Patents

Literature

137481results about How to "Easy maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

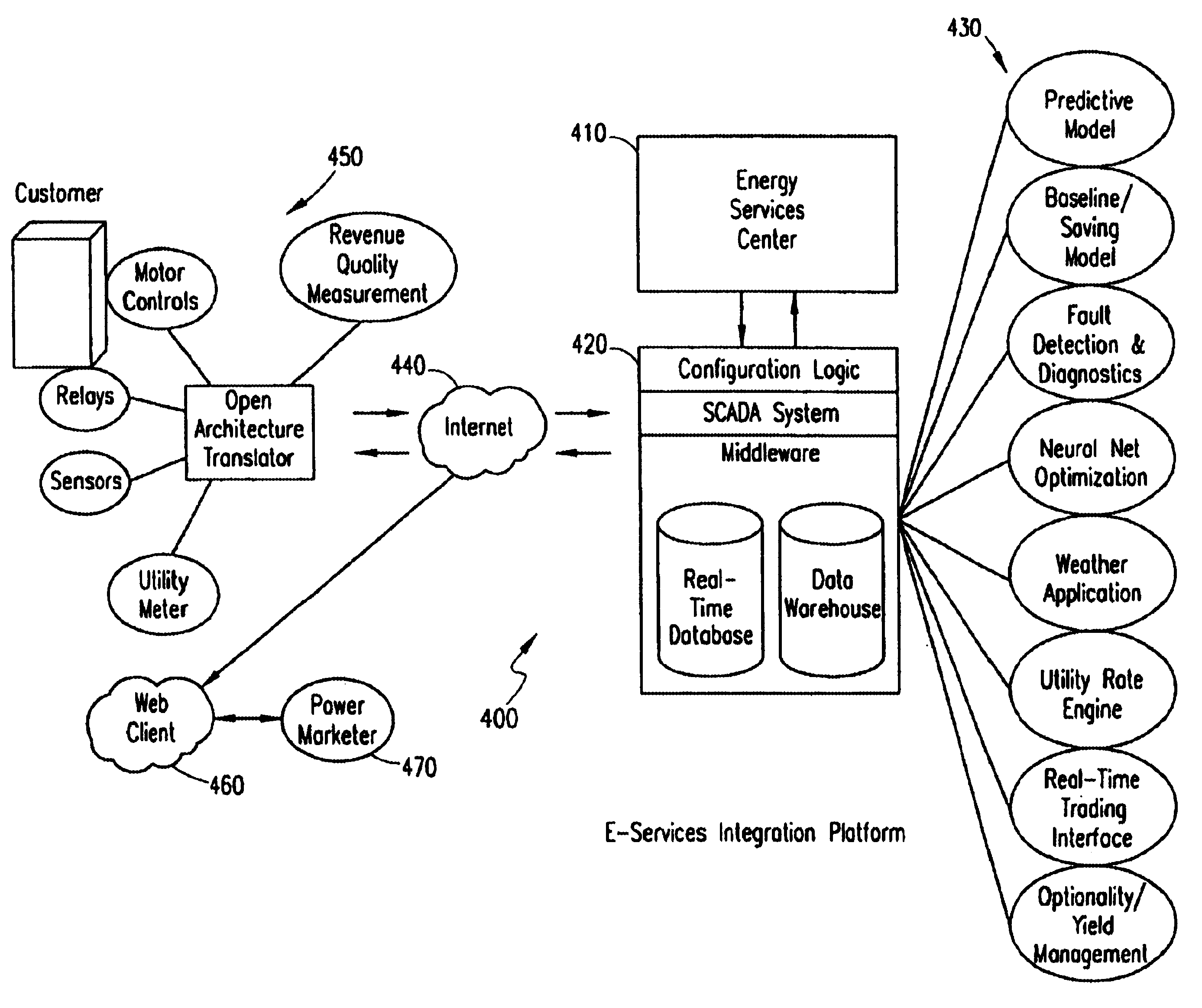

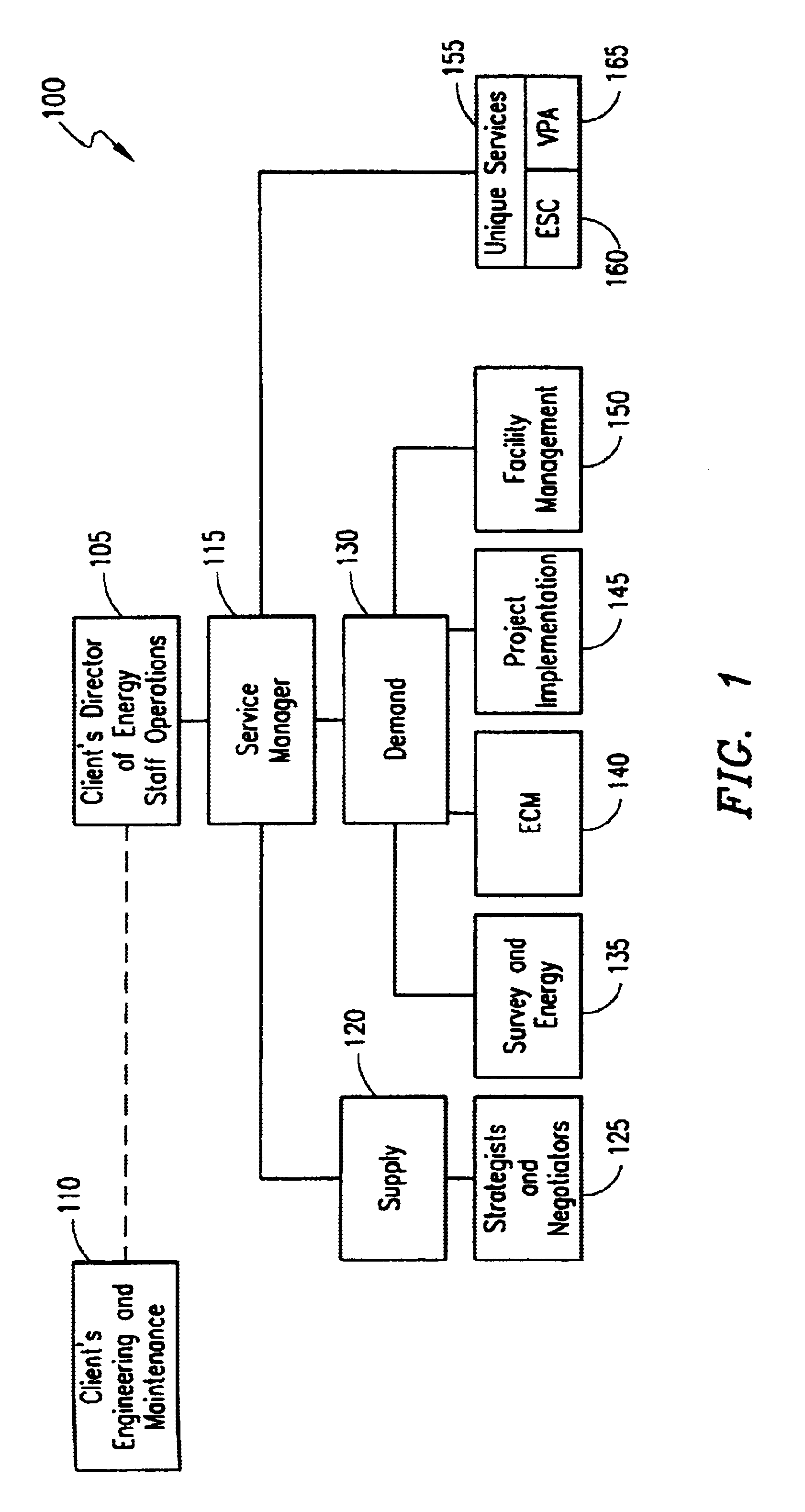

System and method for energy management

InactiveUS6785592B1Economic savingsImprove economyLevel controlSpecial tariff metersConservation energyProcess engineering

A business methodology for optimizing energy procurement energy demand (usage) and energy supply for a facility or complex. After ascertaining a baseline model, energy consumption is monitored and adjusted to reflect dynamic economic factors of operations. With the accumulation of data, contract negotiations with energy suppliers may provide further energy savings. Over time and patterns of usage determined further savings and optimization in energy, equipment, staffing and other operational areas are obtained. Remote access provides efficient monitoring of established systems.

Owner:PEROT SYSTEMS

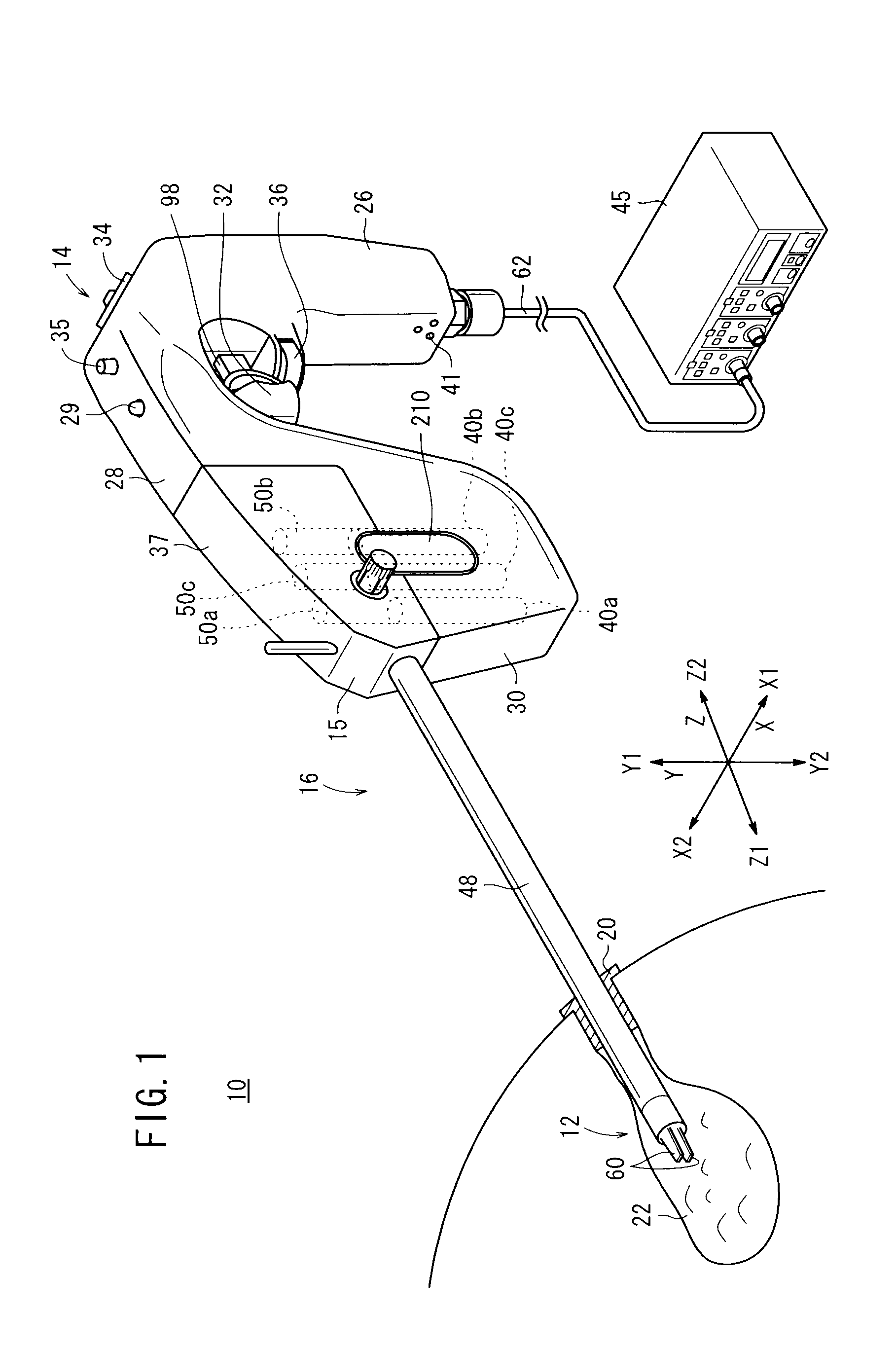

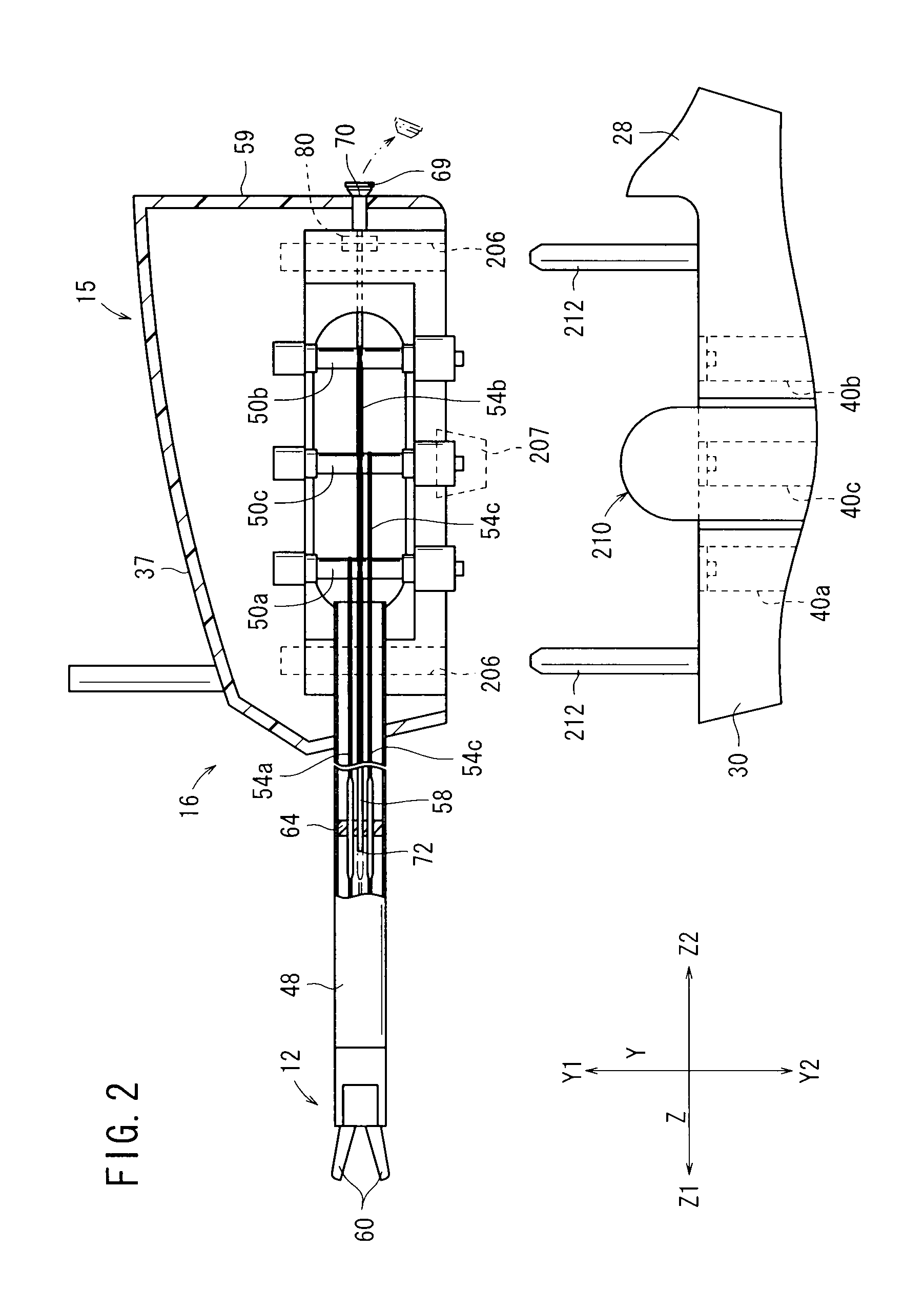

Manipulator

ActiveUS8382790B2Easy to cleanAvoid flowDiagnosticsSurgical instrument detailsEngineeringManipulator

Owner:KARL STORZ GMBH & CO KG

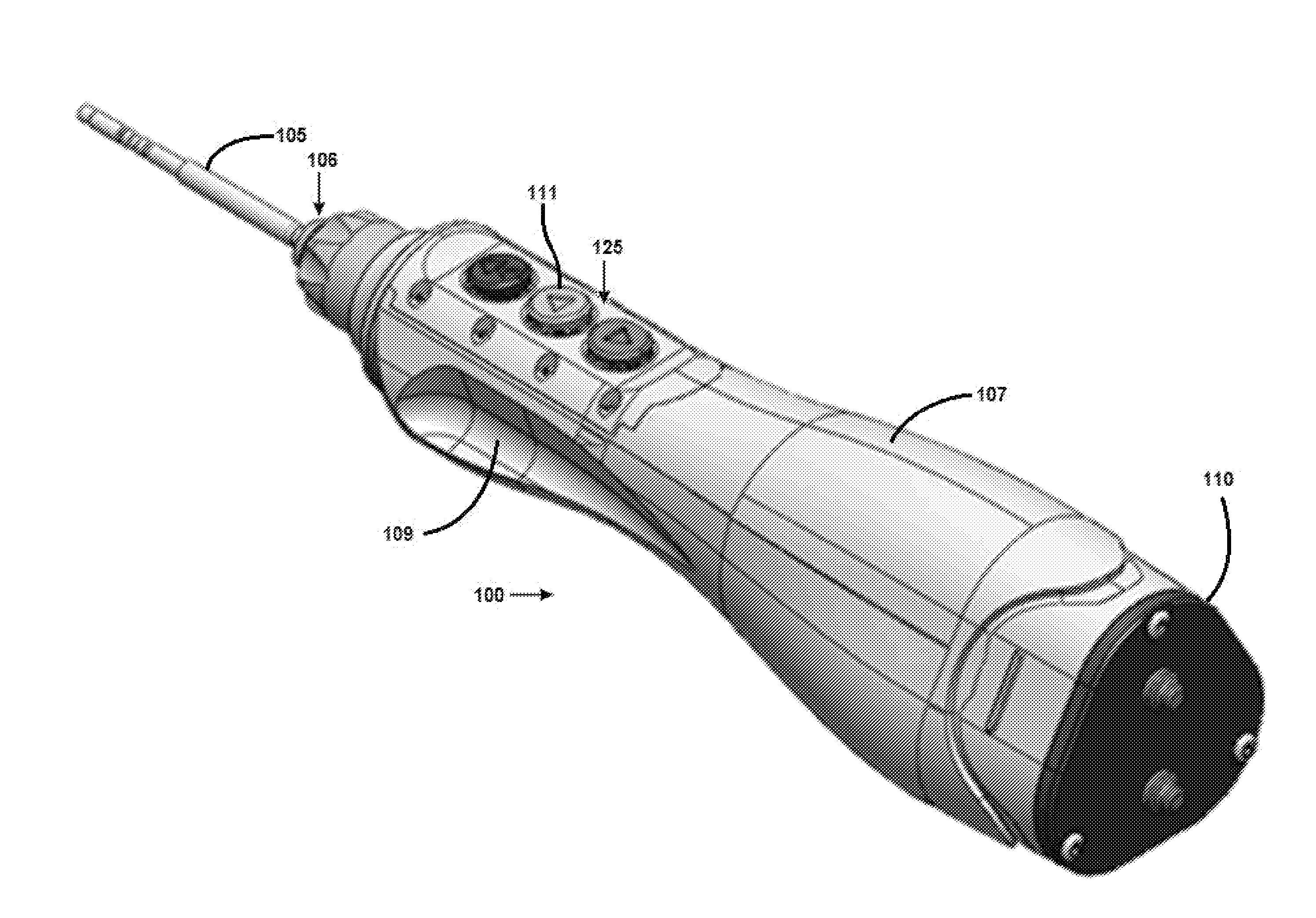

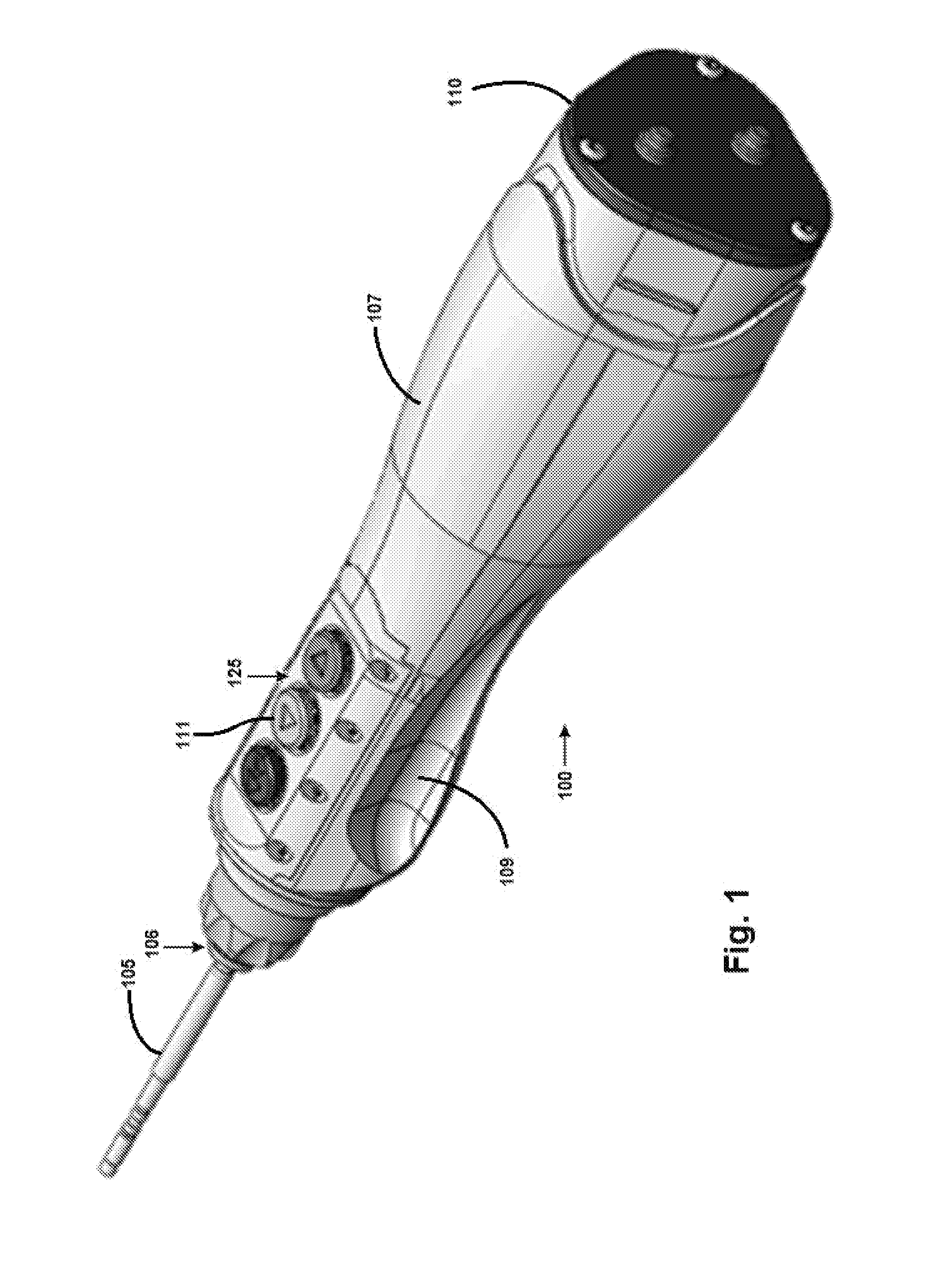

Surgical Handpiece

InactiveUS20150201918A1Improve operationIncreased durabilityDental implantsDiagnosticsSurgical instrumentationEngineering

Embodiments of the present invention provide a unique surgical handpiece having improved operation, durability and reliability. In one embodiment, the present invention provides a motorized handheld surgical instrument having one or more sensors for sensing motion, position, pressure, humidity, and various other environmental conditions relevant to the operation and maintenance of the surgical instrument.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

