Patents

Literature

4251 results about "Spare part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spare part, spare, service part, repair part, or replacement part, is an interchangeable part that is kept in an inventory and used for the repair or replacement of failed units. Spare parts are an important feature of logistics engineering and supply chain management, often comprising dedicated spare parts management systems.

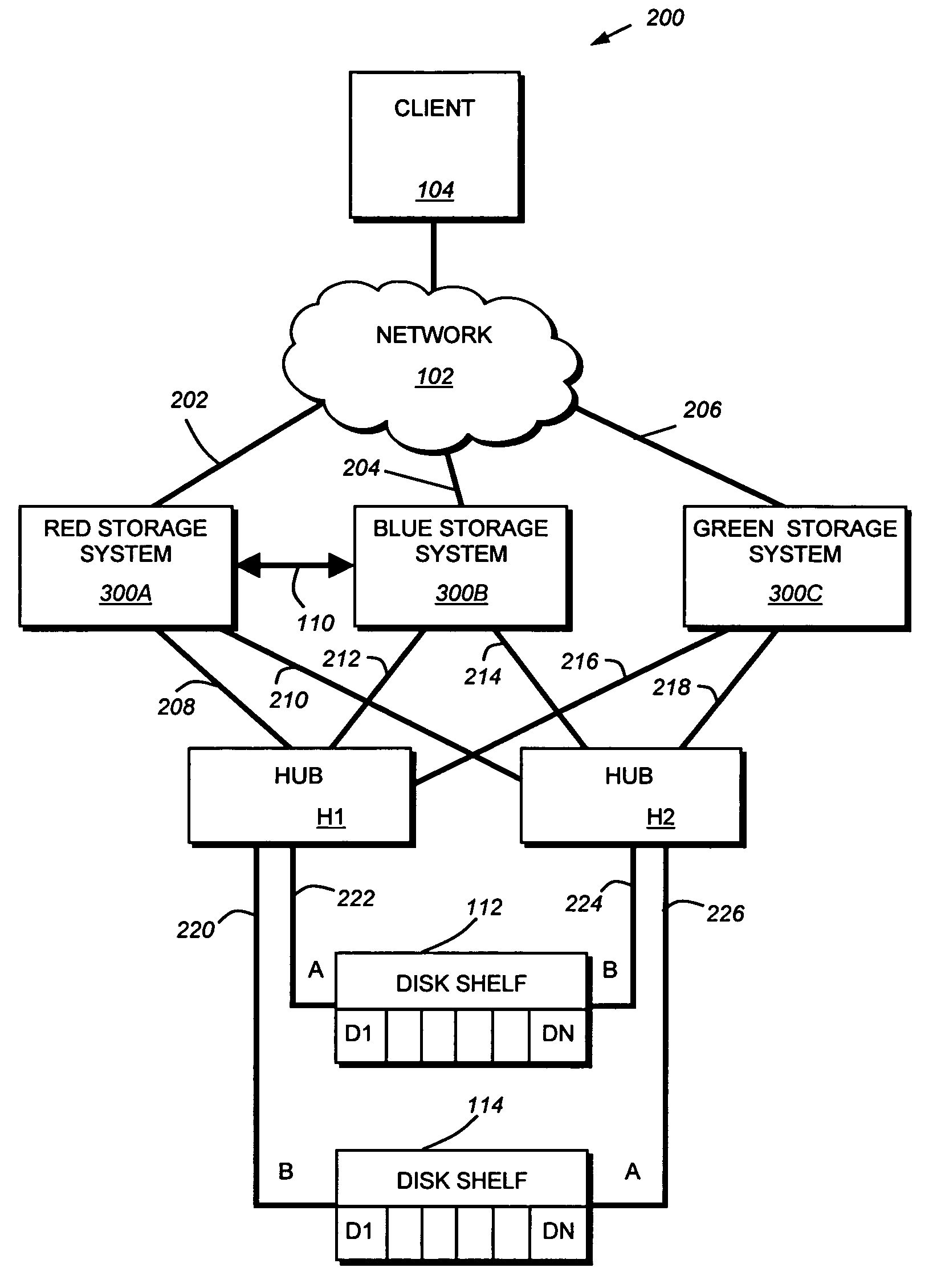

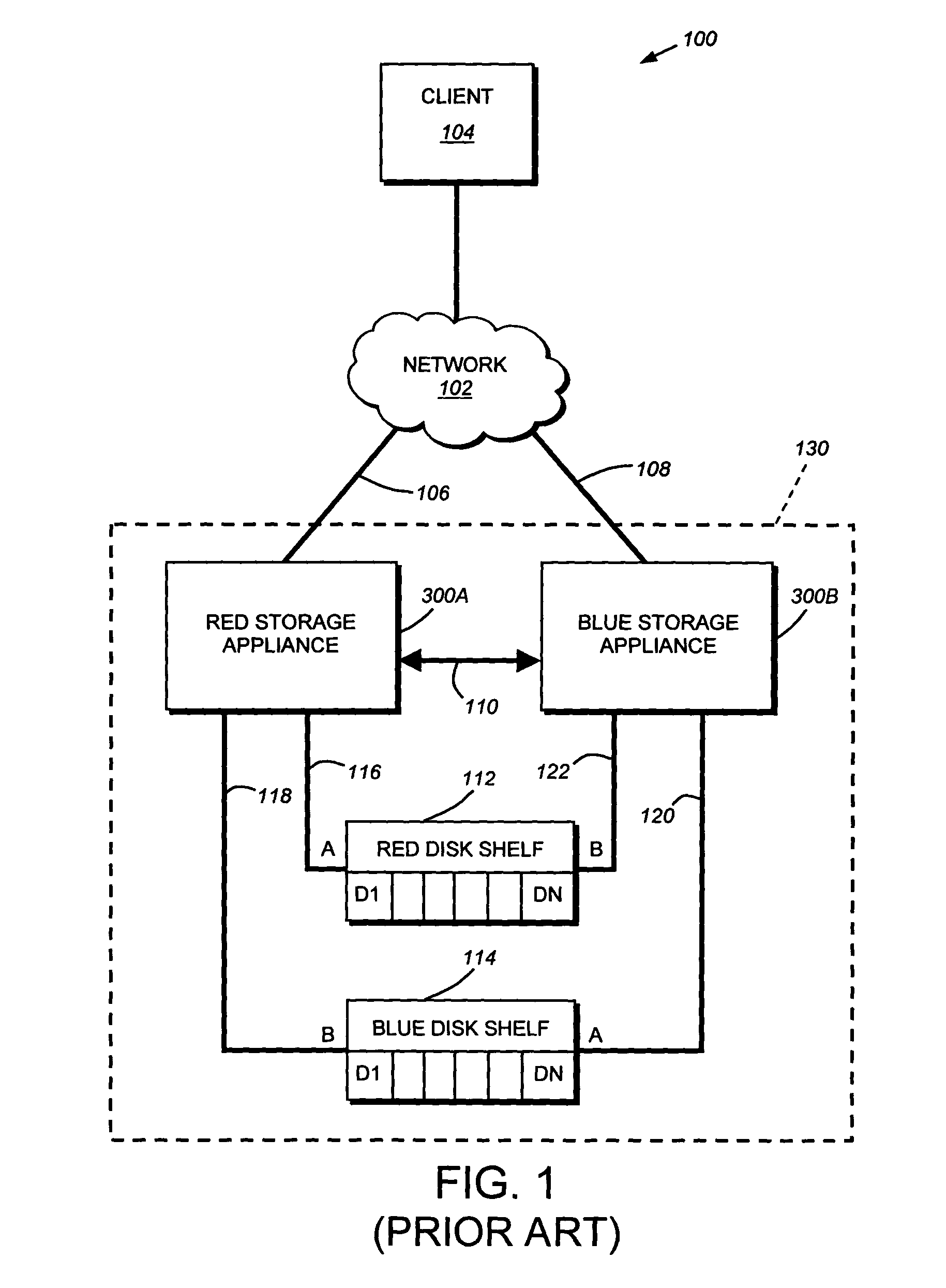

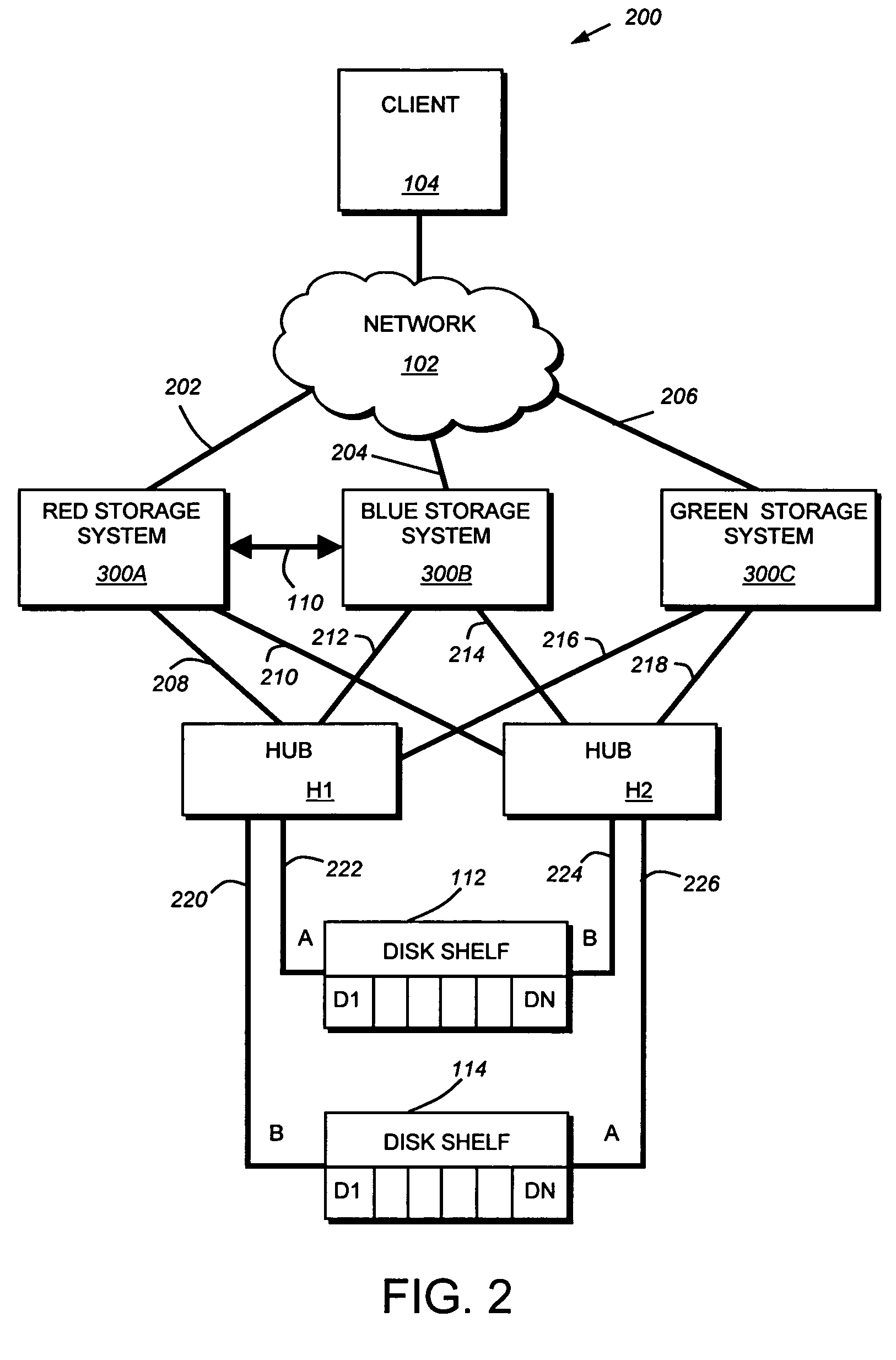

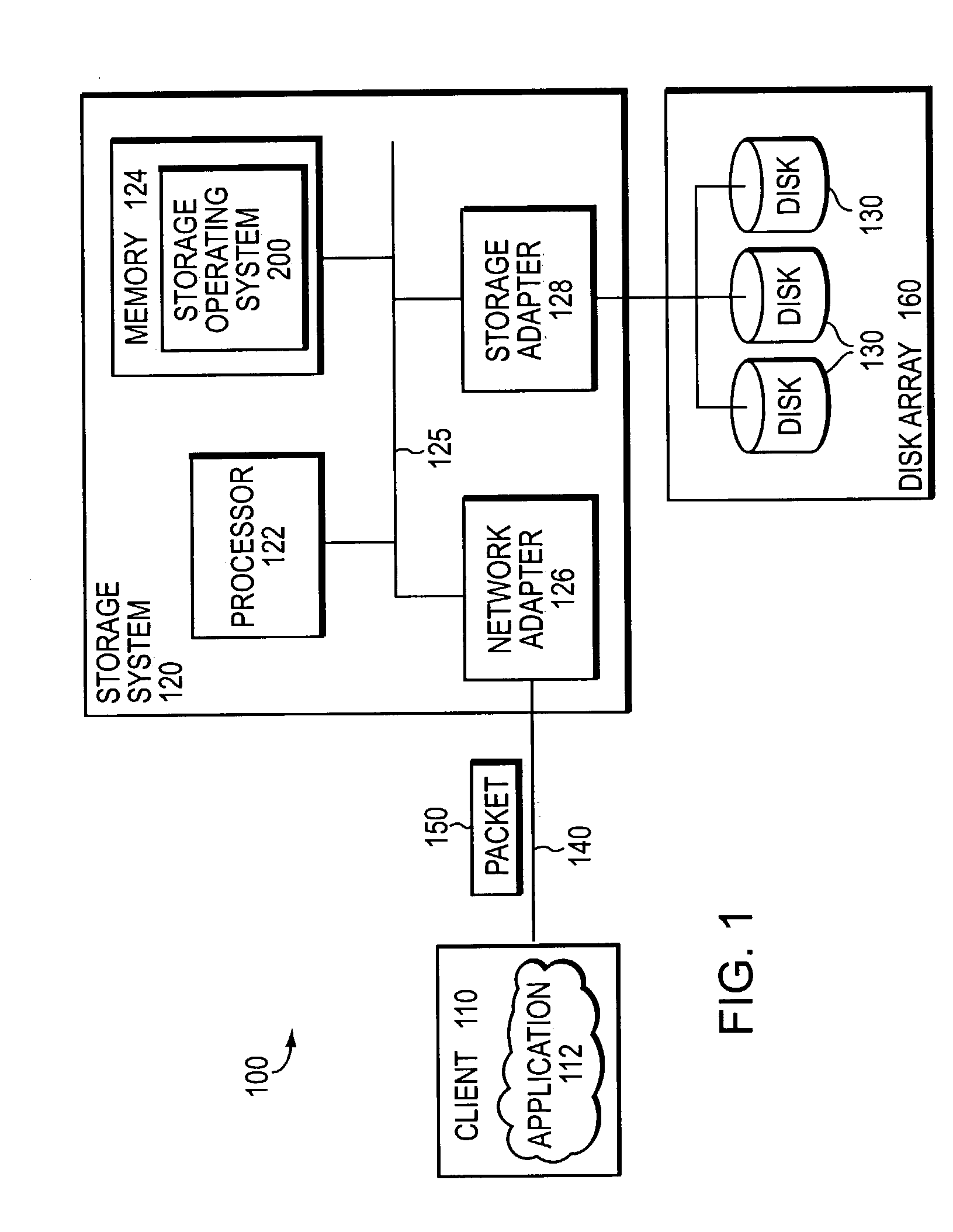

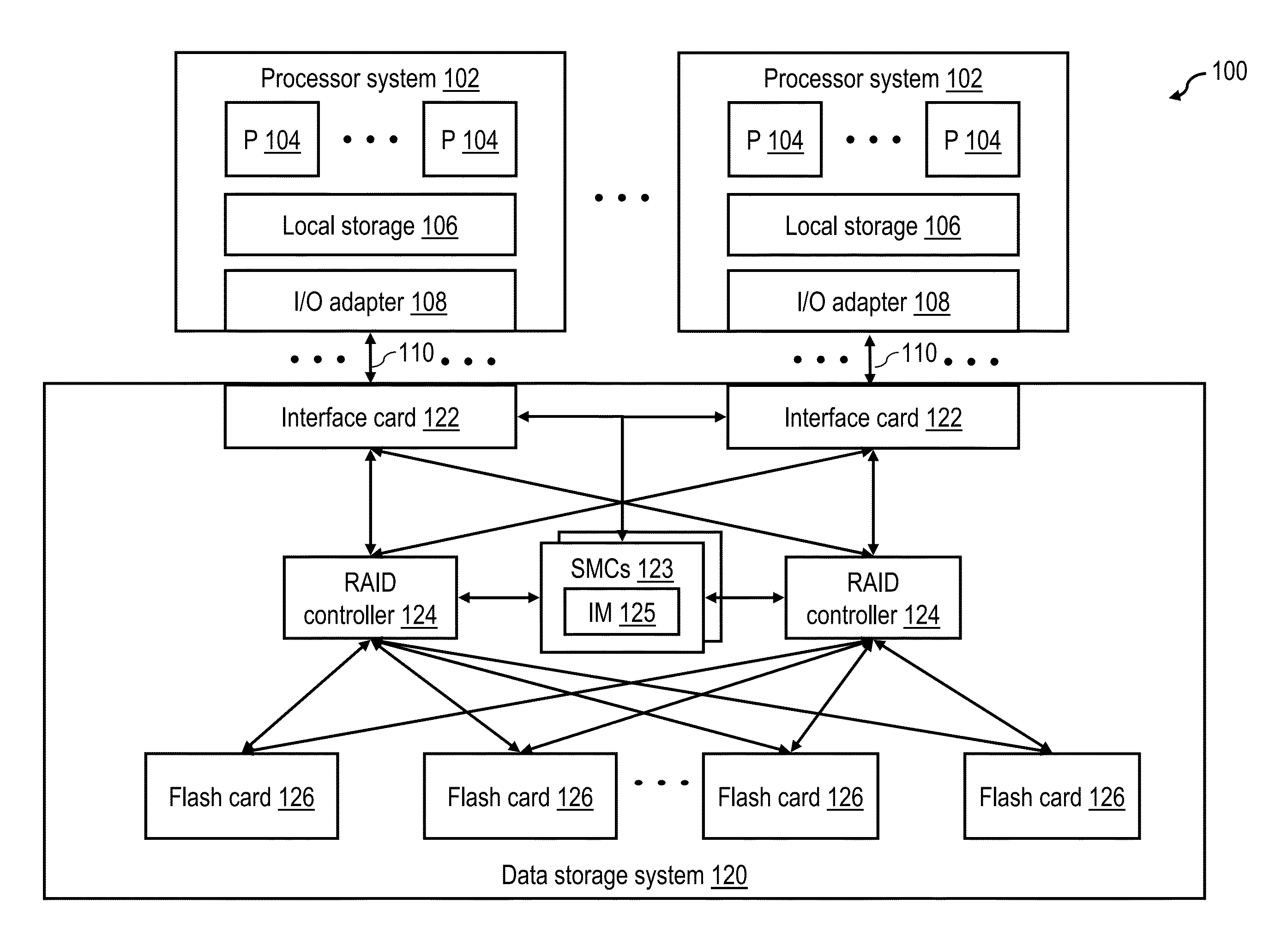

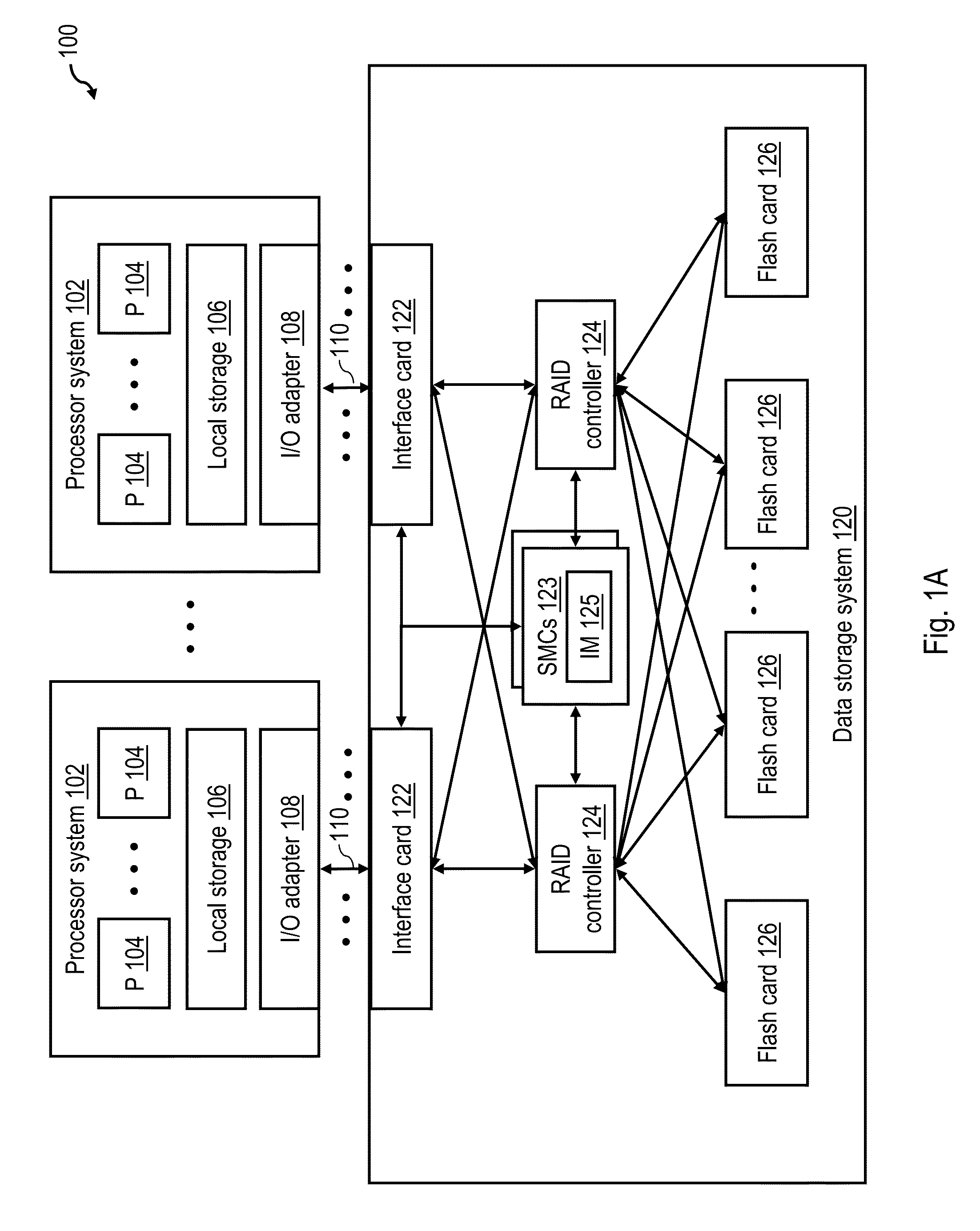

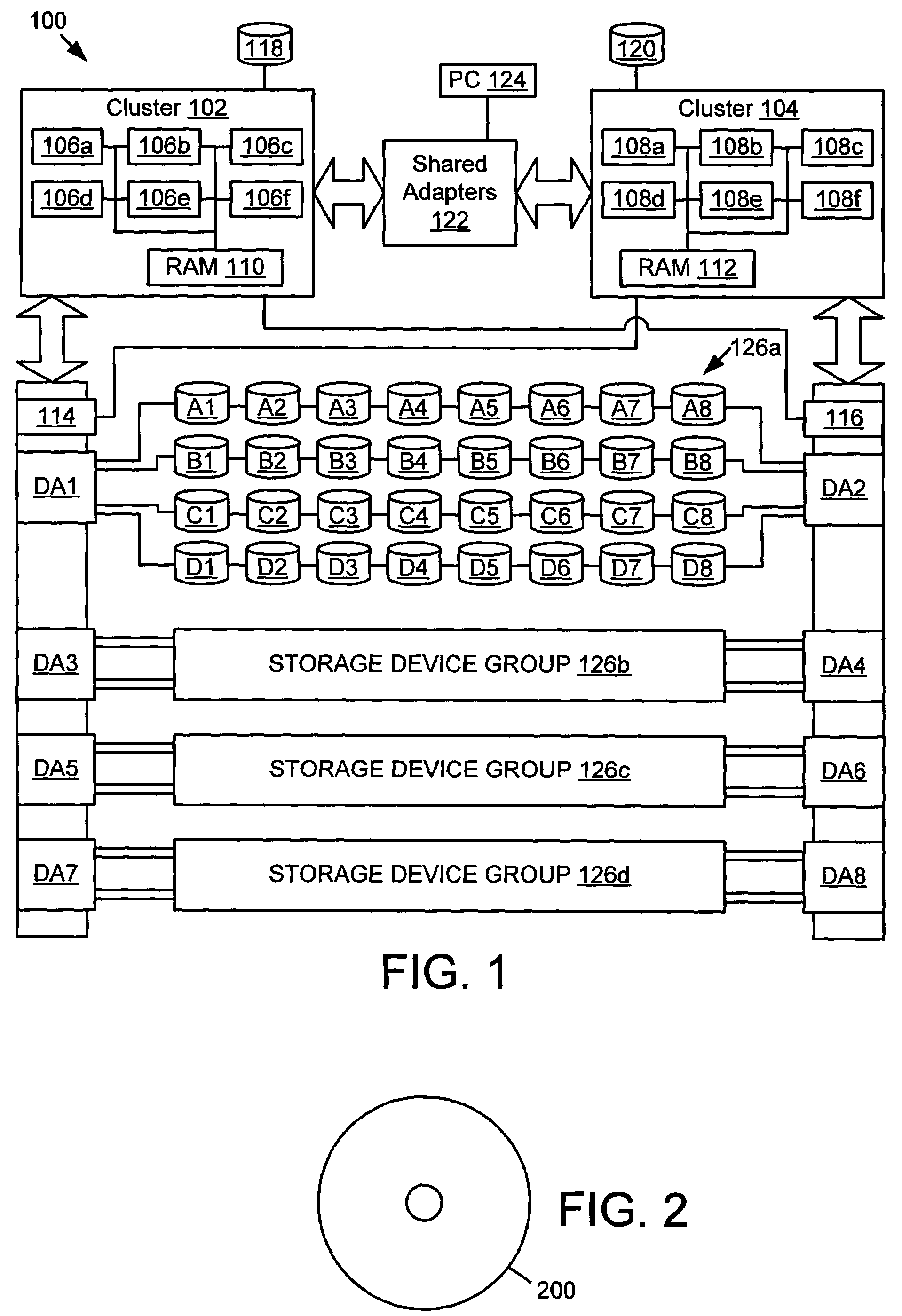

Coordinated shared storage architecture

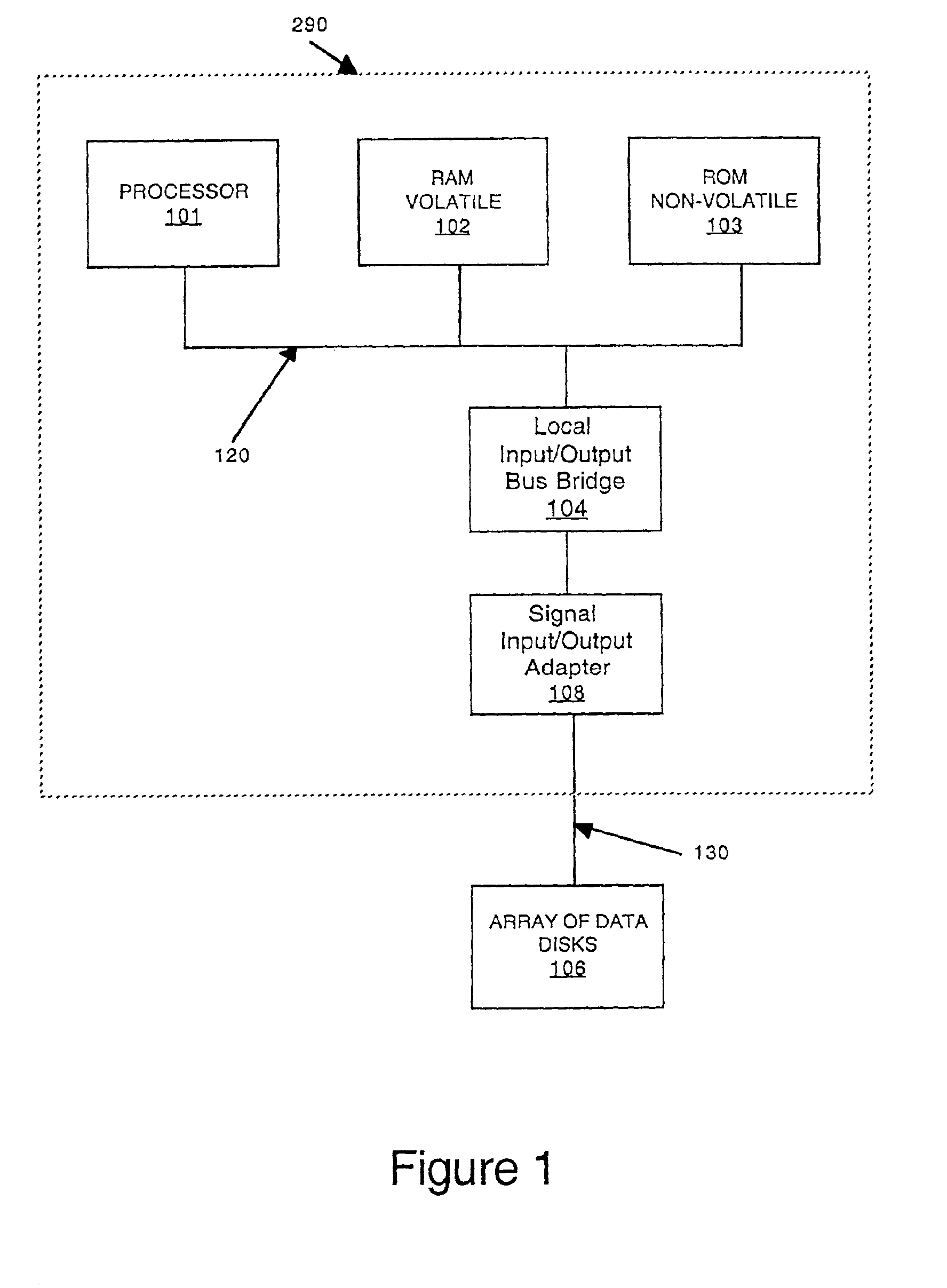

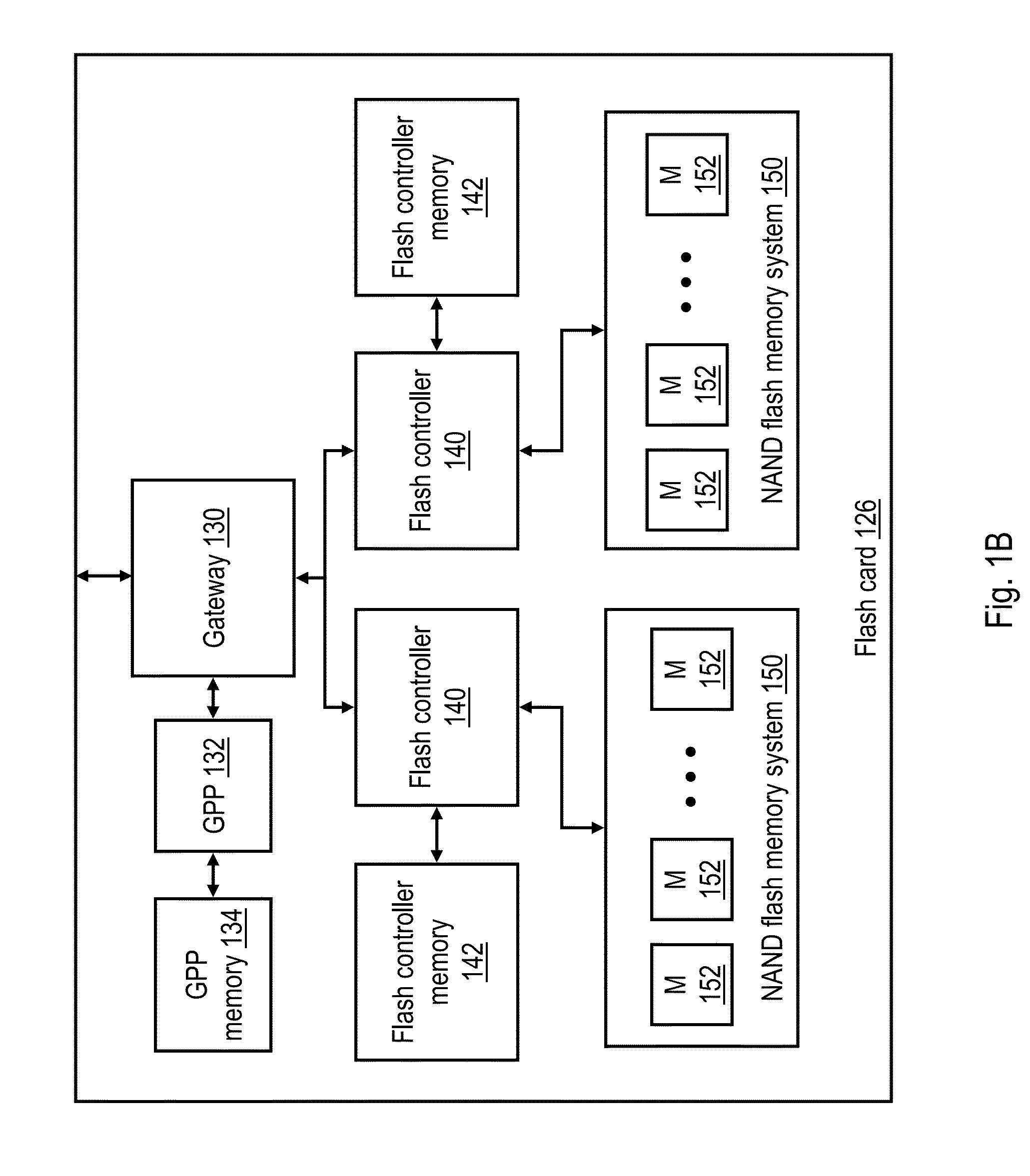

ActiveUS8180855B2Increase the number ofOvercome disadvantagesError detection/correctionMultiple digital computer combinationsSCSIComputer module

