Patents

Literature

102 results about "Grate firing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grate firing is a type of industrial combustion system used for solid fuels. It now is used mainly for burning waste and biomass, but also for smaller coal furnaces.

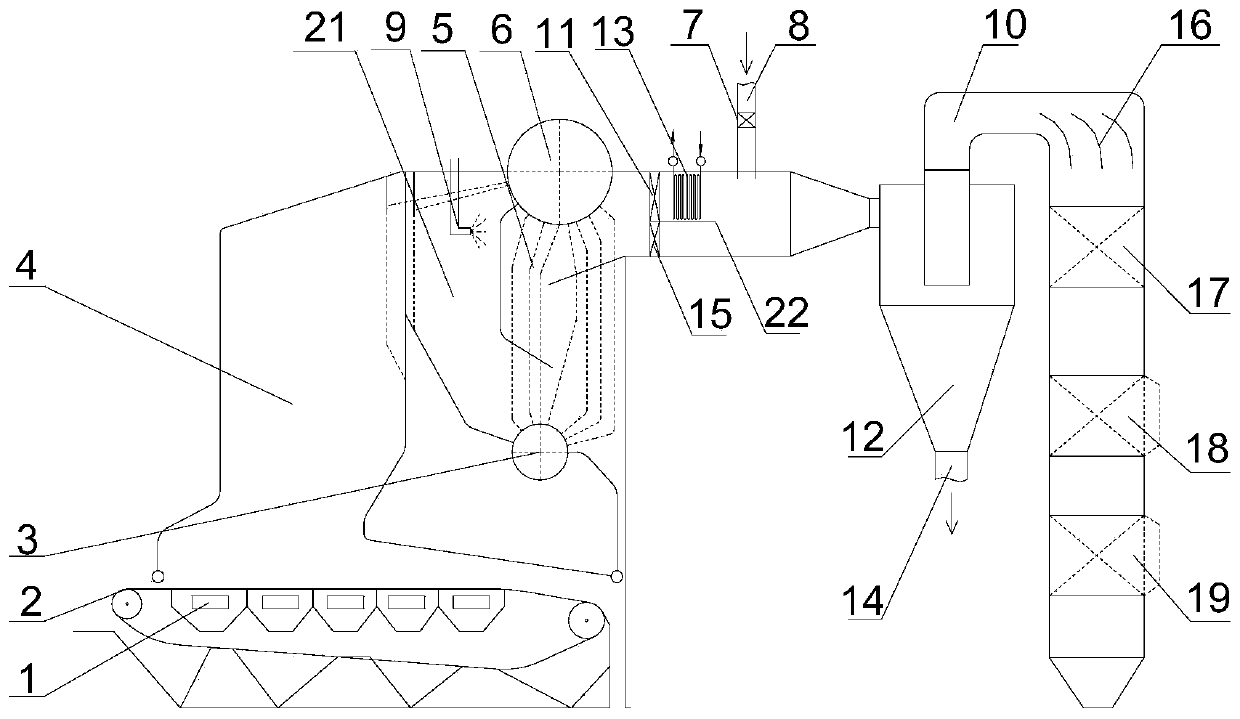

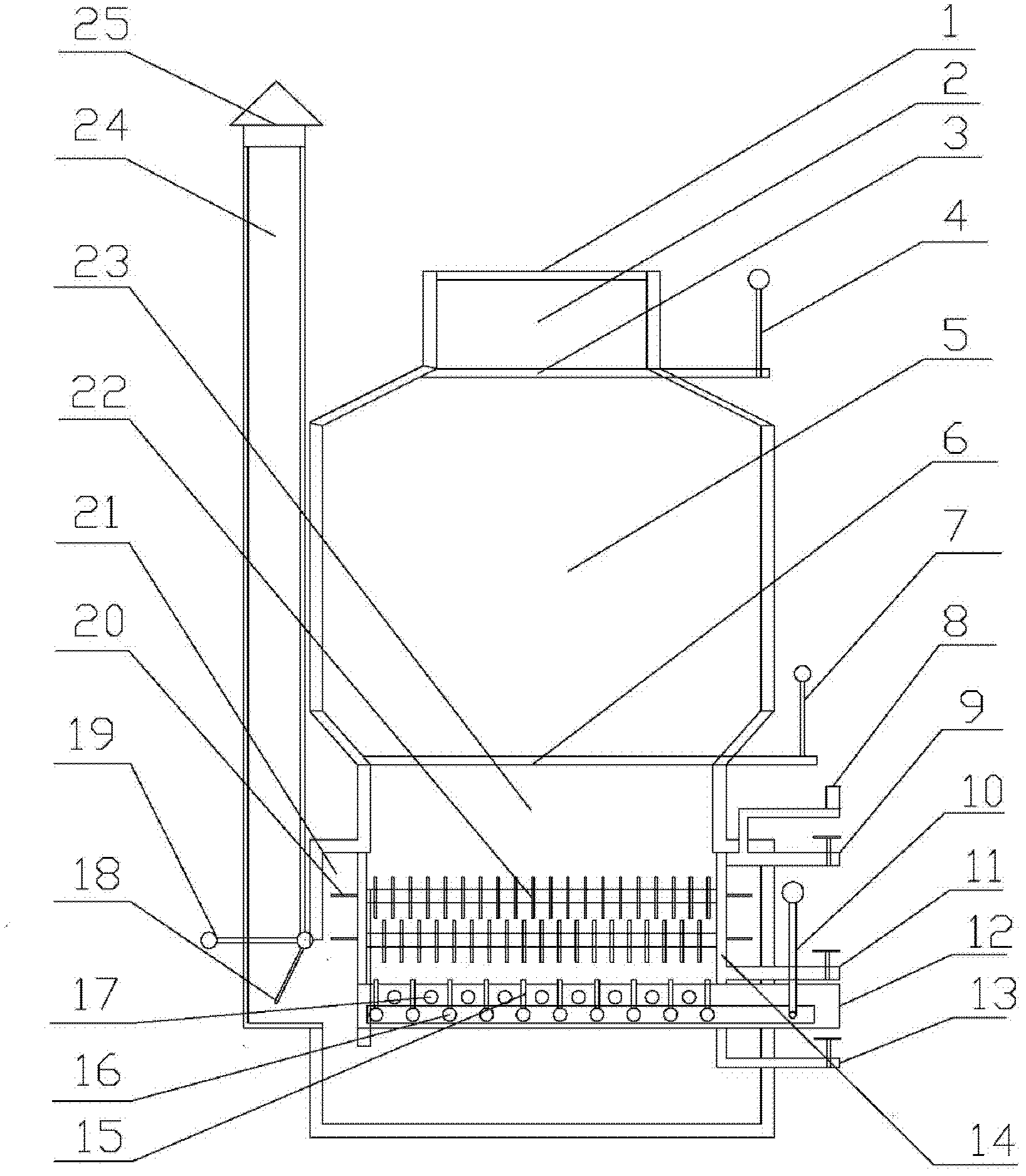

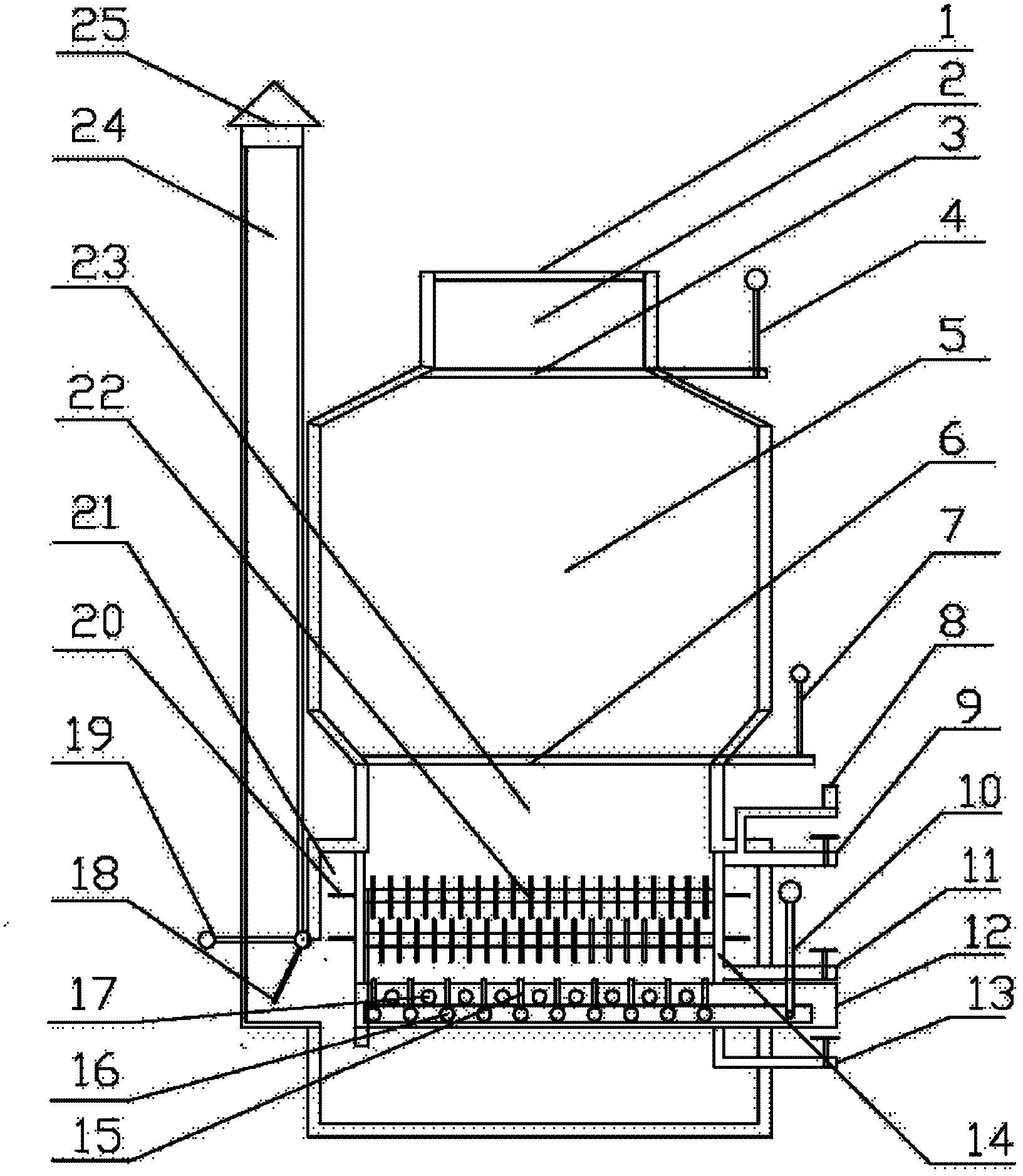

Biomass fuel boiler

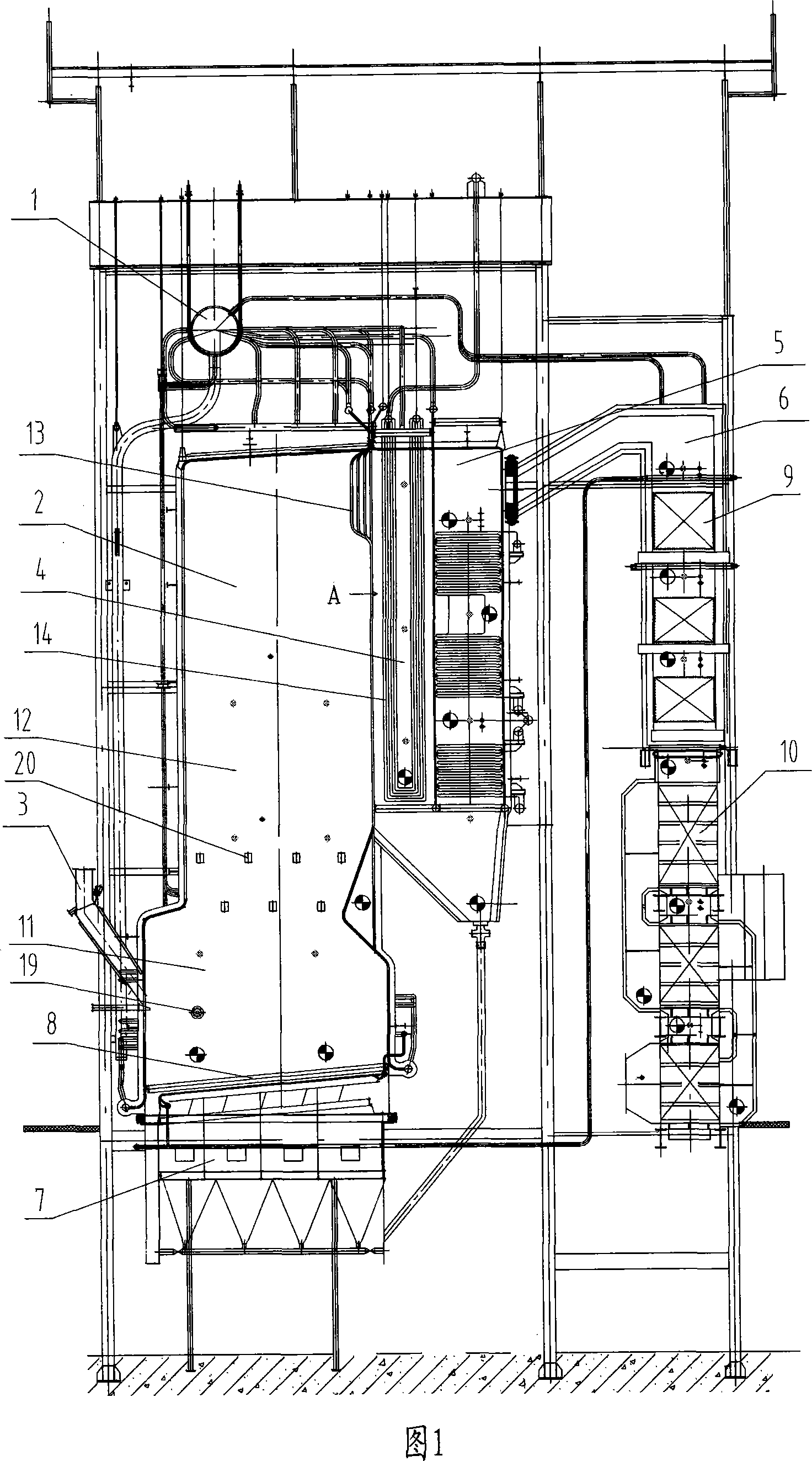

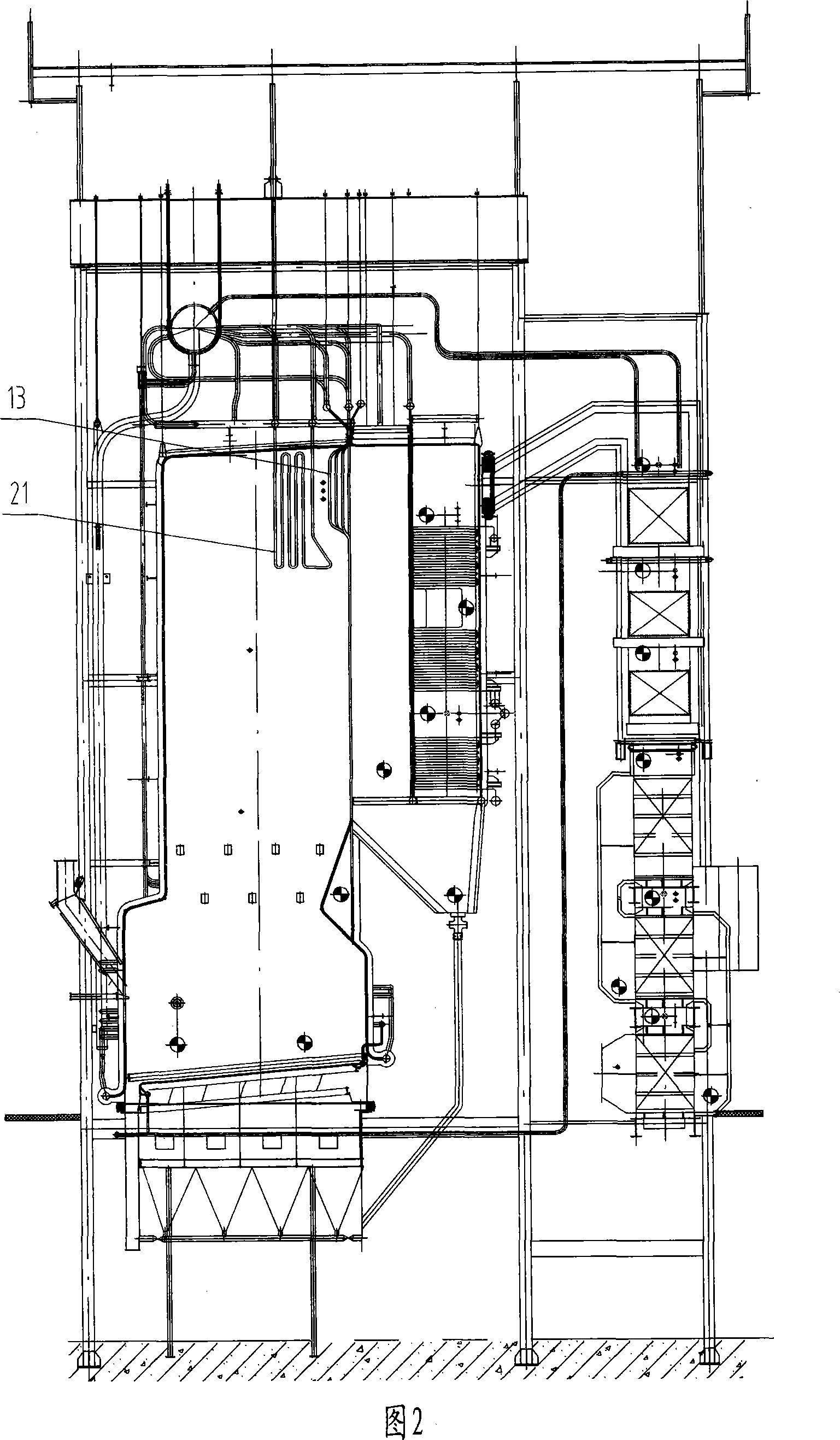

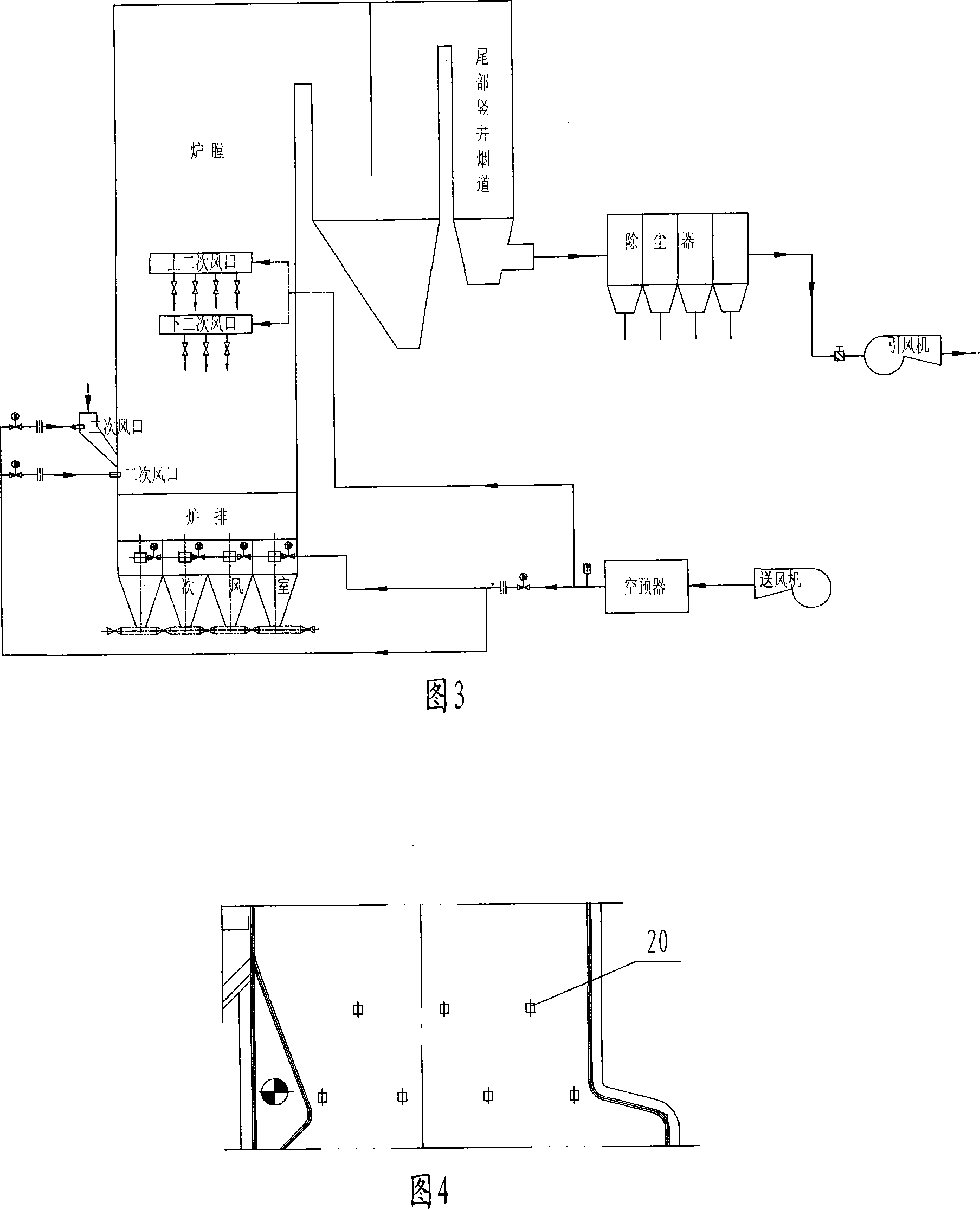

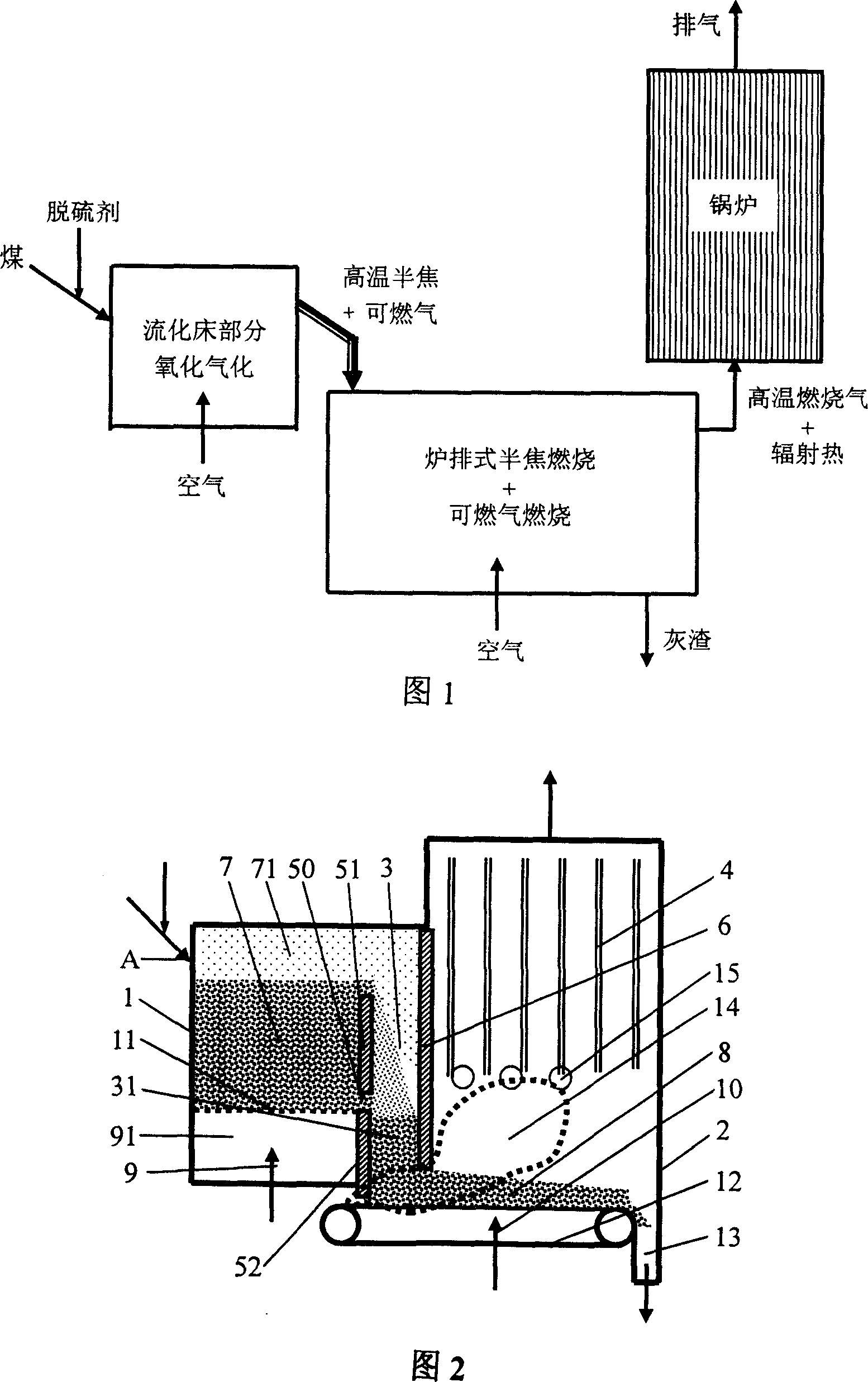

ActiveCN101105336ABurn fullyNot corrodedIndirect carbon-dioxide mitigationWater heatersAir preheaterEngineering

The invention discloses a biomass fuel boiler based on the original coal burning boiler. A primary air chamber, secondary air ports respectively equipped in a feed pipe and in a furnace cavity below the feed pipe, and a plurality of air ports equipped at the left and right sides of the furnace cavity and staggeredly arranged are connected with an air preheater, and a regulating baffle is respectively provided in each air ports. The invention realizes complete combustion of biomass fuel with suspension combustion as main combustion manner and grate firing as auxiliary combustion manner. As an improvement, the cross-sectional area of the combustion zone in the furnace cavity is larger than the burnout zone; a dregs condensing pipe equipped with a cooling water passage is provided at the inlet port of a first smoke flue; superheaters are disposed at different positions of the boiler in accordance with the type of biomass fuel; a vertical shaft smoke flue at tail portion is sequentially connected with a dust remover and an induced fan; and an adjacent furnace heating device is respectively equipped in the furnace cavity and the lower header tanks of the water-cooled wall of the first and second smoke flues. The invention can prevent high temperature corrosion, assure heat exchange efficiency and storage bin safety, shorten starting time, and prolong service life.

Owner:CHINA WESTERN POWER INDAL

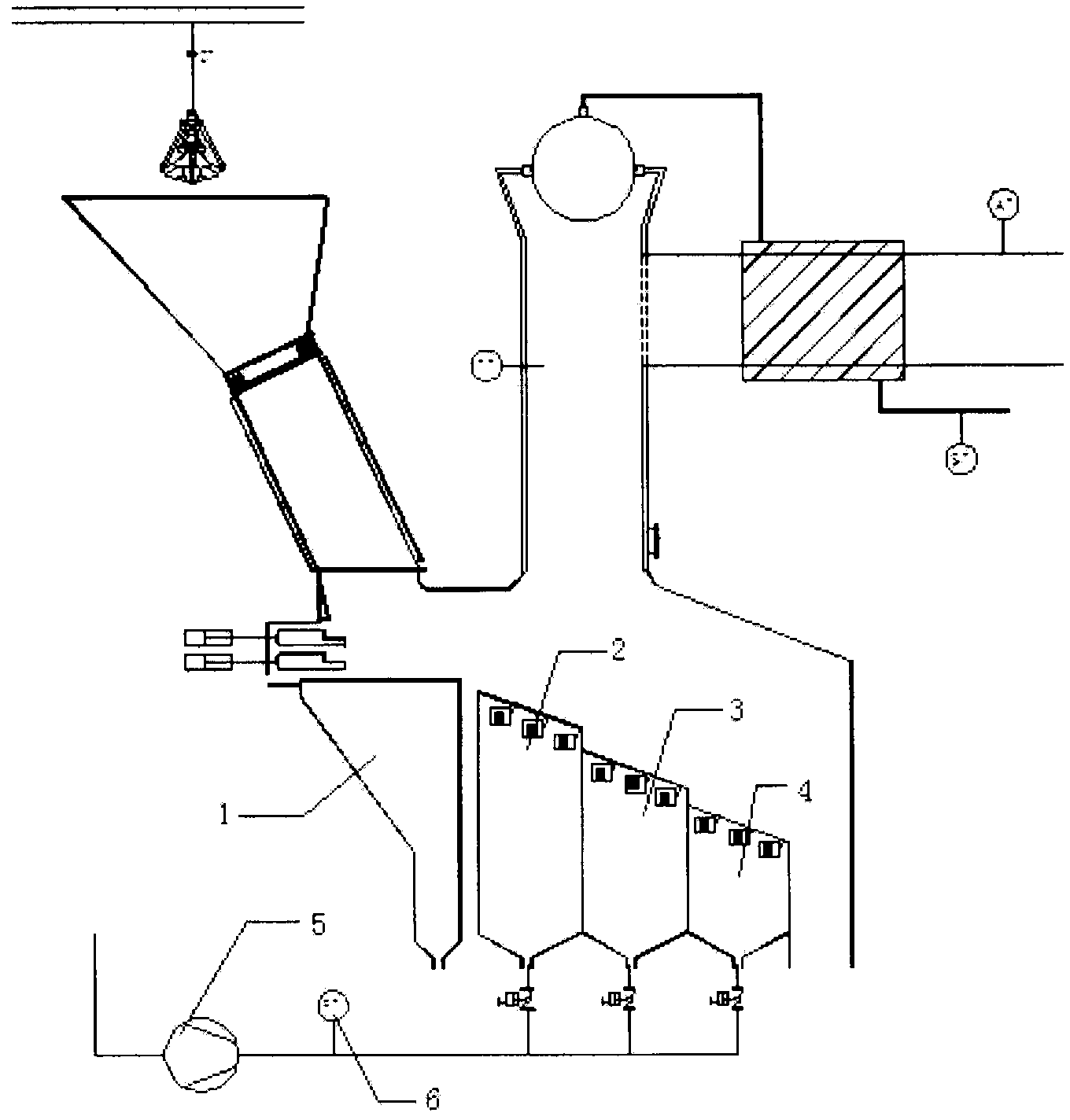

Low-pollution efficient combustion method for coal-burning boiler and combustion apparatus

InactiveCN101025266ASuppress generationEliminate burning black smokeFluidized bed combustionSolid fuel combustionFluidized bedProcess engineering

The invention relates to burning method and the device of low pollution and high efficiency for the coal-burning boiler which divides the burn into two processes. The two processes are the fluidized-bed oxidizing gasification and the burning of the carbocoal and fuel gas in grate burning furnace. The carbocoal and the fuel gas are transferred into the grate burning furnace through the moveable bed channel together; the fuel gas burn at the high temperature carbocoal layer and the carbocoal surface, so it can eliminate the black smoke and NOx; so the carbocoal and the fuel gas can be burned absolutely; the desulfurater added with the coal can remove the sulfide in the fluidized-bed part oxidizing gasification furnace which are dispersed between the carbocoal particle surface and the micropore to remove the oxysulfide sulfoxide of the burning furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

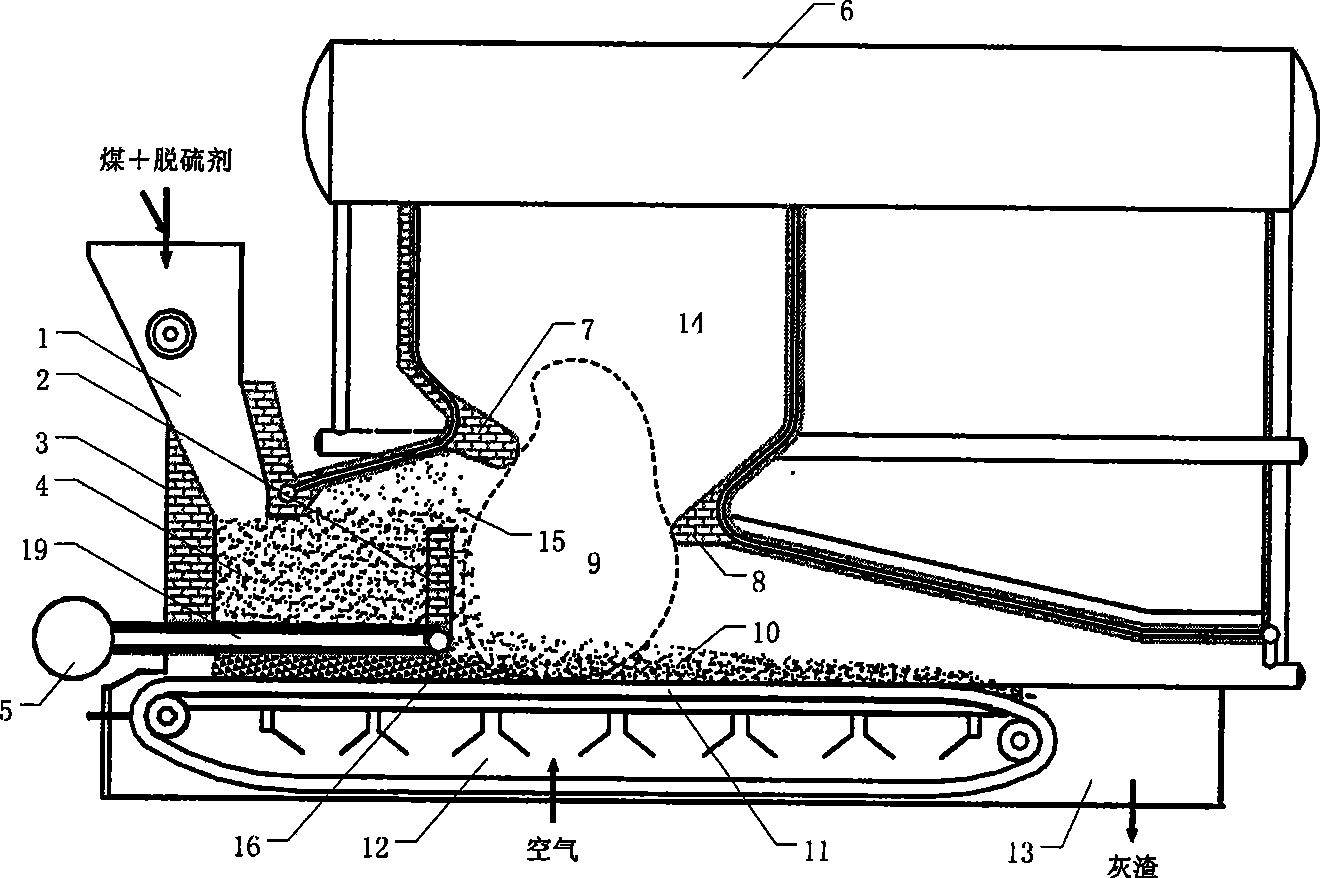

Low emission high efficiency grate-firing combustion device and method

InactiveCN102506418AImprove combustion efficiencyReduce conversionSolid fuel combustionNon-combustible gases/liquids supplyCombustorCombustion chamber

The invention relates to a low emission high efficiency grate-firing combustion device and a method. The method is characterized in that coal dust and a sulfur-fixing agent are fully mixed so as to enter into a grate-fired furnace through a hopper, a gas recirculation and spray water combined technology is utilized to rapidly pyrolyze coal dust so as to generate reducing gas, recirculation fume is utilized to carry the reducing gas and part of fine granule semicoke to enter into a recrudescence region in the furnace, and the combustion flow of the furnace is strengthened; and the purpose of reduction NOx is achieved, the no-burnout grains are continually combusted above a combustor, staged combustion of a fuel in the furnace is realized in a hearth, and meanwhile, and the combustion efficiency of the grate-fired furnace is also improved. According to the invention, the grate-fired furnace is introduced through a fuel staged combustion technology, on the one hand, the NOx and SOx discharge of the grate-fired furnace is reduced through combustion adjustment, namely, the NOx deprivation rate is 35%-55%, the SOx deprivation rate is more than 80%, thereby protecting an atmospheric environment; on the other hand, the combustion efficiency of the grate-fired furnace is improved by 1%-2%.

