Patents

Literature

4025results about "Turbines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

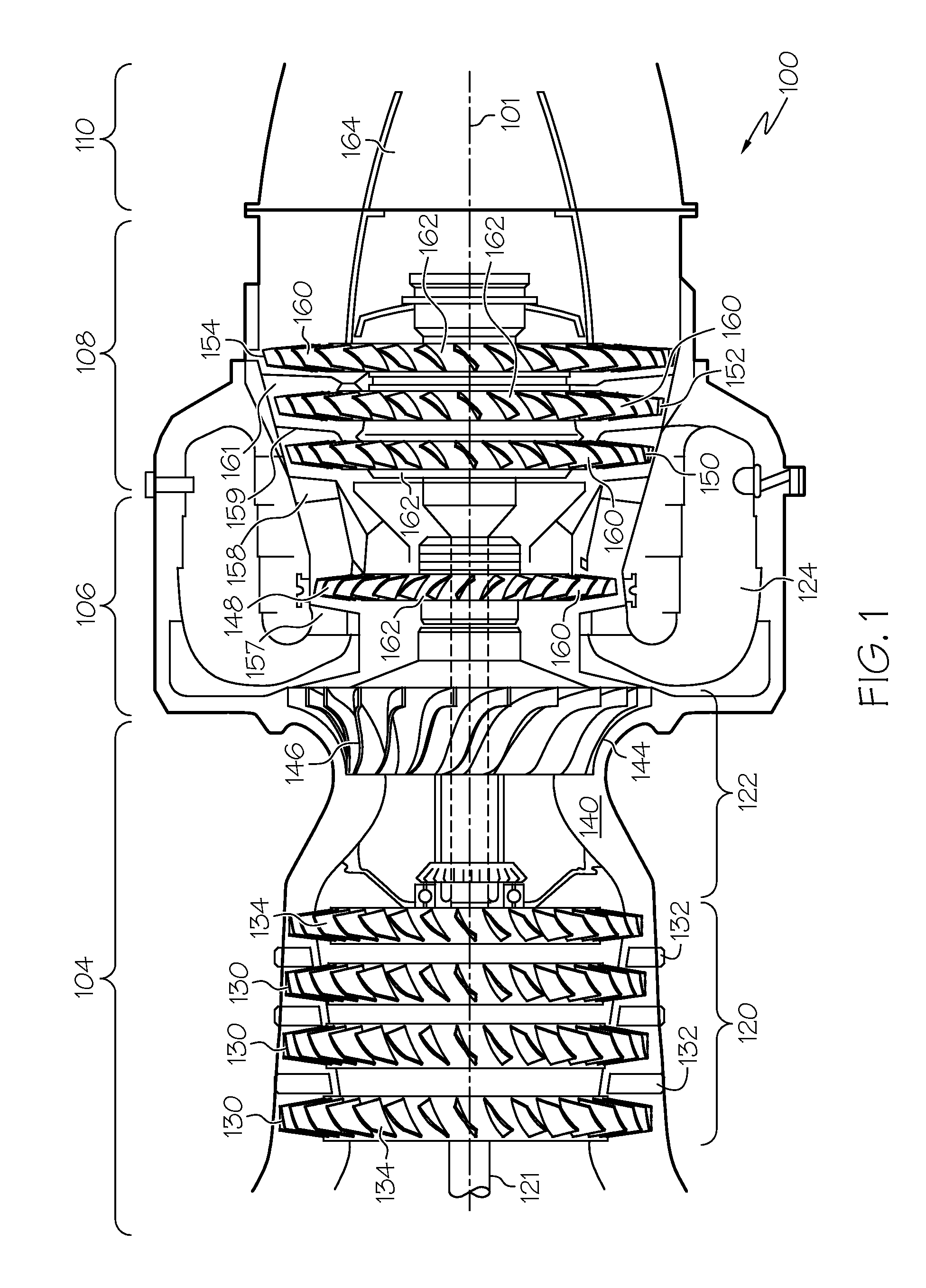

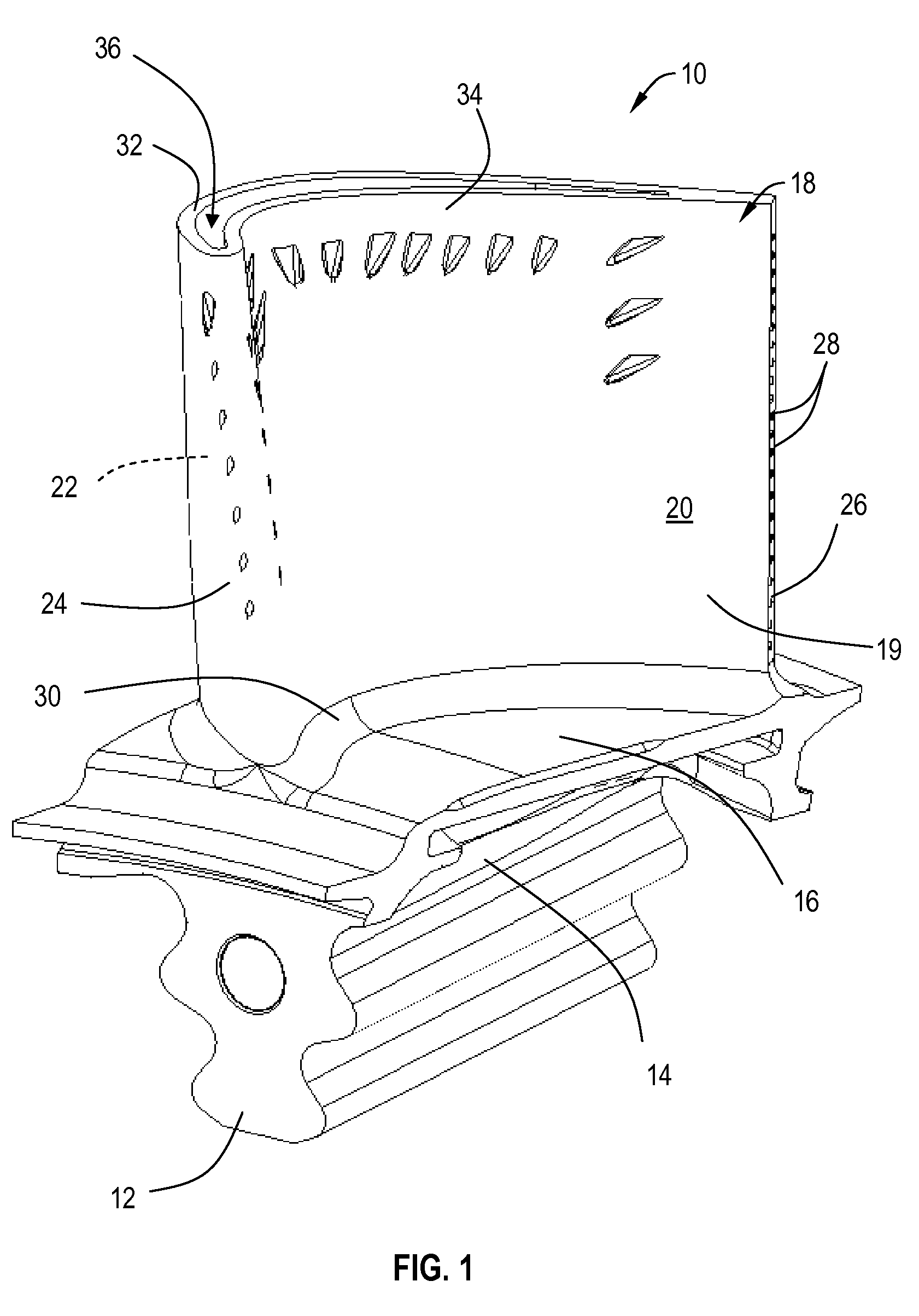

Systems and methods for additive manufacturing and repair of metal components

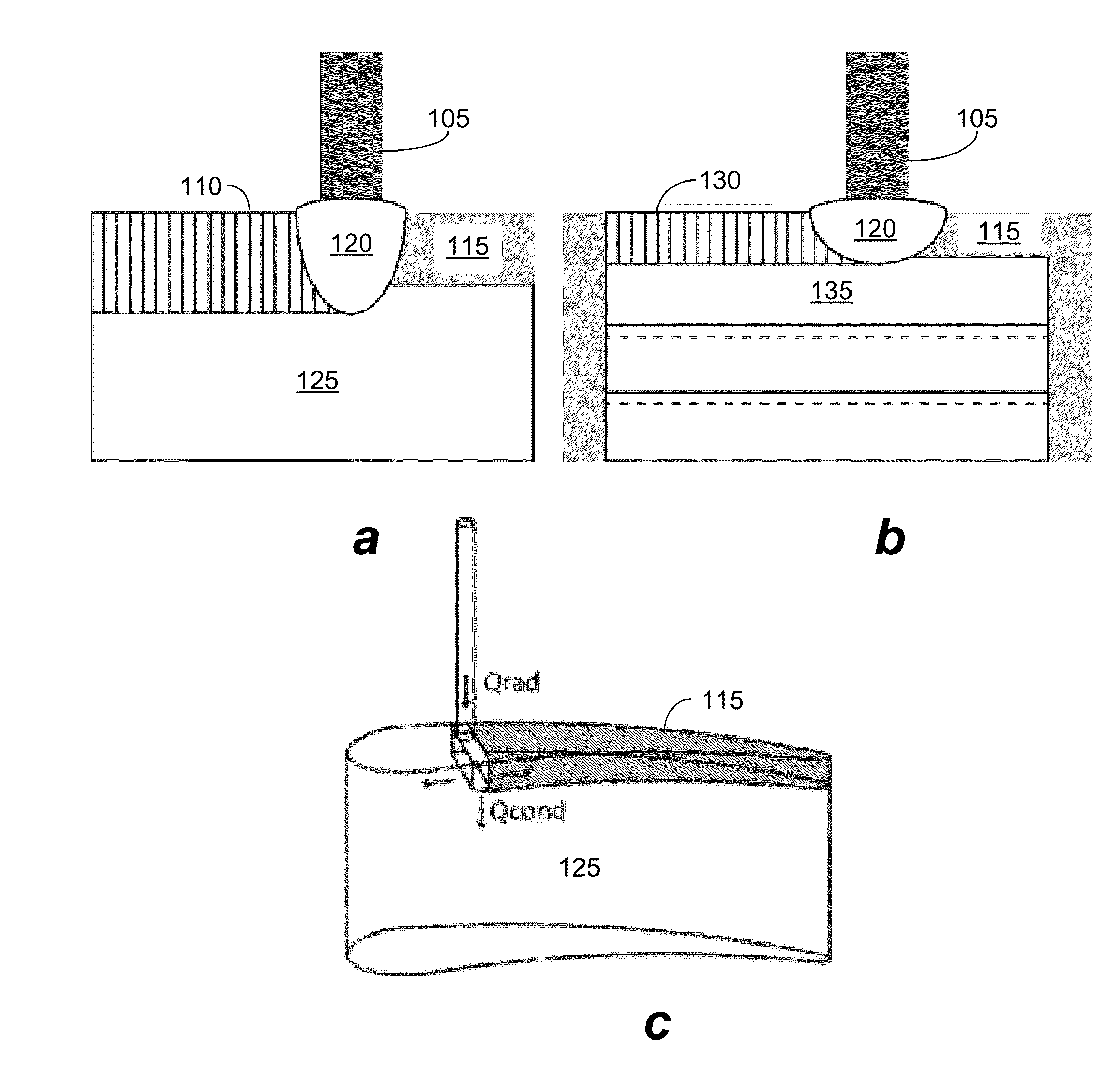

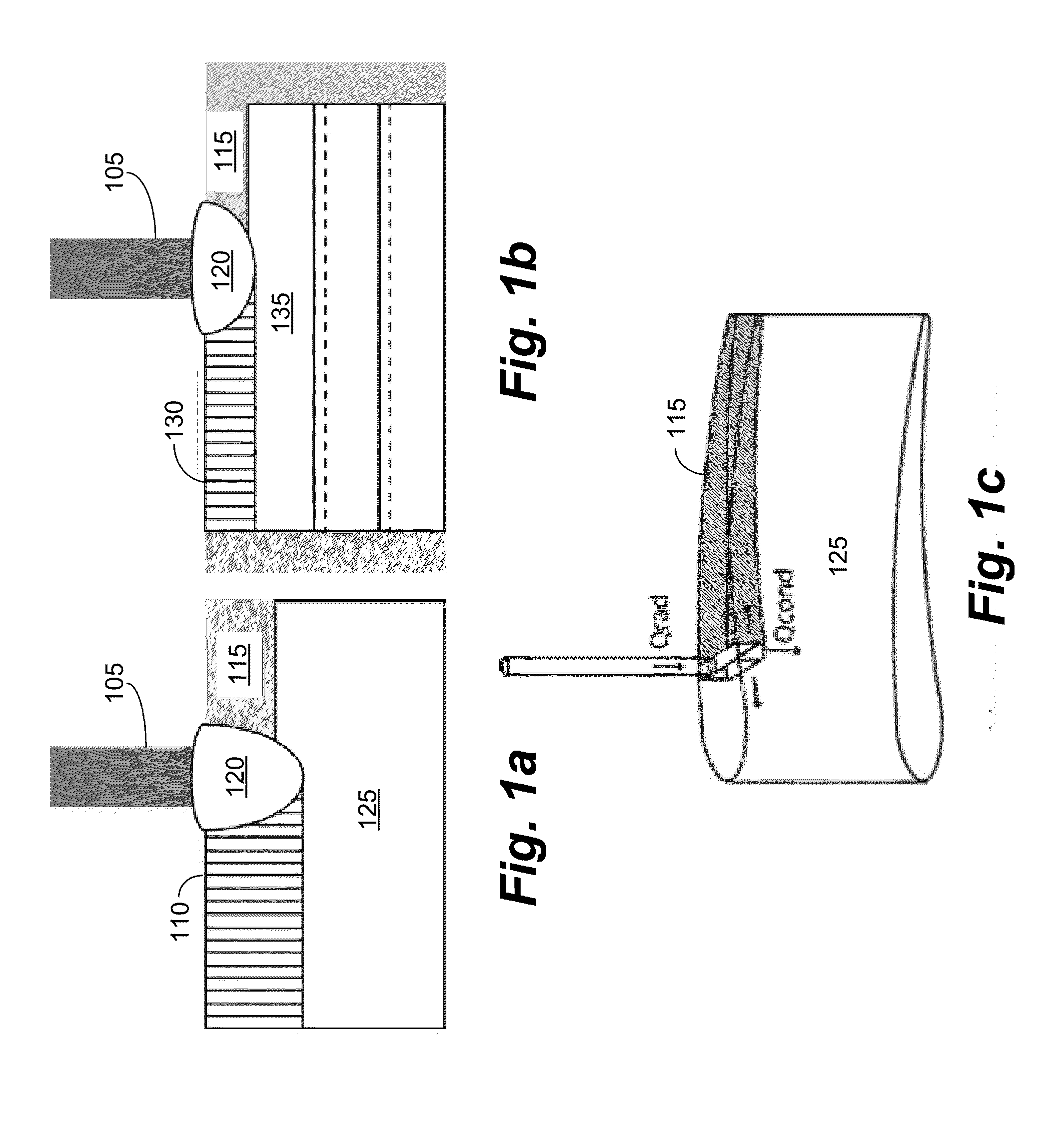

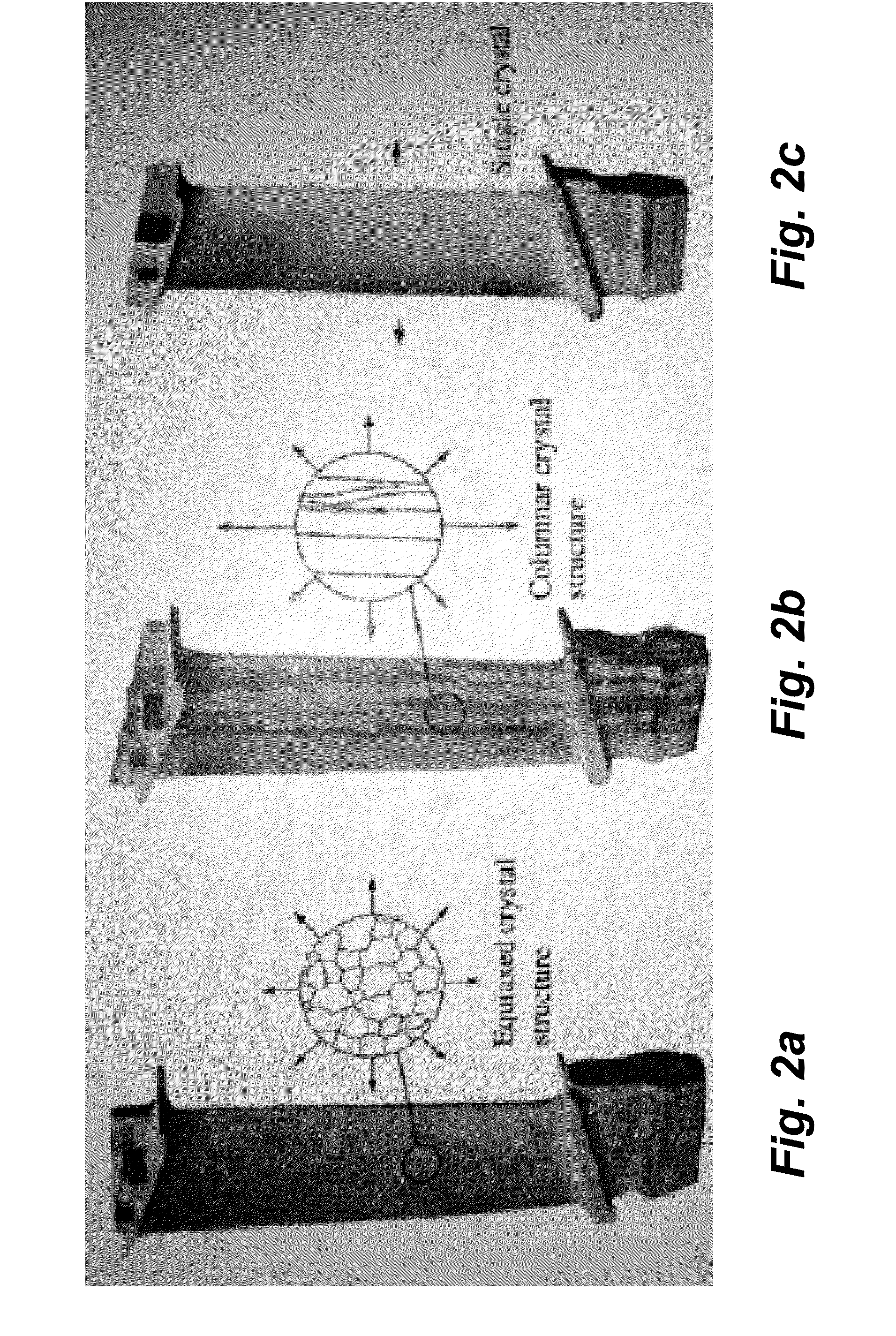

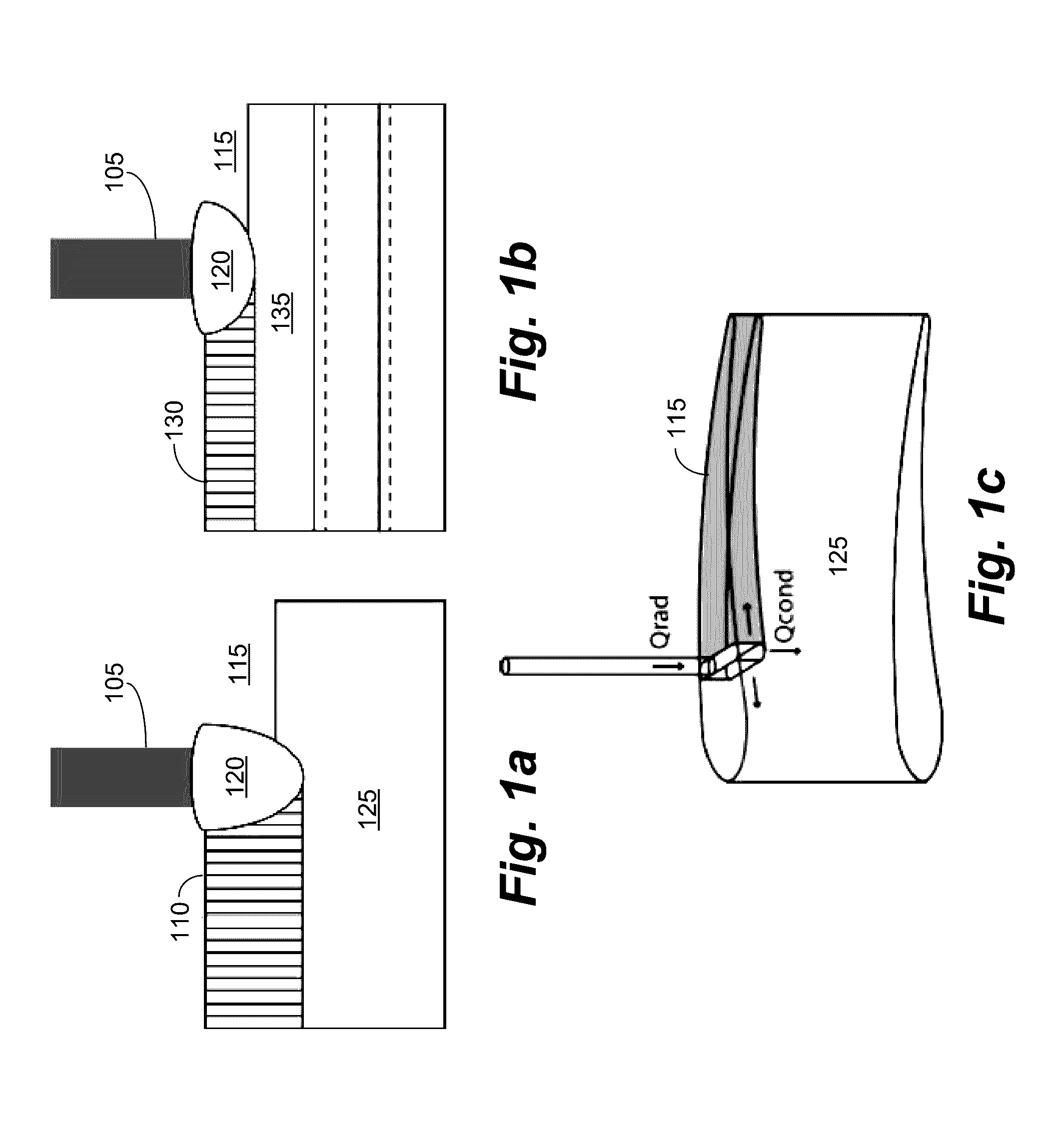

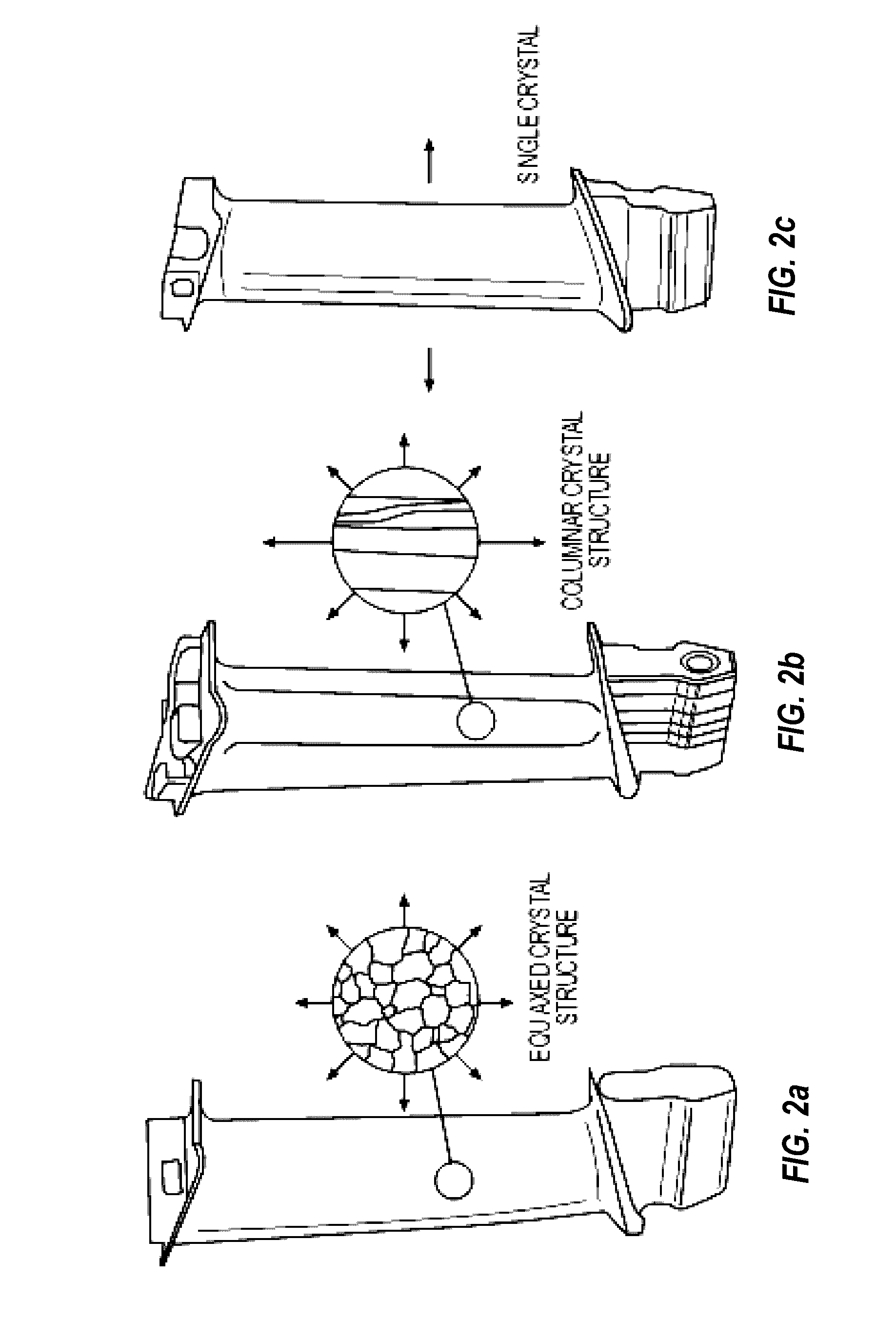

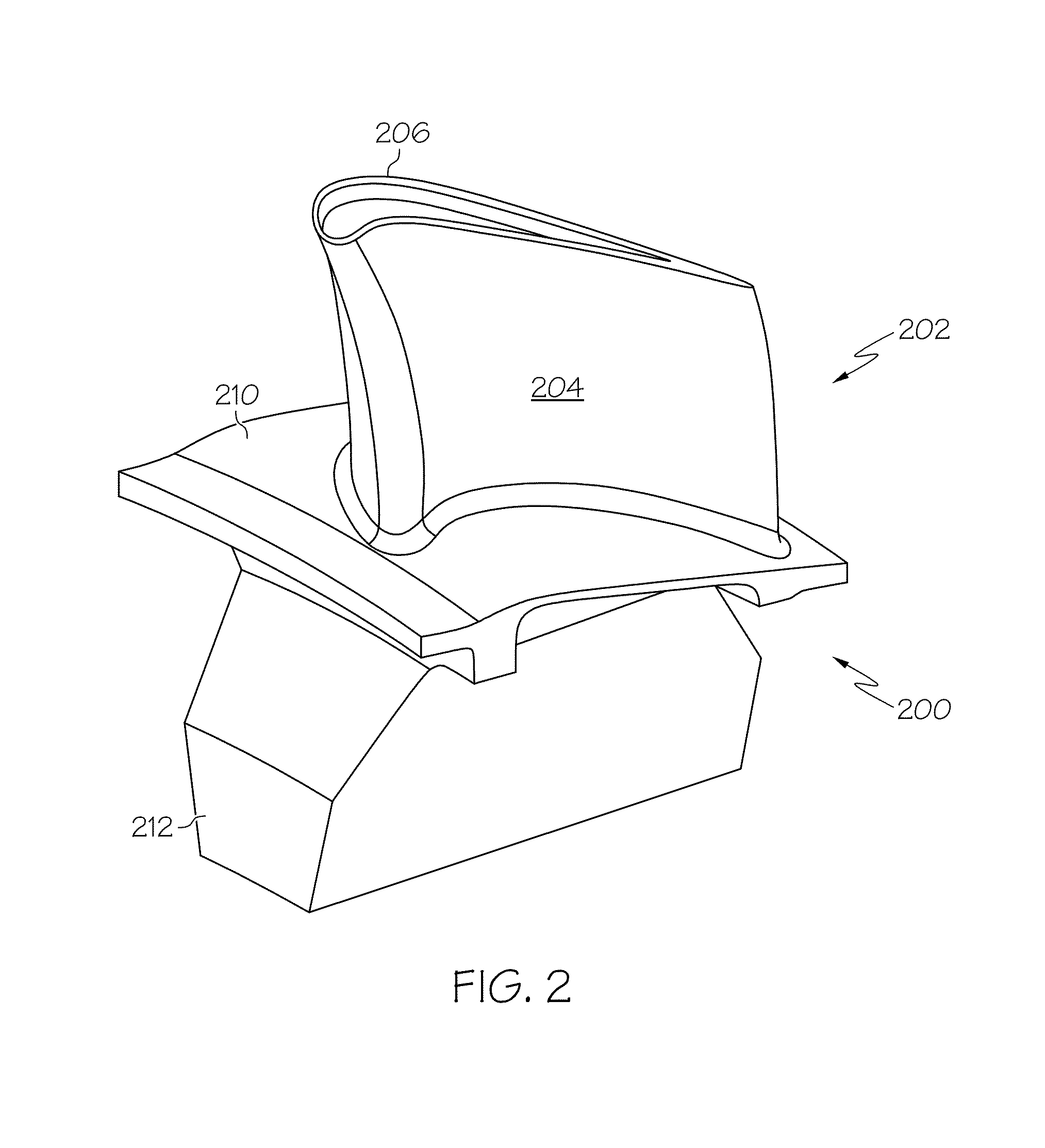

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

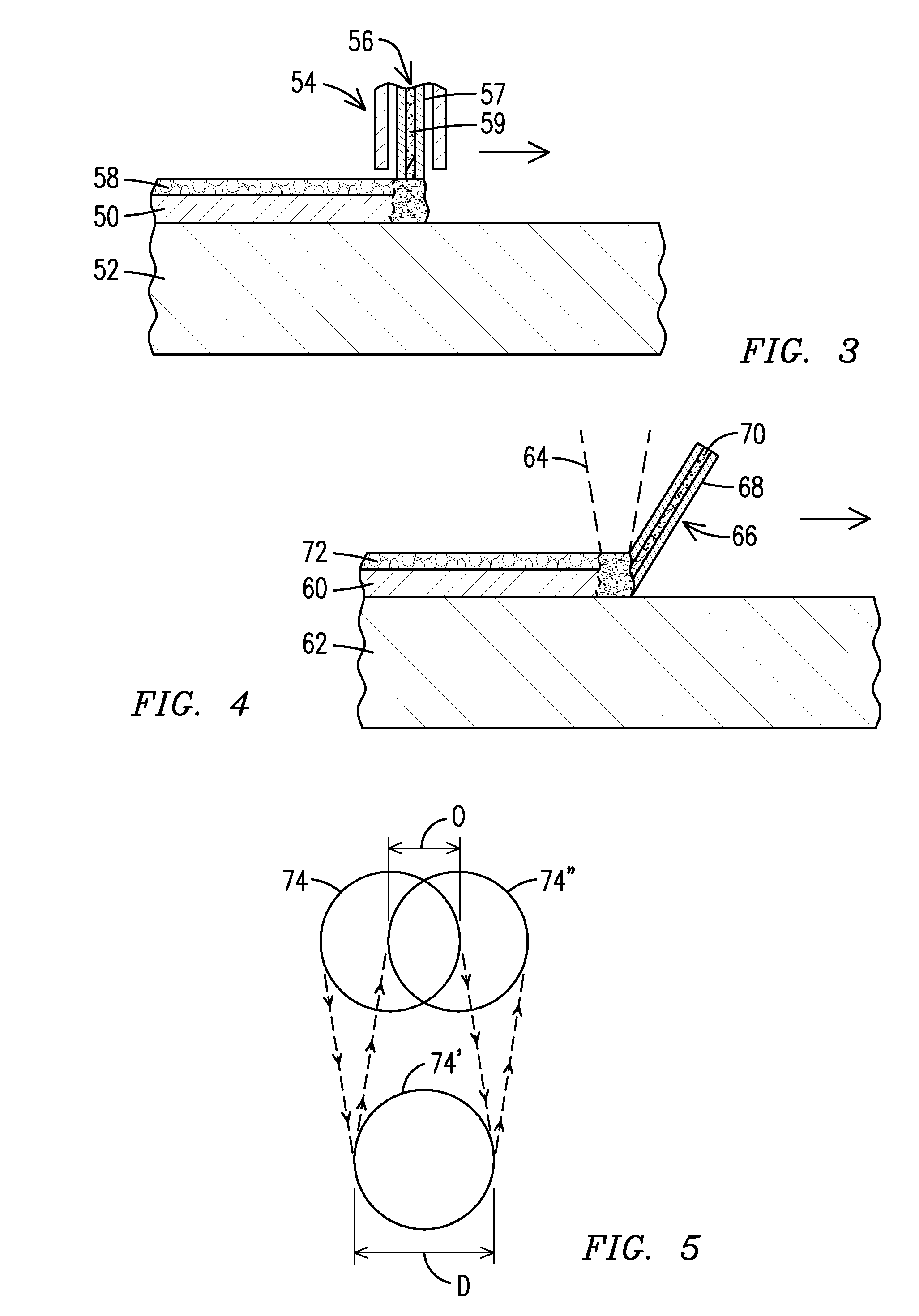

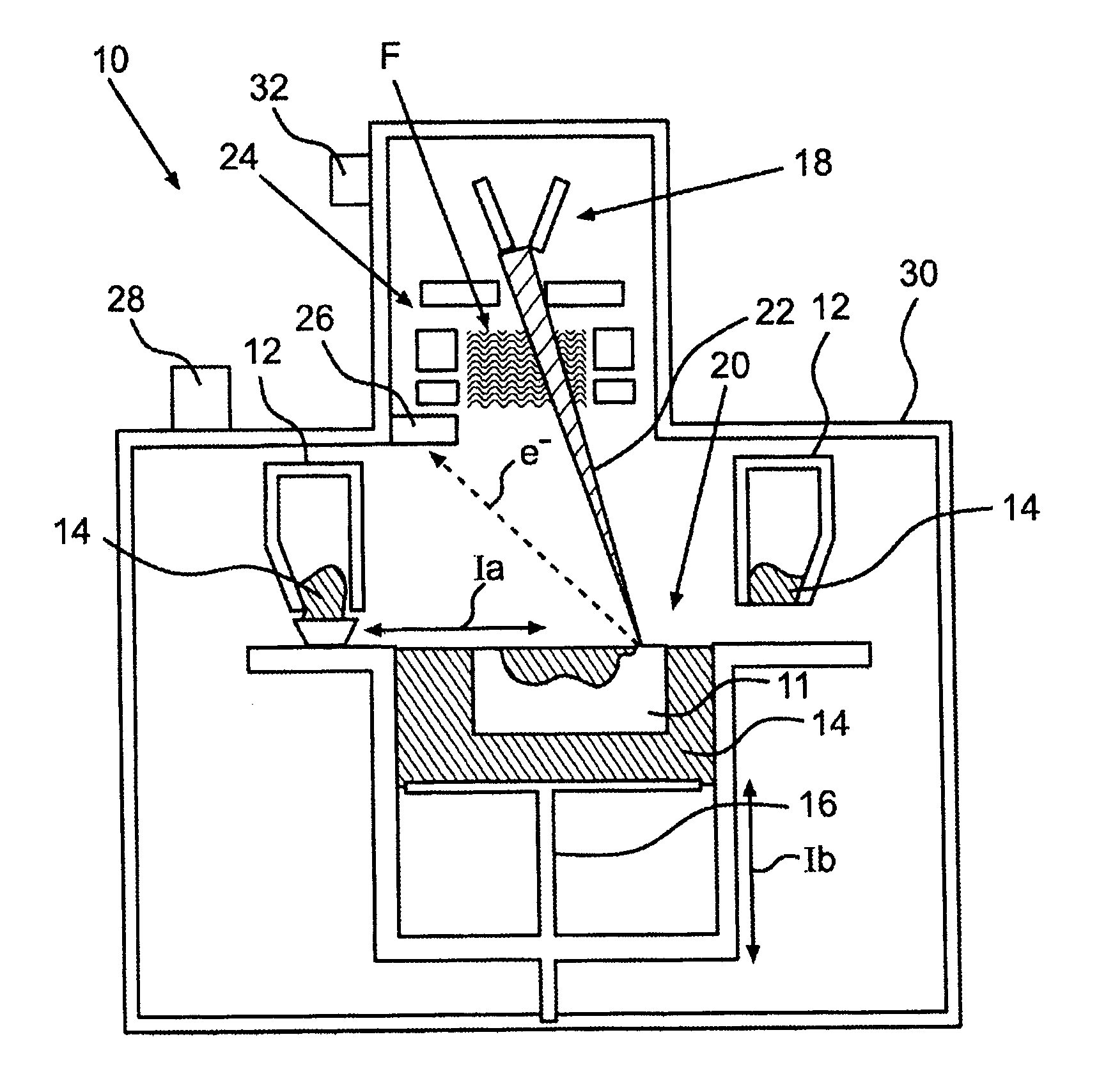

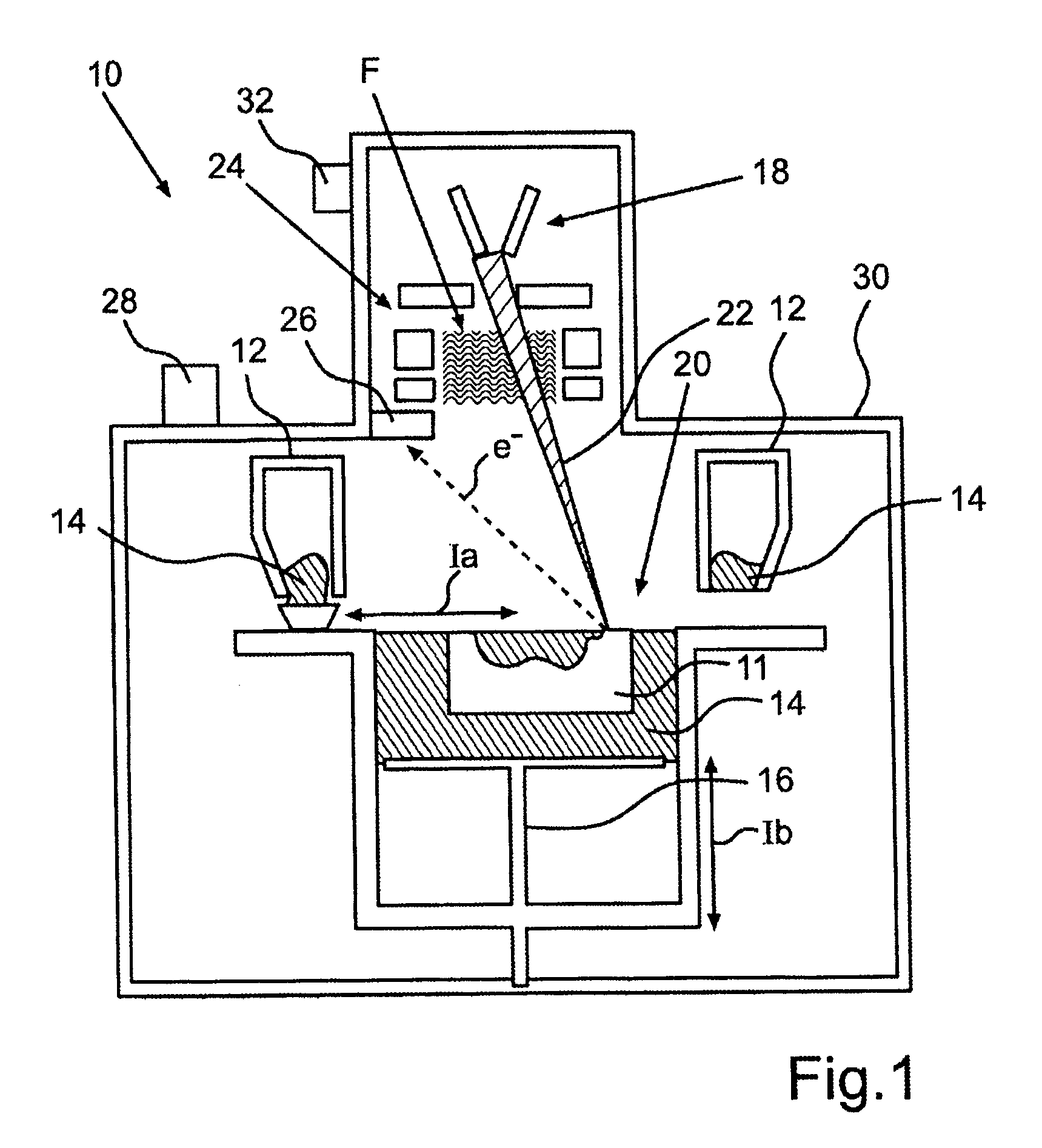

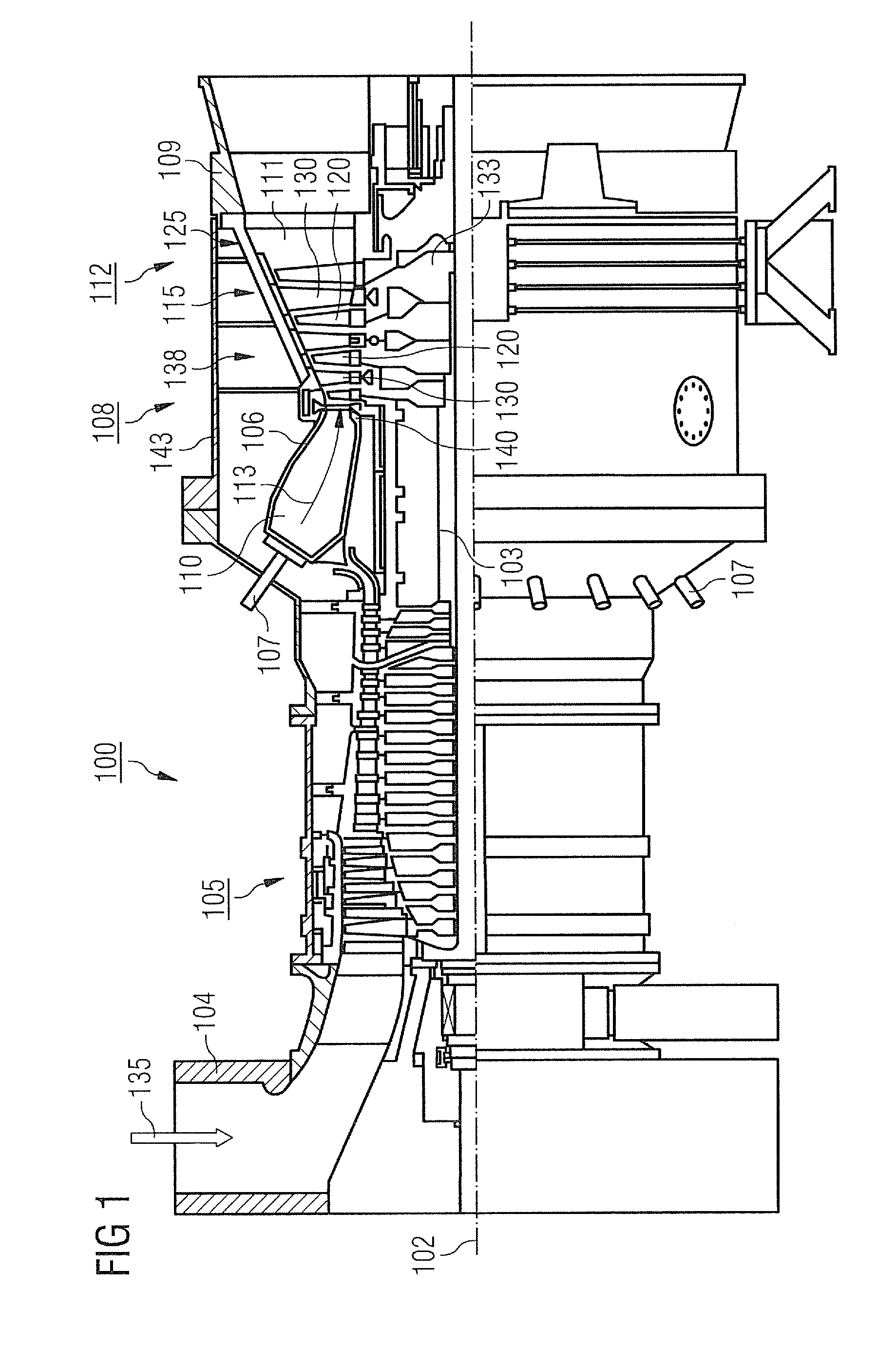

Method and device for producing a component

InactiveUS20130055568A1High build rateSpeed up preparationTurbinesAdditive manufacturing apparatusMetallurgyLayer thickness

A method for manufacturing a component, in particular a component of a turbine or a compressor, in which at least these steps are carried out: application in layers of at least one powdered component material to a component platform in the area of a buildup and joining zone; melting and / or sintering locally in layers of the component material by supplying energy with the aid of at least one electron beam in the area of the buildup and joining zone; lowering of the component platform in layers by a predefined layer thickness; and repeating steps a) through c) until completion of the component. During the manufacturing, electrons emitted due to the interaction of the electron beam with the component material are detected, after which material information, characterizing the topography of the melted and / or sintered component material, is ascertained on the basis of the emitted electrons. Alternatively or additionally, the component material is melted and / or sintered by at least two, preferably at least four electron beams.

