Patents

Literature

2373 results about "Cooling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery Chargers and Methods for Extended Battery Life

InactiveUS20070024246A1Easy to optimizeBatteries circuit arrangementsElectric powerCharge currentBattery cell

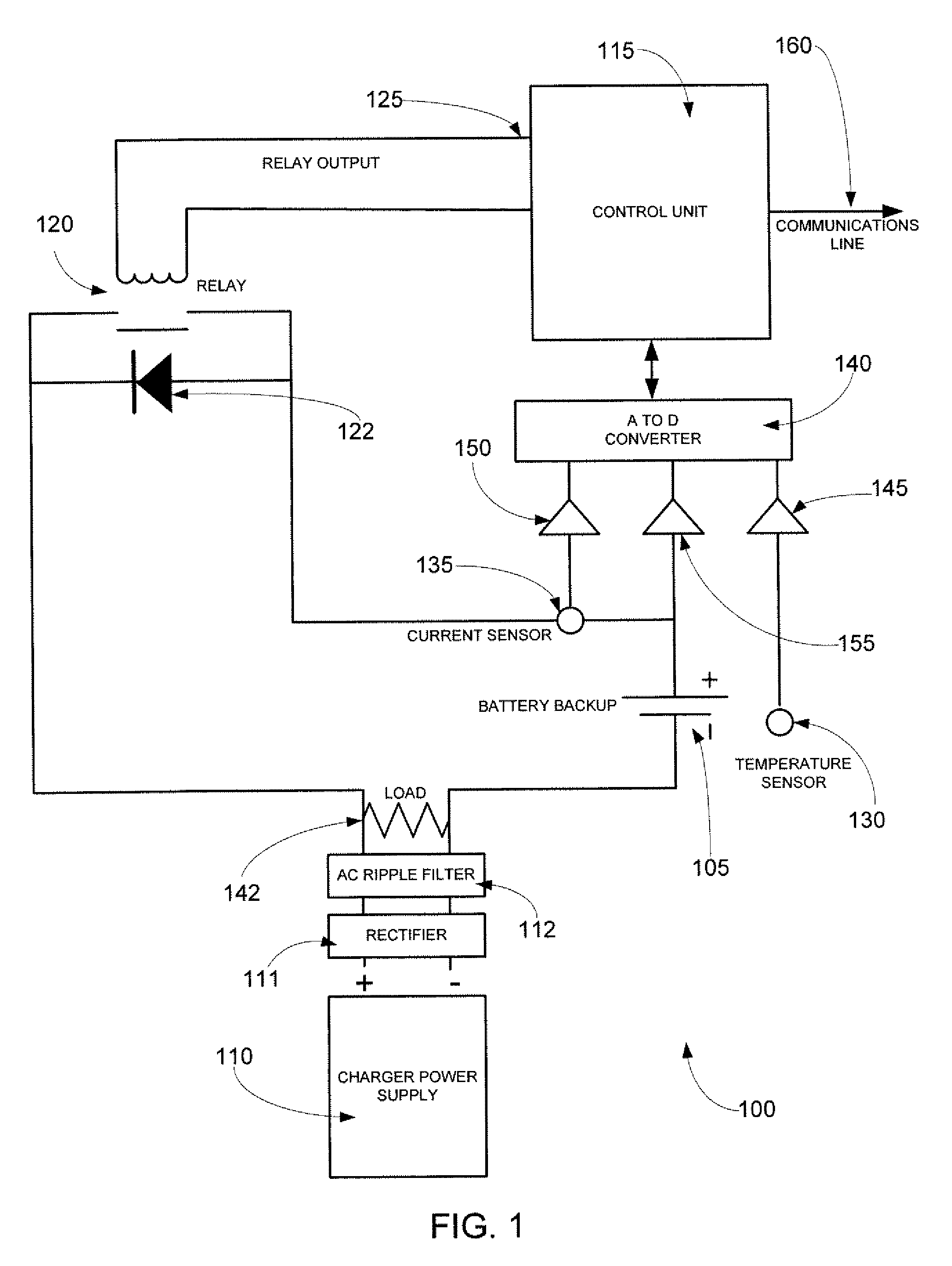

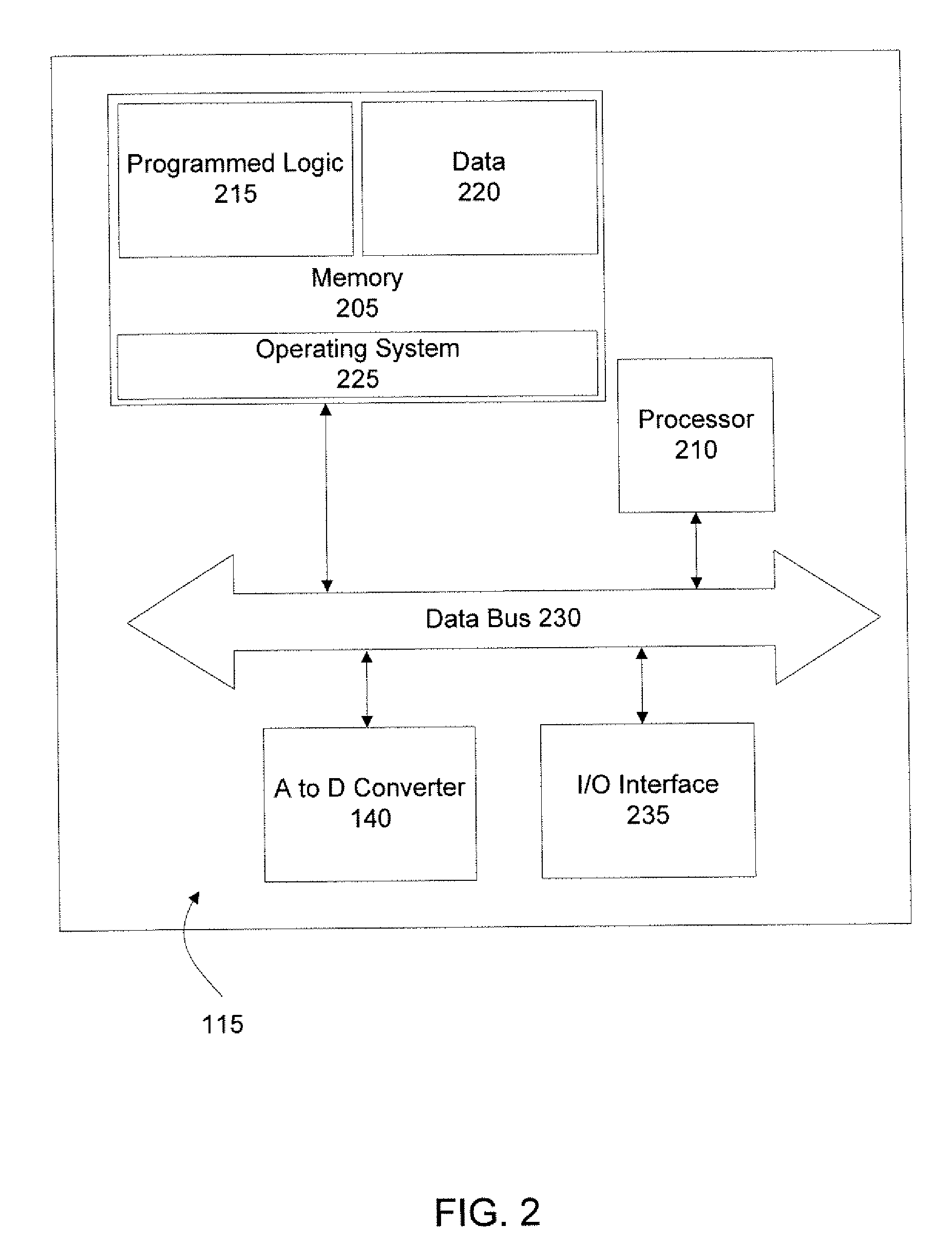

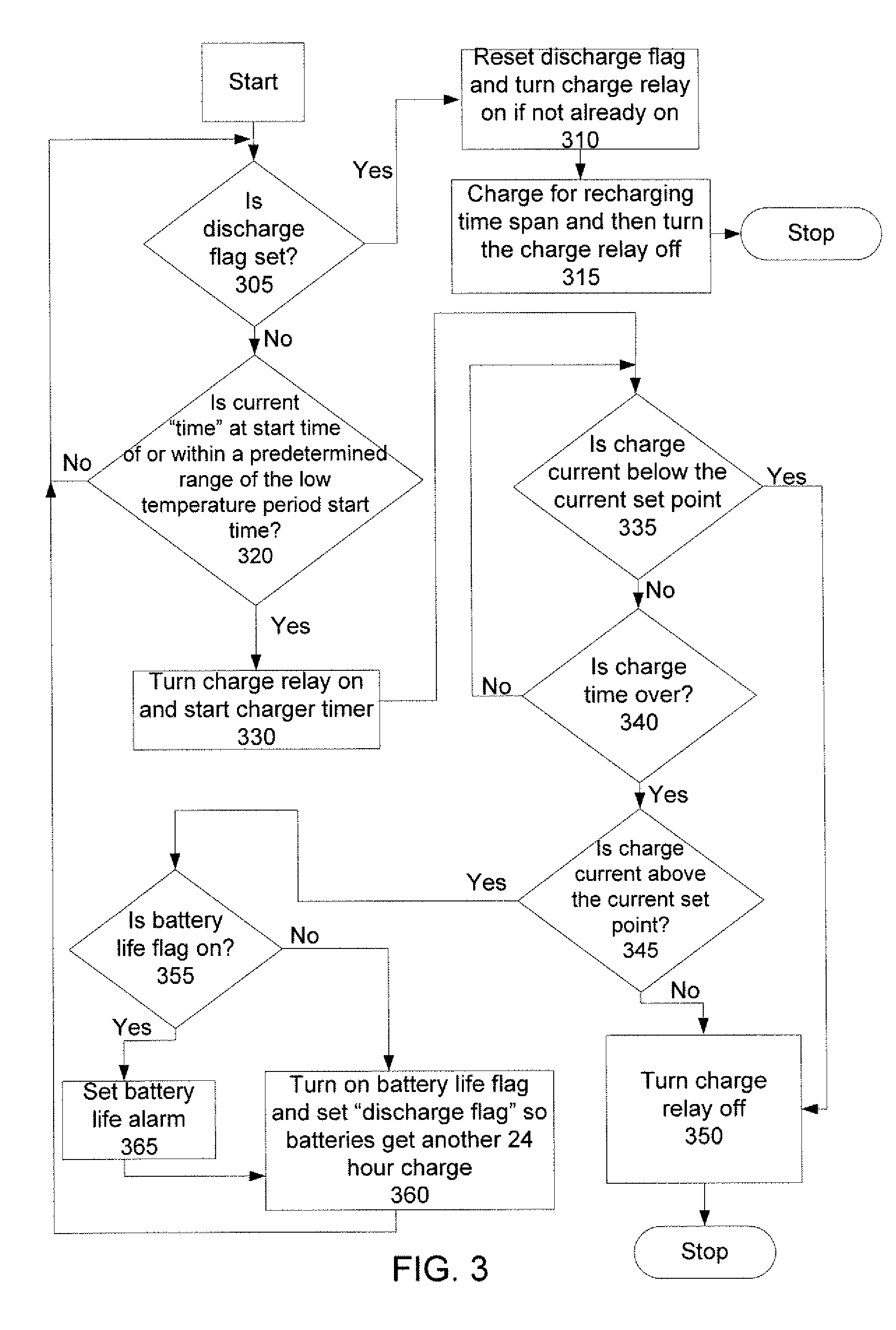

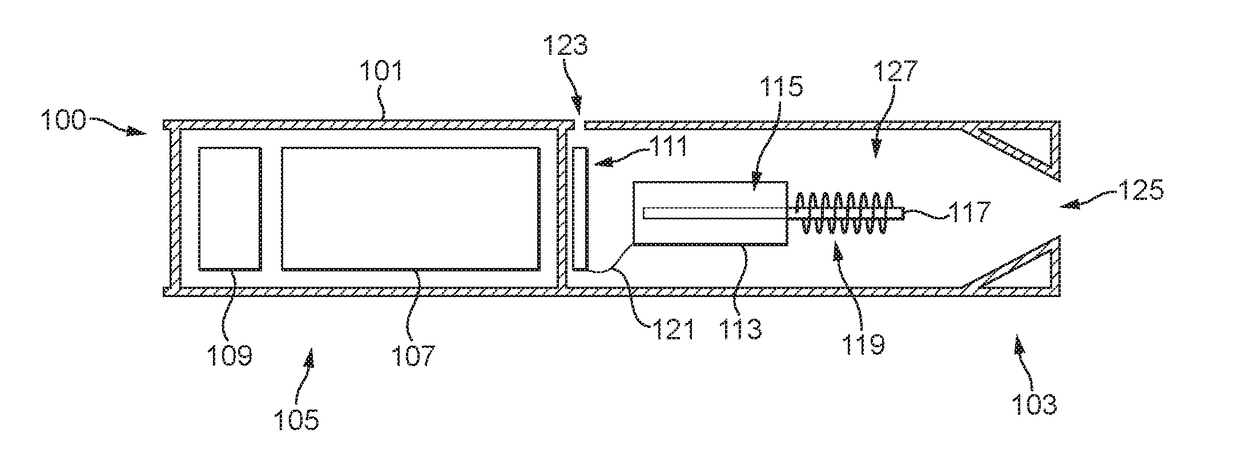

A battery charger that includes a relay, a control unit, and a temperature sensor. The relay controls the flow of an electrical charge current from a power supply to one or more batteries. The temperature sensor continuously measures the ambient temperature of the one or more batteries and communicates the temperature measurements to the control unit. The control unit control the actuation of the relay. The control unit receives the temperature measurements from the temperature sensor, determines a charging time period for the one or more batteries, and selectively actuates the relay for the charging time period. The charging time period has a predetermined duration and represents a coolest time period within a monitoring period of the control unit.

Owner:FLAUGHER DAVID J

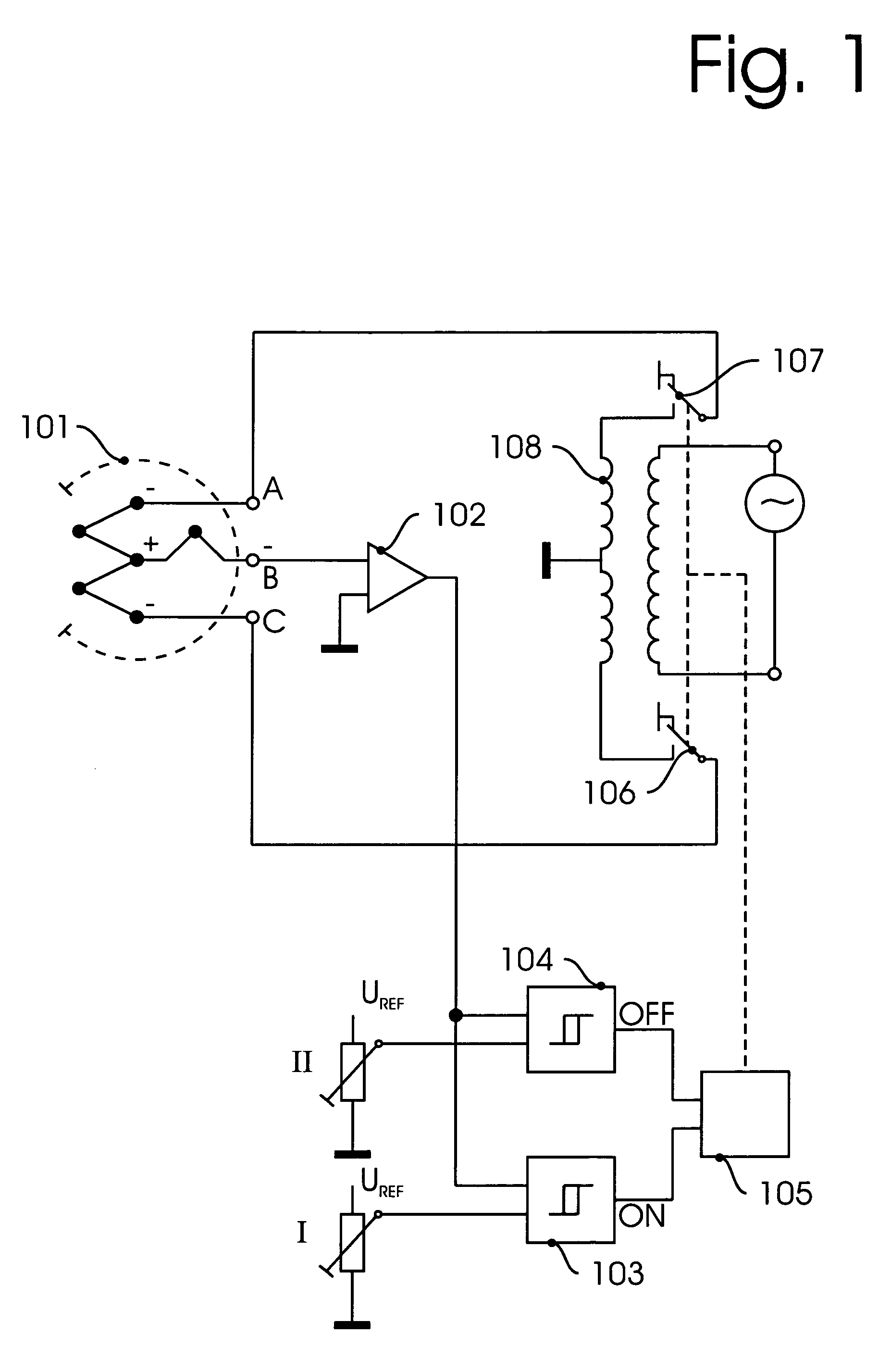

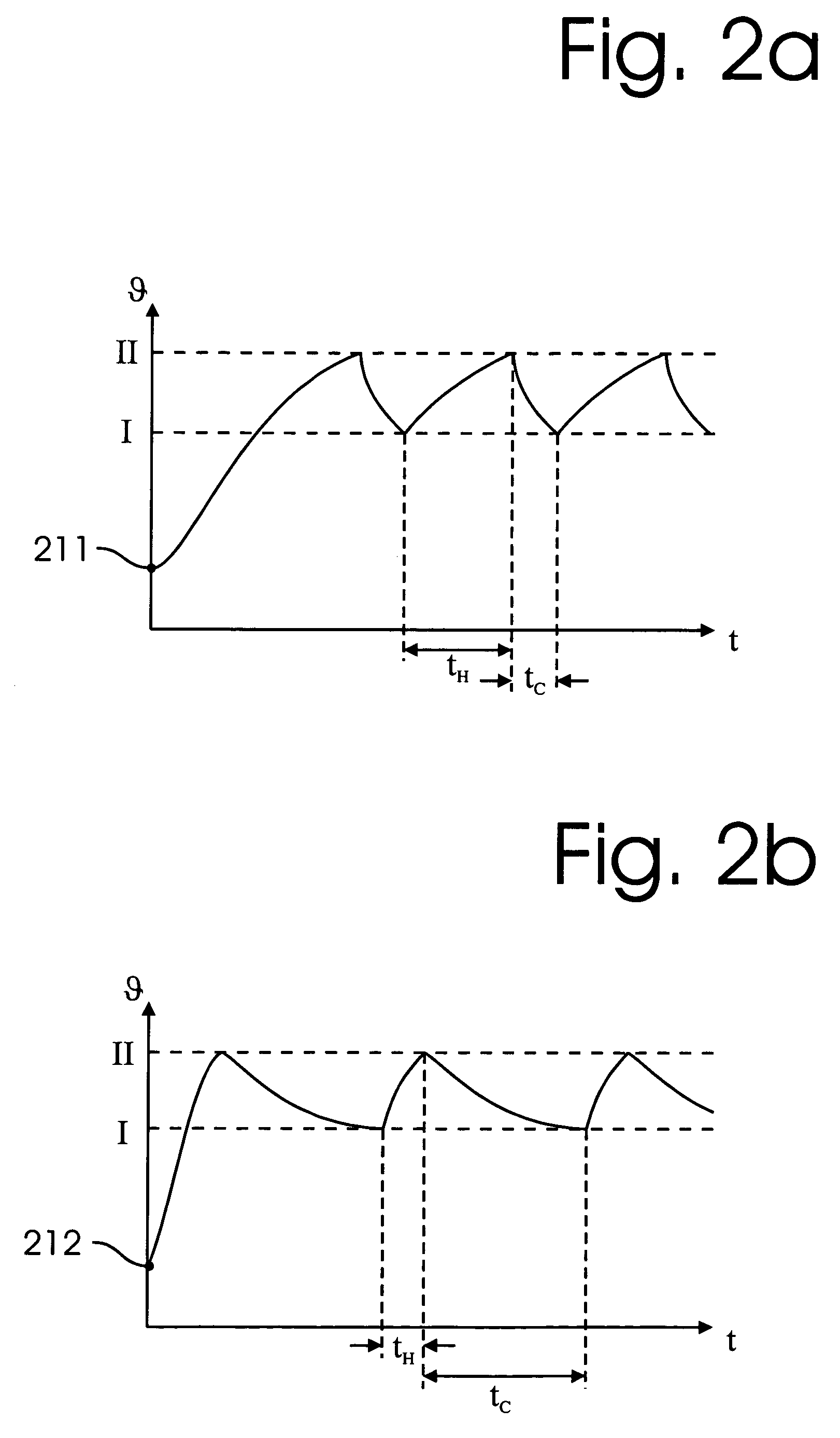

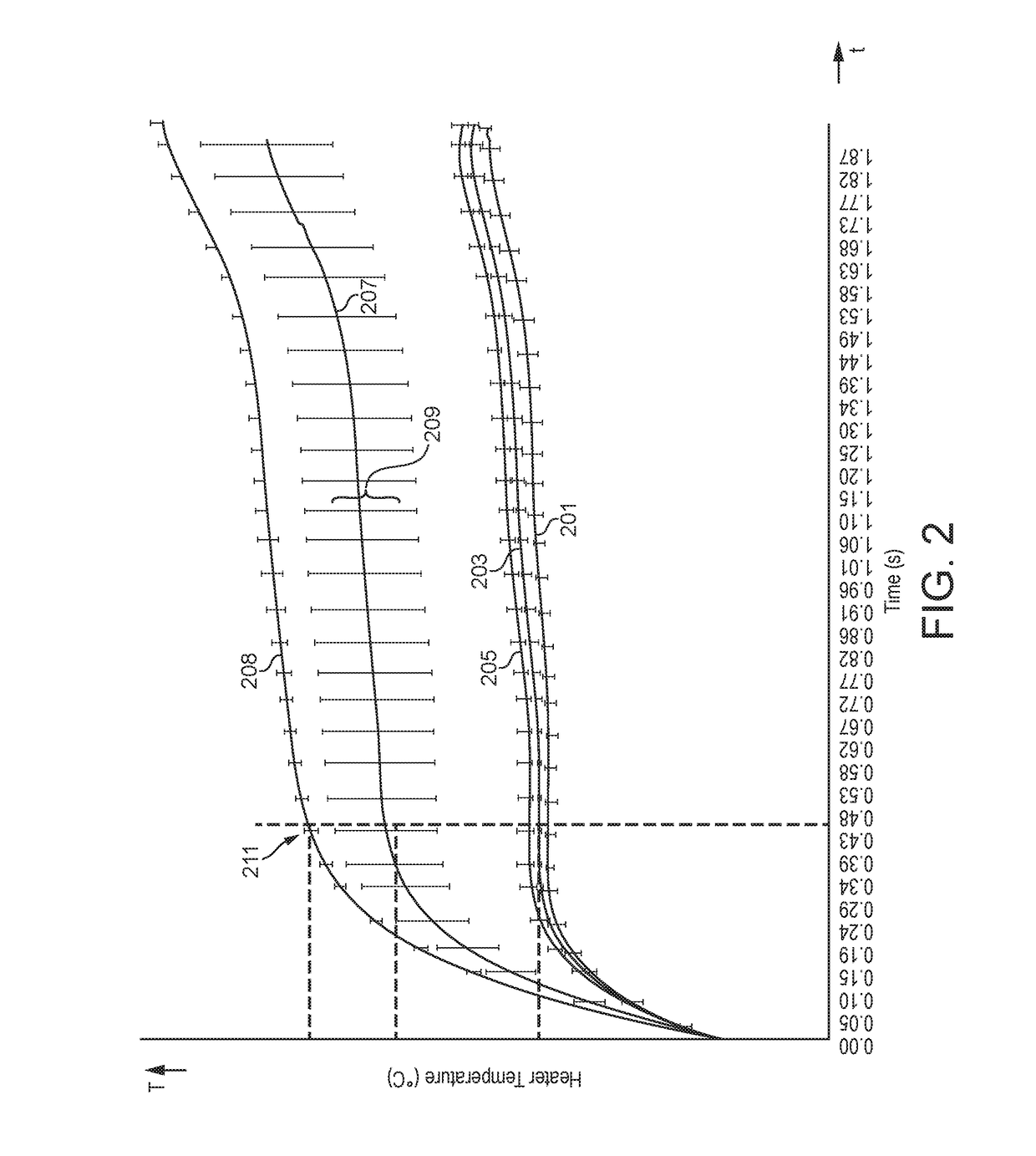

Thermocouple vacuum gauge

InactiveUS8047711B2Reduce heatLow thermal conductivityThermometer detailsVacuum gauge using heat conductivity variationHeating timeEngineering

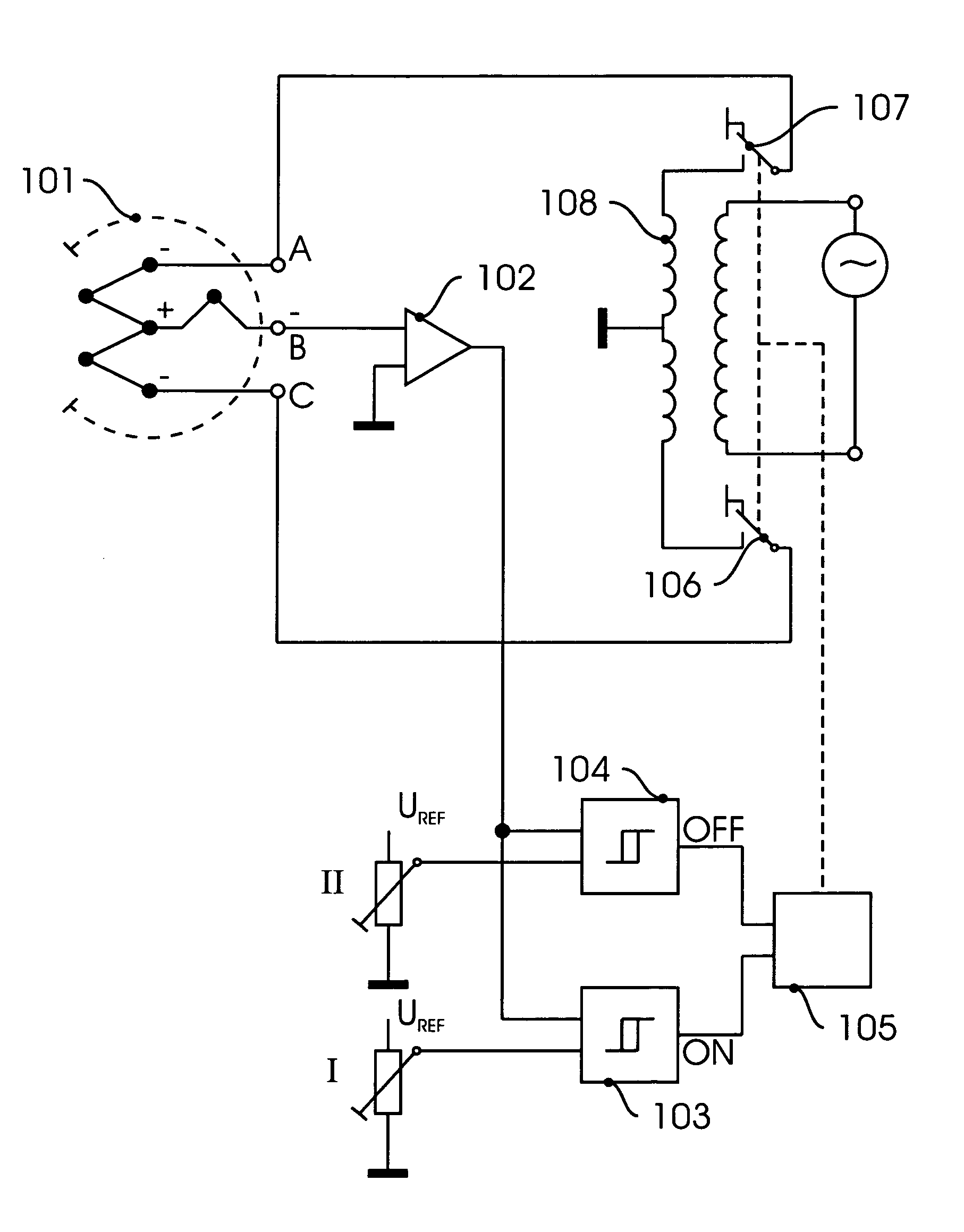

A thermocouple vacuum sensor is provided, the thermocouple being surrounded by a gas or mixture of gases the pressure of which is to be measured. Cyclically the thermocouple is heated until its temperature reaches an upper temperature threshold. The thermocouple is subsequently cooled until its temperature reaches a lower temperature threshold. The heating time required to heat the thermocouple from the lower to the upper temperature threshold is measured. The cooling time required to cool the thermocouple from the upper temperature threshold to the lower temperature threshold may also be measured. The pressure surrounding the thermocouple may then be determined as a function of either the heating time, or the cooling time, or both.

