Method and system for heat management of power battery

A power battery and thermal management technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of short service life and poor energy-saving effect of power batteries, and achieve the effects of fast cooling response, simple algorithm, and improved fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

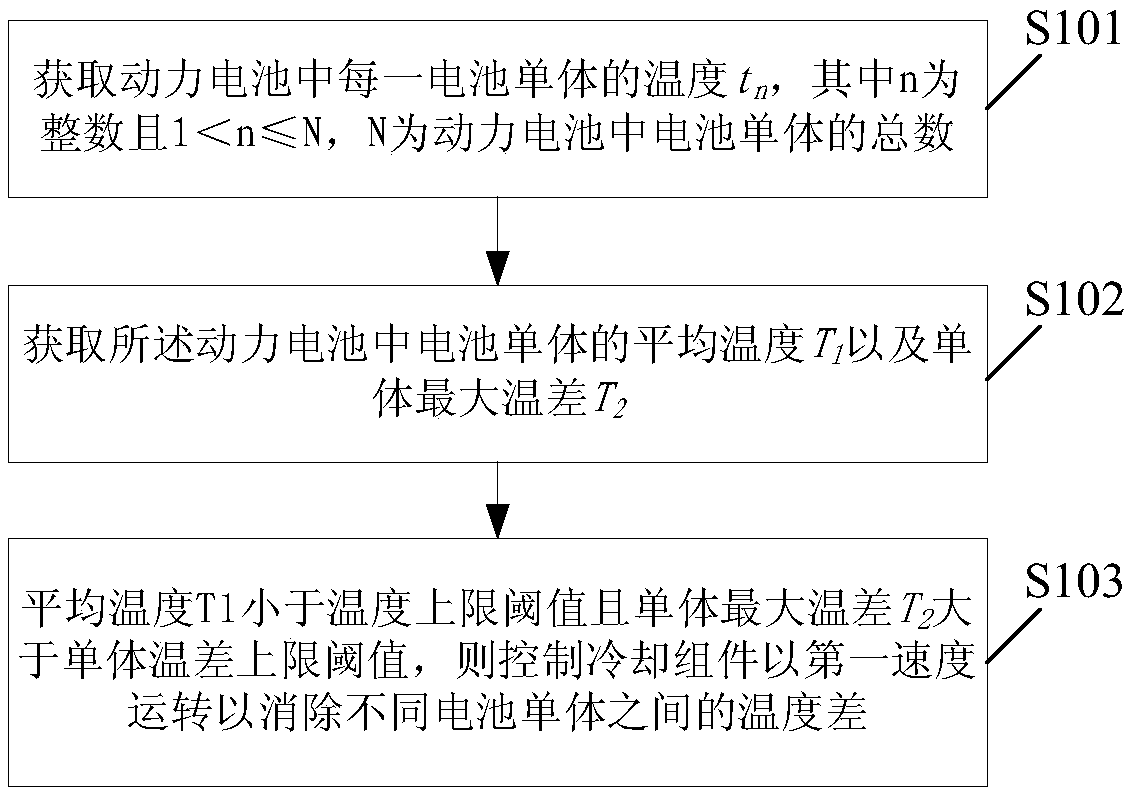

[0026] This embodiment provides a power battery thermal management method, which can be applied to a battery thermal management system, such as figure 1 As shown, it includes the following steps:

[0027] S101: Obtain the temperature t of each battery cell in the power battery n , where n is an integer and 1<n≤N, N is the total number of battery cells in the power battery; the power battery includes N battery cells, and the temperature of the battery cells can be obtained through the temperature detection hardware structure inside the battery pack In this step, the detection result of the temperature detection hardware structure can be obtained directly.

[0028] S102: Obtain the average temperature T of the battery cells in the power battery 1 And the maximum temperature difference T of the monomer 2 , where T 2 =Max(|t n -T 1 |); the average temperature T of the battery cell in the power battery 1 It can be calculated directly by using the calculation method of the av...

