Patents

Literature

5959results about How to "Heating fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

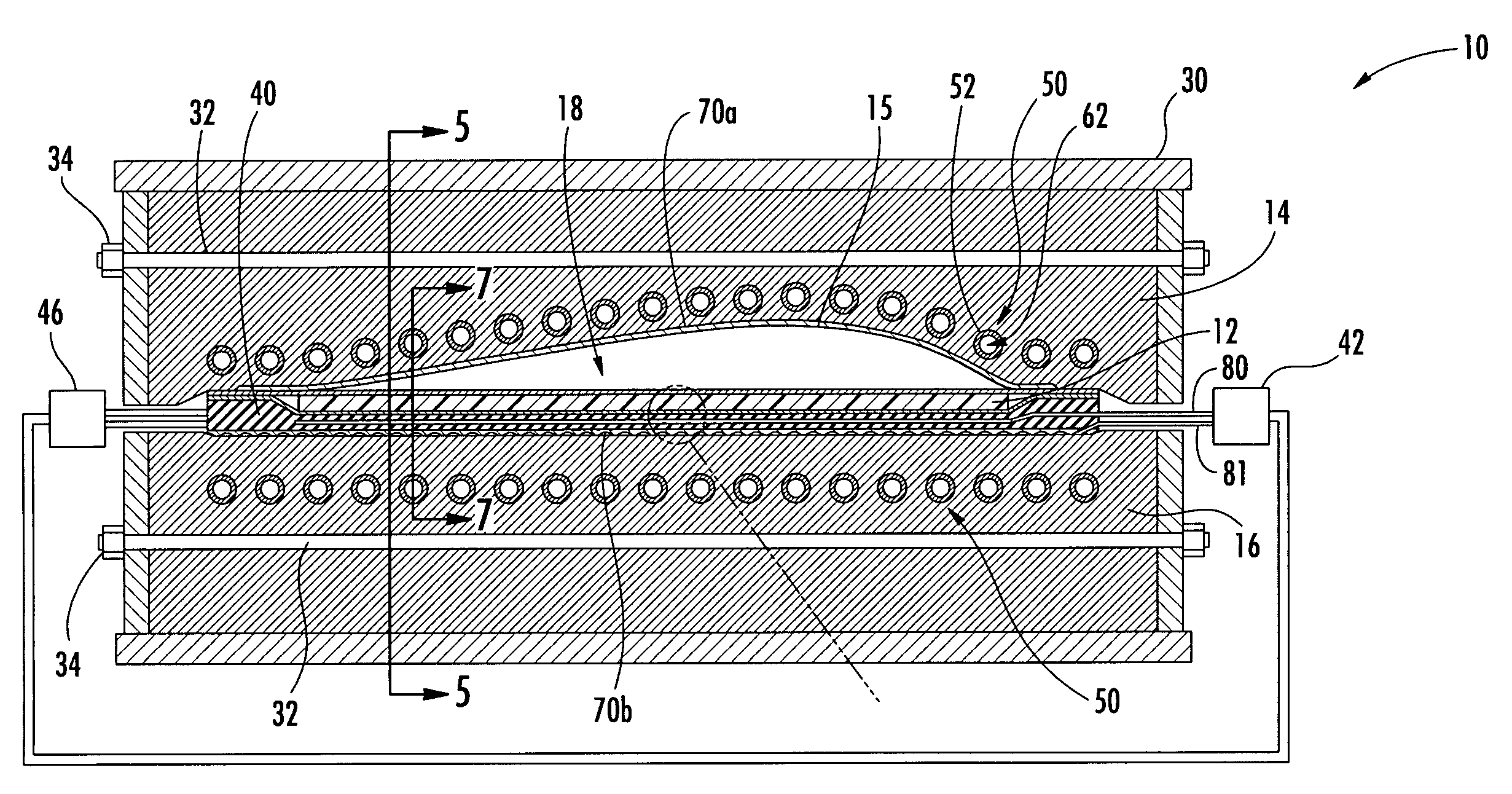

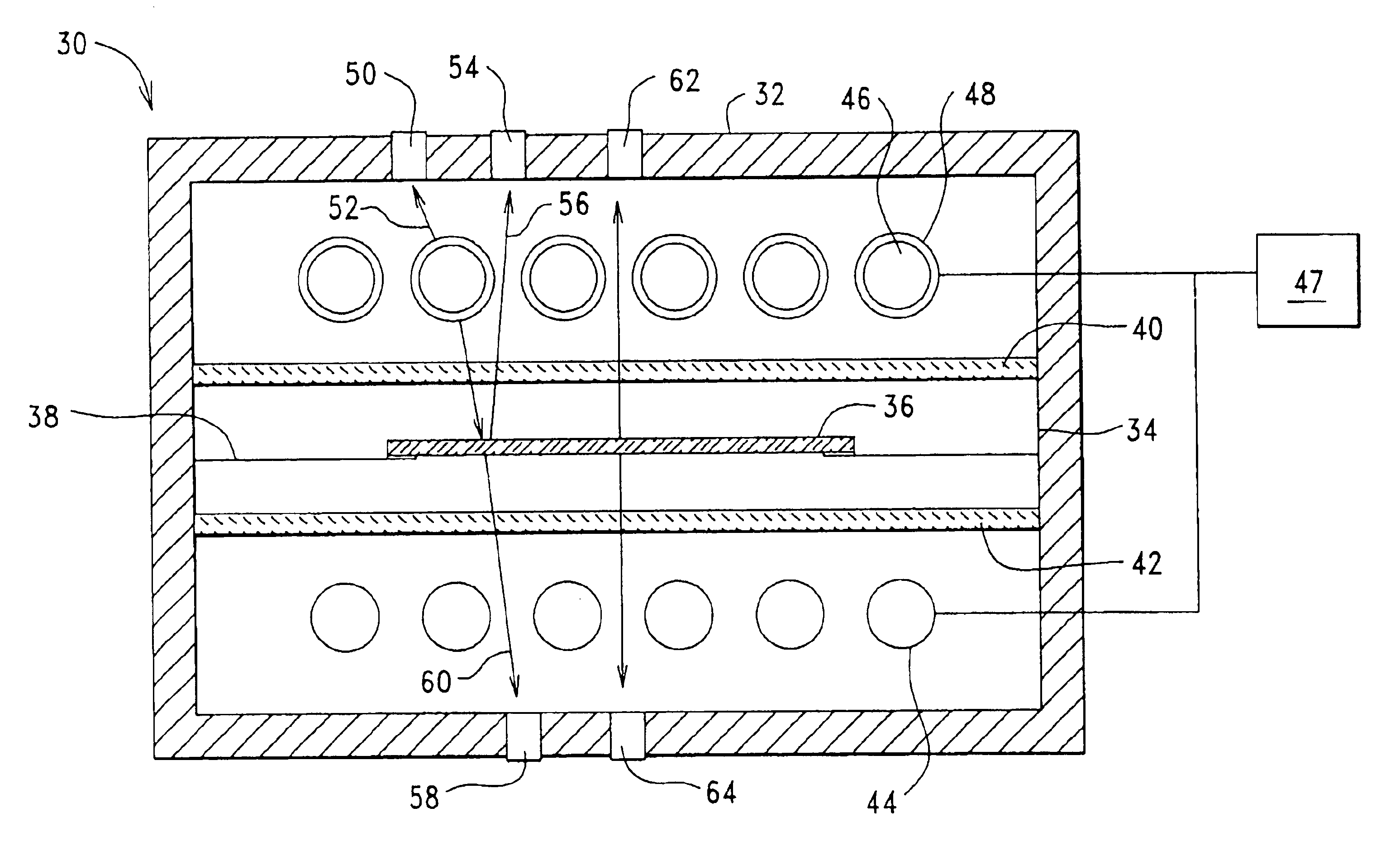

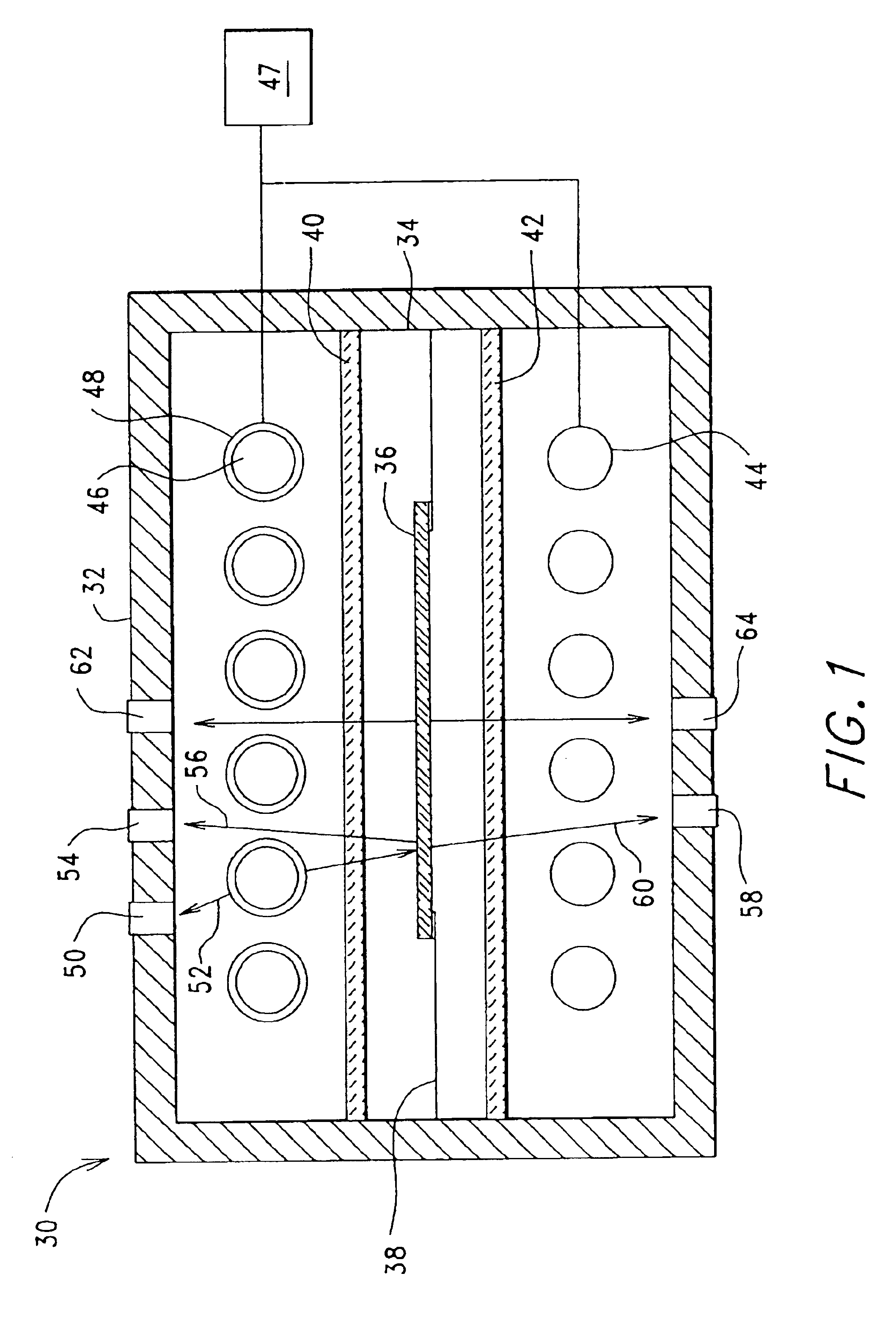

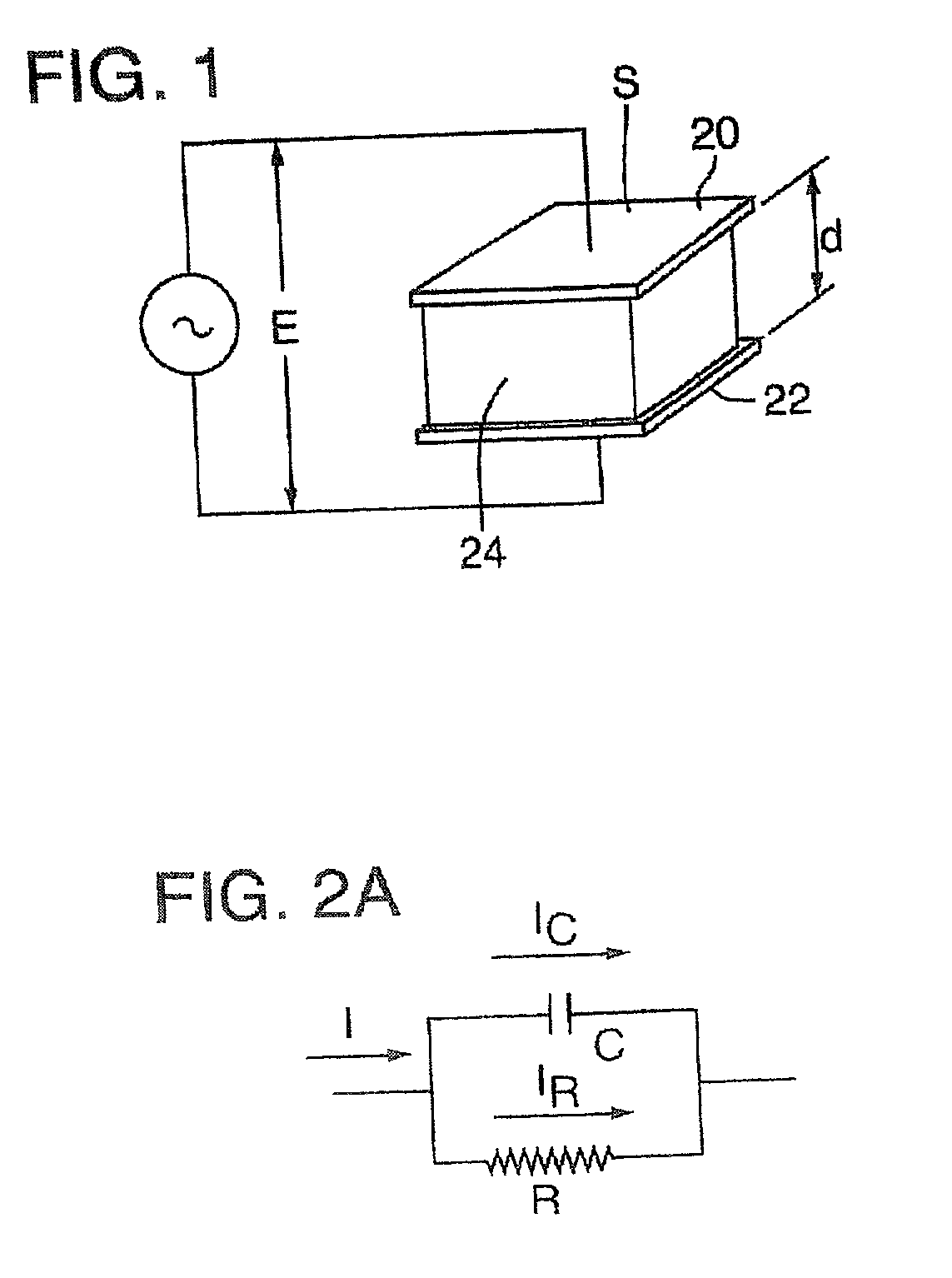

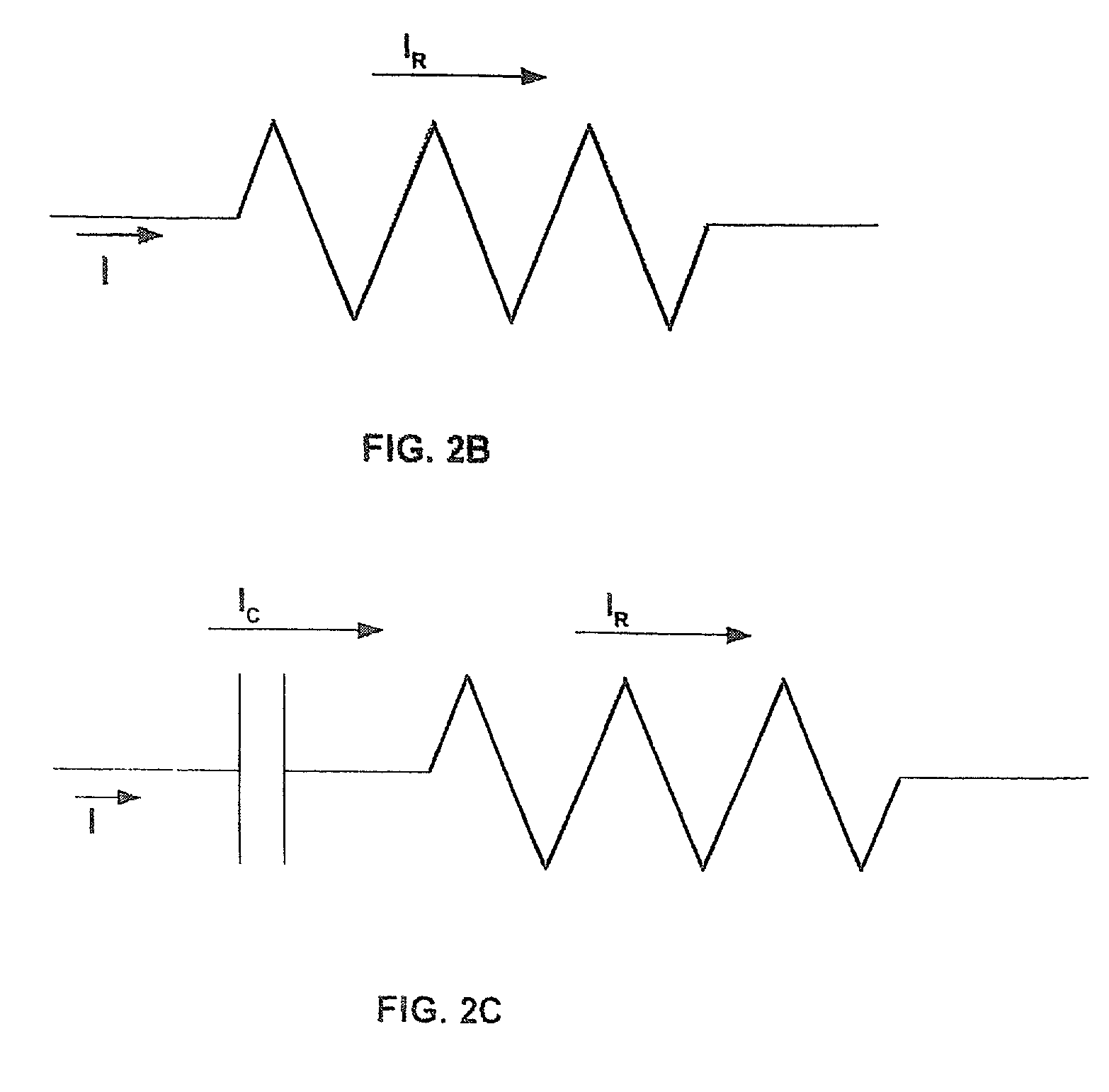

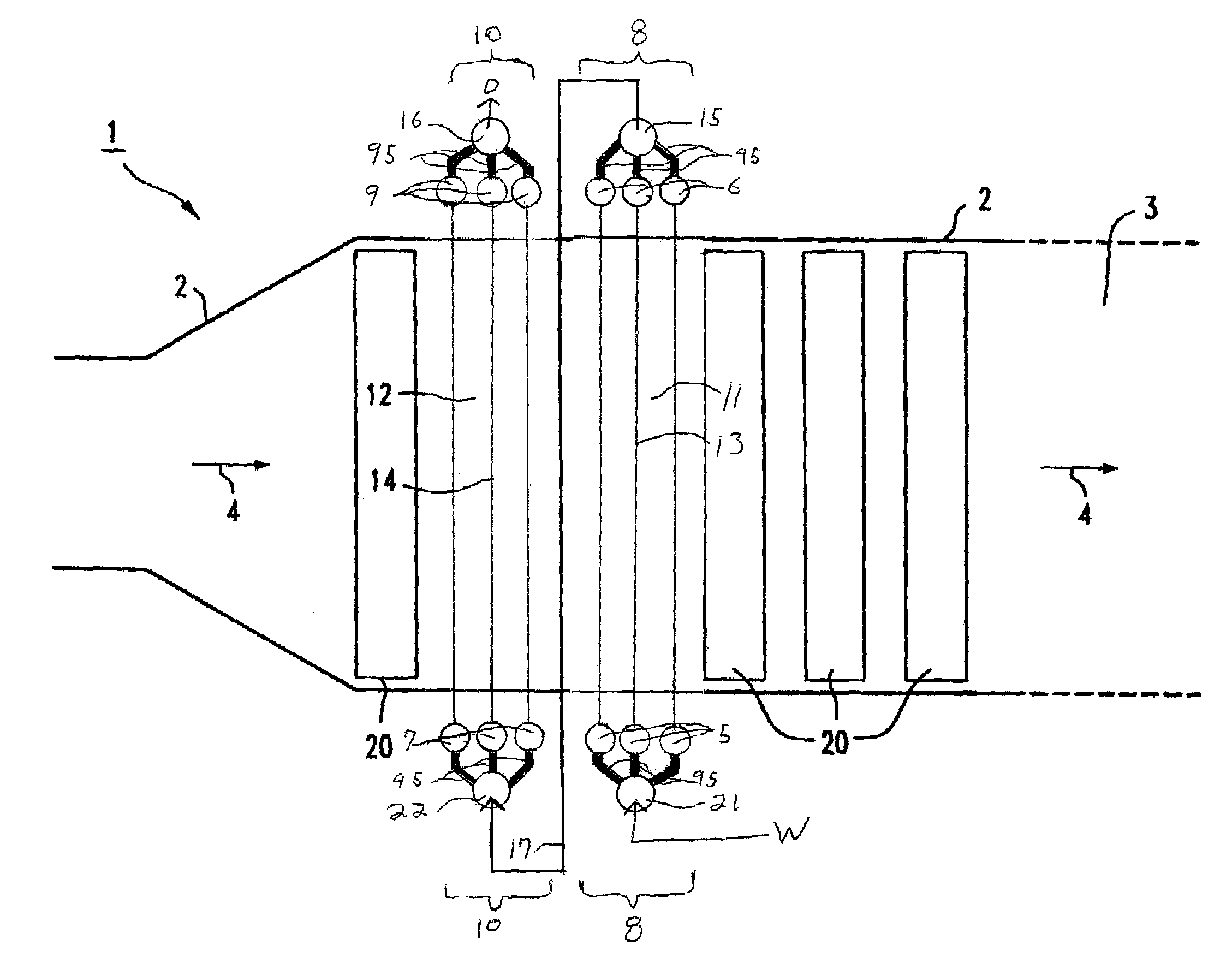

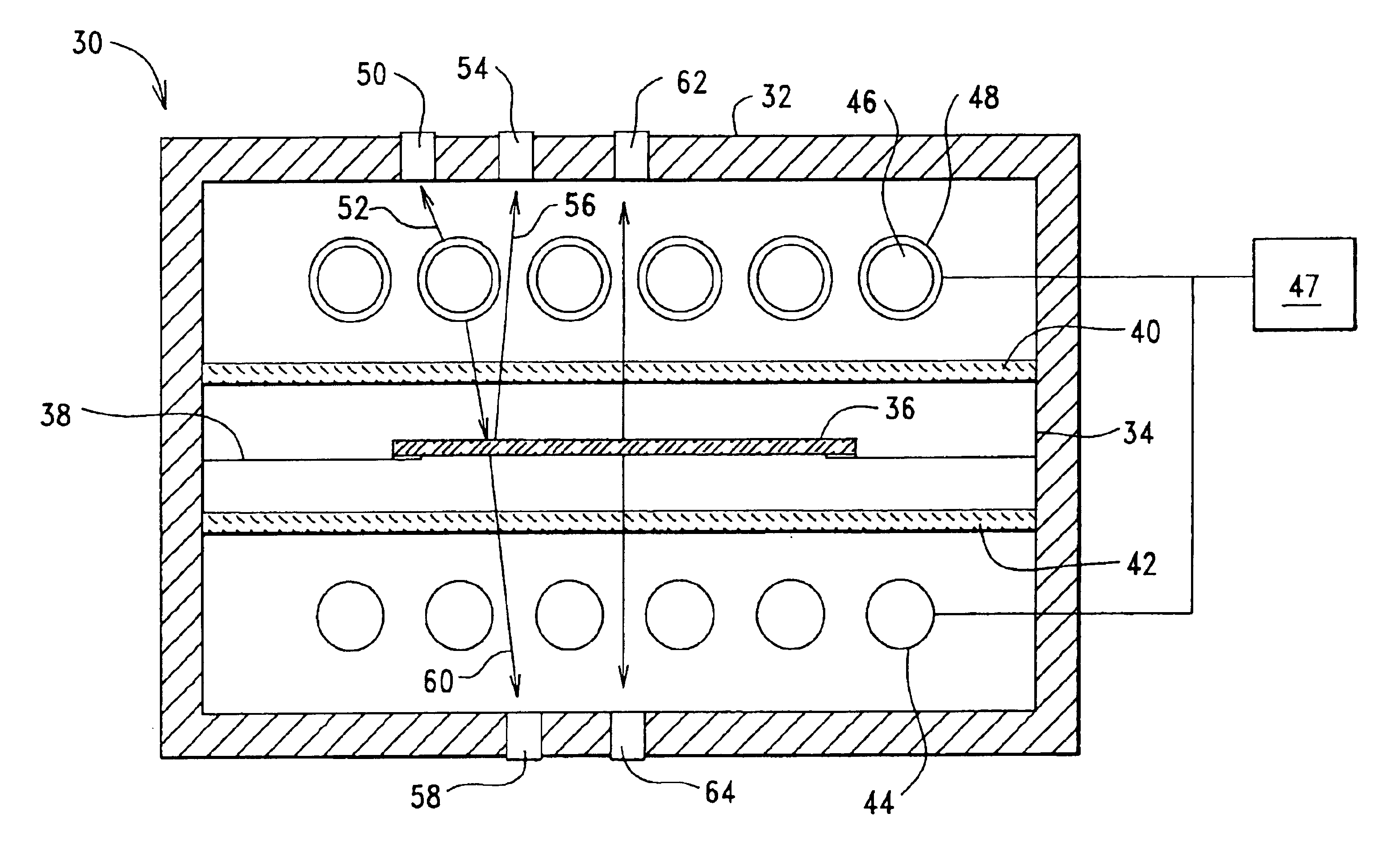

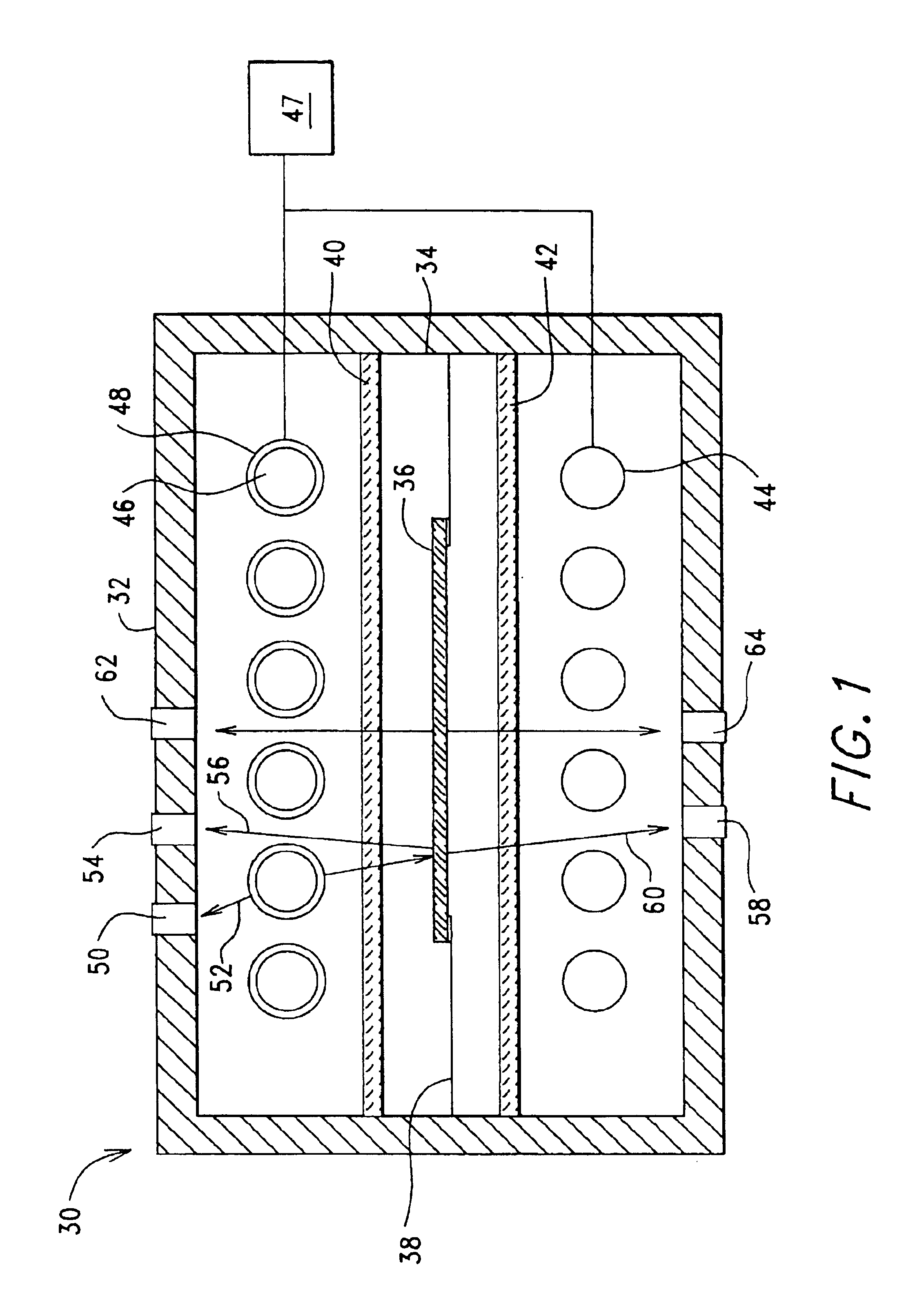

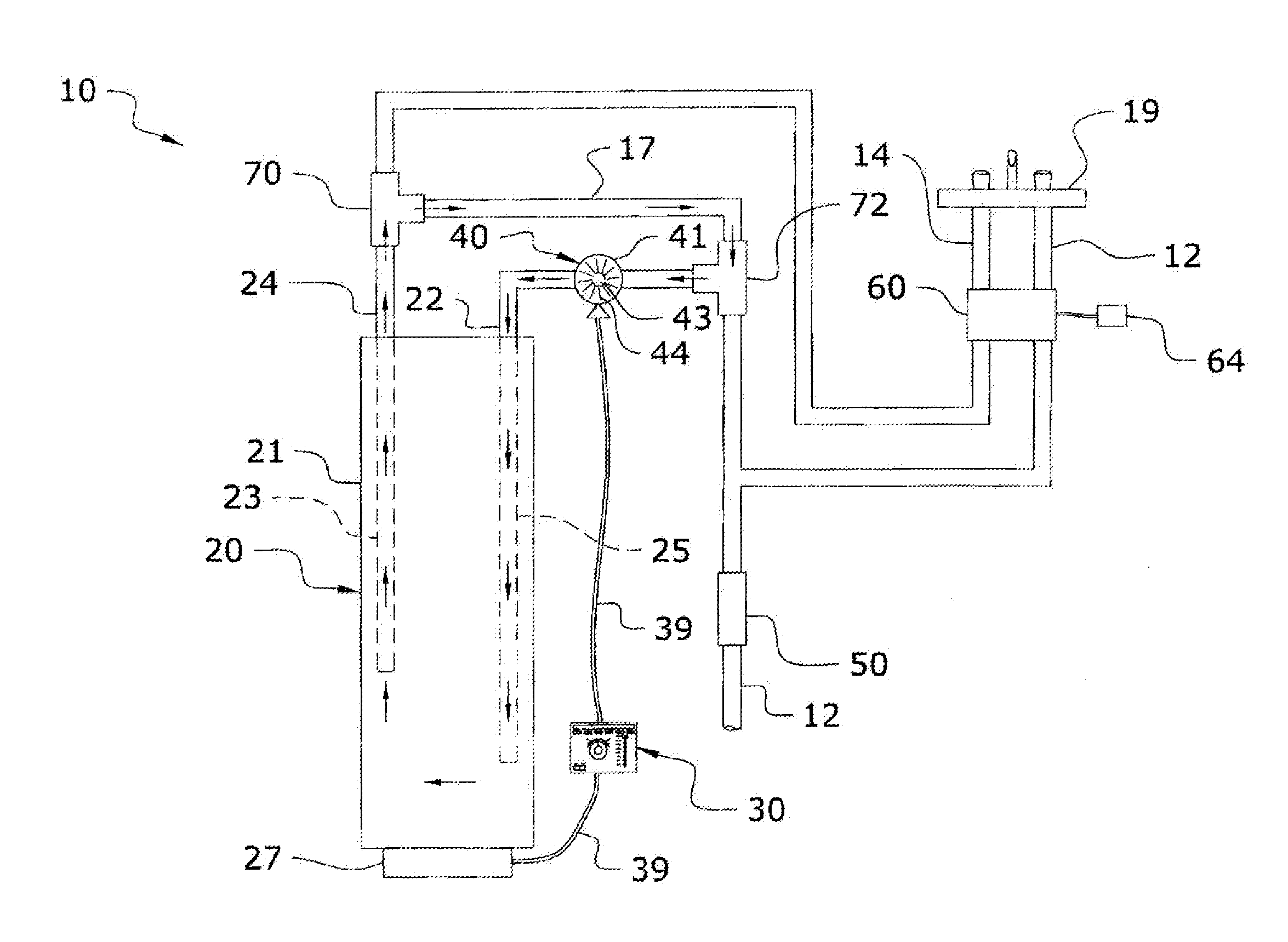

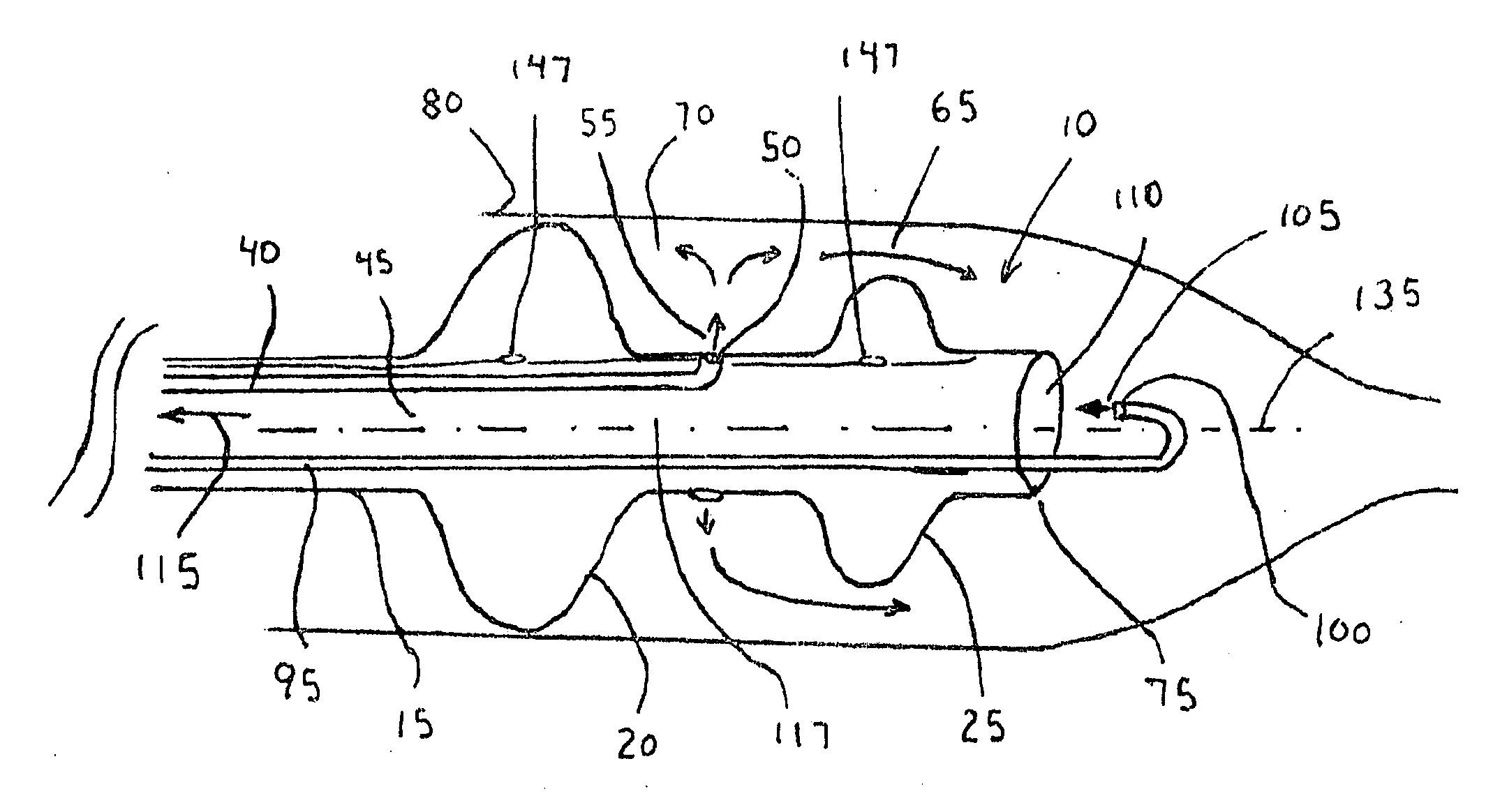

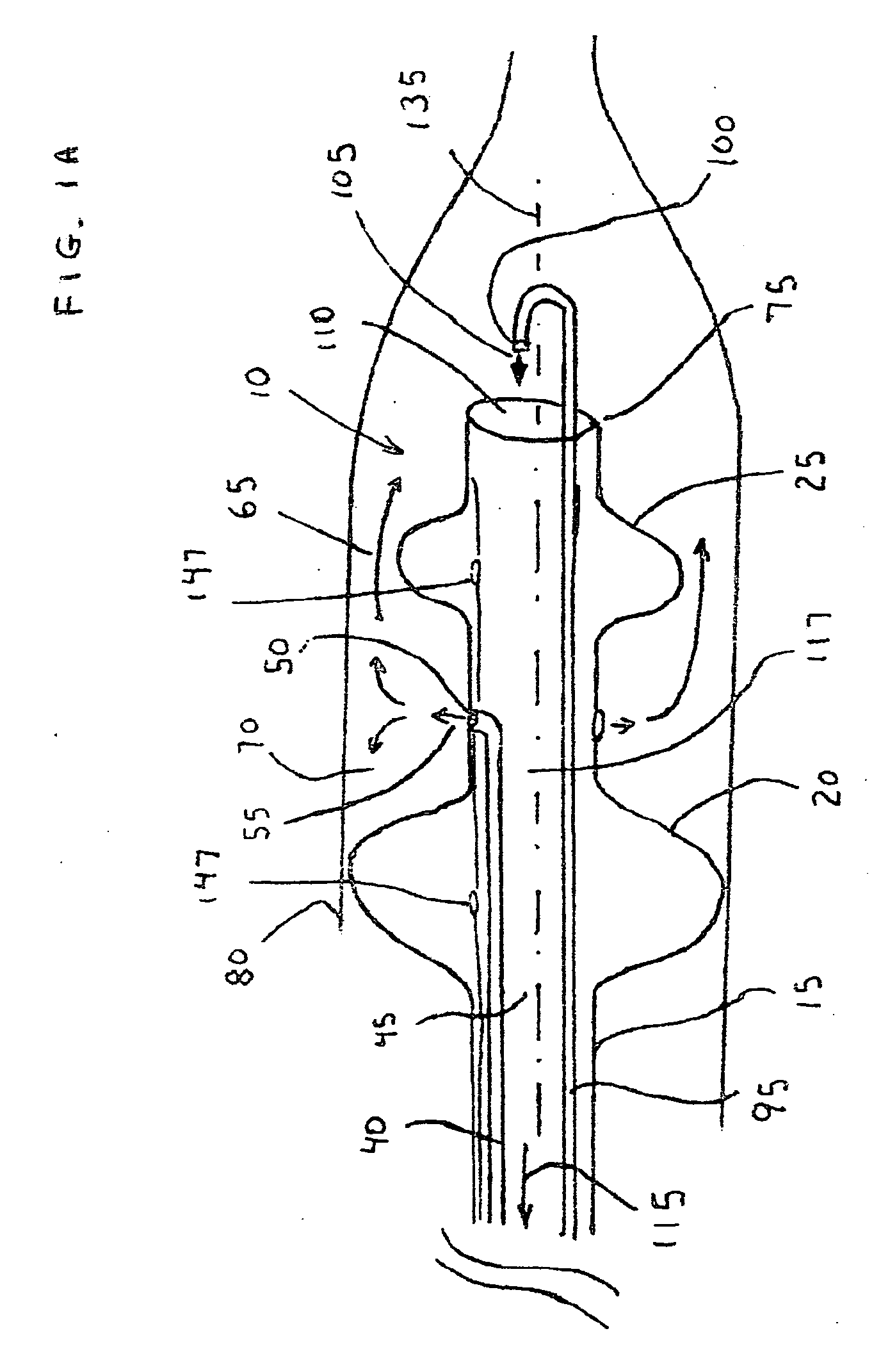

Method and apparatus for supporting a semiconductor wafer during processing

InactiveUS7312156B2Short timeIncrease temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

