Patents

Literature

1271results about How to "Reduce equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

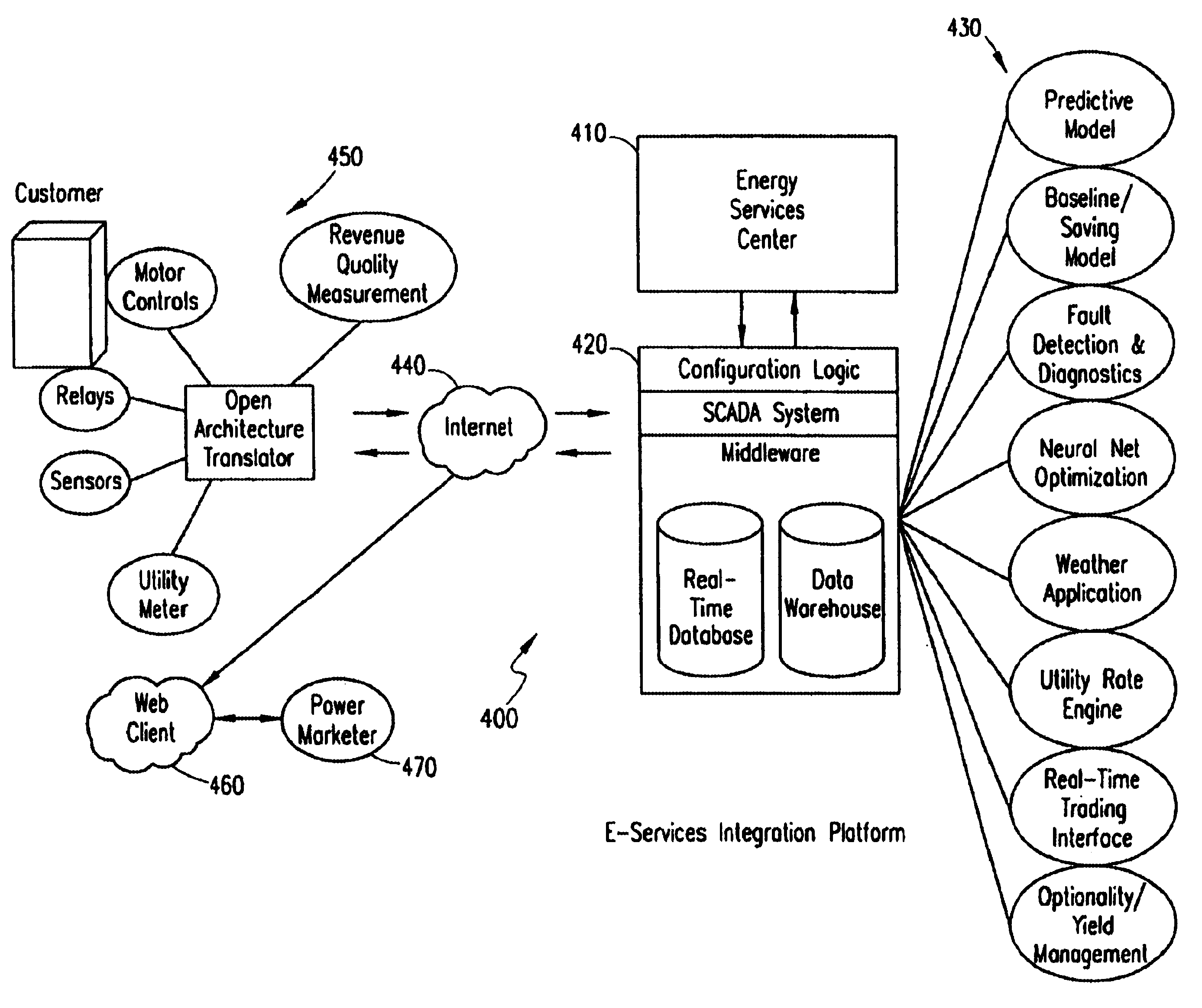

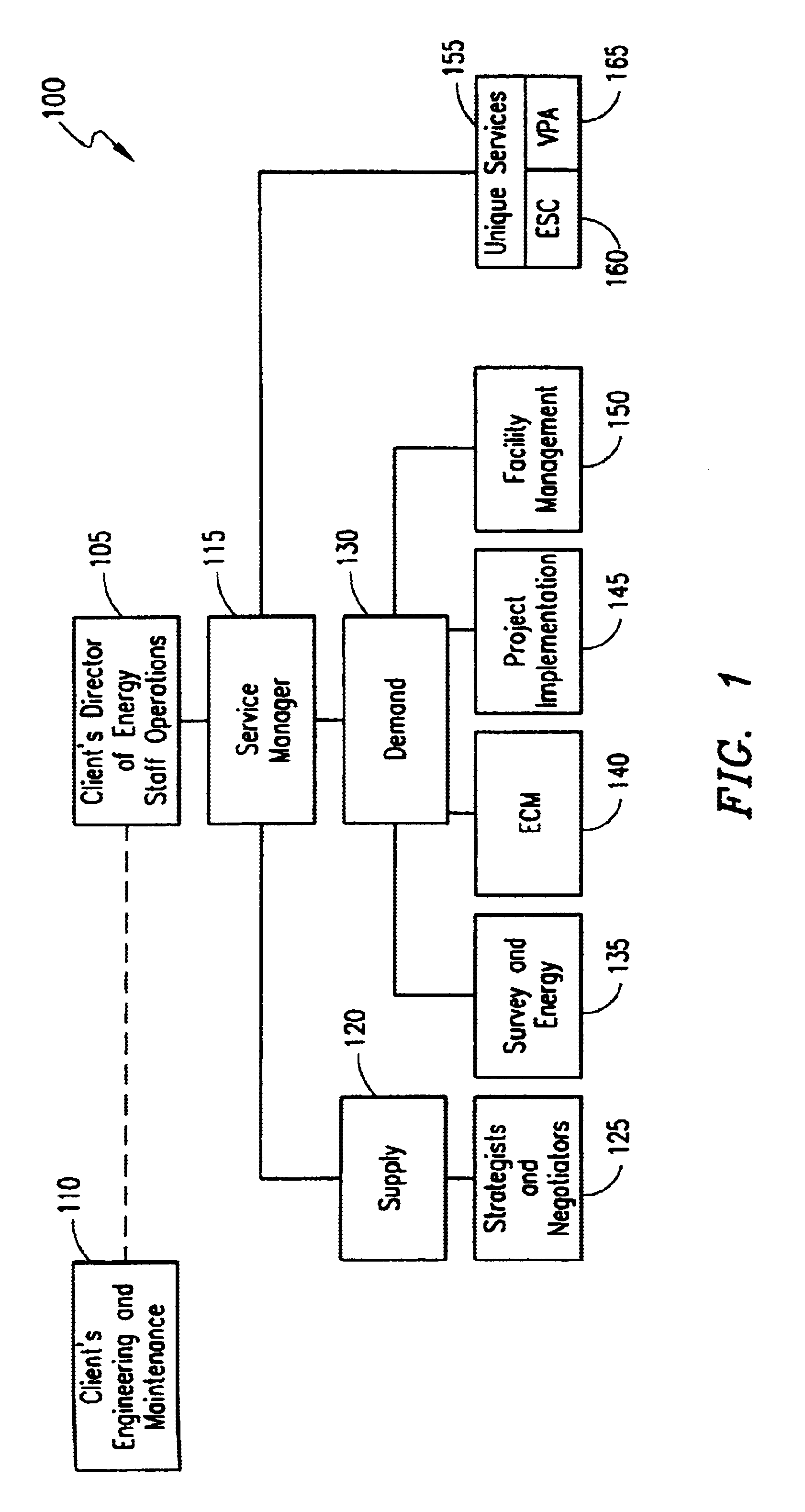

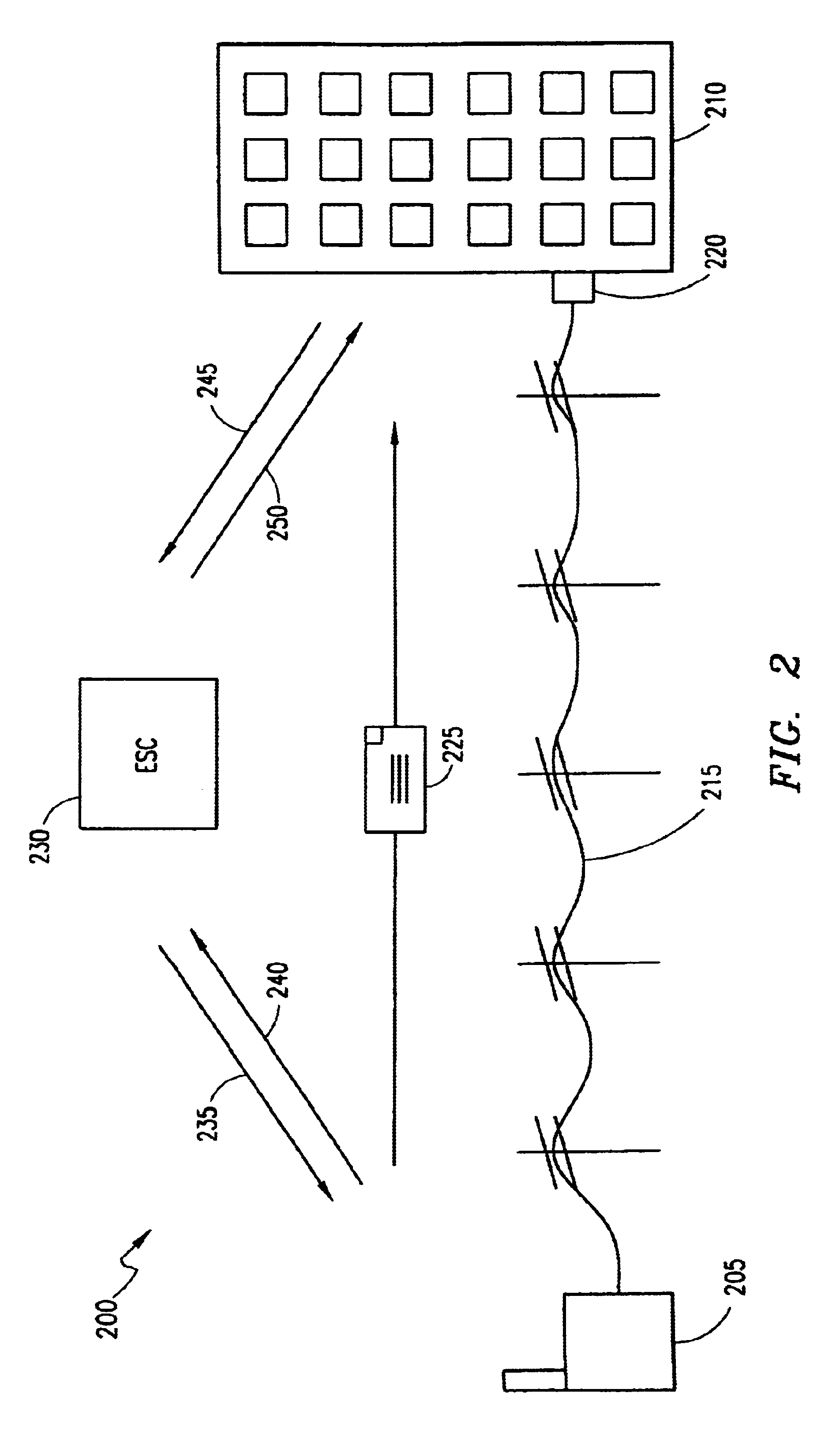

System and method for energy management

InactiveUS6785592B1Economic savingsImprove economyLevel controlSpecial tariff metersConservation energyProcess engineering

A business methodology for optimizing energy procurement energy demand (usage) and energy supply for a facility or complex. After ascertaining a baseline model, energy consumption is monitored and adjusted to reflect dynamic economic factors of operations. With the accumulation of data, contract negotiations with energy suppliers may provide further energy savings. Over time and patterns of usage determined further savings and optimization in energy, equipment, staffing and other operational areas are obtained. Remote access provides efficient monitoring of established systems.

Owner:PEROT SYSTEMS

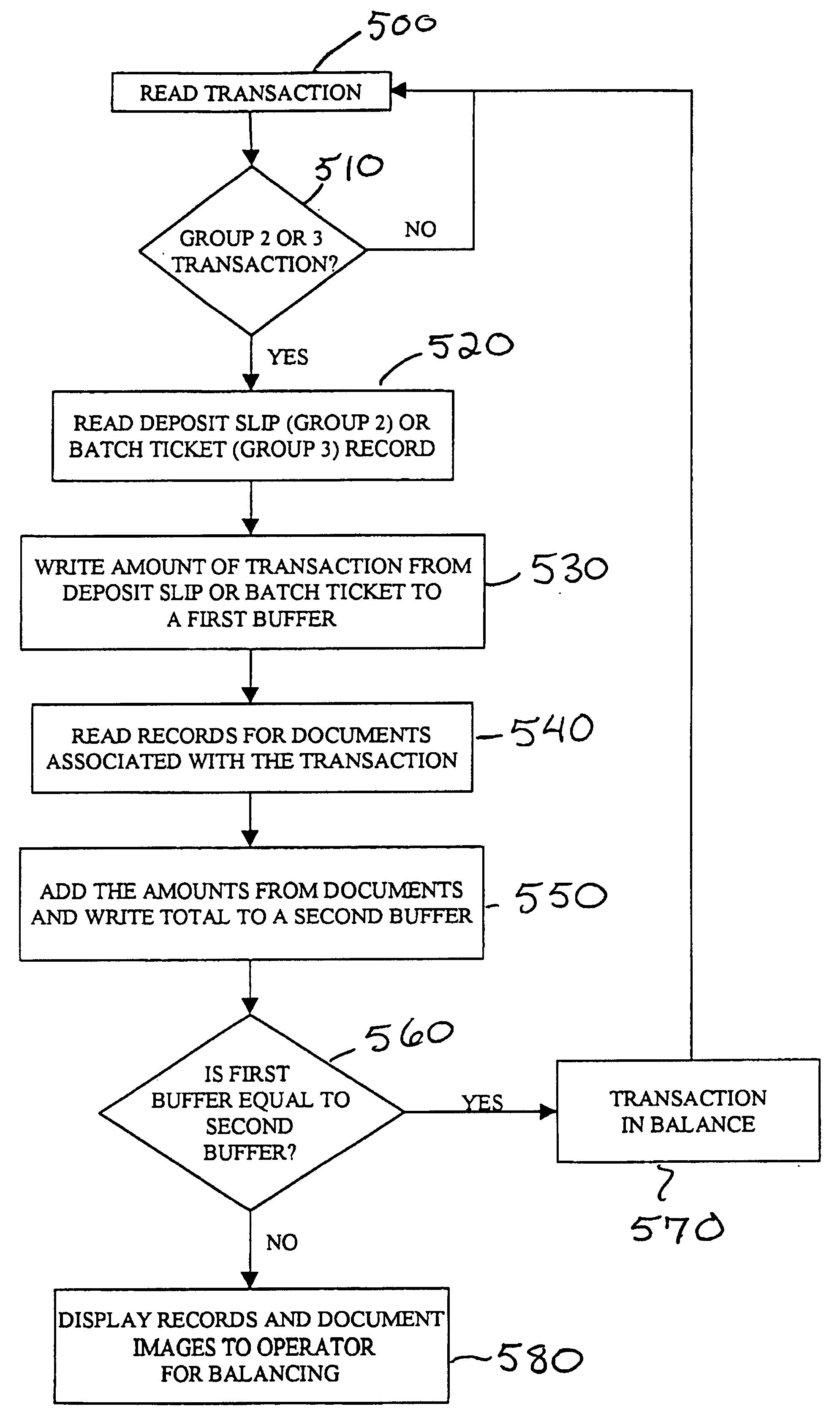

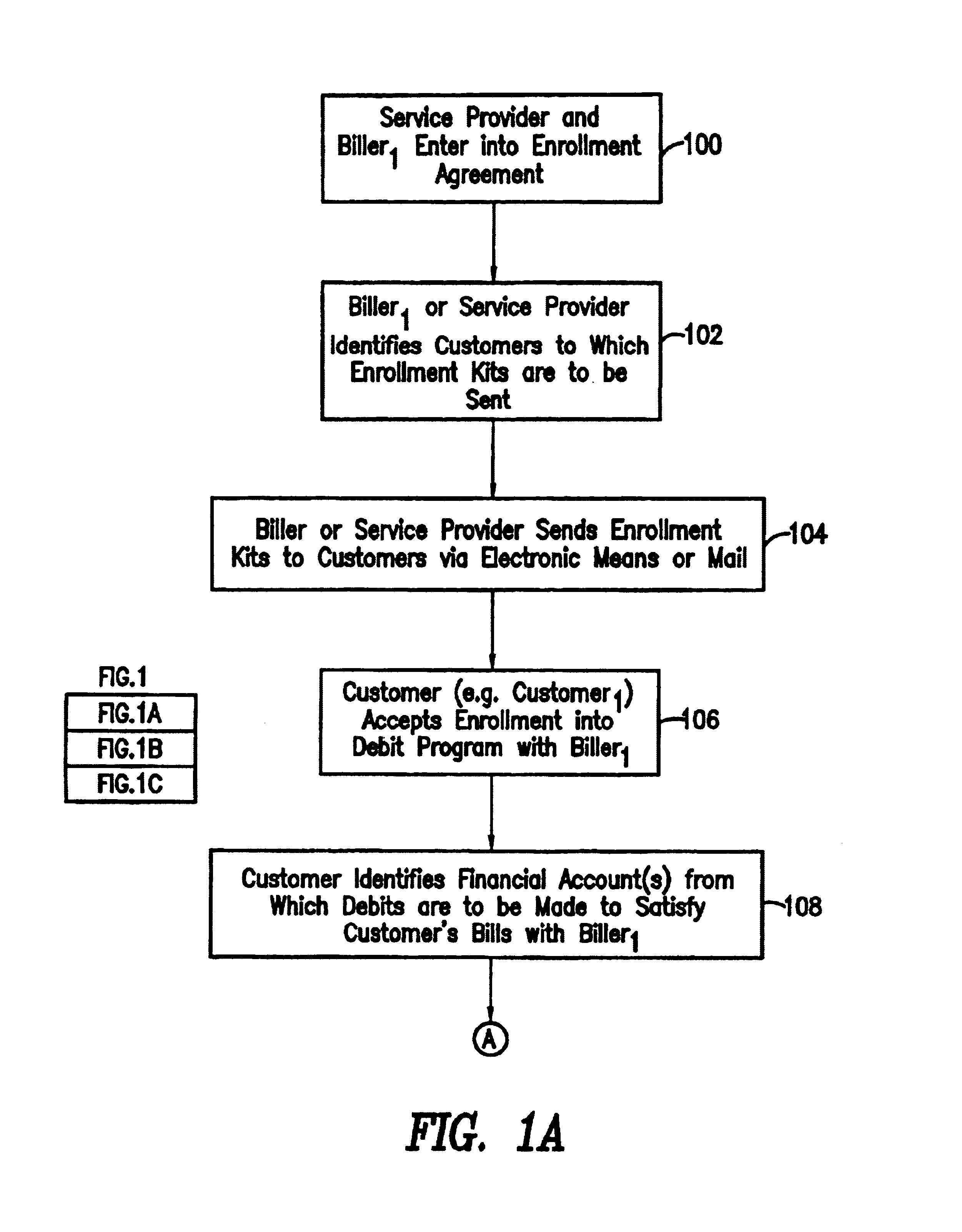

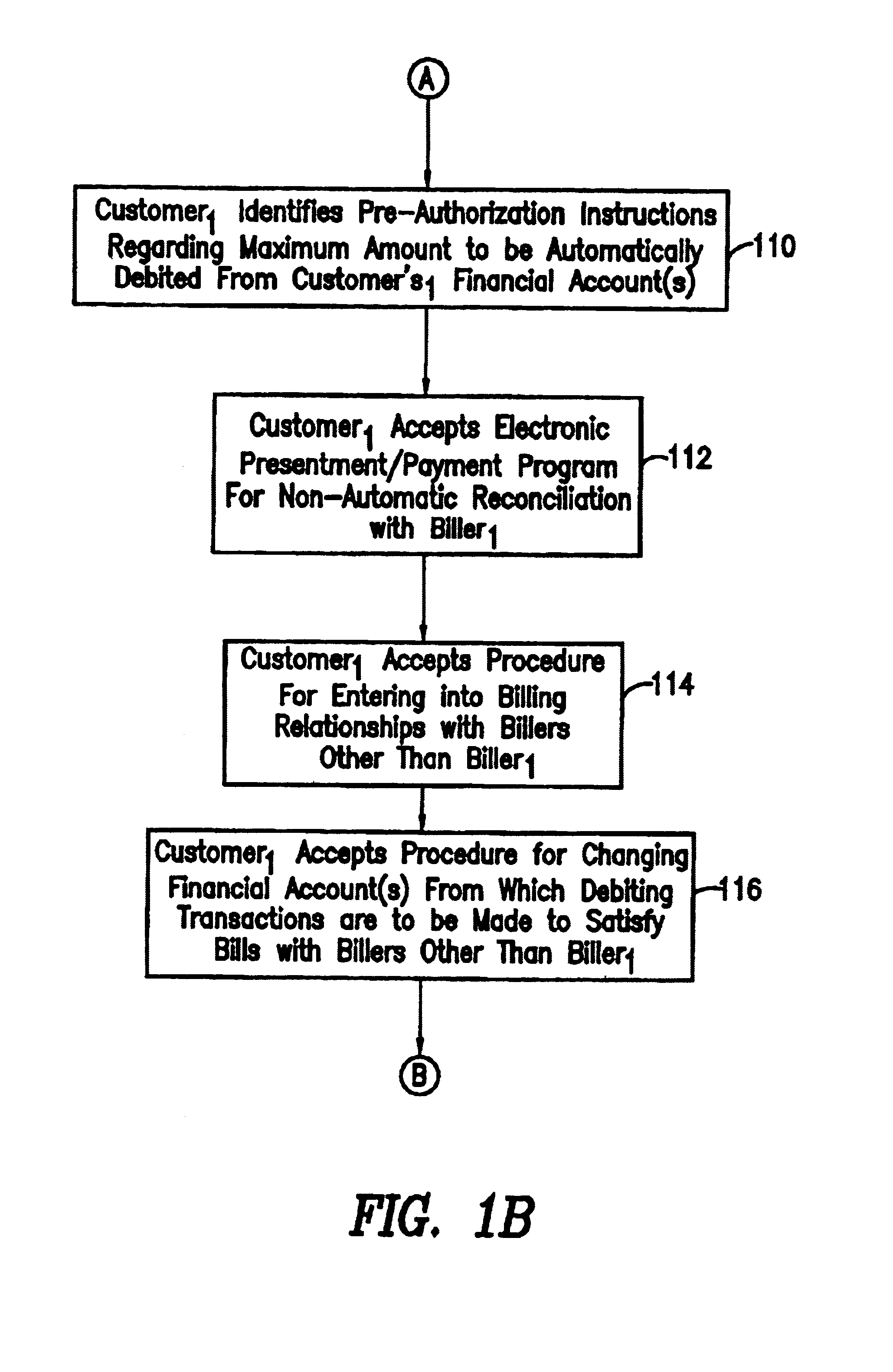

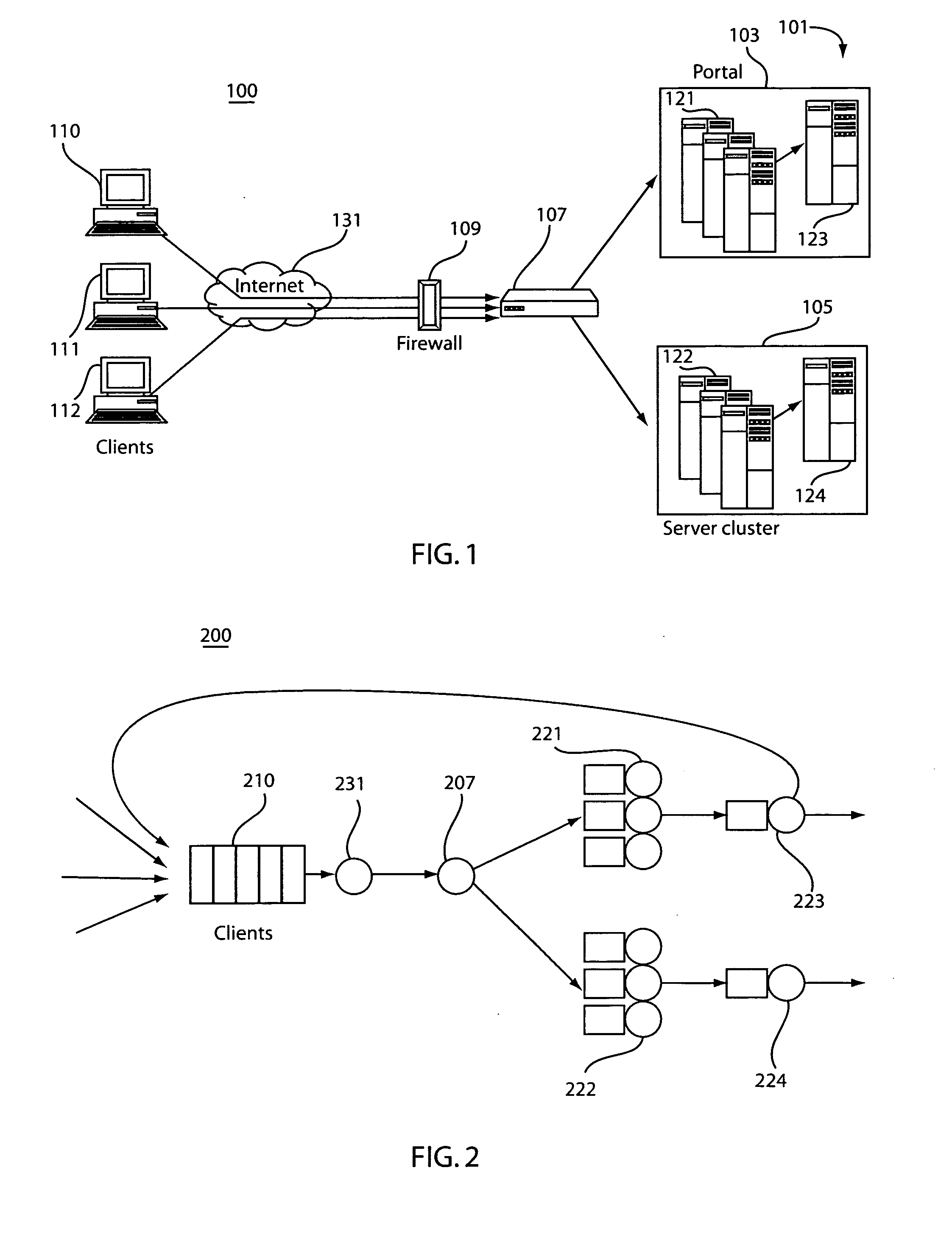

System and method for back office processing of banking transactions using electronic files

InactiveUS7062456B1Reduce equipmentReduce laborFinanceAutomatic teller machinesBank tellerRelevant information

As banking transactions are processed by a bank teller, all of the relevant information with respect to the transaction (e.g., dollar amount) is captured in an electronic file. Each of the electronic files from the various branches of the bank are forwarded to a central back office processing center where the electronic files are combined into a single Transaction Repository. At the end of the branch day, all of the paper associated with the transactions is forwarded from the branches to the back office processing center. The paper transactions are imaged in the conventional manner and the Magnetic Ink Character Recognition (MICR) data is read from the paper. The present invention then automatically correlates the images and MICR data captured from the paper with the complete transaction record contained in the Transaction Repository. Most of the conventional back office processing can now be performed without the need to perform character recognition and without the need for excess human intervention.

Owner:JPMORGAN CHASE BANK NA

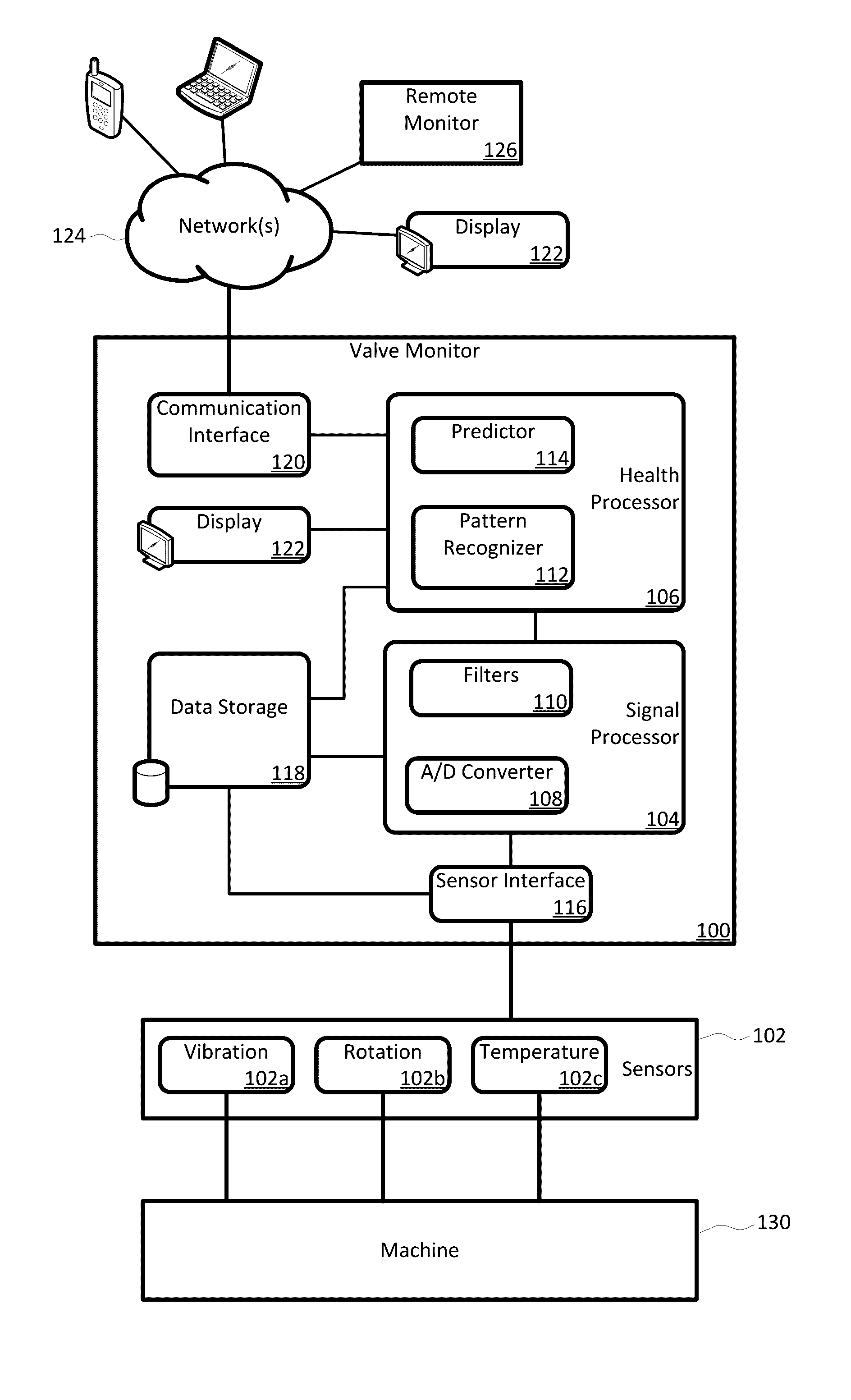

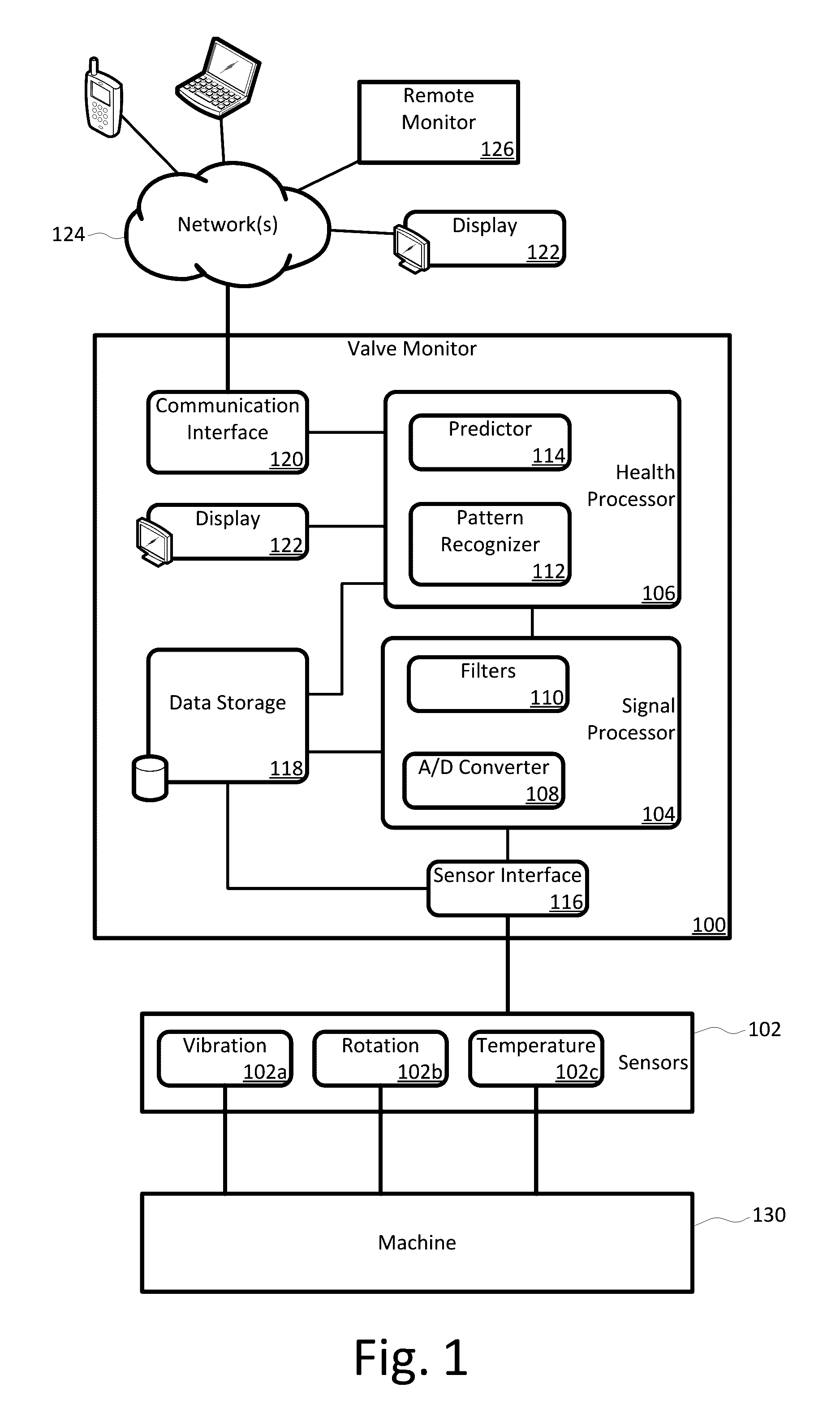

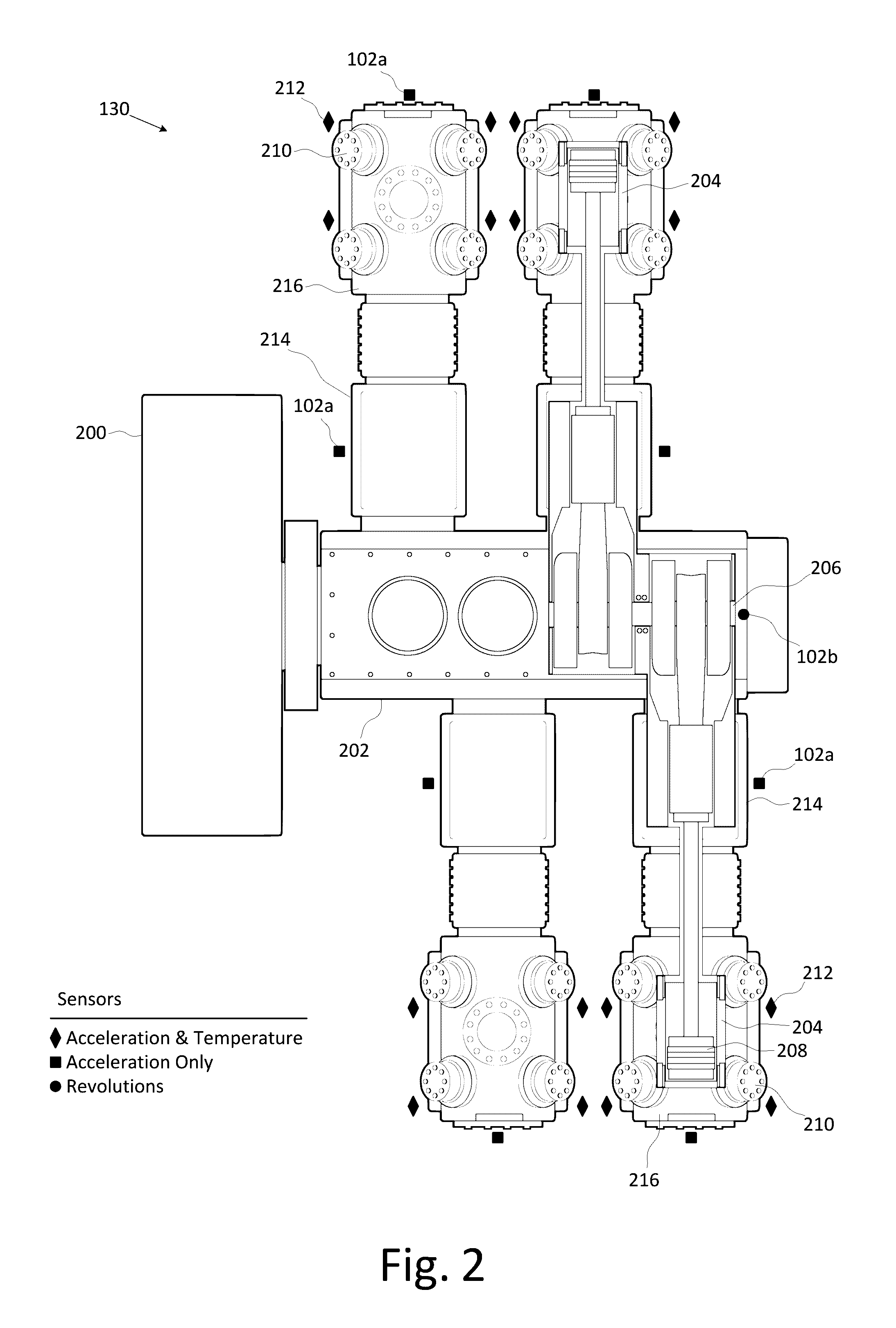

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

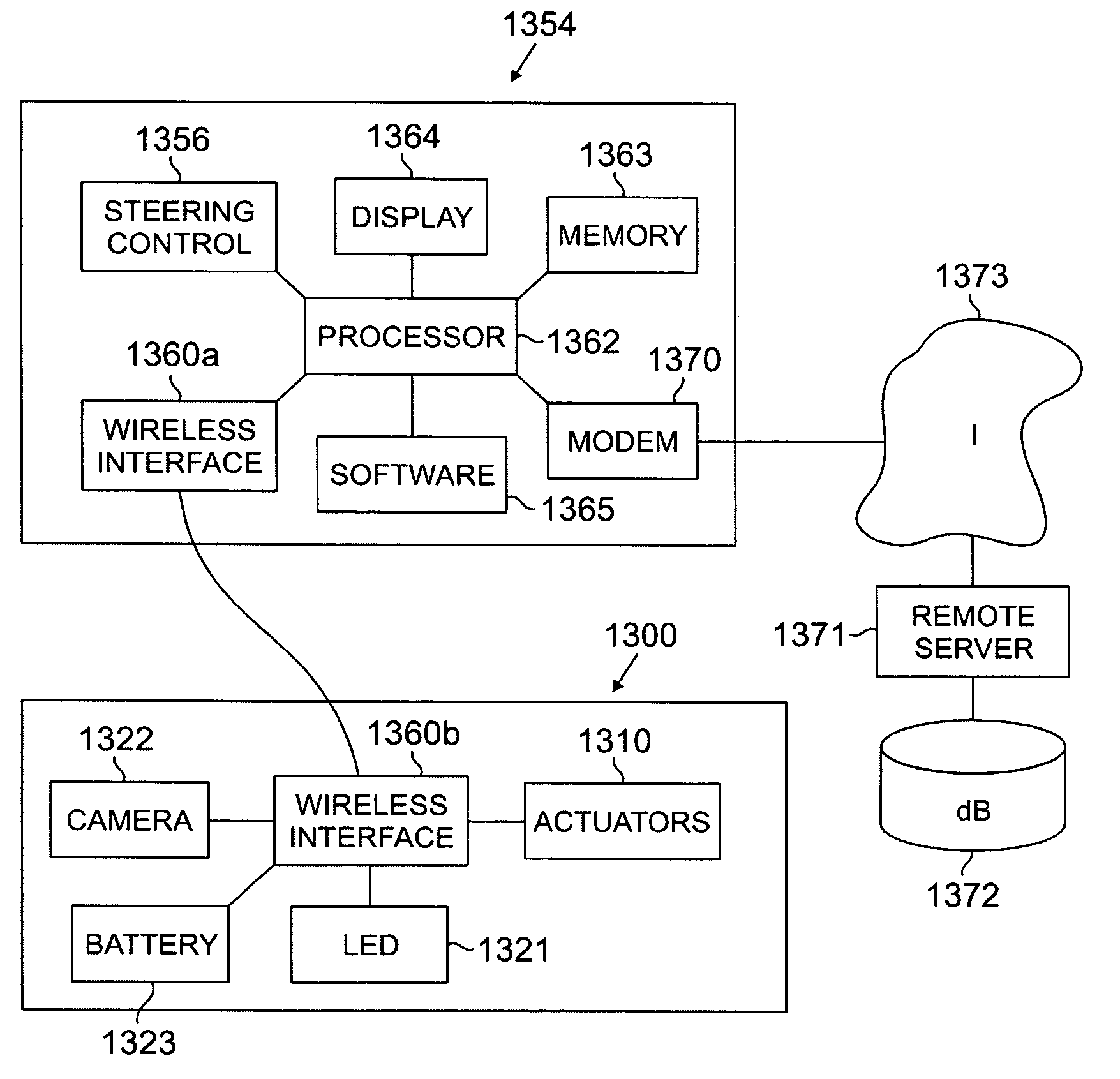

Robotic endoscope with wireless interface

InactiveUS20050065400A1Decrease stockLow costGastroscopesLocal control/monitoringComputer hardwareWireless transceiver

An endoscope apparatus and method of operating the same. The endoscope apparatus comprises an endoscope portion and a control and display unit. The endoscope portion preferably comprises: (i) a sensor disposed at a distal end of the endoscope portion and providing endoscope data; (ii) one or more electronically controlled actuators (e.g., electroactive polymer actuators) controlling the operation of the endoscope portion based on received control signals; (iii) a first wireless transceiver coupled to the sensor and the one or more electronically controlled actuators, transmitting received endoscope data from the sensor and forwarding received control signals to the one or more electronically controlled actuators; and (iv) a portable power source (e.g., a battery) coupled to the sensor, the first wireless transceiver, and the one or more electronically controller actuators. The control and display unit preferably comprises: (i) a second wireless transceiver coupled via a wireless link to the first transceiver in the endoscope portion and receiving endoscope data from the first transceiver and transmitting control signals to the first transceiver; (ii) a control portion coupled to the second wireless transceiver and sending control signals to the one or more actuators in the endoscope portion via the first and second wireless transceivers; and (iii) a display portion that displays information received from the sensor via the first and second wireless transceivers. Another aspect of the present invention is directed to a method for providing single-use endoscopes to one or more hospitals.