Owner:SHANDONG UNIV

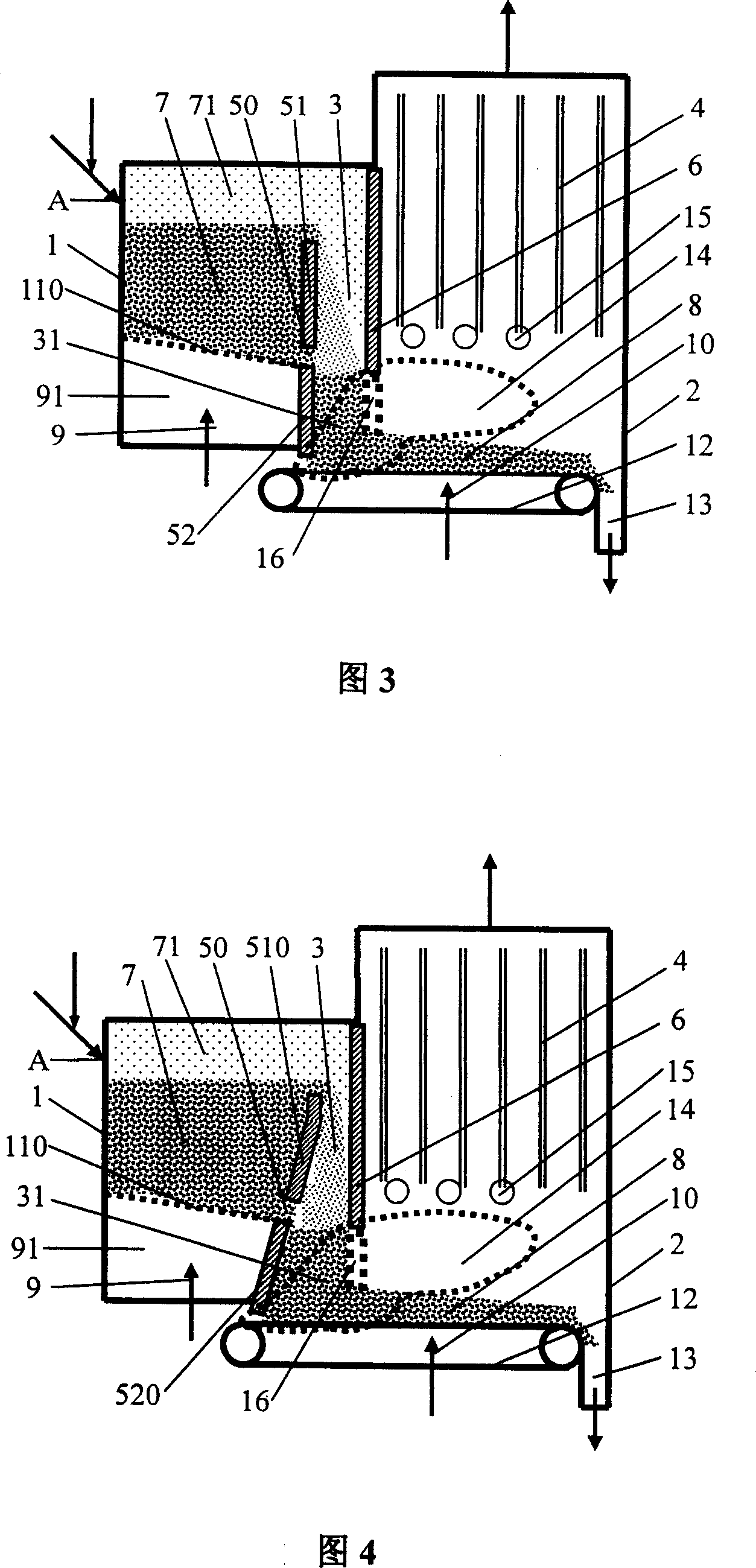

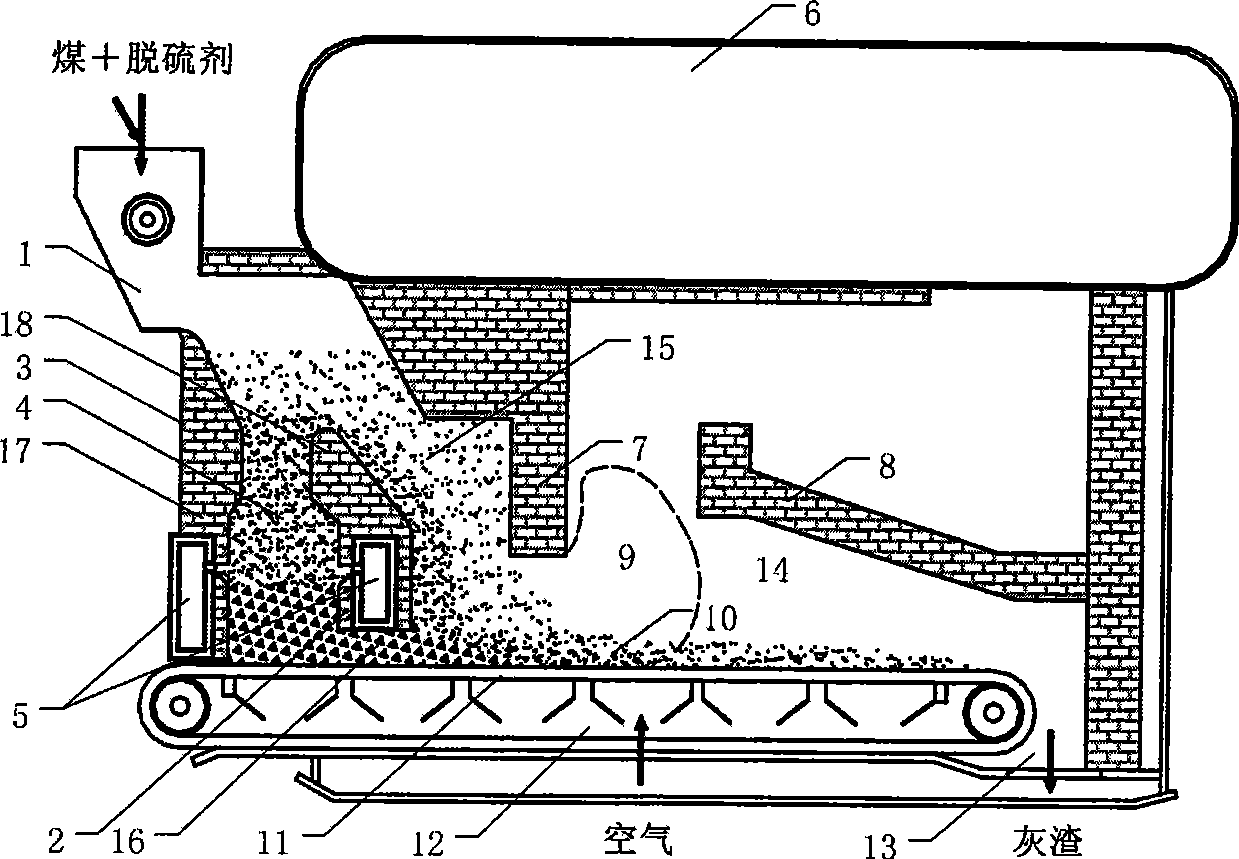

Coal thermal decomposition grate firing apparatus and its combustion method

InactiveCN101368724ASimple structureNo increase in sizeSolid fuel combustionCombustion apparatusCombustion chamberCombustible gas

The invention relates to a coal pyrolysis layer combustion device and the combustion method thereof, including that the furnace body interior of the first layer combustion furnace is divided into an upper oxidation pyrolysis chamber and a lower fire grate layer combustion chamber which is communicated with each other; the coal and desulfurizer are mixed to be fed into the middle part of the oxidation pyrolysis for oxidation pyrolysis through a hopper; the generated combustible gas and the smaller semi-coke particles are overflowed through the upper-connected through port or are carried in the airflow to be fed into the mechanical fire grate layer combustion chamber; the bigger semi-coke particles fall on the mechanical fire grate and are fed into the layer combustion layer for combustion; the mechanical fire grate layer combustion chamber is provided with a front arch and a back arch for organizing the airflow field inside the furnace; the coal pyrolysis layer combustion device and the combustion method thereof adopt the fluidization characteristics of the coal particles with different particle diameters and the high thermal capacity characteristic inside the oxidation pyrolysis chamber to realize the natural separation of the coal particles with different particle diameters and the rapid oxidation pyrolysis of coal, reduce the fire grate coal leakage loss and the incomplete combustion loss caused by the front segment low temperature of the fire grate and reduce the emission of the SOx and NOx pollutant through the combination of the pyrolysis desulfurization and the combustion desulfurization, and the reburning denitration formed by the coal pyrolysis product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

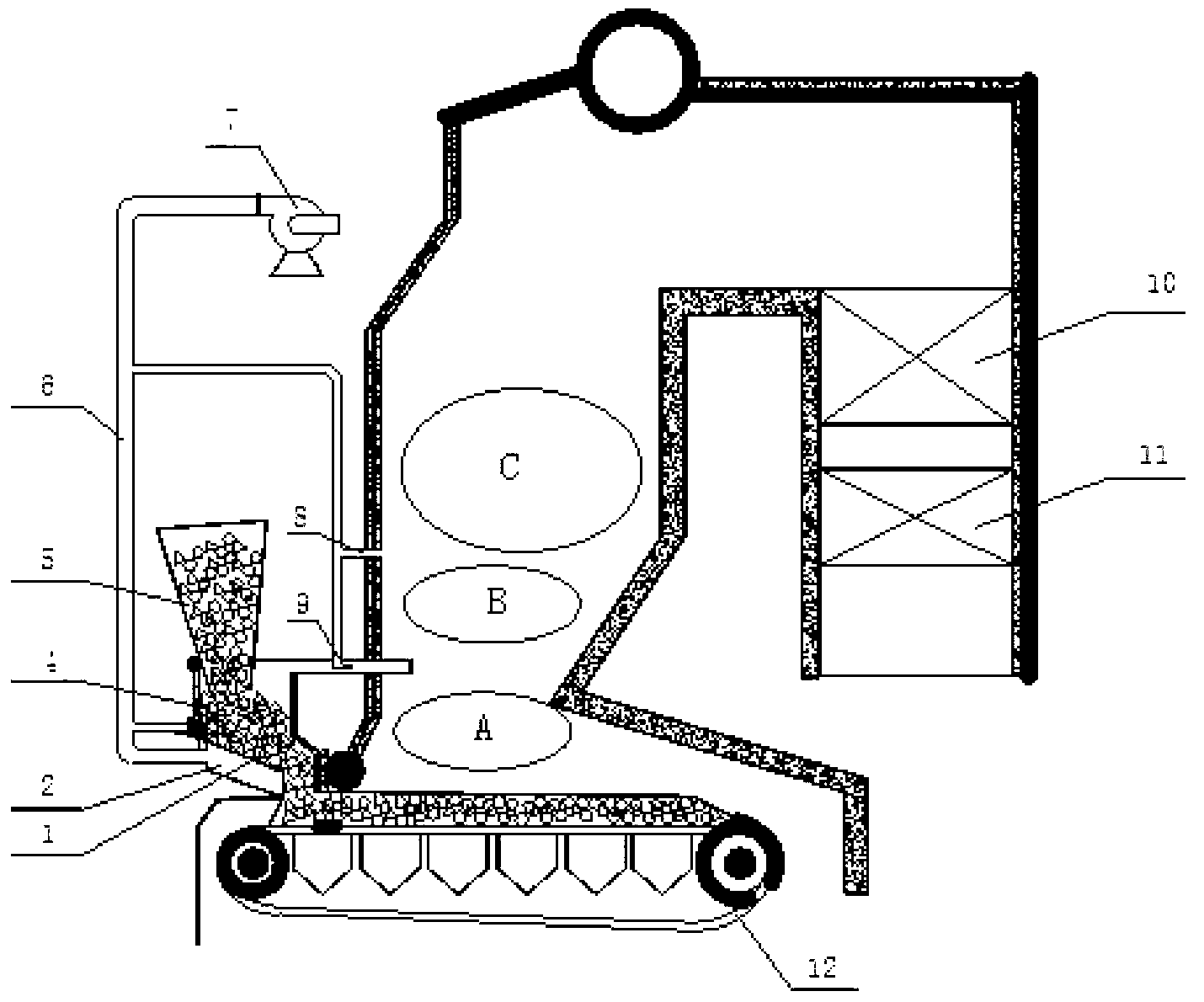

Biological mass-energy fuel boiler and its burning method

InactiveCN1900589AEfficient and clean combustionRealize comprehensive utilizationDamper arrangementSolid fuel combustionFlue gasEngineering

Characters of the invention are that suspension burning plus grate firing carry out in boiler; first, through conveying facilities, biomass energy fuel in sheet, granular or powder is fed equably through feed inlets with adjustable angles; next, secondary air under feed inlets sends fuel to fire box, and suspension burning is carried out in fire box under cooperation of primary air; then, based on burning properties and state to adjust primary / secondary air in order to guarantee high temperature in burning area, and prolong residence time of combustible and flue gas in high temperature; finally, in suspension burning, bigger fuel granules drop to fire grate to carry out grate firing, and adjusting angles of feed inlets and secondary air to make thickness of fuel layer even on fire grate, and adjusting primary air to ensure full burning. The invention strengthens burning and guarantees firing in time and full burning so as to realize clean burning biomass energy fuel.

Owner:上海四方锅炉厂

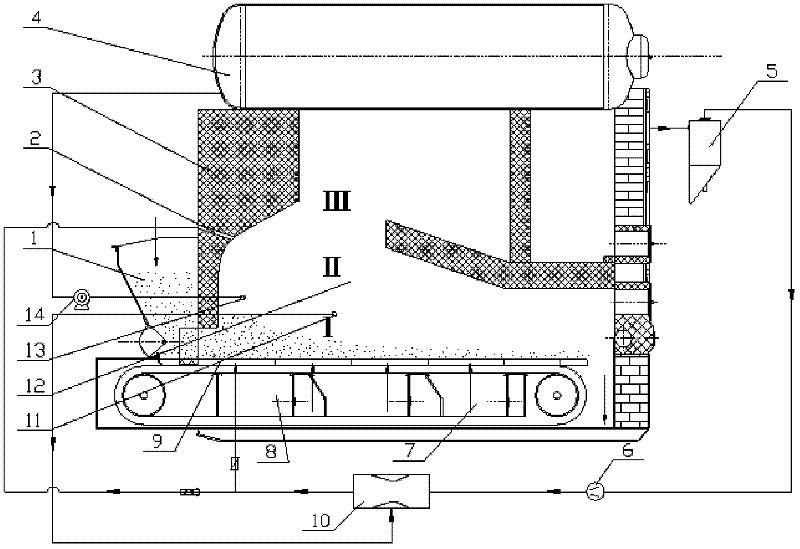

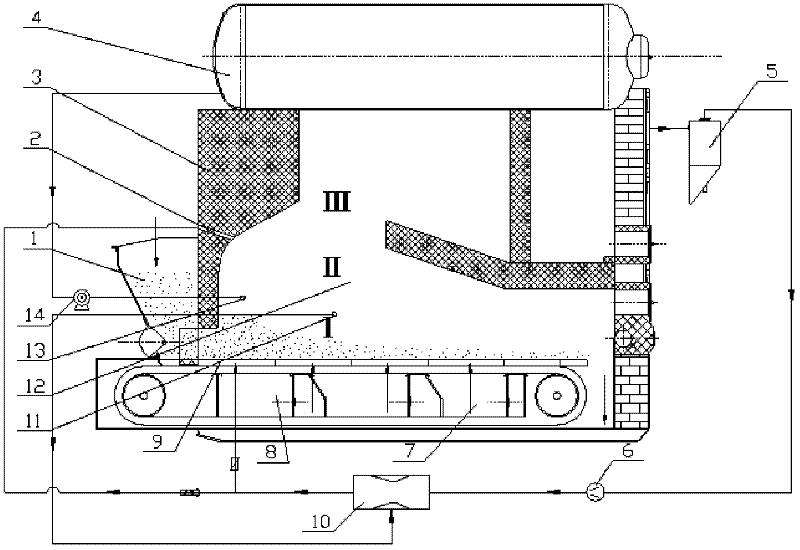

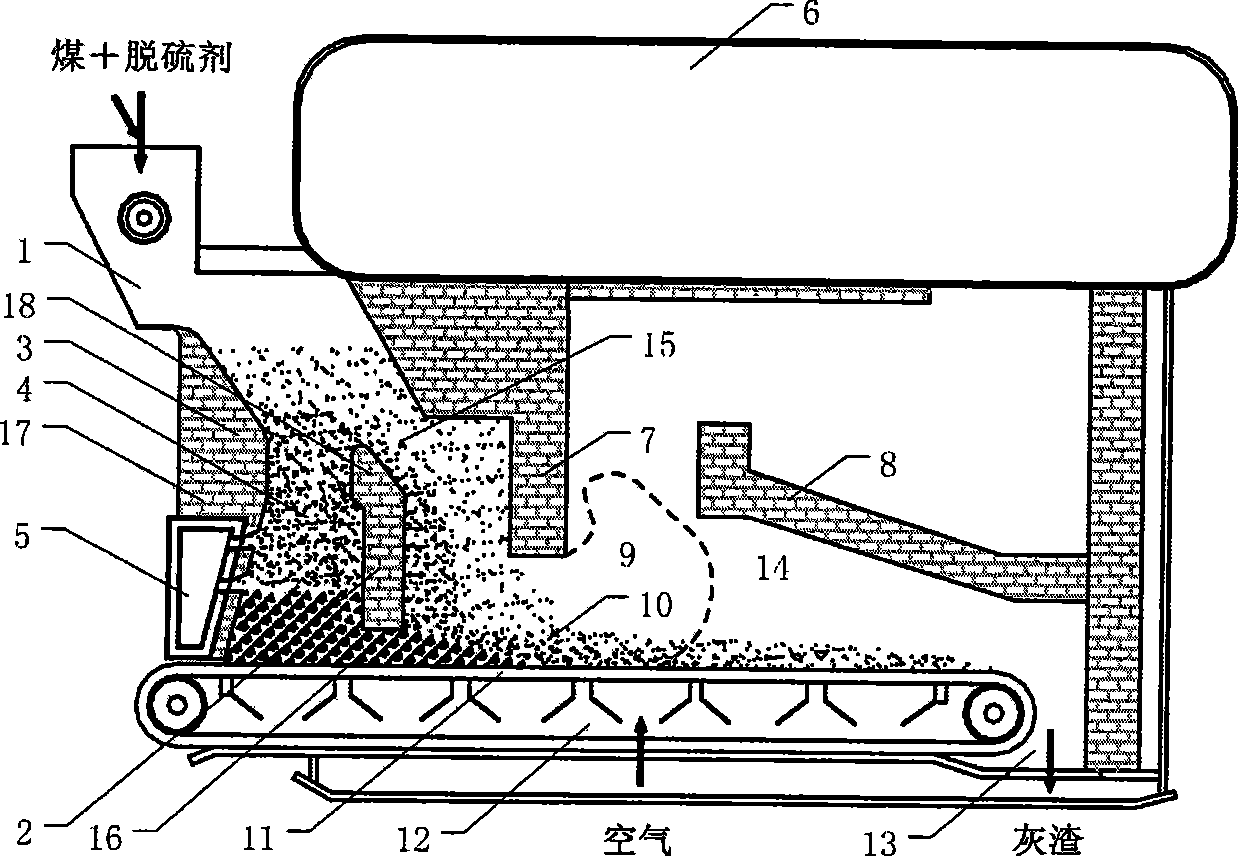

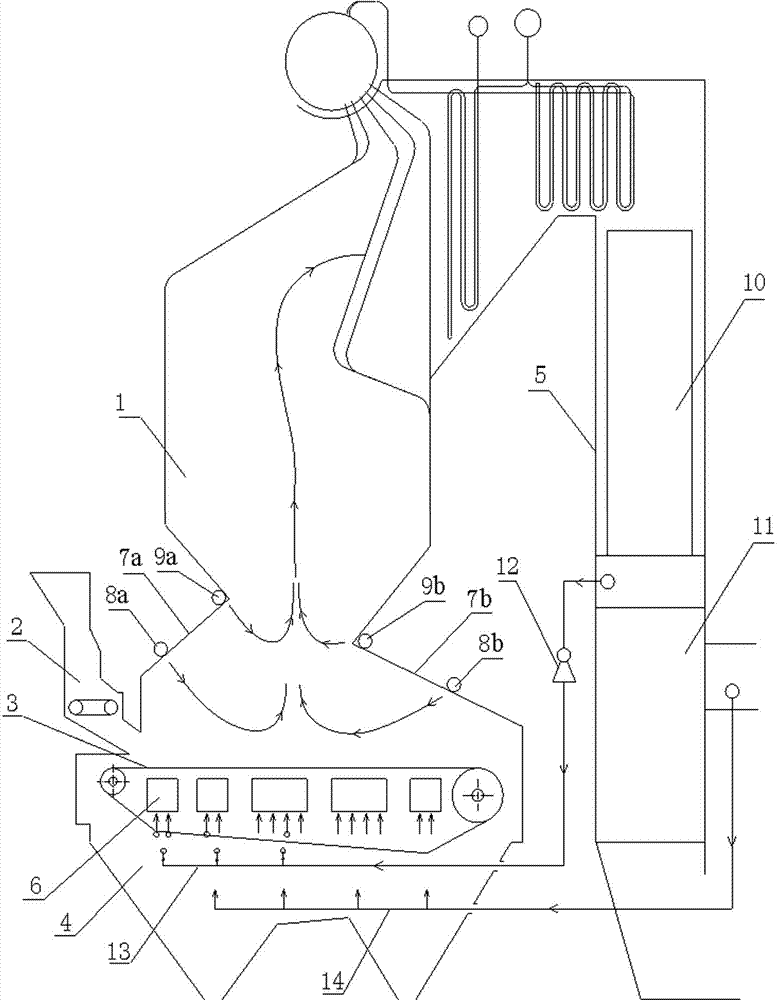

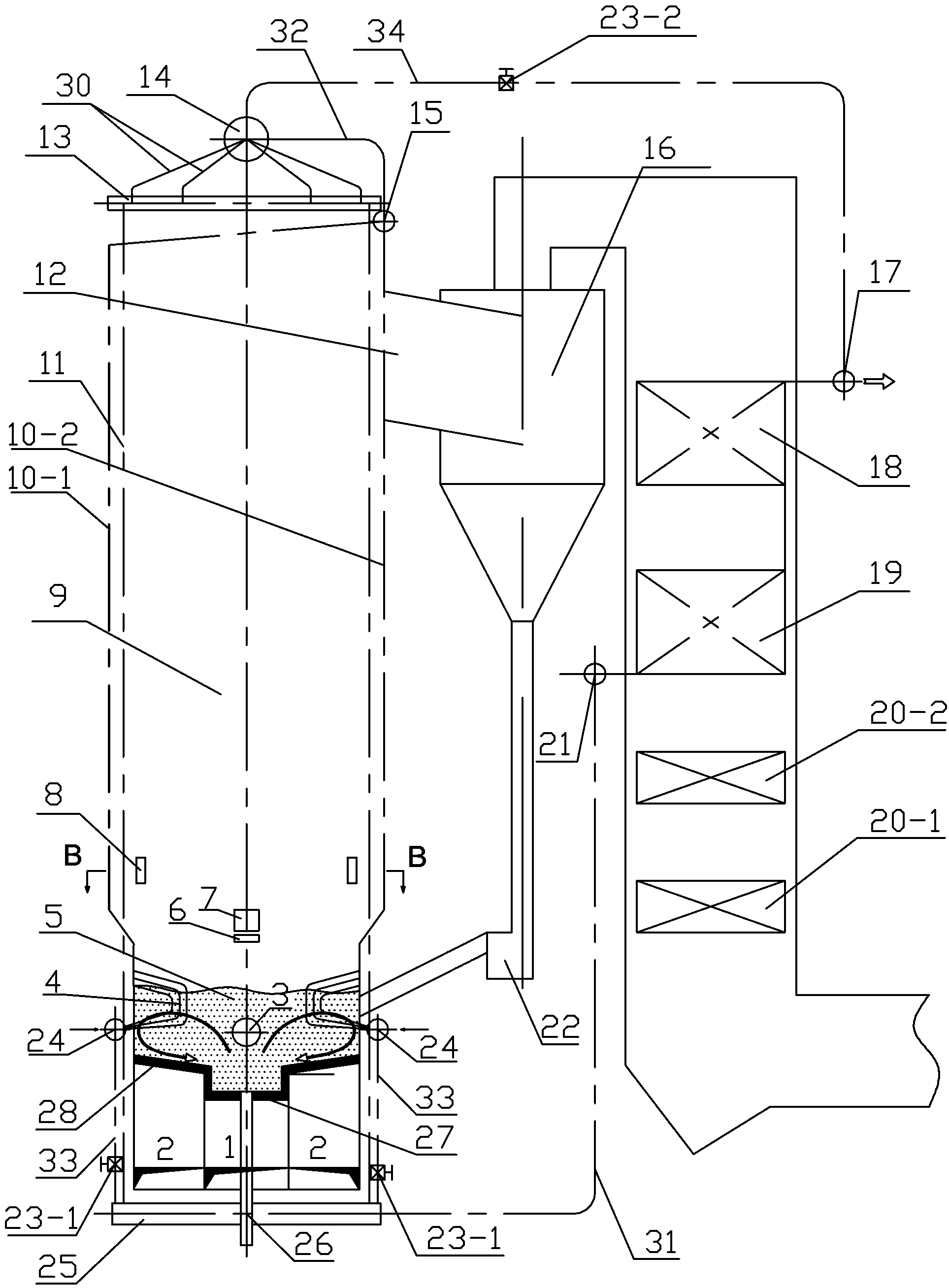

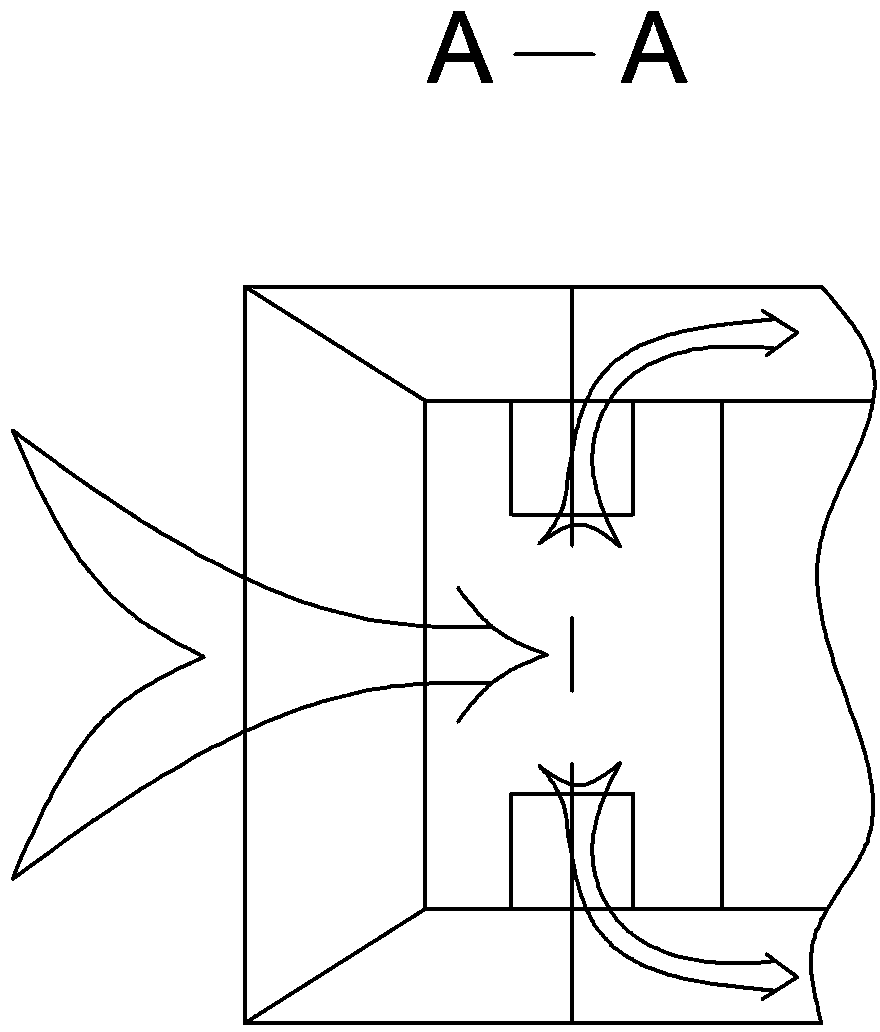

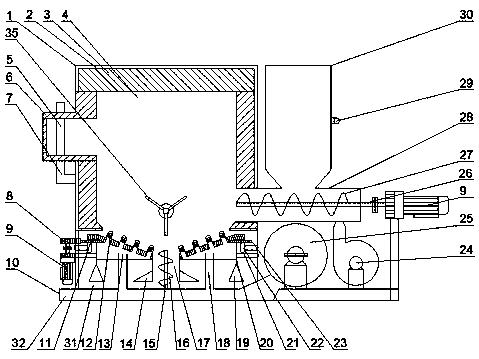

Coupling staged combustion and smoke recirculation low NOx chain grate furnace

ActiveCN104748104APromote fireStable combustion is goodSolid fuel combustionIndirect carbon-dioxide mitigationThermodynamicsSlag

The invention discloses a coupling staged combustion and smoke recirculation low NOx chain grate furnace. The chain grate furnace is composed of a hearth, a coal feeder, a chain grate stoker, a slag hopper and a tail flue. The hearth is divided into an upper hearth part and a lower hearth part through a front furnace arch and a rear furnace arch. Secondary air and over fire air are arranged in a suspension combustion area of the lower hearth body to organize staged combustion in the suspension combustion area, the secondary air of the lower hearth body is fed through secondary air spraying ports in the lower areas of the front furnace arch and the rear furnace arch, the over fire air is fed through over fire air spraying ports in the intersection of the upper hearth body and the lower hearth body, primary air is fed in a segmented mode below the stoker so as to organize the staged combustion of a stocker combustion area, low-temperature furnace smoke is extracted from the tail flue to be fed to the bottom of the stoker through a recirculation draught fan to perform recirculation, coal particles in the furnace are in the state far away from the stoichiometric ratio combustion state for a long time through two-layer staged combustion of the stocker combustion area and the suspension combustion area and smoke recirculation of the stoker combustion area, and efficient and low NOx combustion of the chain grate furnace is achieved.

