Patents

Literature

3795 results about "Rotary stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rotary stage is a component of a motion system used to restrict an object to a single axis of rotation. The terms rotary table or rotation stage are often used interchangeably with rotary stage. All rotary stages consist of a platform and a base, joined by some form of guide in such a way that the platform is restricted to rotation about a single axis with respect to the base. In common usage, the term rotary stage may or may not also include the mechanism by which the angular position of the platform is controlled relative to the base.

Temperature measurement apparatus, method of measuring temperature profile, recording medium and heat treatment apparatus

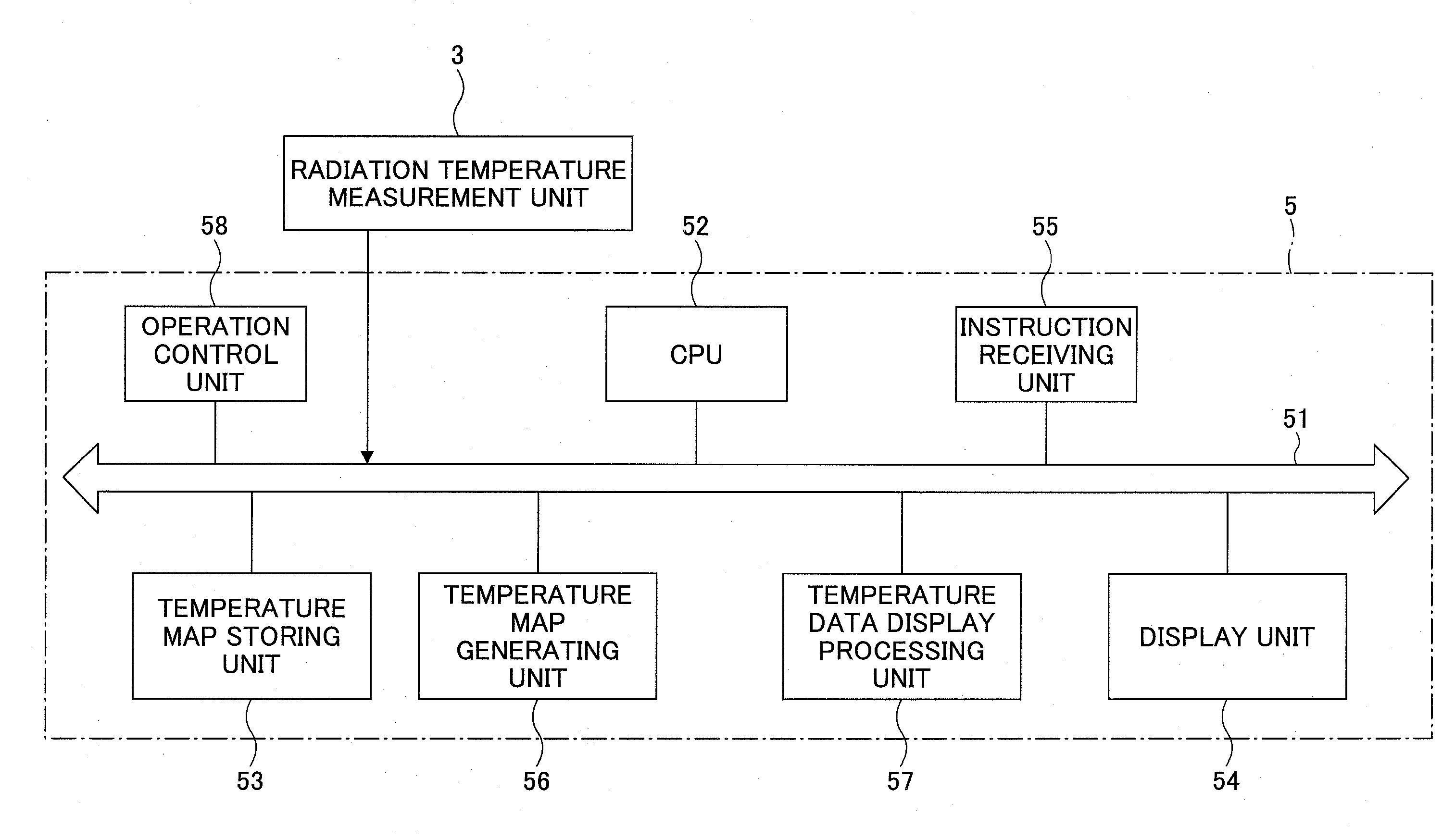

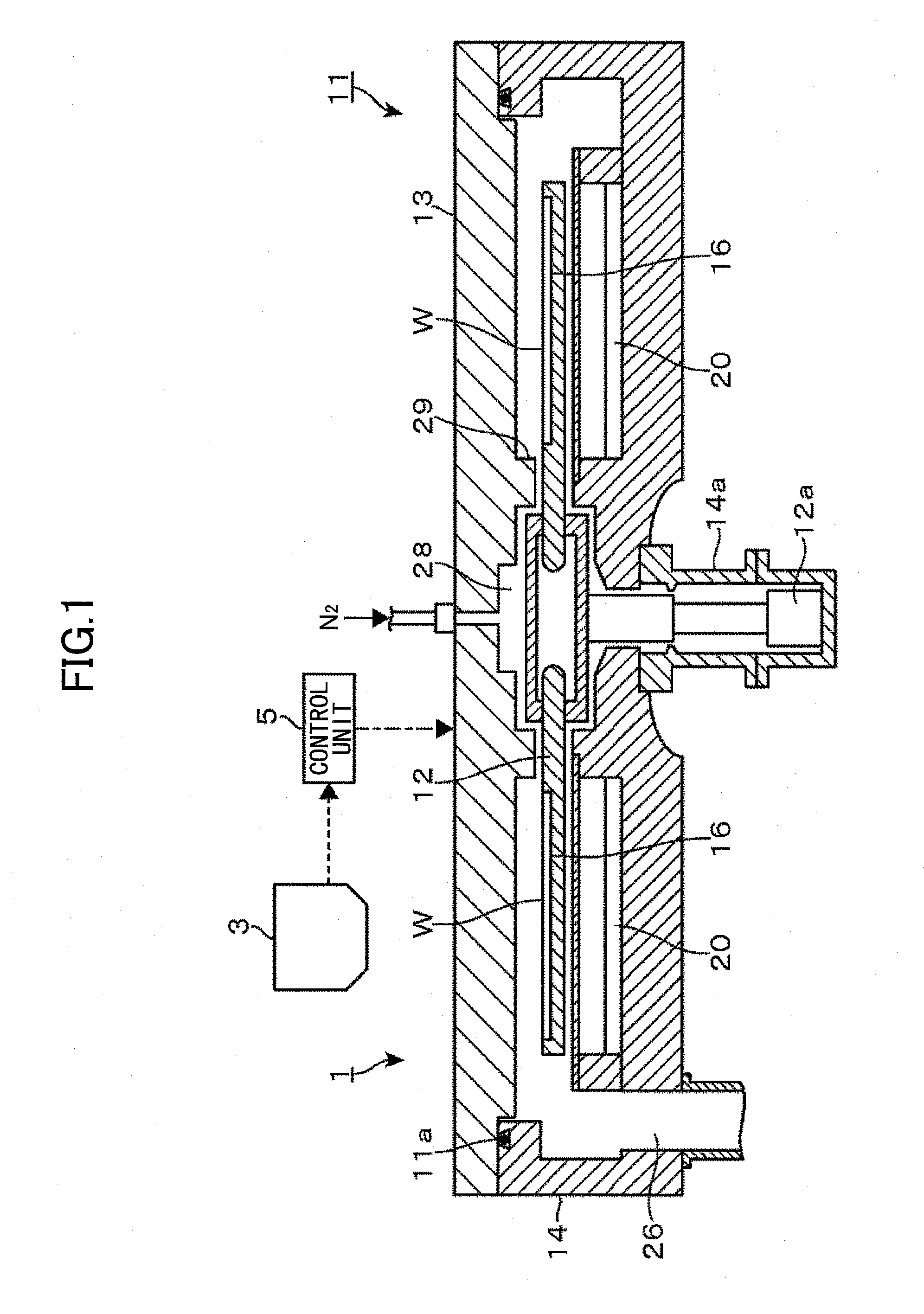

A temperature measurement apparatus for measuring a temperature profile of a substrate mounted on a rotating table, including a radiation temperature measurement unit configured to measure the temperature of plural temperature measurement areas on a surface of the rotating table in a radius direction of the rotating table by scanning the surface of the rotating table in the radius direction; a temperature map generating unit that specifies the address of the temperature measurement area based on the number of the temperature measurement areas measured by the radiation temperature measurement unit for each of the scanning operations in the radius direction of the rotating table, and the rotating speed of the rotating table, and stores the temperature in correspondence with the corresponding address in a storing unit; and a temperature data display processing unit that displays a temperature profile of the rotating table.

Owner:TOKYO ELECTRON LTD

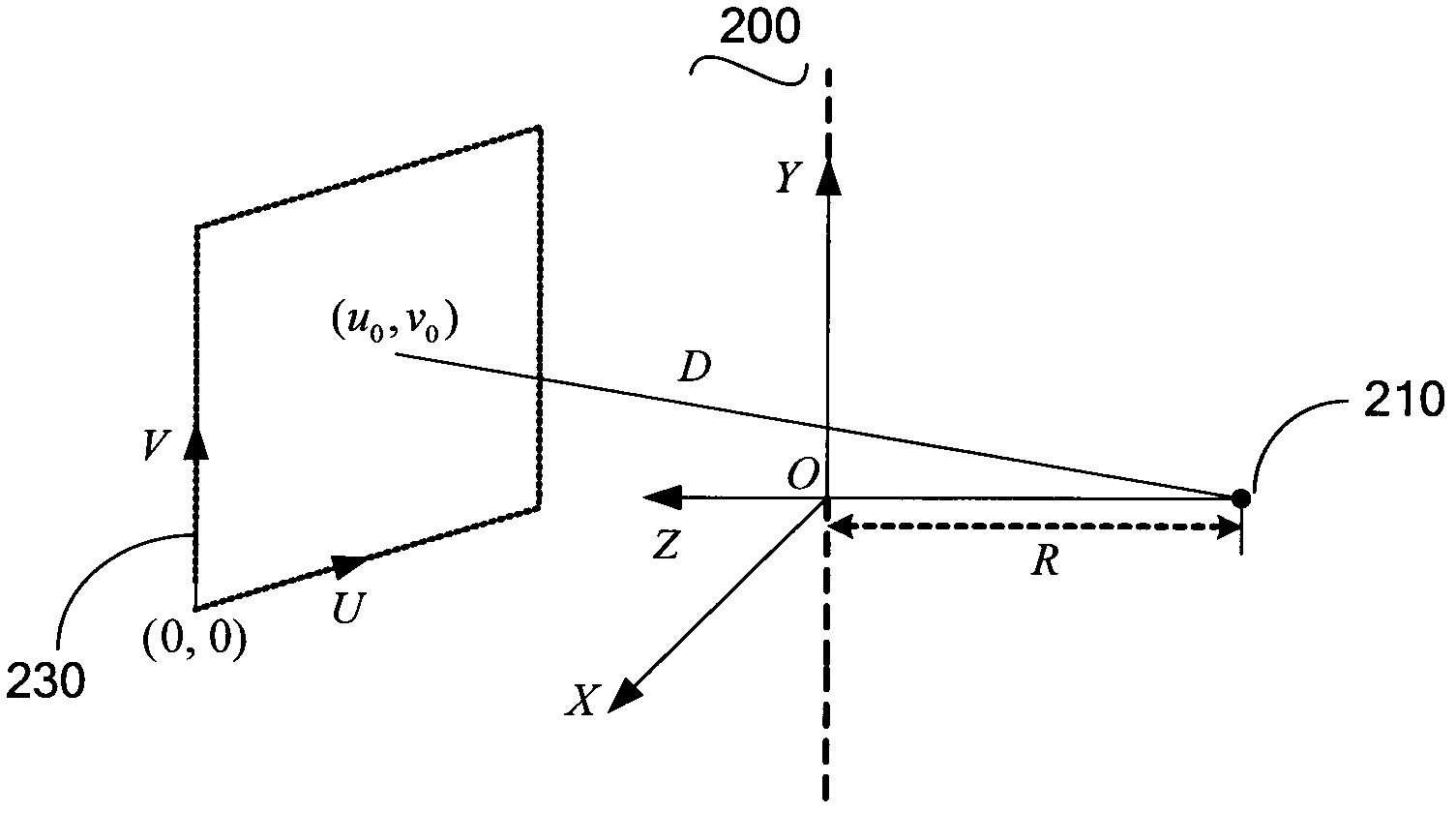

Method for adjusting position of image sensor, method and apparatus for manufacturing a camera module, and camera module

InactiveUS20090180021A1No longer be adjustedShort timeTelevision system detailsColor television detailsCamera lensRotary stage

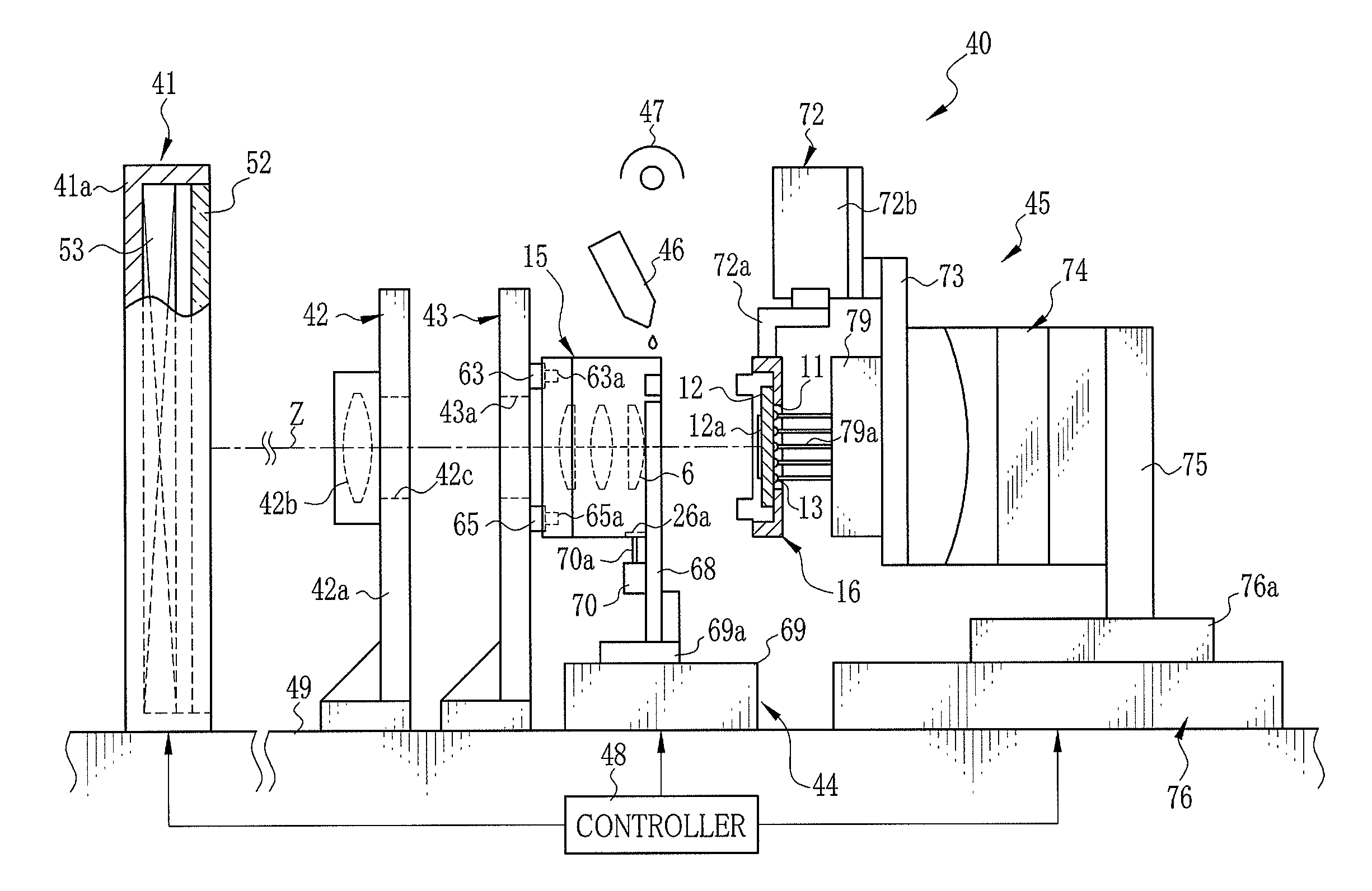

A lens unit and a sensor unit are held by a lens holding mechanism and a sensor shift mechanism. As the sensor unit is moved in a Z axis direction on a second slide stage, a chart image is captured with an image sensor through a taking lens so as to obtain in-focus coordinate values in at least five imaging positions on an imaging surface. An approximate imaging plane is calculated from the relative position of plural evaluation points which are defined by transforming the in-focus coordinate value of each imaging position in a three dimensional coordinate system. The second slide stage and a biaxial rotation stage adjust the position and tilt of the sensor unit so that the imaging surface overlaps with the approximate imaging plane.

Owner:FUJIFILM CORP

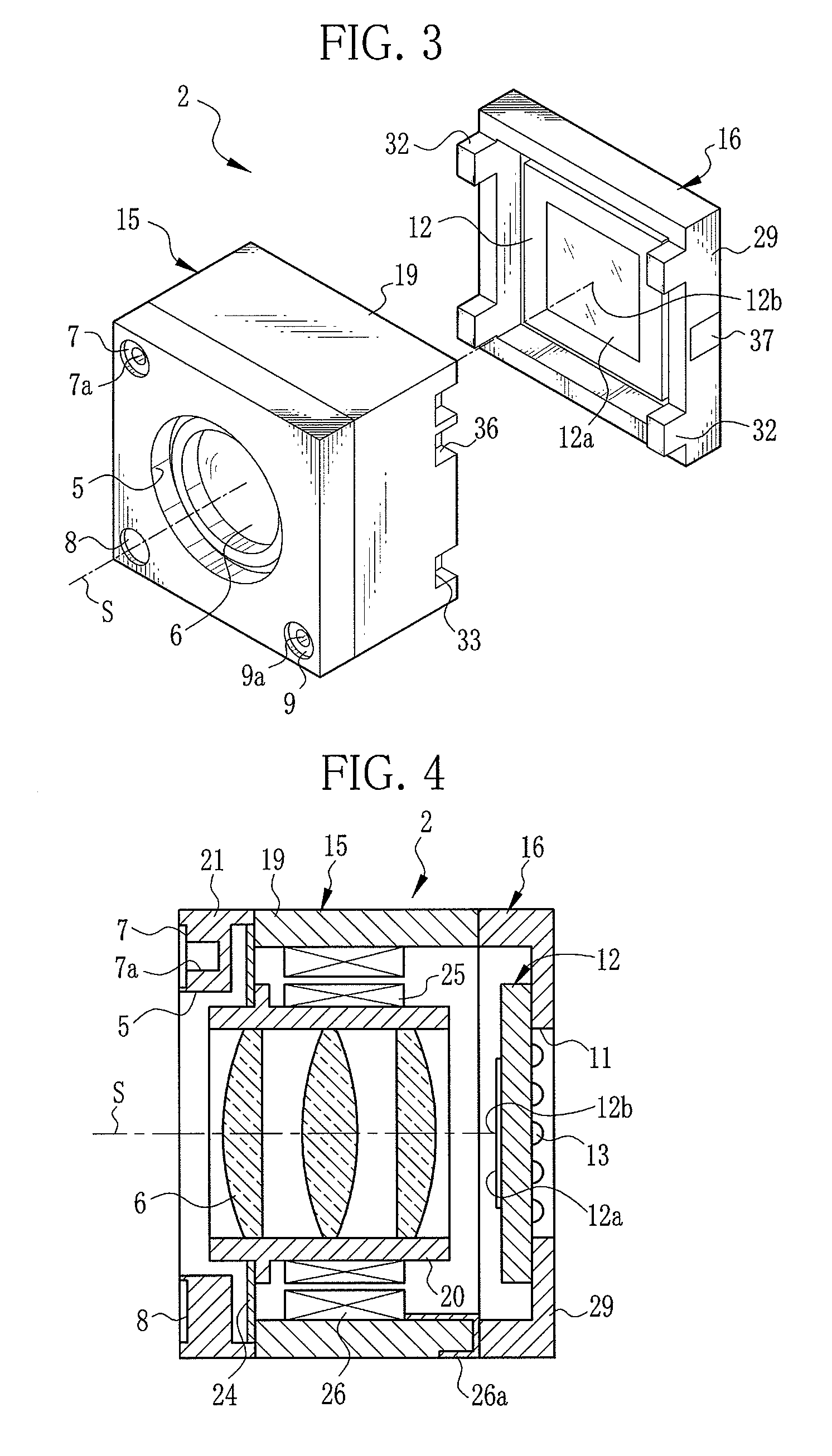

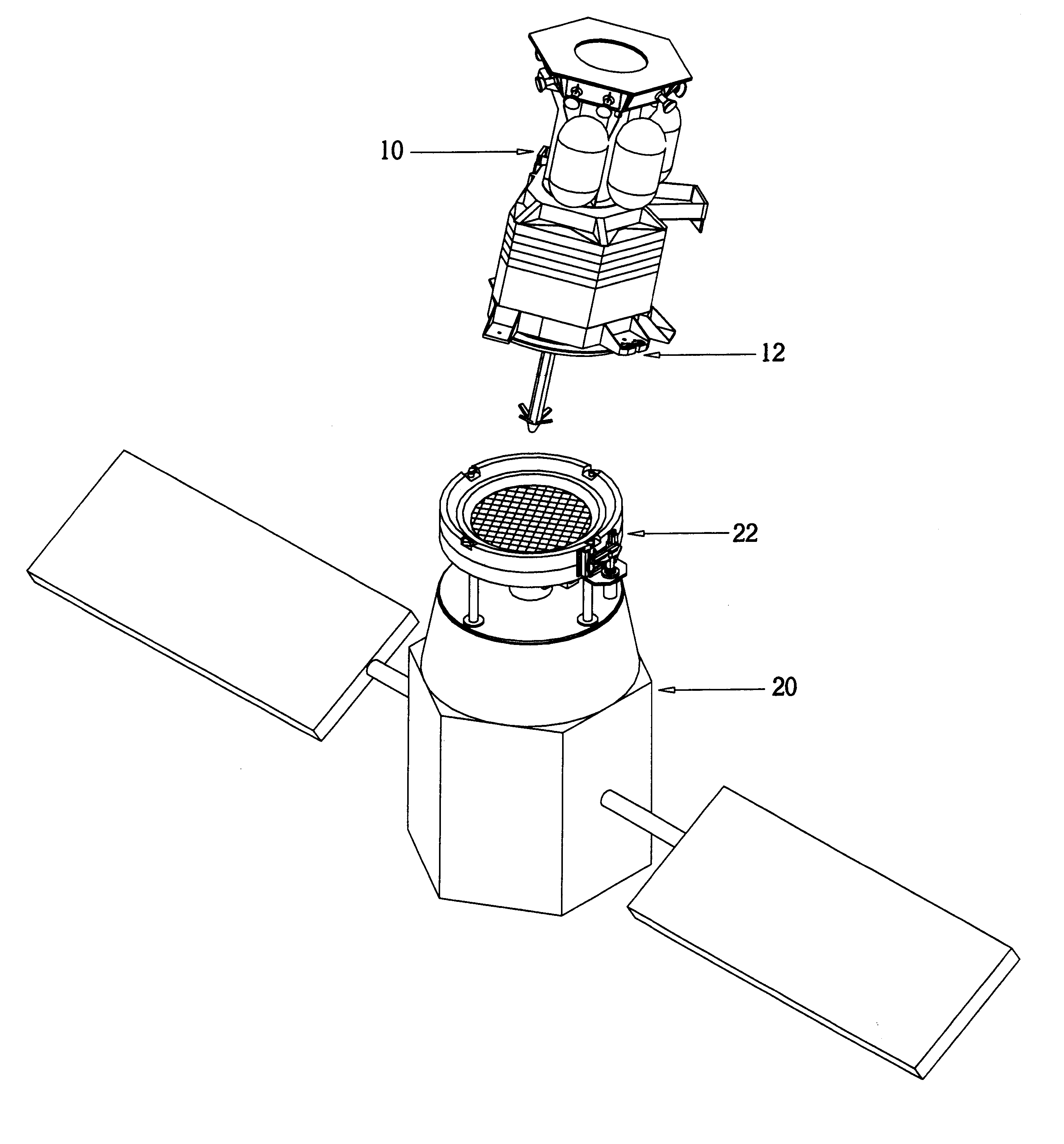

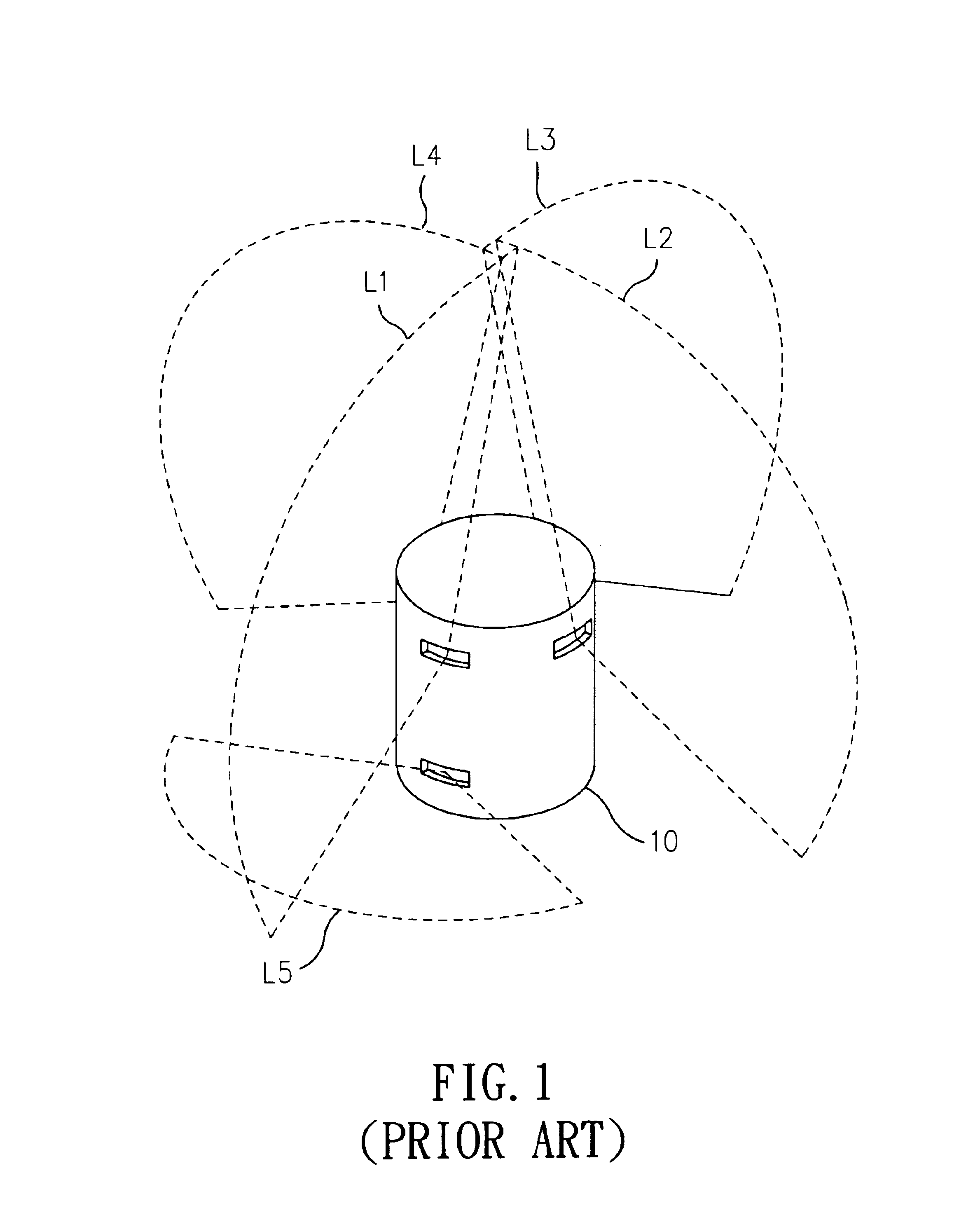

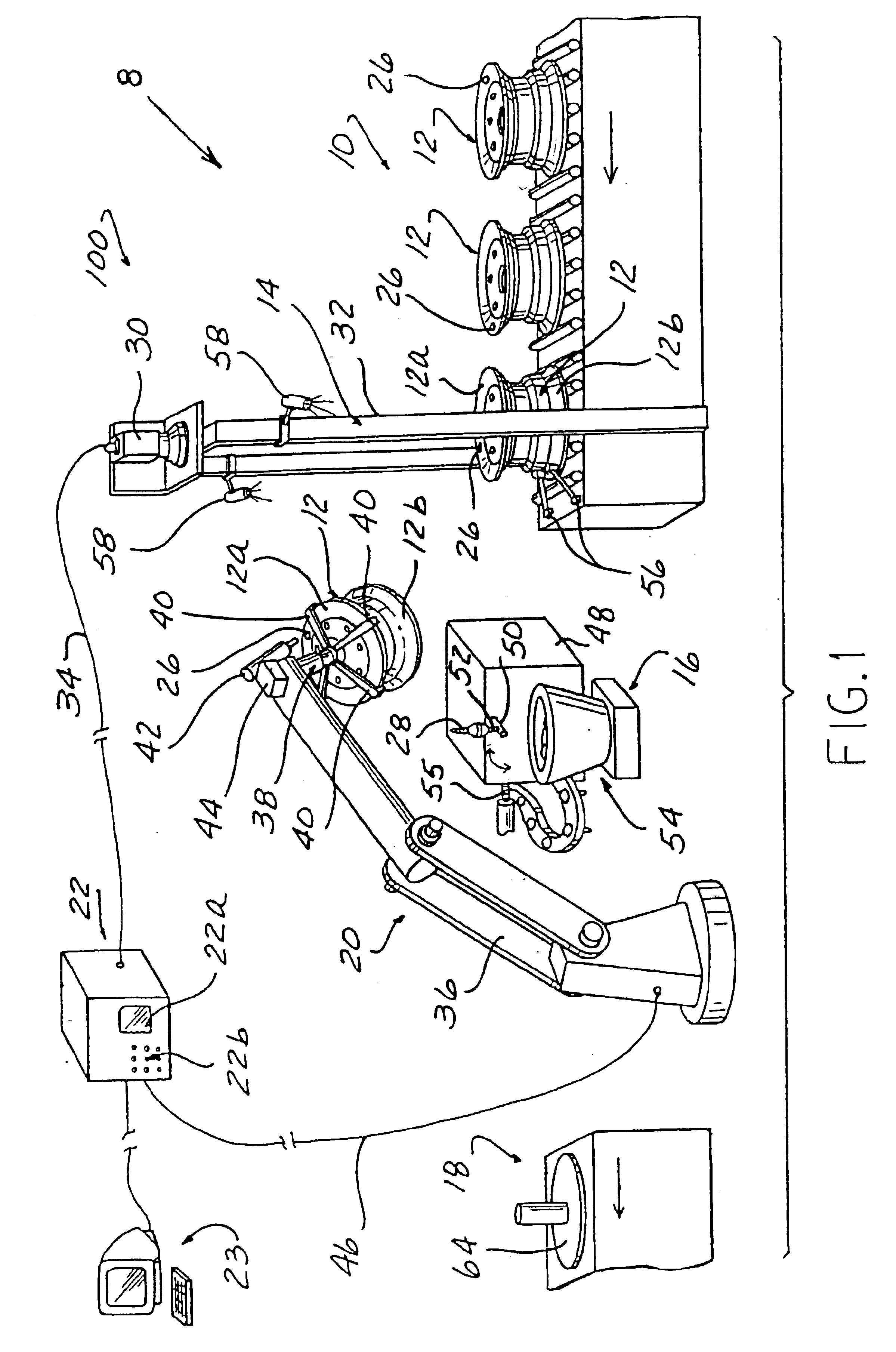

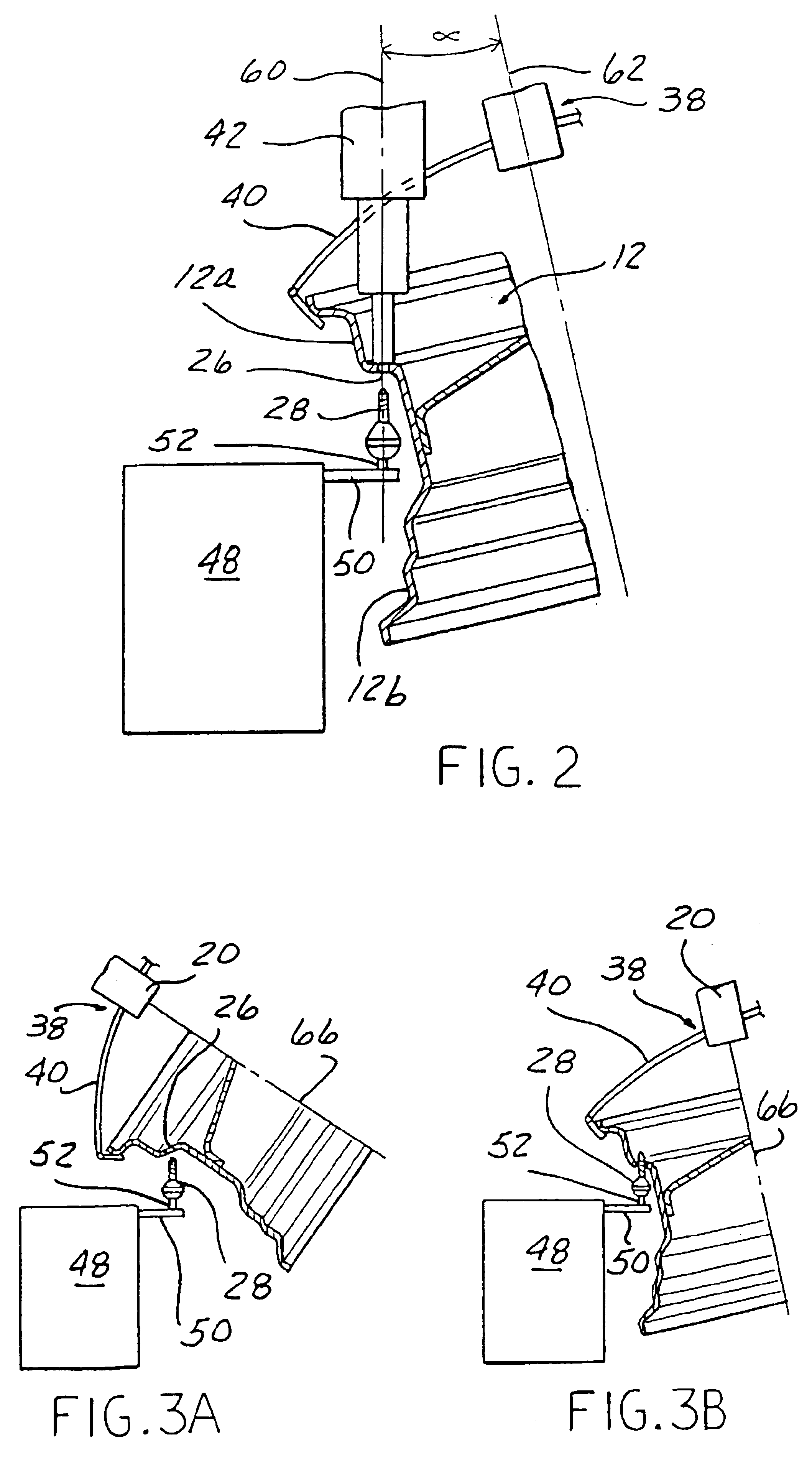

Spacecraft capture and docking system

InactiveUS6299107B1Robust, fail-safe and reliableReduces risk of collision and damageCosmonautic vehiclesSystems for re-entry to earthRotary stageUnderwater vehicle

A system for capturing and docking an active craft to a passive craft has a first docking assembly on the active craft with a first contact member and a spike projecting outwardly, a second docking assembly on the passive craft having a second contact member and a flexible net deployed over a target area with an open mesh for capturing the end of the spike of the active craft, and a motorized net drive for reeling in the net and active craft to mate with the passive craft's docking assembly. The spike has extendable tabs to allow it to become engaged with the net. The net's center is coupled to a net spool for reeling in. An alignment funnel has inclined walls to guide the net and captured spike towards the net spool. The passive craft's docking assembly includes circumferentially spaced preload wedges which are driven to lock the wedges against the contact member of the active craft. The active craft's docking assembly includes a rotary table and drive for rotating it to a predetermined angular alignment position, and mating connectors are then engaged with each other. The system may be used for docking spacecraft in zero or low-gravity environments, as well as for docking underwater vehicles, docking of ancillary craft to a mother craft in subsonic flight, in-flight refueling systems, etc.

