Apparatus for producing reflective membrane with microprism array structure

A technology of array structure and production equipment, applied in optics, optical components, instruments, etc., can solve the limitation of microprism hardness, scratch resistance, heat resistance and solvent resistance, long heating and cooling time, and limitation of processing and use. performance and other issues, to achieve the effects of good product consistency, improved performance, excellent hardness and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

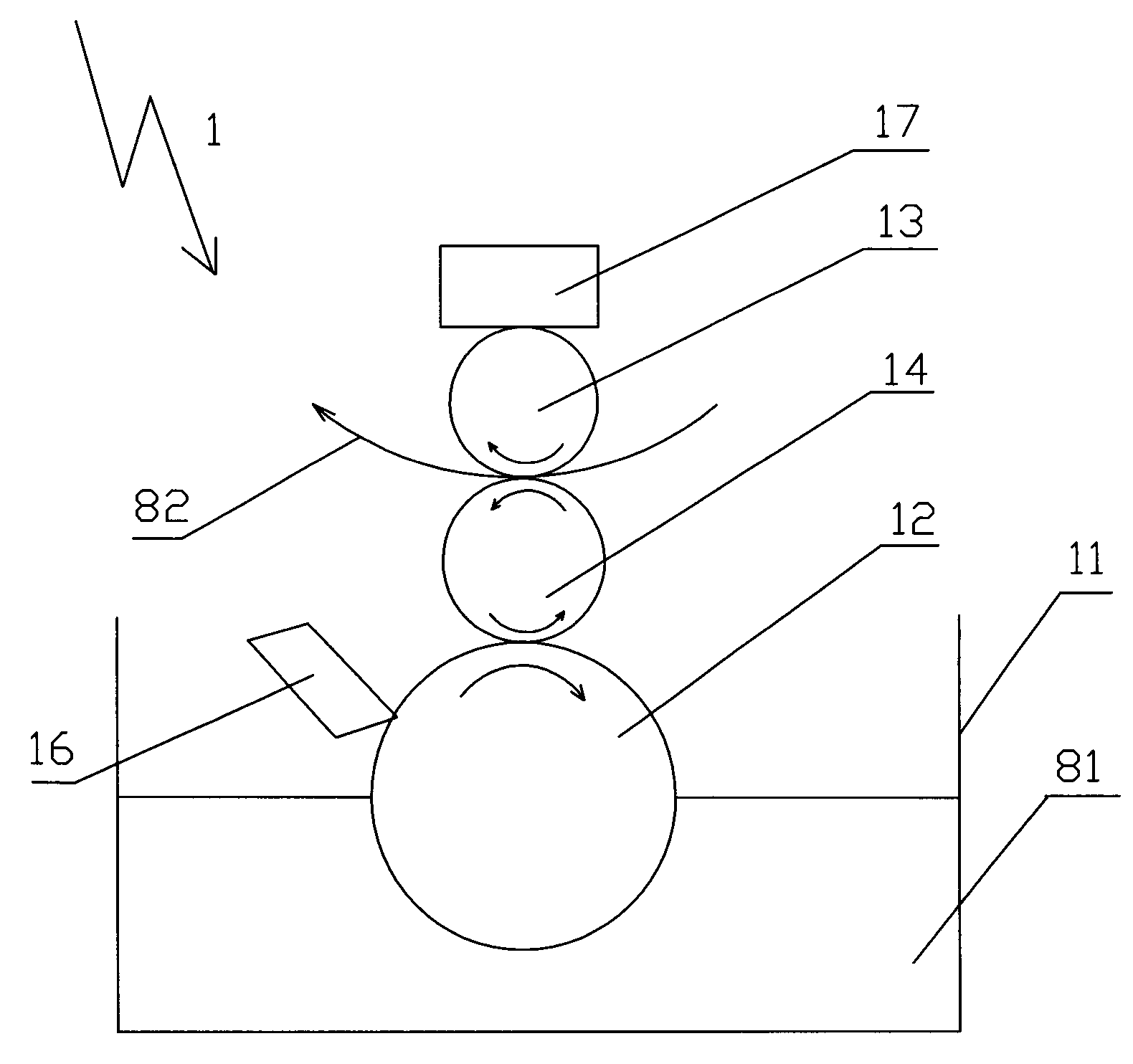

[0044] Such as figure 1 Shown, the production equipment with the reflective film of microprism array structure comprises annular belt mold 6, coating device 1, drying device 2, heating film pressing device 3, UV curing device 4 and cooling device 5; Figure 9 As shown, the annular belt mold 6 has an inner surface 61 and an outer surface 62, and its outer surface 62 has a continuous precision microprism array structure 63 in a convex shape; as Figure 8 and Figure 9 As shown, the coating device 1 coats the photosensitive resin 81 on one side surface of the resin film 82, and the resin film 82 coated with the photosensitive resin 81 is dried by the drying device 2, and then the The side surface of the resin film 82 coated with the photosensitive resin 81 is closely attached to the outer surface 62 of the annular belt mold 6 to be heated and pressed by the heating film pressing device 3, so that the photosensitive resin 81 fills the gaps of the raised microprism structures, an...

