Patents

Literature

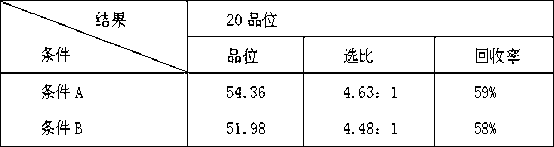

64results about How to "Reasonable temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

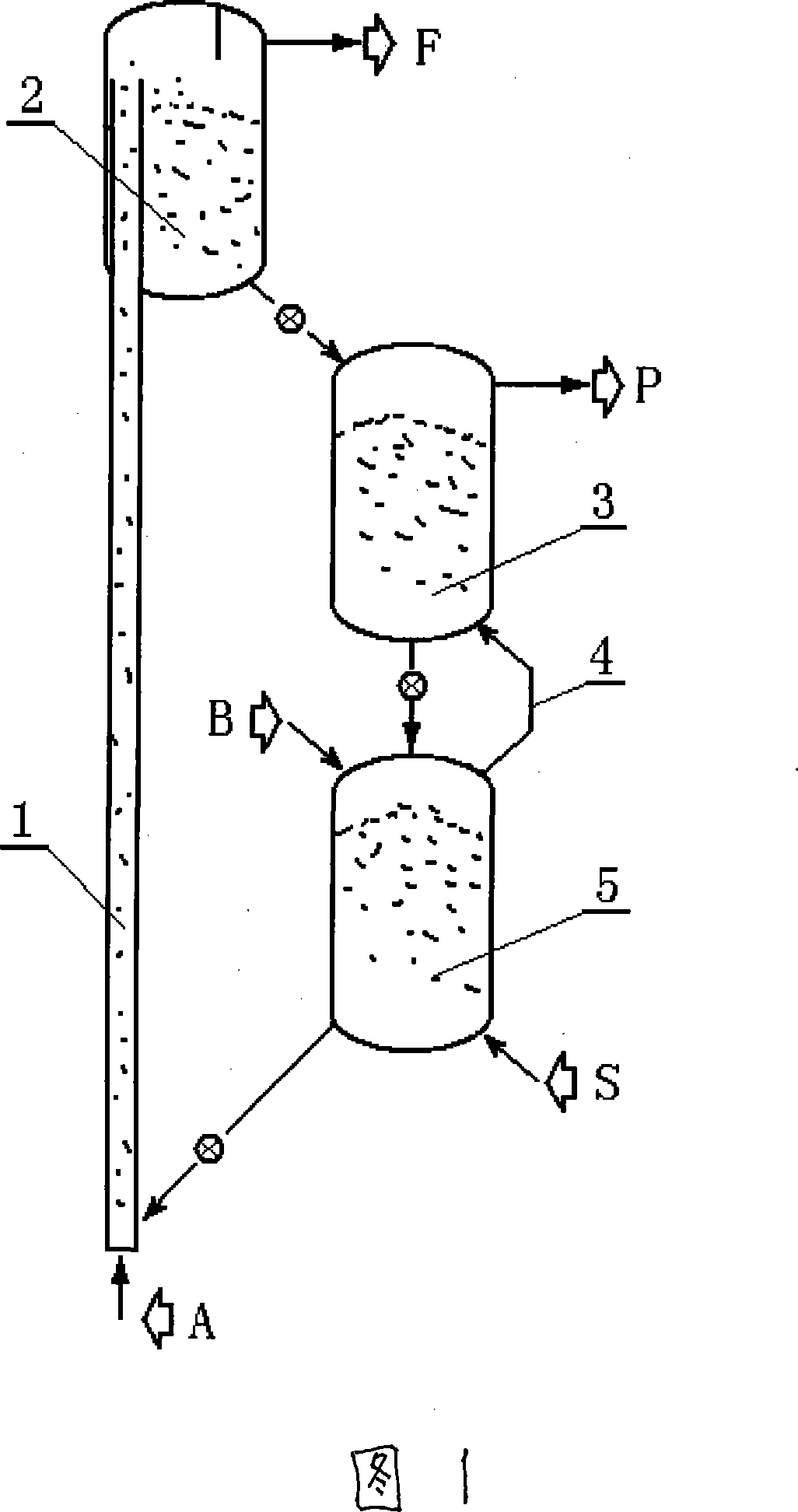

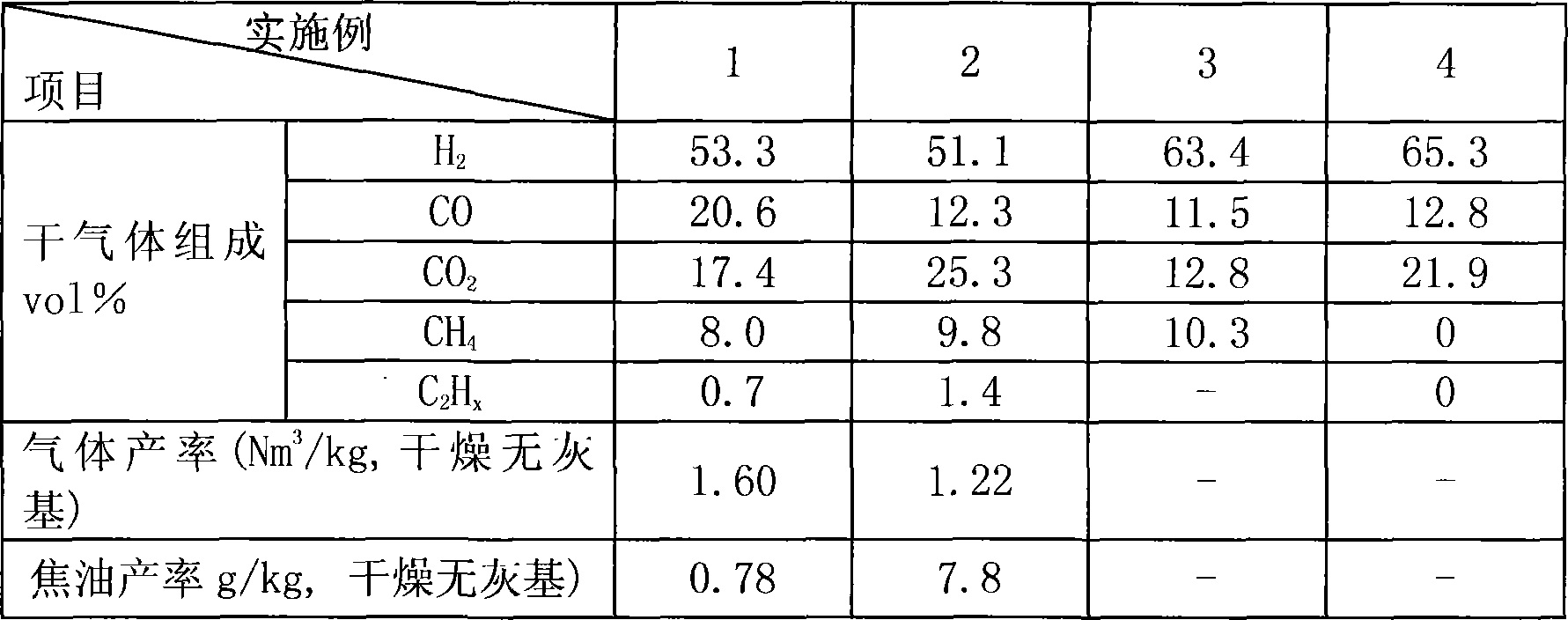

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524AReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingHeat carrier

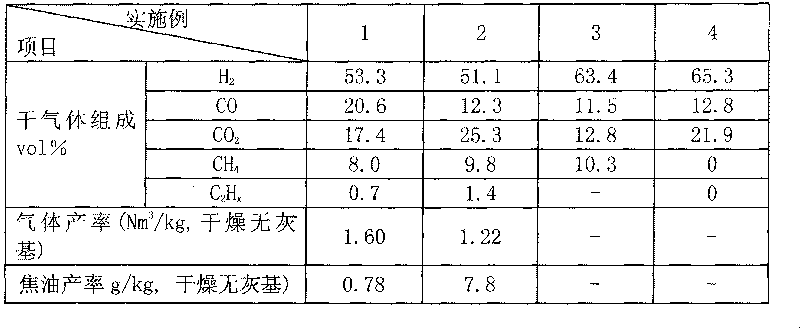

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction. Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

