Patents

Literature

124results about "Inclined grate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

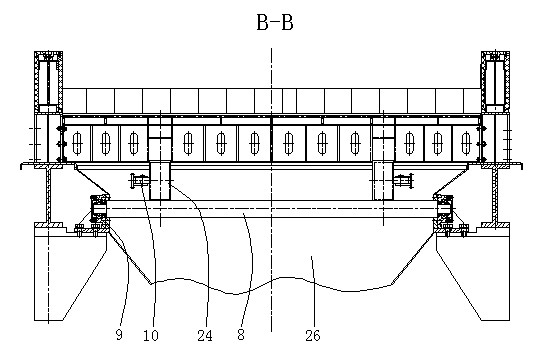

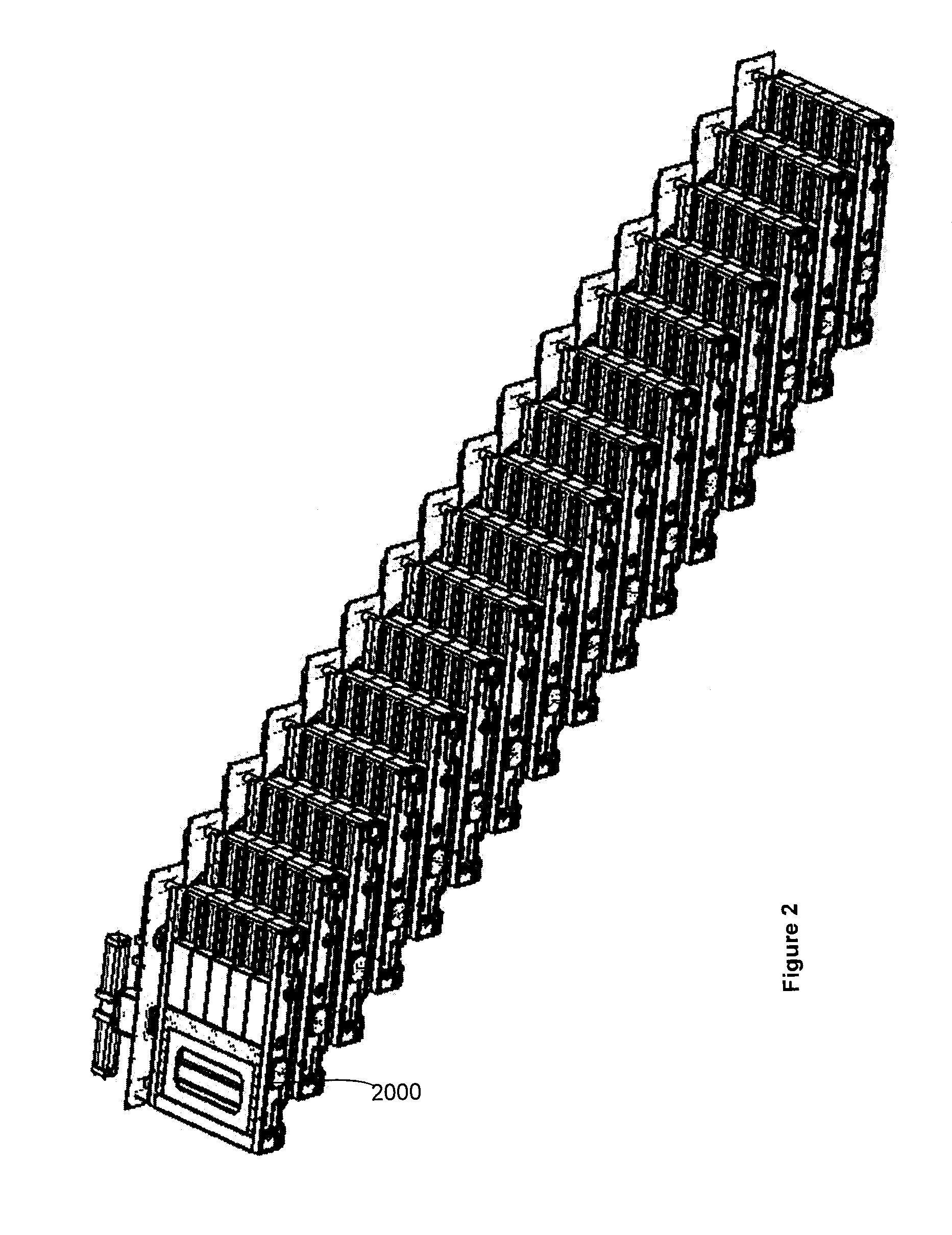

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

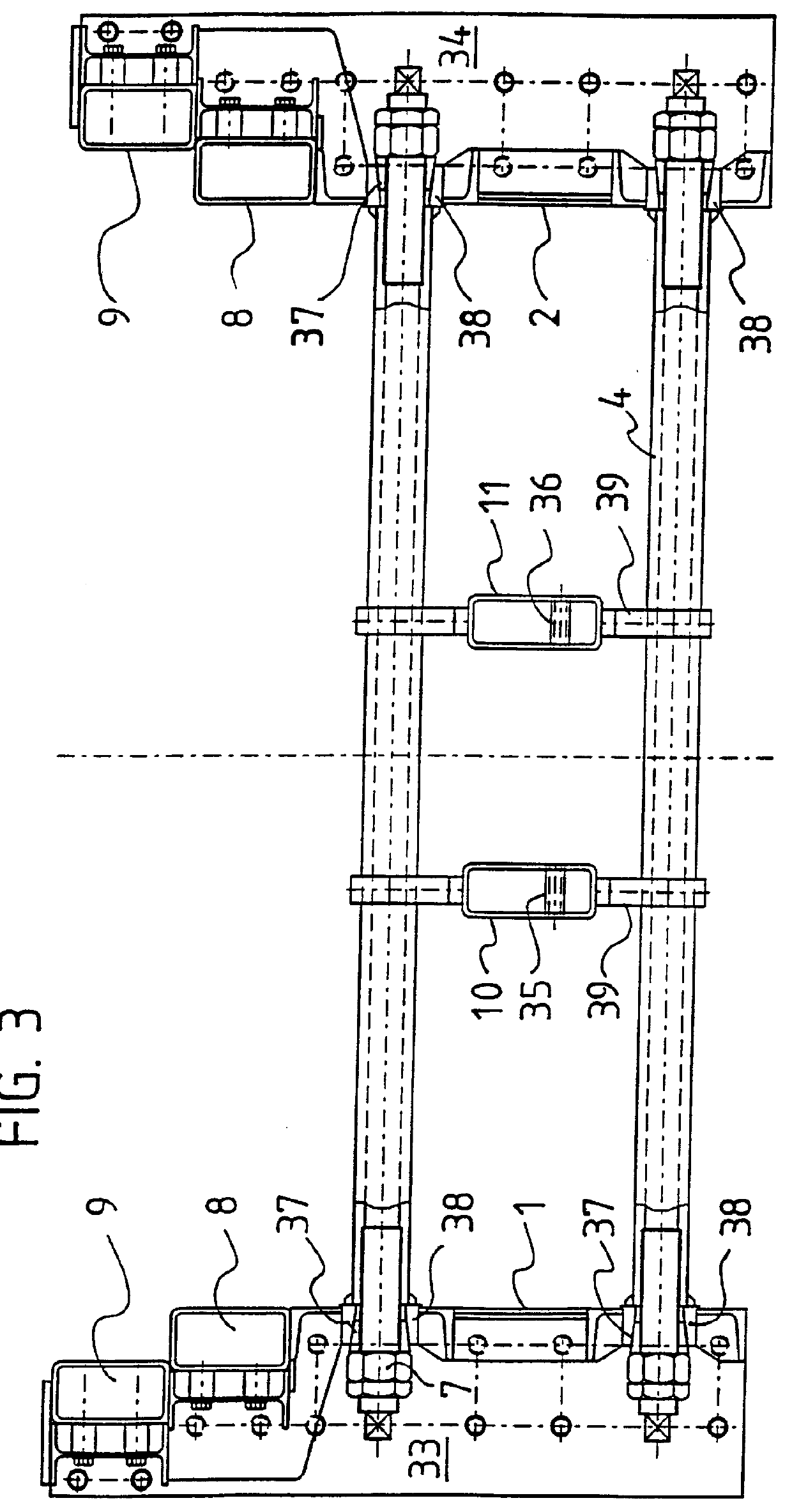

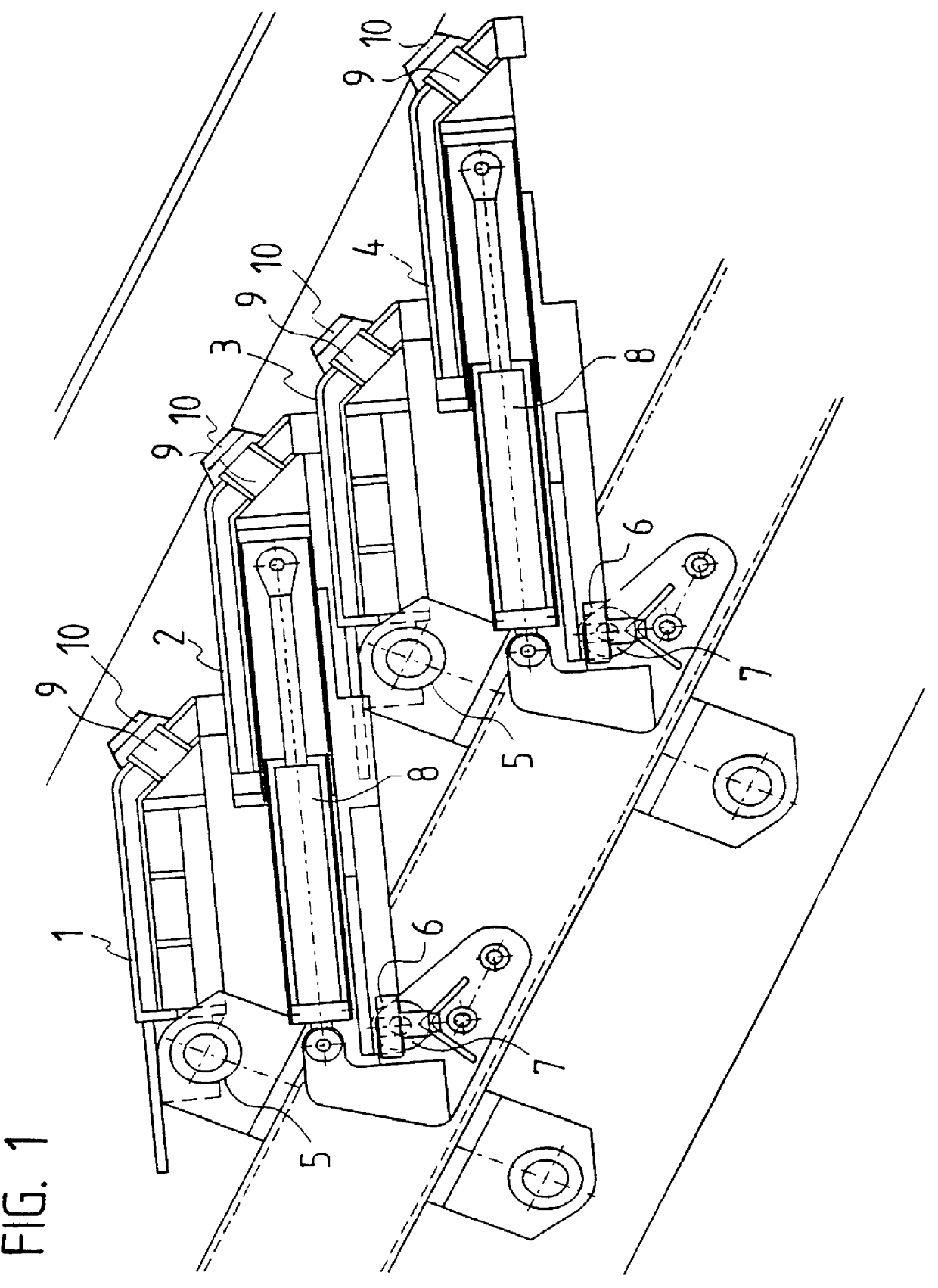

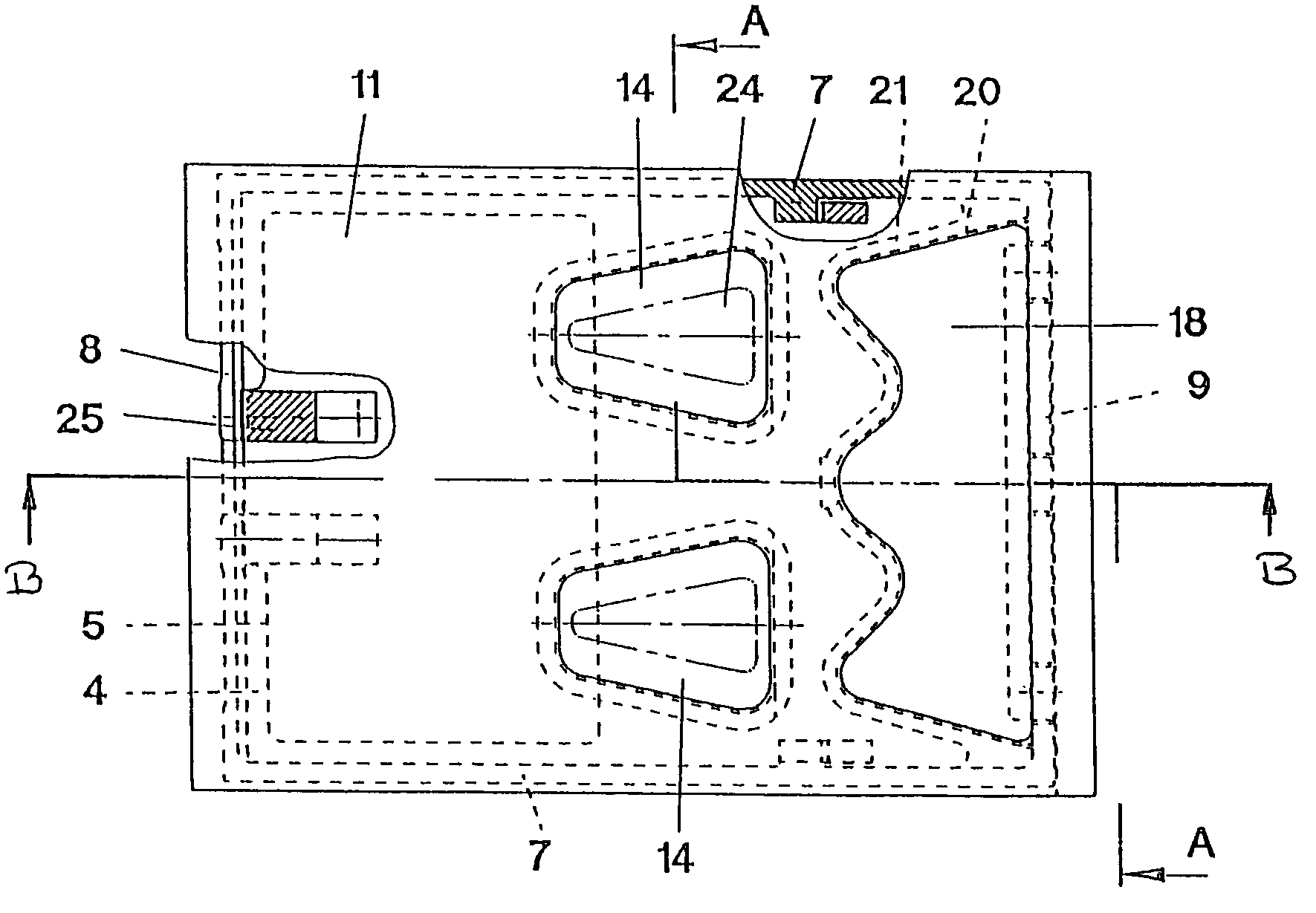

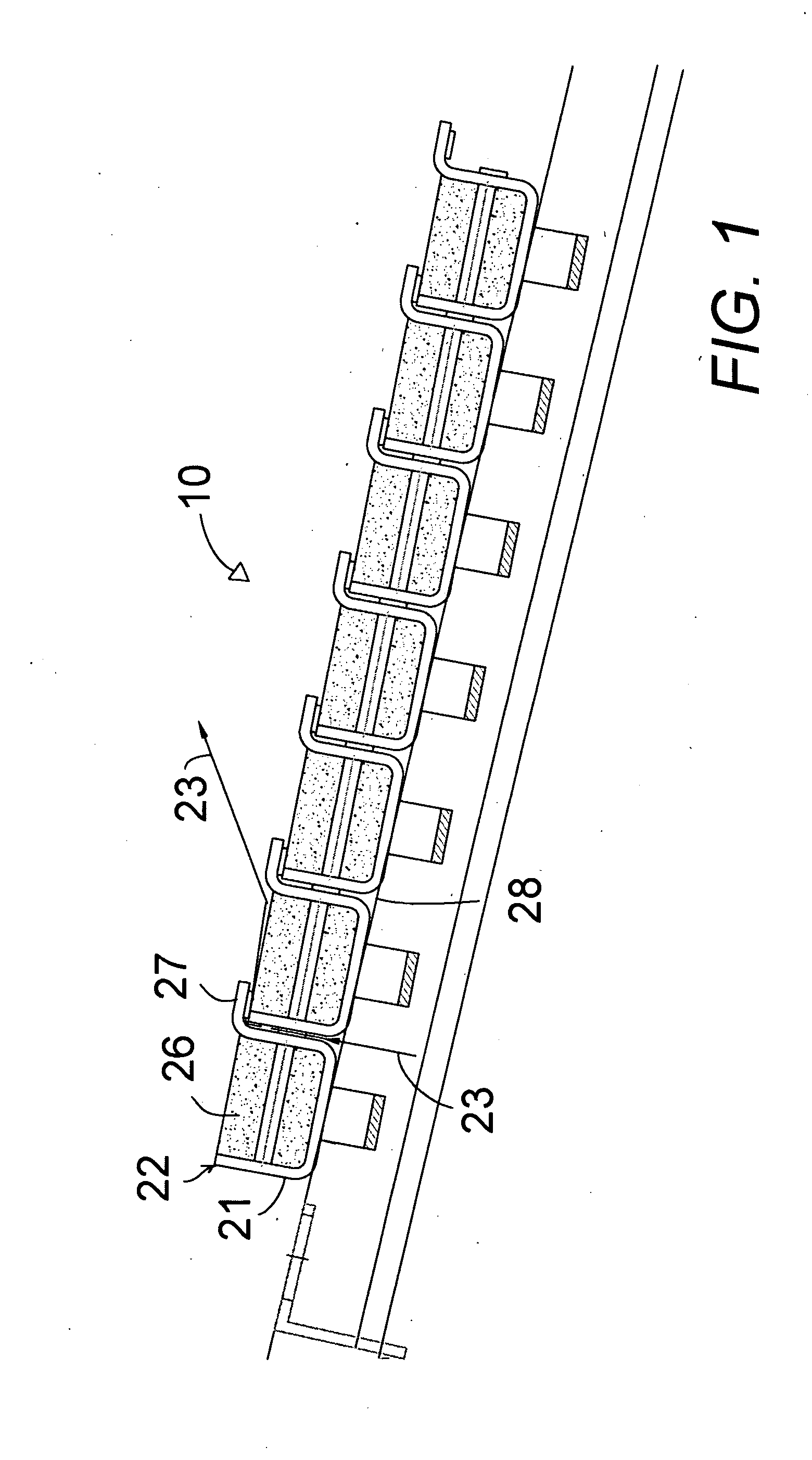

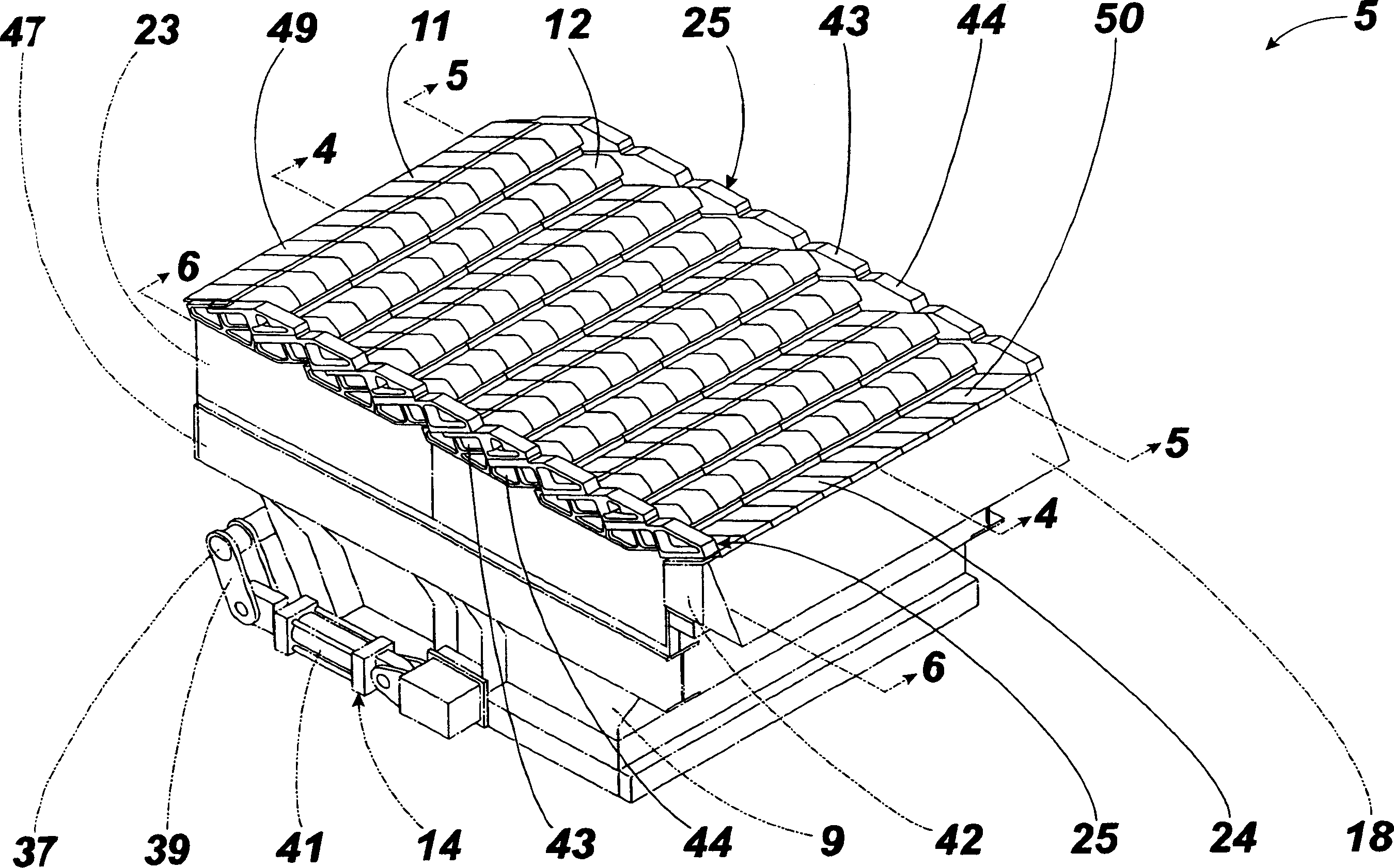

Water-cooled thrust combustion grate

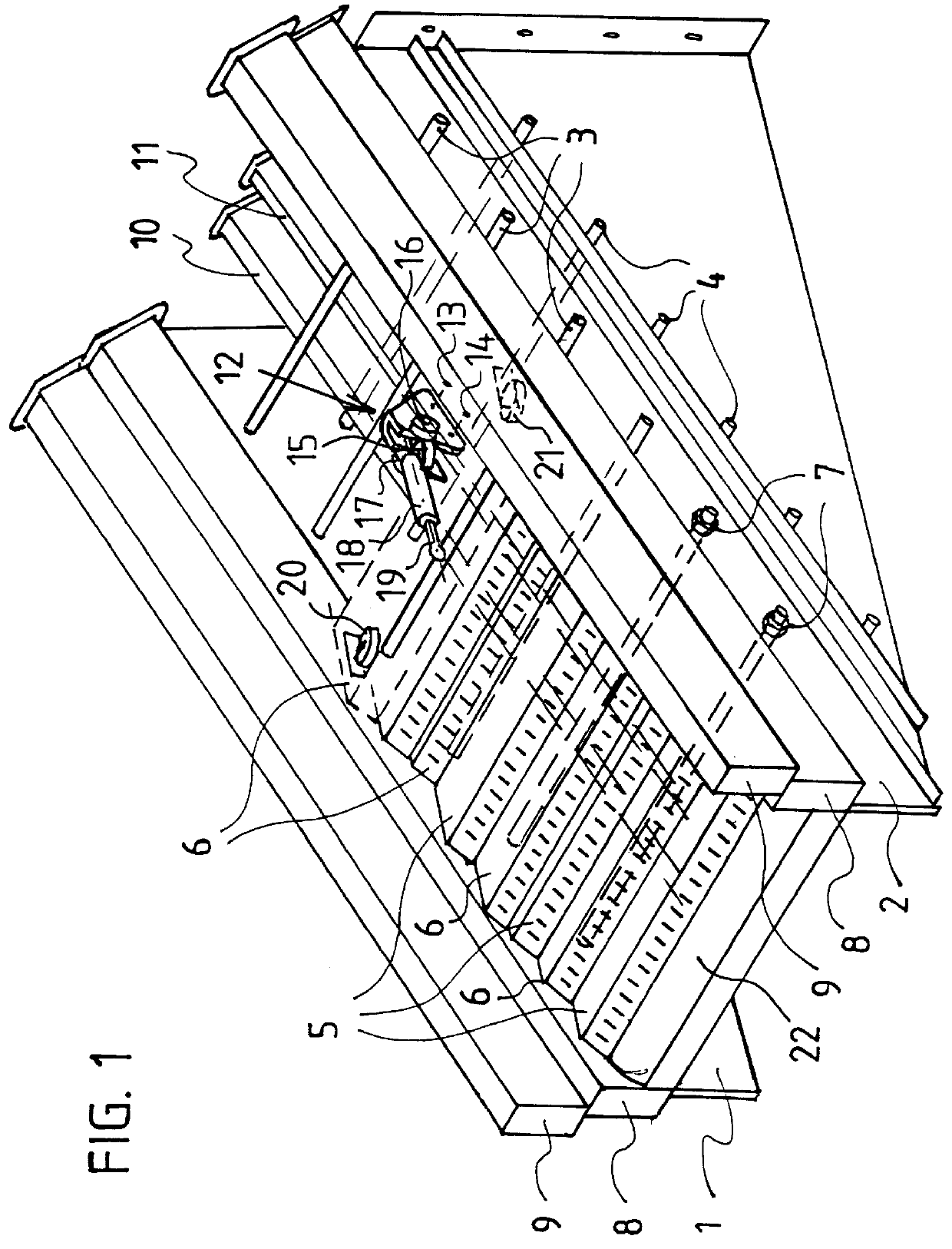

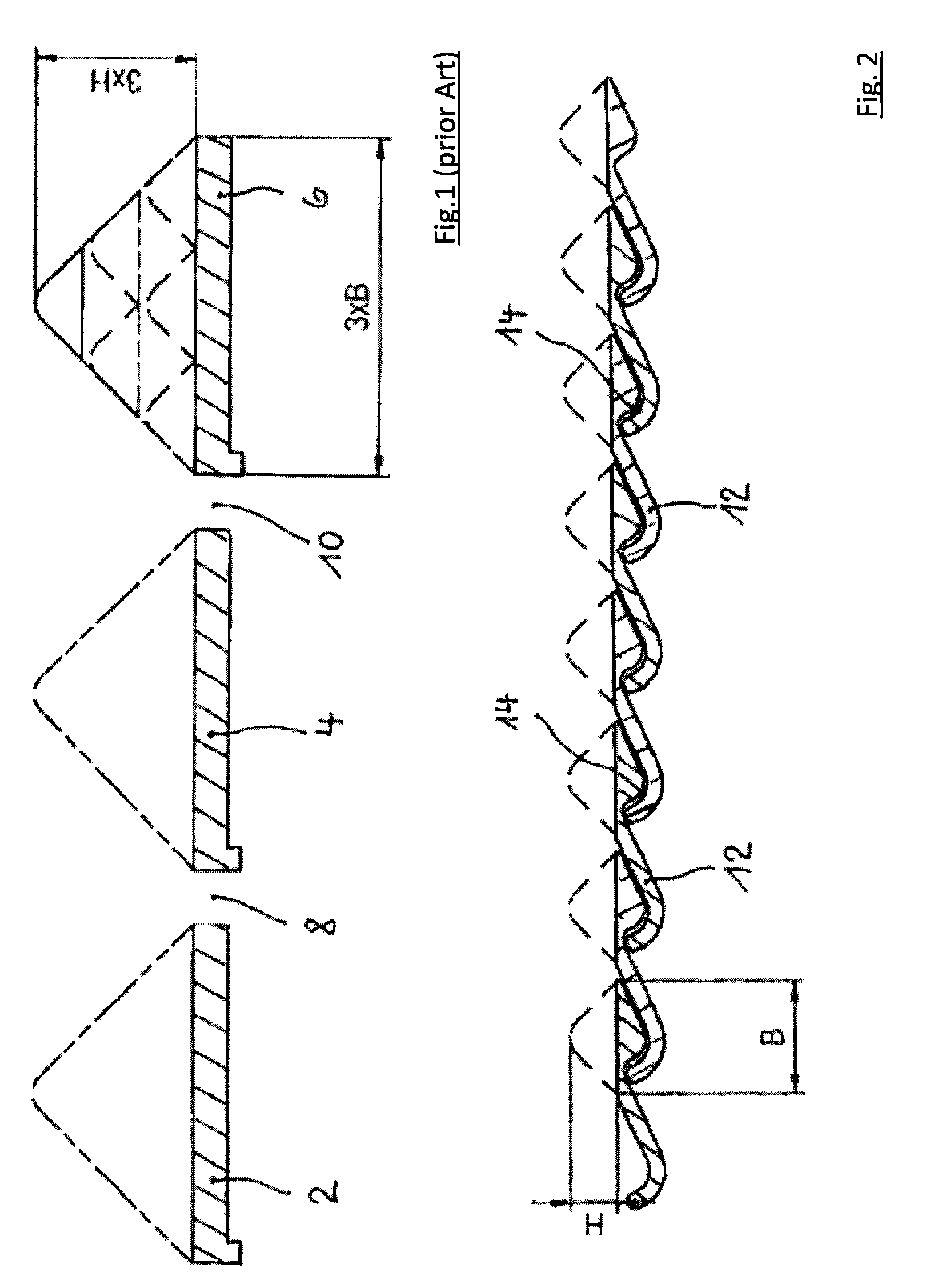

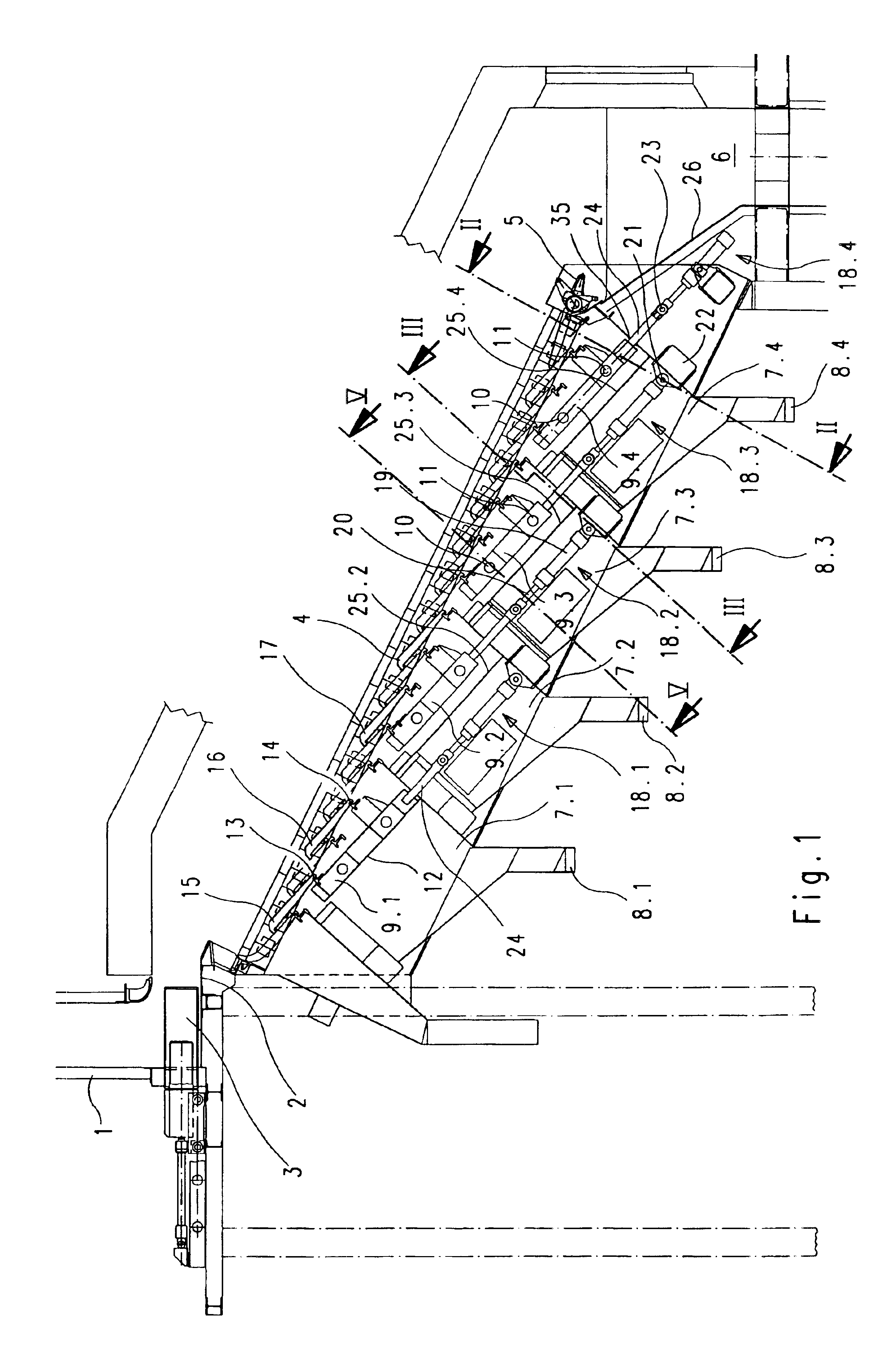

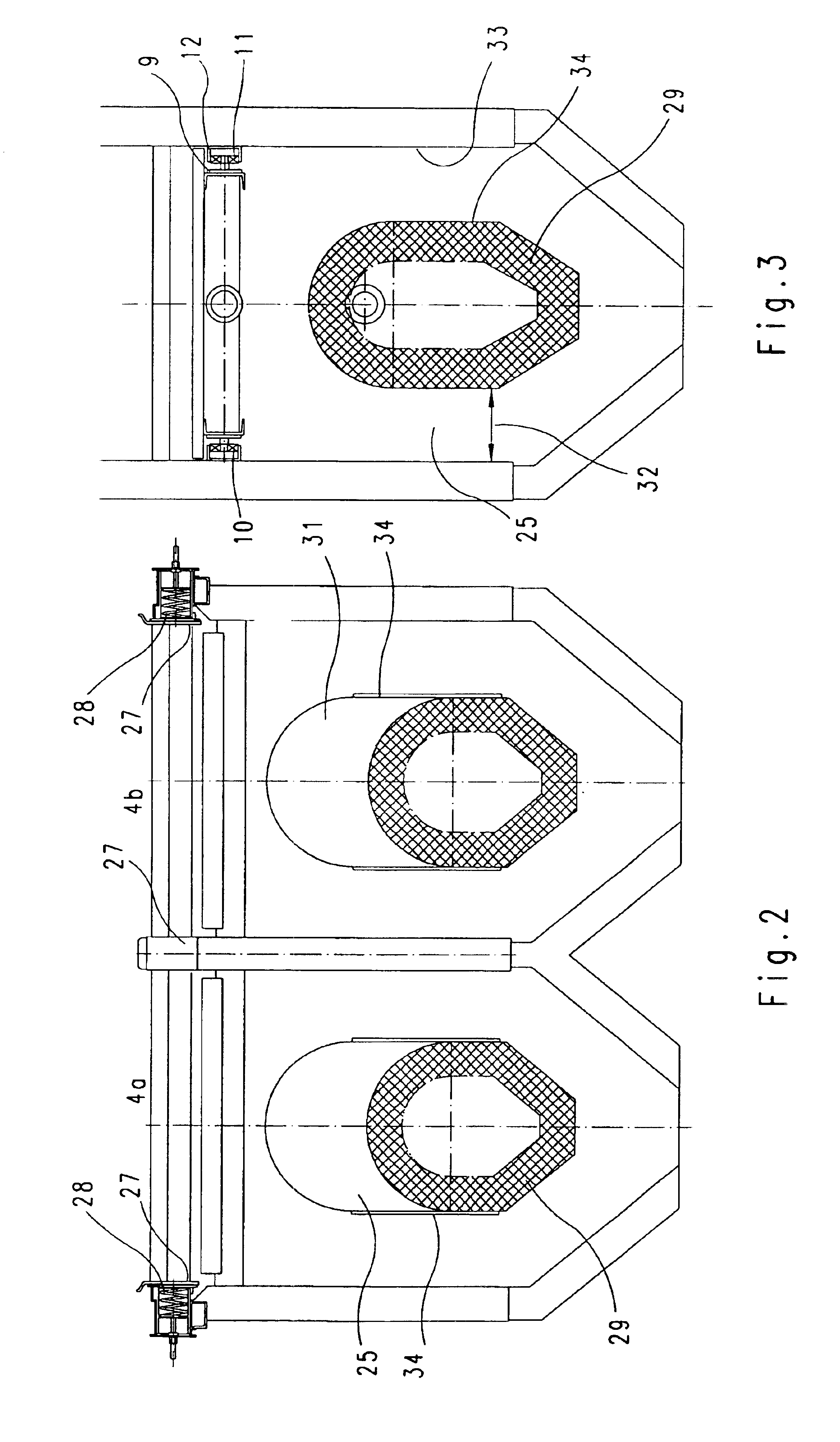

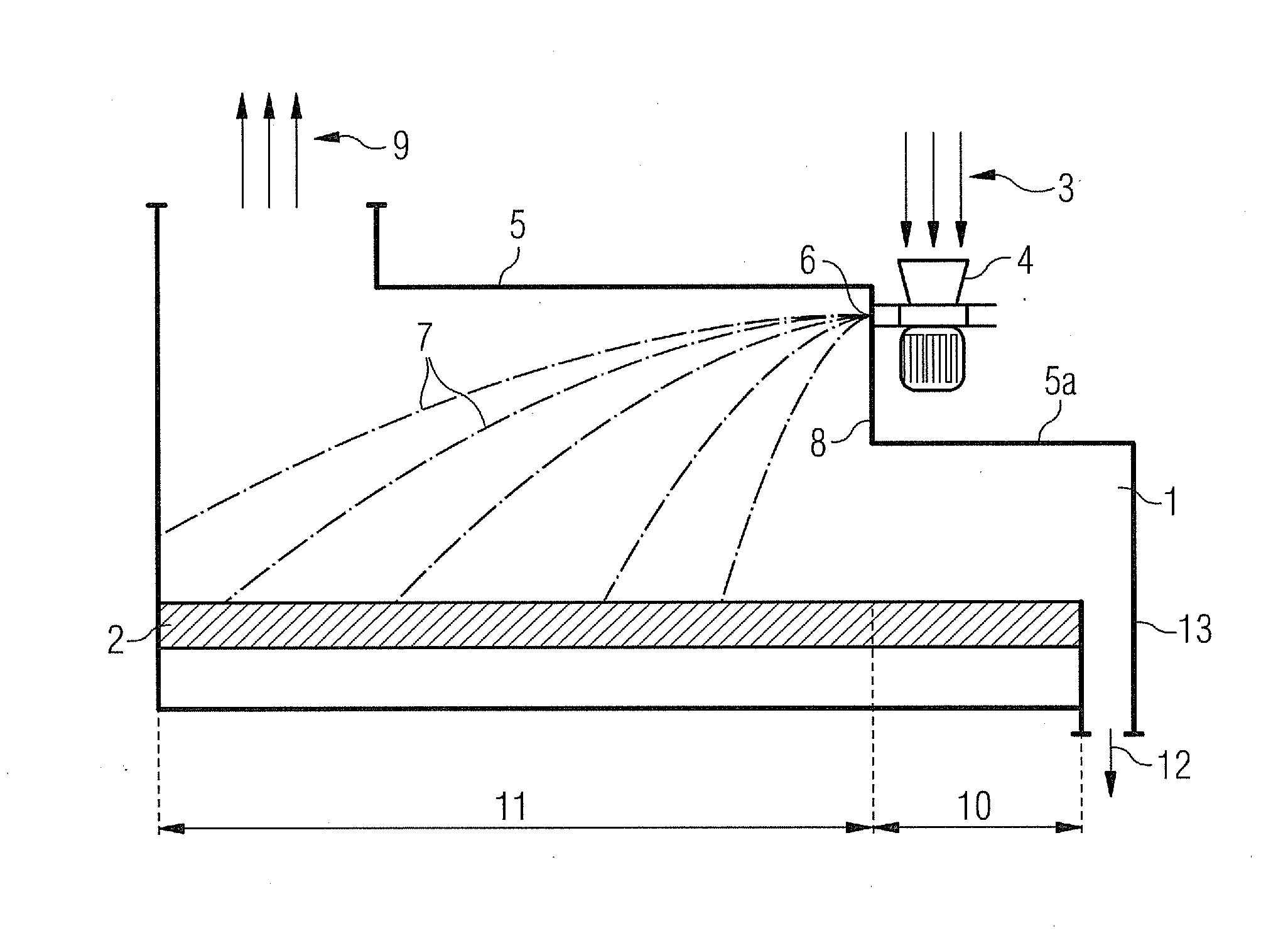

A thrust combustion grate for burning refuse having altemately stationary (5) and movable (6) hollow grate plates (5,6) in a stairway formation, that rest on each other with their front underedge. The grate plates extend across the entire width of the grateway. The movable grate plates (6) are each driven by a hydraulic cylinder-piston unit (18,19). To the sides, the grateway is limited by panels of water-cooled conduits (8,9), which, in the longitudinal direction, each consist of at least two sections sealingly flanged together. The panels are rigidly screwed to each other by a plurality of horizontally disposed distancing bars (3,4) running perpendicular thereto. Running between the panels are two additional conduits (10,11) flanged together in the same way, for feeding primary air and cooling water, which are fixed to certain individual distancing bars (3,4). The back sides of the stationary grate plates (5) each rest on one distancing bar (3) while the back sides of the movable grate plates (6) rest on at least one steel roller (16,17) with a horizontal axis, with each side of their front sides being guided along a steel roller (20,21) whose axis runs perpendicular to the grate plate (6). The front portions of the grate plates (6) form by primary air slots (25).