Embodiment 2

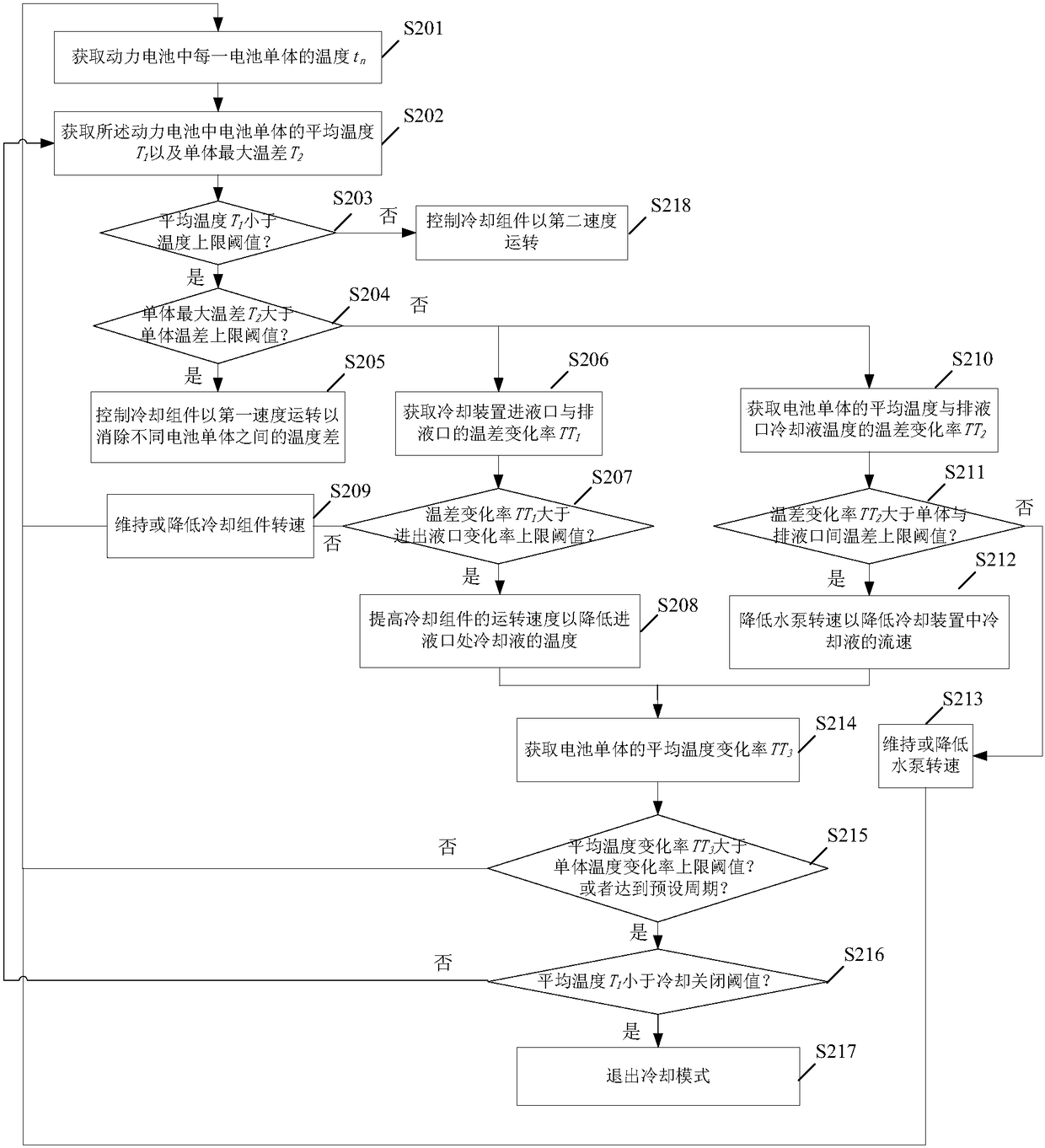

[0032] This embodiment provides a power battery thermal management method, which can be applied to a battery thermal management system, such as figure 2 As shown, it includes the following steps:

[0033] S201: Obtain the temperature t of each battery cell in the power battery n , where n is an integer and 1<n≤N, N is the total number of battery cells in the power battery.