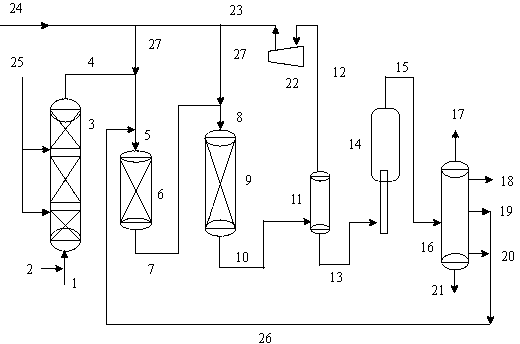

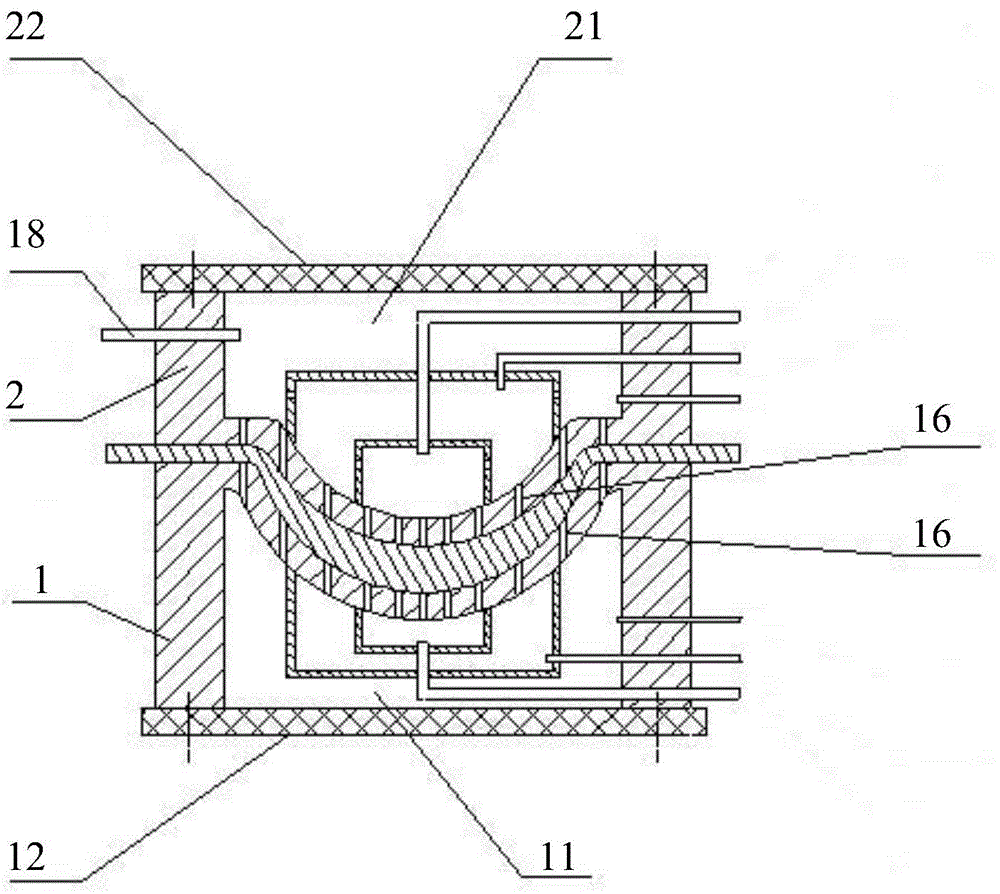

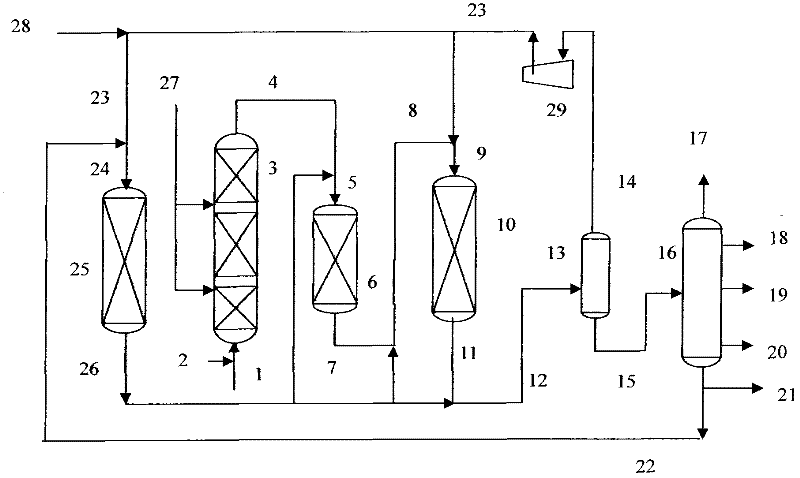