Owner:BOSTON SCI SCIMED INC

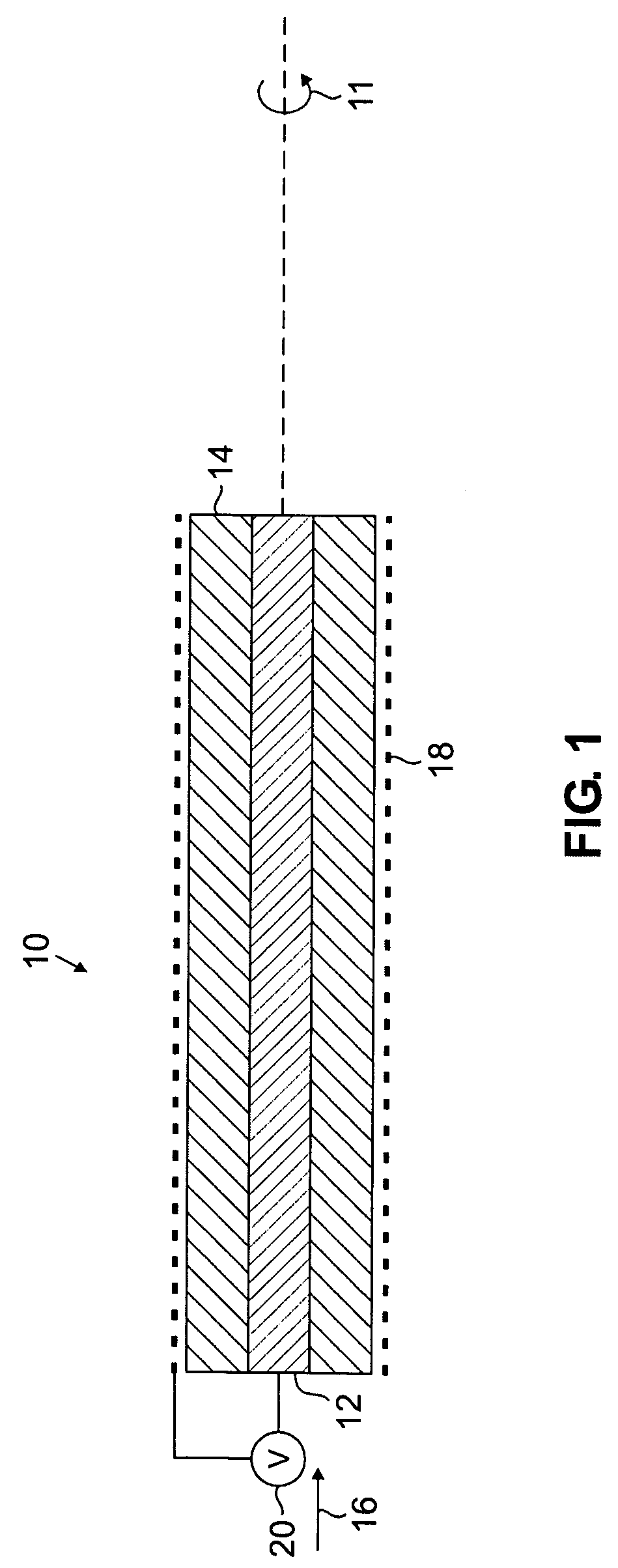

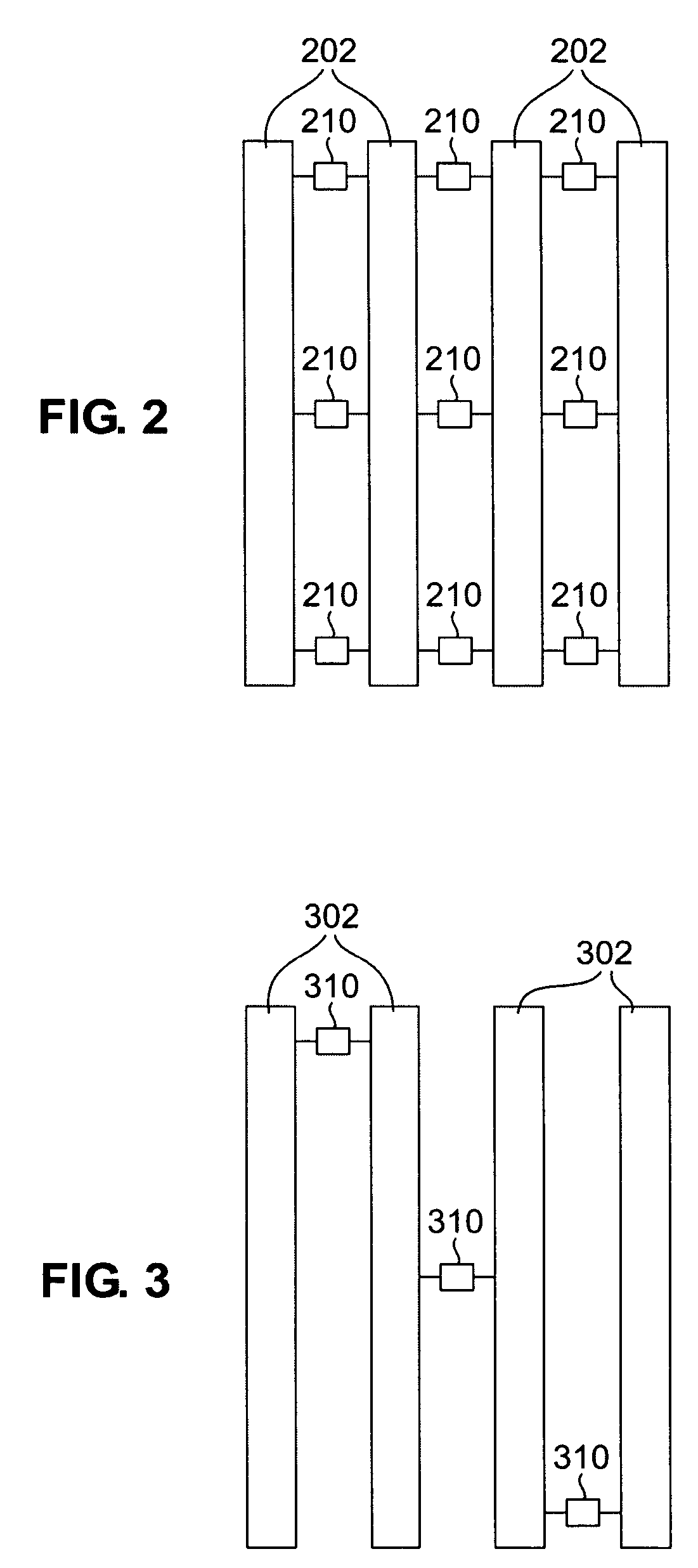

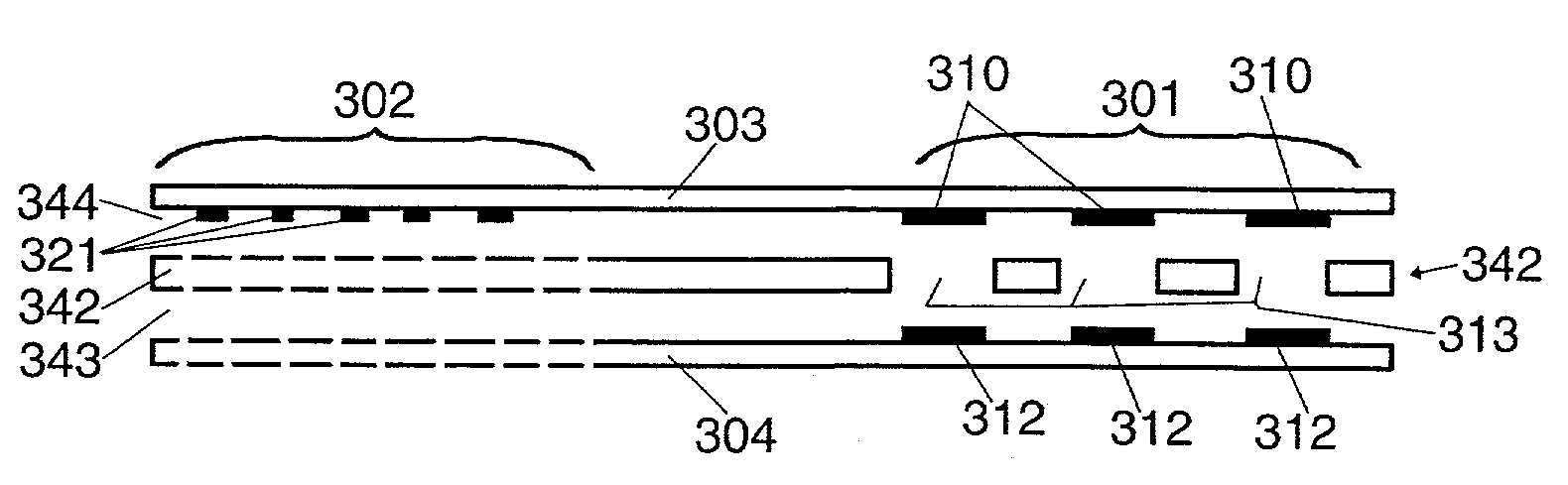

Method and apparatus for providing an integrated membrane switch and capacitive sensor

InactiveUS6943705B1Easy to installReduce the amount requiredElectric signal transmission systemsElectronic switchingCapacitive couplingMembrane switch

A circuit assembly for providing a switch sensor and a capacitive sensor. The circuit assembly has a first pattern of conductive material in a first plane and a second pattern of conductive material in a second plane. An insulating member in an intermediate plane separates the first and second patterns. In a switch sensor area, the insulating member has openings to allow a first conductive element in the first pattern to contact a second conductive element in the second pattern responsive a force being applied to the first conductive element. In the capacitive sensor area, the insulating member maintains spacing between conductive material in the first and second patterns. The circuit assembly also includes a preventative capacitance configuration that limits non-intentional capacitive coupling in the capacitive sensor area.

Owner:SYNAPTICS INC

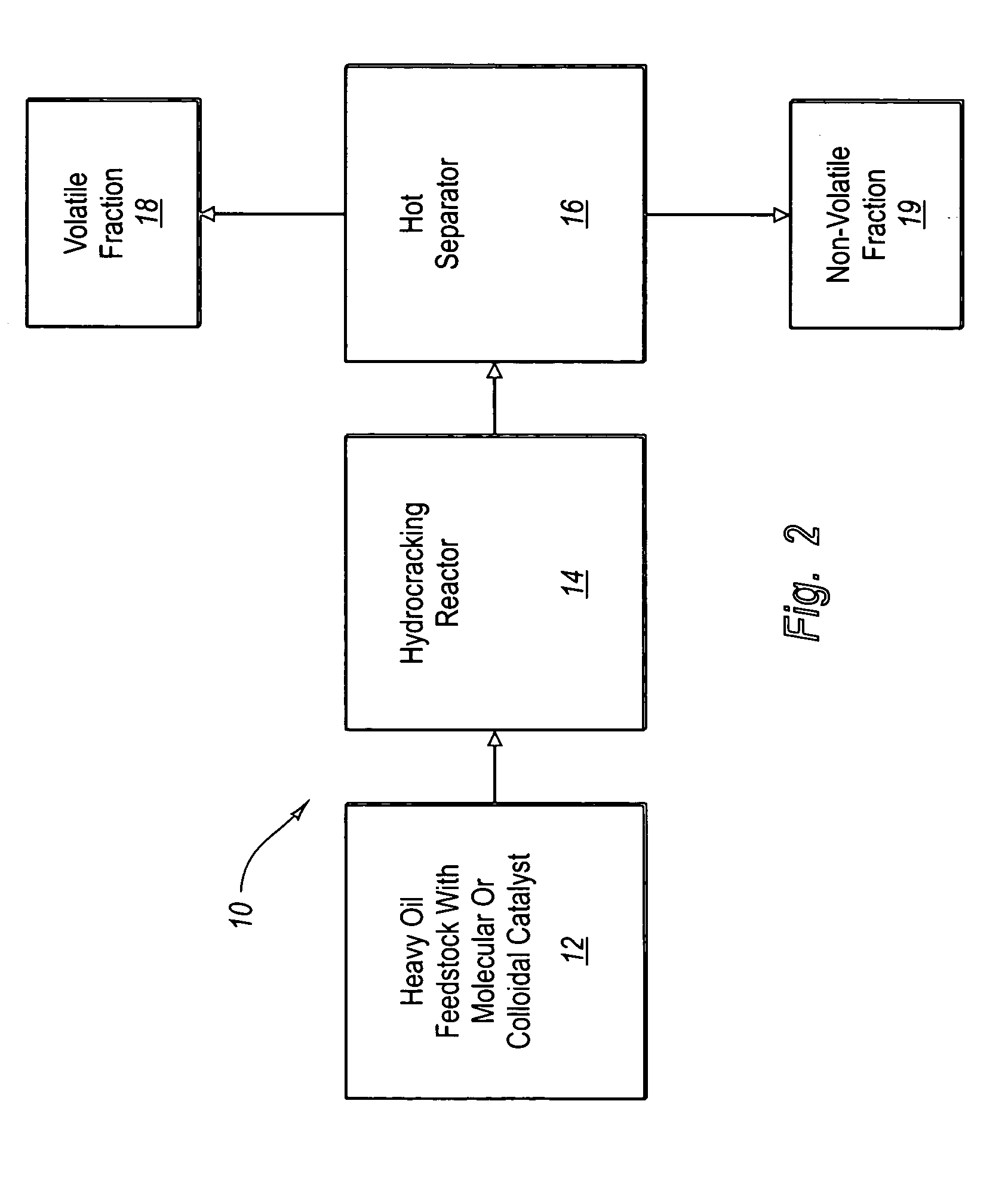

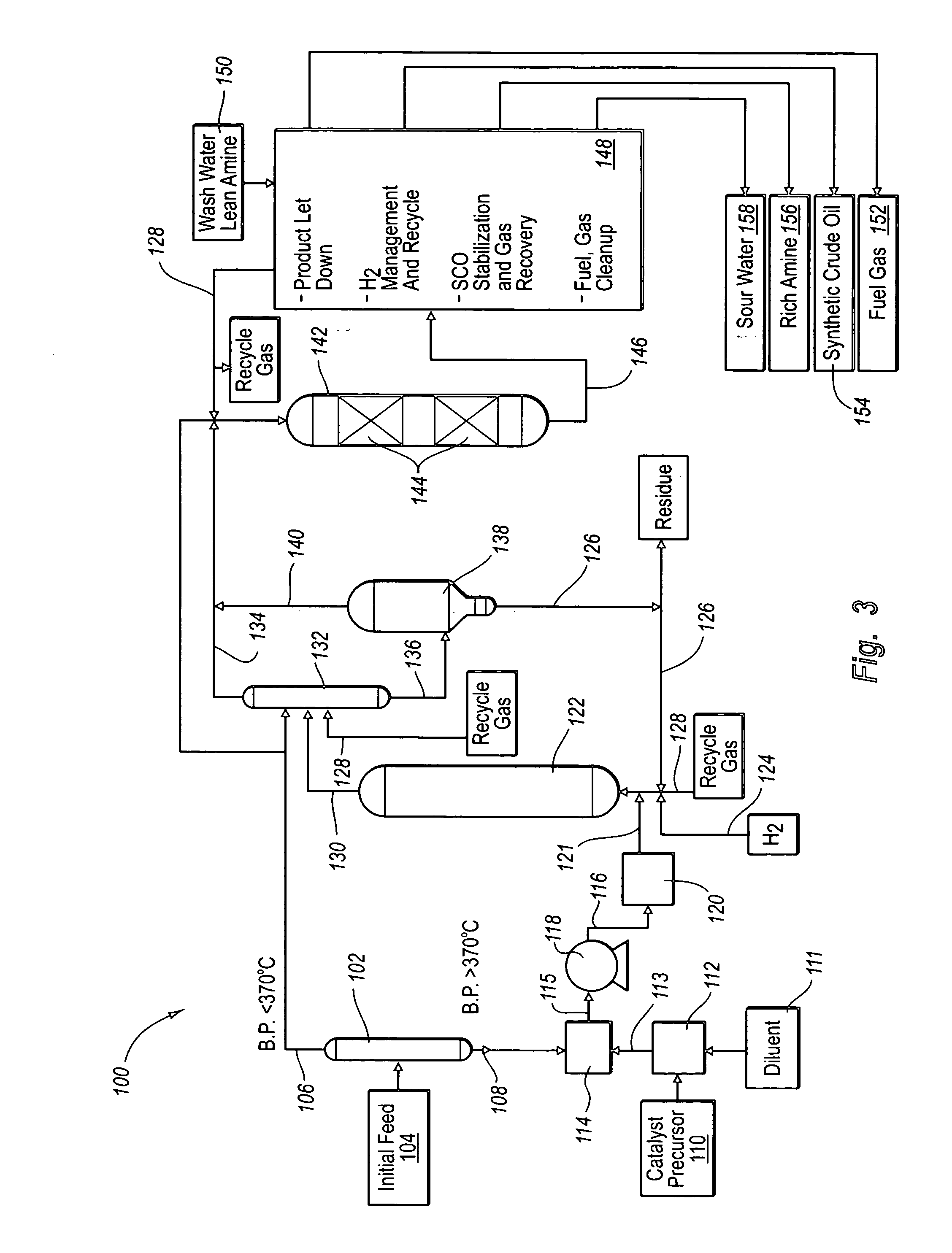

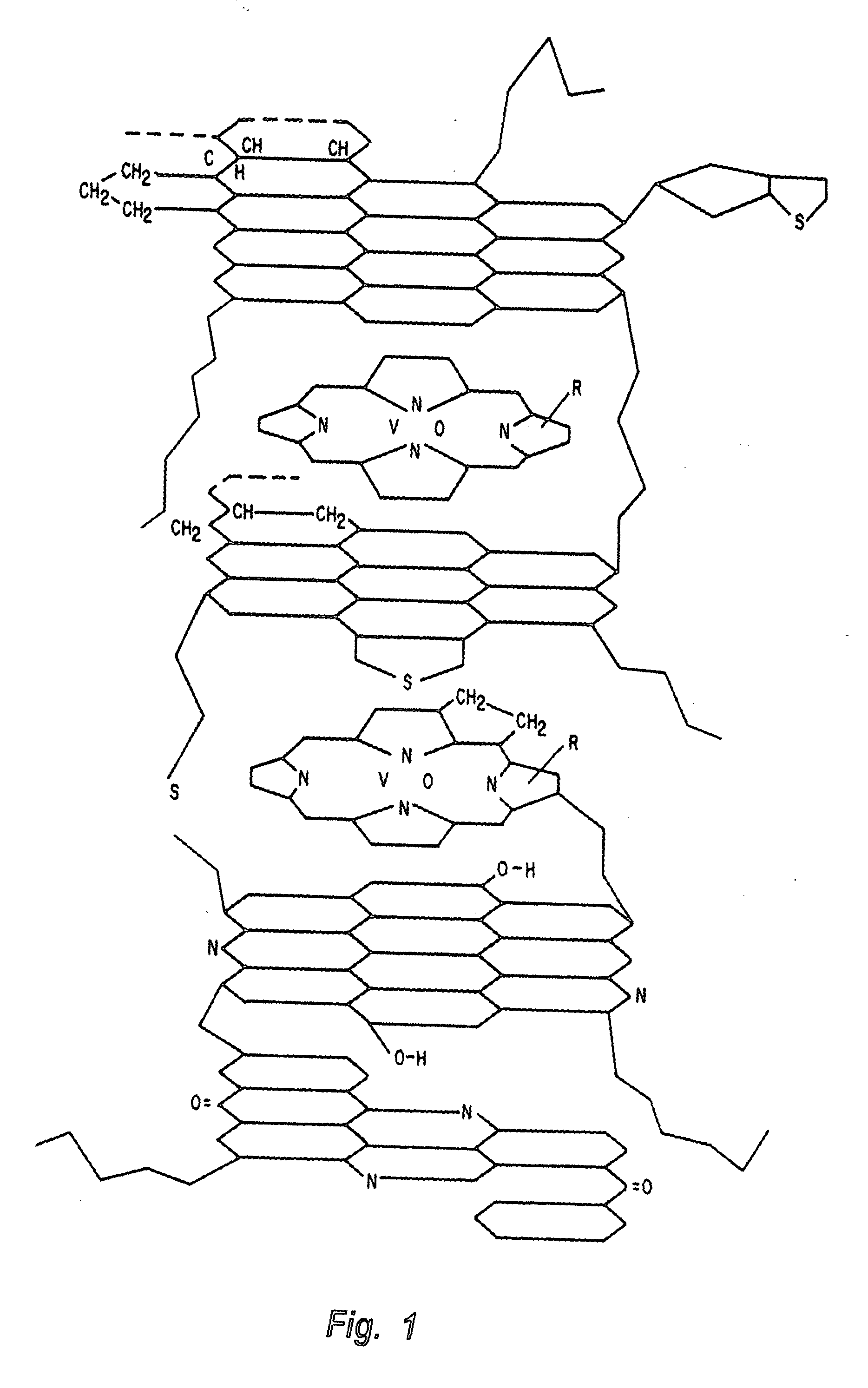

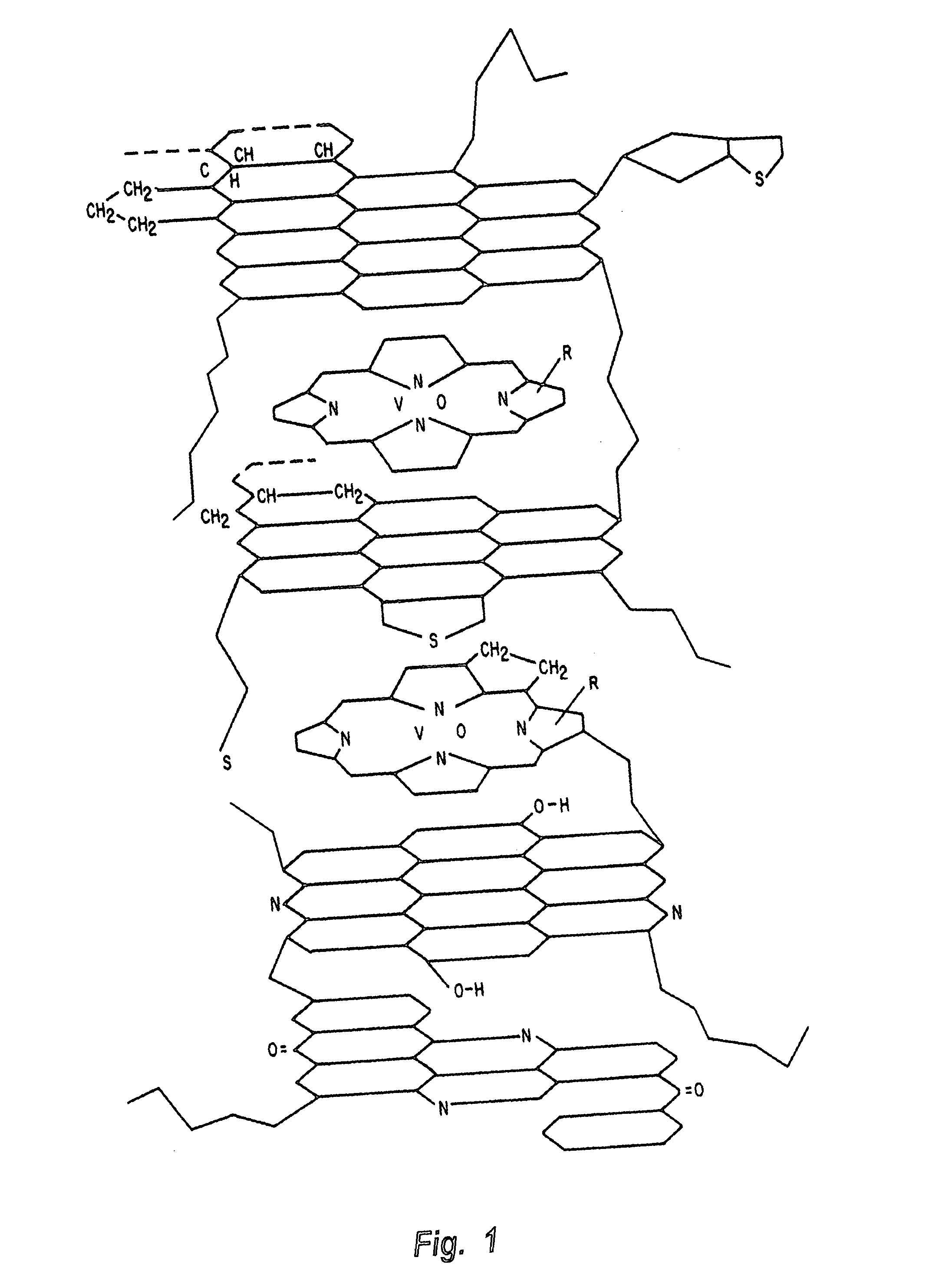

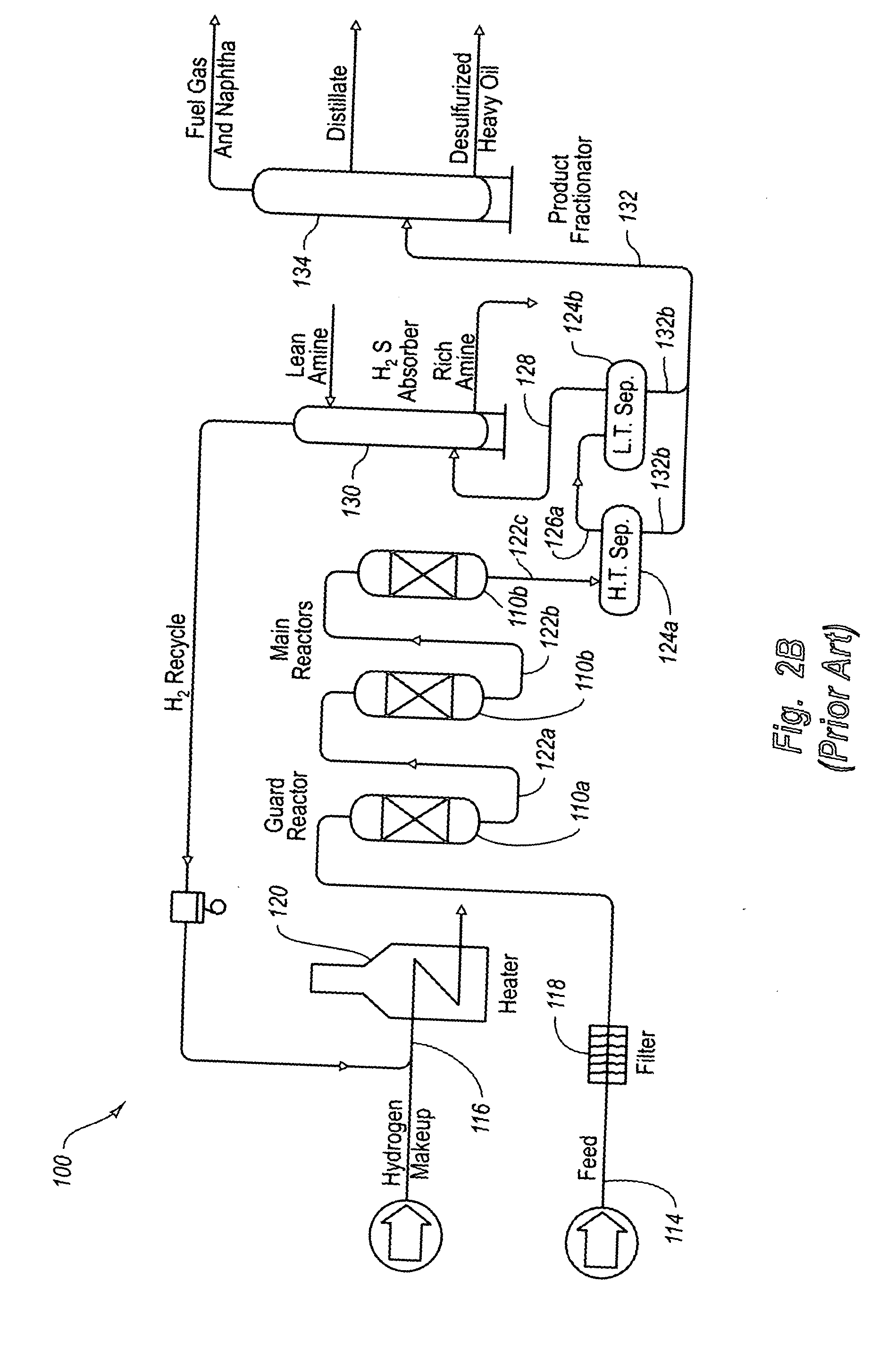

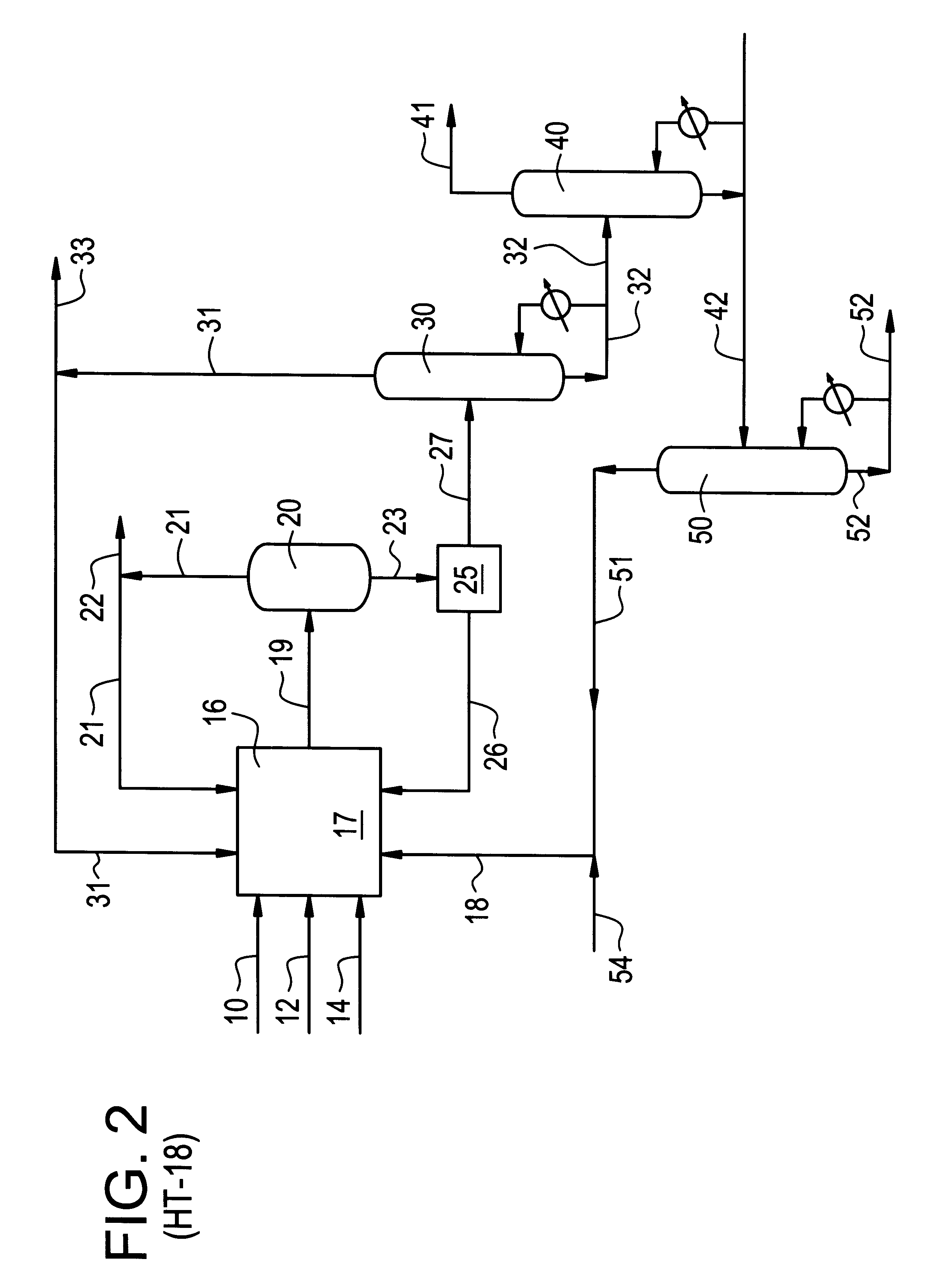

Hydroprocessing method and system for upgrading heavy oil using a colloidal or molecular catalyst

ActiveUS20050241993A1Inhibits eliminates formationEasy to useCatalyst regeneration/reactivationCatalyst activation/preparationColloidFuel oil

Methods and systems for hydroprocessing heavy oil feedstocks to form an upgraded material involve the use of a colloidal or molecular catalyst dispersed within a heavy oil feedstock, a hydrocracking reactor, and a hot separator. The colloidal or molecular catalyst promotes hydrocracking and other hydroprocessing reactions within the hydrocracking reactor. The catalyst is preferentially associated with asphaltenes within the heavy oil feedstock, which promotes upgrading reactions involving the asphaltenes rather than formation of coke precursors and sediment. The colloidal or molecular catalyst overcomes problems associated with porous supported catalysts in upgrading heavy oil feedstocks, particularly the inability of such catalysts to effectively process asphaltene molecules. The result is one or more of reduced equipment fouling, increased conversion level, and more efficient use of the supported catalyst if used in combination with the colloidal or molecular catalyst.