Owner:HONEYBEE ROBOTICS

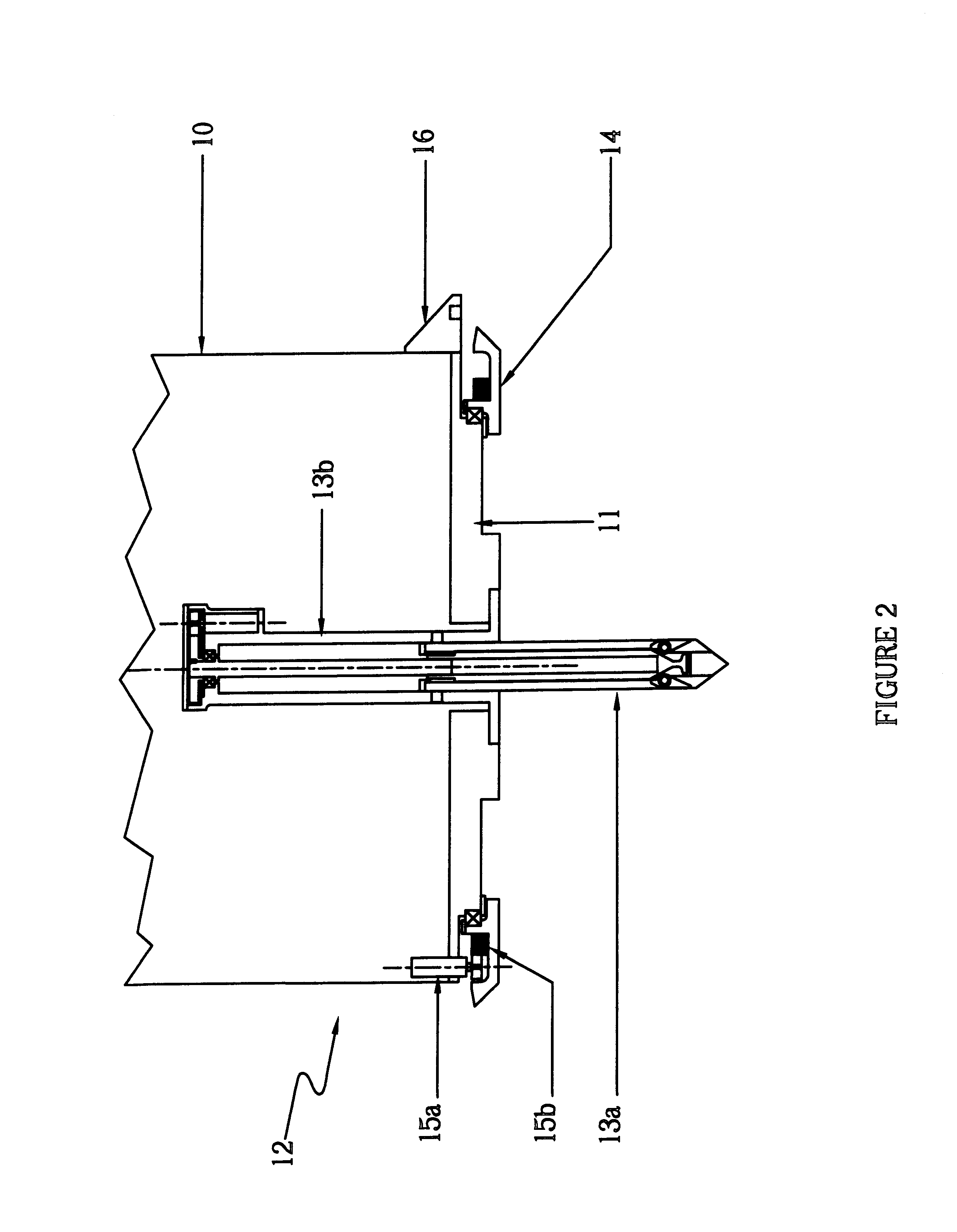

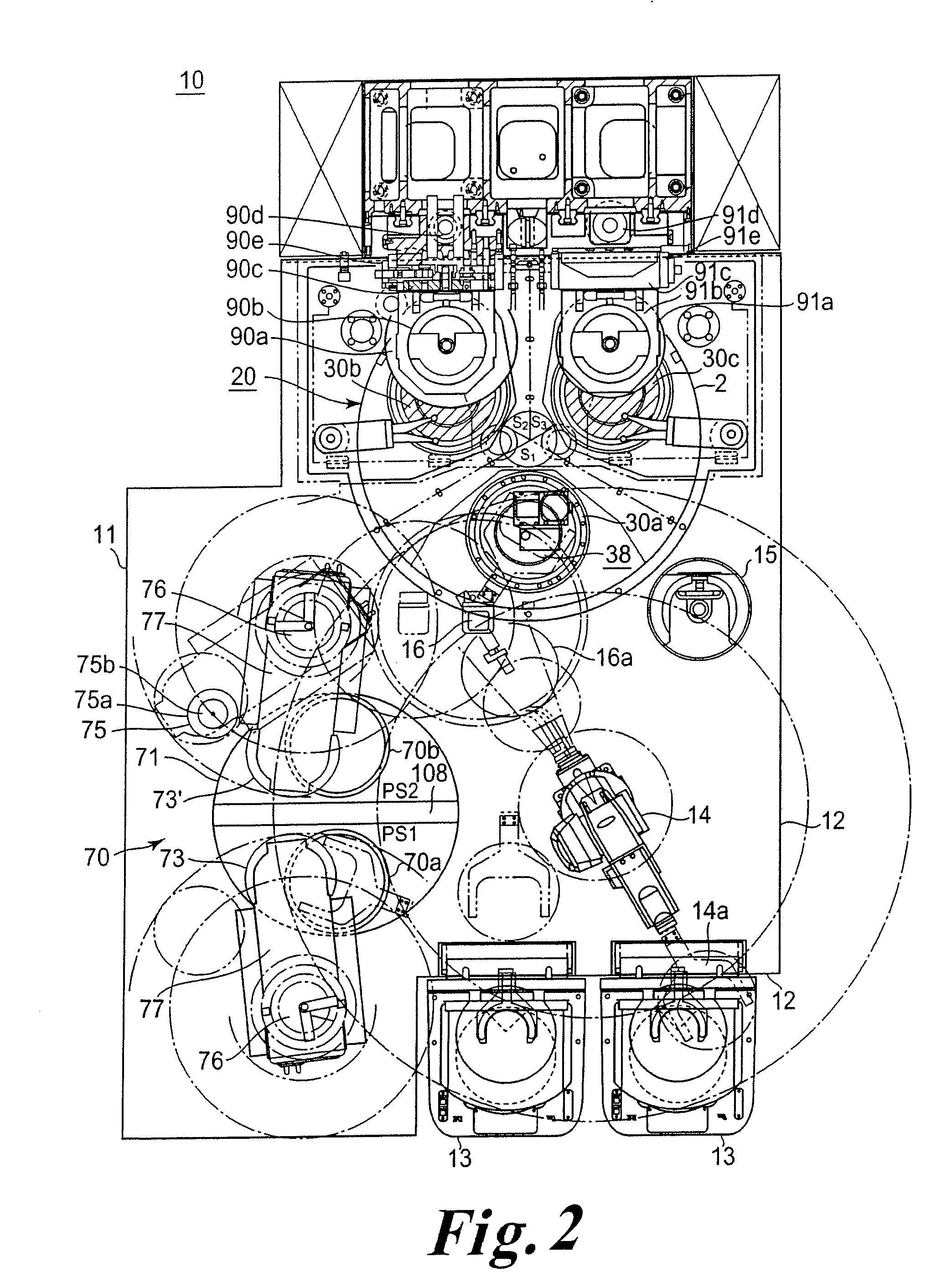

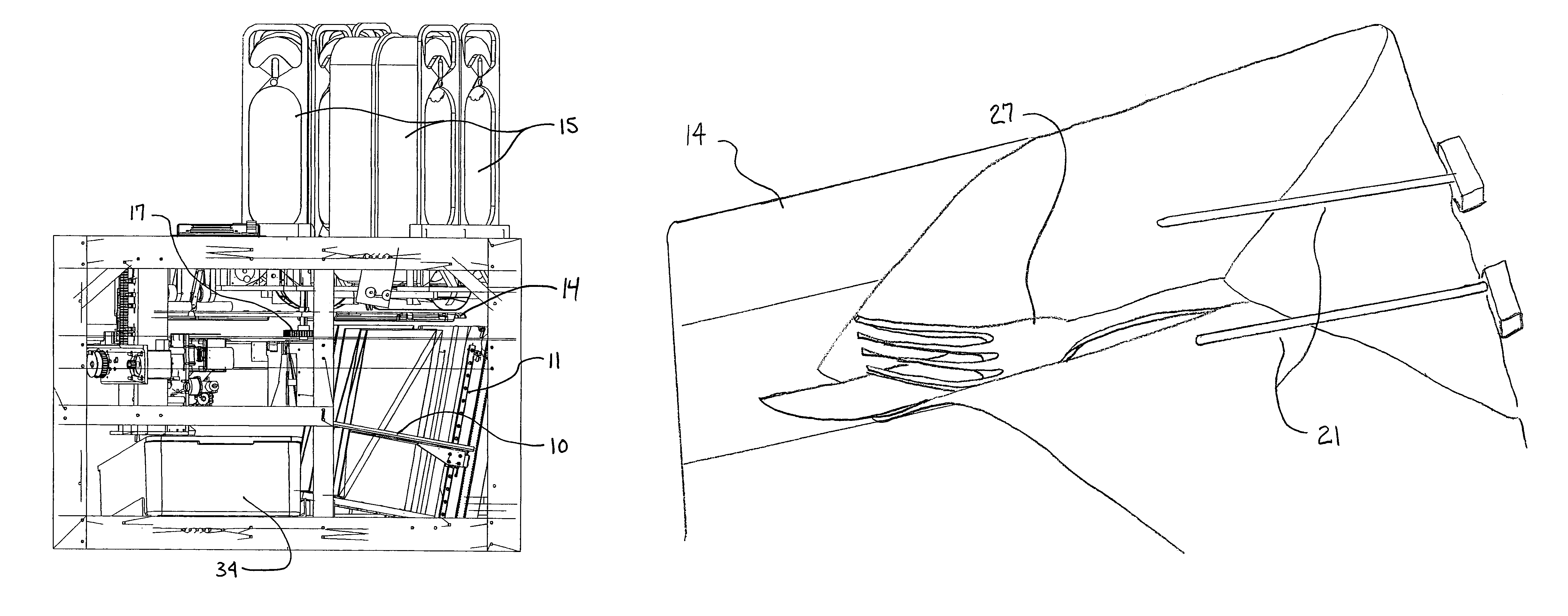

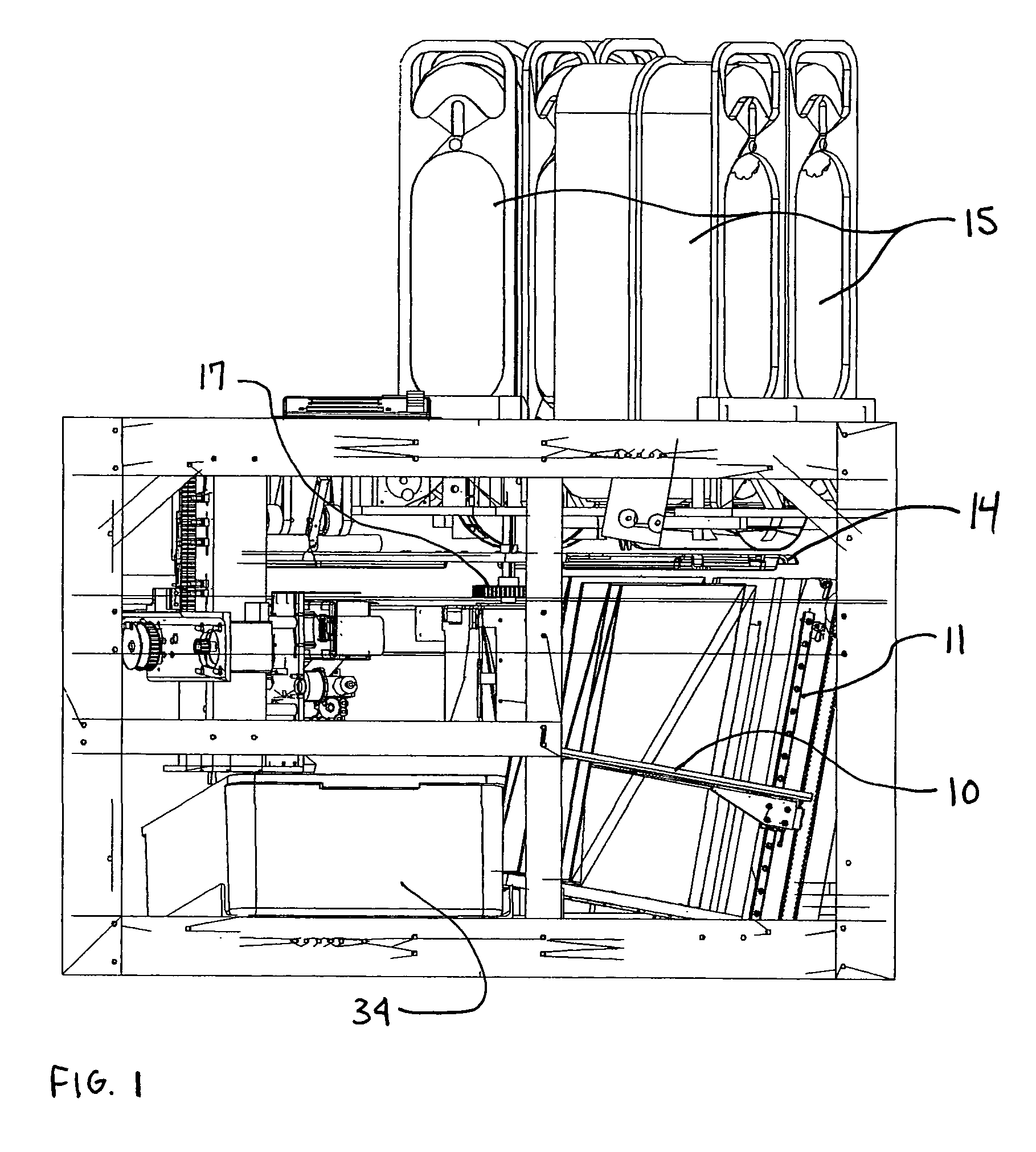

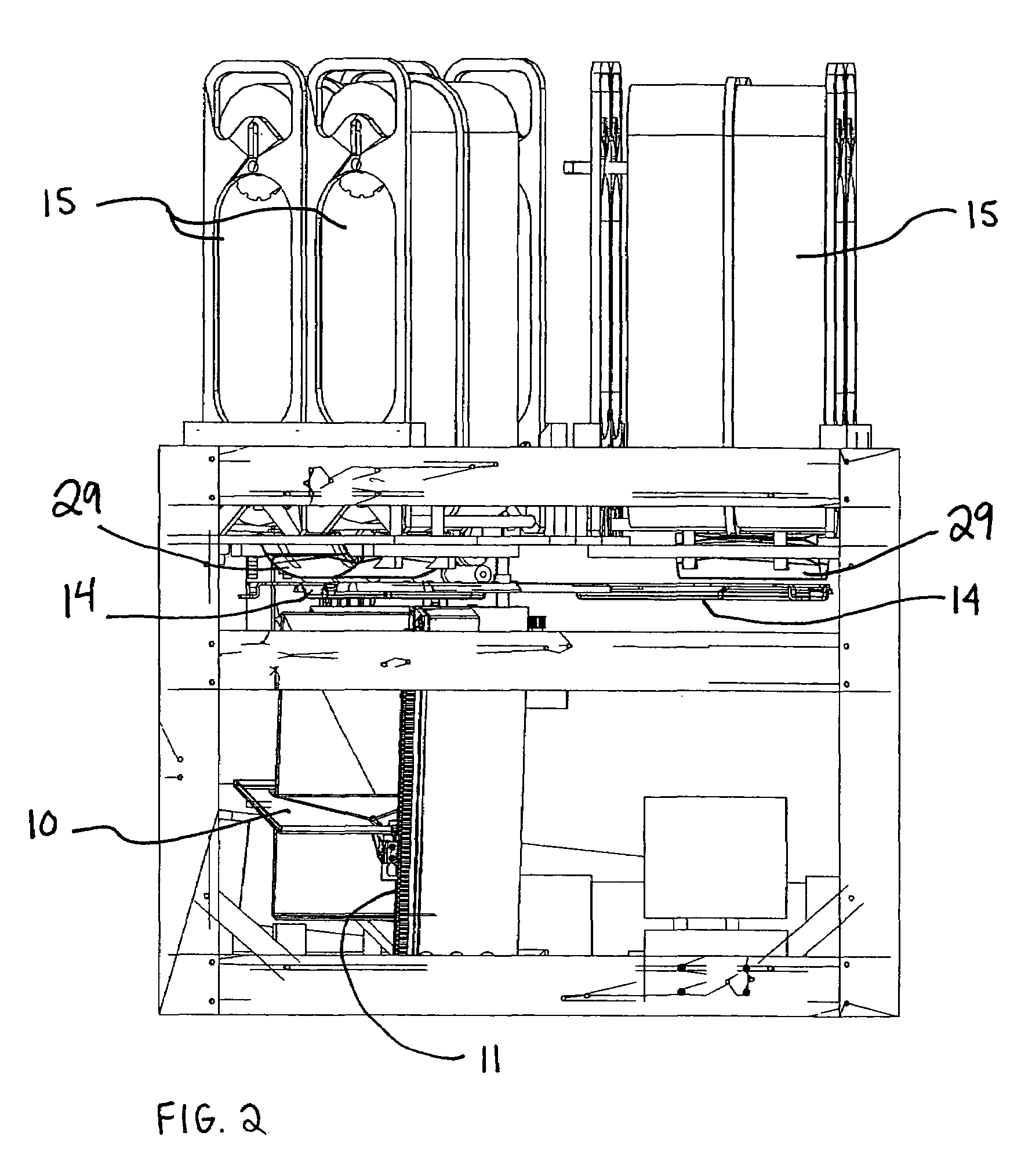

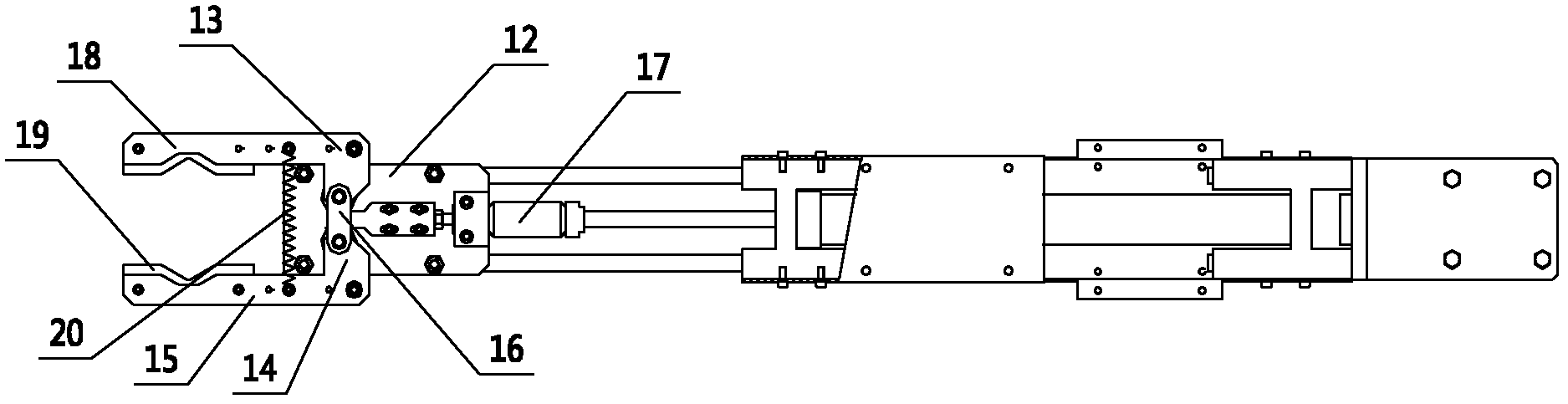

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. The upper wrench has two opposed spinner-roller pairs which translate between open and closed positions for spinning the upper pin coupling when in a closed position. The upper wrench also has two opposed jaw blocks which translate between open and closed positions for gripping the pin coupling in a closed position. The spinner roller pairs and the jaw blocks move in directions perpendicular to each other into and out of a cavity through which the well axis passes vertically. Torque cylinders are provided by which the upper wrench is torqued in a first or "torquing up" direction while the jaw blocks are gripping the pin coupling and in a second or "breaking loose" direction. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator includes a remotely controlled arm and hand assembly which captures a drill pipe section in its hand and transfers the drill pipe while being supported vertically by the drilling rig between the well axis and a position at the side-of the wrench assembly. The drilling rig apparatus includes a bore arranged and designed for placement on the rig floor around the well axis. A slot is provided between frame members for placement of a pneumatically remotely controlled power slip manipulator for setting and releasing slips in the rotary table for supporting the drill pipe string in the well bore during connecting and disconnecting operations of drill pipe sections.

Owner:FORUM US

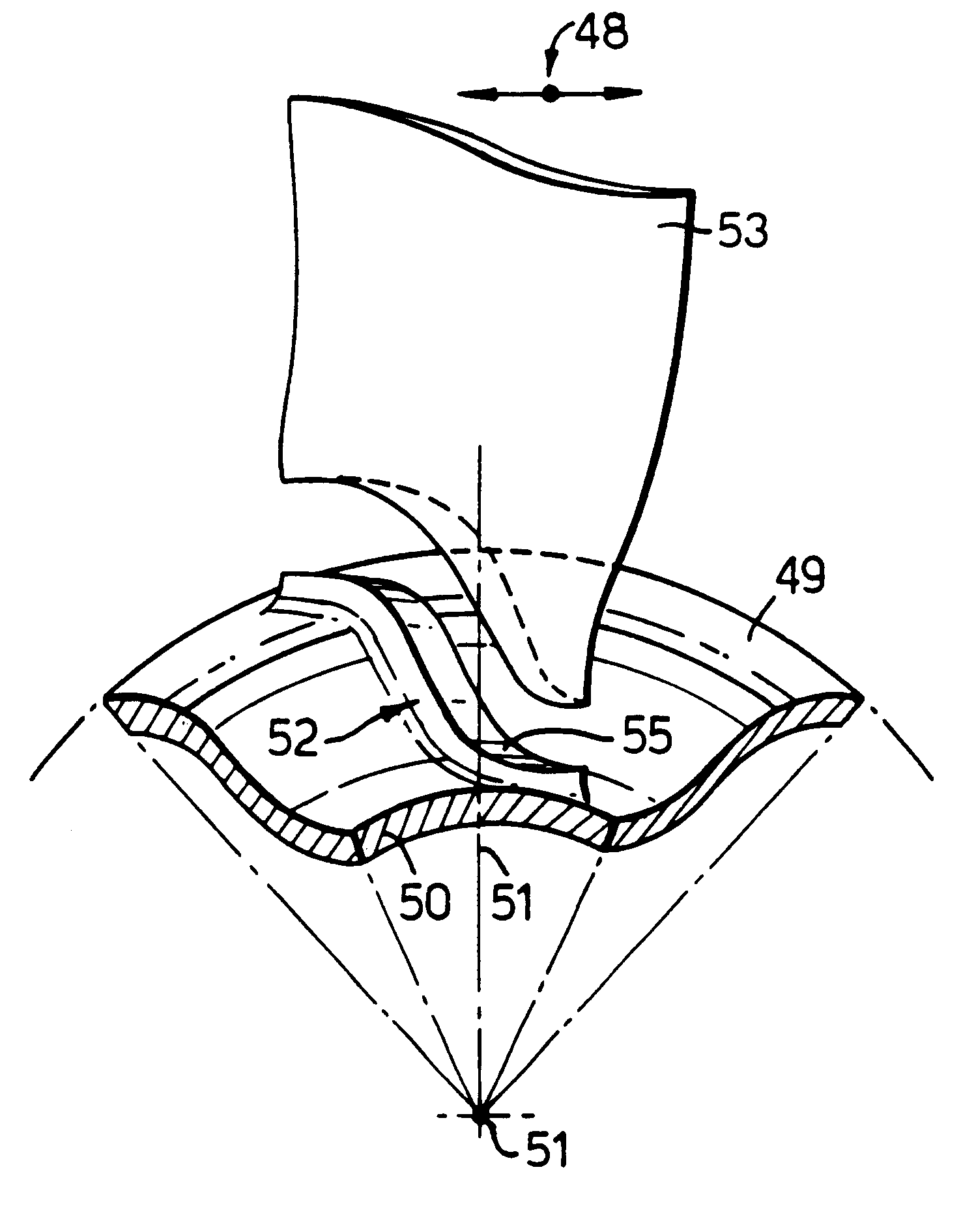

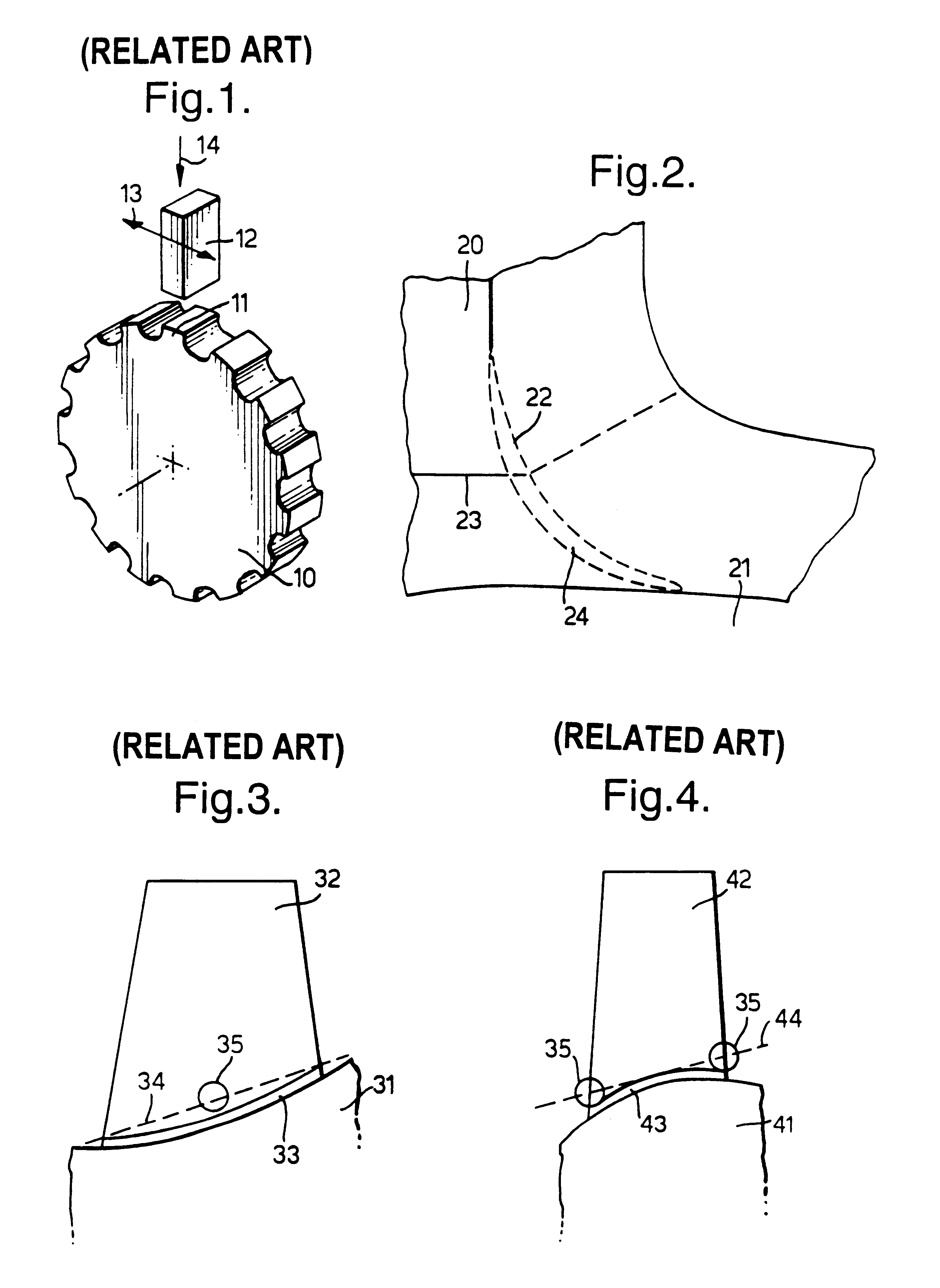

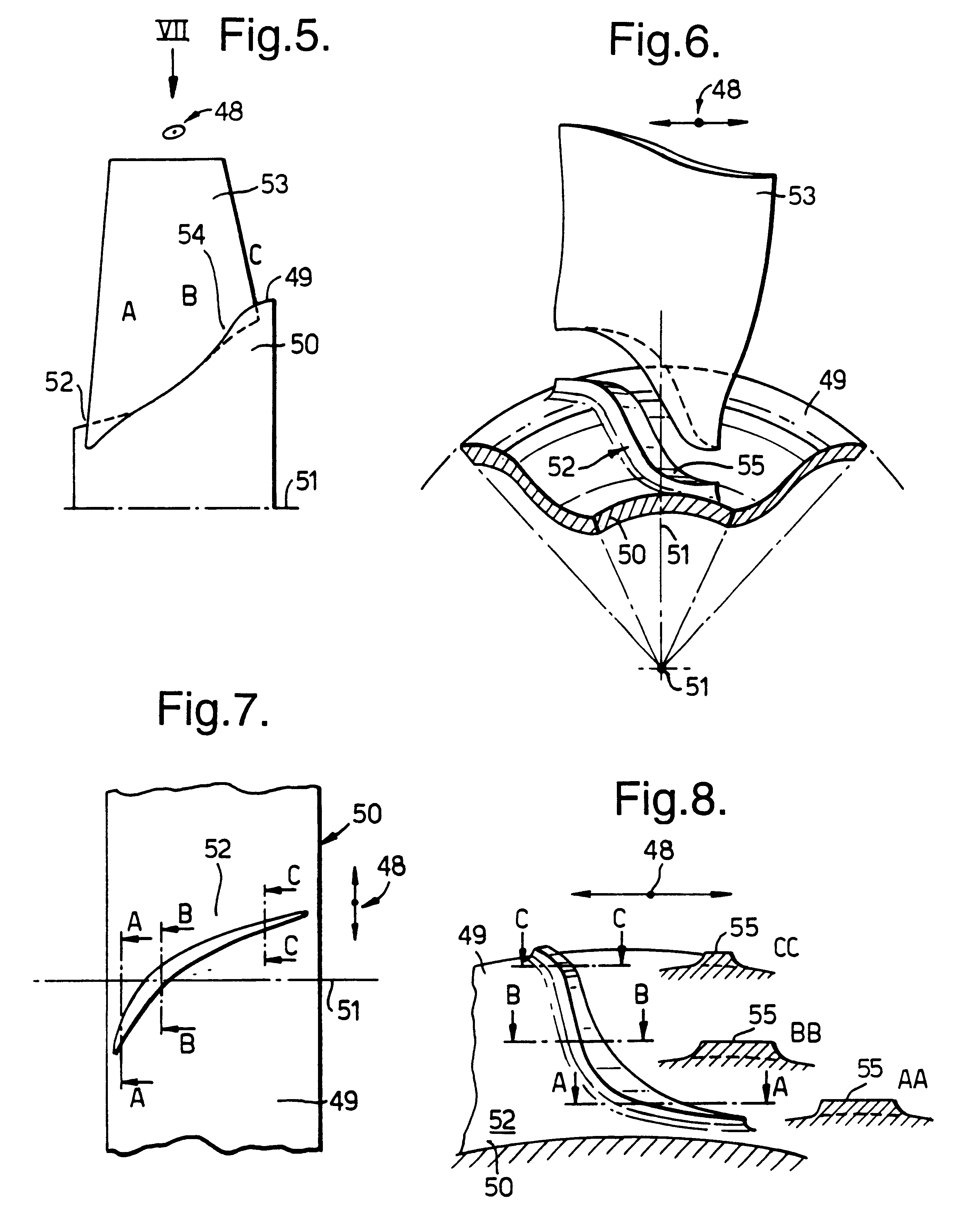

Disk for a blisk rotary stage of a gas turbine engine

A disk for a BLISK rotary stage of a gas turbine engine includes a stub on the tapered circumferential surface of a turbine disk, the stub defining a weld joint surface on the radially outermost face of the stub. The weld joint surface follows the annulus curvature in axial and circumferential directions while remaining flat in a third direction. A blade is applied radially to the stub and linear friction welding of the blade to the stub is effected by oscillating the blade in said third direction while applying a welding force inwardly along the blade.

Owner:ROLLS ROYCE PLC

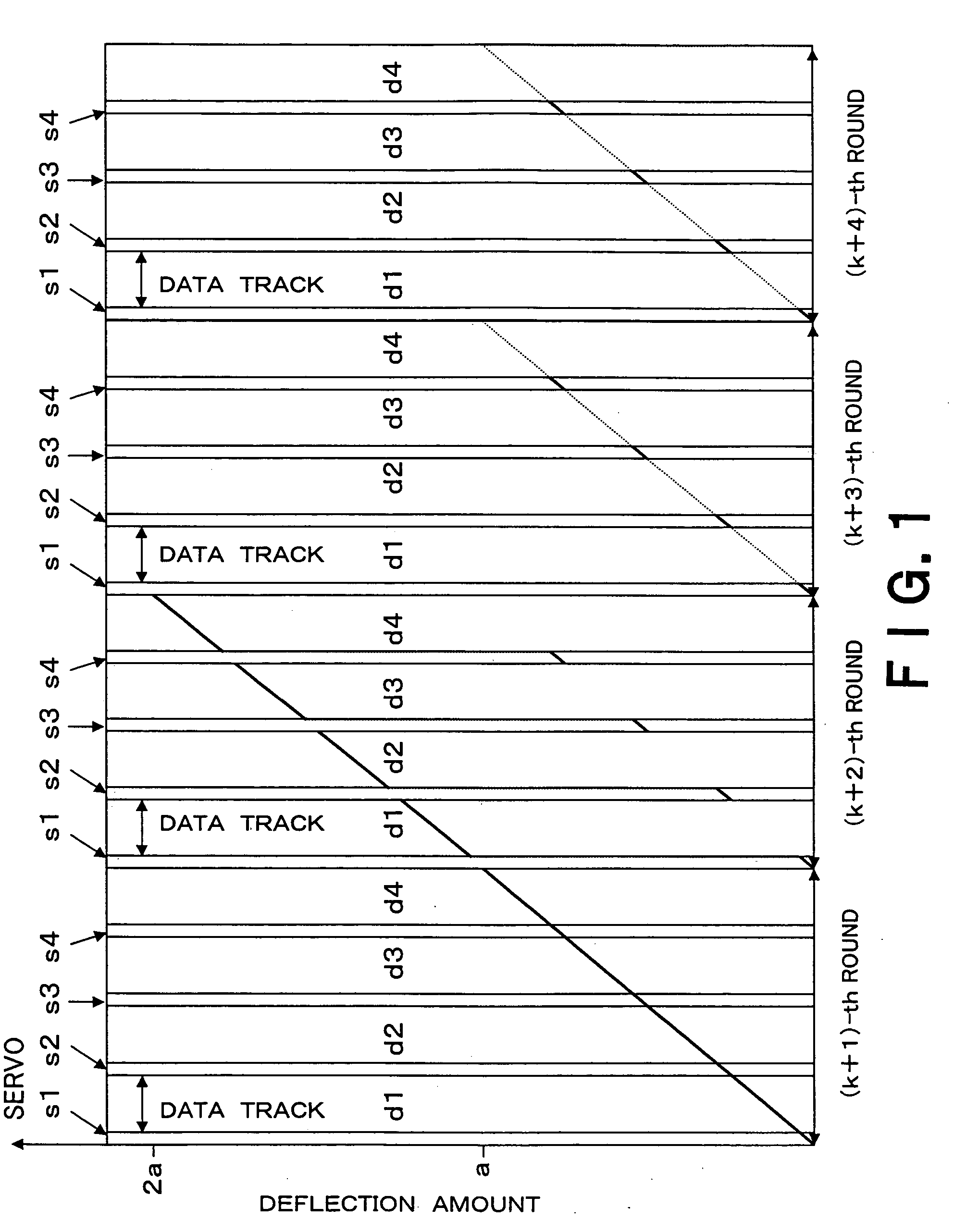

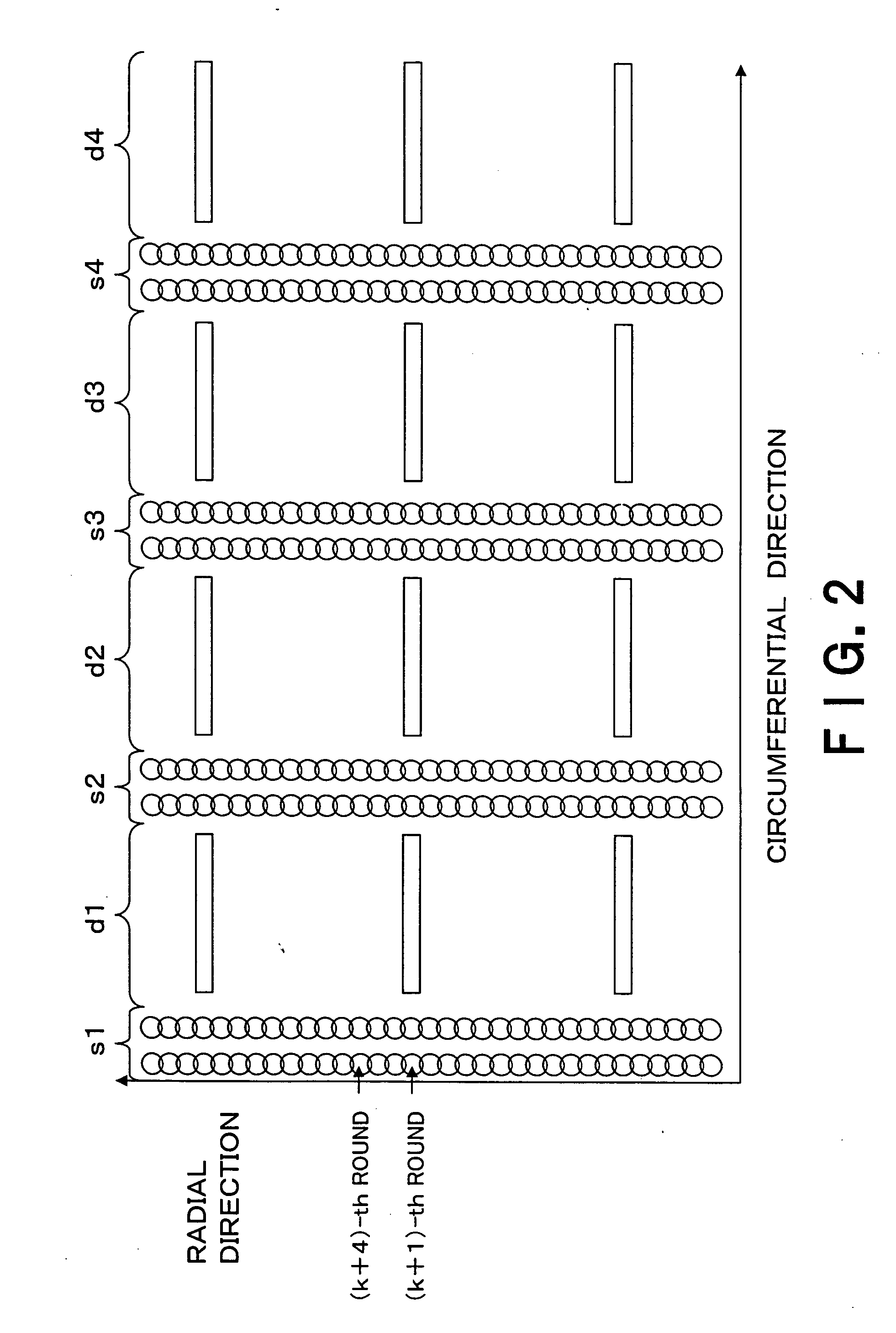

Electron beam irradiating method and manufacturing method of magnetic recording medium

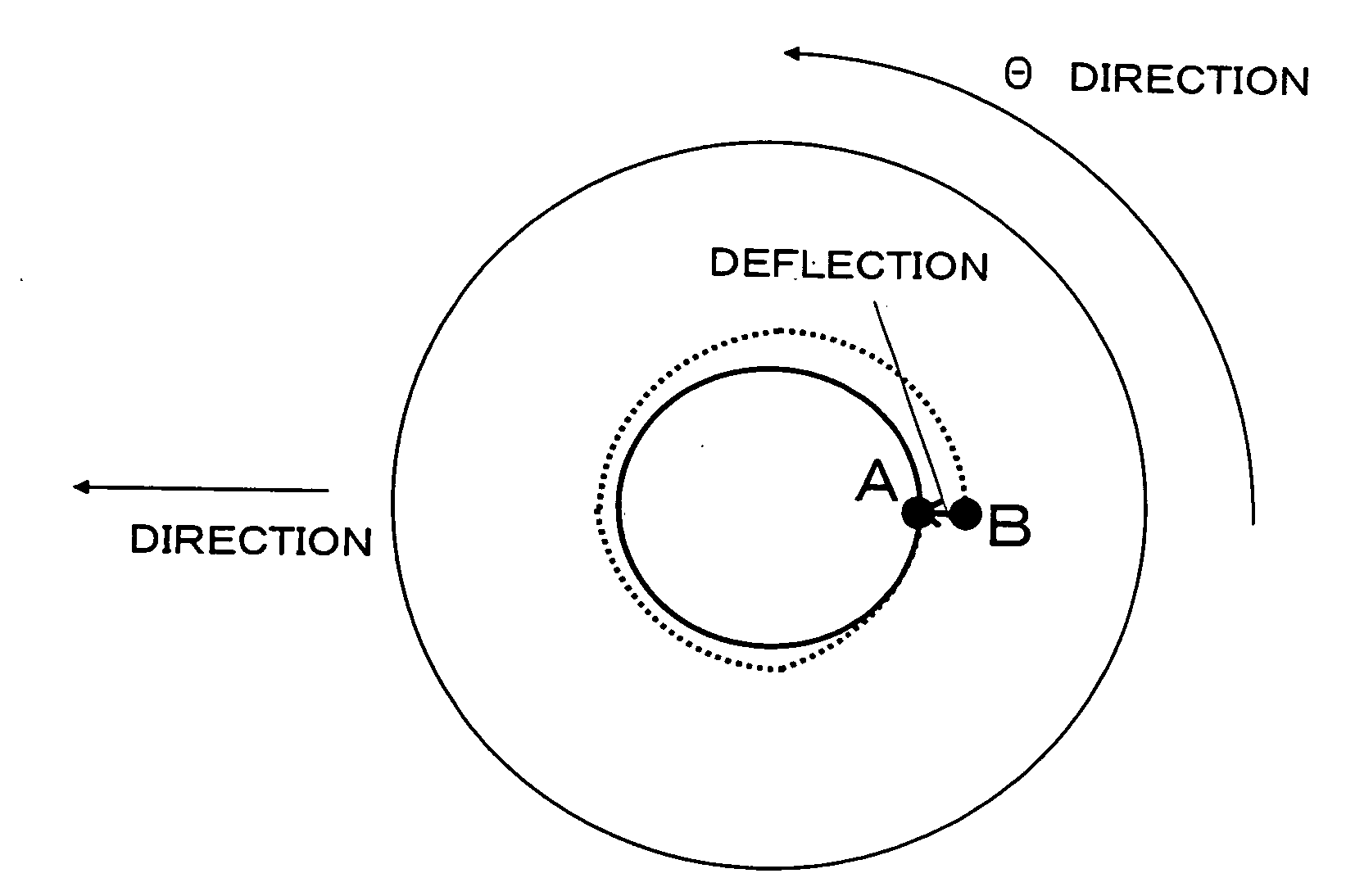

The present invention is to make it possible to form a fine pattern, and improve a recording density on a magnetic recording medium and increase signal intensity. There is provided an electron beam irradiating method which irradiates an electron beam on a resist to perform irradiating using an electron beam irradiating apparatus provided with a moving mechanism which moves a state on which a substrate applied with the resist is put in one horizontal direction, and a rotating mechanism which rotates the stage. The electron beam irradiating method includes: exposing a portion once exposed while changing a deflection amount of the electron beam at least one time in the next round and rounds subsequent thereto, when exposure is performed while a deflection amount of an electron beam is being gradually changed so as to draw a concentric circle for each round.

