Patents

Literature

316results about How to "Fully atomized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

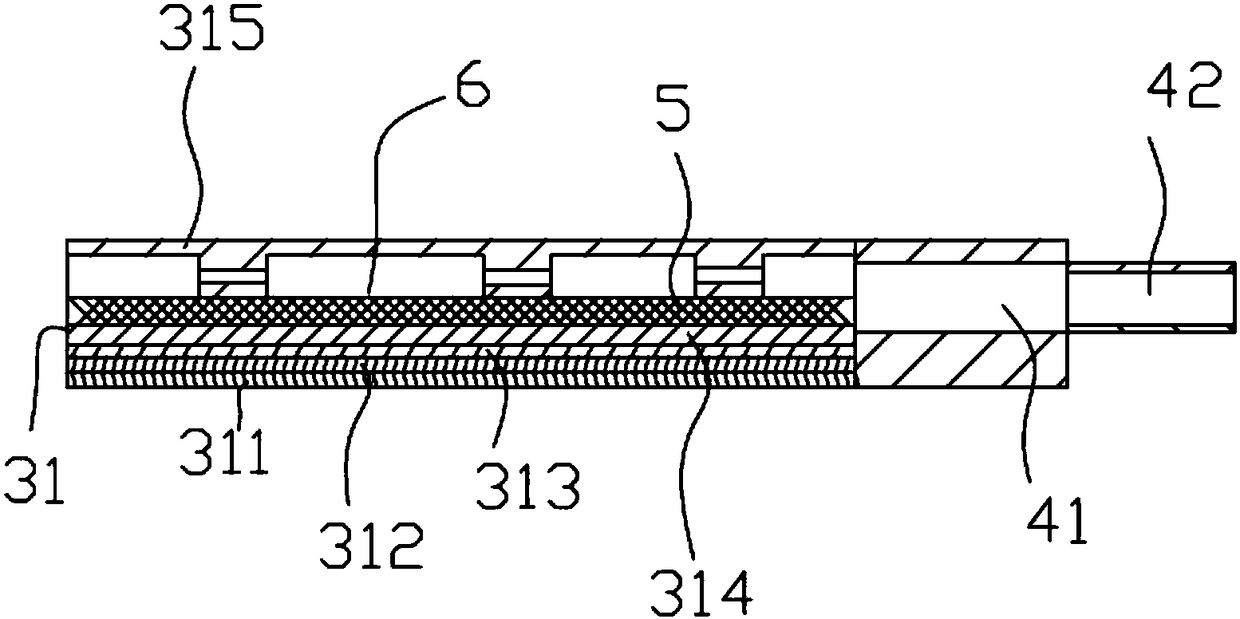

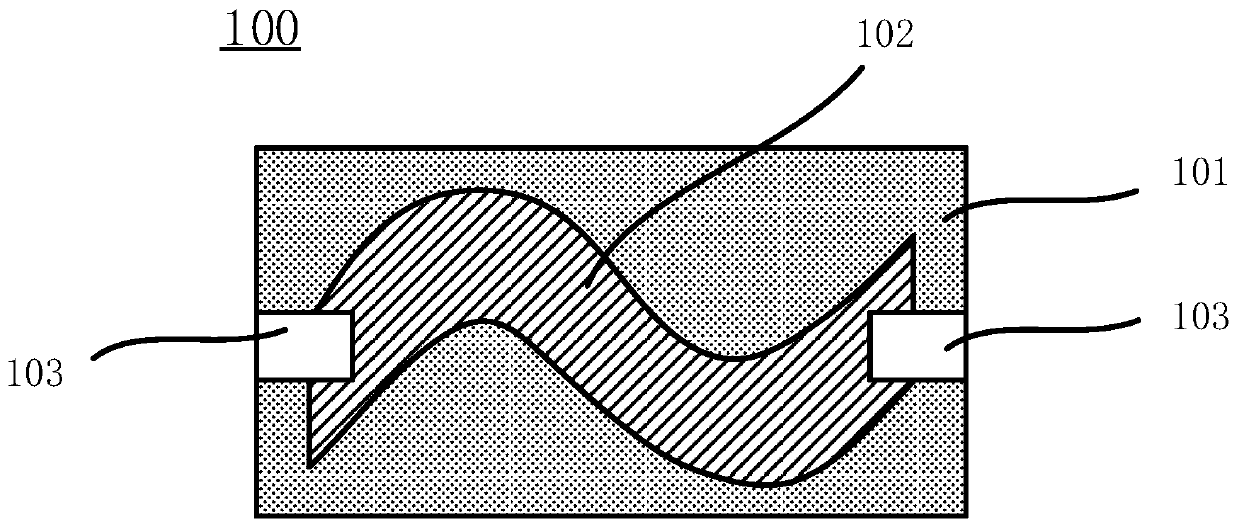

Atomizing electronic cigarette

InactiveUS20120111347A1Promote atomizationFully atomizedRespiratorsHeater elementsCore componentElectronic cigarette

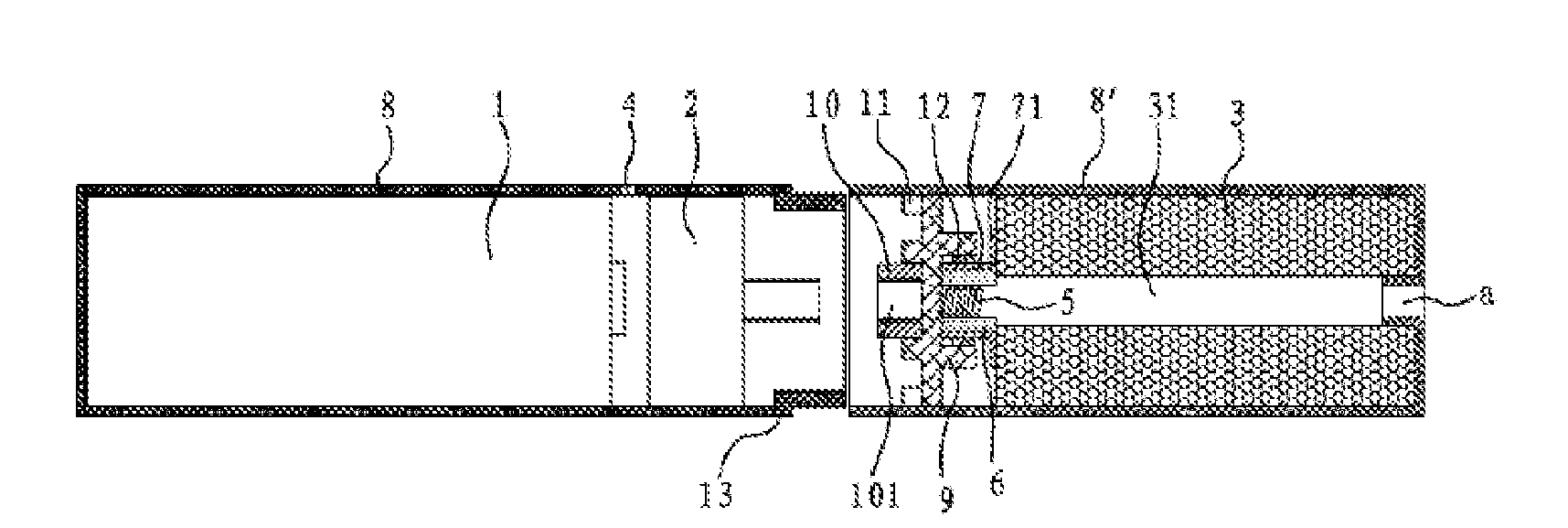

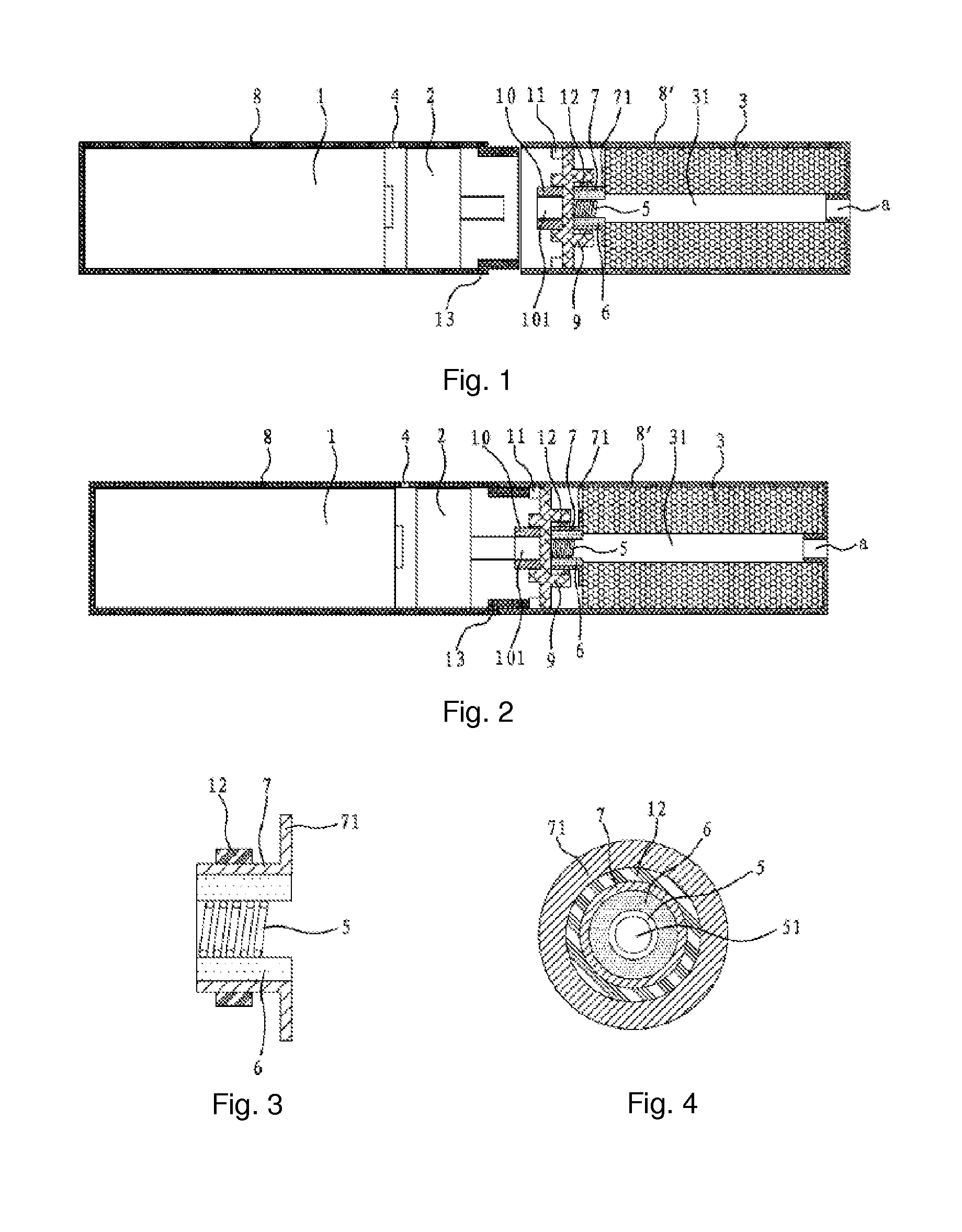

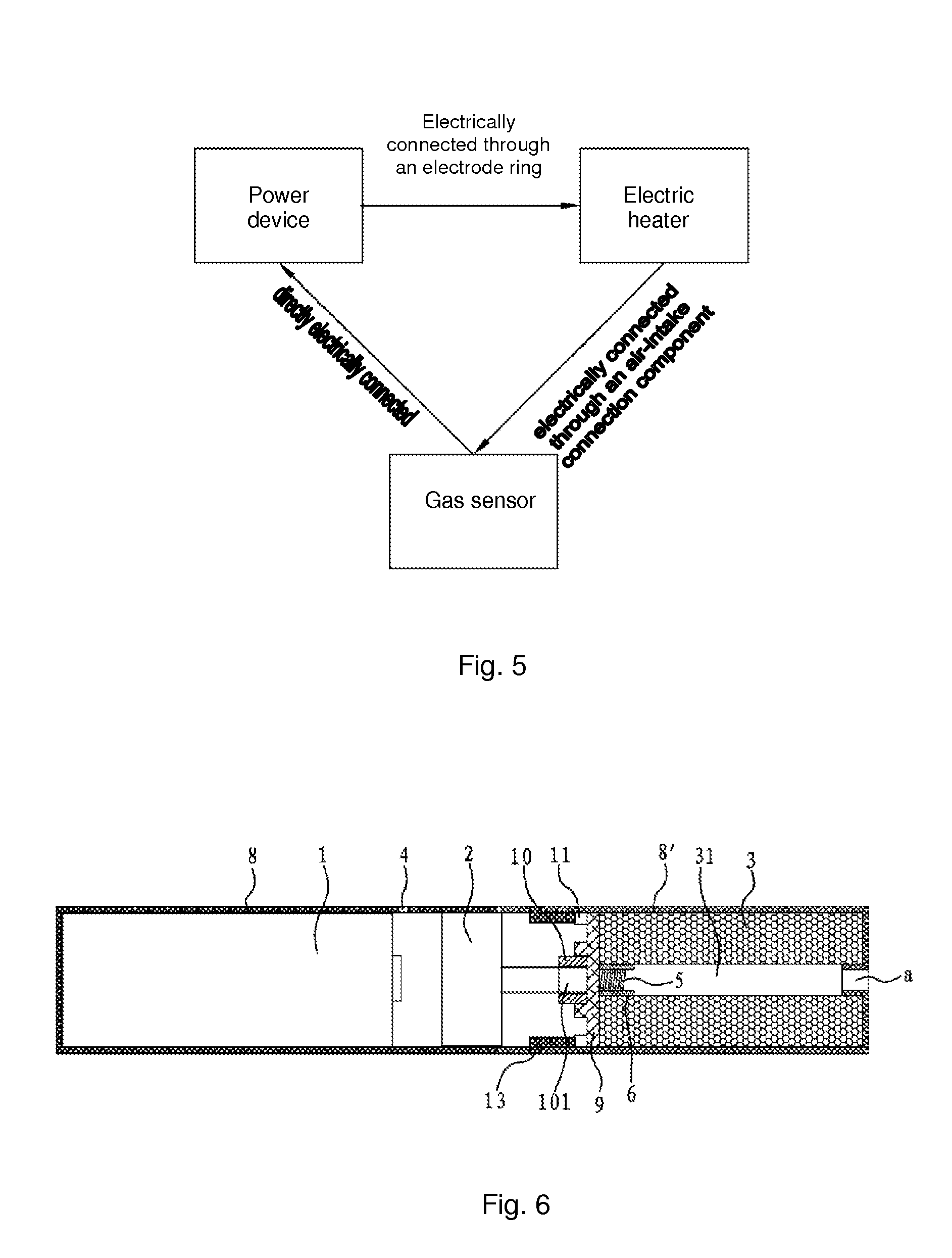

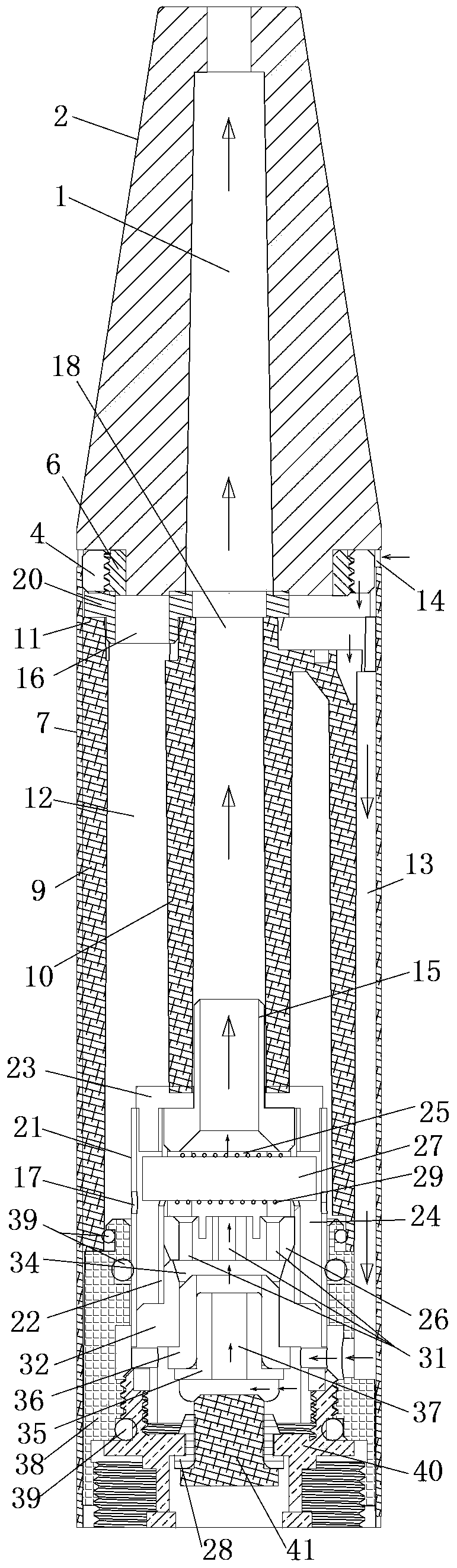

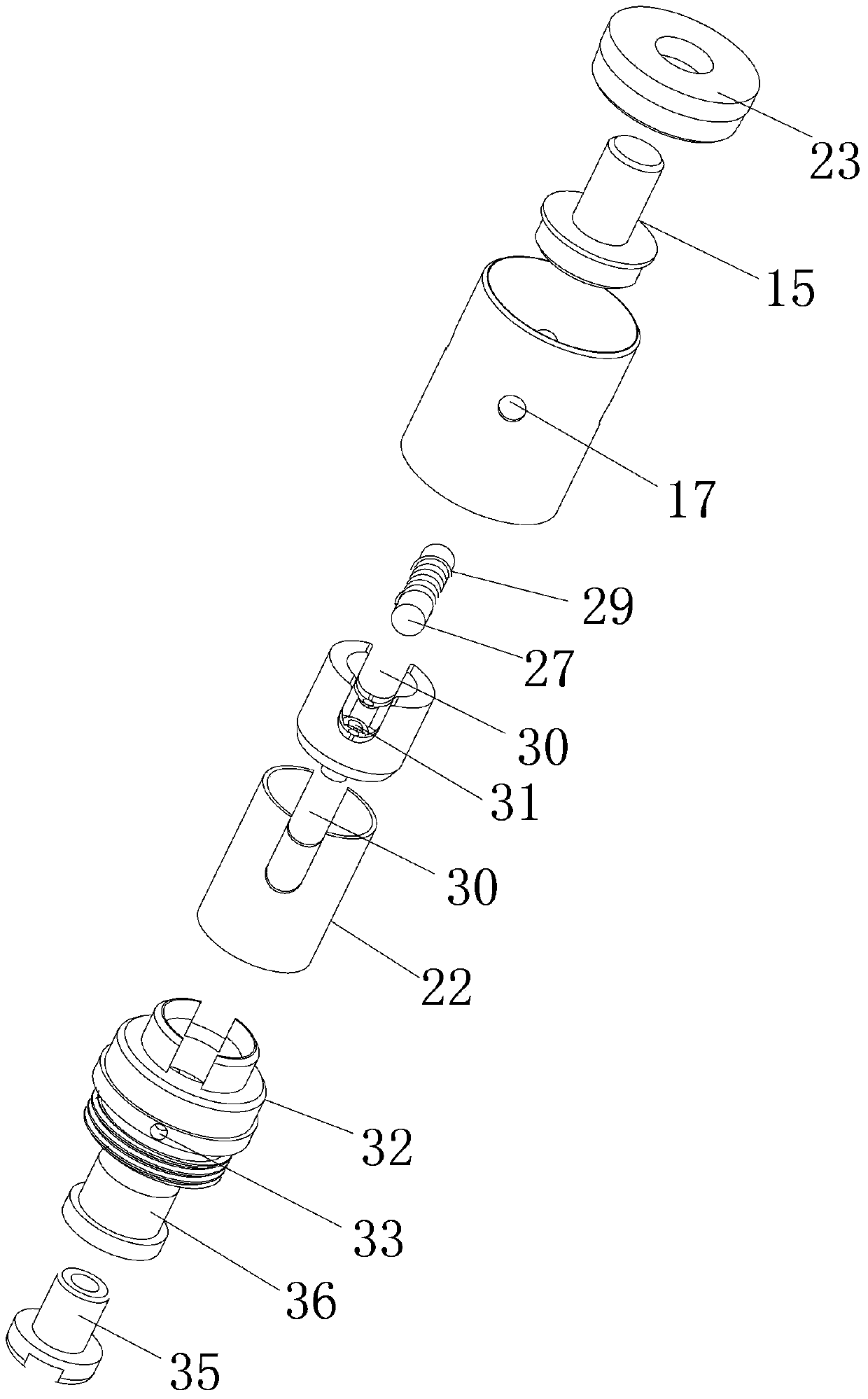

An electronic cigarette has a power device (1), a sensor (2), an atomizing core component and a liquid storage component (3). The atomizing core component includes an electric heater (5) and a liquid permeating component (6). The electric heater (5) has a through hole (51), the liquid storage component (3) has a channel (31), and the sensor (2) is connected with the through hole (51) and the channel (31) to form an airflow loop by the auxiliary air inlet. The liquid permeating component (6) is directly sleeved on the electric heater (5), so that the cigarette can adequately heat gasified smoke with uniform small drops. The electric heater (5) and the liquid storage component (3) are connected with the through hole (51) and the channel (31), so that the vapor generated by the atomizing process can be cooled.