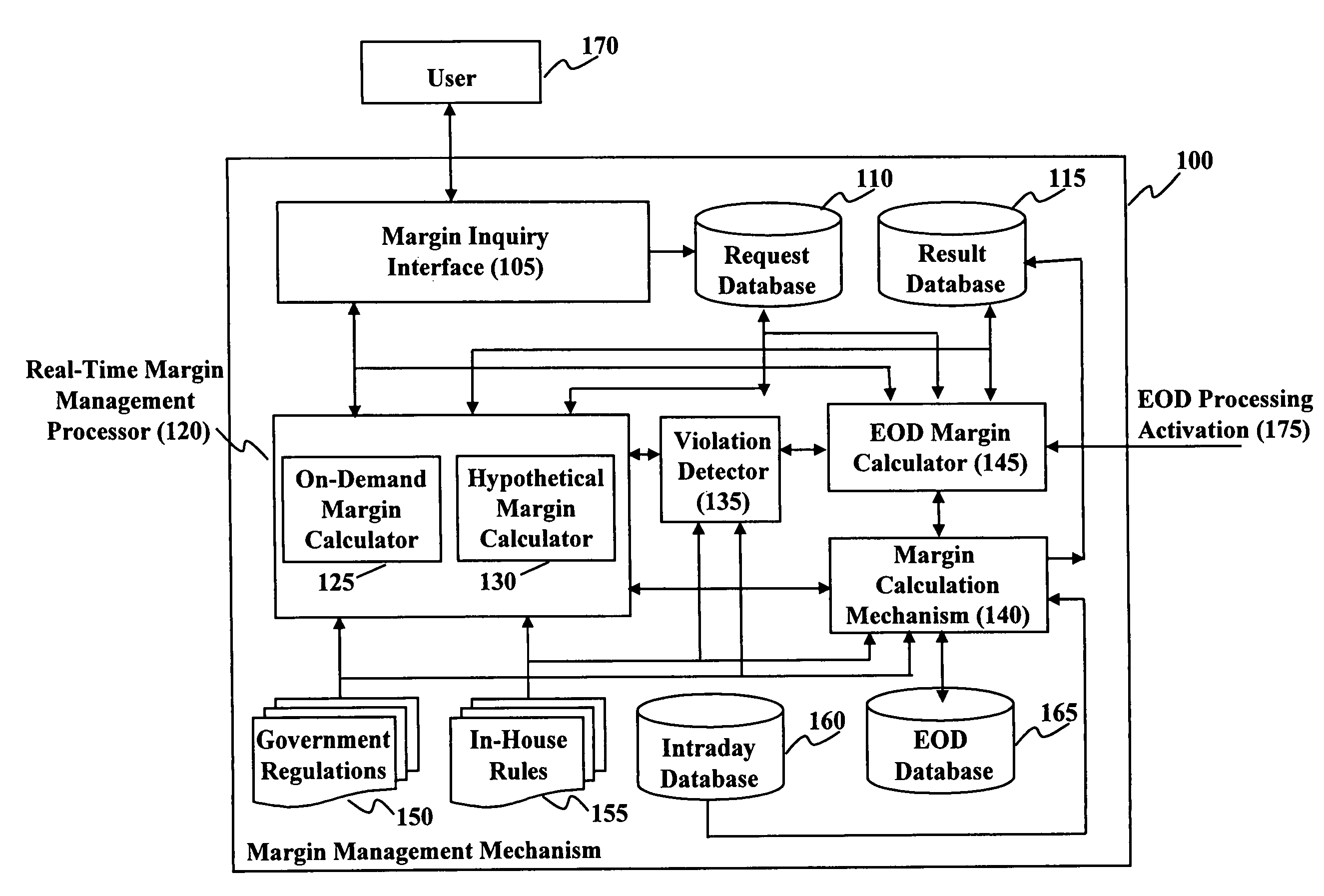

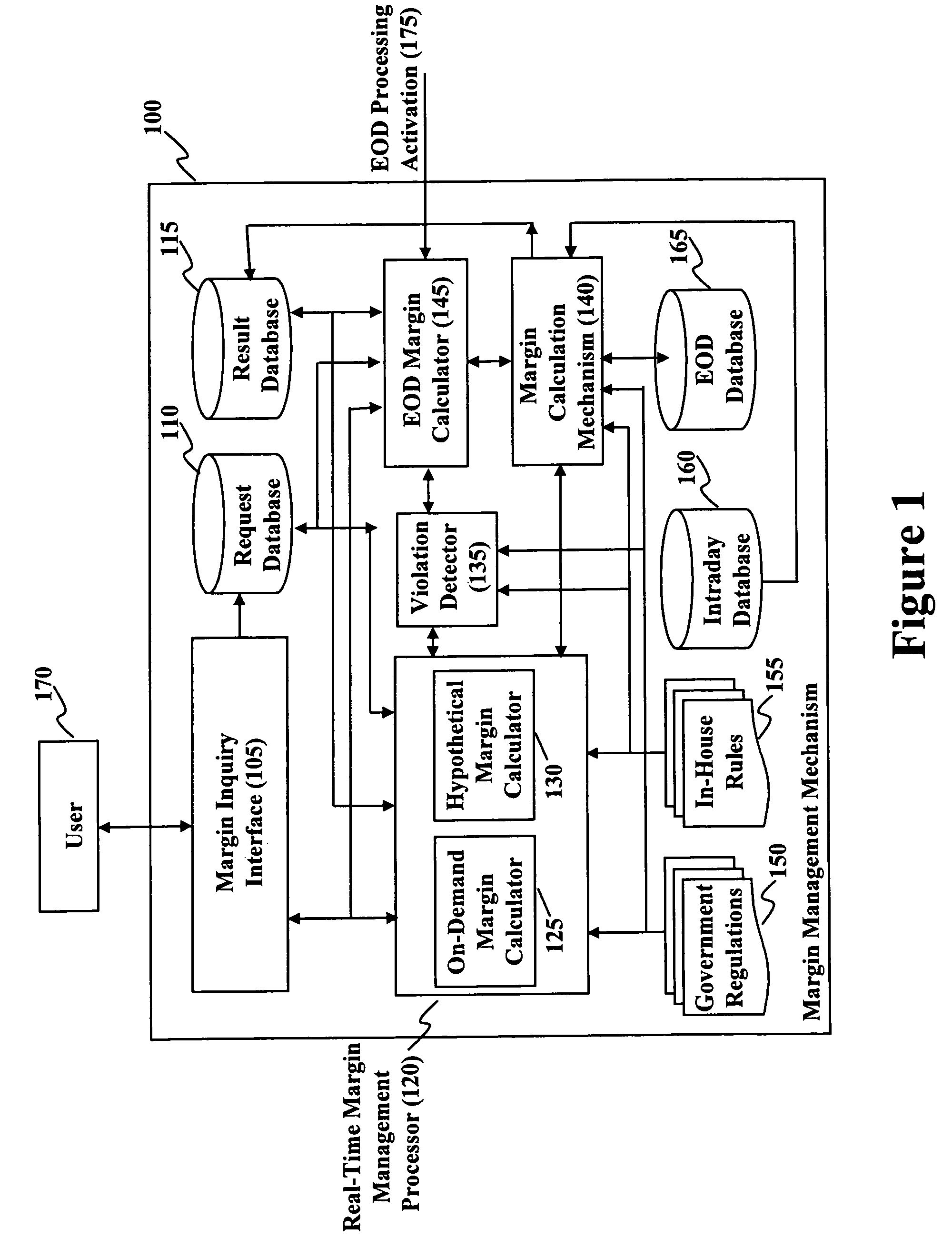

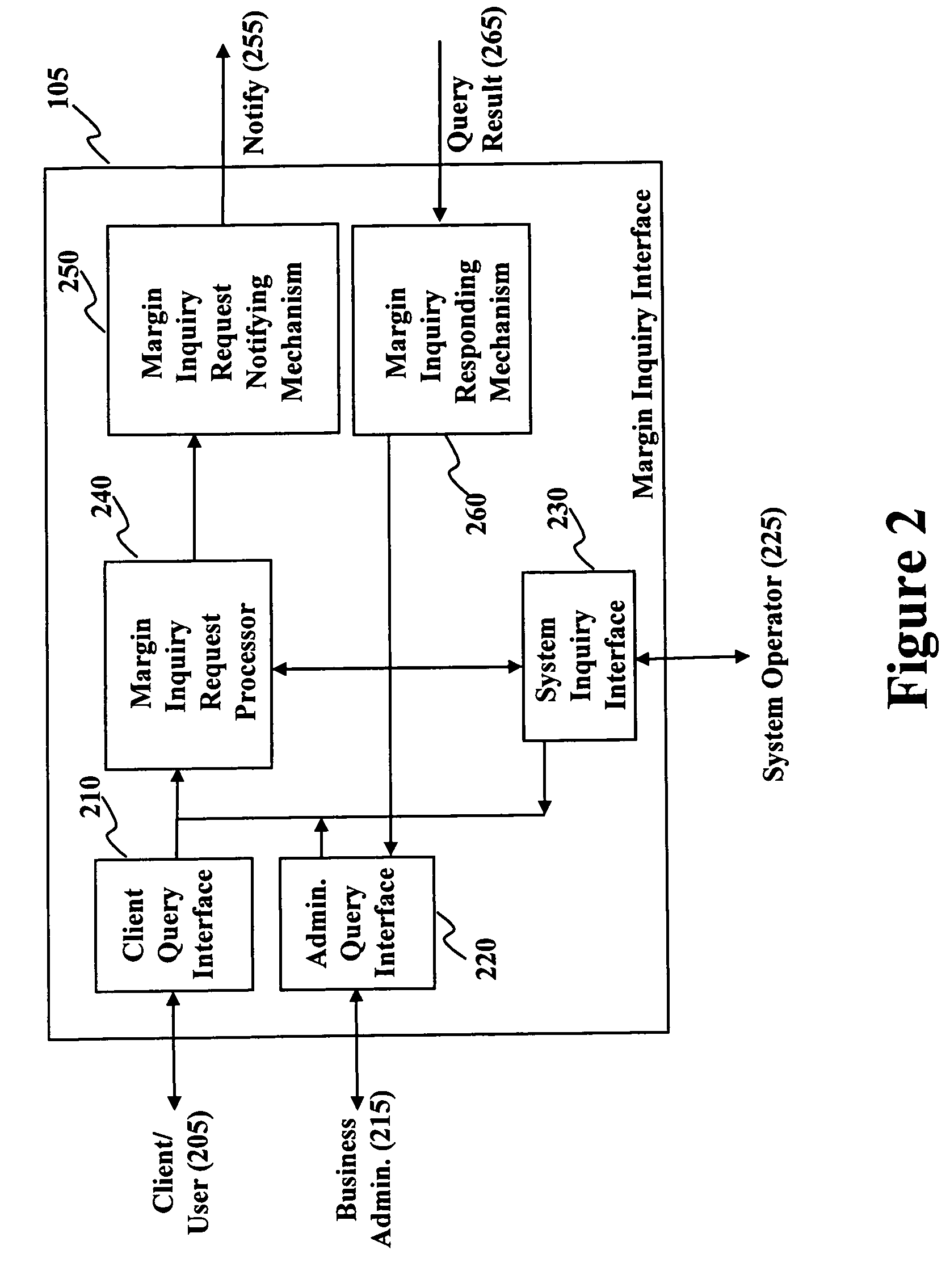

Method and system for real time margin calculation

Owner:UBS BUSINESS SOLUTIONS AG

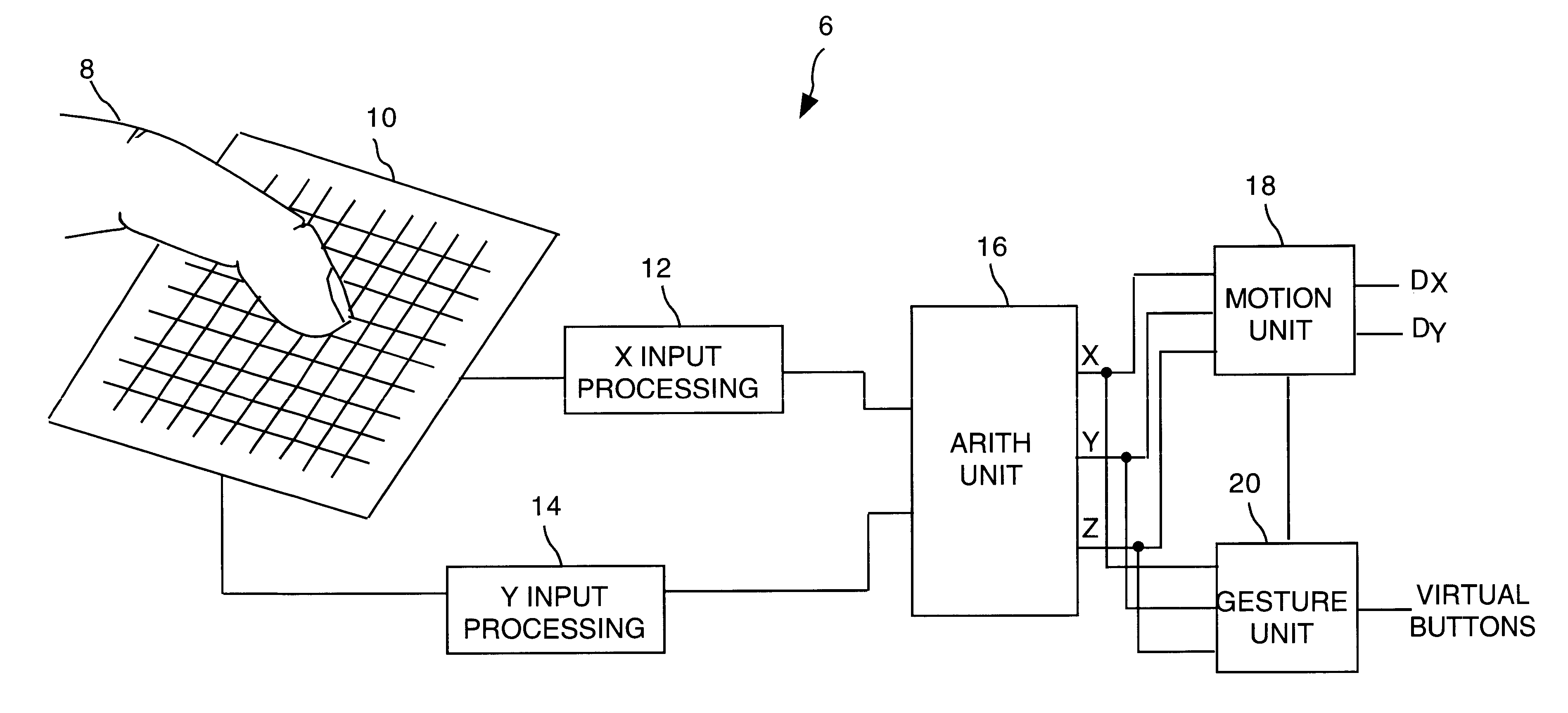

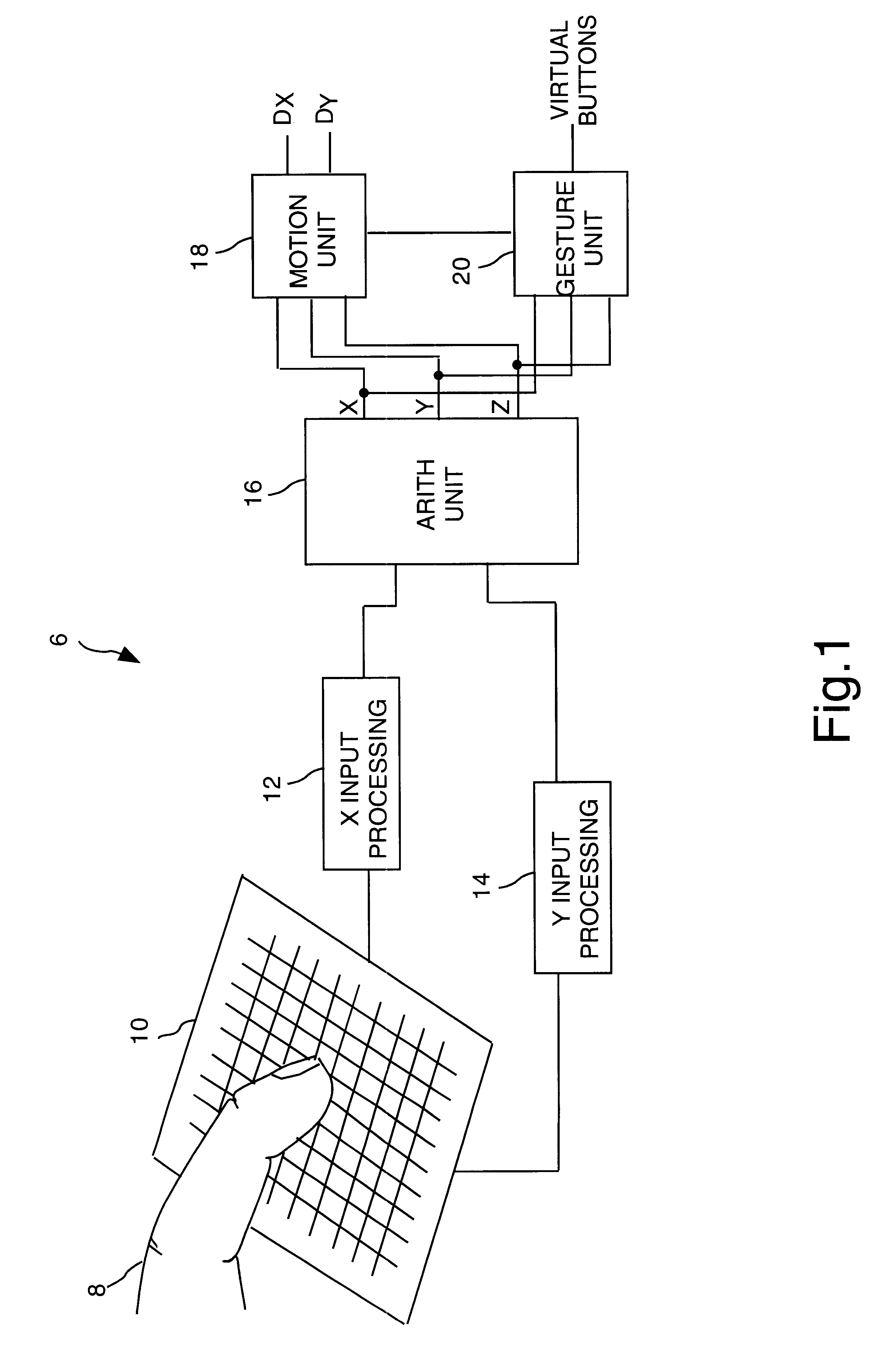

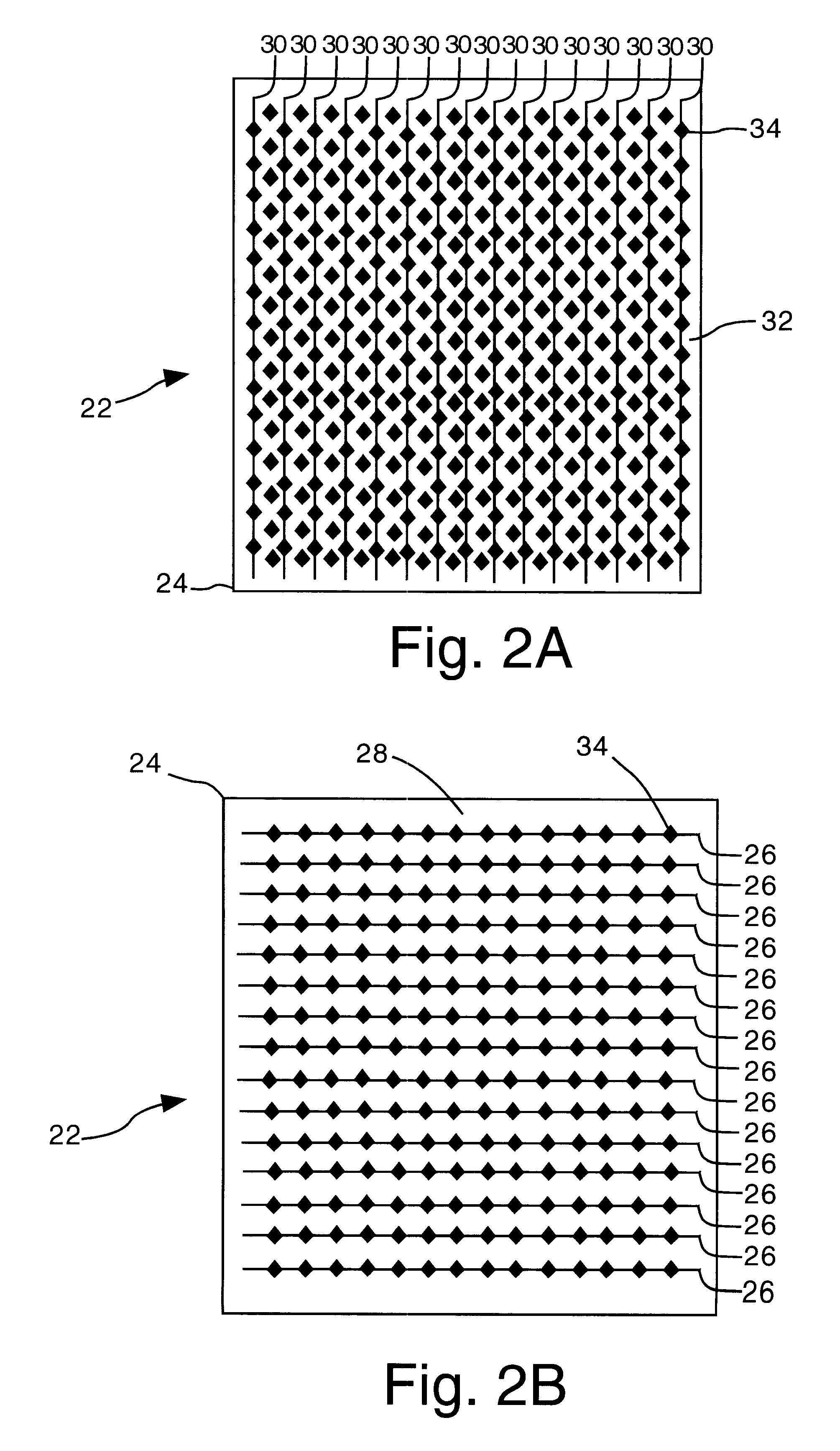

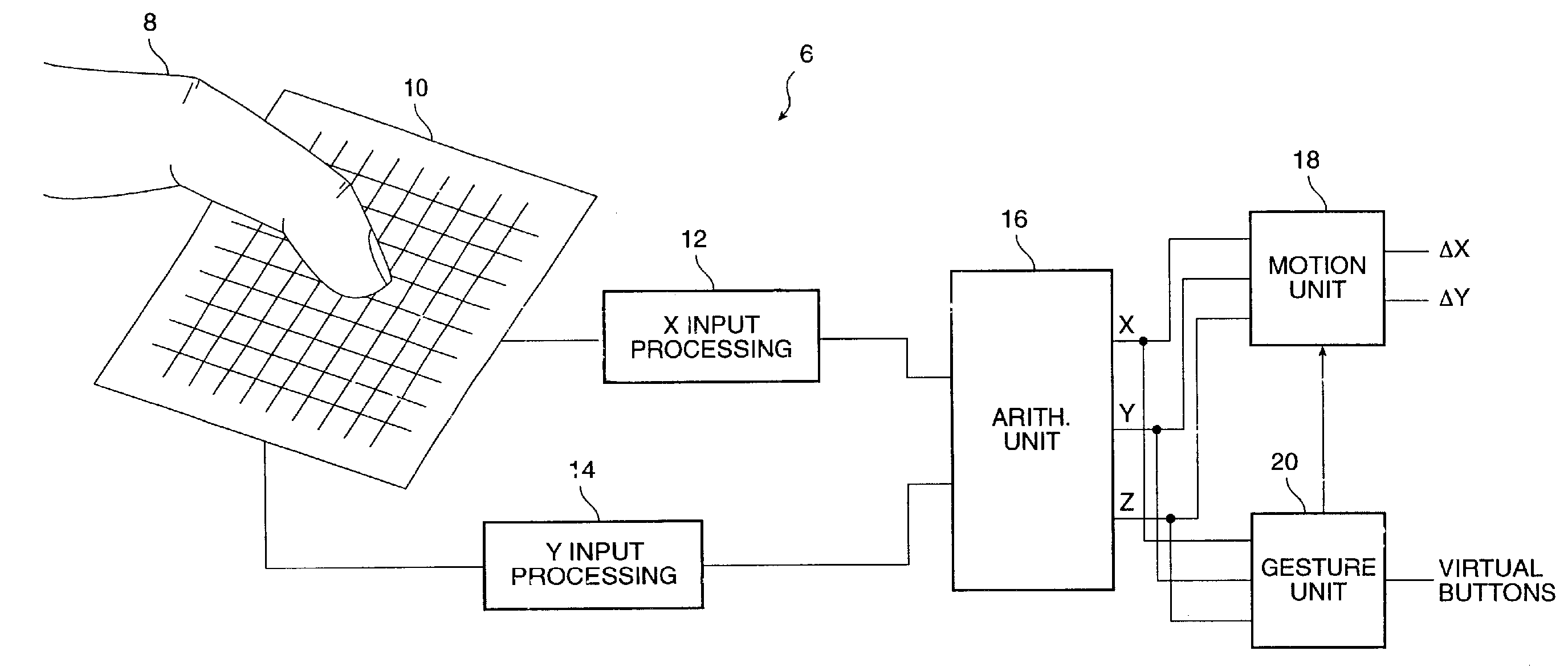

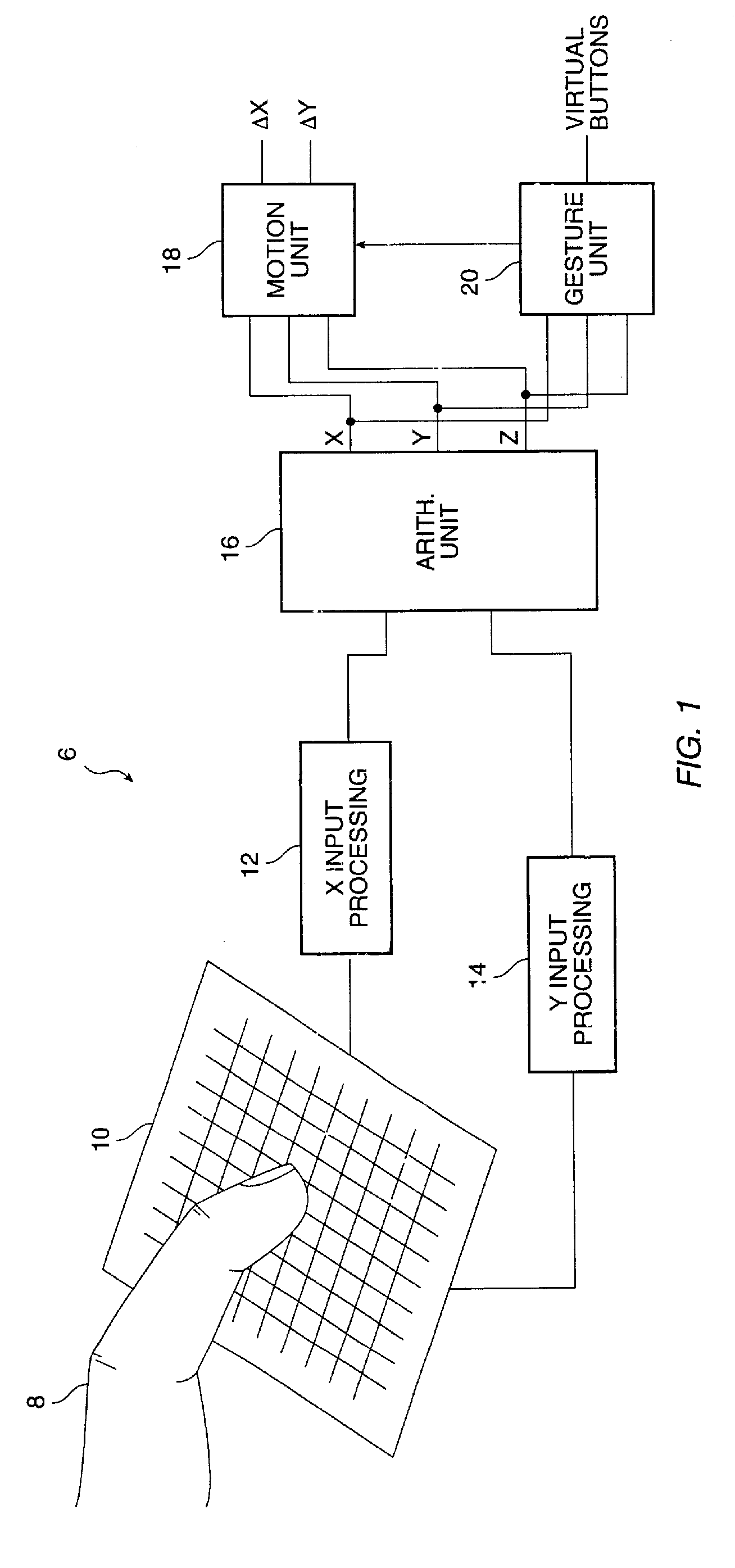

Object position detector with edge motion feature and gesture recognition

InactiveUS6414671B1Highly integratedRapid responseTransmission systemsCharacter and pattern recognitionComputer visionComputer science

Methods for recognizing gestures made by a conductive object on a touch-sensor pad and for cursor motion are disclosed. Tapping, drags, pushes, extended drags and variable drags gestures are recognized by analyzing the position, pressure, and movement of the conductive object on the sensor pad during the time of a suspected gesture, and signals are sent to a host indicating the occurrence of these gestures. Signals indicating the position of a conductive object and distinguishing between the peripheral portion and an inner portion of the touch-sensor pad are also sent to the host.

Owner:SYNAPTICS INC

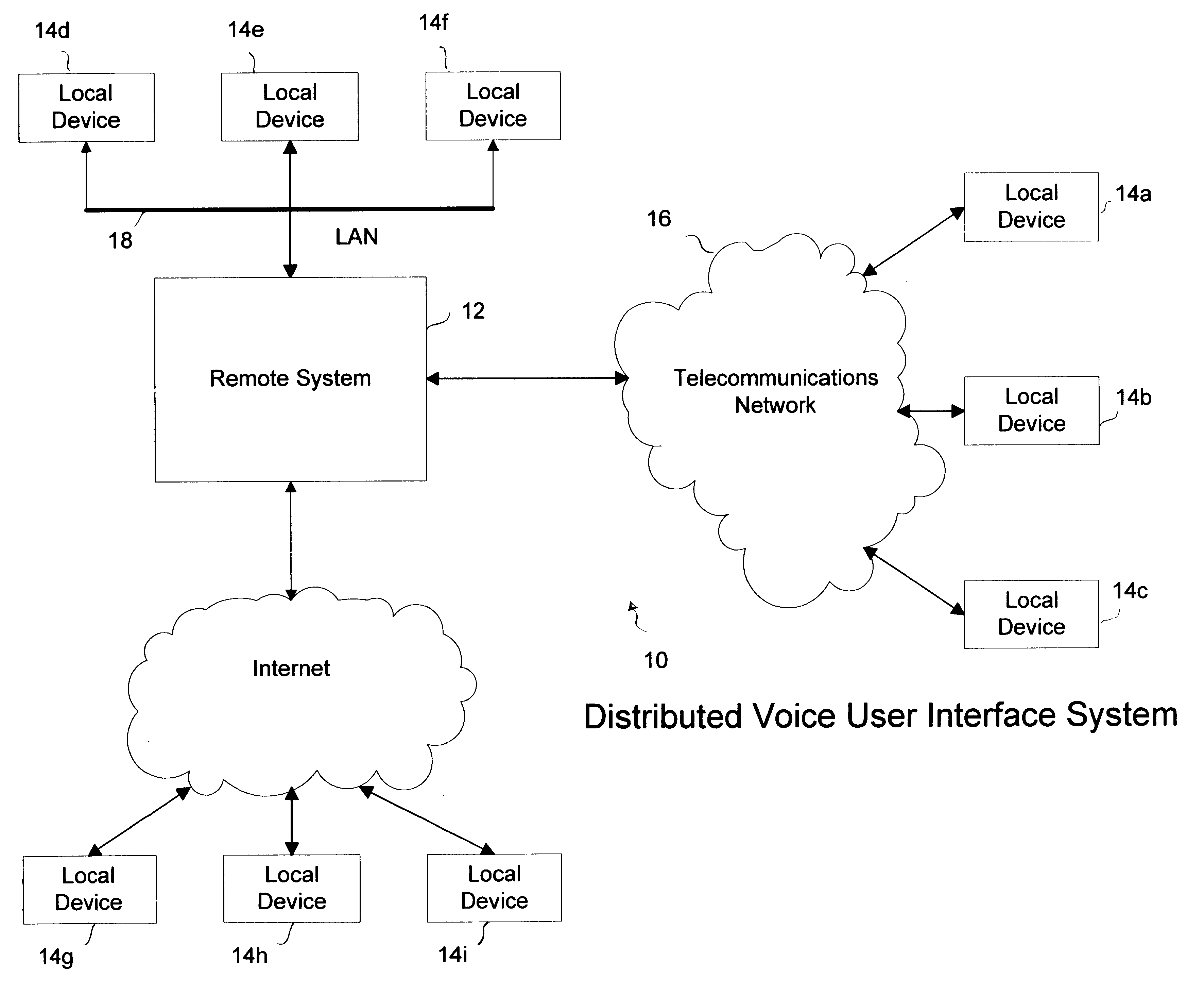

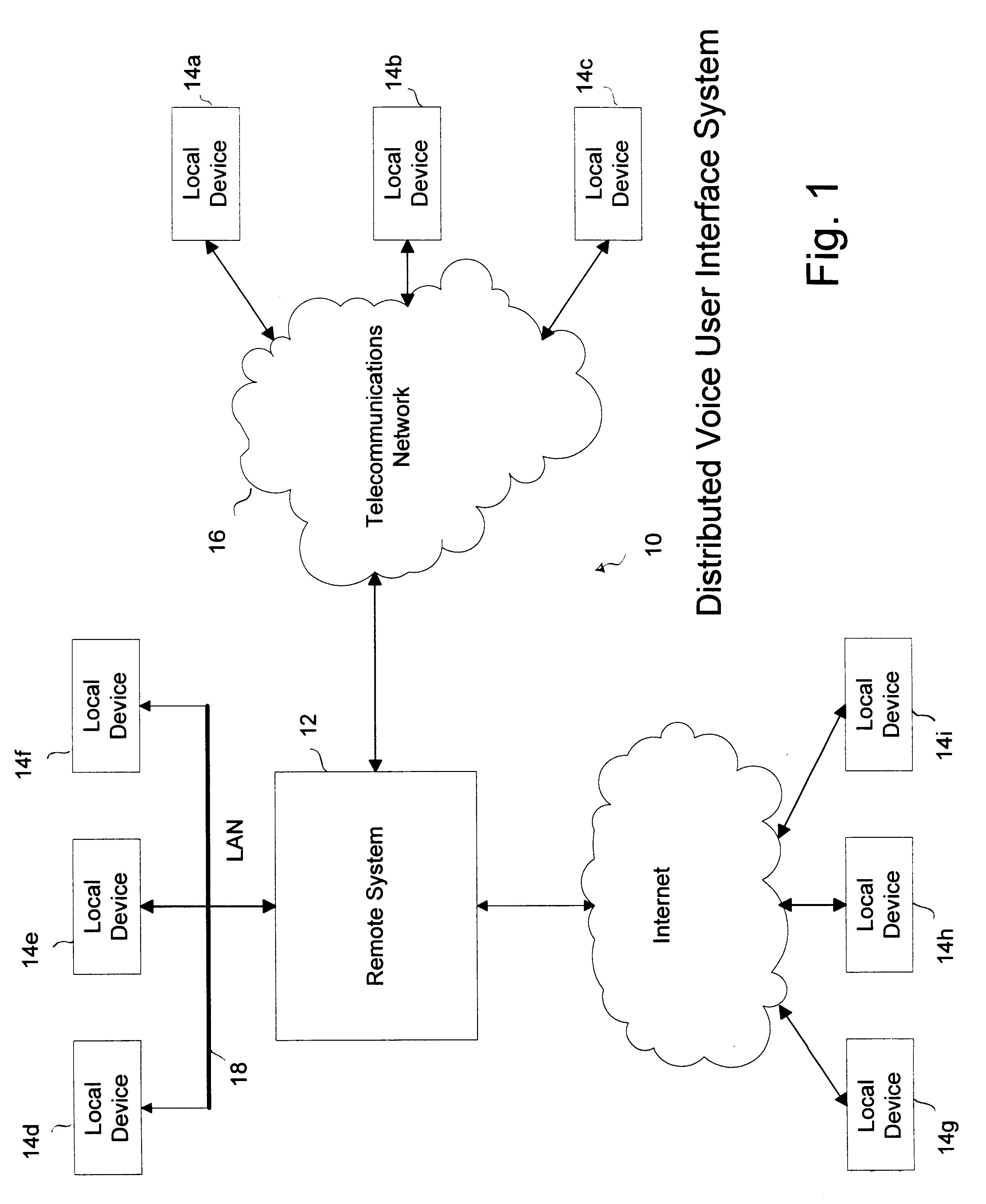

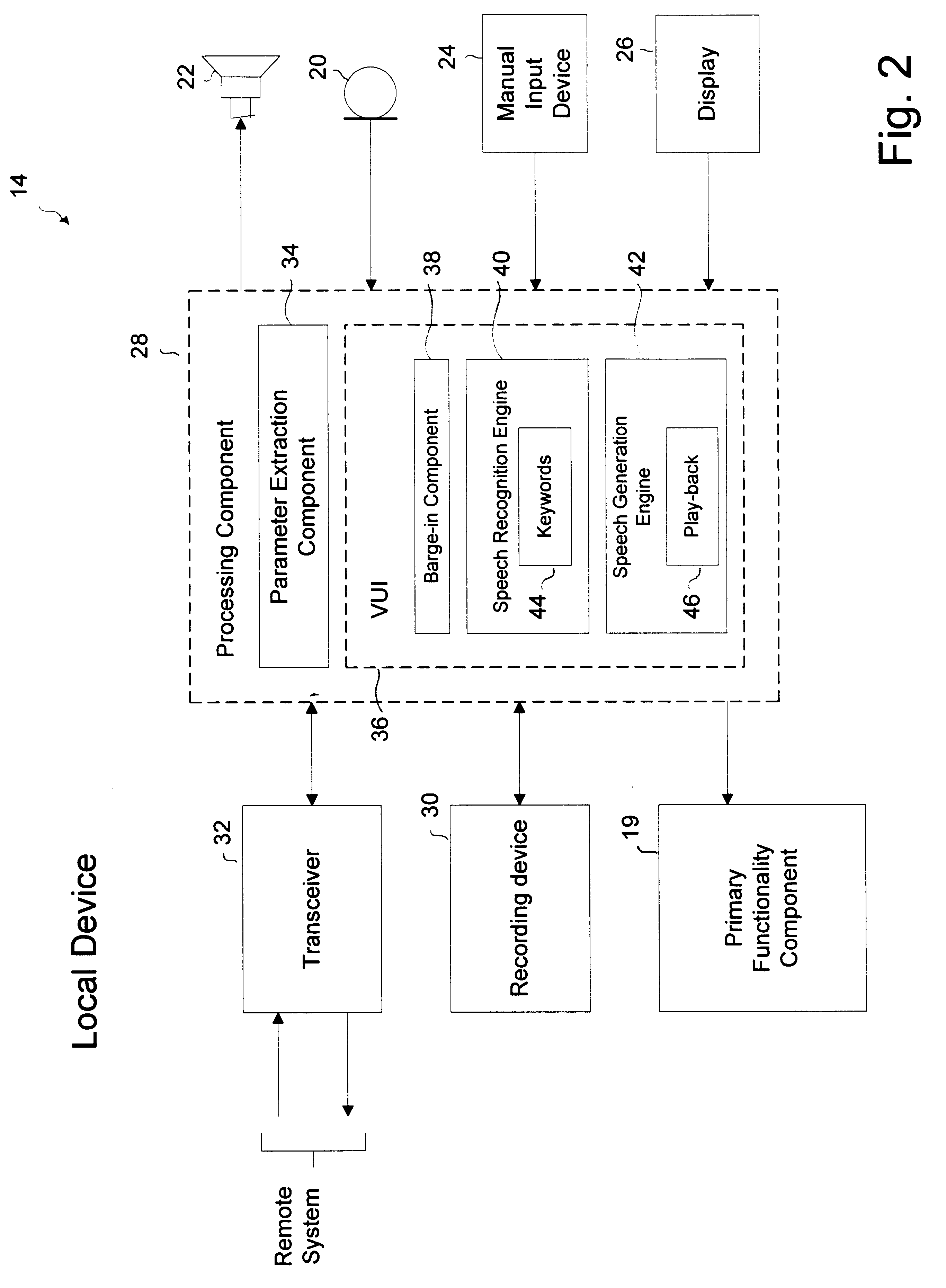

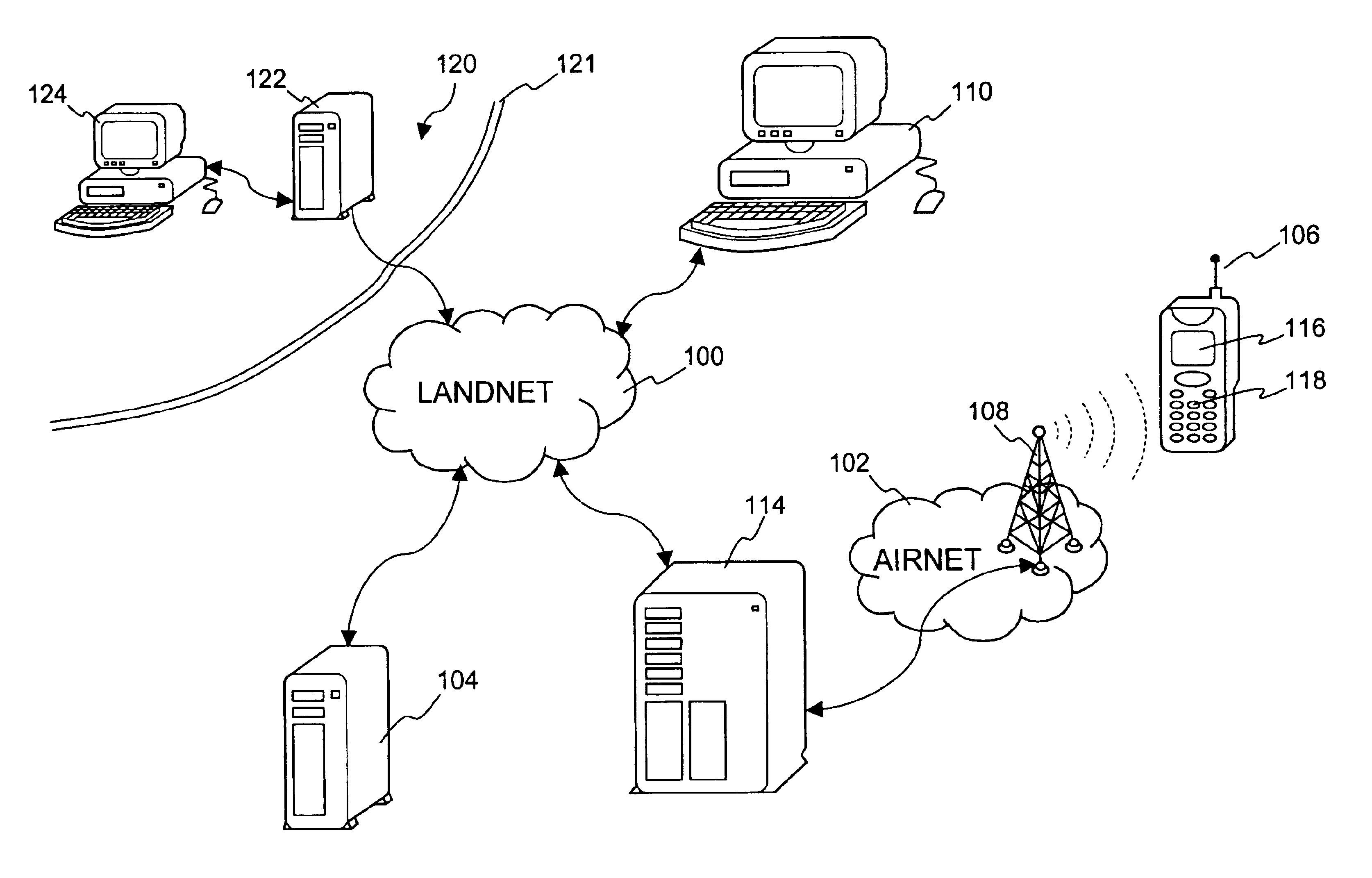

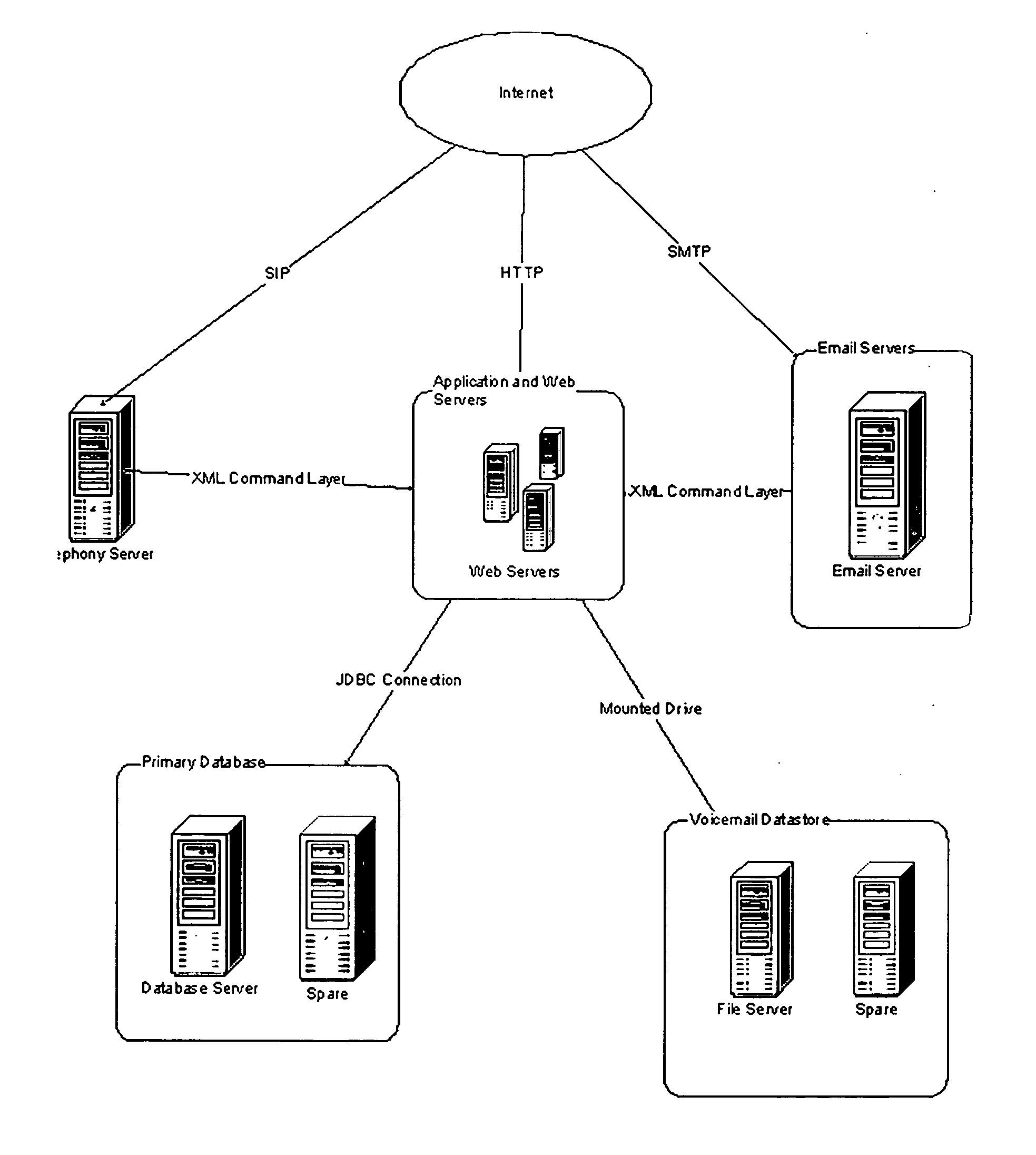

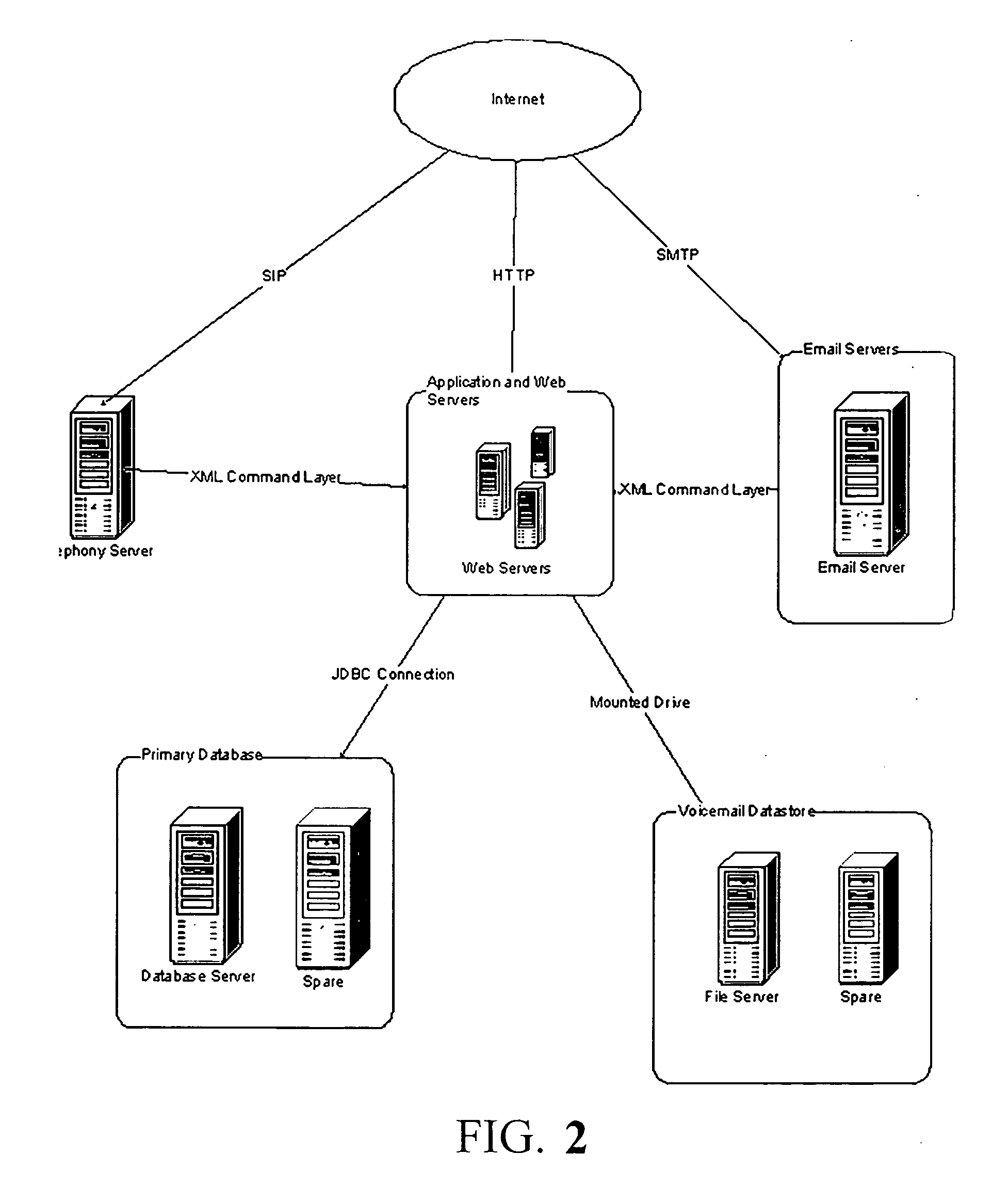

Distributed voice user interface

A distributed voice user interface system includes a local device which receives speech input issued from a user. Such speech input may specify a command or a request by the user. The local device performs preliminary processing of the speech input and determines whether it is able to respond to the command or request by itself. If not, the local device initiates communication with a remote system for further processing of the speech input.

Owner:INTELLECTUAL VENTURES I LLC

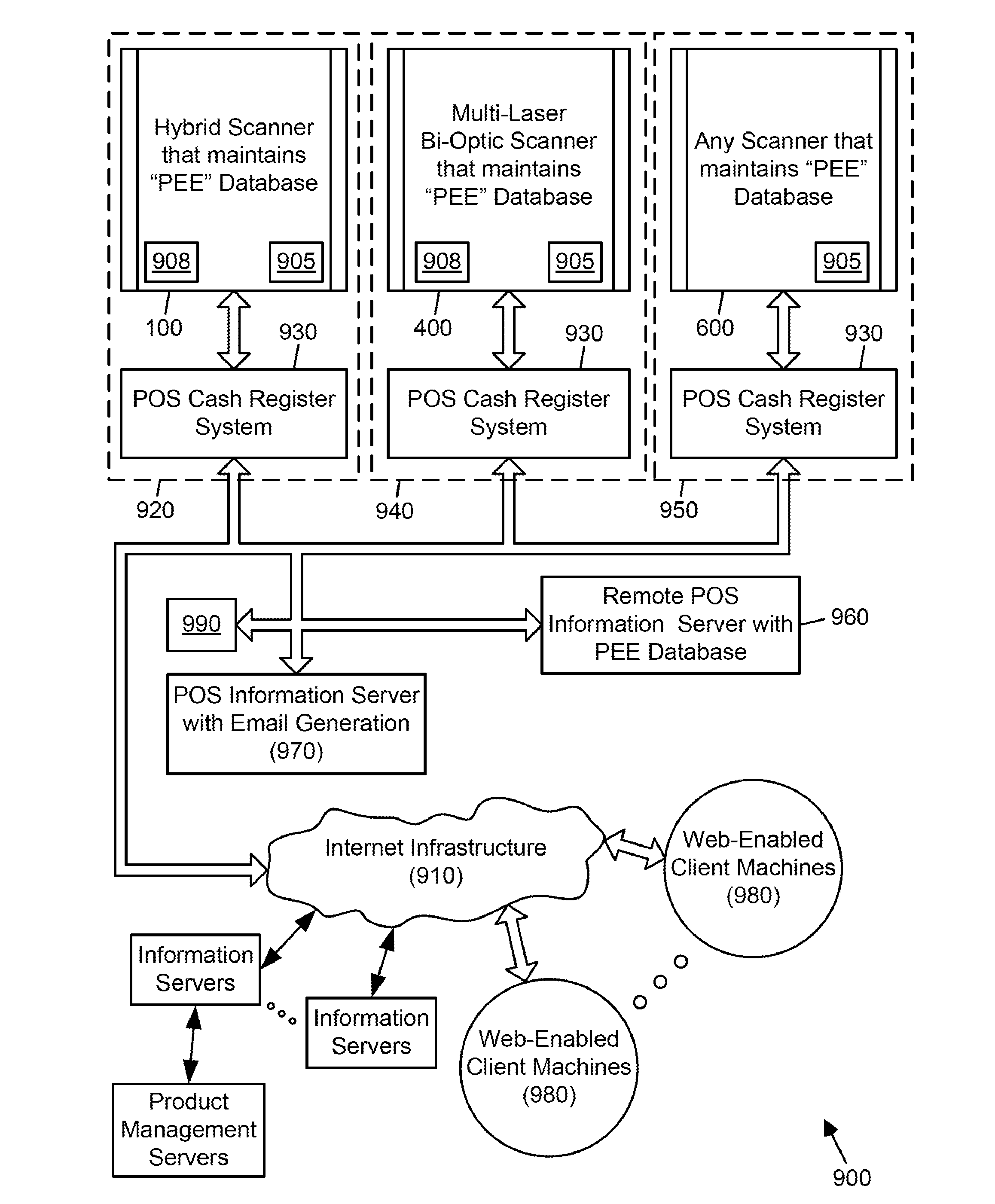

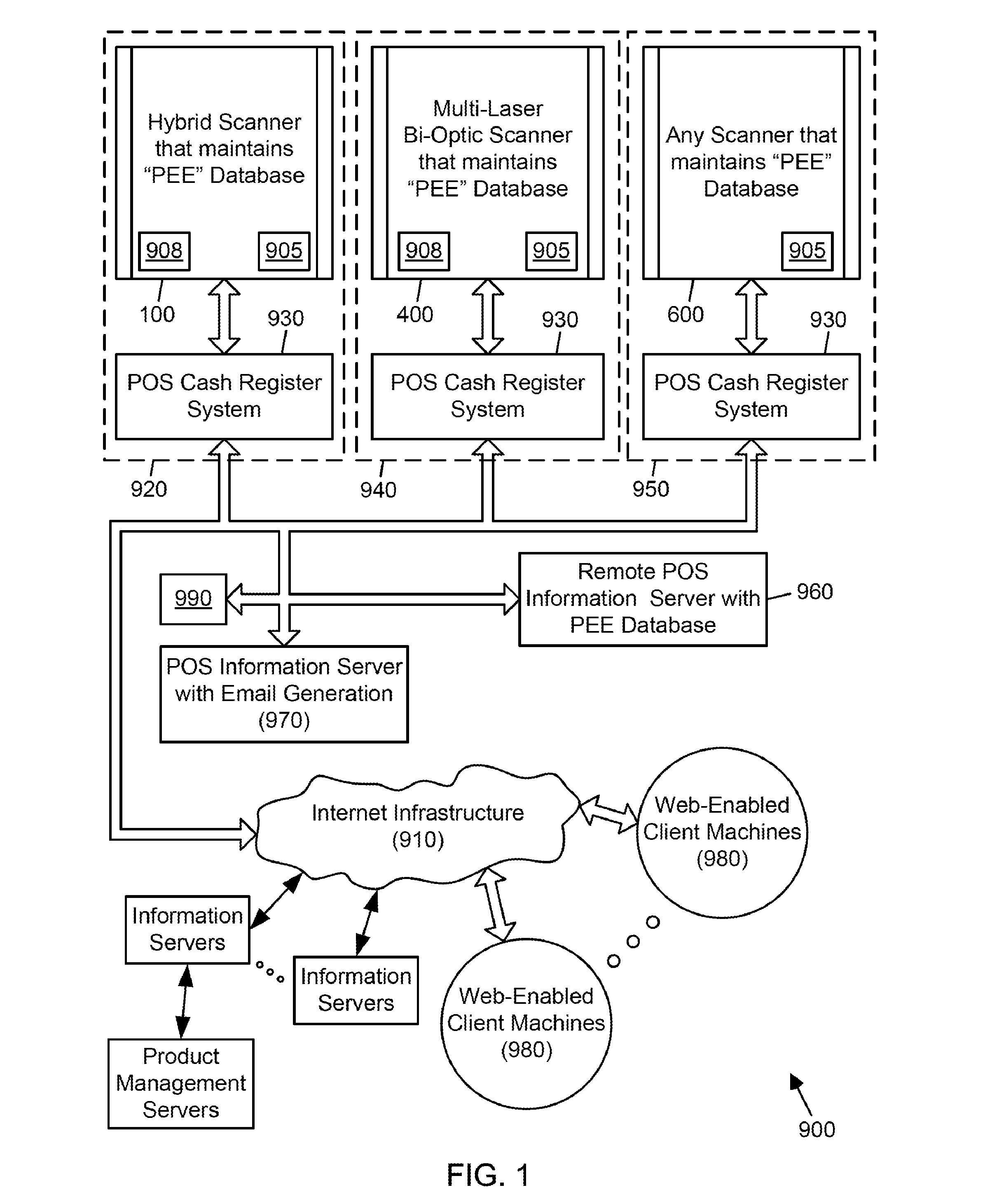

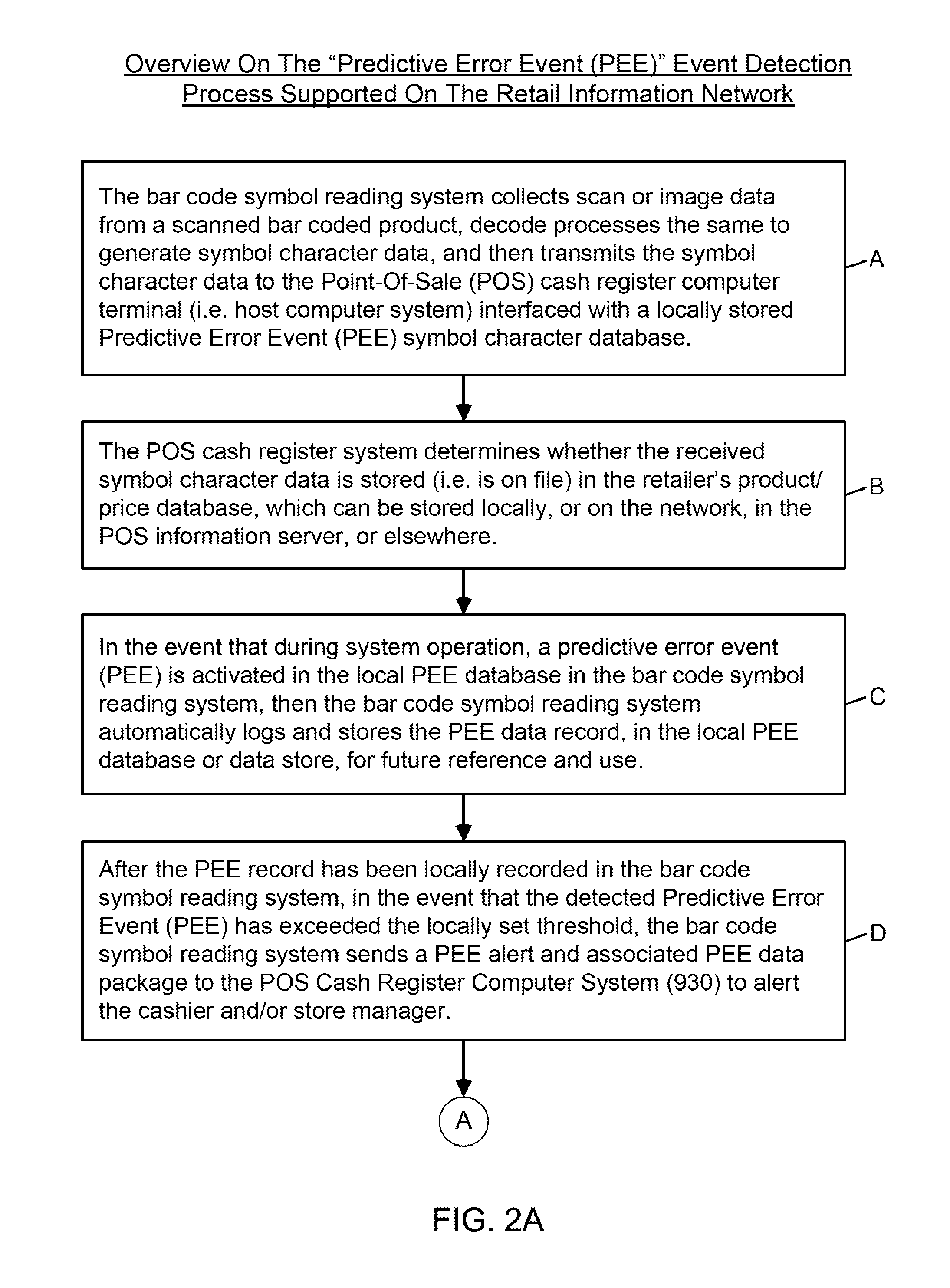

Symbol reading system having predictive diagnostics

ActiveUS9022288B2Improve the level ofEasy maintenanceTesting sensing arrangementsSensing by electromagnetic radiationInformation networksBarcode

A retail information network includes one or more POS scanning and checkout systems, each including (i) a bar code symbol reading subsystem, and (ii) a cash register computer subsystem interfaced with the bar code symbol reading subsystem and a network infrastructure, and each having access to product and price data maintained in a product / price database. The bar code symbol reading subsystem includes a local predictive error event (PEE) data store for logging and storing predictive error events (PEEs) detected within the bar code symbol reading system, wherein said PEEs are subsequently sent to POS information servers used to create predictive error alerts (PEAs) and corresponding instructions to maintain and / or repair certain aspects of the bar code symbol reading system.