Owner:HEADWATERS TECH INNOVATION LLC

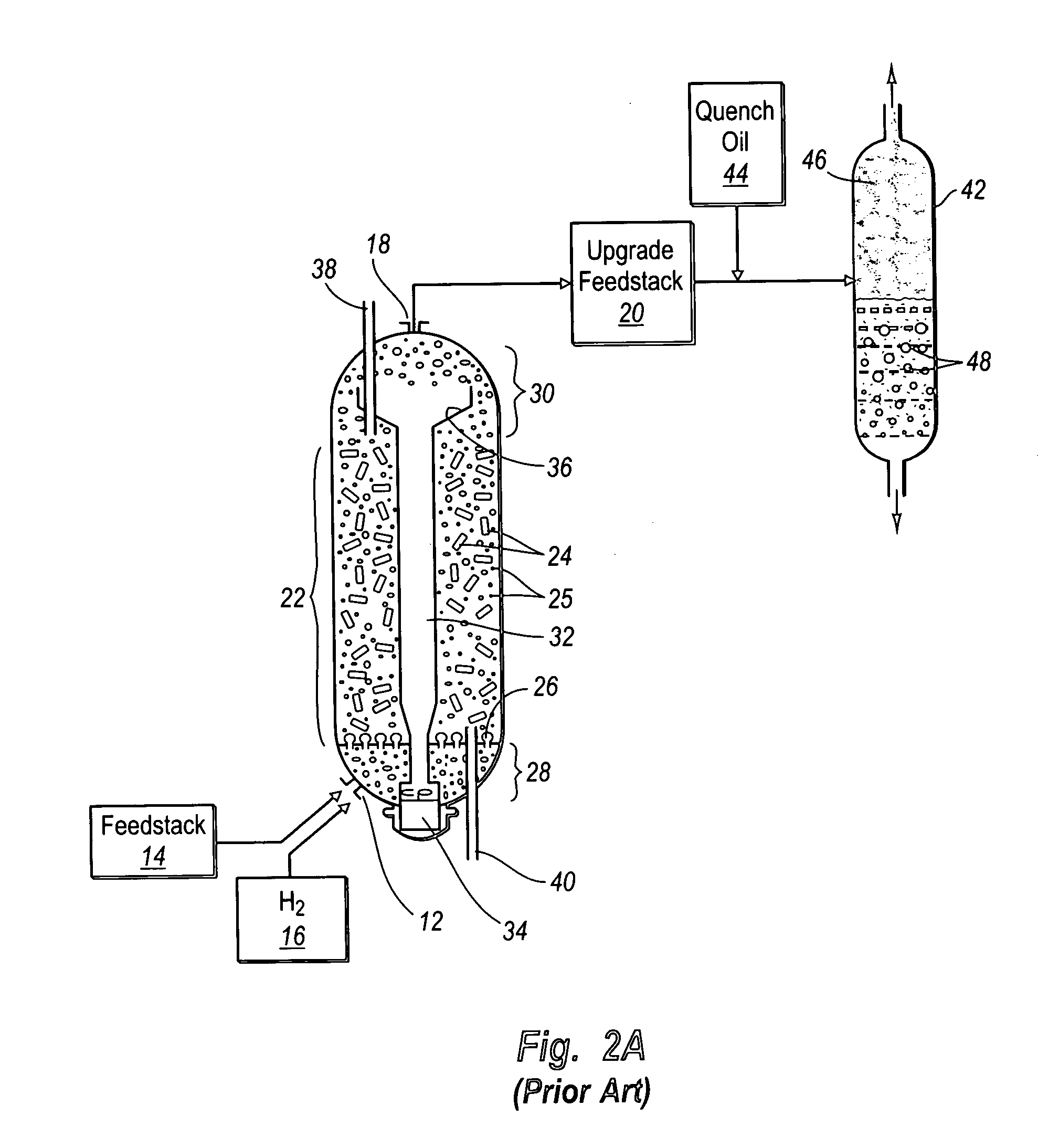

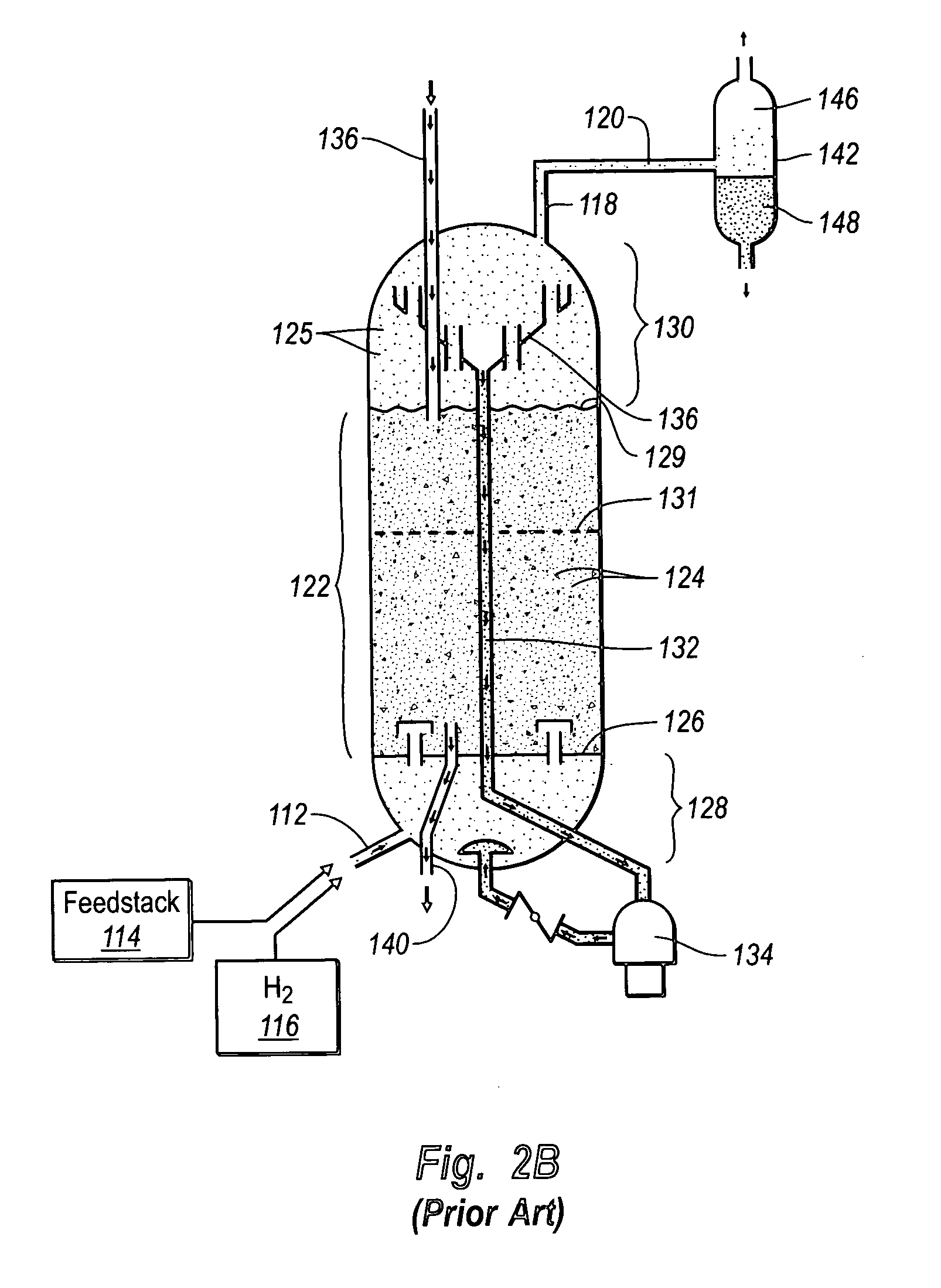

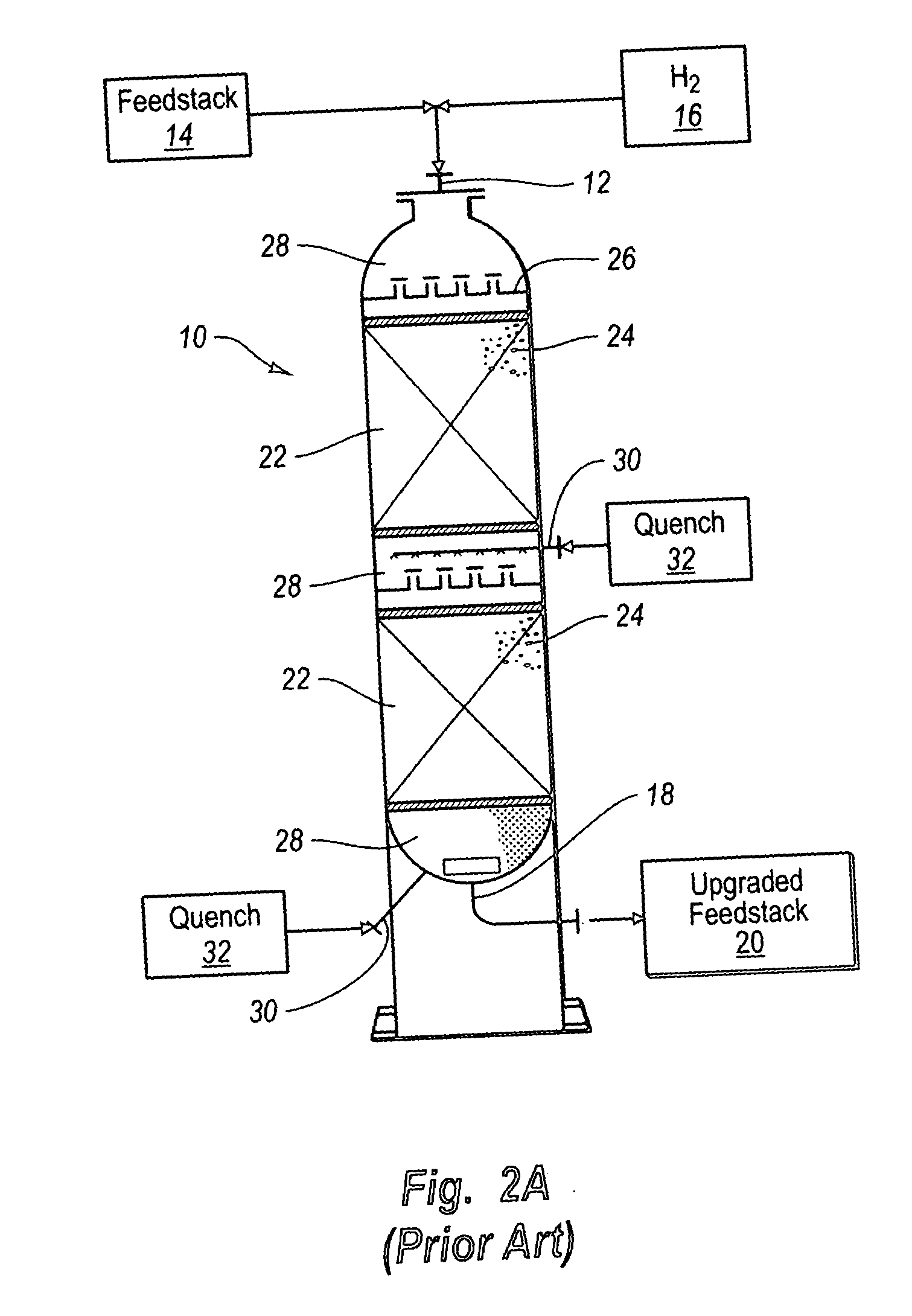

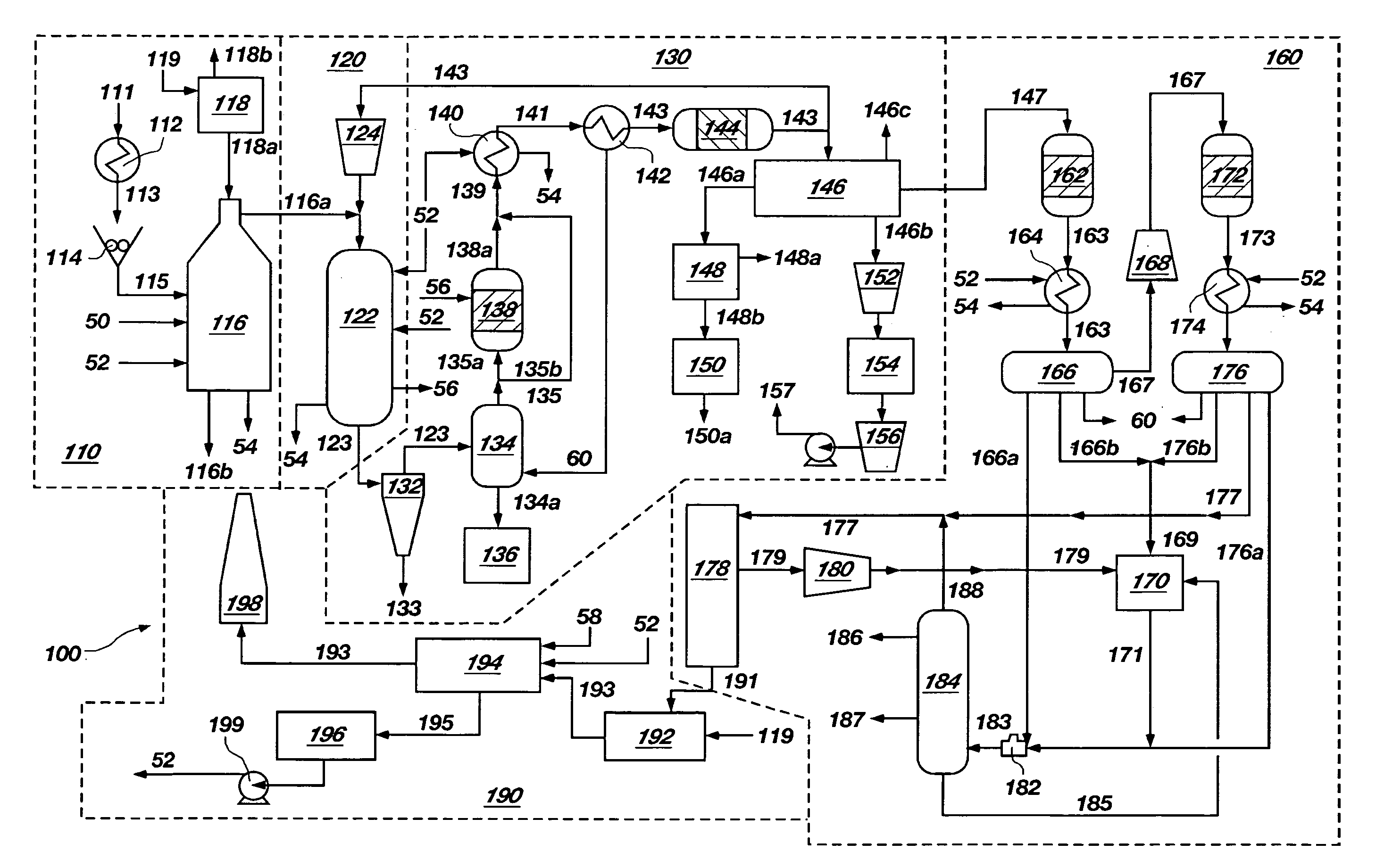

Ebullated bed hydroprocessing methods and systems and methods of upgrading an existing ebullated bed system

ActiveUS20050241991A1Quality improvementReduce formationHydrocarbon oil crackingLiquid hydrocarbon mixture productionHydrogenDecomposition

An ebullated bed hydroprocessing system, and also a method for upgrading a pre-existing ebullated bed hydroprocessing system, involves introducing a colloidal or molecular catalyst, or a precursor composition capable of forming the colloidal or molecular catalyst, into an ebullated bed reactor. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. The improved ebullated bed hydroprocessing system includes at least one ebullated bed reactor that employs both a porous supported catalyst and the colloidal or molecular catalyst to catalyze hydroprocessing reactions involving the feedstock and hydrogen. The colloidal or molecular catalyst provides catalyst in what would otherwise constitute catalyst free zones within the ebullated bed hydroprocessing system. Asphaltene or other hydrocarbon molecules too large to diffuse into the pores of the supported catalyst can be upgraded by the colloidal or molecular catalyst. A slurry phase reactor may be positioned upstream from one or more ebullated bed reactors or converted from a pre-existing ebullated bed reactor.

Owner:HEADWATERS TECH INNOVATION LLC

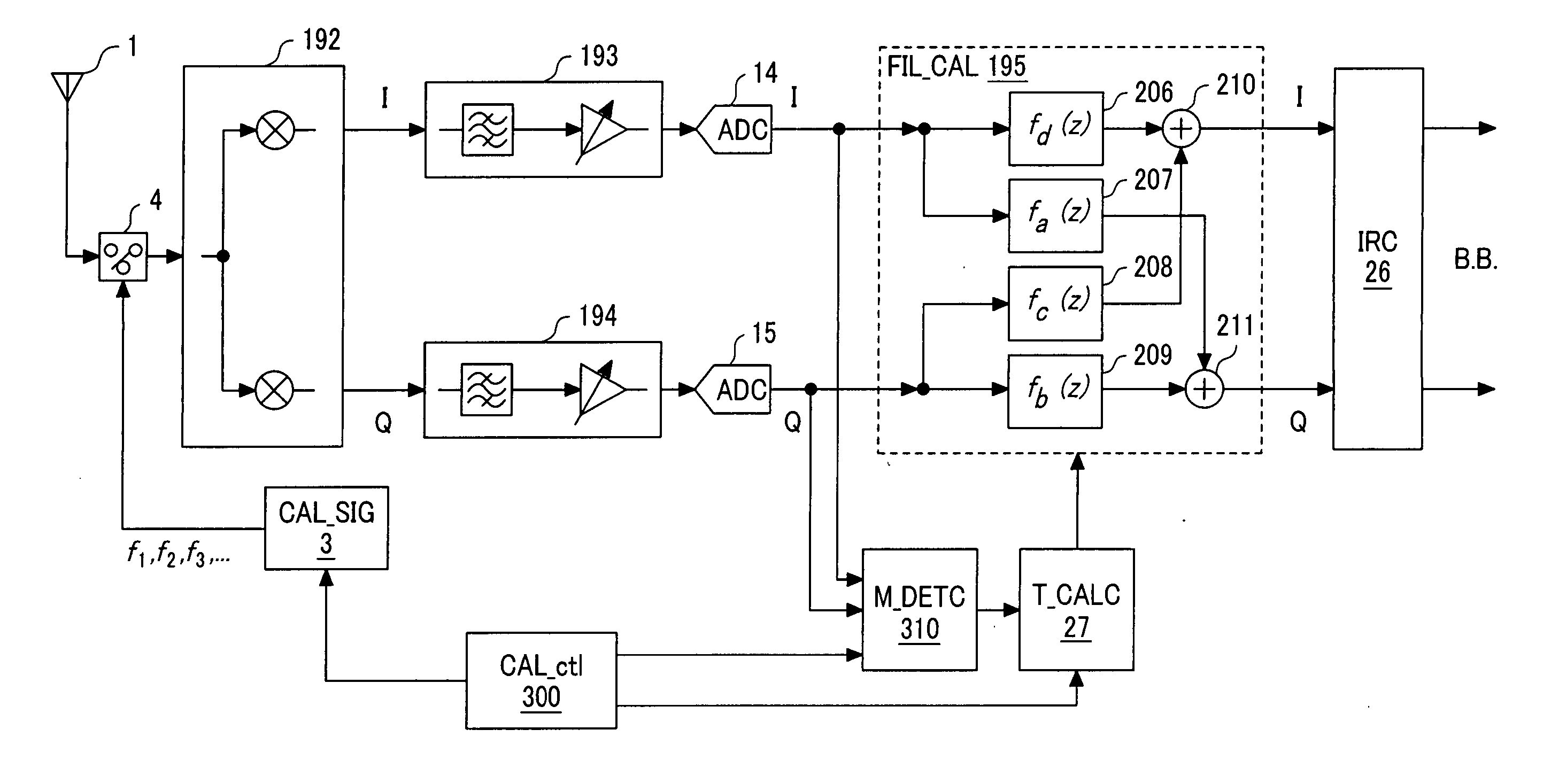

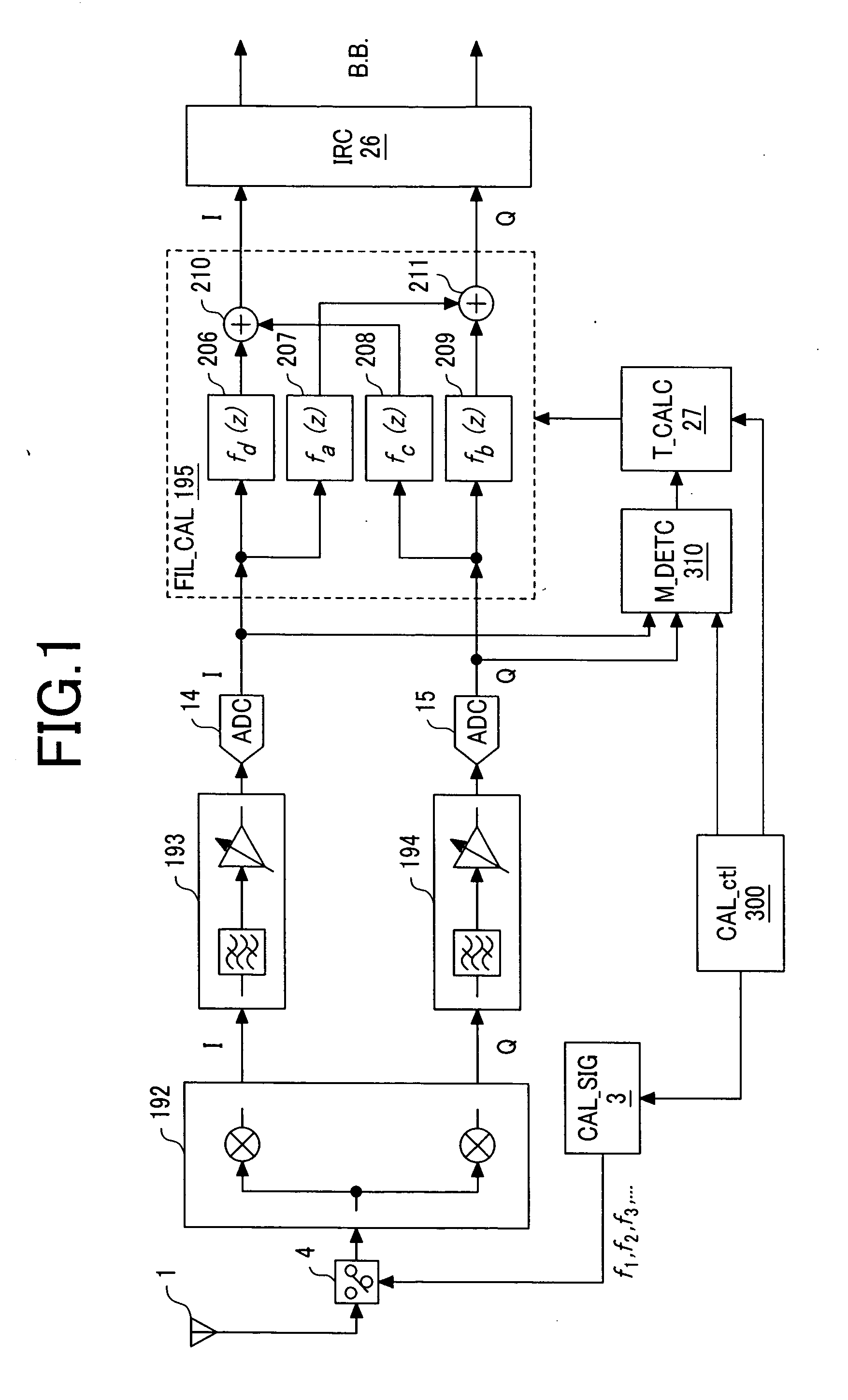

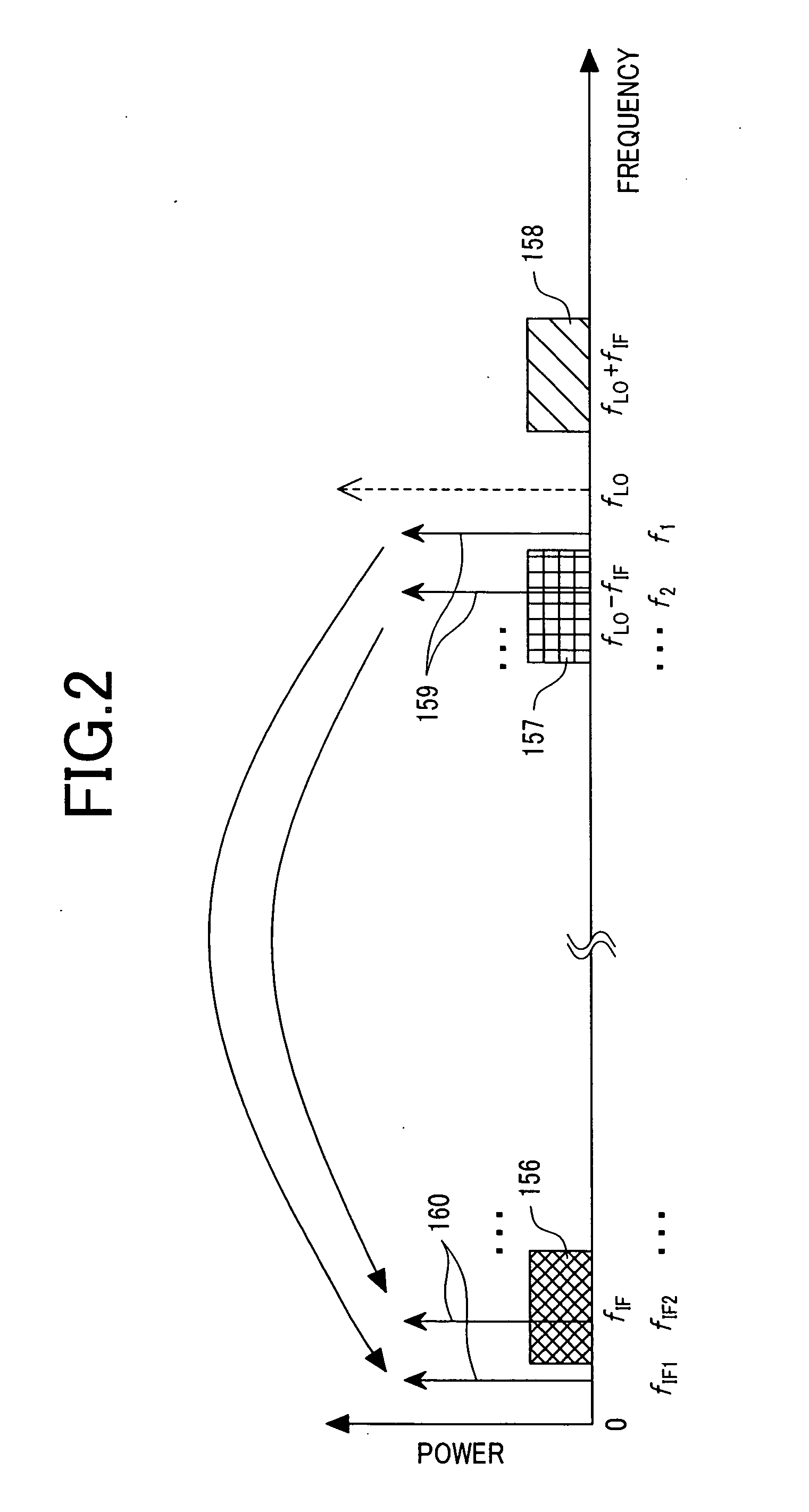

Receiver

InactiveUS20070080835A1Reduce componentsReduce equipmentElectric signal transmission systemsRadio transmissionFrequency bandPhysics

The receiver, which enables rejection of image signals with higher accuracy over wider frequency band, can be provided as a low IF receiver by inputting a calibration signal of frequency fi (1≦i≦N) before reception of signals and determining the frequency response fa(z) to fd(z) of a calibrating filter in a filter mismatch calibrating circuit (FIL_CAL) 195 to make zero amplitude and phase mismatches between the I component and Q component of the quadrature demodulation signal at the frequency fIFi.

Owner:RENESAS ELECTRONICS CORP

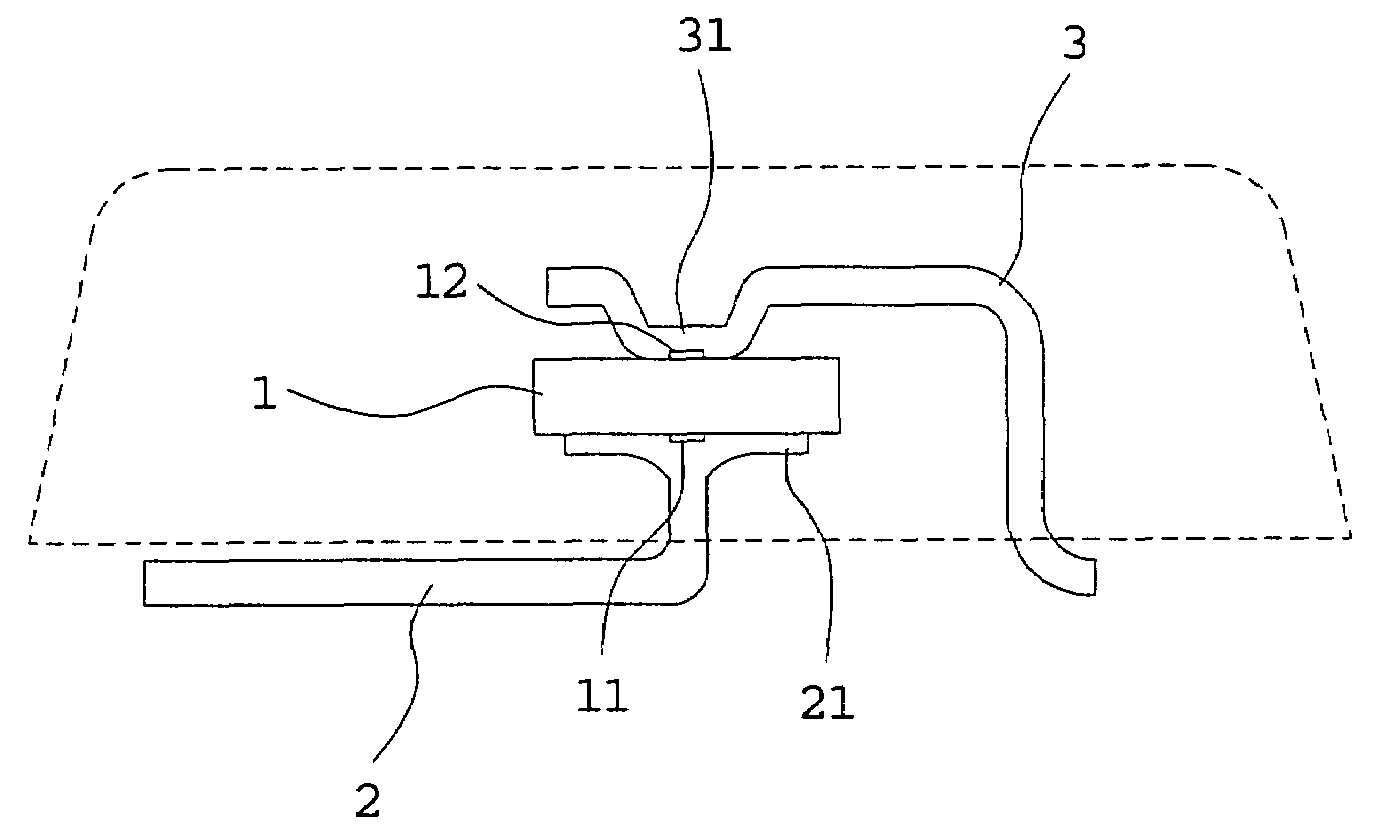

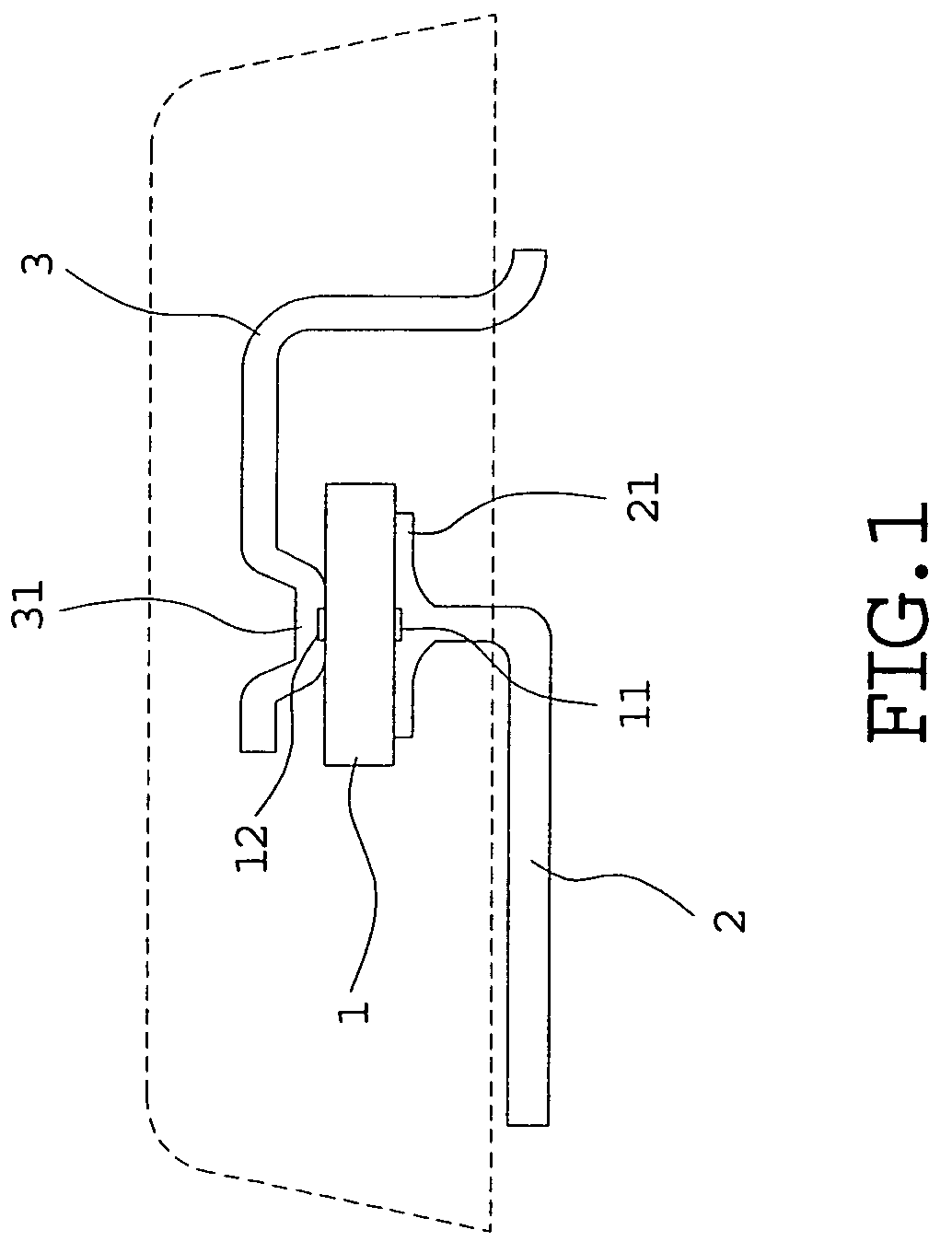

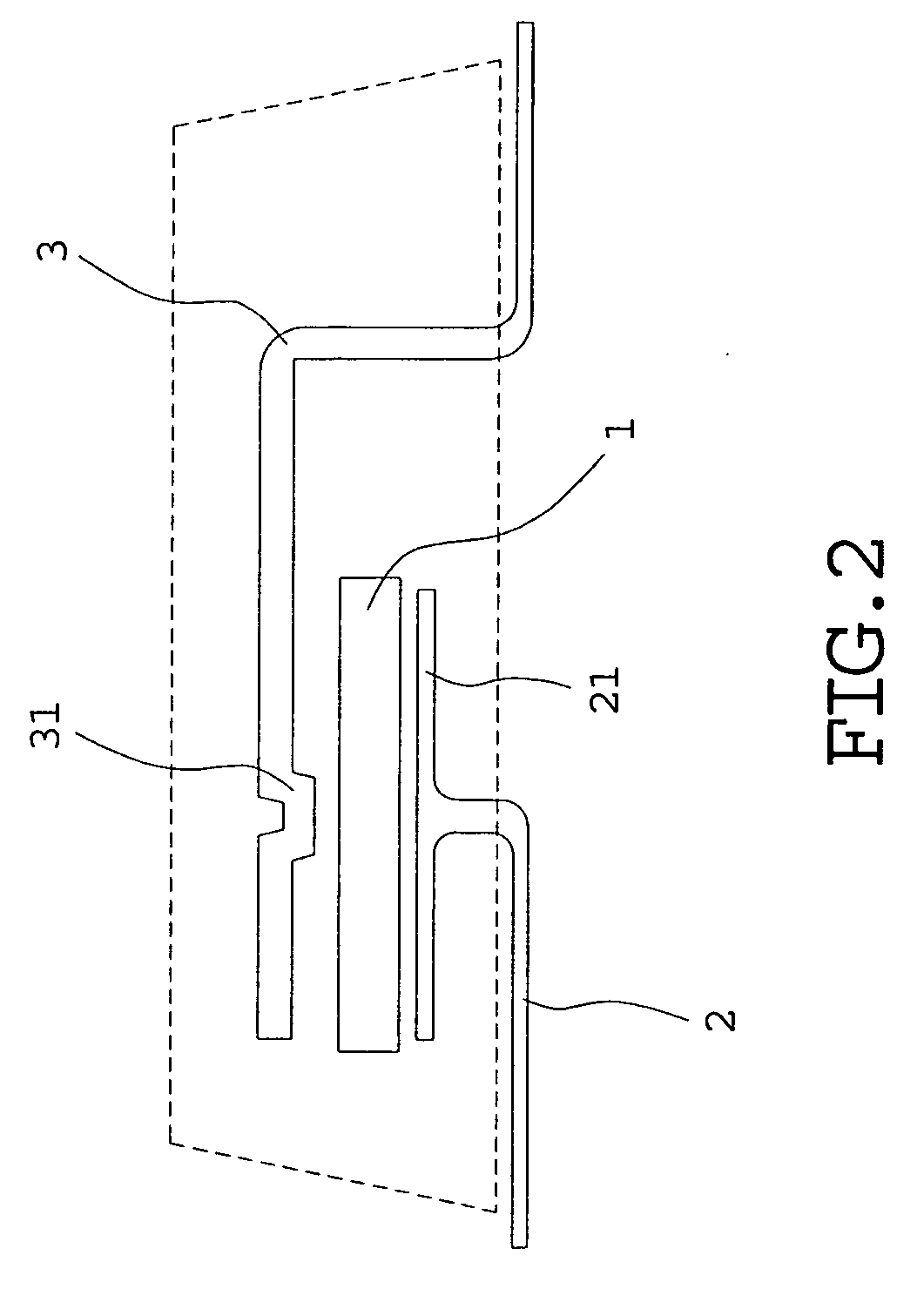

Surface mounting structure and packaging method thereof

InactiveUS20070290325A1Improve space utilizationSimplify System DesignSemiconductor/solid-state device detailsSolid-state devicesState of artSystems design

A surface mounting structure and a packaging method thereof comprises a chip, a first conducting wire and a second conducting wire. The two conducting wires instead of lead frame architecture of the prior art is that the lead frame and a bridge jumper connected with N junction and P junction instead of the two conducting wires. The two conducting wires are drawn out from a bottom of a package, and are pressed and bent to original surface of the surface mounting pins so as to increase space utilization rate. Thereby it is to improve a complicated lead frame architecture of the prior art, increase use space and simplify system design.