Owner:GLOBAL BEAM TECH +1

Methods for manufacturing turbine components

A method is provided for manufacturing a turbine component. The method includes forming a first intermediate turbine article with an additive manufacturing process; encapsulating the first intermediate turbine article with an encapsulation layer to form a second intermediate turbine article; and consolidating the second intermediate turbine article to produce the turbine component.

Owner:HONEYWELL INT INC

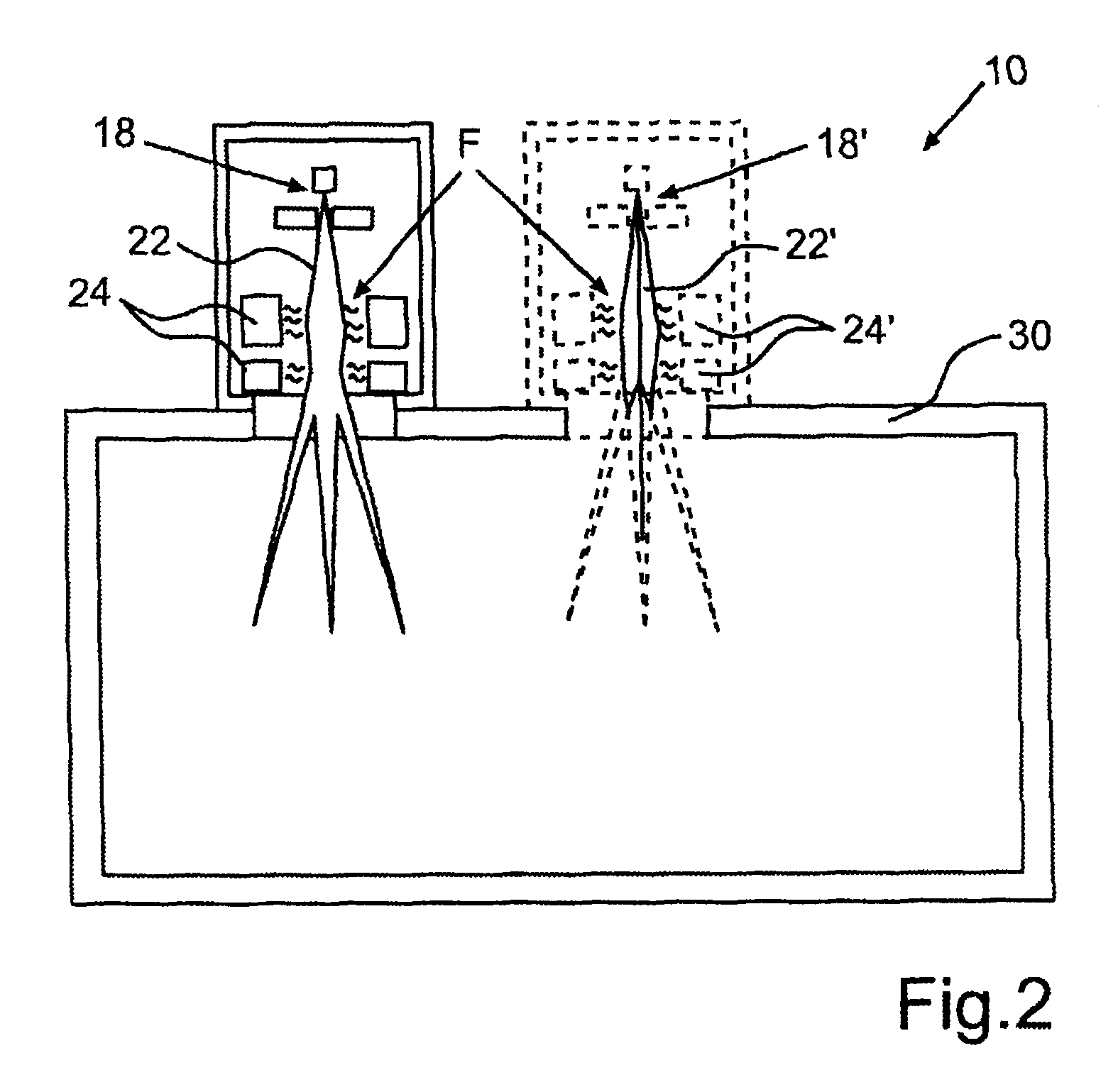

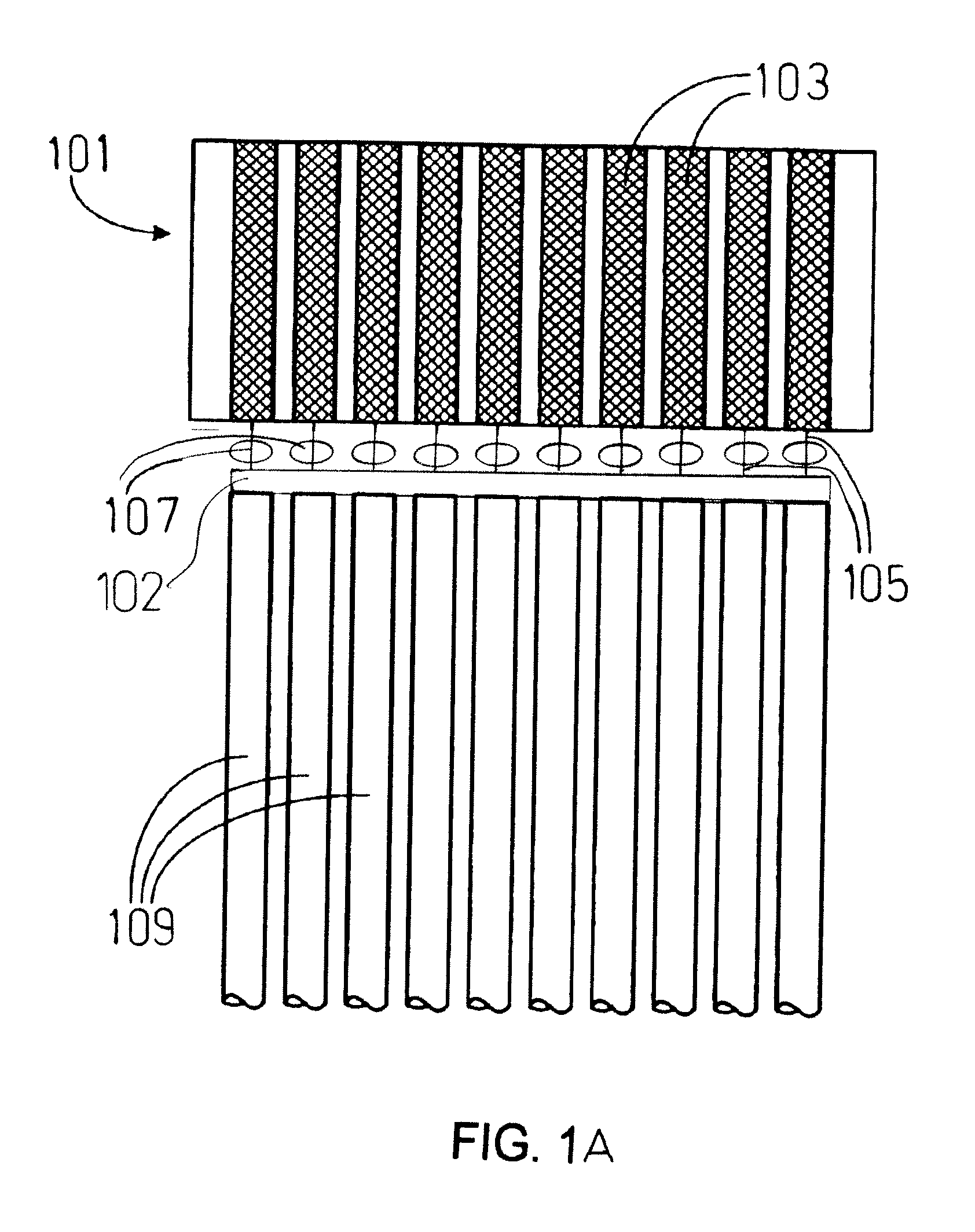

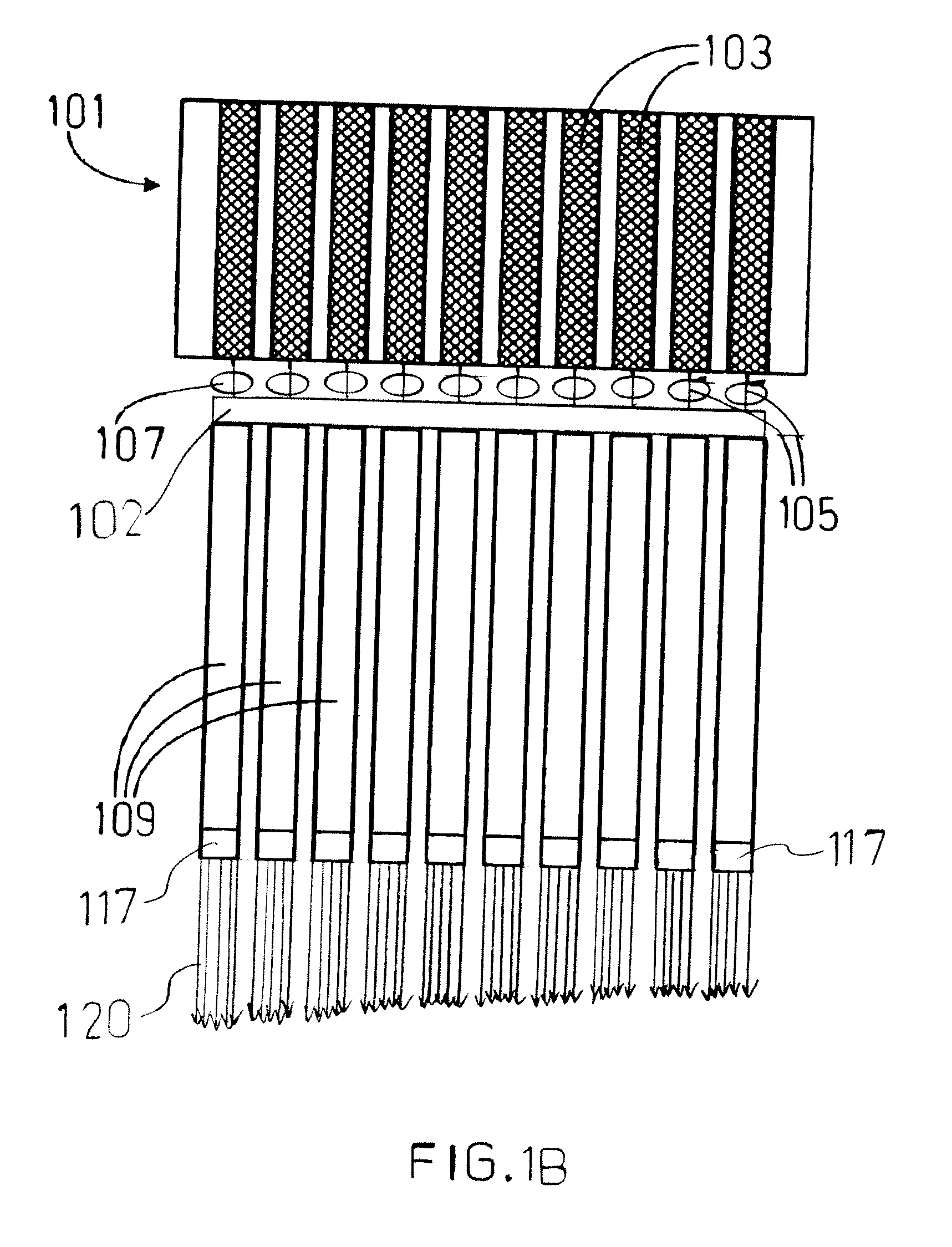

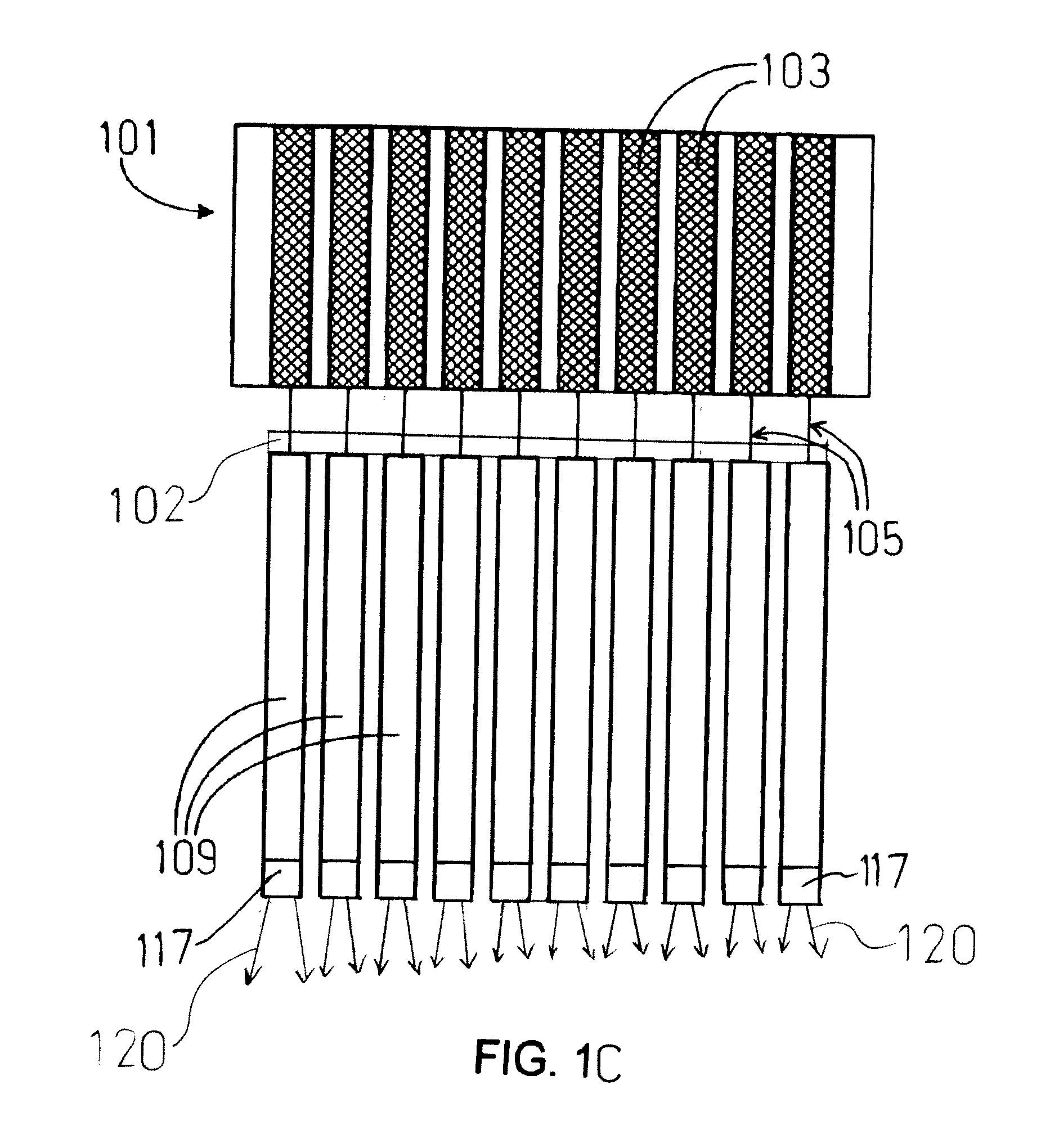

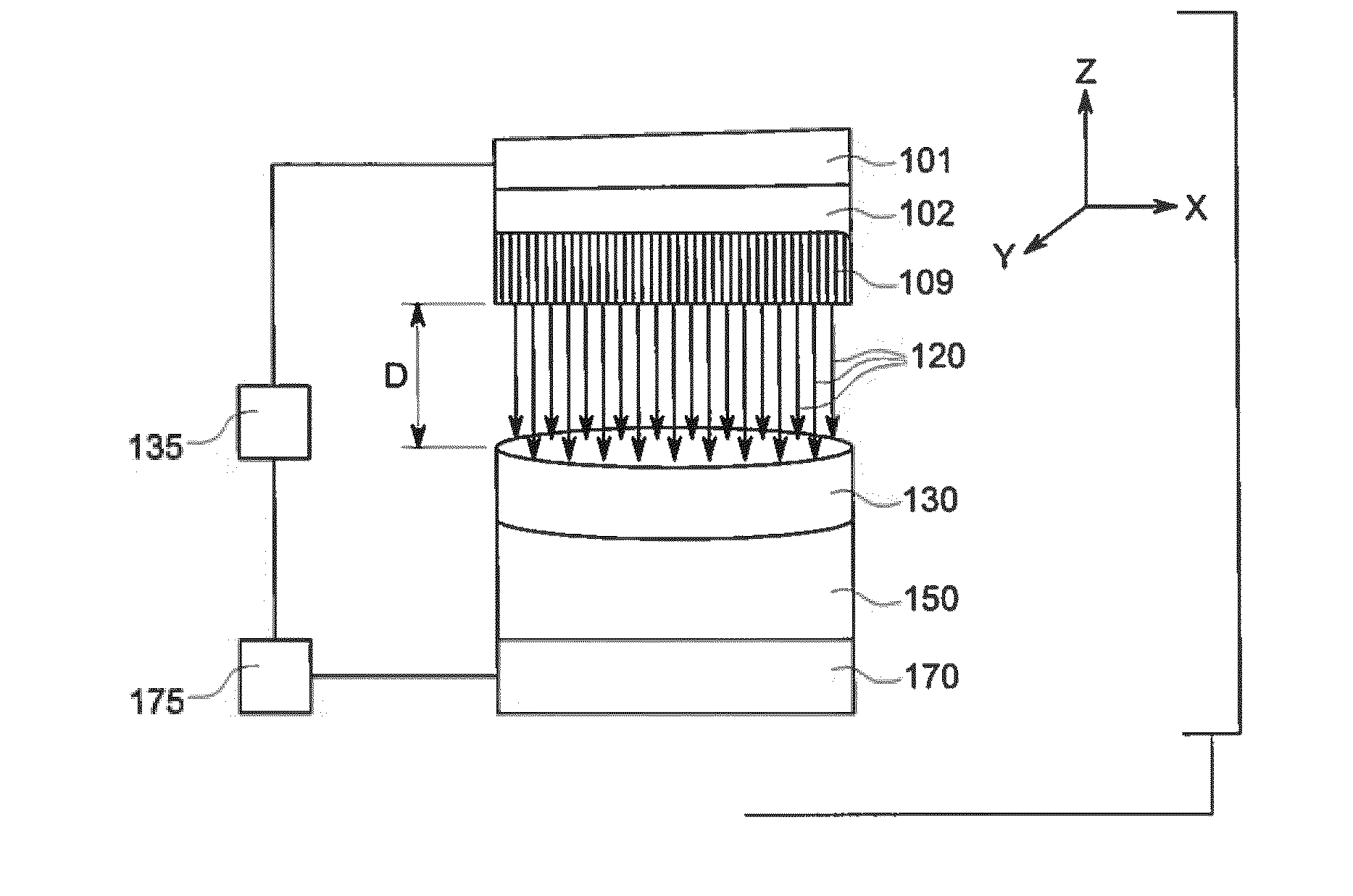

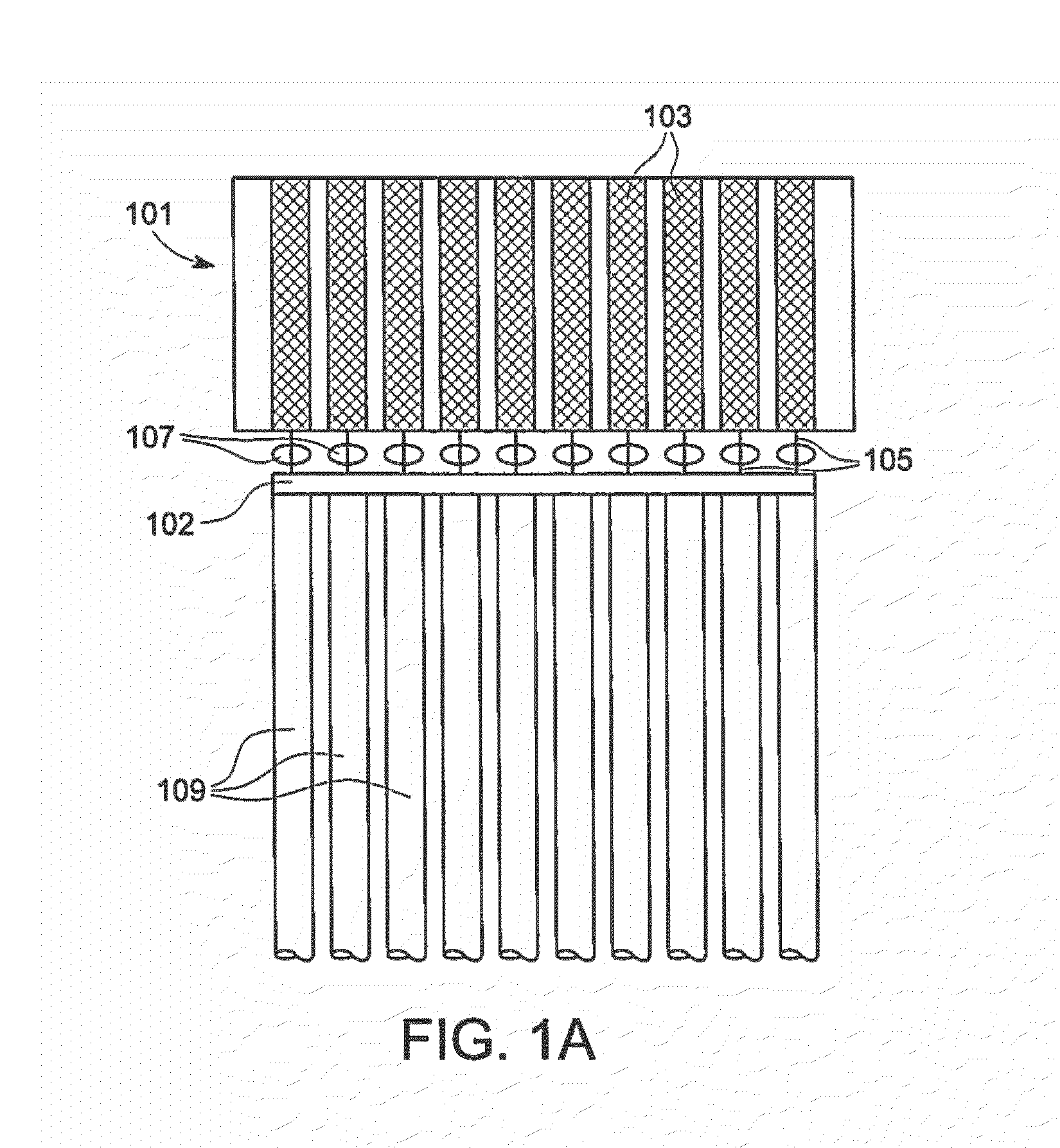

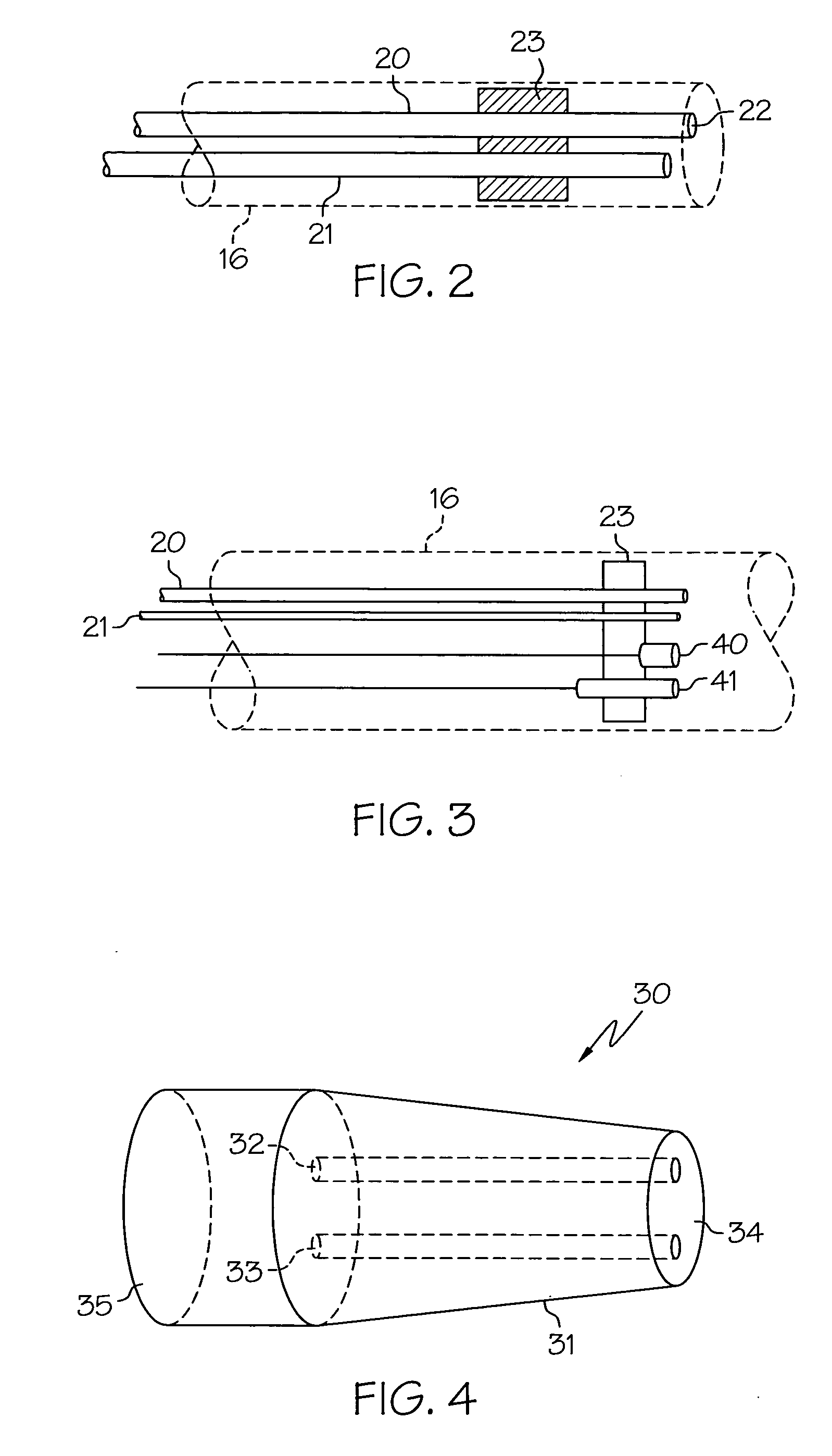

Diode laser fiber array for powder bed fabrication or repair

A method of forming a build in a powder bed includes emitting a plurality of laser beams from selected fibers of a diode laser fiber array onto the powder bed, the selected fibers of the array corresponding to a pattern of a layer of the build; and simultaneously melting powder in the powder bed corresponding to the pattern of the layer of the build. An apparatus for forming a build in a powder bed includes a diode laser fiber array including a plurality of diode lasers and a plurality of optical fibers corresponding to the plurality of diode lasers, each optical fiber configured to receive a laser beam from a respective diode laser and configured to emitting the laser beam; a support configured to support a powder bed or a component configured to support the powder bed at a distance from ends of the optical fibers; and a controller configured to control the diode laser fiber array to emit a plurality of laser beams from selected fibers of the diode laser fiber array onto the powder bed, the selected fibers of the array corresponding to a pattern of a layer of the build and simultaneously melt the powder in the powder bed corresponding to the pattern of the layer of the build.

Owner:GENERAL ELECTRIC CO

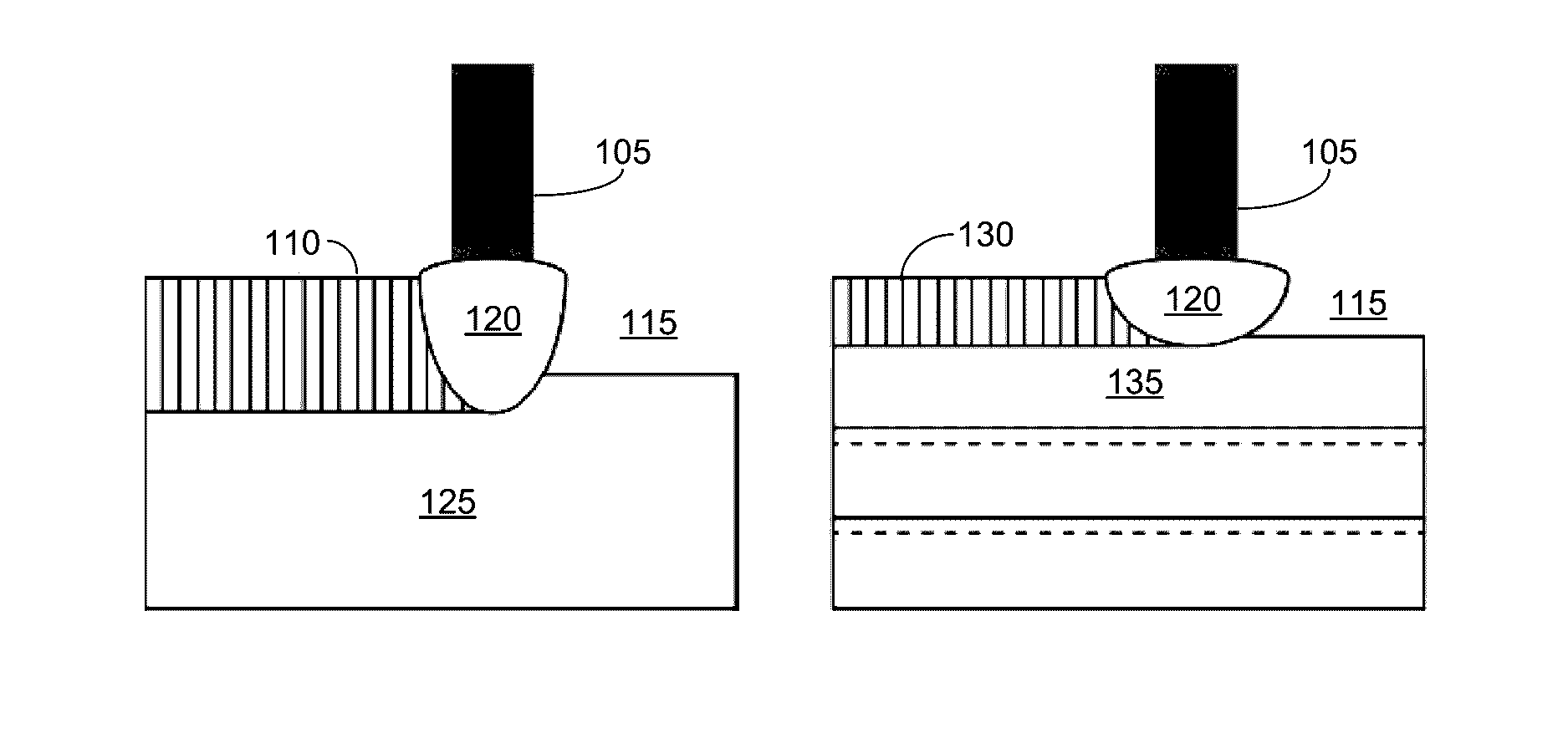

Control of solidification in laser powder bed fusion additive manufacturing using a diode laser fiber array

A method of method of forming or repairing a superalloy article having a columnar or equiaxed or directionally solidified or amorphous or single crystal microstructure includes emitting a plurality of laser beams from selected fibers of a diode laser fiber array corresponding to a pattern of a layer of the article onto a powder bed of the superalloy to form a melt pool; and controlling a temperature gradient and a solidification velocity of the melt pool to form the columnar or single crystal microstructure.

Owner:GENERAL ELECTRIC CO

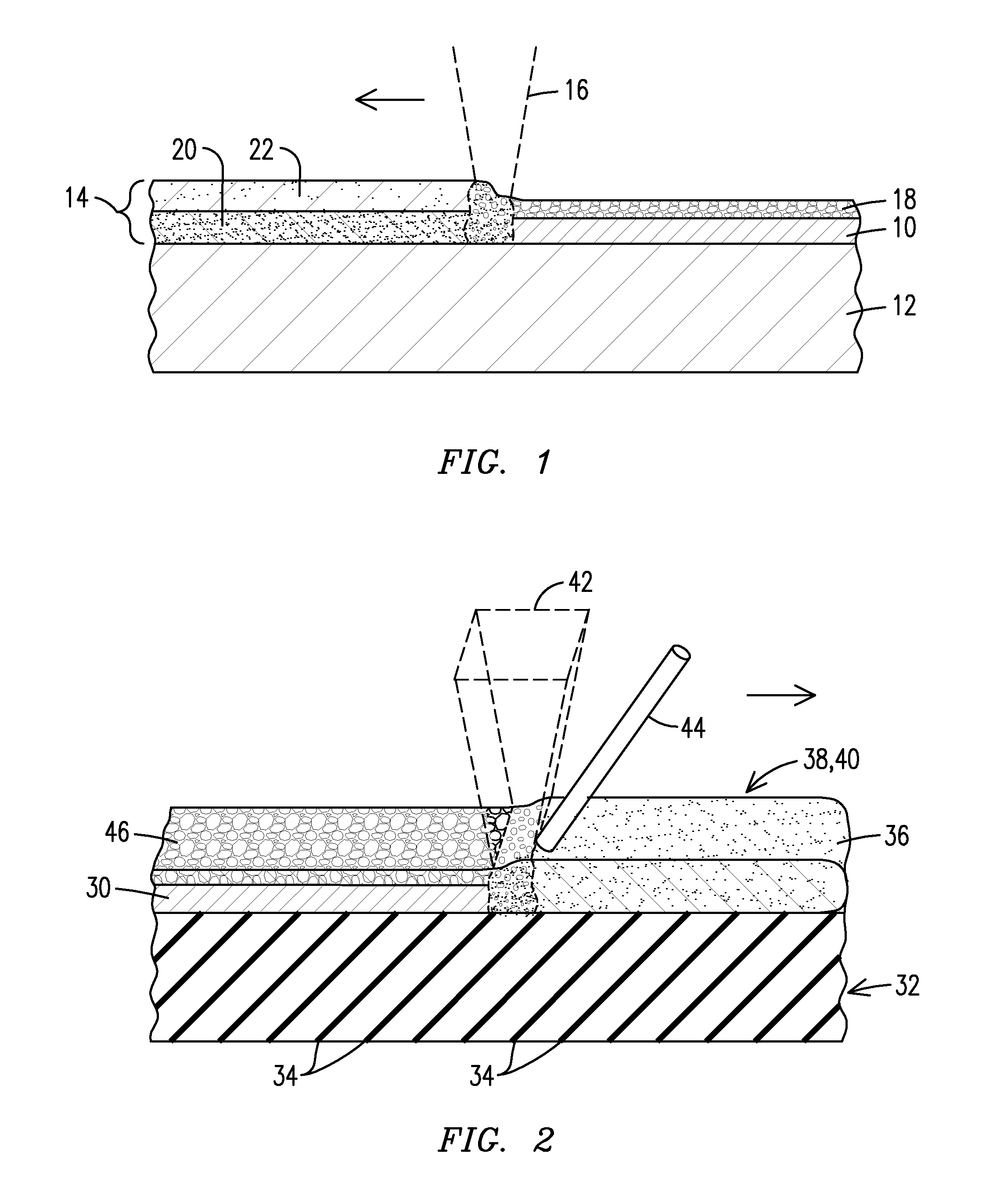

Methods for manufacturing components from articles formed by additive-manufacturing processes

ActiveUS20130071562A1Reduces and substantially eliminates internal defectImprove surface roughnessTurbinesAdditive manufacturing apparatusDiffusion layerAdditive layer manufacturing

A method is provided for manufacturing a component. The method includes forming a diffusion coating on a first intermediate article formed by an additive manufacturing process. The diffusion coating is removed from the first intermediate article forming a second intermediate article having at least one enhanced surface. The diffusion coating is formed by applying a layer of coating material on at least one surface of the first intermediate article and diffusion heat treating the first intermediate article and the layer. The diffusion coating comprises a surface additive layer and a diffusion layer below the surface additive layer. The formation of the diffusion coating and removal thereof may be repeated at least once.

Owner:HONEYWELL INT INC

Mass production of tridimensional articles made of intermetallic compounds

ActiveUS20080014457A1The material is lowReduce oxidationTurbinesAdditive manufacturing apparatusCompound aChemical compound

A process for mass production of three-dimensional articles made of intermetallic compounds based on titanium and aluminium by an electron beam melting technology. The articles are produced in successive sections from powders of the intermetallic compound with which the articles are to be produced. For each section, melting of the powders preceded by a preheating step is performed.