Owner:FONTEM HLDG 1

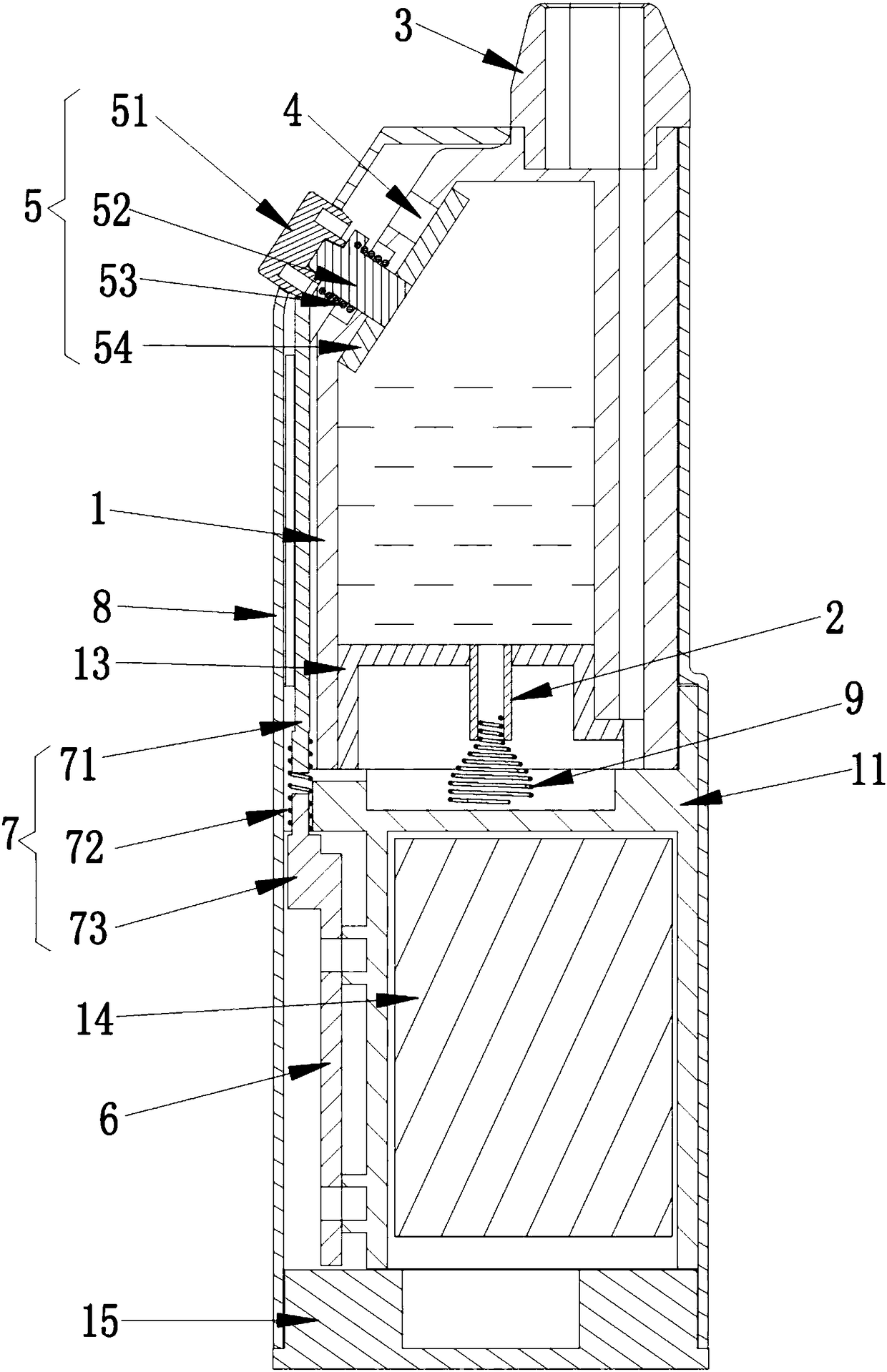

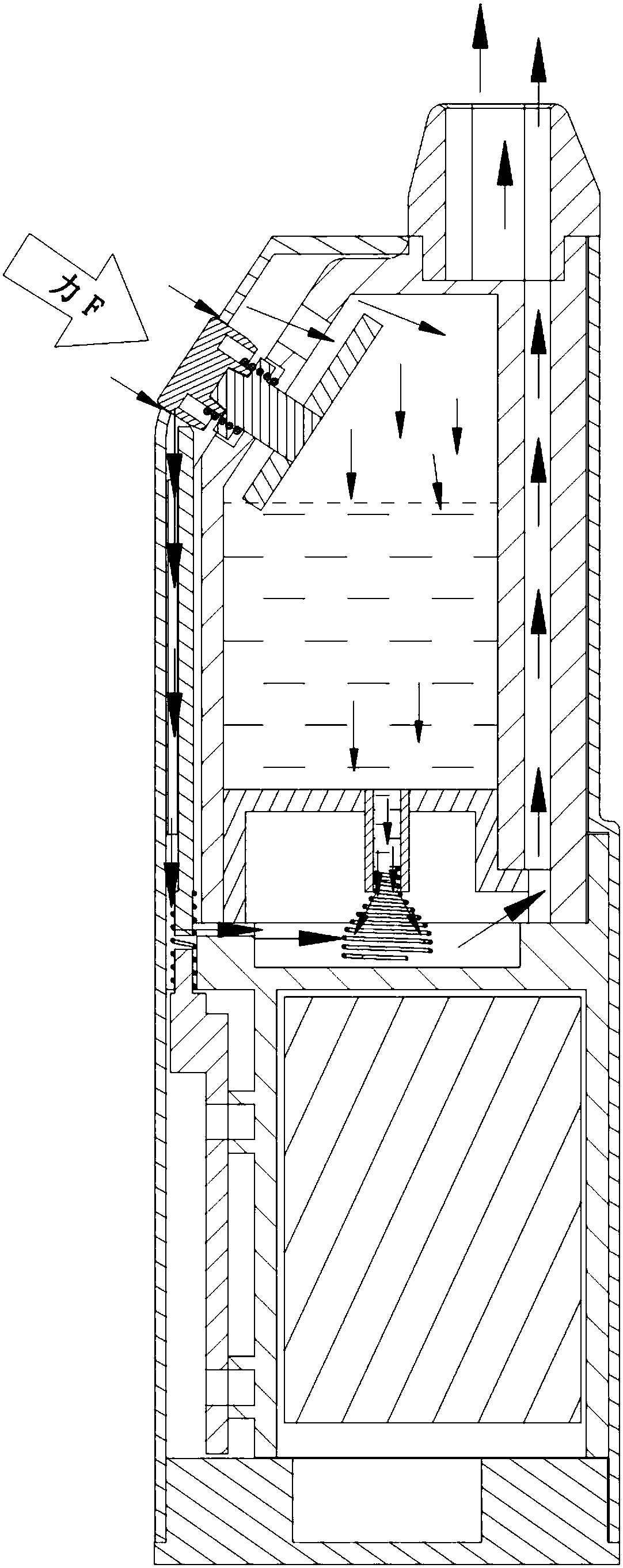

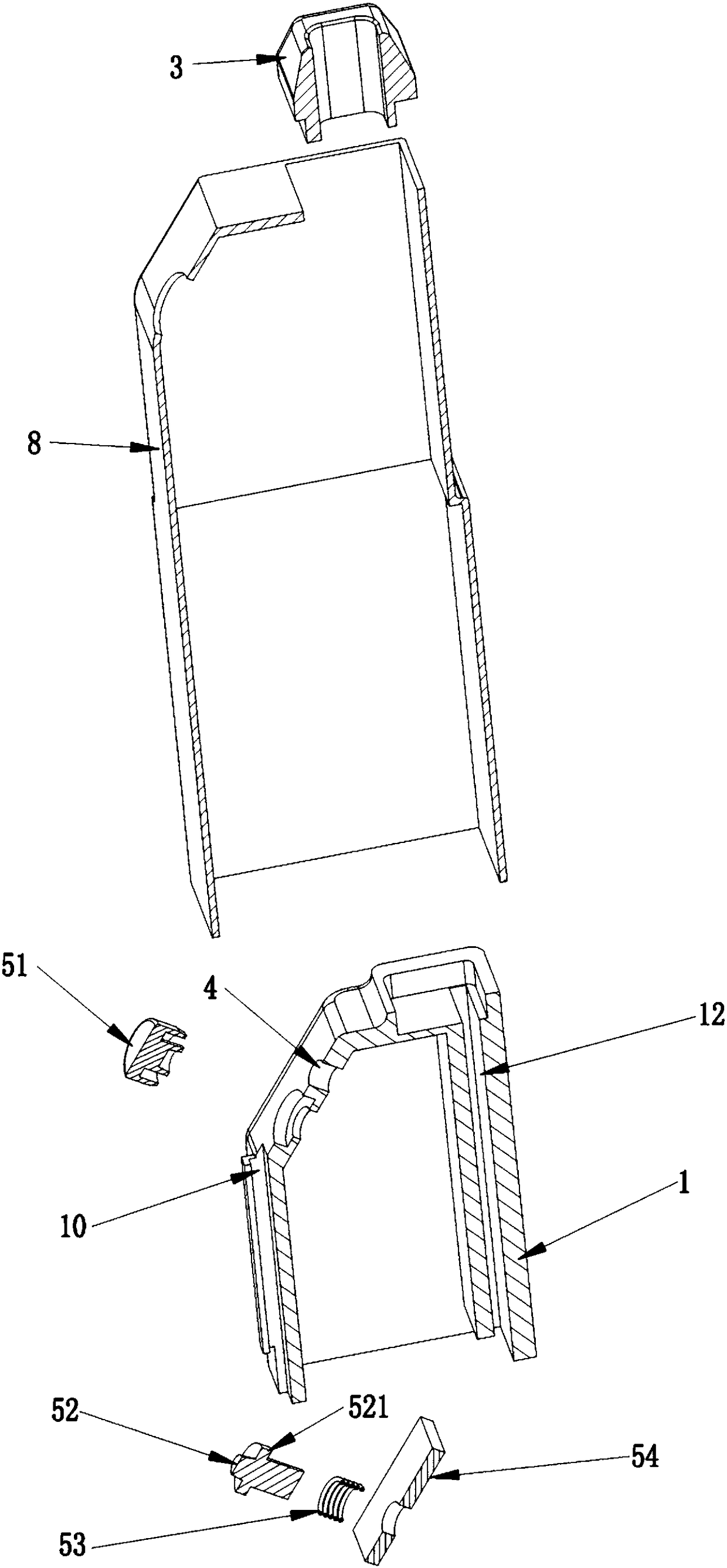

Electronic cigarette atomizer

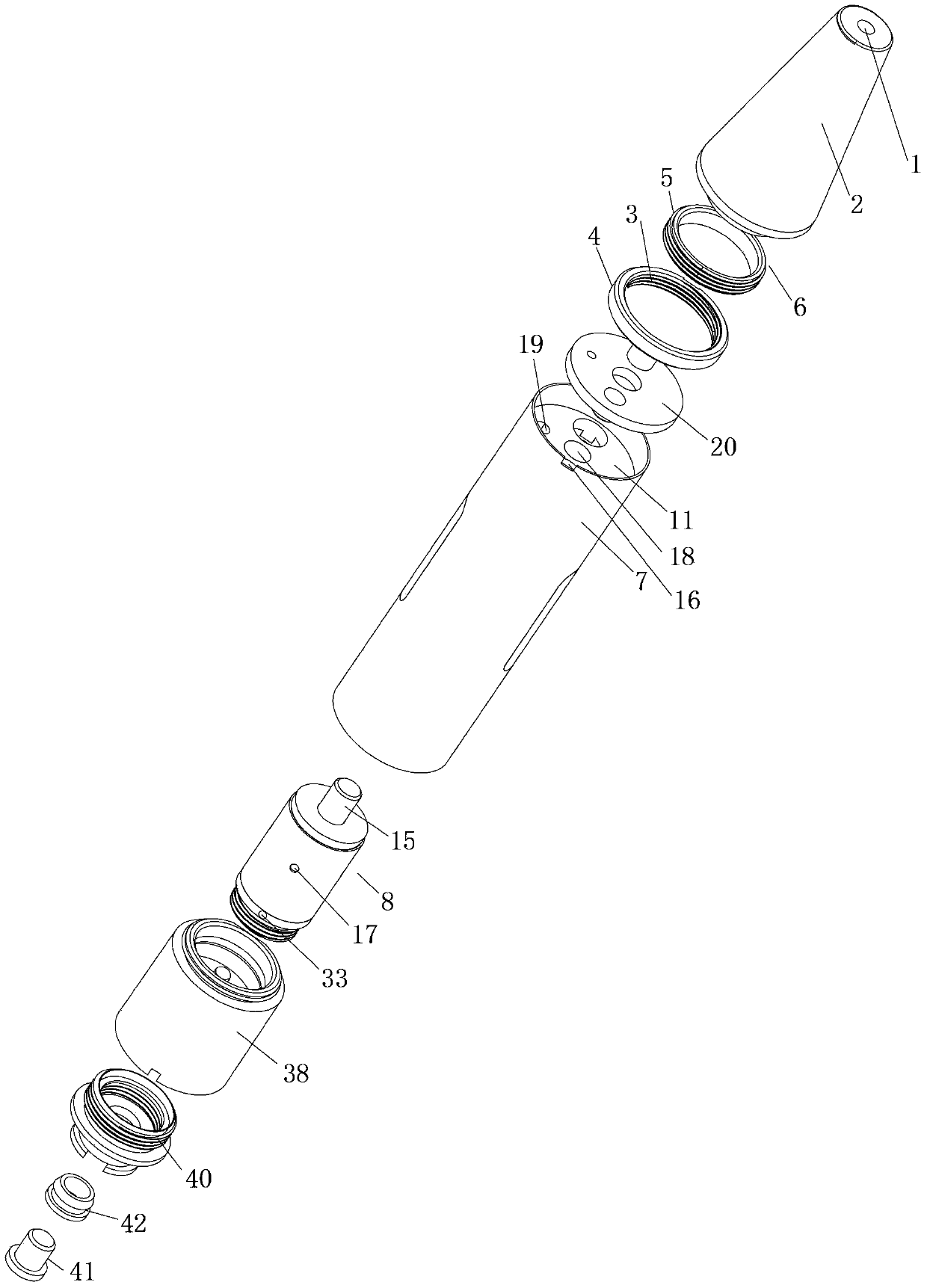

The invention relates to the technical field of electronic cigarettes, in particular to an electronic cigarette atomizer comprising a mouthpiece having a smoke suction hole, an atomizing tube, a second inner tube, and a connecting cap. The atomizing tube is detachably connected with the mouthpiece. An atomizer head is disposed inside the atomizing tube. A first inner tube is disposed inside the atomizing tube. The second inner tube is disposed inside the first inner tube. The same ends of the first and second inner tubes are connected hermetically. The same other ends of the first and second inner tubes are abutted to the atomizer head hermetically. A first liquid storage cavity forms between the first inner tube and the second inner tube. The outer wall of the first inner tube is provided with an intake channel communicated with an air inlet of the atomizer head. The atomizing tube is provided with an intake slot communicated with the intake channel. A smoke outlet tube of the atomizer head is communicated with the second inner tube which is communicated with the smoke suction hole of the mouthpiece. The connecting cap is provided with a liquid filler communicated with the first liquid storage cavity. The atomizer head is provided with a liquid inlet whereby an atomizing cavity of the atomizer head is communicated with the first liquid storage cavity. The electronic cigarette atomizer is simple in structure, reasonable in design, free of liquid leakage, and capable of producing a lot of smoke.

Owner:JOYETECH EURO HLDG

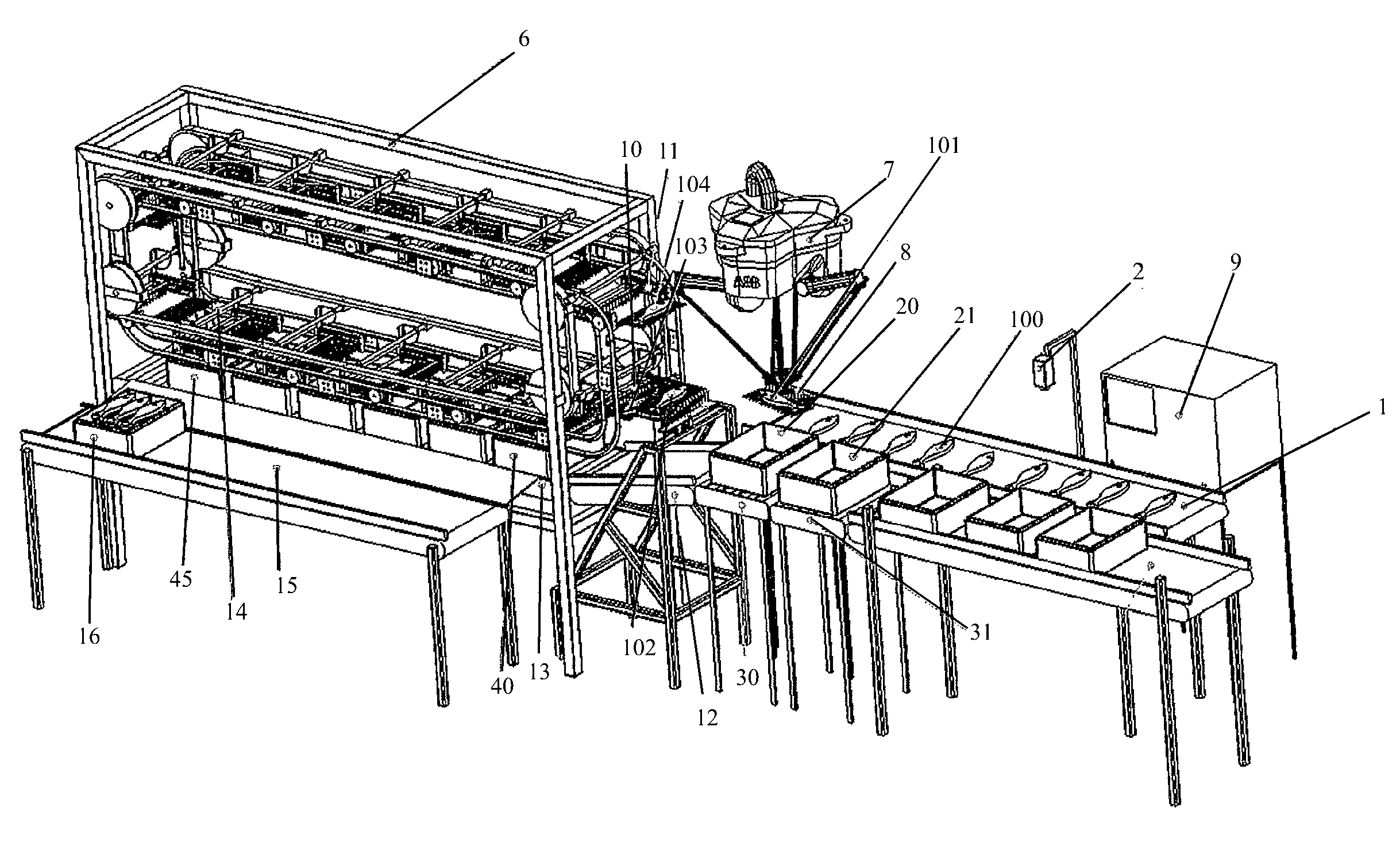

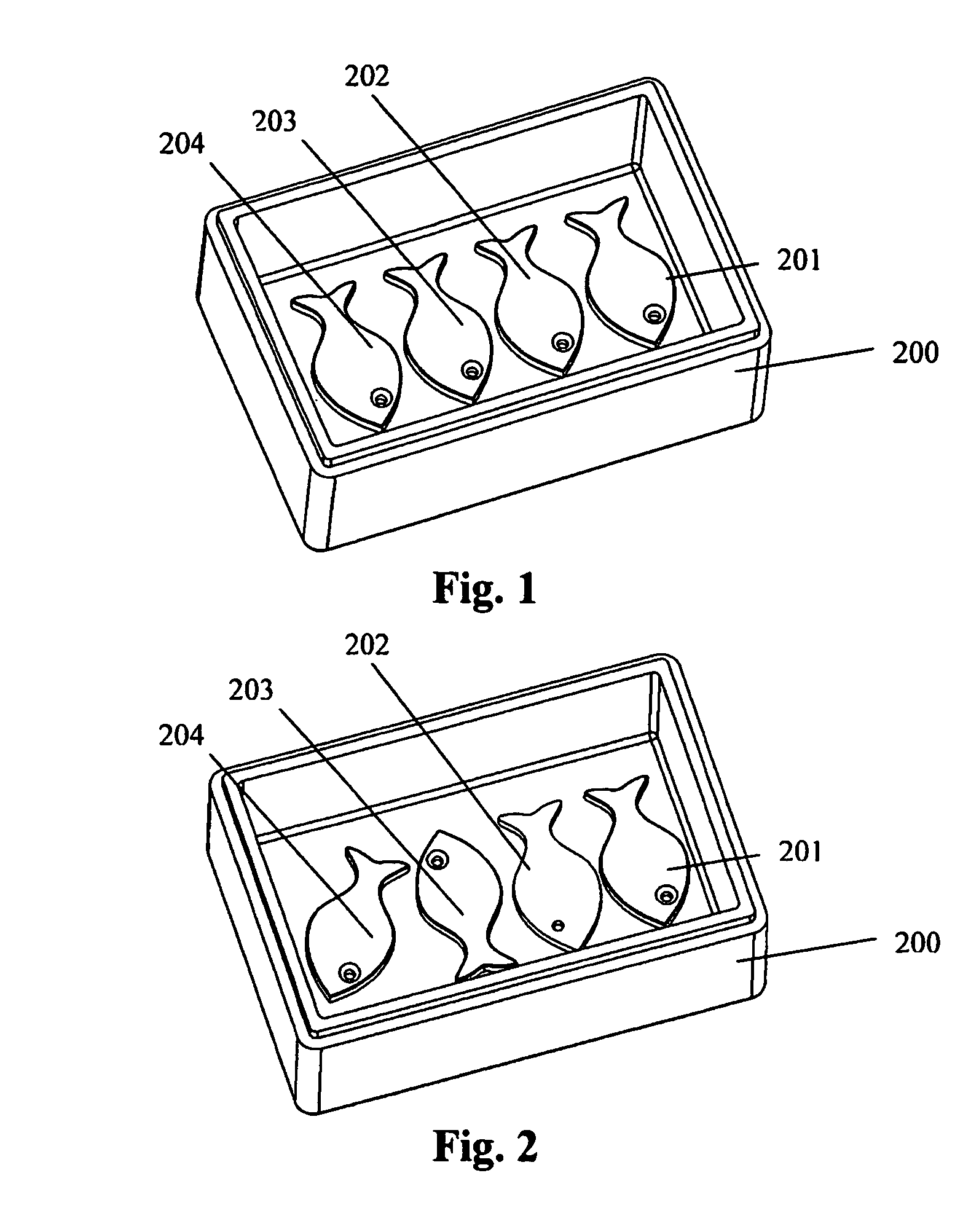

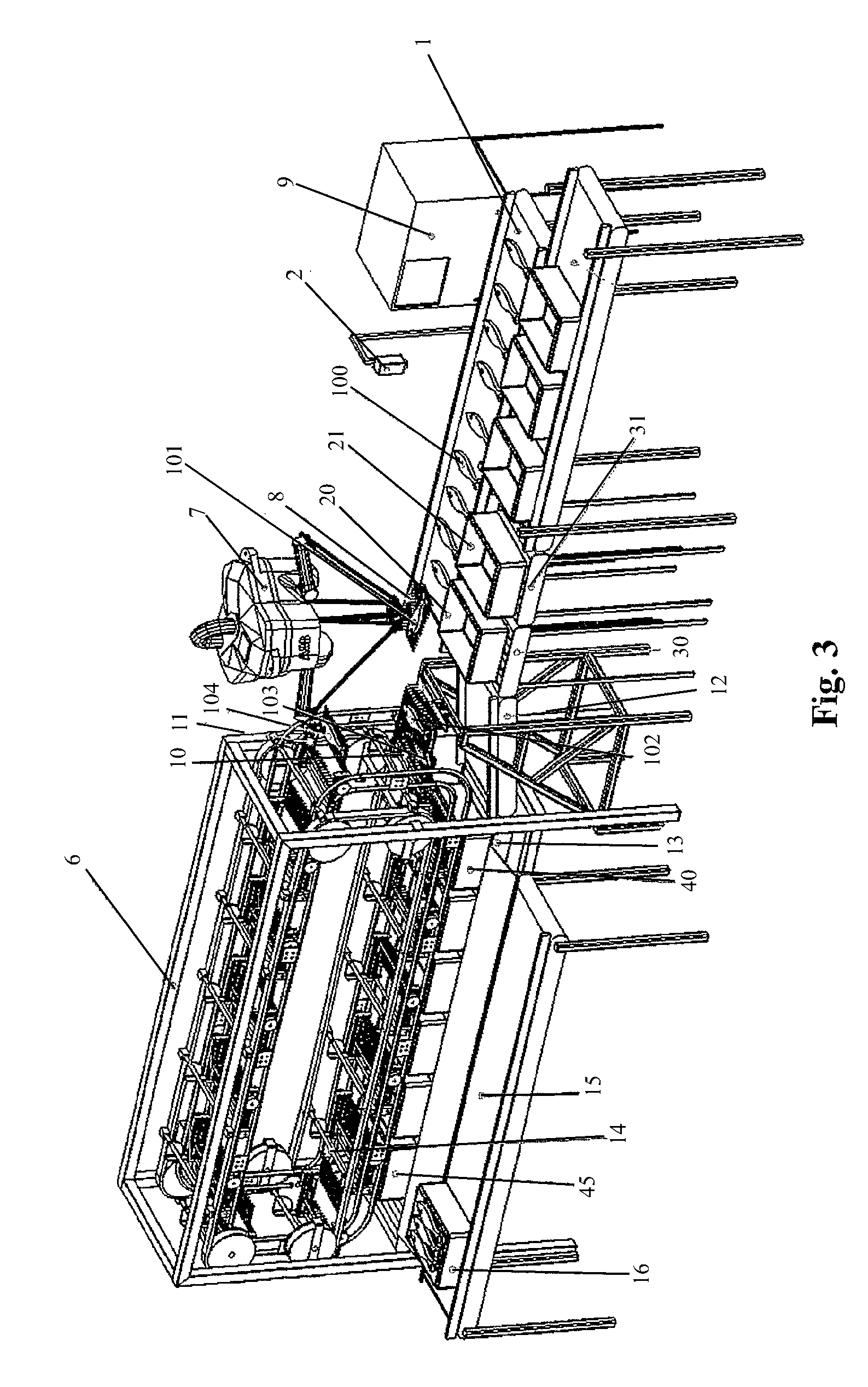

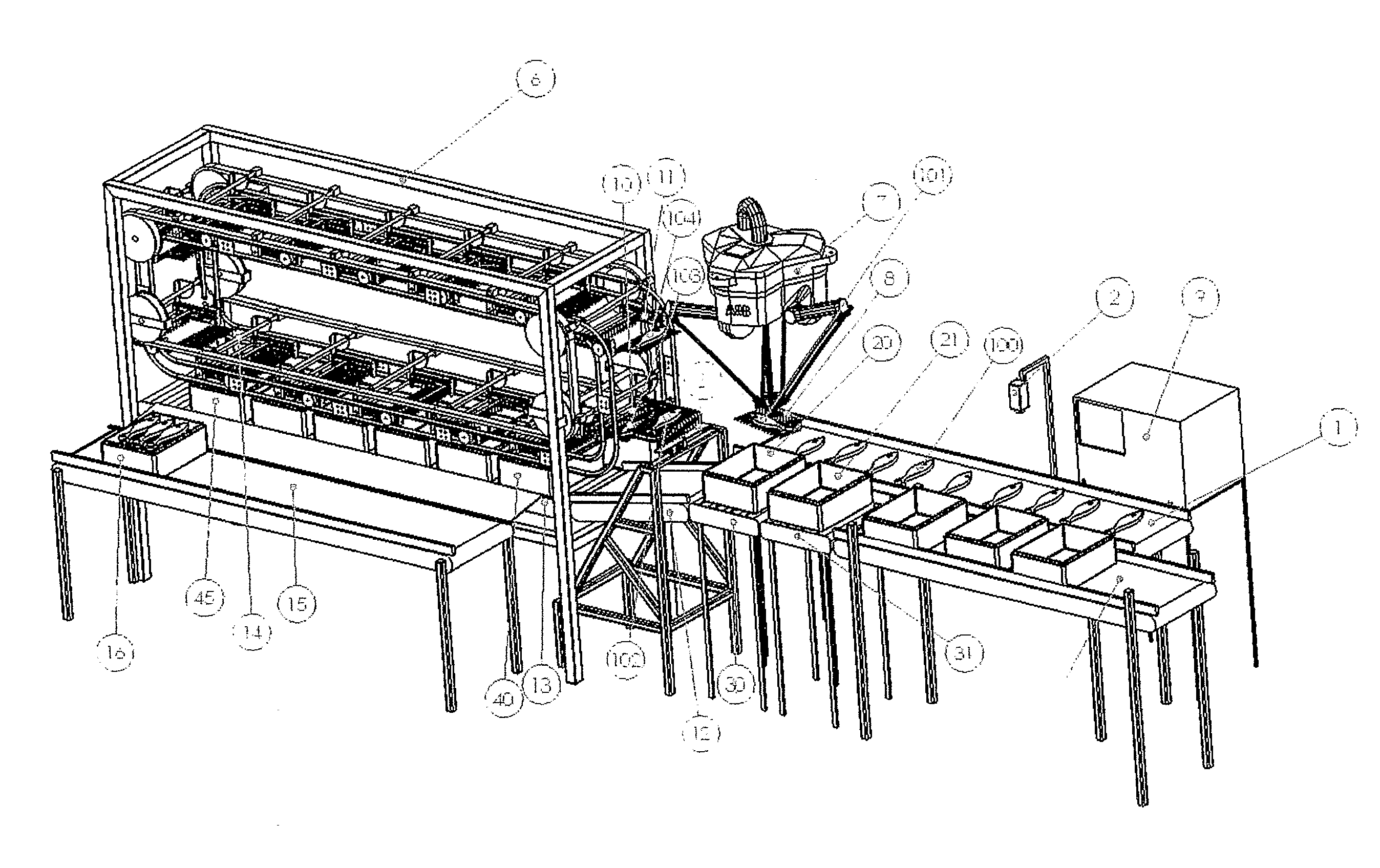

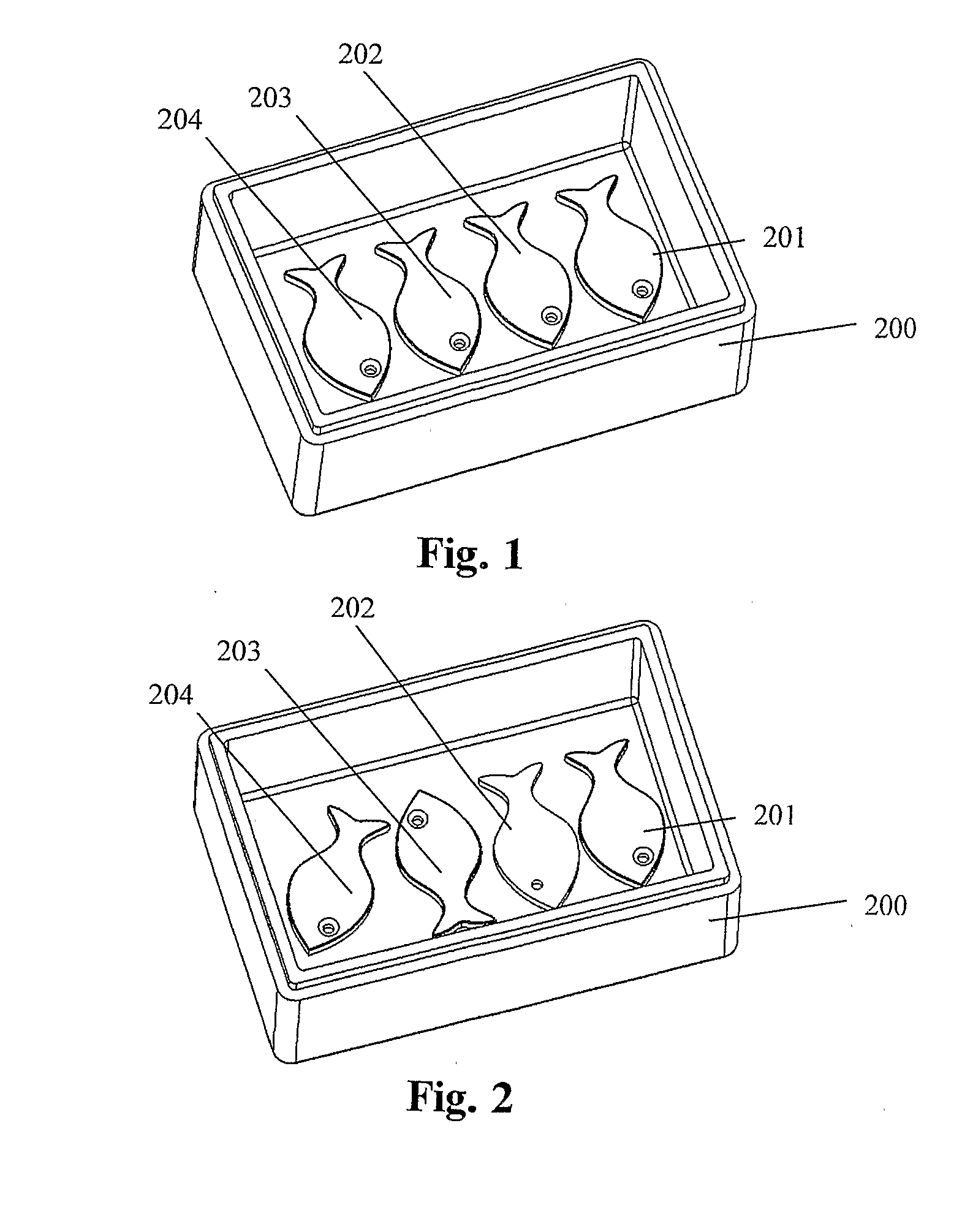

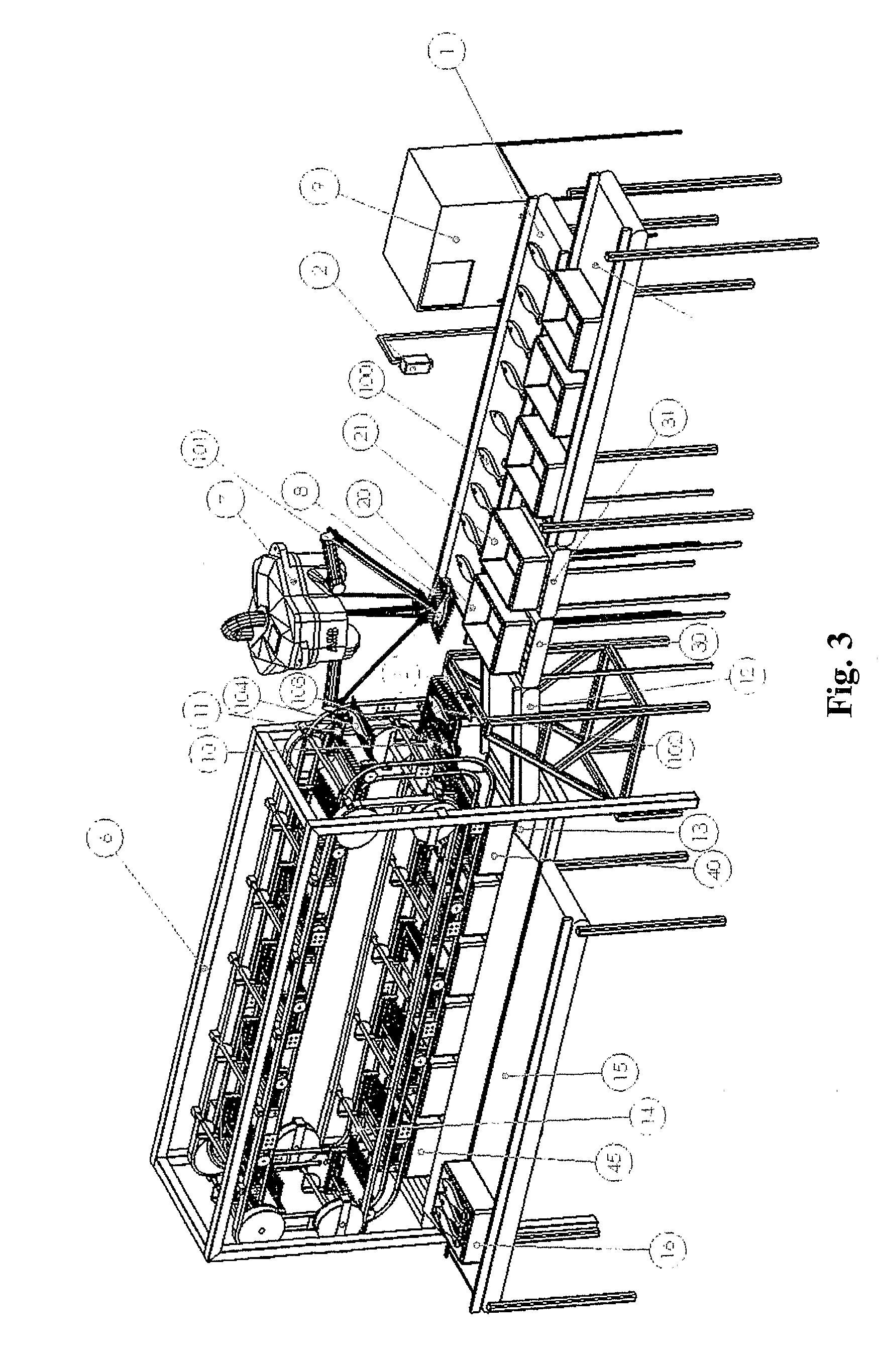

Apparatus and method for grading articles based on weight, and adapted computer program product and computer readable media

ActiveUS7967149B2Fully atomizedAccurate displacementFish sortingProgramme-controlled manipulatorClosed loopMechanical engineering