Owner:LITE ON SEMICON

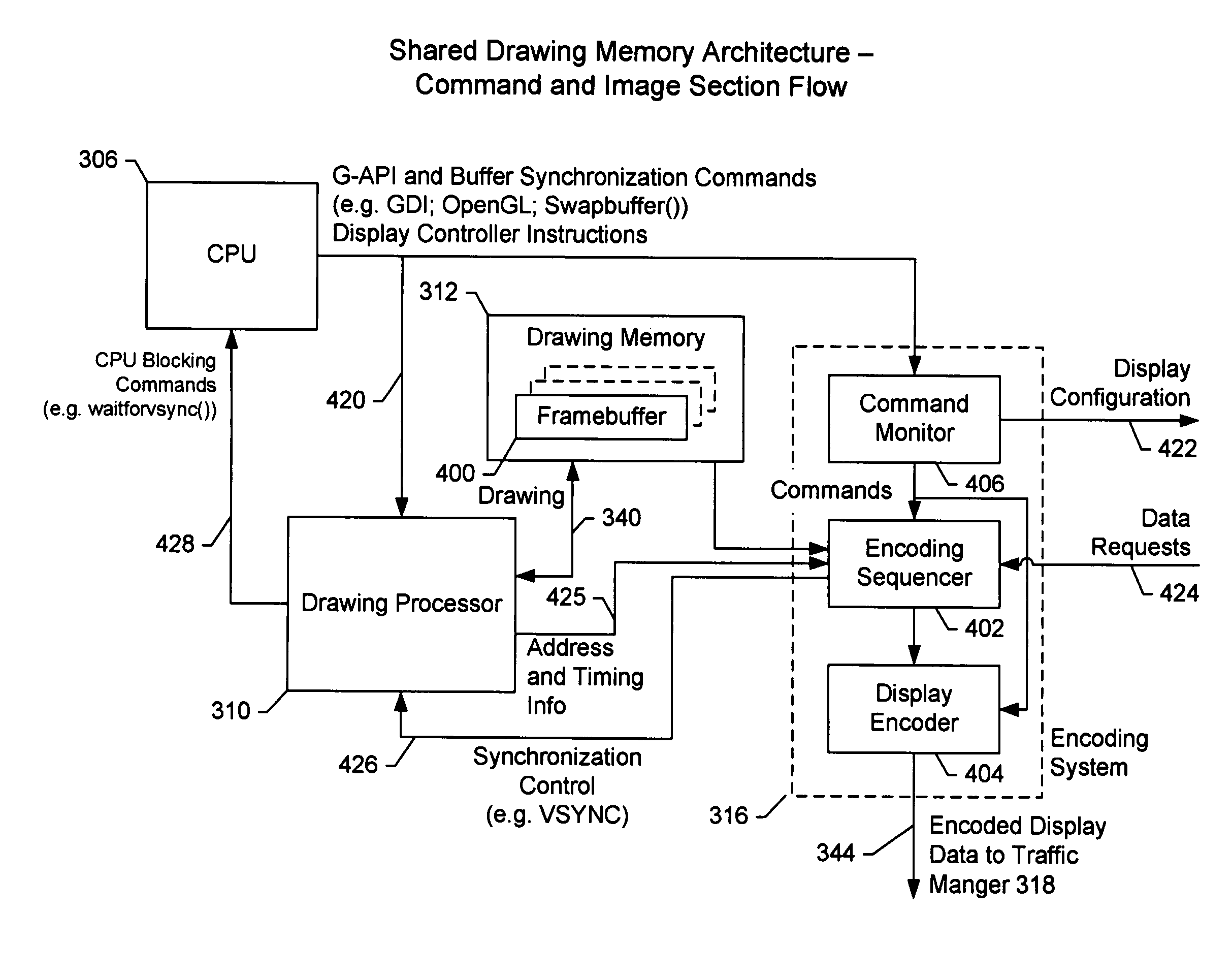

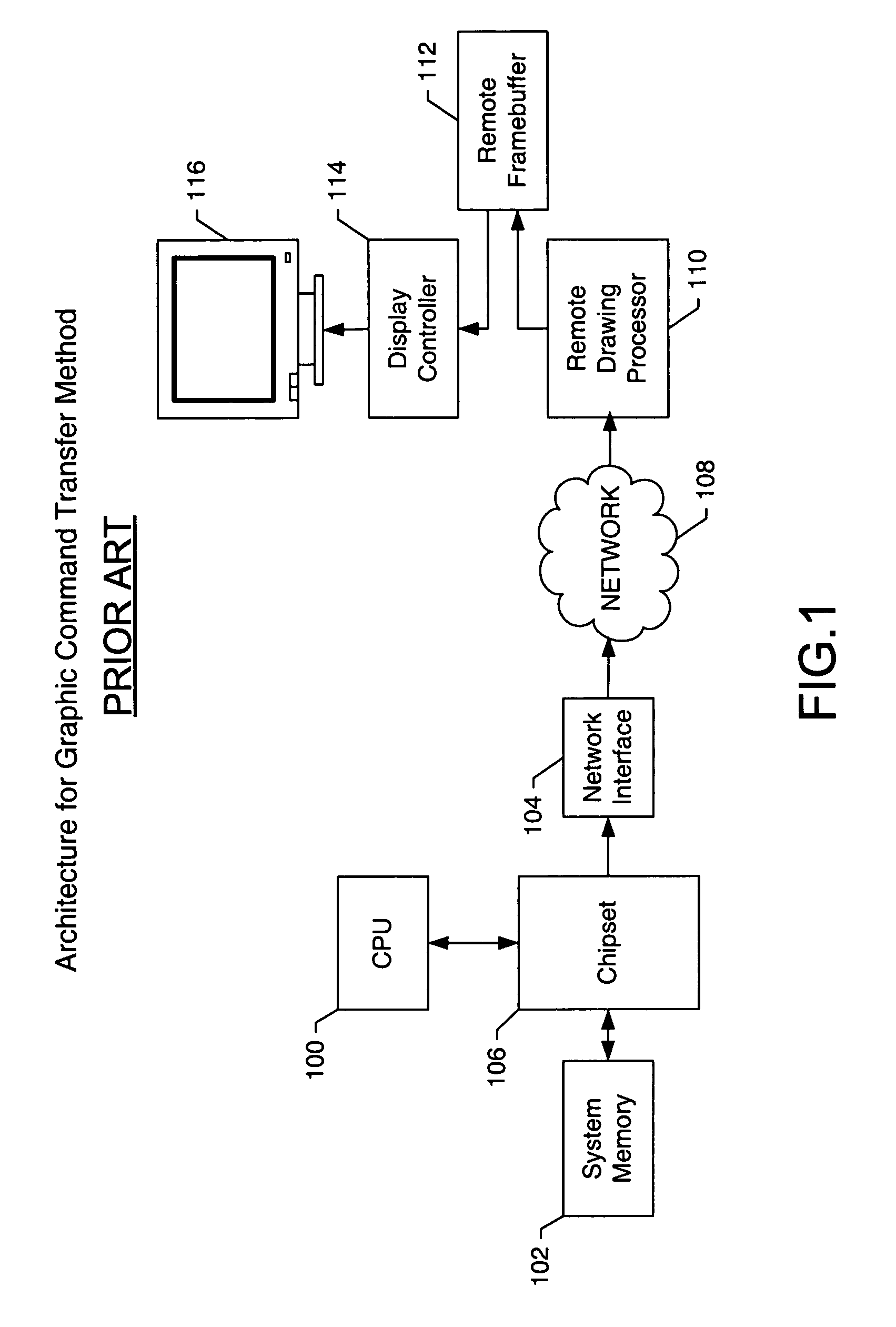

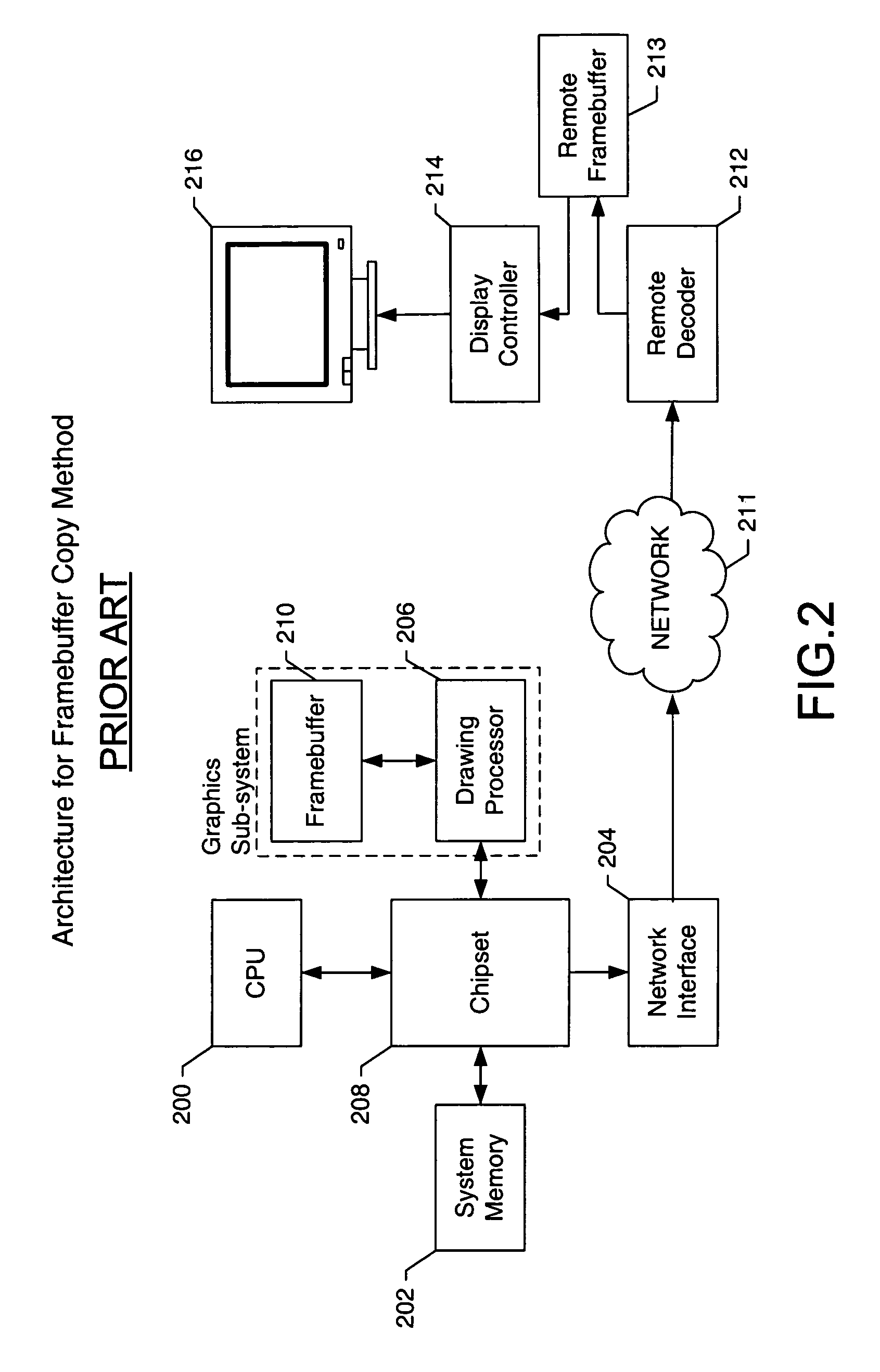

Methods and apparatus for encoding a shared drawing memory

ActiveUS7747086B1Efficient communicationReduce power consumptionStatic indicating devicesImage codingDisplay deviceComputer science

A display encoding system is disclosed. The display encoding system includes at least one processor, an encoding circuit, the encoding circuit having a structure separate from the structure of the processor(s), a communication connection to a computer network, a drawing memory, a traffic manager, and a memory access circuit. The processor(s) are configured to execute drawing commands, access the drawing memory via the memory access circuit to store image representation(s) in the drawing memory. The encoding circuit is configured to access the drawing memory to encode at least a portion of the image representation(s) stored in the drawing memory based on the executed drawing commands. The traffic manager is configured to transmit the encoded image over the communication connection to at least one display device.

Owner:TERADICI CORP

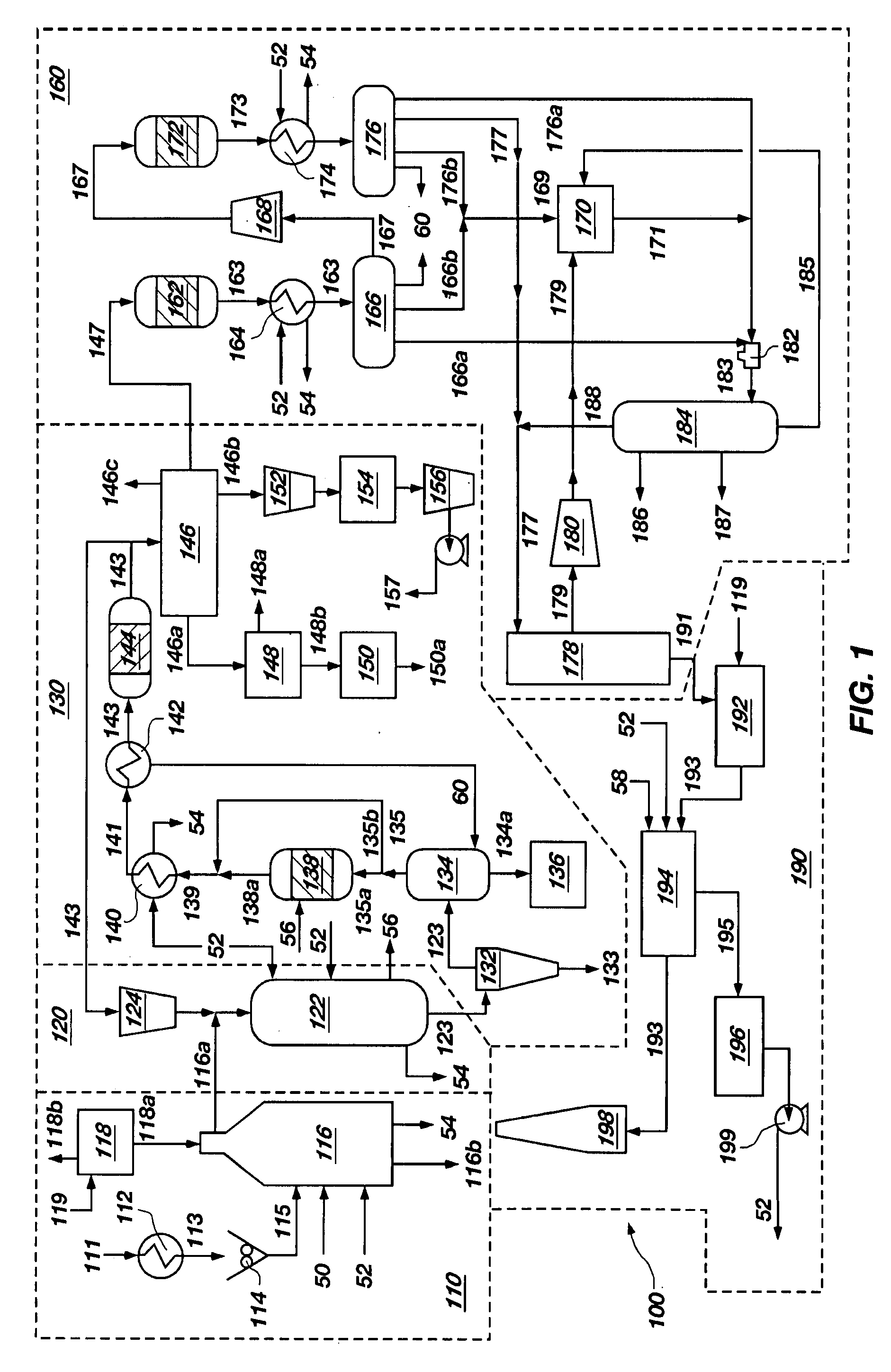

Fixed bed hydroprocessing methods and systems and methods for upgrading an existing fixed bed system

ActiveUS20050241992A1Quality improvementReduce formationCatalyst regeneration/reactivationCatalyst activation/preparationDecompositionFixed bed

A fixed bed hydroprocessing system, and also a method for upgrading a pre-existing fixed bed hydroprocessing system, involves preliminarily upgrading a heavy oil feedstock in one or more slurry phase reactors using a colloidal or molecular catalyst and then further hydroprocessing the upgraded feedstock within one or more fixed bed reactors using a porous supported catalyst. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. Asphaltene or other hydrocarbon molecules otherwise too large to diffuse into the pores of the fixed bed catalyst can be upgraded by the colloidal or molecular catalyst. One or more slurry phase reactors may be built and positioned upstream from one or more fixed bed reactors of a pre-existing fixed bed system and / or converted from one or more pre-existing fixed bed reactors.

Owner:HEADWATERS TECH INNOVATION LLC

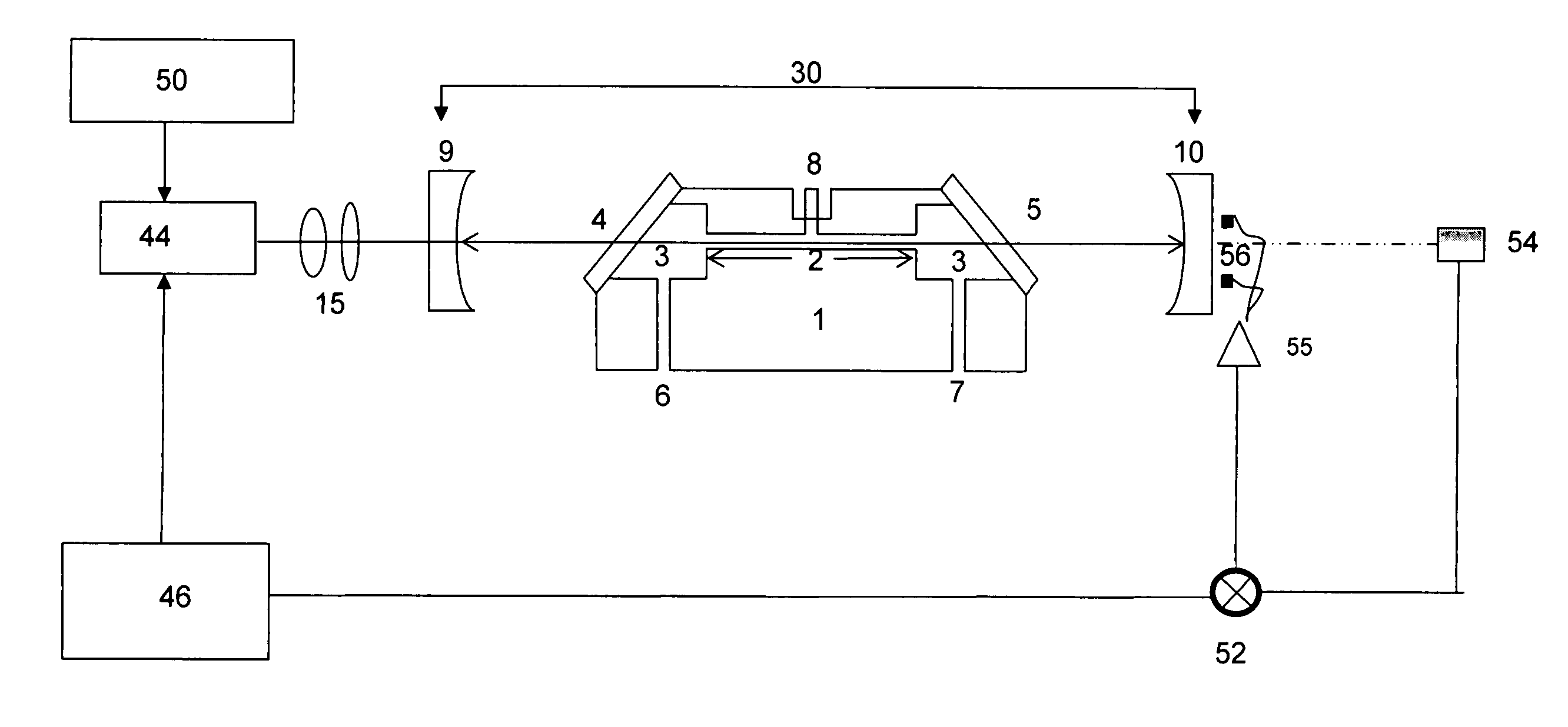

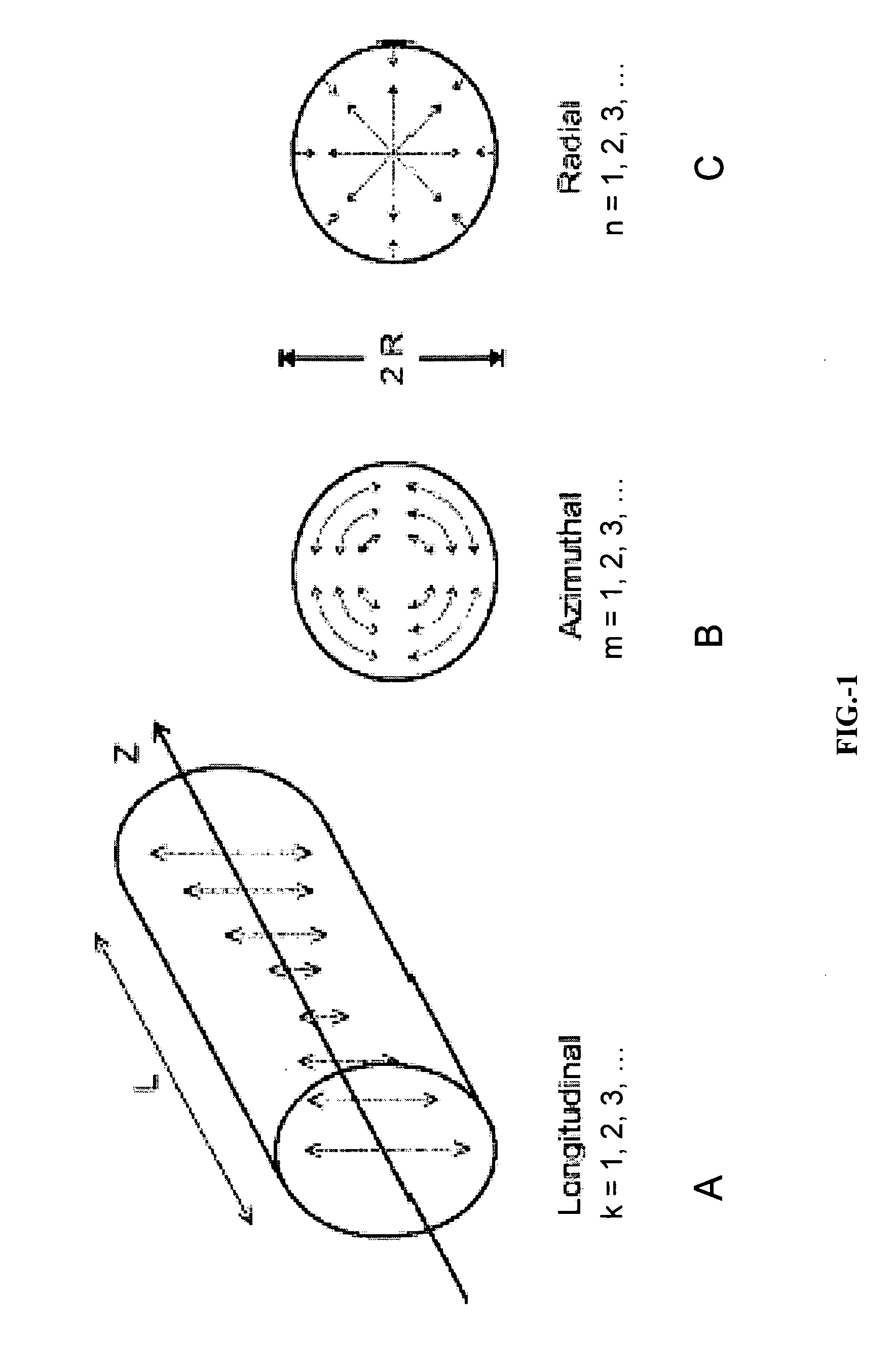

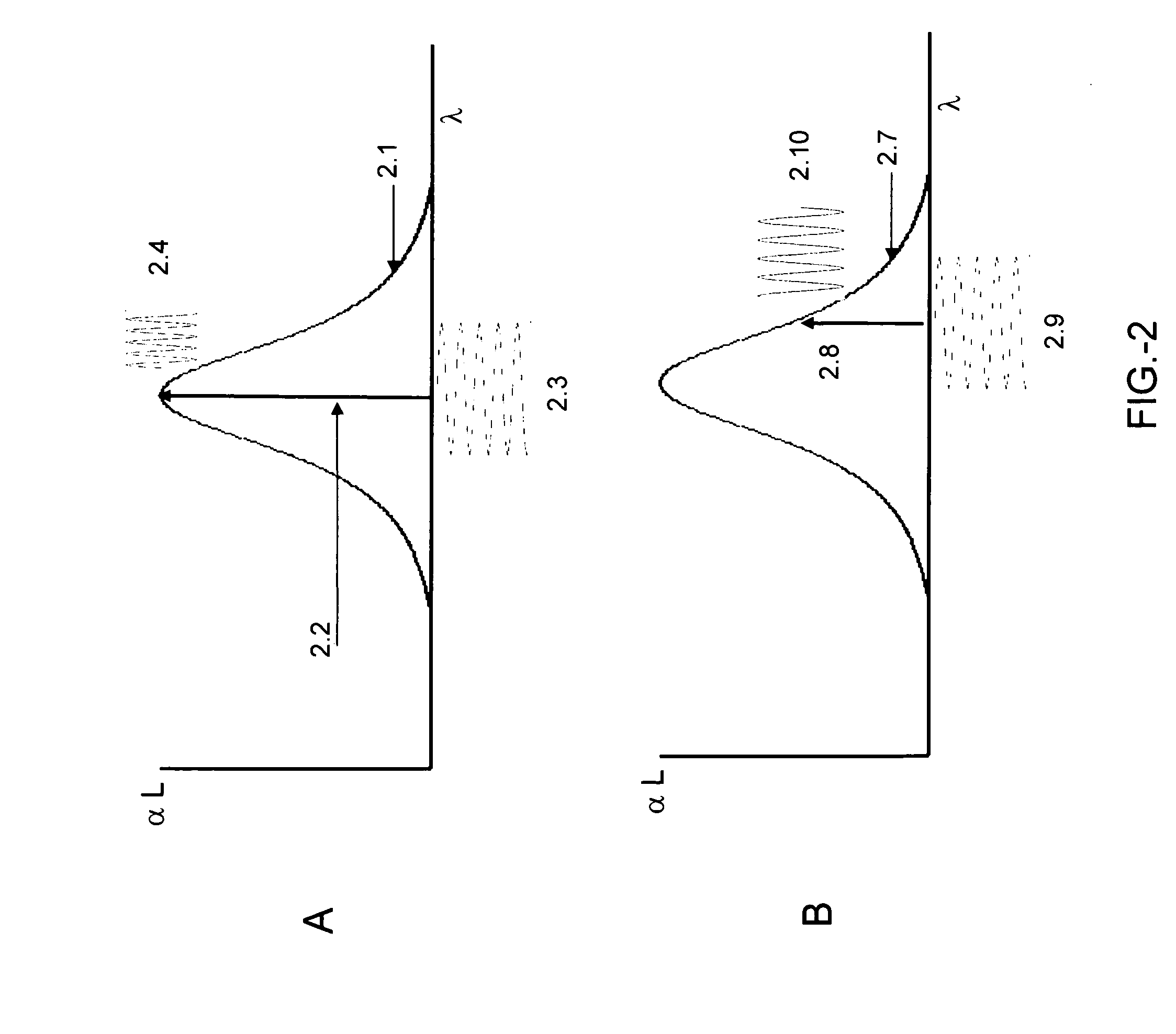

System and method for gas analysis using doubly resonant photoacoustic spectroscopy

ActiveUS20060123884A1Increase productionReduce equipment downtimeMaterial analysis using wave/particle radiationMaterial analysis using microwave meansGas analysisGas detector

A method for analyzing gas concentration using doubly resonant photoacoustic spectroscopy, and a doubly resonant photaoacoustic gas detector comprising: i) a continuous wave light beam whose wavelength coincides with an absorption wavelength of a gaseous analyte; ii) a closed path optical cavity having at least two reflective surfaces; iii) an acoustic resonator chamber contained within said optical cavity, and comprising an acoustic sensor for detecting sound waves generated by a gaseous analyte present within said chamber, the light beam passing sequentially into, through and out of said chamber, and being repeatedly reflected back and forth through said chamber, and being modulated at a frequency which is equal to or equal to one-half of an acoustic resonance frequency of said acoustic resonator chamber.

Owner:LI COR

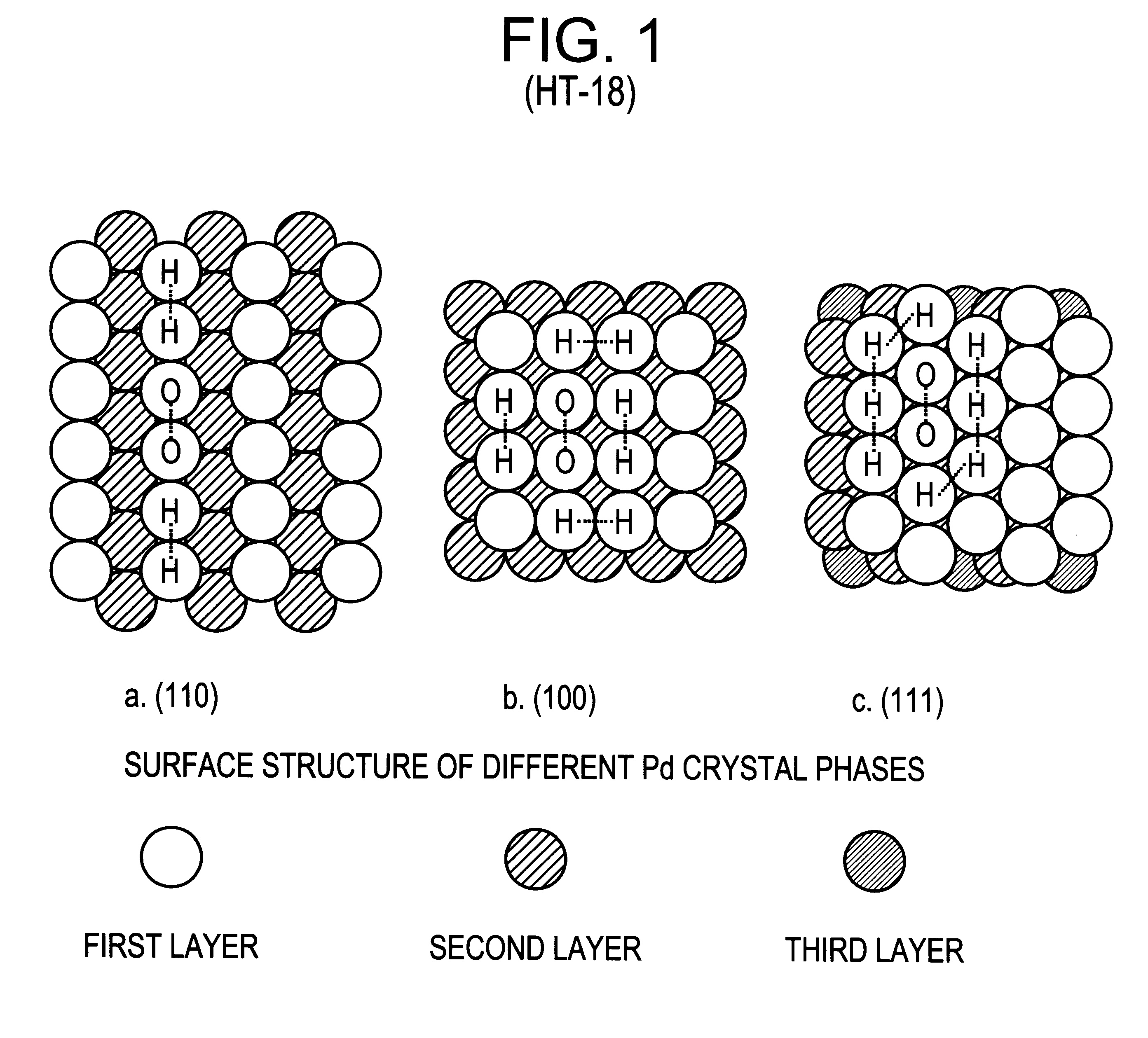

Integrated process and dual-function catalyst for olefin epoxidation

The invention discloses a dual-functional catalyst composition and an integrated process for production of olefin epoxides including propylene oxide by catalytic reaction of hydrogen peroxide from hydrogen and oxygen with olefin feeds such as propylene. The epoxides and hydrogen peroxide are preferably produced simultaneously in situ. The dual-functional catalyst comprises noble metal crystallites with dimensions on the nanometer scale (on the order of <1 nm to 10 nm), specially dispersed on titanium silicalite substrate particles. The dual functional catalyst catalyzes both the direct reaction of hydrogen and oxygen to generate hydrogen peroxide intermediate on the noble metal catalyst surface and the reaction of the hydrogen peroxide intermediate with the propylene feed to generate propylene oxide product. Combining both these functions in a single catalyst provides a very efficient integrated process operable below the flammability limits of hydrogen and highly selective for the production of hydrogen peroxide to produce olefin oxides such as propylene oxide without formation of undesired co-products.