Owner:DOIKOS INVESTIMENTS LTD

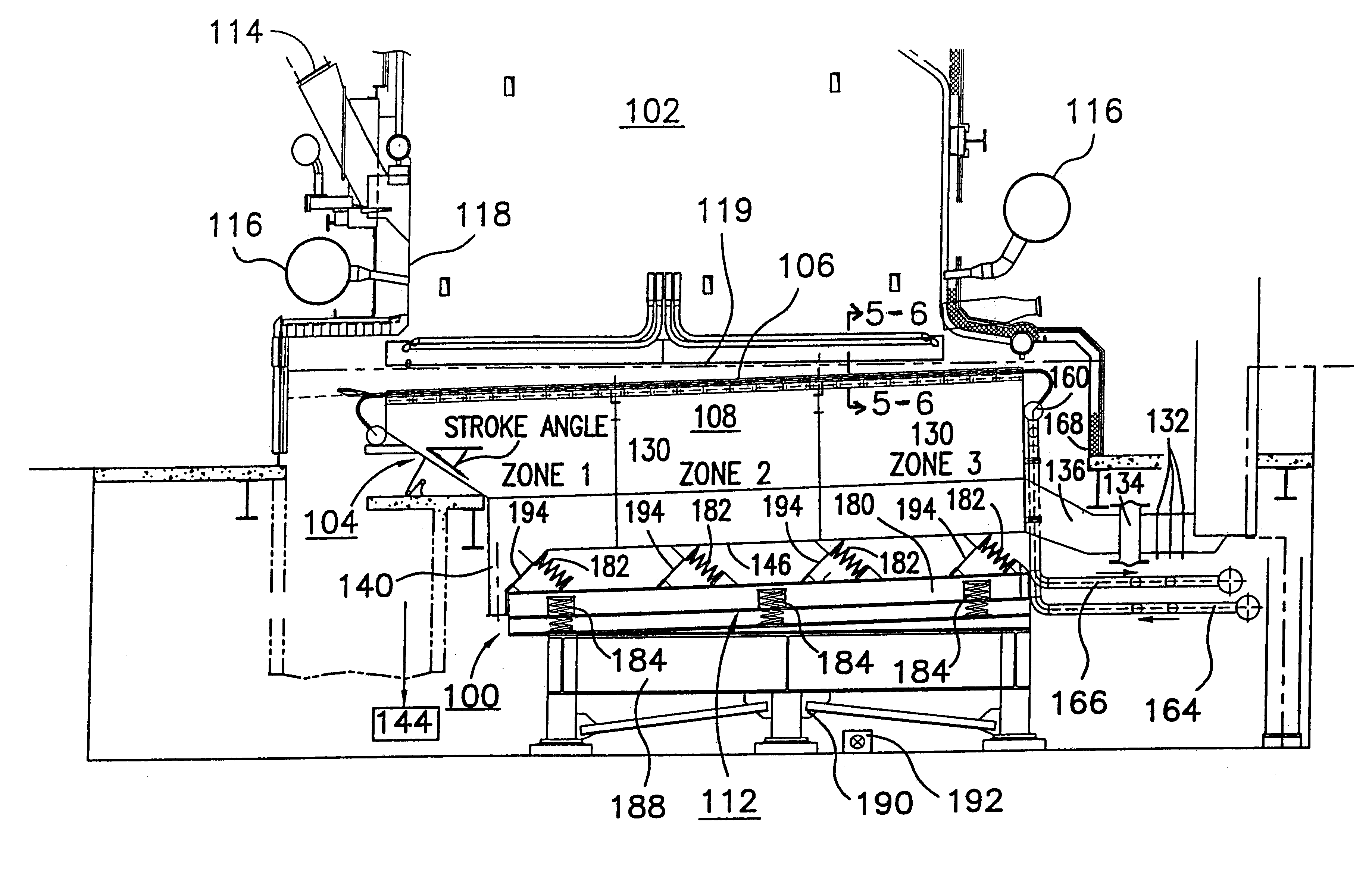

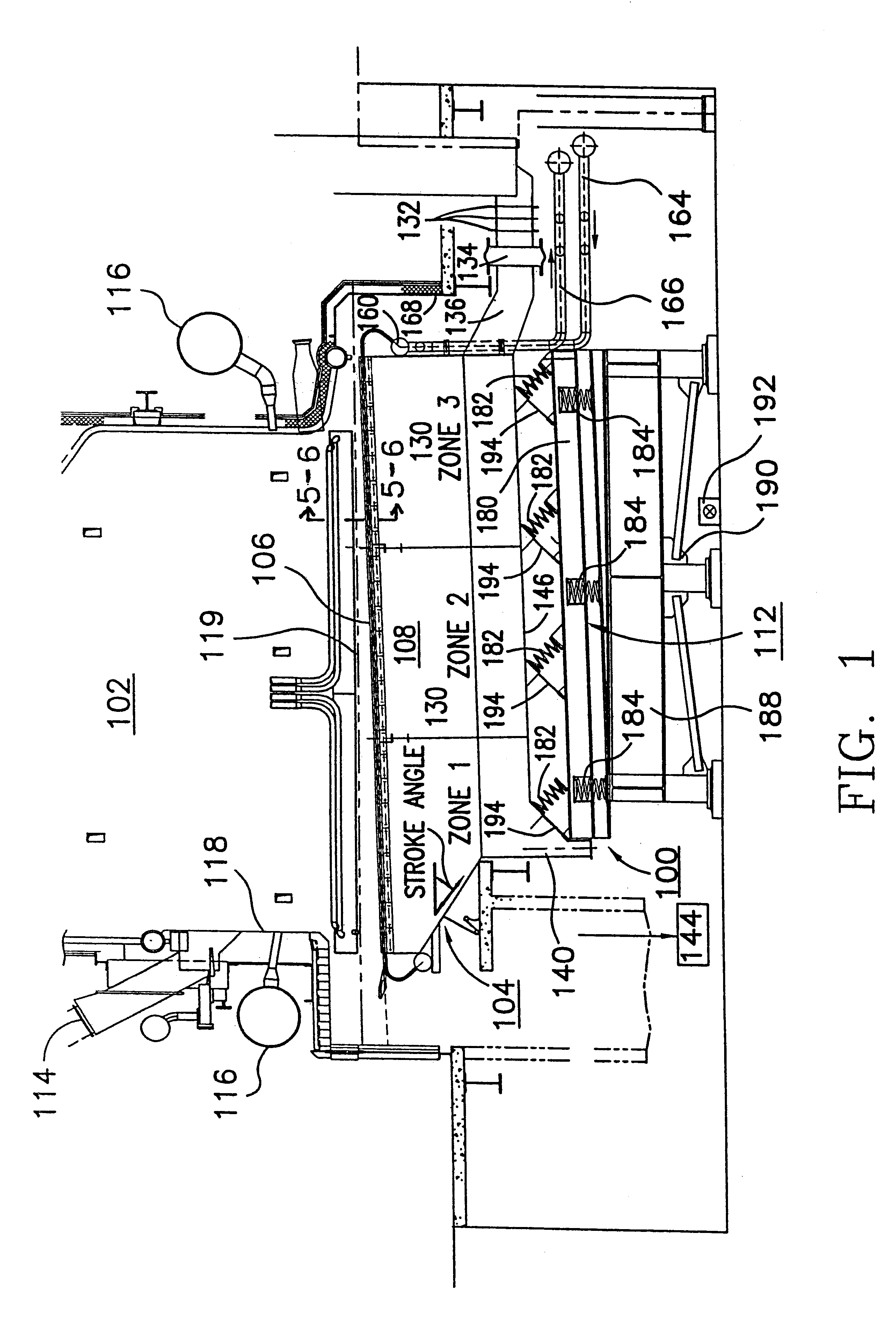

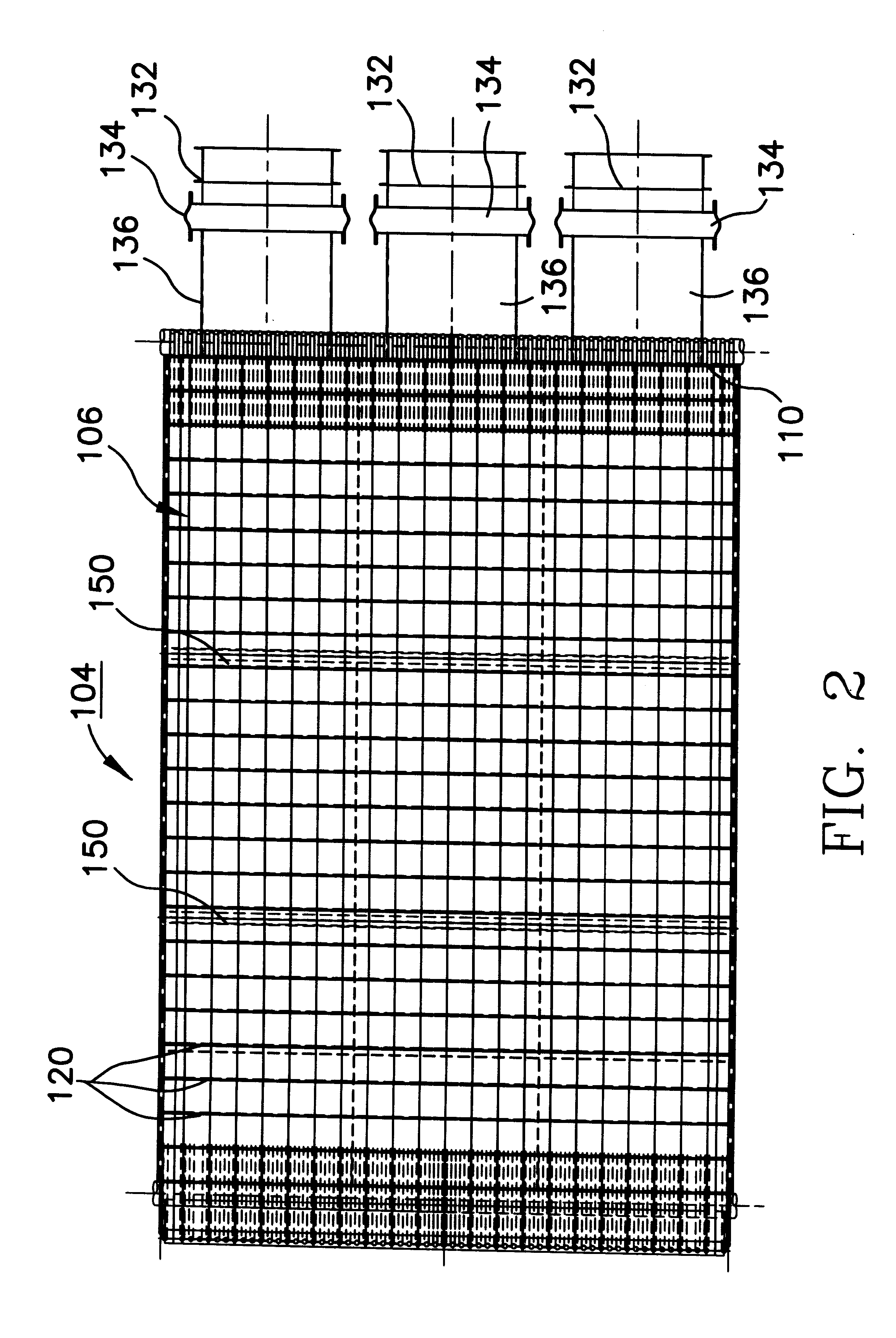

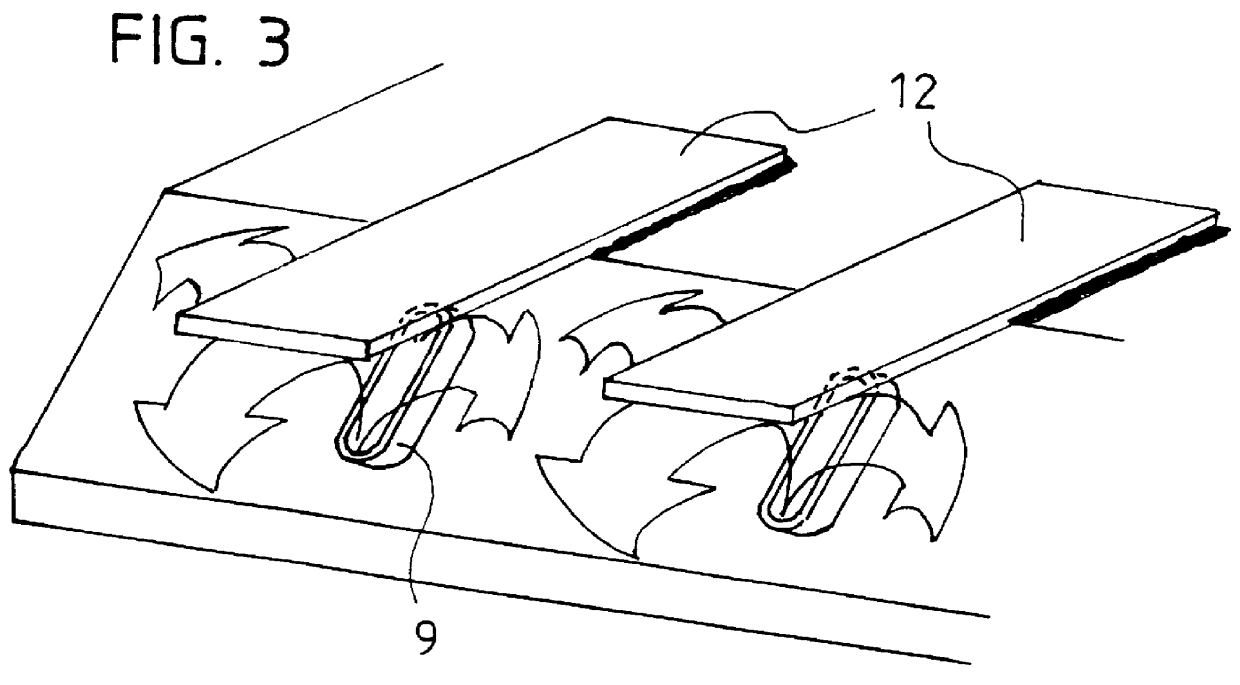

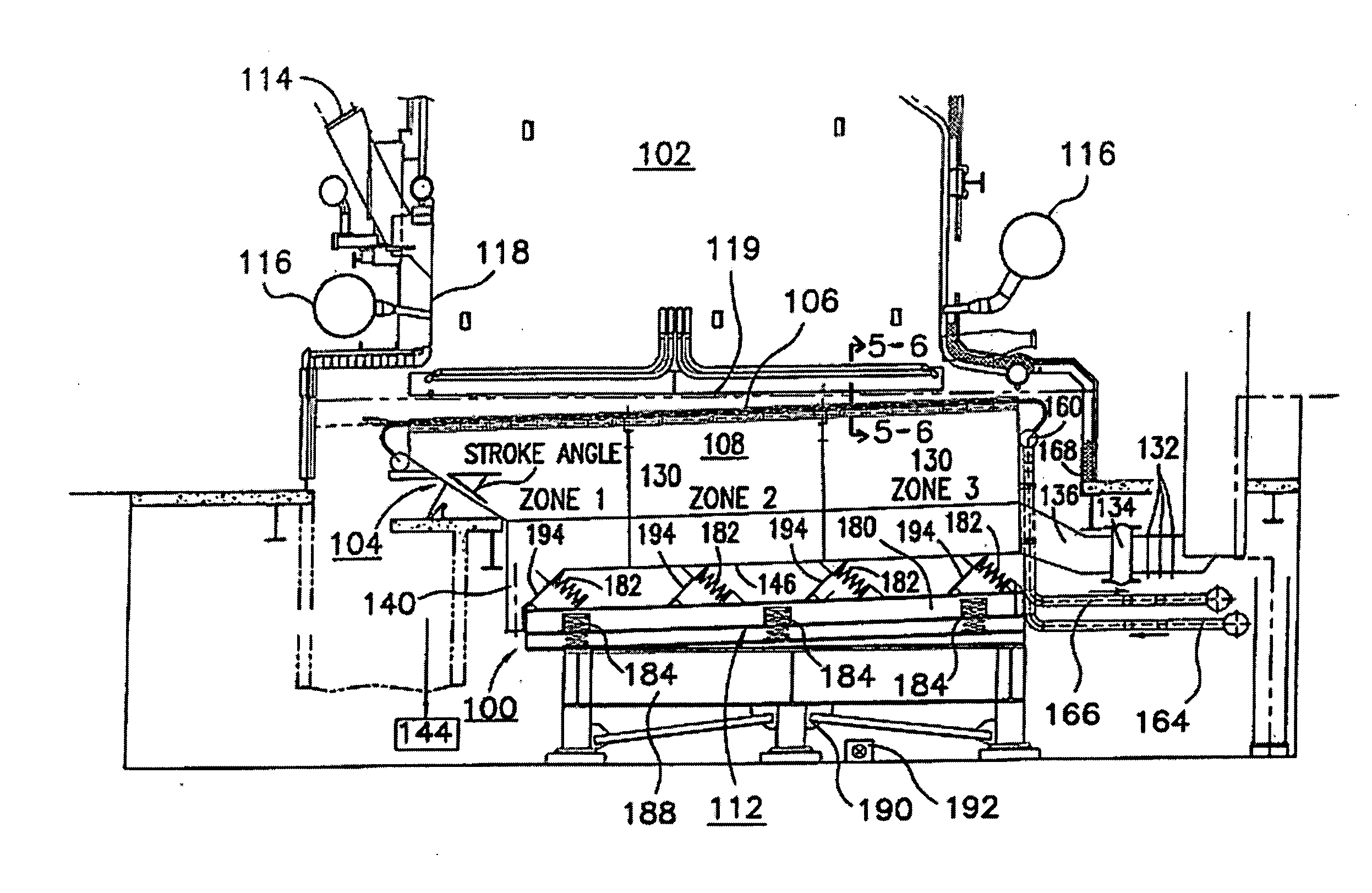

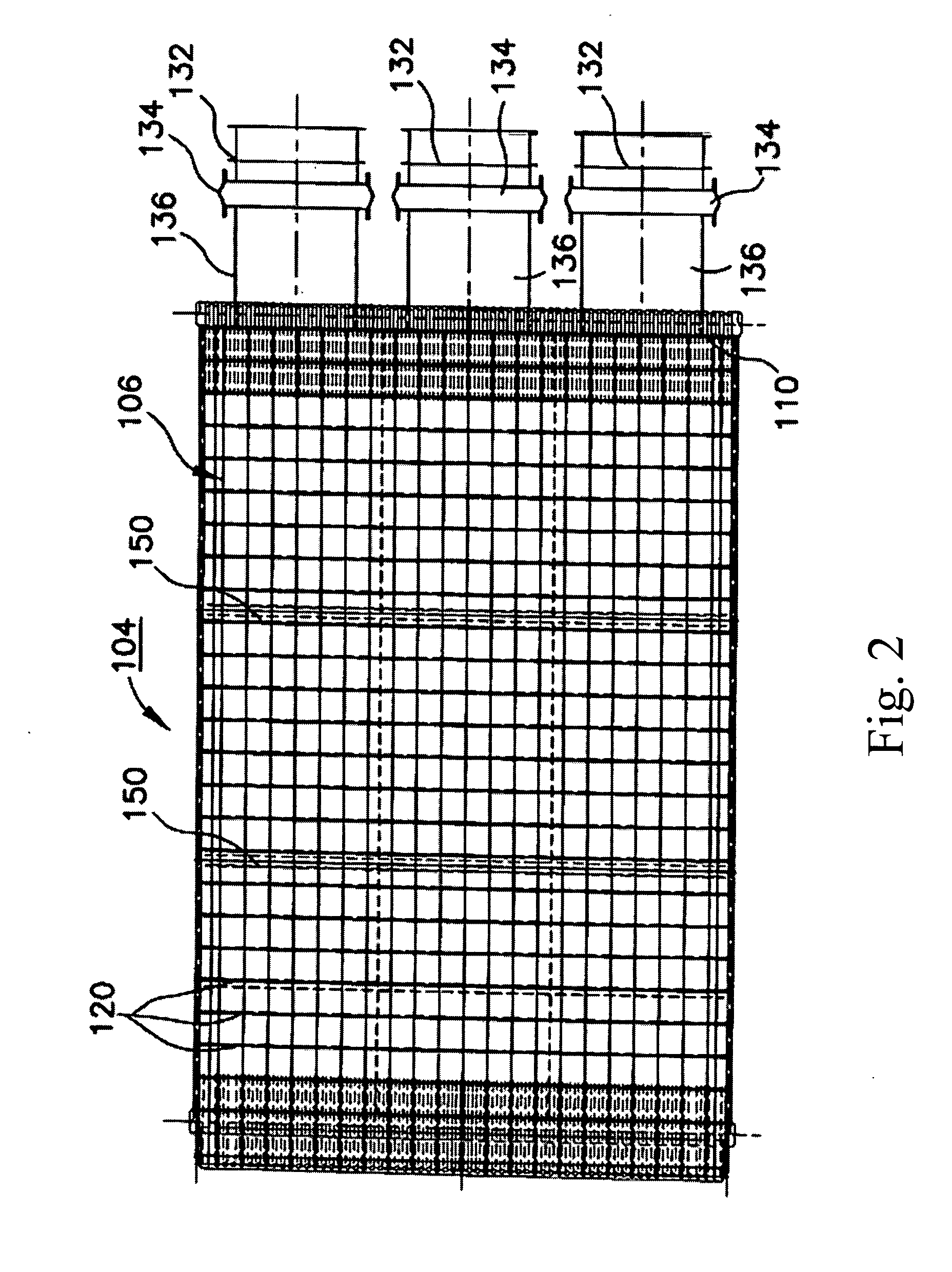

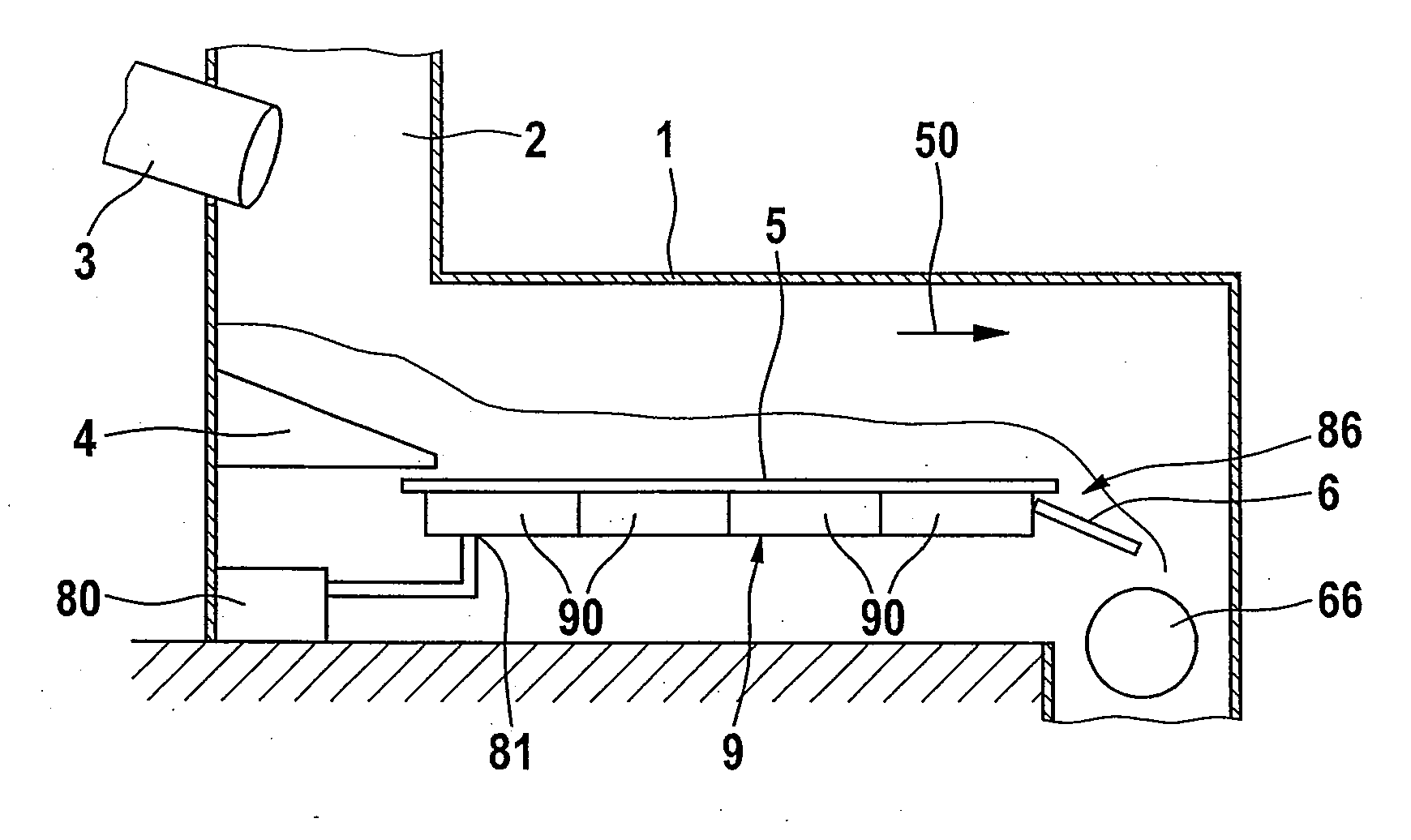

Water-cooled oscillating grate system

InactiveUS6220190B1Minimize under grate air leakageEffective and efficient and reliable operationHollow bar grateSpeed sensing governorsCombustionWater source

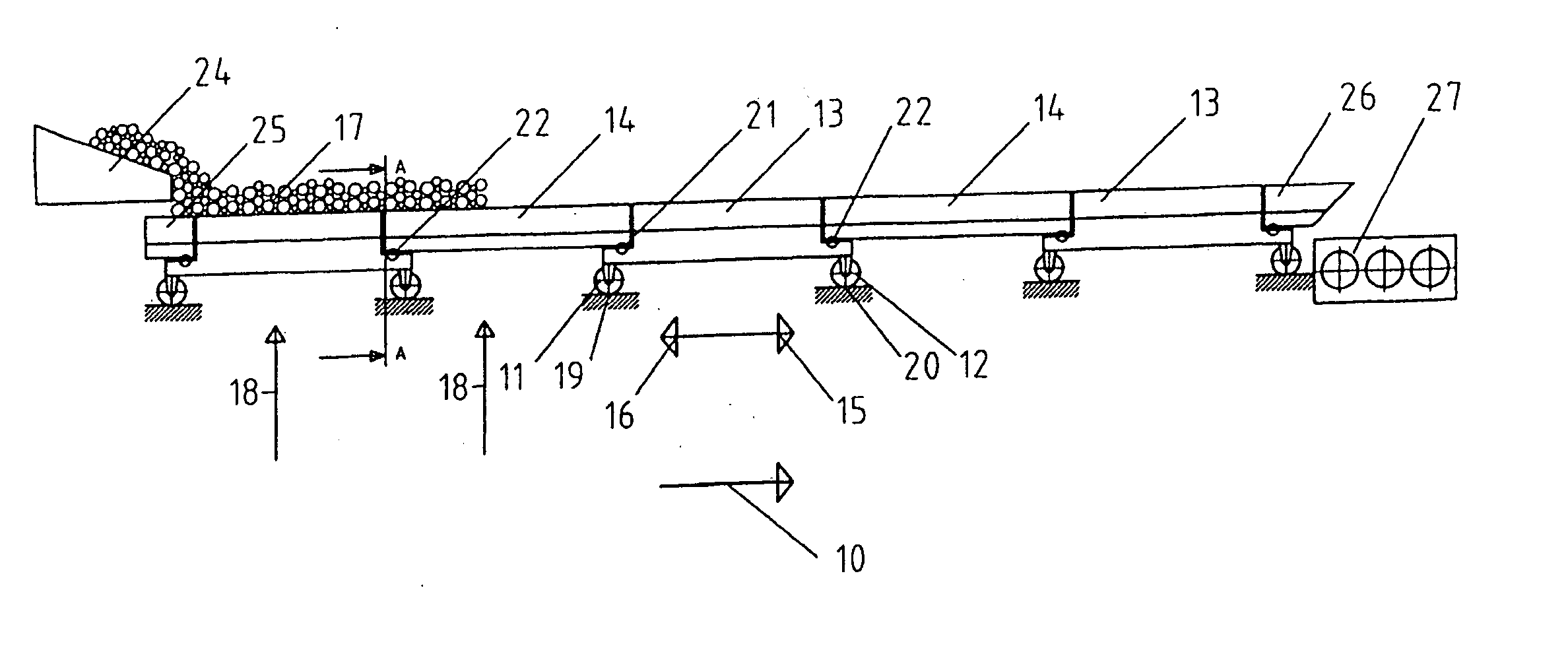

An integral water-cooled, air permeated, vibrating grate system for combusting biomass and other fuels in a boiler includes a grate top surface having air-flow apertures extending therethrough. The grate top surface is supported by a plurality of water-cooling pipes which arc coupled to a water supply. An enclosed air plenum unit is positioned under and attached directly to the grate top surface. The air plenum unit is coupled to an air supply for providing combustion air through the top grate surface air-flow apertures. The air plenum unit includes multiple zones, each of which zones has an associated air flow control damper so that the flow of combustion air can be controlled. Ash siftings formed on the grate top surface when the biomass or other fuel is combusted fall into the air plenum unit and flow toward at least one ash-siftings discharge opening at a discharge end of the air plenum when the grate top surface and the air plenum is vibrated. The grate top surface and the air plenum are vibrated together by a vibratory drive-isolation assembly which includes a longitudinally extending counterbalance member. A plurality of drive springs are supported by the counterbalance member. The drive springs are distributed across the width and the length of the top grate surface and at least one vibratory motor or mechanism is associated with the counterbalance member so that the vibration can be adjustably controlled.