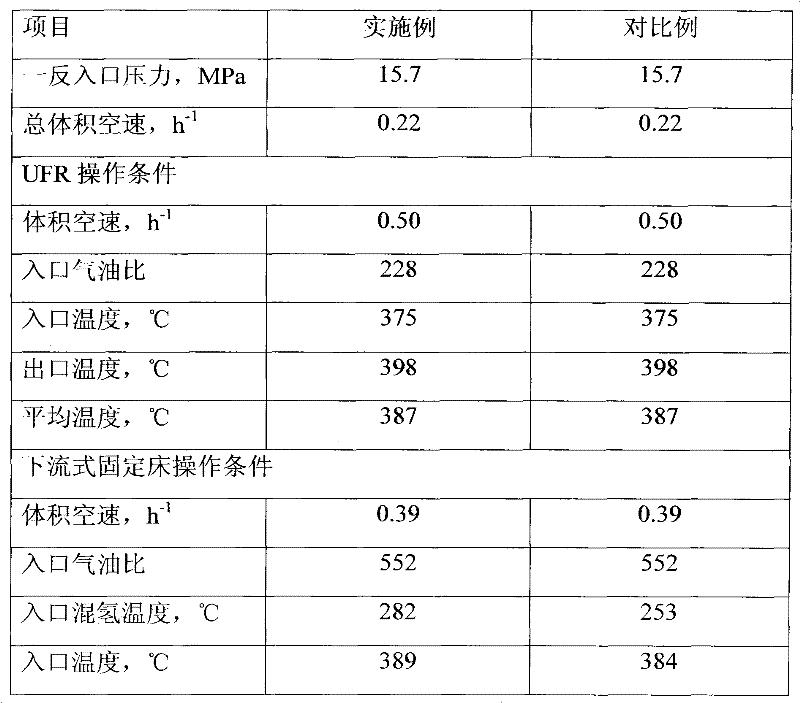

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377AReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