Owner:VALKA EHF

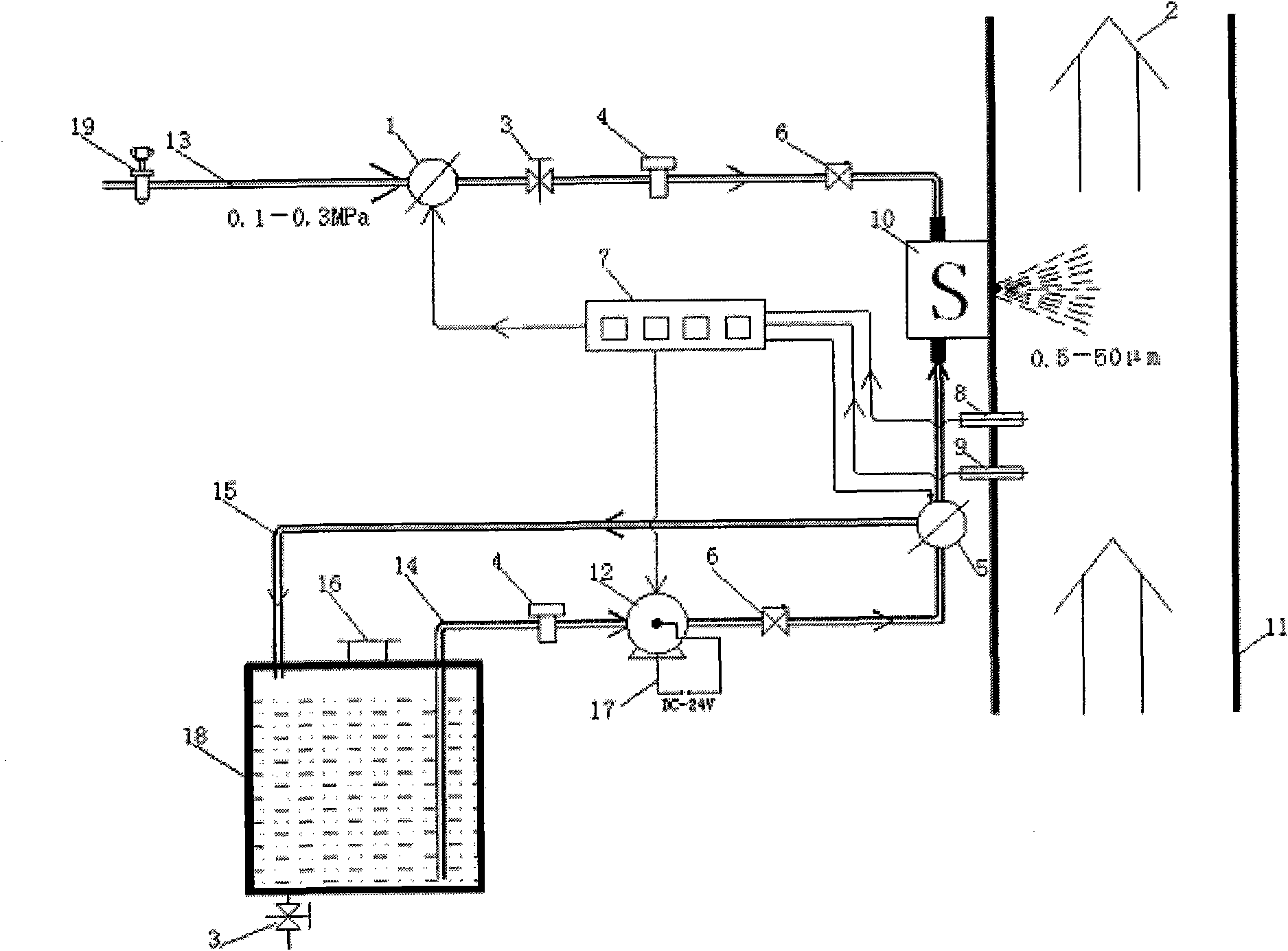

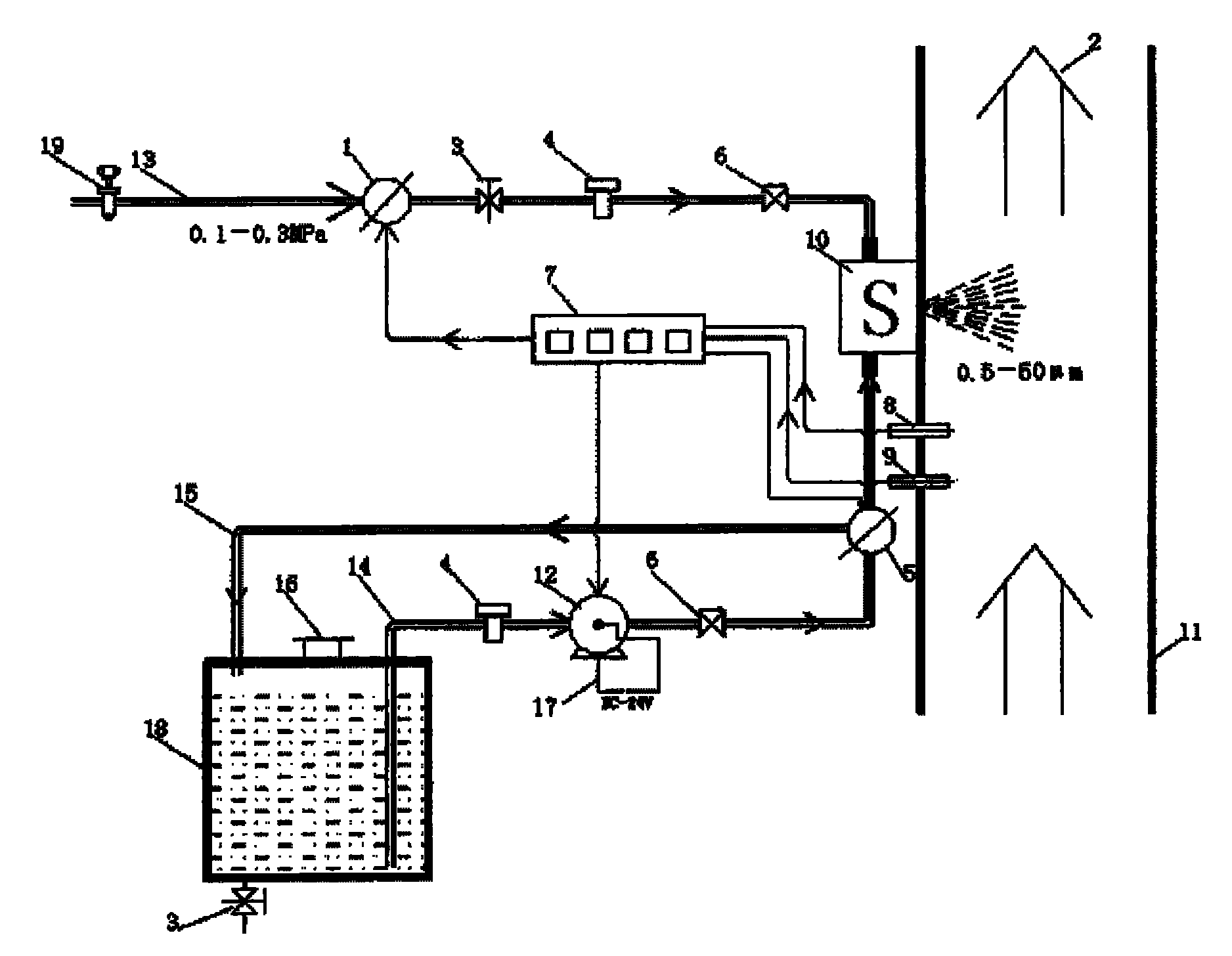

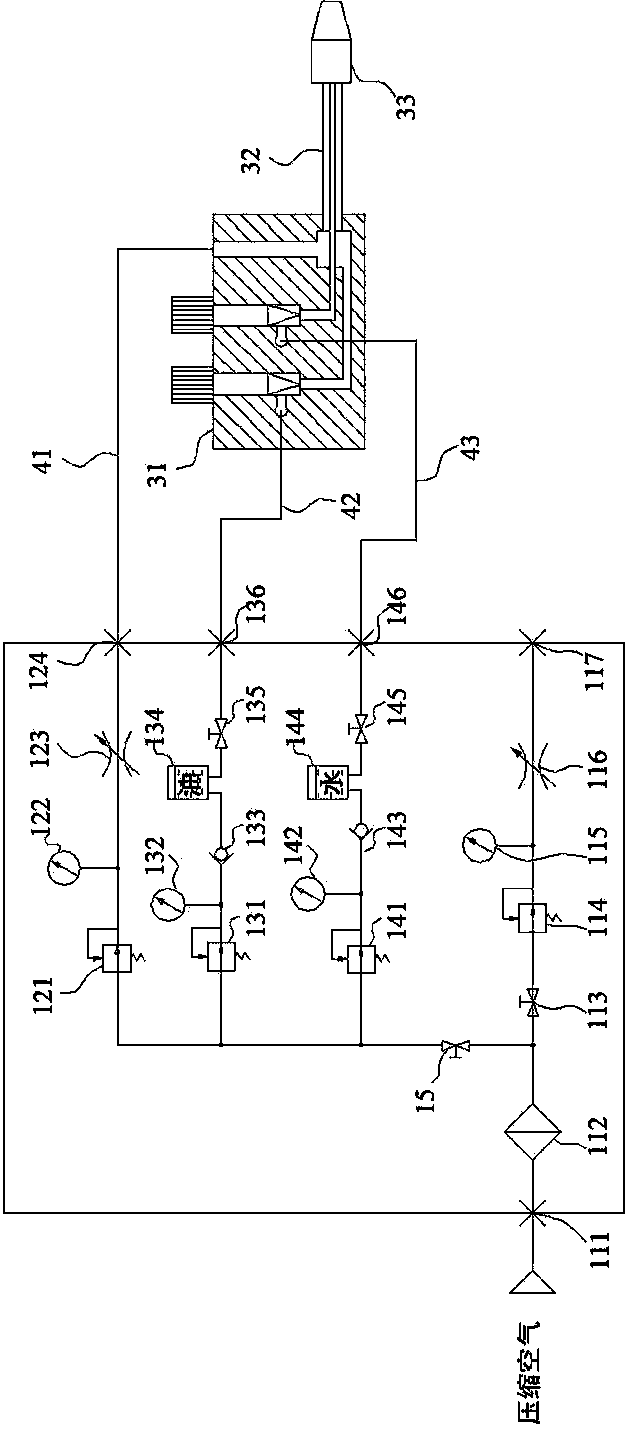

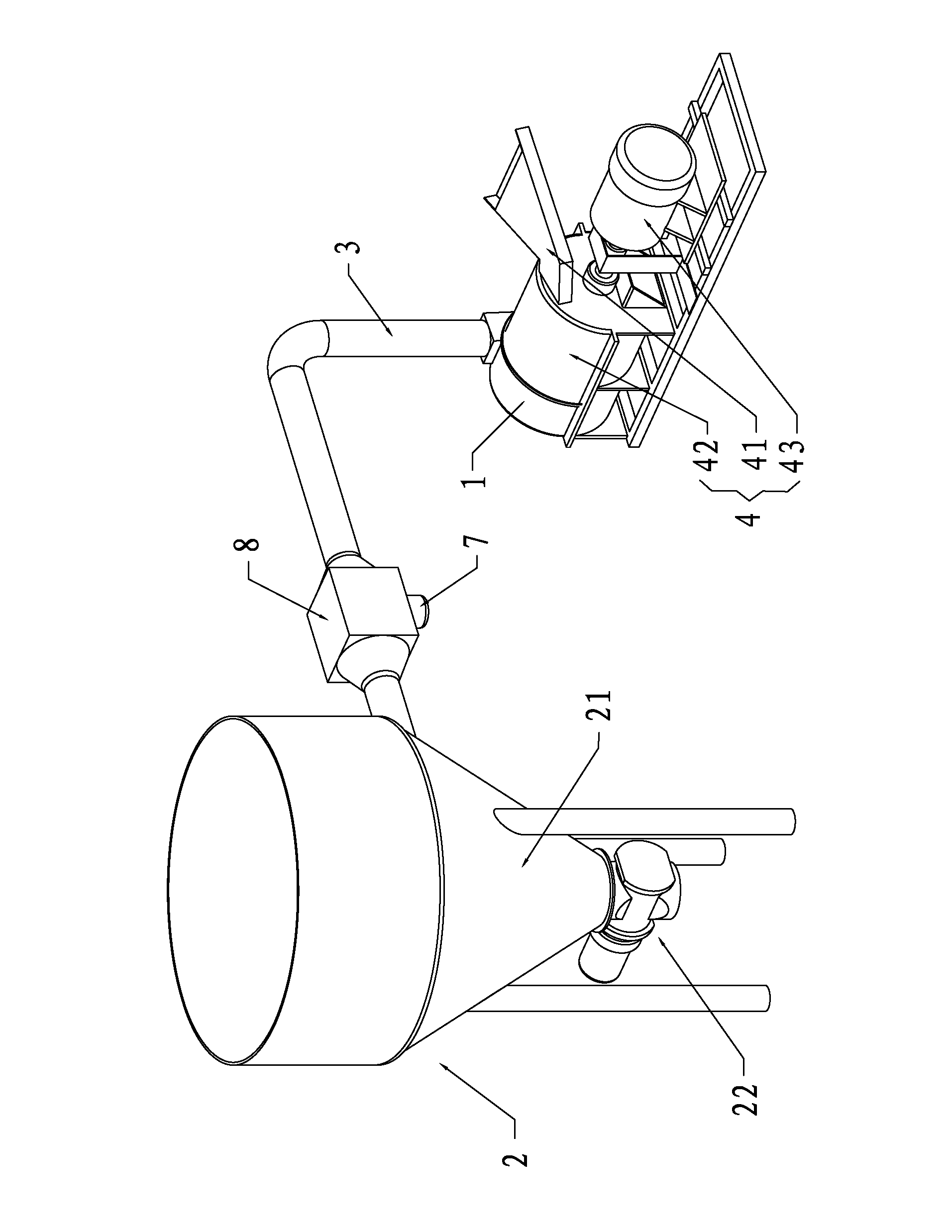

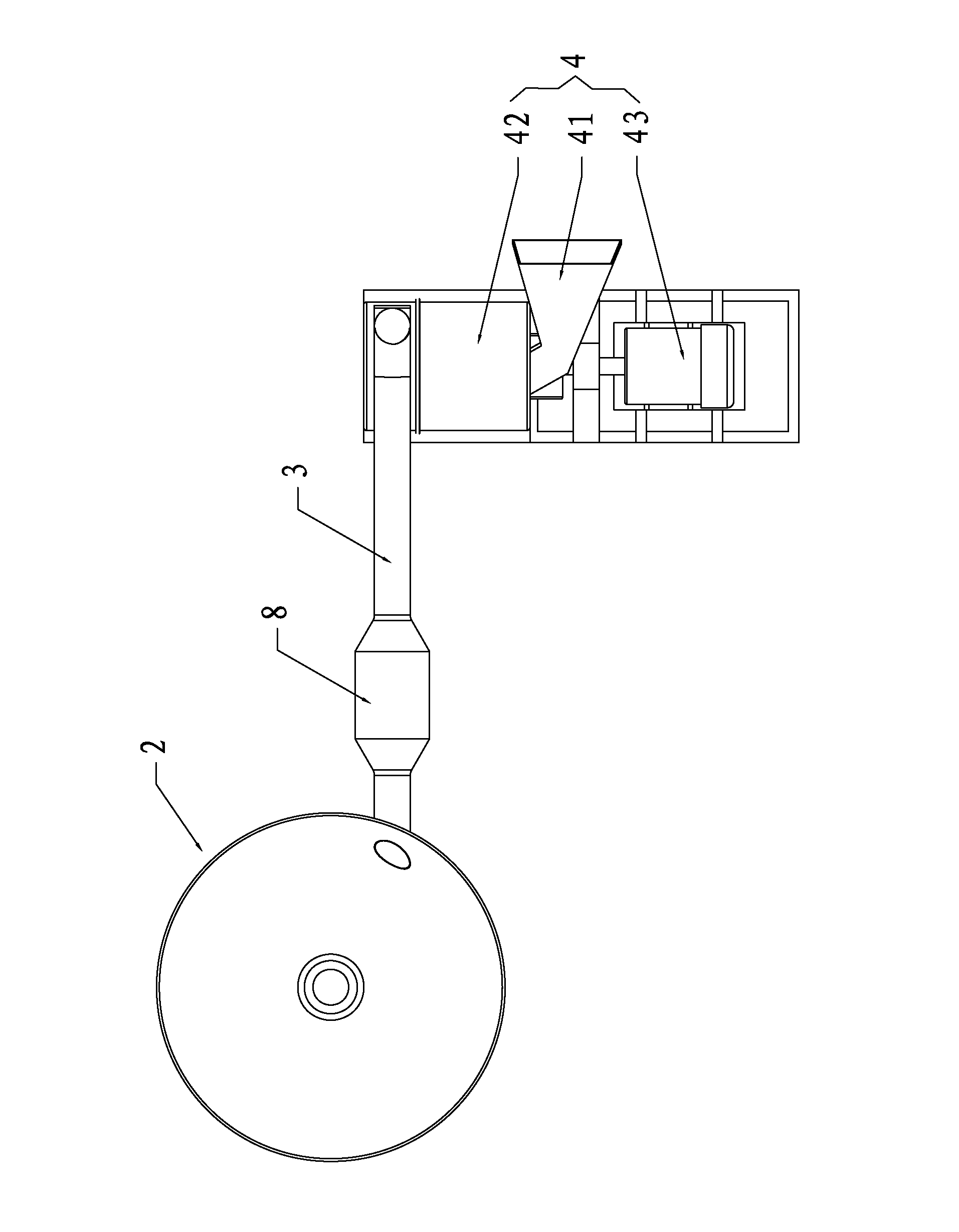

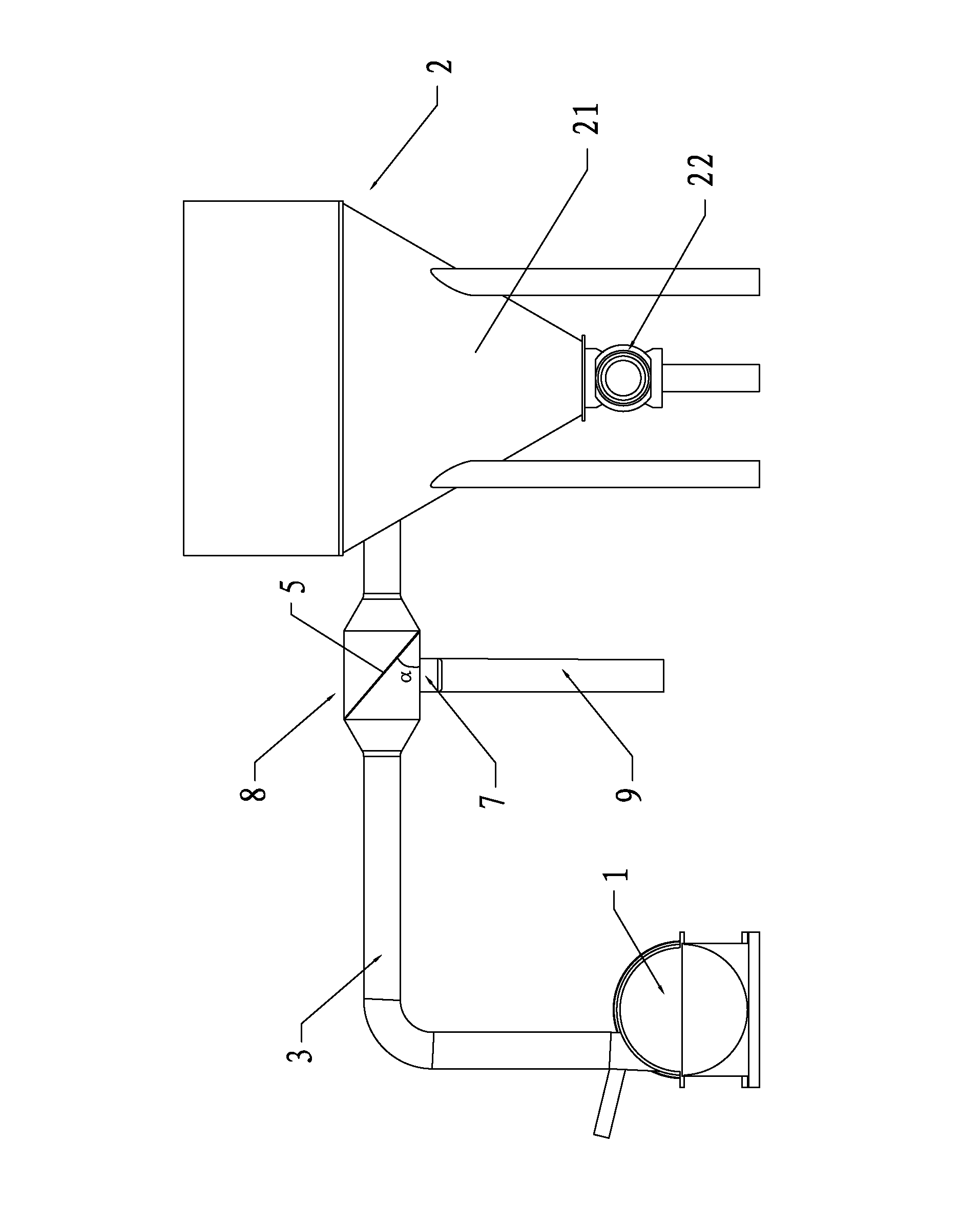

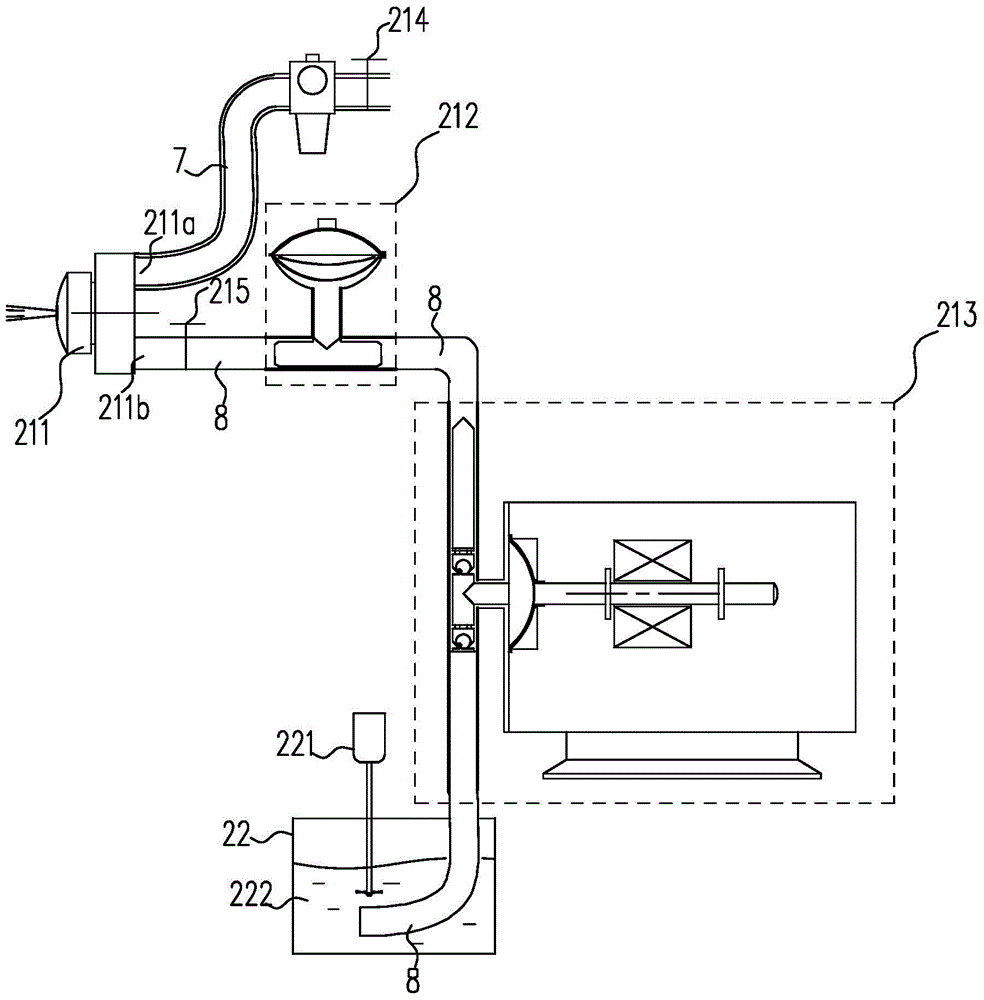

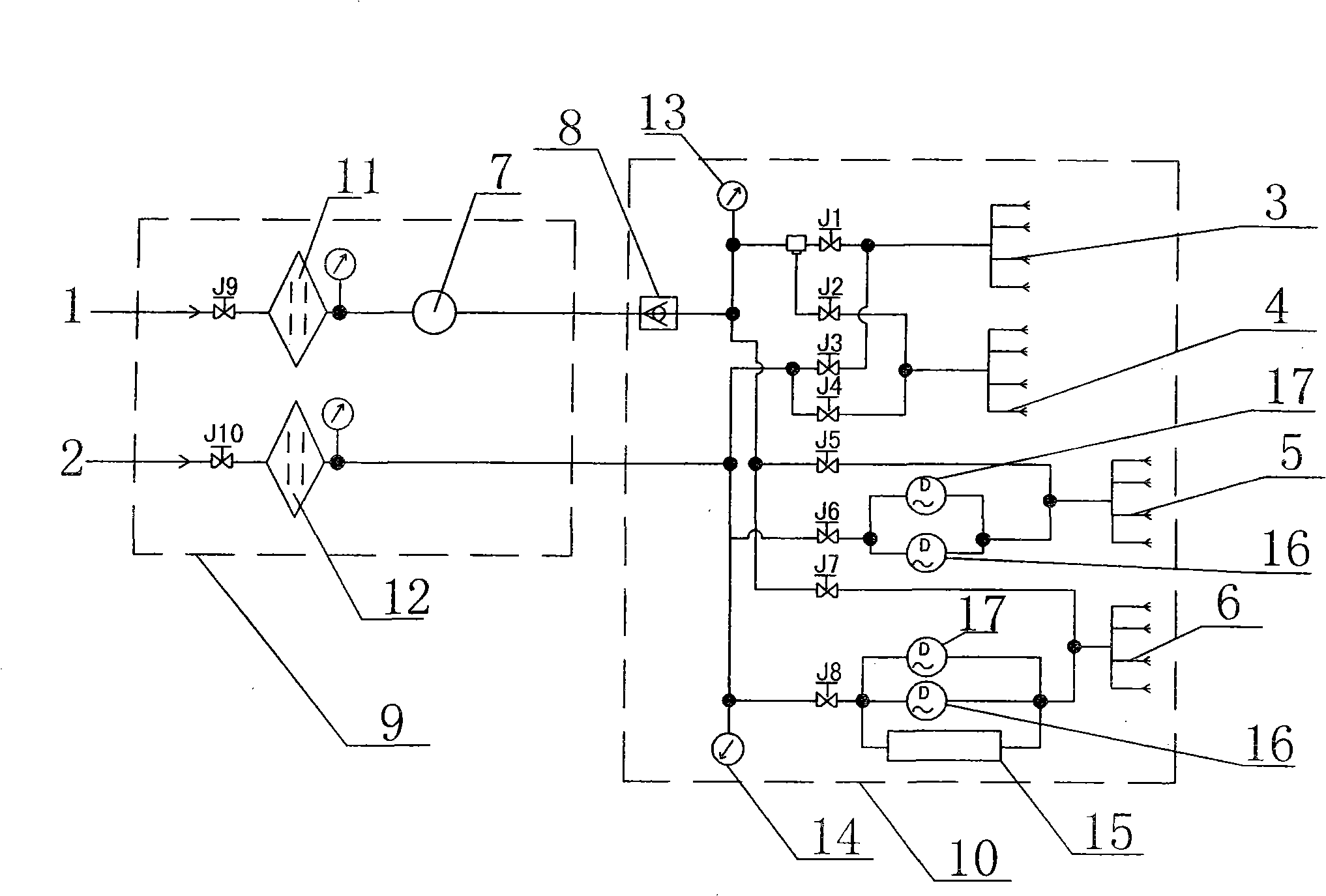

Air-assisted atomized urea reducing agent spraying controlling system of pump power

InactiveCN101806238AFully atomizedImprove reliabilityInternal combustion piston enginesExhaust apparatusSolenoid valveNitrogen oxide sensor

The invention relates to an air-assisted atomized urea reducing agent spraying controlling system of pump power. The system is characterized in that the air inlet end of an air compressing main pipe is provided with a pressure adjusting valve; the air outlet end of the air compressing main pipe is communicated with an urea reducing agent nozzle; an urea reducing agent reflowing pipeline is connected with an urea reducing agent container; a cover of the urea reducing agent container is fixed on the urea reducing agent container; the bottom of the urea reducing agent container is connected with a manual liquid switch; an urea reducing agent pipeline and the urea reducing agent reflowing pipeline are communicated with the urea reducing agent nozzle through a liquid flow solenoid valve; and a temperature sensor and a nitric oxide sensor, which are arranged on an exhaust pipe of an engine, are electrically connected with a control unit. The system has low cost which is about equal to 1 / 2-1 / 3 of the cost of an imported system, high reliability, and high practical applicability, and is easily industrially applied with domestic resources.

Owner:FAW GROUP

Apparatus and method for grading articles based on weight, and adapted computer program product and computer readable media

ActiveUS20090026119A1Fully atomizedAccurate displacementFish sortingProgramme-controlled manipulatorClosed loopMechanical engineering

Owner:VALKA EHF

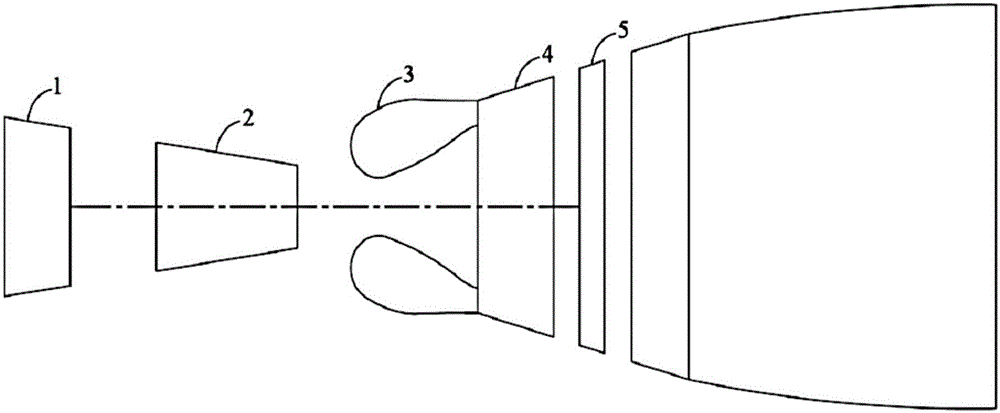

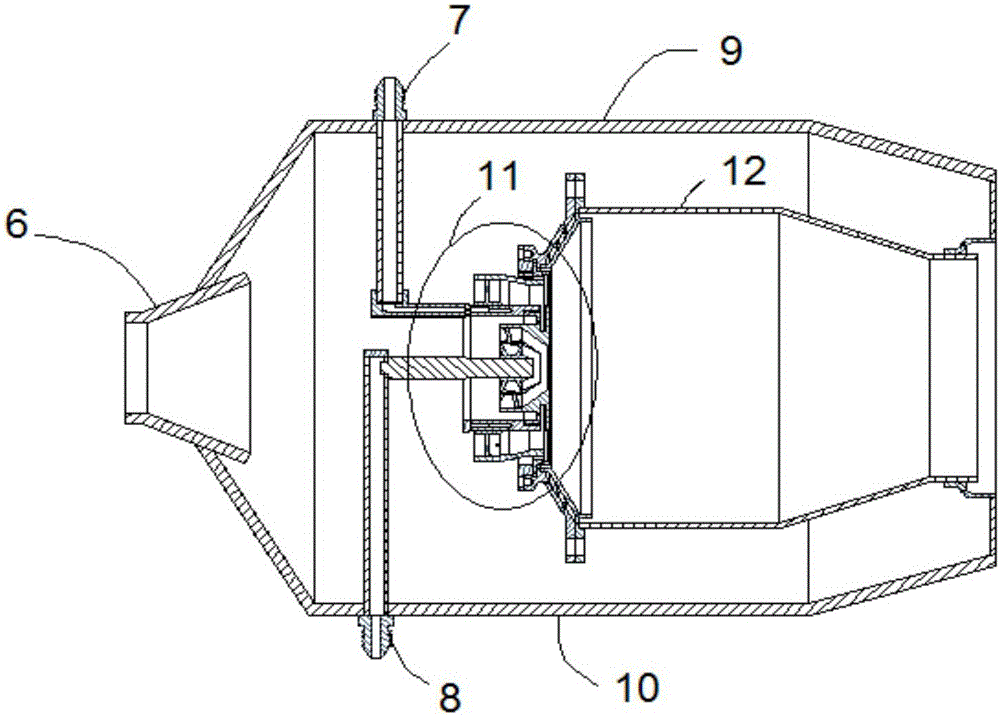

Low-emission combustion chamber with double-layer axial hydrocyclone adopted at precombustion stage

InactiveCN105157062AImprove combustion effectAvoid lossContinuous combustion chamberCombustion chamberPollutant emissions

The invention discloses a low-emission combustion chamber with a double-layer axial hydrocyclone at a precombustion stage. The combustion chamber is of a single annular cavity structure and structurally comprises a pressure expander, a combustion chamber exterior casing, a combustion chamber interior casing, a flame tube and a combustion chamber head; all combustion-used air enters the flame tube through the combustion chamber head, a staged combustion scheme is adopted, and the combustion is divided into into the precombustion stage and a primary combustion stage; a premixed combustion mode is adopted at the primary combustion stage, and a diffusive combustion mode serves as the main mode of the precombustion stage; the double-layer axial hydrocyclone is adopted at the precombustion stage, two blasts of rotational flow can maintain individual flowing through a partition plate, and momentum loss due to the fact that the two blasts of rotational flow make contact with each other too early is avoided; the two blasts of rotational flow are utilized for reinforcing fuel oil atomization and mixing, meanwhile, reasonable recirculating zone distribution is generated, efficient and stable combustion under small working conditions is guaranteed, and meanwhile pollutant emission is lowered; the combustion chamber is simple in structure at the precombustion stage and easy to machine and install, combustion chamber emission under small working conditions can be lowered, and thereby the low emission performance of a total landing and taking-off cycle of the combustion chamber is improved.

Owner:BEIHANG UNIV

Multistage atomization gas-liquid two-phase large-caliber mist nozzle

InactiveCN103861753AImprove energy utilizationReduced gas consumptionLiquid spraying apparatusHollow cylinderAerosolize

The invention relates to a multistage atomization gas-liquid two-phase large-caliber mist nozzle. According to the technical scheme, the middle of a small cylinder body of a liquid inlet pipe (2) is fixedly connected with the center of a top cover (3), and a large cylinder body of the liquid inlet pipe (2) and a conical table of the liquid inlet pipe (2) are located in a rotational flow cylinder (4). The outer wall of the large cylinder body of the liquid inlet pipe (2) has a distance of 3-8 mm with the inner wall of a hollow cylinder body of the rotational flow cylinder (4). The minimum distance of a circular seam (11) formed between the outer wall of the conical table of the liquid inlet pipe (2) and the inner wall of a hollow conical table of the rotational flow cylinder (4) is 0.3-1 mm. The upper portion of the hollow cylinder body of the rotational flow cylinder (4) is horizontally provided with an air inlet pipe (1), and one end of the air inlet pipe (1) penetrates through a shell of the rotational flow cylinder (4) and is tangent with the outer wall of the small cylinder body of the liquid inlet pipe (2). The outer diameter of the air inlet pipe (1) is the difference between the inner diameter of the hollow cylinder body of the rotational flow cylinder (4) and the outer diameter of the small cylinder body of the liquid inlet pipe (2). The air inlet pipe (1) is located between the top cover (3) and the large cylinder body of the liquid inlet pipe (2). The multistage atomization gas-liquid two-phase large-caliber mist nozzle has the advantages that the structure is simple, mist drops are evenly distributed, and the nozzle cannot be blocked.

