Patents

Literature

2914results about How to "Shorten heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

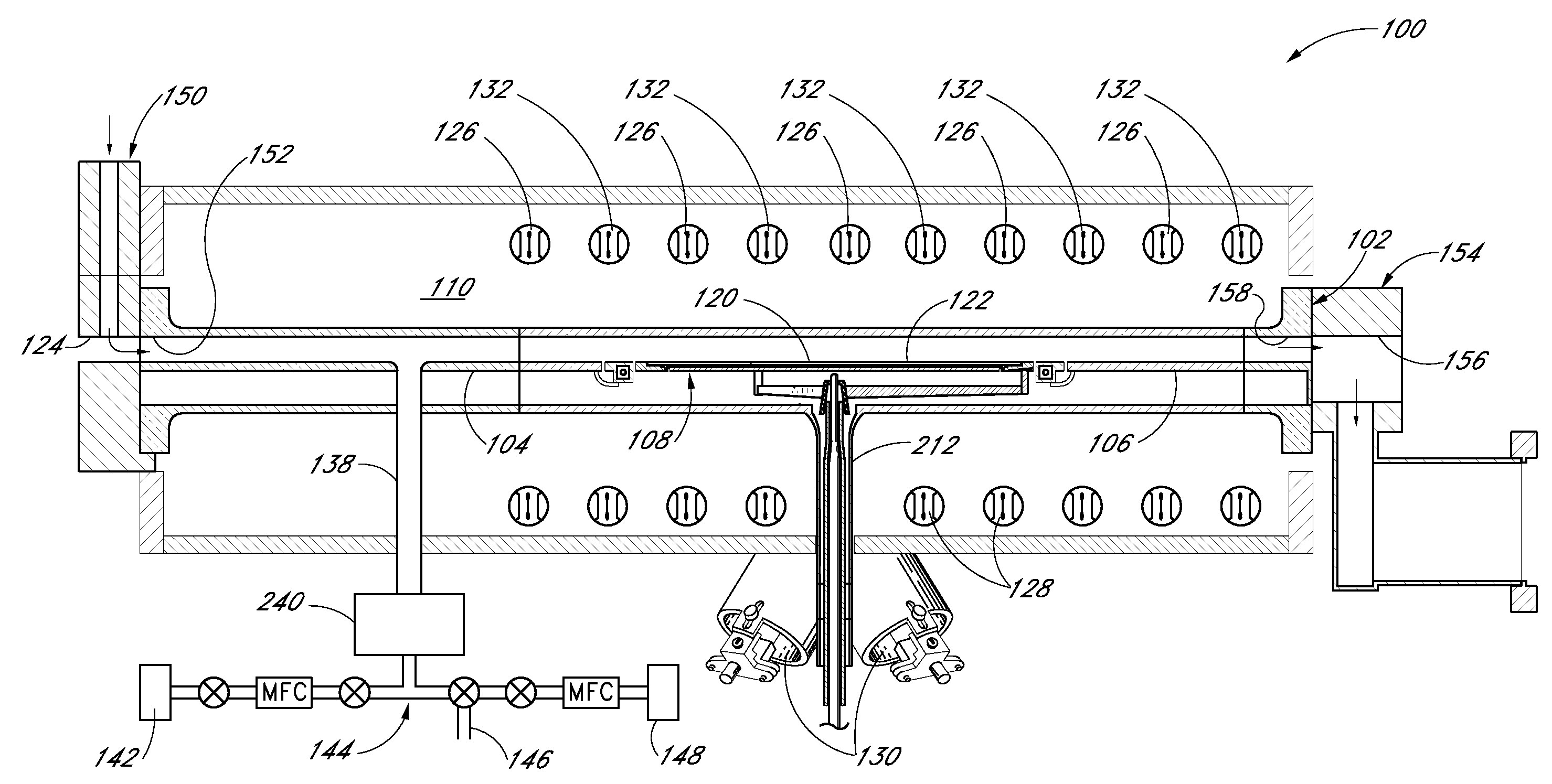

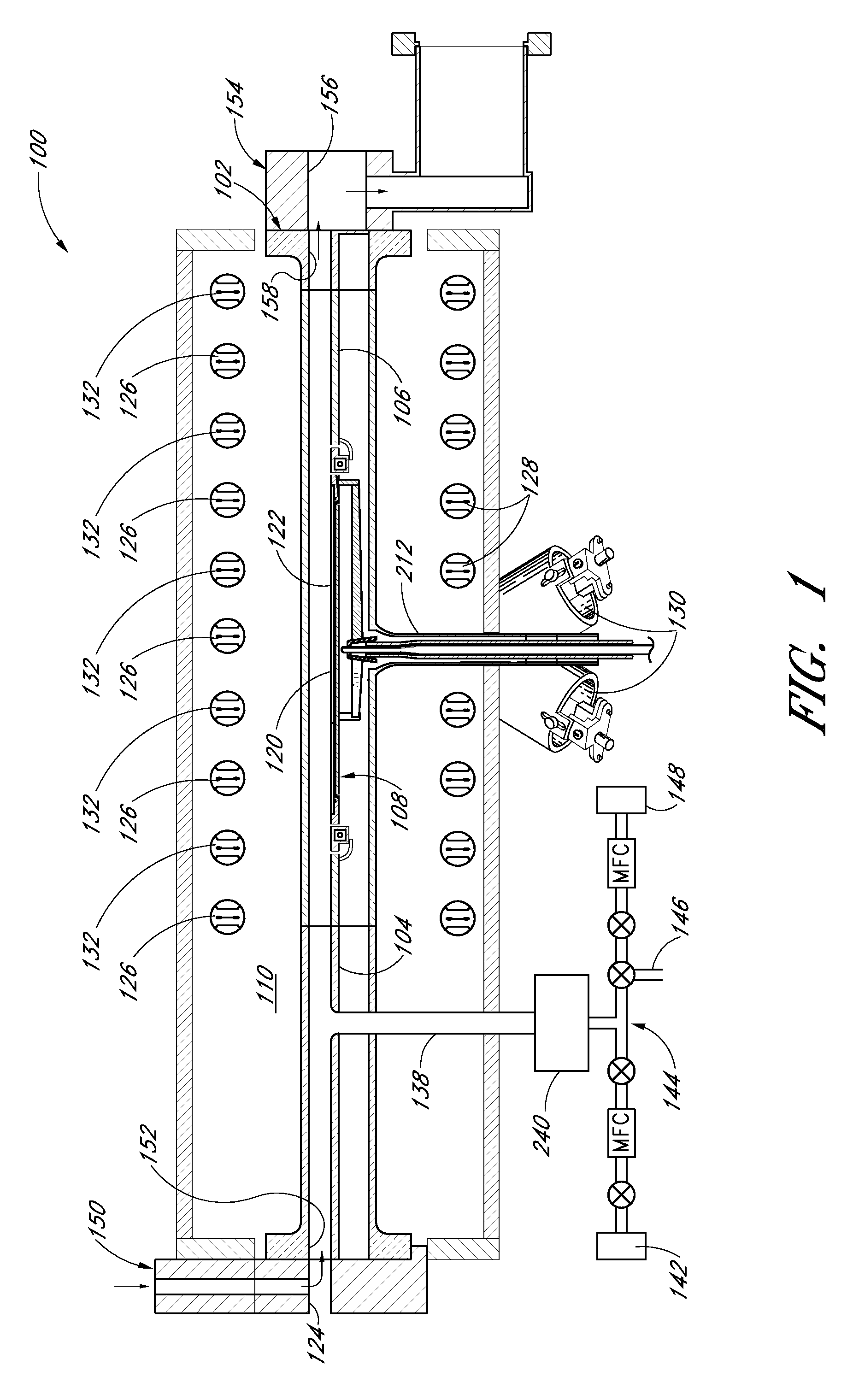

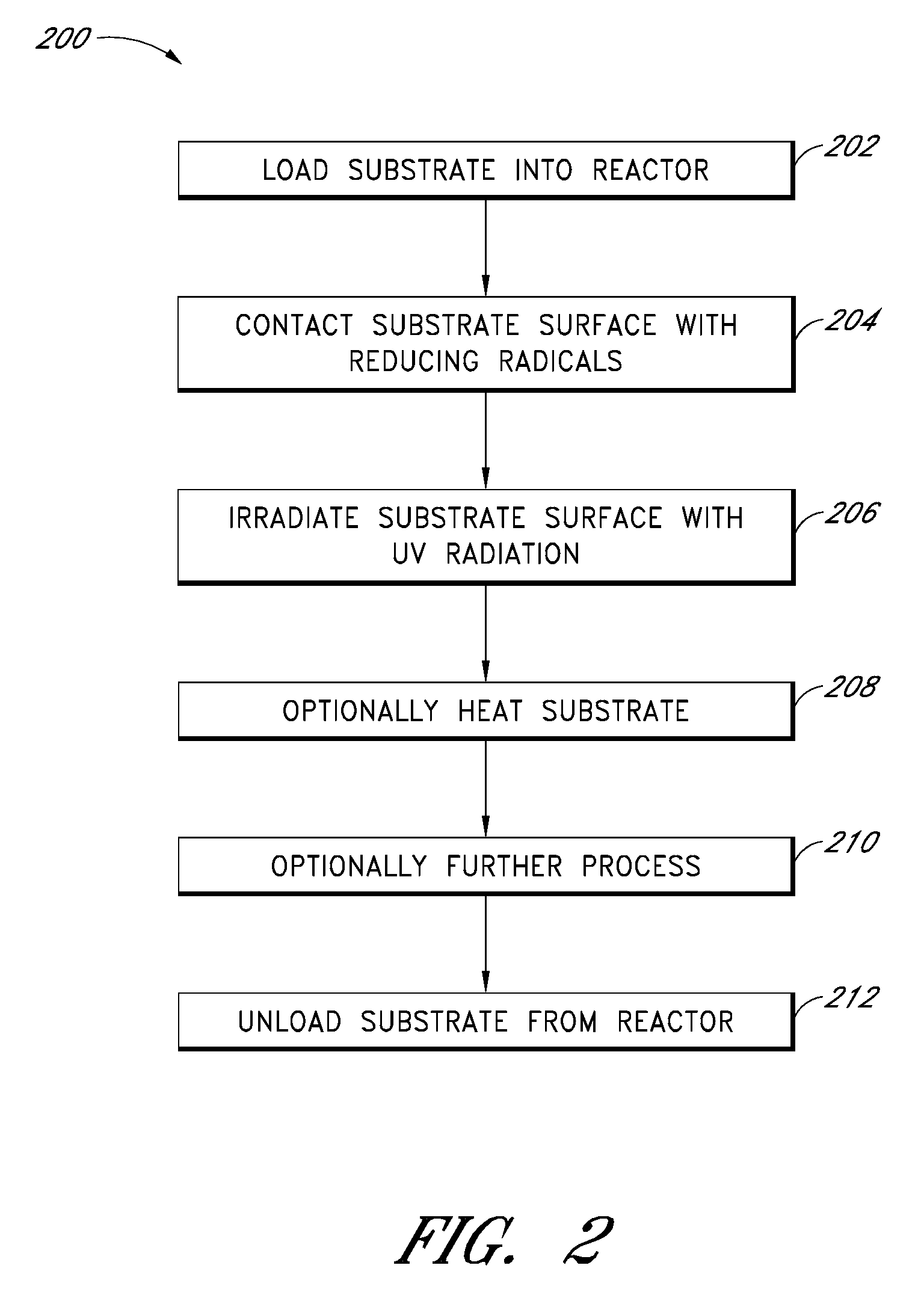

Low-temperature cleaning of native oxide

InactiveUS20080289650A1Reduce vertical sizeReduce device sizeElectrostatic cleaningSemiconductor/solid-state device manufacturingHydrogenSurface cleaning

Disclosed herein is a method of cleaning oxide from a surface in the fabrication of an integrated device using reducing radicals and UV radiation. For silicon surfaces, the cleaning may be performed at a temperature at which a hydrogen-terminated passivated surface is stable, such that the surface remains protected after loading into the chamber until the cleaning is performed. Performing the cleaning at a lower temperature also consumes a reduced portion of the thermal budget of a semiconductor device. Epitaxial deposition can then be performed over the cleaned surface.

Owner:ASM AMERICA INC

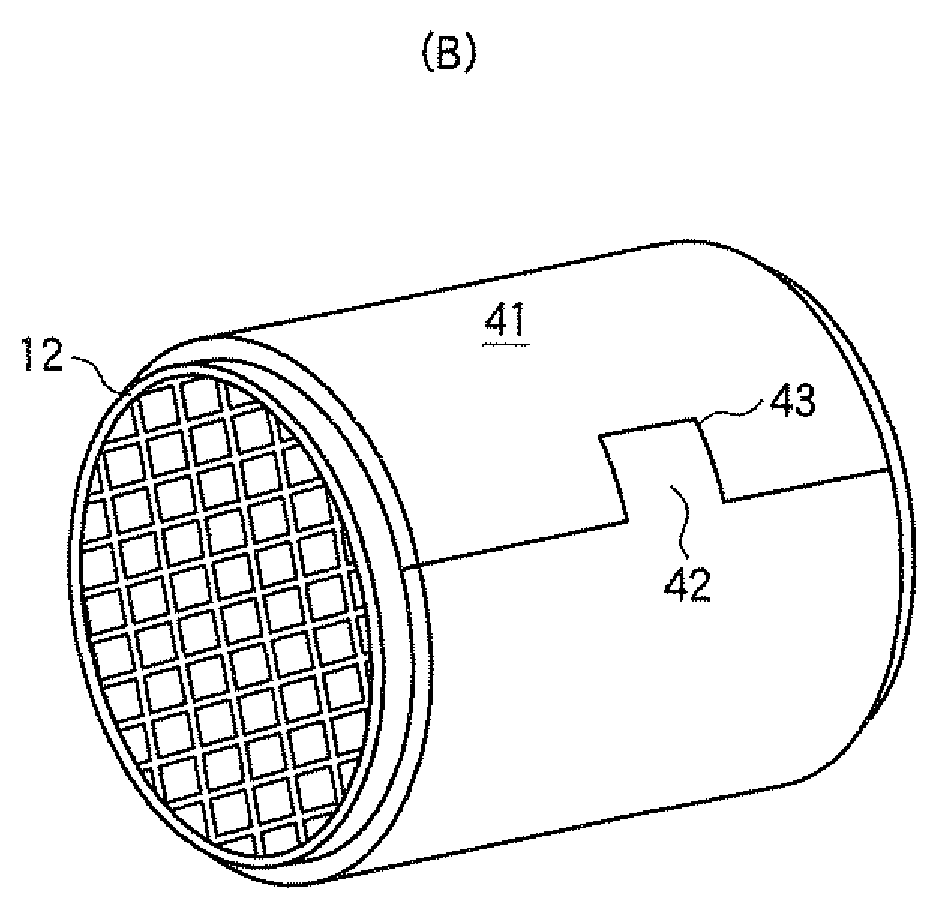

Catalytic converter, holding material for catalytic converter and production method thereof

ActiveUS20090022633A1Improve insulation performanceImprove exhaust gas purification performanceCombination devicesLamination ancillary operationsPorous substrateCatalyst support

The present invention relates to a holding material for a catalytic converter including a catalyst carrier, a metal casing for receiving the catalyst carrier, and the holding material wound around the catalyst carrier and interposed in a gap between the catalyst carrier and the metal casing, the holding material including a low thermal conductivity layer, in which the low thermal conductivity layer includes: a molded material containing an inorganic powder; or a composite material of a porous substrate with an aerogel.

Owner:NICHIAS CORP

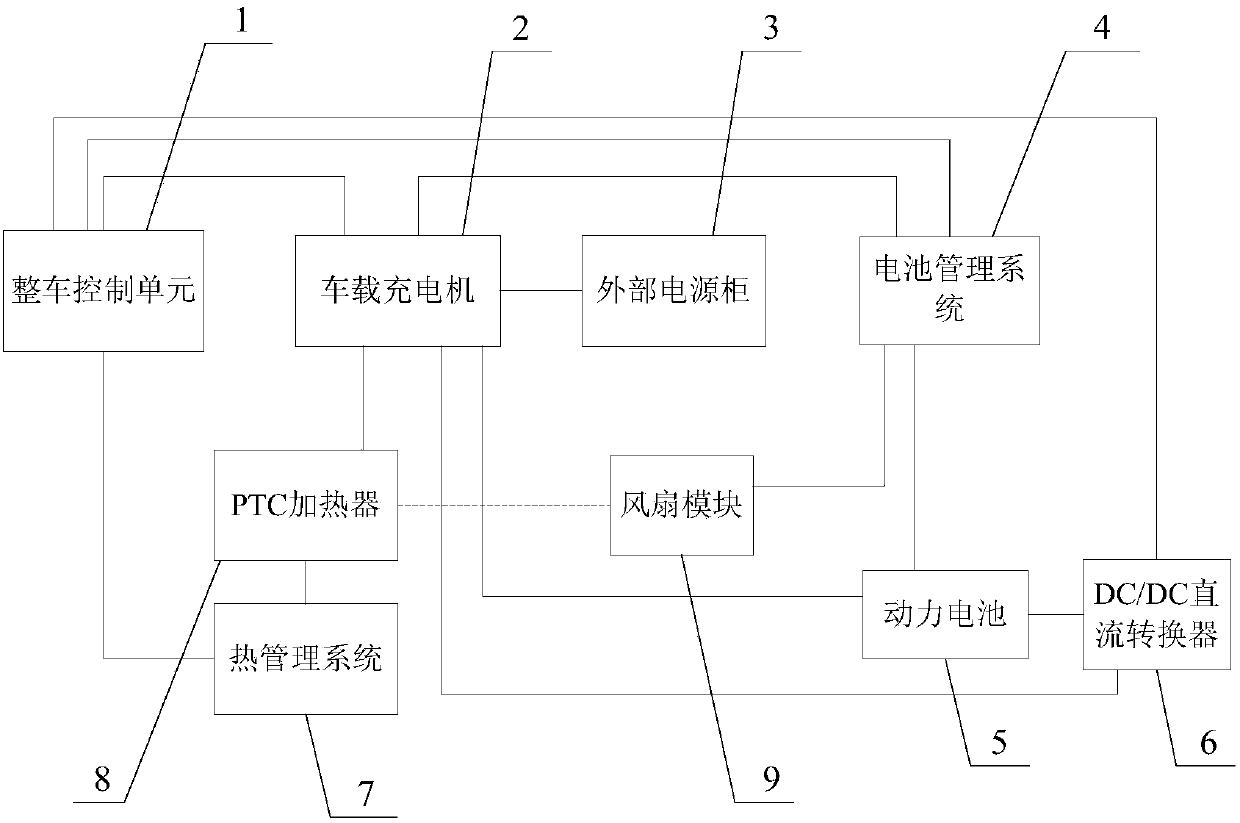

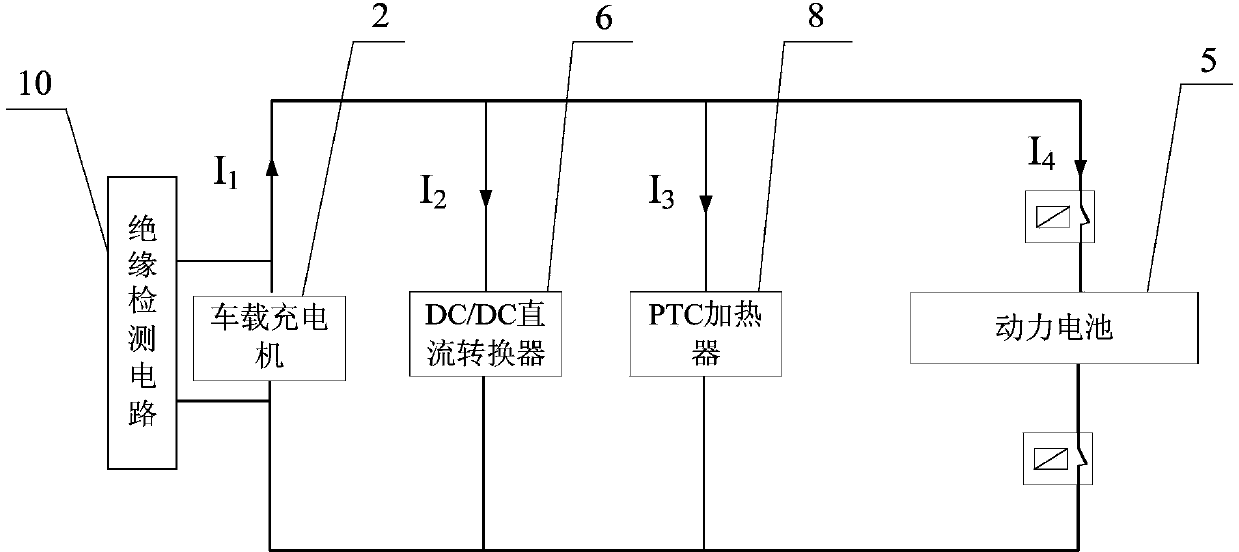

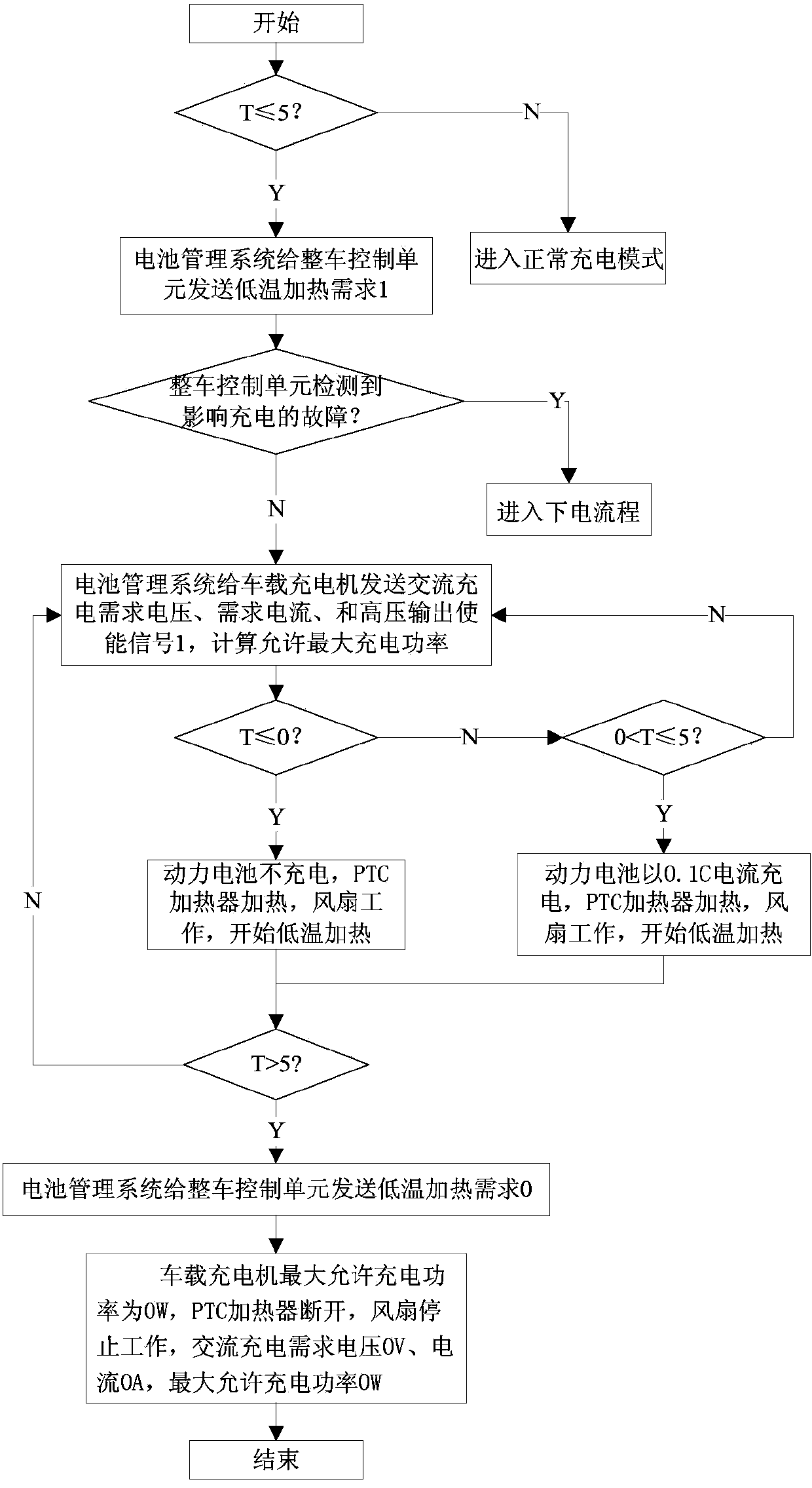

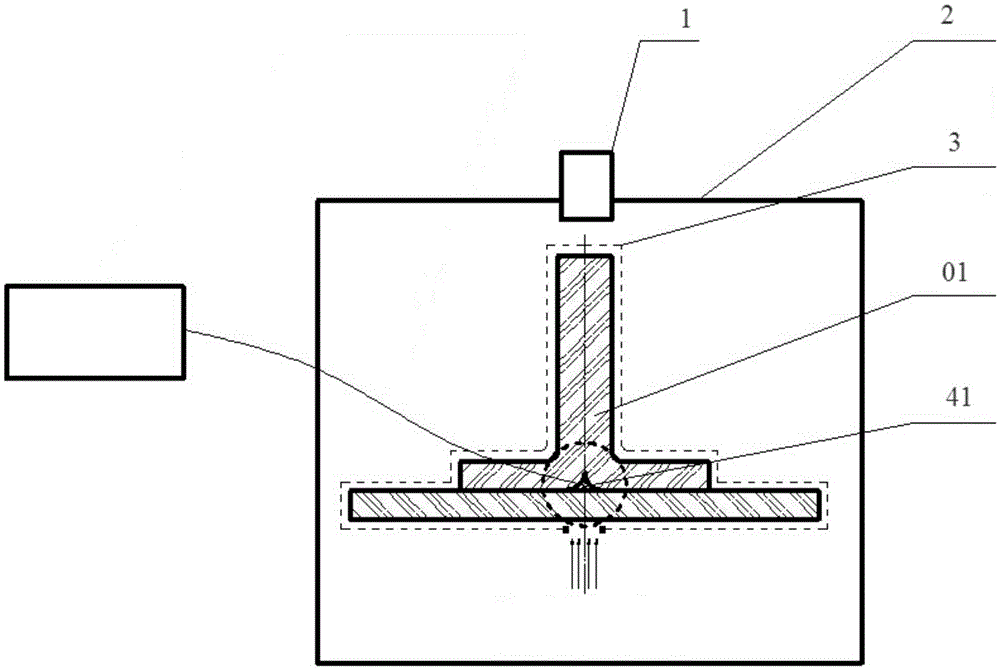

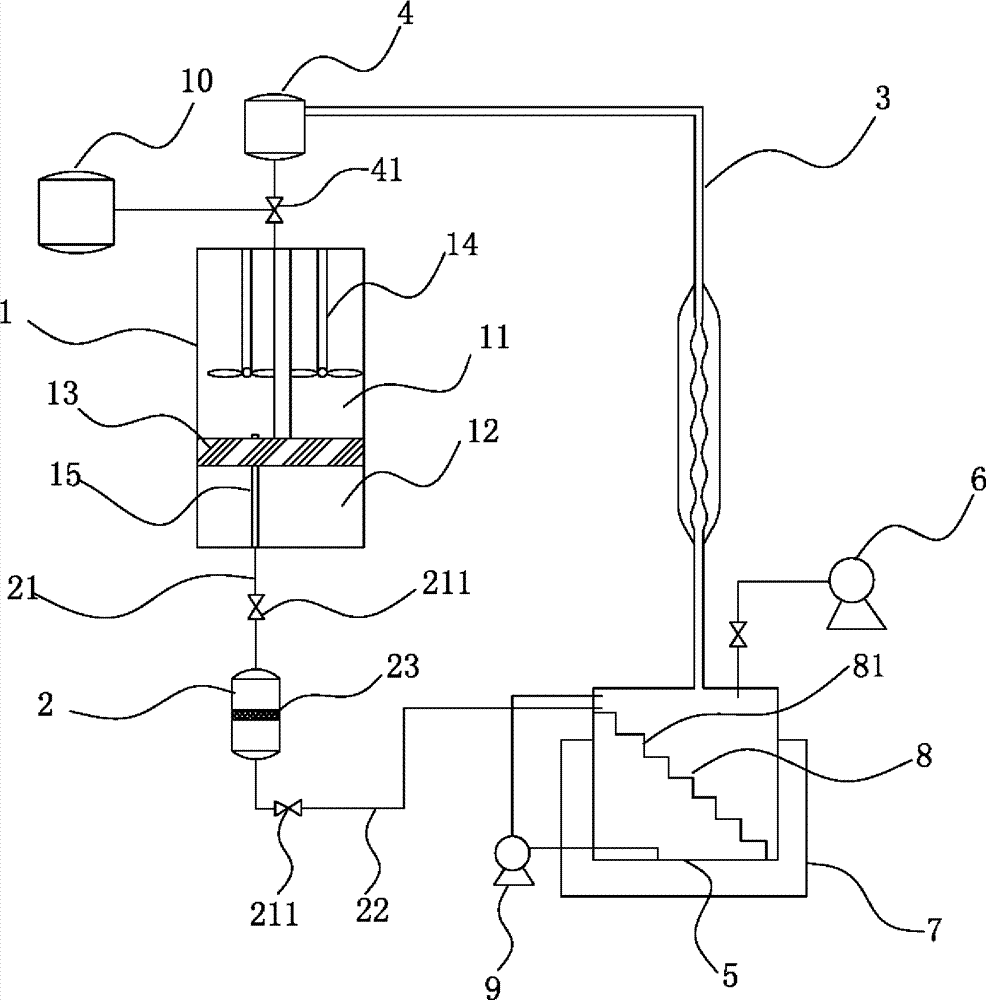

Low-temperature charge and heating system and method for power battery for all-electric vehicles