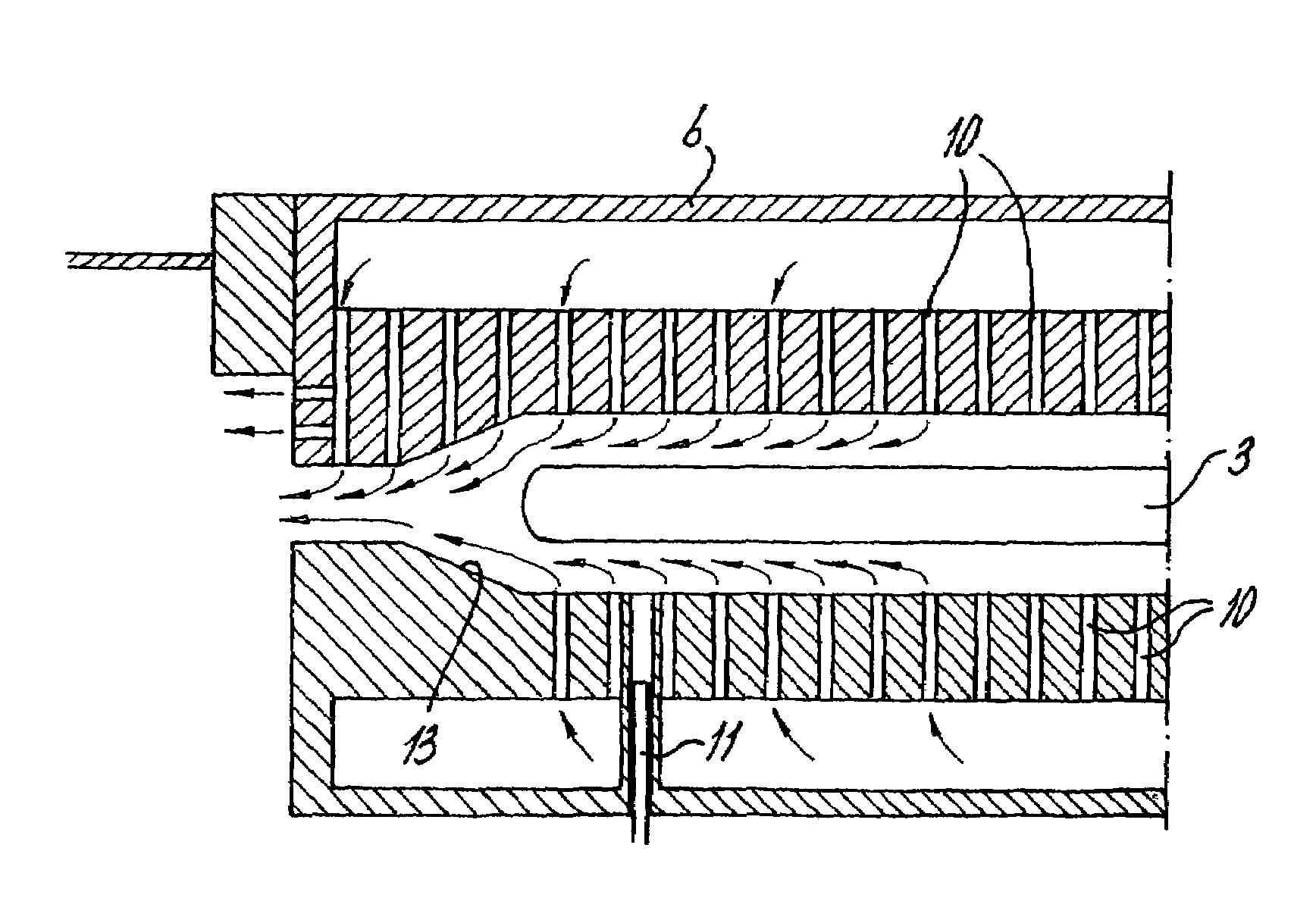

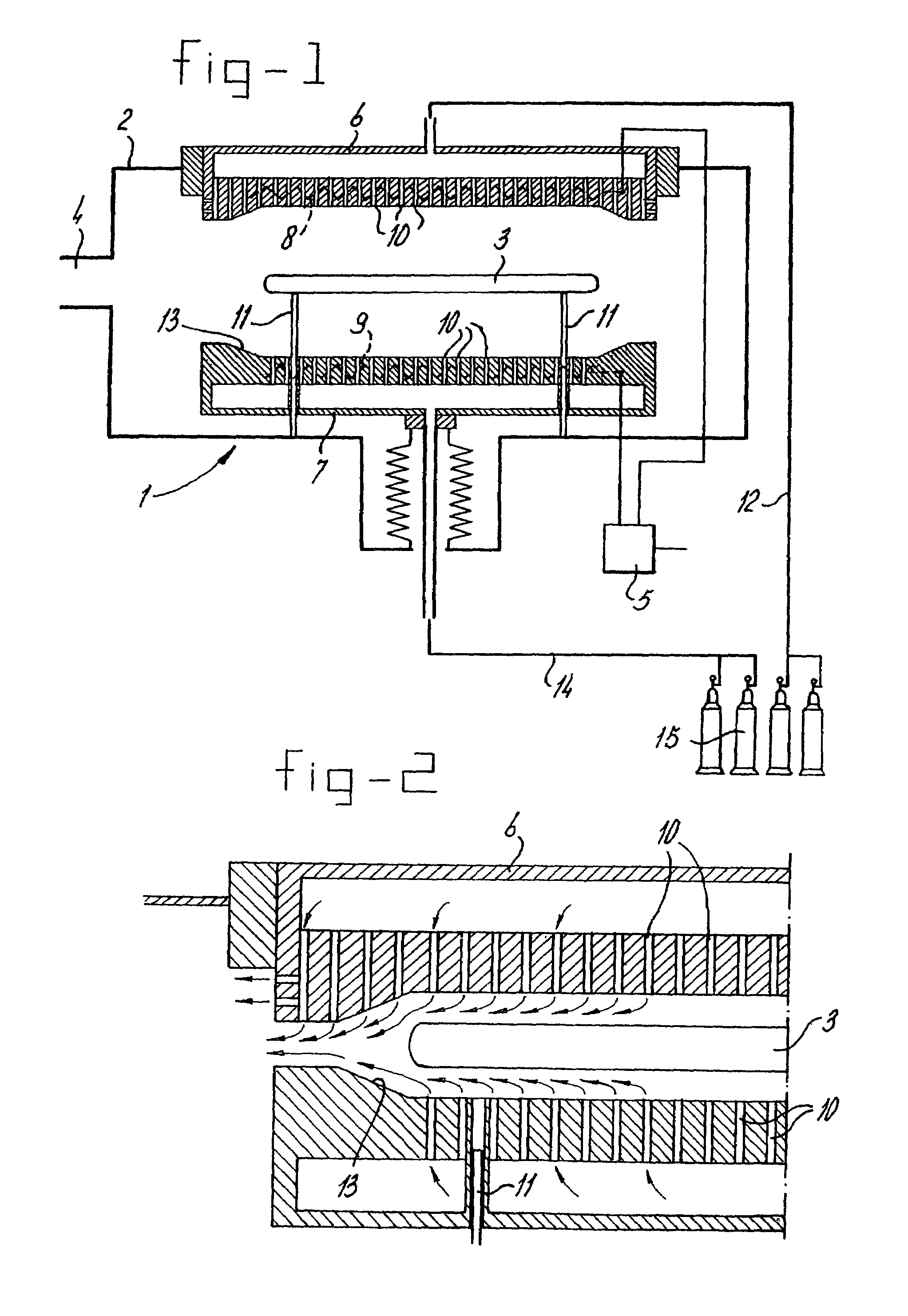

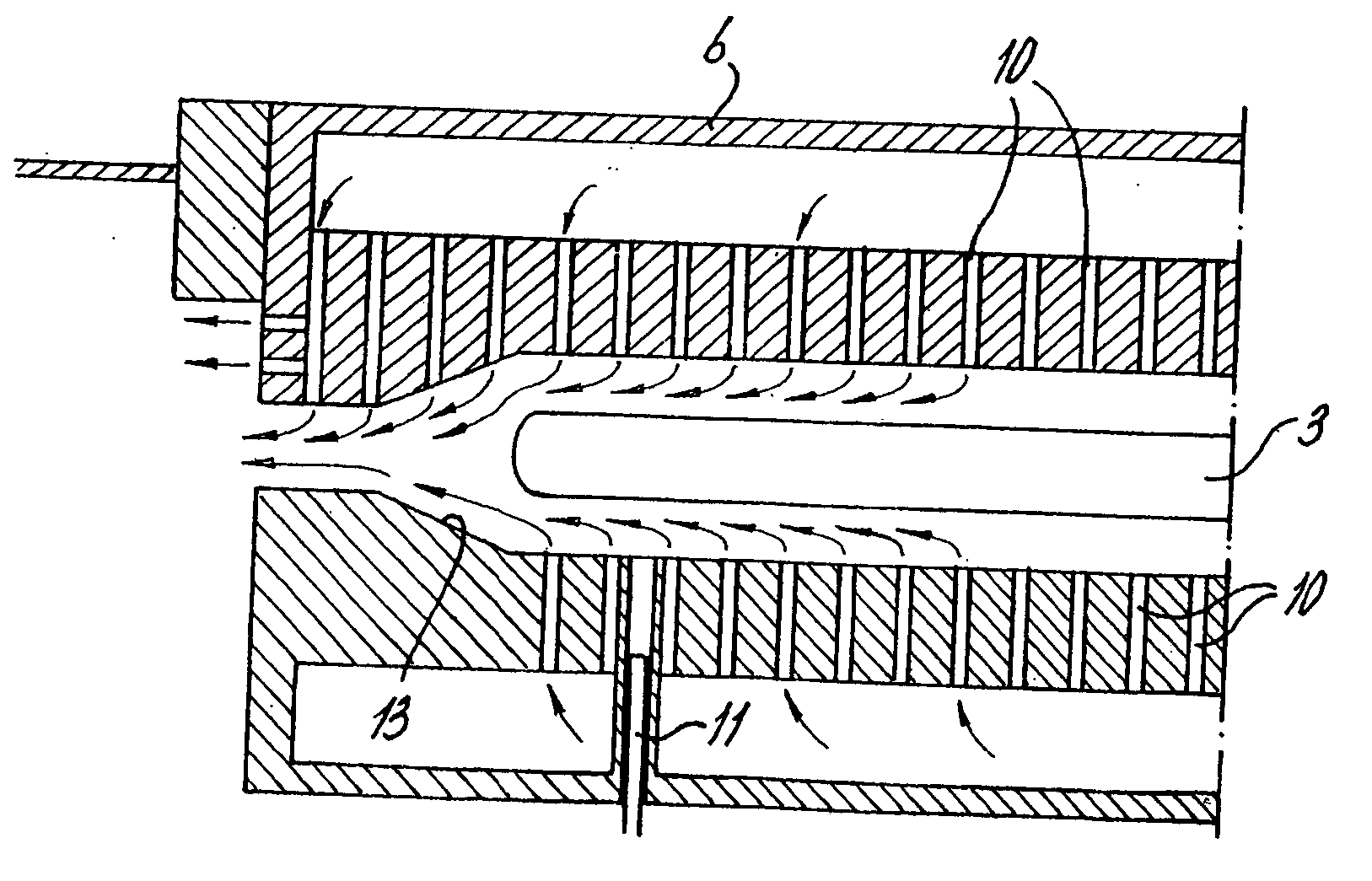

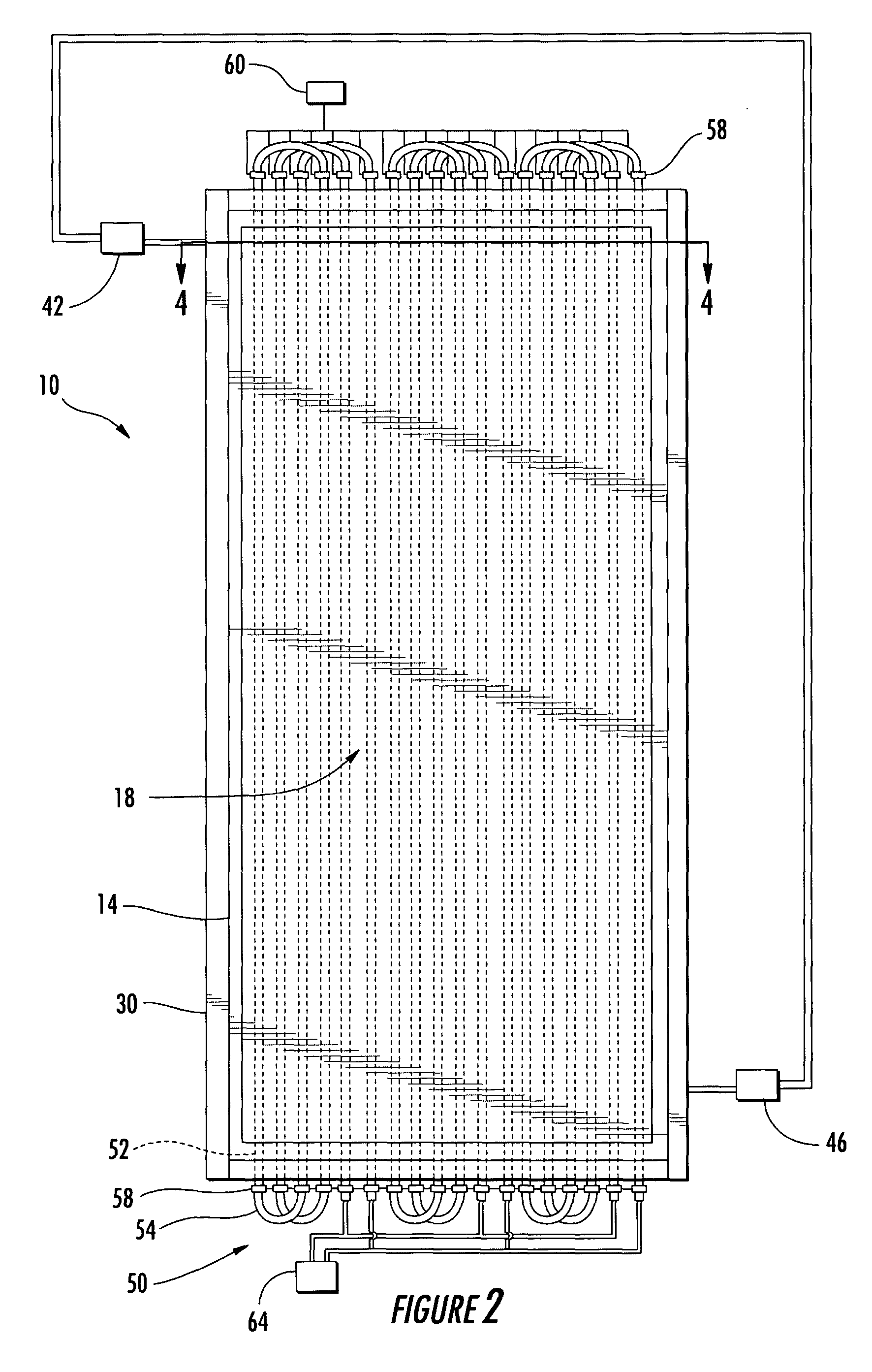

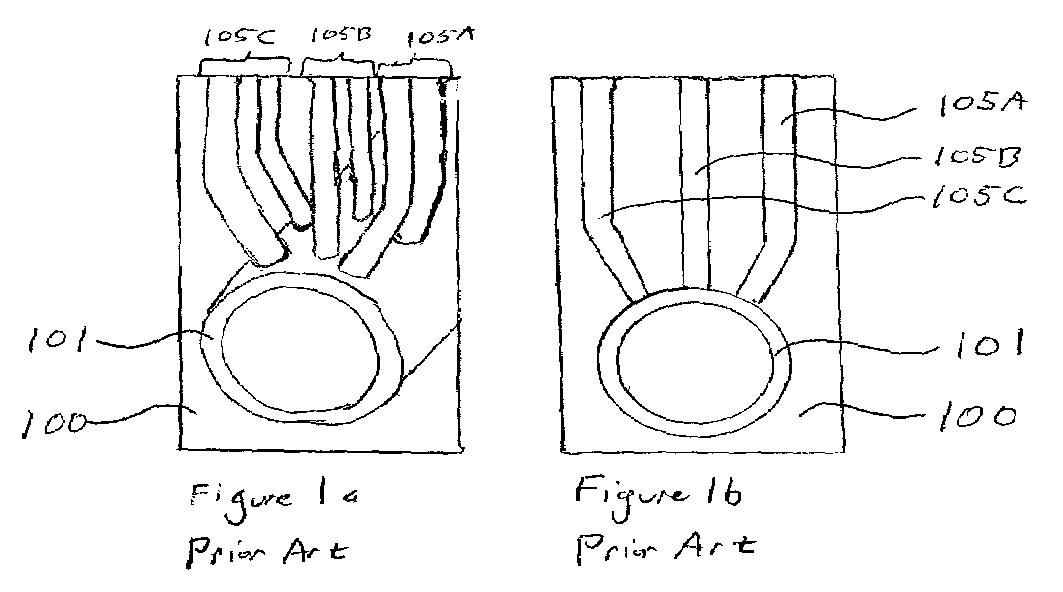

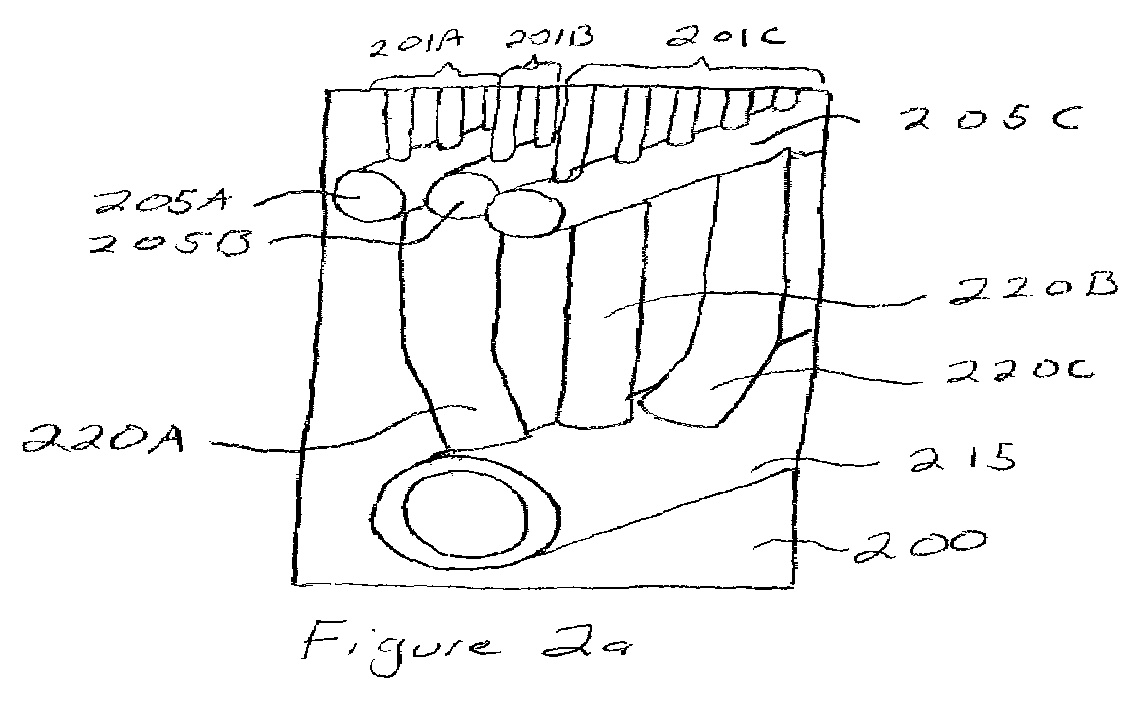

A semiconductor wafer is processed while being supported without mechanical contact. Instead, the wafer is supported by gas streams emanating from a large number of passages in side sections positioned very close to the upper and lower surface of the wafer. The gas heated by the side sections and the heated side sections themselves quickly heat the wafer to a desired temperature. Process gas directed to the “device side” of the wafer can be kept at a temperature that will not cause deposition on that side section, but yet the desired wafer temperature can be obtained by heating non-process gas from the other side section to the desired temperature. A plurality of passages around the periphery of the wafer on the non-processed side can be employed to provide purge gas flow that prevents process gas from reaching the non-processed side of the wafer and the adjacent area of that side section.

Owner:ASM INTERNATIONAL

Method and apparatus for supporting a semiconductor wafer during processing

InactiveUS20050037619A1Short timeIncrease temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasPartial heating

A semiconductor wafer is processed while being supported without mechanical contact. Instead, the wafer is supported by gas streams emanating from a large number of passages in side sections positioned very close to the upper and lower surface of the wafer. The gas heated by the side sections and the heated side sections themselves quickly heat the wafer to a desired temperature. Process gas directed to the “device side” of the wafer can be kept at a temperature that will not cause deposition on that side section, but yet the desired wafer temperature can be obtained by heating non-process gas from the other side section to the desired temperature. A plurality of passages around the periphery of the wafer on the non-processed side can be employed to provide purge gas flow that prevents process gas from reaching the non-processed side of the wafer and the adjacent area of that side section.

Owner:ASM INTERNATIONAL

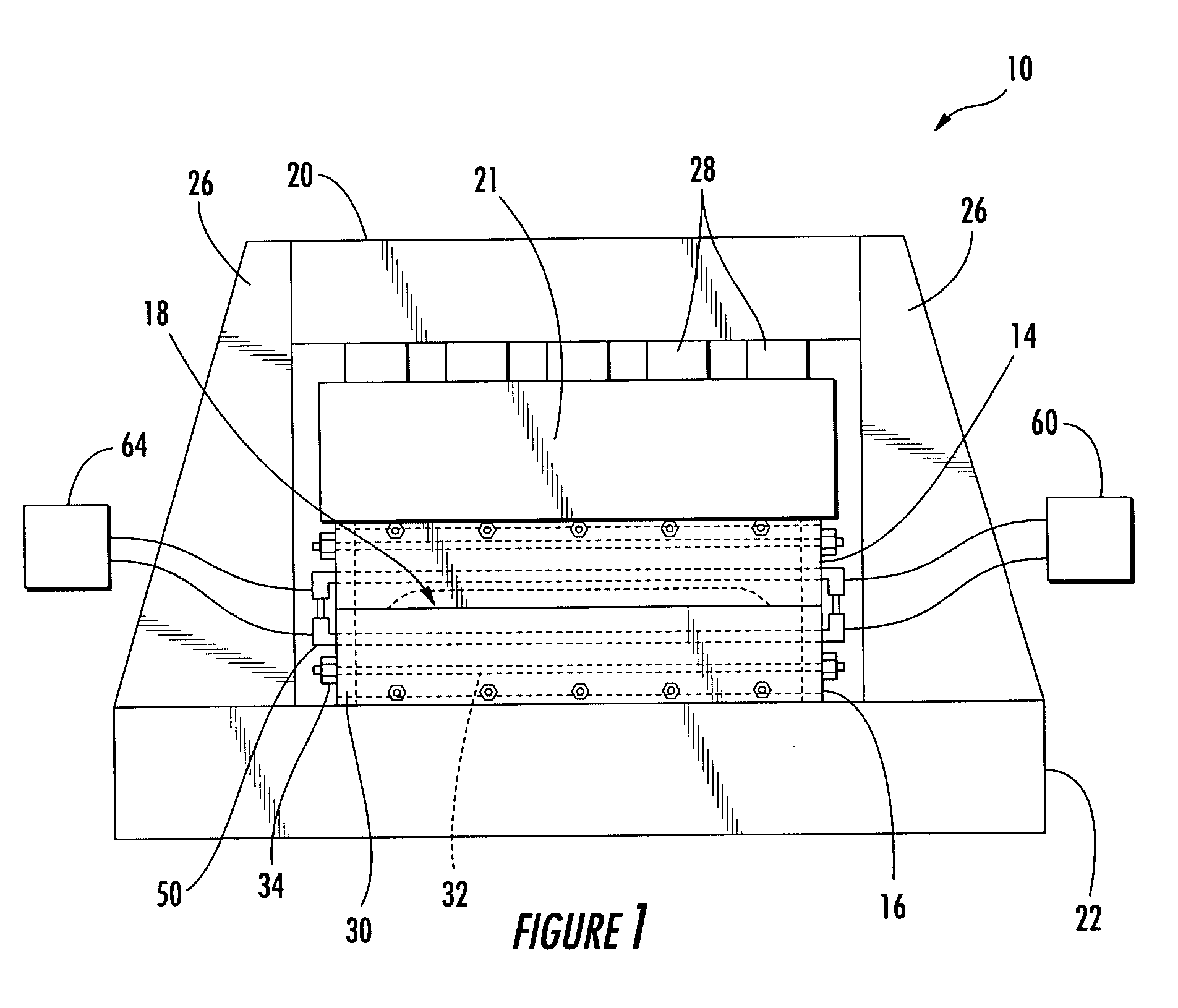

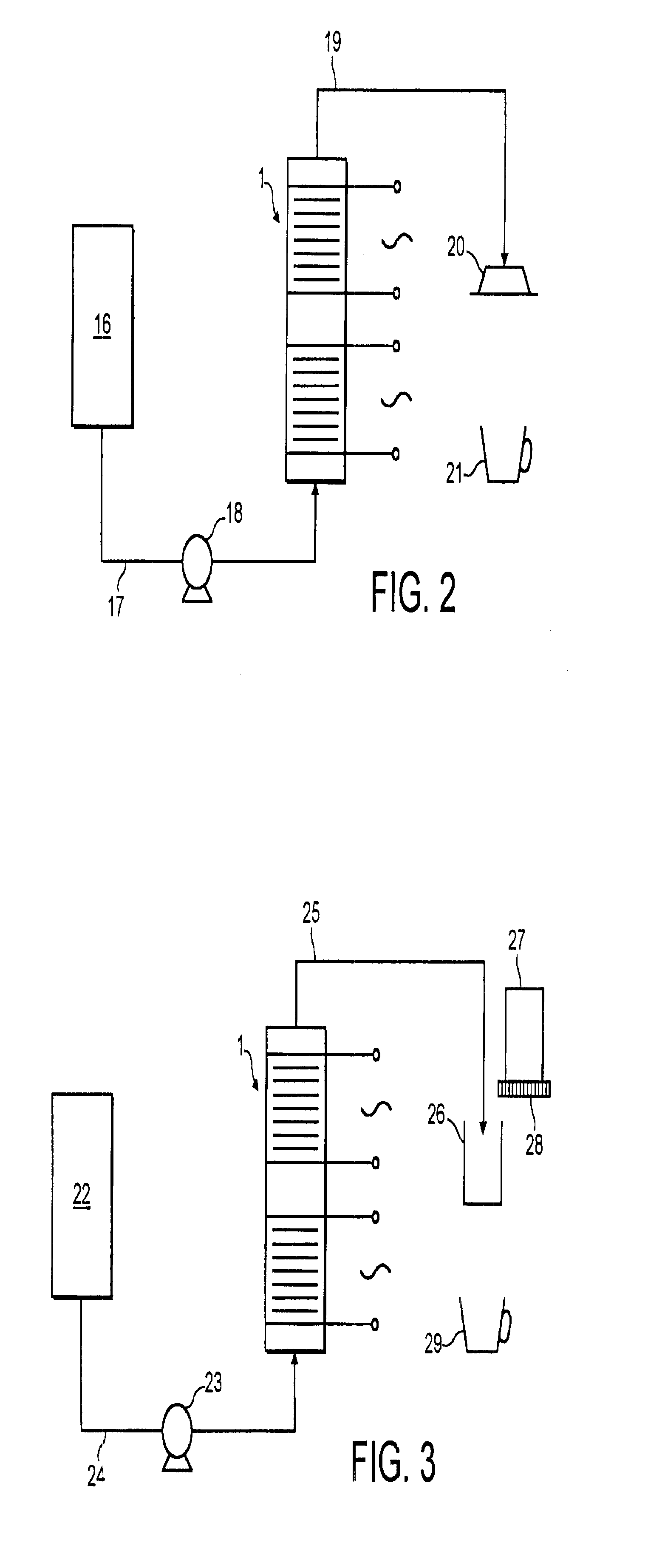

Forming apparatus and method

ActiveUS20050035115A1Reduce time and energyFast heatingMechanical working/deformationLaminationElectromagnetic fieldEngineering

An apparatus and method for forming a composite workpiece are provided. An electromagnetic field generator induces a current in a susceptor, thereby heating the workpiece in a die cavity. An elastomeric bladder in the cavity is inflated and urges the workpiece against a contour surface corresponding to a desired configuration of the workpiece. Coolant fluid can also be circulated through the die cavity to cool the workpiece. Thus, the workpiece can be heated, formed, and cooled quickly and without substantial heating of other components, thereby reducing the time and energy relative to conventional forming methods.

Owner:THE BOEING CO

Wiring Board for Light-Emitting Element

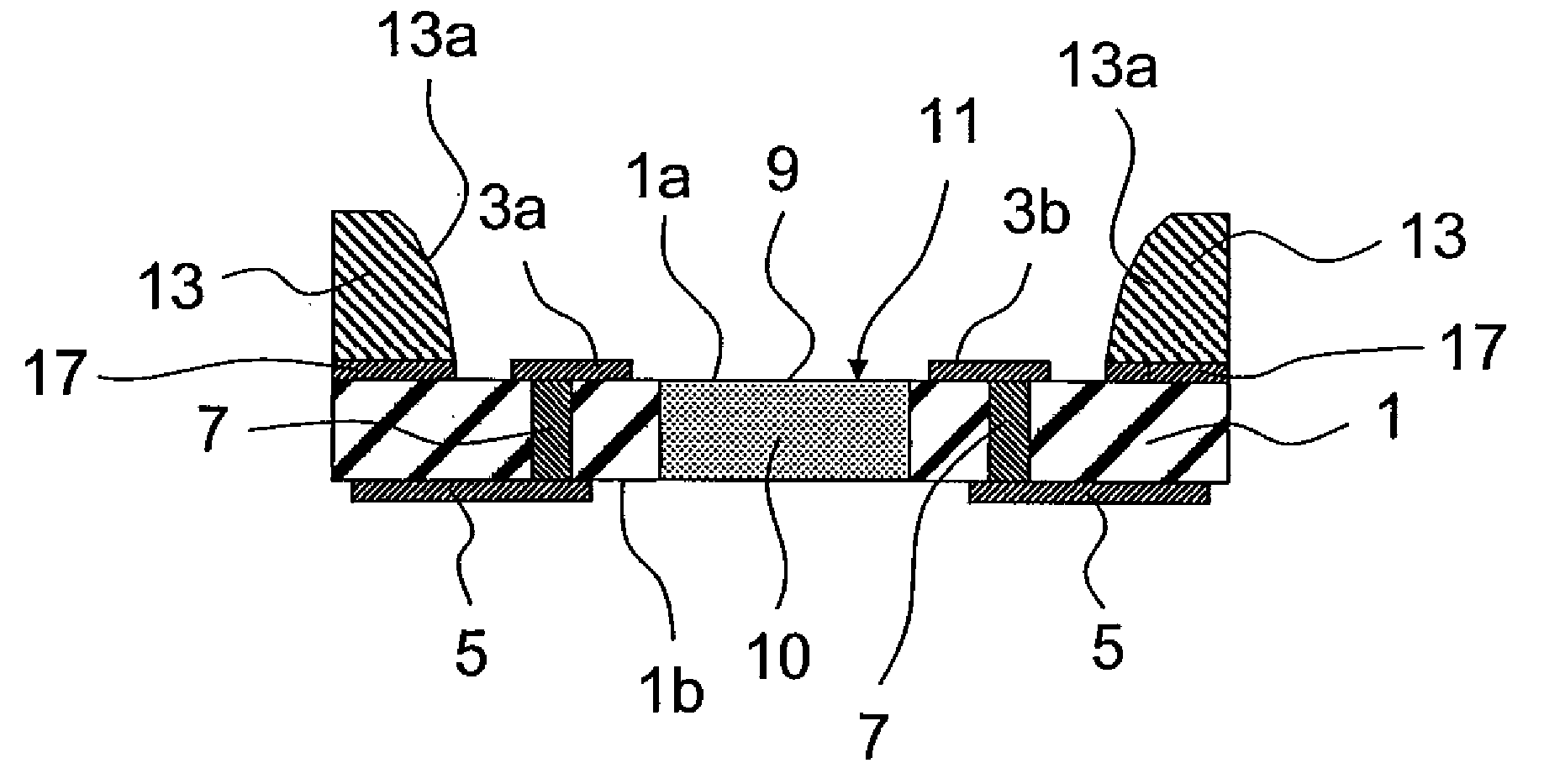

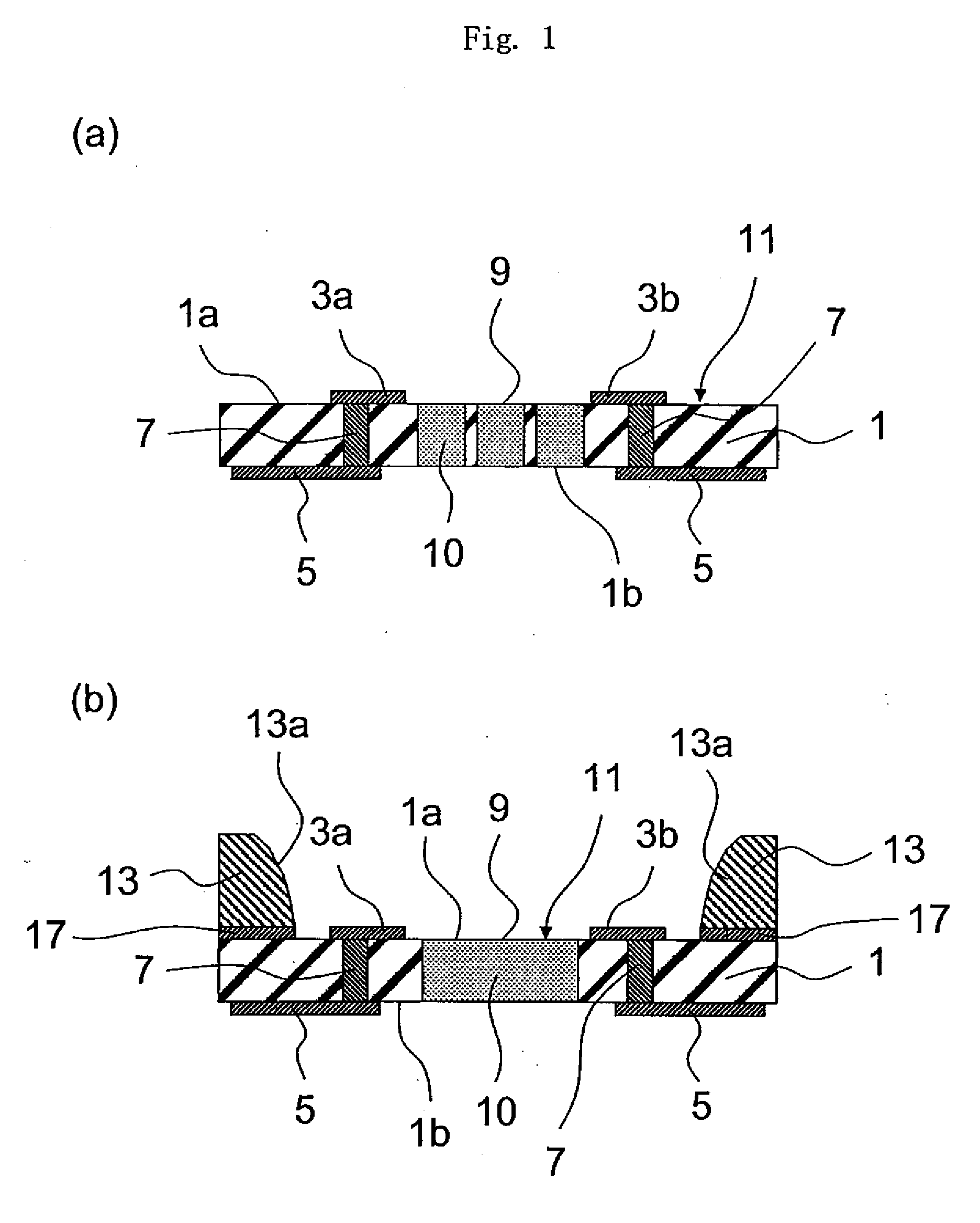

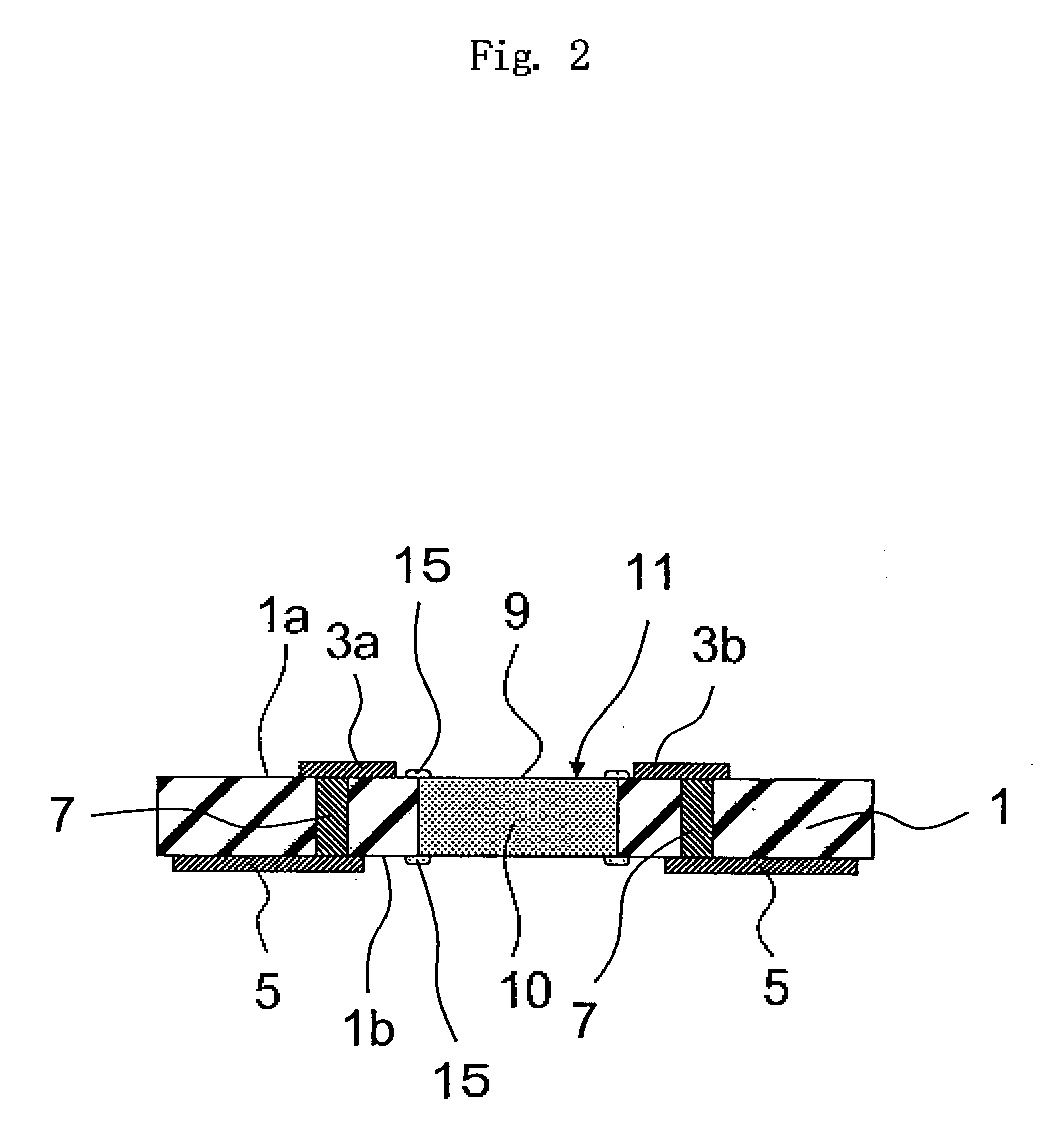

InactiveUS20080043444A1InhibitionHigh bonding strengthPrinted circuit aspectsSolid-state devicesElectrical conductorHeat conducting

A wiring board for light-emitting element, comprising a ceramic insulating substrate, and a conductor layer formed on the surface or in the inside of the insulating substrate, and having a mounting region mounting a light-emitting element on one surface of the insulating substrate; wherein the insulating substrate is provided with a heat-conducting pole-like conductor having a thermal conductivity higher than that of said insulating substrate; and the heat-conducting pole-like conductor is extending through the insulating substrate in the direction of thickness thereof from the light-emitting element mounting region of the insulating substrate, and is formed by the co-firing with the insulating substrate. The wiring board is produced inexpensively by co-firing, features excellent heat-radiating performance, is capable of quickly radiating the heat from the light-emitting element when the light-emitting element is mounted, and effectively prevents a decrease in the brightness of the light-emitting element caused by the heat.

