Patents

Literature

3423 results about "Coke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coke is a grey, hard, and porous fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air — a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.

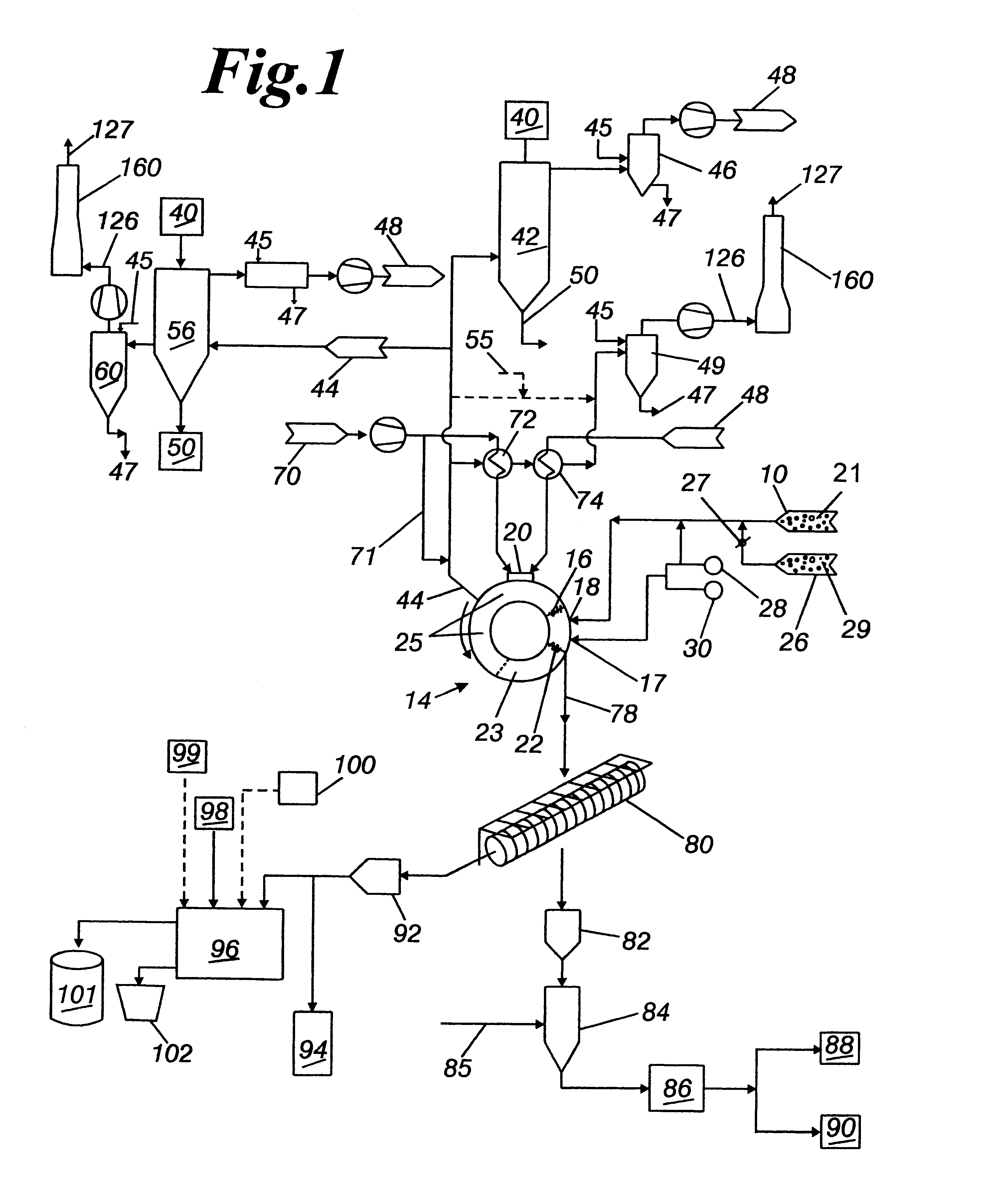

Carbonaceous Fuels and Processes for Making and Using Them

The present invention provides carbonaceous fuels and processes for making them. Moreover, the invention also relates to processes using the carbonaceous fuels in the production of cement products. One embodiment of the invention is a carbonaceous fuel comprising (a) unconverted fines of a carbonaceous feedstock, the carbonaceous feedstock having an ash content of greater than 1%, the fines having an average particle size less than about 45 μm; and (b) a char residue formed by catalytic gasification of the carbonaceous feedstock, the char residue having an ash content of greater than about 30%, wherein the ash includes at least one aluminum-containing compound or silicon-containing compound; and having a weight ratio of fines to char residue in the range of about 4:1 to about 1:4, and a total dry basis wt % of carbon of least about 40%. Another embodiment of the invention is a process of making a cement product comprising: (a) providing a carbonaceous fuel as described above; (b) passing the carbonaceous fuel into a cement-making zone; and (c) at least partially combusting the carbonaceous fuel to provide heat for a cement producing reaction within the cement-making zone.

Owner:SURE CHAMPION INVESTMENT LTD

Modified octahedral zeolite and hydrocarbon cracking catalyst containing the octahedral zeolite

InactiveCN1436727ASimple processReduce manufacturing costCatalytic crackingFaujasite aluminosilicate zeoliteAmmonium compoundsRare earth

The modified octahedral zeolite is prepared through the once exchange reaction of octahedral zeolite, phosphorus compound and ammonium compound, the further reaction inside exchange slurry with introduced RE solution, filtering, washing and roasting in vapor. The catalyst contains the modified octahedral zeolite 5-45 wt%, clay 15-85 wt% and heat resistant inorganic oxide 15-85 wt%. The catalyst is prepared through mixing the zeolite component, clay and the precursor of the heat resistant inorganic oxide, spraying to form and washing. The catalyst has high activity stability, high gasoline yield, low coke yield, strong heavy oil cracking capacity and high heavy metal pollution resistance.