ActiveCN103427137AShorten heating timeImprove securitySecondary cells charging/dischargingVehicular energy storageElectrical batteryHeating system

The invention discloses a low-temperature charge and heating system and method for a power battery for all-electric vehicles. The system comprises a vehicle control unit, a vehicular charger, a battery management system, the power battery, a DC / DC converter, a heat management system, a PTC heater and a fan module. The method includes: during charging, heating is allowed only when the temperature is very low and the temperature T of the power battery is smaller than or equal to 5 DEG C; when the temperature is very low, heating and charging with low current are performed simultaneously; if the temperature T of the power battery is larger than 5 DEG C, low-temperature heating is aborted and a normal charge mode is allowed. The system and the method have the advantages that low-temperature charge and heating time can be shortened, normal charge of the power battery is guaranteed and the service life of the power battery is unaffected.

Owner:重庆长安新能源汽车科技有限公司

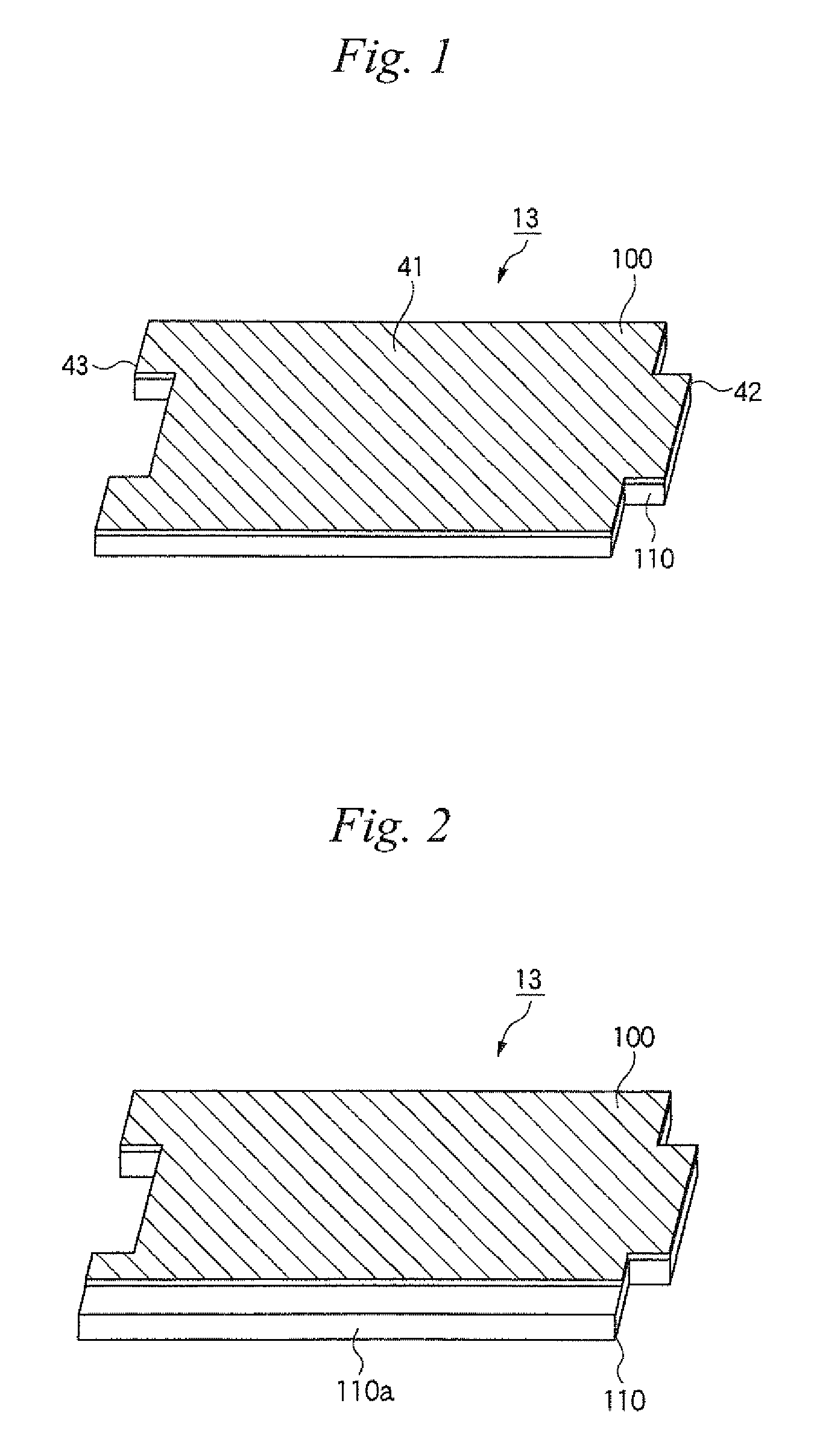

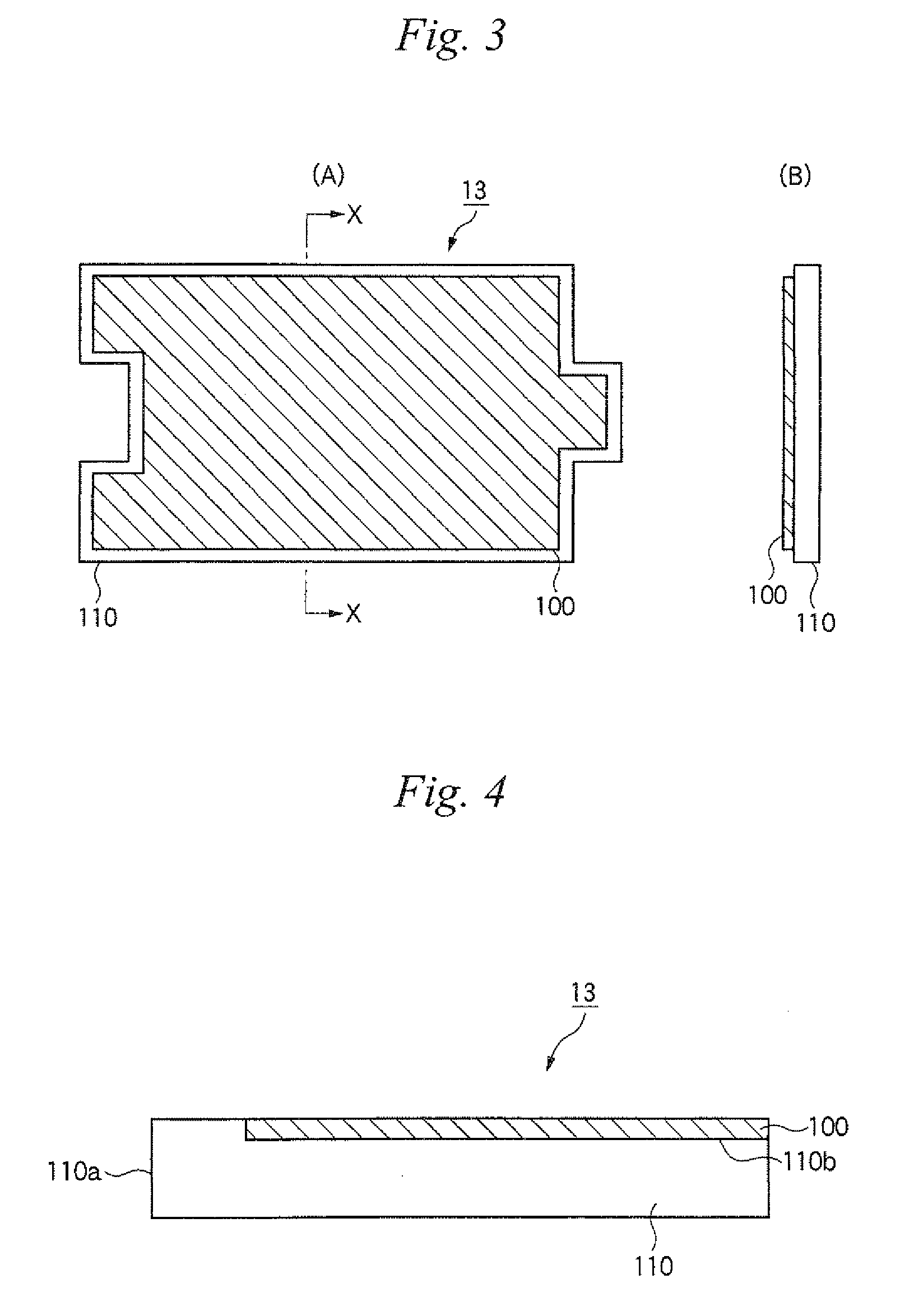

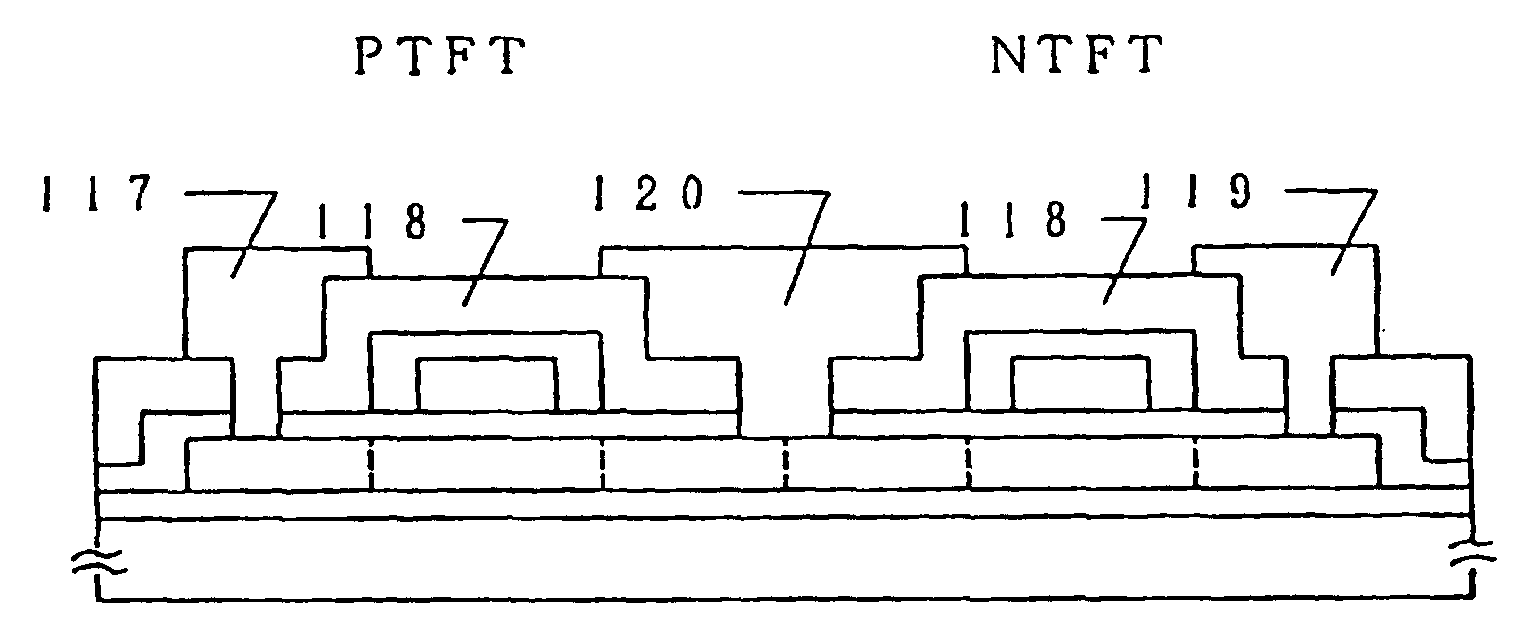

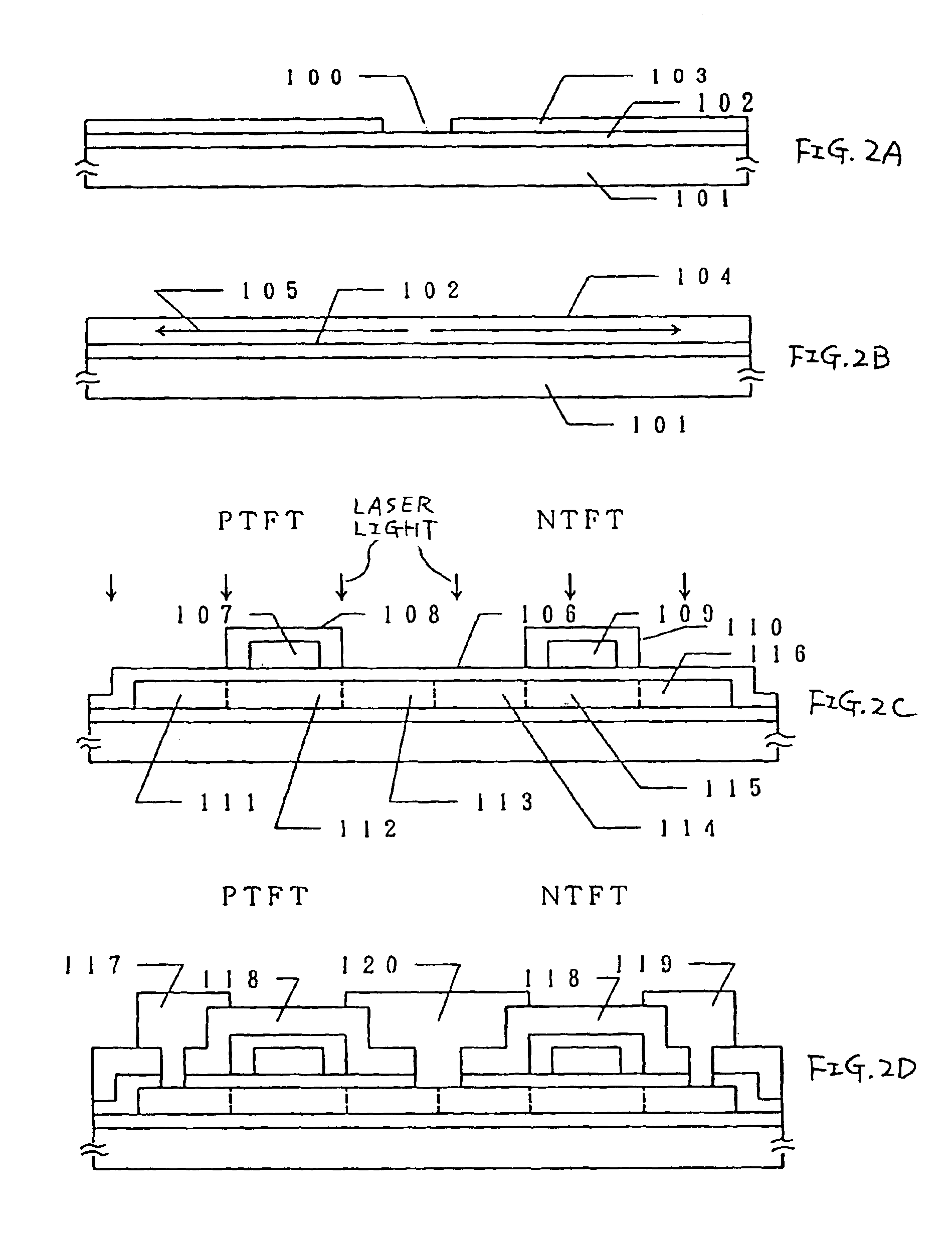

Semiconductor device and fabrication method of the same

InactiveUS6875628B1Reduce the temperatureShorten heating timeSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixImpurity

Nickel is introduced to a predetermined region of a peripheral circuit section, other than a picture element section, on an amorphous silicon film to crystallize from that region. After forming gate electrodes and others, sources, drains and channels are formed by doping impurities, and laser is irradiated to improve the crystallization. After that, electrodes / wires are formed. Thereby an active matrix type liquid crystal display whose thin film transistors (TFT) in the peripheral circuit section are composed of the crystalline silicon film whose crystal is grown in the direction parallel to the flow of carriers and whose TFTs in the picture element section are composed of the amorphous silicon film can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Treatment process for absorbed condensate waste gas

ActiveCN102179129ASo as not to damageShorten heating timeDispersed particle separationVapor condensationNitrogenEnvironmental engineering

The invention provides a treatment process for absorbed condensate waste gas, wherein two active carbon absorbing tanks alternately absorb waste gas; when one active carbon absorbing tank carries out waste gas absorption work, the other active carbon absorbing tank carries out carbon bed reproduction work, wherein the absorbed waste gas in waste gas absorption work is cooled; the carbon bed reproduction work comprises a step of vacuum de-sorption and a step of nitrogen de-sorption in sequence; the step of nitrogen de-sorption comprises flowing heated nitrogen at the temperature of 60-80 DEG Cthrough the carbon bed from top to bottom so that the carbon bed is deeply desorbed, and finally cooling the carbon bed by using unheated cold nitrogen so as to recover adsorptive capacity. The process is simple without providing absorbent on the spot; and the treatment process has high treatment efficiency, and can obtain pure recovery product without causing secondary pollution.