Owner:NETWORK APPLIANCE INC

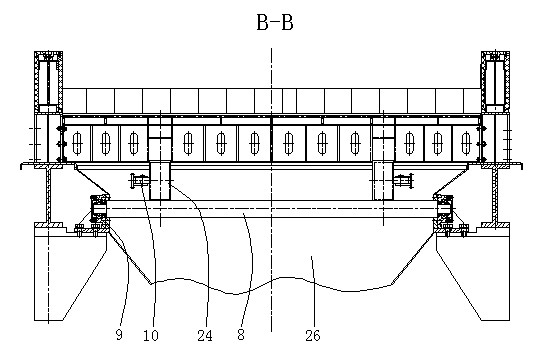

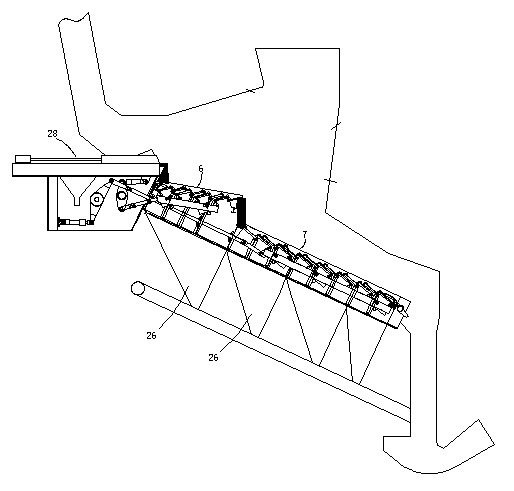

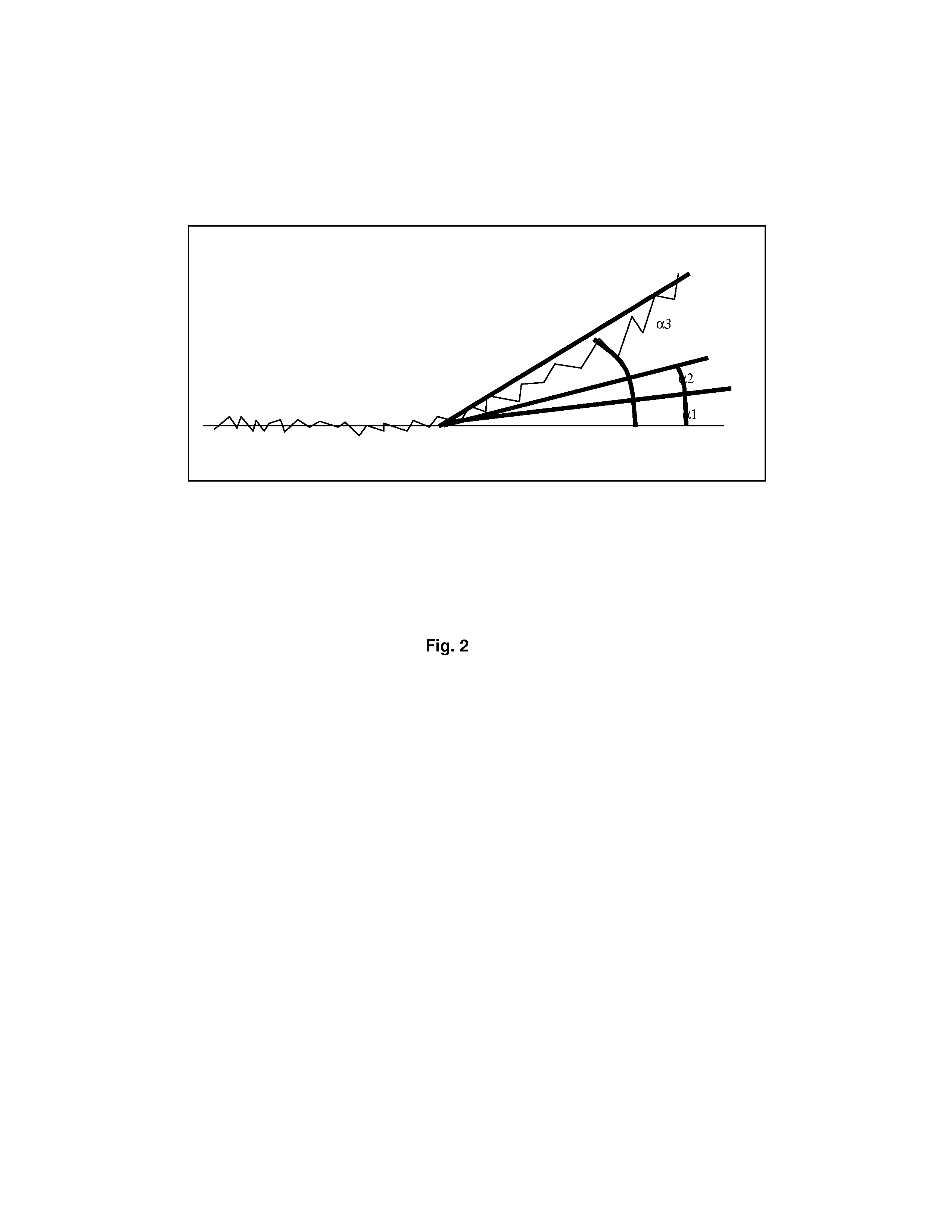

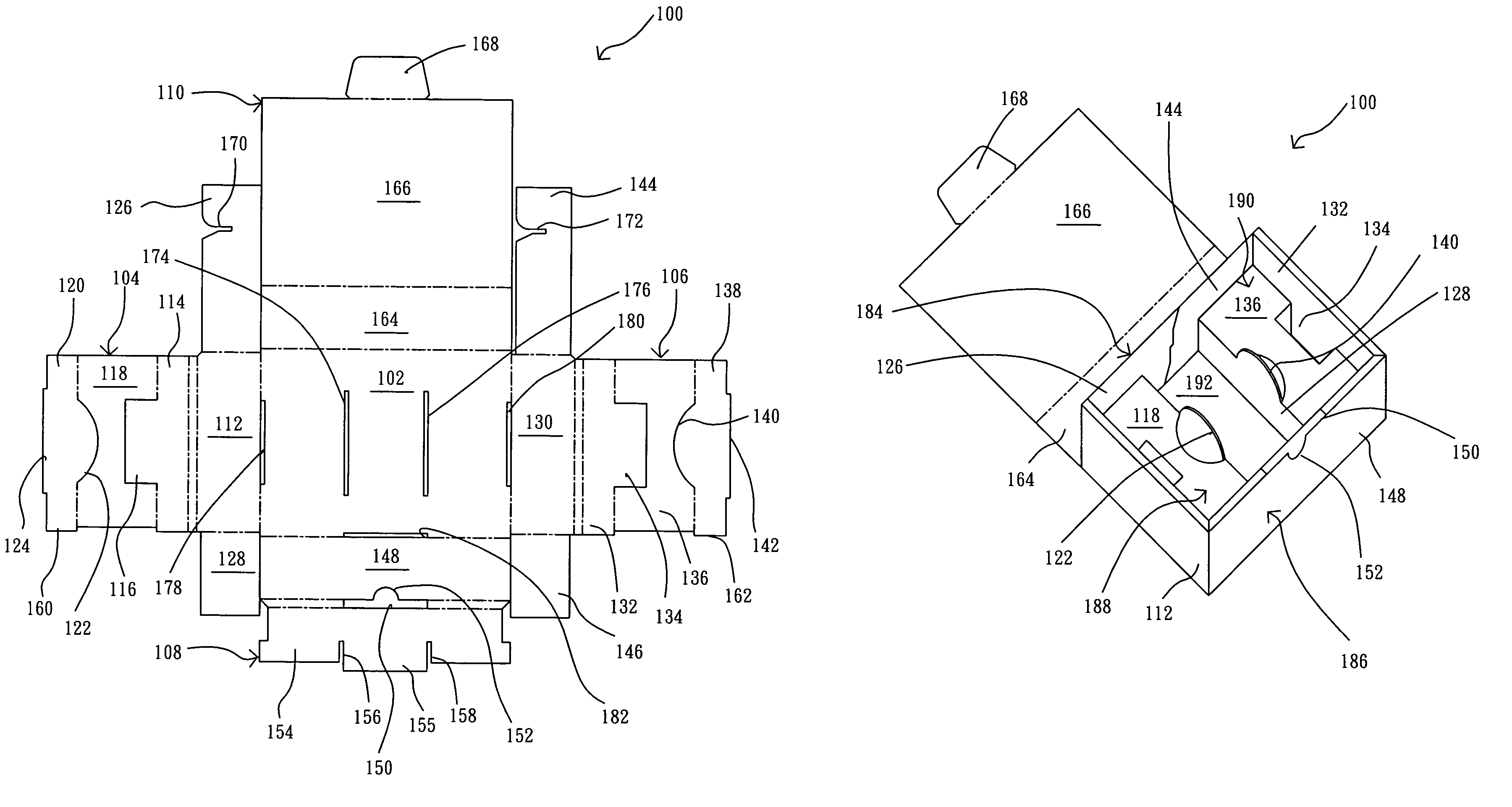

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

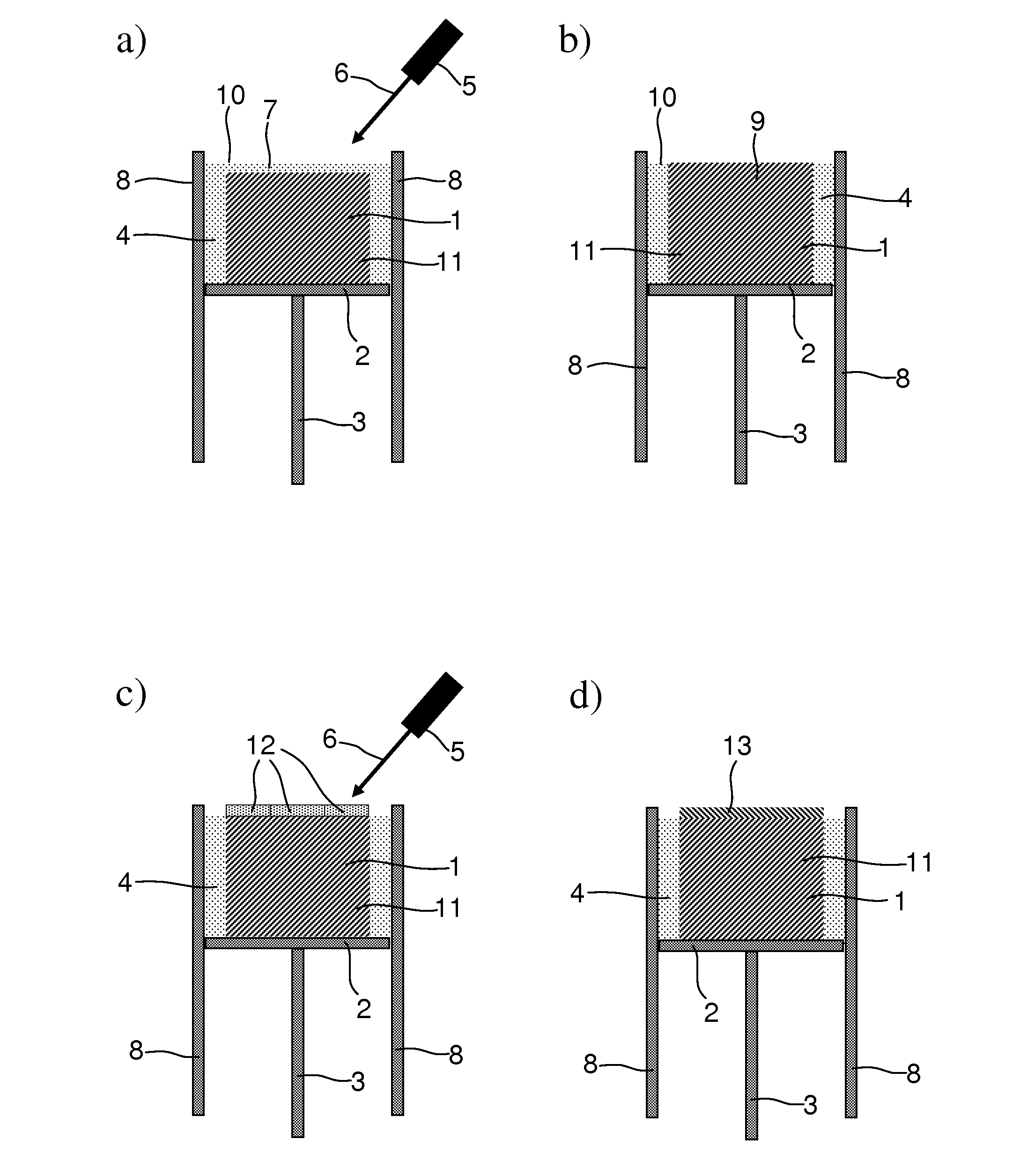

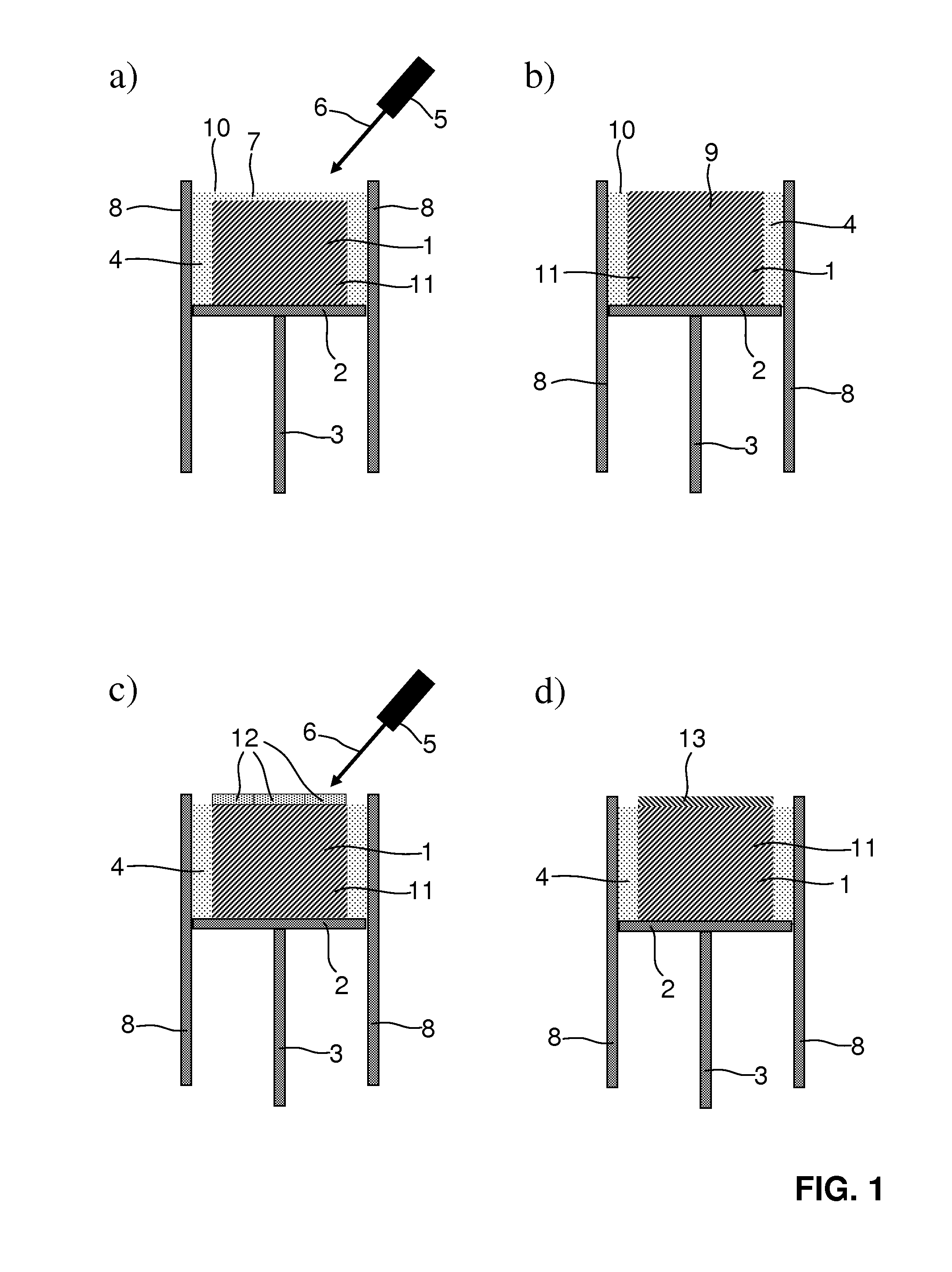

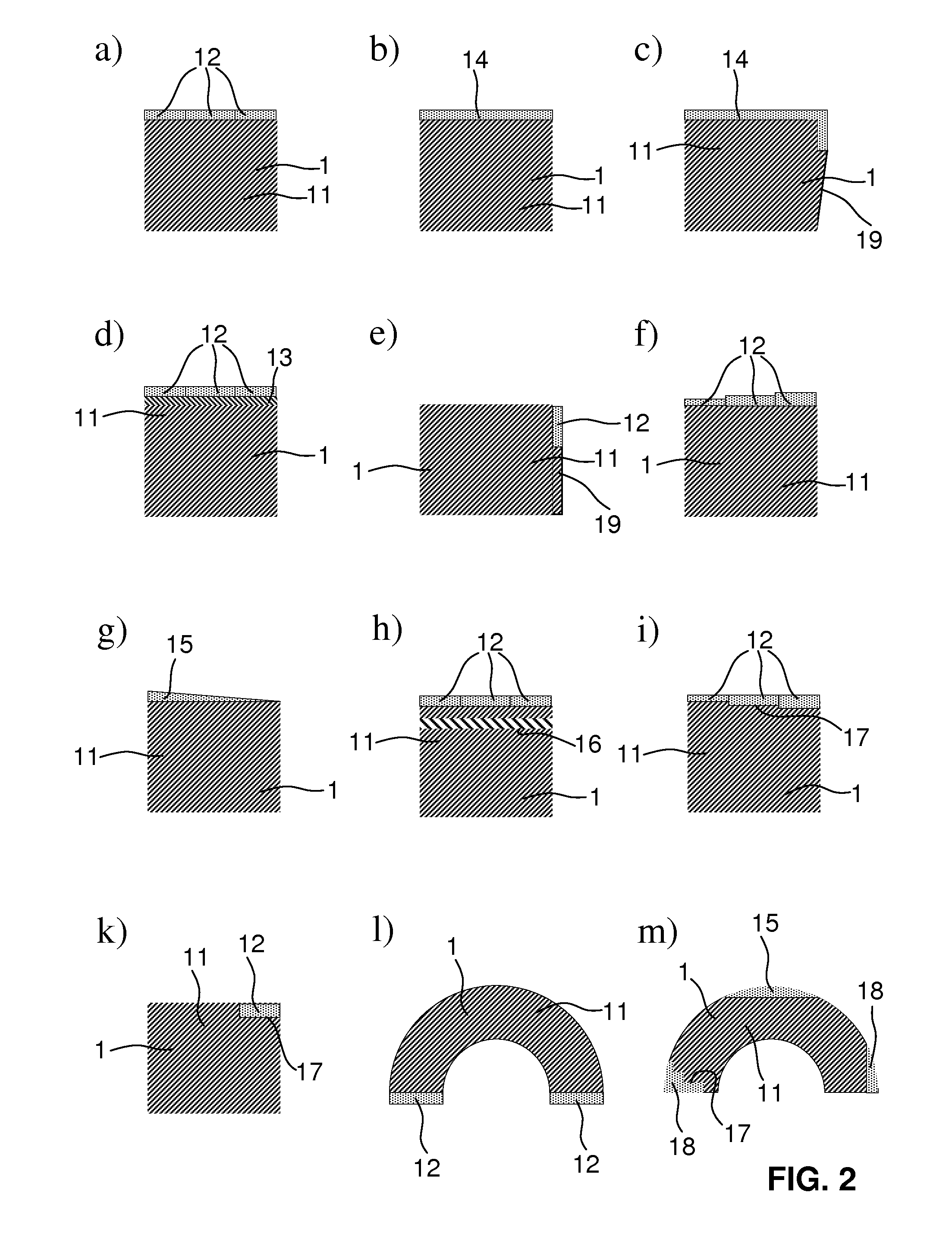

Method of applying multiple materials with selective laser melting on a 3D article

InactiveUS20110106290A1Increase weld ability/brazeabilityEasy to optimizeTurbinesAdditive manufacturingMulti materialSelective laser melting

In a method for manufacturing an article (1), particularly a prototype of a product or component, a tool prototype or spare part, by using selected laser melting, for the application onto the article (1) of a layer (13) or portion of a second metallic material, which is different from the material of the first metallic powder (4), a tape (12), sheet (14), foil or three-dimensional pre-form (18) of a second material is applied to the article (1) and is heated by a focused laser or electron beam (6) to a specified temperature such that the tape (12), sheet (14), foil or pre-form, respectively, are made molten by the electron laser beam (6), wherein the focused beam (6) is applied to a given area corresponding to a selected cross-sectional area of the model of the article (1) under formation of a new layer or part made of second material integral with the article (1).

Owner:ANSALDO ENERGIA IP UK LTD

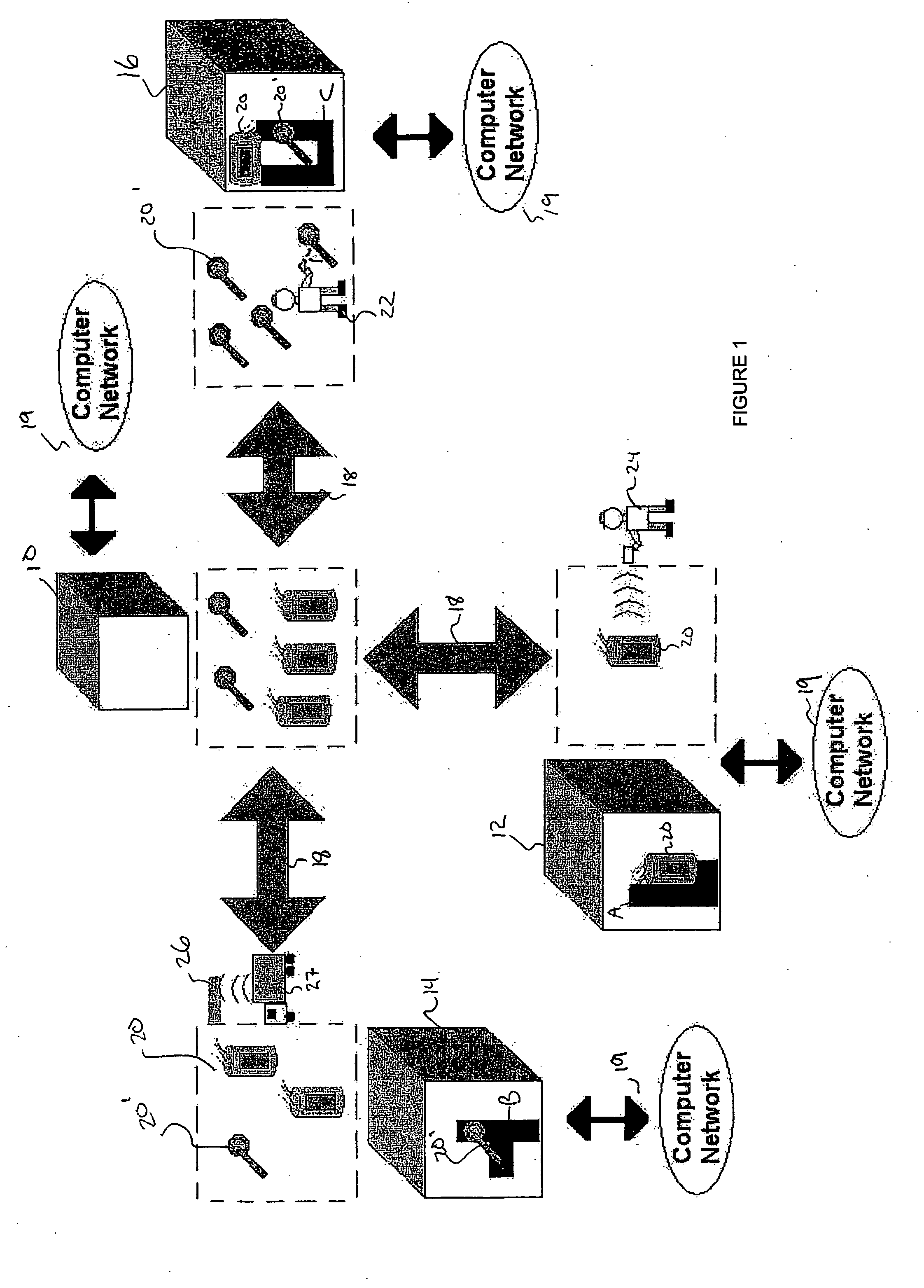

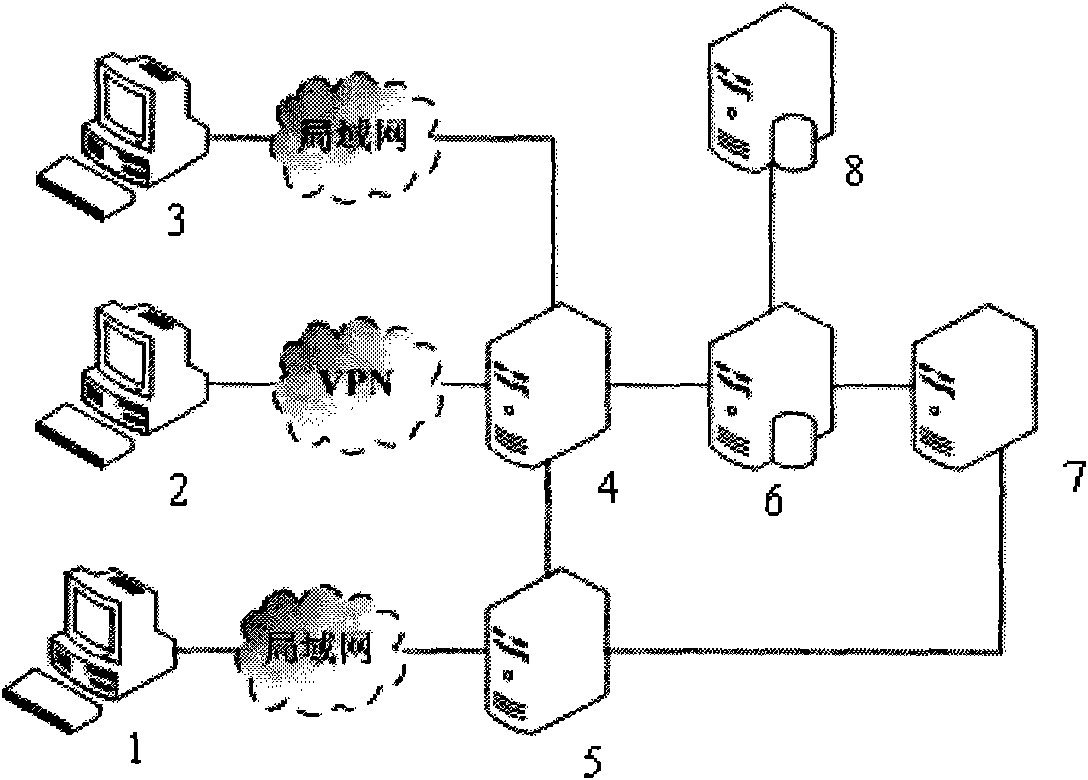

Virtual warehouse parts distribution system and process

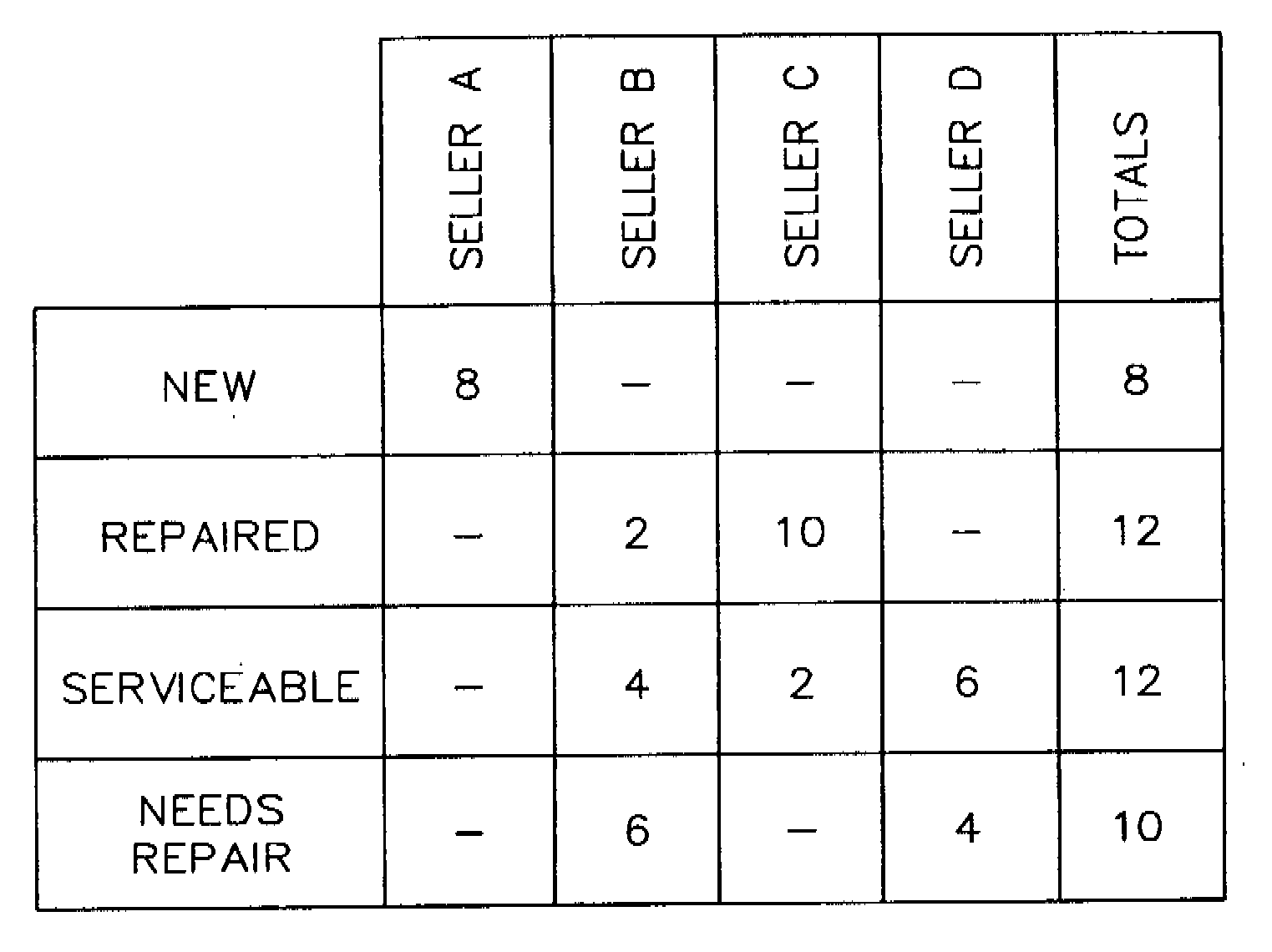

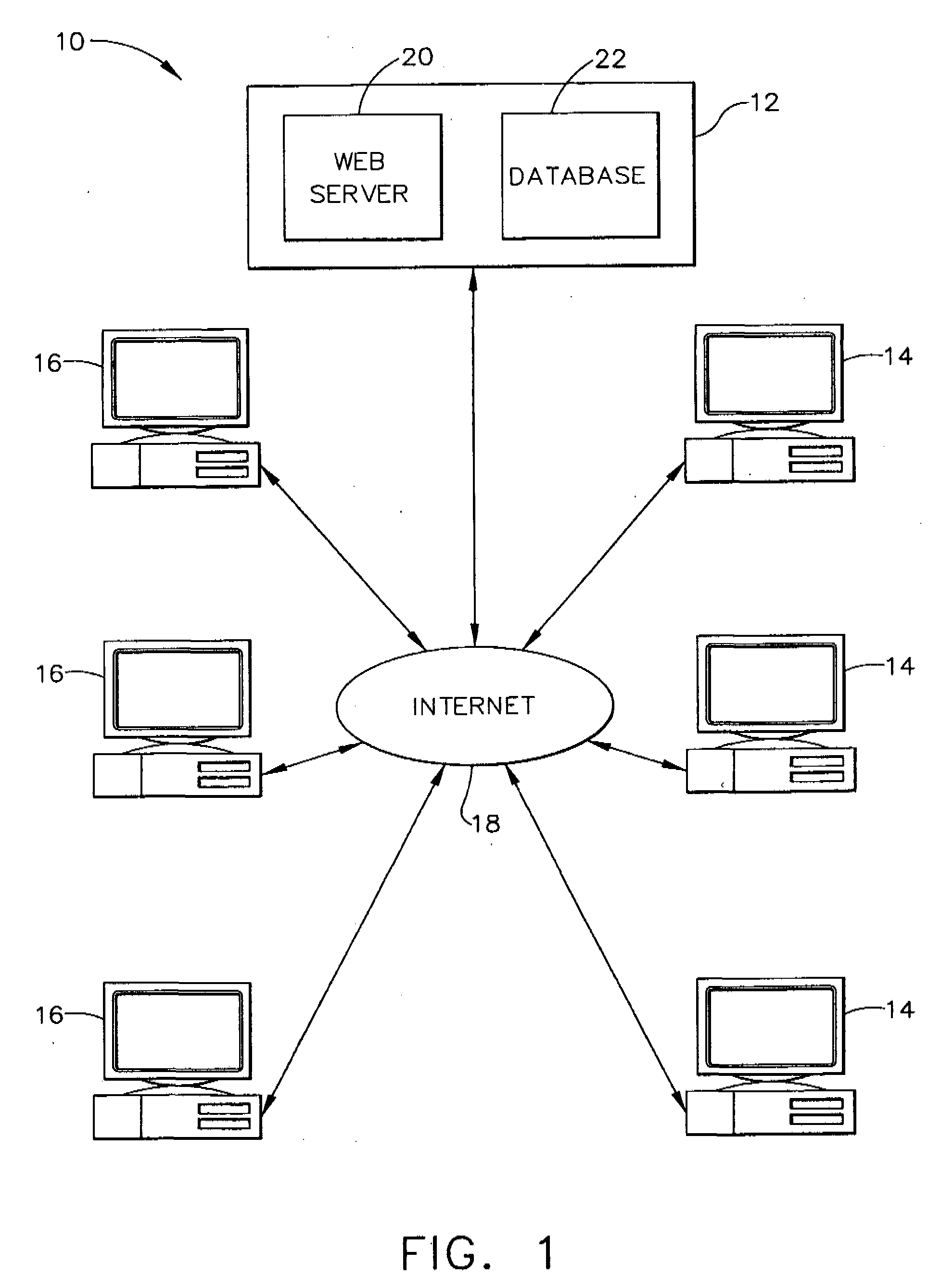

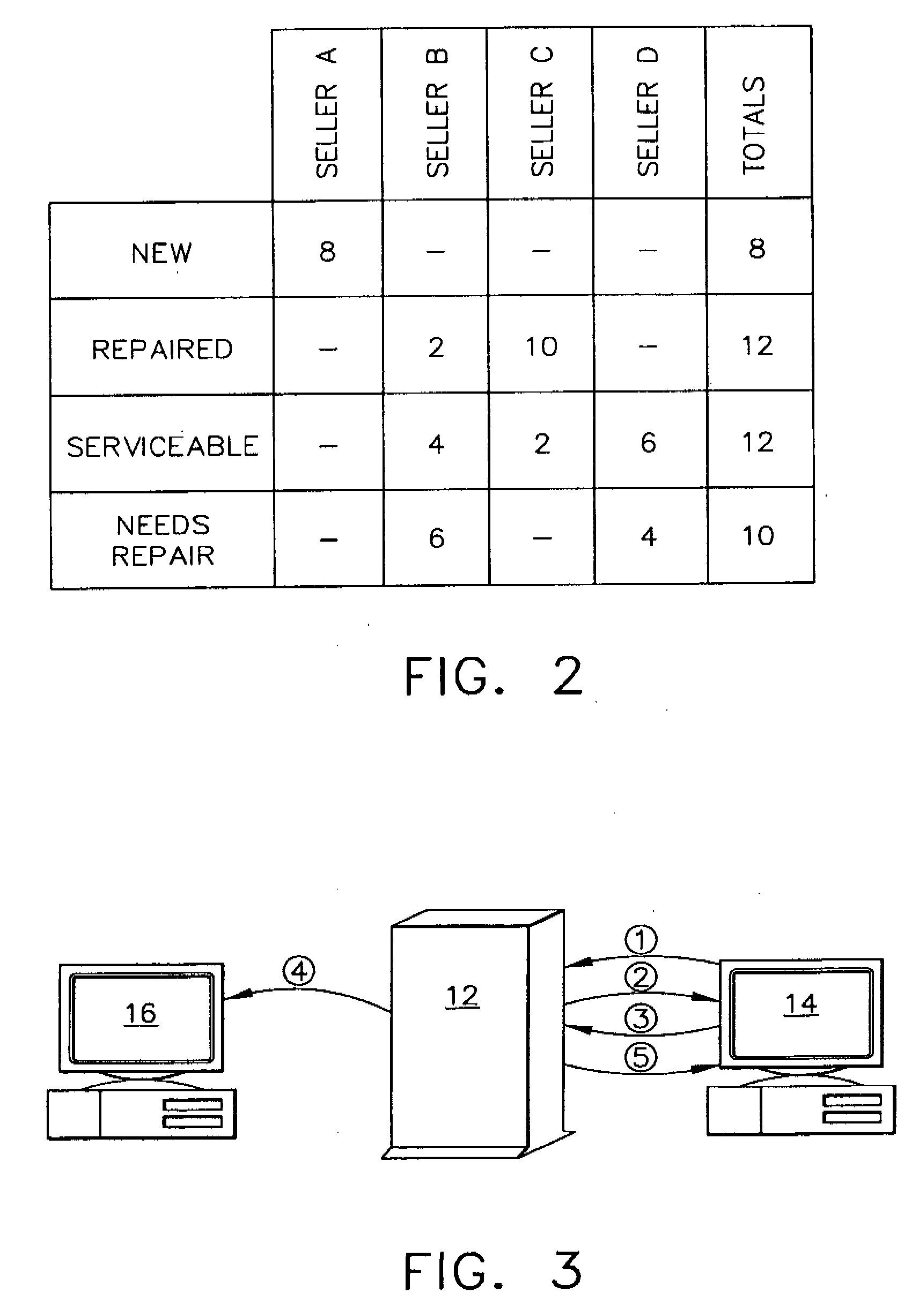

A parts distribution system and process uses a computer network, particularly the Internet, to efficiently distribute spare parts in a cost-effective manner. The system includes a plurality of buyer computers for operation by a system participant desiring to obtain one or more parts, a plurality of seller computers for operation by a system participant desiring to sell one or more parts, and at least one server computer. The buyer computers, seller computers and server computer are interconnected as a computer network. In operation, the seller computers are used to input part related data to the server computer, and the server computer uses the data to maintain a database of all available parts. The buyer computers are used to transmit part requests to the server computer, and the server computer selecting one or more parts from the database in response to the requests.