Owner:HEADWATERS TECH INNOVATION GRP

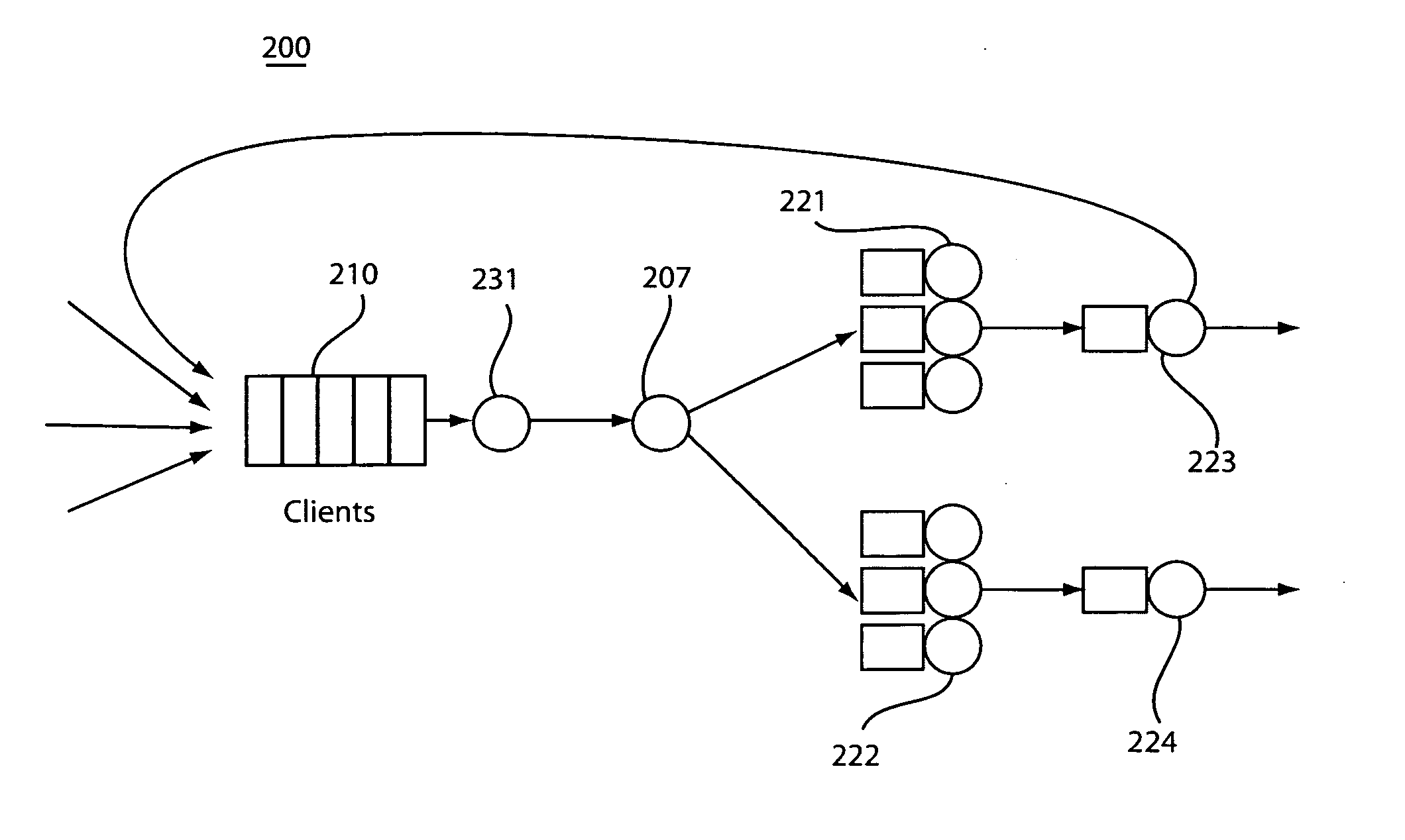

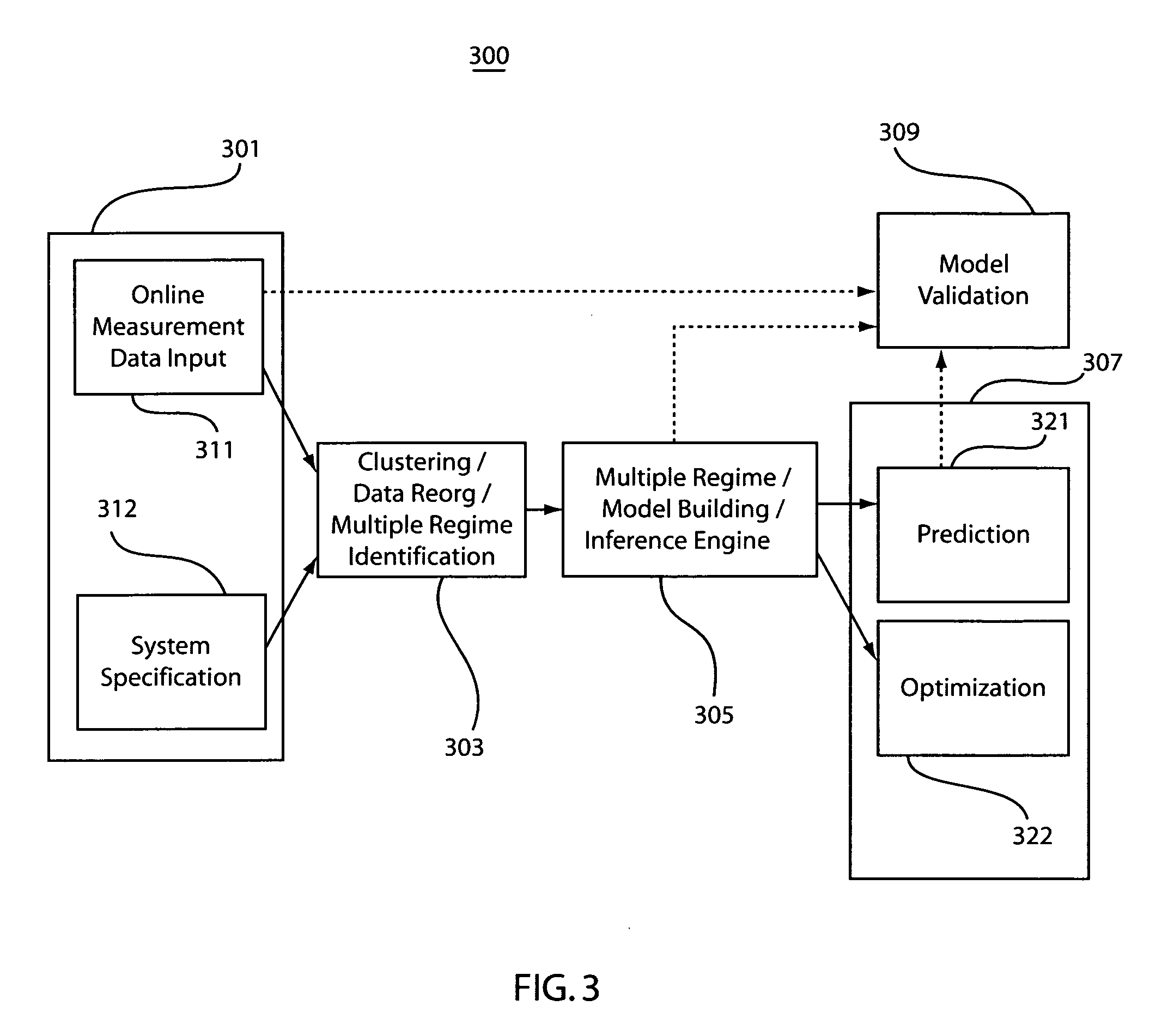

Method and system for on-line performance modeling using inference for real production it systems

ActiveUS20070168494A1Reduce equipmentReduce laborDigital computer detailsNuclear monitoringClustered dataCluster based

A system and method for performance modeling for an information technology (IT) system having a server(s) for performing a number of types of transactions includes receiving data for system topology and transaction flows and receiving performance measurement data for the IT system. The measurement data is clustered into multiple regimes based on similarities. Service demand and network delay parameters may be inferred based on clustered data.

Owner:IBM CORP

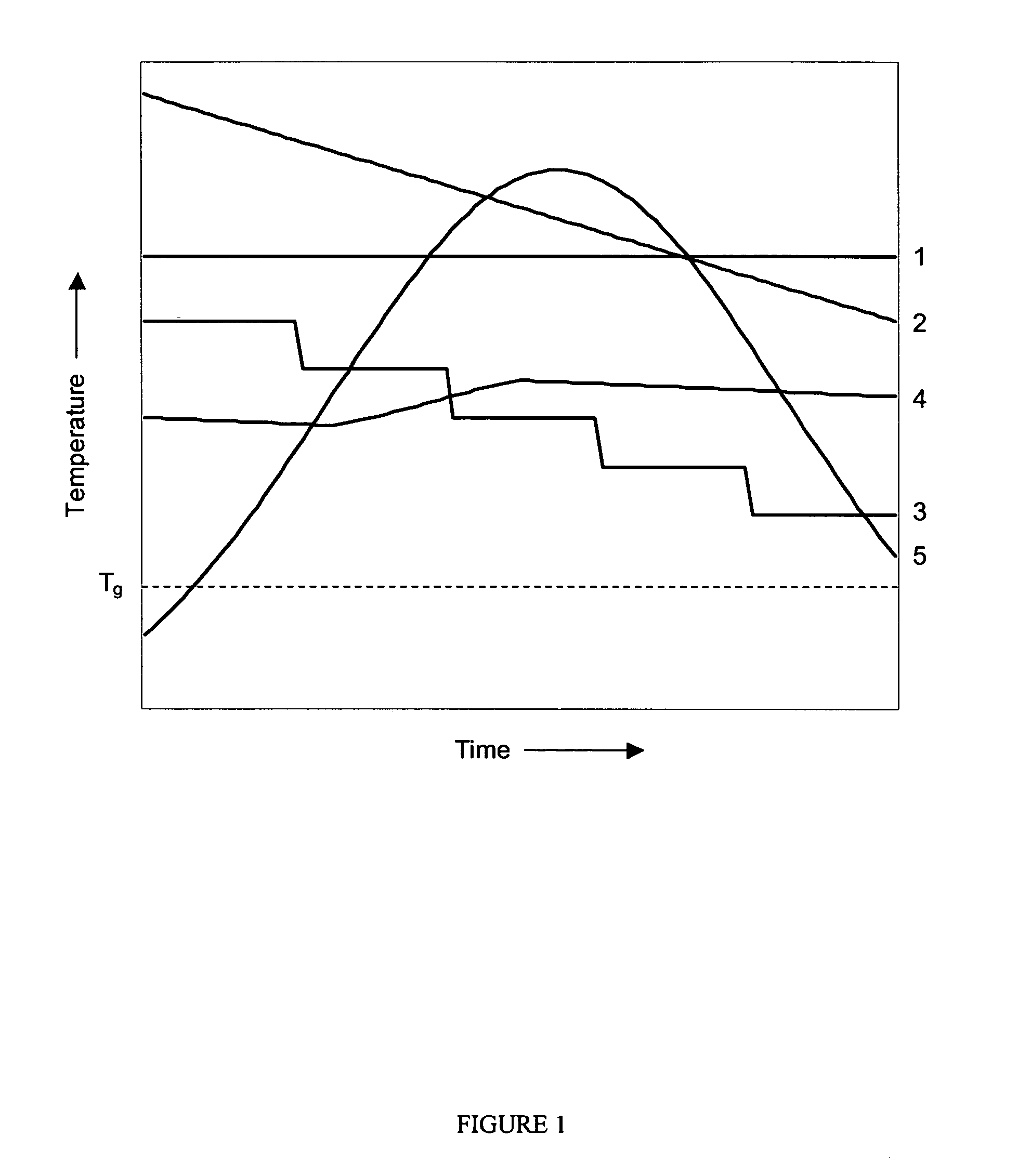

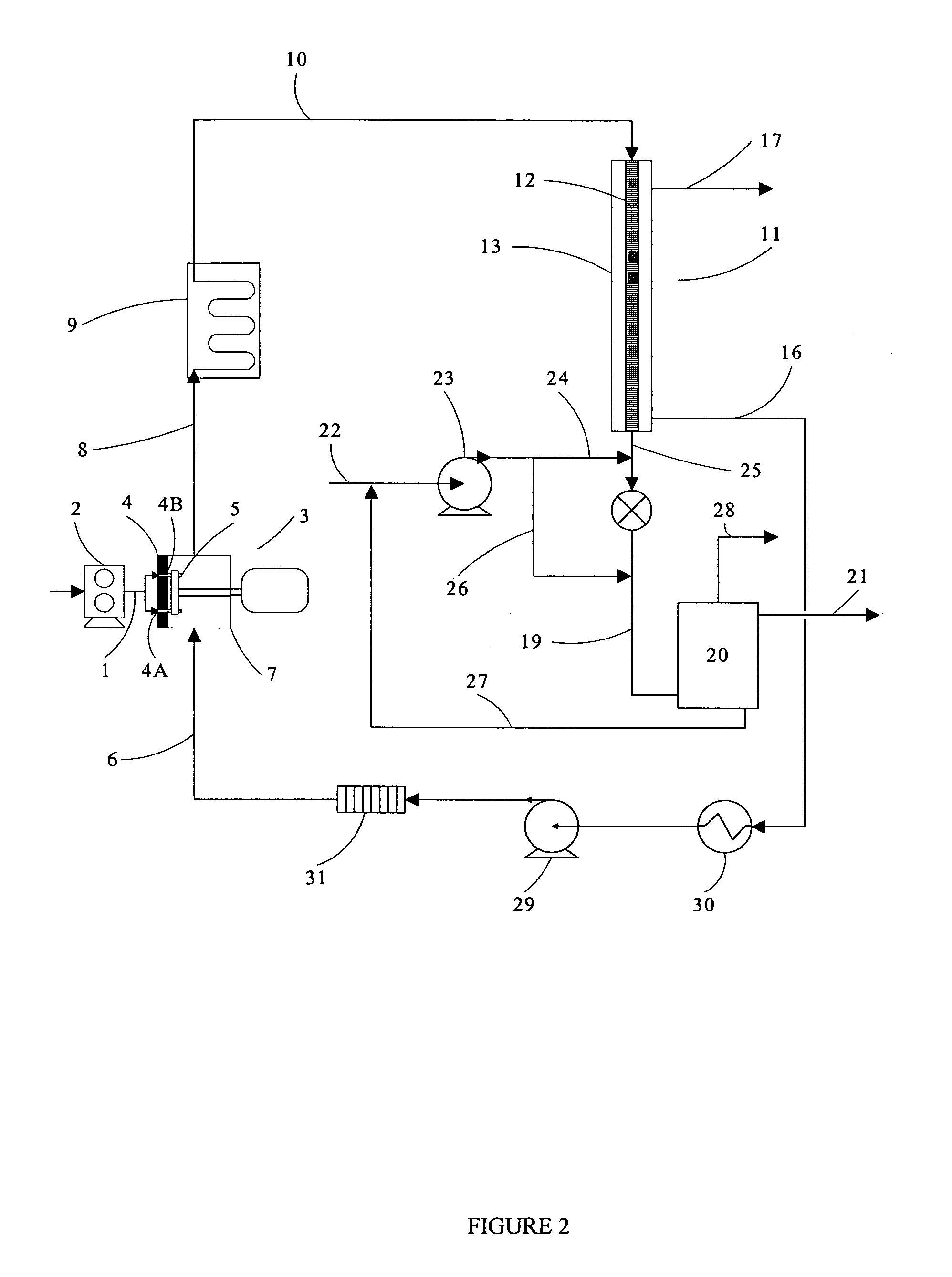

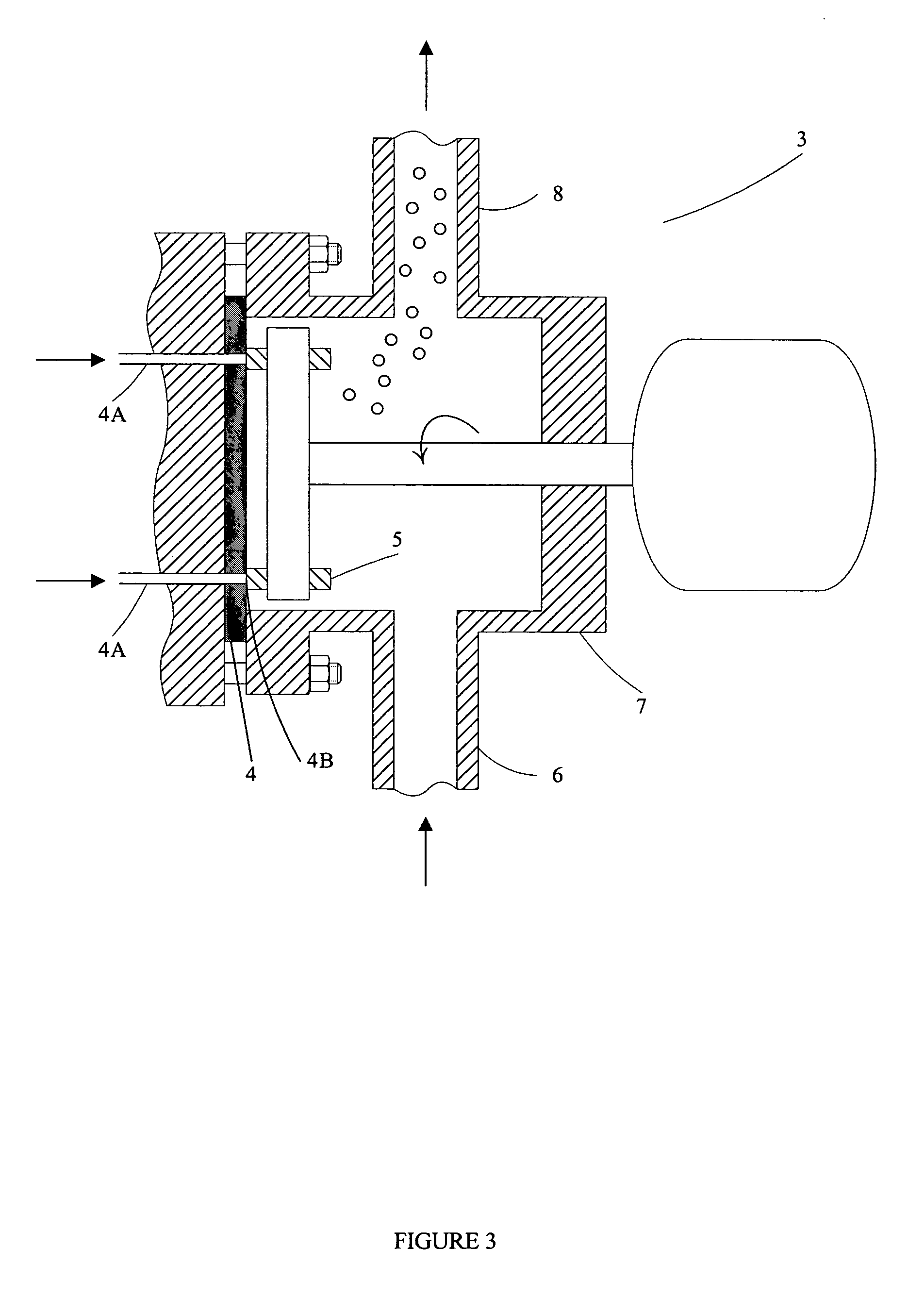

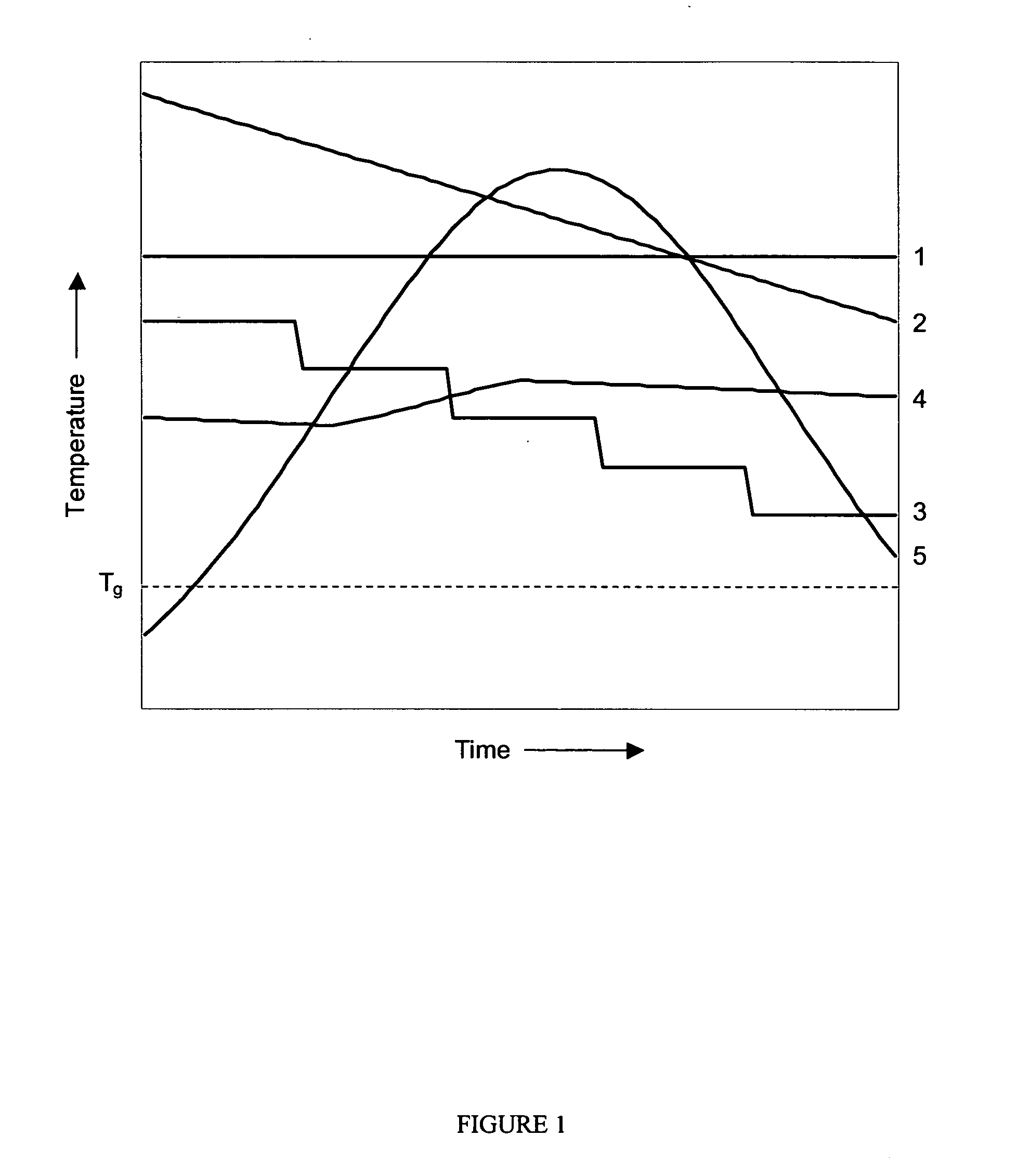

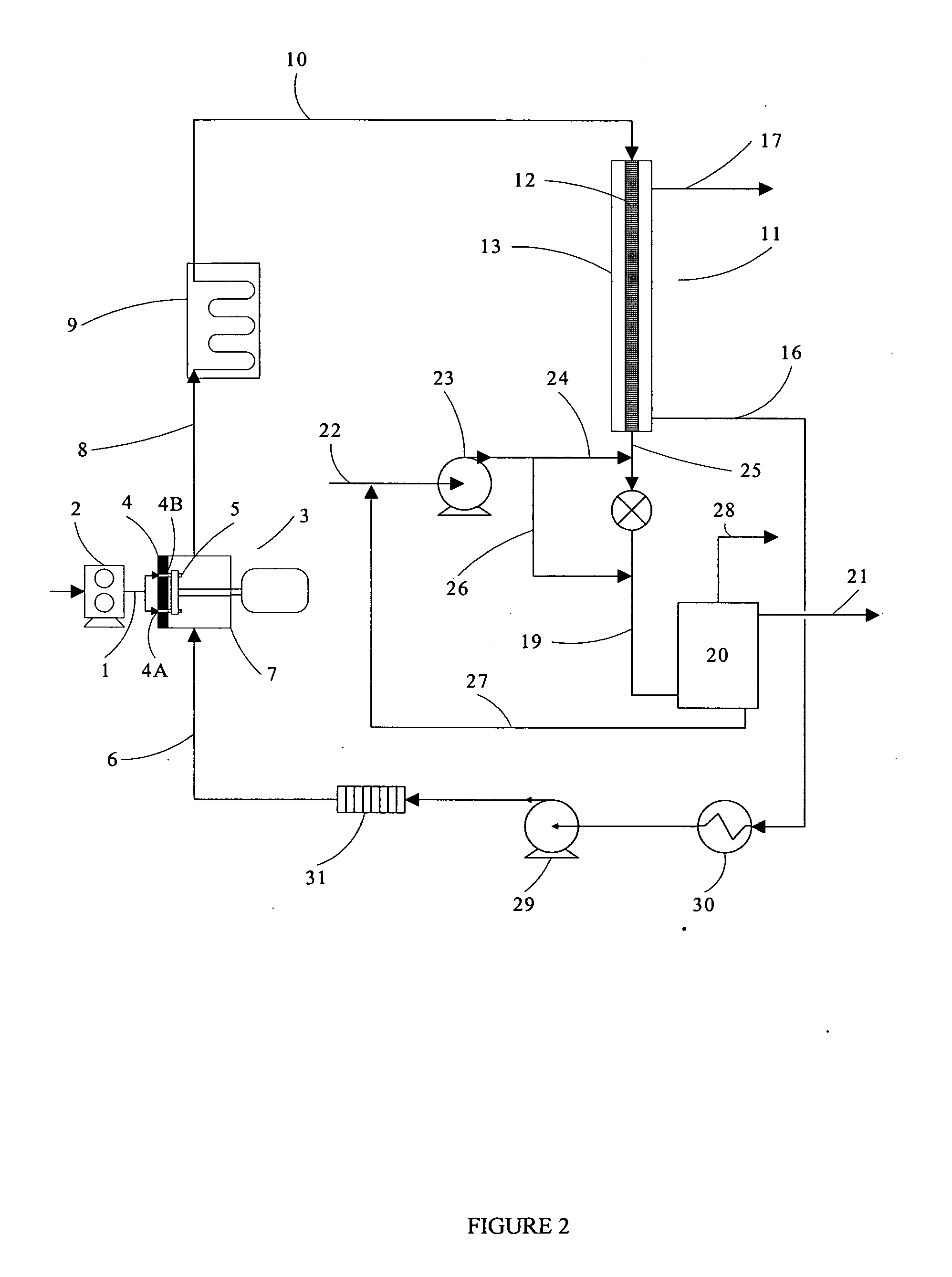

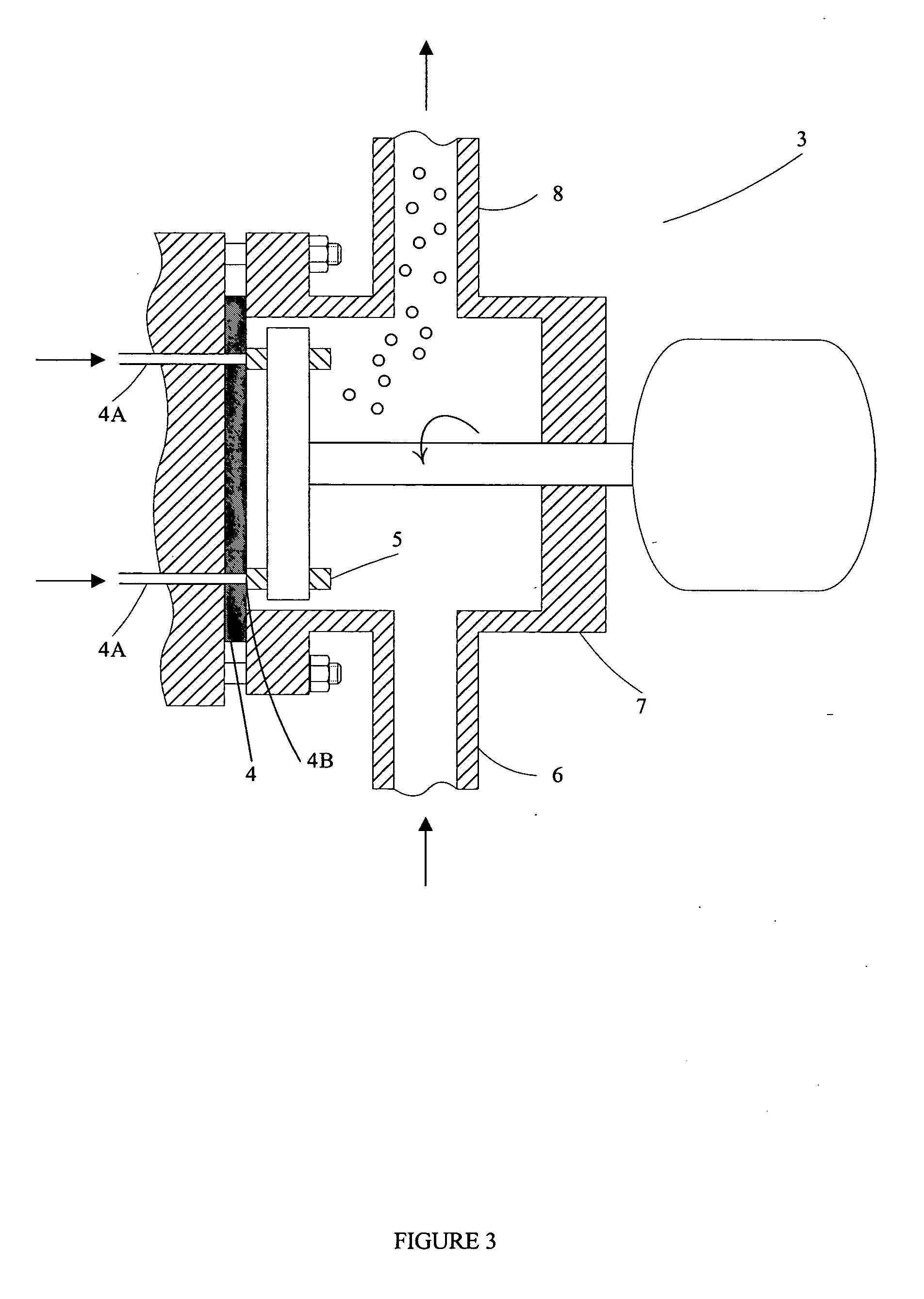

Thermal crystallization of a molten polyester polymer in a fluid

InactiveUS7192545B2Reduce molecular weightEnergy efficiencyDrying gas arrangementsCeramic shaping apparatusPolyesterLiquid medium

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

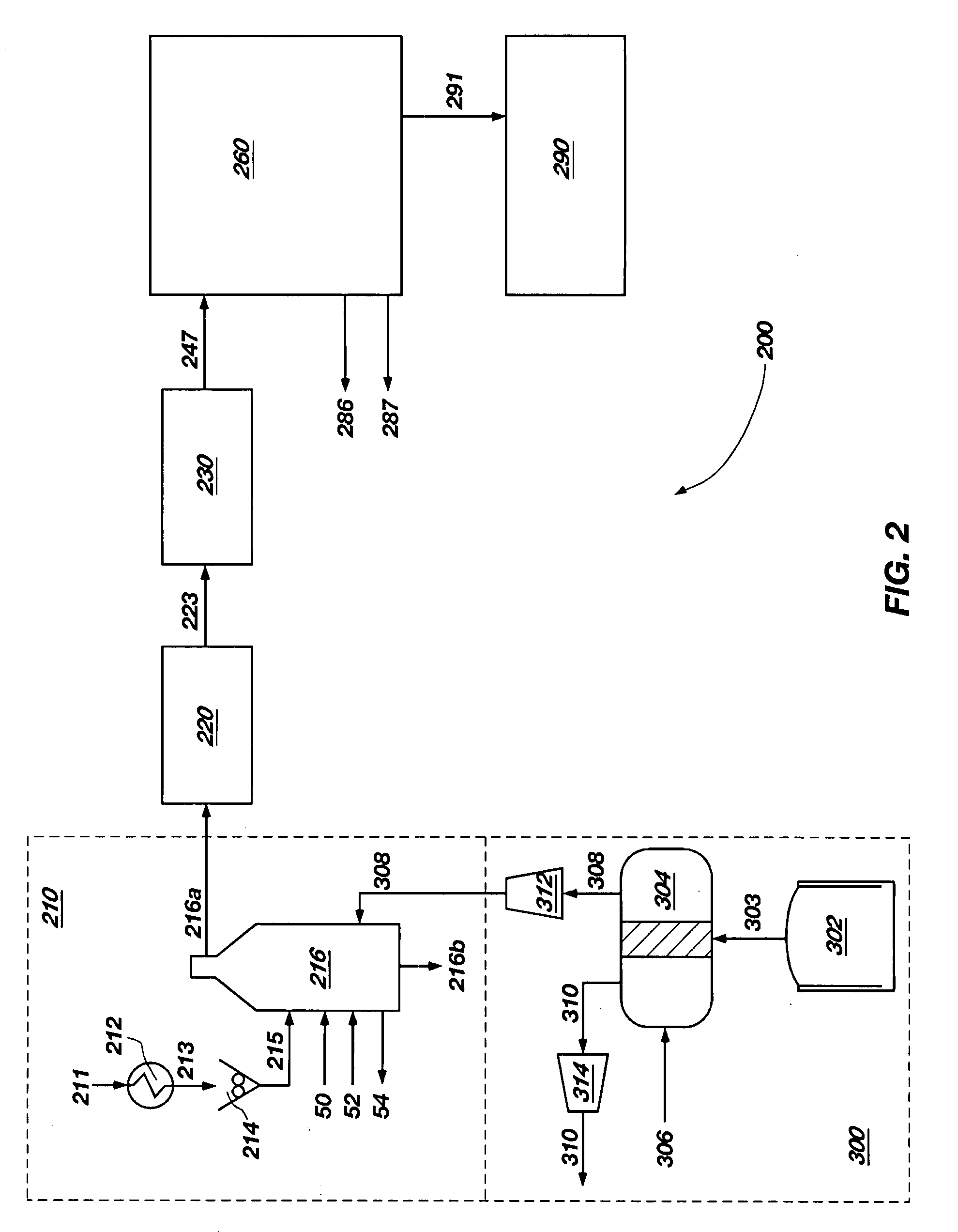

Synthetic fuel production methods and apparatuses

InactiveUS20080098654A1Promote conversionReduce the amount requiredMuffle furnacesRetortsLiquid hydrocarbonsLiquid fuel

Carbon-containing tail gases and pollutants in a coal-to-liquid hydrocarbon production process, or other liquid fuel production process, may be reacted to produce additional synthesis gas which may be used to produce liquid fuels and hydrocarbons or which may be recycled within the liquid fuel production process to improve conversion of carbon to liquid fuels or hydrocarbons.

Owner:BATTELLE ENERGY ALLIANCE LLC

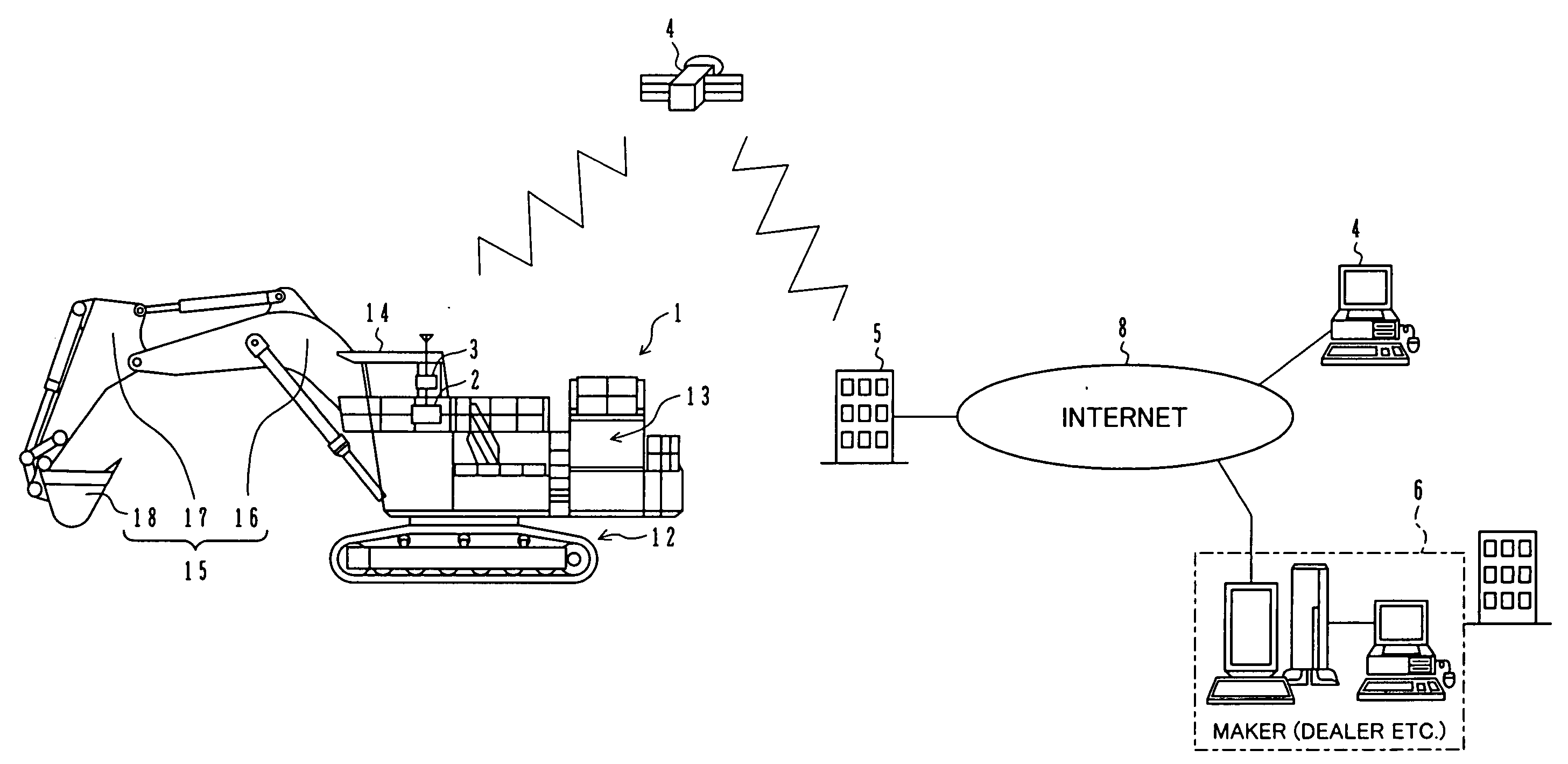

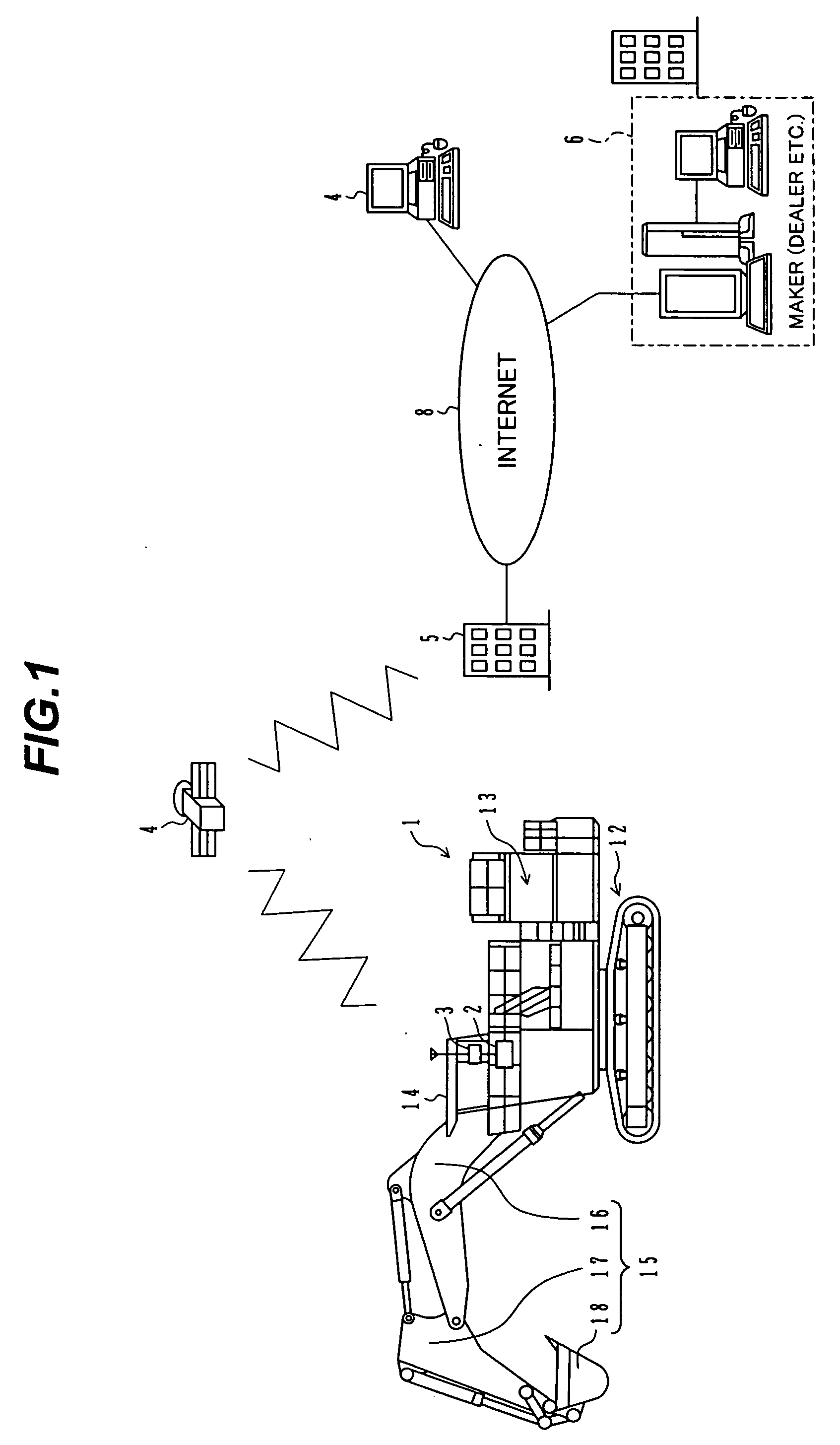

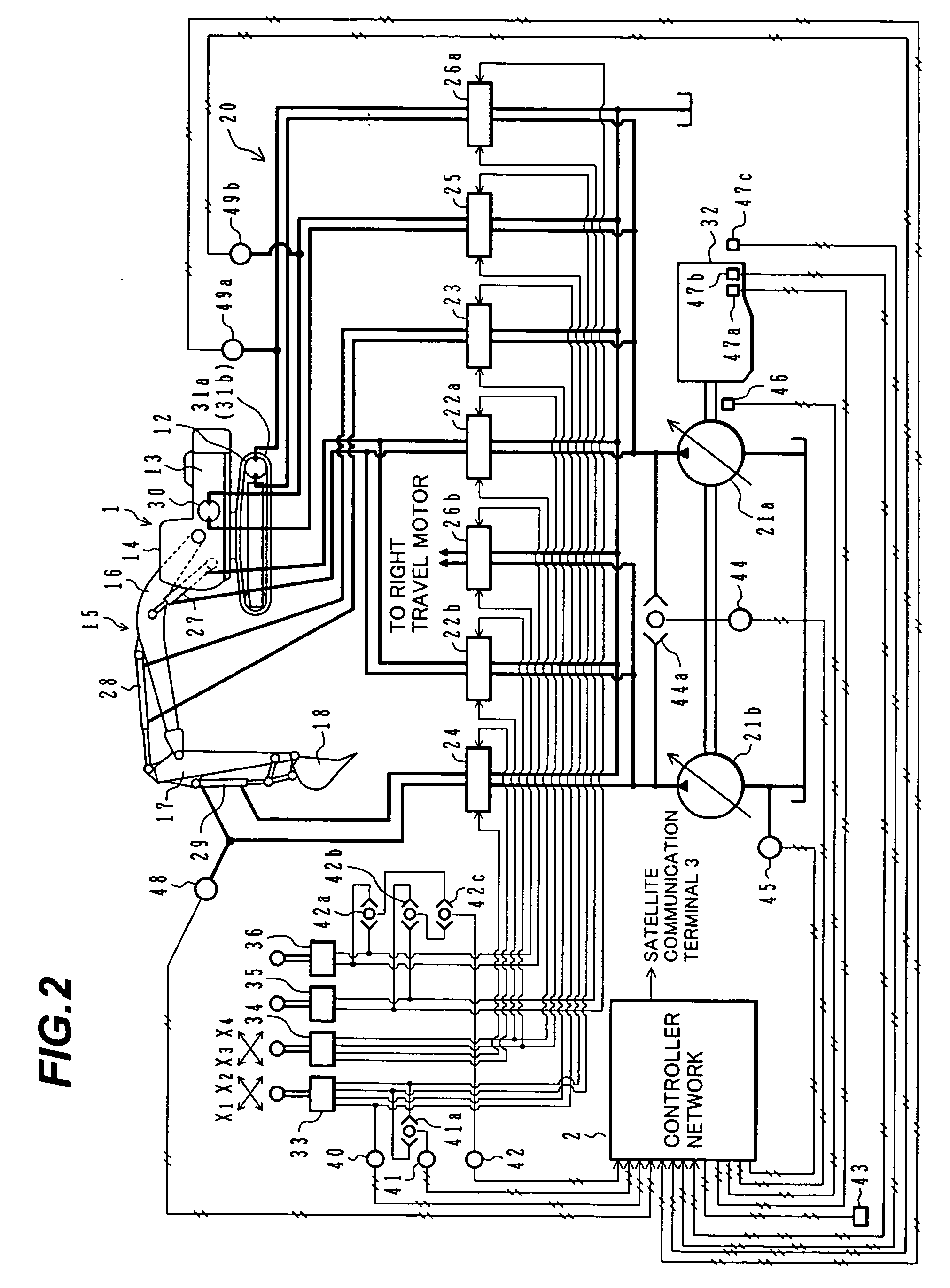

Operation information control device for construction machine and construction machine operation information control system provided with it

InactiveUS20060212203A1Drawback can be obviatedRestraining the drop in productivityVehicle testingData processing applicationsMachineOperational data store

A data recording unit 60 for managing operating situations of a hydraulic excavator 1 comprises a RAM 67 for taking in and storing plural kinds of operational information regarding the hydraulic excavator 1 as operational data, and a CPU 65 for extracting top priority operational data from among the plural kinds of operational data stored in the RAM 67, and transmitting the extracted data to the supervising side via satellite communication. Top priority data among the plural kinds of operational data of the hydraulic excavator, which may bring the hydraulic excavator into rest, can be presented to a supervisor of the hydraulic excavator, etc.