Owner:RILEY STOKER

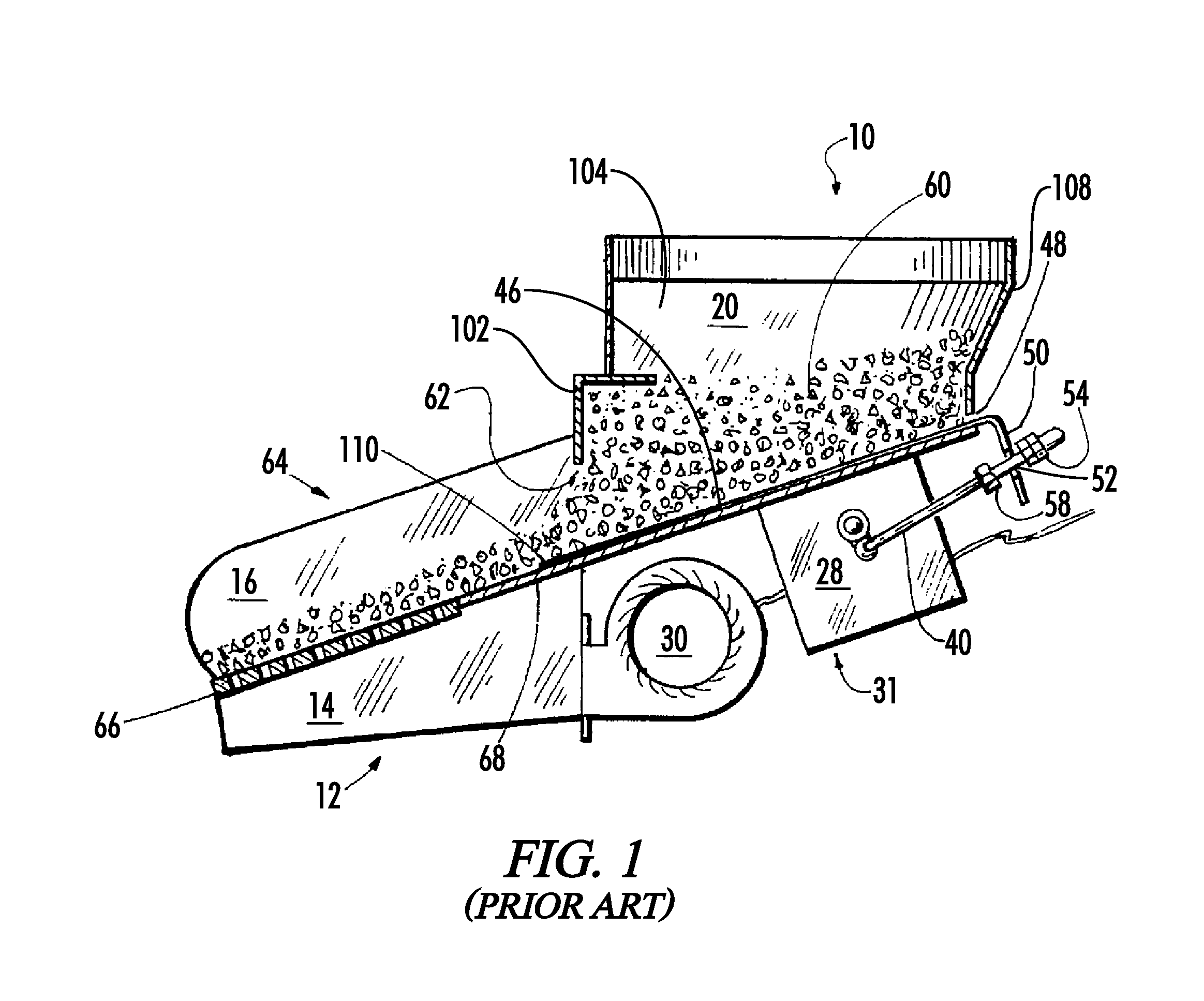

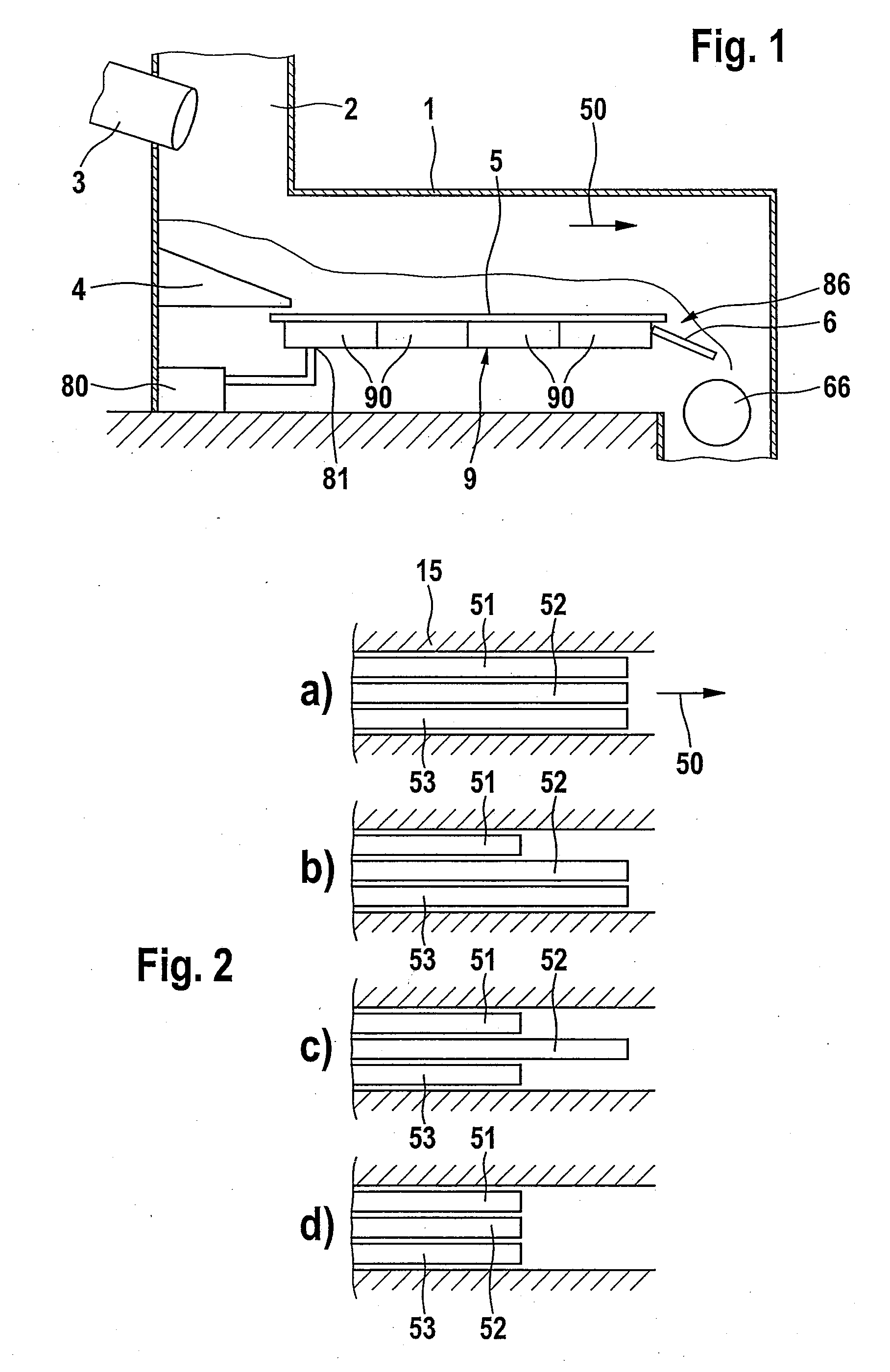

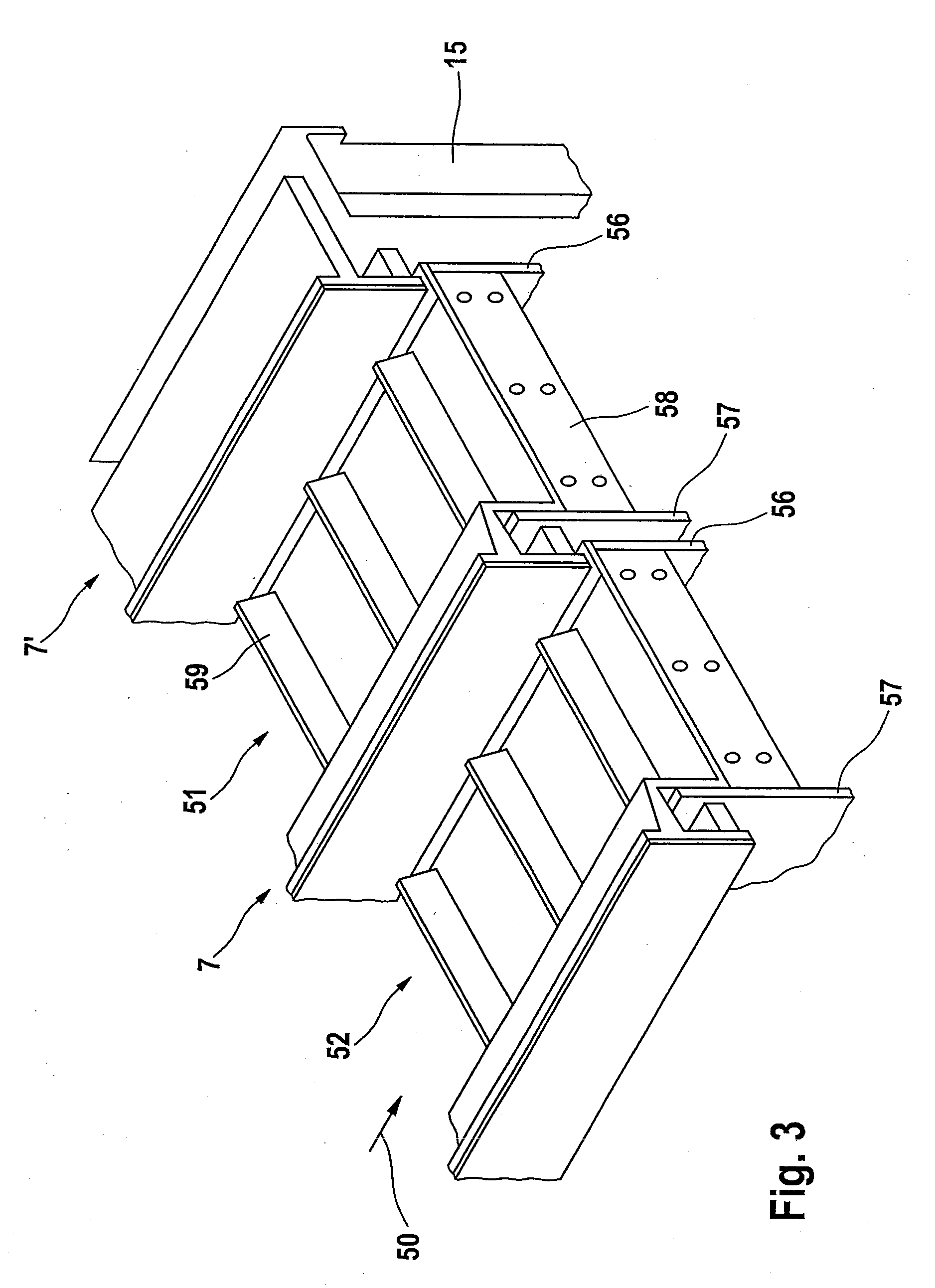

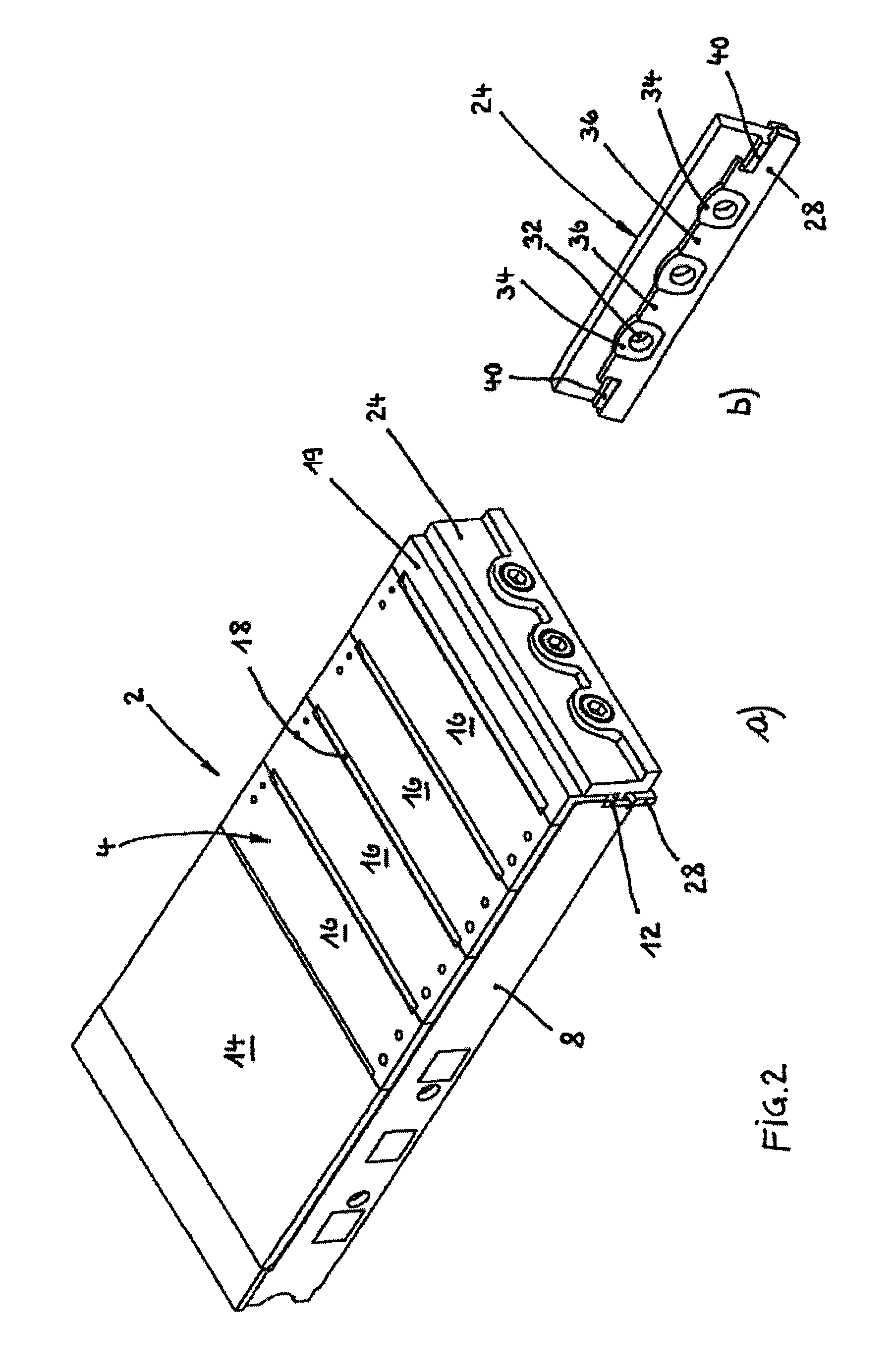

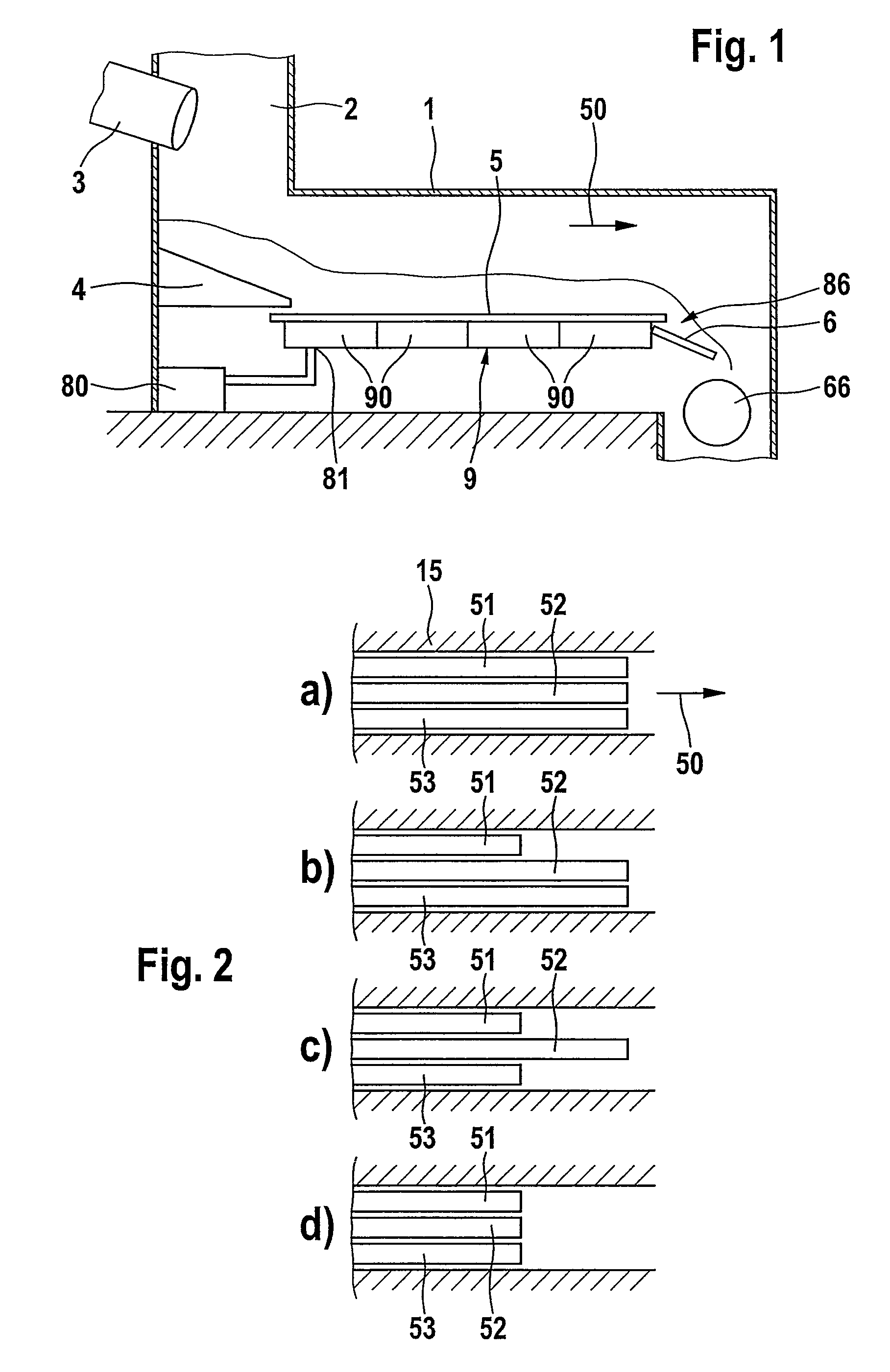

Method and device for cooling a layer of bulk material on a conveyor grate

ActiveUS8132520B2Simple designEasy to manufactureConveyorsMuffle furnacesEngineeringMechanical engineering

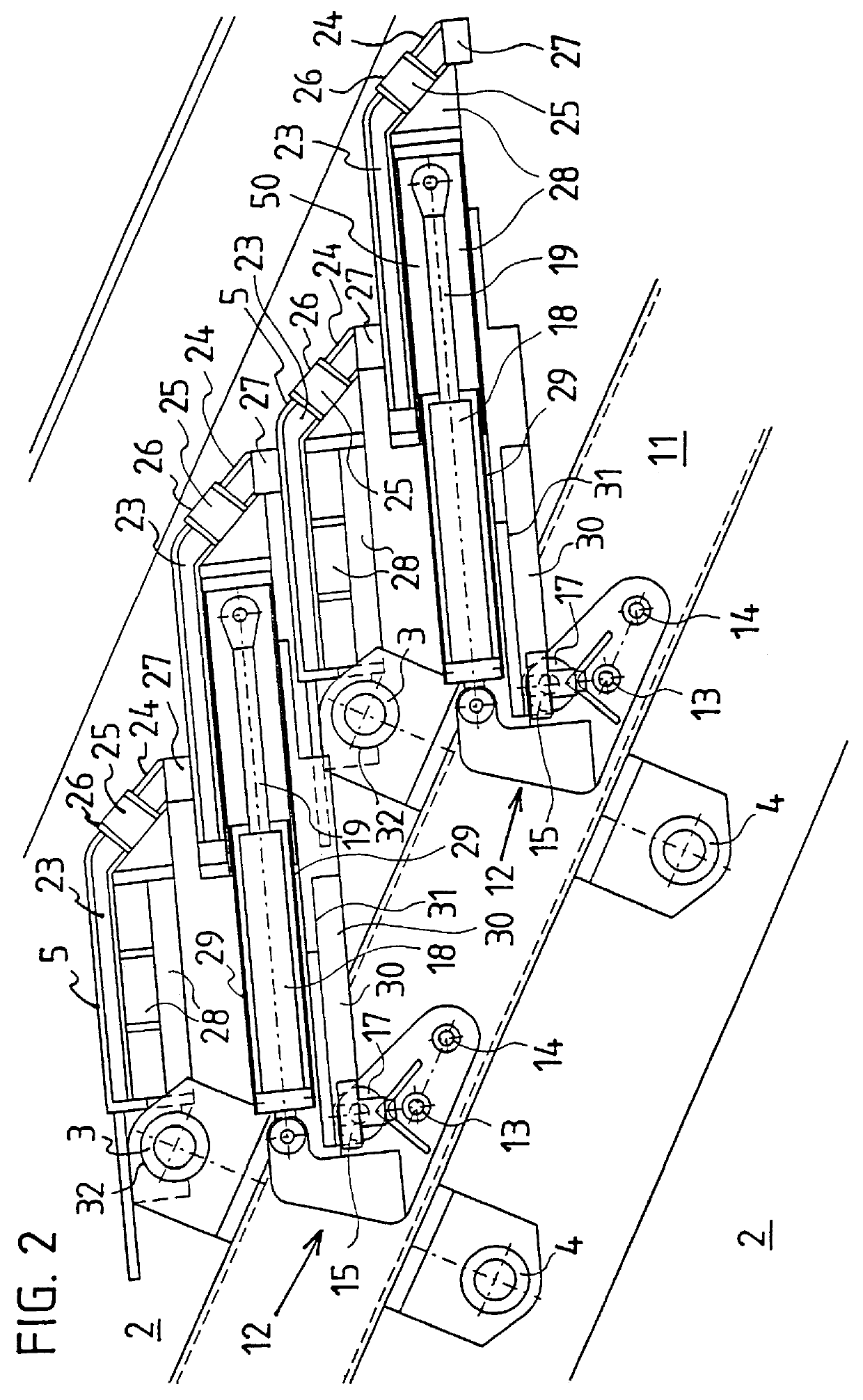

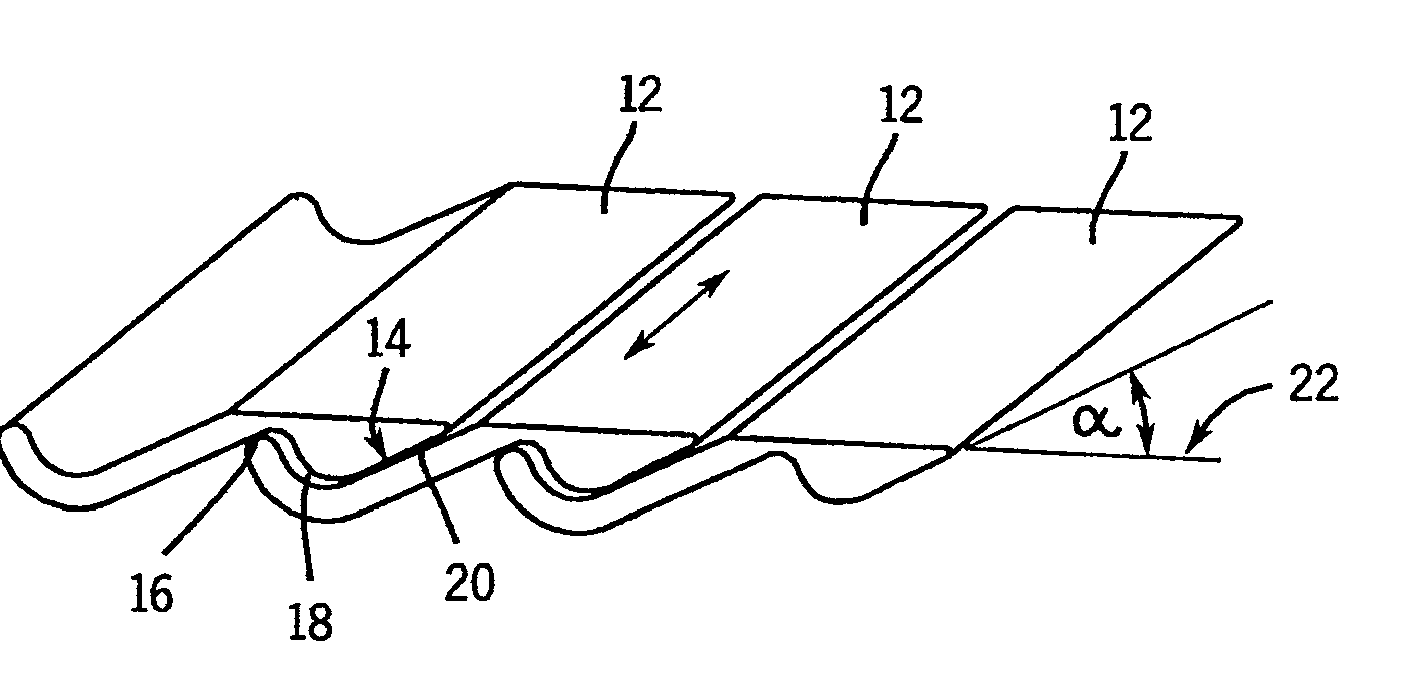

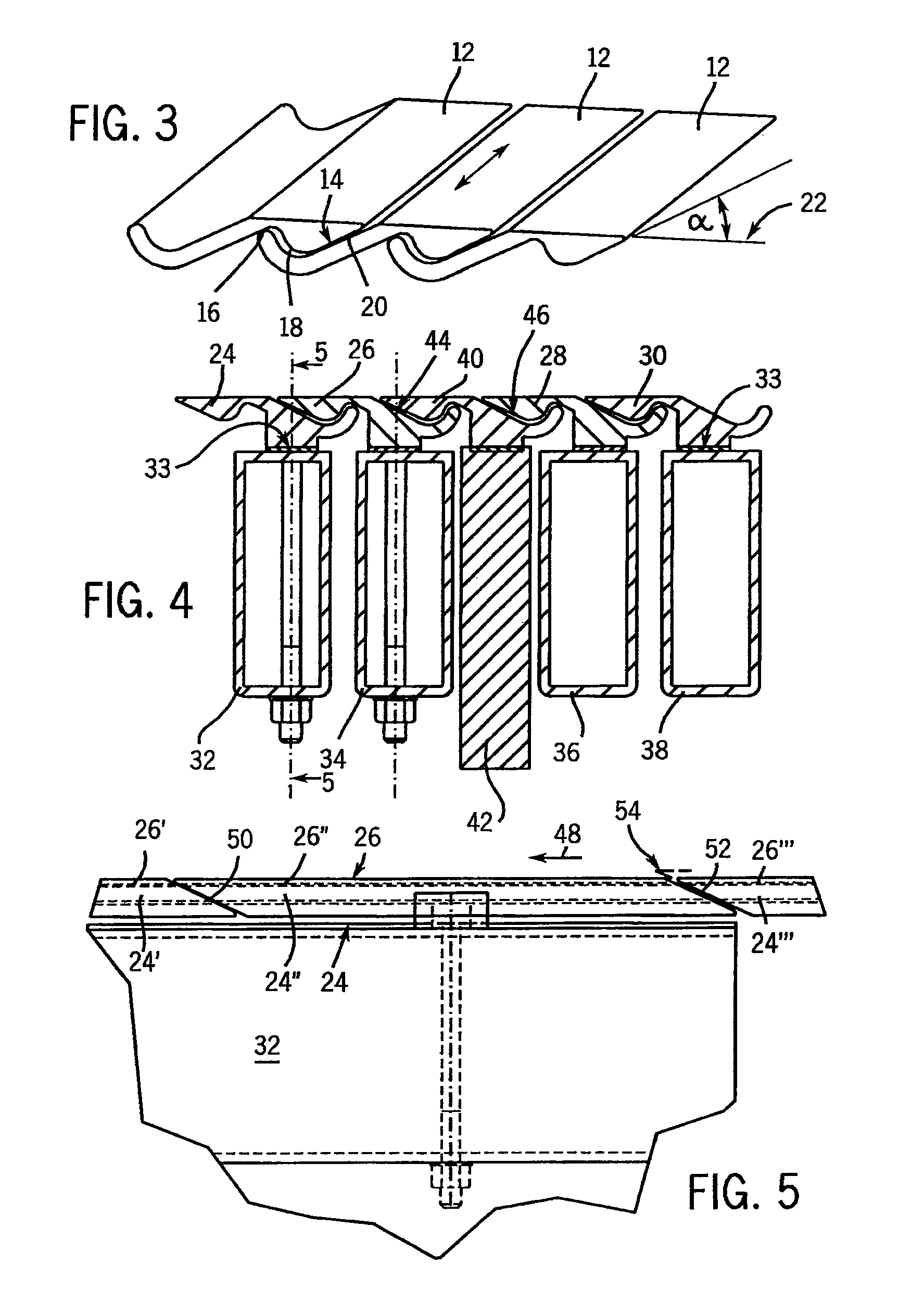

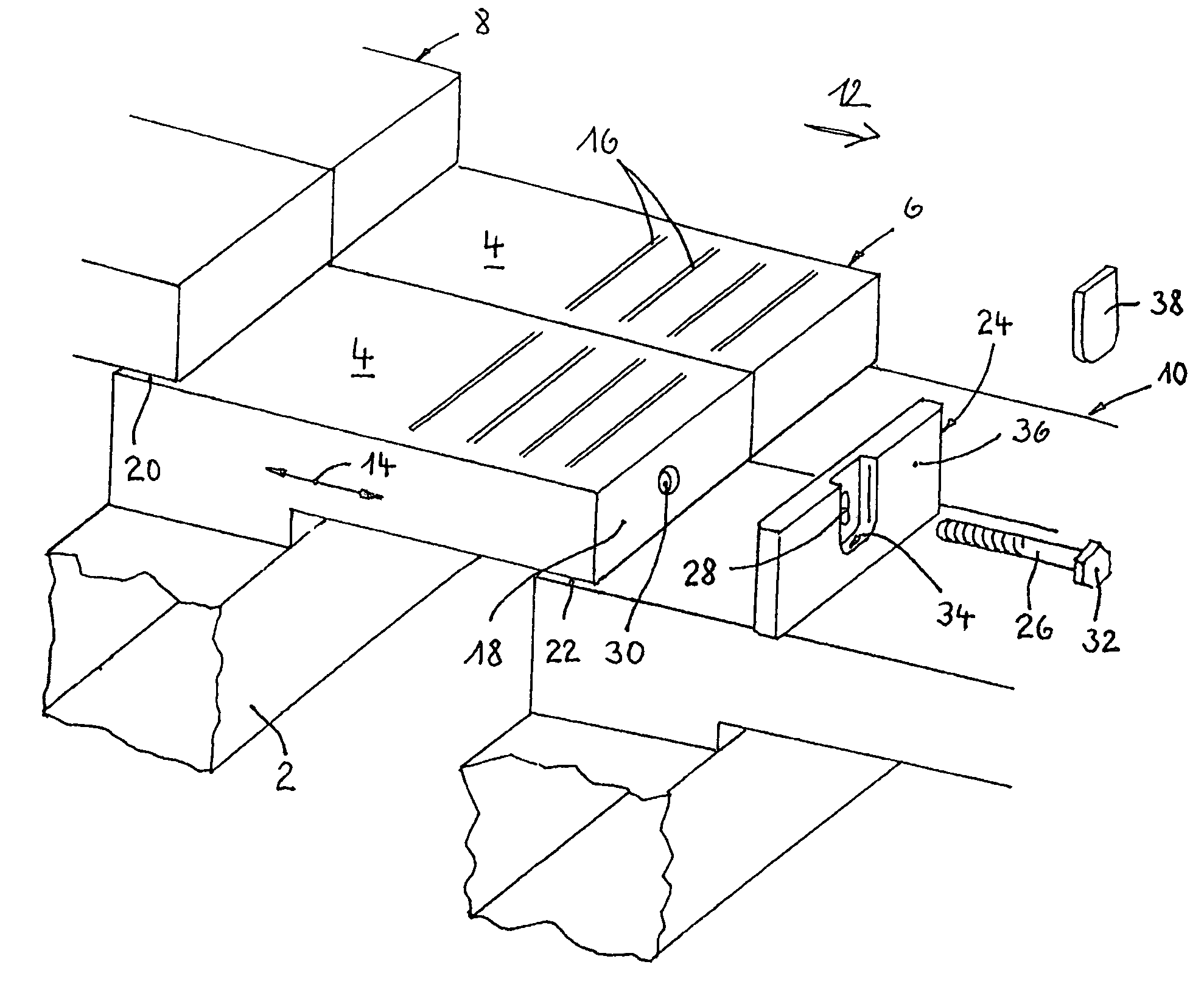

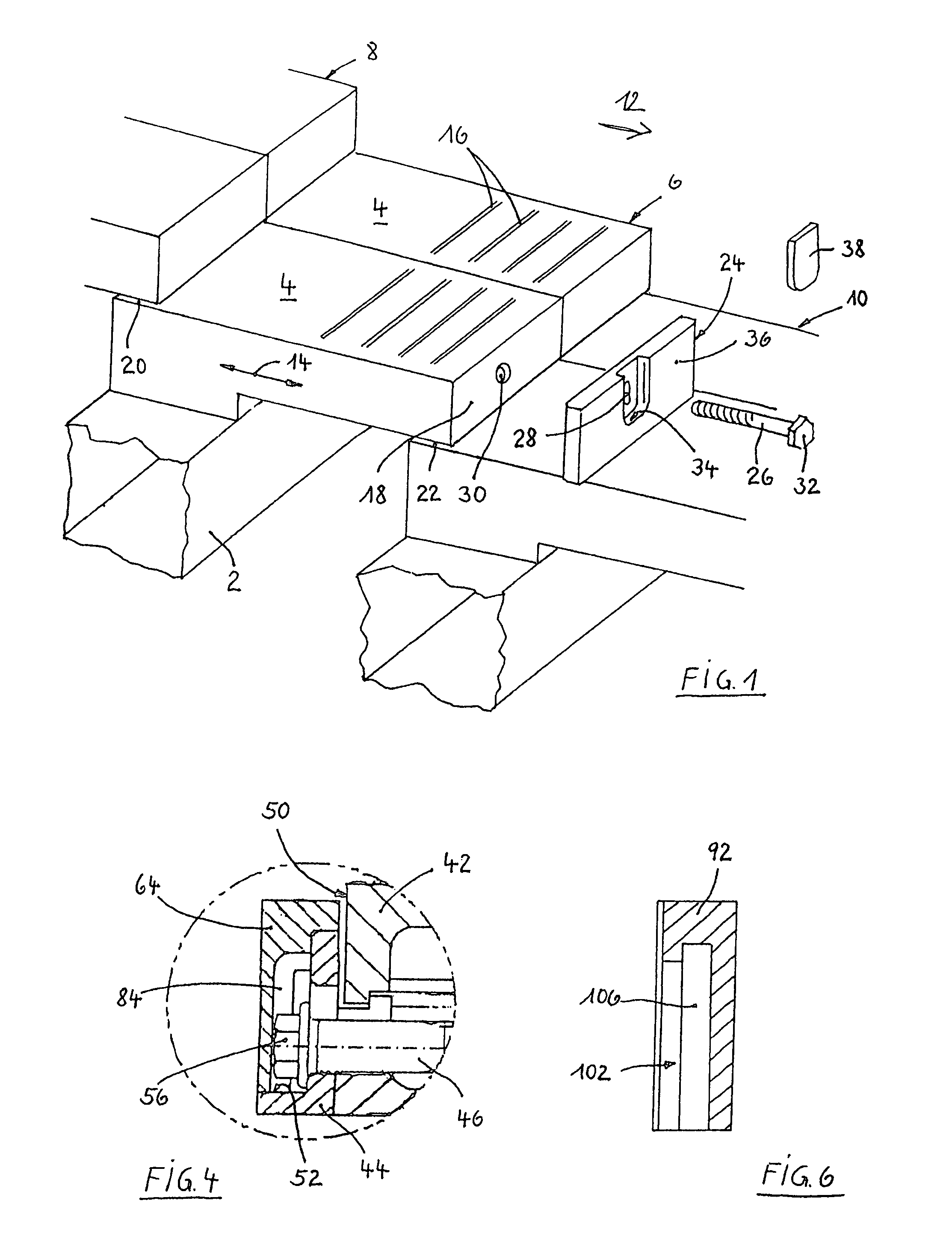

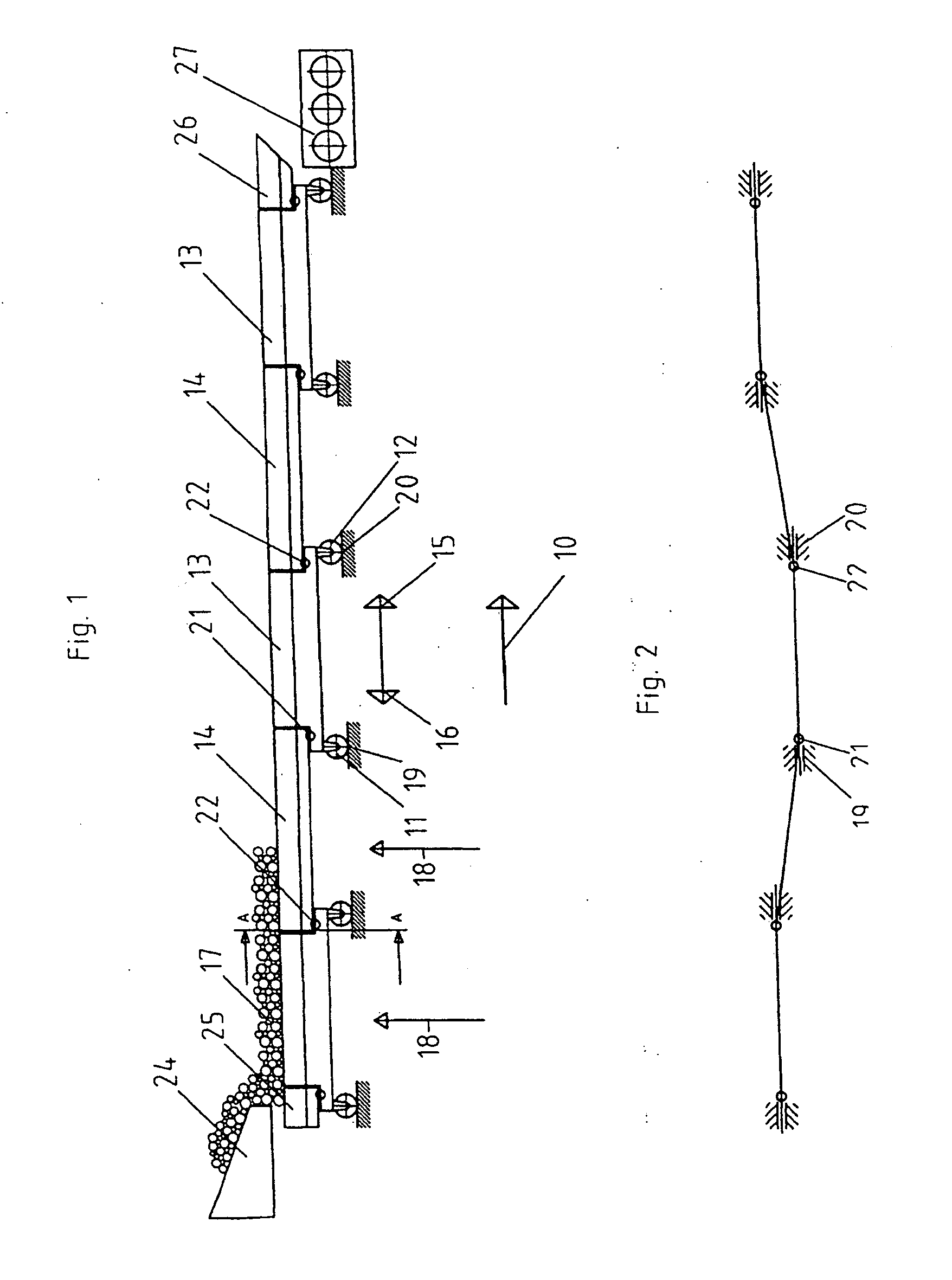

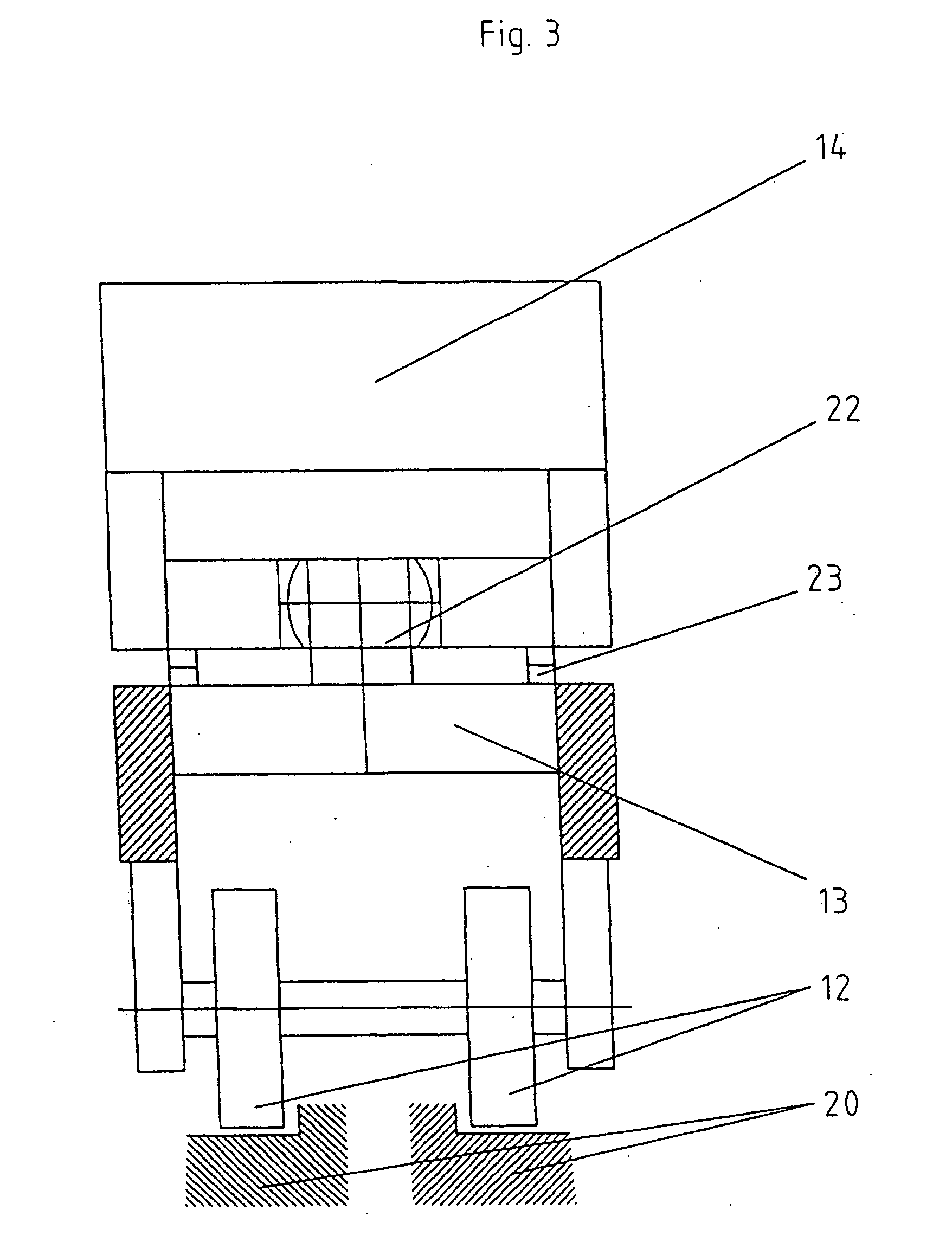

A conveyor grate for the transport and cooling of bulk material, for example cement clinker, comprises a grate floor having multiple planks (12), adjacently situated transverse to the direction of transport on associated support structures and operationally moved longitudinally relative to one another individually or in groups, with moving gaps (14) designed as blow openings situated therebetween, and a method for operating such a conveyor grate. The mutually facing side edges or side edge regions of two adjacent planks (12) form two complementary, mutually engaging profiles between which the moving gap (14) is formed. In the method according to the invention, at least a quantity of the cooling air is blown through the moving gaps (14) which is sufficient to blow the moving gaps (14) completely open.