Owner:KK TOSHIBA

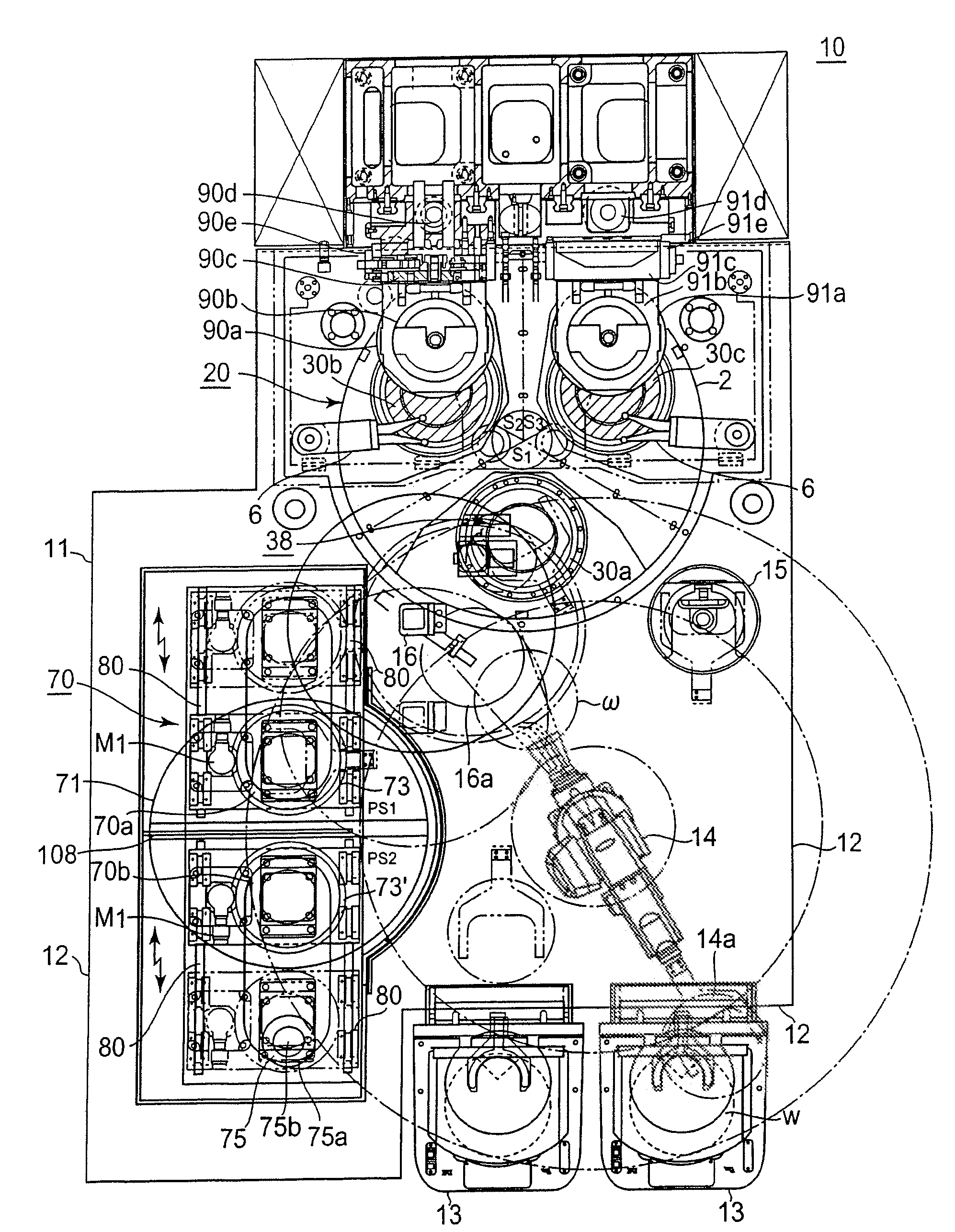

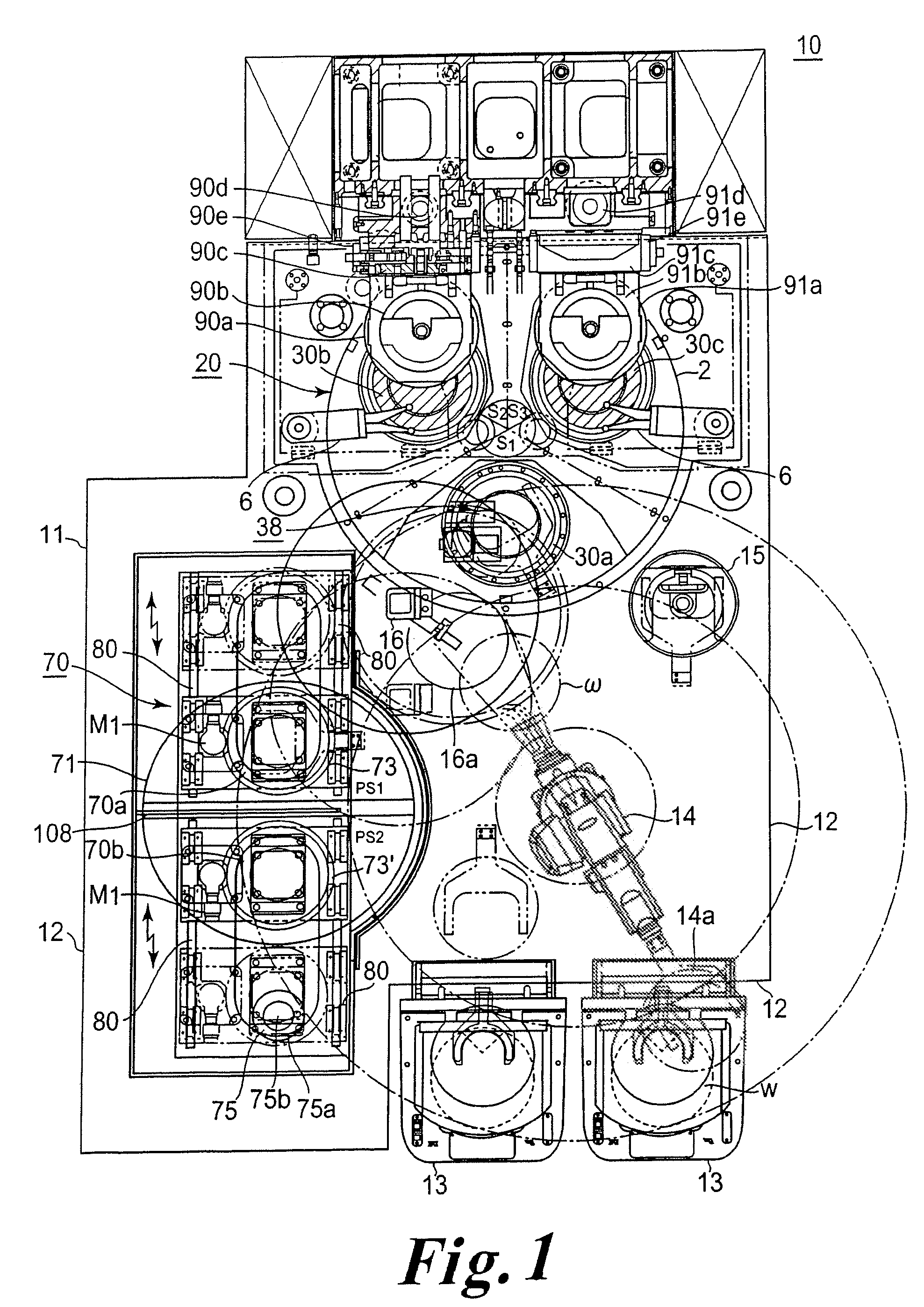

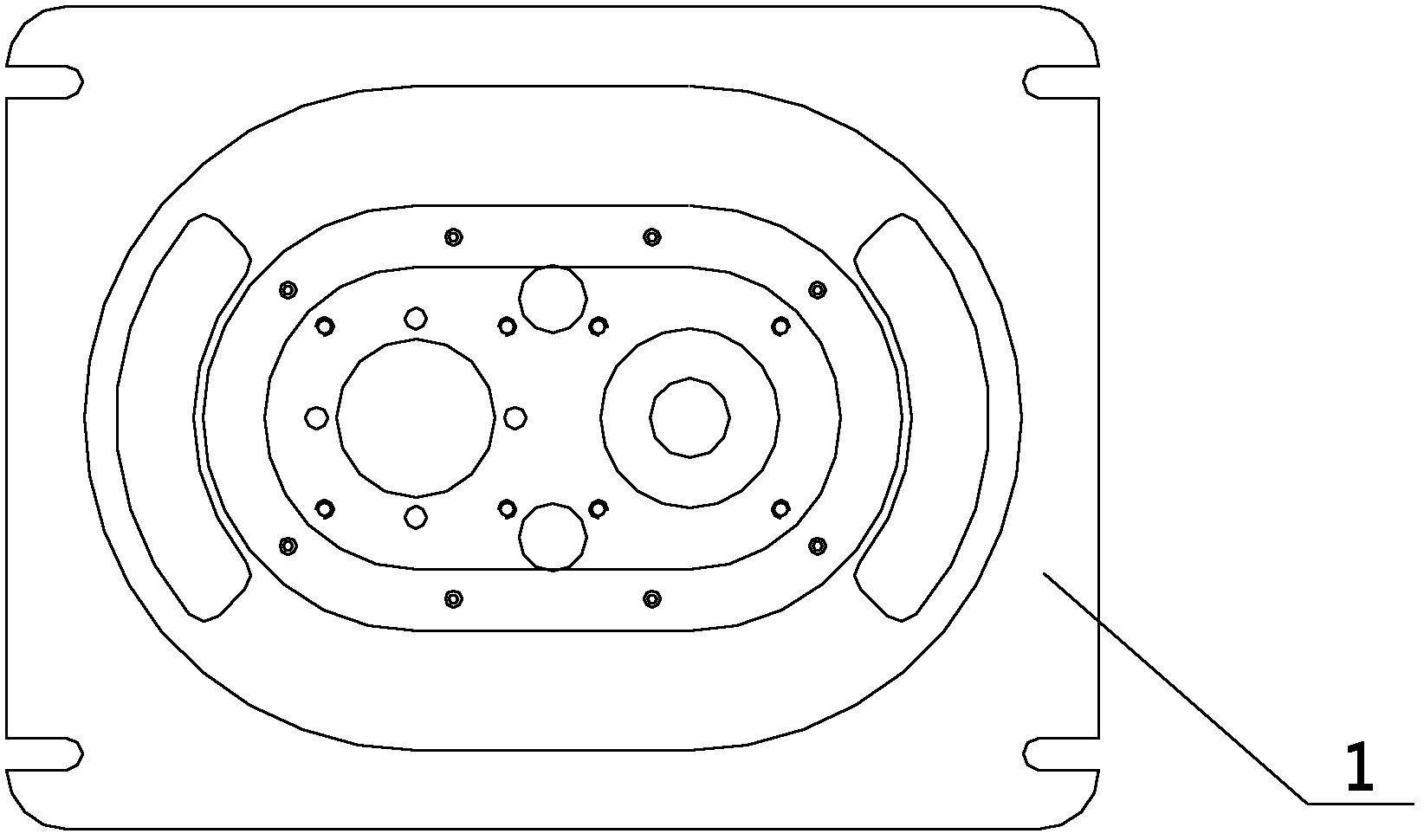

Planarizing device and a planarization method for semiconductor substrates

A substrate-planarizing device and method of using the device comprising a substrate storage stage outside a room, and on a base inside the room, a multi-joint transfer robot, a temporary alignment platform, a movable transfer pad, a grinding process stage in which substrate holders that compose three stages of a substrate loading / unloading stage, a rough grinding stage, a finish grinding stage are arranged in a concentric pattern on the first index rotary table, and a polishing process stage that has a substrate holder table composing a substrate loading / unloading / finish polishing stage as well as a substrate holder table composing a rough polishing stage arranged in a concentric pattern on the second index rotary table.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

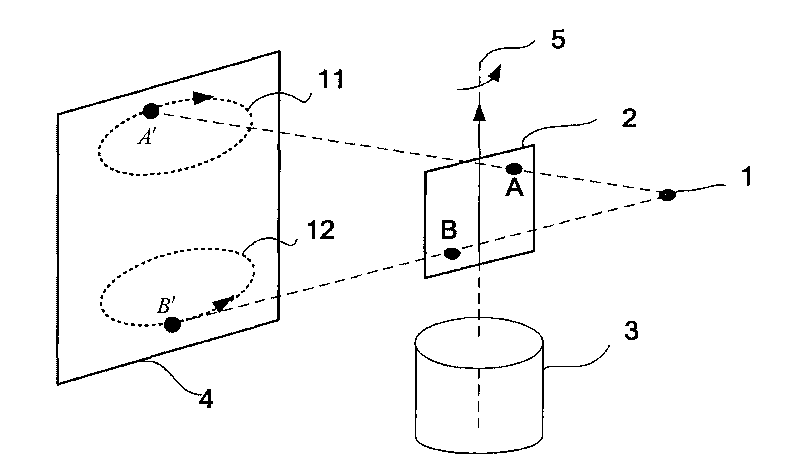

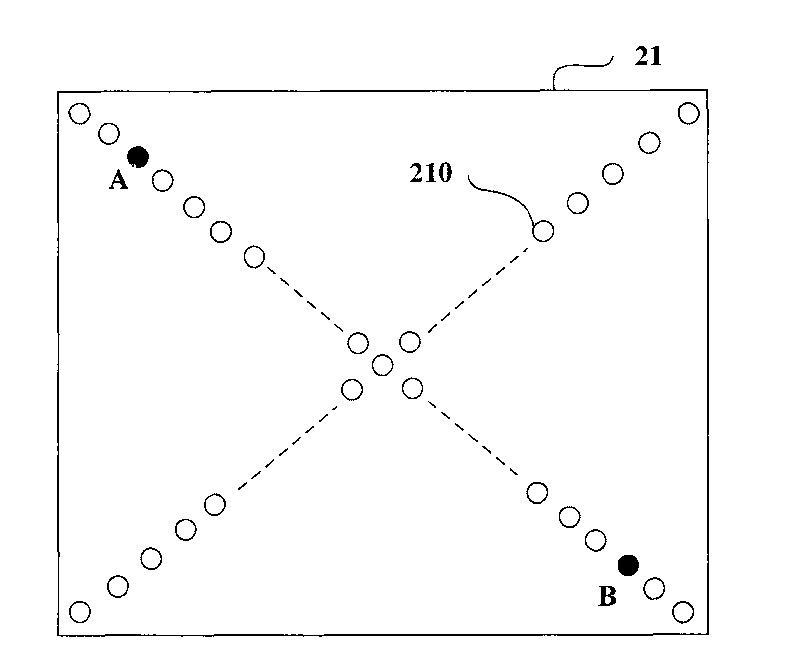

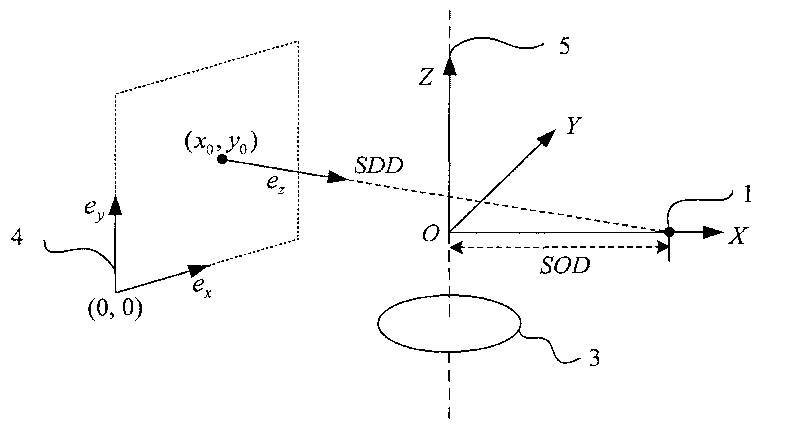

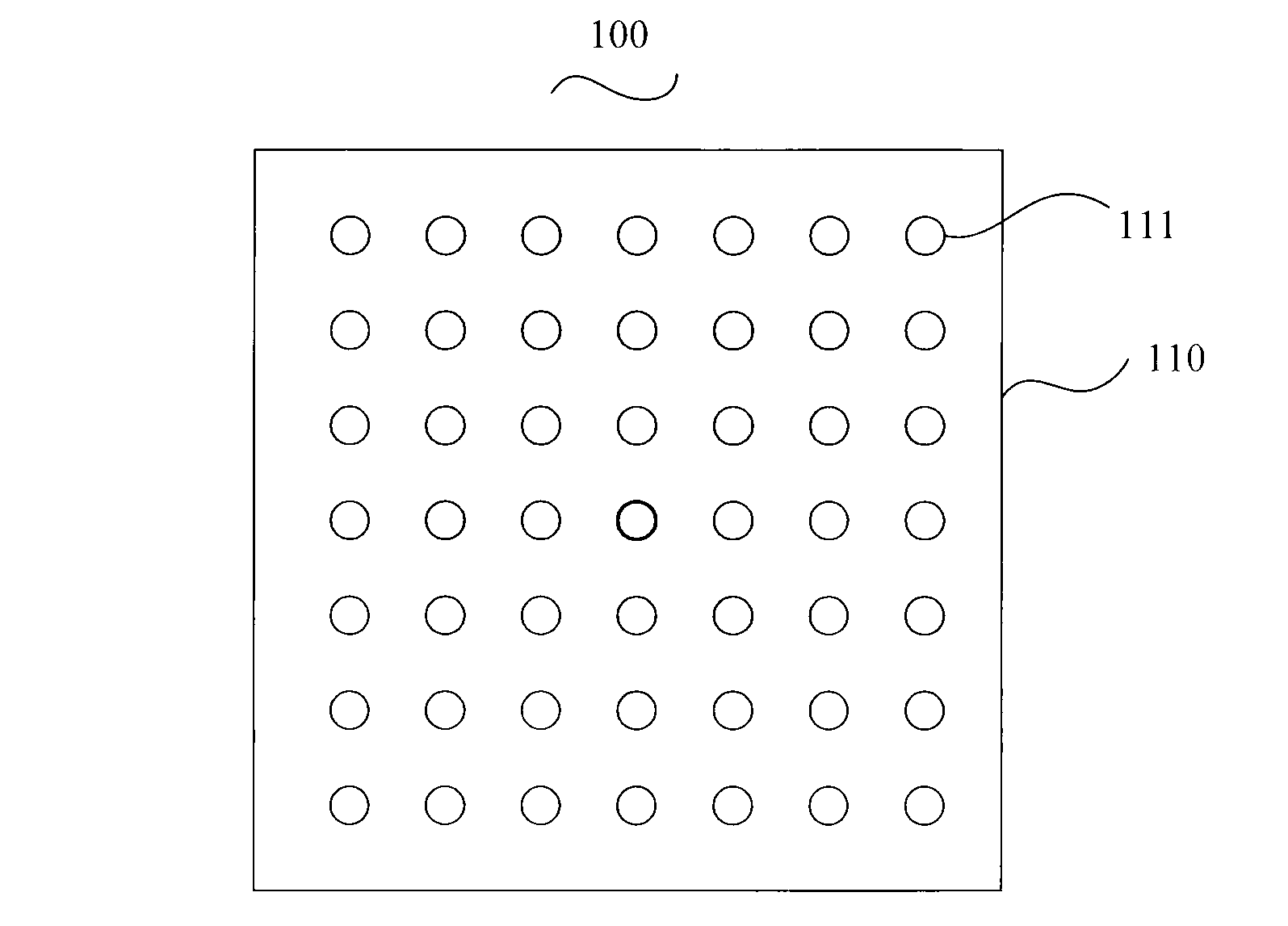

Calibration method, device and calibration phantomof geometric parameters in CT (computer tomography) system

ActiveCN101750021ASimple structureReduce manufacturing costComputerised tomographsTomographyRotary stageProjection image

The invention provides calibration method, device and calibration phantom of the geometric parameters in a CT (computer tomography) system. In the method, the calibration phantom is placed on a rotary table positioned between a light source and a detector, the calibration phantom comprises a calibration plate, as well as a small ball A and a small ball B which are arranged on the calibration plate, the calibration phantom is rotated for a circle along with the rotary table, and a center point coordinates of projection images of the small ball A and the small ball B are collected by the detector; the coordinate of an intersection point of a projective point line of projection ellipses of the small ball A and the small ball B is calculated and obtained according to the center point coordinates of the projection images and and the center coordinates of the projection ellipses of the small balls, and the torsion angle of the detector, the distance from the light source to the detector, the projection center point coordinate of the light source on a imaging plane, the swinging angle of the detector and the distance from the light source to the rotary table can be calculated based on the coordinate of the intersection point of the projective point line and a elliptic equation. The invention can calibrate a plurality of parameters, and can sufficiently meet the requirement of subsequent CT image correction.

Owner:SHENZHEN INST OF ADVANCED TECH

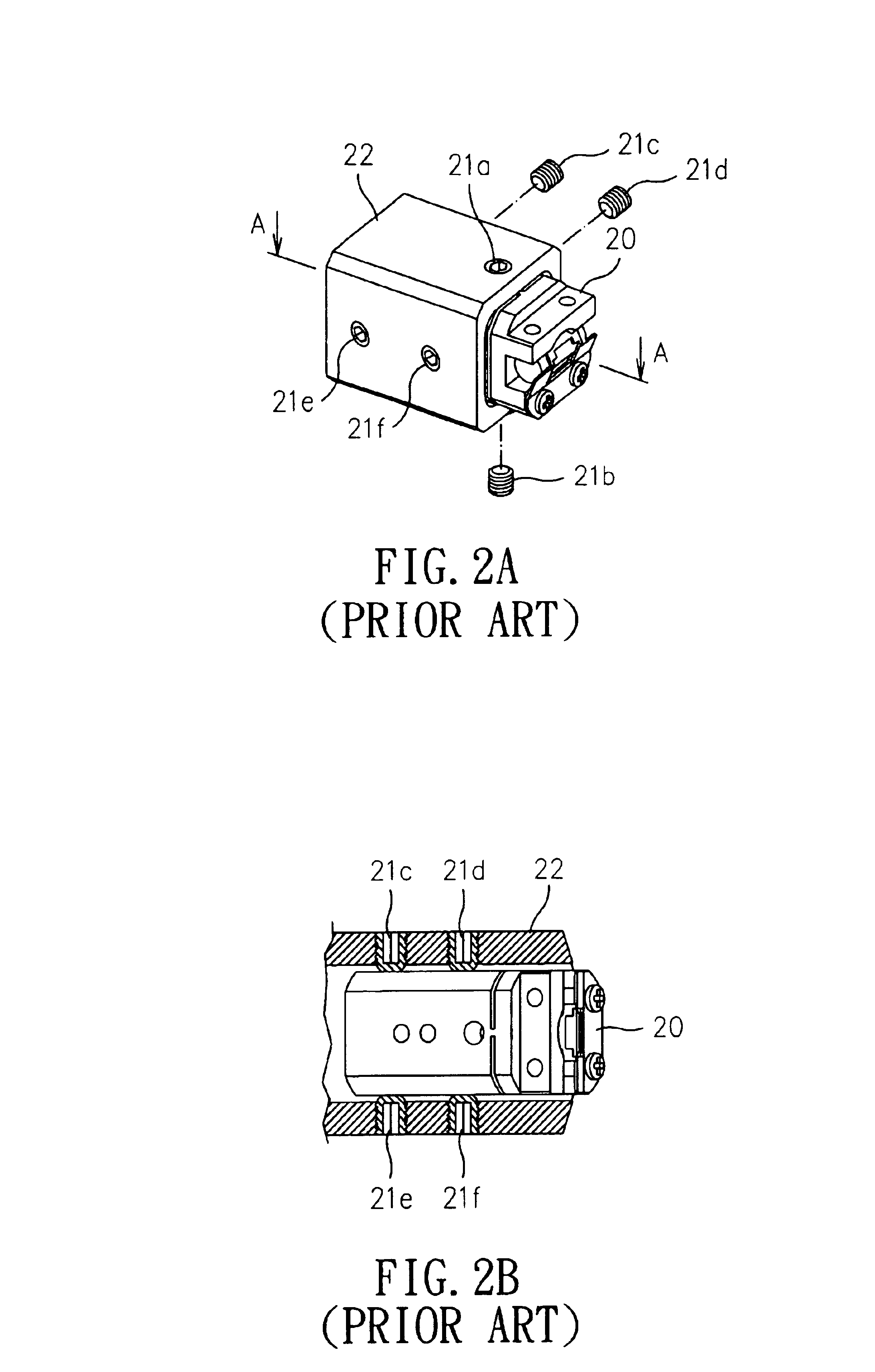

Test probe alignment apparatus

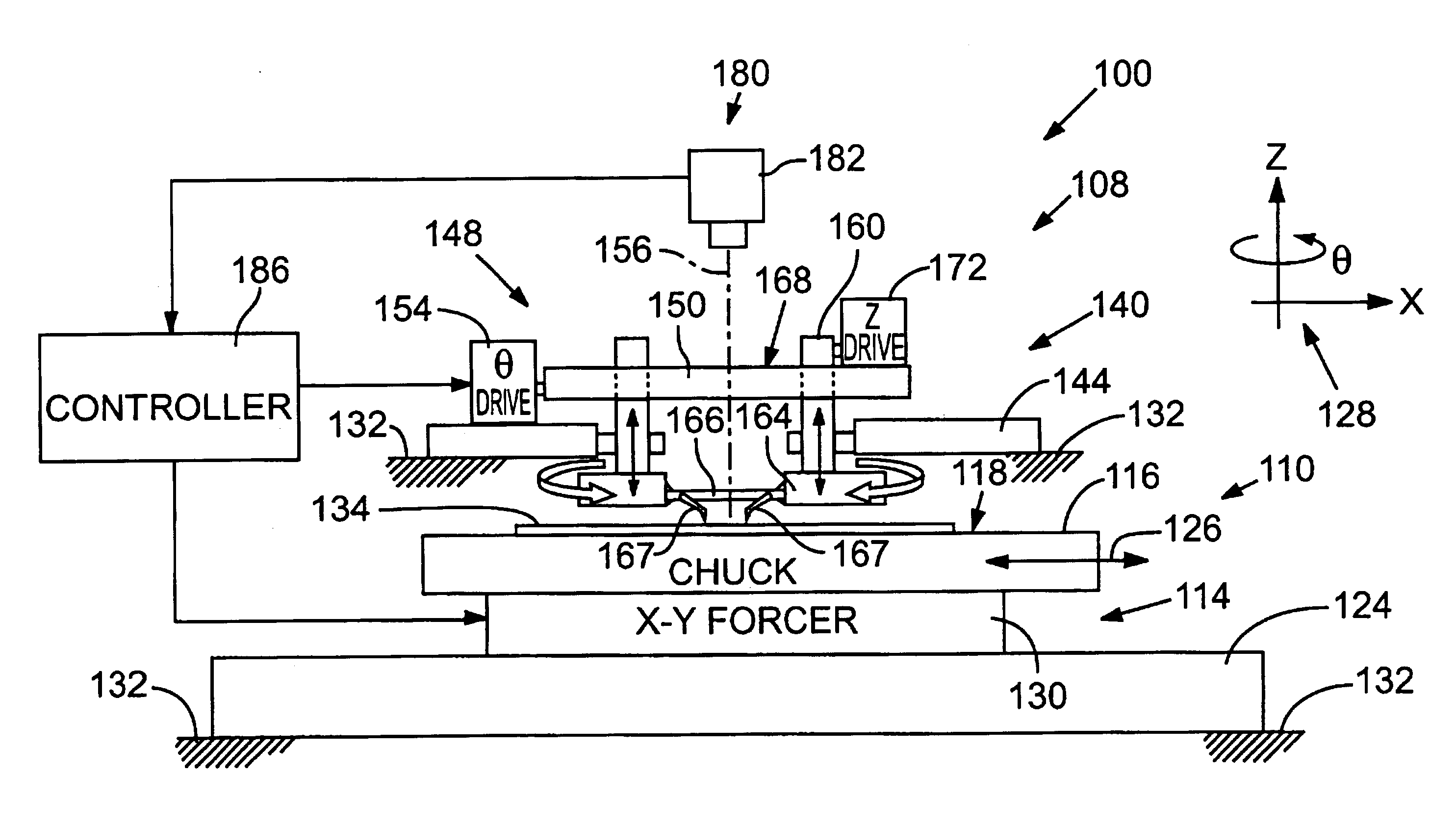

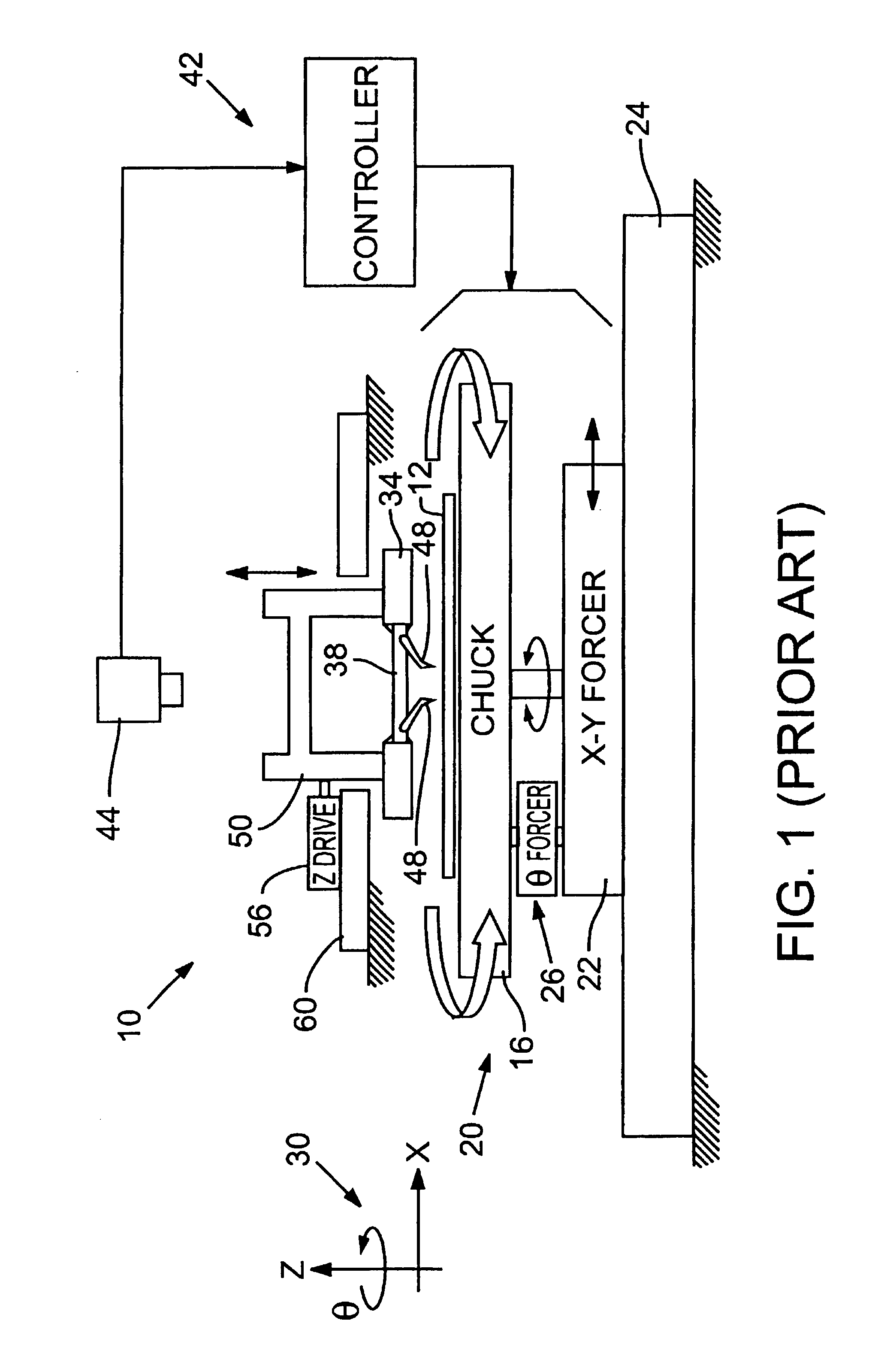

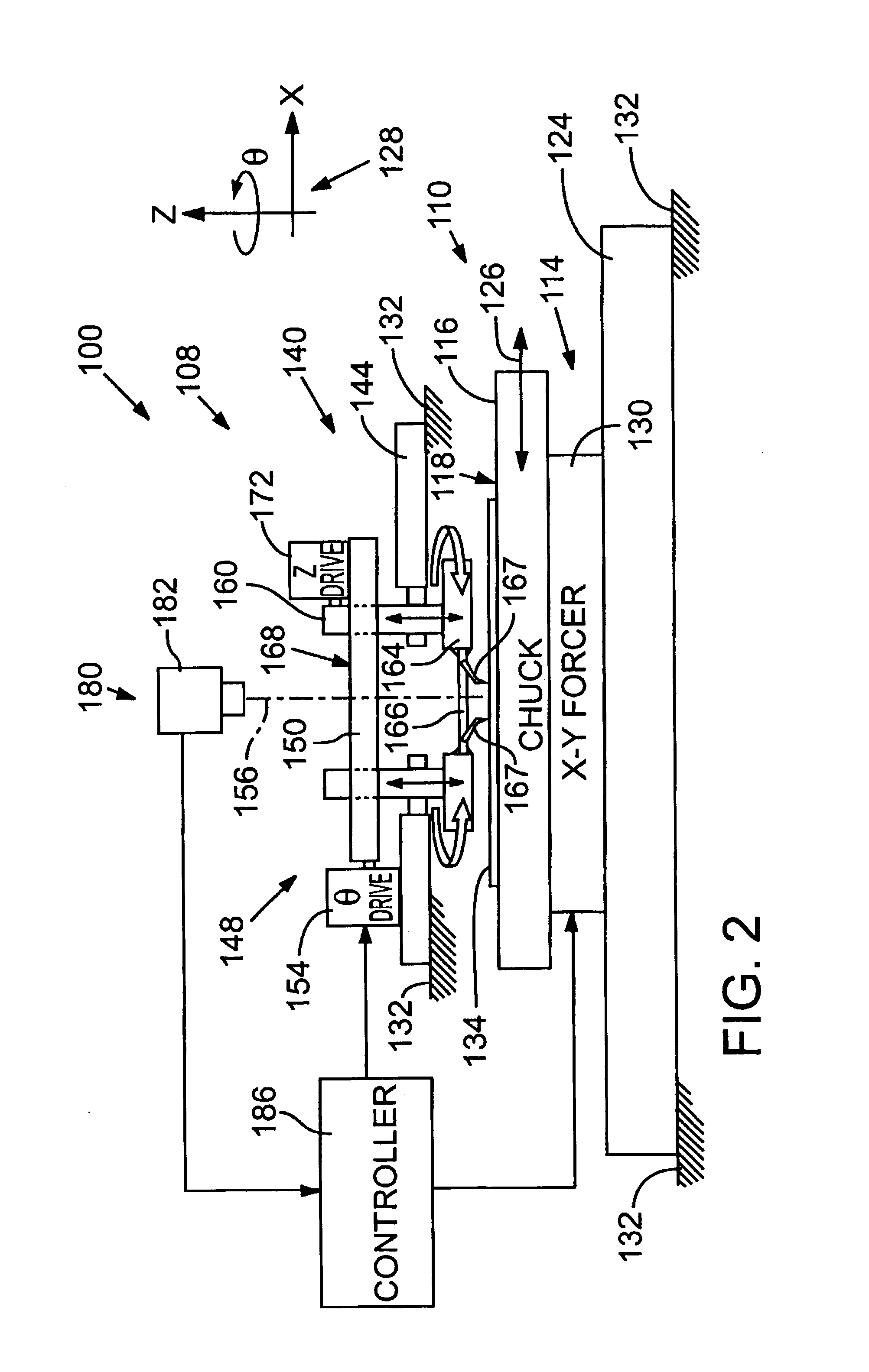

InactiveUS7119566B2Easy to participateAvoid vibrationSemiconductor/solid-state device testing/measurementMeasurement leads/probesRotary stageProbe card

A test probe alignment apparatus includes a rotatable θ stage that is decoupled from a workpiece positioning stage so that the workpiece positioning stage can move a workpiece in an X-Y plane without moving the θ stage, thereby inhibiting vibration in and inertia of the workpiece positioning stage, and improving the speed and accuracy of workpiece movements. The θ stage is driven for rotation about an axis substantially perpendicular to the X-Y plane. The rotatable stage supports a carriage adapted for holding a probe card. The carriage rotates in concert with the θ stage to thereby align the probe card relative to the workpiece. A Z-stage is operatively engaged with the carriage for moving the carriage along the axis of rotation relative to the workpiece. A computer processor performs coordinate transformations on preprogrammed movement vectors, to adjust for angular misalignment of the workpiece as measured by a position sensor.

