Method and device for biomass compound gasification

A gasification device, biomass technology, applied in the direction of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of no integrated biomass composite gasification device, no creativity, etc., to achieve strong load adaptability and stable operation , The effect of strong applicability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

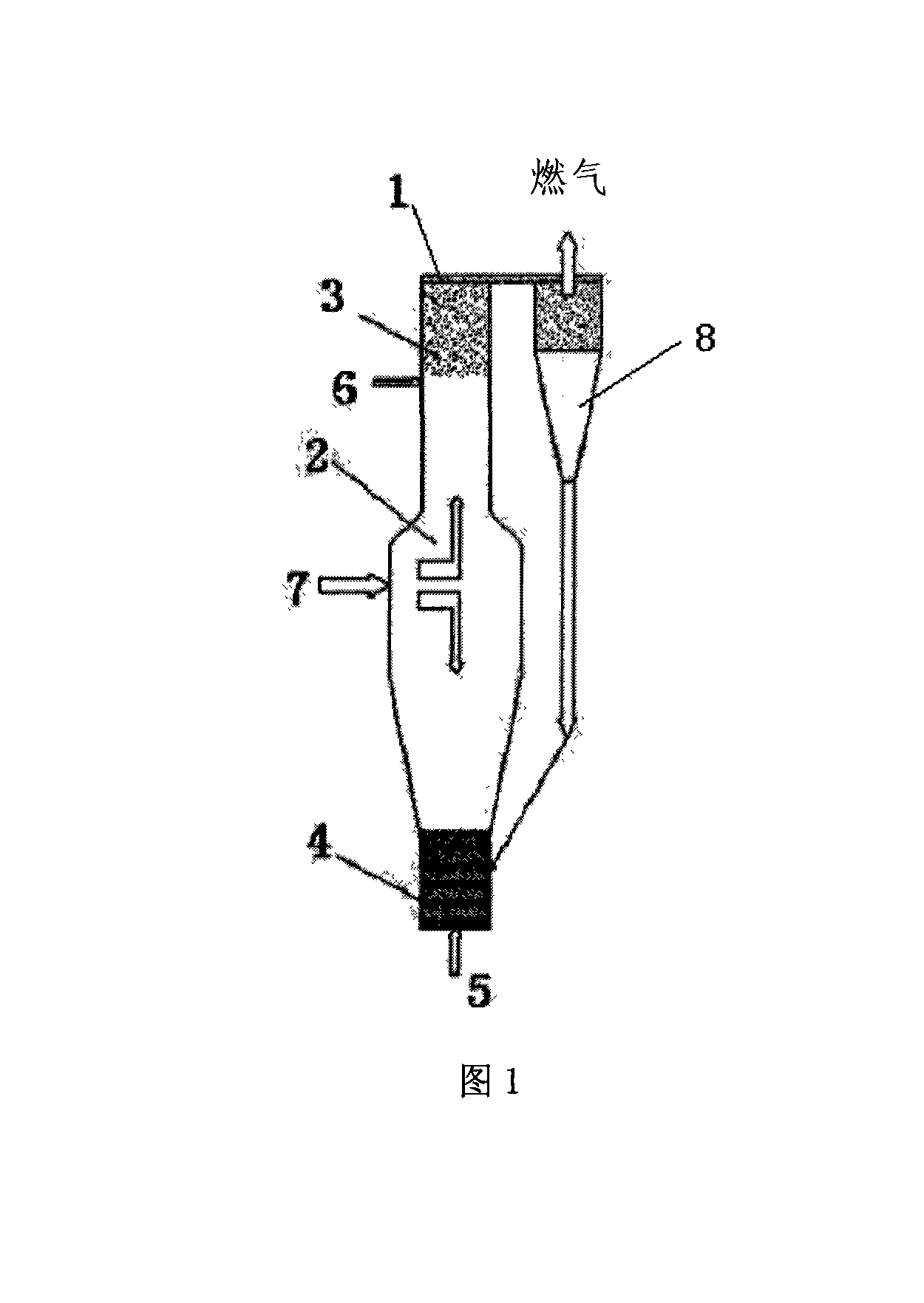

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0021]Please refer to Figure 1, a biomass composite gasification method, the biomass raw material is fed into the composite gasifier 1 from the feed port 7 located in the pyrolysis zone 2, and the pyrolysis reaction occurs at a temperature of 500-600°C. Biomass releases volatile gas and generates solid coke; large coke particles flow downward into the coke gasification zone 4 in the compound gasification furnace 1, and the primary gasification agent is added from the primary gasification agent input port 5, and the primary gasification agent Under the action of , a small part of the coke undergoes an oxidation reaction, making the temperature of the coke gasification zone reach above 1000 ° C, and most of the coke undergoes a gasification reaction to generate combustible gas; the high-temperature gas flowing upward from the coke g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com