Owner:GE AVIO

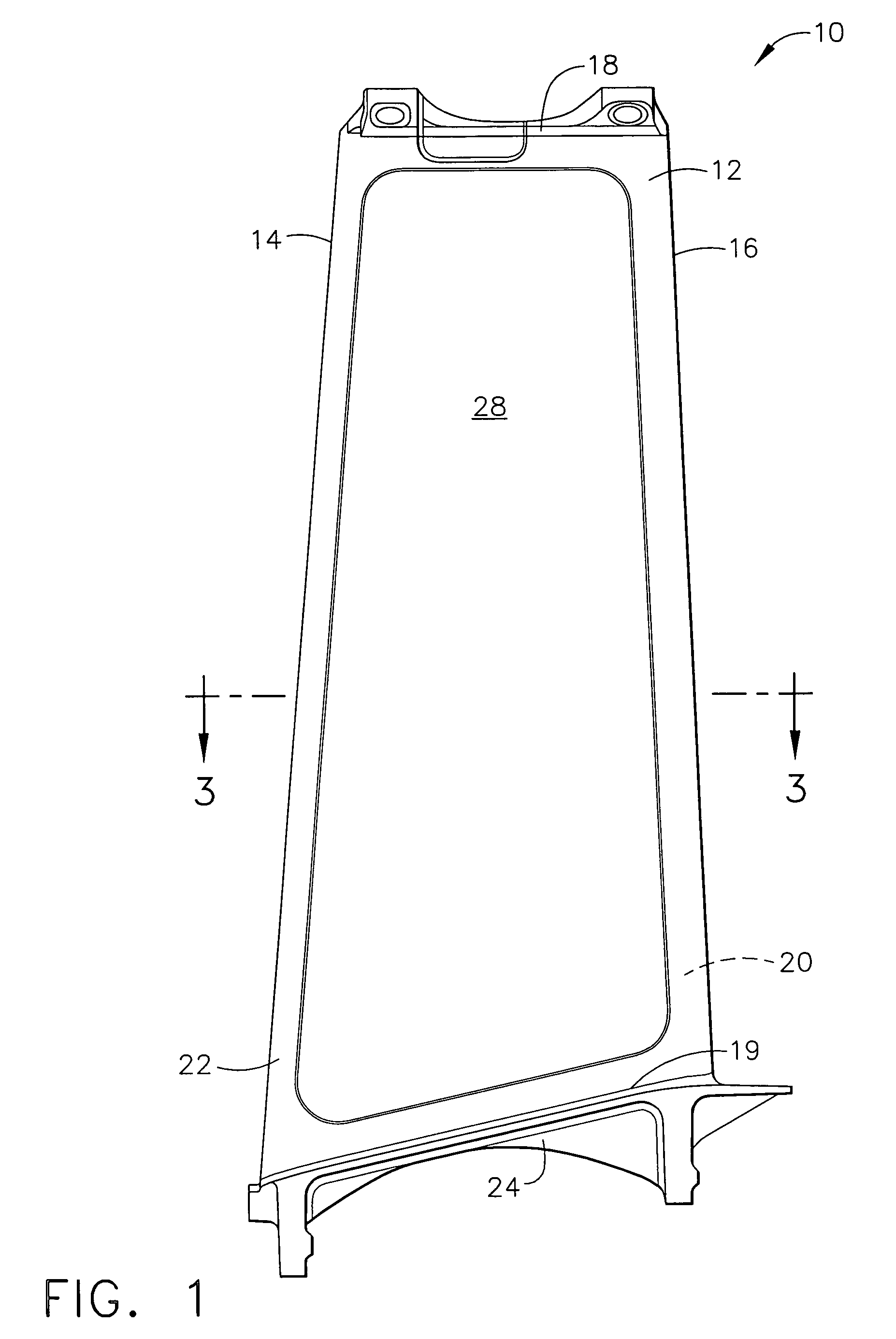

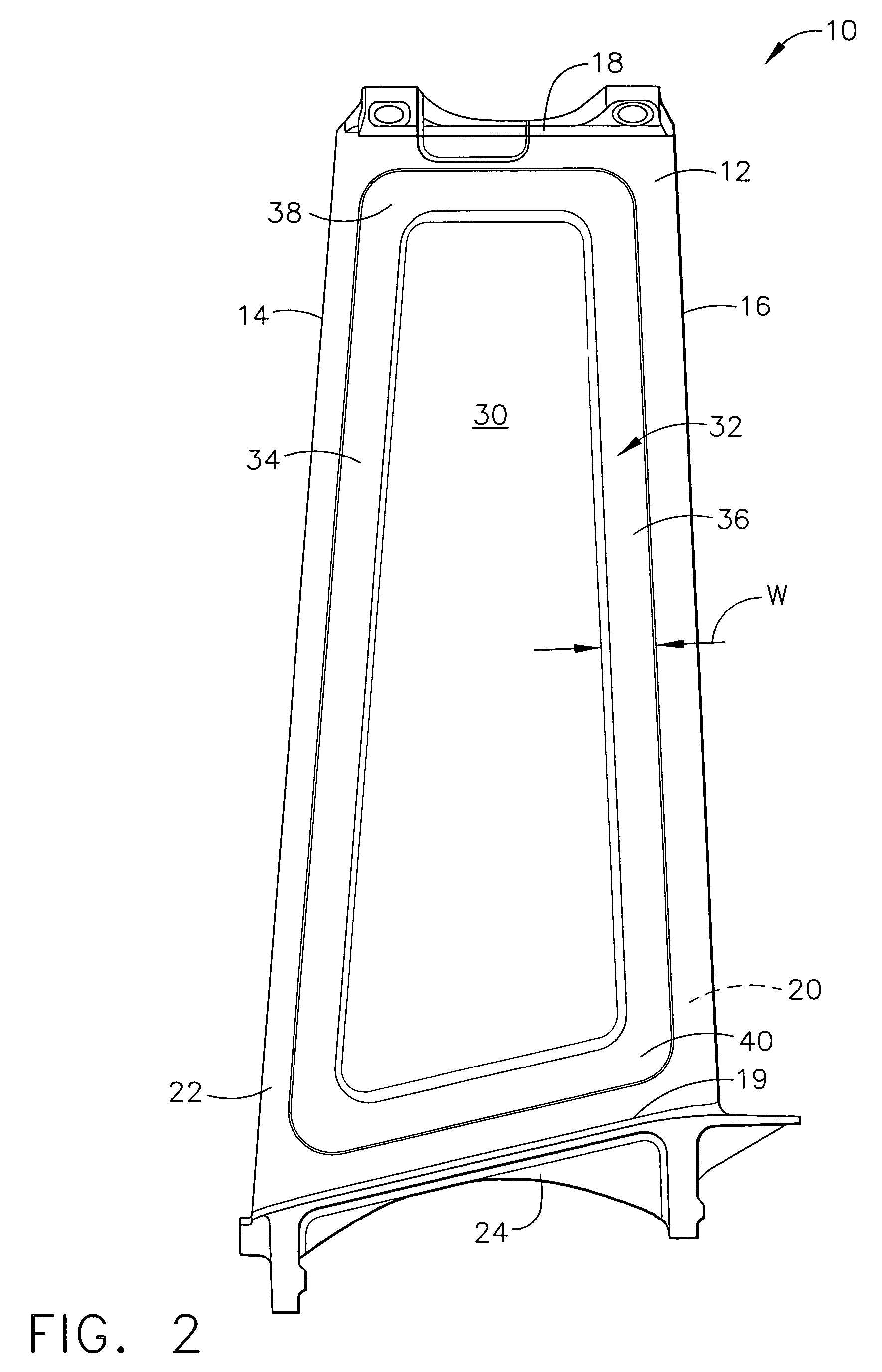

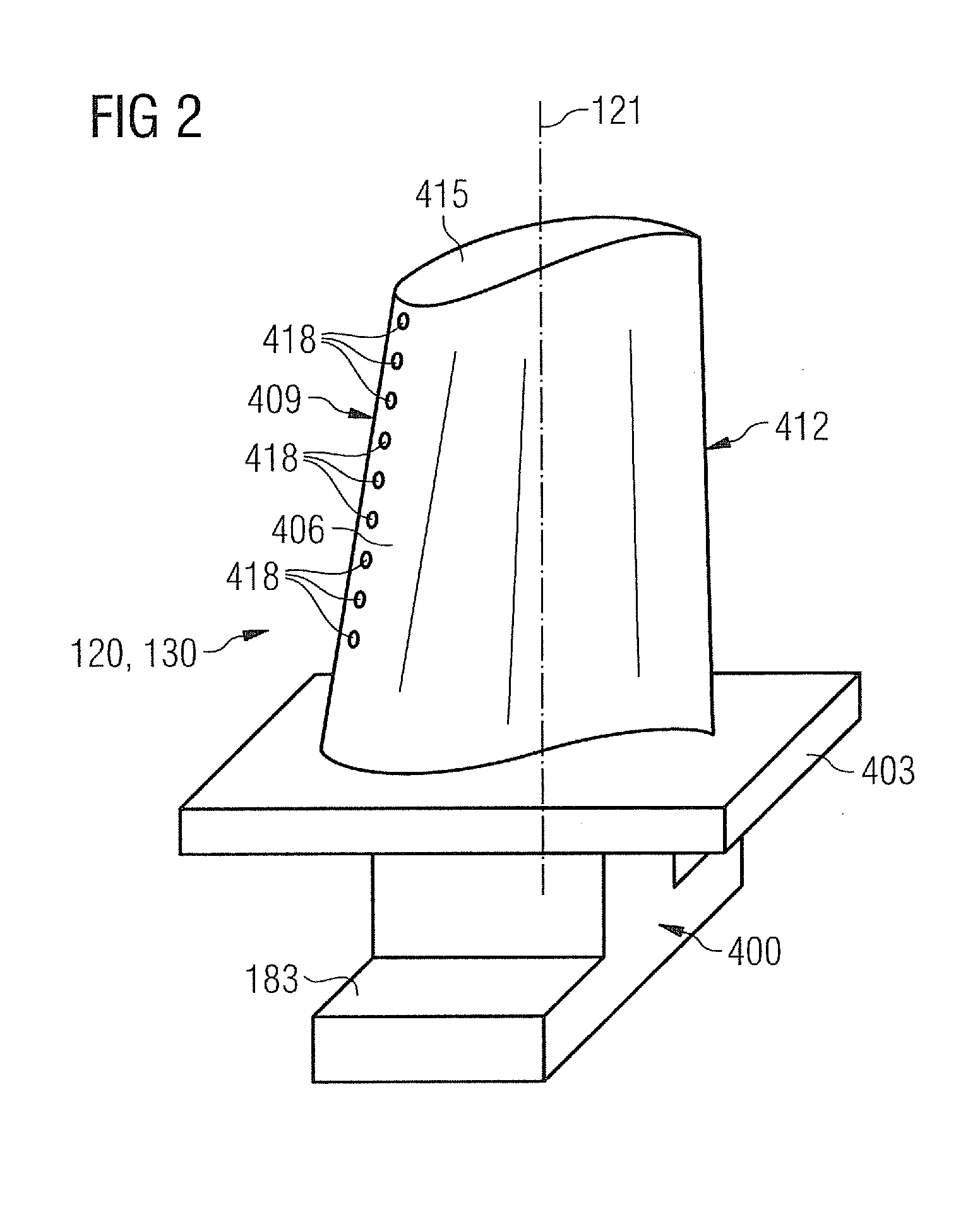

Turbine components for engines and methods of fabricating the same

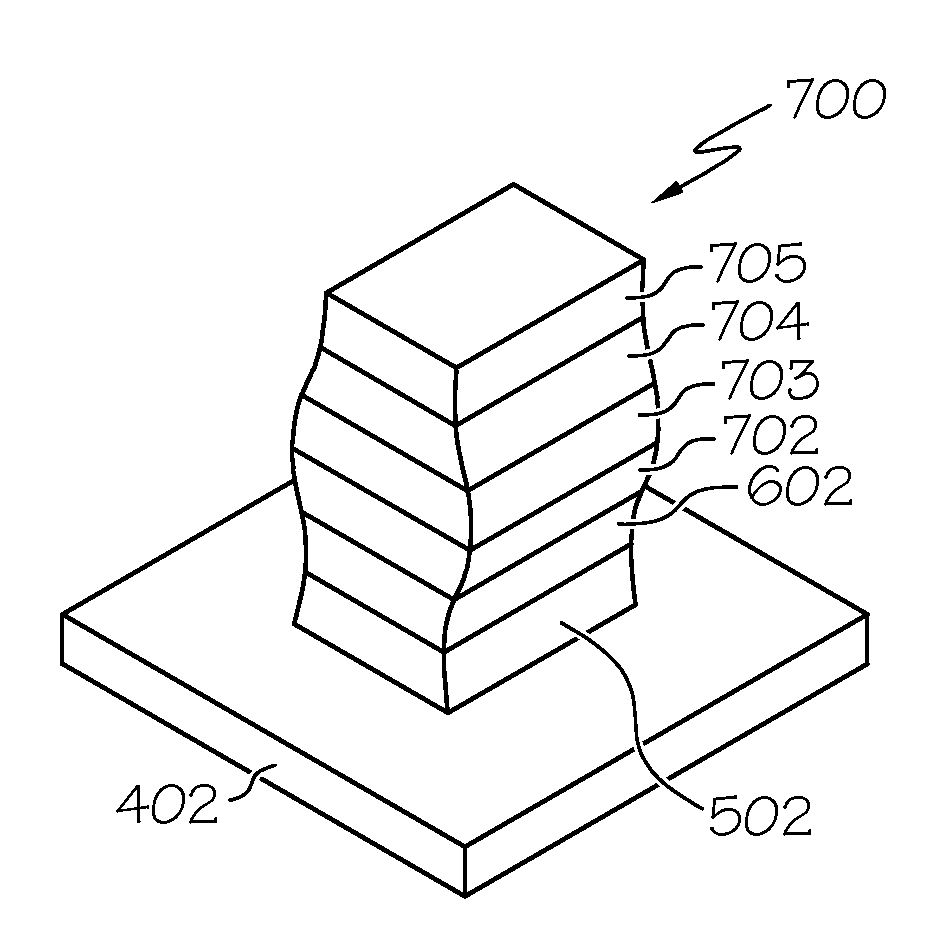

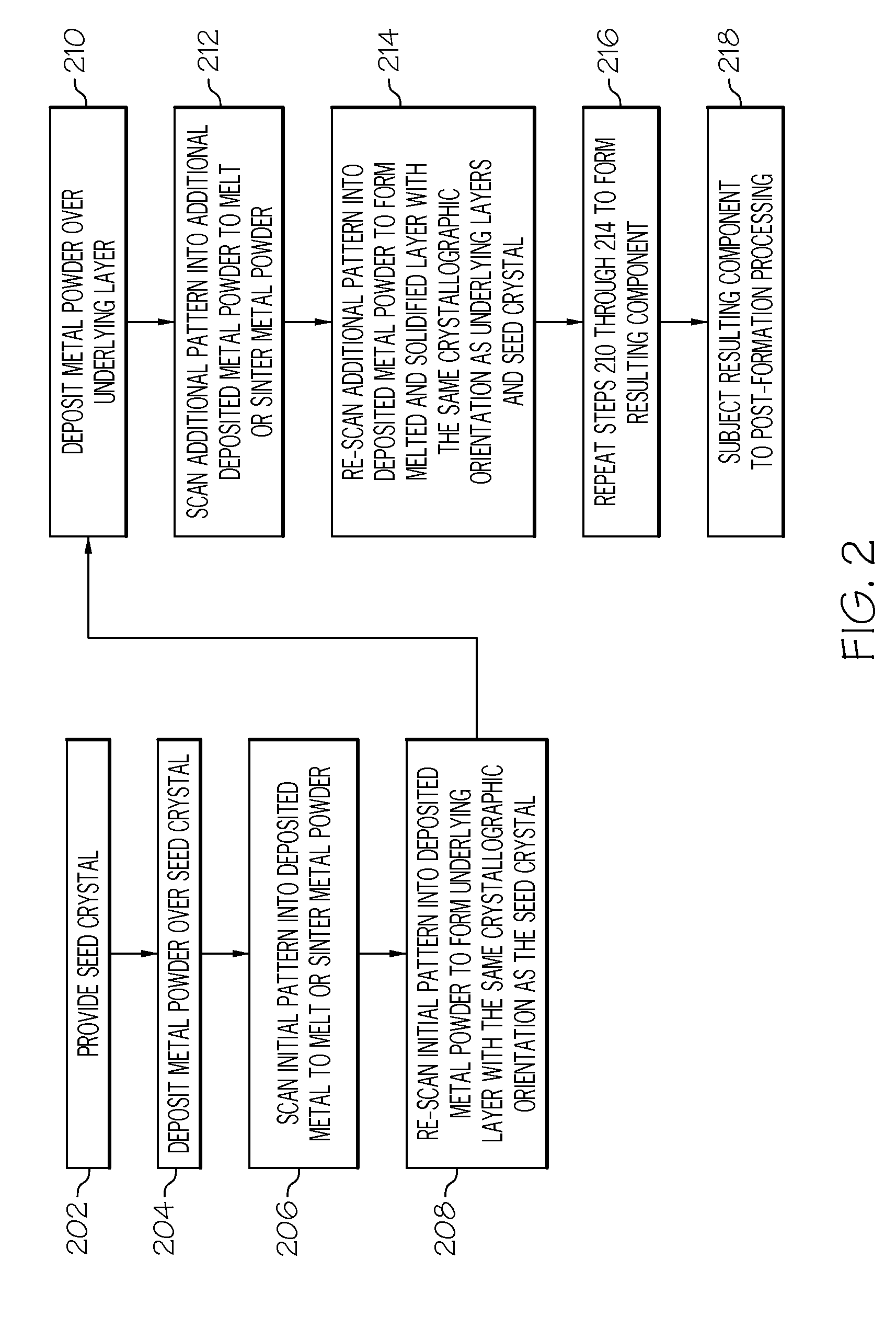

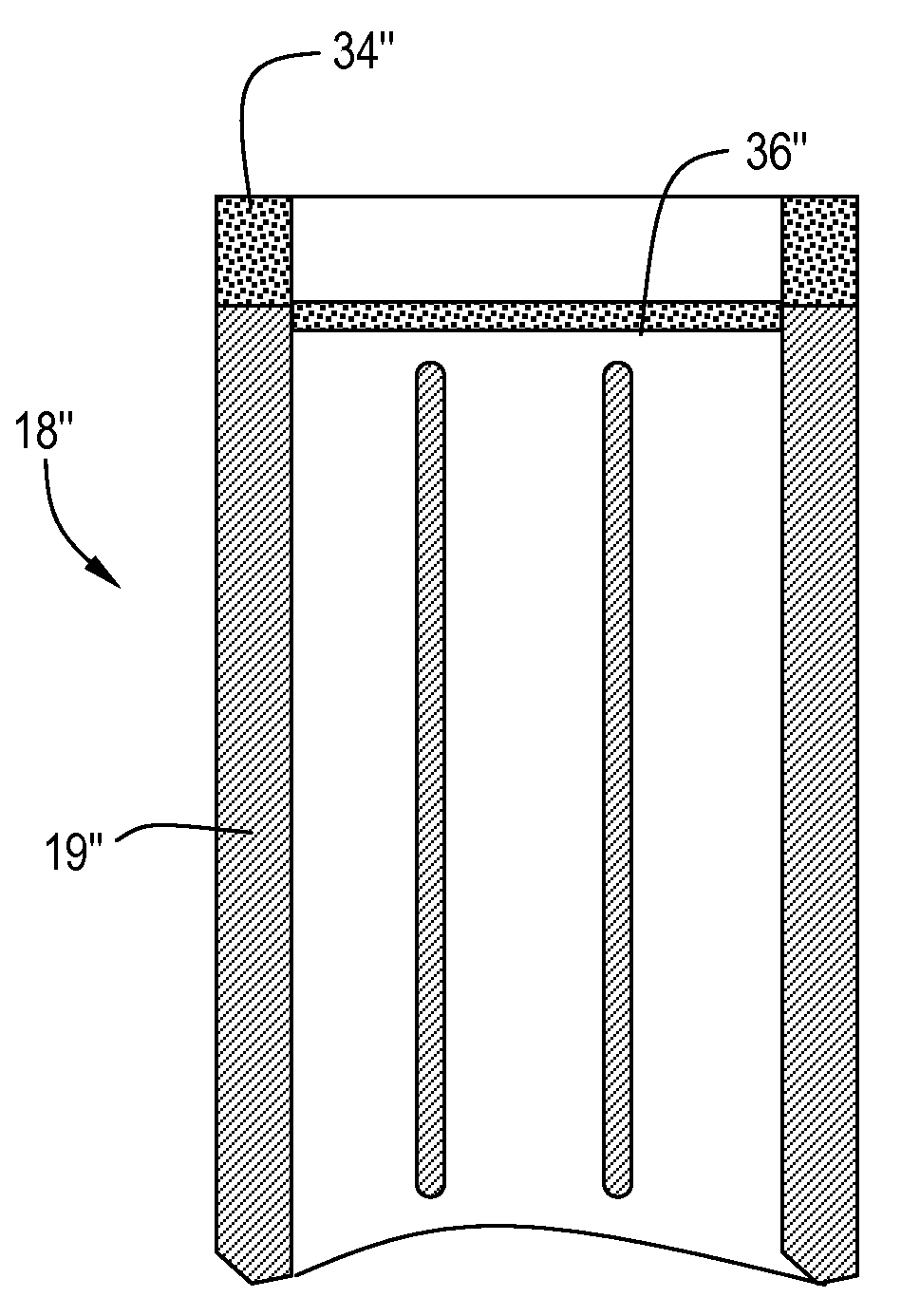

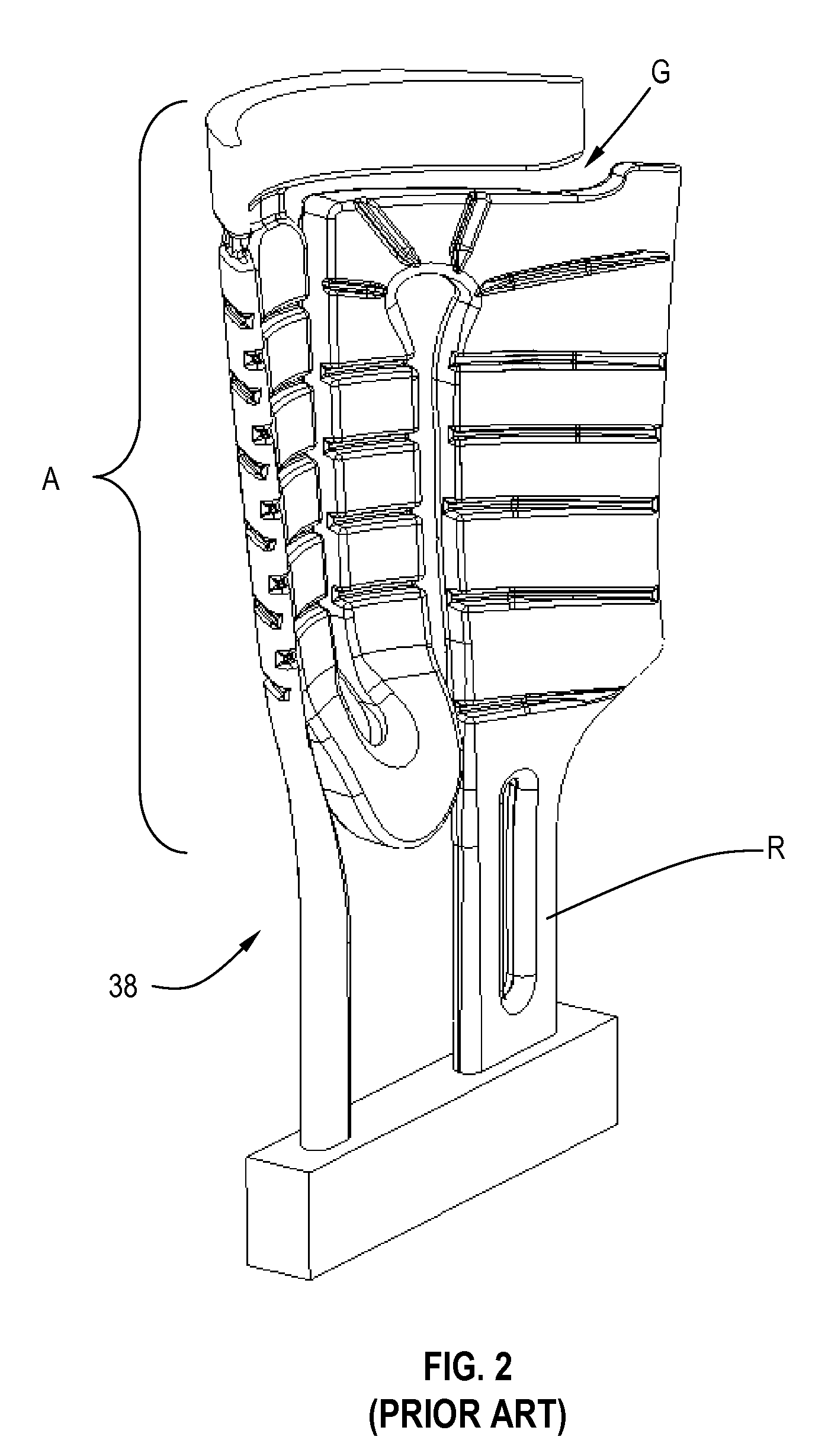

A method is provided that includes depositing metal powder over a seed crystal having a predetermined primary orientation, scanning an initial pattern into the metal powder to melt or sinter the deposited metal powder, and re-scanning the initial pattern to re-melt the scanned metal powder and form an initial layer having the predetermined primary orientation. The method further includes depositing additional metal powder over the initial layer, scanning an additional pattern into the additional metal powder to melt or sinter at least a portion of the additional metal powder, re-scanning the additional pattern to re-melt a portion of the initial layer and the scanned deposited additional metal powder to form a successive layer having the predetermined primary orientation, and repeating the steps of depositing additional metal powder, scanning the additional pattern, and re-scanning the additional pattern, until a final shape of the component is achieved.

Owner:HONEYWELL INT INC

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Methods for manufacturing components from articles formed by additive-manufacturing processes

ActiveUS8506836B2TurbinesAdditive manufacturing apparatusDiffusion layerAdditive layer manufacturing

Owner:HONEYWELL INT INC

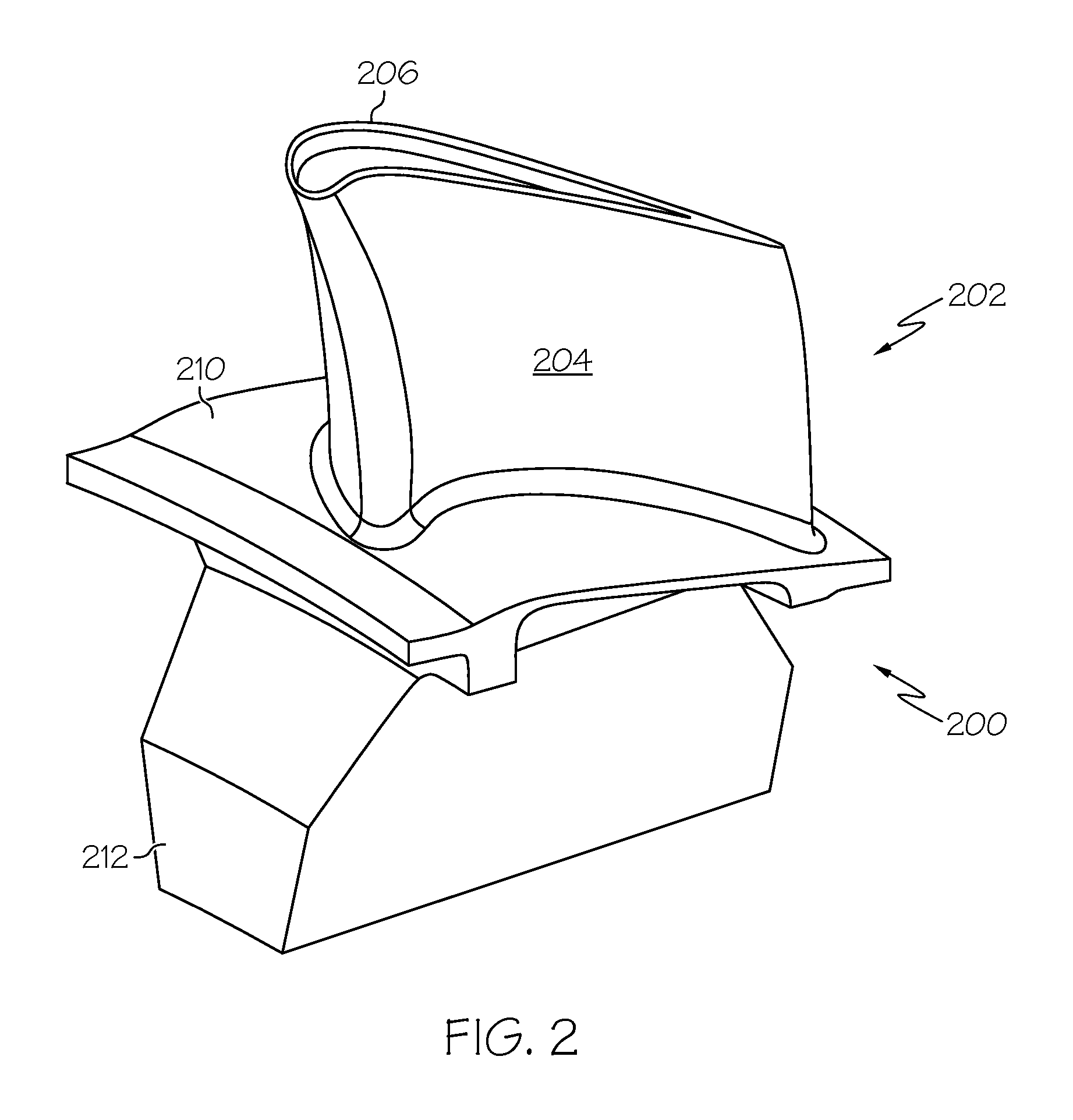

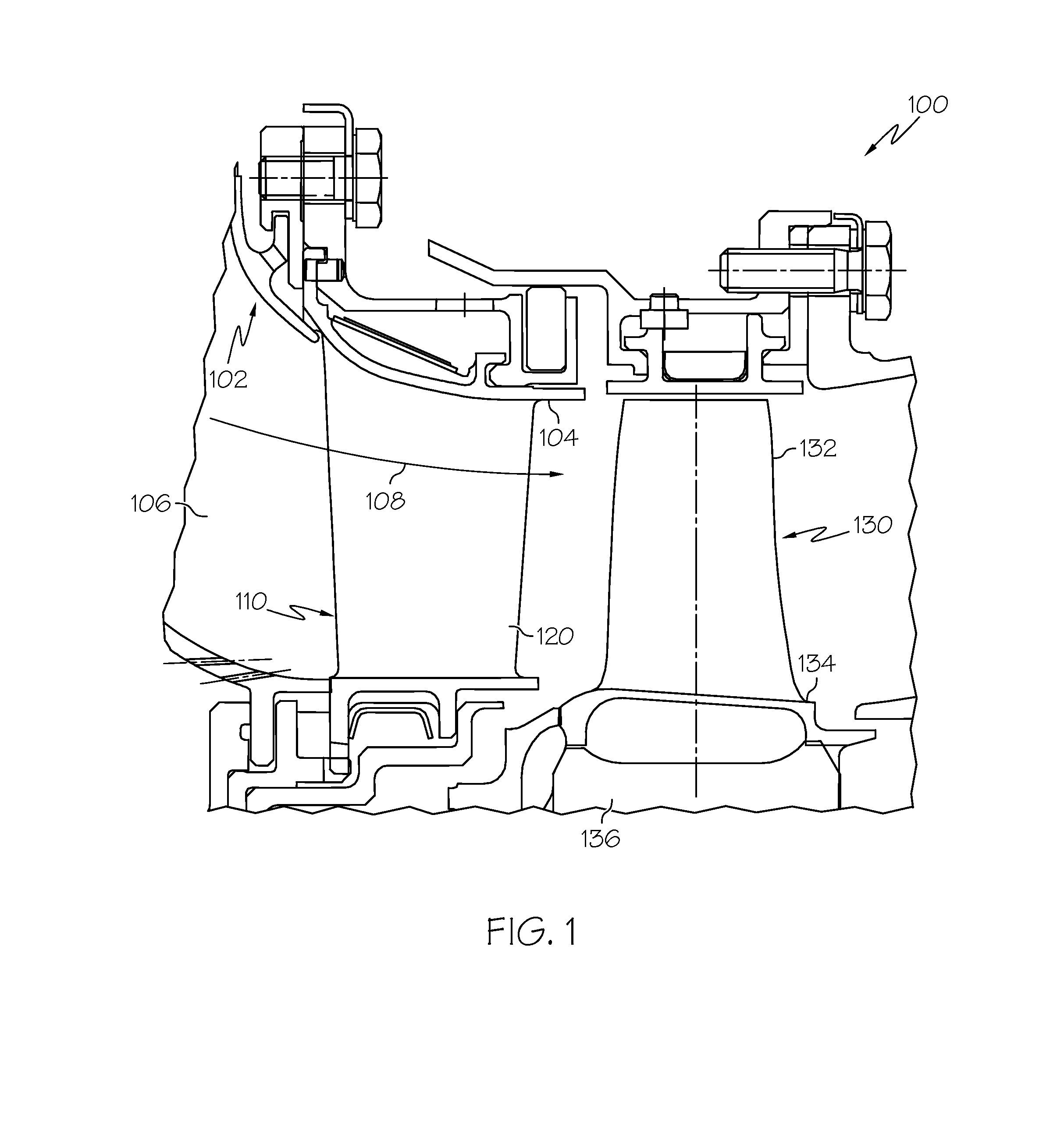

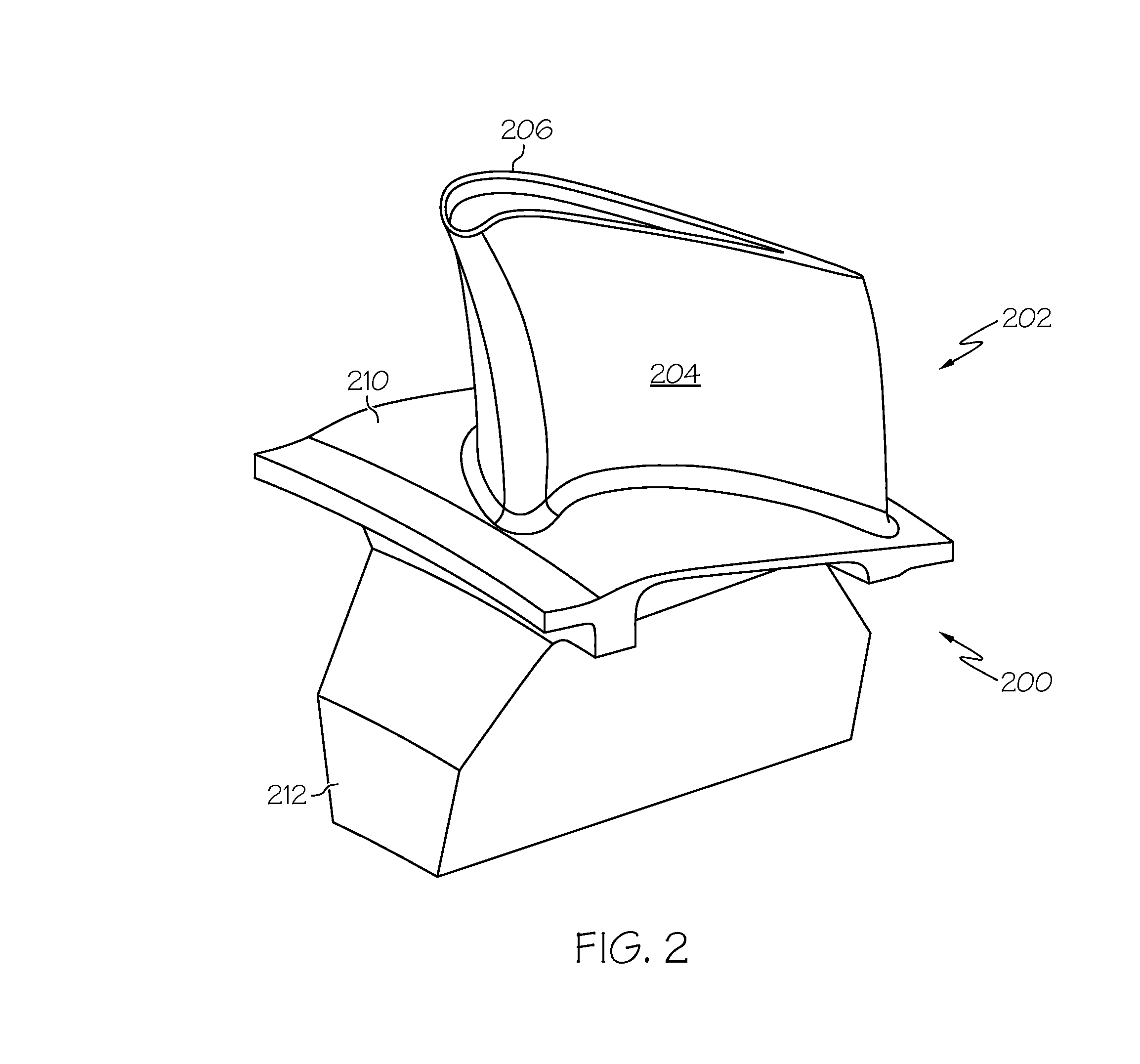

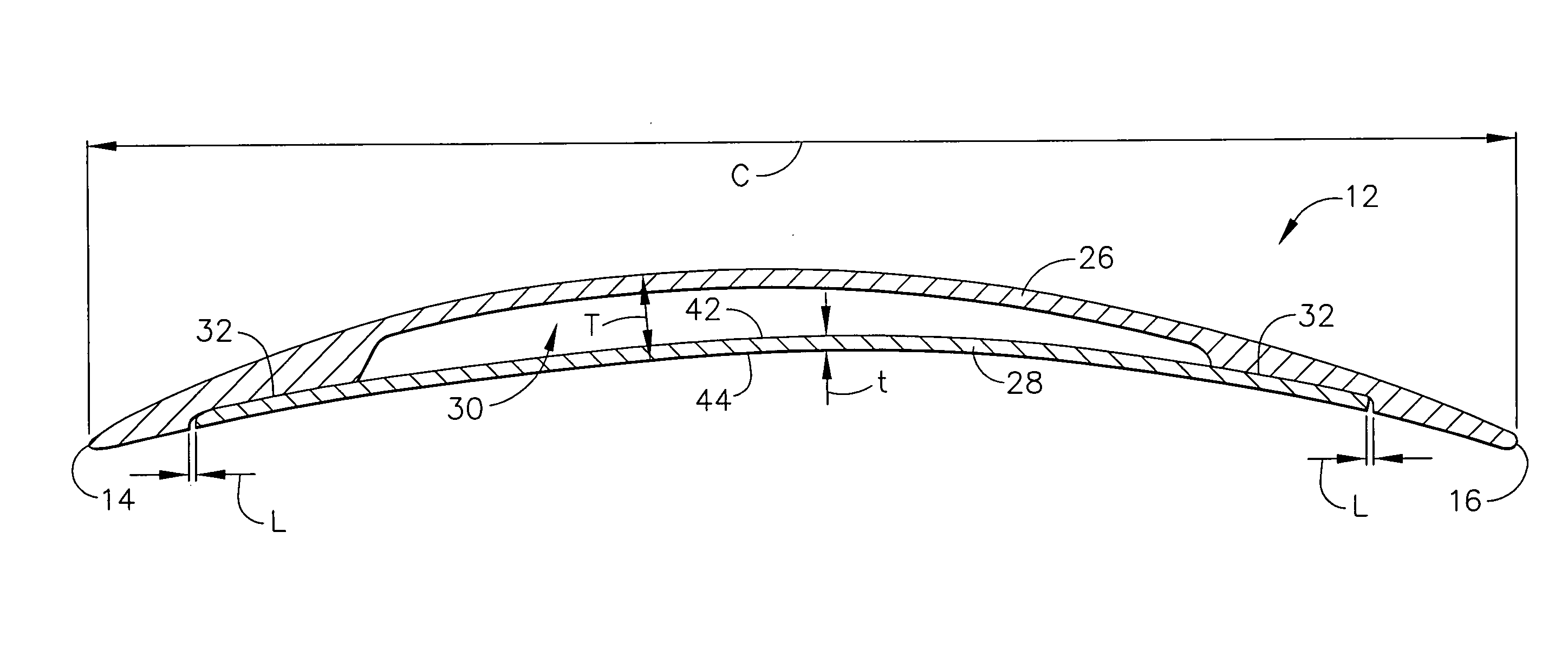

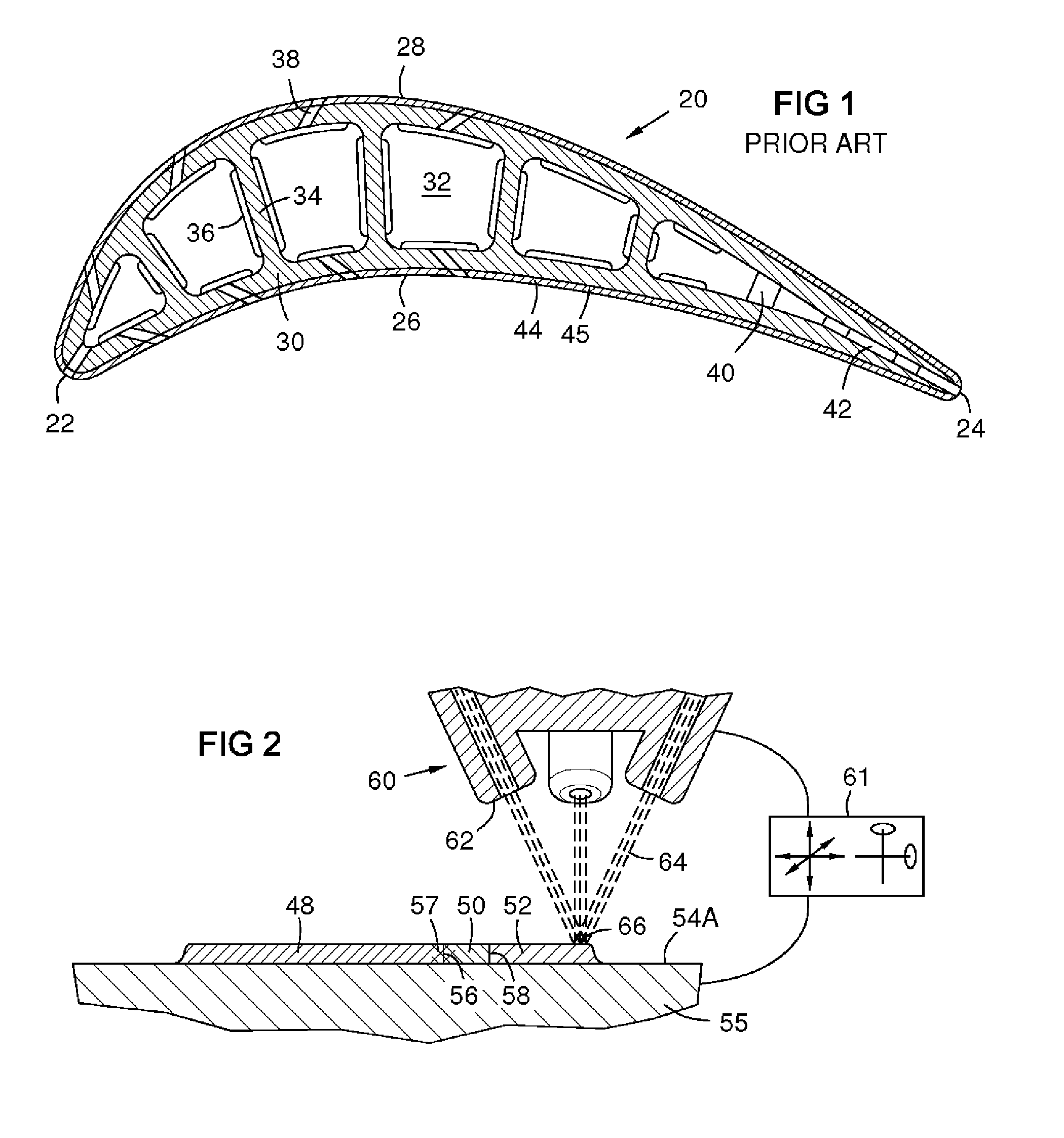

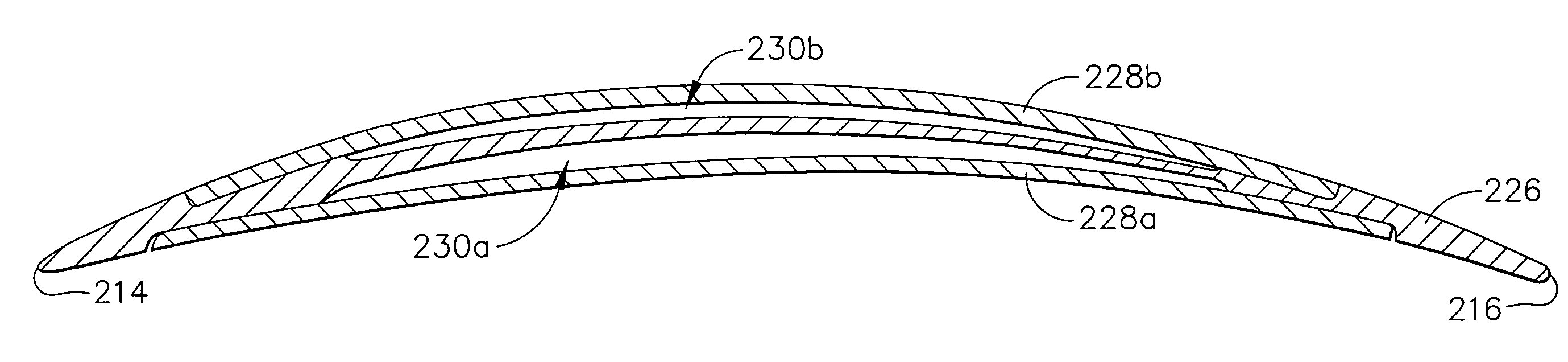

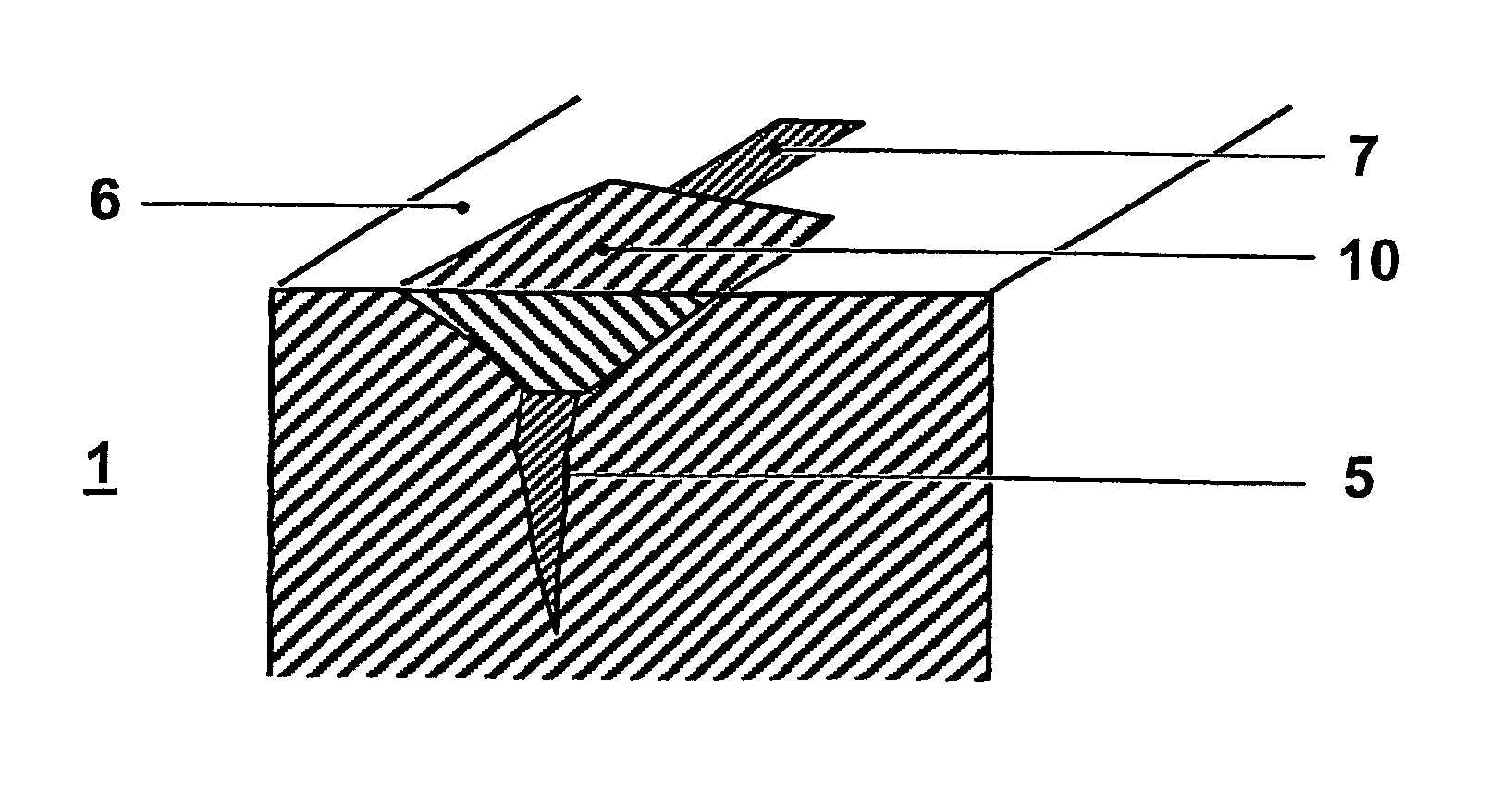

Friction stir welded hollow airfoils and method therefor

A hollow component for gas turbine engine, for example an outlet guide vane, is assembled from a body having at recessed pocket formed therein, and an aerodynamic cover bonded over the pocket. Both the cover and the body are constructed from materials which are not readily fusion weldable. The cover is attached to the body by a solid state bonding process, for example friction stir welding. The hollow component may also be built up from multiple individual components which are bonded to each other by a solid state bonding process such as friction stir welding.