Owner:HEINZ PLOECHINGER

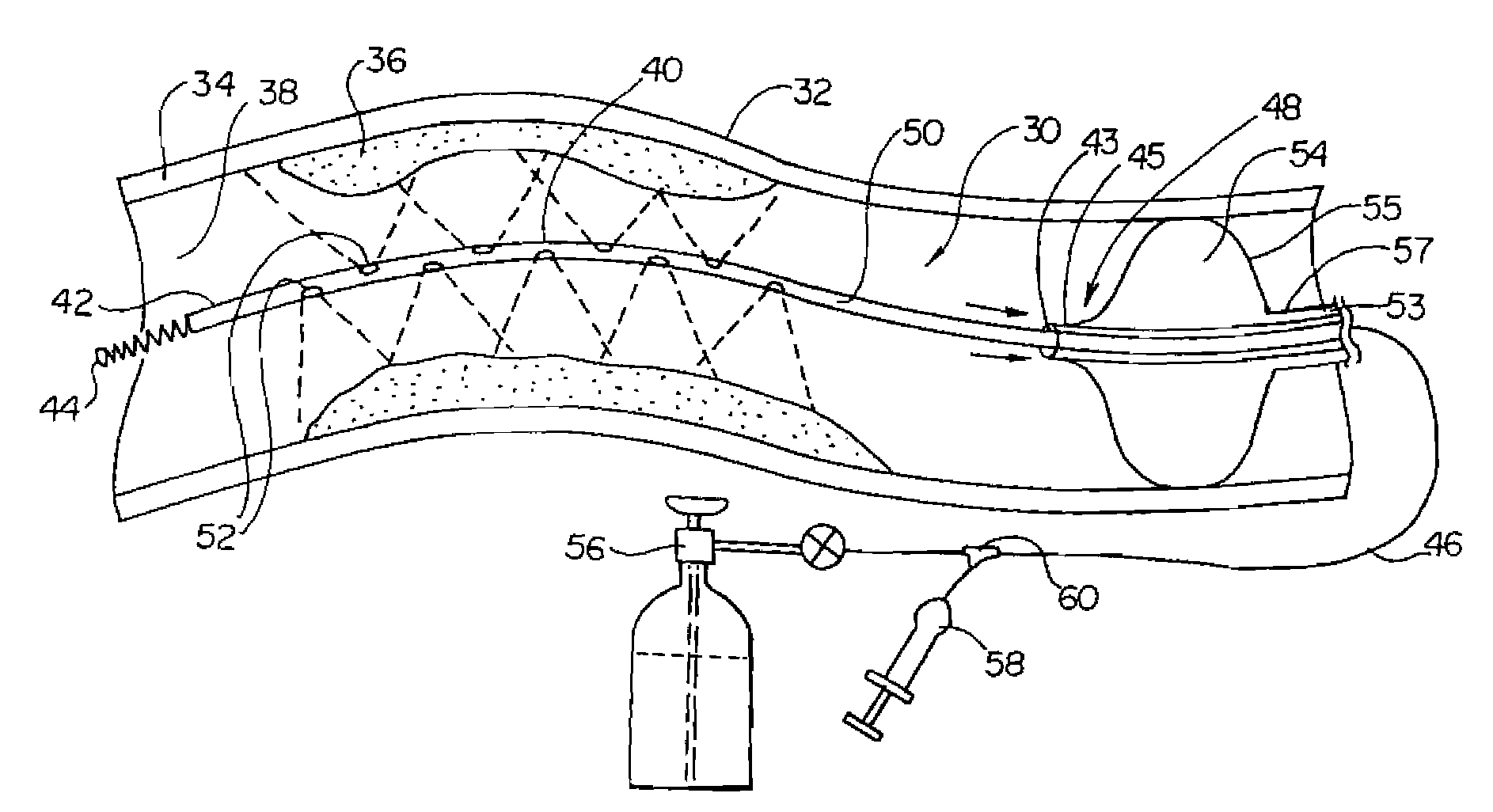

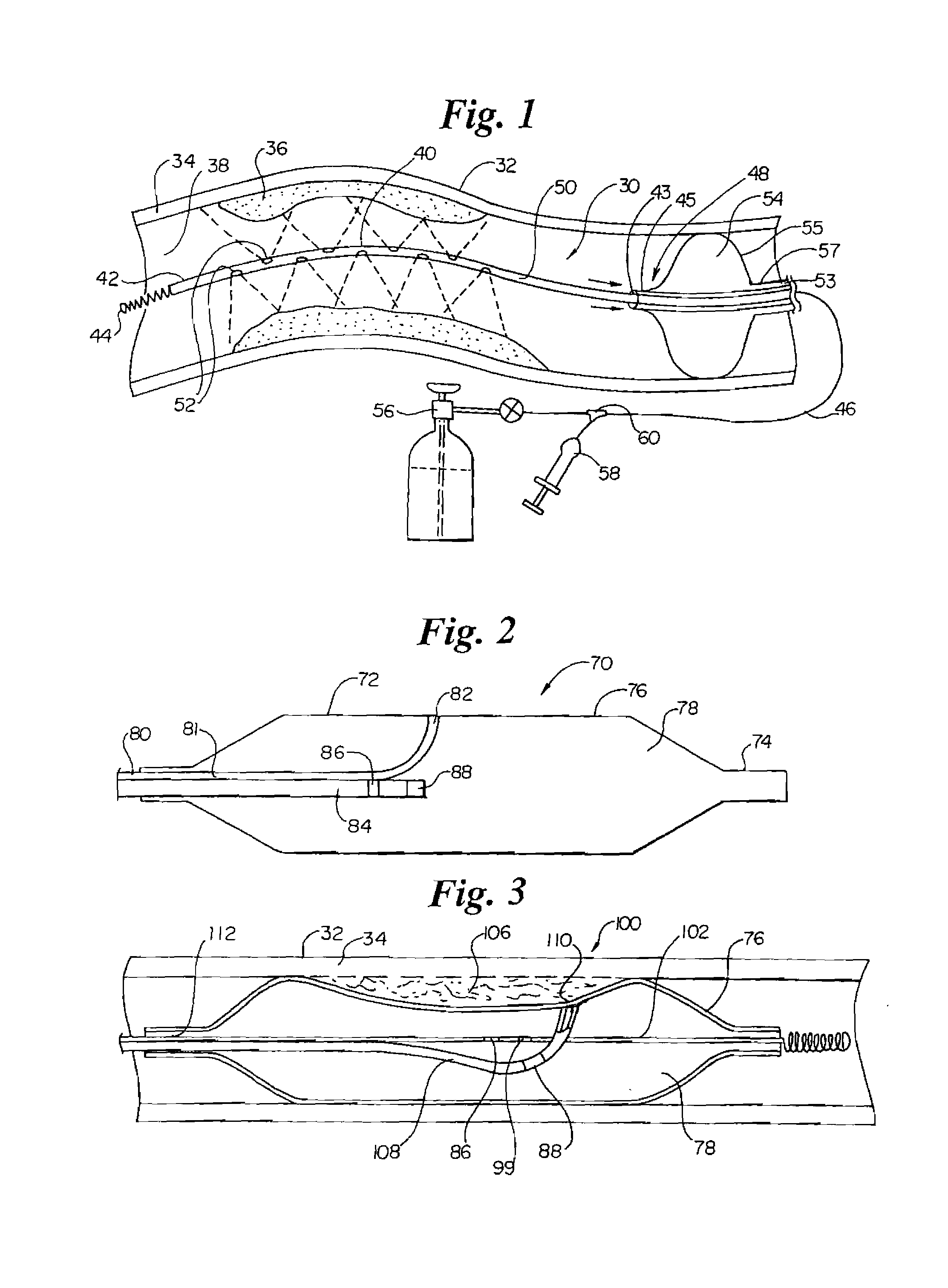

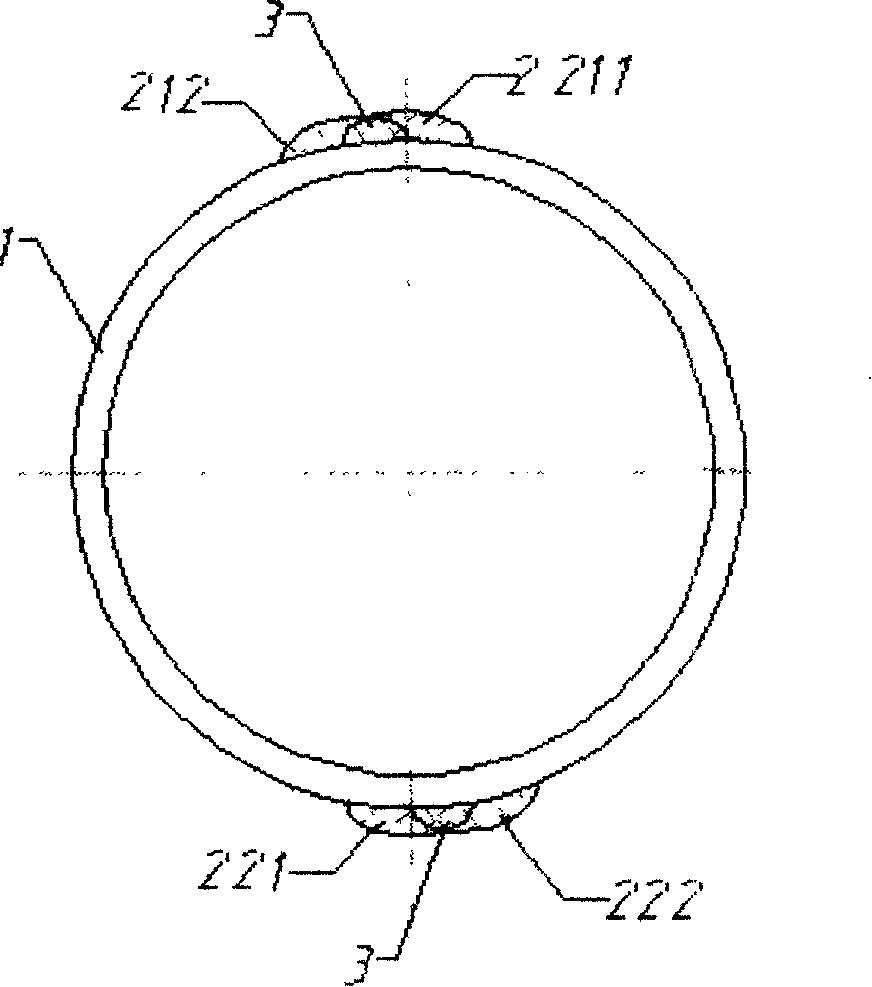

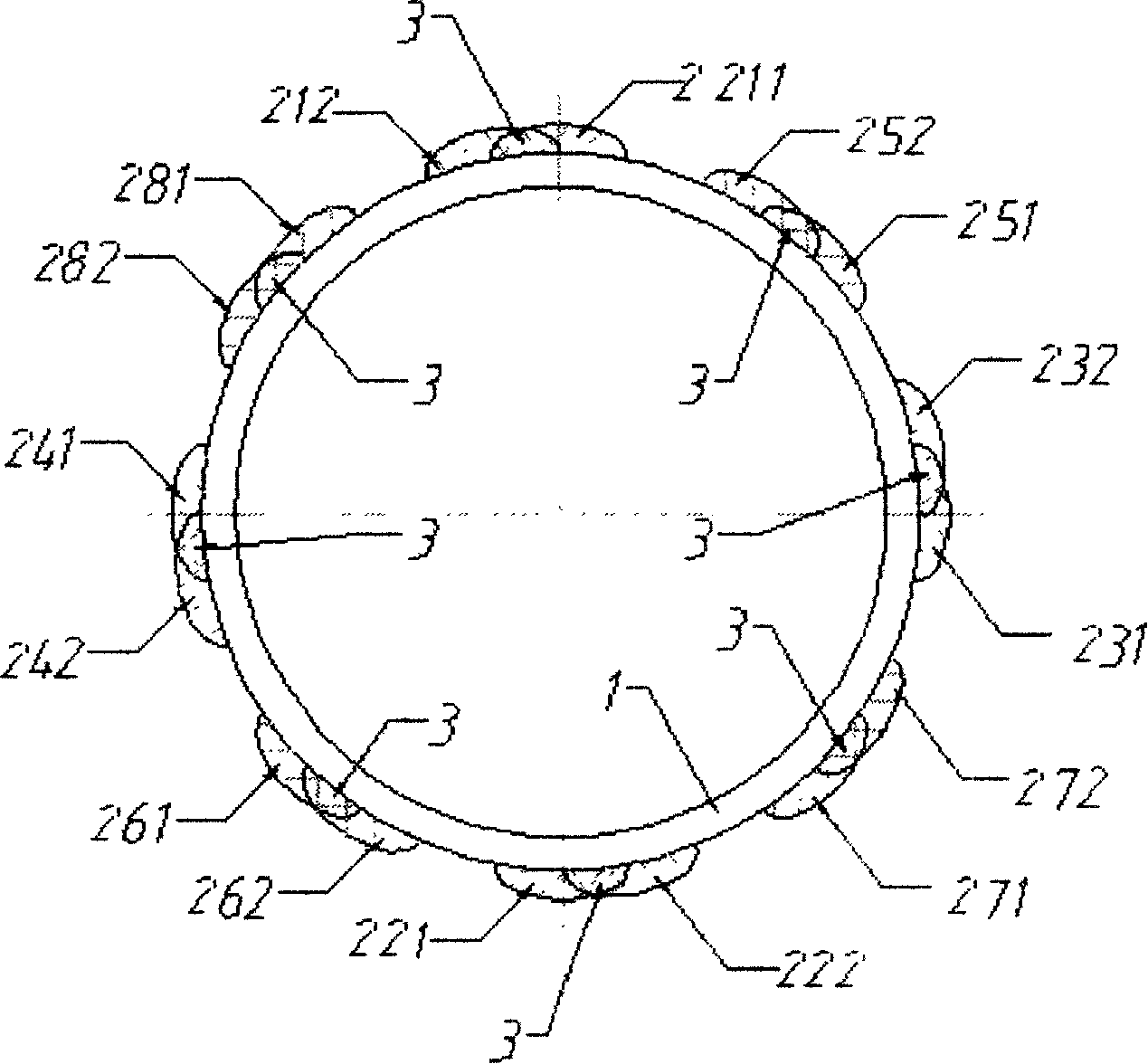

Cryotreatment device and method

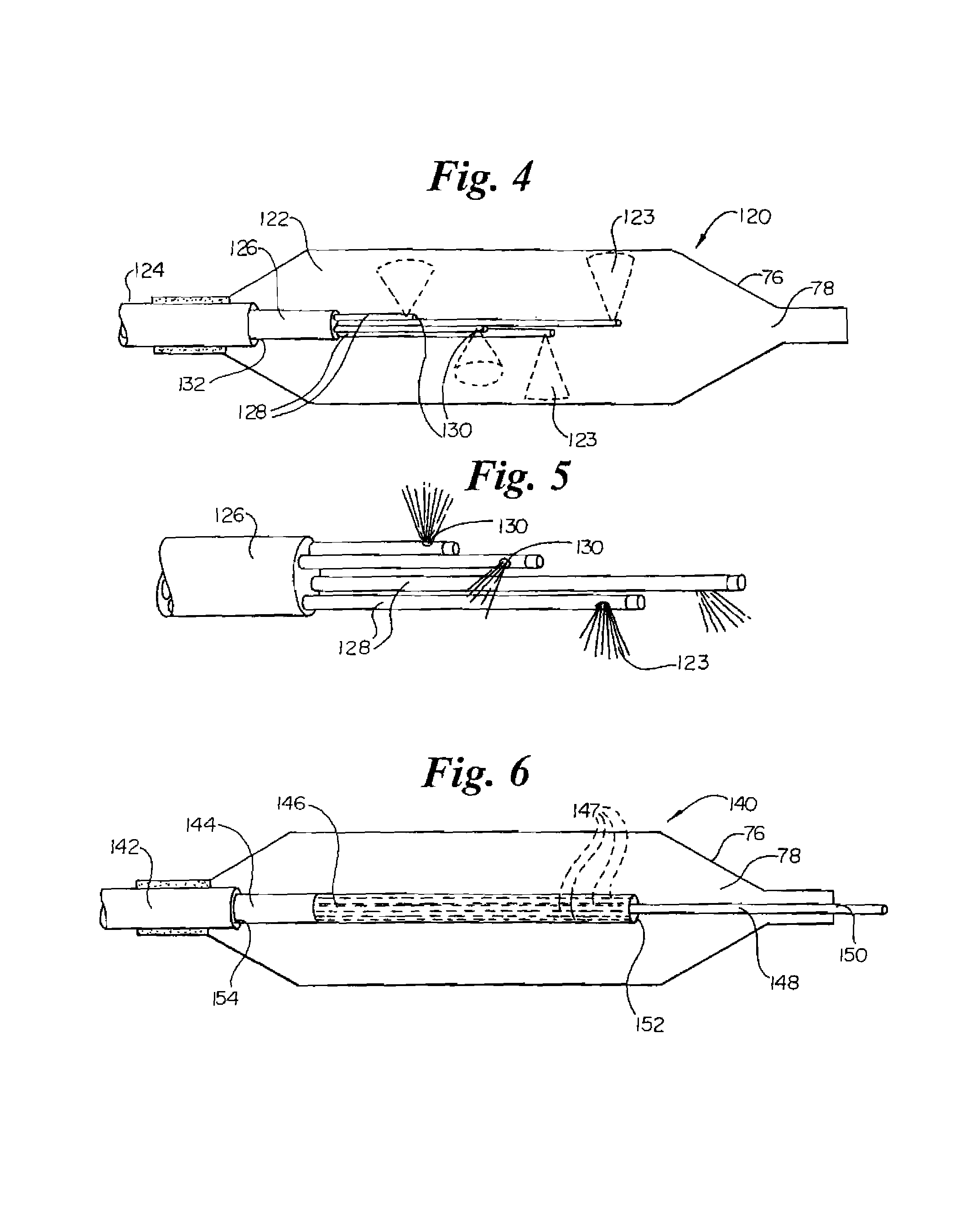

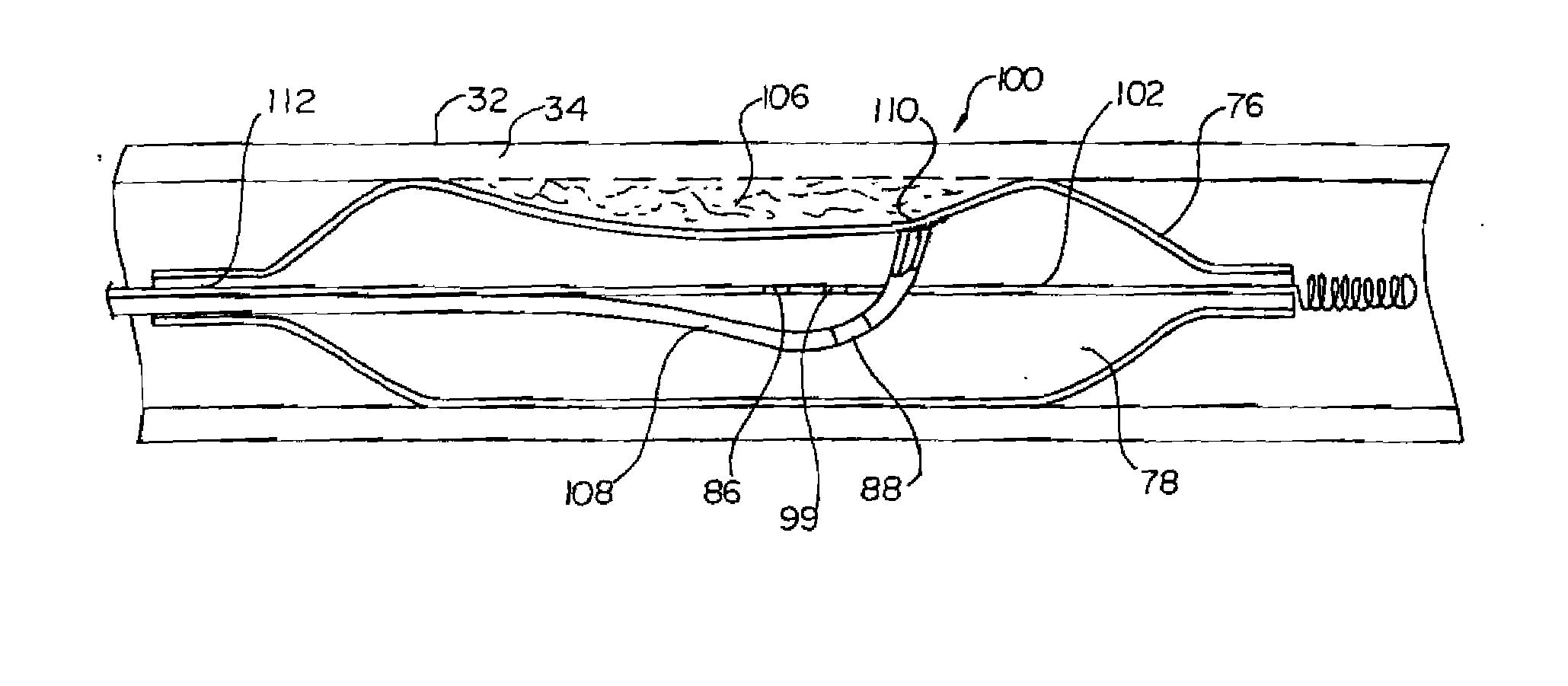

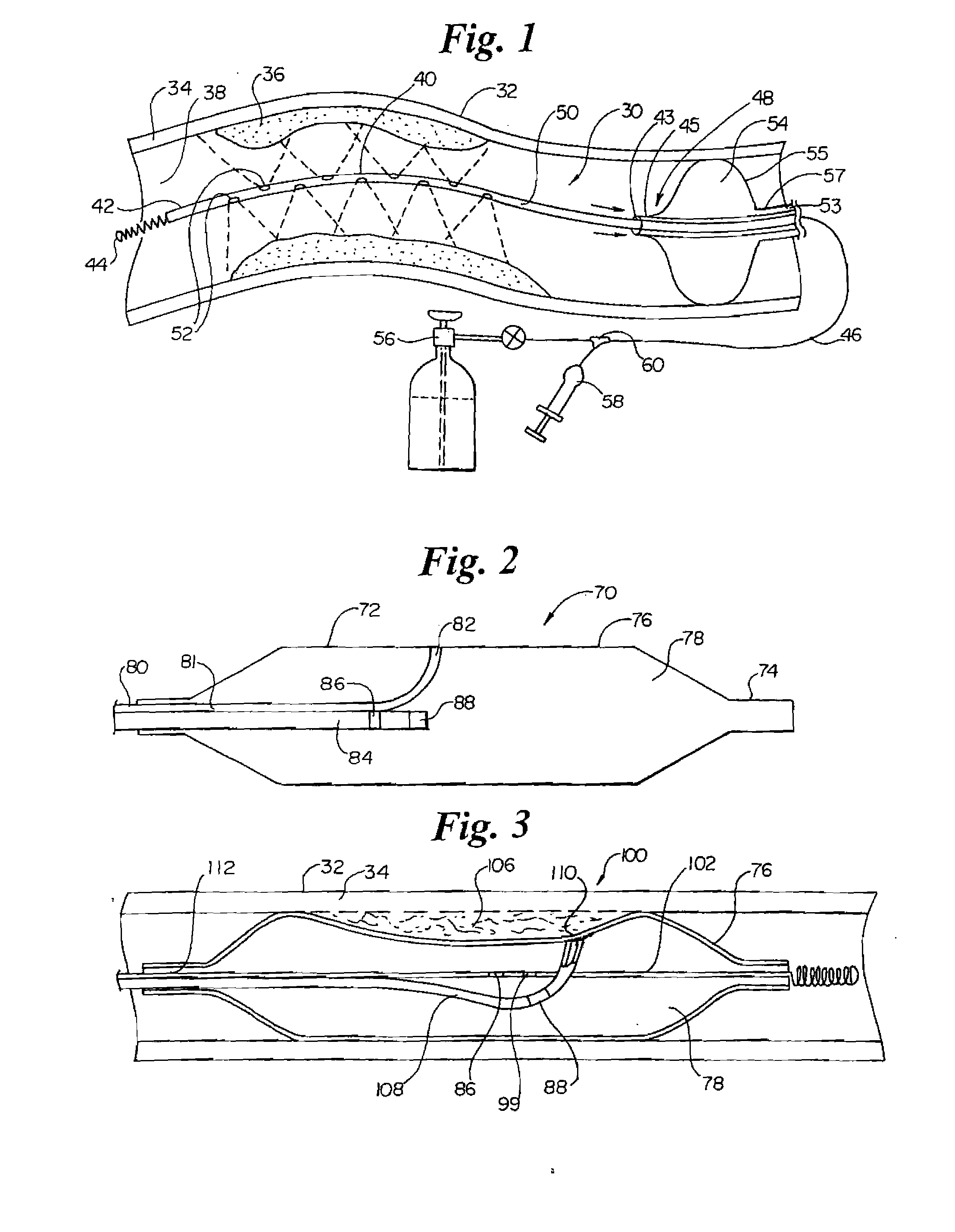

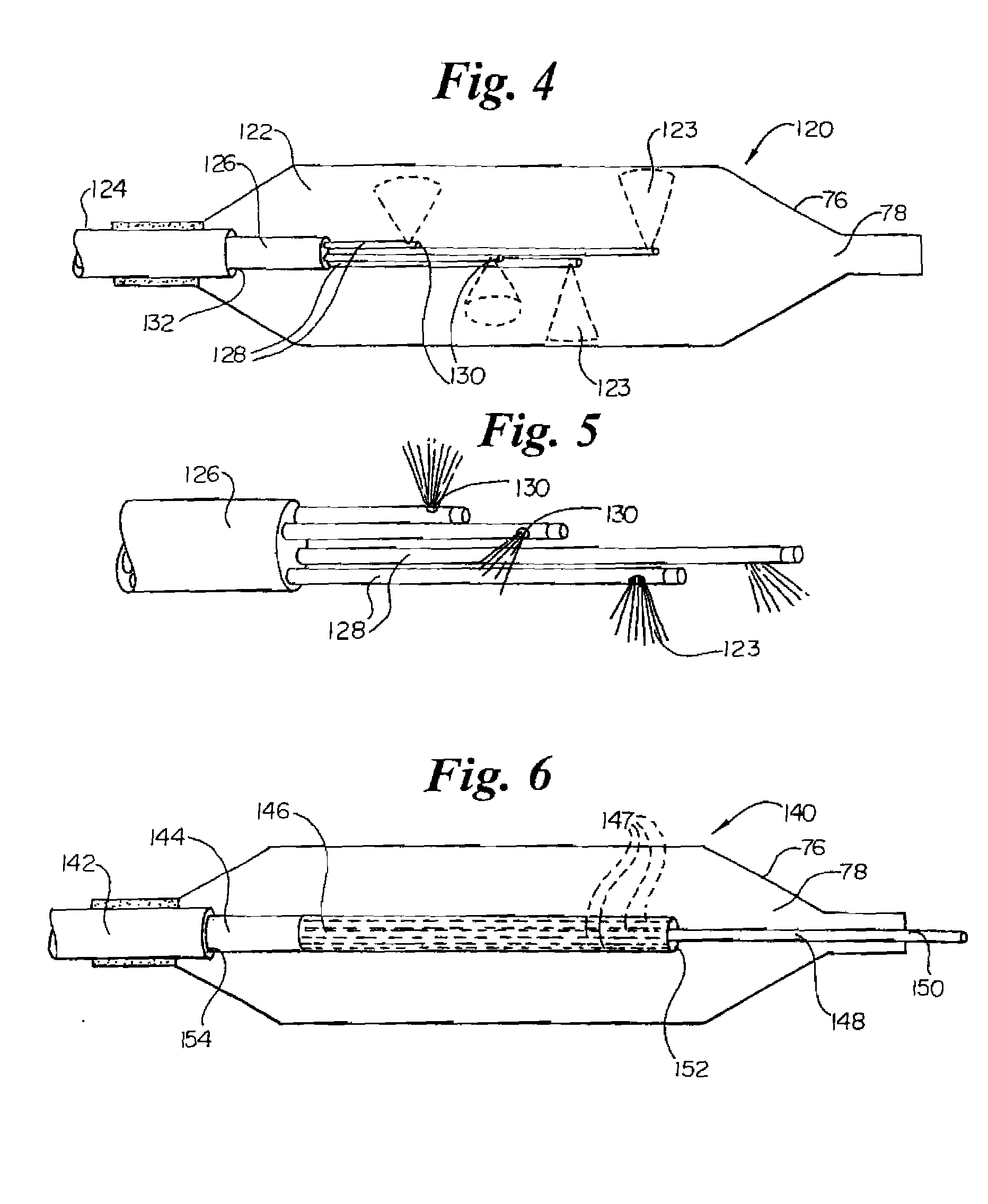

InactiveUS7220257B1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood flow past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffening wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

Cryotreatment device and method

InactiveUS20070250050A1Reduce adverse reactionsReduced responseStentsOther blood circulation devicesCoronary artery angioplastyPercent Diameter Stenosis

Devices and methods for cooling vessel walls to inhibit restenosis in conjunction with medical procedures such as coronary artery angioplasty. Stenosed vessel walls can be cooled prior to angioplasty, after angioplasty, or both. The invention is believed to inhibit restenosis through cooling to a temperature near freezing, preferably without causing substantial vessel wall cell death. One catheter device includes a distal tube region having coolant delivery holes radially and longitudinally distributed along the distal region. In some devices, holes spray coolant directly onto the vessel walls, with the coolant absorbed into the blood stream. In other embodiments, a balloon or envelope is interposed between the coolant and the vessel walls and the coolant returned out of the catheter through a coolant return lumen. Some direct spray devices include an occlusion device to restrict blood now past the region being cooled. Pressure, temperature, and ultrasonic probes are included in some cooling catheters. Pressure control valves are included in some devices to regulate balloon interior pressure within acceptable limits. In applications using liquid carbon dioxide as coolant, the balloon interior pressure can be maintained above the triple point of carbon dioxide to inhibit dry ice formation. Some cooling catheters are coiled perfusion catheters supporting longer cooling periods by allowing perfusing blood flow simultaneously with vessel wall cooling. One coiled catheter is biased to assume a coiled shape when unconstrained and can be introduced into the body in a relatively straight shape, having a stiffeninig wire inserted through the coil strands.