Owner:KYOCERA CORP

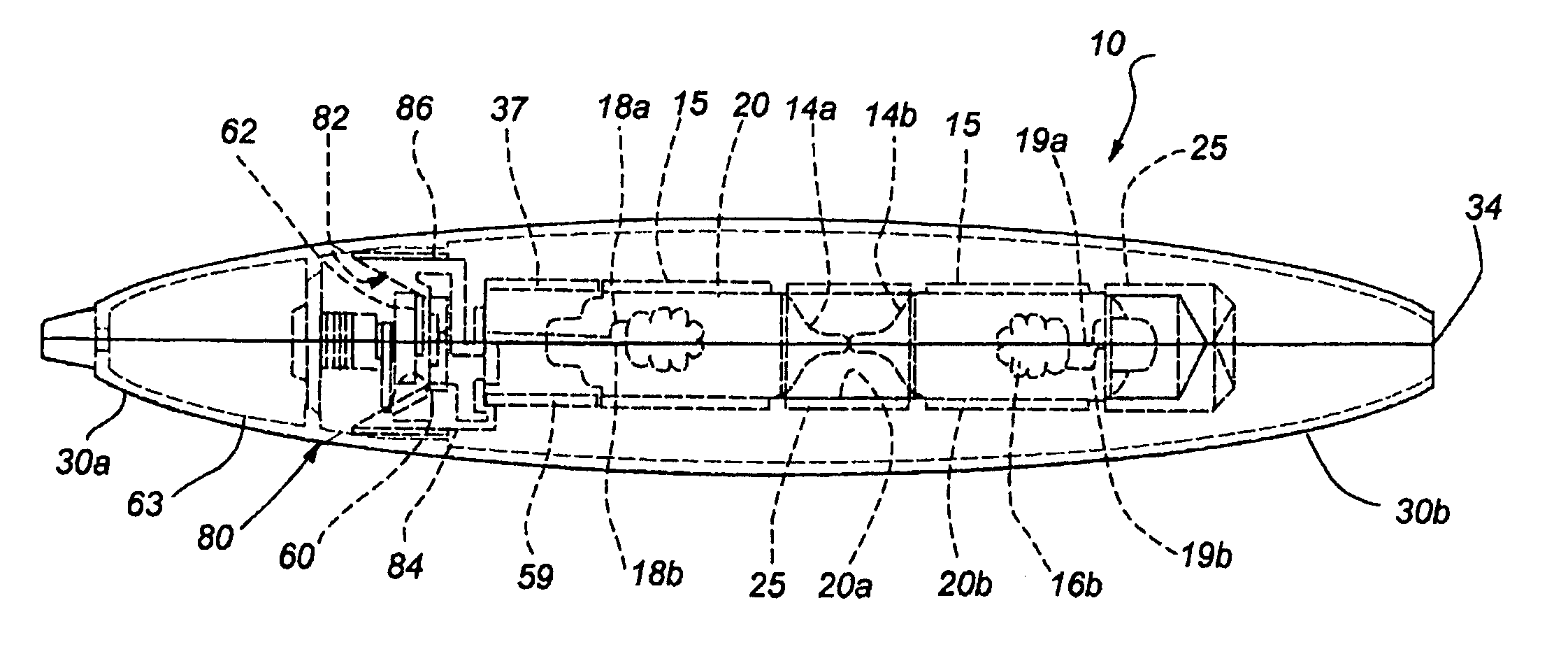

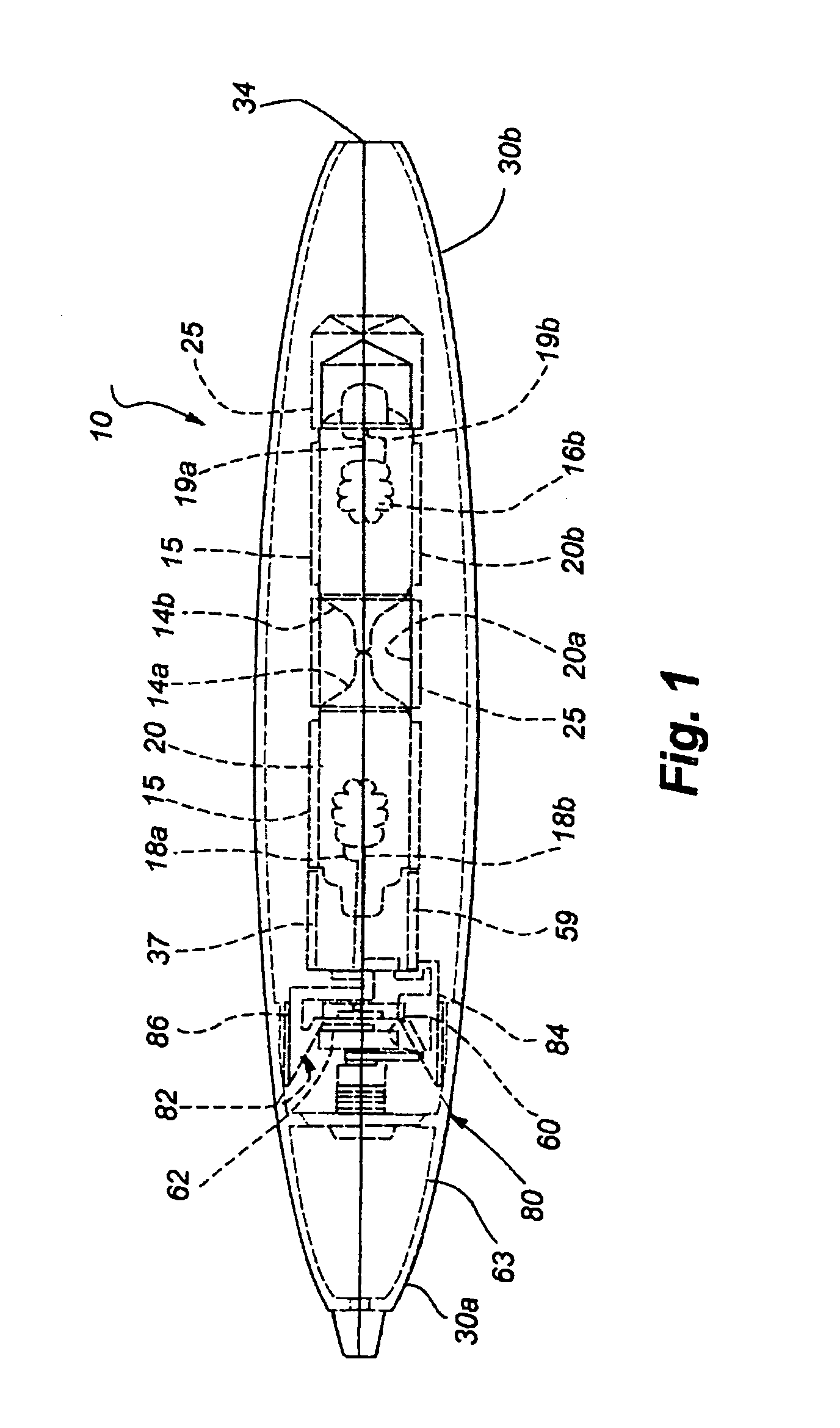

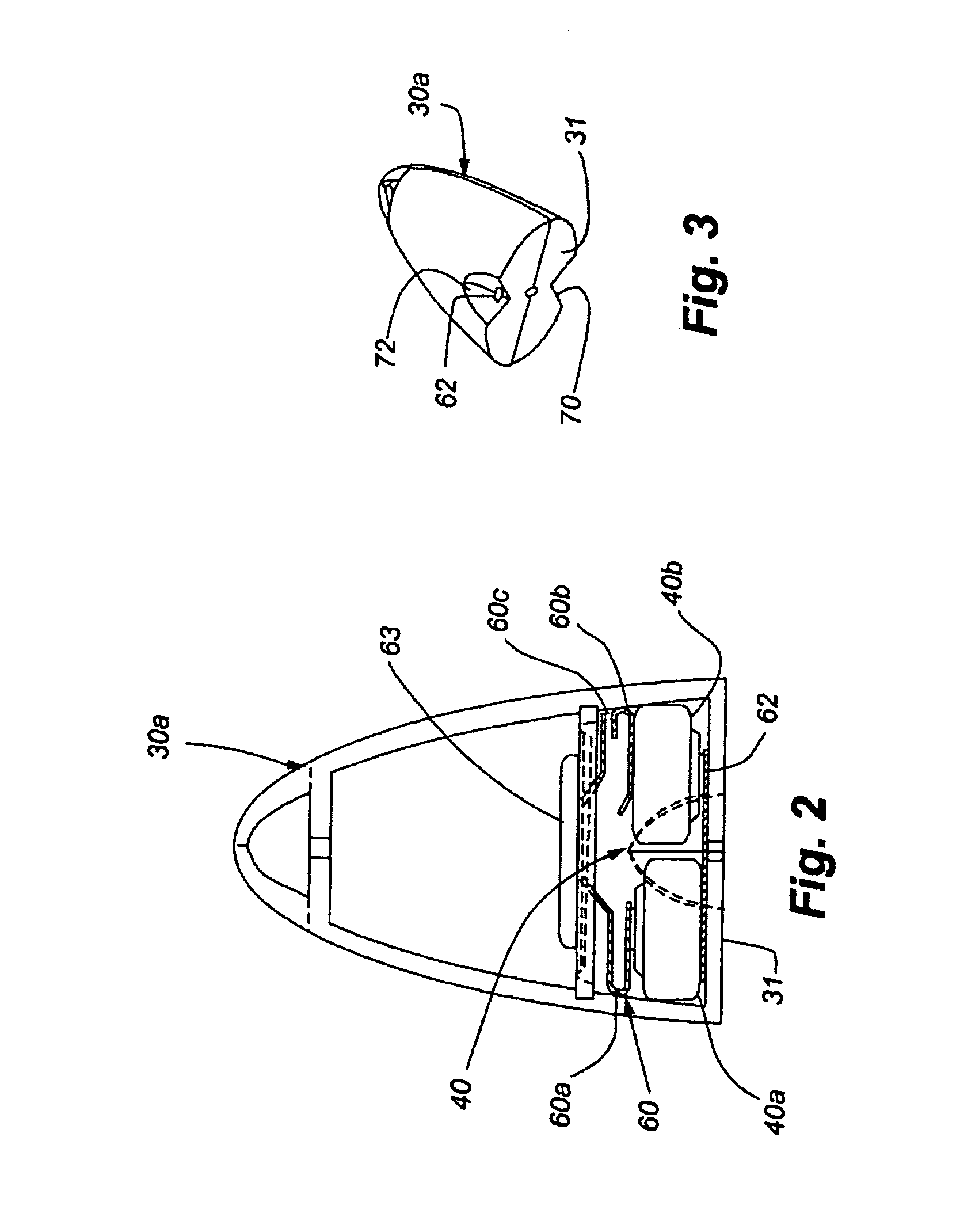

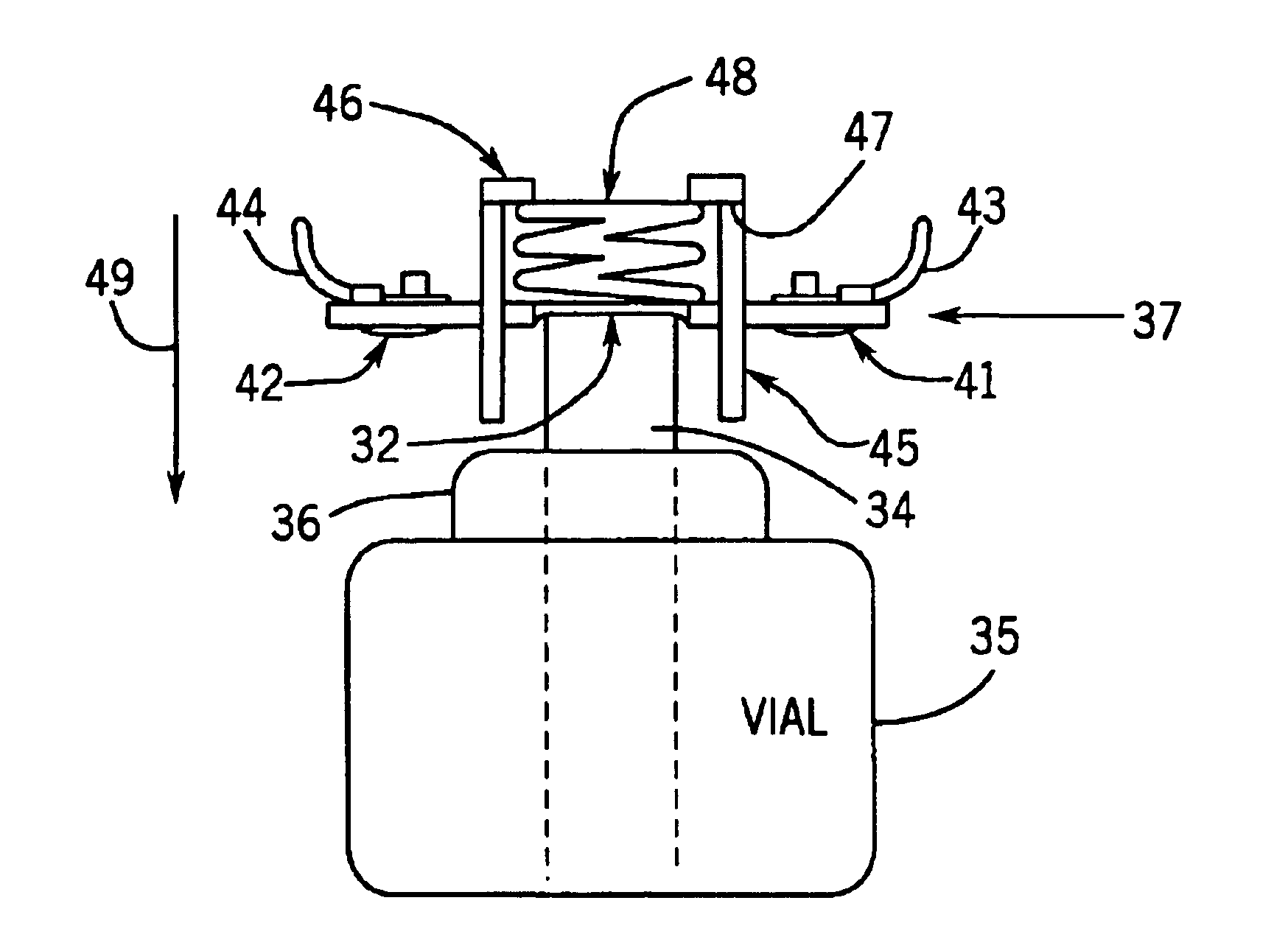

Method and apparatus for vaporizing a compound

ActiveUS7458374B2Heating fastBurn quicklyOther heat production devicesAerosol deliveryInhalationMedicine

Disclosed is a method and device for rapid heating of a coated substance which preferably includes a drug to vaporized for inhalation therapy. A device in accordance with the present invention preferably includes a substrate which has an interior surface surrounding an interior region and an exterior surface upon which the coated substance is to be adhered. Though the substrate is preferably metallic, it does not need to be. A combustible element is placed in the interior region of the rigid substrate and an igniter is connected to the combustible element. The igniter is for initiating oxidation of the combustible element. Preferably, the coated substance is vaporized inside of a housing to allow the vaporized drug to aerosolize and be inhaled by a user.

Owner:ALEXZA PHARMA INC

Localized surface volatilization

InactiveUS6909840B2Improved vaporizationIncrease vapor pressureDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceProduct gas

The present invention relates to an apparatus and method for rapid flash-like volatilization of high and low vapor pressure components from liquid or solid emanators which is in contact with a point or localized heat source. Vaporization is promoted by a geometrically small electrically resistive heating element with variable activation for pulsed or cyclic heating of an emanating surface containing the volatile components. The apparatus is primarily directed towards the treatment of residential air for fragrancing, odor elimination, treatment of insects or pests, air sanitization, air and surface antibacterial or antimicrobial treatment, or other ambient air or surface modification by way of gas or vapor distribution.

Owner:SC JOHNSON & SON INC

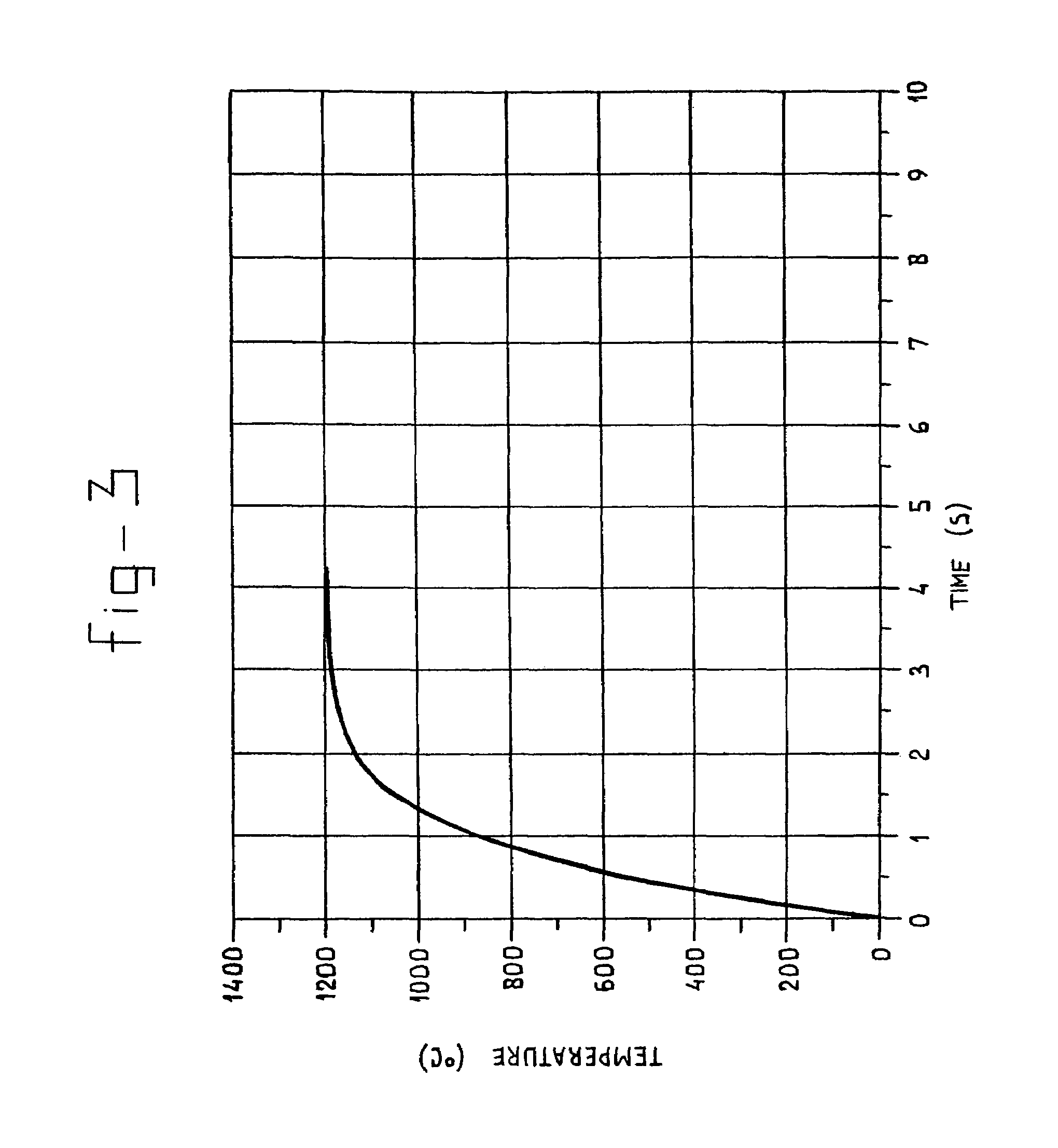

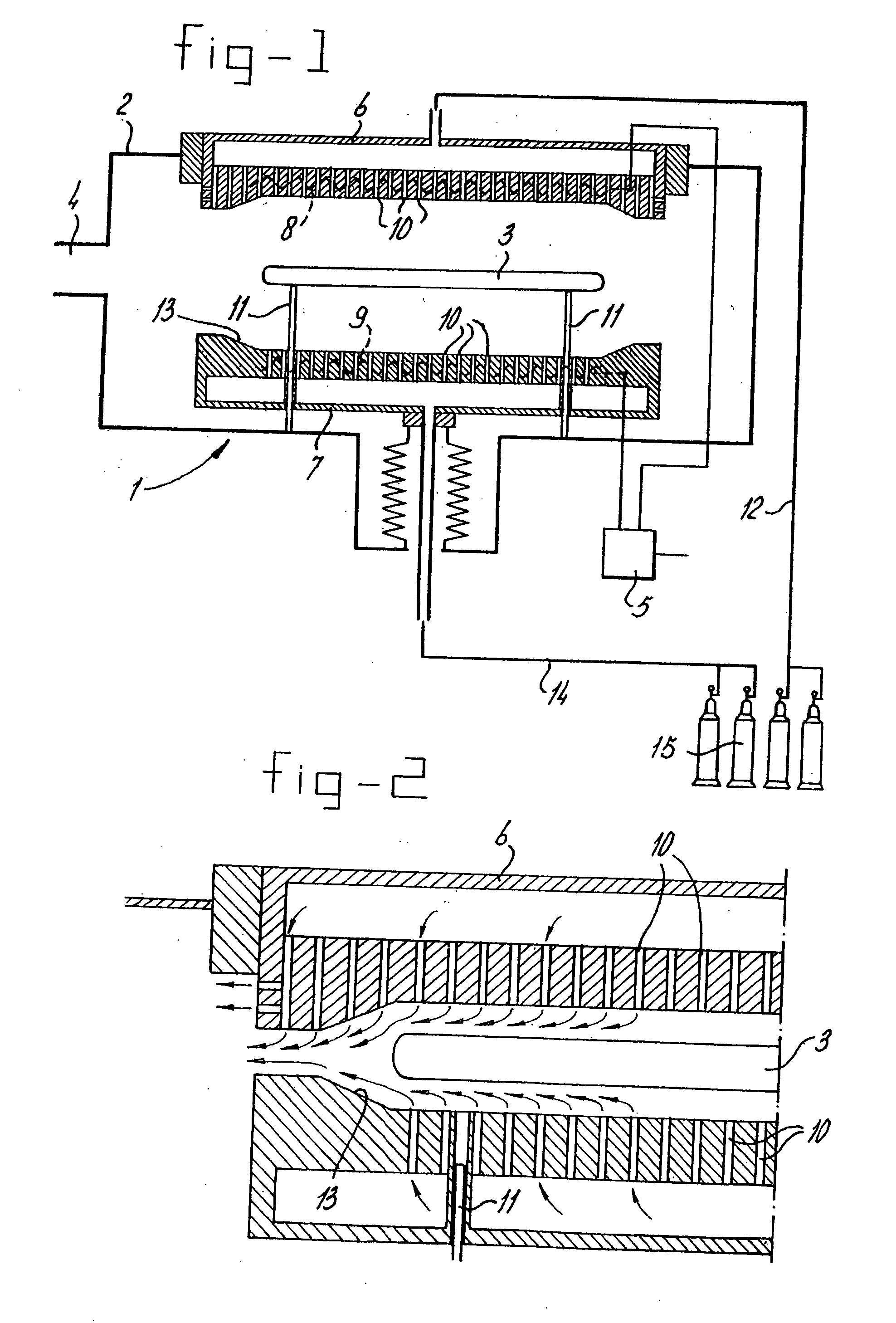

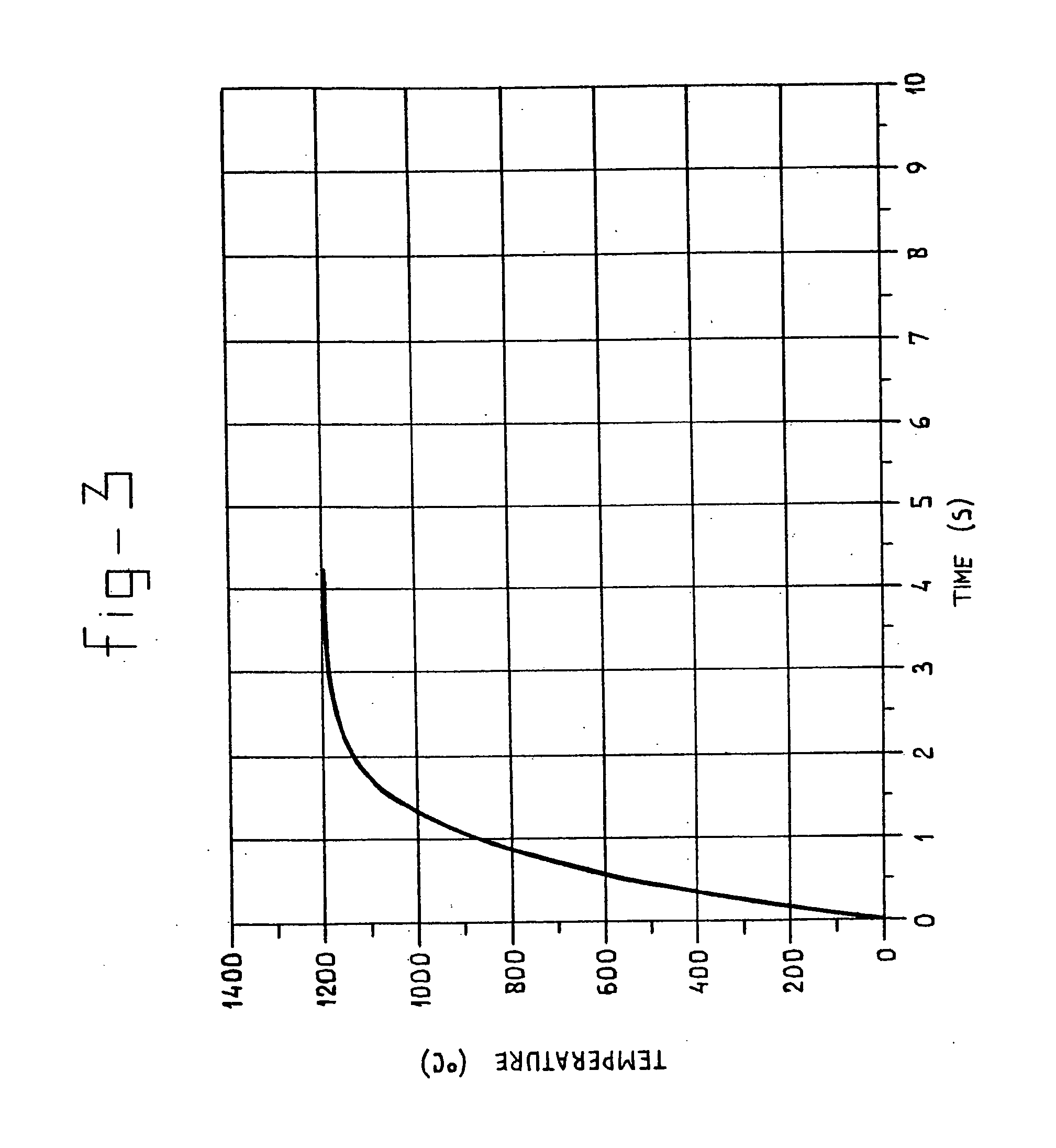

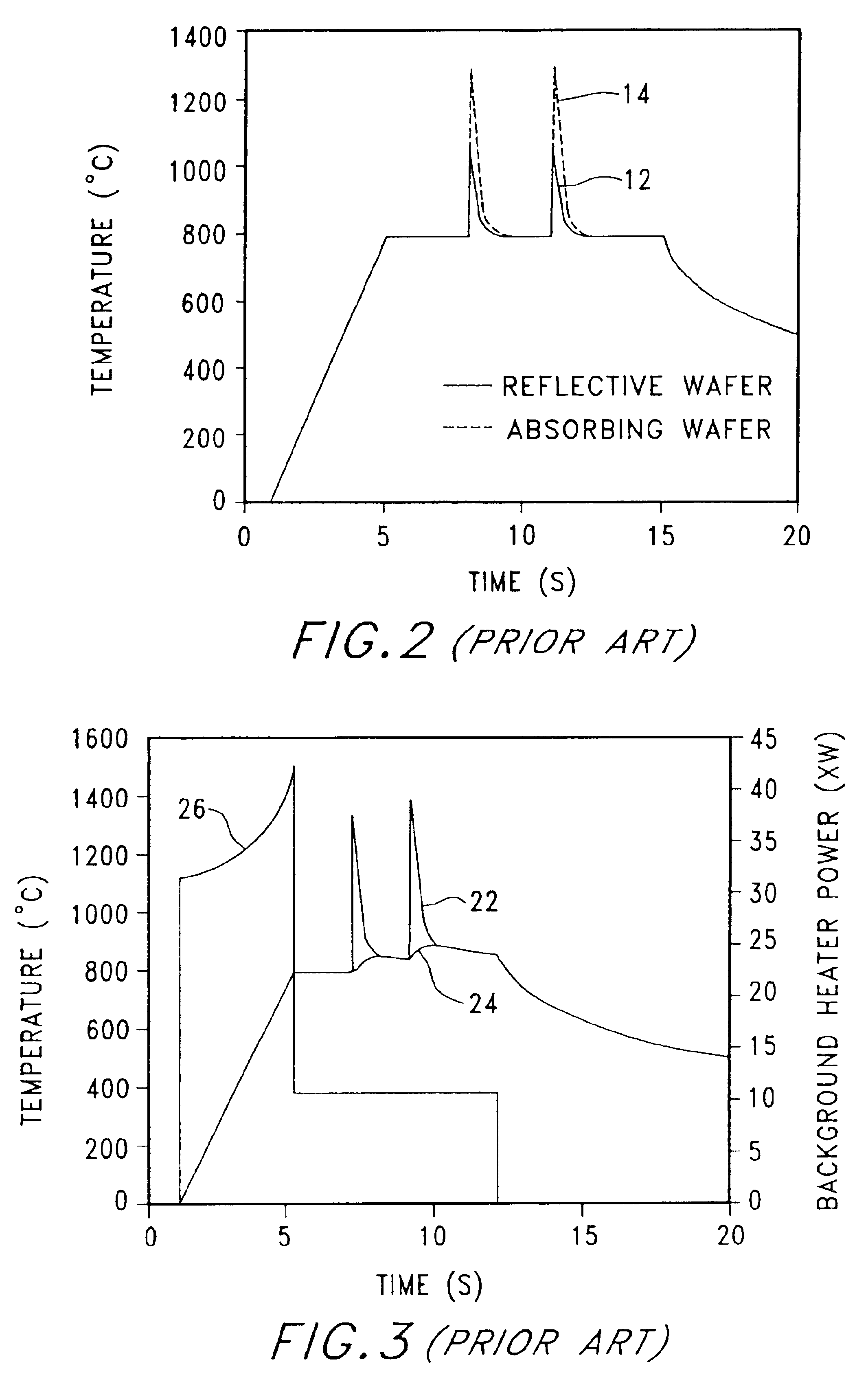

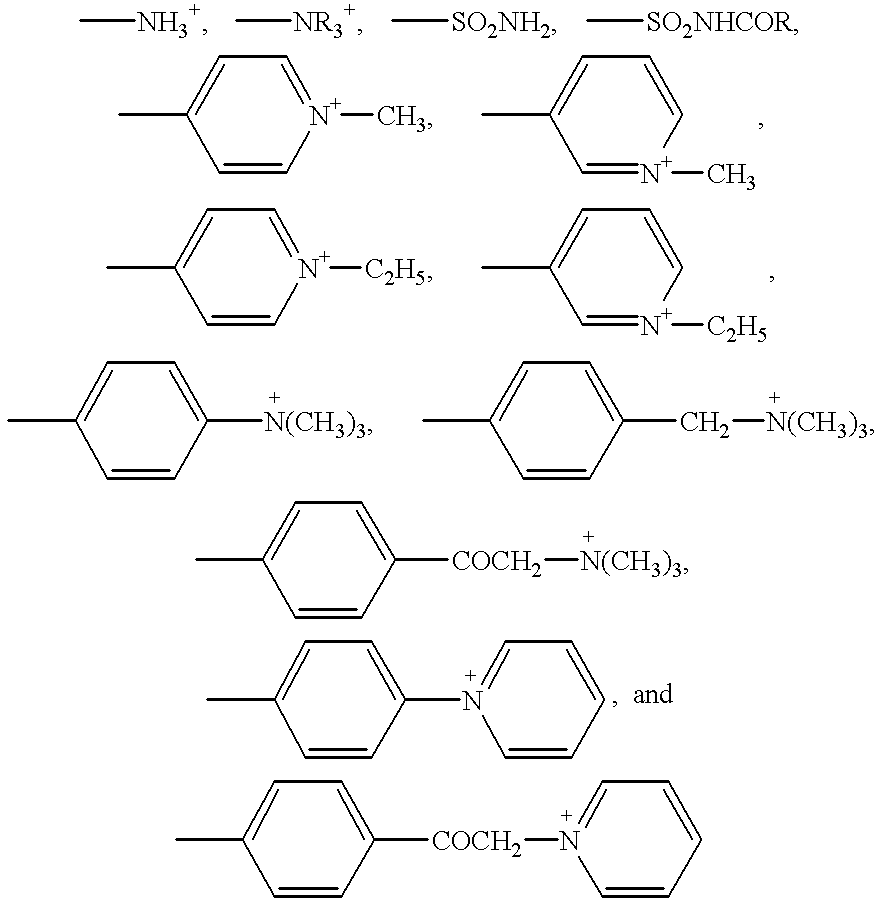

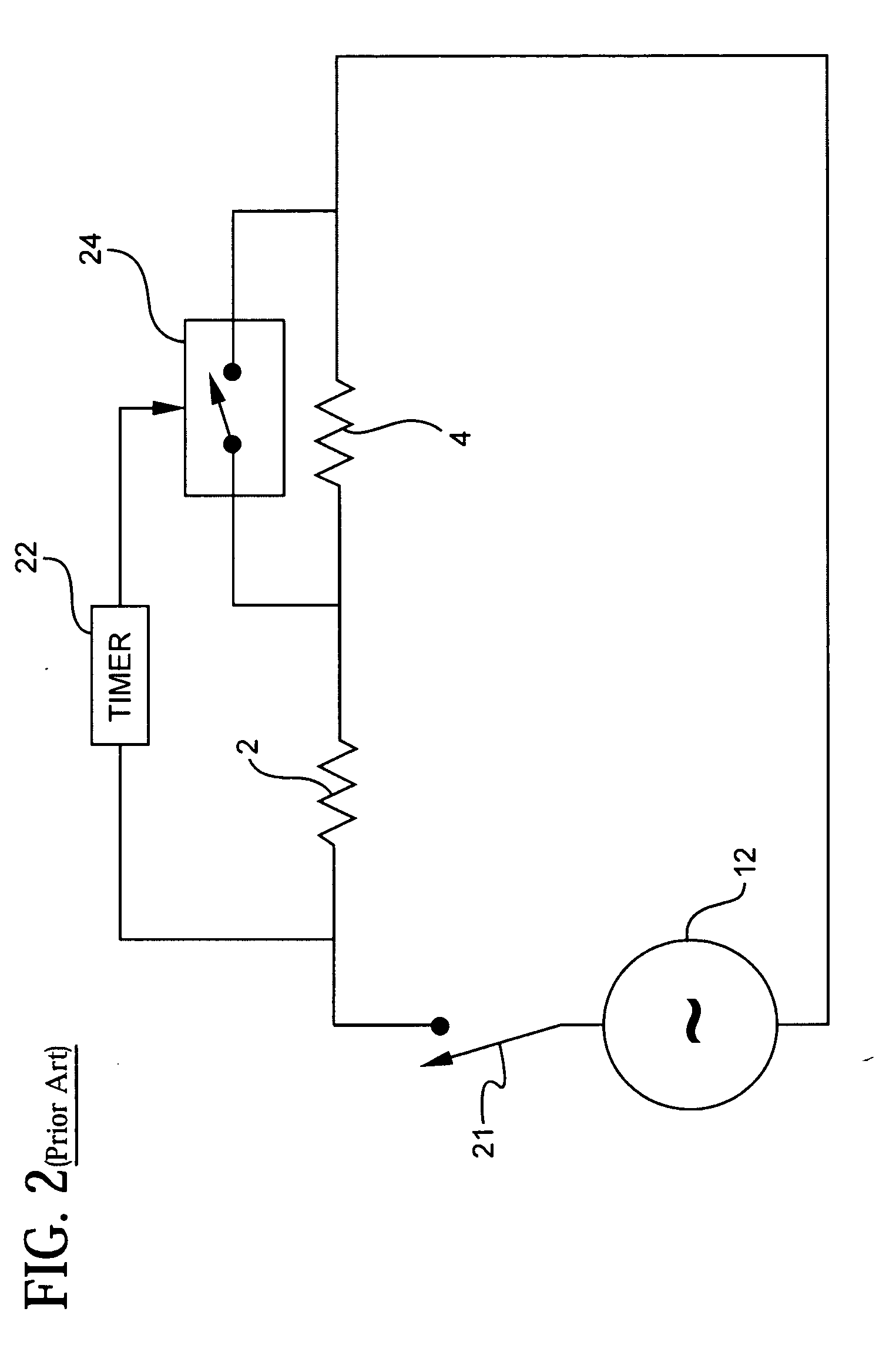

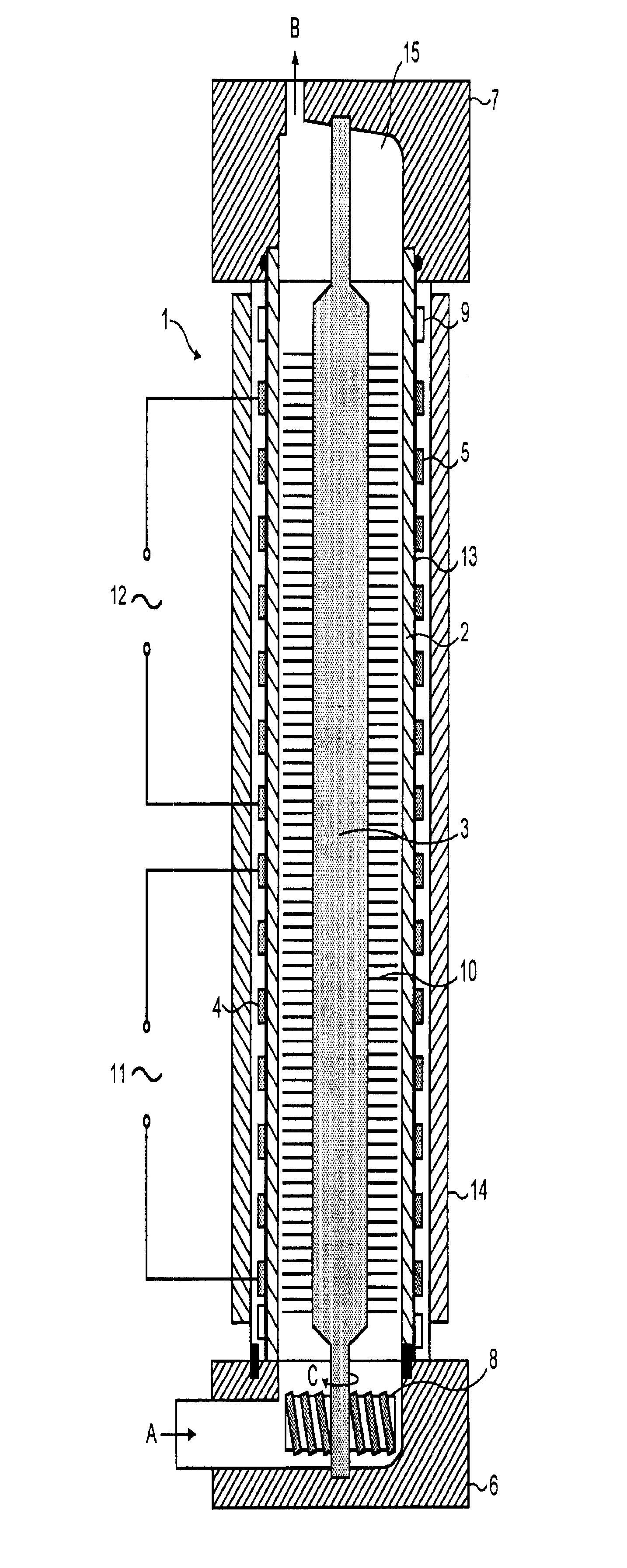

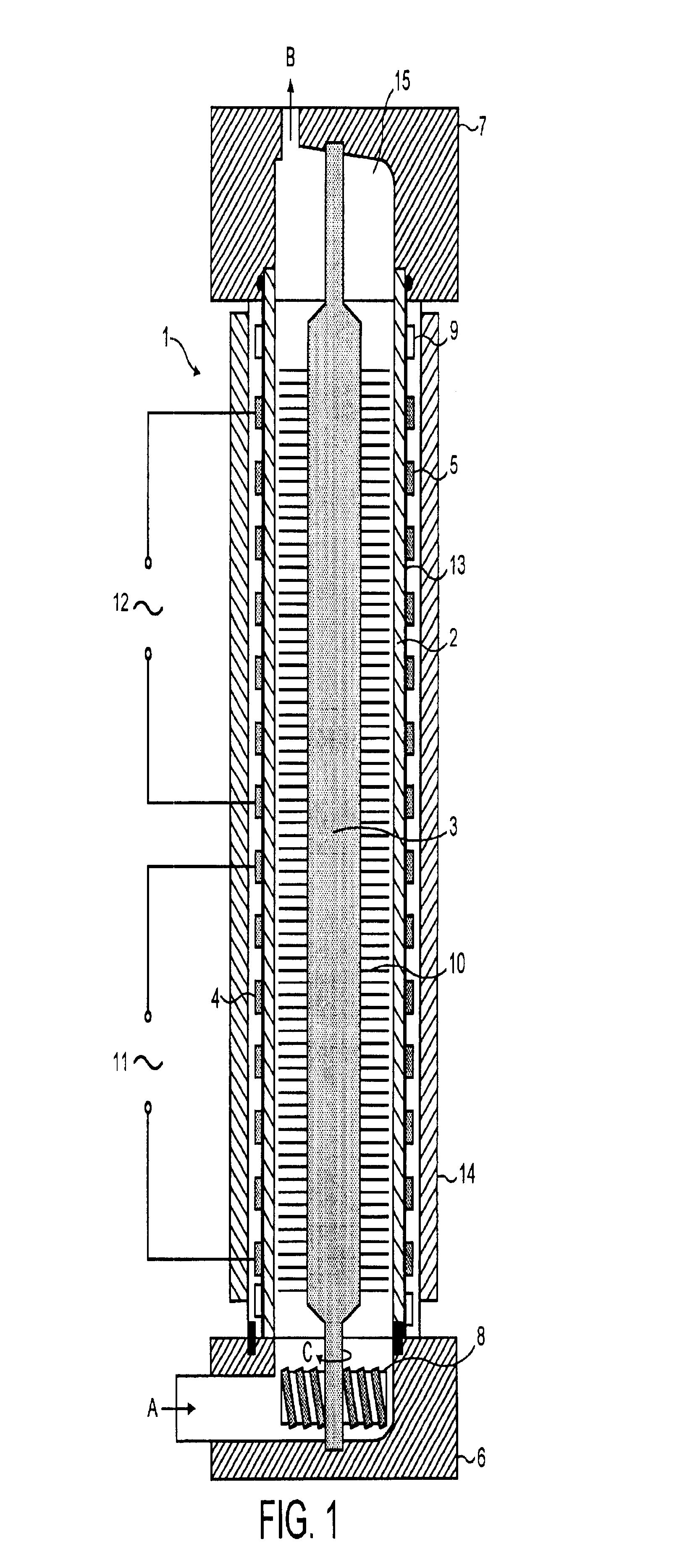

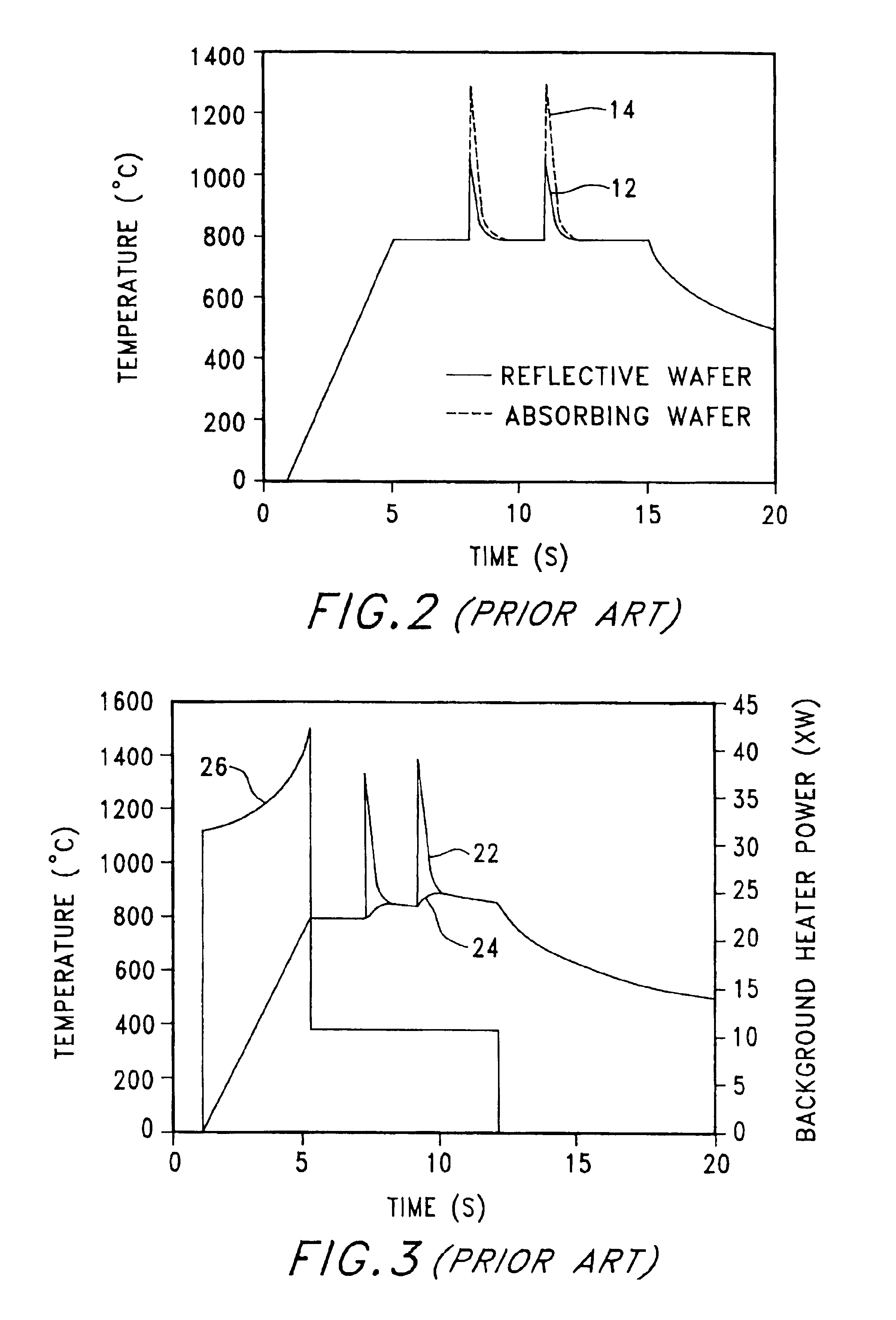

Pulsed processing semiconductor heating methods using combinations of heating sources

InactiveUS6849831B2Heating fastIncrease temperatureDrying solid materials with heatMuffle furnacesPhysicsPulse parameter

Pulsed processing methods and systems for heating objects such as semiconductor substrates feature process control for multi-pulse processing of a single substrate, or single or multi-pulse processing of different substrates having different physical properties. Heat is applied a controllable way to the object during a background heating mode, thereby selectively heating the object to at least generally produce a temperature rise throughout the object during background heating. A first surface of the object is heated in a pulsed heating mode by subjecting it to at least a first pulse of energy. Background heating is controlled in timed relation to the first pulse. A first temperature response of the object to the first energy pulse may be sensed and used to establish at least a second set of pulse parameters for at least a second energy pulse to at least partially produce a target condition.