Owner:PETROCHINA CO LTD

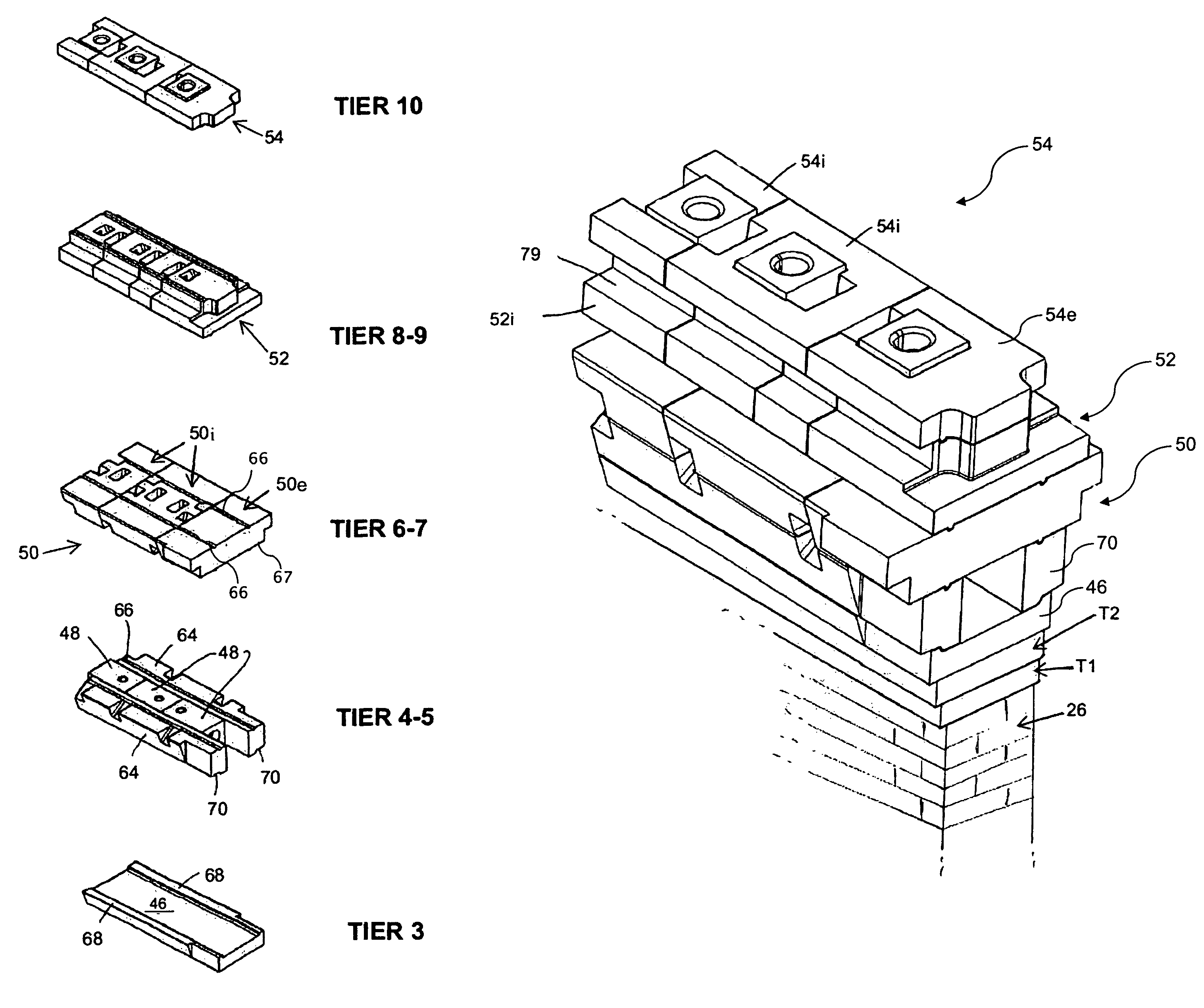

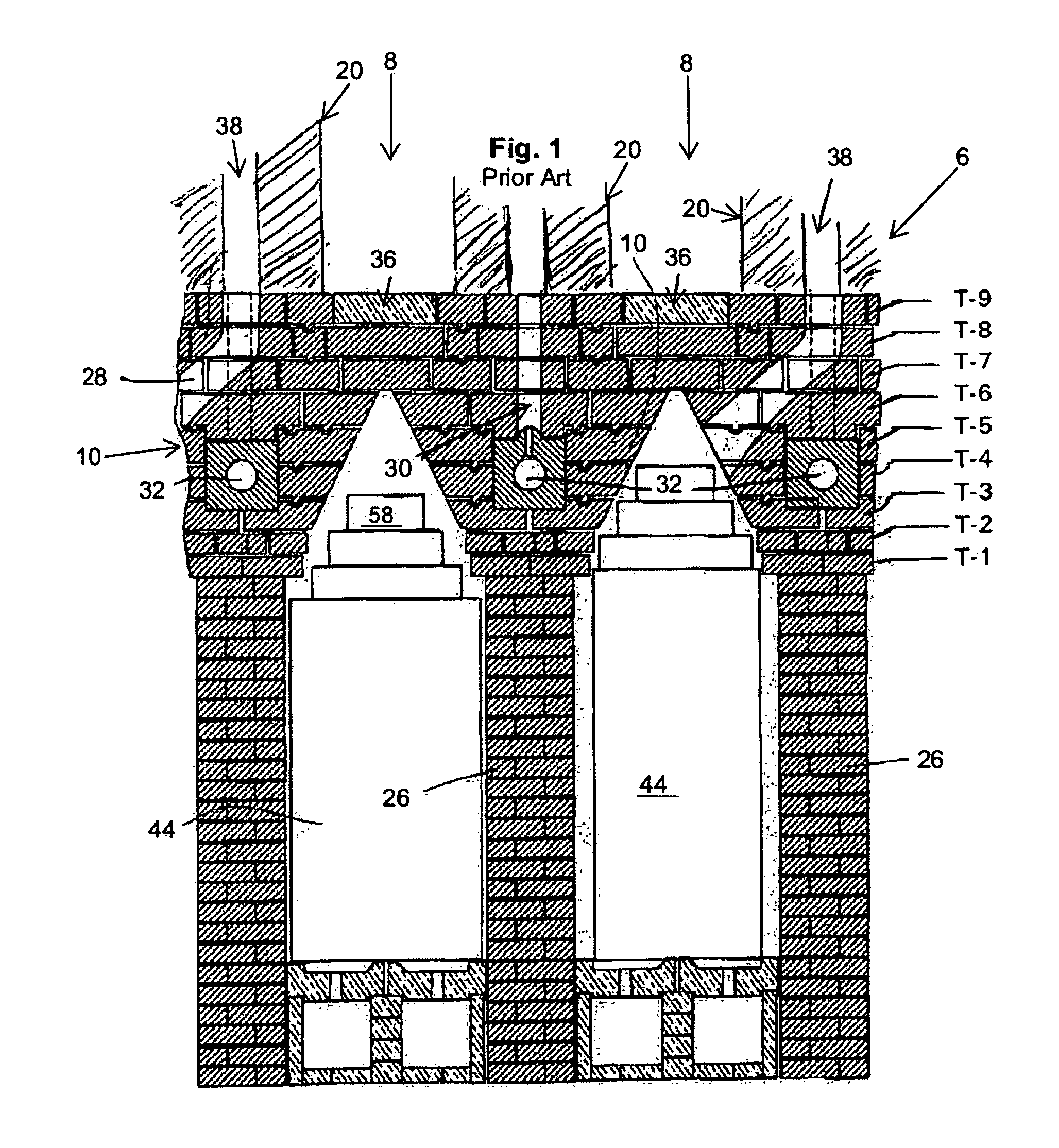

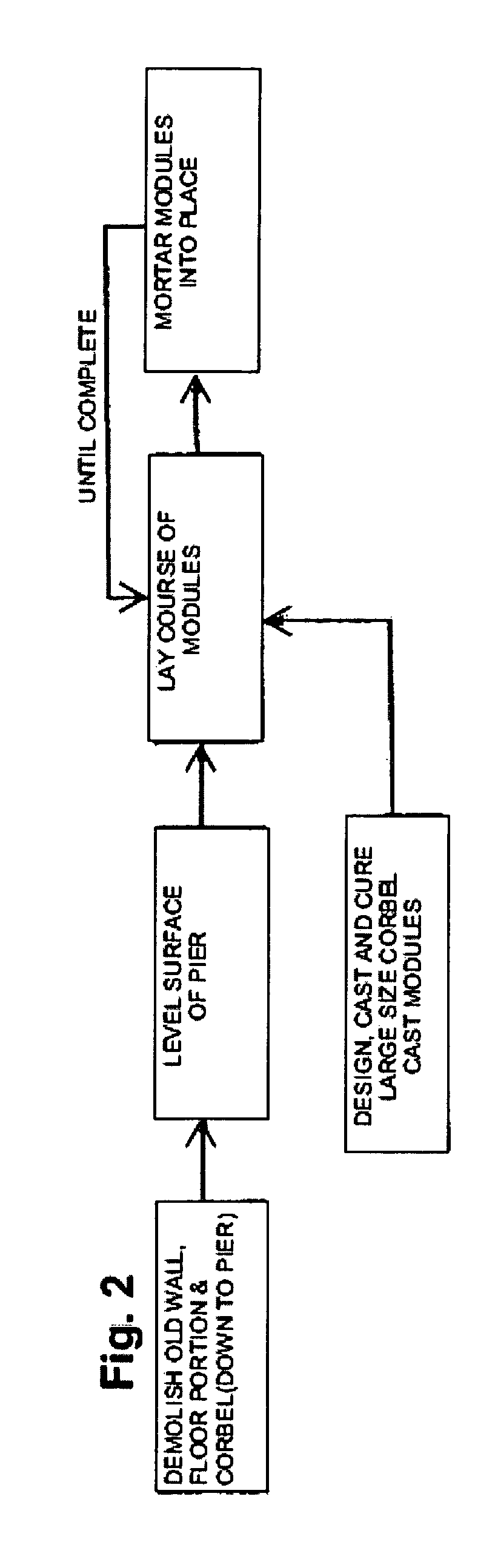

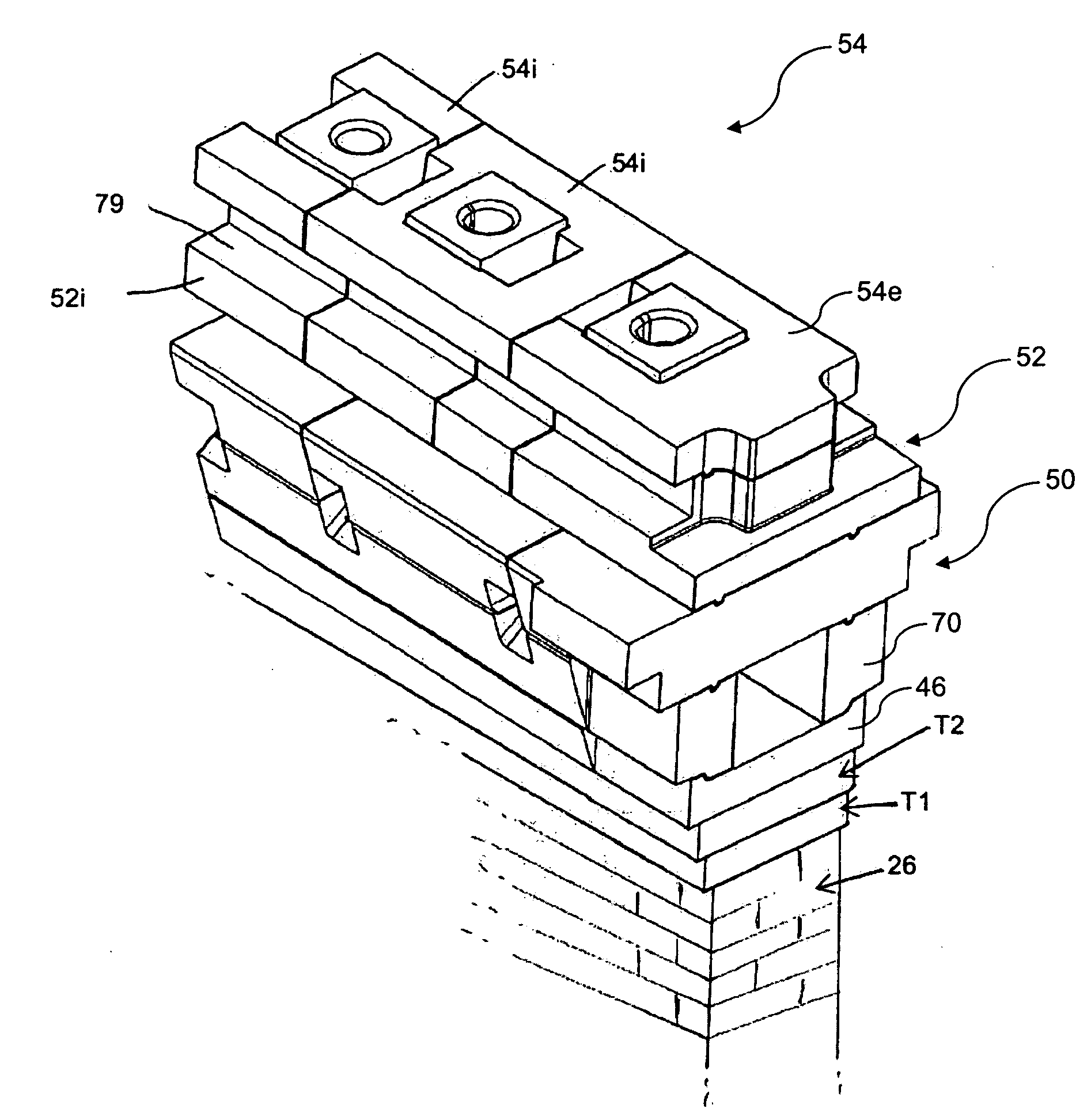

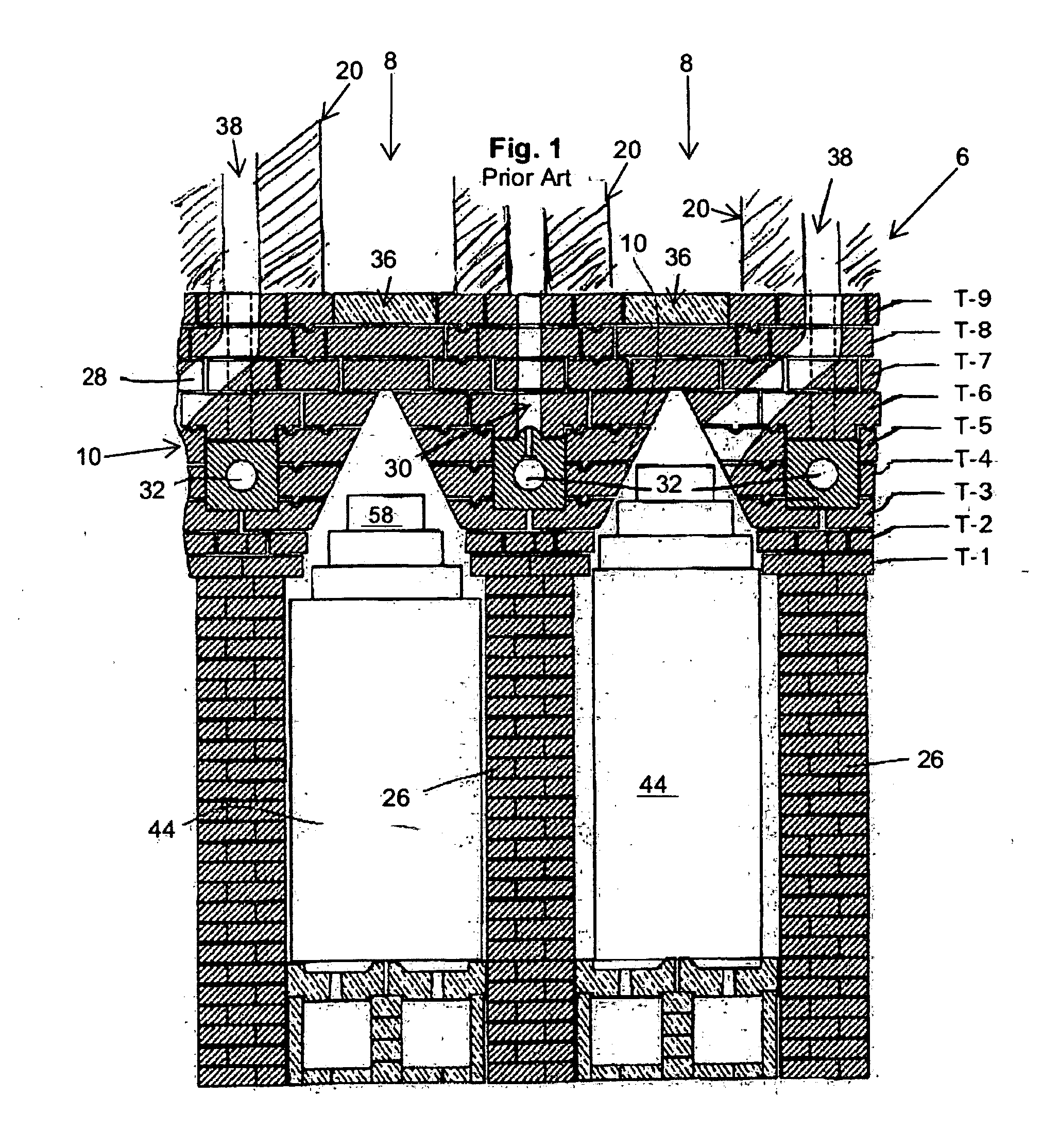

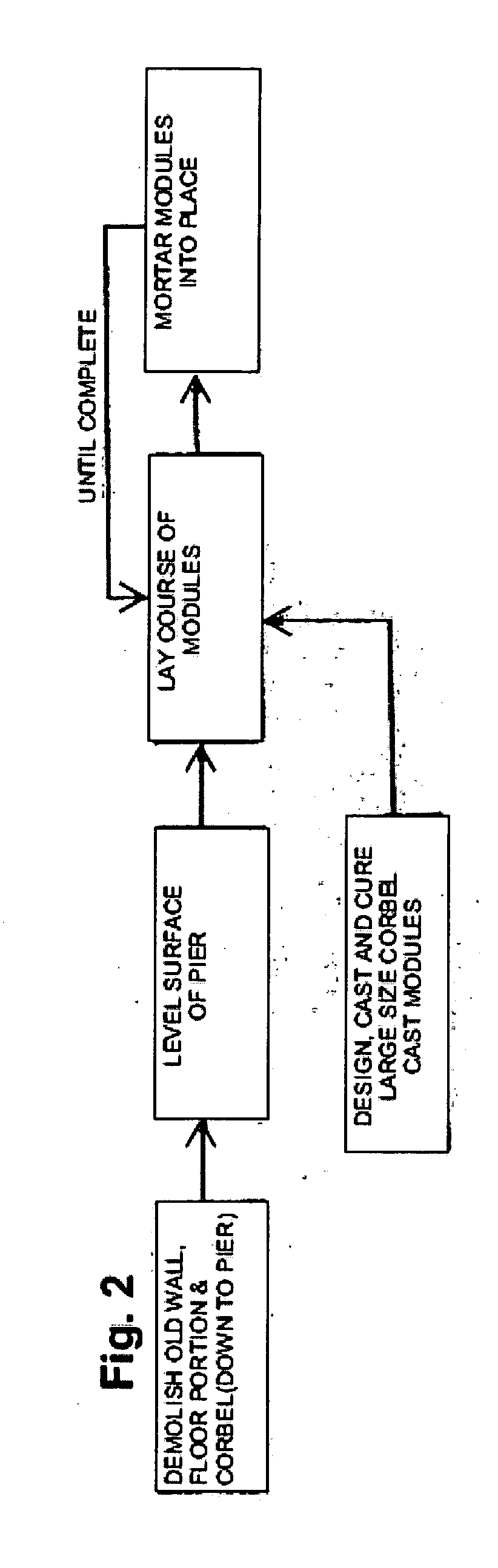

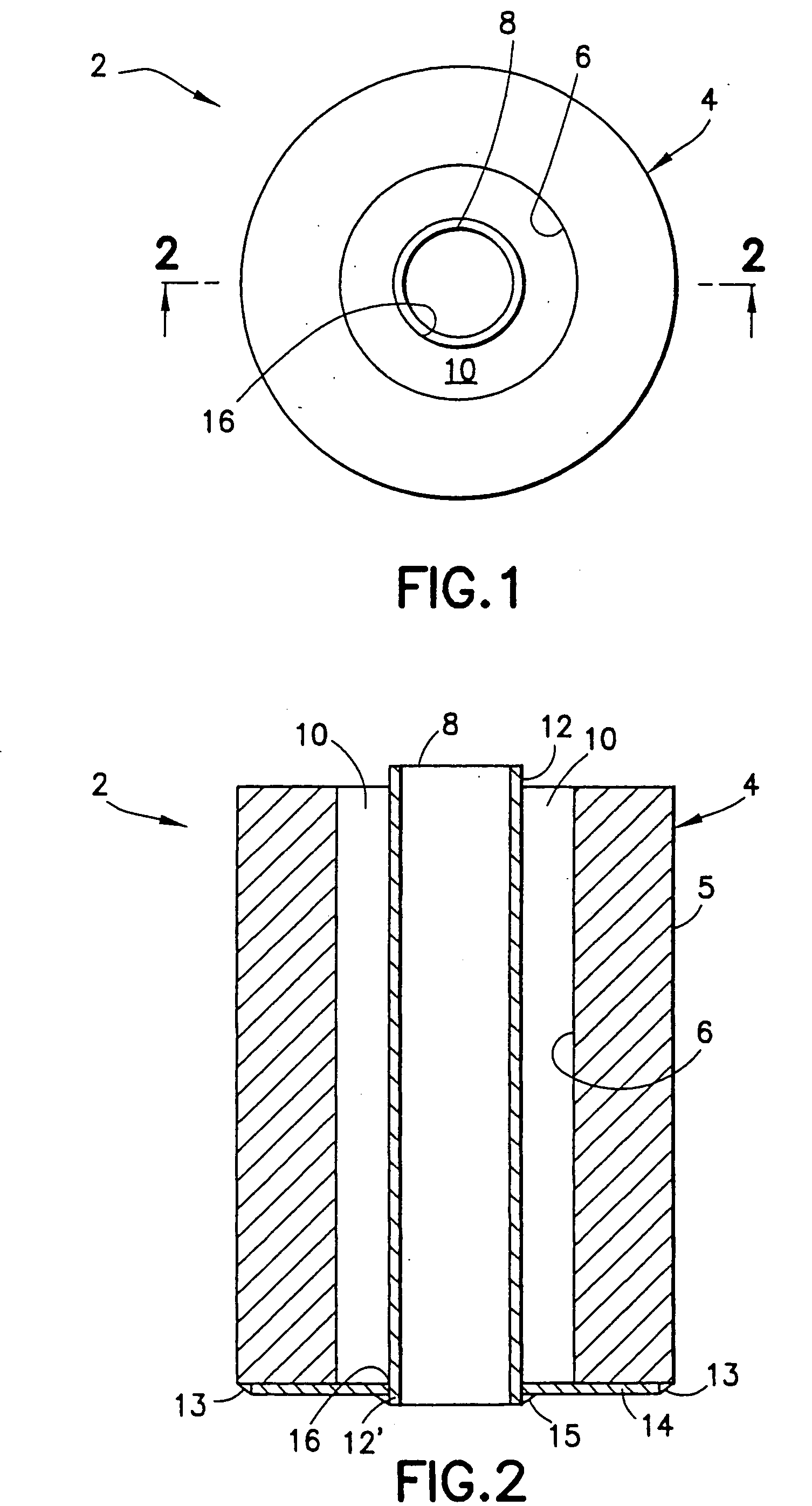

Corbel repairs of coke ovens

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

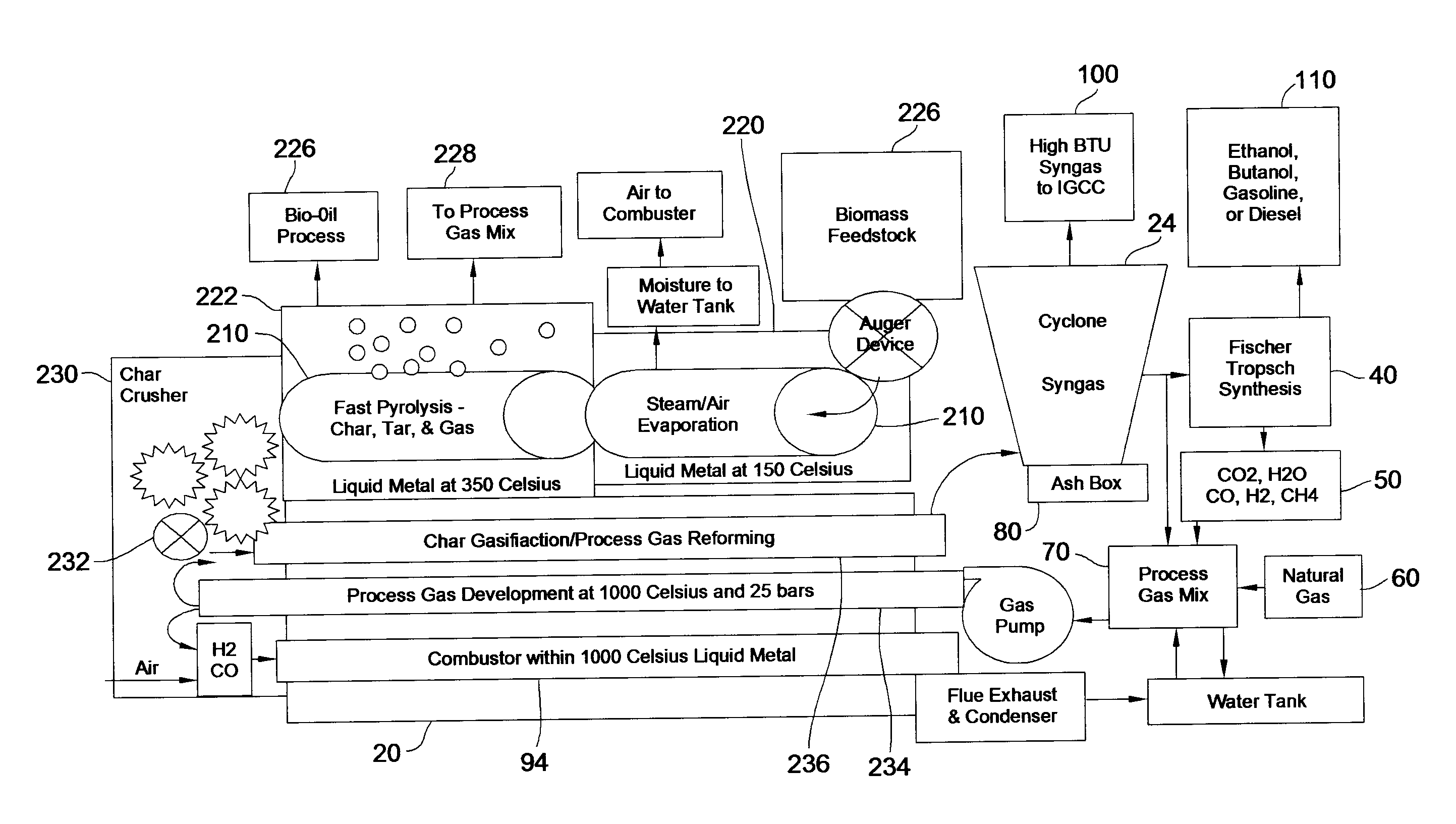

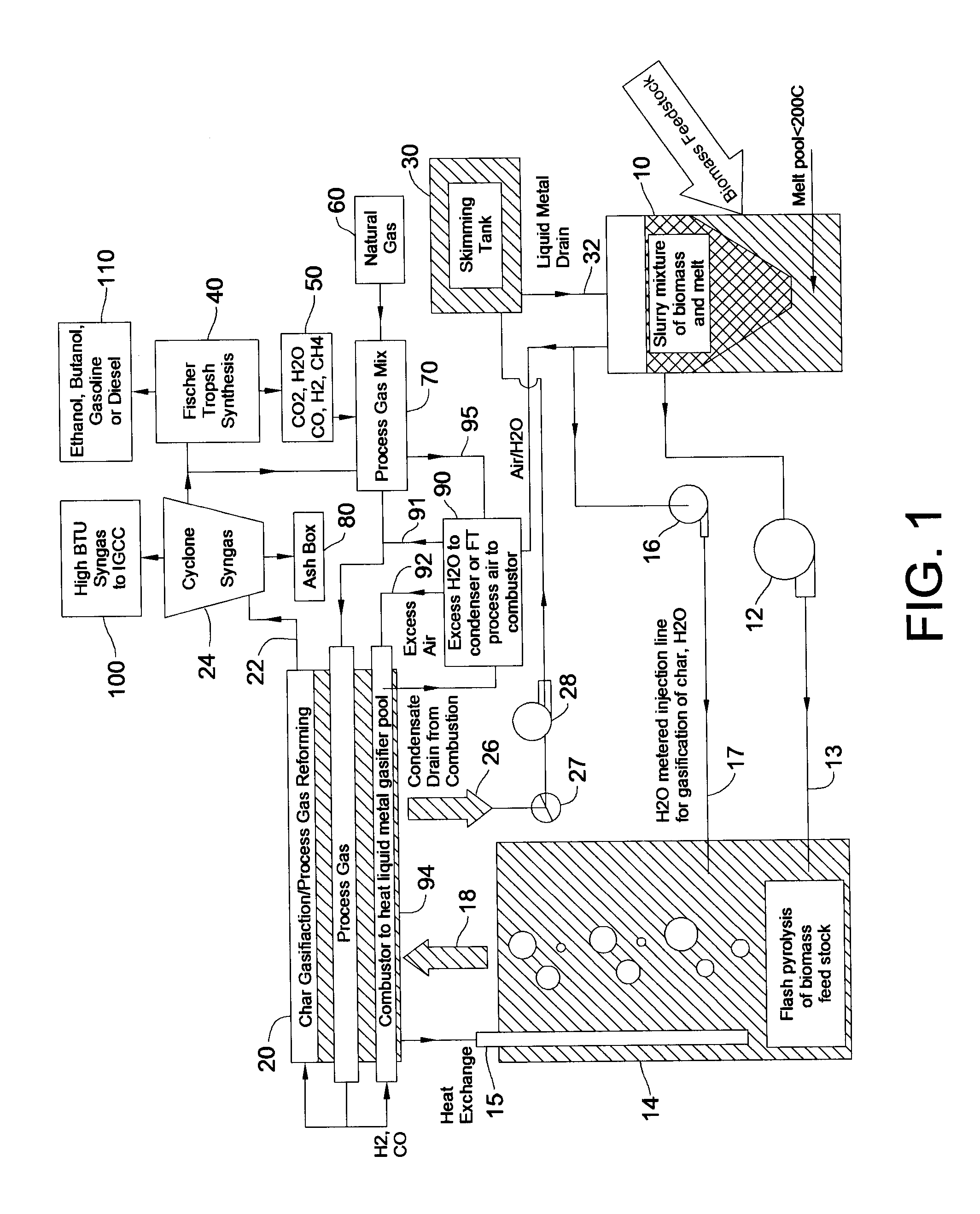

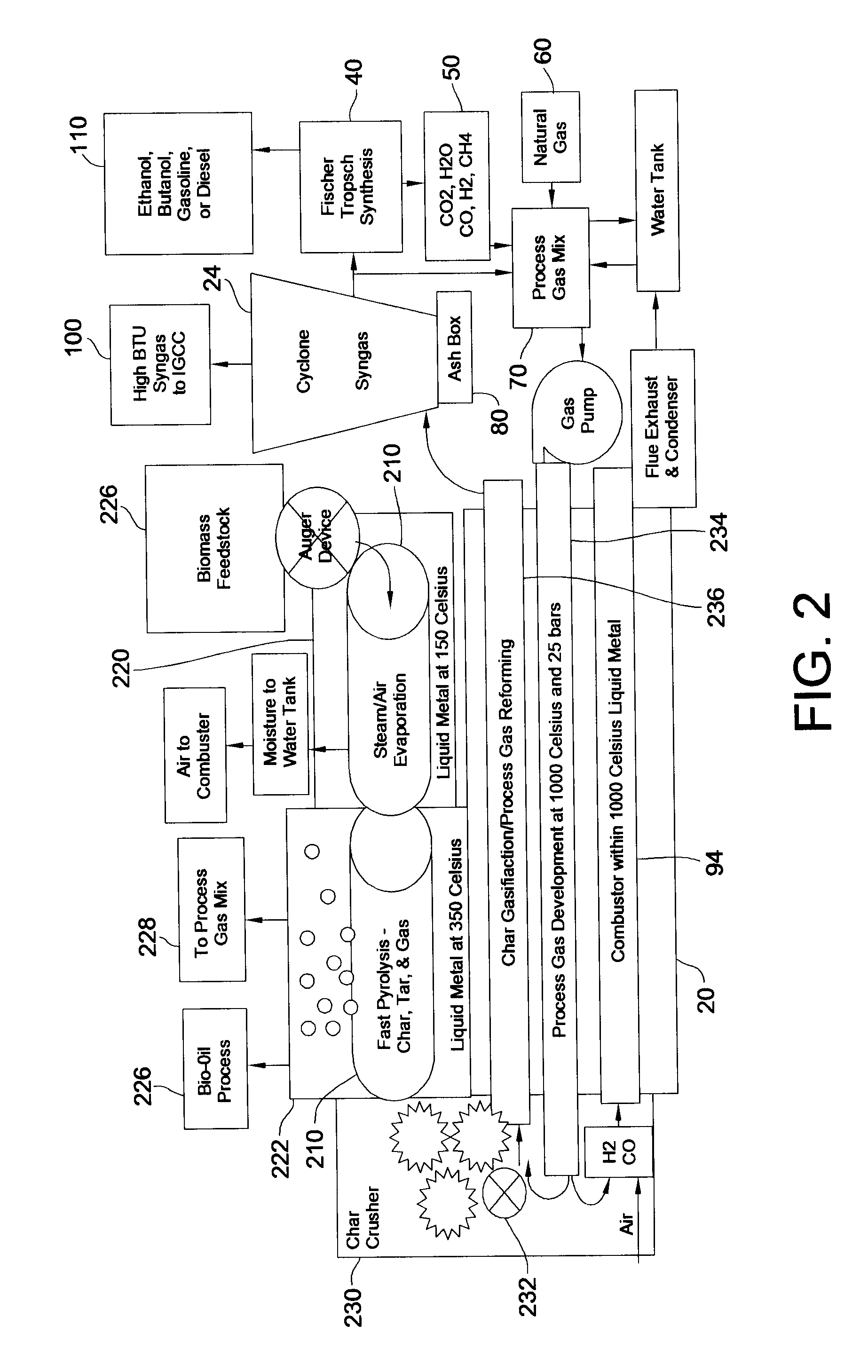

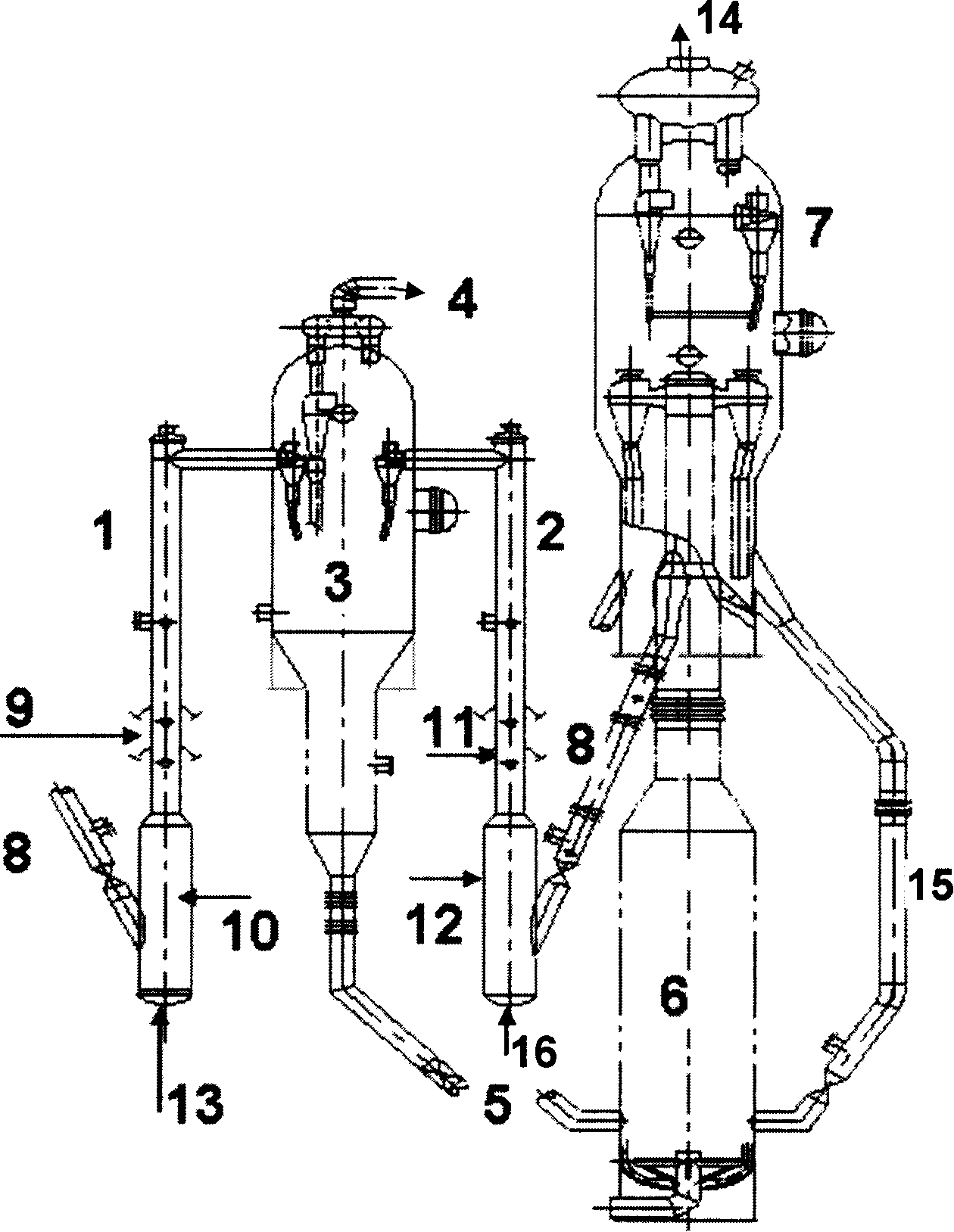

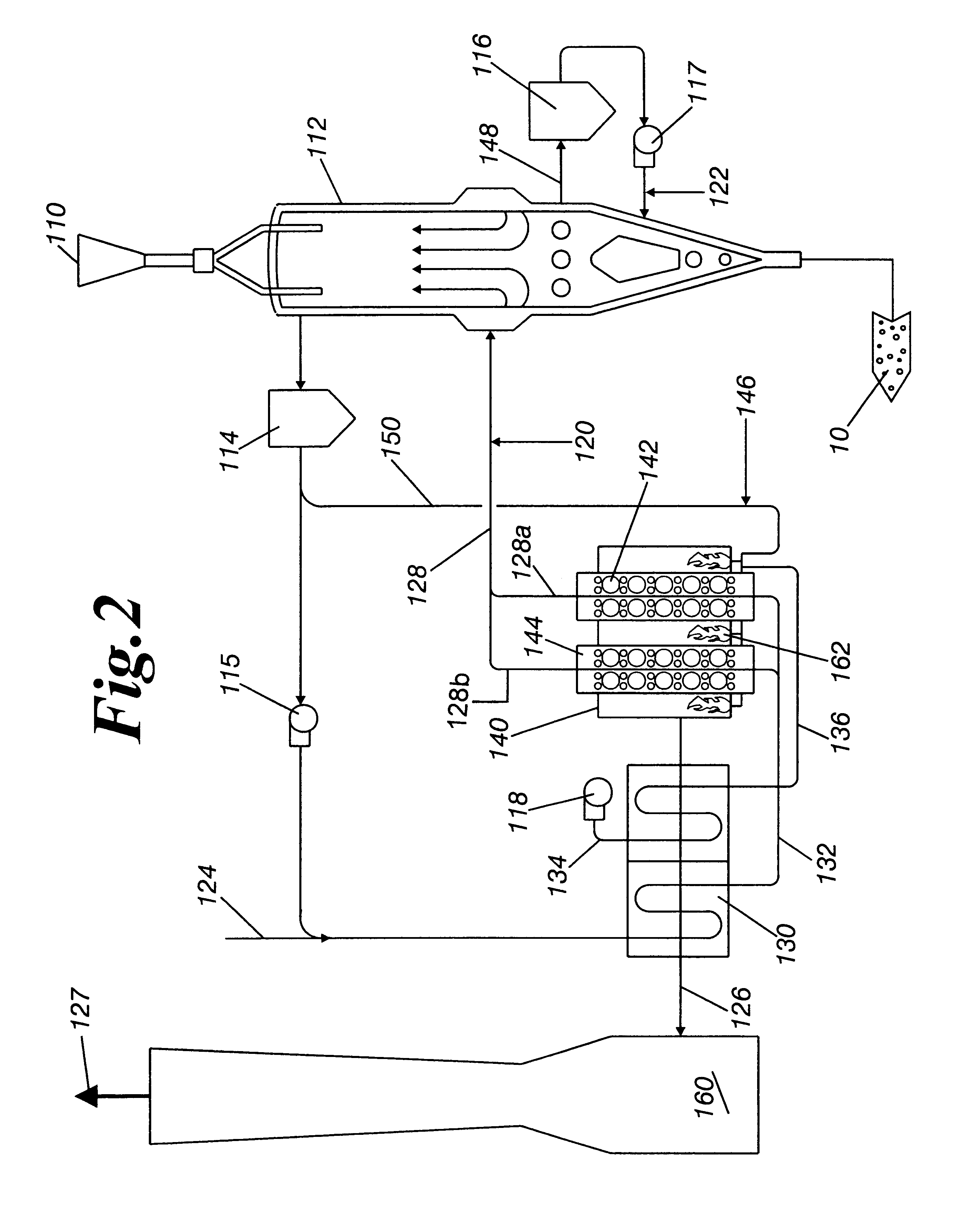

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

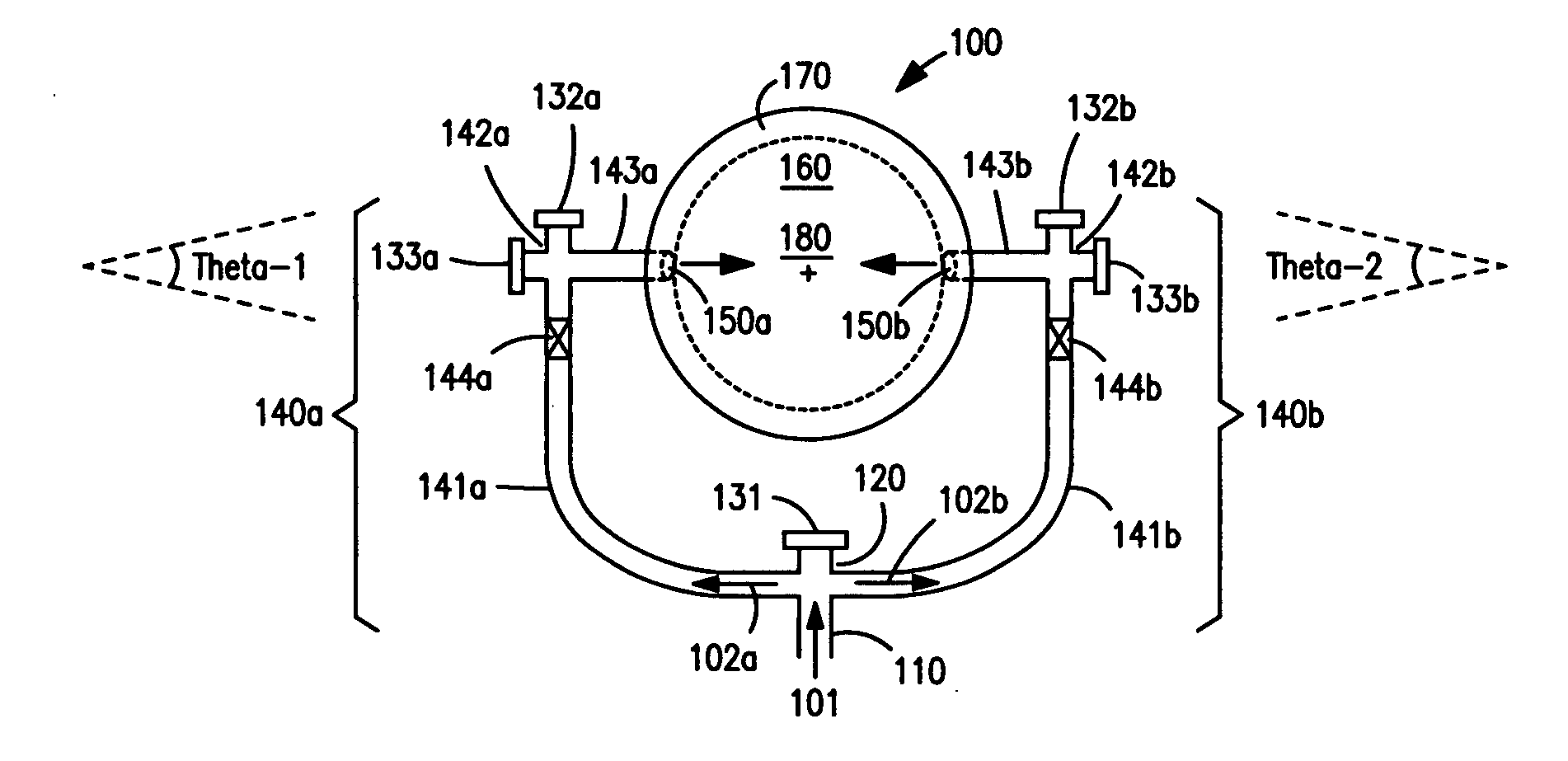

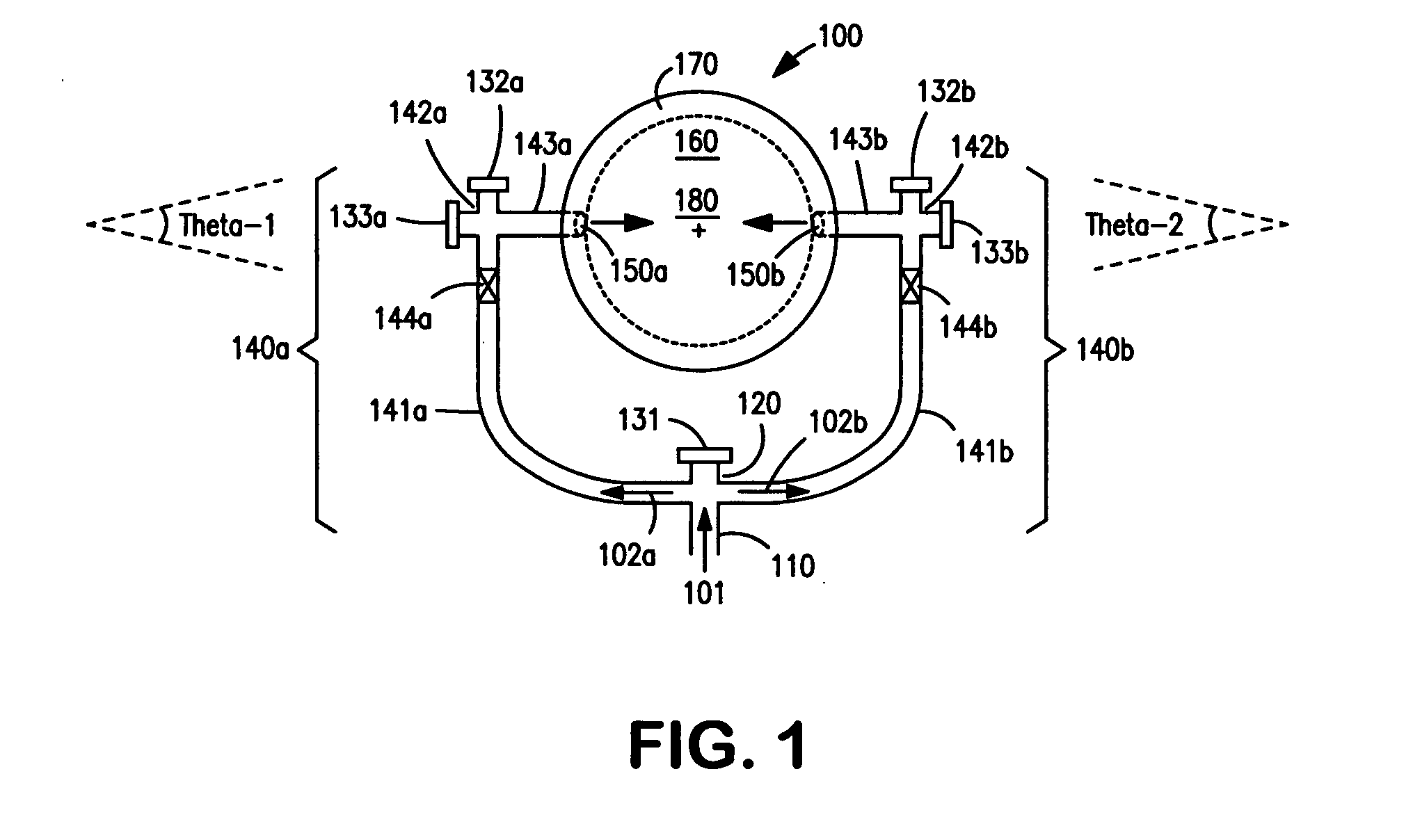

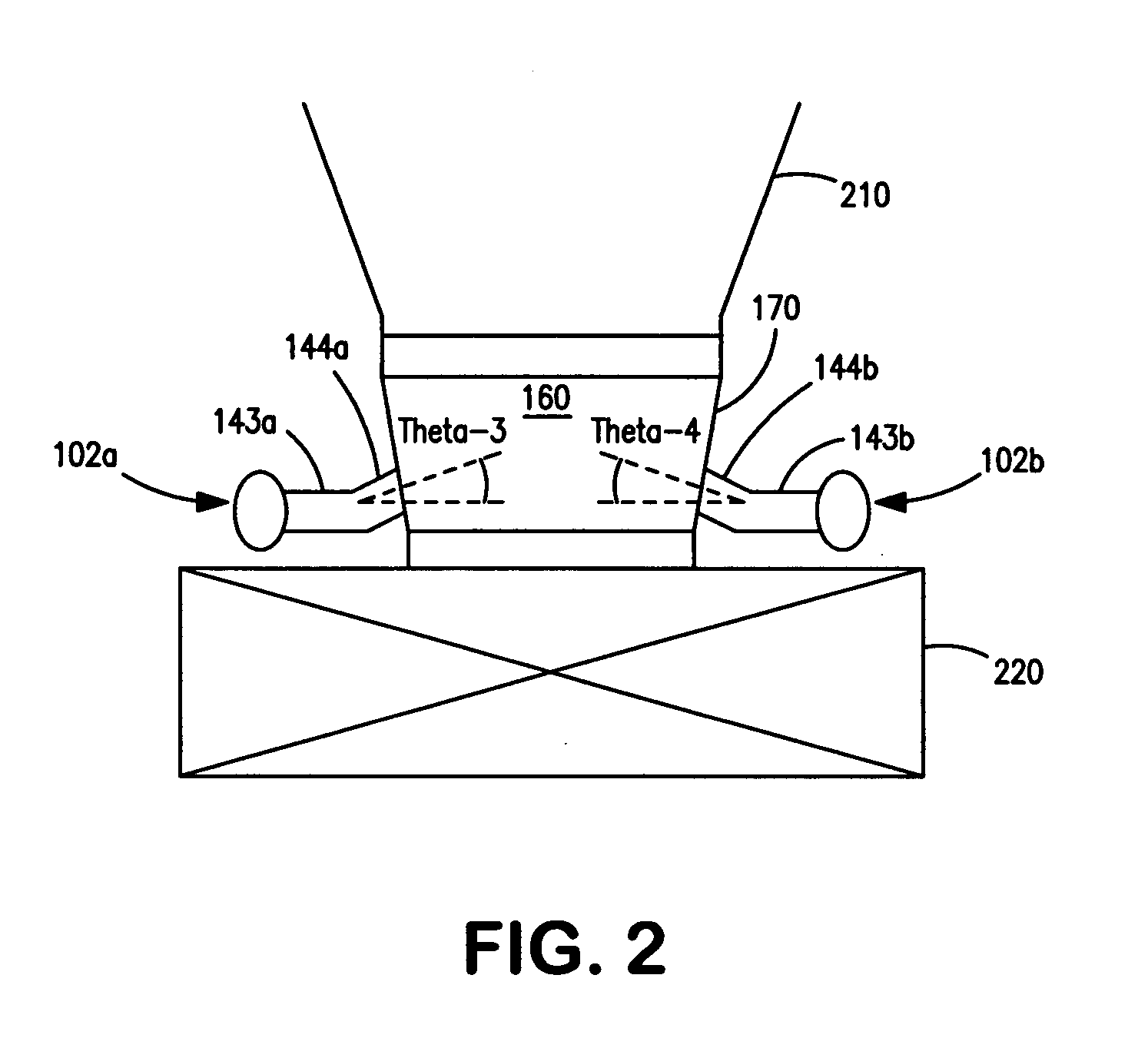

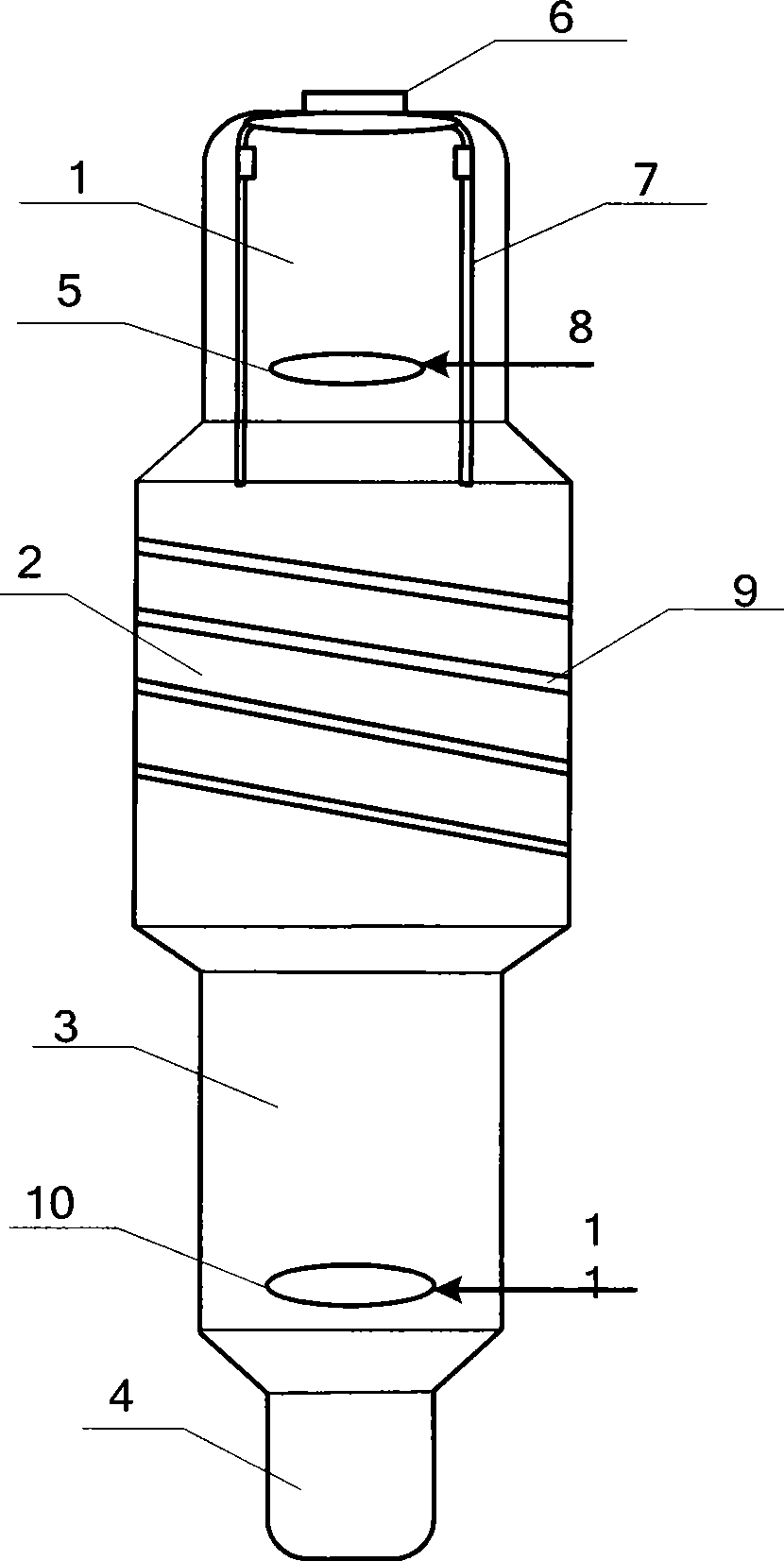