Owner:WUHAN UNIV OF SCI & TECH

Sliver-oxide ternary alloy electrical contact material and production method thereof

InactiveCN102747248AImprove electrical contact performanceImprove wear resistanceSolid state diffusion coatingElectric switchesWire rodLow voltage

The invention discloses a sliver-oxide ternary alloy electrical contact material and a production method thereof. The sliver-oxide ternary alloy electrical contact material comprises, by weight percent, 6%-24% of total ternary alloy oxides, 0.72%-5% of total added element oxides, and the balance of silver. The production method includes smelting the raw materials to obtain ingots by stepwise smelting process or atomizing to produce alloy powder; performing rolling and temperature differential oxidation, or high energy ball milling and temperature differential oxidation; and performing isostatic pressing to obtain primary ingots, subjecting the primary ingots to sintering, hot re-pressing and hot extrusion to obtain wires or strips, and thereby obtaining highly dispersible organizational structure with even and small crystal grains. The obtained material is high in conductivity, low in temperature rise, high in welding resistance, high in arc suppressing and high in electric corrosion resistance, electrical life is prolonged greatly, advantages of comprehensive property are highlighted, and the demands of high-end low-voltage electric appliances are fully met.

Owner:浙江乐银合金有限公司 +1

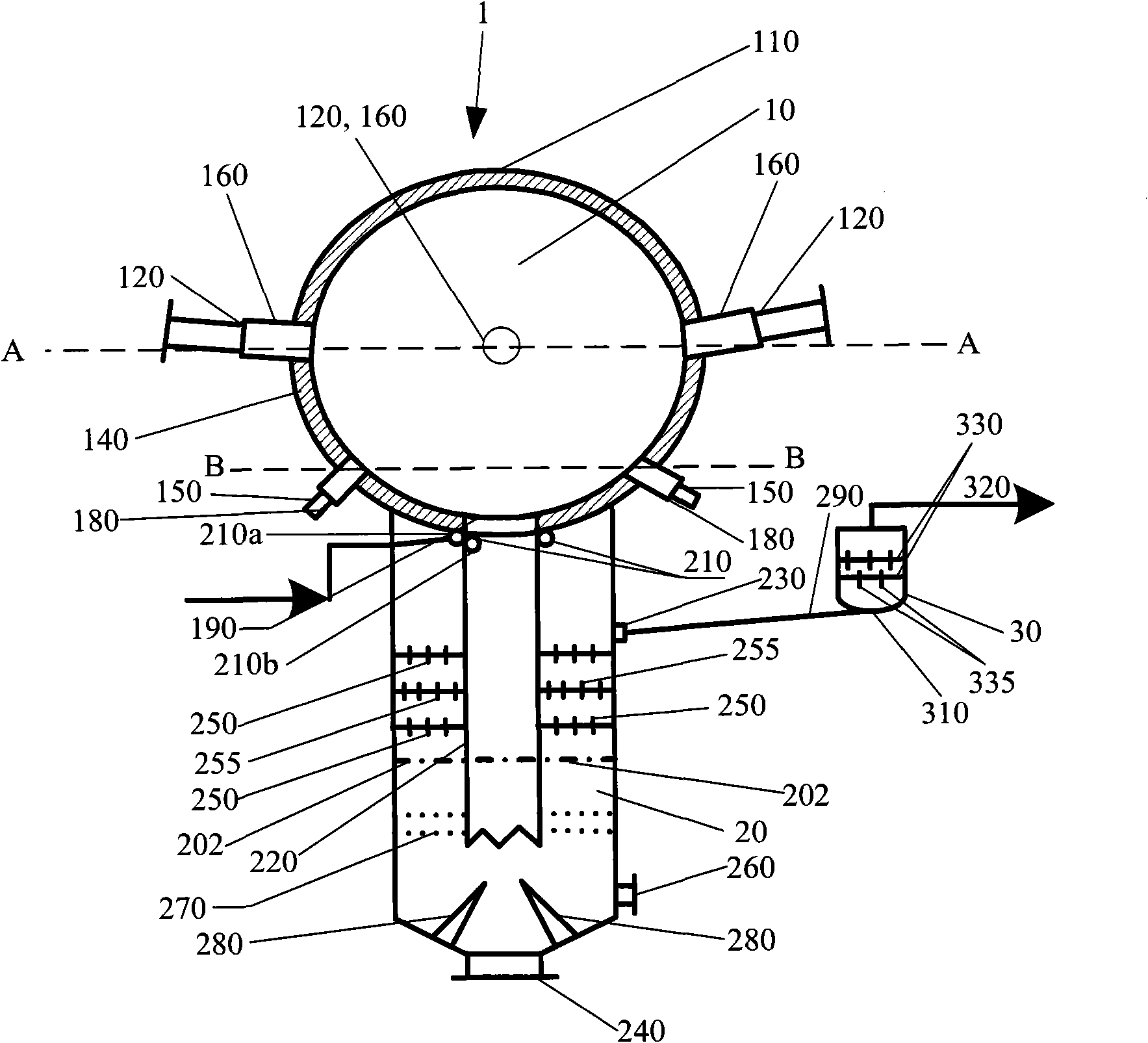

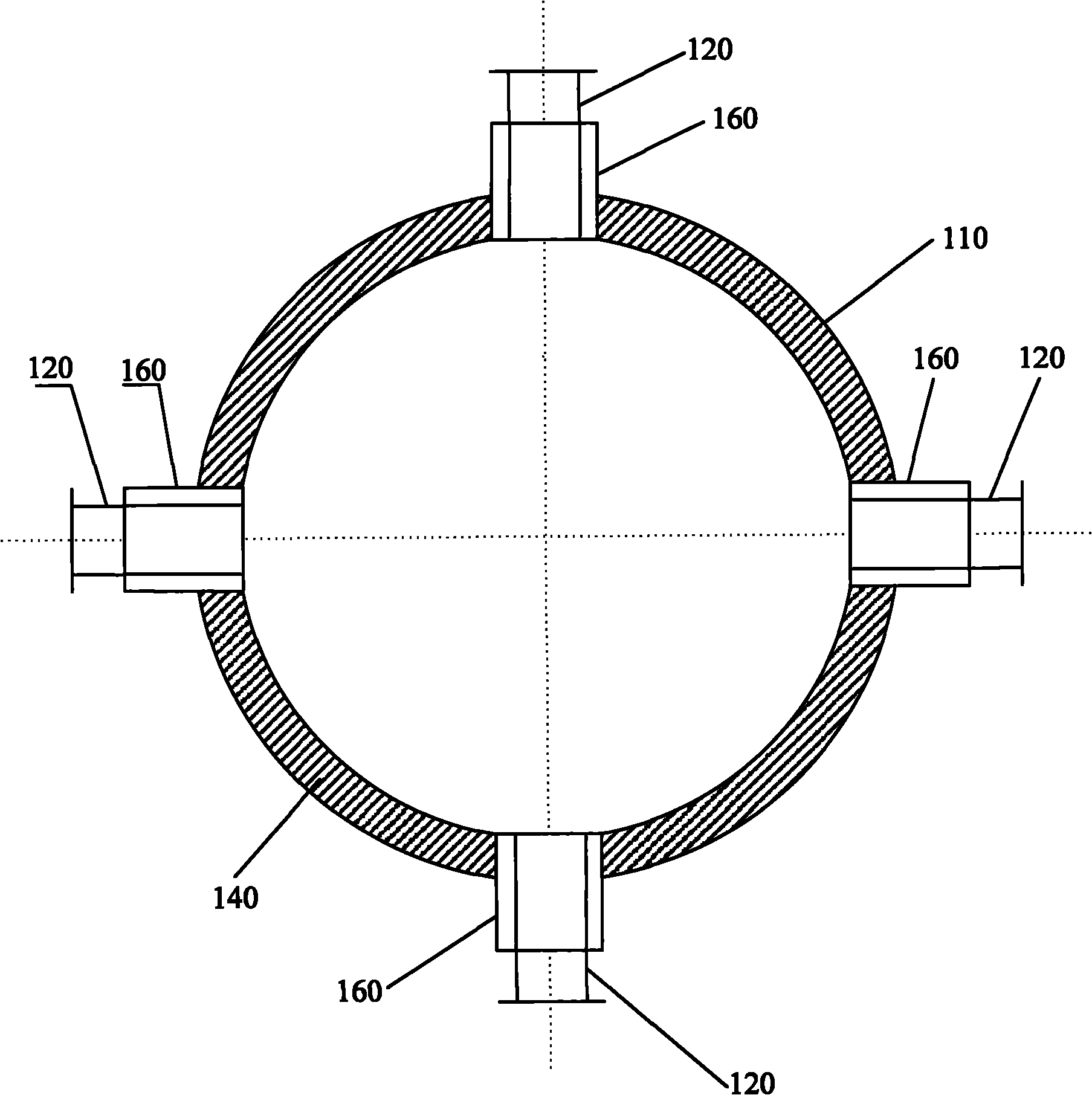

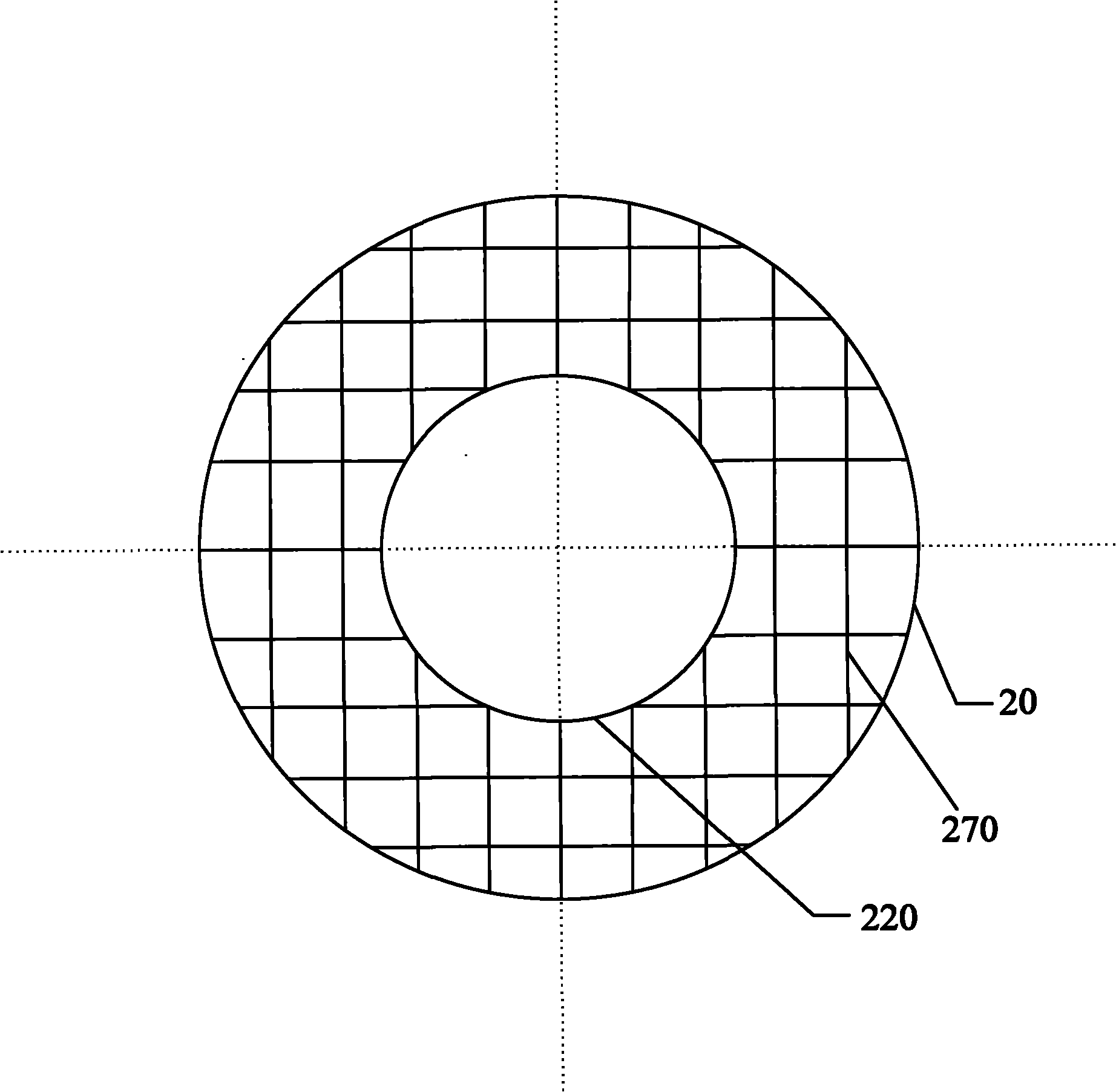

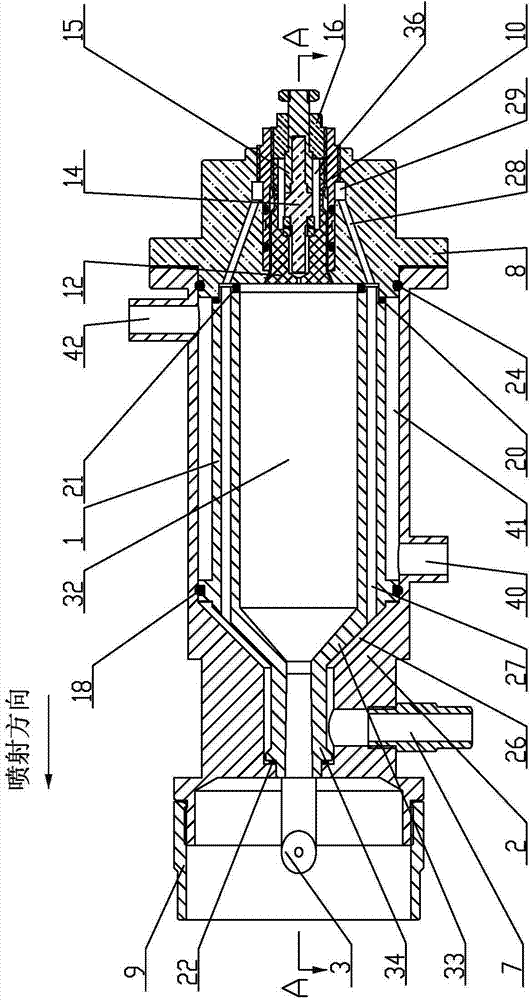

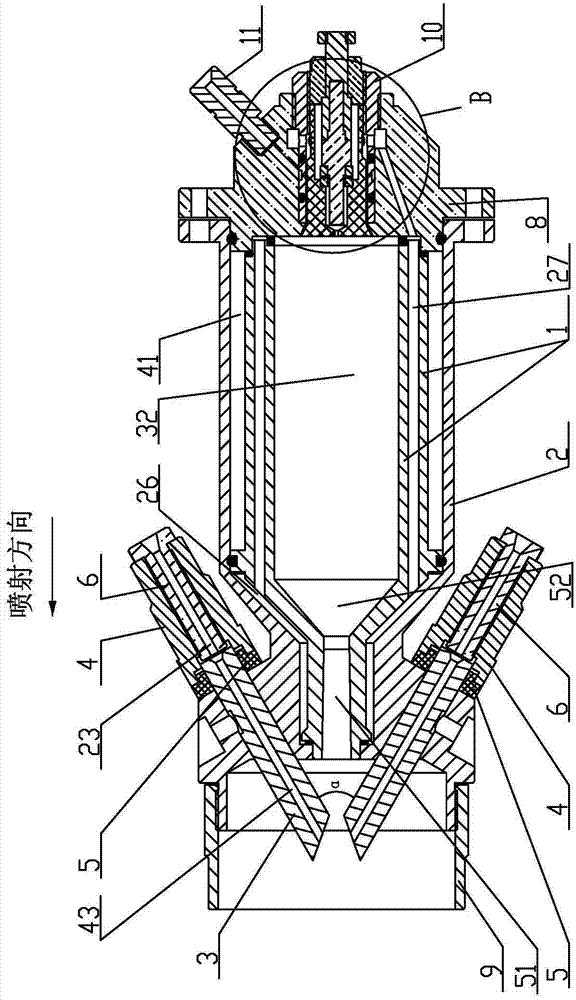

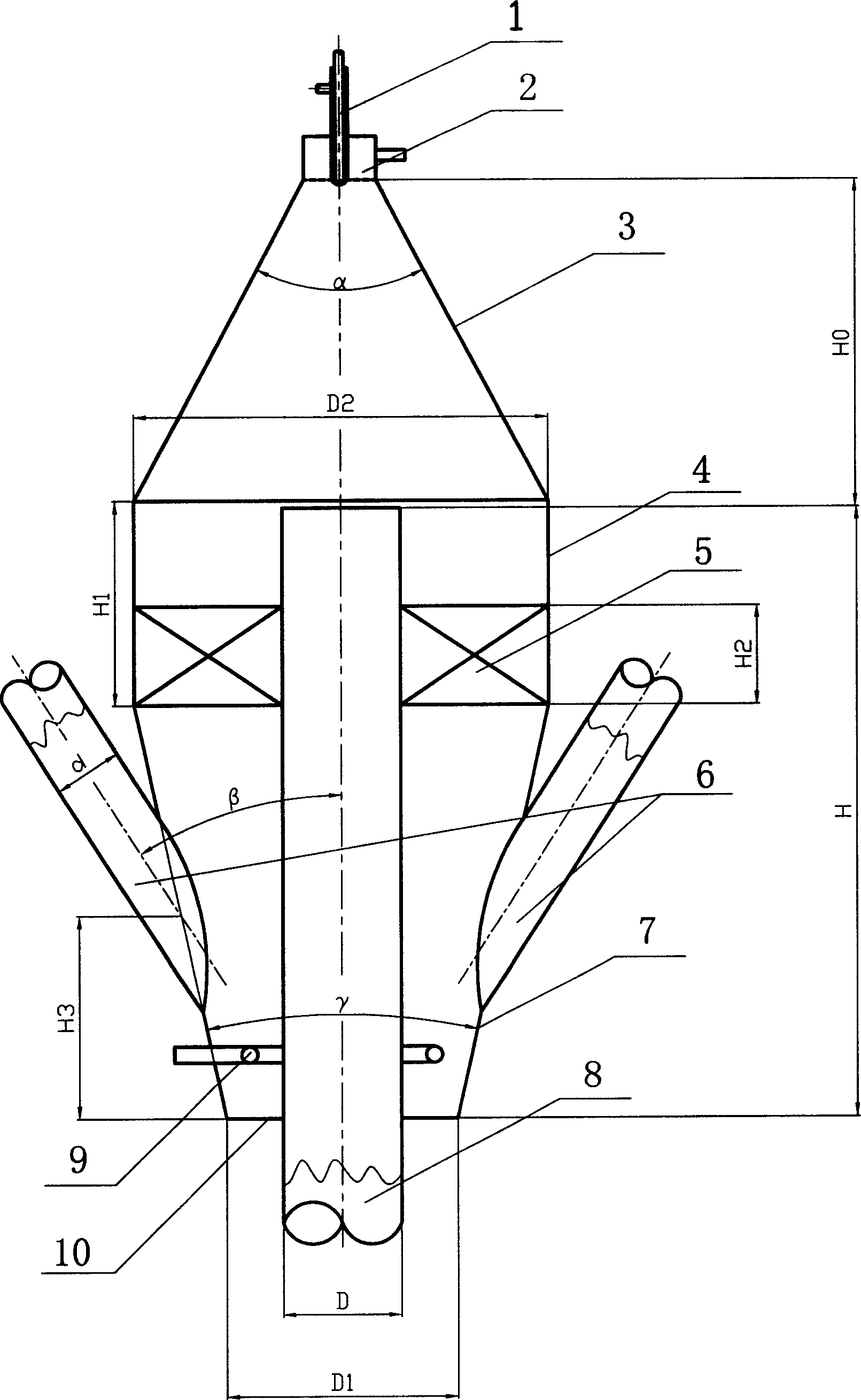

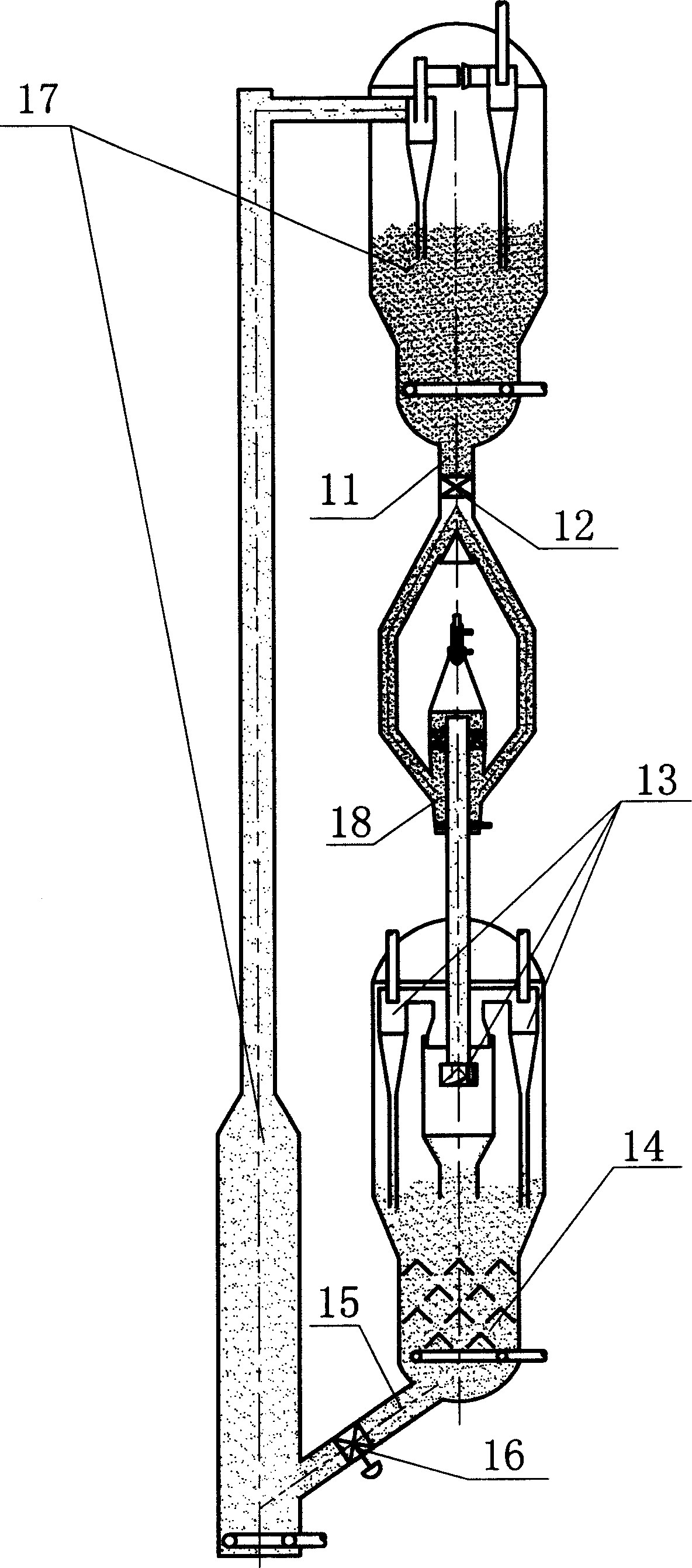

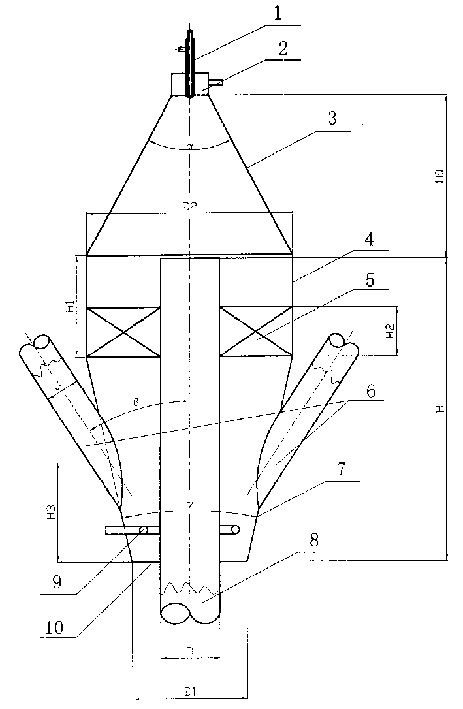

Coal water slurry gasification furnace for gasifying coal water slurry

ActiveCN101892086AFully atomizedImprove gasification efficiencyCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterCombustion chamber

The invention provides a coal water slurry gasification furnace for gasifying coal water slurry, which comprises a combustion chamber and a chilling chamber, and is characterized in that: the combustion chamber further comprises a quasi-elliptic large-diameter combustion chamber shell, at least two coal water slurry and oxygen three-channel process nozzle chambers which are symmetrically arrangedat the large diameter of the combustion chamber shell and slightly incline downwards, at least two coal water slurry and oxygen three-channel nozzles which slightly incline downwards and are detachably arranged in each coal water slurry and oxygen three-channel process nozzle chamber and of which the openings face the inside of the combustion chamber, a fireproof brick which is lined in the combustion shell, at least two oxygen nozzle chambers which are positioned at the periphery below each coal water slurry and oxygen three-channel process nozzle chamber and incline upwards, at least two oxygen nozzles which incline upwards and are detachably arranged in each oxygen nozzle chamber and of which the openings face the inside of the combustion chamber, and a combustion chamber slag hole which is formed at the bottom of the combustion chamber, wherein the chilling chamber is arranged on the lower part of the combustion chamber and below the combustion chamber slag hole.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

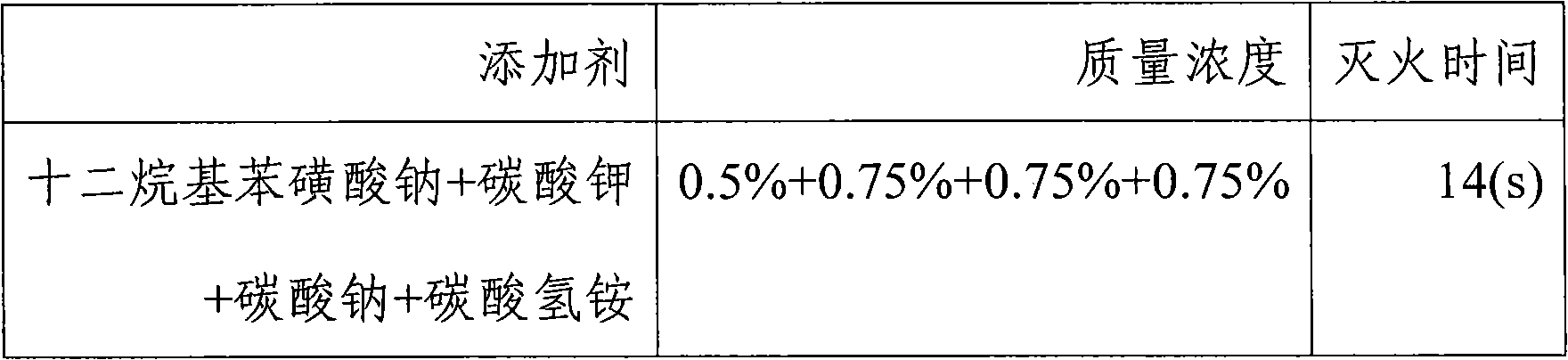

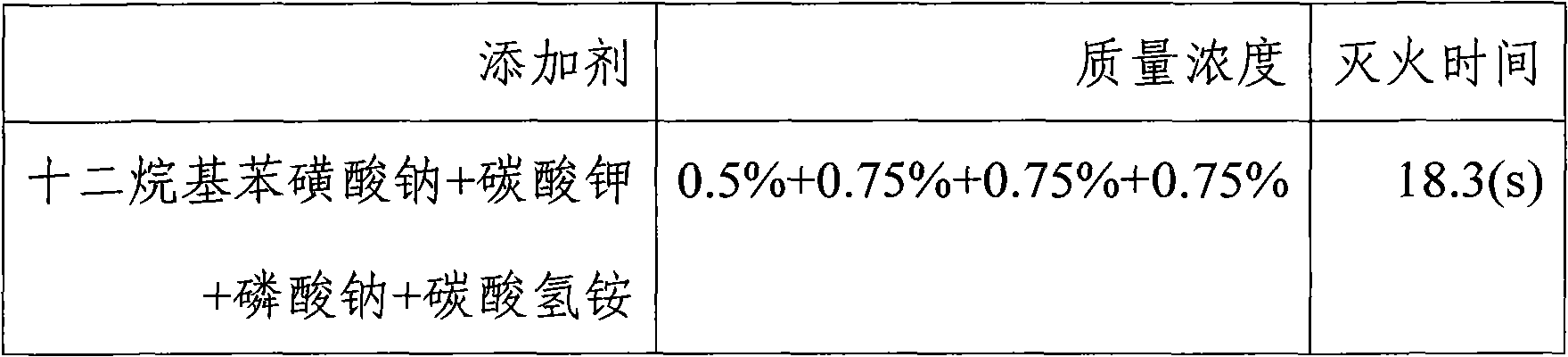

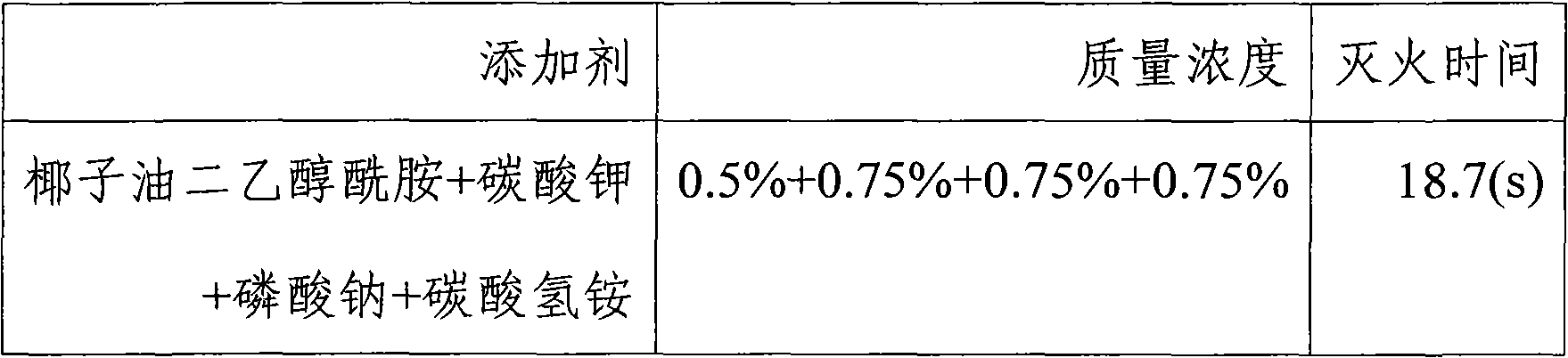

Complex additive used for extinguishment with water mist

InactiveCN102029040ANothing producedNo pollution in the processFire extinguisherSodium lactateSodium phosphates

The invention relates to a compound additive used for extinguishment with water mist, which comprises three kinds of different materials of alkali metal salts, surfactant and diluent according to different action mechanisms of the additive, wherein the alkali metal salts are at least two or a mixture of more of potassium carbonate, sodium carbonate, sodium phosphate, sodium lactate and sodium iodide and account for 1-3 percent of the total mass percent of the additive solution; the surfactant is one or a mixture of sodium dodecyl benzene sulfonate and cocoanut fatty acid diethanolamide and accounts for 0.5-1 percent of the total mass percent of the additive solution; and the diluent is one or a mixture of urea and ammonium bicarbonate and accounts for 0.5-1 percent of the additive solution. The compound additive has simple preparation process, can be rapidly dissolved without adding an organic solvent, has high extinguishment efficiency and no corrosion on extinguishment site equipment, and can be widely applied to water mist extinguishment systems in various occasions and extinguishment occasions.