Owner:VON WEDEL +1

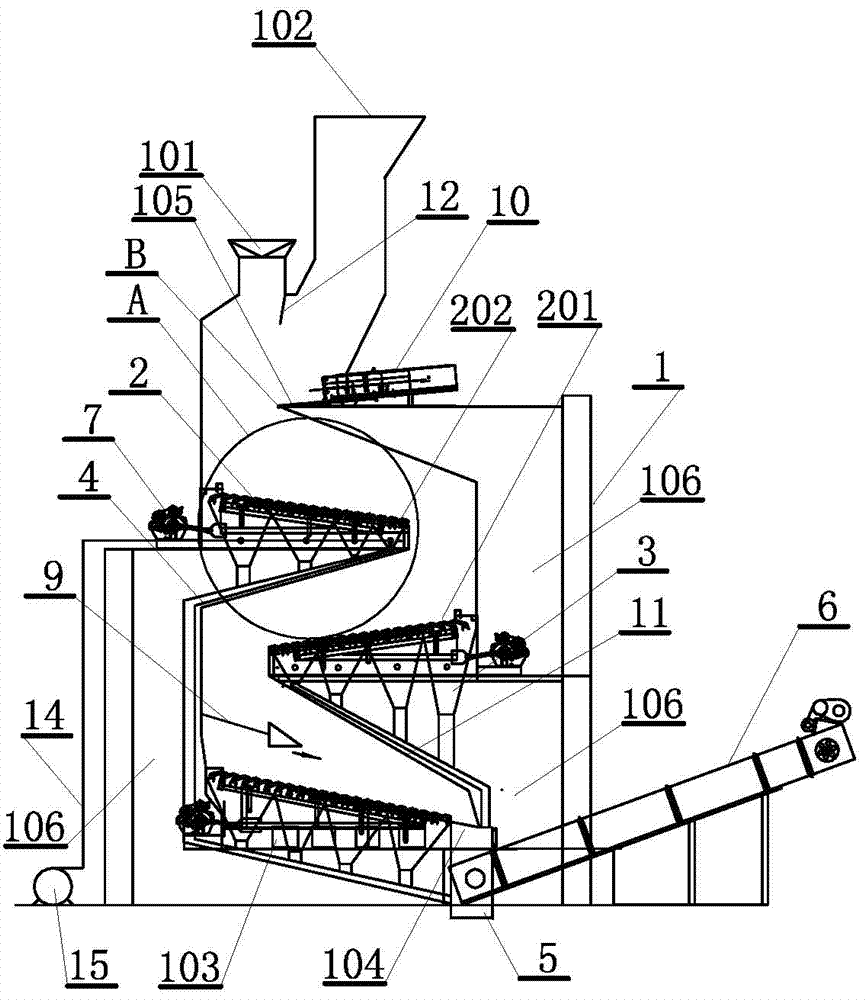

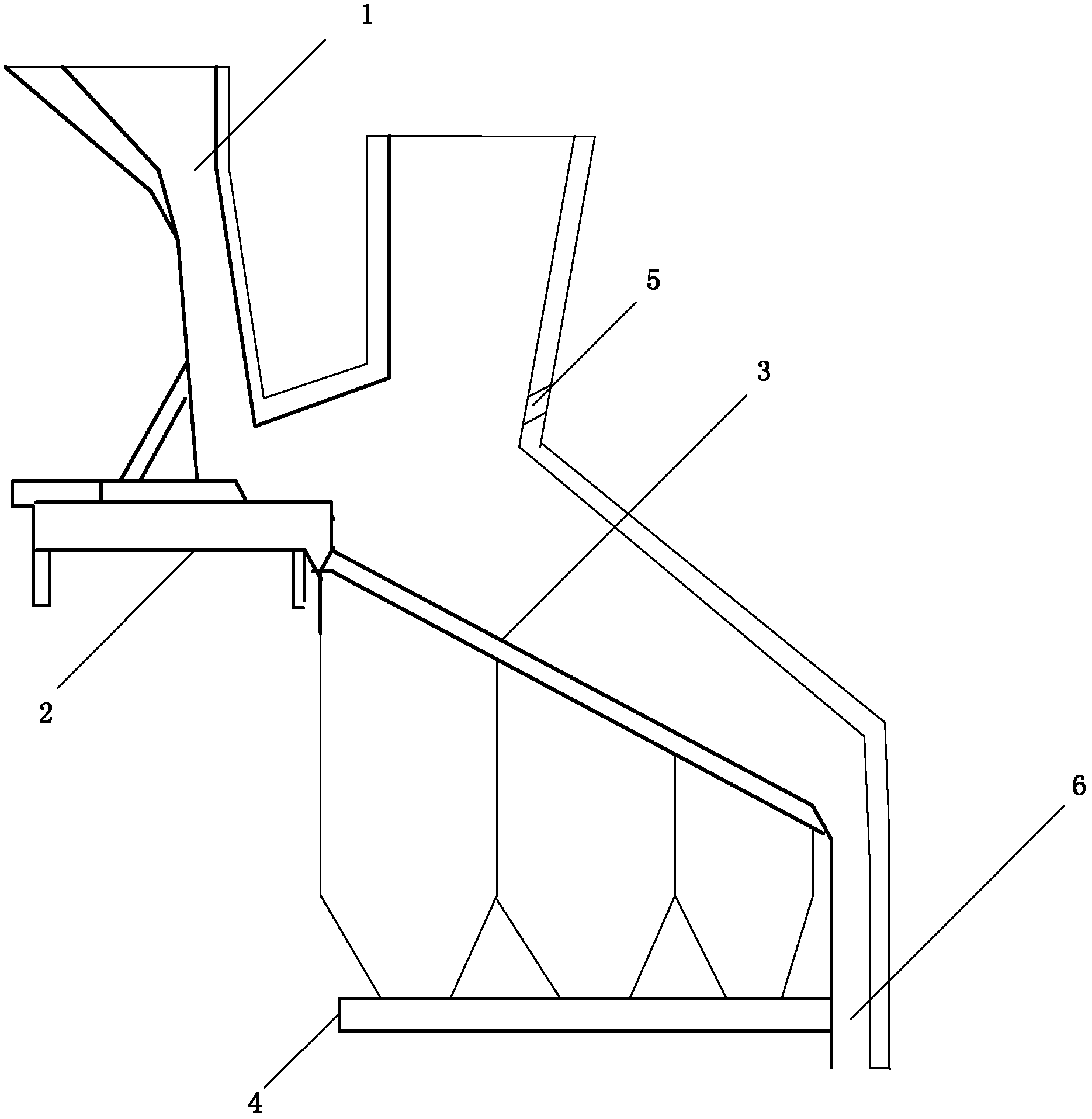

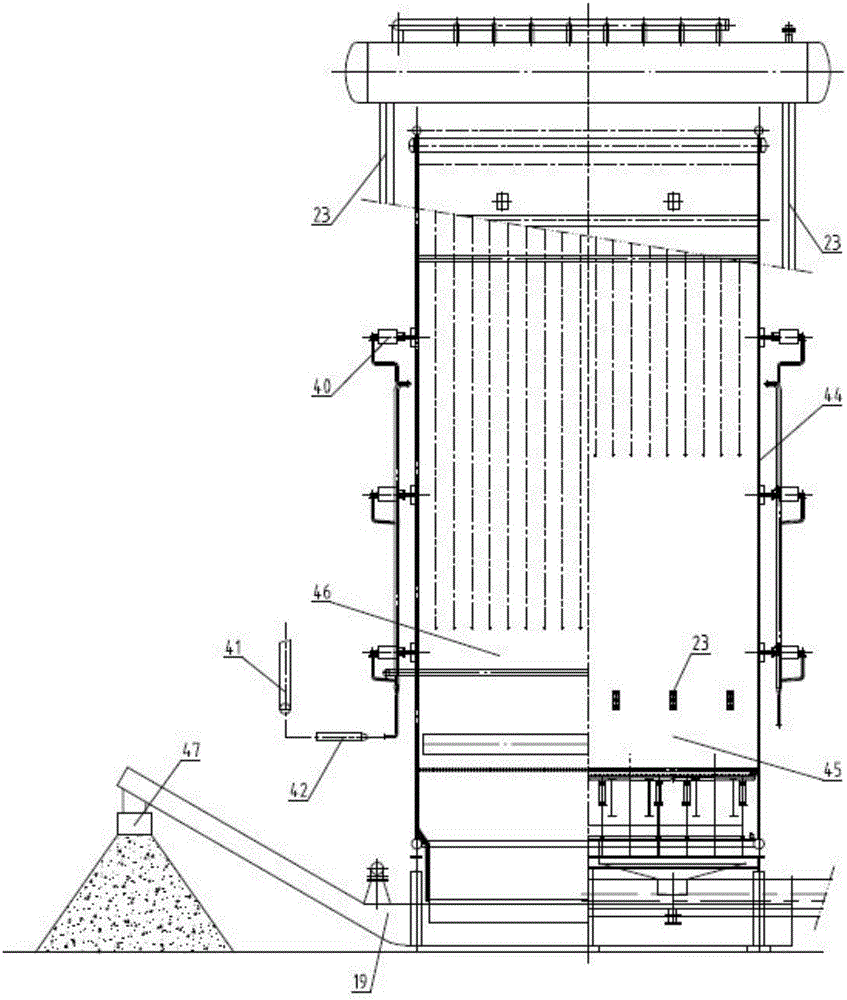

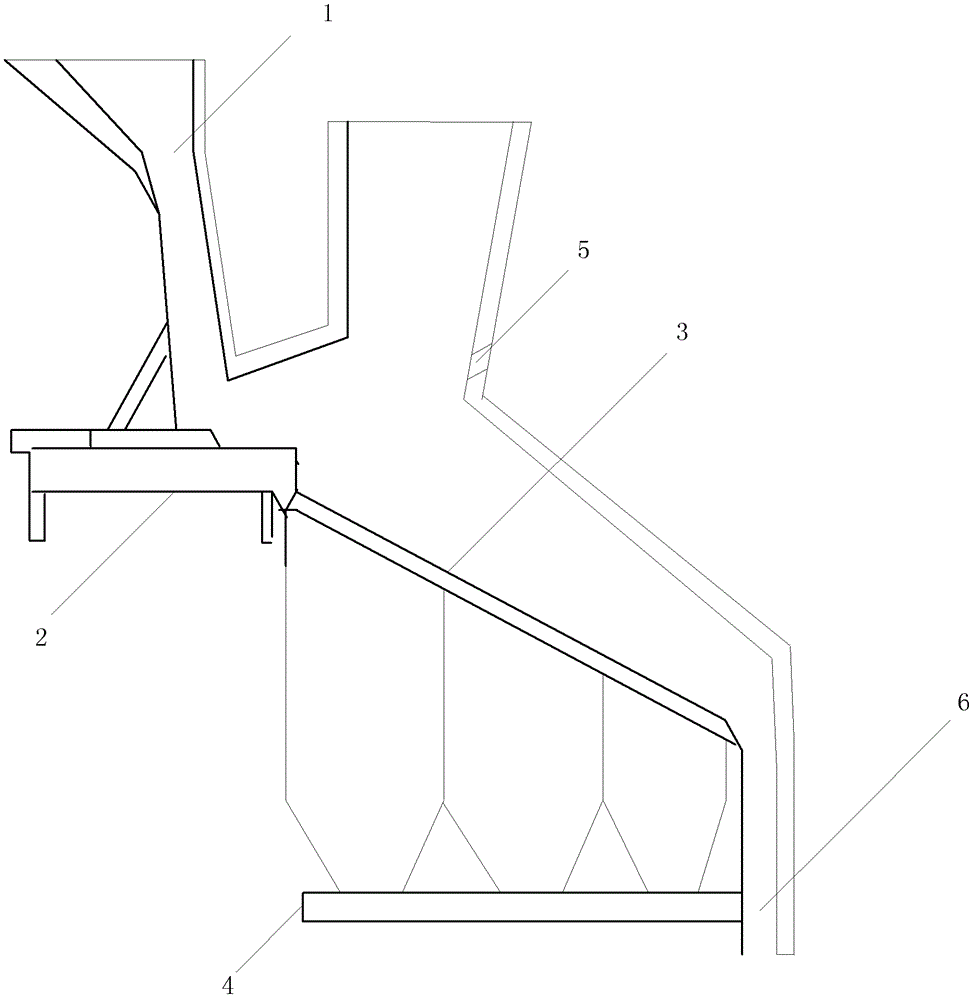

Multi-layer reciprocating type gasified combustion furnace

PendingCN107131503ASmall sizeLarge amount of disposalInclined grateIncinerator apparatusCombustionSlag

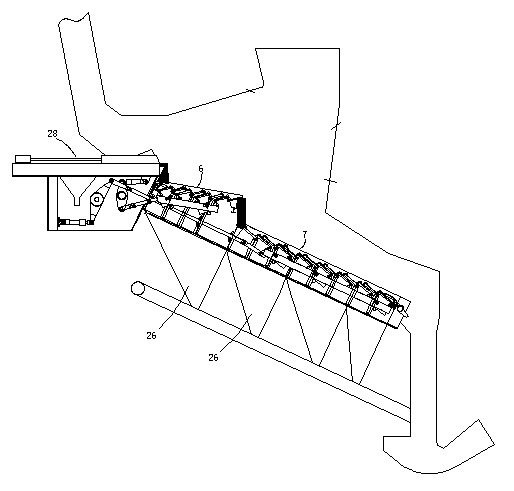

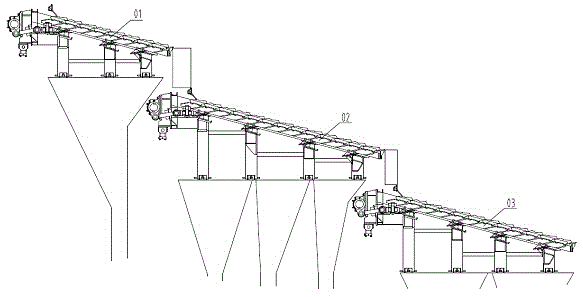

The invention discloses a multi-layer reciprocating type gasified combustion furnace comprising a combustion furnace body. A gasified fume discharging outlet and a gasified raw material garbage feeding inlet are formed in the upper end of the combustion furnace body, and a combustion gas inlet and a slag tapping outlet after combustion of gasified raw material garbage are formed in the lower end side of the combustion furnace body; a hearth in the furnace body is vertically provided with multiple layers of furnace rows from top to bottom; each layer of furnace row is arranged in a downward-inclining mode; the high end sides of the furnace rows at the lower layers stretch out of the low end sides of the furnace rows at the upper layers to enable the gasified raw material garbage on the furnace rows at the upper layers to fall into the high end sides of the furnace rows at the lower layers from the low end sides of the upper layers along the inclining gradient; and dust receiving funnels are arranged on the bottom face of the furnace row at each layer and connected with a dust discharging pipeline to output dust from the bottom side of the combustion furnace body. Because the garbage is fully dried and dehydrated through the multiple layers of furnace rows in the hearth, the heat value is increased, the combustion effect is more full, the structure is simple, the size of the combustion furnace is decreased greatly, investment is reduced, thermal decomposition gasified combustion of the furnace row at each layer can be achieved, and the application range of raw materials is wide.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

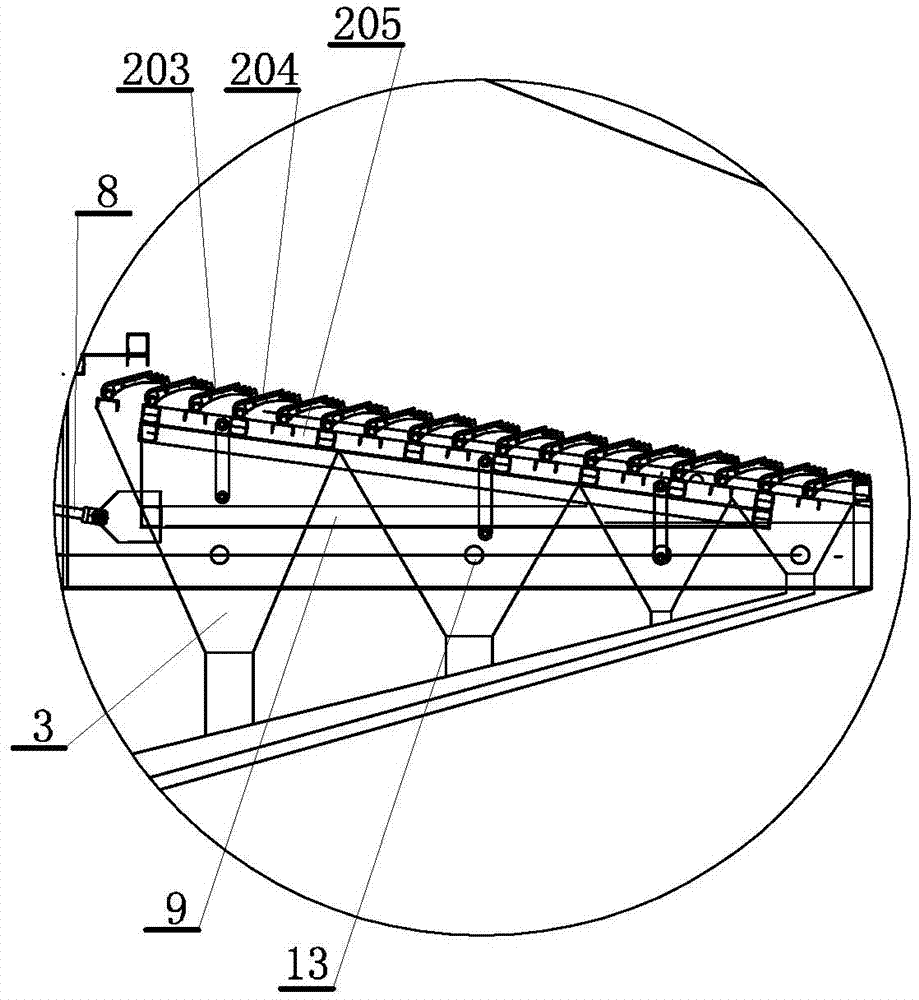

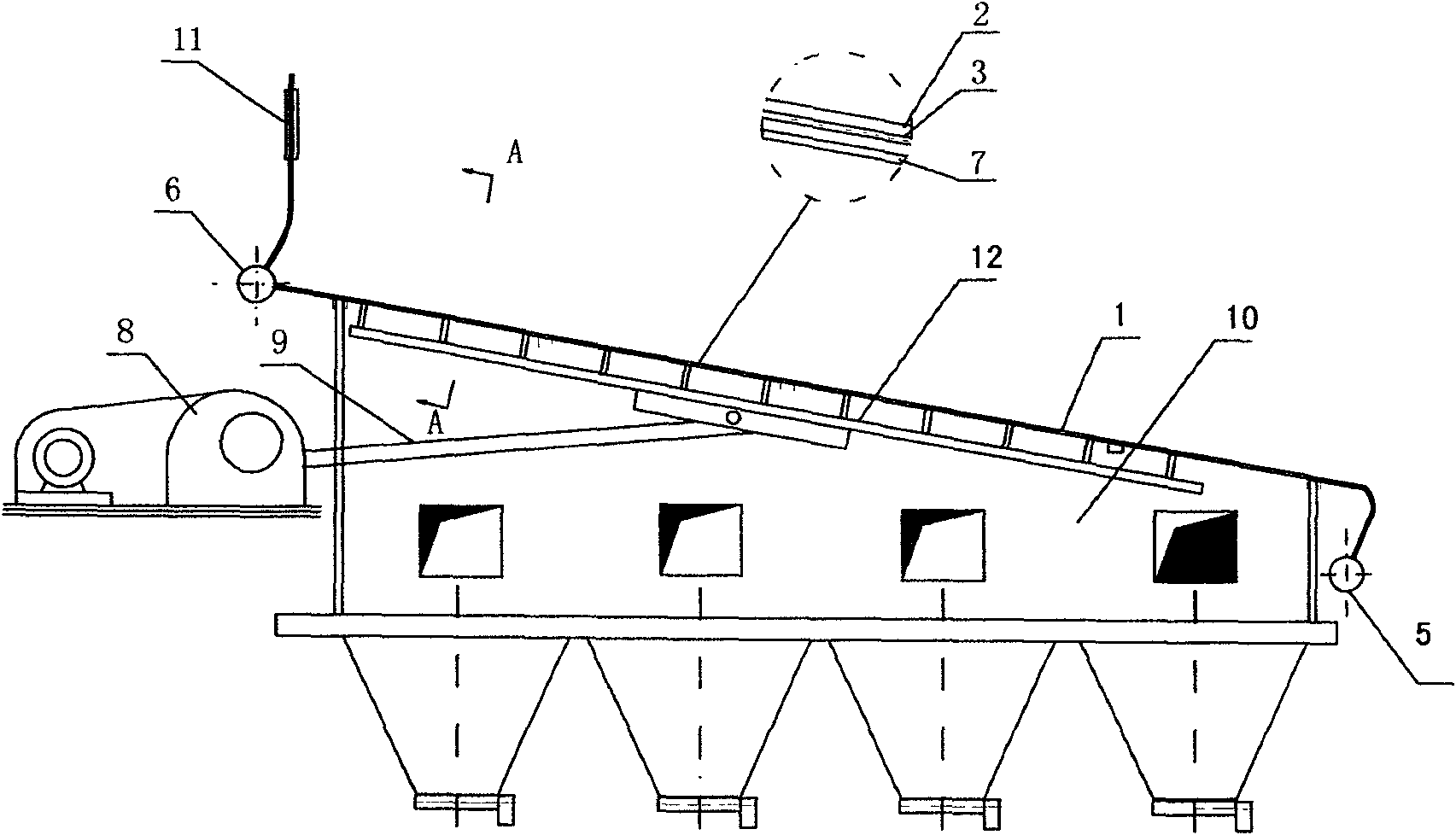

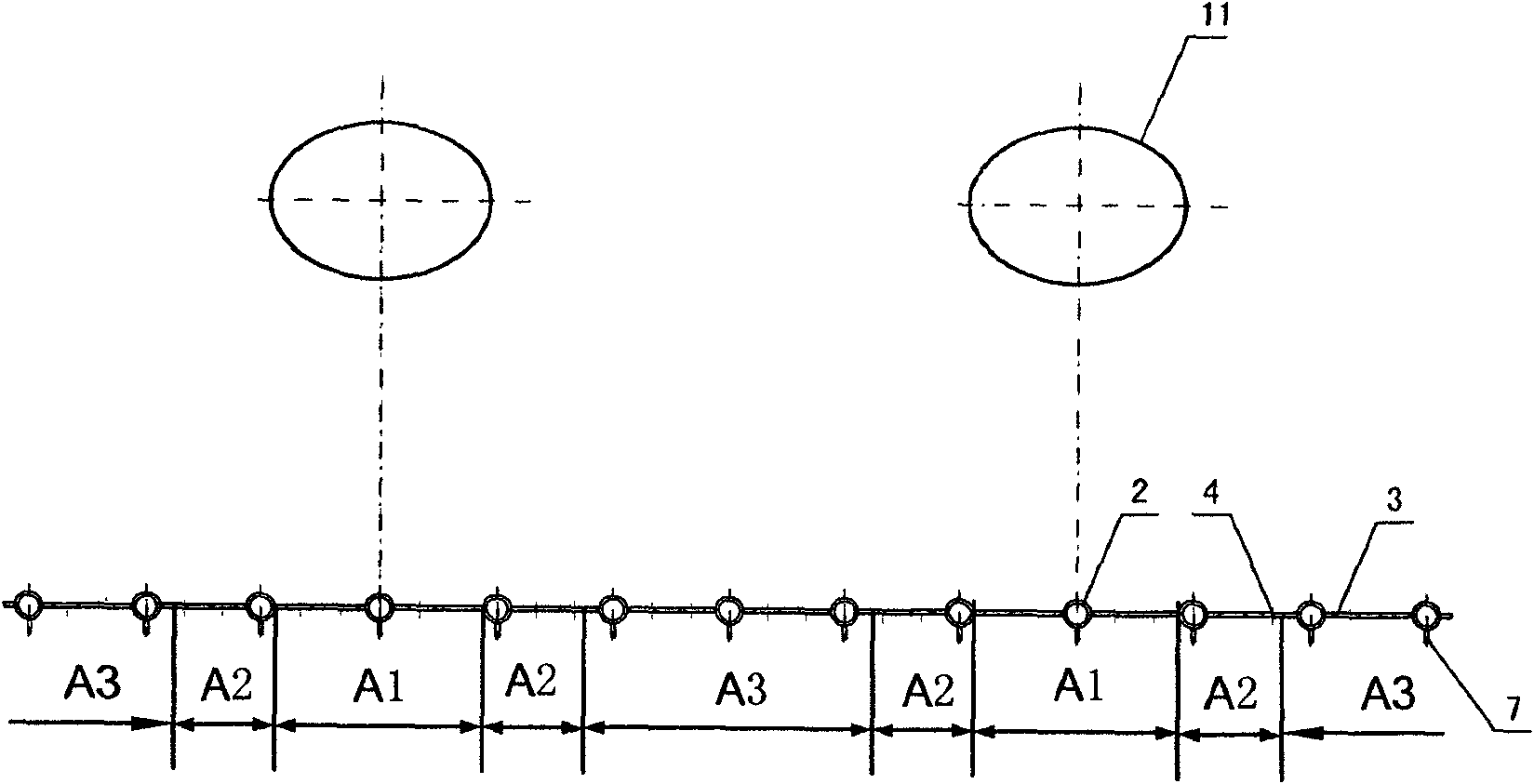

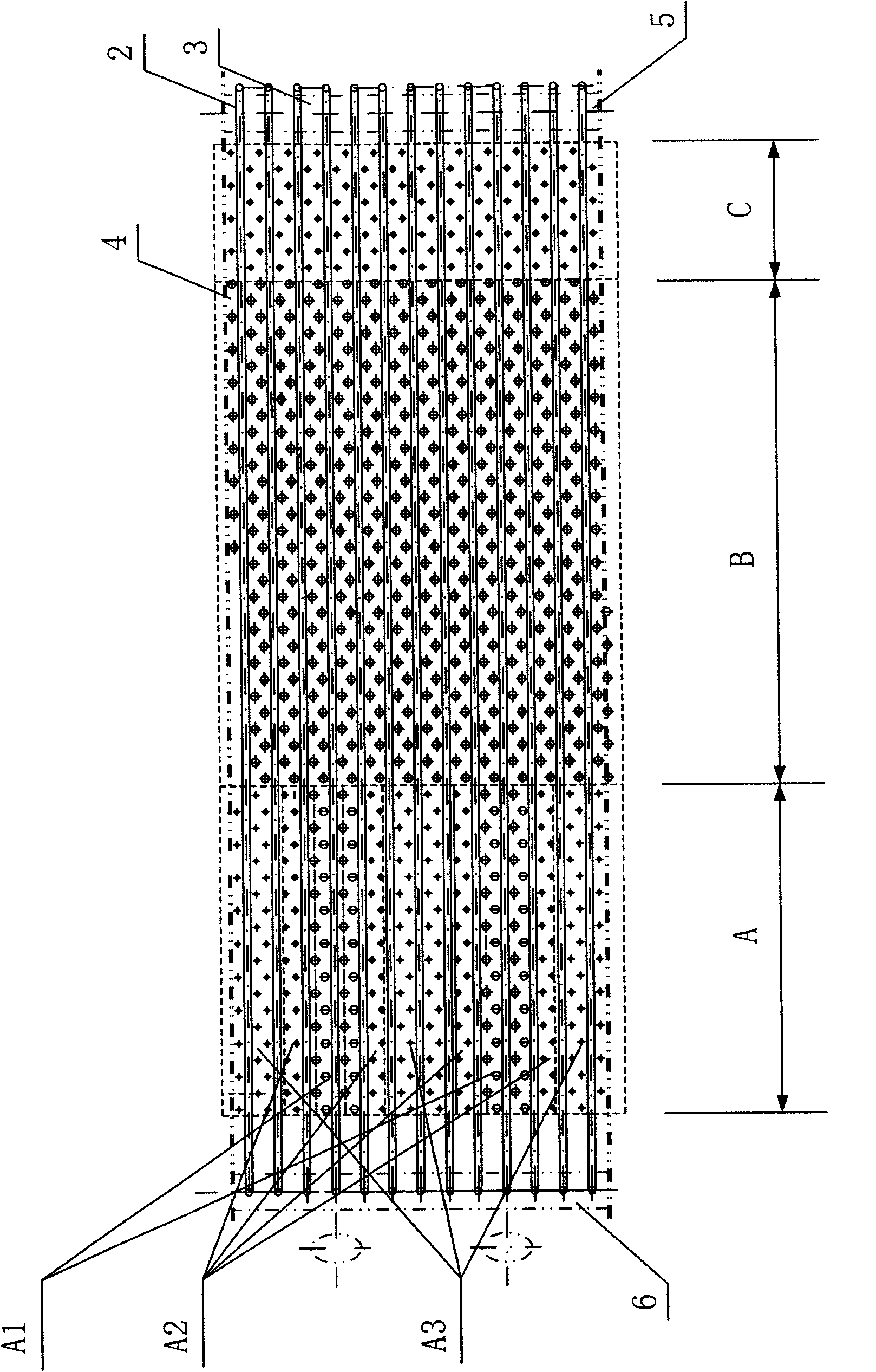

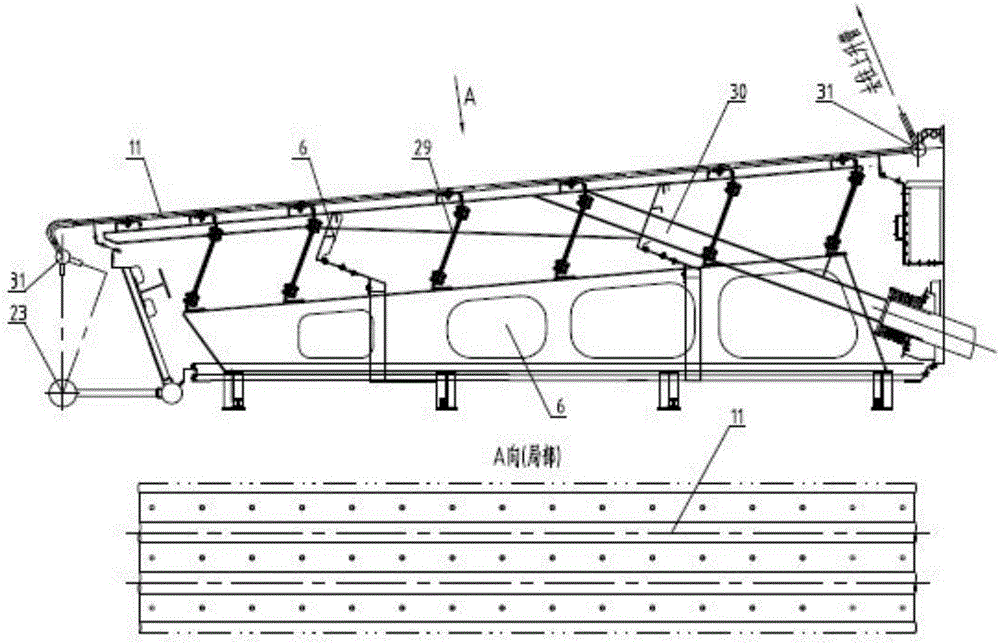

Bidirectional non-uniform matching air distributing water-cooled vibration grate of biomass direct-combustion boiler

InactiveCN101625126ASimple structureWide adaptabilityHollow bar grateRevolving grateDirect combustionEngineering

The invention relates to a bidirectional non-uniform matching air distributing water-cooled vibration grate of a biomass direct-combustion boiler, comprising a grate (1) formed by arranging a plurality of inclined water-cooled pipes (2) in parallel at predetermined intervals, wherein the grate (1) is fixed on a support frame (12); an air chamber (10) is arranged below the support frame (12); a discharge hole (13) is arranged below the air chamber (10); the water-cooled pipes (2) are connected with each other by a membrane (3) which is provided with an air inlet hole (4); an inlet end of the water-cooled pipe (2) is connected with an inlet collection tank (5); an outlet end of the water-cooled pipe (2) is connected with an inlet collection tank (6); and a driving device (8) is connected with the support frame (12) at the lower part of the grate (1) through a connecting rod (9) to provide vibration for the grate (1). A drying initial combustion zone, a primary combustion zone and an after-combustion zone are divided in the moving direction of biomass with different aperture ratios for each zone. In addition, the drying initial combustion zone is divided into three sub-zones according to the feeding amount of biomass with larger aperture ratio closer to the sub-zone of a feeding inlet.