Owner:BAY ENVIRONMENTAL TECH BEIJING

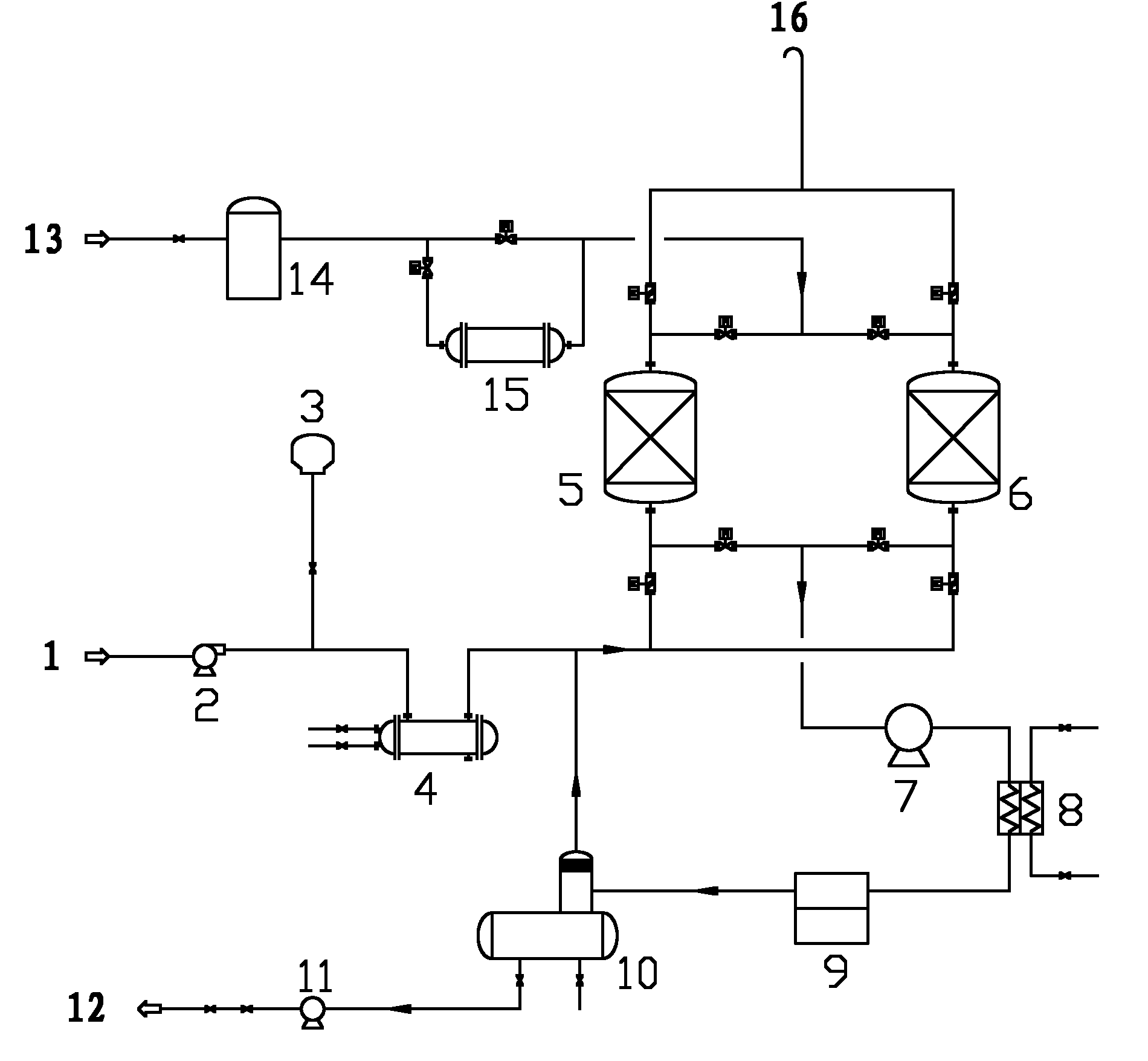

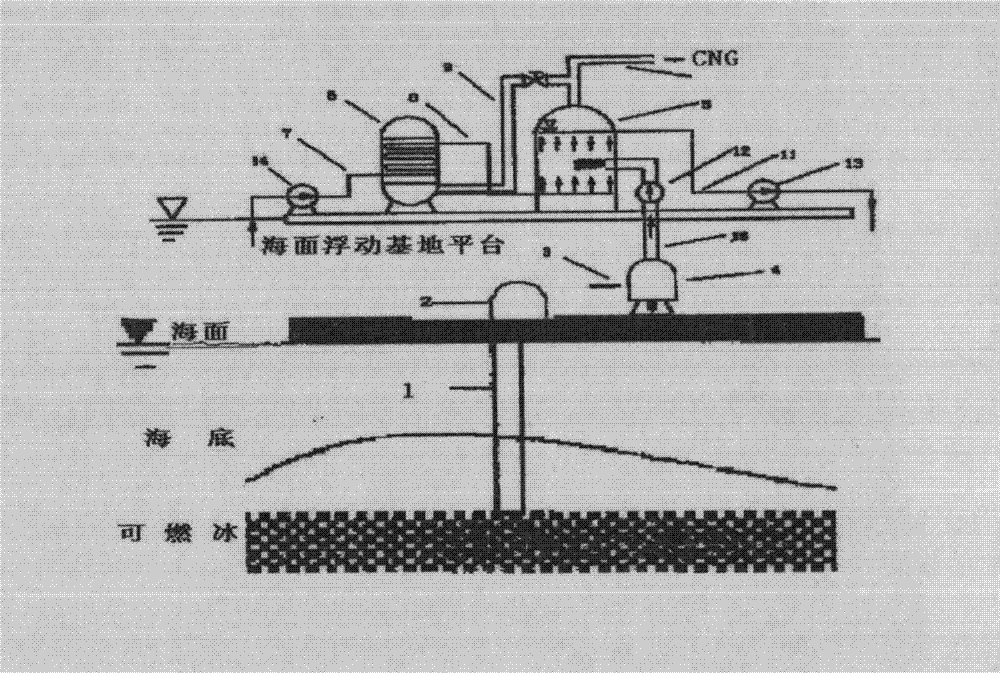

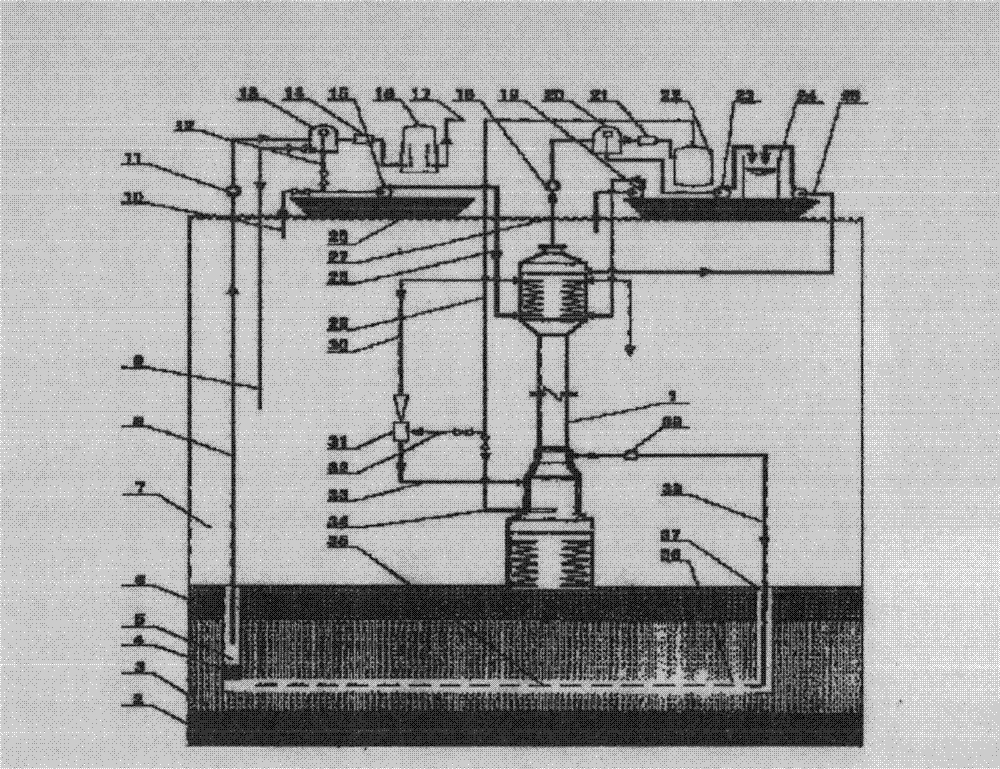

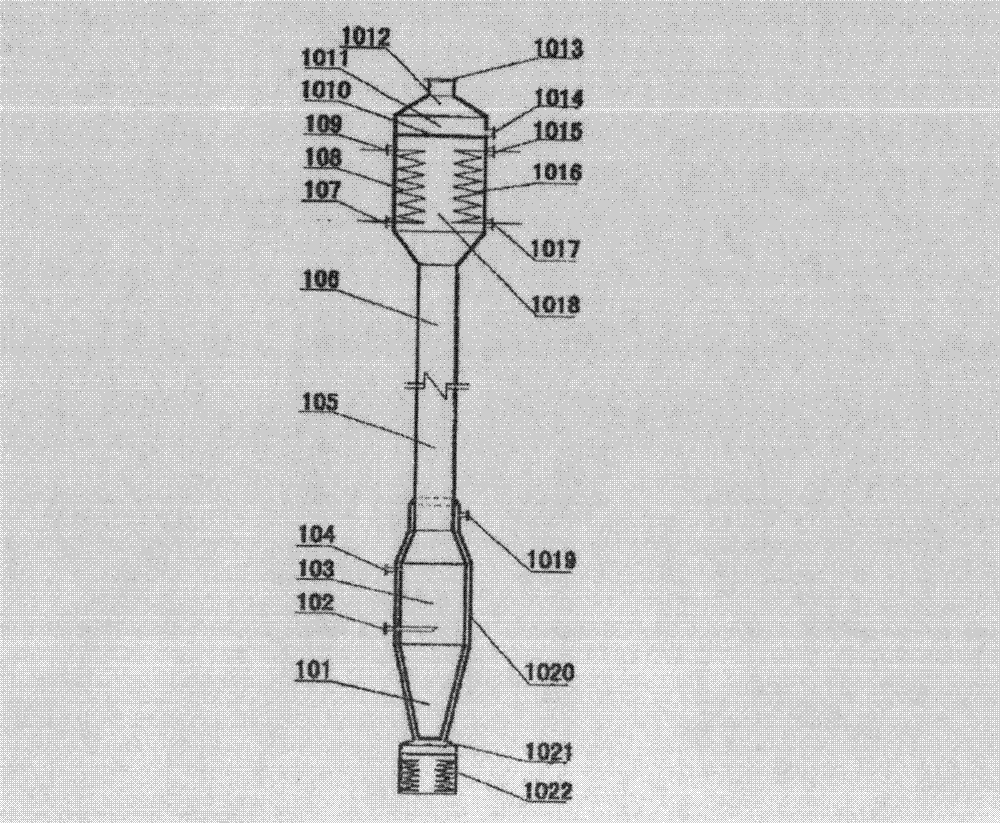

Ocean combustible ice mining device and method

The invention discloses an ocean combustible ice mining method and a mining device adopted by the same. According to the ocean combustible ice mining method, a device for mining combustible ice through heating concentrated saline water is adopted, and heat for heating a combustible ice storage layer is provided by heating the concentrated saline water. The ocean combustible ice mining method is energy-saving and environment-friendly, remarkable in economic benefit, is free from emission and pollution in a mining process, energy-saving and consumption-reducing; and the ocean combustible ice mining device is relatively sample in structure, convenient to use, lower in production cost and convenient for popularization.

Owner:韩中枢

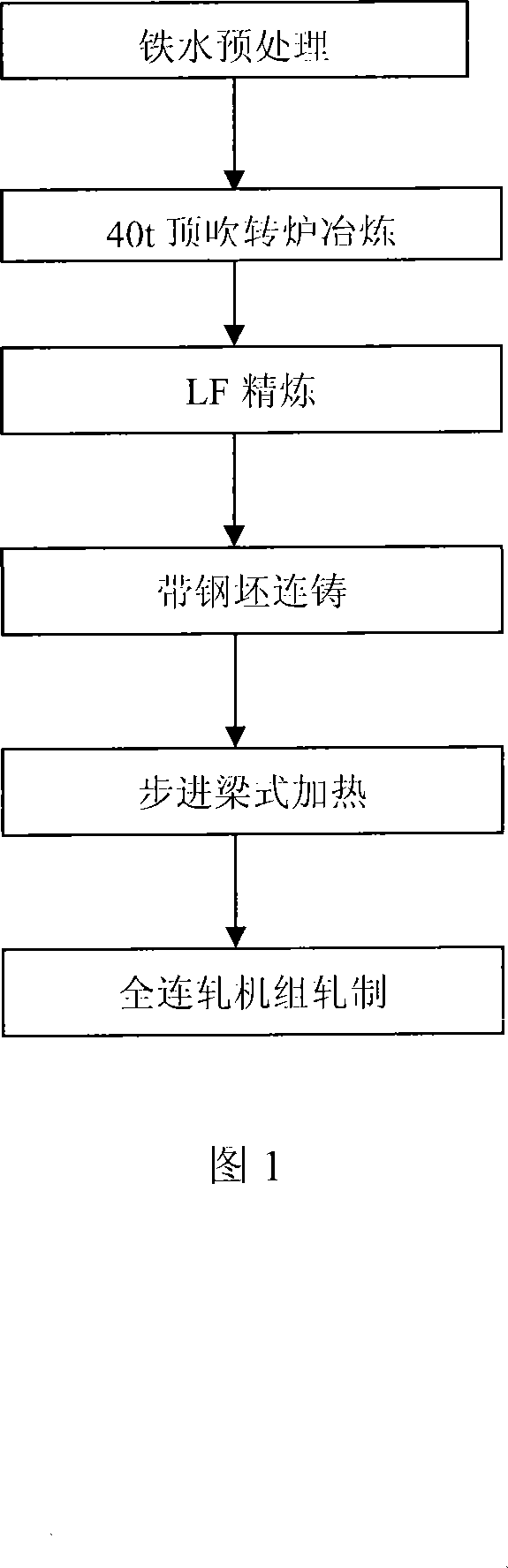

Heating method for preventing high carbon belt steel bloom decarburization

InactiveCN101195853AShort stayHigh recovery rateFurnace typesHeat treatment furnacesHeating timeHigh carbon

The invention discloses a heating method used for preventing the high carbon strip billet from decarburizing. The strip billet is heated in the heating furnace, and the heating process comprises the preheating period, heating period, and heat soaking period. The invention is characterized in that the micro positive pressure and the weak oxidizability environment are adopted during the heating process to heat the strip billet. In the invention method, the heating time is reduced, the standing time of the billet in the high temperature area is reduced, the depth of the decarburizing layer on the surface of the billet can be controlled in a shallow scope, the metal recovery ratio is enhanced; the fuel consumption is reduced, the energy is economized; and compared with the method of coating a protecting layer on the surface of the billet, the cost and the labor intensity are reduced.

Owner:LAIWU IRON & STEEL GRP

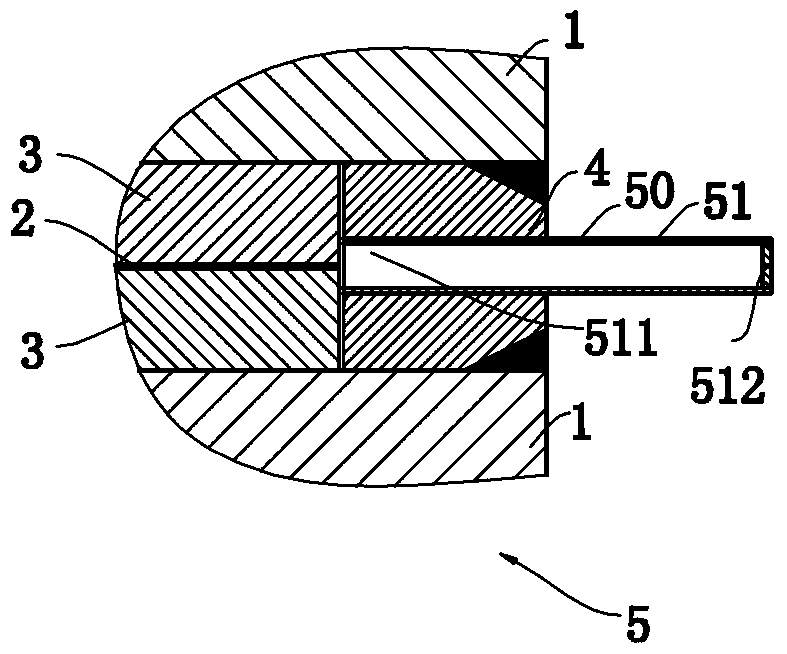

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

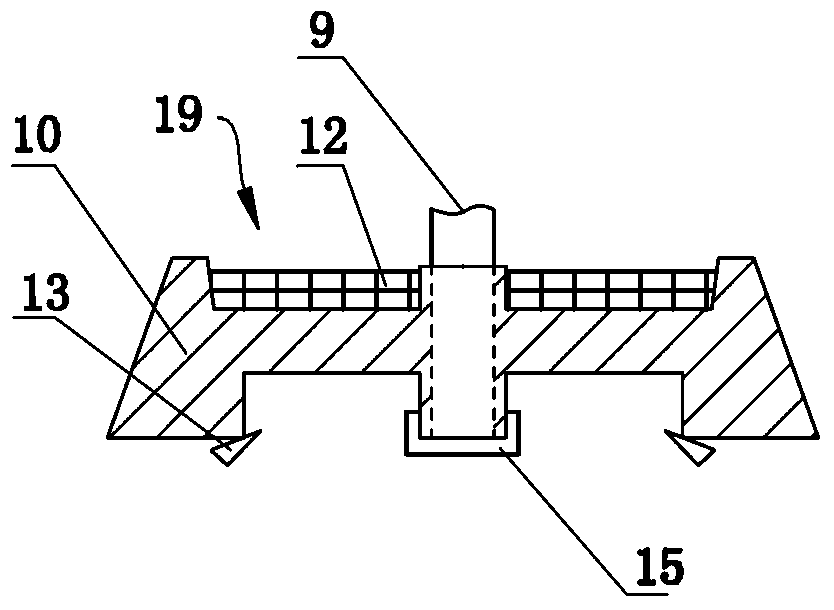

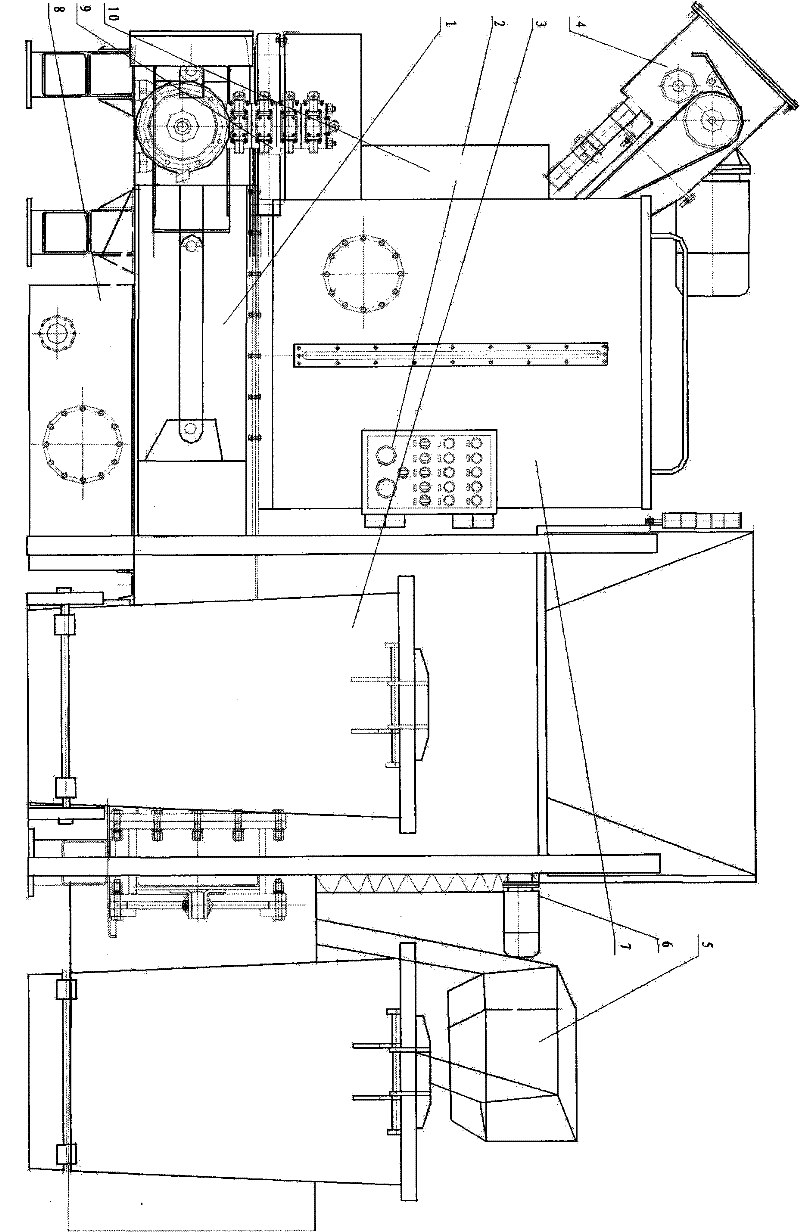

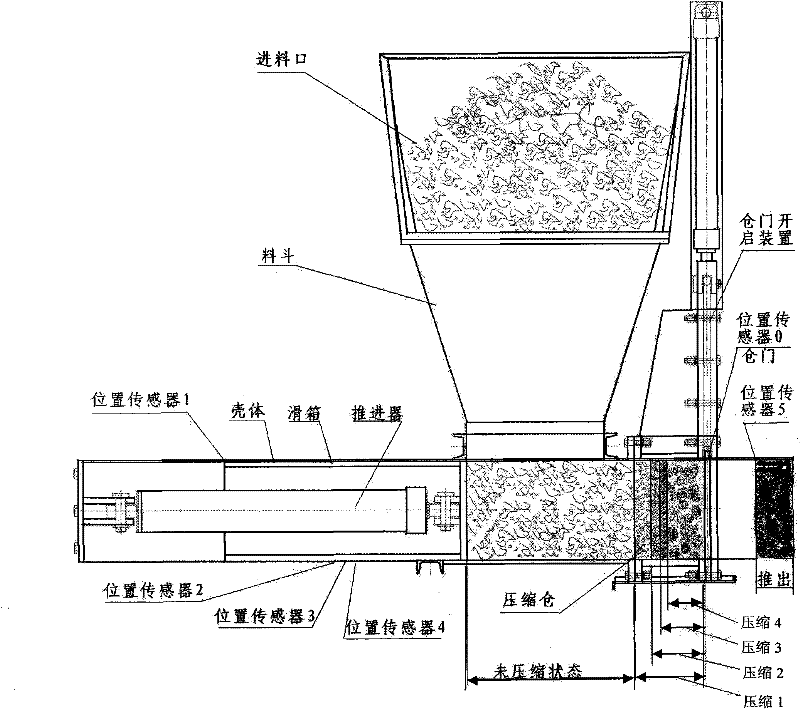

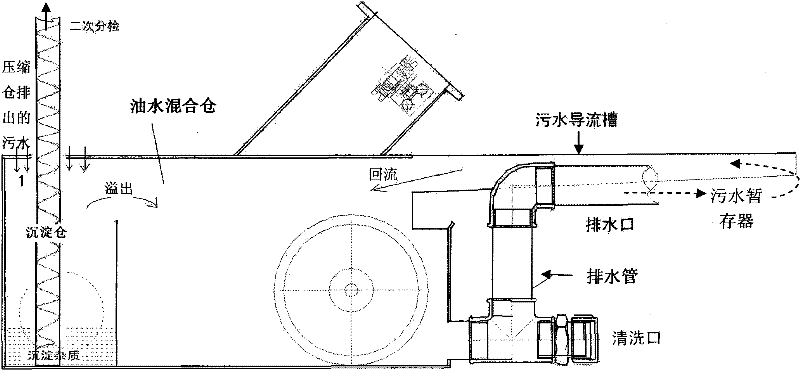

Device for reducing and sorting food waste at the source

InactiveCN102240658AEasy to handleImprove transportation capacitySolid waste disposalDrying solid materials without heatOil and greaseFailure rate

The invention discloses a device for reducing and sorting food waste at the source, and belongs to the technical field of municipal environmental protection machinery. The device is characterized in that: food waste is poured into a feed system and is conveyed into a dehydration system, a sliding box is driven to slide in a housing through a propeller of the dehydration system, a extruding way or a beating way is adopted to complete the food waste dehydrating; the resulting sewage from the dehydration step enters a sewage box from a compression bin to enable a oil and water separation system to extract greases; the solid materials after completing the dehydration are pushed out from the compression bin and enter into a material discharge system; the solid materials are output through the material discharge system and wait for centralized processing. After being processed by the device provided by the present invention, the food waste is divided into three portions comprising the water, the greases and the solid materials so as to conveniently carry out post-treatments such as reuse production of the greases and the solid materials, regeneration treatment of the water source and the like. The device has characteristics of strong processing ability, low failure rate, high automaticity, simple and easy operation and maintenance, no requirement of chemical additives, high dehydration rate, short retention time of the food waste in the device, and the like, and is benefit for improving efficiency of resource reutilization production so as to achieve effect of energy saving and emission reduction.