Owner:METROLOGIC INSTR

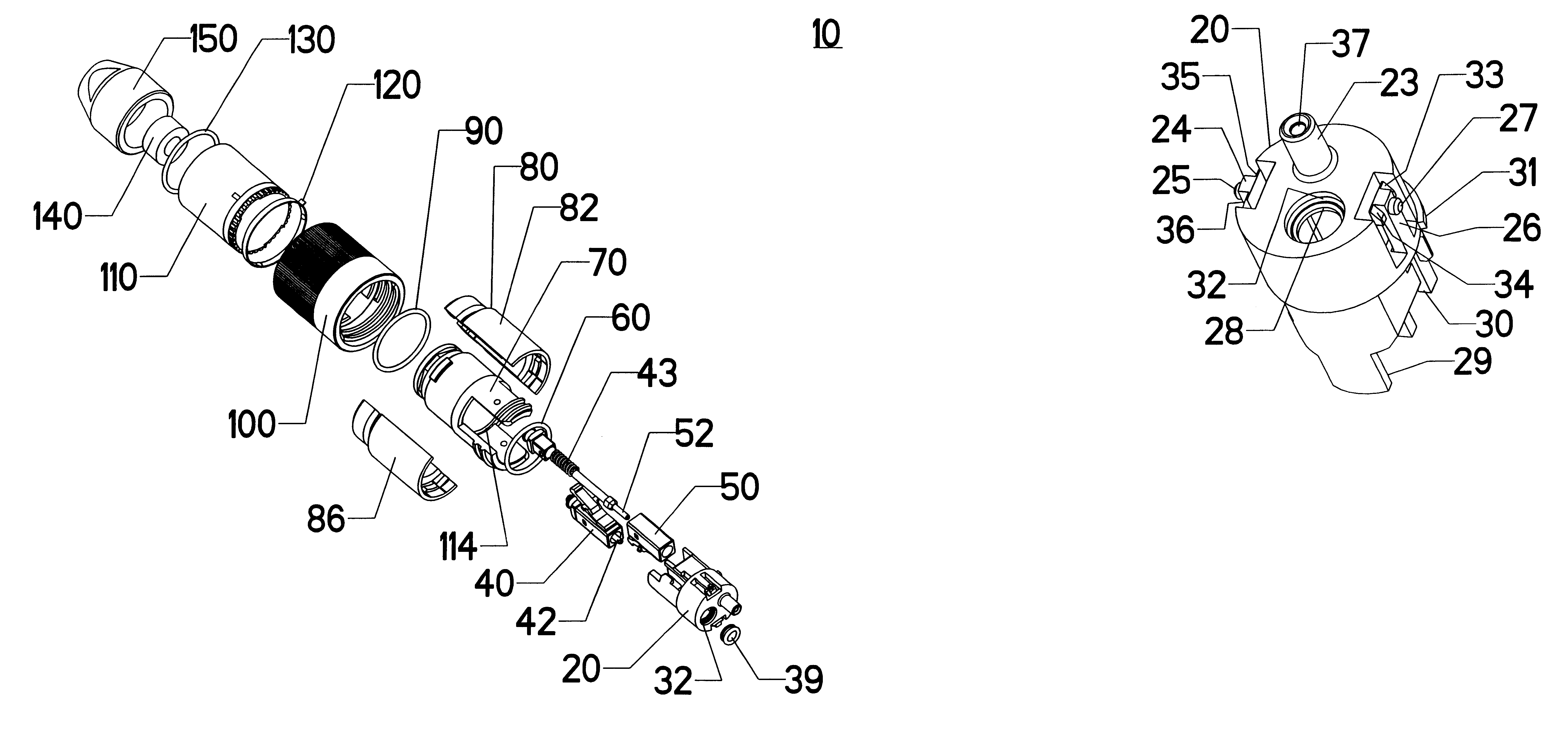

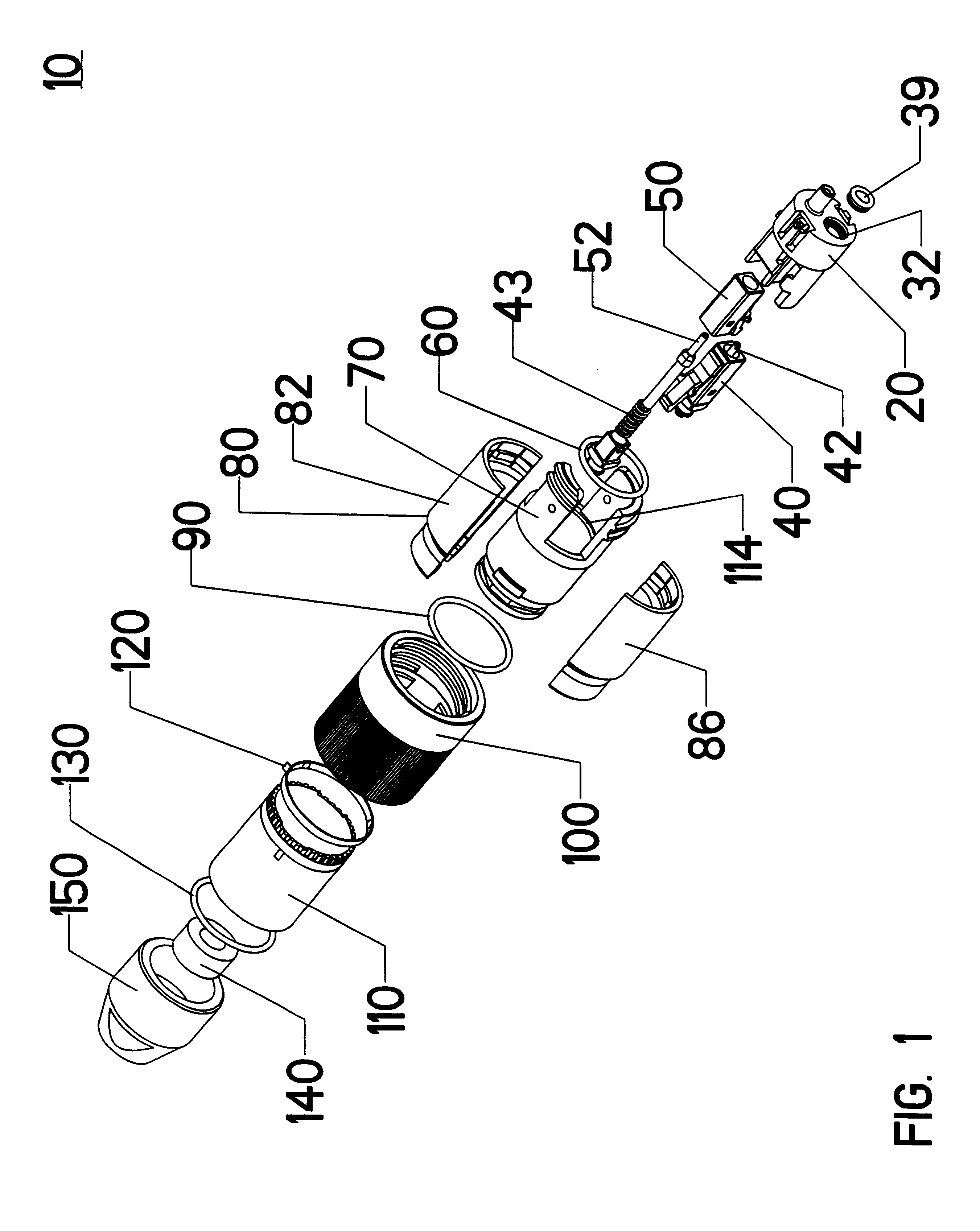

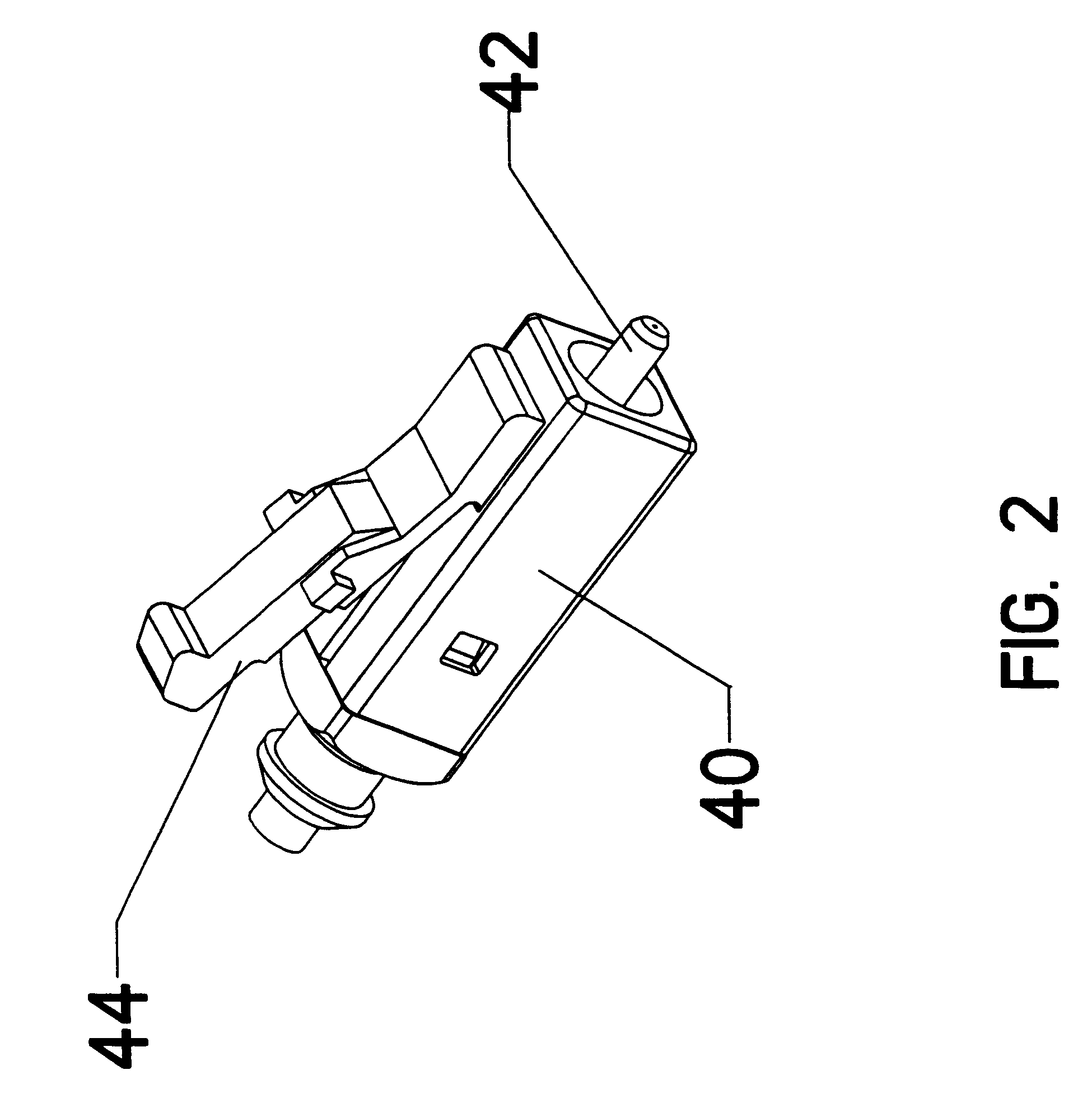

Field repairable hermaphroditic connector

InactiveUS6234683B1Easily repairInexpensive to manufacture and assembleCoupling light guidesMechanical engineeringFerrule

A hermaphroditic fiber optic termination device including a plug insert removably insertable into a front of a housing. The housing having locking holes. The plug insert formed so as to receive ferrules surrounding terminal ends of the optical fibers. The plug insert having spring latches, where each spring latches has a nub. The nub feature being designed so as to spring into the locking holes of the housing.

Owner:STRATOS INT

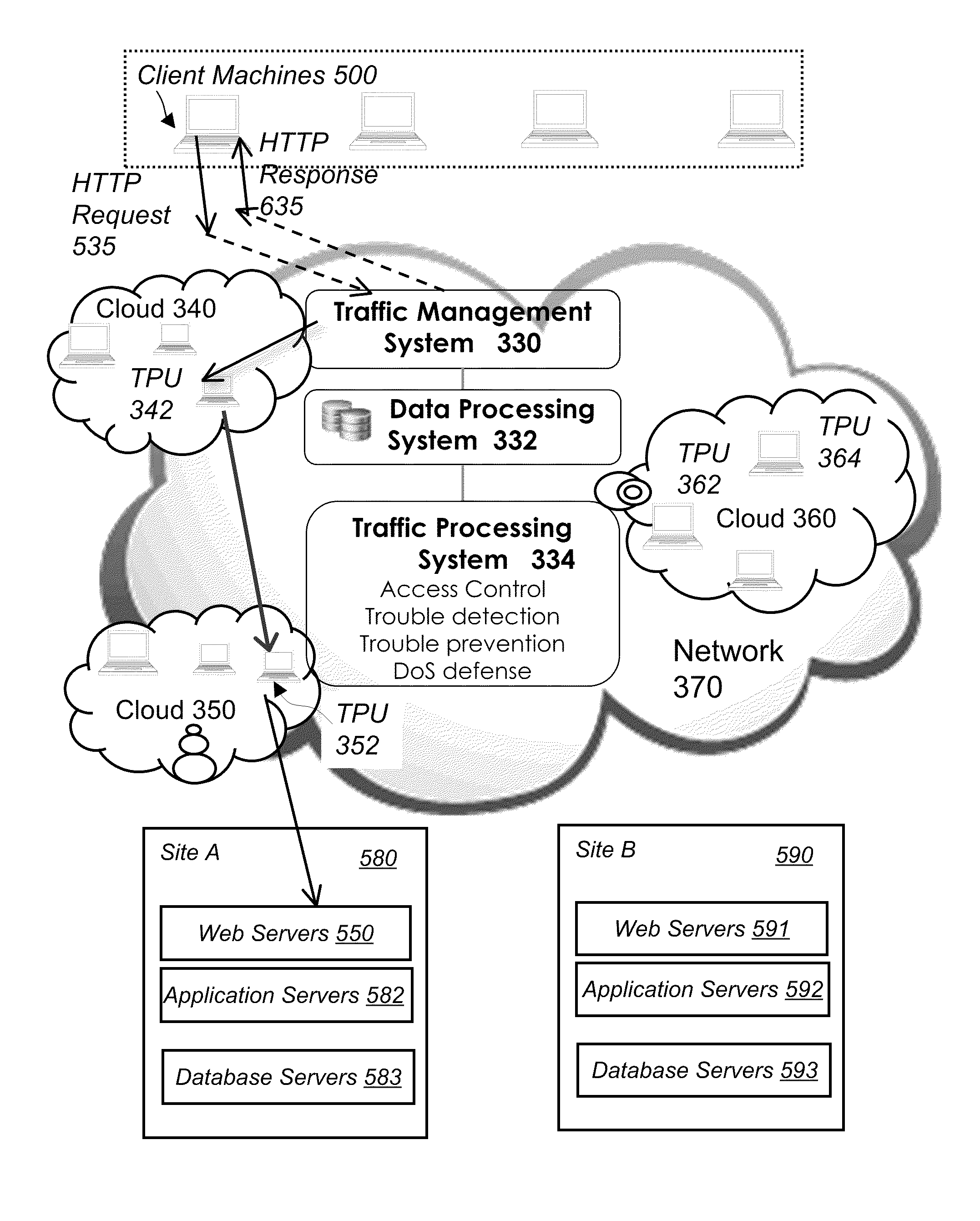

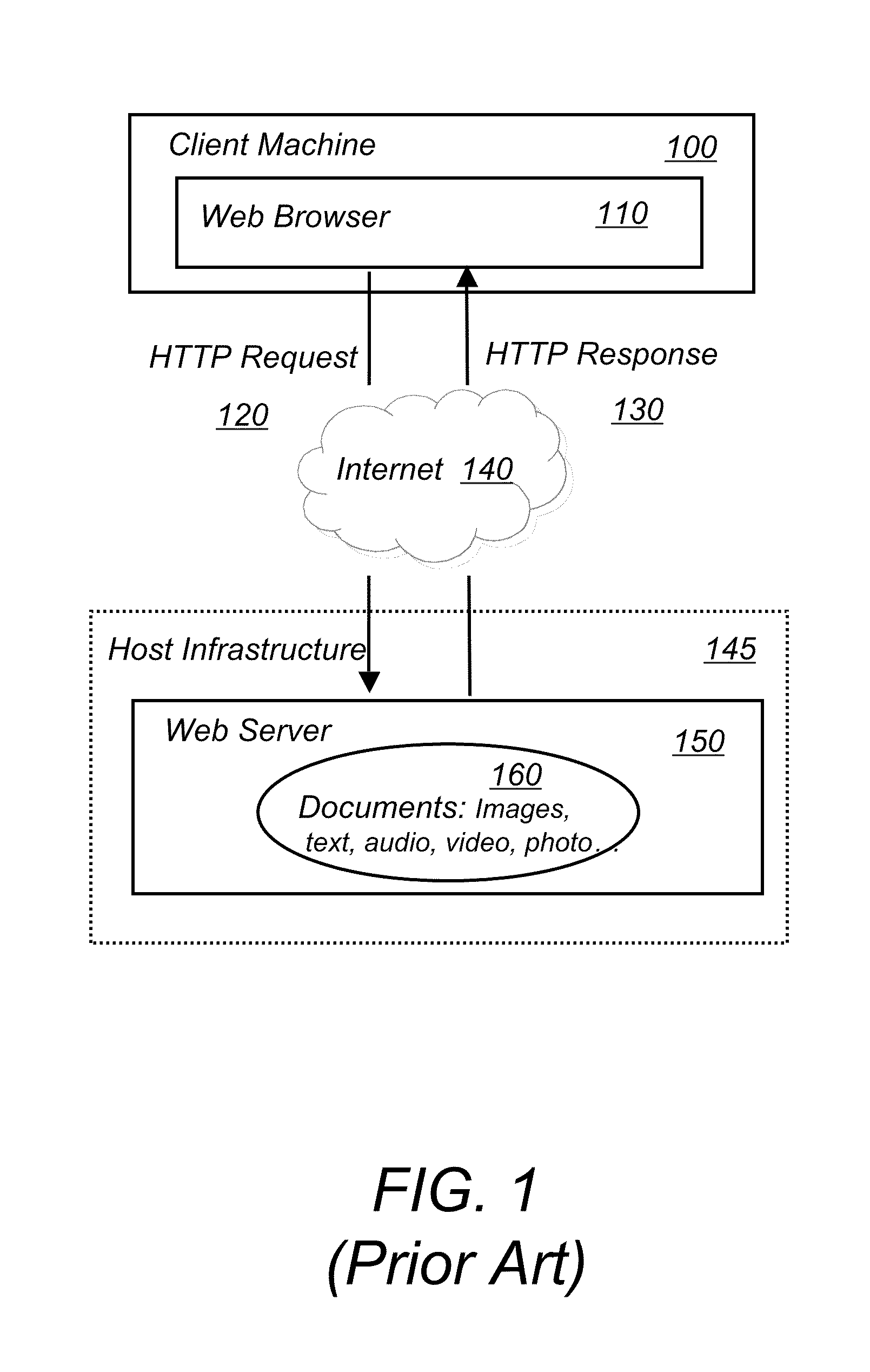

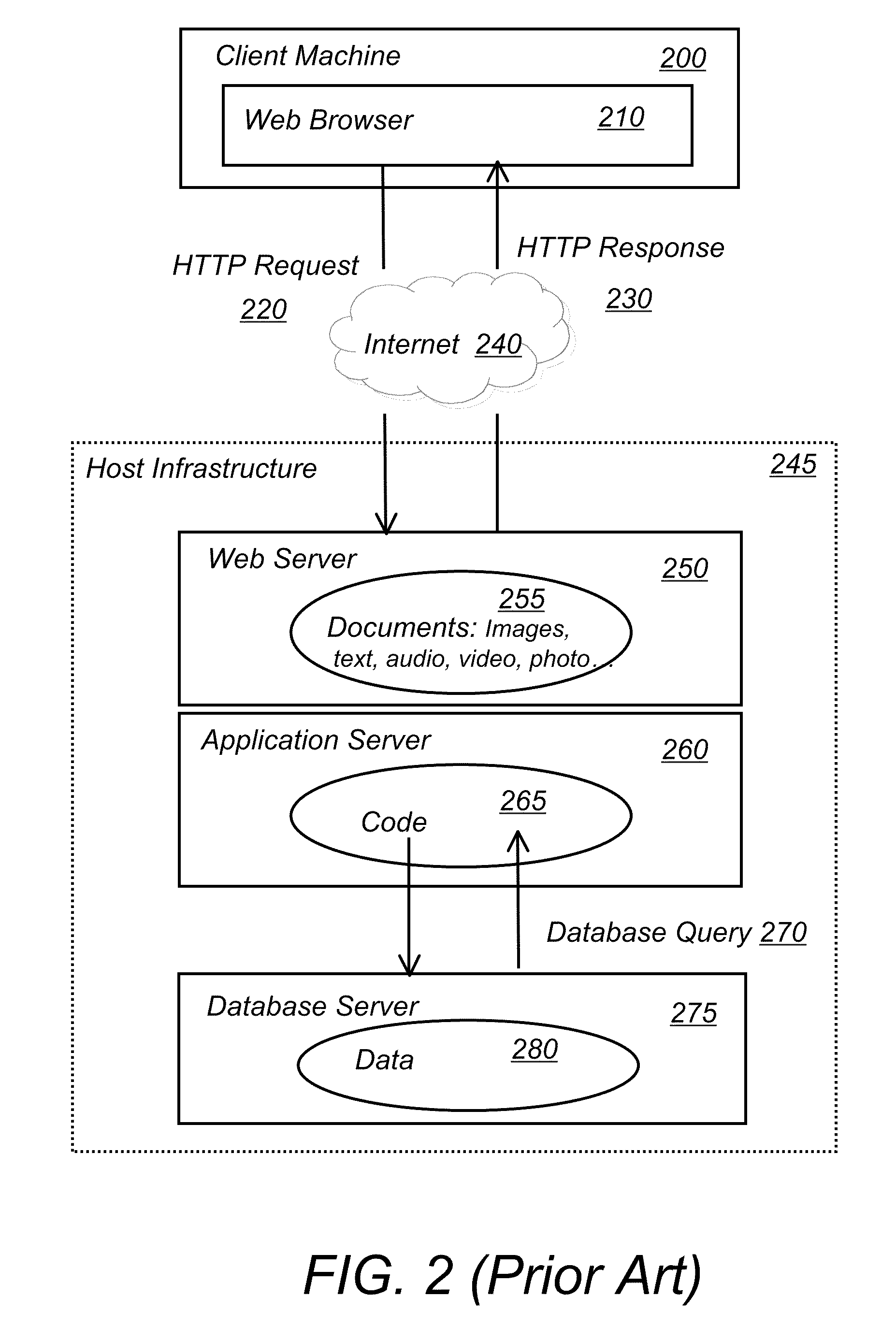

System and method for network traffic management and load balancing

InactiveUS20100223364A1Improve application performanceImprove availabilityMultiple digital computer combinationsLocation information based serviceTraffic capacityFailover

A method for providing load balancing and failover among a set of computing nodes running a network accessible computer service includes providing a computer service that is hosted at one or more servers comprised in a set of computing nodes and is accessible to clients via a first network. Providing a second network including a plurality of traffic processing nodes and load balancing means. The load balancing means is configured to provide load balancing among the set of computing nodes running the computer service. Providing means for redirecting network traffic comprising client requests to access the computer service from the first network to the second network. Providing means for selecting a traffic processing node of the second network for receiving the redirected network traffic comprising the client requests to access the computer service and redirecting the network traffic to the traffic processing node via the means for redirecting network traffic. For every client request for access to the computer service, determining an optimal computing node among the set of computing nodes running the computer service by the traffic processing node via the load balancing means, and then routing the client request to the optimal computing node by the traffic processing node via the second network.

Owner:YOTTAA

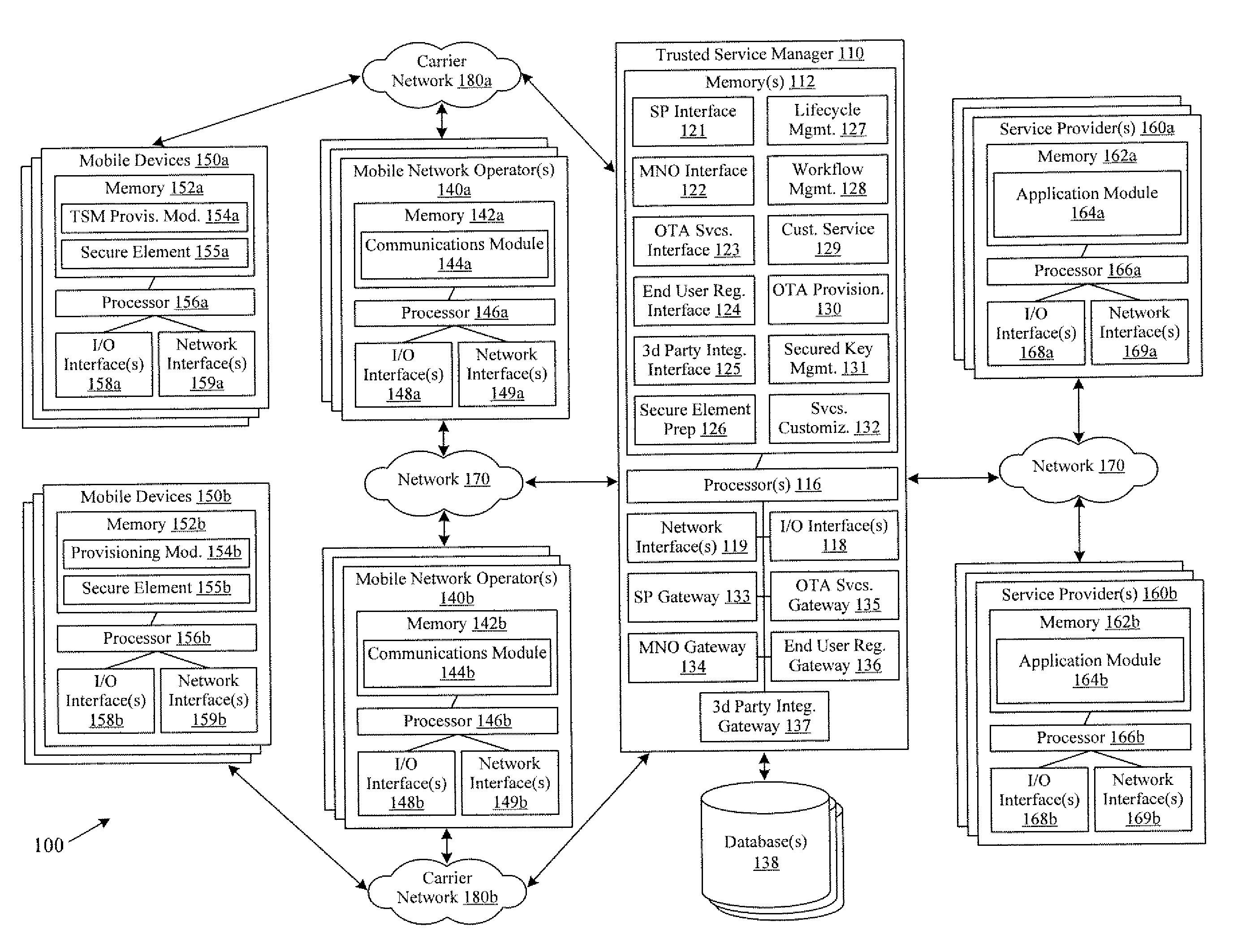

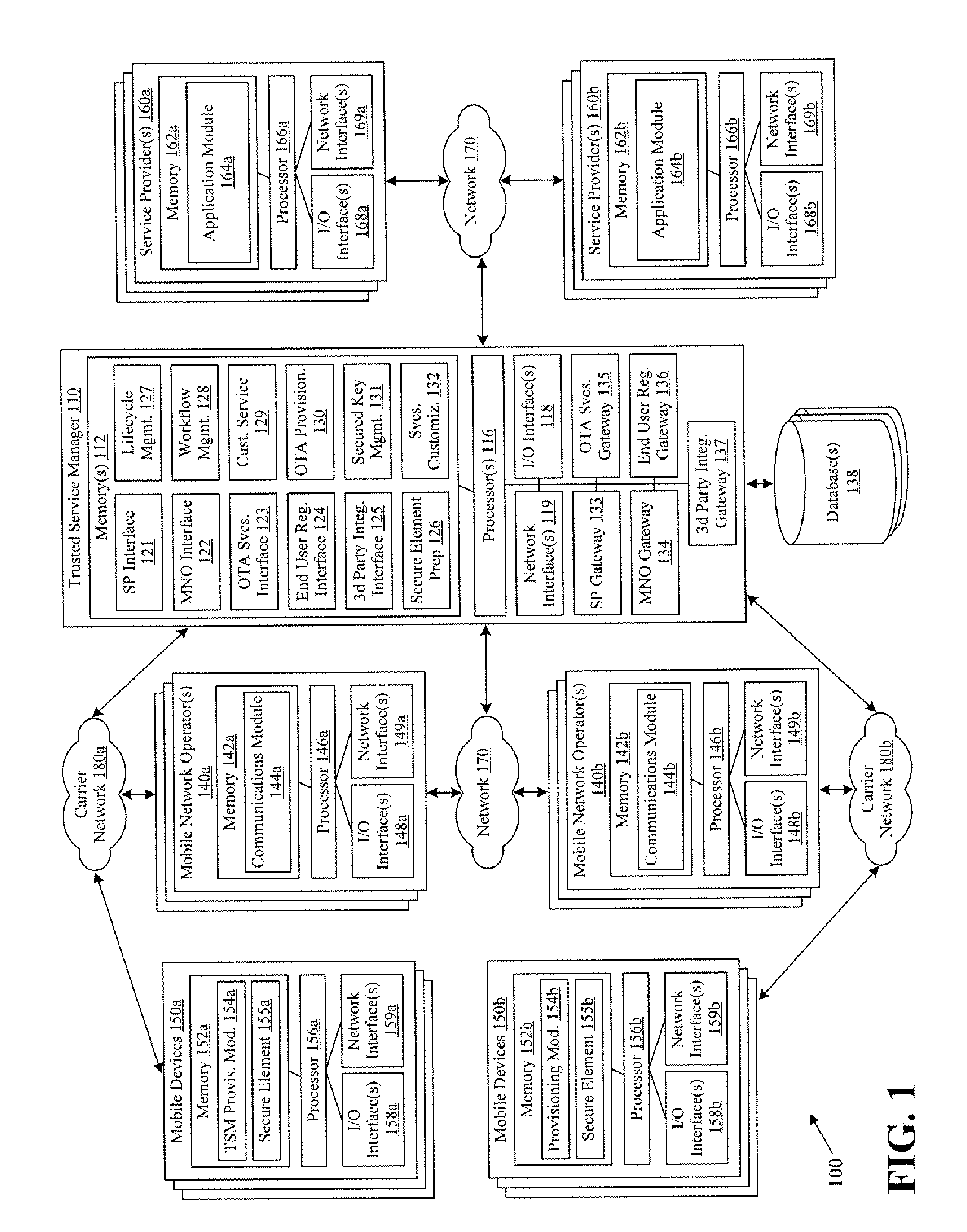

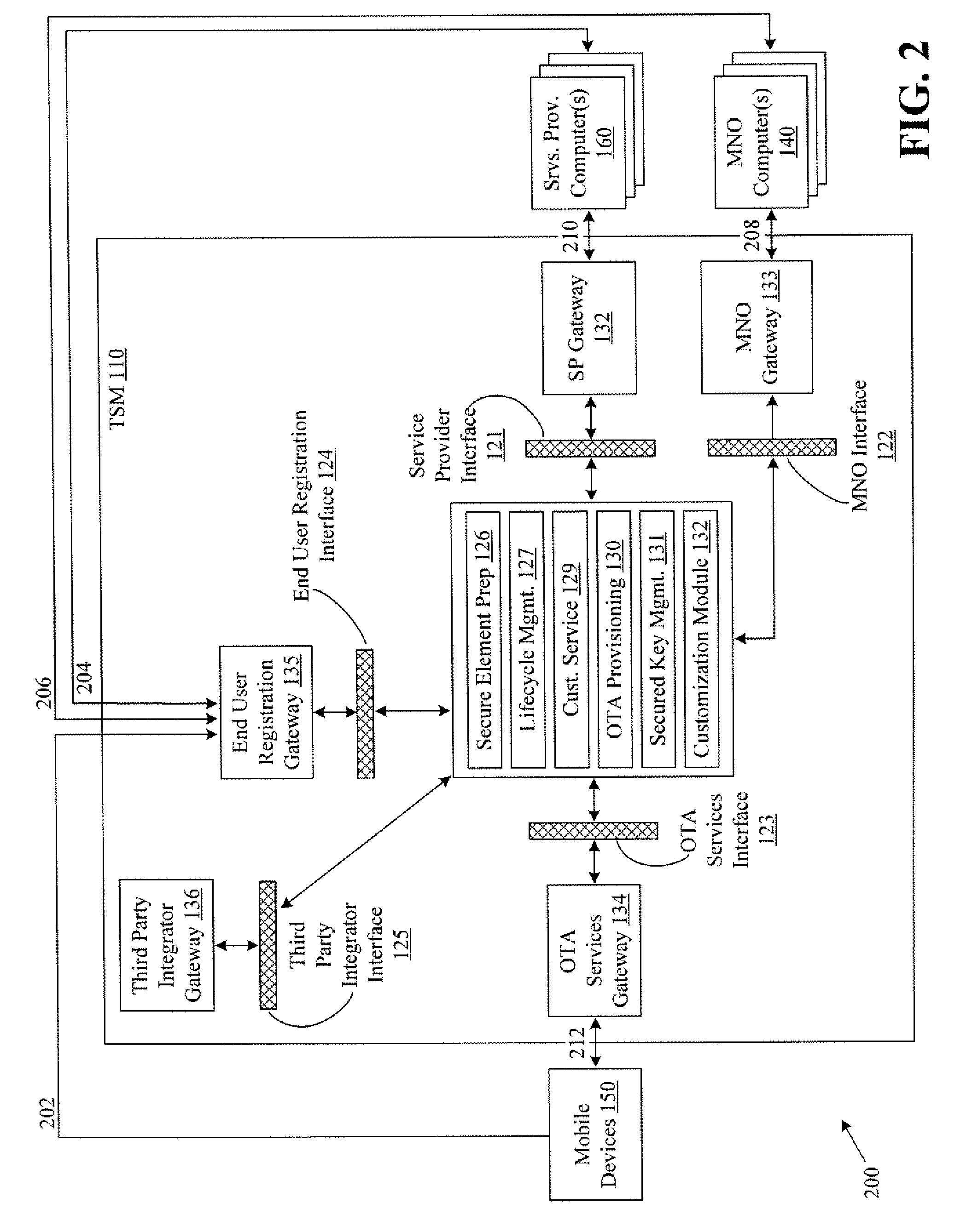

Systems and methods for providing trusted service management services

InactiveUS20100291904A1Easy maintenanceOptimize networkService provisioningSpecial service for subscribersService provisionMobile device

Embodiments of the invention provide systems and methods for providing trusted service management services. According to one embodiment, a system can include at least one service provider gateway operable to receive and transmit messages with multiple service providers; at least one mobile network operator gateway operable to receive and transmit messages with multiple mobile network operators; at least one provisioning gateway operable to transmit mobile device application data with multiple mobile devices and to receive messages from the plurality of mobile devices. The system can further include a processor operable to execute computer-executable instructions to: facilitate service provider communications by providing a common service provider interface for the service providers; facilitate mobile network operator communications by providing a common mobile network operator interface for the mobile network operators; facilitate provisioning multiple mobile device applications with the mobile devices; and facilitate communications with the mobile devices.