Owner:GENERAL ELECTRIC CO

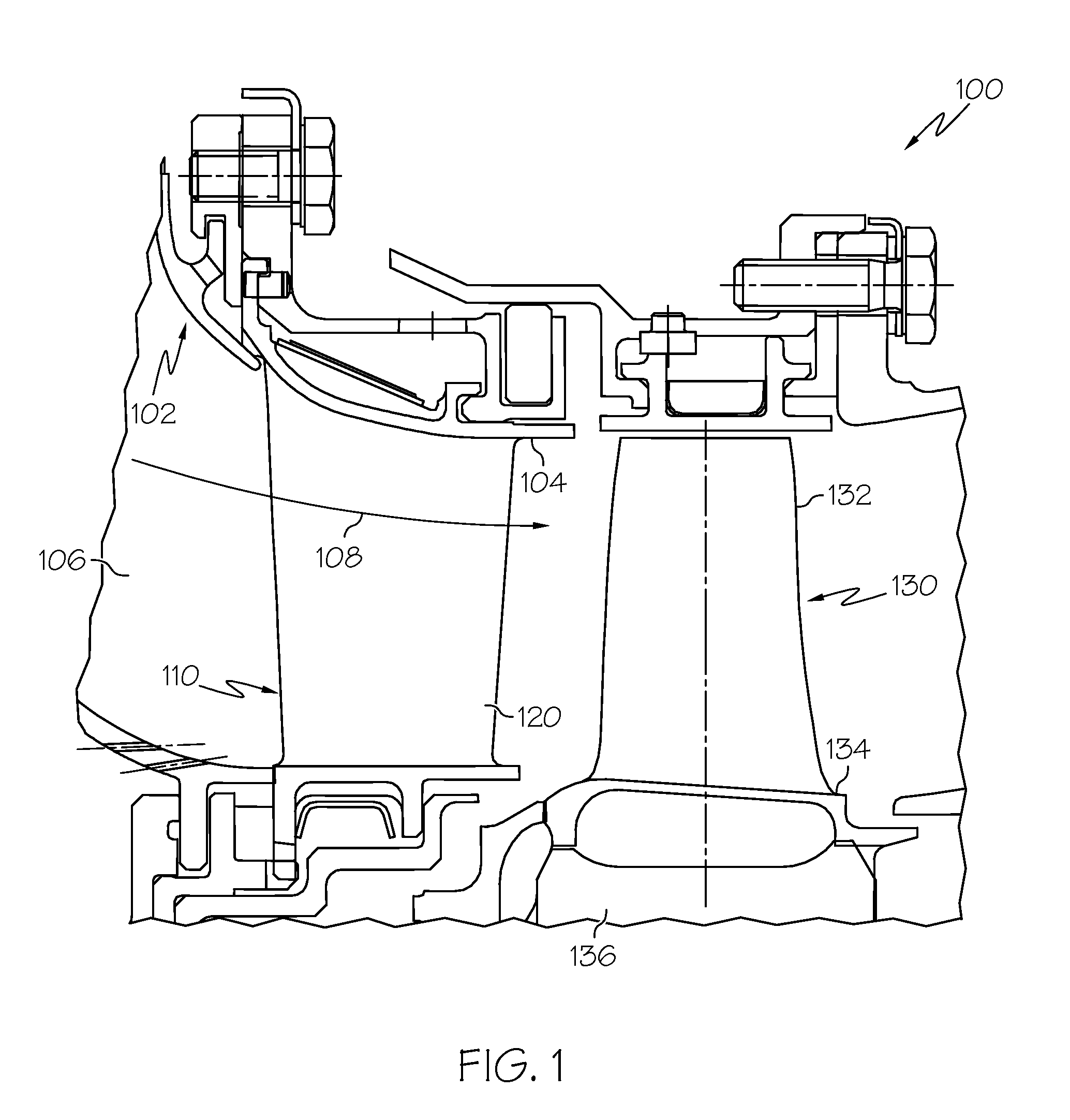

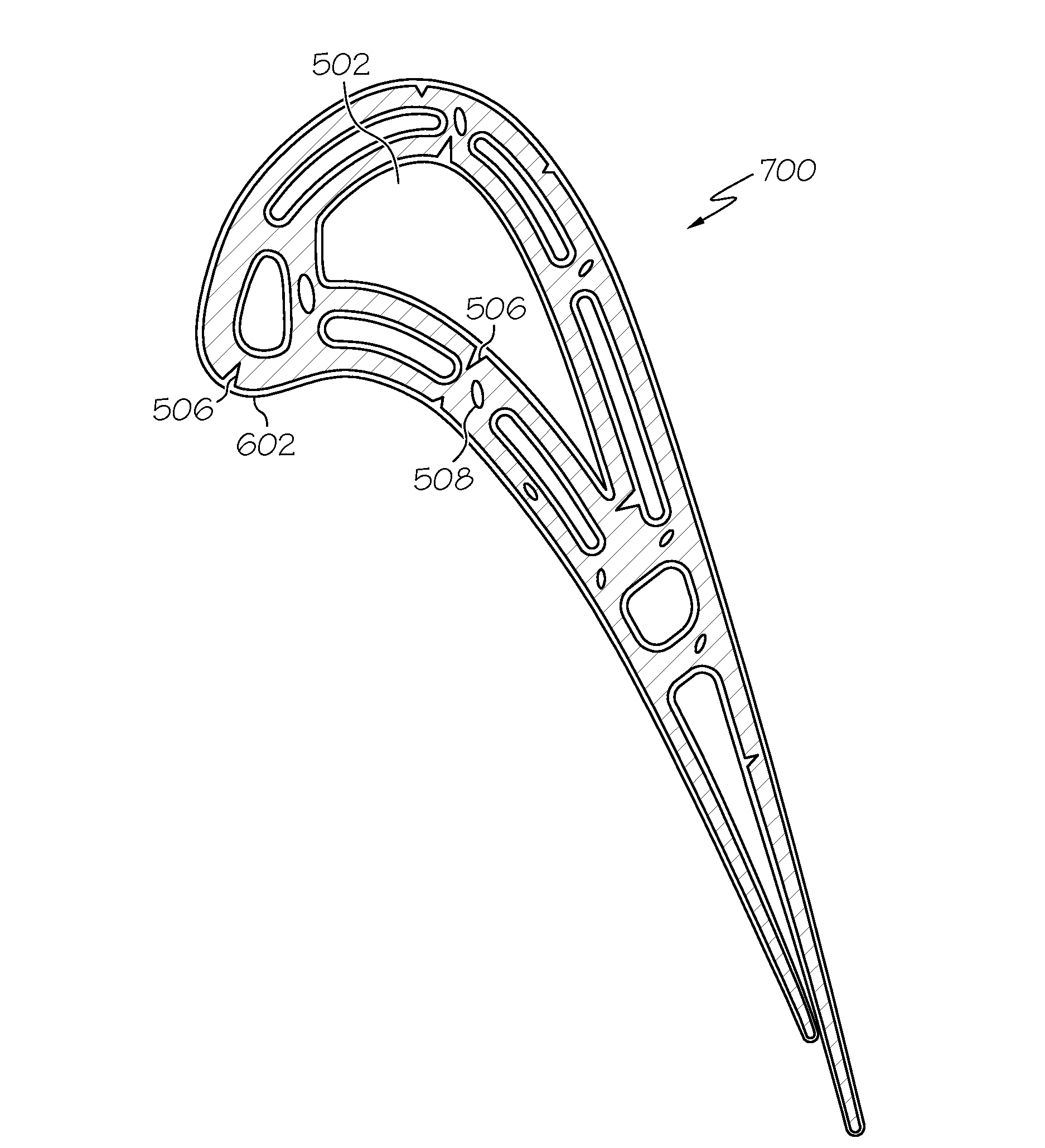

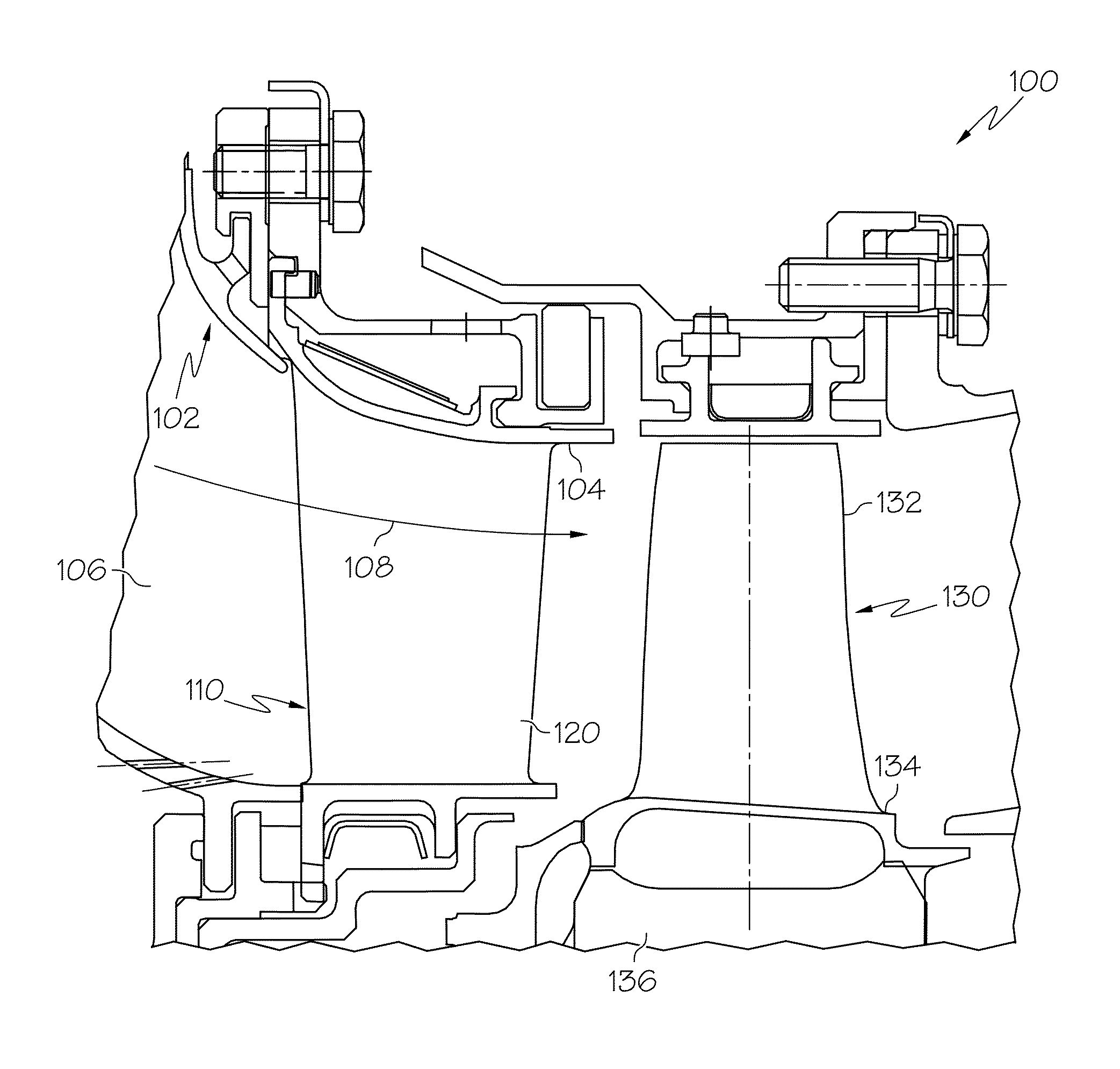

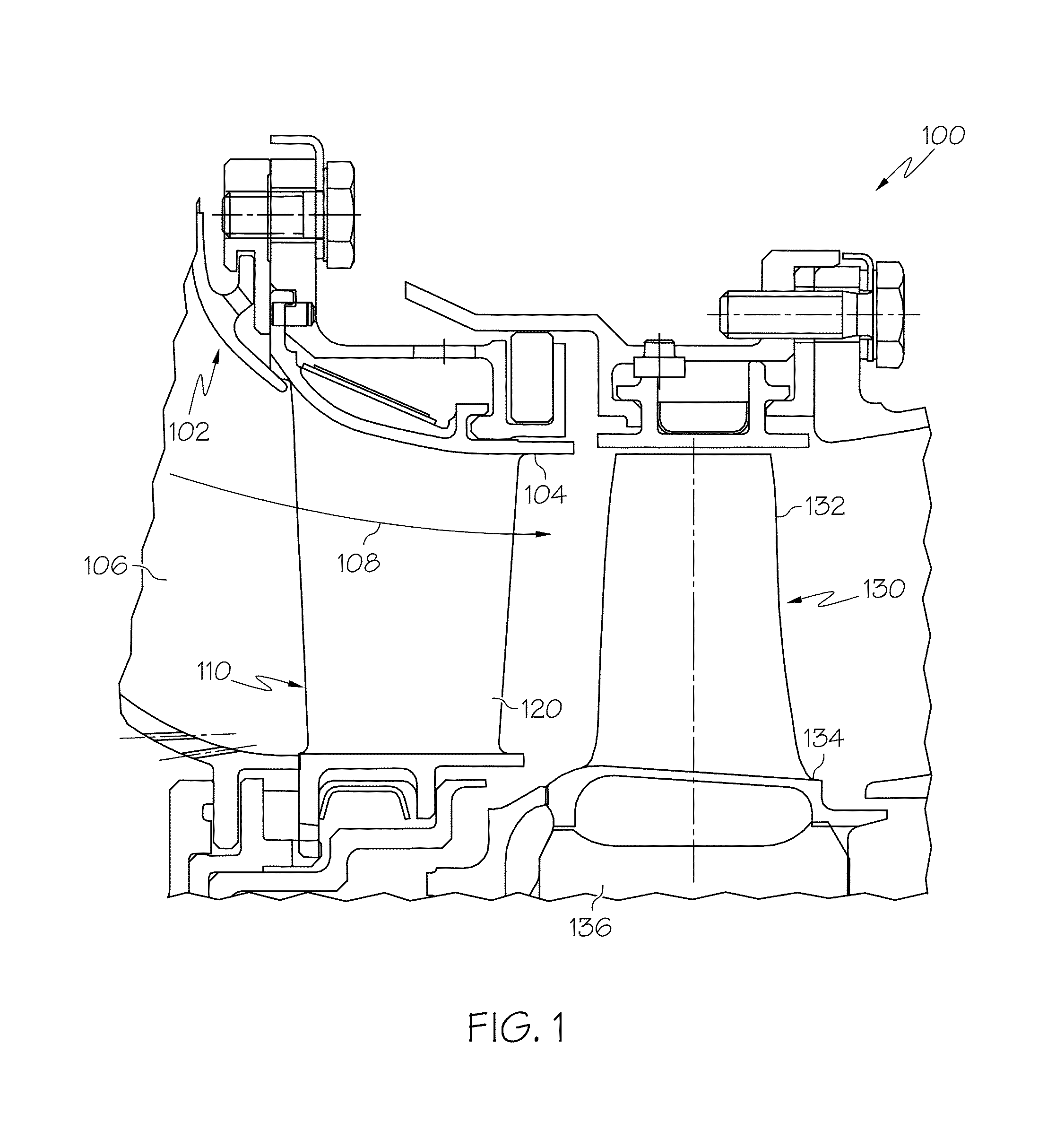

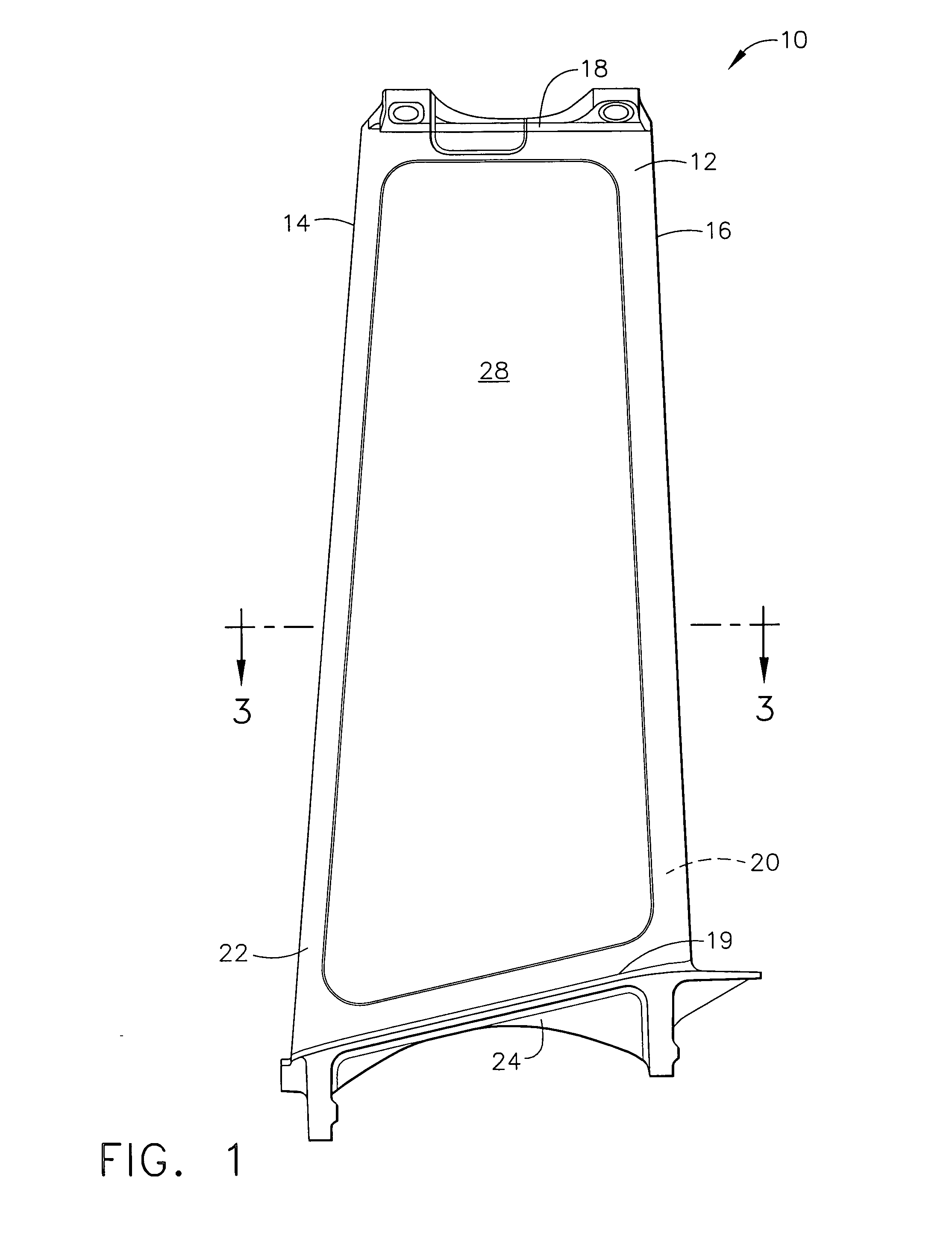

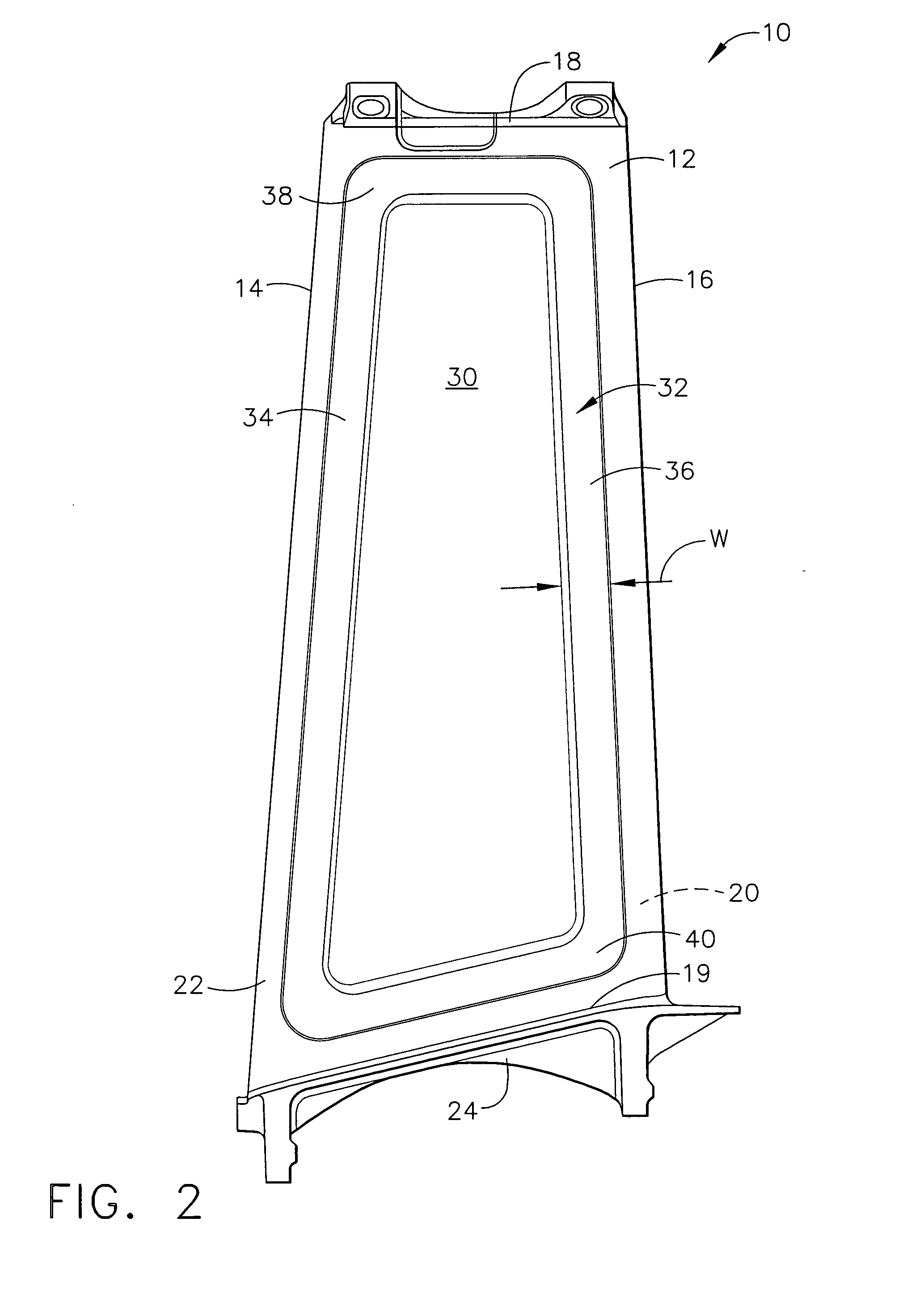

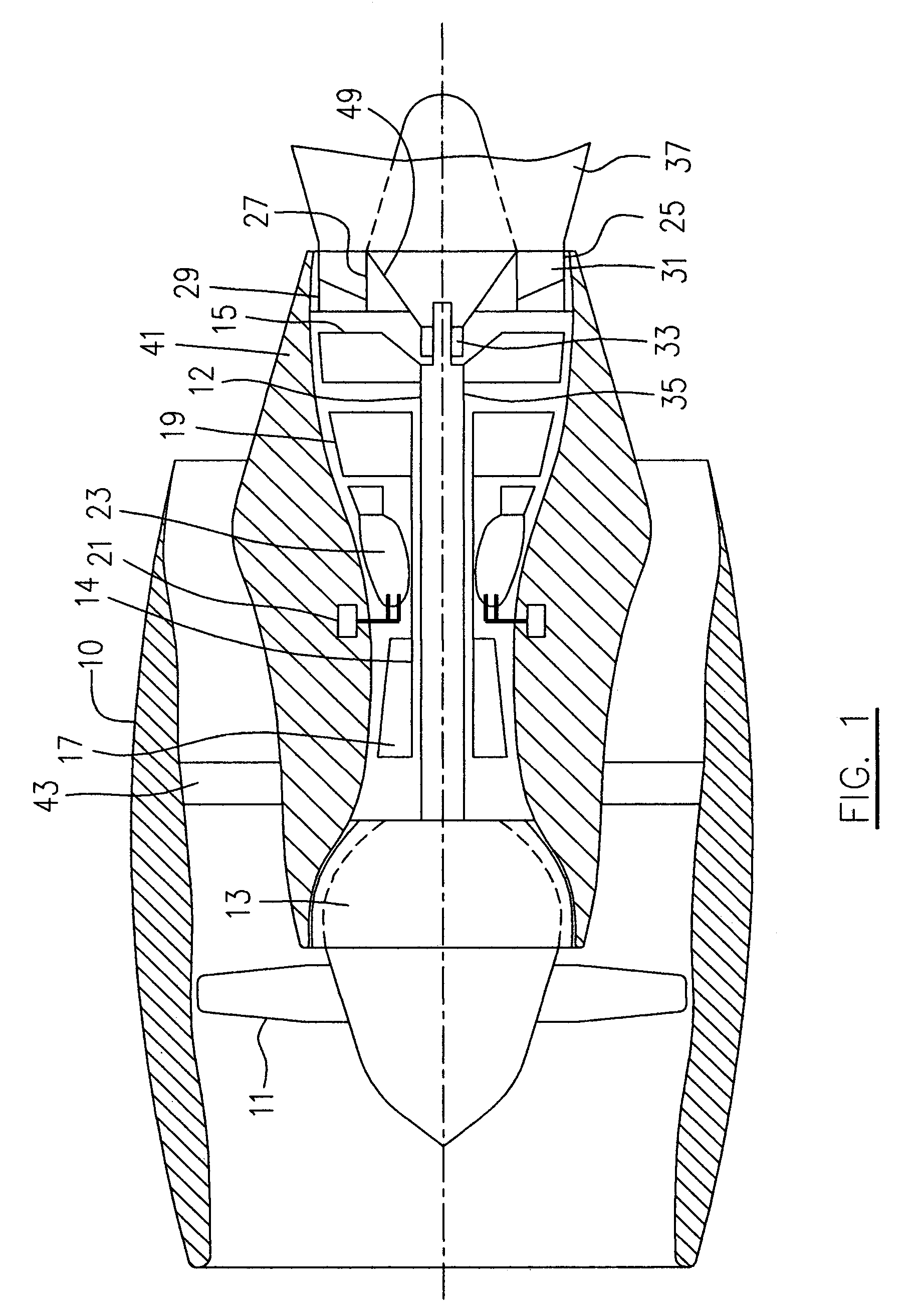

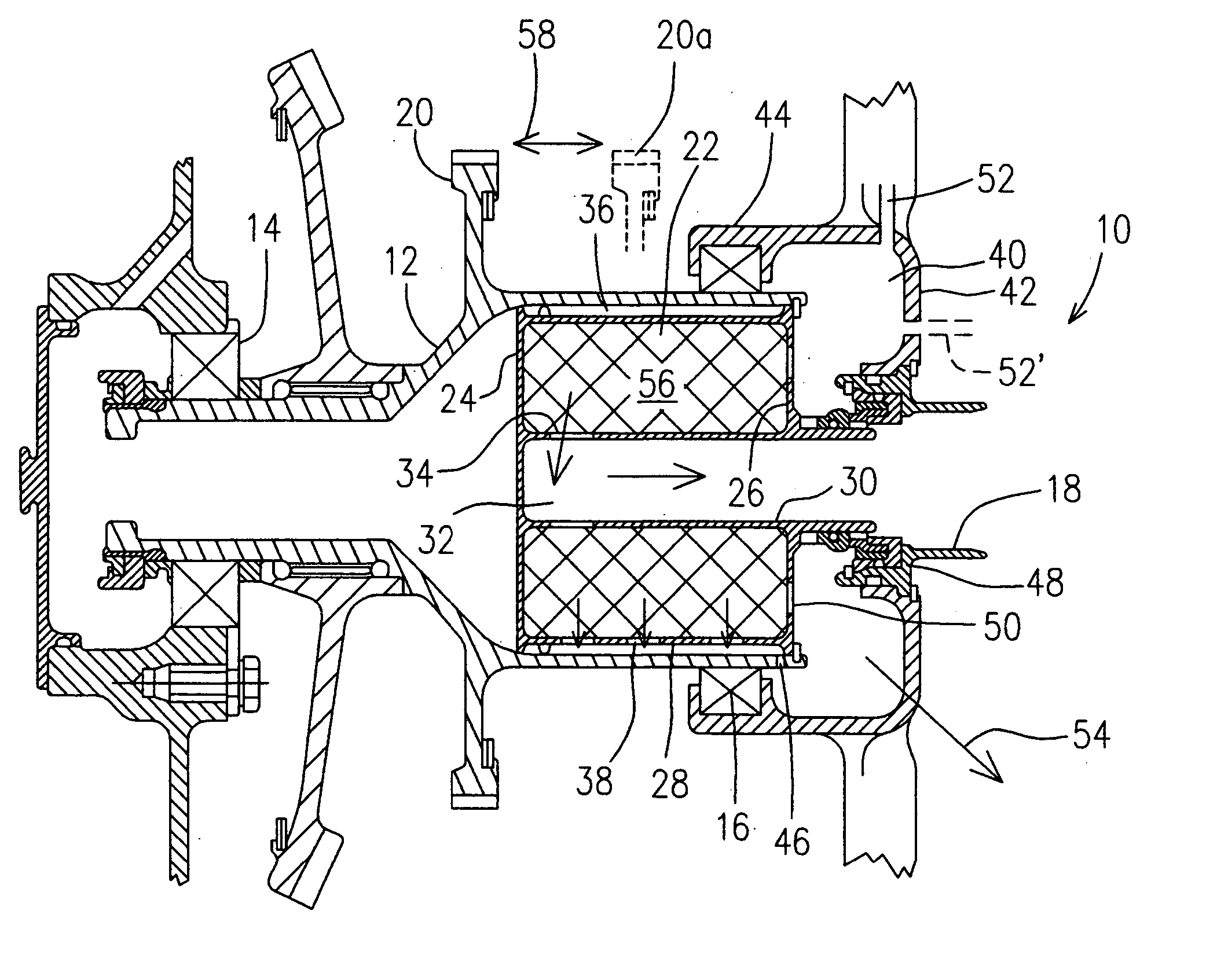

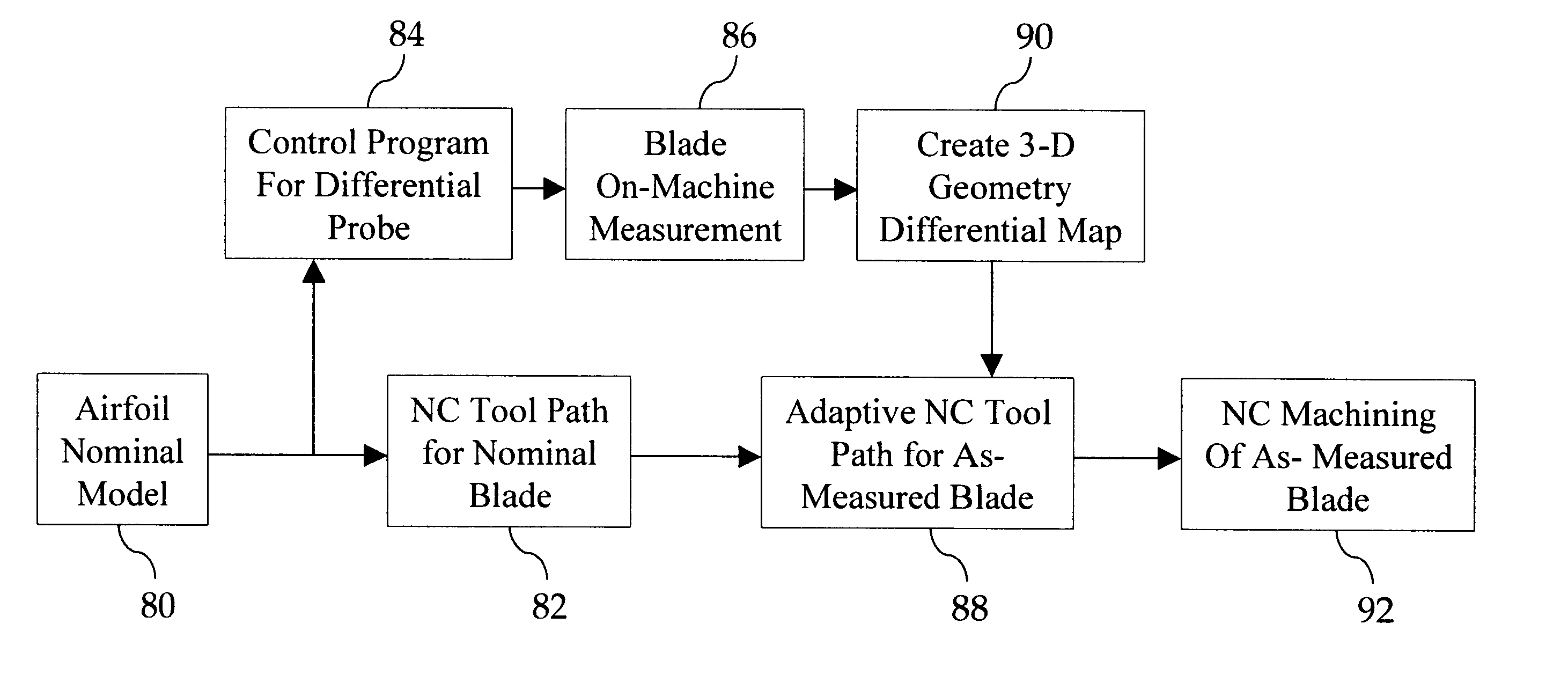

Turbine exhaust case and method of making

A structural turbine exhaust case of a gas turbine engine, comprises inner and outer case portions; a bearing housing connected to the inner case portion for supporting a main spool of the gas turbine engine; and a plurality of airfoils extending between the inner and outer case portions, airfoils structurally connecting the inner case portion to the outer case portion.