Owner:SOUTHEAST UNIV

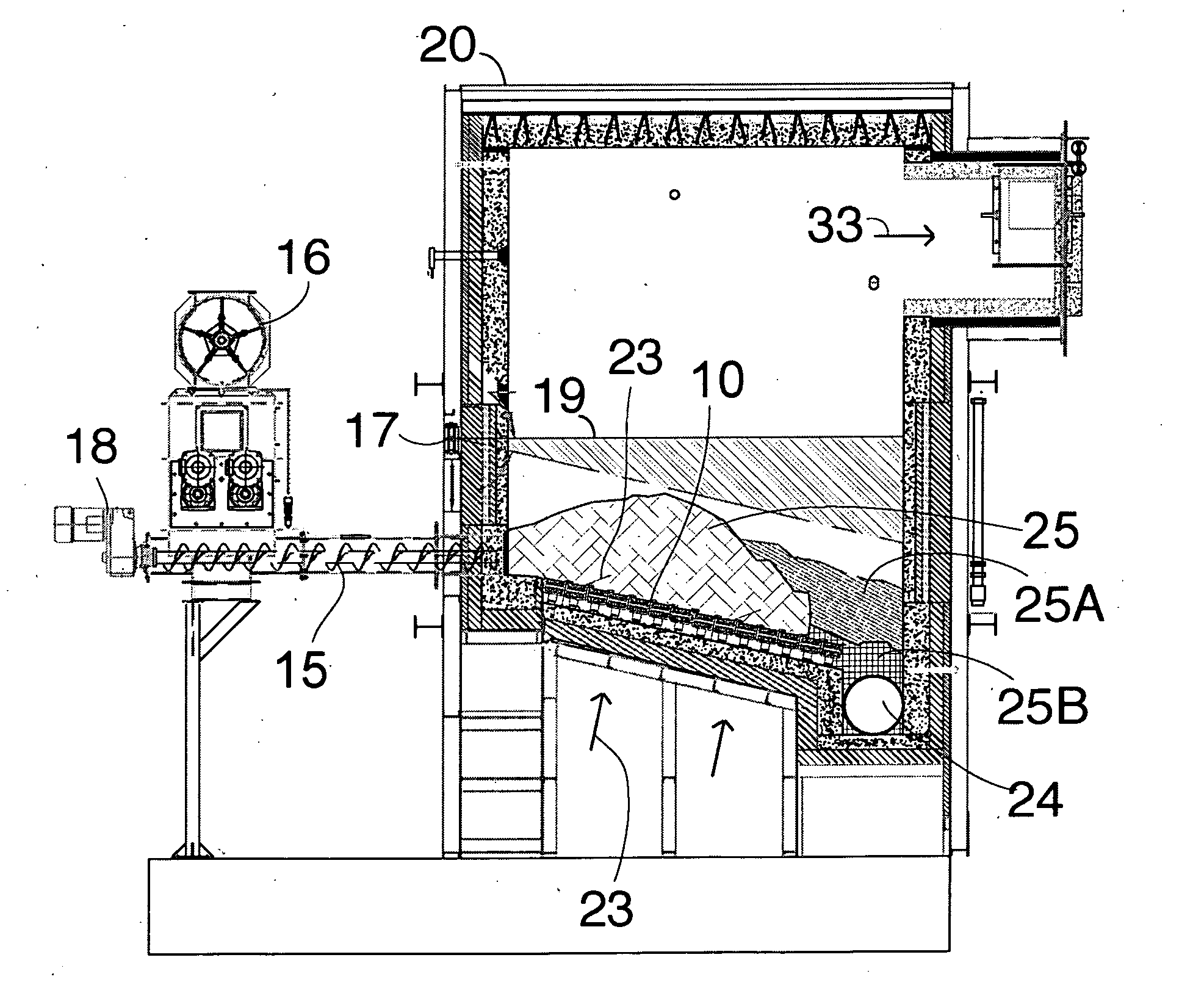

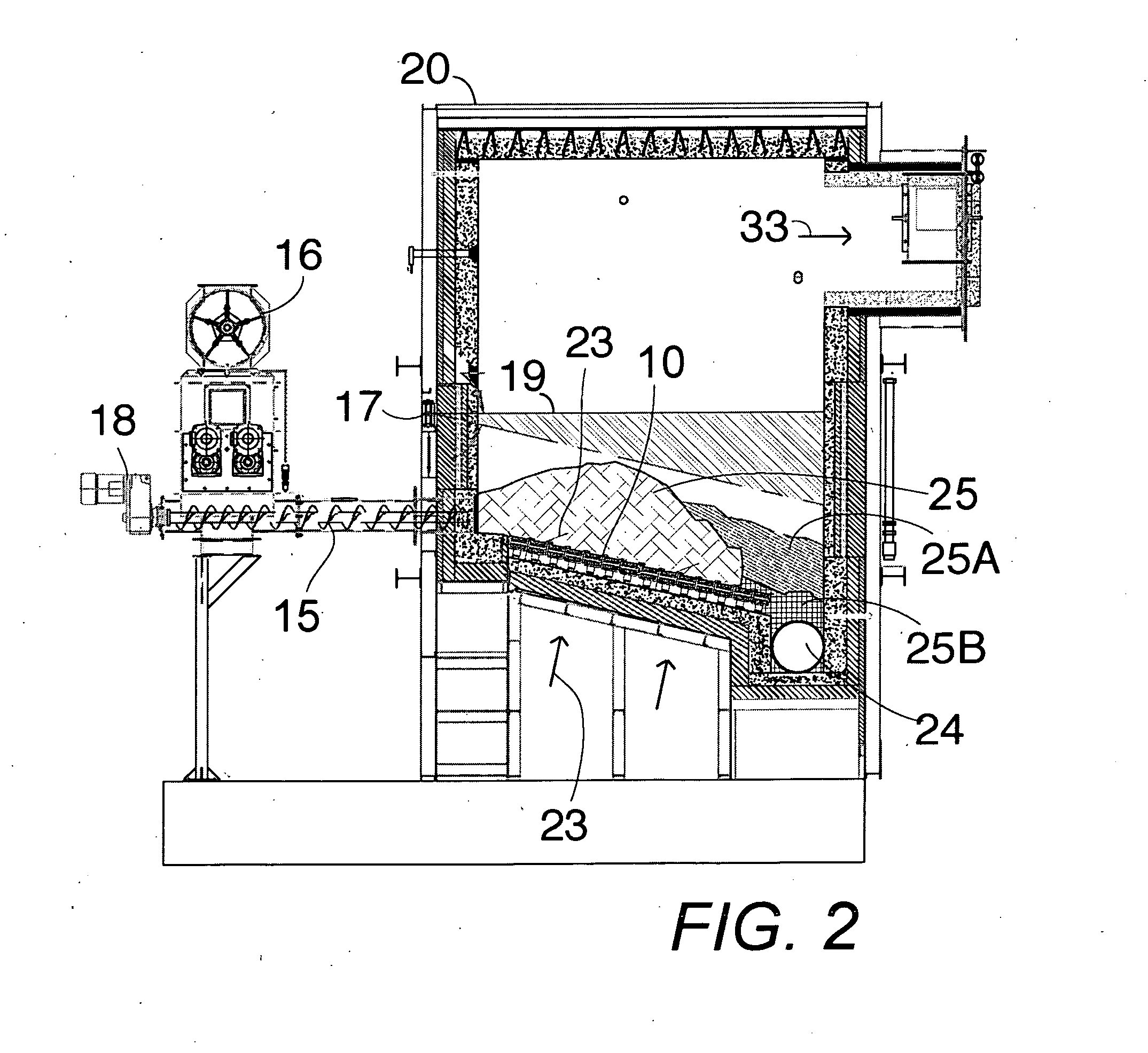

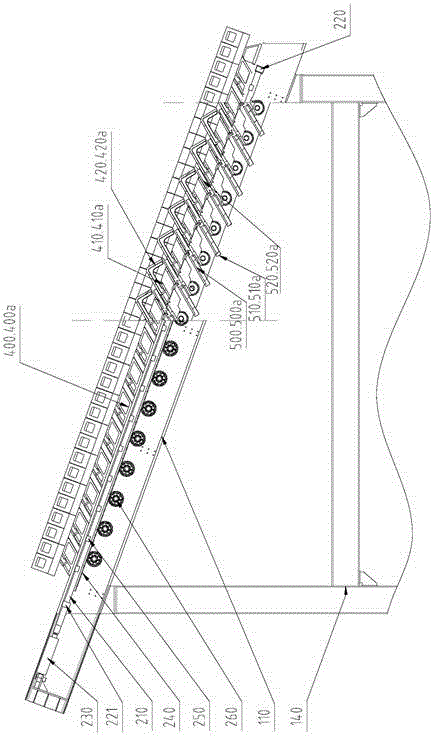

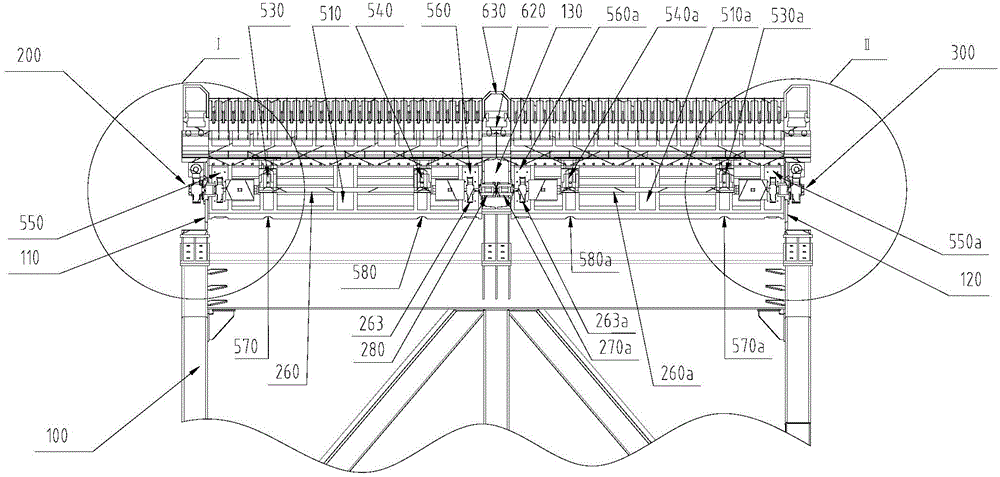

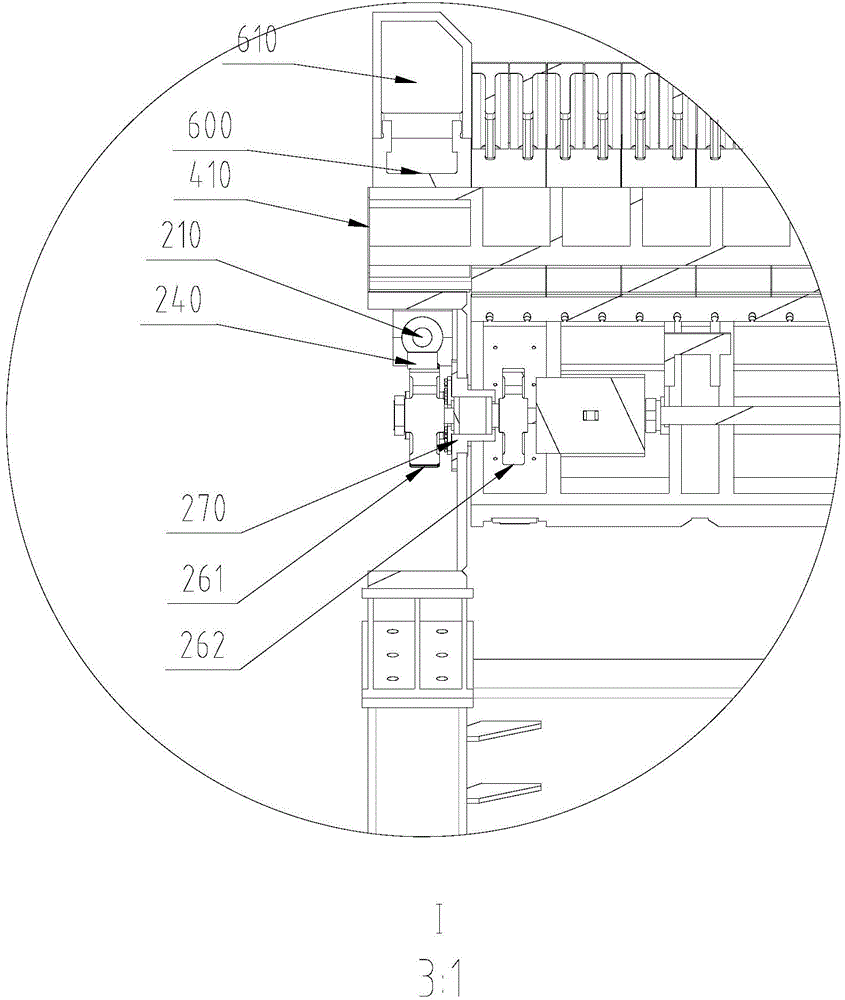

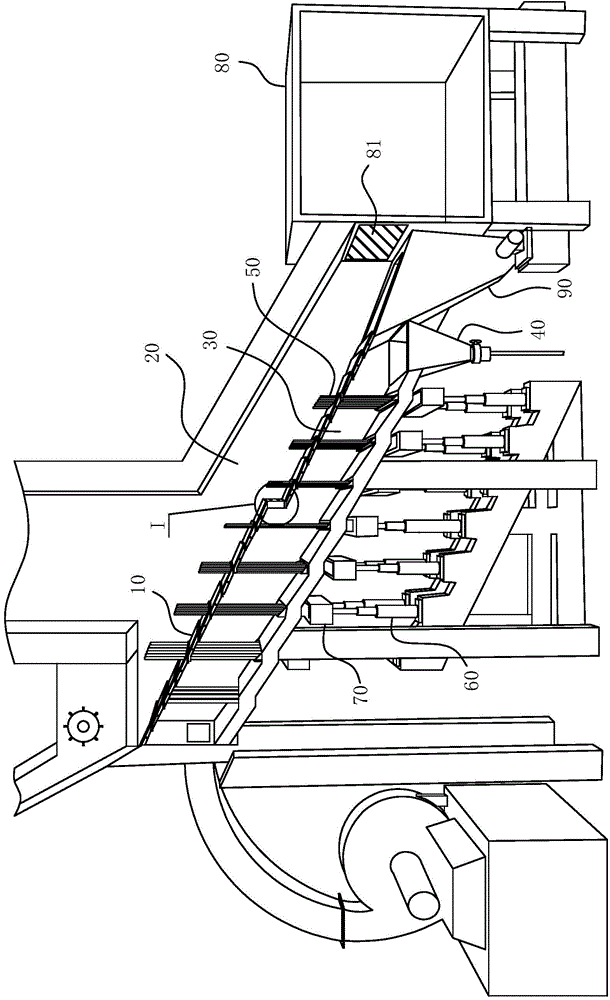

Multistage hydraulic mechanical garbage incinerator and control method for same

ActiveCN102607037AImprove combustionImprove burnout rateHollow bar grateInclined grateHydraulic machinerySteel frame

The invention provides a multistage hydraulic mechanical garbage incinerator and a control method for the same. The multistage hydraulic mechanical garbage incinerator comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally and longitudinally divided into a drying section, a burning section and a burnout section by the five units. The multistage hydraulic mechanical garbage incinerator is characterized in that the fire grate segments in each row of the incinerating fire grate are transversely driven by a shaft and transversely supported by a steel frame at three positions at the least. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +1

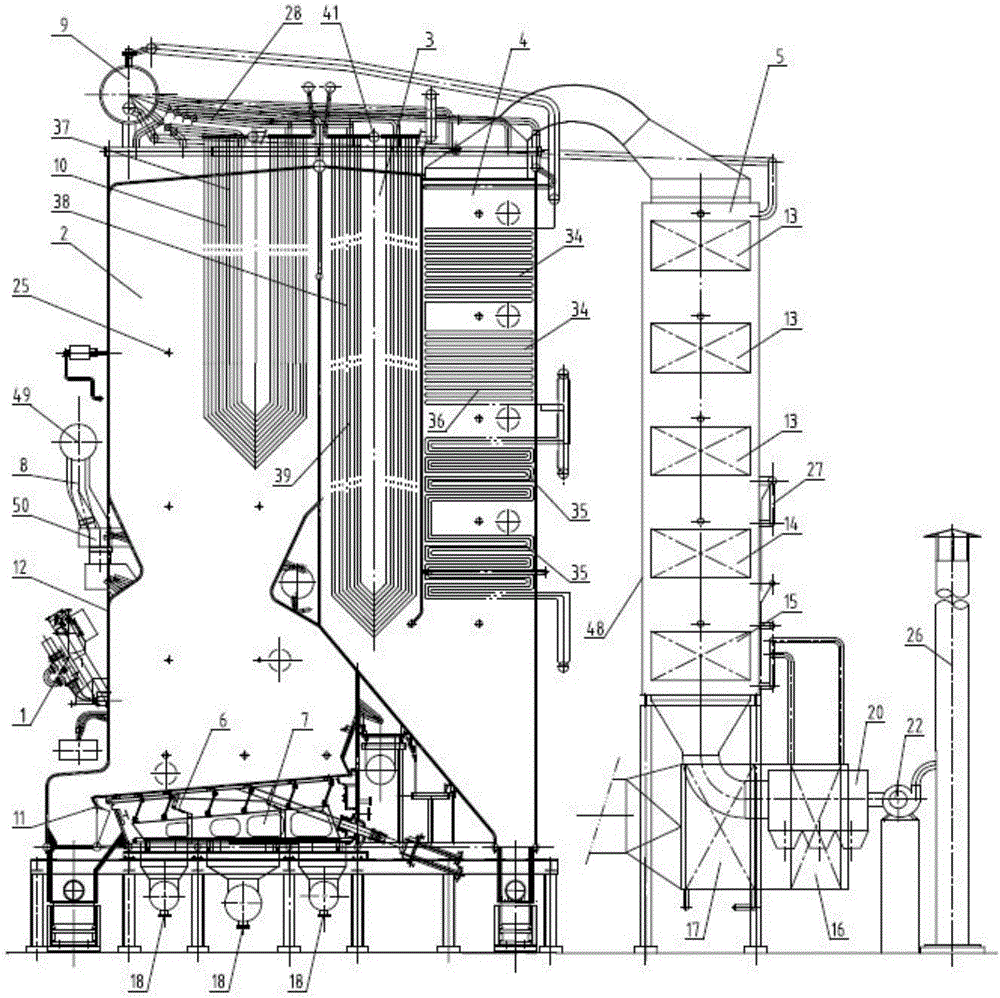

Biomass direct-fired boiler

InactiveCN106594698AIncrease the itineraryHigh thermal efficiencyInclined grateSteam superheatersCombustion chamberFlue gas

The invention discloses a biomass direct-fired boiler. The biomass direct-fired boiler comprises a boiler body, a feeding system, a discharging system, an out-boiler gas flue, a primary air inlet chamber, a secondary air inlet pipe and a distribution device; a combustion chamber which is formed by membrane type water cooling walls and a multi-return stroke gas flue are arranged in the boiler body; a water cooling vibrating fire grate is arranged at the bottom of the combustion chamber; a steam super-heater is arranged in the multi-return stroke gas flue; the feeding system is communicated with the front wall of the boiler body, and is used for inputting a biomass fuel into the combustion chamber; the discharging system is arranged at the bottoms of the multi-return stroke gas flue and the water cooling vibrating fire grate, and is used for outputting burnout things of the biomass fuel out of the boiler; the out-boiler gas flue is communicated with the top of a tail return stroke gas flue; a coal economizer, a secondary air pre-heater and a primary air pre-heater are arranged in the out-boiler gas flue in sequence in a flue gas flowing direction, and are used for preheating fed water and air and feeding the preheated water and air into the boiler; the primary air inlet chamber is arranged below the water cooling vibrating fire grate; the secondary air inlet pipe and the distribution device are arranged on the side wall of the combustion chamber. According to the biomass direct-fired boiler, the biomass fuel adaptability is wide; the combustion and energy resource conversion efficiency is high; the boiler operates safely and stably; high-efficiency utilization of biomass energy resources is realized.

Owner:JIANGSU DONGJIU HEAVY IND

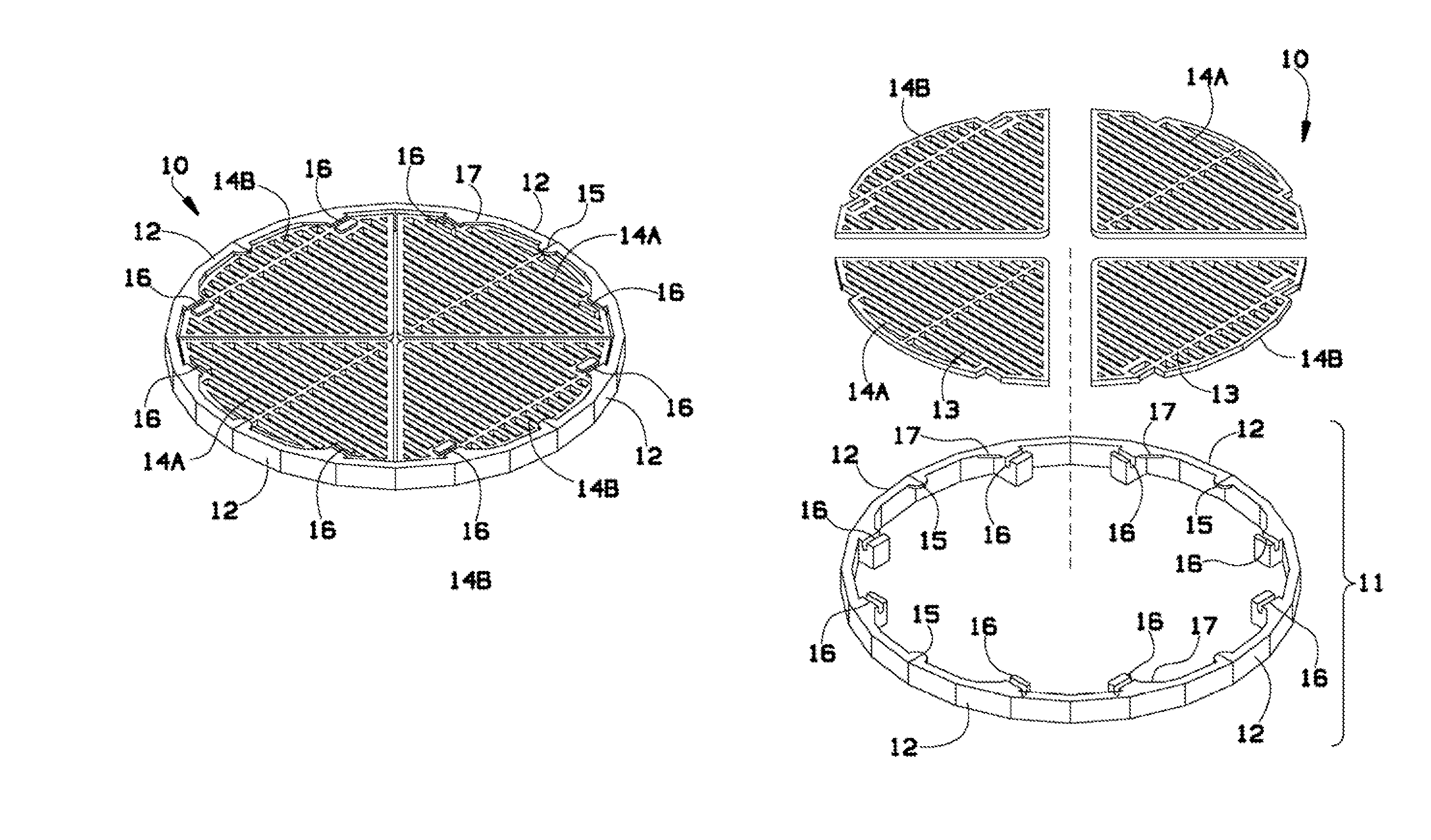

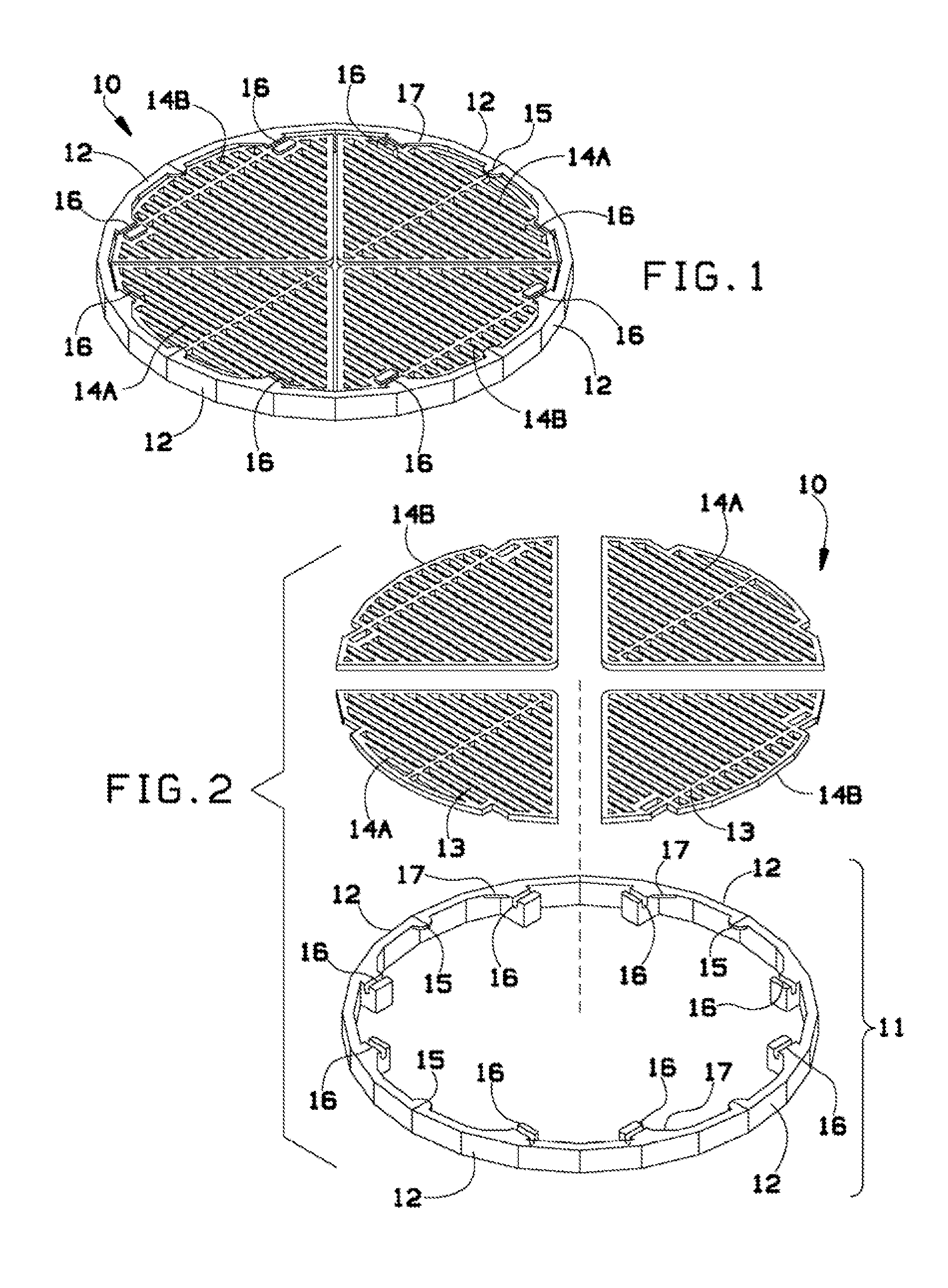

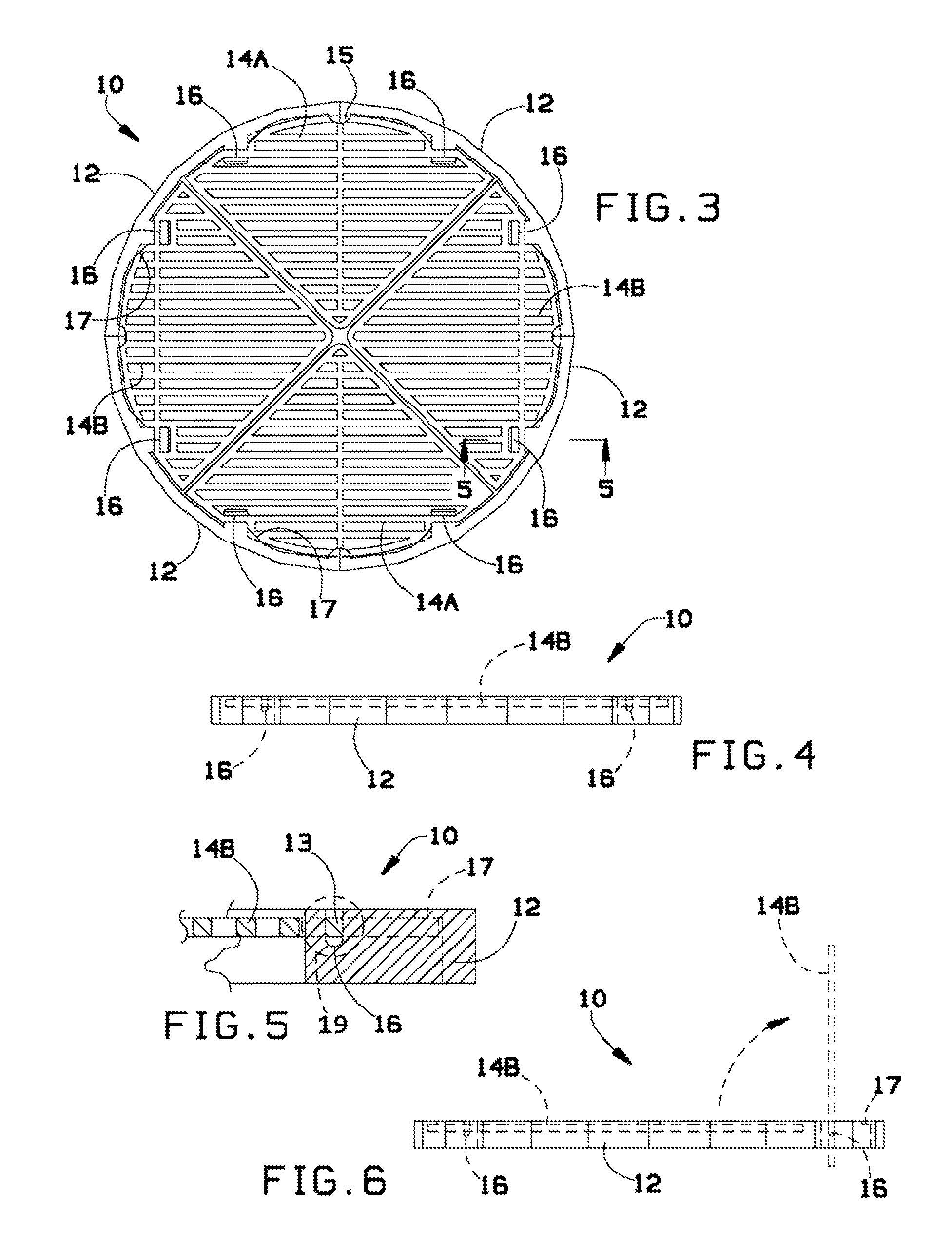

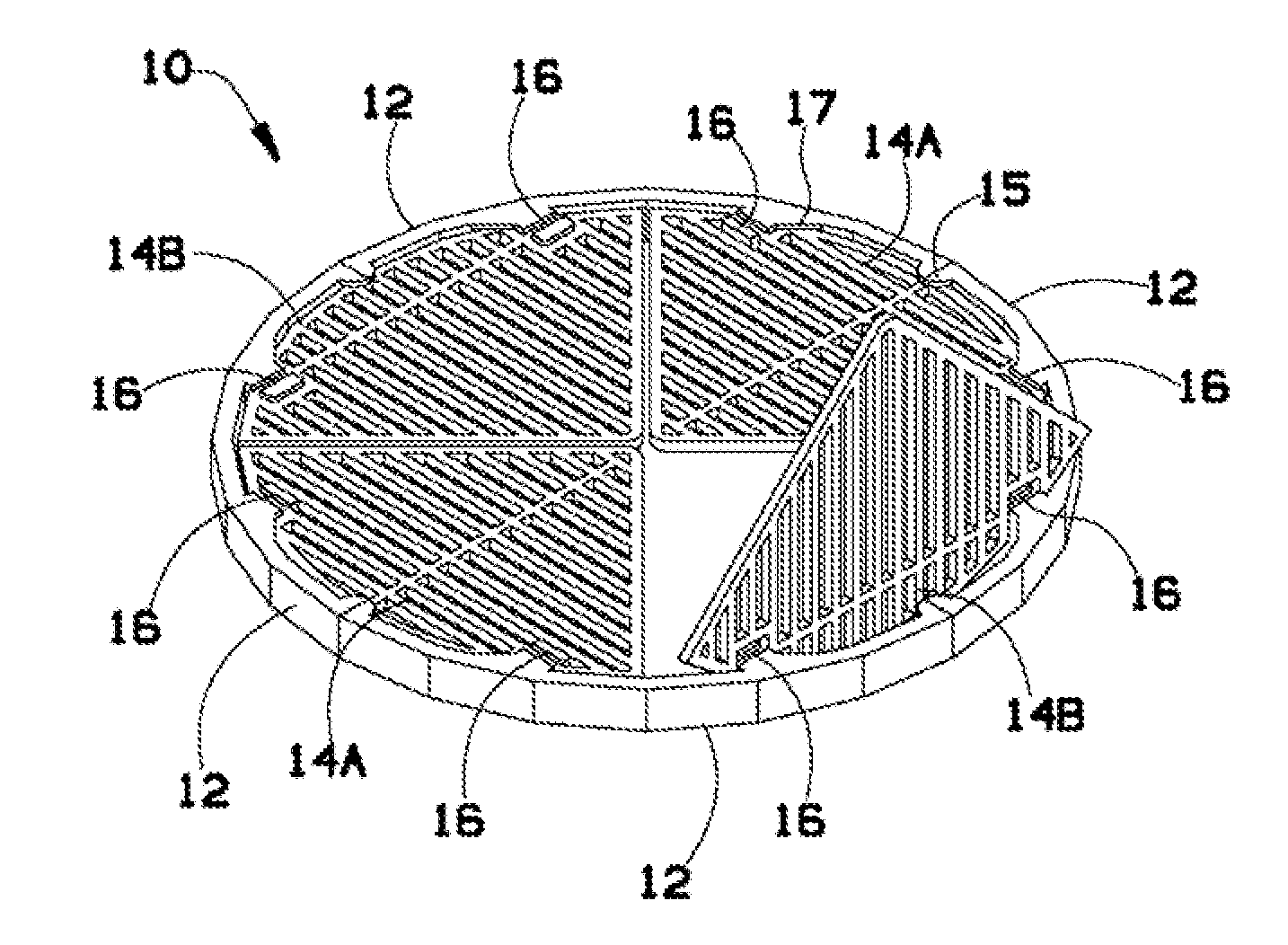

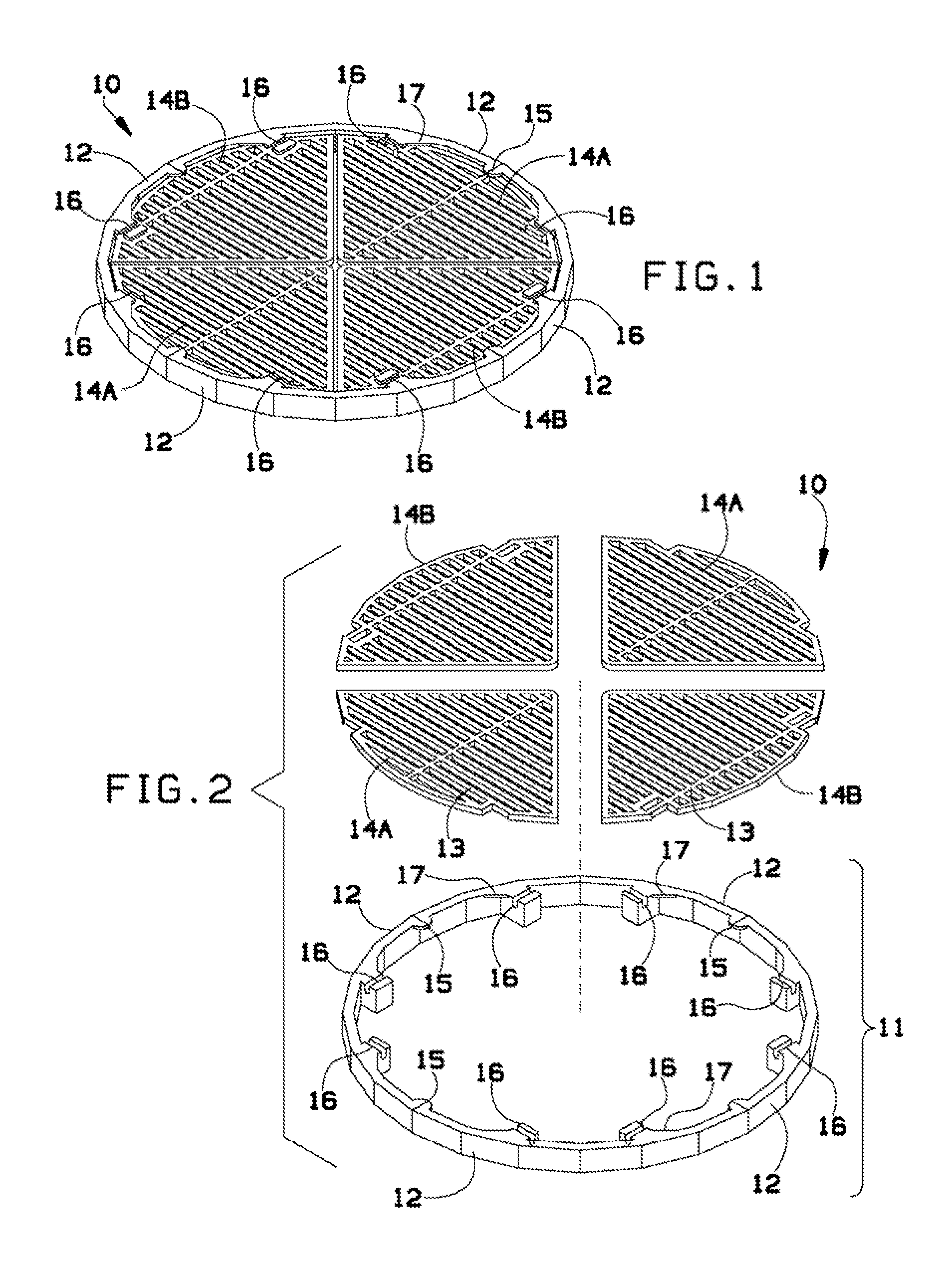

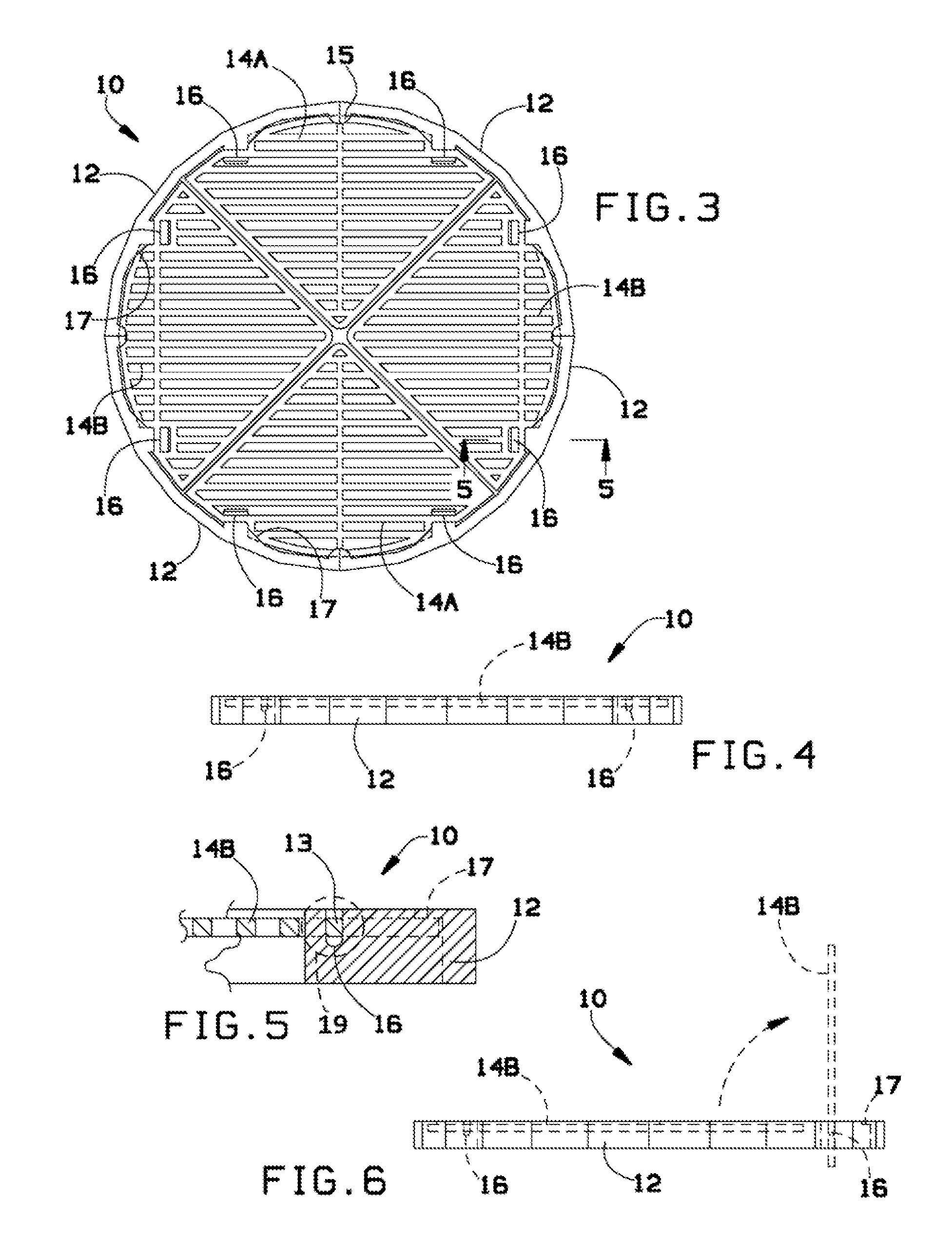

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

Process for incinerating solids on a water-cooled thrust combustion grate, and a grate plate and grate for accomplishing the process

A process wherein primary air supplied to the combustion bed through the thrust combustion grate is deflected after exiting from a surface of the thrust combustion grate by deflector elements mounted on the surface of the thrust combustion grate. The grate required for this purpose has grate plates made from a permeable hollow element with connection pieces for supplying and draining cooling water, with primary air supply ducts that run through the grate plate from a bottom to a top. Deflector elements against which the primary air exiting the outlet is intended to impact, are disposed over openings of the primary air supply ducts.