Owner:曹泽民

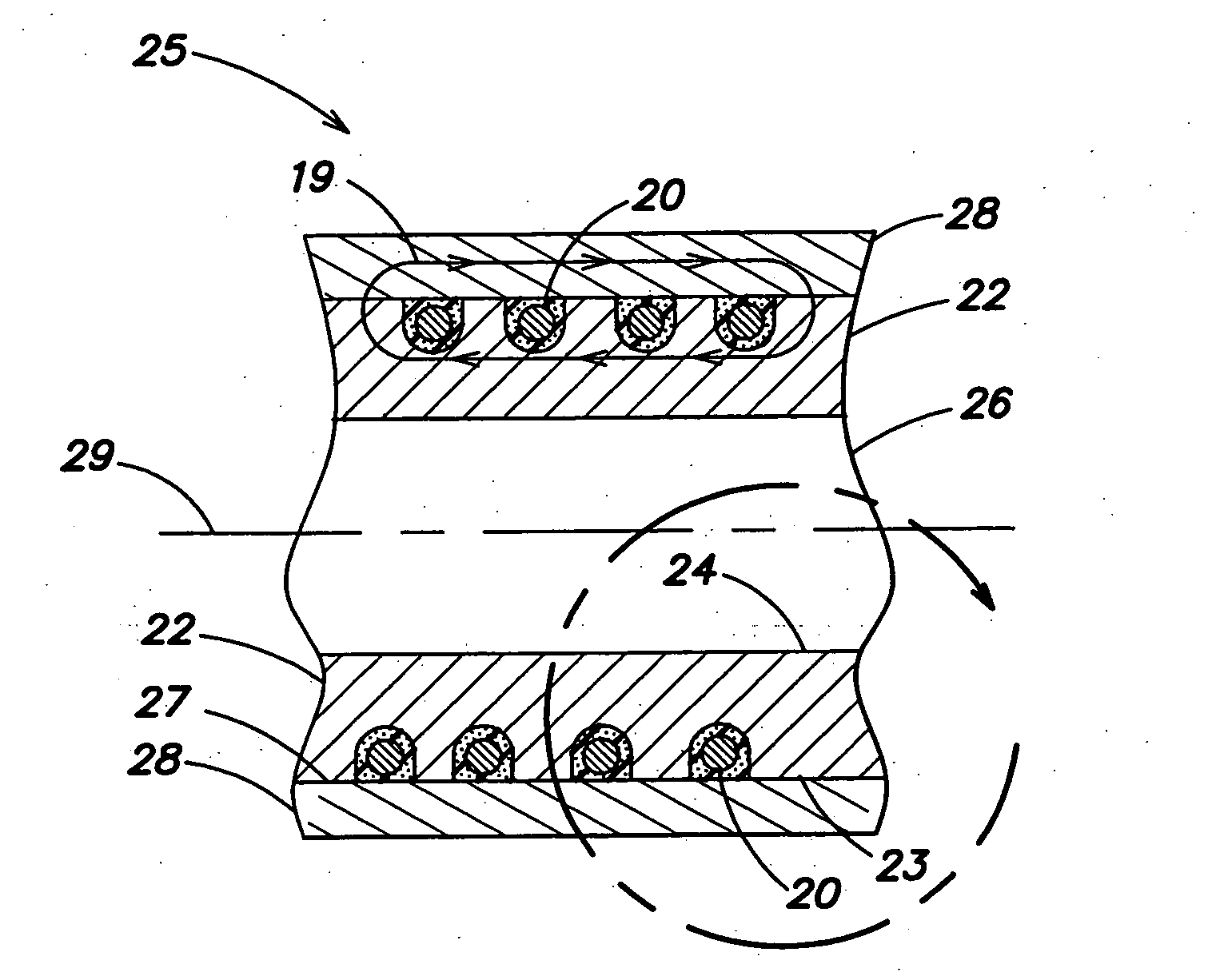

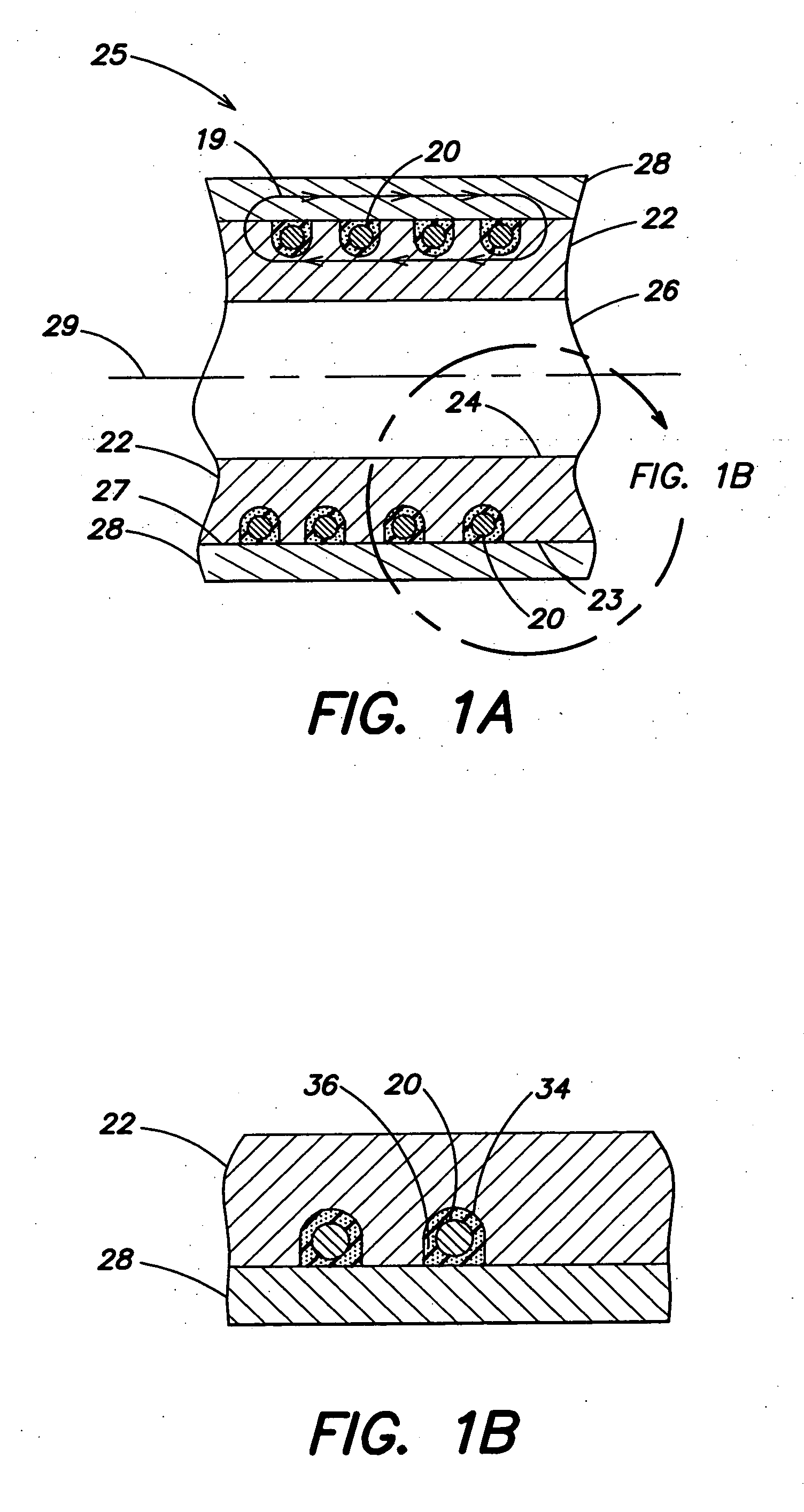

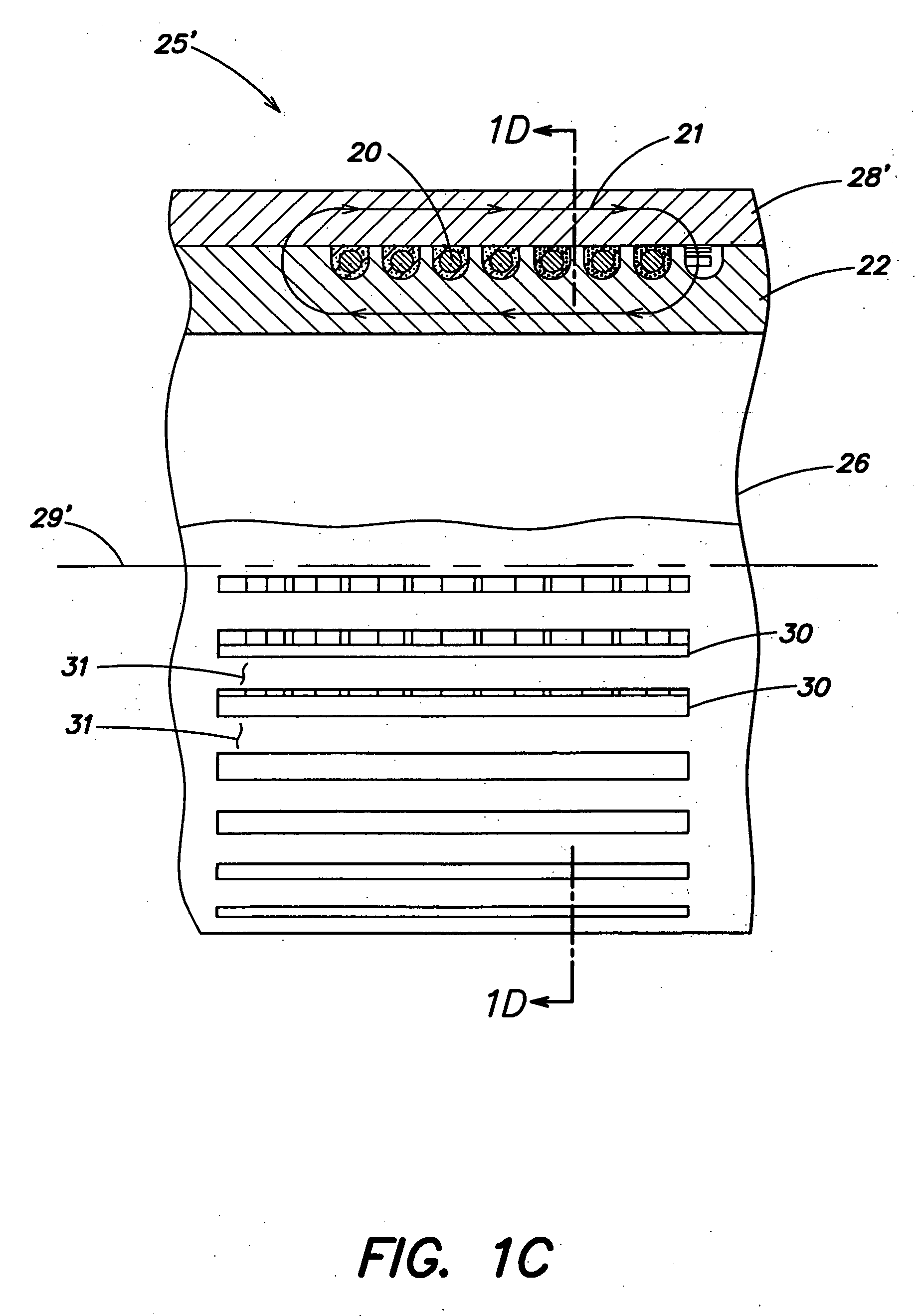

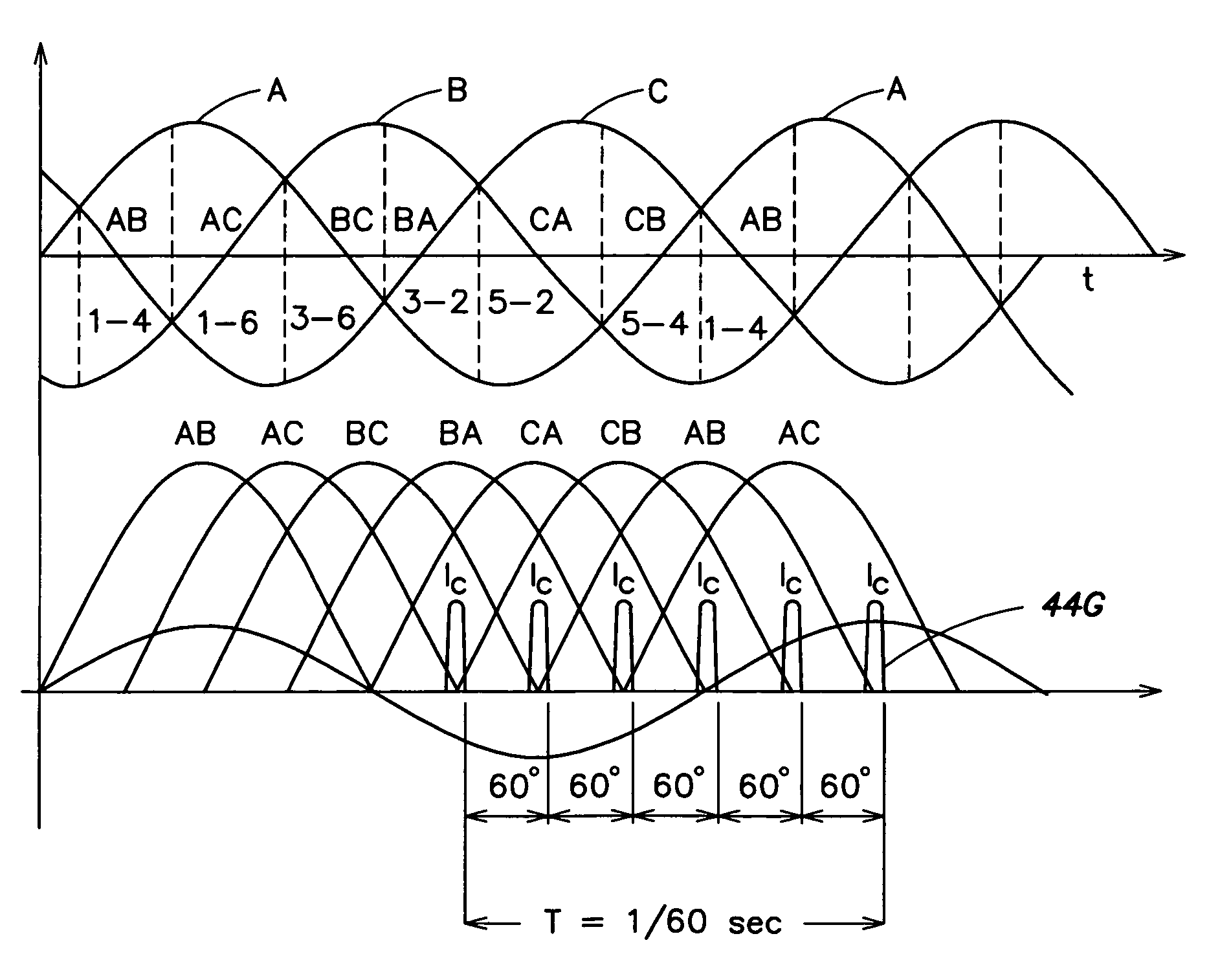

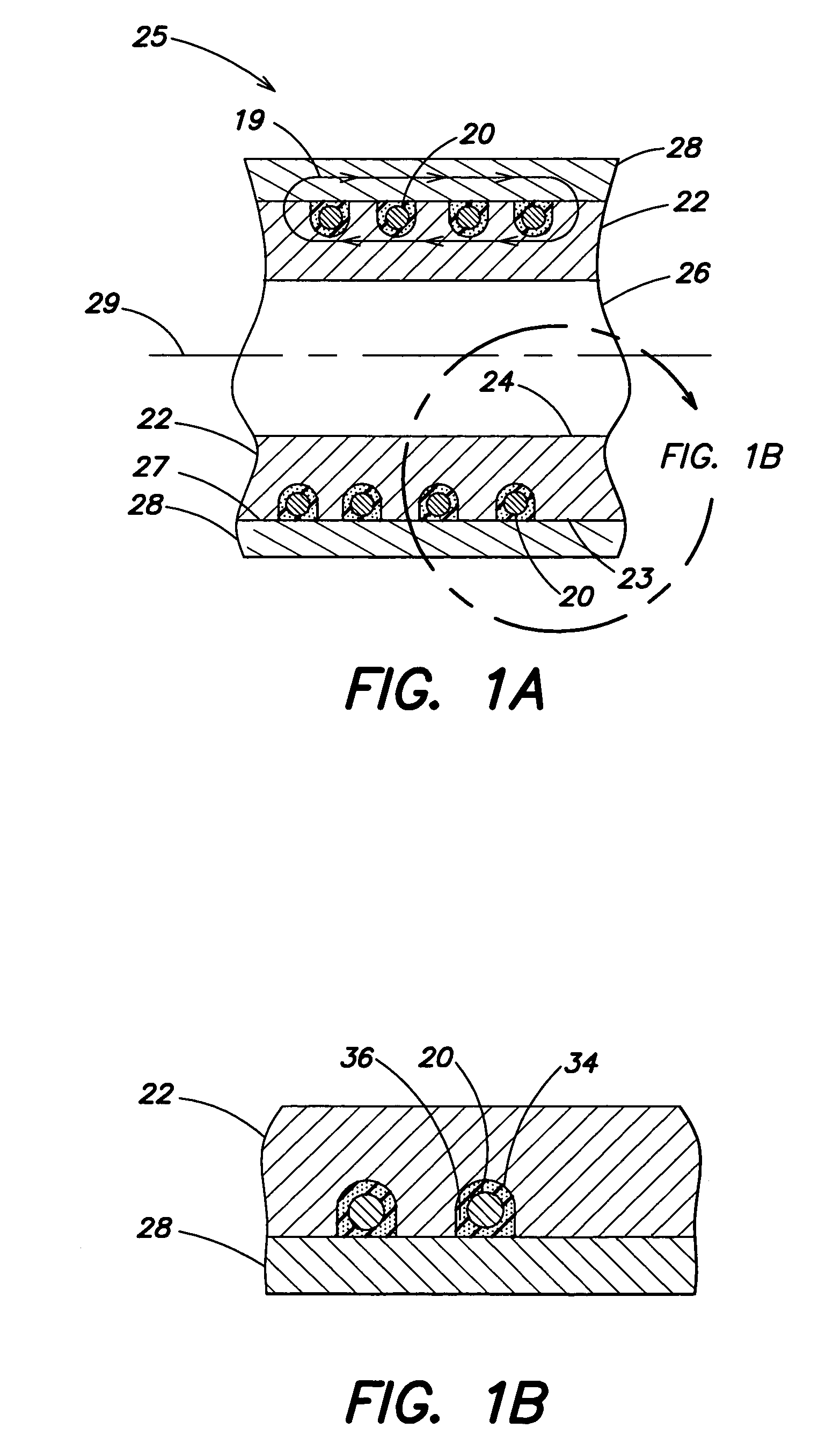

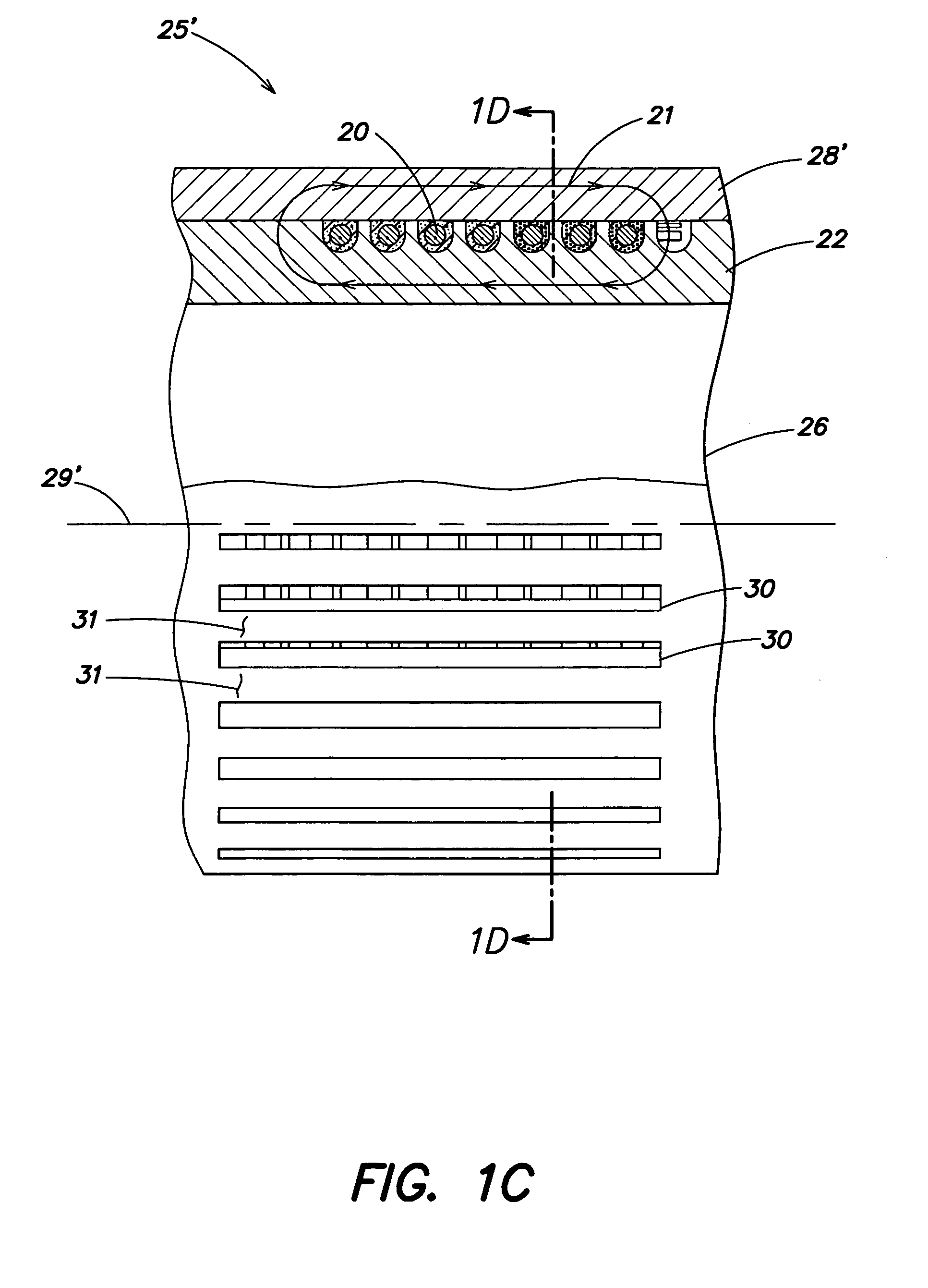

Heating systems and methods

InactiveUS20060219709A1Enhance relative proportion of inductive heatingExtended service lifeOhmic-resistance heatingInduction current sourcesMagnetic fluxHeating system

Heating systems and methods for inductive heating or a combination of resistive and inductive heating. A heater coil is inductively coupled to an article and a current signal is supplied to the heater coil. The heater coil generates a magnetic flux, based on the applied current signal, for inductively heating the article. Current pulses of a certain profile are used to enhance the rate, intensity and / or power of inductive heating delivered by the heating element or coil and / or to enhance the lifetime or reduce the cost of the inductive heating system.

Owner:ITHERM TECH LP

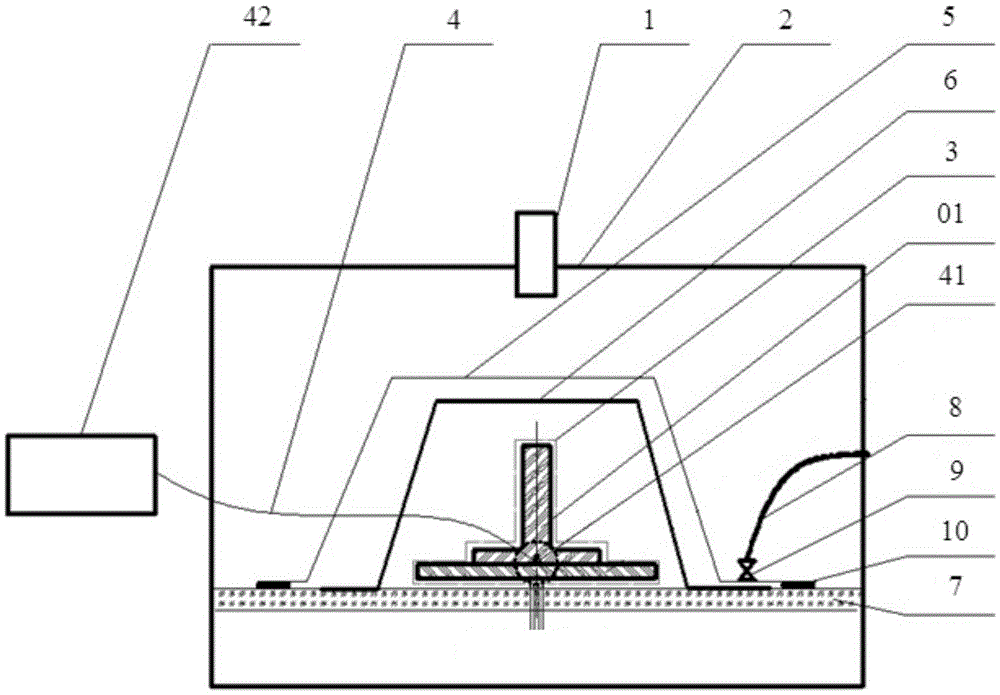

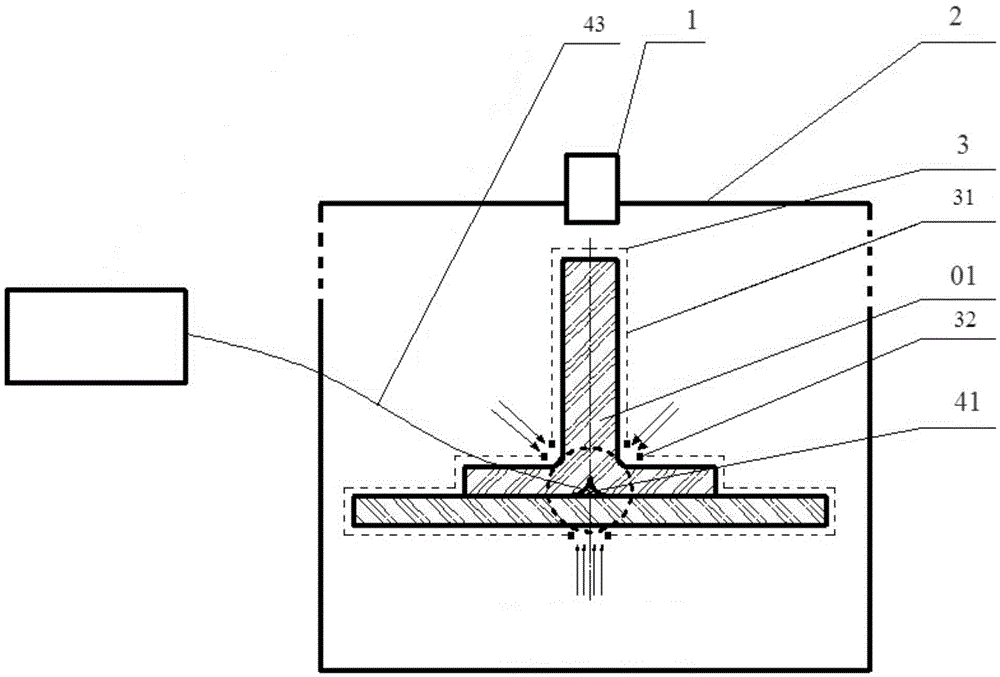

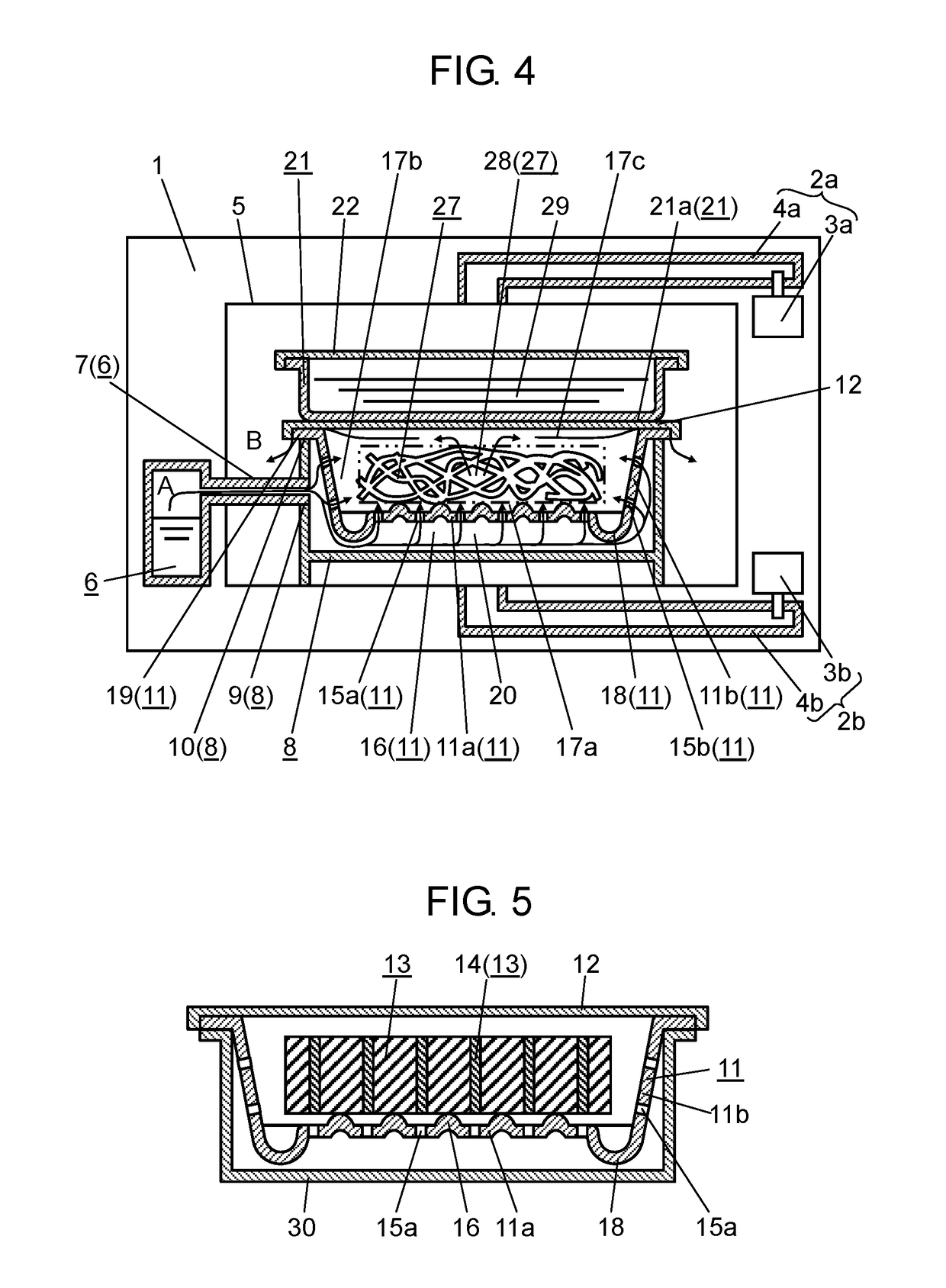

Microwave heating device and method

The invention provides a microwave heating device. The microwave heating device comprises a microwave generator, a microwave cavity and a microwave local shielding part; the microwave generator sends microwaves into the microwave cavity; the microwave cavity is used for placing a wave sucking material; the microwave local shielding part is positioned in the microwave cavity, and is used for covering the outer surface of the wave sucking material; the microwave local shielding part consists of a microwave shielding area and a microwave passing area; and the microwave passing area includes one or more gaps, so that the microwaves in the microwave cavity can enter the wave sucking material from the gaps to be absorbed. The microwave heating device, provided by the invention,can perform fixed-point and / or fixed-direction heating for the wave sucking material.