Owner:FIRST DATA

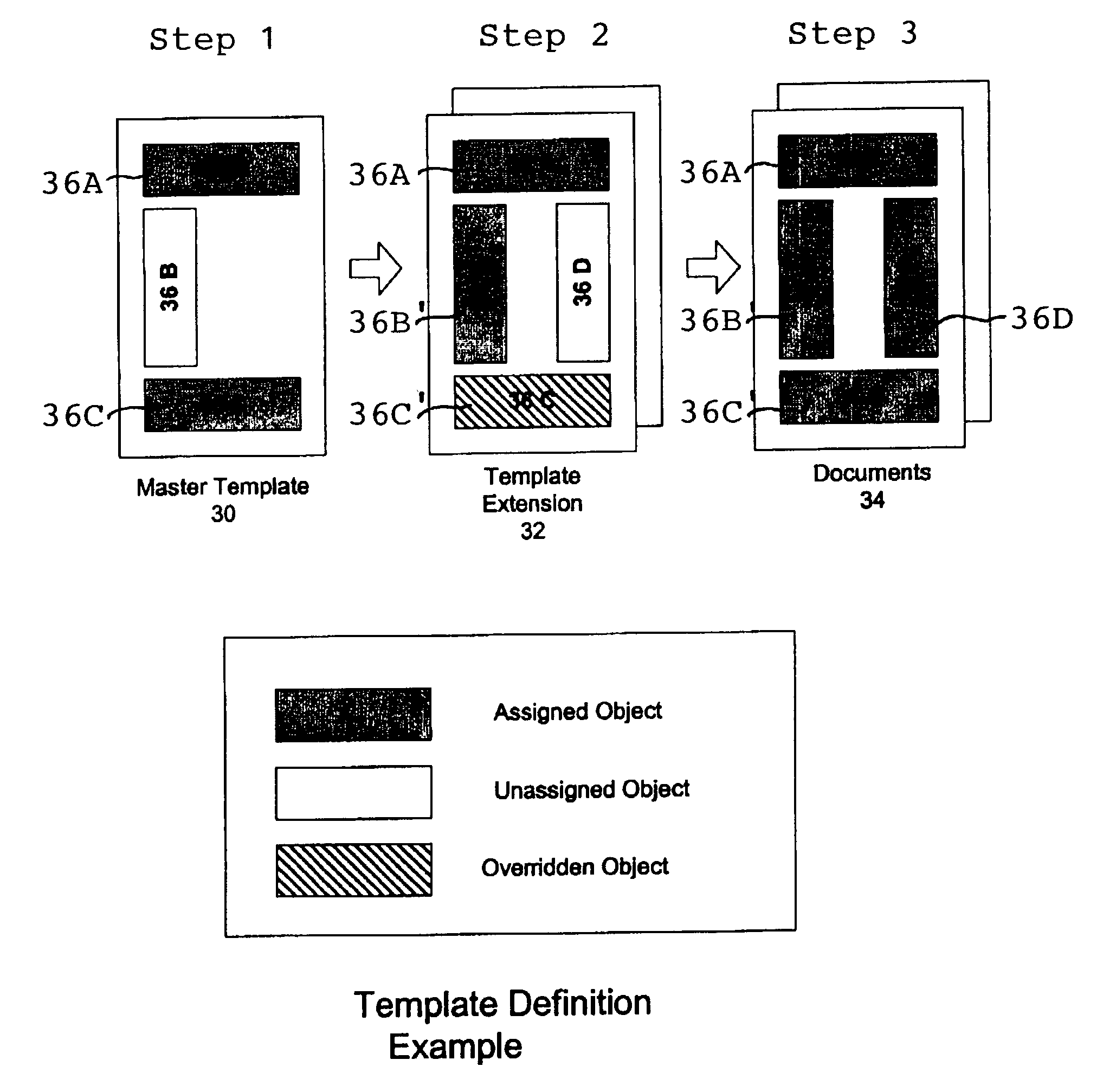

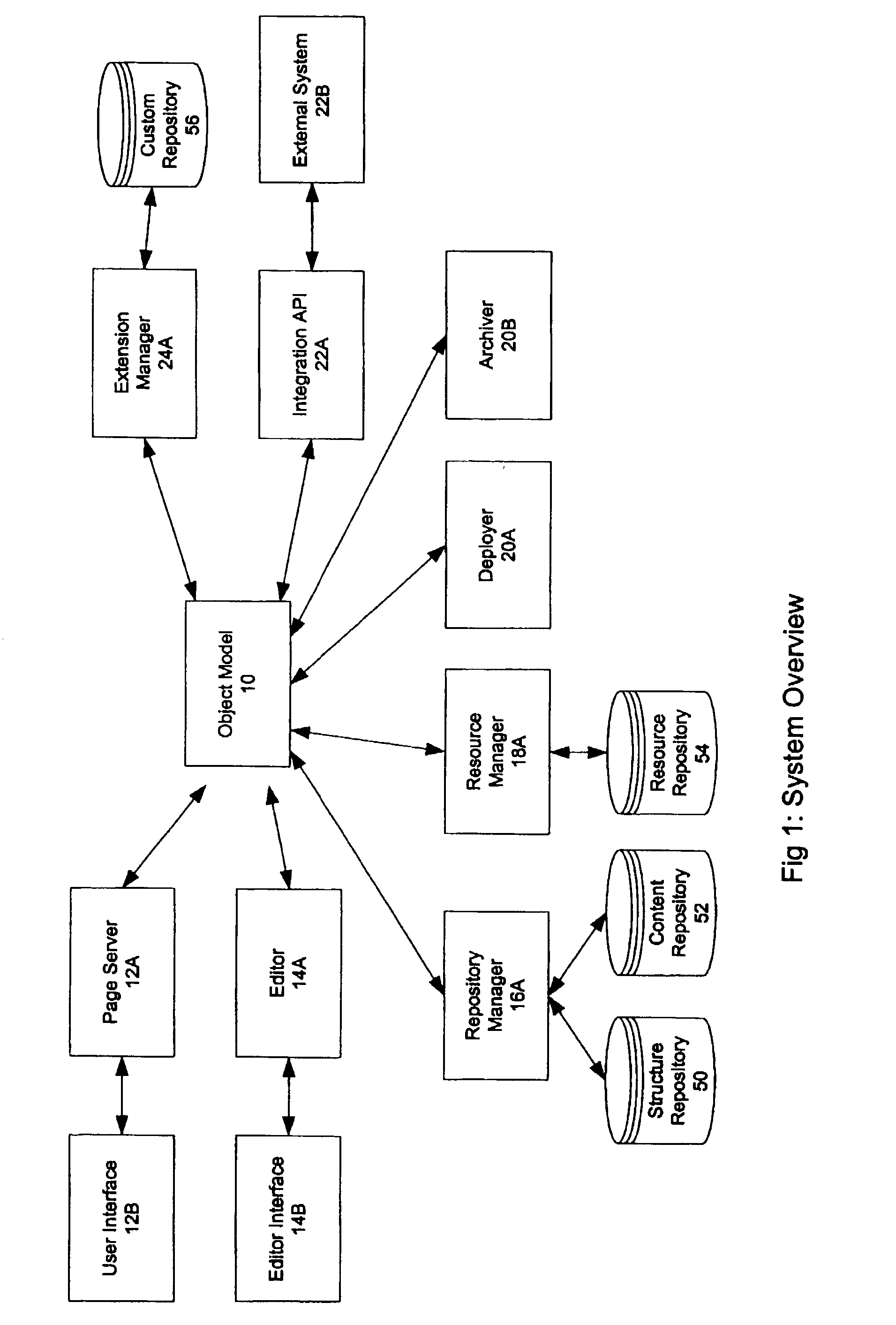

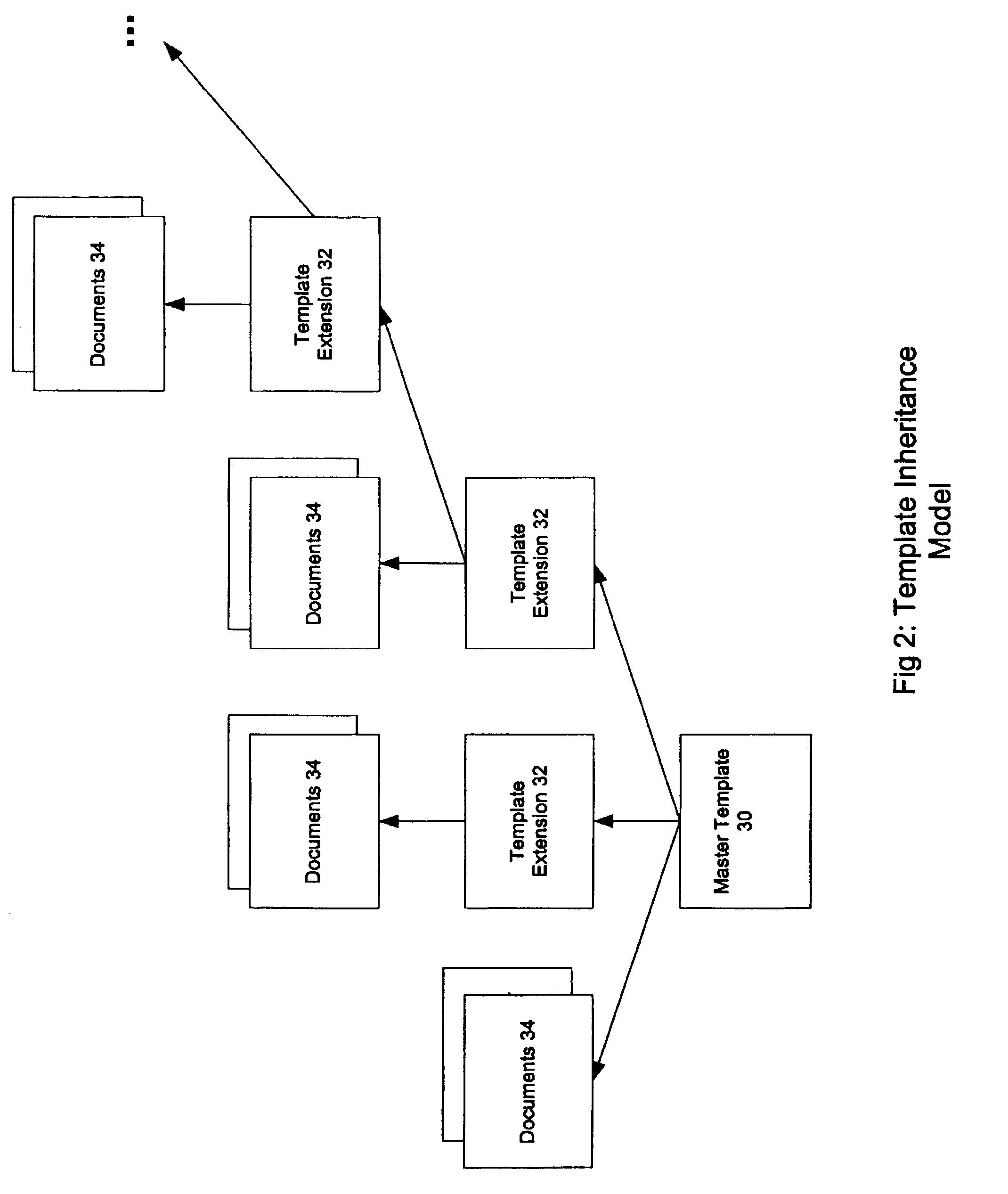

Web site application development method using object model for managing web-based content

InactiveUS20030014442A1Simplify the management processEasy to customizeDigital computer detailsSoftware designWeb siteWeb application

A system and method for developing an application for serving a document to a client in a client / server network employs an Object Model which defines templates, extensions, documents, and content objects in a template inheritance model. The Object Model serves a document, such as a webpage of a Web site application, by combining the structure and content inherited from a template and extensions in the template hierarchy. The templates specify the structure of the document and include tags as placeholders for content objects to be incorporated in the document. Extensions descend from either a template or another extension, and can expand upon the number of tags specified in a parent, add additional formatting to the layout, and / or refine the definition of tags that already exist in the inheritance hierarchy. When a document is to be viewed or served, a page server retrieves the template hierarchy and incorporates all tagged content in the structure inherited from the template and its extensions. The Object Model provides a framework for developing Web sites and other applications that is more robust and simpler to manage than the traditional file directory model of conventional Web applications. This framework makes it possible to create complex and highly structured Web applications that are efficient to develop and easier to maintain, and without ever having to write source code.

Owner:DH LABS

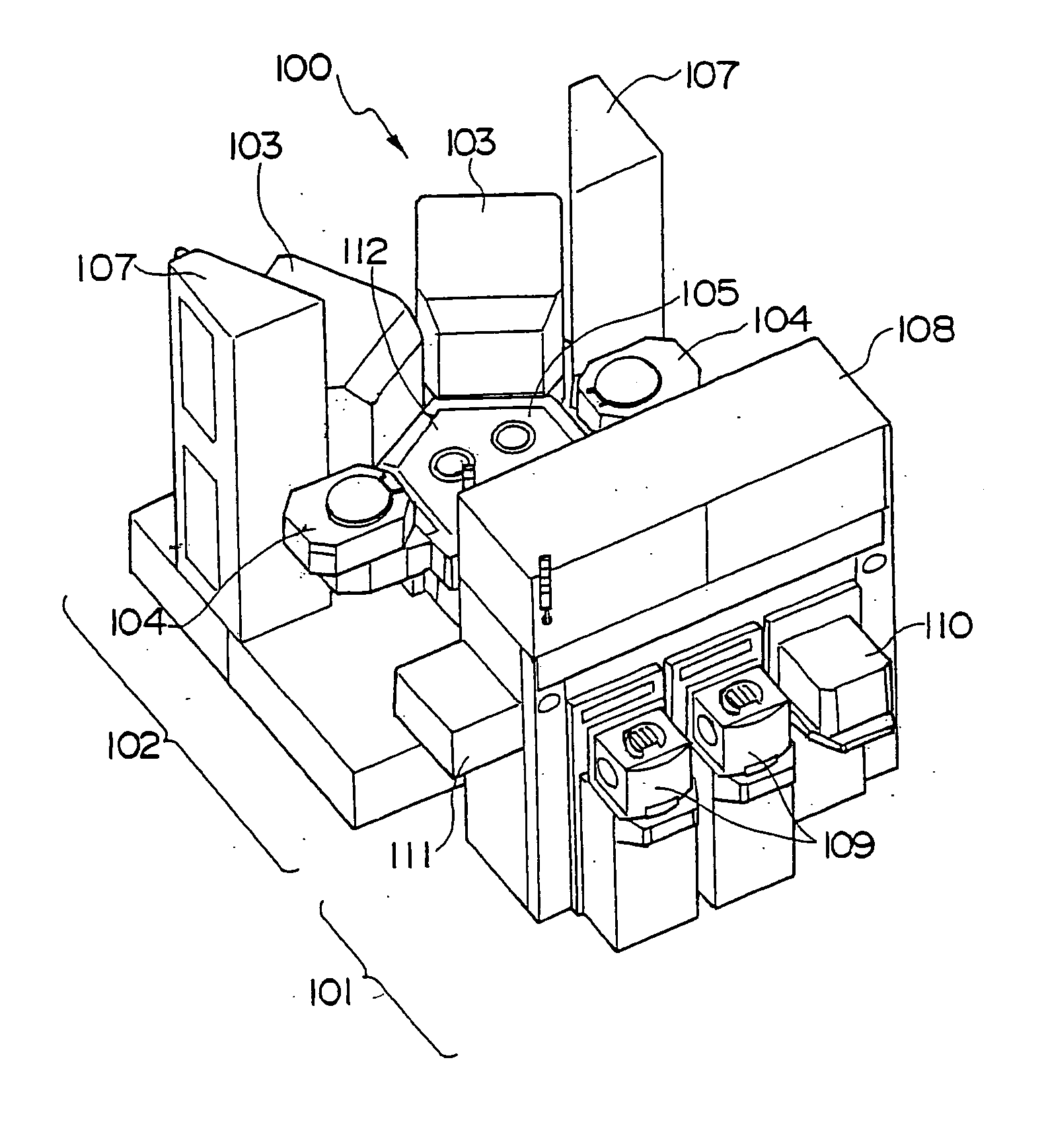

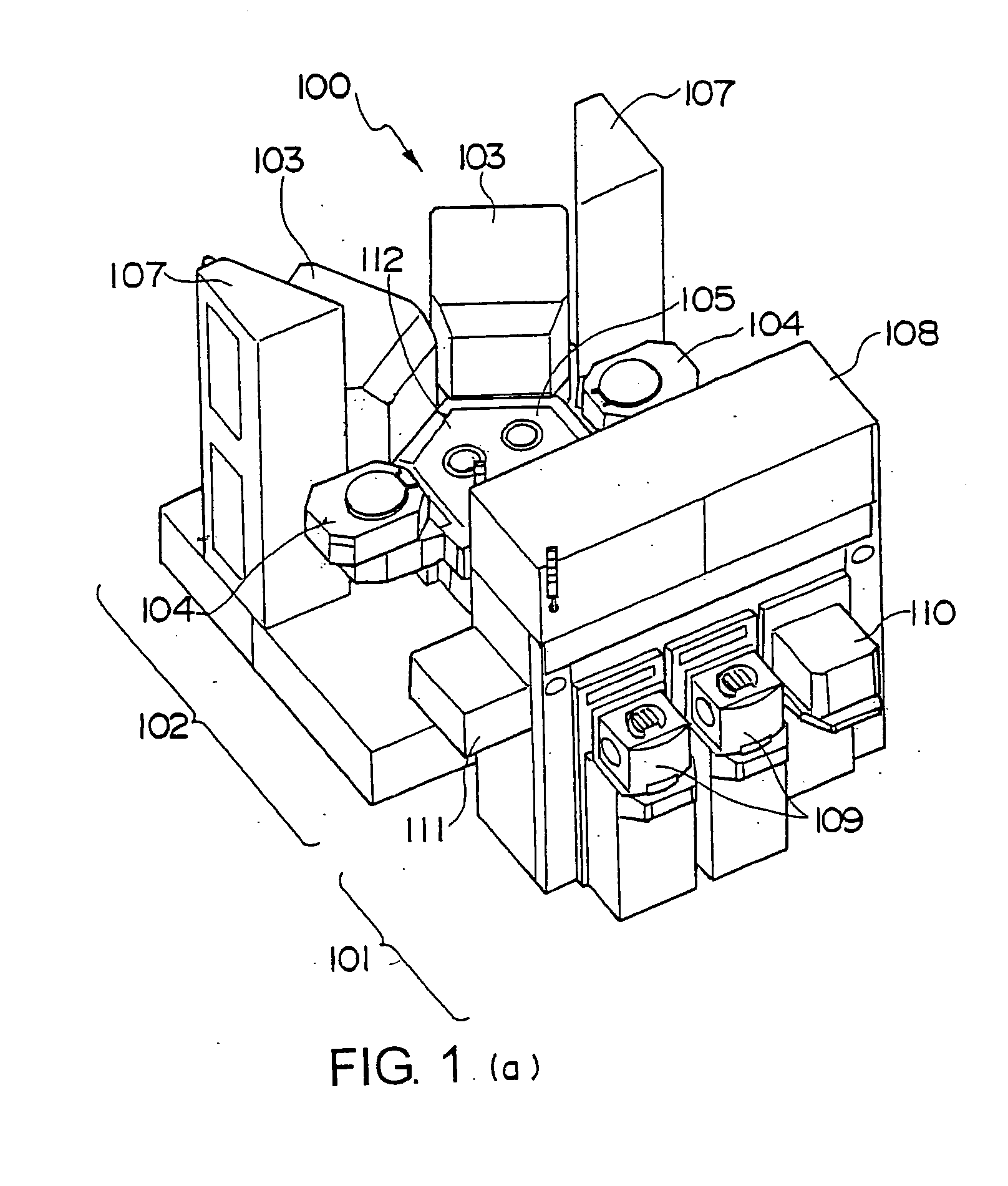

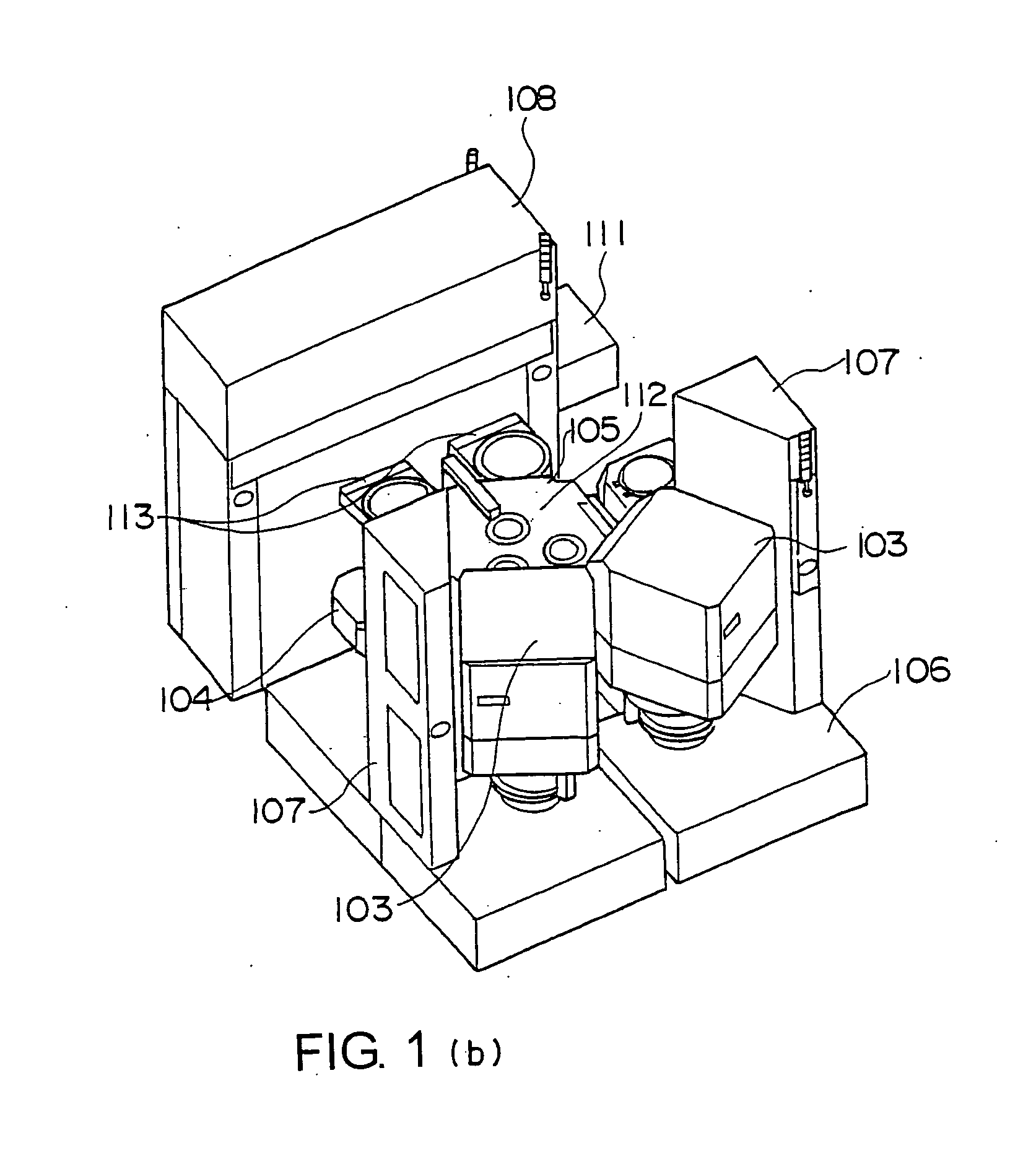

Vacuum processing apparatus

ActiveUS20050051093A1Easy to disconnectOperation efficiency can be improvedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDouble wallEngineering

A vacuum processing apparatus includes a vacuum processing chamber having a processing table for supporting an object to be processed and carrying out processing using a gas. The vacuum processing chamber has an axisymmetric structure, including a double wall structure, and a gate valve for sealing an opening through which the object enters the processing chamber.

Owner:HITACHI HIGH-TECH CORP

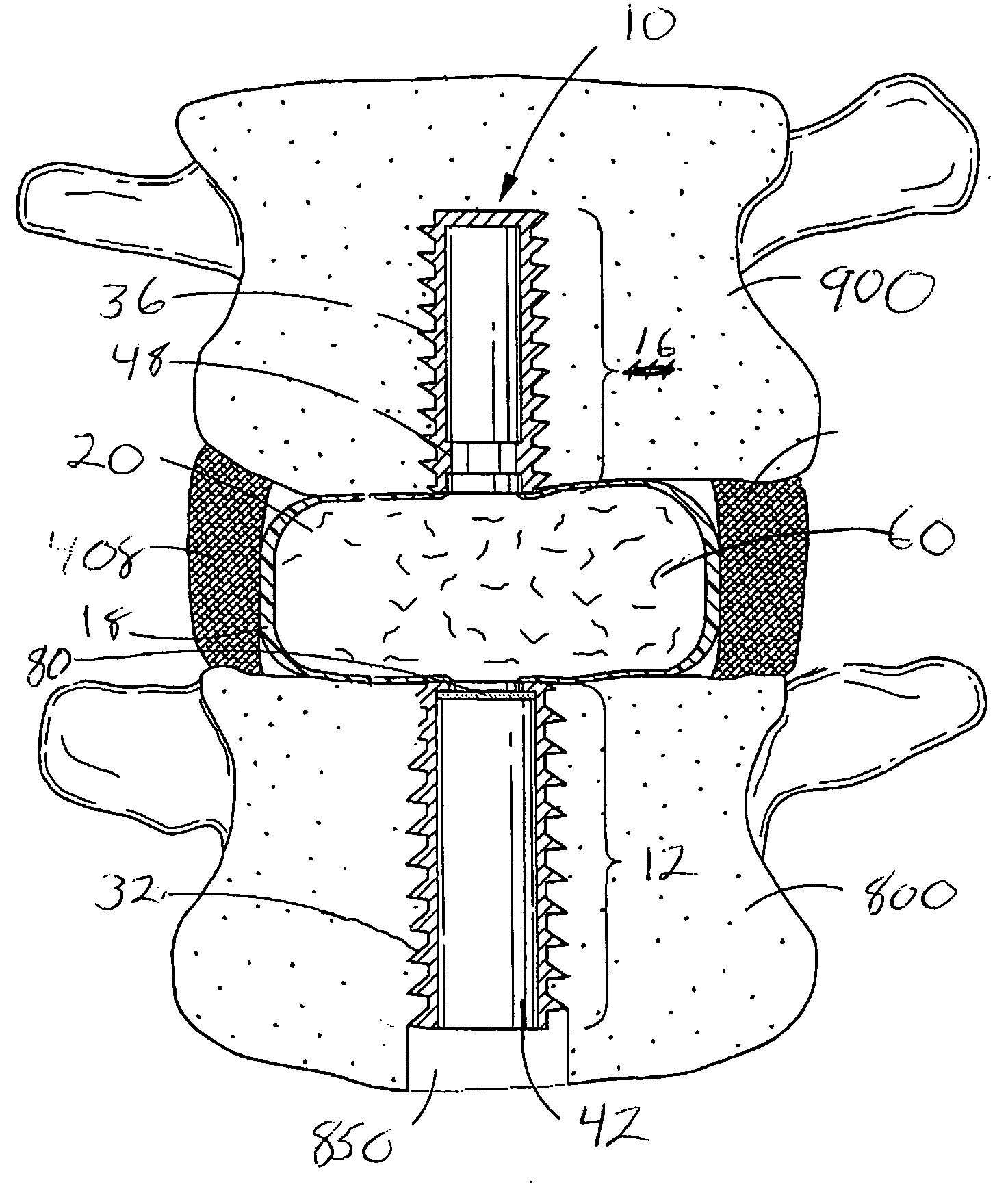

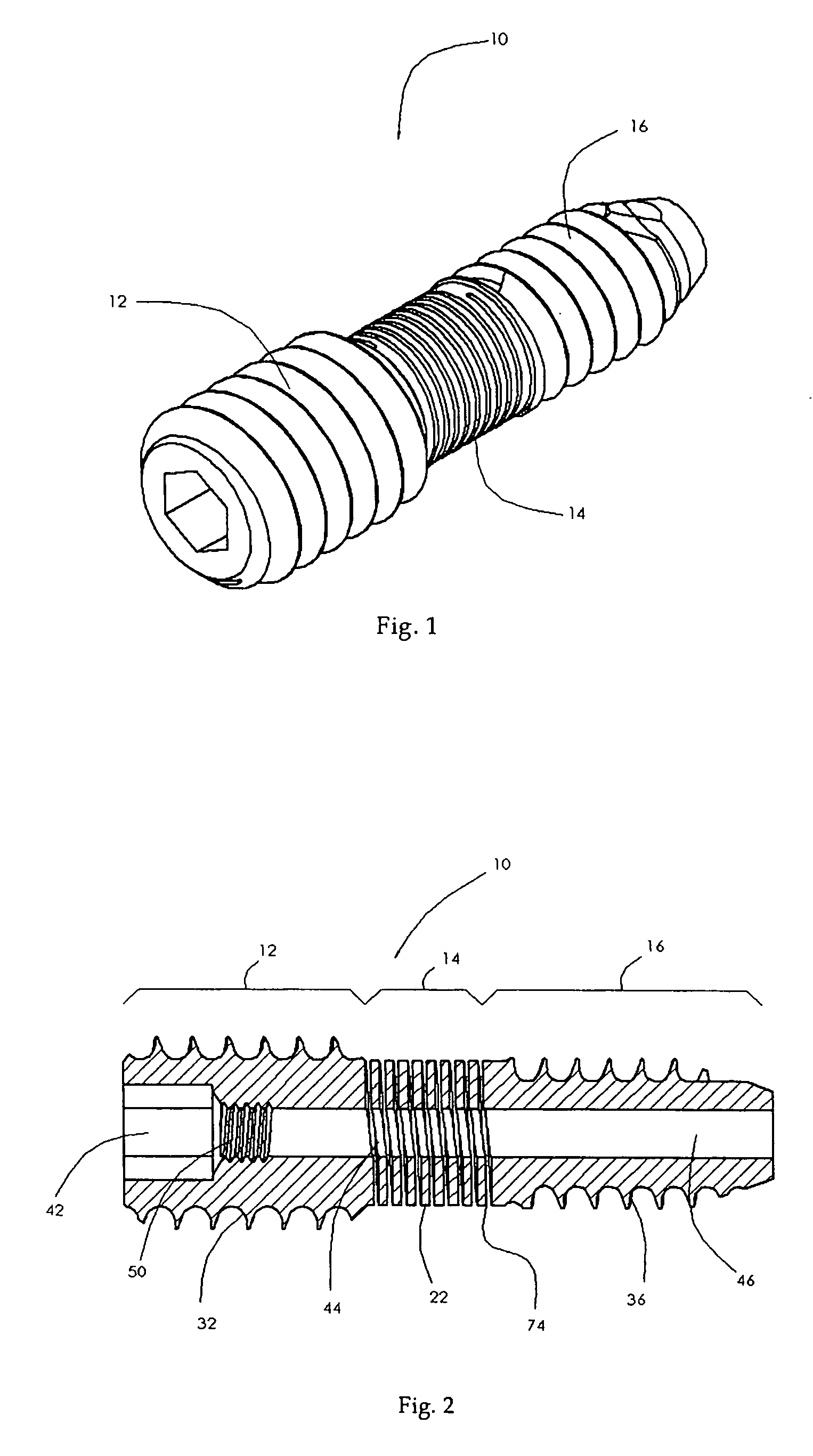

Dual anchor prosthetic nucleus apparatus

InactiveUS20050113928A1Restore and manage range of motionEasy maintenanceSuture equipmentsInternal osteosythesisProsthesisIntervertebral disk

A spinal mobility preservation apparatus and methods are disclosed. The spinal mobility preservation apparatus may include a proximal body, an intermediate body, a distal body, and an expandable membrane. The proximal body and the distal body secure the mobility preservation apparatus to adjacent vertebral bodies. At least one of an intermediate body and an expandable membrane secure the proximal body to the distal body and provide a degree of support to a spinal motion segment defined by the adjacent vertebral bodies. A single proximal body and an expandable membrane may also compose a spinal mobility preservation apparatus. The proximal body secured to one of a superior or an inferior vertebral body and the expandable membrane extending into the intervertebral disc space to support the spinal motion segment.

Owner:MIS IP HLDG LLC +1

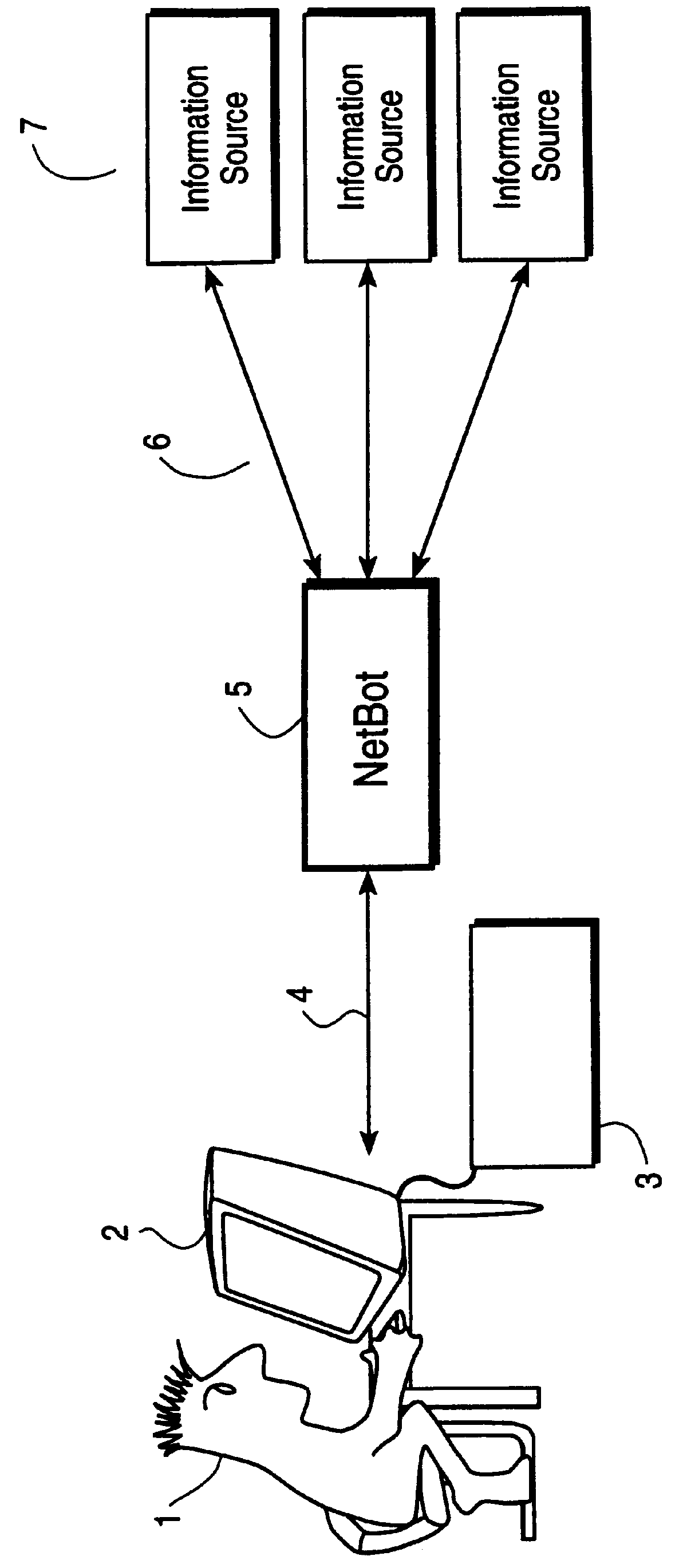

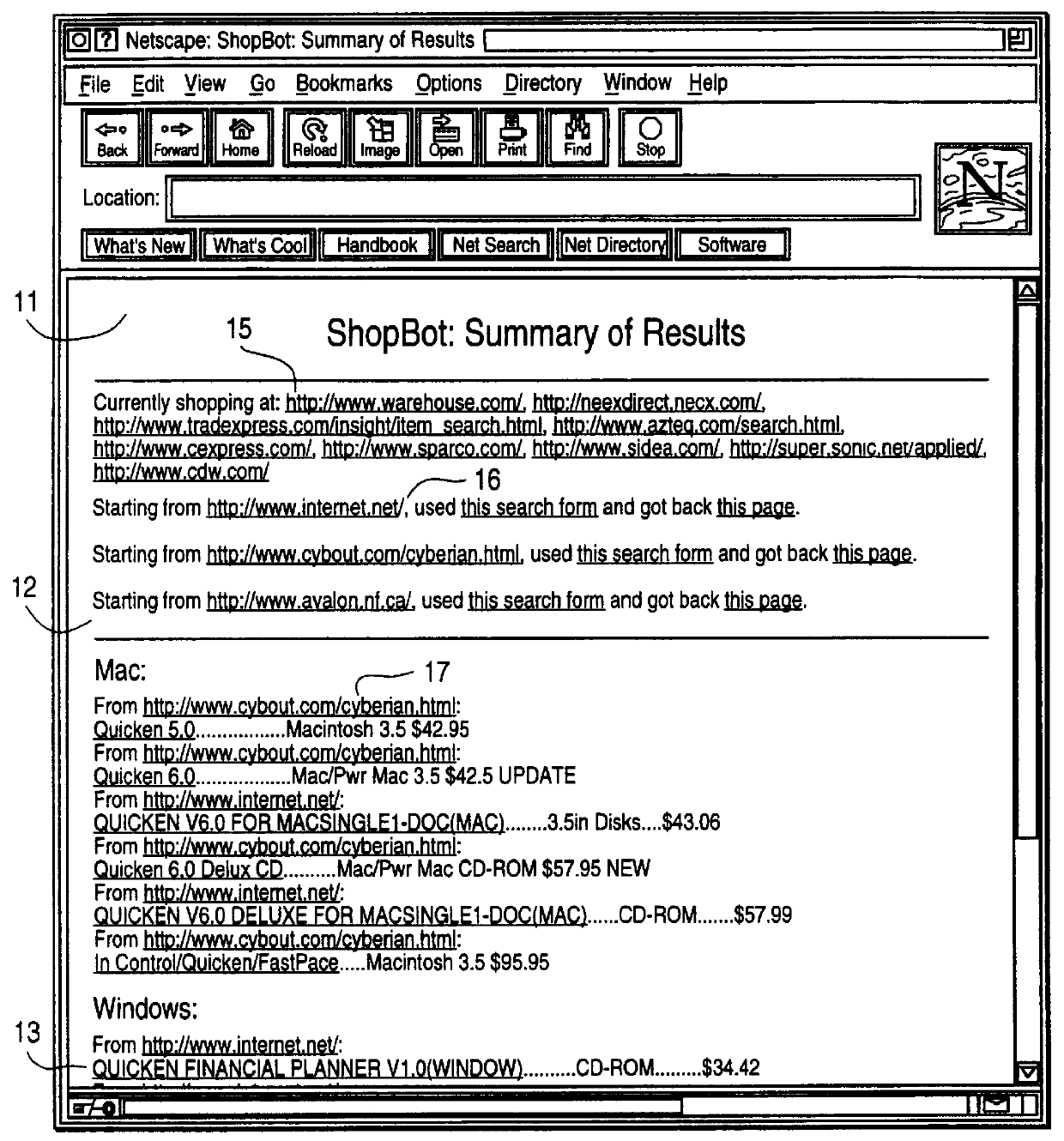

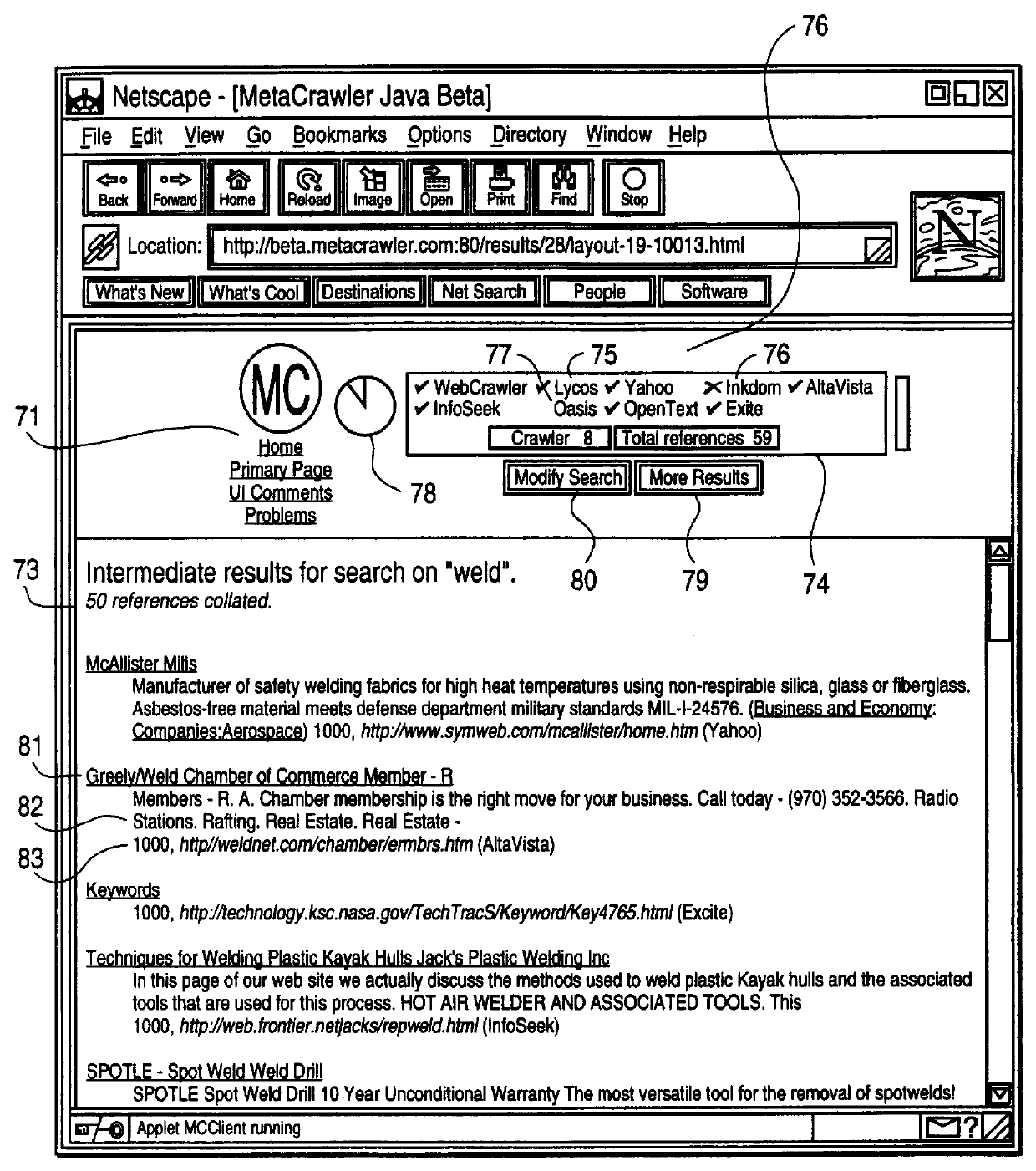

Method and system using information written in a wrapper description language to execute query on a network

InactiveUS6085186AEasy to understandEasy maintenanceData processing applicationsWeb data indexingAccess networkNetwork connection

This invention provides assistance to a user in accessing network attached information sources. In one aspect, the invention is a method for intelligently routing a user query to information sources relevant to that query, extracting relevant data fields from received responses, and intelligently presenting the extracted data in order of estimated relevance. The system of this invention implements one or more steps of the method in a centralized or distributed manner on one or more network attached computers. Further, this invention provides a novel language and implementation that facilitates easily written and maintained descriptions of information source query and response formats.