Owner:PRATT & WHITNEY CANADA CORP

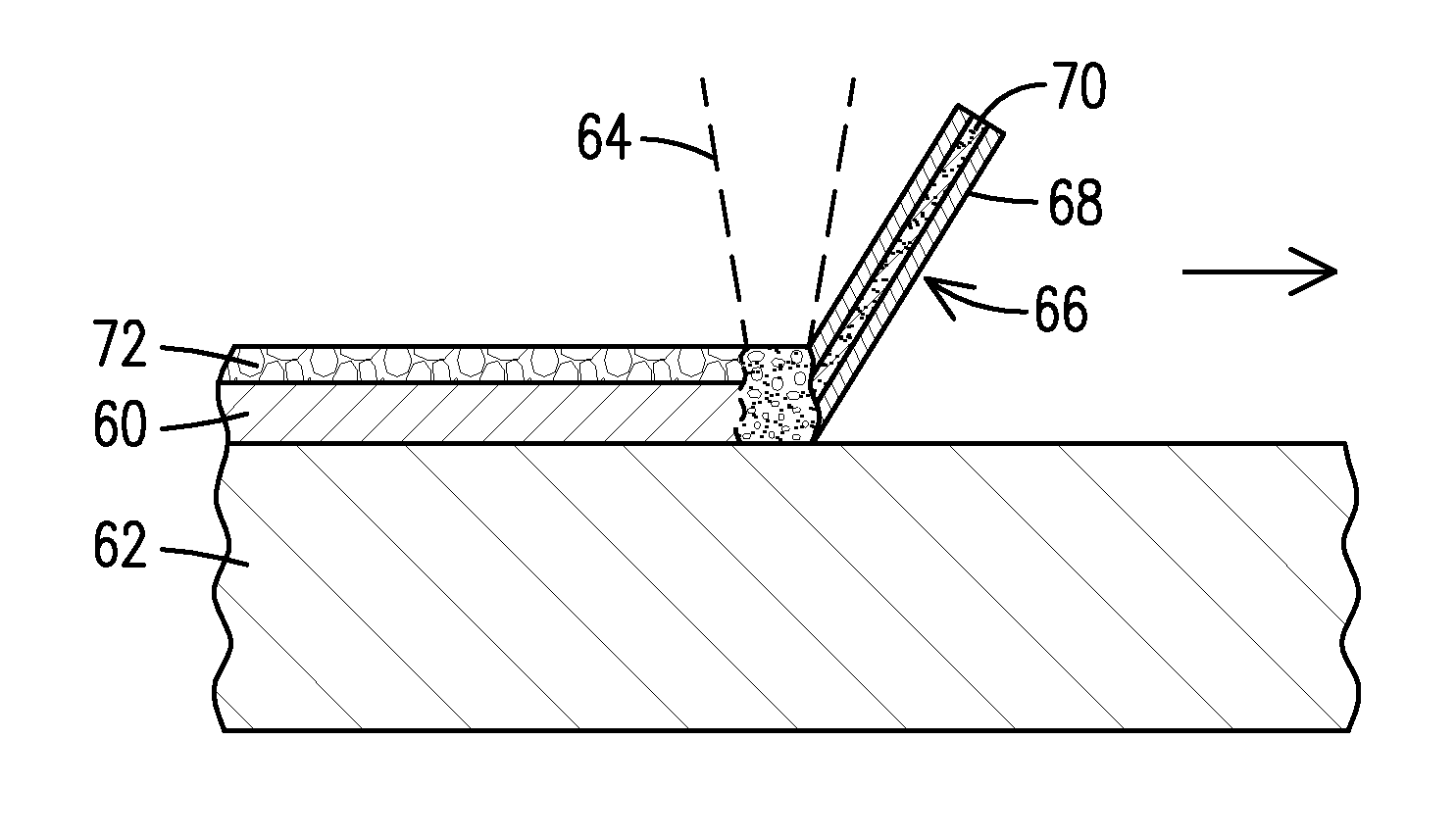

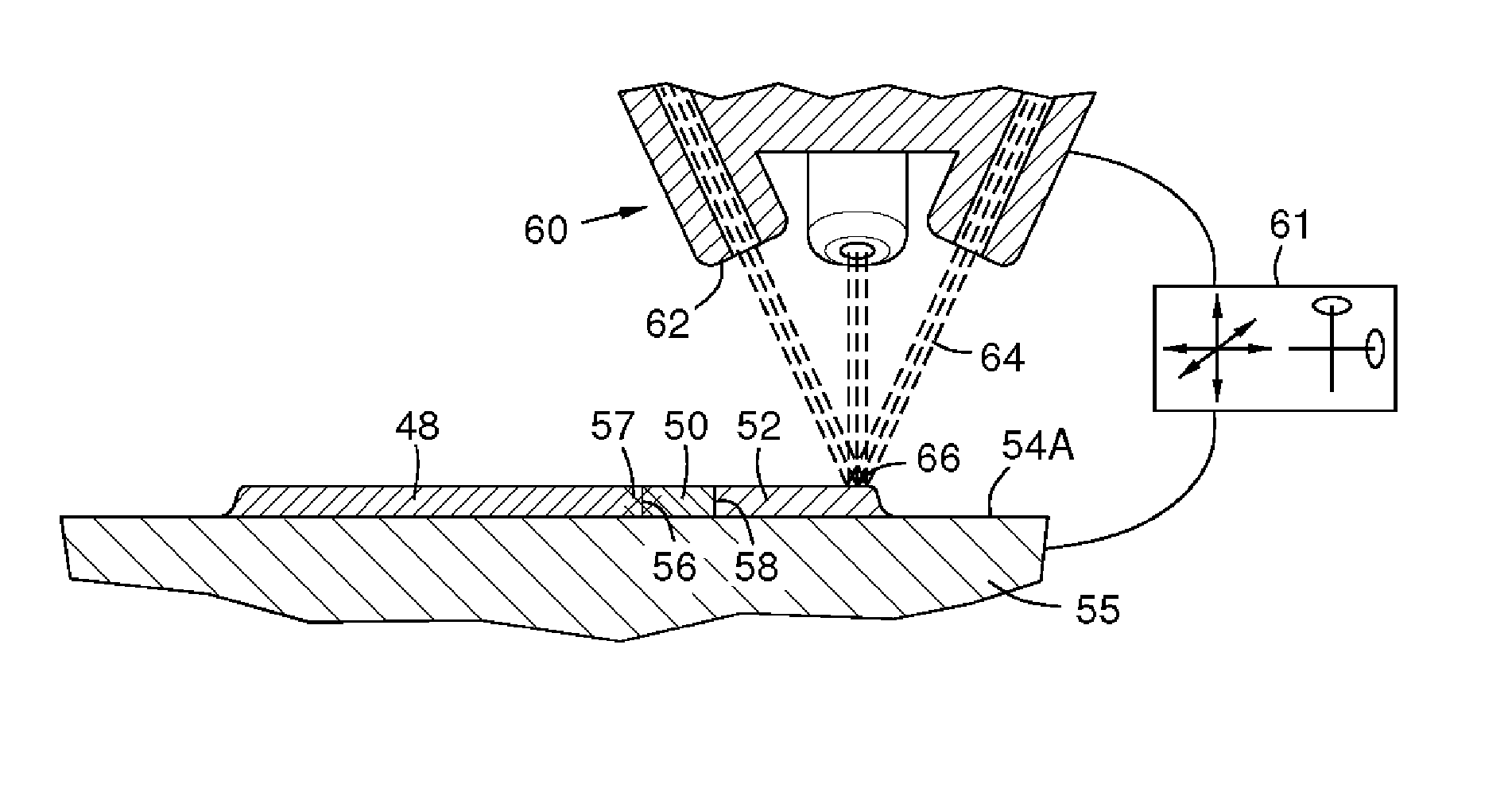

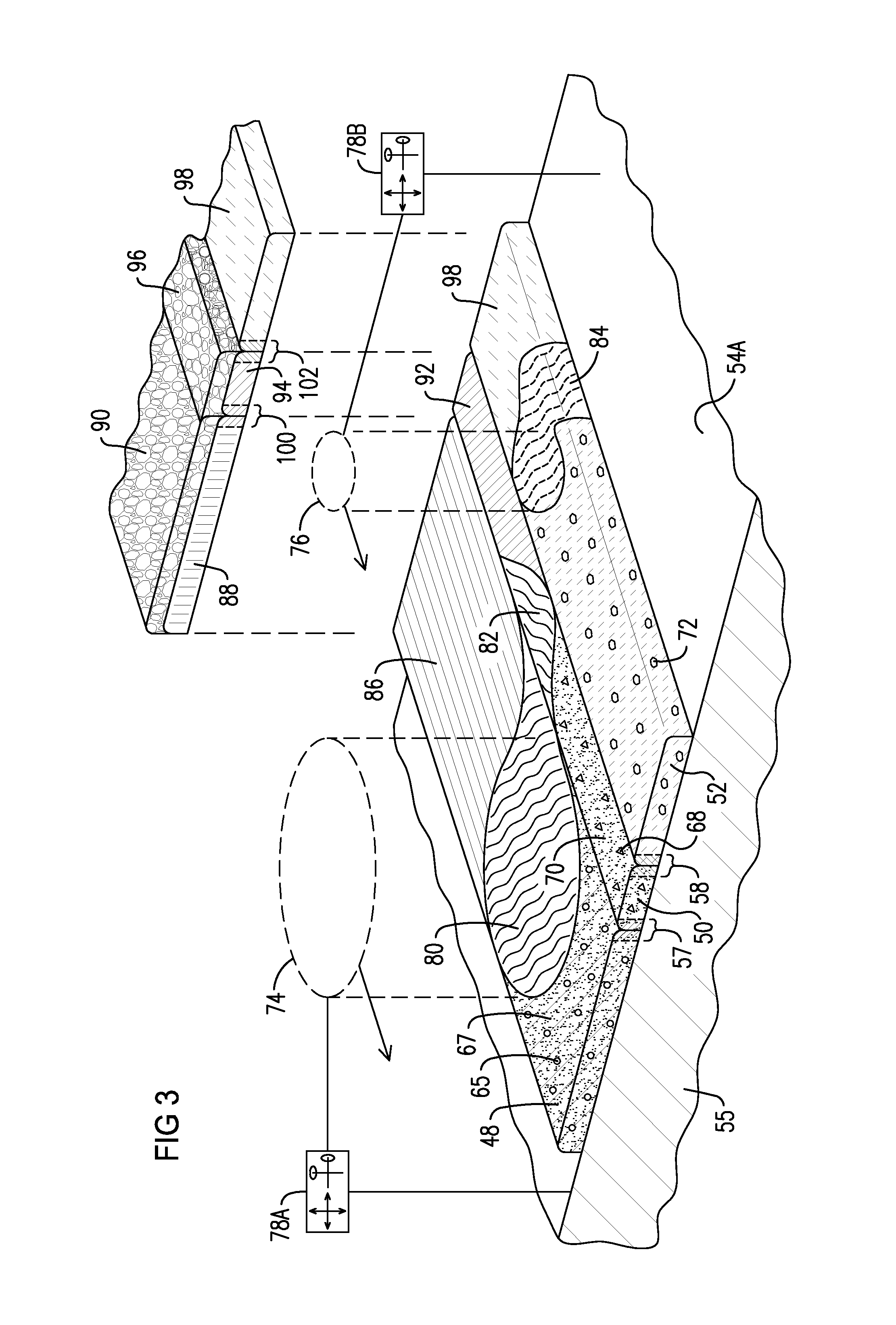

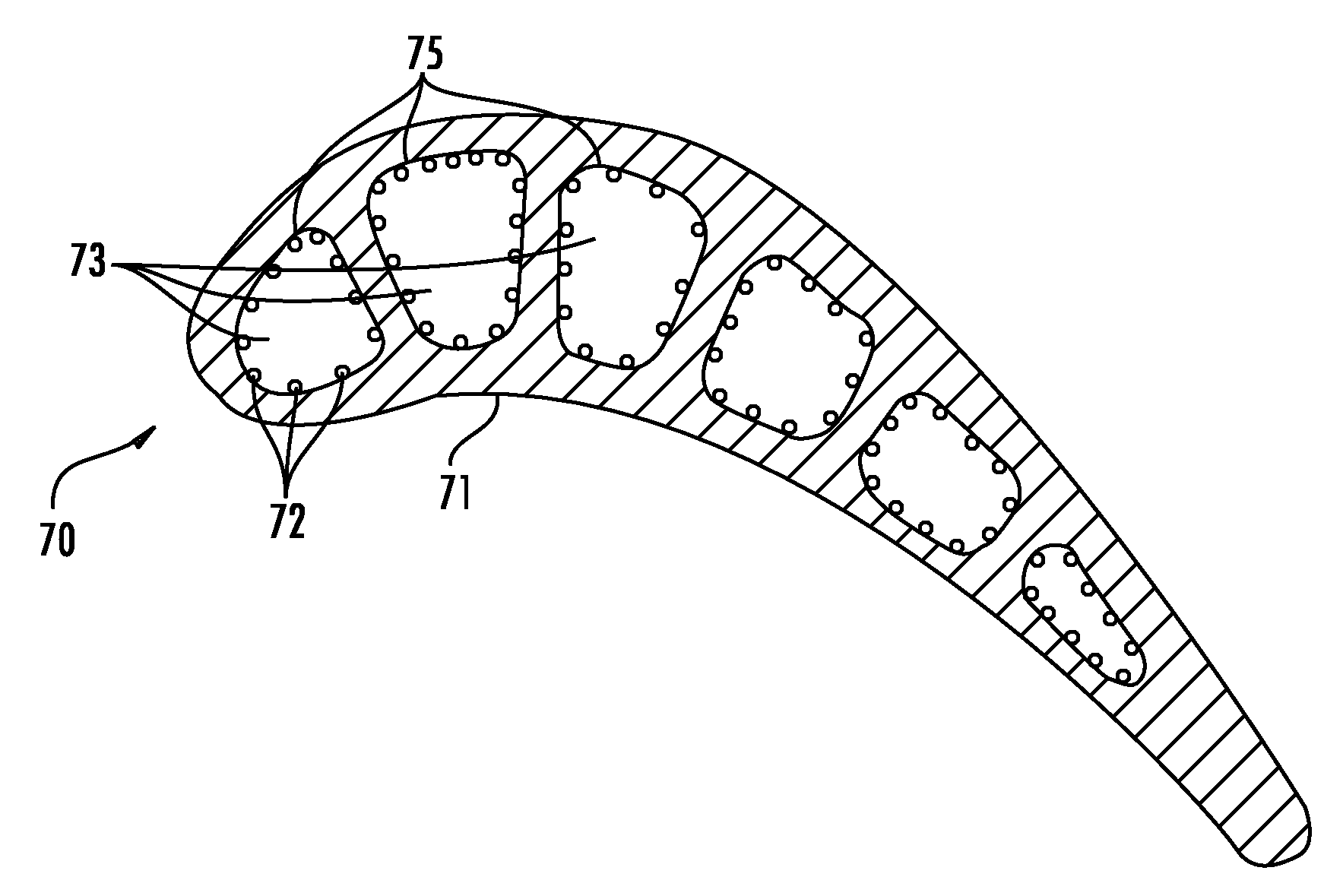

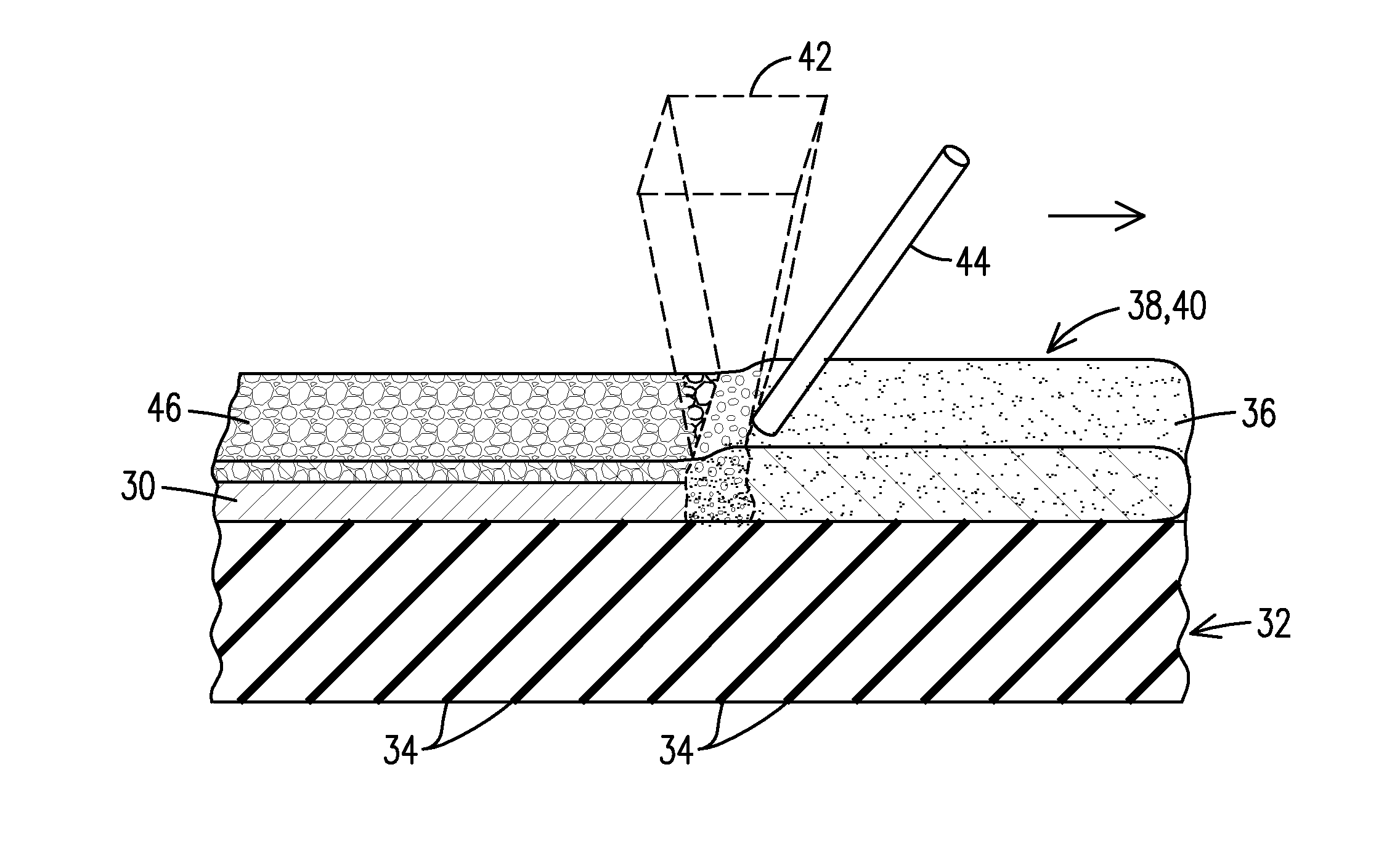

Laser additive manufacture of three-dimensional components containing multiple materials formed as integrated systems

Methods for laser additive manufacture are disclosed in which a plurality of powder layers (48, 50 and 52) are delivered onto a working surface (54A) to form a multi-powder deposit containing at least two adjacent powders layers in contact, and then applying a first laser energy (74) to a first powder layer (48) and a second laser energy (76) to a second powder layer (52) to form a section plane of a multi-material component. The multi-powder deposit may include a flux composition that provides at least one protective feature. The shapes, intensities and trajectories of the first and second laser energies may be independently controlled such that their widths are less than or equal to widths of the first and second powder layers, their intensities are tailored to the compositions of the powder layers, and their scan paths define the final shape of the multi-material component.

Owner:SIEMENS ENERGY INC

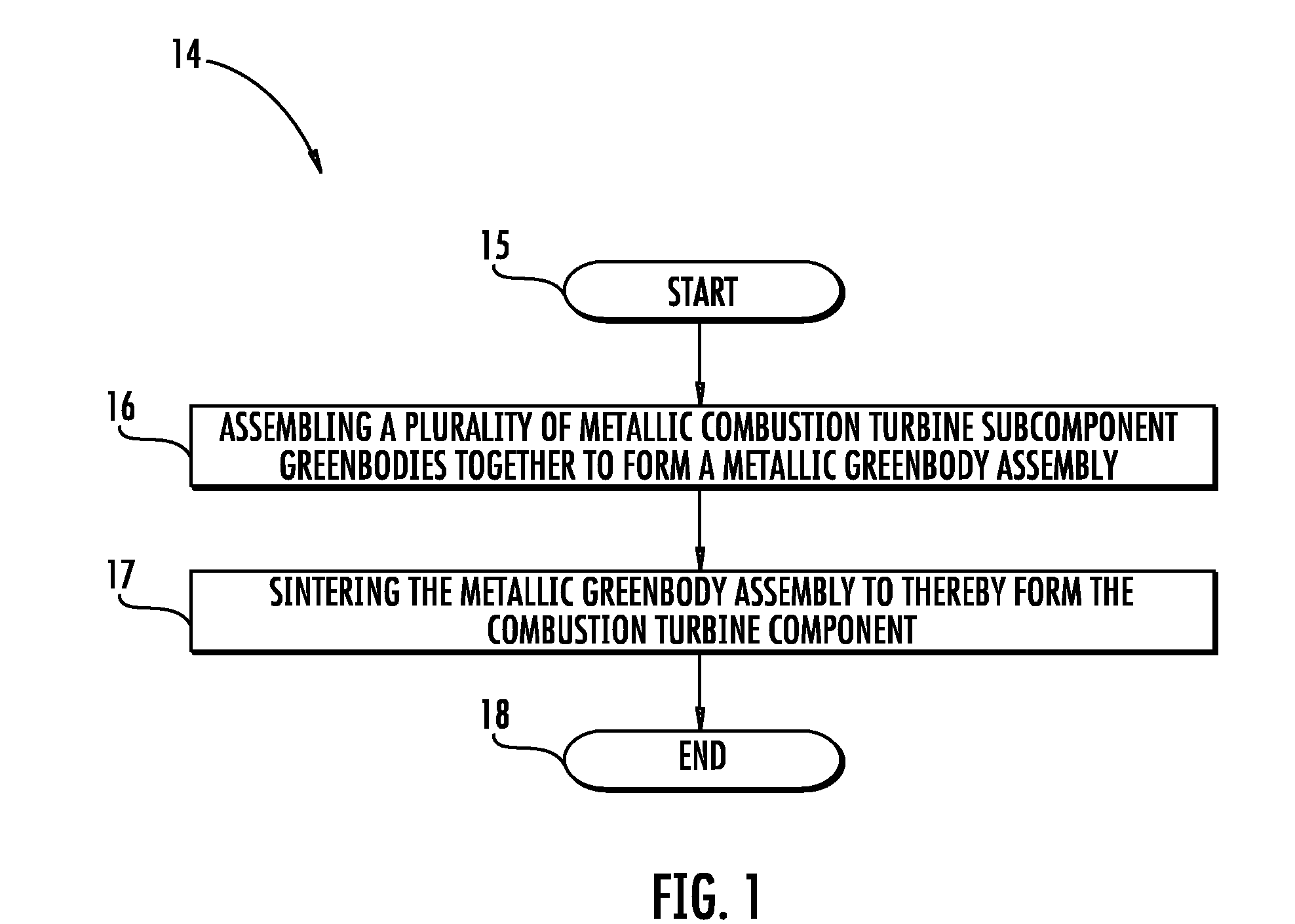

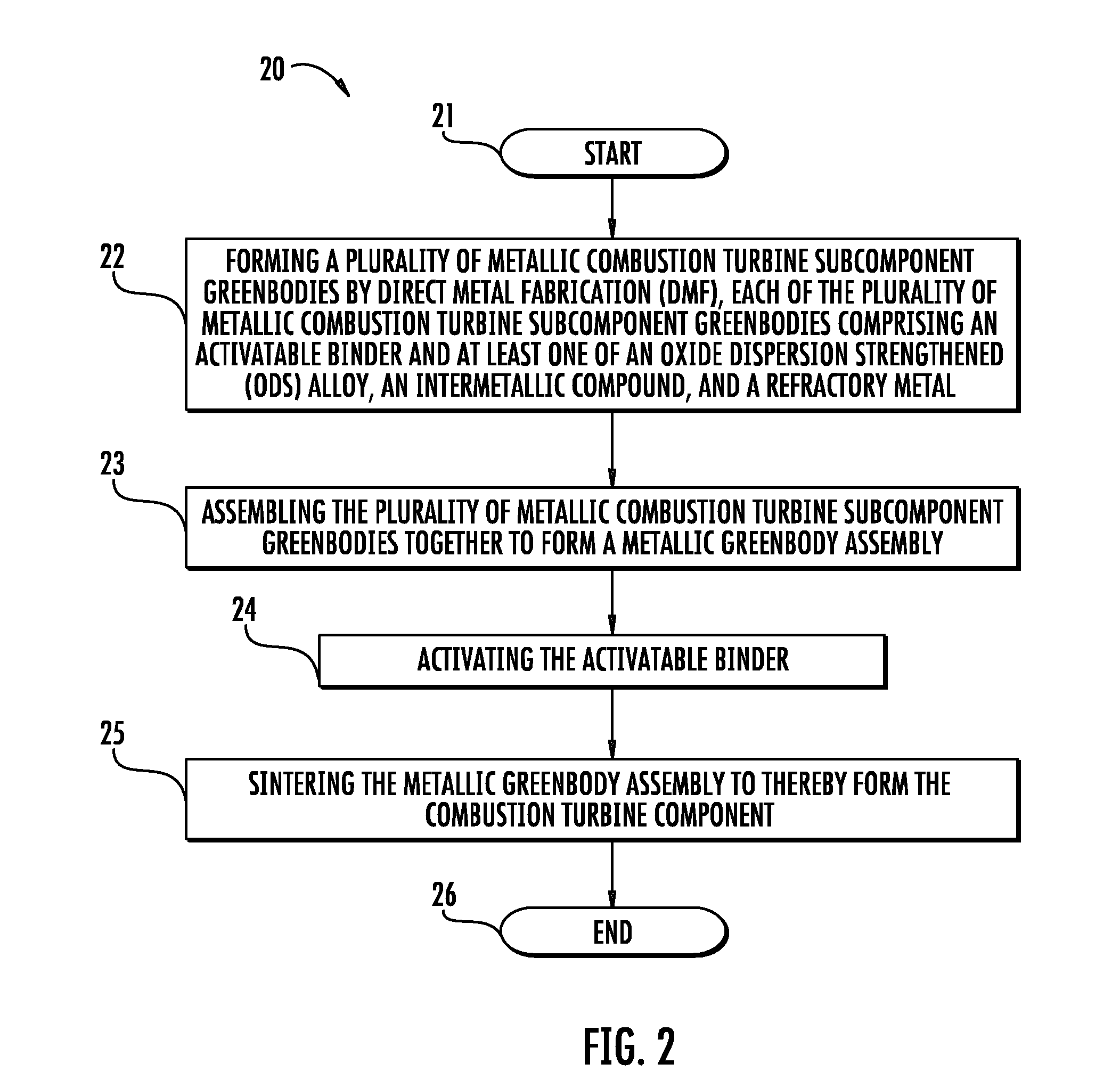

Method of Making a Combustion Turbine Component from Metallic Combustion Turbine Subcomponent Greenbodies

InactiveUS20090183850A1Improve cooling effectHigh temperature resistanceTurbinesAdditive manufacturingCombustionMetal fabrication

A method of making a combustion turbine component includes assembling a plurality of metallic combustion turbine subcomponent greenbodies together to form a metallic greenbody assembly and sintering the metallic greenbody assembly to thereby form the combustion turbine component. Each of the plurality of metallic combustion turbine subcomponent greenbodies may be formed by direct metal fabrication (DMF). In addition, each of plurality of metallic combustion turbine subcomponent greenbodies may include an activatable binder and the activatable binder may be activated prior to sintering.

Owner:MIKRO SYSYTEMS INC +1

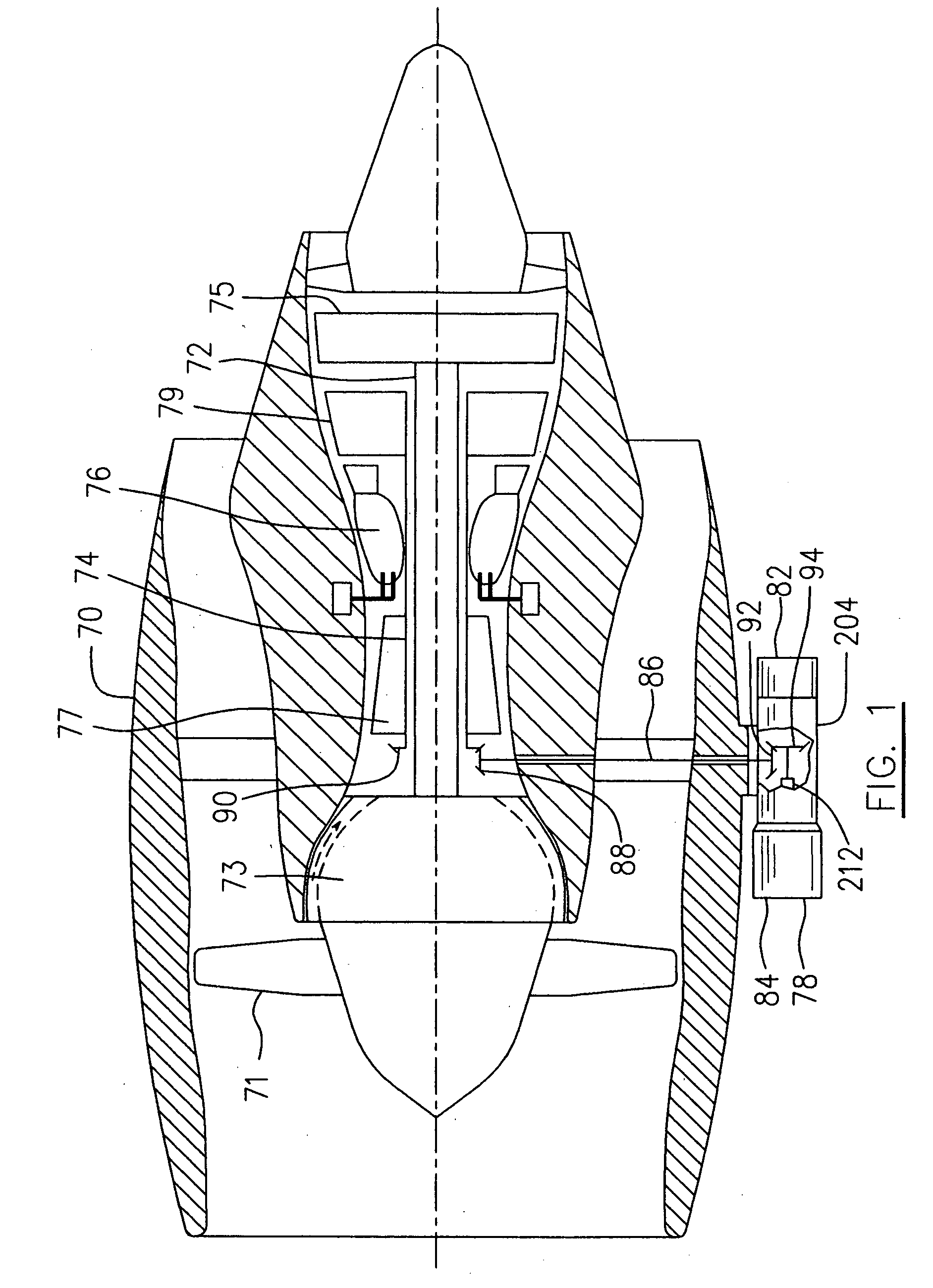

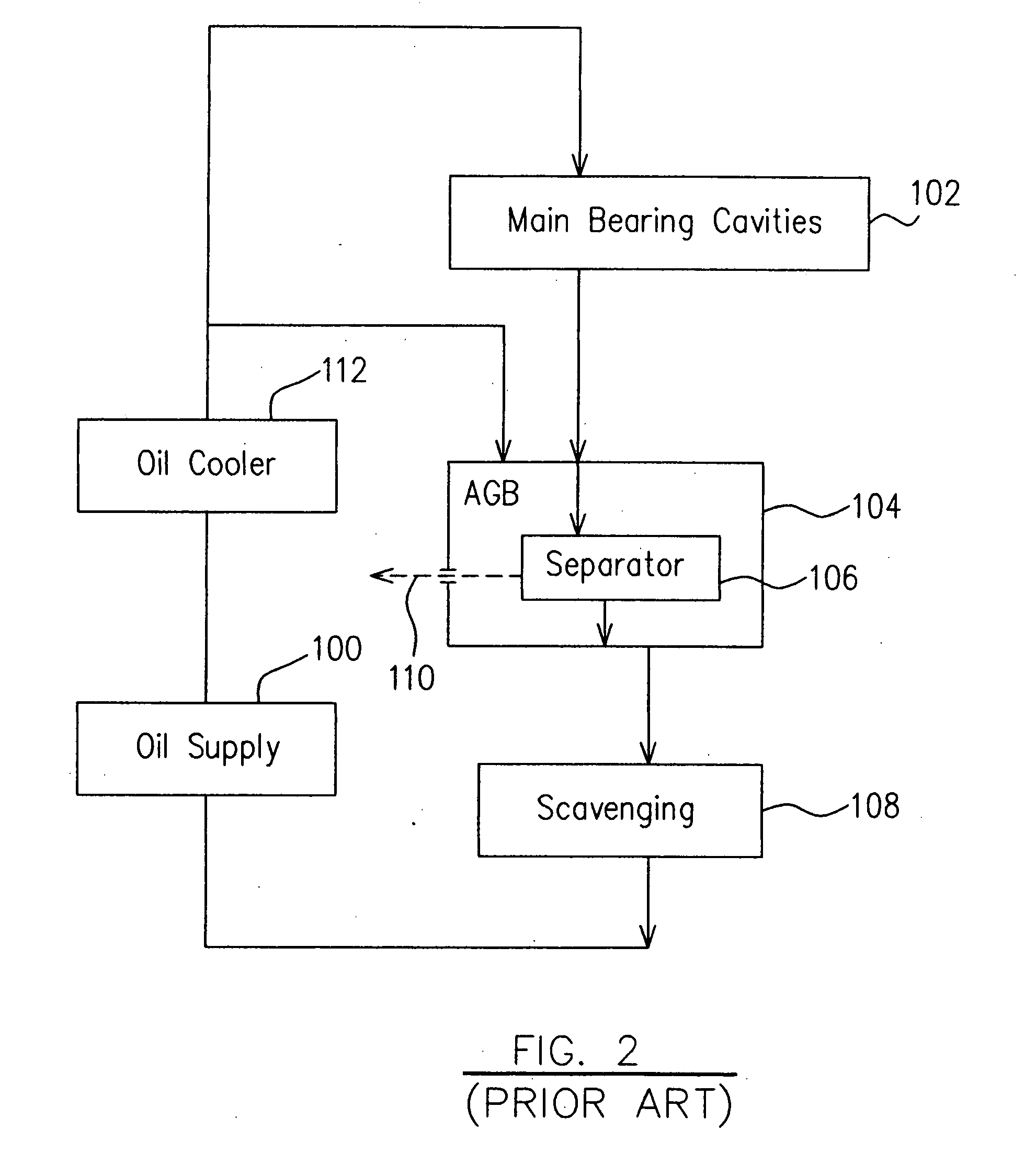

Air/oil separation system and method

ActiveUS20050211093A1Reduce heat transferReduce the temperatureCombination devicesLiquid degasificationOil separationEngineering

A centrifugal air / oil separation system communicates with bearing cavities of the engine and substantially isolates separated oil from contacting the gearbox.

Owner:PRATT & WHITNEY CANADA CORP

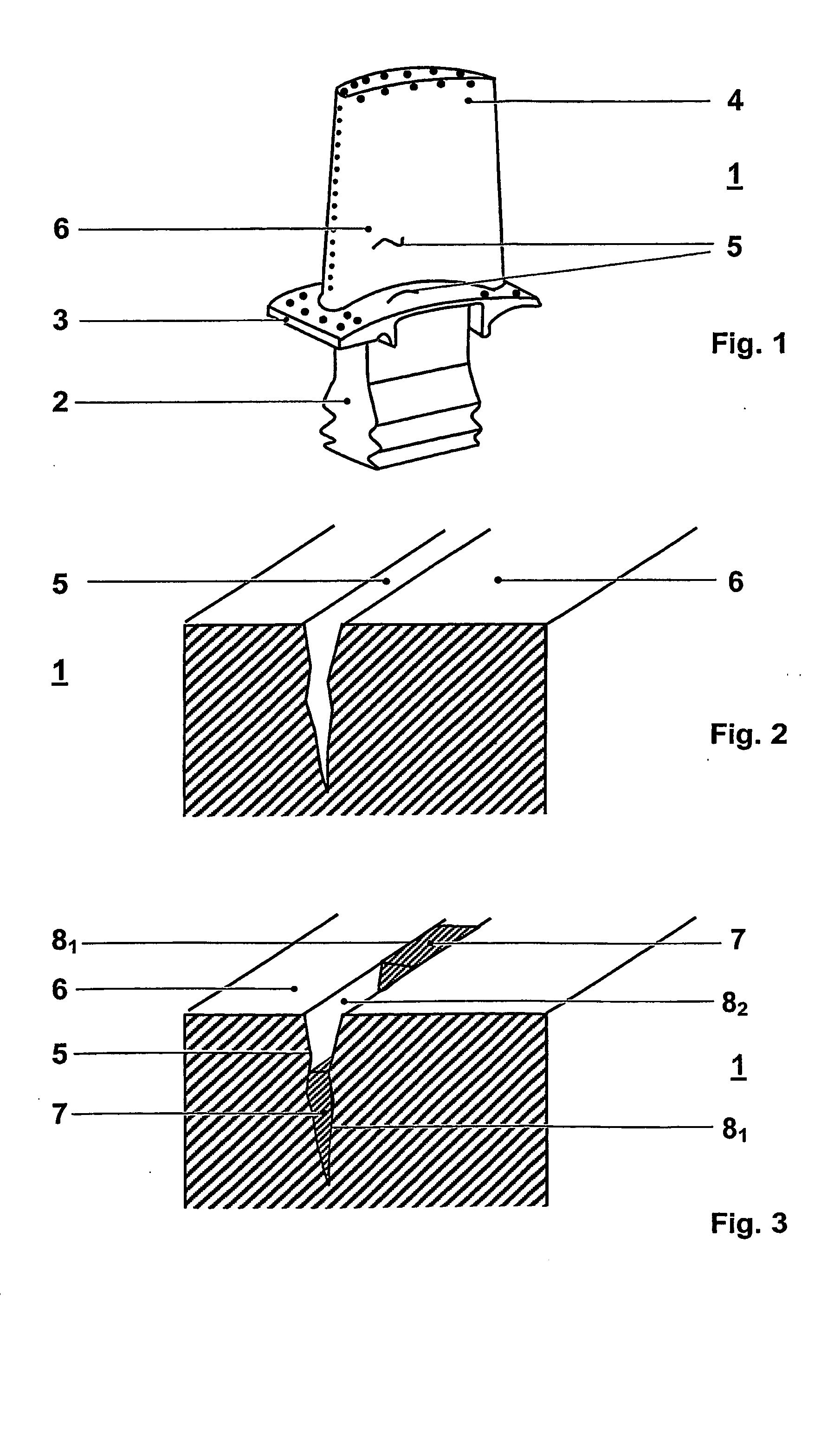

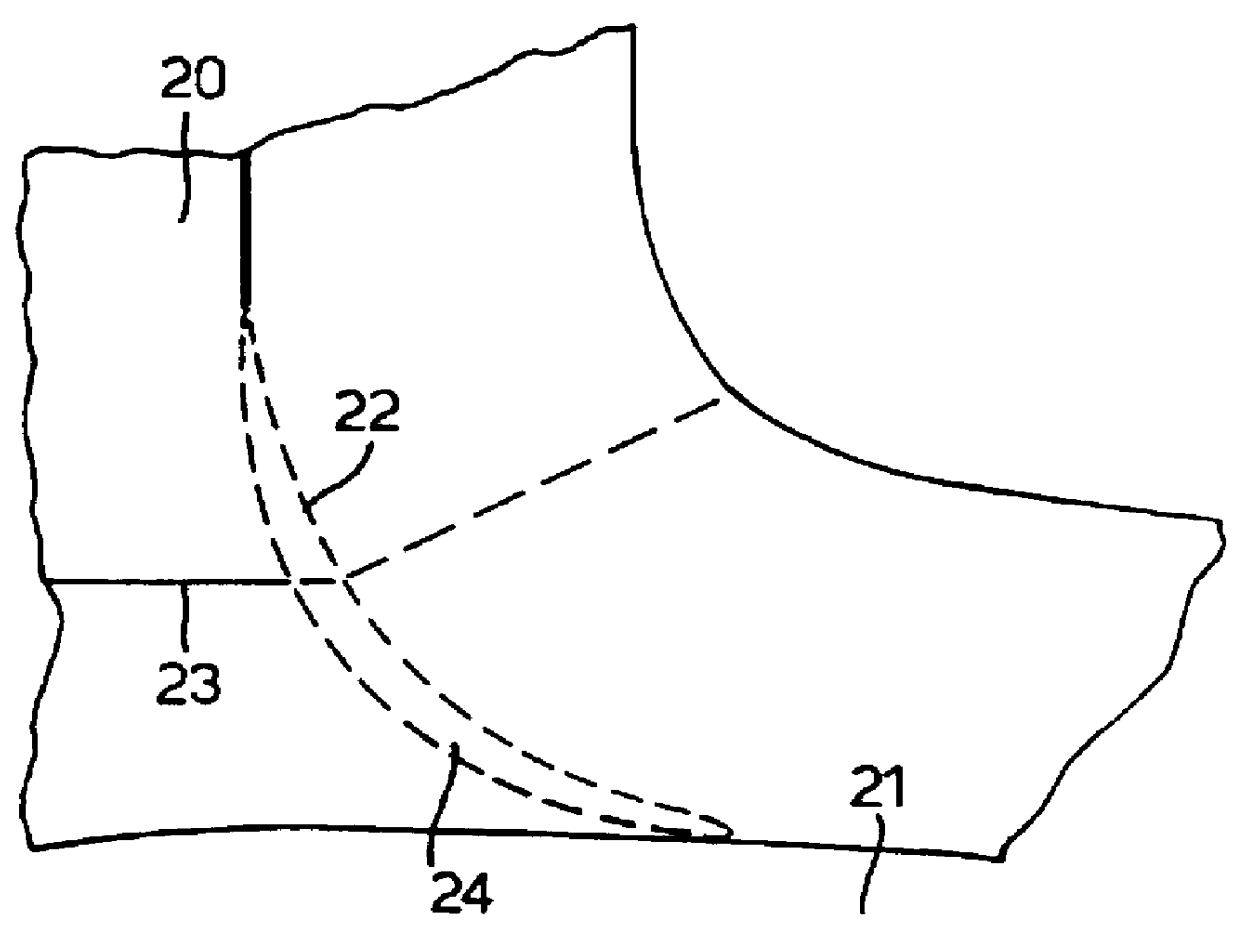

Method of fabricating turbine airfoils and tip structures therefor

InactiveUS20100200189A1Maintaining metallurgical integrityPrevent movementTurbinesWelding/cutting media/materialsTurbineBiomedical engineering

A method for making a turbine airfoil includes providing a mold core and an outer shell which cooperatively define a cavity in the shape of a hollow airfoil having an outer wall, a root, and a tip. A tip portion of the core extends completely through the portion of the cavity defining the tip of the airfoil. The core is restrained to prevent movement between the core and outer shell. Molten metal is introduced into the cavity and solidified to form an airfoil having at least one outer wall which defines an open tip and a hollow interior. A metallic tip cap is formed on the outer wall which substantially closes off the open tip. The tip cap may be formed by packing the airfoil with metallic powder; and laser sintering the exposed powder so as to form a tip cap which is metallurgically bonded to the outer wall.