Owner:ELECTRO SCI IND INC

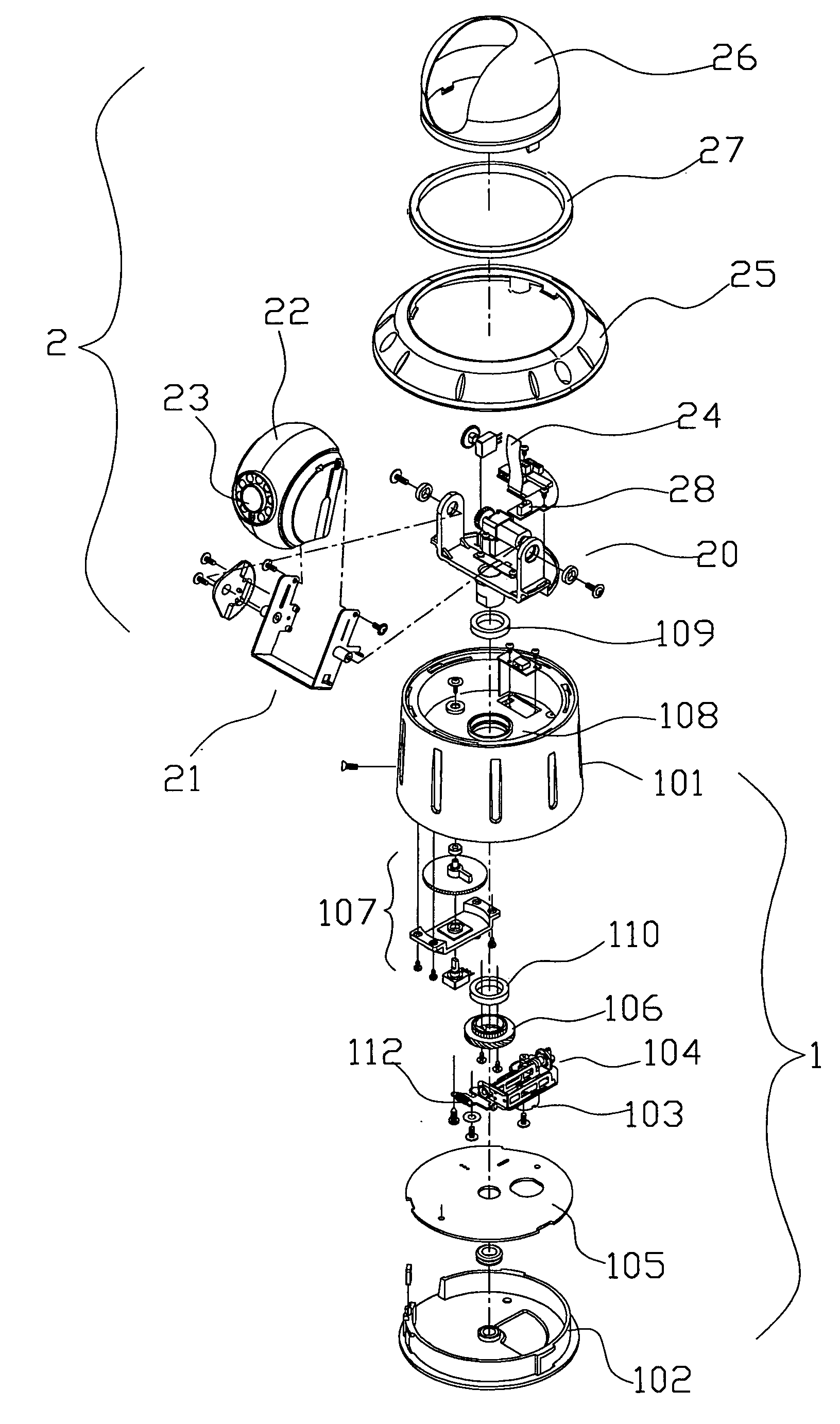

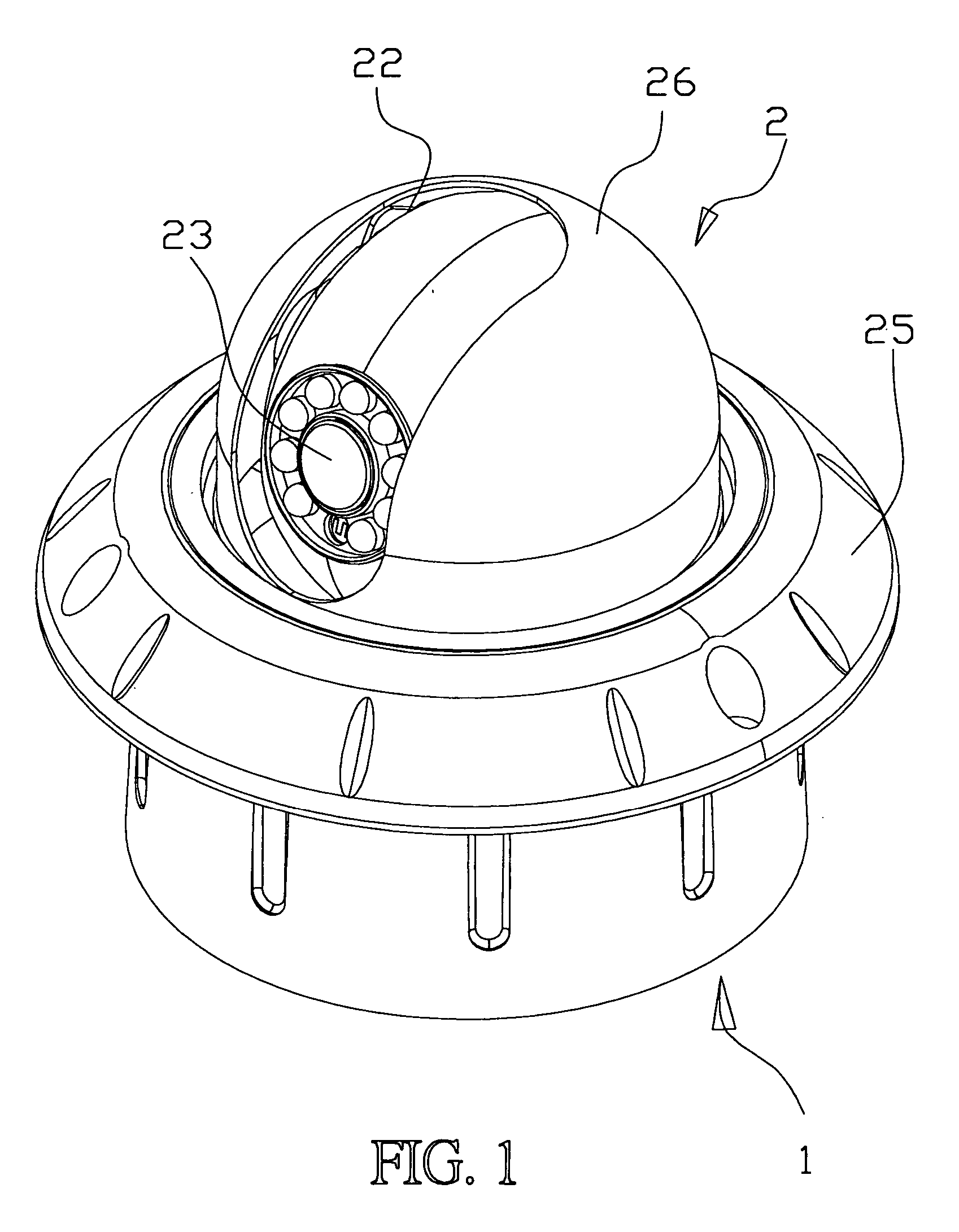

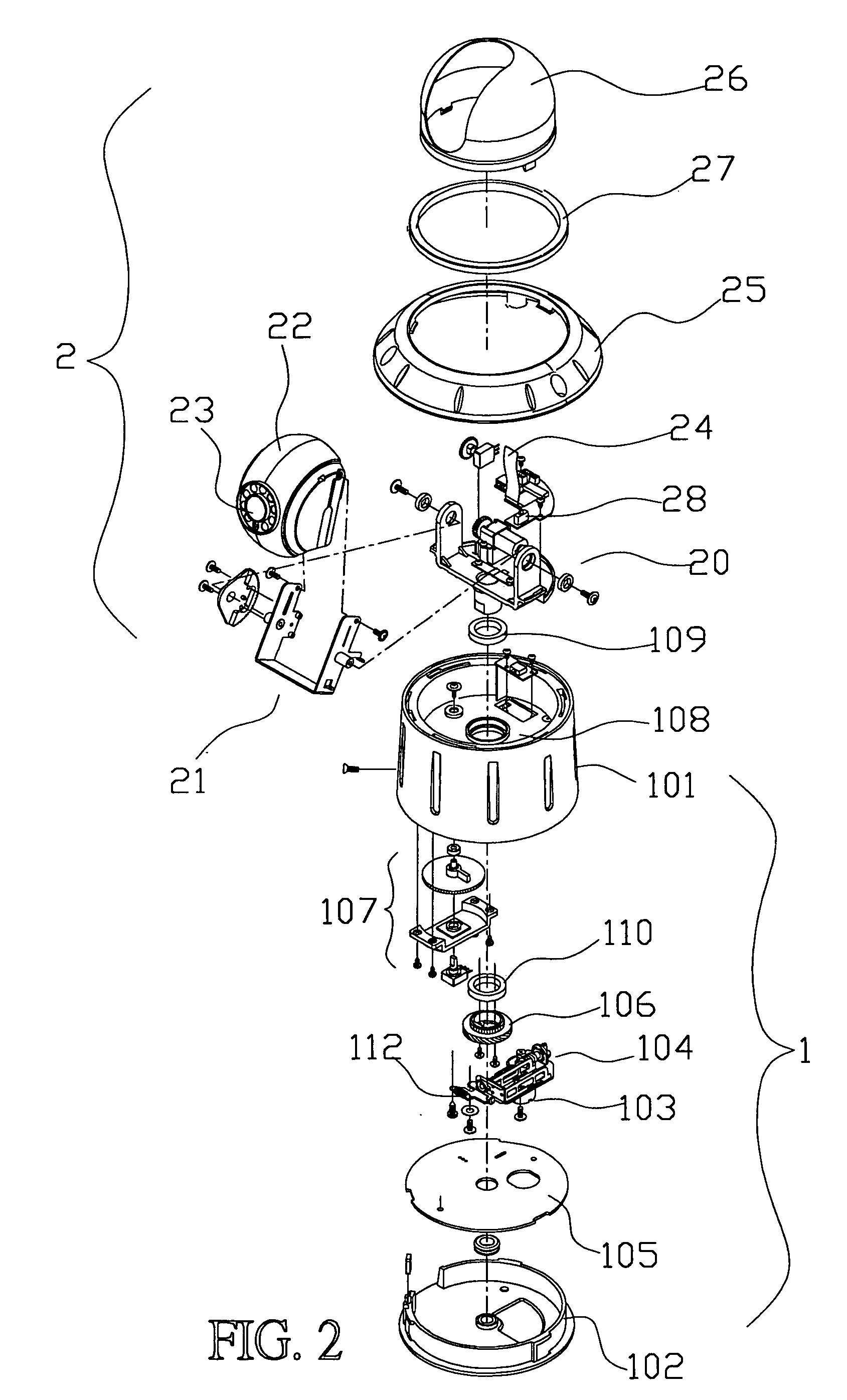

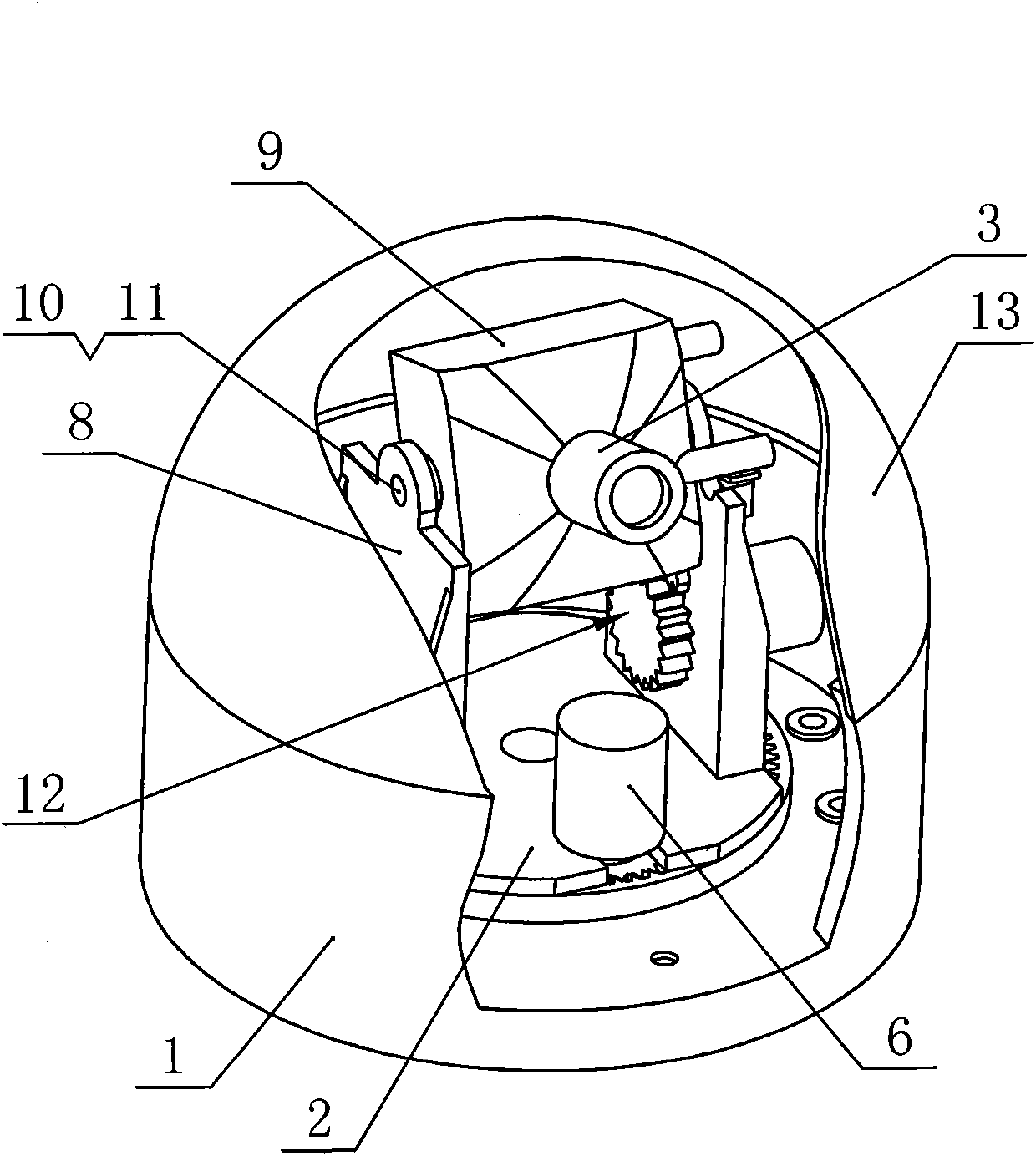

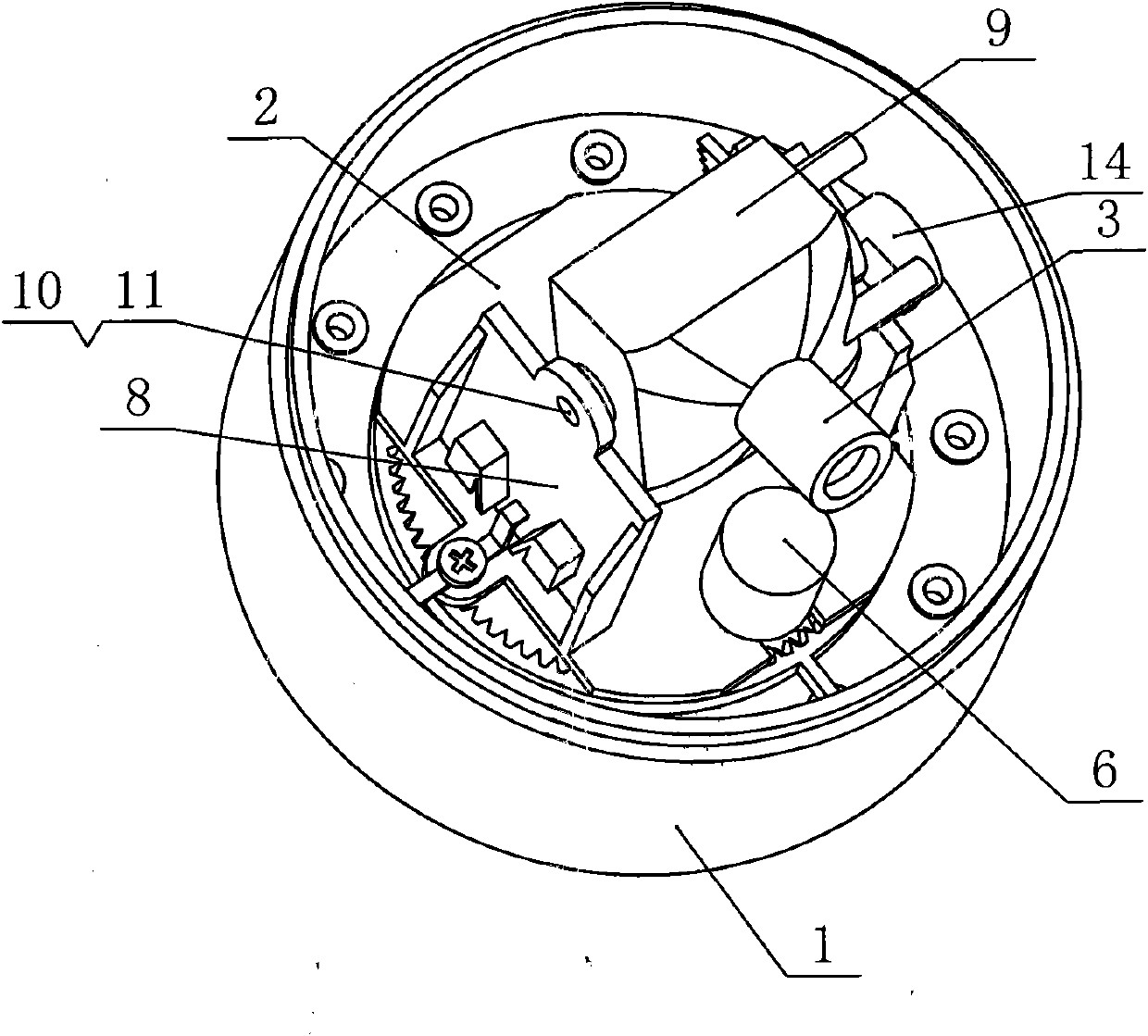

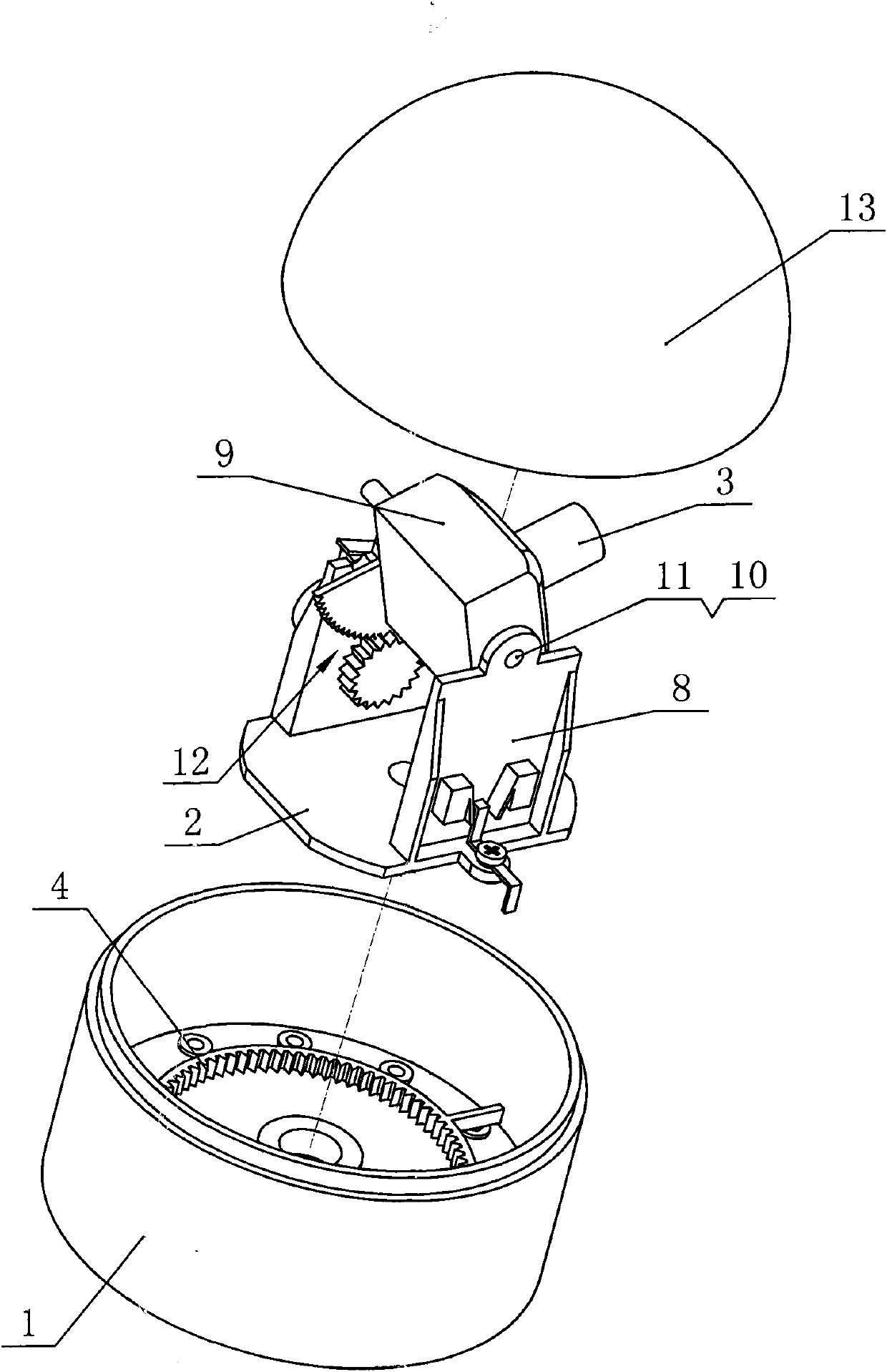

Ball type camera able of changing lens module

InactiveUS20060023113A1Easy to changePromote repairTelevision system detailsColor television detailsRotary stageVertical plane

The ball type camera able of changing a lens module comprises: a swivel table mechanism for rotating in a horizontal plane for 360 degrees without segmentation and a rocking mechanism for rotating up and down for 90 degrees without segmentation. Wherein the rocking mechanism has a rotation seat driven by the swivel table mechanism for rotating for 360 degrees and a rocking member; the rotation seat is mounted thereon with a motor and a driving gear, the rocking member mounted with the lens module is pivotally connected to the rotation seat, the rocking member has thereon a sheet gear engaging with the driving gear; the motor on the rotation seat runs to move the sheet gear through transmitting of the driving gear to make the rocking member move the lens module on the vertical plane for rotating up and down for 90 degrees without segmentation; With this combination, the lens module can be removed from the rocking member for changing.

Owner:ACUTVISTA INNOVATION

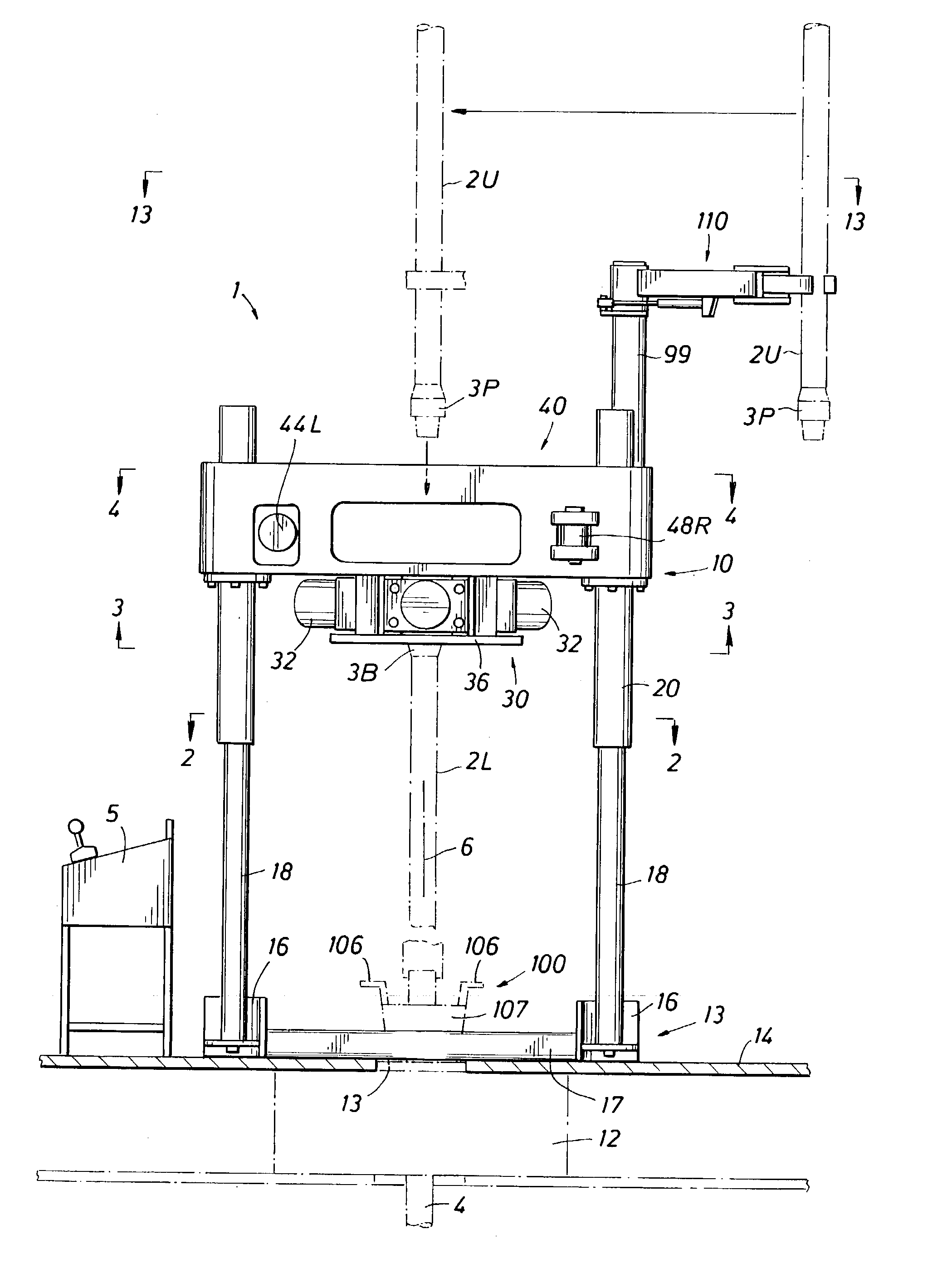

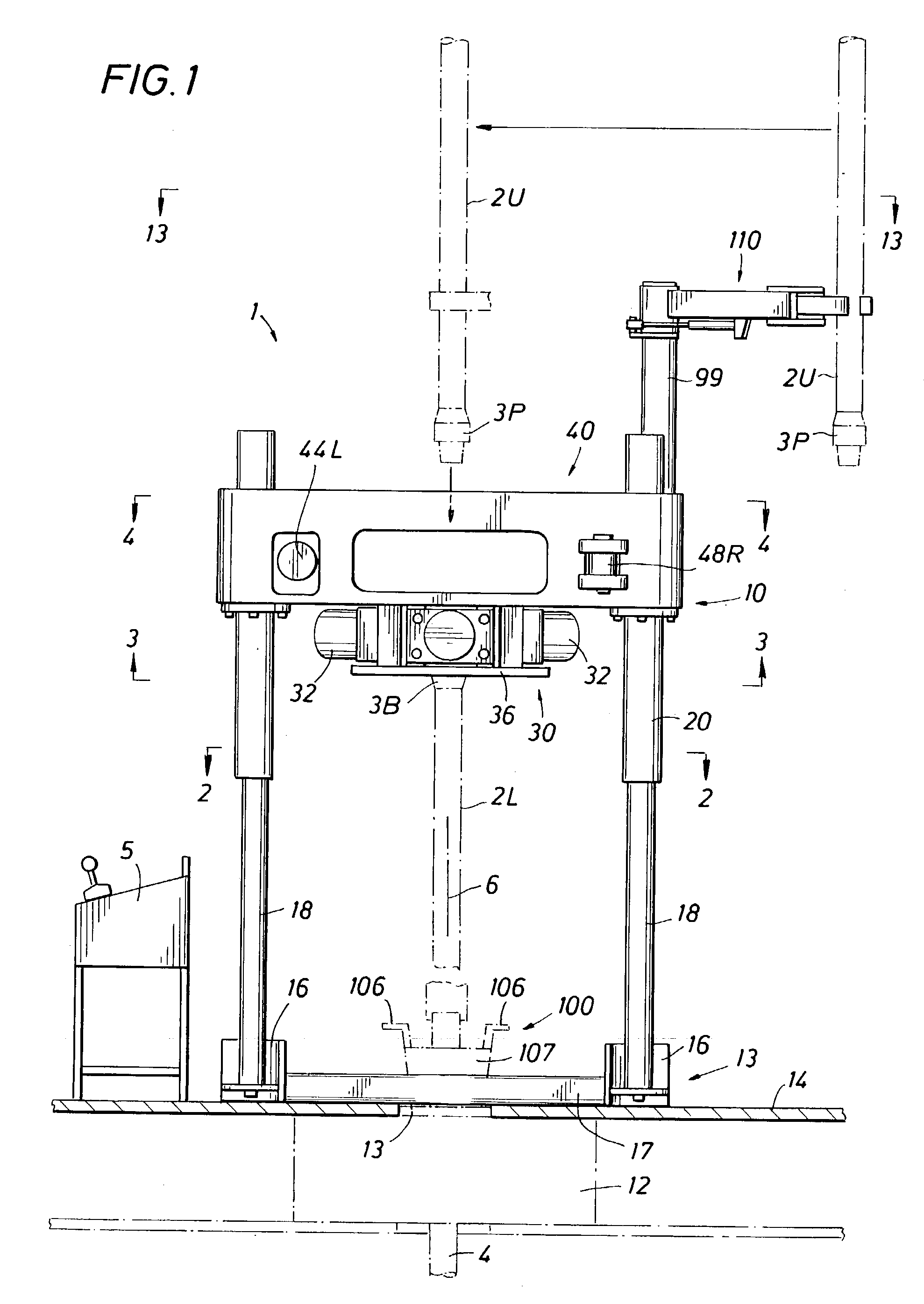

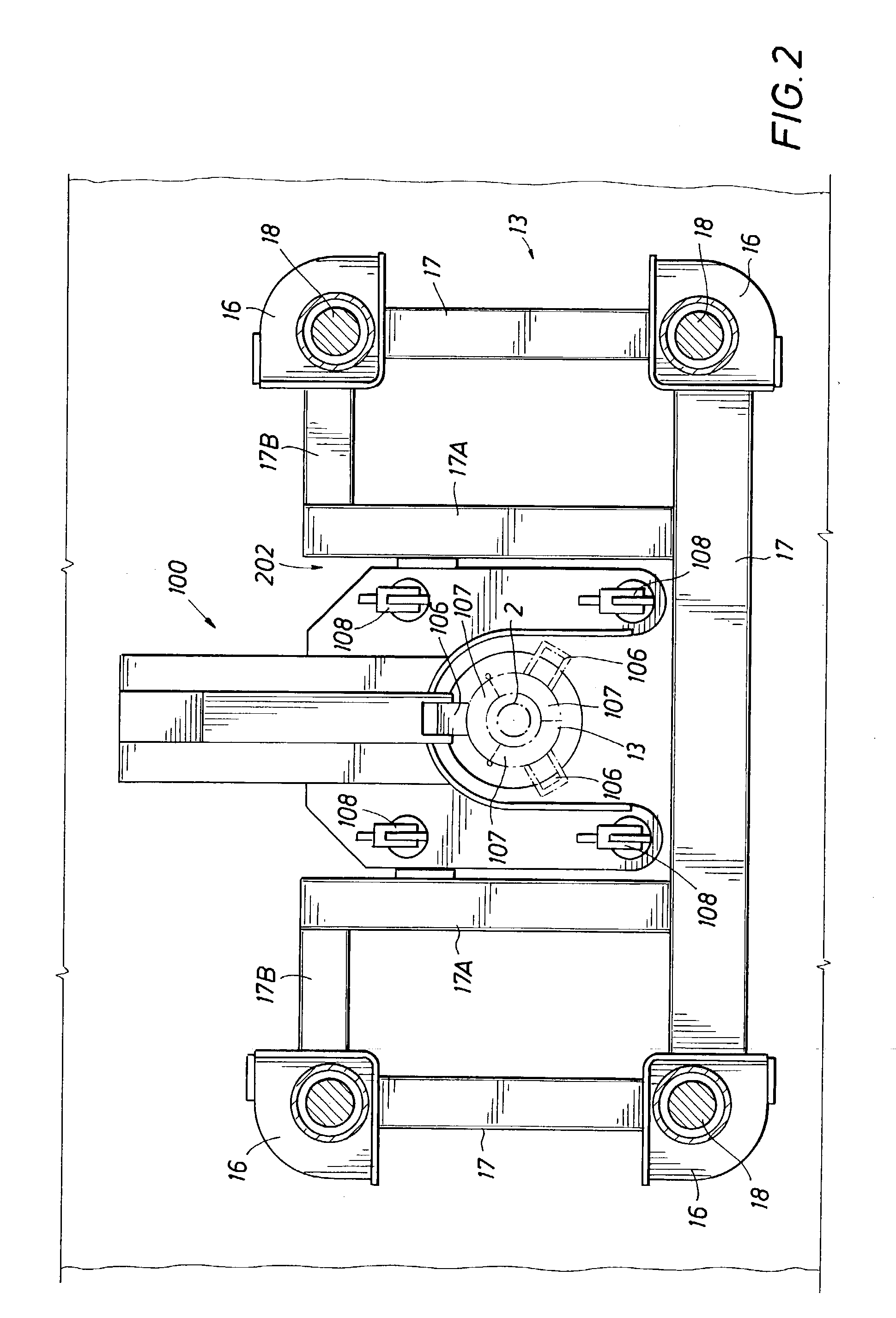

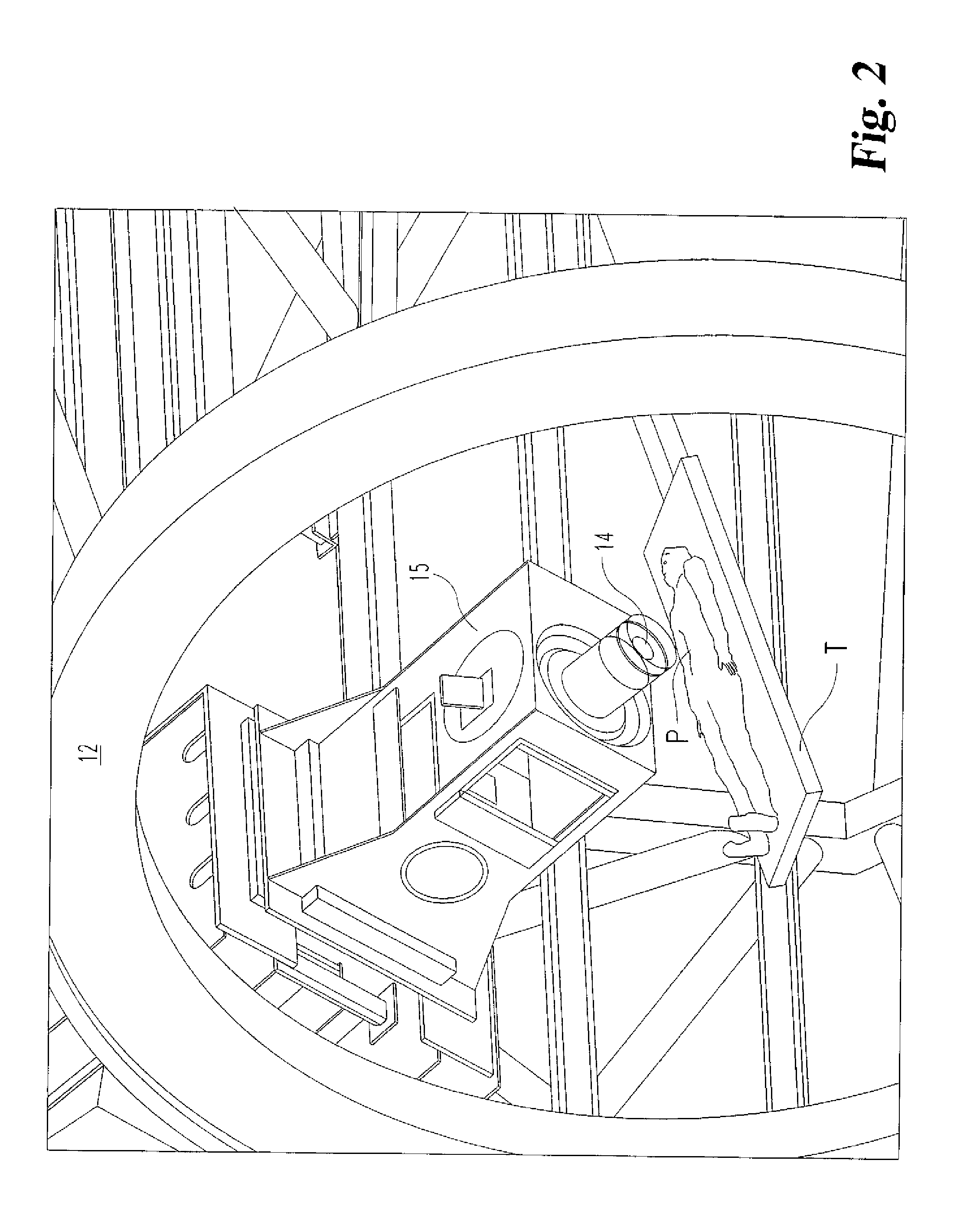

Automatic retractable floor system for a rotating gantry

A movable floor system for use with a rotating gantry in a radiation treatment facility is provided that comprises a carriage assembly slidably supported within the gantry to maintain a substantially constant orientation while the gantry is rotating. An extendable / retractable panel assembly is supported on the carriage assembly that includes a plurality of non-movable floor panels and a like plurality of movable floor panels slidably mounted over corresponding ones of the non-movable panels. The movable panels are sized to span a distance between the carriage assembly and a fixed floor of the treatment room. Each of the movable panels has a platform surface for supporting a person for access to and from the patient table situated within the gantry. A control system coordinates the extension and retraction of the movable floor panels to prevent collisions with the radiation nozzle as it rotates during the patient treatment.

Owner:INDIANA UNIV RES & TECH CORP

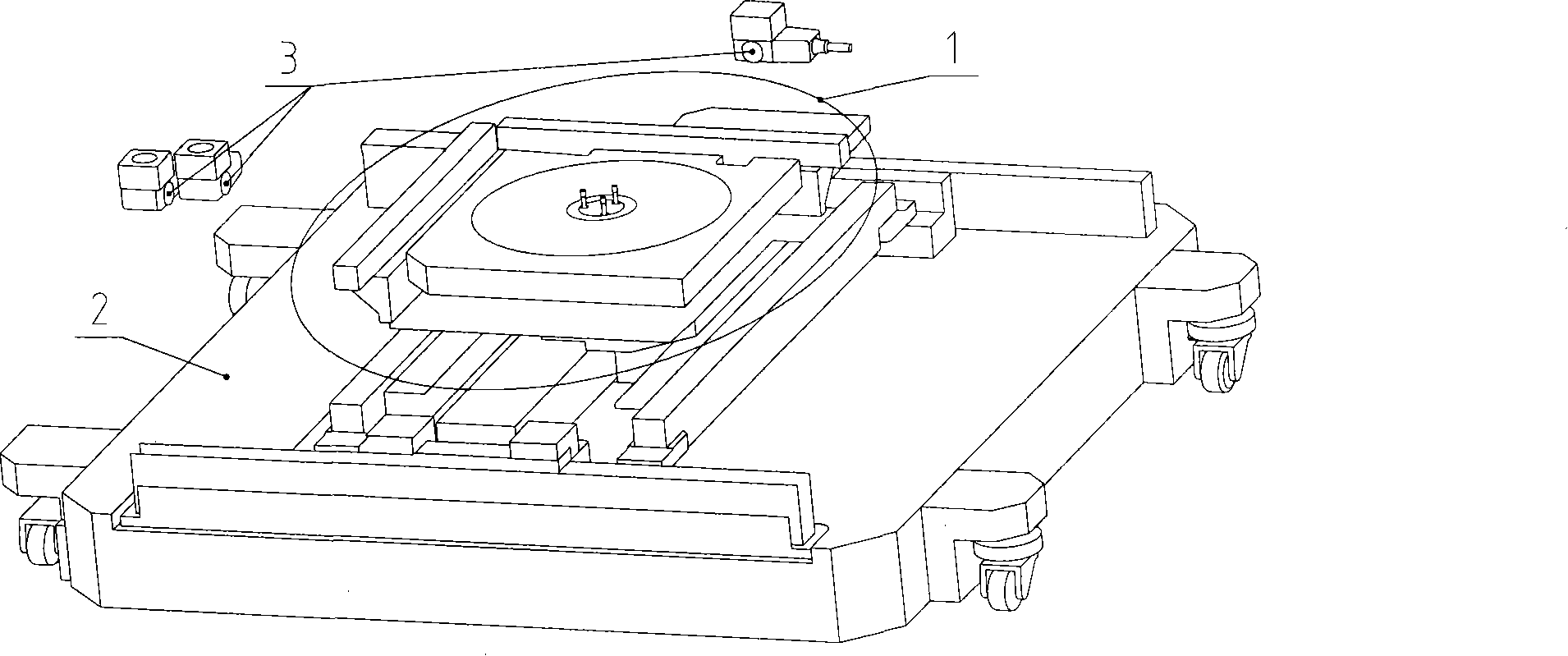

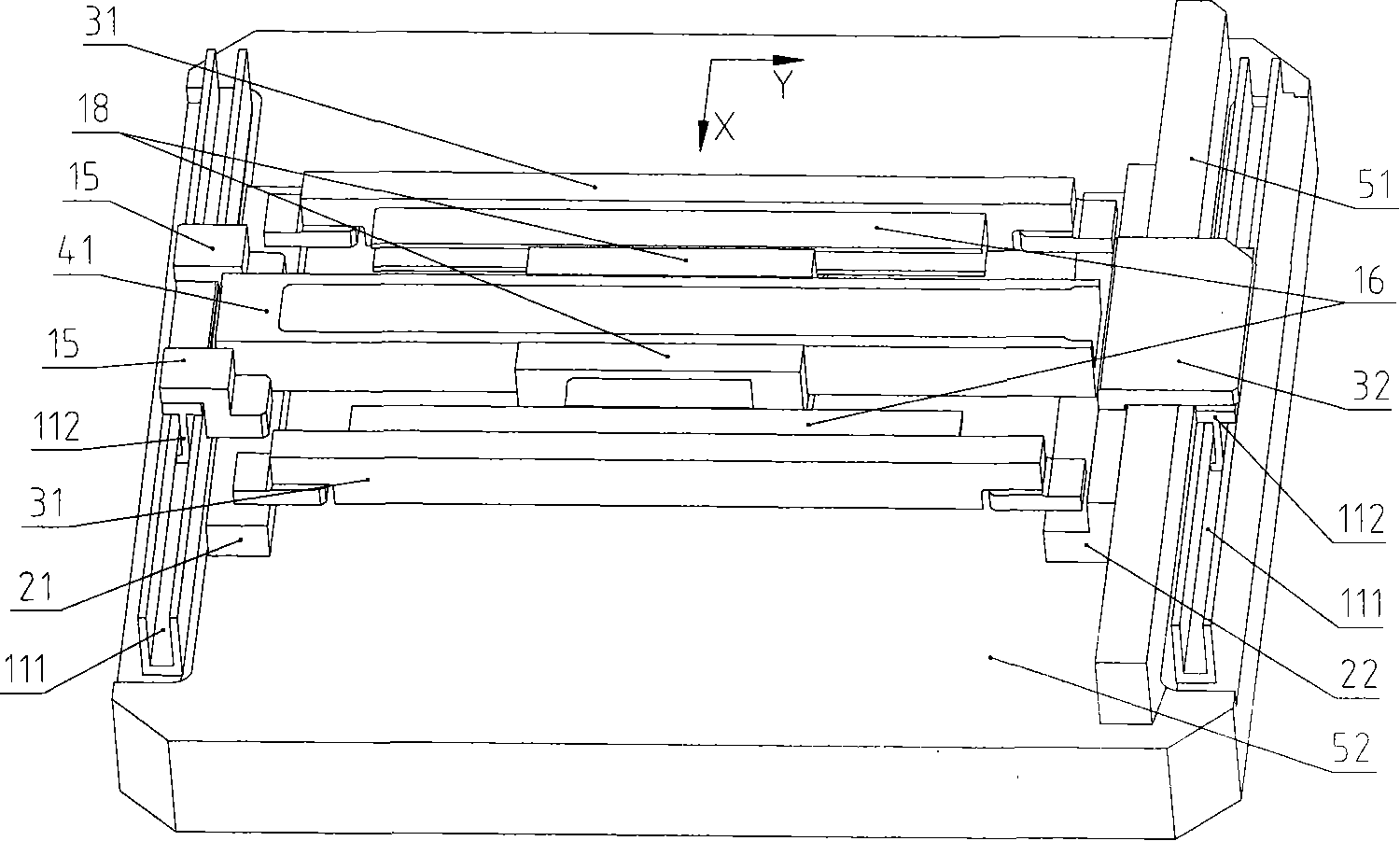

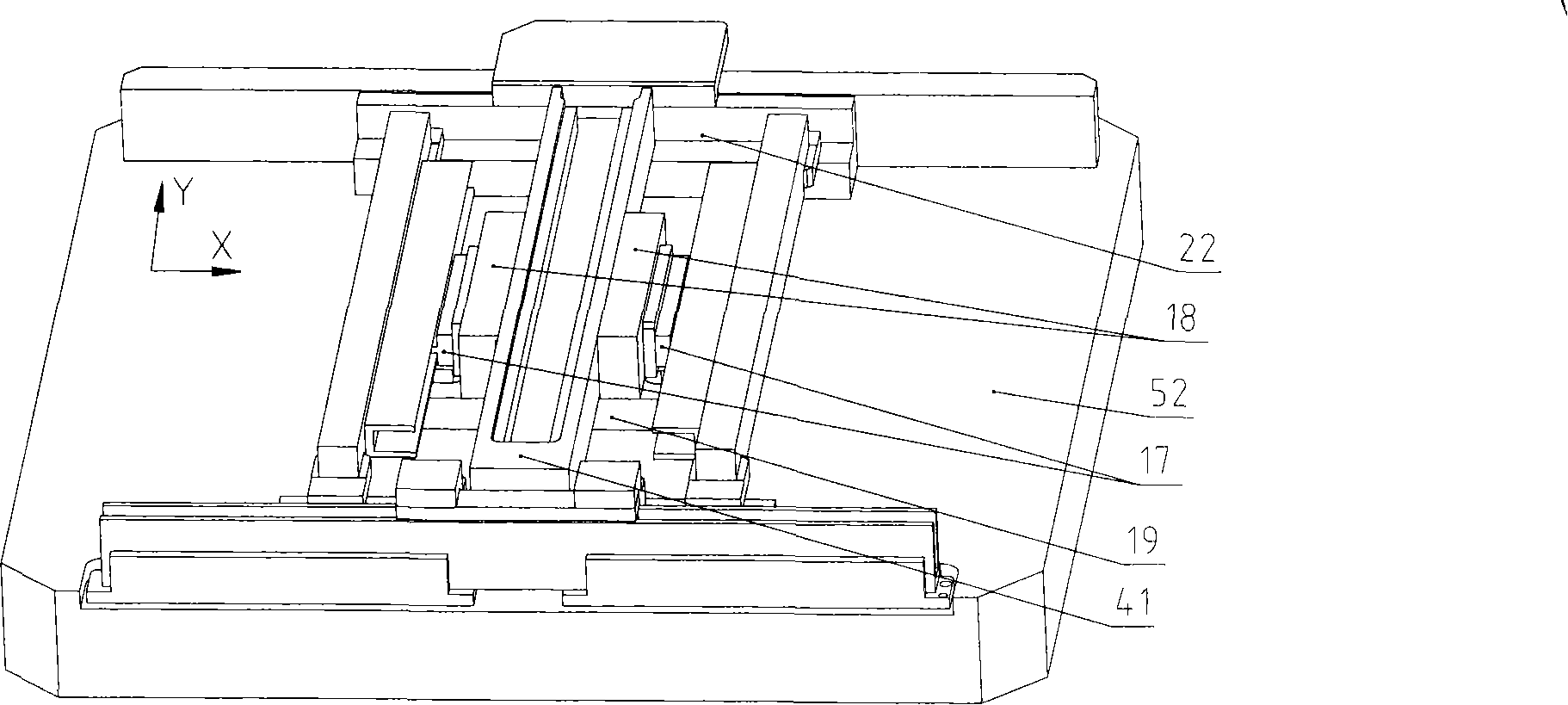

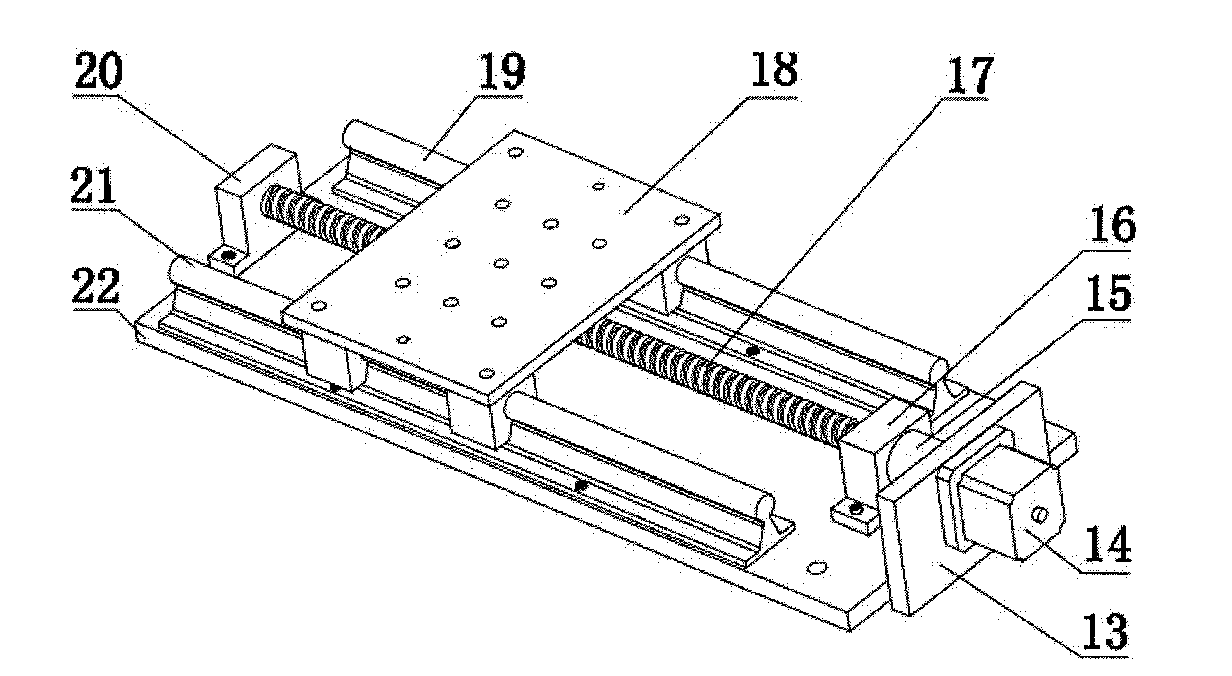

6 freedom degree precision positioning station capable of compensating z-direction position