Owner:AT HOME BONDHOLDERS LIQUIDATING TRUST

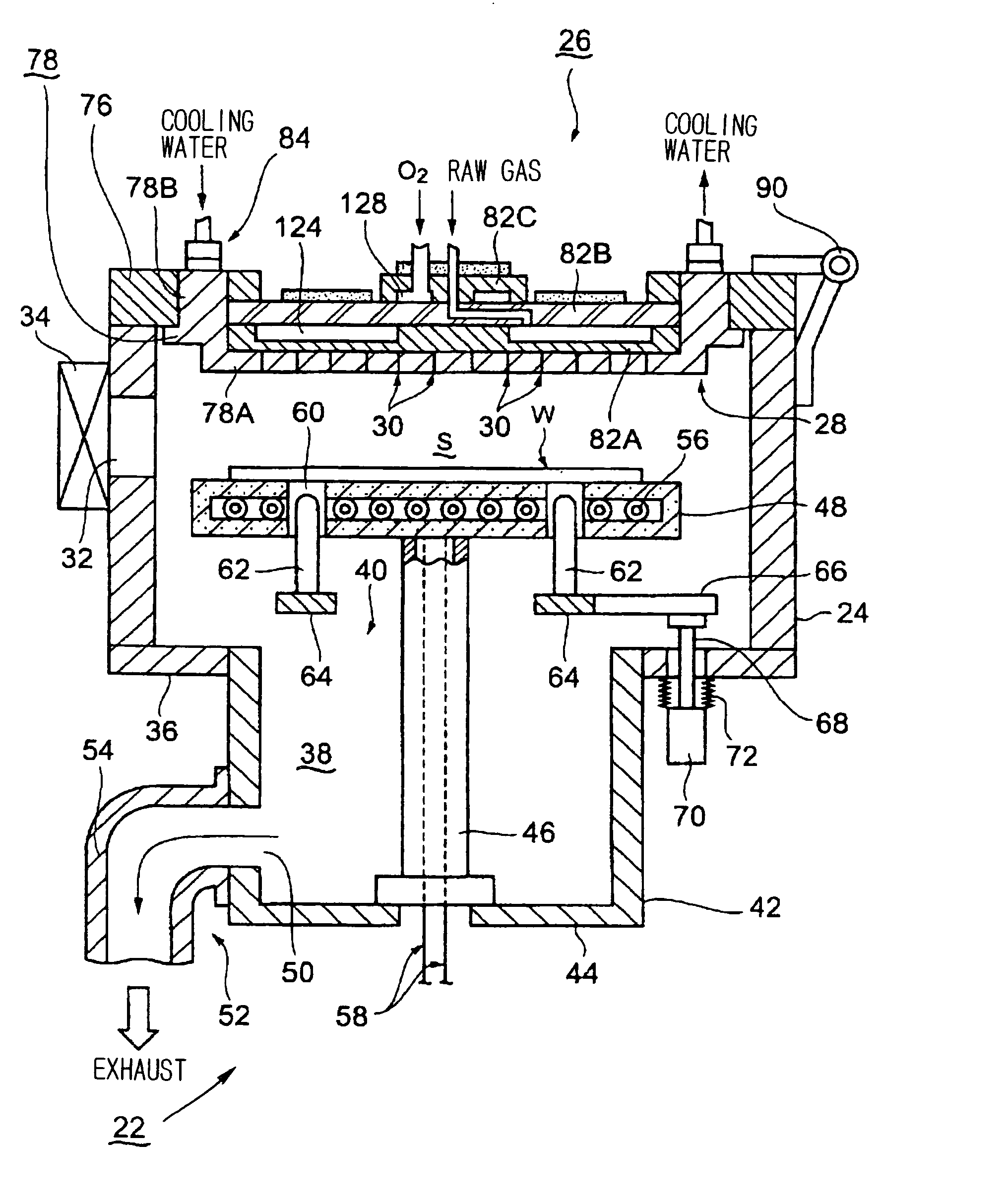

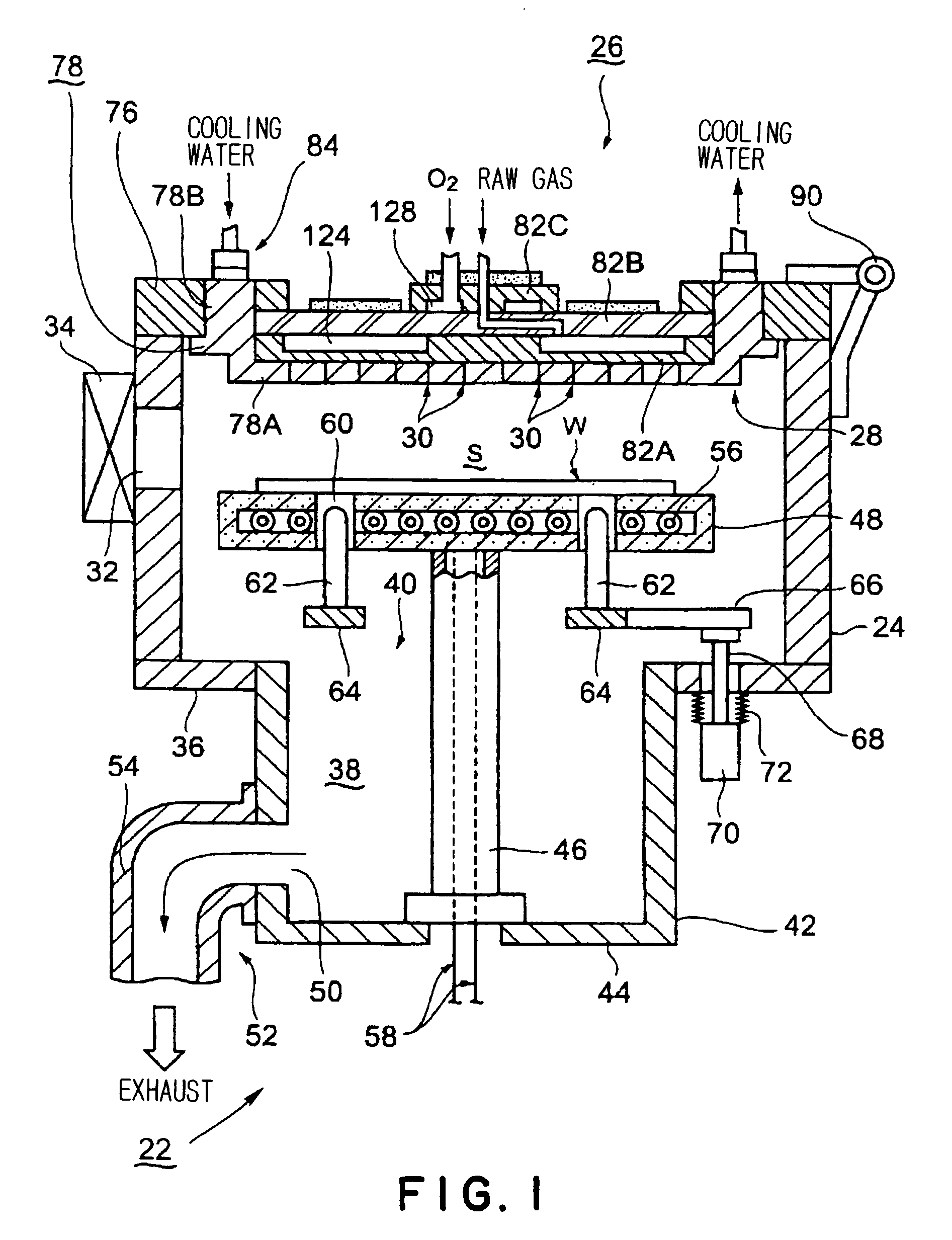

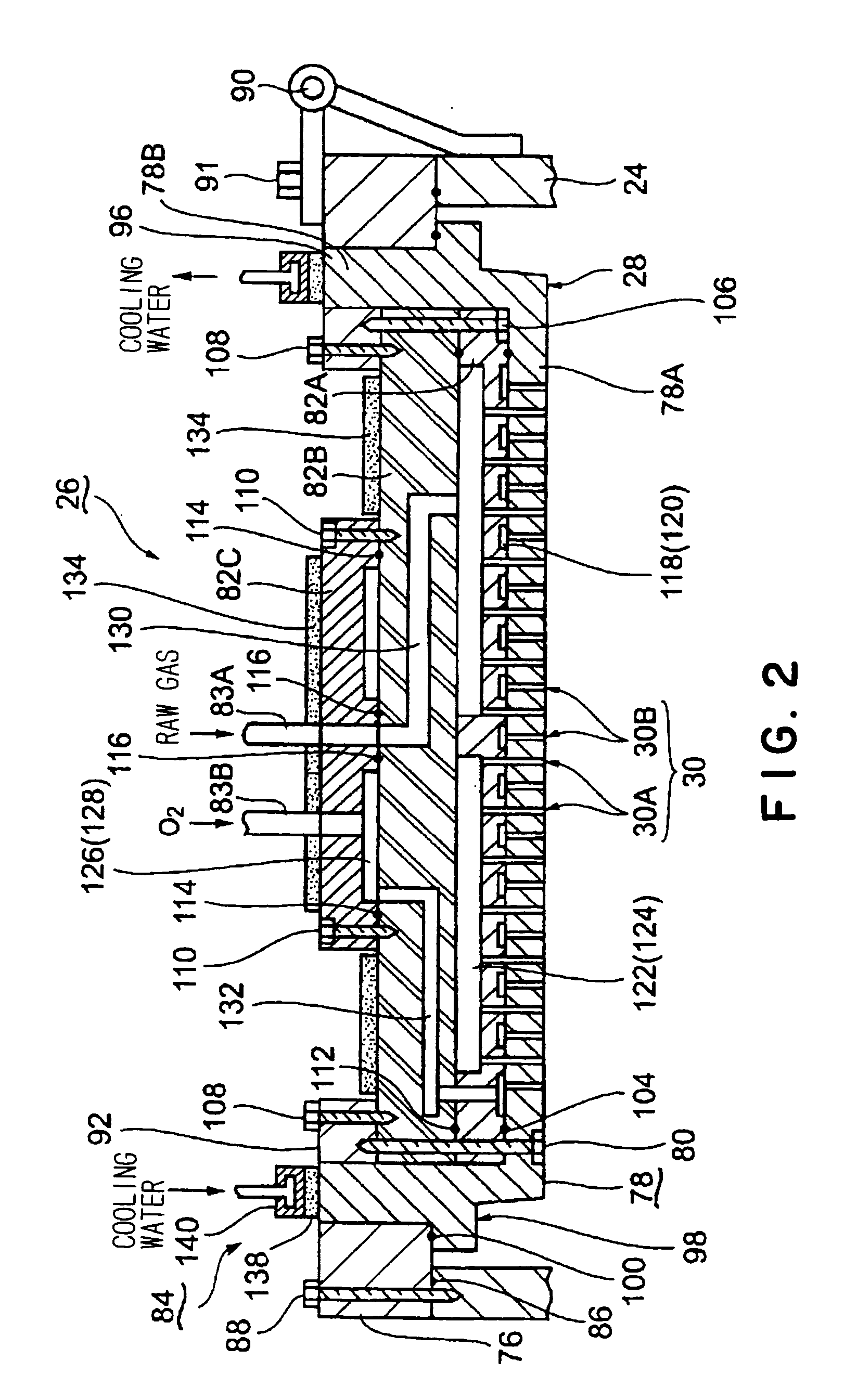

Processing apparatus

InactiveUS20070158026A1High temperature controllabilityEasy maintenanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A shower head structure (26) includes a shower head main body (78) of a one-piece structure formed in a generally cup shape and having a bottom wall (78A) provided with a plurality of gas injection holes (30A, 30B) formed therein and a side wall (78B) rising from a peripheral portion of the bottom wall. A plurality of gas diffusion chamber forming plates (82A-82C) are housed in the shower head main body (78). A through-hole is formed in a head mounting frame (76) disposed on a ceiling of a processing vessel (24). An upper portion of the side wall (78B) of the shower head main body (78) is inserted into the through-hole, so that a part of the side wall (78B) is exposed to the exterior of the processing vessel. A cooling mechanism (84) is disposed at the upper end portion of the side wall (78B). Heat transfer between the cooling mechanism (84) and the bottom wall (78A) is enhanced, so that the temperature of the bottom wall (78A) can be controlled at a proper value, thereby preventing any adhesion of an unnecessary film onto the bottom wall (78A).

Owner:TOKYO ELECTRON LTD

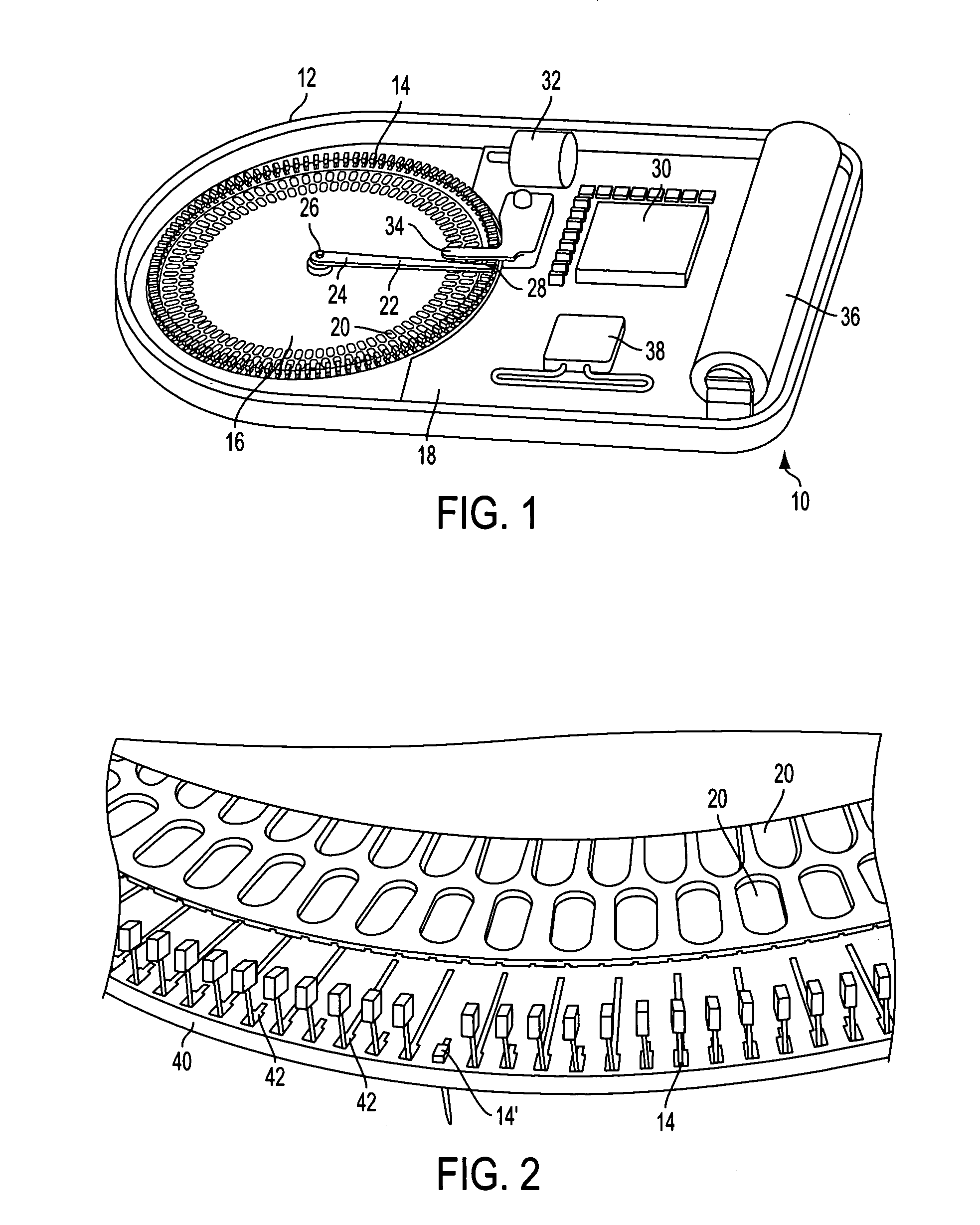

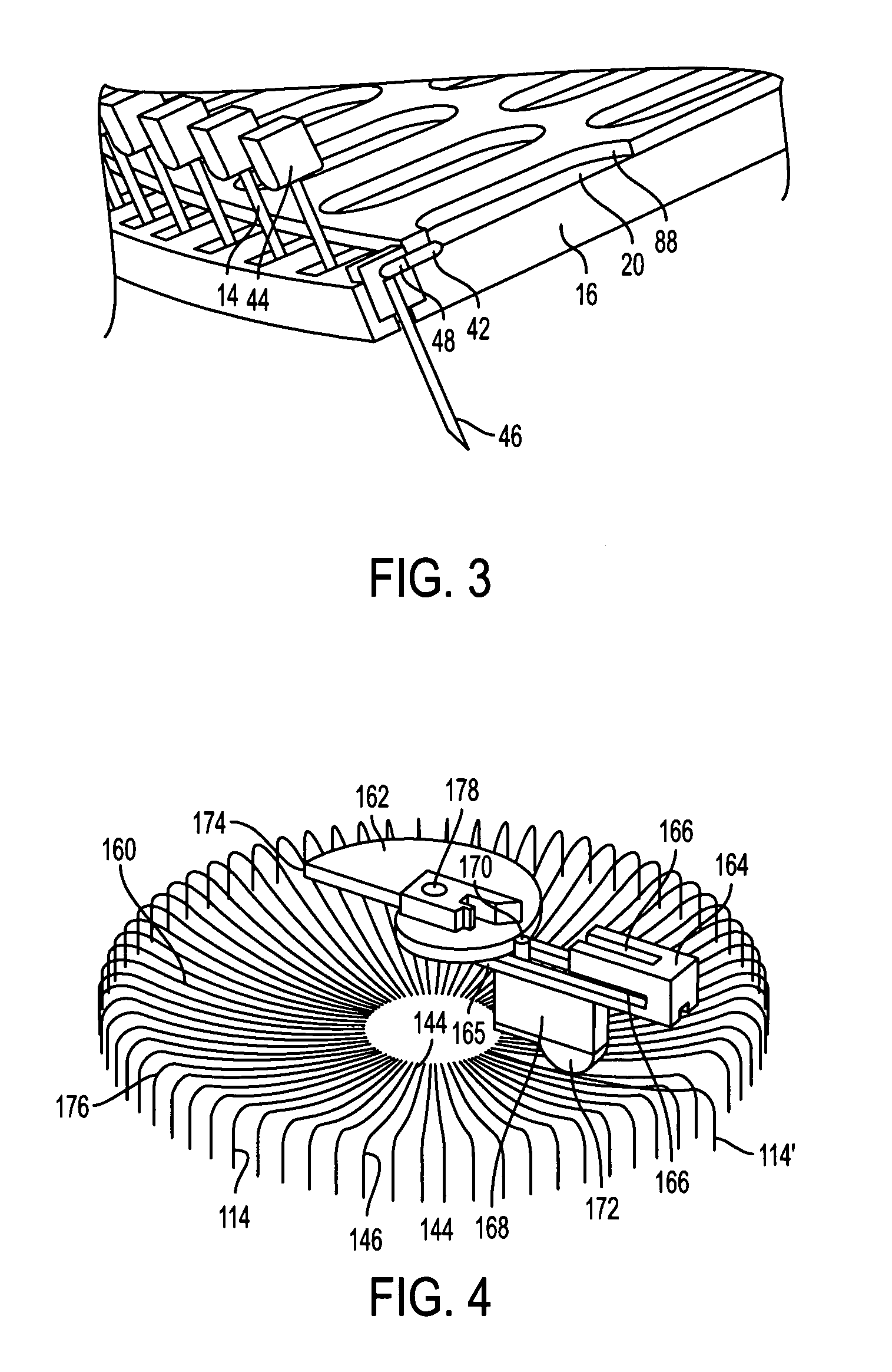

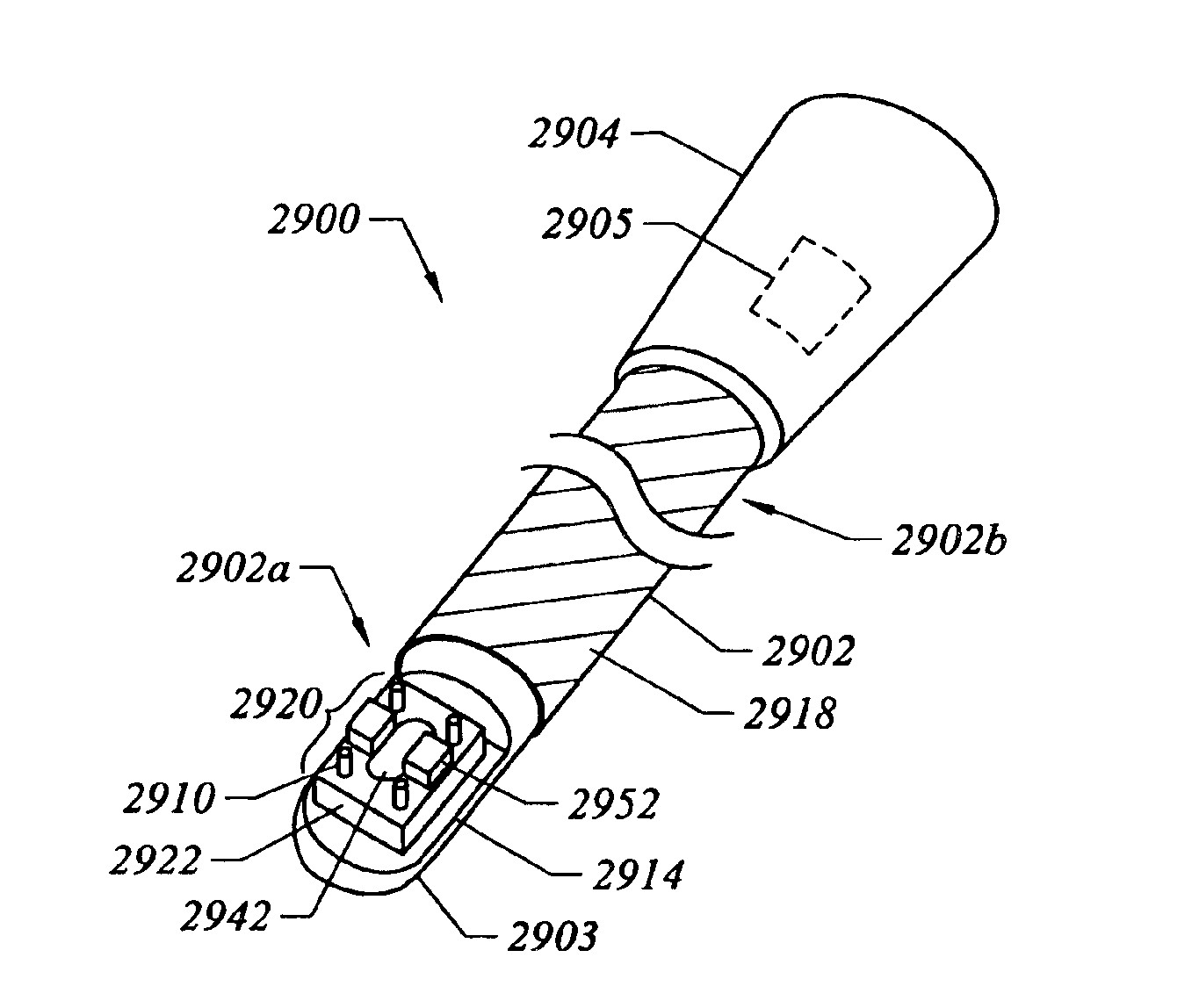

Autonomous, ambulatory analyte monitor or drug delivery device

ActiveUS7004928B2Improve capillary forceMinimize coagulationAutomatic syringesMicroneedlesBiomedical engineeringElectronic equipment

The invention relates to analyte monitoring / drug (pharmaceutical agent) delivery device. The invention is suited for monitoring various blood constituents such as glucose. The device has a housing that at least partially encloses a plurality of microneedles disposed on a carrier and an electronics portion. Each microneedle is in fluid communication with a corresponding microchannel. Each microneedle is individually addressable. That is, each microneedle can be extended and retracted individually via an actuator. The electronics portion includes a processor and associated circuitry (e.g., memory, supporting electronics and the like), a motor or the like, a sensor, a power supply (e.g., battery) and optionally an interface. In general, the processor controls the operation of the device and is data communication with the actuator, motor, sensor and interface. The invention provides for autonomous operation, that is, without intervention of the user. The invention can optionally provide for calibration without intervention of the user. The invention can also provide for semi-continuous monitoring for day and night time. The invention can provide for up to four, or more, weeks of operation. The invention can provide for a device that is relative small in size, and therefore unobtrusive. The invention can also provide for device with remote control and interactive electronics. The invention may be also used for the delivery of various pharmaceutical agents including high potency drugs to minimize patient intervention and minimize discomfort.

Owner:INTUITY MEDICAL INC

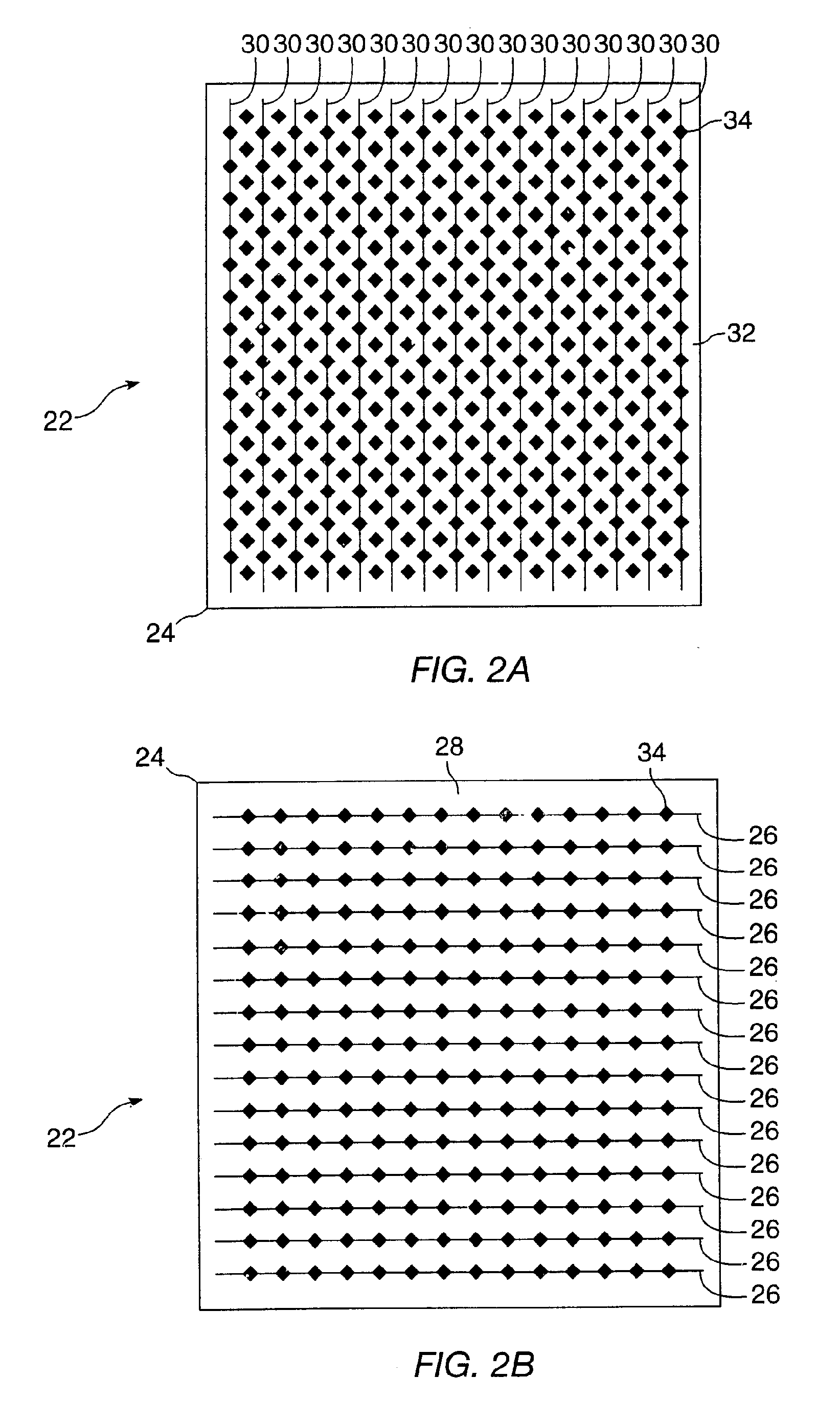

Object position detector with edge motion feature and gesture recognition

InactiveUS20080048997A1Highly integratedRapid responseCharacter and pattern recognitionInput/output processes for data processingCapacitanceElectrical conductor

A method of generating a signal comprising providing a capacitive touch sensor pad including a matrix of X and Y conductors, developing capacitance profiles in one of an X direction and a Y direction from the matrix of X and Y conductors, determining an occurrence of a single gesture through an examination of the capacitance profiles, the single gesture including an application of at least two objects on the capacitive touch sensor pad, and generating a signal indicating the occurrence of the single gesture.

Owner:SYNAPTICS INC

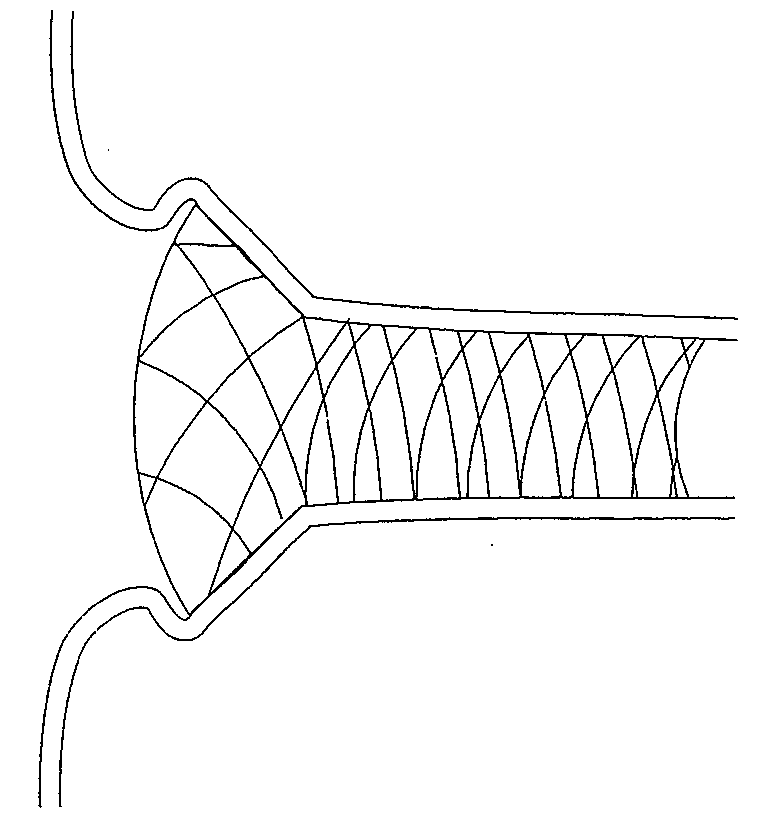

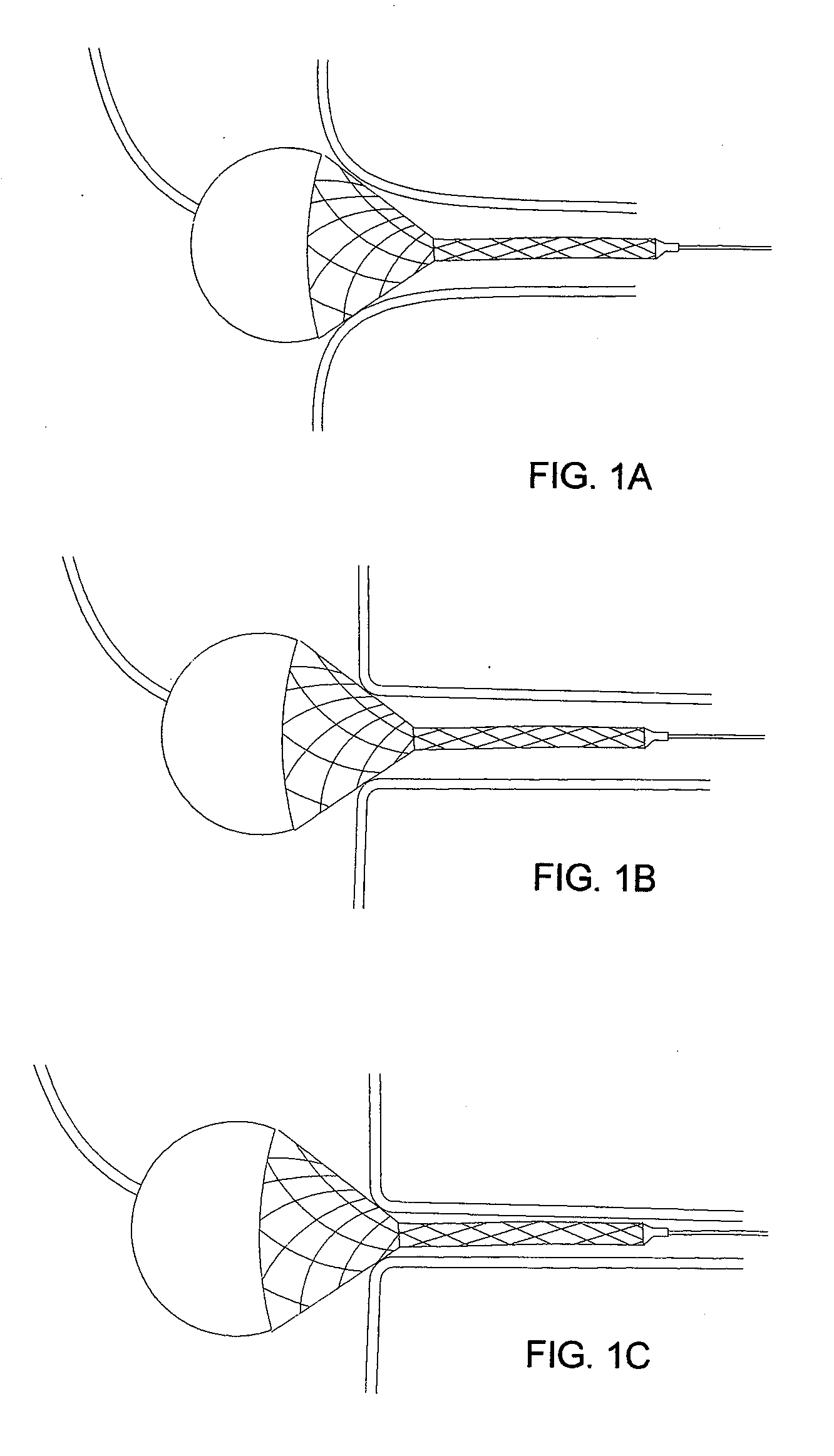

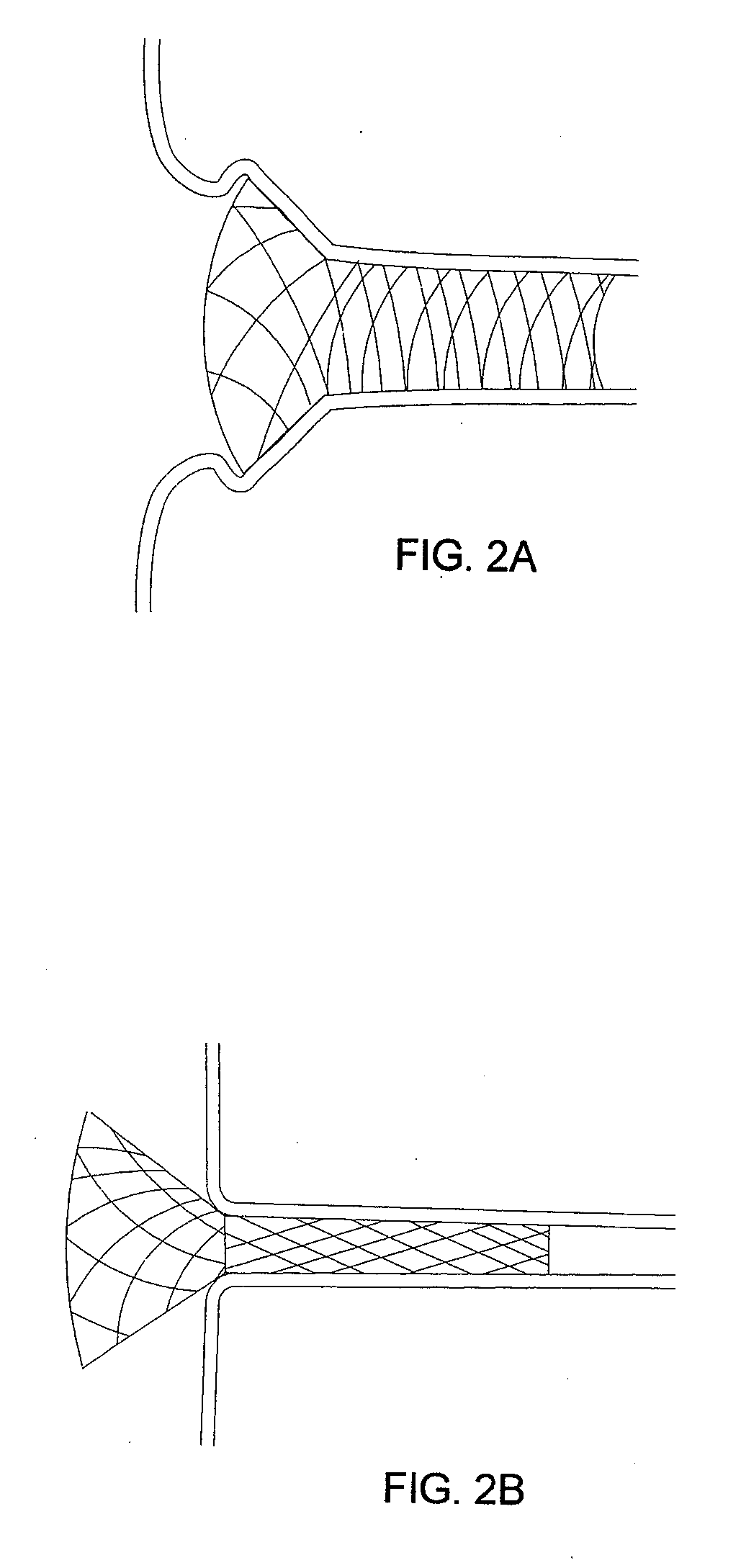

Axially compressible flared stents and apparatus and methods for delivering them

A stent includes a flaring portion and a main portion connected to the flaring portion. The main portion includes a plurality of bands of cells spaced apart axially from one another, adjacent bands of cells being intermittently connected to one another. During use, the stent is introduced into a main vessel in a contracted condition and positioned with the flaring portion adjacent an ostium. The flaring portion is flared, and the stent is advanced at least partially into the ostium. The stent is expanded further such that the main portion expands within the branch body lumen and / or the flaring portion expands adjacent the ostium. The main portion compresses axially during at least one of the steps when the stent is expanded, which may enhance conformance of the stent relative to the ostium and / or enhance reinforcement of the ostium.