Owner:CENT SOUTH UNIV

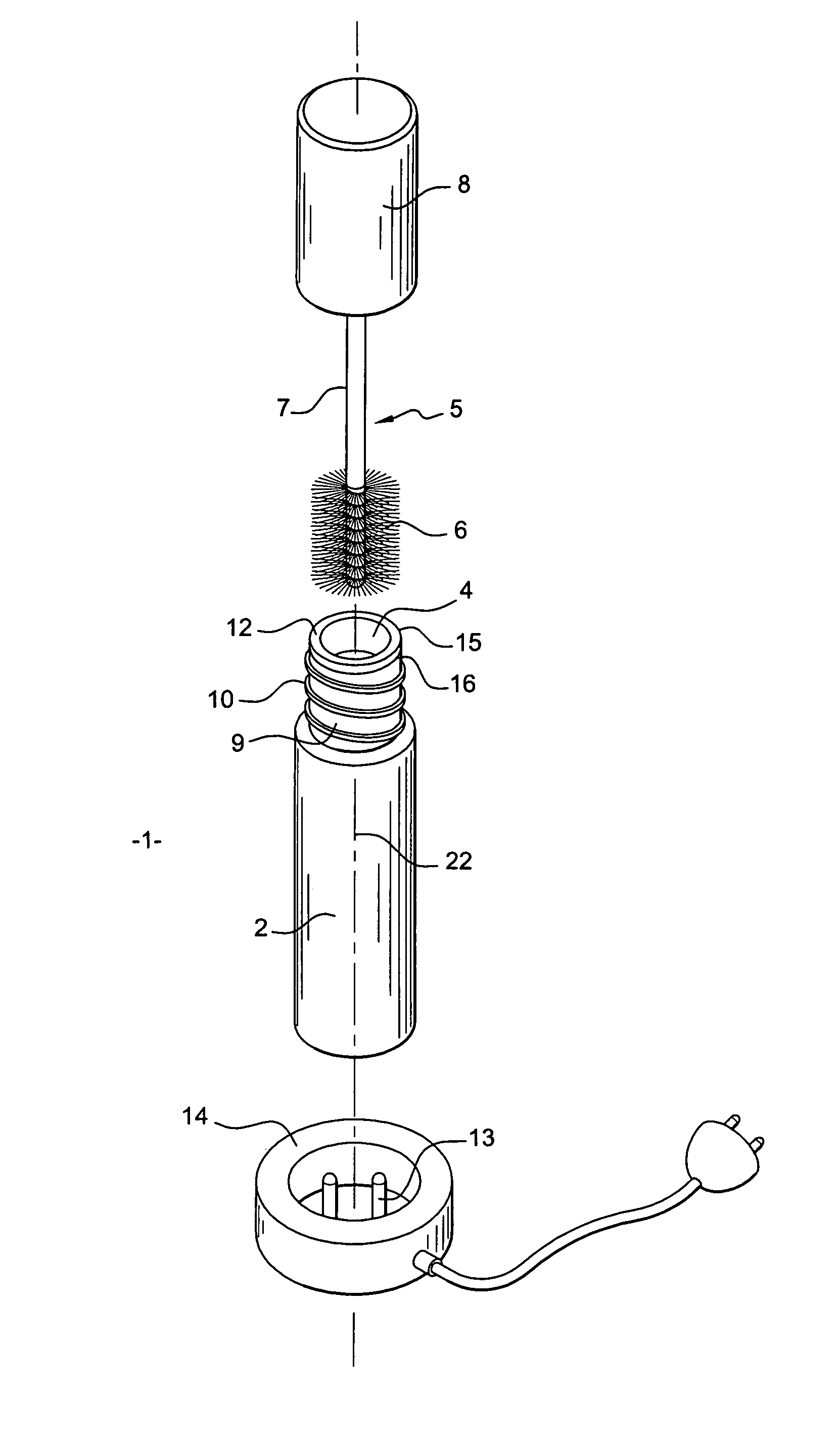

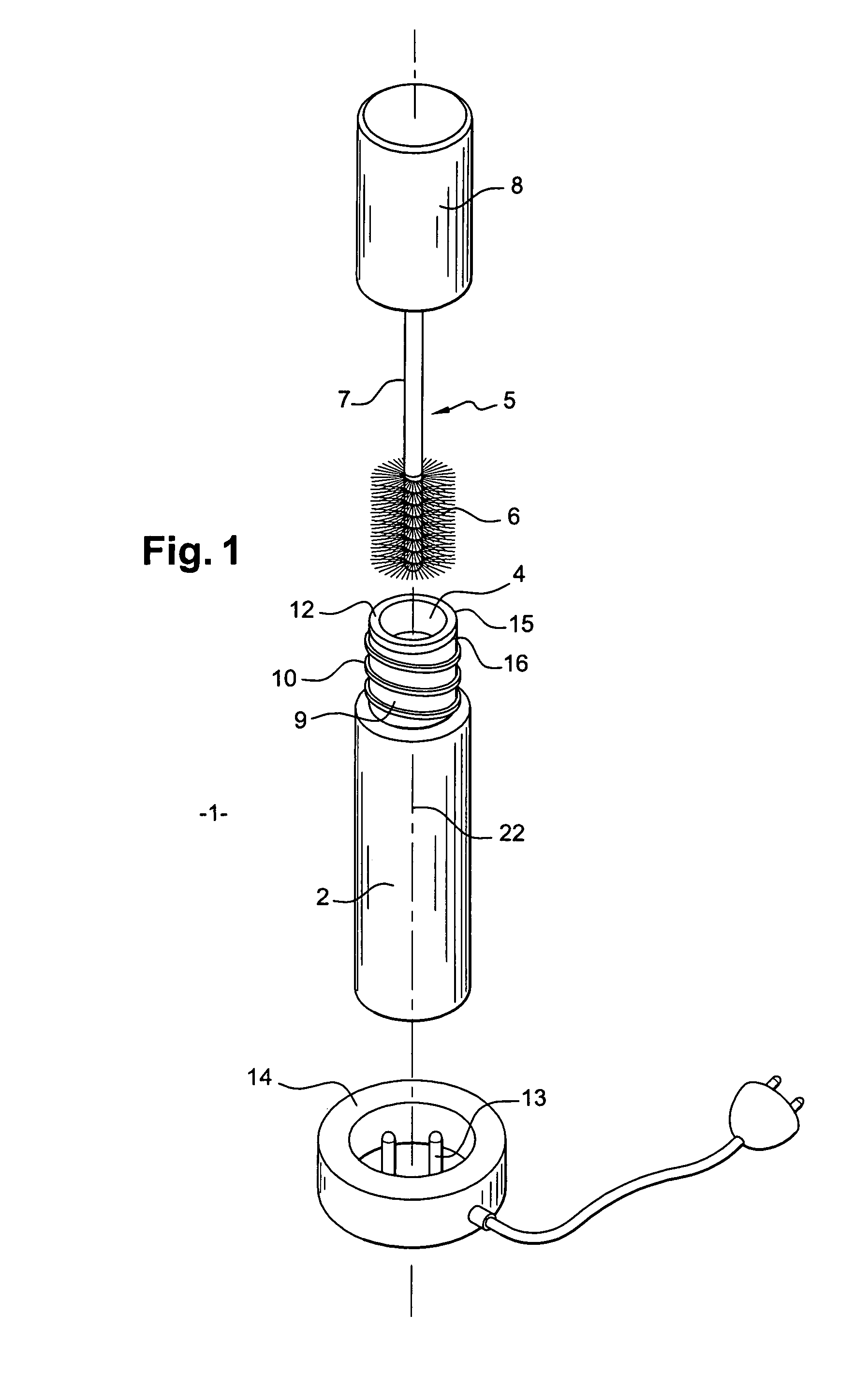

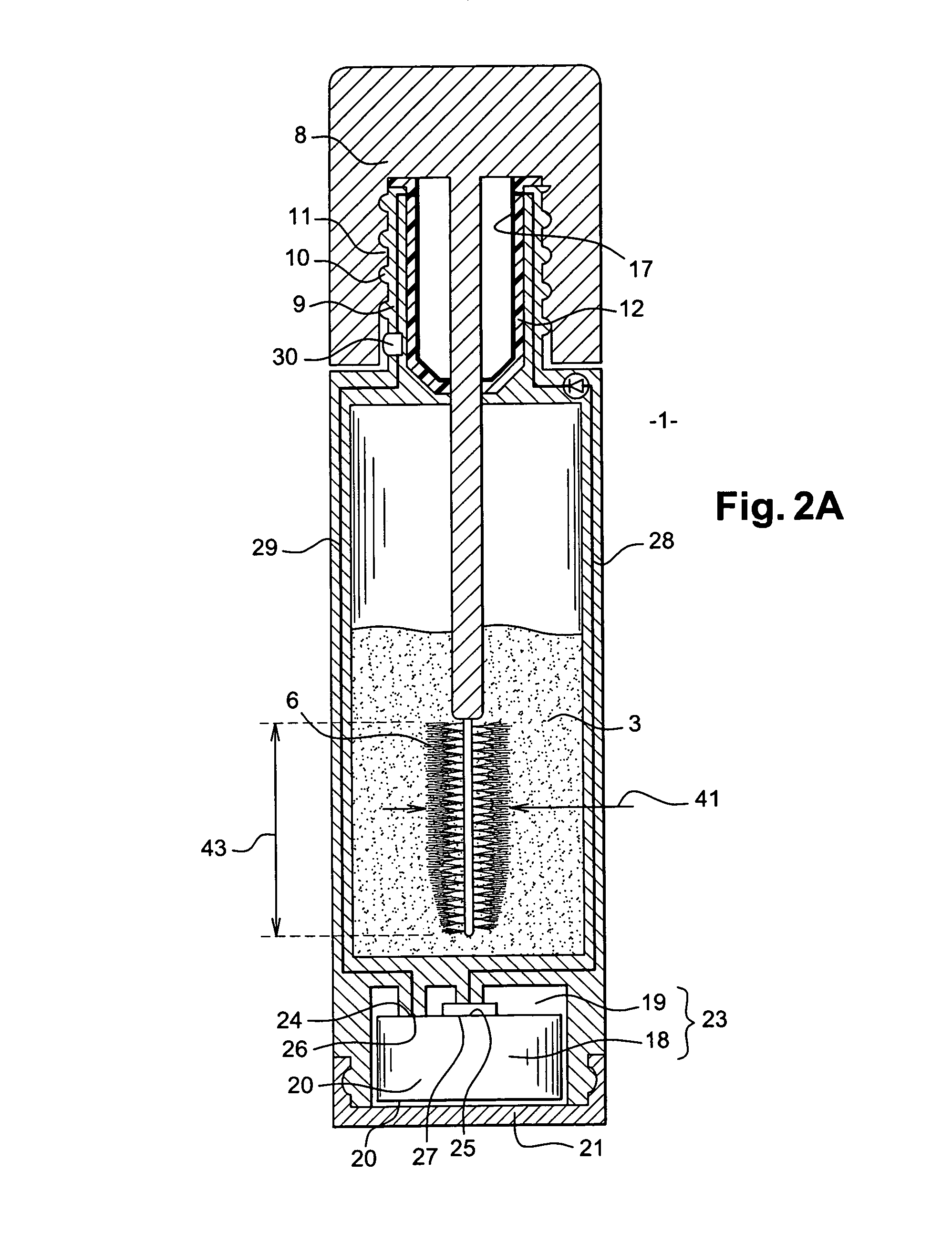

Packaging and applicator device for a cosmetic product and/or a beauty care product incorporating a means of heating

InactiveUS7108438B2Simple actionLimiting and reducing aging and potential deteriorationDispensing apparatusBristleFiberBiomedical engineering

Owner:LOREAL SA

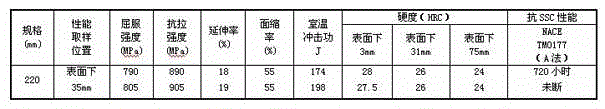

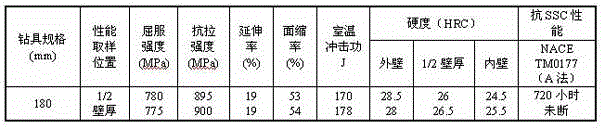

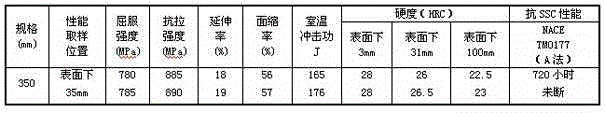

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

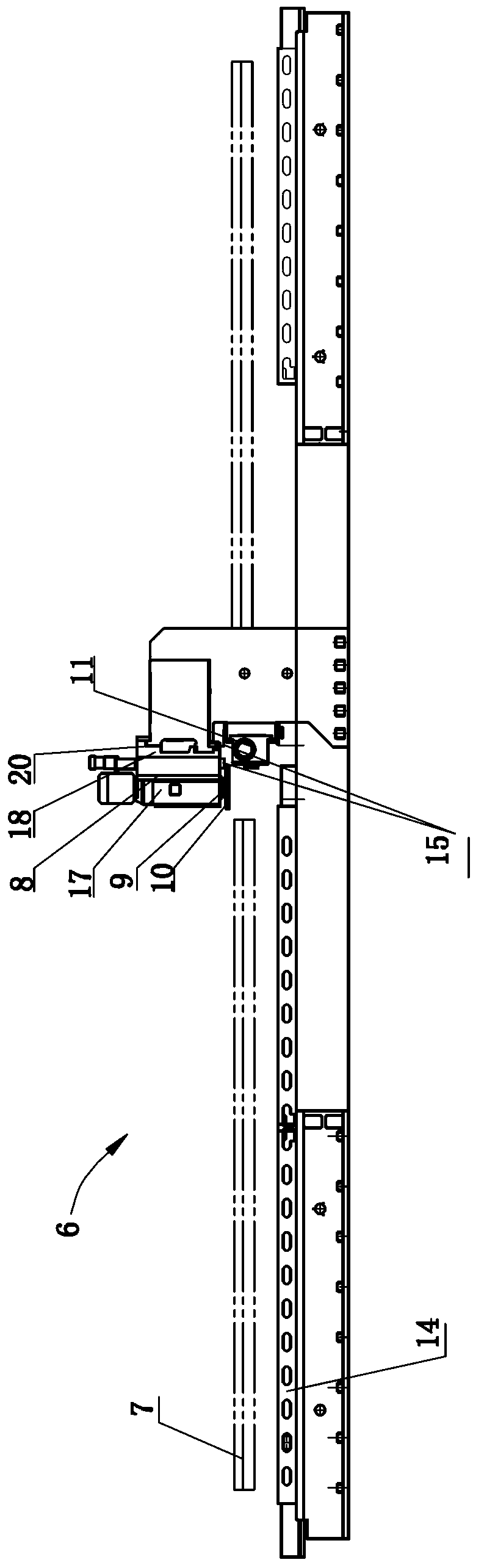

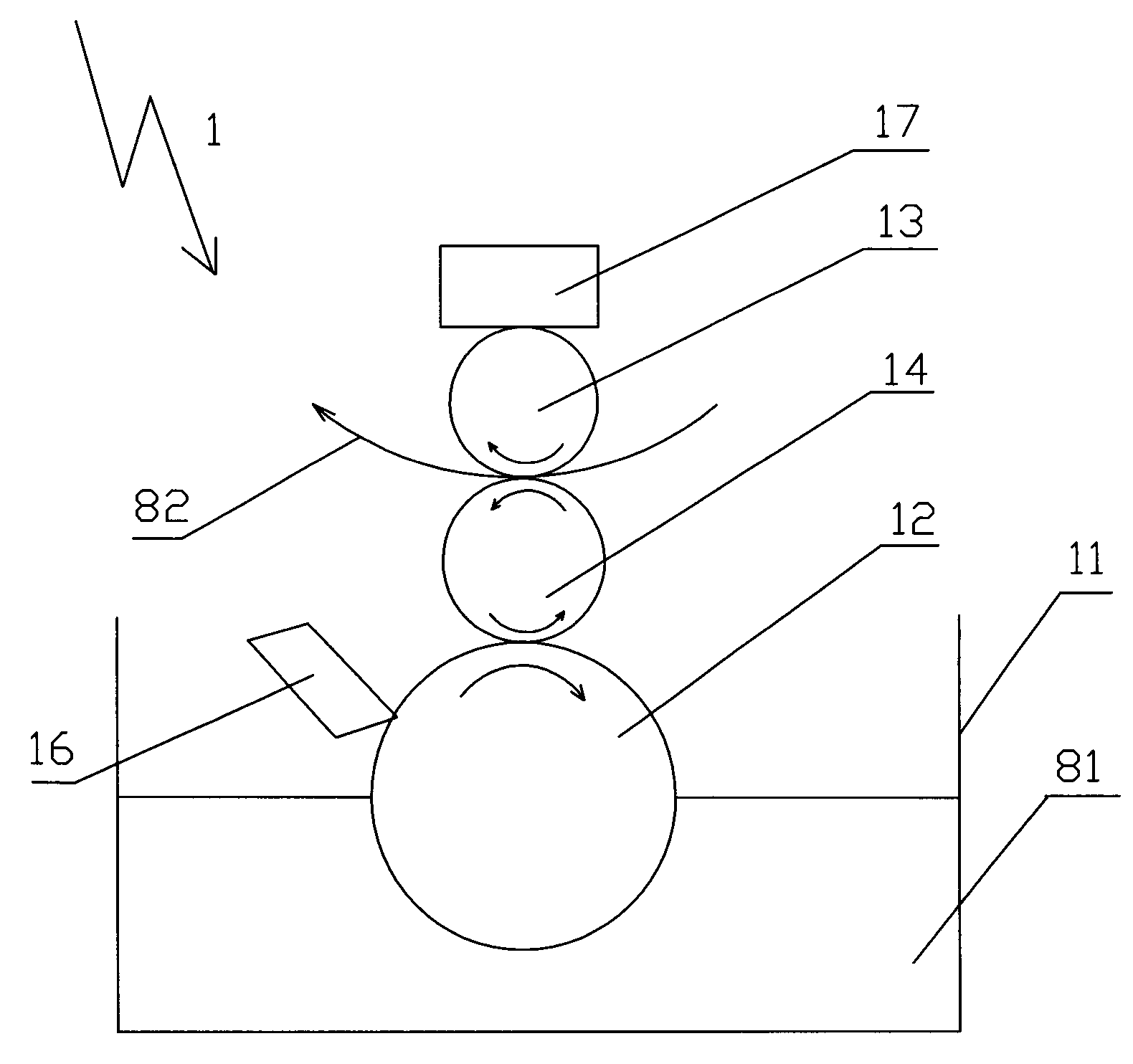

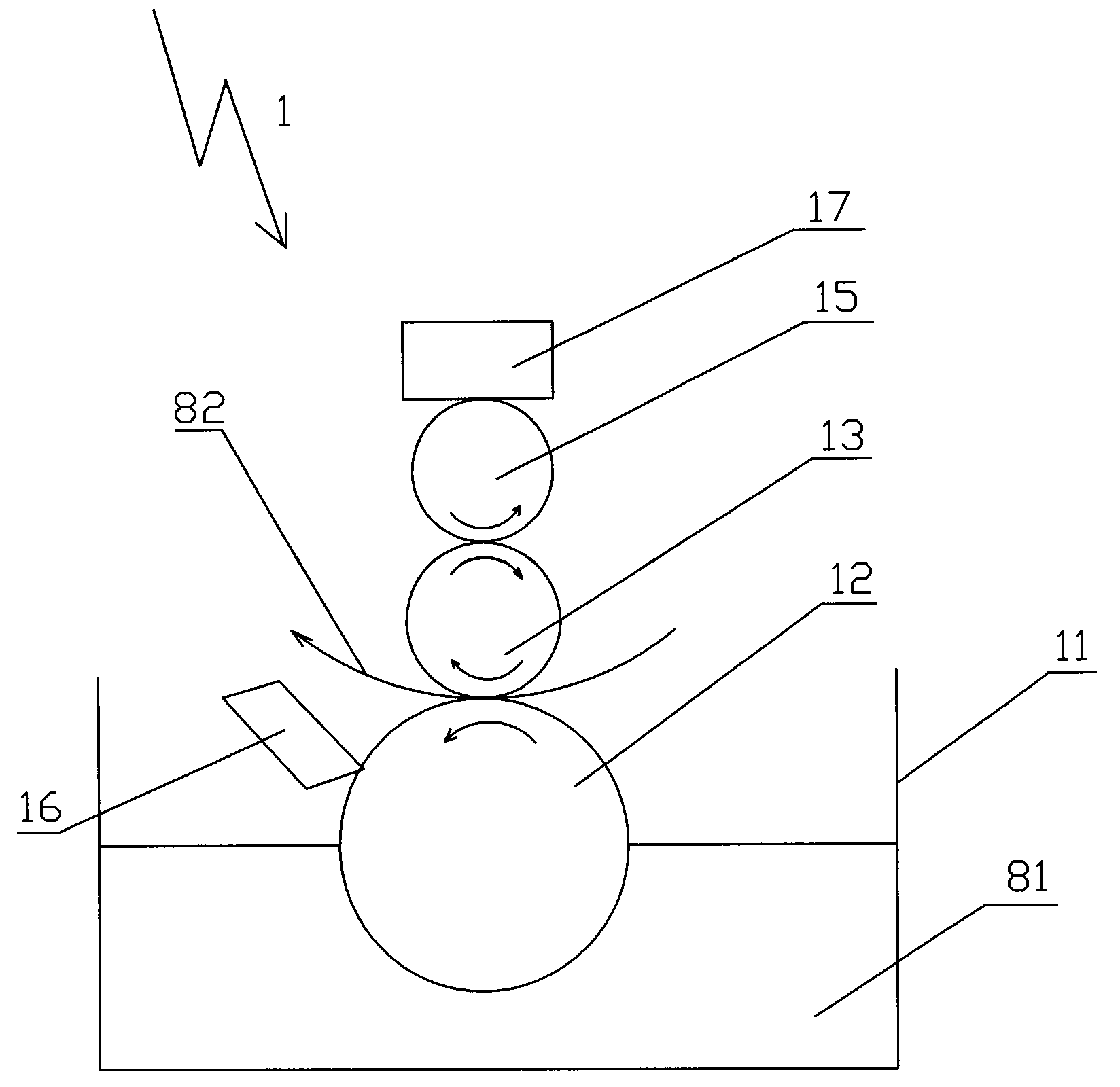

Apparatus for producing reflective membrane with microprism array structure

ActiveCN101672939AImprove work efficiencyImprove performanceOptical elementsUV curingHeat resistance

The invention relates to an apparatus for producing a reflective membrane with a microprism array structure and solves the defects in the prior art that the hardness, scratch resistance, heat resistance and solvent resistance of microprisms are disappointing, the product consistency is poorer, the production speed is lower, the work efficiency is not high, and the like. The apparatus comprises anannular strip-shaped mould, a heating membrane pressing device and a cooling device, wherein the annular strip-shaped mould is provided with an inner surface and an outer surface which is provided with a convex continuous precise microprism array structure. The apparatus also comprises a coating device, a drying device and a UV curing device. By adding the coating device, the drying device and theUV curing device, the microprism structure is formed after the UV curing of photosensitive resin, the hardness, scratch resistance, heat resistance and solvent resistance of microprism of the microprism structure are greatly improved, and the product consistency is fine. In addition, the apparatus can also obviously improve the production speed and the work efficiency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

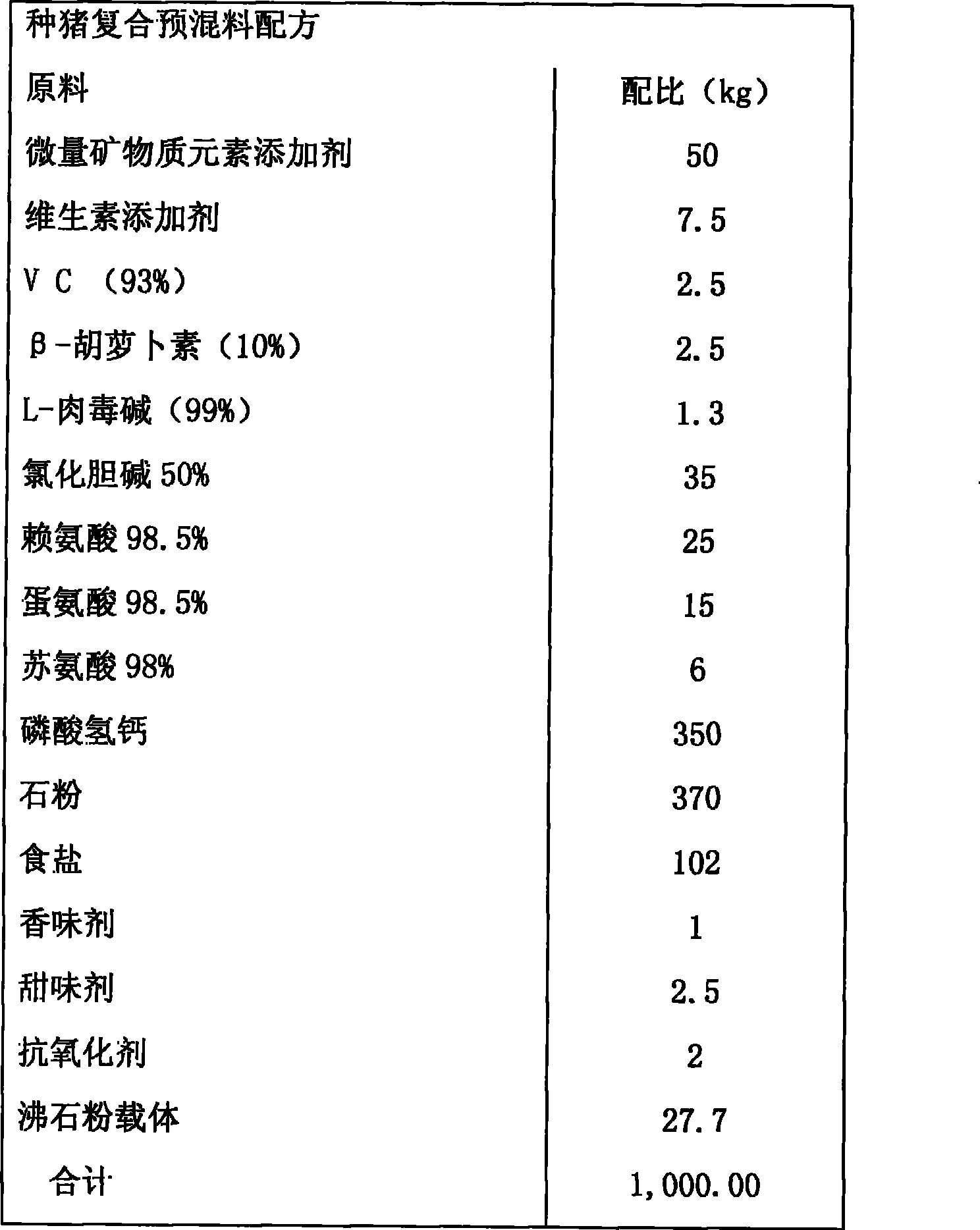

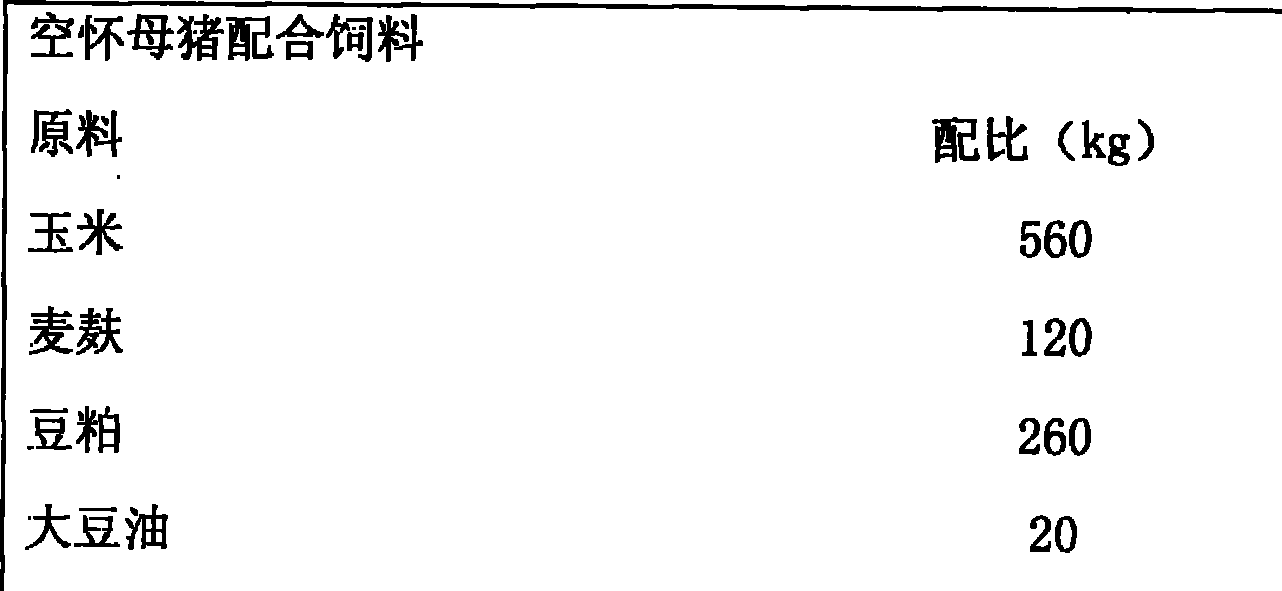

Boar composite premix compound

InactiveCN101390574ARegain weight as soon as possiblePromote secretionAnimal feeding stuffAccessory food factorsPhosphateAntioxidant

A breeding-pig compound premix comprises 0.6-1% of vitamin additive, 3.8-6.3% of trace mineral additive, 4-6% of amino acid additive, 0.5-0.8% of functional additive, 10-12% of flavor, 0.1-0.3% of antioxidant, 2.5-4% of choline chloride, 30-40% of dicalcium phosphate, 30-40% of limestone powder, as well as 2-10% of feed carrier. The adding amount of the premix accounts for 4%; the premix is coupled with the common grain crops, such as corn and soybean meal, and uniformly mixed into full-price formula feed for barren sows, so that the barren sows can timely get rutted and mated to discharge more eggs and produce more litter; therefore, the premix improves the breeding performance of the sows and enhance the economic benefits of the hogpen.