Owner:NIHON KENKI CO LTD

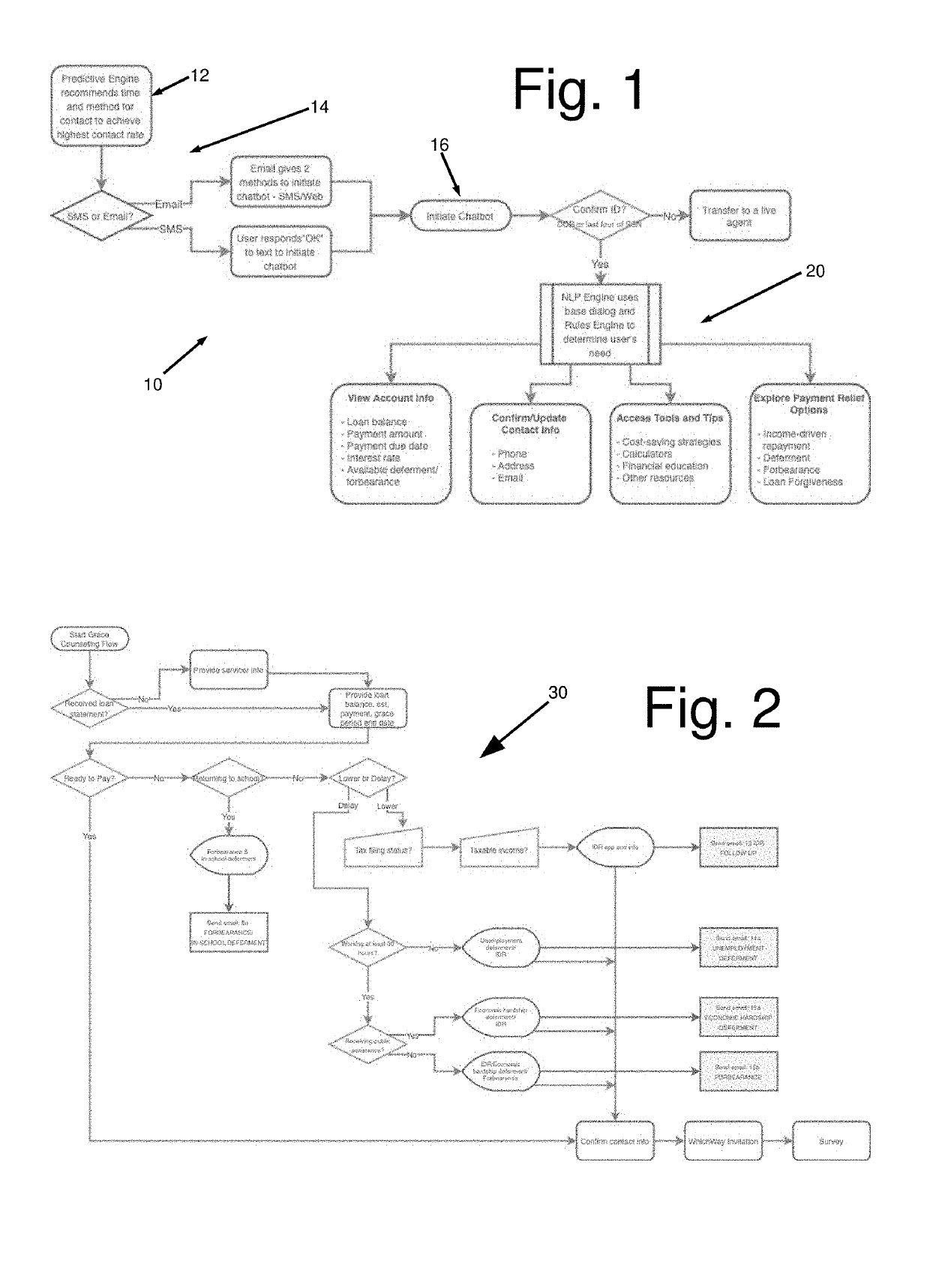

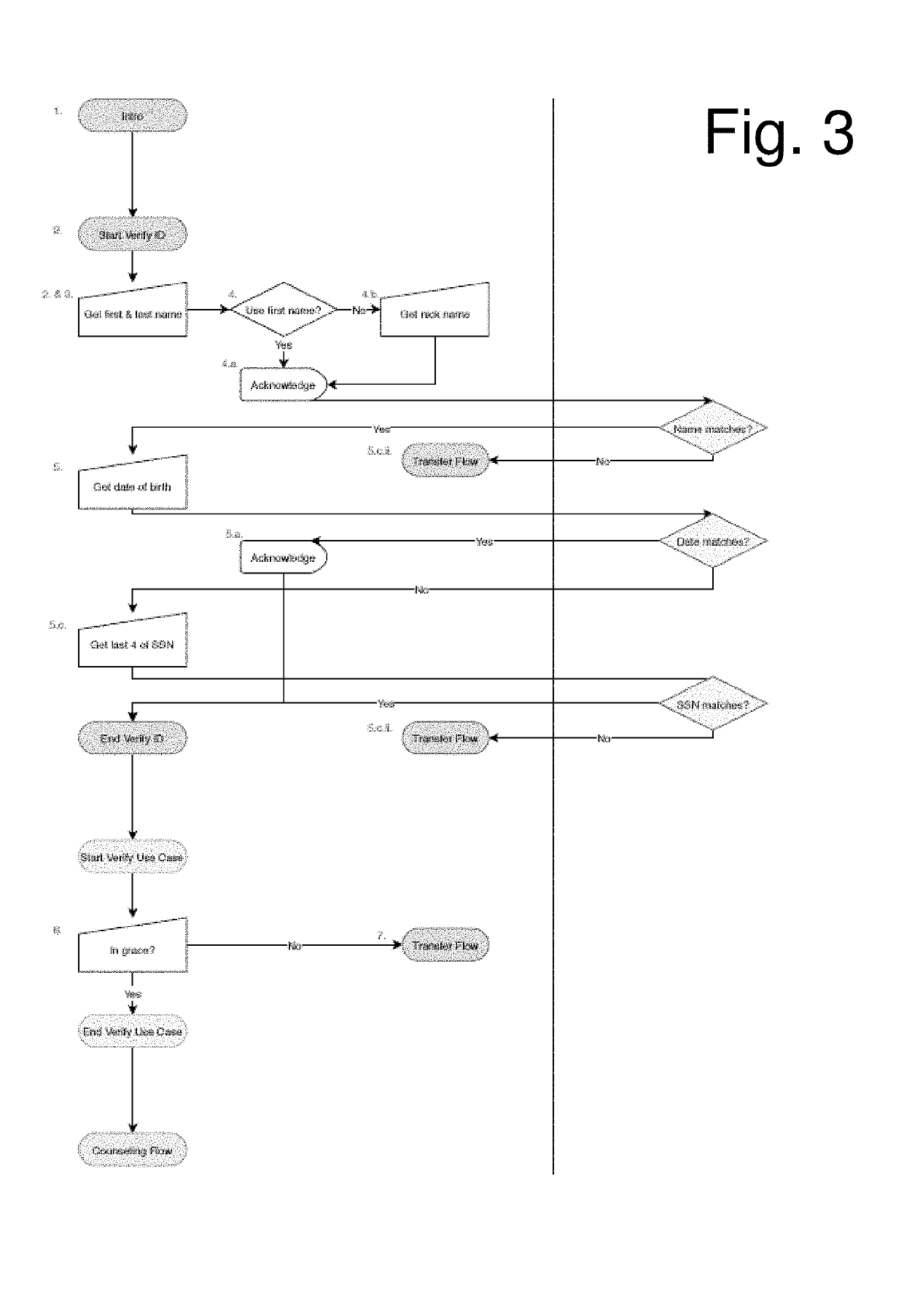

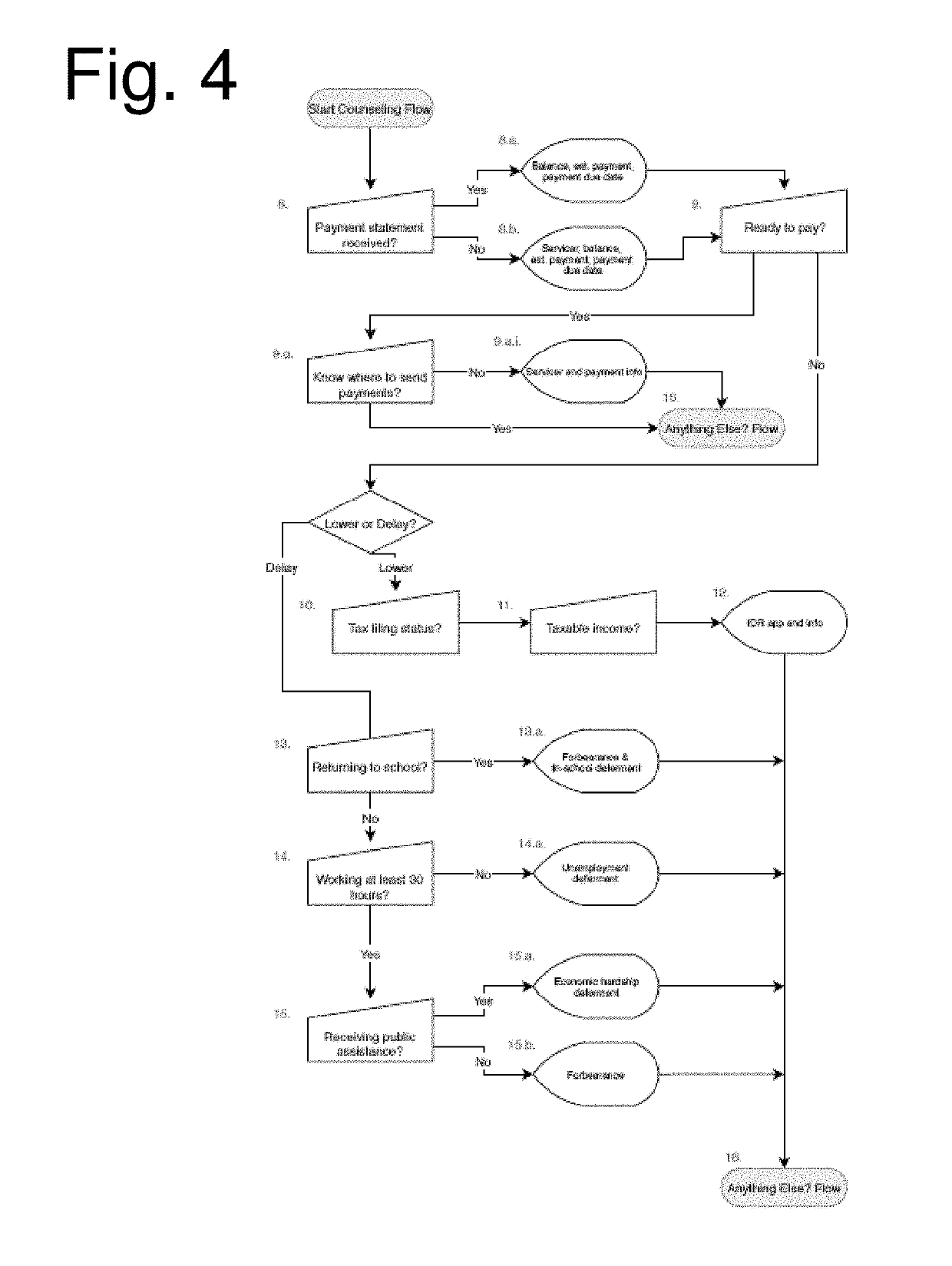

Optimized loan assessment and assistance system

A system and method for assisting loan borrowers in assessing possible repayment options includes collecting borrower information and classifying borrowers according to campaign groups. Borrowers in each campaign group are contacted in a manner specifically designed for that campaign group to optimize the likelihood of generating a response from the borrower. A chatbot is used to generate a text or voice conversation with the borrower utilizing simple and short questions and answers to obtain information from the borrower and determine the borrower's eligibility for different repayment options. The chatbot then provides the borrower with a list of options which the borrower may select from. The system and method also includes providing a complete transcripts of the conversation to the borrower.

Owner:ZURICK ARTIFICIAL INTELLIGENE LLC

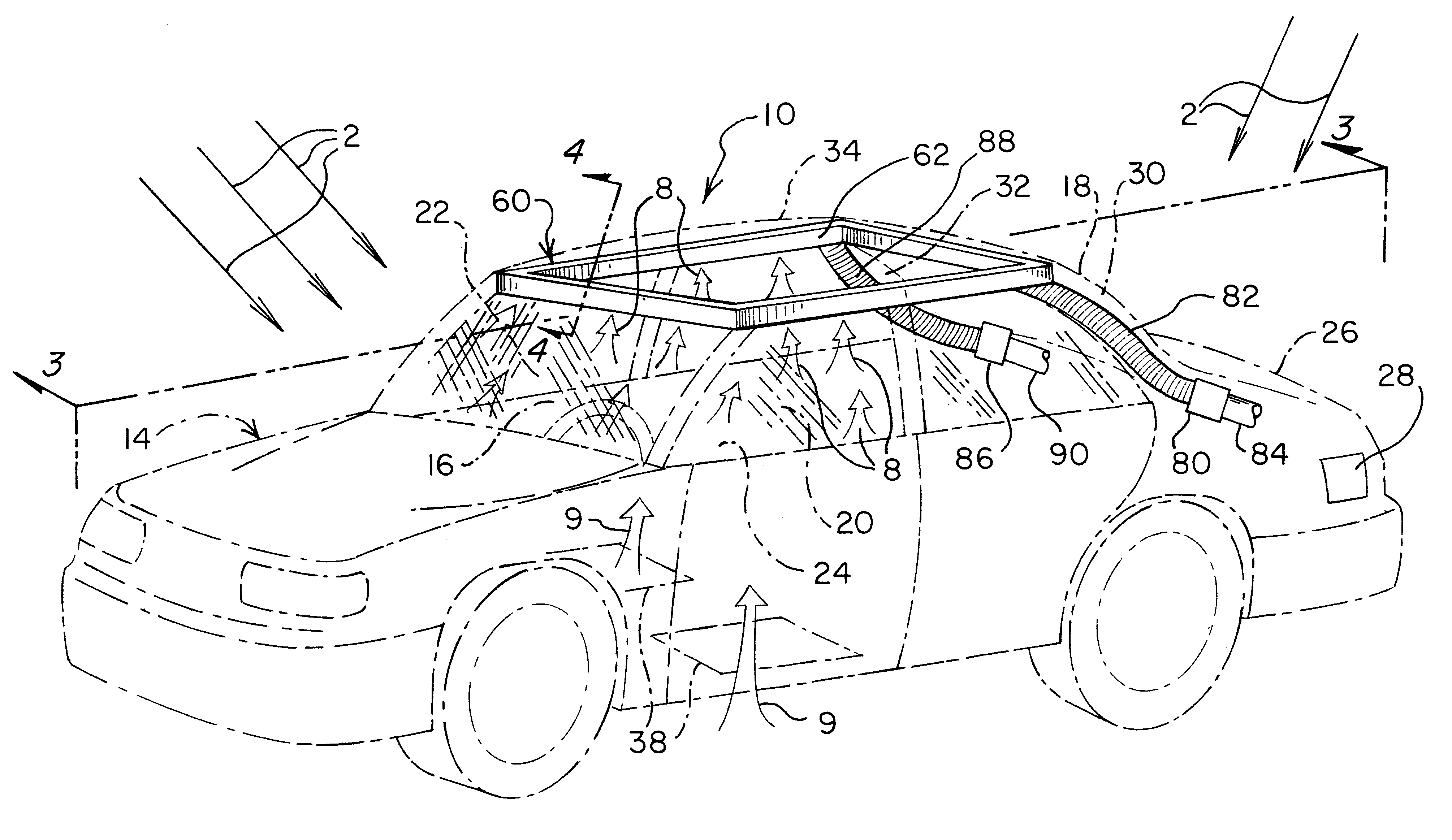

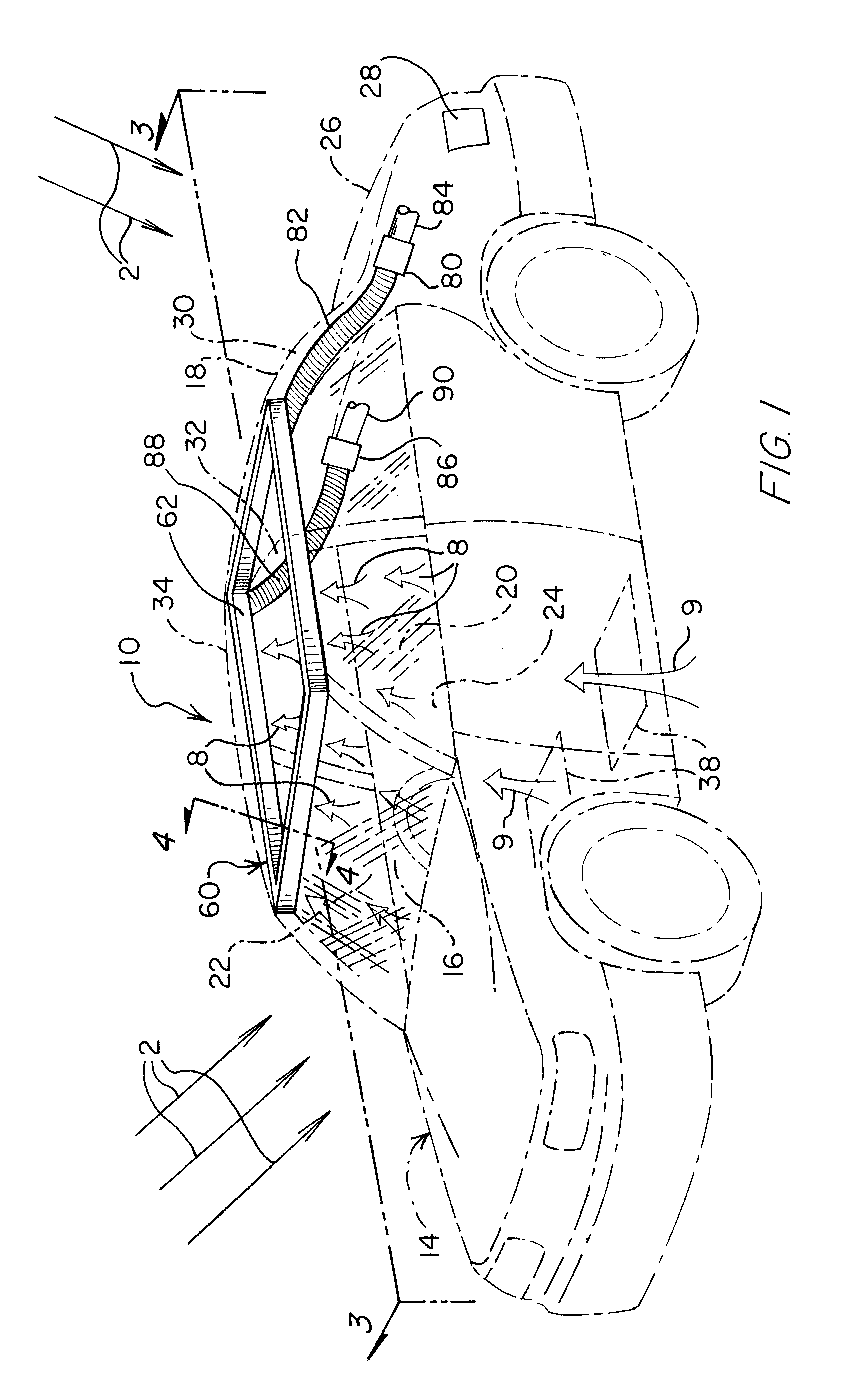

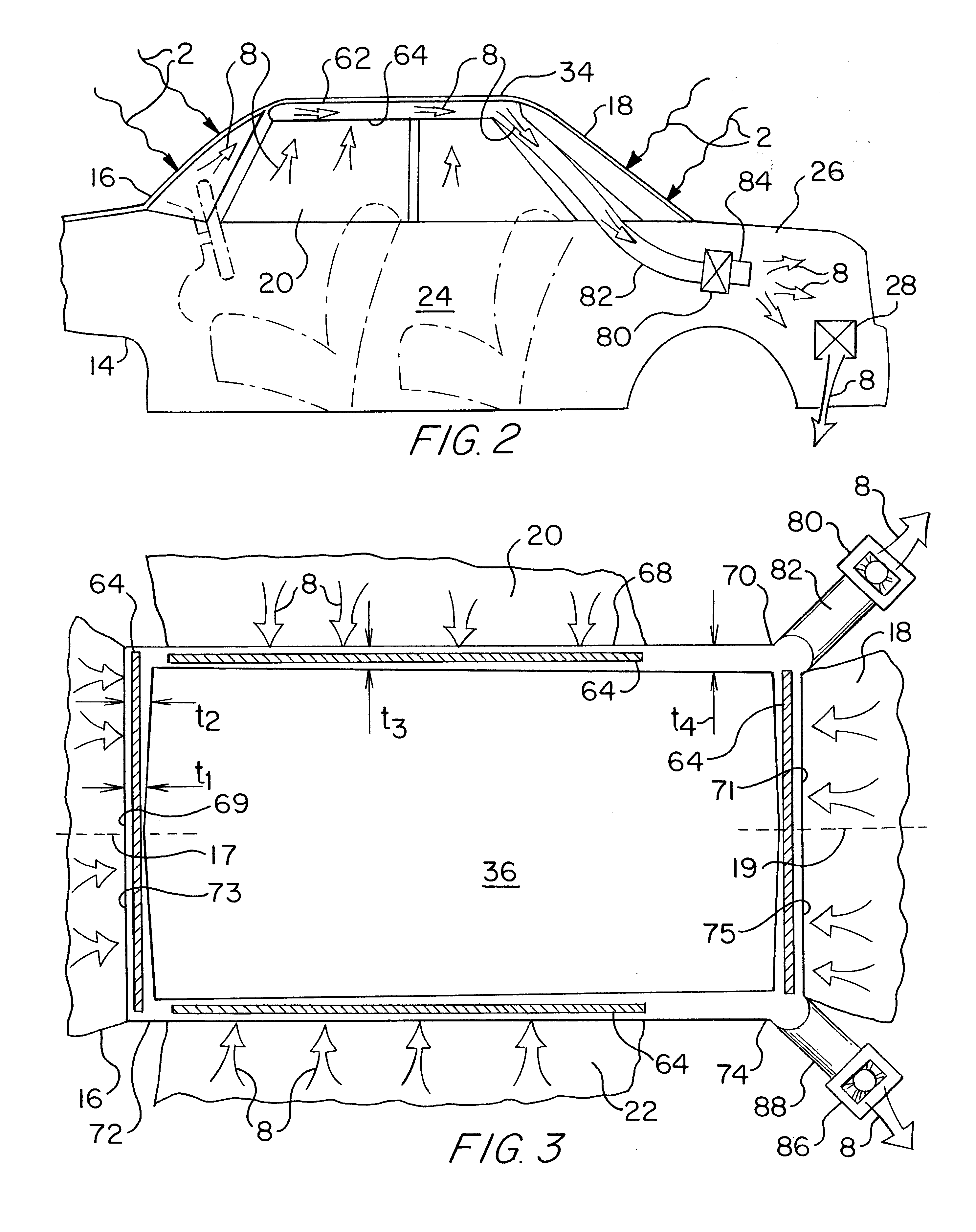

Vehicle cabin cooling system for capturing and exhausting heated boundary layer air from inner surfaces of solar heated windows

InactiveUS6186886B1Uniform pressure dropColor depthAir-treating devicesRailway heating/coolingProximal pointSolar water heating

The cabin cooling system includes a cooling duct positioned proximate and above upper edges of one or more windows of a vehicle to exhaust hot air as the air is heated by inner surfaces of the windows and forms thin boundary layers of heated air adjacent the heated windows. The cabin cooling system includes at least one fan to draw the hot air into the cooling duct at a flow rate that captures the hot air in the boundary layer without capturing a significant portion of the cooler cabin interior air and to discharge the hot air at a point outside the vehicle cabin, such as the vehicle trunk. In a preferred embodiment, the cooling duct has a cross-sectional area that gradually increases from a distal point to a proximal point to the fan inlet to develop a substantially uniform pressure drop along the length of the cooling duct. Correspondingly, this cross-sectional configuration develops a uniform suction pressure and uniform flow rate at the upper edge of the window to capture the hot air in the boundary layer adjacent each window.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Thermal crystallization of a molten polyester polymer in a fluid

ActiveUS20050154183A1Energy efficiencyImprove heat transfer rateDrying gas arrangementsChemical/physical/physico-chemical stationary reactorsThermal crystallizationPolyester

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

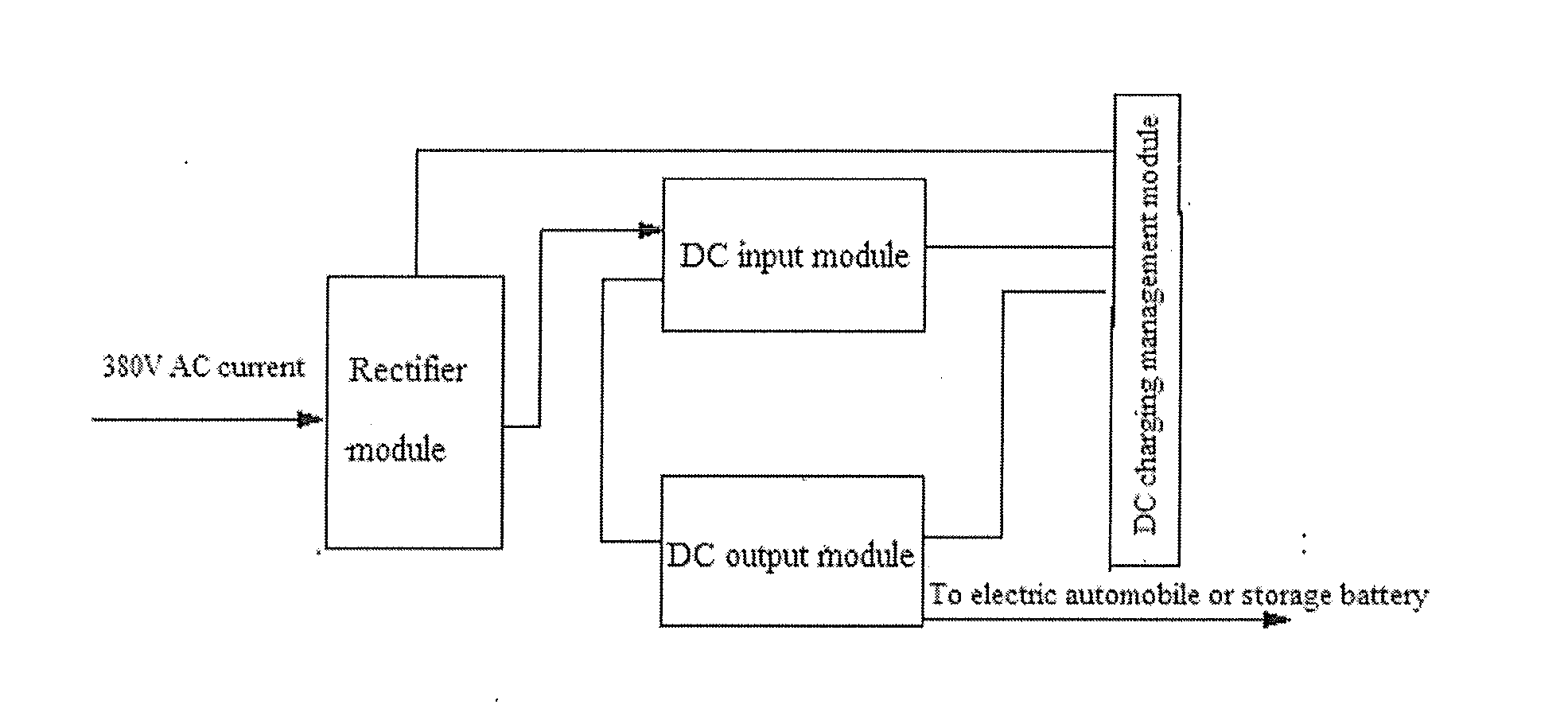

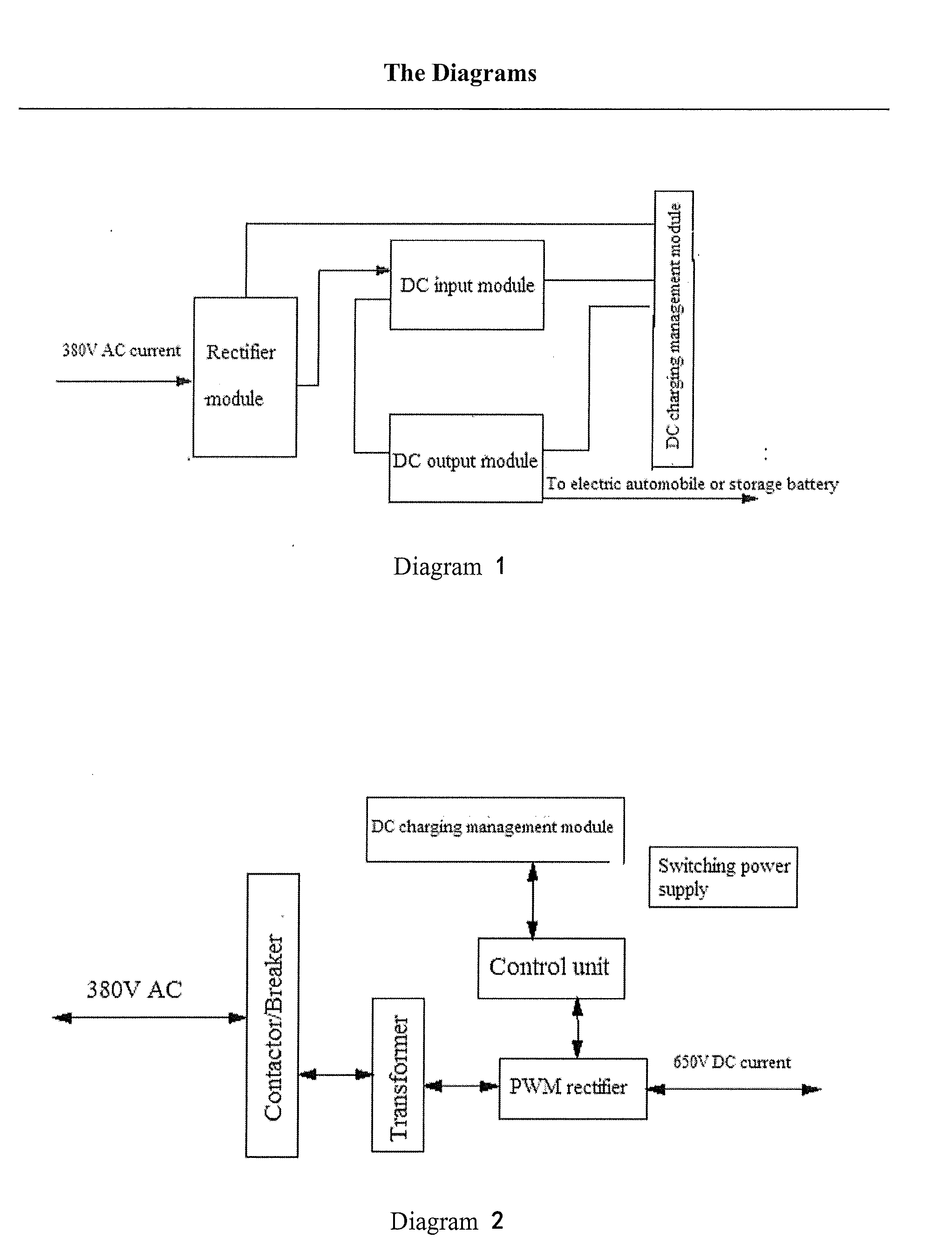

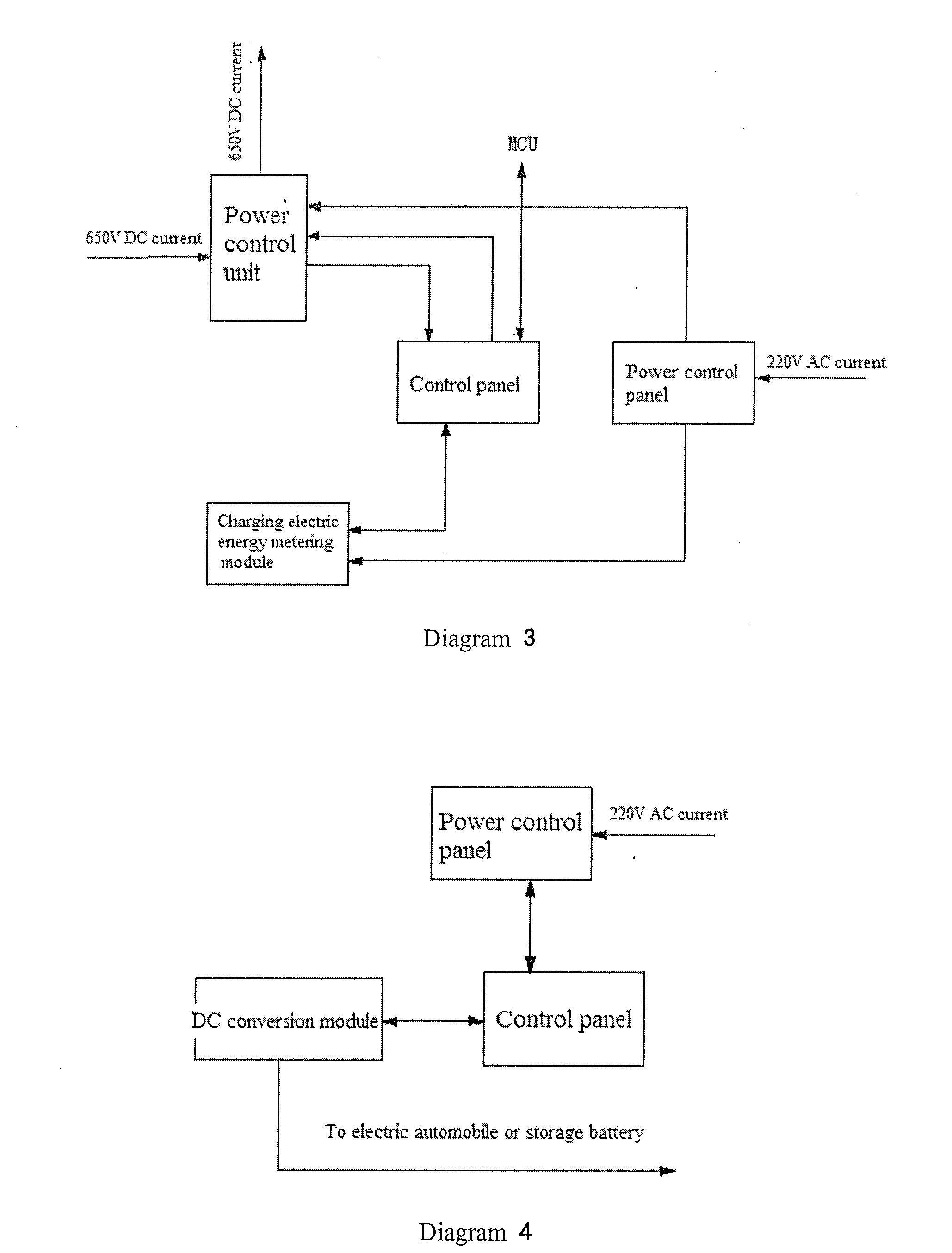

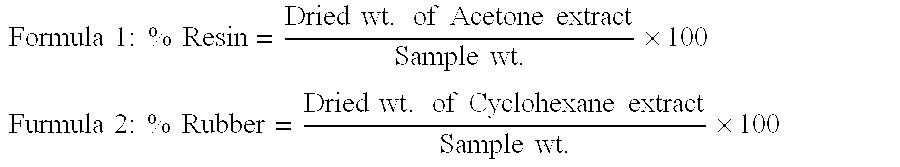

Electric automobile pwm rectification and converting voltage/current pulse charging system