Owner:江苏朗润环保科技有限公司

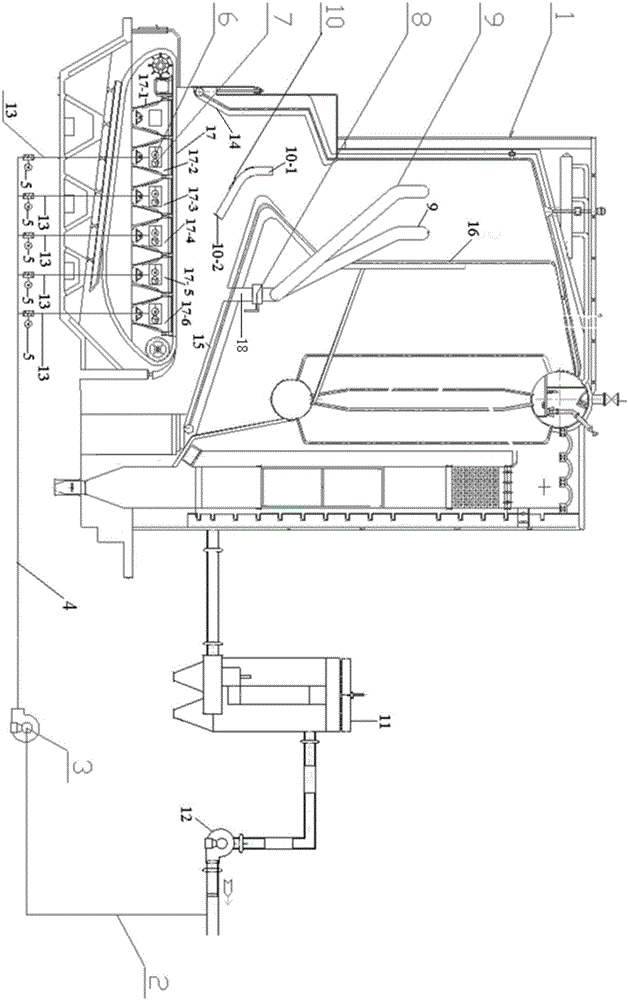

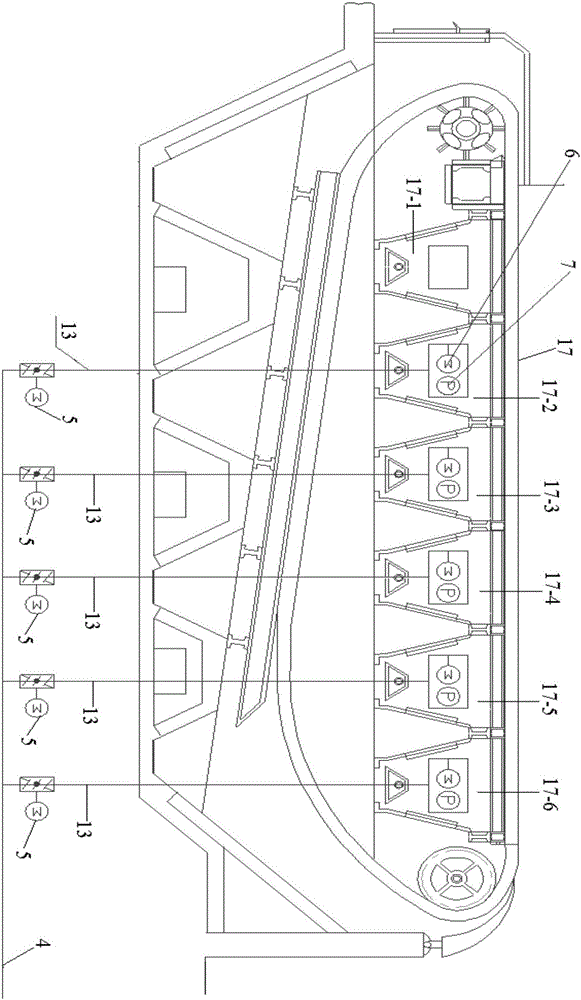

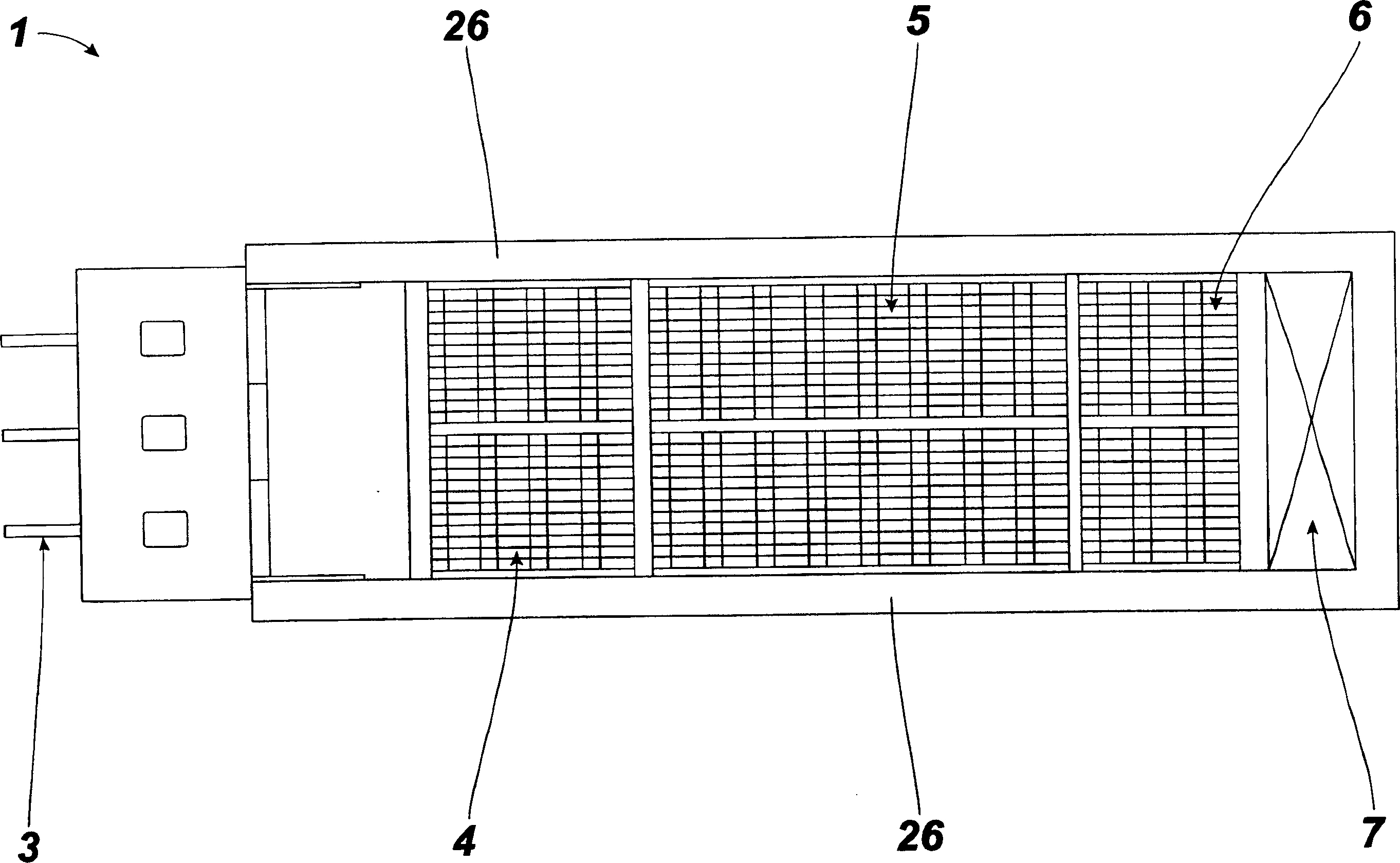

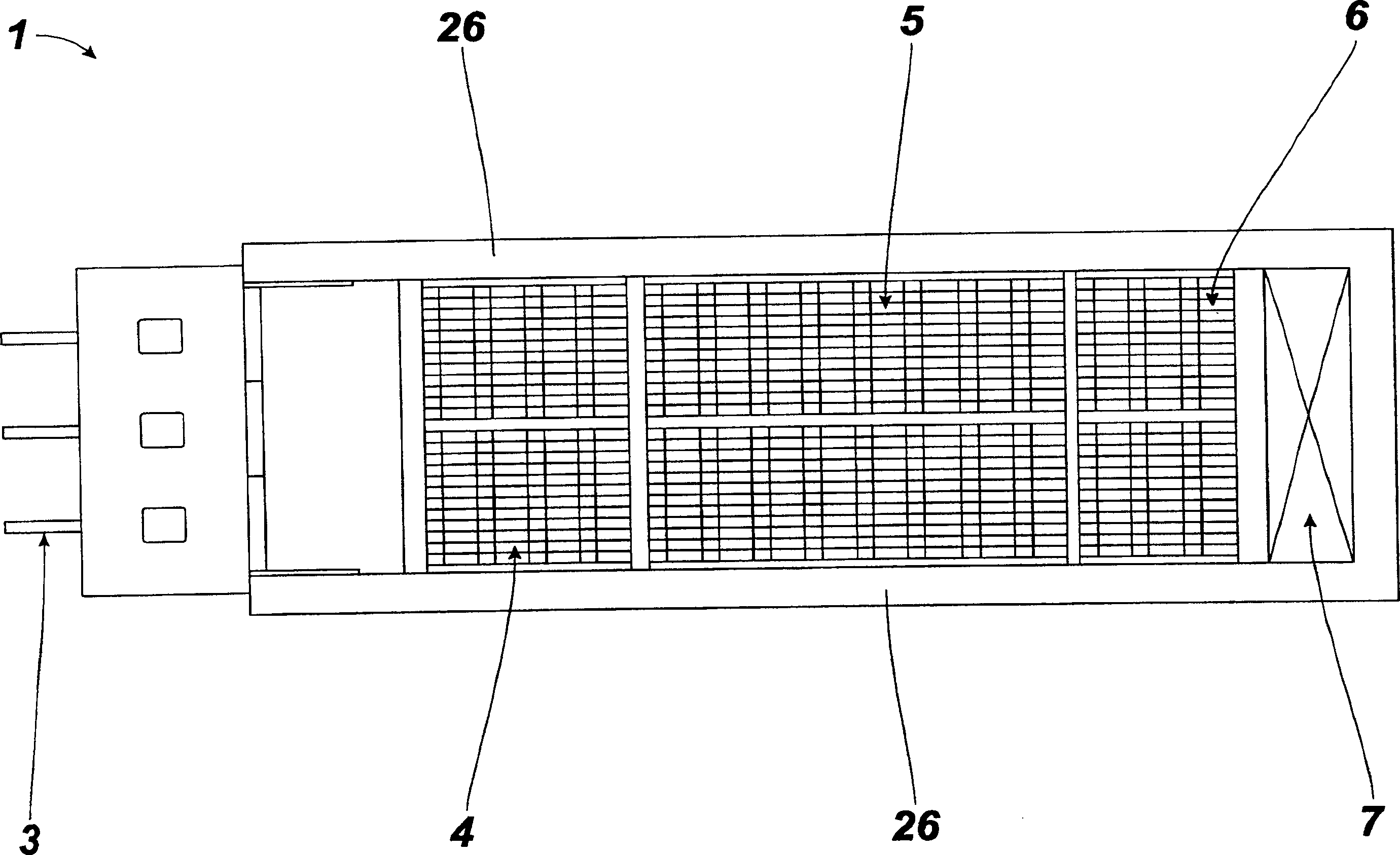

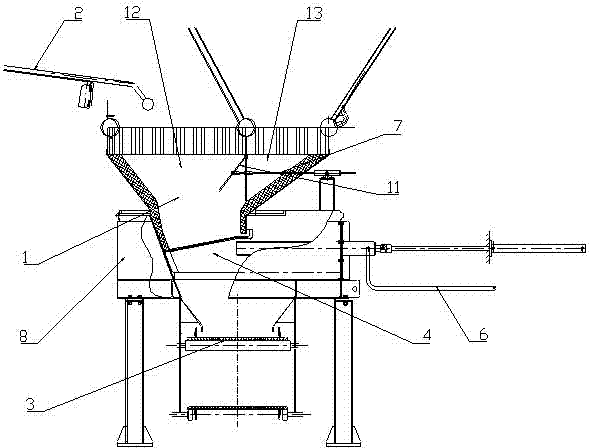

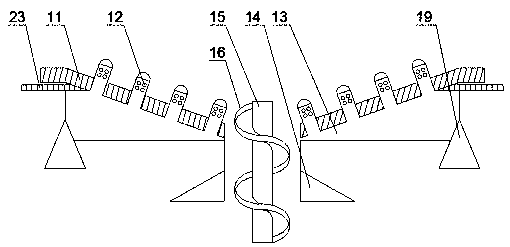

Efficient segmentation control combustion method and system for biomass boiler with charcoal combustion cell

InactiveCN103017145AEasy to removeIncrease the drying medium temperatureSolid fuel combustionCombustion apparatusSlagHearth

The invention discloses an efficient segmentation control combustion method and system for a biomass boiler with a charcoal combustion cell, and belongs to the technical field of the fire grate combustion of a biomass direct-combustion power generation boiler. A water cooling vibration fire grate is arranged on the bottom of a hearth; a smoke and air mixing box and a plurality of primary air bellows are arranged below the water cooling vibration fire grate; the charcoal combustion cell is arranged below the front end of the water cooling vibration fire grate; the bottom of the charcoal combustion cell is provided with a fixed fire grate; and the front end of the charcoal combustion cell is provided with a slag well. The external moisture of biomass fuel is removed in the drying area of the water cooling vibration fire grate; then, the biomass fuel is moved to the pyrolysis combustion area of the fire grate to generate a great quantity of volatile component to enter the hearth; when the volatile component of the biomass fuel is almost burnt, residual fixed carbon covered by ash is vibrated into the charcoal combustion cell; in the falling process, the residual fixed carbon covered by ash is overturned and collided to remove surface ash; oxygen is directly diffused to the surface of the charcoal to react with the charcoal; and the ash slag is blown into the slag well. According to the invention, the biomass fuels of different types and moistures can be subjected to efficient segmentation control combustion on the fire grate of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

