Device for realizing laser welding and seam tracking and control method thereof

A technology of laser welding and control method, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of huge system structure, complex composition, lack of universal, flexible and independent real-time welding seam tracking system, etc. Strong sex, high independence, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

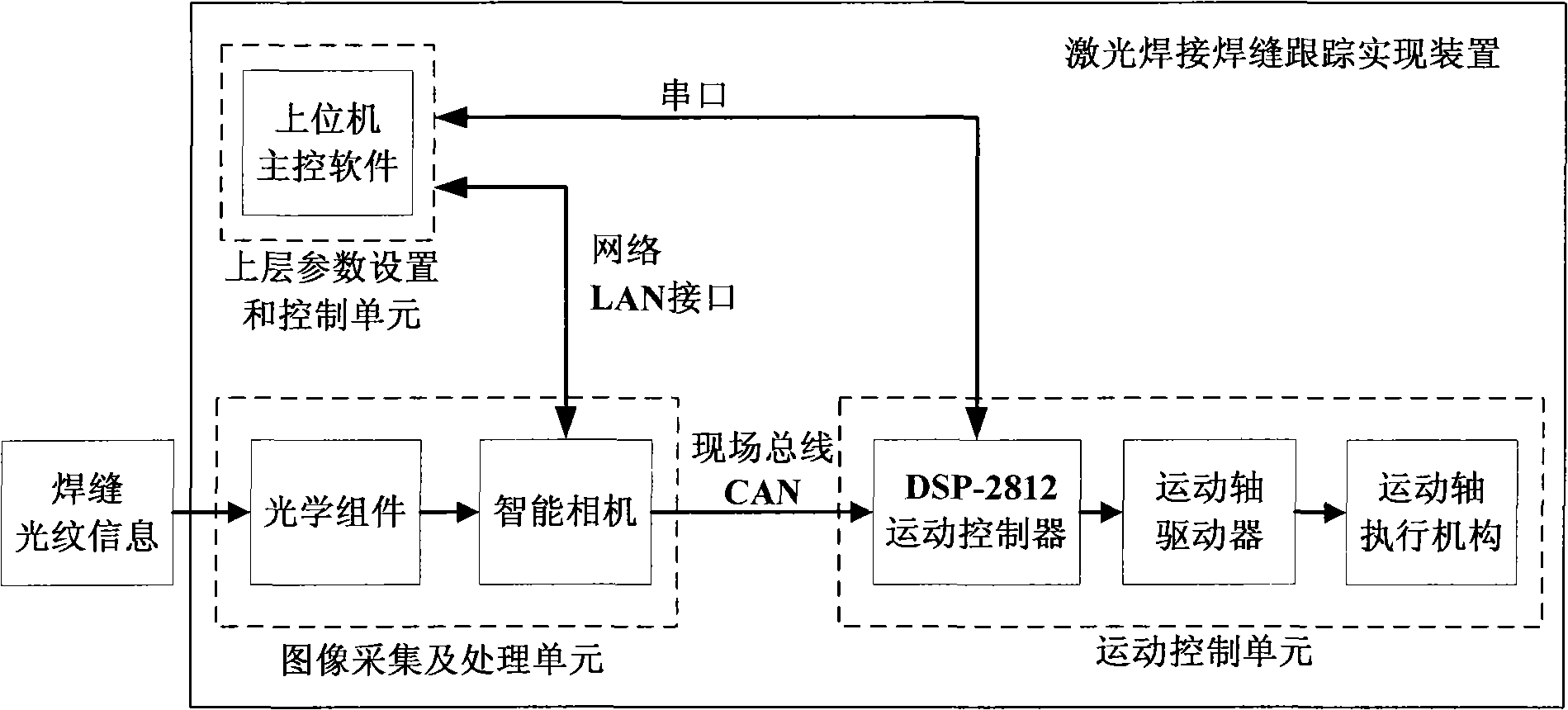

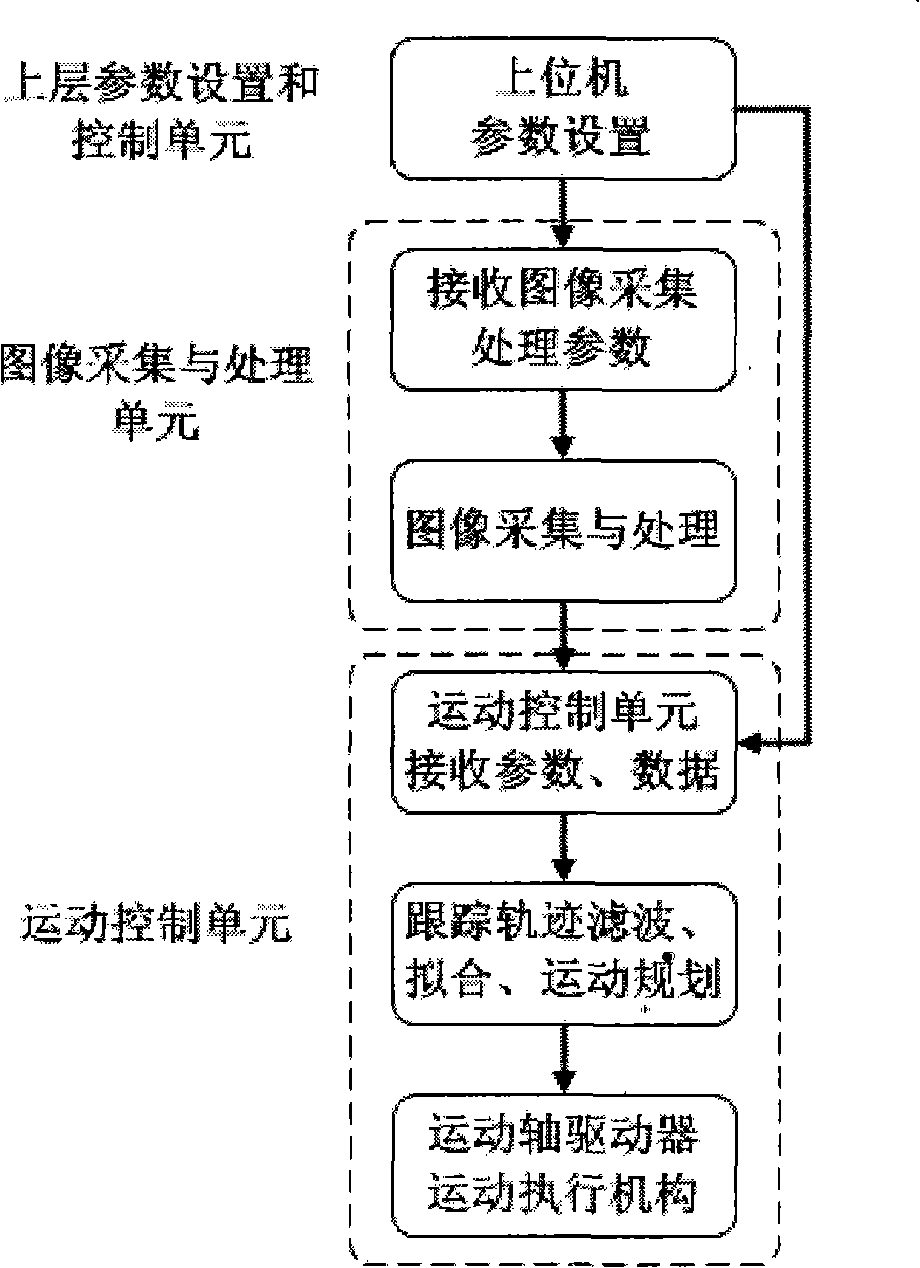

[0071] The device structure of the present invention is as figure 1 shown, including:

[0072] The image acquisition and processing unit collects image data of laser welding seam features, processes the image data and outputs weld position information;