ActiveUS20140035530A1Easy to use and flexibleAvoid damageBattery overcurrent protectionVehicular energy storageEngineeringCurrent pulse

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

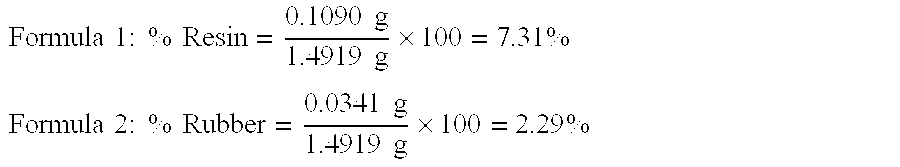

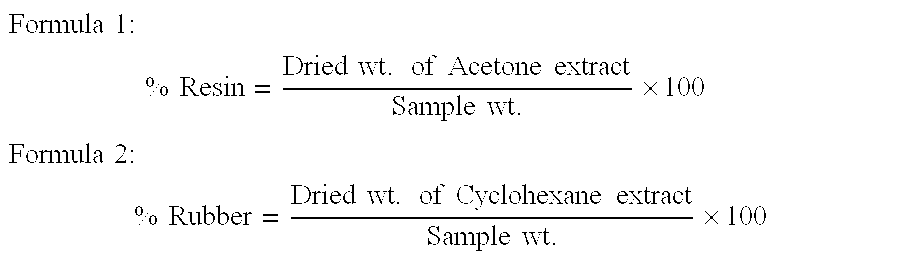

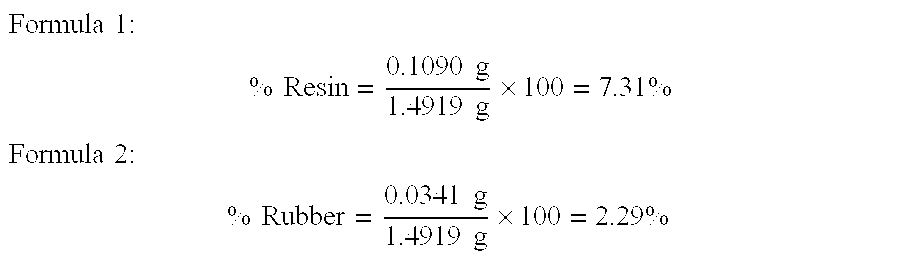

Extraction and fractionation of biopolymers and resins from plant materials

ActiveUS20060106183A1High yieldHigh purityGas current separationSolvent extractionParthenium argentatumBiopolymer

A method for the extraction, separation, fractionation and purification of biopolymers from plant materials using supercritical and / or subcritical solvent extractions is disclosed. Specifically, the process can be used for the separation of resins and rubber from guayule shrub (Parthenium argentatum), and other rubber and / or resin containing plant materials, using supercritical solvent extraction, for example supercritical carbon dioxide extraction. Additionally, polar and / or non-polar co-solvents can be used with supercritical carbon dioxide to enhance the selective extraction of resins and rubbers from the shrub.

Owner:YULEX LLC

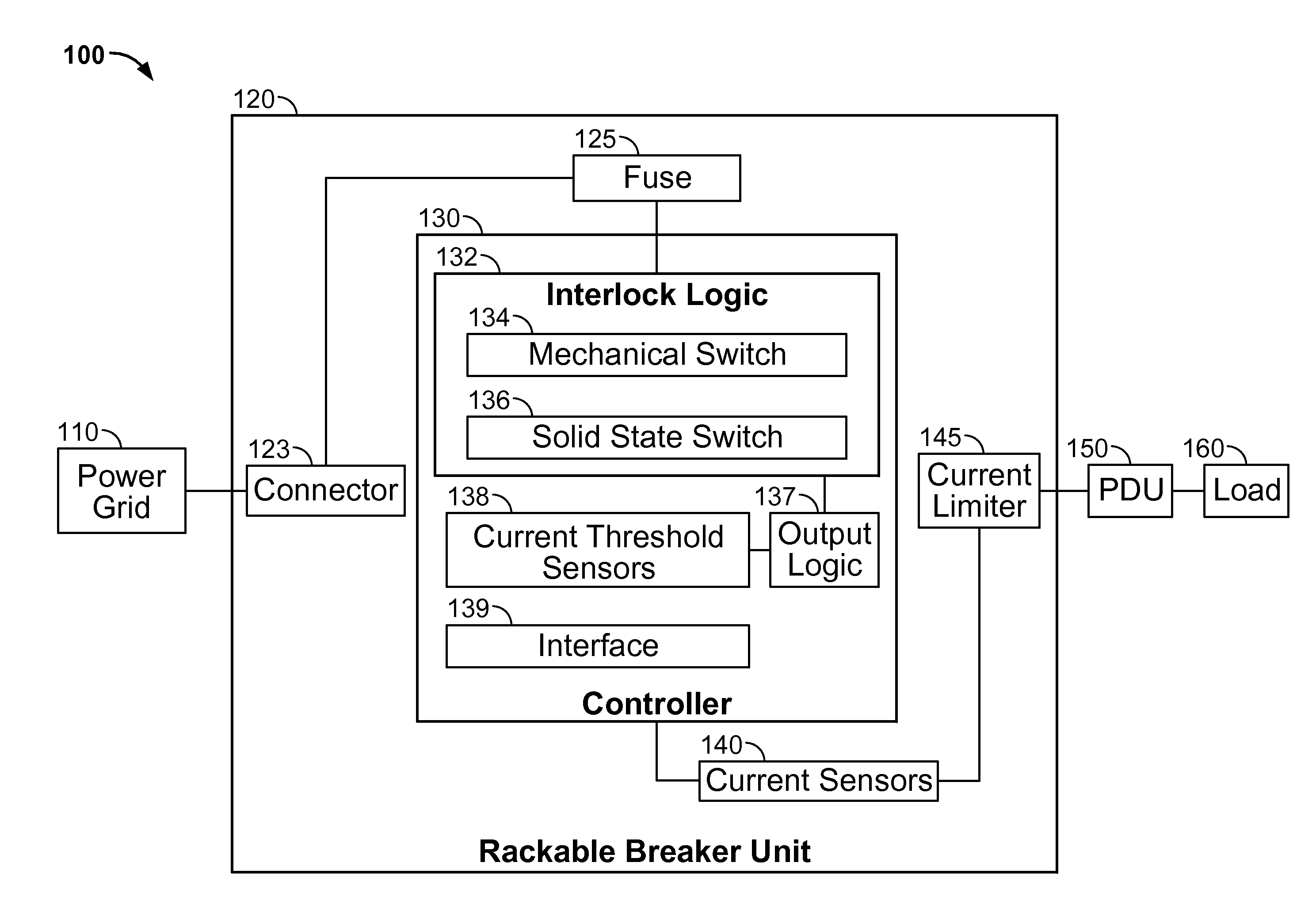

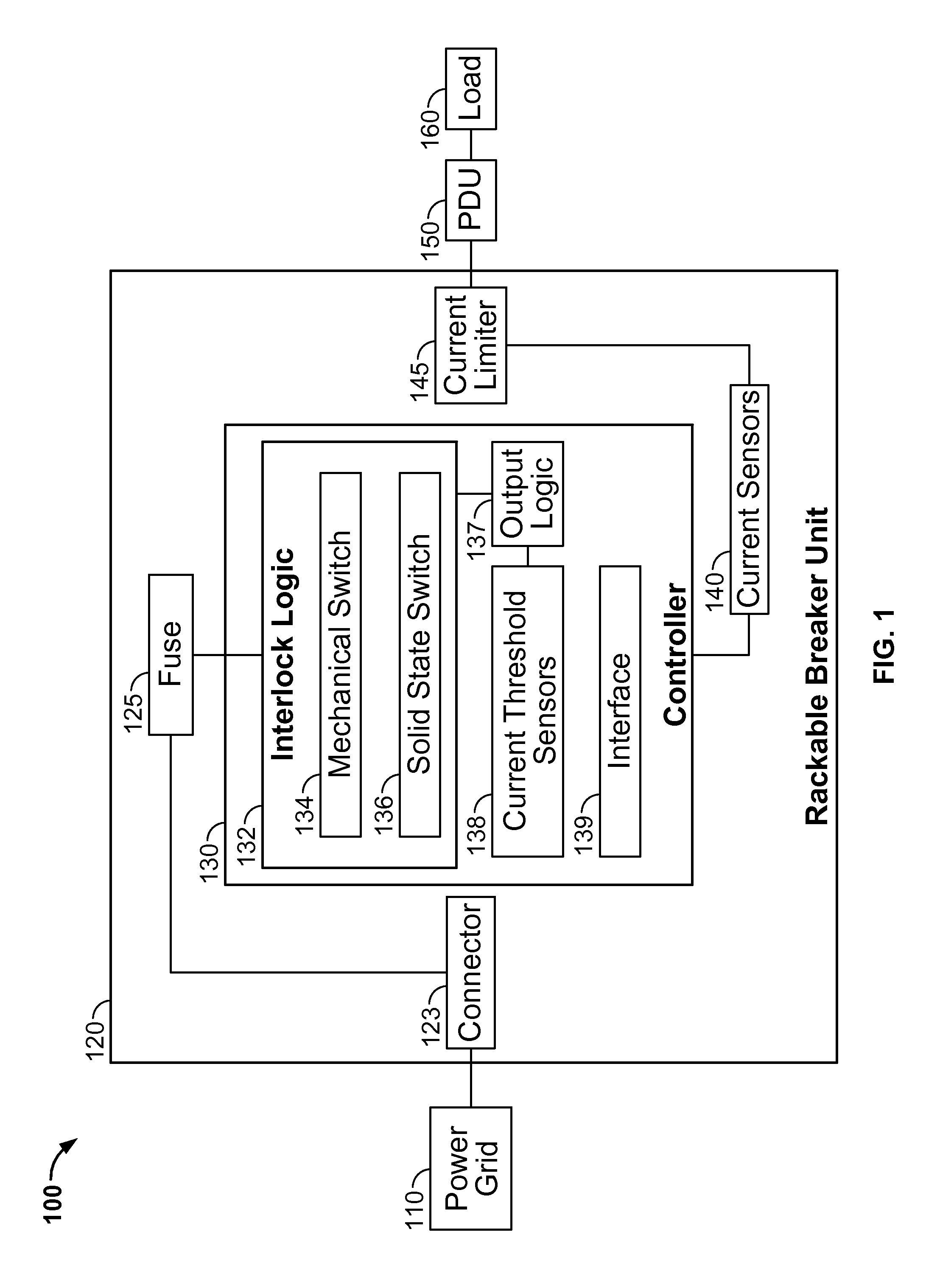

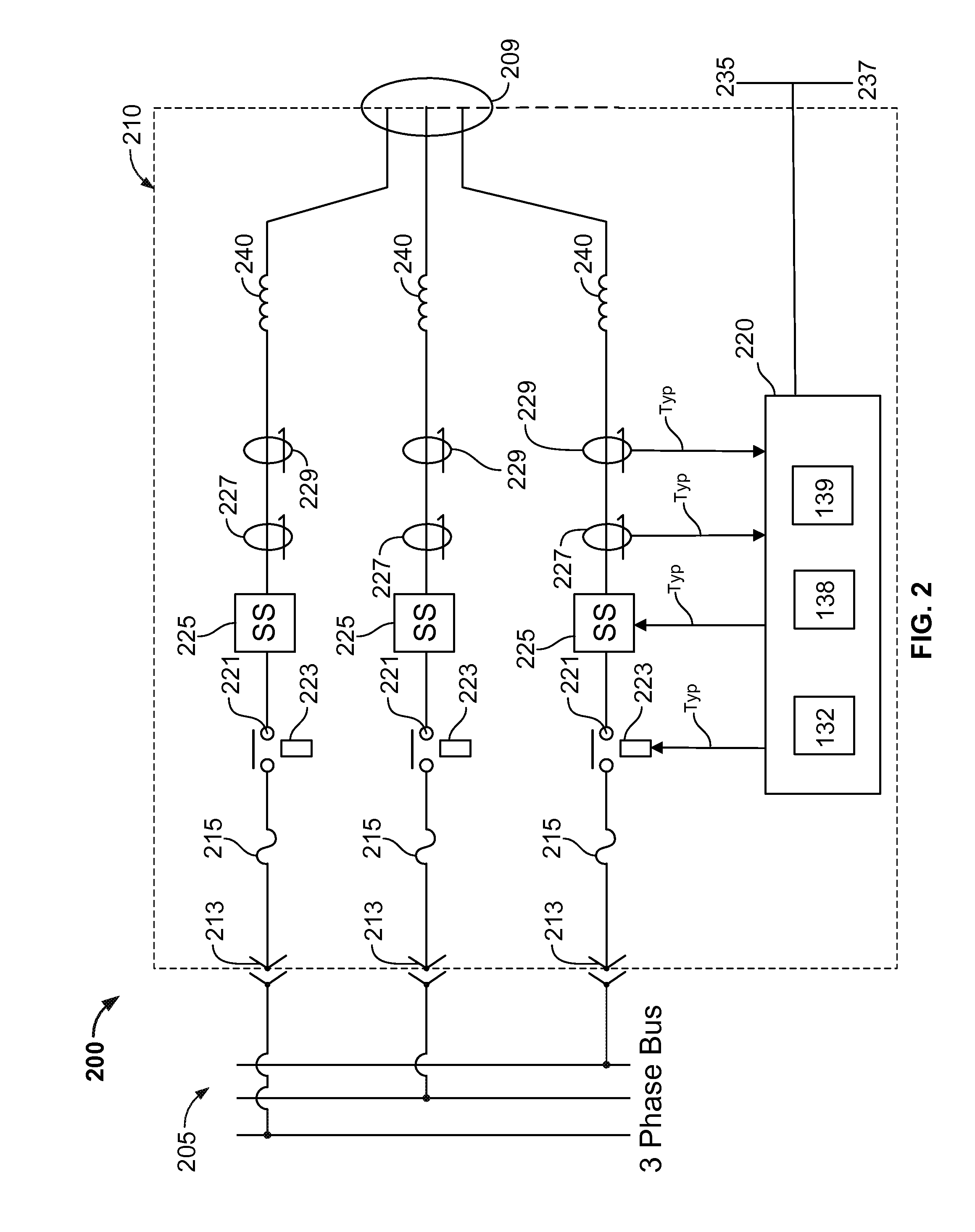

Electrical circuit protector

InactiveUS20170004948A1Quick switchSafely physically openHigh-tension/heavy-dress switchesEmergency protective devicesFault current limiterSolid state circuit breaker

A circuit protection device includes a solid-state interrupter that is operable to open a circuit within a specified response time upon detection of a fault current state. A mechanical interrupter is connected in series with the solid-state interrupter. The mechanical interrupter is operable to open the circuit subsequent to the opening operation of the solid-state interrupter. A controller is coupled with the solid-state interrupter and the mechanical interrupter. The controller is operable to detect the fault current state in the circuit and to control the mechanical interrupter for coordinated operation with the solid-state interrupter. In some implementations, the response time is between two microseconds and twenty microseconds. The mechanical circuit breaker can safely physically open the circuit at a low breaking current (e.g., the solid-state interrupter quickly opens the circuit and prevents current from surging to dangerous levels).

Owner:GOOGLE LLC

Extraction and fractionation of biopolymers and resins from plant materials

ActiveUS7259231B2High yieldHigh purityGas current separationSolvent extractionParthenium argentatumBiopolymer

A method for the extraction, separation, fractionation and purification of biopolymers from plant materials using supercritical and / or subcritical solvent extractions is disclosed. Specifically, the process can be used for the separation of resins and rubber from guayule shrub (Parthenium argentatum), and other rubber and / or resin containing plant materials, using supercritical solvent extraction, for example supercritical carbon dioxide extraction. Additionally, polar and / or non-polar co-solvents can be used with supercritical carbon dioxide to enhance the selective extraction of resins and rubbers from the shrub.

Owner:YULEX LLC

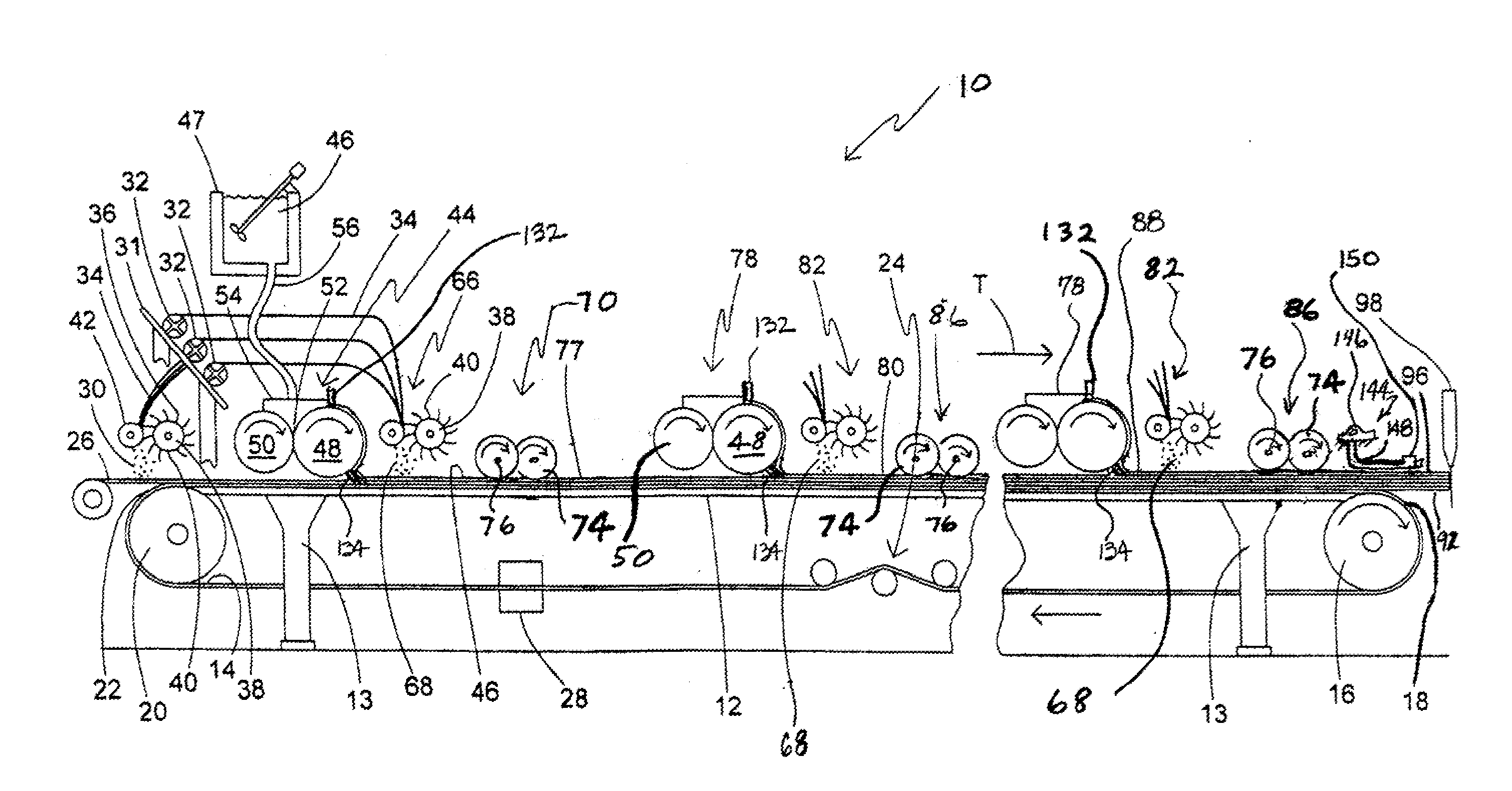

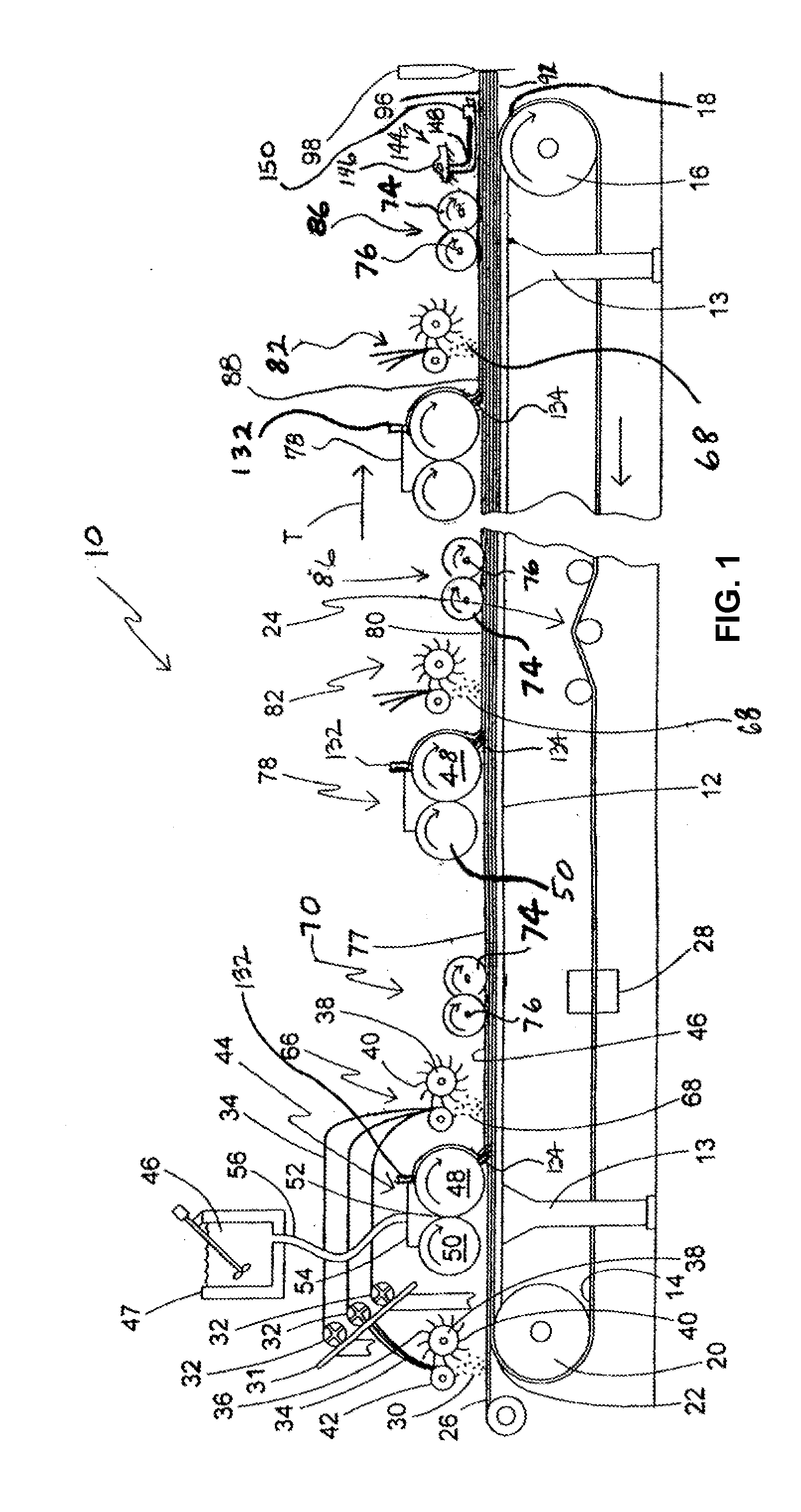

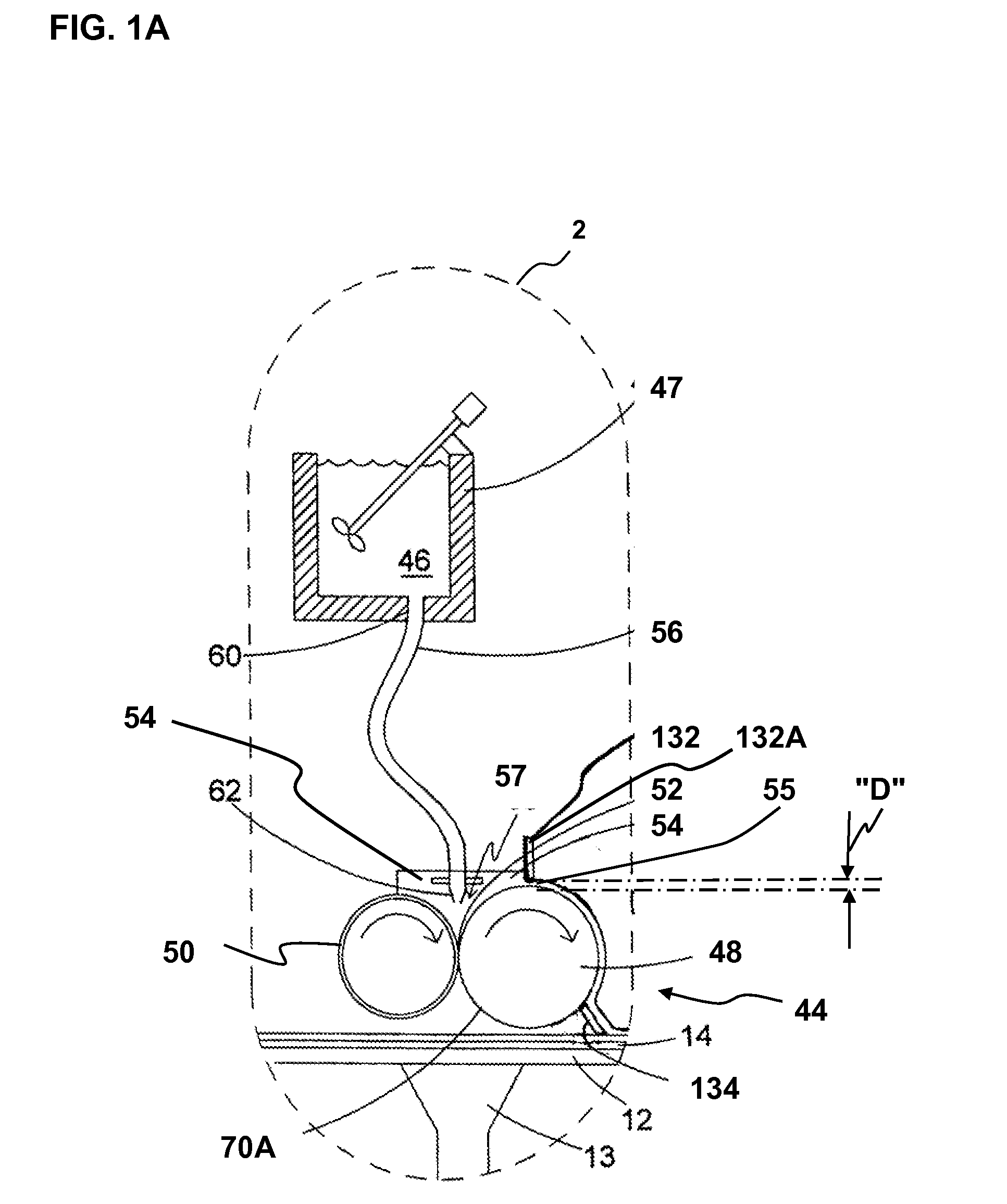

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS20080101150A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed means for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

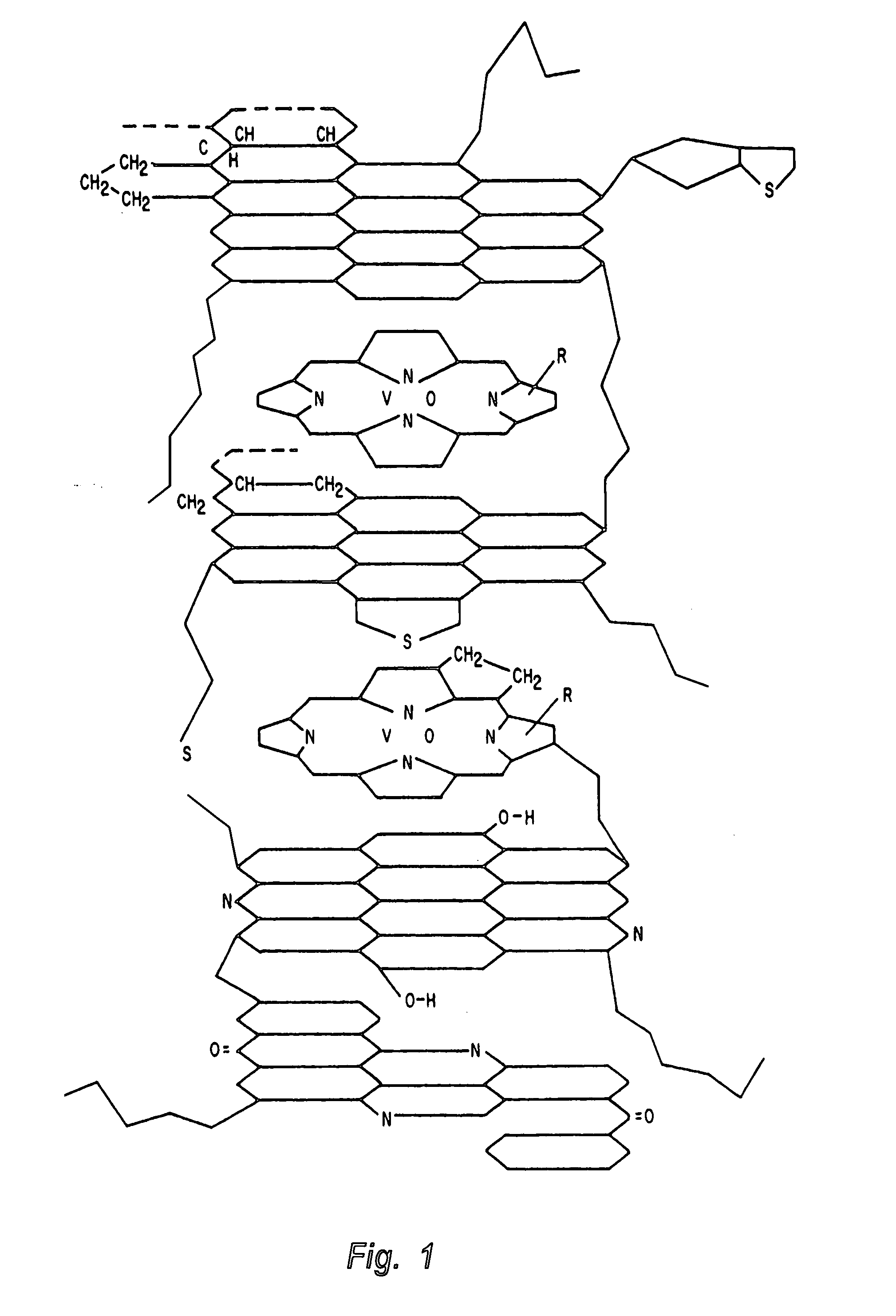

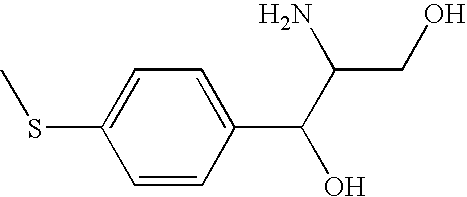

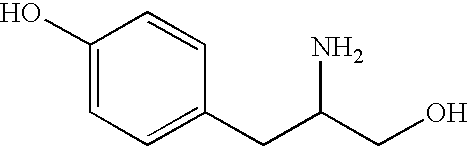

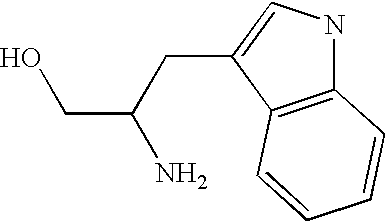

Method for anion-exchange adsorption and anion-exchangers

InactiveUS6702943B1Reduced ligand contentSolve insufficient capacityIon-exchanger regenerationOrganic anion exchangersHydrogenDesorption

A method for the removal of a substance carrying a negative charge and being present in an aqueous liquid (I). The method comprises the steps of: (i) contacting the liquid with a matrix carrying a plurality of ligands comprising a positively charged structure and a hydrophobic structure, and (ii) desorbing the substance. The characterizing feature is that (I) each of said ligands together with a spacer has the formula: -SP-[Ar-R1-N<+>(R2R3R4)] where (A) [Ar-R1-N<+>(R2R3R4)] represents a ligand a) Ar is an aromatic ring, b) R1 is [(L)nR'1]m where n and m are integers selected amongst zero or 1; L is amino nitrogen, ether oxygen or thioether sulphur; R'1 is a linker selected among 1) hydrocarbon groups; 2) -C(=NH)-; c) R2-4 are selected among hydrogen and alkyls; (B) SP is a spacer providing a carbon or a heteroatom directly attached to Ar-R1-N<+>(R2R3R4); (C)-represents that SP replaces a hydrogen in (Ar-R1-N<+>(R2R3R4); (D)-represents binding to the matrix; and (II) desorption. There is also described (a) anion-exchangers having high breakthrough capacities, (b) a screening method and (c) a desalting protocol.