Owner:BEIHANG UNIV

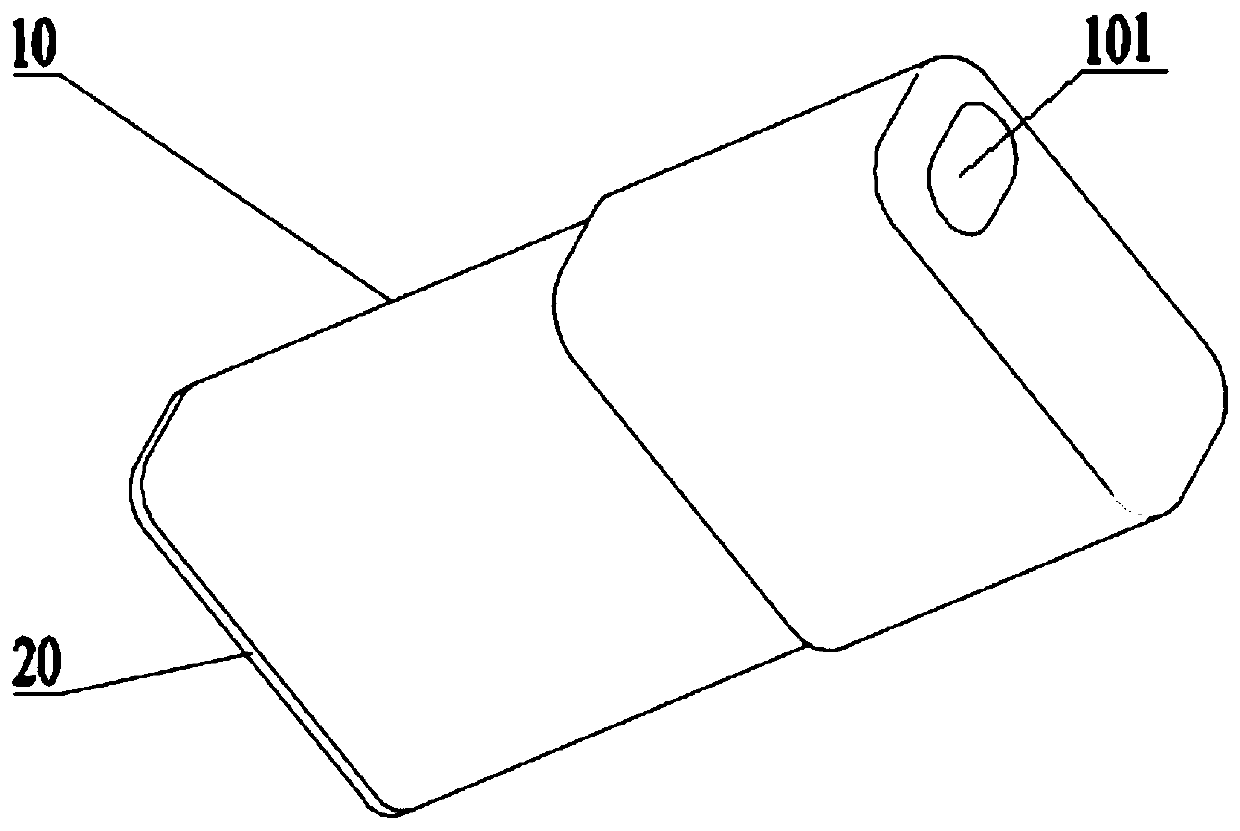

An electronic cigarette atomizer

The invention discloses an electronic cigarette atomizer, which comprises an oil bin, a capillary tube and a suction nozzle. The oil inlet end of the capillary tube is communicated with the oil bin inner cavity, and the oil outlet end of the capillary tube is communicated with the suction nozzle. The oil bin is provided with an air vent which communicates the oil bin inner cavity and the atmosphere, and also comprises a key assembly which can open or close the air vent. A circuit board and a circuit switch assembly for controlling whether a circuit key switch on the circuit board is turned onare also included. The key assembly and the circuit switch assembly are linked, and when the key assembly controls the air vent to open, the circuit switch assembly controls the circuit key switch toturn on; when the key assembly controls the vent to close, the circuit switch assembly controls the key switch to open. As that smoke oil can be quickly and timely supply to the heating component through the capillary tube for atomization, the us is not easy to suck large droplets, the atomization is sufficient, the smoke particles are fine and exquisite, the smoke mouthfeel is good, the smoke amount is large, the oral cavity is not scalded, and the user experience is good.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

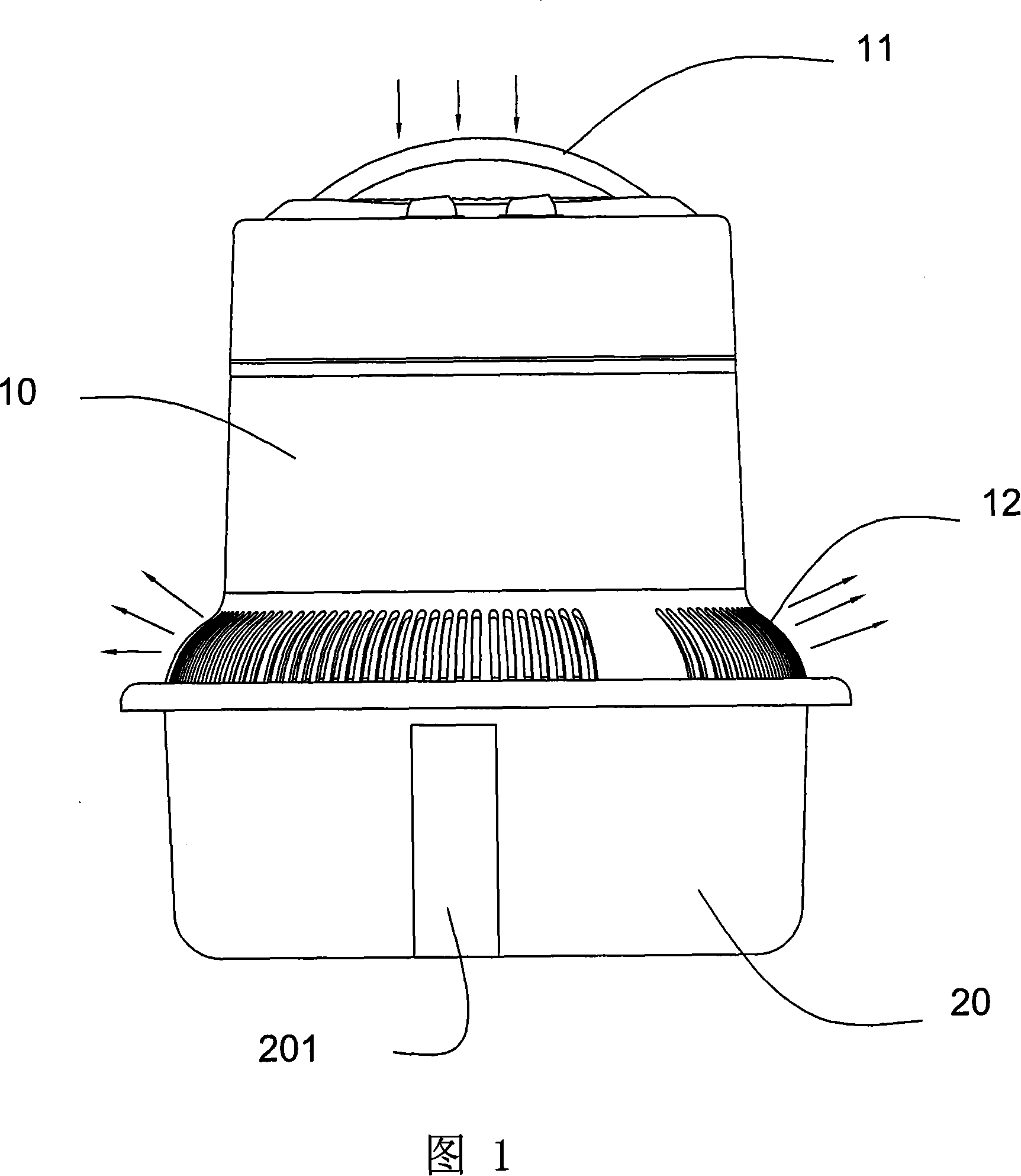

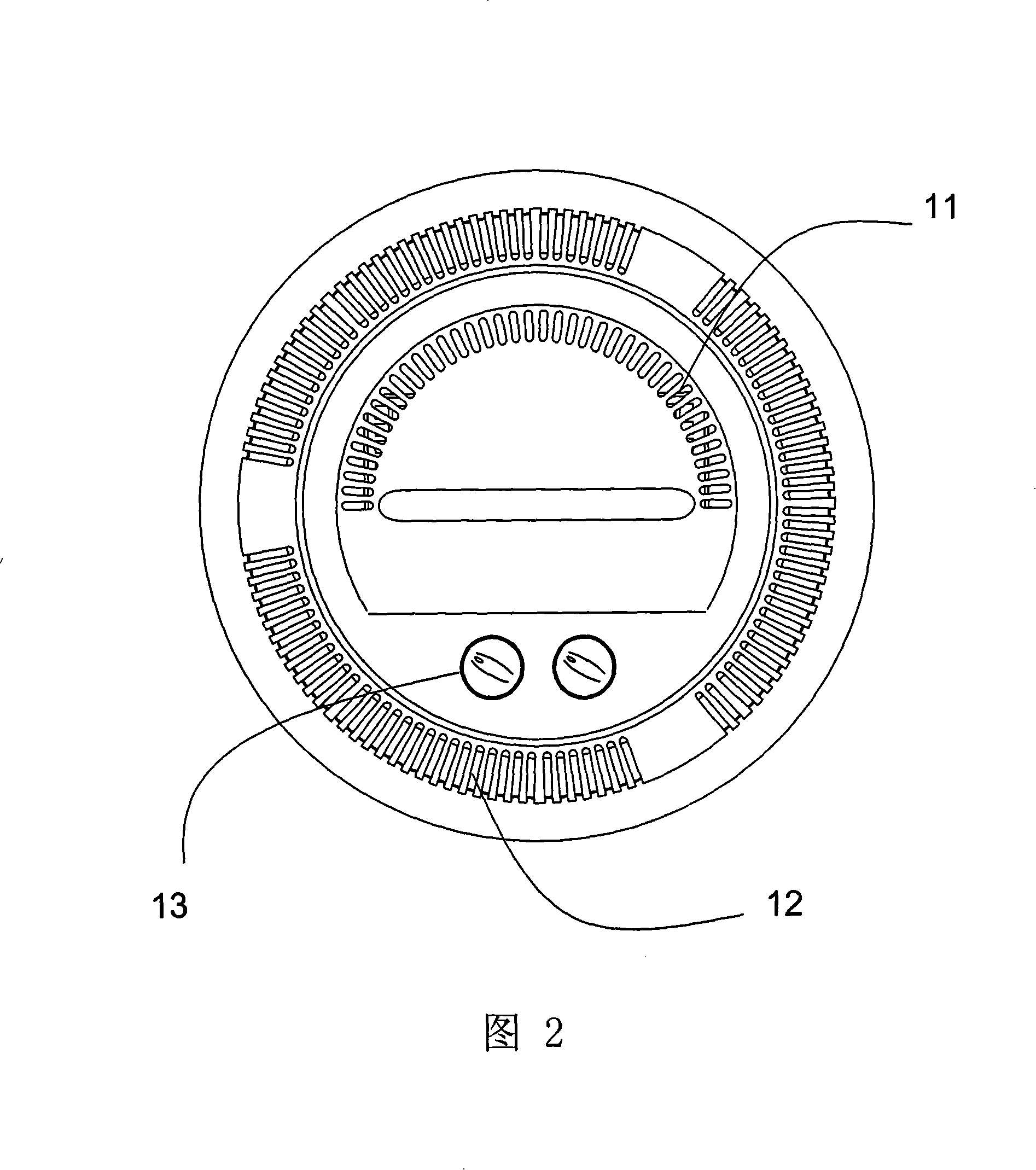

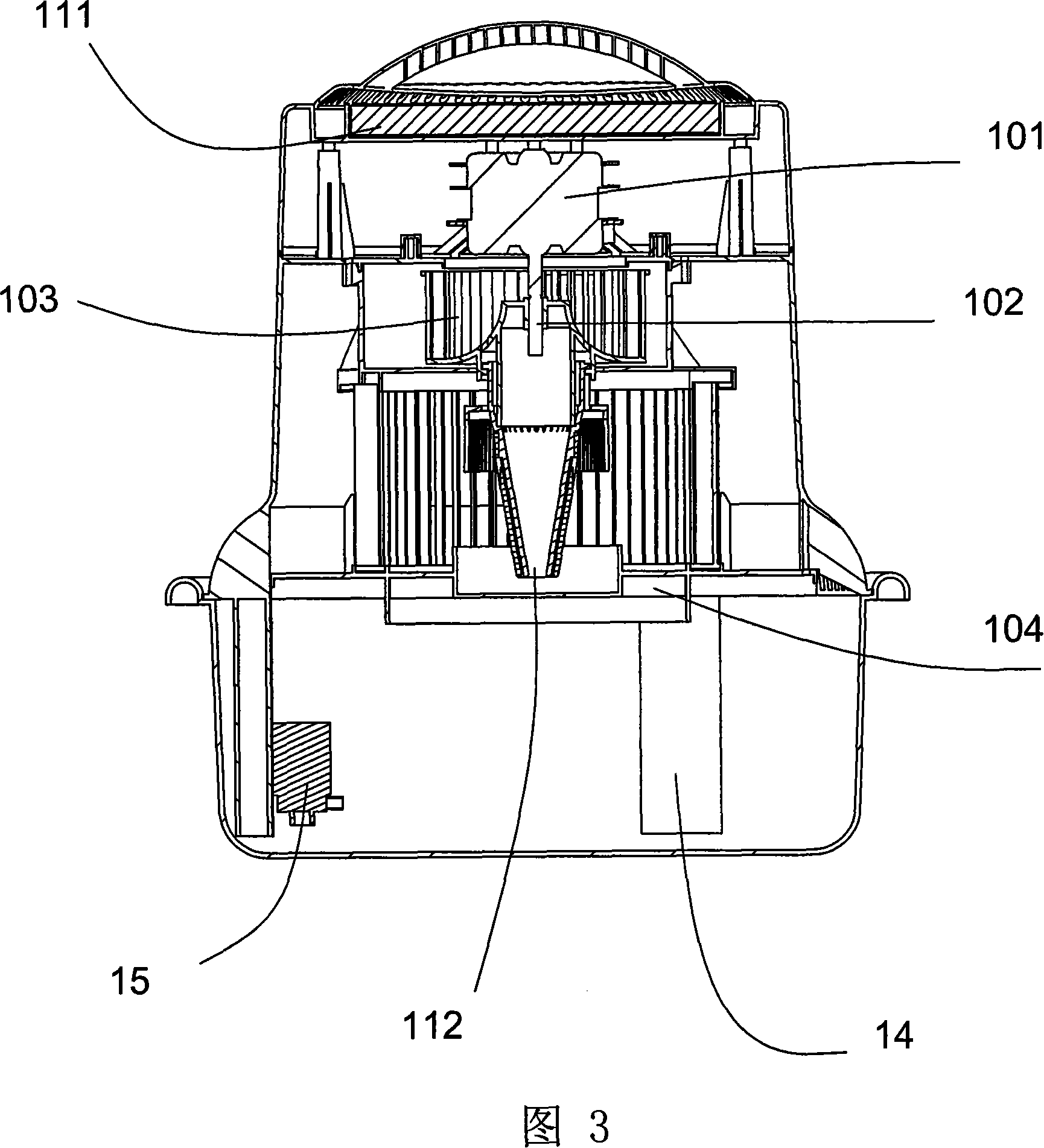

Air humidifying device

ActiveCN101140091AIncrease oxygen contentImprove water absorptionLighting and heating apparatusAir humidification systemsWater qualityEvaporation

The invention relates to an air humidifying device which comprises a machine body provided with an air inlet and an air outlet and a water tank arranged on the lower part of the machine body; the interior of the machine body is provided with a motor, the lower part of the machine body is provided with the water tank, a motor rotation shaft is provided with a centrifugal wind wheel as well as a first top pump and a second top pump arranged on the lower part of the centrifugal wind wheel, the second top pump is arranged on the outer side of the first top pump, the outer side of the second top pump is provided with an evaporation wheel, a pin wheel is arranged between the first top pump and the evaporation wheel, the lower ends of the first top pump and the second top pump commonly use a water drawing opening, and the water drawing opening is embedded into the water tank. Due to the adoption of the two top pumps, the invention increases the water absorbing amount and makes water fully atomized through the two-time crush of the rotary pin wheel and the evaporation wheel, and then the atomized water implements the two-time evaporation mixing with the spiral wind entering a centrifugal wind tunnel, which thereby greatly improves the humidification efficiency; in addition, the invention can make the water in the water tank continuously circulated, which increases the oxygen content of the water in order to keep the clean water quality for a long time.

Owner:MIDEA GRP CO LTD

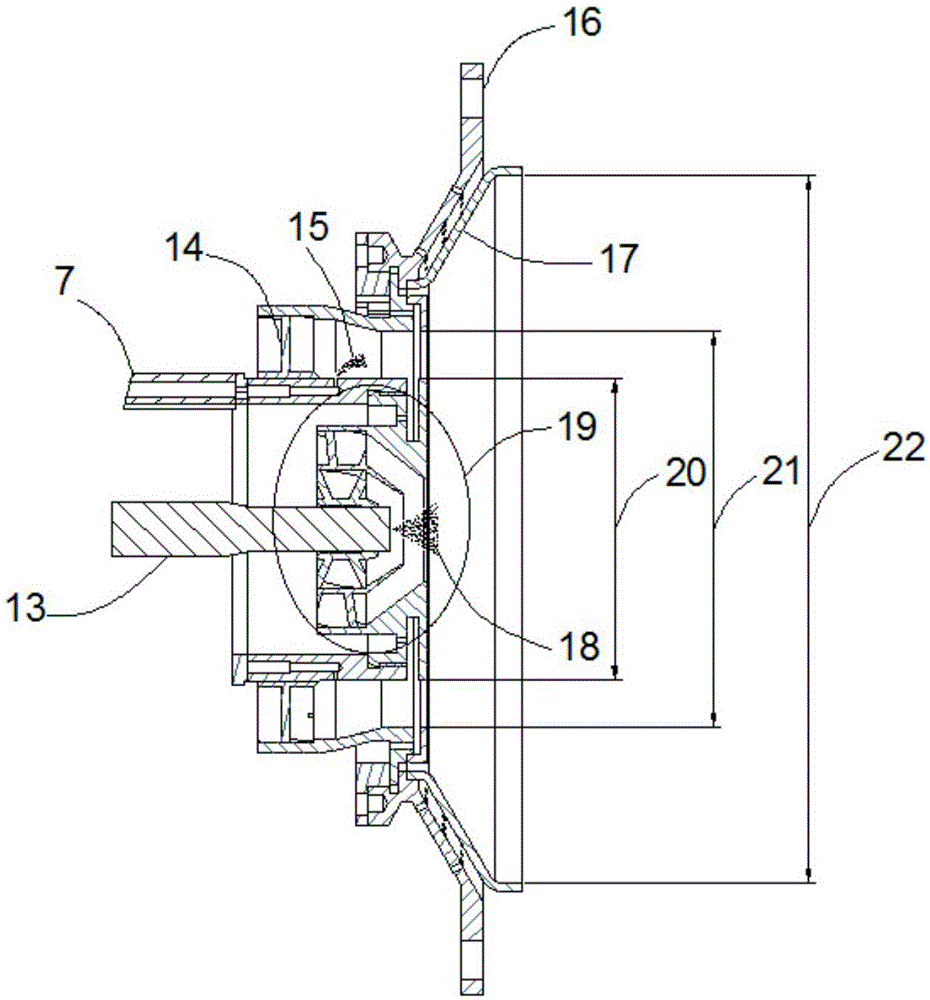

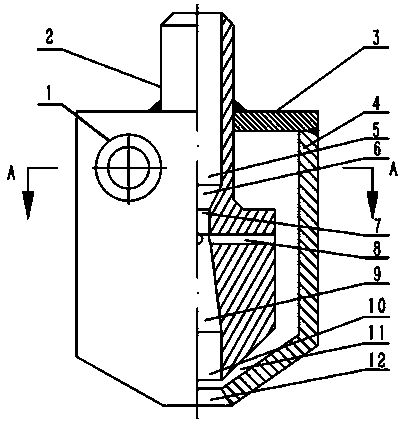

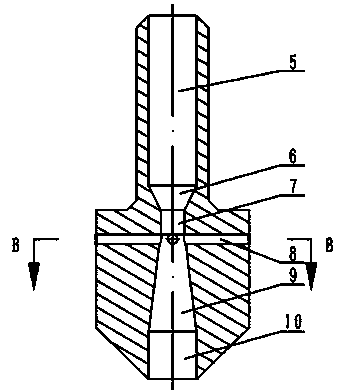

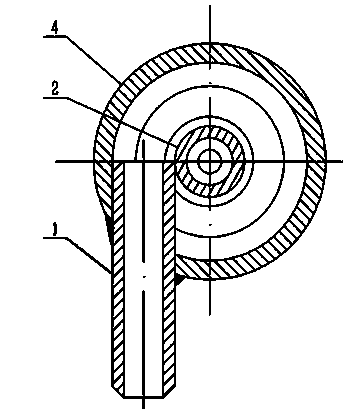

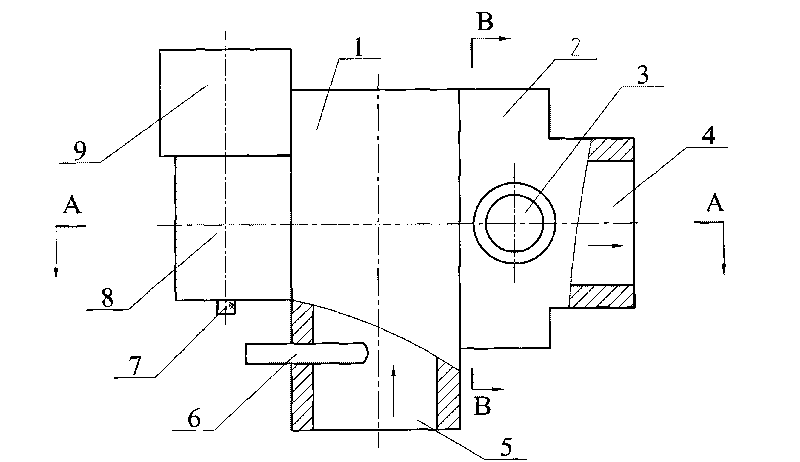

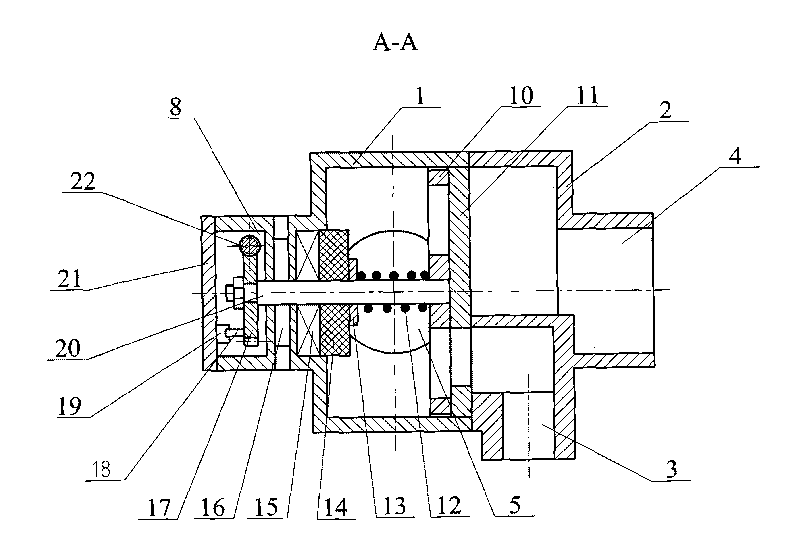

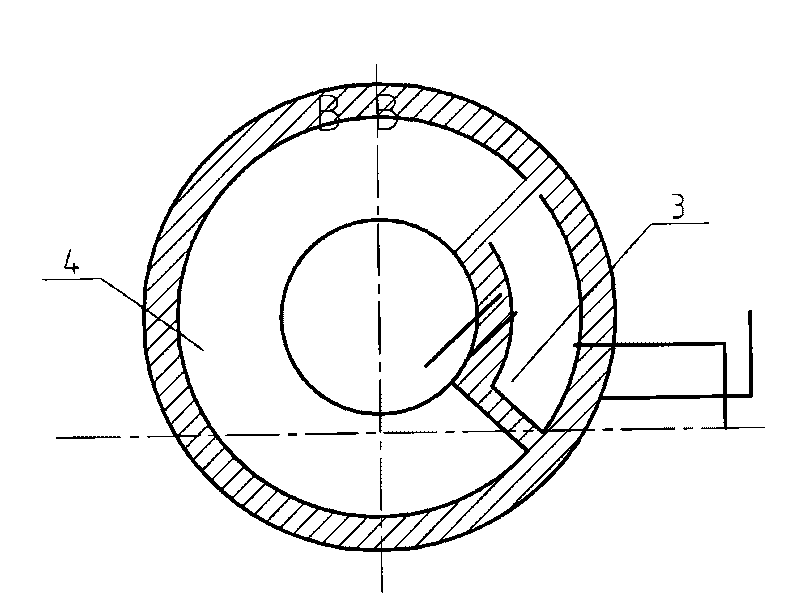

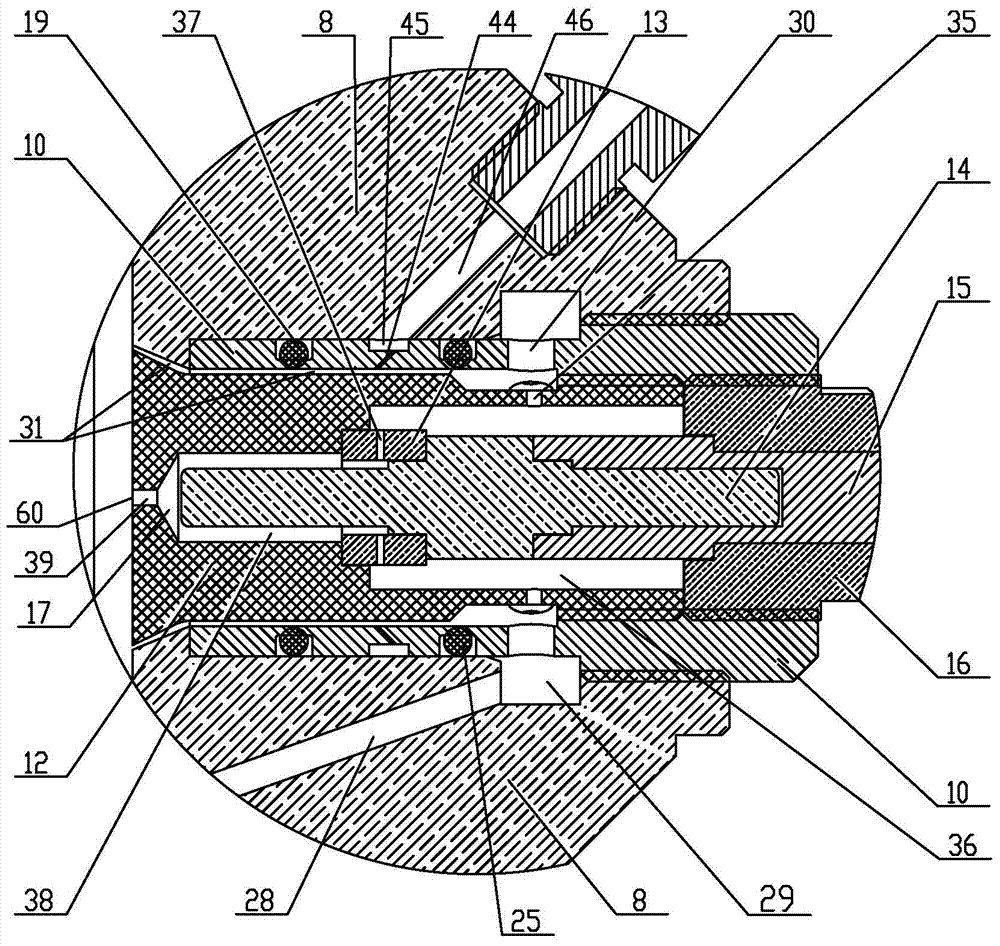

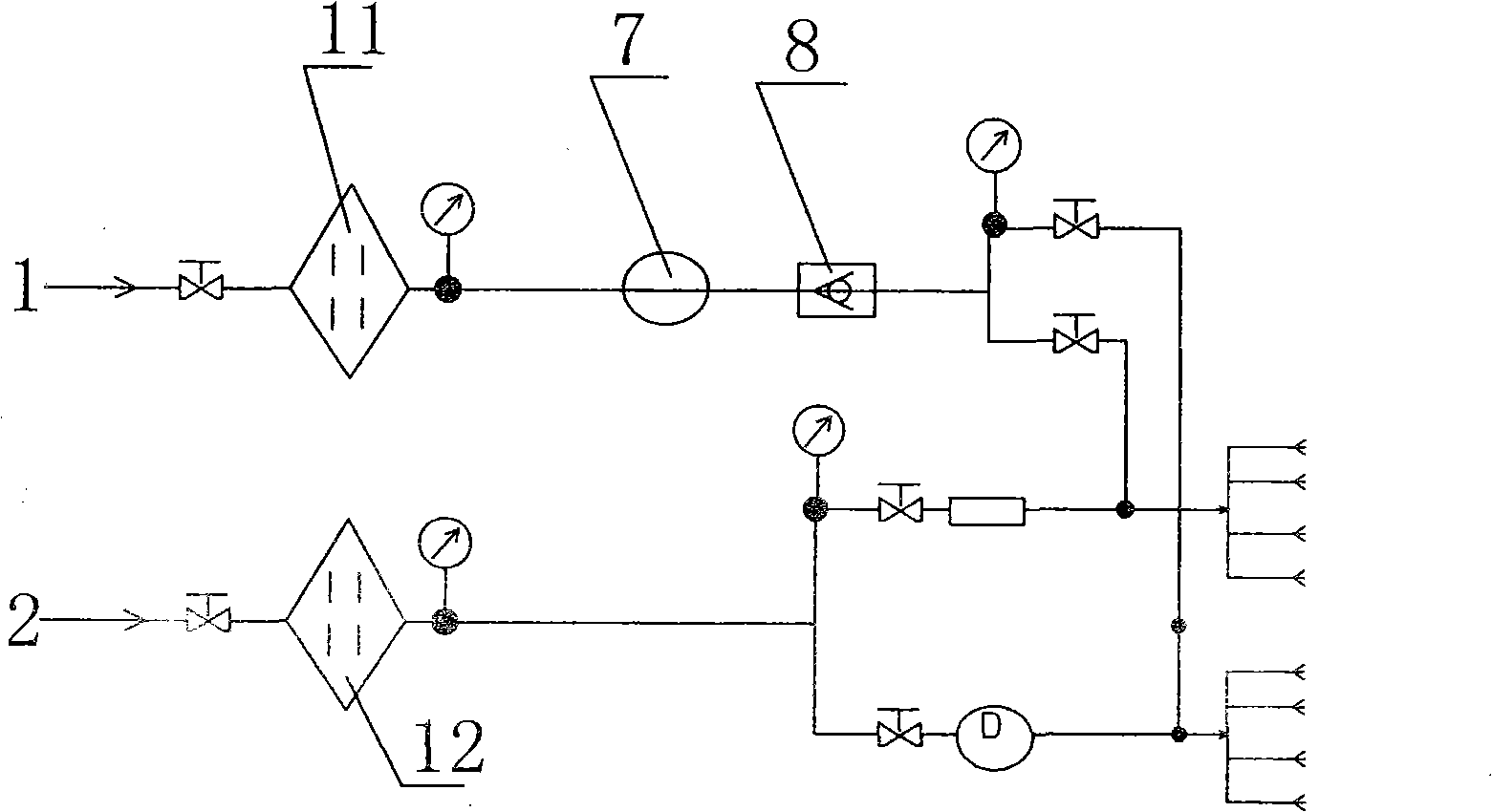

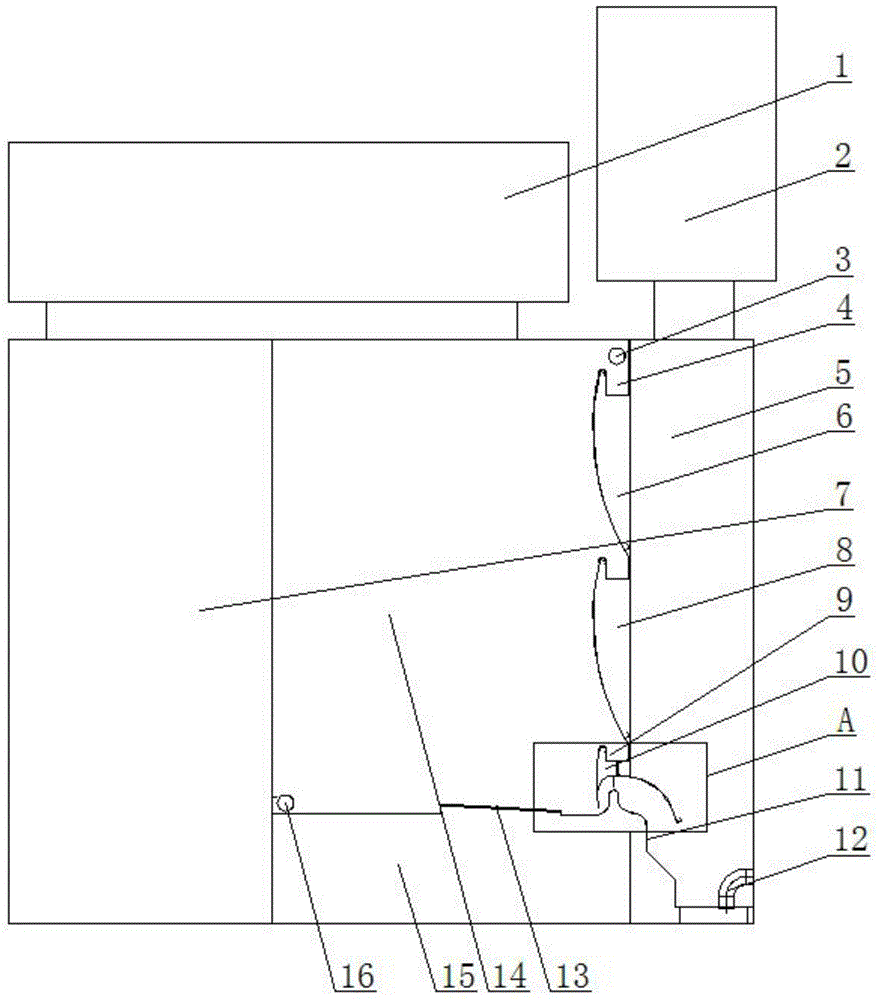

Temperature controller of engine

InactiveCN101737144ABurn fullyFully atomizedCoolant flow controlMachines/enginesTemperature controlAutomatic control

The invention relates to an improved temperature controller of an engine, which can solve the problems that the structure for regulating and controlling the working temperature of the engine in the prior art is poor and can not achieve the ideal requirements. The temperature controller comprises a valve body, a worm gear shaft assembled on the valve body, a temperature control actuating mechanism for controlling a large circulation loop and a small circulation loop of coolant and an automatic control loop for the large circulation loop and the small circulation loop of the coolant, and the automatic control loop mainly consists of a micro-computer control mechanism. The technical key points are as follows: the I type temperature control actuating mechanism is directly driven by utilizing the worm gear shaft, or the II type temperature control actuating mechanism is driven by utilizing the worm gear shaft and a rack shaft which is arranged on the worm gear shaft and meshed with a gear, thereby controlling the large circulation loop and the small circulation loop of the coolant respectively. The structural design is reasonable, and the regulation and the control are accurate and reliable, thereby always keeping the engine at the optimal working temperature state when running under any climate and environment, obviously improving the running performance of the engine, further reducing the fuel consumption, reducing the harmful gas emissions, fully improving the capability of outputting the power of the engine and prolonging the service life of the engine.