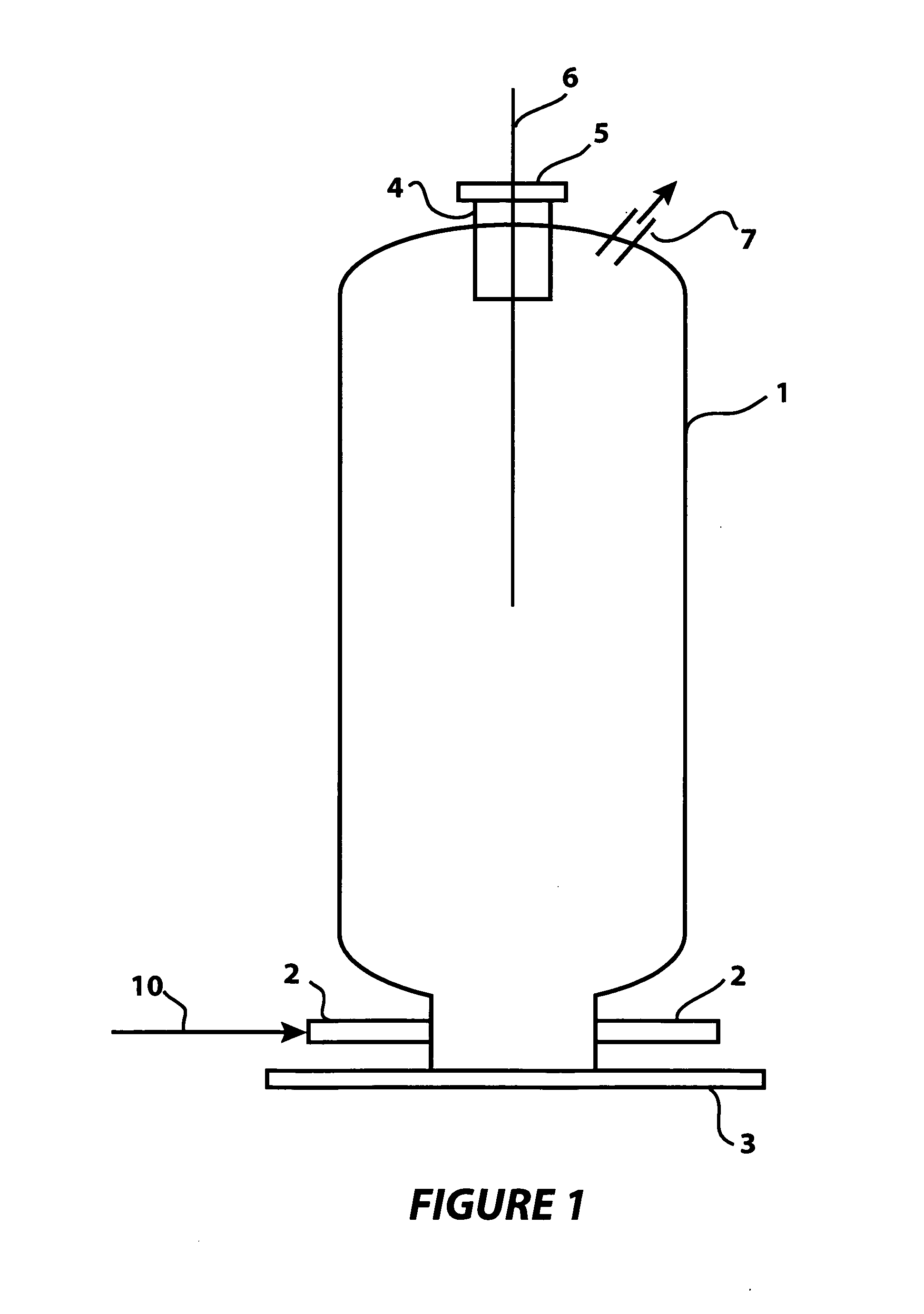

Coker feed method and apparatus

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

Production of propene and high-quality gasoline and diesel oil by two-stage catalyzed crack

ActiveCN101074392AGood natureQuality improvementOrganic chemistryCatalytic crackingMolecular sieveVegetable oil

A method for producing propylene and gasoline diesel-oil by two-section catalyzed cracking style is carried out by adopting two-section lift pipe catalyzing process and catalyst with molecular sieve, taking heavy petroleum hydrocarbon or various animal and vegetable oils containing hydrocarbon as raw materials, optimization combining by charging style for various reactants, and controlling proper reactive conditions. It can improve propene and light-oil recovery rate and quality, and inhibit to generate dry gas and coke.