Owner:DOIKOS INVESTIMENTS LTD

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

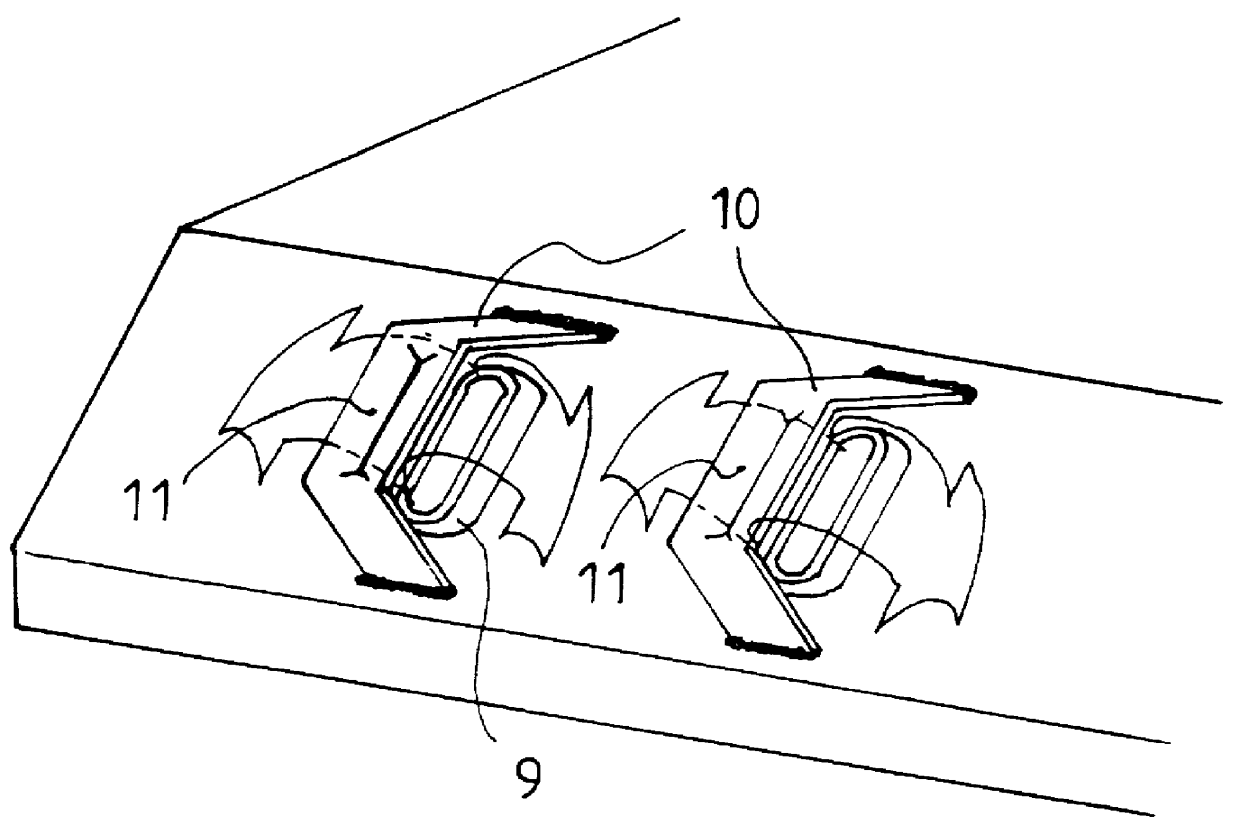

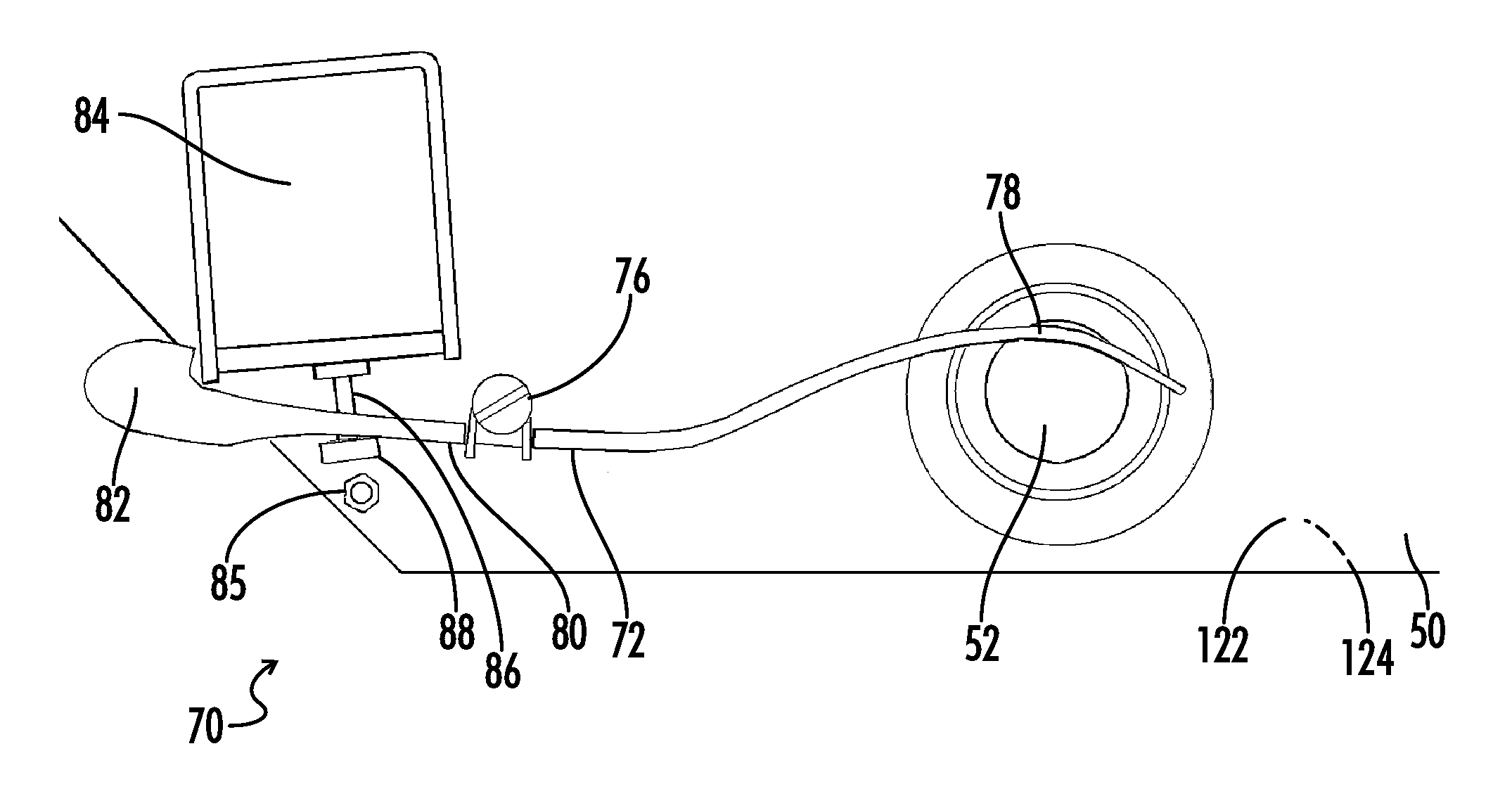

Grating system and sidewall seal arrangement for oscillating grate stoker

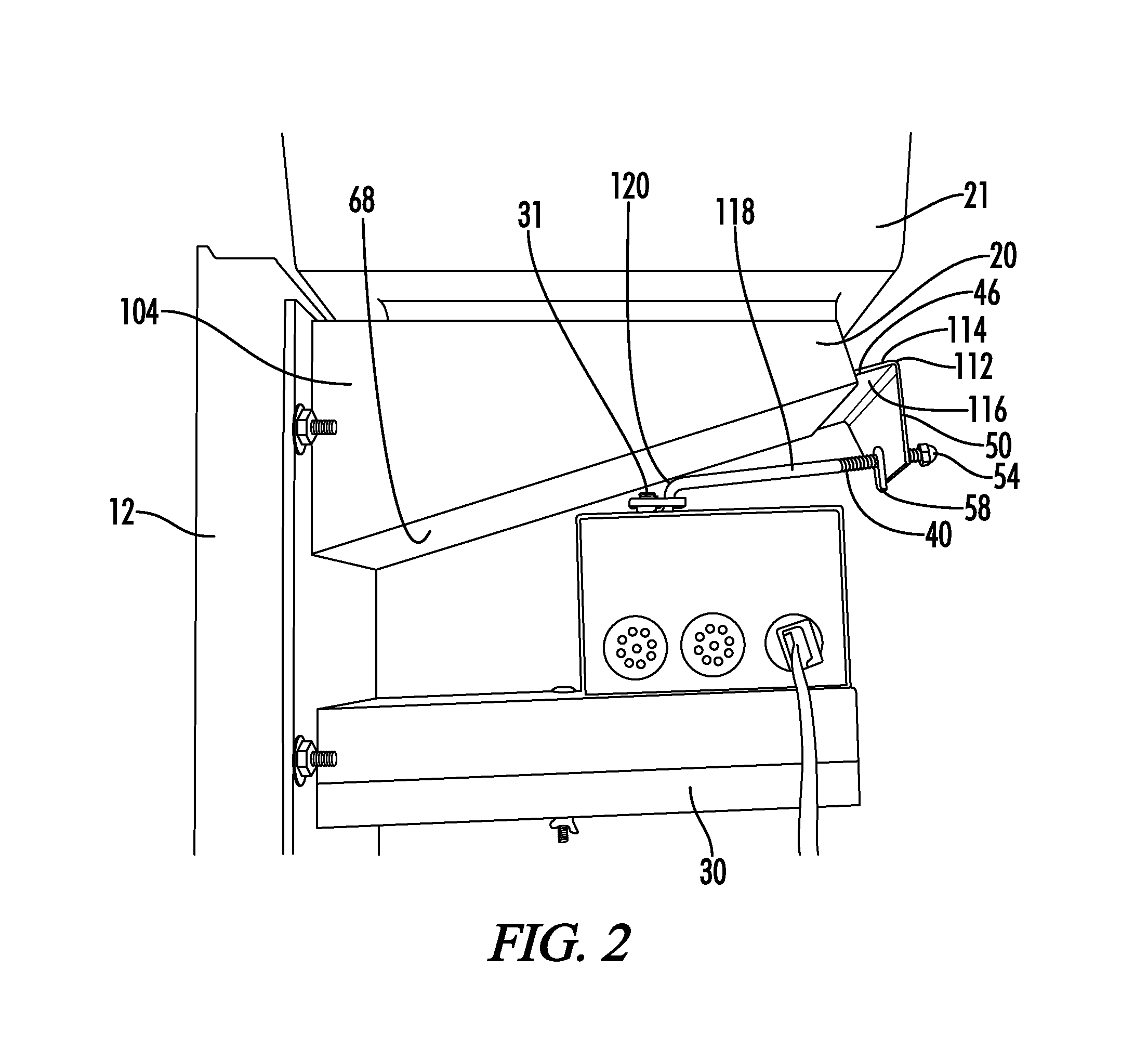

InactiveUS20080276843A1Obstruct passageGood vibration isolationSievingSolid bar grateGratingCombustion

The invention includes a grate system for a boiler. The grate system includes a grate unit and a side header guard. The grate unit supports fuel during combustion thereof, and has an upper surface, a lower surface, and upturned lateral edges. The side header guard is arranged along a side wall of the boiler and has upwardly and downwardly projecting fin portions. The upwardly projecting fin portion is adapted and configured to extend over and protect the boiler side wall from abrasion by fuel. The downwardly projecting fin portion is adapted and configured to extend over the upturned lateral edge of the grate unit, inhibiting passage of fuel therebetween.

Owner:RILEY STOKER

Feed regulator for thermostatic control

InactiveUS8607719B1Speed up the flowIncrease volumeFuel supply regulationFuel feeding arrangementsEffective lengthControl arm

The effective length of a control arm having manually alterable stops repositionable along is rendered automatically changeable by means of a solenoid movable strip arranged to be either pressed against the control arm or removed from contact with the control arm by operation of the automatically operated solenoid which may usually be operated by a change in the surrounding ambient temperature.

Owner:KUZNI GEORGE

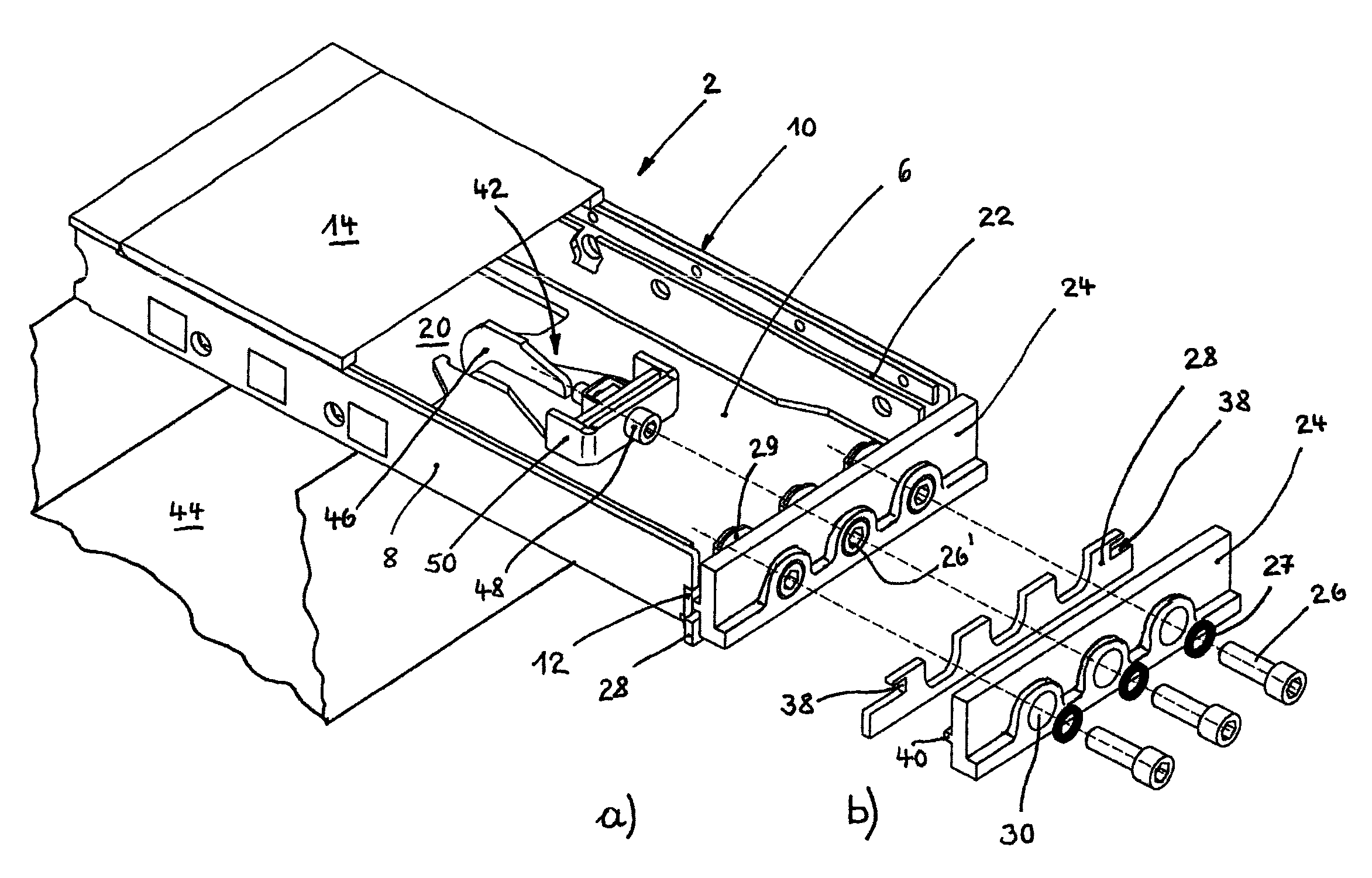

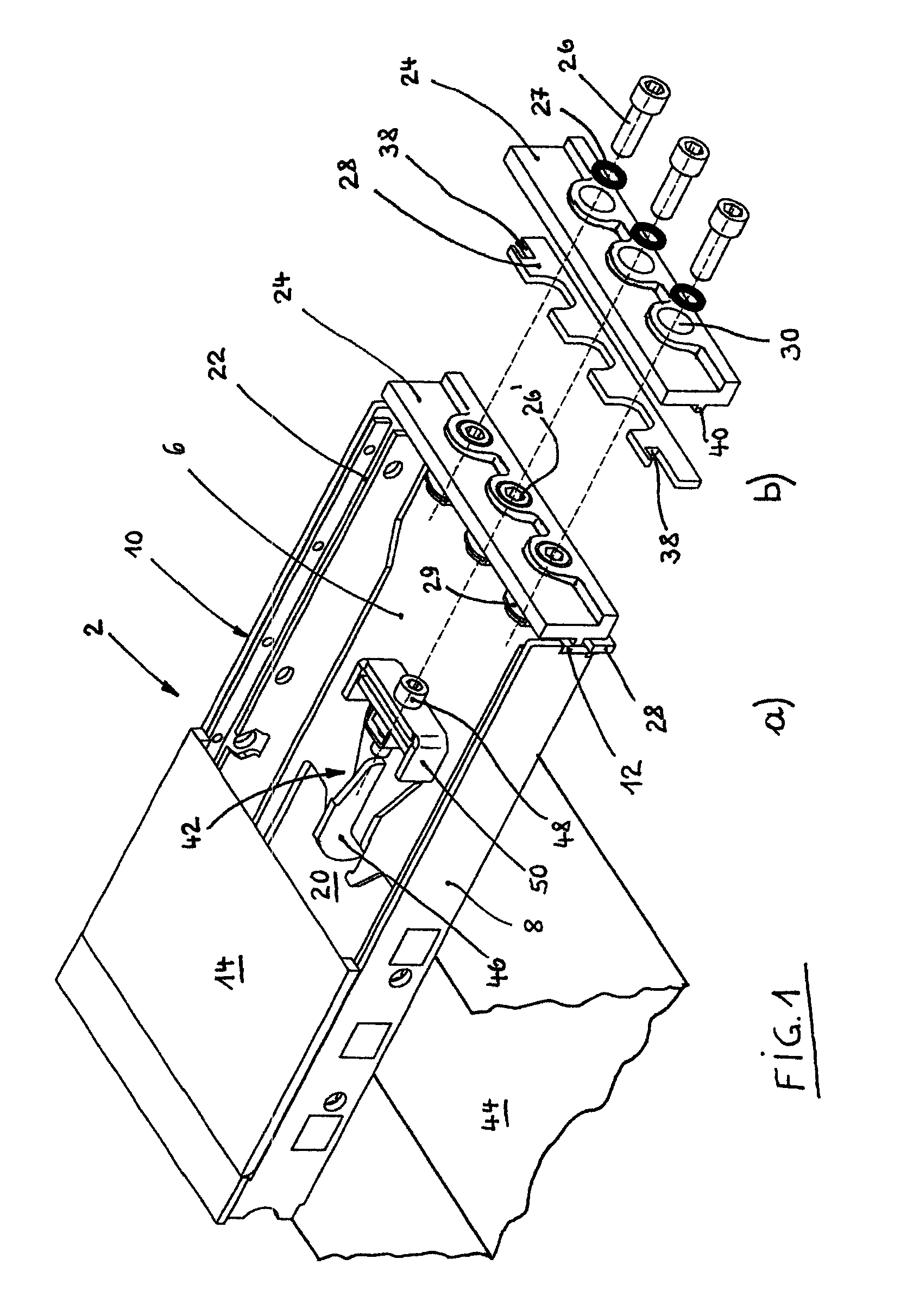

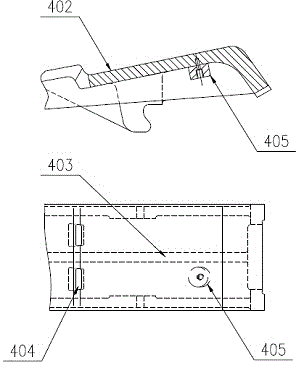

Plate for a sliding cooler grate

InactiveUS7021928B1Great riskLess vertical playInclined grateHandling discharged materialEngineeringBearing surface

Grate plate for the push-type grate of a clinker cooler, which has a topside bearing surface exposed to the hot material to be cooled. The grate plate including a rear region having devices for connection to a grate-plate carrier, such that the grate plate front projects over an adjacent grate plate. Longitudinally extending edge strips are connected in a force-transmitting manner to the devices for connection to the grate-plate carrier to support the plate front. The topside bearing surface is formed by a cover plate which is free of the edge strips, at least in front of the grate-plate carrier, and which has freedom of expansion in the horizontal direction in relation to the support part comprising the edge strips.

Owner:CLAUDIUS PETERS TECH

Grate clearing and ash removal system for gasification furnace

A relatively level fuel grate surface angle cooperates with multiple feed screws that press solid fuel material into and across the grate surface to continually clear off the grate. Air spaces between each pair of adjacent grate elements for under fire air each have a ninety degree deflector flange at the top of the air space extending from one grate element across the air space and up and over an adjacent grate element to deflect under fire airflow across the adjacent grate element to act as a grate sweeper. The smooth curved surface of the deflector flange between grate elements facilitates movement of the fuel and ash material and prevents from one grate element to the next and prevents clogging of the airflow space.

Owner:BENDER ROBERT J +2

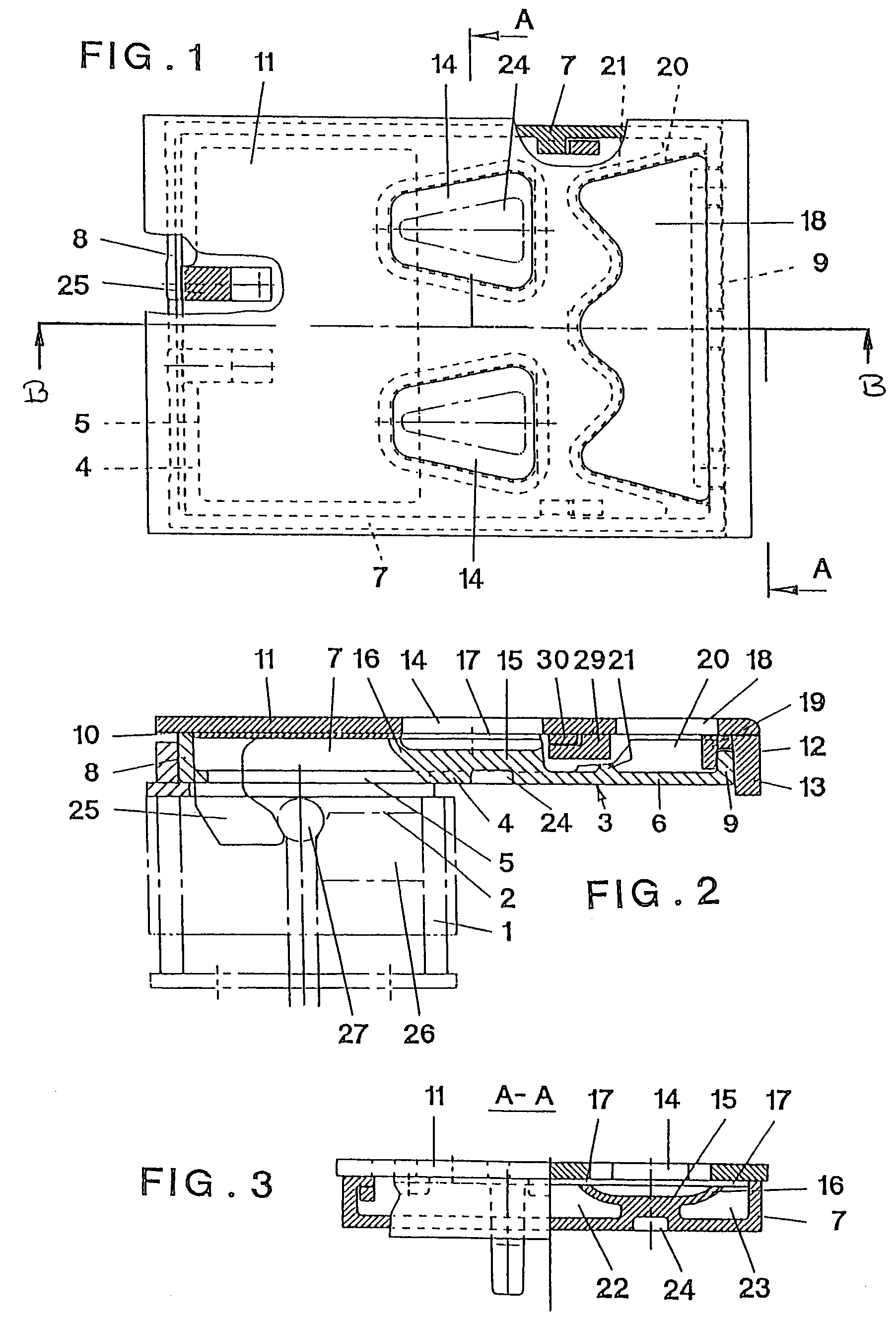

Cooler for bulk material having a sealing device between adjoining conveying planks

InactiveUS20100170103A1Eliminate riskProtection wearConveyorsDrying chambers/containersEngineeringBatten

An apparatus for cooling bulk material with a grate flowed through by cooling gas. The apparatus comprises a plurality of planks configured to move forward and back in the direction of conveyance and, between the planks, a sealing device having spatially separate outer and inner sealing elements. The sealing device has between the sealing elements a conveying duct, which runs along the length of the planks and on which a gas supply is configured to produce a gas stream along the length of the conveying duct. Bulk material which has infiltrated through the outer sealing element can be transported away before it can reach and migrate through the inner sealing element. The accompanying sealing effect can considerably reduce the undesirable material through-fall, while enabling the use of low-wearing seals, which provide excellent wear resistance.

Owner:CLAUDIUS PETERS PROJECTS

Fire grate for motor grate combustion appts. and grate body for forming grate

A mechanical grate assembly for the garbage incinerator is composed of the fixed grates and movable grates, which are alternatively arranged to form a three-step mechanical grate assembly, which is formed through fastening the fixed and movable grates on a frame of furnace bed in parallel mode, and transversely inserting the connecting rod through the grate body. Its advantage is easy assembling and disassembling.

Owner:TAKUMA

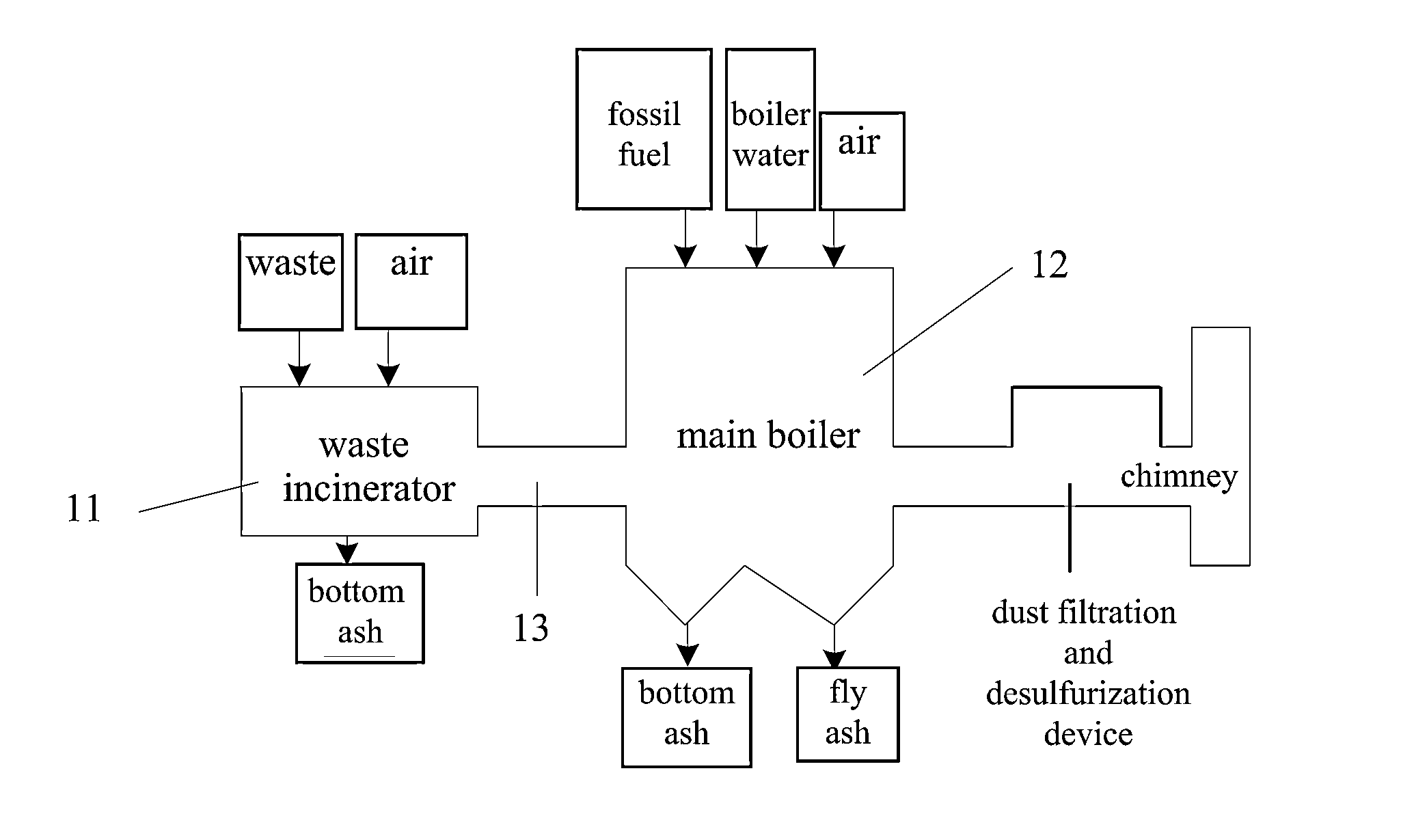

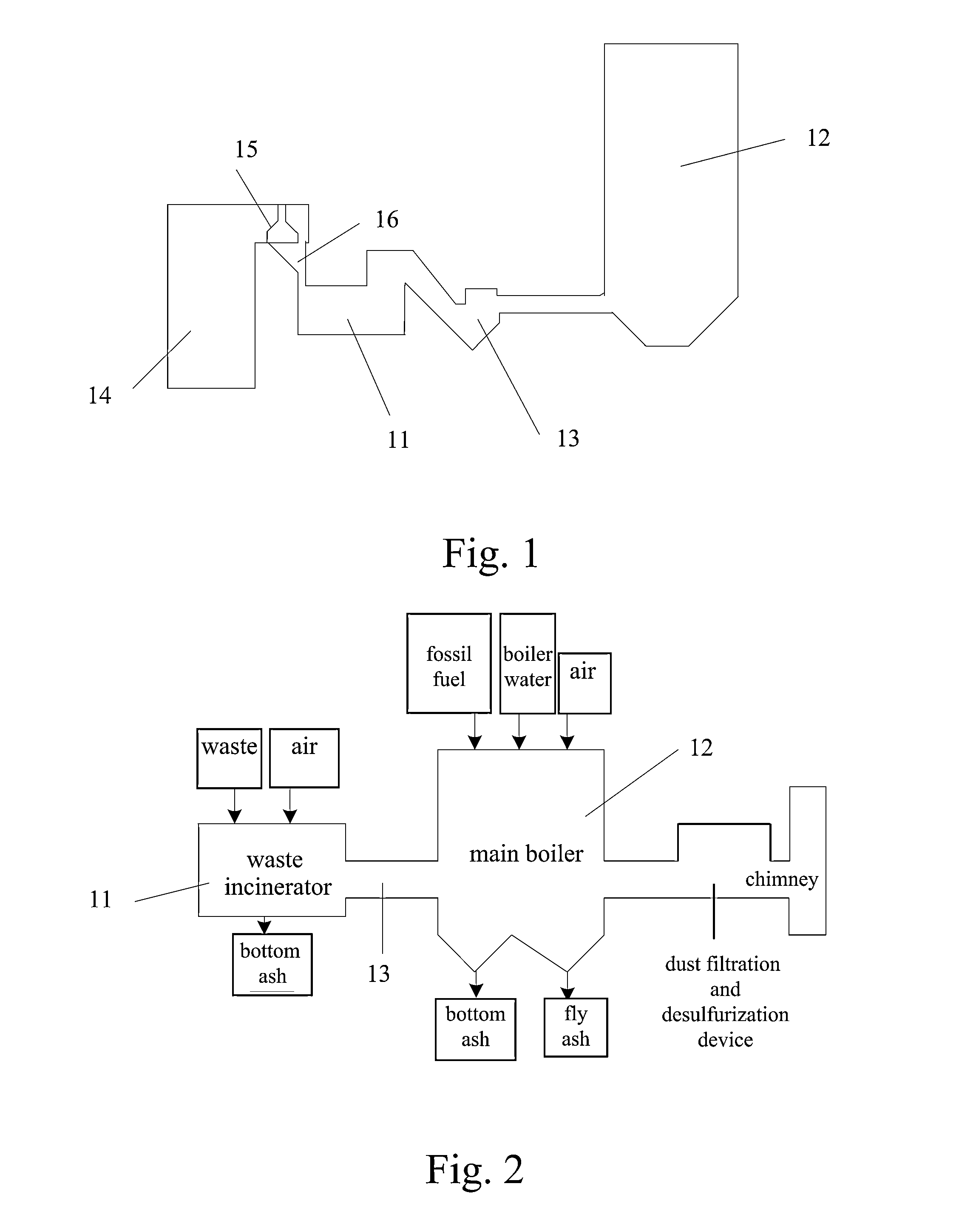

Fossil-fuel power generation system assisted by waste incineration

ActiveUS20150267916A1Improve thermal efficiencyRaise the combustion temperatureSolid waste disposalSteam generation plantsThermal energyCombustion

A fossil-fuel power generation system assisted by waste incineration includes a waste incineration subsystem and a fossil-fuel power generation subsystem; wherein: the waste incineration subsystem includes a waste incinerator and the fossil-fuel power generation subsystem includes a main boiler; a flue gas channel is provided between a furnace of the waste incinerator and the main boiler; flue gas generated by waste incineration of the waste incinerator enters the main boiler through the flue gas channel; and the flue gas channel is located in a low part of the main boiler. Based on a high-temperature combustion environment of the main boiler, thermal energy of combustible waste is fully released and a thermal efficiency is increased; moreover, the flue gas discharged by the waste incinerator contains harmful substances which are mostly burned down by a high-temperature incineration of the main boiler. A secondary incineration greatly reduces the harmful substances and protects environment.

Owner:WEN XIANGYUAN

Grate plate arrangement

InactiveUS8397654B2Easy to adjustAvoid lateral displacementConveyorsInclined grateMechanical engineering

Owner:IKN GMBH

Grate furnace

A grate furnace with a grate includes grate steps made of grate elements lying next to one another. Every second grate step in the longitudinal direction of the grate can be driven for carrying out stoking movements and the grate steps in each case lying therebetween are stationary. Drive devices for driving the moveable grates are arranged in housing chambers and are in this way protected against impairment caused by material falling through the grate. A certain section of the housing chamber is open toward the bottom so that it is accessible even during operation of the grate furnace.

Owner:MARTIN GMBH FUR UMWELT UND ENERGIETECHNIK

Grate plate arrangement for step plates

InactiveUS7219610B2Easy to disassembleUnnecessary useConveyorsHollow bar grateEngineeringMechanical engineering

Owner:IKN GMBH

Cooler for bulk material having a sealing device between adjoining conveying planks

InactiveUS7886457B2Reduces the through-fall through the grateConveyorsDrying chambers/containersEngineeringBatten

An apparatus for cooling bulk material with a grate flowed through by cooling gas. The apparatus comprises a plurality of planks configured to move forward and back in the direction of conveyance and, between the planks, a sealing device having spatially separate outer and inner sealing elements. The sealing device has between the sealing elements a conveying duct, which runs along the length of the planks and on which a gas supply is configured to produce a gas stream along the length of the conveying duct. Bulk material which has infiltrated through the outer sealing element can be transported away before it can reach and migrate through the inner sealing element. The accompanying sealing effect can considerably reduce the undesirable material through-fall, while enabling the use of low-wearing seals, which provide excellent wear resistance.