ActiveCN101241314ACompact structureEasy to implementPhotomechanical exposure apparatusWork benchesRotary stageSlice thickness

The invention provides a six-freedom precision positioning stage capable of compensating Z-direction position, comprising a XY stage and an exposure stage structurally. The XY stage is a horizontal precision positioning stage for implementing horizontal (X, Y directions) precision positioning by a set of horizontal driver, an accurate and effective transmission device and closed-loop control; the exposure stage is divided from the top down into three layers which are a rotating stage, a leveling and focusing mechanism and a silicon slice thickness compensating mechanism. A silicon anastomosis mechanism is disposed between the rotating stage and the silicon slice compensating mechanism. The invented six-freedom precision positioning stage capable of compensating Z-direction position can be used in an occasion with a large stroke, a high speed and a high precision in horizontal direction, and can implement submicron precision adjustment in three freedoms in vertical direction.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

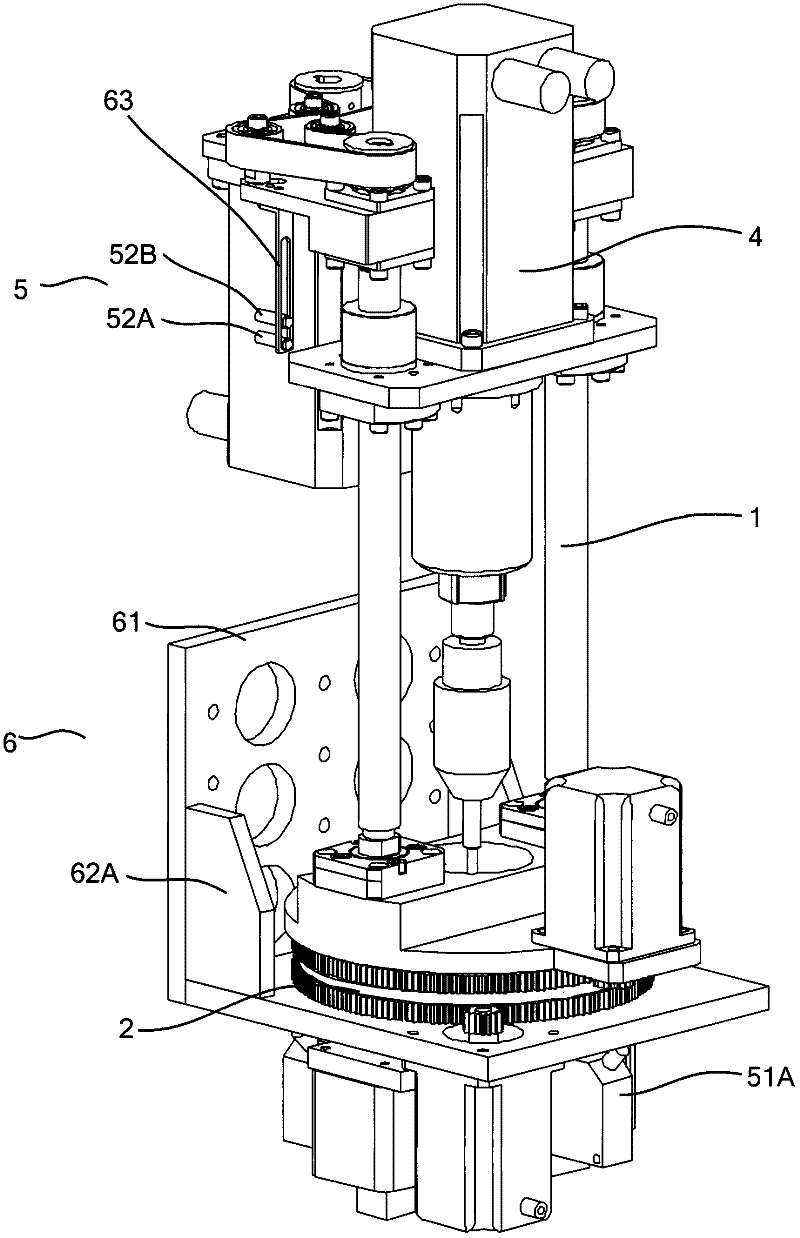

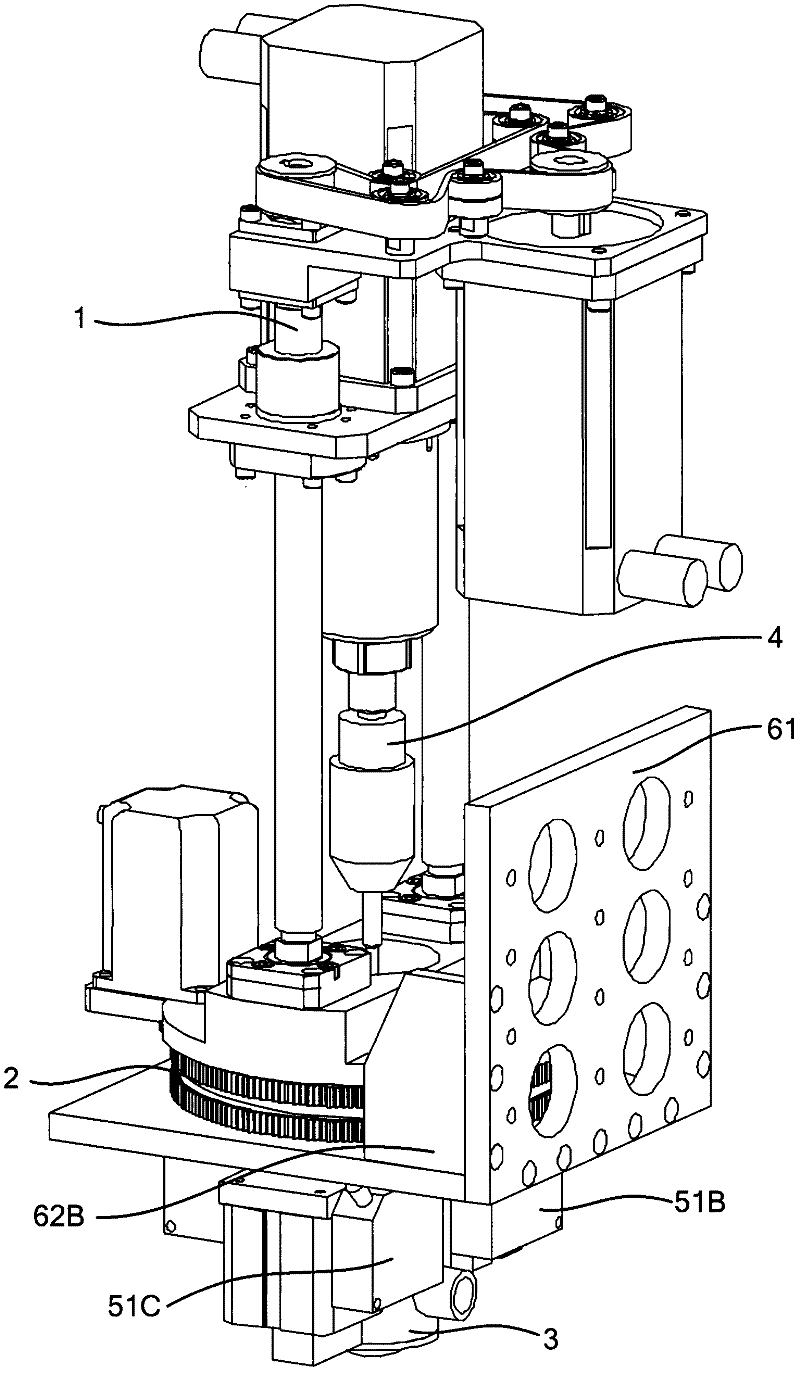

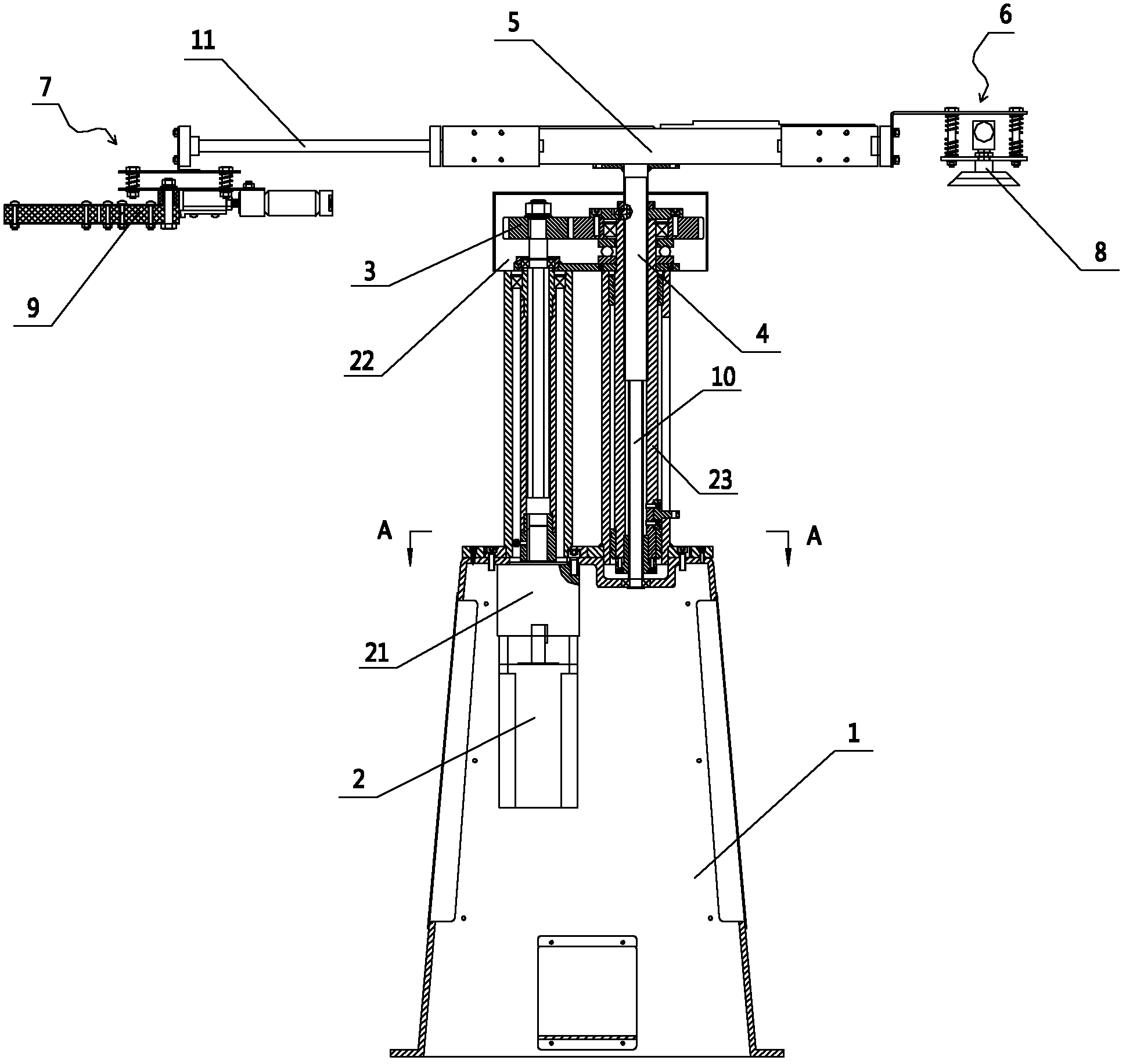

Aviation hole-forming robot end effector capable of adjusting attitude

InactiveCN102513575AFree replacementImprove hole making efficiencyPositioning apparatusBoring/drilling componentsAviationRotary stage

The invention provides an aviation hole-forming robot end effector which is suitable for plane skin drilling and can be used for automatically adjusting the attitude. The end effector comprises a leading screw feeding module, a binary angle adjusting mechanism, a compacting chip-absorbing module, a drilling module and a sensor module. The leading screw feeding module mainly comprises a leading screw driving motor, a synchronous transmission component and a dual-ball leading screw and is used for realizing feeding motion of drilling; the binary angle adjusting mechanism mainly comprises a stepping motor, a transmission gear, a wedge-shaped turn table and a spherical hinge and is used for realizing the automatic adjustment of the tail end attitude; the compacting chip-absorbing module mainly comprises a cylinder, a pressing cylinder, a cylinder connecting rod and a compacting head and is used for realizing compaction of a skin and the absorption of metal drill chips; the drilling module mainly comprises a drilling servo motor, a transmission shaft, a drill chuck and a drill bit and is used for realizing high-accuracy drilling; and the sensor module comprises a proximity sensor and a laser distance-measuring sensor and is used for realizing zero addressing and limiting of the movement of a main shaft, and the measurement of the normal line of a drilling point.

Owner:袁培江

Multidirectional laser indicator

A laser indicator includes a weight mechanism having a bracket with a weight secured to the bracket in a manner where the weight is suspended by gravity. A plurality of laser generators are arranged about the weight, including a horizontal beam generator, a center laser generator arranged at the axial center of the bottom of the weight for emitting a laser point coaxial to the axial line of the weight, and a plurality of vertical beam generators positioned in spaced-apart manner around the axial center of the weight at the top of the weight. The laser indicator can include a stand that includes a seat having a plurality of legs, and a rotary table having a plurality of legs, with the weight mechanism coupled to the rotary table, and the rotary table removably coupled to the seat so that altitude of the weight mechanism can be adjusted. In addition, the laser indicator can include a securing mechanism for coupling the weight to the upper bracket of the bracket.

Owner:QUARTON

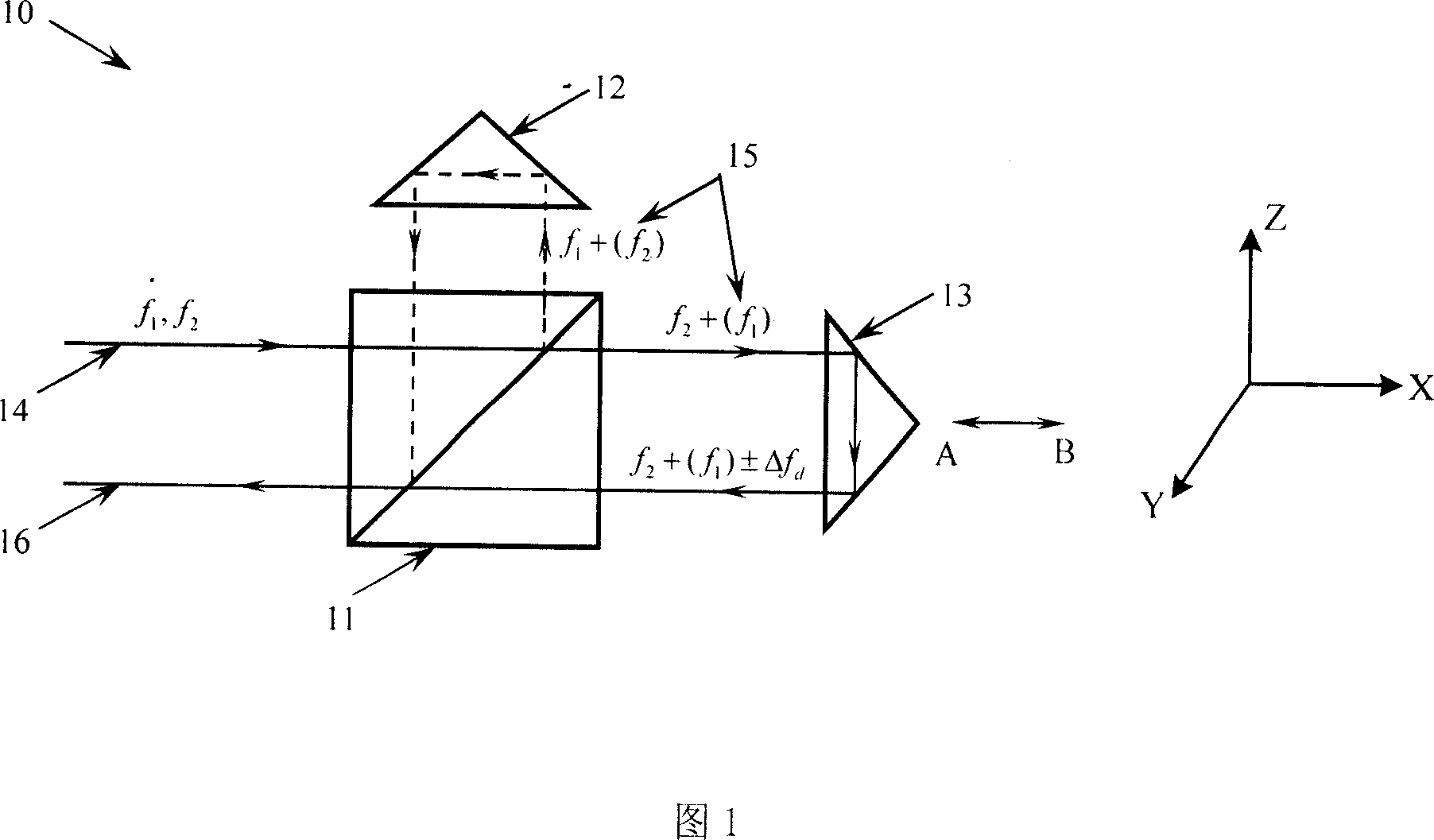

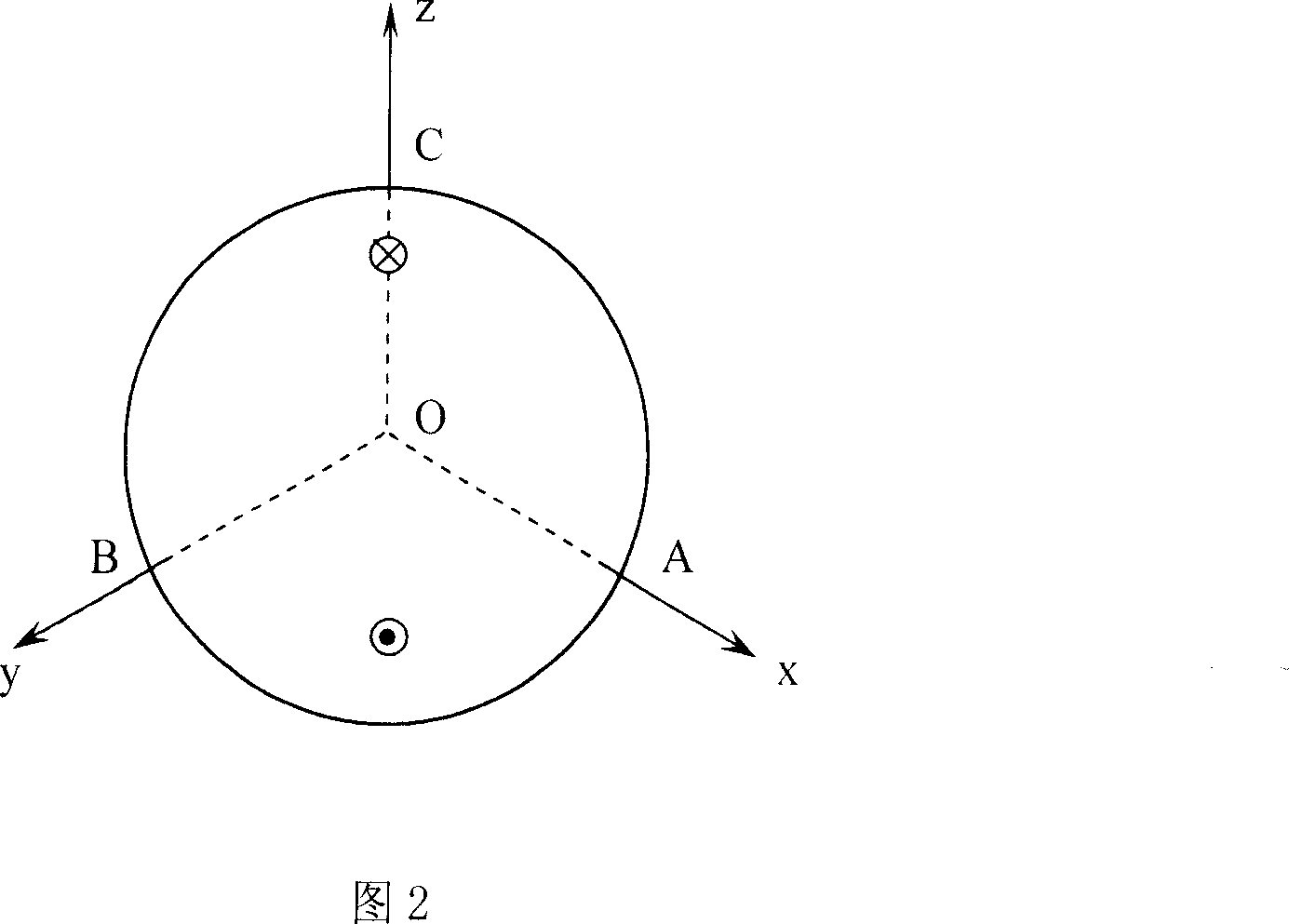

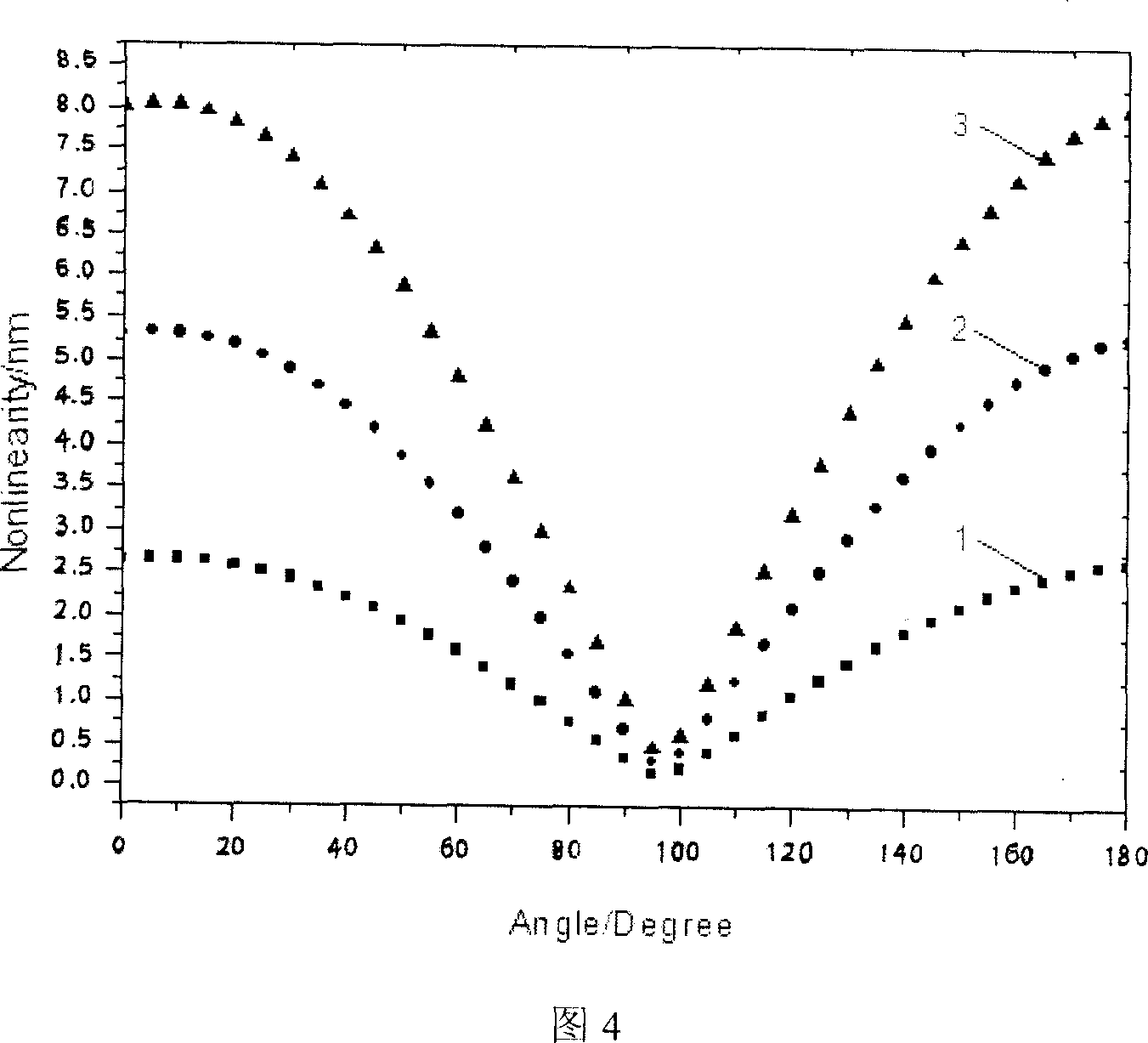

Method and apparatus for reducing heterodyne interference nonlinear error first harmonic component

InactiveCN101067546AReducing Nonlinear Errors of Laser Heterodyne InterferometrySimple methodUsing optical meansRotary stagePrism

The invention relates to a method of reducing the heterodyne interference non-linear error first harmonic component and its equipment, the existing kinds of system and the method are all very complex. The invention includes: the light beams which contains two frequencies, two polarization directions and sends out by the double frequency laser; this light beam divides into two bunches of light after the spectroscope, the reflected light forms the reference signal after the analyzer by the photo detector receive; the transmitted light enters the polarization spectroscope to divide into two bunches of light which includes the reflected light of polarization direction vertical paper surface and parallel paper surface transmitted light, the reflected light reflects to the polarization spectroscope after the reference pyramid prism, the transmitted light after survey pyramid prism installed on the swivel table also reflects the polarization spectroscope; above two bunches of light converge in the polarization spectroscope place, and formed the survey signal by the reflector reflection after the analyzer by the photo detector; swivel table axial revolves the survey pyramid prism along the survey pyramid prism heading, swivel table anti-clockwise or clockwise axial revolves 97 degree. The invention uses to increase the heterodyne interference measuring accuracy.

Owner:HARBIN INST OF TECH

High-precision positioning rotational station

ActiveCN101907217AHigh measurement accuracyImprove measurement reliabilityStands/trestlesRotary stageLongitude

The invention relates to a high-precision positioning rotational station, comprising a horizontal rotating platform, a vertical rotating platform, a horizontal driving motor, a vertical driving motor and a controller. The controller comprises a power supply unit, a data communication circuit, a control unit and a motor drive unit. The high-precision positioning rotational station is characterizedin that the control unit comprises a data processing unit, a real-time longitude and latitude memory, a positioning longitude and latitude memory and a comparator. Because of the arrangement of the real-time longitude and latitude memory, the positioning longitude and latitude memory and the comparator, a control center can send out final positioning longitude and latitude information of the horizontal rotating platform and the vertical rotating platform and can continuously send out the information for more than one time for improving the reliability, and the controller of the rotational platform can control the horizontal driving motor and the vertical driving motor to work after the comparison of the comparator to obtain a relative longitude and latitude position only by receiving the final positioning longitude and latitude once, thereby improving the measurement precision and the reliability of the high-precision positioning rotational station.