Owner:梁国胜

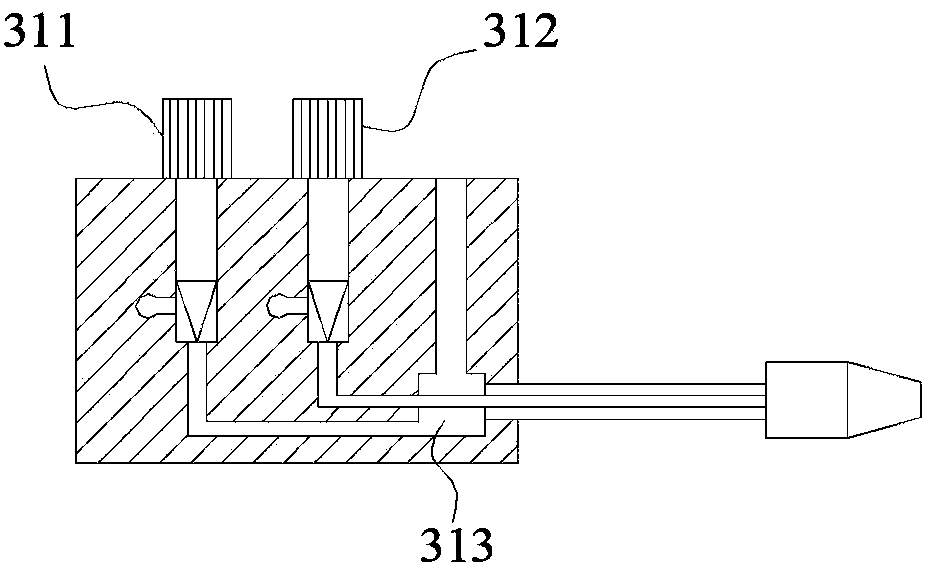

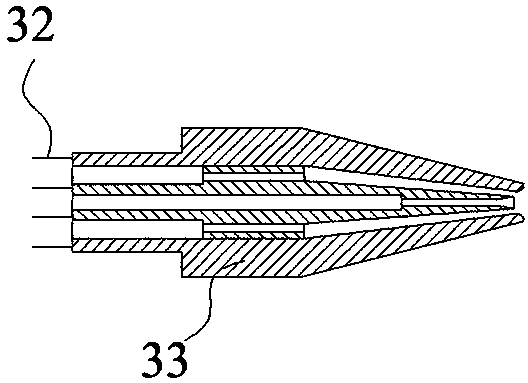

Tool box for pneumatic cutting lubrication and method for calibrating and adjusting supply quantity

ActiveCN103831664AFully atomizedHigh speed jetMaintainance and safety accessoriesEngineeringPressure reduction

The invention discloses a tool box for pneumatic cutting lubrication and a method for calibrating and adjusting a supply quantity. The tool box comprises a box body, a box cover, an injection device and a hose bundle, and is characterized in that the box body comprises a cutting air source adjusting loop for cutting air supply and a trace composite injection loop providing cutting lubrication, the trace composite spray loop comprises an air injection branch pipe, a lubrication branch pipe, a cooling branch pipe and the like, and the tool box can carry out on-off control over oil, water and air and adjust the supply quantity. When the tool box is used for calibrating and adjusting the supply quantity, the supply quantity of oil liquid can be adjusted through the method of fixing an oil path adjusting needle valve at a certain position firstly and then adjusting a pressure reduction valve of the lubrication branch pipe. The supply quantity of the water can be adjusted through the method of fixing a pressure reduction valve of the cooling branch pipe at a certain position firstly and then adjusting an adjusting needle valve of a water path. The tool box has the advantages of being simple in structure, high in integration degree, convenient to adjust, stable in supply, good in lubrication effect, convenient to carry and the like.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

High-speed gas-electric arc composite thermal spraying method and spray gun used in same

ActiveCN104498862AReduces severe oxidation problemsQuality improvementMolten spray coatingLiquid spraying apparatusKeroseneSpray coating

The invention discloses a high-speed gas-electric arc composite thermal spraying method and a spray gun used in the same. The thermal spraying method comprises the following steps: igniting an annular high-speed jet oil-gas mixed flow obtained by mixing kerosene and compressed air by virtue of an air plasma ignition manner; continuously burning the oil-gas mixed flow fully, accelerating to form a supersonic gas and then spraying to a wire material; and electrifying the wire material for arc starting and melting, atomizing and accelerating the wire material under the action of the supersonic gas jet flow, and depositing on the surface of a to-be-sprayed part to form a coating layer. On the basis of the thermal spraying method disclosed by the invention, the wire material subjected to arc melting can be used for realizing efficient spraying on the surface of the to-be-sprayed part under the action of the low-oxygen-content supersonic gas formed when the compressed air supports the combustion of kerosene, and an obtained spray coating layer is good in quality.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Environmental-protection diesel oil and preparation method thereof

InactiveCN103980959ASolve the reuse problemReduce generationLiquid carbonaceous fuelsOil and greaseVegetable oil

The invention discloses environmental-protection diesel oil and a preparation method thereof. The diesel oil is prepared from the following components by weight percentage: 12-20% of vegetable oil and fat, 30-60% of a distilled waste oil extraction liquid, 15-30% of fusel oil, and 15-30% of raffinate oil. The preparation method comprises the steps: metering the mass ratios of various raw materials, mixing and stirring, metering and pumping into a normal-temperature and normal-pressure vessel, cycling for 2-3 times through a high-shear emulsifying mixer, standing overnight, and filtering to obtain the product. The environmental-protection diesel oil has the advantages that the diesel oil makes full use of waste resources and renewable energy sources, can ease exploitation and consumption of petroleum resources, is wide in raw material sources, low in cost, good in economic benefits, rich in oxygen, good in combustion performance, complete and full in combustion, high in thermal efficiency and low in sulfur content, has a few of exhaust gas emission pollutants reduces machine corrosion and sulfide emissions, and can be widely applied in the application fields of transport vehicles, ships, engineering machinery halls and the like adopting the petroleum diesel oil.

Owner:宁海鹏静再生资源科技有限公司

Double-atomization capturing electrostatic paint spray booth

InactiveCN104437949AImprove capture abilityLarge specific surface areaLiquid surface applicatorsSpraying apparatusSpray nozzleWater curtain

The invention relates to a double-atomization capturing electrostatic paint spray booth which comprises an electrostatic paint spray booth. An electrostatic spray nozzle is mounted in the electrostatic paint spray booth, a main water curtain plate and side water curtain plates are arranged on the inner wall of the electrostatic paint spray booth, a steam-water separation chamber is connected to the back of the main water curtain plate of the electrostatic paint spray booth, a bevel flushing plate is arranged on the lower portion of the main water curtain plate, the electrostatic paint spray booth is communicated with the steam-water separation chamber via a double-atomization paint mist capturing structure which is connected with the lower end of the bevel flushing plate, and a bottom plate flow guide structure is arranged at the bottom of the electrostatic paint spray booth. The double-atomization capturing electrostatic paint spray booth has the advantages that the double-atomization capturing electrostatic paint spray booth is simple in structure, scientific and reasonable in design, low in cost and high in paint mist capturing efficiency, and follow-up environmental protection treatment load can be effectively reduced.

Owner:赛智环保科技(天津)有限公司

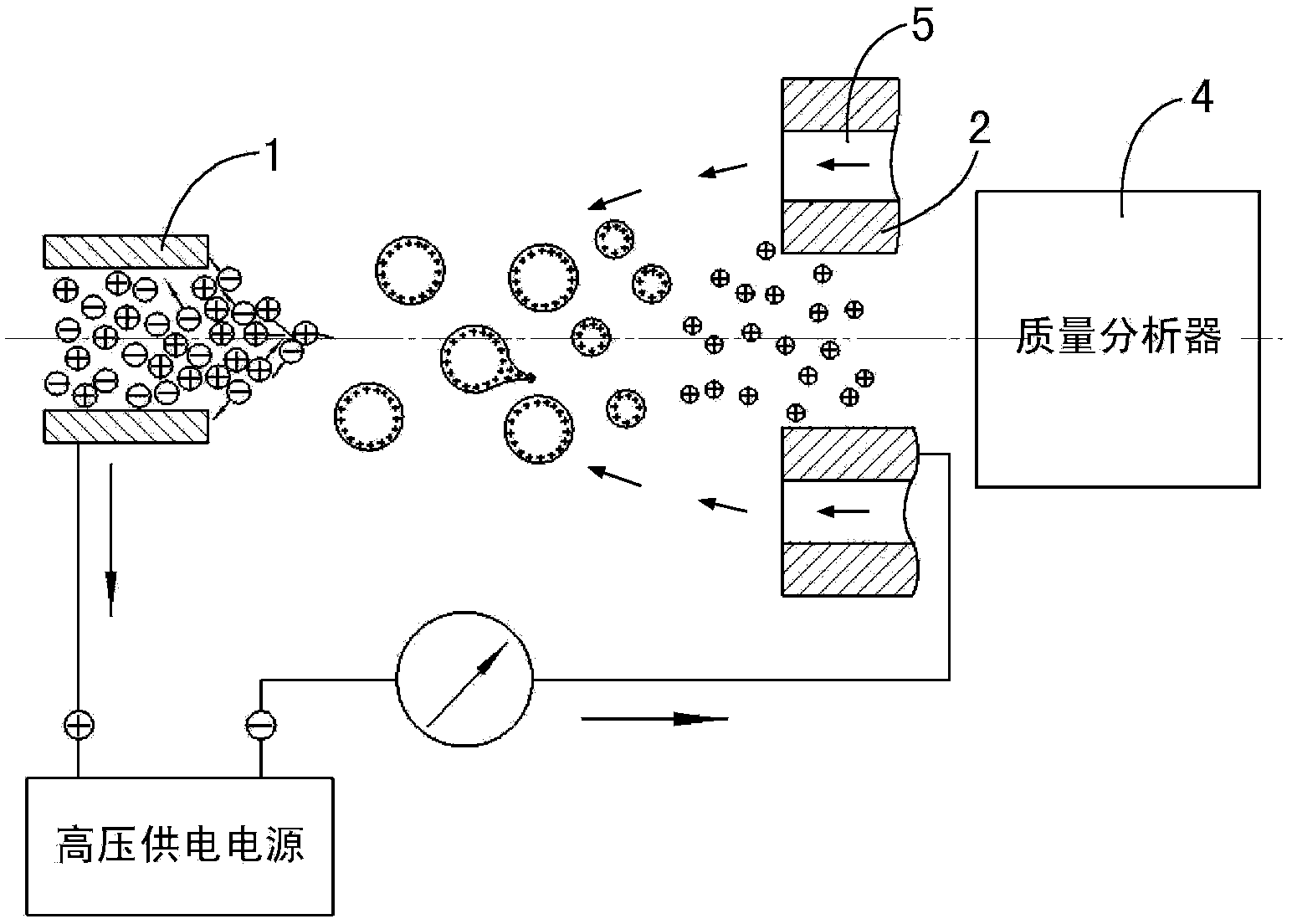

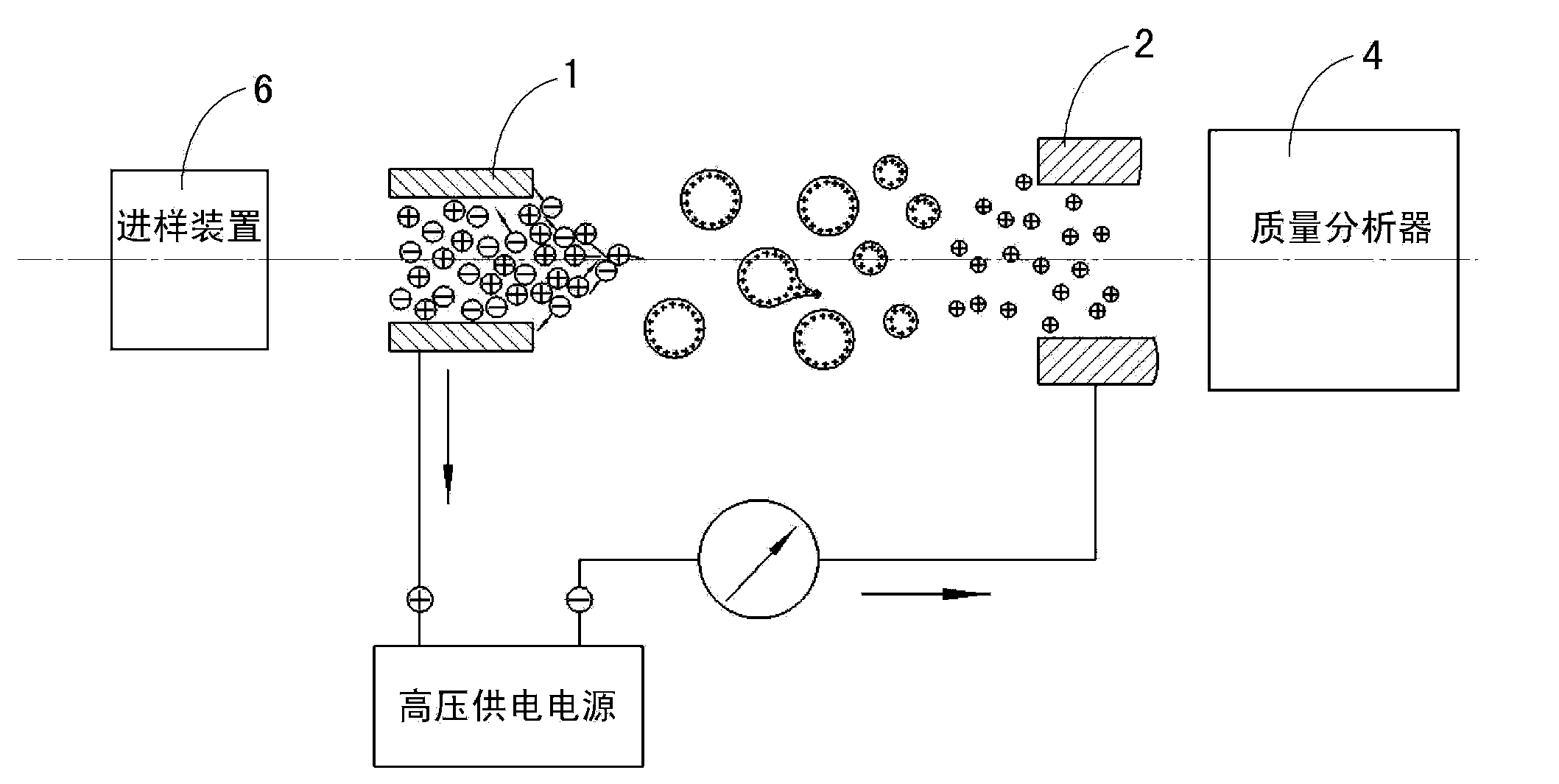

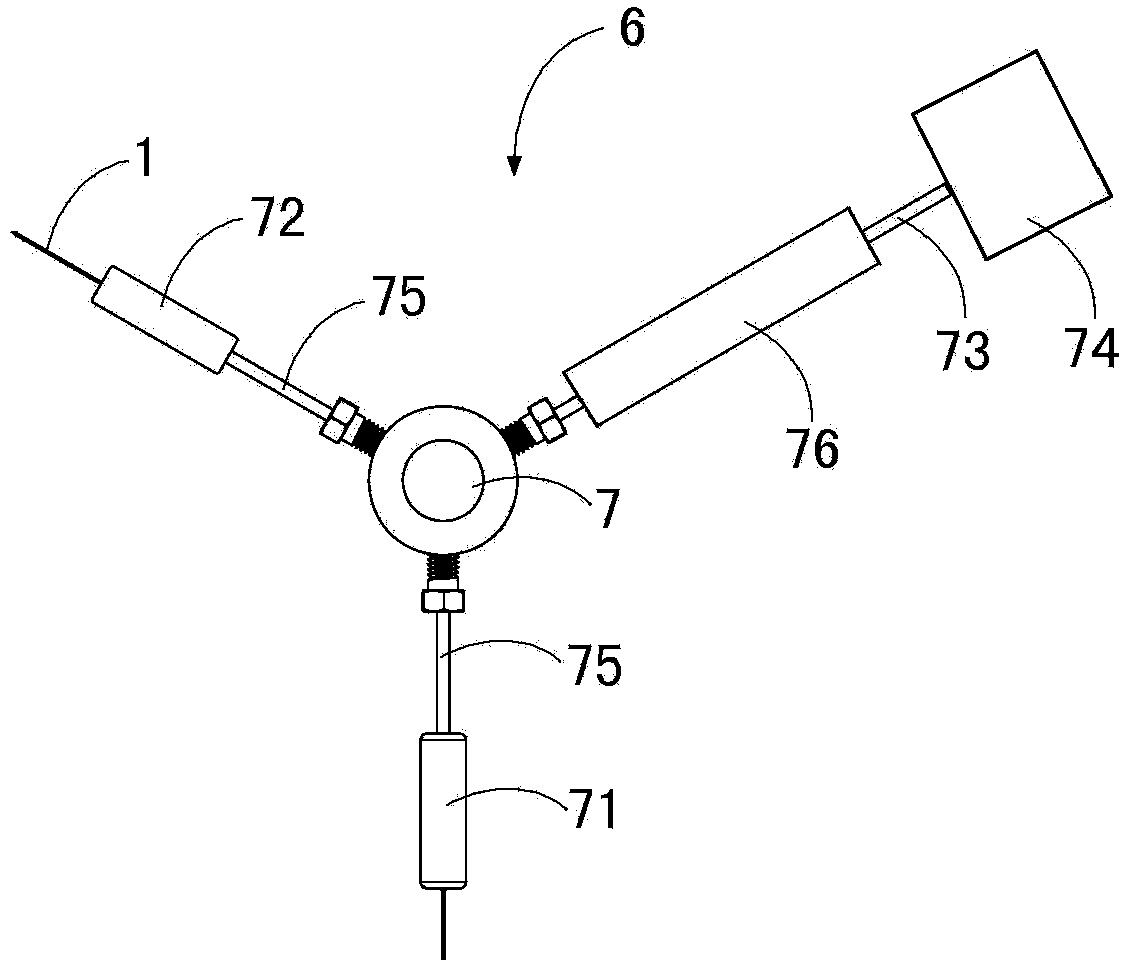

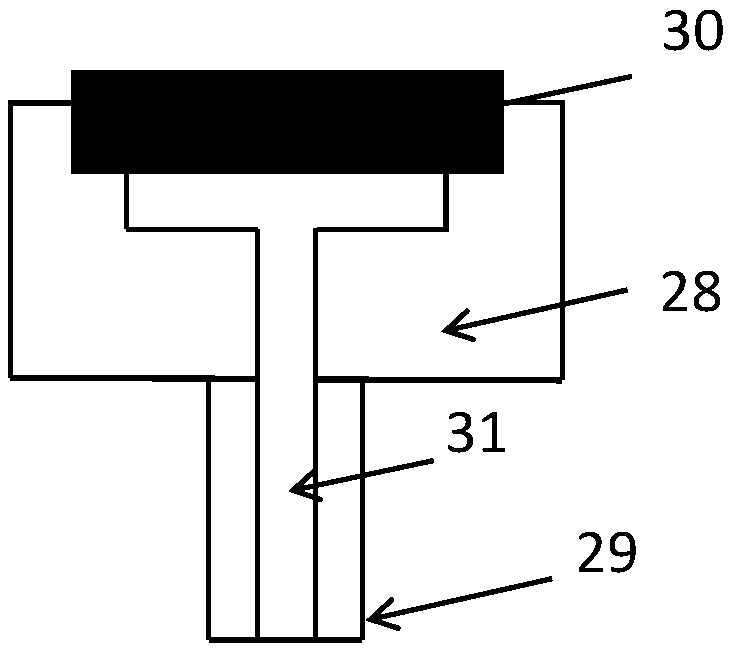

Mass spectrum ion source and mass spectrometer

InactiveCN104124131AFully atomizedComplete atomizationSamples introduction/extractionIon sources/gunsElectricityMass analyzer

The invention provides a mass spectrum ion source and a mass spectrometer. The mass spectrum ion source includes a sampling device, a spray needle and a capillary pipe. The sampling device includes a T-junction, and a liquid sample inlet pipe, a liquid sample outlet pipe and a waste-liquid pipe, which are connected to the T-junction, and a constant-pressure valve installed at the waste-liquid pipe. The spray needle enables a liquid sample to become charged ions through an electrospray process. The capillary pipe guides the charged ions to a mass analyzer. When the quantity of the liquid sample which enters the T-junction via the liquid sample inlet pipe is overly large, the constant-pressure valve is started so that redundant liquid sample flows out from the waste-liquid pipe and thus the pressure and flow of the liquid sample outlet pipe are maintained at set values. In the mass spectrum ion source and mass spectrometer, the flow rate of only a specific quantity of liquid sample which enters the spray needle via the liquid sample outlet pipe is constant without changing with the flow rate of the injected sample. Therefore, the spray needle is kept at an optimal flow rate, an atomization effect is great and charged ions which are smaller in size can be formed without using an atomized gas or a blowback gas and thus the use cost of the mass spectrum ion source is low.

Owner:BEIJING PURKINJE GENERAL INSTR

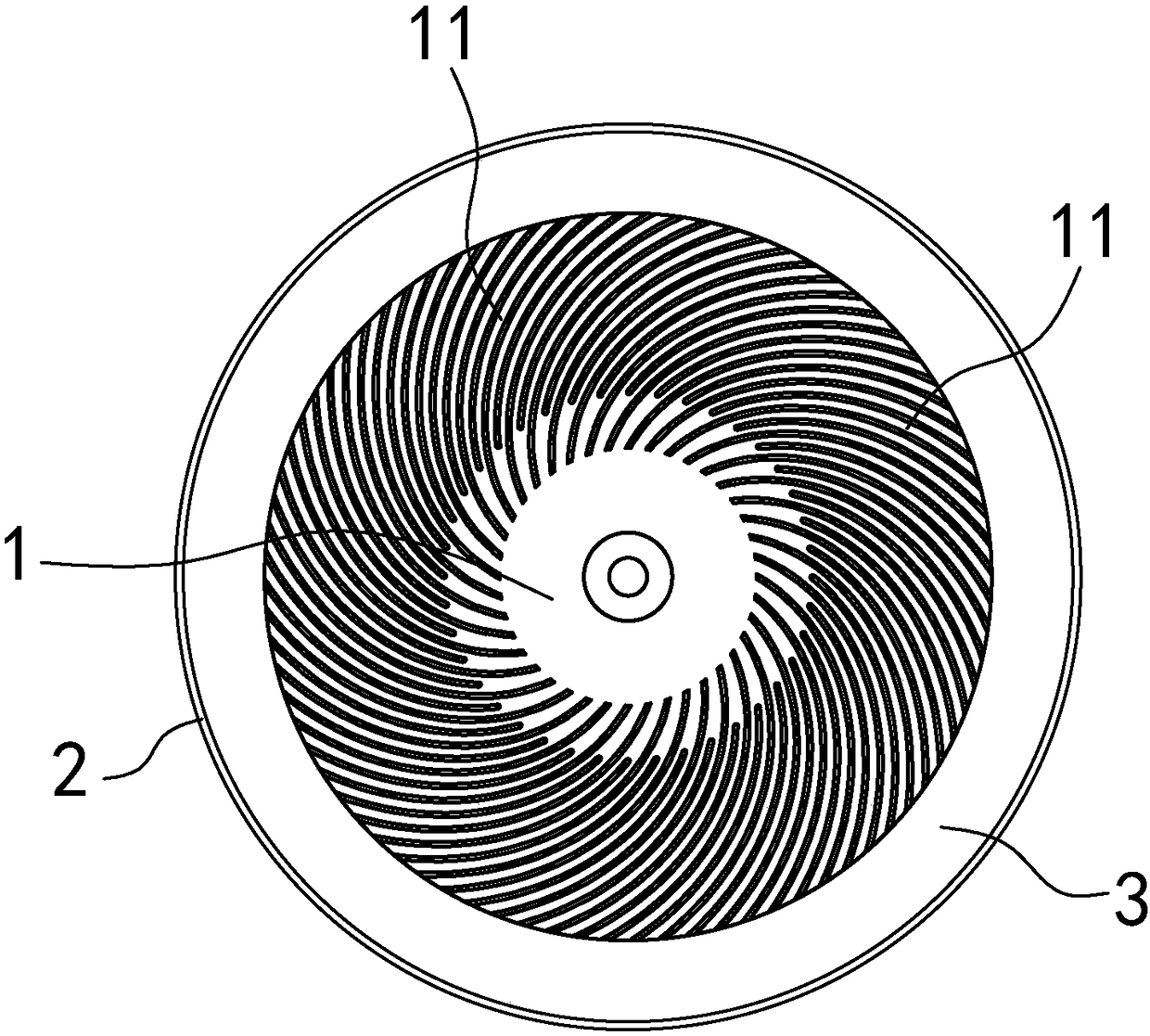

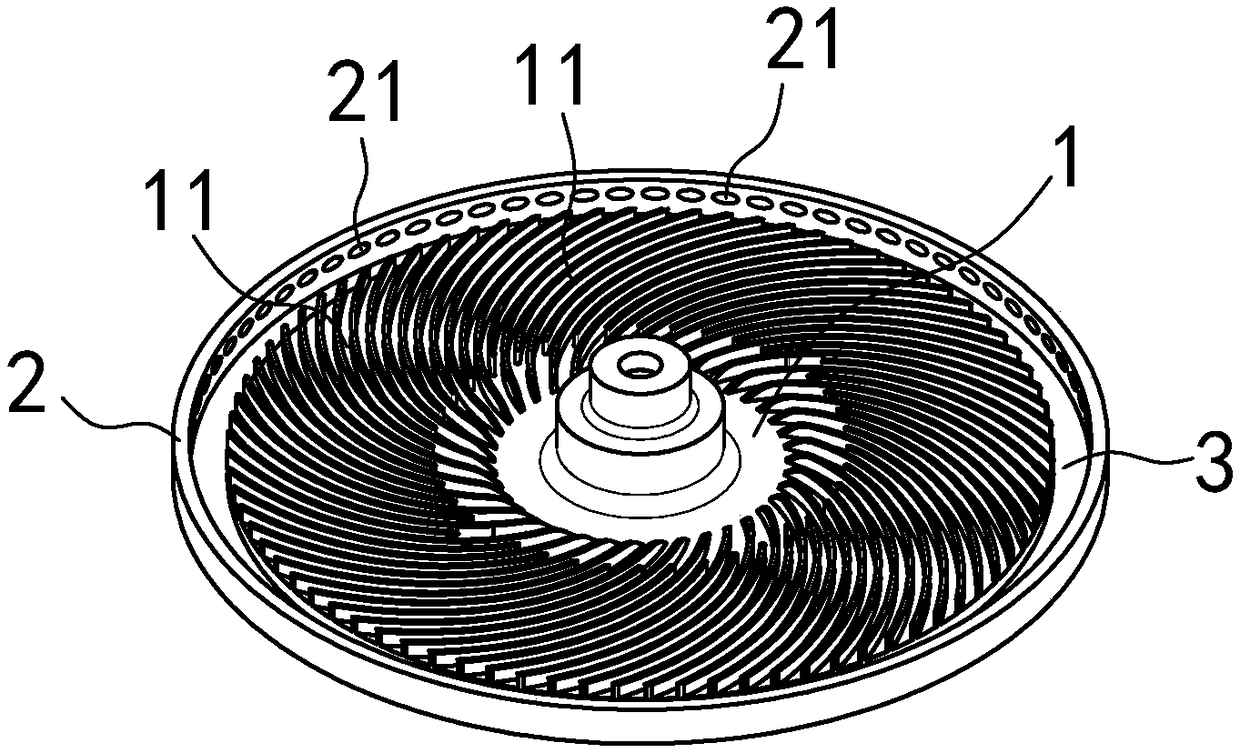

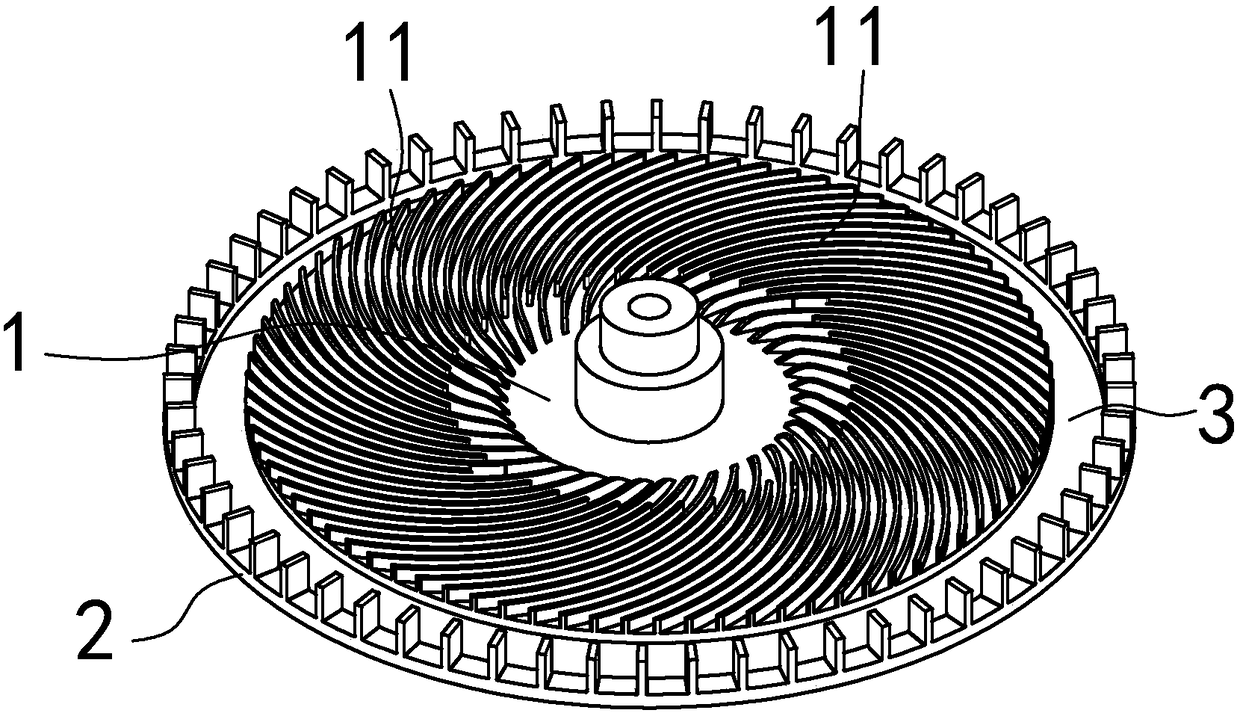

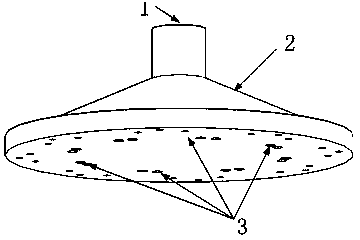

Centrifugal atomizing device

PendingCN108568358AIncrease speedSpeed does not need to be increasedMovable spraying apparatusWind fieldEngineering

The invention discloses a centrifugal atomizing device which comprises a centrifugal atomizing disc, wherein multiple diversion trenches are formed in the centrifugal atomizing disc. The centrifugal atomizing device is characterized in that a ring body is arranged on the outer side of the centrifugal atomizing disc; the ring body and the centrifugal atomizing disc are coaxial with each other and are rotationally arranged relative to each other; a spacing is formed between the ring body and the centrifugal atomizing disc in a radial direction; the centrifugal atomizing disc rotates at the periphery to form a positive wind field; the positive wind field rotates clockwise and anticlockwise around the center of the centrifugal atomizing disc; the ring body provides a reverse wind field betweenthe ring body and the centrifugal atomizing disc in an operating state; and the reverse wind field weakens or reverses the positive wind field, so that an accelerated wind zone is formed between thecentrifugal atomizing disc and the ring body. Therefore, the relative velocity of liquid drops and air is increased, and the aim of multiplying the atomizing effect is achieved.