Owner:MATTSON TECHNOLOGY +1

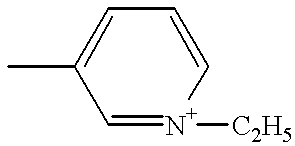

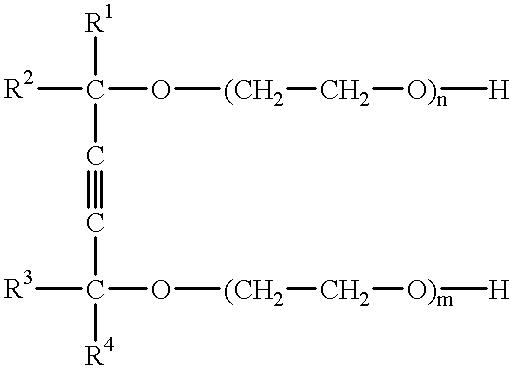

Ink, ink-jet recording process, recording unit, ink cartridge and ink-jet recording apparatus

InactiveUS6375317B1Stable formationQuality improvementMeasurement apparatus componentsInksPolymer scienceAqueous medium

An ink comprising particles of self-dispersing carbon black having at least one hydrophilic group at the surface thereof, and calcium in an aqueous medium. The ink can form images excellent in fastness properties such as water fastness and light fastness and character quality, and can be stably ejected from a recording head irrespective of printing environment.

Owner:CANON KK

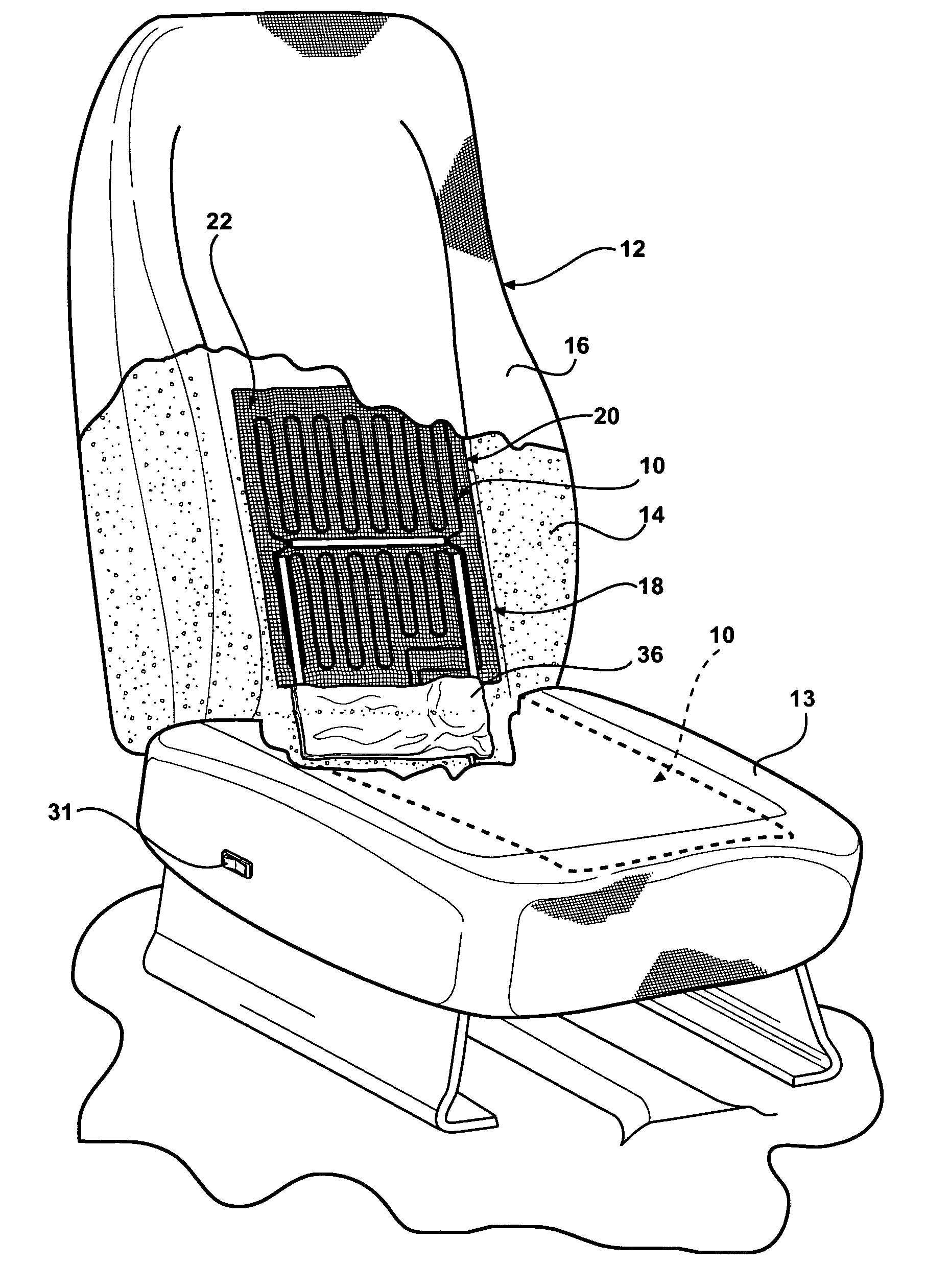

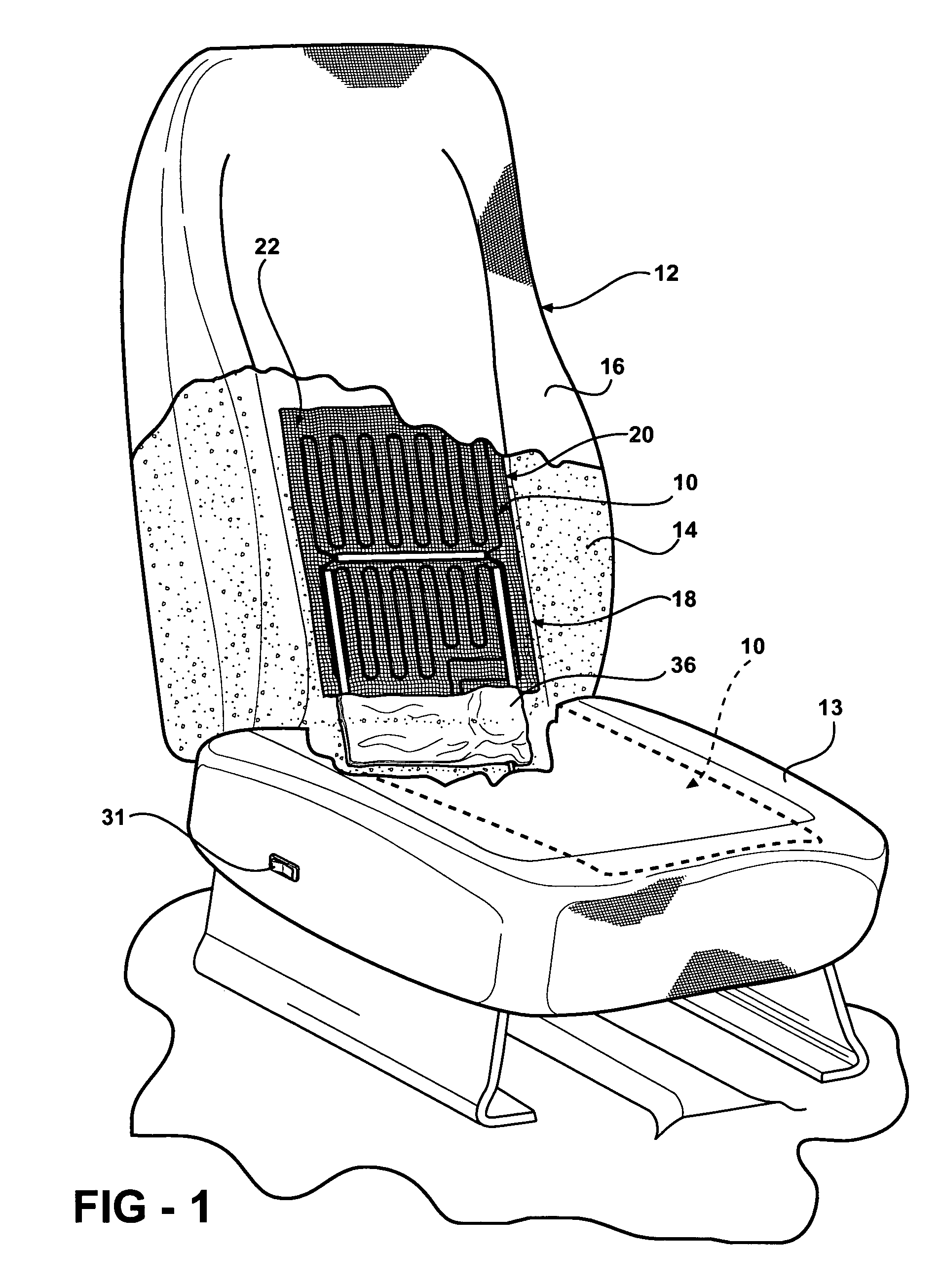

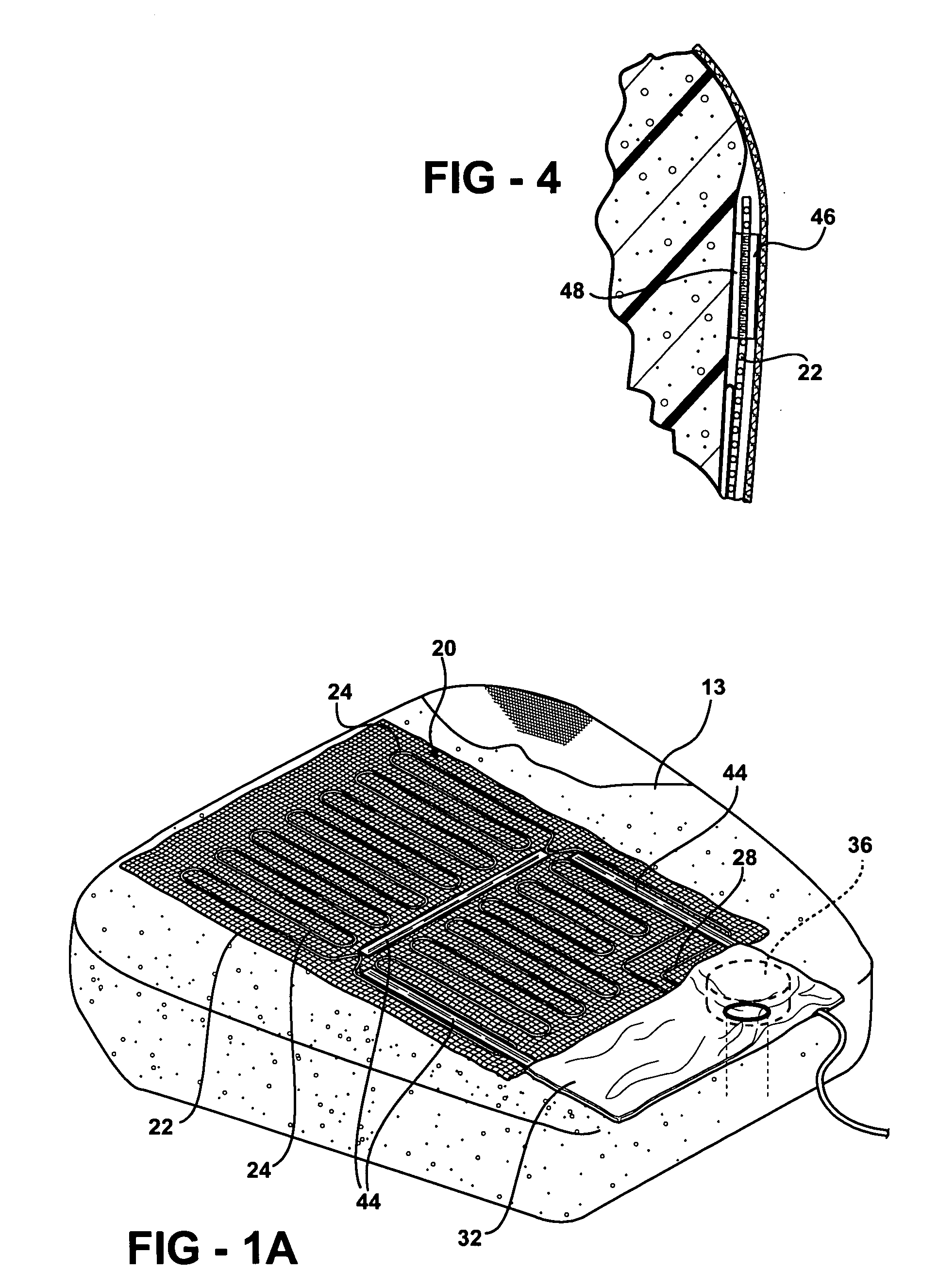

Arrangement and method for providing an air flow within an upholstered seat

InactiveUS6988770B2Large runnerHeating fastSeat heating/ventillating devicesStoolsSolid massEngineering

An arrangement and method for producing an air flow within an upholstered seat back or bottom in which a seat insert has a blower mounted in a pouch at the crotch region between the seat back and bottom and has an outlet which directs air flow up through a spacer layer so as to distribute air flow out through a porous seat back cover or beneath a nonporous cover. A solid plastic backing sheet underlies the spacer layer to direct all air flow out from the spacer layer, the plastic sheet also forming the blower pouch. A mesh layer is bonded to the plastic sheet and used to attach the insert to the seat cushion as well as to carry a heating element pattern extending thereover to also enable electrical heating of the seat back or bottom.

Owner:WITCHIE RONALD G

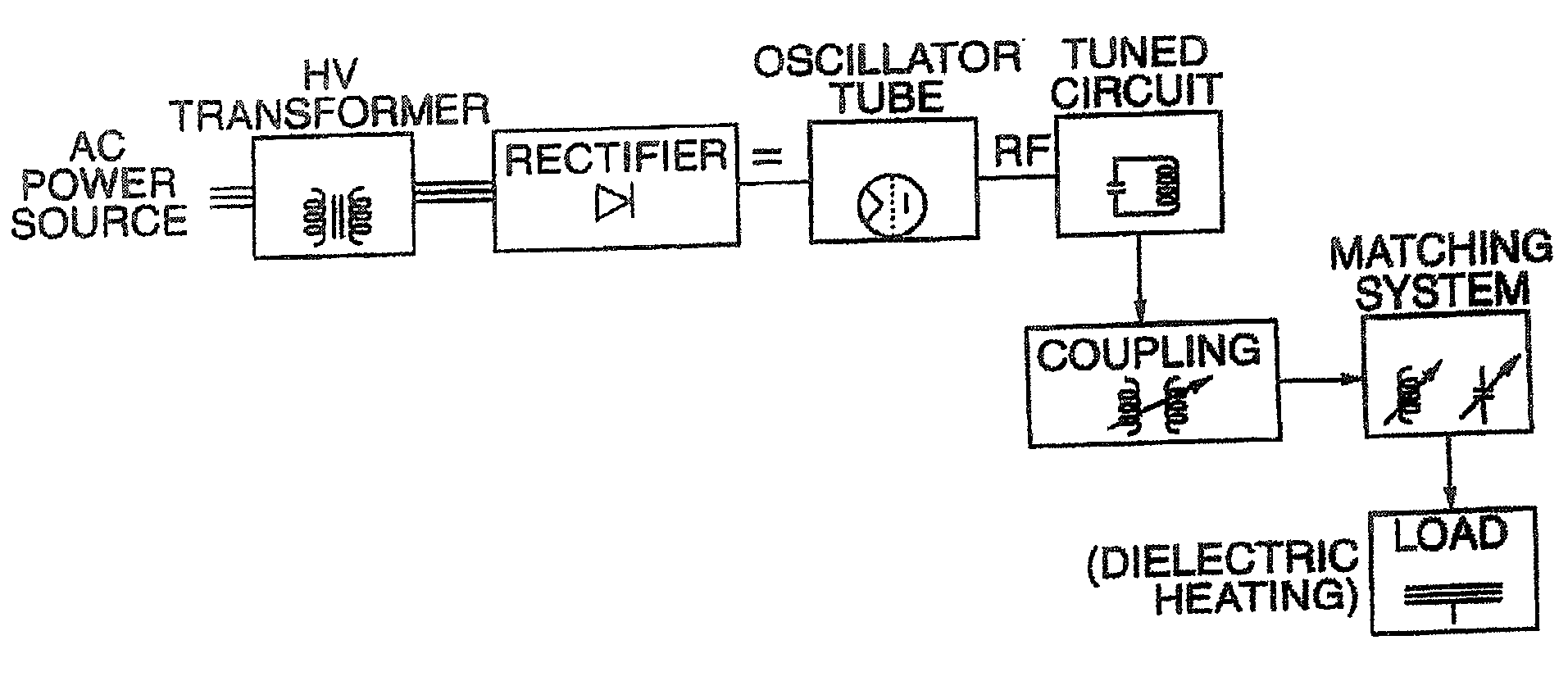

Variable frequency automated capacitive radio frequency (RF) dielectric heating system

InactiveUS20020047009A1Improve sealingLowering gap impedanceMeat/fish preservation by heatingDielectric heating circuitsRadio frequencyHeating system

A food product is heated by maintaining the food product in an AC electrical field generated by an RF signal. As the heating takes place, maximum energy is delivered to the food product using automatic impedance matching to adjust the rate of the process.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV +1

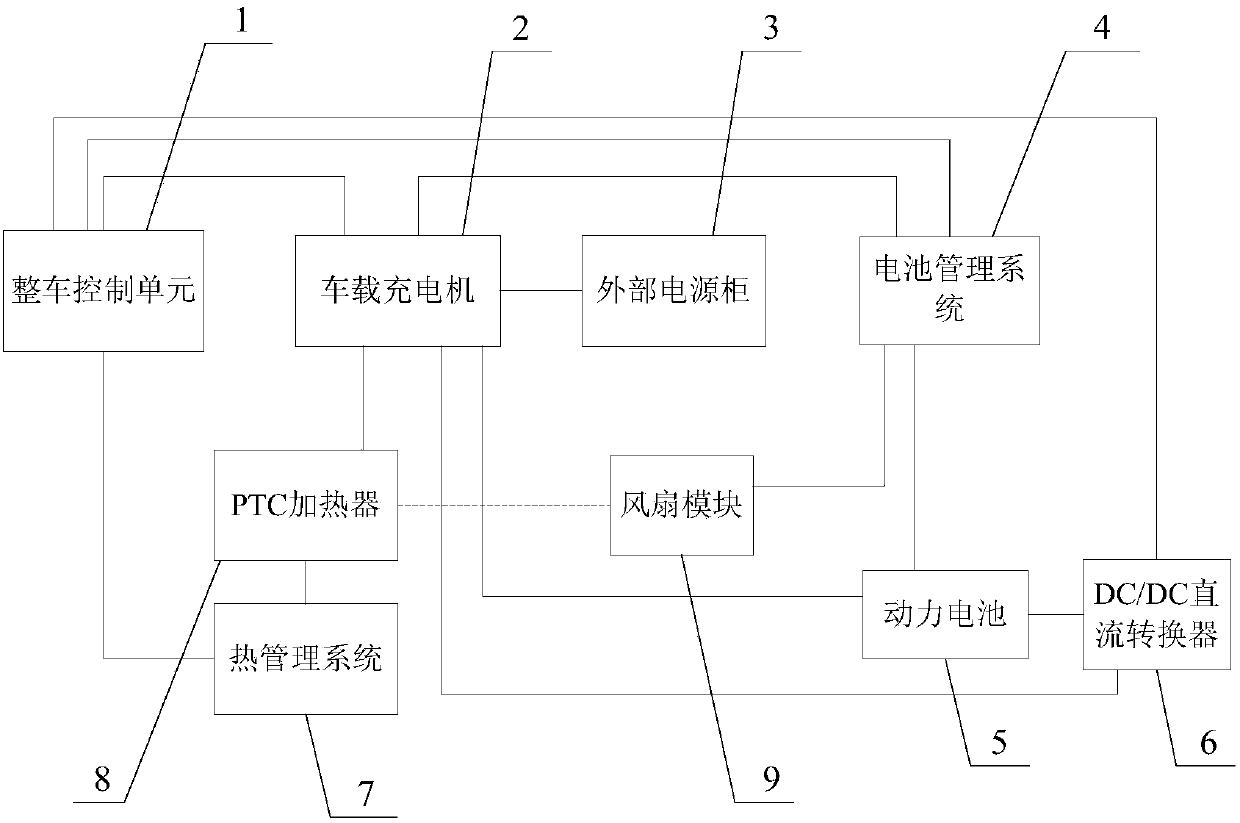

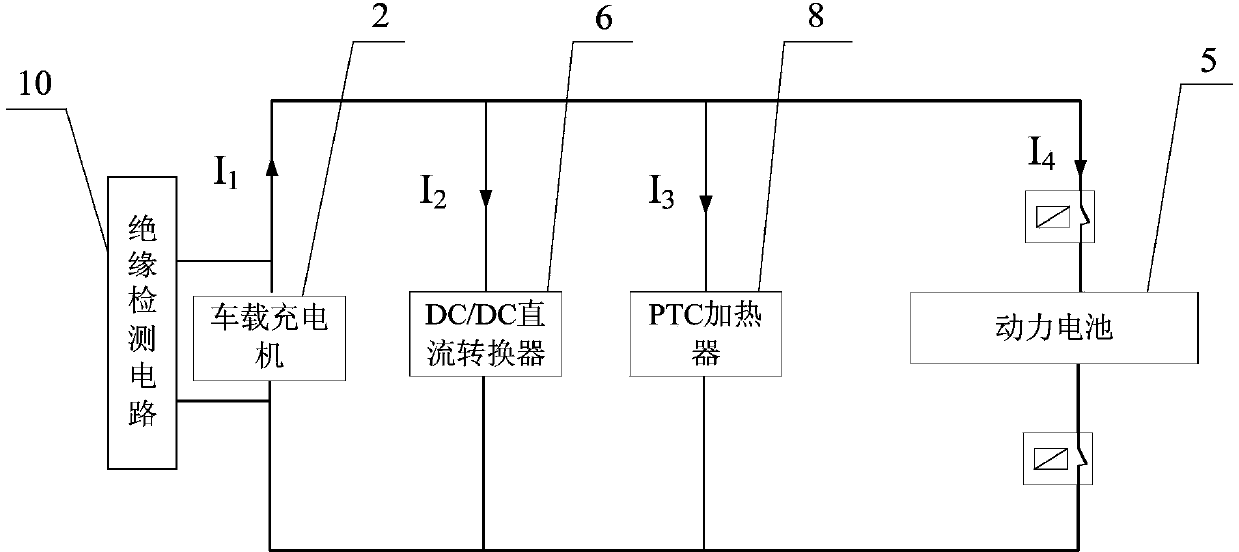

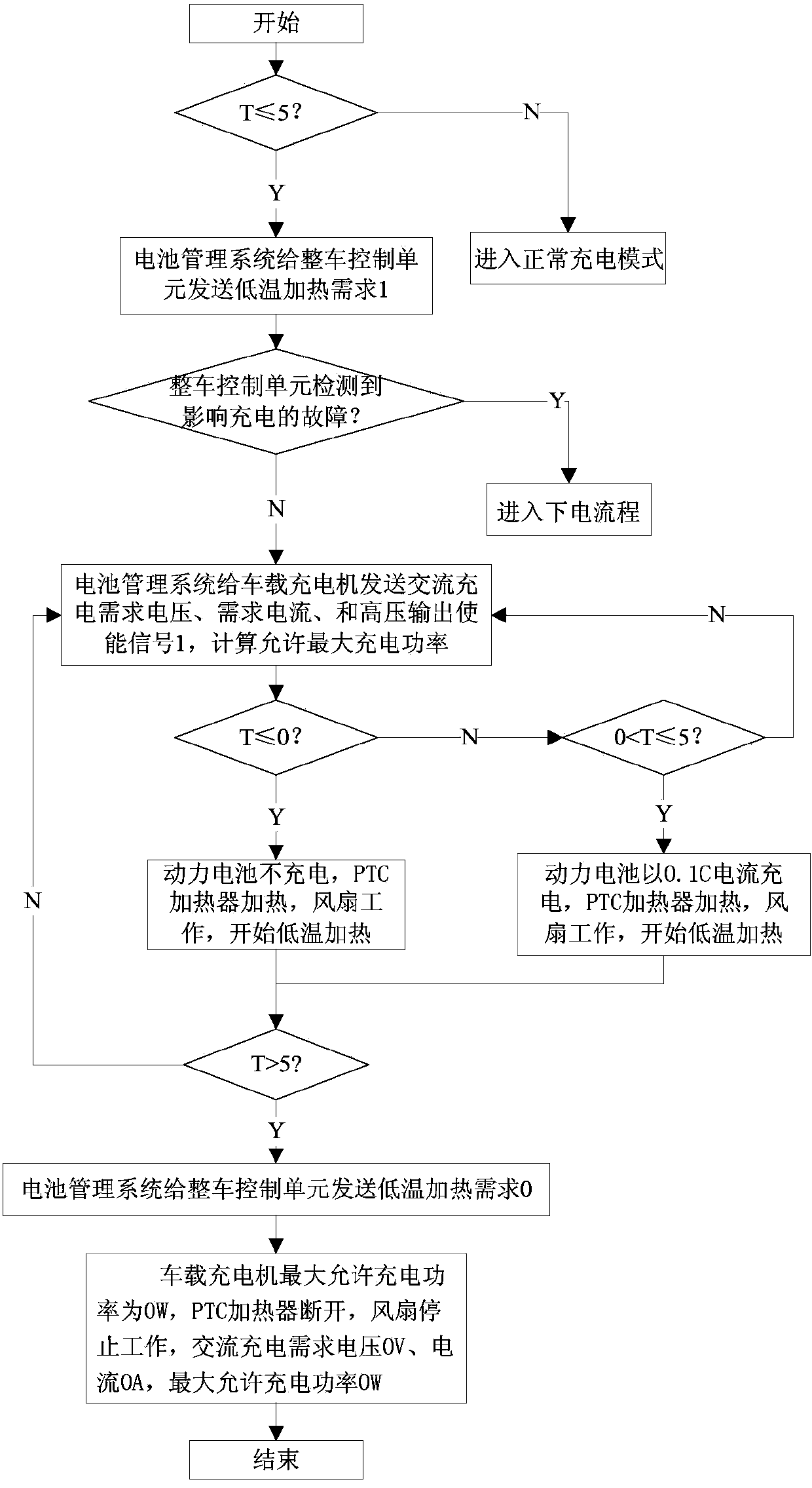

Low-temperature charge and heating system and method for power battery for all-electric vehicles

ActiveCN103427137AShorten heating timeImprove securitySecondary cells charging/dischargingVehicular energy storageElectrical batteryHeating system

The invention discloses a low-temperature charge and heating system and method for a power battery for all-electric vehicles. The system comprises a vehicle control unit, a vehicular charger, a battery management system, the power battery, a DC / DC converter, a heat management system, a PTC heater and a fan module. The method includes: during charging, heating is allowed only when the temperature is very low and the temperature T of the power battery is smaller than or equal to 5 DEG C; when the temperature is very low, heating and charging with low current are performed simultaneously; if the temperature T of the power battery is larger than 5 DEG C, low-temperature heating is aborted and a normal charge mode is allowed. The system and the method have the advantages that low-temperature charge and heating time can be shortened, normal charge of the power battery is guaranteed and the service life of the power battery is unaffected.

Owner:重庆长安新能源汽车科技有限公司

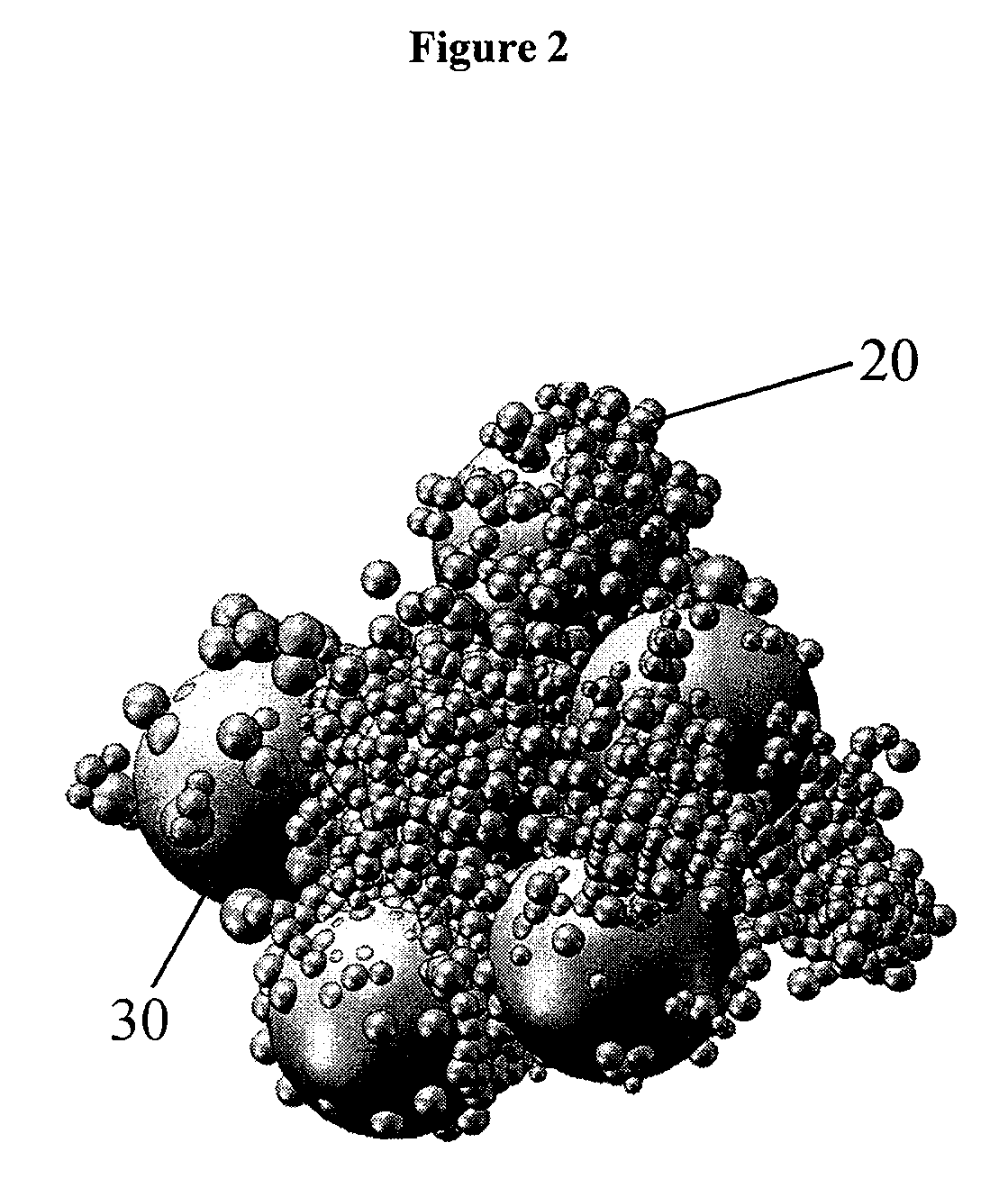

Porous, non-degradable implant made by powder molding

InactiveUS20080213611A1Sufficient pore volumeSufficient volumeLayered productsPharmaceutical delivery mechanismDecompositionShell molding

Owner:CINVENTION AG

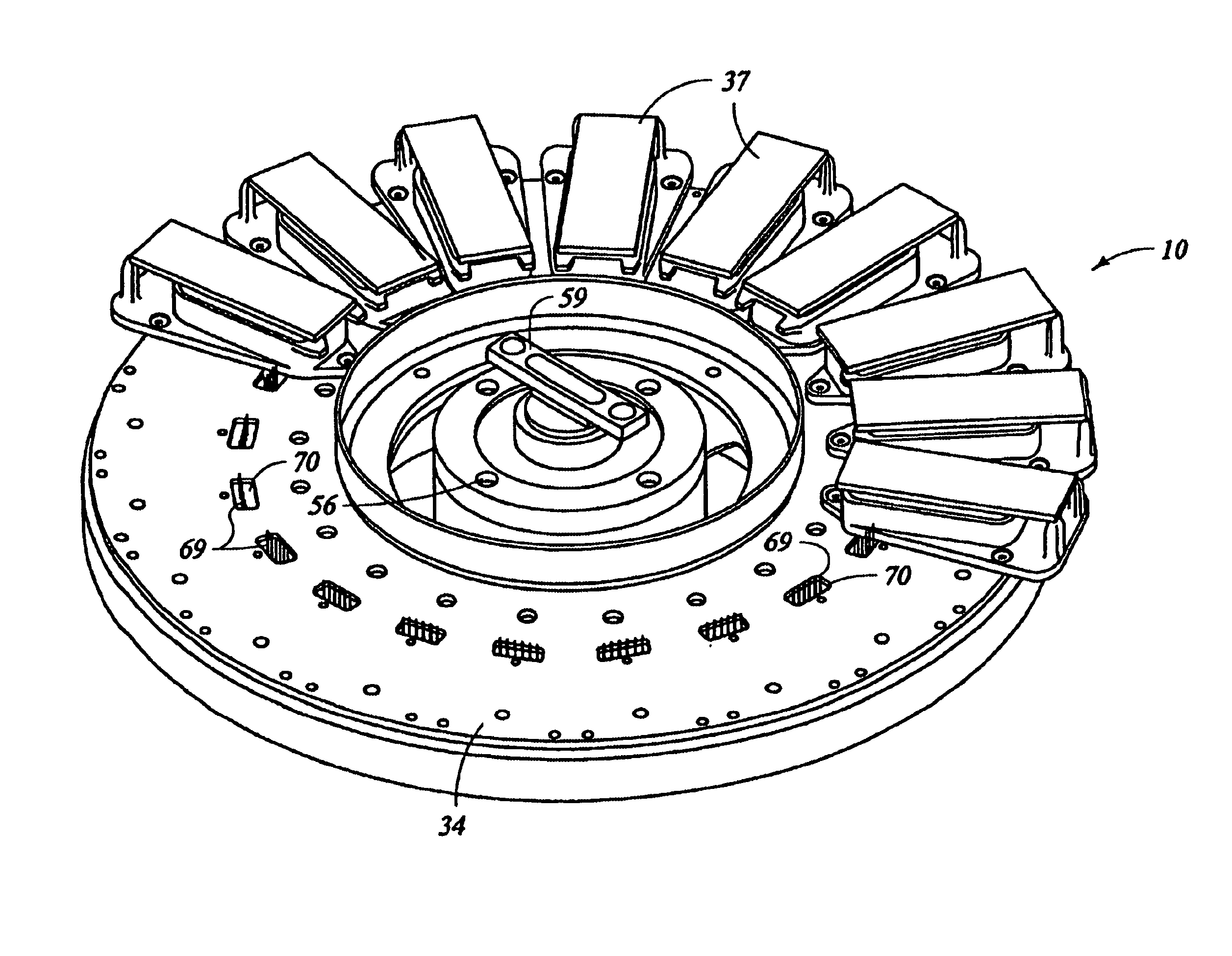

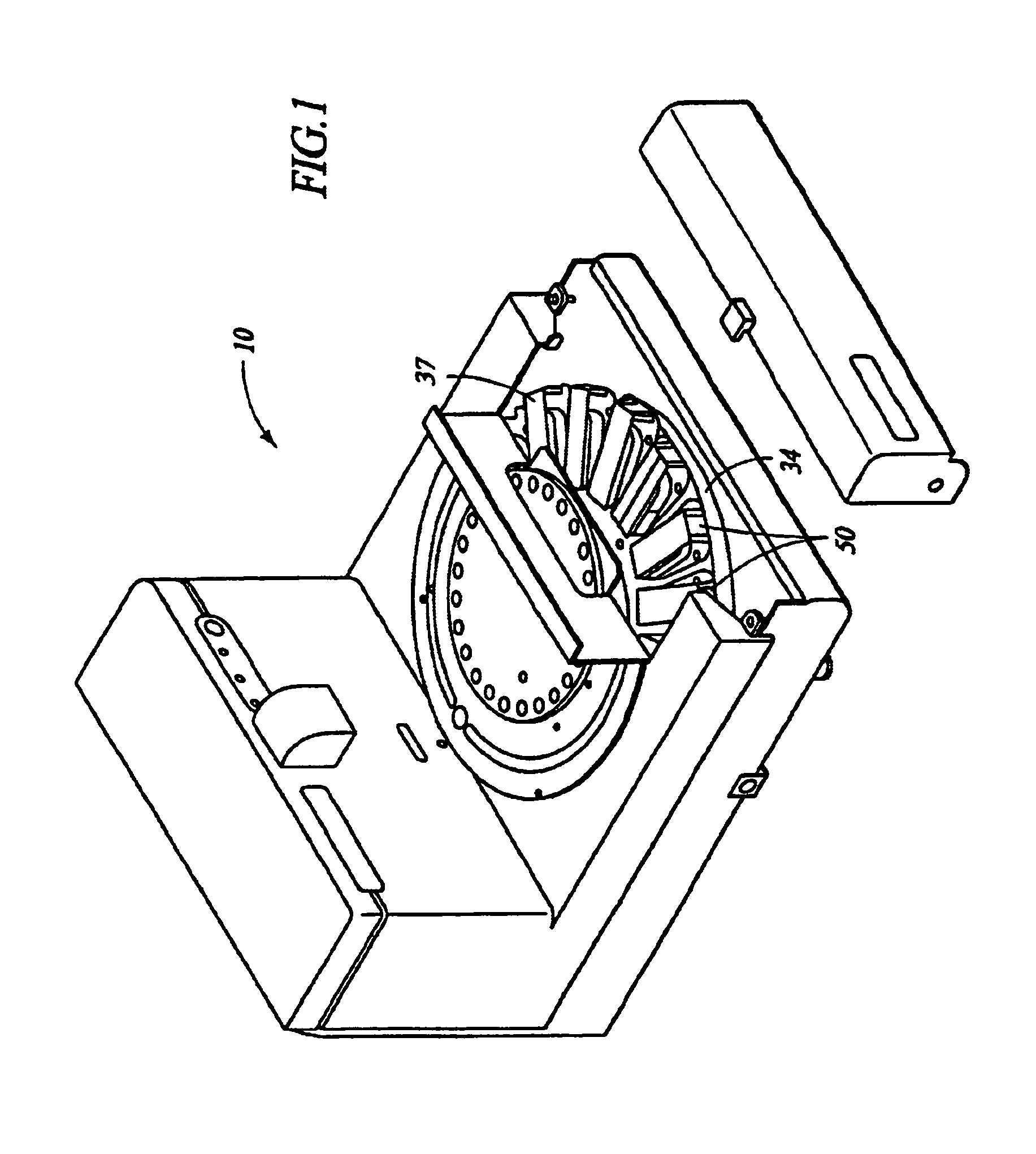

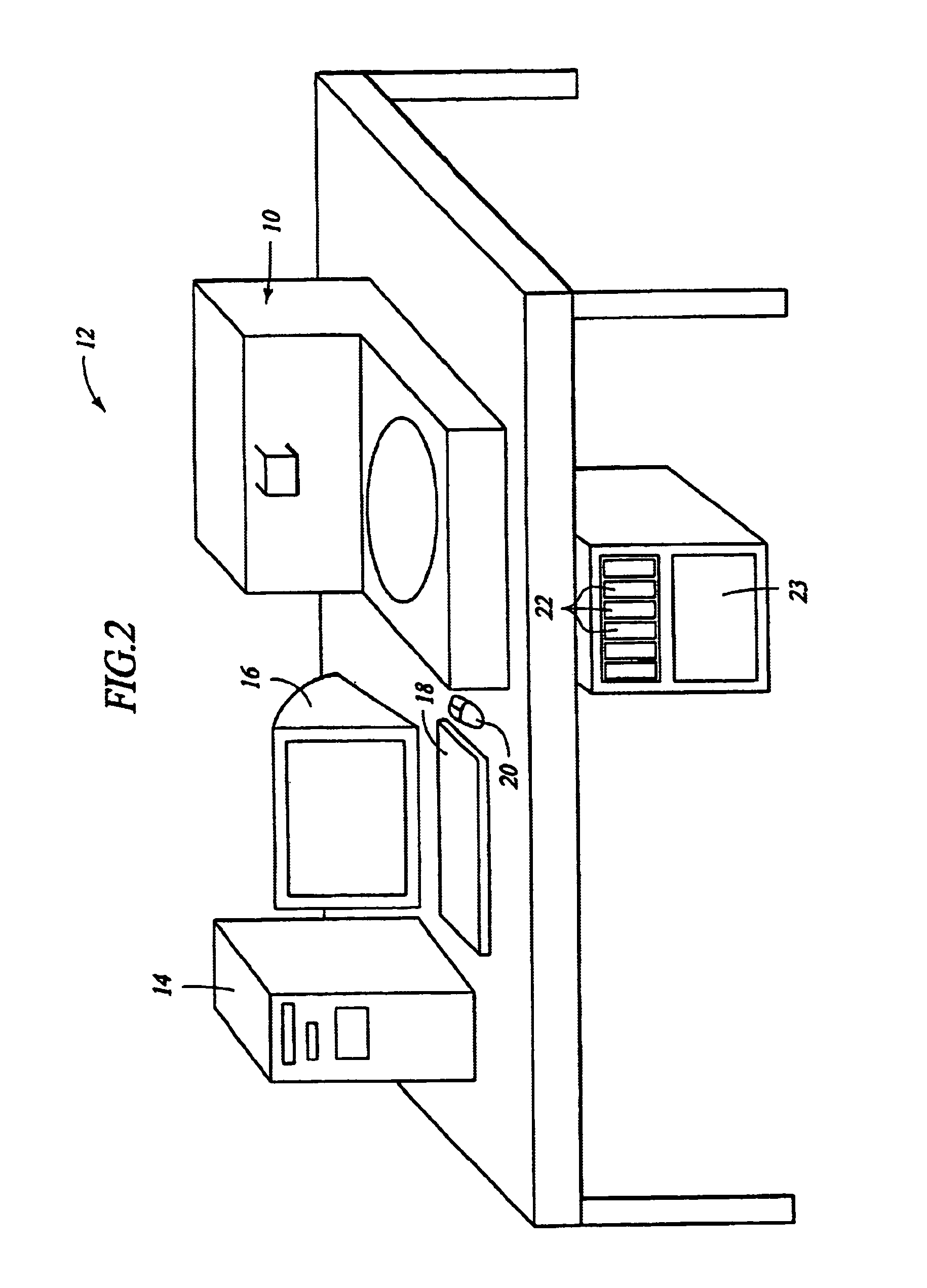

Automated molecular pathology apparatus having independent slide heaters

InactiveUS7396508B1Narrow temperature rangeEvenly heatHeating or cooling apparatusWithdrawing sample devicesHeating systemBiomedical engineering

Apparatus and methods for automatically staining or treating multiple tissue samples mounted on microscope slides are provided. Individualized slide temperature control is accomplished by the heating system according to the present invention that has thermal platforms radially mounted to the carousel for heating the slides and sensing the temperature of each. The heating system also permits automated de-waxing if necessary.