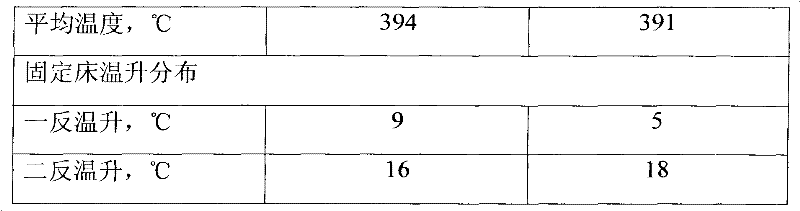

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

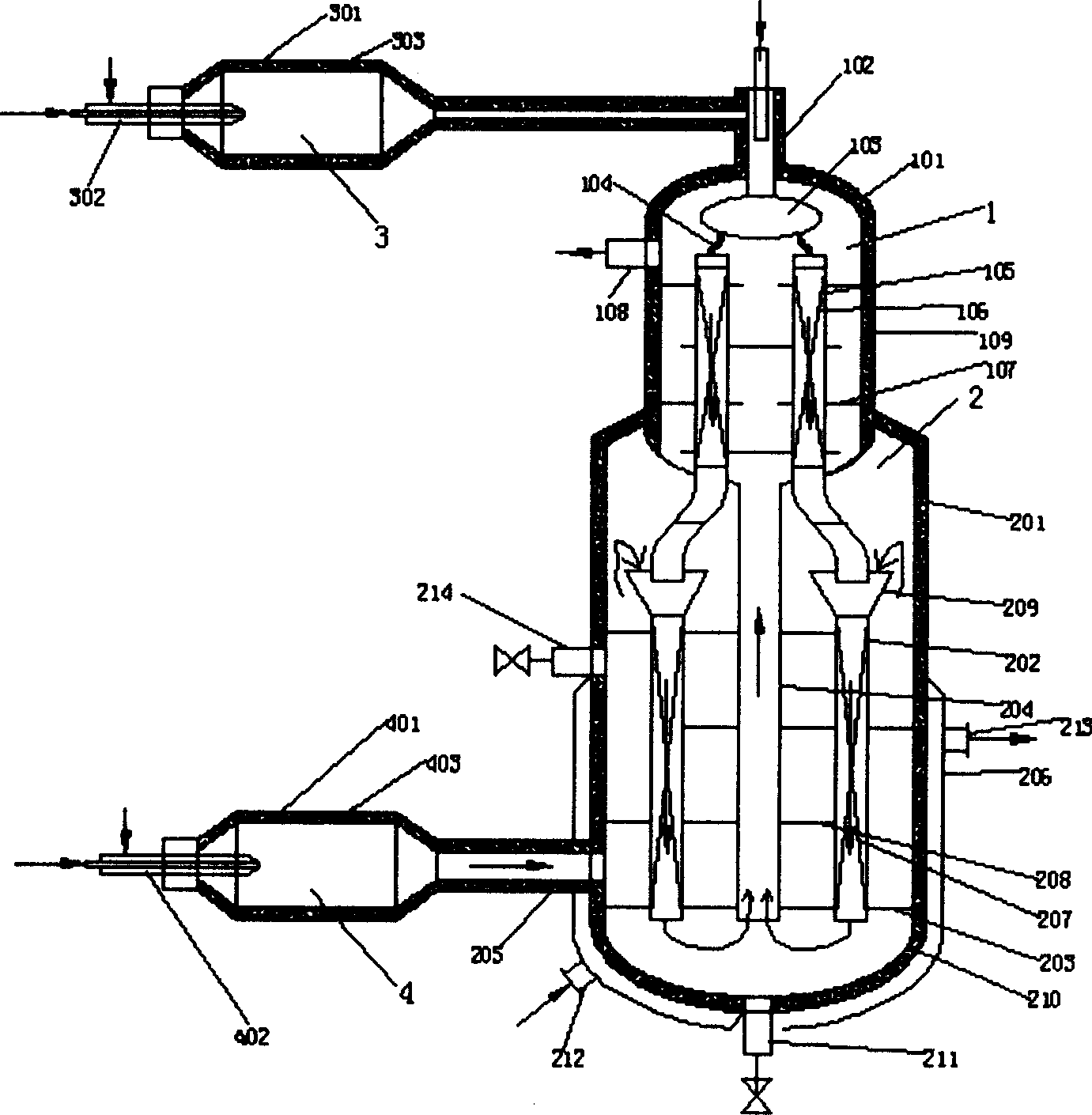

Hydrocarbon-converting synthetic gas producing apparatus and method

InactiveCN1636861AOptimizing Energy UtilizationReduce energy consumptionHydrogenChemical industrySyngasChemistry

The present invention relates to apparatus and method of producing synthetic gas with hydrocarbon. The hydrocarbon burning product or CO2 separated from the subsequent decarbonation process is led to hydrocarbon and water vapor converting reactor to replenish carbon to the system, to make the synthetic gas possess proper H2 / CO ratio for subsequent synthesis of liquid hydrocarbon fuel and to reach heat self feeding of the reactor. The apparatus includes two-section vapor converting furnace inside one container and two external hydrocarbon burner. The burning product of the external burner is made to exchange heat with gas inside the reactor or mix directly to supply heat and carbon source for the reaction. The present invention has the advantages of simultaneous completion of preparing synthetic gas and recovering heat, H2 / CO ratio adjustable in 1.5-2.7, high heat utilization, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