Owner:SUZHOU EAVISION ROBOTIC TECH CO LTD

Device and method for preparing spherical metal powder for 3D printing

The invention provides a device and method for preparing spherical metal powder for 3D printing. The device for preparing the spherical metal powder comprises a shell, a crucible and a collecting bin,wherein the crucible is arranged in the shell, and the collecting bin is arranged on the lower portion of the shell. The device for preparing the spherical metal powder for the 3D printing is characterized in that a rotating disc arranged in a powder collection area is of a inlaying structure, materials with poor thermal conductance are selected as a substrate part of the rotating disc, metal materials with a wetting angle less than 90 degrees with liquid drops are selected to be inlayed into a main part to be used as an atomized plane, and a ventilation hole is formed in the rotating disc. The invention further discloses a method for preparing the spherical metal powder for the 3D printing, a pulse microporous injection method and a centrifugal atomization method are mainly combined, a rotating disc structure is matched, and the surface of the rotating disc is subjected to induction heating, so that molten metal breaks through a split mode of traditional molten metal, a fibrous splitmode which can be realized only when an atomization medium is an aqueous solution or an organic solution is realized, high melting point metal powder which meets requirements is prepared, the particle size is fine and grain size is controllable, the sphericity is high, no satellite droplet is achieved, the mobility and the spreadability are good, and the preparation method is suitable for industrialized production.

Owner:DALIAN UNIV OF TECH +1

Descending naphtholite catalytic cracking method

A down-flow catalytic cracking process for hydrocarbon oil includes such steps as spraying the raw hydrocarbon oil in an reactor by nozzle, atomizing in atomizing chamber, contacting with catalyst, reacting in reaction pipe, quick separating of oil mixture, introducing the oil gas to the followed separation system, and stripping and regenerating the used catalyst for cyclic use. It can increase the conversion power of heavy oil and improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Micron-level powder material sieving equipment and sieving method

ActiveCN102430520ASimple structureReduce manufacturing costGas current separationProcess engineeringMaterials science

The invention relates to the technical field of sieving equipment, in particular to micron-level powder material sieving equipment and a sieving method thereof. The micron-level powder material sieving equipment comprises an air supply device, a material collecting device and an airflow pipeline arranged between the air supply device and the material collecting device; the air supply device is connected with a feeding device; the position of the airflow pipeline near the material collecting device is provided with a sieve screen slot; the sieve screen inserting slot is arranged obliquely; theinclined angle is 20-80 degrees; the sieve screen inserting slot is provided with a sieve screen inserting plate which is matched with the sieve screen inserting slot; a sieve screen is detachably paved on the sieve screen inserting plate; and the position of the airflow pipeline near the lower end of the sieve screen inserting slot is provided with a coarse material outlet. According to the invention, the airflow and powder materials are mixed uniformly, and the powder materials are fully atomized; moreover, the micron-level powder material sieving equipment has the characteristics of simplified technique, low production cost, high sieving efficiency, good sieving effect, high efficiency, energy saving, and convenience for widespread popularization and application.

Owner:李文胜

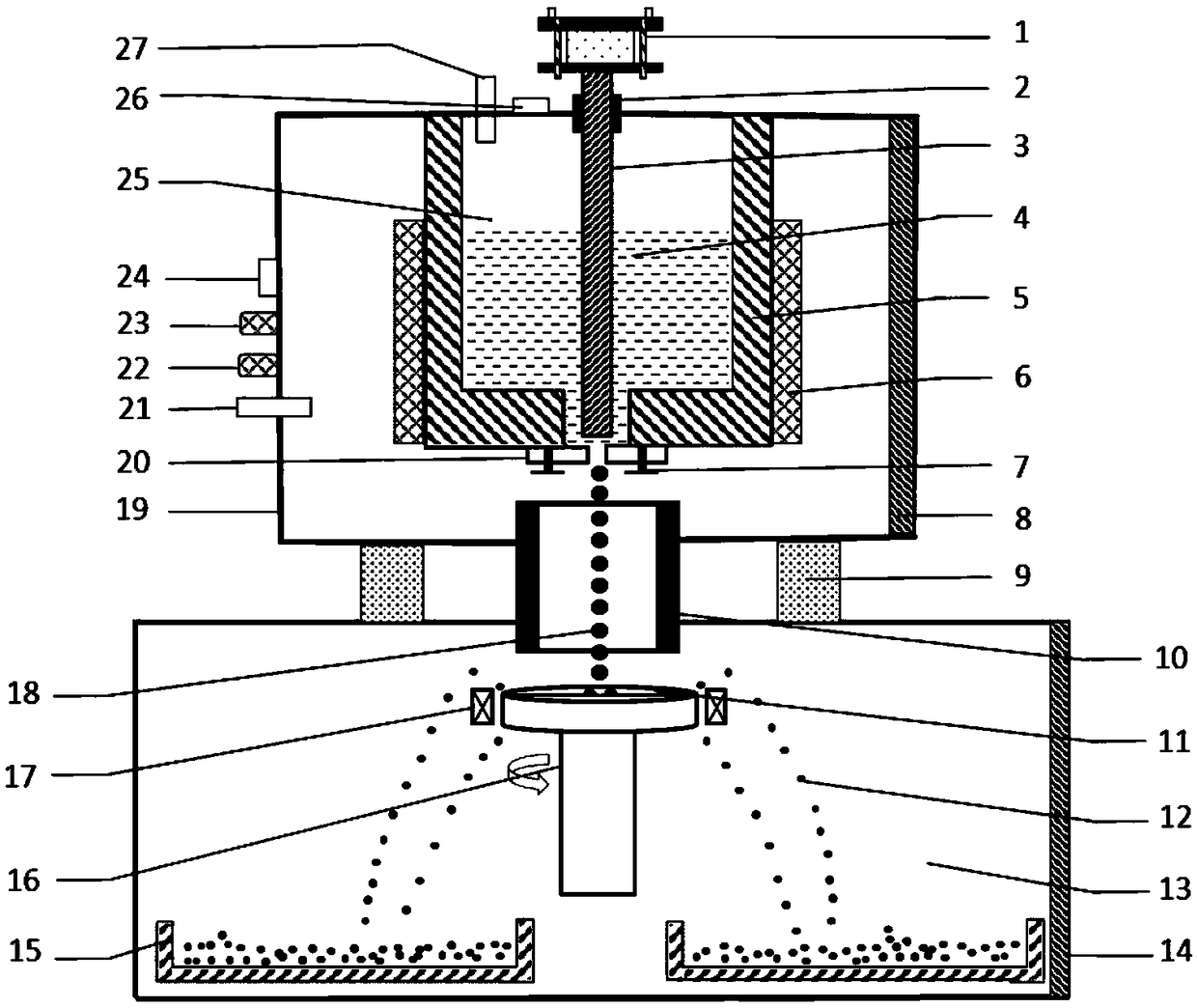

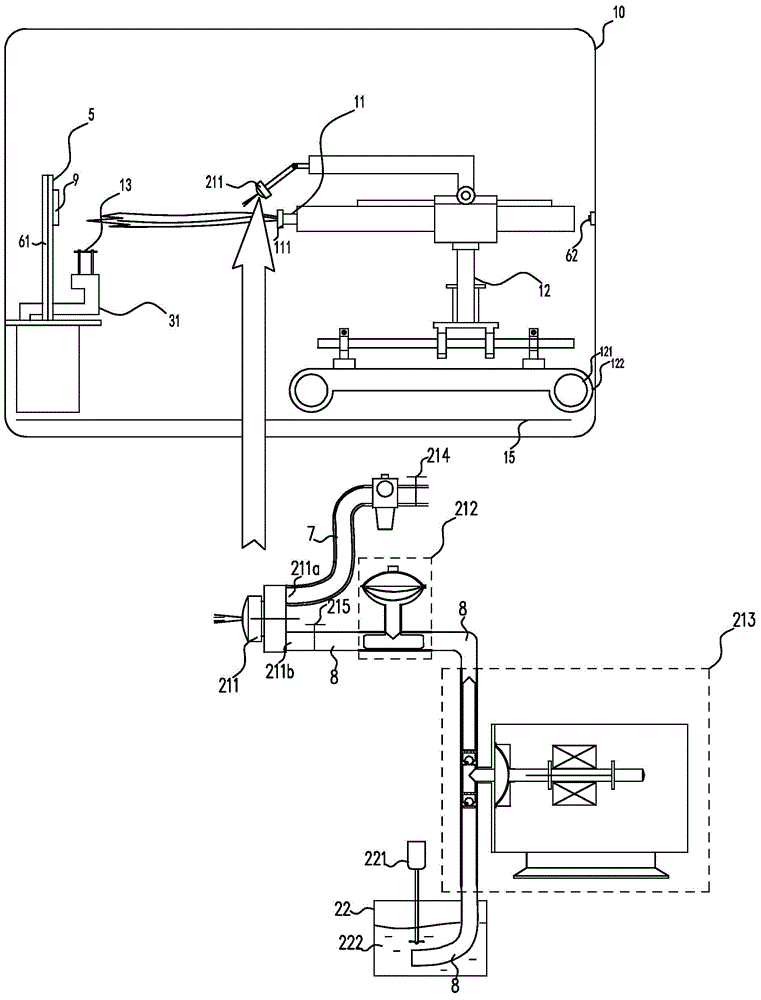

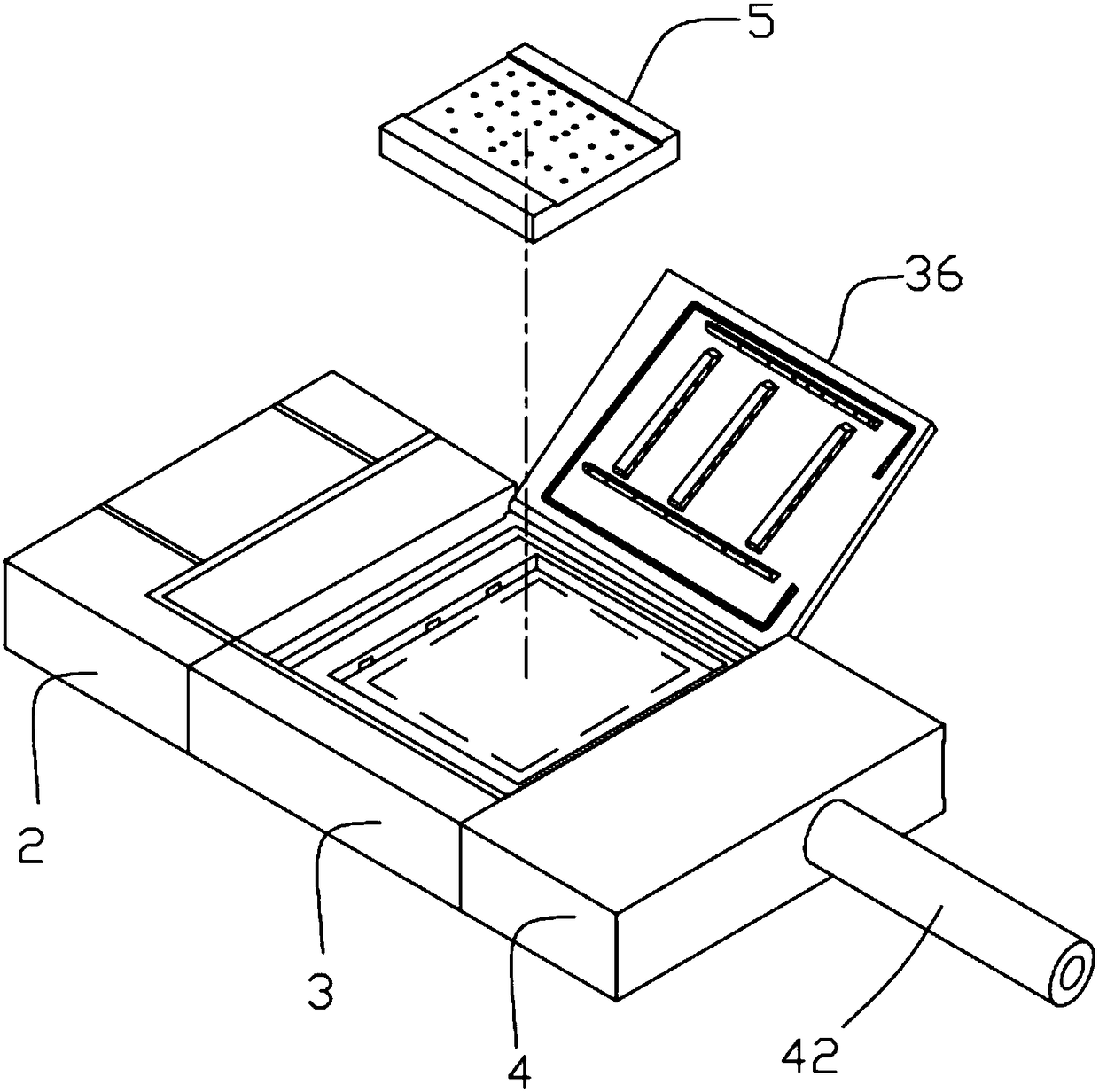

Test apparatus for thermal shock life evaluation of thermal barrier coating

InactiveCN105865961ARealize simulationEffective simulationStrength propertiesCombustionAutomatic control

The invention provides a thermal shock life evaluation test device for thermal barrier coatings, which includes: a heating system, a CMAS liquid material delivery system, a cooling system and a control system; the heating system provides a combustion flame jet to realize the simulation of the high-temperature environment of the test sample heating , and achieve cyclic heating under a certain temperature gradient; the CMAS liquid material delivery system transports the CMAS suspension while the heating system is heating, and the CMAS suspension is atomized by the air jet and injected into the combustion flame at a set angle and speed to Simulate the actual state of CMAS; after the heating, the cooling system cools the test sample through a cooling air circuit; the control system connects and controls the heating system, CMAS liquid material delivery system and cooling system to achieve high temperature and gradient temperature , Simulating the service environment of thermal barrier coatings under CMAS coupled environmental conditions and automatically controlling the entire process test process.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

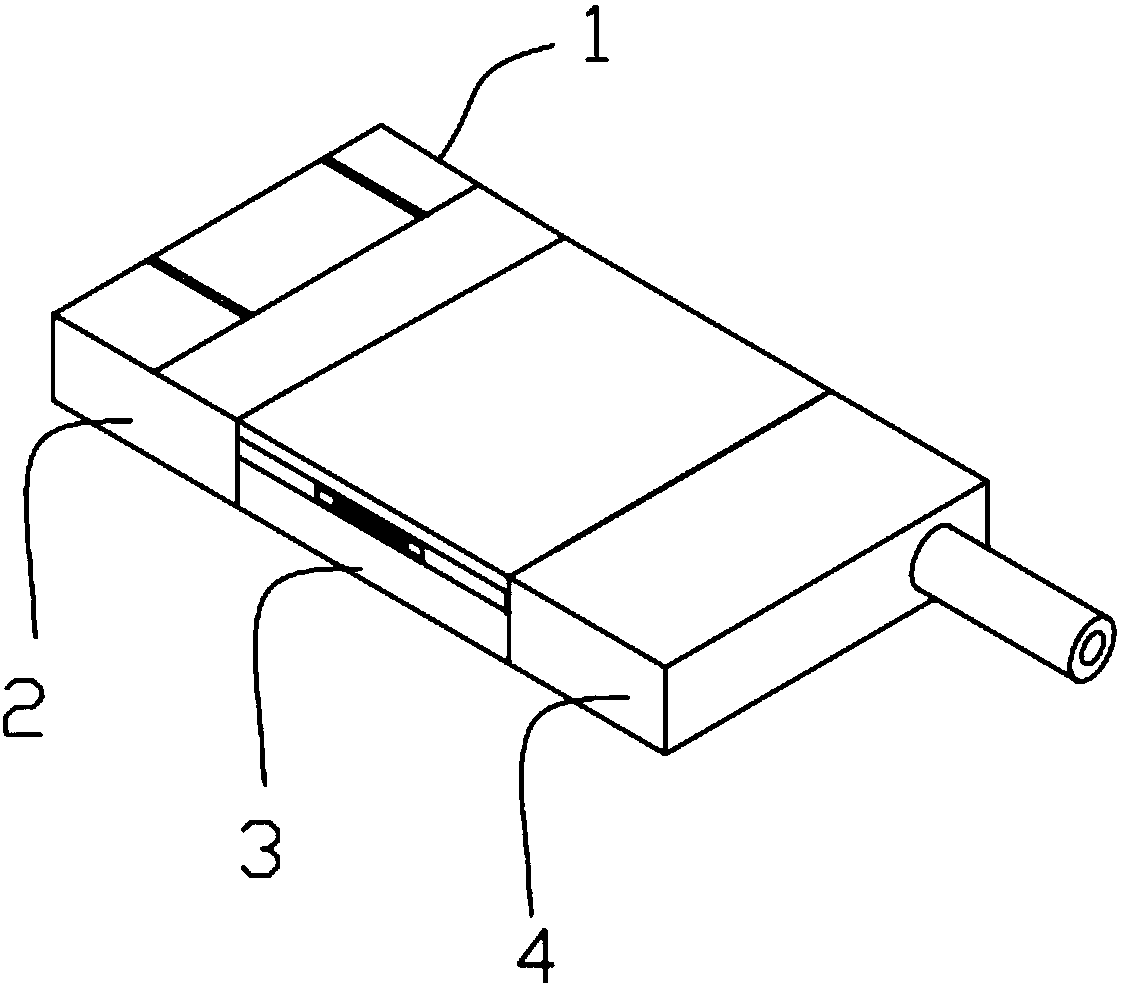

Thin-sheet type heated-noncombustible device

InactiveCN108185525AEfficient heatingHeating fastTobacco devicesElectromagnetic inductionEngineering

The invention provides a thin-sheet type heated-noncombustible device, which comprises a main body, wherein the main body is represented as a flat plate, and the main body comprises a battery component area, a control area, a heating area and a smoke flowing area; a battery component is arranged in the battery component area; the battery component is connected to the control area; the control areais connected to the heating area; the heating area is provided with a gas inlet and a gas outlet; the gas inlet communicates with the external side; a smoke channel is arranged in the smoke flowing area; the gas outlet communicates with the smoke channel; the heating area is designed as at least one electromagnetic induction heating device or at least one resistance-type heating device or a combination of the electromagnetic induction heating device and the resistance-type heating device; the heating area further comprises a heating cavity; the heating cavity is represented as a flat plate; and a thin-sheet type tobacco is arranged in the heating cavity. The device can achieve efficient and rapid heating of the thin-sheet type tobacco; the device is constant in heat generating, uniform inheating and easy to control; and in addition, the device can prevent dry burning.

Owner:SHENZHEN INNOKIN ELECTRONICS TECH CO LTD

Wind water mixed atomizing method for down-hole coal cutter fully-mechanized coal winning machine

InactiveCN101307691AEfficient captureSolve slippageDust removalFire preventionWater sourceWater vapor

The invention belongs to a wind-water mixing spray technology which can be applied in underground comprehensive mining, comprehensive digging and in places requiring settling dust so as to improve safe production of a coal mine. The invention is characterized in that the technology is realized through the steps as follows: a wind source pipeline which is connected from a ground forcing fan to an extraction working surface with a selectable wind pressure of between 0.5 and 0.7MPa is in parallel connection with a water source pipeline which has certain pressure with a selectable hydraulic pressure of between 3 and 5MPa, and the volume ratio of the mixed wind and water is between 100-135 to 1; the wind source pipeline and the water source pipeline are both connected to nozzles of internal spraying and external spraying of a coal mining machine and a mechanical boring machine, so that wind-water mixing atomized water vapor is sprayed with a flow rate of between 15 and 20M<3> / minute; and the atomized water vapor captures coal dust, and disperses local gas generated during cutting a coal body. The invention aims to solve the problems caused by the local gas which is generated during settling dust and cutting coal and can not be dispersed in time, such as safety threat in production, water resource waste, affected coal quality, slipping belt, slipping goods, bin blockage or other problems.

Owner:李本学 +1

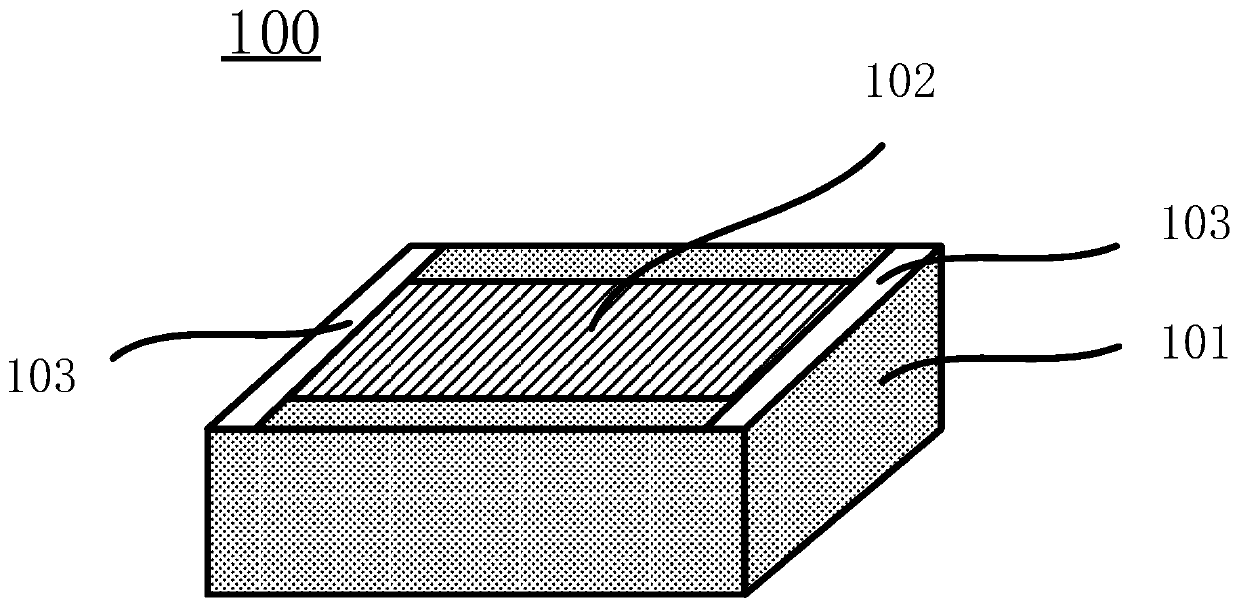

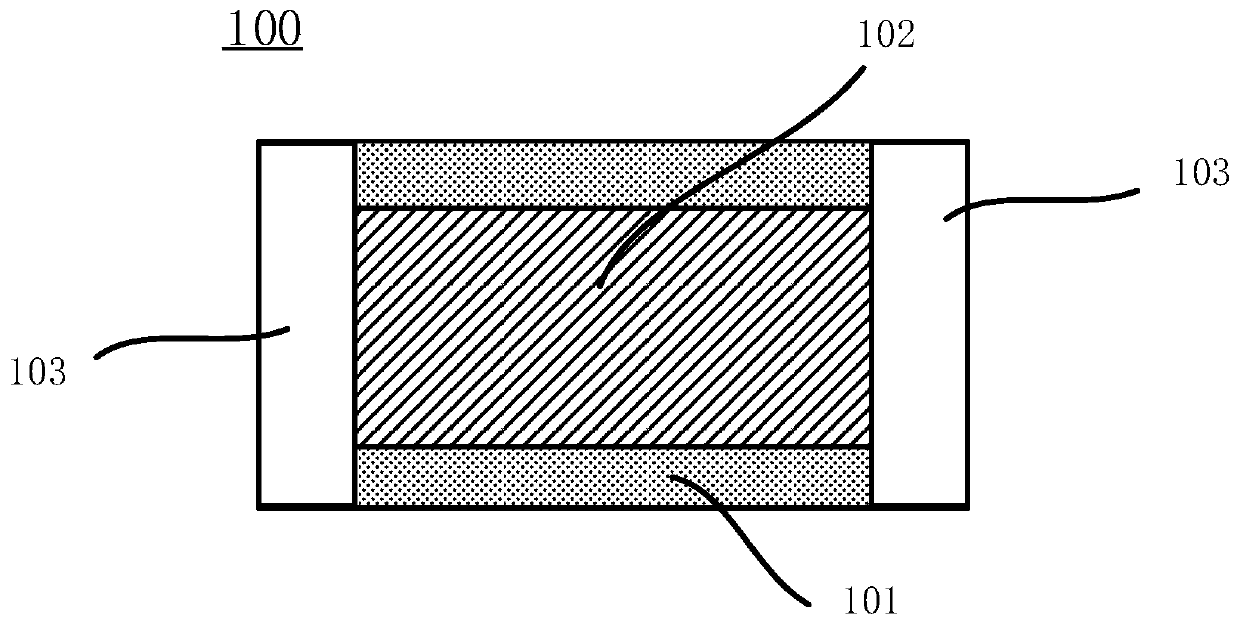

Atomizing element and electronic cigarette

PendingCN110447962AFully atomizedIncreased atomization specific areaTobacco devicesHeating element materialsMetallurgyTar

The invention relates to an atomizing element and an electronic cigarette. The atomizing element comprises a porous ceramic part and a porous metal part contacted with the porous ceramic part; at least partial pores of the porous ceramic part communicate with the pores of the porous metal part; and the thickness of the porous metal part is not less than 30 microns. The atomizing element can sufficiently atomize the tobacco tar, thereby effectively improving the smoke taste.