Owner:GENERAL ELECTRIC CO

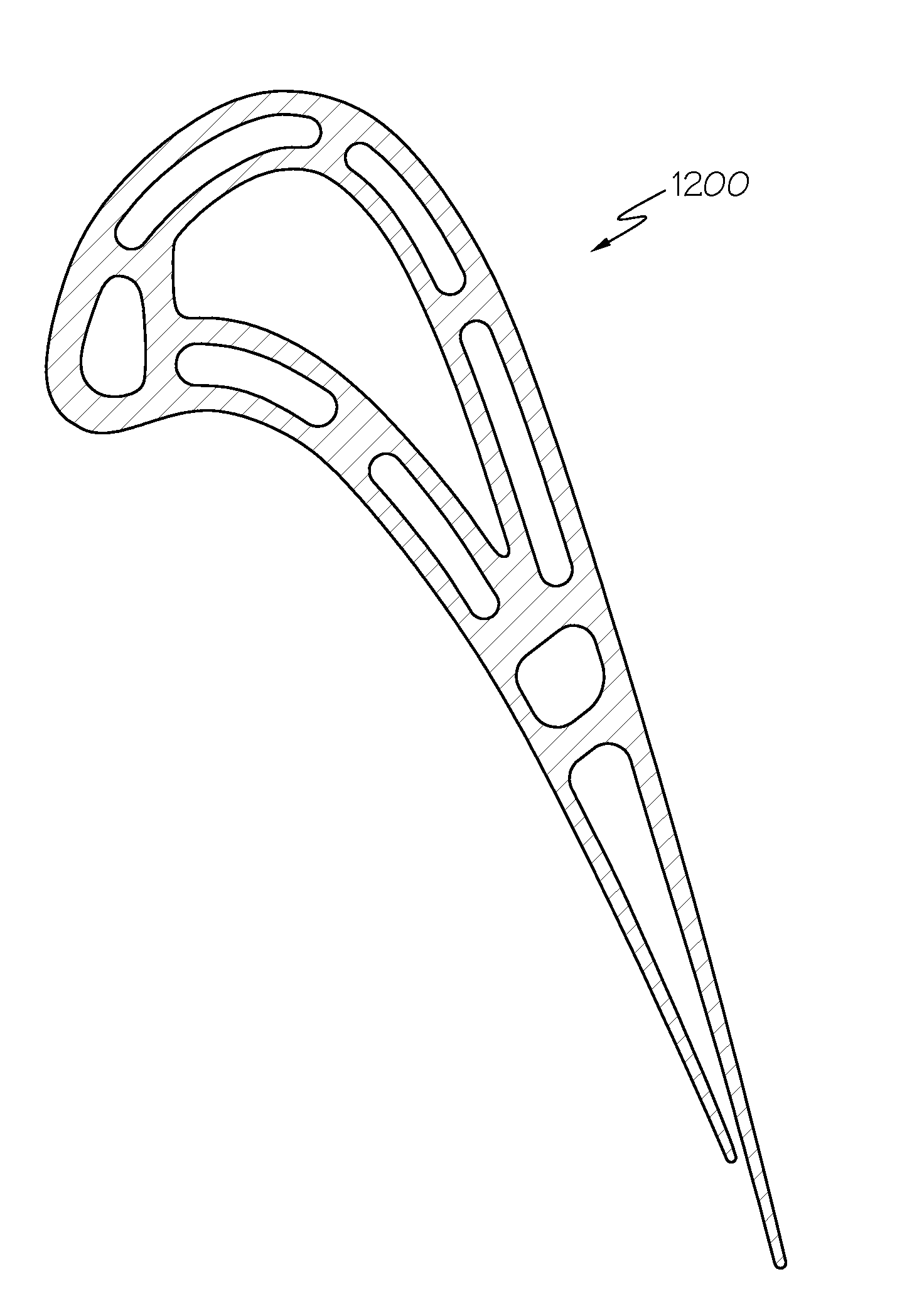

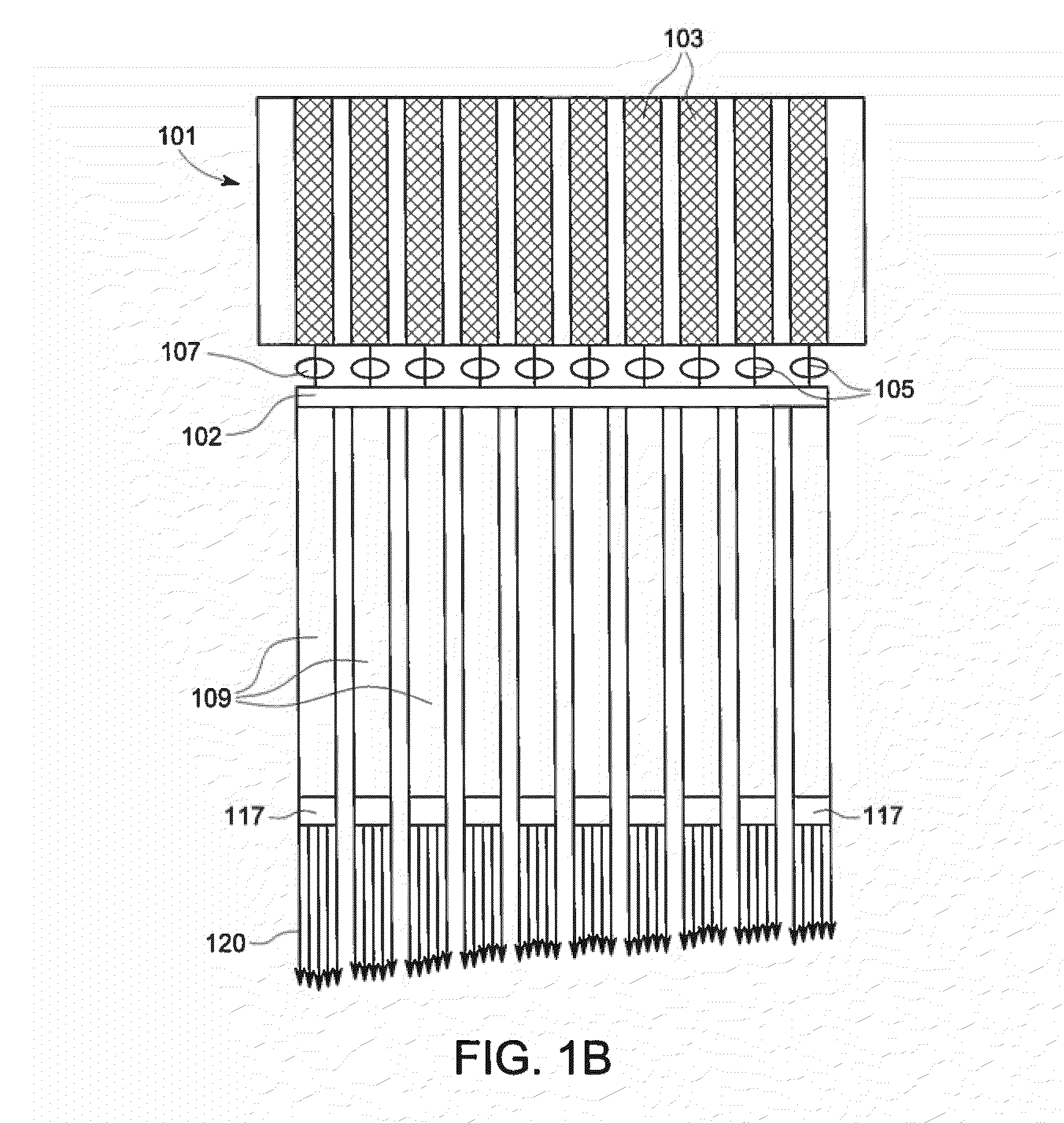

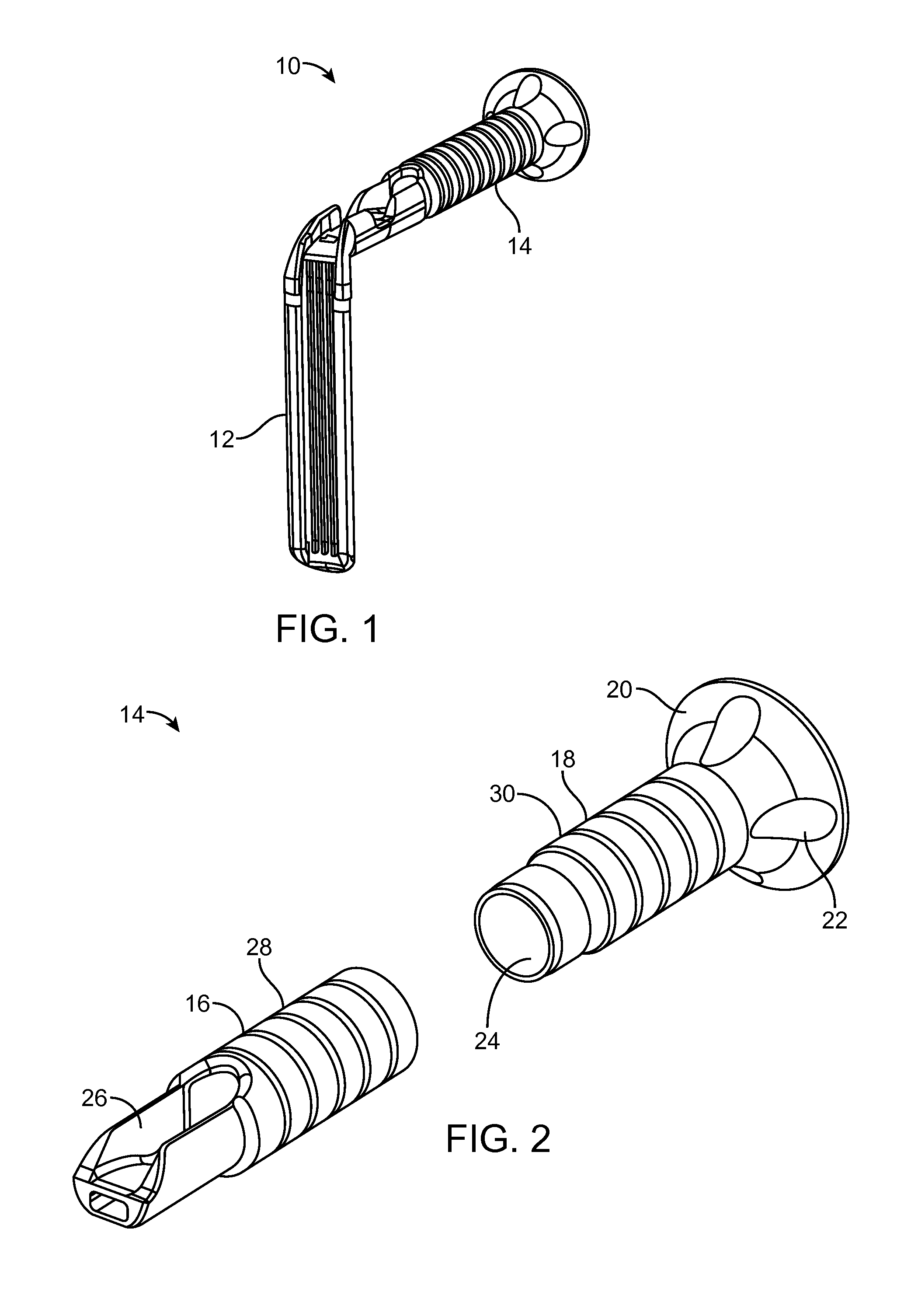

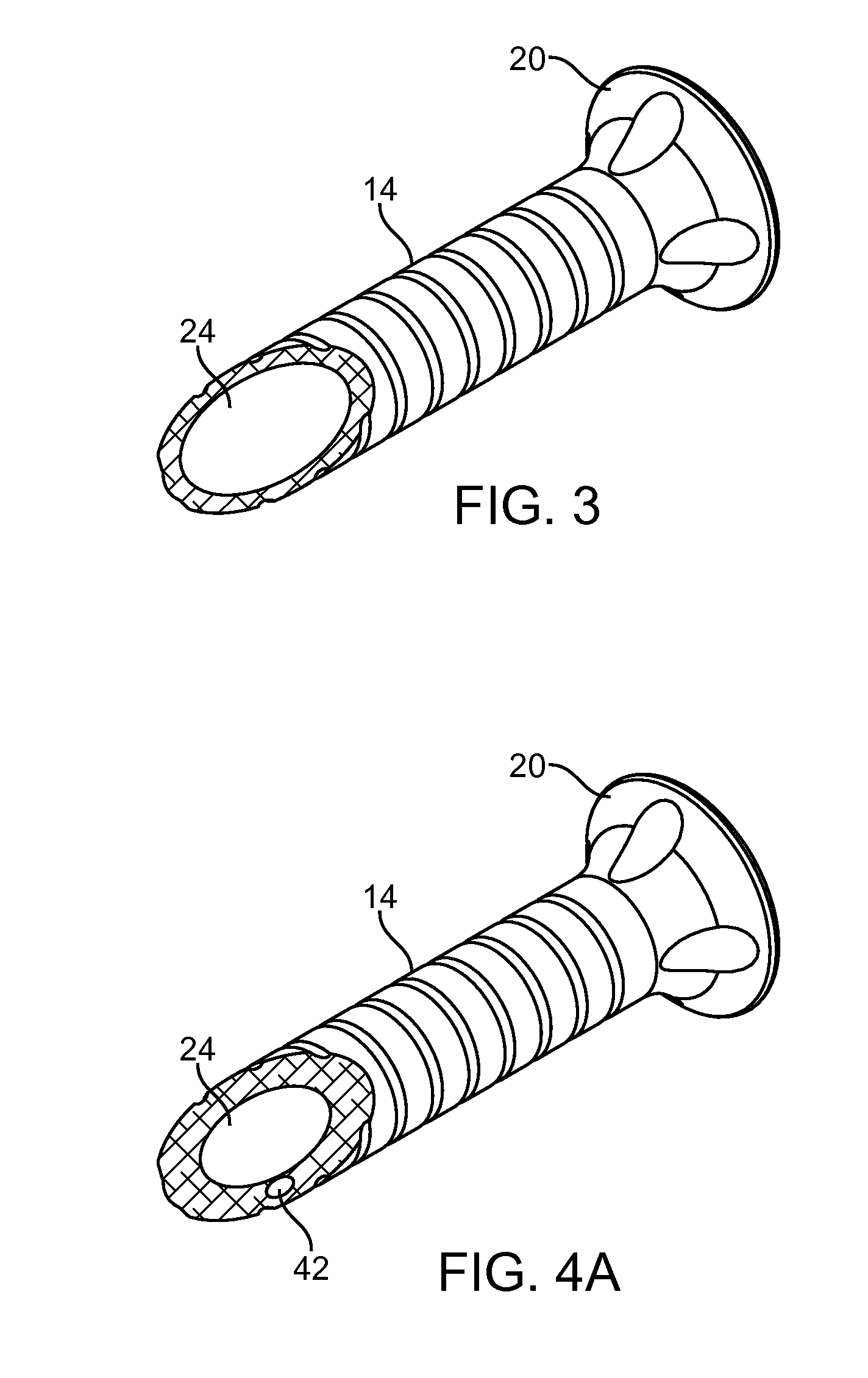

Illuminated and modular soft tissue retractor

ActiveUS20130267786A1Maintaining minimal profileTurbinesAdditive manufacturing apparatusTotal internal reflectionFast release

A surgical retractor for illuminating a surgical field includes an ergonomic handle, a retractor blade coupled with the handle, a quick release mechanism, and an illuminator blade. The retractor blade is adapted to engage and retract tissue, and the quick release mechanism is adapted to couple the handle with the retractor blade. The illuminator blade acts as a waveguide to transmit light by total internal reflection. Light is extracted from the illuminator to illuminate the surgical field. The retractor blade is releasable from the handle without requiring uncoupling of the illuminator blade from the handle and also without requiring optical uncoupling of the illuminator blade from a light source. The retractor may also be adapted to evacuate smoke from the surgical field.

Owner:INVUITY

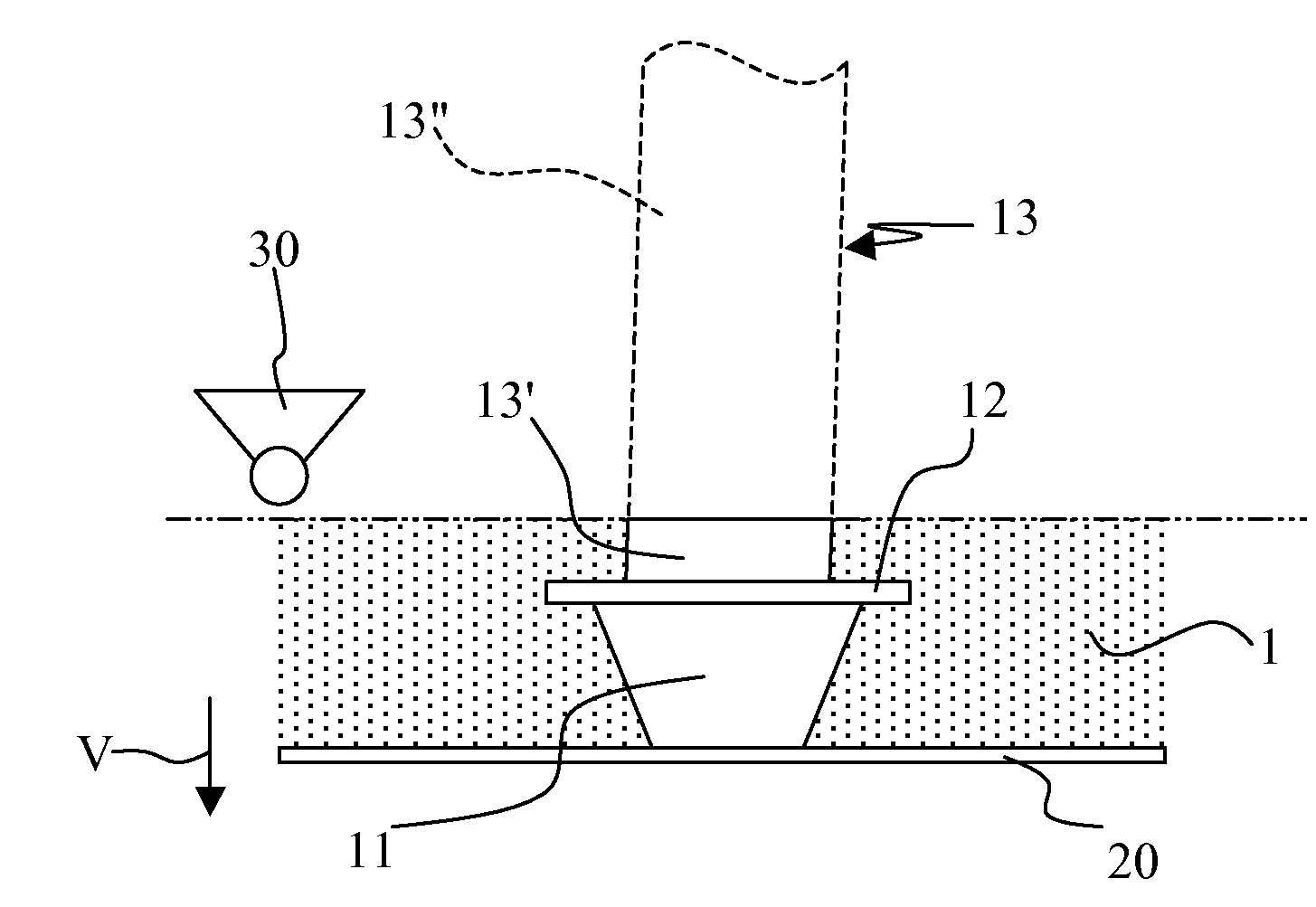

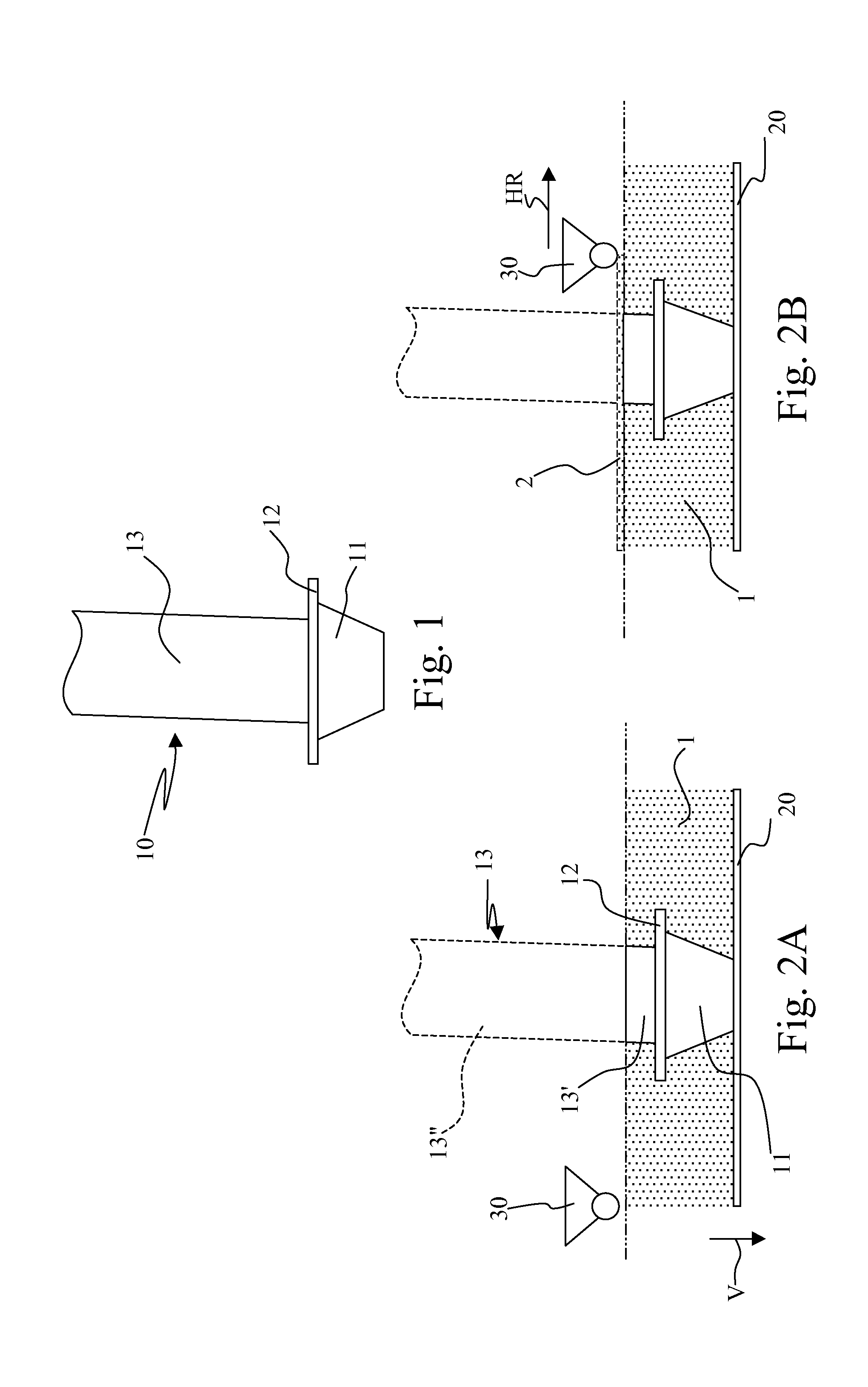

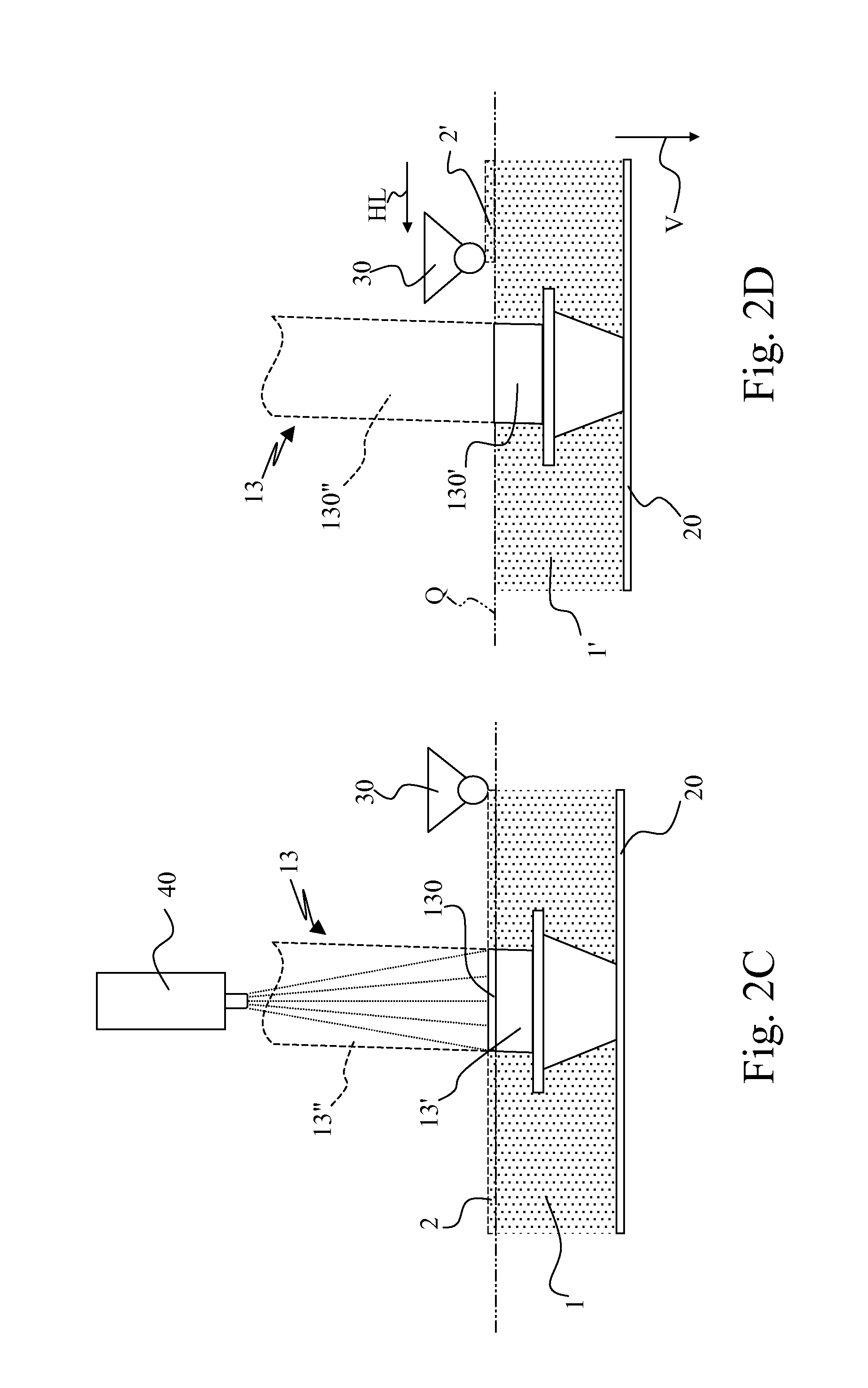

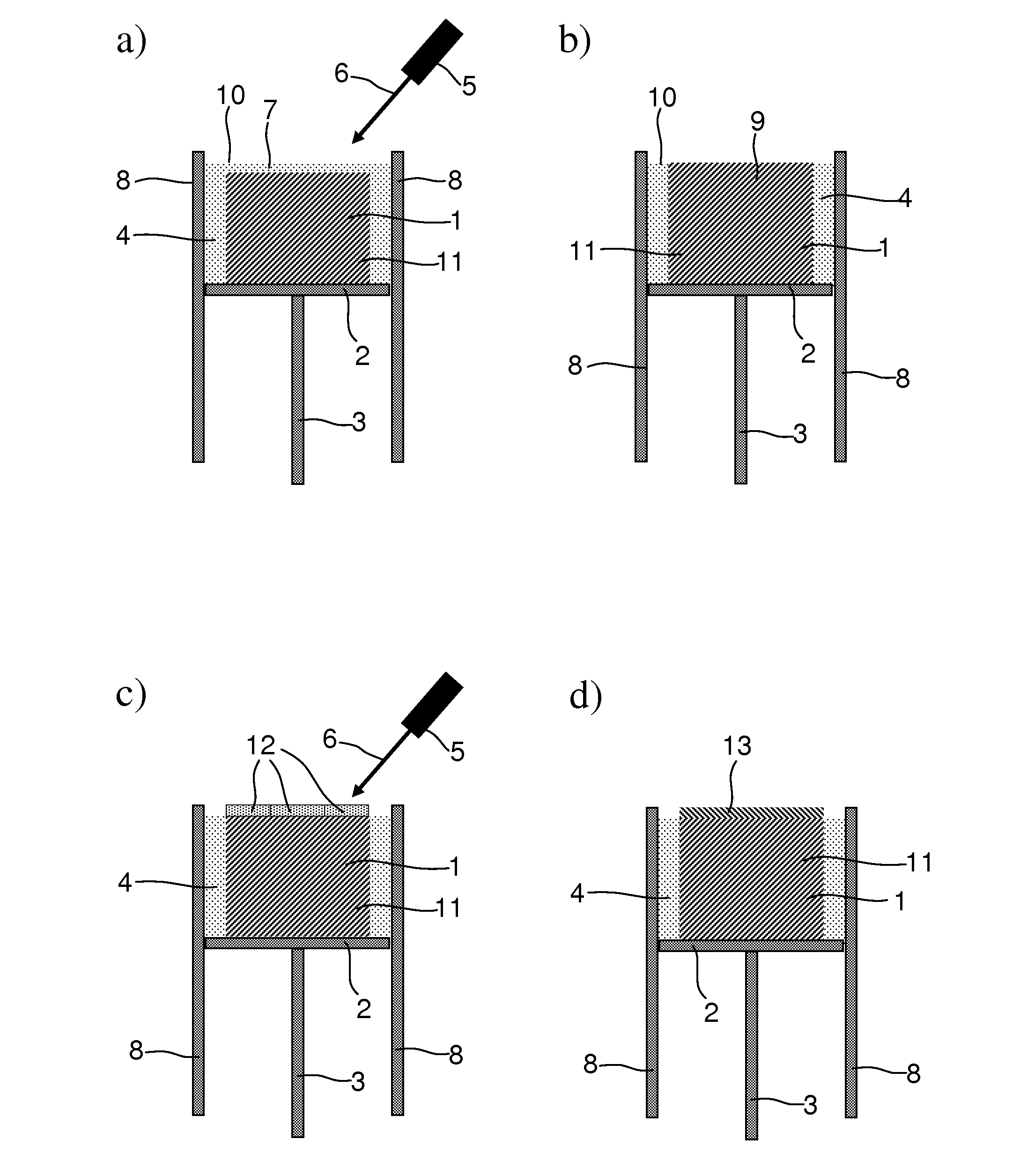

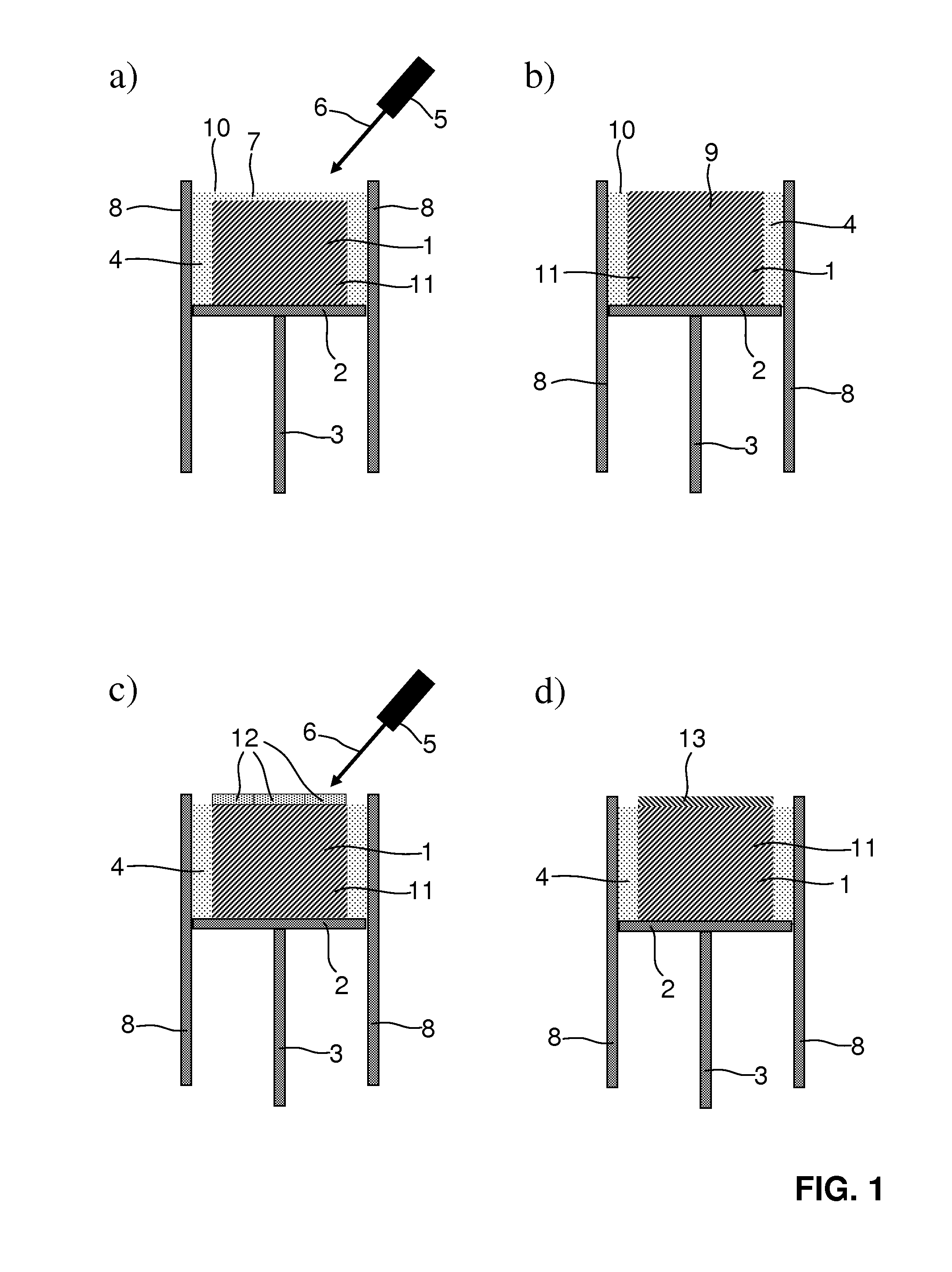

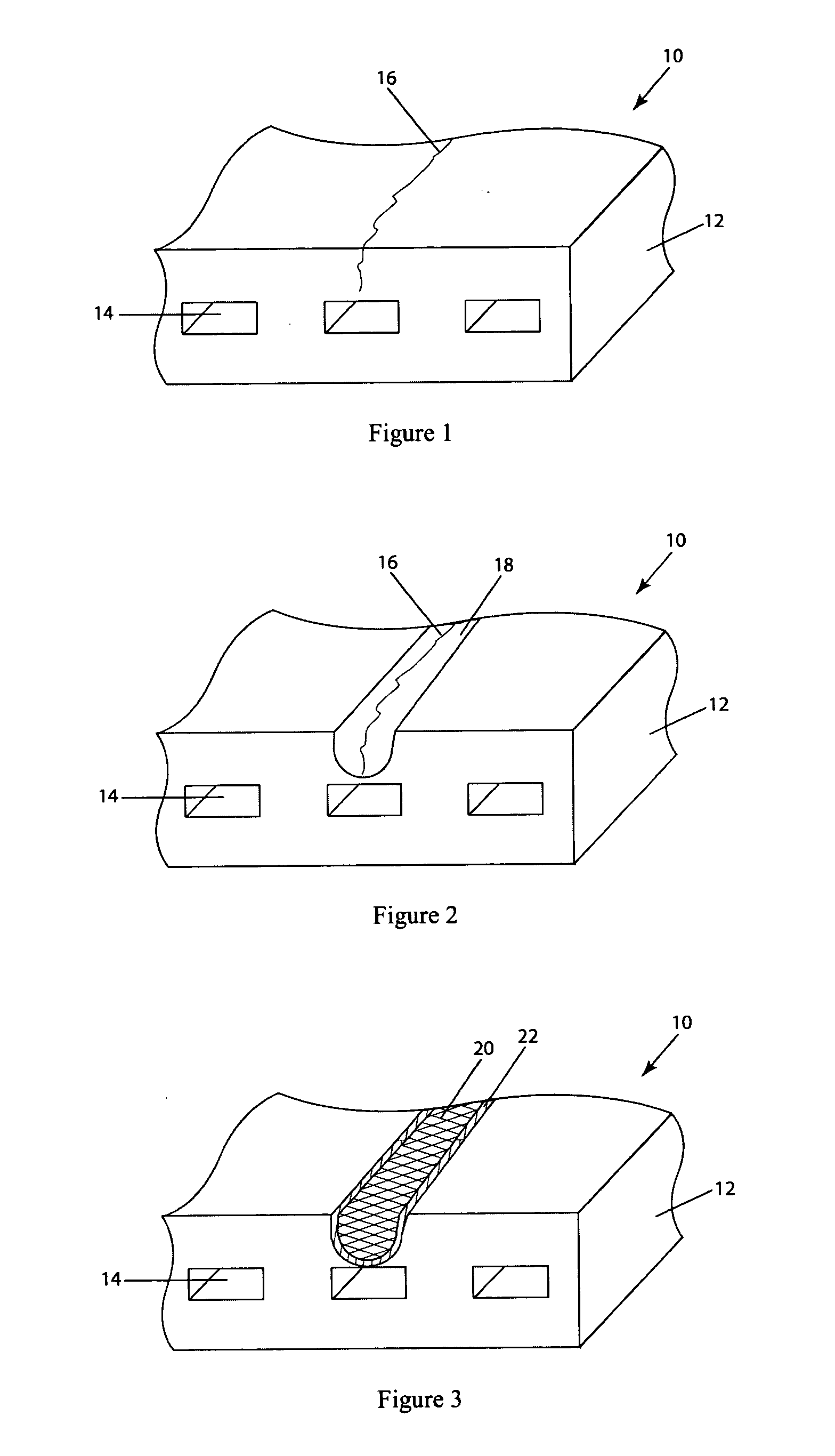

Method of applying multiple materials with selective laser melting on a 3D article

InactiveUS20110106290A1Increase weld ability/brazeabilityEasy to optimizeTurbinesAdditive manufacturingMulti materialSelective laser melting

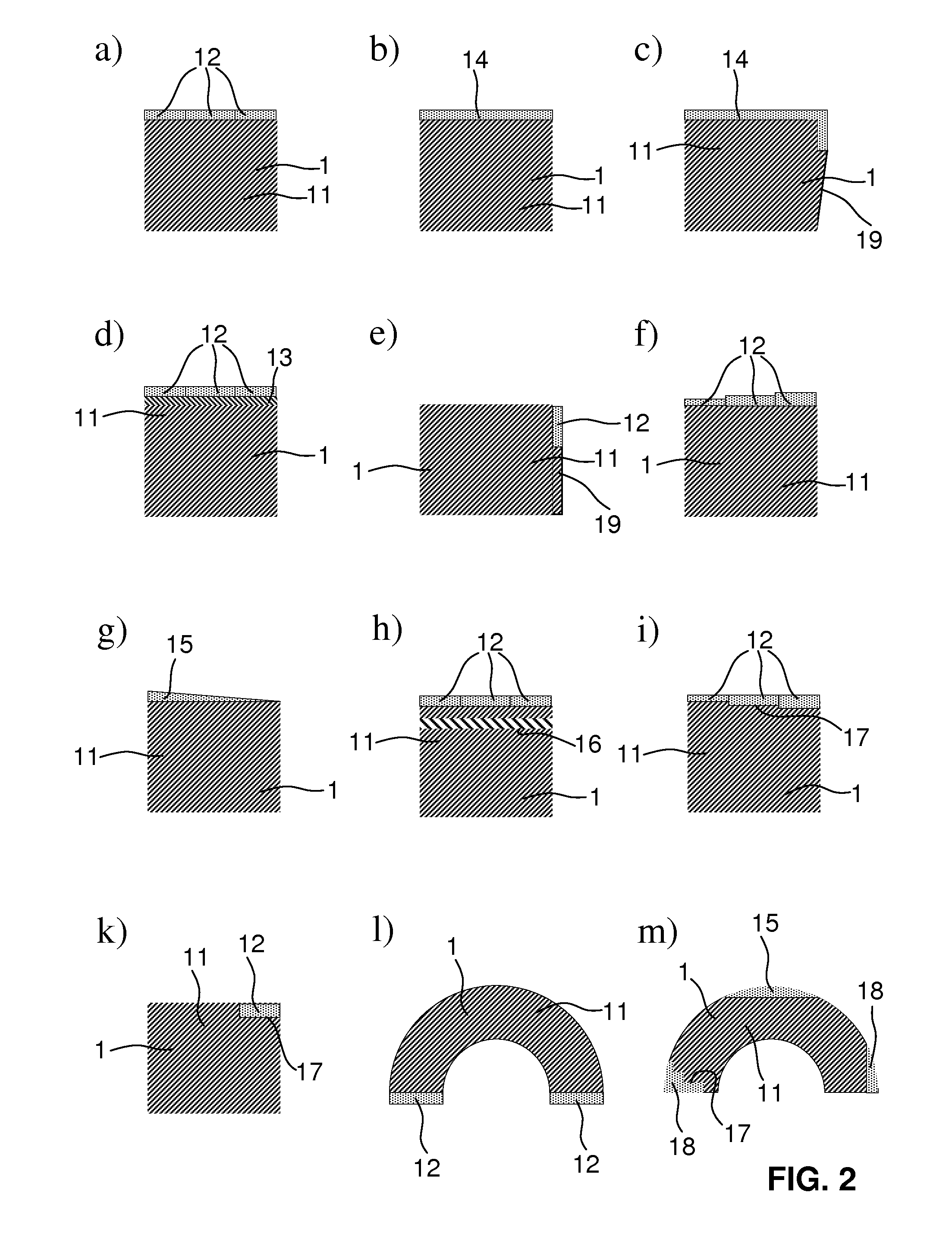

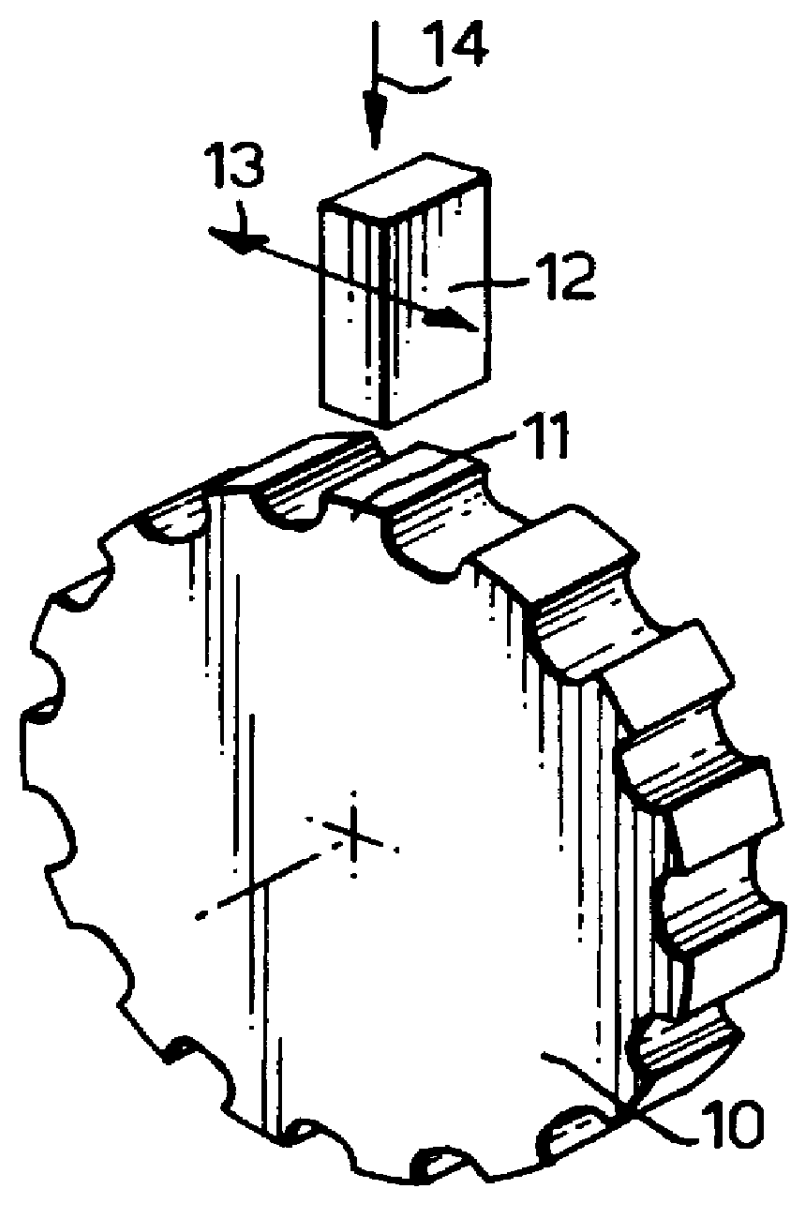

In a method for manufacturing an article (1), particularly a prototype of a product or component, a tool prototype or spare part, by using selected laser melting, for the application onto the article (1) of a layer (13) or portion of a second metallic material, which is different from the material of the first metallic powder (4), a tape (12), sheet (14), foil or three-dimensional pre-form (18) of a second material is applied to the article (1) and is heated by a focused laser or electron beam (6) to a specified temperature such that the tape (12), sheet (14), foil or pre-form, respectively, are made molten by the electron laser beam (6), wherein the focused beam (6) is applied to a given area corresponding to a selected cross-sectional area of the model of the article (1) under formation of a new layer or part made of second material integral with the article (1).