Owner:CLAUDIUS PETERS PROJECTS

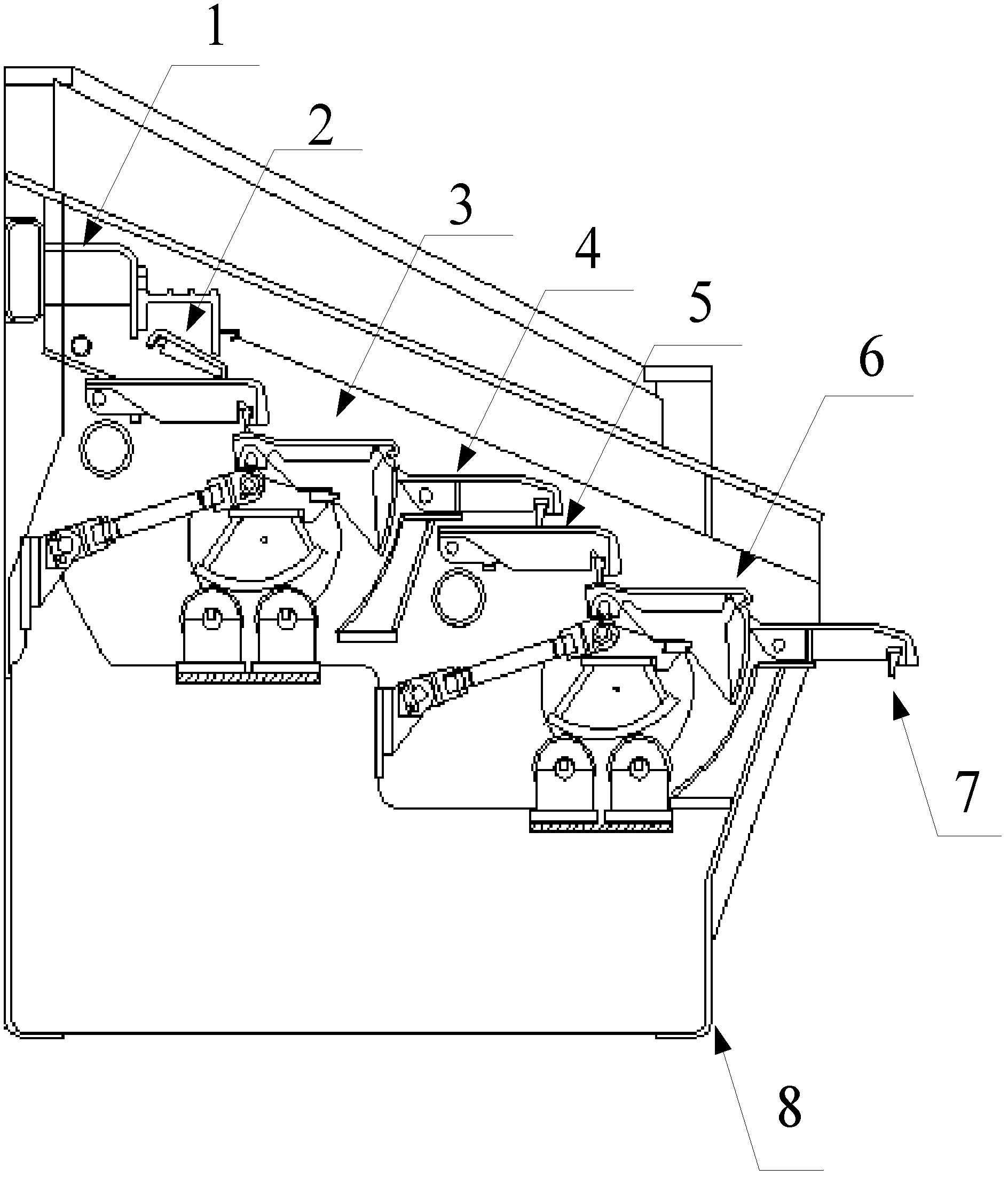

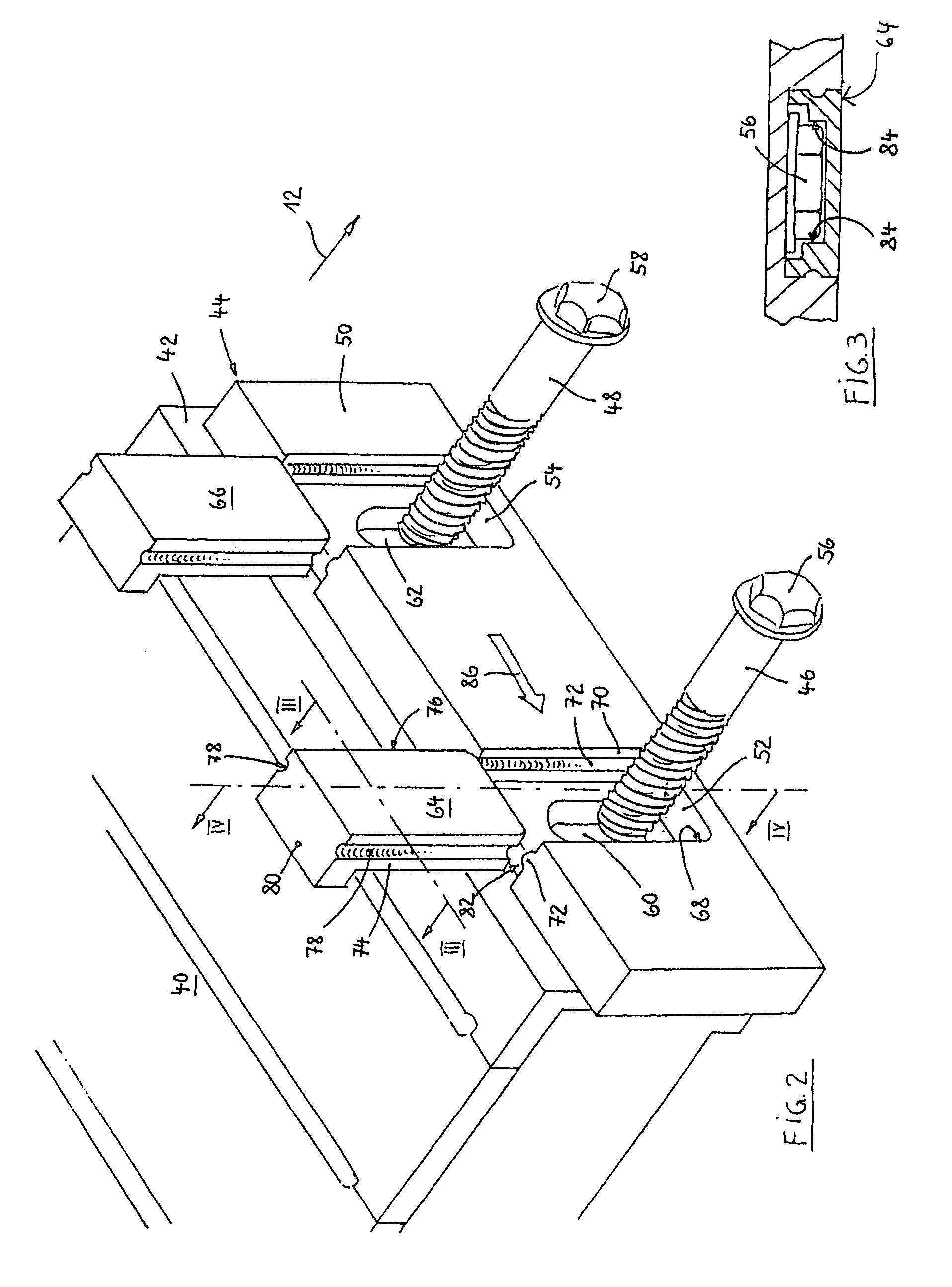

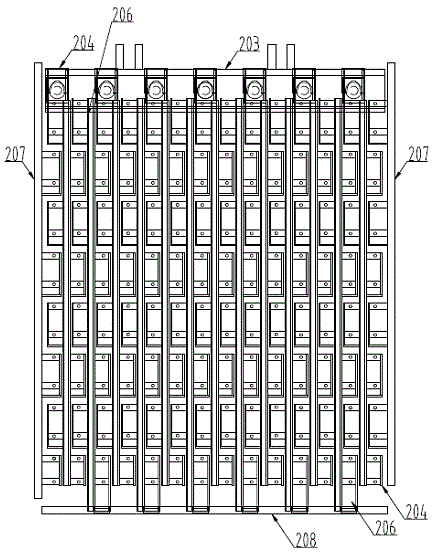

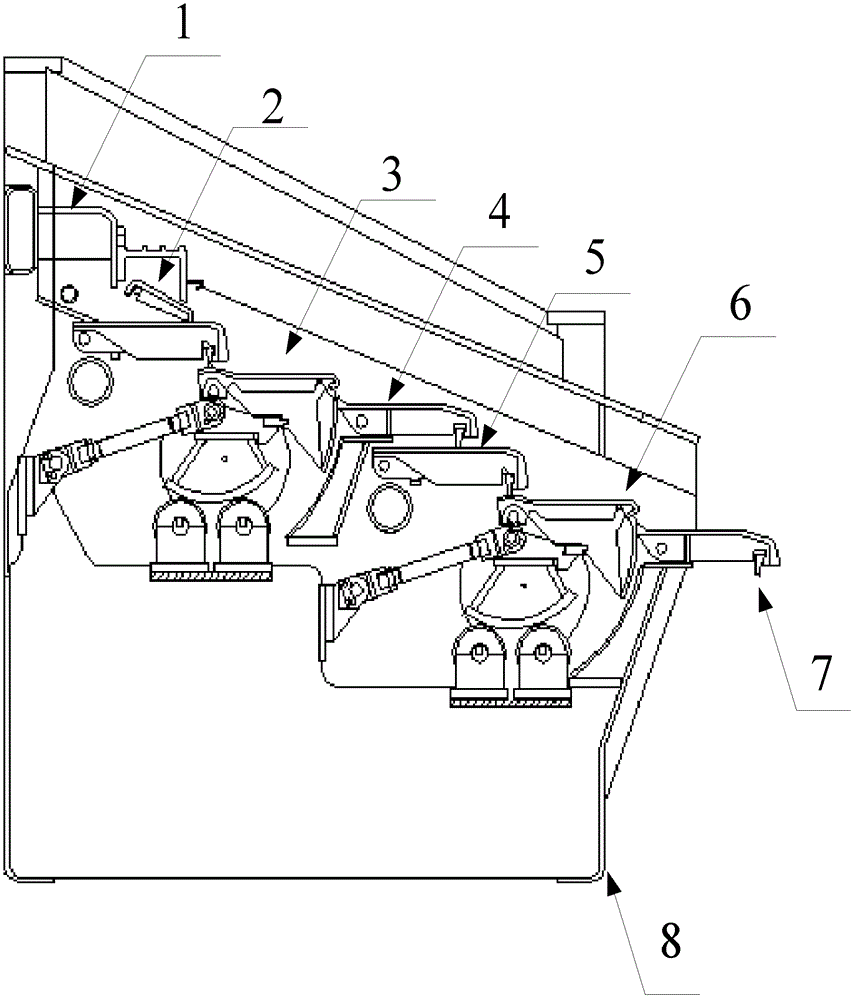

Pick push type reciprocating fire grate device correspondingly driven by double oil cylinders from two sides

The invention discloses a pick push type reciprocating fire grate device correspondingly driven by double oil cylinders from the two sides. The pick push type reciprocating fire grate device comprises multiple supports, a fixed fire grate frame installed on the supports, a left region movable fire grate drive mechanism and a right region movable fire grate drive mechanism arranged on the left region and the right region of the fixed fire grate frame respectively, left region fixed fire grate sets, right fixed fire grate sets, left region movable fire grate sets, right region movable fire grate sets, a left wall protecting cover assembly, a right wall protecting cover assembly and a middle partition cover assembly. The left region movable fire grate sets and the left region fixed fire grate sets are arranged alternately. The right region movable fire grate sets and the right region fixed fire grate sets are arranged alternately. The left wall protecting wall assembly and the right wall protecting wall assembly are arranged on the left side and the right side of the fixed fire grate frame respectively, and the middle partition cover assembly is arranged between the left region and the right region of the fixed fire grate frame. The left region movable fire grate sets and the right region movable fire grate sets are driven by the left region movable fire grate drive mechanism and the right region movable fire grate drive mechanism to conduct reciprocating motion according to the set upward pick dip angle and the set motion distance, waste is picked and pushed forwards and stirred, the good effect of picking the waste to be dried and burnt is achieved, and therefore household garbage with the low heating value can be incinerated without the combustion-supporting condition.

Owner:上海煜工环保科技有限公司

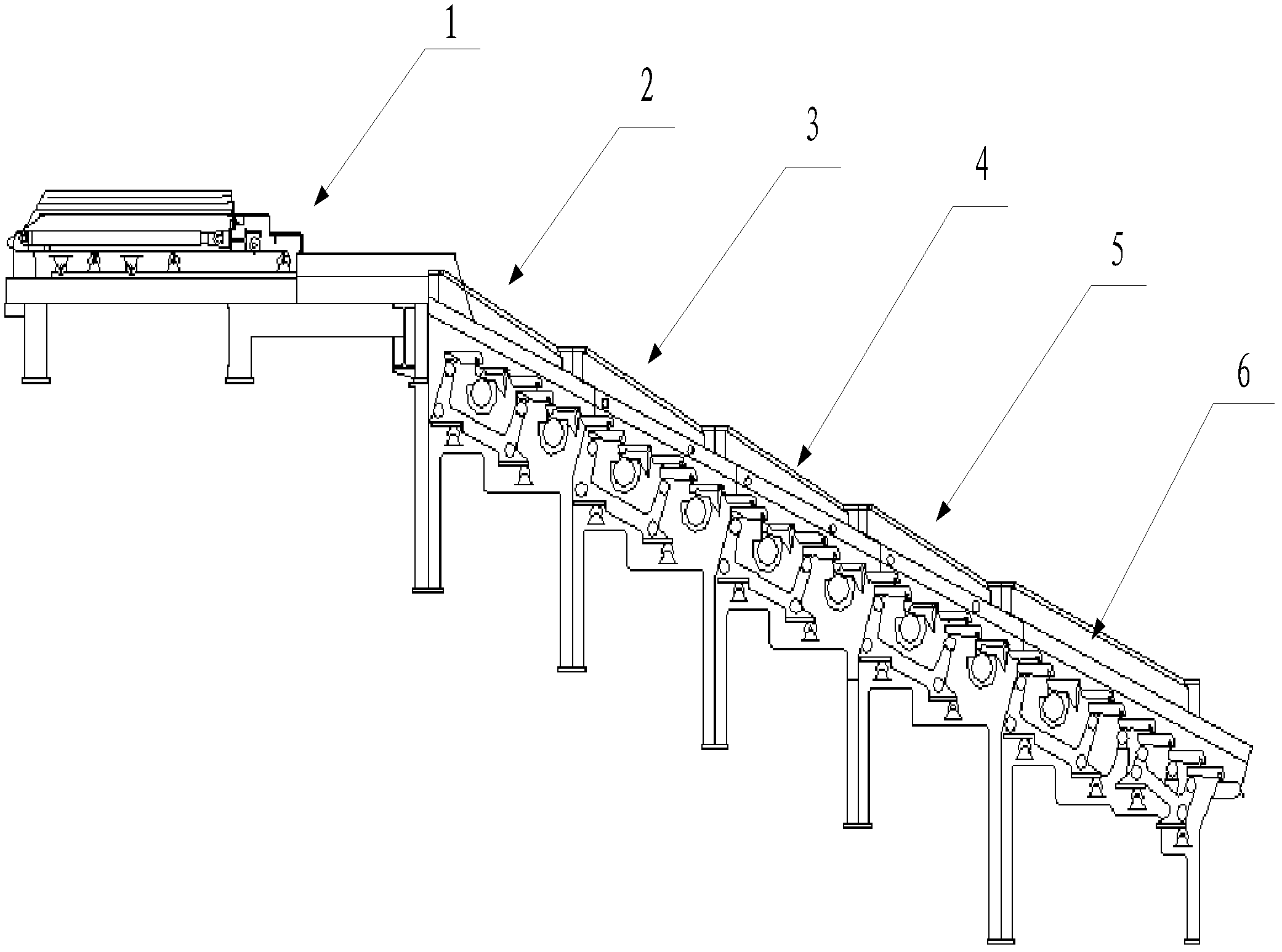

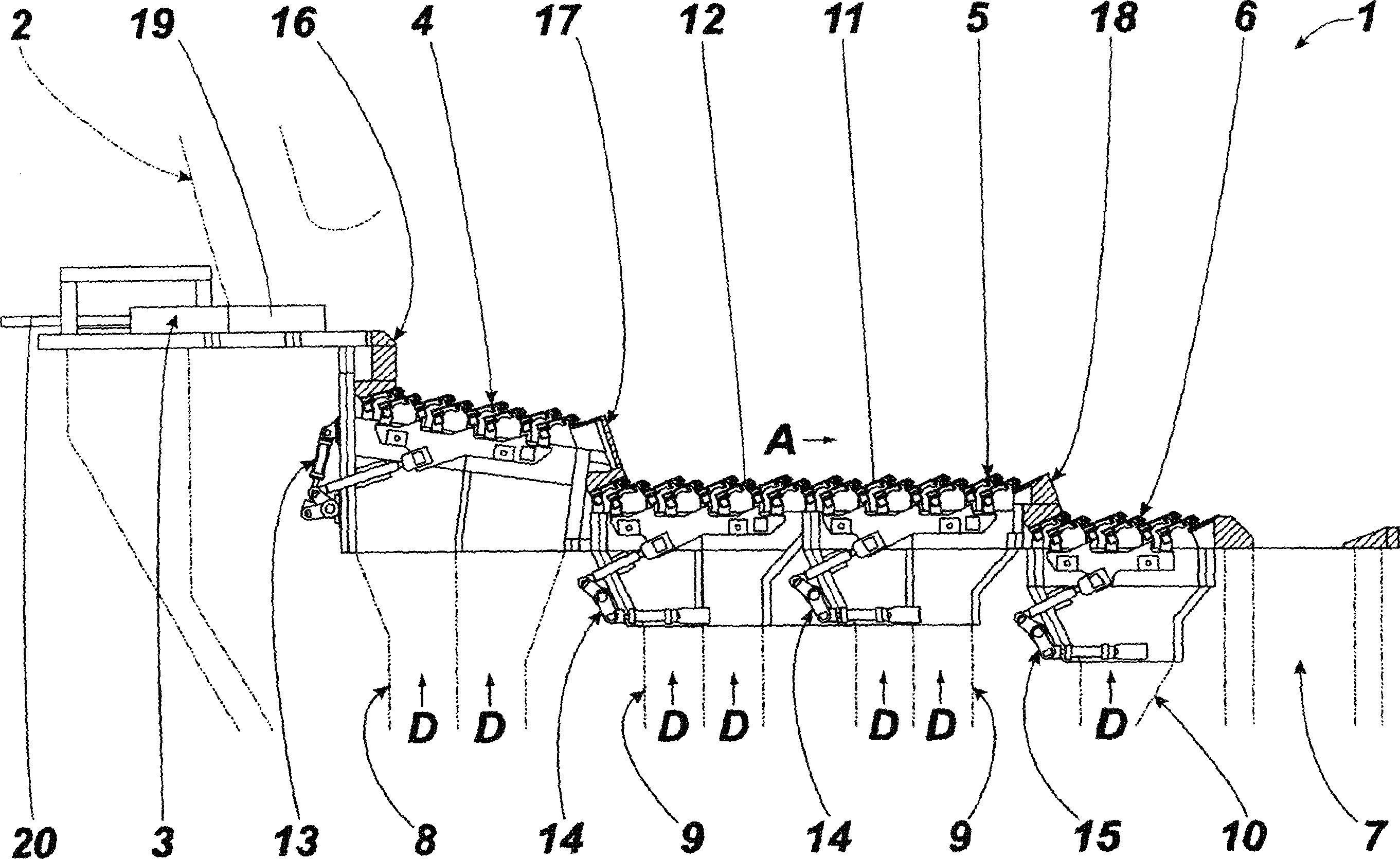

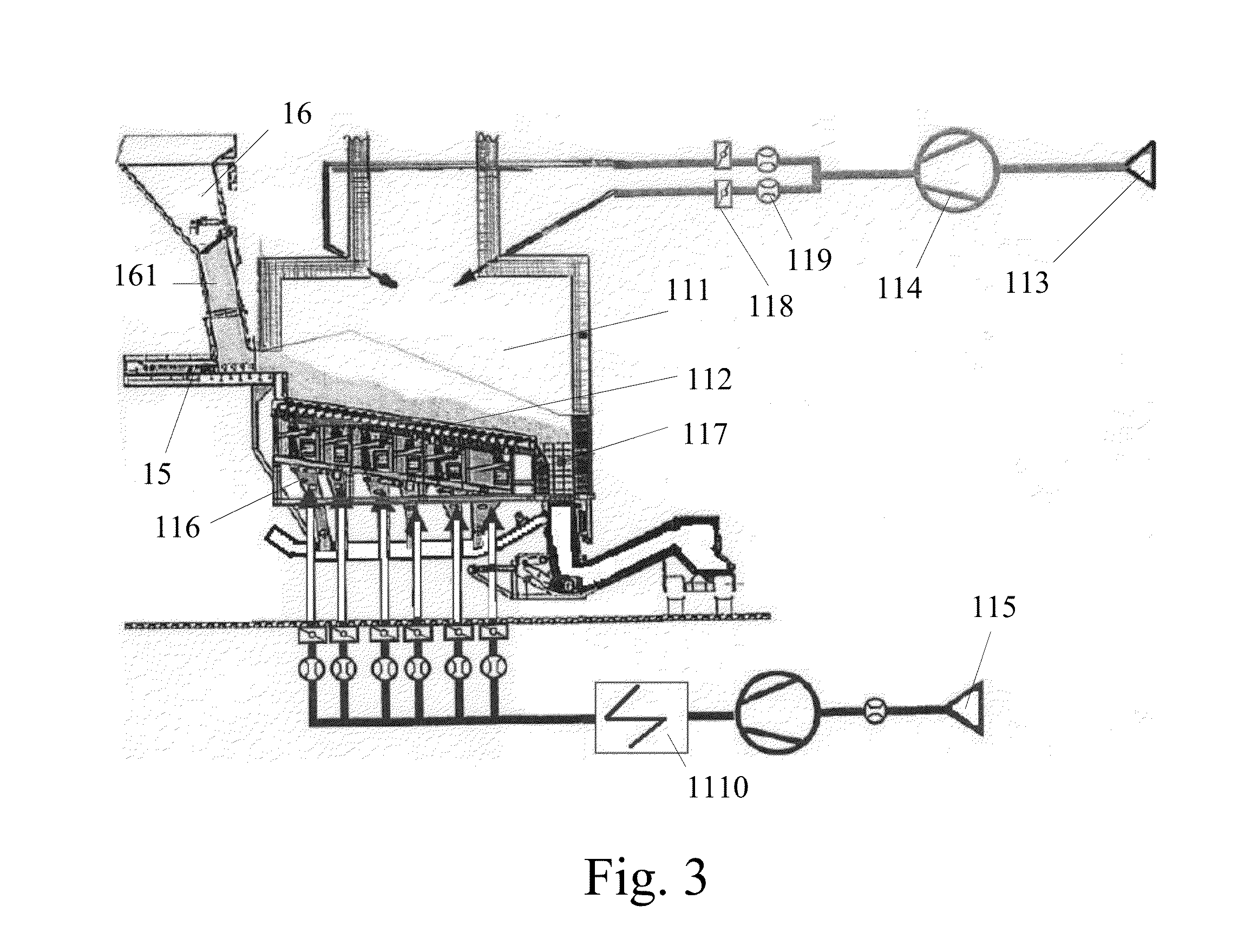

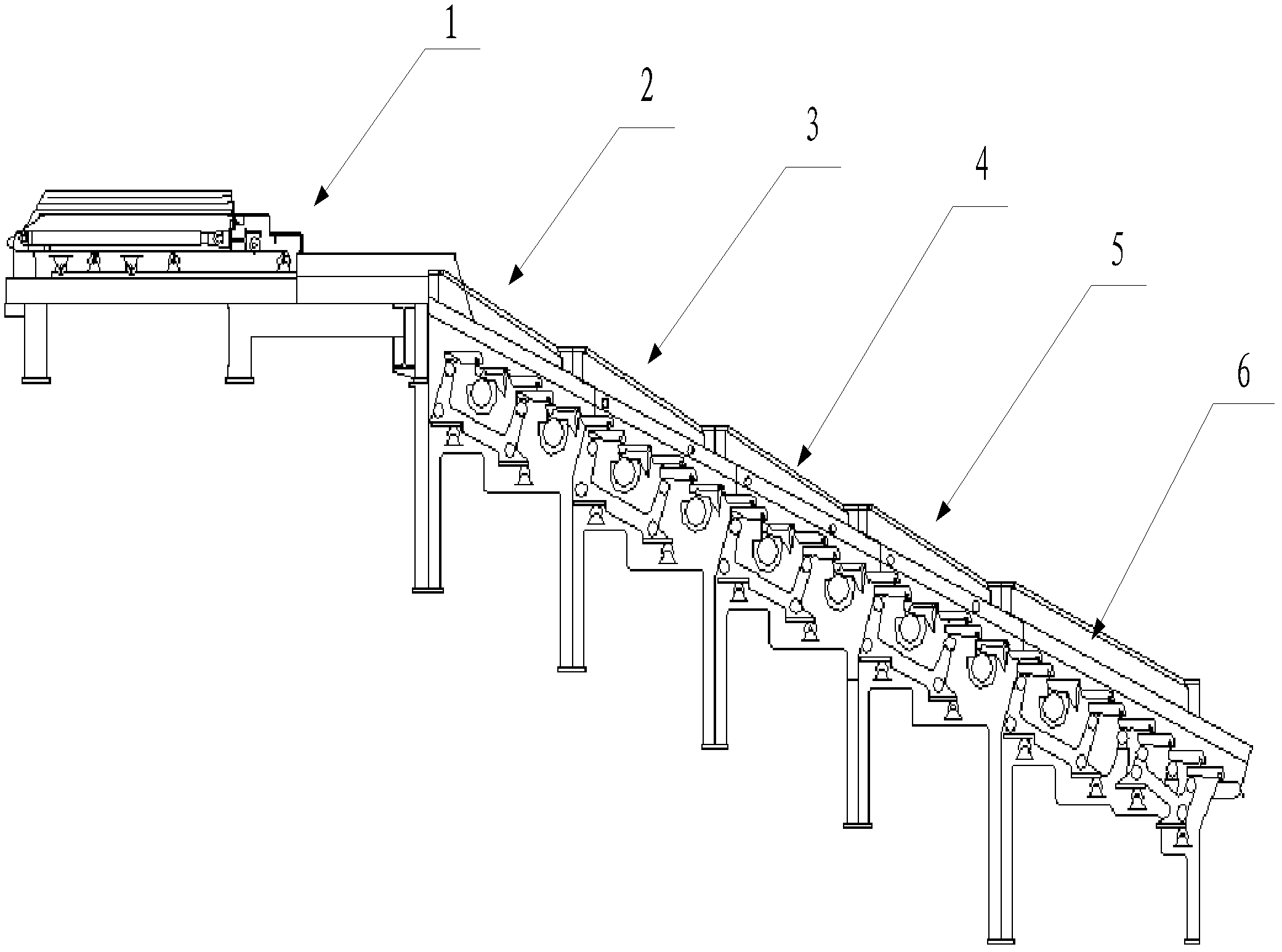

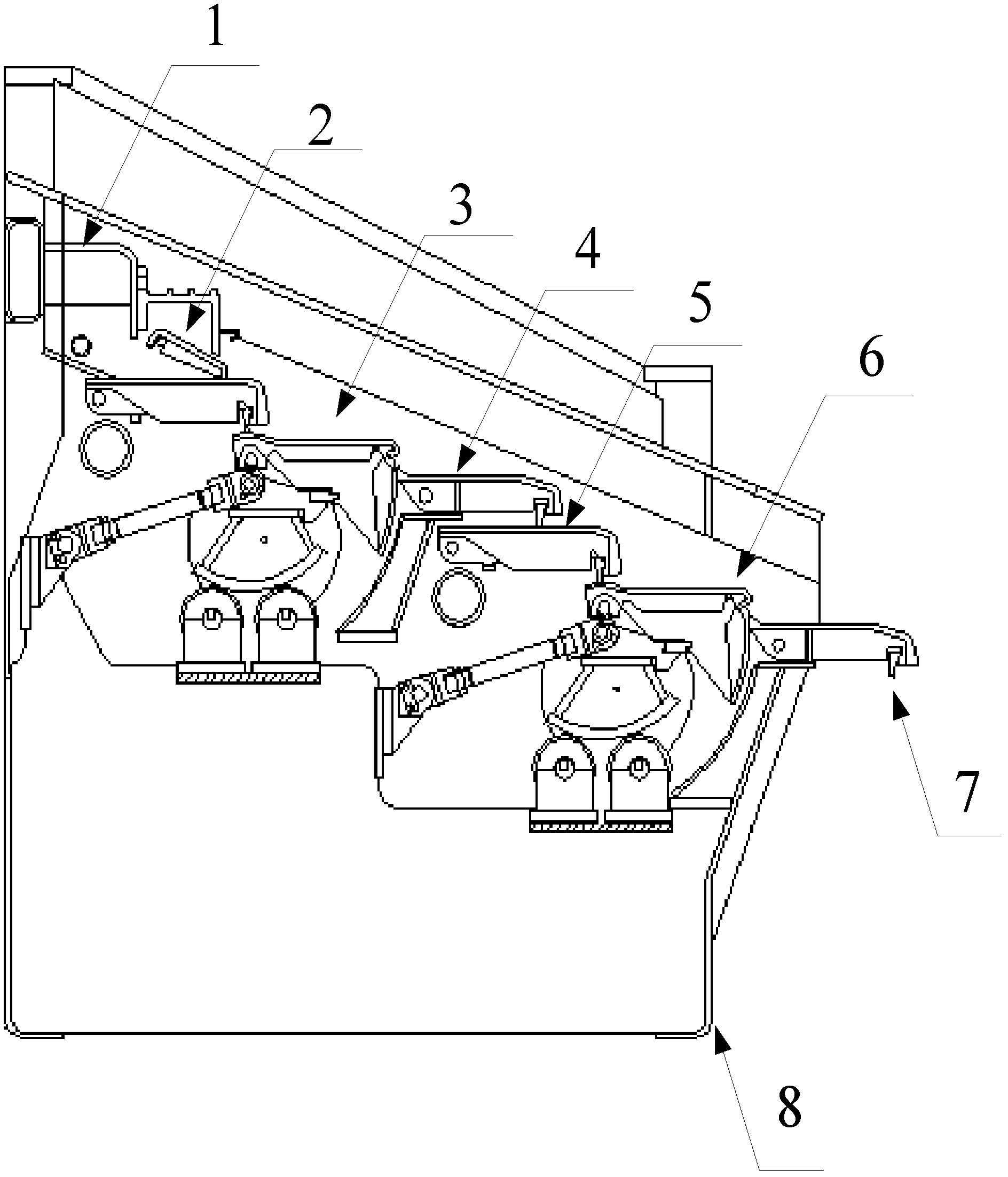

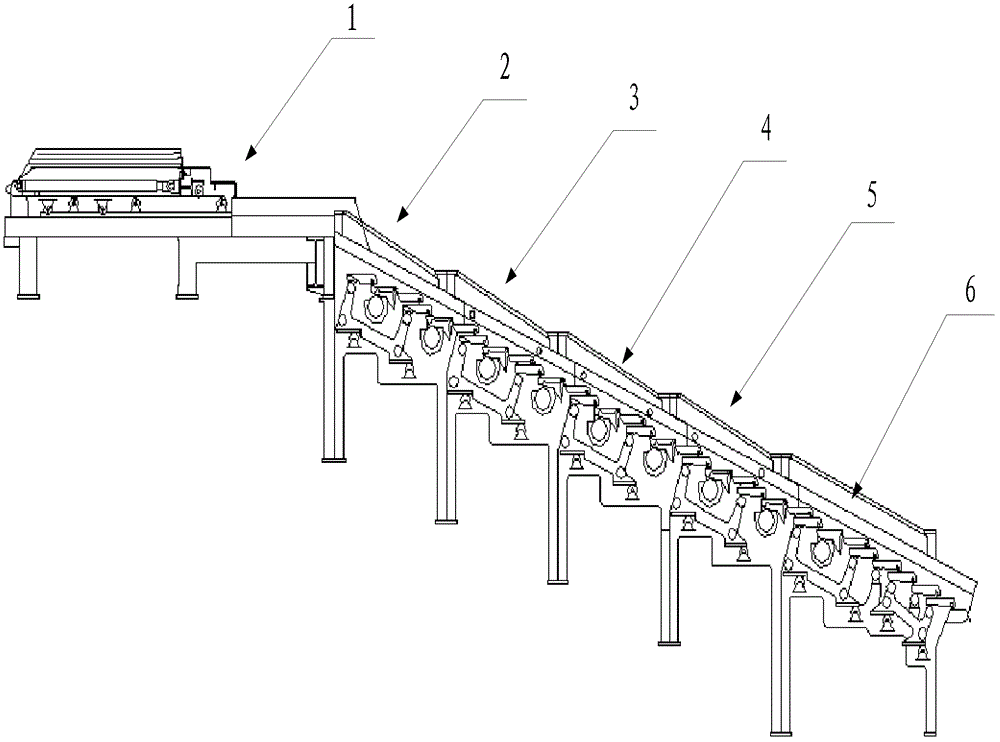

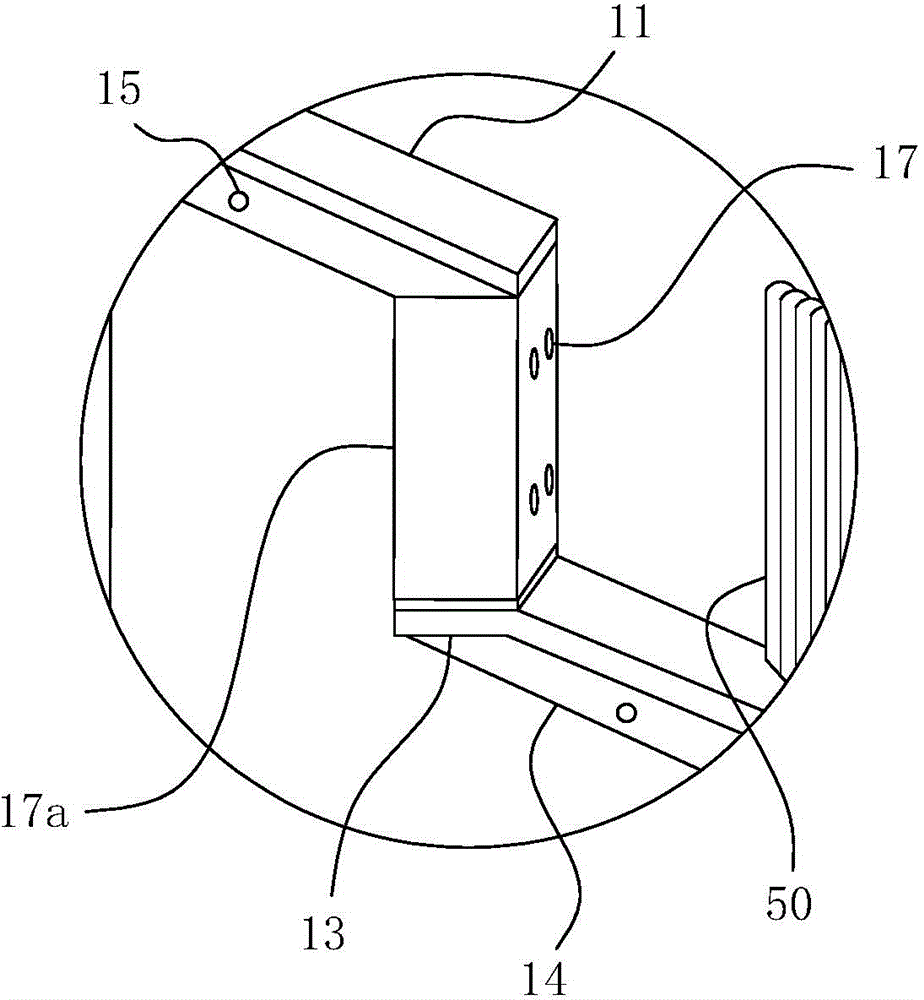

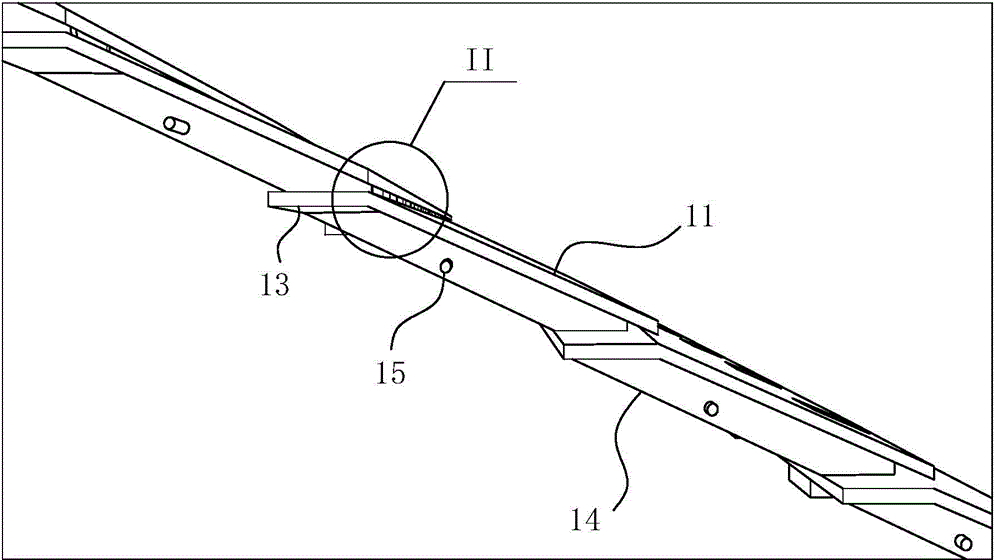

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036ASolve technical problemsGuaranteed uptimeHollow bar grateInclined grateHydraulic machineryIncineration

The invention provides a multistage hydraulic mechanical garbage incinerator, which comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally divided into a drying section, a burning section and a burnout section by the five units along the garbage moving direction. The multistage hydraulic mechanical garbage incinerator is characterized in that a limiting support device for limiting a feeding trolley to move upward is arranged on the upper surface of a tail of the feeding trolley of the feeding fire grate. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