Owner:PETROCHINA CO LTD +1

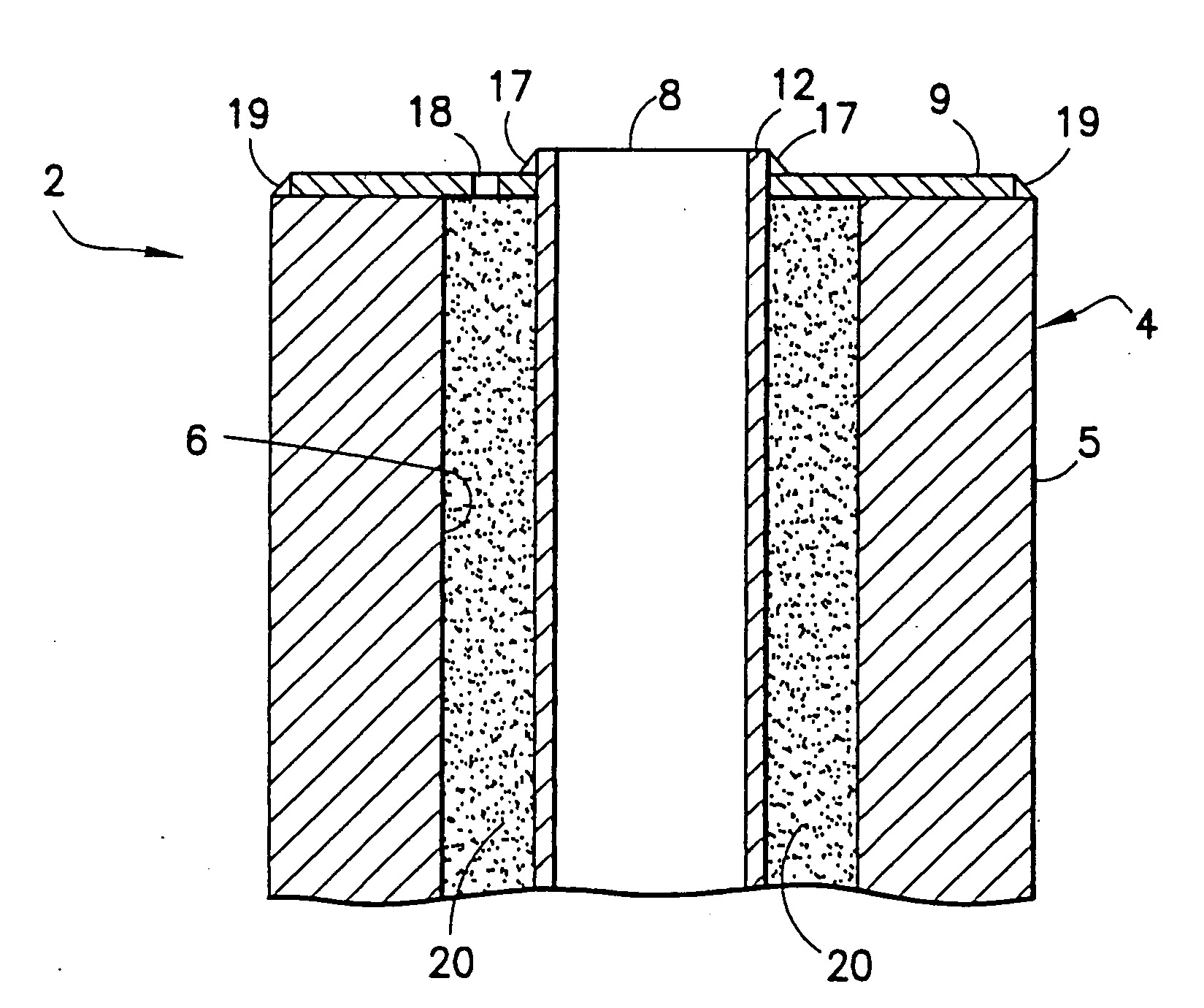

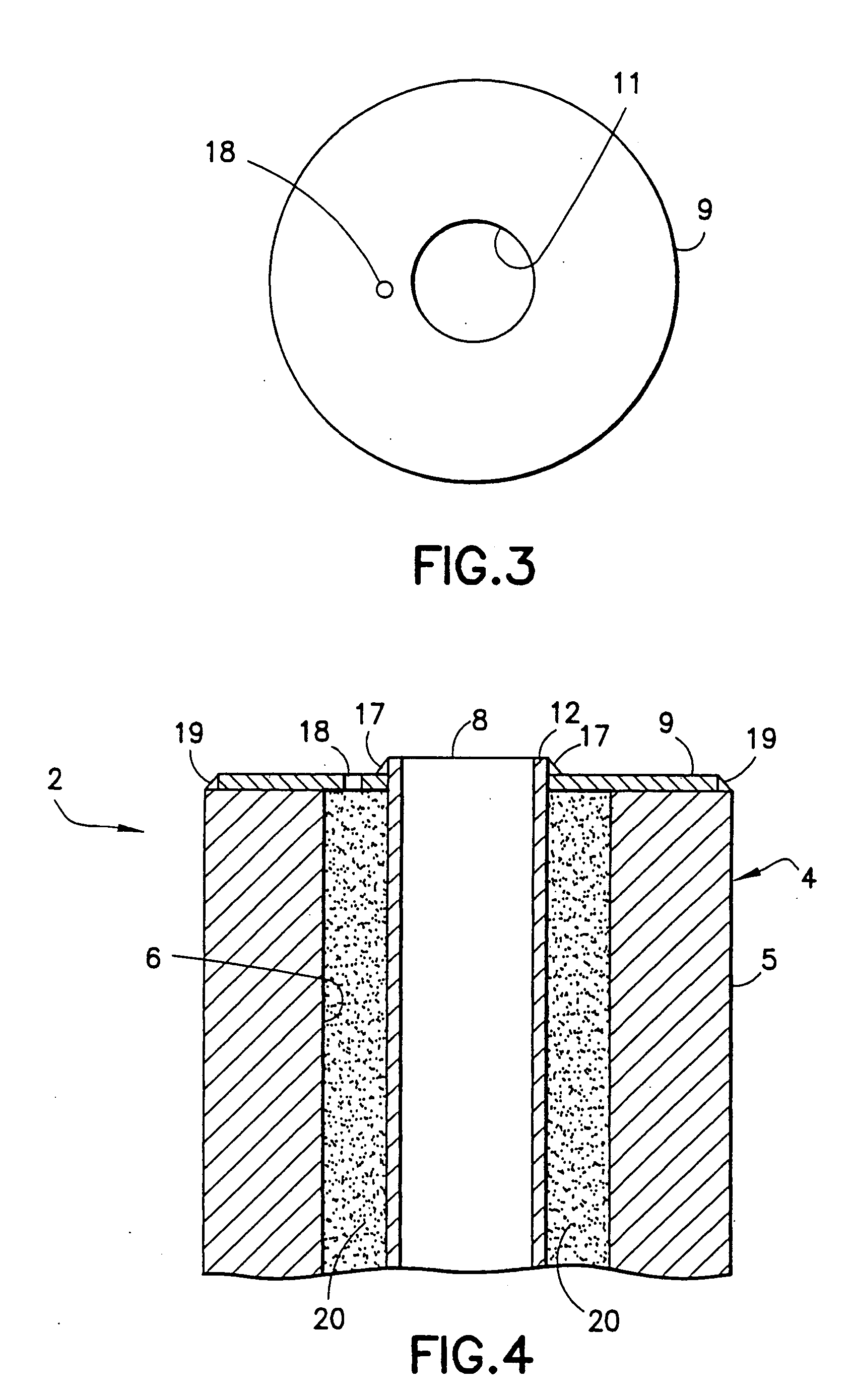

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

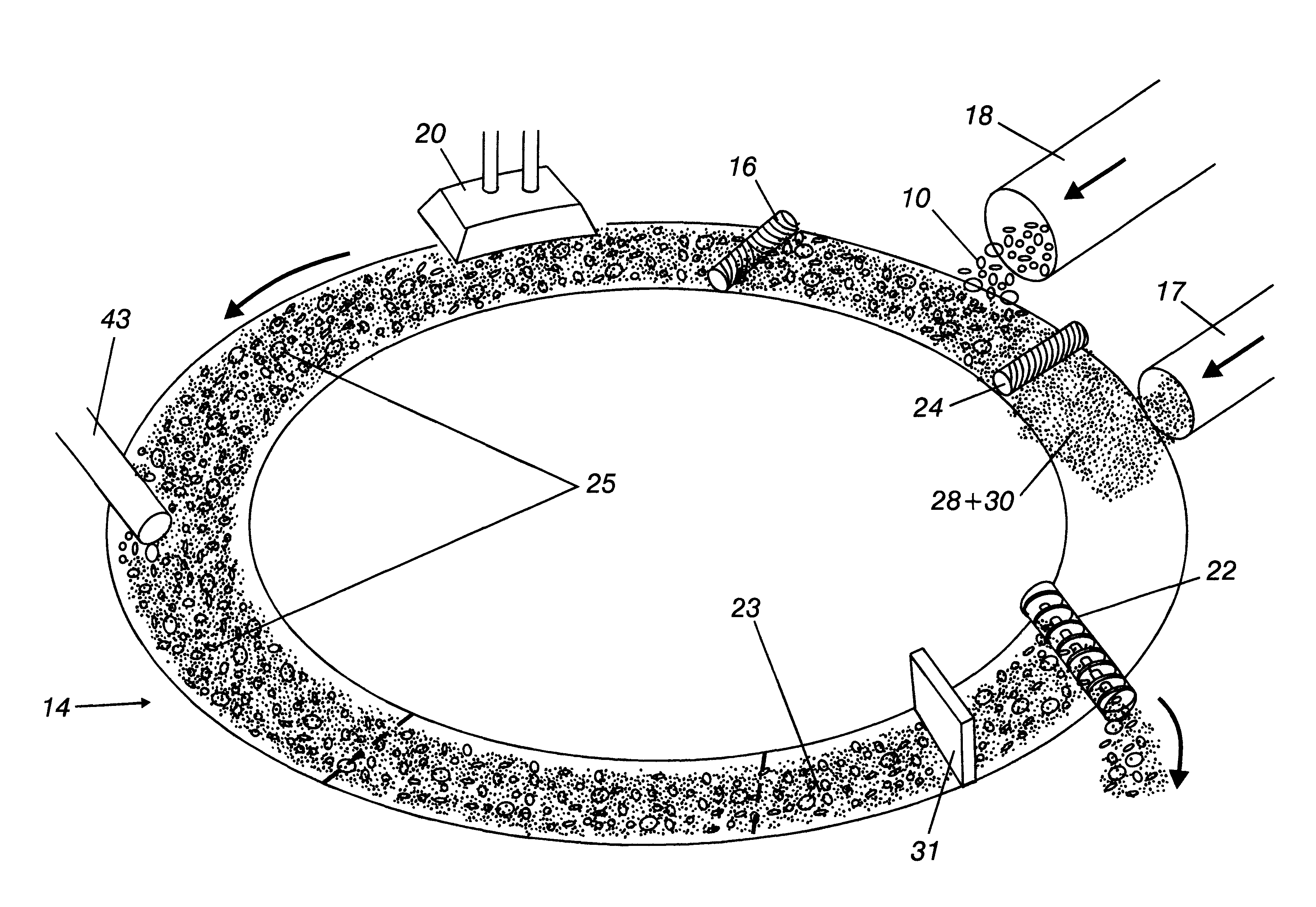

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

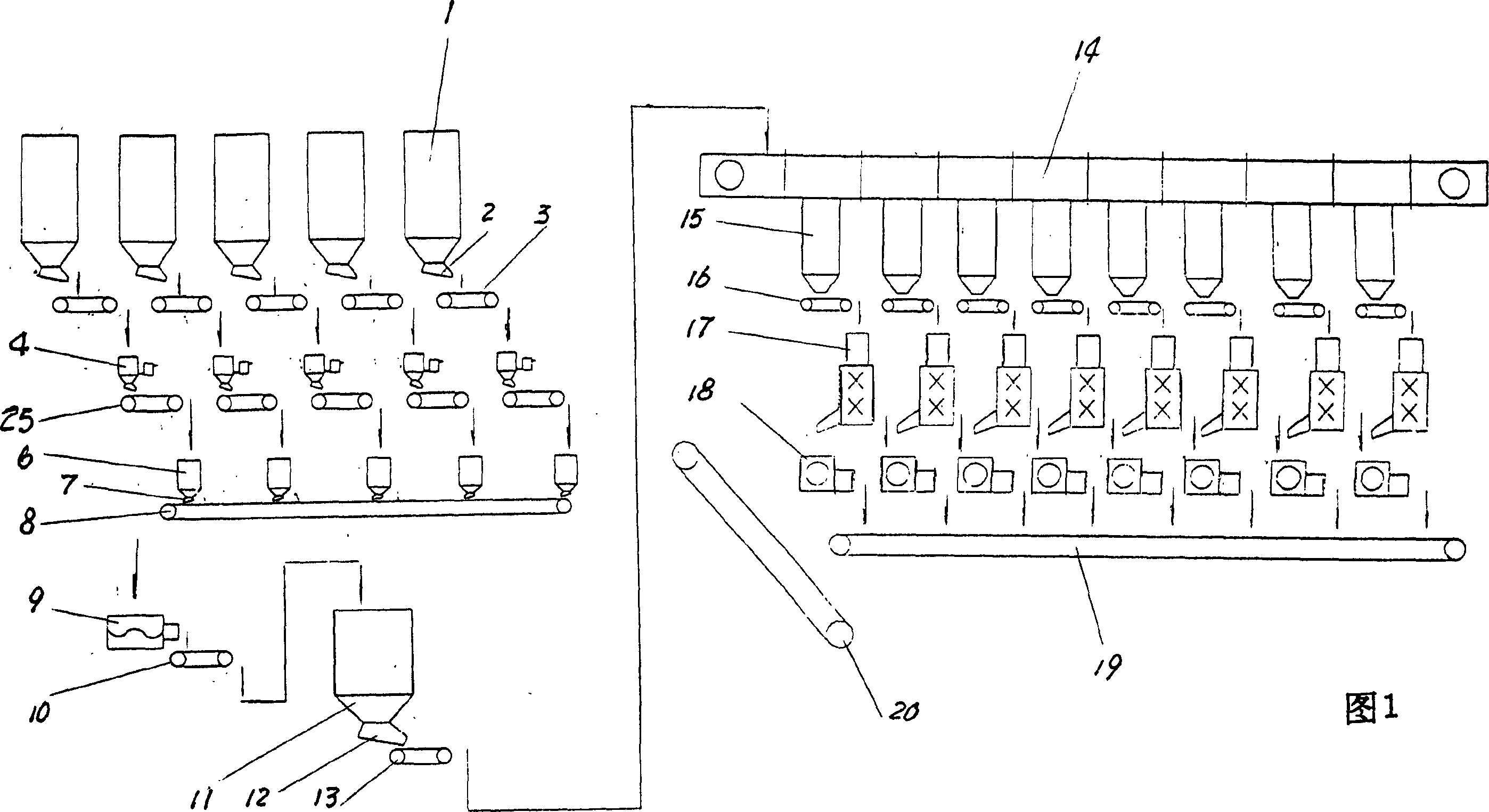

Method for making coal fine into form coke by microwave energy

InactiveCN101497835AReduce manufacturing costIncrease productivitySolid fuelsMicrowave heatingMicrowaveWork in process

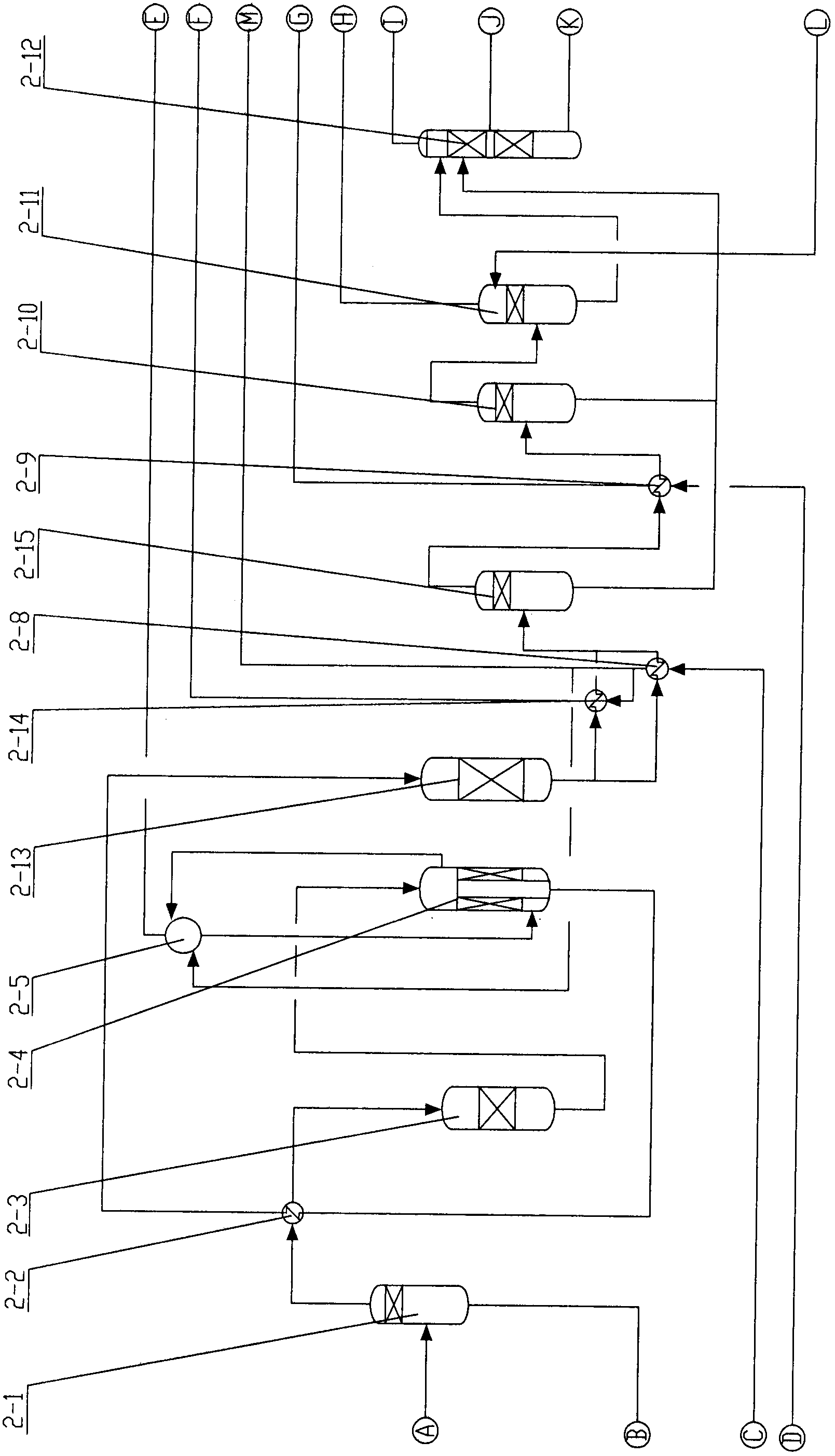

The invention relates to a method for producing formed coke, in particular to a method for preparing coal powder into the formed coke by microwave. The method adopts coal powder as raw material and comprises the following steps: sieving the coal powder for preparing fine coal powder, sending the fine coal powder into a first microwave heating device for dehydration until the water content of the heated fine coal powder is below 1 percent, and sending the heated fine coal powder into a second microwave heating device by a conveying device for dry distillation; performing the dry distillation to the fine coal powder by the second microwave heating device to analyze other materials in the coal powder, preparing carbocoal after the dry distillation, sending the carbocoal into a mixer by the conveying device to prepare the mixture after adding bonding material; sending the mixture to a forming machine by a conveyer for forming so as to prepare a formed coke semi-finished product; sending the reformed coke semi-finished product into a third microwave heating device for being heated and carbonized to prepare red coke, and sending the carbonized red coke into a coke car to prepare a formed coke product. The invention has low production cost, high production efficiency, cleanness and environment protection because coke powder and waste are not produced during the production.