Owner:INCEPT LLC

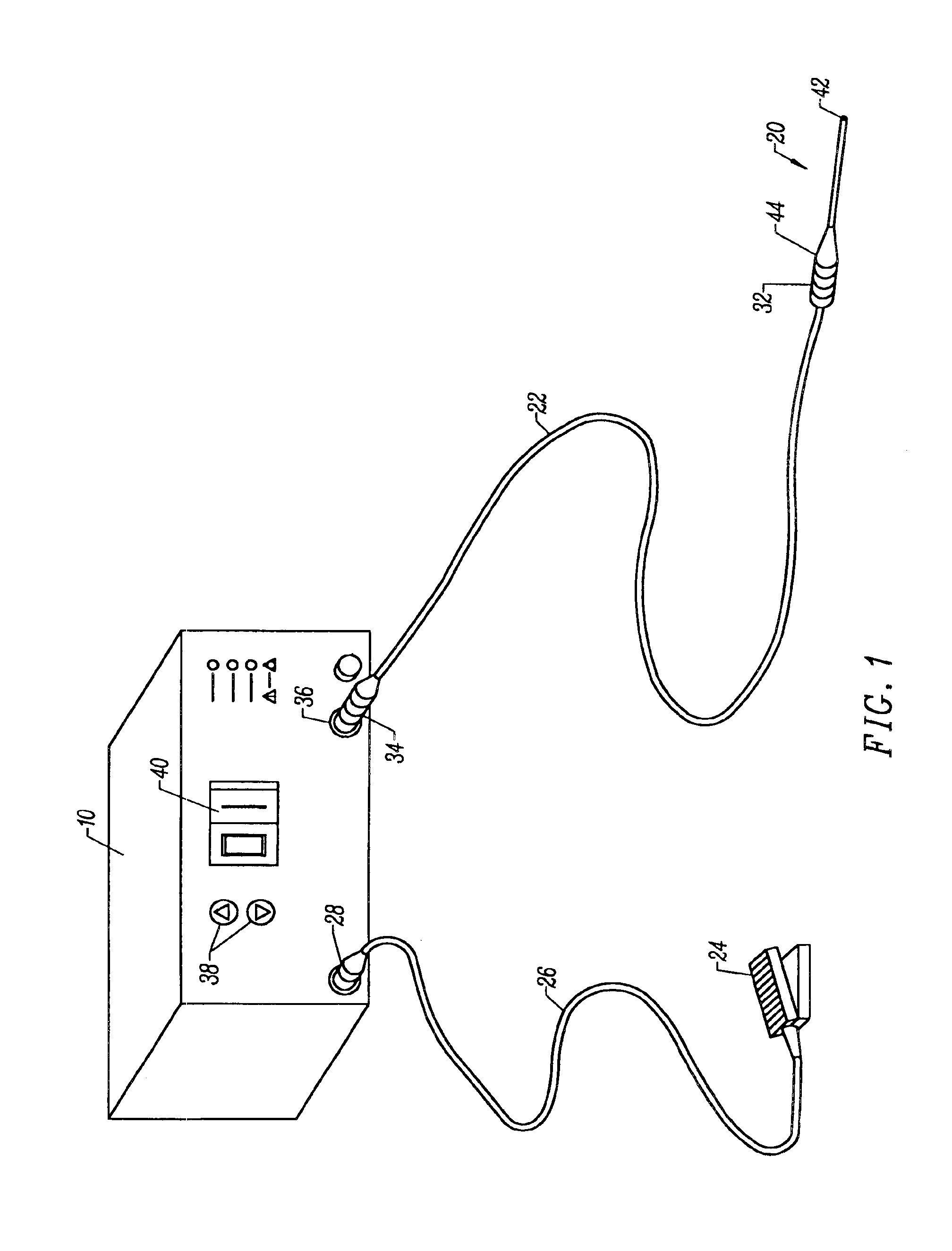

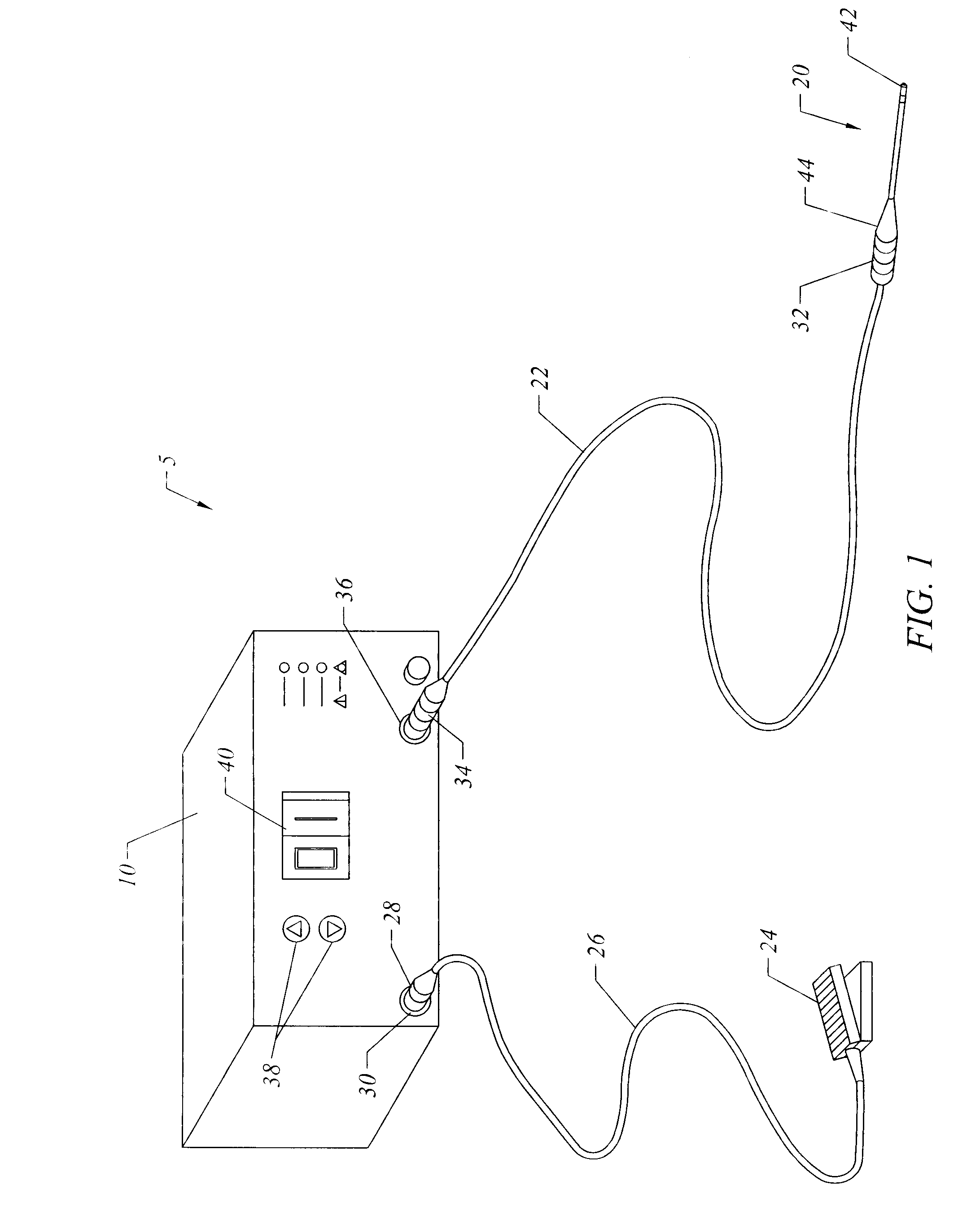

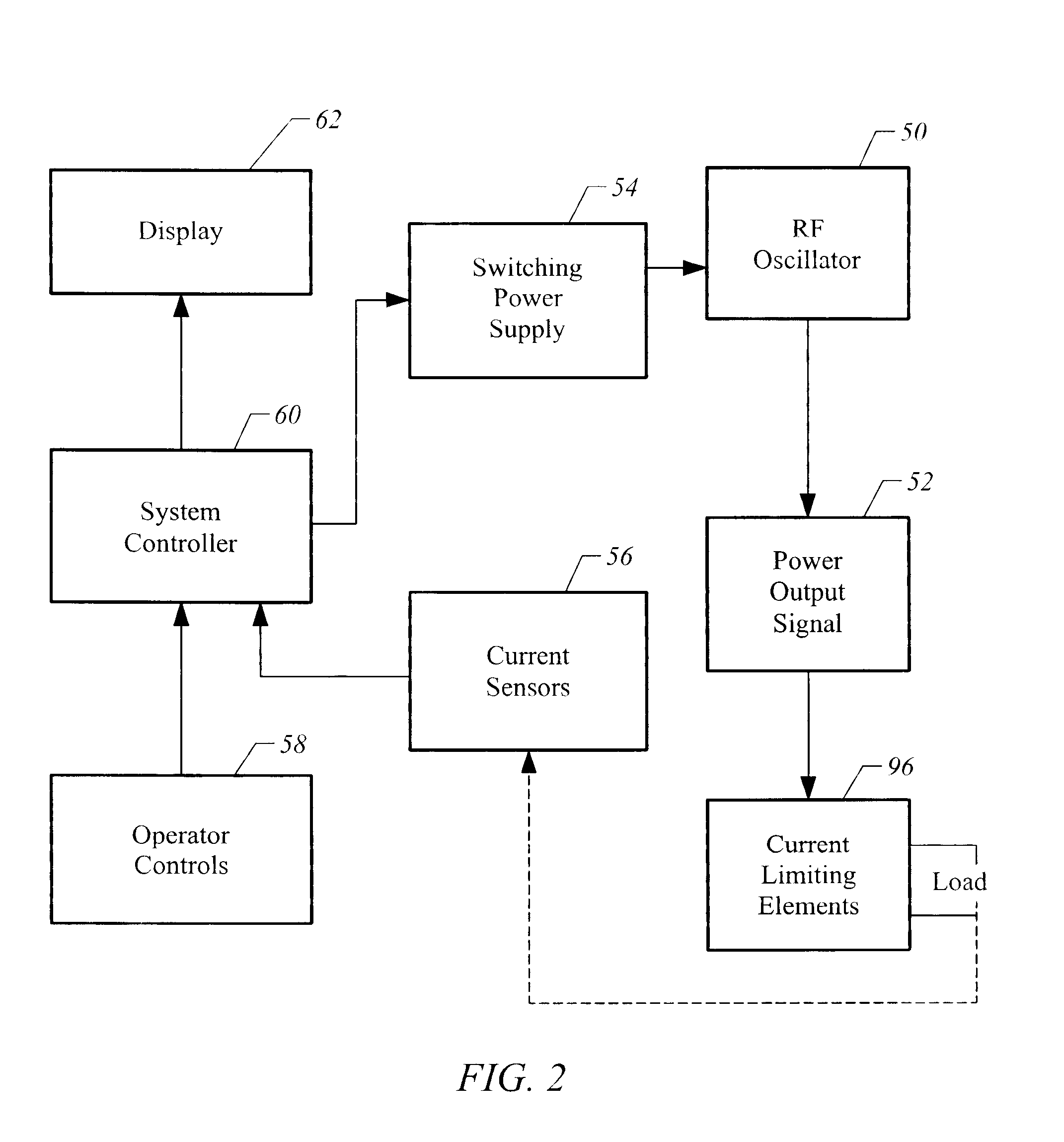

Electrosurgical ablation and aspiration apparatus having flow directing feature and methods related thereto

InactiveUS6949096B2Facilitates removing and ablatingImprove visualizationSurgical instruments for heatingSurgical instruments for aspiration of substancesSurgical siteActive electrode

Electrosurgical methods, systems, and apparatus for the controlled ablation of tissue from a target site of a patient. An electrosurgical apparatus of the invention includes an active electrode assembly having an active electrode screen surrounded by a plurality of flow protectors. Each flow protector defines a shielded region of the active electrode screen, each shielded region of the screen characterized by enhanced plasma formation. The active electrode assembly is adapted for removing tissue from a surgical site, and the active electrode screen is adapted for digesting fragments of resected tissue. In one embodiment, the apparatus is particularly suited to simultaneously removing both hard and soft tissue in, or around, a joint.

Owner:ARTHROCARE

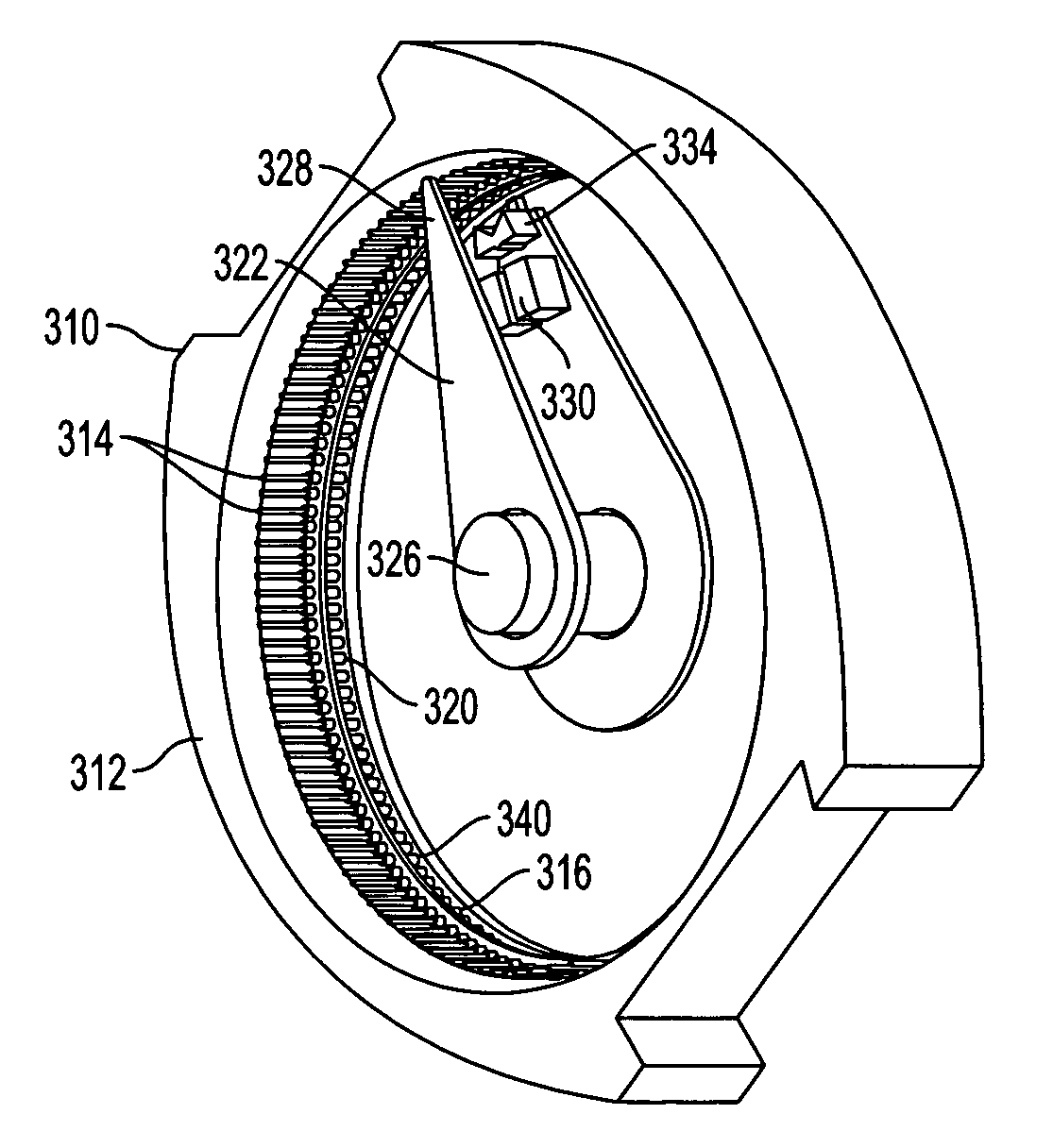

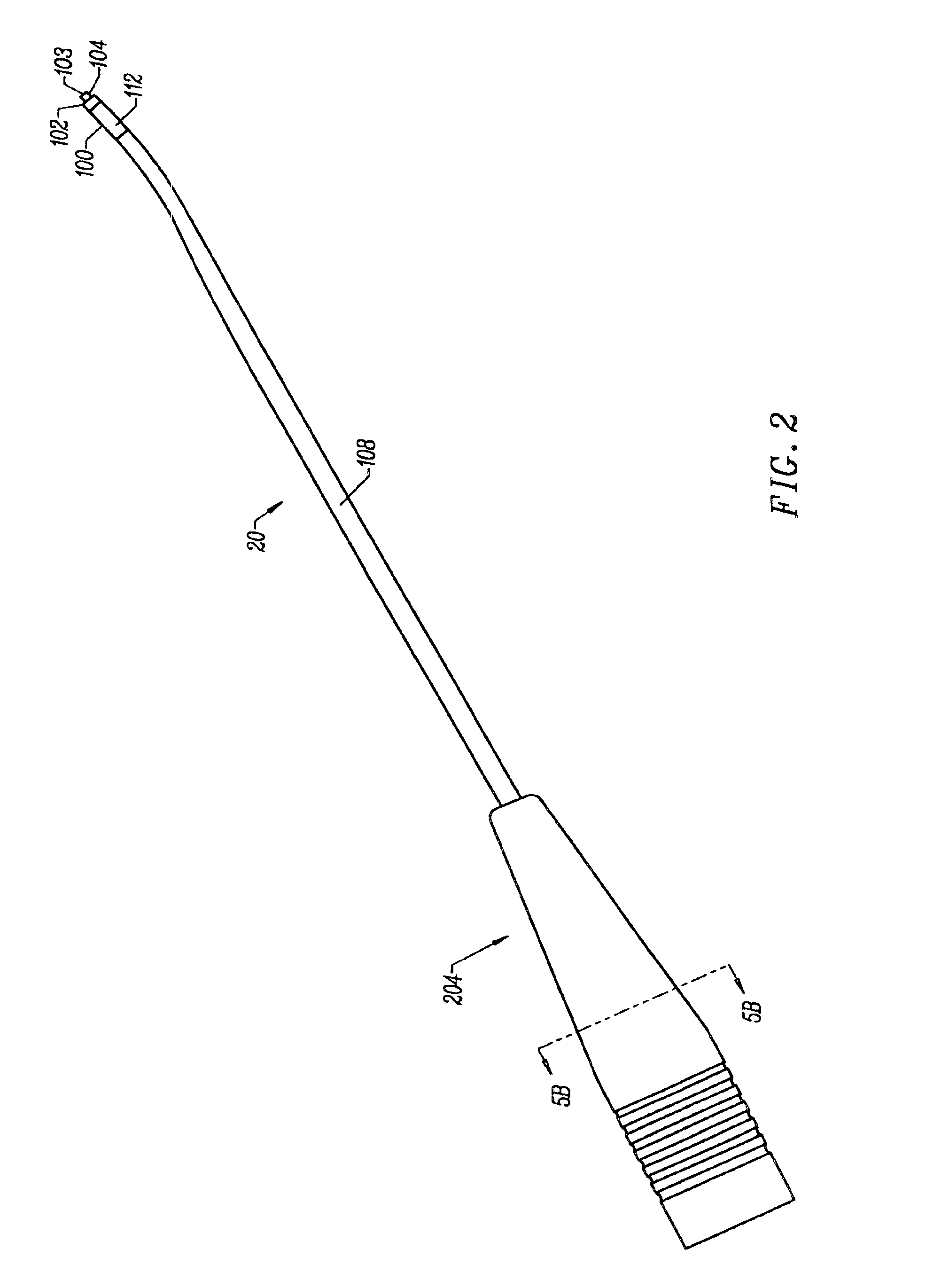

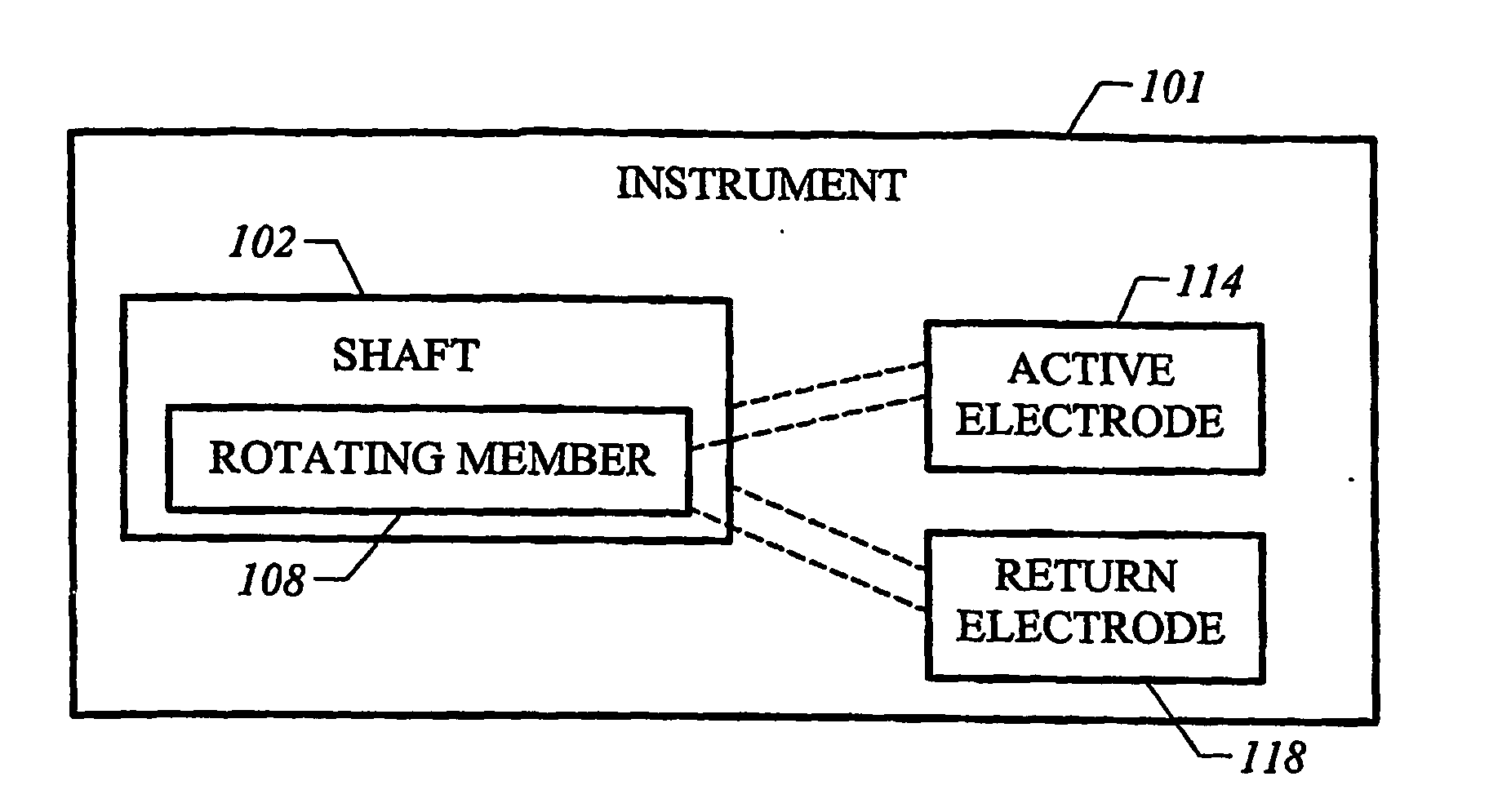

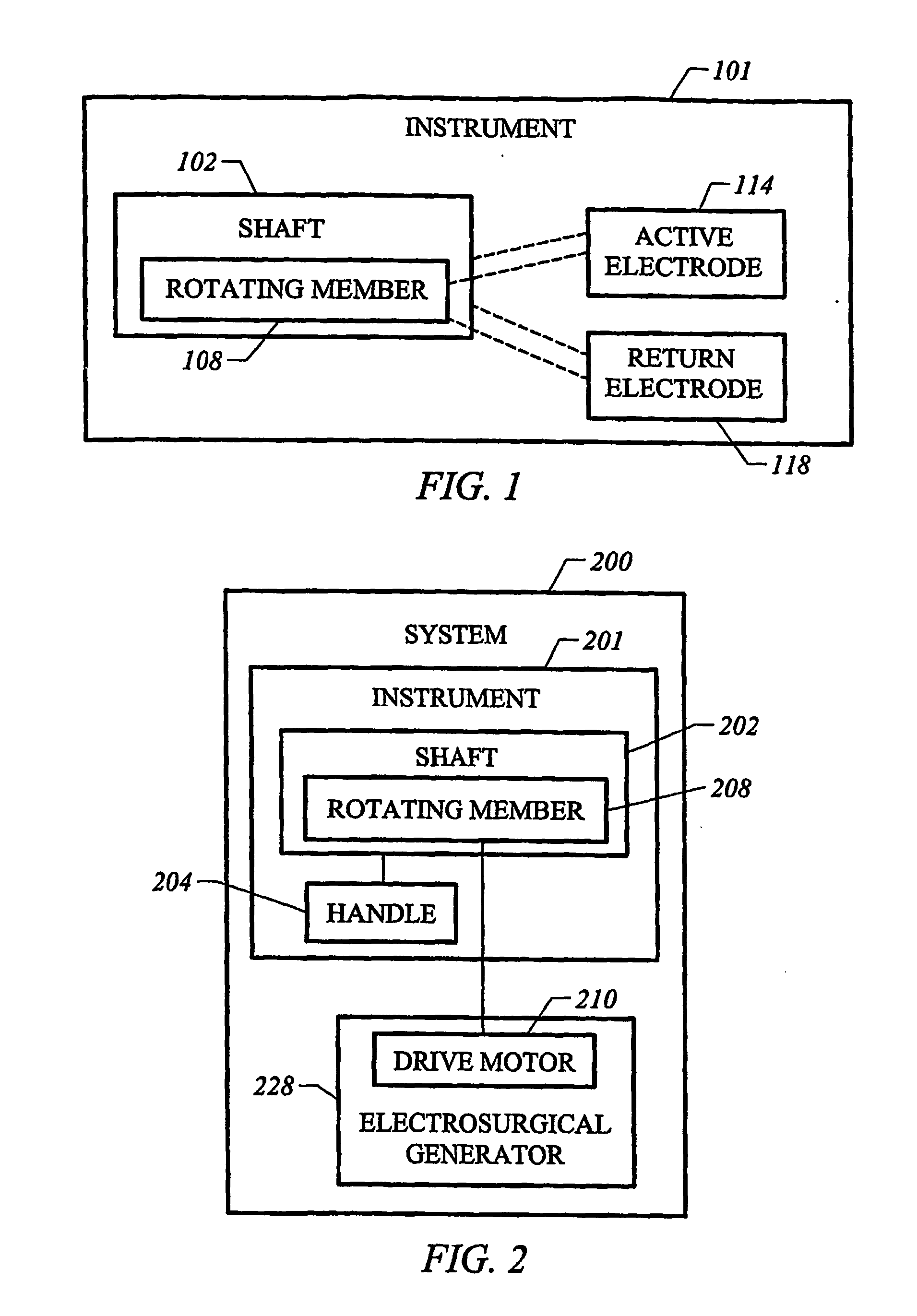

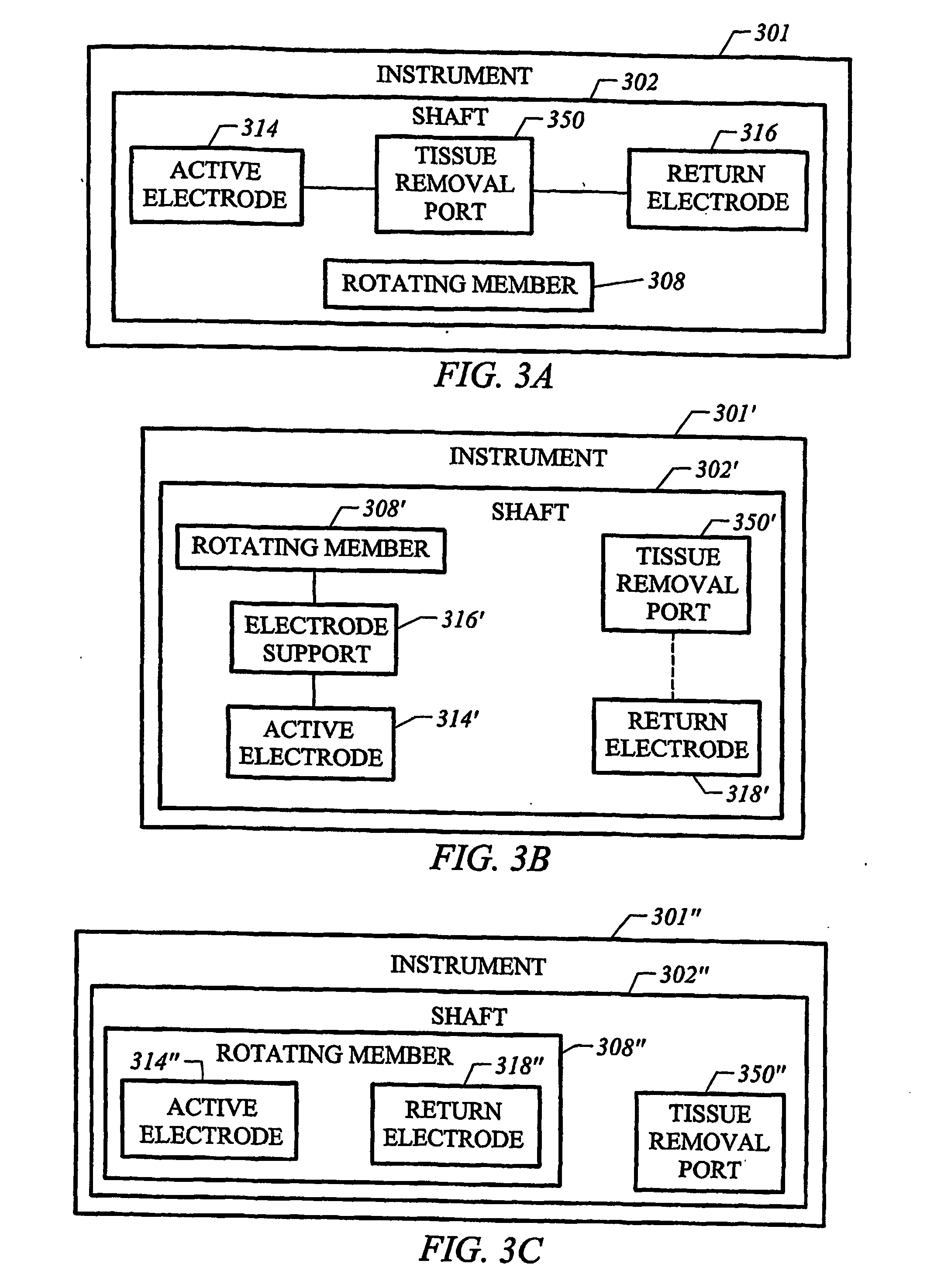

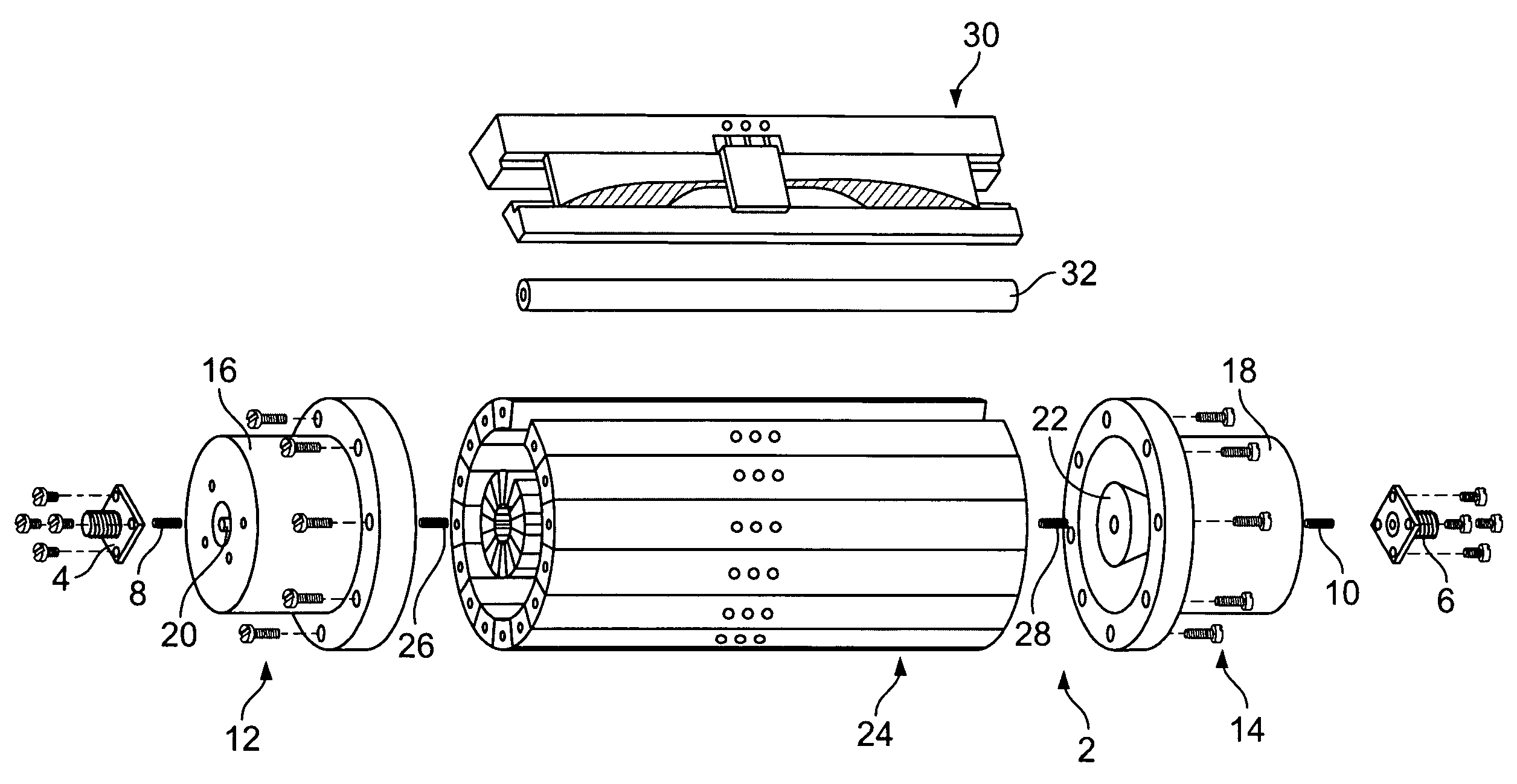

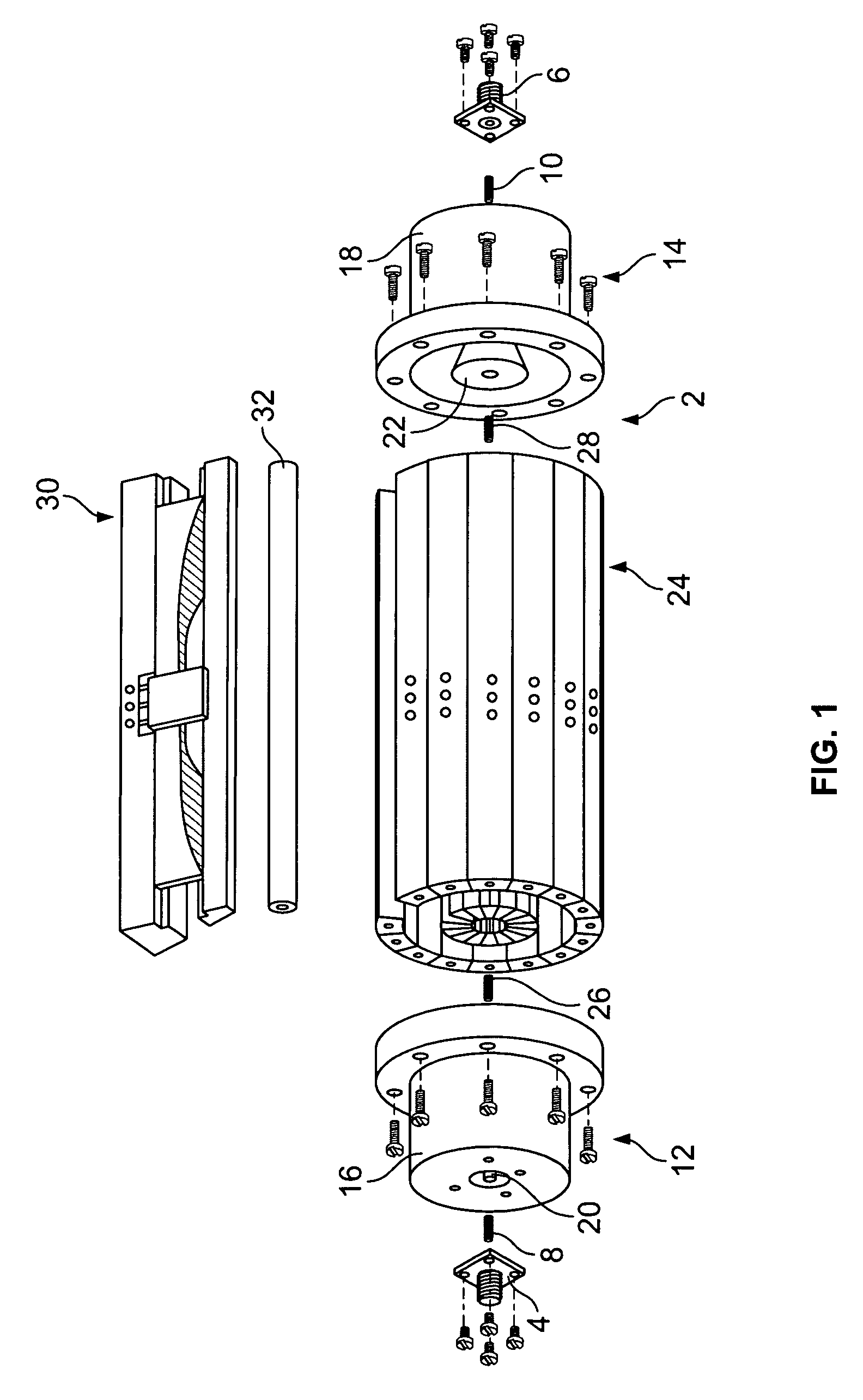

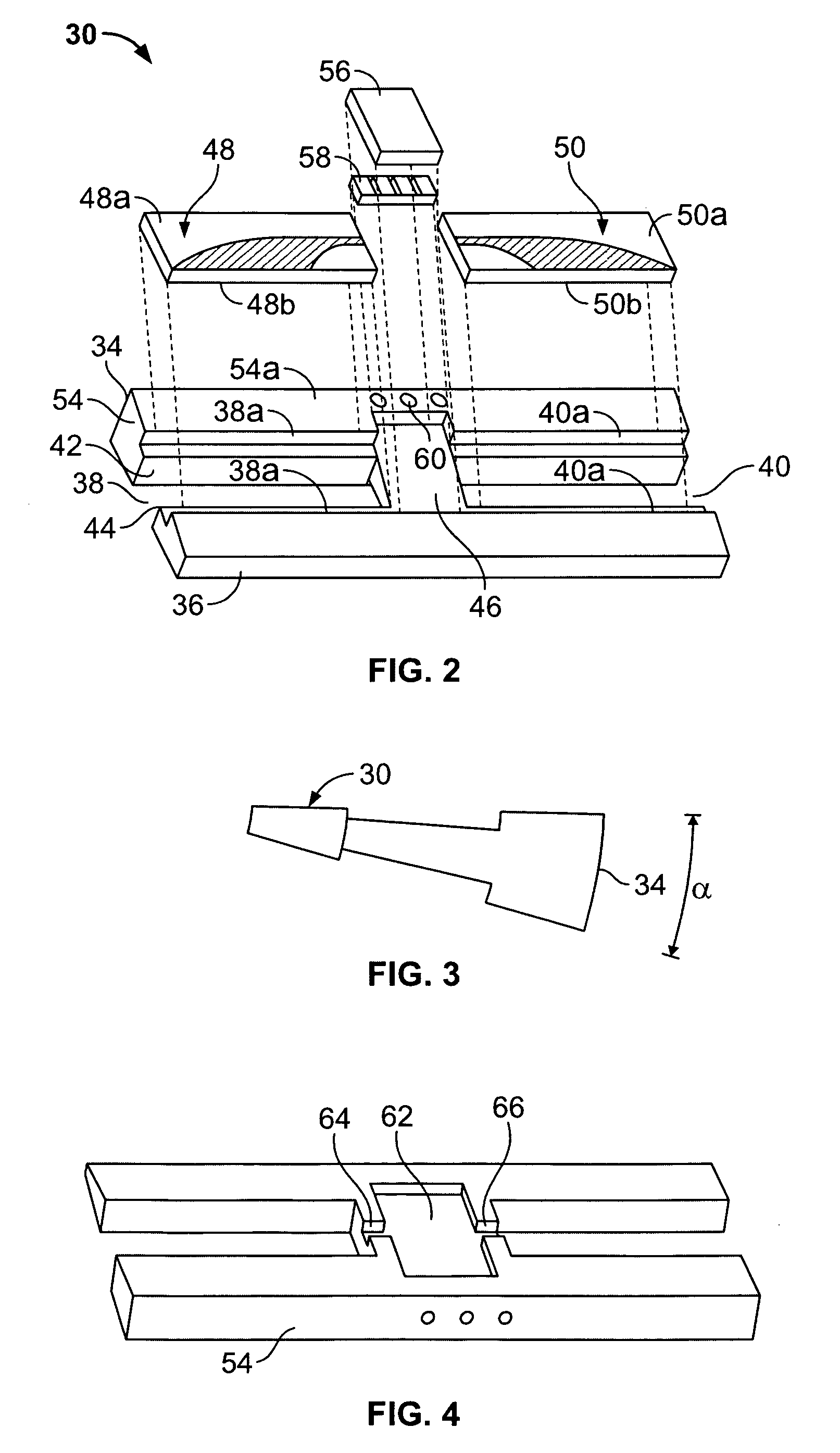

Rotary electrosurgical apparatus and methods thereof

InactiveUS20060178670A1Increase awarenessEasy maintenanceEndoscopesCatheterActive electrodeTarget tissue

Electrosurgical systems, apparatus, and methods for the controlled removal and treatment of a target tissue. An instrument of the invention includes a rotating member housed longitudinally within a shaft, a tissue removal port disposed at the shaft distal end portion, and an active electrode disposed at the instrument distal end. The active electrode is adapted to electrosurgically remove at least a portion of the target tissue as the rotating member rotates within the shaft. According to alternative embodiments, the active electrode may be disposed on the rotating member or on the shaft.