Owner:COFCO BEIJING FEED TECH +2

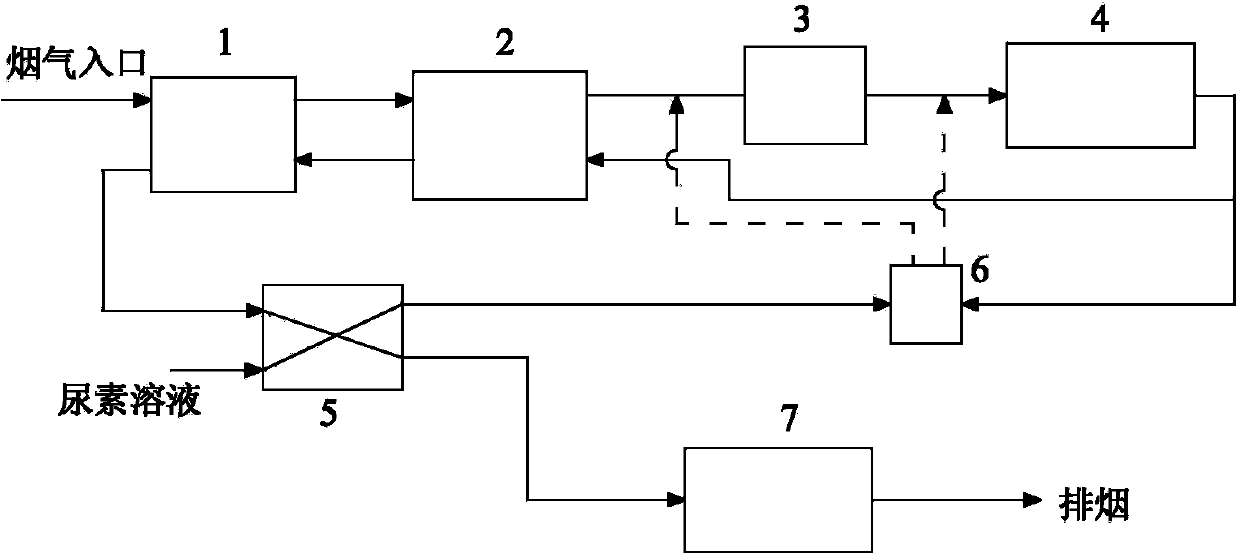

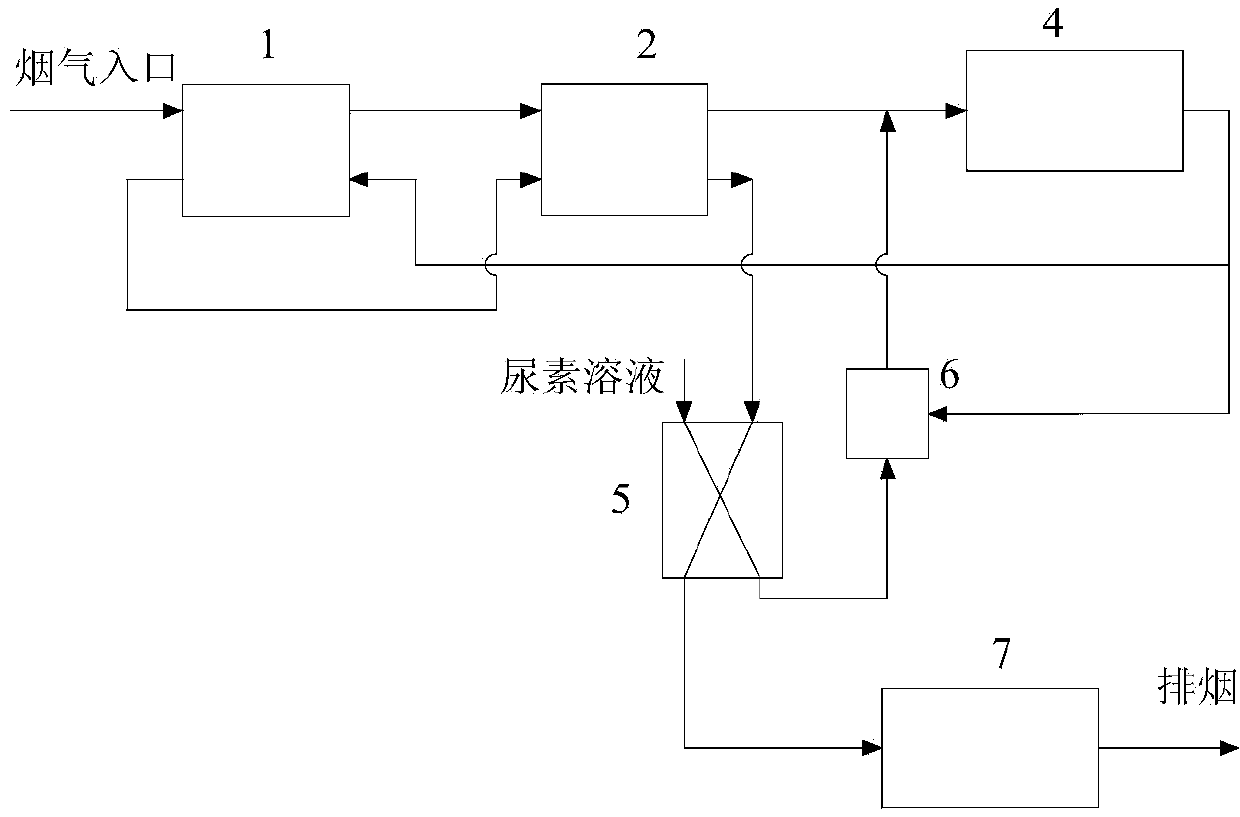

Flue gas desulphurization and denitration method as well as its apparatus

ActiveCN103585867AIncrease temperatureReduce electric heating energy consumptionDispersed particle separationAmmonia productionAtmospheric air

The invention relates to a flue gas desulphurization and denitration method as well as its apparatus, and especially relates to a desulphurization and denitration technology system for flue gas from large-scale mobile facilities such as ships. The method comprises the following steps: flue gas is passed through a heat pipe exchanger and a heat pump in order for increasing temperature of flue gas, and flue gas is selectively passed through an electric heater for heating to the temperature of 340-350 DEG C, an urea solution is used for preparing ammonia gas in a hydrolysis reactor, ammonia gas is diluted by partial high temperature flue gas at an outlet of a SCR reactor and then mixed for injecting flue gas which is undenitrated, the mixed flue gas enters into the SCR reactor for a flue gas denitration reaction, the flue gas after denitration is passed through the heat exchanger, the heat pump and the hydrolysis reactor and cooled, and then enters into a desulfurization tower, flue gas after desulphurization is directly discharged into atmosphere, and an absorption liquid adds alkali and seawater for regeneration and cycle usage. In the method, the heat exchanger and the heat pump are used for recovering waste heat of flue gas, and the energy consumption is greatly reduced. The ammonia production method through hydrolysis is capable of increasing the mixing degree of ammonia and flue gas, so that denitration efficiency can be further increased.

Owner:湖州旧馆頔南污水处理有限公司

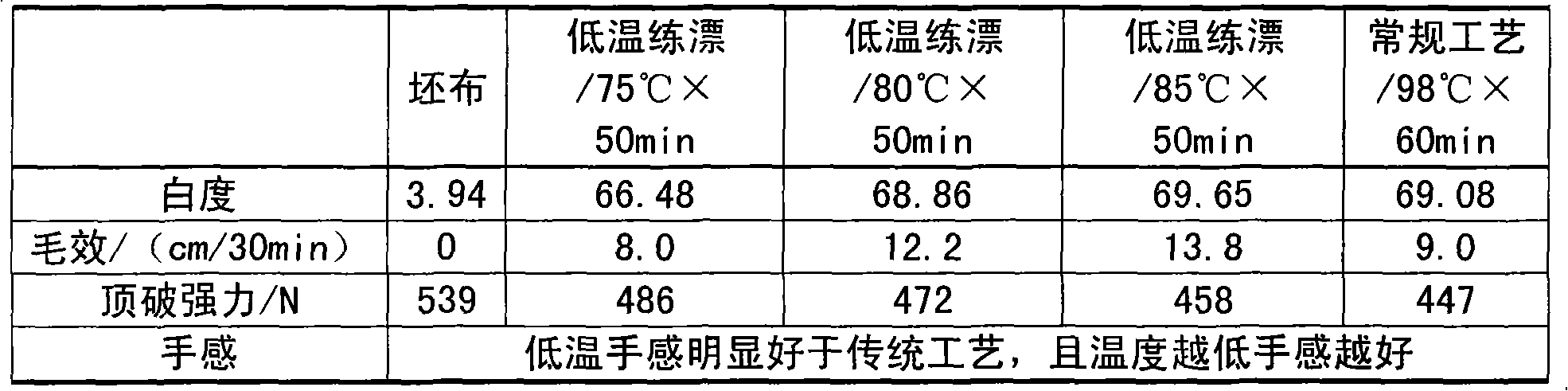

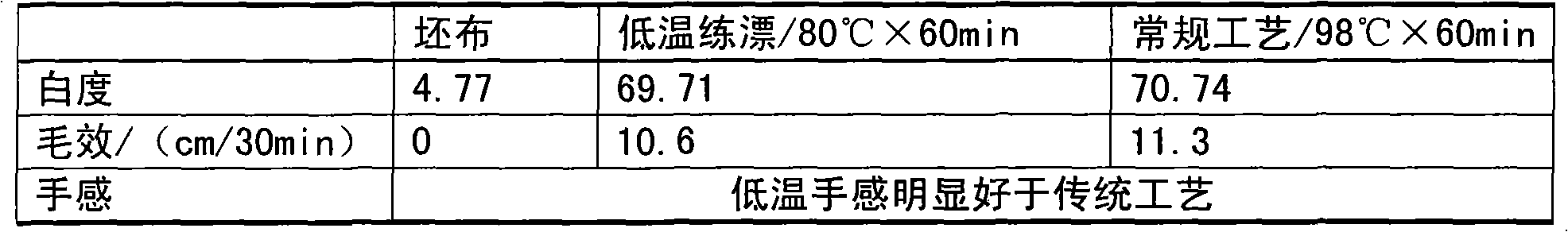

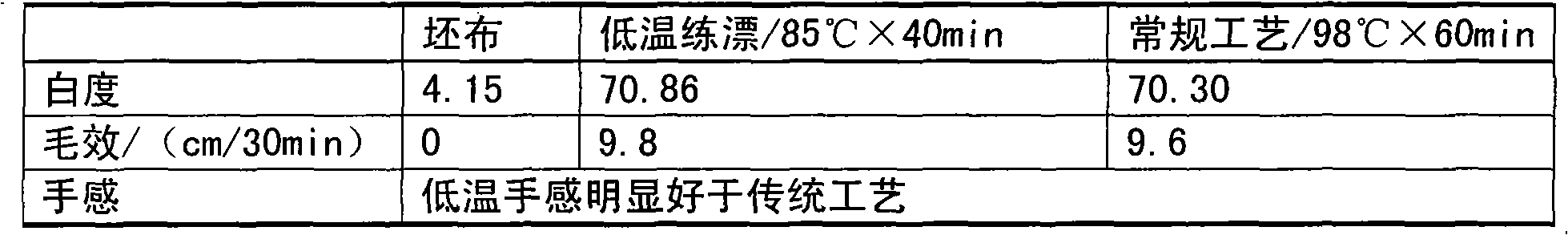

Low-temperature scouring and bleaching assistant and preparation method and application thereof

InactiveCN101845744AEasy to washReduce sewage dischargeBleaching apparatusDefoaming AgentsSewage treatment

The invention relates to a low-temperature scouring and bleaching assistant and a preparation method and application thereof. The low-temperature scouring and bleaching assistant is a mixed assistant formed by 25-60 percent by weight of low-temperature oxidation bleaching activating agent and 40-75 percent by weight of matched scouring agent, wherein the low-temperature oxidation bleaching activating agent consists of sodium nonanoyloxy benzene sulfonate, an activating agent promoter, a bleaching promoter and ammonium polycarylate; and the matched scouring agent consists of an emulsifying agent, a penetrating agent, a chelated dispersing agent, a defoaming agent and water. Cellulose fiber unfinished textiles treated by the low-temperature scouring and bleaching assistant have better whiteness, capillary effect, strength and hand feeling than the performances of textiles treated by the traditional process. Compared with the traditional method, the invention can effectively save the consumption of steam and power, reduce the treatment pressure of sewage and reduce the treatment expense of the sewage.

Owner:DYMATIC CHEM

Heating systems and methods utilizing high frequency harmonics

InactiveUS7034264B2Enhance relative proportion of inductive heatingExtended service lifeCoil arrangementsAuxillary shaping apparatusElectrical resistance and conductanceHarmonic

Heating systems and methods for inductive heating or a combination of resistive and inductive heating. A heater coil is inductively coupled to an article and a current signal is supplied to the heater coil. The heater coil generates a magnetic flux, based on the applied current signal, for inductively heating the article. Current pulses of a certain profile are used to enhance the rate, intensity and / or power of inductive heating delivered by the heating element or coil and / or to enhance the lifetime or reduce the cost of the inductive heating system.

Owner:ITHERM TECH LP

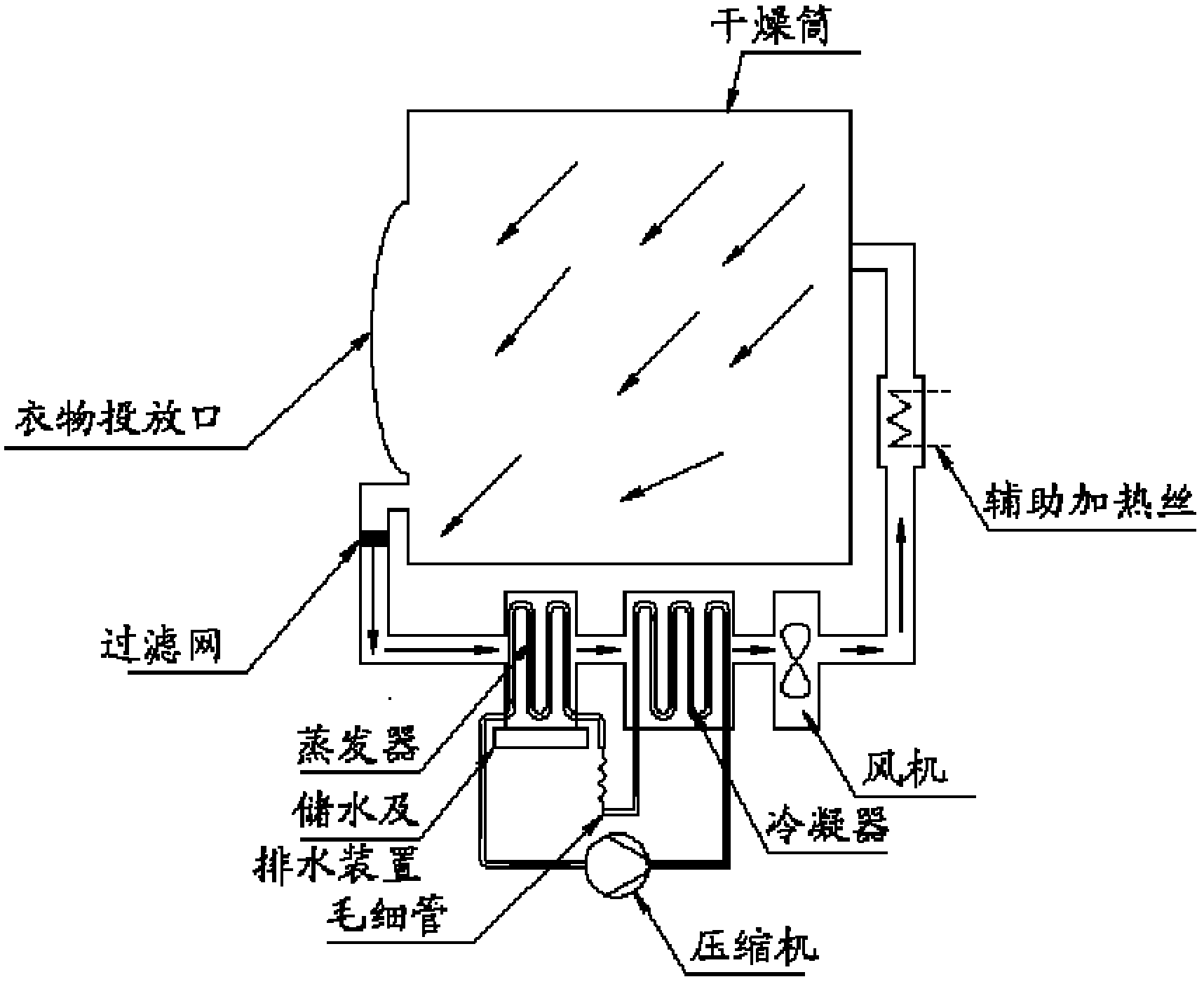

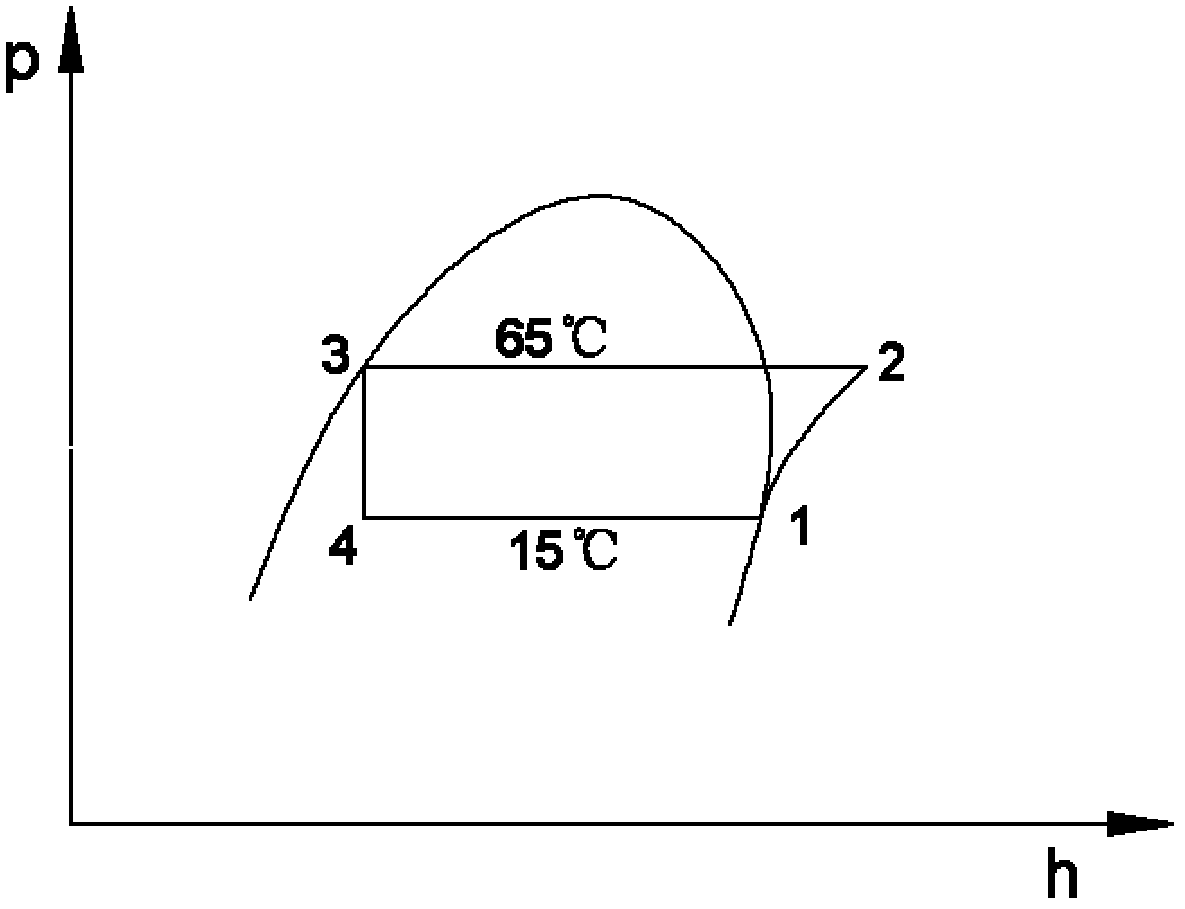

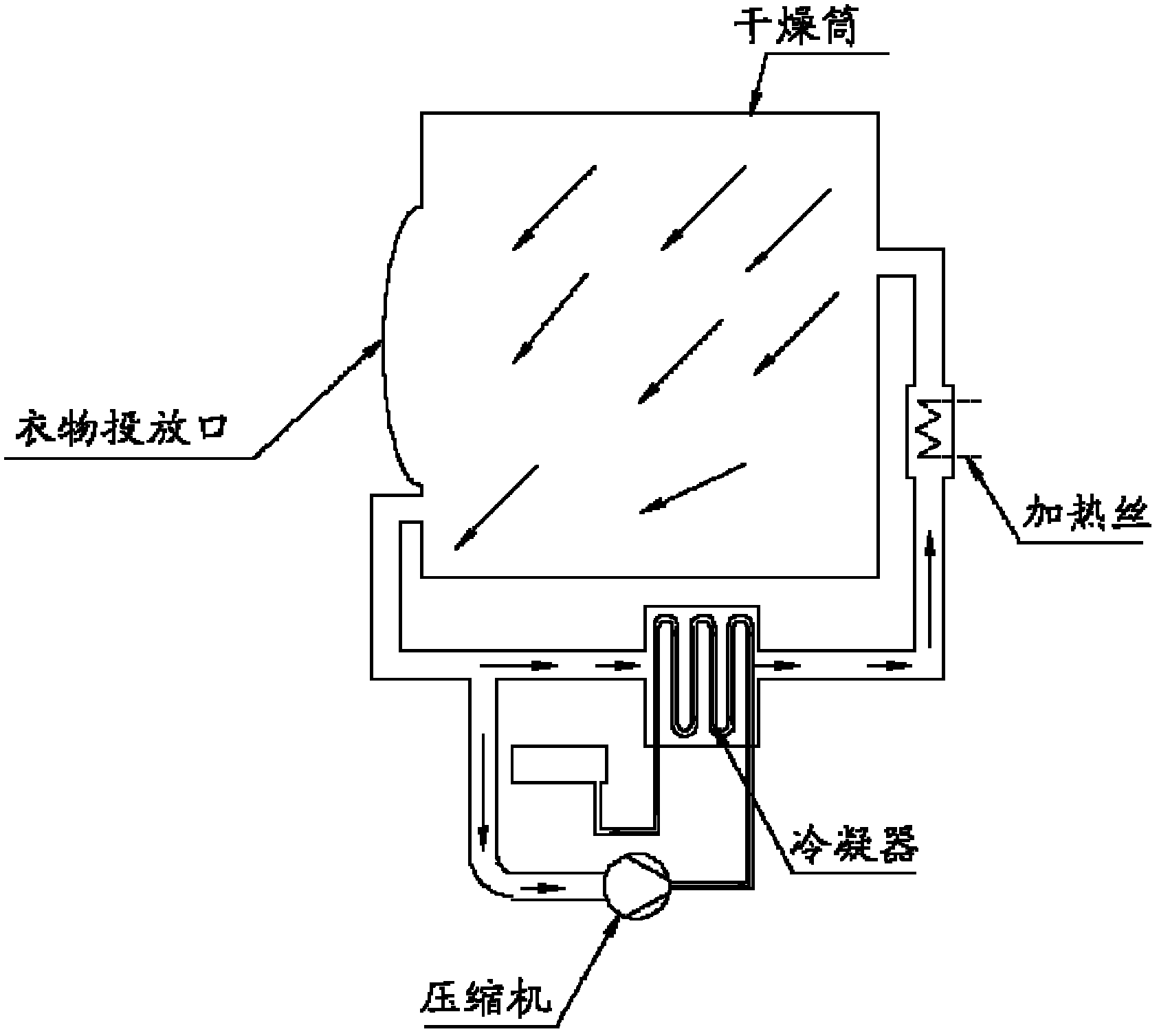

Clothes dryer and drying method thereof

ActiveCN102677438AReduce power consumptionShorten drying timeTextiles and paperLaundry driersPulp and paper industryDrying time

The invention discloses a clothes dryer and a drying method thereof. The clothes dryer comprises a drying drum, a condenser, a steam compressor and heating wires. An air inlet end of the condenser is connected with an air exhaust end of the drying drum, an air exhaust end of the condenser is connected with an air inlet end of the drying drum, an air inlet end of the steam compressor is connected with an air exhaust end of the drying drum, an air exhaust end of the steam compressor is connected with a refrigerant inlet of the condenser, and the heating wires are arranged in a passage between the air exhaust end of the condenser and the air inlet end of the drying drum. The problem that drying time of a clothes dryer in the prior art is lengthened when energy consumption is reduced is solved, and power consumption of the clothes dryer is reduced, and drying time thereof is shortened.