Owner:唐山金强恒业压力型焦有限公司

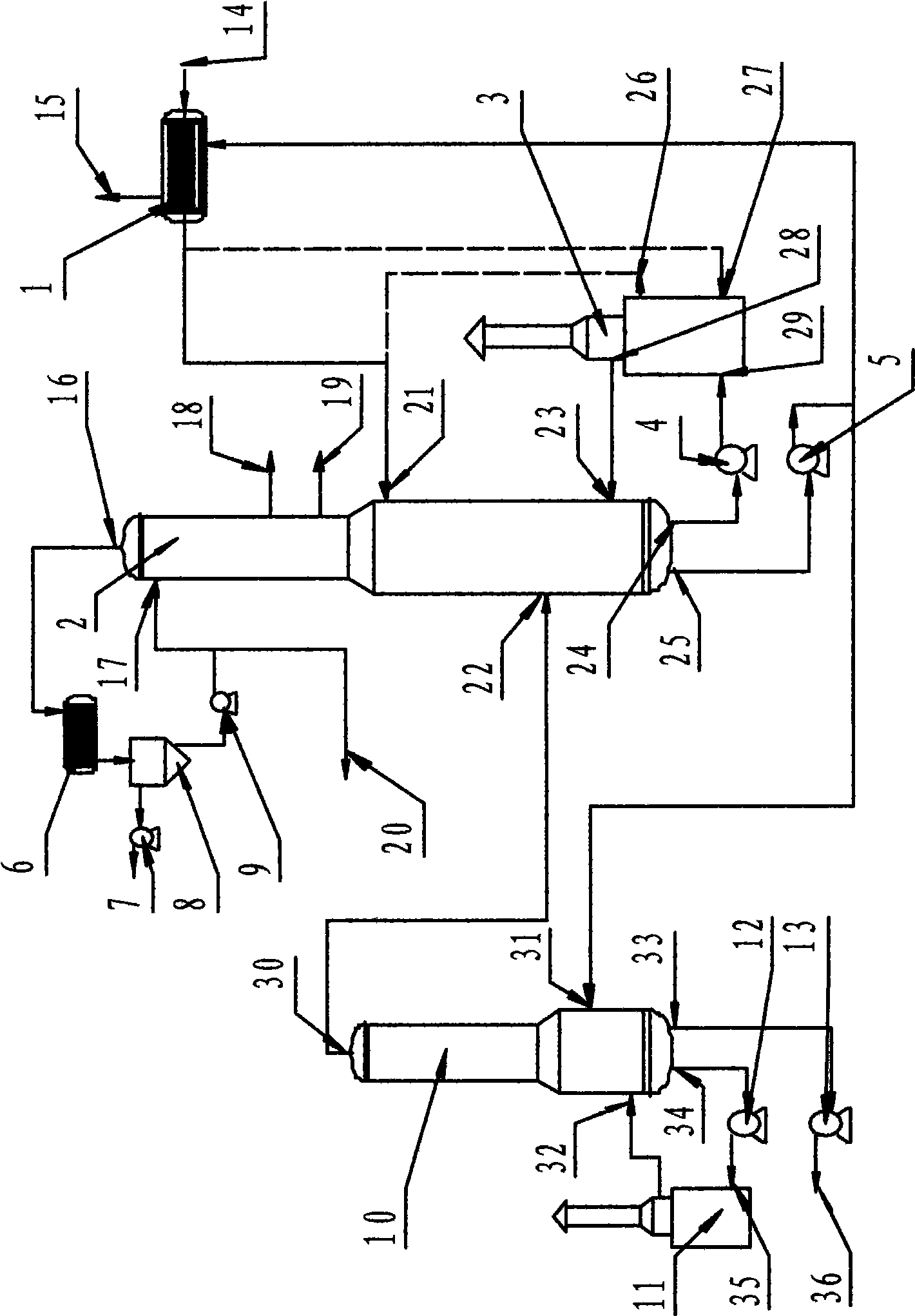

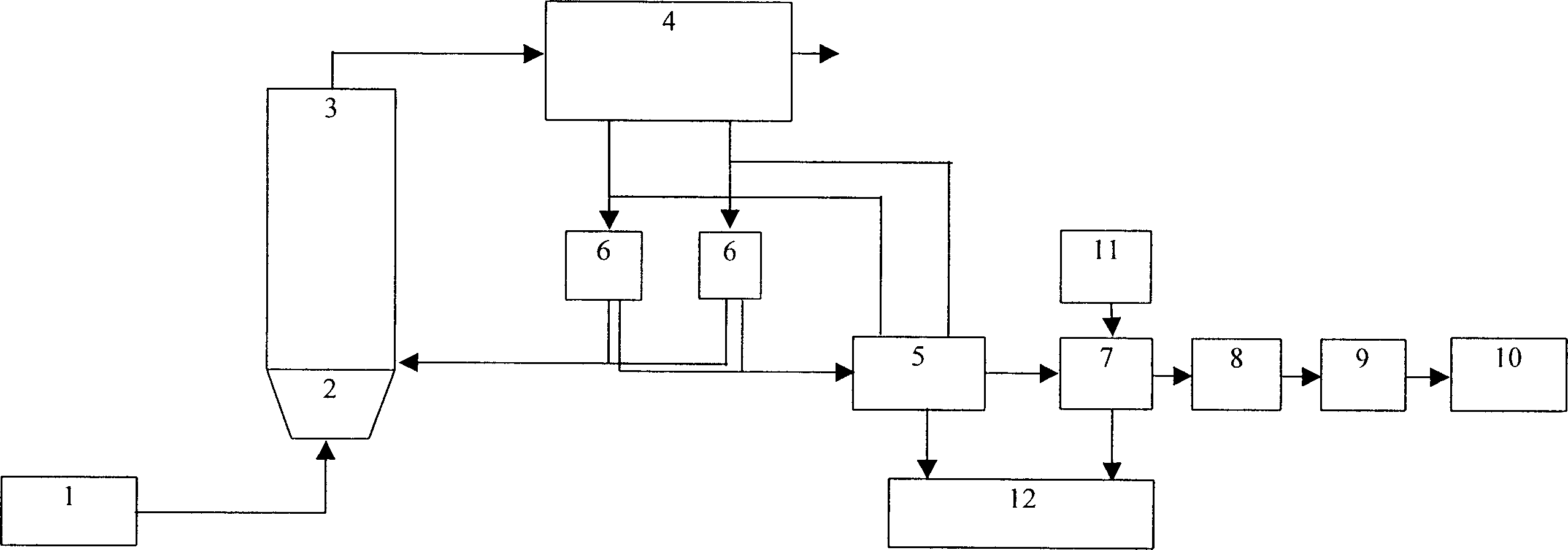

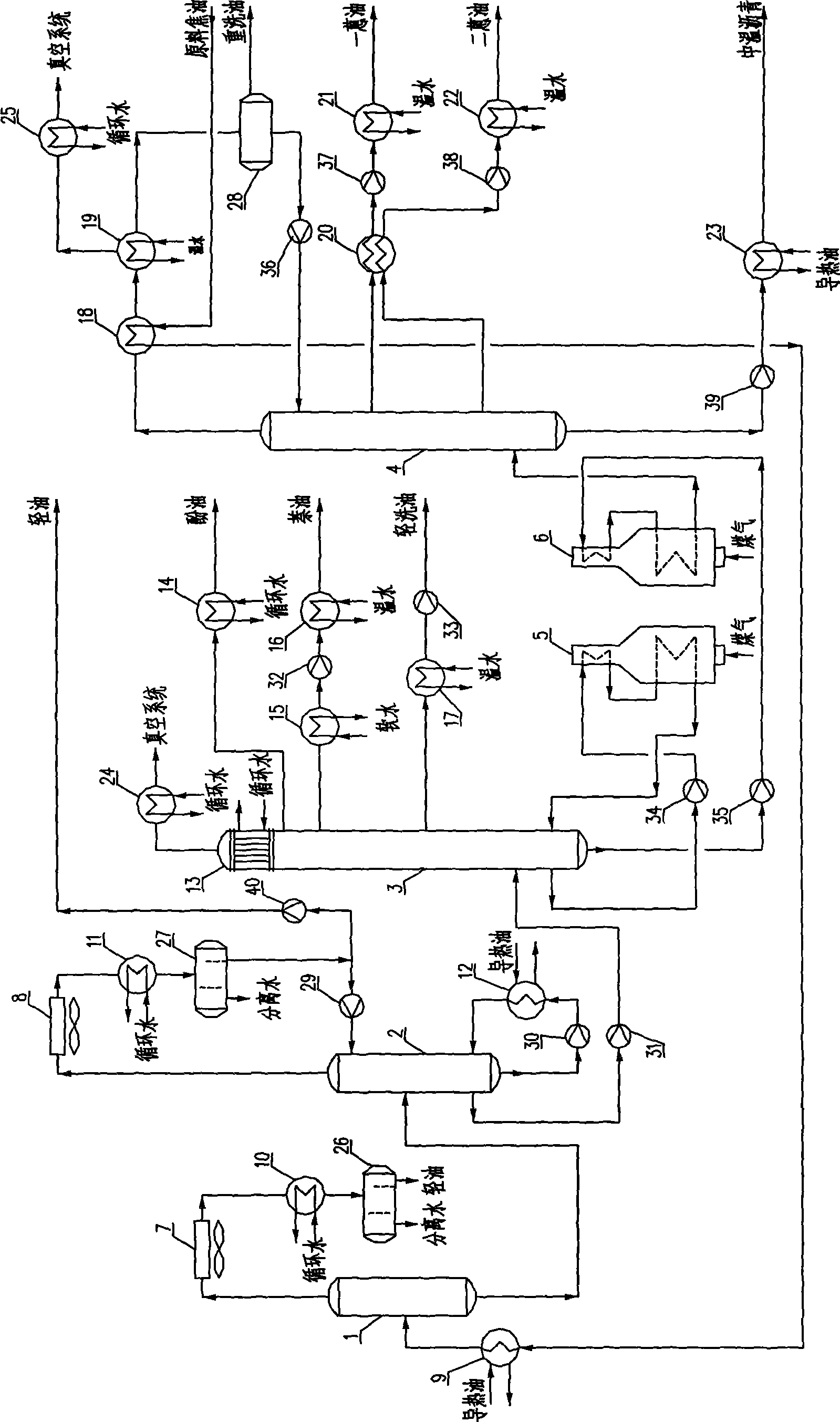

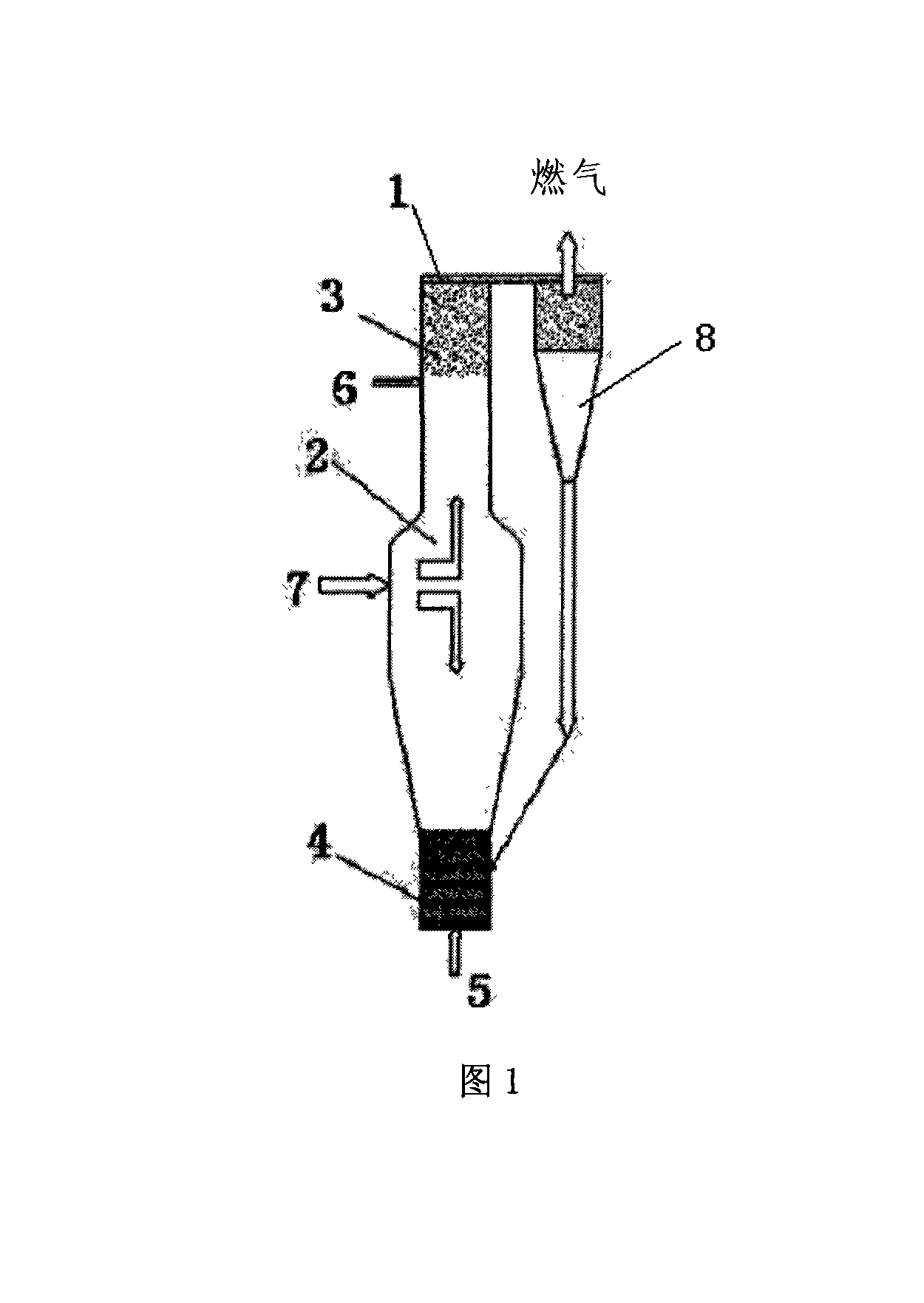

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

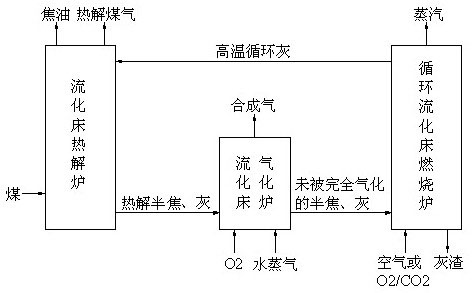

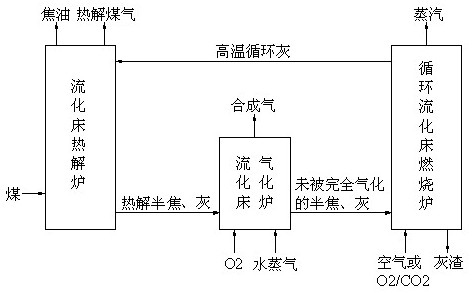

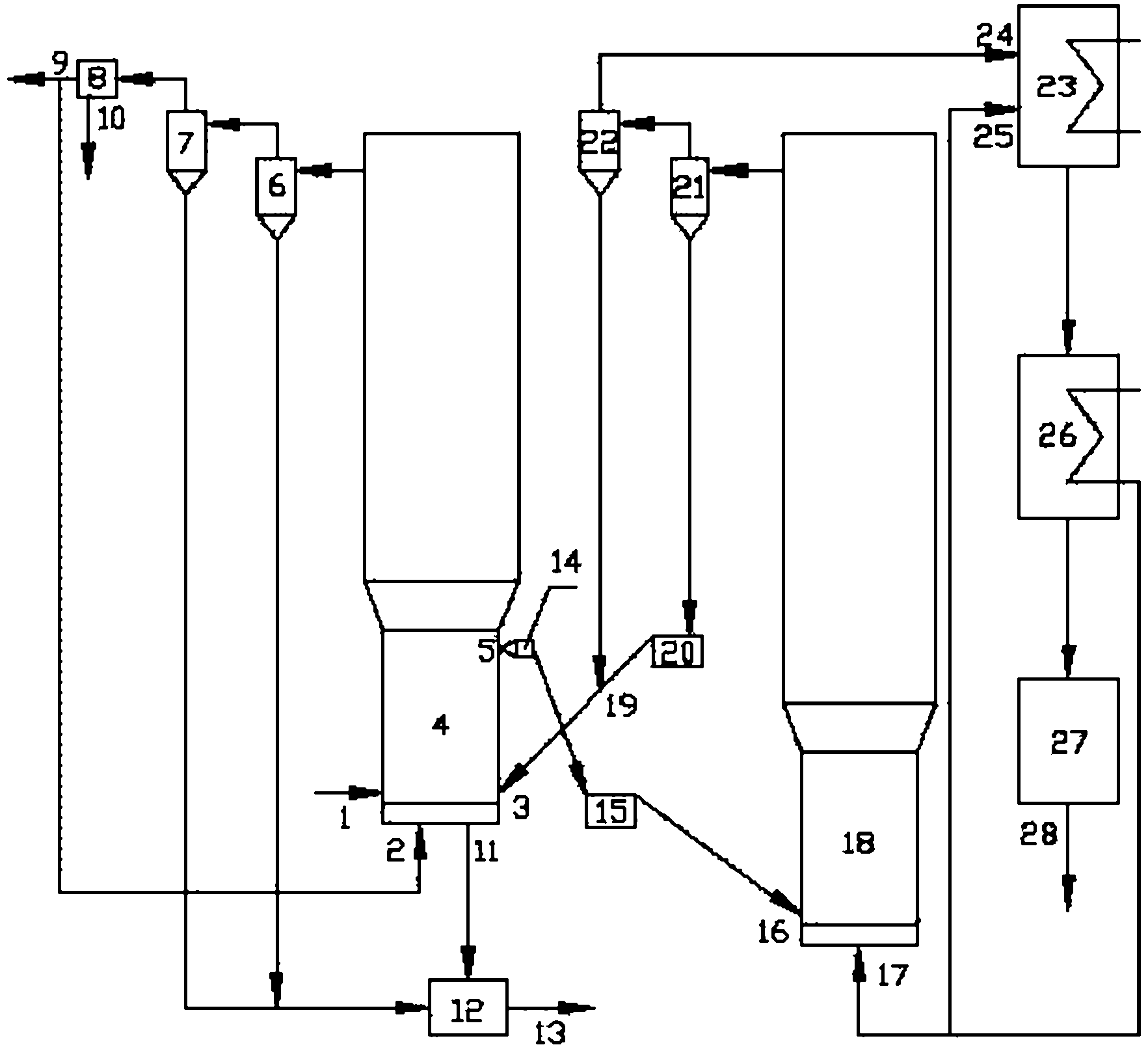

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

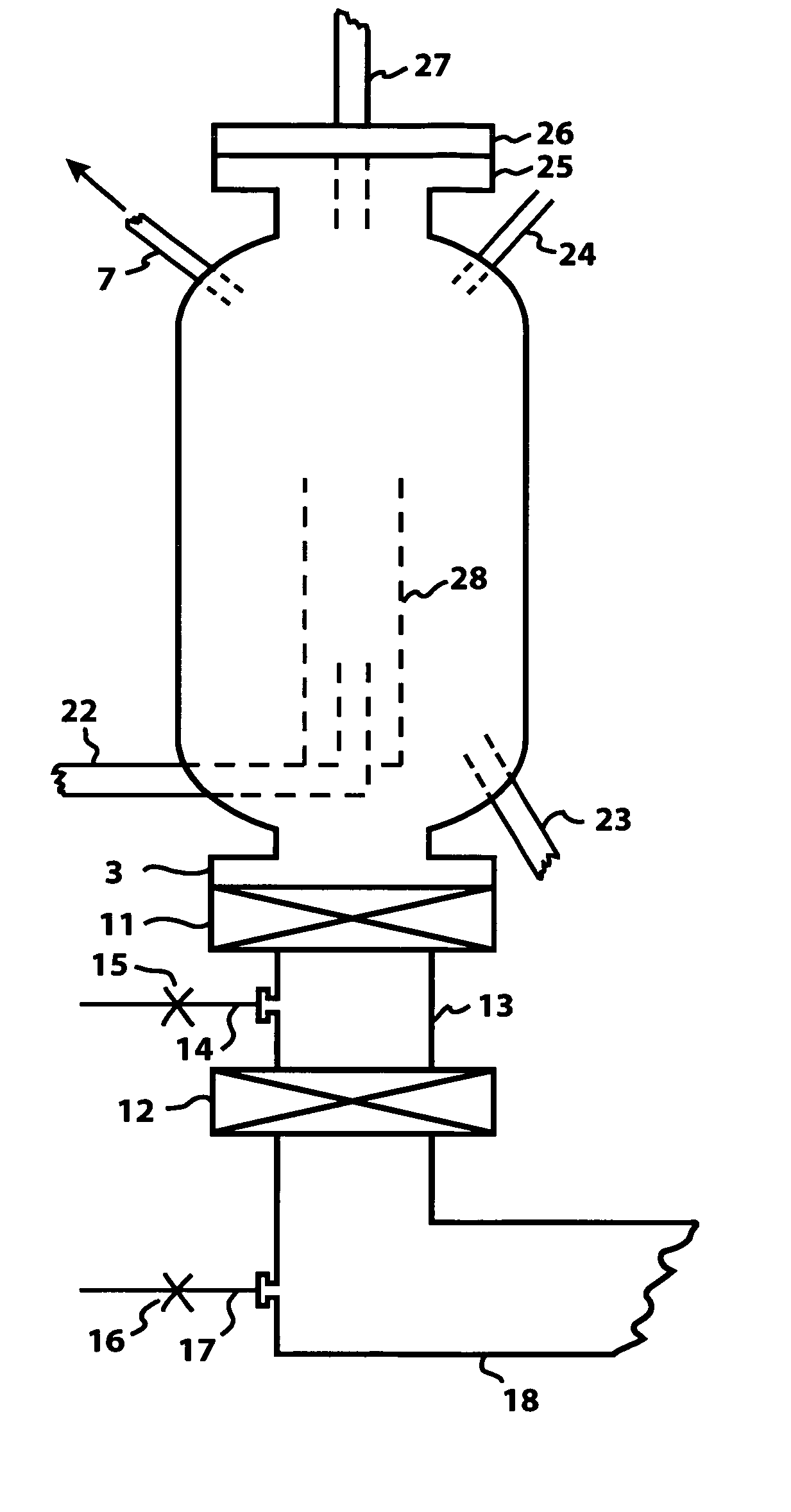

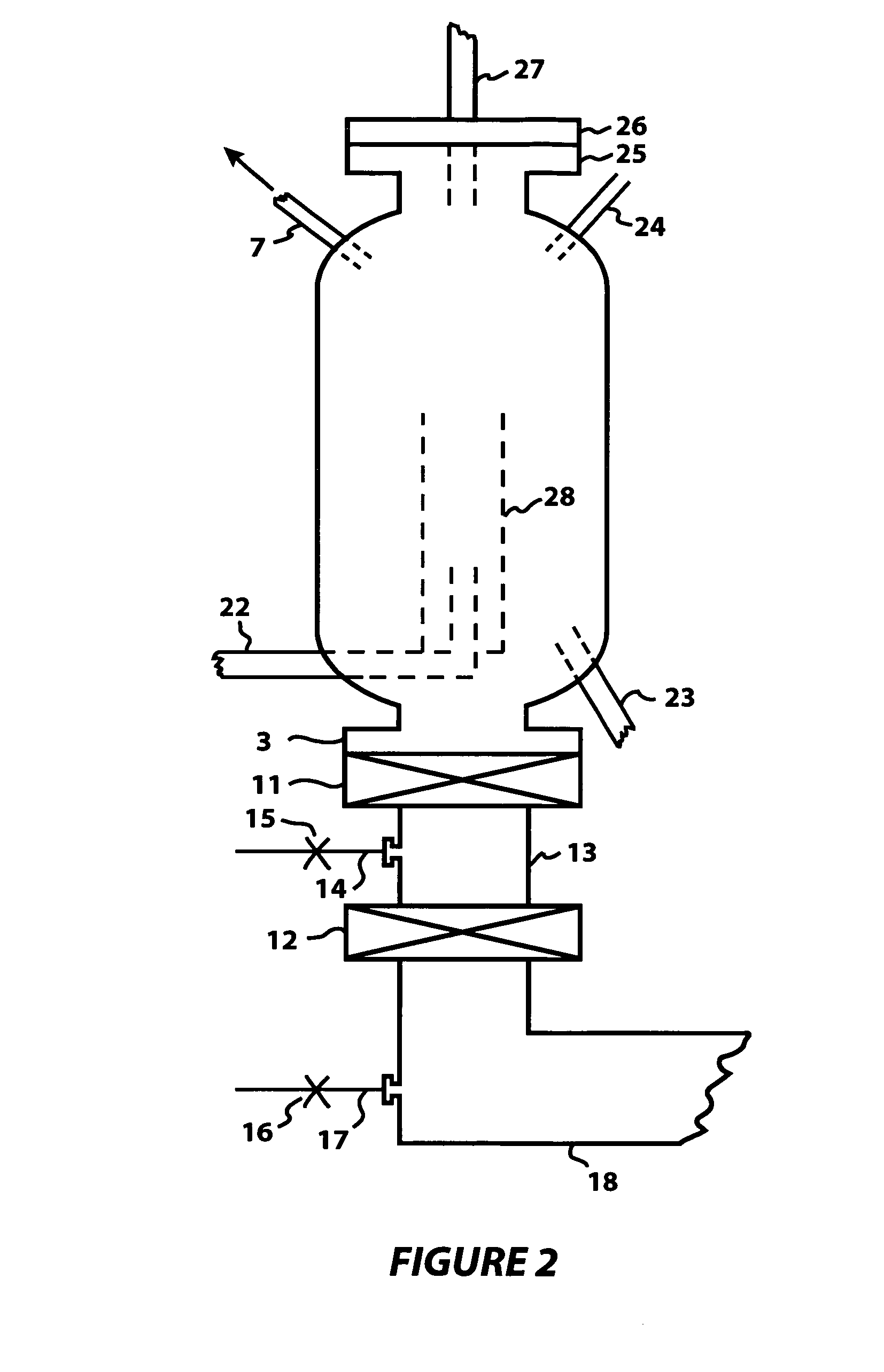

Continuous coking process

InactiveUS20070108036A1Thermal non-catalytic crackingCombustible gas coke oven heatingThermodynamicsCoke

The invention relates to a thermal conversion process for continuously producing hydrocarbon vapor and continuously removing a free-flowing coke. The coke, such as a shot coke, can be withdrawn continuously via, e.g., a staged lock hopper system.

Owner:EXXON RES & ENG CO

Combustible material plasma high-temperature gasification technique and equipment thereof

ActiveCN101671578AImprove gasification efficiencyImprove carbon conversionCombined combustion mitigationFixed-bed gasificationSyngasSlag

The invention relates to a combustible material plasma high-temperature gasification technique and equipment thereof. The technique comprises the following steps: firstly, laying a coke bed layer at the bottom part of a gasification furnace; secondly, putting the combustible material, a fluxing agent and an extra coke on the coke bed layer continuously to form a fuel bed layer; then injecting a primary oxidizing agent, starting a first-stage plasma torch to generate high temperature and high heat, forming a fusing zone at the joint of the coke bed layer and the fuel bed layer, forming a gasifying zone above the fusion zone, gasifying the combustible material to generate crude synthesis gas, and discharging the generated fused slag from the bottom part of the gasification furnace; then introducing the crude synthesis gas into a gas-solid separator for removing impurities to obtain purified synthesis gas; and finally introducing the purified synthesis gas into a detarrer, injecting a secondary oxidizing agent, starting a second-stage plasma torch to generate high temperature and high heat, cracking residual tar therein to obtain fined synthesis gas. The equipment mainly comprises three parts, namely the gasification furnace, the gas-solid separator and the detarrer. The fuel has good adaptability, high gasification efficiency, few tar content in the synthesis gas and high activeingredient.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

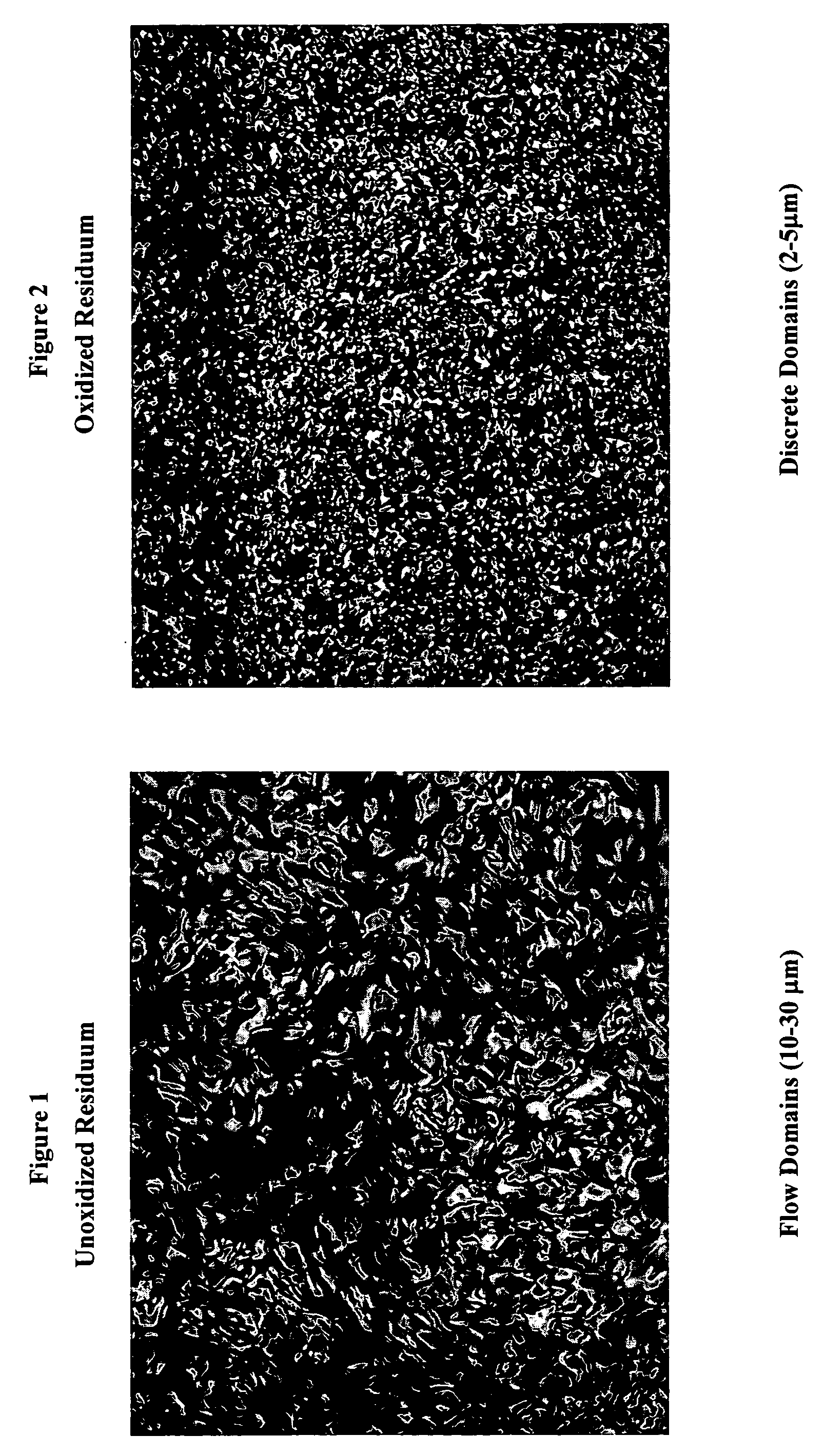

Delayed coking process

InactiveUS20060060506A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyChemistryFree flow

The present invention relates to an improved delayed coking process. A coker feed, such as a vacuum resid, is treated with (i) a metal-containing agent and (ii) an oxidizing agent. The feed is treated with the oxidizing agent at an oxidizing temperature. The oxidized feed is then pre-heated to coking temperatures and conducted to a coking vessel for a coking time to allow volatiles to evolve and to produce a substantially free-flowing coke. A metals-containing composition is added to the feed at at least one of the following points in the process: prior to the heating of the feed to coking temperatures, during such heating, and / or after such heating.