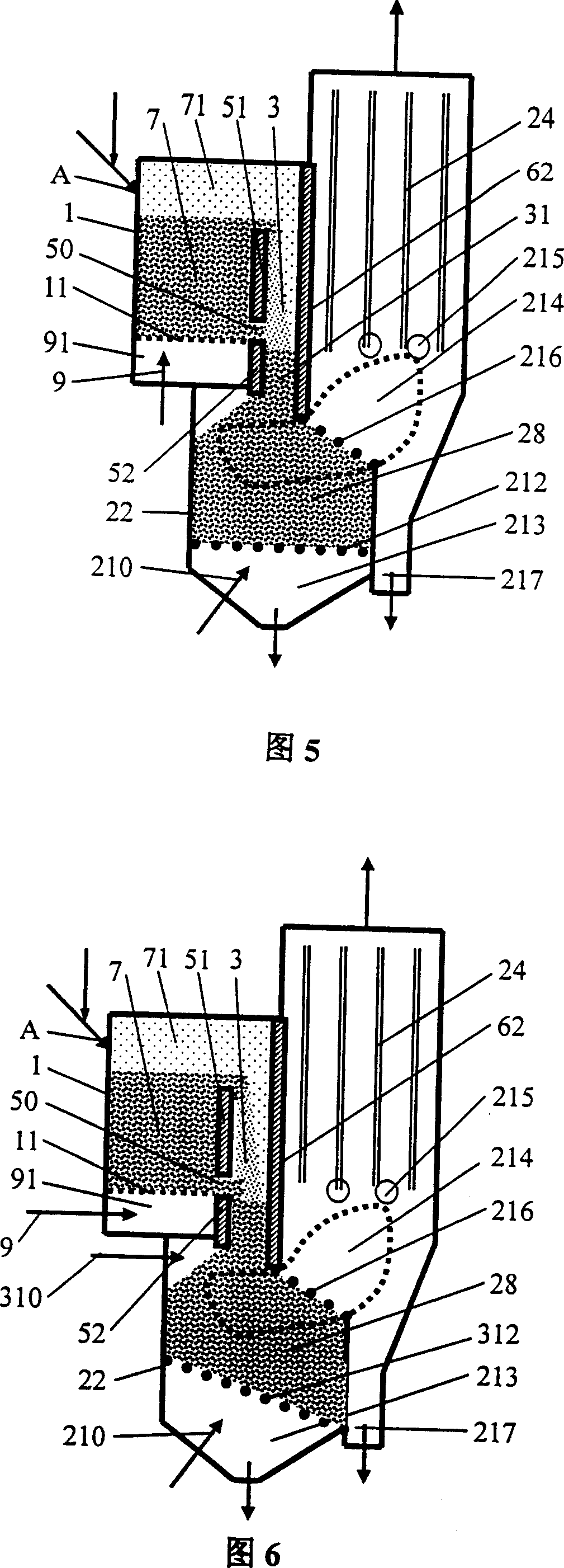

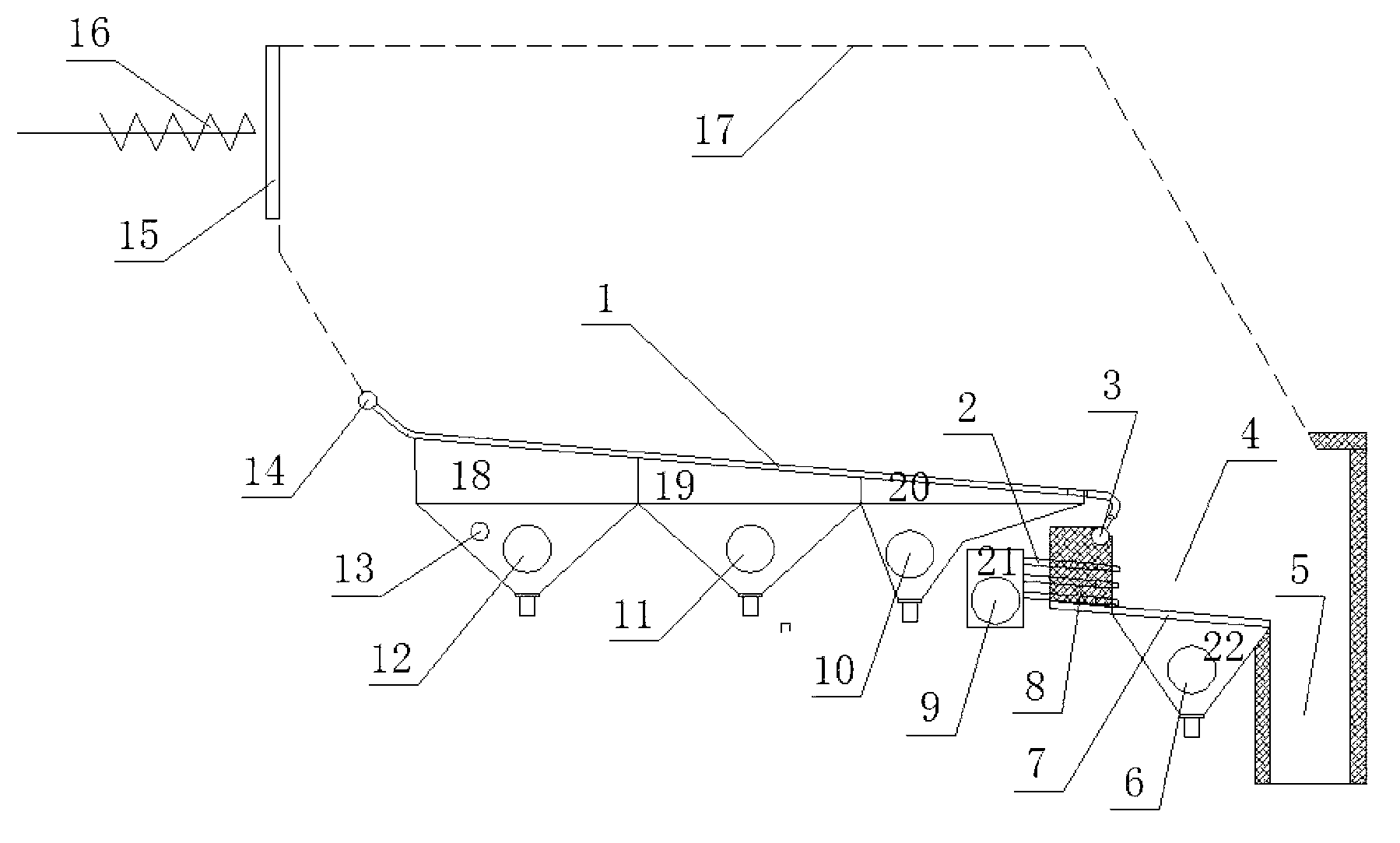

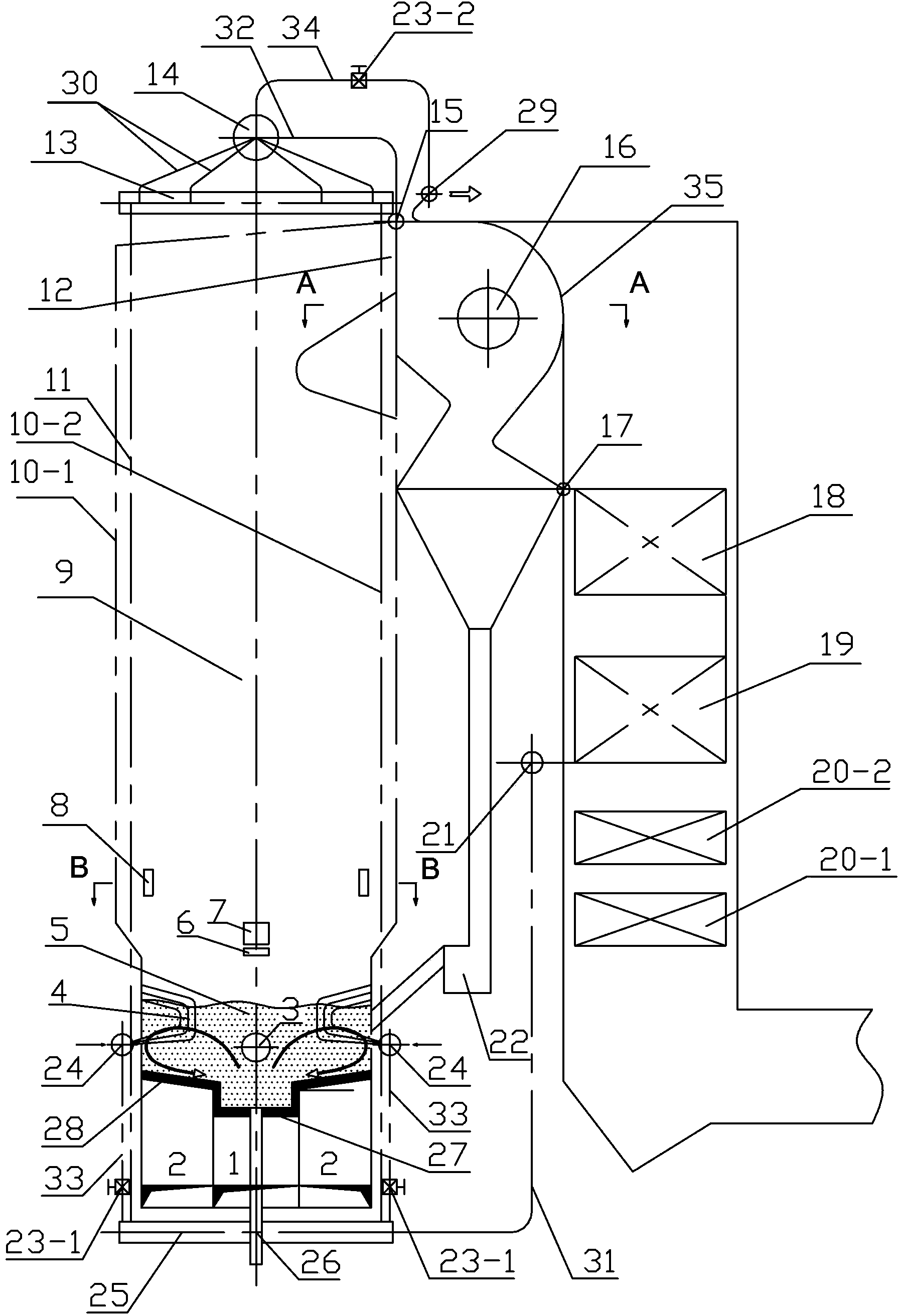

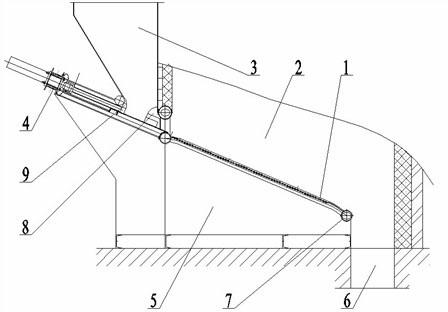

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

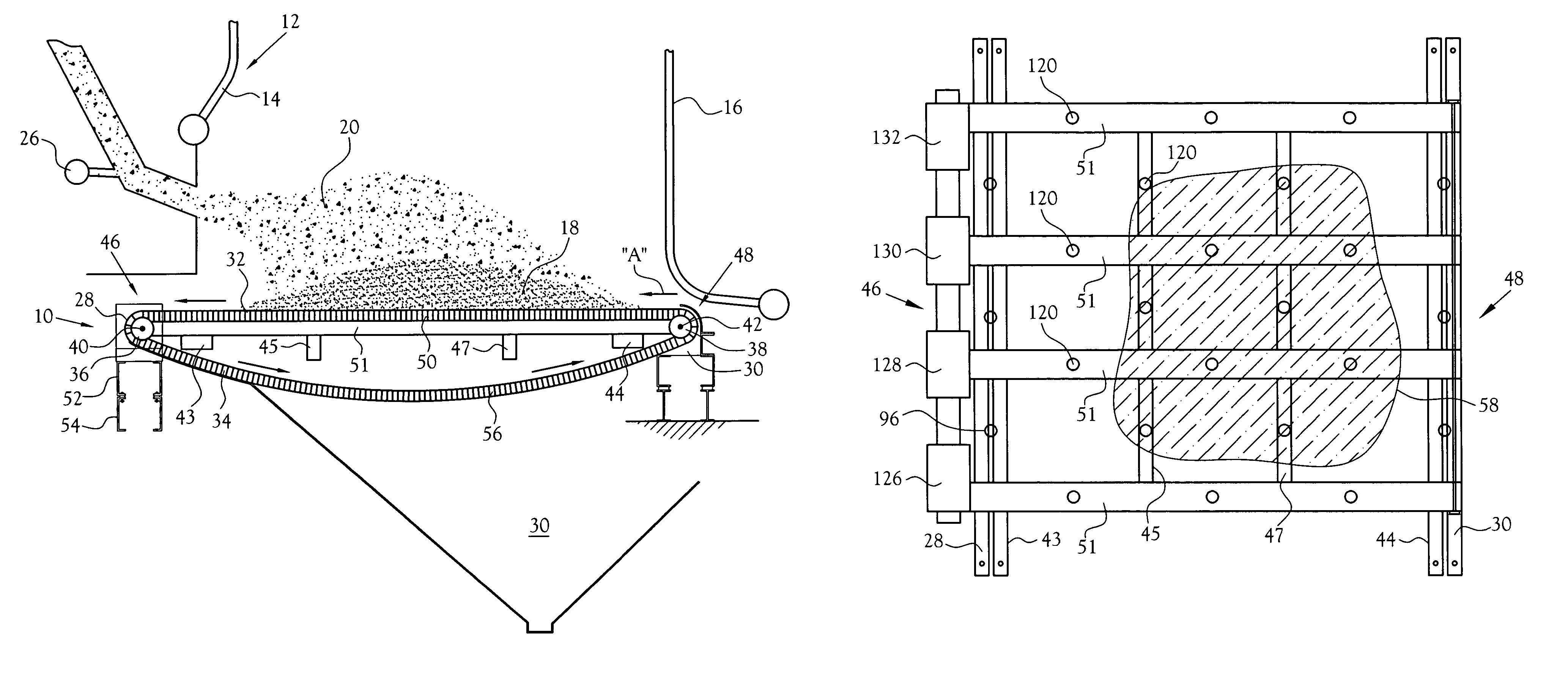

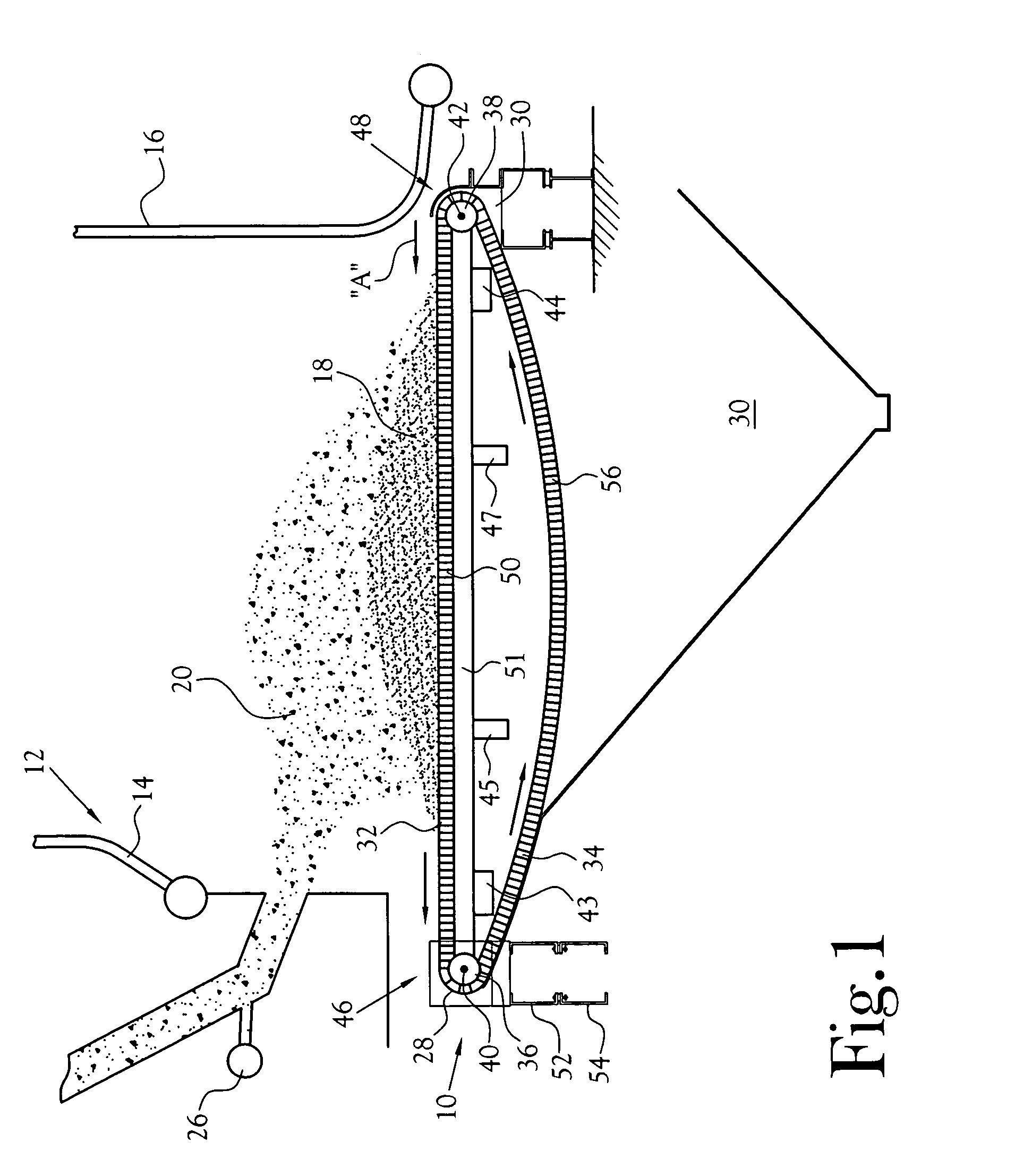

Monitoring of fuel on a grate fired boiler

Owner:INT PAPER CO

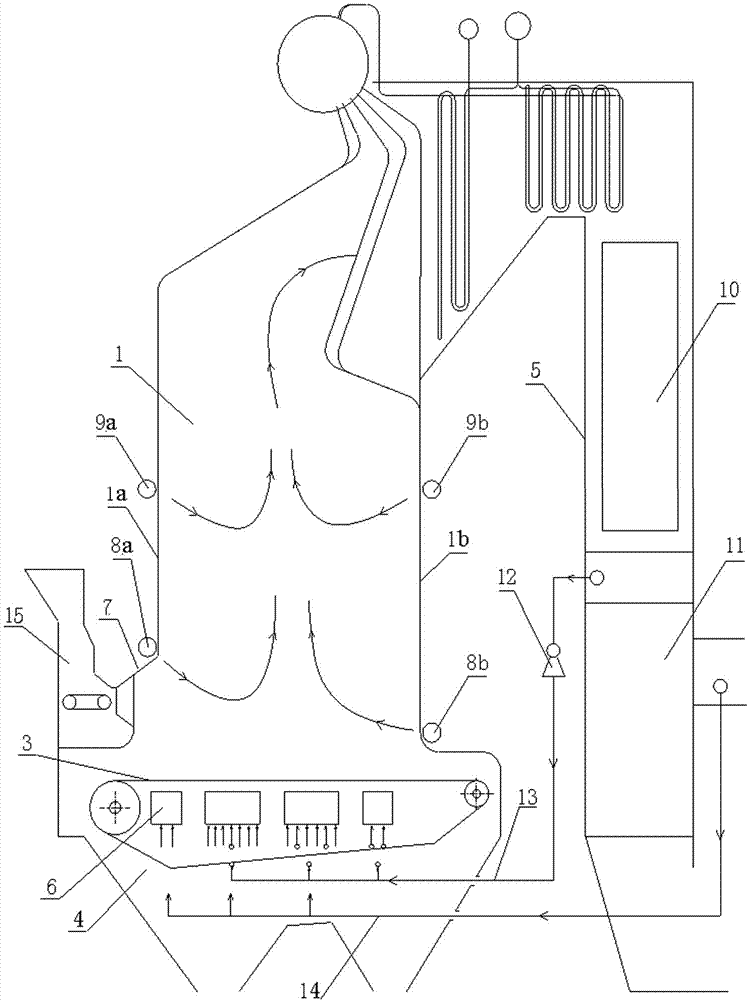

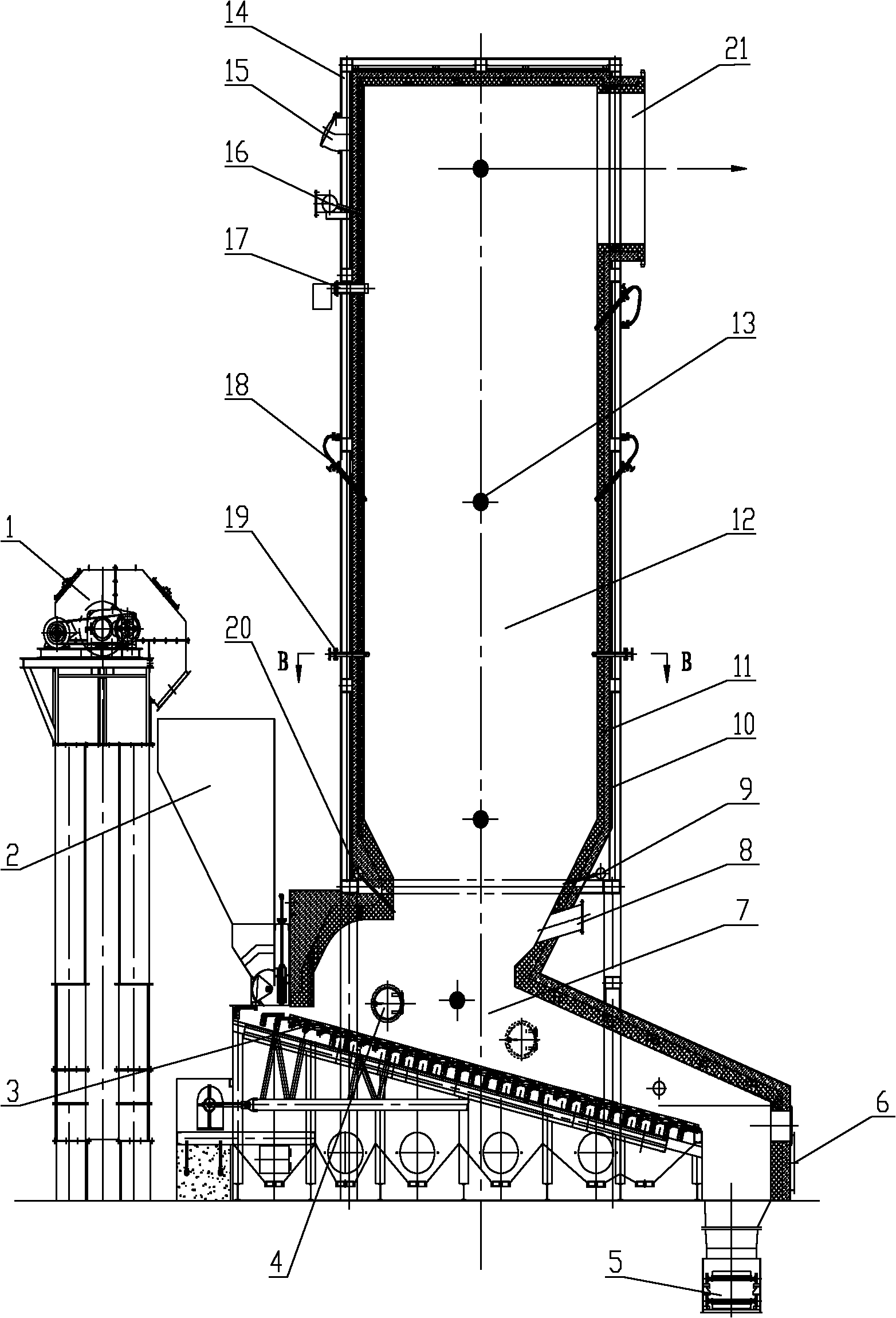

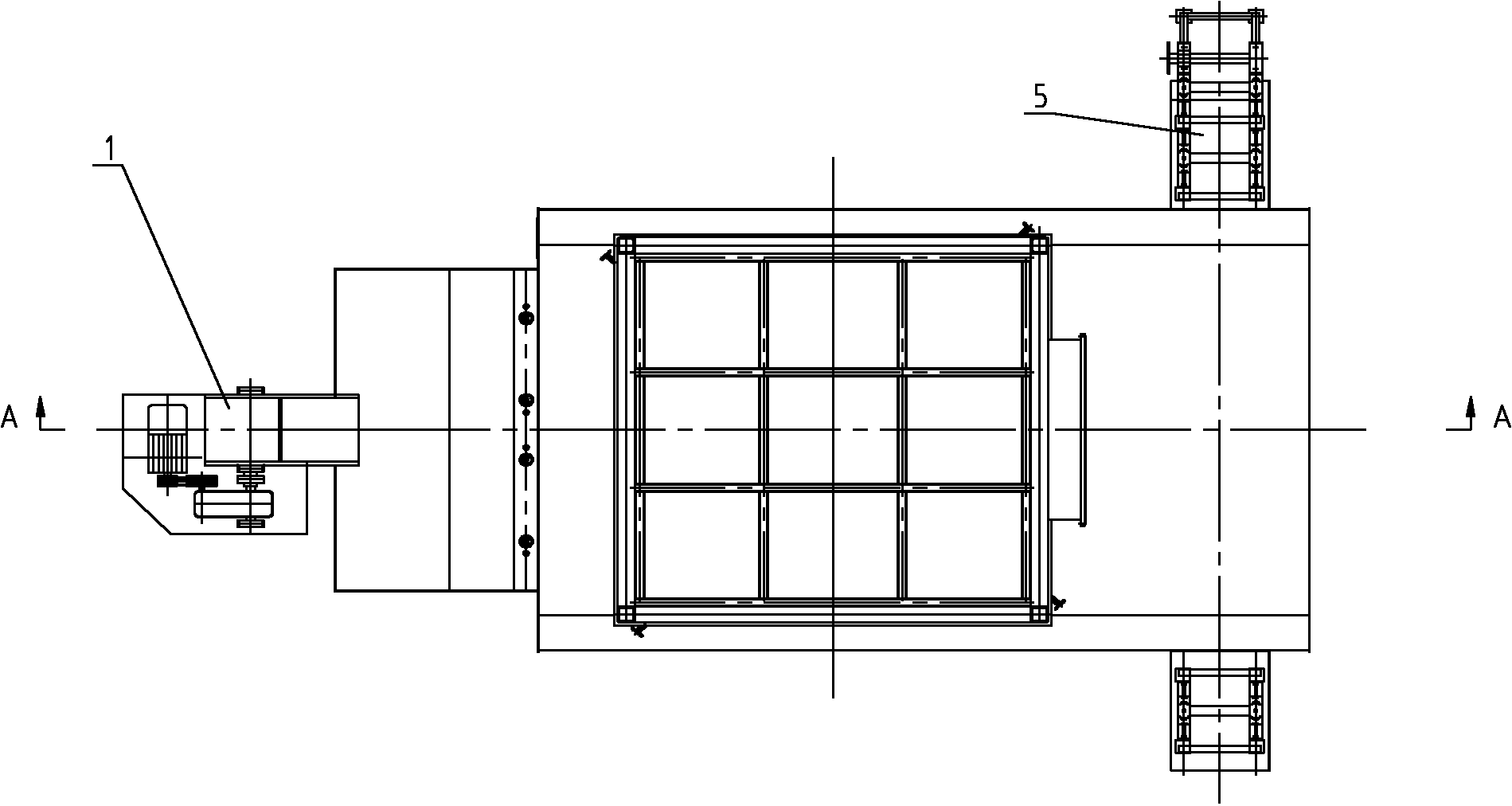

Low-nitrogen combustion stokerfeed boiler with two-stage smoke recirculation function

ActiveCN104791772AReduce generationDilute oxygen concentrationSolid fuel combustionAir/fuel supply for combustionLow nitrogenEngineering

The invention discloses a low-nitrogen combustion stokerfeed boiler with a two-stage smoke recirculation function. Segmentation wind supply is adopted for a fire grate combustion region, and over-fire air is deployed above the secondary air in a suspended combustion region so as to organize staged combustion; smoke with the low temperature ranging from about 250 degrees to 300 degrees is extracted from a tail smoke channel and sent into a plurality of wind chambers in the front of a fire grate so as to organize the first-level smoke recirculation in the fire grate combustion region; reducibility smoke with volatile component N, namely smoke with the medium temperature ranging from about 450 DEG C to 500 DEG C is extracted from the lower region of a front arch and jet into a burnout region below a furnace arch of a hearth at a high speed to be used for organizing the second-level smoke recirculation in the hearth burnout region. With the help of two-layer staged combustion of the fire grate combustion region and the suspension combustion region and smoke recirculation in the fire grate combustion region, NOx generation is inhibited greatly; furthermore, with the help of the medium-temperature reducibility flue smoke of the second-level smoke recirculation, NO generated in the ascending smoke in the burnout region is reverted to N2, and finally efficient low-nitrogen combustion of the stokerfeed boiler is achieved.

Owner:江苏宇澄环境工程设备有限公司

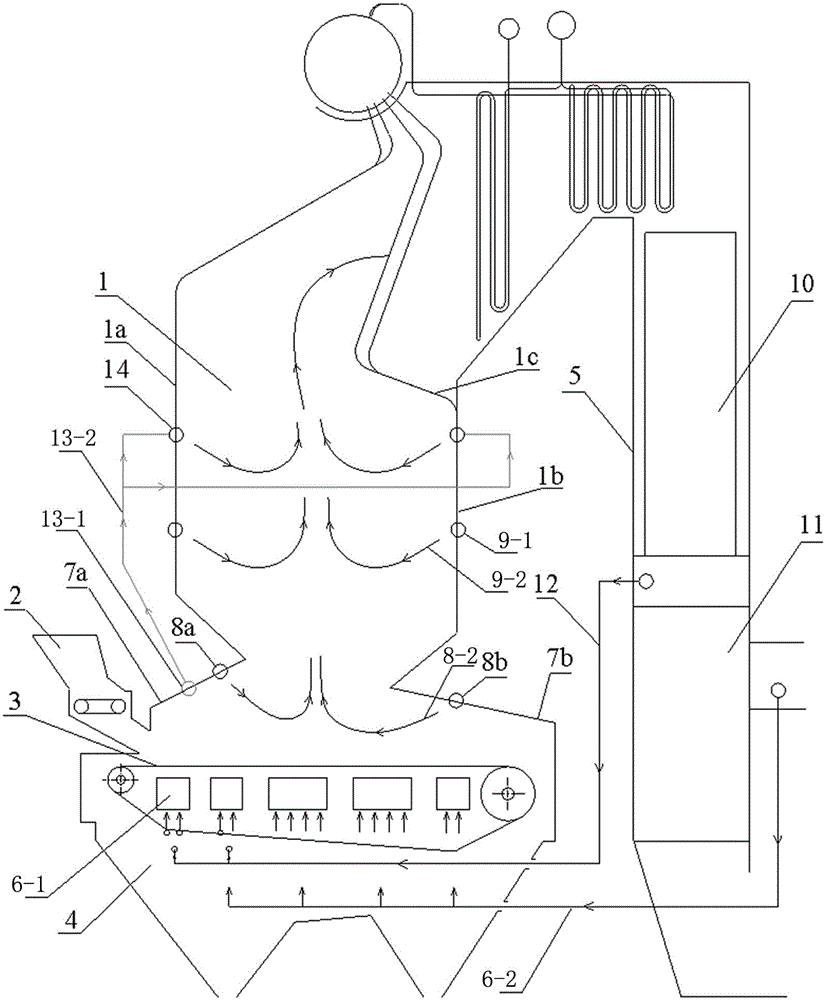

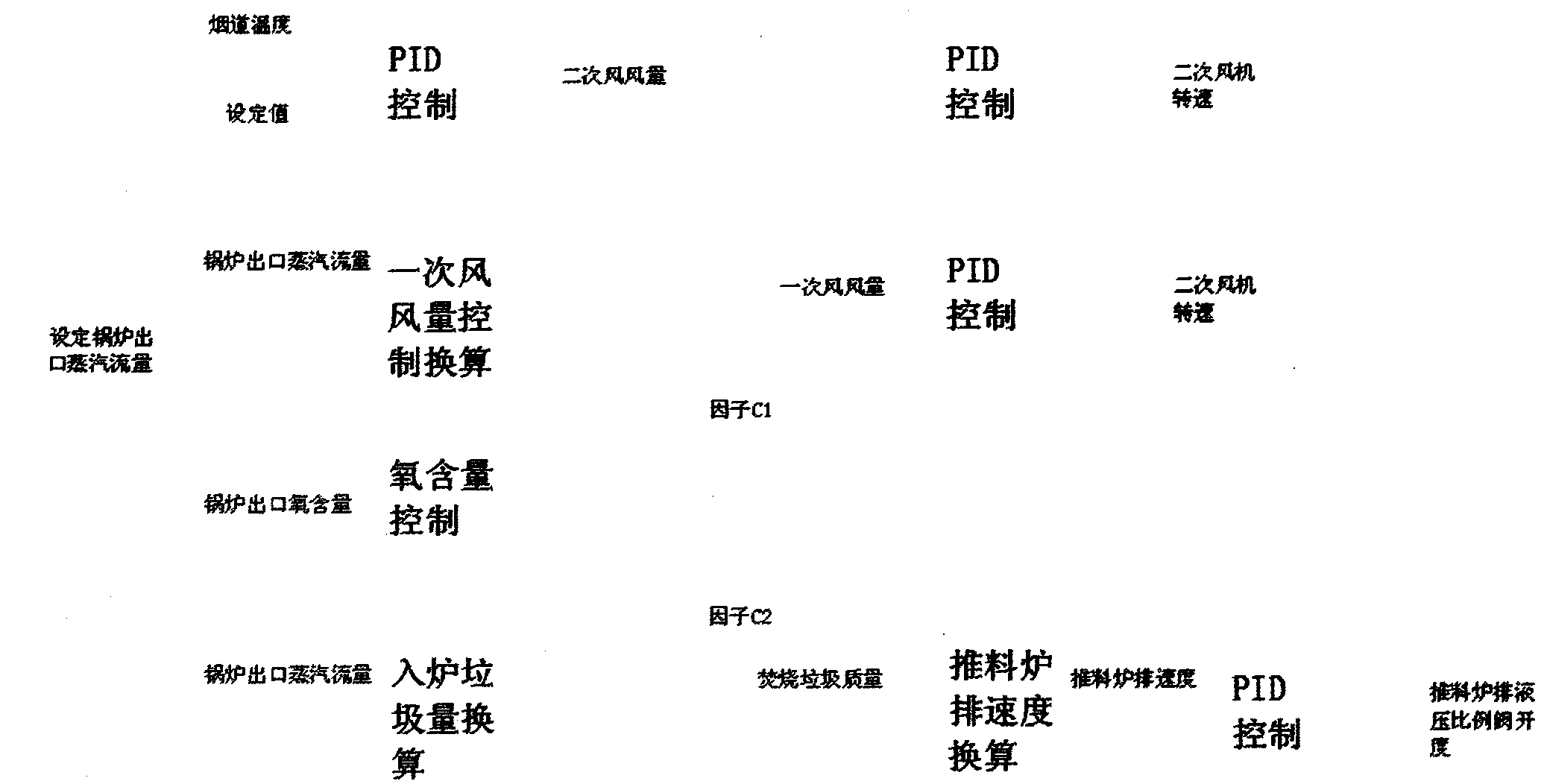

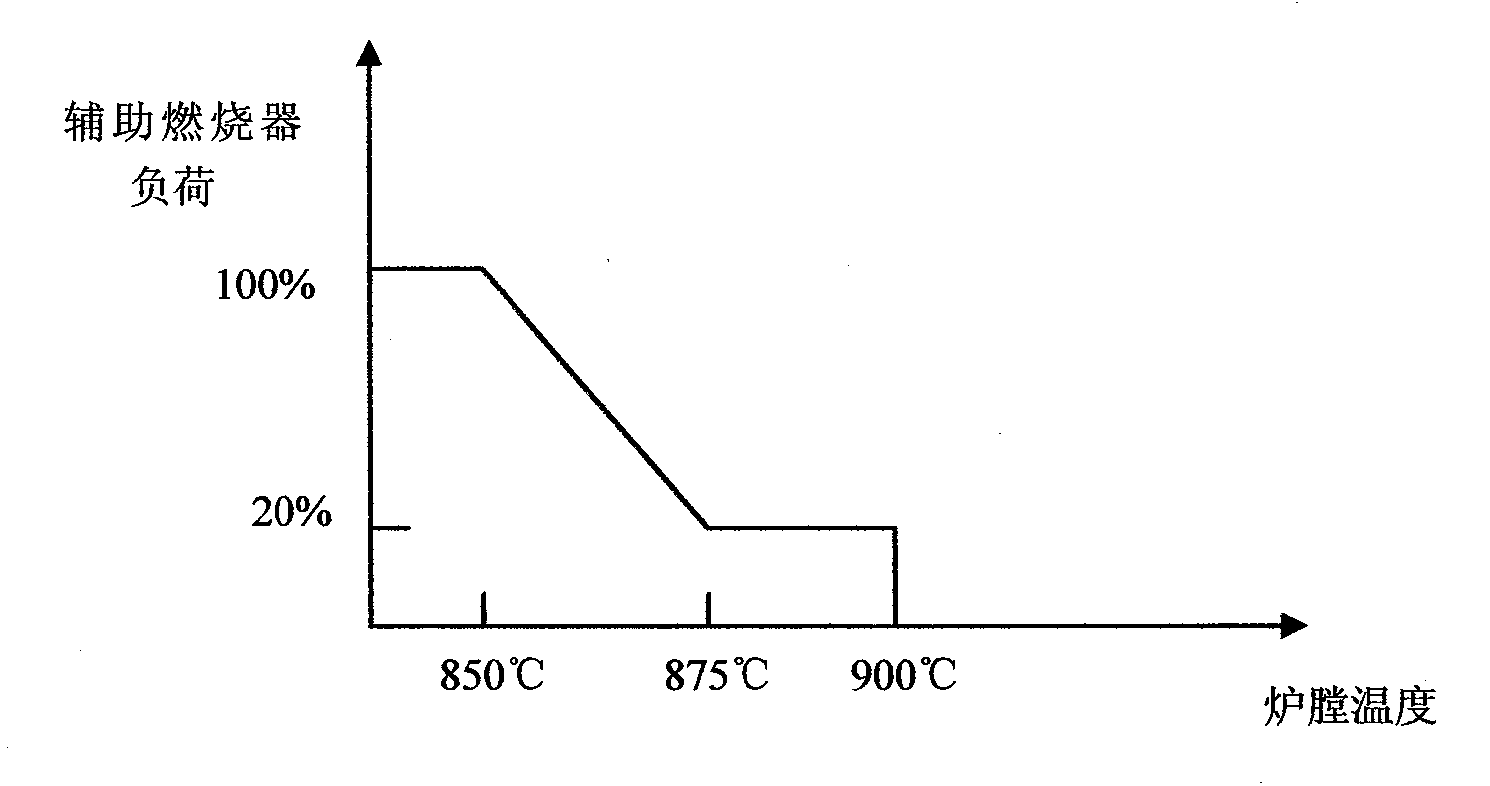

Self-service combustion control method of sectional type fire grate garbage incinerator

ActiveCN103438463AReal-time adaptation to calorific value changesThe control method overcomes the deficiencies in the existing waste incineration control processIncinerator apparatusCombustorProportion integration differentiation

The invention discloses a self-service combustion control method of a sectional type fire grate garbage incinerator. A control device needed by the self-service combustion control method comprises a feeding fire grate; the tail end of the feeding fire grate is sequentially provided with a drying section fire grate, a combustion end fire grate and a burn-out end fire grate in parallel; a primary air fan is connected with the drying section fire grate, the combustion end fire grate and the burn-out end fire grate by a primary air flow meter. The control method comprises the steps of: (1) establishing a garbage calorific value judgment model; (2) establishing a controller for controlling different garbage calorific value types; (3) converting the primary air quantity and the garbage feeding quantity according to the set target steam flow rate and the measured oxygen content at an outlet of a boiler; (4) calculating by proportion integration differentiation (PID) according to the strategy built by the controller; (5) formulating the operation strategy of an auxiliary burner in the whole cycle of operation. The self-service combustion control method aims at the defects of the existing garbage incineration control technology, can adapt to the garbage calorific value change in real time, overcomes the defects on the control of the original auxiliary burner, and avoids the generation of dioxin.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

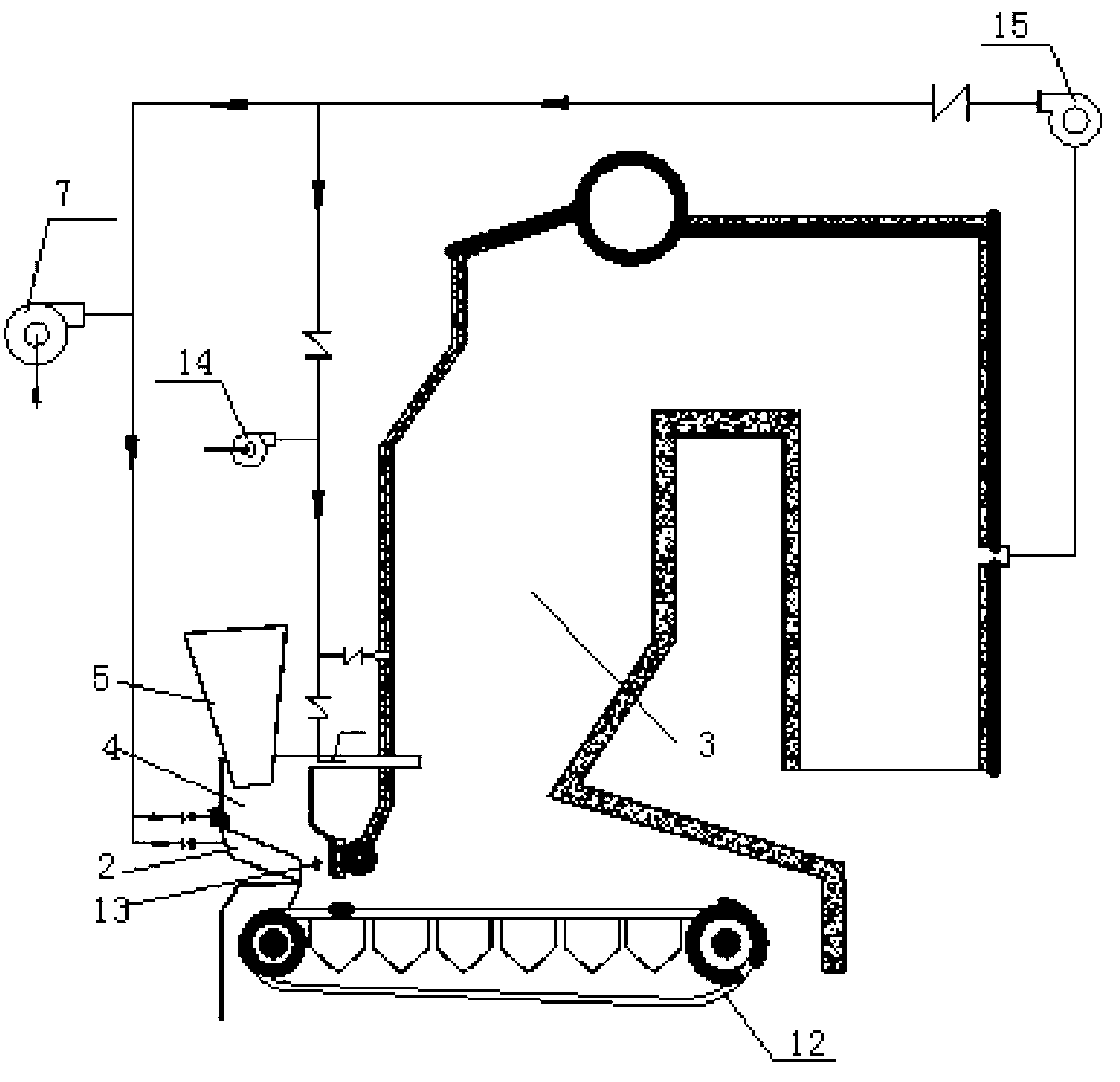

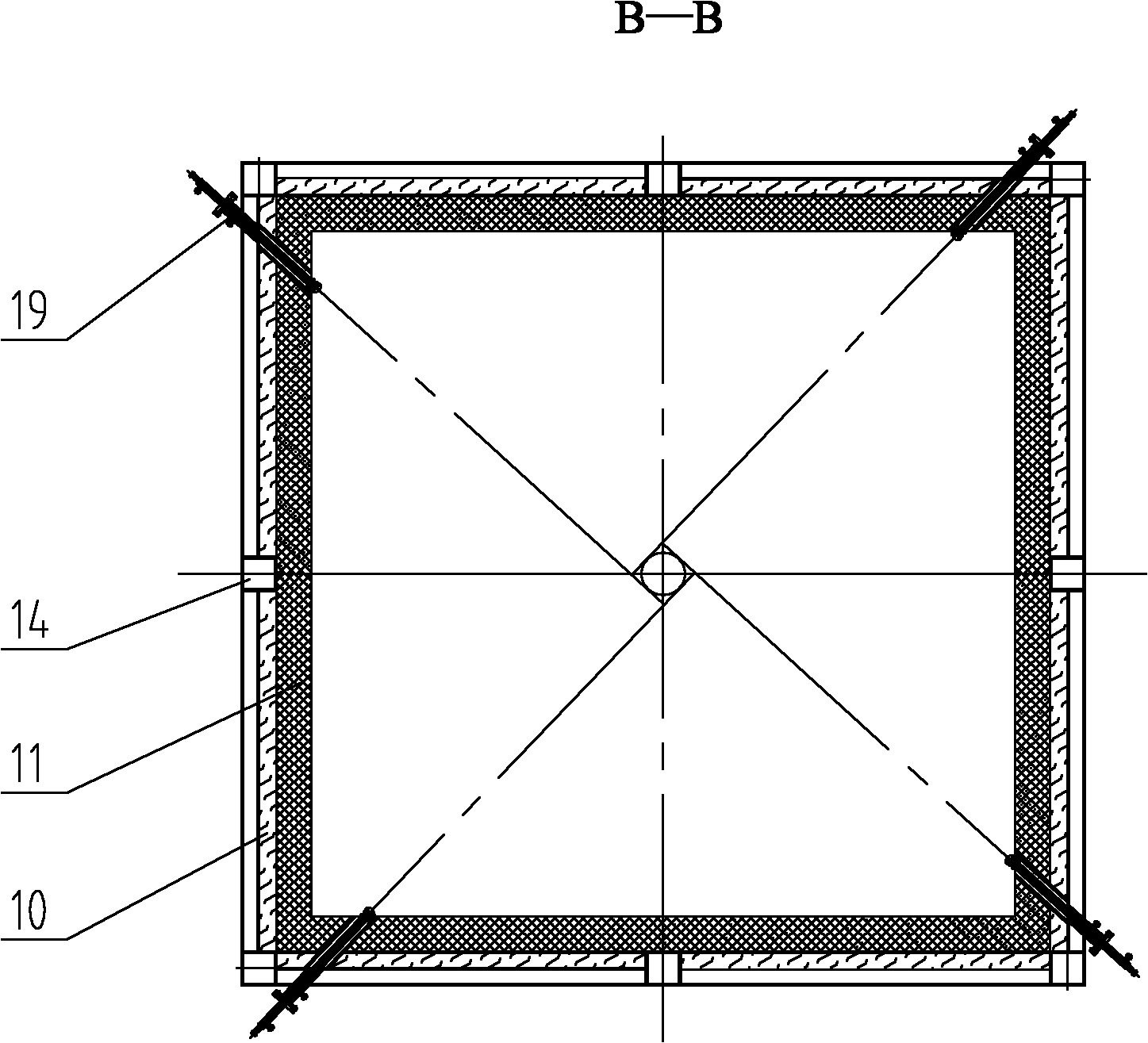

Independent partitioned grate firing flue gas circulation combustion system and use method thereof

ActiveCN106594710ARealize the reduction reactionAchieve burnoutSolid fuel combustionAir/fuel supply for combustionCombustion systemLow nitrogen

The invention provides an independent partitioned gate firing flue gas circulation combustion system and a use method of the independent partitioned gate firing flue gas circulation combustion system and relates to a low-nitrogen combustion system and a use method of the low-nitrogen combustion system. The independent partitioned gate firing flue gas circulation combustion system aims at solving the technical problem of generating a large amount of NOx in the combustion process of an existing gate firing boiler. The system is composed of a recirculation induced draft fan, branch pipeline electric regulating valves, a flue gas communication pipeline from a rear arch to the back wall of a boiler, a communication pipeline regulating valve and a partitioned arch. An inlet of the recirculation induced draft fan communicates with an outlet of a gate firing boiler induced draft fan. An outlet of the recirculation induced draft fan communicates with fire grate air chambers. Each recirculation branch pipeline is provided with the electric regulating valve. The flue gas communication pipeline which is on the rear arch of a hearth and is guided out of the rear arch of the hearth to the back wall of the boiler is provided with the regulating valve. The partitioned arch is arranged below the rear arch of the hearth. The use method of the system includes the steps that firstly, the total amount of recirculation flue gas is controlled; secondly, the recirculation flue gas amount in all the air chambers is controlled; and thirdly, the communication pipeline regulating valve is controlled. The independent partitioned gate firing flue gas circulation combustion system and the use method have the following beneficial effect that the nitrogen reduction efficiency ranges from 25% to 27%.