Owner:HAIER GRP CORP +1

Method for drying cell of high-capacity lithium-ion battery

ActiveCN104142045AReduce moistureReduce dosageFinal product manufactureDrying solid materials without heatManufacturing technologyEngineering

The invention discloses a method for drying a cell of a high-capacity lithium-ion battery, and belongs to the technical field of manufacturing of lithium batteries. The method comprises the following steps: (1) a to-be-dried battery cell is placed in a drying oven, the drying oven is heated to increase the oven temperature, vacuumizing is performed until the relative vacuum degree is smaller than or equal to minus 99.0; (2) vacuum is unloaded by gas until the relative vacuum degree reaches minus 5.0 to minus 85.0; (3) a blast apparatus in the drying oven is operated, and heat is preserved; (4) vacuumizing is performed until the relative vacuum degree is smaller than or equal to minus 99.0 and is performed continuously; and (5) the steps (2), (3) and (4) are circulated sequentially. According to the method, the battery cell is dried with a method of alternately circulating a convection state and a vacuum state of dry and wet hot air in the oven, and moisture in the battery cell can be reduced effectively with fewer circulation times, so that the drying speed and efficiency of the battery cell are increased, and circulation air amount and consumed heat are reduced.

Owner:中创新航科技(江苏)有限公司

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614AIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

The invention relates to the technical field of extracting and concentrating of the traditional Chinese medicine, and in particular relates to a method and a device for extracting and concentrating the traditional Chinese medicine. The method for extracting and concentrating structurally comprises an extracting unit and a concentrating unit, wherein the extracting unit comprises an extracting tank and a liquid medicine storage tank, wherein a piston capable of moving up and down is arranged in the extracting tank; when the piston moves upwards under the action of the driving force, dredges of decoction in a pressurizing chamber are pressurized and further squeezed; the concentrating unit comprises a concentrating container, a vacuum pump and a heating device for heating up the concentrating container, wherein a step-shaped evaporation plate assembly of a liquid medicine thin film is formed in the concentrating container, so that the liquid medicine can be circulated and concentrated. Compared with the prior art, the extracting and concentrating efficiency is high, the heating time is short, and the damages to the active ingredients of the medicine are reduced.

Owner:GUANGDONG MEDICAL UNIV

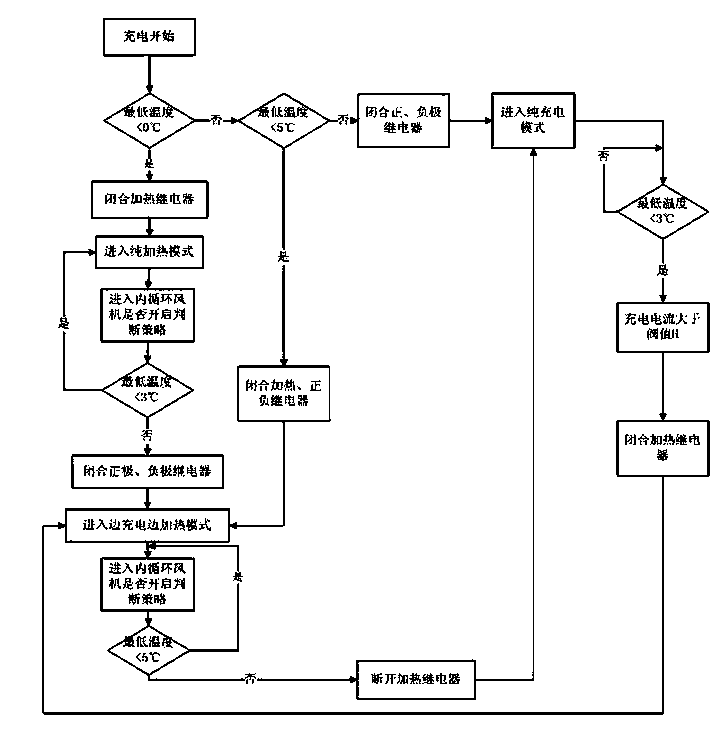

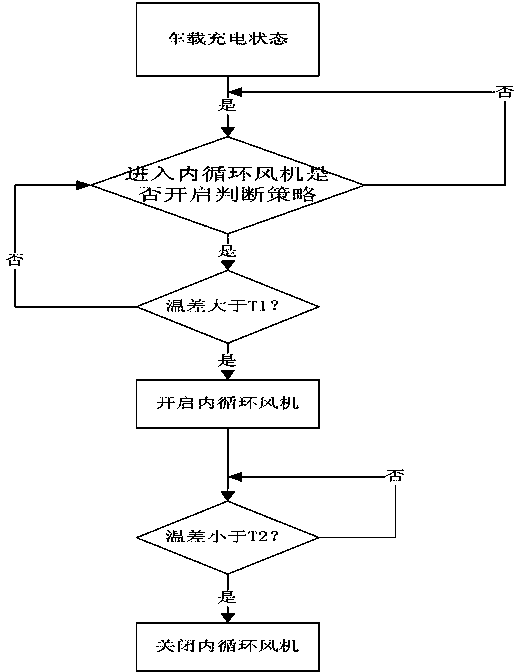

Charging method of power battery of electric vehicle

InactiveCN104393357AFast fullTemperature balanceSecondary cells charging/dischargingBatteriesPower batteryHeating time

The invention provides a charging method of a power battery of an electric vehicle. The charging method comprises the following steps: S1, detecting the maximal temperature and the minimal temperature of a battery, and judging whether the minimal temperature is lower than a first threshold temperature or not, if so, executing a step S2; if not, continuing to judge whether the minimal temperature is higher than a second threshold temperature or not, if so, executing a step S4, if not, executing a step S3; S2, entering a pure-heating mode; S3, entering a charging and heating mode; and S4, entering a pure-heating mode. According to the charging method of the power battery of the electric vehicle, provided by the invention, the power battery at low temperature is charged, the power battery enters different charging procedures according to the minimal temperature of the battery, namely, the pure-charging mode, the heating and charging mode and the pure-charging mode, so that the low-temperature charging and heating time can be shortened, and the rapid charging of the battery is ensured.

Owner:HUIZHOU EPOWER ELECTRONICS

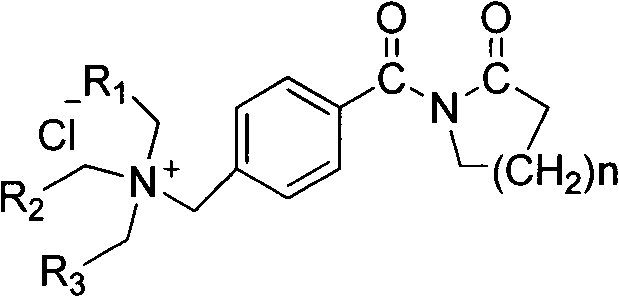

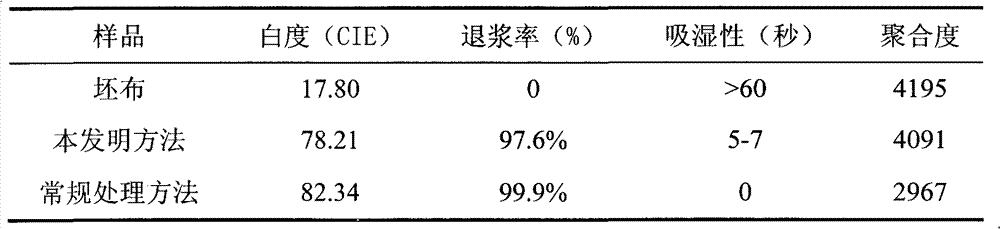

Method for pretreating cotton fabric at low temperature by using biological enzymes and hydrogen peroxide through one bath process

ActiveCN103046383AReduce consumptionSave energyBiochemical fibre treatmentBleaching apparatusFiberMoisture absorption

The invention relates to a method for pretreating a cotton fabric at low temperature by using biological enzymes and hydrogen peroxide through one bath process. The method adopts N-[4-(trialkyl ammonium methylene)benzoyl] lactam chloride activator, hydrogen peroxide, a desizing enzyme, a scouring enzyme and supporting aids and has the characteristics of low temperature of 25-60 DEG C in the whole course, nearly neutral reaction condition (with pH value being 6.5-7.5) and low fiber damage. The cotton fabric treated by the adopting the method has no residual sizing agent and cottonseed hull, is equivalent to the cotton fabric treated by adopting the conventional method in whiteness and moisture absorption and is superior to the cotton fabric treated by adopting the conventional method in strength and handfeel. The process of the method is shortened greatly, the energy is saved, and the sewage treatment burden is lightened.

Owner:QINGDAO FRONTIERCHEM

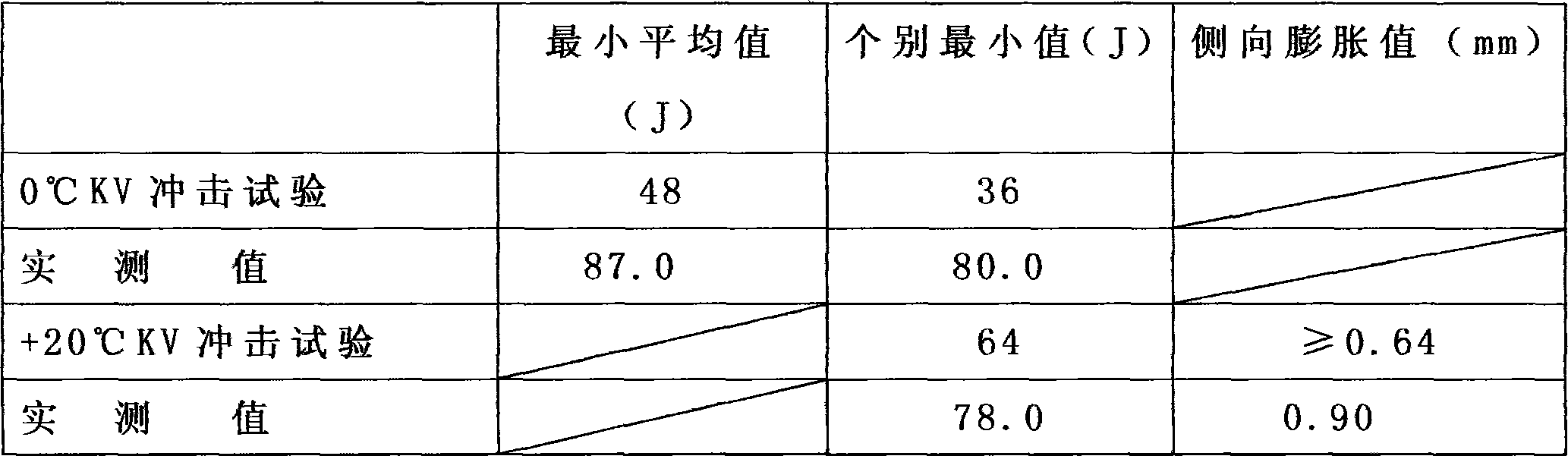

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

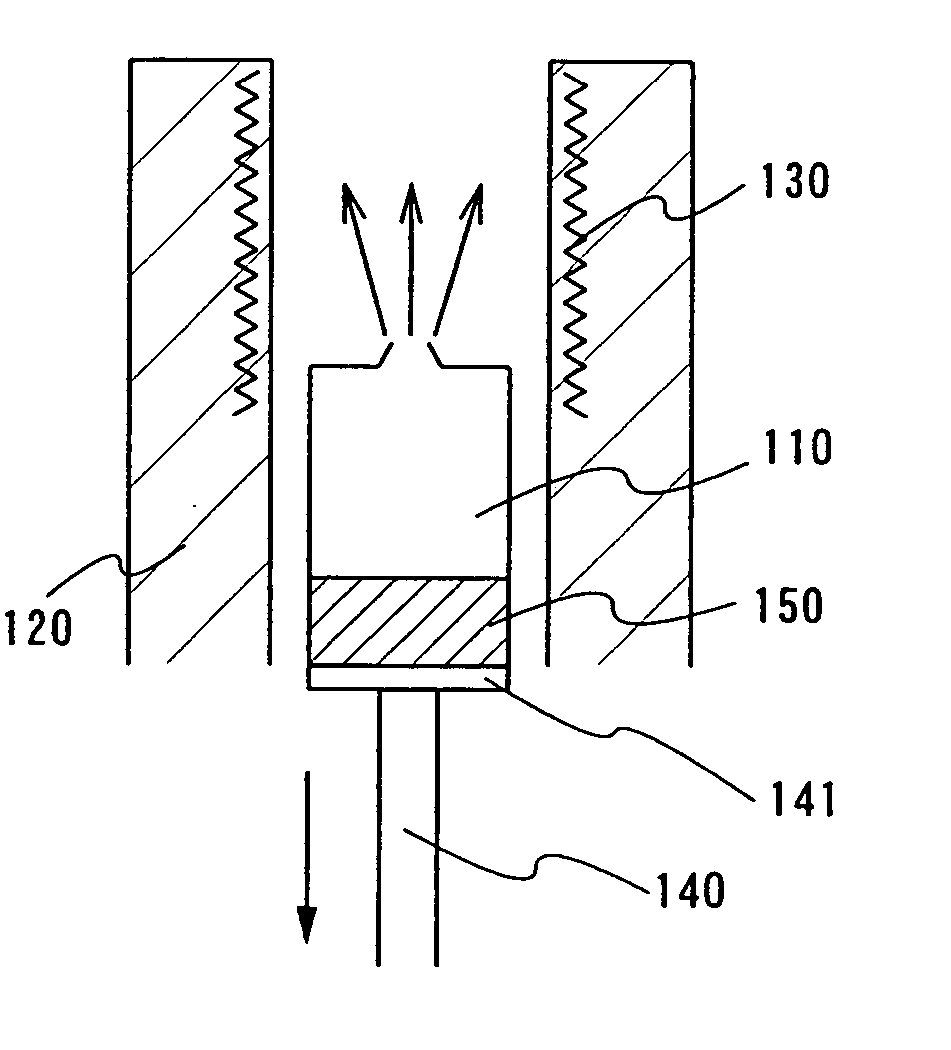

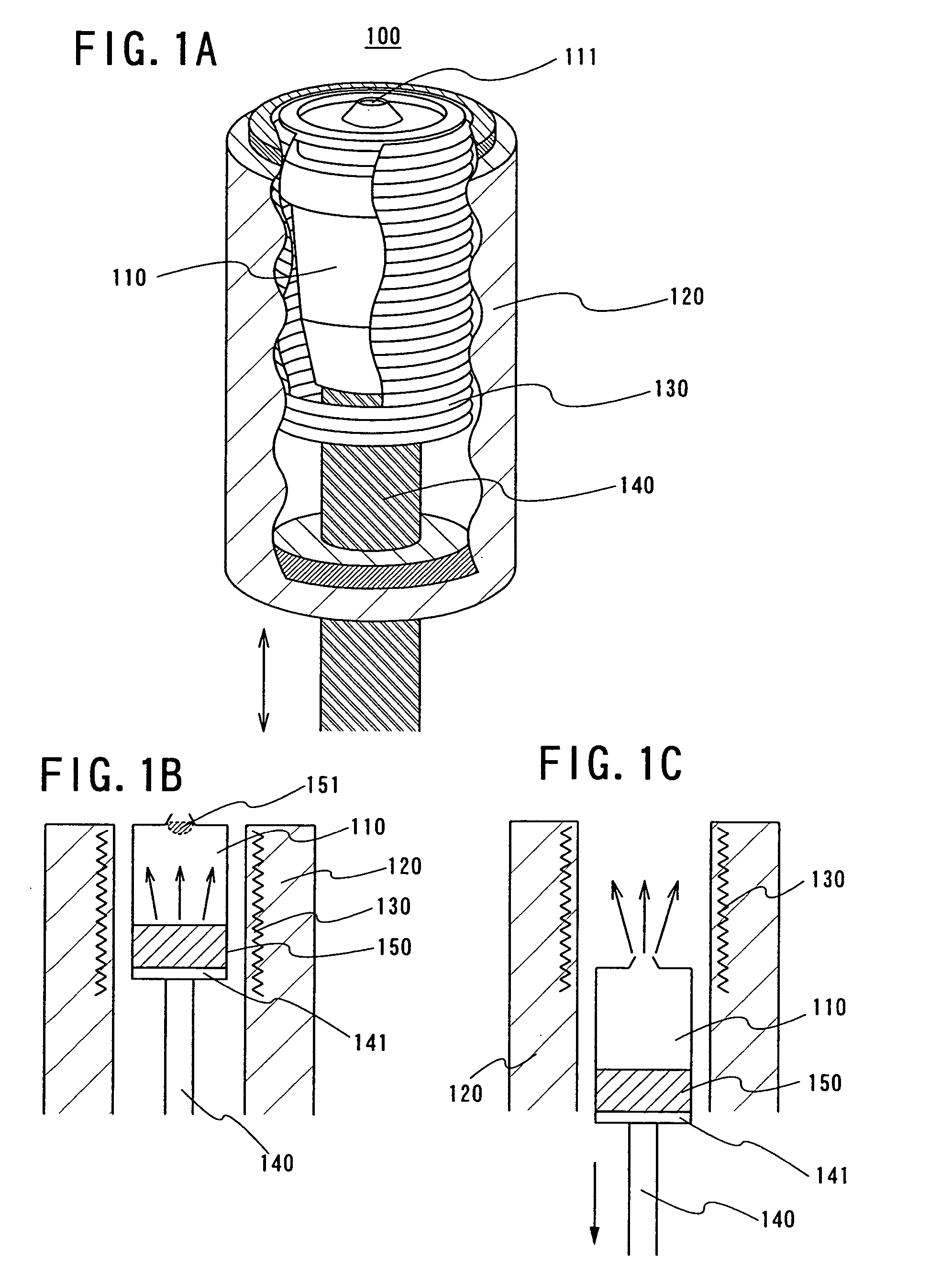

Deposition apparatus and manufacturing apparatus

InactiveUS20050034671A1Improve throughputEvaporation stableElectrical apparatusElectroluminescent light sourcesProduction rateCrucible

An object of the present invention is to carry out stable film deposition for a long stretch of time without an evaporation material being stuck in a manufacturing apparatus that carries out evaporation. A driving portion that can move a crucible up and down is provided for an evaporation source of an evaporation apparatus. When the opening of the crucible is clogged with the evaporation material, the crucible is moved down and sealed in the evaporation source. The heater of the evaporation source can heat the opening efficiently; therefore, the evaporation material with which the opening is filled is evaporated; therefore, the blockage can be dissolved. Thereafter, the crucible is moved above and heated to carry out evaporation. It is possible to carry out film deposition without exposure to the atmosphere for a long stretch of time, which can improve the productivity of an organic EL element.

Owner:SEMICON ENERGY LAB CO LTD

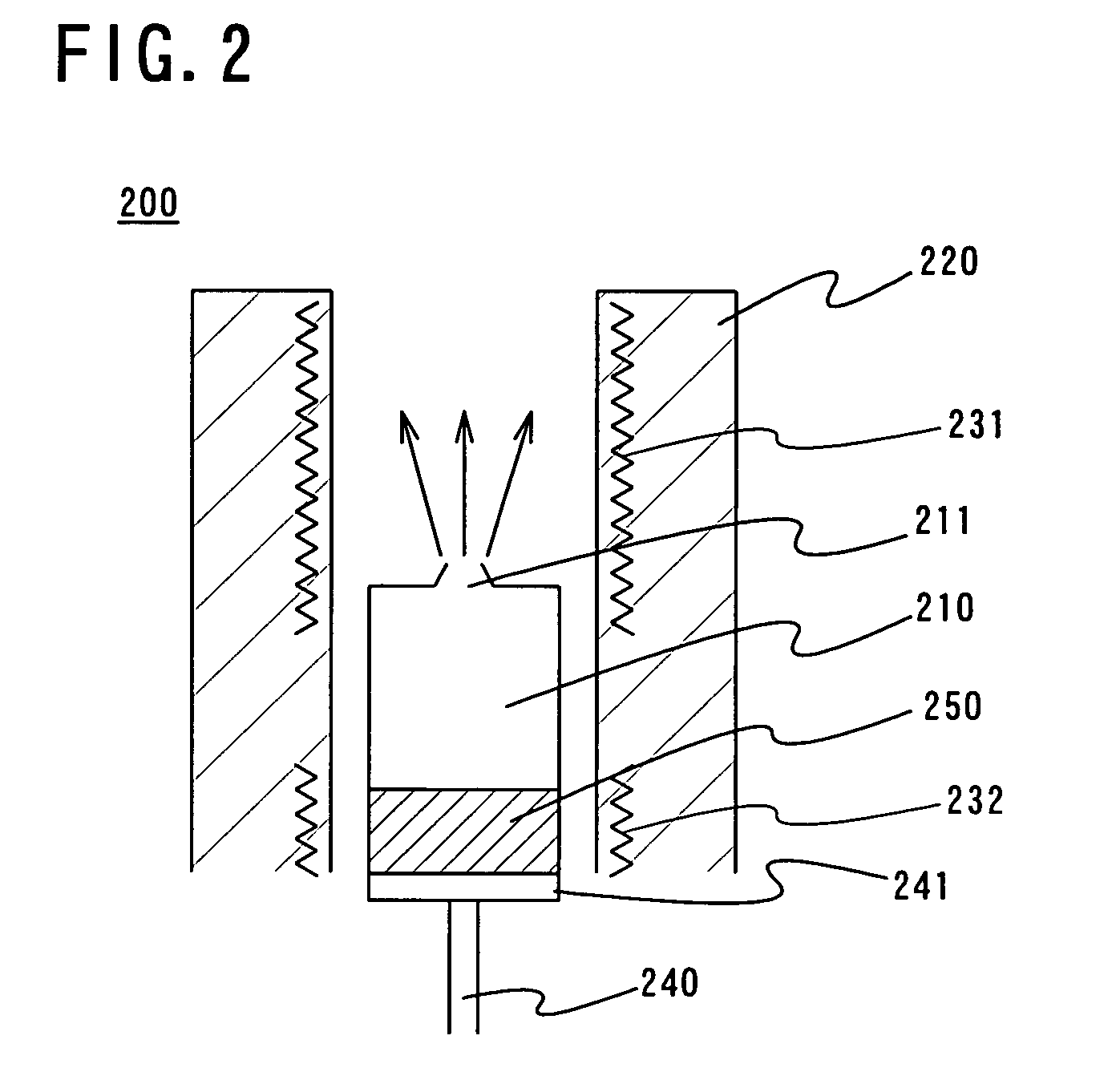

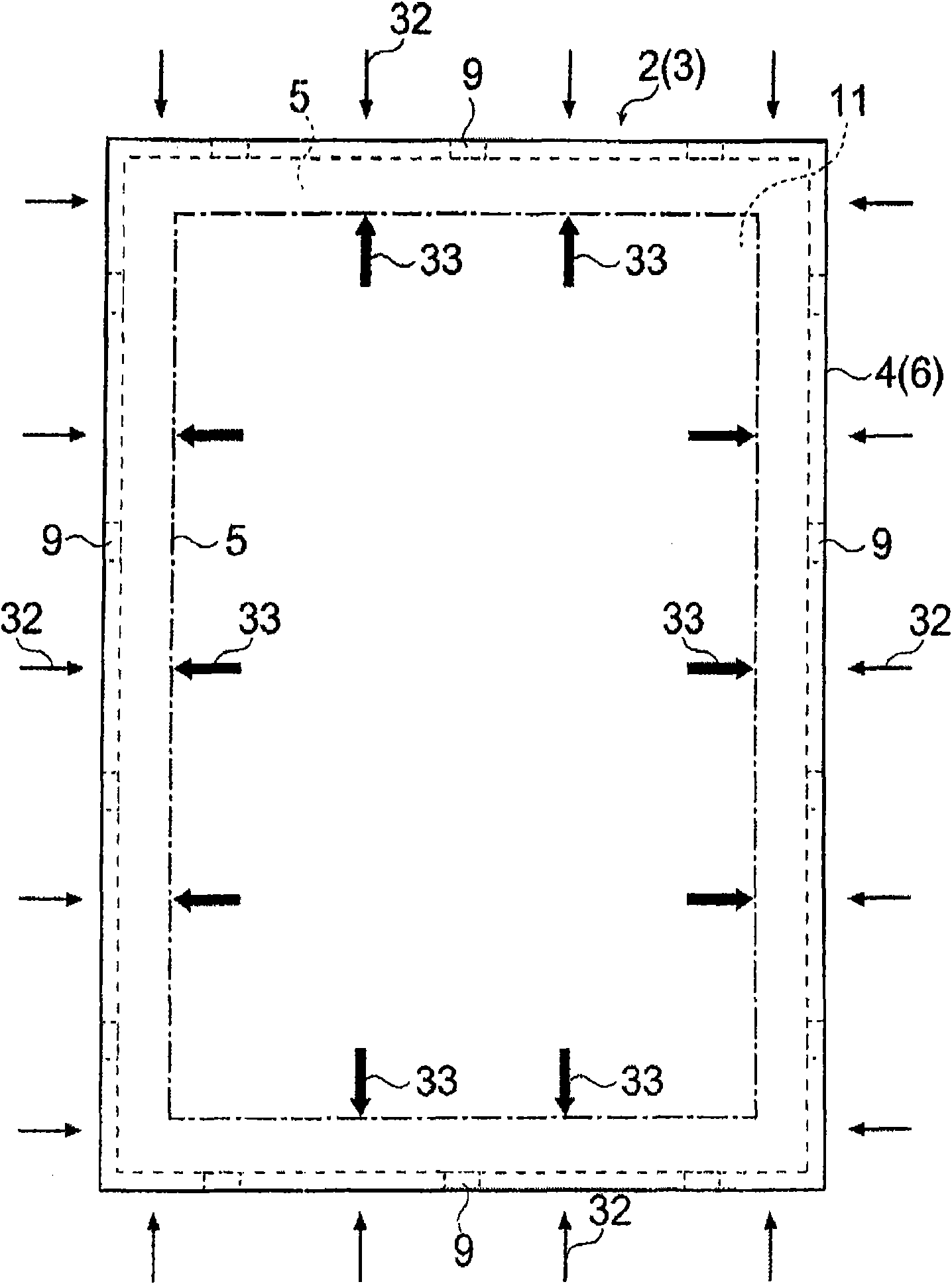

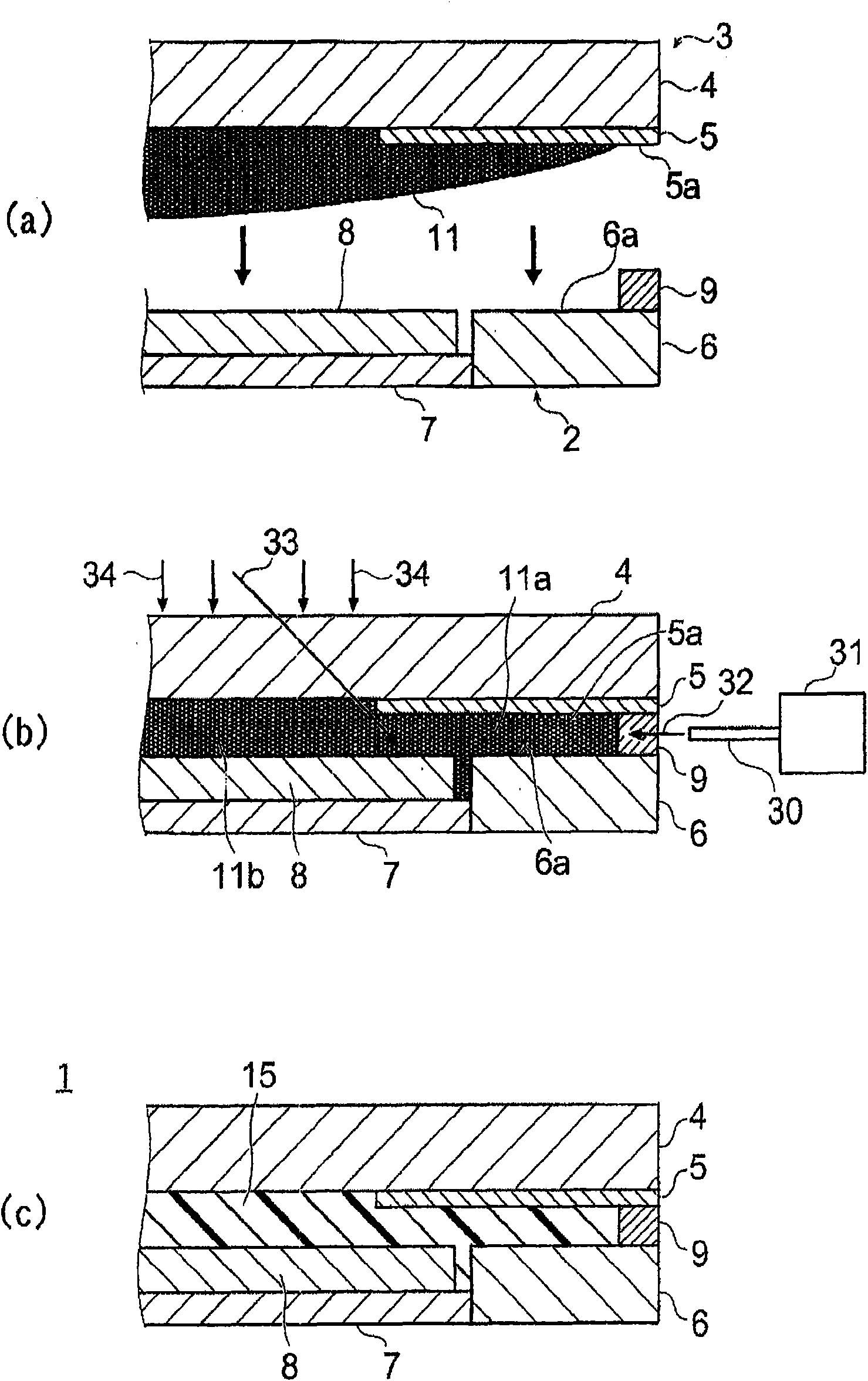

Method for manufacturing image display

ActiveCN101652803APrevent orientation confusionFully curedNon-linear opticsIdentification meansHigh contrastTransmittance