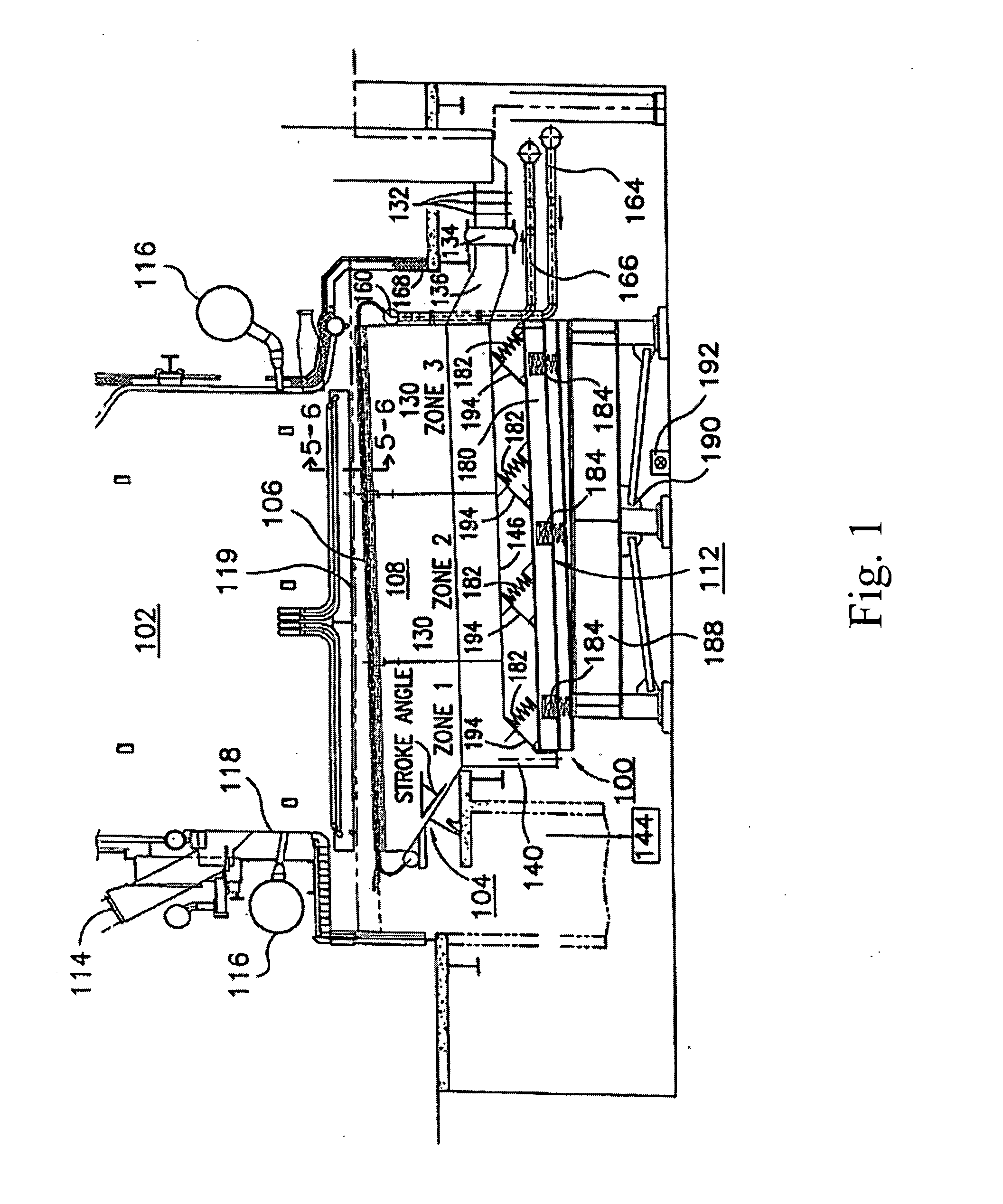

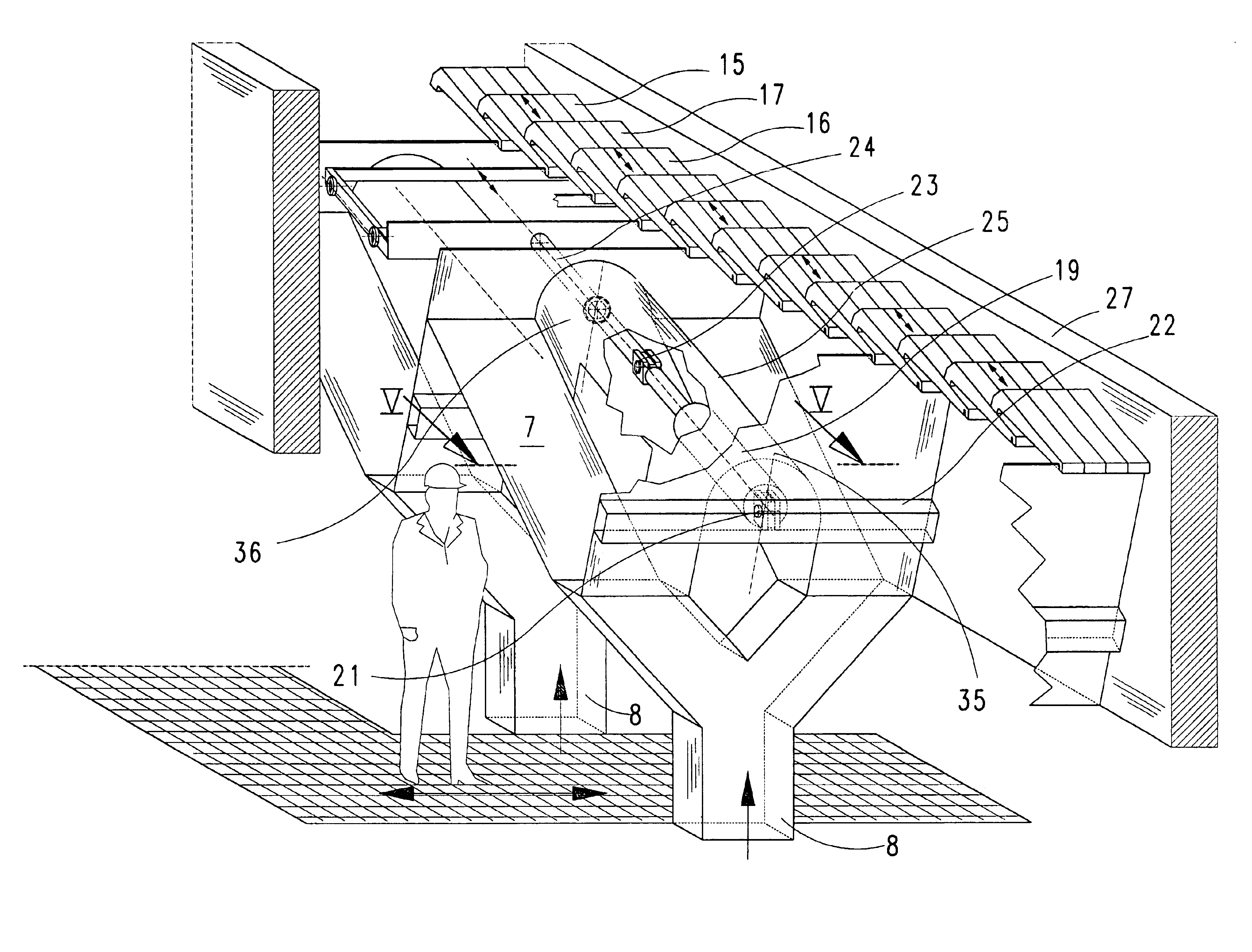

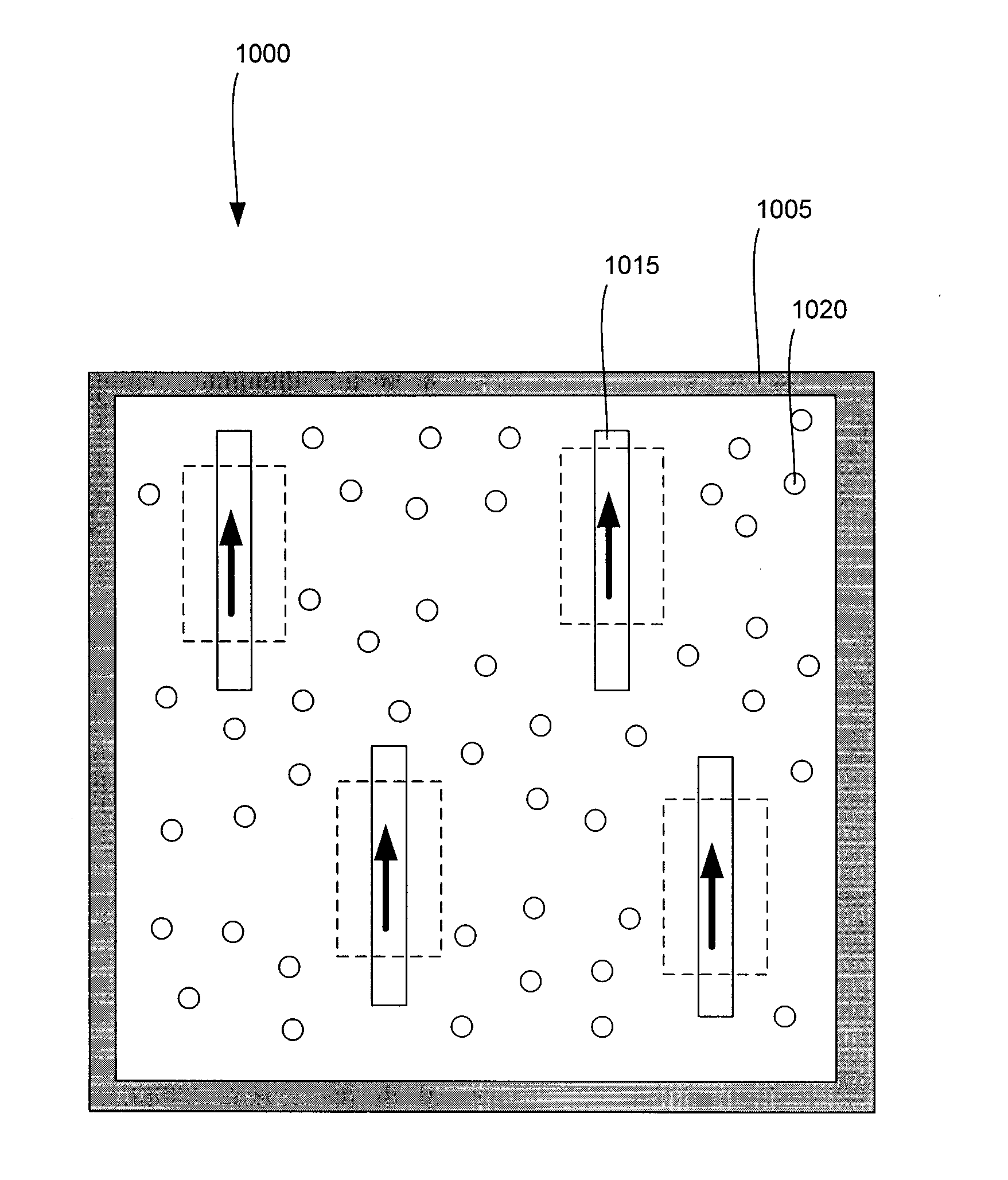

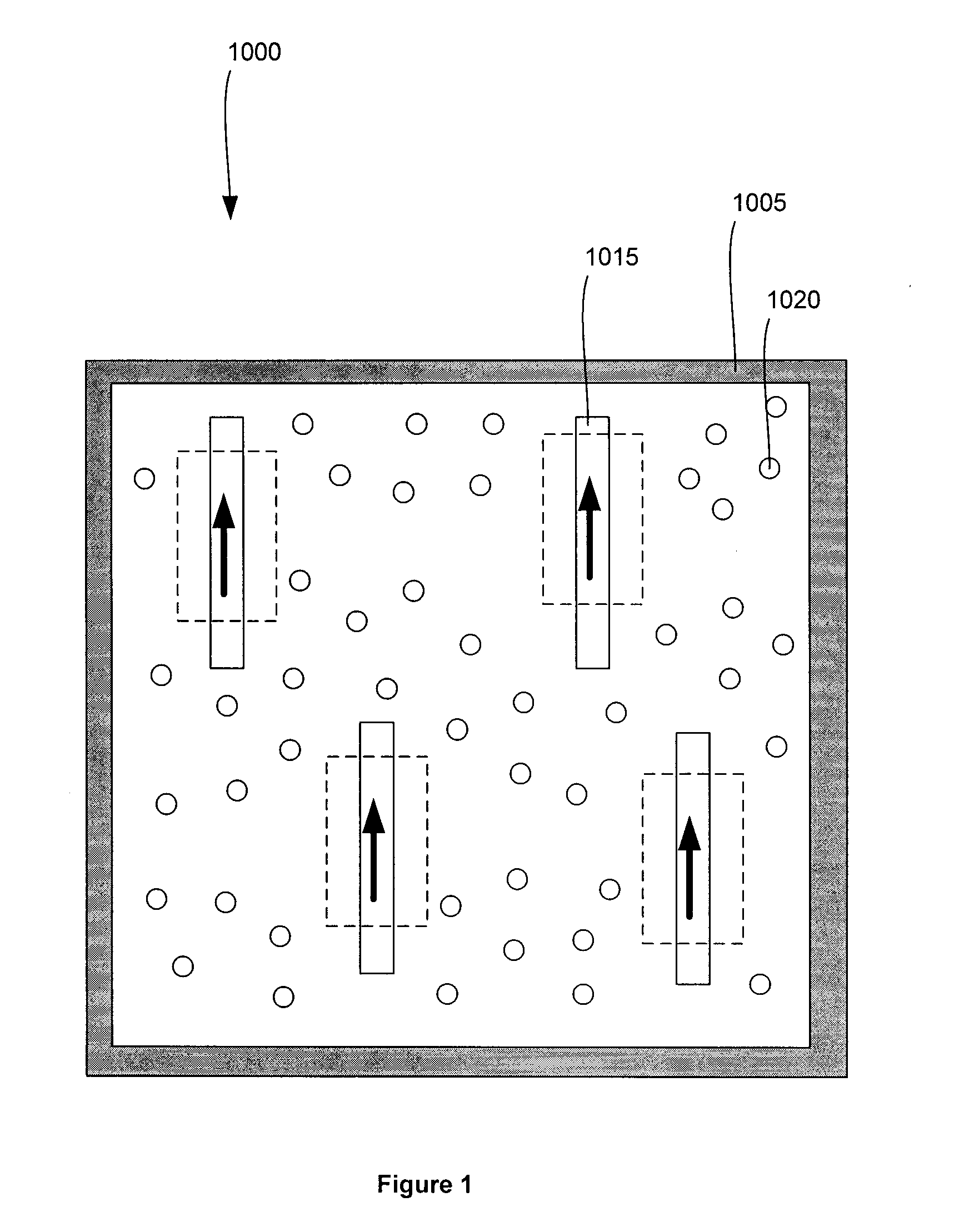

A Lateral Transfer System

InactiveUS20120067257A1Mechanical conveying coke ovensGasifier mechanical detailsTransfer systemDowntime

A modular lateral transfer system for use in a horizontally oriented processing chamber is provided. Each module has the ability to deliver process gas in addition to moving the reactant material through the horizontally oriented processing chamber. The modular design enables the operator to remove and replace a module of the system, thereby substantially minimizing the downtime of the chamber required during servicing.

Owner:PLASCO ENERGY GROUP INC

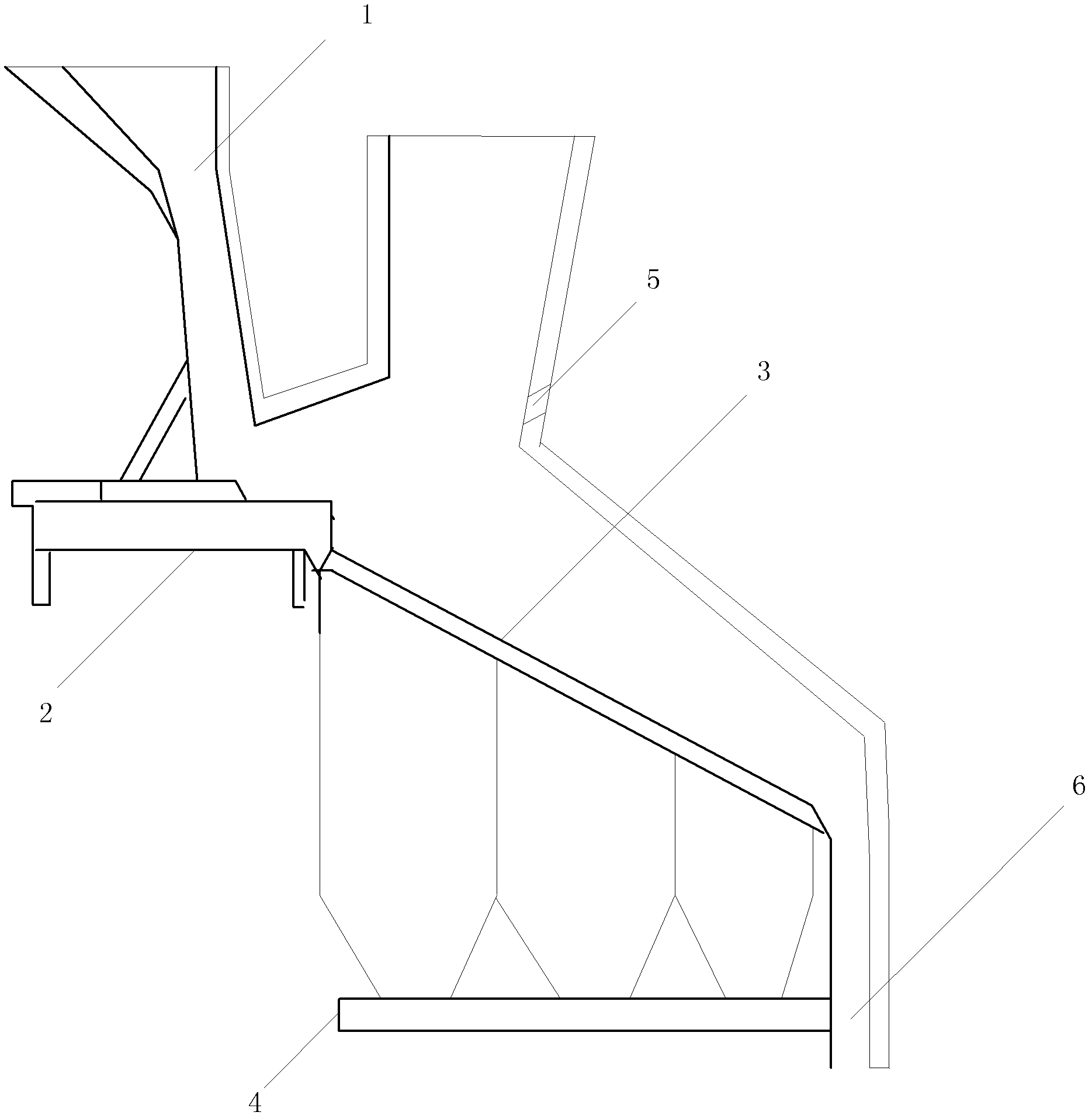

Staggered forward-push household garbage incineration fire grate structure

ActiveCN104949133AImprove cooling effectImprove loosenessInclined grateIncinerator apparatusCombustionAir volume

The invention relates to household garbage incineration equipment, in particular to the improvement of the structure of a staggered forward-push fire grate. The staggered forward-push household garbage incineration fire grate structure comprises three sections, namely, a drying section, a combustion section and an ash section, wherein each section of the fire grate has an independent drive system and has the fall; the fire grate comprises fixed fire grate bodies, sliding fire grate bodies, covering fire grate bodies and discharging fire grate bodies; the sliding fire grate bodies and the fixed fire grate bodies are arranged in a staggered manner, the sliding fire grate bodies driven by sliding fire grate beam slide on a support frame, the fixed fire grate bodies on fixed fire grate beams are kept static, the covering fire grate bodies are arranged in the front of all the sections of fire grate, and the discharging fire grate bodies are arranged at tails of all the sections of fire grate. By the aid of the fire grate structure, the garbage loosening effect is better, combustion is more uniform, the combustion condition is easier to adjust and control, the running power consumption is low, so that the air volume and the air pressure are controlled to be more ideal, dust produced after combustion is low in concentration and large in particle size, the slag leakage rate is low, and the structure is more suitable for complex garbage components.

Owner:SHANGHAI SUS ENVIRONMENT

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036BImprove combustionImprove burnout rateHollow bar grateInclined grateCombustionHydraulic machinery

A multi-stage hydraulic mechanical garbage incinerator comprising a material inlet, a material-feeding grate (4), an incineration grate, a primary air supply system, and a secondary air supply system. The incineration grate is divided along the longitudinal direction into five units, where the first to the fourth of the units are standard units, and where the fifth unit is an end extension unit, while each unit consists of several sliding grate plates, flipping grate plates, and fixed grate plates. The five units divide the entire incineration grate along a direction of garbage movement into a drying section, a combustion section, and a burnout section. A limiting support apparatus (2) for use in limiting upward movement of a material-feeding trolley (3) of the material-feeding grate (4) is provided on the upper surface at the tail part of the material-feeding trolley (3).

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

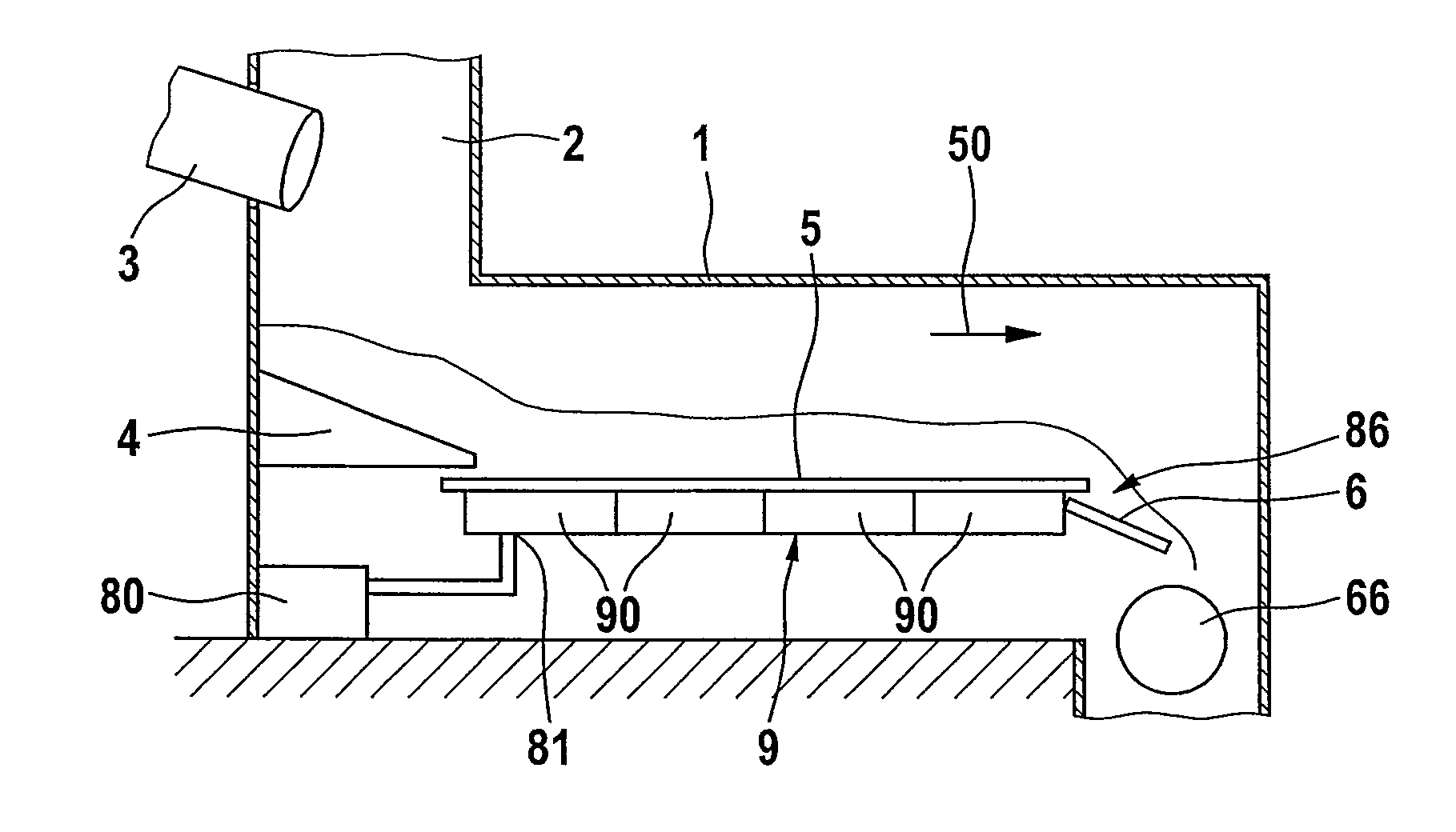

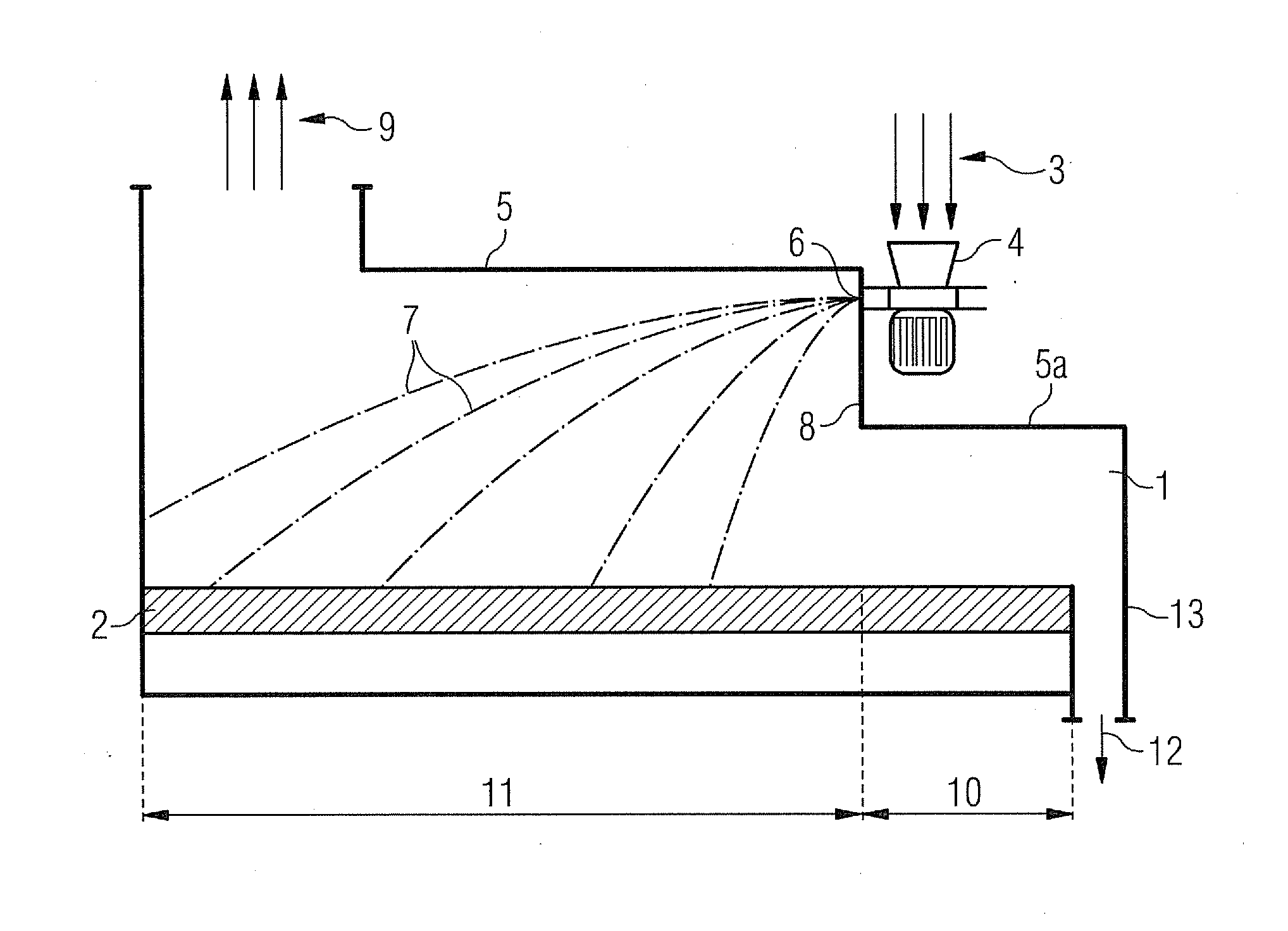

Method for mechanical stoking in firing installations and firing installation

InactiveUS20100323310A1Reduction in residual carbon content of ashComplete combustionFuel supply regulationInclined grateCombustion chamberEngineering

A method for mechanical stoking in firing installations and a firing installation is provided. Fuel is applied to a grate using a mechanical stoker, the grate being disposed in a firing chamber, wherein the mechanical stoker is oriented opposite a delivery direction of the grate. The fuel is introduced directly below a firing chamber ceiling, viewed in the delivery direction of the grate before the end of the grate such that a burnout zone, which does not have fresh fuel applied thereto, is created on the grate between the mechanical stoker and the end of the grate.

Owner:SIEMENS AG OESTERR

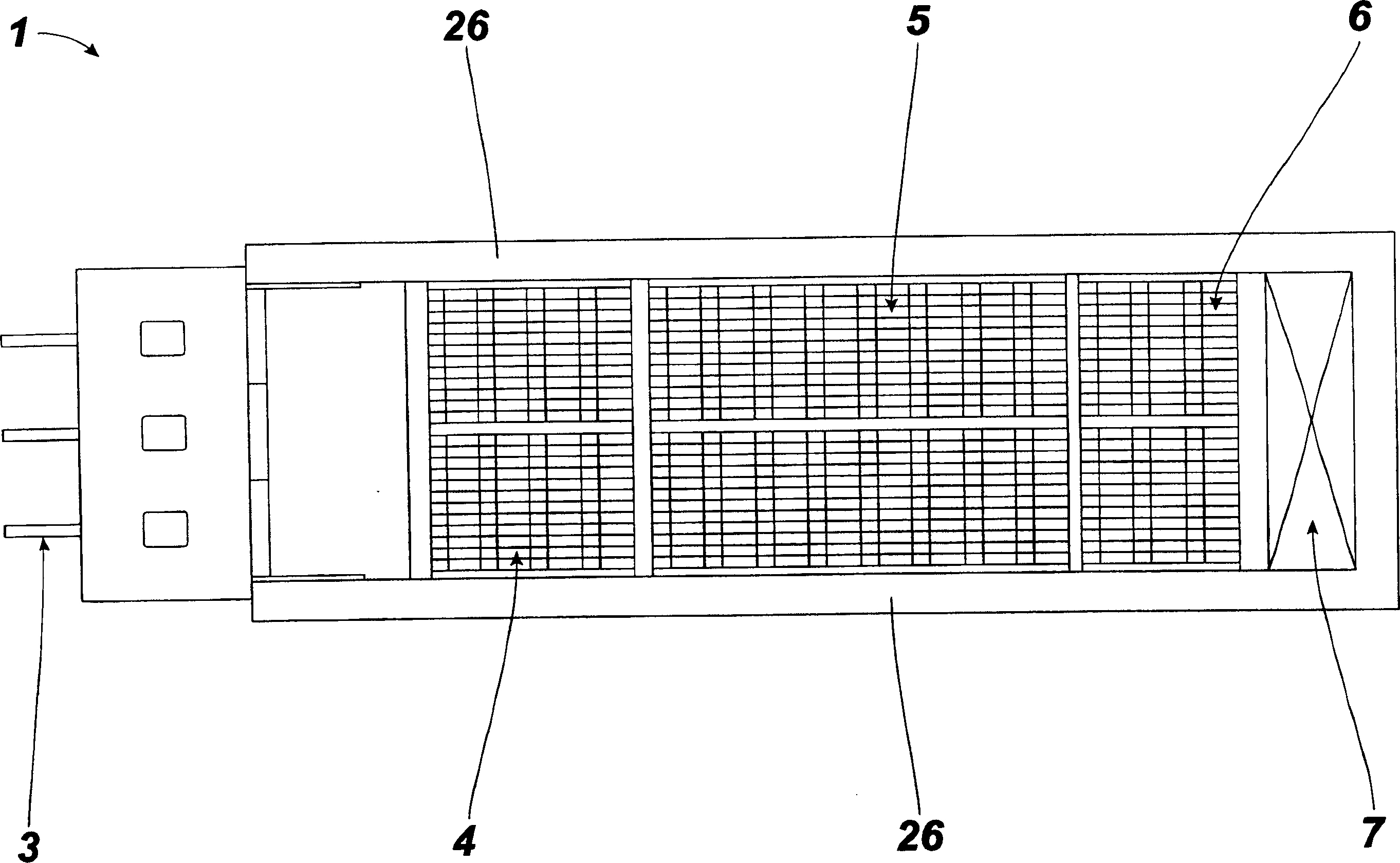

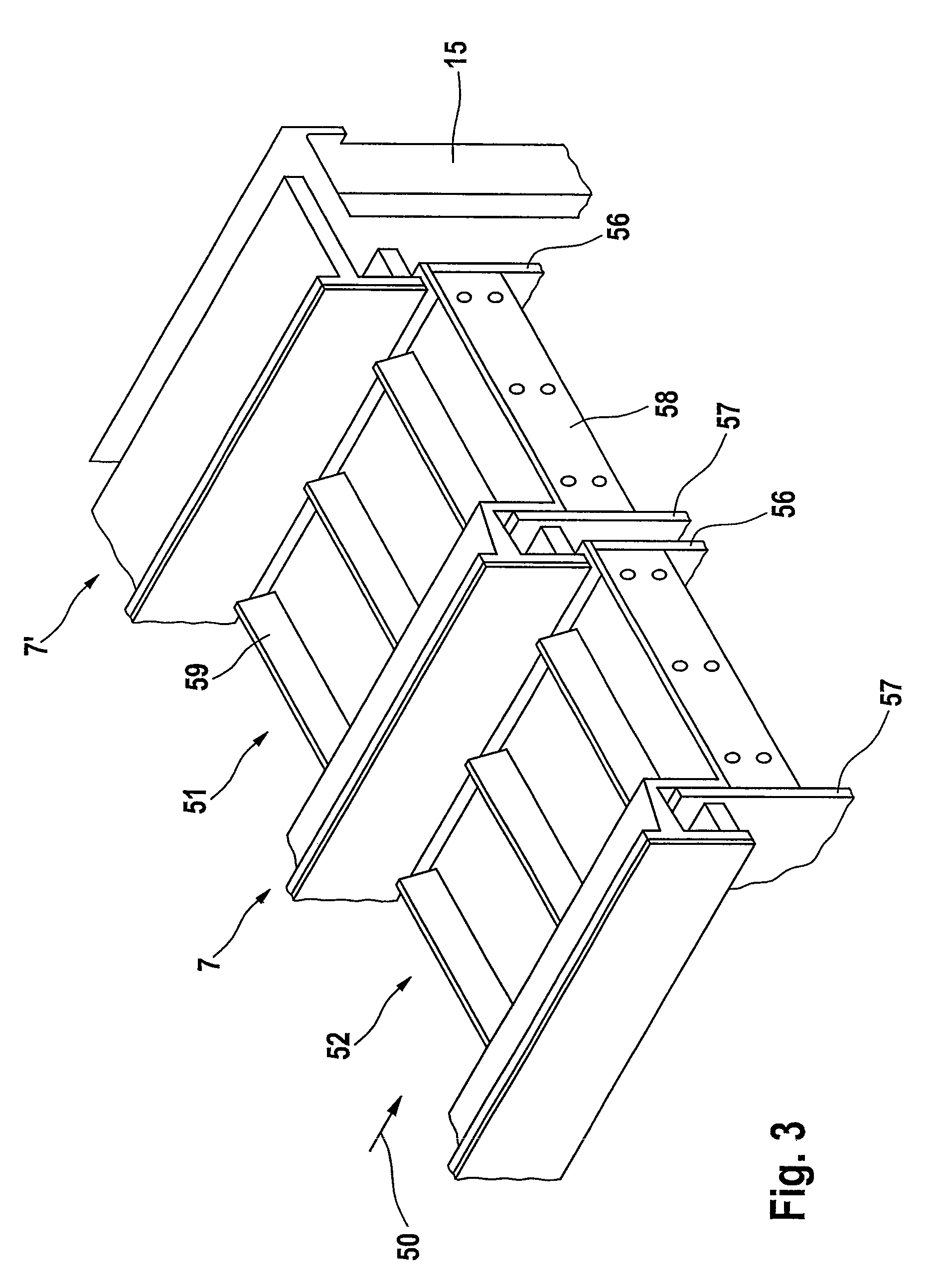

Bulk-Material Cooler for Cooling Hot Material to be Cooled

The aim of the invention is to design a bulk-material cooler, particularly one for cooling cement clinker, which operates according to the walking floor principle, so that its cooling grate can be composed of a multitude of ventilated cooling grate modules, which can be assembled in an easy and variable manner, in order to obtain large lengths and widths of the cooler. When these cooling grate modules move between an advancing and returning position, even lateral and / or height offset of the guiding elements can be compensated for in a kinematic manner. To this end, the invention provides that the cooling grate, when viewed over the length and width of the cooler, is composed of a multitude of modules (13, 14) ventilated with cooling air. The coupling of the cooling grate modules of each longitudinal row of cooling grate modules is effected by an articulated joint.

Owner:KHD HUMBOLDT WEDAG GMBH

Fixed grate and incineration system applying same

InactiveCN104595907AGuaranteed structural rigidityGuaranteed to be constantInclined grateIncinerator apparatusCombustion chamberHot blast

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate and an incineration system applying the same. The fixed grate at least comprises grate plates; the arrangement heights of the grate plates are gradually reduced so as to form a step type grate body structure of the fixed grate; a spacing is formed between plate bodies of each two adjacent grate plates in the perpendicular direction so as to form a ventilation pore running through a grate body; the grate plates are provided with extending plates; the plate faces of each extension plate and the plate body of the previous grate plate are crossed mutually to form a wind guide port structure. The incineration system comprises a main combustion chamber, the fixed grate and a grate ejector rod, wherein the main combustion chamber is isolated and divided into a combustion cavity and a hot blast cavity by the fixed grate; the air inlet end of the hot blast cavity is also the feed end of the fixed grate; the grate ejector rod is used for overturning and ejecting materials on the incineration face; the grate ejector rod passes through a through hole and runs through the material layer on the fixed grate in the maximum lift range. The fixed grate and the incineration system have reasonable and practical structures; the grate body has a good ventilation effect; material incineration efficiency is high.

Owner:安徽盛燃焚烧炉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com