Owner:GENERAL ELECTRIC CO

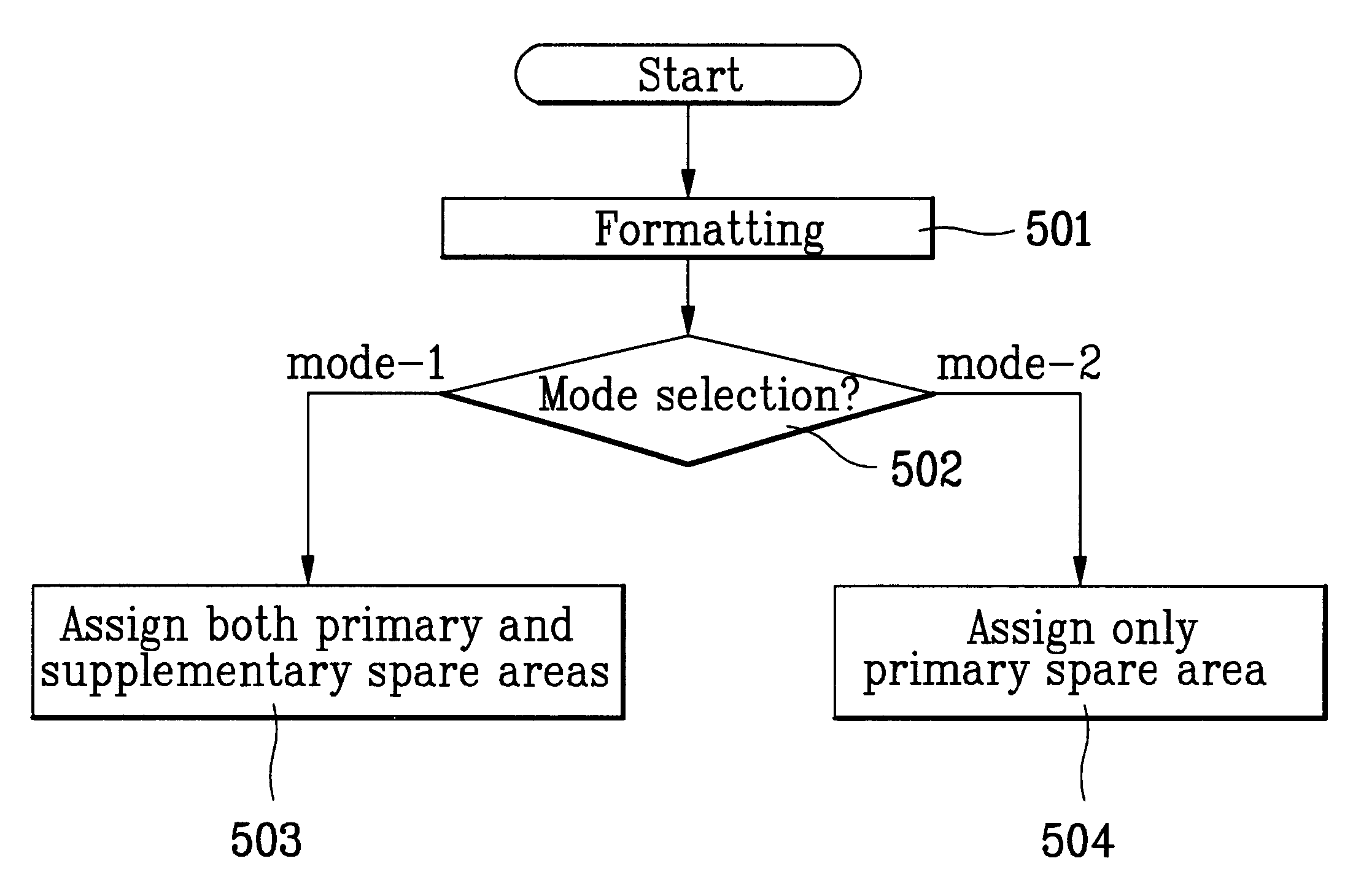

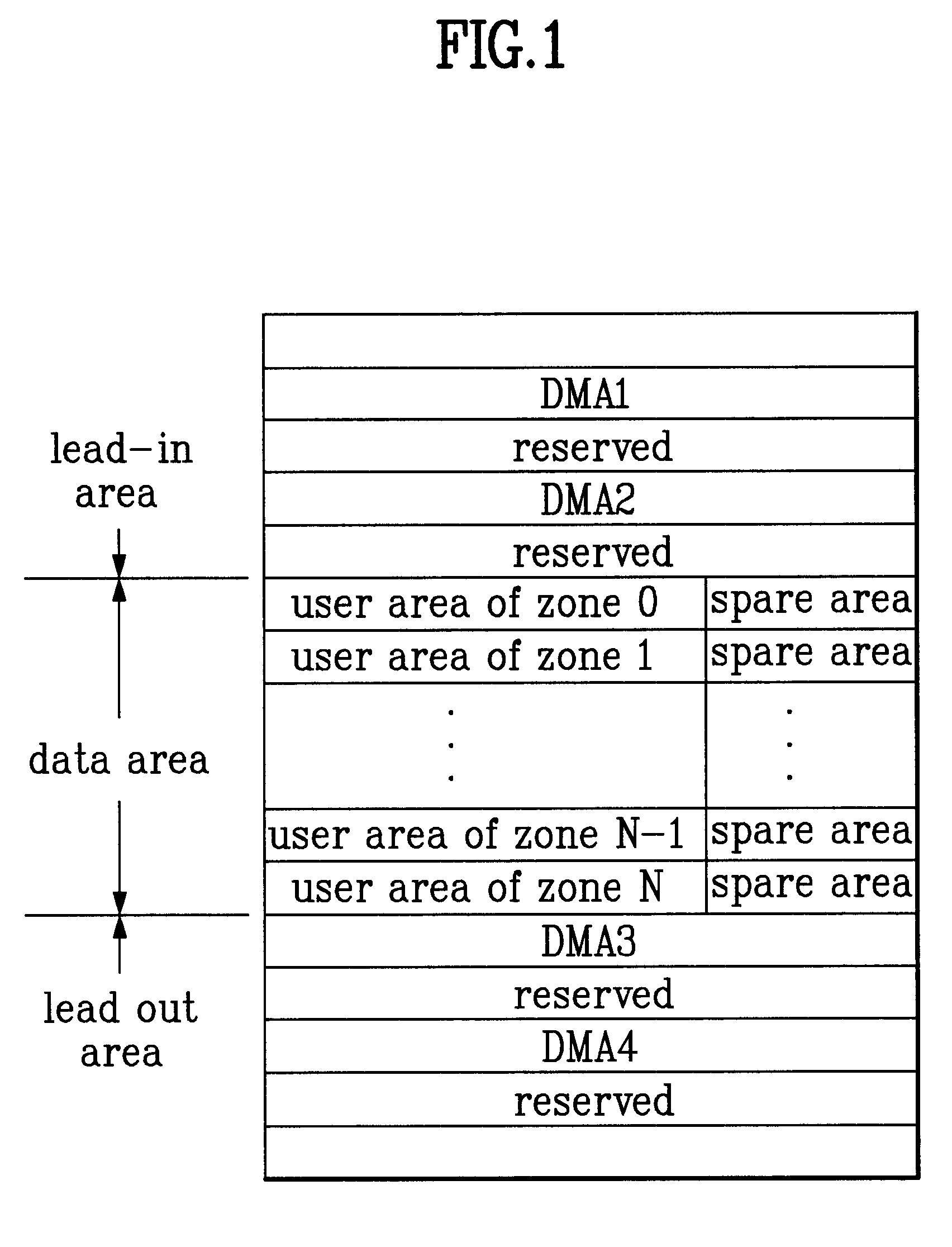

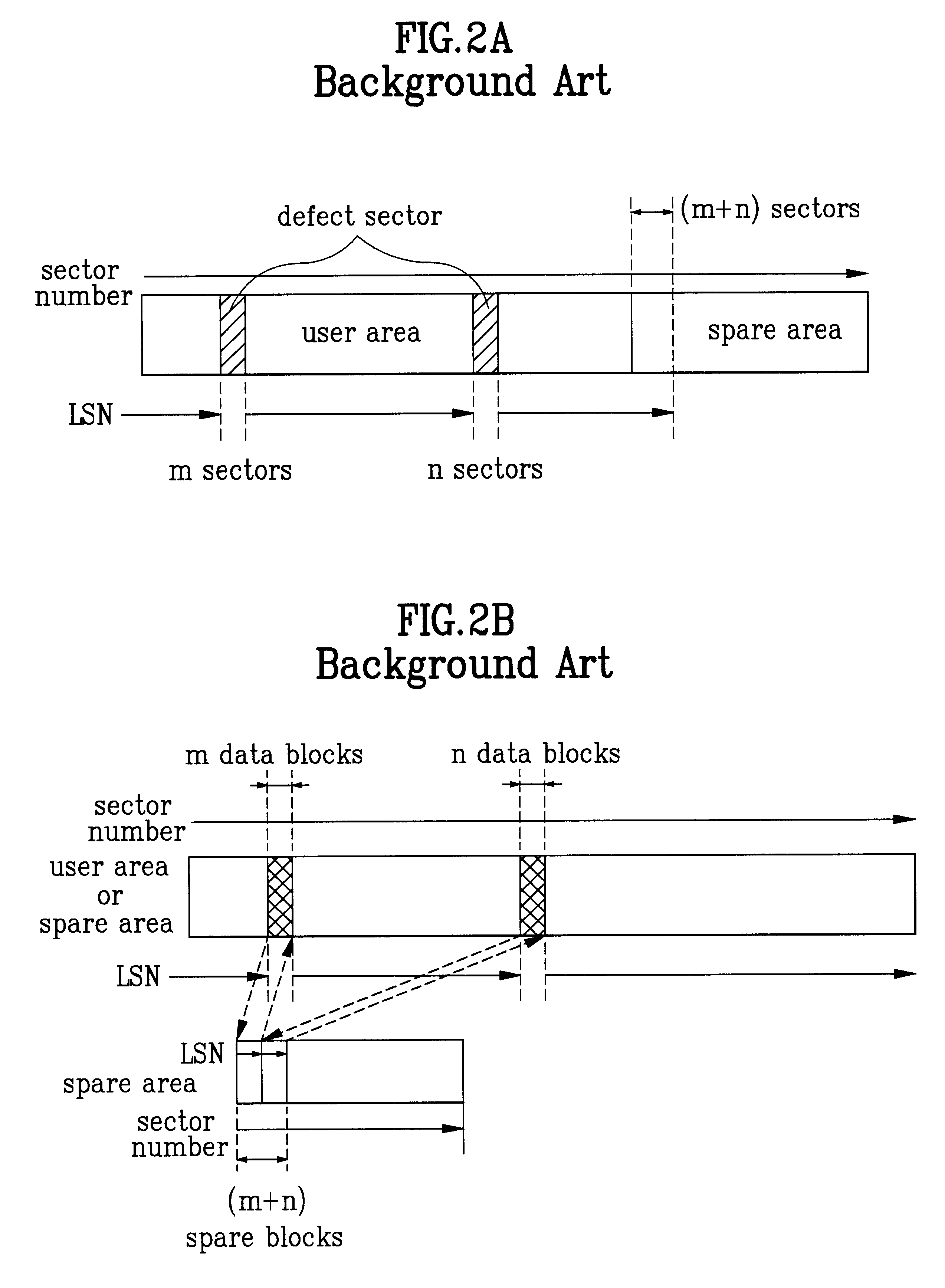

Optical recording medium and method of assigning its spare area

InactiveUS6477126B1Television system detailsDisc-shaped record carriersComputer hardwareOptical recording

A rewritable optical recording medium and a method of assigning a spare area in the rewritable optical recording medium is disclosed. In the present invention, a primary spare area of optical discs, which have the same disc size and track pitch but different initial user sizes, are assigned to have a same size, thereby improving the compatibility the discs.

Owner:LG ELECTRONICS INC

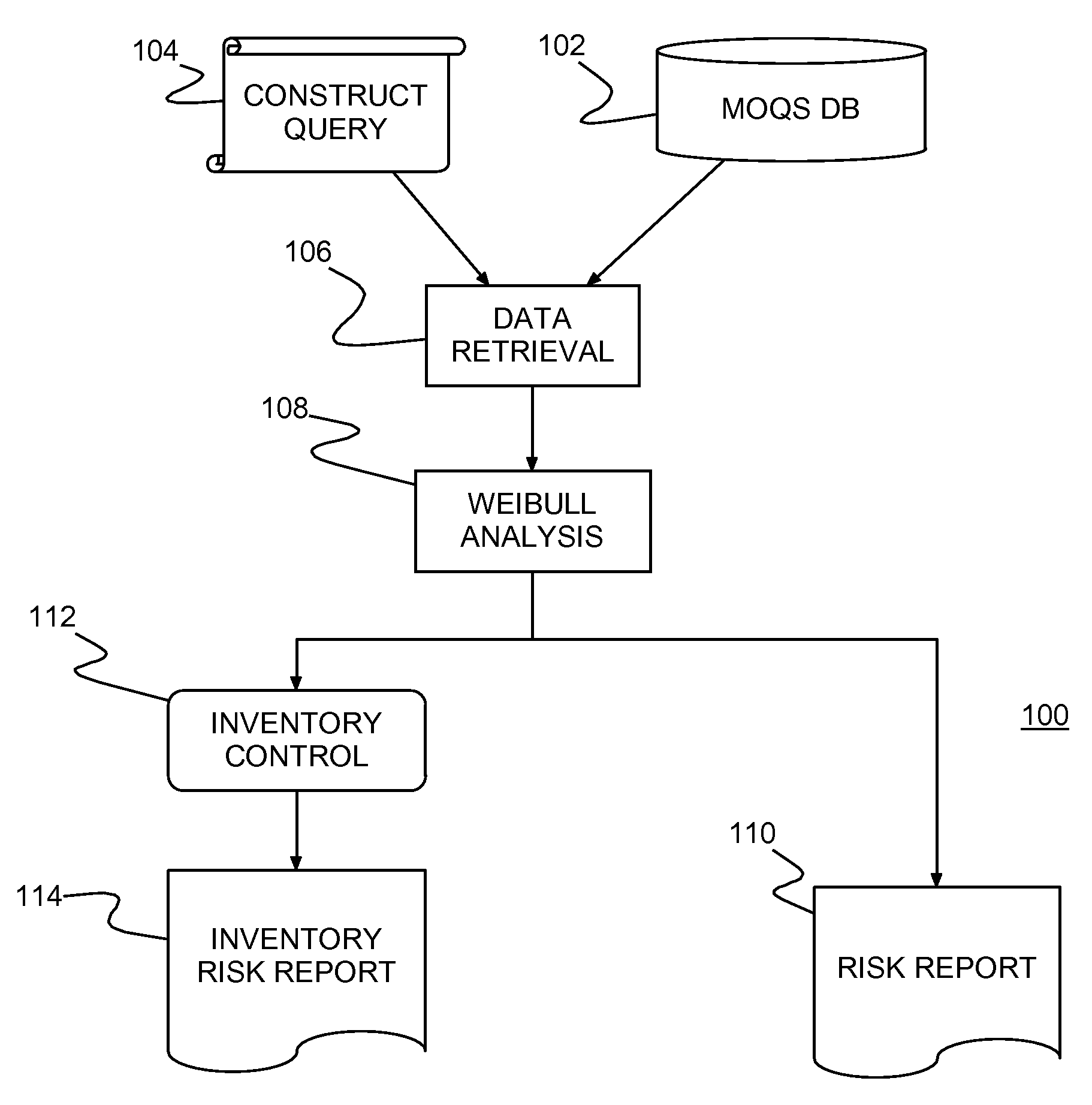

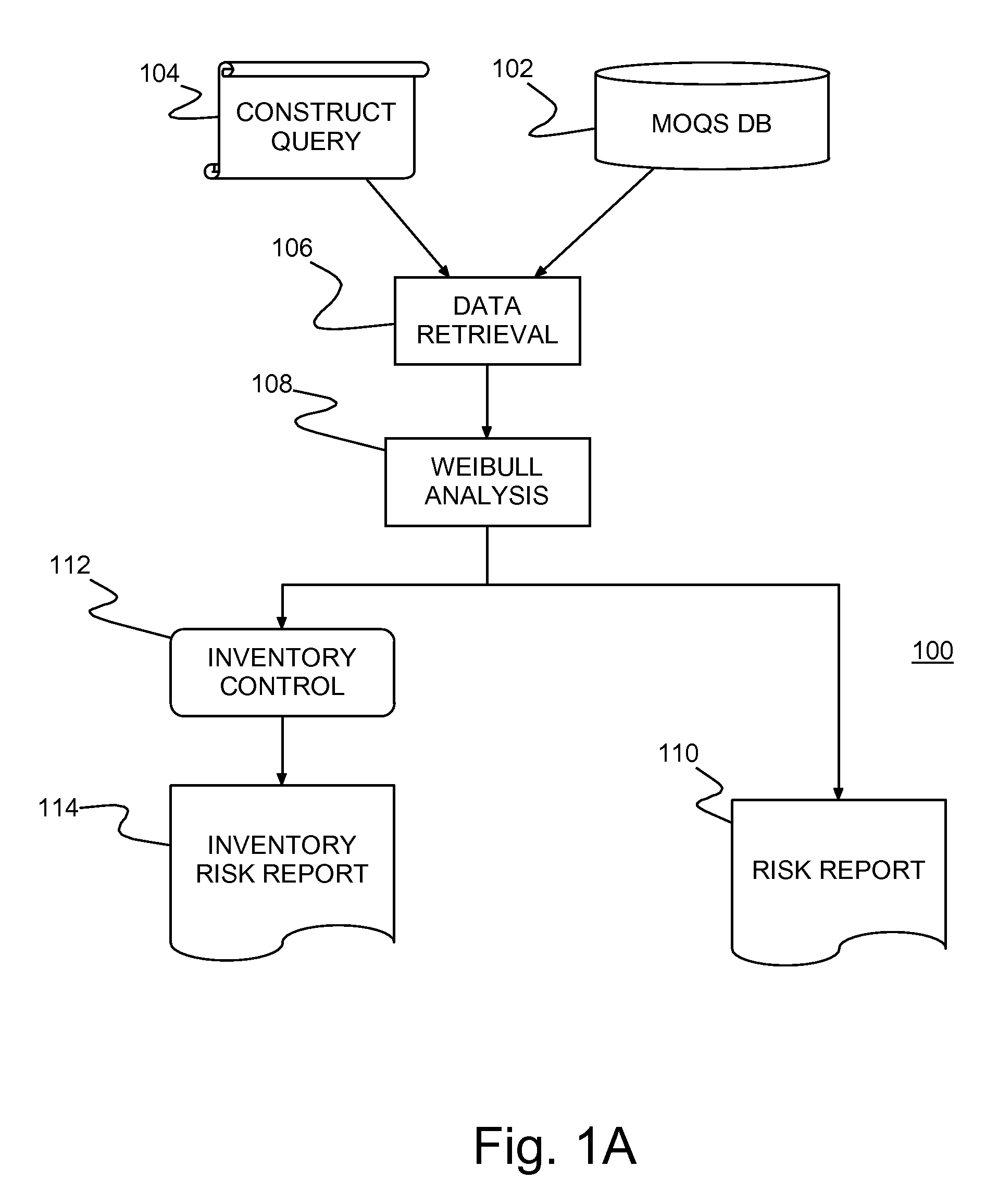

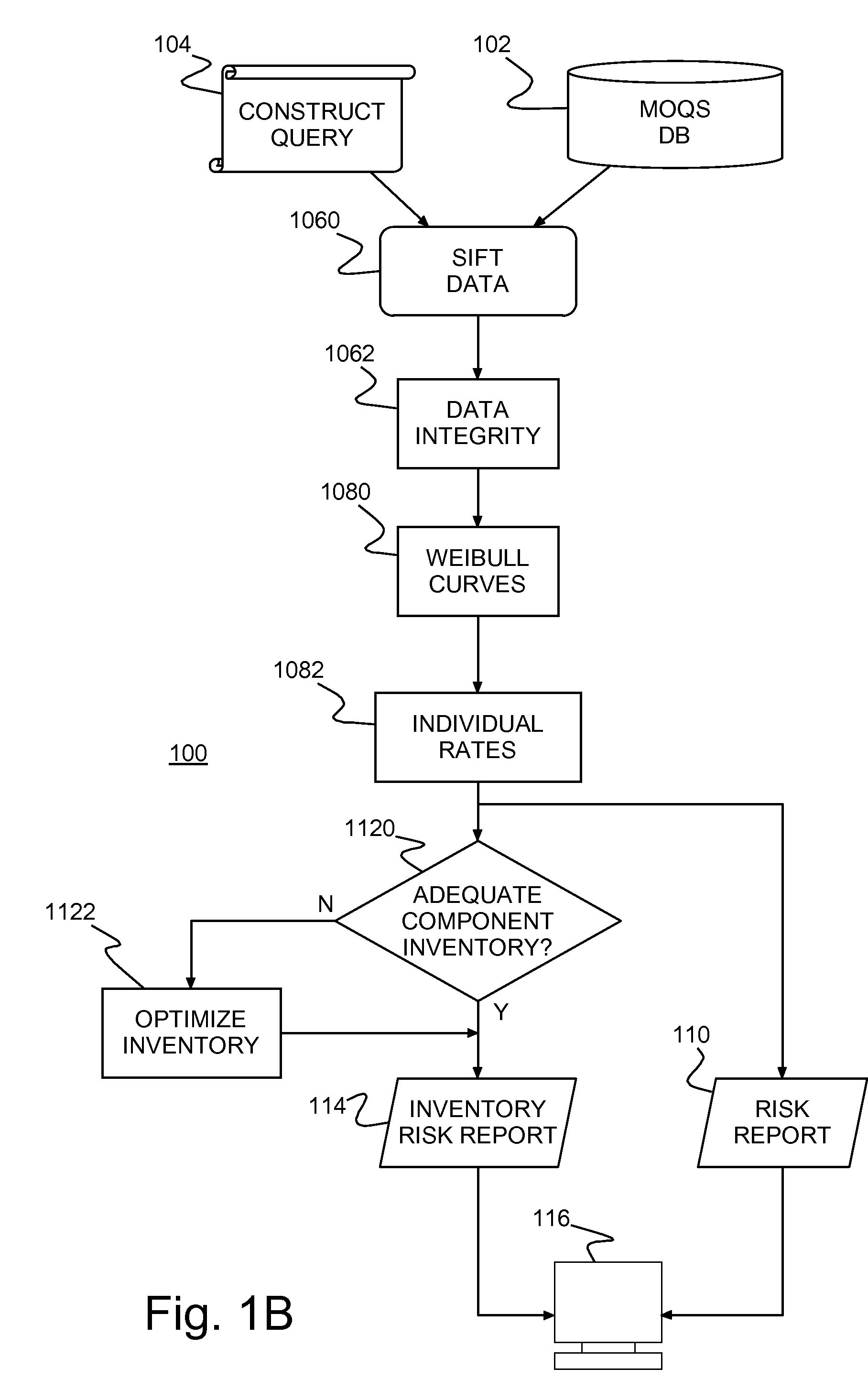

System, method and program product for predicting fleet reliability and maintaining a fleet of vehicles

InactiveUS20080154458A1Accurately predict part-level repair-shop throughputReduce part costVehicle testingRegistering/indicating working of vehiclesSpare partAirplane

A system, method and program product for maintaining fleet performance for a fleet of platforms, especially for a fleet of aircraft. Part removal data is contained in a maintenance database. A query is constructed for extracting part removal data from the maintenance database. Weibull analysis is applied to extracted part removal data. Exposed aircraft with parts being likely to fail within a given time period are identified from the Weibull analysis results. Overall part failure numbers are generated for each failing part. Inventory is checked to determine if sufficient spares are available to repair all expected failures. Any shortfalls may be covered. A risk report is generated for the fleet and for inventory. Each risk report highlights likely problems that may require immediate attention.

Owner:THE BOEING CO

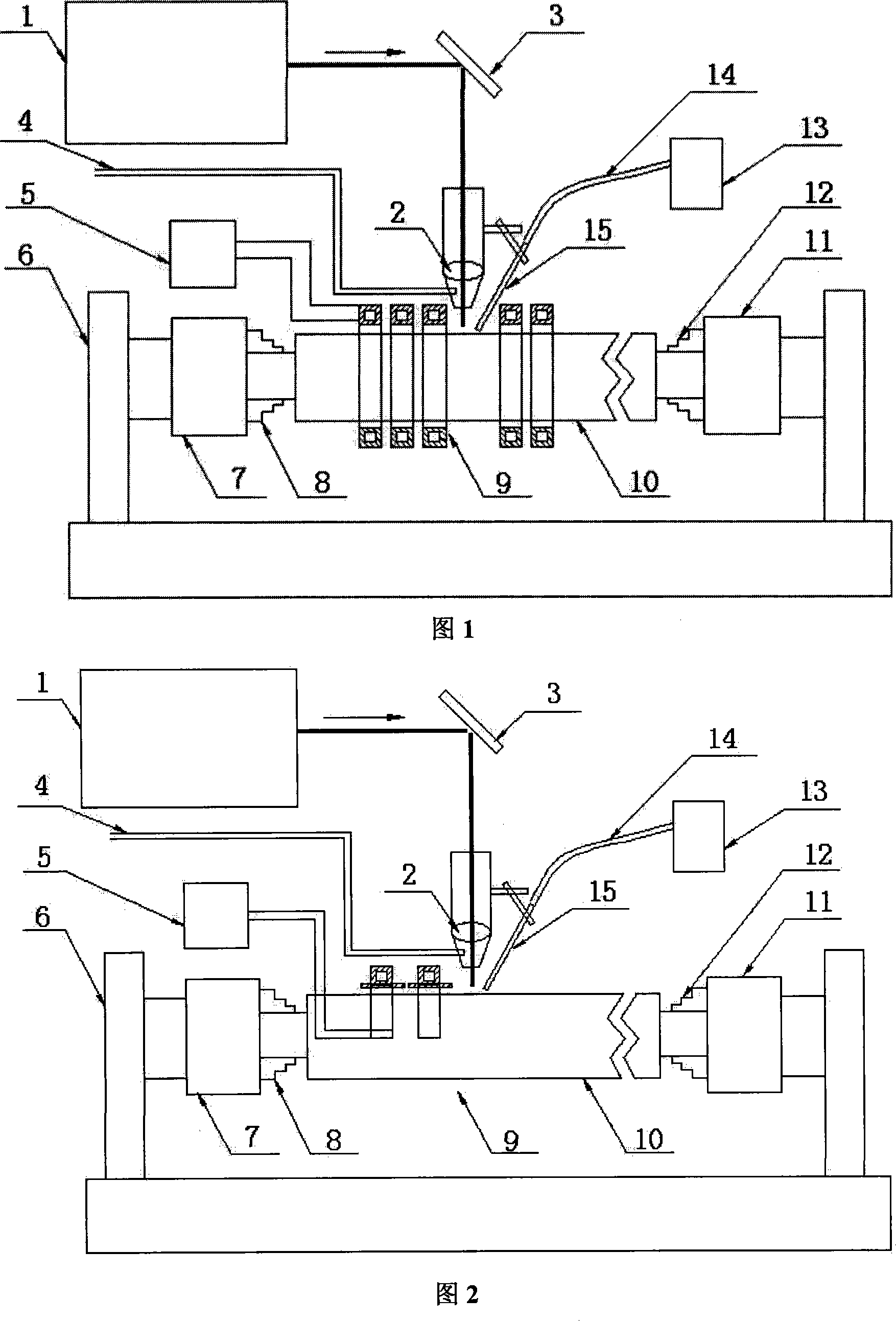

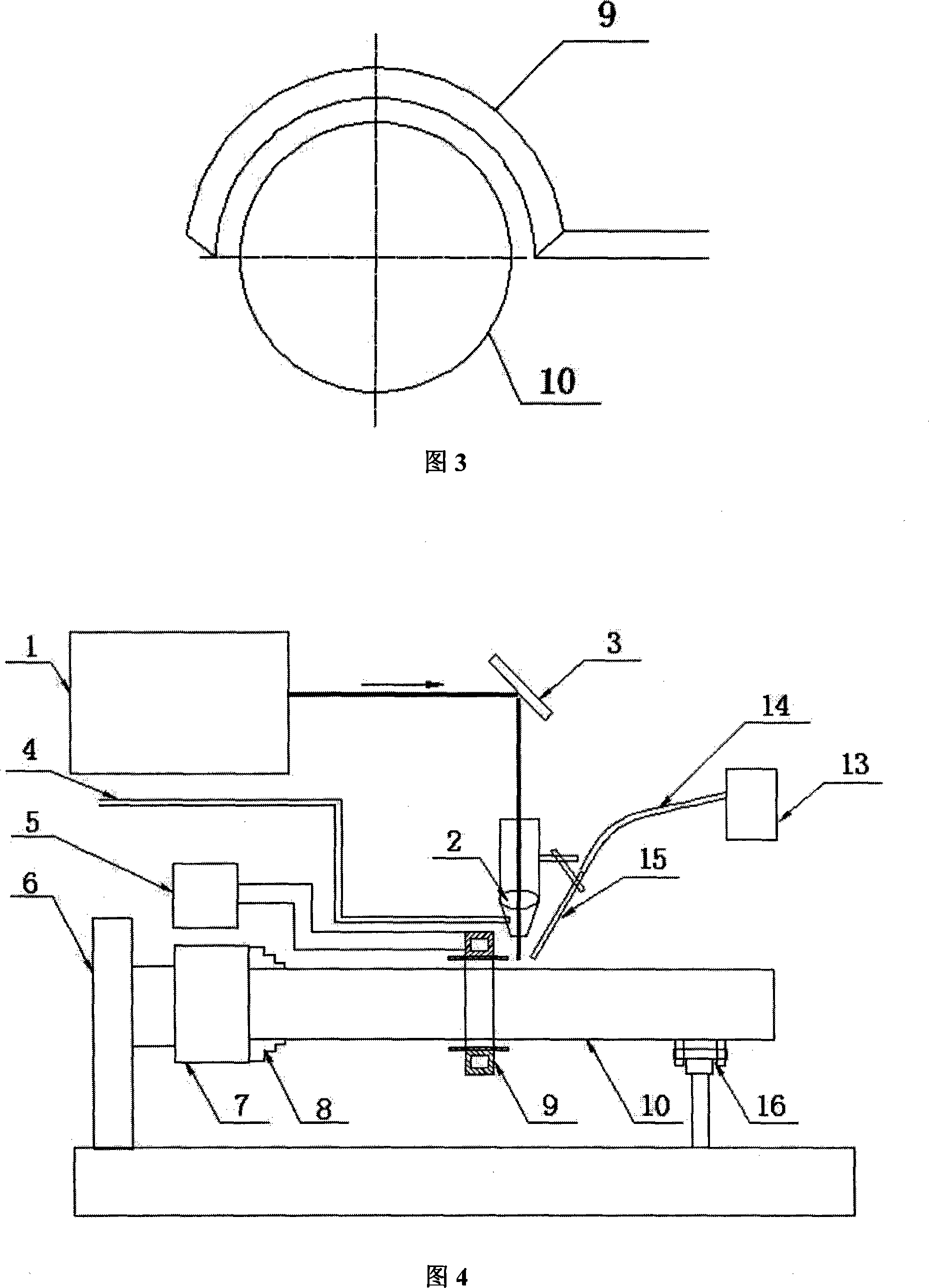

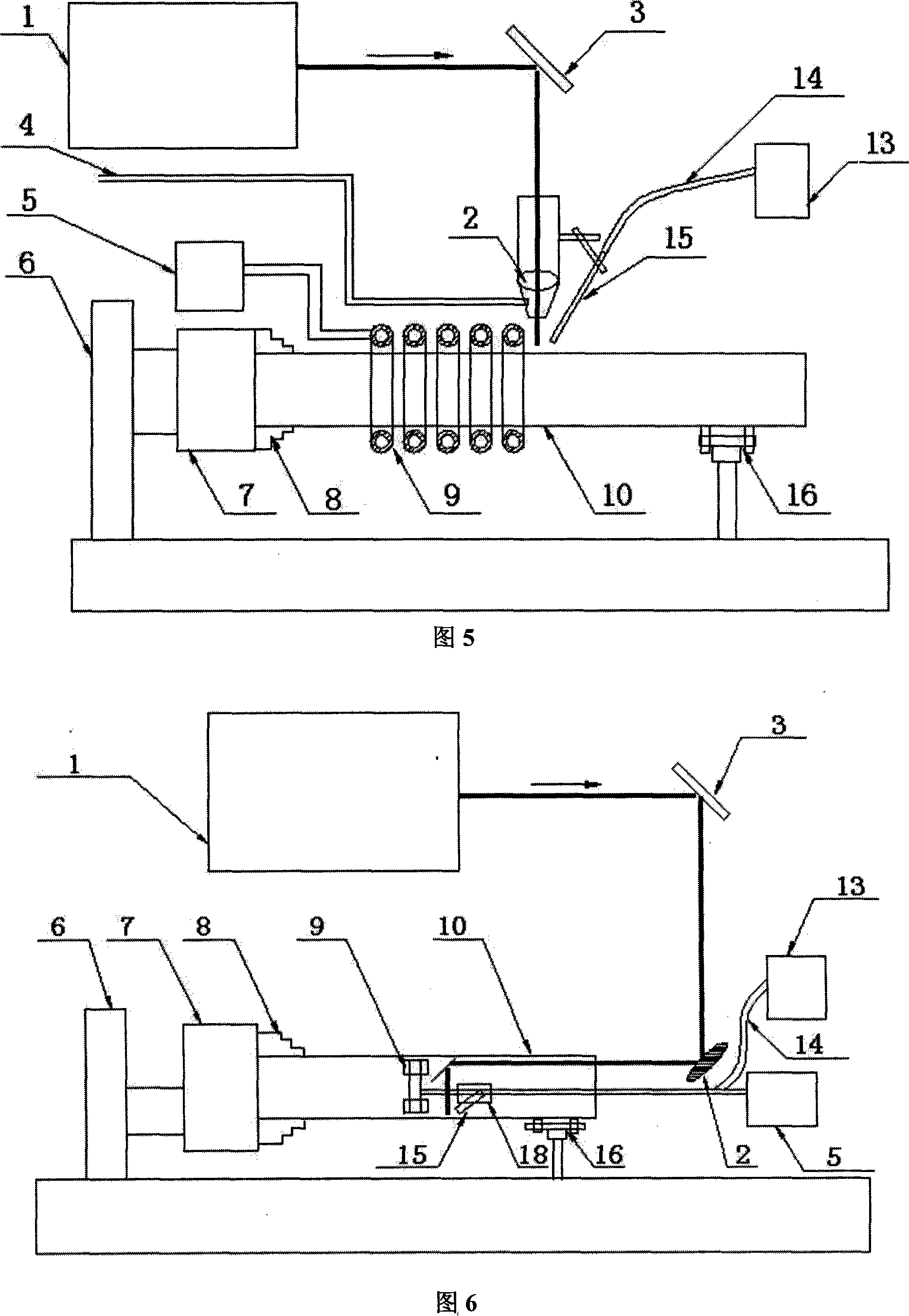

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

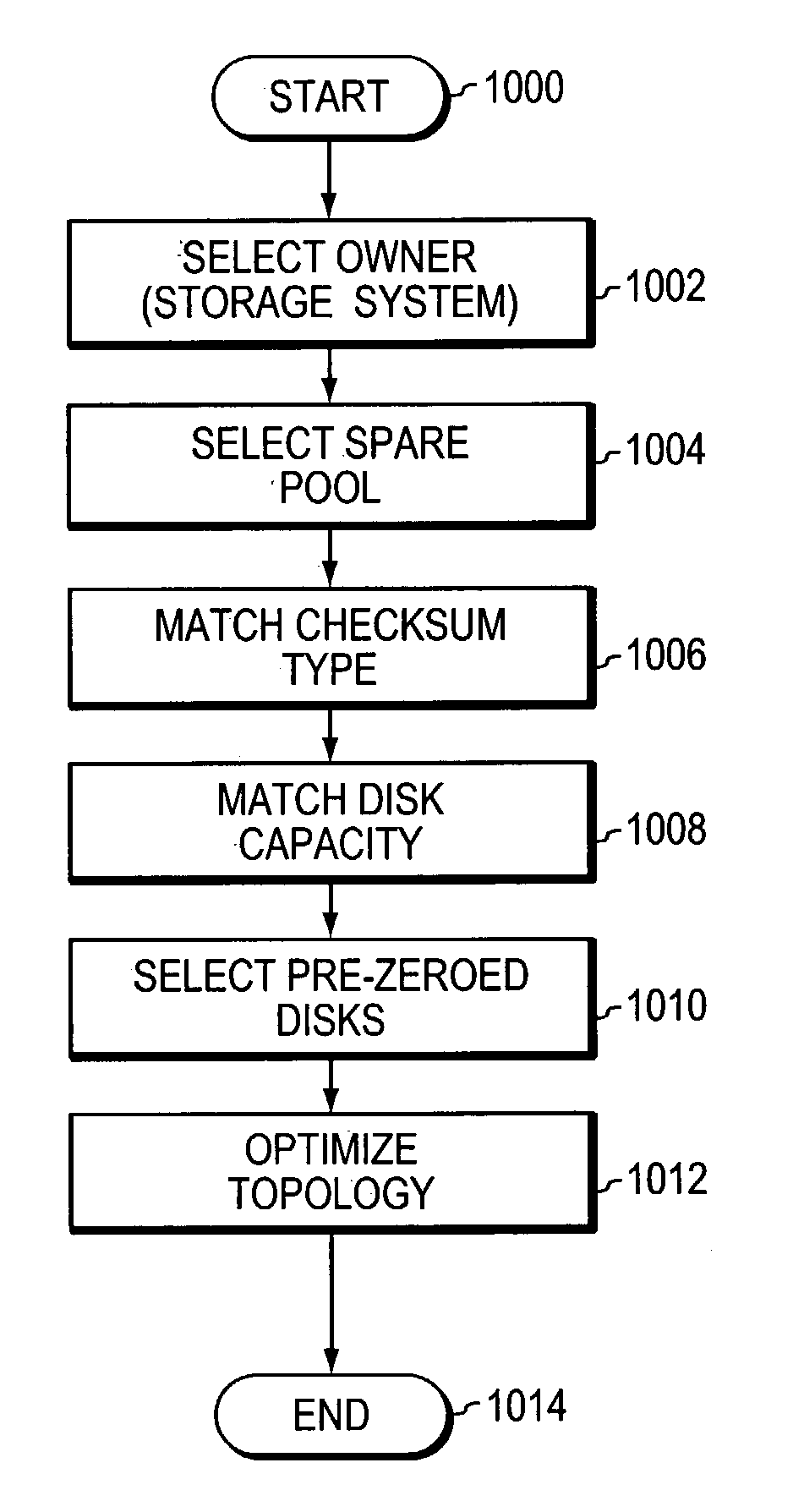

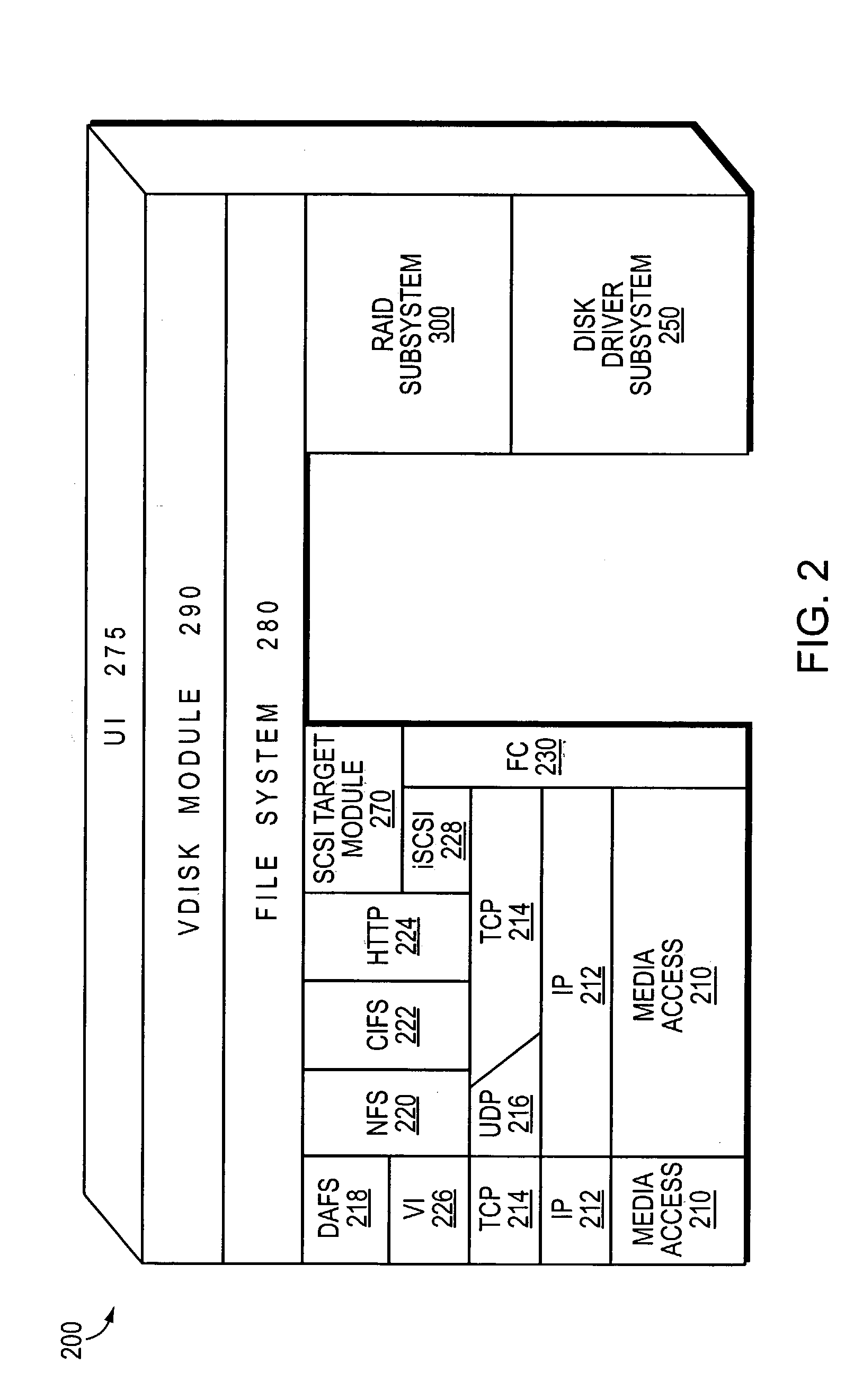

Query-based spares management technique

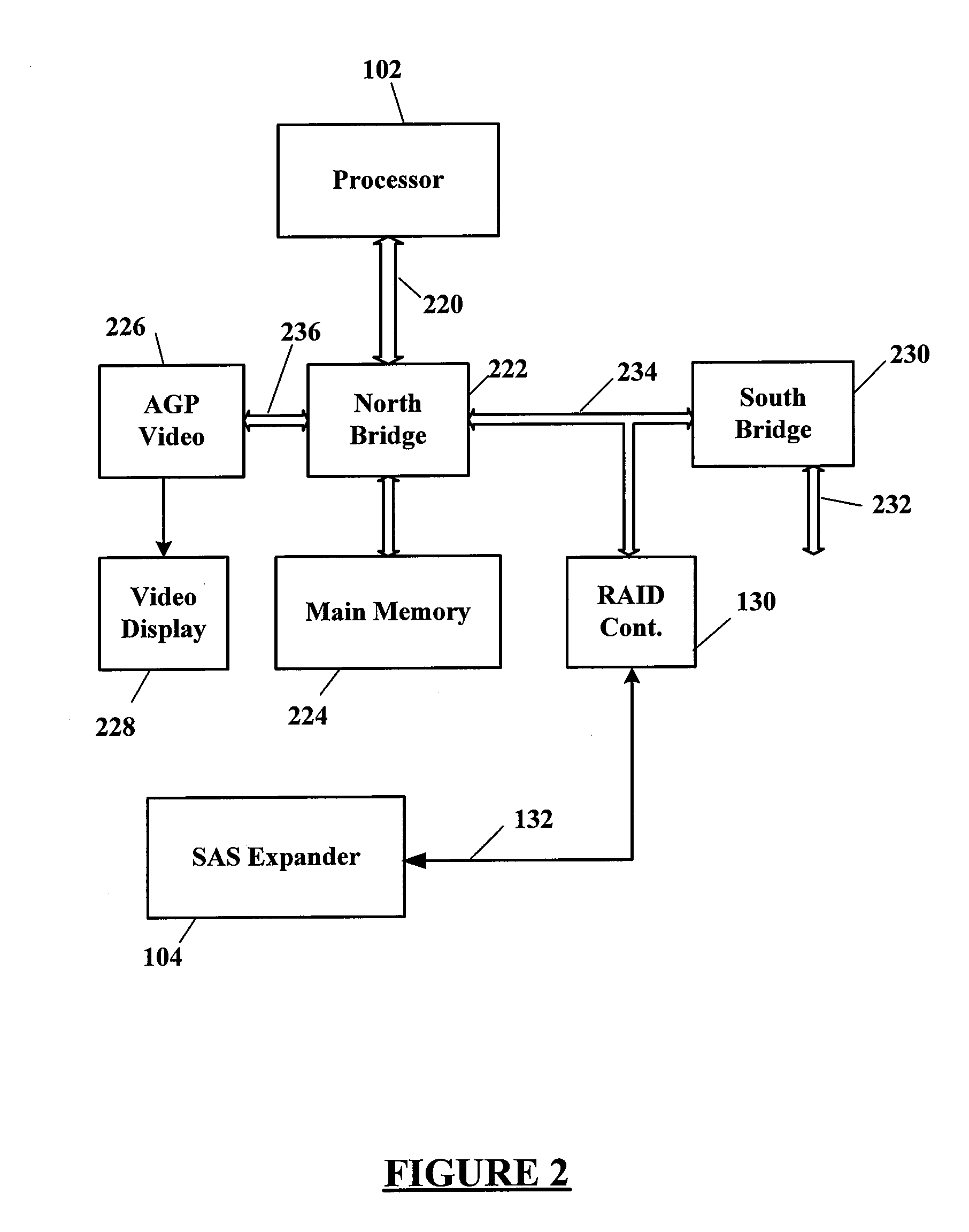

ActiveUS20050114593A1High bandwidthInput/output to record carriersMemory systemsRAIDOperational system

A query-based spares management technique enables a storage operating system of a storage system to select disks to be added to one or more RAID groups of a volume. The spares management technique includes an attributes-based disk selection procedure that is performed by the storage operating system in response to an operator-initiated request to add disks to the volume or in response to a demand-driven request resulting from a requirement imposed by the system to add disks to the volume. The disks that are added to the RAID groups of the volume are retrieved from one or more spare pools of disks maintained by the storage system.