Owner:BOSTON SCI SCIMED INC

Thermal printer and method for operating same

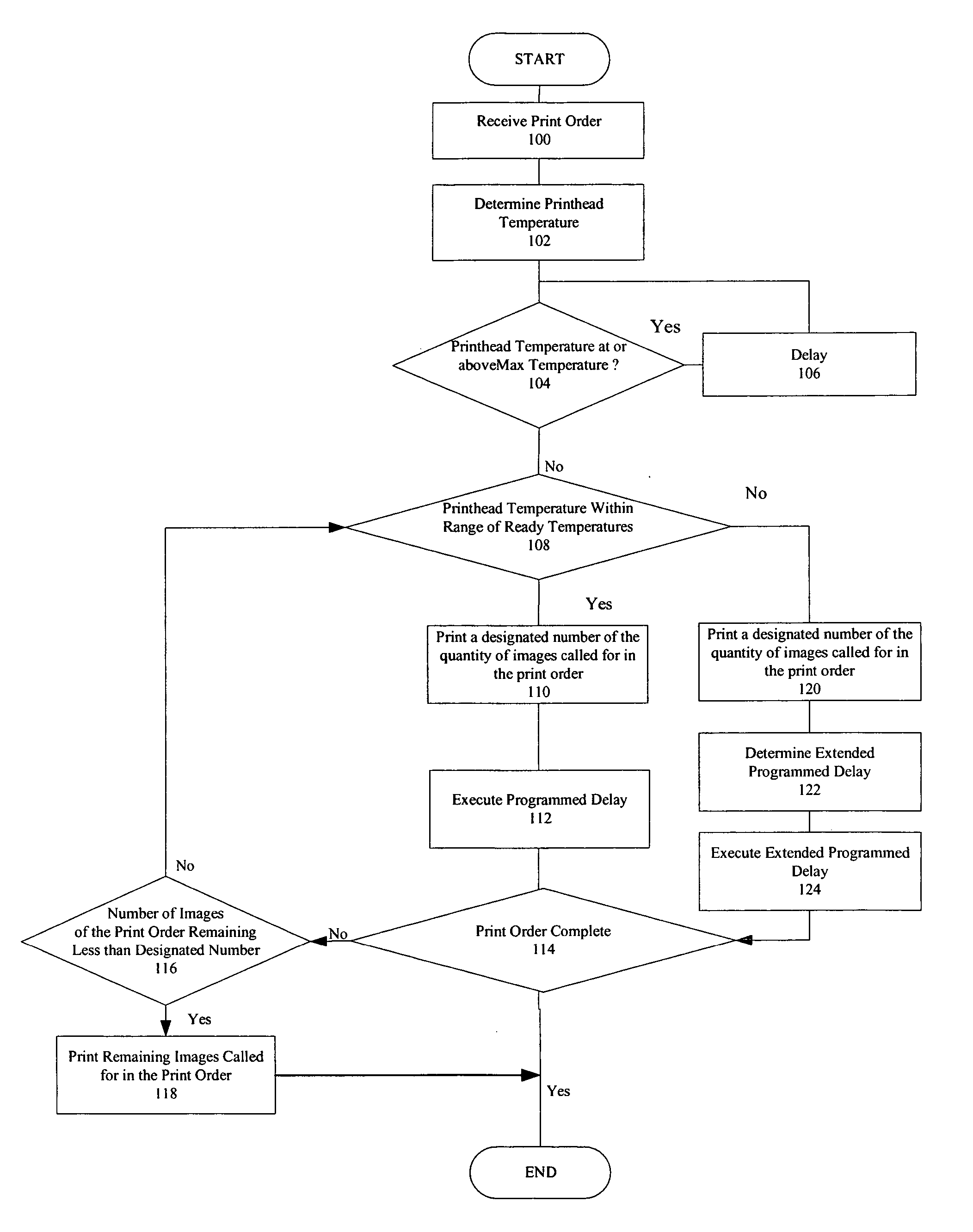

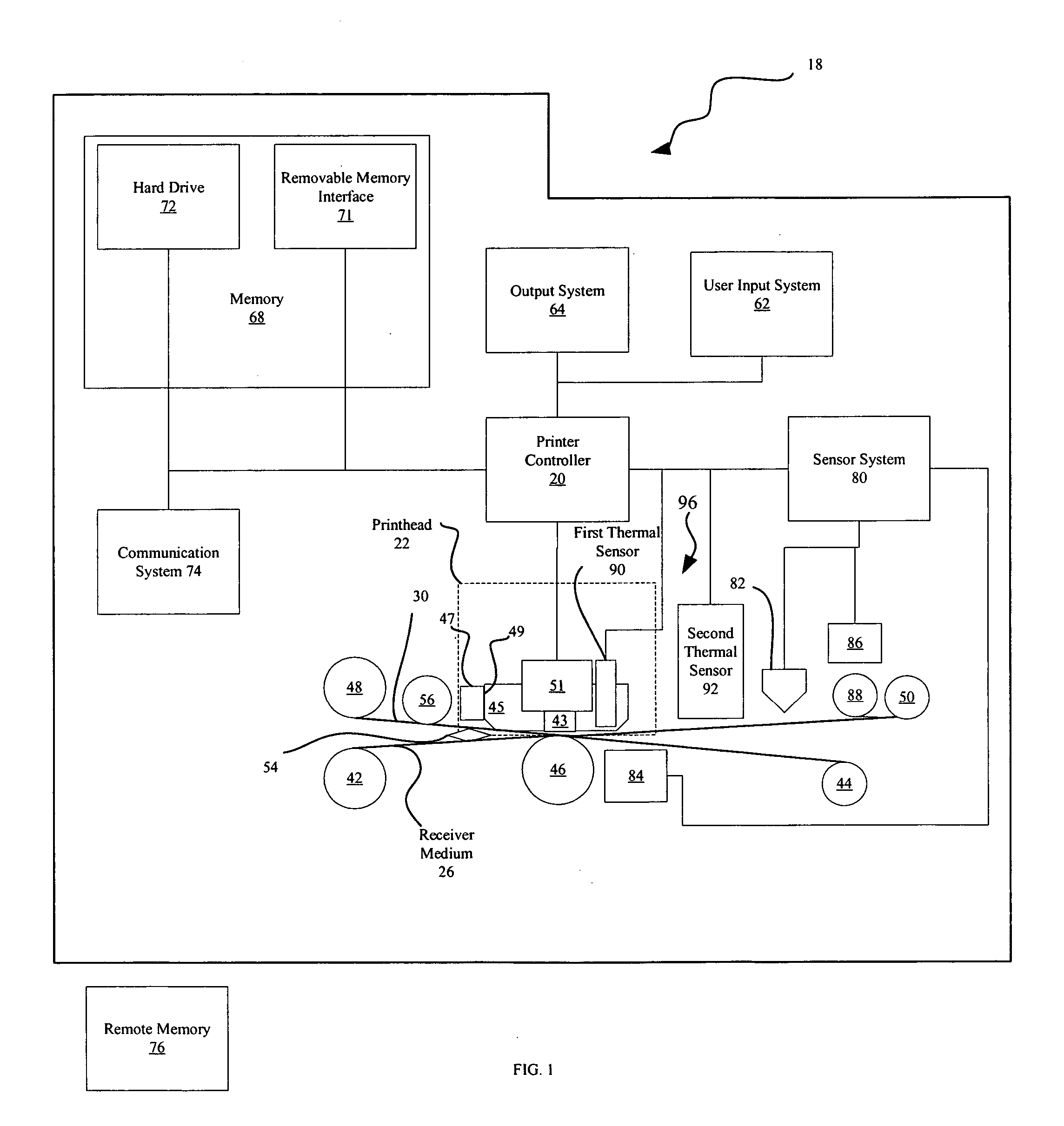

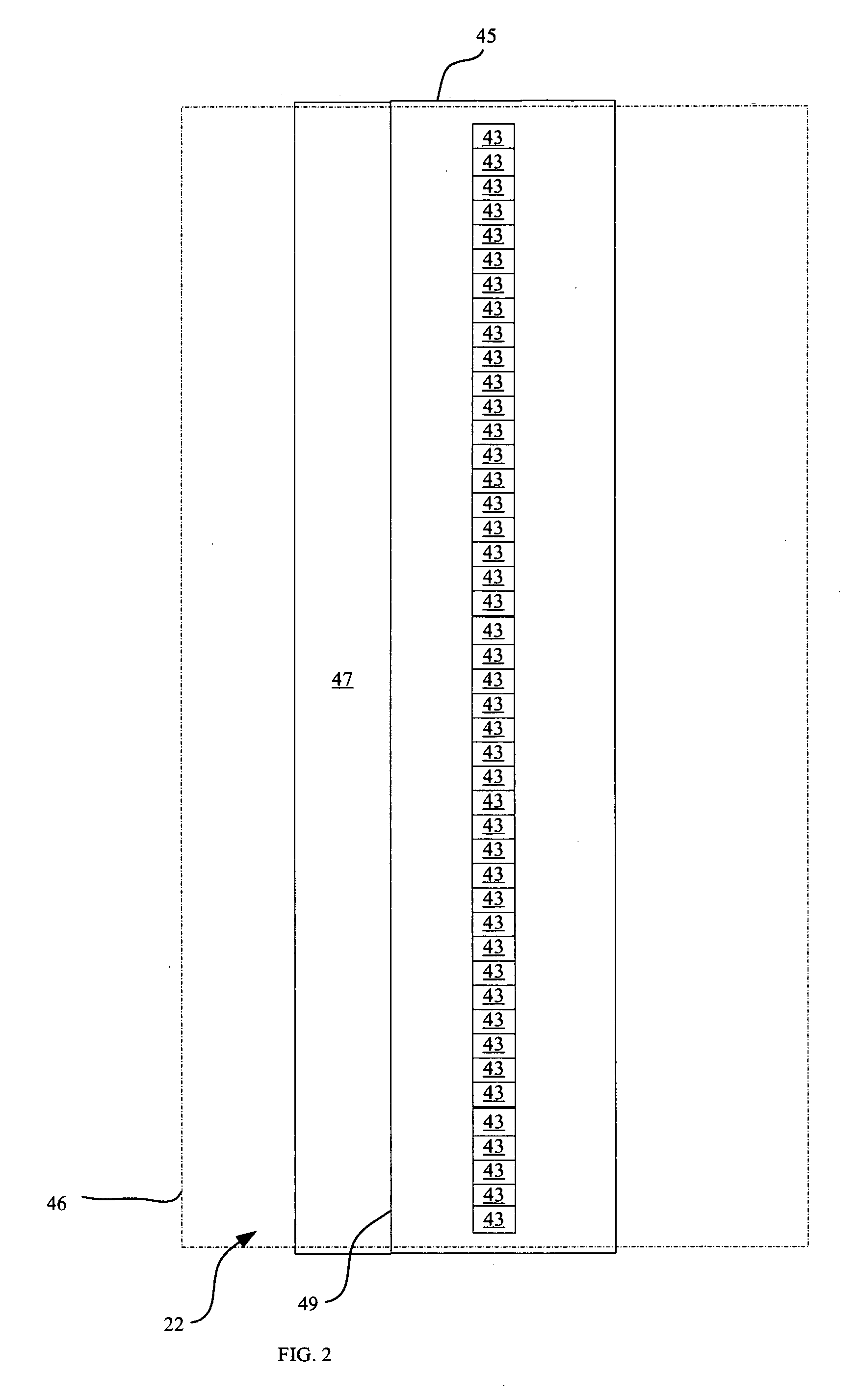

A printer that applies donor material from donor patches on a donor web to a receiver medium using a thermal printhead that generates heat and a method for operating such a printer are provided. The method comprises the steps of: receiving a print order requesting the printing of a quantity of images; determining a temperature of the printhead; printing a designated number of the quantity of the images in a sequence; determining a length of time of a programmed delay; delaying the printing for the determined length of time of the programmed delay; and printing remaining images from the quantity of images. The length of each programmed delay is determined by using the temperature of the printhead and a time rate of cooling of the printhead and, is determined in a manner that provides a sufficient cooling time to prevent the printhead from reaching a maximum printhead temperature during printing.

Owner:KODAK ALARIS INC

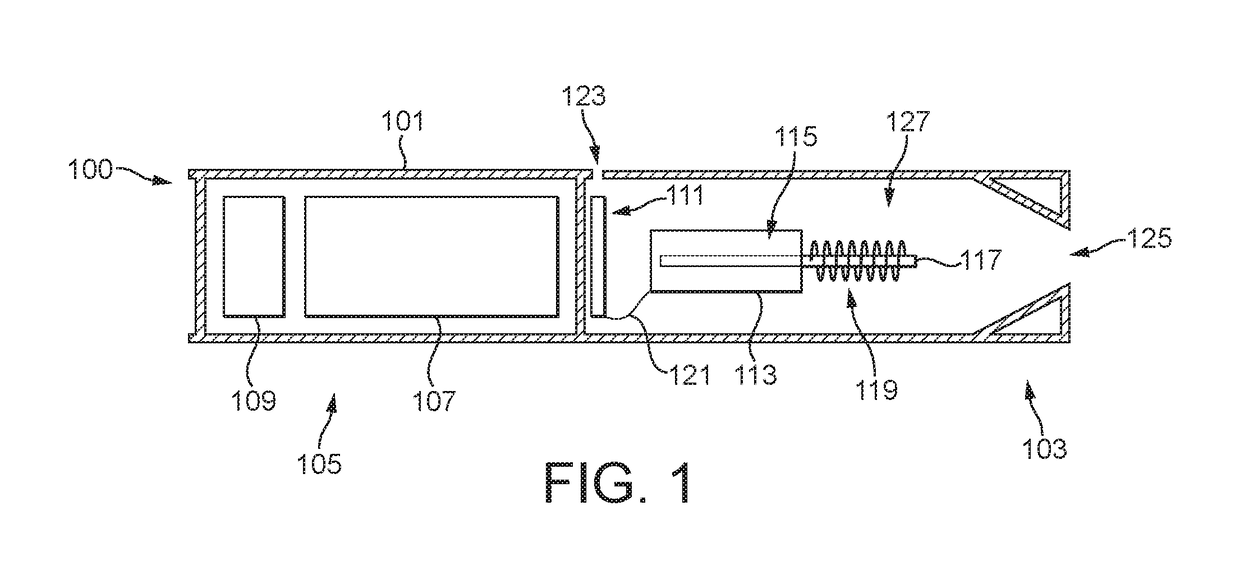

Aerosol-generating systems with liquid level determination and methods of determining liquid level in aerosol-generating systems

An electrically operated aerosol-generating system may include a liquid storage portion configured to store a liquid from which aerosol may be generated, an electric heater, a capillary wick extending between the liquid storage portion and the electric heater and configured to convey liquid from the liquid storage portion to the electric heater and electric circuitry connected to the electric heater. The electric circuitry may be configured to: activate the electric heater for a first heating time period in response to an input to vaporize liquid in the capillary wick, activate the electric heater for a second heating time period upon the elapse of a first cooling time period after the first heating time period, record a temperature measurement of the electric heater during the second heating time period, and determine an amount of liquid in the liquid storage portion based on the temperature measurement.

Owner:AKRIA CLIENT SERVICES LLC

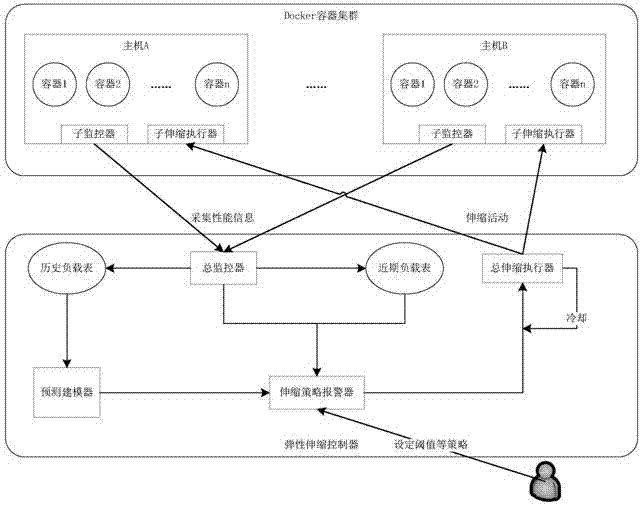

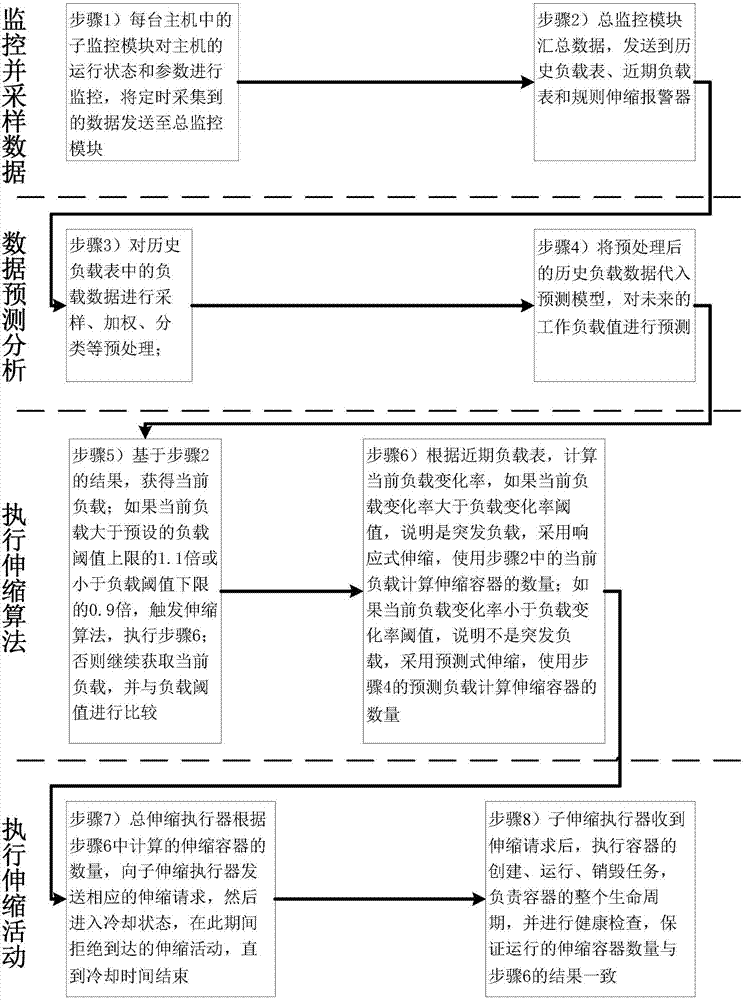

Intelligent elastic telescoping method based on Docker container cluster

InactiveCN106961351ARapid responseReduce resource usageResource allocationData switching networksResponse typeData prediction

The invention relates to an intelligent elastic telescoping method based on a Docker container cluster; the method comprises the following steps: monitoring and sampling data; data prediction and analysis; executing a telescoping algorithm; executing telescoping motions. The prediction type telescoping error can be made up and adjusted through response type telescoping according to different load changes; the response type telescoping lag can be smoothly transited through the prediction type telescoping; the method can better cope with a periodical load and a burst load, can fast transversely intelligently telescope the Docker container, and uses the elasticity telescoping tolerance and a cooling time to prevent the shaking conditions.