Owner:ZHEJIANG TENDENCY TECH

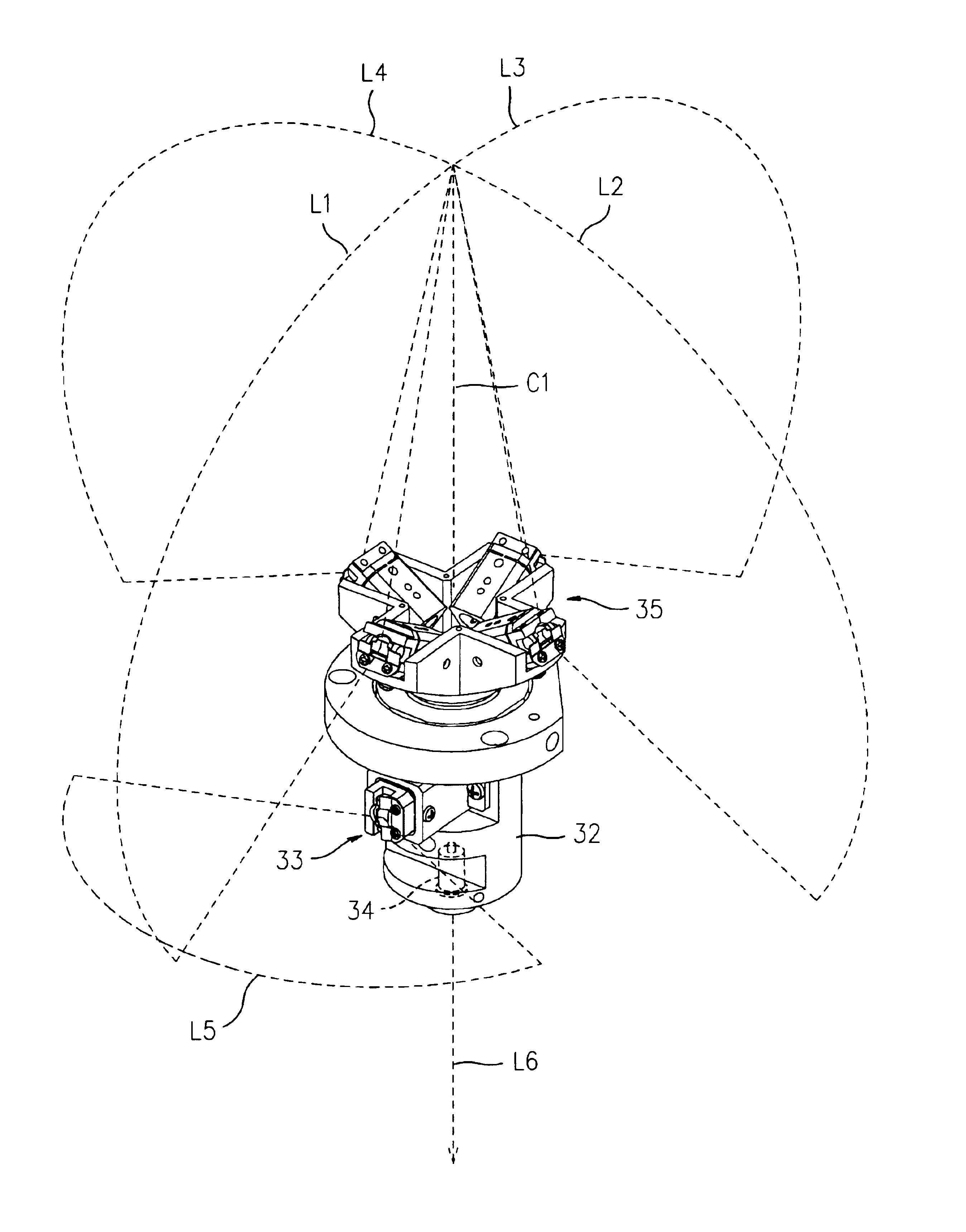

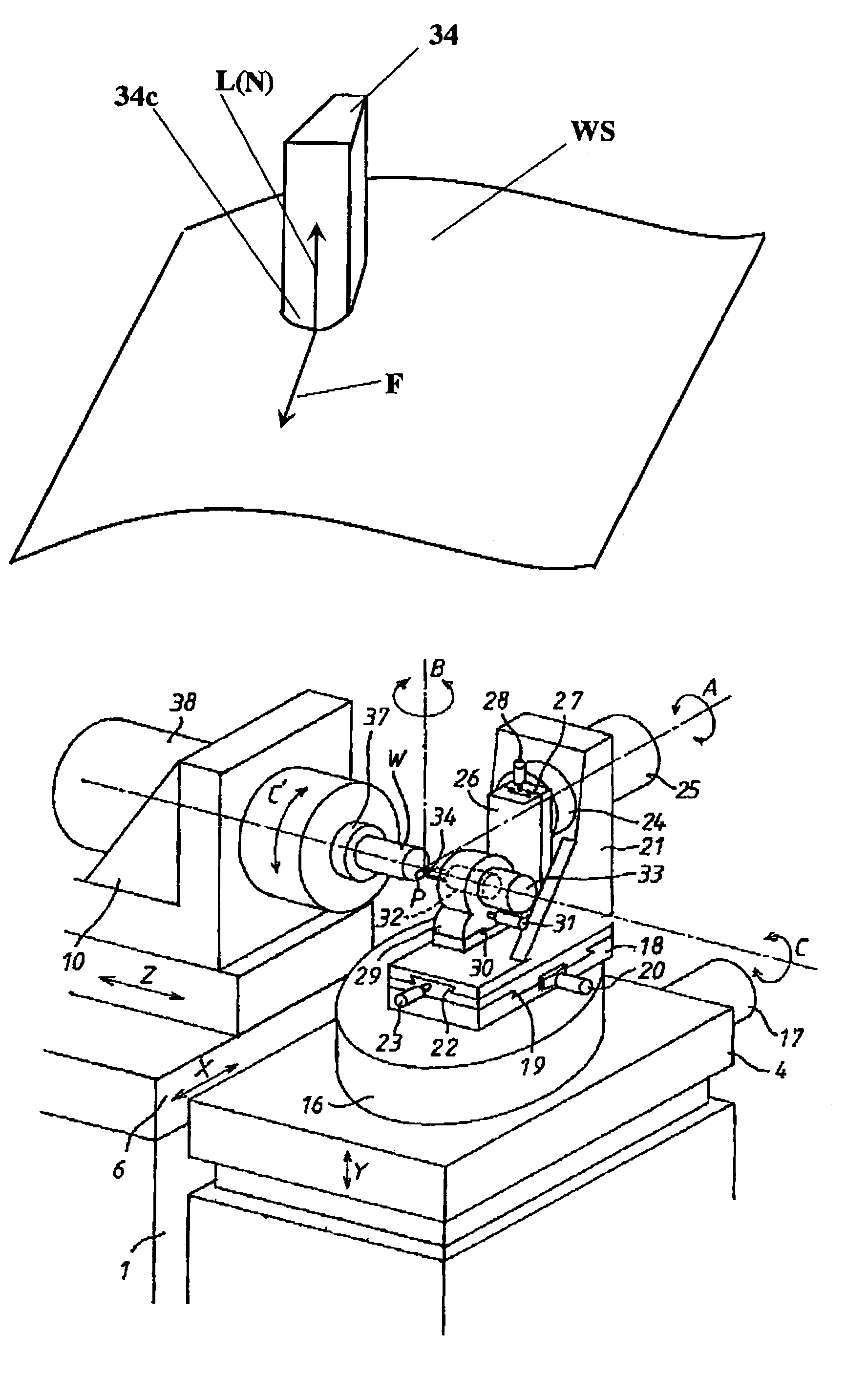

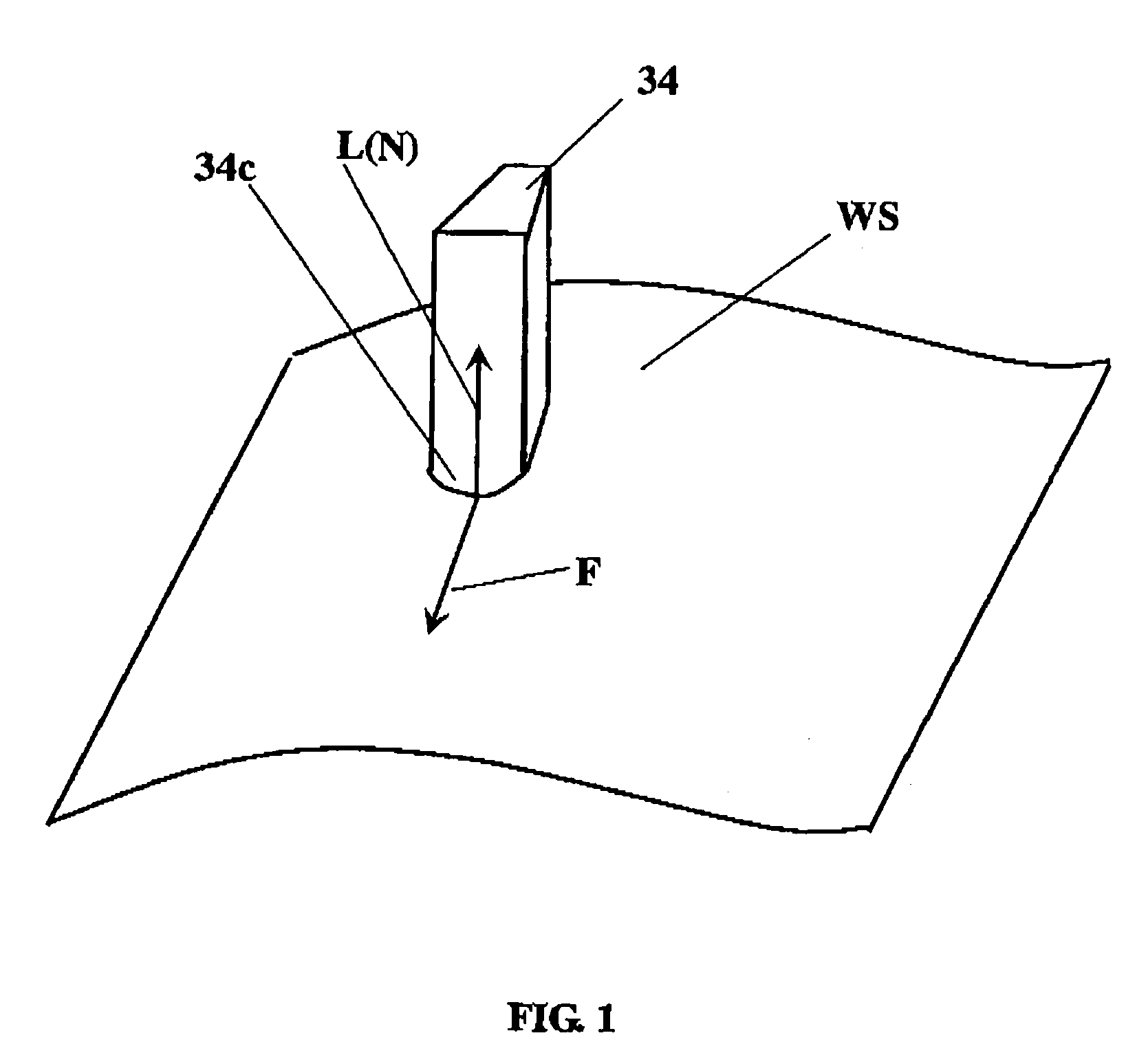

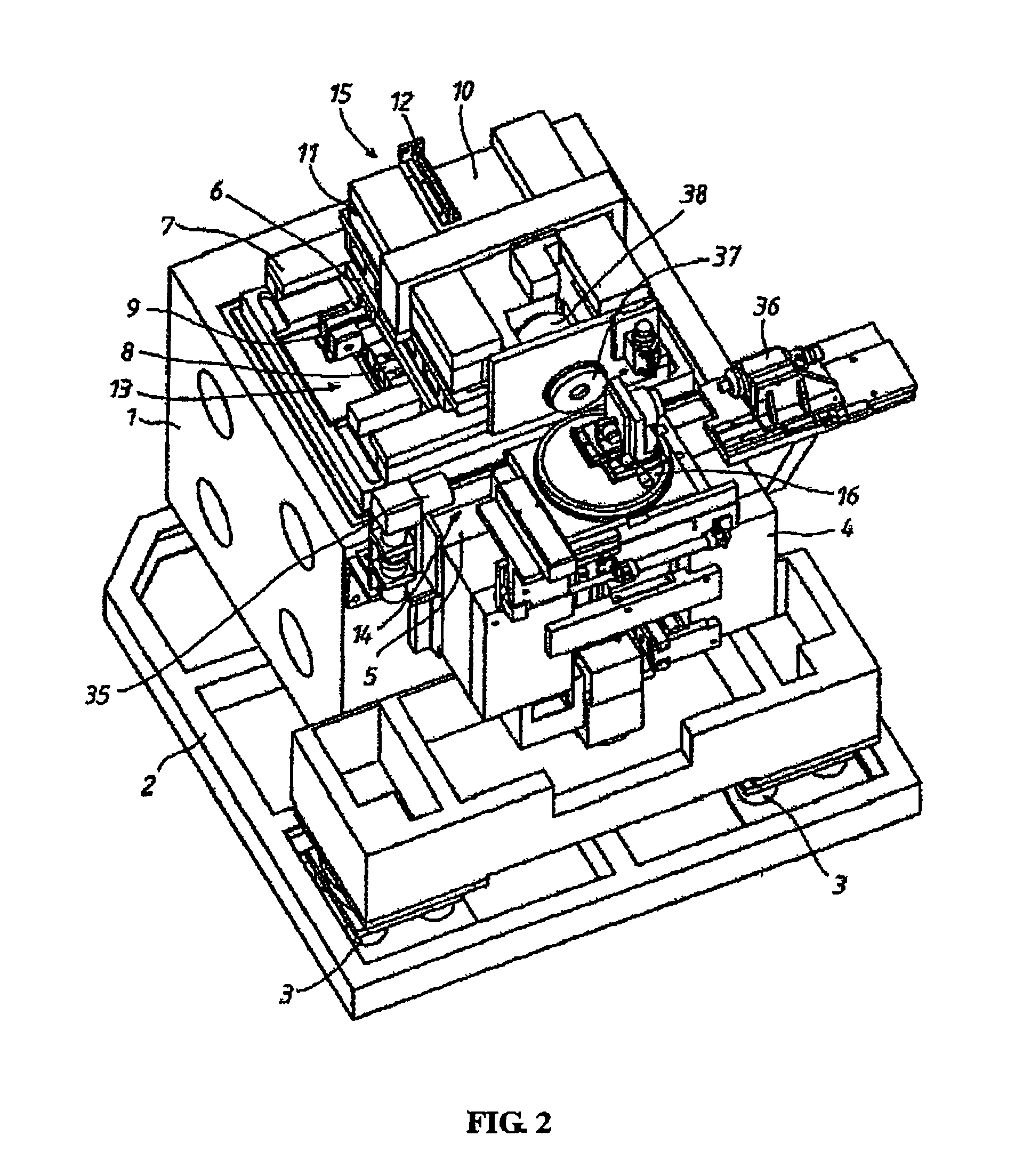

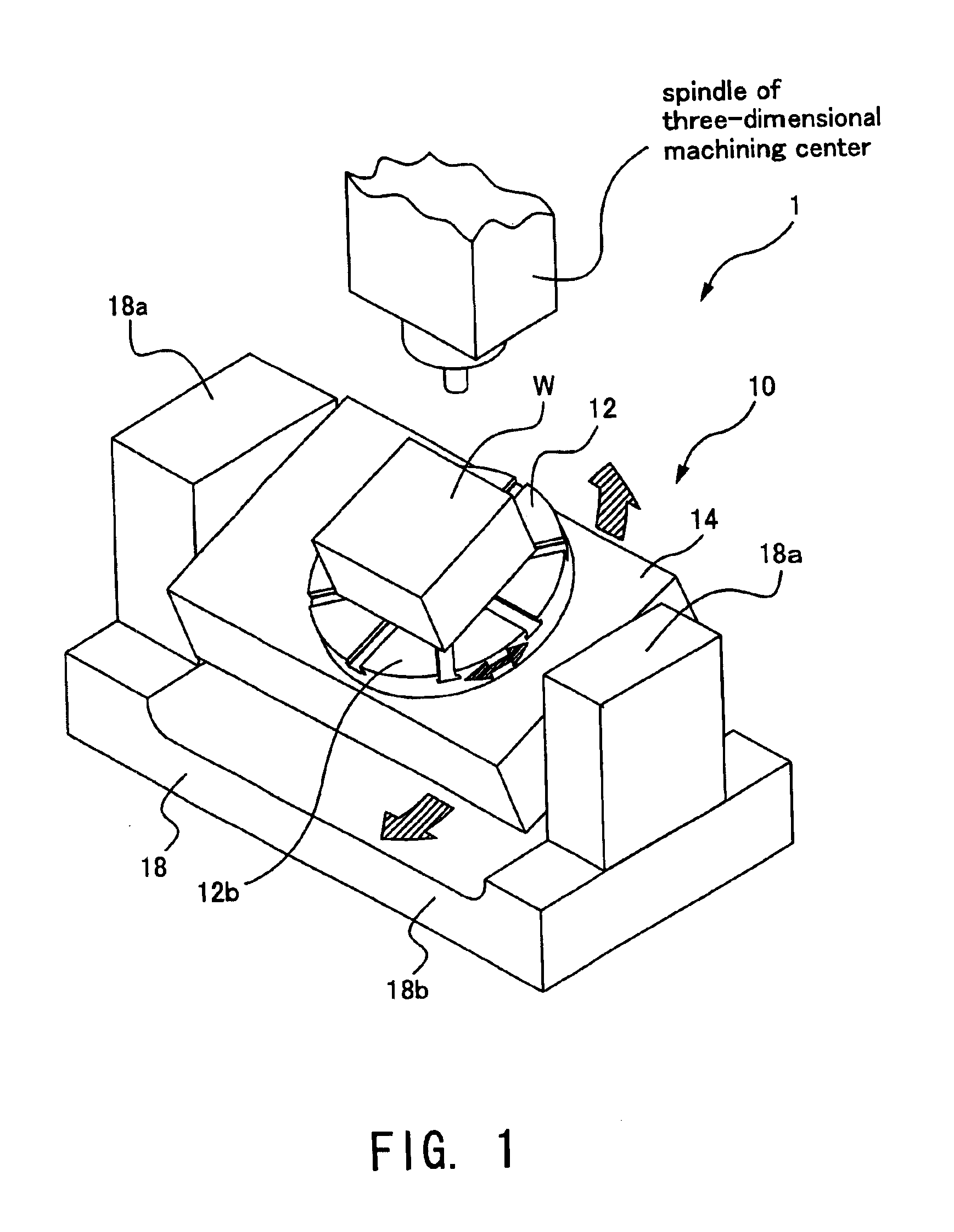

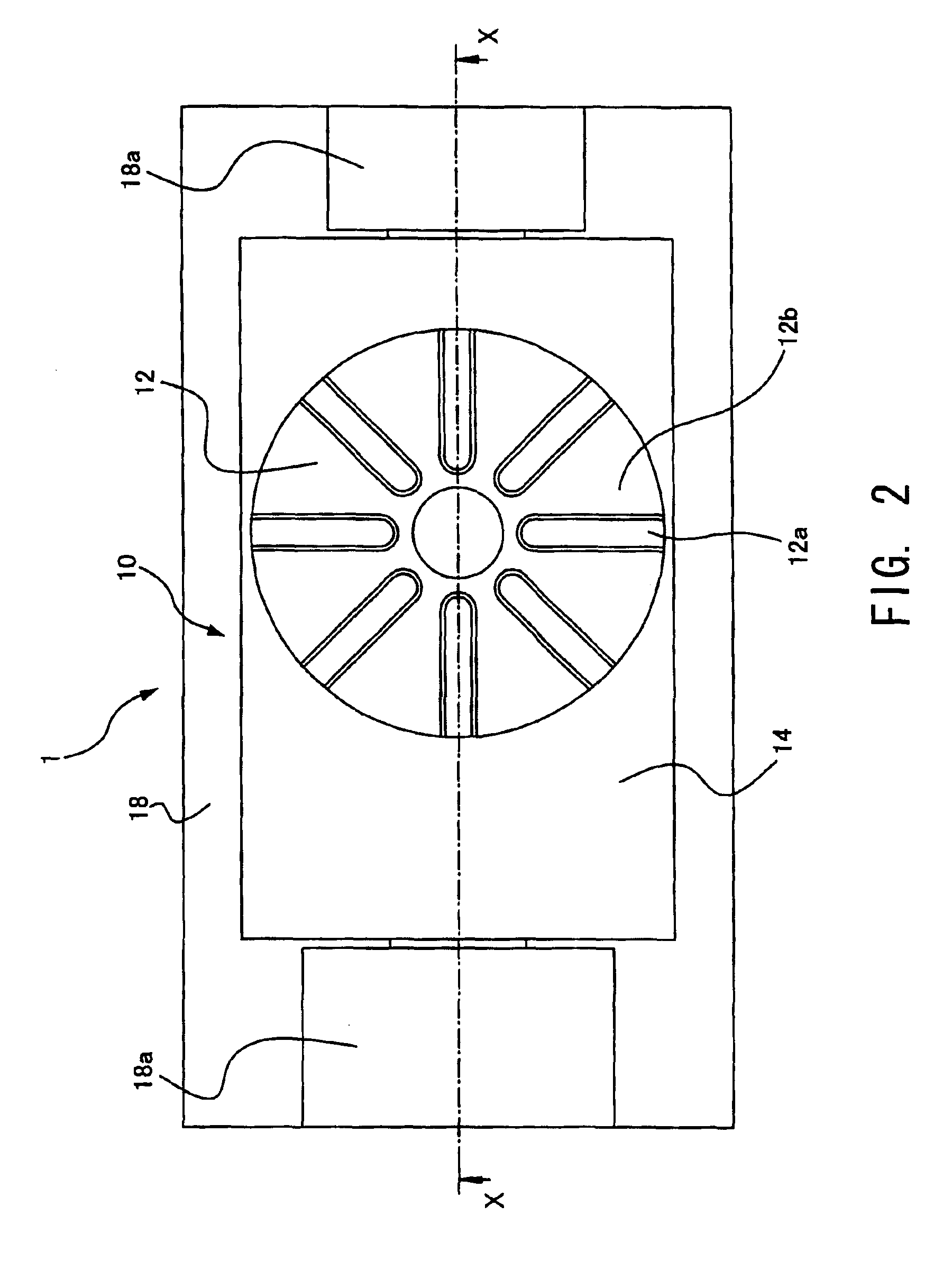

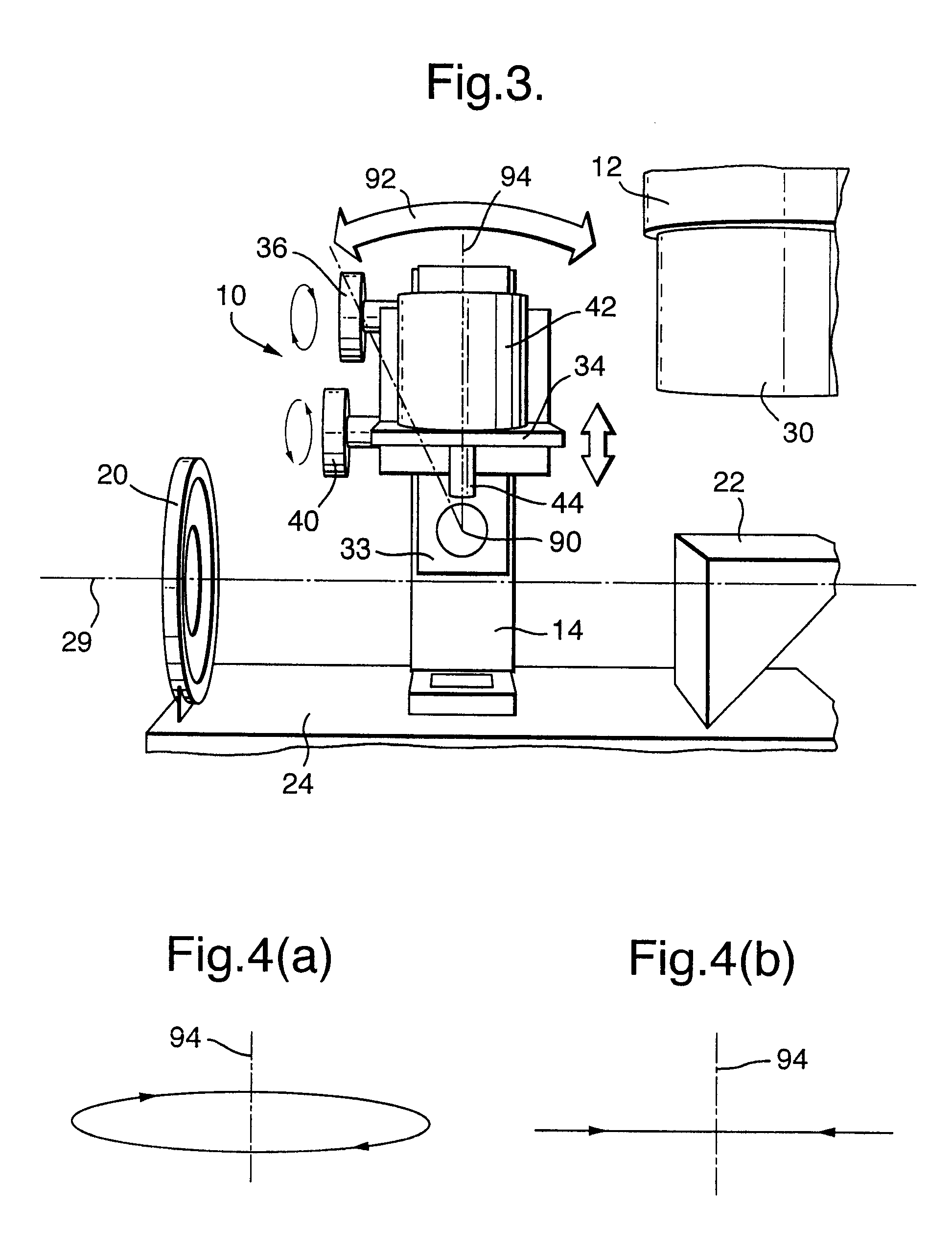

Hale-machining method and apparatus

InactiveUS7089836B2Easy to prepareHigh geometric accuracyLathesAutomatic/semiautomatic turning machinesRotary stageRotational axis

It is one object of a hale-machining method and apparatus thereof according to the present invention to achieve an easy preparation of an NC machining program and perform a high geometrical accuracy in the predetermined three-dimensional free curved surface.A haling tool 34 is set on a tool holder 32 in such a manner that a cutting point P of the haling tool 34 is substantially coincided with an intersection of a first rotating axis B, a second rotating axis A and a third rotating axis C. A rotary table 16 and a rotary base 24 are rotated in such a manner that a tool axis direction of said haling tool is substantially coincided with a normal direction of said machined surface. A tool holder 32 is rotated in such a manner that a front rake surface of the haling tool 34 is substantially directed in perpendicular to a feeding direction of said haling tool 34. A workpiece table holding a workpiece and the tool holder are relatively moved along a machined surface of said workpiece in three perpendicular axes including an axis parallel to said first rotating axis.

Owner:TOYODA MASCH WORKS LTD

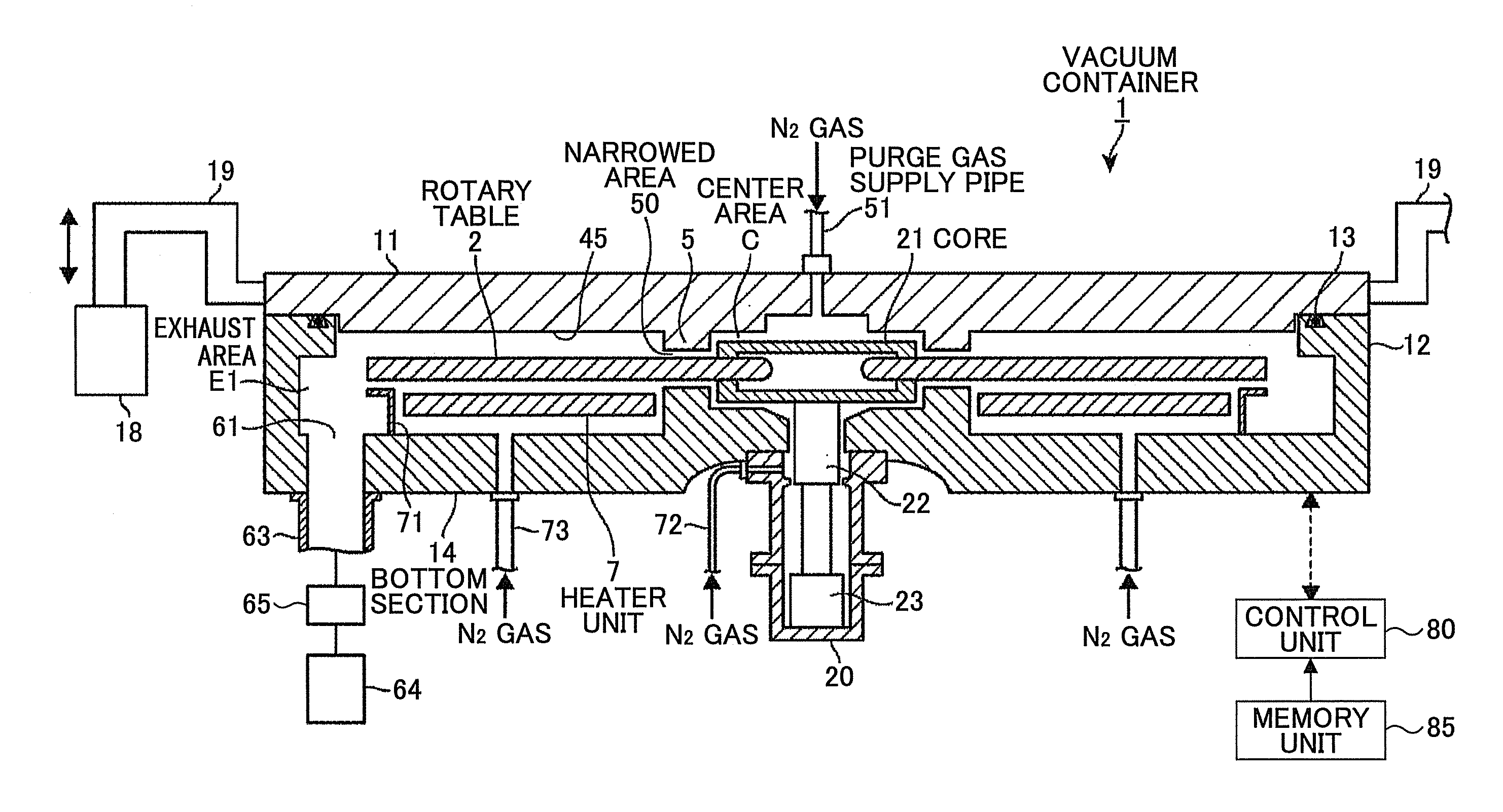

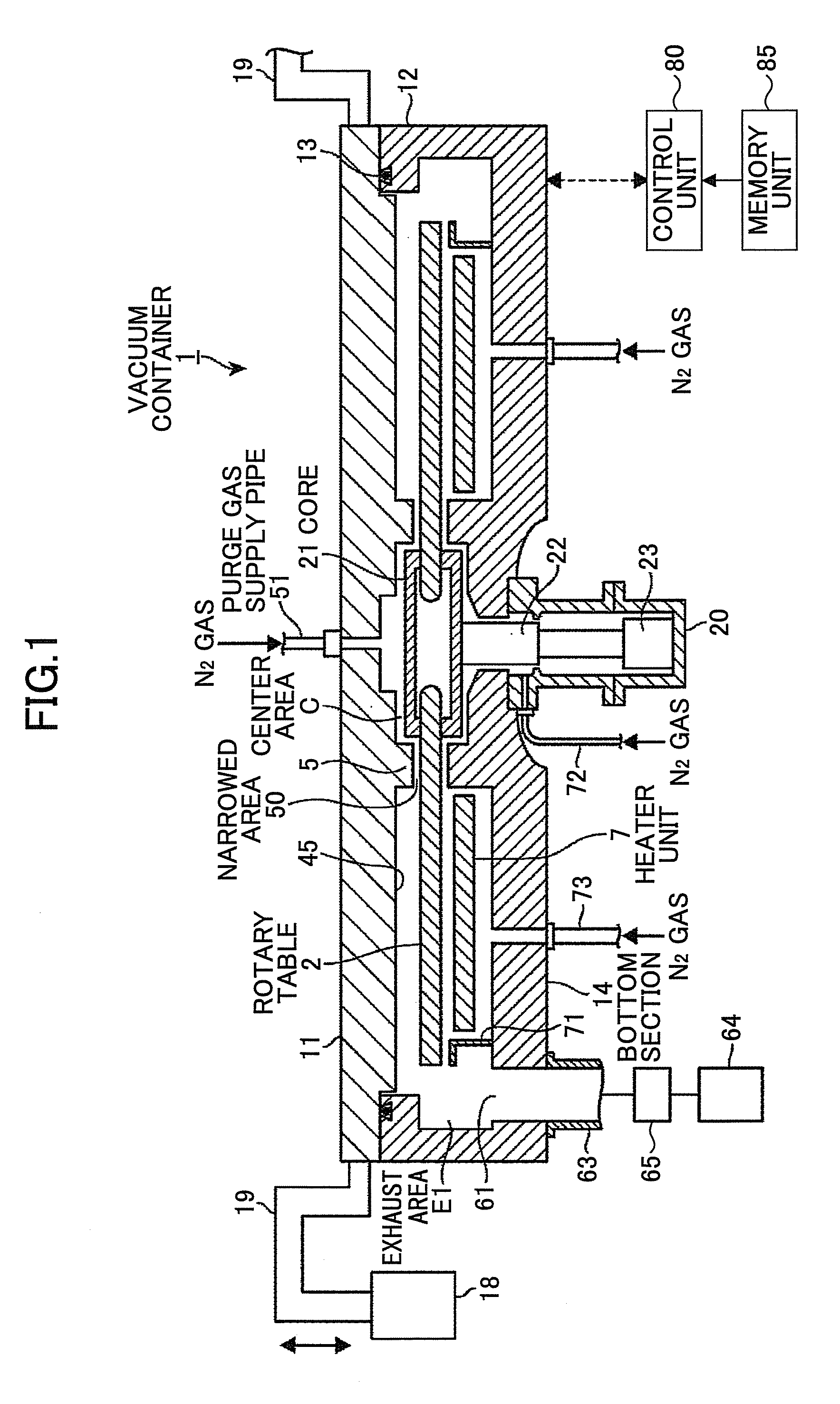

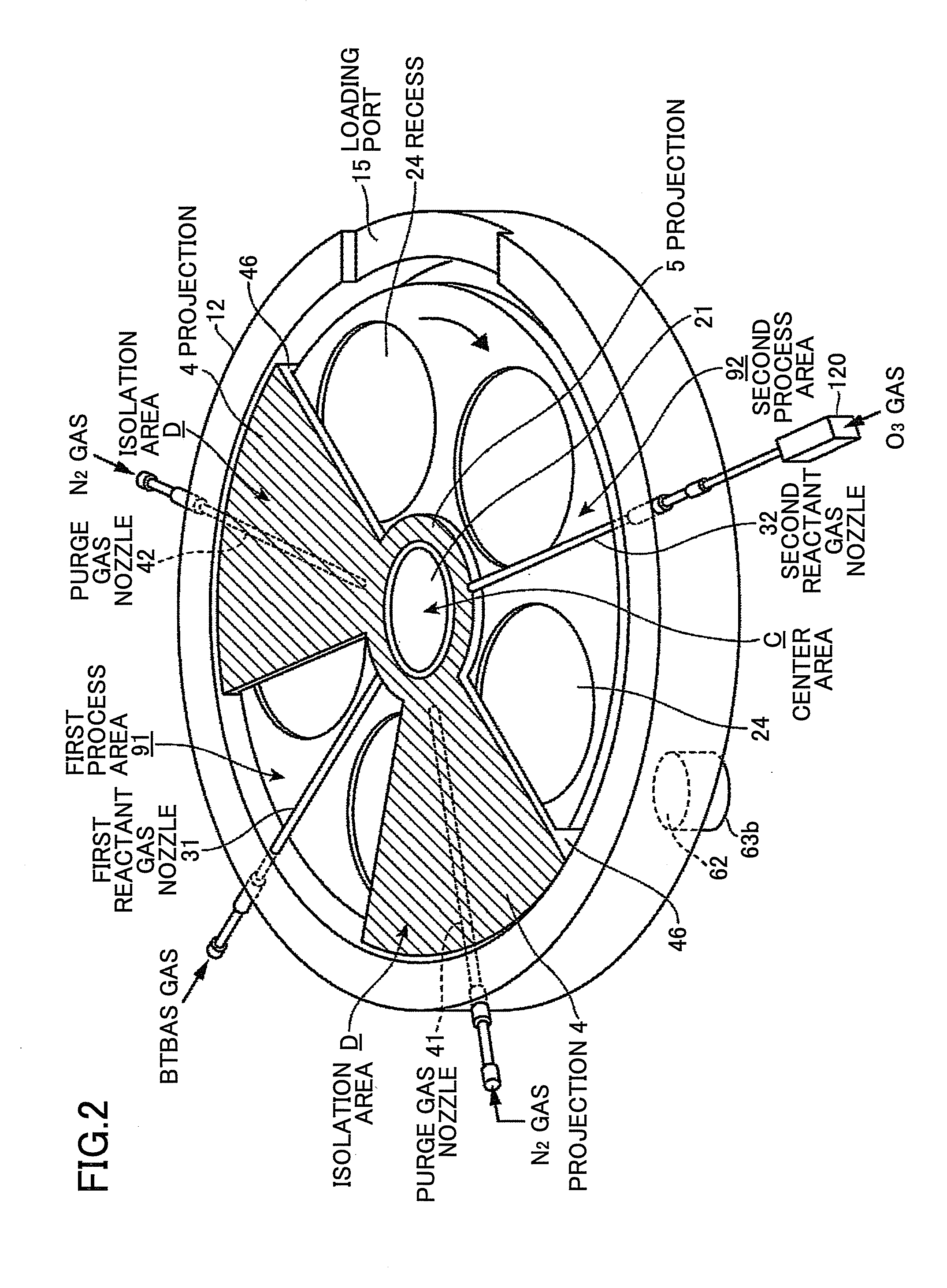

Film deposition apparatus

ActiveUS20100132614A1Easy maintenanceSimple working processSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRotary stageEngineering

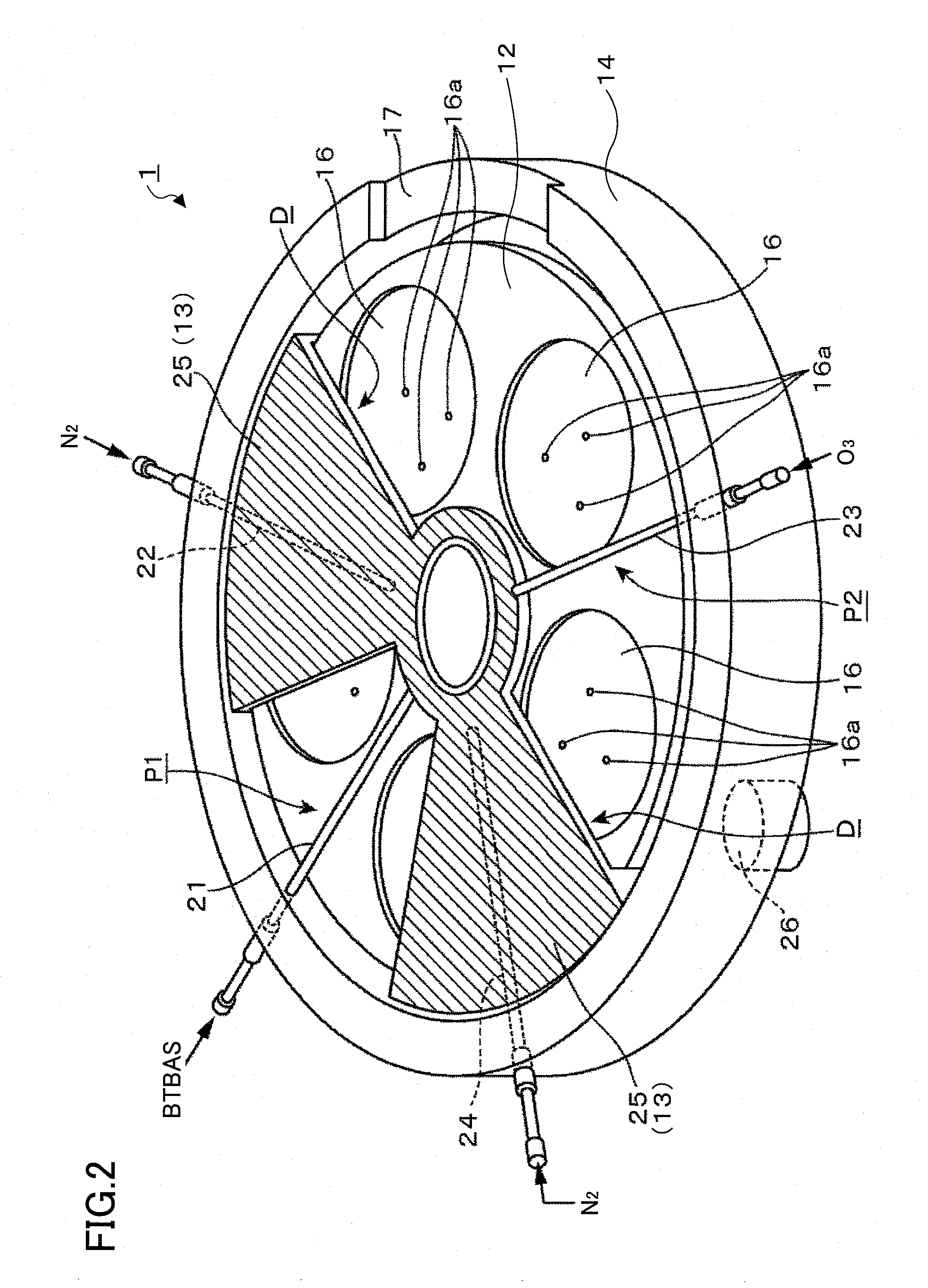

A film deposition apparatus includes a rotary table having a substrate placement area to support a substrate, a vacuum container including a container and a top panel, an open-and-close mechanism configured to open and close the top panel, reactant gas nozzles disposed through and supported by an outer wall of the container to be situated at different angular positions with respect to a rotation center of the rotary table to face areas in which the substrate placement area passes, the reactant gas nozzles having gas discharge ports arranged in radial directions to supply respective reactant gases to the wafer thereby to form respective process areas, a discharge gas supply unit situated at an angular position between the process areas to supply purge gas to form an isolation area that isolates atmospheres of the process areas from each other, and an exhaustion unit configured to exhaust atmosphere inside the vacuum container.

Owner:TOKYO ELECTRON LTD

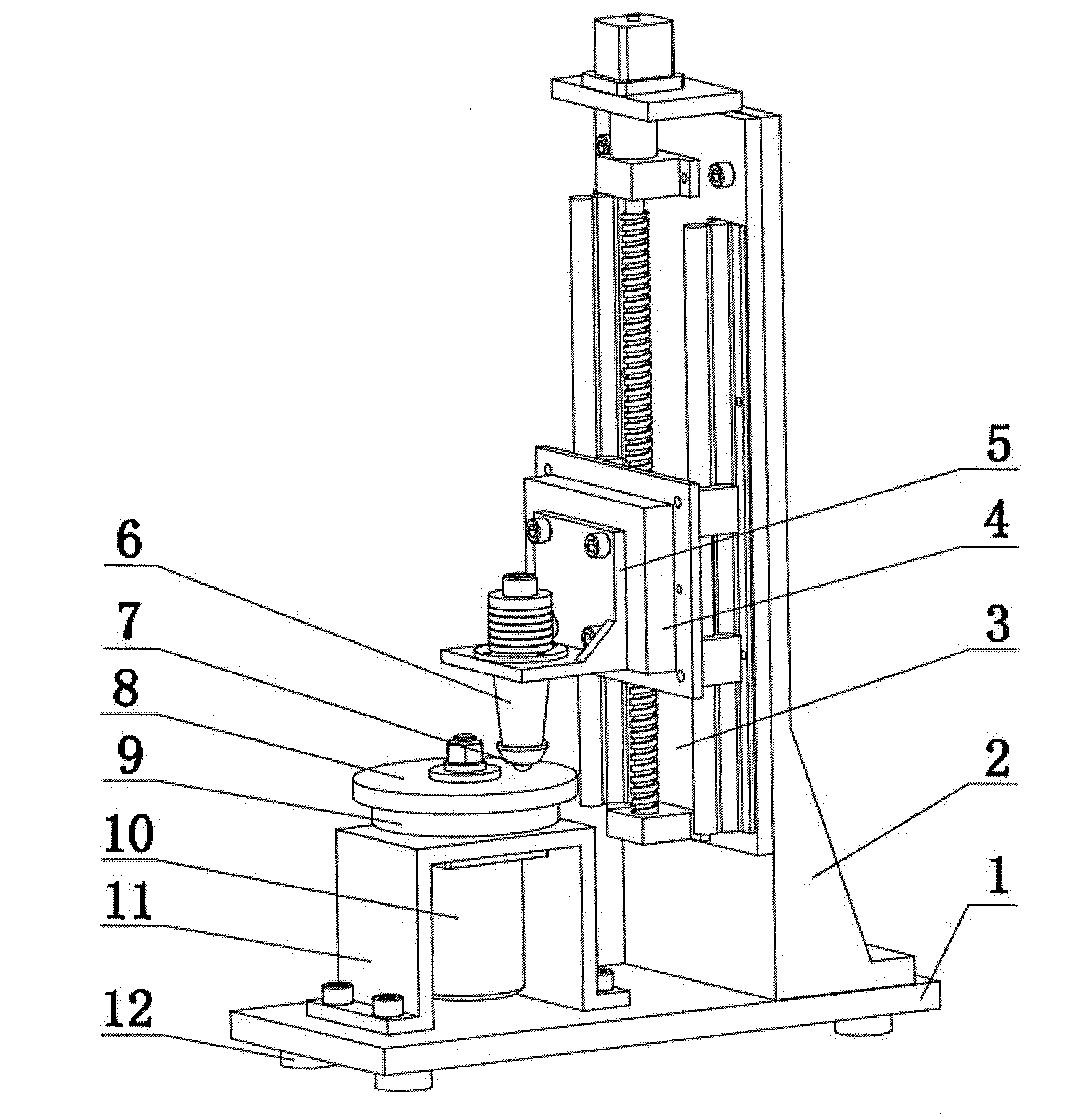

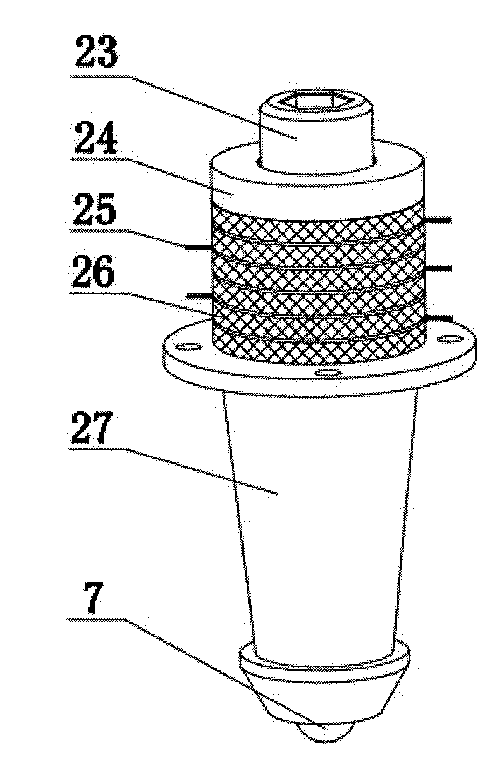

Spherical contact type friction characteristic testing device under ultrasonic vibration

InactiveCN103278411APrecise control of test parametersHigh degree of automationUsing mechanical meansInvestigating abrasion/wear resistanceRotary stageVibration amplitude

The invention discloses a spherical contact type friction characteristic testing device under ultrasonic vibration. The device consists of a main movement unit, a loading unit and a dynamometer unit, wherein the torque output by a step motor is converted into axial pressure of a sliding table through a lead screw nut pair of a trapezoidal screw, and an upper sample and a lower sample which are arranged at the bottom of a piezoelectric micromachined ultrasonic transducer are contacted with each other, and certain pressure is applied to the lower sample; when the piezoelectric micromachined ultrasonic transducer is connected with an ultrasonic power supply, the upper sample produces ultrasonic frequency vibration with micron-grade amplitude in the horizontal direction or the vertical direction, the lower sample rotates together with a rotating platform and forms a friction pair with the upper sample, so that the friction characteristic of the spherical contact under ultrasonic vibration can be tested. The device can be used for accurately controlling the testing parameters, is high in degree of automation, and can be used for performing spherical contact friction experiments of various types of friction materials under different ultrasonic vibration frequencies and vibration amplitudes.