Owner:NETWORK APPLIANCE INC

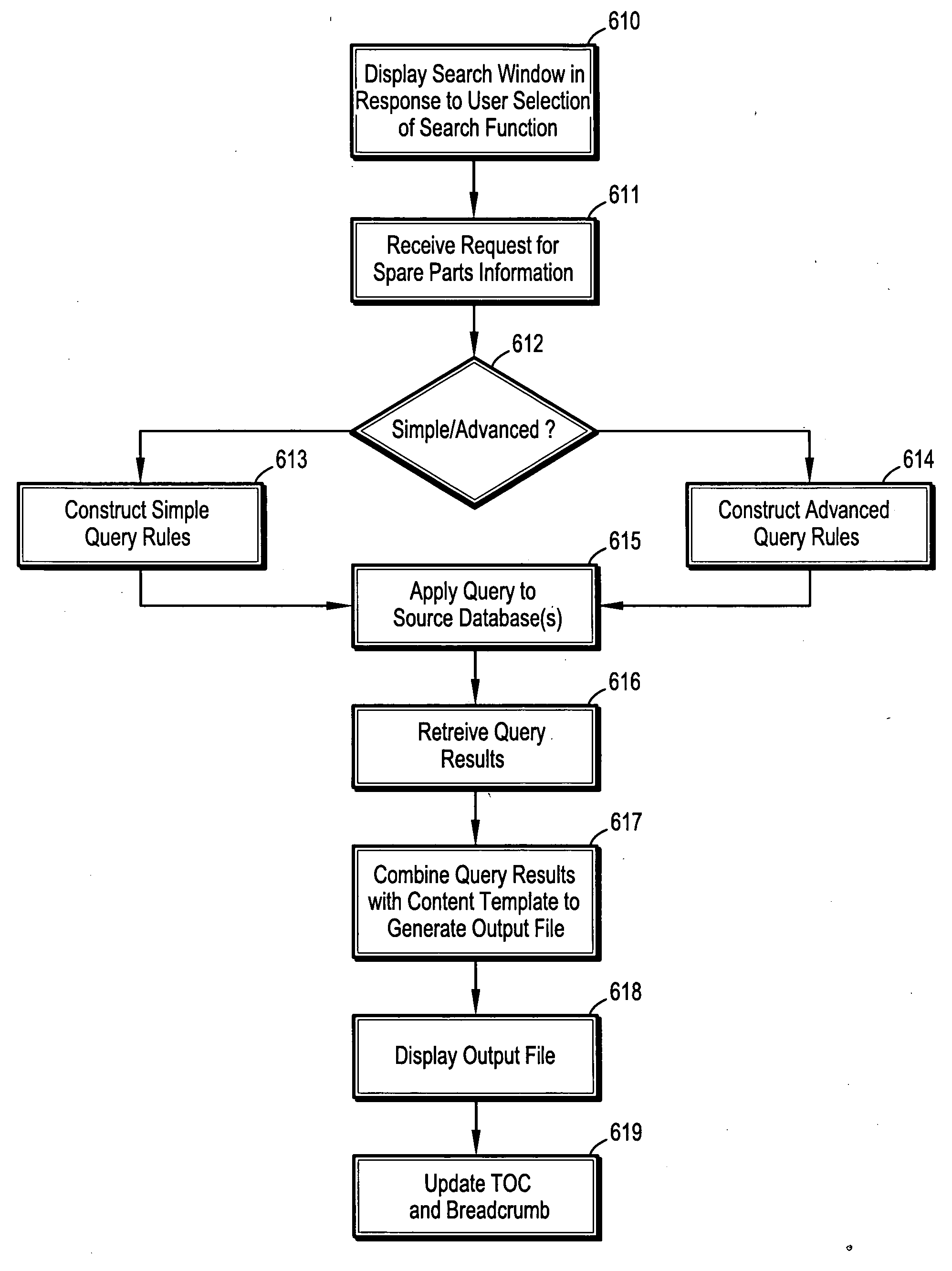

Automated systems and methods to support electronic business transactions for spare parts

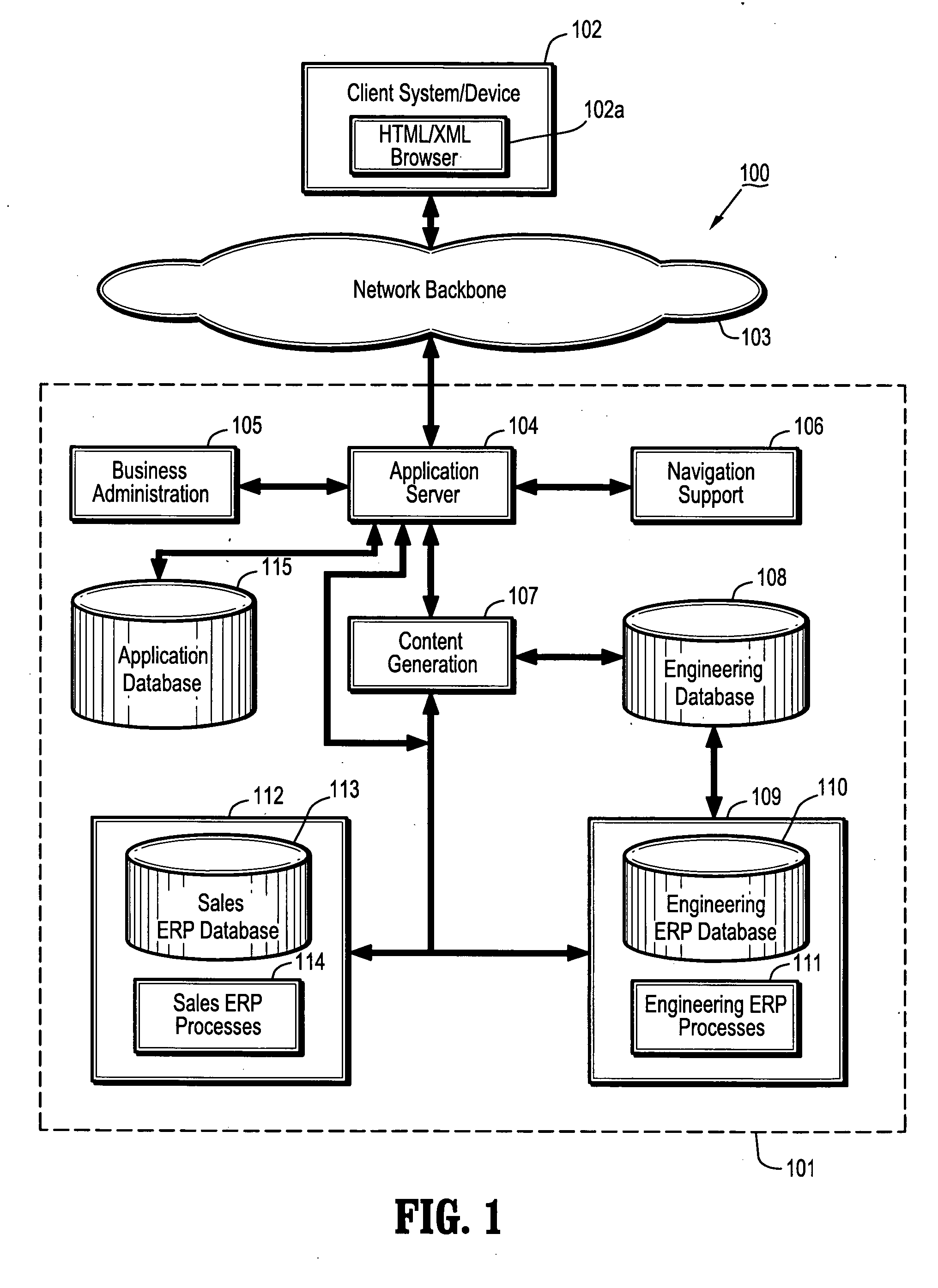

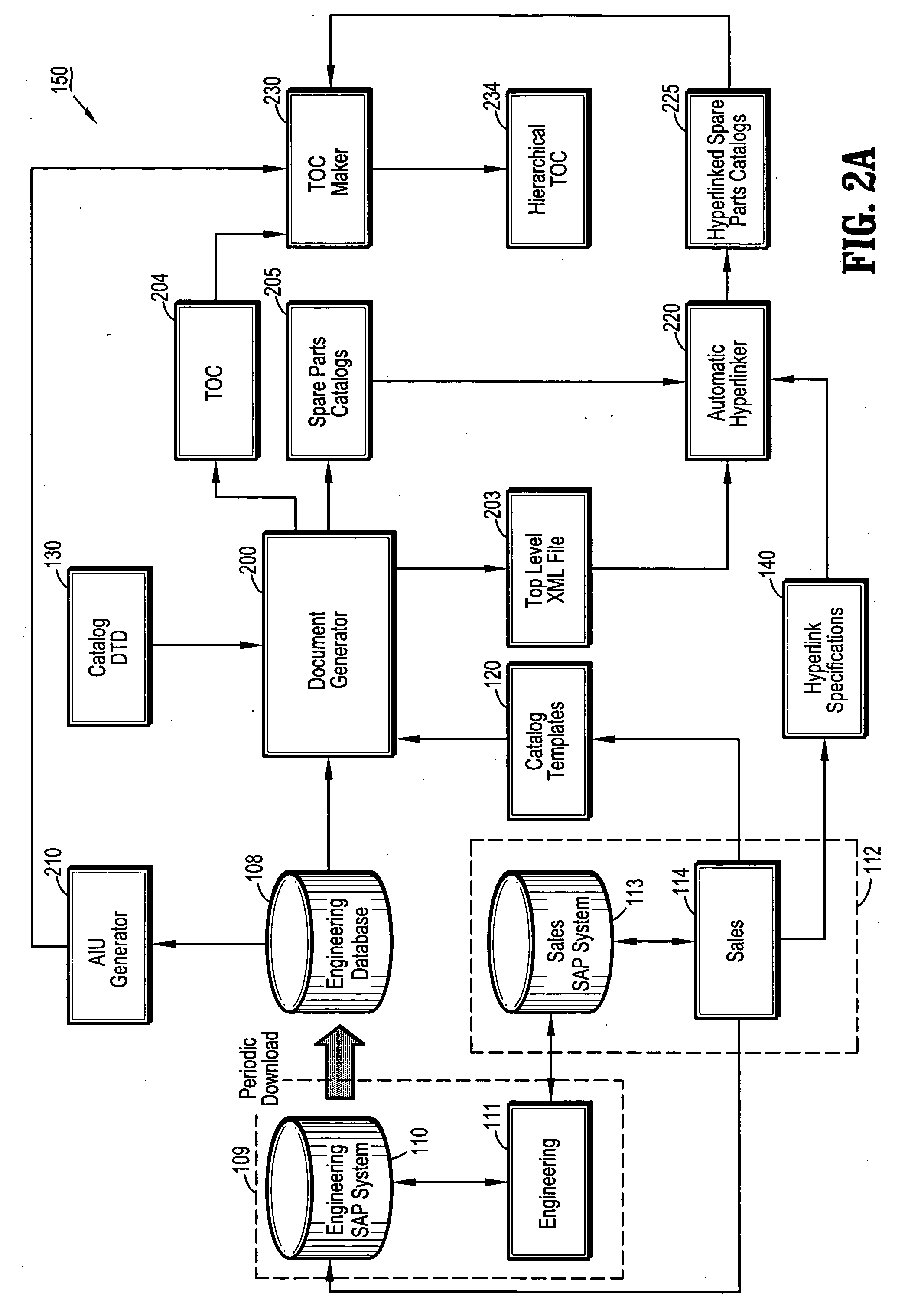

Systems and methods are provided for implementing electronic business applications for managing and selling spare parts, wherein electronic catalogs of spare parts are used to present static and / or real-time spare parts data from disparate backend data sources in a uniform, integrated manner, and wherein business logic programs are provided to support transaction activities using the electronic catalogs of spare parts, such as navigating the catalog content, and retrieving static and / or real-time spare parts data and initiating spare parts sales with the backend business information systems and spare parts data sources.

Owner:SIEMENS CORP +1

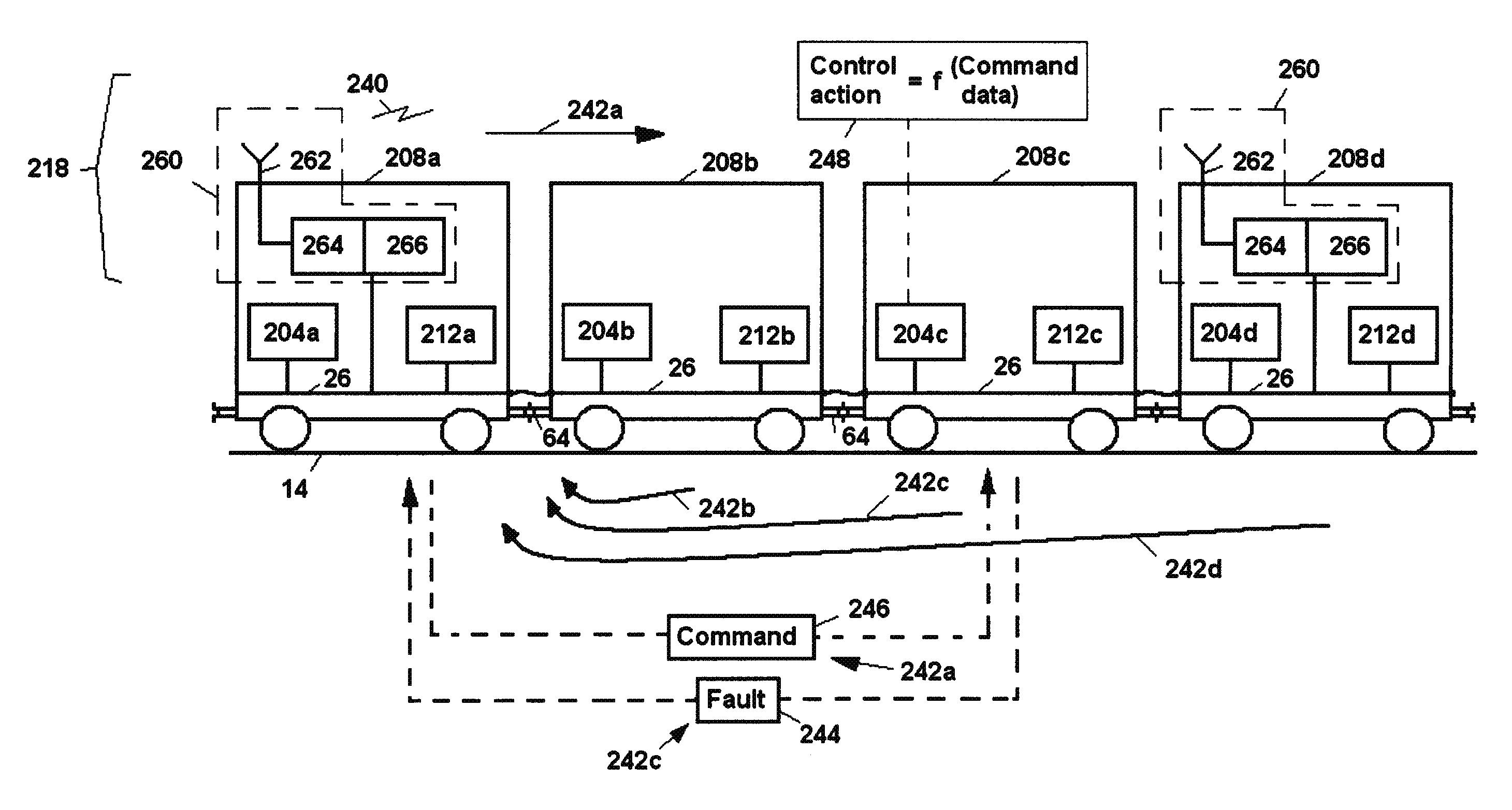

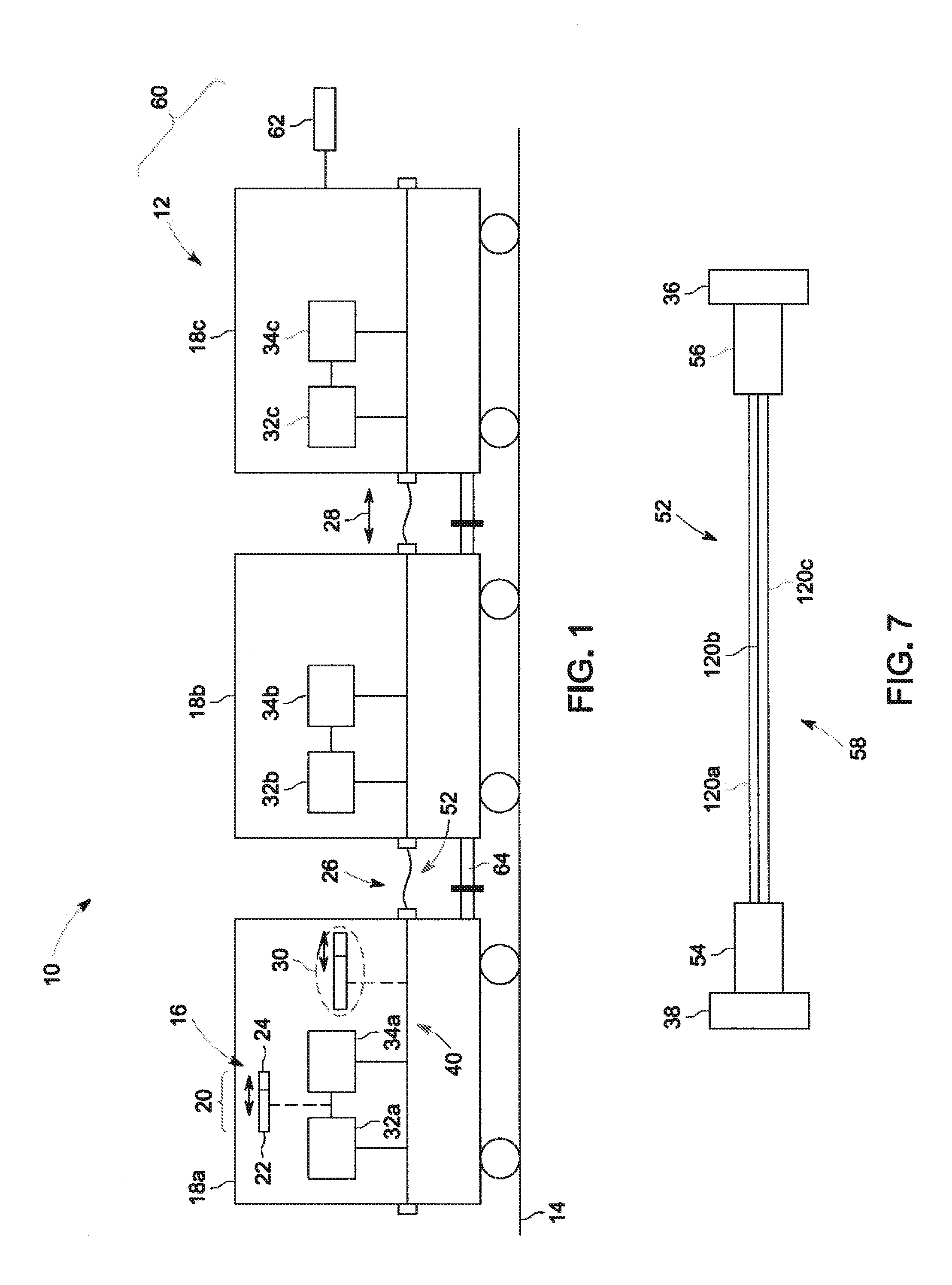

System and method for locomotive inter-consist equipment sparing and redundancy

ActiveUS20110099413A1Improve performanceImprove system reliabilitySignalling indicators on vehicleRedundant hardware error correctionData operationsElectronic component

In a system and method for communicating data in a locomotive consist or other vehicle consist (comprising at least first and second linked vehicles), a first electronic component in the first vehicle of the vehicle consist is monitored to determine if the component is in (or enters) a failure state. In the failure state, the first electronic component is unable to perform a designated function. Upon determining the failure state, data is transmitted from the first vehicle to a second electronic component on the second vehicle, over a communication channel linking the first vehicle and the second vehicle. The second electronic component is operated based on the transmitted data, with the second electronic component performing the designated function that the first electronic component is unable to perform.

Owner:GE GLOBAL SOURCING LLC

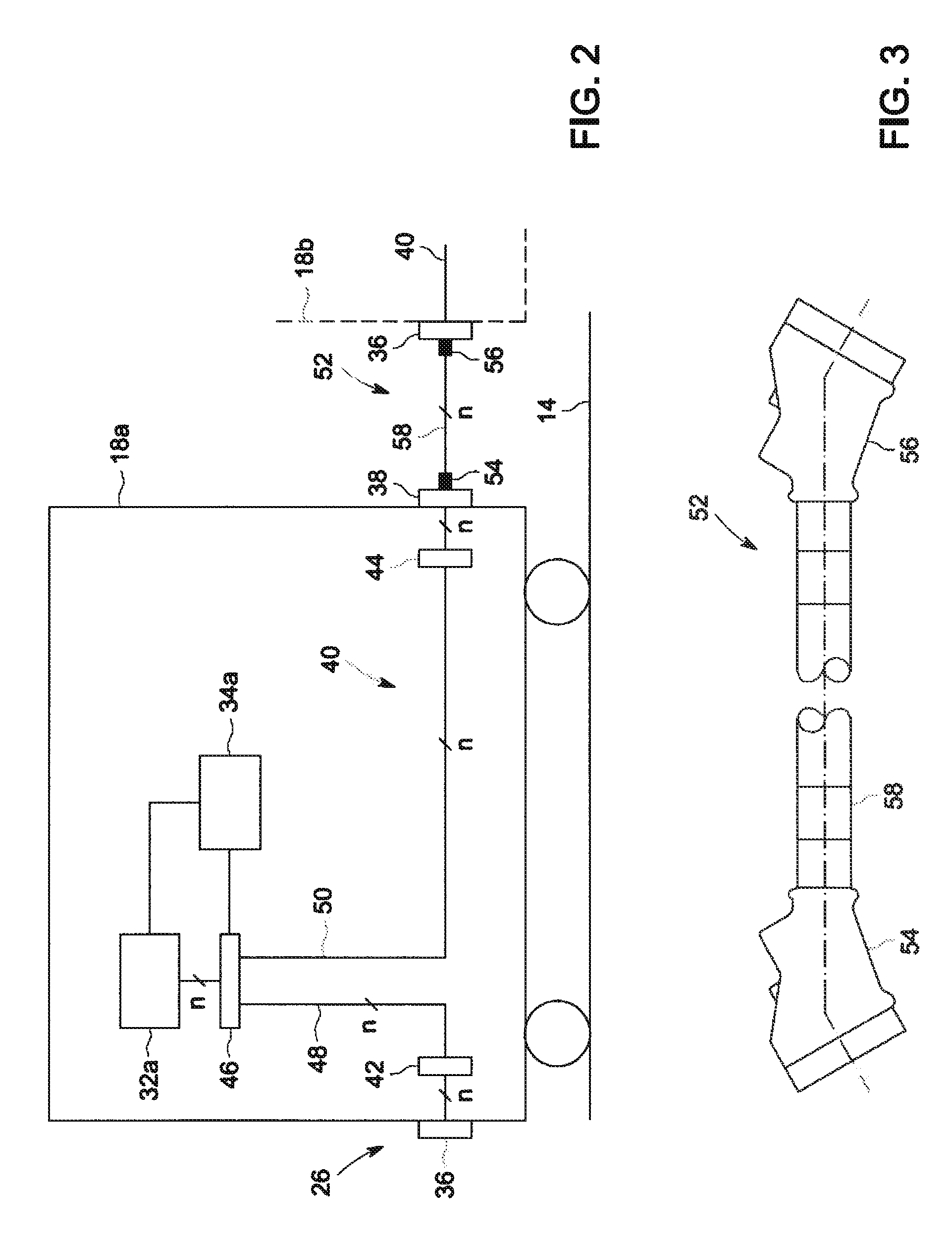

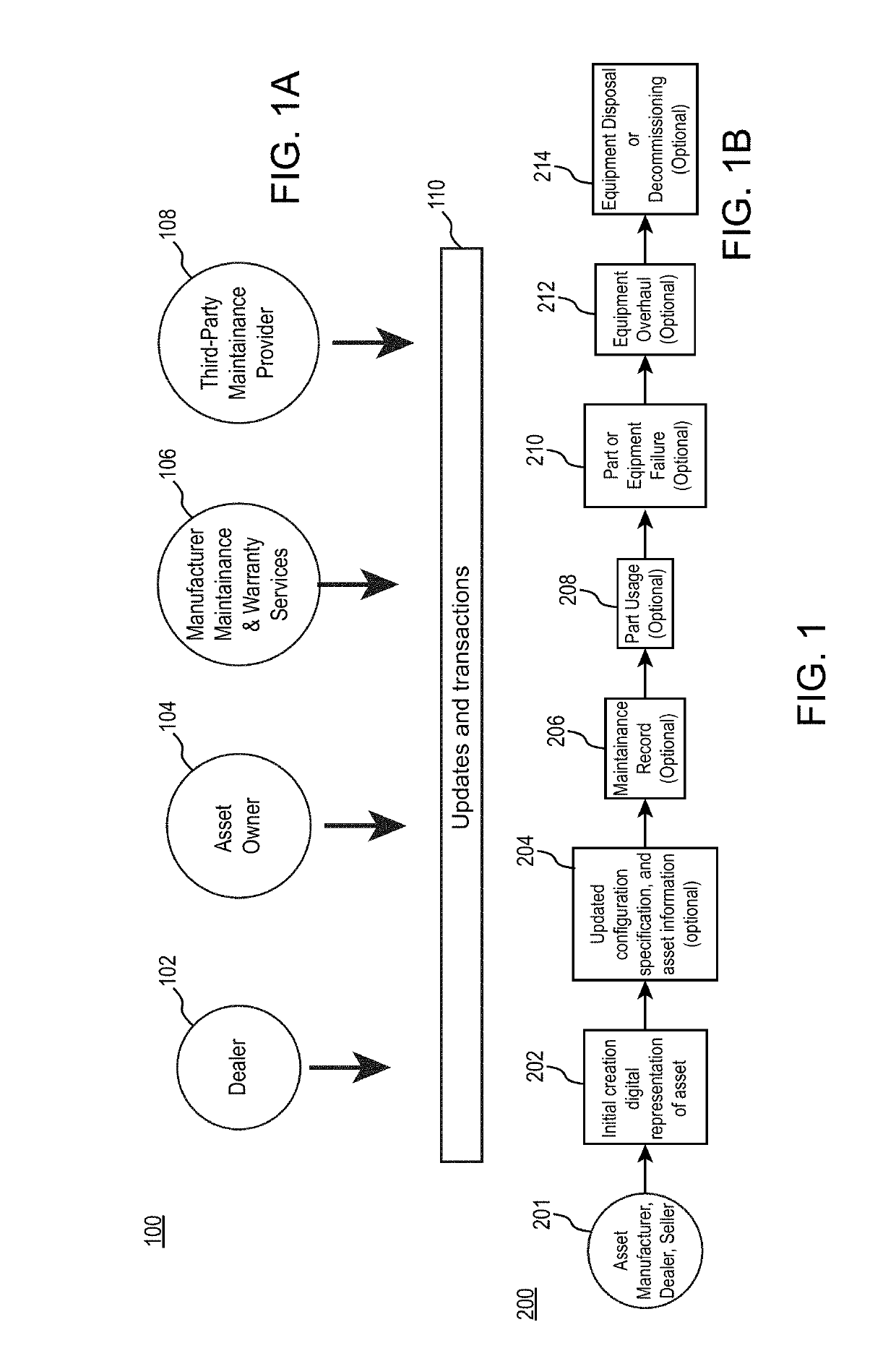

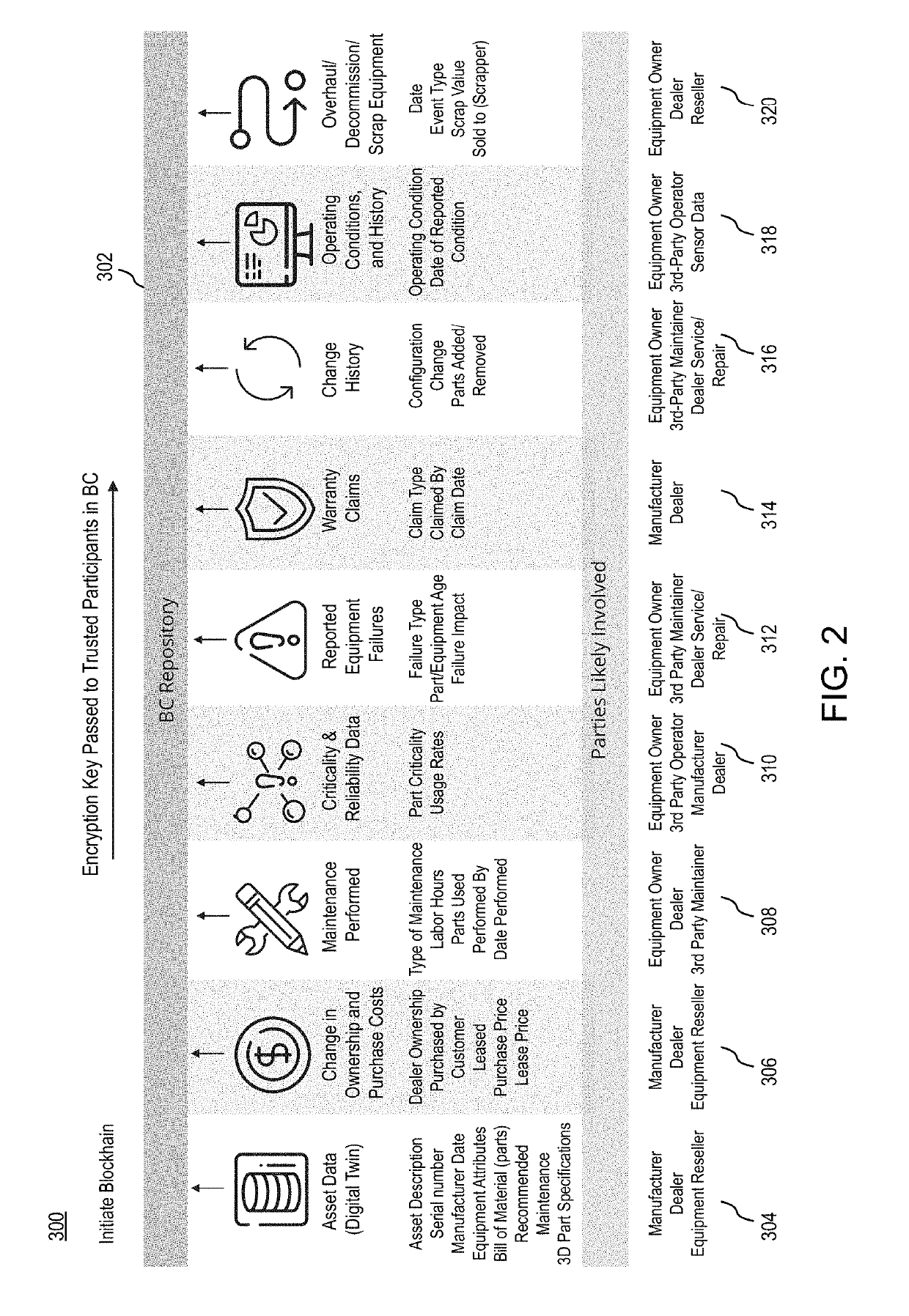

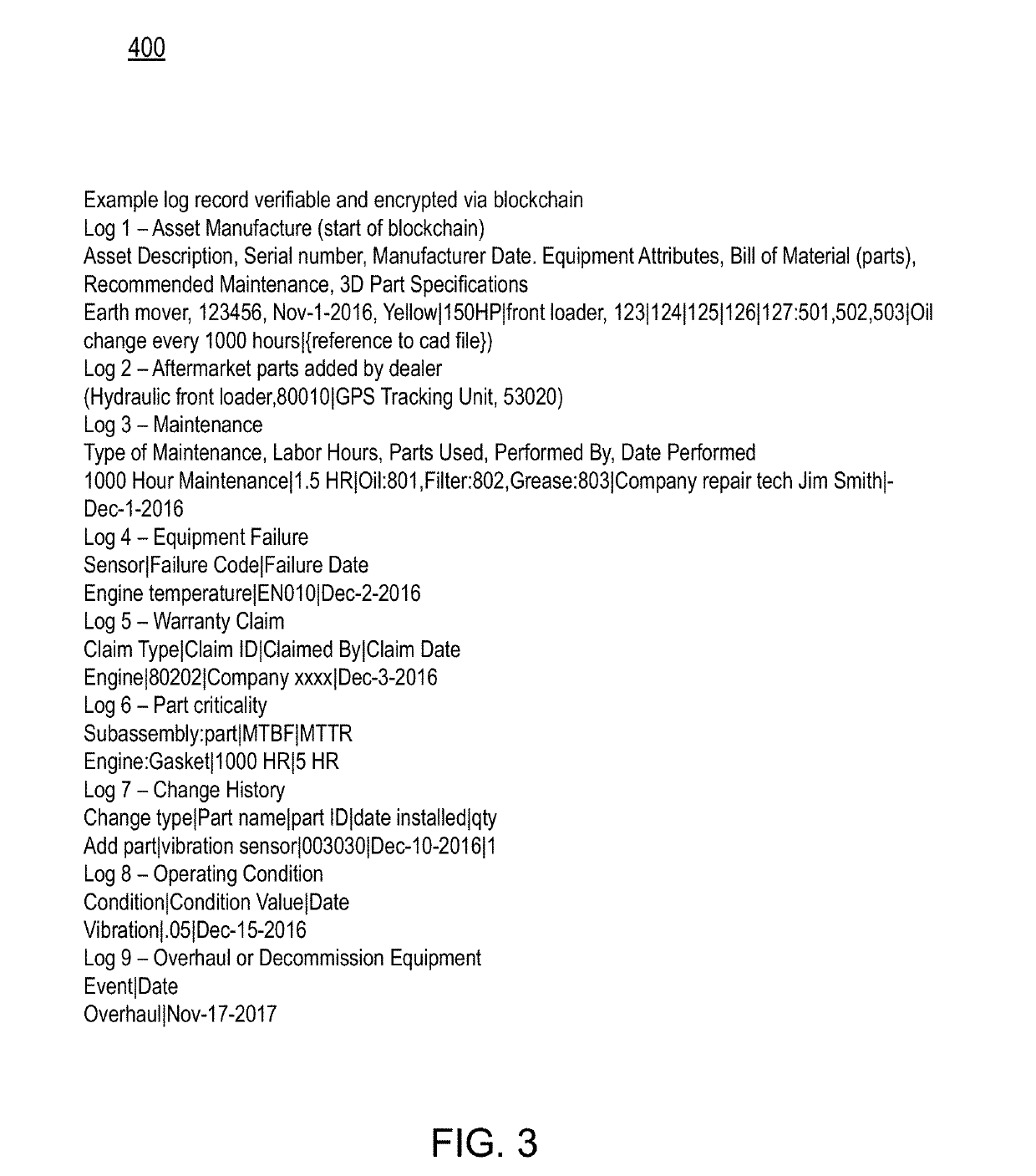

Exchanging Asset, Maintenance, And Spares Parts Information Via Blockchain

InactiveUS20190158270A1Encryption apparatus with shift registers/memoriesPublic key for secure communicationElectronic documentDocumentation procedure

A system for generating, tracking, and recording a digital representation of an asset including an electronic log of the attributes, specifications, bill of material, information to replicate parts on a 3D printer or other part duplication device, the assets warranty and claims, recommended maintenance, actual maintenance and parts (a digital footprint or digital twin) for an asset from initial creation, to its sale, during its usage and through decommissioning. The system uses block chain and encryption technology to register information about an asset that is manufactured and for which the digital footprint is to be tracked and recorded. Through use of encryption key pairs and blockchain encryption technology, an electronic document is created in an encrypted transaction log updated at each change to the equipment including the parts and its maintenance records. From the manufacturer or distributor, the asset is shipped with an encryption key that provides access to the equipment information and allows further updates on parts that are added or removed, maintenance performed, warranty work completed and operating metrics are to be provided as available.