Owner:HARBIN INST OF TECH

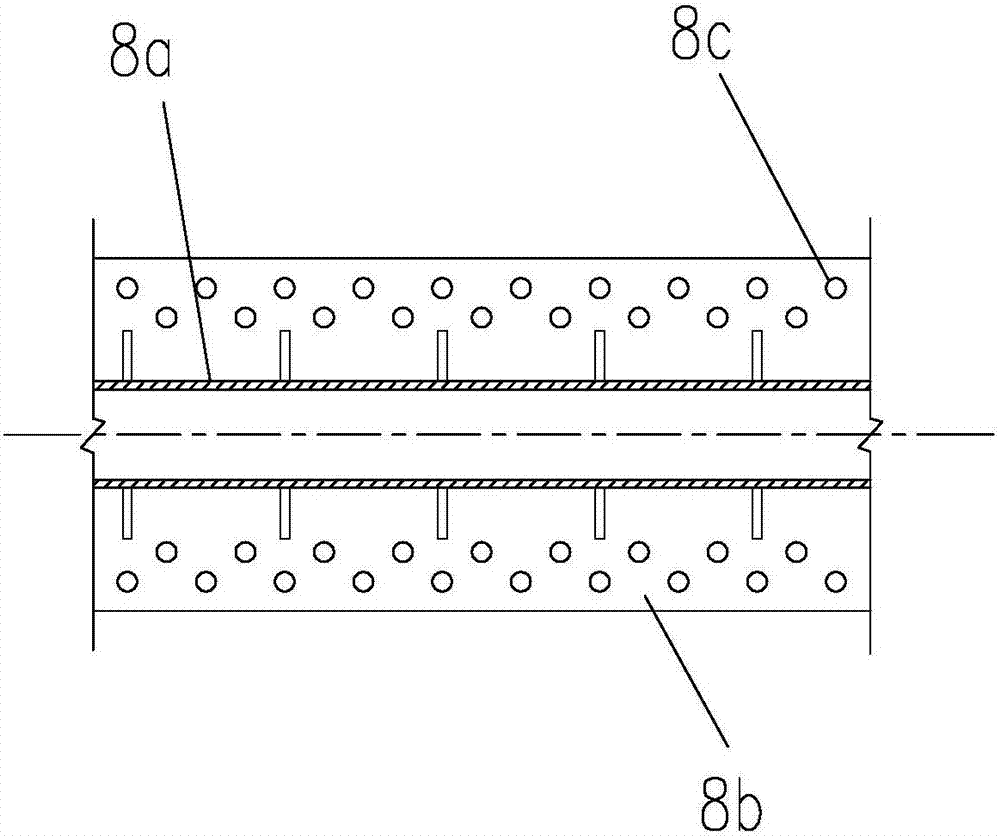

Low-range circulating fluidized bed water boiler for combusting inferior fuel and combustion method thereof

ActiveCN102901212BReduce wearReduce carbon contentFluidized bed combustionIndirect carbon-dioxide mitigationFluidized bedEngineering

The invention relates to a low-range circulating fluidized bed water boiler for combusting inferior fuel and a combustion method of the low-range circulating fluidized bed water boiler, and particularly relates to a circulating fluidized bed water boiler and a combustion method of the low-range circulating fluidized bed water boiler. The invention aims to solve the problem that the conventional grate firing water boiler can only combust high-quality coal and the water wall of the conventional circulating fluidized bed water boiler is seriously abraded when inferior fuel is combusted. Multiple buried pipes are uniformly arranged on both sides in a low-speed bed in a dense-phase area on the lower part of the boiler body; both sides of a high-speed bed air chamber are respectively provided with a low-speed bed air chamber; an intermediate wind-distribution plate is arranged at the upper part of the high-speed bed air chamber; the upper part of each low-speed bed air chamber is respectively provided with a side wind-distribution plate; a two-side wall water-cooling wall upper header is arranged at the upper end of the boiler body; a two-side wall water-cooling wall lower header is arranged at the lower end of the boiler body; a boiler barrel is arranged on the upper part of the two-side wall water-cooling wall upper header; and the two-side wall water-cooling upper header is communicated with the boiler barrel through a first connecting pipe. The low-range circulating fluidized bed water boiler for combusting inferior fuel is applied to the fields of utility boilers, industrial boilers and waste disposal utilization.

Owner:哈尔滨红旗锅炉有限公司

Incinerator of multi-element multi-dimension chemical hazardous waste

ActiveCN102192513AGuaranteed temperaturePromote decompositionIncinerator apparatusLiquid wasteCombustion chamber

The invention discloses an incinerator of multi-element multi-dimension chemical hazardous waste. The incinerator comprises an auxiliary fuel feeding device, a tilting-type reciprocating grate, a primary air system, a secondary air system, a tertiary air system, a lower part grate combustion chamber, an upper part furnace combustion chamber, a waste liquid nozzle, a waste gas nozzle, a solid waste throw-in mouth, a secondary auxiliary combustion system and a slag removing device; the incinerator is provided with a high-temperature fire bed and a larger furnace chamber space; and after the waste is thrown into the incinerator, the waste can be combusted in the furnace through preheating and decomposition, the combustion is rapid and thorough, and poisonous substances in the chemical hazardous waste can be removed effectively. The incinerator provided by the invention has the advantages of simple manufacturing process and is safe and stable in operation, is convenient to maintain, can burn waste gas, waste liquid, solid waste and the like simultaneously, and is suitable for popularizing and using in the burning treatment of the multi-element waste.

Owner:大连科林能源工程技术开发有限公司

Partition cavity type small-sized rubbish pyrolysis and gasification incinerator

PendingCN107120658ASimple structureReduce construction costsIncinerator apparatusCombustion chamberThermodynamics

The invention discloses a partition cavity type small-sized rubbish pyrolysis and gasification incinerator comprising a hopper, a gate, a drying cavity, an upper fire grate, a combustion hearth cavity, a lower fire grate and a secondary combustion chamber. High-temperature smoke in the secondary combustion chamber is guided into a pyrolysis gasification cavity. A part of high-temperature smoke flows upward into the drying cavity to dry rubbish, generated steam is guided into a condensation liquefying tank to be liquefied through a steam suction cavity, odor flows back into the combustion hearth cavity for high-temperature calcinations treatment, and smoke and the odor are prevented from escaping. The other part of high-temperature smoke flows downwards and is combined with heat generated by the combustion hearth cavity to form convection and radiation, rubbish is made to conduct pyrolysis and gasification at the same time, gasified gas flows out downwards from the upper fire grate to enter the combustion hearth cavity to be combusted, rubbish carbon overturned downwards by the upper fire grate is combusted on the lower fire grate, an opposite firing flame is formed between the upper fire grate and the lower fire grate, the gasified gas and pyrolyzed rubbish carbon form complementary combustion in the combustion hearth cavity, a durable high temperature keeping area enables dioxin type harmful matter to be decomposed, and heat energy generated by combustion is fully recycled.

Owner:重庆航天工业有限公司

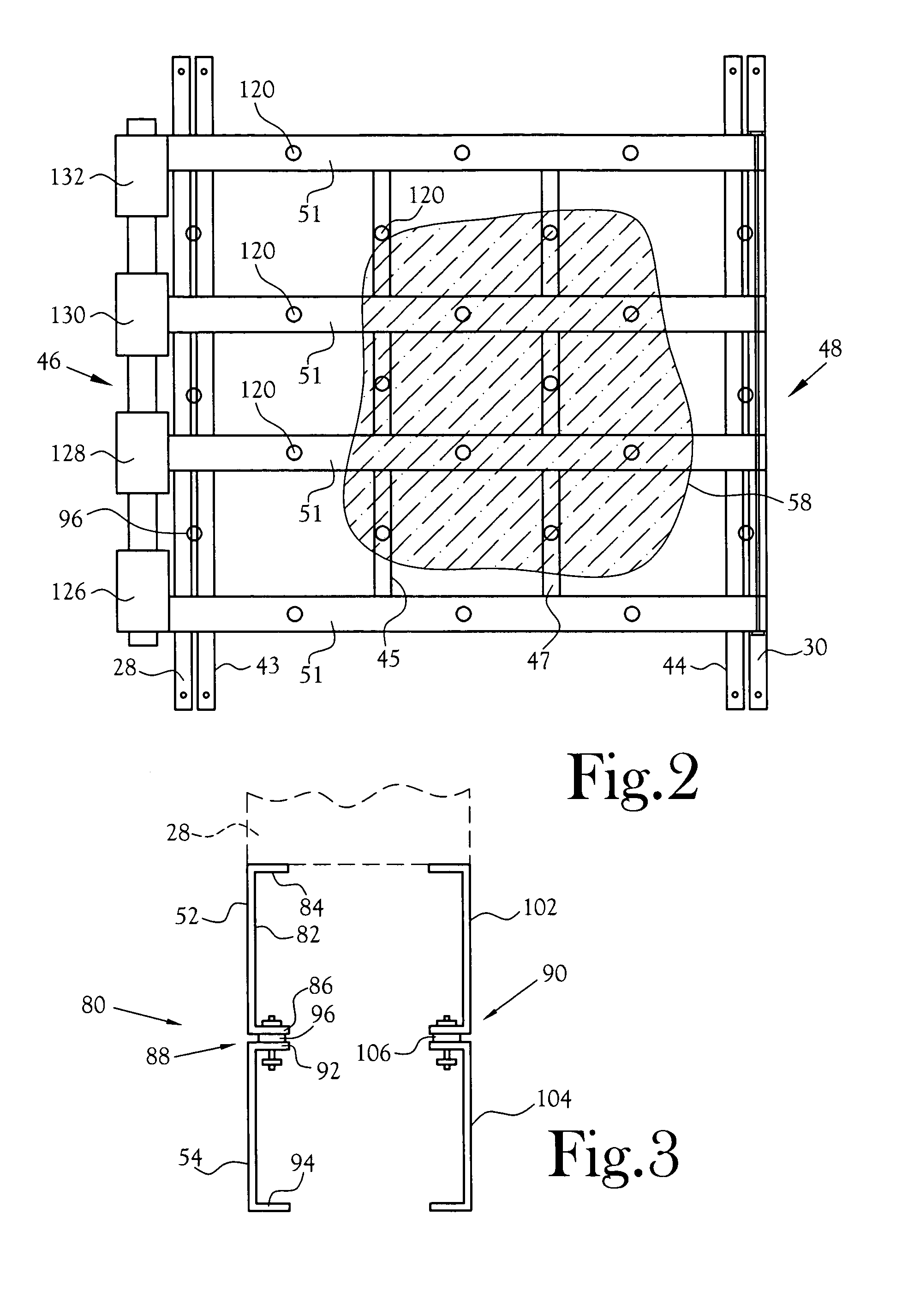

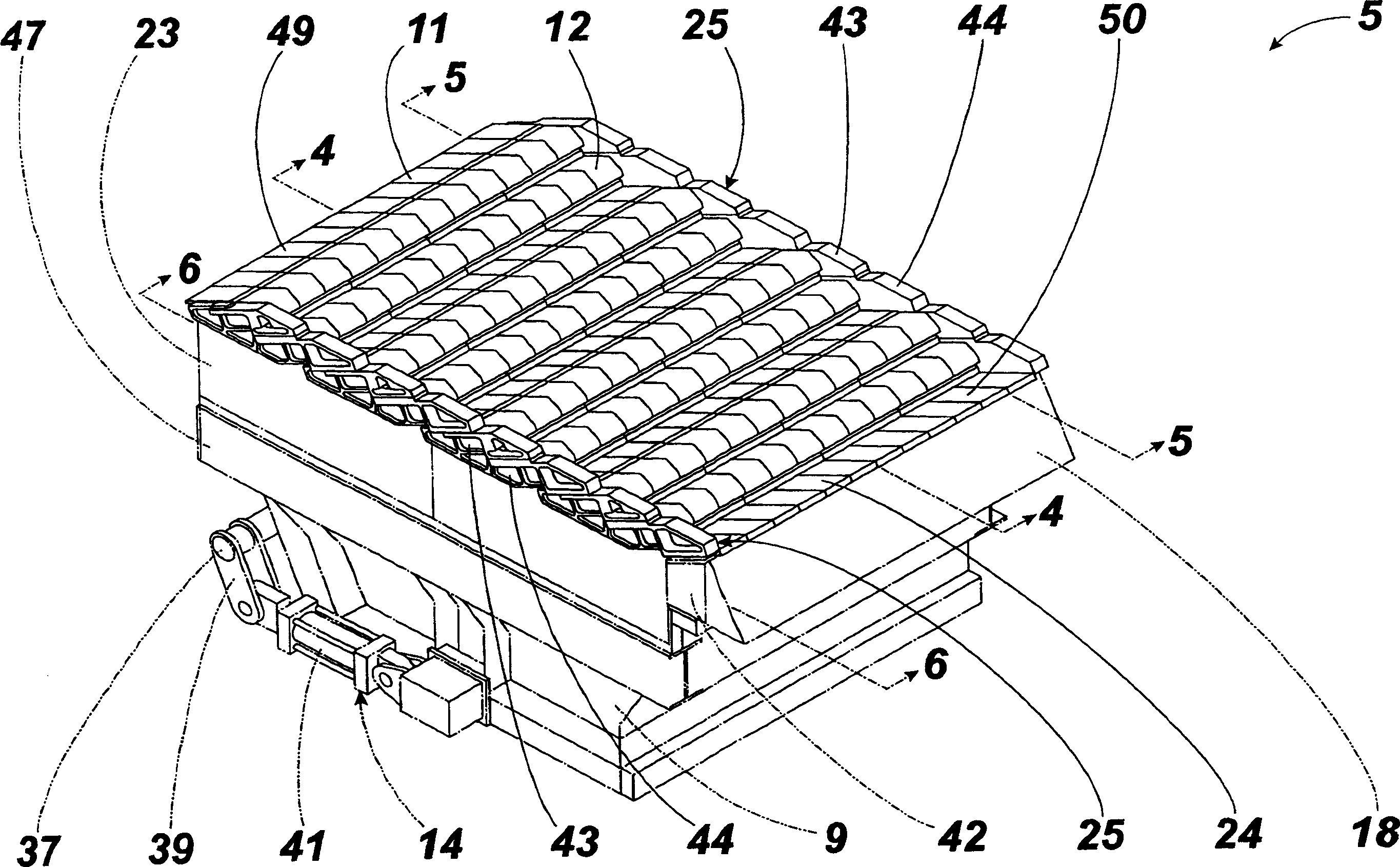

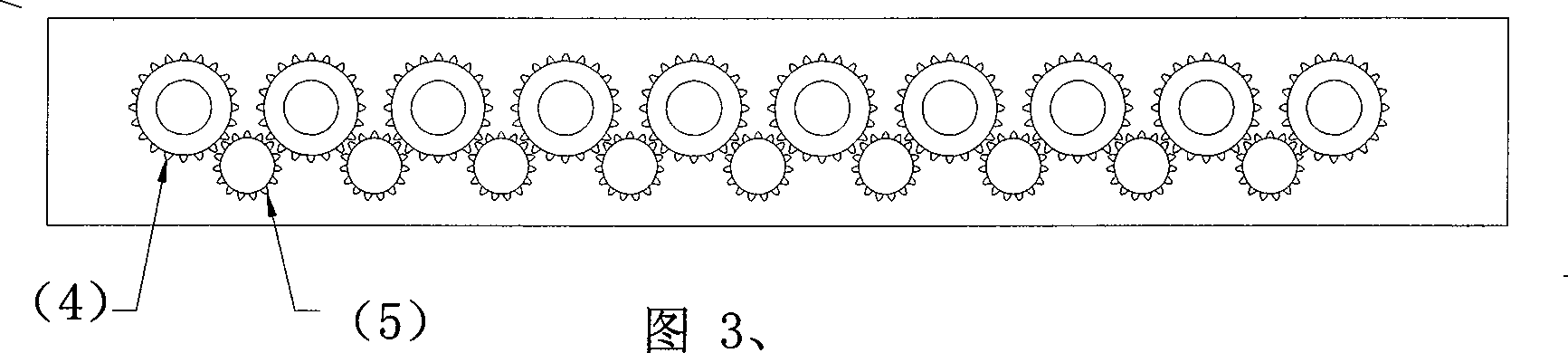

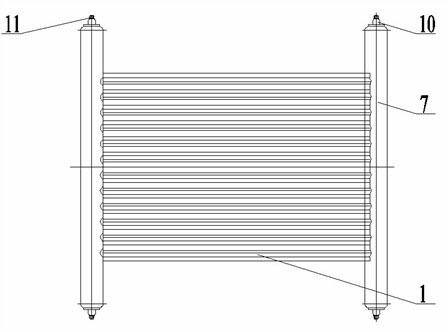

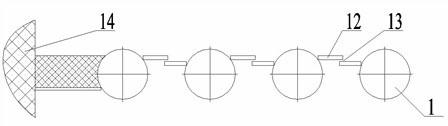

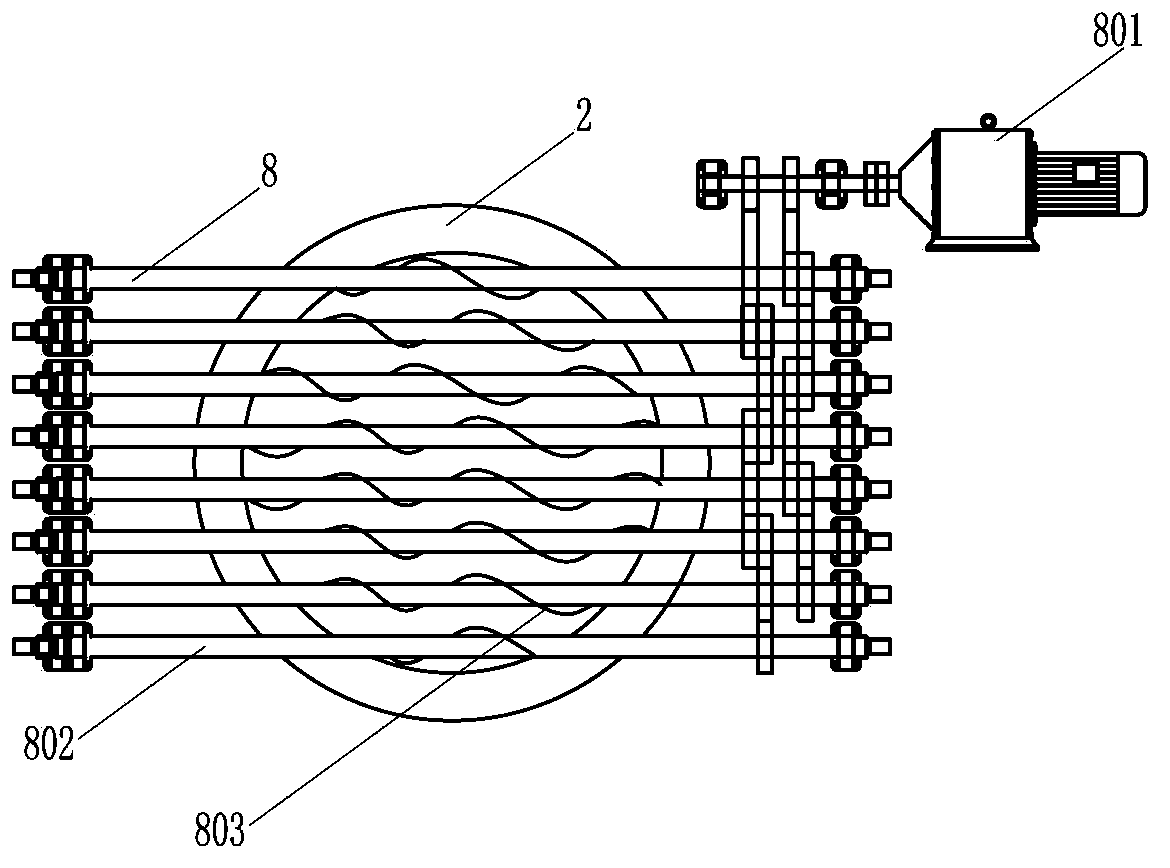

Fire grate for motor grate combustion appts. and grate body for forming grate

A mechanical grate assembly for the garbage incinerator is composed of the fixed grates and movable grates, which are alternatively arranged to form a three-step mechanical grate assembly, which is formed through fastening the fixed and movable grates on a frame of furnace bed in parallel mode, and transversely inserting the connecting rod through the grate body. Its advantage is easy assembling and disassembling.

Owner:TAKUMA

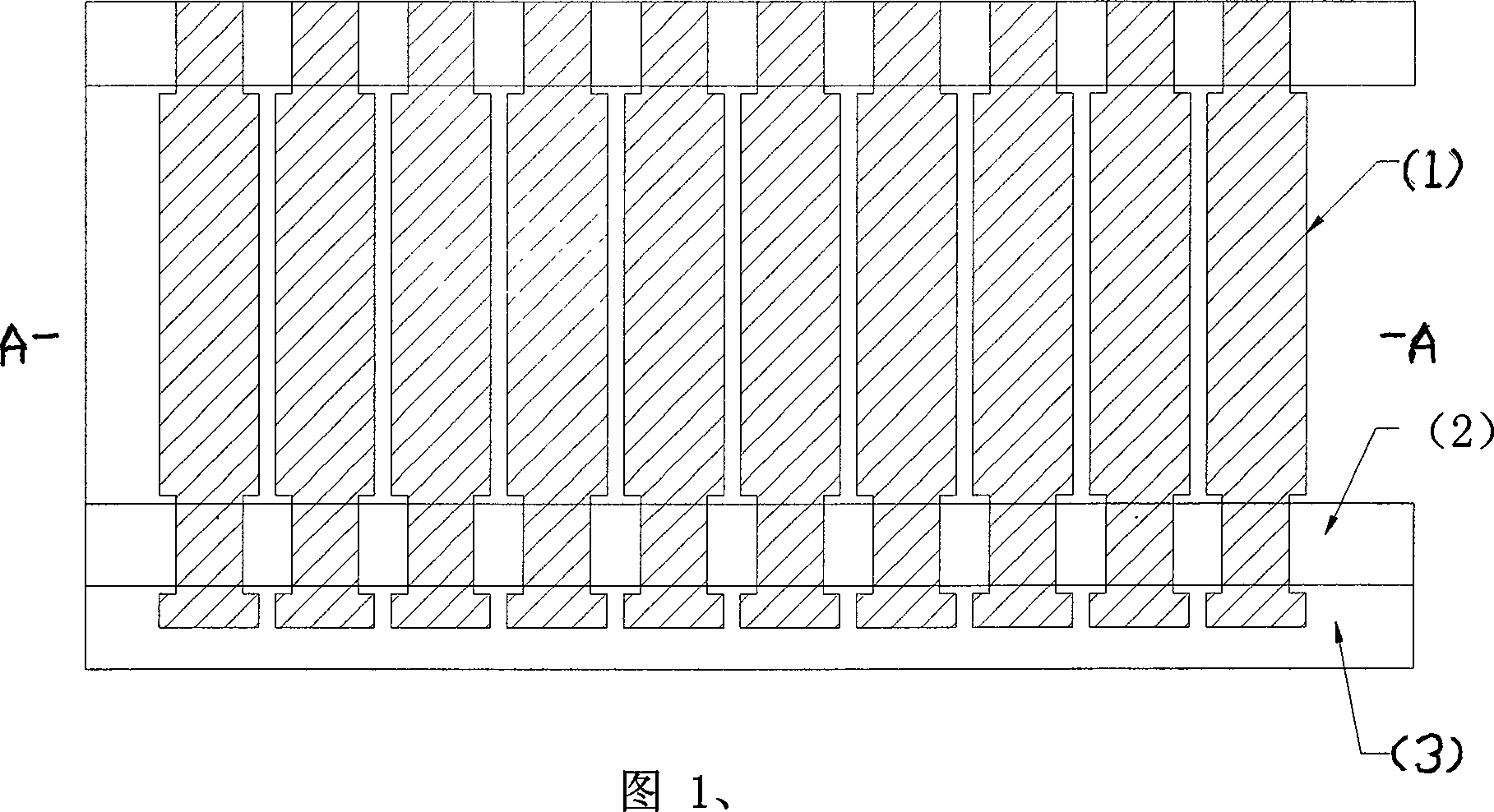

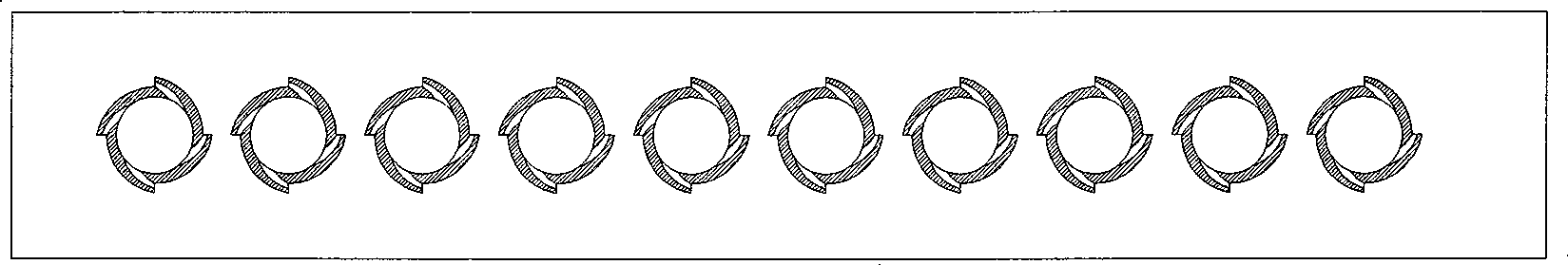

Boiler air bin air distributing device with built-in flow stabilization and flow shunting and guide functions

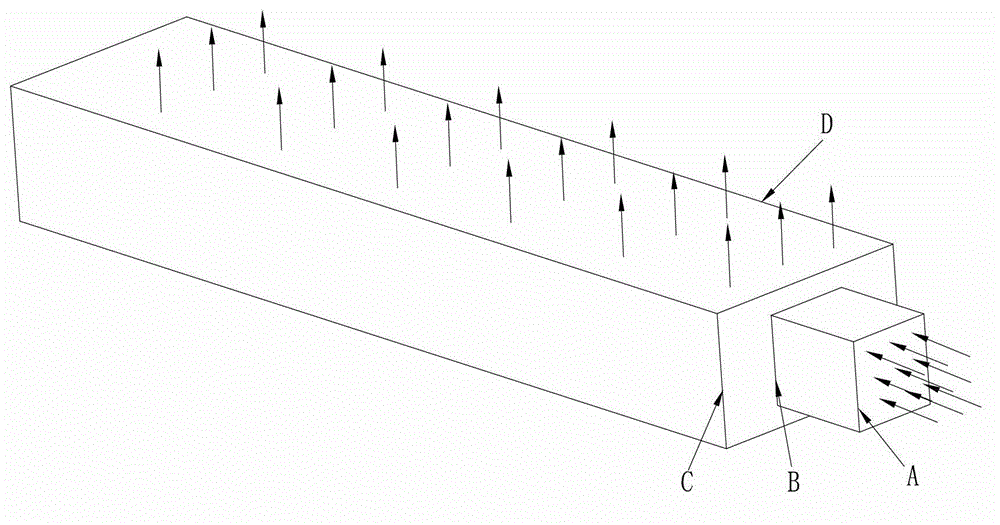

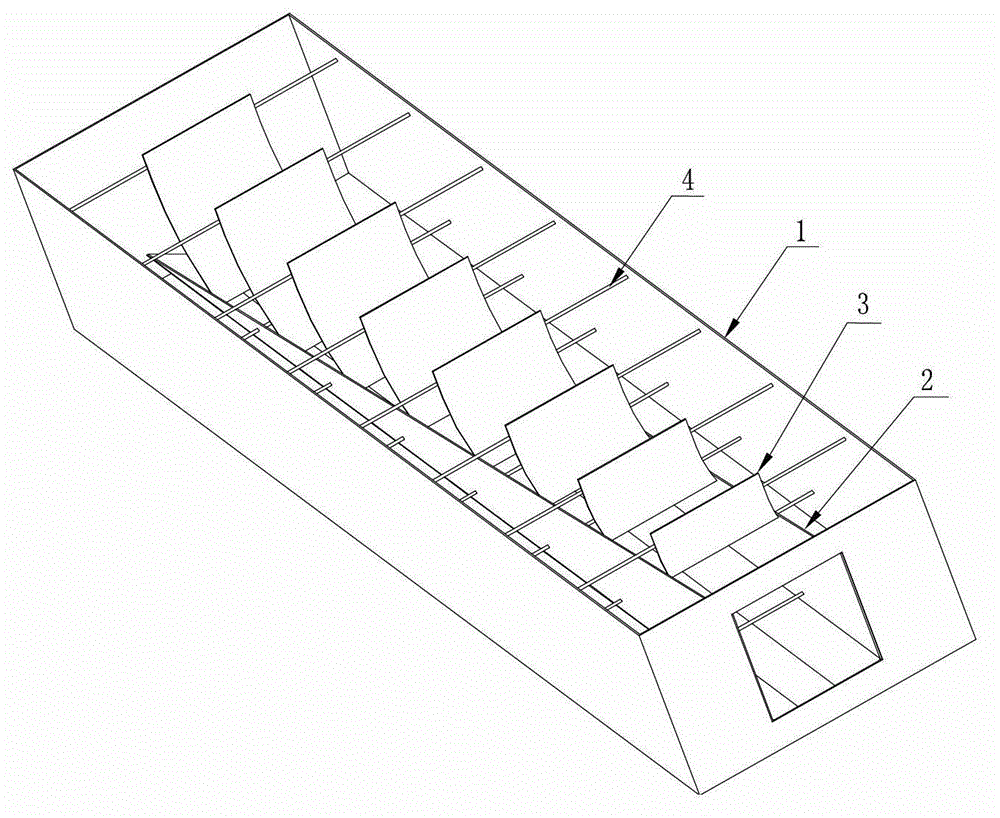

InactiveCN102878574AImprove applicabilitySimple structureAir/fuel supply for combustionGratingEngineering

The invention belongs to the field of energy source utilization, and aiming at chain grate stoker grate firing boilers, relates to a boiler air bin air distributing device with built-in flow stabilization and flow shunting and guide functions. The boiler air bin air distributing device with the built-in flow stabilization and flow shunting and guide functions comprises three main components including an air bin outer shell, a built-in flow stabilization cavity and a distributary flow guide plate; the built-in flow stabilization cavity and the flow shunting and guide plate are fixed by adopting a fixed grating; the built-in flow stabilization cavity is directly connected with an air chamber air inlet, can prevent vortex generated at the inlet because of flow pass expansion, and plays a flow stabilization effect. A group of circular arc flow shunting and guide plates are distributed along the air flow direction of an air chamber inlet, and play roles of flow shunting and guide effects so as to achieve the requirement of horizontal air distribution uniformity. The boiler air bin air distributing device with the built-in flow stabilization and flow shunting and guide functions provided by the invention can be suitable for requirements of chain grate stoker boilers with different tonnages, is also suitable for the air bin structure transformation of old chain grate stoker boilers, can effectively improve the horizontal air distribution uniformity of a grate, and achieves the energy-saving and emission-reduction effects.