Owner:ANSALDO ENERGIA IP UK LTD

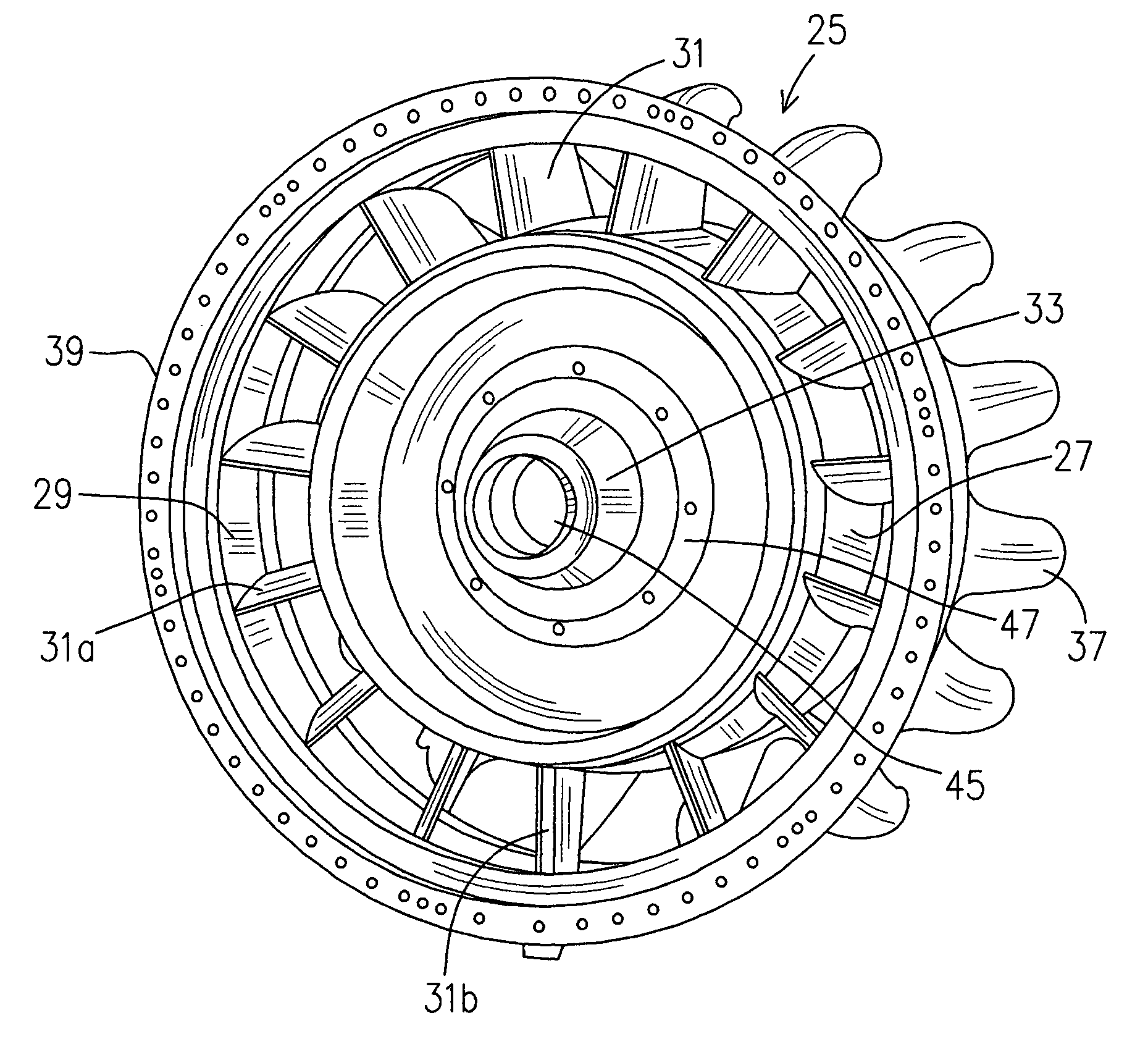

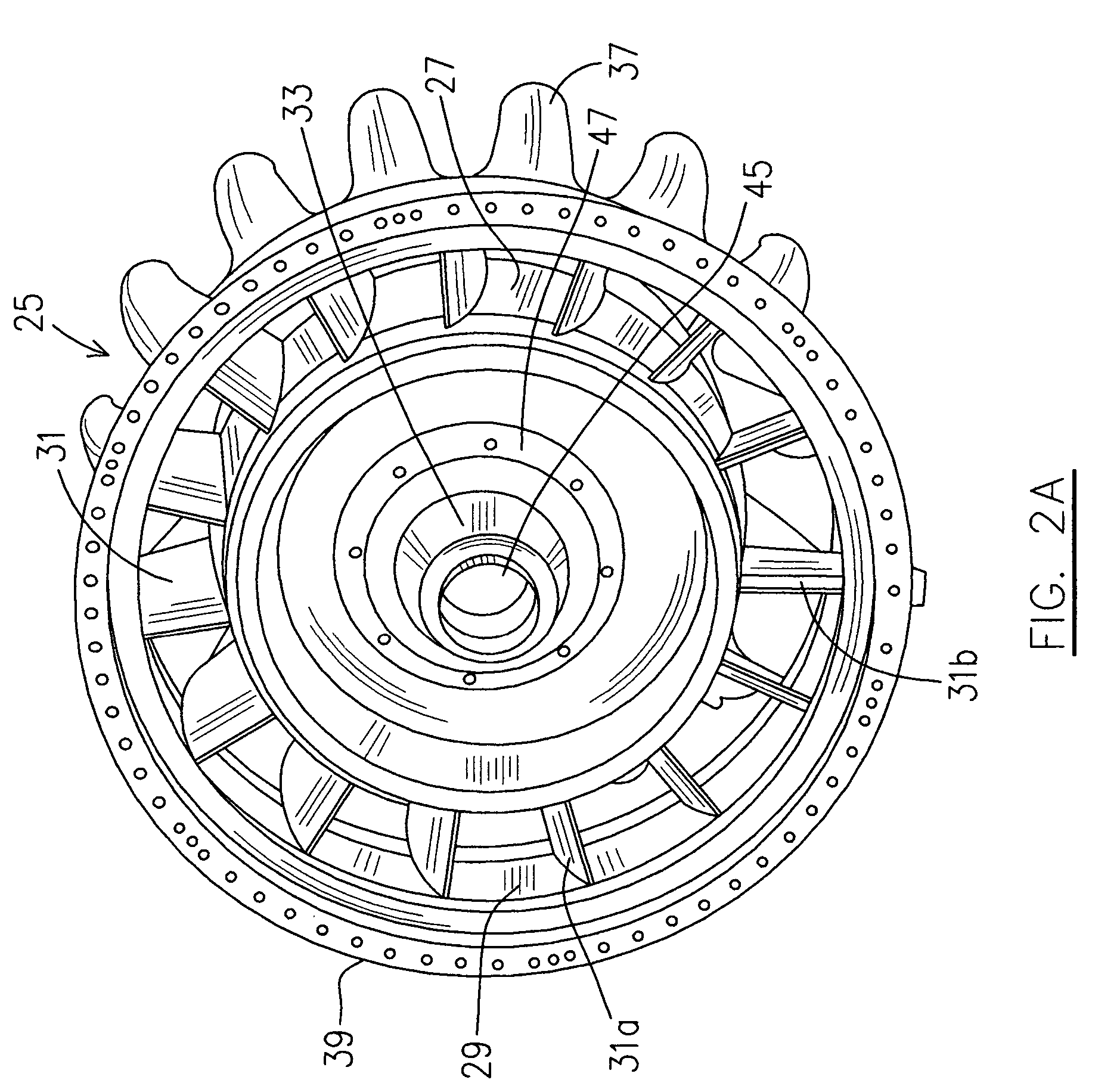

Disk for a blisk rotary stage of a gas turbine engine

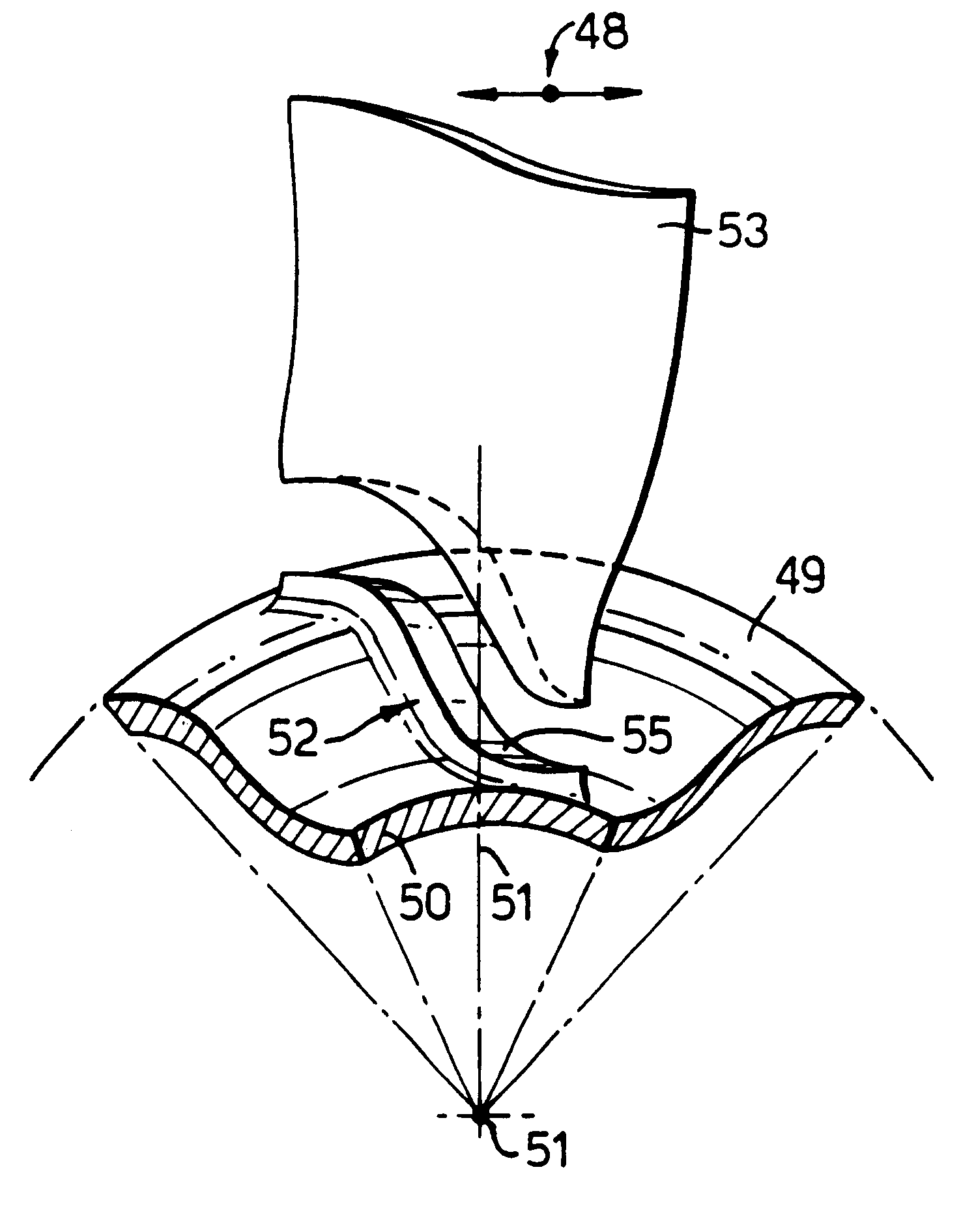

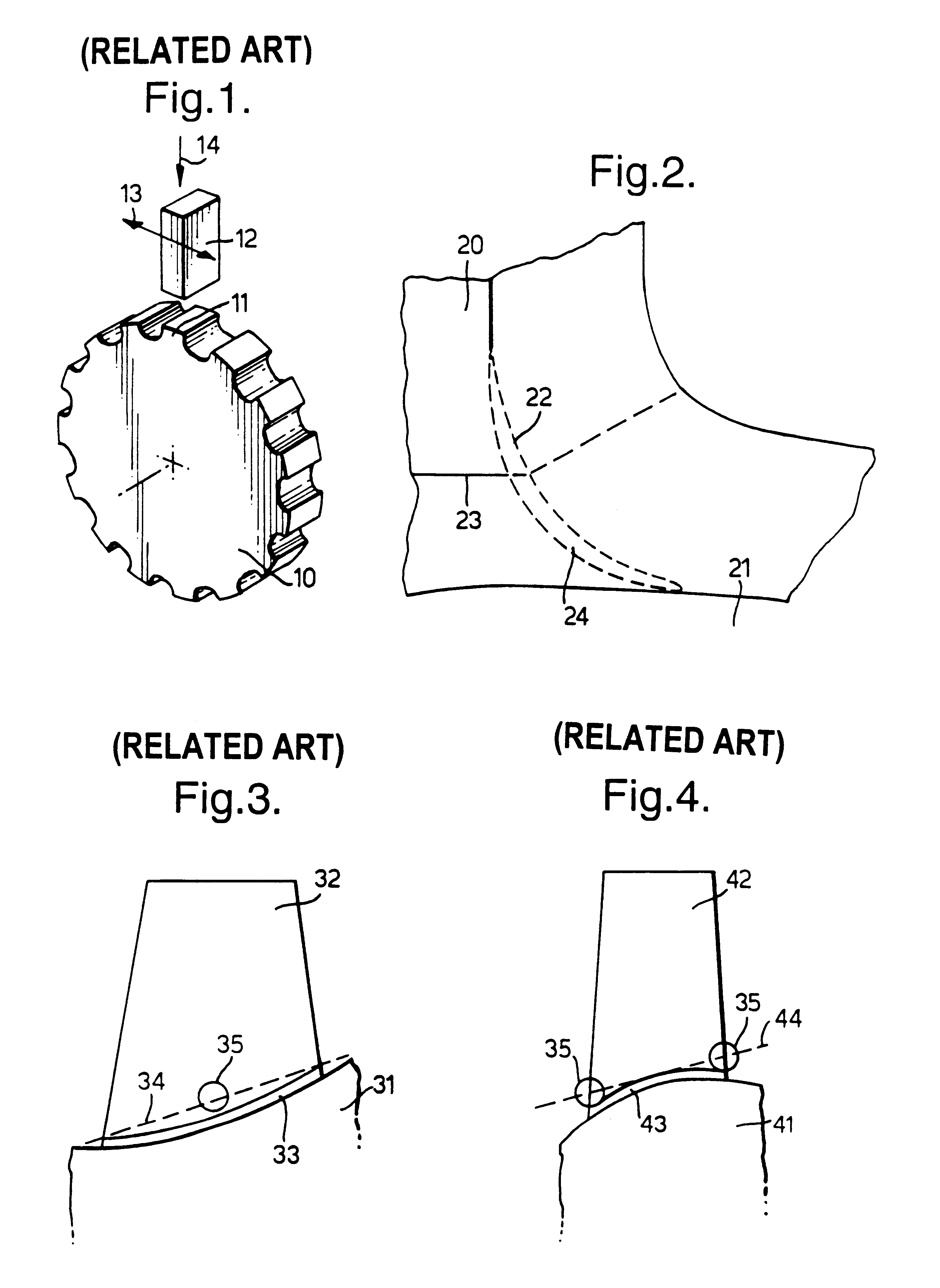

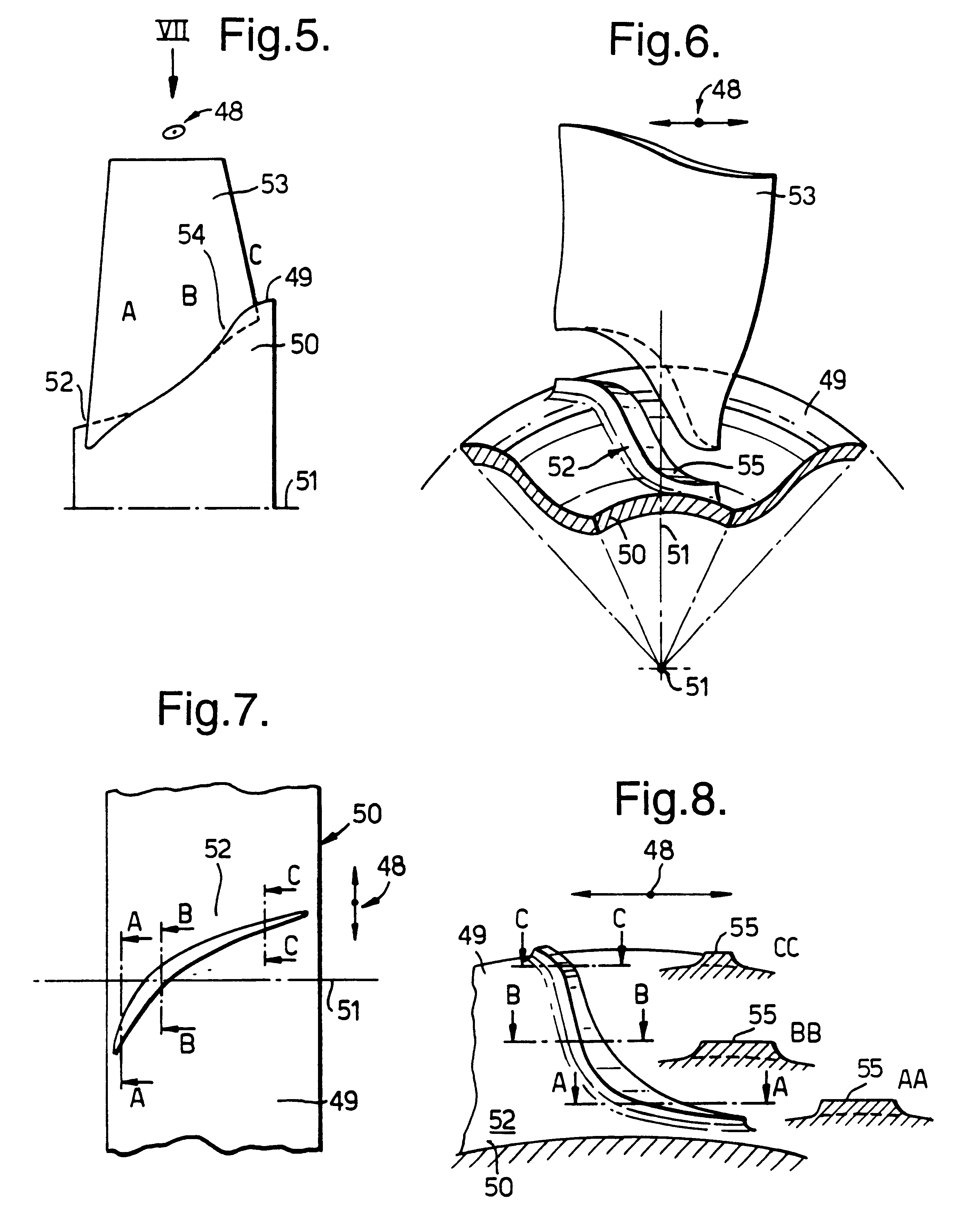

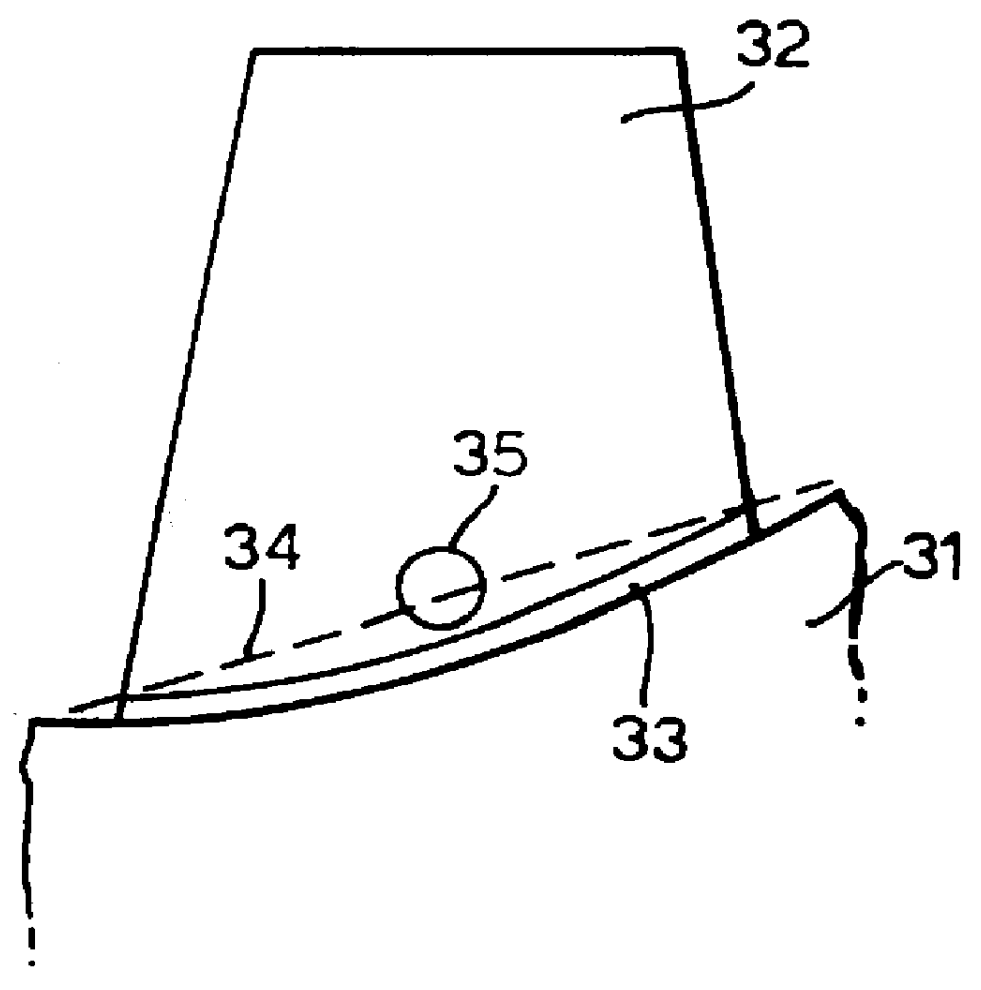

A disk for a BLISK rotary stage of a gas turbine engine includes a stub on the tapered circumferential surface of a turbine disk, the stub defining a weld joint surface on the radially outermost face of the stub. The weld joint surface follows the annulus curvature in axial and circumferential directions while remaining flat in a third direction. A blade is applied radially to the stub and linear friction welding of the blade to the stub is effected by oscillating the blade in said third direction while applying a welding force inwardly along the blade.

Owner:ROLLS ROYCE PLC

Friction stir welded hollow airfoils and method therefor

A hollow component for gas turbine engine, for example an outlet guide vane, is assembled from a body having at recessed pocket formed therein, and an aerodynamic cover bonded over the pocket. Both the cover and the body are constructed from materials which are not readily fusion weldable. The cover is attached to the body by a solid state bonding process, for example friction stir welding. The hollow component may also be built up from multiple individual components which are bonded to each other by a solid state bonding process such as friction stir welding.

Owner:GENERAL ELECTRIC CO

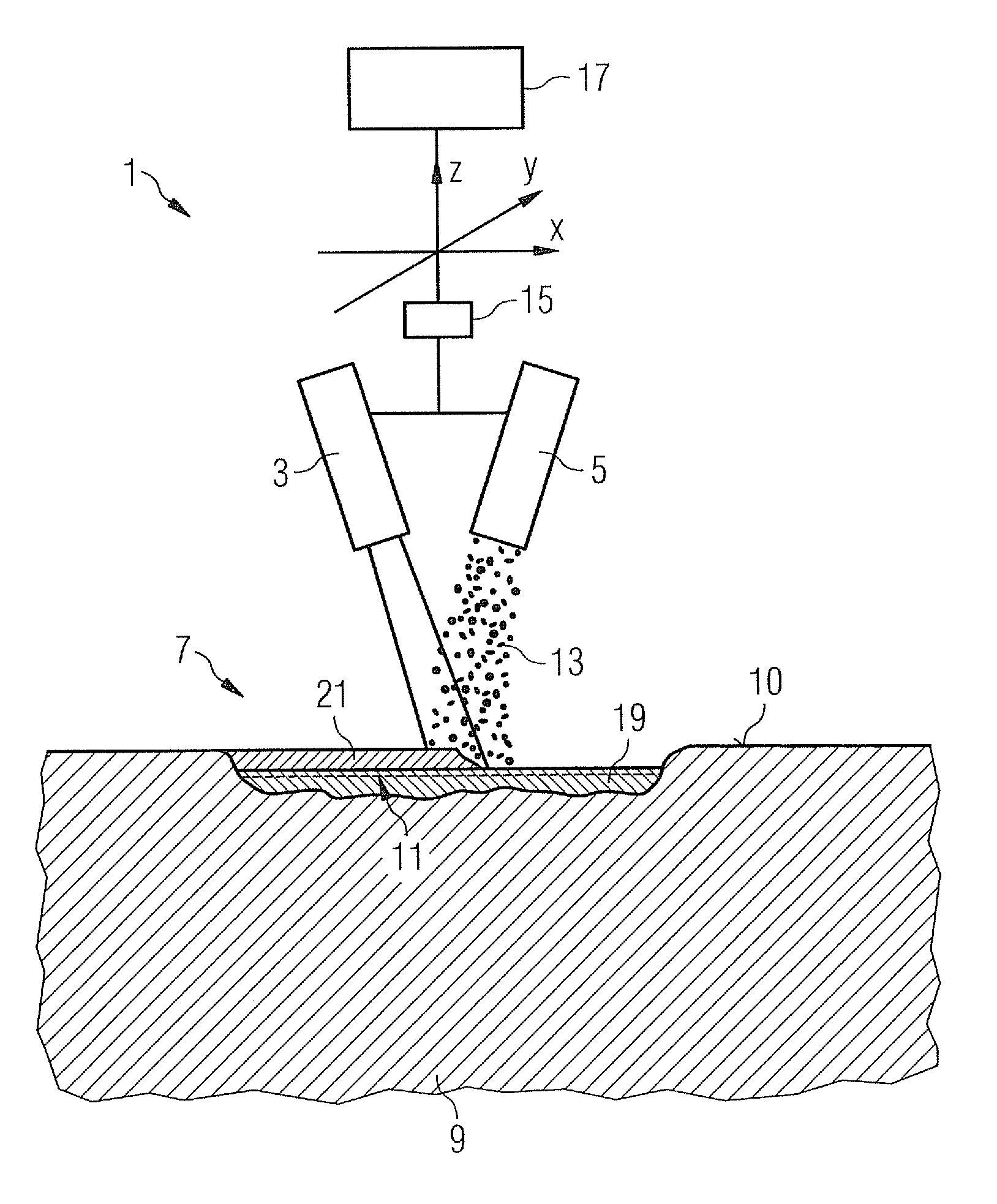

Method for welding workpieces made of highly heat-resistant superalloys, including a particular mass feed rate of the welding filler material

InactiveUS20120267347A1Improve cooling effectIncrease chanceTurbinesEngine manufactureHeat resistanceRelative motion

A welding method for welding workpieces made of highly heat-resistant superalloys is provided. The method includes generating a heat input zone on the workpiece surface by means of a heat source, feeding welding filler material into the heat input zone by means of a feeding device, and generating a relative motion between the heat source and the feeding device on one hand and the workpiece surface on the other hand by means of a conveying device. Furthermore, according to the welding method, the mass feed rate is ≦350 mg / min.

Owner:SIEMENS AG +1

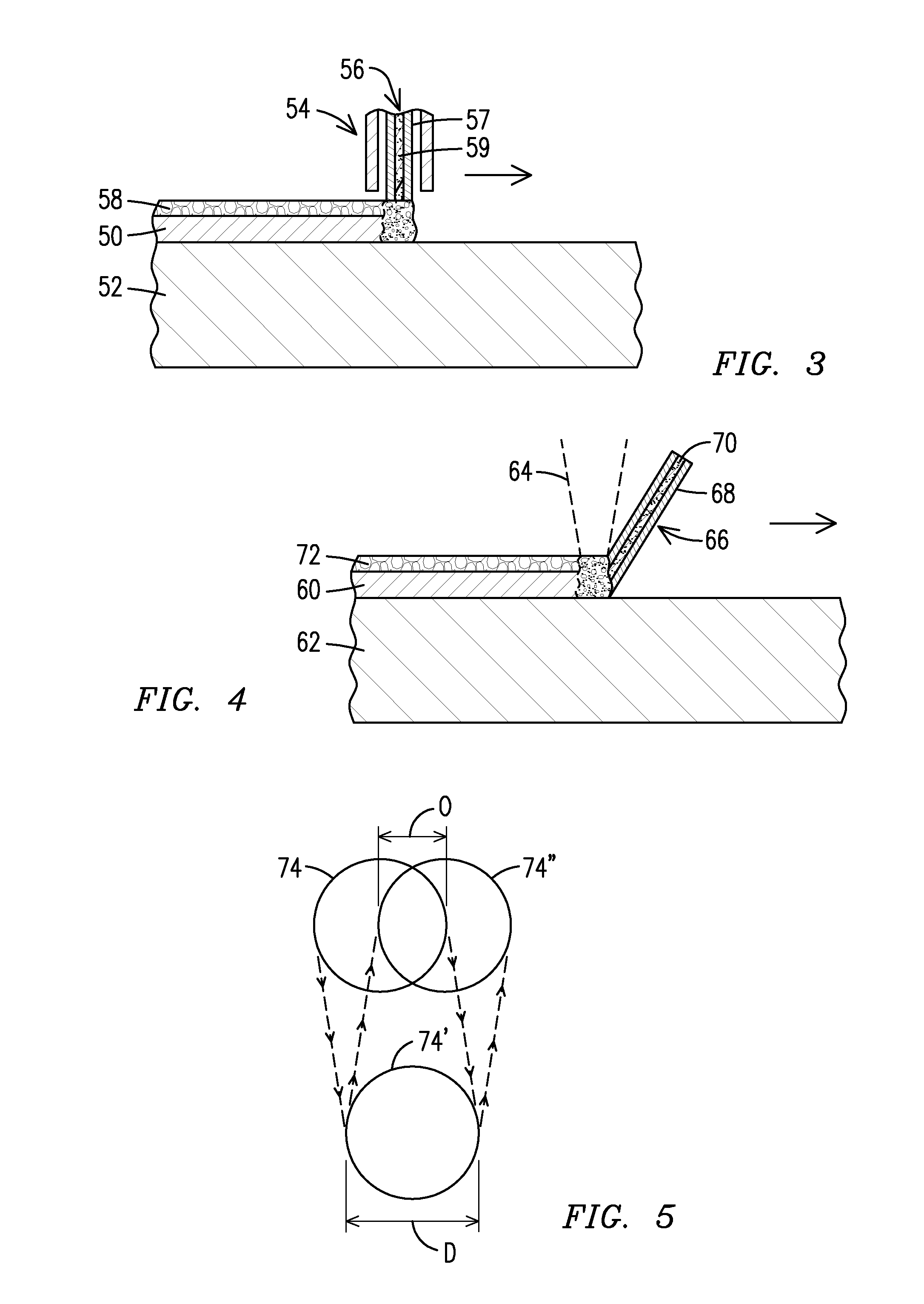

Deposition of superalloys using powdered flux and metal

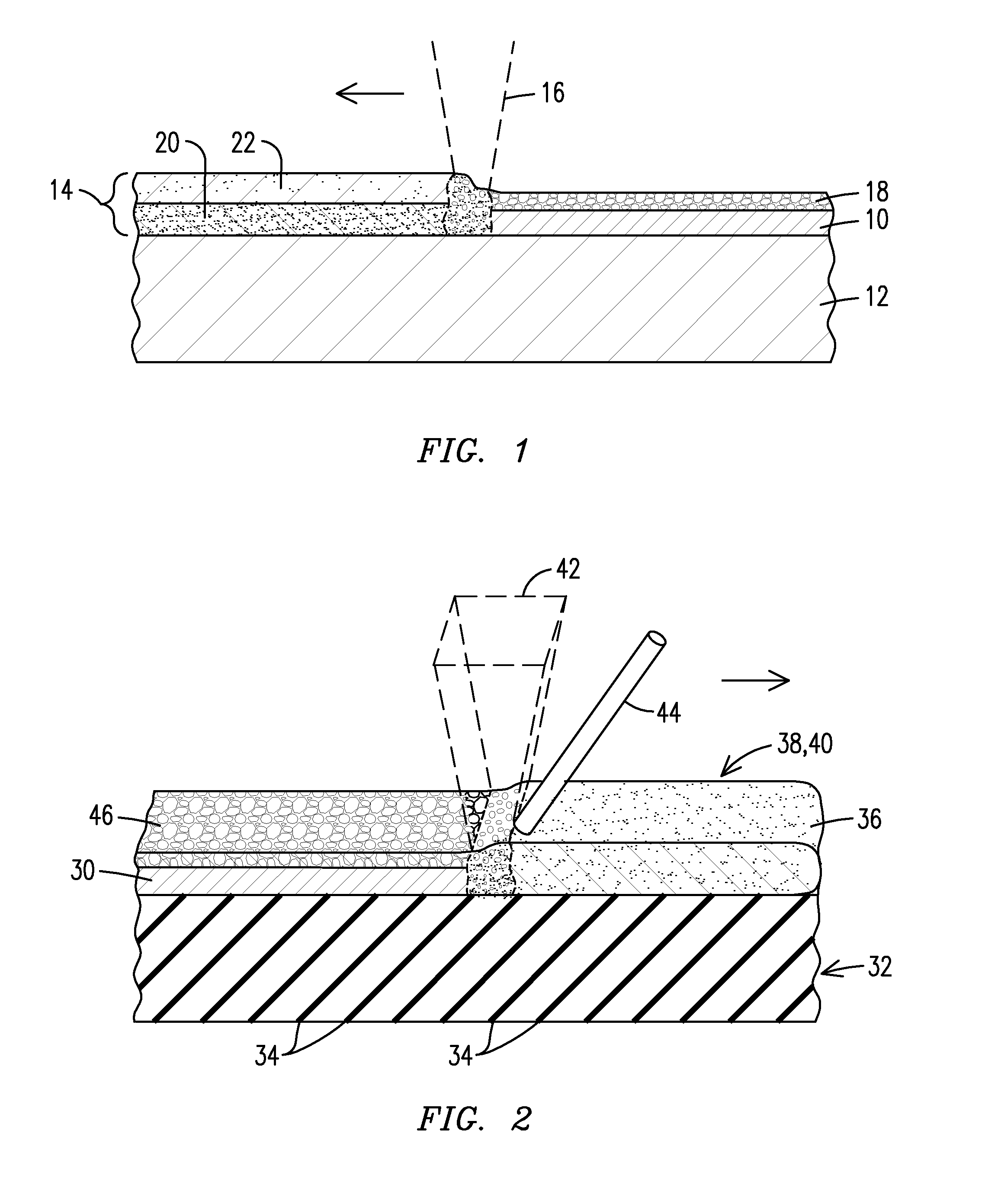

A method for depositing superalloy materials. A layer of powder (14) disposed over a superalloy substrate (12) is heated with an energy beam (16) to form a layer of superalloy cladding (10) and a layer of slag (18). The layer of powder includes flux material and alloy material, formed either as separate powders or as a hybrid particle powder. A layer of powdered flux material (22) may be placed over a layer of powdered metal (20), or the flux and metal powders may be mixed together (36). An extrudable filler material (44) such as nickel, nickel-chromium or nickel-chromium-cobalt wire or strip may be added to the melt pool to combine with the melted powder to give the superalloy cladding the composition of a desired superalloy material.

Owner:SIEMENS ENERGY INC

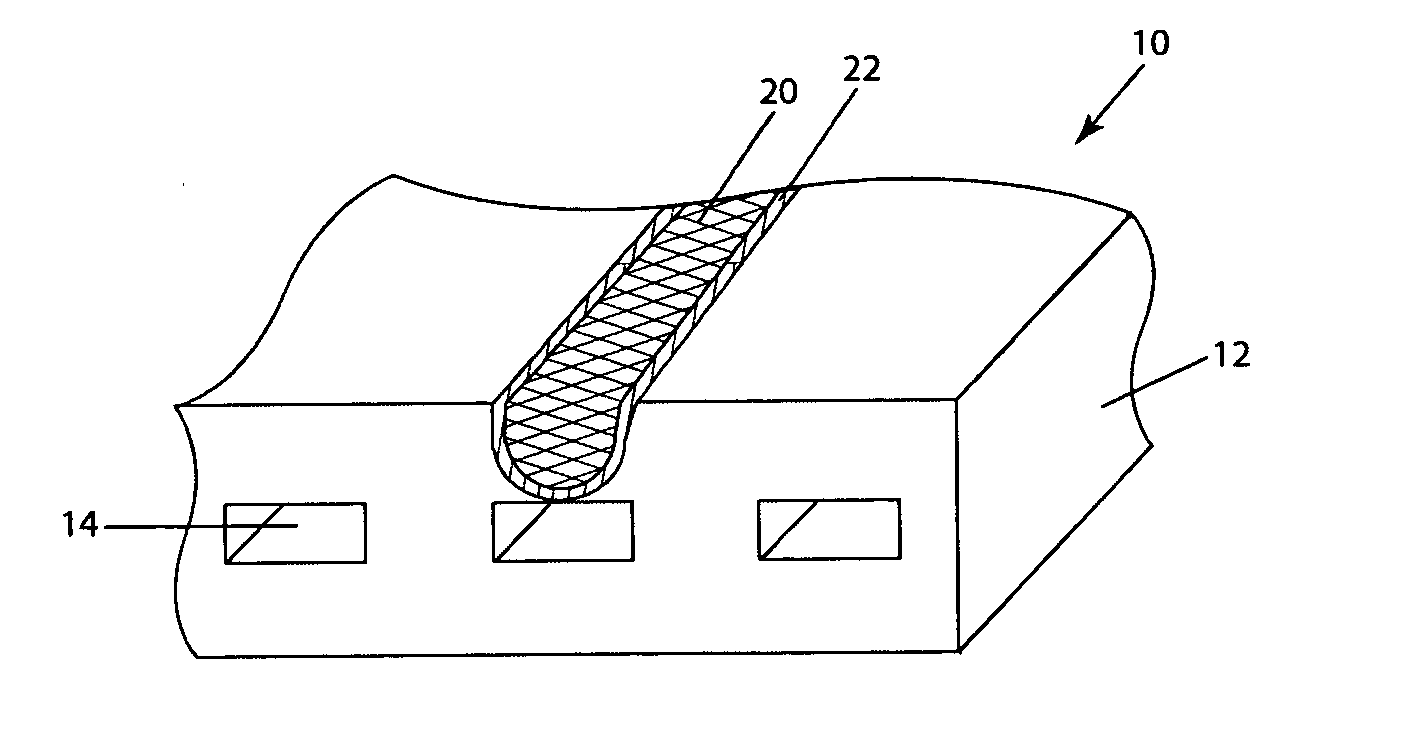

Repair of combustion turbine components

A method of repairing a combustion turbine component having damage located at or near a cooling hole or hollow or geometrically complex portion of the component is provided. The method comprises forming a preparatory groove that extends from a surface of the component to the damaged area but does not extend to the cooling hole or hollow or geometrically complex portion of the component, the groove extending 40-90% the distance from the component to the damaged area; spraying a filler material into the groove with a micro-plasma torch at a current of less than 50 amperes; and filling the groove with the filler material such that the heated filler material substantially extends from the cooling hole or hollow or geometrically complex portion of the component to a surface of the component.

Owner:SIEMENS ENERGY INC

Crack repair method

InactiveUS20050067466A1Rapid and inexpensive mannerMinimize cracksTurbinesArc welding apparatusCrazingGas turbines

A method of repairing cracks on a surface of a component such as gas turbine components includes the steps of repairing the cracks of the component by brazing, detecting remaining cracks on the surface or below the surface, which were not properly filled with braze material during the repair brazing operation, and repairing the crack zones with a focussed low-heat input welding method using an appropriate weld filler materials.