Owner:VENTANA MEDICAL SYST INC

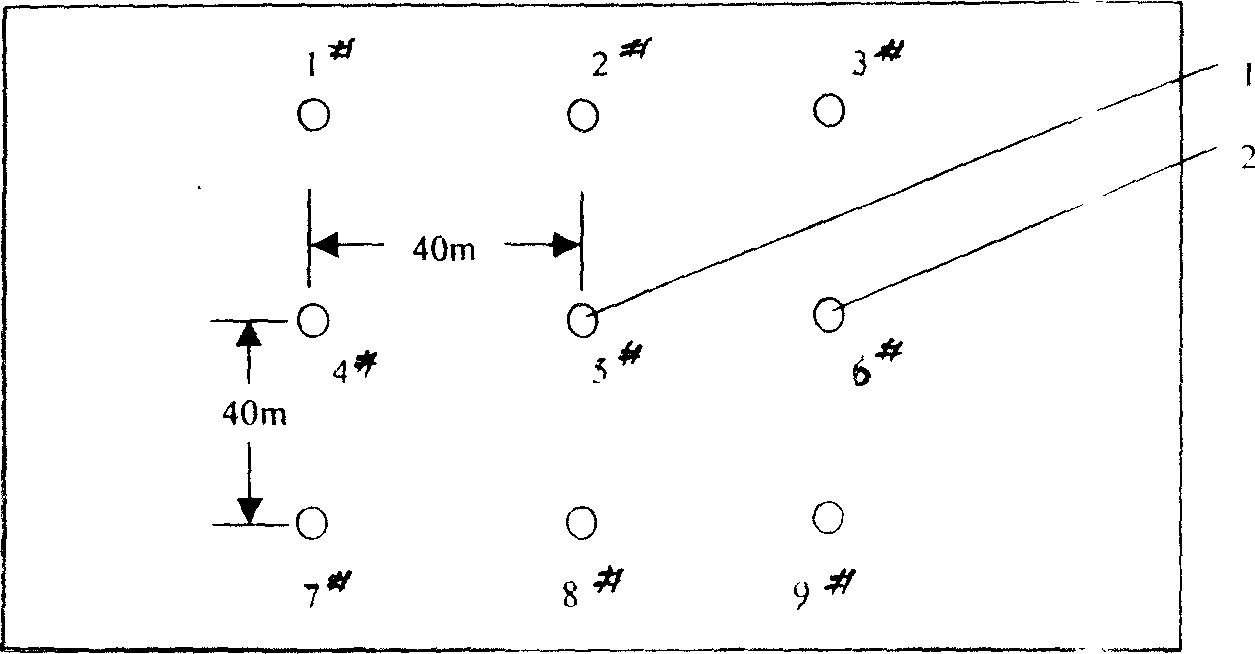

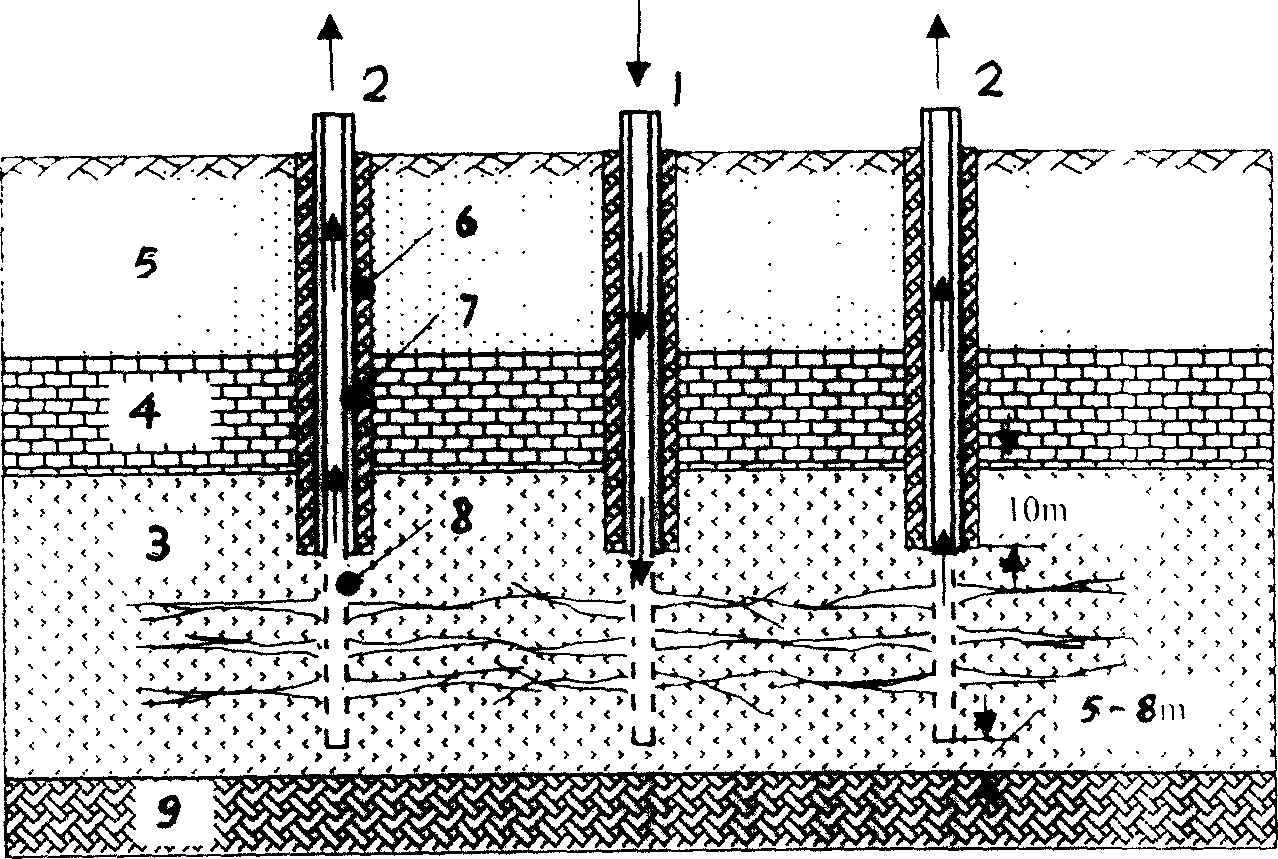

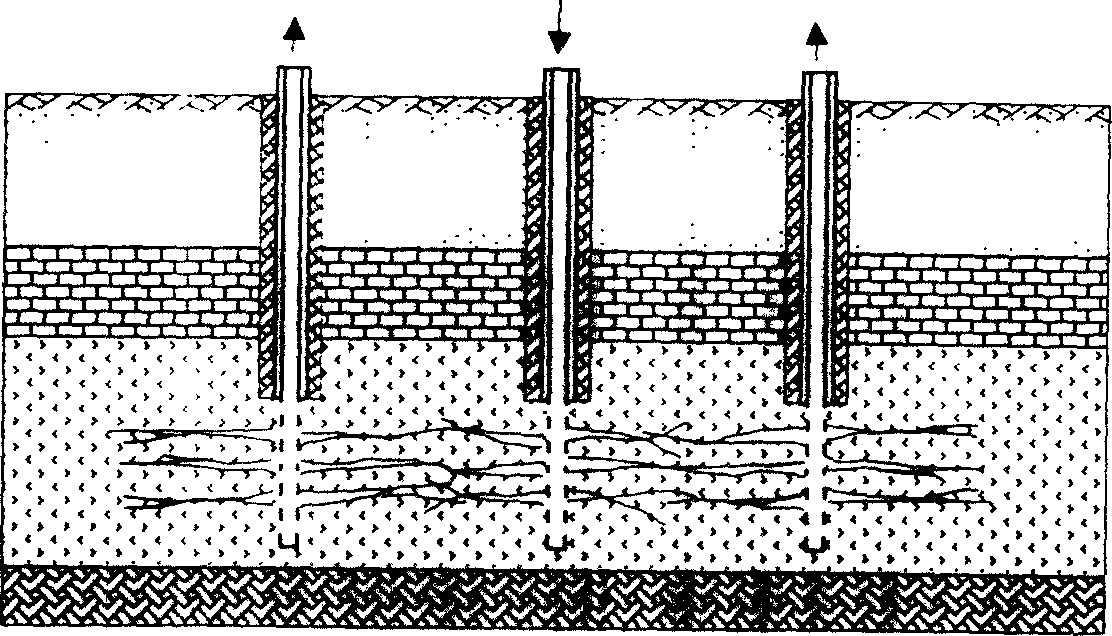

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

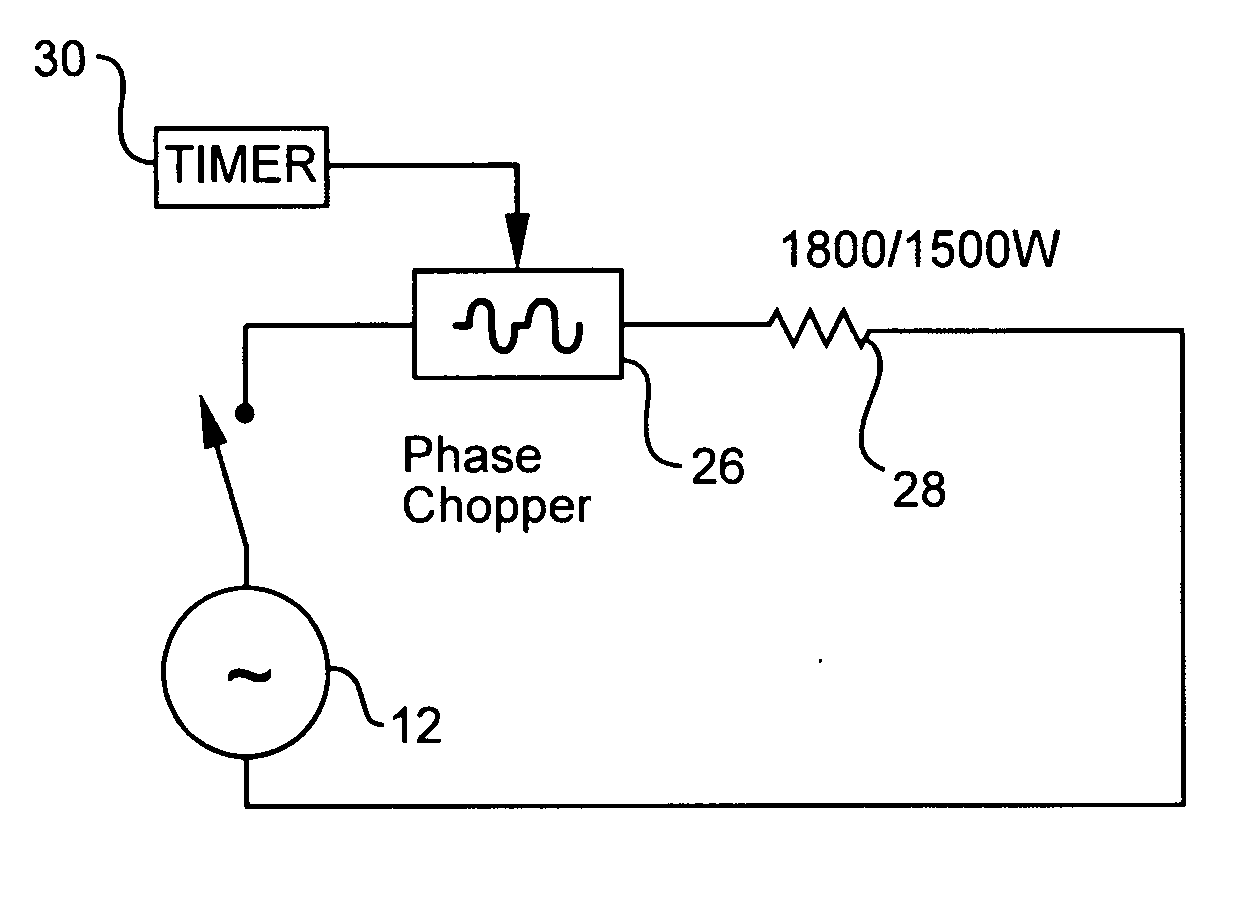

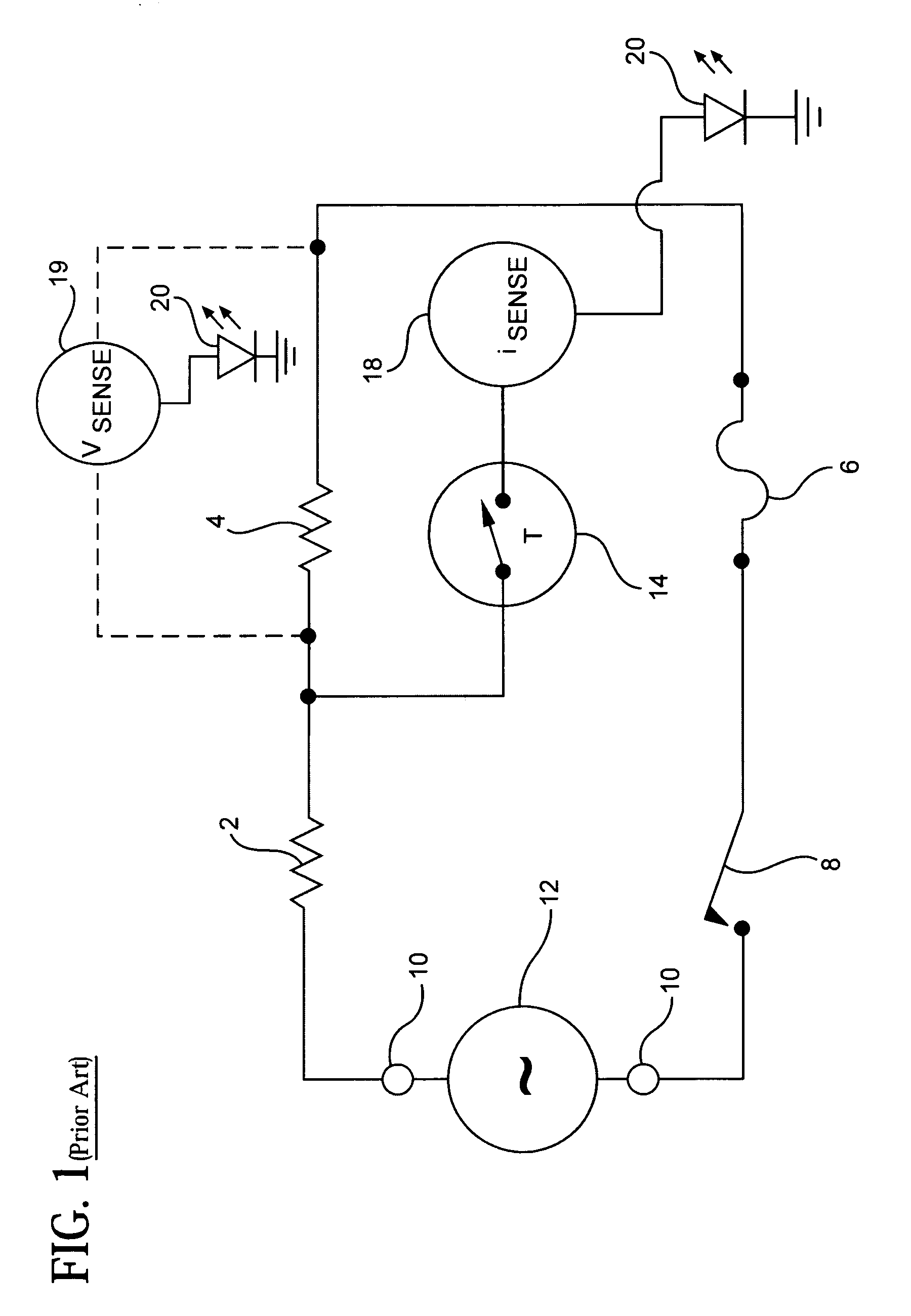

Multi-power multi-stage electric heater

InactiveUS20060263073A1Rapid heatingSlow heatingElectric heating systemAir heatersContinuous operationPositive temperature

A heater operates at a first power to heat a space and a second power to maintain the temperature. The heater uses a first heating element and a second heating element, which are configured to automatically supply the first power during an initial heating period, then step down to the second power for continuous operation. The heater may use a phase chopper circuit and heating element; switched diode and heating element; positive temperature coefficient thermostat, isolated heater, and heating element; latching mechanical timer switch and heating element; and / or a positive temperature coefficient heating element and multi-speed fan to provide dual power levels. The heater may include a first heating element energized during a portion of a heating cycle and a second heating element continuously energized during the heating cycle. The heating cycle is repeated for a period after which both elements are de-energized.

Owner:SUNBEAN PROD INC

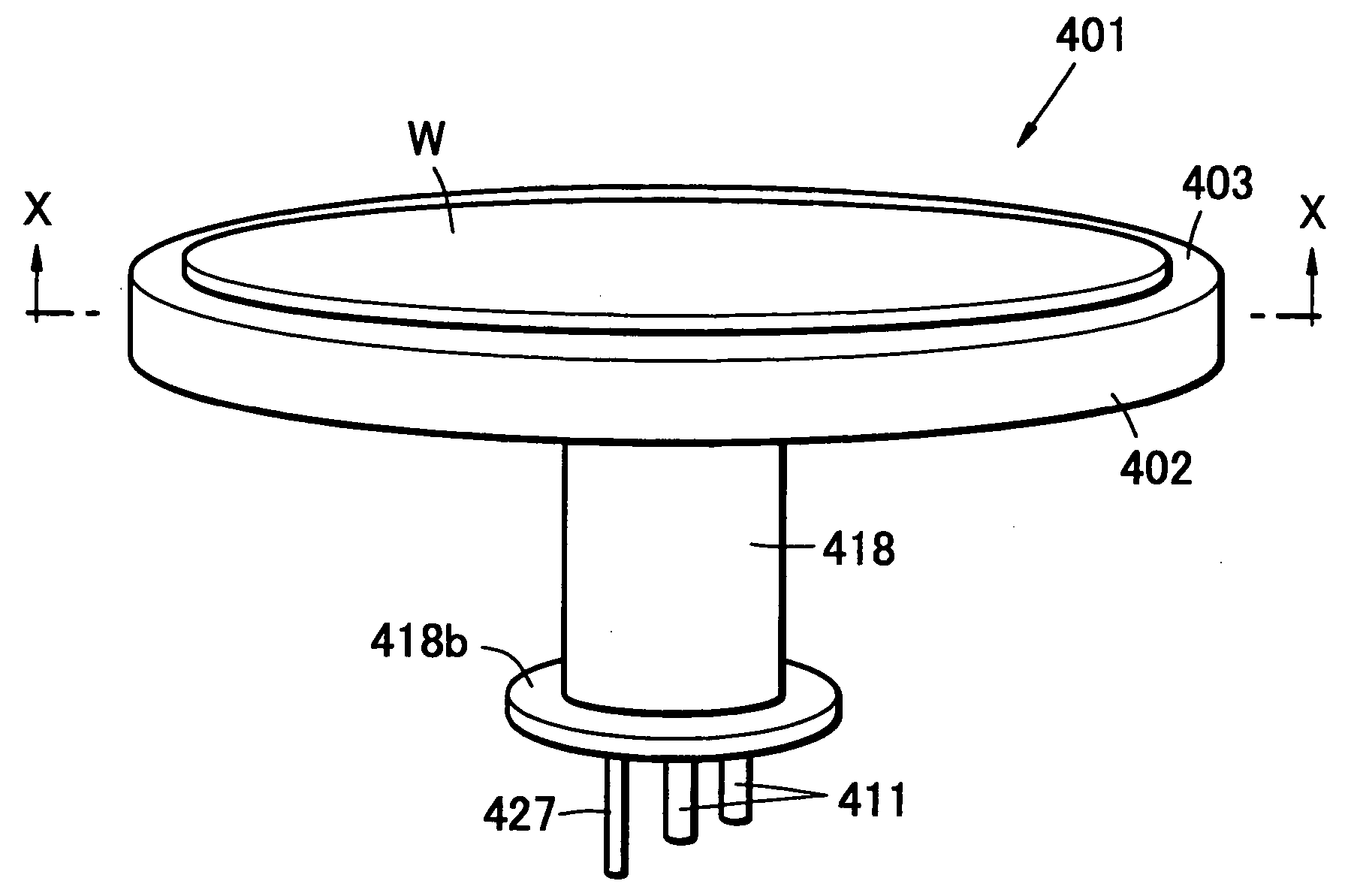

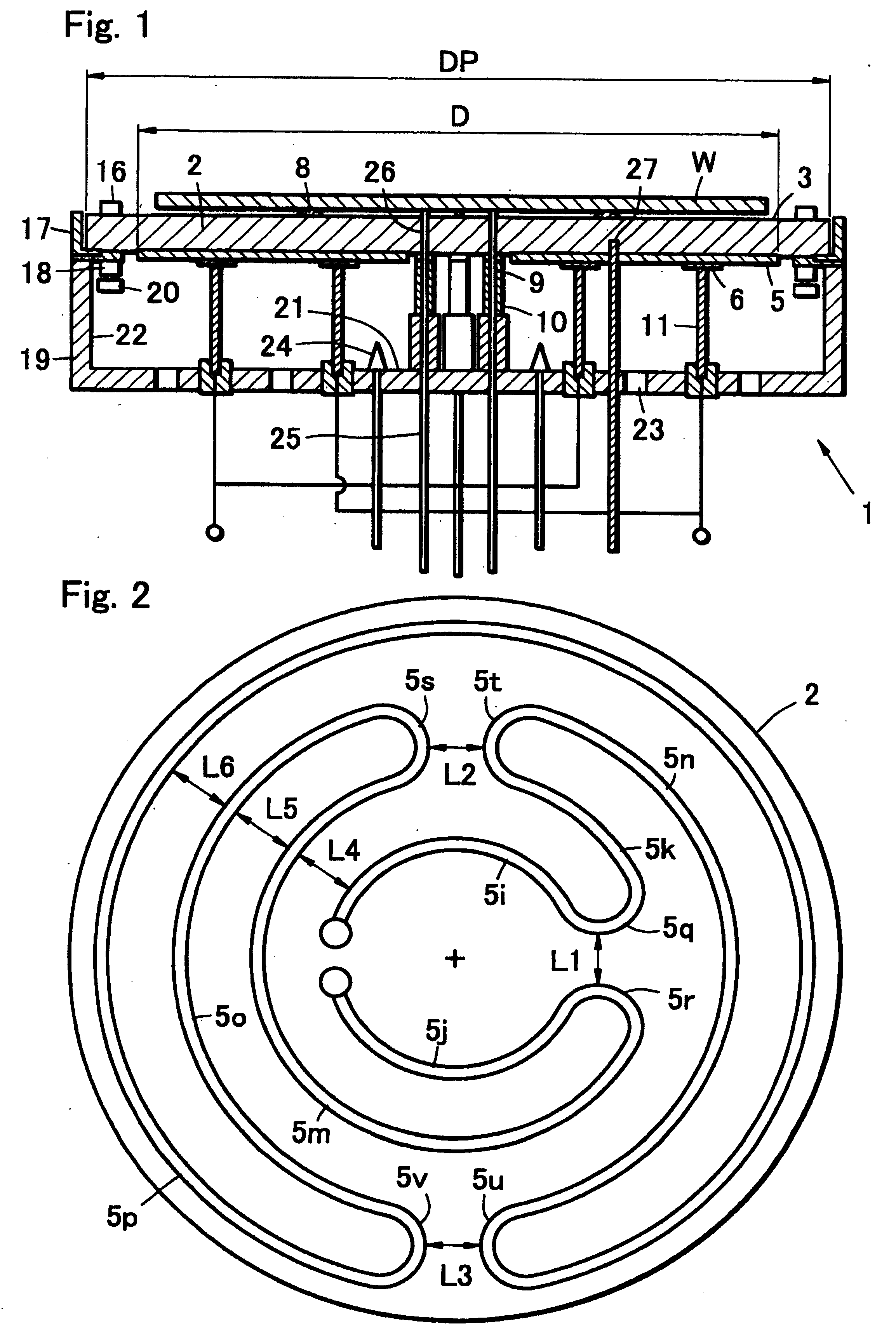

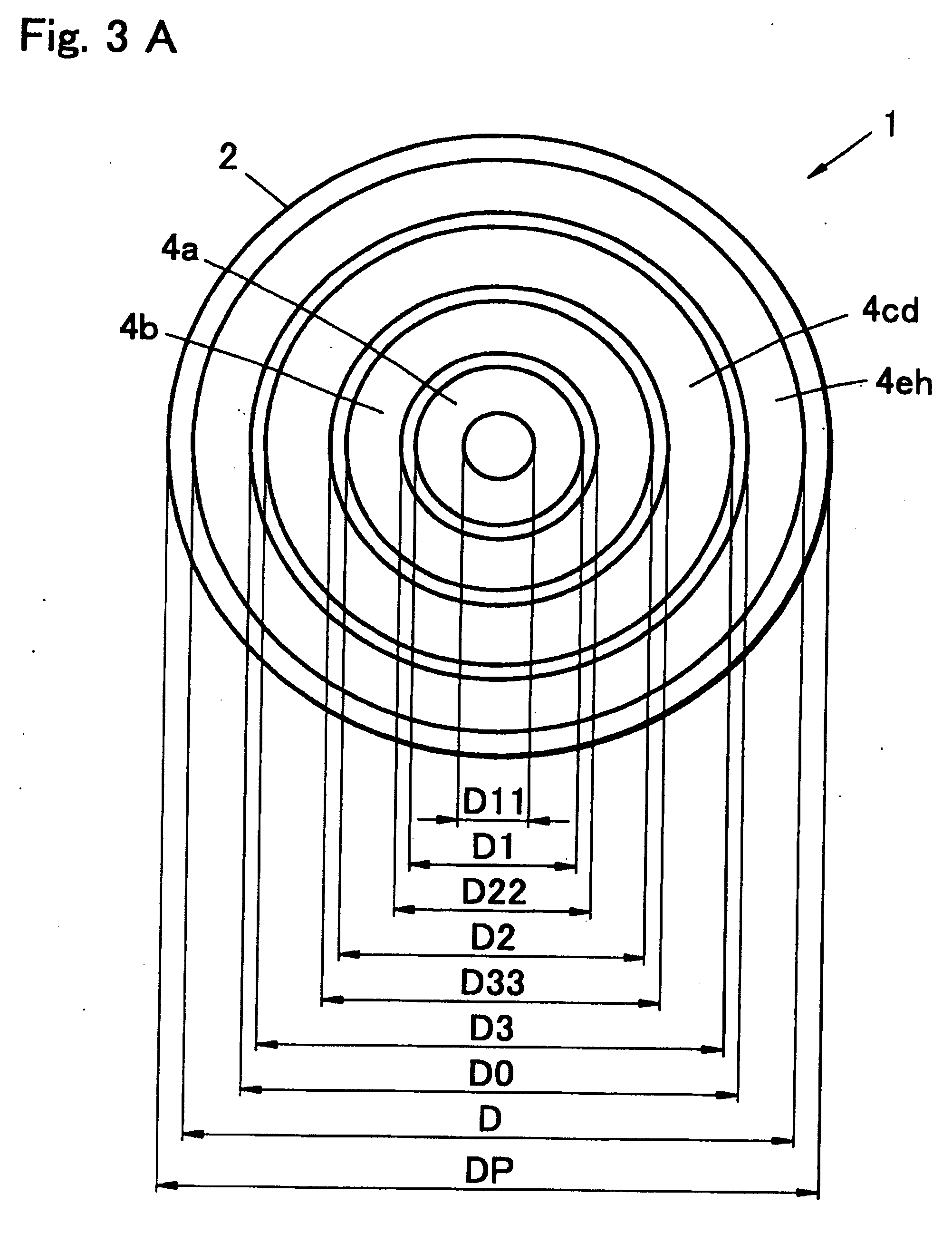

Heater, wafer heating apparatus and method for manufacturing heater

ActiveUS20060096972A1Short timeMinimize temperature differenceSemiconductor/solid-state device manufacturingHot plates heating arrangementsTemperature differenceEngineering

A heater that is capable of heating a object to a desired temperature in a short period while minimizing the temperature difference the surface of the object is provided. The heater comprising a plate having a first surface and a second surface, the first surface being a mount surface whereon an object is placed and having a resistive heating member; wherein the resistive heating member is formed in a continuous band having arc bands located on one of two concentric circles of different radii, at least one arc band located on the other circle, and linkage arc band that connects the arc band located on the one circle and the arc band located on the other circle; while the distance between the adjacent linkage arc bands is smaller than the distance between the arc band located on the one circle and the arc band located on the other circle.

Owner:KYOCERA CORP

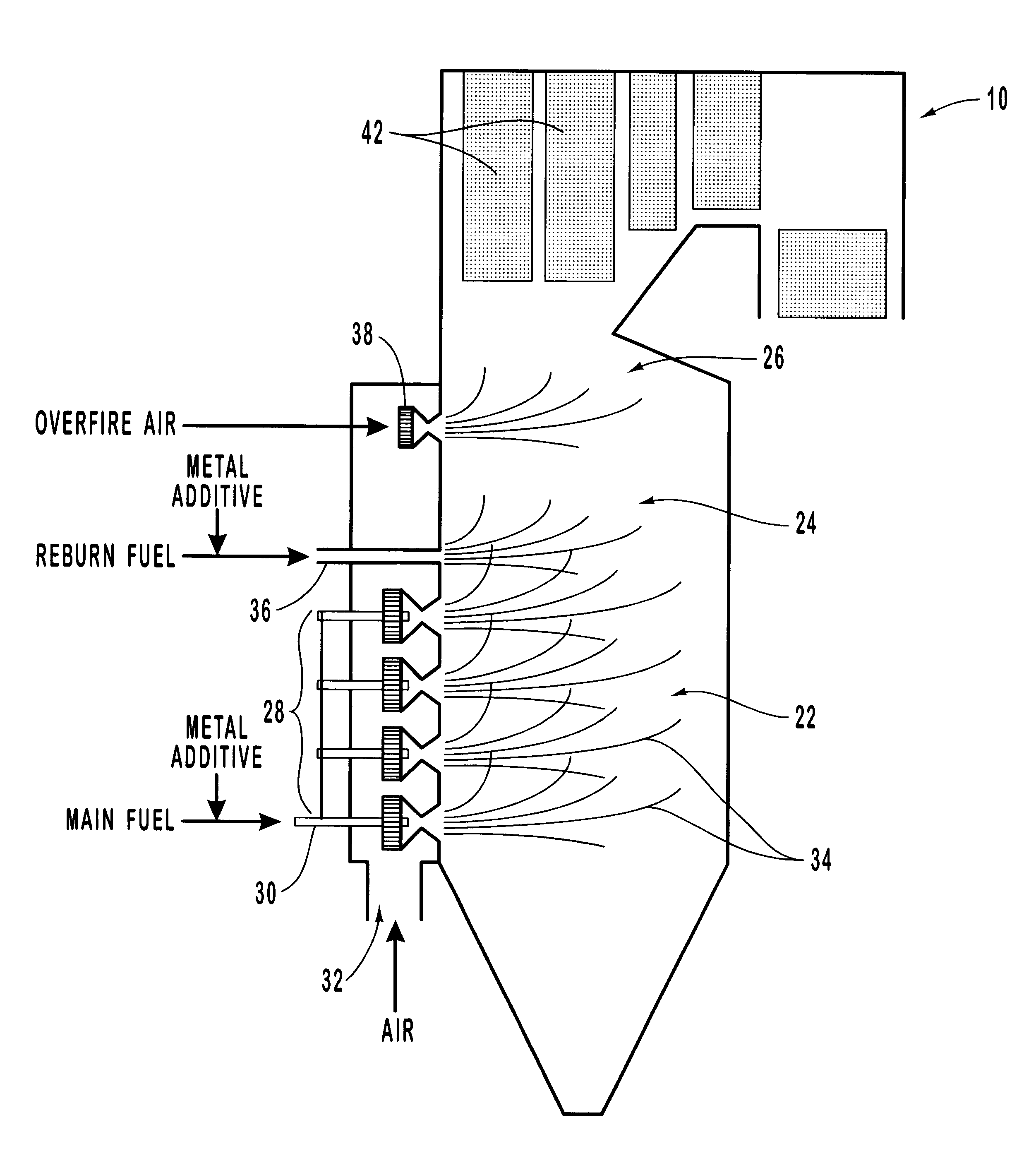

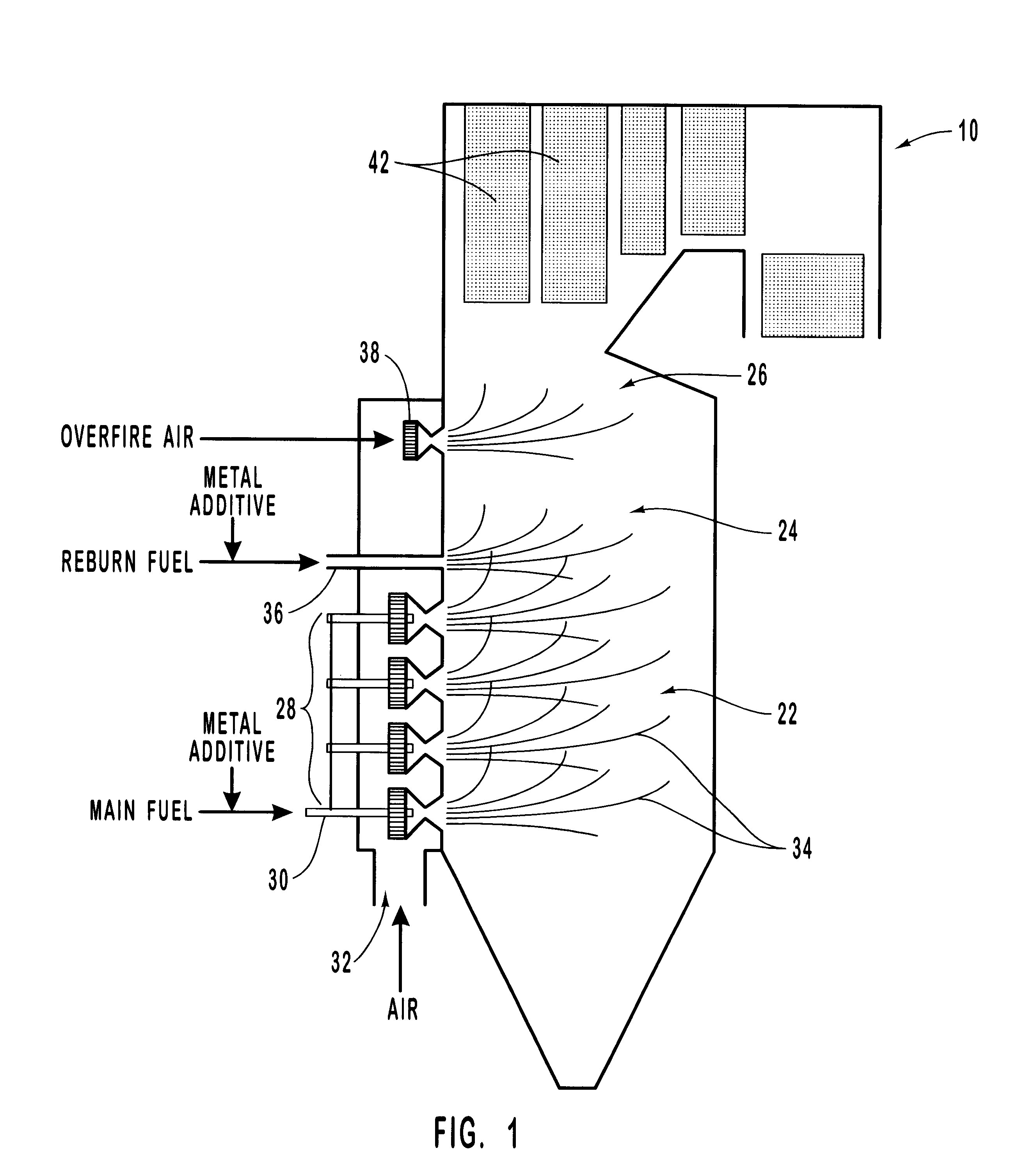

Methods for reducing NOx in combustion flue gas using metal-containing additives

InactiveUS6471506B1Simple and inexpensive methodReduce penetrationDispersed particle separationIncinerator apparatusAtmospheric airMolecular nitrogen

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

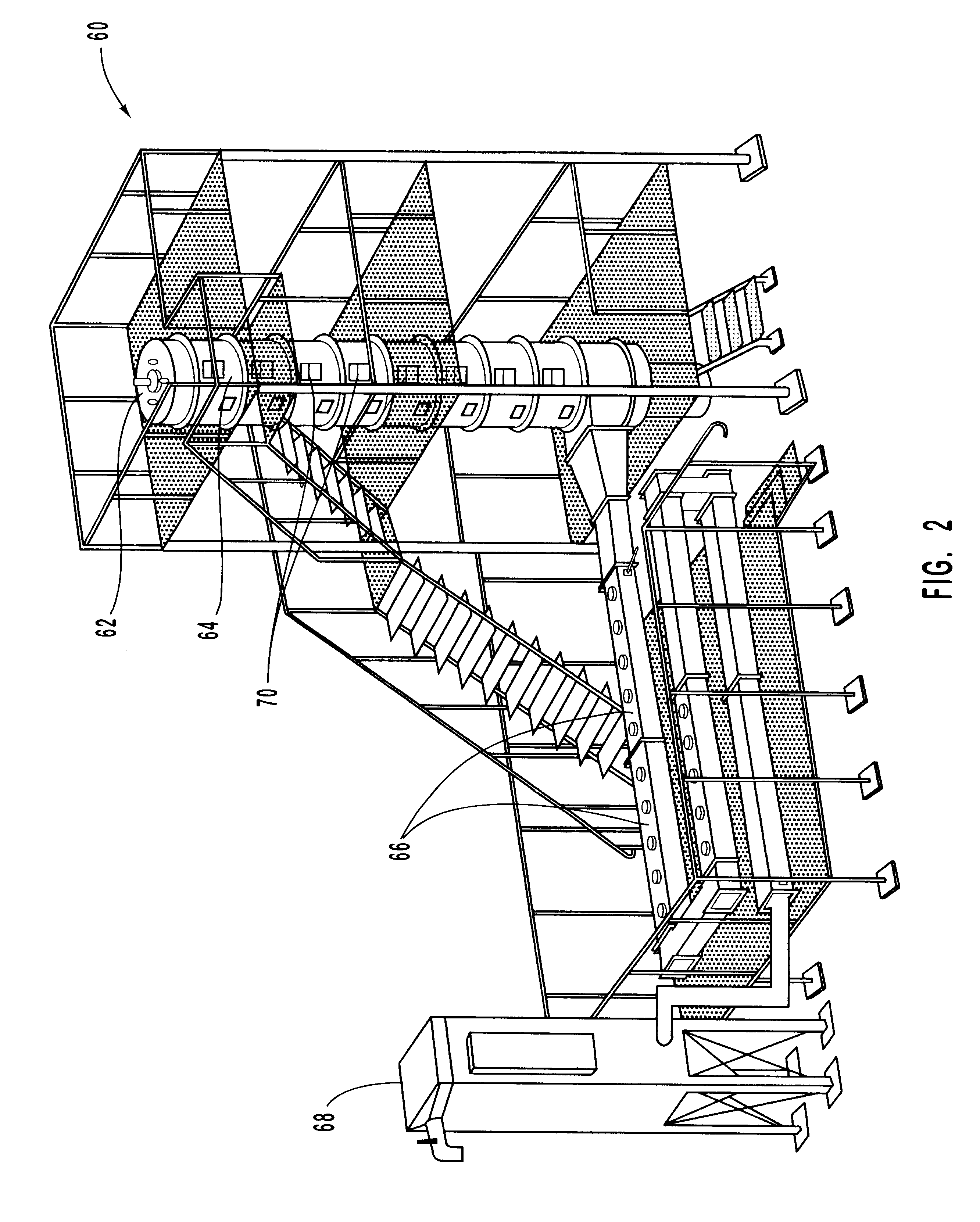

Flexible assembly of once-through evaporation for horizontal heat recovery steam generator

ActiveUS6957630B1Rapid heating and coolingHeating fastWater circulationSteam engine plantsHeat recovery steam generatorProcess engineering

A steam generator is disclosed herein. The steam generator includes an inlet manifold, a discharge manifold, a heating gas duct, and at least one once-through heating area in the heating-gas duct. The once-through heating area is formed from multiple single-row header-and-tube assemblies. Each single-row header-and-tube assembly includes a plurality of steam generator tubes connected in parallel, an inlet header connected to the inlet manifold, and a discharge header connected to the discharge manifold. Each inlet header is connected to the inlet manifold by one of multiple first link pipes, and each discharge header is connected to the discharge manifold by one of multiple second link pipes. Each said steam generator tube of each of the single-row header-and-tube assemblies has an inside diameter that is less than an inside diameter of any of the first or second link pipes.