Owner:DALIAN UNIV OF TECH

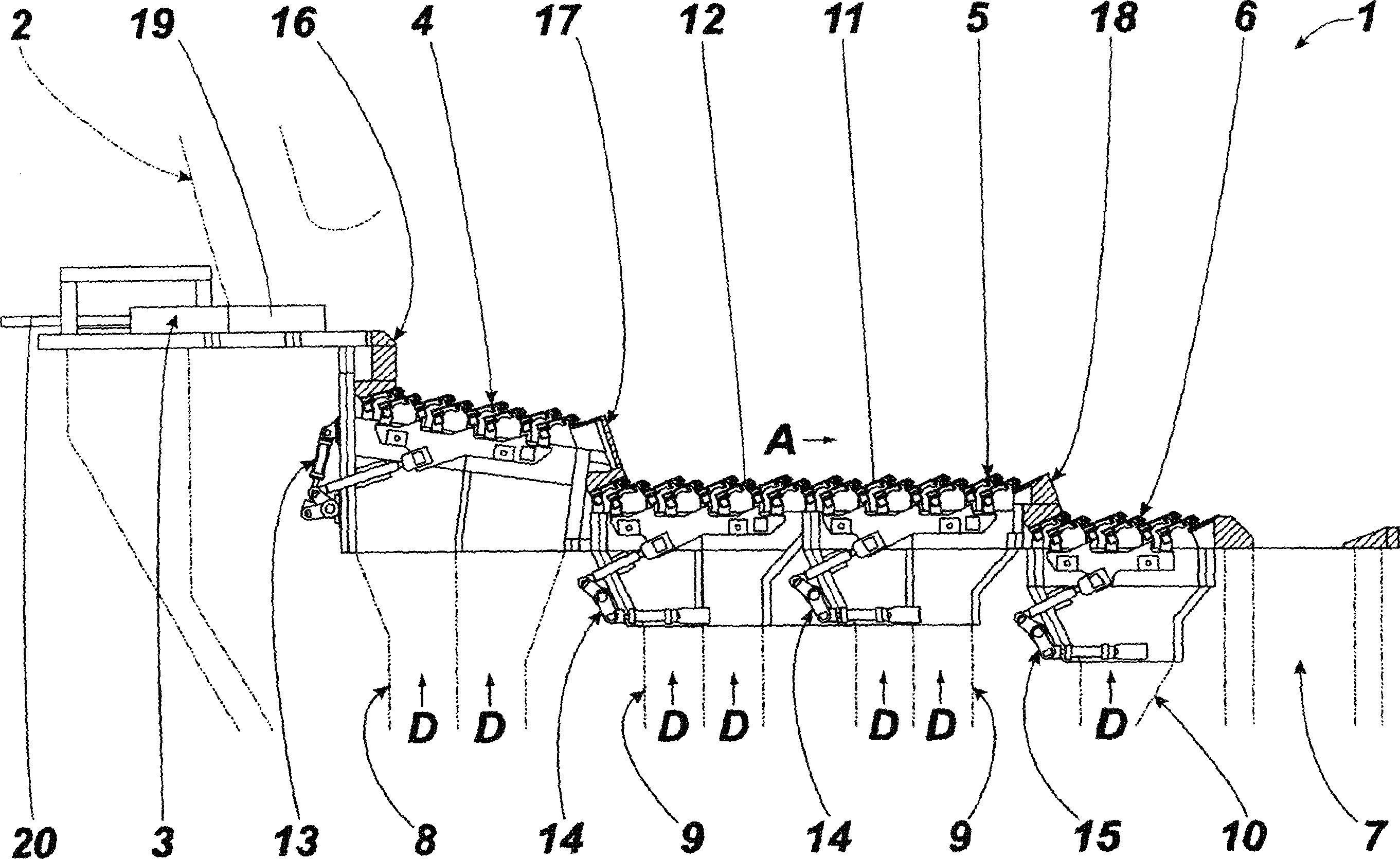

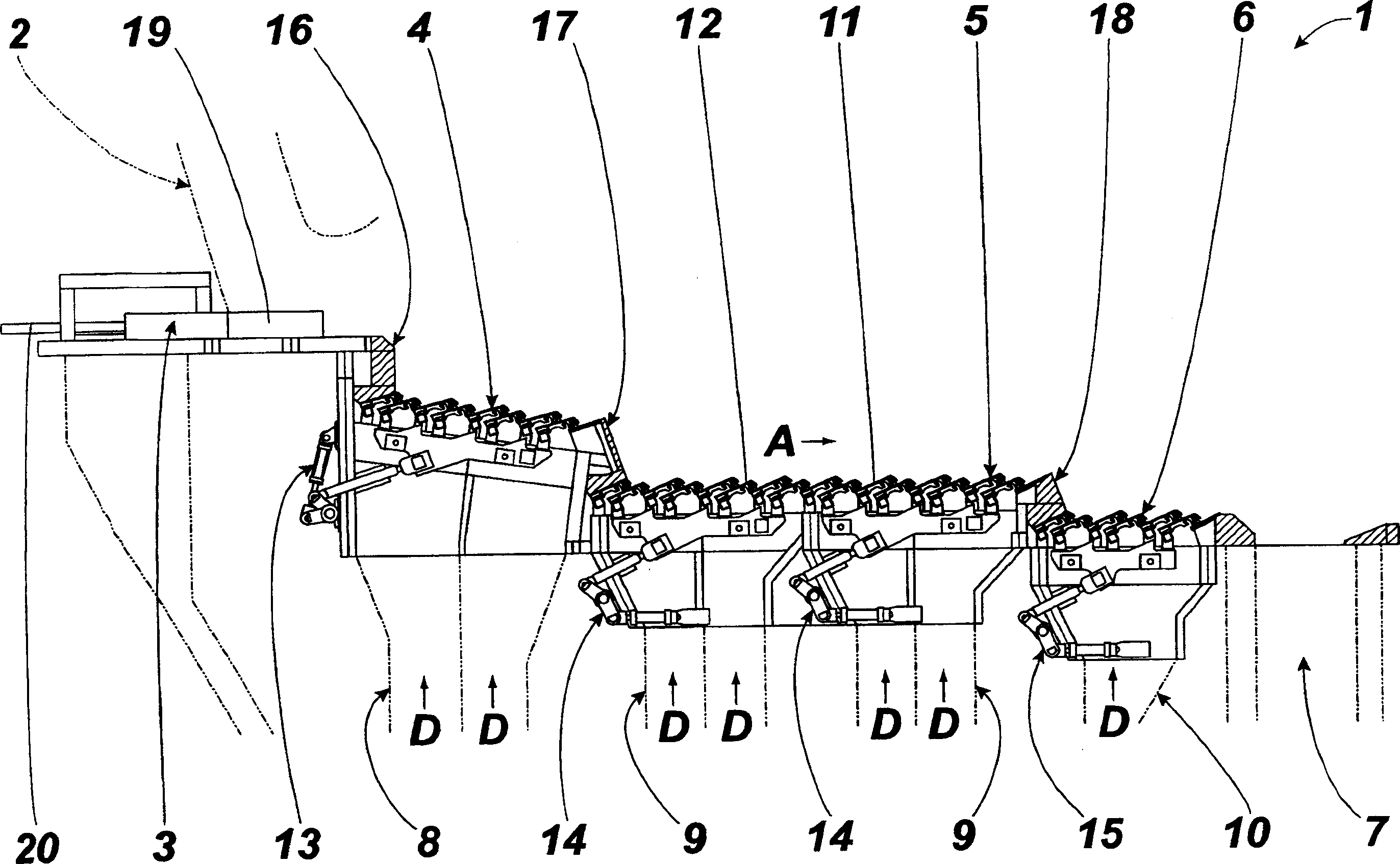

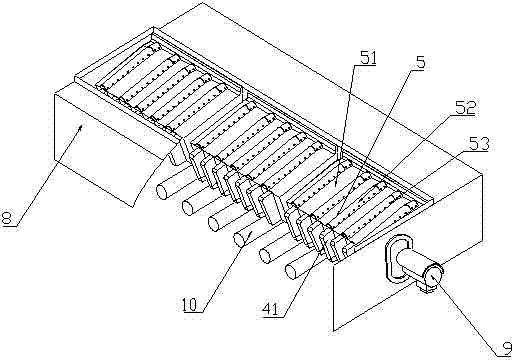

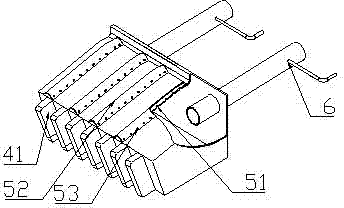

Step motor-driven grate burniag device of garbage furnace

InactiveCN1538108AGood effectAchieve compartmentalizationIncinerator apparatusMotor driveGrate firing

A burner with stepped moving grate for garbage incinerator features that the drying grate, combustion grate and post-combustion grate are arranged in a row with step between adjacent grates, the feed hoppers sunder the grates are used to supply the primary burning air upward to the garbage on grates for continuously burning, and all the grates are driven respectively by the drivers for moving them.

Owner:TAKUMA

Slag combustion apparatus of biomass boiler

InactiveCN102829466AImprove efficiencyReduce consumption costSolid bar grateSolid waste disposalSlagGrate firing

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

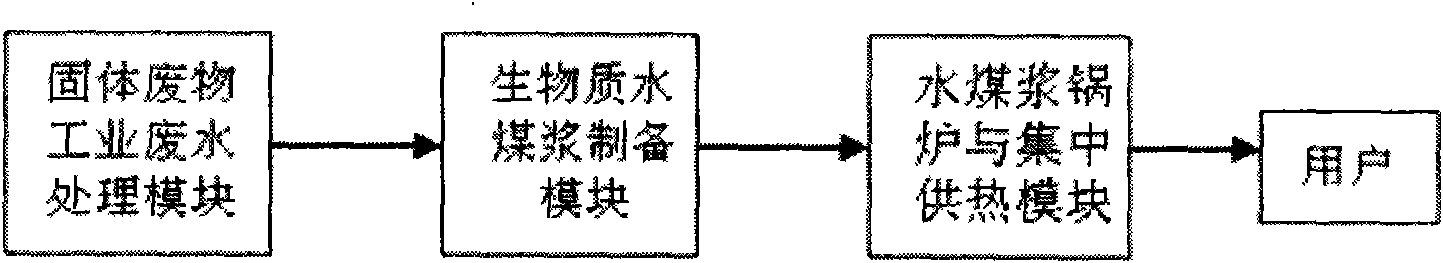

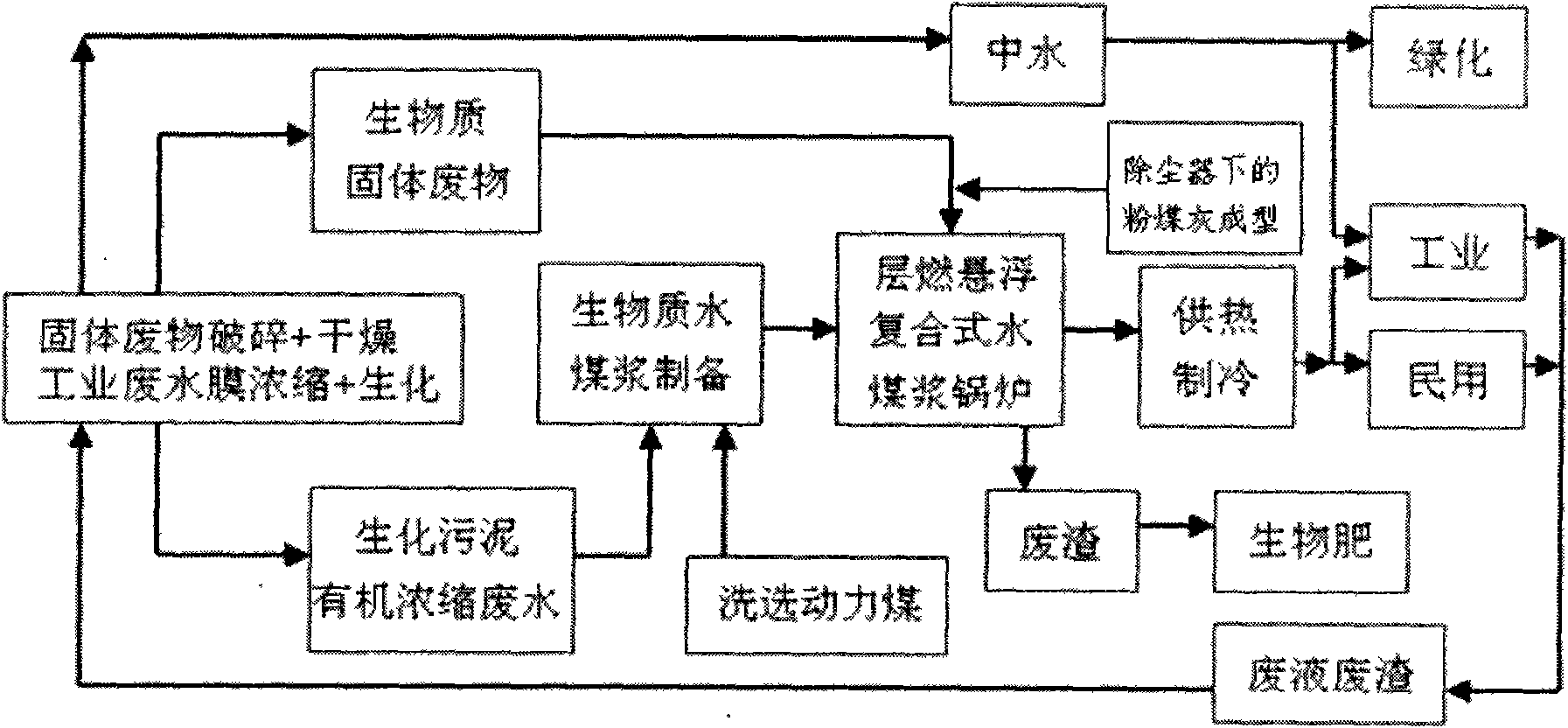

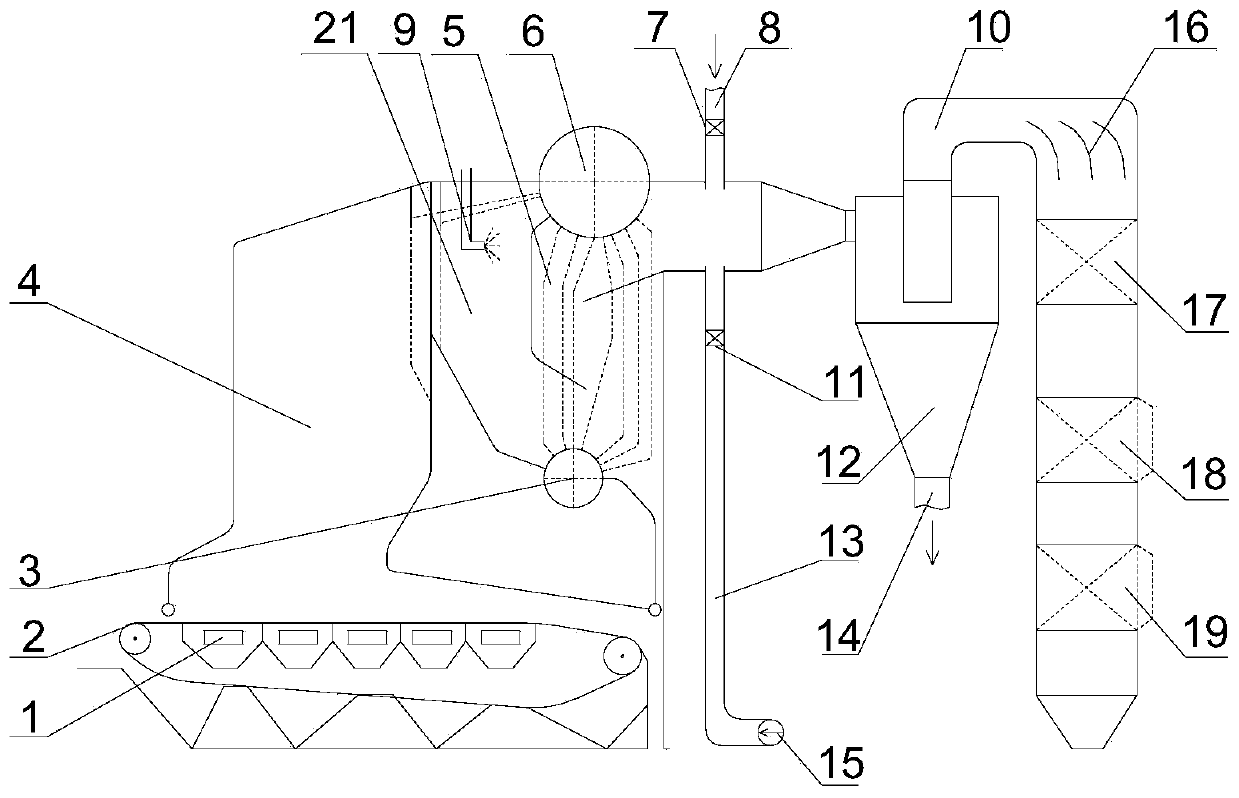

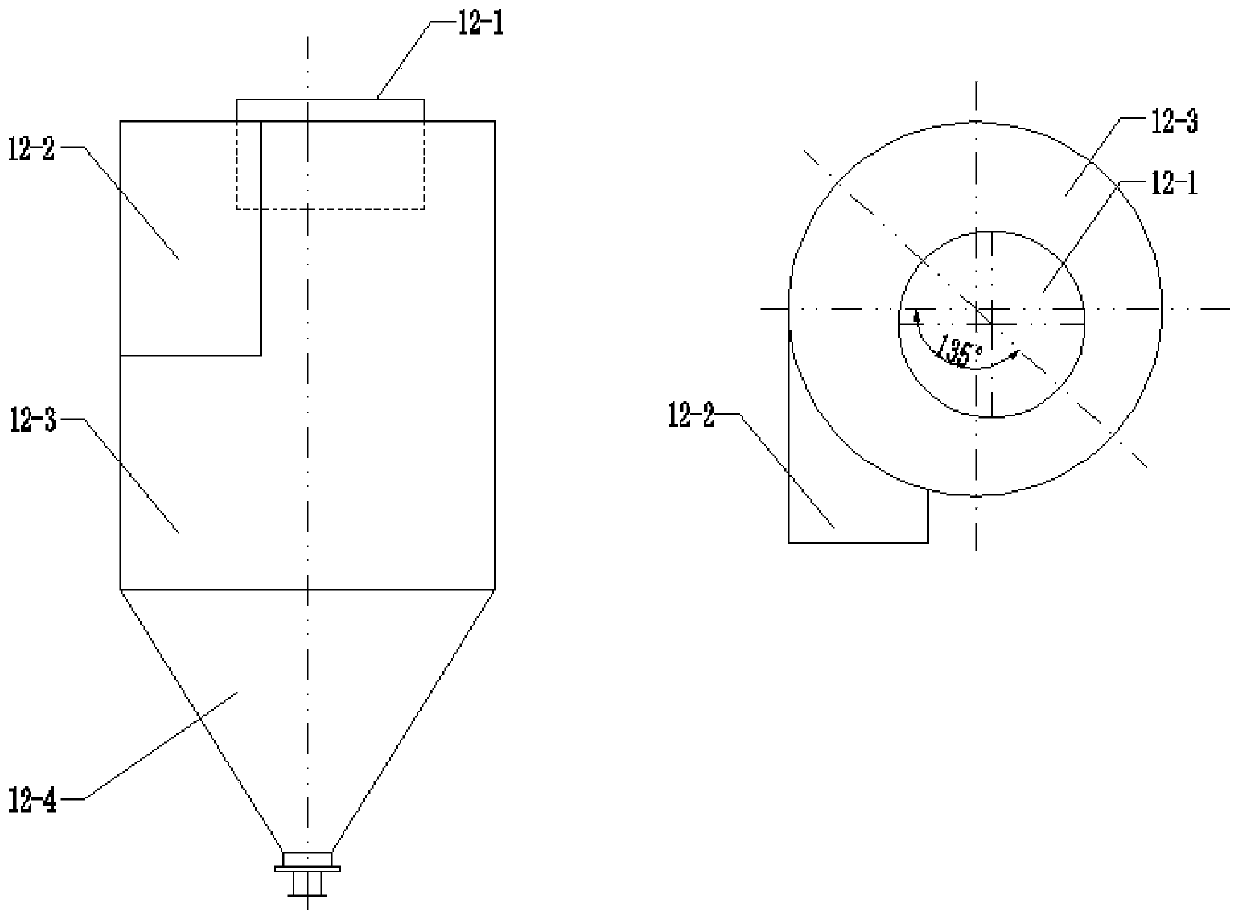

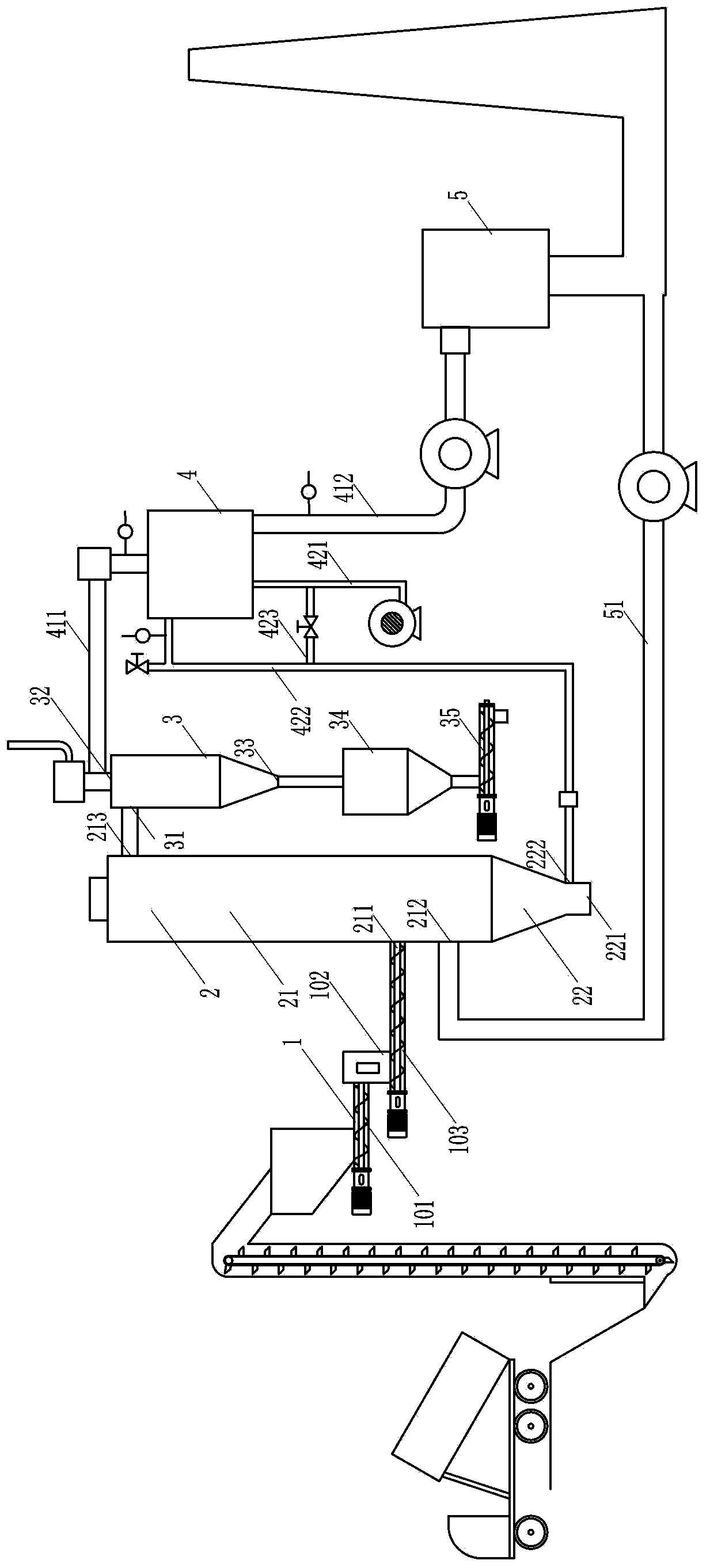

Biomass water-coal-slurry slurring and combustion method and integrated system

InactiveCN101639225AChange processing philosophyEasy to handleWater/sewage treatment by centrifugal separationFluidized bed combustionIndustrial waste waterSludge

The invention relates to a biomass water-coal-slurry slurring and combustion method and an integrated system. The integrated system is provided with a solid waste and industrial waste water processingmodule, a biomass water-coal-slurry slurring module and a water-coal-slurry boiler and integrated heating system and is characterized in that firstly, solid combustible waste and waste water are putinto the solid waste and industrial waste water processing module for being processed; and then film concentrate which takes biochemical sludge and organic concentrated waste water as main and is processed by film concentration and 30-40% of film concentrate of washing steam coal processed according to 60-70% of film concentration processing of the washing steam coal are matched and put in the biomass water-coal-slurry slurring module for blending to prepare biomass water-coal-slurry; and the prepared biomass water-coal-slurry is put in the water-coal-slurry boiler and integrated heating system for grate firing suspension combined type or circulating fluid-bed suspension combined type combustion; and during the combustion, crushed and dried solid combustible waste is added in batch type mode.

Owner:贵州蓝宇环保能源服务有限公司

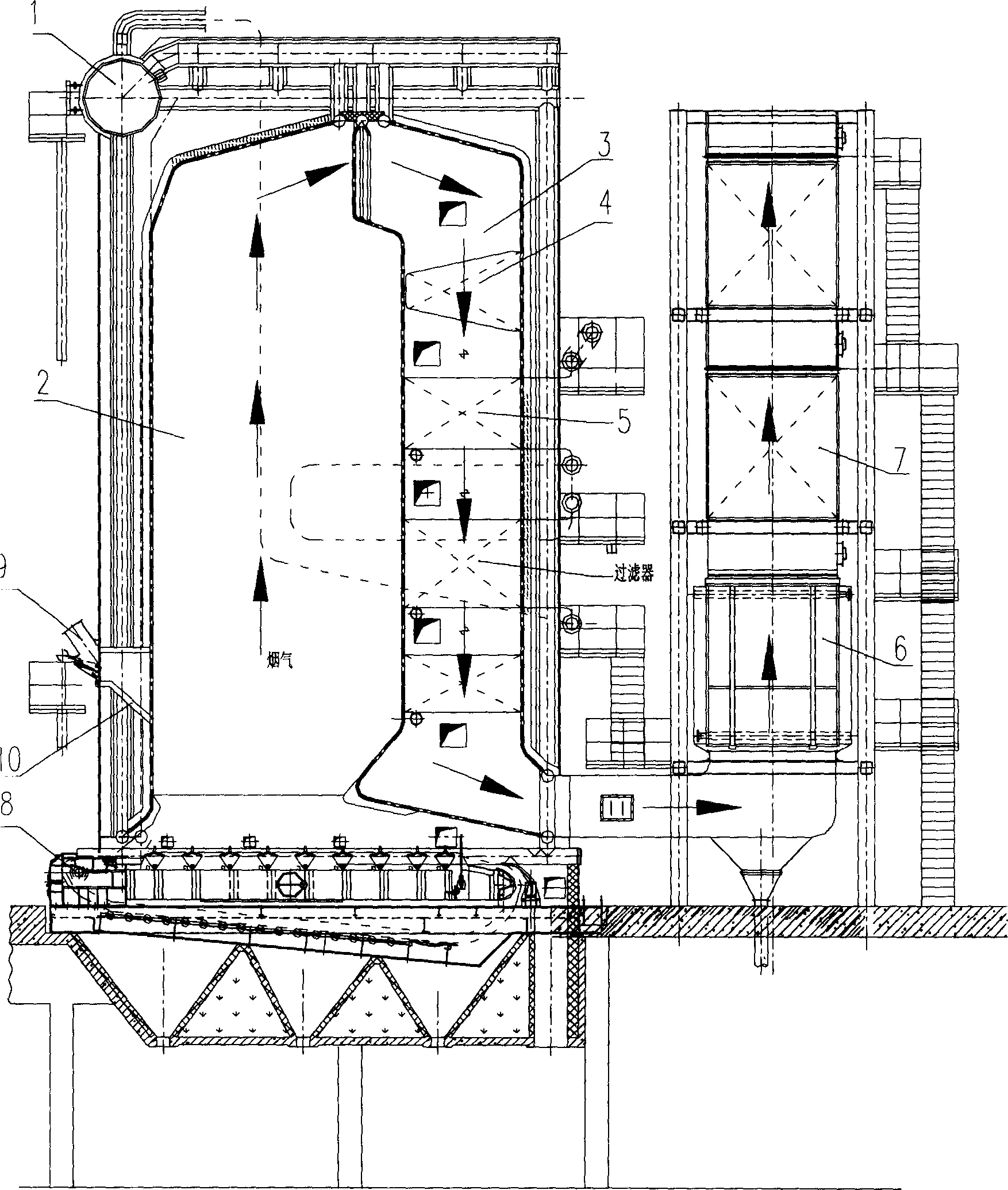

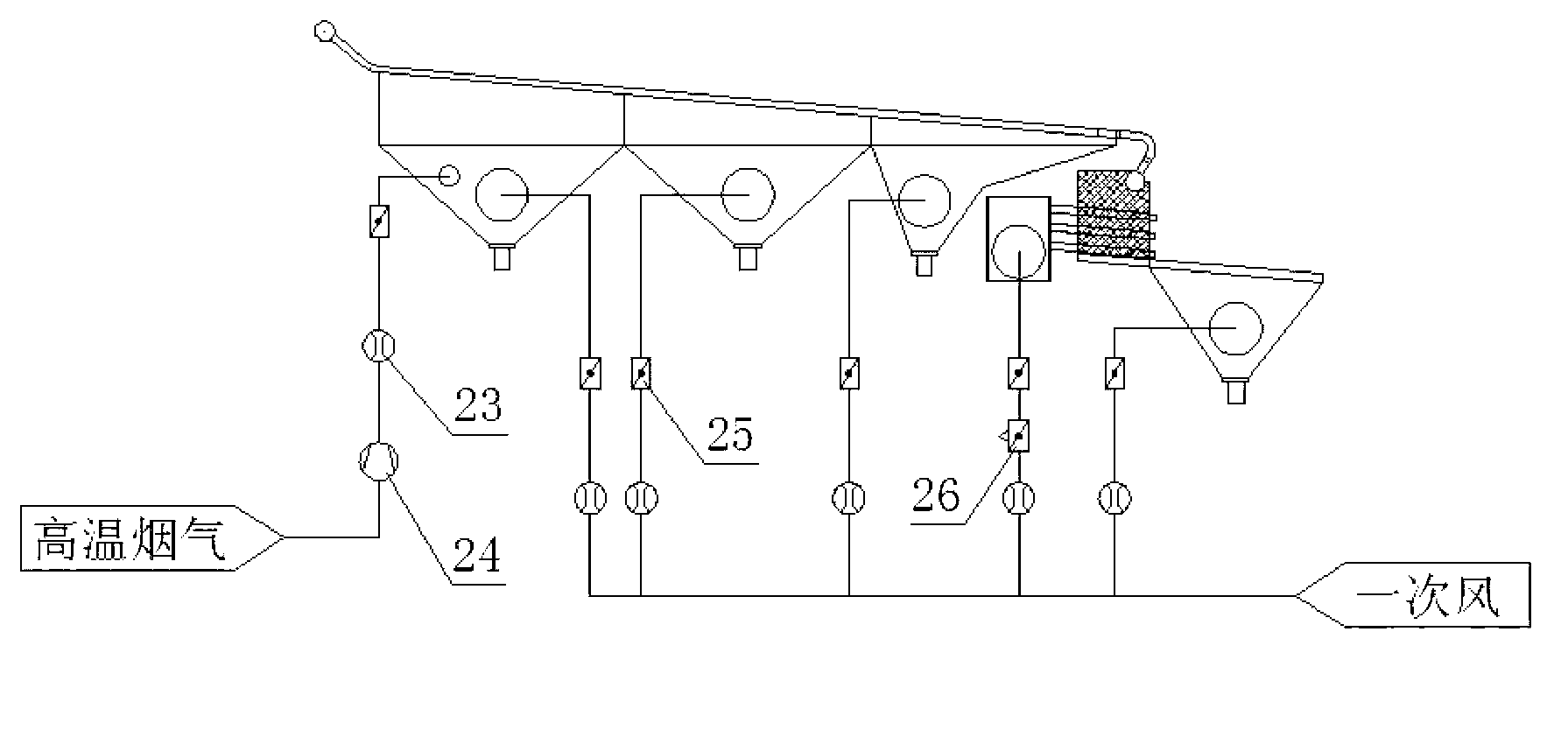

SCR inlet flue gas pre-treatment system and method

PendingCN110038433AUniform sectionSection NH

<sub>3</sub>

evenly distributedDispersed particle separationSolid fuel combustionAir preheaterHandling system

The invention relates to an SCR inlet flue gas pre-treatment system and method, relates to boiler pollutant control technology, and are used for new construction or renovation projects of ultra-cleanNOx emission of grate-firing coal-fired boilers. The SCR inlet flue gas pre-treatment system comprises a temperature regulating system, a urea solution or ammonia water solution ejector, and a cycloneequalization system. The system adopts a heating way of extracting high-temperature flue gas from a hearth outlet and then introducing the high-temperature flue gas into a cyclone tube, and a coolingway of adding a temperature-regulating economizer or extracting low-temperature flue gas from flue gas at a boiler dust collector outlet or an air preheater outlet and then introducing the low-temperature flue gas into the cyclone tube through a cold flue, and the average temperature of SCR inlet flue gas is controlled within the working range of catalysts. A urea solution is ejected in a burnoutchamber through the urea solution ejector; an ammonia water solution is ejected at an inlet pipe of a cyclone separator through the ammonia water solution ejector; NH3 is produced under the action ofthe high-temperature flue gas and mixed into the flue gas. Under the combined action of a flow equalization board and the cyclone tube, the flue gas and NH3 are mixed uniformly to achieve the effectsof equal temperature, equal concentration field and equal velocity, thereby meeting the requirements on the temperature, concentration field and velocity field at an SCR inlet.