Owner:NANJING UNIV OF POSTS & TELECOMM

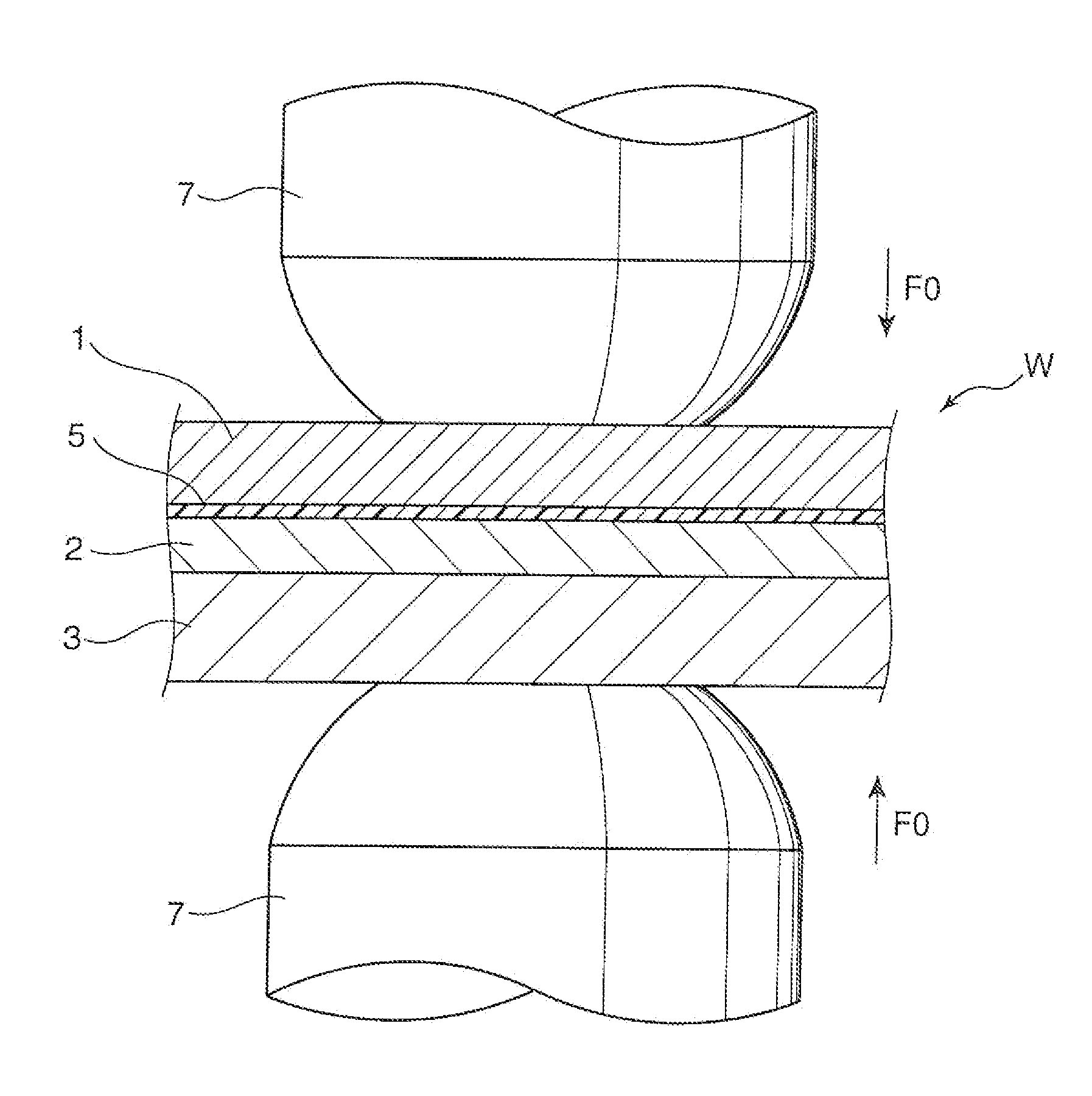

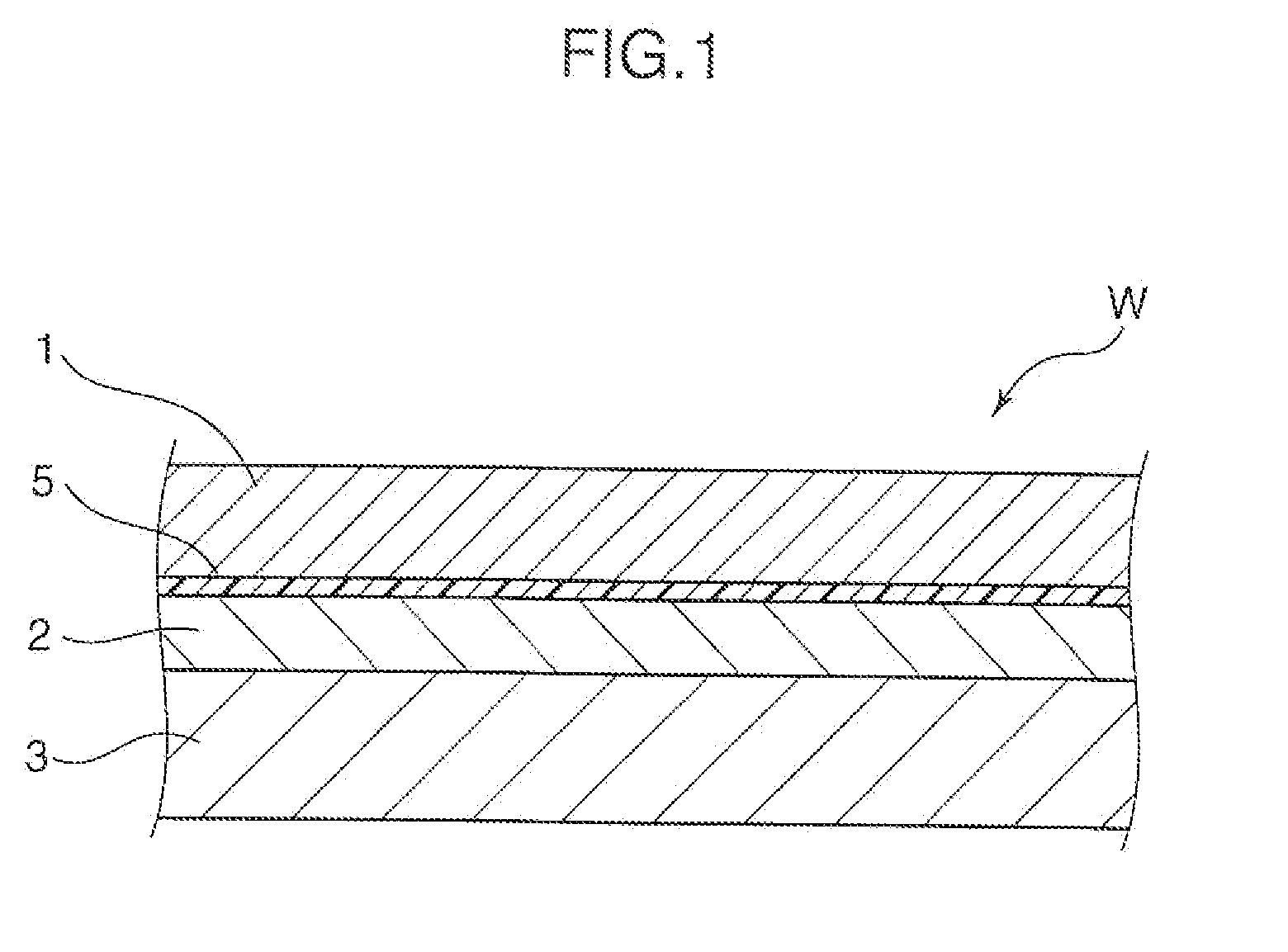

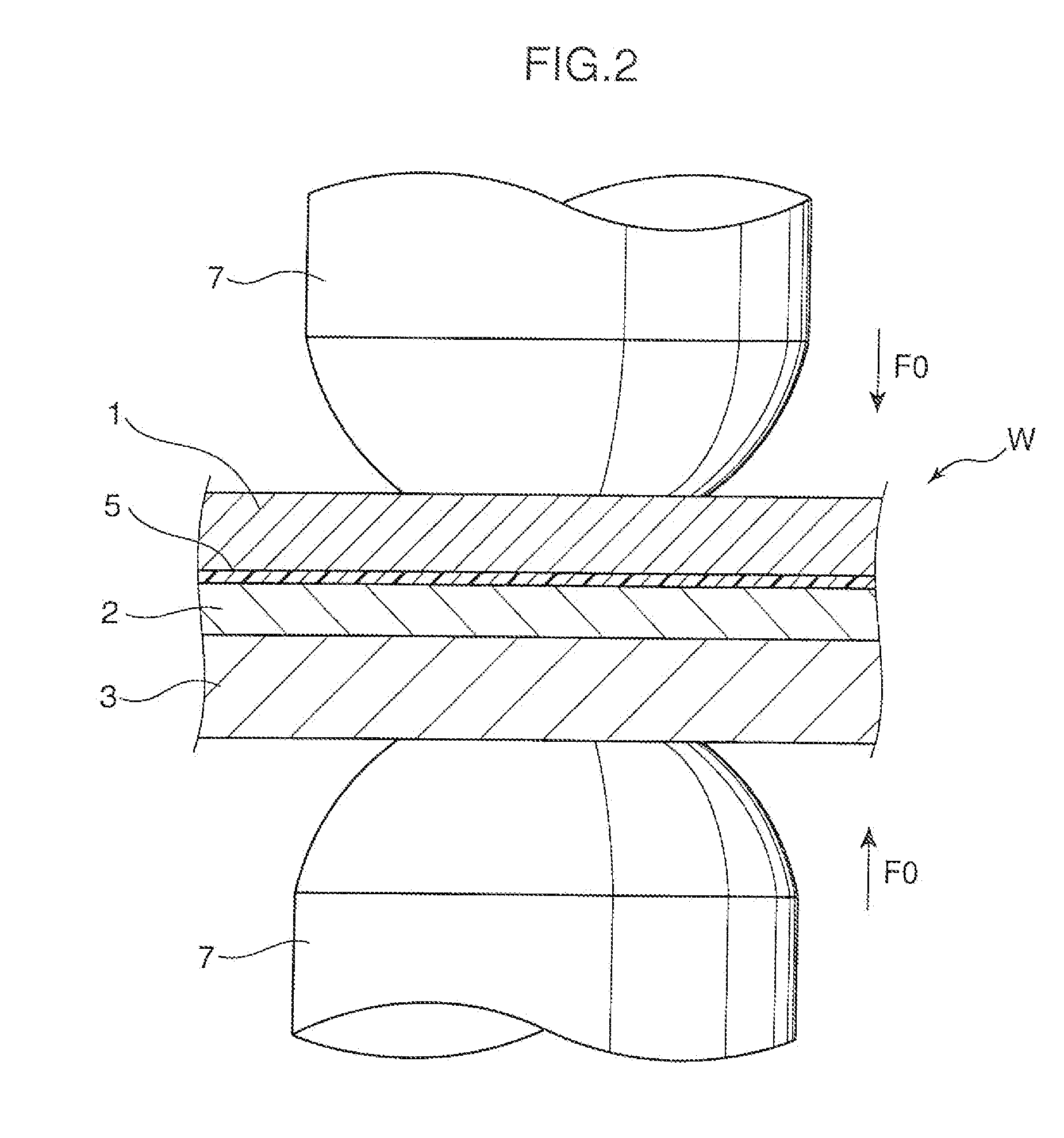

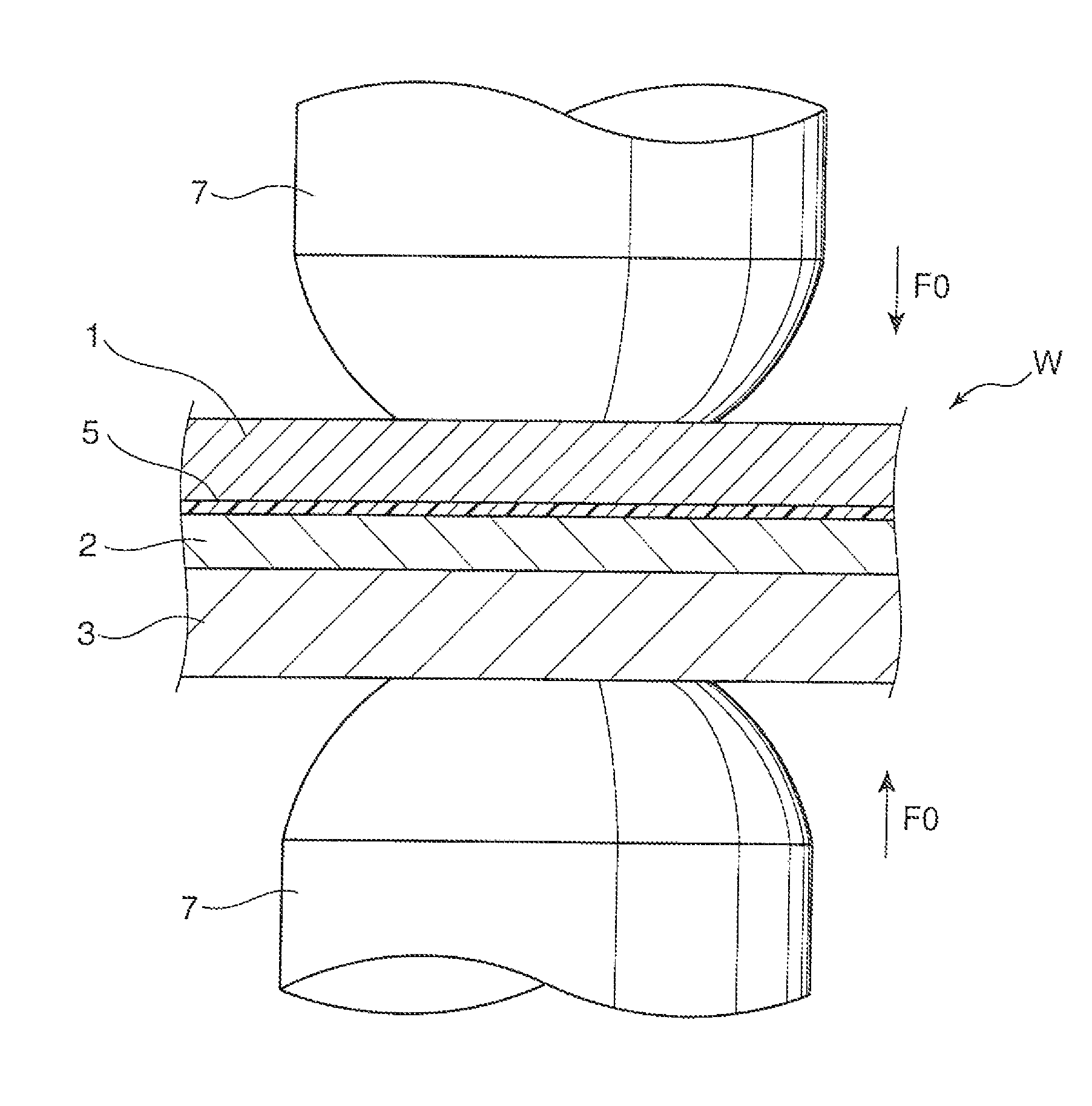

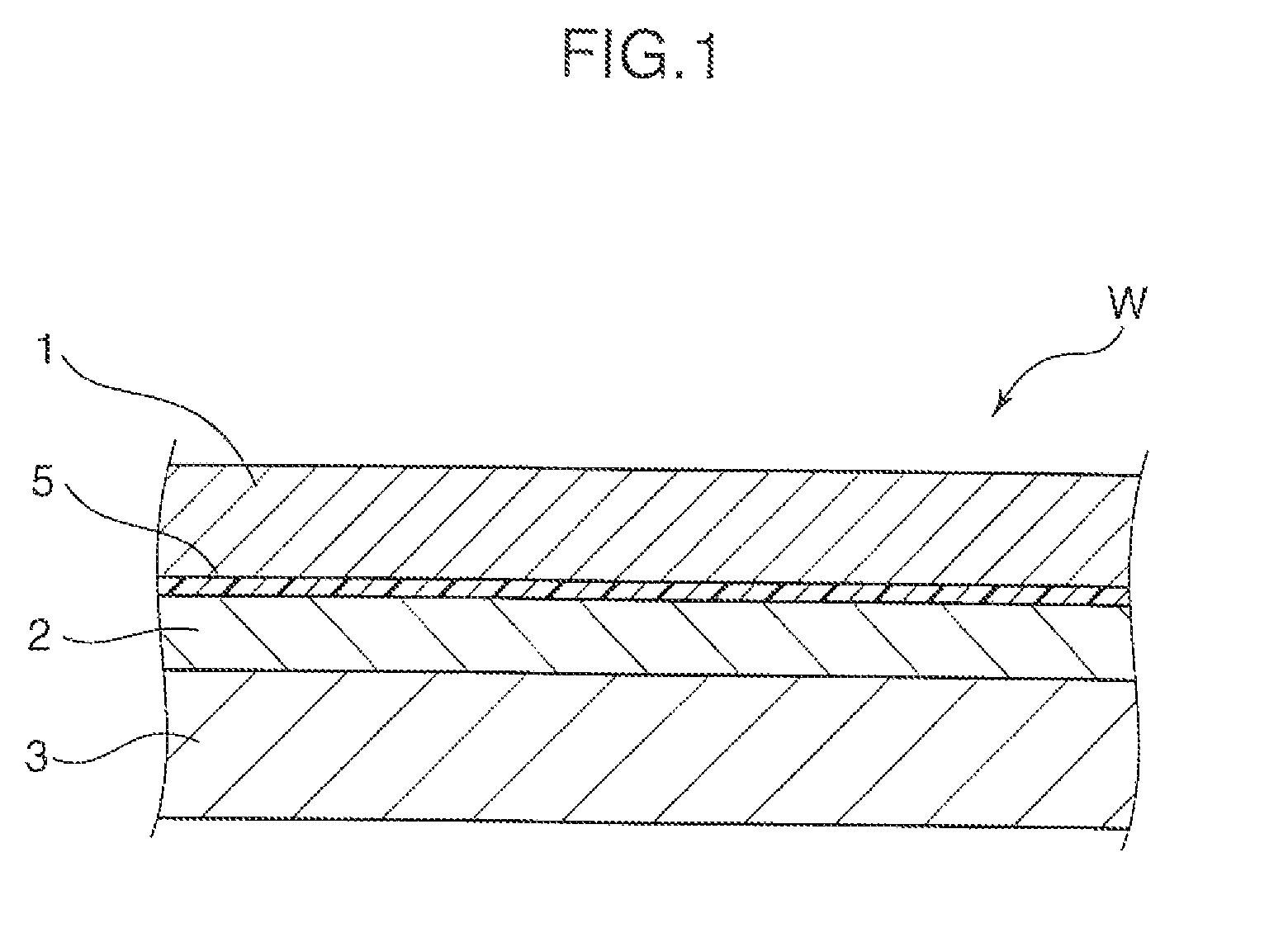

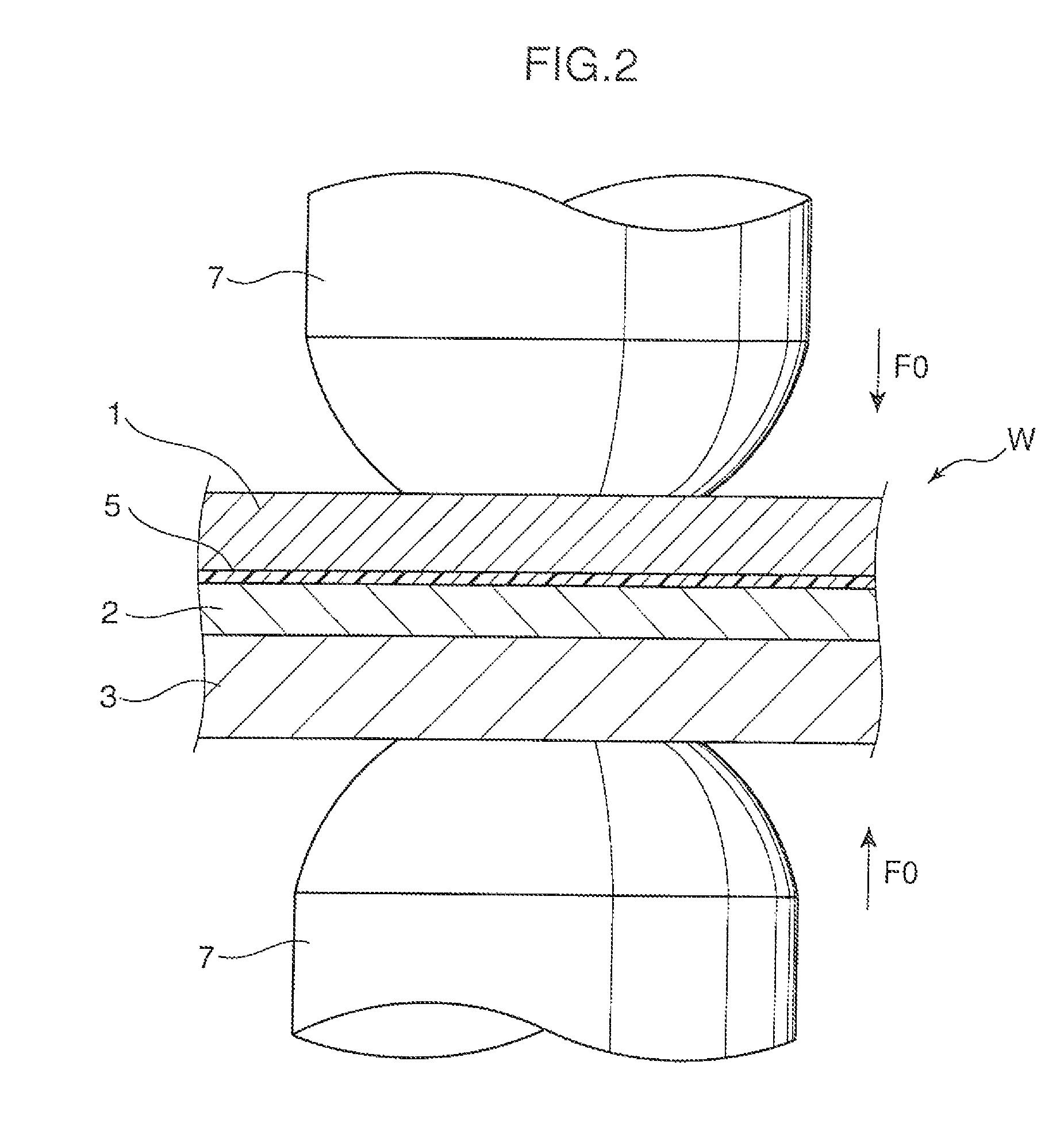

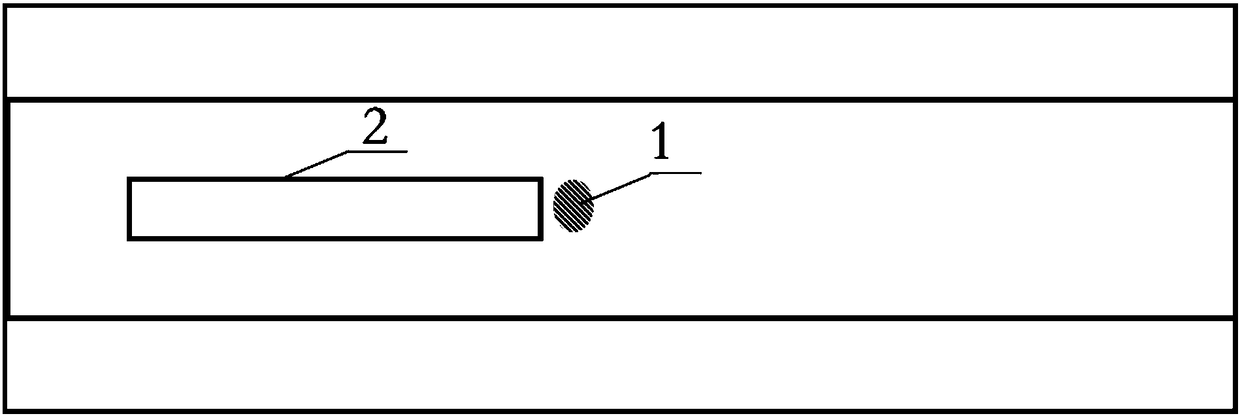

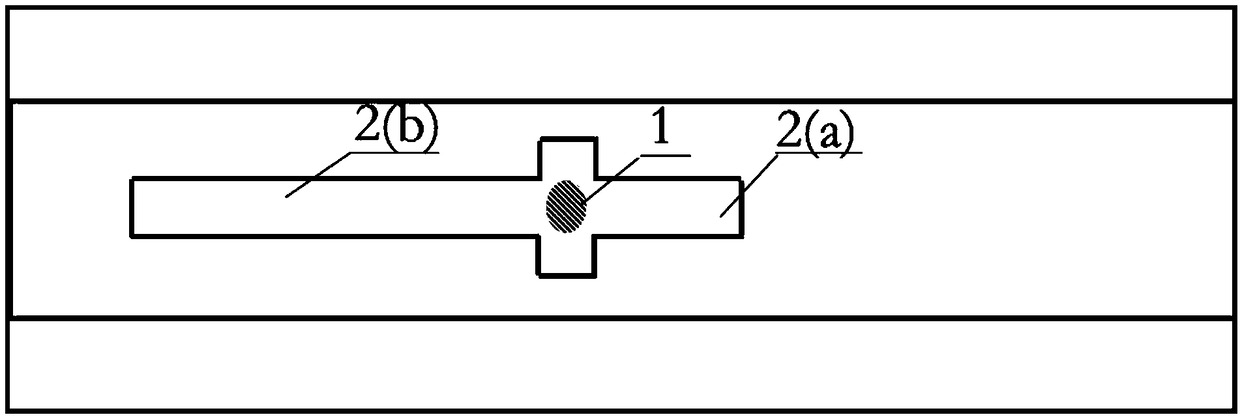

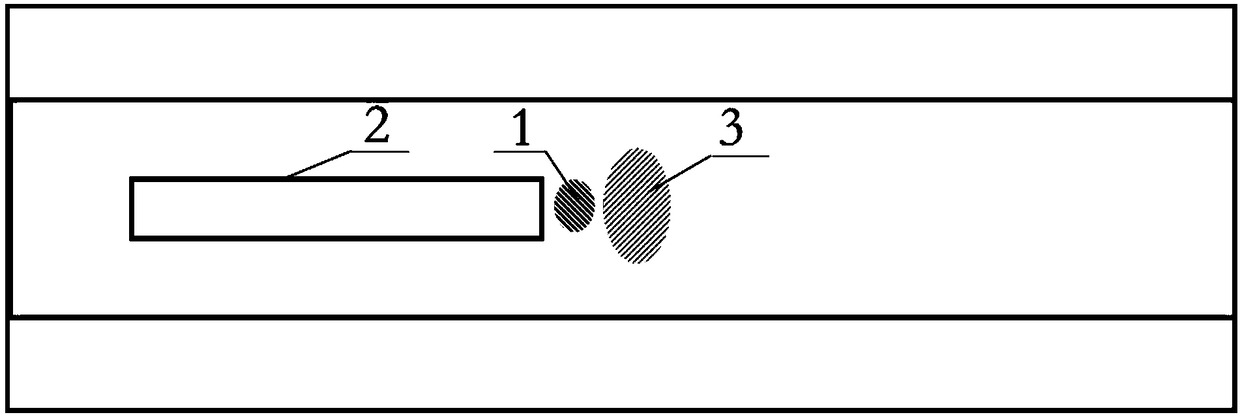

Joining method of dissimilar metal plates and dissimilar metal joined body

ActiveUS20110097594A1Improve joint strengthWelding electric supplyArc welding apparatusPower flowAdhesive

The joining method of the present invention includes a lapping step of lapping the aluminum alloy plate (1) and the plated steel plate (2) via the adhesive (5), a pre-heating step of clamping both of the metal plates (1, 2) that have been lapped in the lapping step between a pair of electrodes (7, 7) for spot welding and applying pressure thereto, and applying a current between the pair of electrodes (7, 7), a cooling step of pressurizing, after the pre-heating step, both of the metal plates (1, 2) at a pressing force which is higher than that at the start of the pre-heating step in a state where conduction between the electrodes (7, 7) is stopped, and continuing this pressurization over a predetermined cooling time, and a welding step of pressurizing, after the cooling step, both of the metal plates (1, 2) at a pressing force which is higher than that at the start of the pre-heating step, and welding both of the metal plates (1, 2) by applying a current which is higher than the conduction current value in the pre-heating step between the pair of electrodes (7, 7). It is thereby possible to firmly join the dissimilar metal plates (1, 2) by combining adhesion due to an adhesive and spot welding.

Owner:MAZDA MOTOR CORP +1

Anti-addiction control method and system of mobile terminal, and mobile terminal

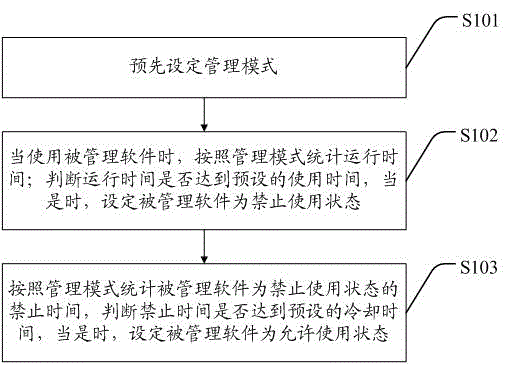

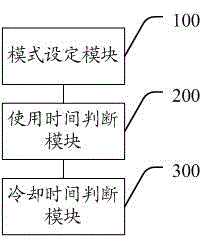

InactiveCN105120080AControl gameControl timeEavesdropping prevention circuitsControl systemRunning time

The invention discloses an anti-addiction control method and system of a mobile terminal, and the mobile terminal, wherein the method includes the steps of: A, pre-setting a management mode; B, when managed software is used, counting operation time according to the management mode, and judging whether the operation time reaches pre-set use time, if so, setting the managed software as a state of prohibition of use; and C, counting the prohibition time when the managed software is in the state of prohibition of use according to the management mode, and judging whether the prohibition time reaches pre-set cooling time, if so, setting the managed software as a state of allowance of use. The anti-addiction control method and system count the operation time of the managed software by setting the management mode. When the pre-set use time is exceeded, the managed software is forbidden to be used. When the cooling time ends, the managed software can be used again. The anti-addiction control system is similar to a screen locking function. The time can be set. Mobile phone users or parents are assisted to effectively control mobile games and the time online.

Owner:TCL COMM TECH NINGBO CO LTD

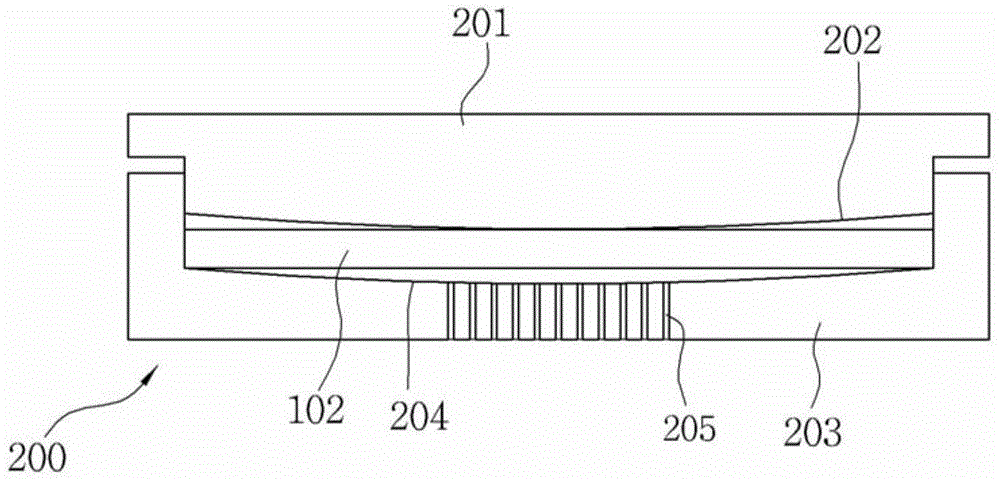

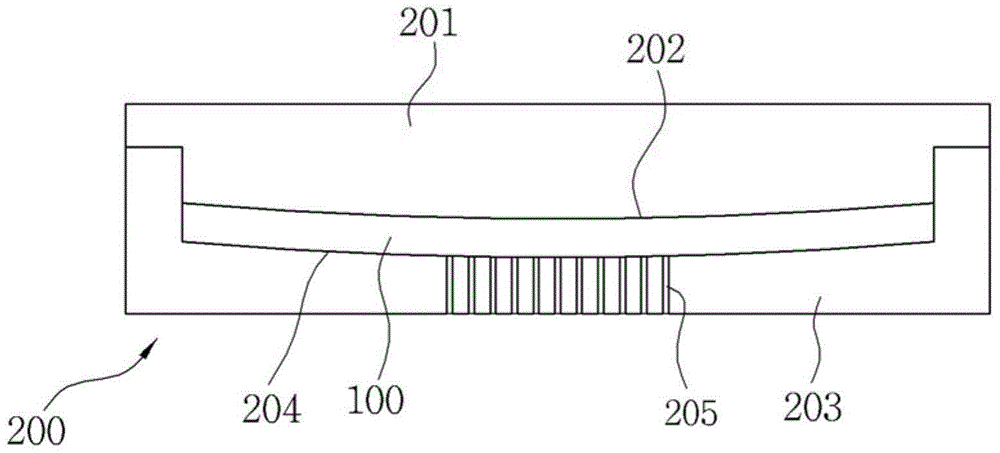

Molding device of glass molding articles

ActiveCN104556644AReduce CooldownReduce molding cycle timeGlass reforming apparatusVacuum pressureMaterials science

The invention relates to a molding device of glass molding articles. More specifically, the molding device of the glass molding articles comprises a pre-heating mechanism contacted with a mold body in a non-load state for pre-heating, a discharge cooling line provided with a cooling water line is formed at an outlet side of a molding chamber, the cooling time in the molding chamber is shortened, the whole molding period time of glass with a curved surface portion is further shortened, a plurality of suction holes into which vacuum pressure flows are formed at the bottom of a lower mold of the mold body, vacuum pressure absorption materials flowing into the suction holes are employed during molding motions, the glass with the excellent curved surface portion is molded, an inlet side of the molding chamber is provided with a vacuum mechanism for vacuum treatment of the mold body, and the molding device can be applied to the molding of infrared glass optical lenses.

Owner:DAEHO TECH CO LTD

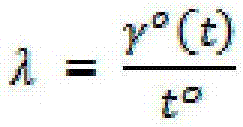

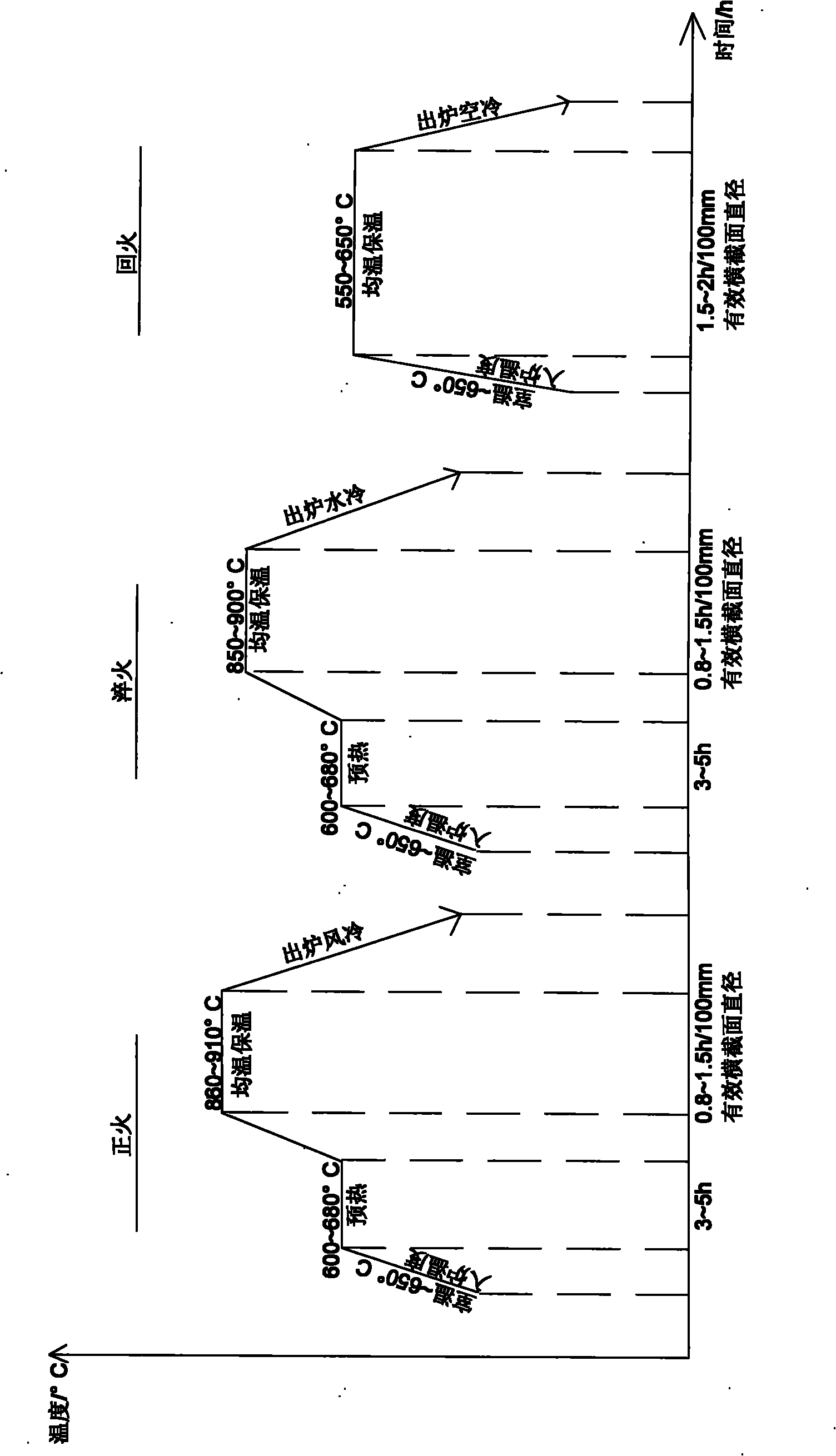

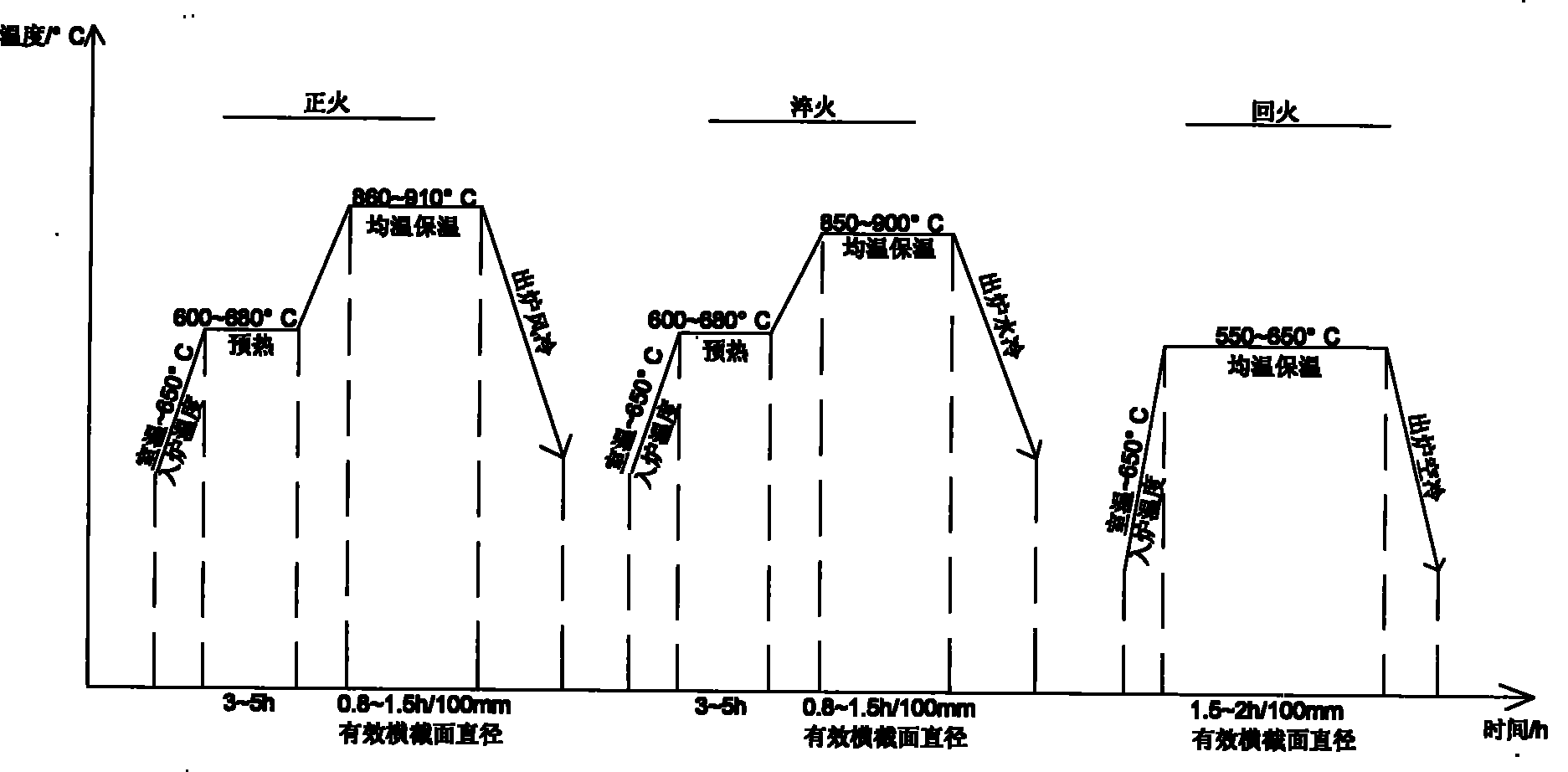

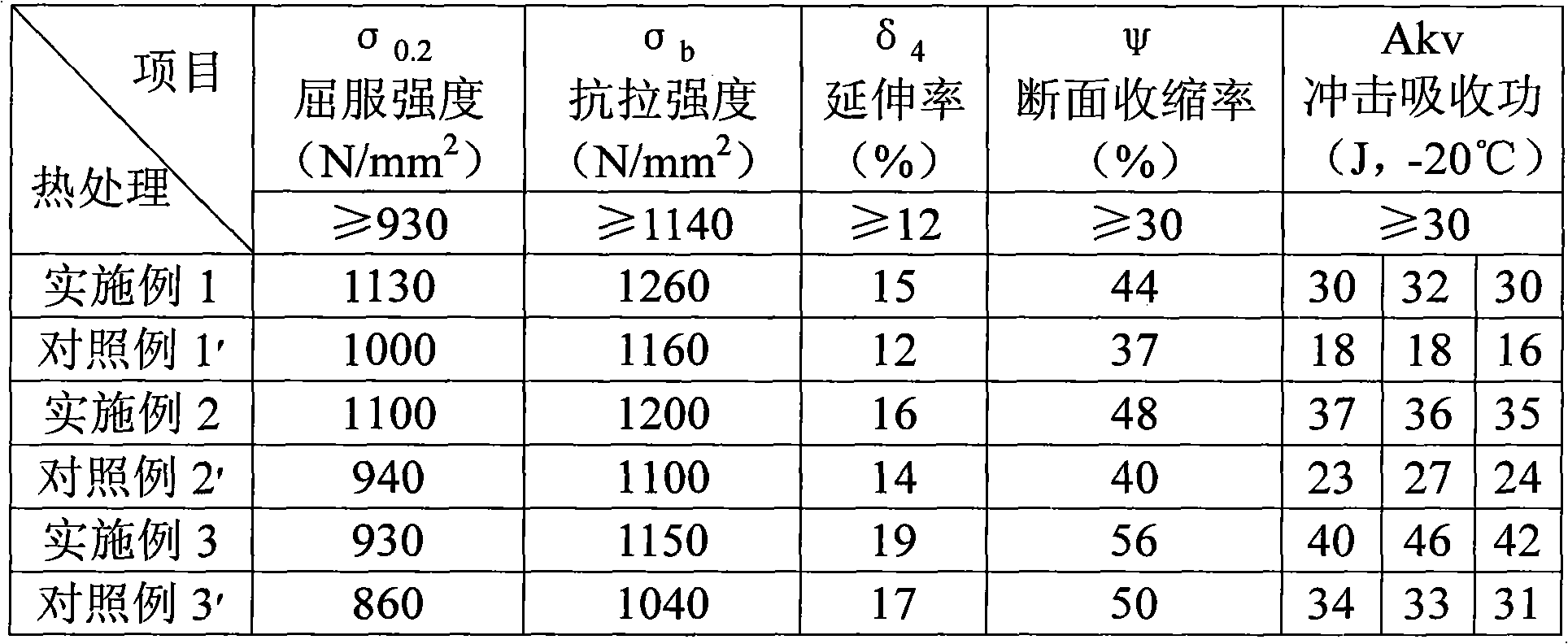

Heat treatment process of AISI4340 steel forgings

The invention belongs to the technical field of the production technology of steel forging products used in low temperature and discloses a heat treatment process of AISI4340 steel forgings. In the heat treatment process, air cooling is performed after normalization; the temperature of water-cooling after quenching is 10-20 DEG C, the dimension unit of the effective cross-section is millimeter, the unit of cooling time is second, and the cooling time is 2-3 times of the effective cross-section dimension of AISI4340 steel forgings. By using the heat treatment process of the invention, the strength of the AISI4340 steel forgings can be enabled and the low-temperature impact toughness is effectively improved, thus the service life of forgings is prolonged.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Joining method of dissimilar metal plates and dissimilar metal joined body

The joining method includes a step of lapping the aluminum alloy plate and the plated steel plate via adhesive, a pre-heating step of clamping both metal plates lapped in the lapping step between a pair of electrodes for spot welding and applying pressure thereto, and applying a current between the pair of electrodes, a cooling step of pressurizing both metal plates at a pressing force higher than that at the start of the pre-heating step in a state where conduction between the electrodes is stopped, and continuing this pressurization over a predetermined cooling time, and a welding step of pressurizing both metal plates at a pressing force higher than that at the start of the pre-heating step, and welding both of the metal plates by applying a current higher than the conduction current value in the pre-heating step between the pair of electrodes.

Owner:MAZDA MOTOR CORP +1

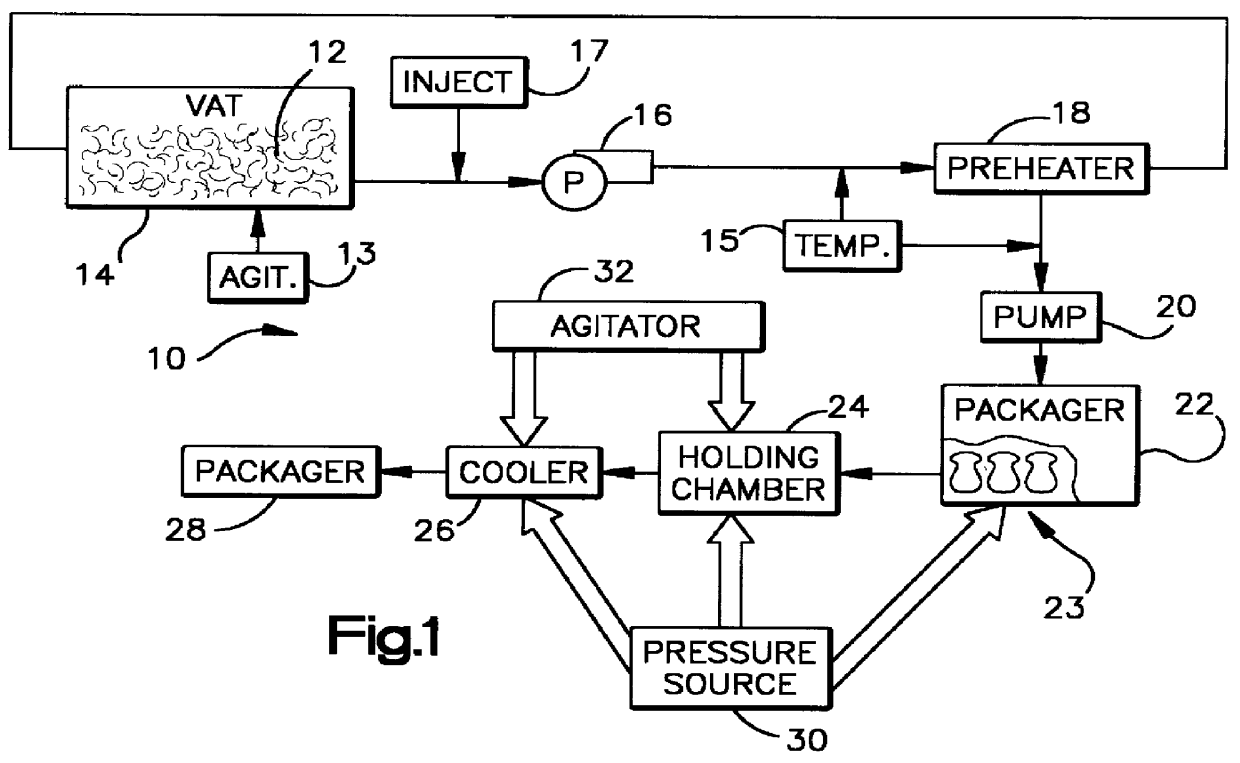

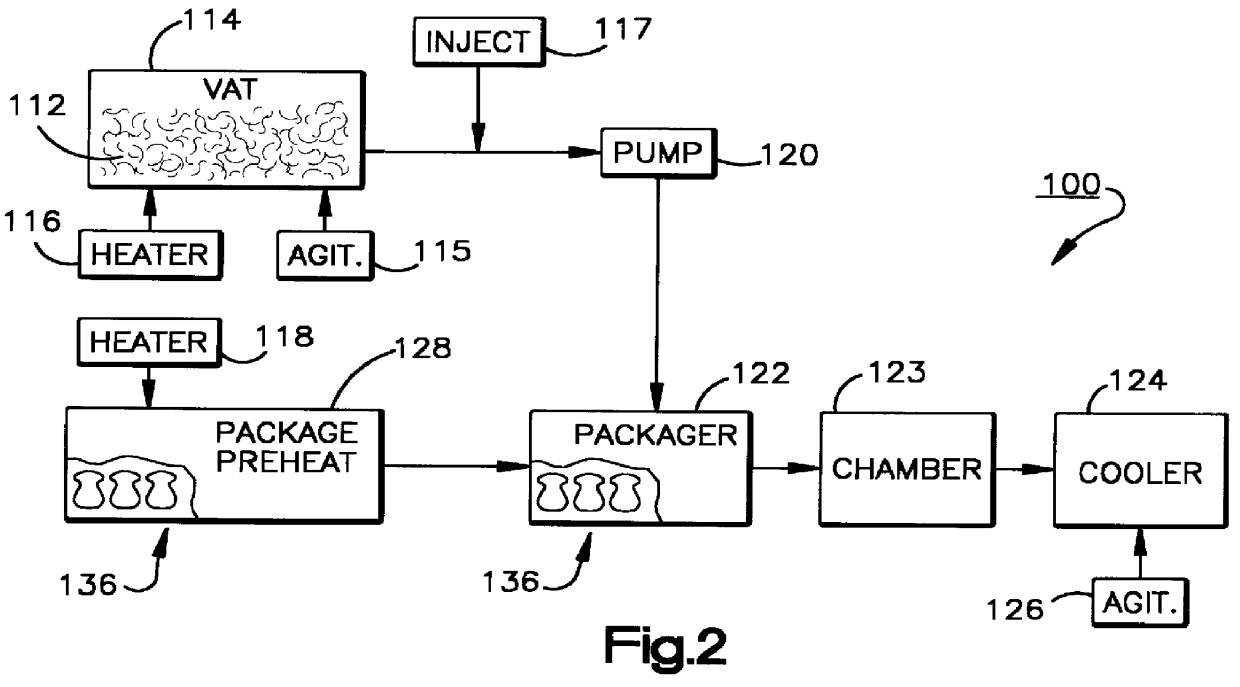

Egg processing system and method of using same to extend the refrigerated shelf life of liquid egg product

InactiveUS6090425AExtend refrigerated shelf lifeIncrease capacityEggs preservation by heatingPackaging protectionRefrigeration temperatureBiology

A process for producing pasteurized liquid egg product utilizing a vat or tank for holding raw egg product. The raw egg product is preheated as rapidly as possible to a temperature of about 140 DEG F. and then, without holding the temperature at a constant level, the preheated raw egg is transferred to a suitable package. The package containing the preheated raw egg product is then sealed and heated and maintained at a suitable temperature in order to pasteurize the liquid raw egg products in the packages. The heated containers and pasteurized liquid egg product are then cooled rapidly to a refrigeration temperature to further inhibit germination of any remaining bacterial spores. The containers are then stored in refrigeration conditions for distribution and use. In another embodiment, an egg product package is preheated to a temperature between 71.1 DEG C. and 55 DEG C. and then hot filled with a egg product treated to about the same temperatures as the package. The hot filled package is then sealed and allowed to stand for about 30 seconds and then it is rapidly cooled to at least about 5 DEG C. in a cooling time period of about 5 mintues.