Owner:GENERAL ELECTRIC TECH GMBH

Process and module for heating liquid

InactiveUS6459854B1Accurate temperature rangeImprove heat transfer performanceImmersion heating arrangementsLiquid transferring devicesAxis of symmetryEngineering

A liquid heating module for use in a hot beverage machine, a beverage forming system that includes the module, and a process for heating liquid for forming beverages. The liquid heating module includes a hollow metal tube, a cylindrical insert which is disposed inside the hollow tube along its entire length and substantially along its axis of symmetry, at least one electrical resistor on a first outer part of the tube for preheating liquid flowing through the tube, and at least one additional electrical resistor on a second outer part of the tube for temperature adjustment of the liquid flowing through the tube.

Owner:NESTEC SA

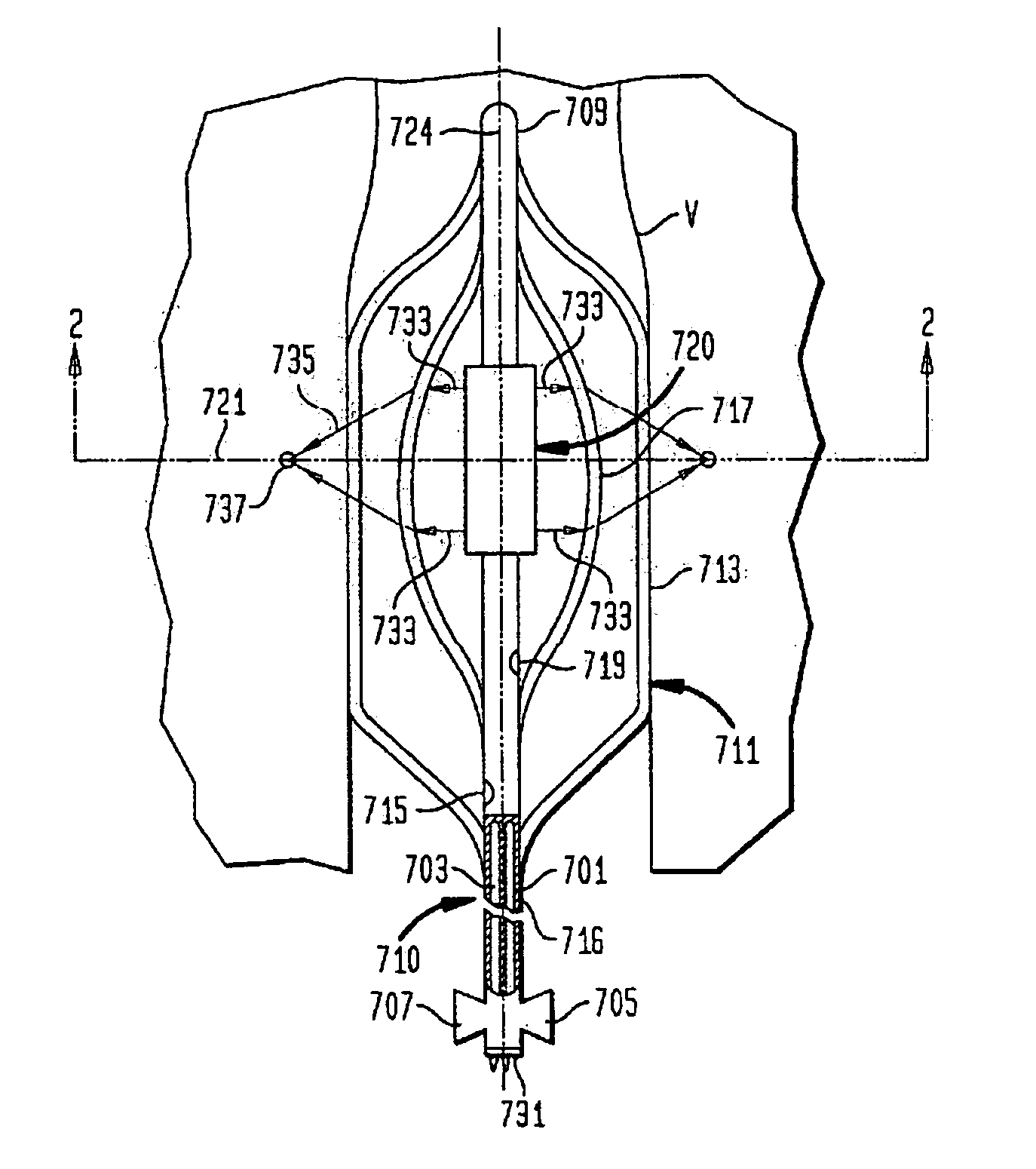

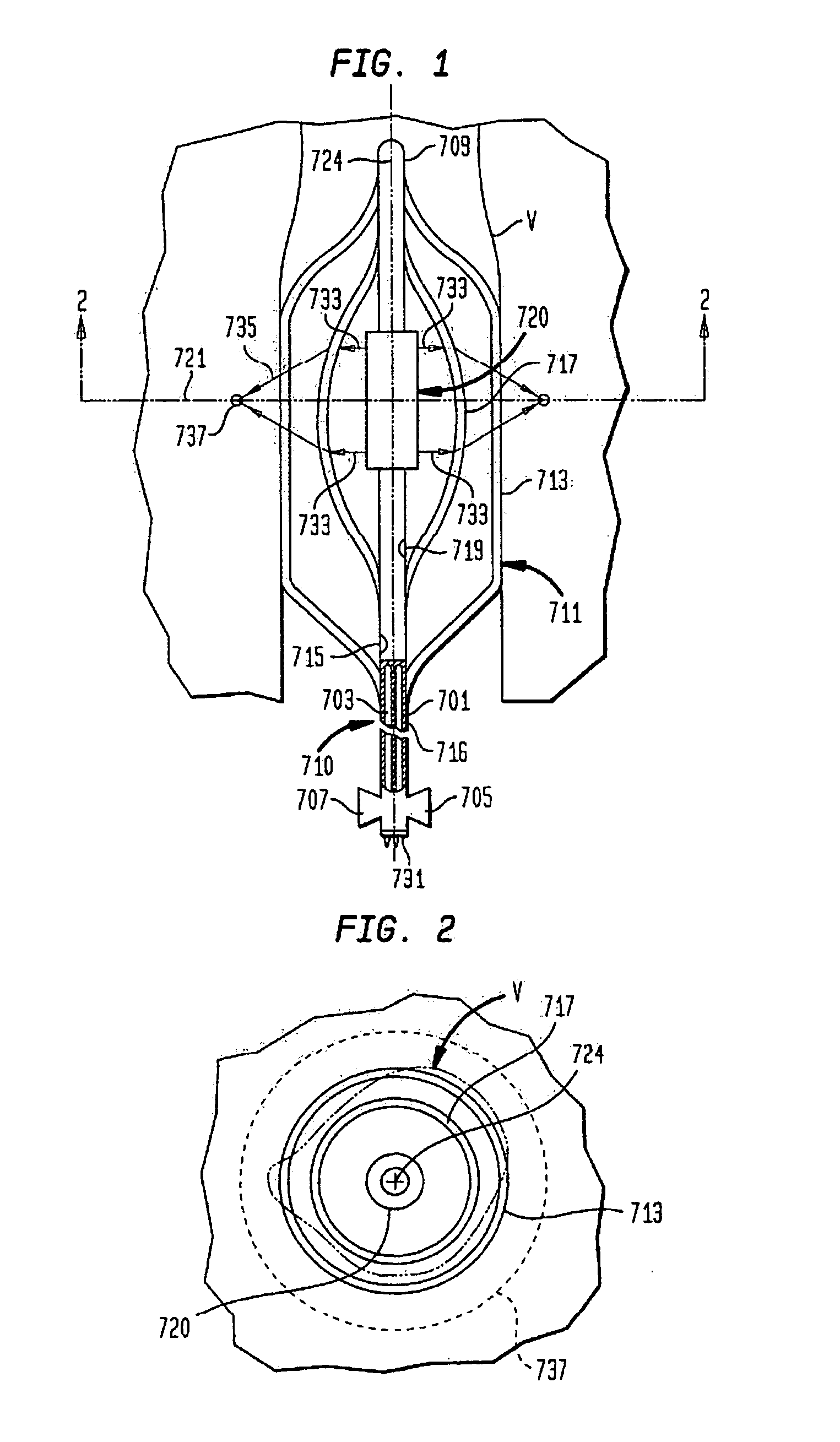

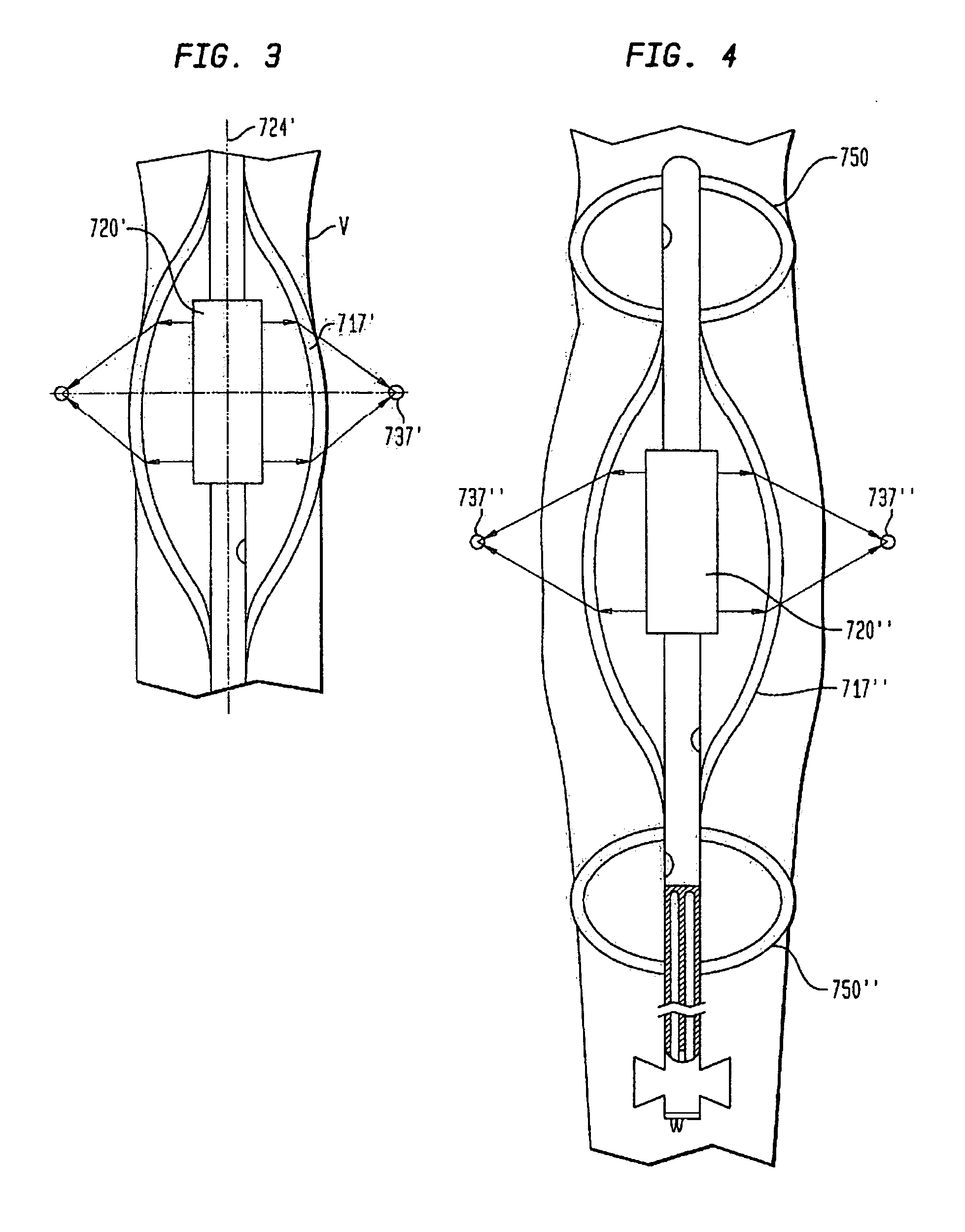

Energy application with inflatable annular lens

InactiveUS20060058711A1Minimize damageEffective treatmentUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyAnatomical structuresUrethra

Apparatus and methods for ablating tissue surrounding a tubular anatomical structure such as the wall of a blood vessel or prostatic tissue surrounding the urethra. The apparatus includes an ultrasonic emitter such as a cylindrical emitter and an inflatable annular lens balloon surrounding the ultrasonic emitter. The lens balloon is inflated with a liquid having acoustic velocity different than that of the surrounding medium, so as to form an annular refracting surface. The acoustic energy from the emitter is focused into an annular focal region.

Owner:BOSTON SCI SCIMED INC +1

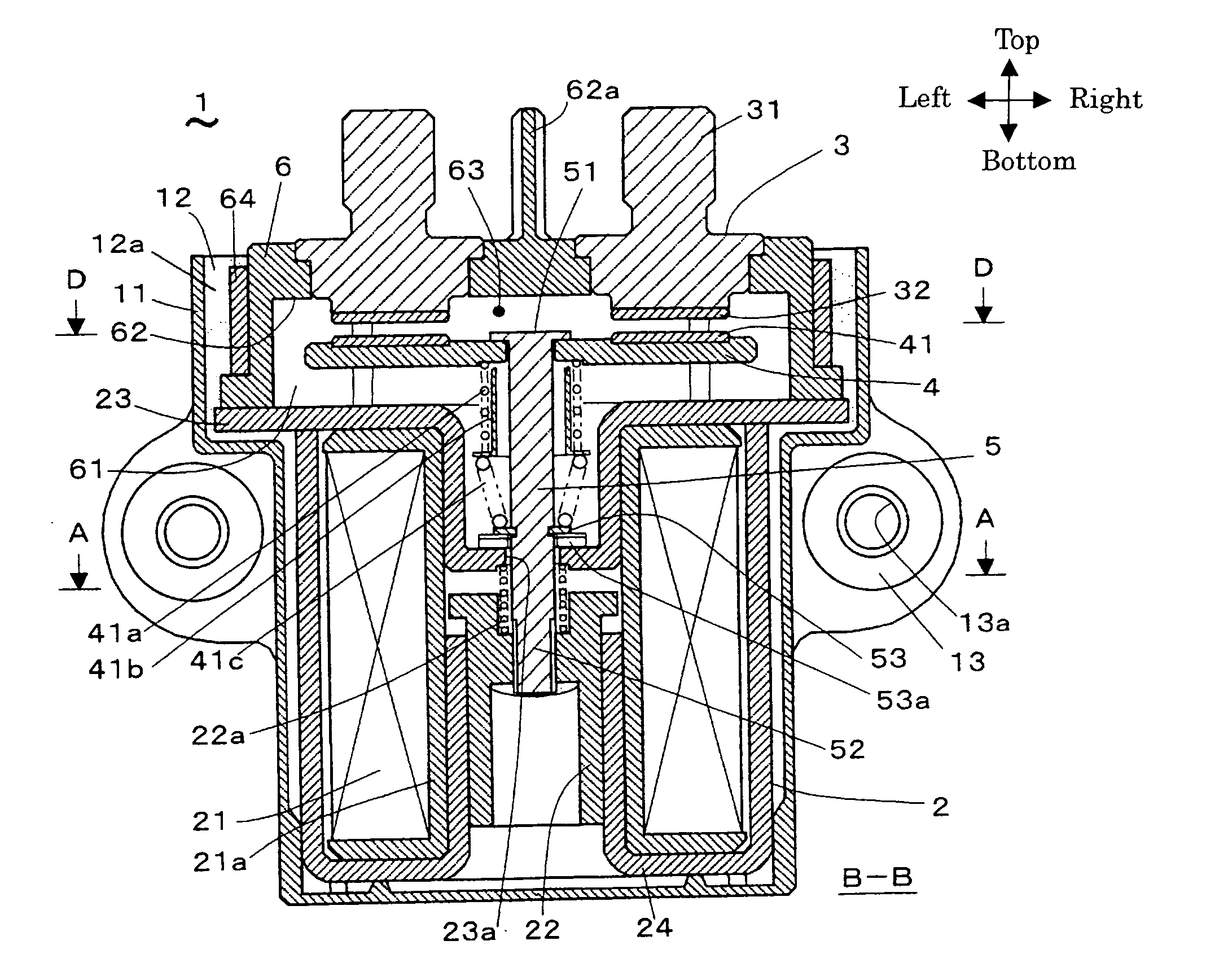

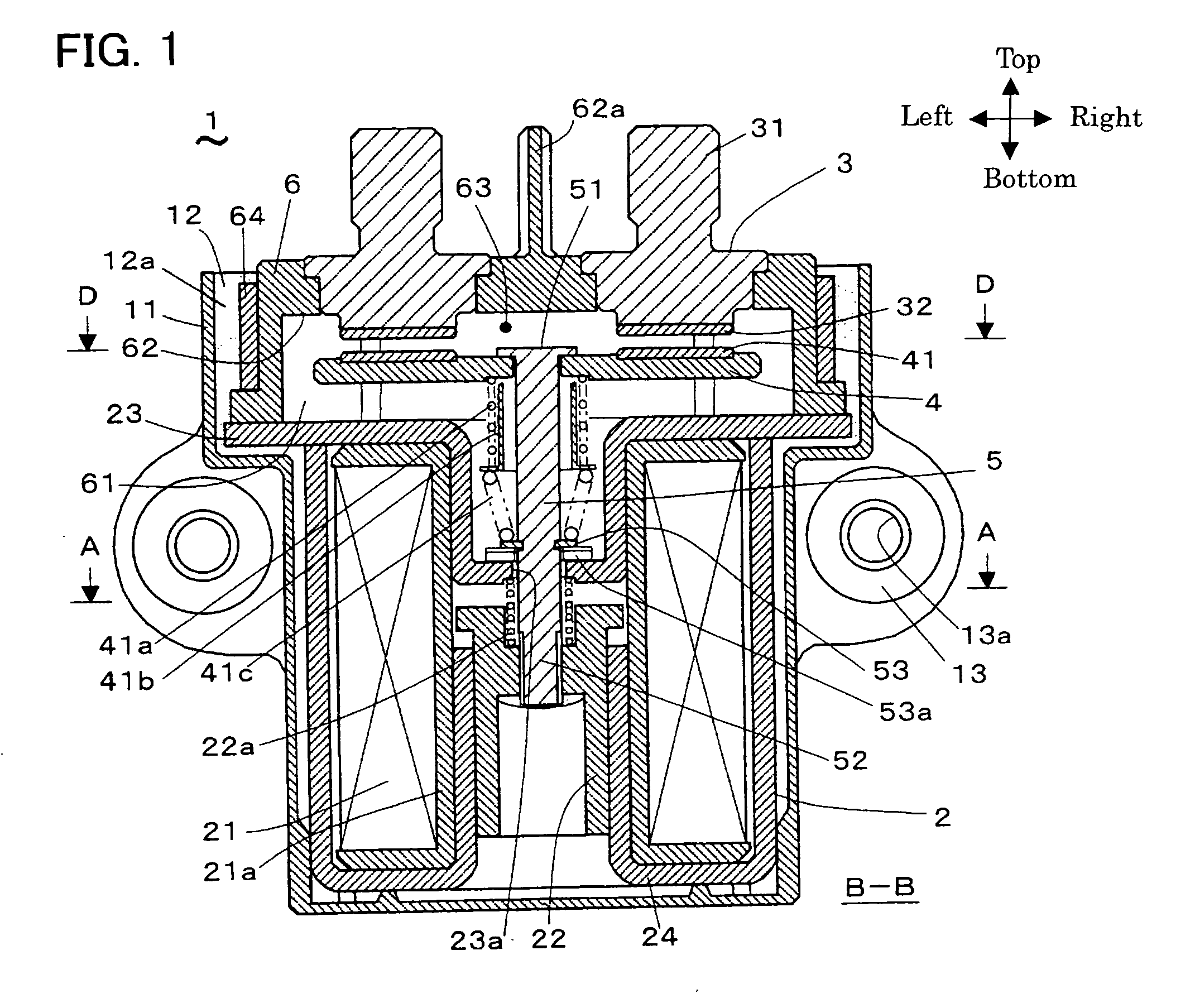

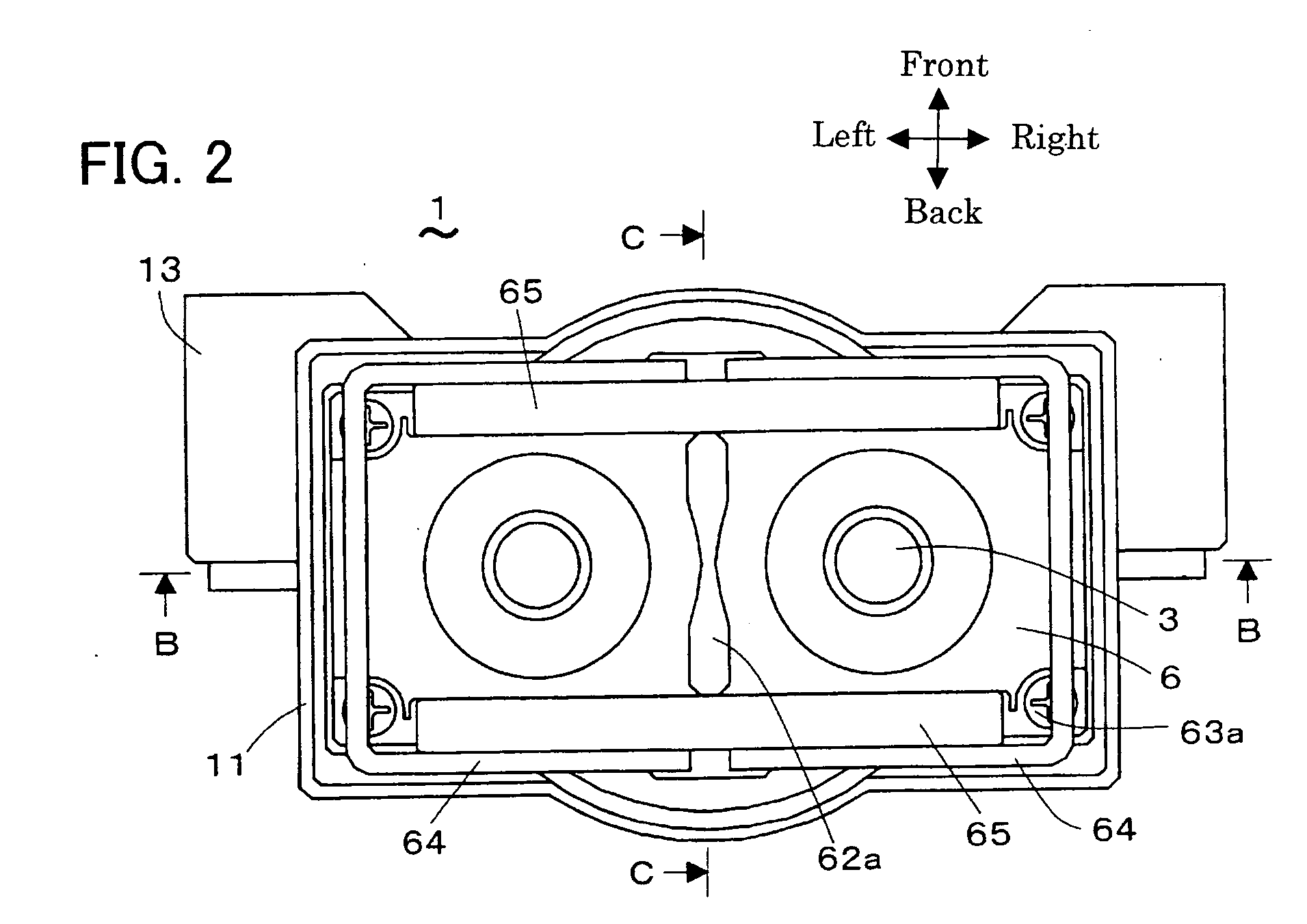

Electromagnetic switching device

InactiveUS20060050466A1Avoid vibrationImprove abilitiesElectric switchesElectromagnetic relay detailsMiniaturizationEngineering

In the electromagnetic switching device, it is possible to miniaturize and have low costs, have quiet operation noise, and also quickly extinguish the arc. The electromagnetic switching device has an electromagnetic actuator with a movable iron core, a pair of fixed terminals that respectively have a fixed contact point, a movable contact that has movable contact points on the right and left ends, a shaft, and an enclosing component that holds the movable contact points and the fixed contact points. The pair of movable contact points respectively contact with and detach from the pair of fixed contact points, and the pair of fixed contact points respectively conduct each other and are insulated again through the shaft by moving the movable iron core along the axis using the electric magnetic actuator. A quasi-hermetically sealed space, which is the extinguishing space, is formed by the enclosing component and a first yoke. A potting compound is charged, into the space between a body and the quasi hermitically sealed space.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Pulsed processing semiconductor heating methods using combinations of heating sources

InactiveUS6951996B2Heating fastIncrease temperatureMuffle furnacesSemiconductor/solid-state device manufacturingPulse parameterEngineering

Pulsed processing methods and systems for heating objects such as semiconductor substrates feature process control for multi-pulse processing of a single substrate, or single or multi-pulse processing of different substrates having different physical properties. Heat is applied a controllable way to the object during a background heating mode, thereby selectively heating the object to at least generally produce a temperature rise throughout the object during background heating. A first surface of the object is heated in a pulsed heating mode by subjecting it to at least a first pulse of energy. Background heating is controlled in timed relation to the first pulse. A first temperature response of the object to the first energy pulse may be sensed and used to establish at least a second set of pulse parameters for at least a second energy pulse to at least partially produce a target condition.

Owner:MATTSON TECHNOLOGY +1

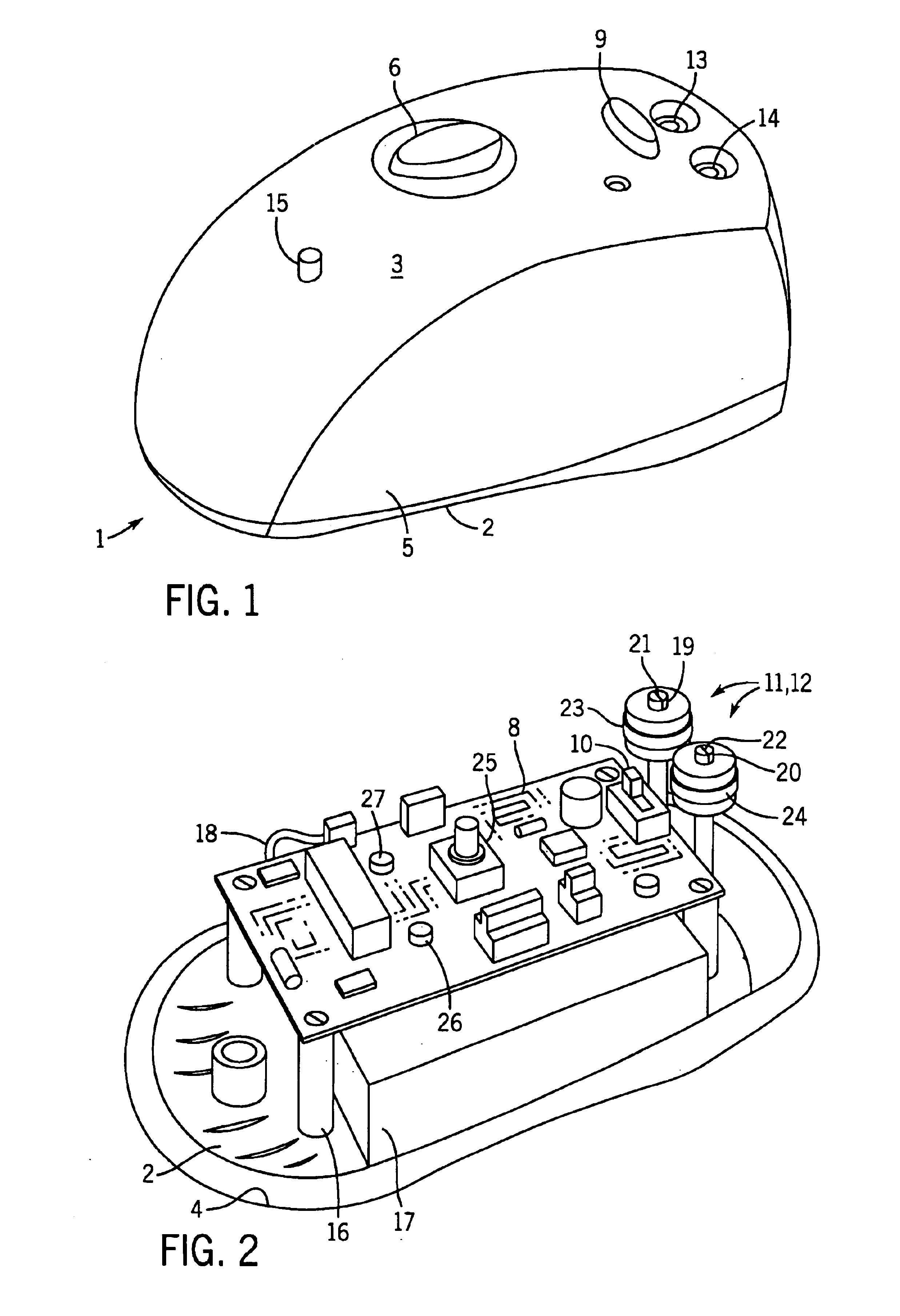

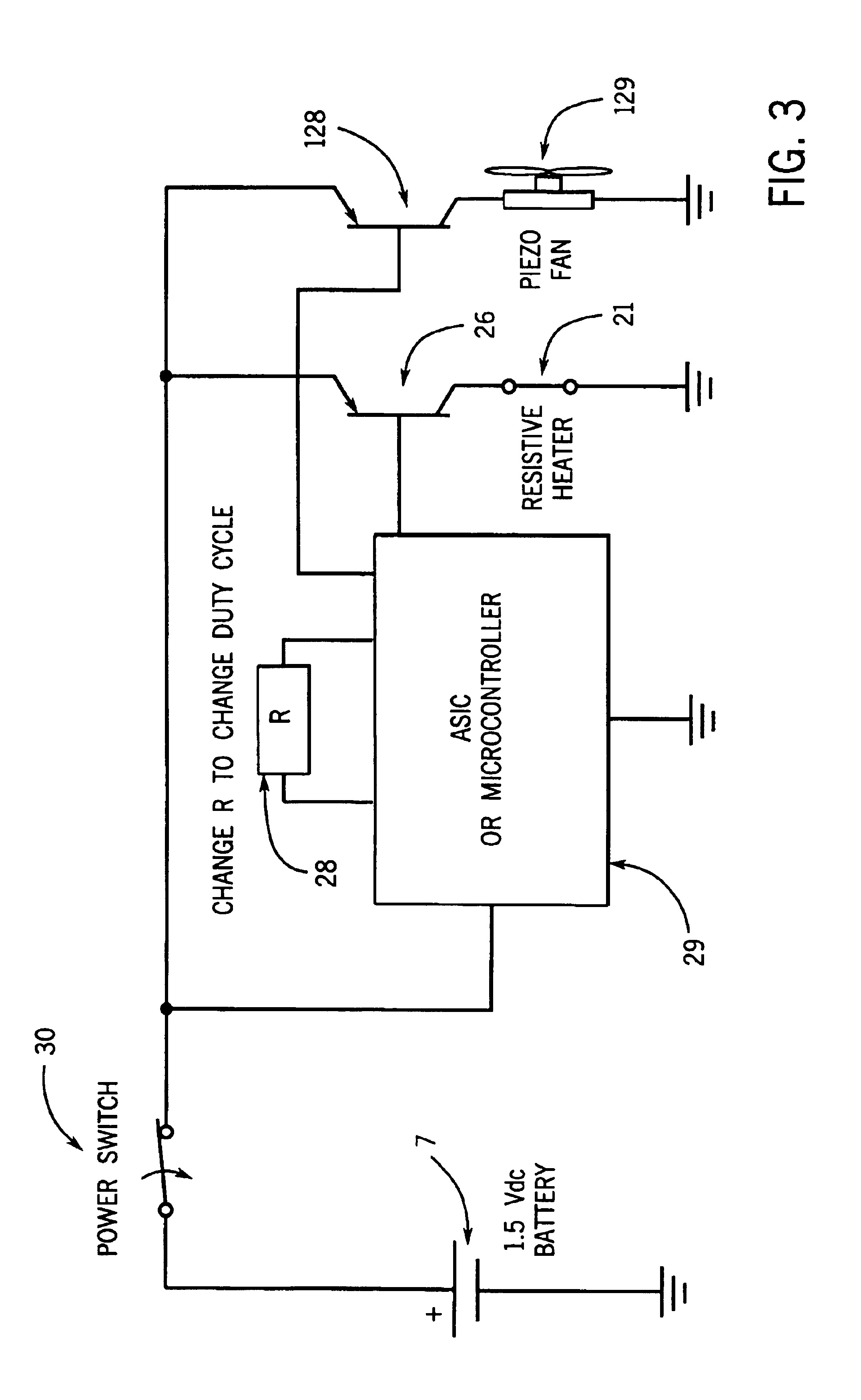

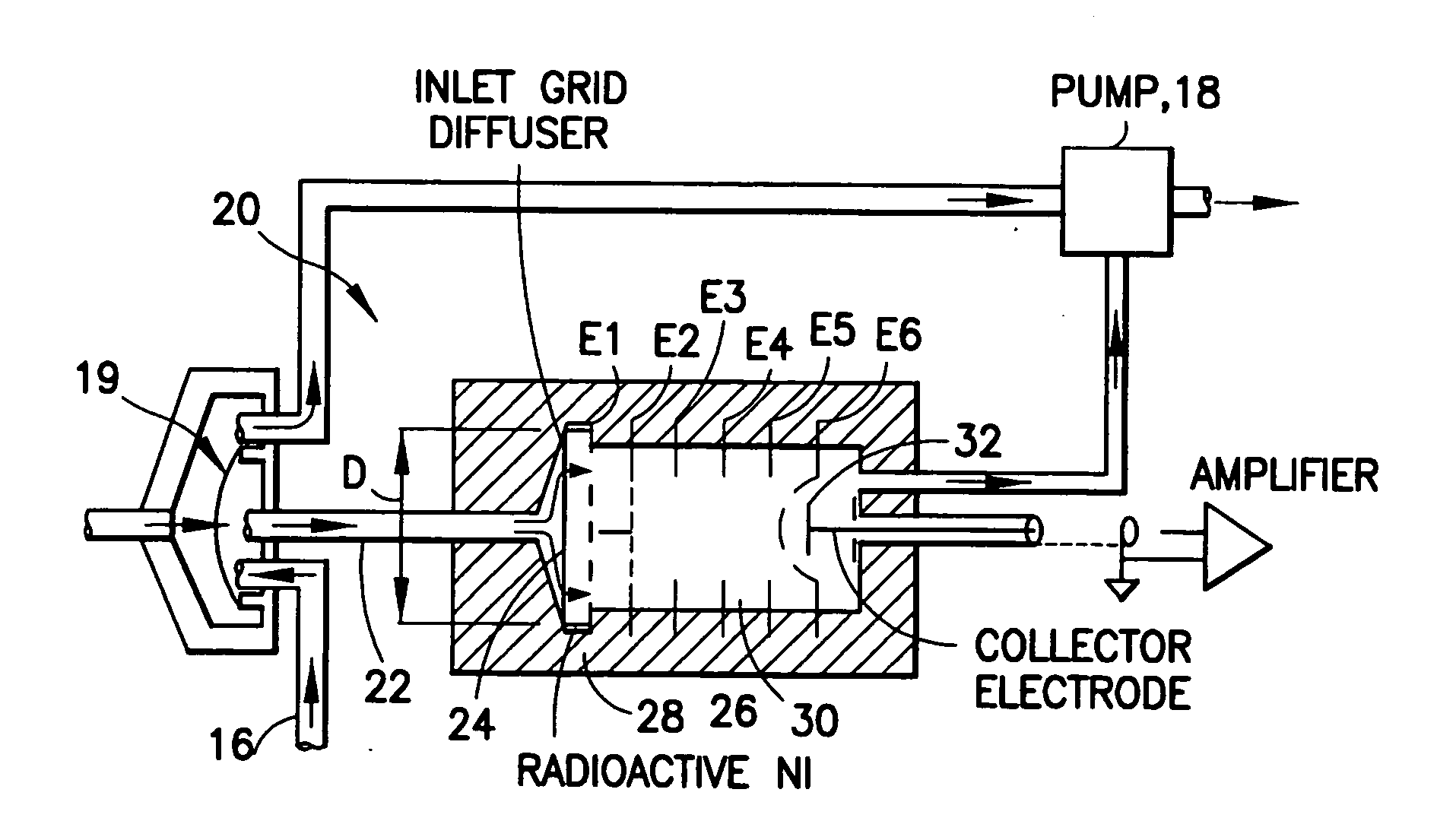

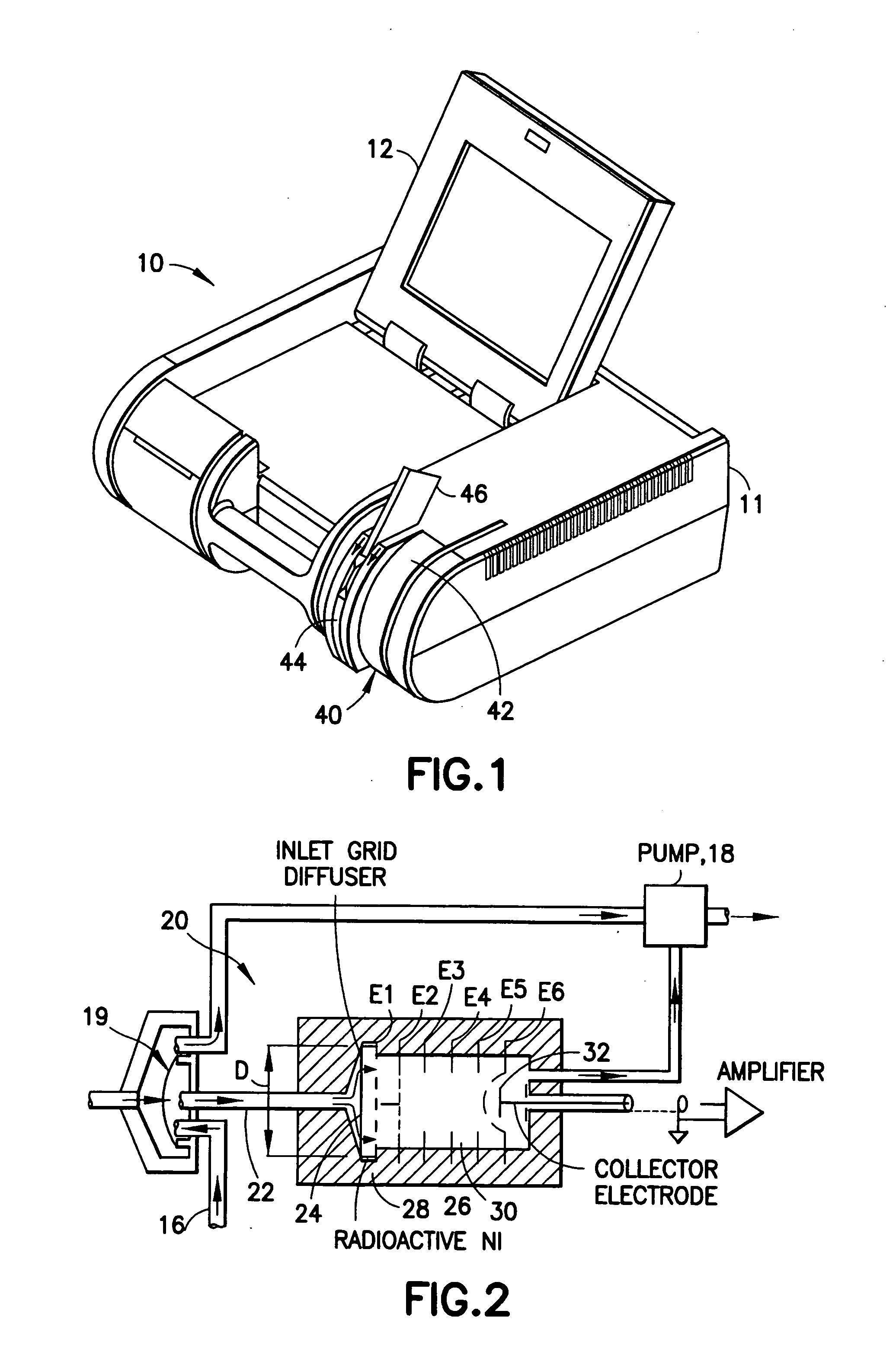

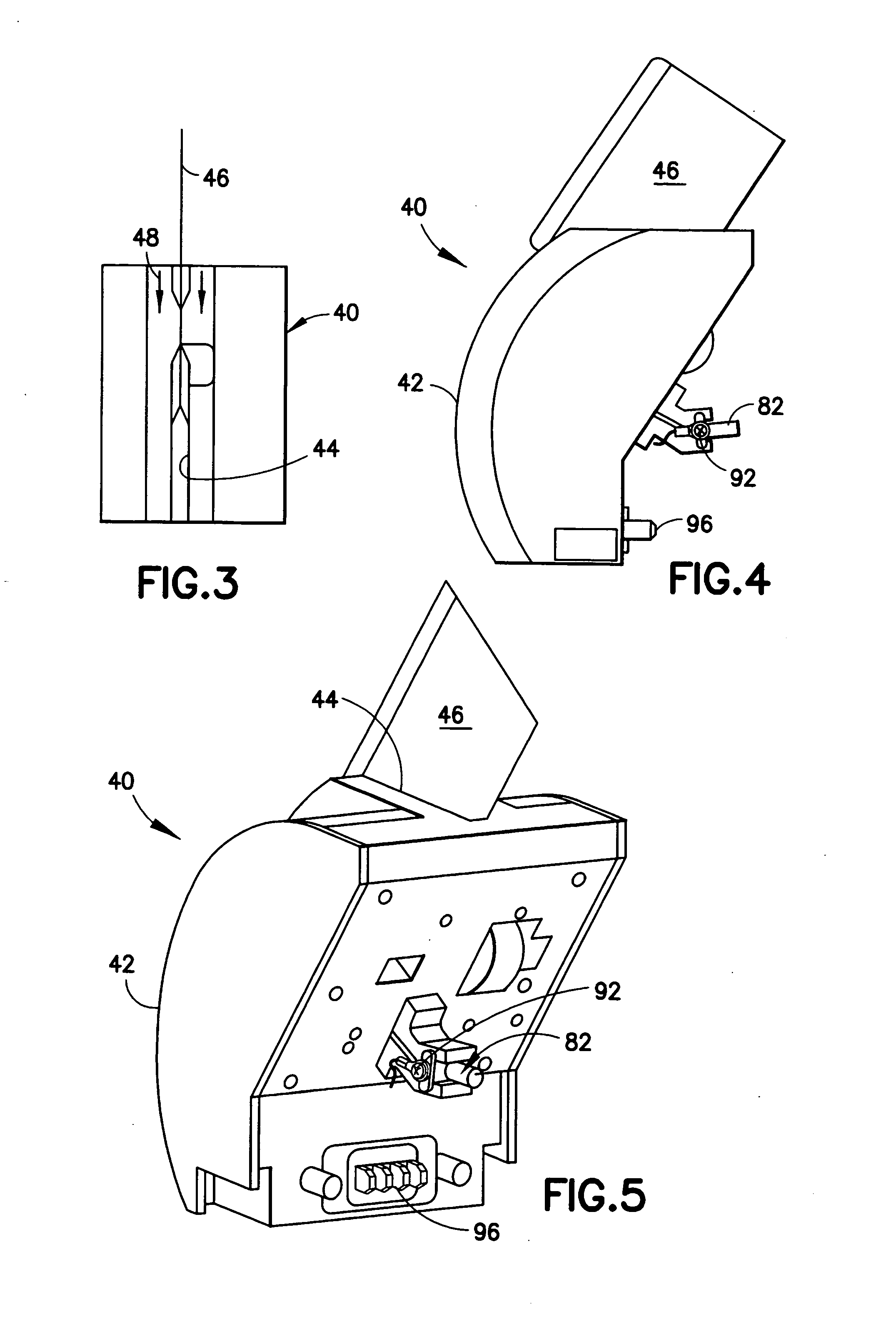

Device for testing surfaces of articles for traces of explosives and/or drugs

InactiveUS20050019220A1Laborious and time-consumingHeating fastMaterial analysis using wave/particle radiationTime-of-flight spectrometersExplosive materialMetal

A device is provided for testing surfaces of a card for the presence of explosives, drugs or other substances of interest. The device includes a slot for receiving the card. Thin metallic wiper blades are dispose in alignment with the slot and wipe over surfaces of the card as the card is passed through the slot. Thus, substances on the surface of the card are transferred to the wiper blade. The wiper blade then is enclosed and rapidly heated to desorb the material retrieved from the card. The enclosure then is placed in communication with a detector to test for the presence of substances of interest.