Owner:ARTHROCARE

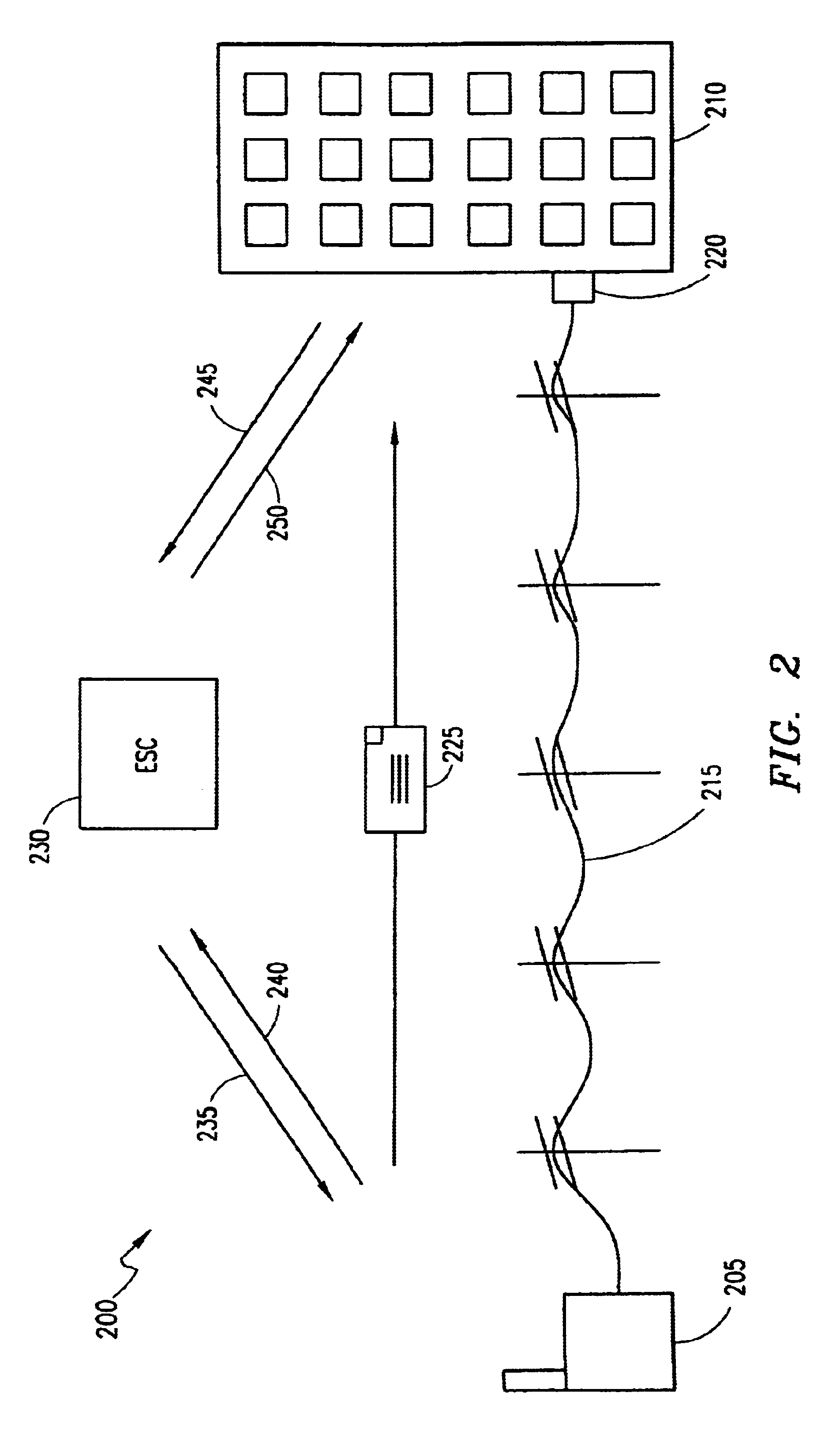

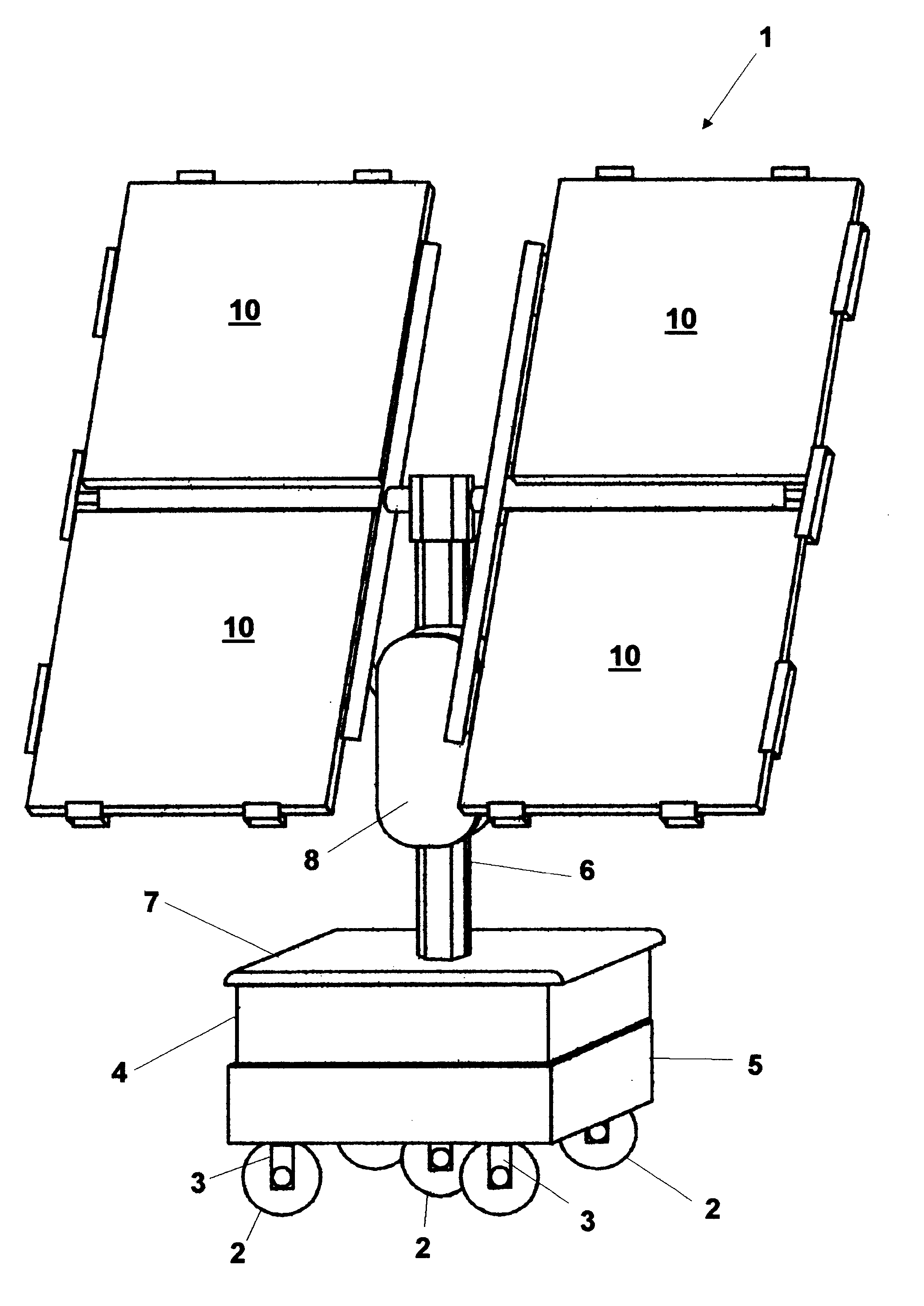

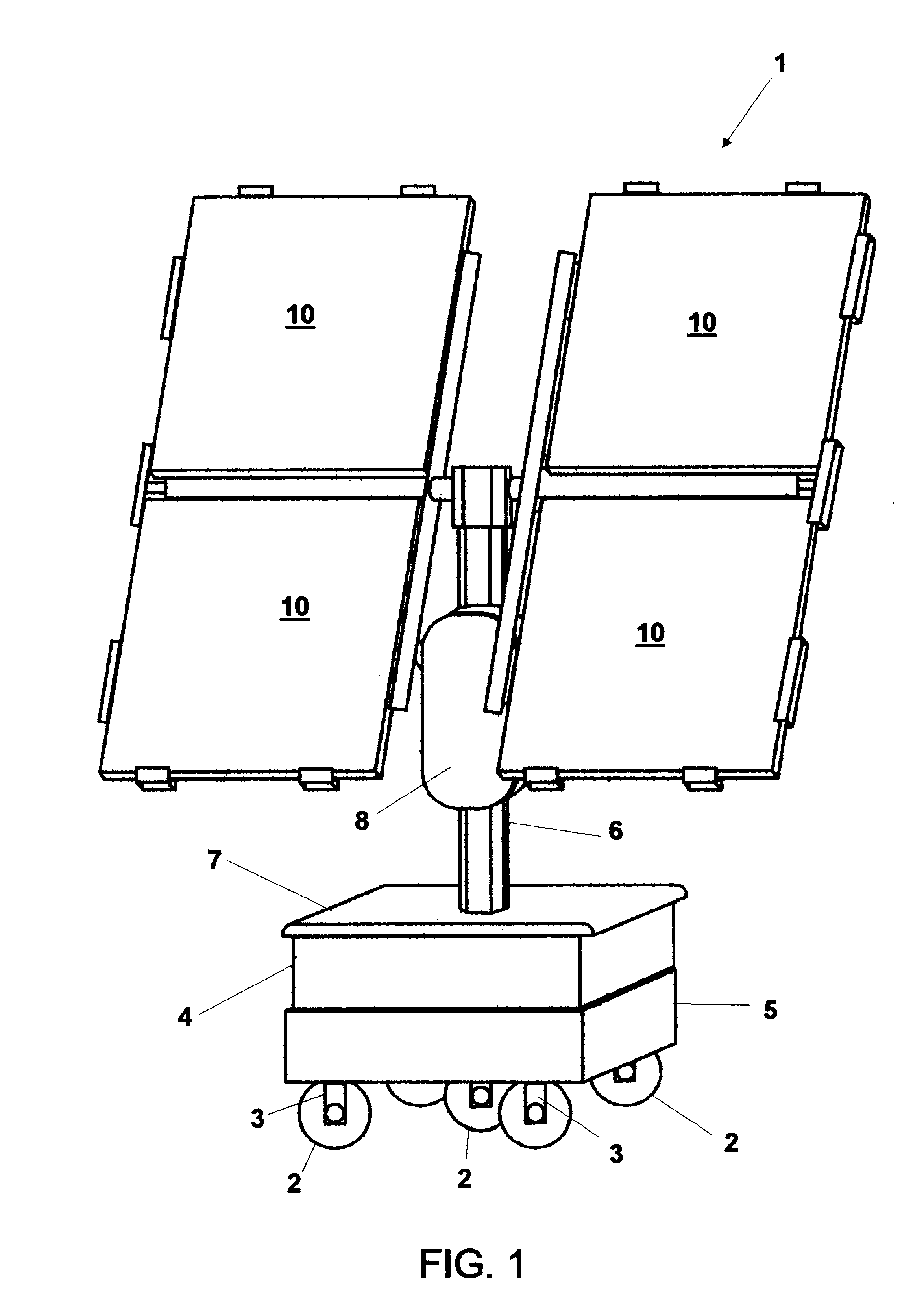

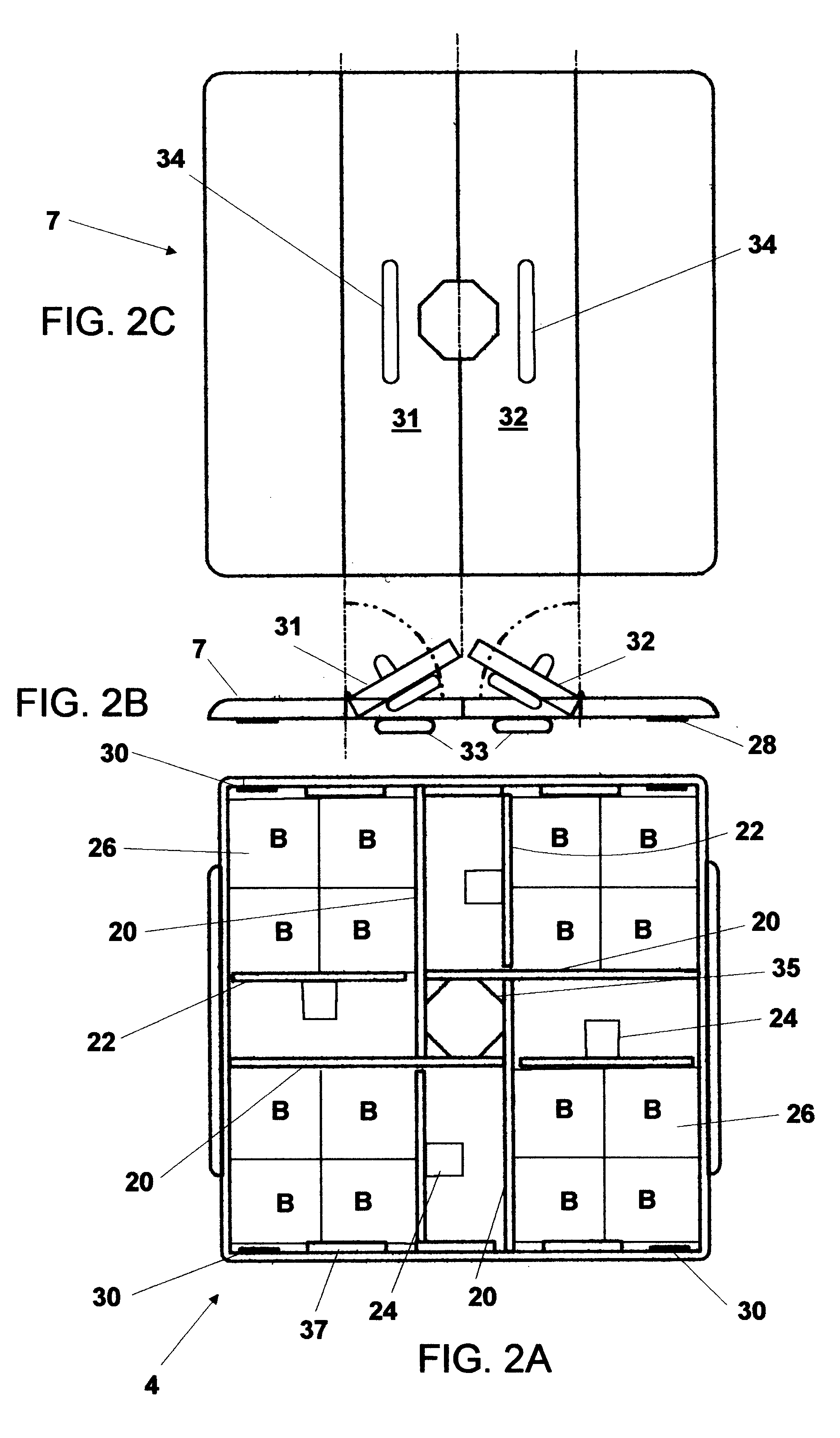

Portable solar generator

InactiveUS6396239B1Easy to installEasy maintenancePhotovoltaic supportsSolar heating energySolar generatorElectrical battery

A portable PV modular solar generator. A plurality of wheels are attached to the bottom of a rechargeable battery container. At least one rechargeable battery is contained inside the rechargeable battery container. A power conditioning panel is connected to the rechargeable battery container. At least one photovoltaic panel is pivotally connected. In a preferred embodiment, the rechargeable battery container is a waterproof battery enclosure having a knife switch connection. A mast having a rotation bar is supported by the waterproof battery enclosure. At least one solar panel support brace for supporting the photovoltaic panel is attached to the rotation bar. The power conditioning panel is waterproof, is attached to the mast and has a door. When the door is opened, at least one safety switch is opened, breaking an electric circuit. The waterproof power conditioning panel has a charge controller and an inverter. The charge controller is electrically connected to at least one rechargeable battery and at least one photovoltaic panel, and is capable or receiving auxiliary power inputs.

Owner:BENN WILLIAM M +1

Method for generating and distributing telecom and internet revenue

InactiveUS6754833B1Easy to useGenerate revenueUser identity/authority verificationInformation formatMobile wirelessWeb site

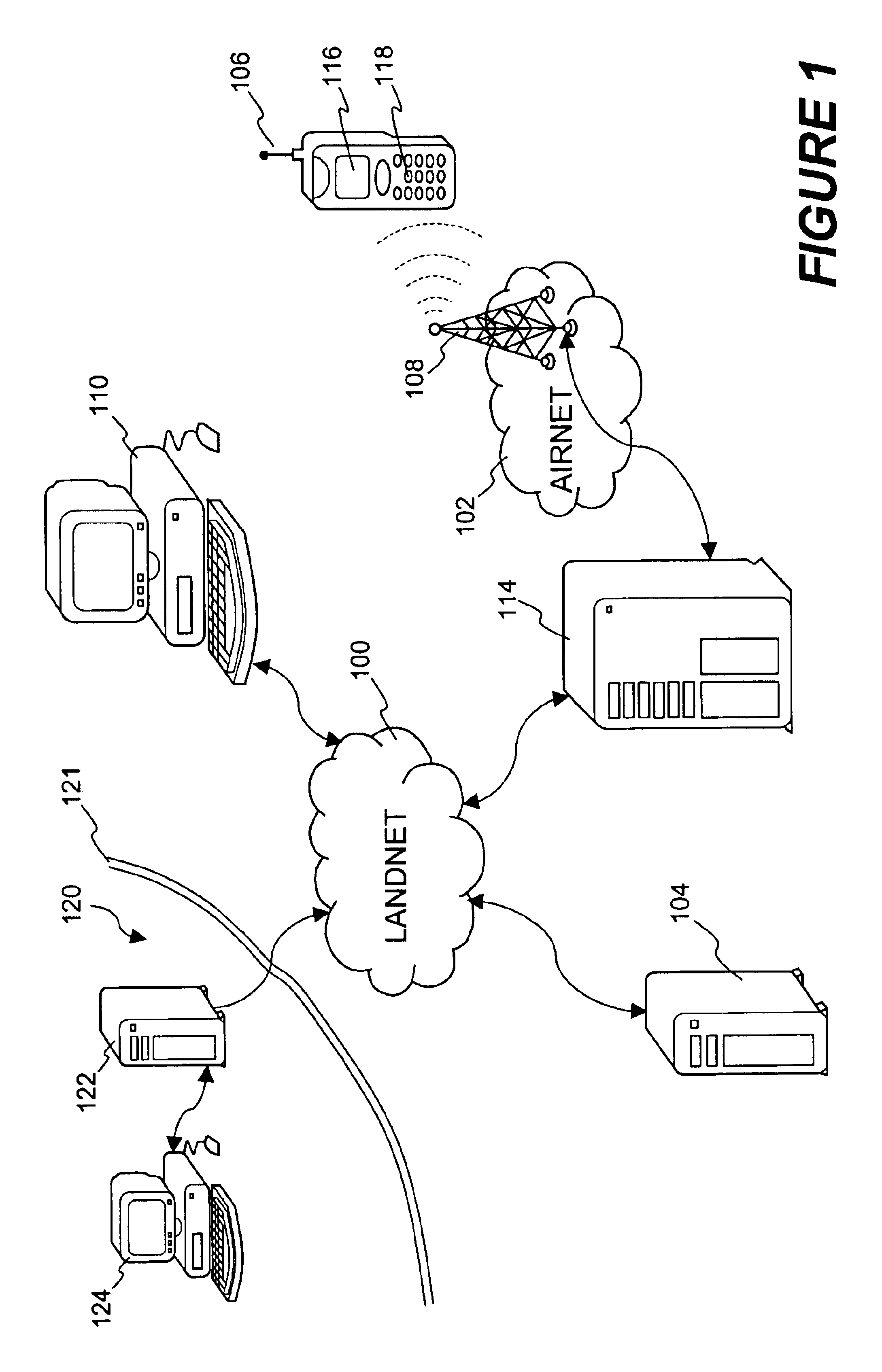

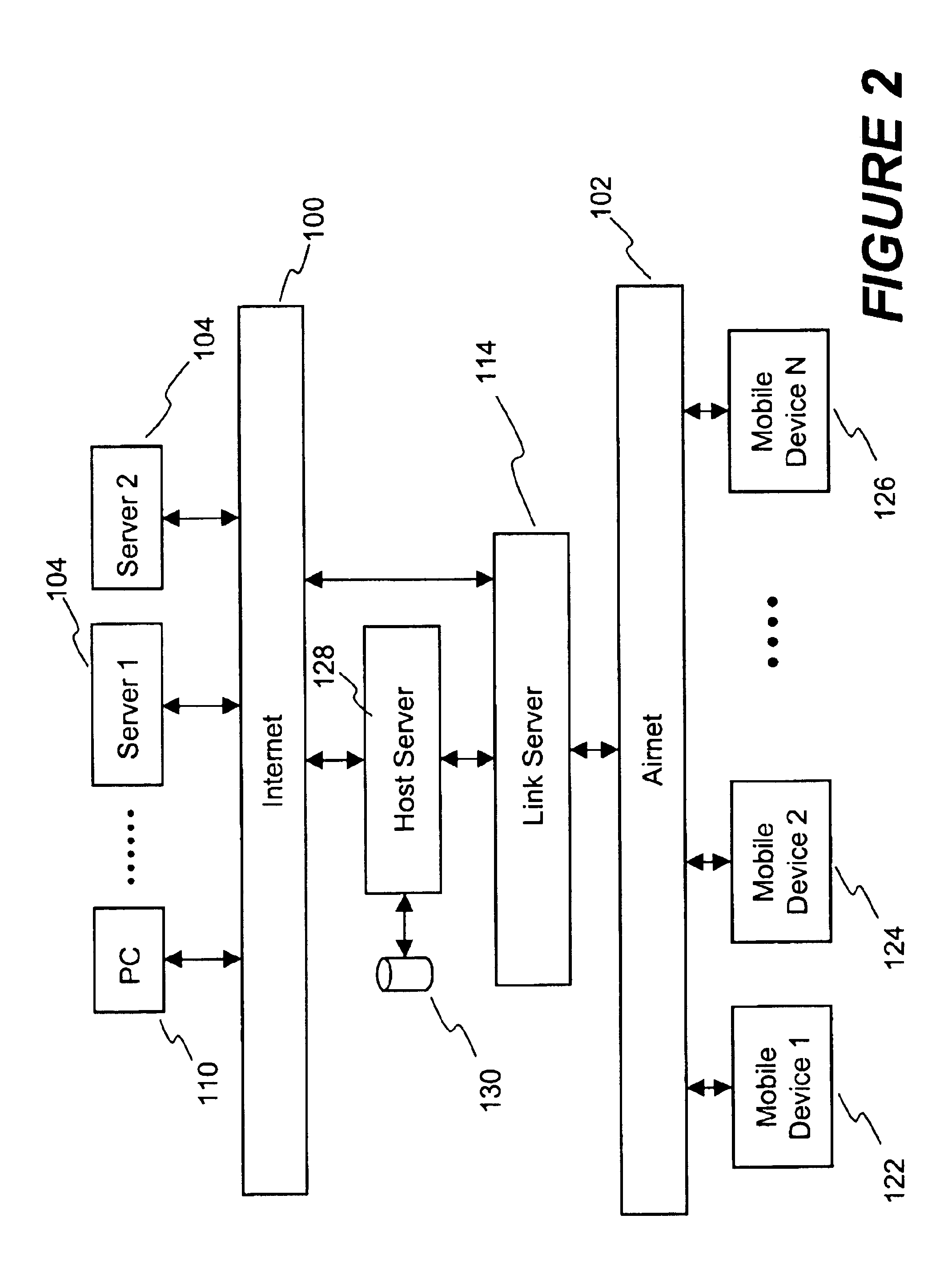

The present invention is directed to a business model and method for generating and distributing Telecom and Internet revenue between a wireless network operator and an Internet Partner company. The inventive business model provides an Internet web-site for the carrier's subscribers, with the web-site being developed by the Internet Partner. The web-site features applications and services tailored to the subscribers in their role as users of a mobile wireless communications device. The invention provides incentives to increase network usage and conduct transactions that generate value for both the wireless network operator and the Internet Partner.

Owner:UNWIRED PLANET

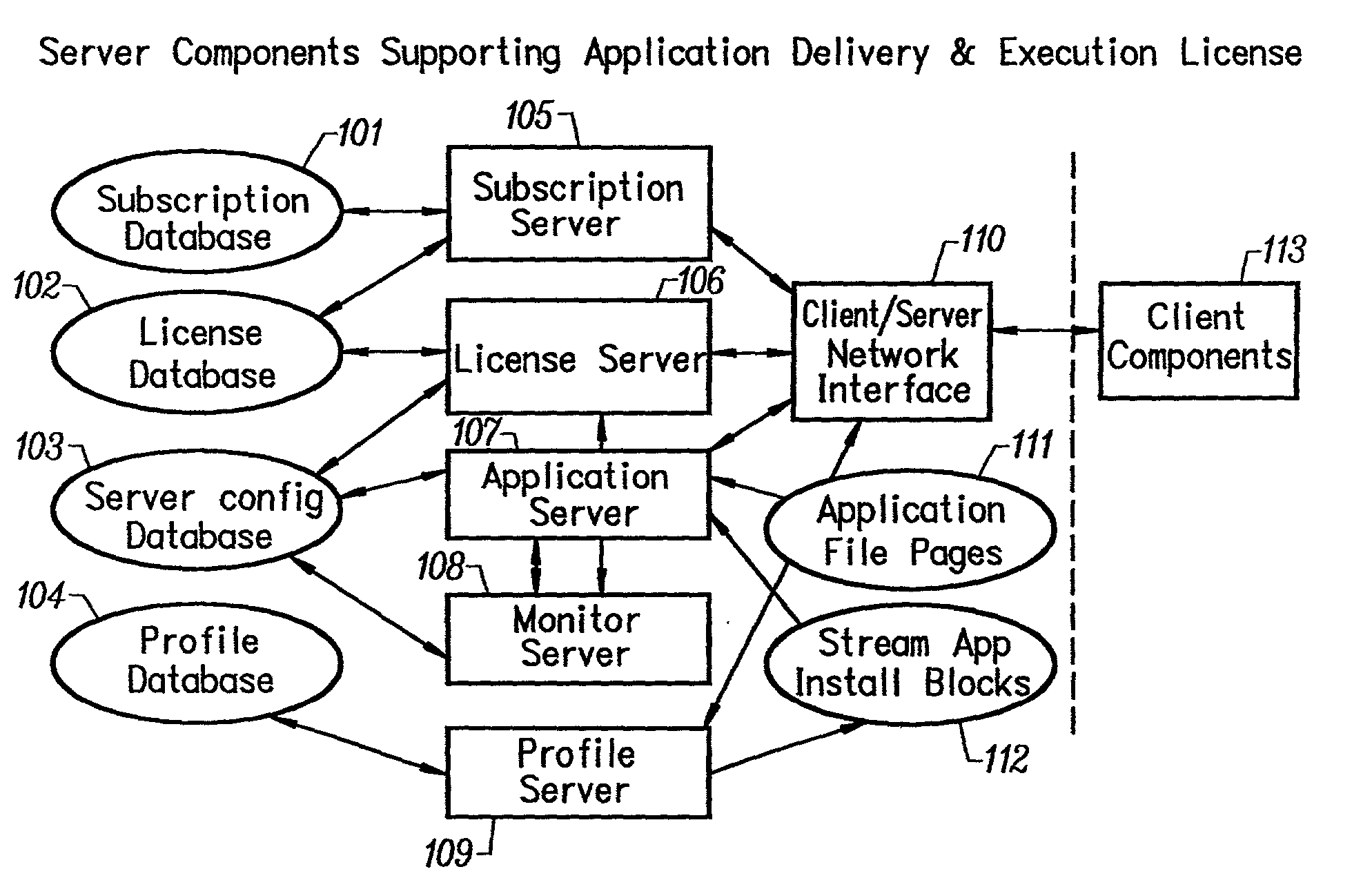

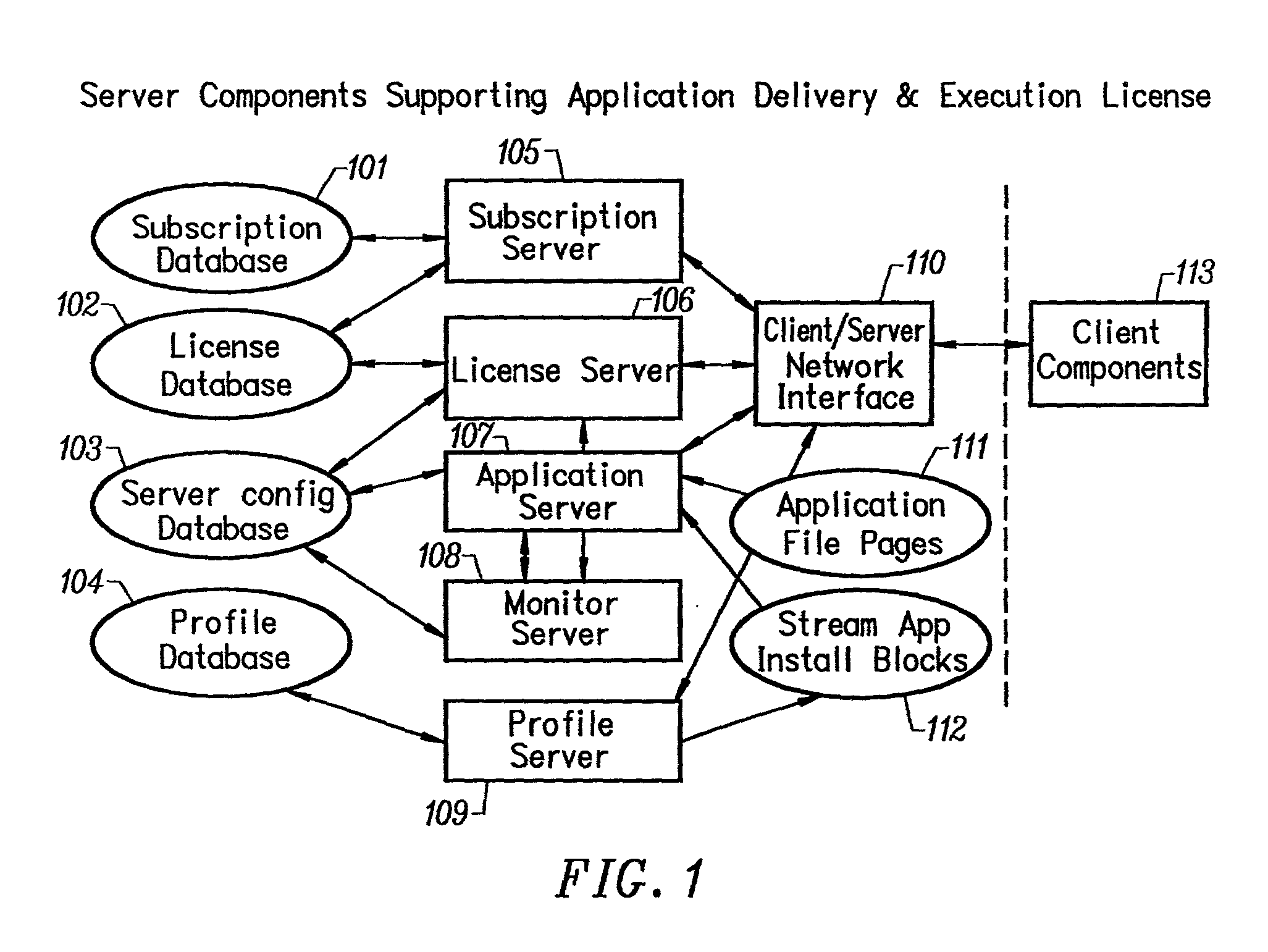

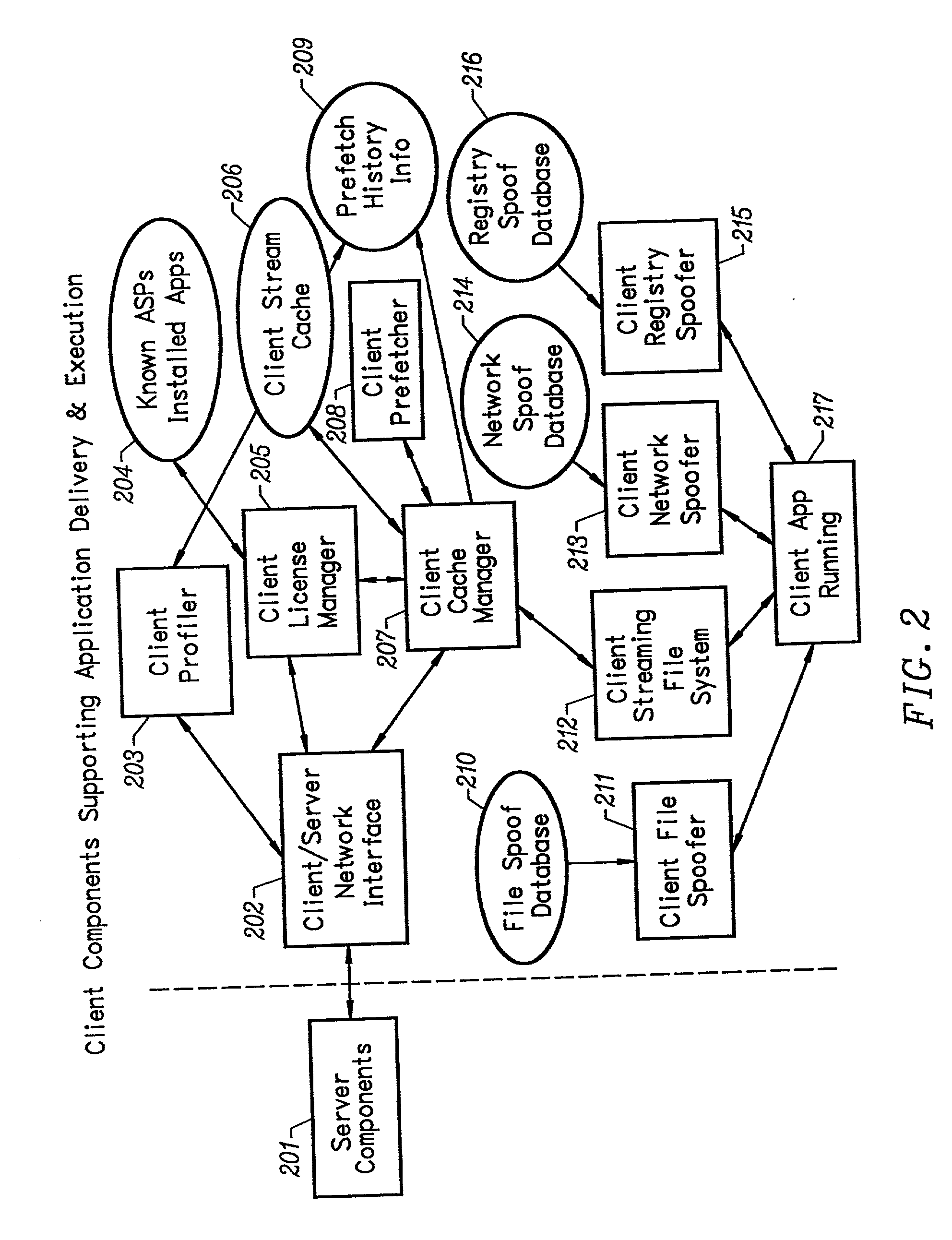

Optimized server for streamed applications

ActiveUS20030004882A1Efficient deliveryEasy maintenanceComputer security arrangementsSecret communicationApplication serverThe Internet

An optimized server for streamed applications provides a streamed application server optimized to provide efficient delivery of streamed applications to client systems across a computer network such as the Internet. The server persistently stores streamed application program sets that contain streamed application file pages. Client systems request streamed application file pages from the server using a unique set of numbers common among all servers that store the particular streamed application file pages. A license server offloads the streamed application server by performing client access privilege validations. Commonly accessed streamed application file pages are stored in a cache on the streamed application server which attempts to retrieve requested streamed application file pages from the cache before retrieving them from persistent storage. Requested streamed application file pages are compressed before being sent to a client as well as those stored in the cache.

Owner:NUMECENT HLDG

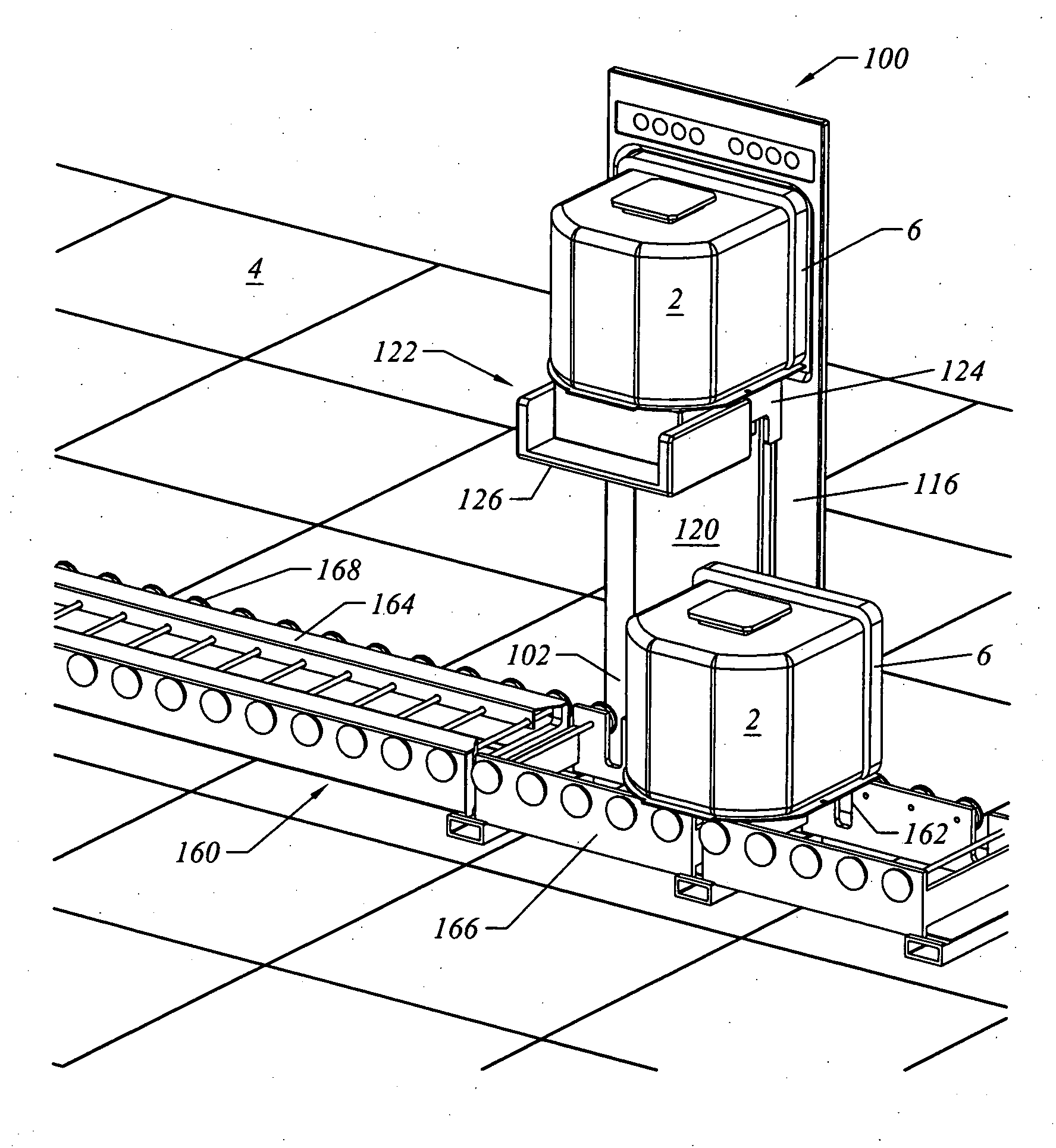

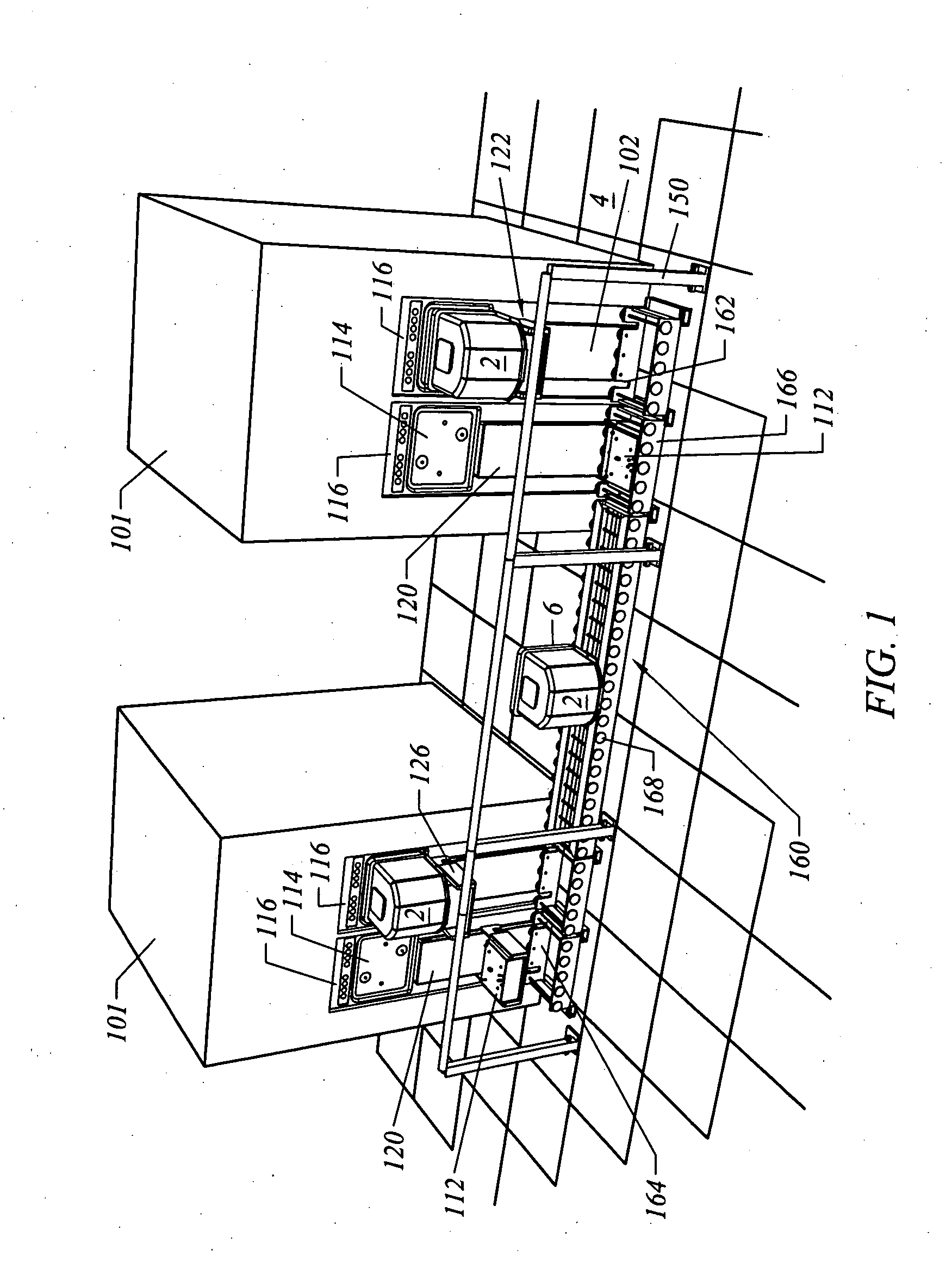

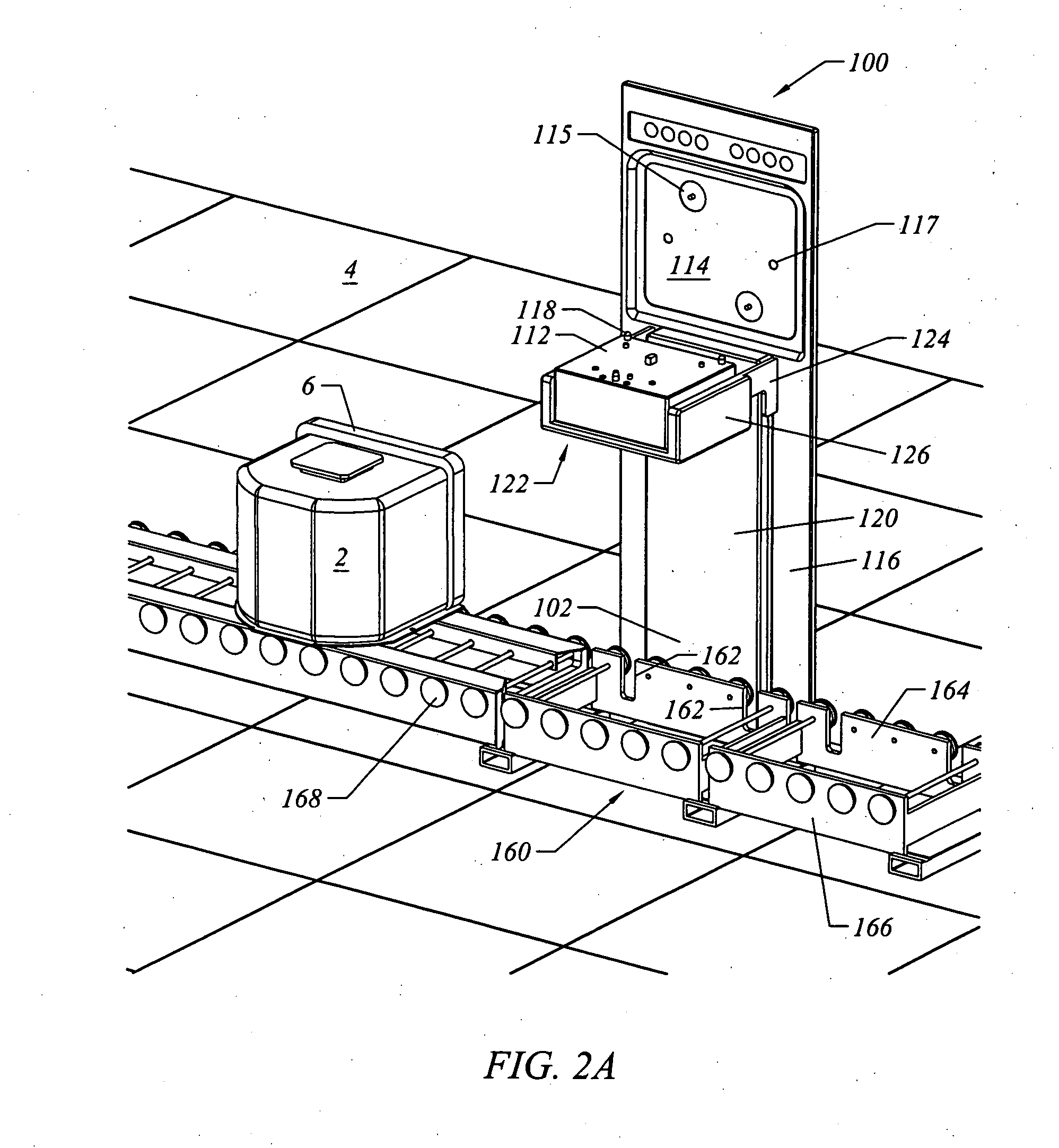

Direct tool loading

InactiveUS20060188360A1Effective movementConveyor—reducing the number of times the container is handledSemiconductor/solid-state device manufacturingStorage devicesTransport systemEngineering

The present invention comprises a load port for providing access to an article that is stored in a container having a container door removably coupled to a container shell. The load port preferably loads / unloads a container directly from a container transport system. In one embodiment, the load port includes a plate having an opening, a container support plate, a drive assembly for moving the support plate vertically and a shroud to partially enclose the opening. The shroud, which may be affixed to the mounting plate, has an open top and bottom. The shroud contains a mechanism for retaining the container shell at a controllable height. During operation, a container is raised from the transport system into the shroud until the container shell is retained by the mechanism. After the container shell is uncoupled from the container door, the container support plate is lowered until the article is accessible through the opening. The container shell remains located at the controllable height. The container shell, in combination with the shroud, creates a mini-environment isolating the article from ambient conditions in the fabrication facility.