Disclosed is a method for manufacturing an image display (1), which comprises a step wherein a photocurable resin composition (11) is interposed between a base unit (2) having an image display unit such as a liquid crystal display panel (8) and a light-transmitting protective unit (3) having a light-shielding portion (5), and a cured resin layer (15) is formed by photocuring the resin composition(11). In this method, a resin composition having a curing shrinkage rate of not more than 5% and a storage modulus of the cured product at 25 DEG C of not more than 1.0 OE10<7> Pa, which enables to obtain a cured resin layer (15) having a visible light transmittance of not less than 90% is used as the photocurable resin composition (11). The method further comprises a step wherein a curable resincomposition (11a) containing a thermal polymerization initiator is interposed at least between the light-shielding portion (5) and the base unit (2) and then the curable resin composition (11a) is heated. Consequently, the resin in a forming-region of the light-shielding portion (5) is sufficiently cured, while attaining a high-luminance, high-contrast display without having display defects due todeformation of the image display unit (8), during manufacture of the thin image display (1) wherein the resin is interposed between the protective unit (3) having the light-shielding portion (5) andthe image display unit (8).

Owner:DEXERIALS CORP

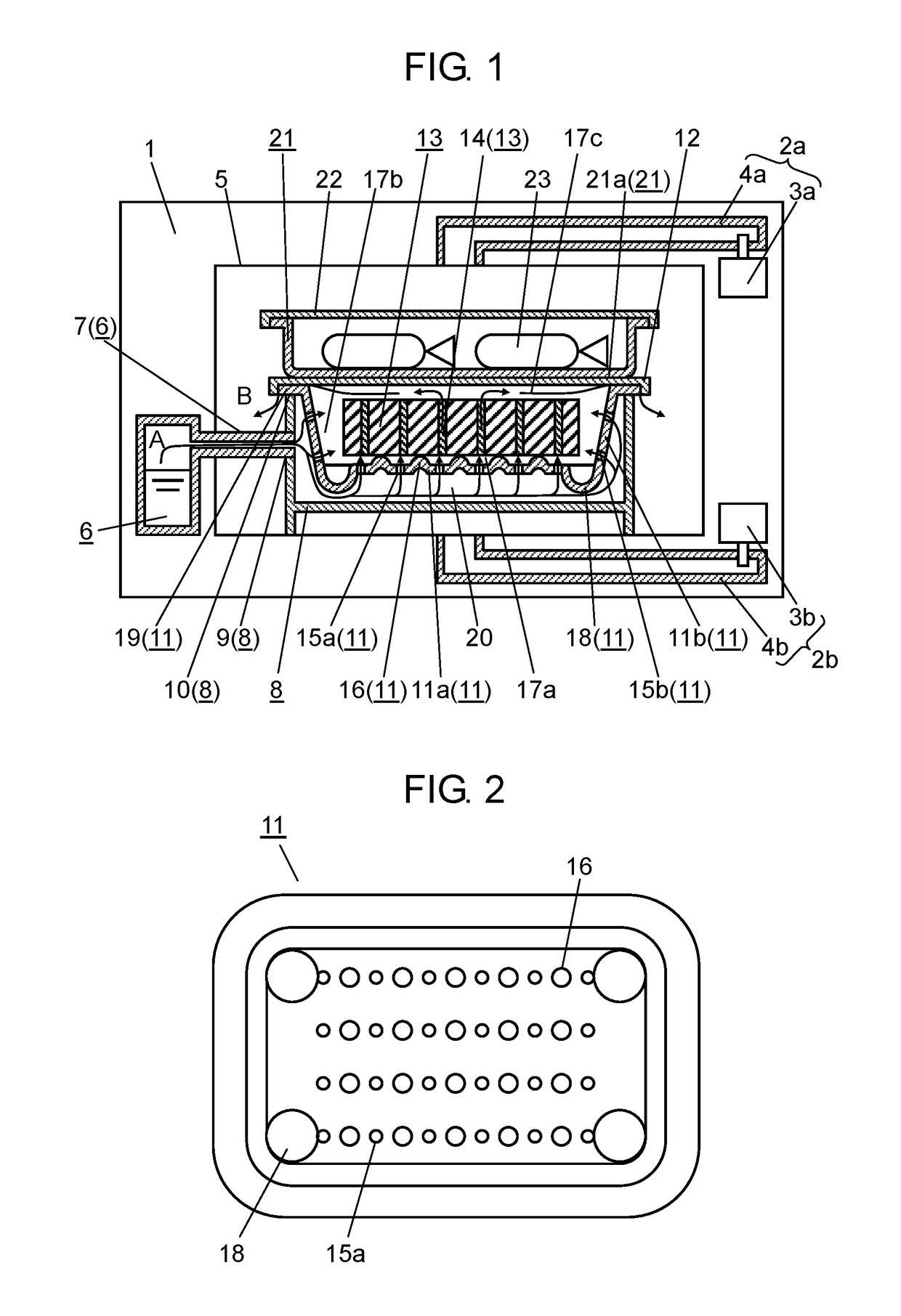

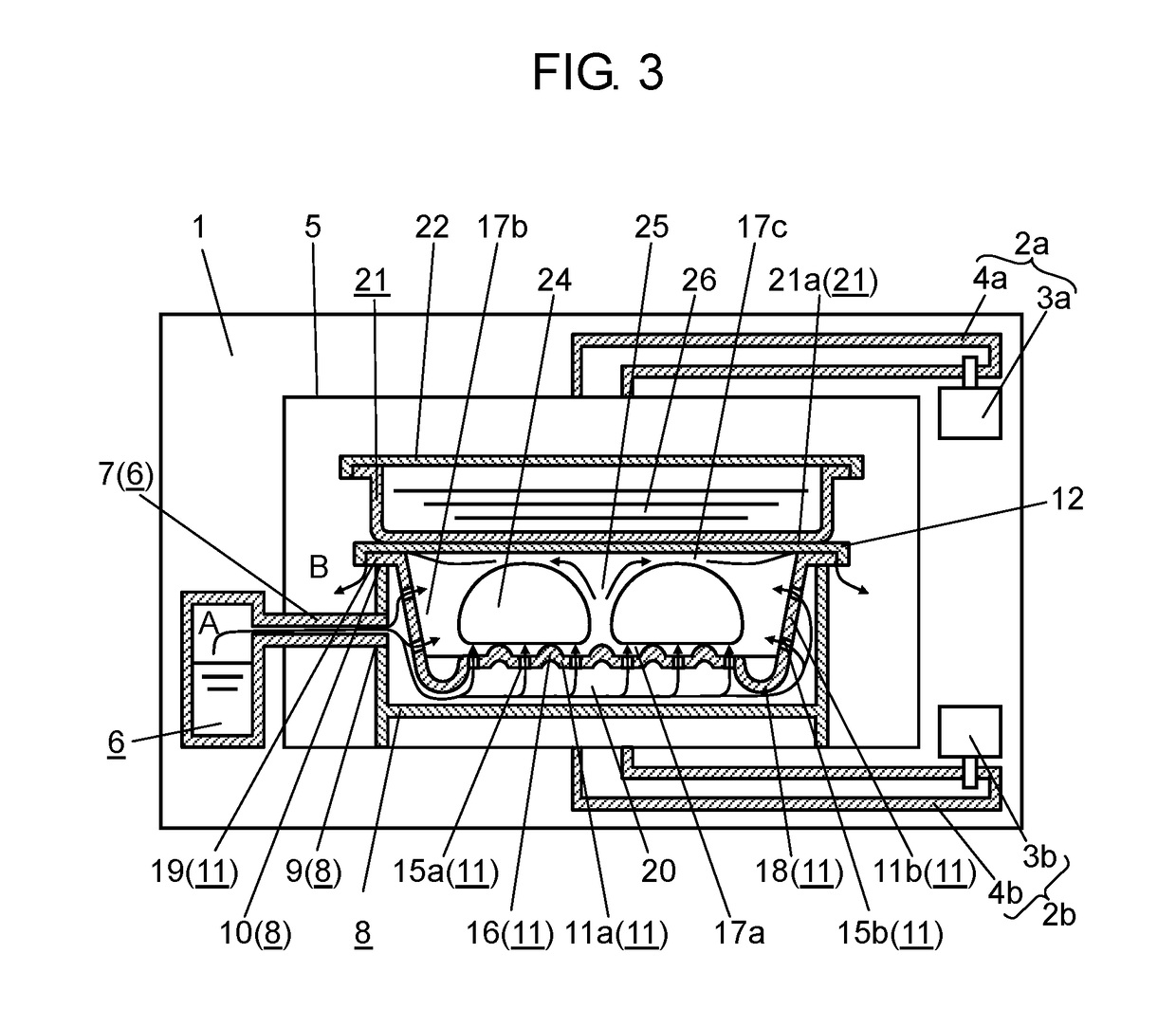

Heating cooker provided with cooking container

ActiveUS10143324B2Heating fastSimple configurationDomestic stoves or rangesLighting and heating apparatusMicrowaveEngineering

The heating cooker includes microwave generation devices that transfer microwaves to a cooking chamber, and a steam generation device that generates steam. The generated steam is guided to a first container, and a second container is provided on the first container. Then, a first foodstuff in the first container is heated by microwaves, and is also directly heated by the steam. A second foodstuff in the second container is heated by the microwaves, and is also indirectly heated by the steam. Accordingly, the heating cooker provided with cooking container capable of quickly heating a plurality of foodstuffs while improving the taste can be realized by using the heat of the microwaves and the steam.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

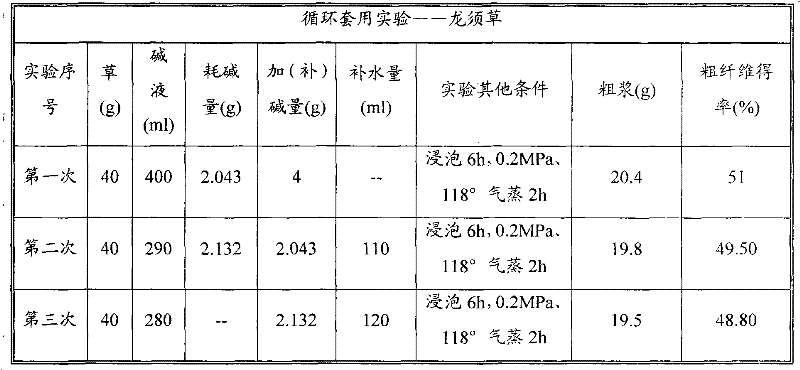

Novel cellulose extraction process

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

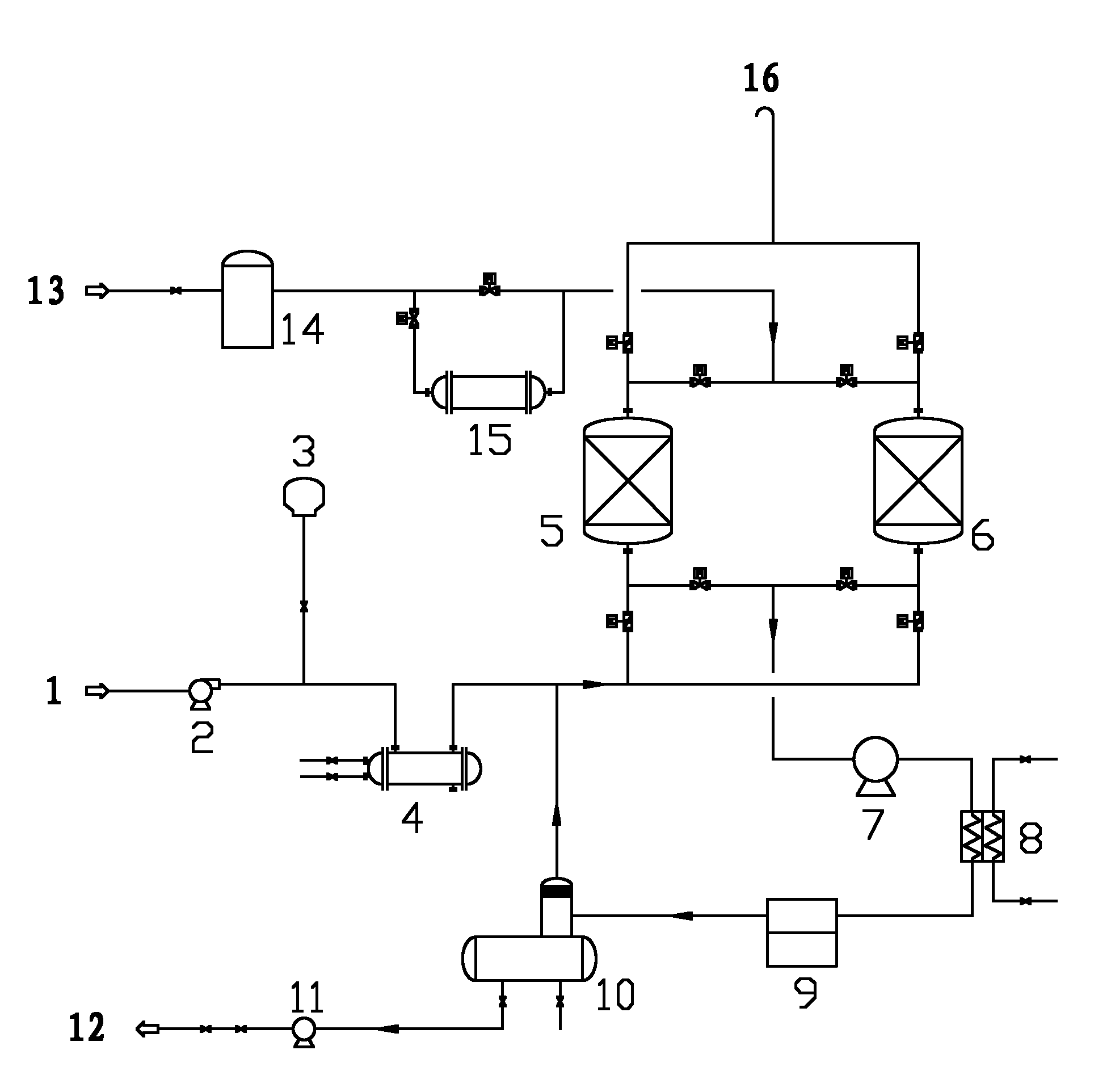

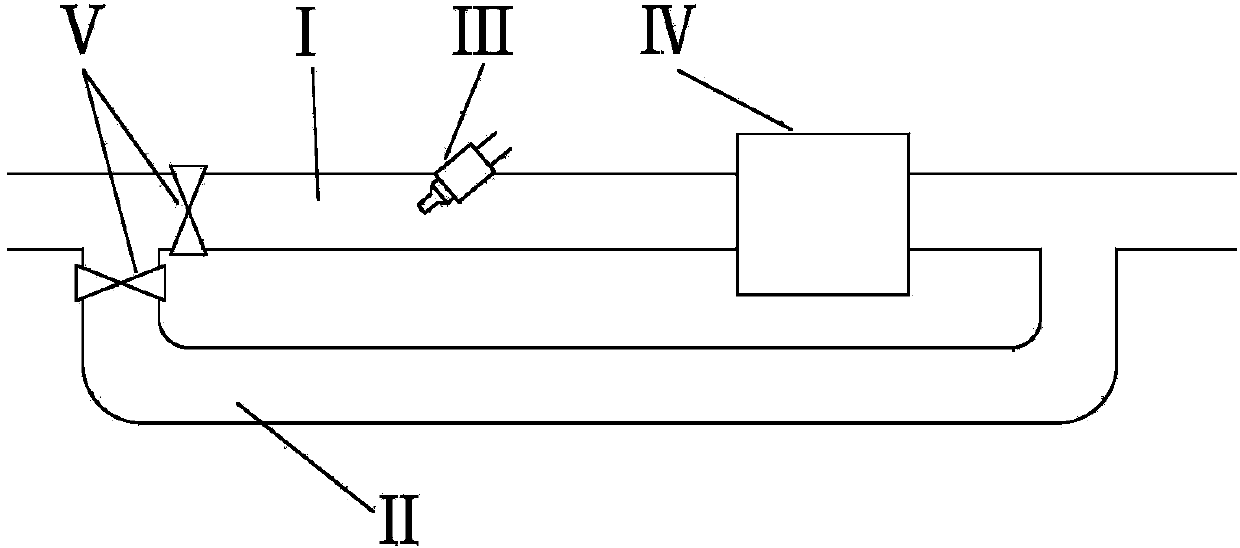

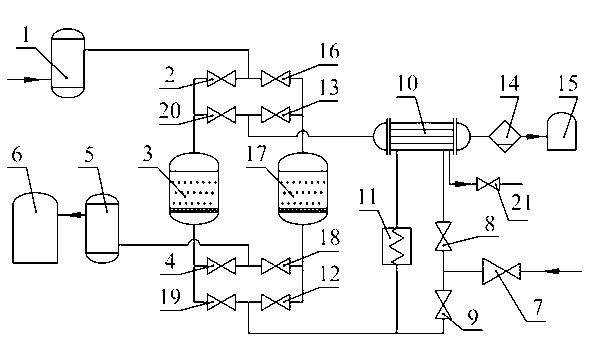

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

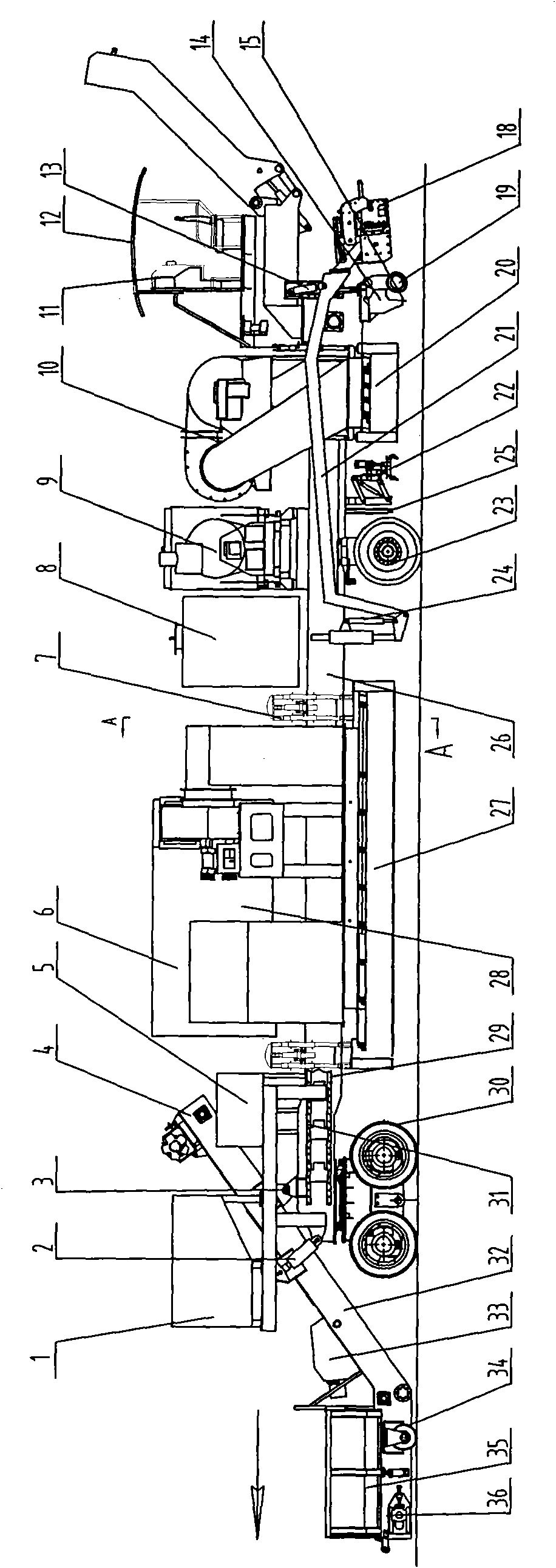

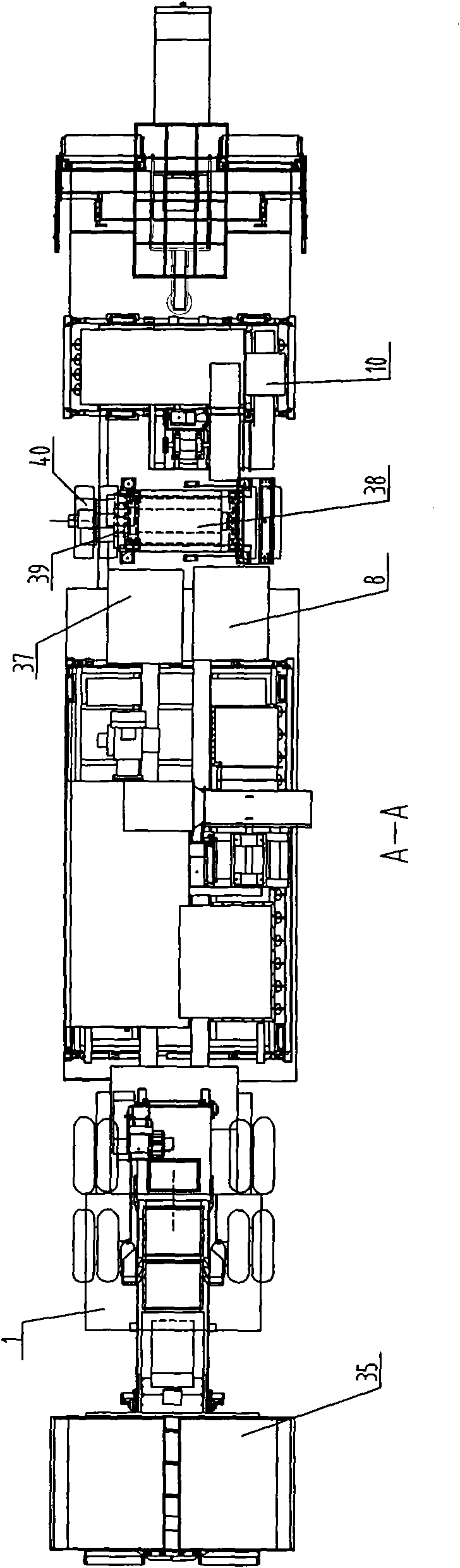

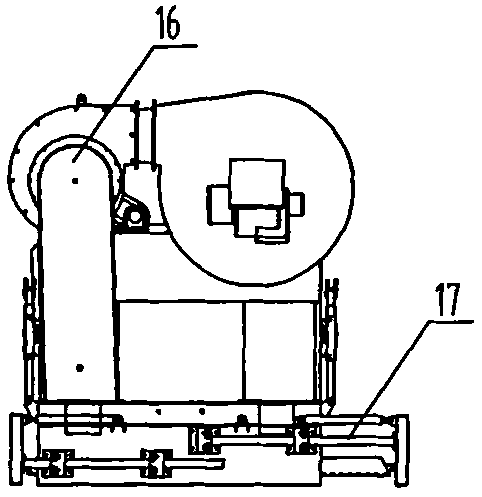

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com