Owner:RAPISCAN SYST INC (US)

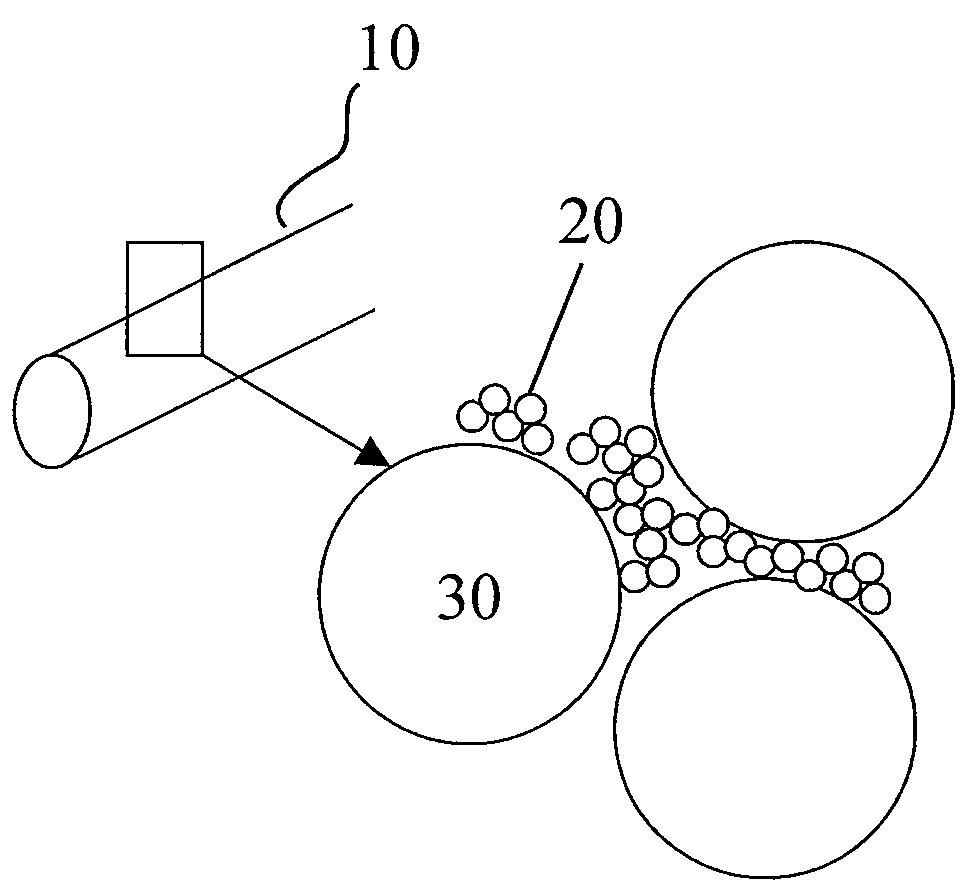

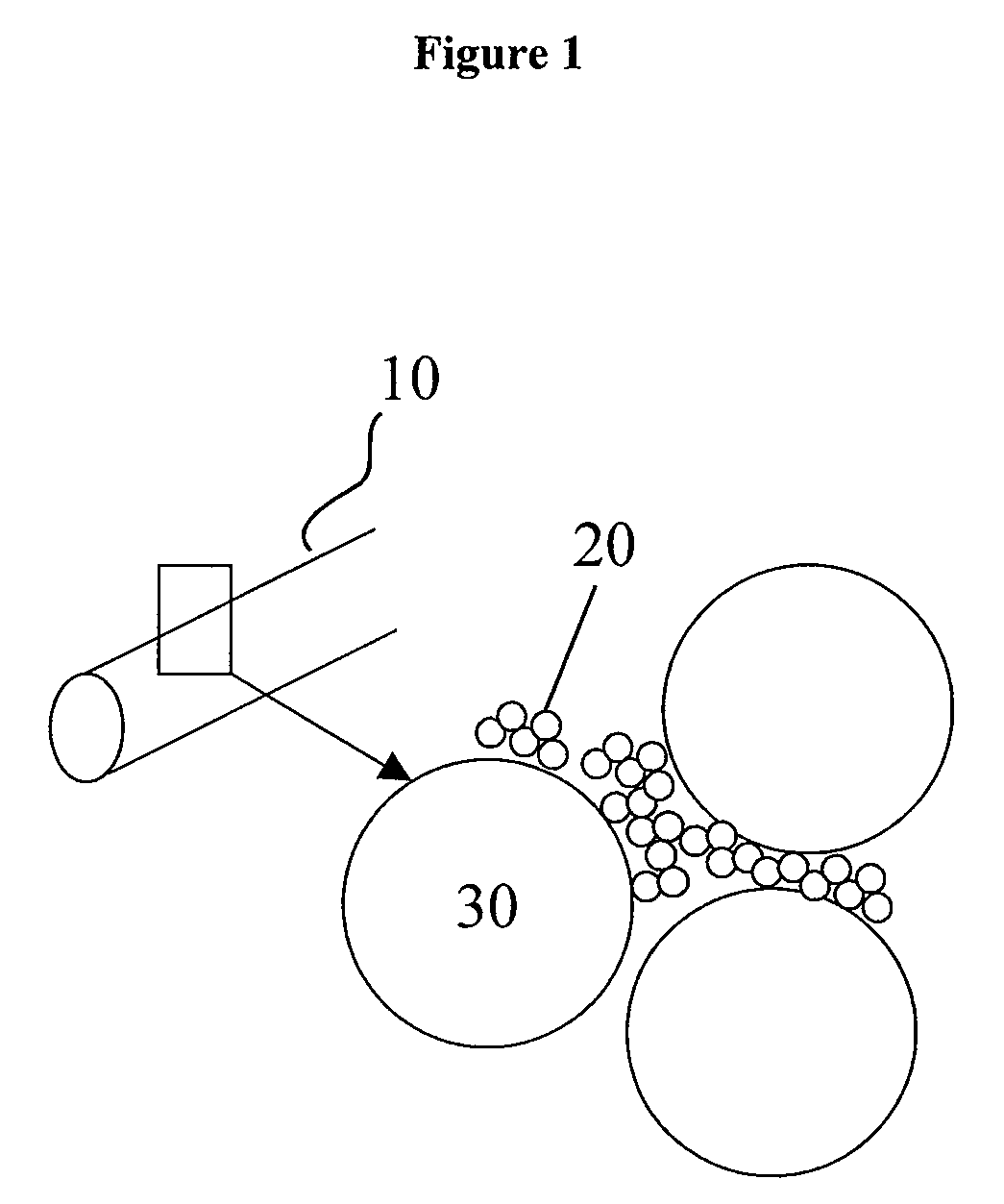

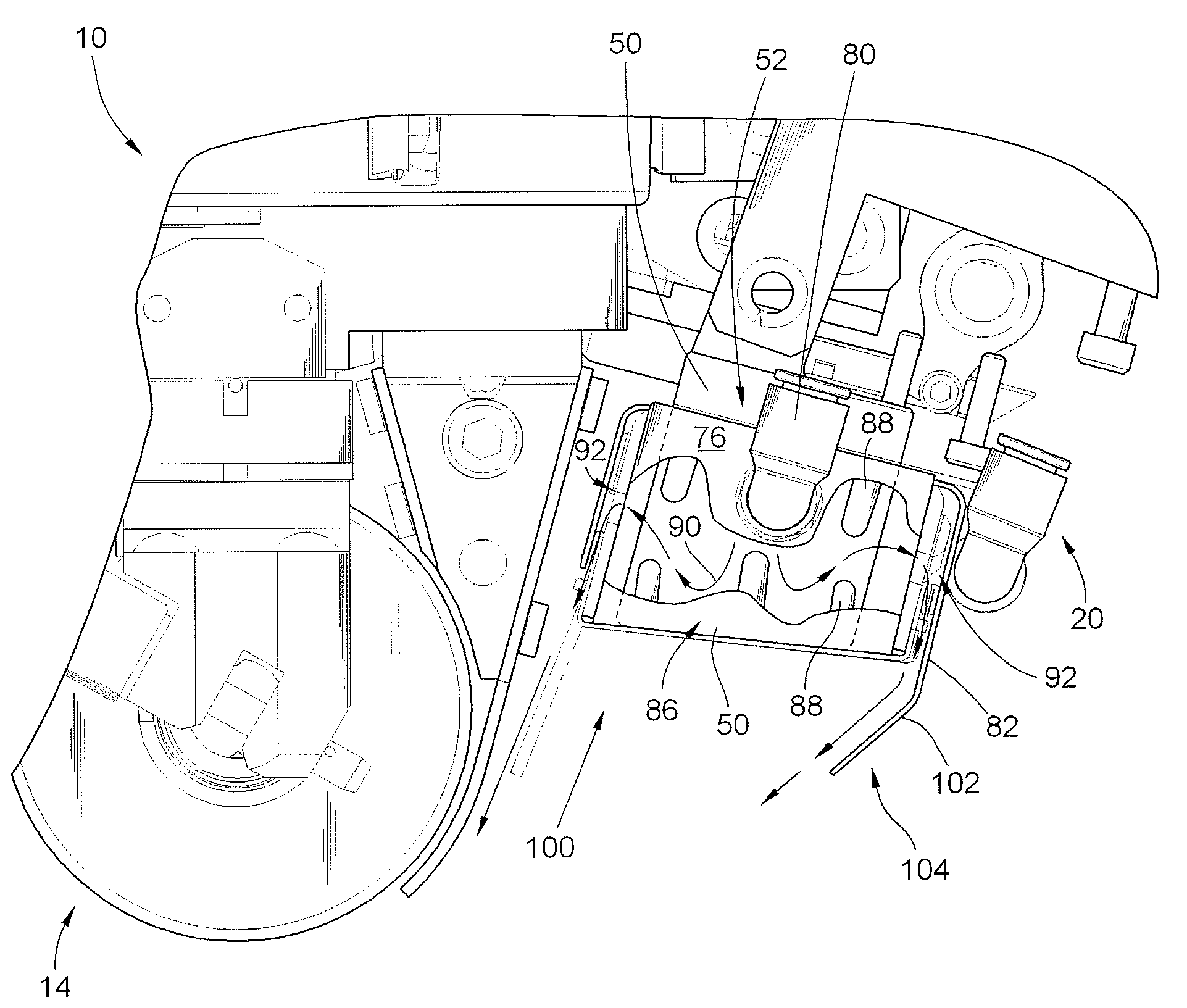

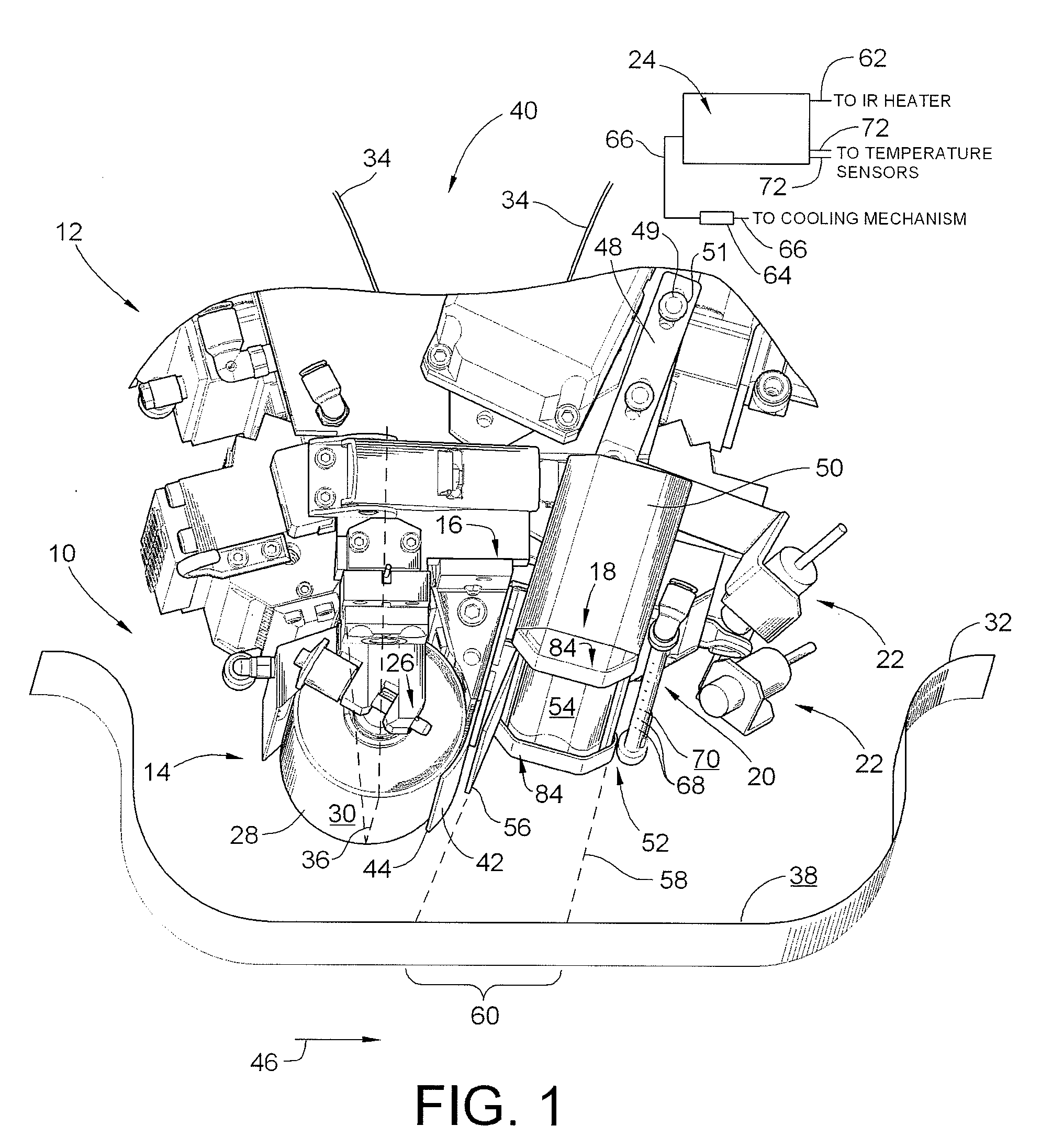

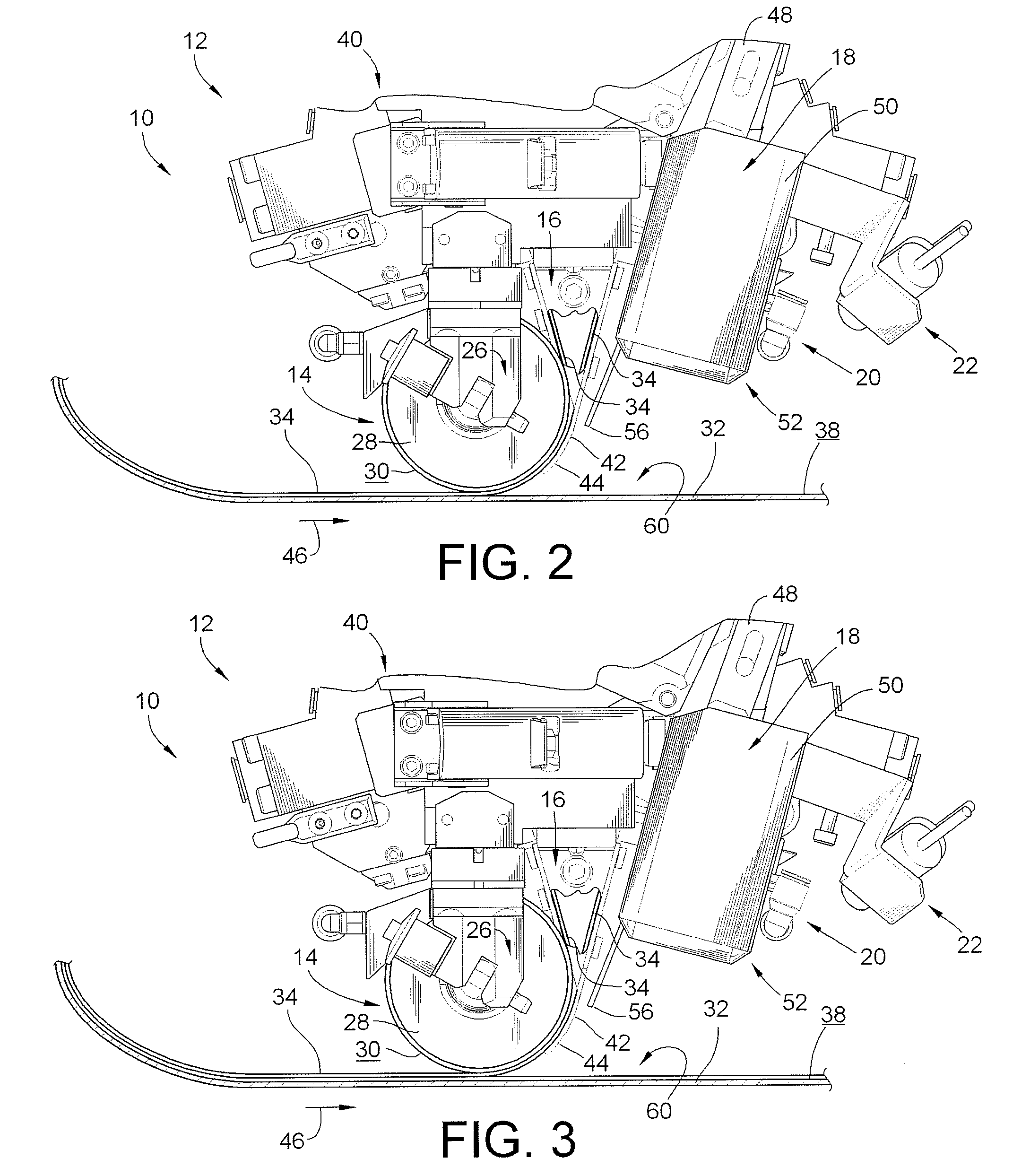

System and method for heating carbon fiber using infrared radiation in a fiber placement machine

ActiveUS7731816B2Heating fastInexpensive and quick to reactLamination ancillary operationsLaminationFiberCarbon fibers

An apparatus comprising a fiber placement head assembly and an infrared heating assembly is provided. The fiber placement head assembly includes a compaction roller assembly and a feeder assembly. An infrared heating assembly, a cooling mechanism, temperature sensors, and a controller are operably coupled to the fiber placement head assembly. The infrared heating assembly includes an infrared heater that generates a heating profile. The heating profile defines a heating zone on either a tool or previously laid tows. If the burn point of either the tool or previously laid tows within the heating zone is approached, the controller, which receives temperature readings from the temperature sensors, simultaneously disables the infrared heater and activates the cooling mechanism. As such, the tool and the previously laid tows are protected from being ruined due to an over temperature condition.

Owner:INGERSOLL MACHINE TOOLS

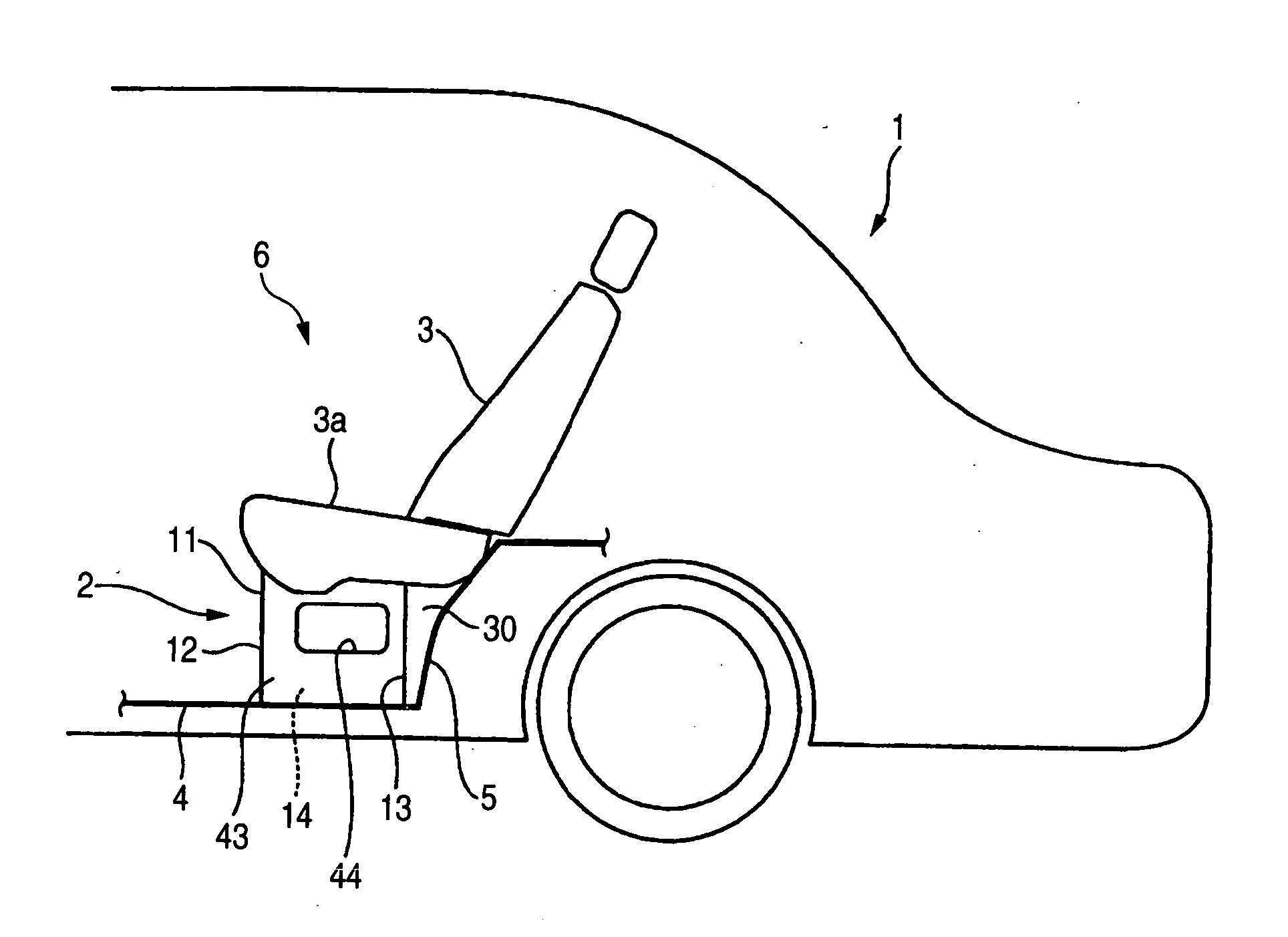

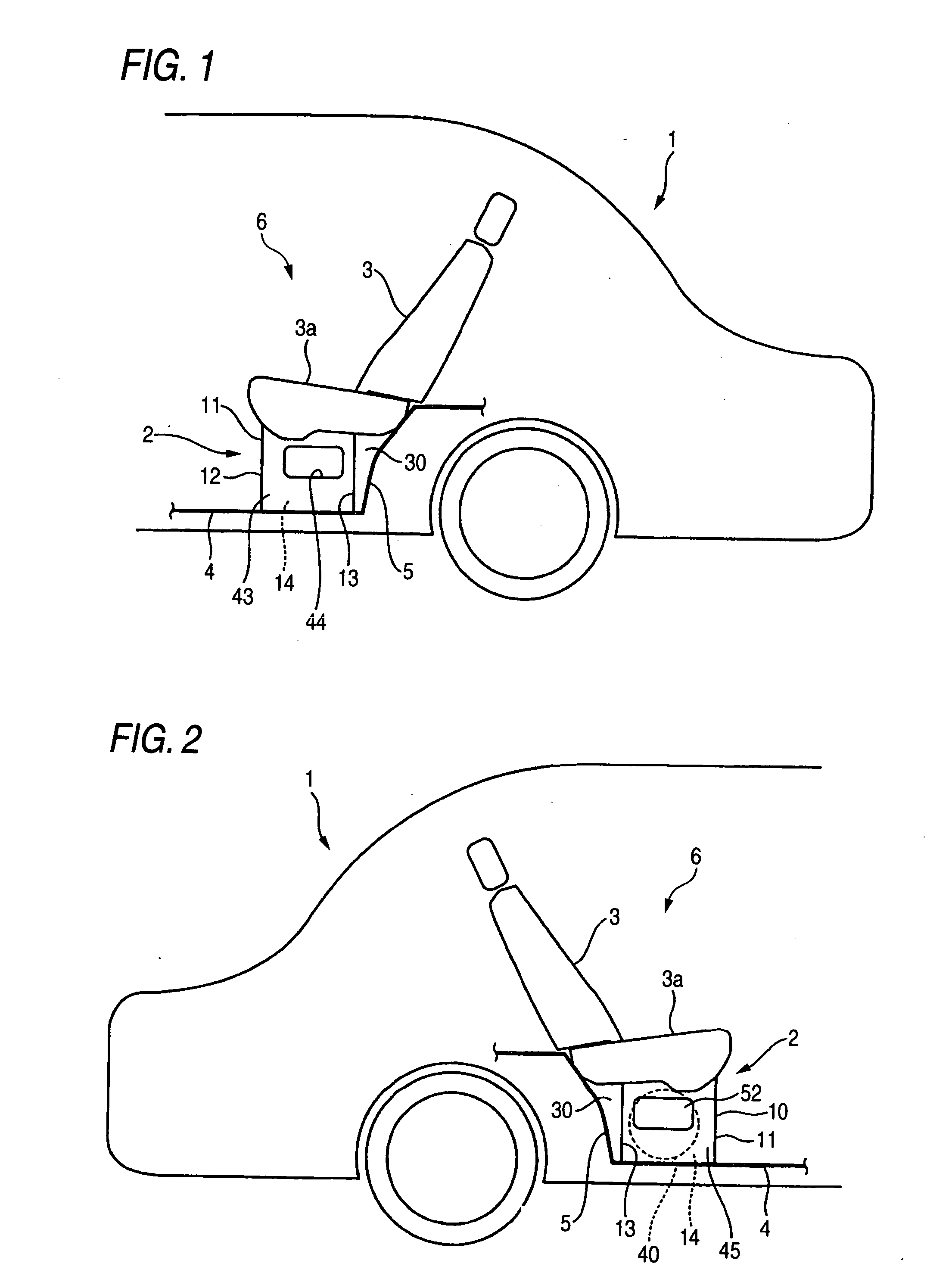

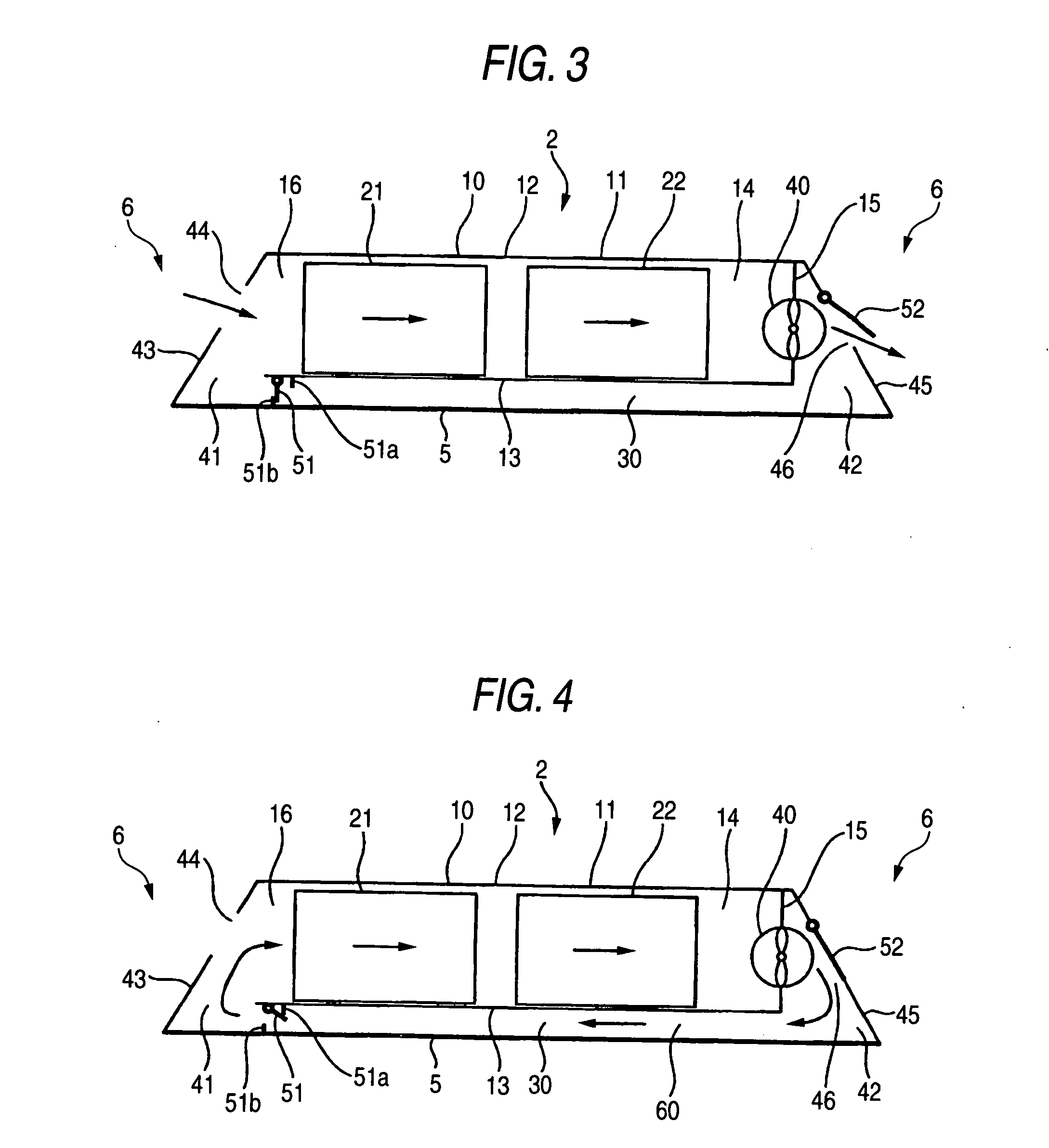

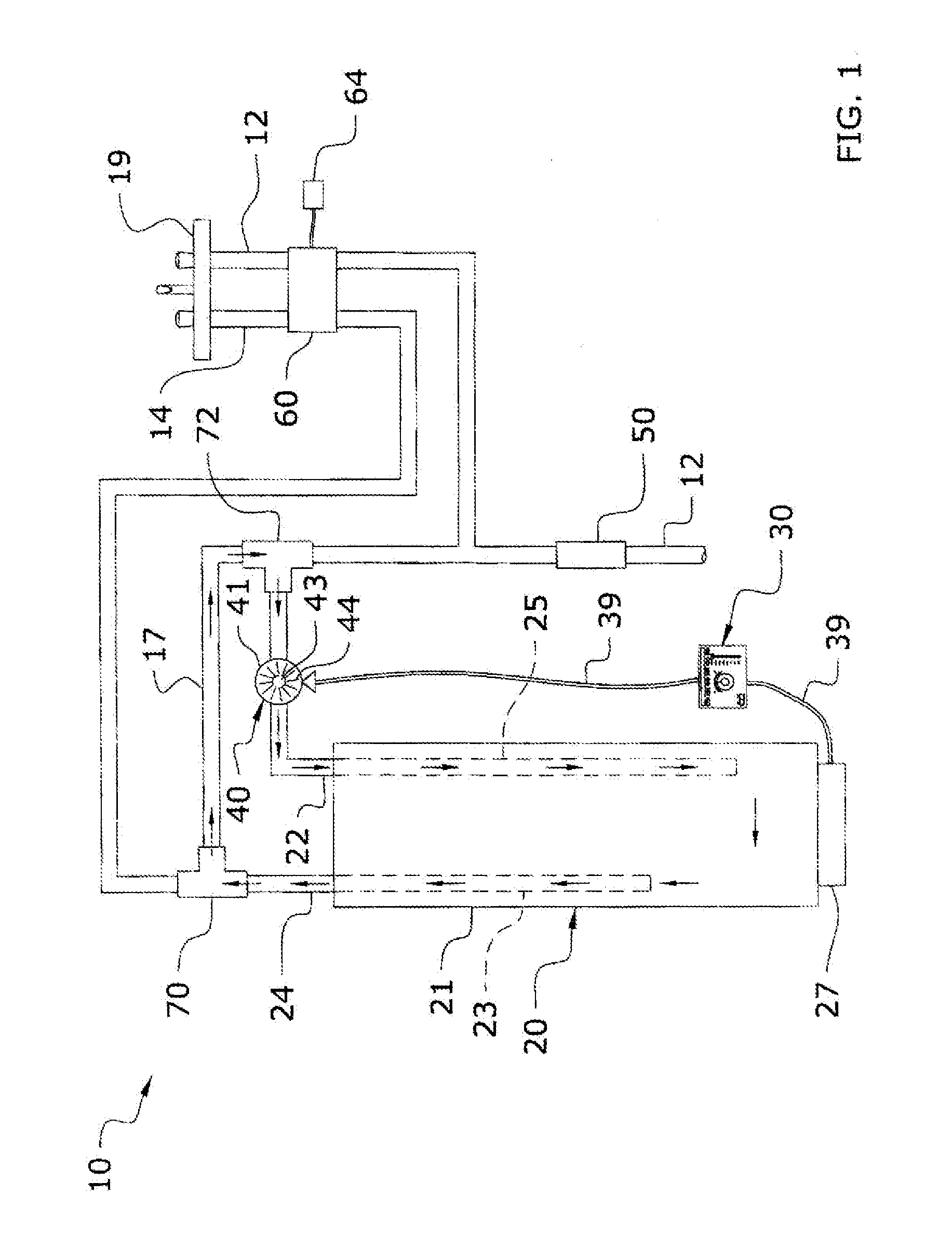

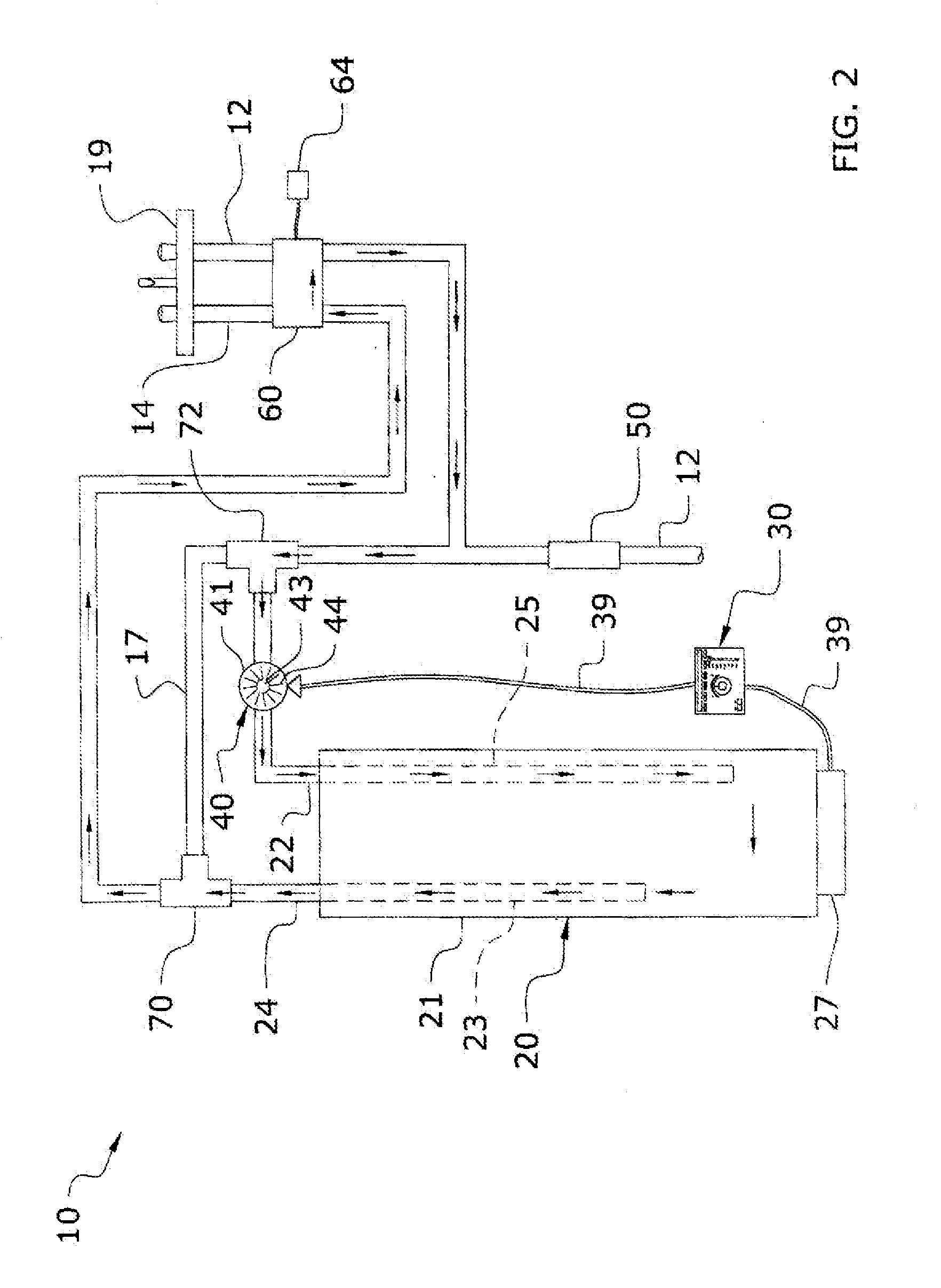

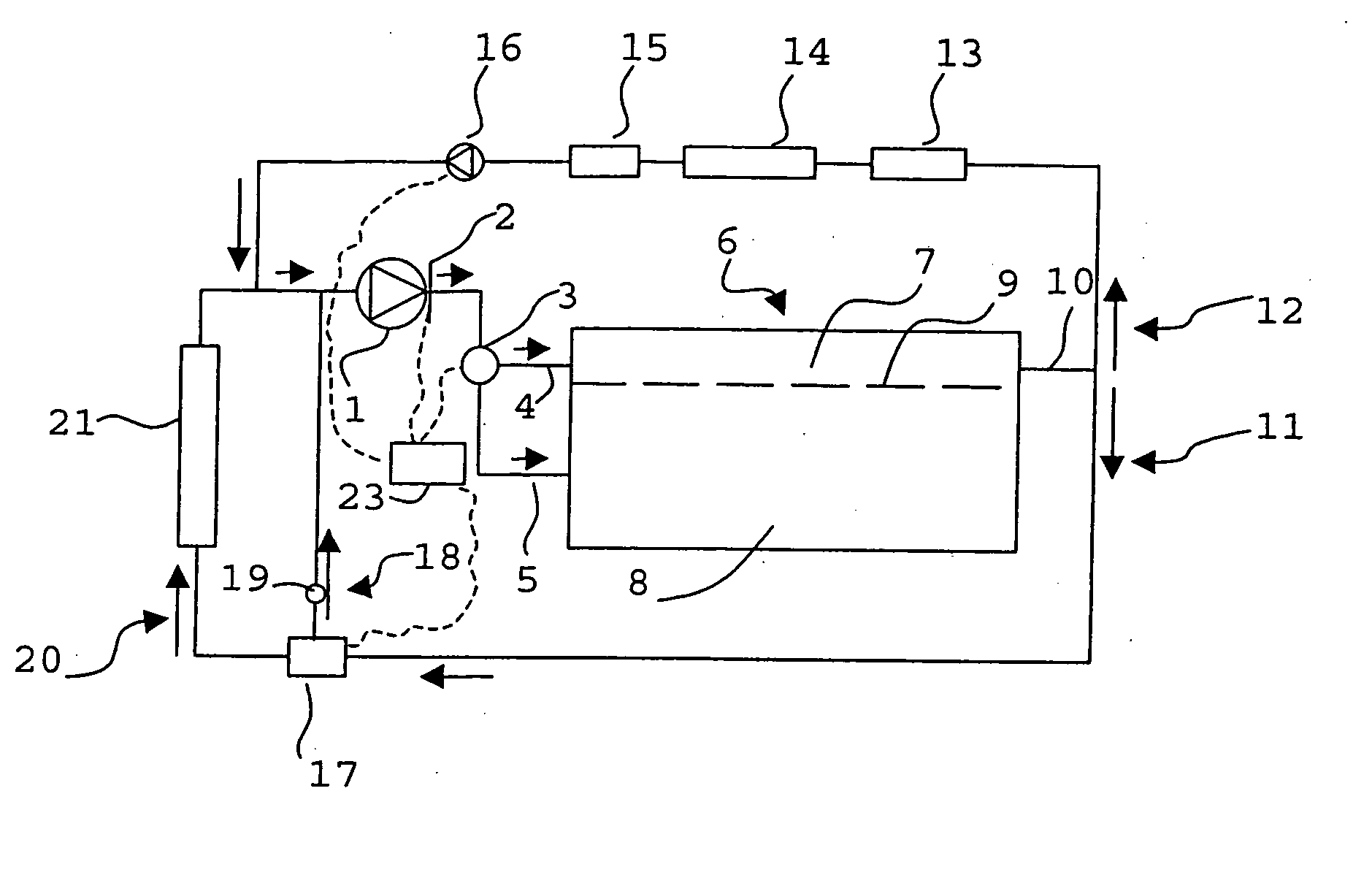

Vehicular electrical equipment unit heating and cooling system and hybrid vehicle

ActiveUS20050011692A1Reduce volumeReduce component countAir-treating devicesElectric propulsion mountingElectrical devicesEngineering

A vehicular electrical equipment unit heating and cooling system includes a vehicular electrical equipment unit 10 including a battery 21 and an inverter YBU5 22 which are accommodated in a primary air passageway 14, an air inlet 44 through which air in a passenger compartment 6 is admitted to the primary air passageway 14, an air outlet 46 through which air flowing in the primary air passageway 14 is discharged to the outside of the electrical equipment unit 10, a subsidiary air passageway 30 connected to and cut off from the primary air passageway 14 to make a closed circuit 60 when connected to the primary air passageway 14, and a fan 40 for generating a flow of air in the primary air passageway 14.

