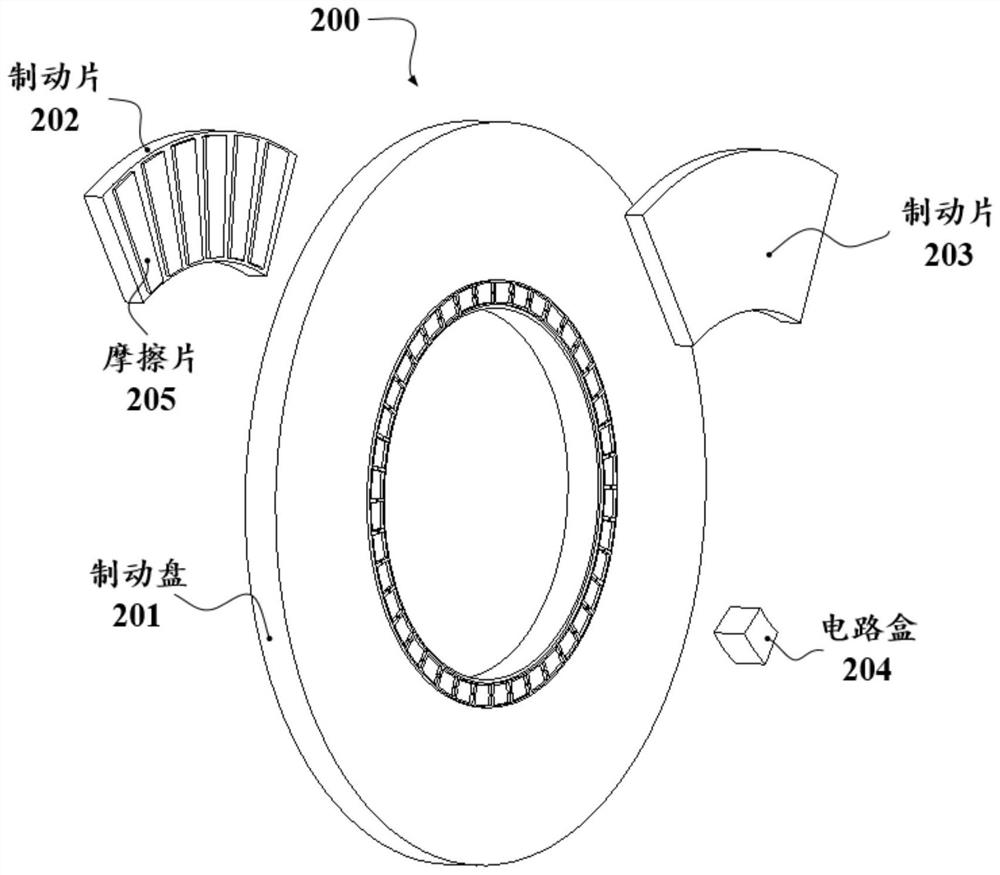

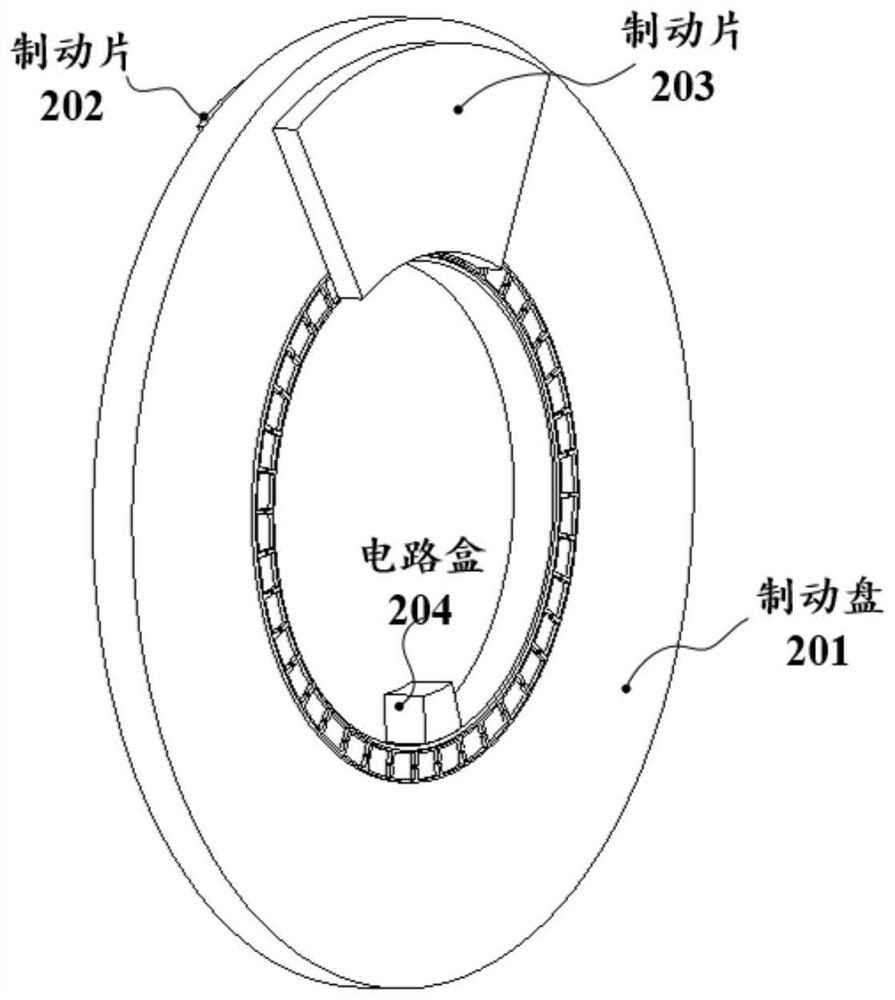

Friction power generation device based on friction brake and friction brake

ActiveCN111692250AImprove efficiency under different loadsImprove stabilityBraking drumsBraking membersContact frictionBrake force

The invention provides a friction power generation device based on a friction brake and the friction brake. The friction type brake comprises a first friction assembly and a second friction assembly which are oppositely arranged, when the first friction assembly generates contact friction relative to the second friction assembly, friction braking force is generated, and charges are generated; thefriction power generation device comprises a first induction electrode, a second induction electrode and a charge acquisition circuit, wherein the first induction electrode and the second induction electrode are arranged in the first friction assembly, when the first friction assembly generates contact friction relative to the second friction assembly, first induction charges are generated on thefirst induction electrode, and second induction charges are generated on the second induction electrode; and the charge acquisition circuit is connected with the first induction electrode and the second induction electrode and stores charges acquired from the first induction electrode and the second induction electrode. The friction power generation device is simple in structure, high in reliability, stable in circuit and high in capacity recovery efficiency.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Rock joint sample direct shearing test box

InactiveCN107036906AStudy Dilatation PropertiesFreedom of movementMaterial strength using steady shearing forcesUpper jointEngineering

The invention relates to a rock joint sample direct shearing test box. The test box comprises a base, an upper shearing box and a lower shearing box which are used for placing a rock joint sample and a normal loading cushion block presses upon an upper joint block of a rock. A fixing support arranged downward is installed on the upper shearing box, a bearing support arranged upward is installed on the lower shearing box, a guiding rod is inserted into the fixing support and the bearing support in a penetrating mode, pin holes are formed in