Owner:SAMIMI MOHAMMAD H

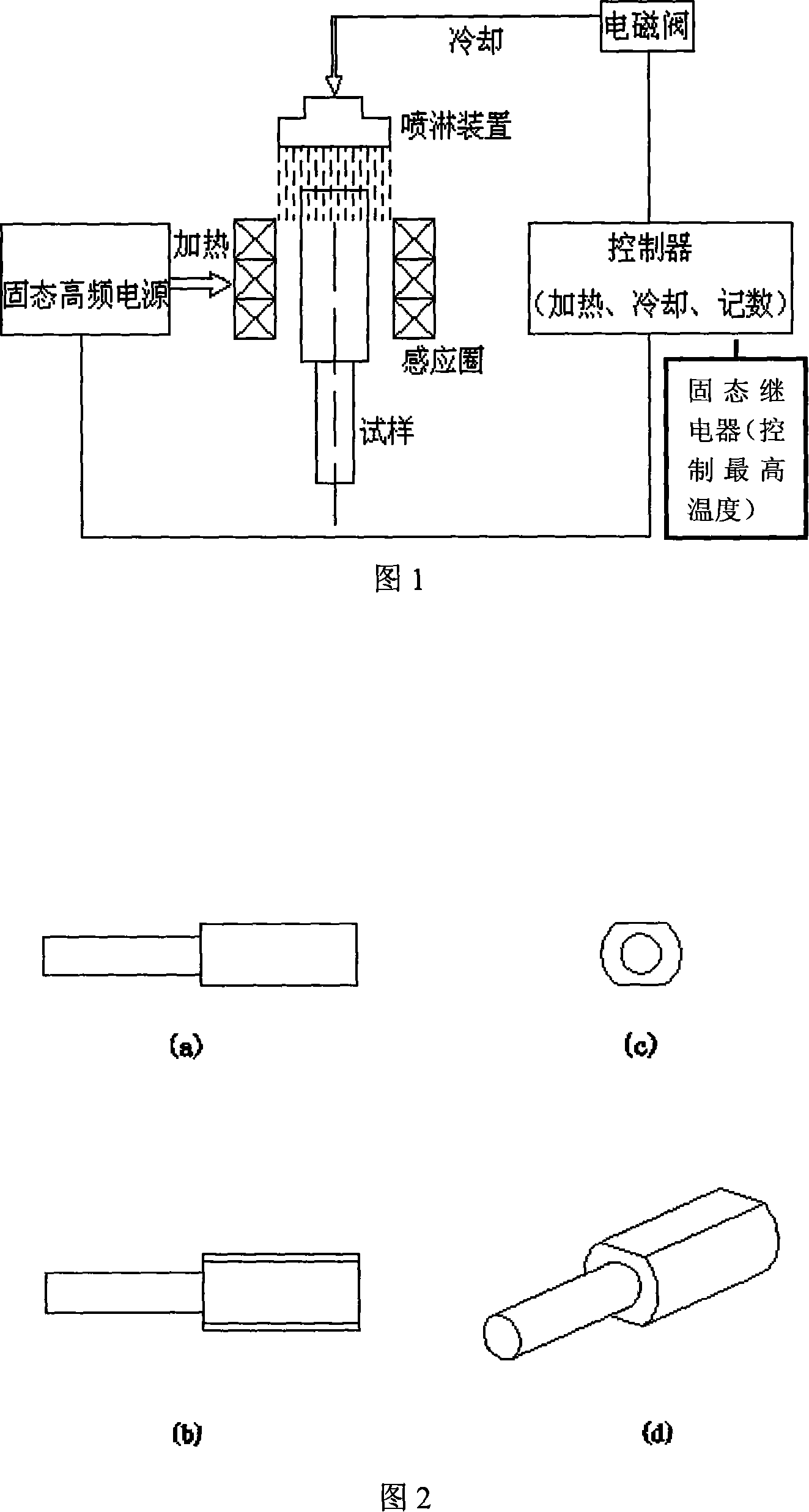

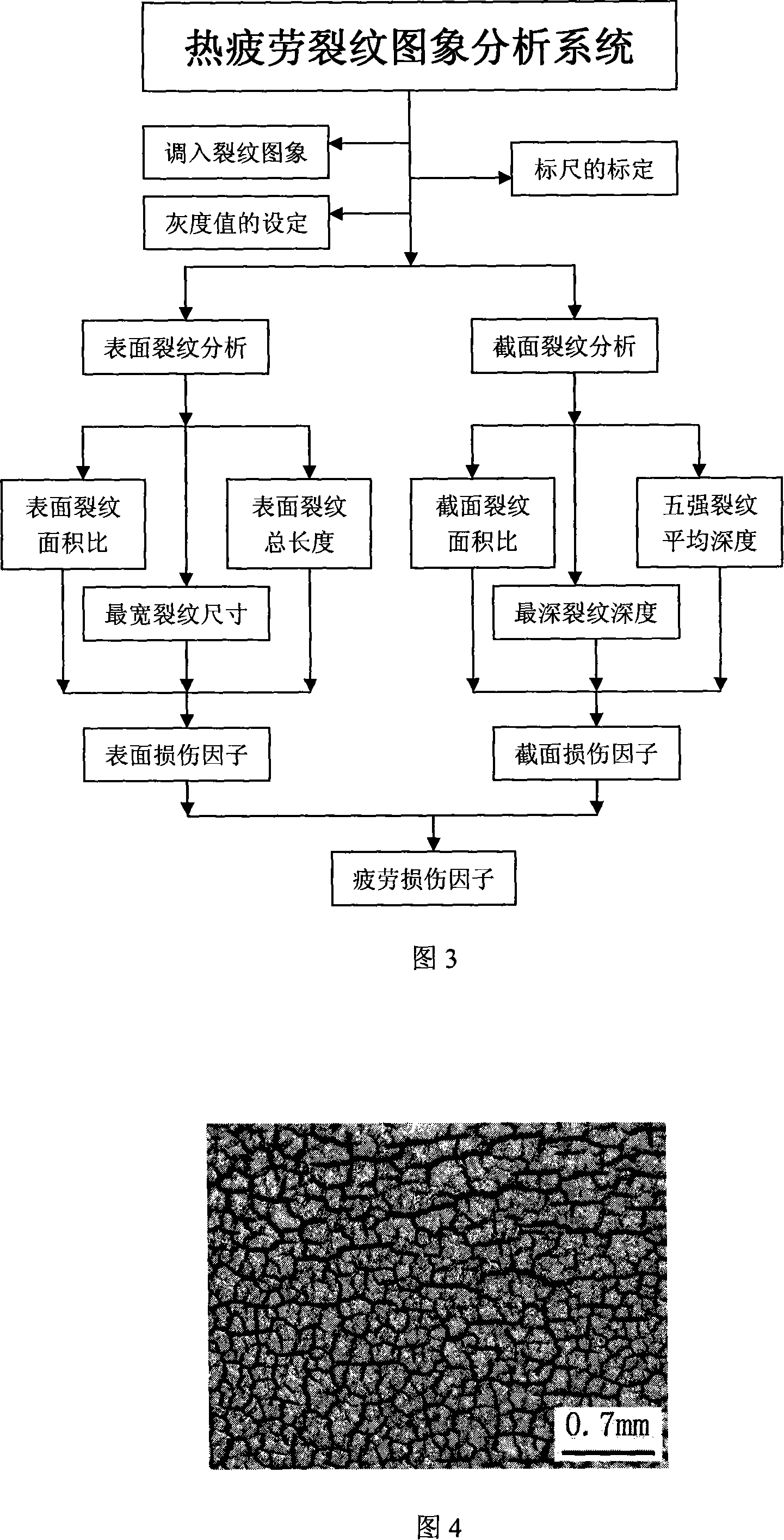

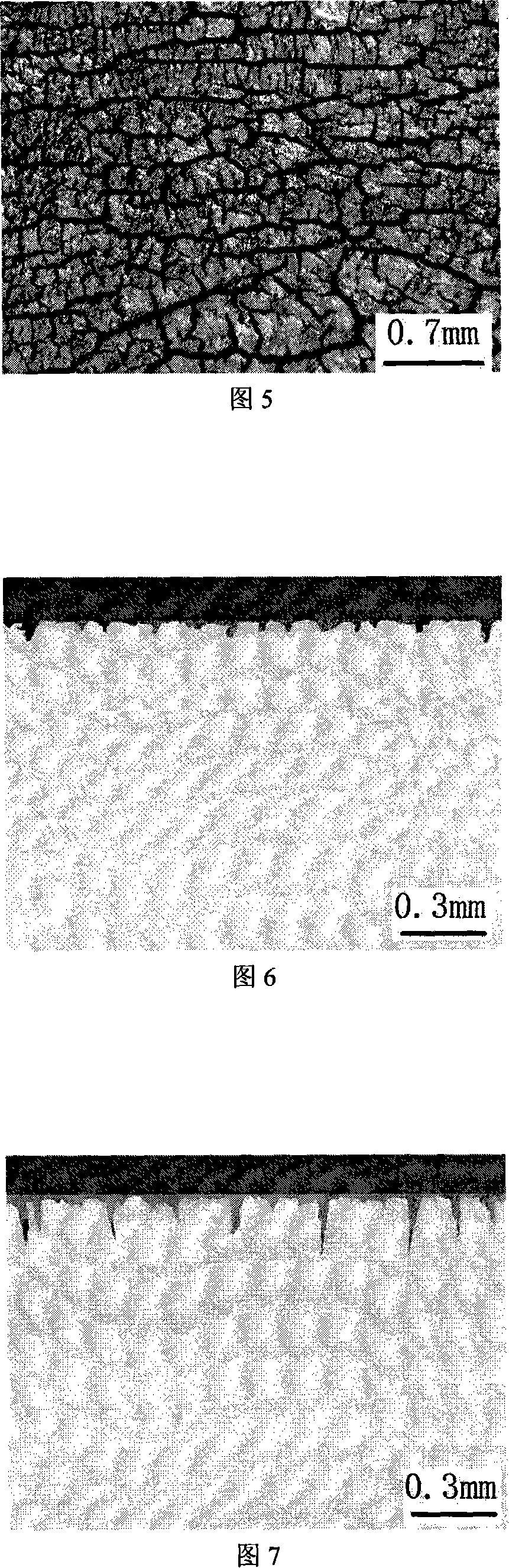

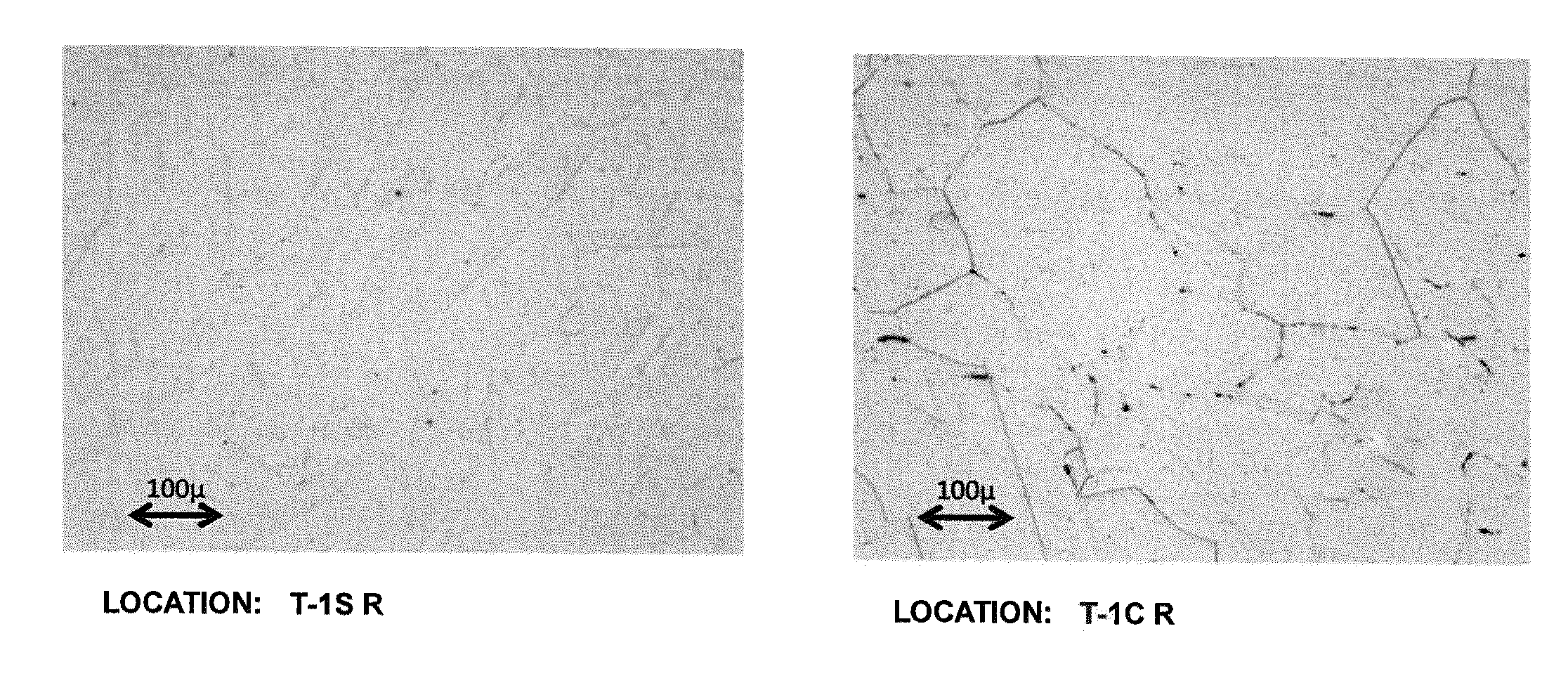

Hot fatigue performance test and analysis method for steel

InactiveCN101105436ASimulate thermal fatigue working conditionsAvoid human errorsOptically investigating flaws/contaminationStrength propertiesMetallic materialsStereo microscope

The invention relates to a test and analysis method of the heat weary performance of steel, which belongs to the field of the performance and test analysis of metal material. The invention is characterized in that the quantitative research and analysis of the heat weary performance is realized. And the invention has following technological processes and steps: (1) the specimen is processed into a shape which has two side surfaces, one of the two surfaces is connected with temperature controlling equipment through a thermo-element, and the highest heating temperature of the specimen can be controlled. The two surfaces are both grinded into the state of polishing. (2) The specimen is put in the center of the induction coil of the heat weary performance testing machine, and then is cooled by circulation cooling water; the highest heating temperature is set, and the cooling time is set. After the heat weary performance testing, the specimen is processed with etch cleaning, and the oxide skin on the surface of the specimen is removed; cracks on the surface of the specimen is given a photo by zoom stereo microscope; the specimen is cut crosswise along the closest packed cracks, and then is grinded and polished and is again given a photo of the sectional plane. (3) The photo is input into the computer, and the cracks are quantitatively analyzed by heat weary performance cracking image analysis system.

Owner:SHANGHAI UNIV

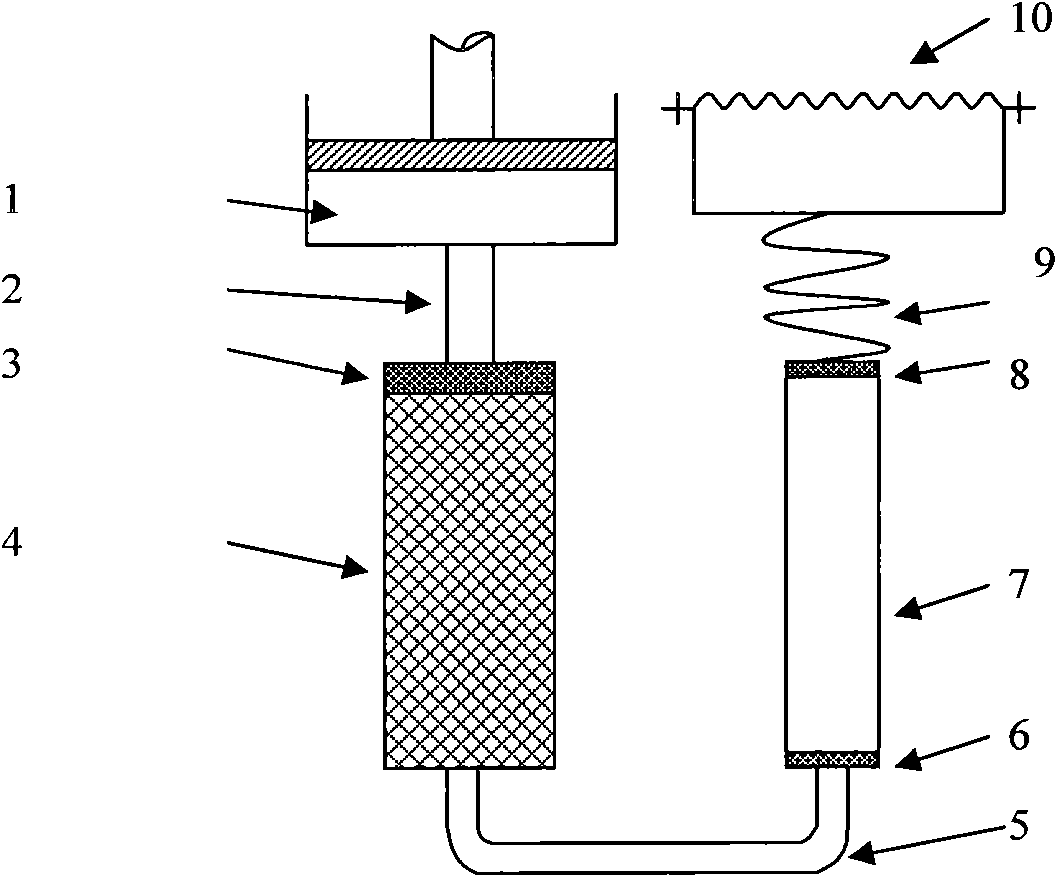

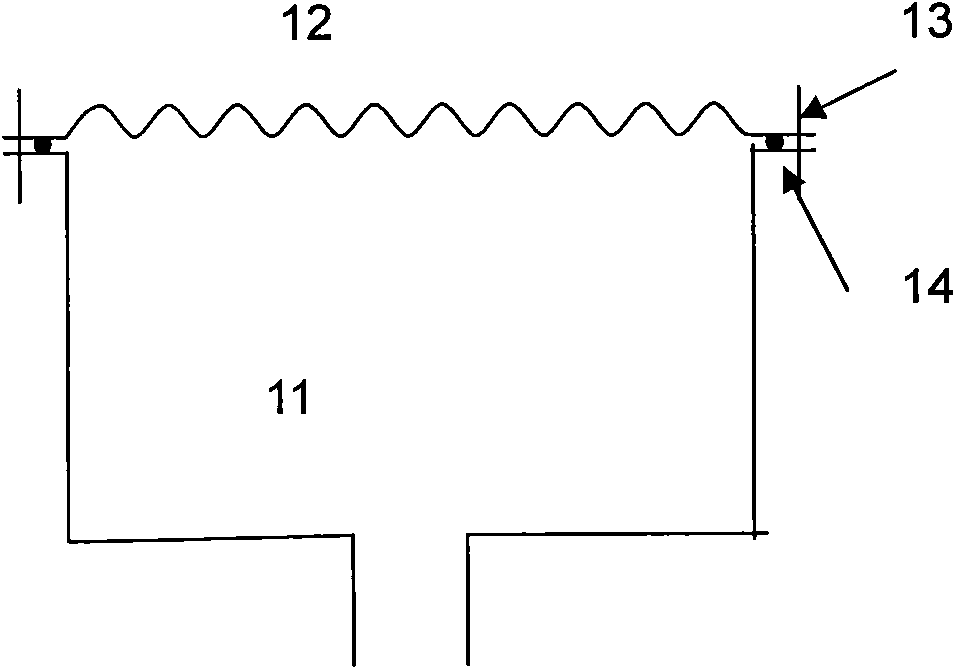

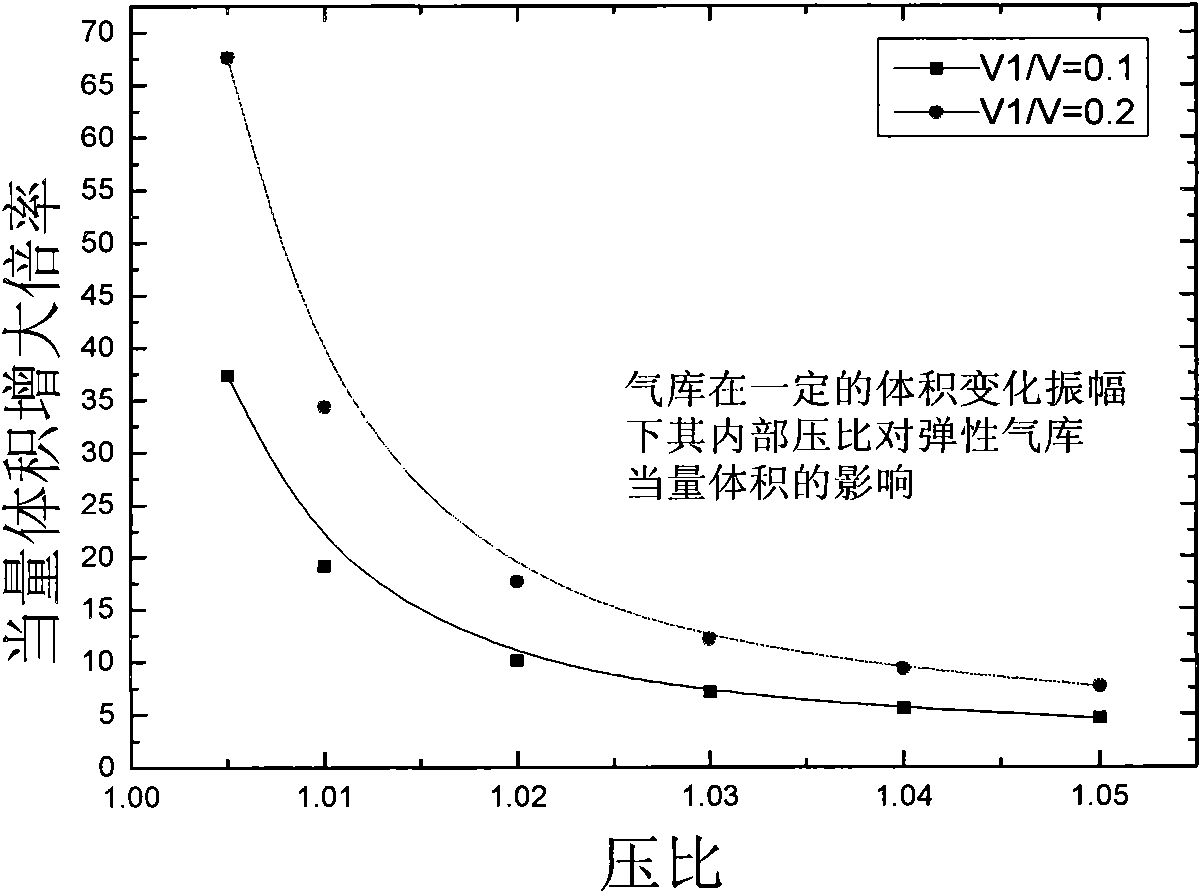

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675AShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

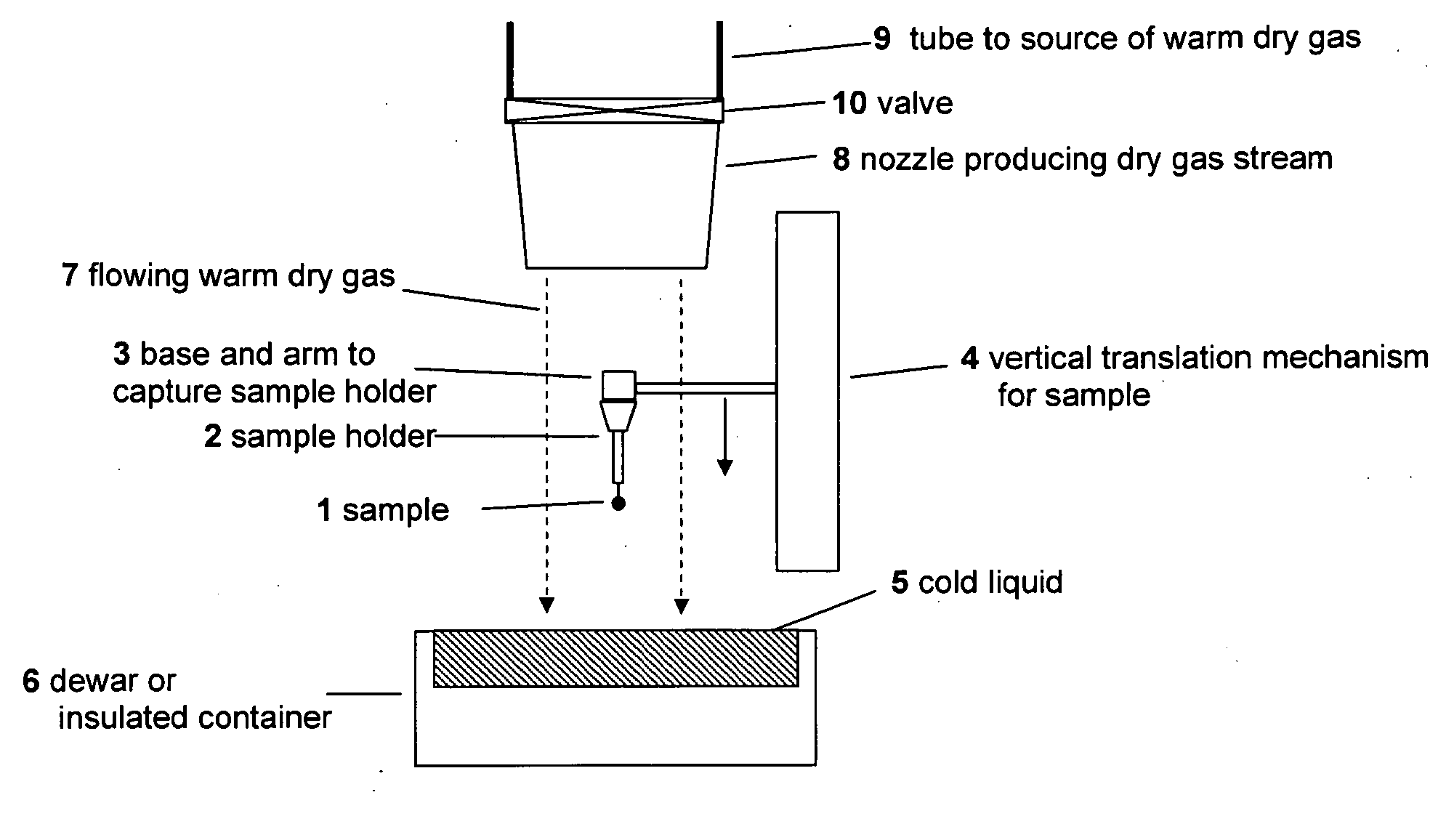

System and method for increased cooling rates in rapid cooling of small biological samples

ActiveUS20090133410A1Reduce condensationReduce freezingPreparing sample for investigationDead animal preservationProcess engineeringLiquid nitrogen