Owner:SHENZHEN SMOORE TECH LTD

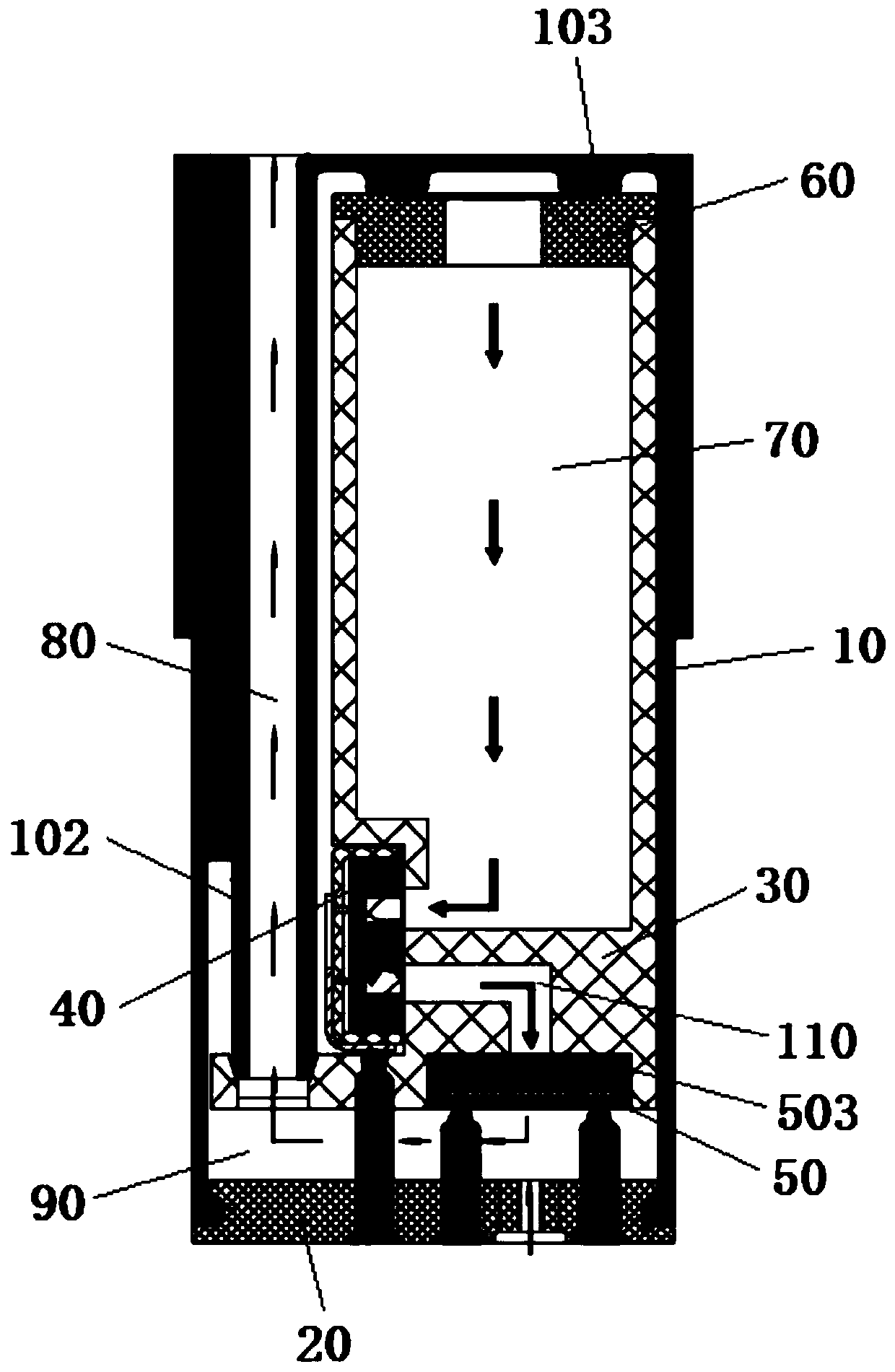

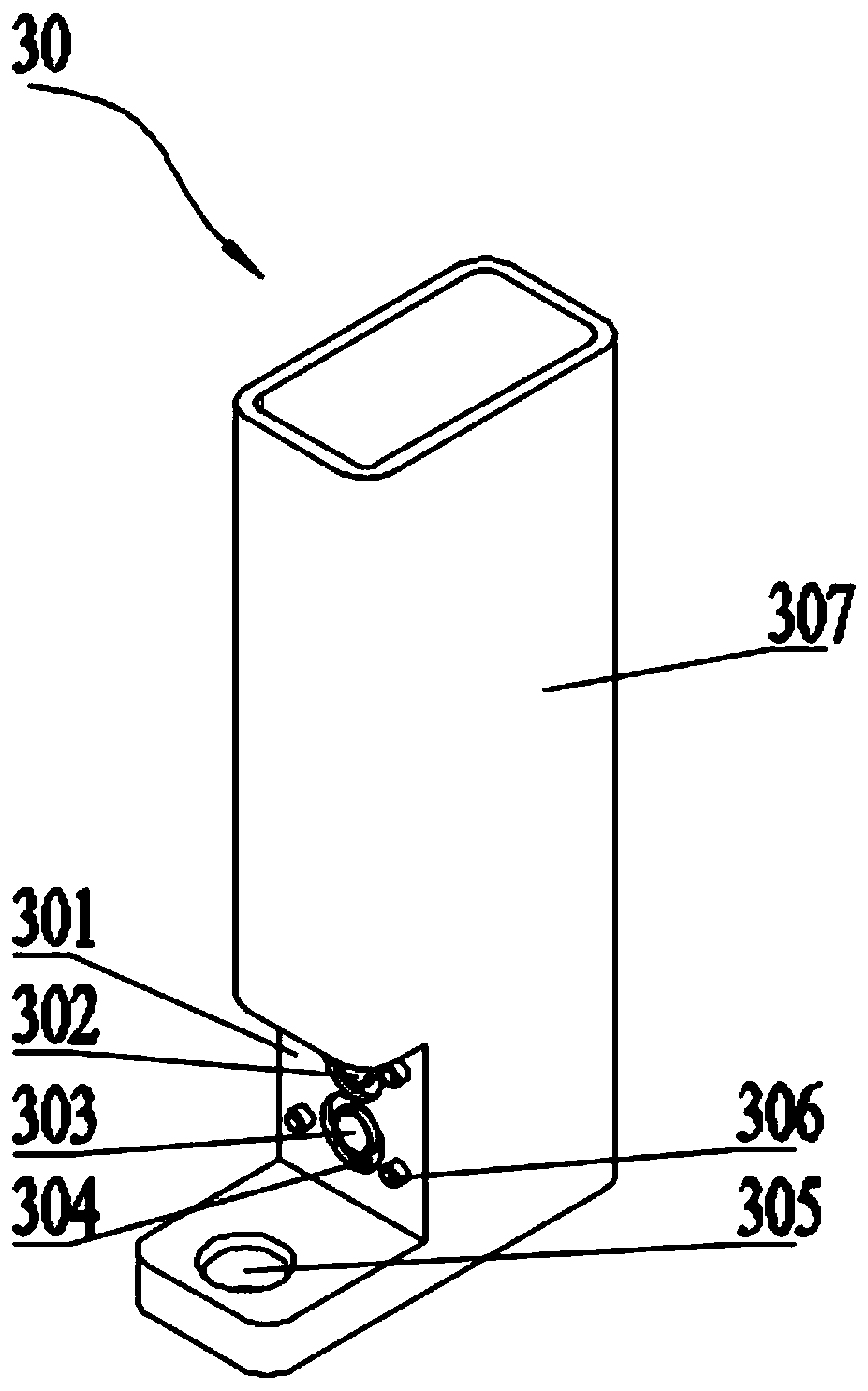

Micro liquid pump-based active tar supply type electronic atomized cigarette ball and control method thereof

PendingCN109805459AStable, faster and more timely deliveryDynamic balance of supply and consumptionTobacco devicesMouth pieceAir pump

The invention relates to the technical field of electronic cigarettes, in particular to a micro liquid pump-based active tar supply type electronic atomized cigarette ball and a control method thereof. The micro liquid pump-based active oil supply type electronic atomized cigarette ball comprises a shell and a base which are in sealing fit, wherein a mouth piece and an air pipe are integrally formed on the shell; a mounting seat is arranged in the shell; a sleeve is formed at the upper end of the mounting seat, and a tobacco tar cavity is hermetically formed at the top; the lower end of the mounting seat is matched with the base to form an atomization chamber; a micro liquid pump is mounted on one side of the mounting seat; a ceramic heating body is mounted at the bottom of the mounting seat; the micro liquid pump is communicated with the tobacco tar cavity; the air pump is communicated with the atomization chamber; tobacco tar in the tobacco tar cavity is conveyed to a heating surfaceof the ceramic heating body through pressure of the micro liquid pump; the tobacco tar enters the atomization chamber after being atomized by the ceramic heating body; during smoking, negative pressure is formed in the atomization chamber, and air can enter the atomization chamber under the action of the negative pressure to deliver aerosol produced by tobacco tar atomization into a mouth along the air pipe. The micro liquid pump-based active oil supply type electronic atomized cigarette ball can solve the problems of tar frying and tar leakage due to dry burning of an atomizer and excessivetar supplying which are caused by late tar supplying or less tar supplying generated by uncontrollable tar supply of an existing cigarette ball product.

Owner:常州威图流体科技有限公司

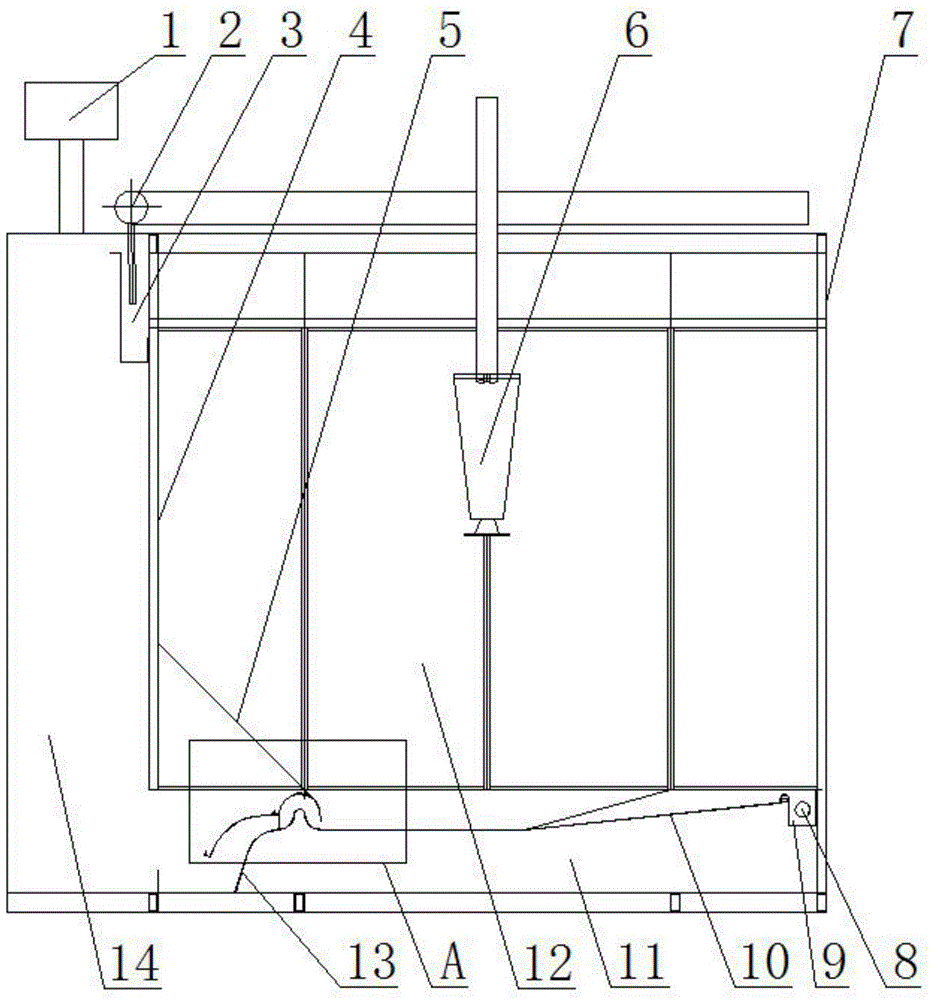

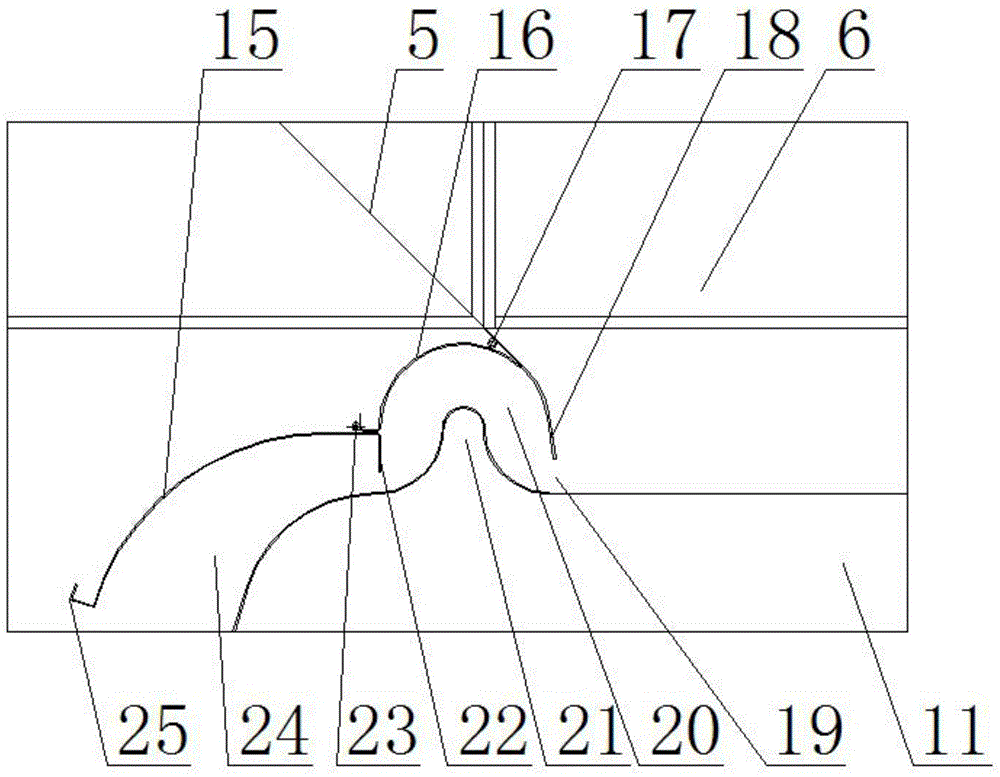

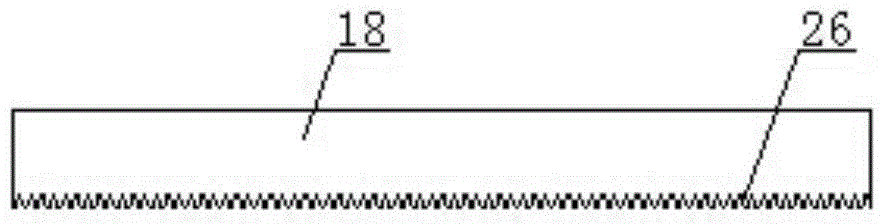

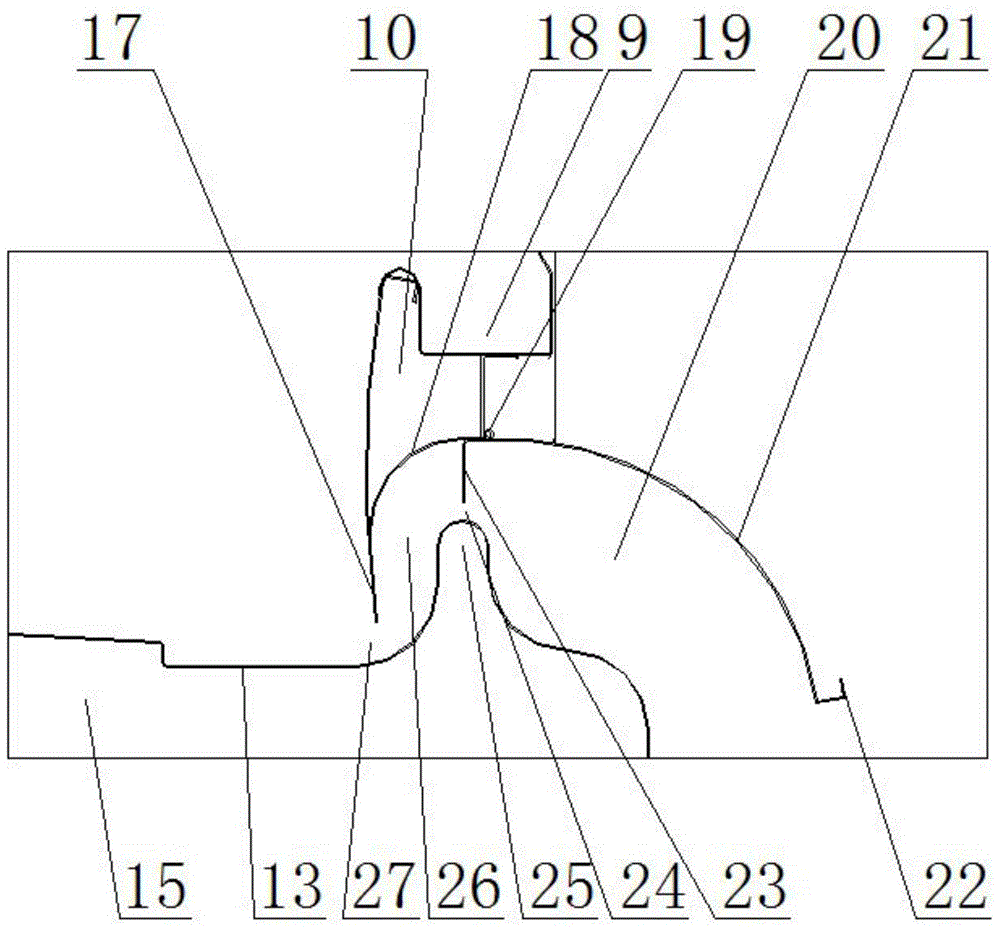

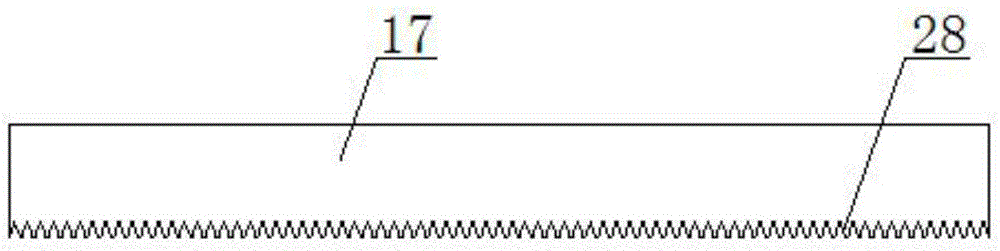

Paint spraying room with double atomizing paint mist catching structure

InactiveCN104399629ASimplify manufacturing difficultyDoes not affect horizontal distributionLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention relates to a paint spraying room with a double atomizing paint mist catching structure. The paint spraying room comprises a paint spraying room body. A water screen plate is installed on the wall of the paint spraying room body. The paint spraying room further comprises a base plate flow guide structure and a main sawtooth plate which are arranged below the paint spraying room. The water screen plate is arranged above the base plate flow guide structure. The main sawtooth plate is fixedly installed at the bottom end of the water screen plate, an arc lifting section is manufactured at the bottom end of the water screen plate, a flow guide sawtooth plate is installed on the lateral wall of the water screen plate at the upper end of the arc lifting section, the flow guide sawtooth plate integrally extends to form the arc flow guide face, the arc flow guide face is matched with the base plate flow guide structure, a first vortex atmozing space is formed among the main sawtooth plate, the flow guide sawtooth plate, the arc lifting section at the bottom end of the water screen plate and the base plate flow guide structure, and a second vortex atomizing space is formed between the flow guide sawtooth plate and the base plate flow guide structure. The paint spraying room is simple in structure, scientific and reasonable in design, low in cost, high in paint mist catching efficiency and capable of effectively reducing the follow-up environment protection processing load.

Owner:赛智环保科技(天津)有限公司

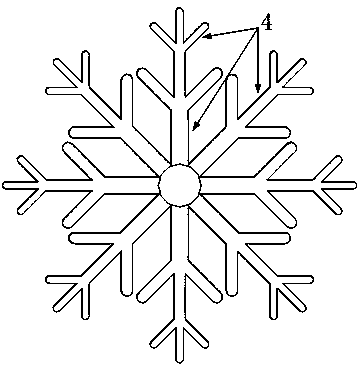

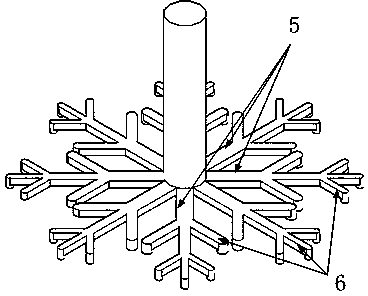

Blade skeleton type atomizing sprayer

ActiveCN104028410ALarge coverage areaReduce trafficSpray nozzlesLiquid spraying apparatusSprayerStructural engineering

The invention discloses a blade skeleton type atomizer. The blade skeleton type atomizer consists of a sprayer body and an ultrasonic atomizer, wherein the sprayer body comprises a liquid delivery channel and a liquid outlet; the liquid outlet is positioned in the tail end of the liquid delivery channel and is used for atomizing and spraying liquid through the ultrasonic atomizer; the liquid delivery channel is a blade skeleton type channel and consists of a main delivery channel and (i) m ( / i) forked blade skeleton channels; each forked blade skeleton channel comprises a main channel and branch channels; each main channel comprises at least two grading channels with different diameters; and the grading channels comprise high-level channels and low-level channels connected to the high-level channels end to end. The blade skeleton type channel comprises the main channels and the branch channels; the diameters of the main channels are gradually reduced; and the multi-level grading channels extend outwards, the forked channels are distributed in a radiating manner, channel outlets are formed in limited space to the great extent, the flow of the liquid is gradually reduced, the liquid can be uniformly distributed within the limited range, the atomizing effect is improved, and the liquid is easily atomized.

Owner:SOUTHEAST UNIV

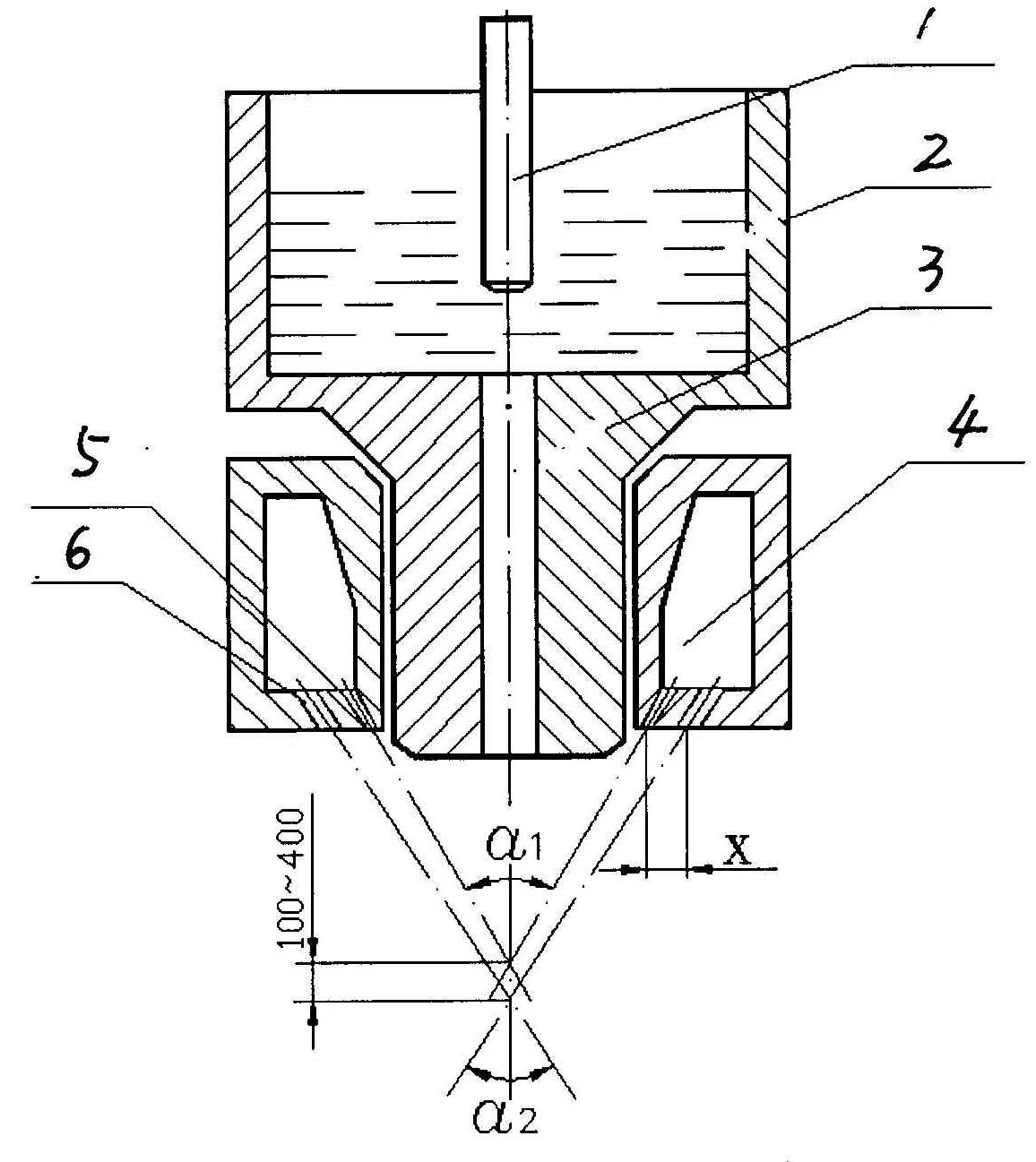

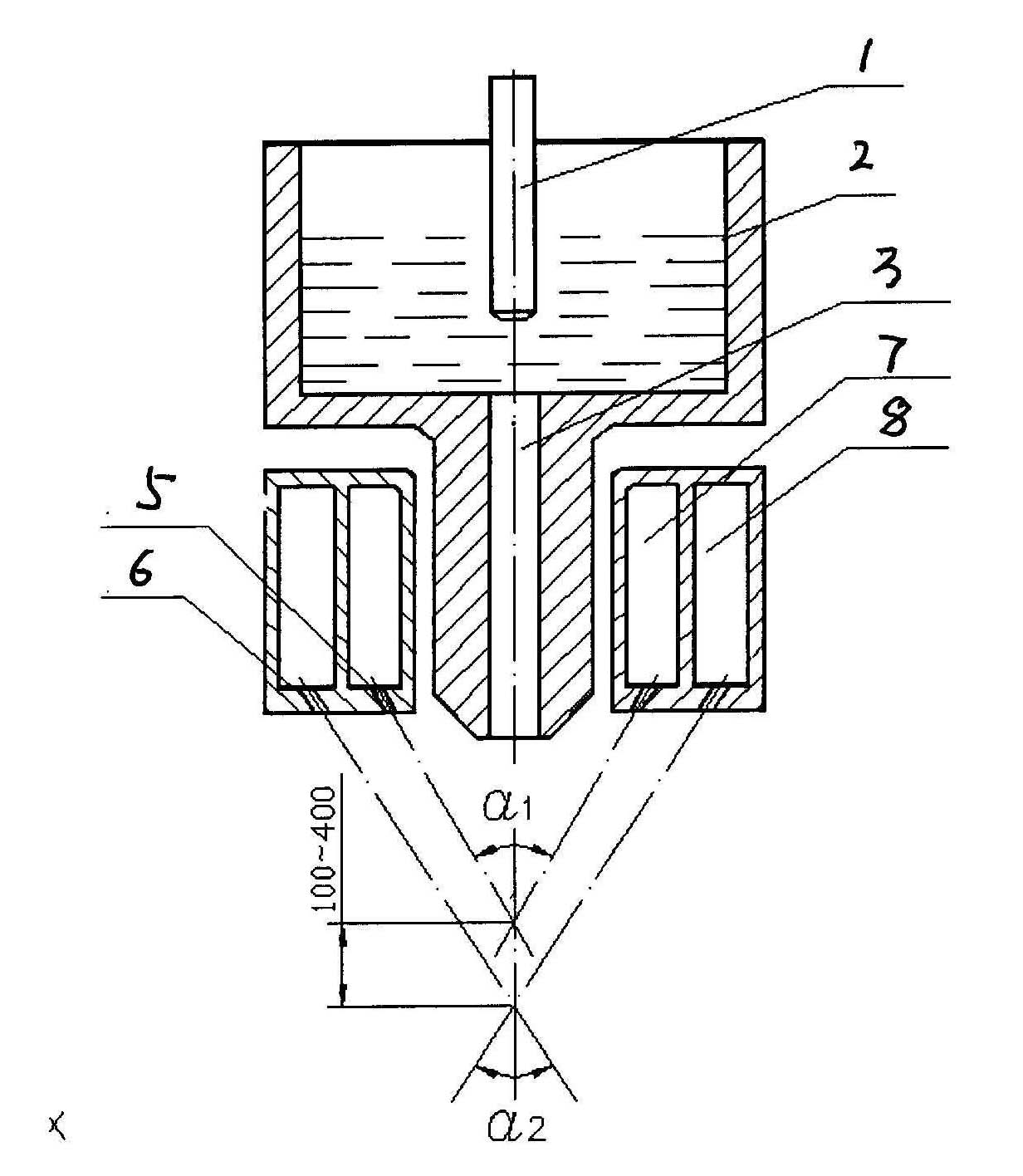

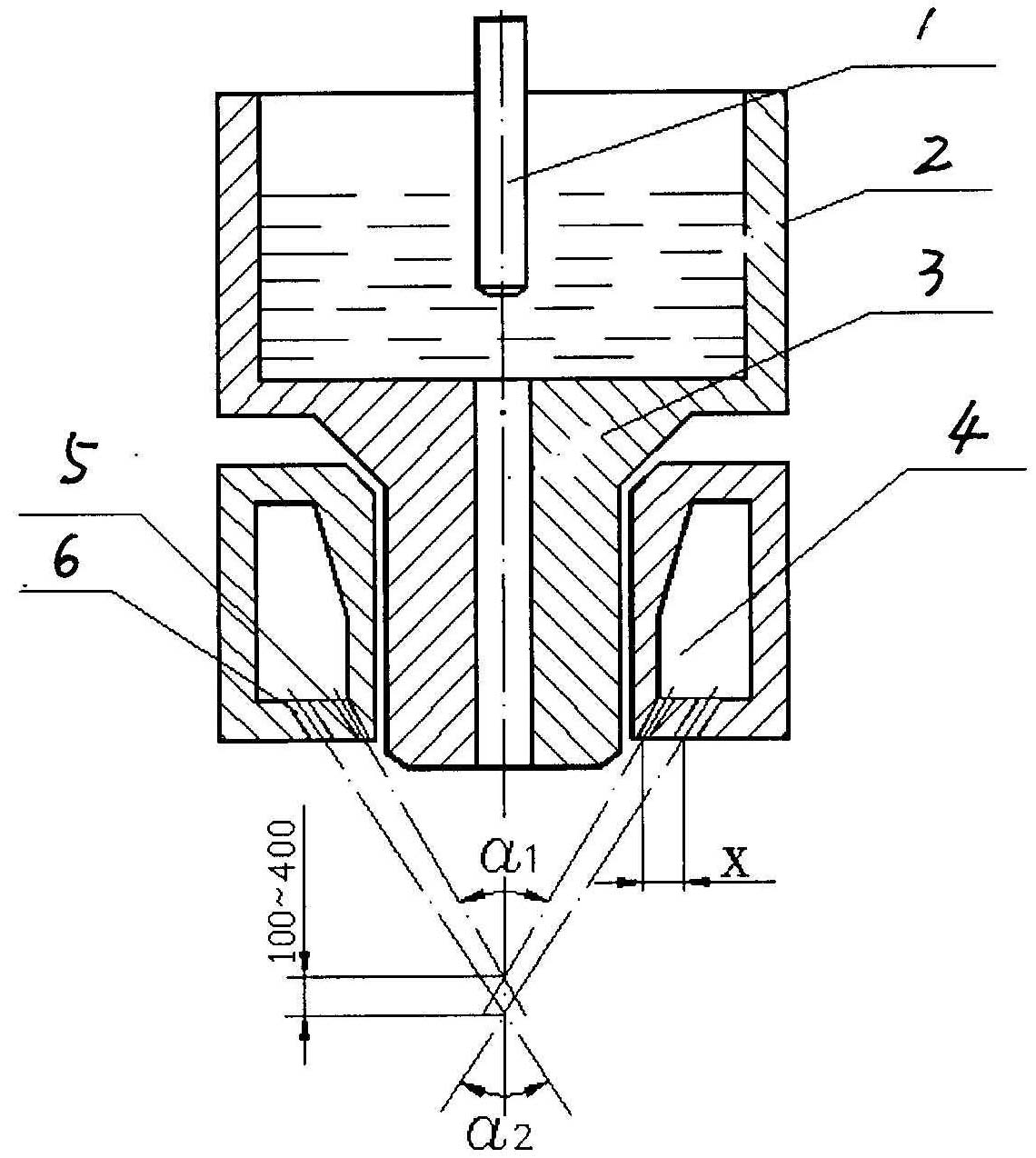

Composite atomizer for manufacturing gas atomization quick-coagulation spherical superfine metal powder

The invention relates to a composite atomizer for manufacturing gas atomization quick-coagulation spherical superfine metal powder, which comprises a crucible for containing metal liquid and an atomizer stationing chamber which is arranged around a metal liquid guiding pipe at the bottom of the crucible, is communicated with a high-speed airflow source and has an annular structure. The composite atomizer is characterized in that: inner and outer nozzle rings which are formed by a plurality of nozzles arranged in a mode of uniform distribution and have structures of concentric circles are formed around the annular bottom surface of the atomizer stationing chamber, and the nozzles are arranged in a skew mode which makes the axes of the nozzles intersected with the lower extended line of the axis of the liquid guiding pipe, wherein the axes of all nozzles on the inner nozzle rings close to the axis of the liquid guiding pipe and the axis of the liquid guiding pipe intersect at a vertical angle point alpha 1 in an atomizing area II, the axes of all nozzles on the outer nozzle rings away from the axis of the liquid guiding pipe and the axis of the liquid guiding pipe intersect at a vertical angle point alpha 2 of an atomizing area III, and the distance between the two vertical angle points is between 0.1 and 0.4 millimeter; and the atomizing pressure is controlled to be between 0.5 and 2.5 MPa.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com