the fixing support, the guiding rod and the fixing support are fixed through a locating pin, and a linear motion bearing used for connecting the guiding rod with the bearing support is arranged in the slot of the bearing support. Compared with the prior art, by means of the test box, not only can free motion of the lower shearing box in the shearing direction in the rock joint sample shearing process be guaranteed, but also the problem that the upper shearing box is reversed upward is effectively solved; contact friction between the upper and lower shearing boxes in the rock joint sample shearing process and friction between the upper shearing box and the upper joint block of the rock are effectively reduced, so that the shearing process is more in line with the real condition.

Owner:TONGJI UNIV

Sorting system

The invention discloses a sorting system comprising a conveying device, a sorting device, a position sensor and a control system; the conveying device comprises a conveying belt and conveying power; the sorting device comprises a sorting conveyer belt, a jacking roller, a lifting power element and a sorting and conveying power element; a sorting hole is formed in the side of the sorting conveyer belt comprising a base belt and a plurality of balls; the control system is used for controlling the lifting power element to drive the jacking roller to ascend to realize contact friction with the balls when determining that a to-be-sorted object reaches a sorting position, the balls roll to drive the to-be-sorted object to move towards the sorting hole, and a ball mounting shaft is axially and obliquely arranged relative to the width direction of the base belt; the sorting system jacks the jacking roller by the lifting power element to generate friction with the sorting conveyer belt, and the sorting conveyer belt forwards conveys the friction to drive the jacking roller to rotate so as to drive the balls to rotate; and the ball mounting shaft is axially and obliquely arranged and drives the to-be-sorted object on the sorting conveyer belt to move towards a side to realize sorting. The sorting system is free of complex manipulators, simple and easily-realized in structure and small in floor area.

Owner:GUANGDONG SIWUN LOGISTICS EQUIP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com