Owner:MURATA MASCH LTD

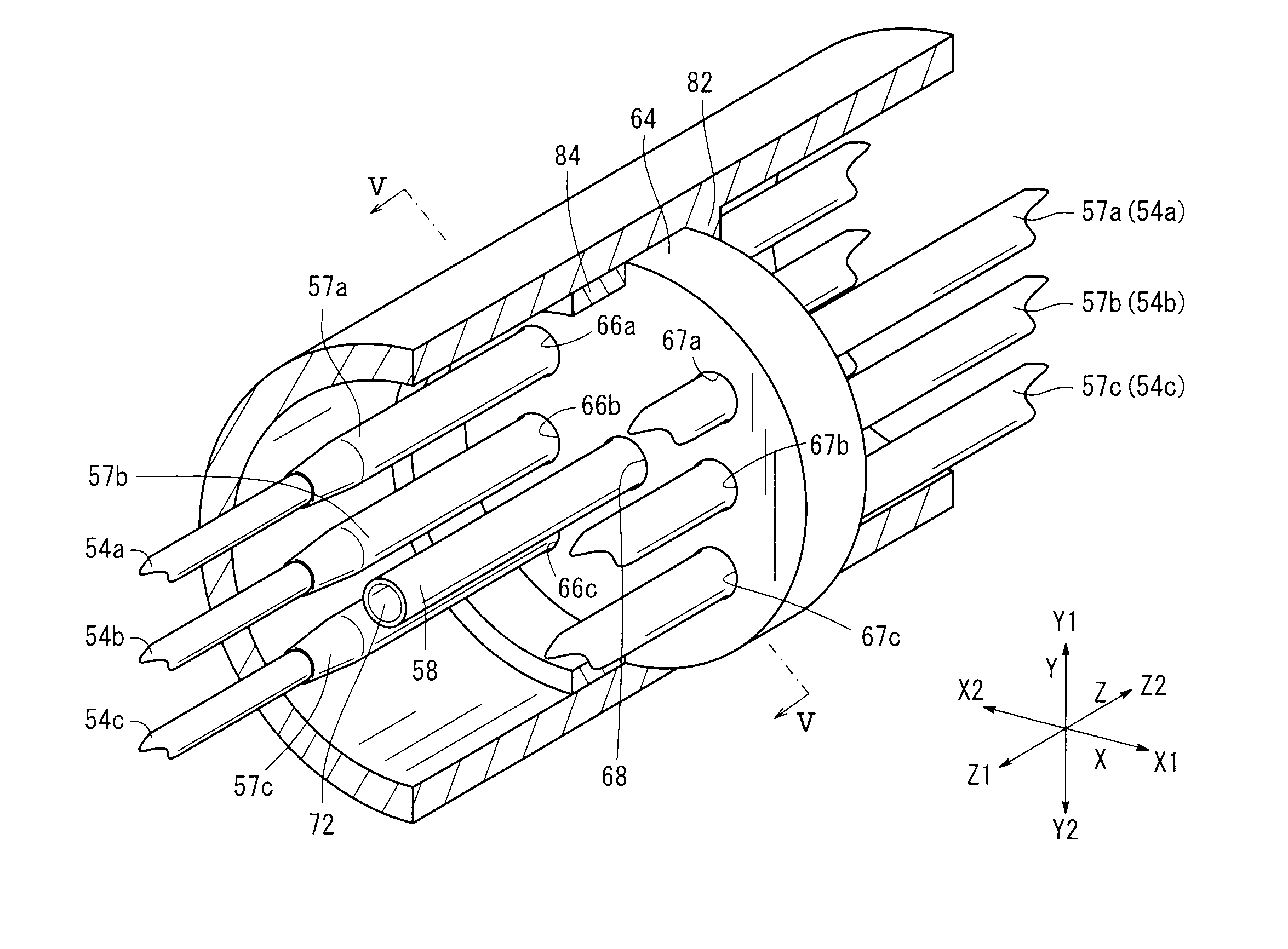

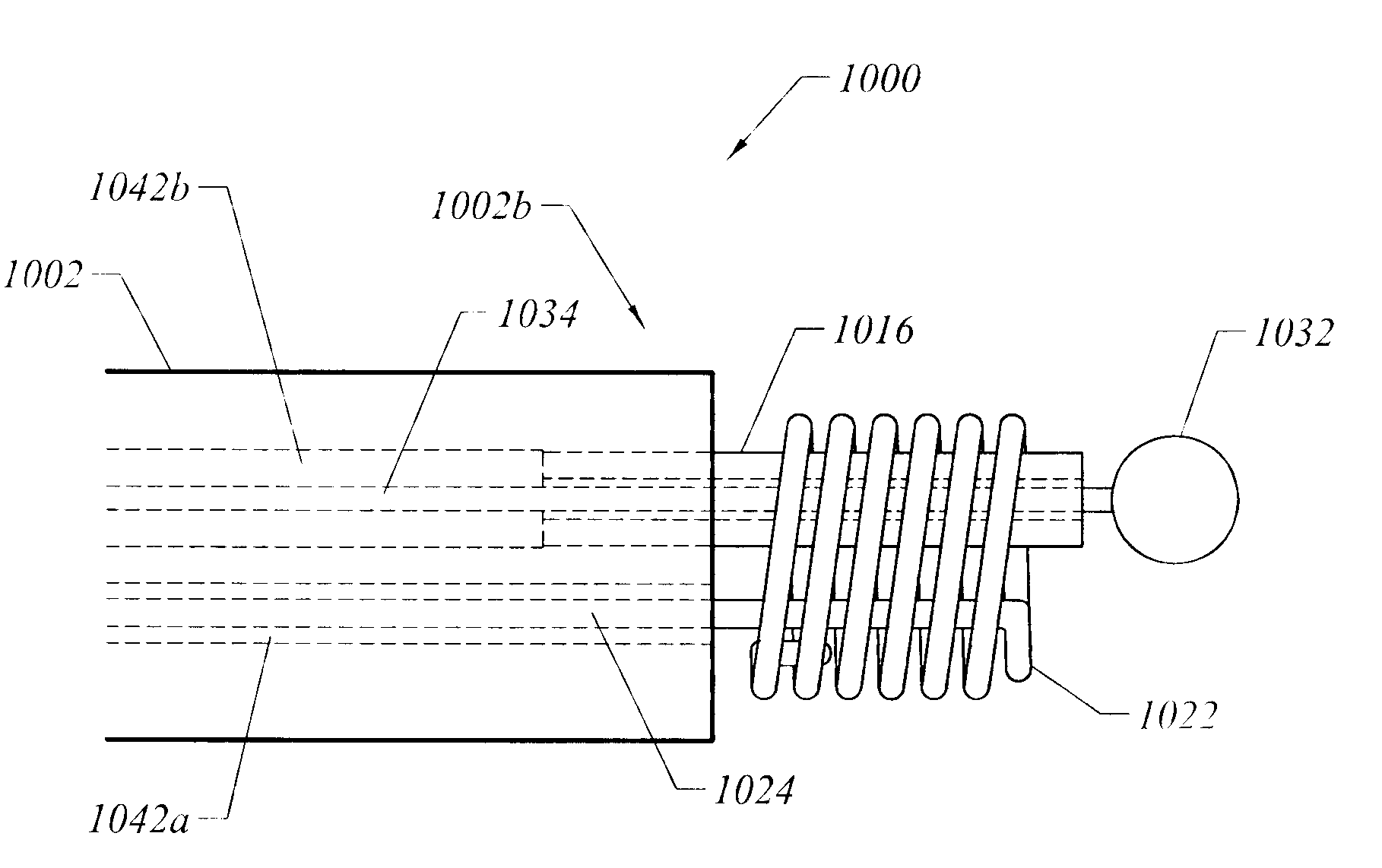

Electrosurgical apparatus and methods for treatment and removal of tissue

InactiveUS7186234B2Promote wettingReduce the possibilitySurgical instruments for heatingActive electrodeTarget tissue

Apparatus and methods for ablating, severing, cutting, shrinking, coagulating, or otherwise modifying a target tissue to be treated. In a method for treating a target tissue, an active electrode of an electrosurgical probe is positioned in at least close proximity to the target tissue in the presence of an electrically conductive fluid. A high frequency voltage is then applied between the active electrode and a return electrode, wherein, the high frequency voltage is sufficient to volumetrically remove (ablate), sever, or modify at least a portion of the target tissue. The probe comprises a multi-lumen shaft having a plurality of internal lumens, and a return electrode coil oriented substantially parallel to the shaft distal end. The active electrode may be in the form of a metal disc, a hook, or an active electrode coil. In the latter embodiment, the active electrode coil is typically arranged substantially orthogonal to the return electrode coil. Methods of making an active electrode coil, a return electrode coil, and an electrosurgical probe are also disclosed.

Owner:ARTHROCARE

Internet voice & data messaging (IVDM) portal

InactiveUS20050041647A1Simple stepsEasy maintenanceSpecial service for subscribersGraded-service arrangementsPaymentToll-Free Number

An online voice messaging service that integrates all tools needed for an advertising sales representative to resell to their customers, in real time, a blind “ad box” including a temporary anonymous toll-free phone number with attached Internet Voice & Data Messaging (IVDM) service for collecting ad responses, such that the toll-free phone number can be incorporated into the text of the customer's advertisement as it is being booked. The software includes a portal or web interface that facilitates reselling of the service via a channel of resellers, such as media companies with sales representatives that have a service agreement with the service. The software also includes a separate portal for direct sales. Various value-added, user-options are provided including notifications of new messages, the ability to receive rental and / or credit applications, payments from customers, management of multiple ad boxes with one logon, and to retrieve messages as .wav files, emails as .txt files, and faxes as .pdf (or similar) files.

Owner:STINNIE DESMOND L

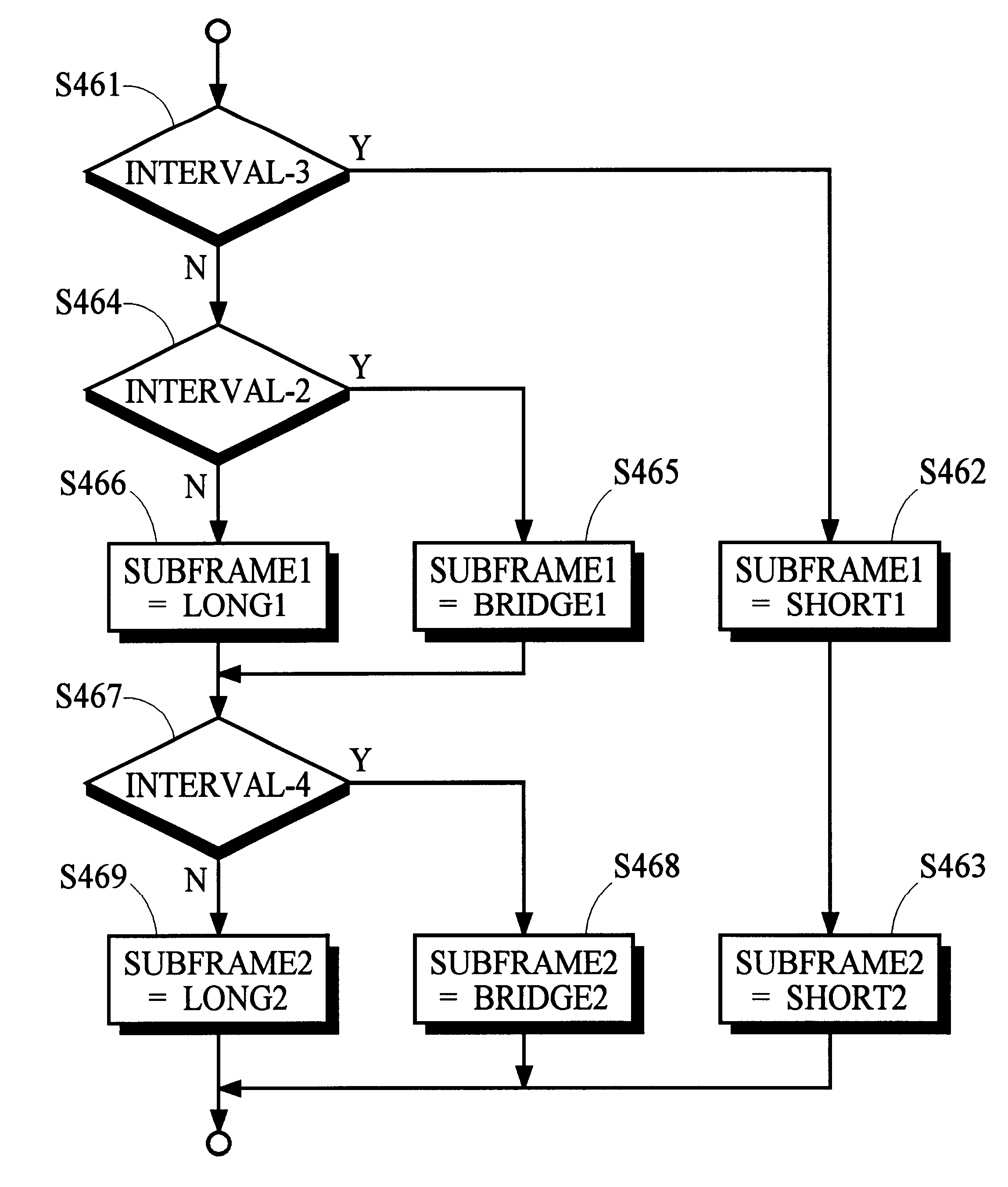

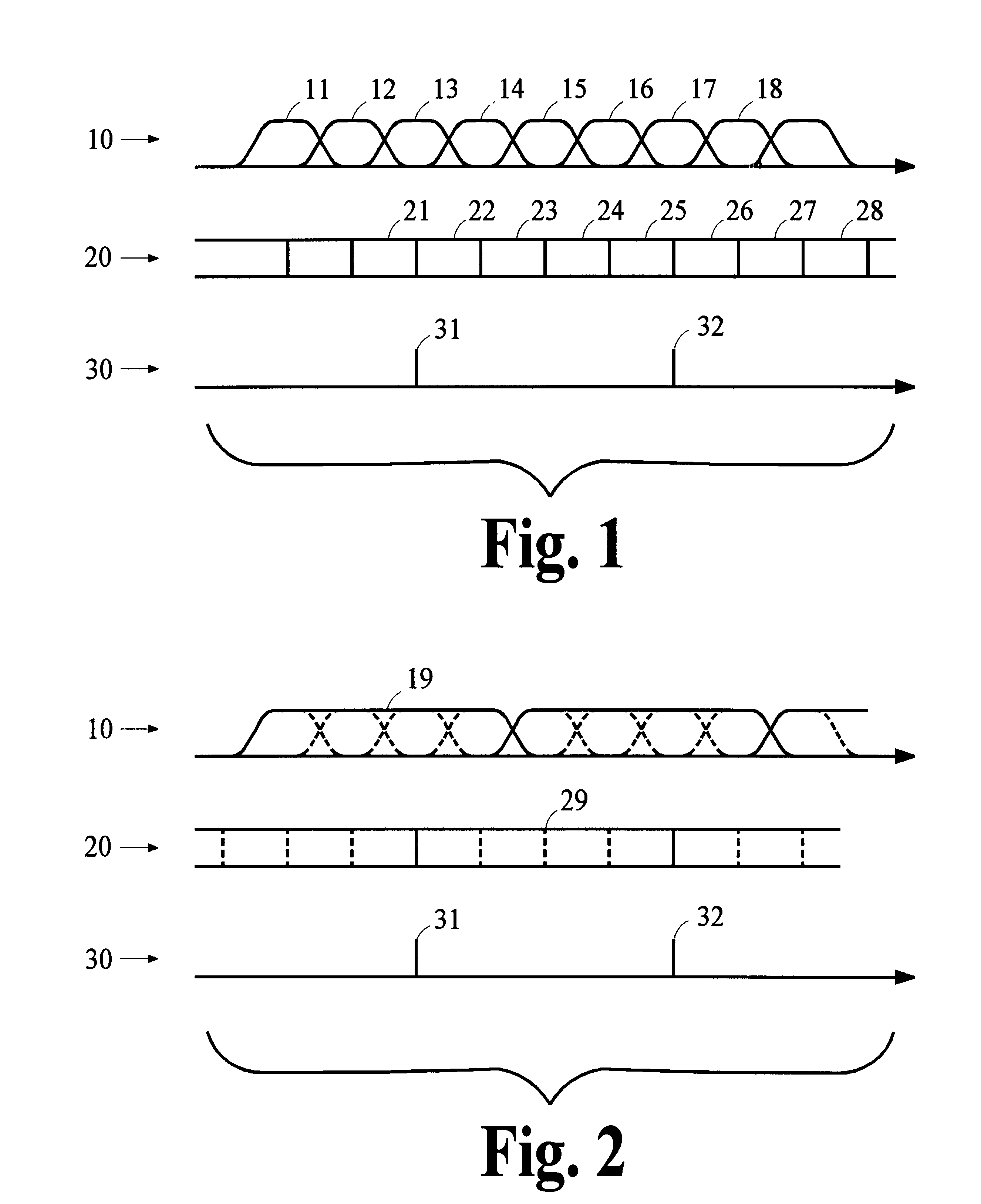

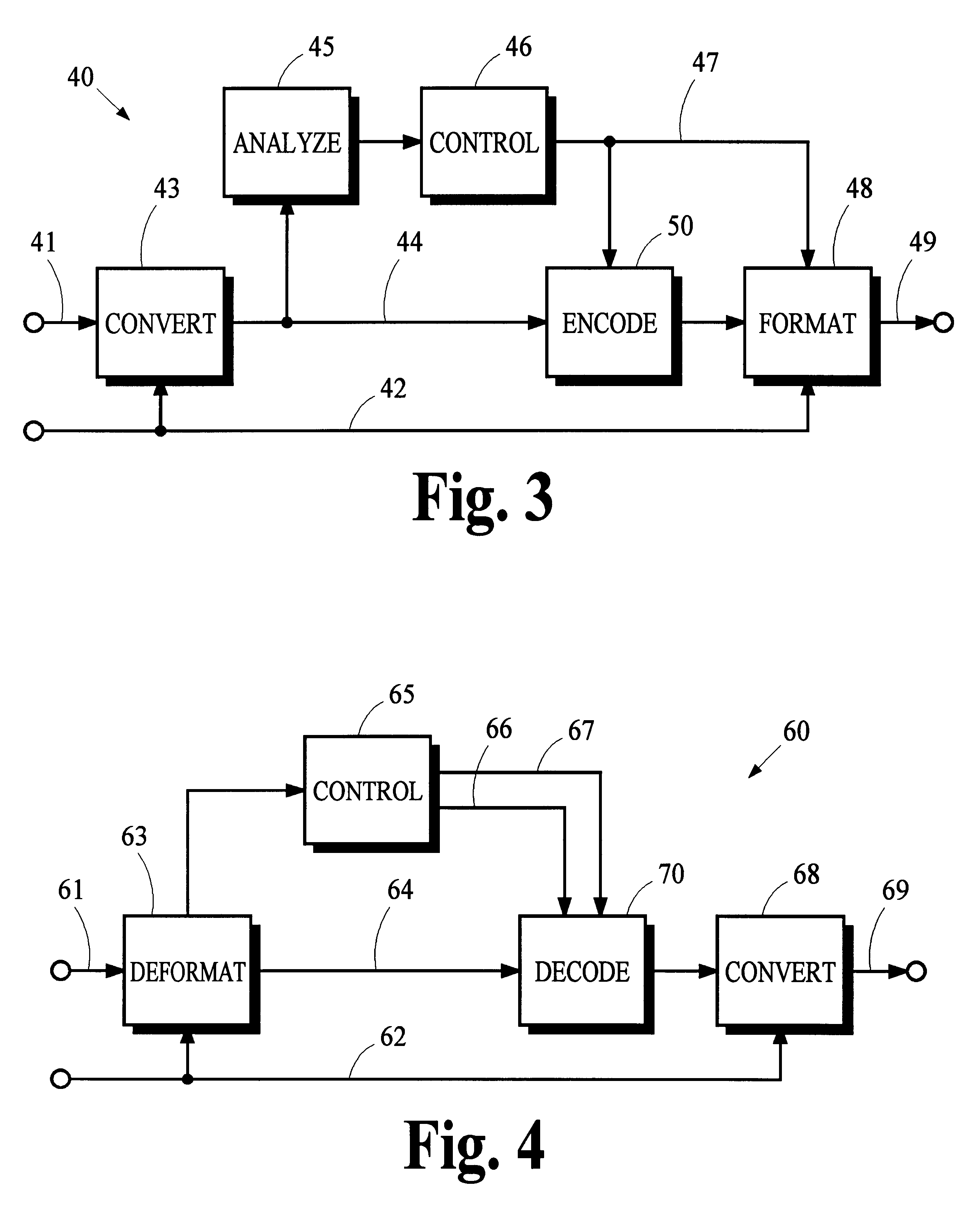

Data framing for adaptive-block-length coding system

InactiveUS6226608B1Easily maintain video/audio synchronizationMinimize artifactElectronic editing digitised analogue information signalsColor television signals processingTime domainControl signal

An audio encoder applies an adaptive block-encoding process to segments of audio information to generate frames of encoded information that are aligned with a reference signal conveying the alignment of a sequence of video information frames. The audio information is analyzed to determine various characteristics of the audio signal such as the occurrence and location of a transient, and a control signal is generated that causes the adaptive block-encoding process to encode segments of varying length. A complementary decoder applies an adaptive block-decoding process to recover the segments of audio information from the frames of encoded information. In embodiments that apply time-domain aliasing cancellation (TDAC) transforms, window functions and transforms are applied according to one of a plurality of segment patterns that define window functions and transform parameters for each segment in a sequence of segments. The segments in each frame of a sequence of overlapping frames may be recovered without aliasing artifacts independently from the recovery of segments in other frames. Window functions are adapted to provide preferred frequency-domain responses and time-domain gain profiles.

Owner:DOLBY LAB LICENSING CORP

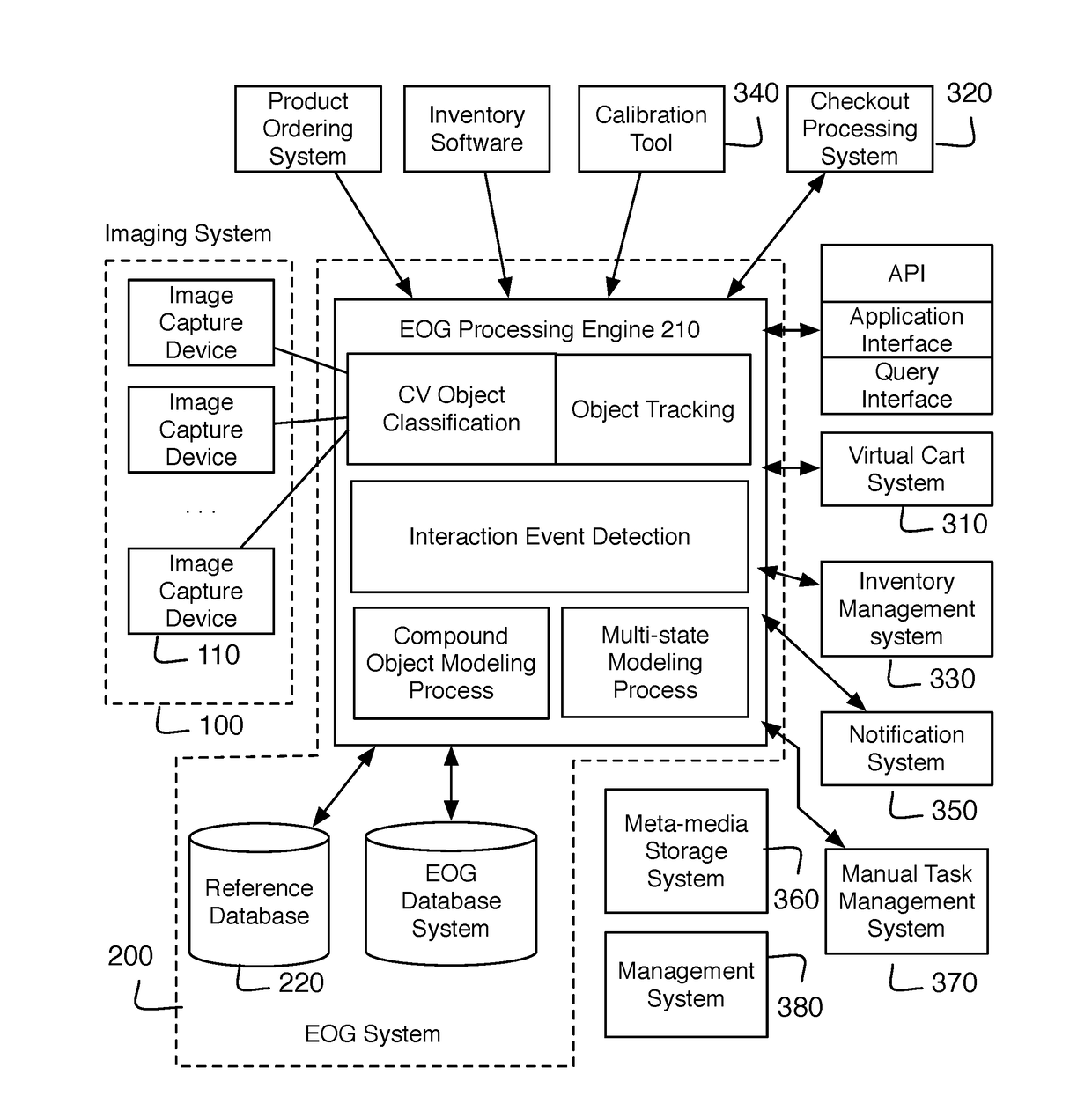

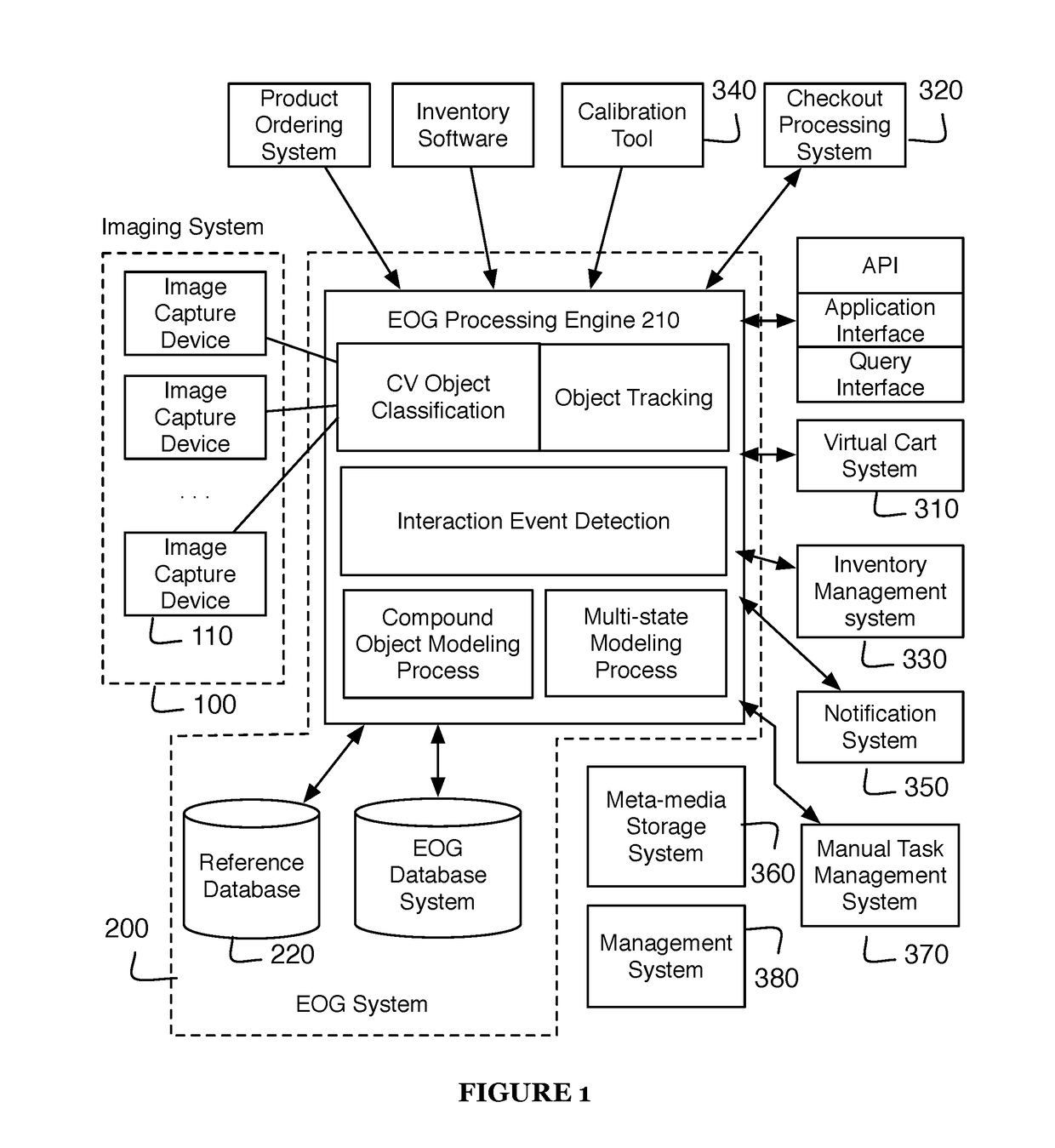

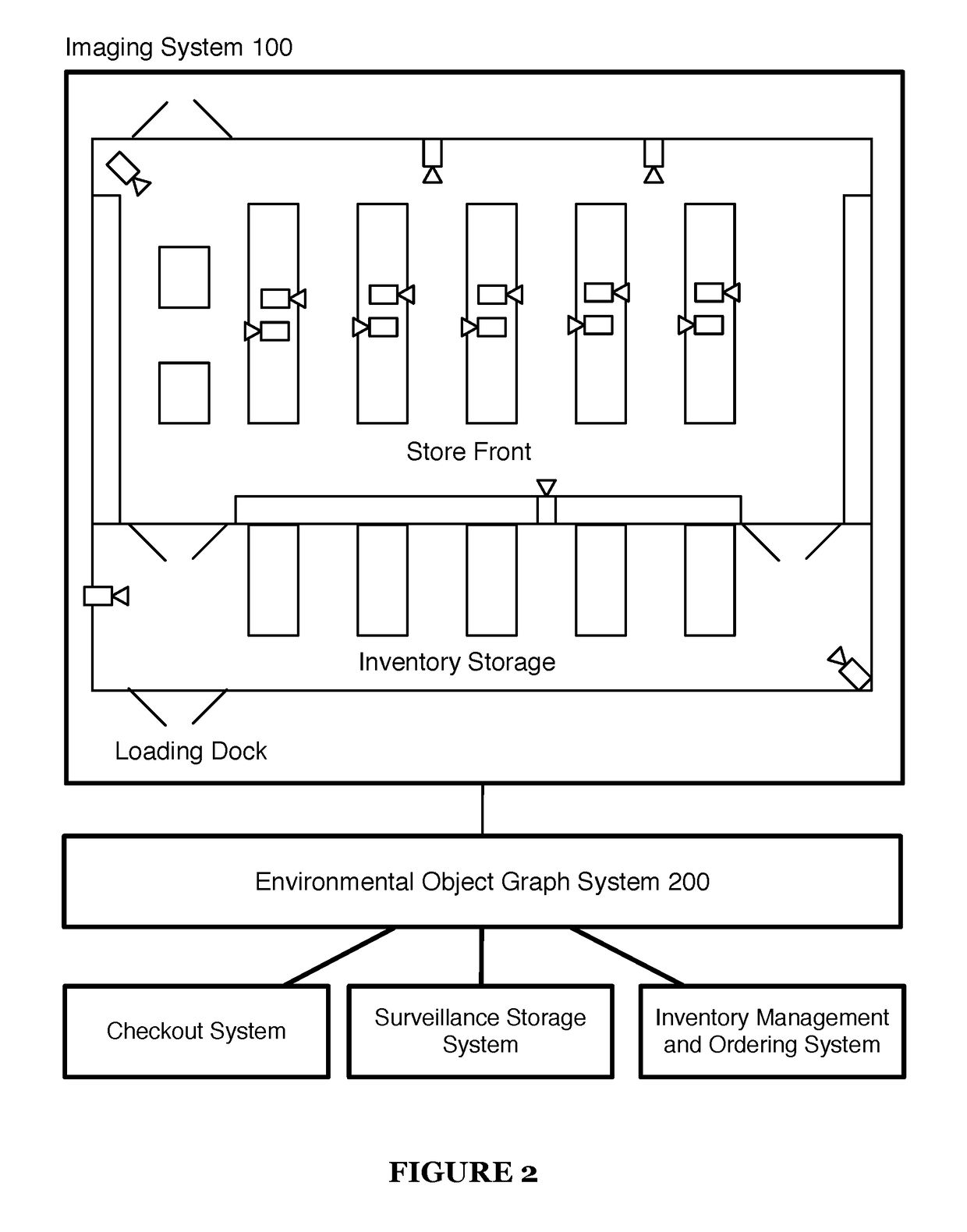

System and method for computer vision driven applications within an environment

ActiveUS20170323376A1Easy maintenanceConfidenceCharacter and pattern recognitionClosed circuit television systemsSystem integrationState dependent

A system and method for computer vision driven applications in an environment that can include collecting image data across an environment; maintaining an environmental object graph from the image data whereby maintaining the environmental object graph is an iterative process that includes: classifying objects, tracking object locations, detecting interaction events, instantiating object associations in the environmental object graph, and updating the environmental object graph by propagating change in at least one object instance across object associations; and inspecting object state for at least one object instance in the environmental object graph and executing an action associated with the object state. The system and method can be applied to automatic checkout, inventory management, and / or other system integrations.

Owner:GRABANGO CO

Broadband power combining device using antipodal finline structure

ActiveUS7215220B1Easy to manageThermal resistance minimizationWaveguidesCoupling devicesWedge angleHermetic seal

A broadband power combining device includes an input port, an input waveguide section, a center waveguide section formed by stacked wedge-shaped trays, an output waveguide section, and an output port. Each tray is formed of a wedge-shaped metal carrier, an input antipodal finline structure, one or more active elements, an output antipodal finline structure, and attendant biasing circuitry. The wedge-shaped metal carriers have a predetermined wedge angle and predetermined cavities. The inside and outside surfaces of the metal carriers and surfaces of the cavity all have cylindrical curvatures. When the trays are assembled together, a cylinder is formed defining a coaxial waveguide opening inside. The antipodal finline structures form input and output arrays. An incident EM wave is passed through the input port and the input waveguide section, distributed by the input antipodal finline array to the active elements, combined again by the output antipodal finlines array, then passed to the output waveguide section and output port. A hermetic sealing scheme, a scheme for improving the power combining efficiency and thermal management scheme are also disclosed. The broadband power combining device operates with multi-octave bandwidth and is easy to manufacture, well-managed thermally, and highly efficient in power combining.

Owner:CW ACQUISITION

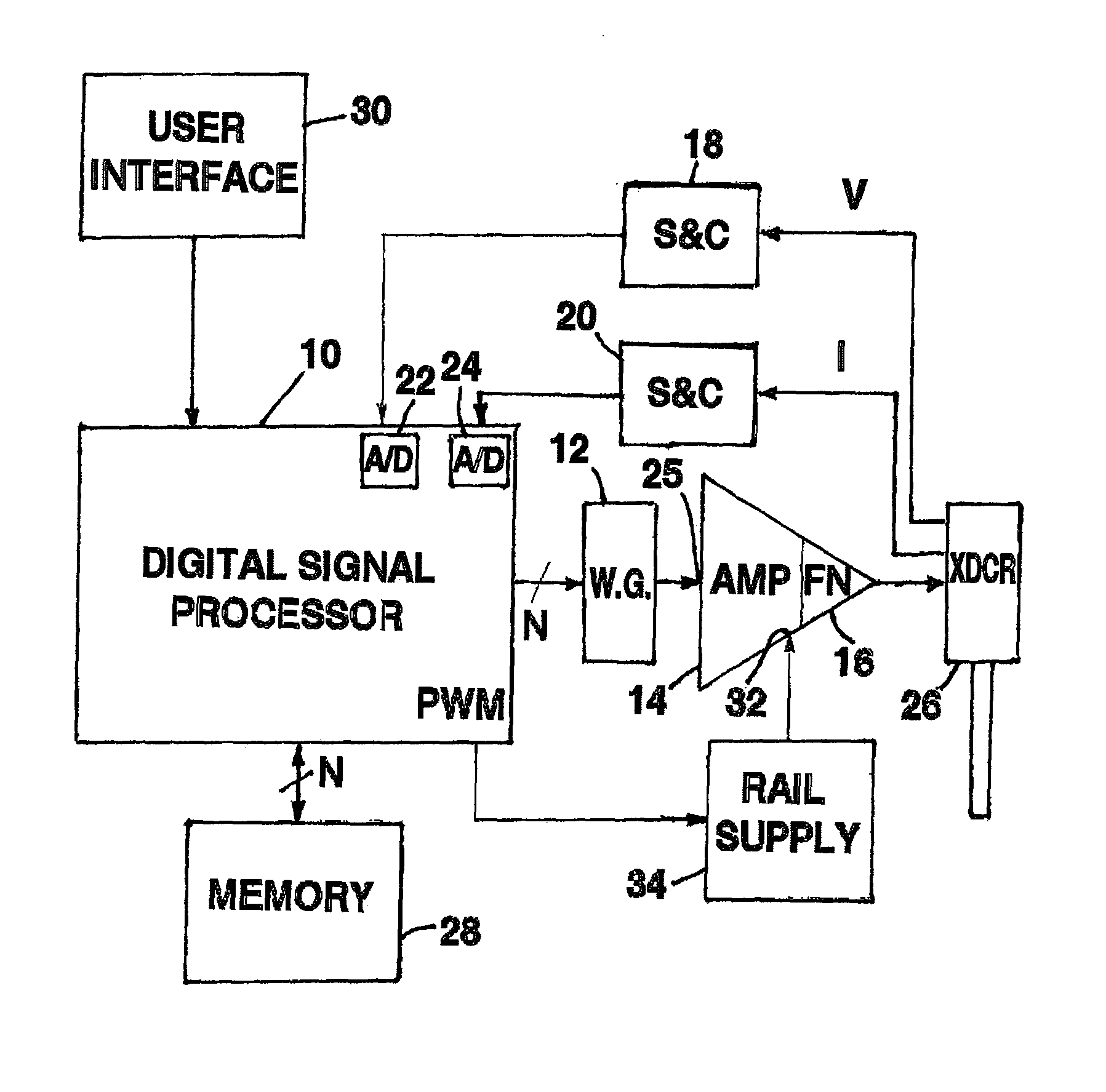

Waveform generator for driving electromechanical device

ActiveUS8659208B1Small and inexpensiveReduce monetary roadblockPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationDigital memoryAnalog-to-digital converter

An electrical waveform generator for driving an electromechanical load includes a digital signal processor connected to a waveform generator component in turn connected to an amplifier section with a filter network, the latter being connected to sensing and conditioning circuit componentry that is in turn connected to analog-to-digital converter circuitry. A digital memory stores digitized voltage and current waveform information. The processor determines a phase difference between voltage and current waveforms, compares the determined phase difference to a phase difference command and generates a phase error or correction signal. The processor also generates an amplitude error signal for inducing the amplifier section to change its output amplitude to result in a predetermined amplitude error level for a respective one of the voltage and current waveforms.

Owner:MISONIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com