Owner:ALSTOM TECH LTD

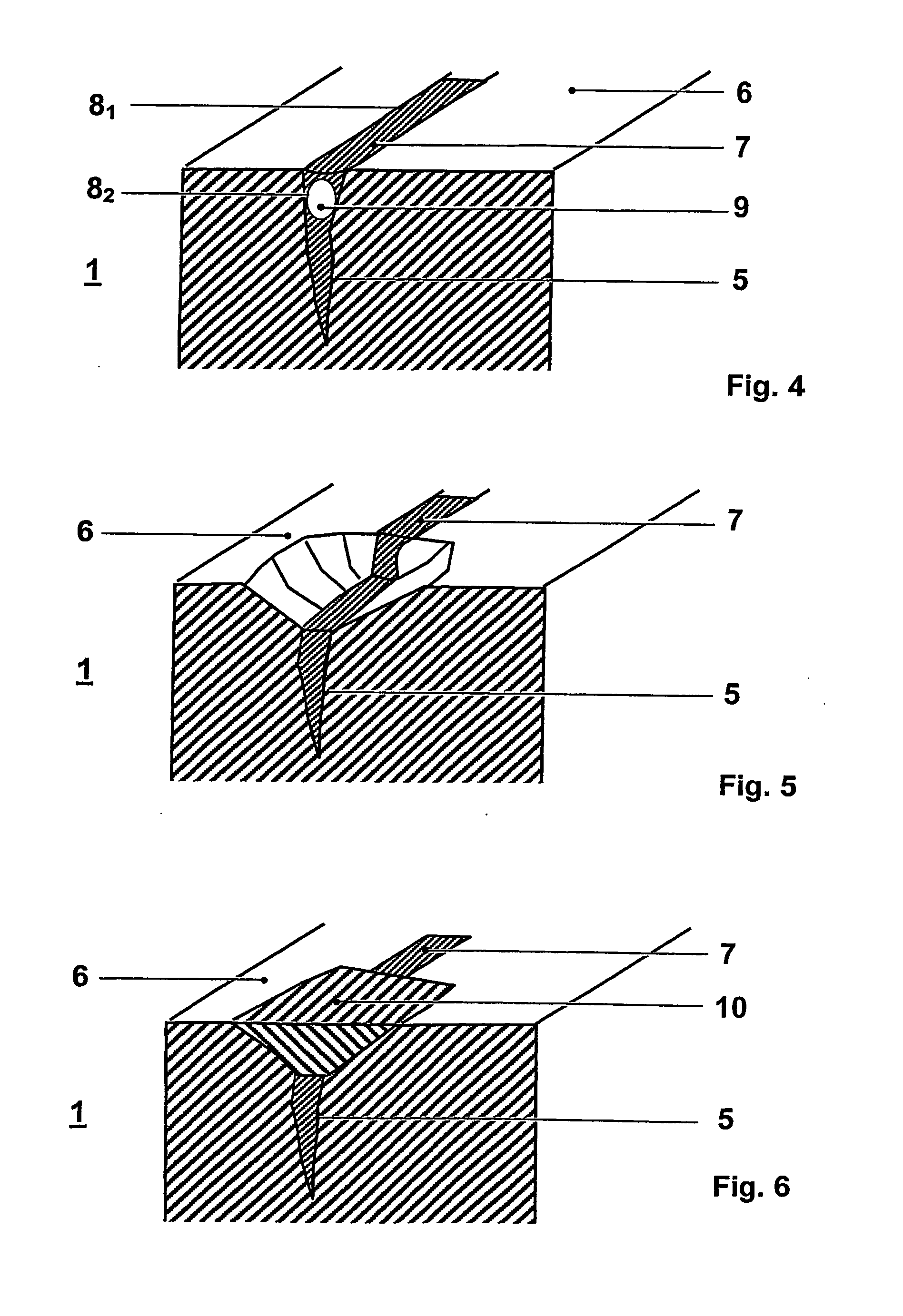

Systems and methods for automated sensing and machining for repairing airfoils of blades

InactiveUS6912446B2AdaptableEasy maintenanceProgramme controlTurbinesNumerical controlData acquisition

A method for repairing an airfoil comprising creating a nominal numerically-controlled tool path based on a nominal shape of the airfoil, measuring the airfoil using a displacement sensor, capturing differences in the airfoil shape as compared to the nominal shape, creating a three-dimensional map by synchronizing x, y and z coordinates and readings from the sensor, modifying the tool path based on the three-dimensional map, and machining the airfoil. A system for measuring and machining an airfoil comprising a computer operable for data acquisition and numerically-controlled tool path generation, a numerically-controlled machine, a cutting tool holder comprising a plurality of cutting tools, and a displacement-sensing probe.

Owner:GENERAL ELECTRIC CO

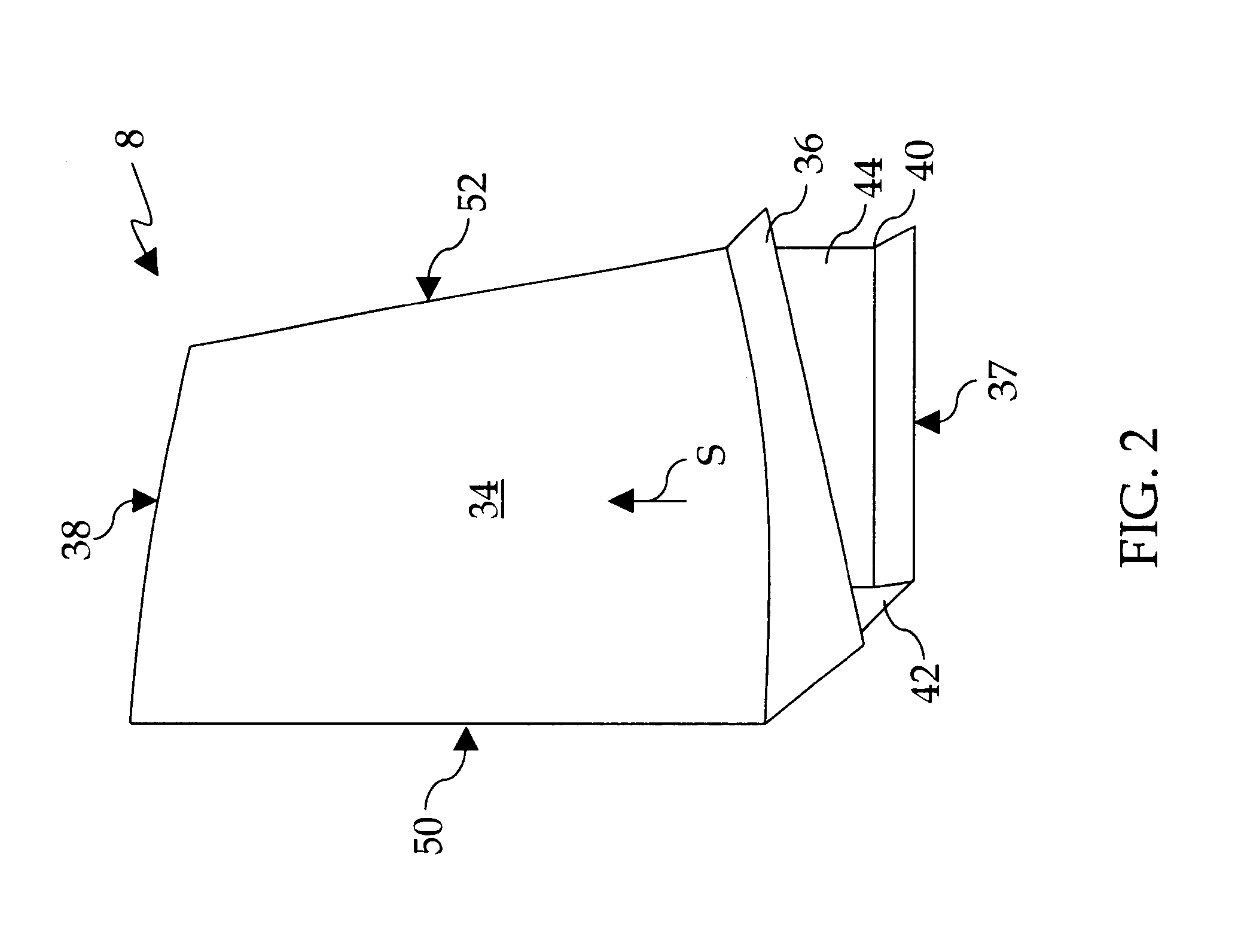

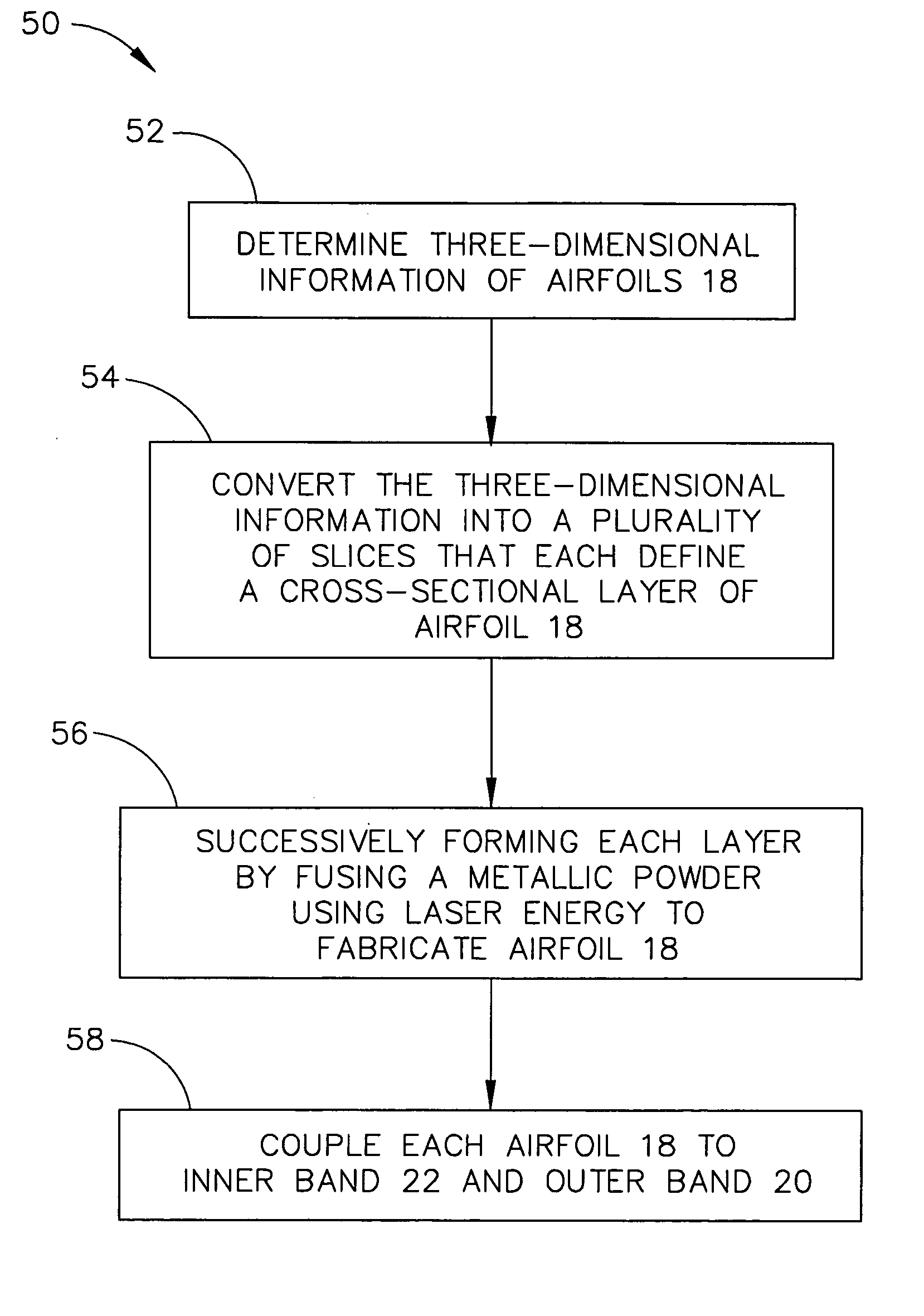

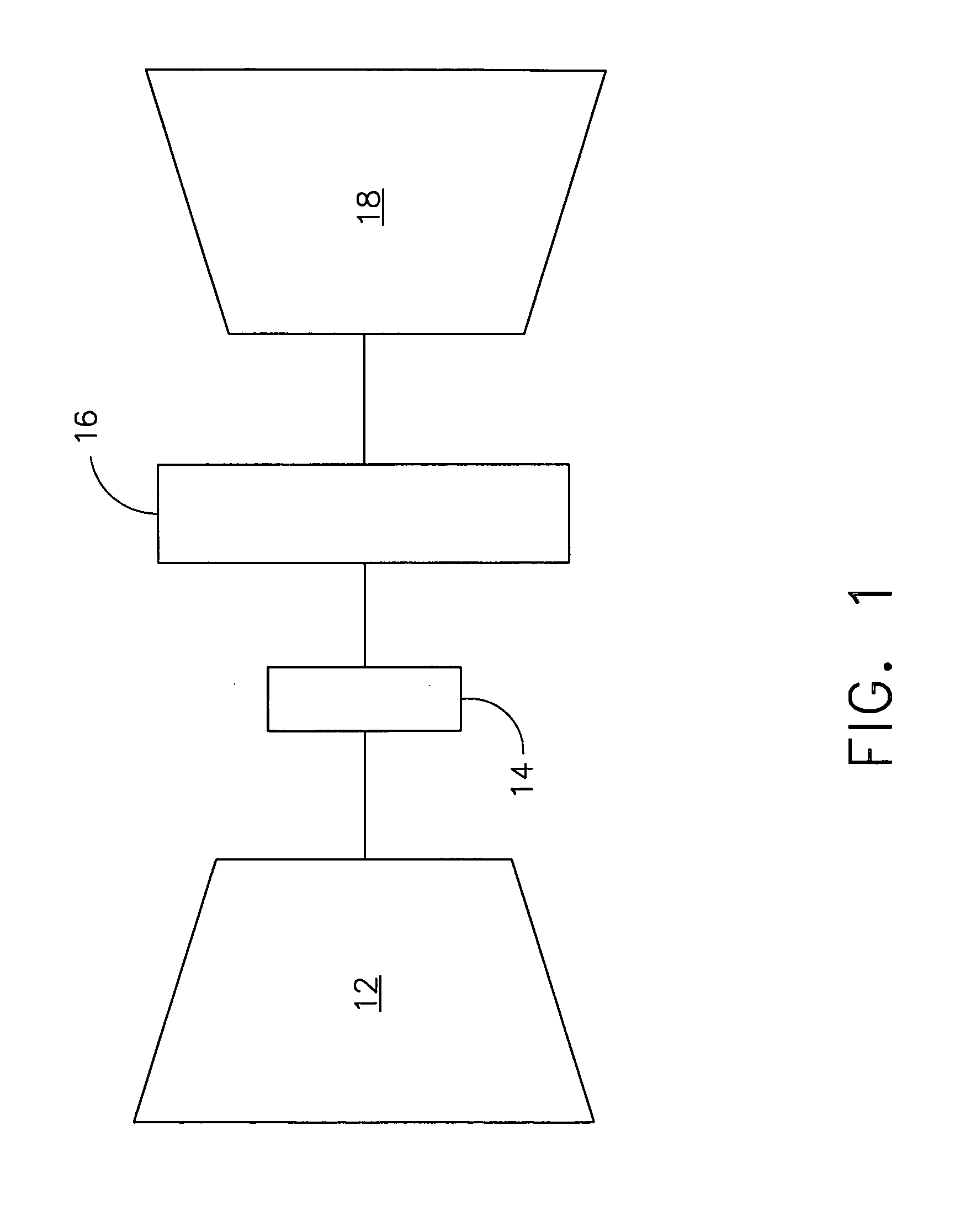

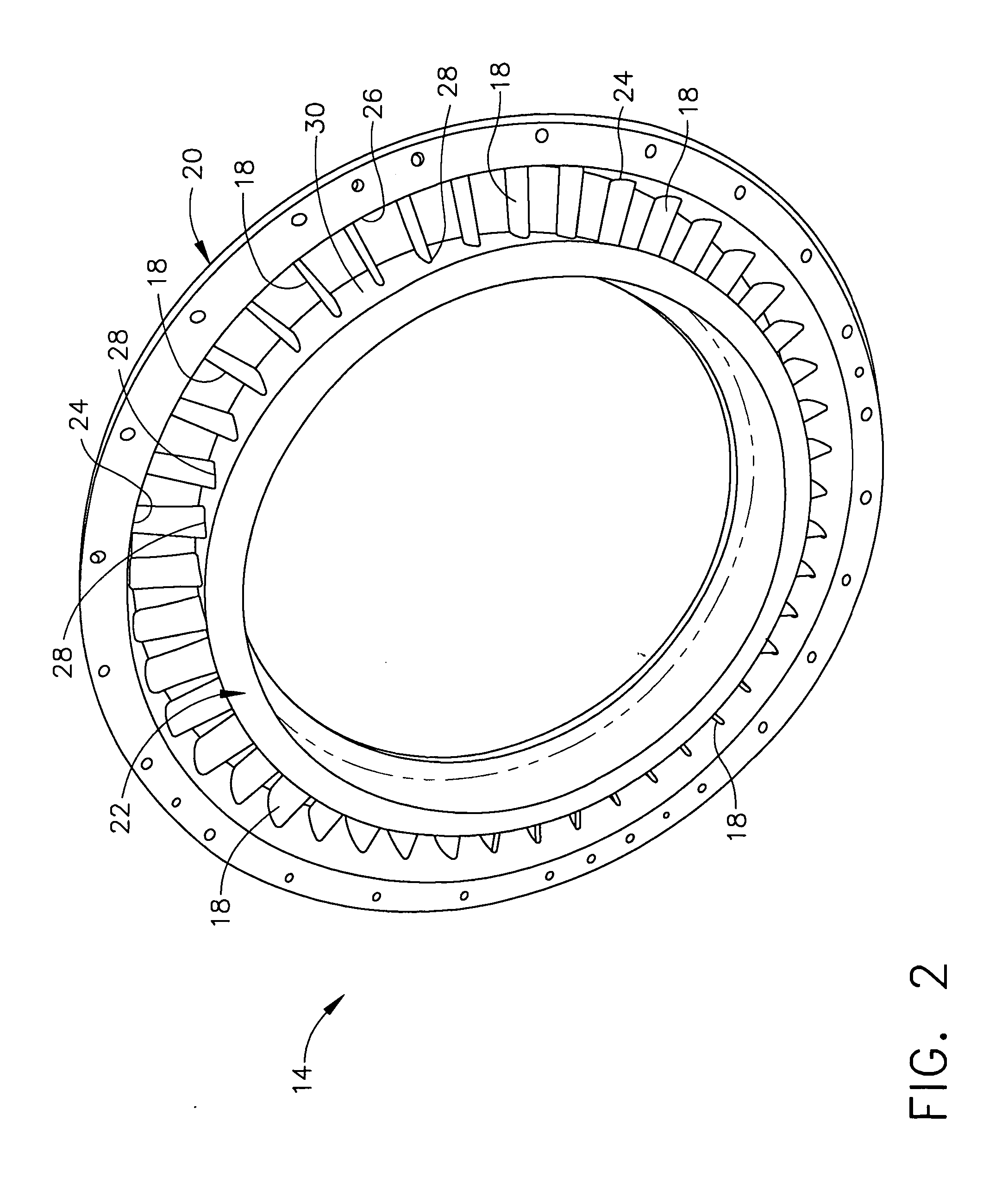

Methods for fabricating components

A method for fabricating an assembly having an airfoil extending radially outwardly from a member includes determining three-dimensional information of the airfoil, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the airfoil, successively forming each layer of the airfoil by fusing a metallic powder using laser energy, and coupling the airfoil to the member such that the airfoil extends radially outward from the member.

Owner:GENERAL ELECTRIC CO

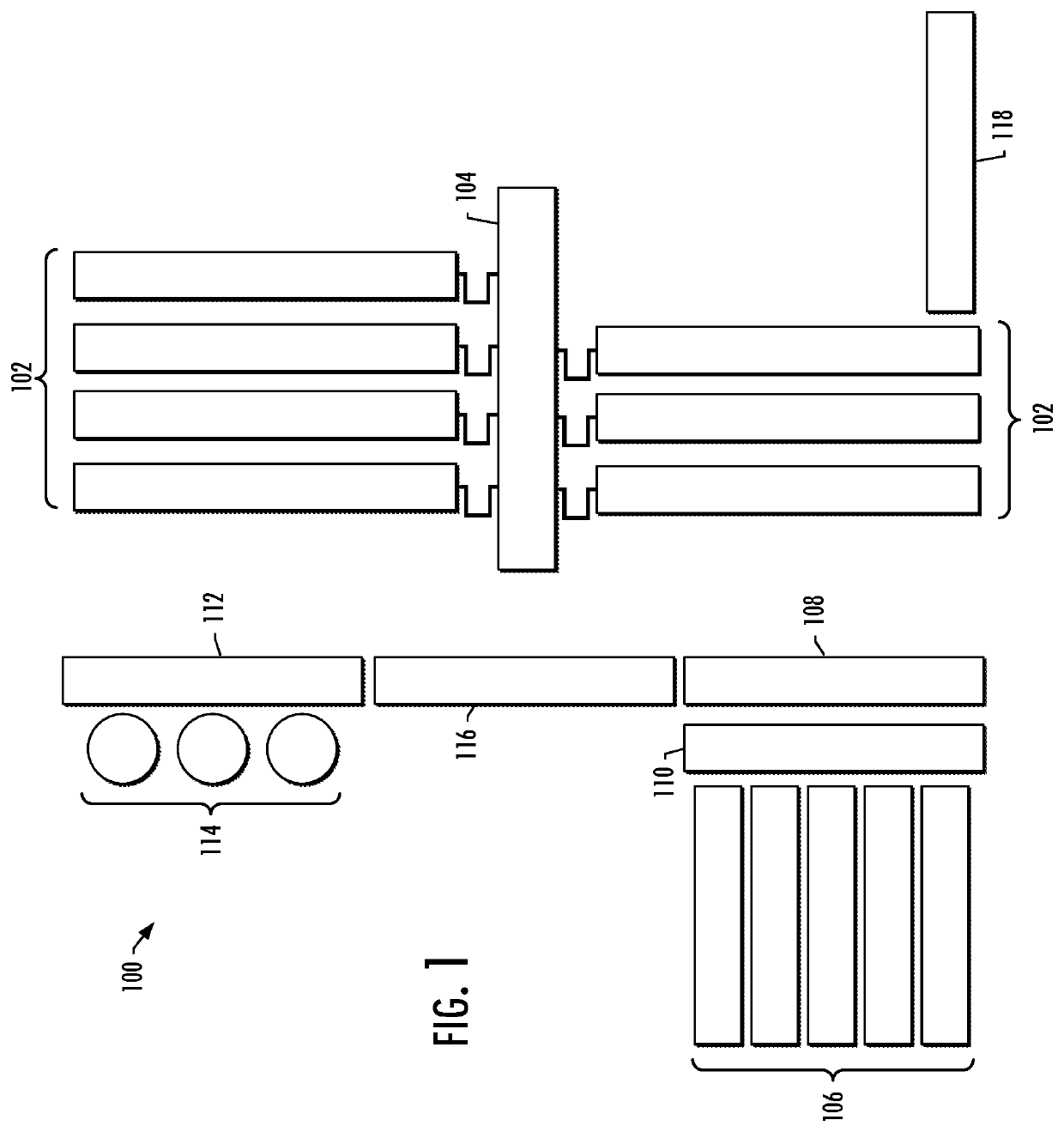

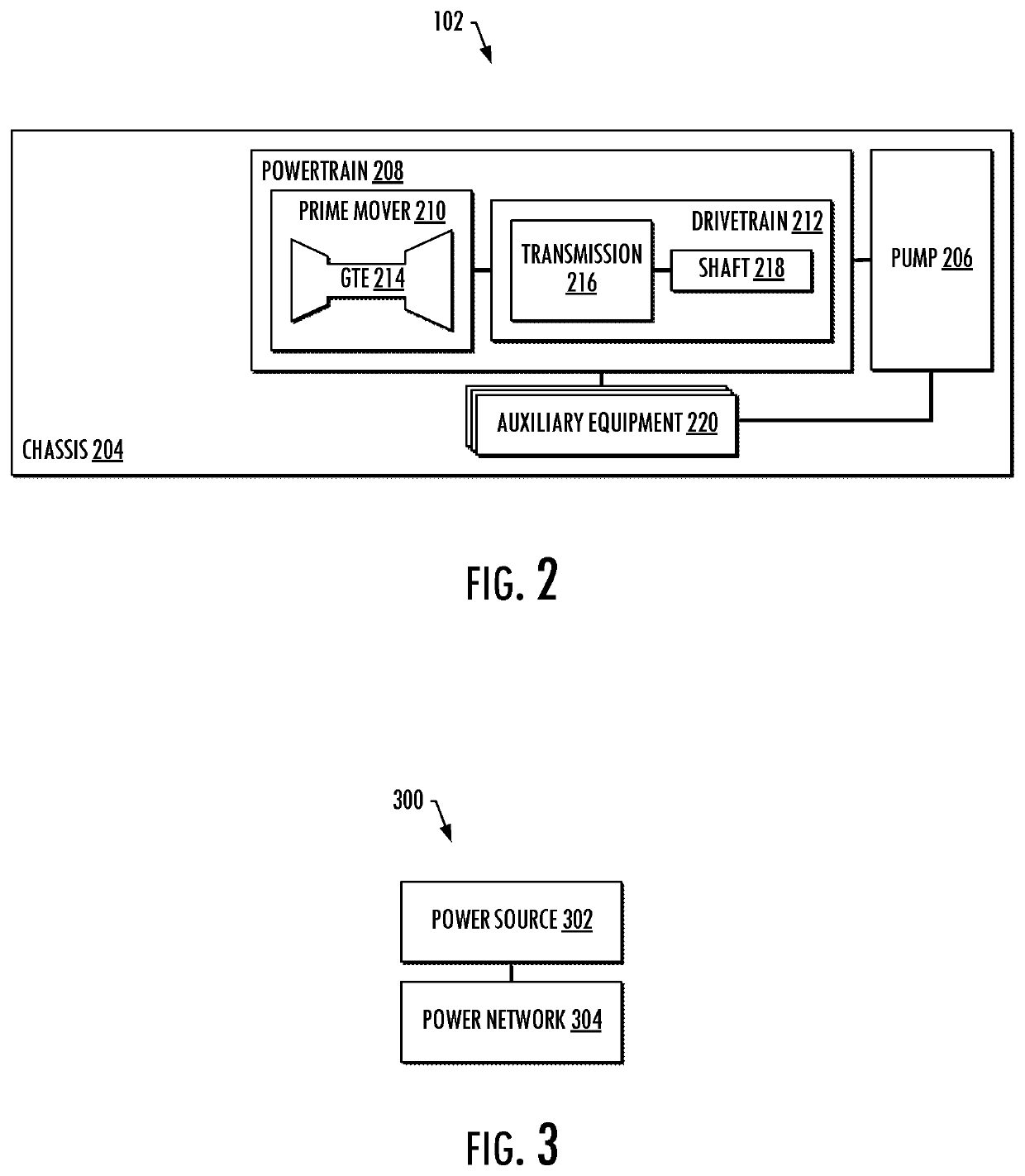

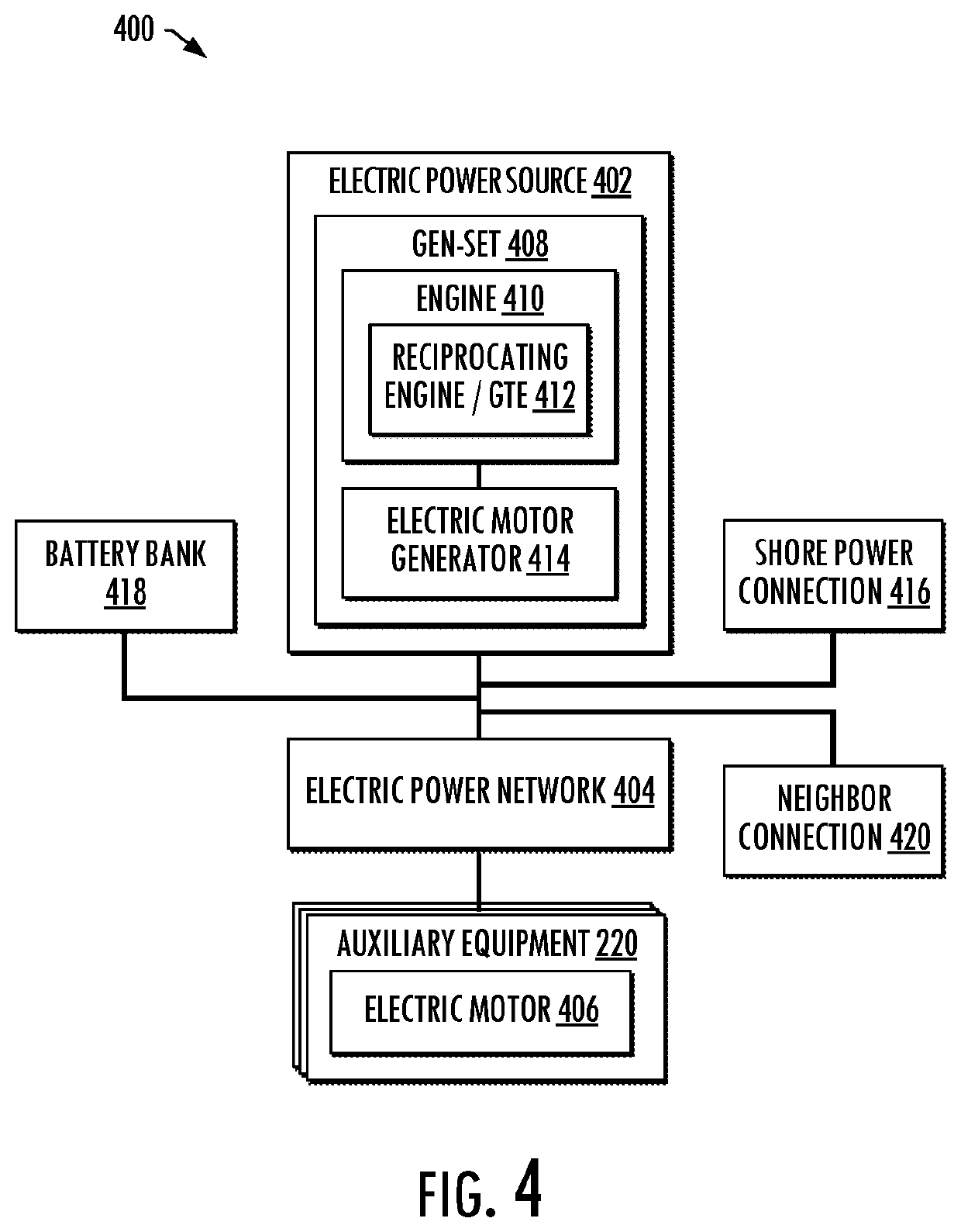

Power sources and transmission networks for auxiliary equipment onboard hydraulic fracturing units and associated methods

Embodiments of systems and methods disclosed provide a hydraulic fracturing unit that includes a reciprocating plunger pump configured to pump a fracturing fluid and a powertrain configured to power the reciprocating plunger pump. The powertrain includes a prime mover and a drivetrain, the prime mover including a gas turbine engine. The hydraulic fracturing unit also includes auxiliary equipment configured to support operation of the hydraulic fracturing unit including the reciprocating plunger pump and the powertrain. A power system is configured to power the auxiliary equipment. The power system includes a power source and a power network. The power source is configured to generate power for the auxiliary equipment. The power network is coupled to the power source and the auxiliary equipment, and configured to deliver the power generated by the power source to the auxiliary equipment. Associated systems including a plurality of hydraulic fracturing units are also provided.

Owner:BJ ENERGY SOLUTIONS LLC

Method for the manufacture or repair of a blisk by linear friction welding

A method of making a BLISK by linear friction welding, comprises providing a stub on the circumferential surface of a turbine disk and defining a weld joint surface on the radially outermost face of the stub. The weld joint surface follows the annulus curvature in axial and circumferential directions while remaining flat in a third direction. A blade is applied radially to the stub and linear friction welding of the blade to the stub is effected by oscillating the blade in said third direction while applying a welding force inwardly along the blade.

Owner:ROLLS ROYCE PLC

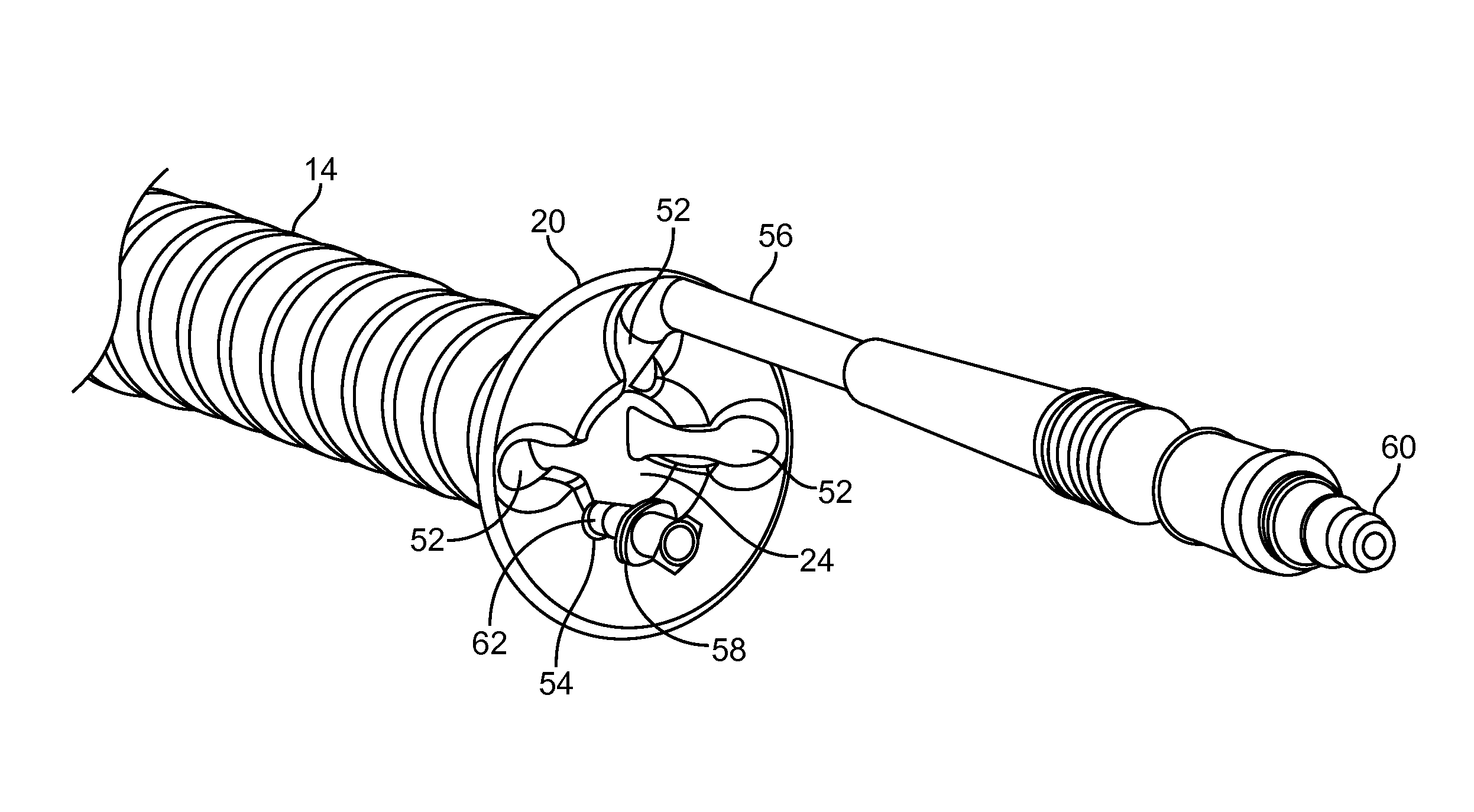

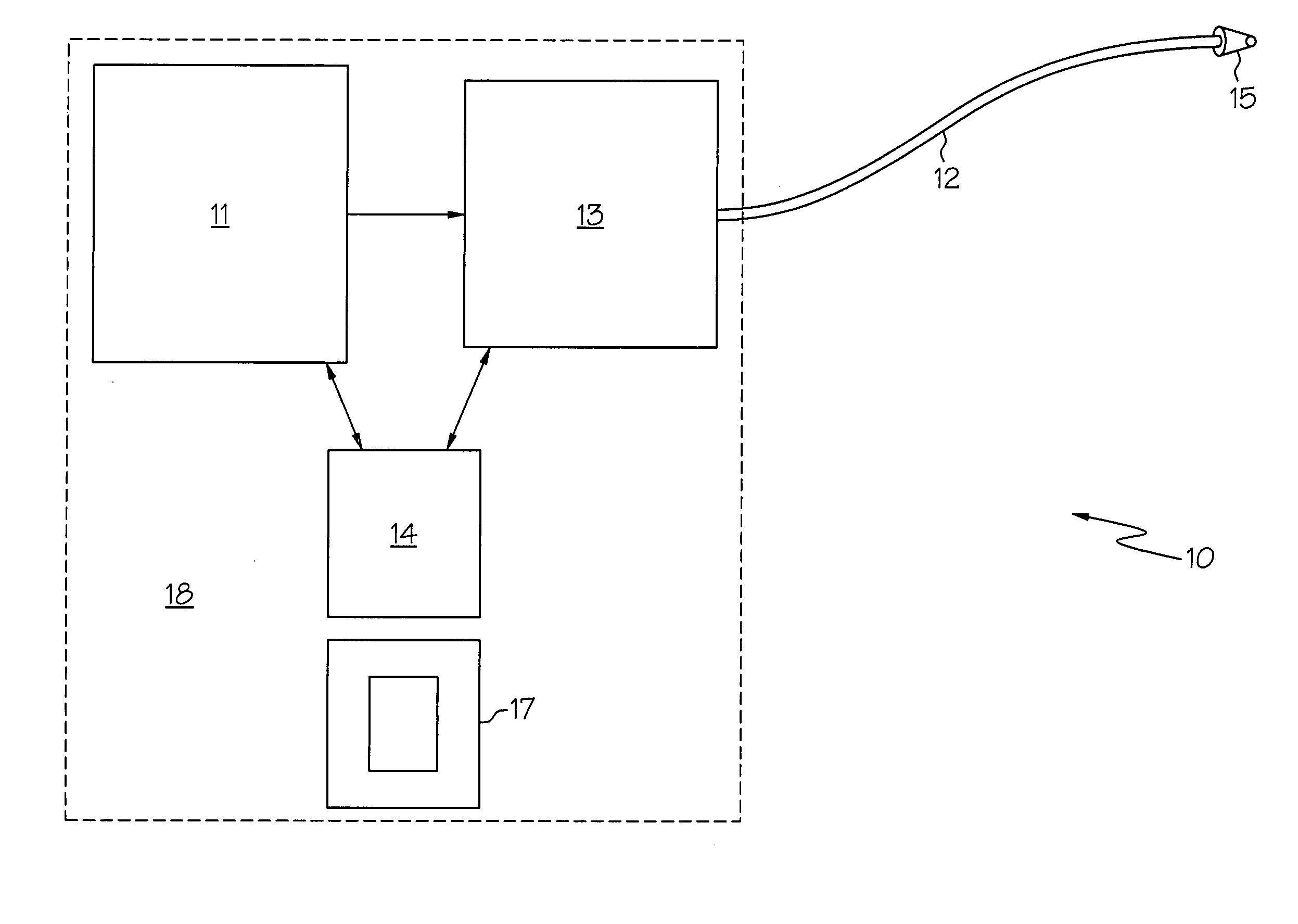

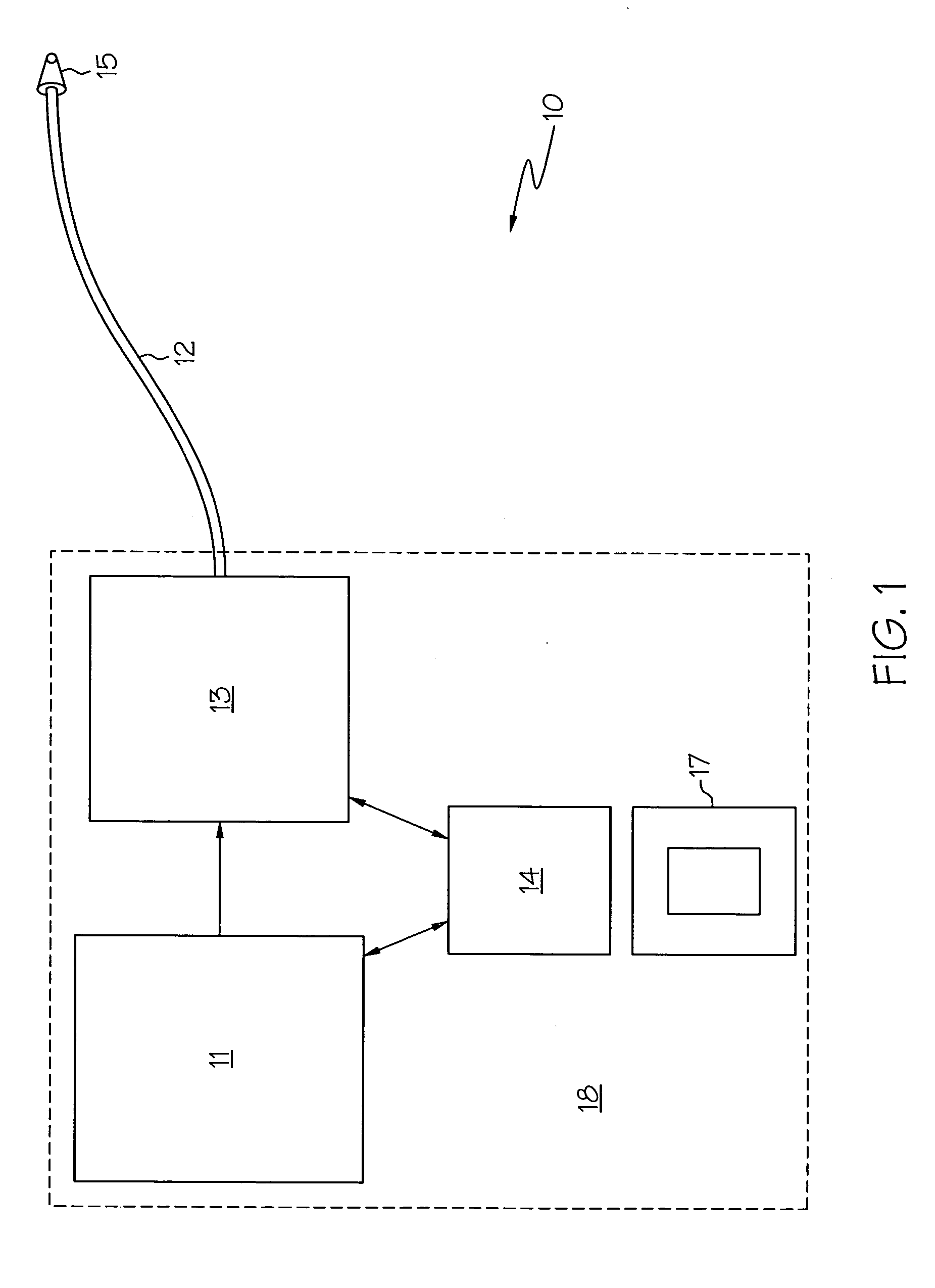

Repair of turbines on wing

The present invention provides an apparatus for repairing turbine blades of a gas turbine engine by a laser welding operation. The method uses a miniaturized laser and related apparatus. The miniaturized laser is fed through a borescope access hole to a desired location such as a high pressure turbine blade. The laser is then powered and manipulated so as to perform the desired welding operation. Filler material may also be provided in situ to accomplish the welding procedure. The method realizes a significant cost savings to the vehicle operator in that repairs can be accomplished without the need to remove the engine or disassemble the engine.

Owner:HONEYWELL INT INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com