[0073] The motion control unit receives the above welding seam position information for analysis and processing, and sends a motion control command to the motion axis actuator;

[0074] The upper layer parameter setting and control unit sets image acquisition and processing parameters and motion control parameters, and communicates with the image acquisition and processing unit and motion control unit respectively.

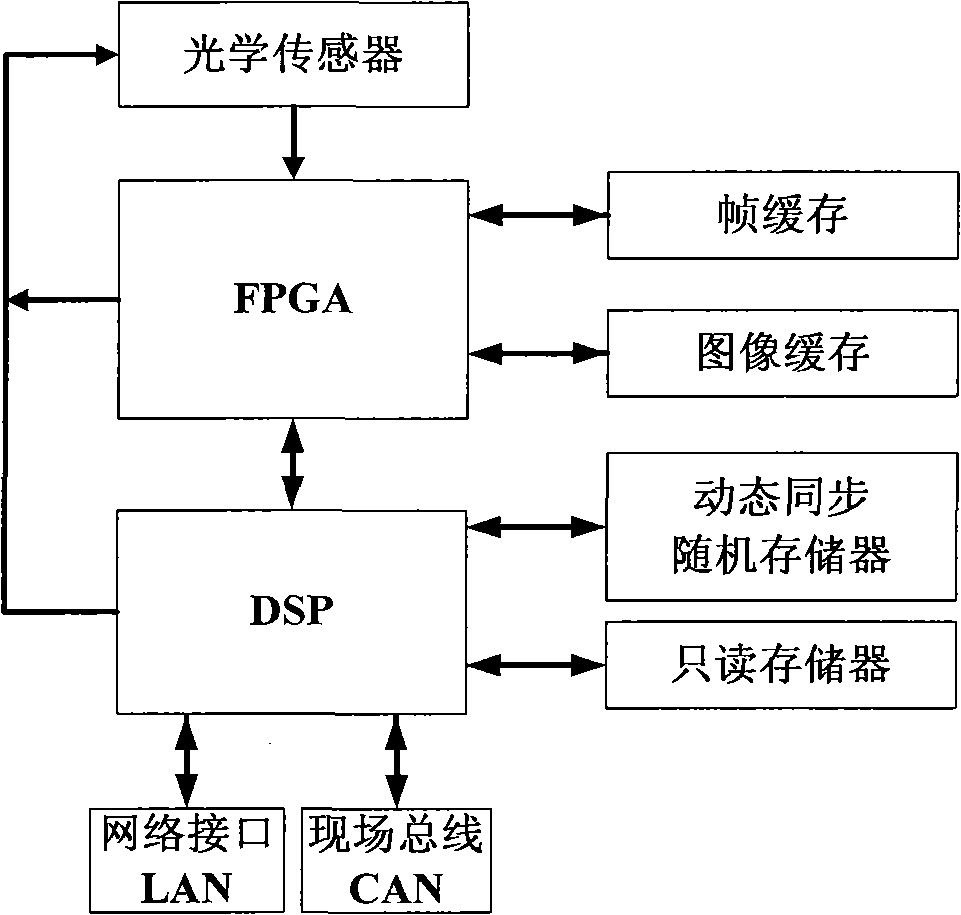

[0075] The image acquisition and processing unit includes a laser light source, an optical component and a smart camera, wherein the linear laser generated by the laser light source is reflected by the welding workpiece, and is collected by the smart camera through the optical component.

[0076] The motion cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com