Owner:EXXON RES & ENG CO

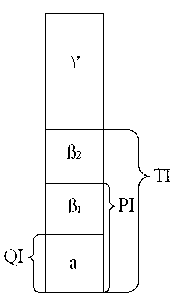

Technology for preparing needle coke raw material from coal-tar pitch

ActiveCN103013566ASuitable for adjusting extraction volumeHigh desulfurization efficiencyWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystCoke

The invention provides a technology for preparing a needle coke raw material from coal-tar pitch. The technology comprises the following steps of 1, fully mixing asphalt and a solvent, and removing insoluble substances in the mixture by a physical separation method, wherein the solvent is a mixture of coal light oil and coal aromatic oil or is a mixture of BTX and coal aromatic oil; a mass ratio of the coal light oil or the BTX to the coal aromatic oil is in a range of (20: 80) to (95: 5); and a mass ratio of the solvent to the asphalt is in a range of 0.5 to 10, 2, feeding a clear liquor without the insoluble substances into a separator, and separating the light solvent from the clear liquor to obtain a heavy fraction having low QI, and 3, carrying out hydrotreatment on the heavy fraction in the presence of a hydrogenation catalyst at a temperature of 300 to 450 DEG C under the pressure of 5 to 20MPa. The needle coke raw material obtained by the technology has low sulfur content and a small expansion coefficient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

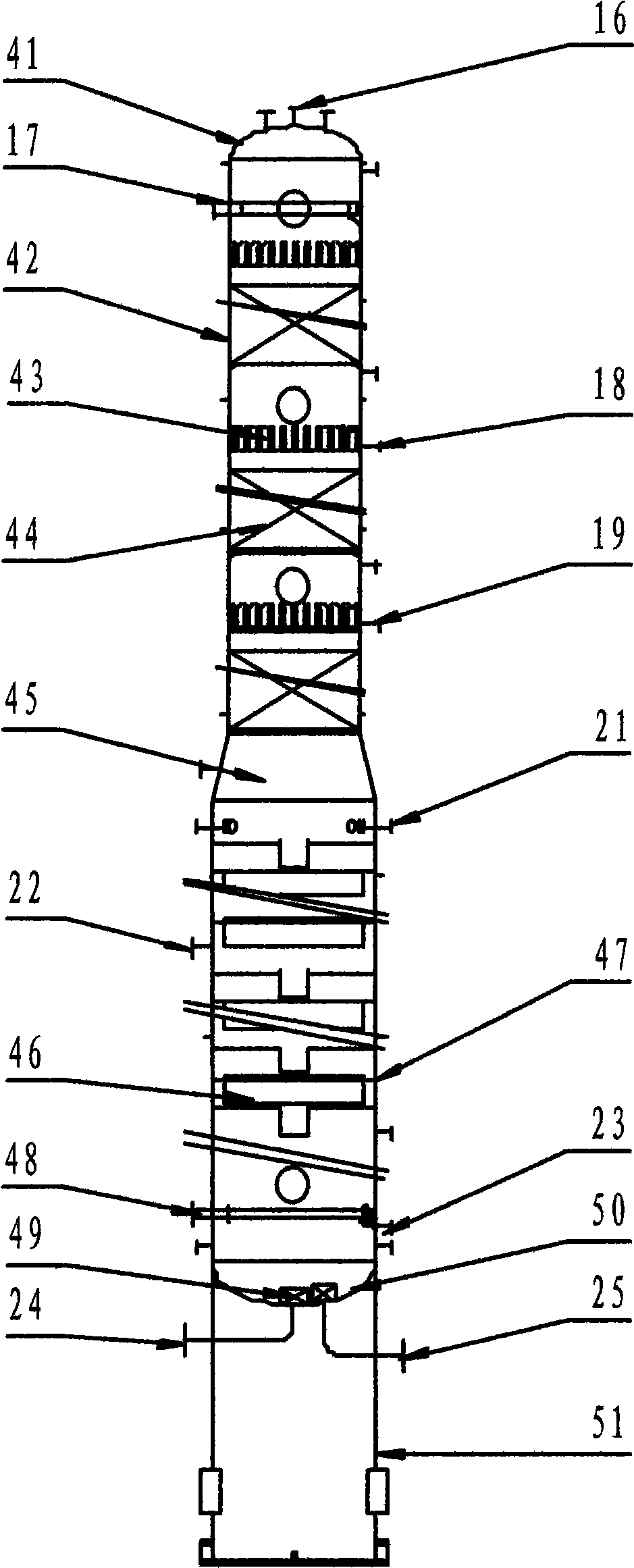

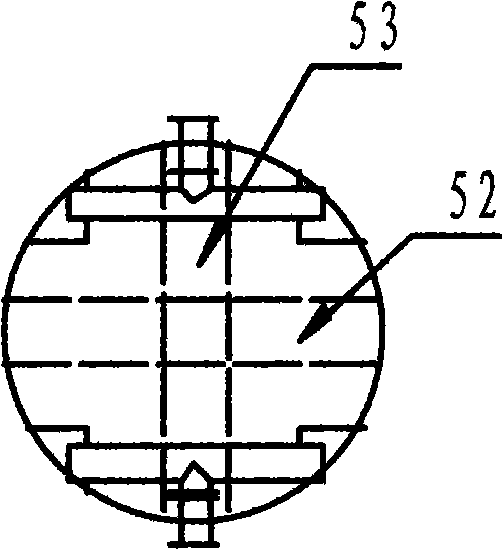

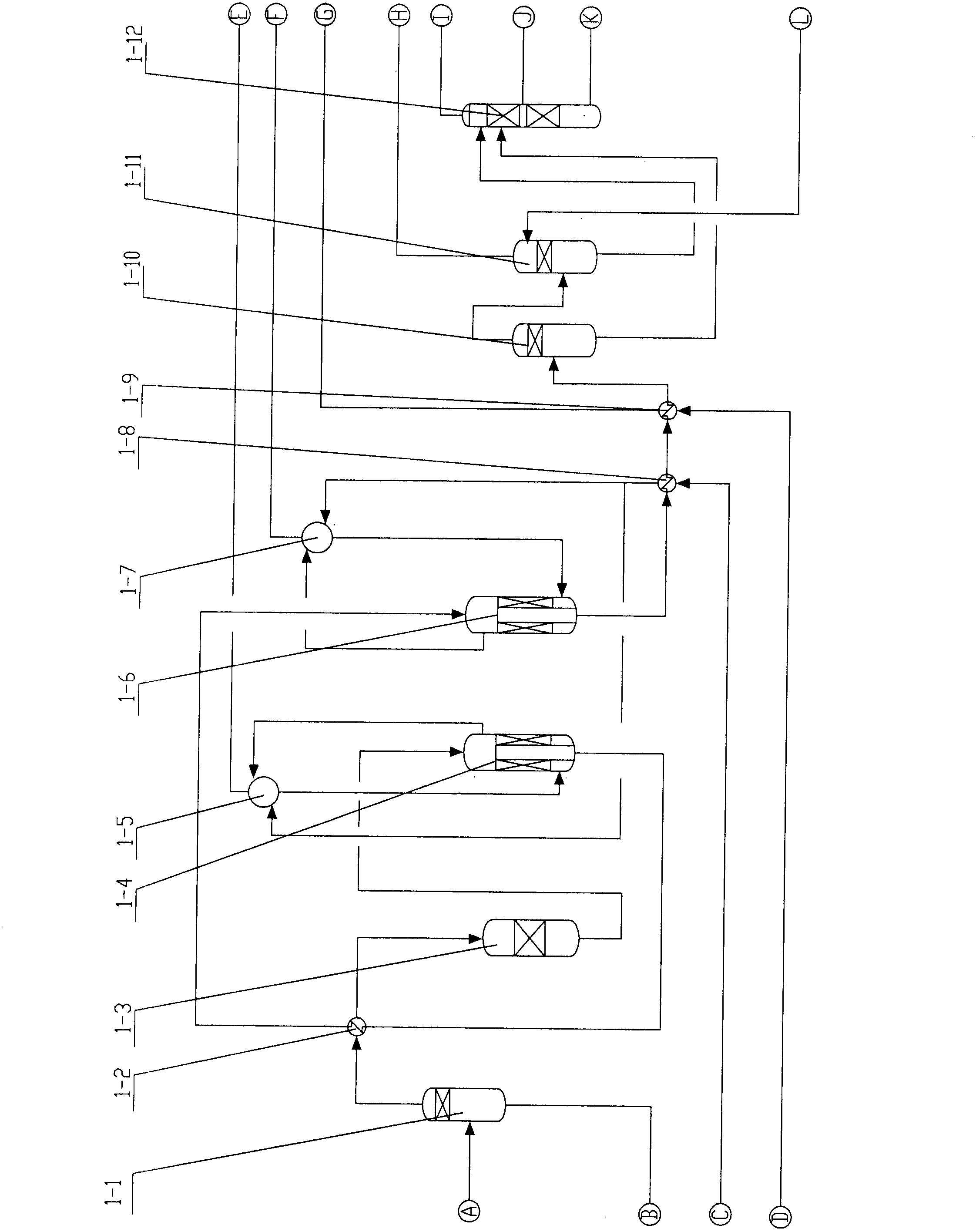

Process and equipment for negative pressure benzene removal

ActiveCN101544913ALow boiling pointReduce partial pressureCombustible gas purificationBenzeneThermodynamics

The invention discloses a process and equipment for negative pressure benzene removal , belonging to technology and equipment for recovering resultant in the coking industry, in particular to technology and equipment for removing and recovering benzene contained in coke gas. To solve the problems existing in the prior art, the invention develops the process for non-steam and non-distillation debenzolization under the negative pressure operation condition is developed and designs a novel debenzolization tower thus the disadvantages of equipment and process for benzene removal by adopting tubefurnace for heating rich oil under normal pressure can be overcome. The invention mainly has the advantages that firstly, as benzene is removed by the negative pressure process, the boiling point of the benzene and the partial pressure of the benzene in gaseous phase are lowered, and the benzene can be removed without using direct steam for steaming and blowing, thus waste water generated by the steam is reduced and the environment can not be polluted; secondly, the productive rate of dry coal due to benzene removal is increased to be more than 1.35 percent from the original 1 percent, and the recovery ratio of the benzene is increased to be more than 35 percent; and thirdly, compared with the existing benzene removal process, the process reduces the energy consumption by more than 20 percent.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

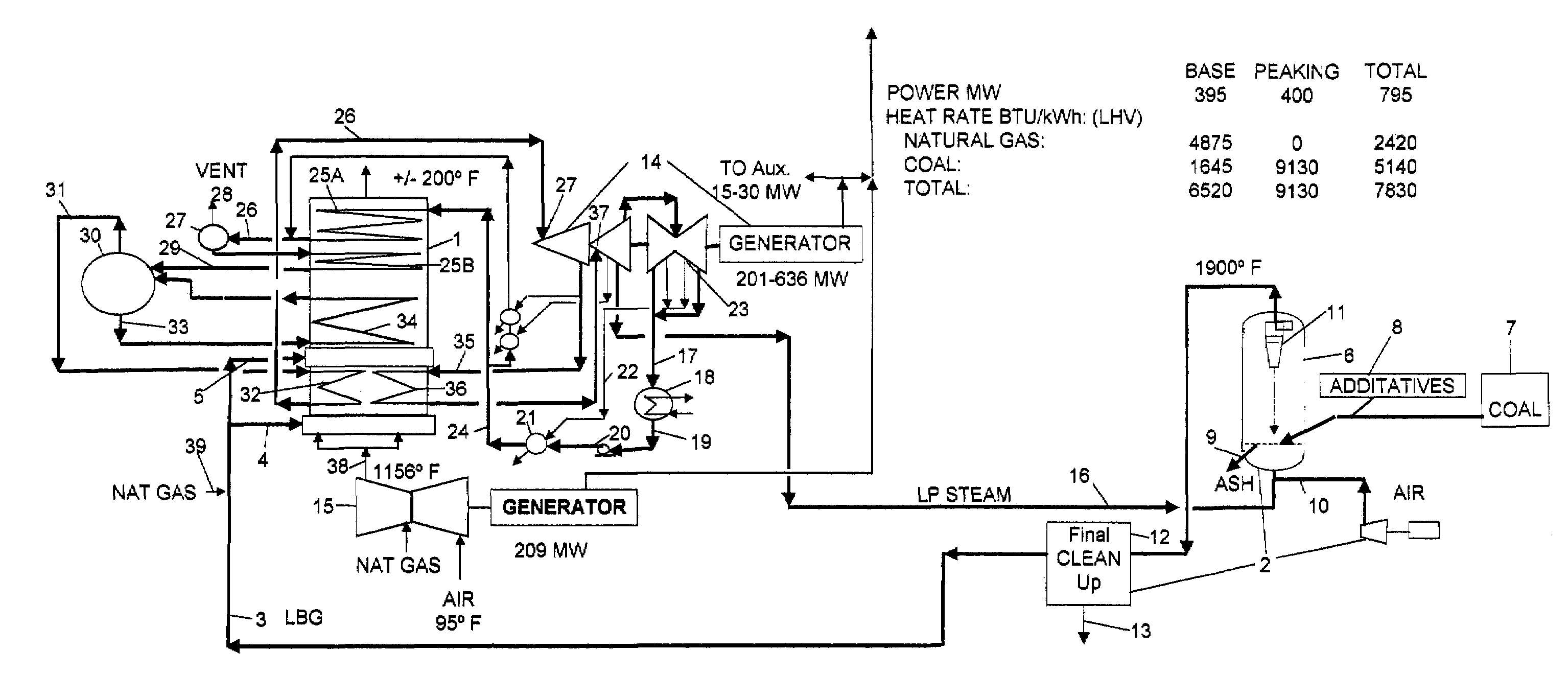

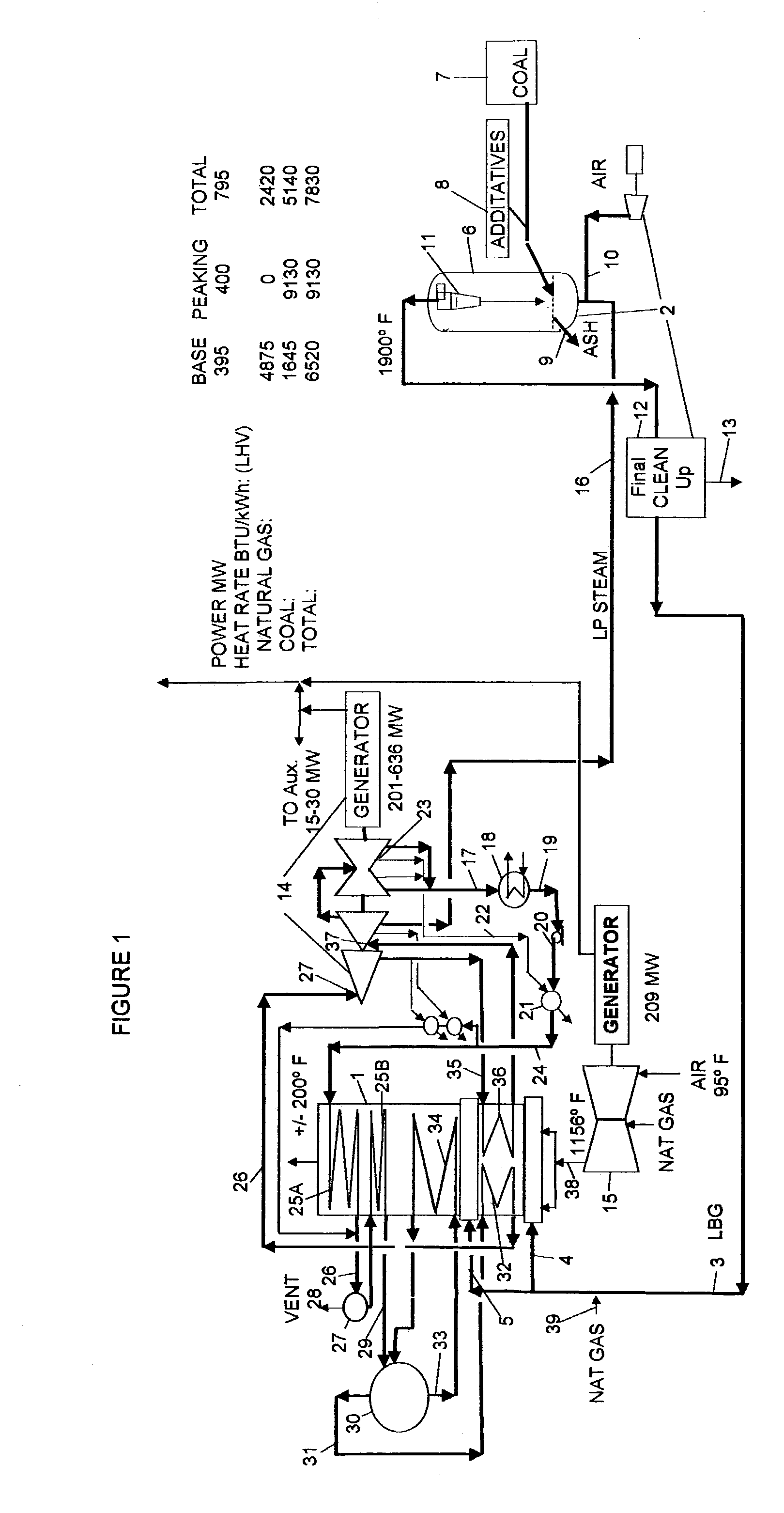

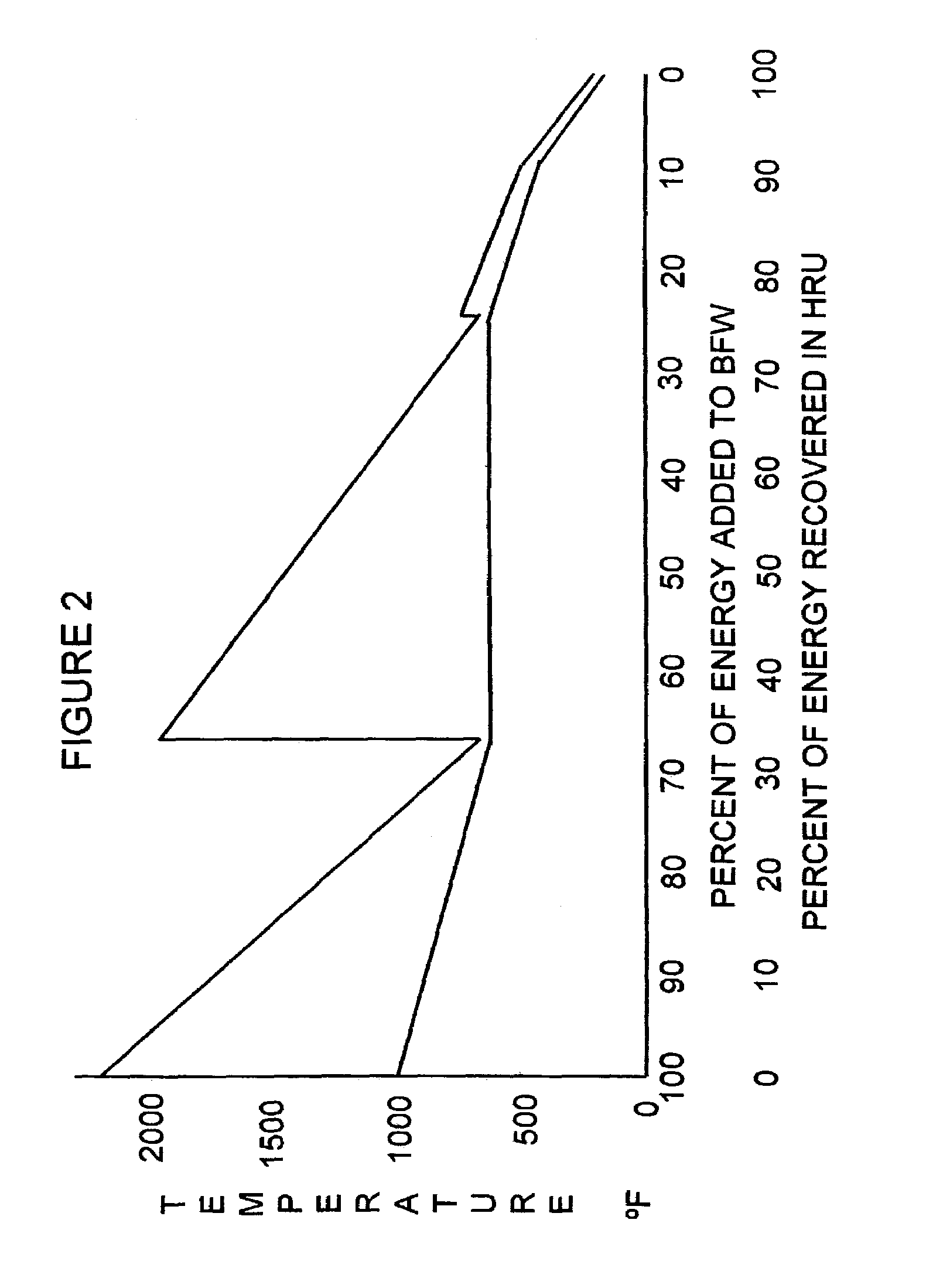

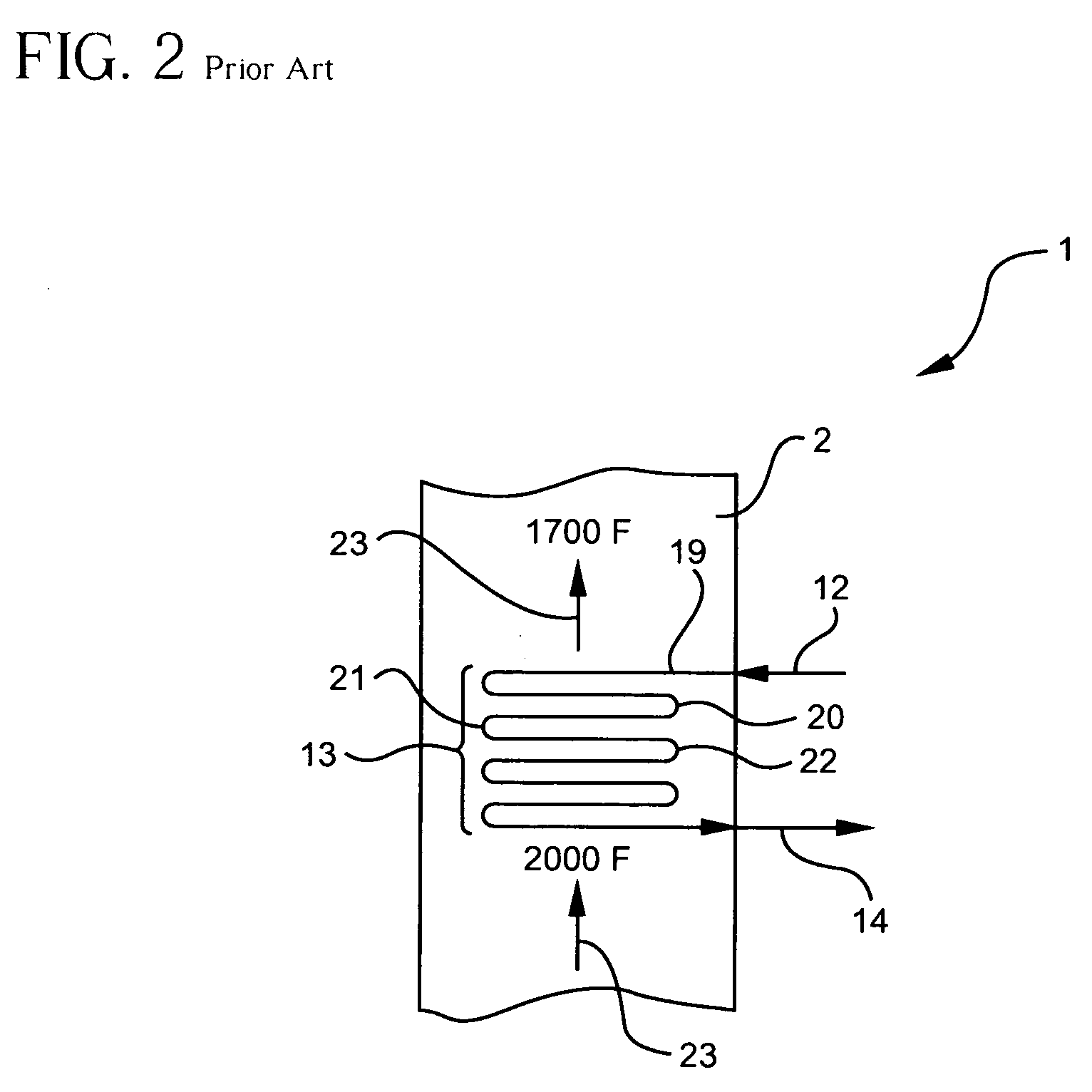

Combined cycle for generating electric power

InactiveUS6966190B2Low costImprove fuel efficiencyBiofuelsCombustion enginesBrown coalHydrocotyle bowlesioides

A combined cycle process that includes gas turbines, a steam turbine train, a heat recovery unit, and a gasification unit that produces low or mid BTU fuel gas from coal, lignite, coke, biomass, or other suitable hydrocarbon containing material wherein the fuel gas is burned in the heat recovery unit at one or more points to increase steam rate to the steam turbine train.The fuel gas injection flow rates into the heat recovery unit are controlled to avoid exceeding peak temperatures in the heat recovery unit of about 2500 F.Optionally, the fuel gas from the gasification unit is cooled by transferring sensible heat to condensate from the steam turbine train to convert the condensate to high pressure steam for driving the steam turbine train.Optionally, a steam boiler unit is integrated into the combined cycle process to raise additional high pressure steam for the steam turbine train. The steam boiler feed water is condensate from the steam turbine train. The steam boiler produces saturated high pressure steam that is superheated in the heat recovery unit.

Owner:WYLIE INVENTIONS

Cyclic fluidized bed active coke desulfurating and sulfur reutilization method

InactiveCN1435273ALow priceHigh mechanical strengthDispersed particle separationSulfur preparation/purificationFluidized bedFlue gas

A desulfurizing process with circulating fluidized bed for the flue gas at 70-200 deg.C containing SO2 and NOx is characterized by that said flue gas and the active coke as desulfurizing agent are continuously fed in the reactor of desulfurizing tower for removing dust, SO2 and NOx, the clean flue gas flows in chimney for exhausting it, the active coke is regenerated then in regenerating tower for further using it in desulfurizing tower, and SO2 is reduced to become sulfur to be recovered. Its advantages are high desulfurizing efficiency, low cost and water consumption, and no secondary pollution.

Owner:国家电站燃烧工程技术研究中心 +3

Ni-Cr-Fe alloy and its production process

InactiveCN1847440ASave resourcesOptimize the smelting processBlast furnace detailsRecycling and recovery technologiesGranularityManganese

The present invention is Ni-Cr-Fe alloy and its production process. The Ni-Cr-Fe alloy contains Ni 1.5-6.0 wt%, Cr 3.0-21.0 wt%, Si 0.6-2.0 wt% and Mn 0.3-0.8 wt%, except Fe, and can meet the requirement for use as material smelting stainless steel. The production process includes the following steps: producing Ni-Cr agglomerate with industrial Ni-Cr waste, Ni-Cr ore powder of granularity smaller than 10 mm, flux, coke and water and through pelletizing, sintering and sieving; and smelting with the Ni-Cr agglomerate, Ni-Cr ore of granularity greater than 10 mm, flux and coke in a blast furnace. The present invention has sang in resource and environment friendship.