Owner:ONIQUA PTY LTD +1

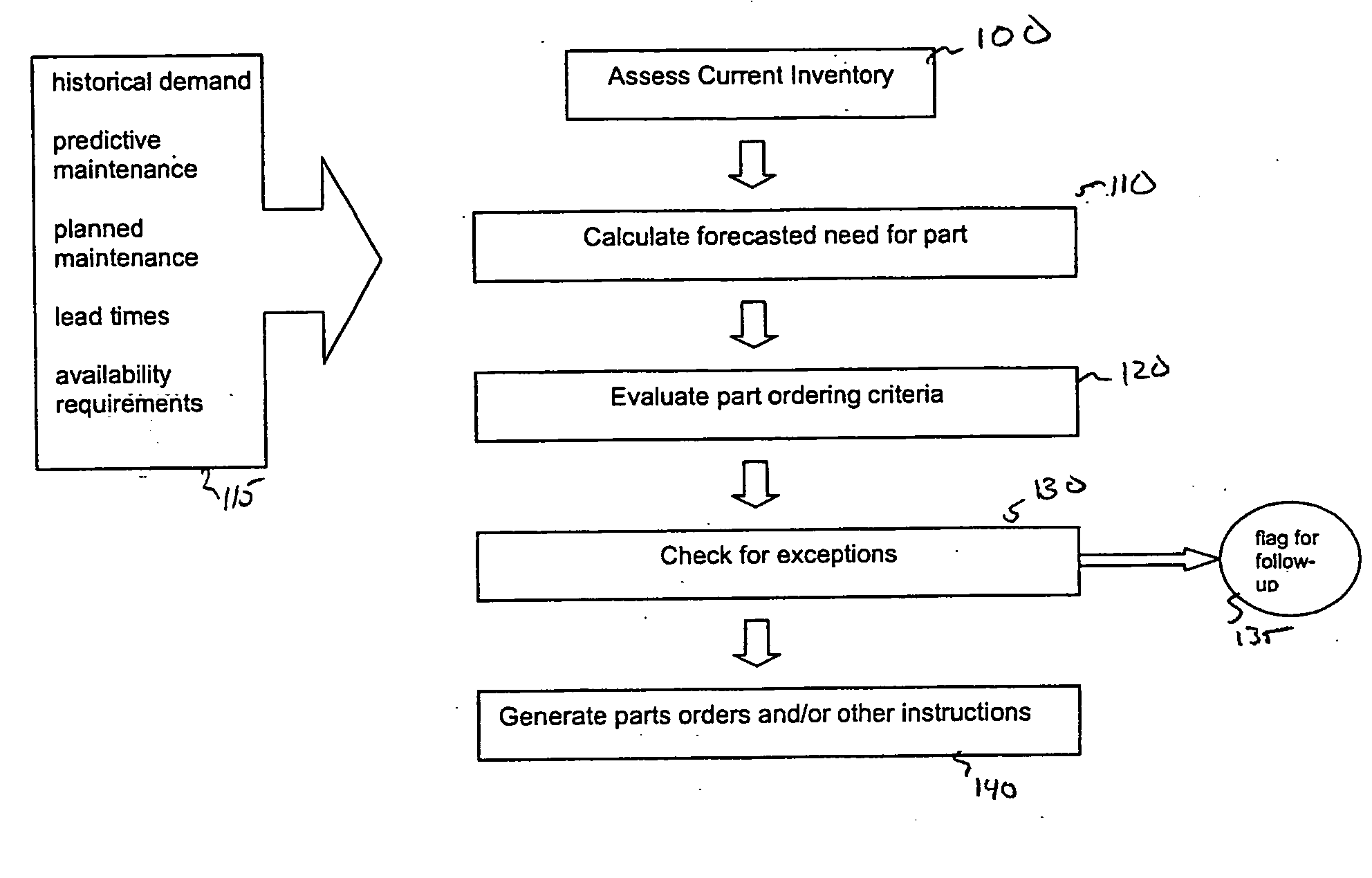

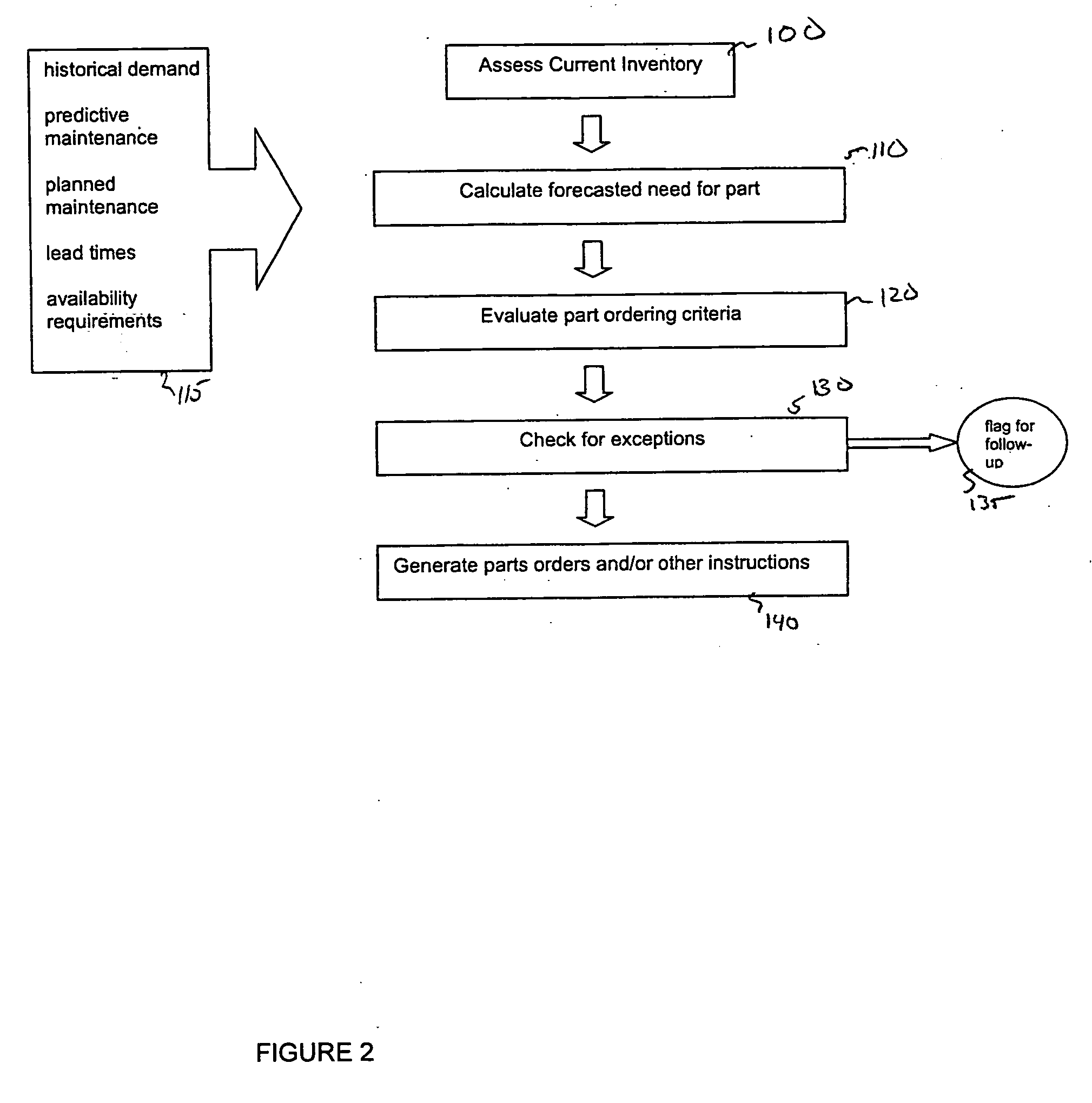

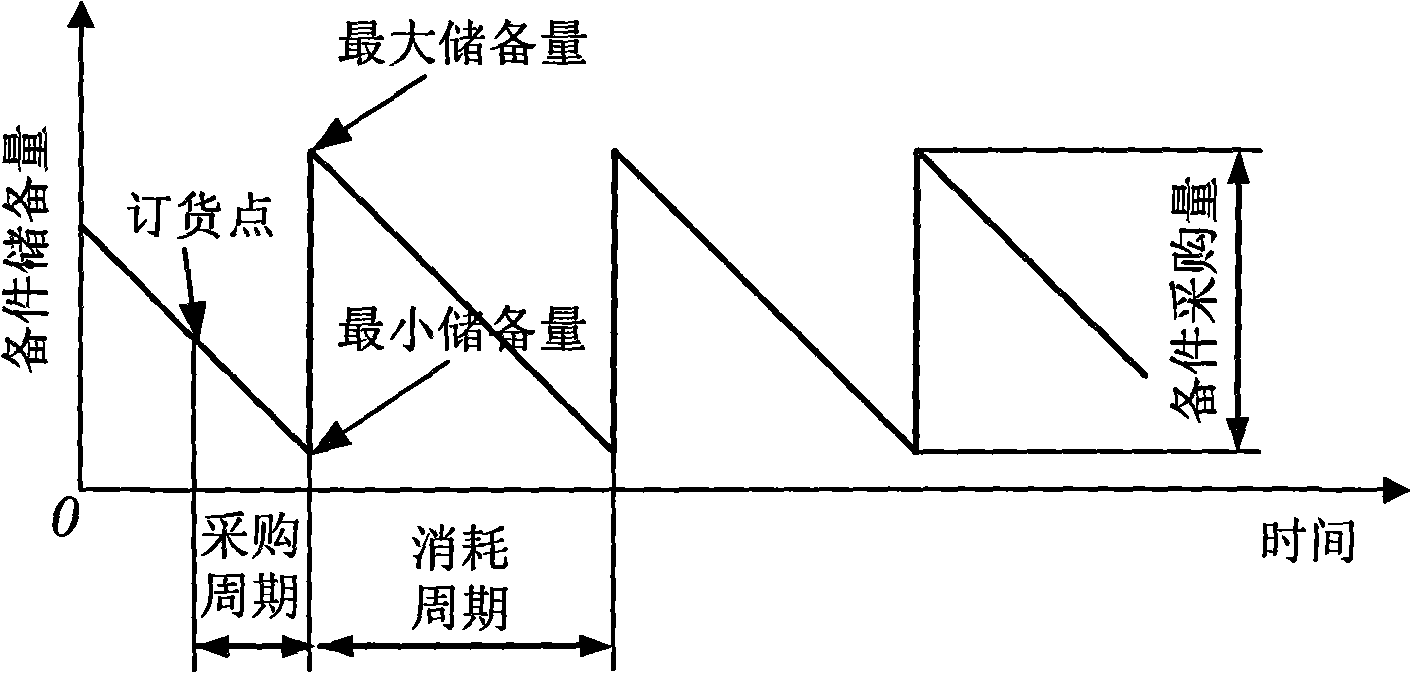

Spare parts inventory management

A method for managing spare parts and tools for a manufacturing enterprise is disclosed. Historical demand values are statistically analyzed to determine optimal stocking levels for spare parts based upon required availability percentages, parts lead times, and the statistical distribution parts demand levels. Parts stocking decisions can also be based upon planned and preventative maintenance timeframes with such parts ordered on an as-needed basis in accordance with lead times. Spare parts inventory management can utilize an enterprise-wide computer system to integrate parts demand planning with systems used for engineering and other changes to manufacturing processes and facility maintenance systems. The computer system can perform varying degrees of the parts reordering and planning process and automate certain steps while providing for decision of other issues by parts management personnel.

Owner:CALLAHAN CELLULAR L L C

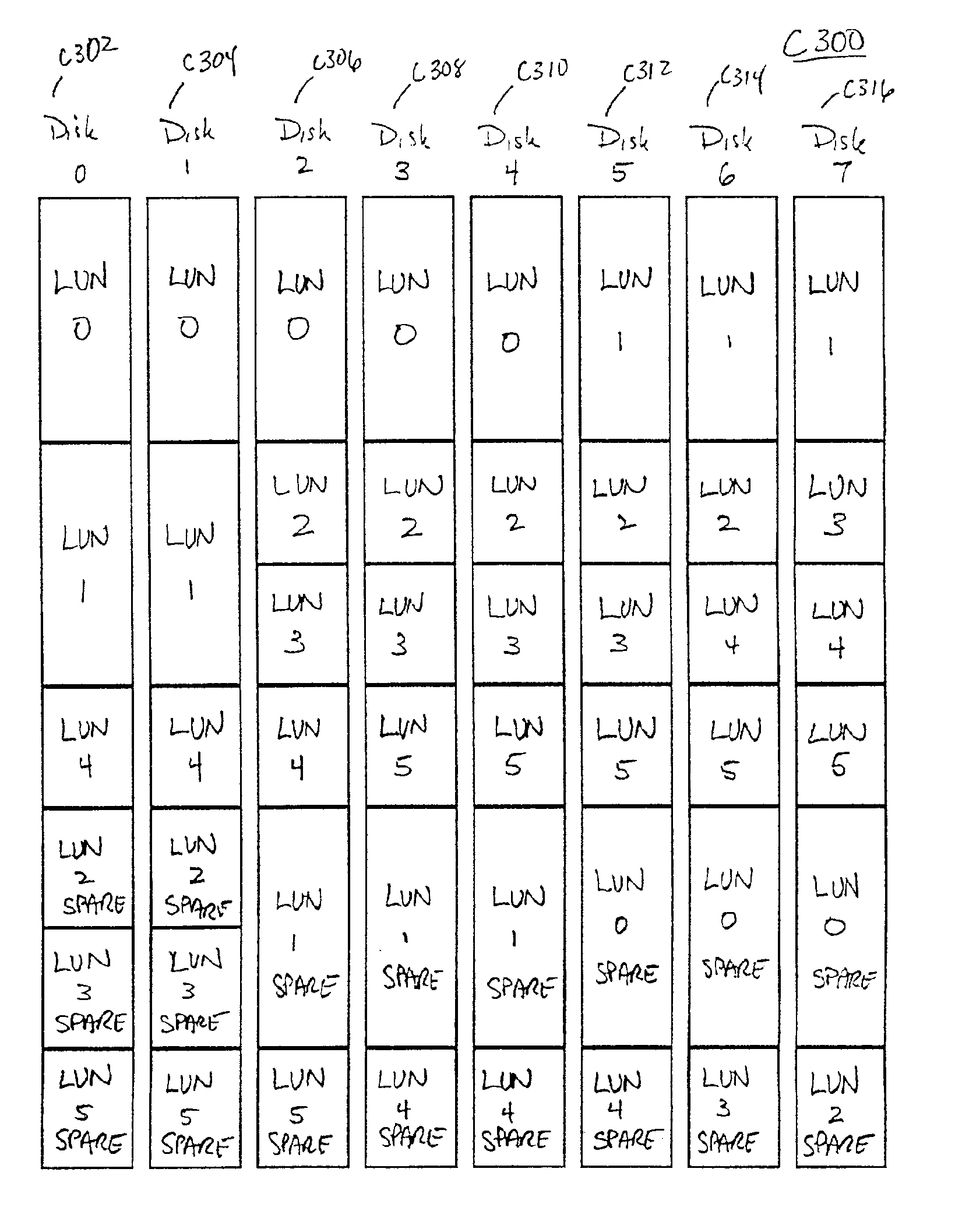

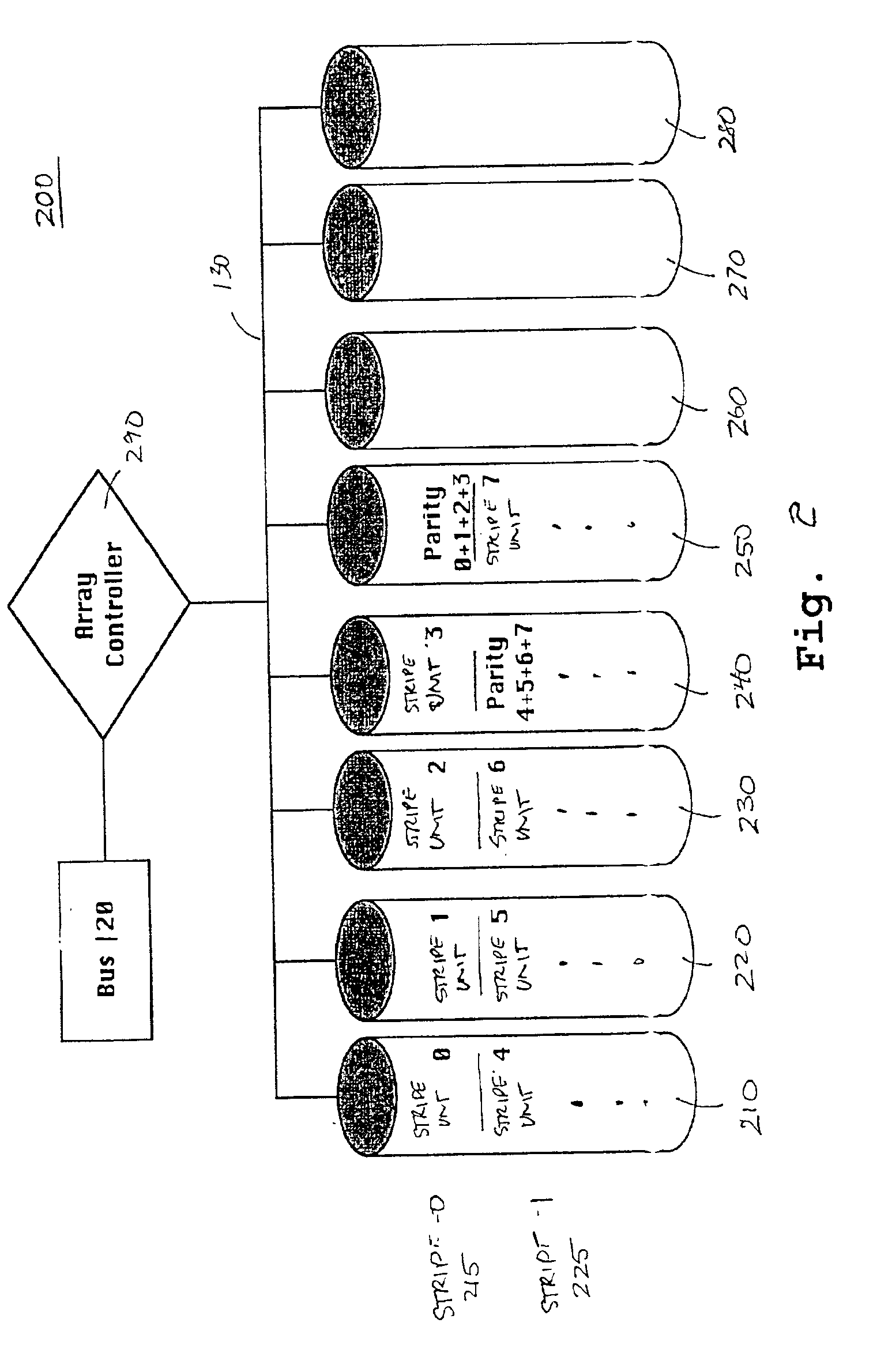

Method and system for striping spares in a data storage system including an array of disk drives

InactiveUS6934804B2Improve reliabilityImprove performanceMemory loss protectionRedundant data error correctionGranularityData store

Method and apparatus for striping spare storage in a data storage system. Specifically the present invention describes a method and apparatus for storing data and spare storage in a data storage system having a plurality of physical storage devices. The plurality of physical storage devices is partitioned into a plurality of slices. Logical units of storage (LUNs) are created, wherein each LUN contains data, spare, and data redundancy. Each of the plurality of slices is assigned to one of the plurality of LUNs so as to distribute storage of data, data redundancy, and spare across all of the plurality of physical storage devices. Distribution of spare storage is concentrated at the inner zone of each of the plurality of physical storage devices. The data and spare storage can be distributed uniformly or with varying granularities across all of the plurality of physical storage devices.

Owner:ORACLE INT CORP

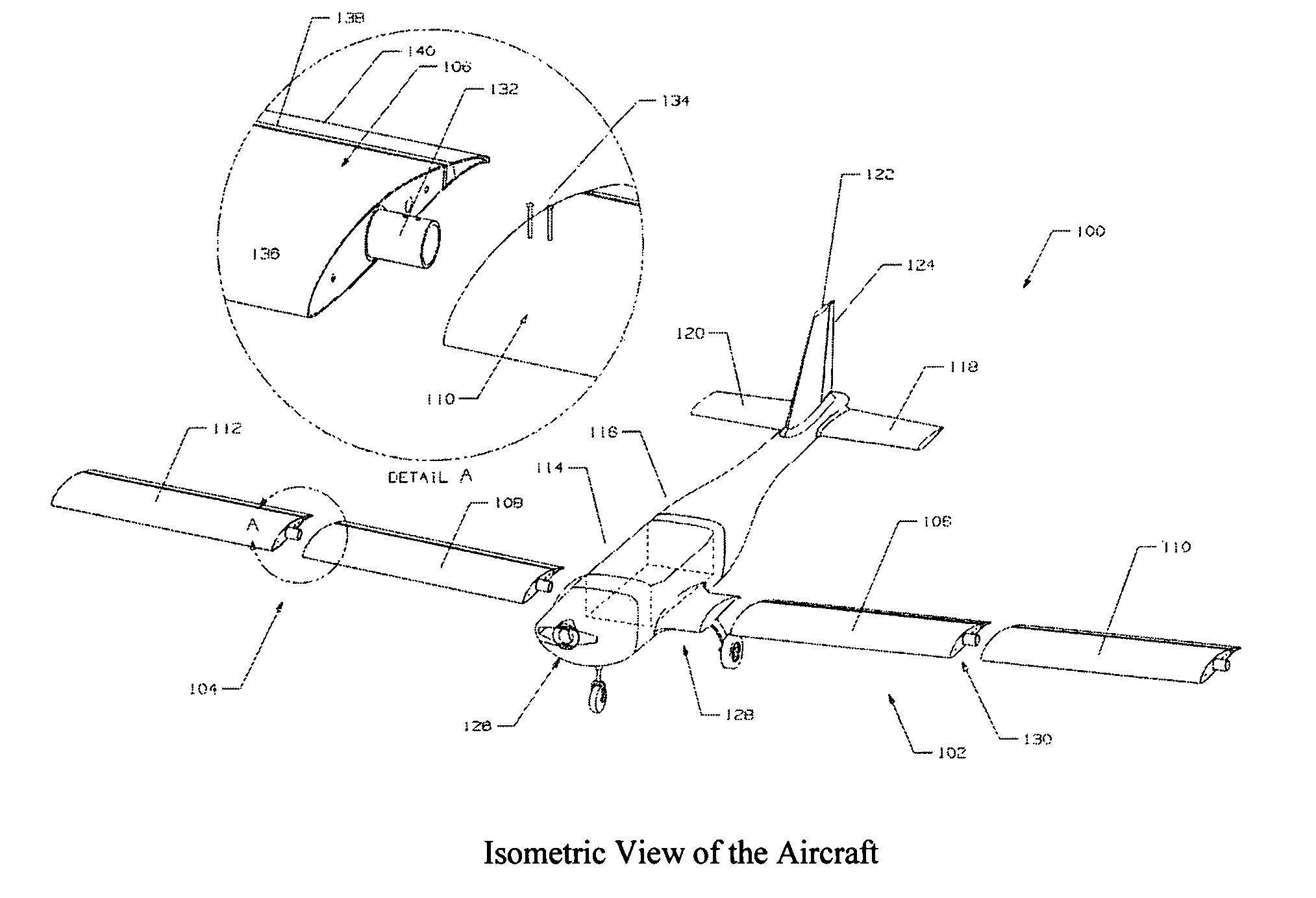

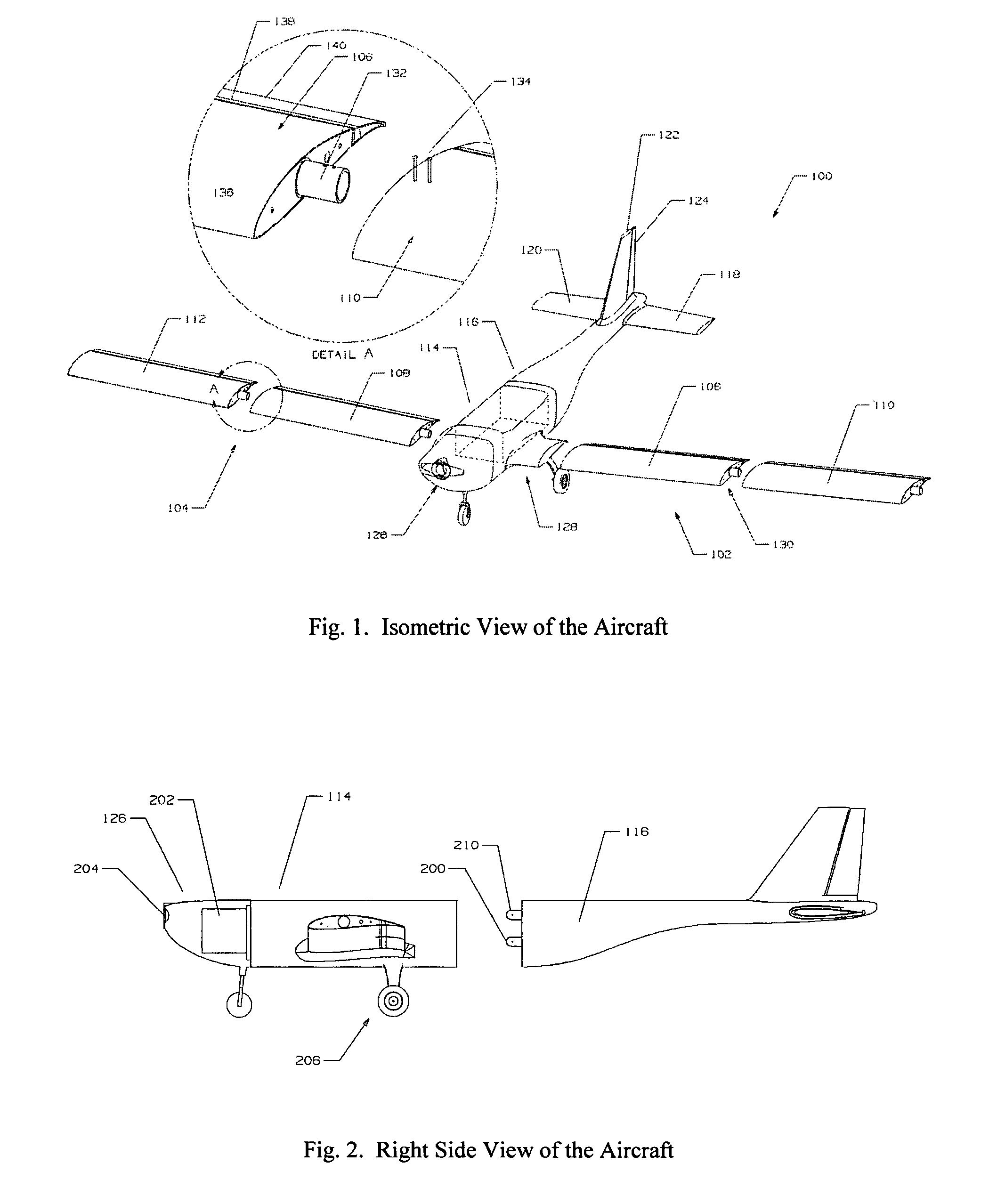

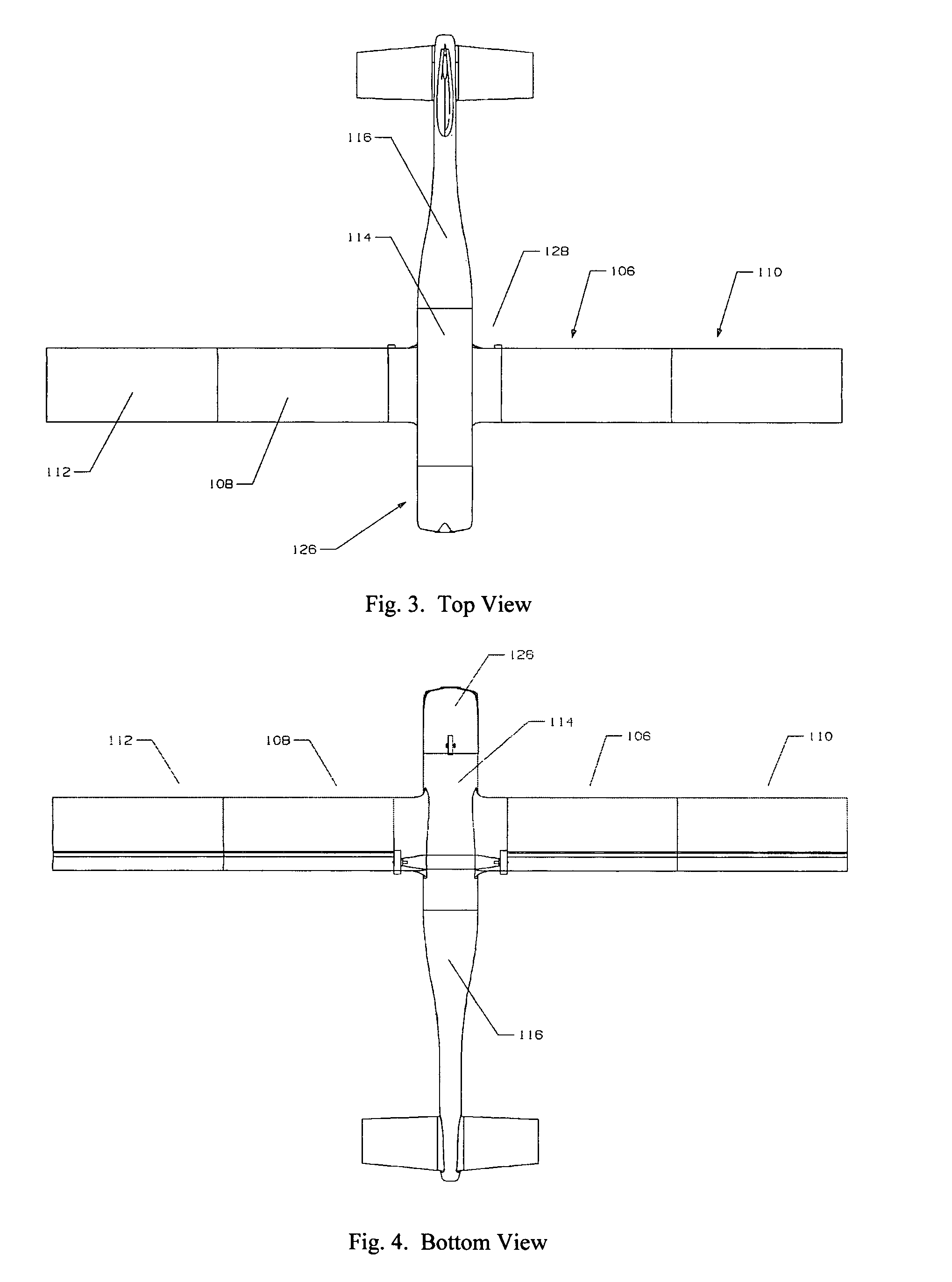

Modular unmanned air-vehicle

InactiveUS7922115B2Lower life cycle costsEasy to transportAircraft stabilisationUnmanned aerial vehiclesJet aeroplaneFlight vehicle

The present invention is an unmanned air vehicle designed for reconnaissance, surveillance, data acquisition, and general research. The air vehicle is a monoplane that consists of several pieces that can easily be assembled using a minimal amount of tools. The air vehicle consists of a forward and aft fuselage section, two identical horizontal stabilizers, and four identical wing sections. The aircraft can fly with all four wing sections, or with just two wing sections (the short wing configuration). Each of the four wing sections of the air vehicle can be interchanged with any of the other wing sections for the purpose of minimizing assembly time and spare parts.

Owner:COLGREN RICHARD D +2

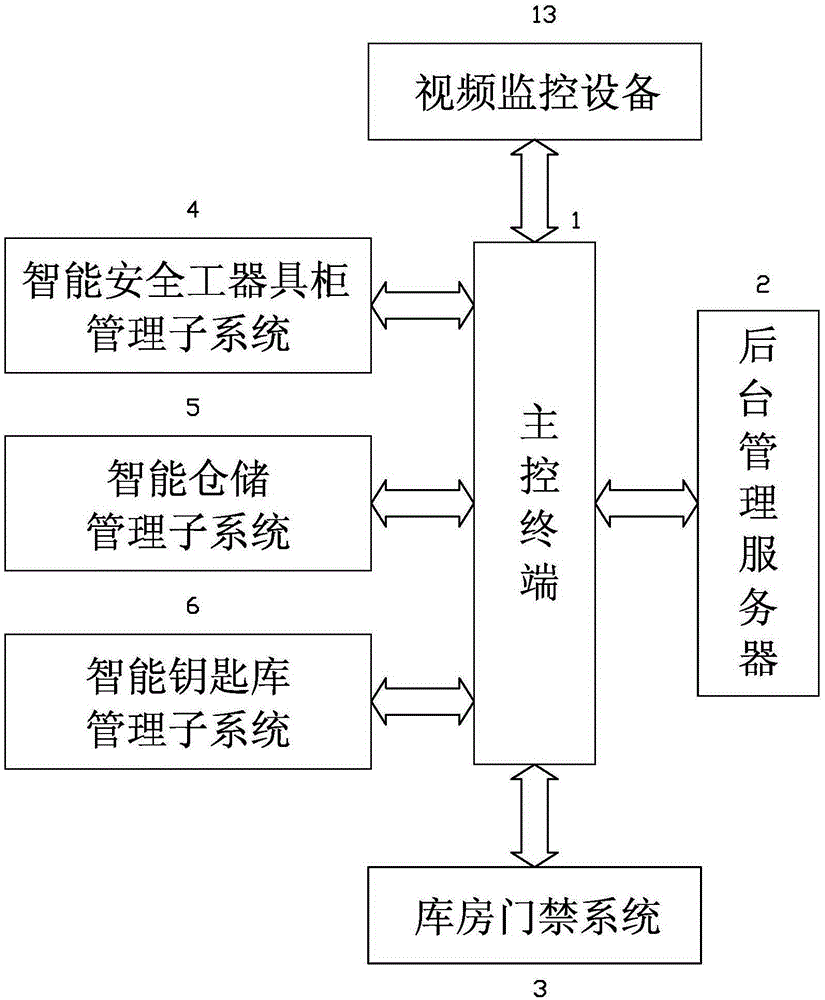

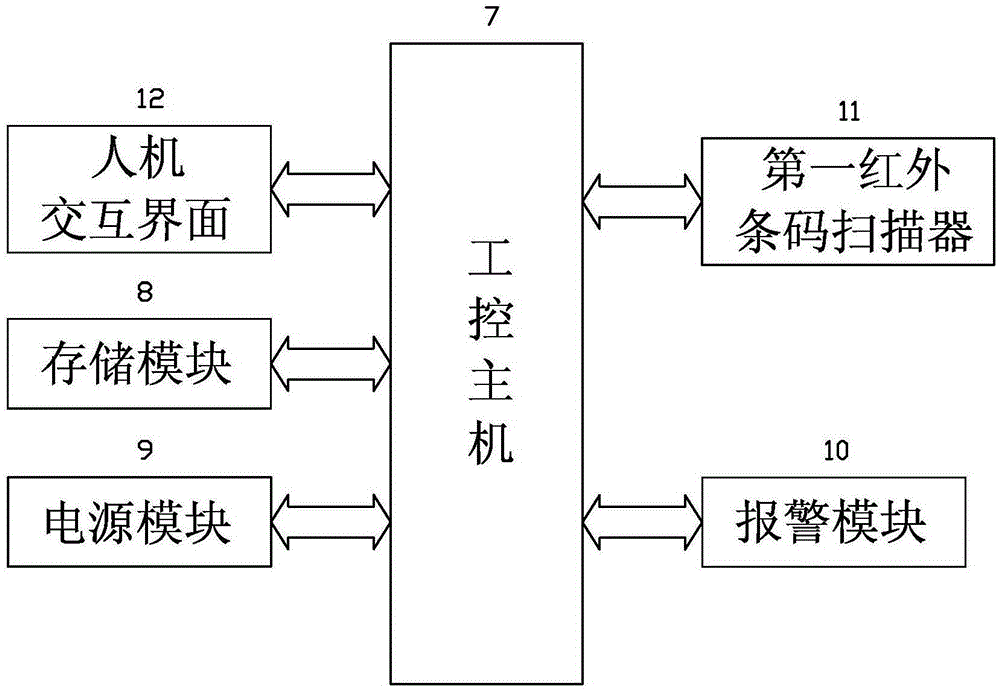

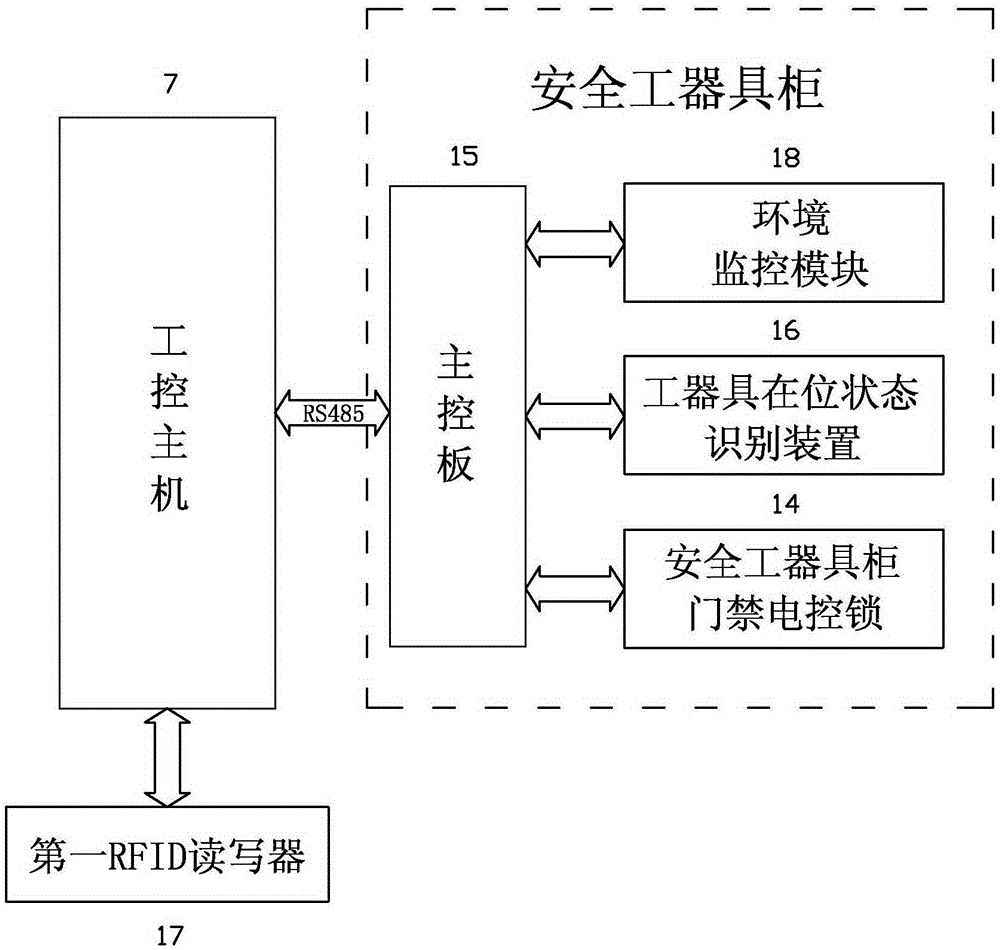

Intelligent power supply station storeroom management system and method based on internet of things

ActiveCN105160748ALearn about usageAvoid abuseData processing applicationsIndividual entry/exit registersThe InternetEngineering

The invention provides an intelligent power supply station storeroom management system and method based on the internet of things. The intelligent power supply station storeroom management system comprises a master control terminal, a background management server connected to the master control terminal, an intelligent security tool cabinet management sub system capable of being connected to the master control terminal in a communication mode, an intelligent warehouse management sub system and an intelligent key library management sub system. The master control terminal is internally provided with intelligent security tool cabinet management system software, intelligent warehouse management software and intelligent key library management system software. A three-in-one comprehensive management model of real-time voice, data and images is adopted for the system, use of a security tool, consumption of spare parts and borrowing of keys are managed through an intelligent means, the failure repair time of a response field can be effectively shortened, the failure reaction speed is increased, the agricultural distribution network construction, overhauling and repairing work efficiency is improved, the work procedure of operation personnel is standardized, the safe production awareness is enhanced, a novel intelligentized power supply station storeroom based on a technology of the internet of things is constructed, and powerful guarantee is provided for safe production of a power enterprise.