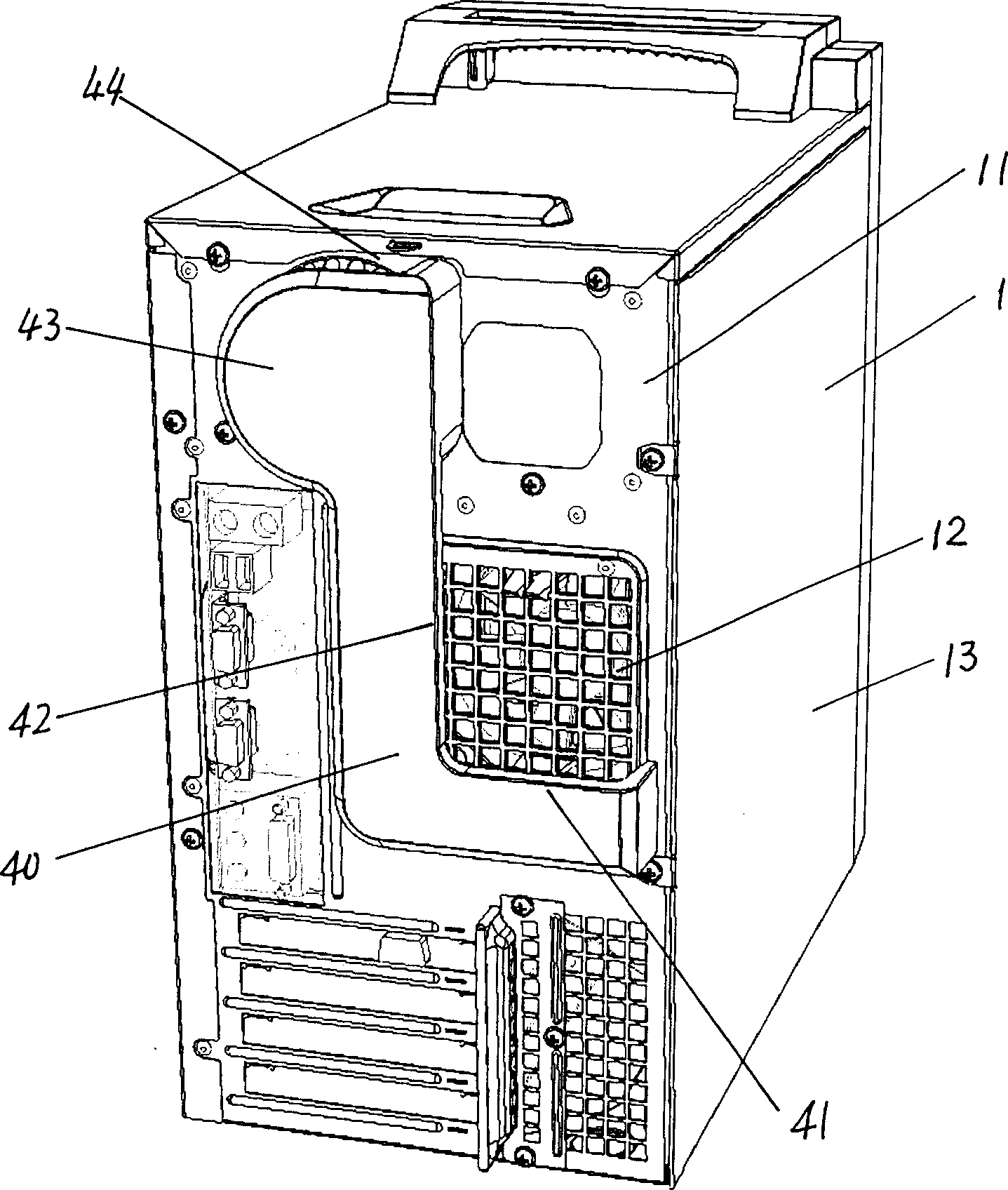