Owner:DONGDA CASTING WUJIANG

Coal gas, tar, semi-coke and steam poly-generation method based on fluidized bed pyrolysis technology

ActiveCN102585913AImprove qualityEasy to controlEnergy inputSpecial form destructive distillationAir preheaterHeat carrier

The invention relates to a coal gas, tar, semi-coke and steam poly-generation method based on a fluidized bed pyrolysis technology. The method comprises the following steps of: mixing coal and high-temperature semi-coke serving as a heat carrier in a fluidized bed pyrolysis furnace, heating, precipitating volatiles, and cooling and separating the volatiles to obtain tar and pyrolysis coal gas; discharging one part of semi-coke to obtain a semi-coke product, feeding the other part of semi-coke into a fluidized bed semi-coke heating furnace, performing combustion reaction with a small amount of fed air, heating all the fed semi-coke by using heat released after a small amount of semi-coke is combusted, feeding the heated semi-coke into a cyclone separator along with flue gas, and feeding the separated high-temperature semi-coke serving as the heat carrier into the fluidized bed pyrolysis furnace; and feeding the flue gas subjected to gas-solid separation into a complementary combustion waste heat boiler, completely combusting a small number of combustible components in the flue gas, producing steam, feeding into an air preheater to heat air required by combustion, removing dust by using a dust remover, and emptying. The method has the advantages of realizing the fractional conversion of the coal and improving the utilization efficiency and benefit of the coal.

Owner:ZHEJIANG UNIV

Composite tube for ethylene pyrolysis furnace and methods of manufacture and joining same

InactiveUS20050058851A1OptimizationSolve the real problemThermal non-catalytic crackingArc welding apparatusHigh resistanceHydrocotyle bowlesioides

A process for making a composite tube uniquely suited for use in ethylene pyrolysis furnaces wherein the tube comprises an outer shell made from a wrought or cast Fe—Ni—Cr heat resistant alloy and an inner core made from INCOLOY® alloy MA956 powder. The outer shell and powder core are heated and simultaneously extruded to form a composite tube. The process is carried out at temperature, and time at temperature, preferably less than 1200° C. so as to prevent recrystalization of the very fine grain structure in the alloy MA956. This un-recrystalized fine grain structure permits pilgering and / or cold drawing of the extruded composite tube to final size. The composite tube provided by the present invention is uniquely suited for use in the petrochemical and chemical process industries, so as to increase the efficiency and productivity of their respective processes. The thin core layer of alloy MA956 provides high resistance to carburization and coke formation heretofore caused by the hydrocarbon feedstock flowing through the composite tube, while the outer shell of Fe—Ni—Cr heat resistant alloy provides overall strength and rigidity to the tube. The use of the outer shell in the composite tube also solves the joining problem heretofore encountered in joining alloy MA956. A root pass or passes using an alloy MA956 filler metal followed by overlay welding passes using a filler metal compatible with the heat resistant alloy, such as INCONEL alloy 617 or FM 25 / 35, joins the outer shells of adjoining composite tubes and, thus, solves the welding problem.

Owner:HUNTINGTON ALLOYS CORP (US)

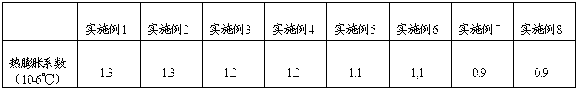

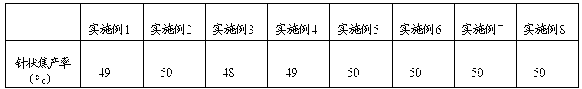

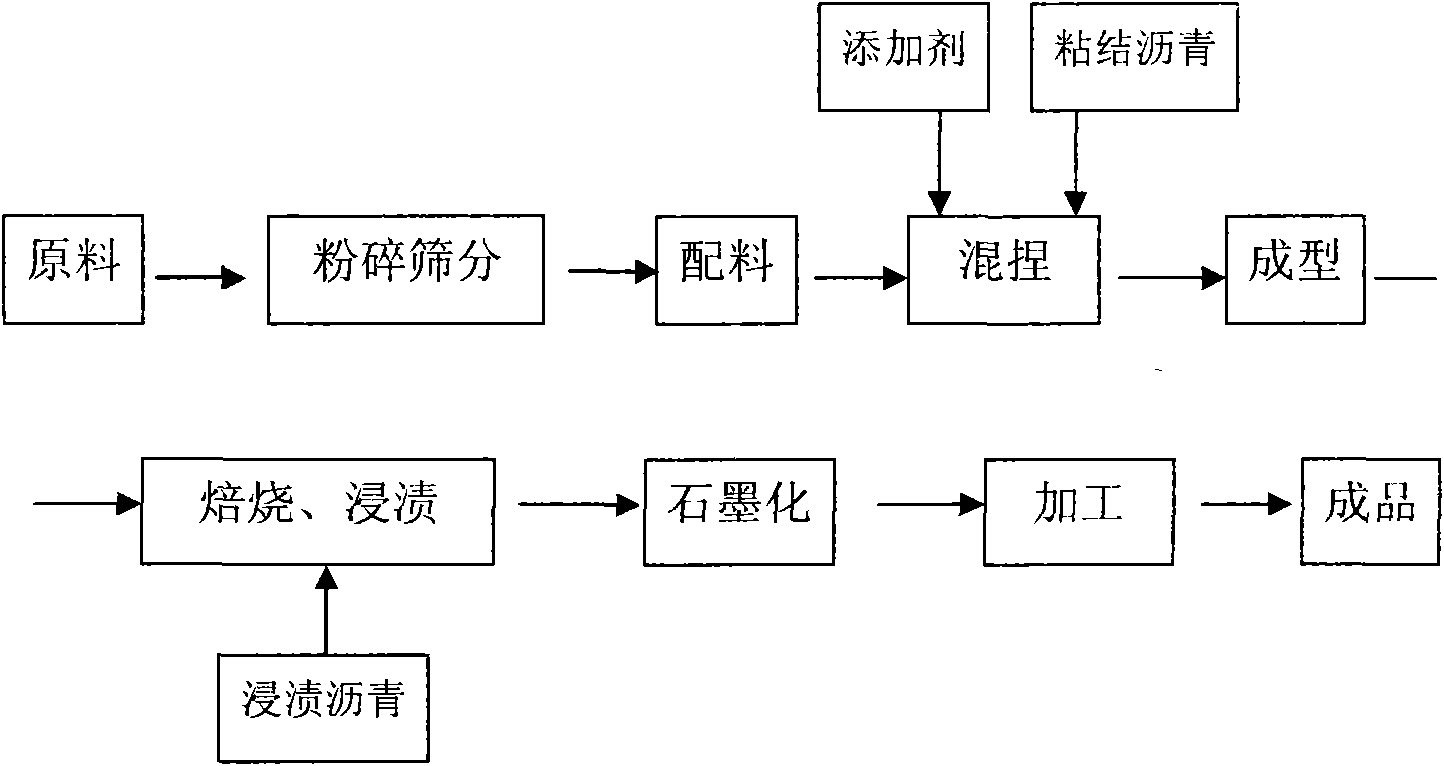

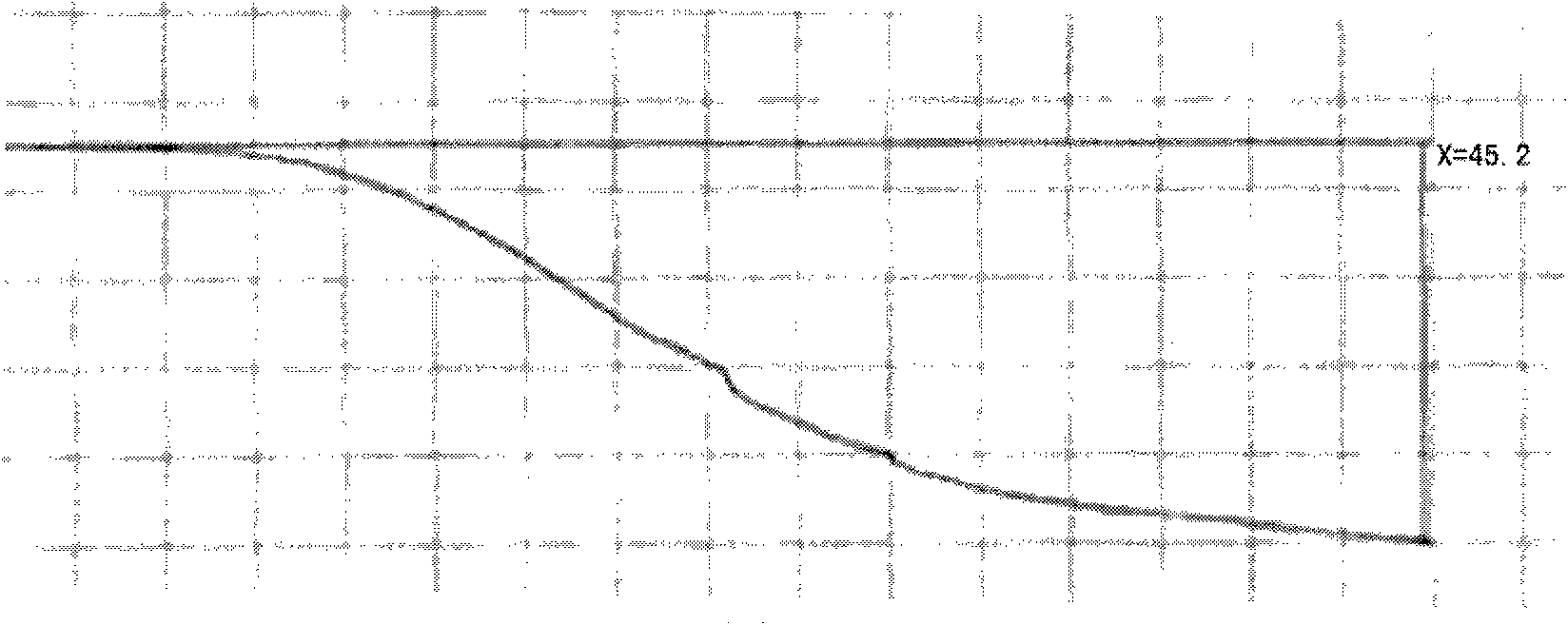

Ultra high power graphite resistor rod with 600mm diameter and method for producing the same

ActiveCN101553060ASolve capacitySolve the scale-up problemElectric discharge heatingVolumetric Mass DensityCoal

The present invention provides an ultra high power graphite resistor rod with 600mm diameter and a method for producing the same. The method utilizes domestic coal series acicular coke with low true density in main physicochemical standard, high heat expansion coefficient and sulphur content for producing the large-size ultra high power graphite resistor rod with 600mm diameter. Volumetric density, bending strength, elastic modulus, electric resistivity and heat expansion coefficient of the product reaches the international standard after detecting which can solve difficult problem that the domestic coal series acicular coke can not produce the large-size ultra high power graphite resistor rod with 600mm diameter because of low true density in main physicochemical standard, high heat expansion coefficient and sulphur content, and can realize localization for raw material acicular coke of the large-size ultra high power graphite resistor rod, simultaneity, also can solve problem that the acicular coke depends on importation in a long time and has high cost for restricting expanding yield and scale of the ultra high power graphite resistor rod in carbon industry. The product can reduce cost and improve economic performance.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

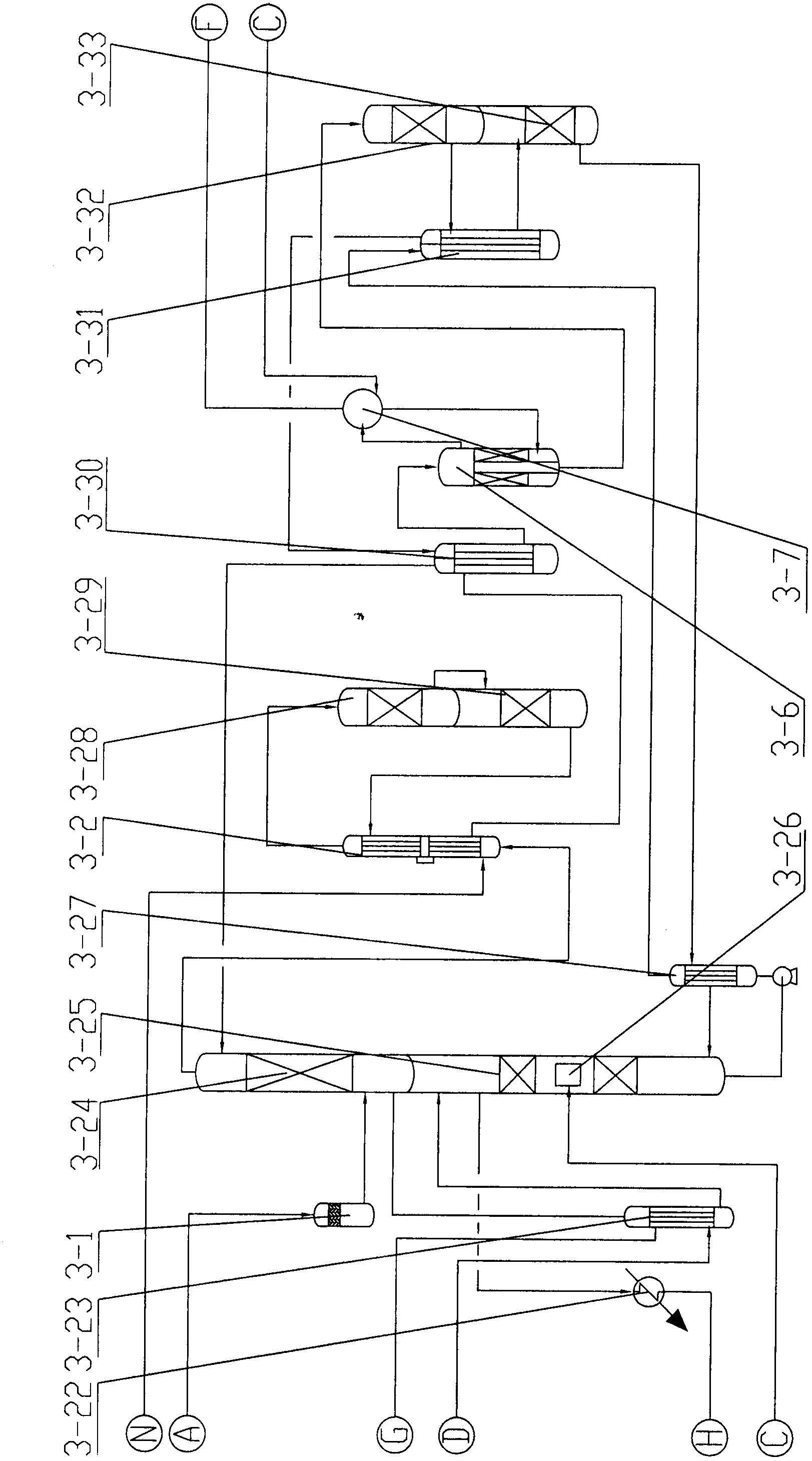

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819ASolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationReboilerHeat conducting

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in a No.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and then performing flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for 1/3 coking coal to participate in coking and blending coal

The invention relates to a method for 1 / 3 coking coal to participate in coking and blending coal. The method comprises the following steps: (1) detecting the 1 / 3 coking coal; (2) classifying the 1 / 3 coking coal according to a detection result of the step (1); and (3) blending the coal. The invention carries out reasonable classifying and blending according to the 1 / 3 coking coal of each mineral site by characteristics, such as coal rock indexes, technological properties, a microstructure and the like, divides the 1 / 3 coking coal into four classes, controls the weight percent of each class of 1 / 3 coking coal in coking and blending coal and enhances the quality stability of coke.

Owner:武汉钢铁有限公司

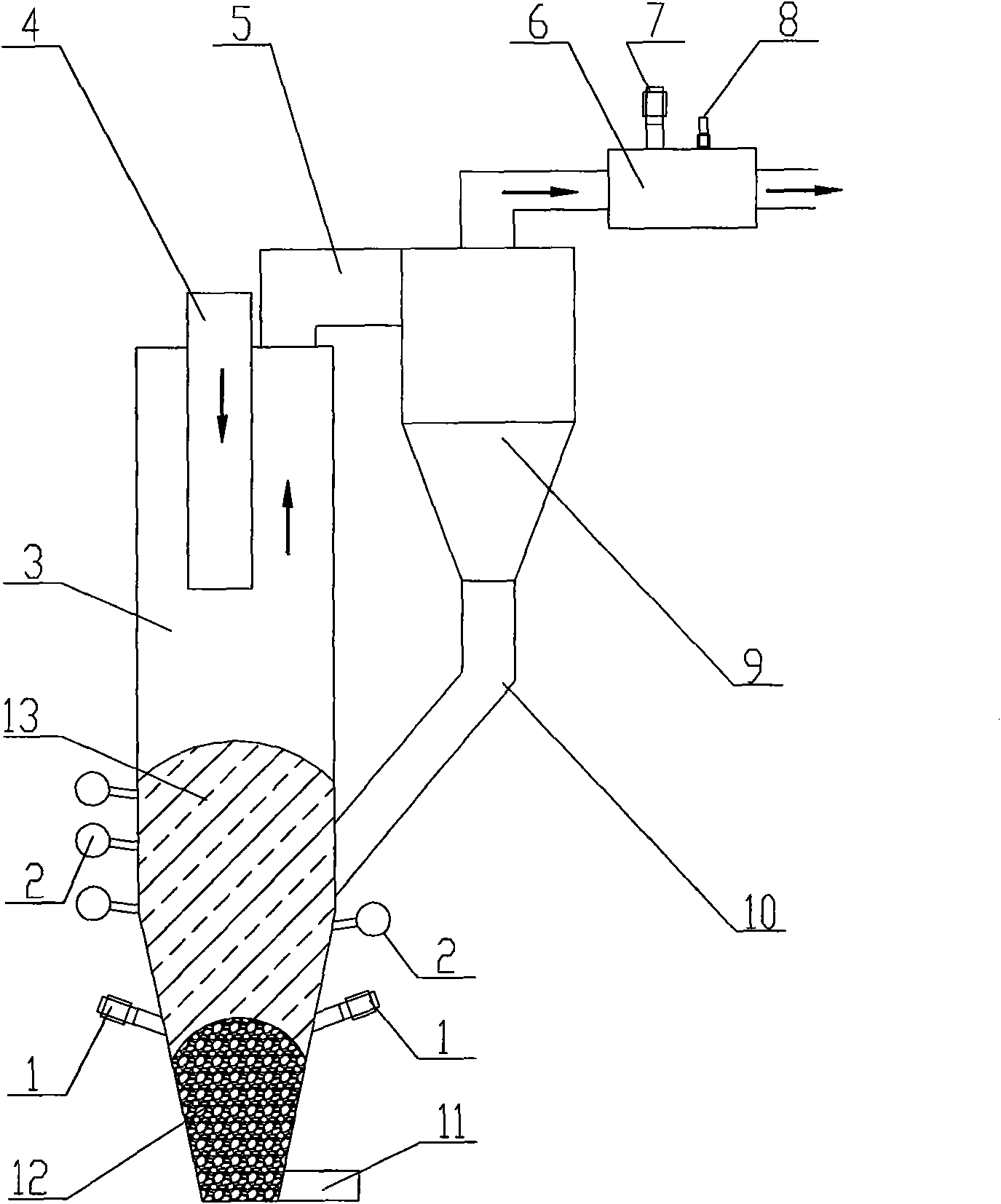

Method and device for biomass compound gasification

InactiveCN101225315AImprove gasification efficiencyReduce tar contentBiofuelsSpecial form destructive distillationTarBiomass

The invention discloses a biomass complex gasification method and a device of the gasification. The thermal decomposition, the gasification, part of the oxidation process are combined in one reactor by the integrating the fluidized bed and the airflow bed. Firstly, the biomass is decomposed at 500 to 600 degrees C and generates hard coke; secondly, the hard coke with large grain sizes are partly oxidized and gasified in the hard coke gasifying section, which provides heat and generates combustible gas for the thermal decomposition section; thirdly, the reaction gases with small hard coke grains discharged from the thermal decomposition section and the catalyst fast flows upwards through the macromolecular gasifying section, and the reaction gas are partly oxidized because of the function of the secondary gasifying agent, the heavy tar component is forced simultaneously through thermal cracking reaction and catalytic cracking reaction with the catalyst at the temperature over 1000 degrees C and transformed to lightweight combustible gas; at last, the unreacted hard coke is sent back to the furnace through the gas-solid separation device and the solid recycling device. The biomass complex gasification method has the advantages of high gasification efficiency, low tar content, high control ability of the gas component, stable operation and easy enlargement.

Owner:江苏中科龙城能源系统有限公司

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

No-water stemming material for blast furnace taphole and its prepn

InactiveCN1810723AShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsSlagRefractory

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

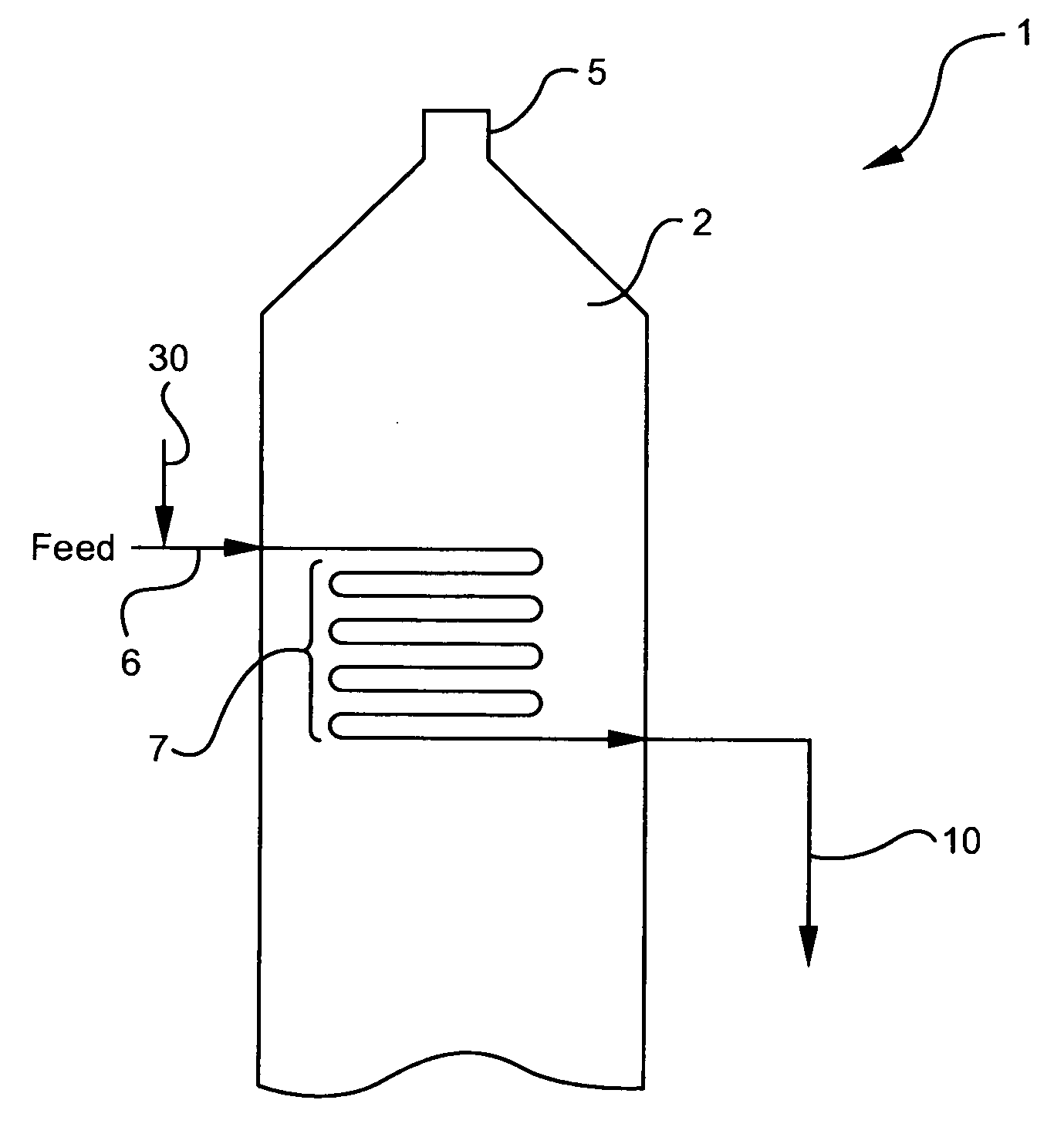

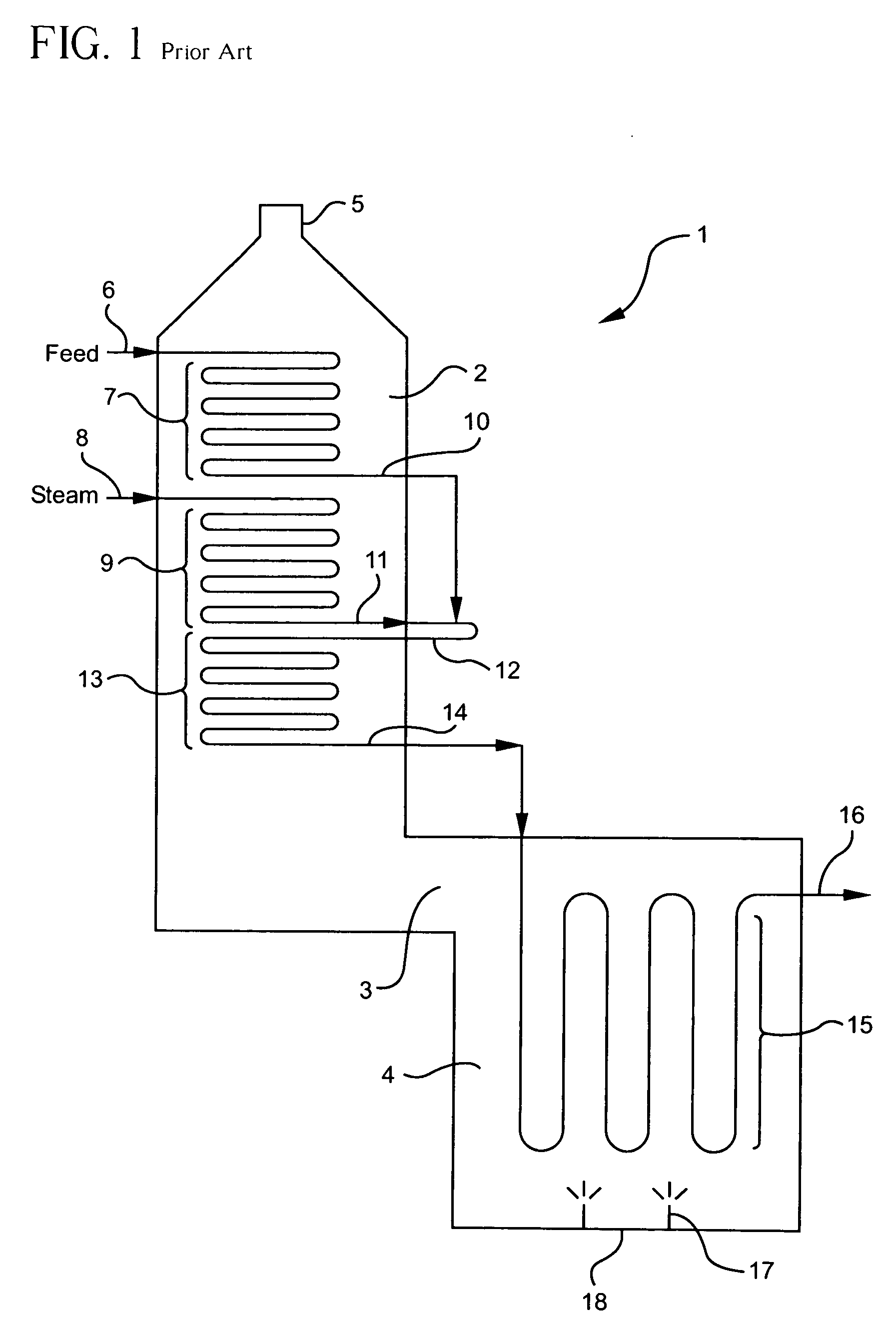

Method for reducing coke and oligomer formation in a furnace

A method for reducing the formation of coke and oligomers in the convection section of a hydrocarbon pyrolysis furnace, the method comprising reducing the partial pressure of the hydrocarbon feed to the furnace before that feed is mixed with dilution steam.

Owner:EQUSR CHEM LP

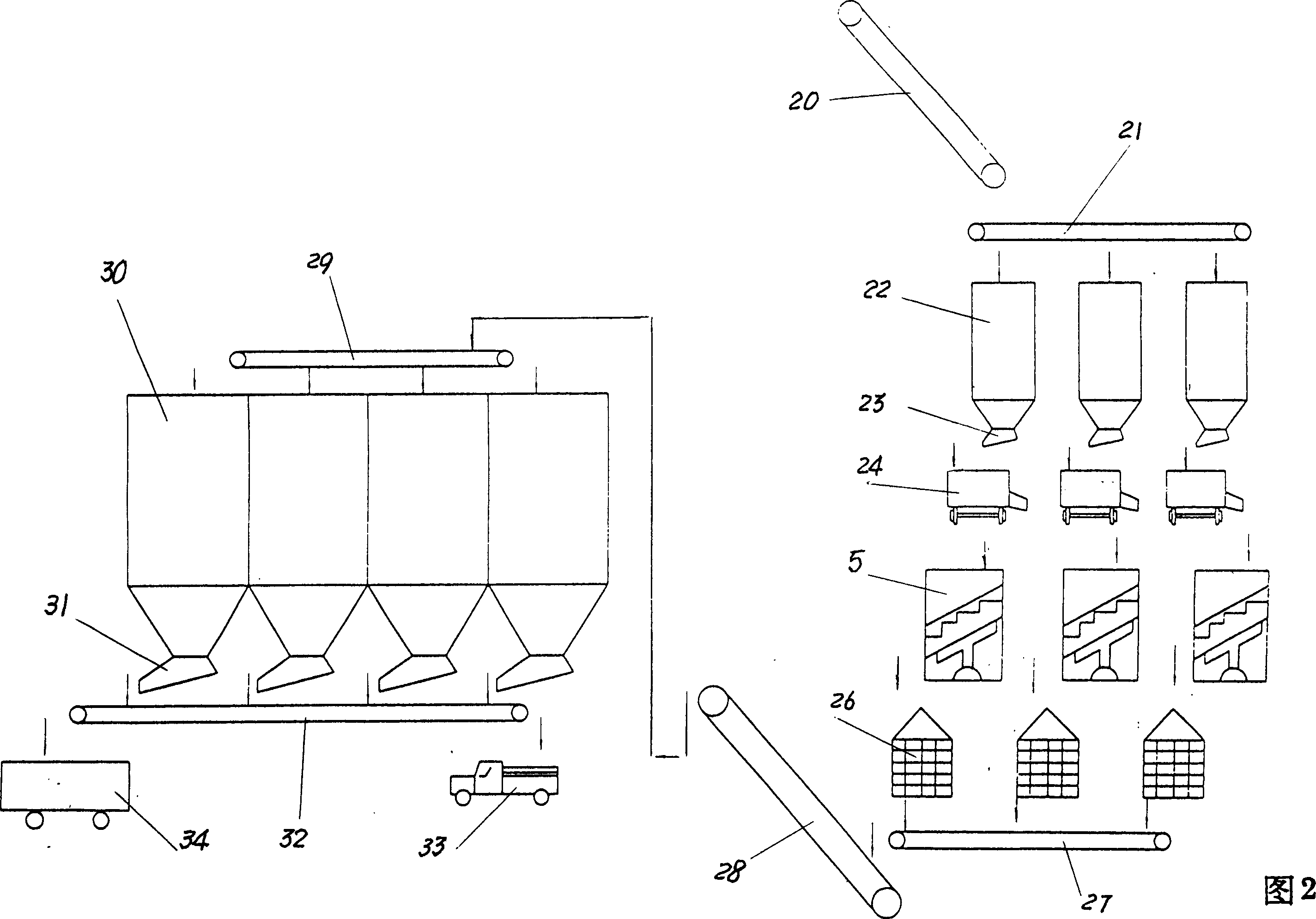

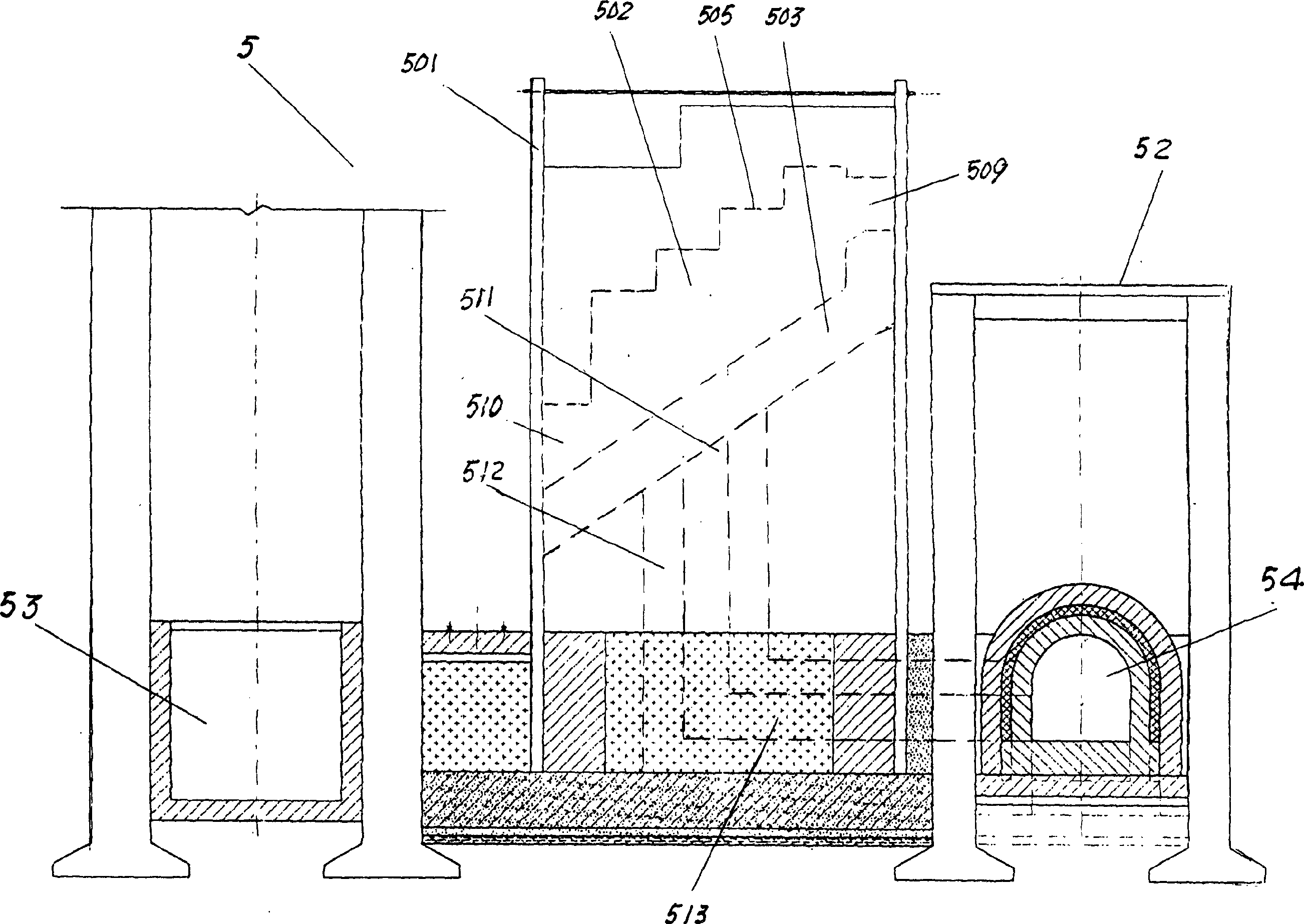

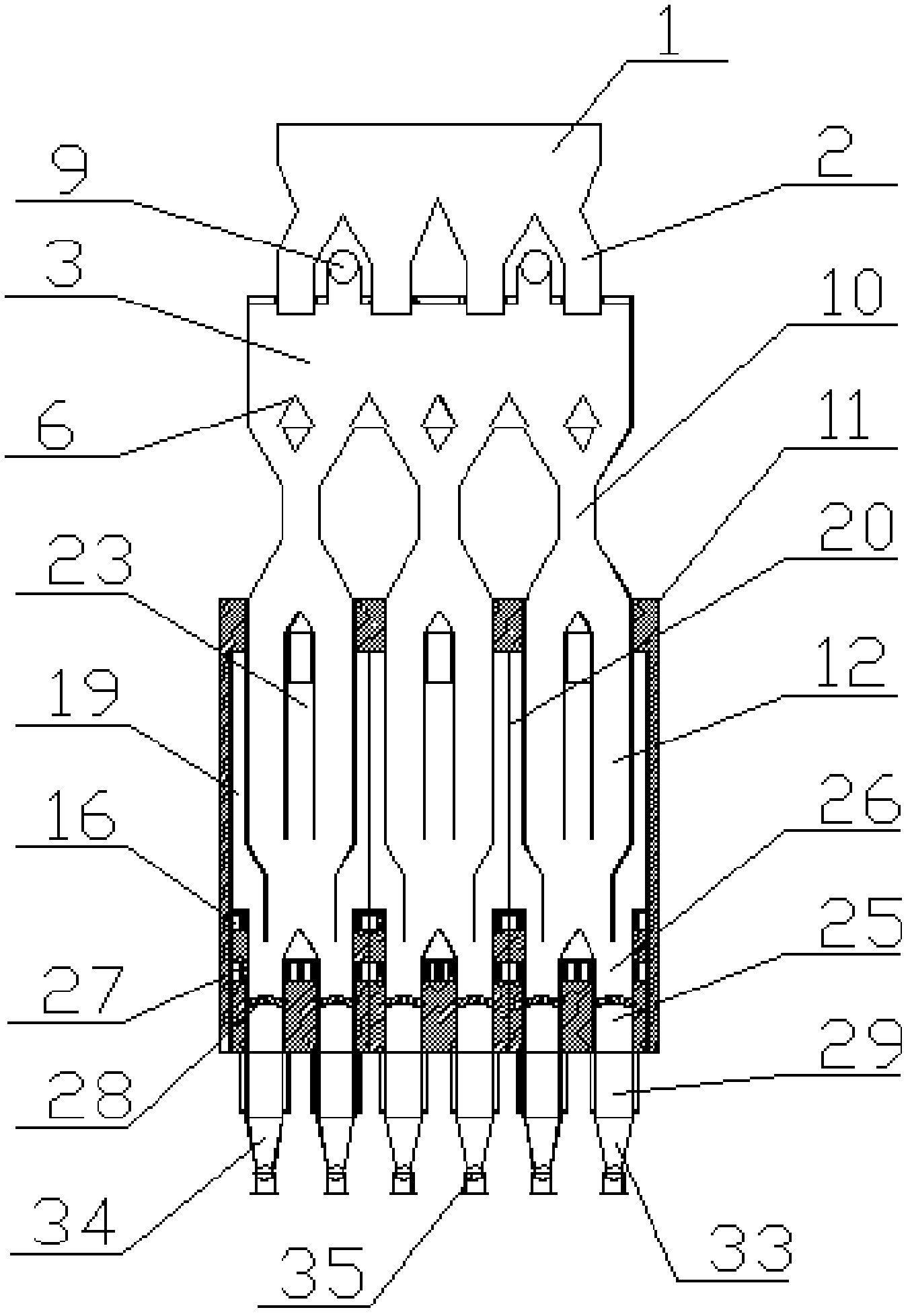

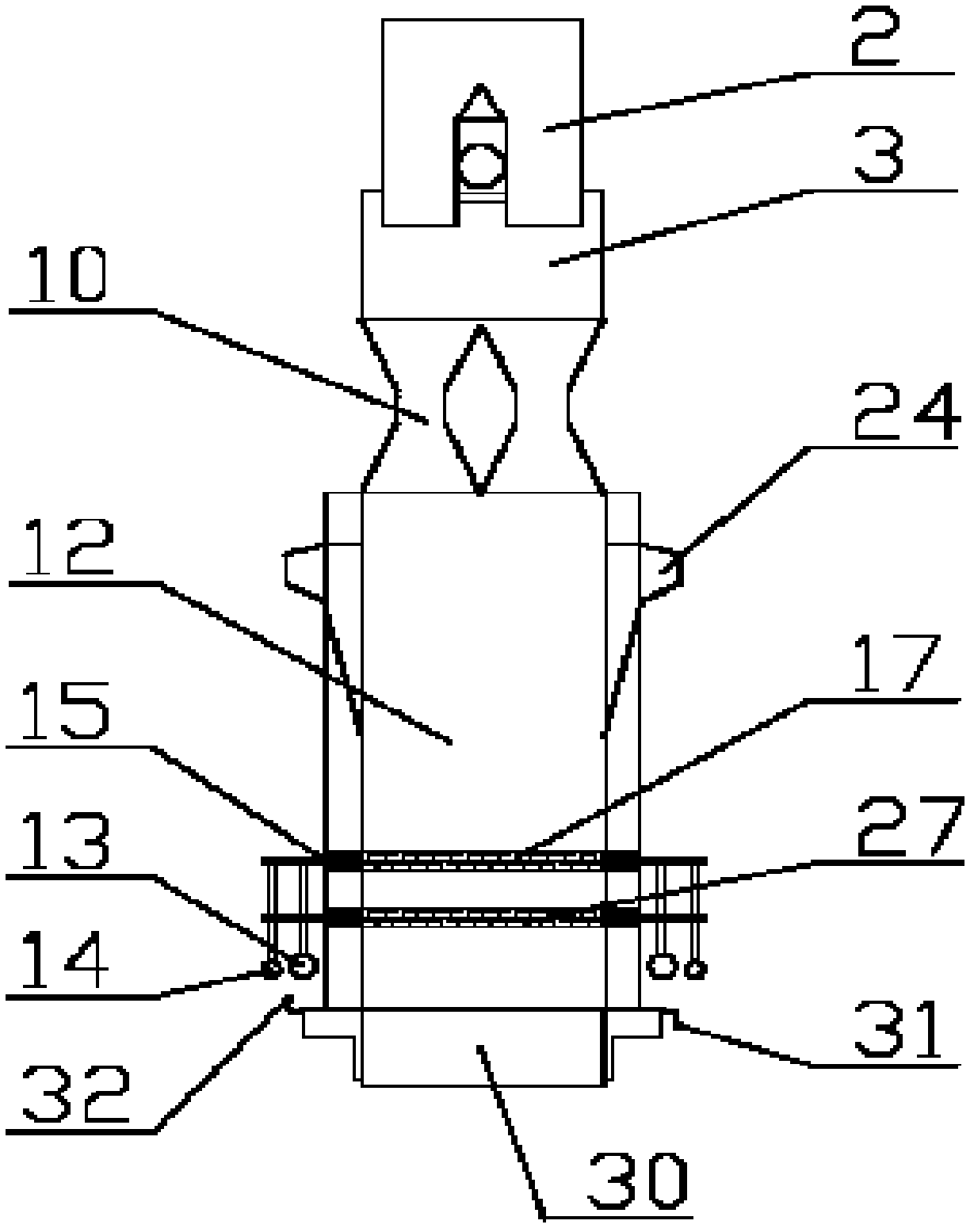

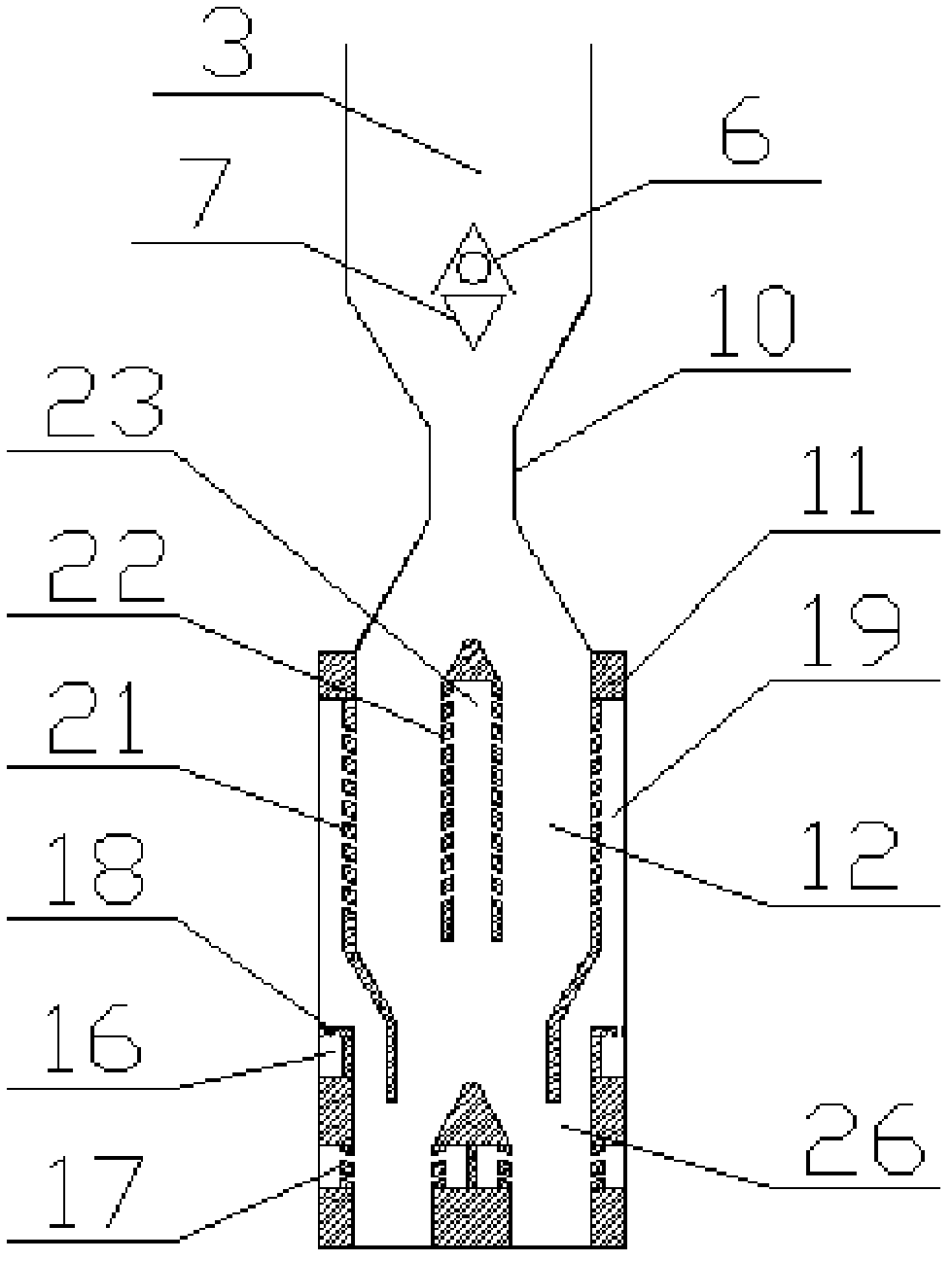

Casting type coke production method and apparatus system used thereof

The present invention relates to a production method of foundry shaped coke and its equipment system for producing said foundry shaped coke. Said method includes the procedures of preparing material,pulverizing, cold stirring, hot stirring, forming and carbonization and coking, and its equipment system includes material-preparing chamber, pulverizing machine, cold stirring machine, hot stirring machine, forming machine and carbonizing furnace, etc.

Owner:商丘市普天工贸有限公司煤化工研究所

Gas heat carrier low-temperature pyrolyzing furnace and gas heat carrier low-temperature pyrolyzing method

InactiveCN102676187AImprove heat utilization efficiencyReduce contact timeCoke quenchingDirect heating destructive distillationHeat carrierBrick

The invention discloses a gas heat carrier low-temperature pyrolyzing furnace and a gas heat carrier low-temperature pyrolyzing method. High-moisture materials are subjected to drying preprocessing in the pyrolyzing furnace by means of a gas heat carrier convection drying method, and hot gas is uniformly distributed in a drying section under the action of a gas distribution umbrella. Dried materials enter a dry distillation area where gas heat carriers transversely penetrate through materials, and exchange heat with the gas heat carriers prior to heating to enable low-temperature pyrolytic reaction. Gas in the furnace is formed by mixing lower coke quenching coal gas with hot flue gas in a combustion area, enters a flame path, then flows across a material layer from a flame path lattice wall to a gas collection lattice wall to enter a gas collection chamber, and is finally led out of the furnace through a gas collection passage formed by double-faced gas collection lattice walls and gas collection chamber gas distribution bricks. Pyrolyzed product hot semi-cokes enter a combined dry quenching device to be cooled and pass through a coal gas quenching area and a water-cooling heat exchange area sequentially. A guide chute on the lower portion of the furnace is connected with a discharger and a conveyor, and semi-cokes are uniformly led out and conveyed to a semi-coke storage yard under the action of the discharger and the conveyor.

Owner:北京德天御投资管理有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com