Owner:HARBIN INST OF TECH

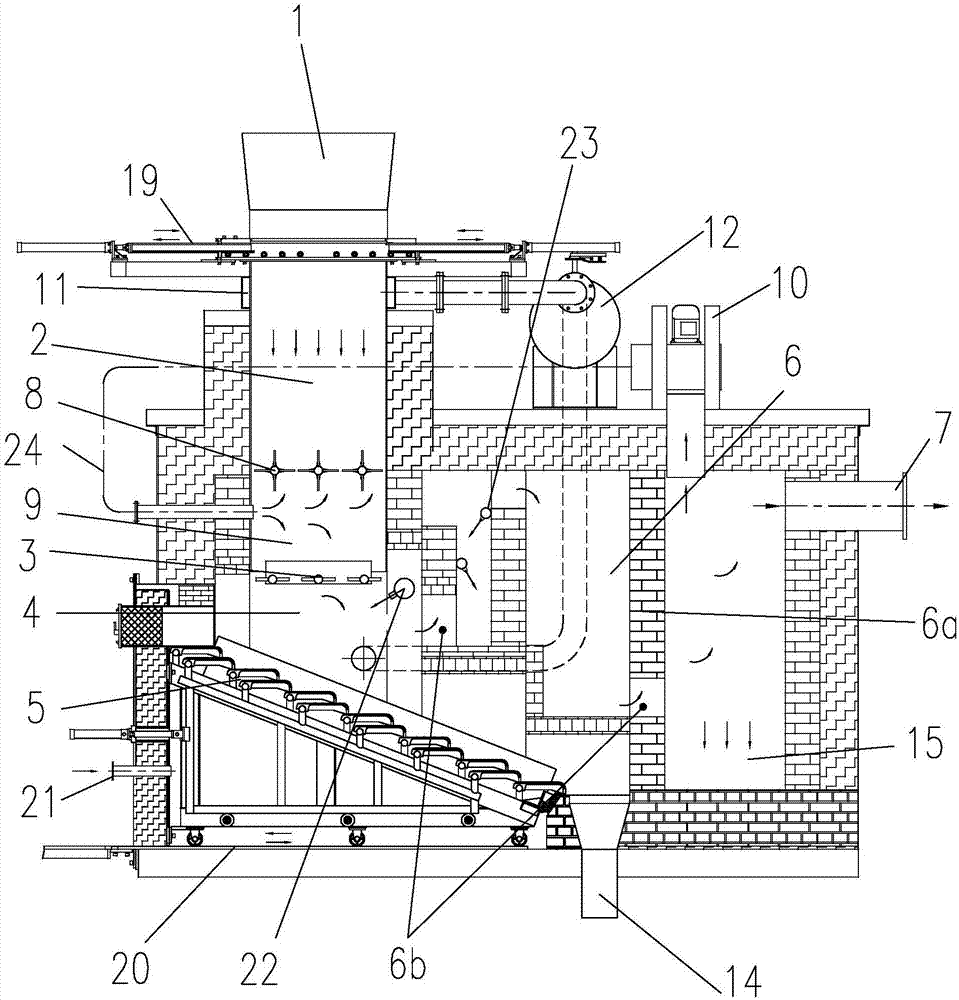

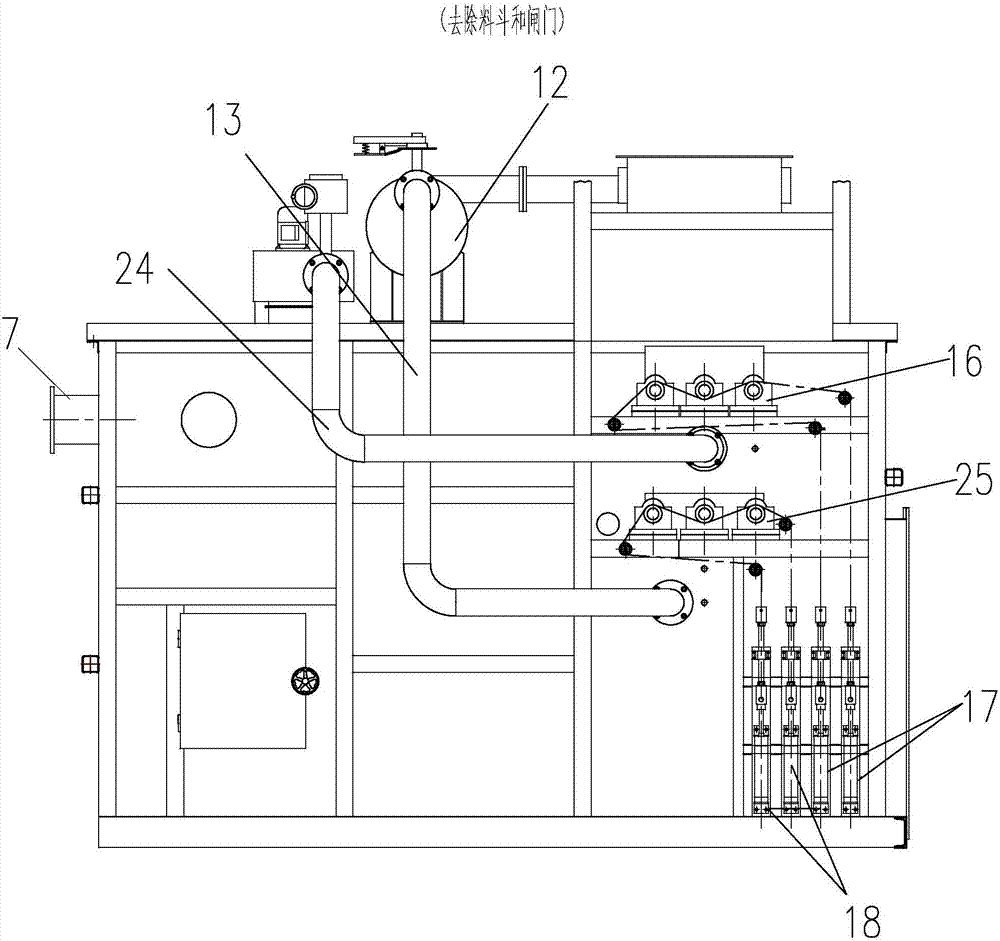

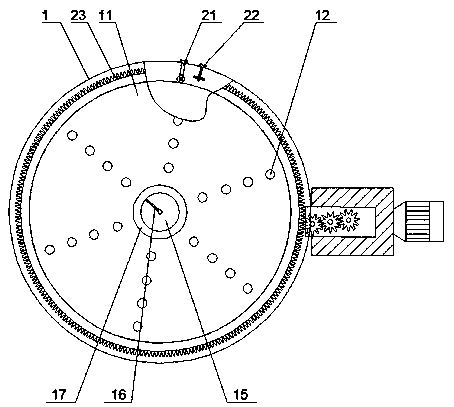

Biomass rotary fire grate combustor

PendingCN109442387AAvoid blockingBurn fullySolid fuel combustionAir/fuel supply for combustionCombustorSlag

The invention relates to a biomass combustor, in particular to a biomass rotary fire grate combustor which is suitable for mass biomass fuel and capable of preventing slag bonding and coking. The biomass rotary fire grate combustor comprises a furnace body, a rotary fire grate device arranged in the furnace body, a three-dimensional slag cleaning mechanism arranged in the furnace body, and a furnace body base located at the lower part of the furnace body, wherein a wind inlet device is arranged on the furnace body base; a feeding device is arranged above the wind inlet device; the wind inlet device communicates with the furnace body base and a flaming mouth of the furnace body; and the feeding device is connected with a feeding opening of the furnace body. According to the biomass rotary fire grate combustor disclosed by the invention, an auxiliary rotary slag cleaning machine is arranged at an ash falling opening of the furnace body and the rotary fire grate device, so that firstly, fuel accumulated on the rotary fire grate is sufficiently stirred; then the fuel is sufficiently combusted, bonded slags and cokes which are not sufficiently combusted on the rotary fire grate can be effectively crushed, and are transported to an ash outlet groove through a rotary auger arranged on the auxiliary rotary slag cleaning machine, so that the situation that the ash falling opening is blocked by the too much bonded slags and the too much cokes is avoided.

Owner:辛集市卓伟生物质压块燃烧机有限公司

Shaft-rotating coal stirring boiler

InactiveCN101457927AEasy to manufactureEasy transferRevolving grateSolid fuel combustionFluidized bedProcess engineering

The invention provides a pivot coal spreading boiler, belonging to an industrial boiler. The boiler combines the advantages of a grate furnace, a double-layered grate furnace, a coal tossing furnace and a chain furnace such as mechanical coal transportation, uniform fire coal spreading, multizone and multimode burning, sufficient burning, inferior coal adaptability, high heating efficiency, fast load adjustment and the like; and overcomes the defects of the furnaces. The invention has the characteristics of high efficiency, energy saving, environmental protection, and the like, and is very practical. The structure of the boiler comprises a pivot coal spreading horizontal boiler and a pivot coal spreading fluidized bed furnace and is composed by the combination of pivot coal spreading grates and general grates or a fluidized bed; and the pivot coal spreading grate comprises a fin arris, a pivot tube and vents. The best characteristic of the pivot coal spreading boiler is that the pivot coal spreading grate has functions of fire coal transporting, grinding and spreading; the boiler is provided with an upper grate layer and a lower grate layer with multiple burning modes such as grate firing, float firing, boiling and the like, the heating efficiency is high and the application range of the coal variety is wide; the rotating speed of the grate is adjustable, thus changing the coal supply quantity and adapting to the load change; furthermore, the rotation and production are simple, assembly is simple and fast and replacement is convenient and fast.

Owner:袁吉增

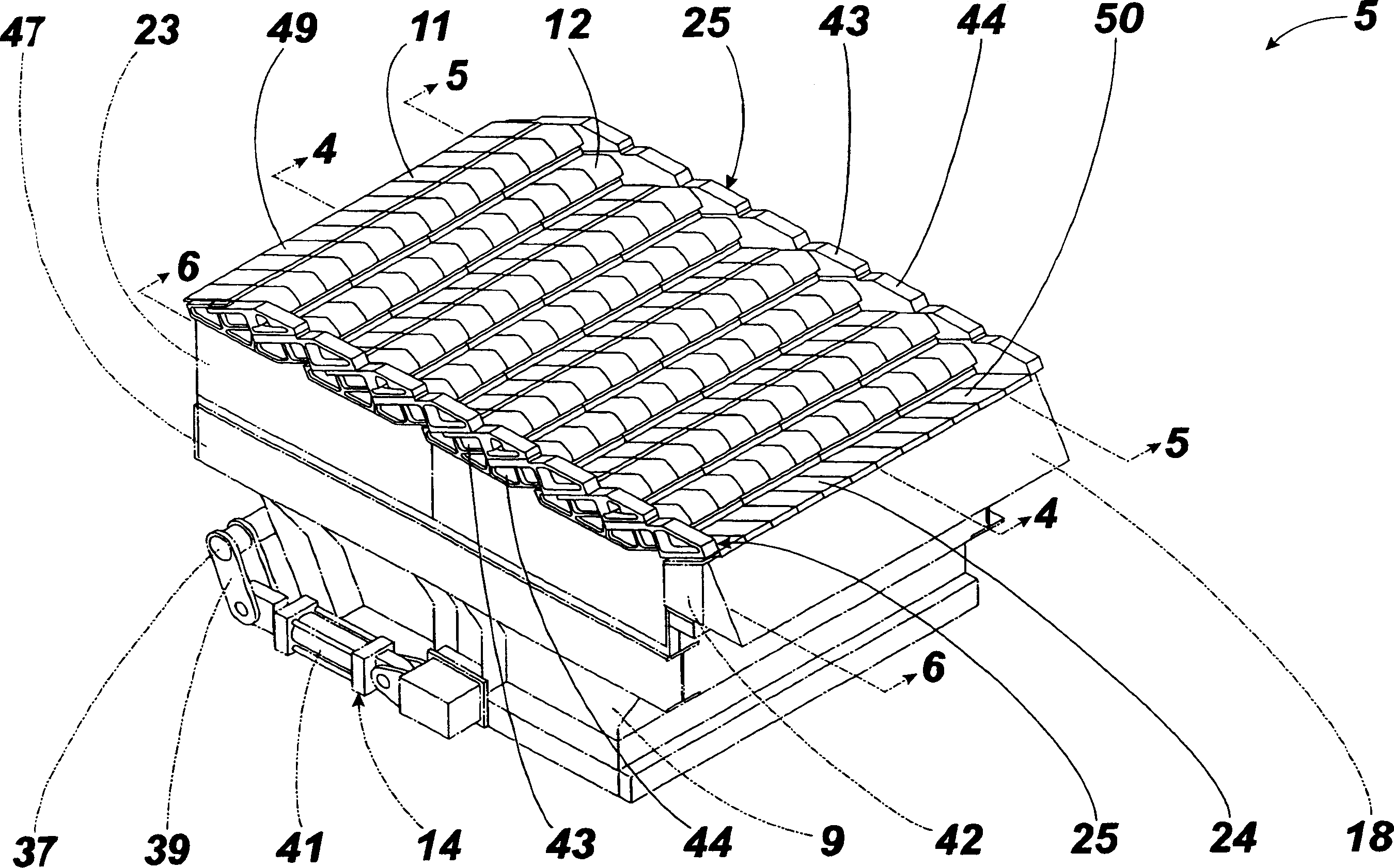

Water-cooled grate combustor

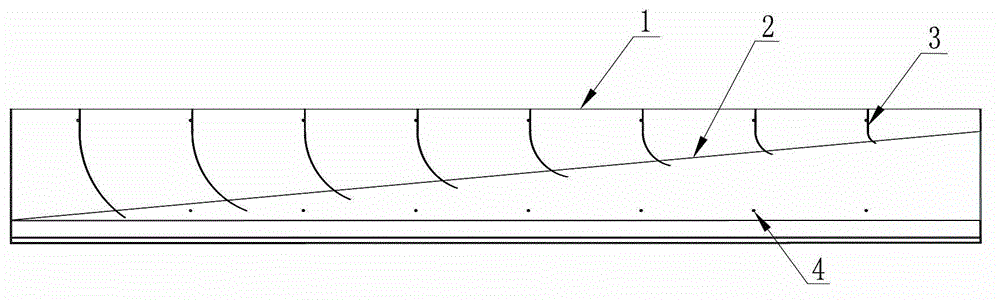

InactiveCN102650426AHigh temperature will not burnReduce maintenance rateHollow bar grateSolid fuel combustionThermodynamicsCombustor

A water-cooled grate combustor comprises a fixed water-cooled grate, a feed hopper, a feed mechanism, a fixed wind chamber, a combustion chamber and an ash pit, the feed hopper is arranged on the front upper part of the combustion chamber, the feed mechanism is arranged in front of the hopper, the fixed wind chamber is arranged under the grate, the combustion chamber is arranged upon the grate, and the ash pit is arranged at the front lower end of the grate. The technical points are as follows: the fixed water-cooled grate is downwardly inclined by 1 to 30 degrees along the moving direction of fuel, the arrangement direction of the tubes of the fixed water-cooled grate accords with the moving direction of the fuel, headers with water inlets and water outlets are perpendicularly connected with the upper and the lower ends of the tubes of the fixed water-cooled grate, leakage-proof spacing baffles which are lapped at the front and the rear or the left and the right are evenly fixed between each two neighboring tubes of the fixed water-cooled grate, and an intake passage is reserved between each two neighboring spacing baffles. Because the grate of the fixed and inclined water-cooled grate combustor provided by the invention is cooled by water, the grate cannot be burnt out by high temperature, the maintenance rate is low, and coal and biomass can be burnt.

Owner:冯之军

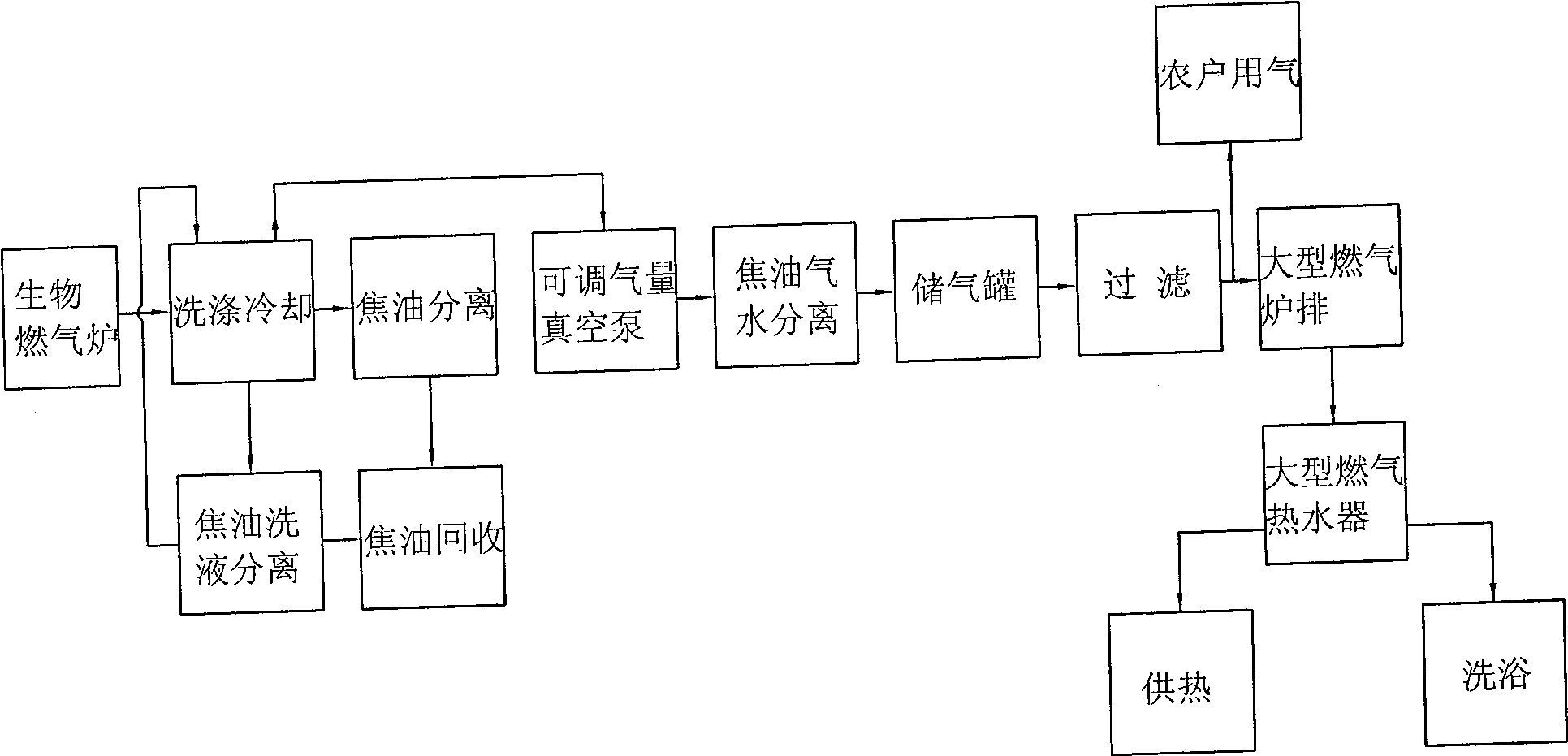

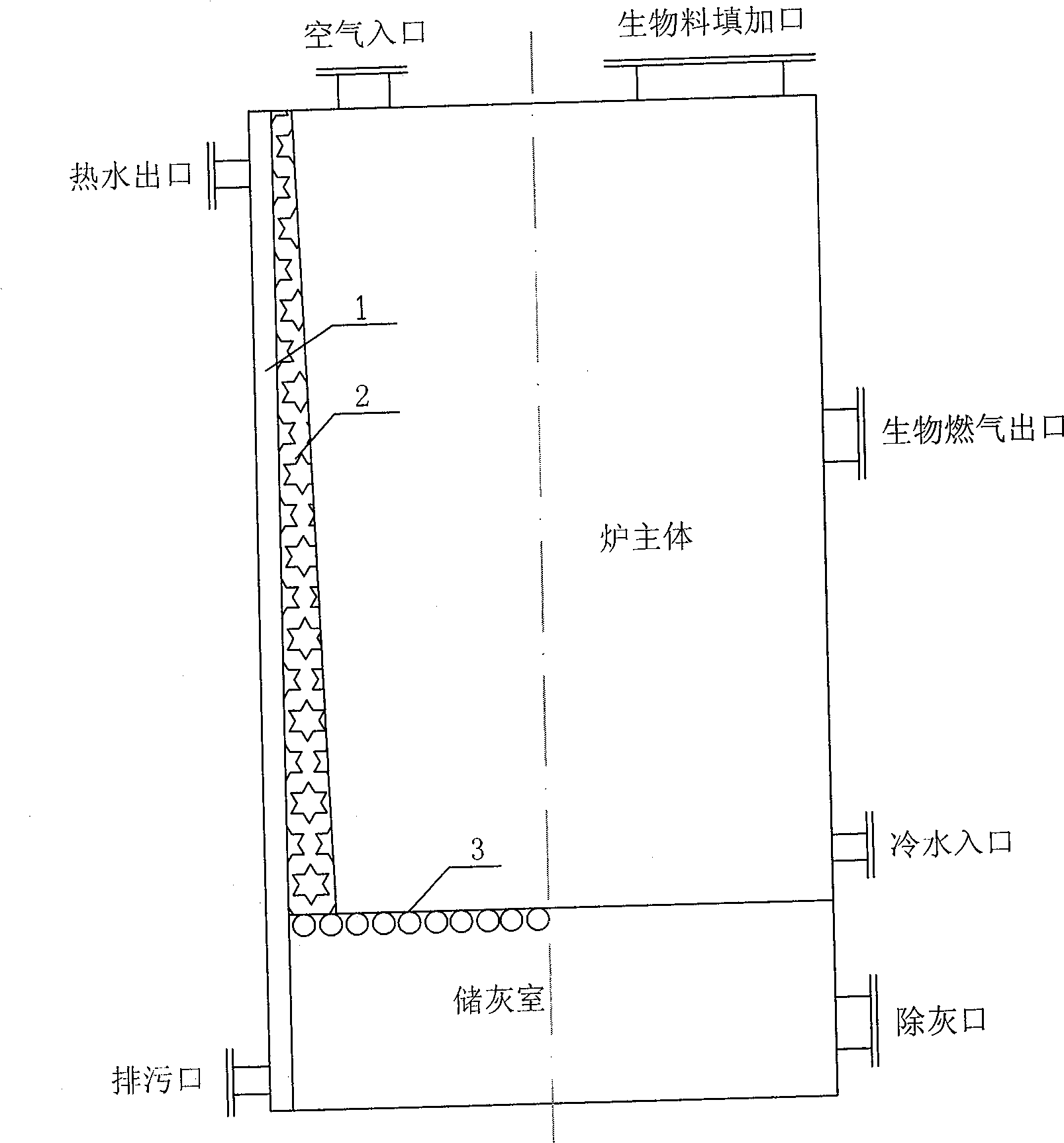

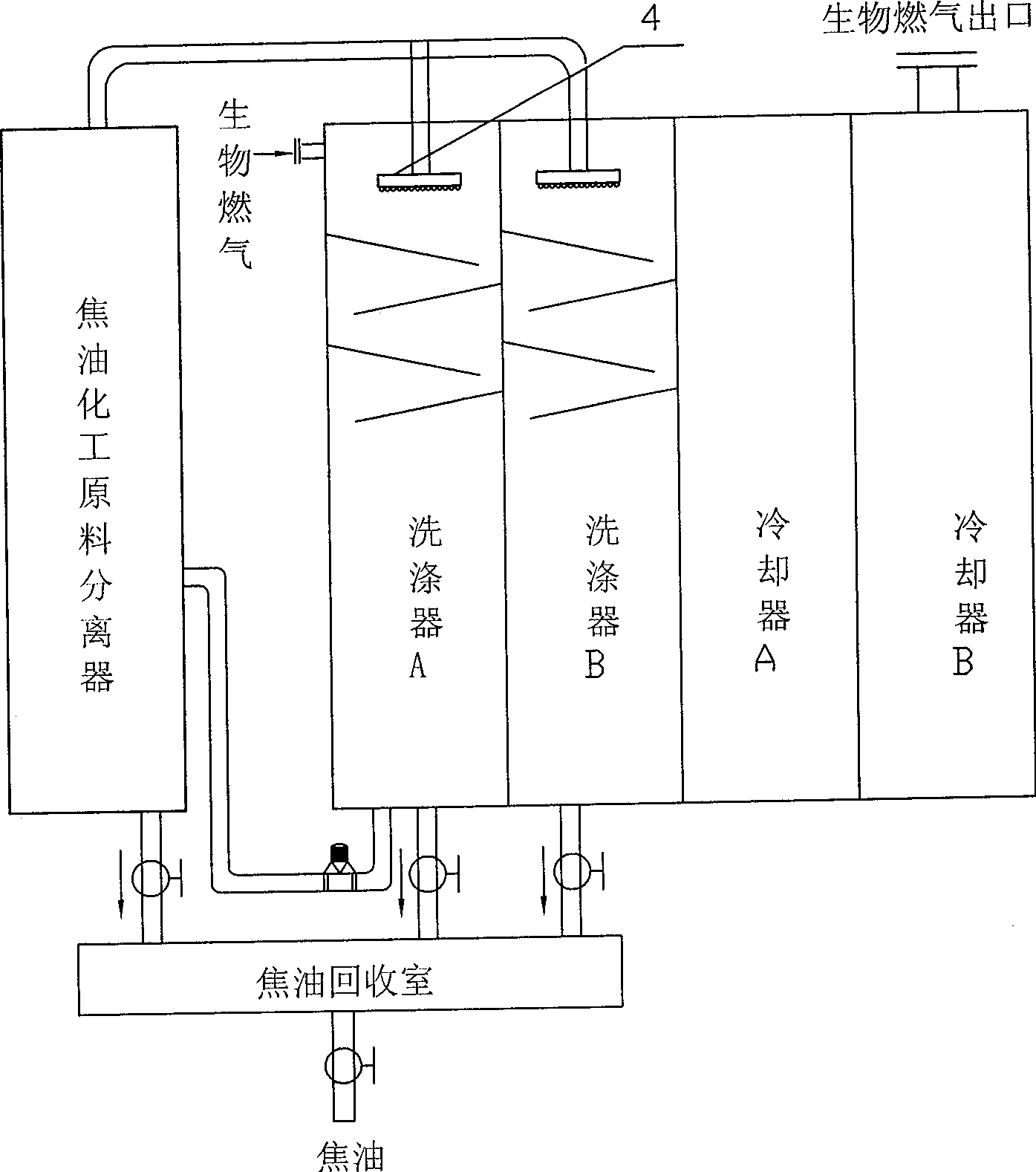

System for heating large heat receiver by biological gas

InactiveCN101487627AEradicate dependencyReduce pollutionCombination devicesWater heatersProcess engineeringGrate firing

The invention discloses a system which adopts bio-gas to heat a large heat receiver, relating to the heating system technical field. The system comprises a biological gasification furnace, a purifying device, a large fuel gas grate and a large fuel gas heat receiver; wherein, the bio-gas outlet of the biological gasification furnace is connected with the bio-gas inlet of the purifying device, the bio-gas outlet of the purifying device is connected with the bio-gas inlet of the large fuel gas grate, the large fuel gas heat receiver is arranged on the large fuel gas grate; the large fuel gas grate has an area of 0.25-30m, the large fuel gas heat receiver has a capacity of 0.2t-20t; the bio-gas produced by the biological gasification furnace is purified by the purifying device and output to the large fuel gas grate for burning at a speed of 3-80m per minute by a vacuum pump featuring adjustable air flow, and the heat obtained from the burning is used to heat the large fuel gas heat receiver. The large heat receiver of the invention has the beneficial effects of saving energy, reducing environmental pollution and improving heating efficiency of the heat receiver.