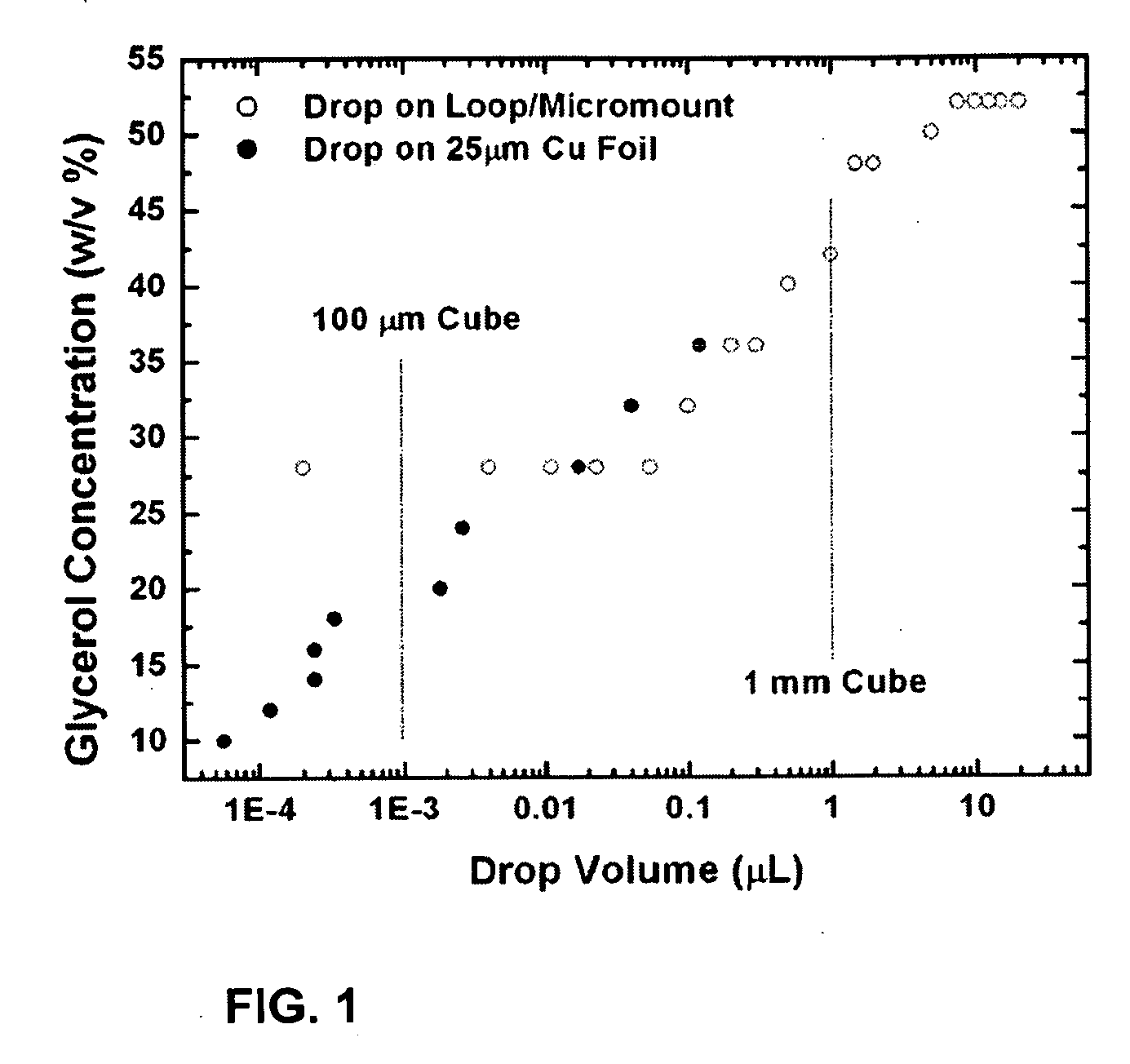

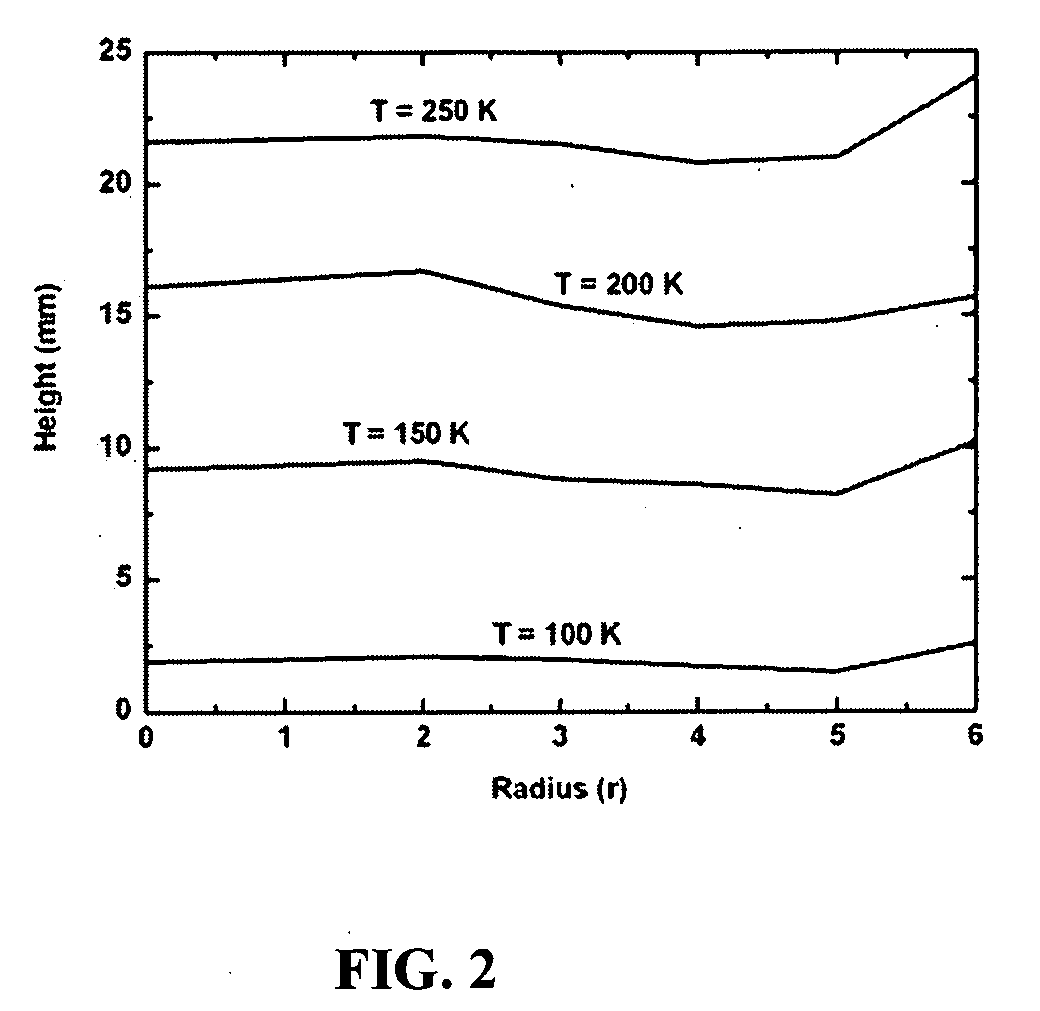

A method and devices for rapid cooling of small biological samples by plunging them in a cryogenic liquid, such as liquid nitrogen, or contacting them with a cryogenic metal surface, reduce or eliminate the cold gas layer that forms above the liquid cryogens or cryogenic surfaces, producing an abrupt transition from ambient (e.g., room) temperature to the cryogen temperature as the sample enters the liquid or contacts the surface. To reduce or eliminate the effects of the cold gas layer, a flow of warm dry gas can be directed along the plunge path, for example. By removing this cold gas layer, cooling times for a 10 micron sample (the size of single cells and the smallest protein crystals now used protein crystallography) will decrease to ˜0.001 s.

Owner:CORNELL RES FOUNDATION INC

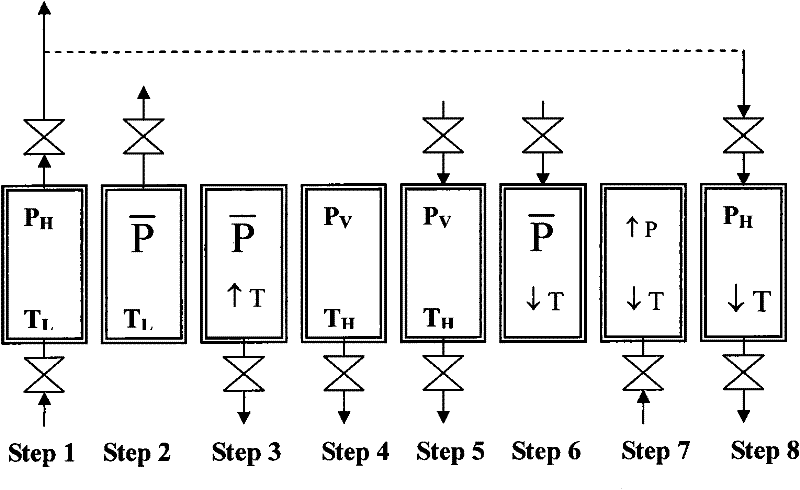

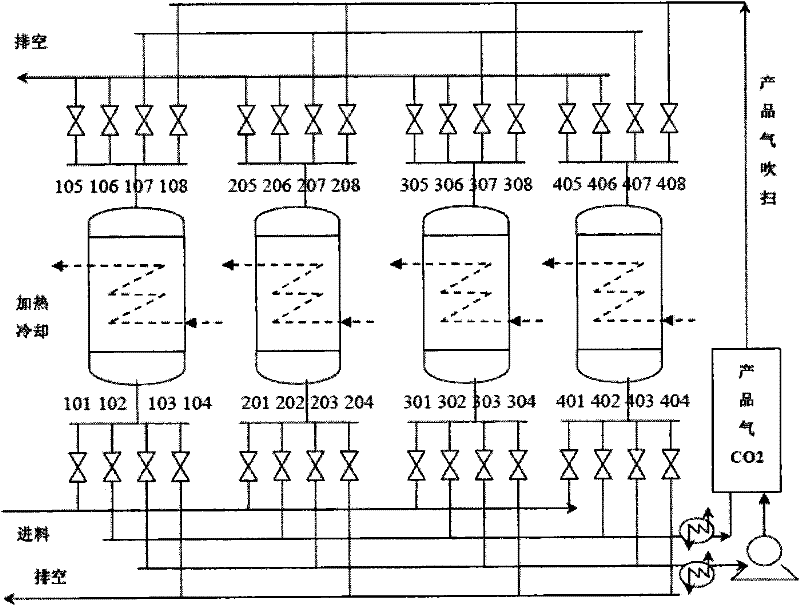

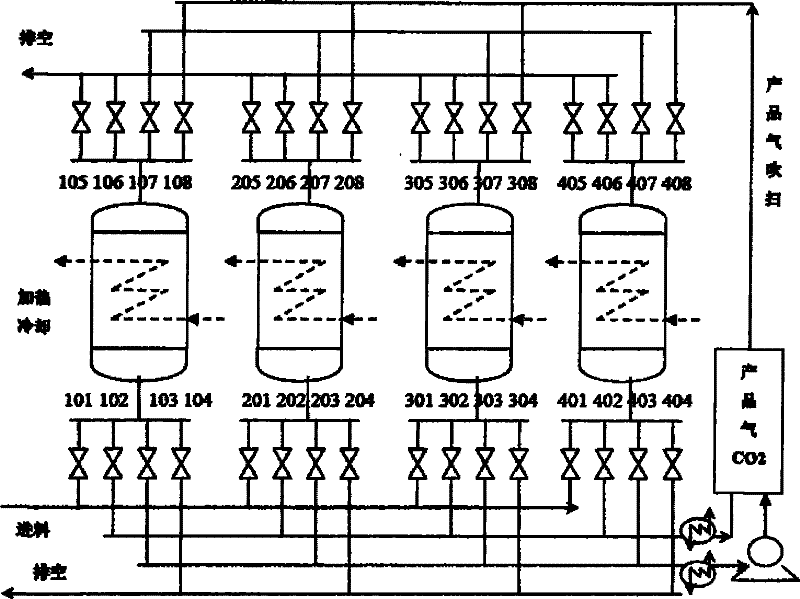

Method for vacuum pressure and temperature varying coupling adsorbing and trapping carbon dioxide in flue gas

The invention relates to a trapping method of carbon dioxide, namely a method for multi-tower vacuum pressure and temperature varying coupling adsorbing and concentrating the carbon dioxide. The method comprises the following main steps: (a) under the conditions of 10-50 DEG C of temperature and 1.1-5.0 atm of pressure, adopting an adsorbent for adsorbing the carbon dioxide to adsorb the carbon dioxide in flue gas; (b) under the conditions of 80-150 DEG C of temperature and 1-10 kPa of vacuum, desorbing the adsorbent in step (a), and cooling the obtained gas containing the carbon dioxide to enter a gas collector. The method has the advantages that under the auxiliary condition of heating temperature rising, the adsorbent is desorbed in vacuum, and the power consumption and the cost of vacuum equipment are reduced; pipe-shell absorbers or the absorbers of enhanced heat transfer elements of tower inbuilt fin type, coils, and the like to increase the indirect heating and cooling efficiency; and adopting low-temperature exhaust gas discharged from the top end of an adsorption tower to directly regenerate a post adsorbent in a bed to shorten the cooling time. Compared with the prior art, the method reduces the trapping and post processing cost of the carbon dioxide.

Owner:EAST CHINA UNIV OF SCI & TECH

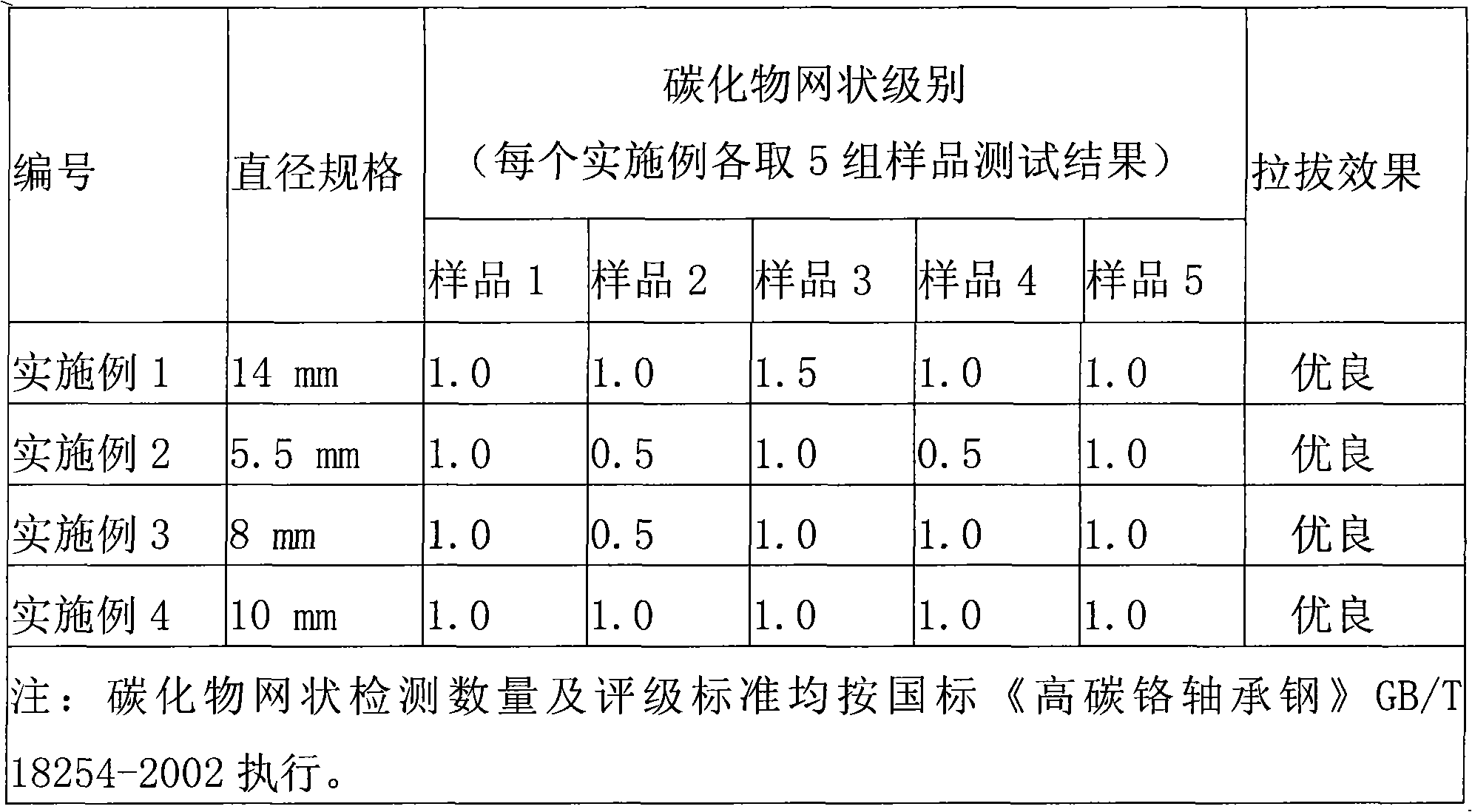

Method for reducing net level of bearing steel wire rod carbide

The invention discloses a method for reducing net level of bearing steel wire rod carbide, including the following steps: firstly, bearing steel continuous casting billet is heated and warmed up, and rough rolling, medium rolling and pre-finishing treatments are carried out at the temperature of 1030 to 1130 DEG C, so that the accumulated elongation percentage n1 of rolled pieces is 65 to 120 times; secondly, pre-hydrocooling treatment of rolled pieces is carried out, the cooling speed is controlled in the range of 10 to 40 DEG C per second, and the cooling time is controlled in the range of 0.8 to 2.2 seconds; then 4 to 10 sub-finishing treatments of rolled pieces are carried out, the start-rolling temperature is controlled in the range of 900 to 950 DEG C, and the final-rolling temperature is controlled in the range of 920 to 990 DEG C; then the rolled pieces are in hydrocooling treatment, the cooling speed is controlled in the range of 50 to 350 DEG C per second, the spinning temperature is controlled in the range of 760 to 820 DEG C, and dispersed rolls are manufactured; finally, the dispersed rolls are in air-cooled treatment, the air-cooled speed is controlled in the range of 2 to 10 DEG C per second, the roll collection temperature when the dispersed rolls come out of air-cooled roller way is controlled in the range of 330 to 450 DEG C, and the dispersed rolls are disposed in environmental air and cooled till room temperature. The products produced by using the method have 95% of carbide whose net level is less than or equal to 1.0 in which the average level is 0.95, thereby being capable of increasing abrasion resistance and service life of steel.

Owner:武钢集团有限公司

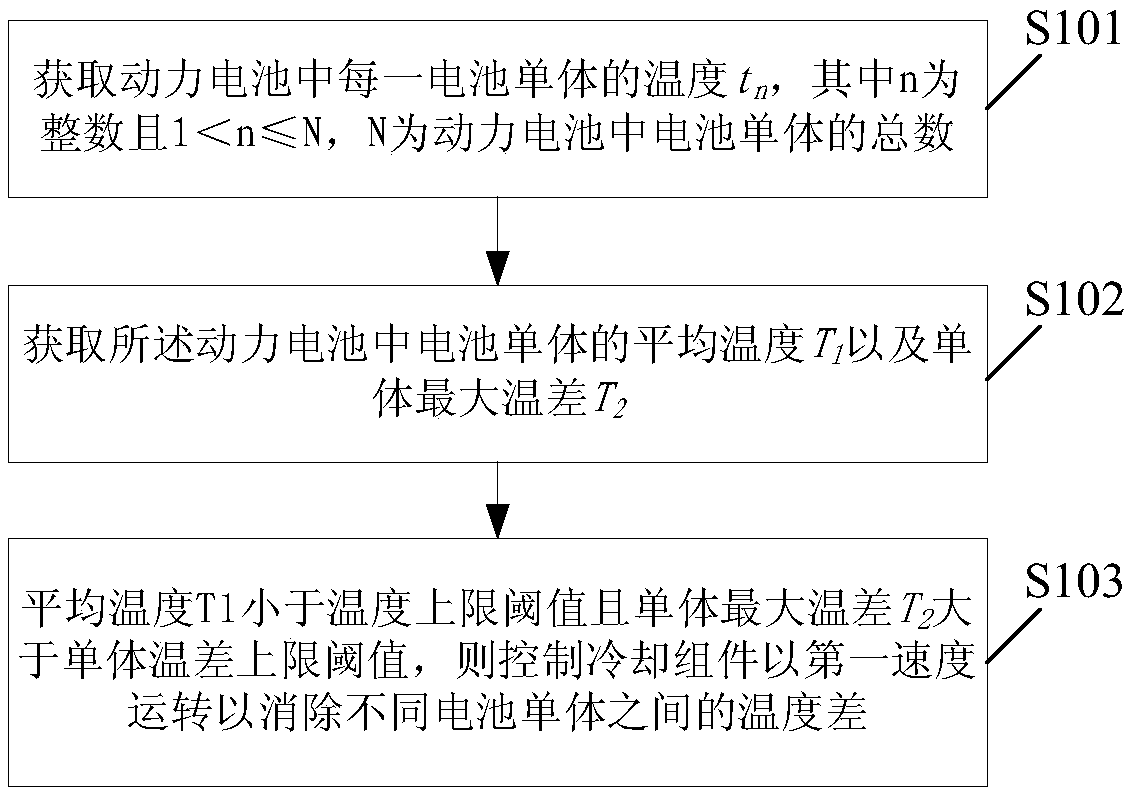

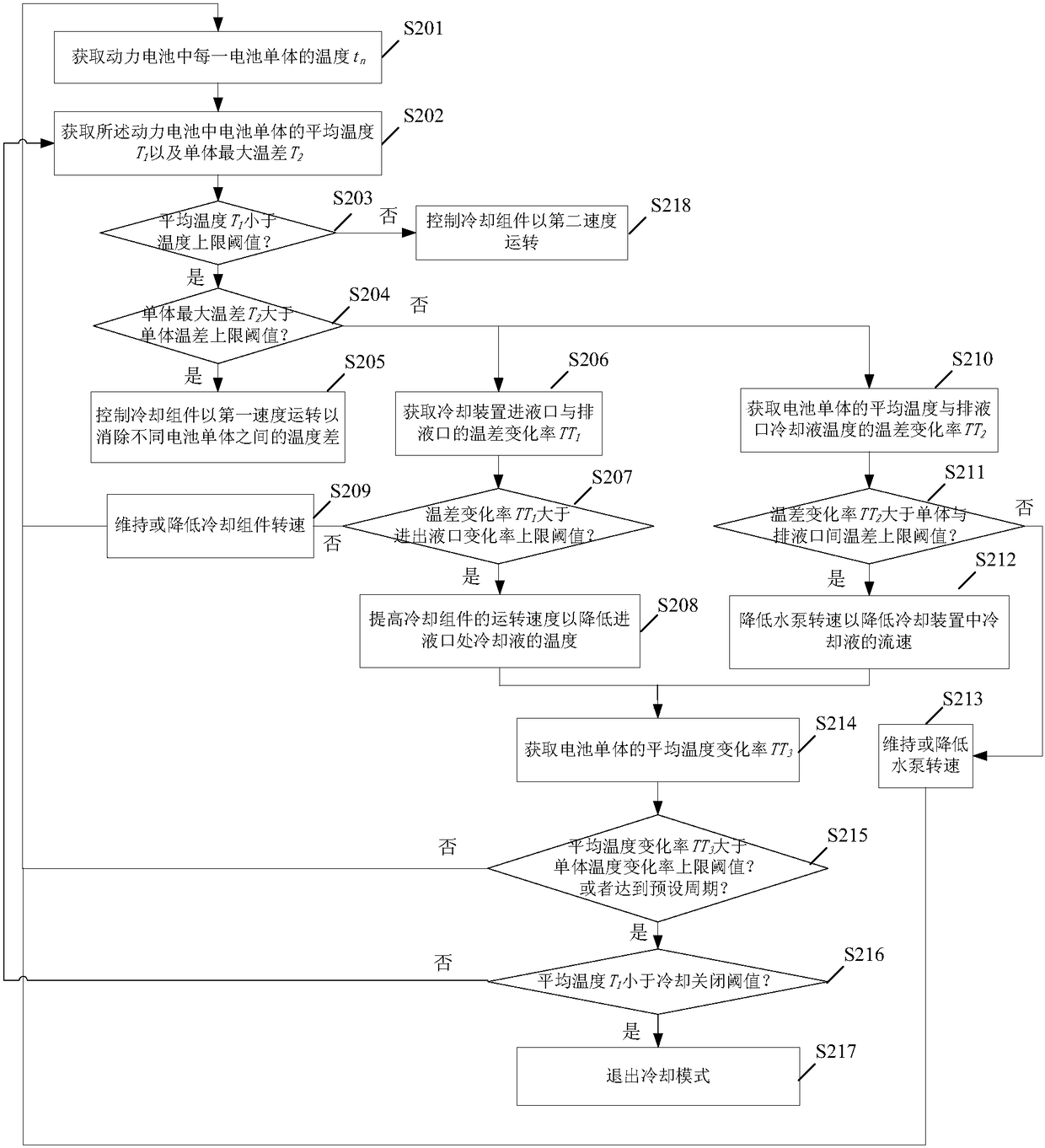

Method and system for heat management of power battery

The invention provides a method and system for heat management of a power battery. The method comprises the following steps: obtaining temperature tn of each battery cell in the power battery, whereinn is an integer and greater than 1 but less than or equal to N, and N is a total number of battery cells in the power battery; obtaining average temperature T1 of the battery cells in the power battery and a maximum temperature difference T2 of the cells, wherein T2 is equal to Max (Itn-T1I). If the average temperature T1 is less than an upper threshold value of temperature and a maximum temperature difference T2 of the cells is greater than the upper threshold value of the temperature difference of the cells, a cooling component is controlled to run at a first speed to remove the temperaturedifference between different battery cells, the first speed is greater than a speed threshold value, wherein the speed threshold value can be selected to be 50% or above of a nominal speed accordingto actual situation, and the required cooling time is shorter if the first speed is higher. Namely, when the temperature difference between various battery cells is relatively great, the various battery cells enter an imbalanced cooling mode firstly to guarantee that the temperature of the various battery cells reach an identical state, so that the output power of the power battery can be improvedmaximally and the service life of the power battery is prolonged.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Continuous casting blank hot charging and hot conveying process for preventing surface crack of steel plate

InactiveCN102059331AAvoid Surface Crack DefectsMake full use of waste heatMetallic materialsMaterials processing

The invention relates to a continuous casting blank hot charging and hot conveying process for preventing a surface crack of a steel plate under the condition of raising temperature of continuous casting blank hot charging, belonging to the technical field of metal material processing. The process comprises the following steps of: cutting a continuous casting blank on a cutting roller way, then introducing the cut continuous casting blank into a conveying roller way located between a continuous casting machine and a rolling mill, and spraying water and cooling the continuous casting blank quickly; reducing the temperature of the surface of the continuous casting blank to about 600 DEG C; controlling the cooling rate of the surface of the continuous casting blank to be 20-50 DEG C / s; controlling the cooling time of the surface of the continuous casting blank to be 15-60s; and cooling the continuous casting blank, and then introducing the cooled continuous casting blank to a heating furnace within 15min and heating. The process has the advantages that the temperature inside the continuous casting blank is ensured to be higher than 800 DEG C under the condition of ensuring the surface temperature of the continuous casting blank introduced into the heating furnace to be lower than 600 DEG C, therefore, the surface crack defect of the rolled steel plate is prevented, the waste heat of the continuous casting blank can be fully utilized, and the favorable energy saving effect is achieved.

Owner:SHOUGANG CORPORATION

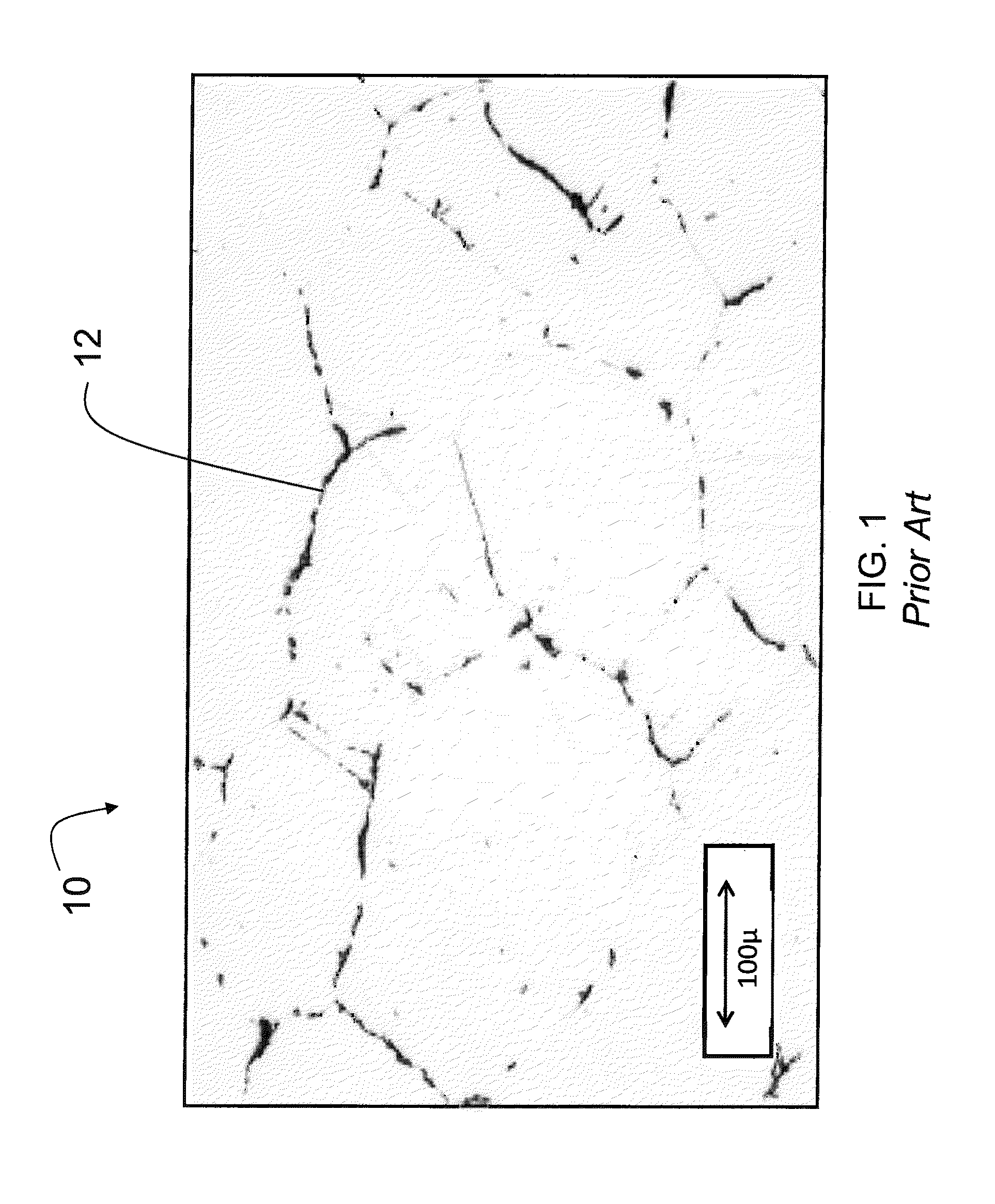

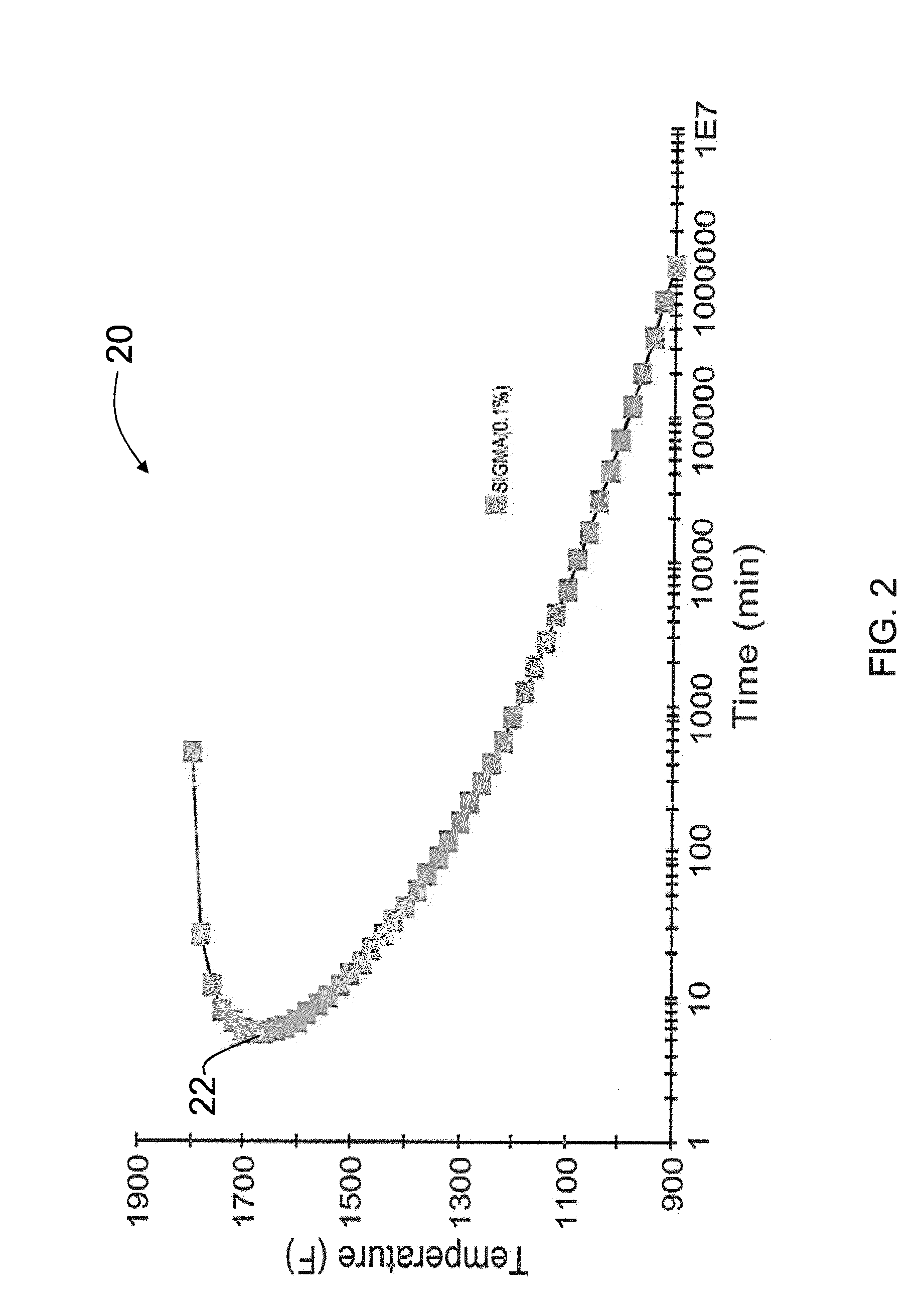

Methods for processing alloys

A method of processing a workpiece to inhibit precipitation of intermetallic compounds includes at least one of thermomechanically processing and cooling a workpiece including an austenitic alloy. During the at least one of thermomechanically working and cooling the workpiece, the austenitic alloy is at temperatures in a temperature range spanning a temperature just less than a calculated sigma solvus temperature of the austenitic alloy down to a cooling temperature for a time no greater than a critical cooling time.