Owner:JILIN UNIV

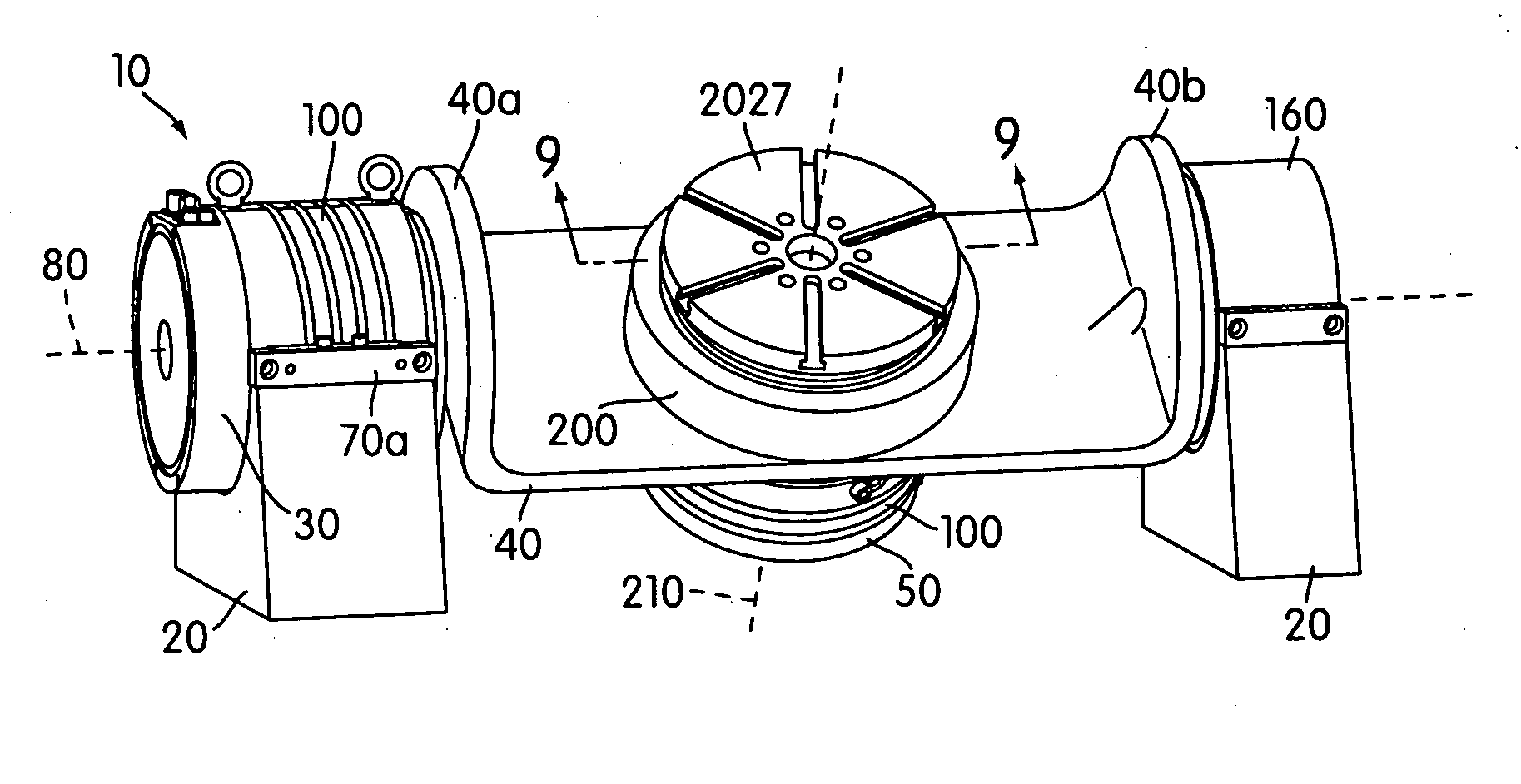

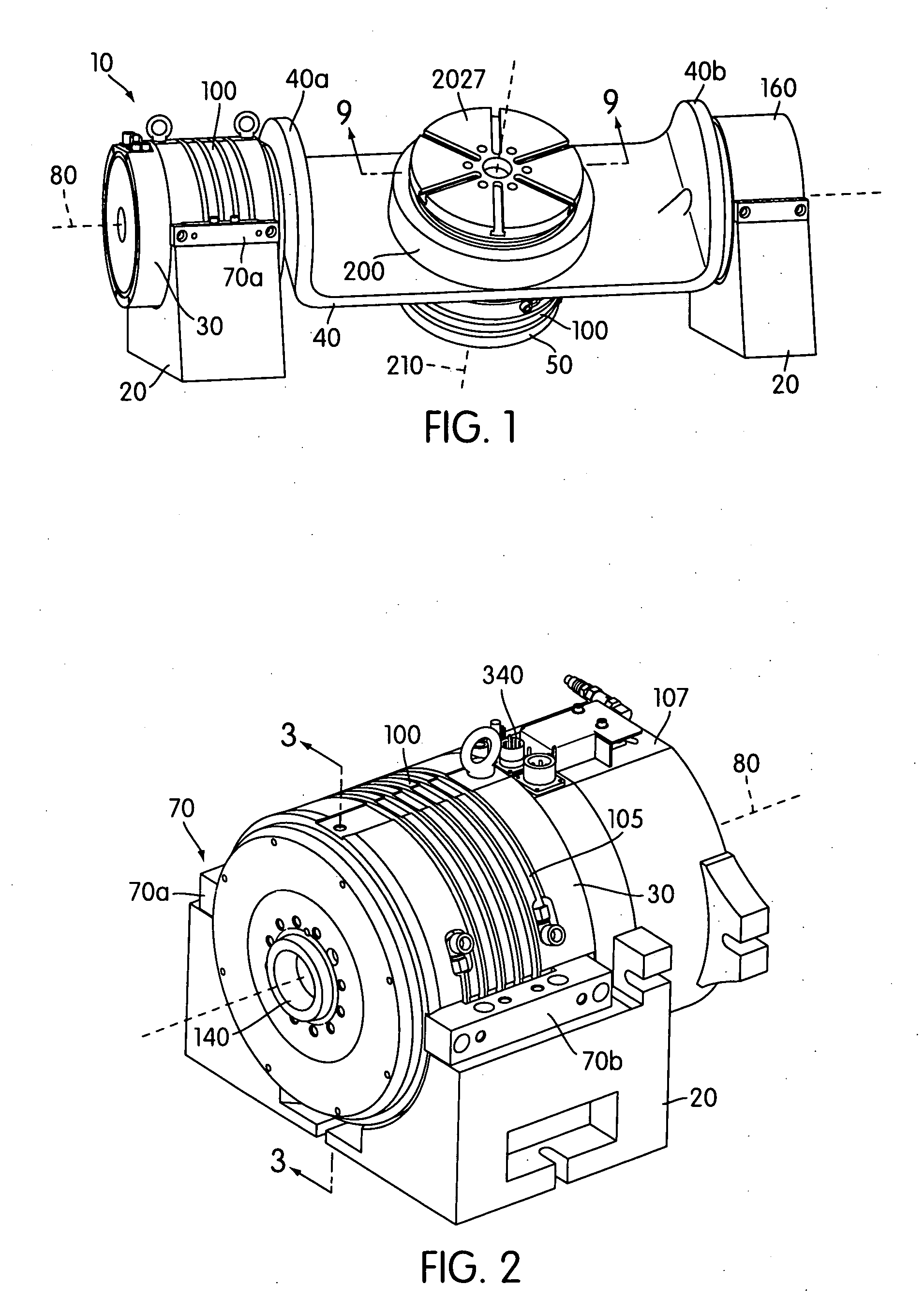

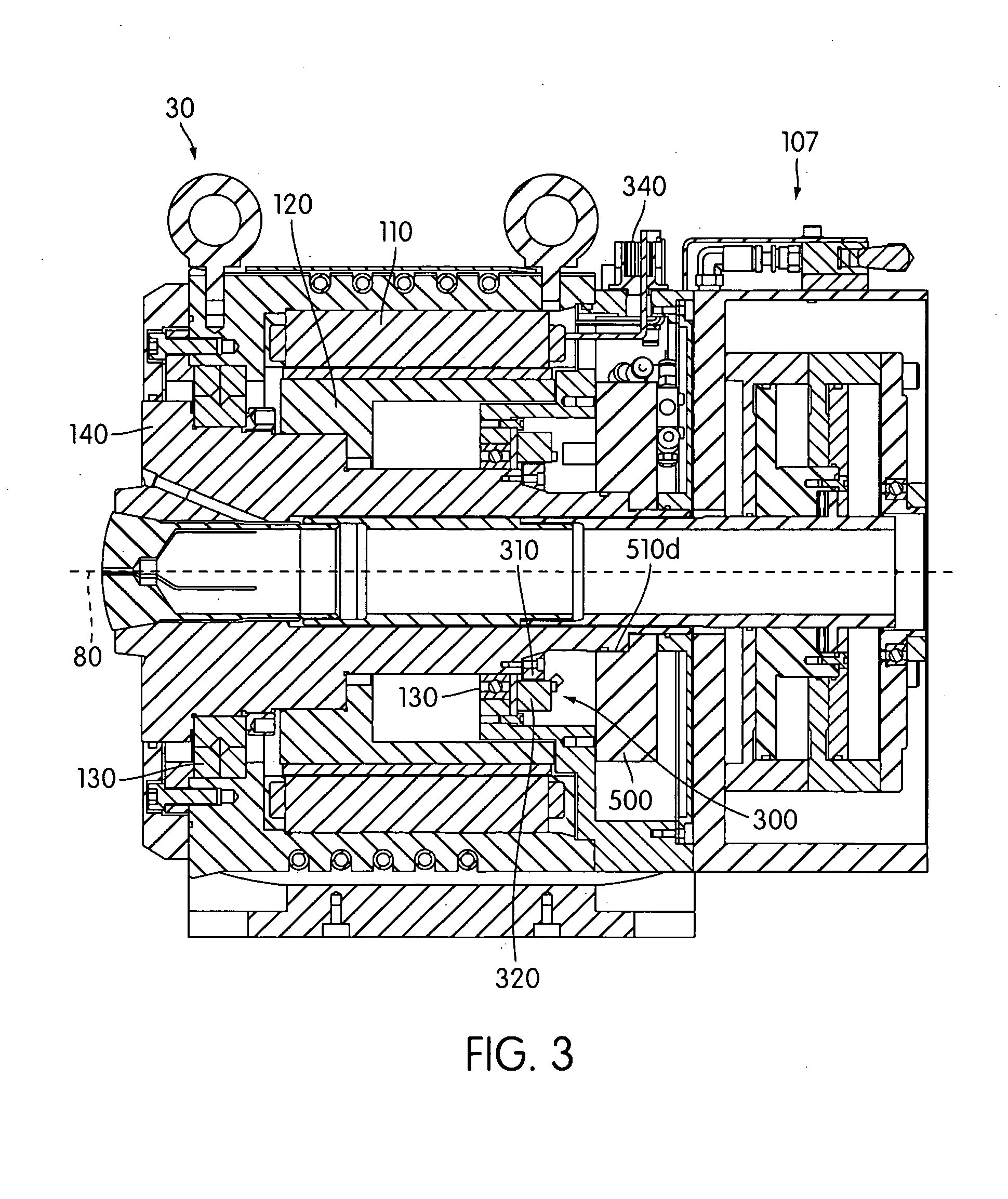

Rotary table with frameless motor

InactiveUS20080047120A1Precise positioningAvoid inaccuraciesMachine tool componentsTurning toolsRotary stageRotational axis

A rotary table for a material processing machine such as a vertical milling machine utilizes direct drive motor(s) to precisely angularly position a work piece along one or more pivotal axes. The direct drive motor(s) are thermally insulated from the remainder of the machine to limit misaligning thermal expansion of the components of the machine. The motors may be symmetrically attached to their respective supports such that thermal expansion / contraction of the motor and surrounding components occurs symmetrically with respect to the motor to limit misalignment of the motor's rotational axis. A motor may mount to its respective support only at a first axial end thereof such that thermal expansion of a second axial end of the motor does not adversely shift the position of the first end. Axially narrow clamps selectively secure the rotors of the motors in desired positions.

Owner:HARDINGE INC

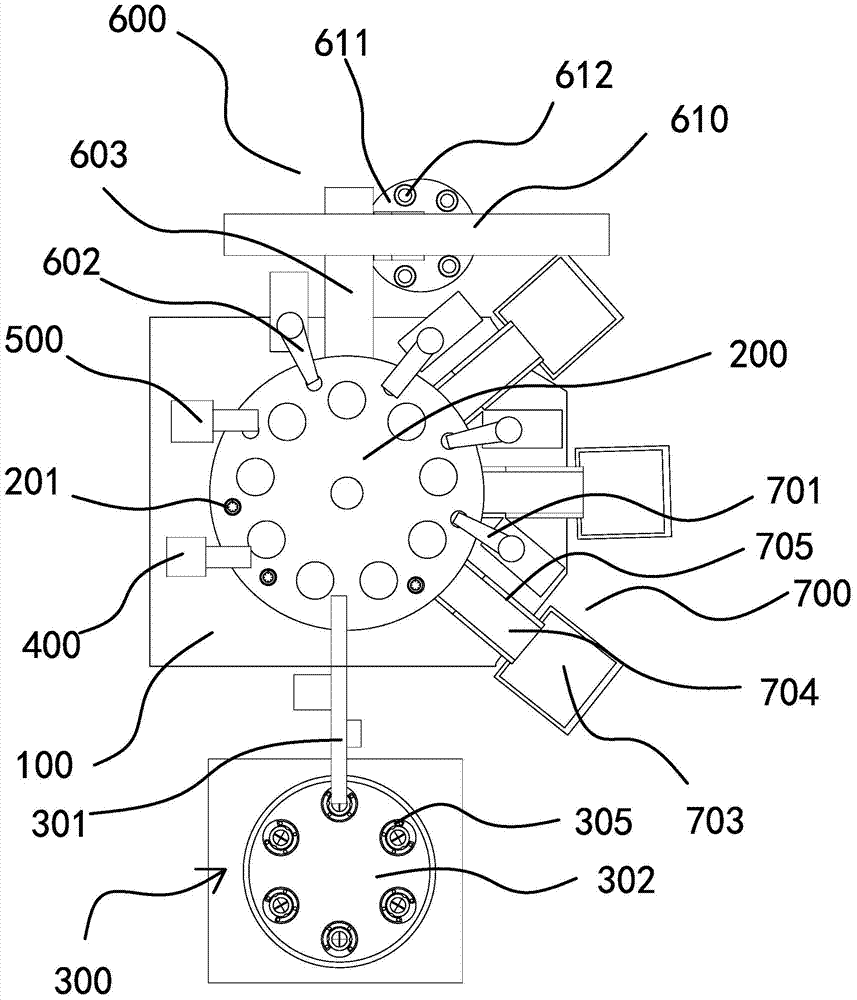

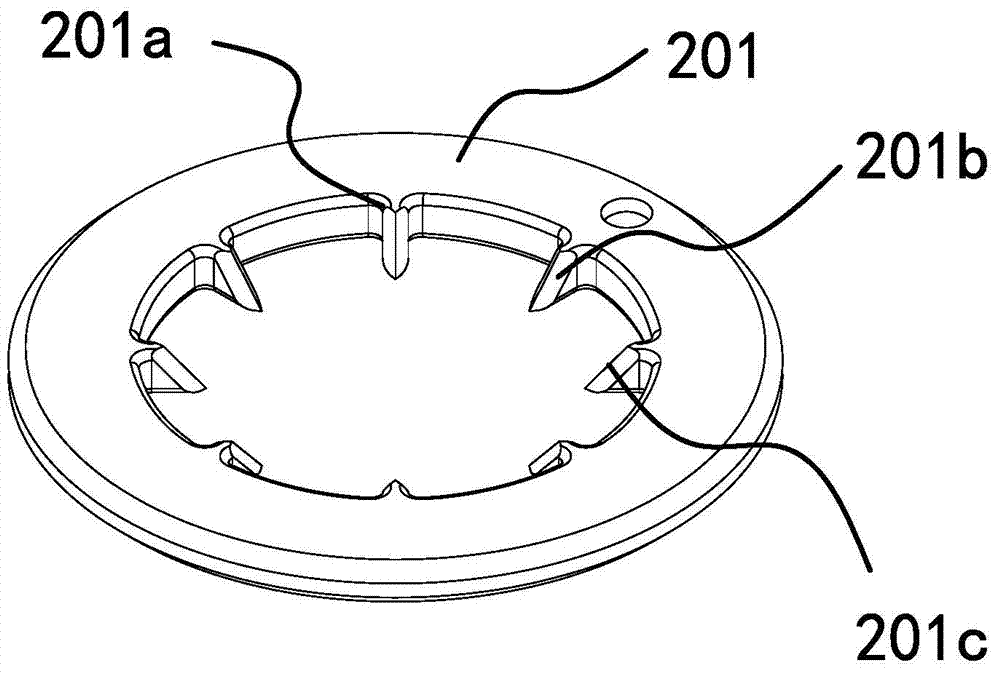

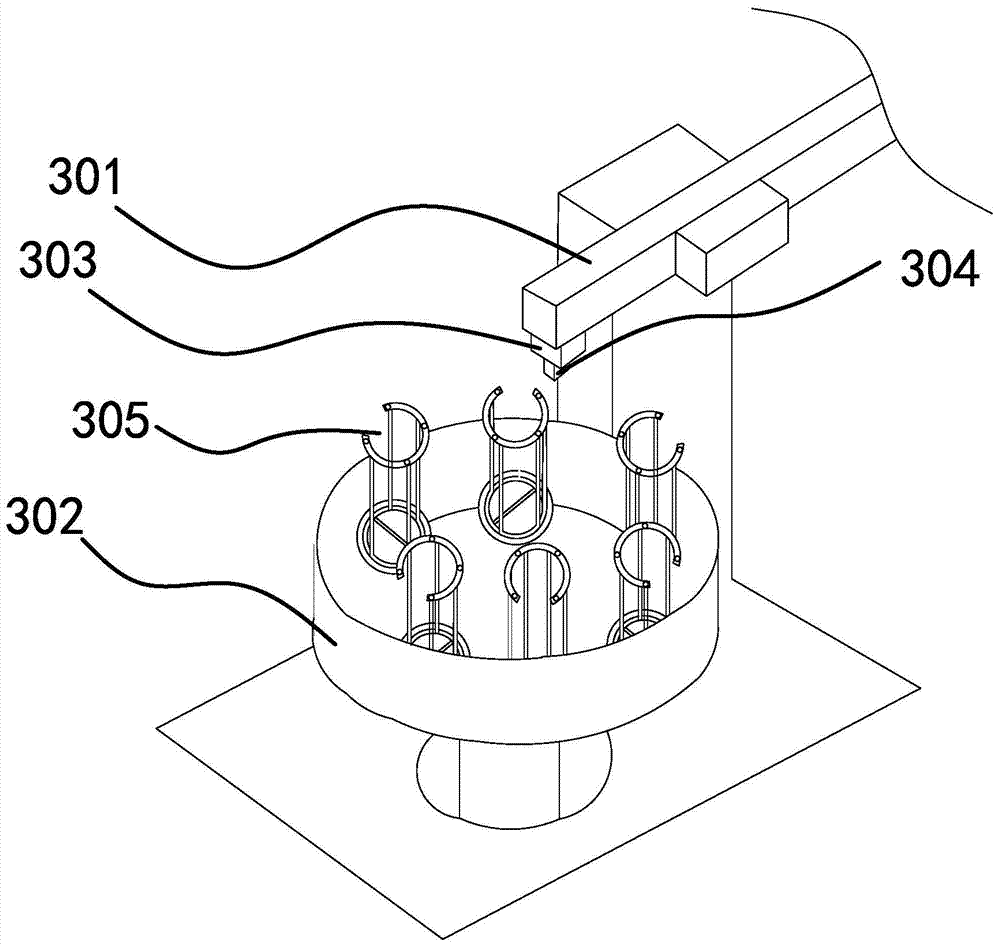

Automatic detection apparatus

ActiveCN103920650ASolve the problem of low efficiency and omissions in manual feedingImprove detection efficiencySortingRotary stageGas cylinder

The present invention provides an automatic detection apparatus, and belongs to the technical field of machinery, wherein the problem that the material feeding and the material discharge of the existing work-piece detection equipment adopt the artificial manner so as to provide low efficiency is solved. The automatic detection apparatus comprises a rack and a rotation disk, wherein the rack is provided with a material inlet device, a first detection device, a second detection device, a qualified product receiving device and a defective product receiving device, a plurality of benchmark plates are uniformly distributed on the rotation disk, the material inlet device comprises a guide column, a rotation table and a rotating motor, the guide column is vertically provided with a material taking telescopic gas cylinder, the material taking telescopic gas cylinder is provided with a material inlet suction nozzle, a product placement fixture is placed on the rotation table, the qualified product receiving device comprises a material storage mechanism and a material receiving mechanism arranged on the rack, the defective product receiving device comprises a recovery assembly and a grabbing assembly, and the detected defective product work-piece can be transferred into the recovery assembly with the grabbing assembly. The automatic detection apparatus has advantages of high work efficiency, high detection precision and high automation degree.

Owner:ZHEJIANG GREEN NEW MATERIALS

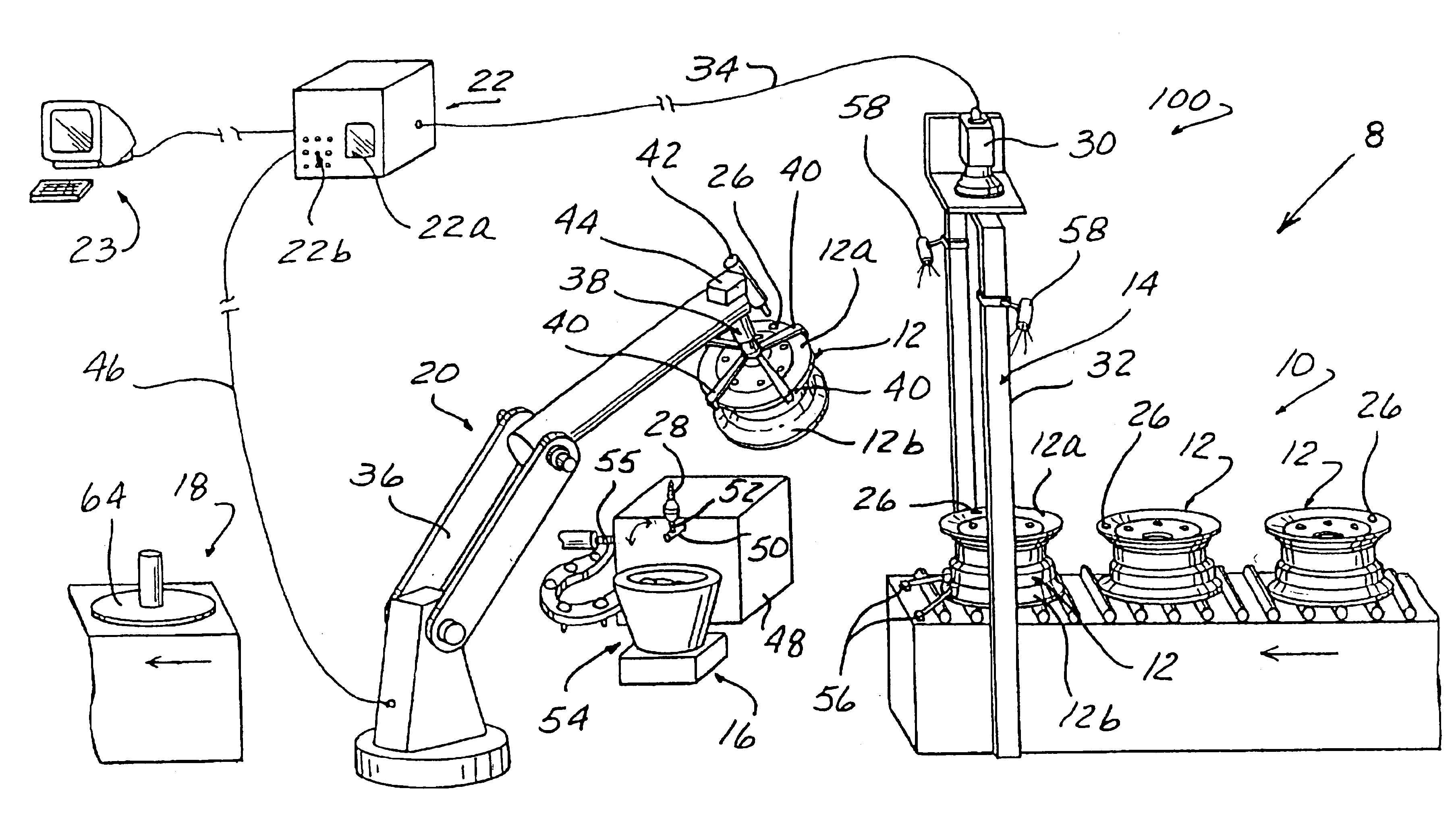

Robotic apparatus and method for mounting a valve stem on a wheel rim

InactiveUS6886231B2Accurate insertionIncrease volumeProgramme-controlled manipulatorAutomatic control devicesRotary stageElectronic control system

An apparatus and method for mounting a valve stem to the rim of an automotive vehicle wheel includes rims being supplied in series by a conveyor to a gauging station where the type and / or size of the rim and the location and alignment of an aperture for receiving the valve stem is determined by a machine vision system. An electronic control system directs a robotic manipulator to grasp either the valve stem or the rim, move the valve stem or the rim to a mounting station, position the valve stem or the rim with respect to the other such that the aperture in the rim is in coaxial alignment with the valve stem, and insert the valve stem through the aperture in the rim. If necessary, a power-actuated nut runner, mounted on the robotic manipulator or adjacent the mounting station, is used to tighten a nut over the valve stem. As an alternative to the machine vision system, the gauging station can use a rotating table which rotates the wheel about a central axis, and an “electric eye” optical sensor directing a beam of infrared light onto the rim. As the rim rotates through the beam, the presence or lack of a reflection of the light beam is used to detect the location of the aperture, and rotation of the table is stopped when the aperture is in alignment with the beam. A probe mounted on the gauging station can be extended to project into the aperture to confirm that the aperture is at the desired position and reposition the rim slightly to provide a precise positioning of the aperture.

Owner:BURKE E PORTER MACHINERY

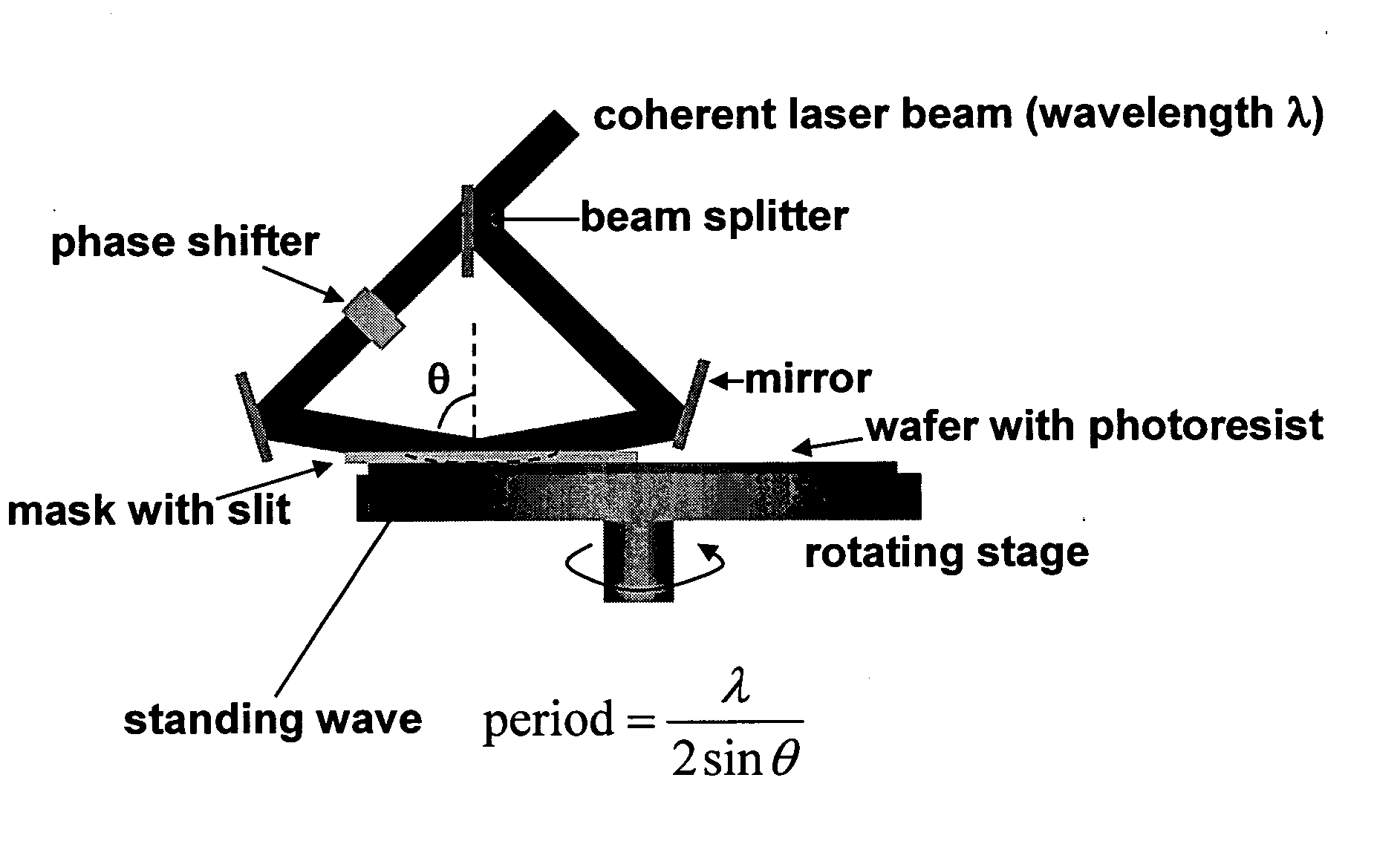

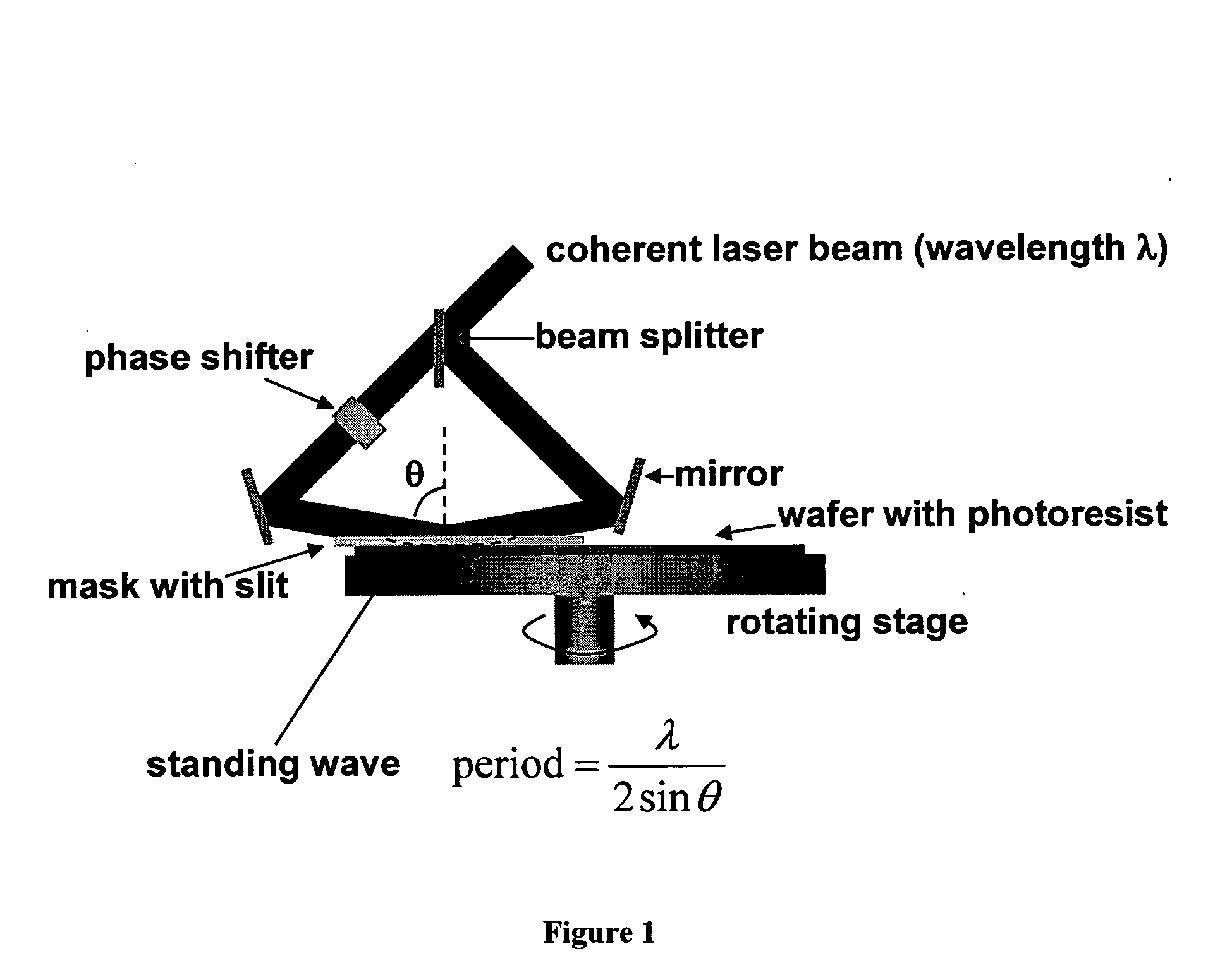

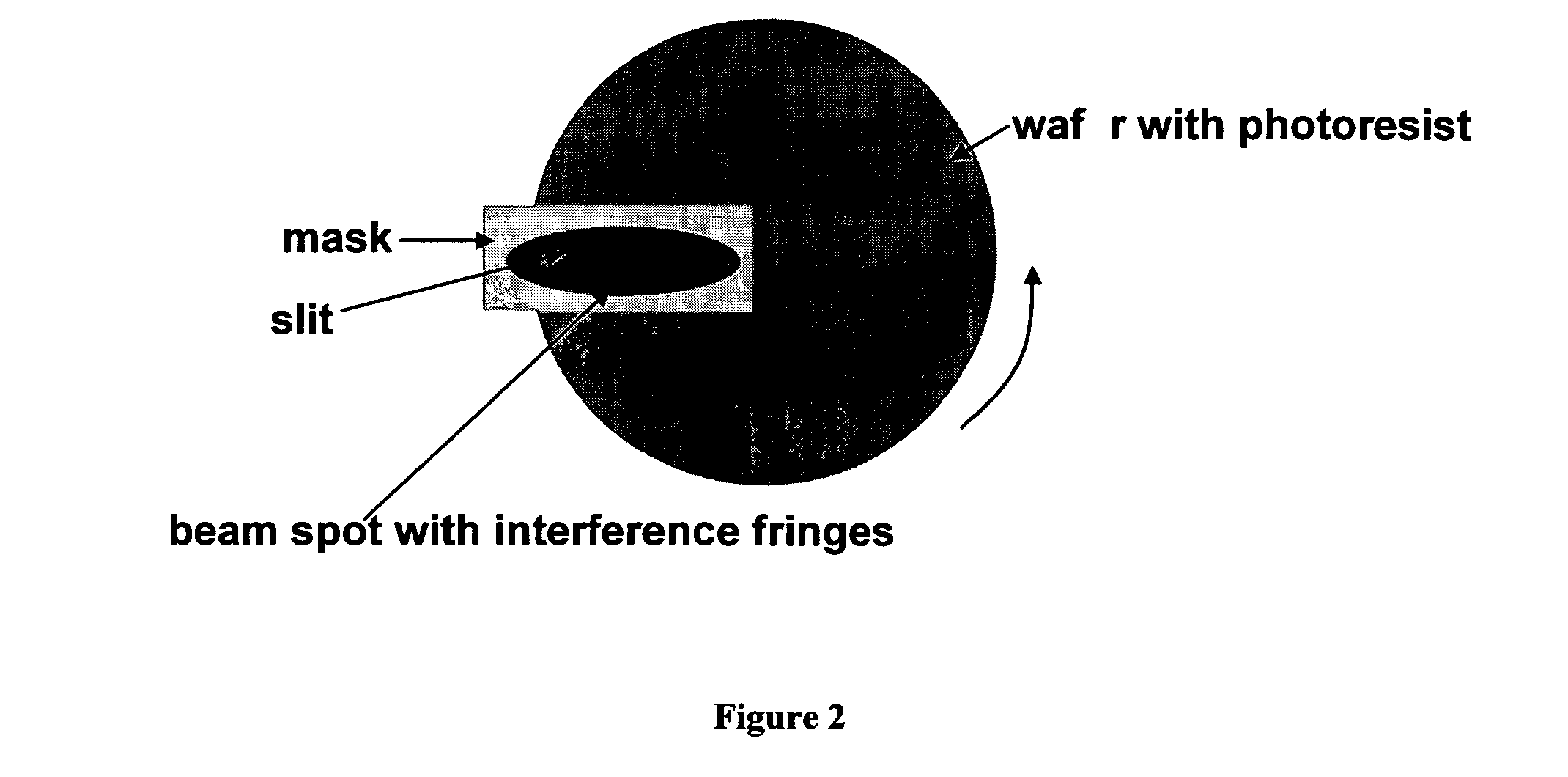

Rotary apertured interferometric lithography (RAIL)

ActiveUS20050064297A1Record information storagePhotomechanical exposure apparatusHard disc driveRotary stage

A rotary apertured interferometric lithography (RAIL) system that includes interferometric lithography tools, a mask with a slit preferably with an arc shape, and a rotating stage is disclosed. The RAIL system could create a servo pattern of a recording-head trajectory of a hard disk drive in a master for magnetic-contact printing. The master can could be used to form arrays of sub-micron sized magnetic elements on a magnetic disk media for high-density magnetic recording applications.

Owner:SEAGATE TECH LLC

Apparatus and method for wrapping

Owner:RUBIN RICHARD HOWARD

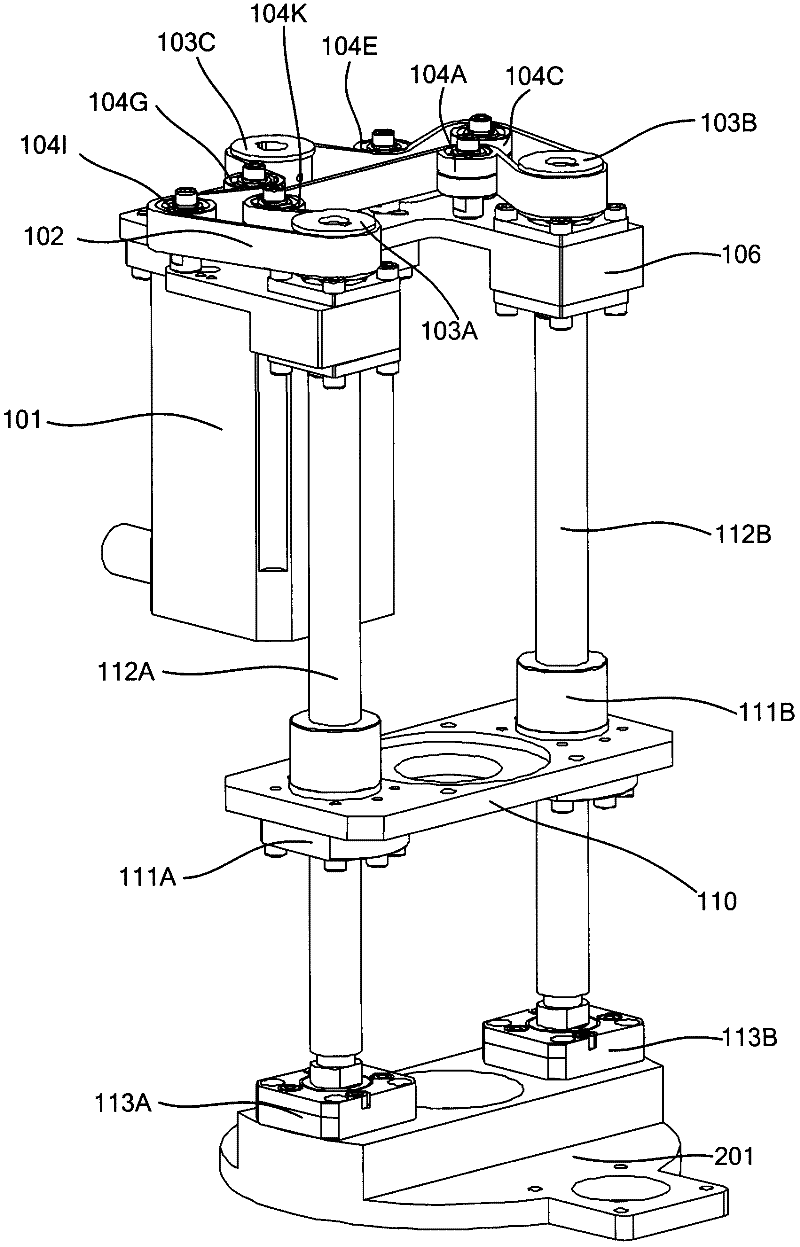

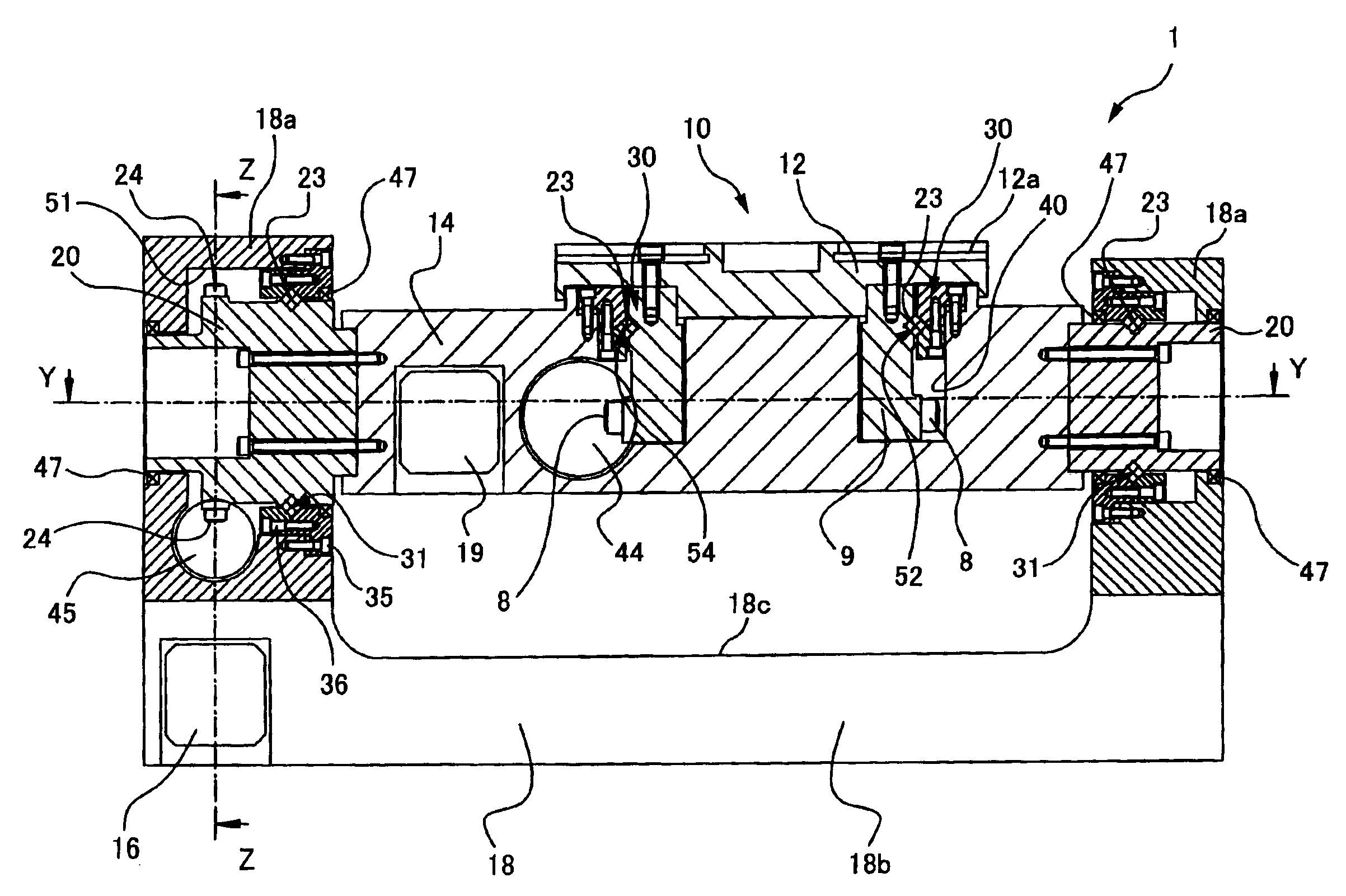

Inclining and rotating table apparatus

ActiveUS6955345B2Improve accuracyPrecision positioning equipmentRoller bearingsRotary stageEngineering

An inclining and rotating table apparatus comprises a rotating table device having a rotating table, and a support base for rotatably supporting the rotating table having a shaft body provided perpendicular to a rotation axis of the rotating table, and a base for rotatably supporting the rotating table device using the shaft body. A table surface of the rotating table is inclined by making the rotating table device rotate. A first V-shaped groove is directly formed in the shaft body along its rotating direction. The base has a second V-shaped groove opposing the first V-shaped groove. A cross roller bearing is structured by providing rolling bodies, which are placed in contact with the first and second V-shaped grooves and are capable of rolling therebetween, between the shaft body and the base, and arranging a rolling axis of a rolling body perpendicular to that of an adjacent rolling body.

Owner:SANKYO SEISAKUSHO

Calibration phantom, calibration device and calibration method for calibrating geometric parameters in CT (Computed Tomography) system

ActiveCN103006251ASimple structureReduce manufacturing costComputerised tomographsTomographyRotary stageImage correction

The invention relates to a calibration phantom for calibrating geometric parameters in a CT (Computed Tomography) system. The calibration phantom comprises two same calibration plates which are arranged in parallel, and pellets, wherein the calibration plates are correspondingly provided with a plurality of same small holes respectively; and at least four pellets are arranged in the small holes in the calibration plates respectively. The invention relates to a calibration device for calibrating geometric parameters in a CT system. The calibration device comprises a CT system and the calibration phantom, wherein the CT system consists of a light source, a rotary platform and a detector; and the calibration phantom is vertically placed on the rotary platform between the light source and the detector. Furthermore, the invention further provides a calibration method for calibrating geometric parameters in a CT system. According to the calibration device and the calibration method, all seven geometric parameters of the CT system can be calibrated simultaneously by only performing one-time projection on the calibration phantom, so that operation is easy, and subsequent image correction of the CT system is met greatly.