[0034] S202: Obtain the average temperature T of the battery cells in the power battery 1 And the maximum temperature difference T of the monomer 2 , where T 2 =Max(|t n -T 1 |).

[0035] S203: Determine the average temperature T 1 Whether it is lower than the temperature upper limit threshold, if so, execute step S204; otherwise, execute step S218.

[0036] S204: Determine the maximum temperature difference T of the monomer 2 Whether it is greater than the upper threshold of body temperature difference, if so, perform step S205, otherwise, perform step S206 and / or S210, and the steps S206 and S2...

Embodiment 3

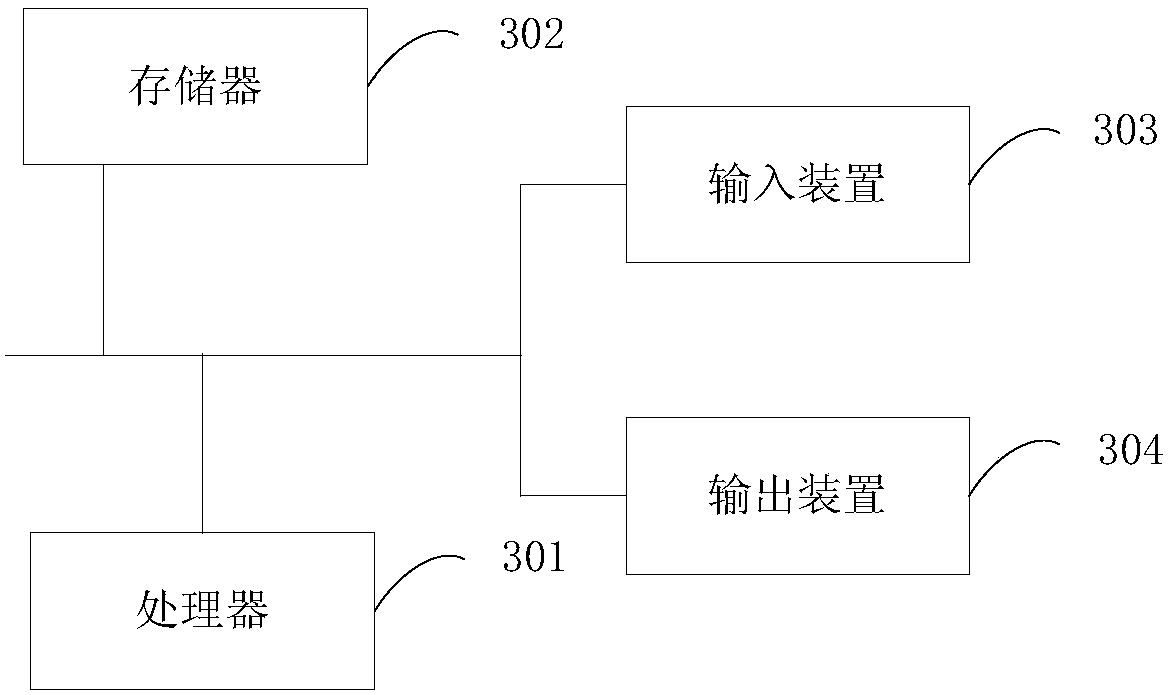

[0065] This embodiment provides a computer-readable storage medium, in which instruction information is stored, and the computer can execute the power battery thermal management method described in any solution in Embodiment 1 or 2 after reading the instruction information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com