Owner:刘金山

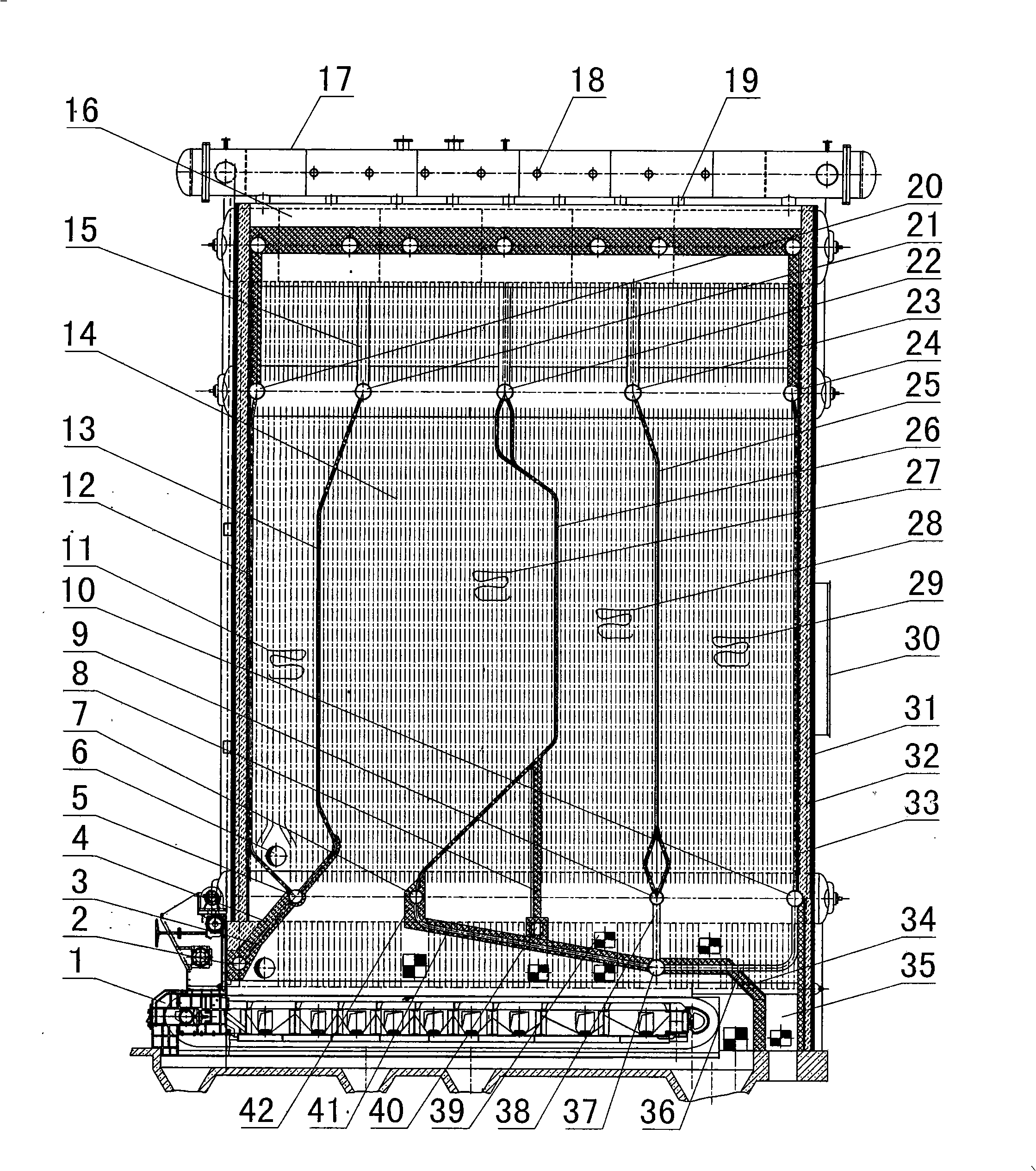

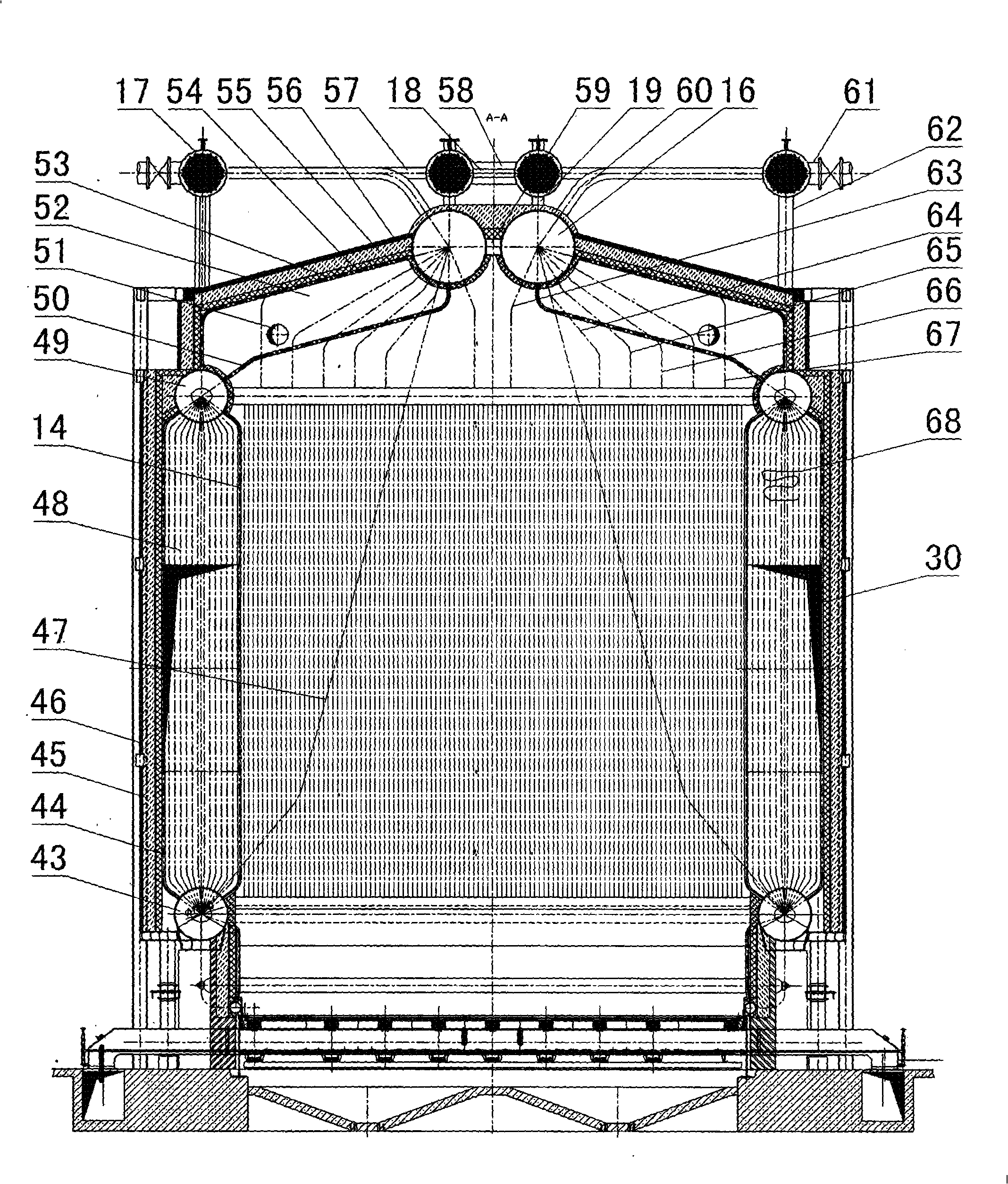

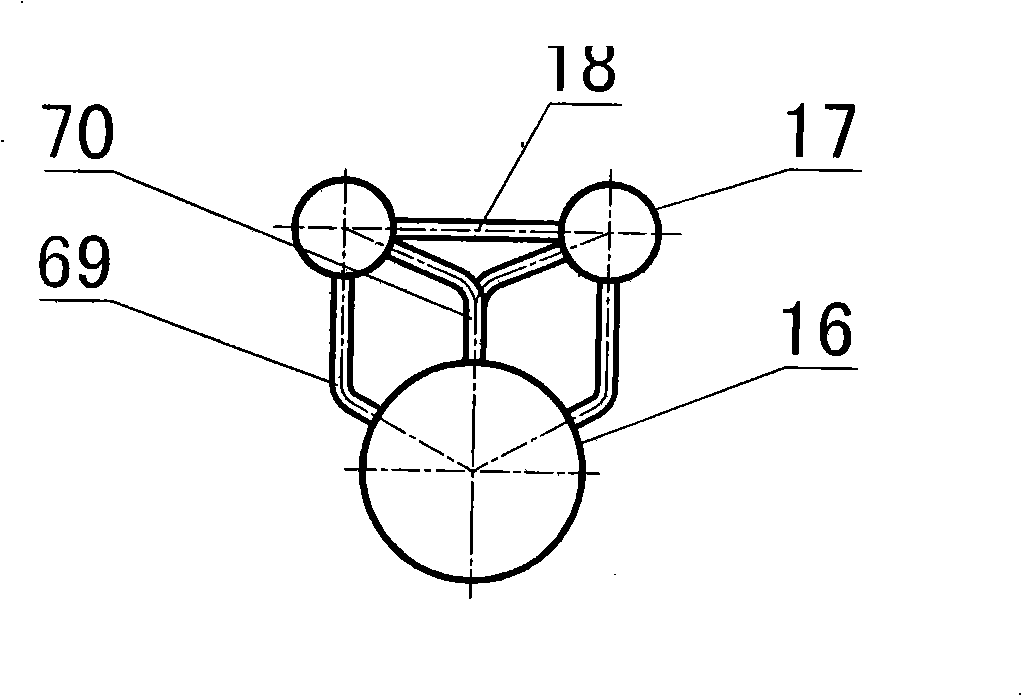

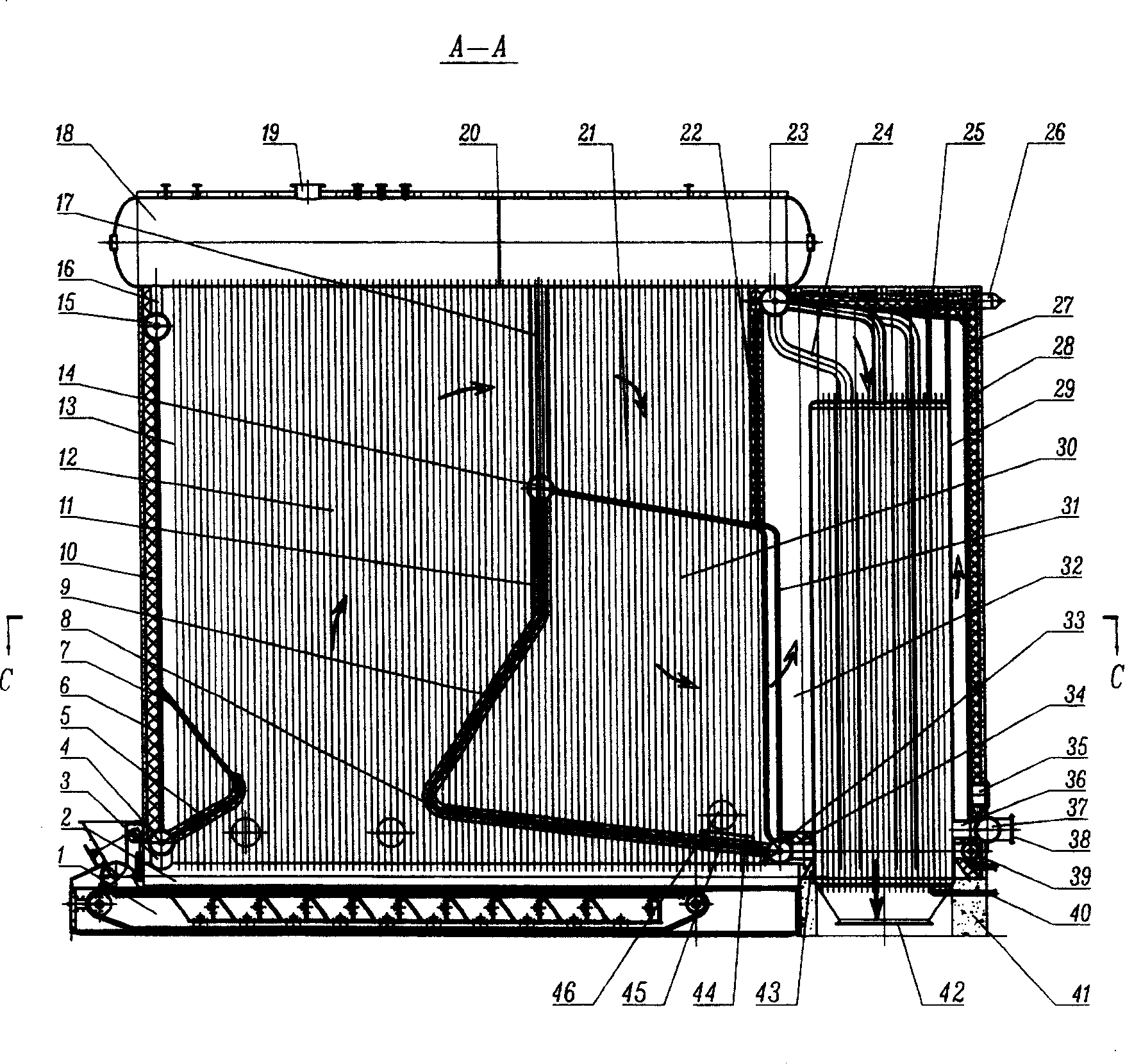

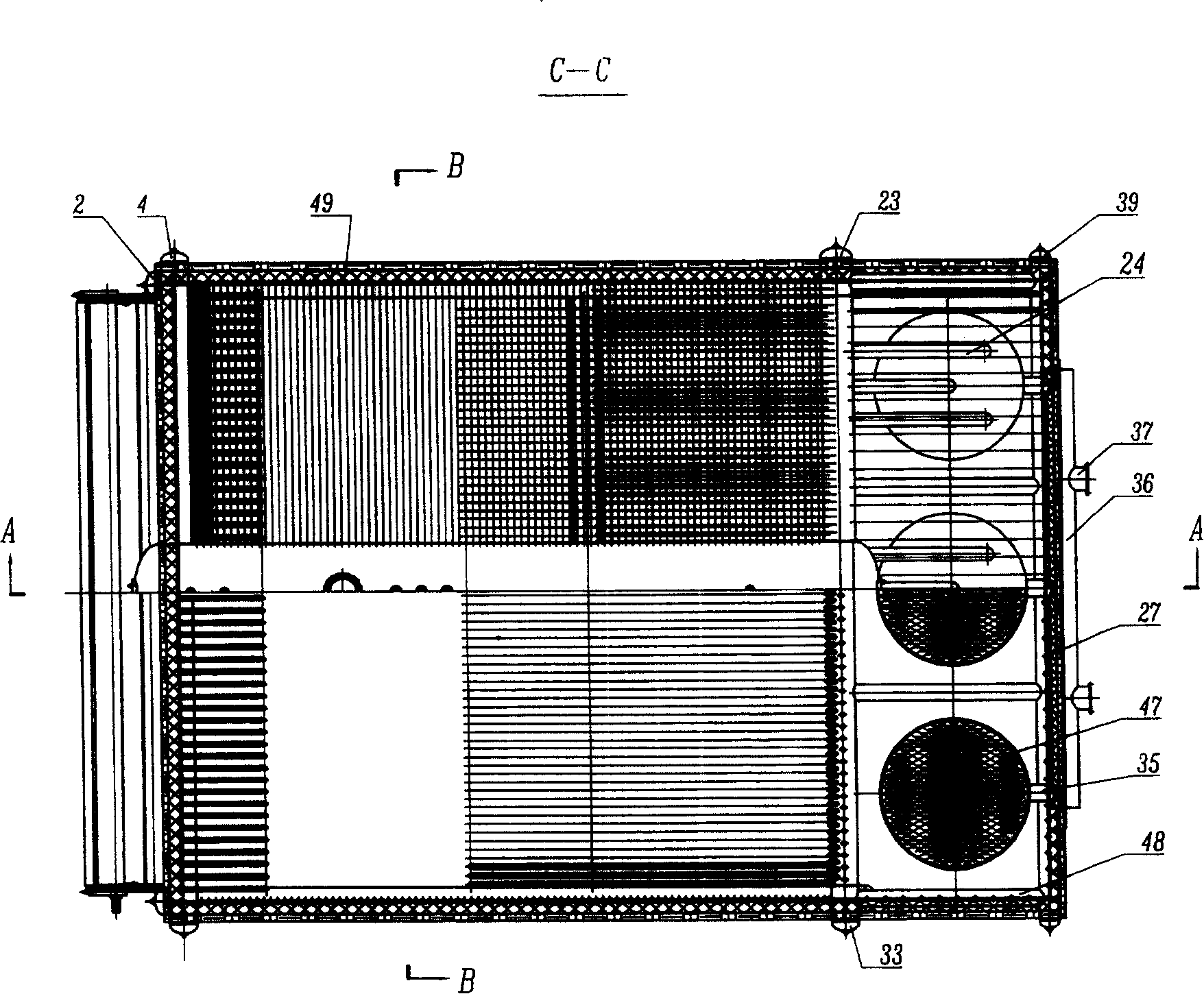

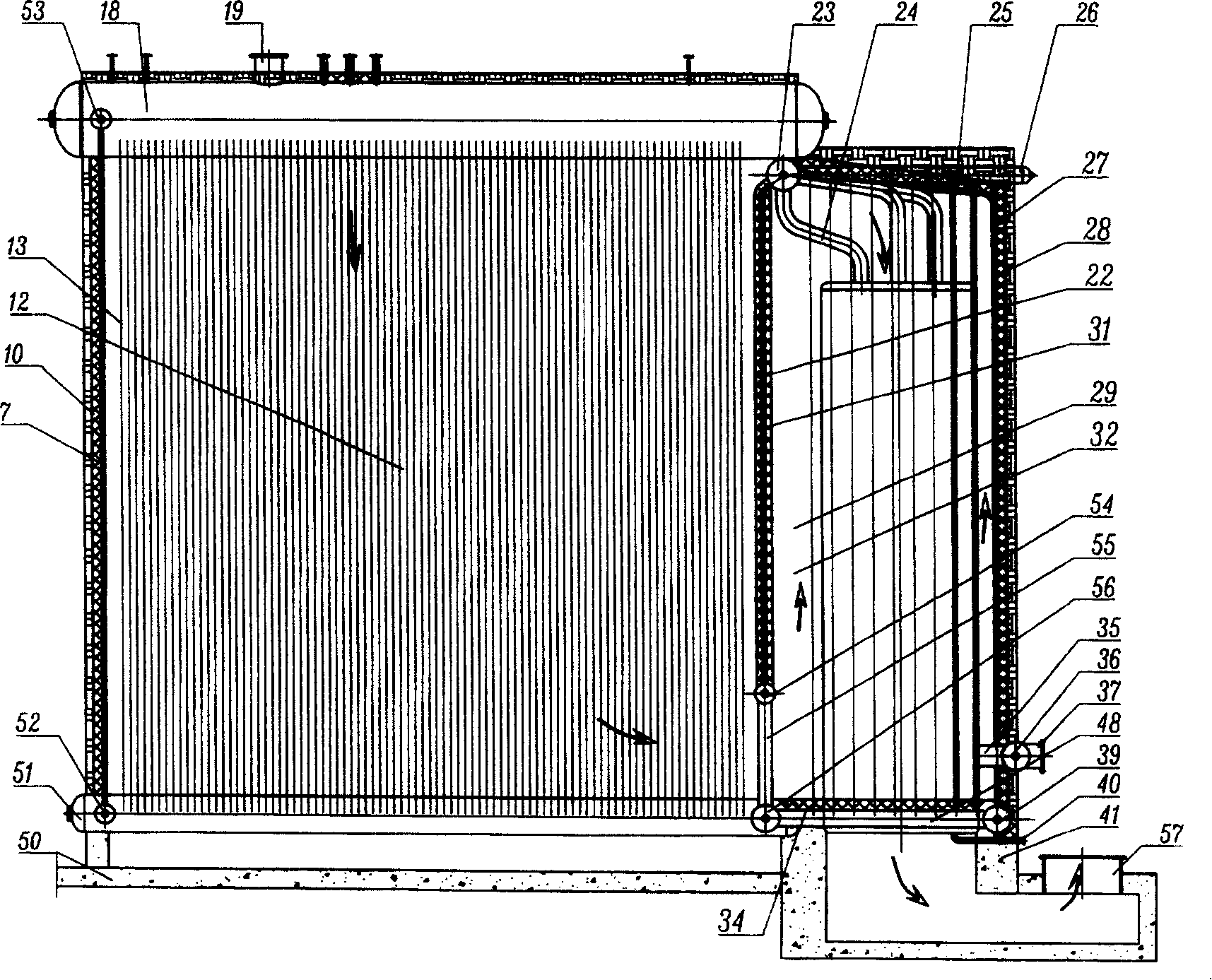

Large-sized grate firing pressurized phase inversion heat-exchanging hot water boiler

InactiveCN101338943AImprove product qualityEasy maintenanceStorage heatersEnergy industryEngineeringWater circulation

The invention relates to a large grate firing, pressure, phase transition and heat exchange hot water boiler, which can be widely applied in the industrial field of large-scale centralized heat supply. The hot water boiler is composed of a longitudinal boiler barrel, a crossbar container, a communication pipe, a wall pipe, a waterwall, a convection bank and a heat exchanger; the boiler body is compact in structure with strong integrity, which greatly reduces the steel support of the non-heating surface; the water channel of the heat exchanger characterized by multipass and non-clapboard is perfectly matched with the boiler; the water circulation in the boiler is uniformly descended or ascended by automatic adjustment; the dust in the boiler is subsided by gravitation after a plurality of times of capacity expansion and deceleration, and then the dust is separated by inertia in a multipass flow, in this way, the initial emission concentration of dust is greatly reduced; the vertical arrangement of the convection bank and transverse scouring greatly reduce the heating surface and lower the heat resistance and flow resistance. By adopting a full membrane water wall, the hot water boiler of the invention has a long flow of dust, good heat exchange effect and high heat availability. Besides, the hot water boiler is characterized in that the boiler is free from scaling, oxygen corrosion and pollution discharging, and free from using a water softening plant or a de-oxygenization device. Therefore, the boiler of the invention is a centralized heating boiler characterized by remarkable high efficiency, energy and water conservation, power consumption reduction, and carbon emission reduction.

Owner:王森

Low discharge high energy efficiency vertical shell type water-fire tube boiler

InactiveCN101187501AIncrease the lengthShorten the lengthWater heatersSteam boilersHigh energyCogeneration

A water-fire tube boiler of a low discharging high-performance vertically-arranged boiler casing type relates to eight boiler series, namely a large or middle water-fire tube grate firing, a chamber combustion, hot-water, steam, and phase-change and distributed type cogeneration boiler. The invention comprises a longitudinal barrel, a crossbar collecting box, a wall-cooling tube, a vertically-arranged boiler casing, a screw-thread fire tube and the like. The invention changes flue direction of current water-fire tube boilers from a longitudinal flue which is horizontally returned in front and back direction to a transversal flue which is vertically returned in up and down direction. Twice large dilatancies are naturally realized before smoke enters into the flue, and the vertically-arranged boiler casing is entirely barely heated in the rear portion of the flue of the boiler. The volume of a furnace and the flue and a radiative-convective heating surface are significantly enlarged with same size and same quantity of steel consumption, a five return journey of a whole forced-circulating waterway for coal and hot water is only provided with a baffle board, and a three journey of a whole forced-circulating waterway for gas (oil) is not provided with any baffle boards. Inlet water roses slowly after entering into the boiler casing, and firstly washes an upper tube sheet, and then enters into a rising tube. The invention eliminates tube explosion, tube-plate fracture and flue abrasion, the initial discharging concentration of smoke is greatly reduced, and consumption of steel and electricity is decreased.

Owner:王森

Boiling type biomass gasification process

InactiveCN103666578ALess ashShort pyrolysis timeGranular/pulverulent flues gasificationEngineeringGrate firing

The invention provides a boiling type biomass gasification process. According to the boiling type biomass gasification process, reaction is carried out in a gasification furnace, and the gasification furnace comprises a reaction section and a tail ash section; the reaction section and the tail ash section are arranged with one being above the other, and a furnace grate is arranged between the reaction section and the tail ash section; and the boiling type biomass gasification process comprises the following steps: (1) feeding biomass raw material into a feeding opening formed in the side part of the reaction section of the gasification furnace, wherein the feeding opening is positioned below the middle part of the reaction section and arranged in the position having a distance being 1 / 4-1 / 2 of the height away from the bottom of the reaction section, and the height of the material accumulated in the reaction section is below 30% of the height of the reaction section; and introducing a gasification medium from the side part of the tail ash section of the gasification furnace; and (2) firstly grate firing the biomass raw material in the gasification furnace on the furnace grate; and then increasing the introduction speed of the gasification medium so that the biomass raw material in the gasification furnace has gasification reaction in a boiling state to generate fuel gas.

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

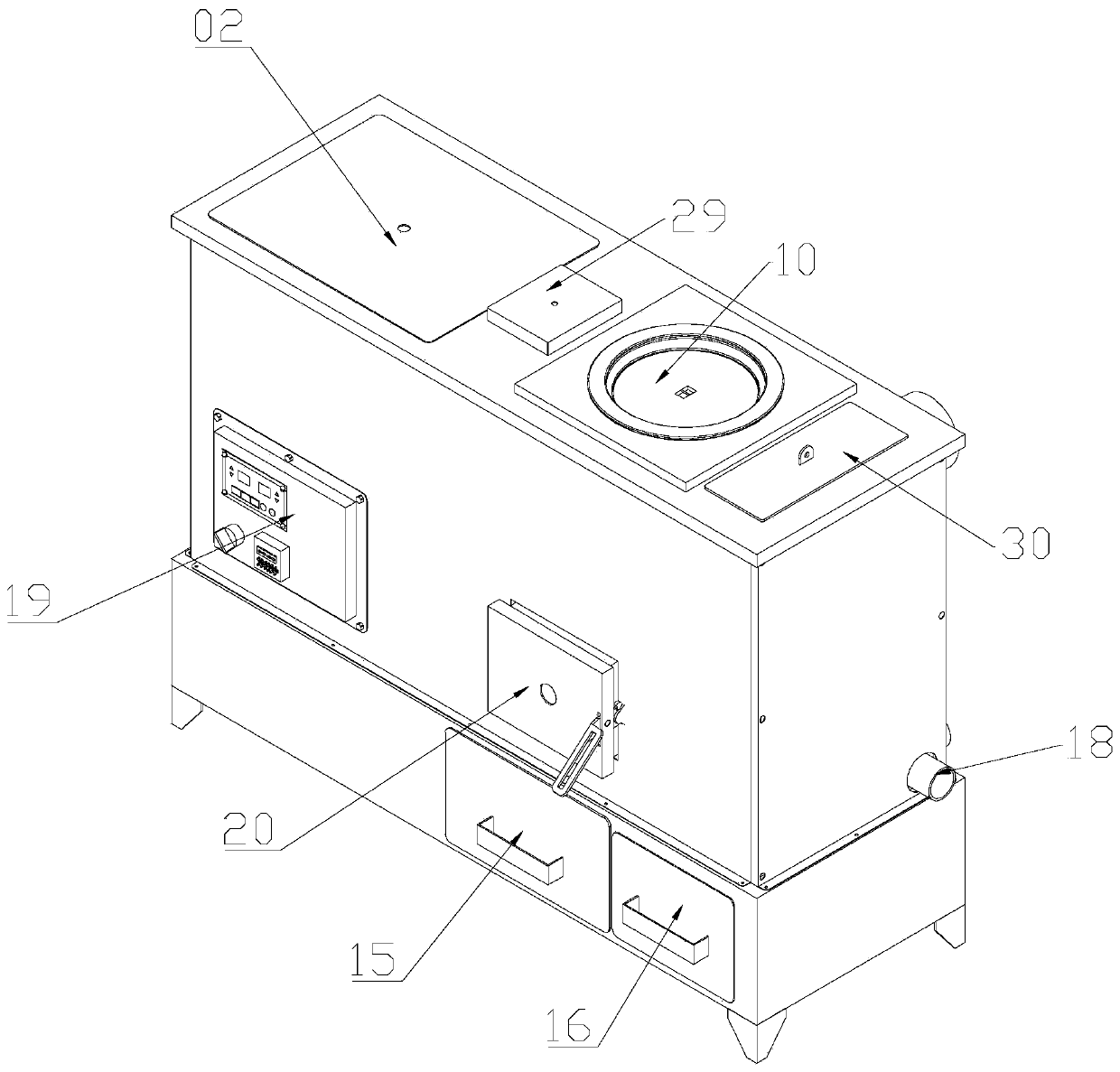

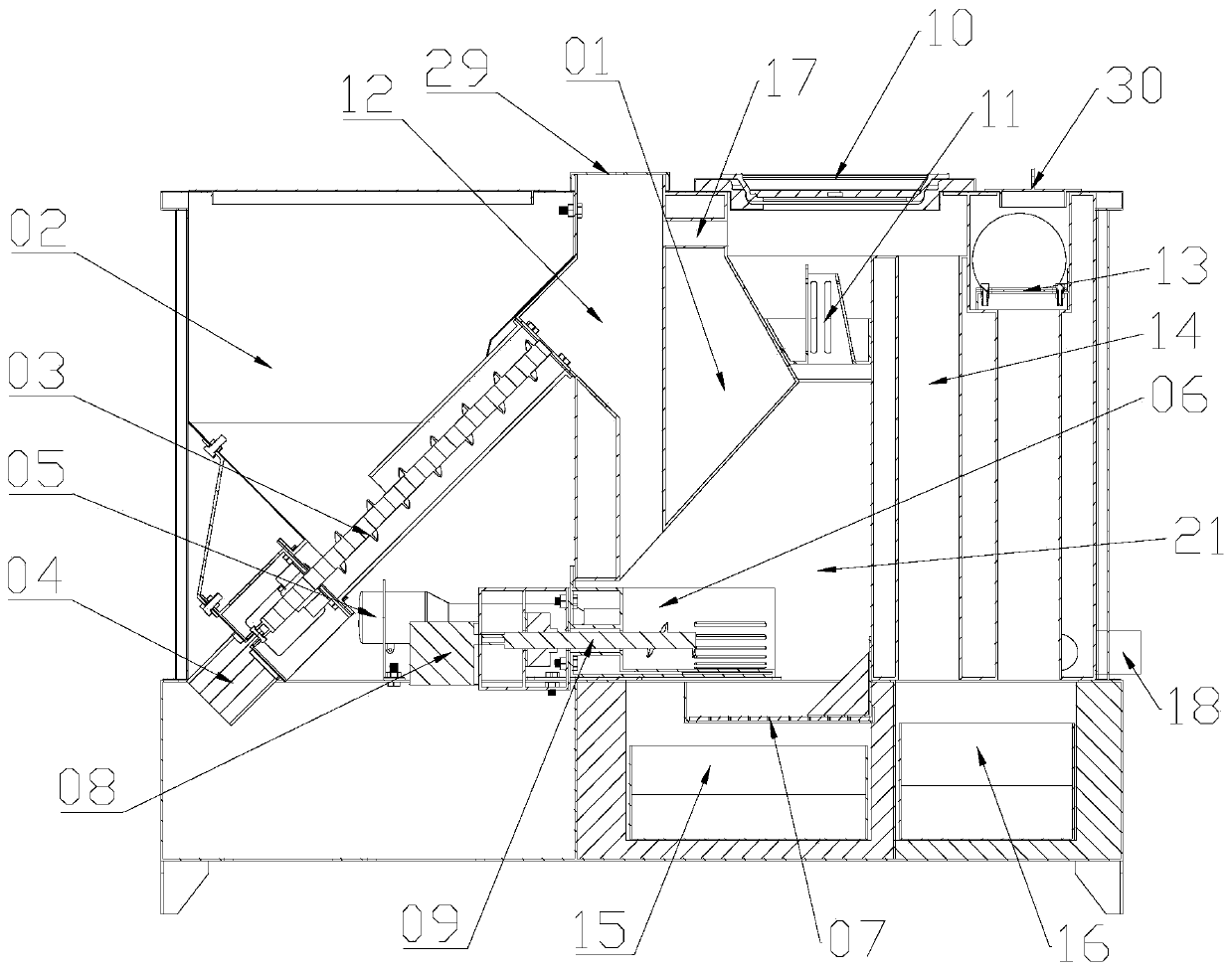

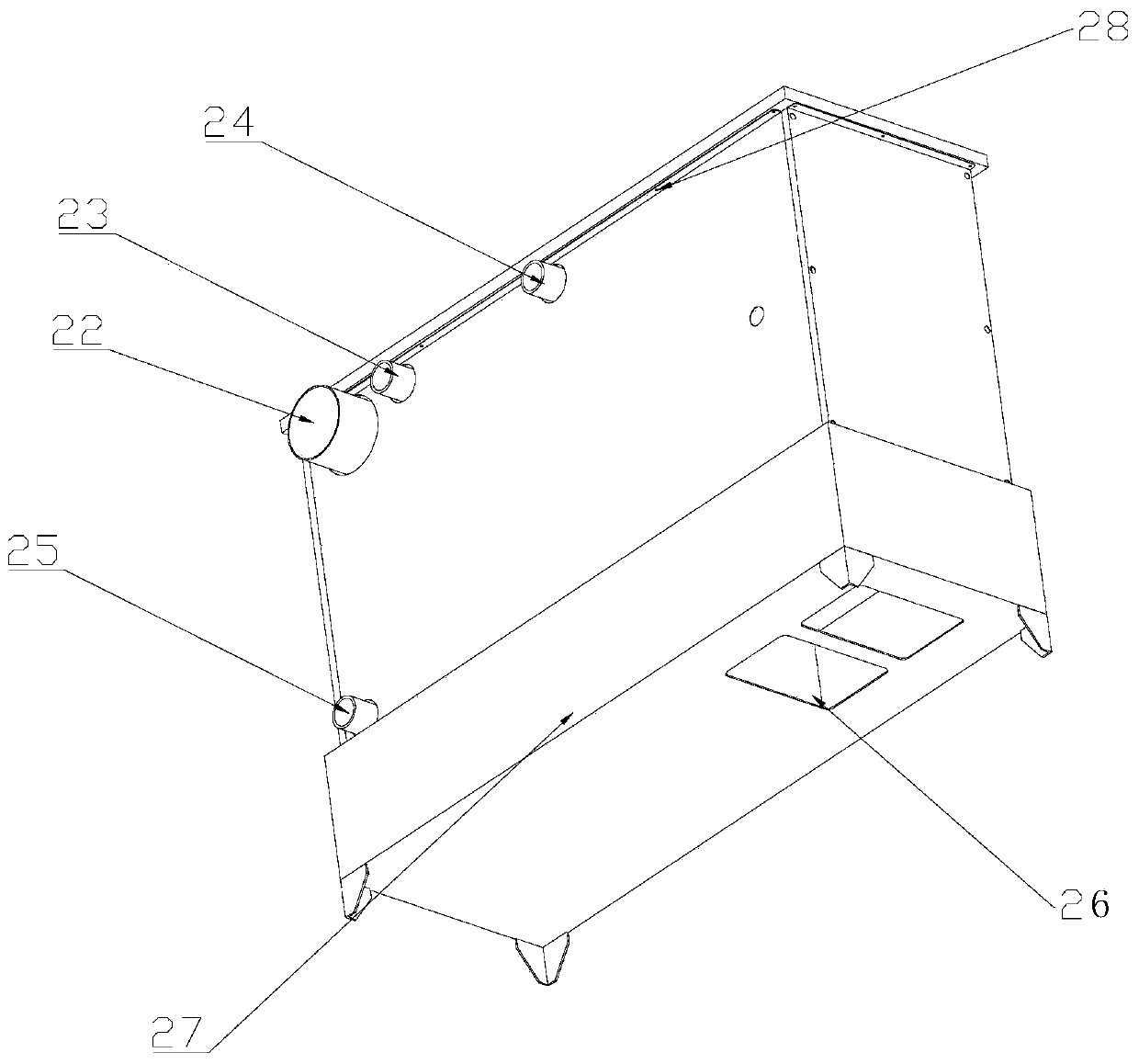

Biomass hot water cooking and heating stove with double-layer micro-dynamic fire grates

InactiveCN110822483APrevent flashbackImprove burnout rateLighting and heating apparatusStove/ranges for heating waterCombustion systemEnvironmental engineering

The invention discloses a biomass hot water cooking and heating stove with double-layer micro-dynamic fire grates. The biomass hot water cooking and heating stove comprises a stove body, a controllersystem, a feeding and fire-returning prevention system, a slag removal and fire grate combustion system, an air distribution system, a heat exchange application system and a cleaning and purifying system; the slag removal and fire grate combustion system comprises a hearth arranged in the stove body, the movable fire grate arranged at the bottom of the hearth, an igniter for igniting fuel accumulated on the movable fire grate, the fixed fire grate, a slag removal auger, a slag removal motor and an ash box; the biomass fuel falls into the front section of the primary movable fire grate and slowly moves under the slight rotation of the slag removal auger to prevent coking and slagging as well as to complete preheating, volatilizing and partial burning of fixed carbon in the process; and theunburned fixed carbon is finally combusted on the secondary fixed grate. The zoned and sectionalized micro-dynamic combustion structure not only has high burn-out rate, but also effectively avoids thecommon coking and slagging problems of the biomass stove.

Owner:联合优发生物质能源徐州有限公司

Inverted grate-firing boiler

ActiveCN102563853AReduce the number of additionsStable combustionWater heatersCombustion systemInsulation layer

The invention discloses an inverted grate-firing boiler, which comprises a feeding system, a combustion system, a heat exchange system, a slag removal system and a smoke exhaust system and is provided with a cylindrical boiler body. A combustion chamber is arranged on the lower portion of the boiler body, a feeding port is disposed on the top of the boiler body, a bin is arranged below the feeding port, a separation sealing door is disposed between the bin and the combustion chamber, sealing heat-insulation layers are arranged on the upper surface and the periphery of the boiler body, an air inlet is only arranged at a fire grate of the lower portion of the combustion chamber, and a smoke exhaust channel is positioned on a side surface of the lower portion of the combustion chamber. A combustion mode of the inverted grate-firing boiler is completely different from a combustion mode of a traditional fixed fire grate or mechanical movable fire grate. The inverted grate-firing boiler hasthe advantages that the inverted grate-firing boiler has a stable combustion layer, a heat conduction mode is efficient, and a heat exchange water pipe is always positioned in the stable combustion layer. In addition, standards of selected fuel are lowered, and simultaneously, frequency of adding fuel within unit time is reduced. Theoretically speaking, the total amount of materials added at one step can be increased unlimitedly as long as the boiler can be structurally manufactured properly.

Owner:于耀中

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com