Owner:HONDA MOTOR CO LTD

Instant hot water delivery system

InactiveUS20100096018A1Efficiently heatEfficiently heating waterValve members for heating/coolingPipe heating/coolingWater deliveryEngineering

An instant hot water delivery system for efficiently heating water when necessary to provide instant hot water to a faucet. The instant hot water delivery system generally includes a water heater including an inlet and an outlet, a cold water supply line introducing cold water into the inlet, a hot water supply line connecting the outlet to a faucet and a recirculation line connected to the hot water supply downstream of the outlet and the cold water supply line upstream of the inlet. The recirculation line forms a first recirculation loop for water within the water heater to flow during a first water heating process. A recirculation pump is connected to the cold water supply line between the recirculation line and the inlet for circulating the water during the water heating process. In one embodiment, the control unit is used to retrofit an existing gas or electric water heater.

Owner:WYLIE JACOB E +1

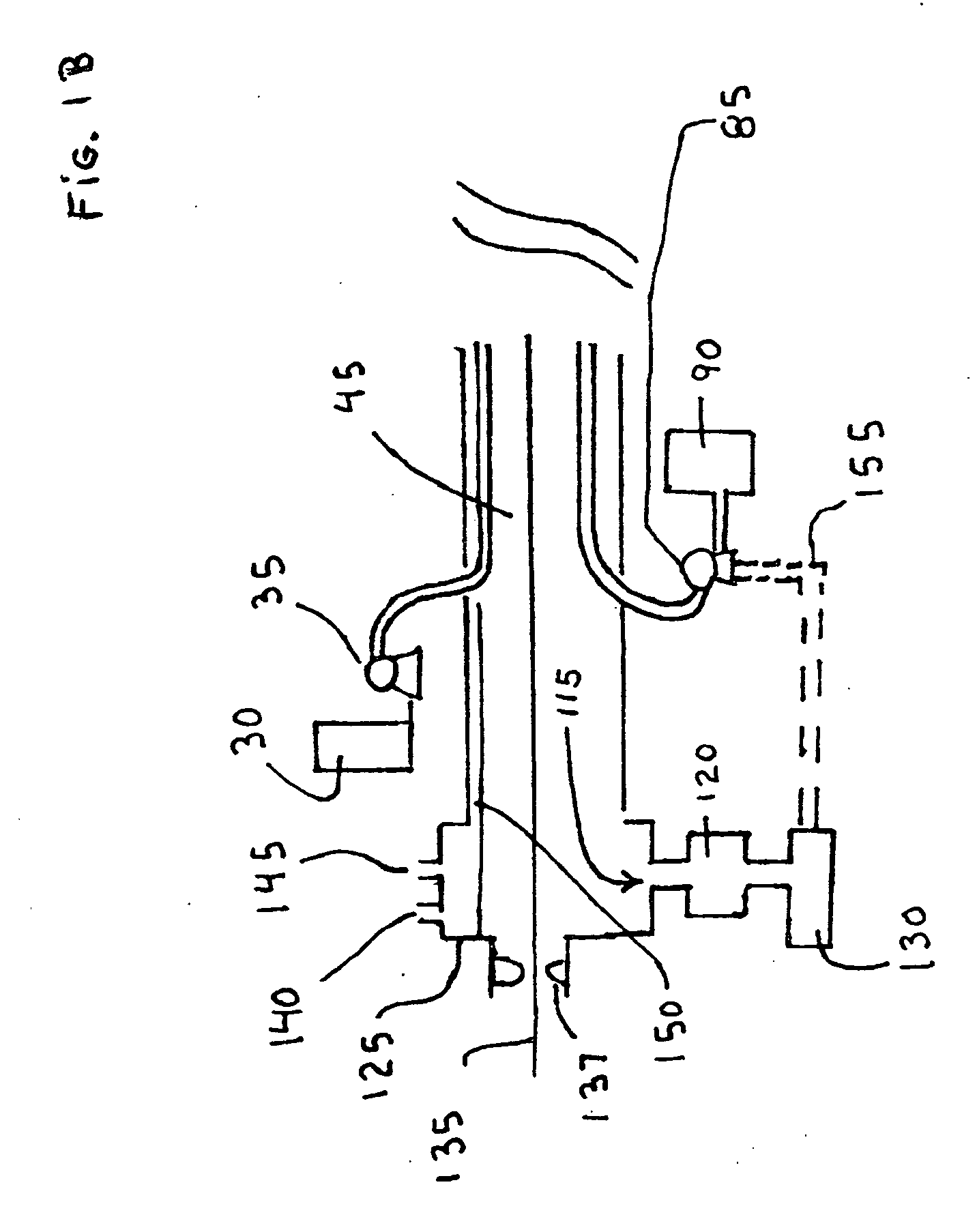

Venous heated ablation catheter

InactiveUS20130030410A1Improve efficiencyFluid handlingBalloon catheterMedical devicesVeinLaser probe

A catheter for delivery of sclerosant to a tubular member or vein of the body to cause ablation. The catheter has one or more balloons located near the distal end to enhance effectiveness of the sclerosant and prevent its delivery to the deep venous system. The catheter has an orifice located near the distal end of the catheter to direct the sclerosant into the vessel and one or more effluent openings to provide for removal of the sclerosant fluid. A heating member such as an electrical resistance element, a Laser probe, or an RF electrode located within the catheter lumen or on the outside of the catheter shaft heats the sclerosant fluid to improve its ablation effectiveness.

Owner:DRASLER WILLIAM JOSEPH +2

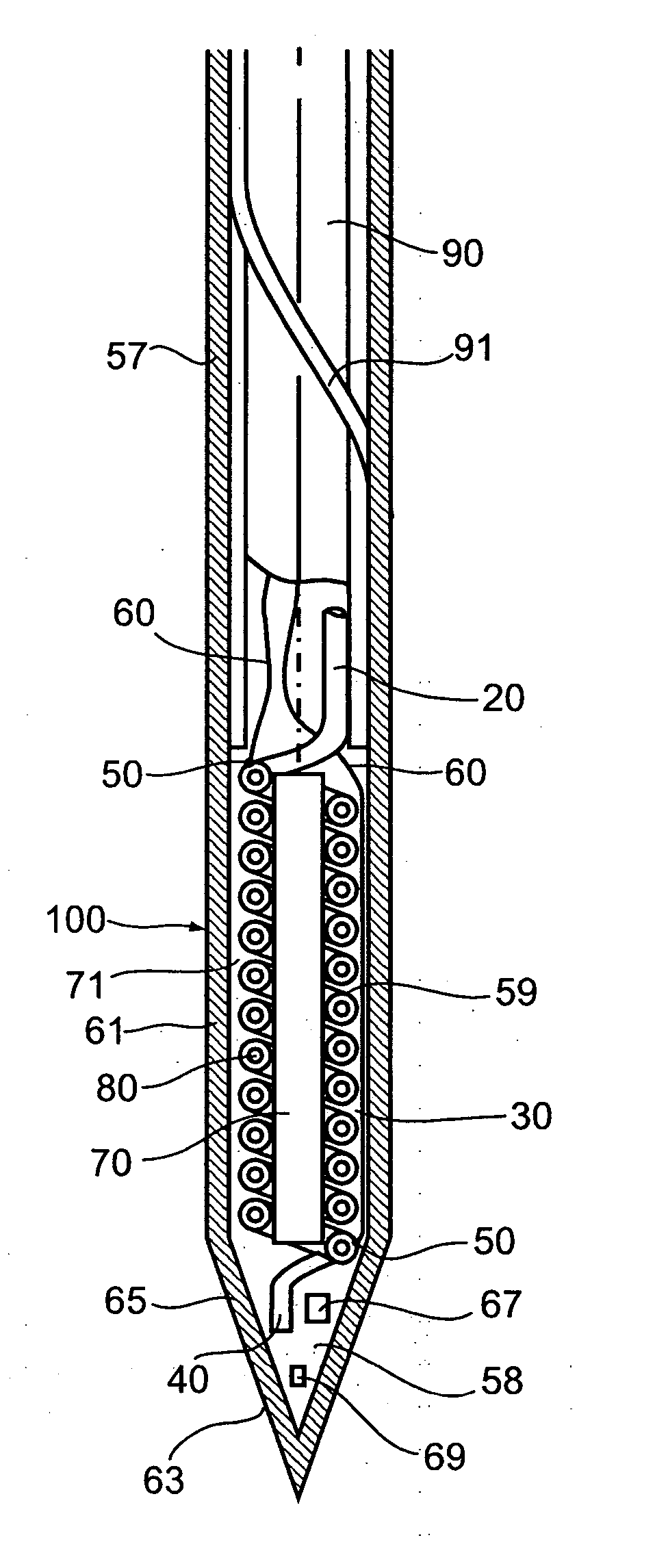

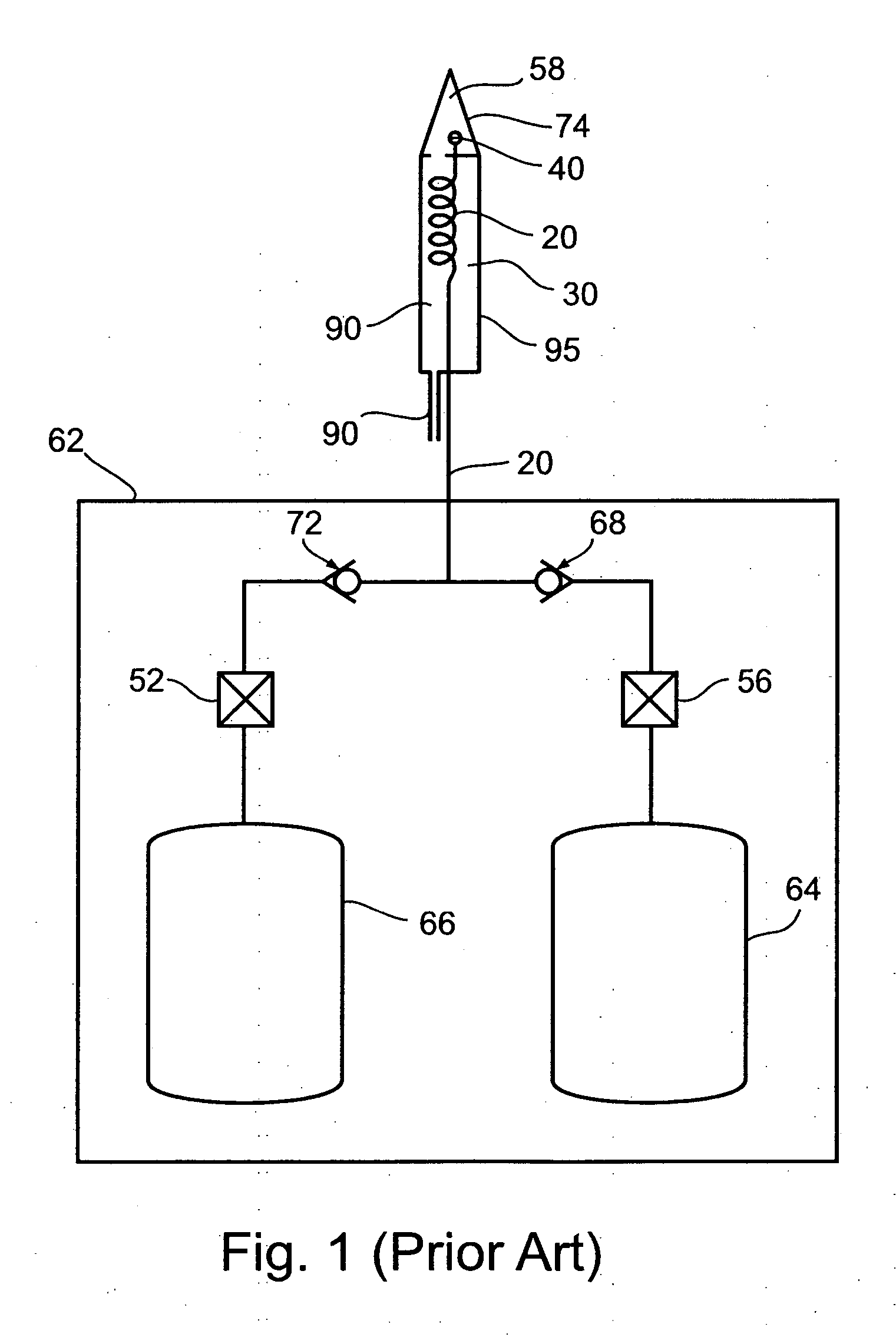

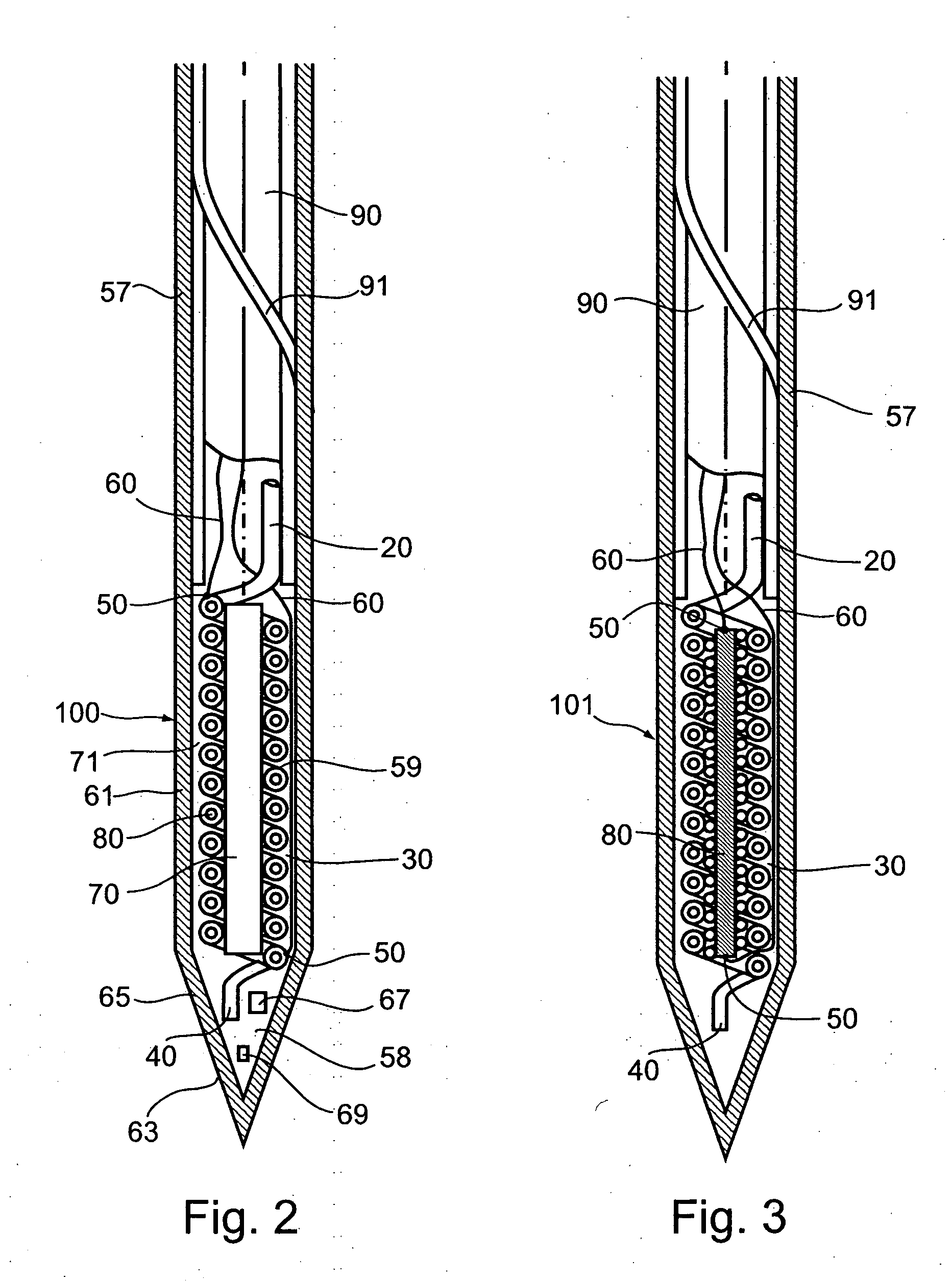

Gas-heated gas-cooled cryoprobe utilizing electrical heating and a single gas source

ActiveUS20060122590A1Quick switchHeating fastSurgical instruments for coolingElectrical resistance and conductanceElectricity

The present invention is of device, system, and method for cooling and heating an operating tip of a cryoprobe using a single source of compressed gas. Cooling of the operating tip is effected by Joule-Thomson expansion of a high-pressure cooling gas through a Joule-Thomson orifice into an expansion chamber. Heating of the operating tip is effected by electrical resistance heating. In preferred embodiments, heating of the operating tip is effected by electrical resistance heating of low-pressure gas flowing towards the operating tip. Preferably, gas from a single gas source is supplied to the probe during both cooling and heating phases, a cooling gas being supplied at high pressure when used for cooling and at low pressure when used for heating. Low-pressure gas supplied during the heating phase is heated as it flows towards the operating tip, preferably by electrical resistance heating within the body of the probe. A single gas input lumen is used during both cooling and heating phases to transport gas into the probe, and a single gas exhaust lumen is used during both cooling and heating phases to conduct gas out of the probe.

Owner:GALIL MEDICAL

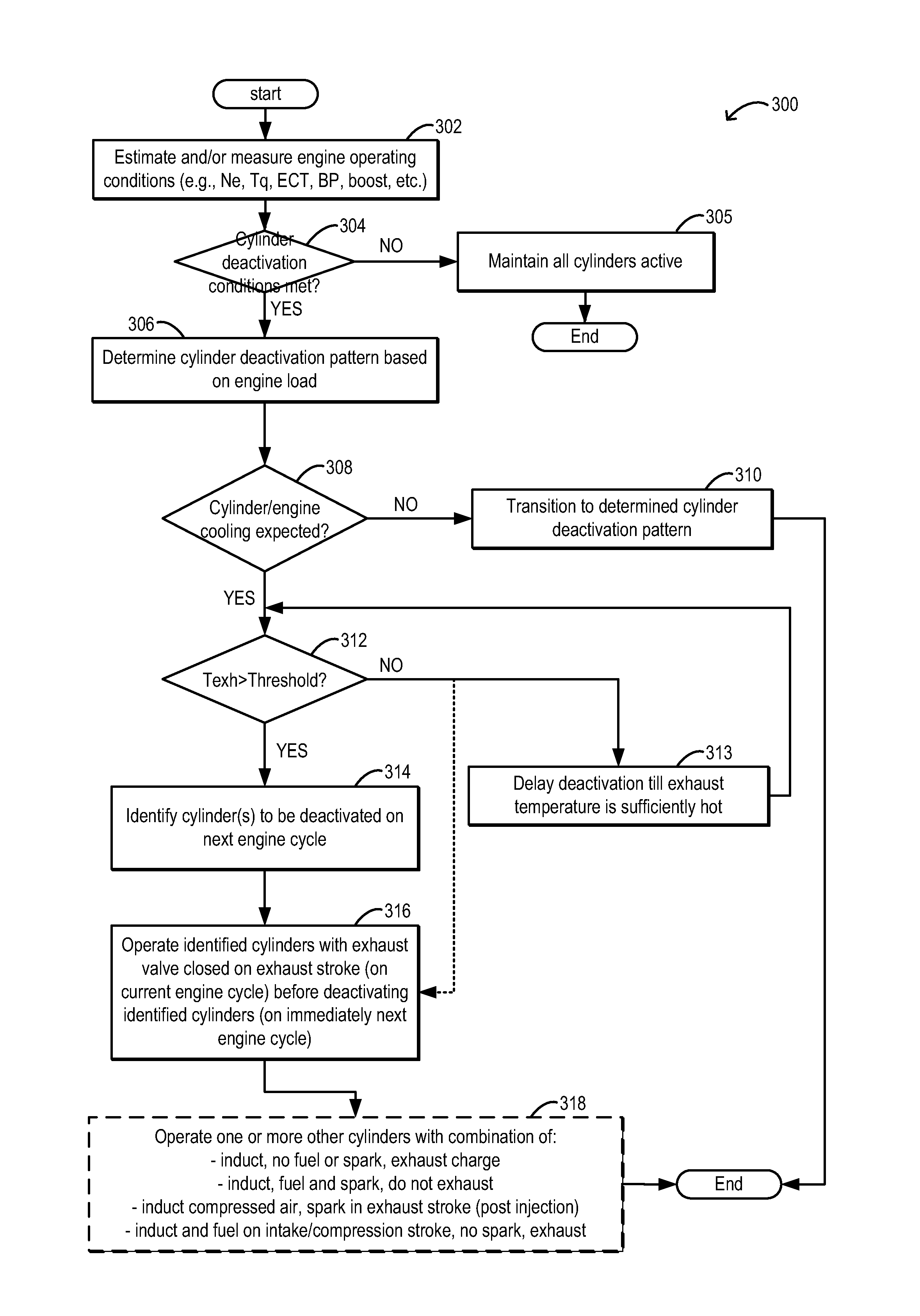

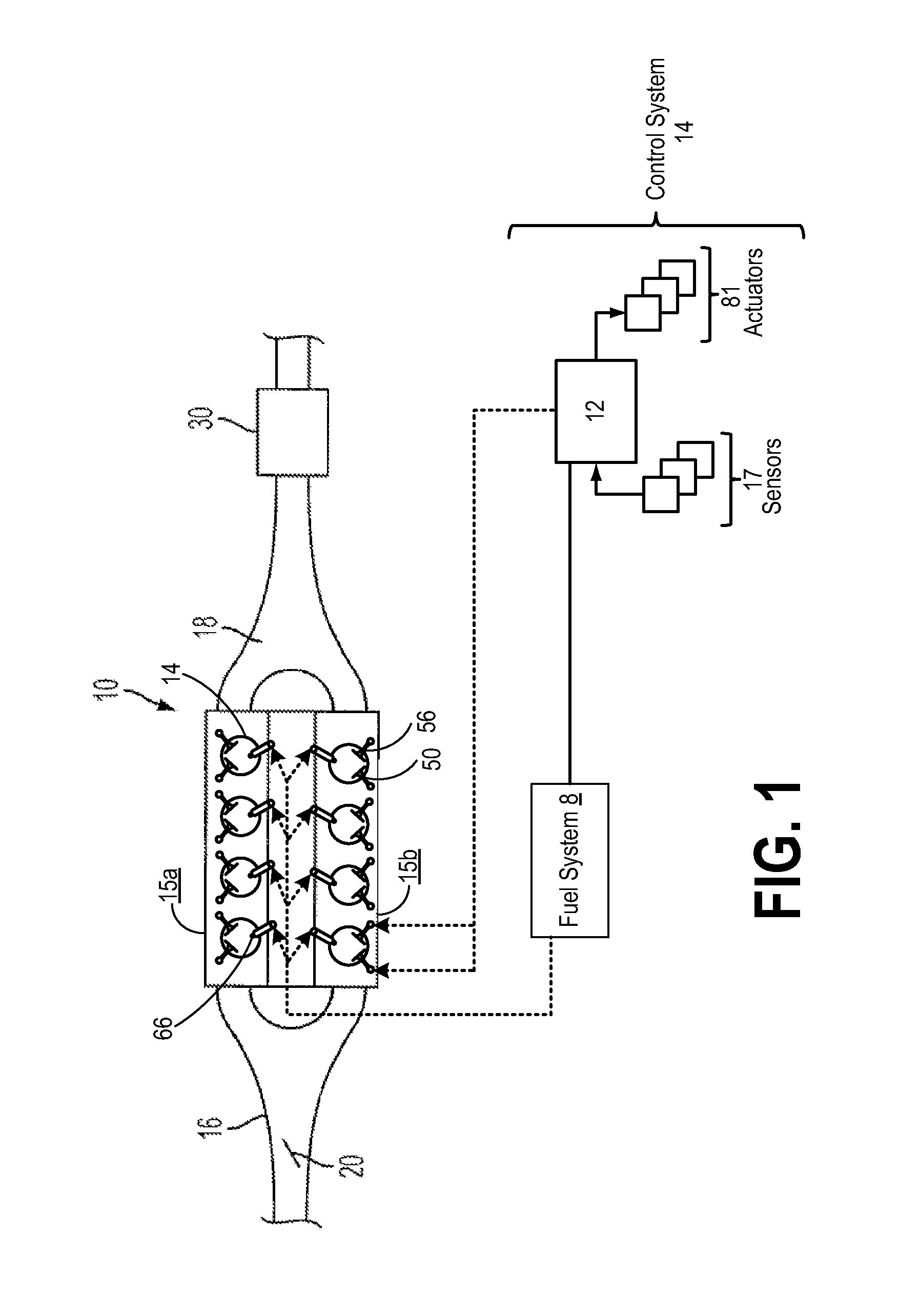

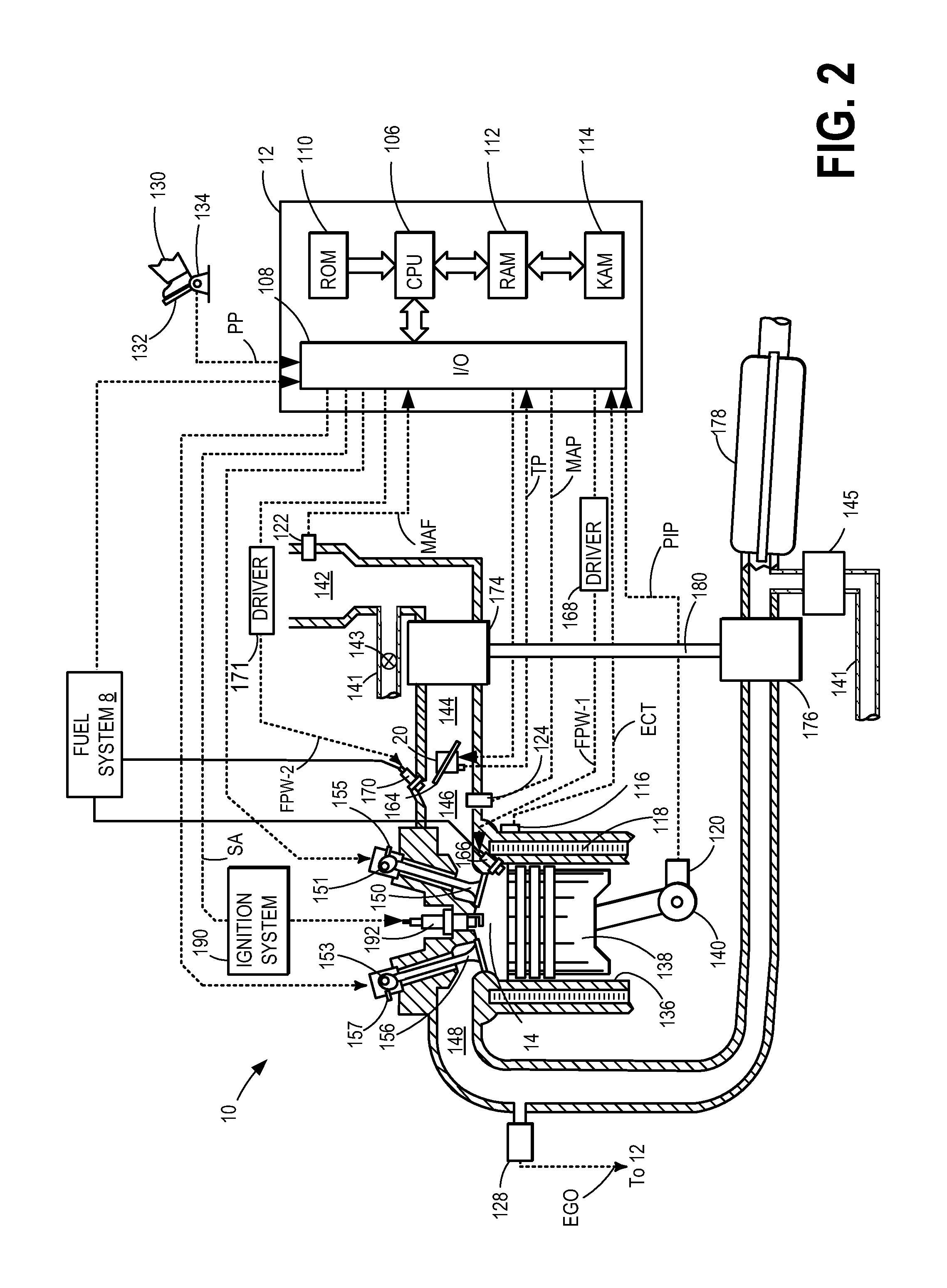

Method and system for engine temperature control

ActiveUS20160115884A1Increased hydrocarbonExhaust emission be highElectrical controlInternal combustion piston enginesTemperature controlExhaust valve

Methods and systems are provided to improve engine temperature control. Cylinders scheduled for deactivation may have their exhaust retained in the cylinder by holding an exhaust valve closed on the preceding firing cycle. In this way soot emissions on reactivation are reduced.

Owner:FORD GLOBAL TECH LLC

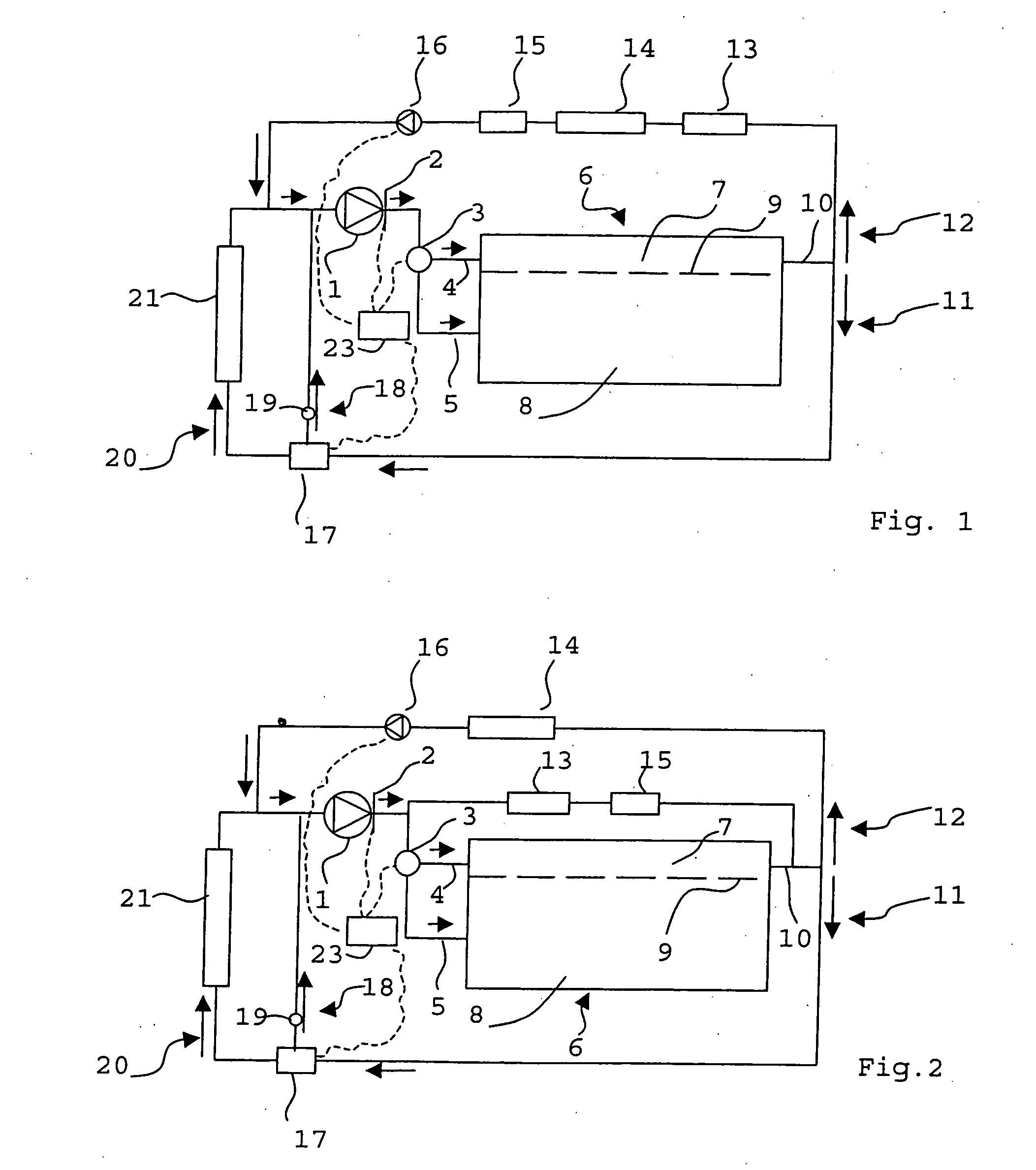

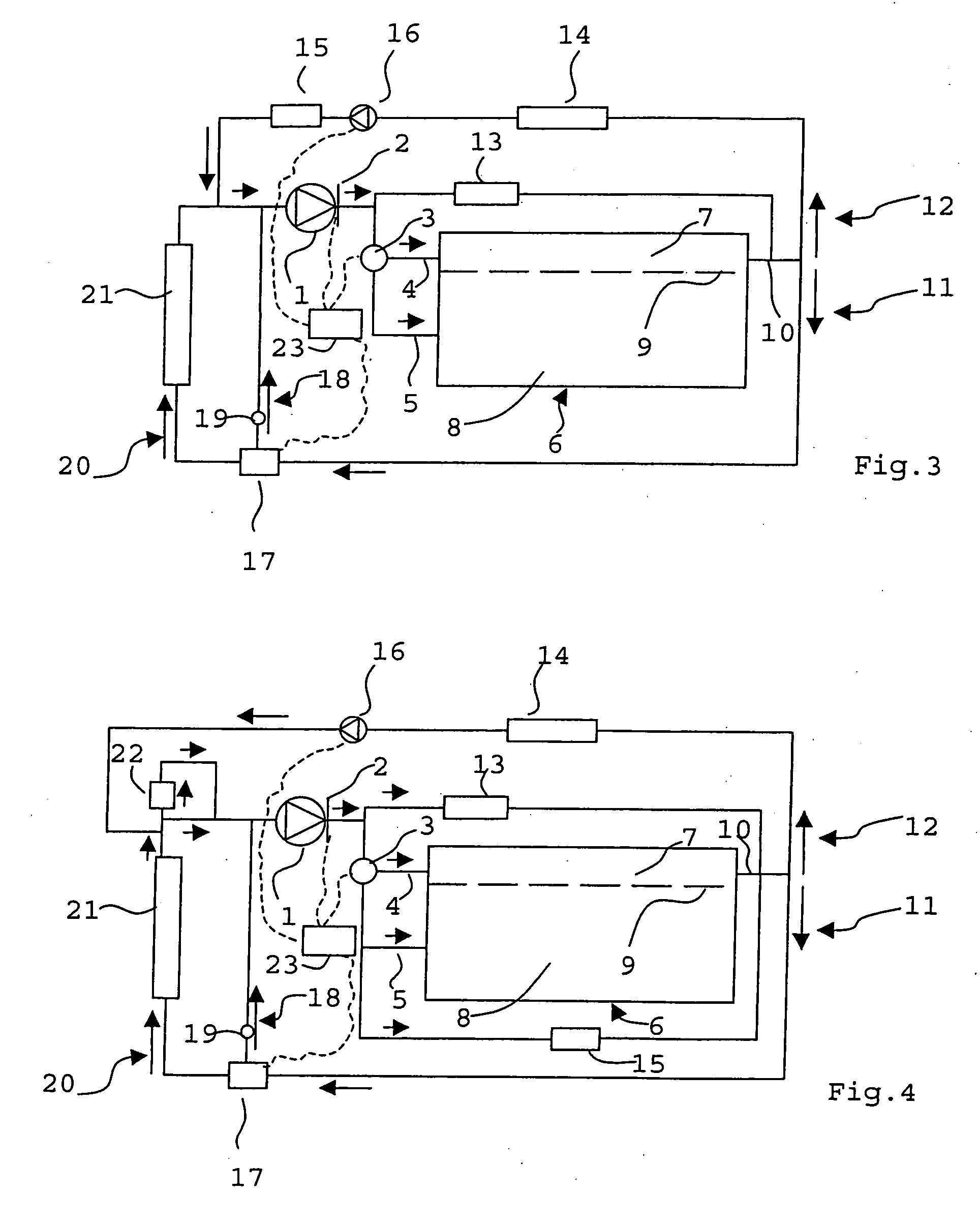

Internal combustion engine for a motor vehicle

InactiveUS20060157002A1Reduce the ratioHeating fastLiquid coolingCoolant flow controlCylinder headEngineering

In an internal combustion engine for a motor vehicle, having a cylinder head and an engine block, each with a coolant inlet port and a coolant outlet port which is common to the cylinder head the engine block, a main coolant pump having an intake side connected to the coolant outlet port and a pressure side connected to a first control valve via which coolant reaches the inlet port of the cylinder head and the inlet port of the engine block depending on the temperature of the coolant, and to a method for operating such an internal combustion engine, wherein the main coolant pump is selectively actuated to pump the coolant through at least one of the cylinder head and the engine block or is shut down depending on the engine operating state.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com