Embodiment 2

[0054] Such as image 3 As shown, the coating device 1 includes a trough 11, a feed roller 12, a squeeze roller 13, a booster roller 15 and a free-rising pressurization system 17 directly connected to the booster roller 15. The pressurizing roller 15 is positioned above the extrusion roller 13, and the resin film 82 is positioned above the feed roller 12 and below the extrusion roller 13, and the photosensitive resin 81 is housed in the storage tank 11. The material roller 12 is immersed in the described feed tank; during the rotation of the material roller 12, the photosensitive resin 81 flows to the surface of the material roller 12; The direction of motion in the direction is the same. Through the action of the pressure system 17 on the pressurizing roller 15 and the extrusion roller 13, the resin film 82 is close to and attached to the upper feed roller 13, and on the upper feed roller 12 and the extrusion roller. The tangent position of the roller 13 transfers the photos...

Embodiment 3

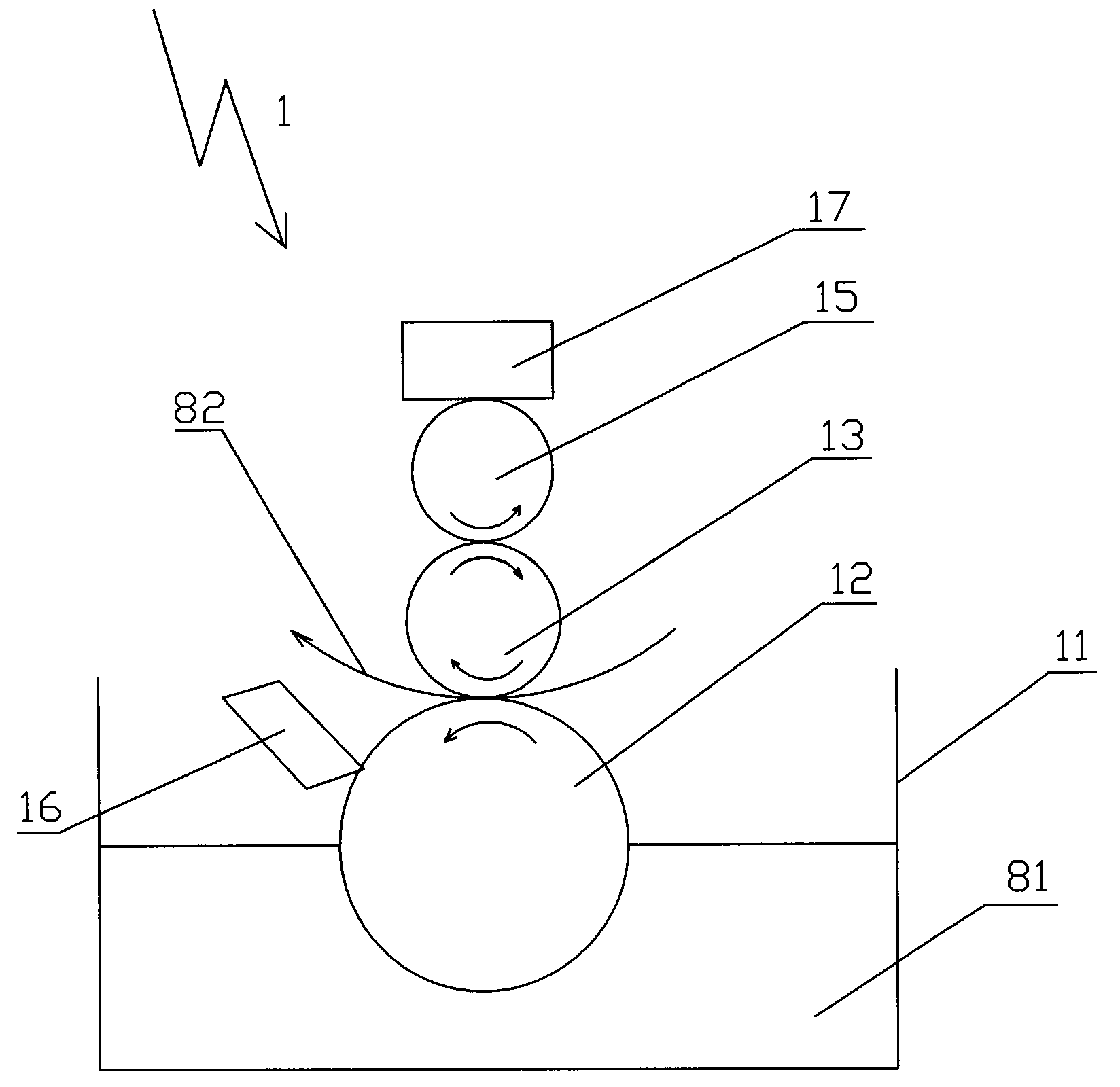

[0057] Such as Figure 4 As shown, the coating device 1 includes a storage tank 111, a feed roller 12, a transfer roller 14, a squeeze roller 13, a freely lifting pressurizing system 17 directly connected to the squeeze roller 13, a recovery tank 112 and The scraper 161 is a hollow cavity, the delivery pipe 18 is connected between the cavity of the scraper 161 and the bucket 111, and the delivery pipe 18 transports the photosensitive resin 81 in the bucket 111 to the scraper through the delivery pump In the cavity of 161, the side of the scraper 161 facing the feeding roller 12 basically coincides with the feeding roller 12, and there is a slit on this surface, and the photosensitive resin 81 flowing out from the cavity of the scraper 161 follows the feeding roller The rotation flow of 12 transfers to the outer surface of feeding roller 12, and described resin film 82 is positioned at the top of feeding roller 12 and transfer roller 14, the below of squeeze roller 13, in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com