Owner:ATI PROPERTIES LLC

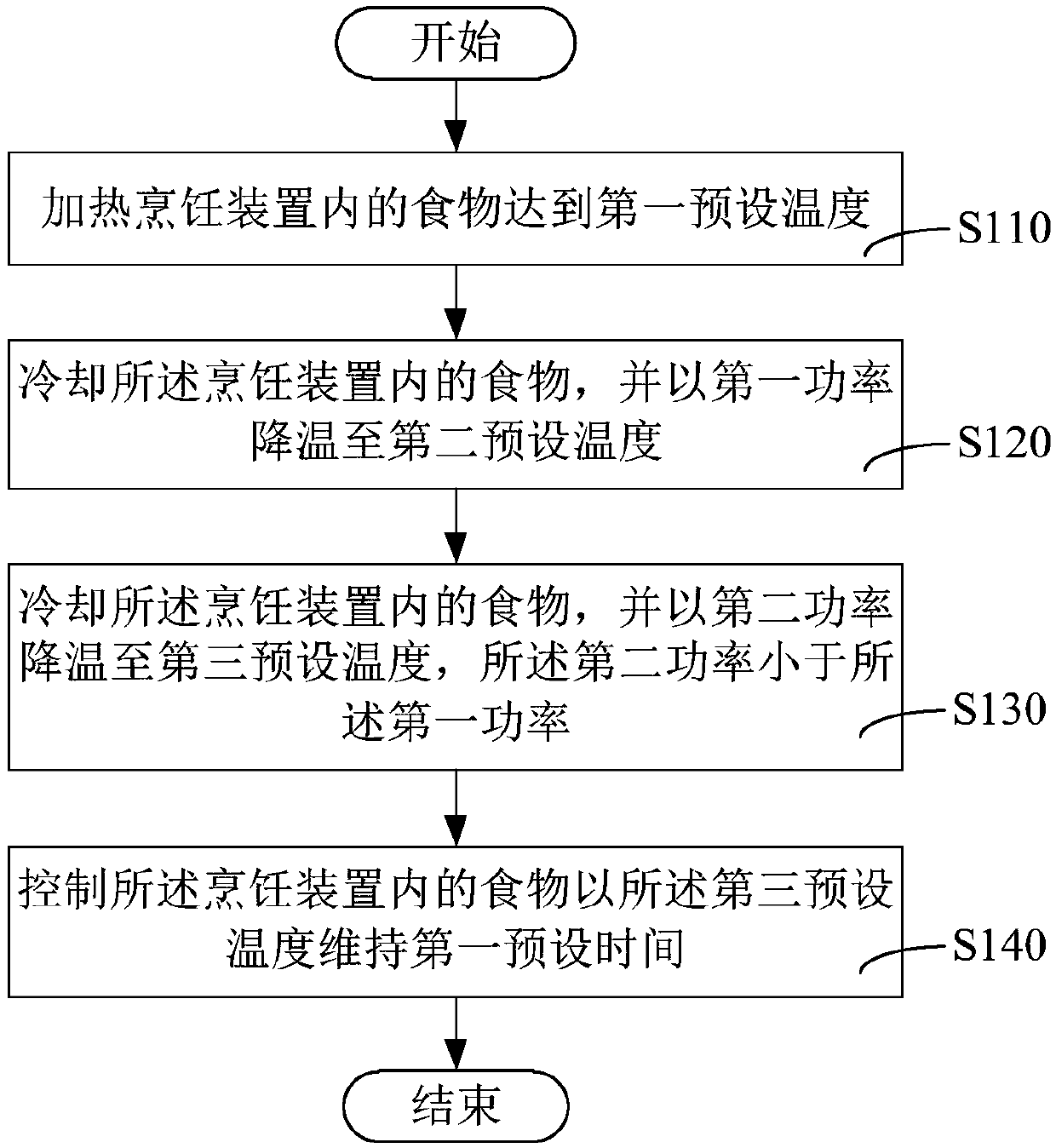

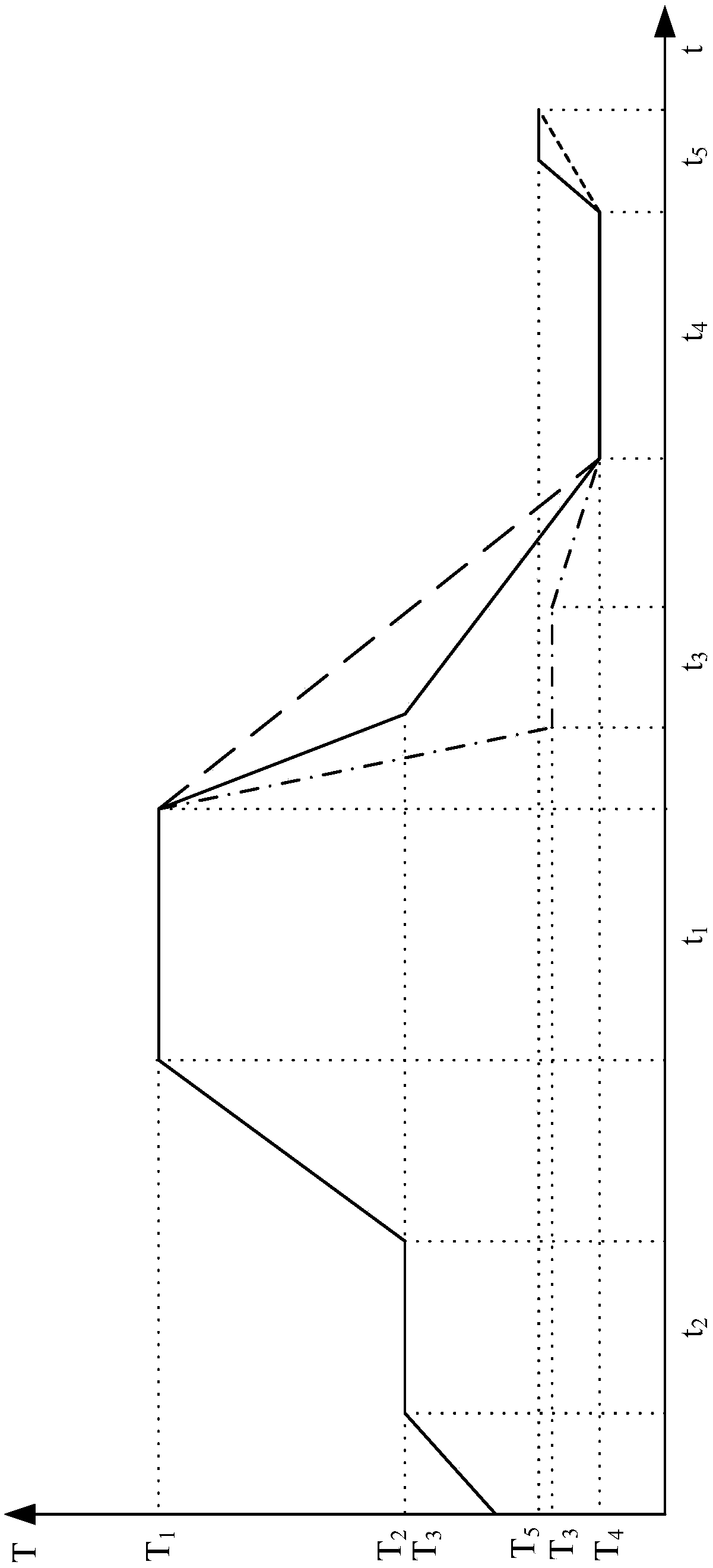

Cooking control method and cooking device

The invention relates to a cooking control method and a cooking device. The method comprises the steps that food is put into a containing cavity of a shell, and a controller controls a heater to heatfood to reach a first preset temperature; the controller controls a cooler to cool the food at the first power to a second preset temperature; furthermore, the food is cooled to a third preset temperature at the second power, wherein the second power is smaller than the first power; when the food is cooled at the first power, the food can be cooled to the second preset temperature at high speed, the efficiency of resistant starch generation is effectively improved, and the time which is not beneficial to resistant starch generation is shortened; when cooling is conducted at the second power, the cooling time can be effectively prolonged, which is more beneficial to formation of crystal nucleus of resistant starch in the food at the early stage; the food is subjected to heat preservation form first preset time at the third preset temperature, so that the food keeps at the third preset temperature which is beneficial to resistant starch generation, and the content of the resistant starchin the food can be further increased.

Owner:GREE ELECTRIC APPLIANCES INC

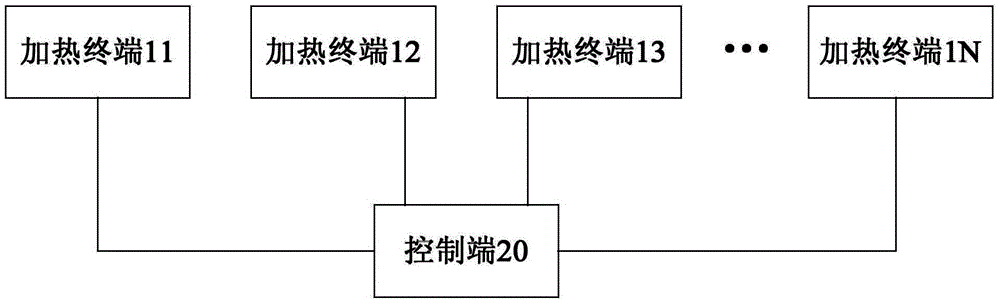

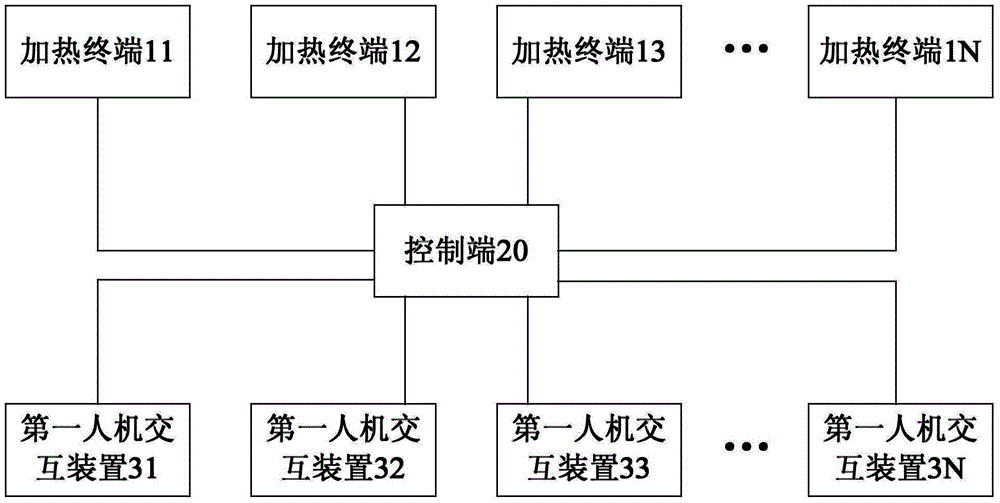

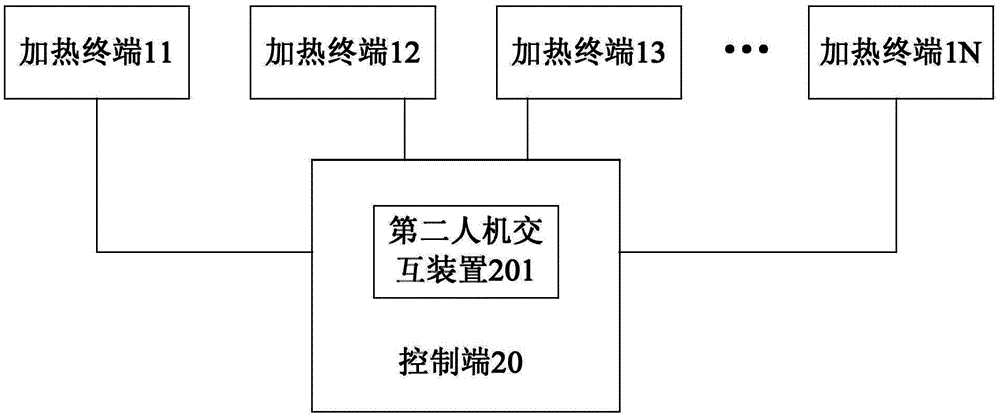

Automatic cooking system and control method thereof

ActiveCN105204451AConsistent cooking timeSame end timeCooking vesselsProgramme total factory controlLife qualityStart time

The invention discloses an automatic cooking system comprising multiple heating terminals and a control terminal for controlling the multiple heating terminals. The control terminal acquires the cooling time of a dish to be cooked by each of the heating terminals about to work in the multiple heating terminals, generates corresponding start time according to the cooking time of each heating terminal about to work, and controls the starting of the corresponding heating terminals about to work according to the start time of the heating terminals about to work so as to enable the end time of the dishes cooked by the heating terminals about to work to be consistent. According to the automatic cooking system, the multiple terminals for cooking different dishes can complete cooking at the same time, the cooking time is greatly reduced, and convenience is brought to users. Moreover, multiple different dishes are completed at the same time, users do not need to wait, users can feel that all the multiple different dishes are just taken out of the pot, and the living quality of people is improved. The invention further discloses a control method of the automatic cooking system.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

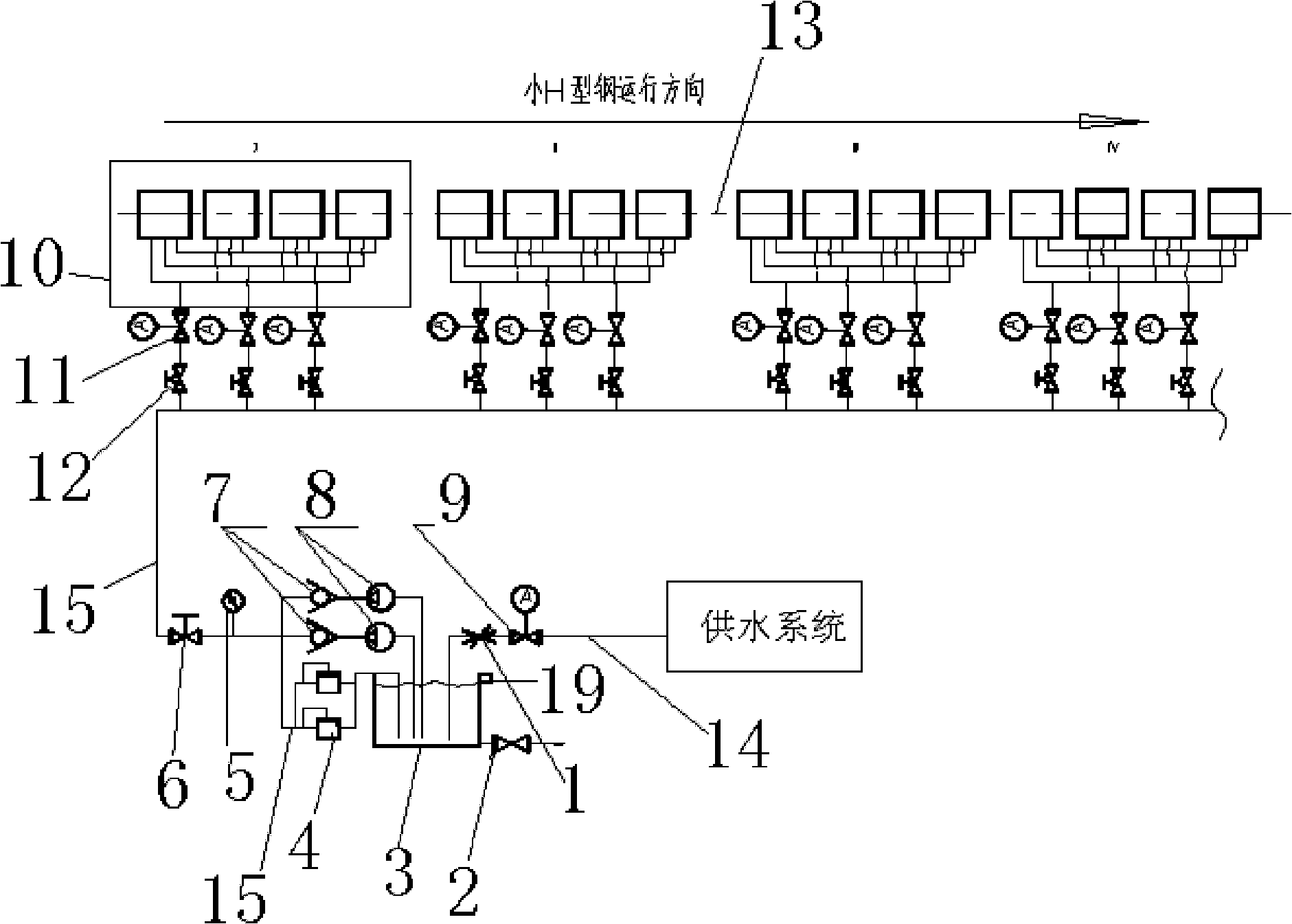

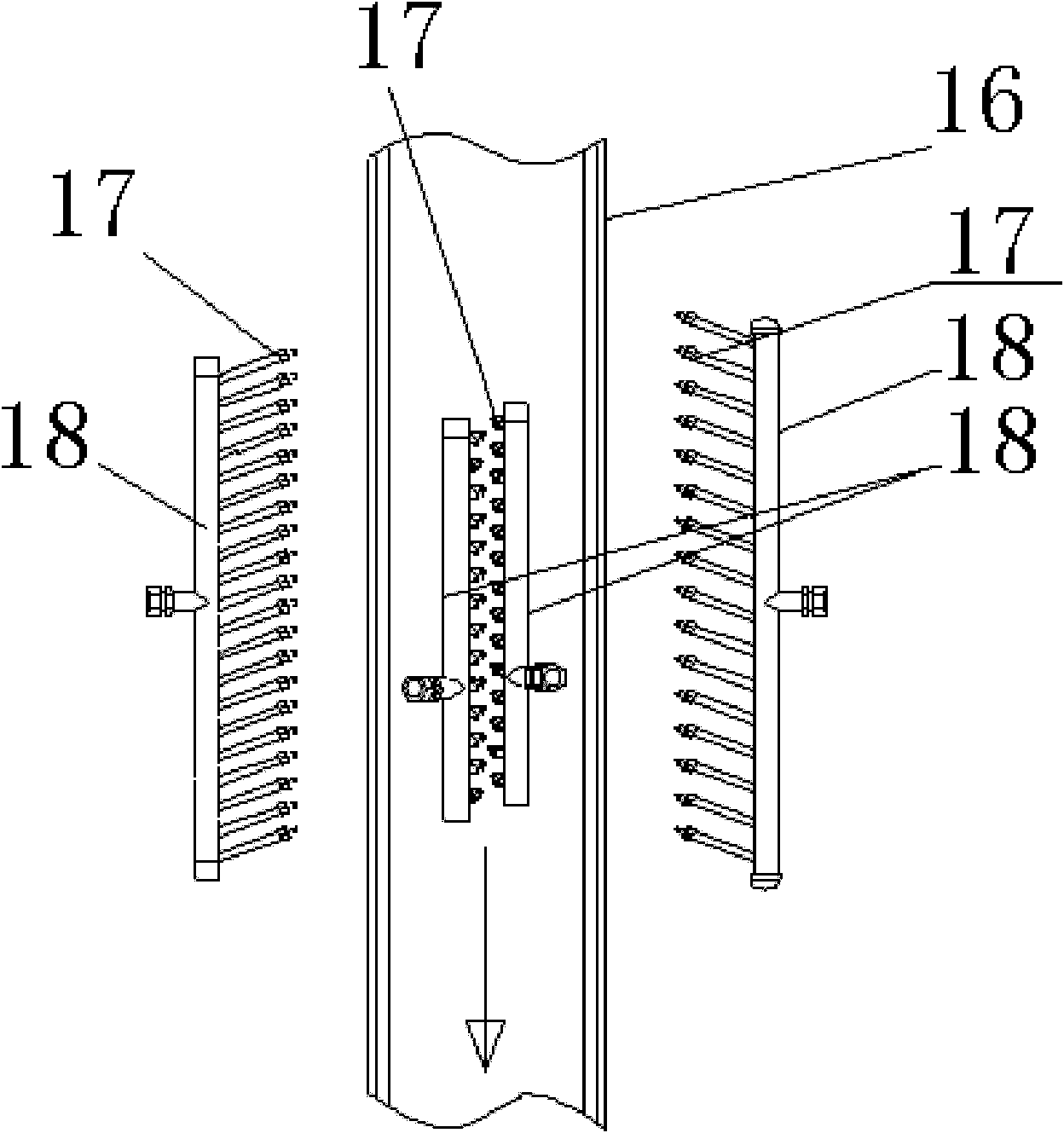

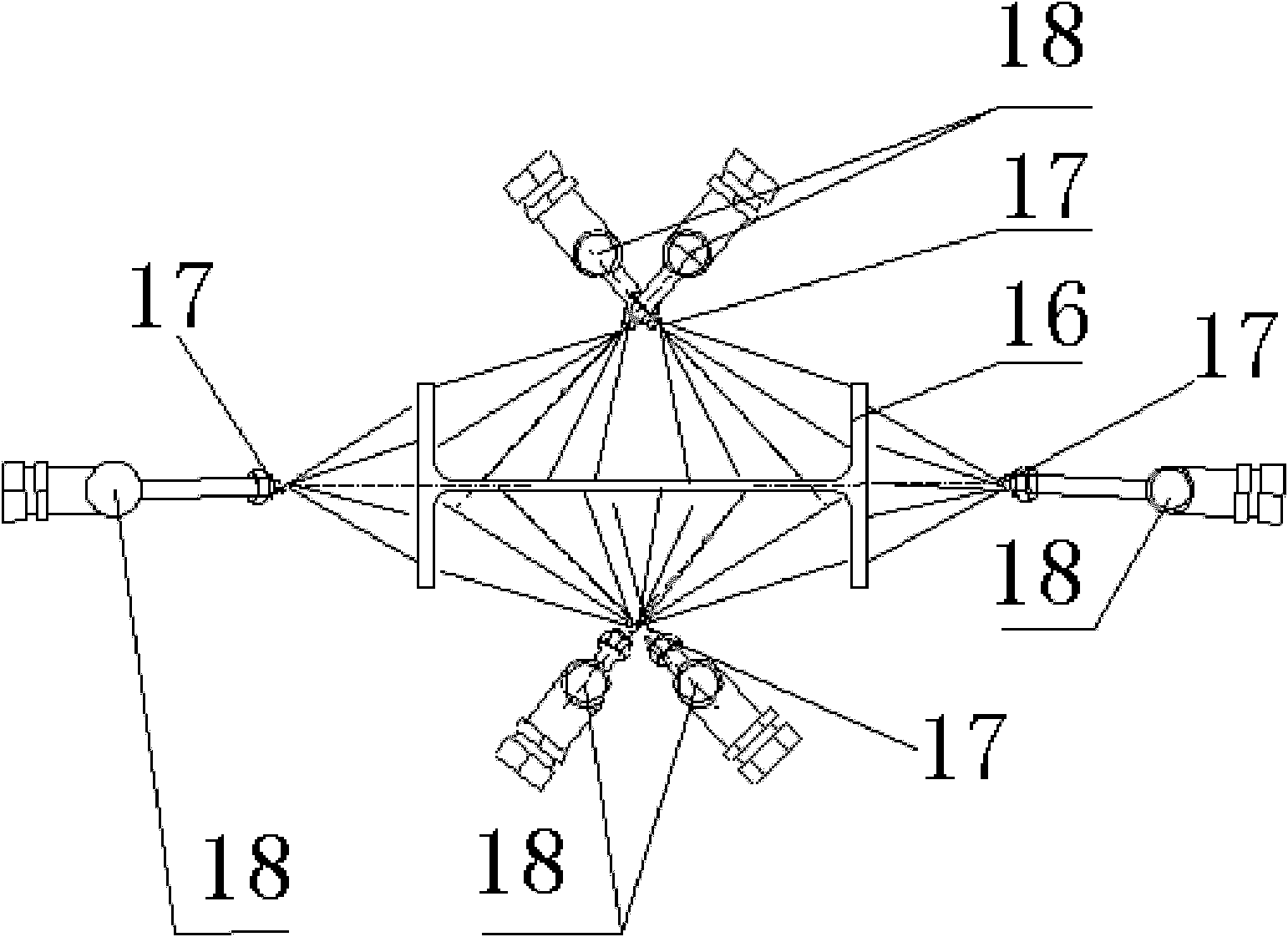

System and process for cooling after H-shaped steel is hot-rolled

ActiveCN102069097ARealize online forced coolingHigh yield strengthWork treatment devicesMetal rolling arrangementsControl systemEngineering

The invention discloses a system and a process for cooling after H-shaped steel is hot-rolled. The cooling system comprises a control system, a cooling module, a water tank, a water inlet pipeline and a water outlet pipeline, wherein one side of the water inlet pipeline is connected with a water supply system, and the other side of the water inlet pipeline is connected with the water tank; and one side of the water outlet pipeline is connected with the water tank, and the other side of the water outlet pipeline is connected with the cooling module. The cooling process comprises the following steps of: feeding the hot-rolled H-shaped steel into the cooling system, aligning upper and lower R parts of the hot-rolled H-shaped steel with cooling nozzles arranged on the upper and lower sides, aligning flange centers on the left and right sides of the hot-rolled H-shaped steel with cooling nozzles arranged on the left and right sides, performing spray cooling, and controlling the pressure of cooling water to be between 8 and 10MPa, the flow of the cooling water to be between 400 and 600m<3> / h, the continuous cooling time of each cross section on section steel to be between 10 and 15 seconds and the cooling rate to be between 30 and 50 DEG C / s. The cooling system with small investment is particularly suitable for improving the strength of the hot-rolled H-shaped steel of small specification of below 400mm*200mm.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