Owner:STATE GRID FUJIAN JINJIANG POWER SUPPLY

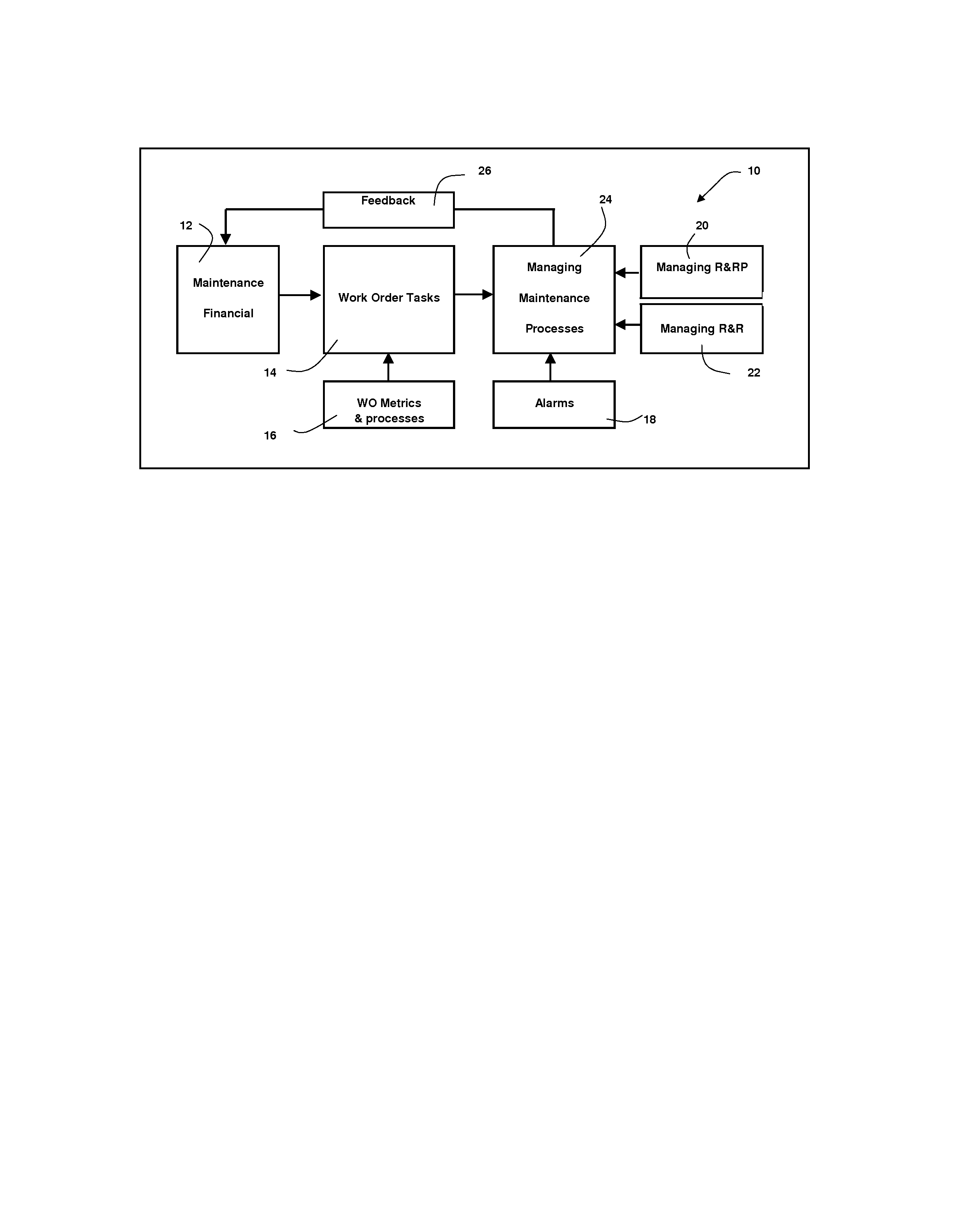

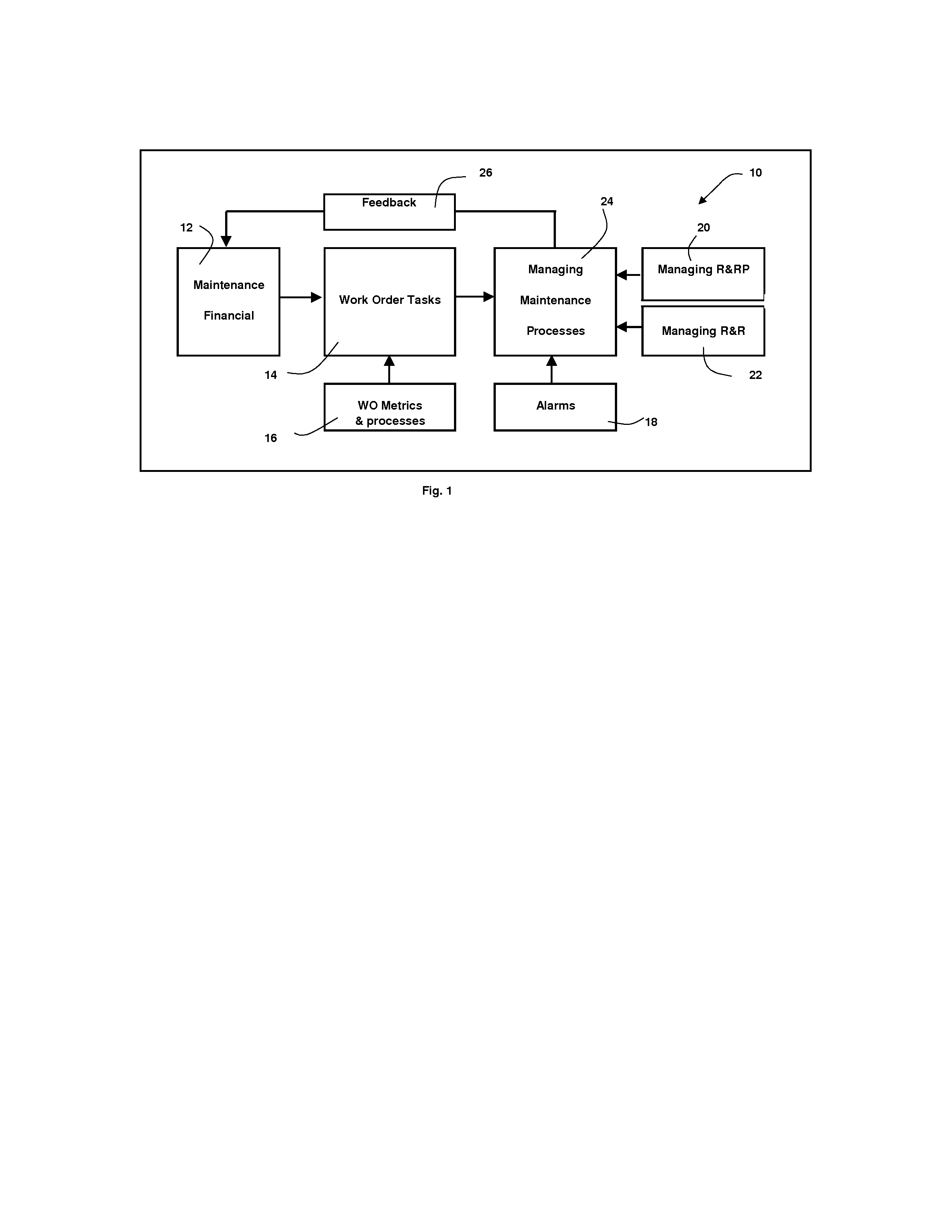

Eliminating sources of maintenance losses

Processes and software are provided for eliminating sources of maintenance losses in machine intensive environments such as manufacturing, processing and assembly plants.The processes and software include creating financial and work order metrics to trend maintenance variables, a process for creating work orders, a process for using alarms for integrating measurement technologies and spare parts, a process for managing repair and replacing activities and projects by improving documenting and communicating processes while involving users such as executives and senior managers.

Owner:ROSSI SERGIO J

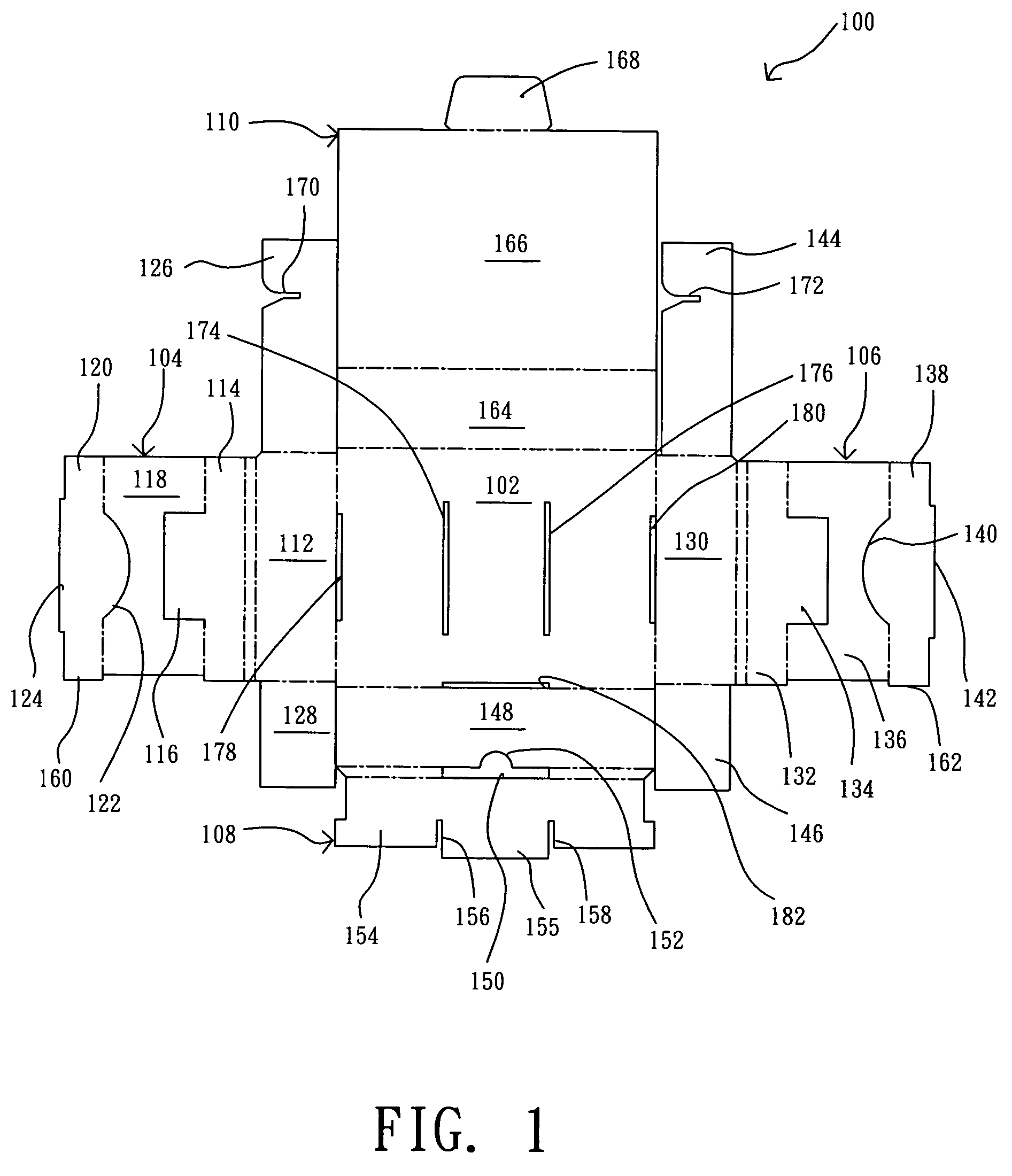

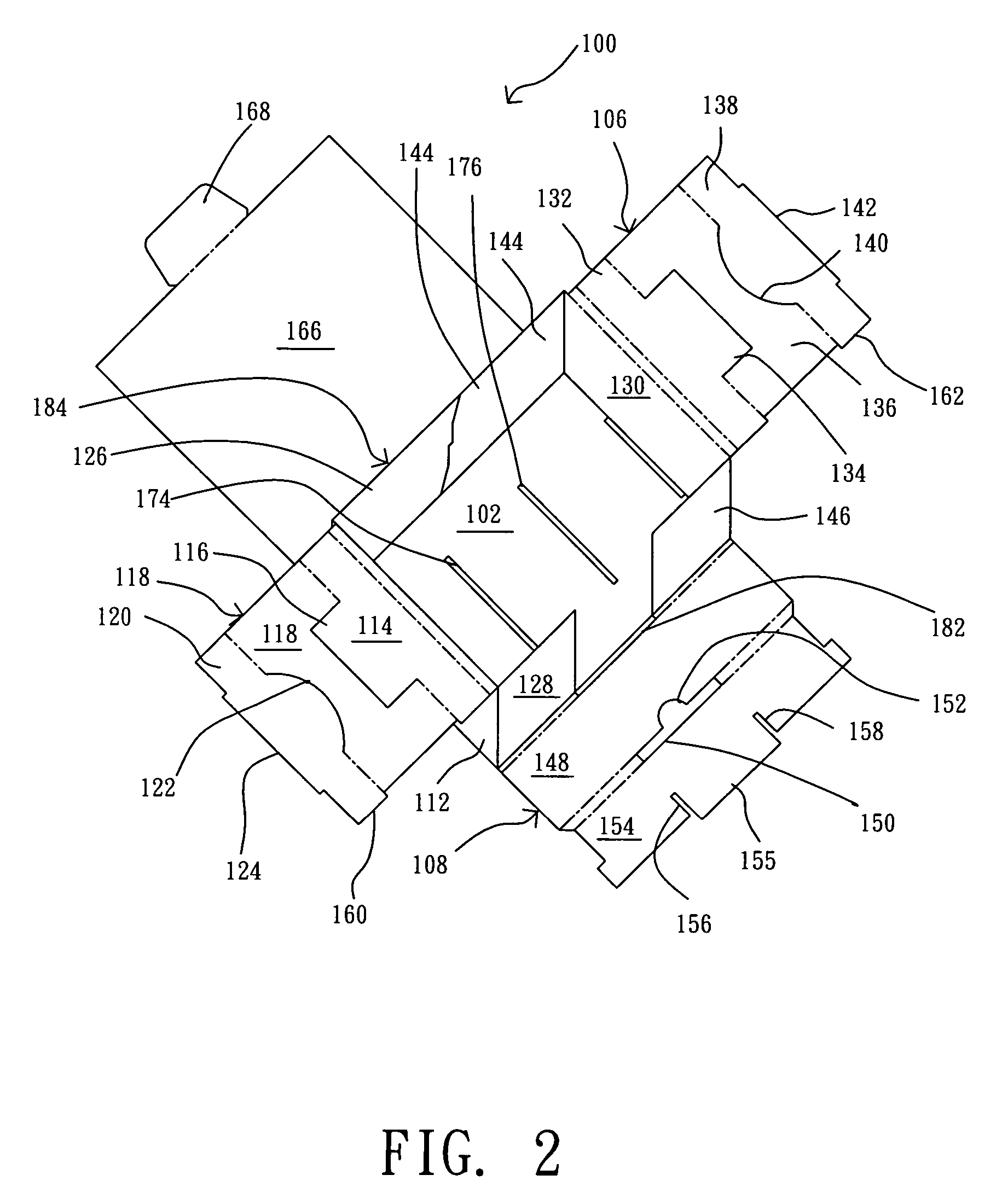

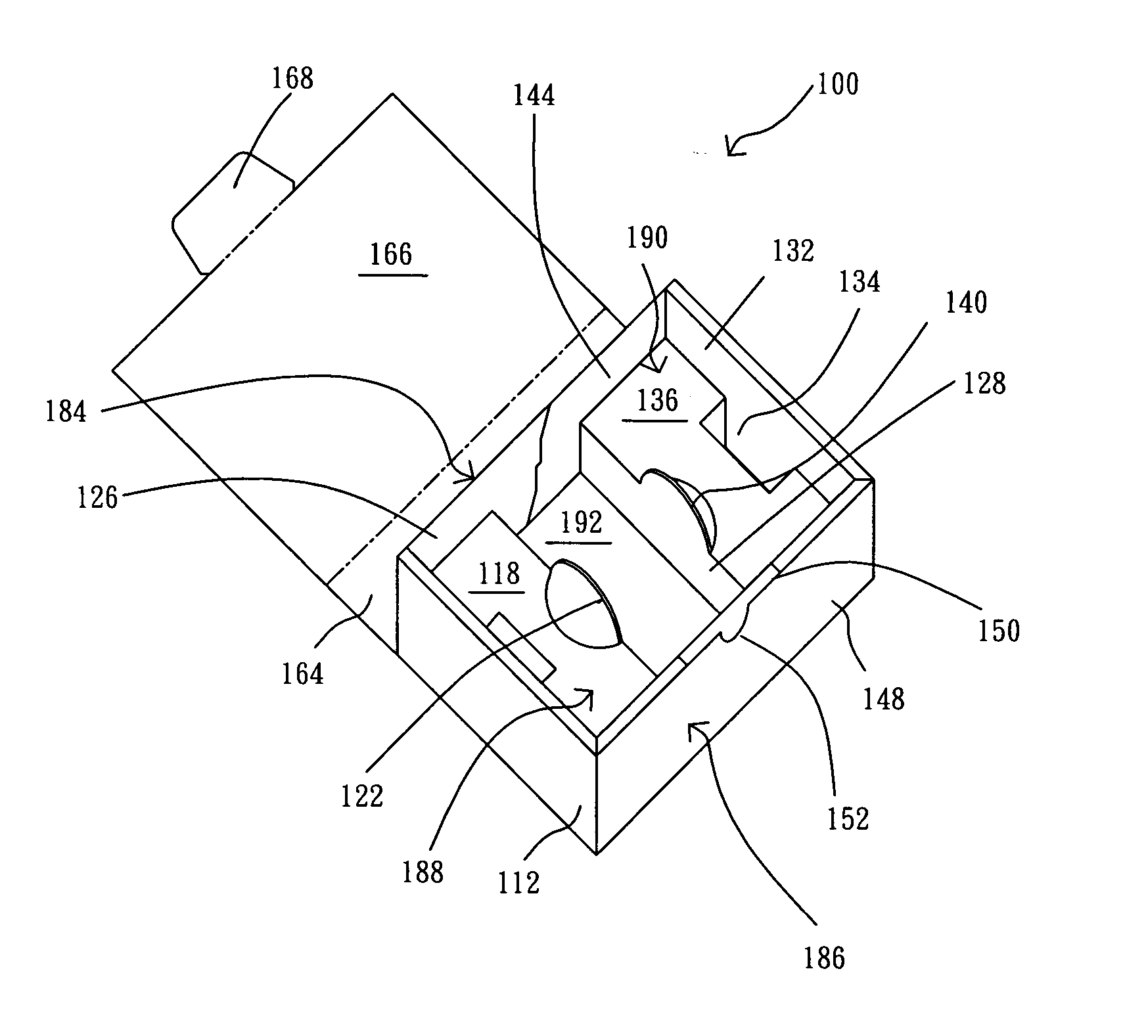

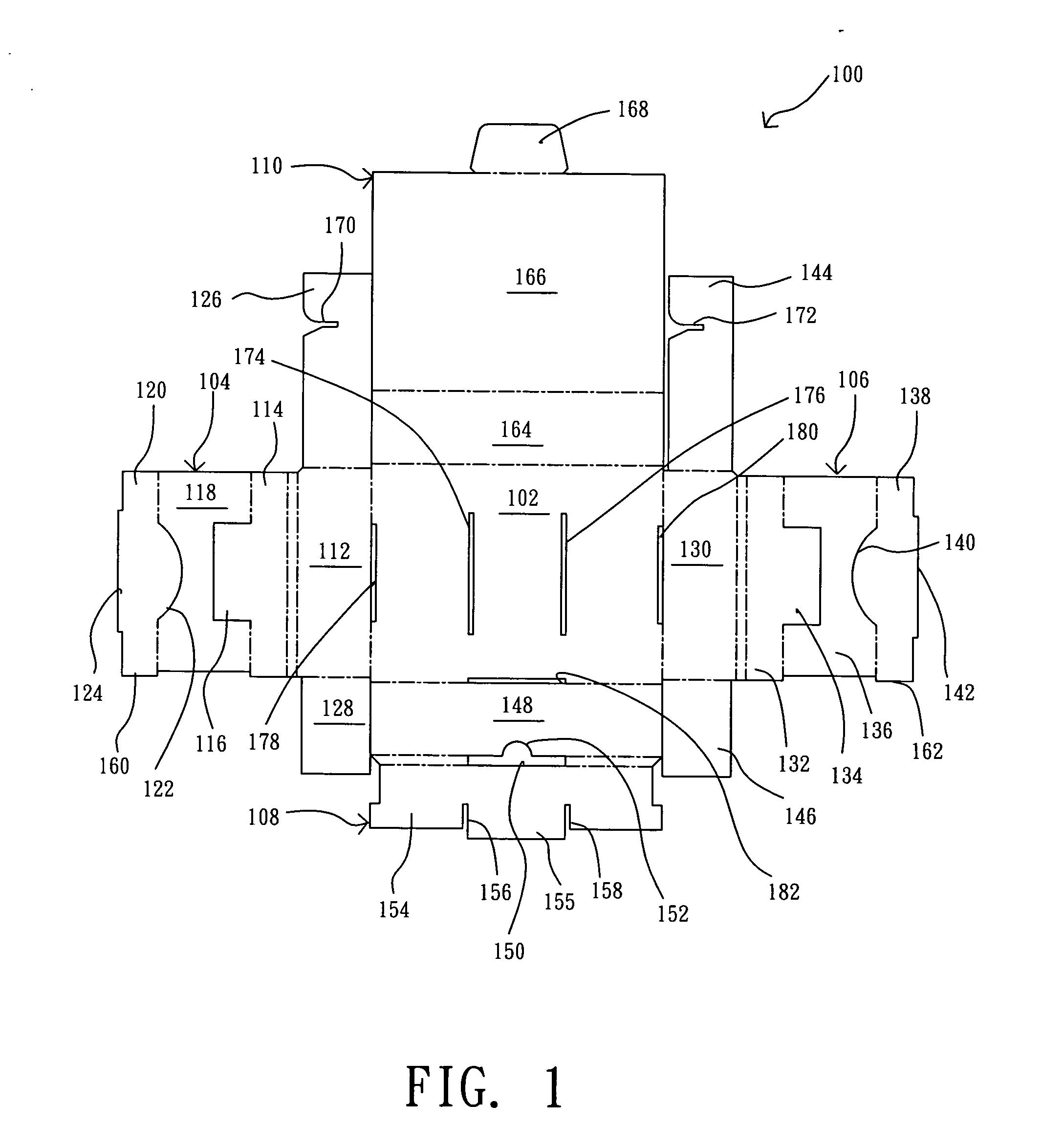

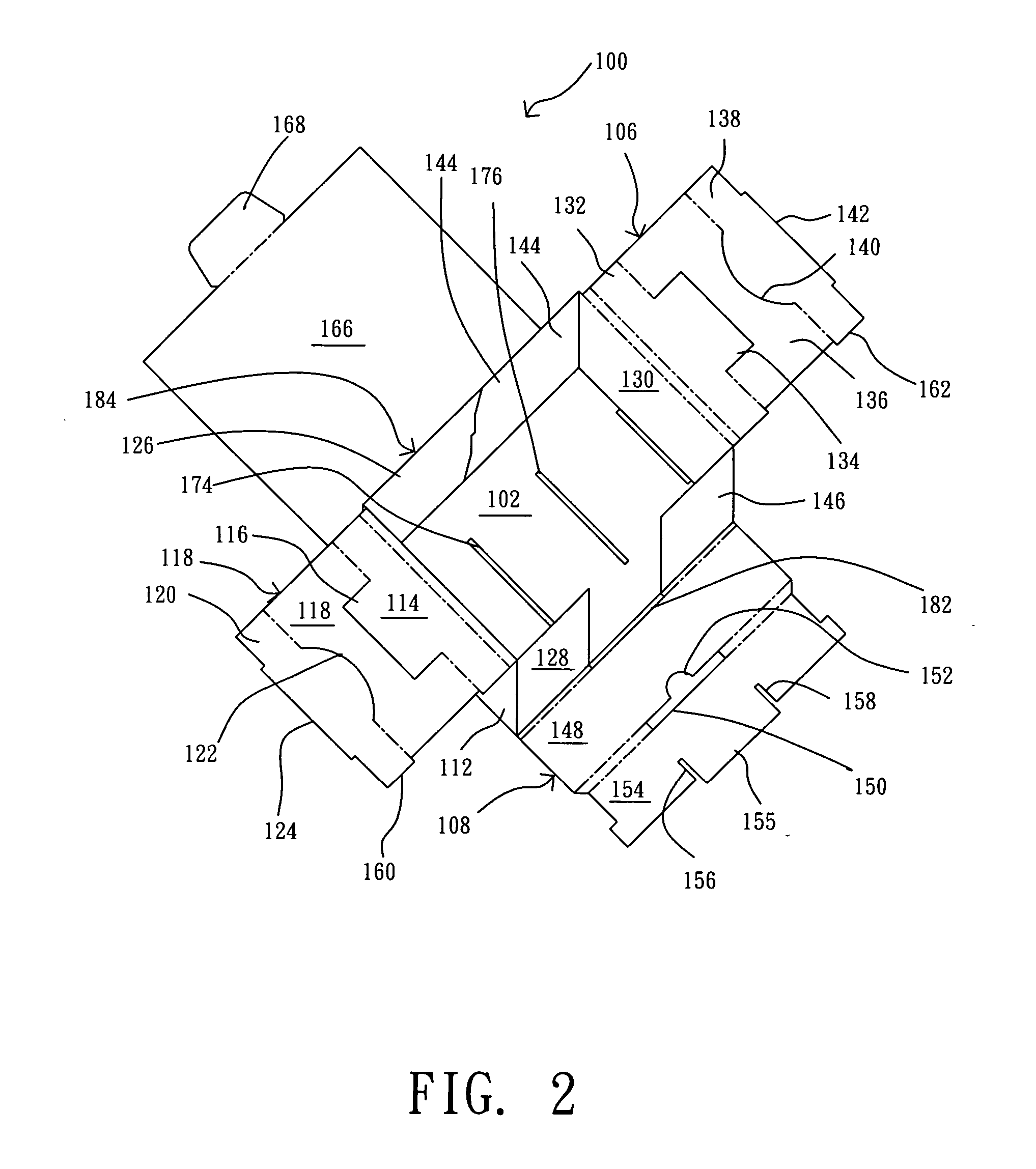

Packaging carton

InactiveUS7097043B2Reduce environmental burdenMeet the requirementsOther accessoriesContainers to prevent mechanical damageCartonEngineering

A packaging carton is disclosed, suitable for packaging an electronic product, such as a peripheral product, a mobile phone, or a spare part. The packing carton is formed by folding a paper material and is one piece, and is fabricated by linking two clip slots. Furthermore, the packaging carton comprises two hollow buffer structures beside two sides of a storage chamber and two upper holding pieces adjacent to both sides of the storage chamber to protect an object packaged in the packaging carton.

Owner:QUANTA COMPUTER INC

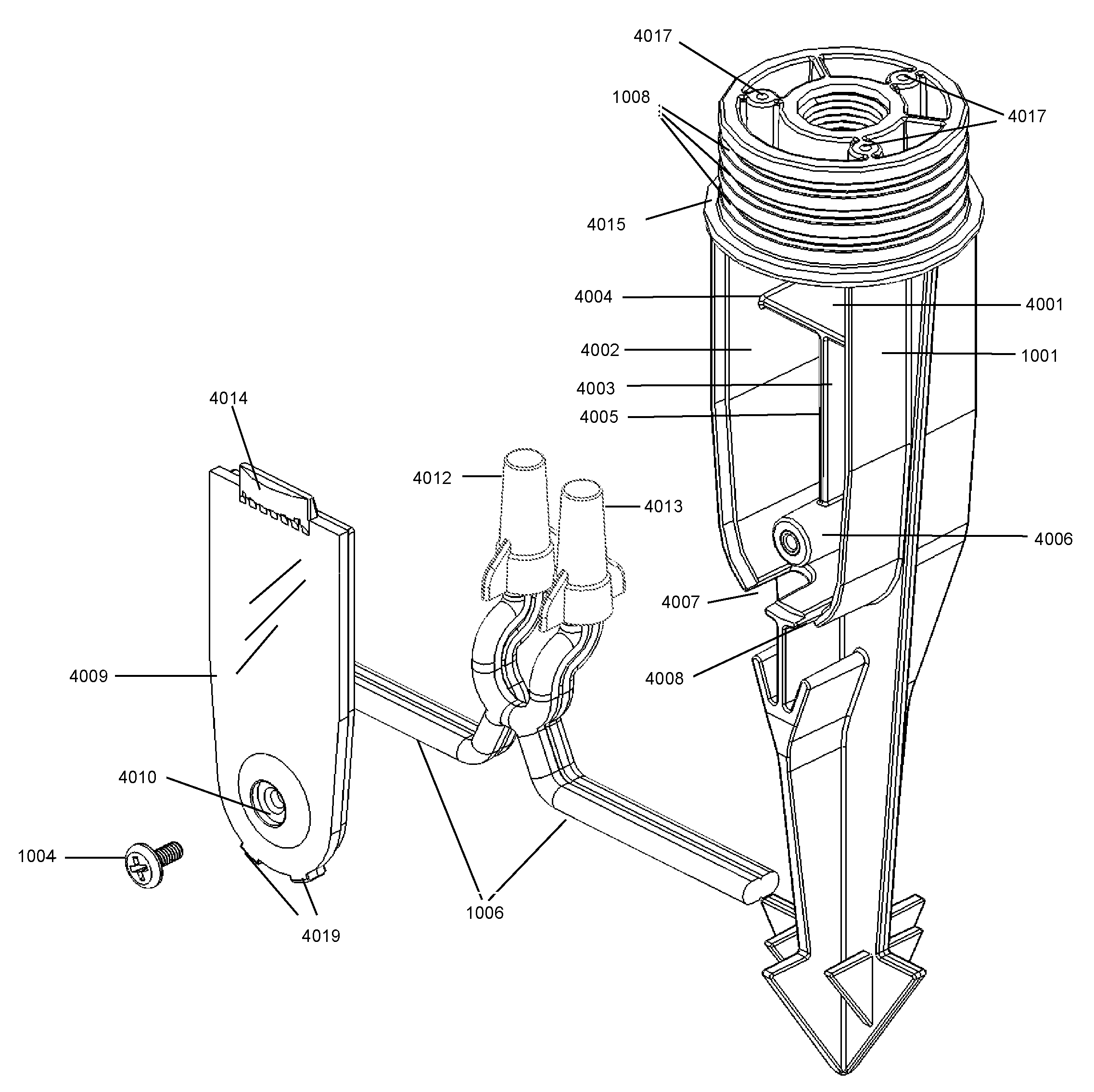

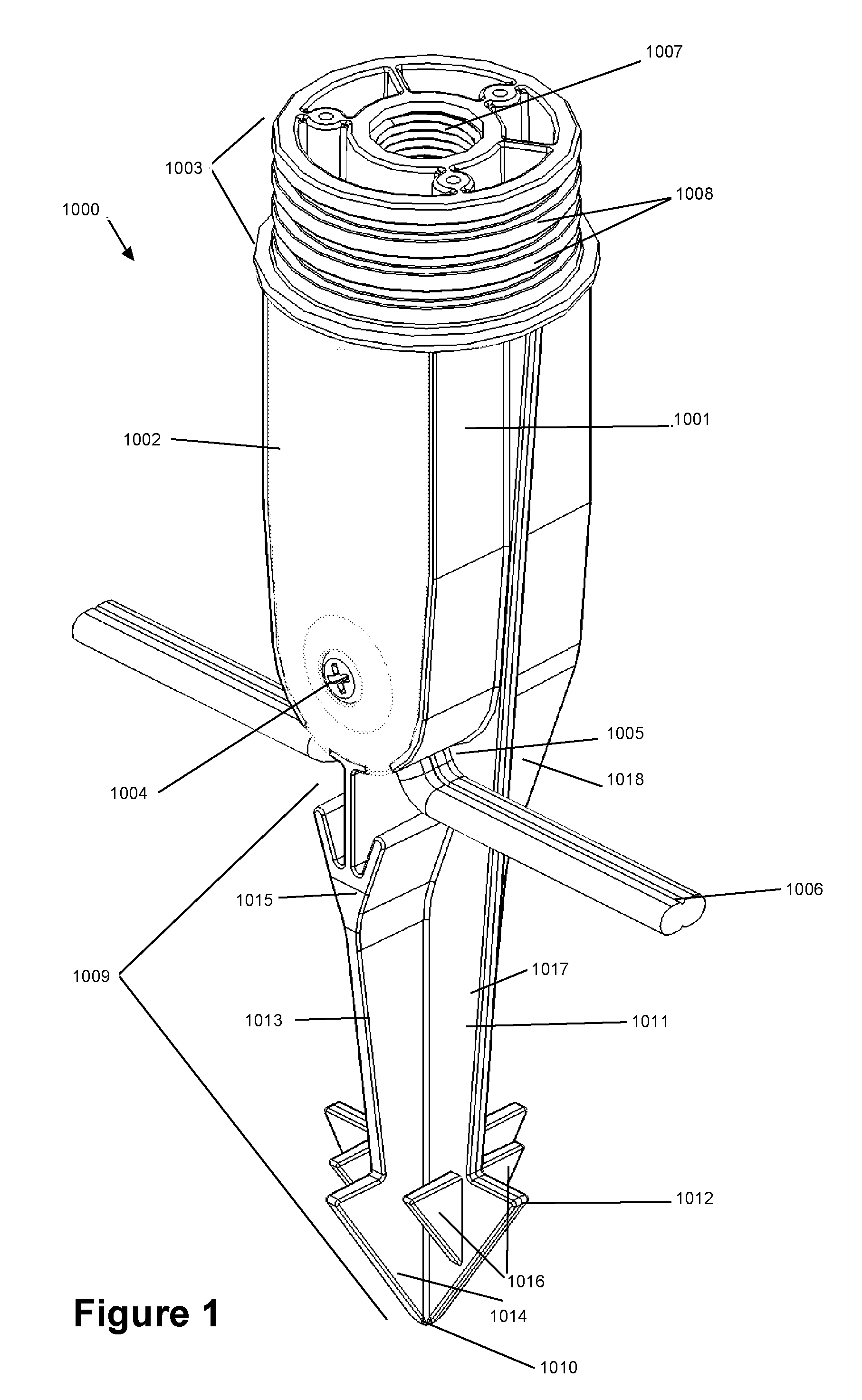

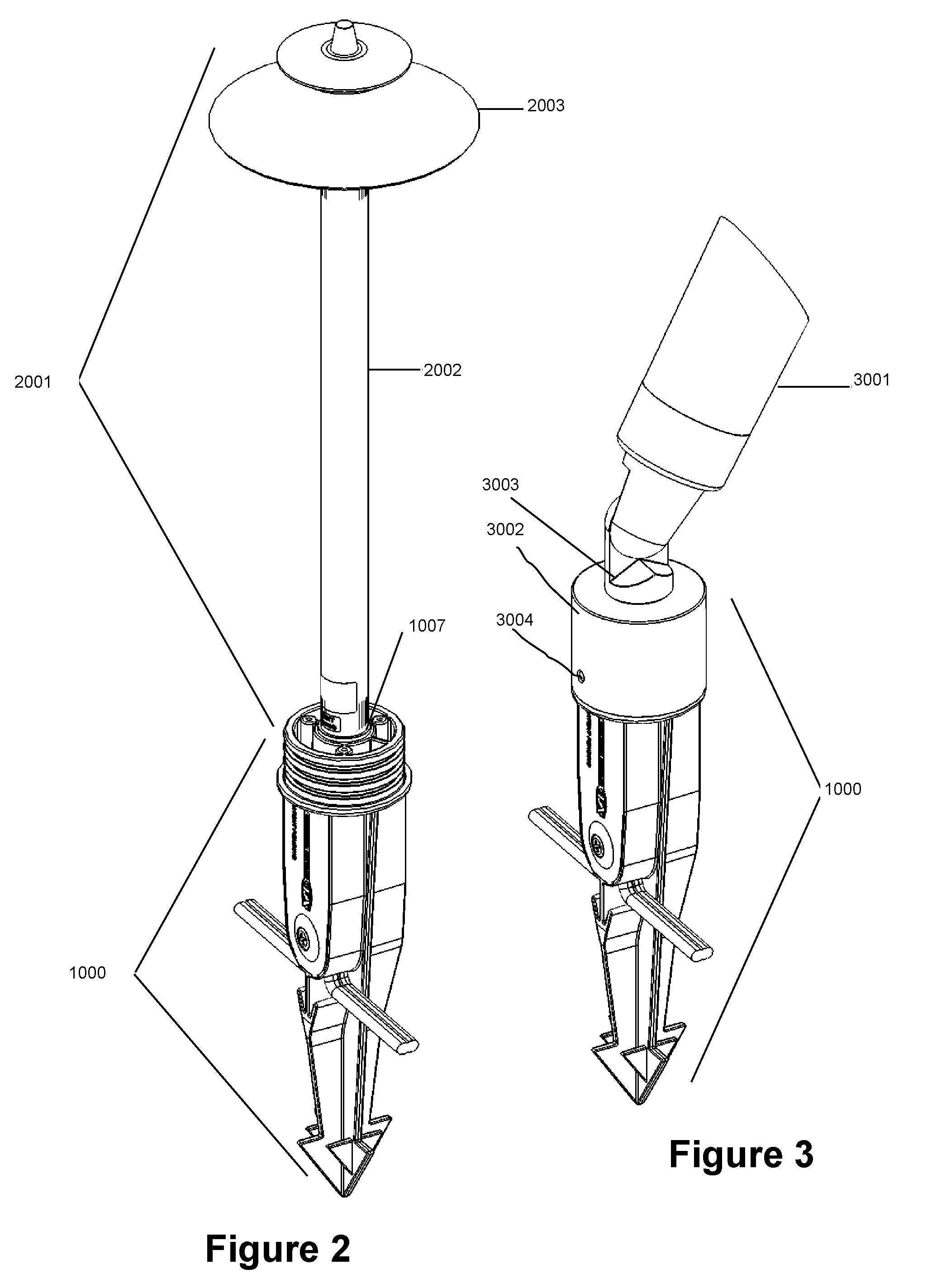

Spike for outdoor lighting fixture

ActiveUS20090122564A1Easy to cleanEasy to viewNon-electric lightingMechanical apparatusEffect lightSpare part

A spike for outdoor lighting fixture includes a receptacle portion integrated into the body of the spike with an open section and a removable transparent window that is configured to enclose the receptacle portion. The transparent window is attached to the receptacle portion using one or more screws or other fasteners. The spike can include an internally threaded upper portion for receiving a post upon which a lighting fixture is mounted and / or a lamp socket can be attached to the top of the spike and a protective housing fitted around the outer edges of the top of the spike. In a preferred embodiment, the receptacle portion is divided into multiple compartments, e.g., for storing excess cable or spare parts for the fixture, such as wire nuts or lamps, or for securing connection points of a wiring installation. The transparent window permits visual examination of the connection within the receptacle without removing the transparent window.