Owner:CYTIVA BIOPROCESS R&D AB

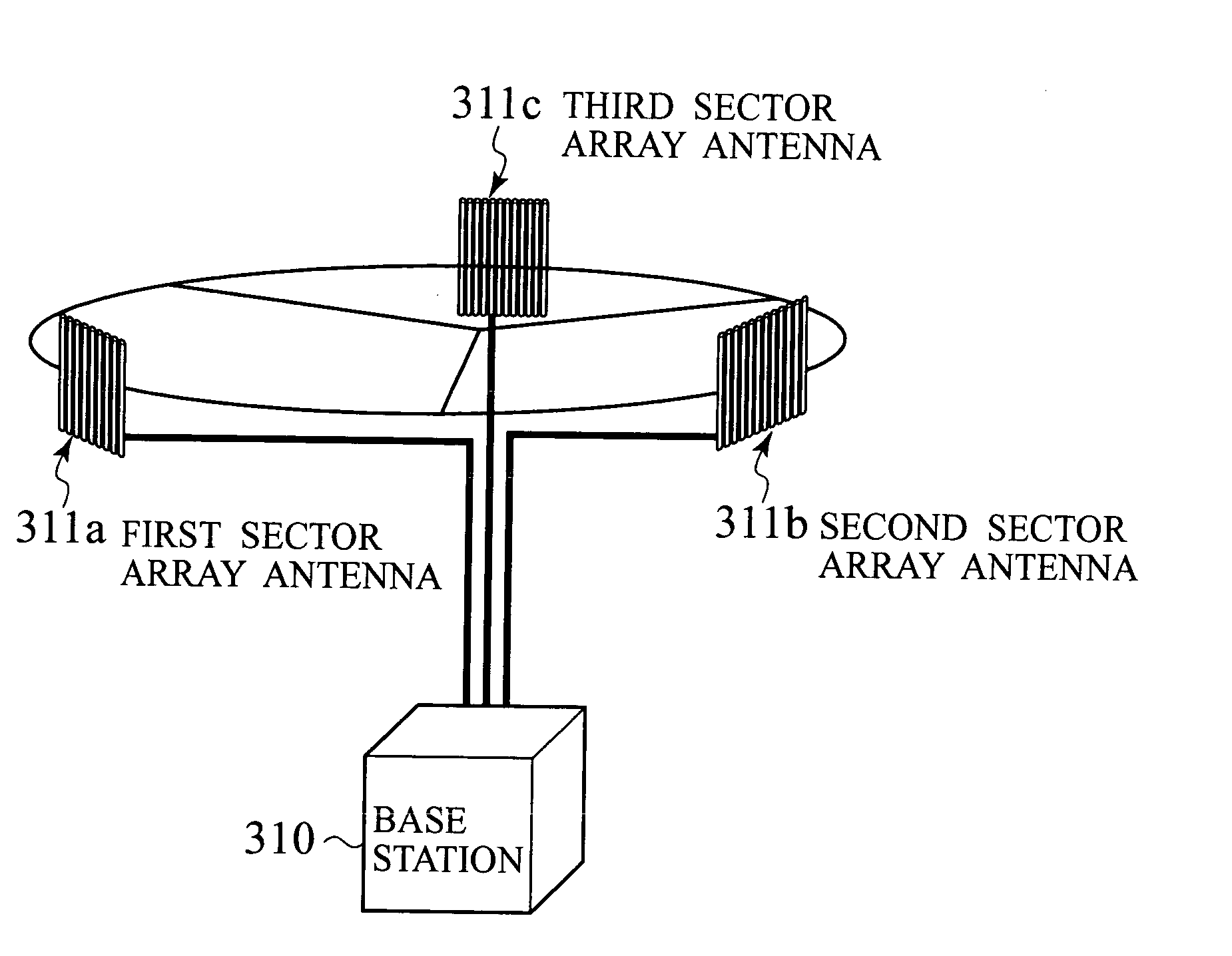

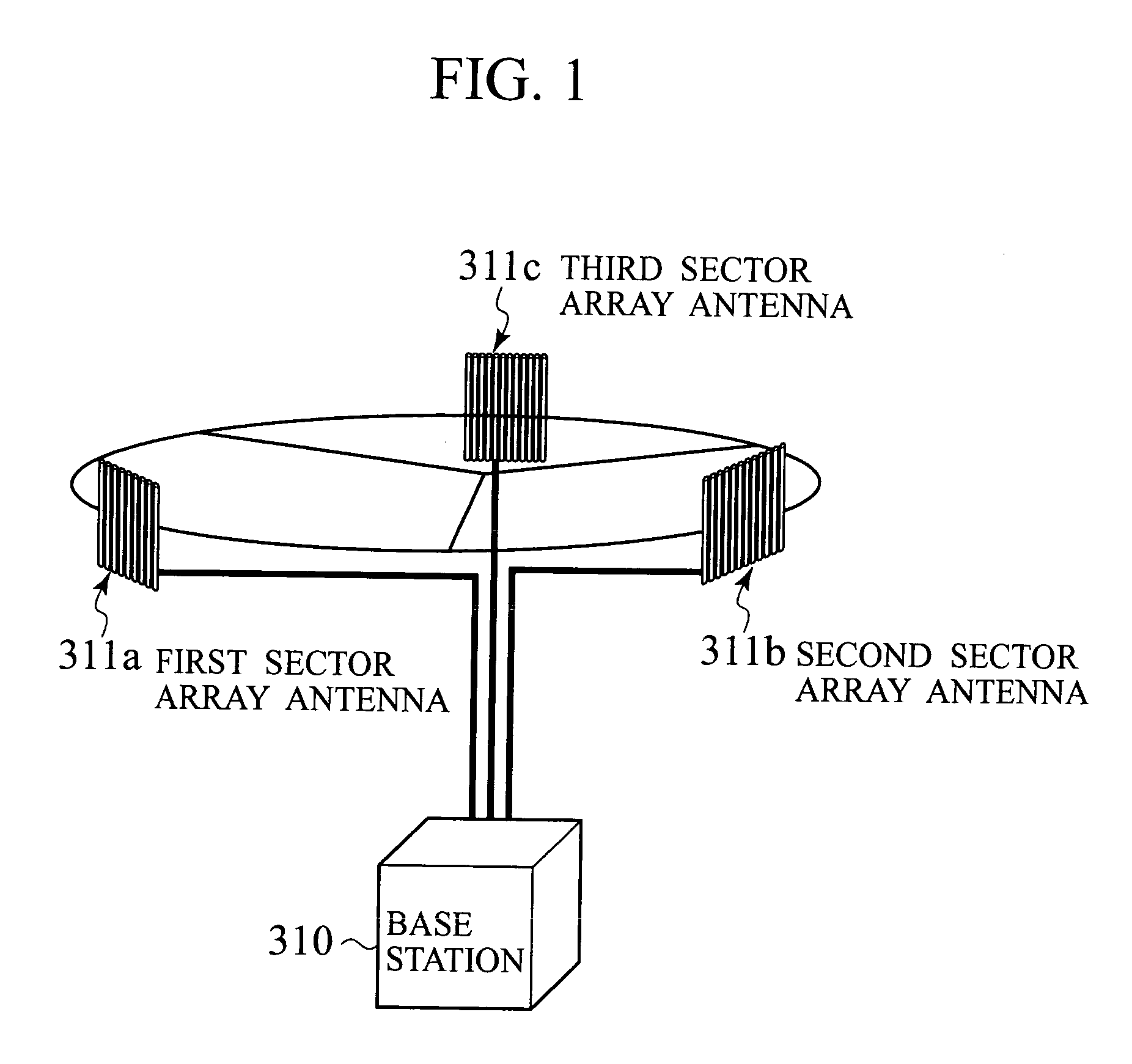

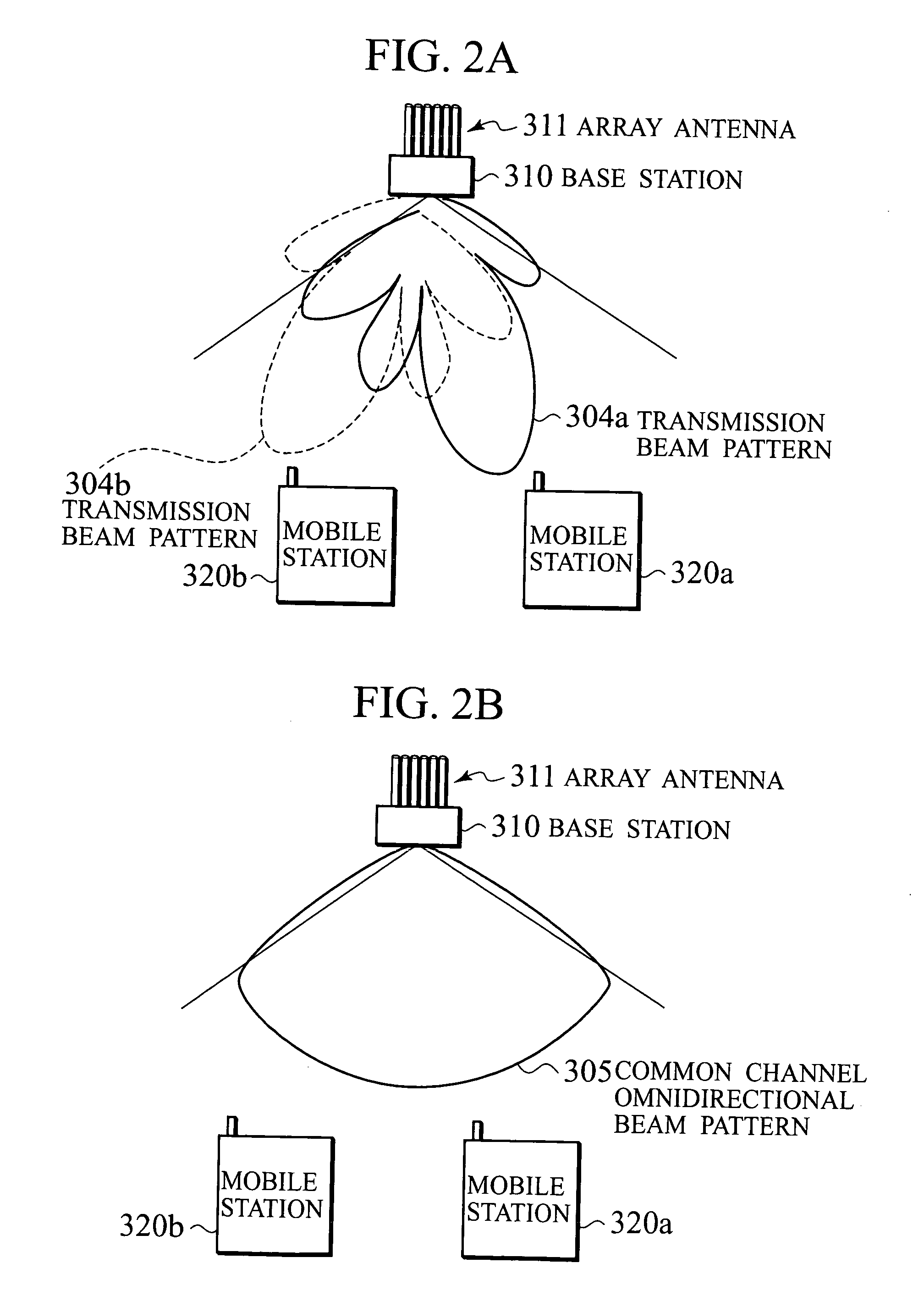

Base station, mobile communication system, and communication method

InactiveUS20040038713A1Increase powerReduce equipmentSpatial transmit diversitySubstation equipmentOmnidirectional antennaDirectional antenna

A base station comprises a directional antenna configured to transmit a directional beam to a mobile station, an omnidirectional antenna configured to transmit an omnidirectional beam to the mobile station, and an antenna controller configured to determine whether or not the mobile station is capable of receiving the directional beam, and select the directional antenna as an antenna for transmitting individual data in a case of being capable of receiving the directional beam, or select the omnidirectional antenna as an antenna for transmitting the individual data in a case of being incapable of receiving the directional beam.

Owner:NTT DOCOMO INC

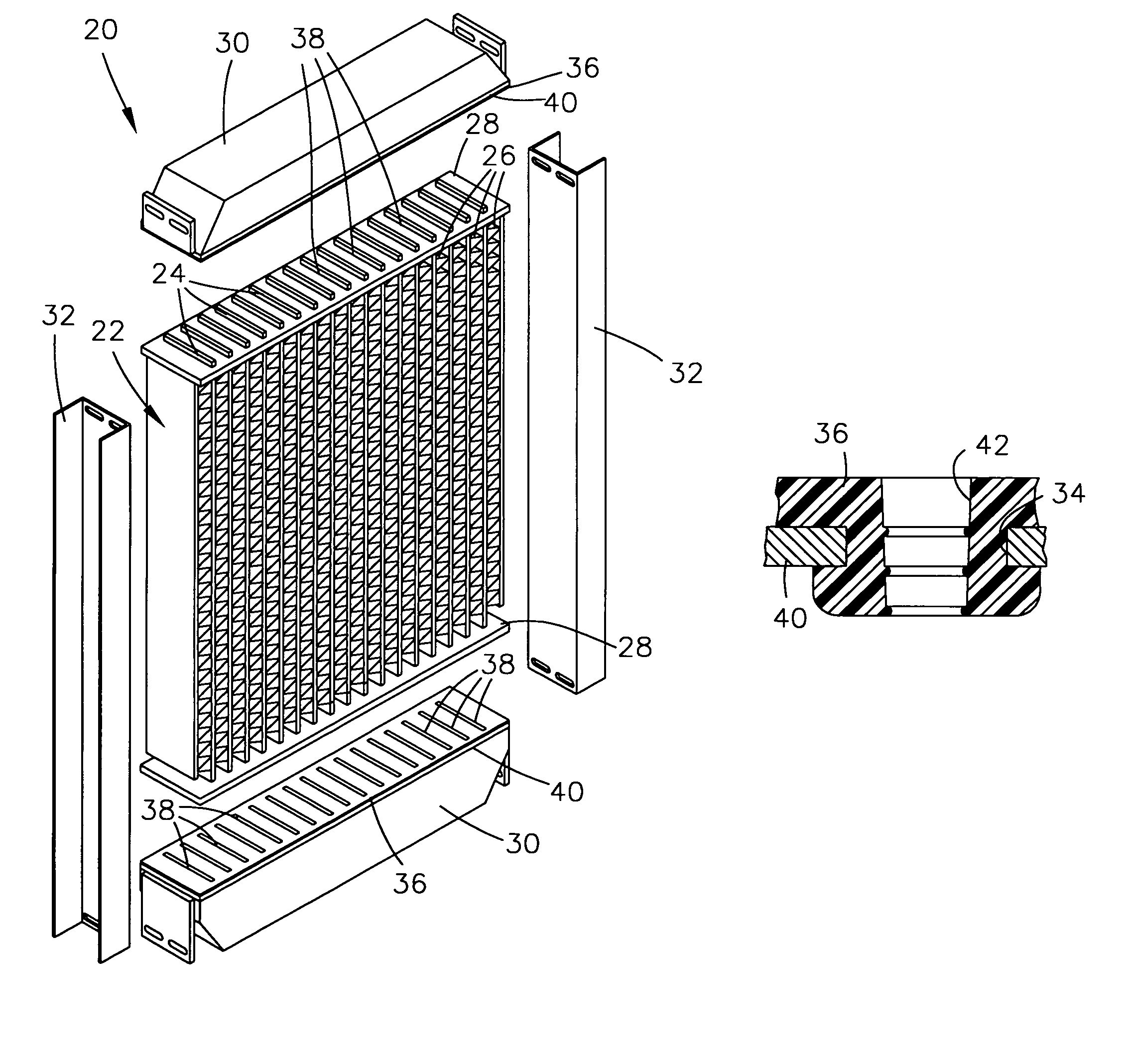

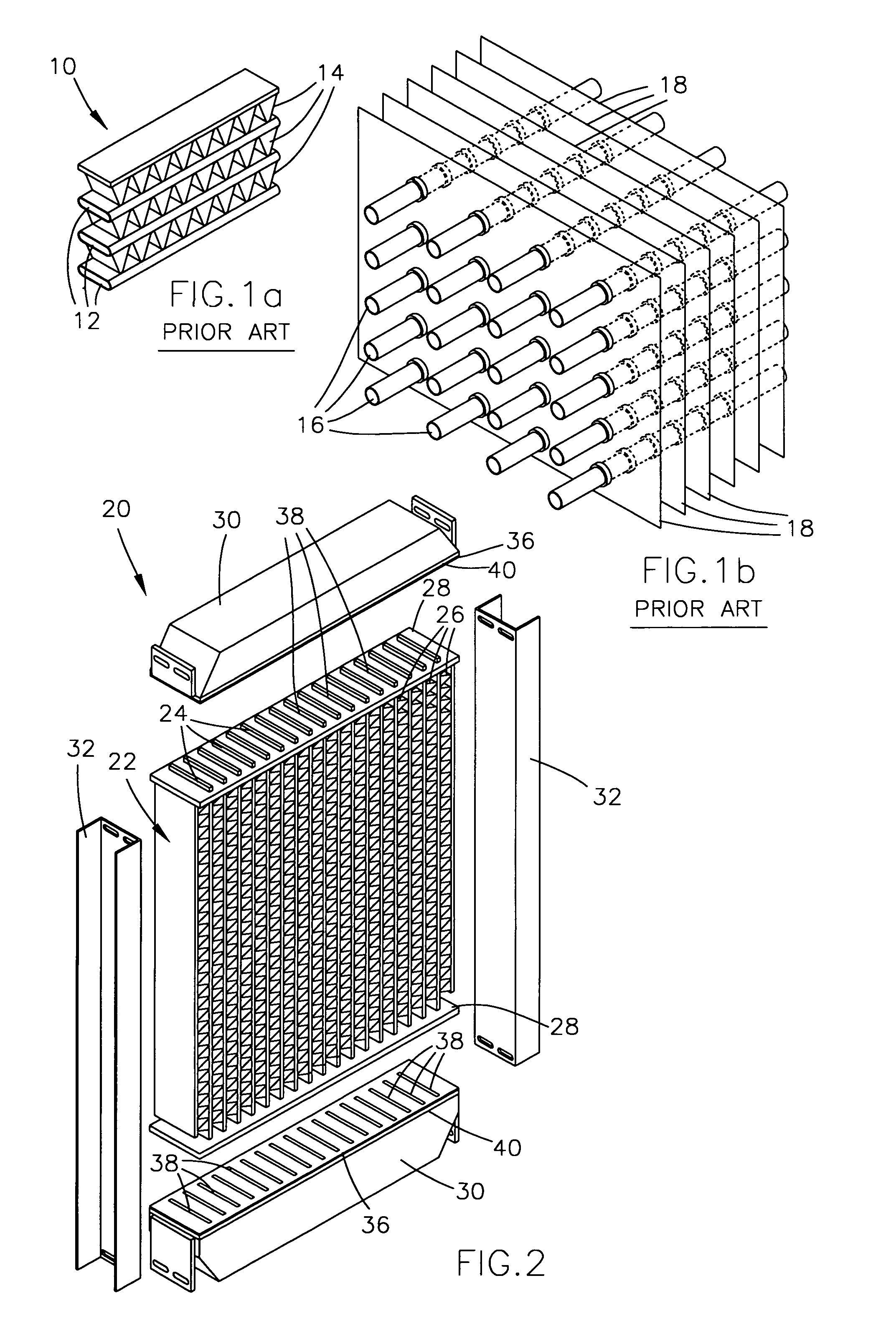

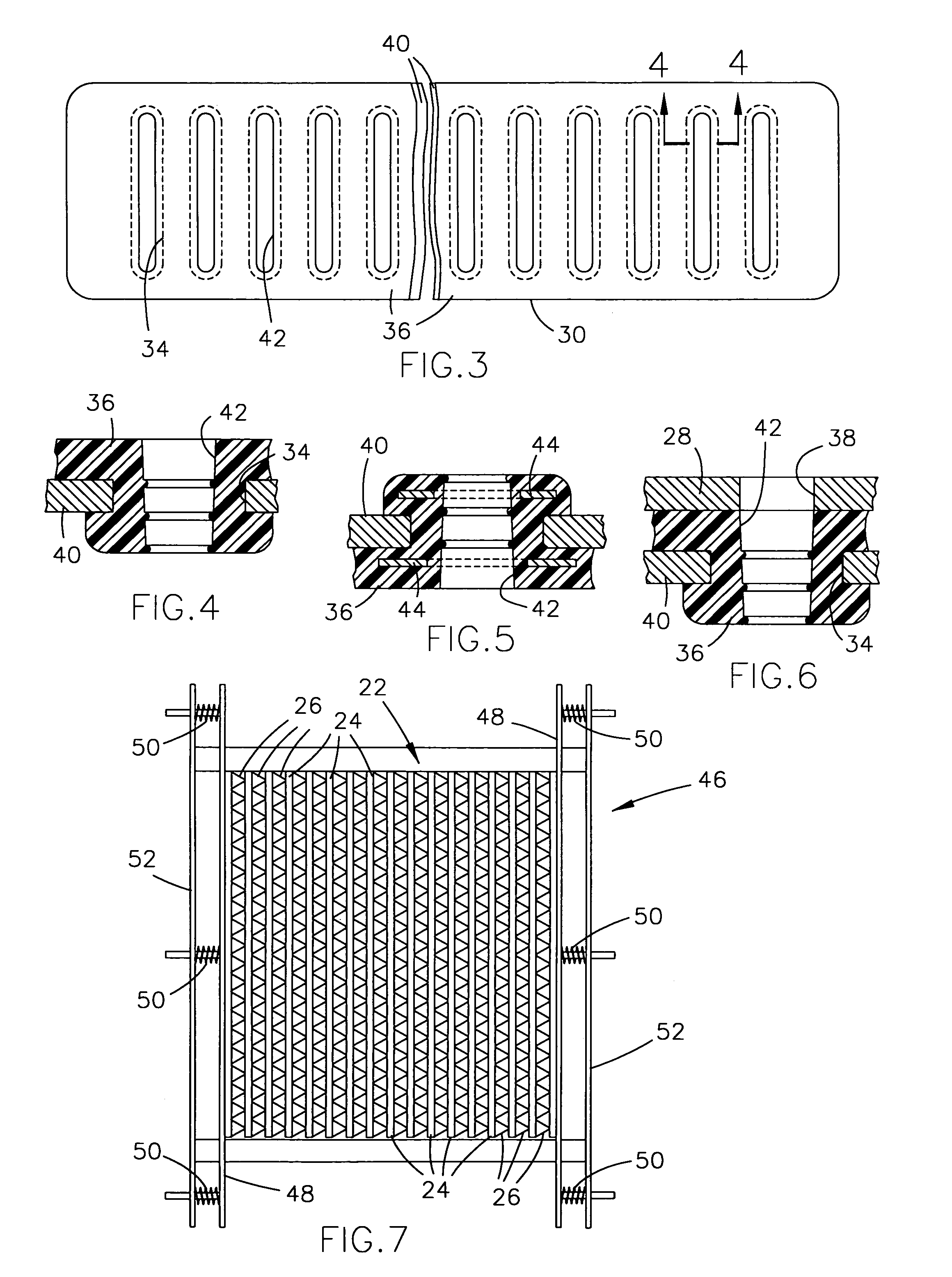

Modular heat exchanger having a brazed core and method for forming

InactiveUS7234511B1Improve heat transfer efficiencyReadily dismantled and rebuiltReinforcing meansSafety devices for heat exchange apparatusPosition toleranceNuclear engineering

An improved modular heat exchanger suitable for automotive applications, and particularly radiators for heavy duty equipment, and methods for forming the modular heat exchanger. The modular heat exchanger construction incorporates a brazed core assembly composed of flat-type cooling tubes and sinusoidal centers. The ability to use a brazed core assembly within a modular heat exchanger construction promotes enhanced heat transfer efficiencies associated with the use of flat tubes and sinusoidal centers, as compared to mechanically-joined round tubes and fins. The required positional tolerances of the tubes for mating with the remainder of the heat exchanger are maintained within the brazed core assembly by eliminating core shrinkage attributable to the use of clad aluminum alloy components to construct the core assembly. In two embodiments, core shrinkage is physical suppressed through the use of an expandable brazing fixture or the inclusion of sub-headers in the brazed core assembly. In a third embodiment, a clad slurry containing a braze alloy is deposited prior to brazing on a core assembly composed of unclad tubes and centers.

Owner:LESAGE PHILIP GEORGE

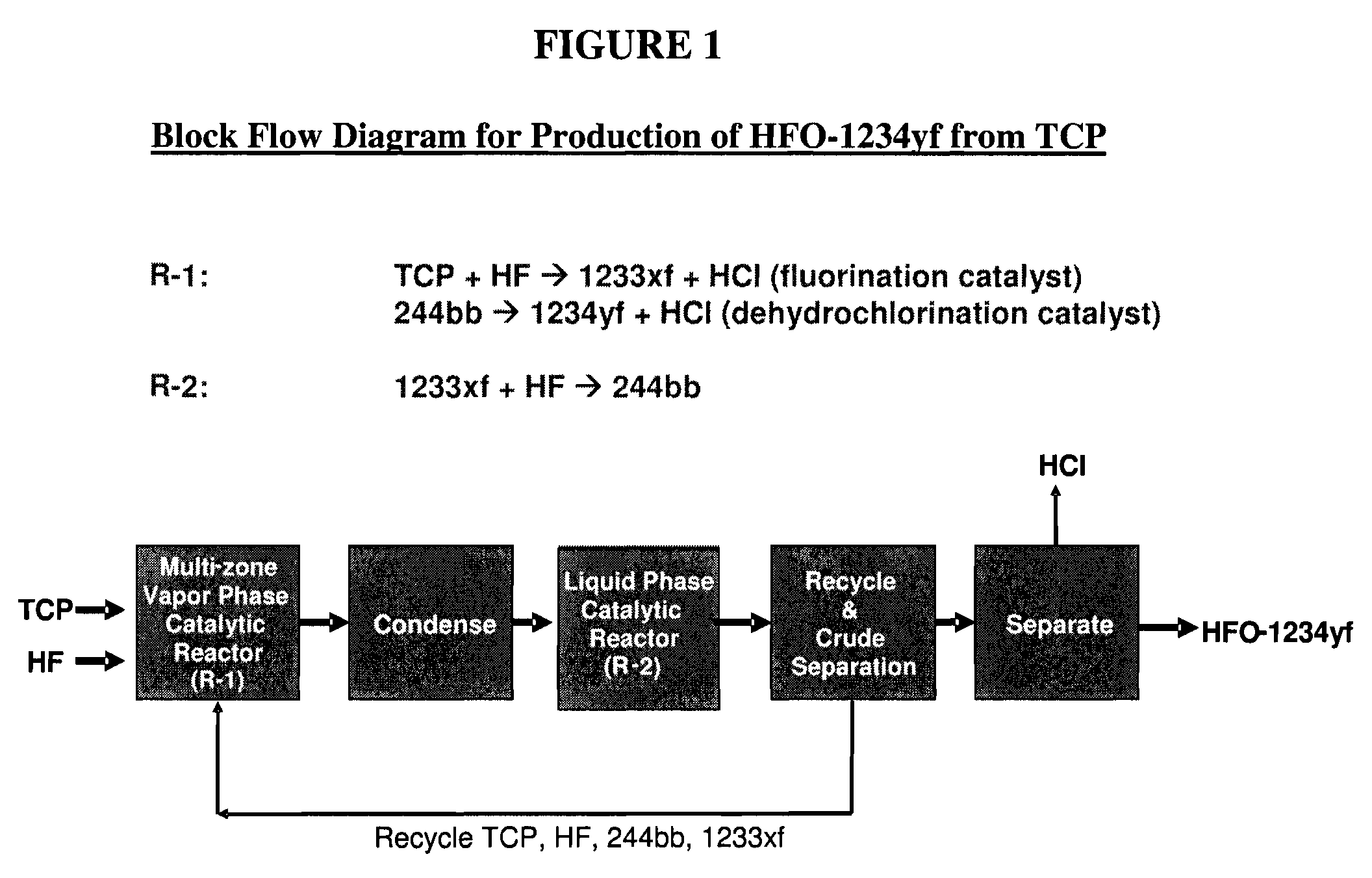

Method for producing fluorinated organic compounds

ActiveUS20090287026A1Economical processReduce equipmentPreparation by hydrogen halide split-offPreparation by halogen halide additionChemistryHydrogen fluoride

Disclosed is a process for producing tetrafluoropropene comprising: (a) catalytically fluorinating at least one tetrafluoropropene in a first reactor to produce HCFO-1233xf; (b) reacting said HCFO-1233xf with hydrogen fluoride in a second reactor to produce HCFC-244bb; (c) recycling at least a portion of said HCFC-244bb back to said first reactor as recycled HCFC-244bb; and (d) catalytically dehydrochlorinating said recycled HCFC-244bb in said first reactor to produce HFO-1234yf.

Owner:HONEYWELL INT INC

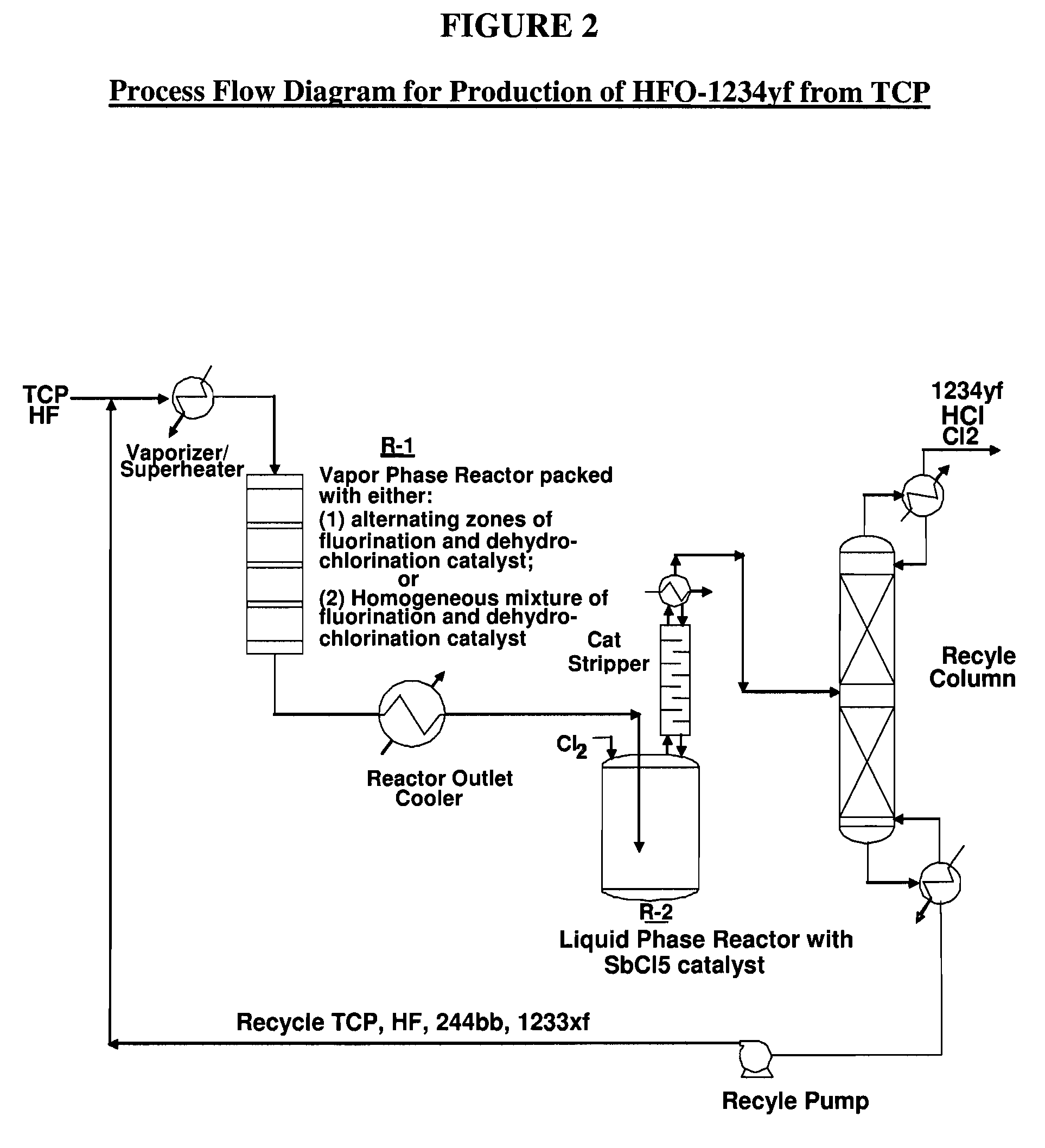

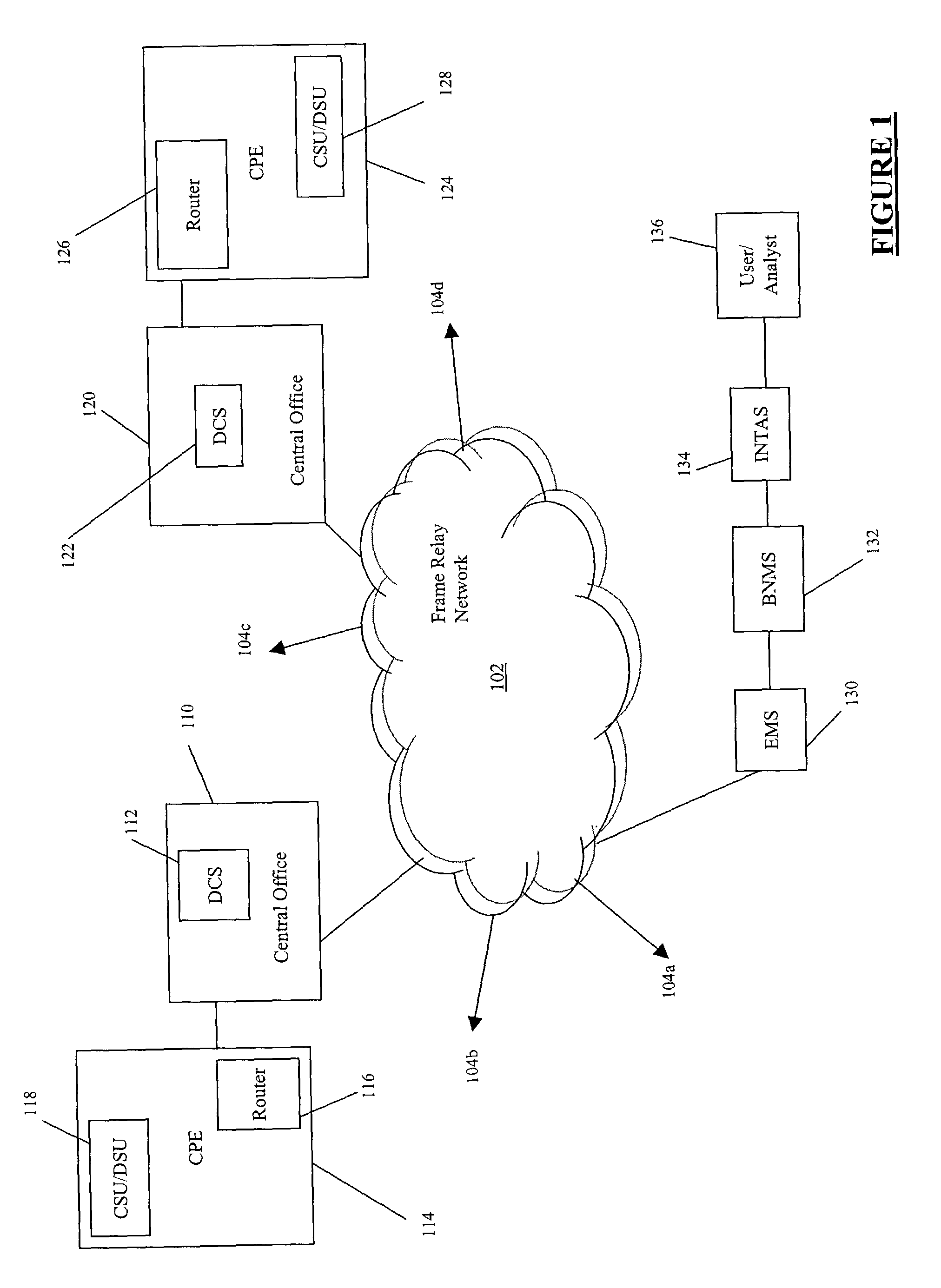

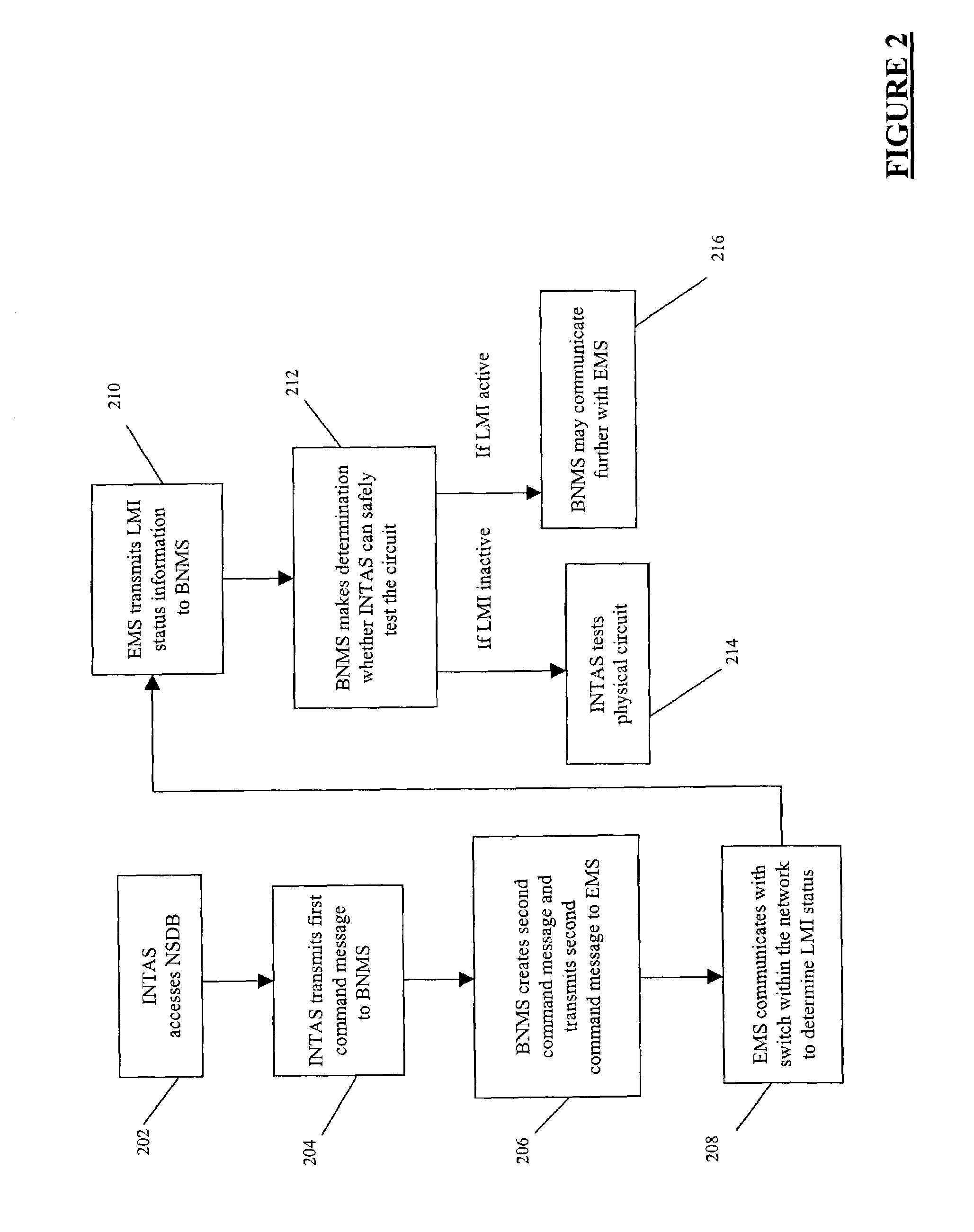

Method and system for retrieving link management interface status for a logical port

InactiveUS7209452B2Reduce equipment costsReduce personnel costsError preventionTransmission systemsFrame RelayIntegration testing

Systems and methods for obtaining logical layer information in a frame relay and / or asynchronous transfer mode (ATM) network are described. In an exemplary embodiment, a physical layer test system, such as an integrated testing and analysis system, communicates with a broadband network management system, which in turn communicates with an element management system for a frame relay and / or ATM network.

Owner:AT&T INTPROP I L P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com