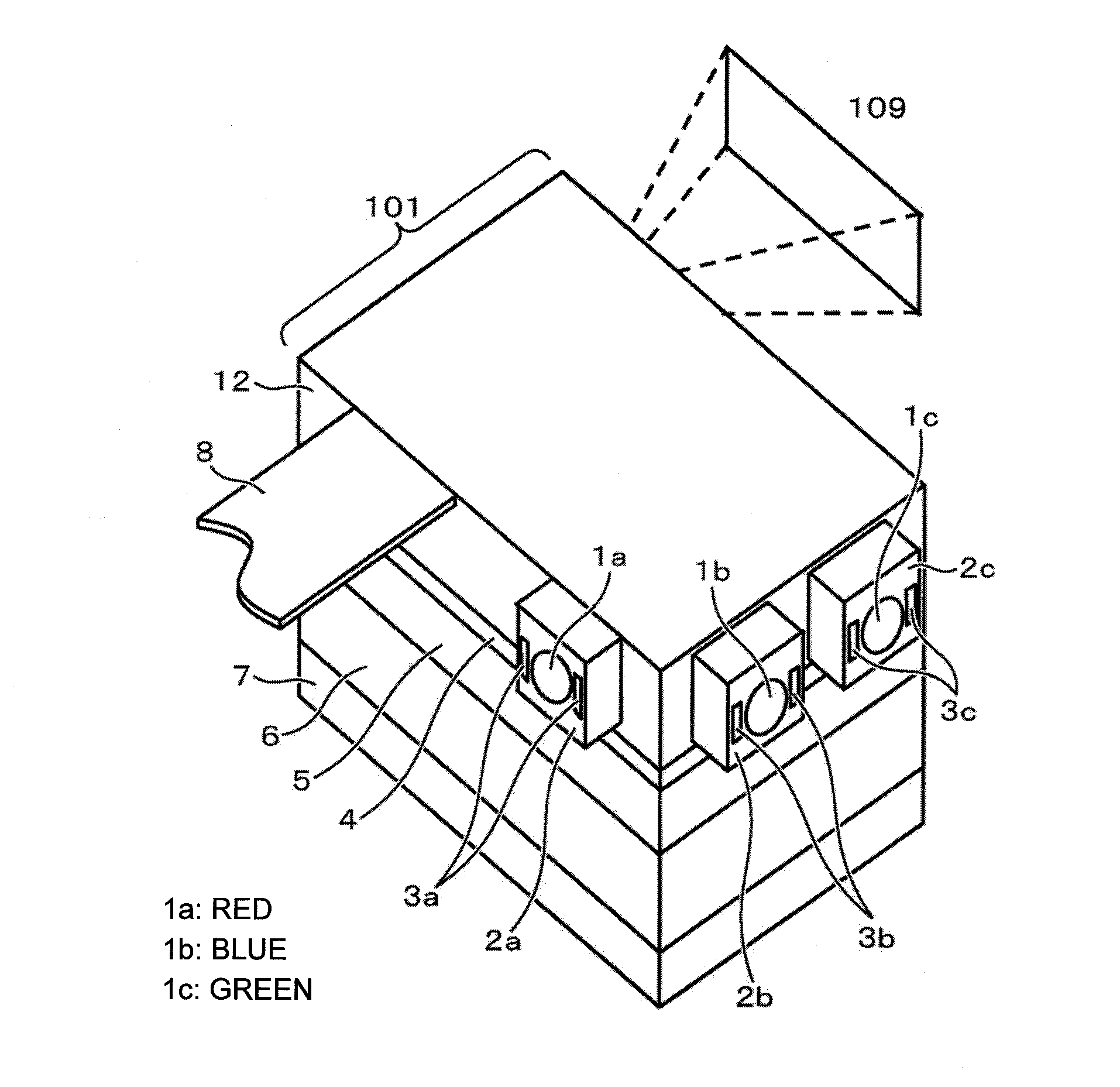

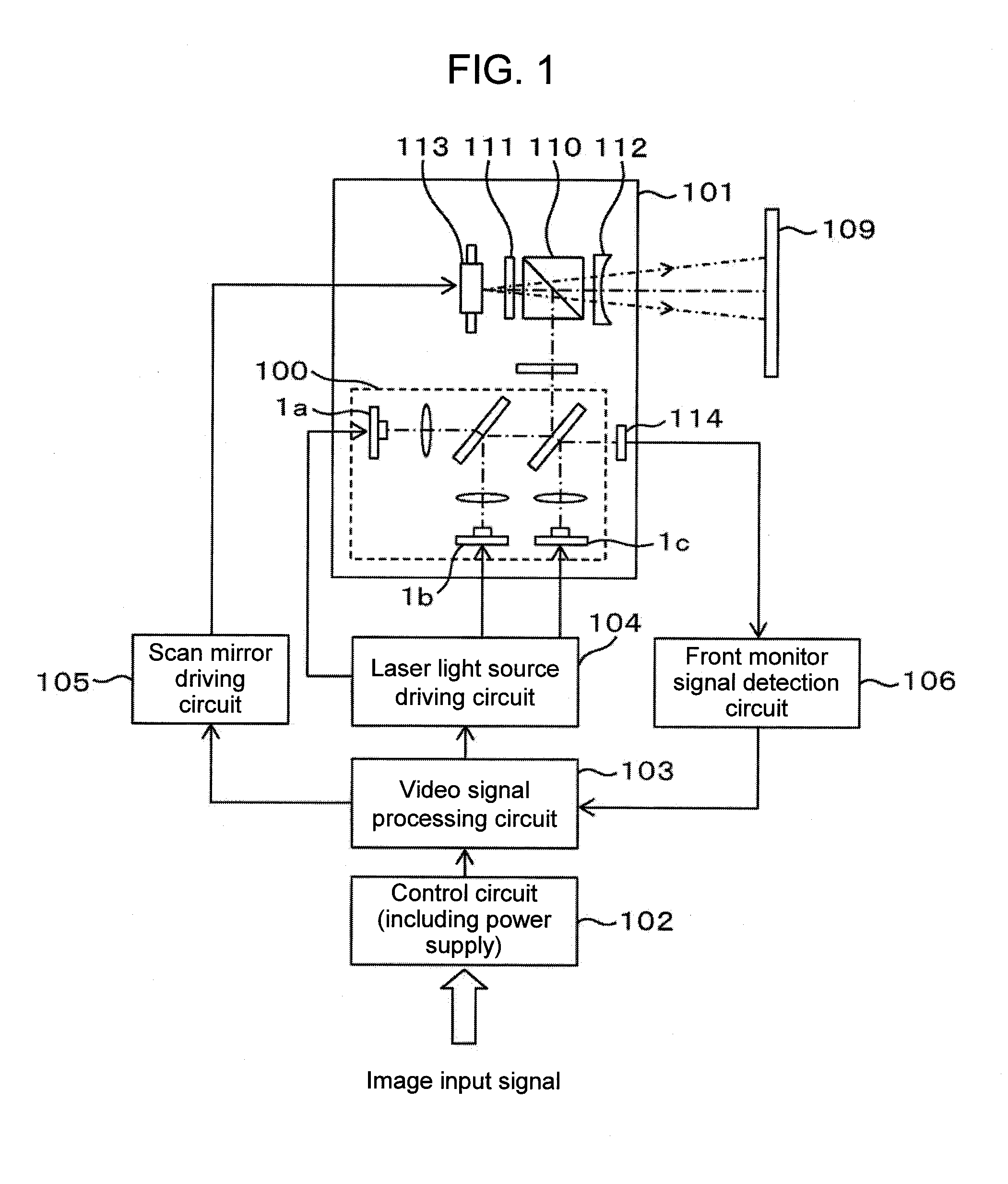

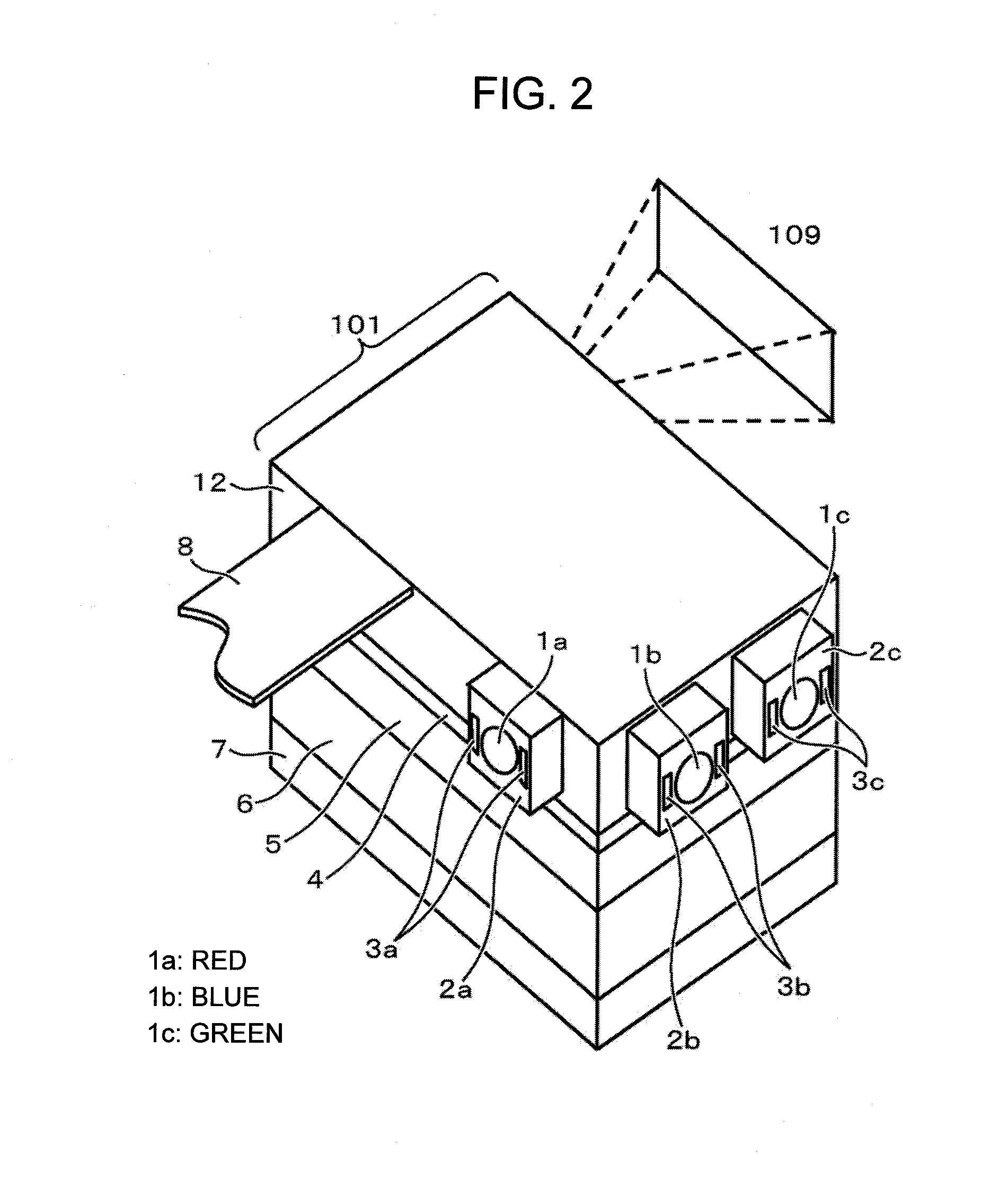

Optical module and scanning image display device

InactiveUS20130242265A1Suppress positionalSuppress a relative positional displacement of each spotLighting support devicesLighting heating/cooling arrangementsHeating timeOptical Module

In an optical module that aligns light beams from lasers of the three colors of red, green, and blue along a single combined beam optical axis, when the ambient temperature range is wider than the guaranteed operating range of the lasers, relative positional displacements of beam spots of the three colors that are generated due to a displacement or a deformation resulting from a temperature range at a heating time or a cooling time are suppressed. The optical module, which has mounted thereon a plurality of lasers, and emits light beams from the plurality of lasers, includes a cooling device that cools the entire optical module via a case on which the optical module is mounted, and heating devices that are provided on respective laser holders and individually heat the respective lasers.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

Laser molten overlying process of thin-walled cylindrical device

InactiveCN101204757AImprove performanceEvenly distributed inputLaser beam welding apparatusHeating timeEngineering

Owner:SHENYANG DALU LASER TECH

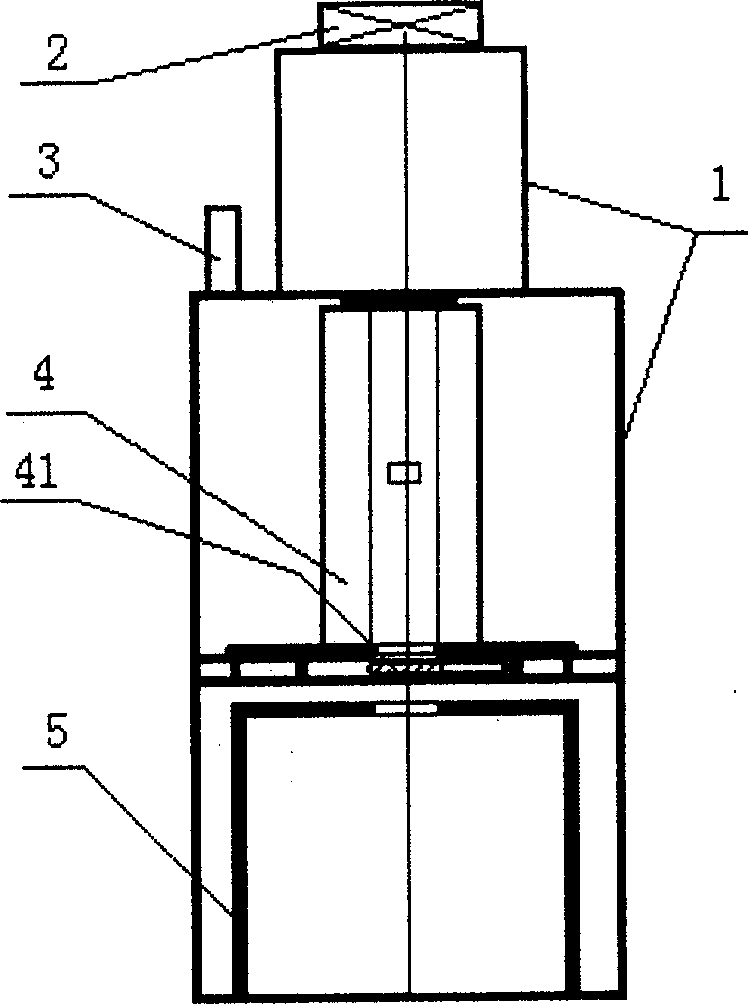

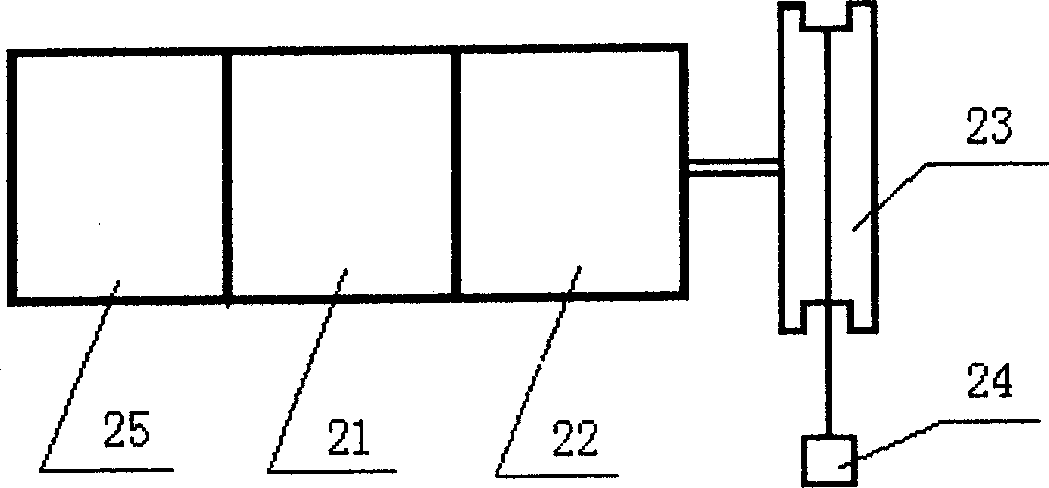

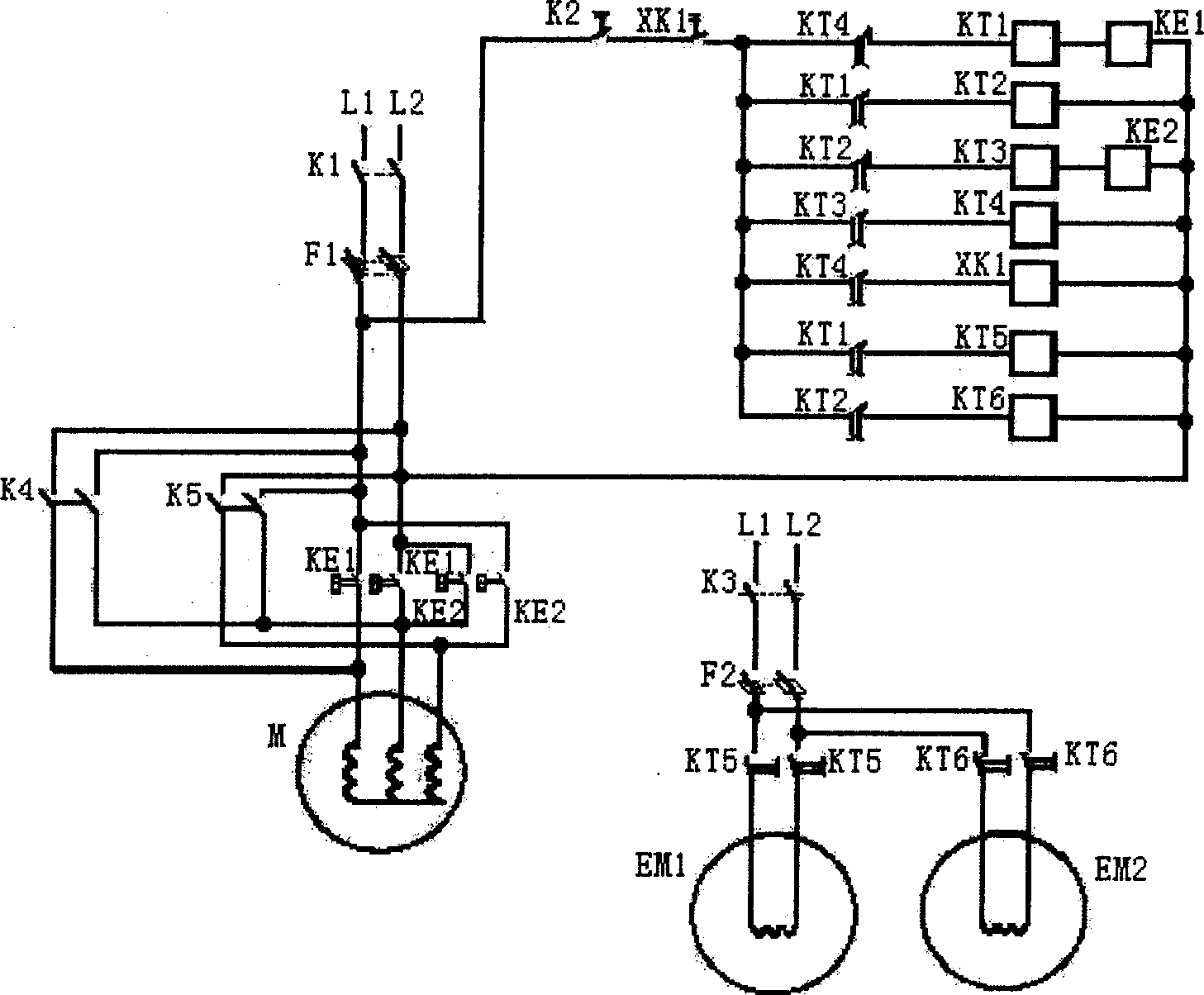

Thermal fatigue tester

InactiveCN1796970AFlexible operationPrecise positioningMaterial thermal analysisStrength propertiesEngineeringCooling time

The invention provides a thermal fatigue tester, where a cooling system, a heating system, a control system and a lift system are arranged on a bracket; the cooling system is composed of a water tank and a thermometer inserted in the water, the heating system is composed of a resistance furnace, a slide gate and a thermocouple inserted in the resistance furnace, and the electric machine of the lift system drives a test piece through reduction gearbox and rotary table; the control system is composed of raising control circuit, heat insulating time control circuit, lowering control circuit, cooling time control circuit, slide gate control circuit, circulating counting control circuit and the like; the contacts of a raising time relay are in the heat insulating time control circuit and the power supply circuit of a slide gate closing electromagnetic relay; the contacts of a heat insulating time relay are in the lowering control circuit and the power supply circuit of a slide gate opening electromagnetic relay; the contacts of a lowering time relay are in the cooling time control circuit; the contacts of a cooling time relay are in the raising control circuit and the counting control circuit; the contacts of a counter are in the main circuit of the control system. The advantages: completely automatic, flexible to operate and accurate to locate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

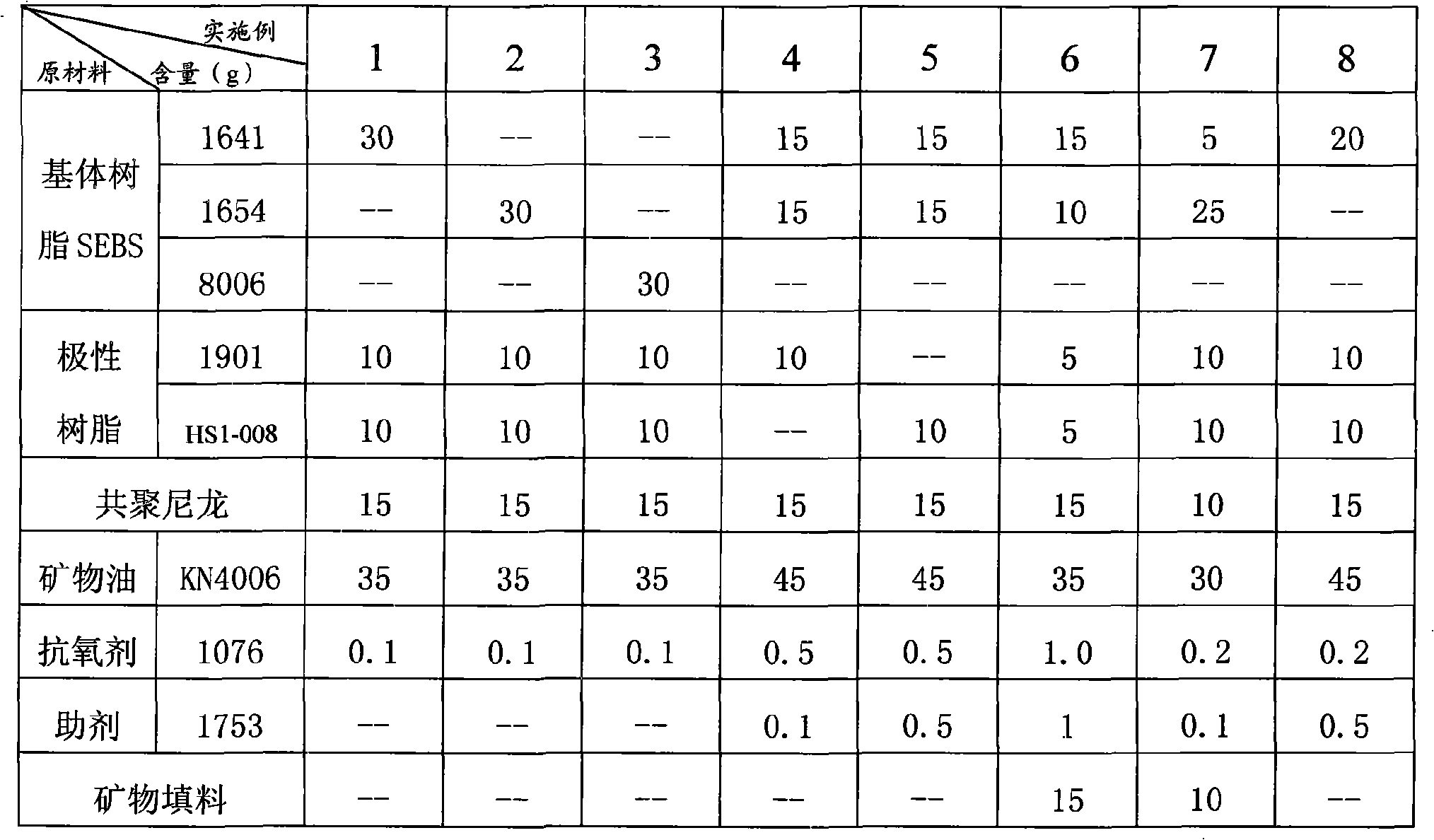

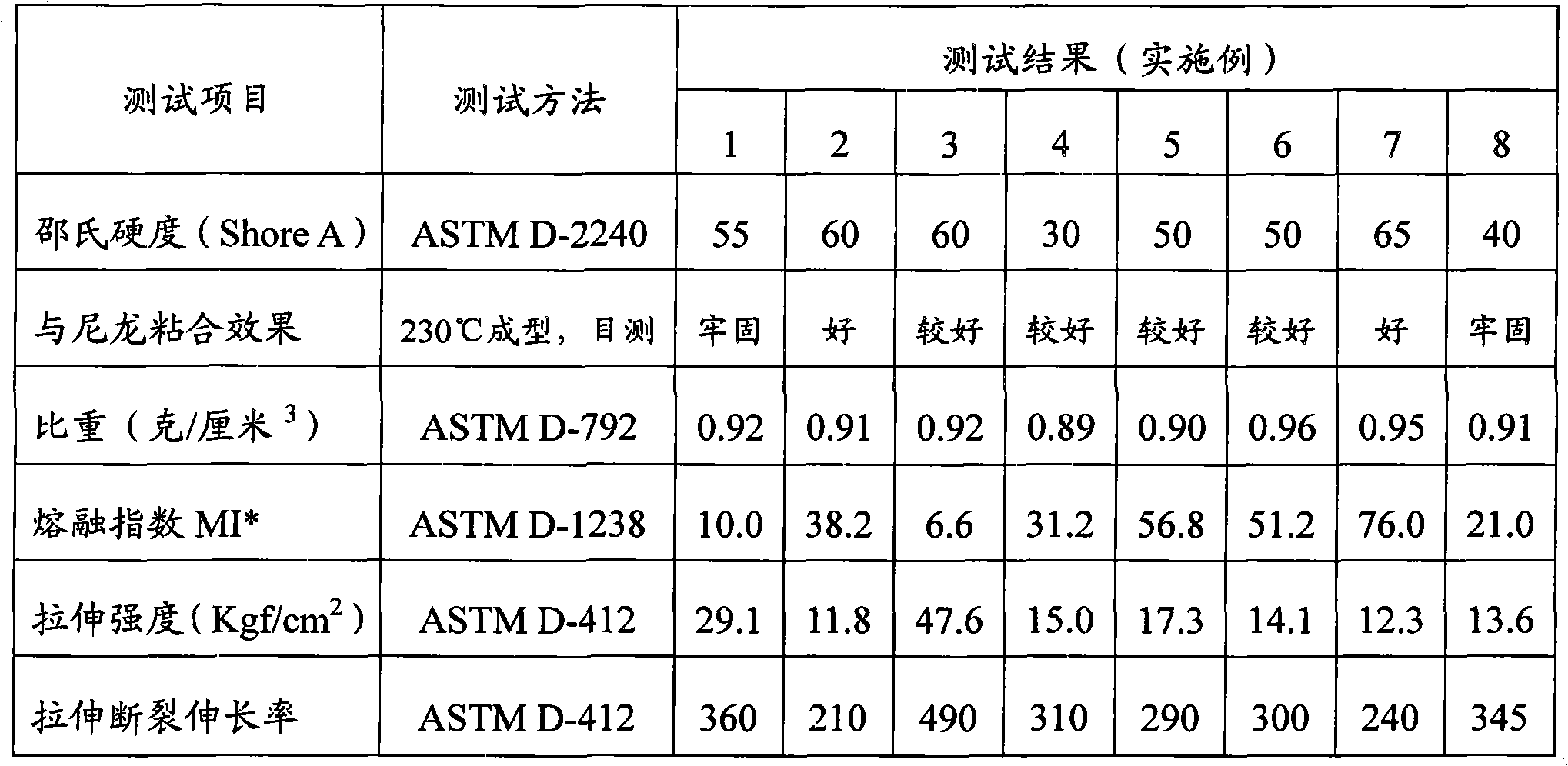

Thermoplastic elastomer for nylon material secondary injection adhering

ActiveCN101255263AEasy to adjust hardnessReduce compounding componentsNylon materialProcedure Agents

The invention relates to a thermoplastic elastomer for second encapsulating nylon, comprising: 20-30 portions of matrix resin SEBS, 10-20 portions of polarity resin, 10-15 portions of mineral oil, 0.1-1 portions of antioxidant and selectively adding 10-15 portions of mineral filler and 0.1-1 portions of processing agents. The raw material of the thermoplastic elastomer does not contains coupling agent and the injection moulding temperature is low during second encapsulating nylon composites and the cooling time of the forming is reduced and the production efficiency is increased. The second encapsulation between the obtained end product and nylon is firm and the shaping is good, with better hand feeling compared to the present product with lower hardness.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

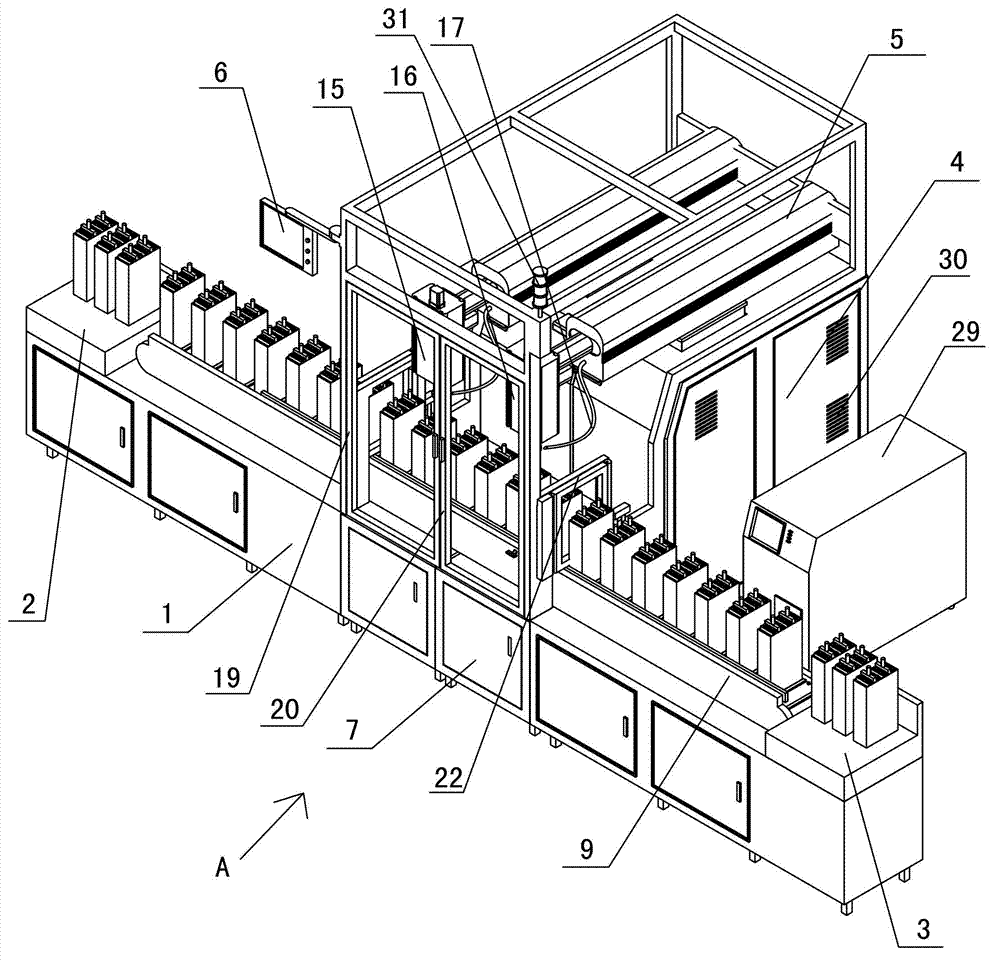

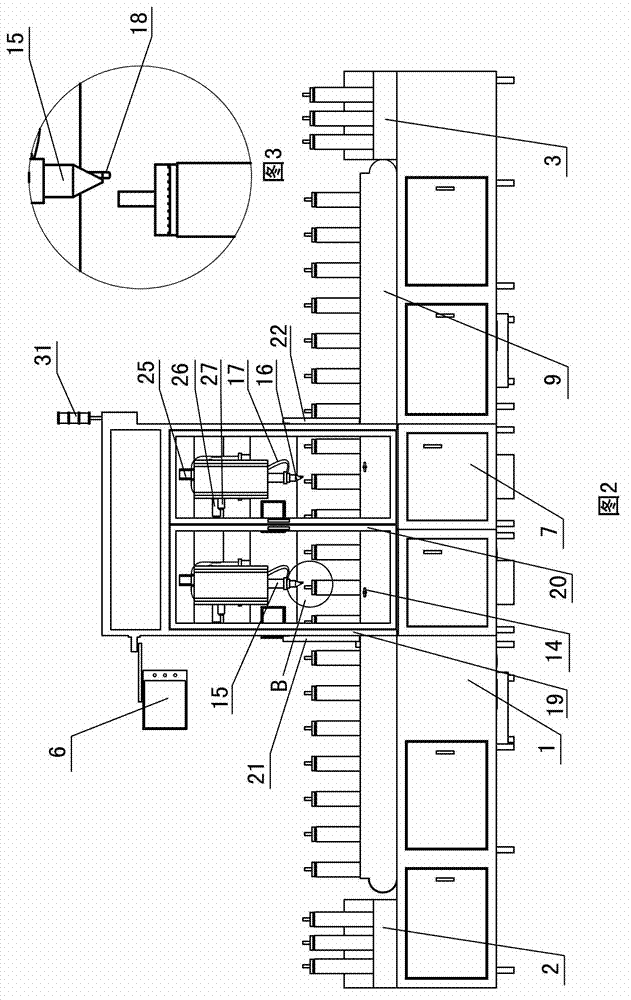

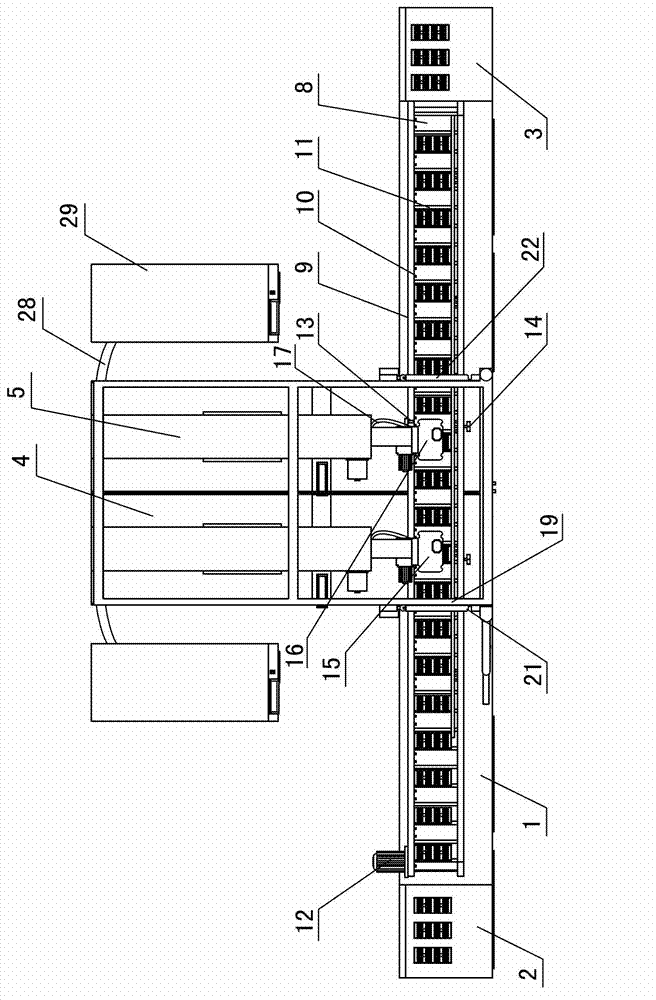

Linear type laser-beam welding machine of capacitance battery and welding method of linear type laser-beam welding machine

ActiveCN103028845ASimple designReasonable process layoutLaser beam welding apparatusCapacitanceEngineering

The invention relates to a linear type laser-beam welding machine of a capacitance battery and a welding method of the linear type laser-beam welding machine. The linear type laser-beam welding machine comprises a working platform, a front placing platform, a transmission device, a rear placing platform, a welding mechanism and a control panel, wherein the control panel is internally provided with a function control module. The welding method comprises the following steps of placing a to-be-welded battery workpiece which is placed on the front placing working platform in a locating device on the transmission device, starting the control panel, controlling a conveyor belt to move, and welding the front half part and the rear half part of the battery workpiece. According to the linear type laser-beam welding machine and the welding method, disclosed by the invention, the linear type operation is realized, the design is simple, the process layout is reasonable, and continuous feeding and locating can be carried out; the distance can be automatically fixed during a feeding process, the locating time of a photograph detection device is shortened, and the automation efficiency is increased; the moving distance of a laser welding head is shortened, the cooling time of a welding workpiece is enough, and the welding quality is increased; and a pole can be recycled and reused after the battery is scraped, and the manufacturing cost of the laser-beam welding machine is further reduced.

Owner:淄博国利新电源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com