Owner:NAT INST OF ADVANCED MEDICAL DEVICES SHENZHEN

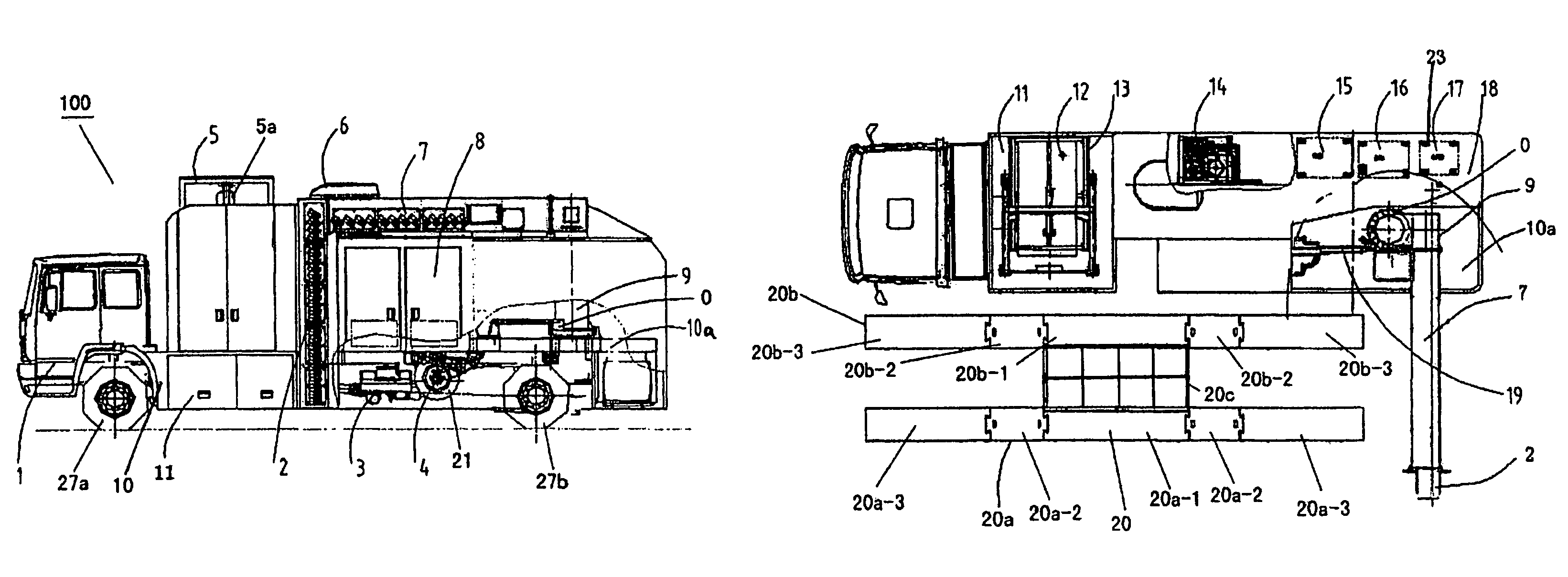

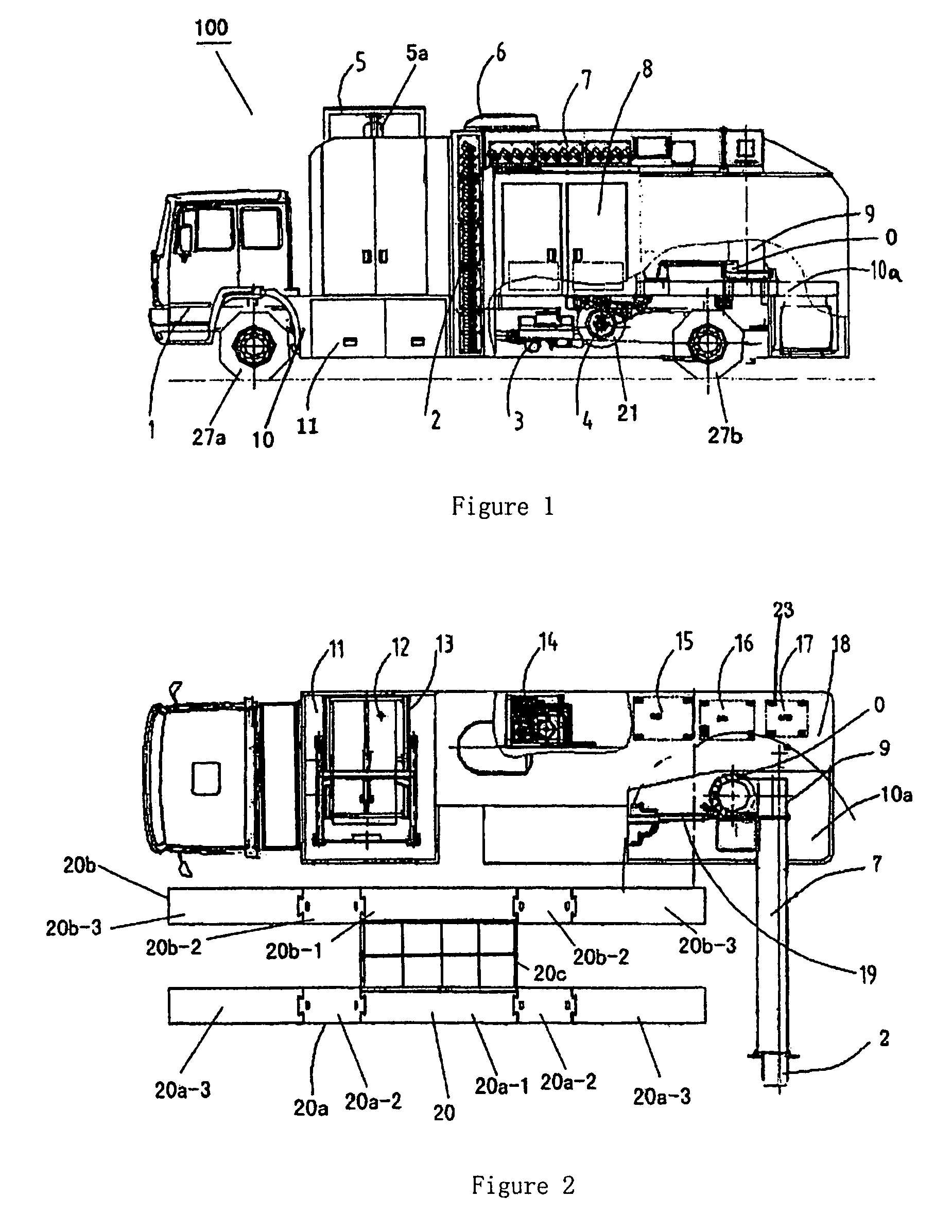

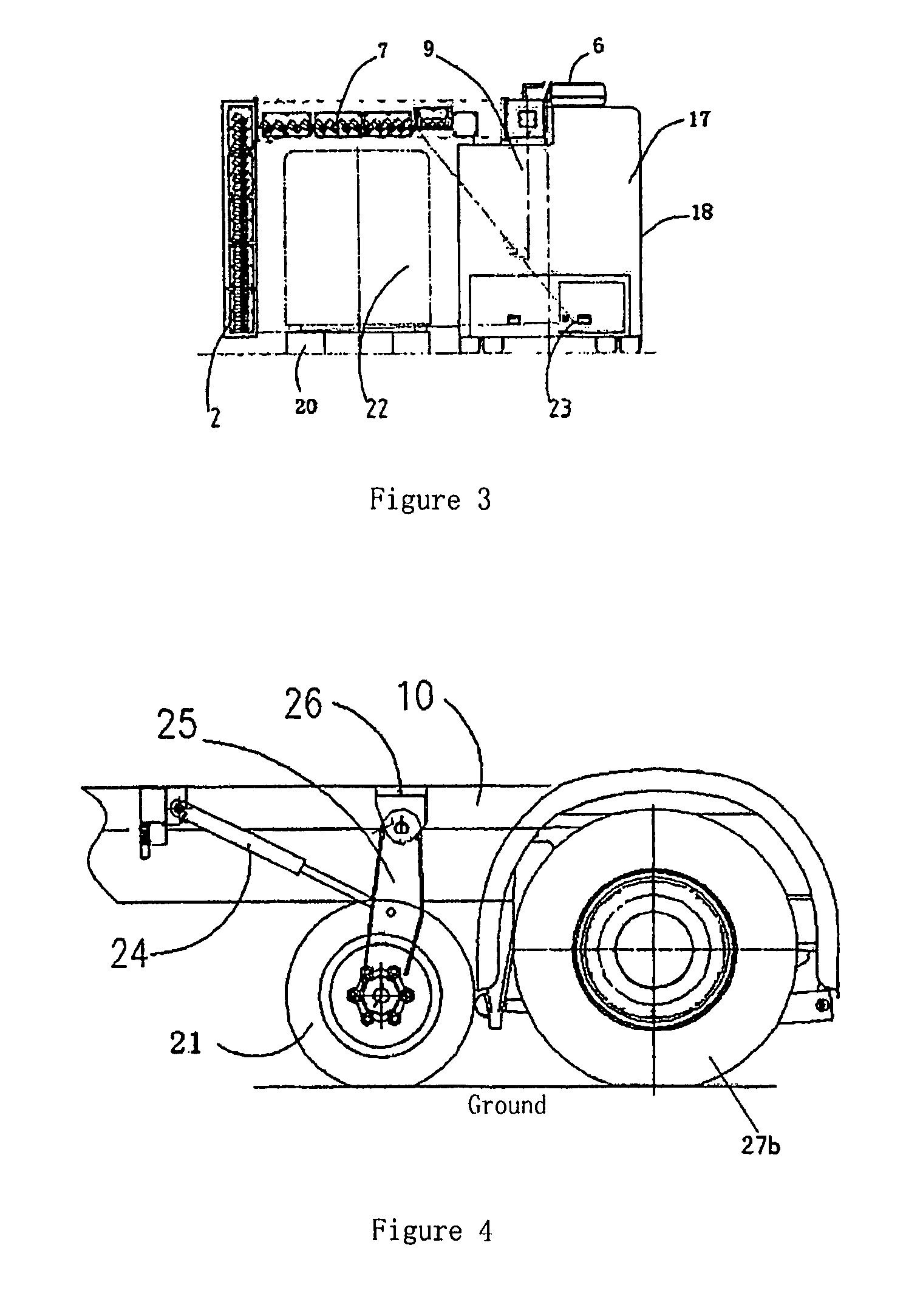

Mobile vehicle inspection system

ActiveUS7497618B2Simple structureEasy to adjustRadiation/particle handlingX-ray apparatusMobile vehicleRotary stage

A mobile vehicle inspection system includes a moving device; a driving device for driving the moving device to move during scanning inspection; a radiation source disposed on the moving device for emitting a ray; a rotary table pivotally disposed on the moving device; an upright post installed on the rotary table at a lower end of the upright post; transverse detector beam having an end connected with an upper end of the upright post; the upright detector beam having an upper end connected with the other end of the transverse detector beam, and extending downwards from the other end of the transverse detector beam so that the upright post, the transverse detector beam and the upright detector beam constitute a frame of a substantial inverted “U” shape, a ray emitted from the radiation source so as to inspect a vehicle to be inspected which passes through the inverted-“U”-shaped frame.

Owner:TSINGHUA UNIV +1

Loading and unloading manipulator

InactiveCN102554920AReduce labor costsReduce manufacturing costProgramme-controlled manipulatorMetal-working feeding devicesRotary stageRotational axis

The present invention relates to a loading and unloading manipulator which is characterized by comprising a workbench, a motor, a speed reducing device, a rotating shaft, a rotating platform, a loading mechanism and an unloading mechanism. The motor is controlled by a controller and fixed in the workbench; the input end of the speed reducing device is connected with the motor, and the output end is connected with a gear pair in a gear box; the other end of the gear pair is connected with the rotating shaft; the rotating shaft is arranged vertically; two ends of the rotating shaft are arranged above the workbench through screws; one rotating platform is fixed on the top end of the rotating shaft, and the rotating platform is perpendicular to the rotating shaft; the loading mechanism and the unloading mechanism are fixed on two ends of the rotating platform; the loading mechanism is a sucking disc; and the unloading mechanism is a clamping claw. Due to the adoption of the loading and unloading manipulator during the mechanical processing, the manpower and the production cost are reduced effectively, the occurrence of personal safety accident in the production process is avoided, the requirement of the mass production of the modern industry is met, the production efficiency is improved, and the great economic benefits are brought to the manufacturers.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

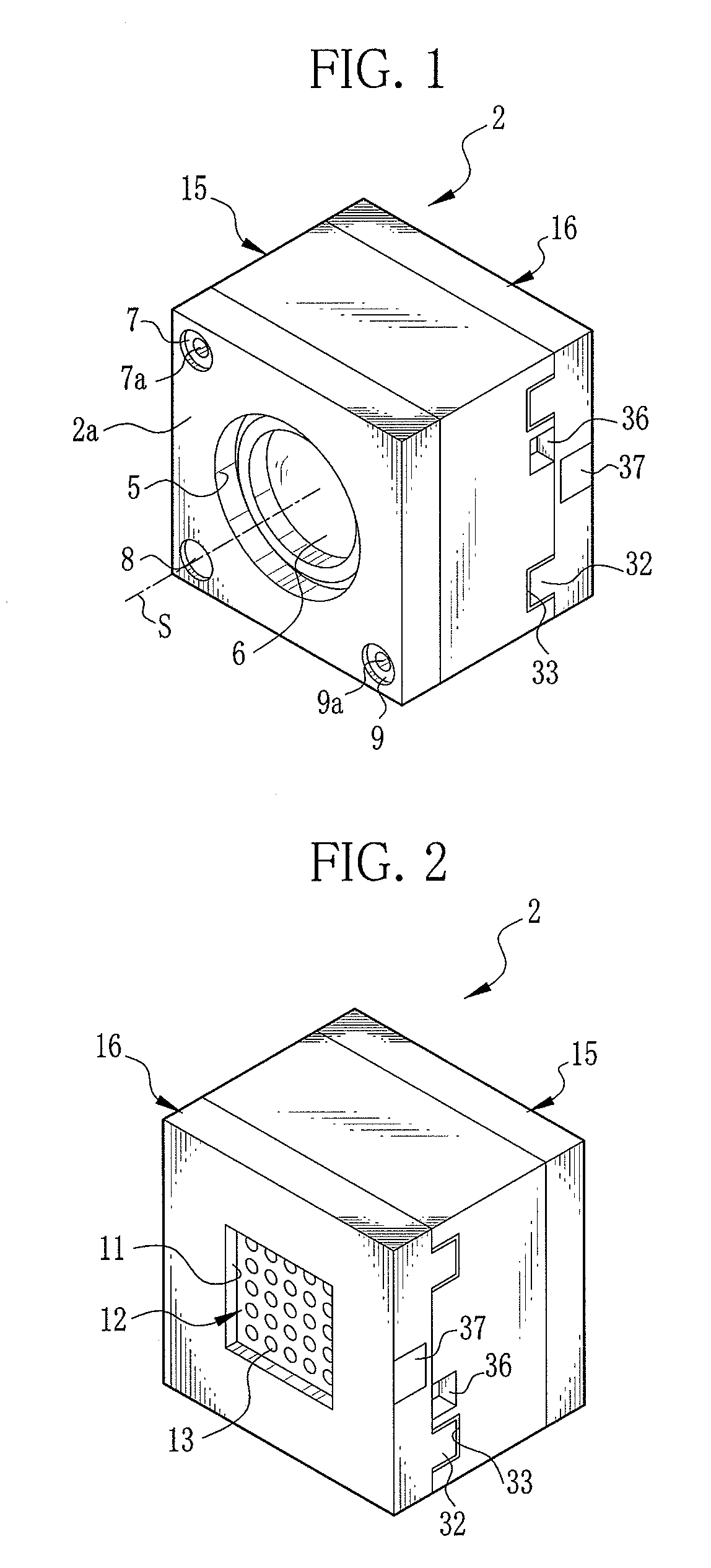

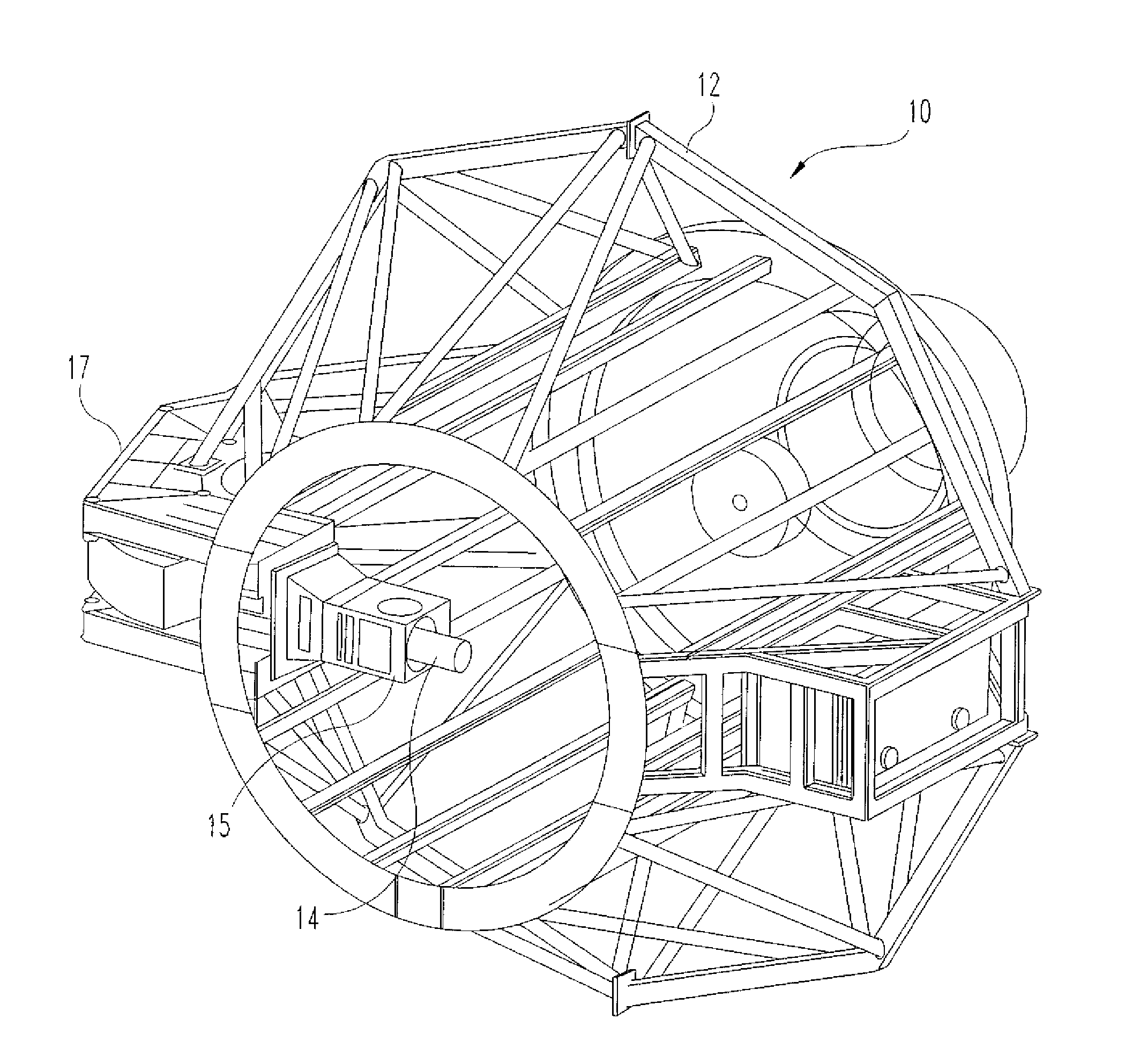

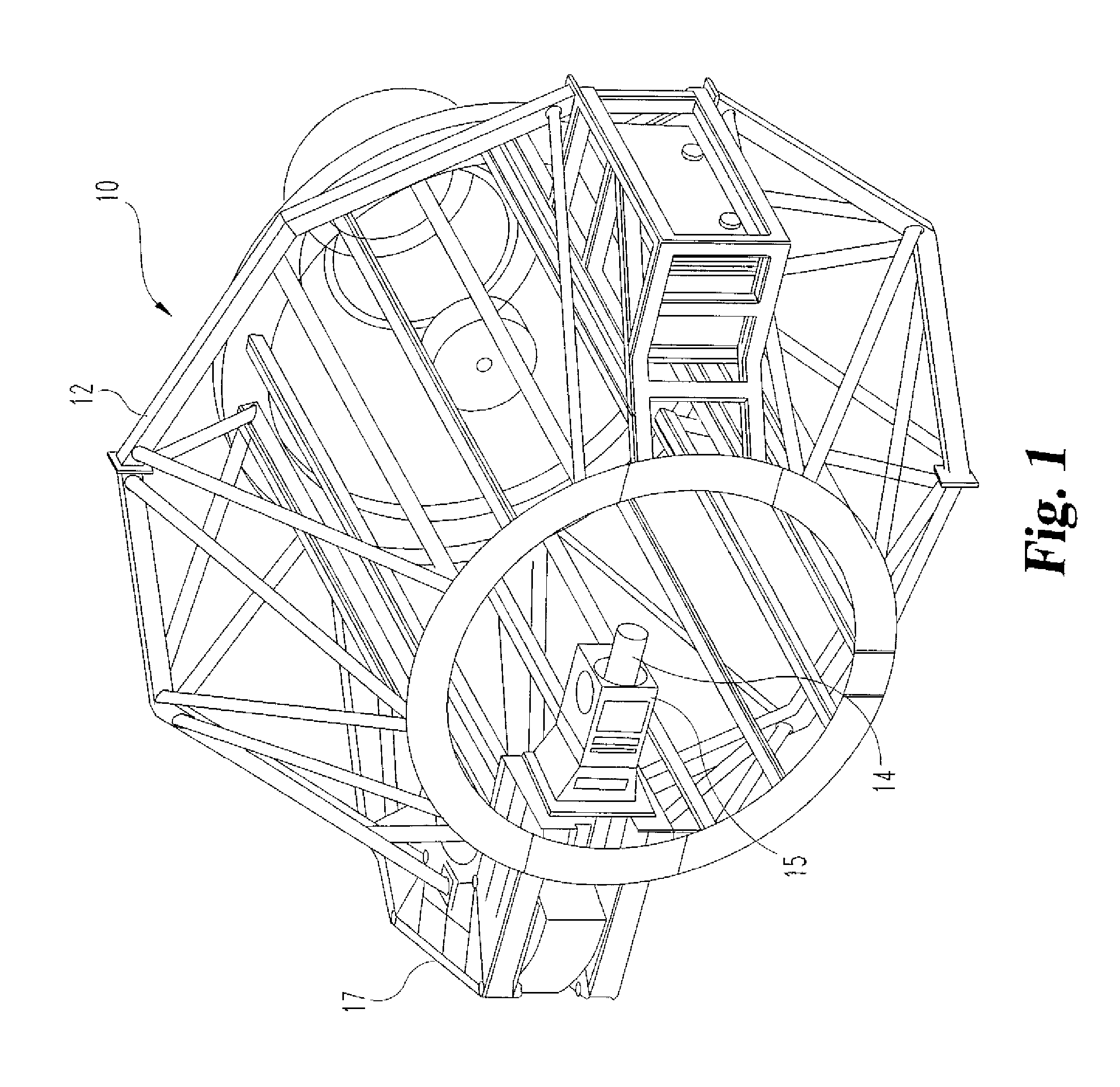

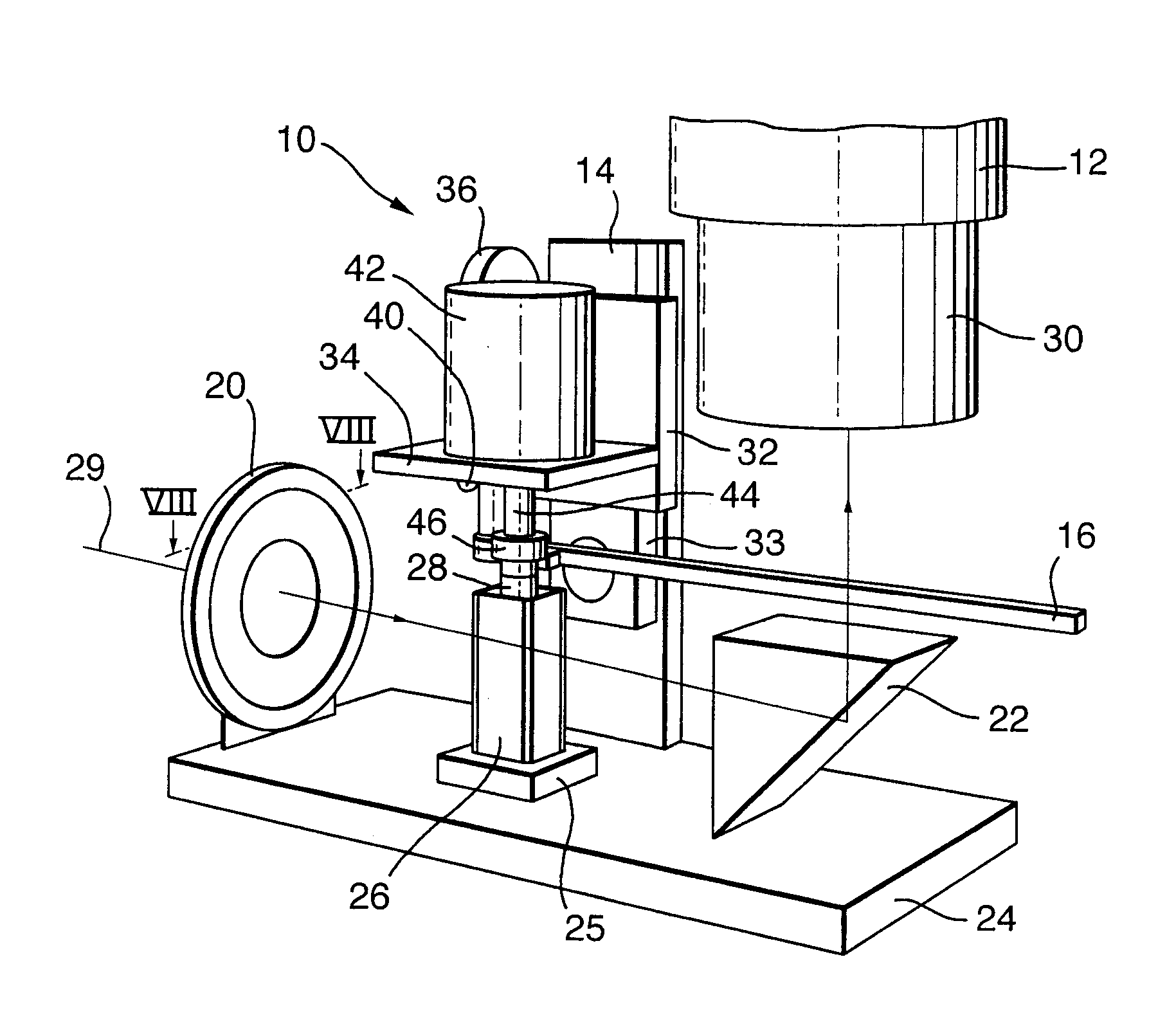

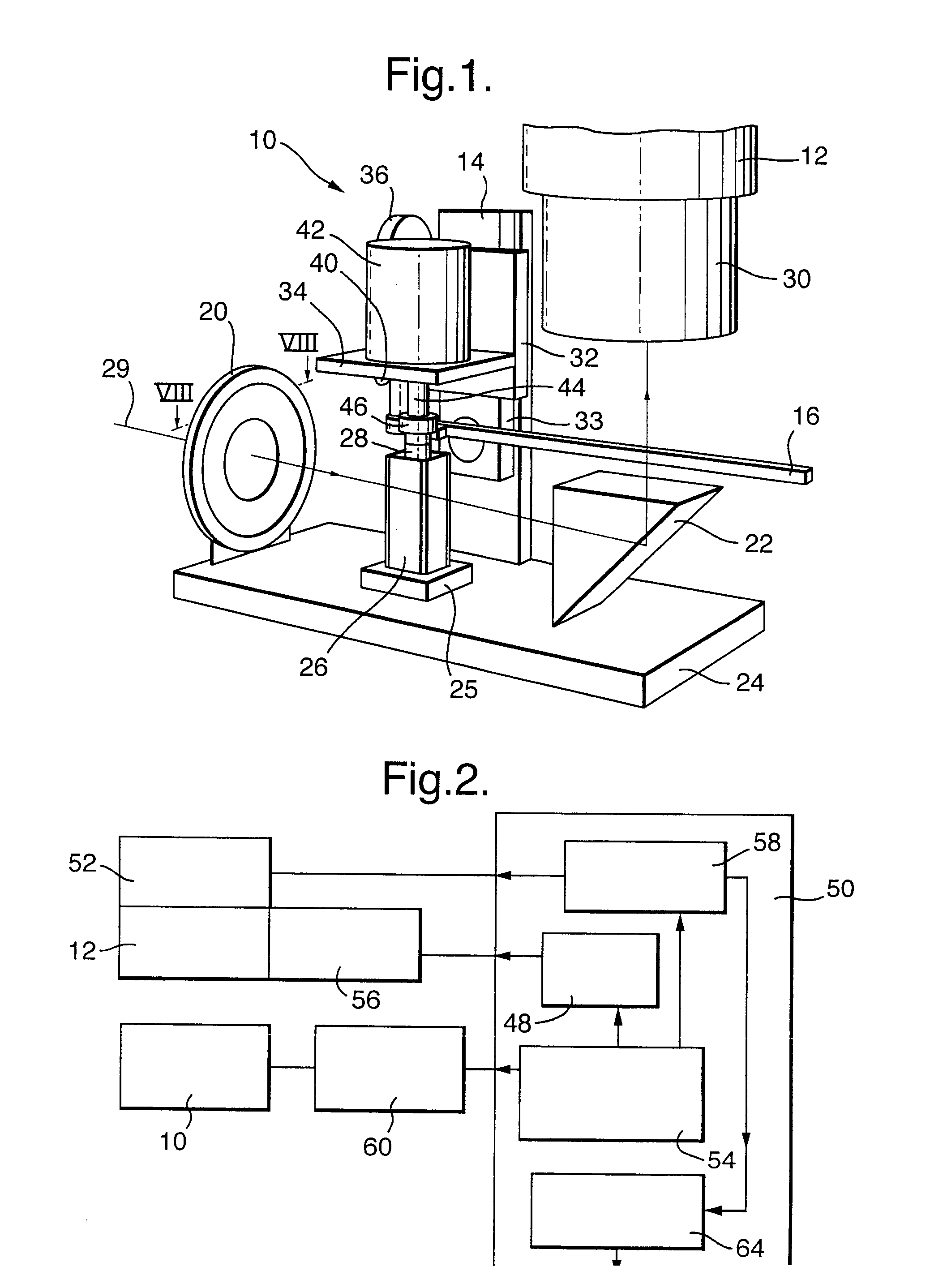

Rotary stage for imaging a specimen

InactiveUS7218393B2Precise positioningImprove accessibilityMicroscopesFluorescence/phosphorescenceRotational axisRotary stage

A rotary stage (10) for use in optical projection tomography includes a stepper motor (42) with a rotatable vertical shaft (44) the lower end of which carries a specimen (28) to be imaged so that the specimen is rotated about a substantially vertical axis. The stepper motor (42) is mounted on a table (34) the position of which is accurately adjustable in tilt and in vertical position to ensure that the rotational axis of the specimen is perpendicular to the optical axis (29). The specimen (28) rotates within a stationary chamber (26) and the rotary stage is used with a microscope which provides a three-dimensional image of the specimen.

Owner:MEDICAL RESEARCH COUNCIL

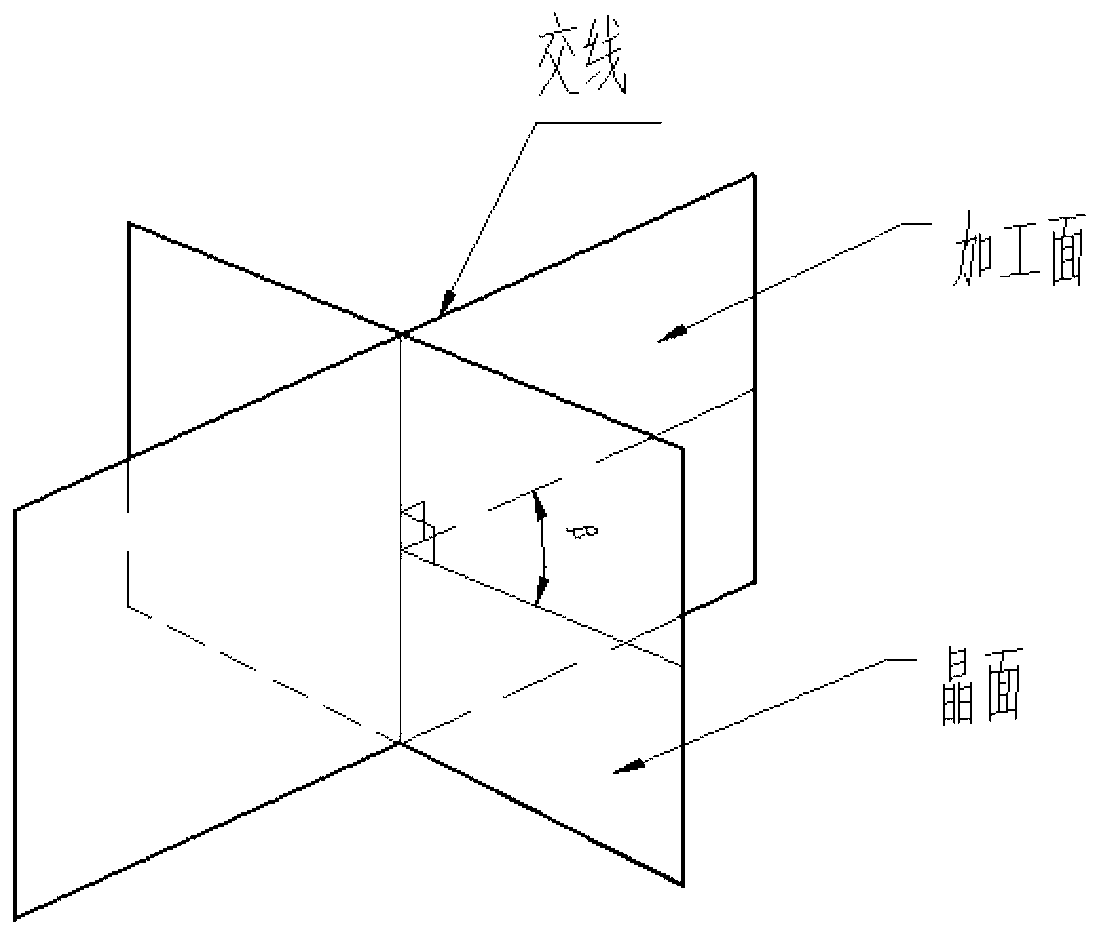

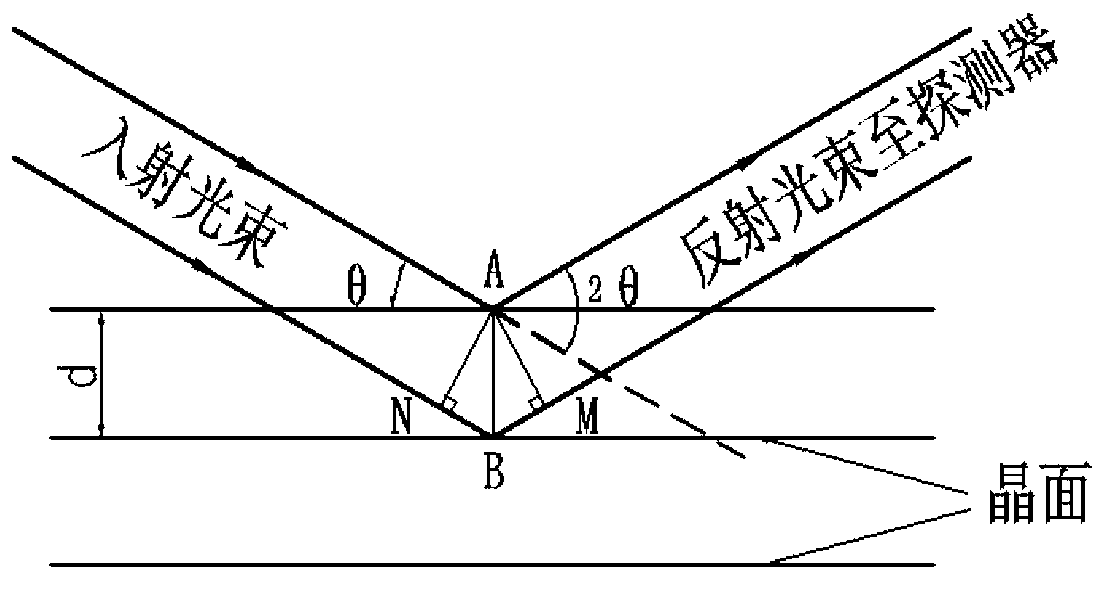

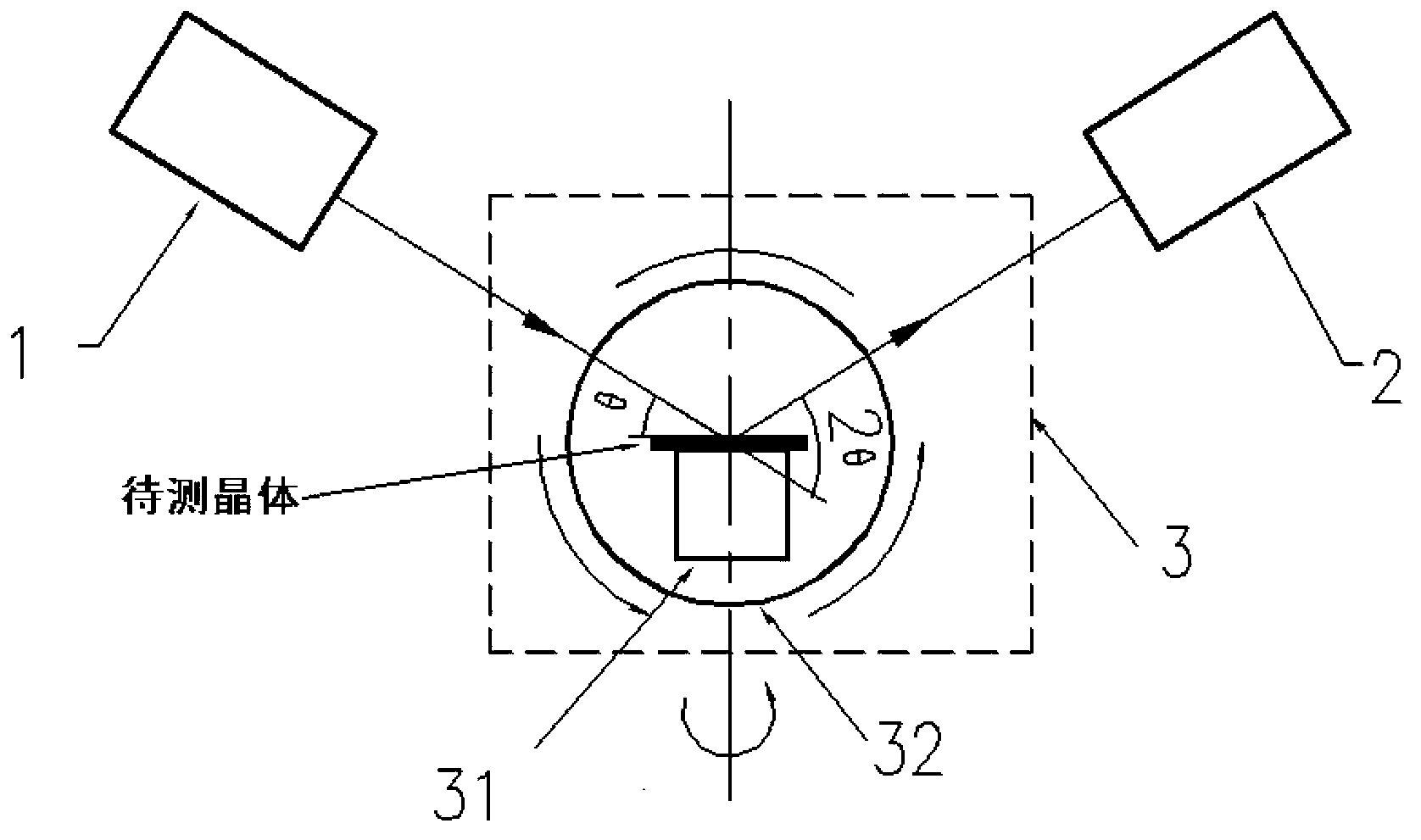

Crystal direction finder for directly measuring deflecting angle in crystal orientation and measurement method thereof

InactiveCN103257150APrevent leakageAvoid duplicationMaterial analysis using wave/particle radiationRotary stageMachined surface

The invention provides a crystal direction finder for directly measuring deflecting angle in crystal orientation, which is characterized in that one side of an objective table is connected with an X-ray generator, and the other side is connected with an X-ray detector, and an objective table is provided with a horizontal revolving bench, and the horizontal revolving stage can revolve a crystal to be measured parallely to the light propagation surface, and the center of the horizontal revolving bench is fixed with a vertical revolving stage, and the vertical revolving stage can revolve the crystal to be measured on the plane which is perpendicular to the light propagation surface; the crystal direction finder is used for directly finding the intersection line of the machined surface and the crystal face, and an angle measuring instrument of the objective table can be used for directly reading the deflecting angle beta in crystal orientation. The invention overcomes the defects that the present X-ray crystal direction finder has a complex operating method, wherein, the measurement process needs multiple times of rotations, dismountings and fixations of the detected crystal with low measurement efficiency, which is easy to induce cumulative errors and X-ray leakage.

Owner:YUNNAN KIRO CH PHOTONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com