Owner:HUNTER INDUSTRIES

Packaging carton

InactiveUS20050023162A1Simple processReduce packaging costsOther accessoriesContainers to prevent mechanical damageCartonEngineering

A packaging carton is disclosed, suitable for packaging an electronic product, such as a peripheral product, a mobile phone, or a spare part. The packing carton is formed by folding a paper material and is one piece, and is fabricated by linking two clip slots. Furthermore, the packaging carton comprises two hollow buffer structures beside two sides of a storage chamber and two upper holding pieces adjacent to both sides of the storage chamber to protect an object packaged in the packaging carton.

Owner:QUANTA COMPUTER INC

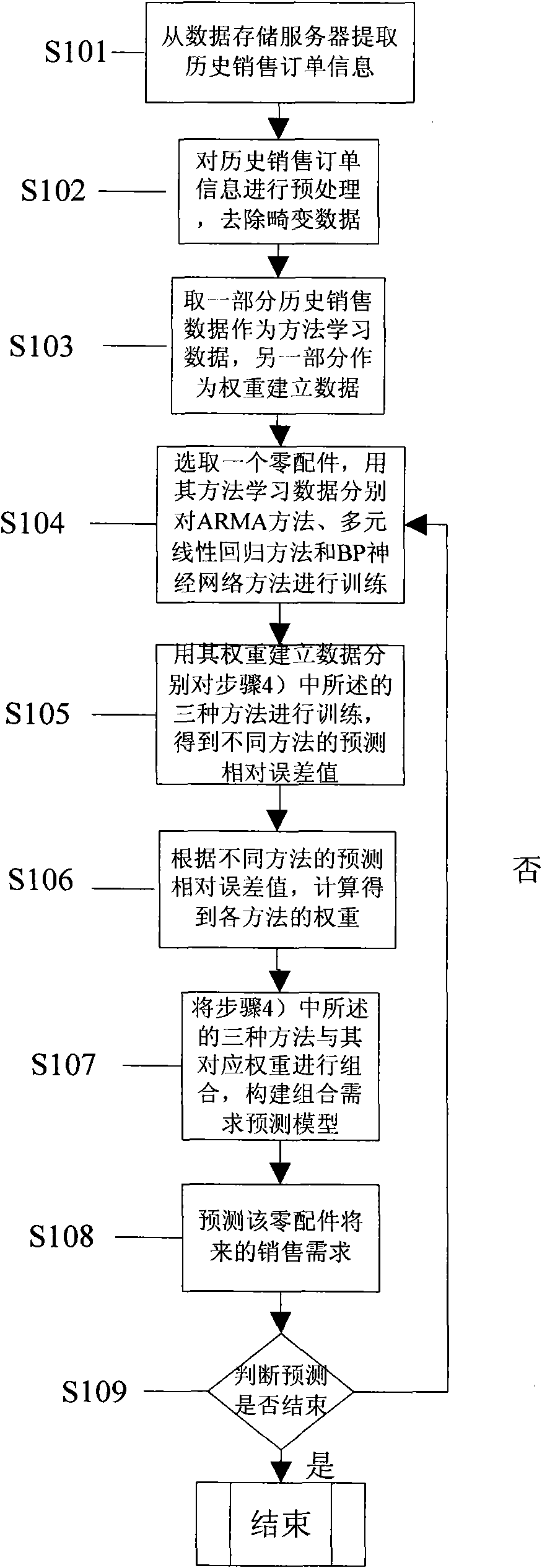

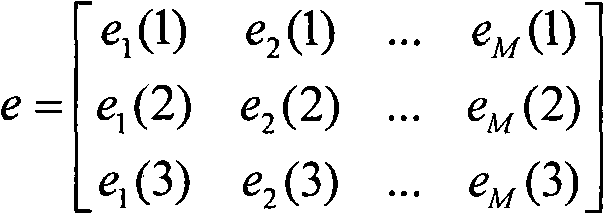

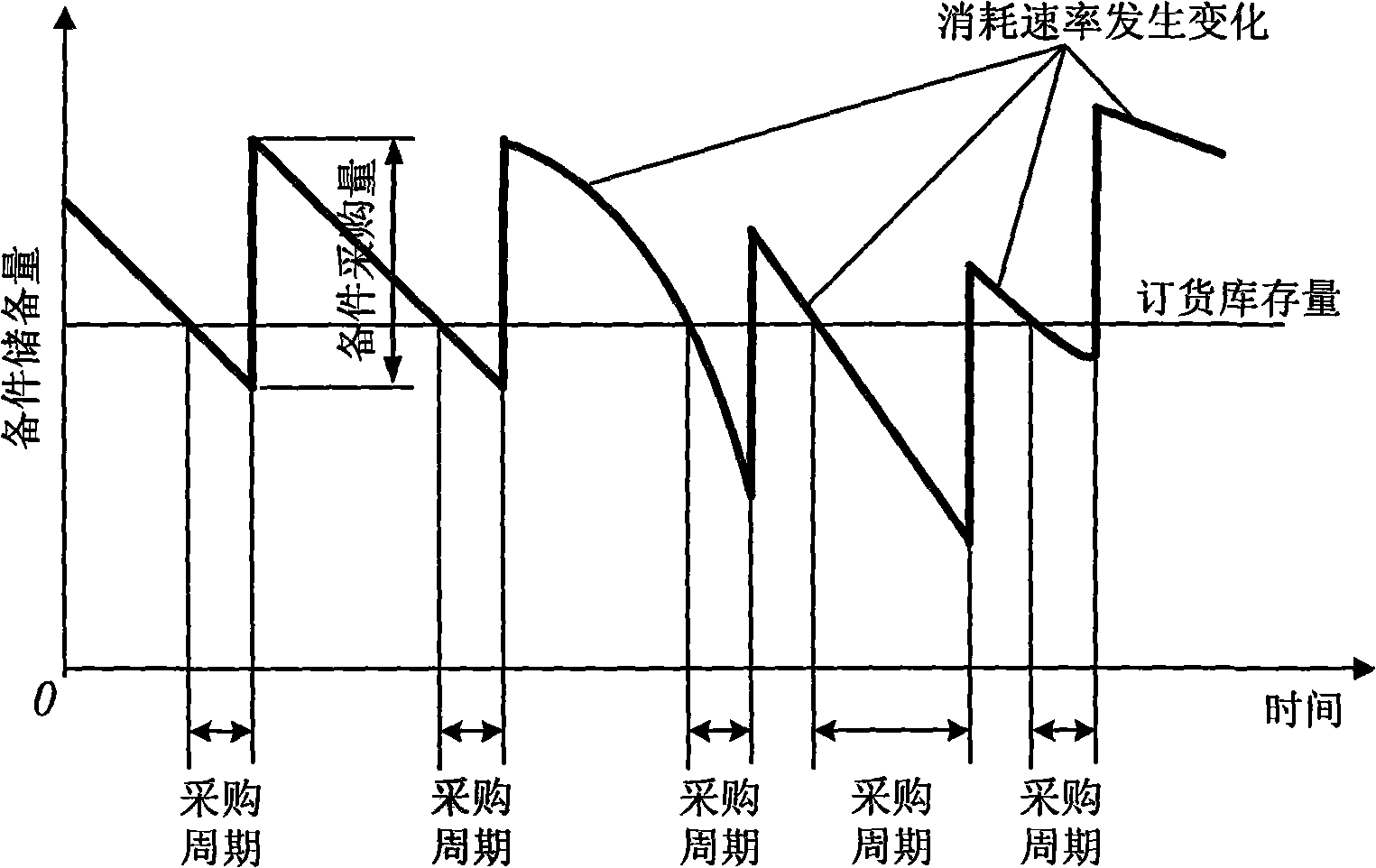

Spare part assembling demand forecasting information processing method applied to inventory management

InactiveCN102385724AImprove management efficiencyImprove satisfactionLogisticsMoving averageInformation processing

The invention relates to a spare part assembling demand forecasting information processing method applied to inventory management, comprising the following steps:1) take one part of historical sales data as method learning data and take the other part of the historical sales data as weight building data; 2) use the method learning data to practice an ARMA (Autoregression and Moving Average) method, a multiple linear regression method and a BP (Back Propagation) neural network approach respectively for each spare part; 3) apply the above three methods respectively by using the weight building data, so as to obtain forecasting relative error values for different methods; 4) calculate the weights of the above methods; 5)construct an assembling demand forecasting model; 6) forecast the future sales demands of all spare parts. Compared with the prior art, the method is suitable for the spare parts with different demand features, and has the advantages of strong objectivity, high forecasting precision, and can greatly reduce the inventory cost on the premise of having a certain service level and improves the supply chain management efficiency and customer satisfaction.

Owner:SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

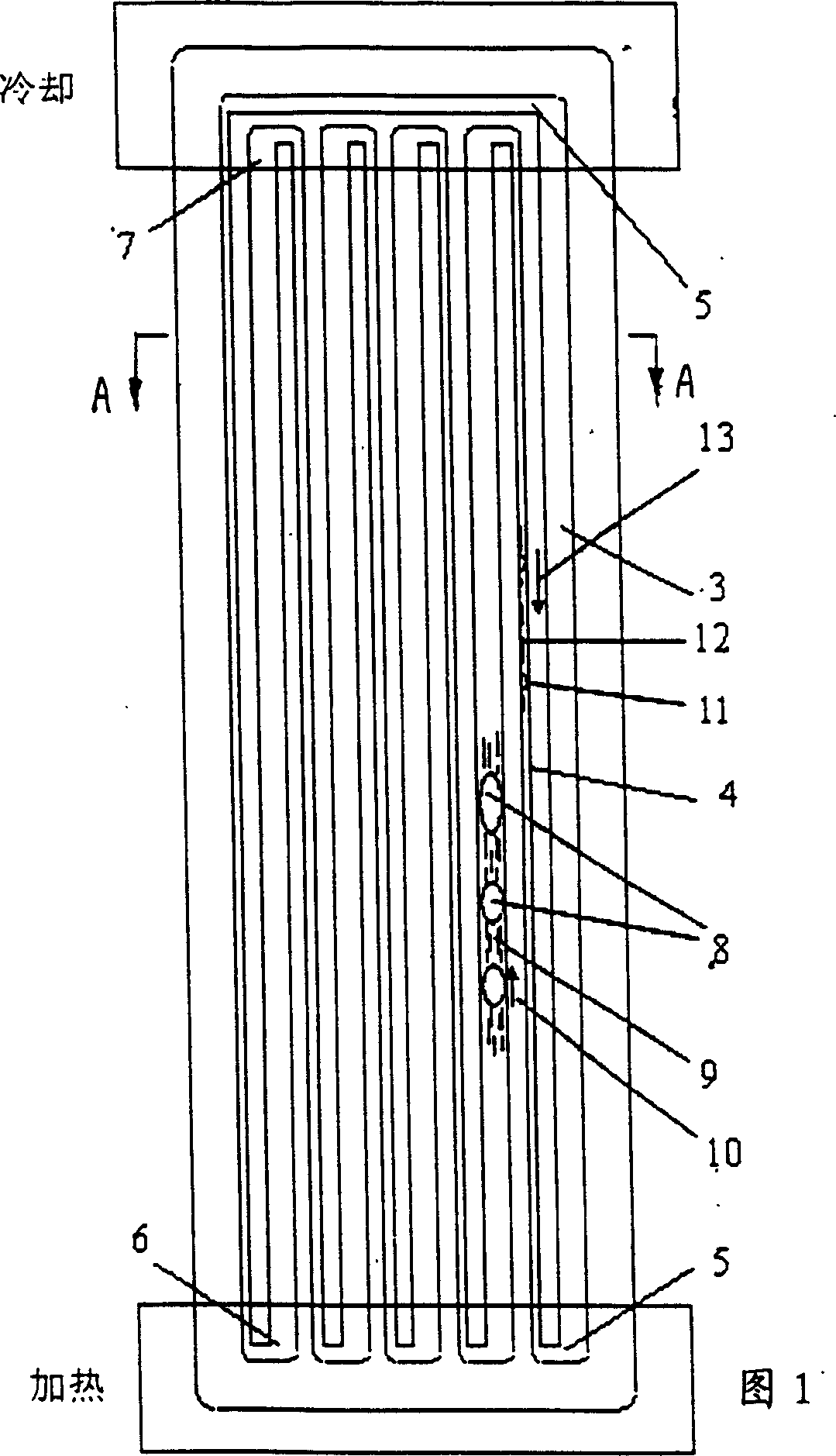

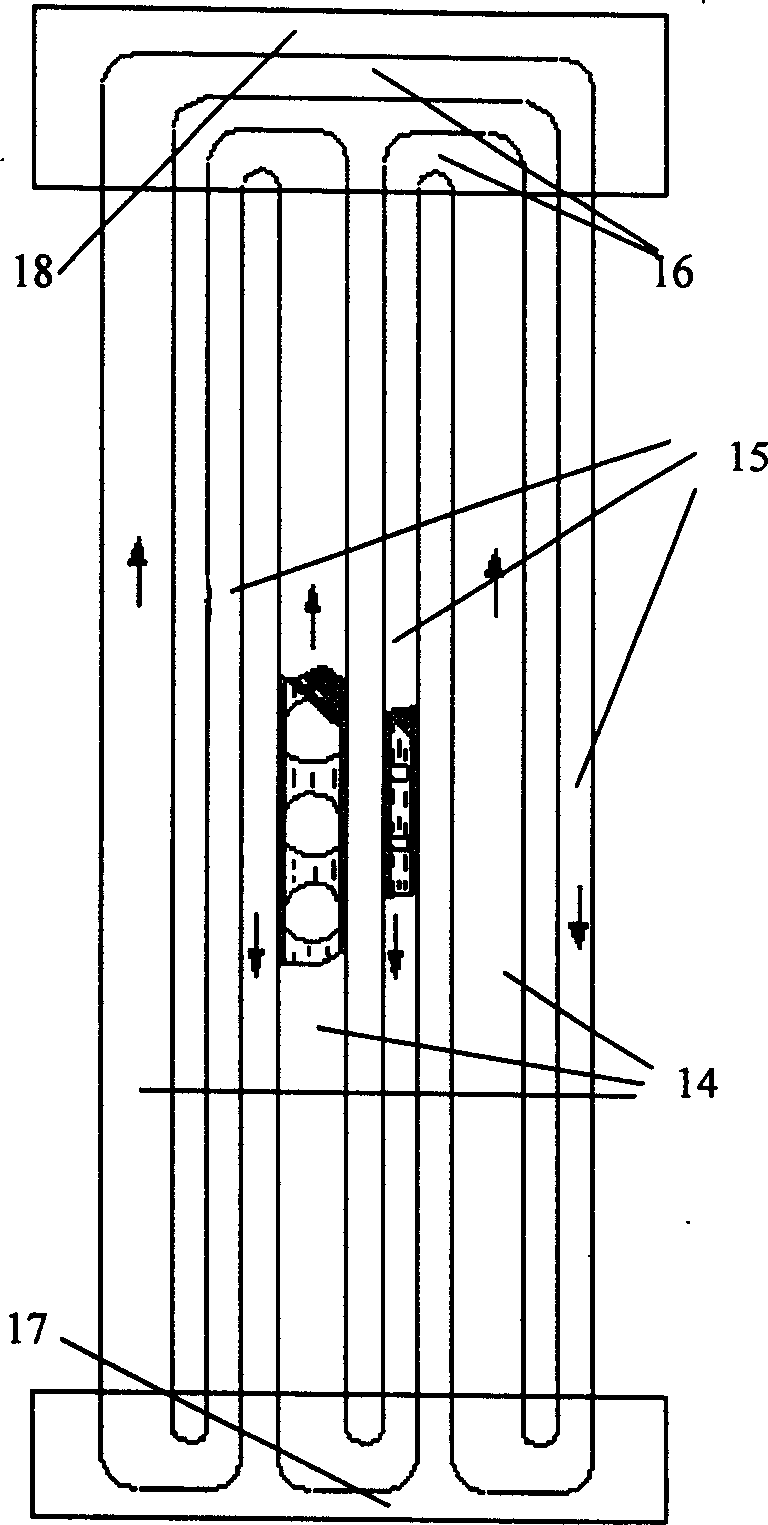

Circulation flowing pulsating heat pipe for cooling electronic device

InactiveCN1684252AIncrease heat transfer limitReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

This invention relates to a circulation flow pulsation thermal tube suitable for cooling spare part of semiconductor devices and other solid devices composed of two connected and mutually parallel-arrayed thick straight channel and thin straight channel, two adjacent channels are connected by an angle pipe. A heat conduction working solution forms a single-way plug flowing under the pressure generated by heat action in the channel, which absorbs heat and evaporates at the heating section and discharges heat and condenses at the radiation section. This invented pulsation thermal tube has high conduction limit and low resistance.

Owner:CENT SOUTH UNIV

Data storage system employing a hot spare to store and service accesses to data having lower associated wear

ActiveUS20160188424A1Reduce access latencyReduce wear rateRedundant hardware error correctionData setAccess frequency

A controller monitors access frequencies of address ranges mapped to a data storage array. Based on the monitoring, the controller identifies frequently accessed ones of the address ranges that have lower associated wear, for example, those that are read more often than written. In response to the identifying, the controller initiates copying of a dataset associated with the identified address ranges from the data storage array to a spare storage device while refraining from copying other data from the data storage array onto the spare storage device. The controller directs read input / output operations (IOPs) targeting the identified address ranges to be serviced by access to the spare storage device. In response to a failure of a failed storage device among the plurality of primary storage devices, the controller rebuilds contents of the failed storage device on the spare storage device in place of the dataset associated with the identified address ranges.

Owner:IBM CORP

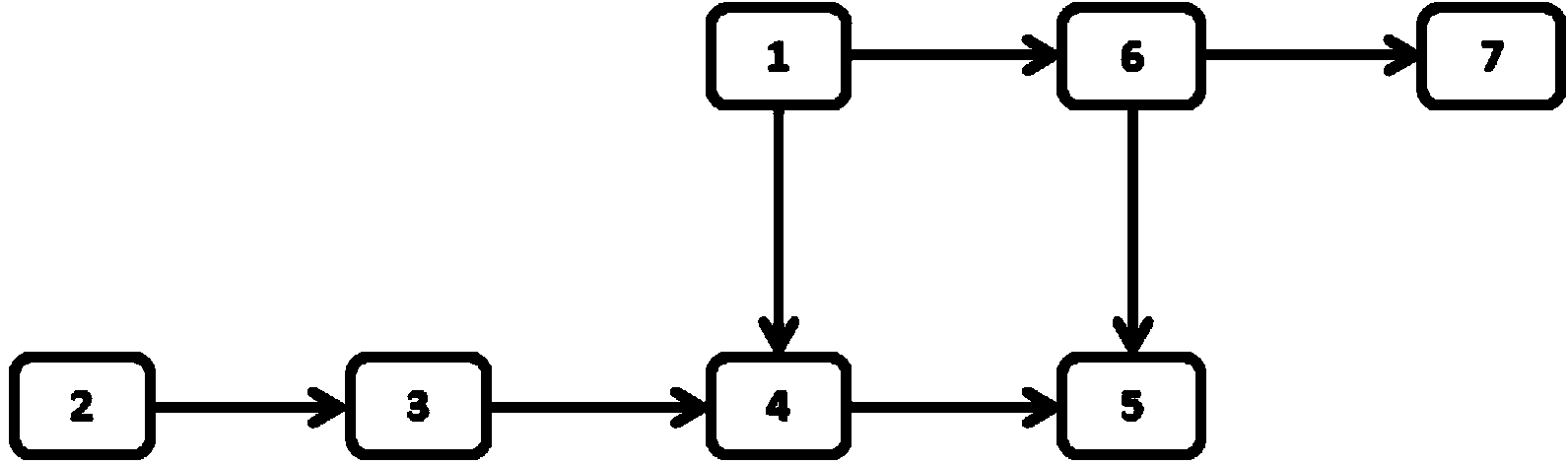

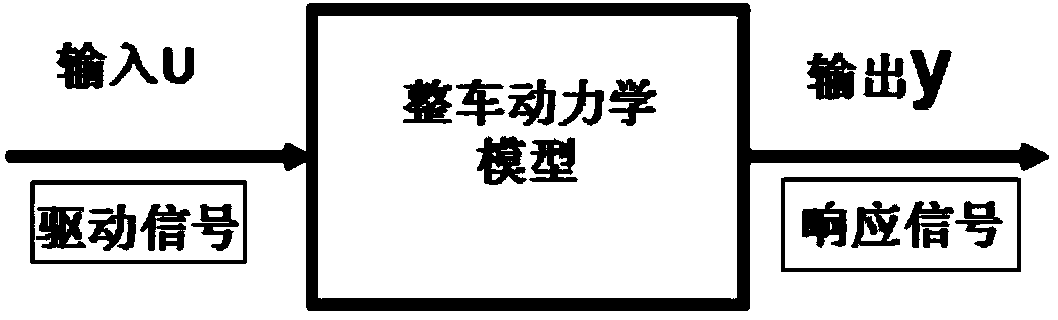

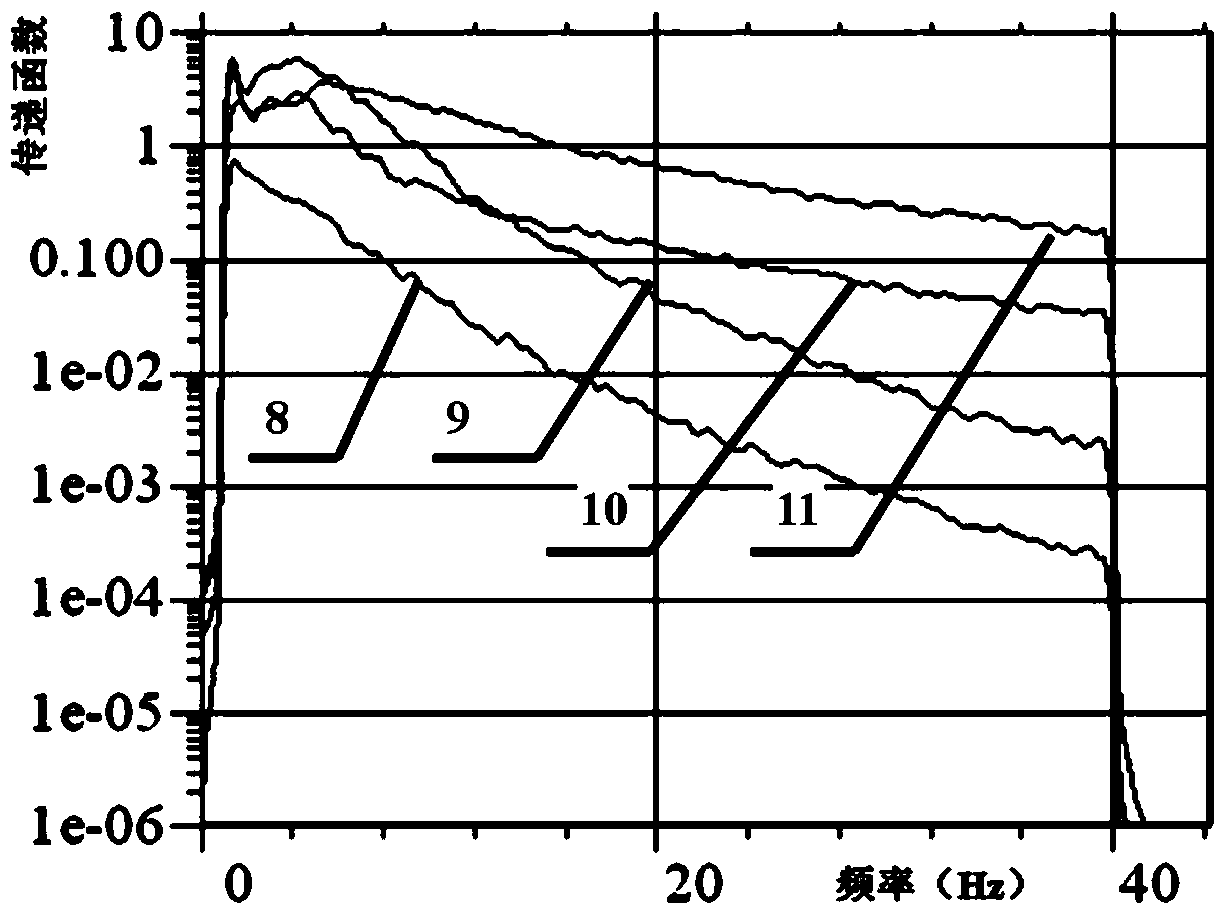

Load analysis method for four-wheel six-component road spectrum of finished automobile

InactiveCN104239734AAvoid influence of simulated load resultsSolve technical bottlenecksSpecial data processing applicationsStress conditionsDynamic models

The invention relates to a load analysis method for a four-wheel six-component road spectrum of a finished automobile. The method comprises the following steps: 1 testing a four-wheel six-component road spectrum of a finished automobile; 2 collecting the design data of the finished automobile; 3 building and adjusting a dynamic model of the finished automobile; 4 carrying out virtual iteration; 5 obtaining Z-direction displacement of a wheel center; 6 decomposing the load of the finished automobile; 7 processing the load result. The six components of four wheel centers of the finished automobile are directly measured as external road excitation input; the actual stress condition of each wheel center under the typical characteristic road excitation of test site reliability is reflected; the technical effect of obtaining the load of the finished automobile system and spare parts is realized by a virtual iteration technique and a dynamics simulation technique; the anti-fatigue performance of the finished automobile structure can be accurately predicted and optimized at the earlier stage; problem rectification of the sample automobile stage is reduced; the research and development cycle is shortened; the research and development cost is also reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

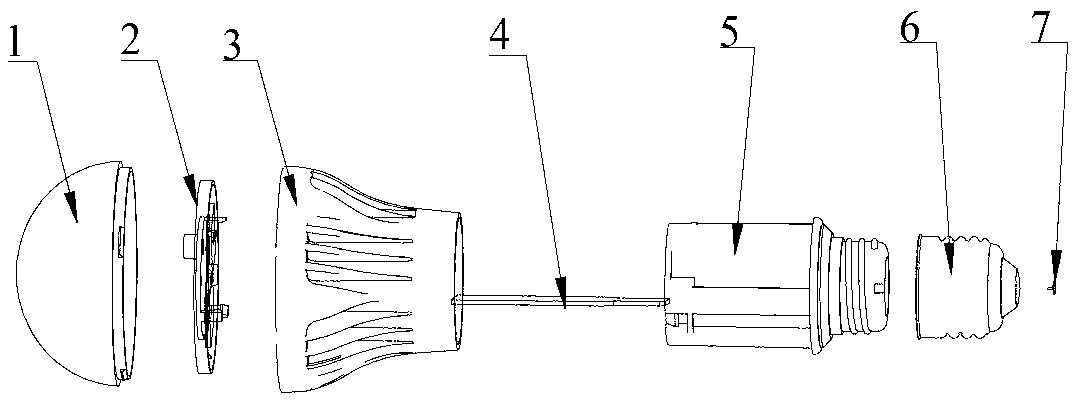

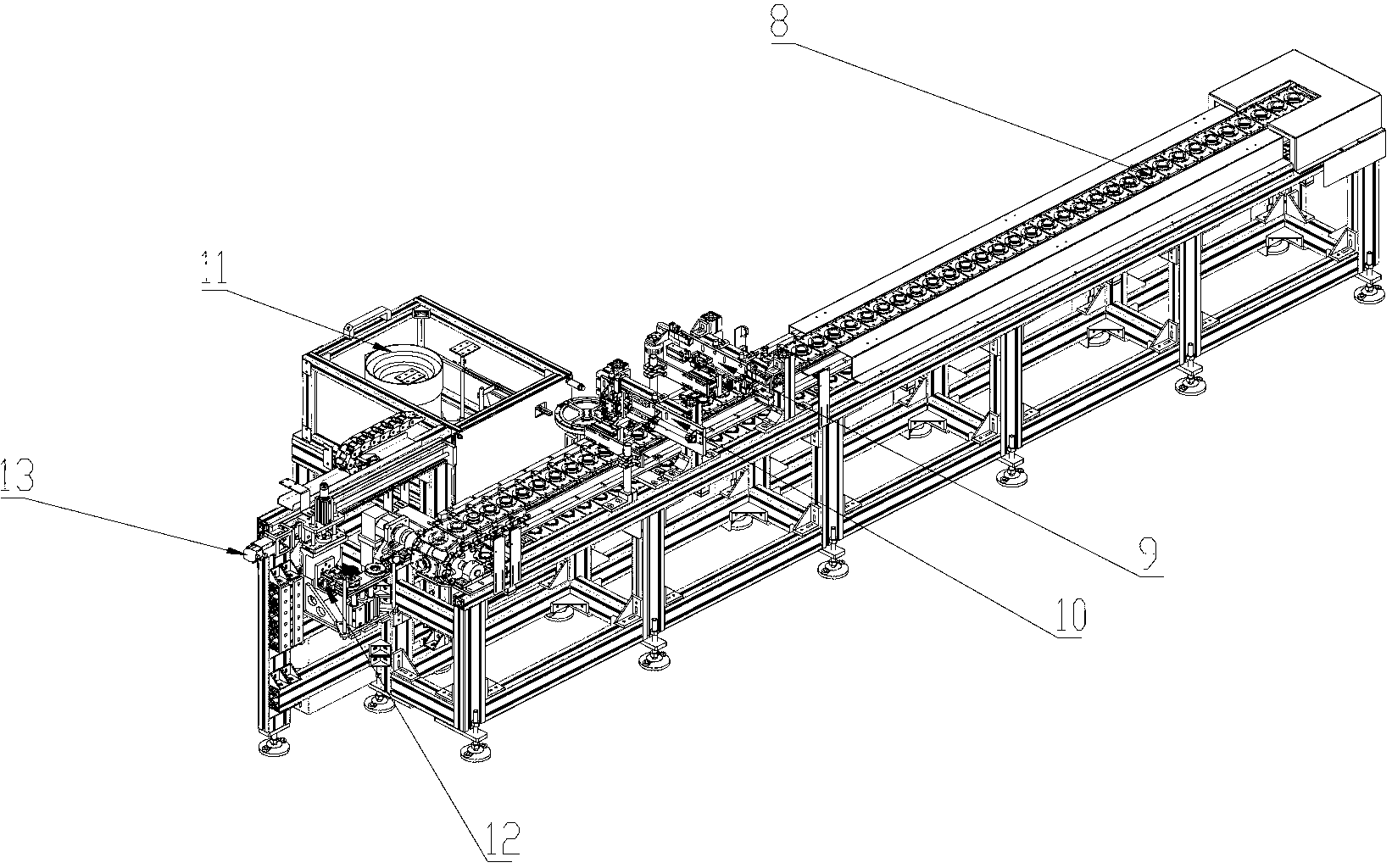

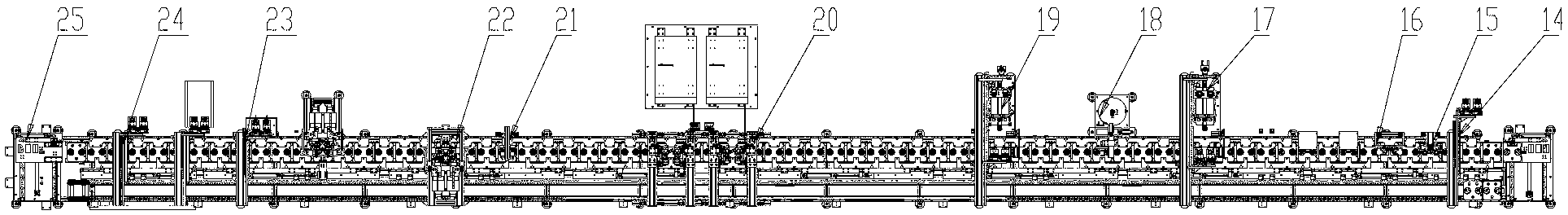

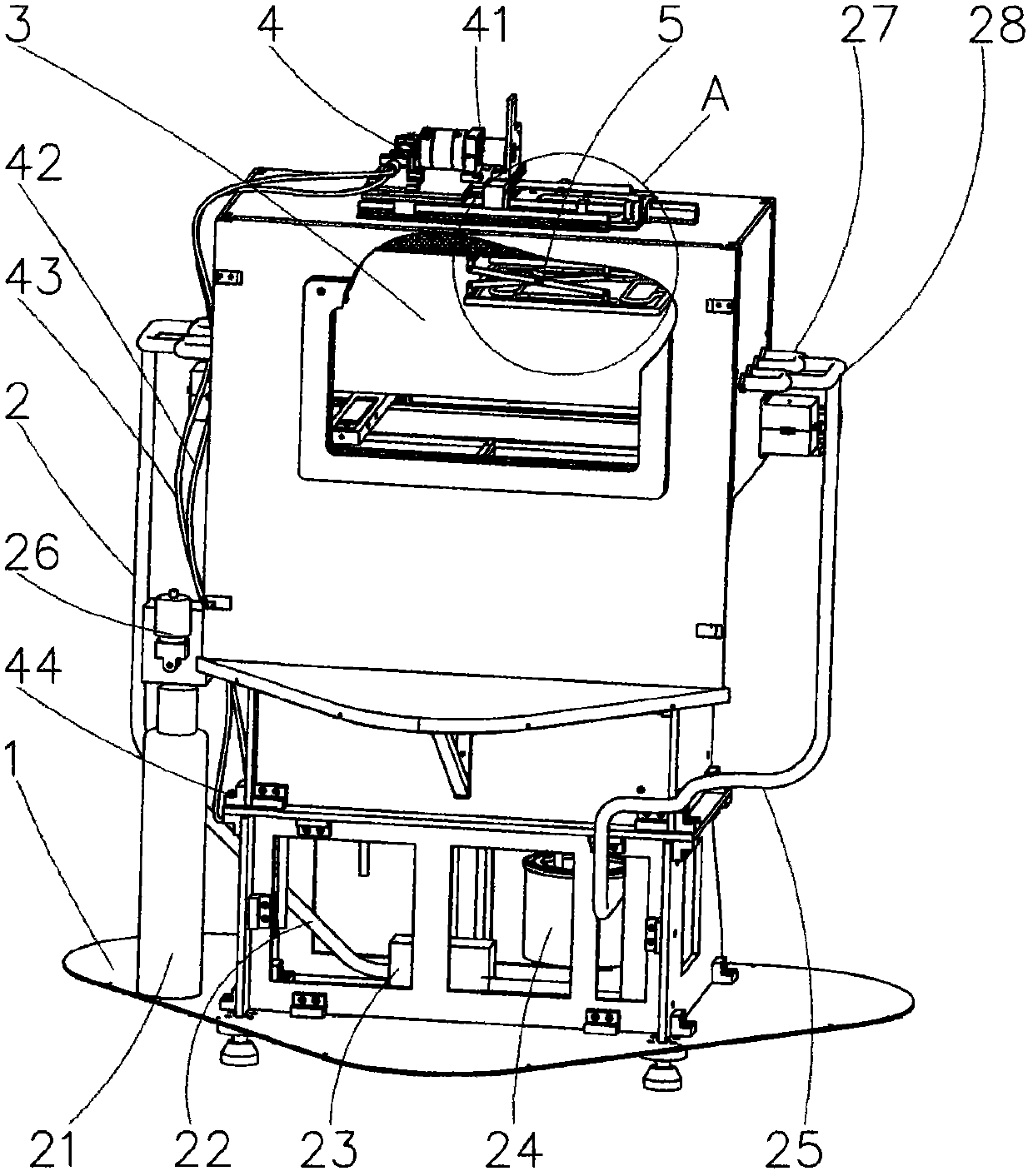

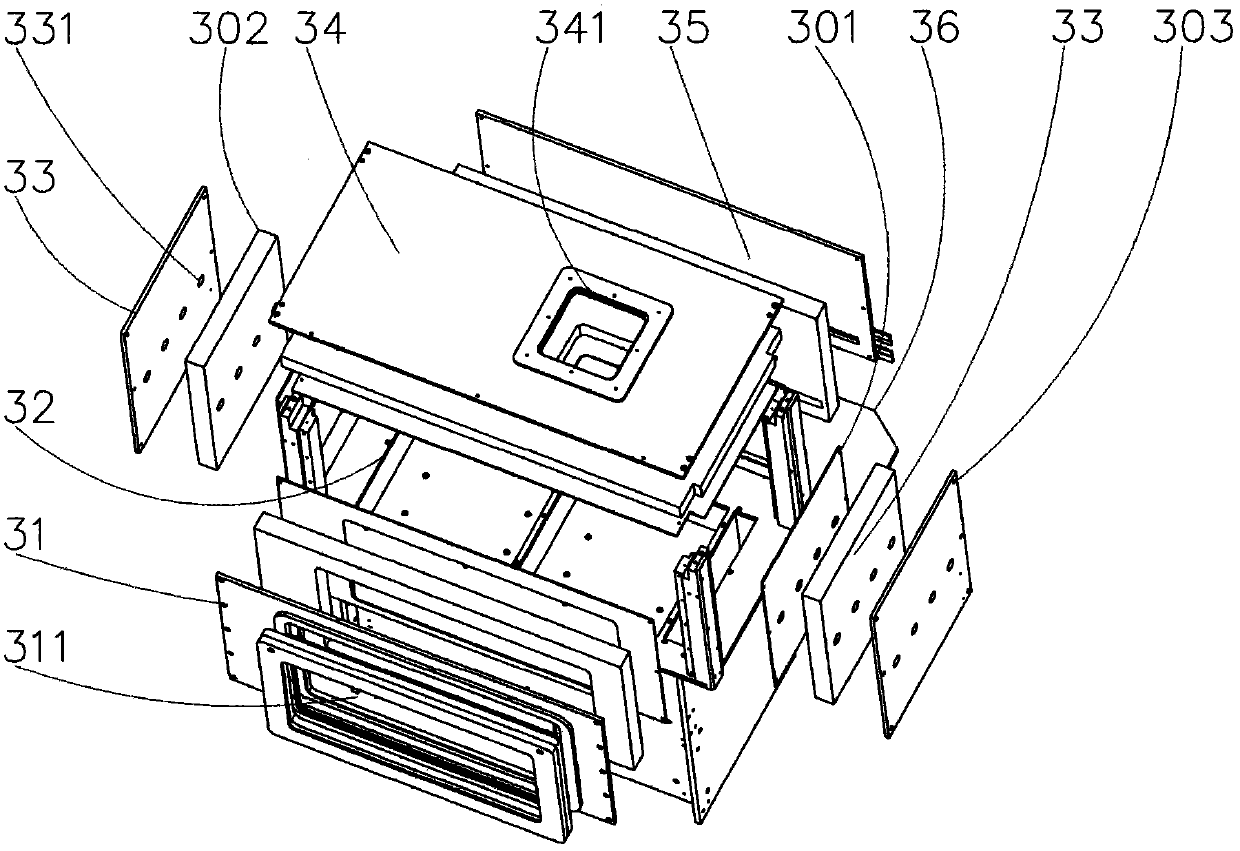

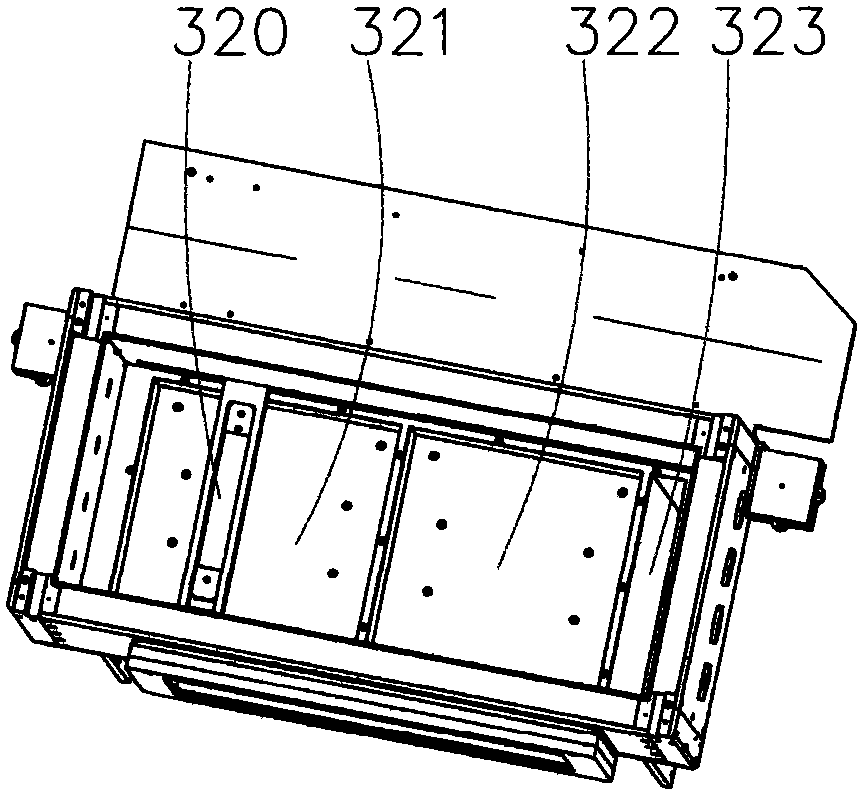

LED bulb lamp assembly and production equipment

ActiveCN103307487AIncrease production capacityImprove stabilityPoint-like light sourceLighting heating/cooling arrangementsEngineeringManipulator

The invention discloses LED (light emitting diode) bulb lamp assembly and production equipment which comprises a rivet assembly part, a light source plate assembly part, a lamp shade assembly part and a lamp shade stack feeding mechanism, wherein the rivet assembly part sequentially comprises a chain conveying mechanism, a central wire collation mechanism, a rivet assembly mechanism, a rivet vibrating disk, a turnover carrying manipulator and a transfer station, and the light source plate assembly part and the lamp shade assembly part consist of a plurality of different components respectively. The LED bulb lamp assembly and production equipment has the advantages that the production efficiency can be improved; spare parts of an LED bulb lamp can be assembled together according to procedures and working steps; and the stability is high.

Owner:HANGZHOU ZHONGWEI PHOTOELECTRICITY

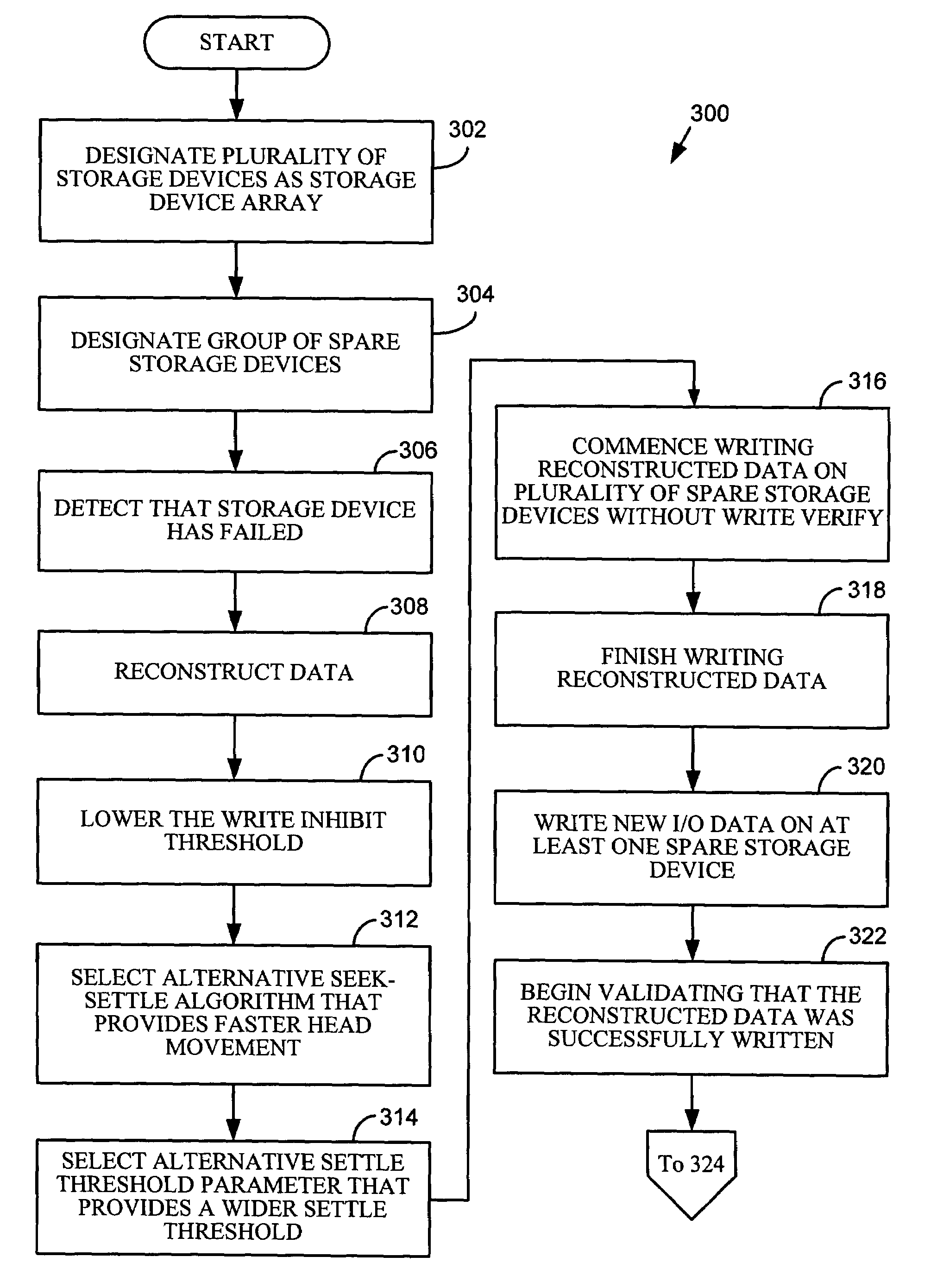

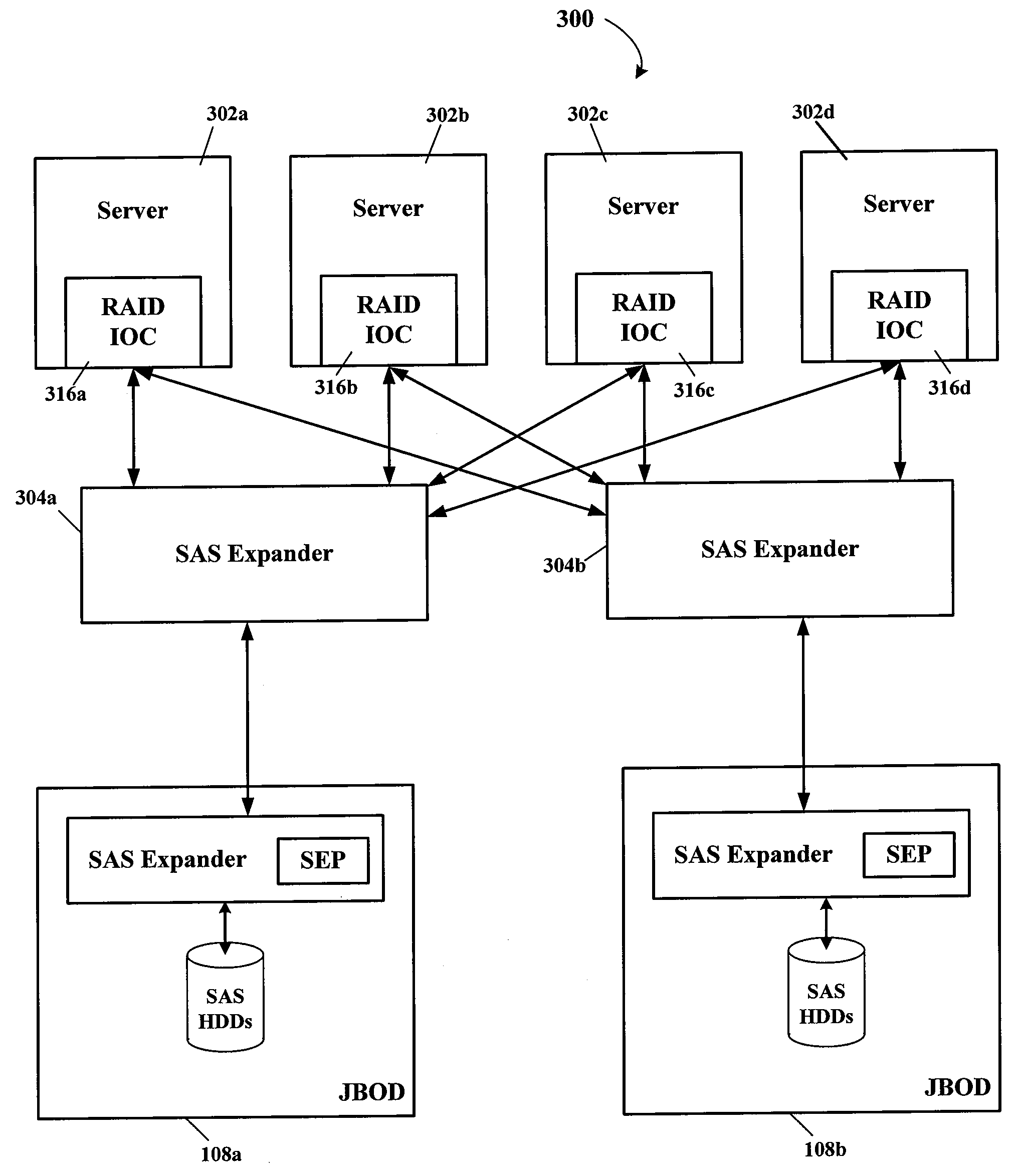

Using redundant spares to reduce storage device array rebuild time

InactiveUS7143305B2Reduce probabilityShorten the timeEmergency protective arrangements for automatic disconnectionRedundant data error correctionOperating systemSpare part

Owner:LINKEDIN

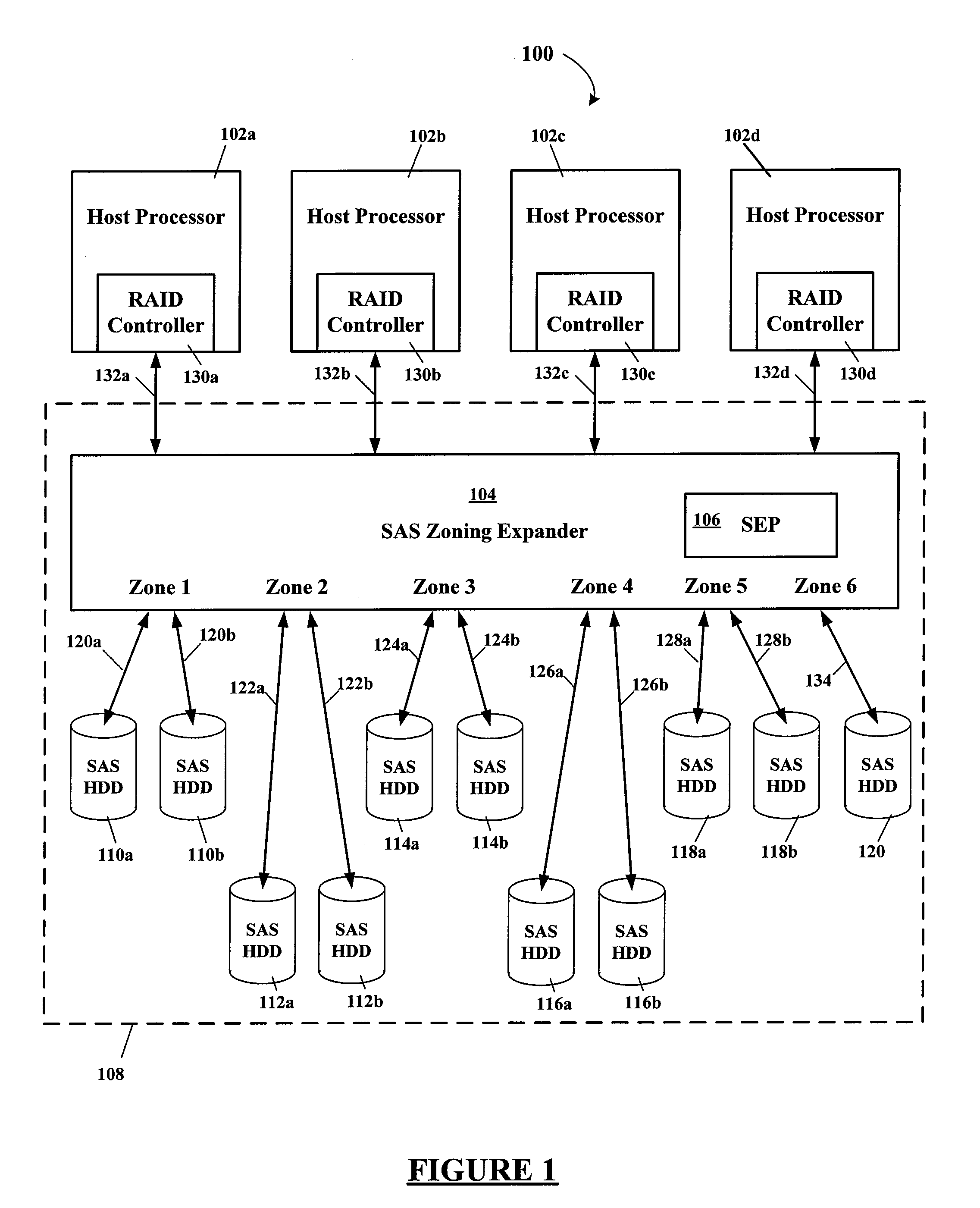

Using SAS address zoning to add/replace hot spares to RAID set

Certain ones of a plurality of SAS hard disk drives are assigned to different SAS zones using a SAS zoning expander(s). A processor and SAS RAID controller have access to only those SAS hard disk drives assigned to the same zone(s) as the processor and SAS RAID controller. Each SAS RAID controller determines when a RAID hard disk drive in its zone fails, and then notifies the RAID hard disk drive failure to a service enclosure processor (SEP) of the SAS zoning expander. The SEP re-allocates an available hot-spare hard disk drive to the zone of the failed RAID hard disk drive. When the SAS RAID controller detects that a functional hard disk drive is now available in its zone, the RAID image is rebuilt using the zone reassigned hot-spare hard disk drive that then becomes one of the RAID hard disk drives of that zone.

Owner:DELL PROD LP

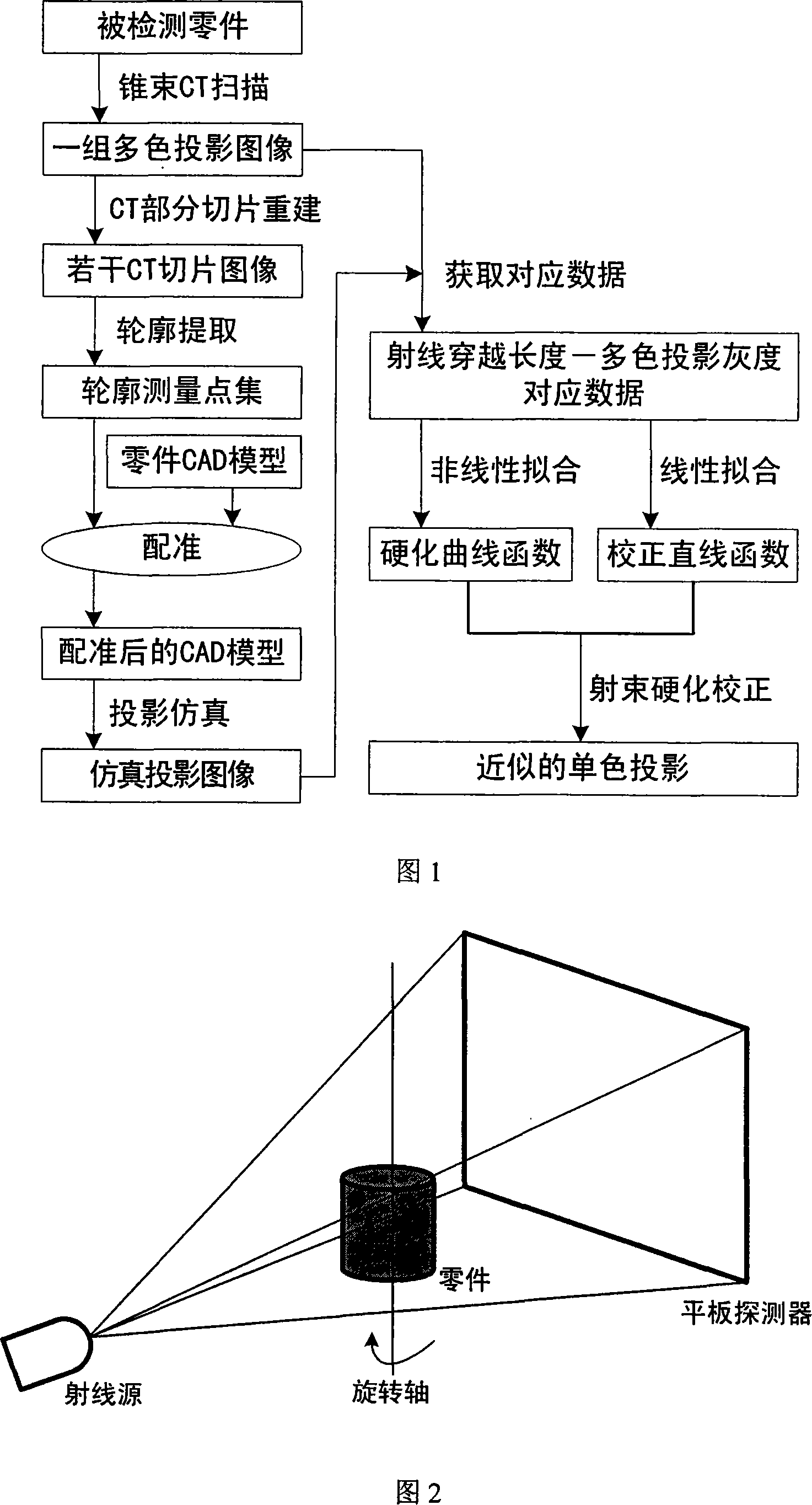

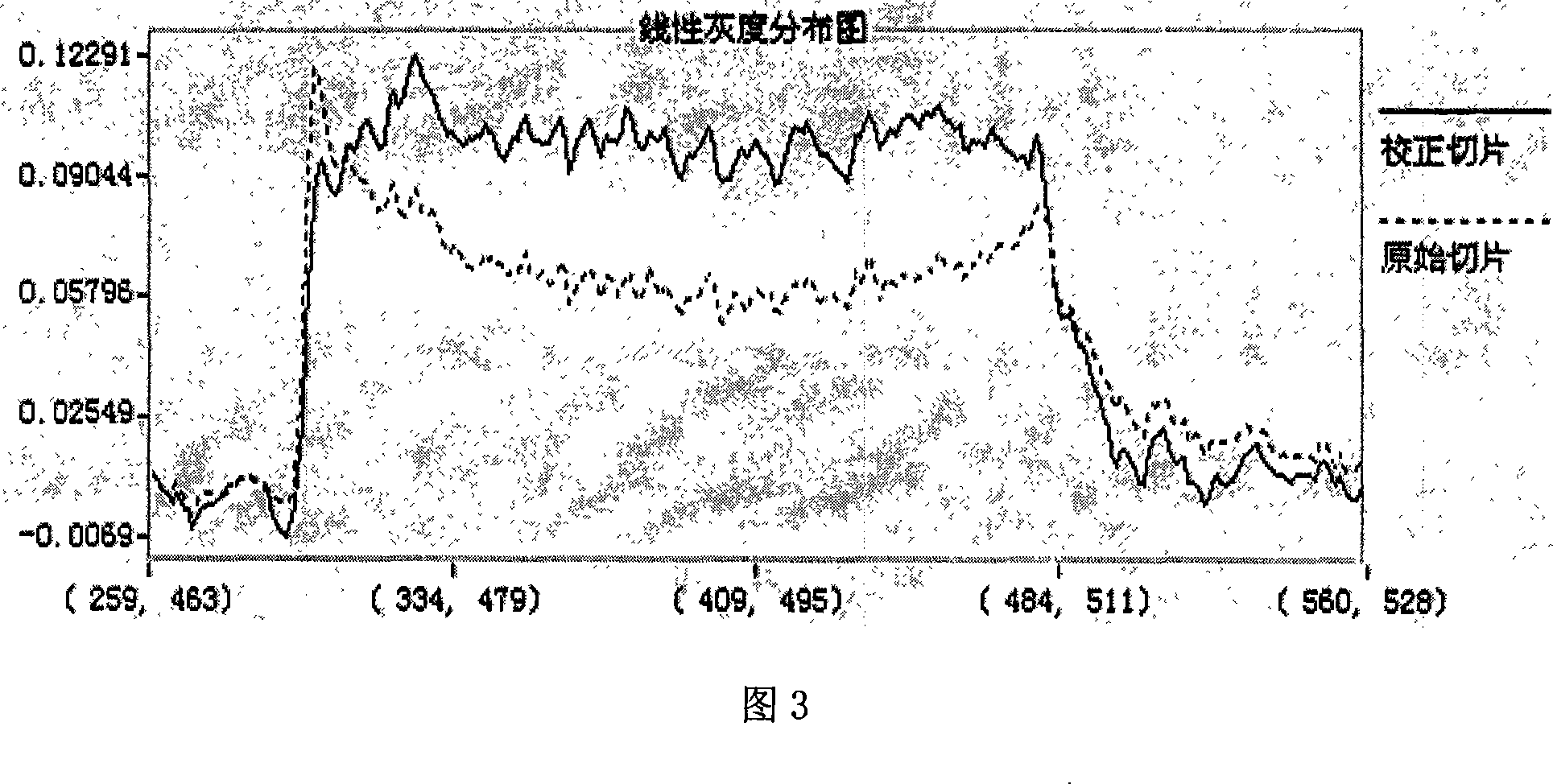

Cone-beam CT beam hardening calibration method based on registration model emulation

InactiveCN101126722AFlexibleReduced beam hardening artifactsImage enhancementImage data processing detailsMeasurement pointBeam hardening

The utility model discloses a beam hardening correction method of cone beam CT based on registration model simulation, which acquires multi-color projection data through circle locus cone beam CT scanning to a spare part. After acquiring CT images of sequence slices by cone beam CT reconstitution to the multi-color projection, the contour of certain pieces of the images are extracted so that a measurement point formed a plurality of closed contour lines is acquired. Projection simulation is processed after the registration of the measurement point and the CAD model of the part, and then the length of the part passing through the part at every imaging point is acquired. A hardening curve that passes through the original point is acquired by nonlinear fitting and a straight line that passes through the original point is acquired by linear fitting. The beam hardening constructed defect of the cone beam CT is corrected according to the hardening curve and the rectifying straight line. The utility model is flexible in application, and can approximately corrected through multi-color projection to unique color projection, and the beam hardening artifacts is reduced obviously after correction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

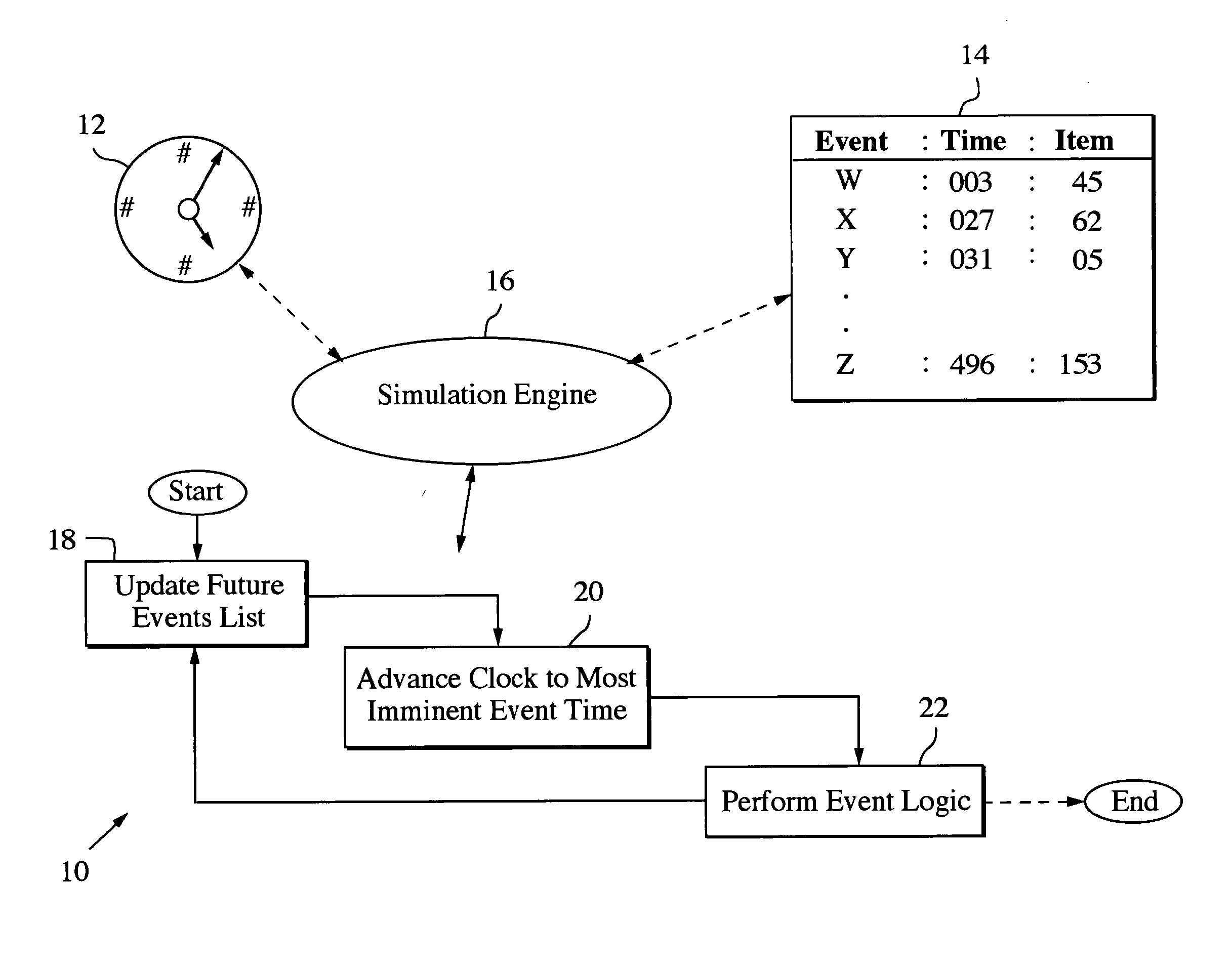

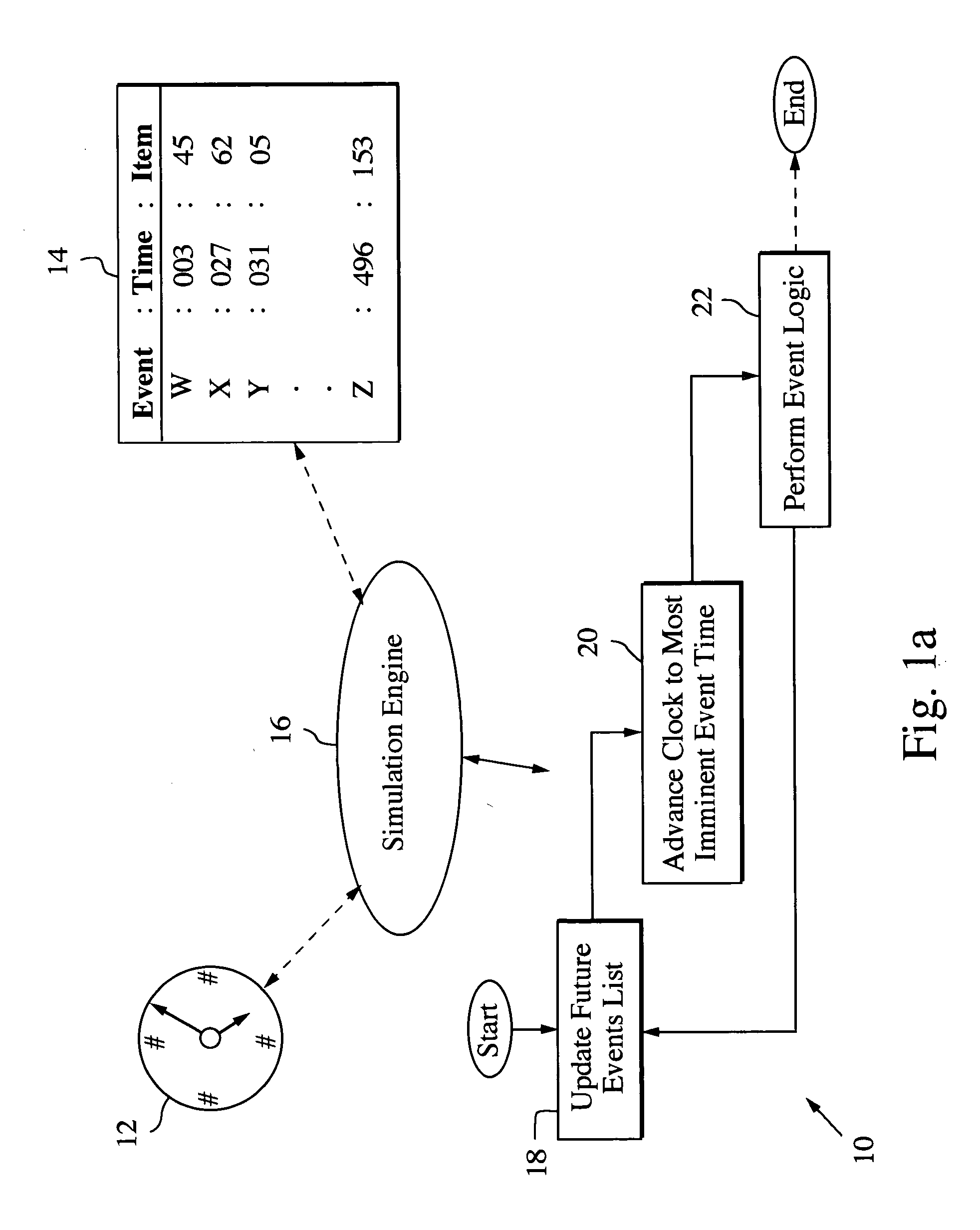

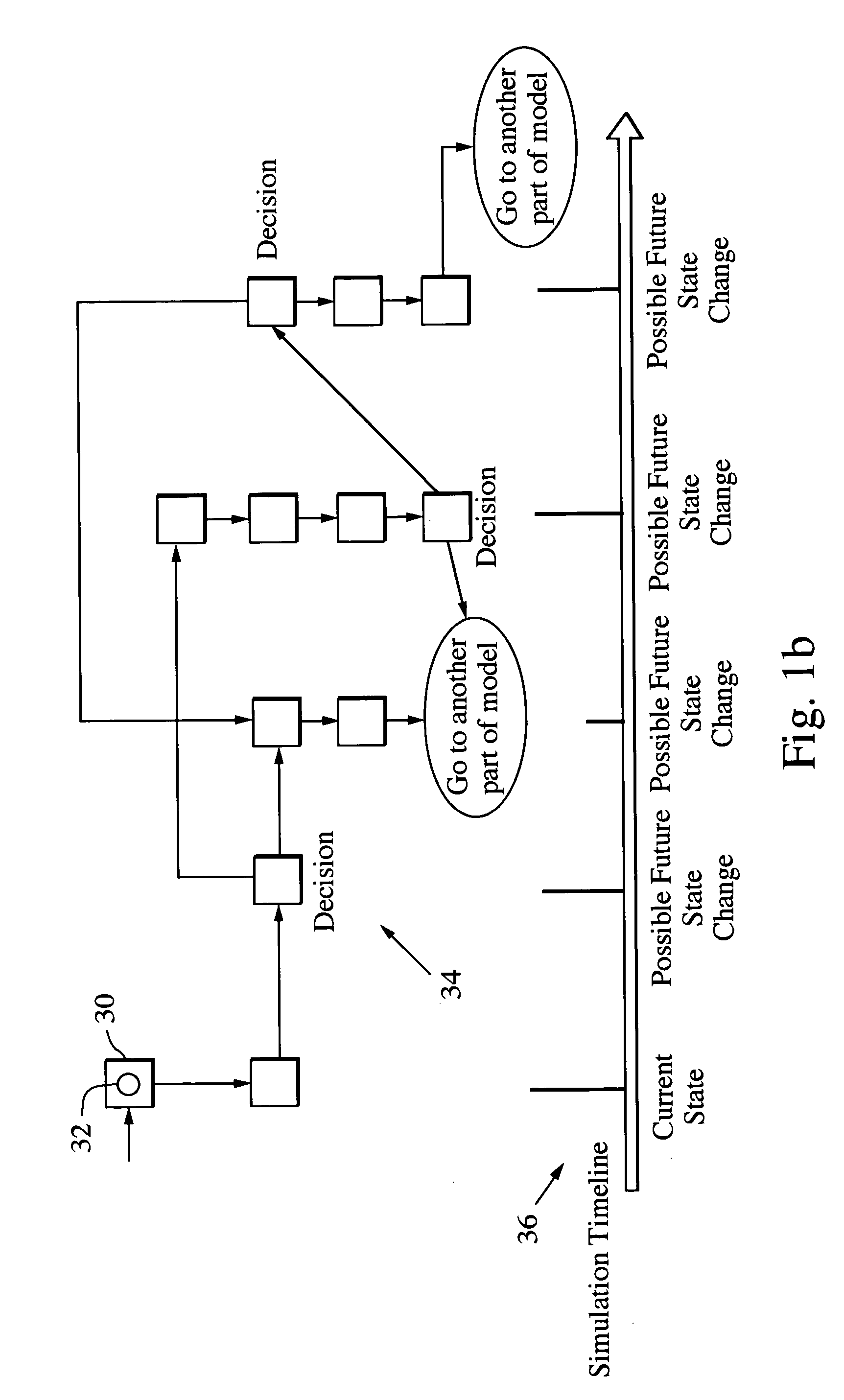

Operations and support discrete event simulation system and method

ActiveUS20050177353A1Improve consistencyImprove accuracyDigital computer detailsDesign optimisation/simulationLogistics managementParallel computing

A discrete event simulation (DES) and method of model development provide affordable, accurate, pre-validated, reusable and portable models and simulations that capture the complexity, interdependencies and stochastic nature of the operations and support (O&S) of weapons systems. A model of the O&S problem is created based on a service use profile (SUP) that describes a logical structure of delivery, maintenance, deployment, testing policy, infrastructure and logistics constraints. That model is translated into a DES, preferably using a “toolkit” including common attributes for the weapons and pre-validated common blocks and sub-models that define higher level functionality. The DES calculates a time-based prediction of weapons availability, maintenance activities, and spare parts stock over a life cycle of the weapons system.

Owner:RAYTHEON CO

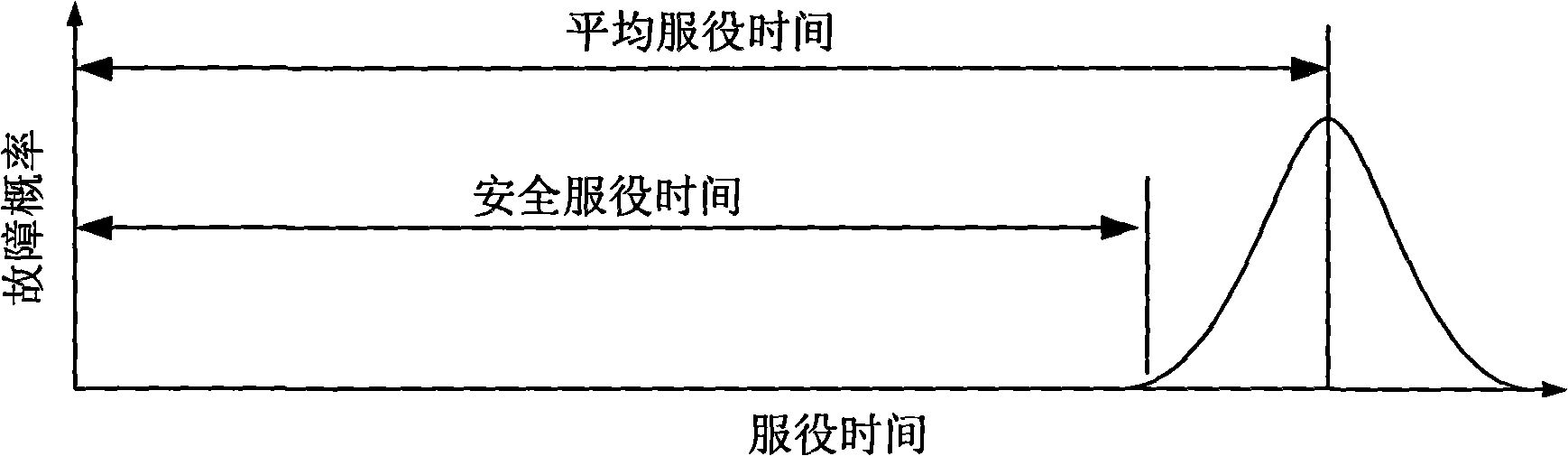

Spare part demand forecast method based on in-service lift estimation

InactiveCN101320455AMeet the statistical reliabilityReasonable Personalized EstimatesSpecial data processing applicationsPredictive methodsOne step prediction

The present invention discloses an in-service life evaluation based spare part demand forecasting method. The present invention uses the historical record of changing parts and components during equipment running process to establish a statistic model and evaluate the life of a spare part under the current in-service condition; spare part demand function is defined according to the evaluation value of in-service life and practical service life, and the spare parts demand total quantity of a plurality of sets of equipment within certain rang of time is forecasted further. The method combines the spare part life evaluation with practical service condition closely, improves the accuracy for forecasting the spare part demand, is applicable to the maintenance instruction of frequently changed parts and components at the equipment and has important meaning for the enterprise to ensure the supply of the spare part and reduce the spare part stock.

Owner:XI AN JIAOTONG UNIV

Manufacturing equipment of laser additive

ActiveCN103737933AReduce in quantityReduce lossesIncreasing energy efficiencyEngineeringProtection system

The invention provides manufacturing equipment of a laser additive. The manufacturing equipment comprises a frame, a work cavity, a laser system, an atmosphere protection system and a preheating system, wherein the work cavity is a sealed cavity defined by a heat insulation sandwich panel; a scanning galvanometer of a laser system is arranged at the top of the external part of the work cavity; the preheating system is a three-dimensional flexible heating system, and has a plurality of radiation heating layers with adjustable interlayer spaces arranged at the top inside the work cavity; an air feed pipe and an air return pipe of the atmosphere protection system are divided into a plurality of passages to be respectively connected with two sides of the work cavity through U-shaped tee joints, so that the circulation of inactive gas inside the work cavity is achieved. By adopting the manufacturing equipment of the laser additive, the space can be effectively saved, the heat loss is reduced, the heating efficiency is improved, the energy consumption is reduced, the temperature inside the work cavity is relatively even in distribution, the protective effect on the processing process caused by an internal atmosphere is obvious, different types of materials (metal, macromolecule and the like) can be molded, the processing deformation is reduced, and the excellent quality of molded spare parts is ensured.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com