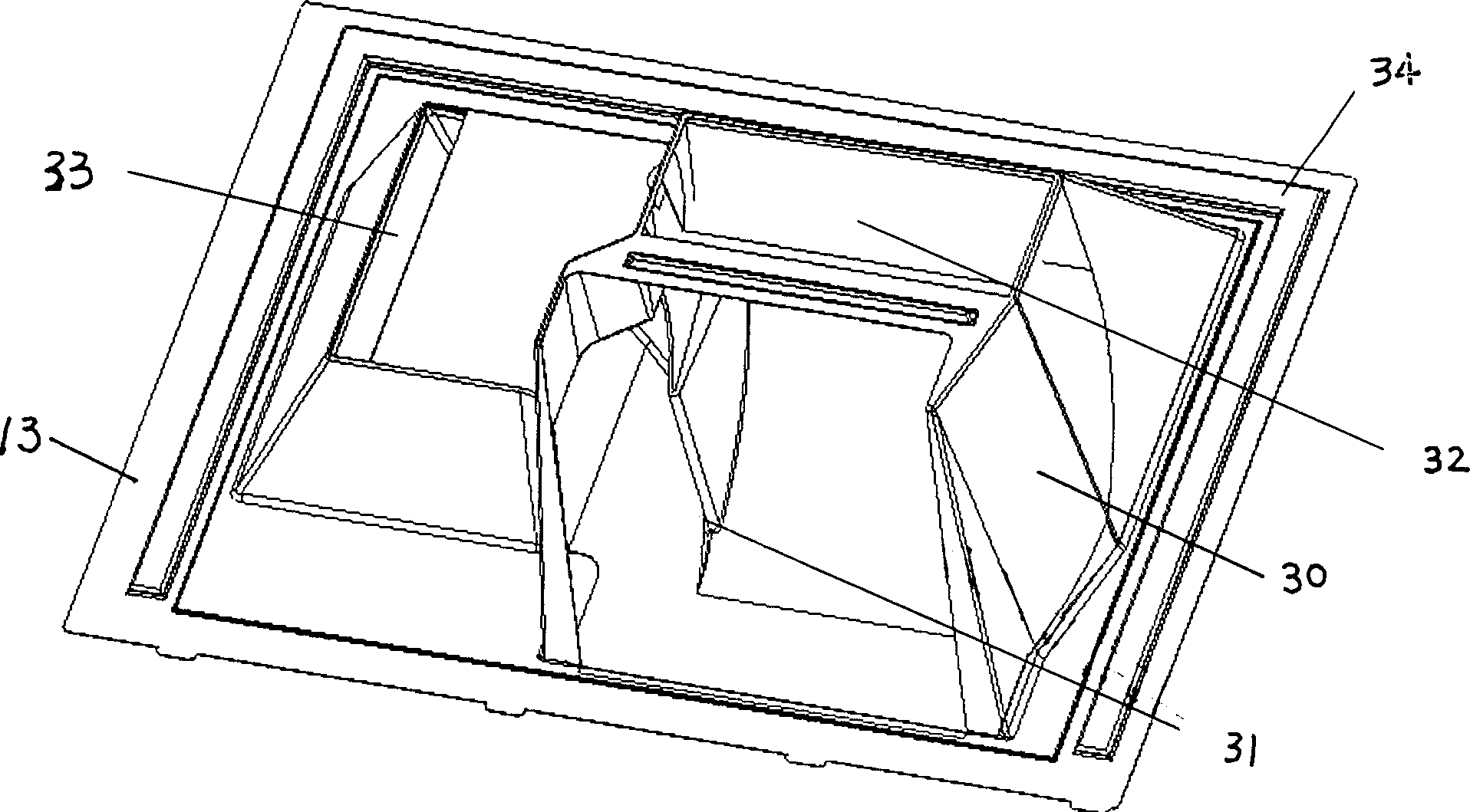

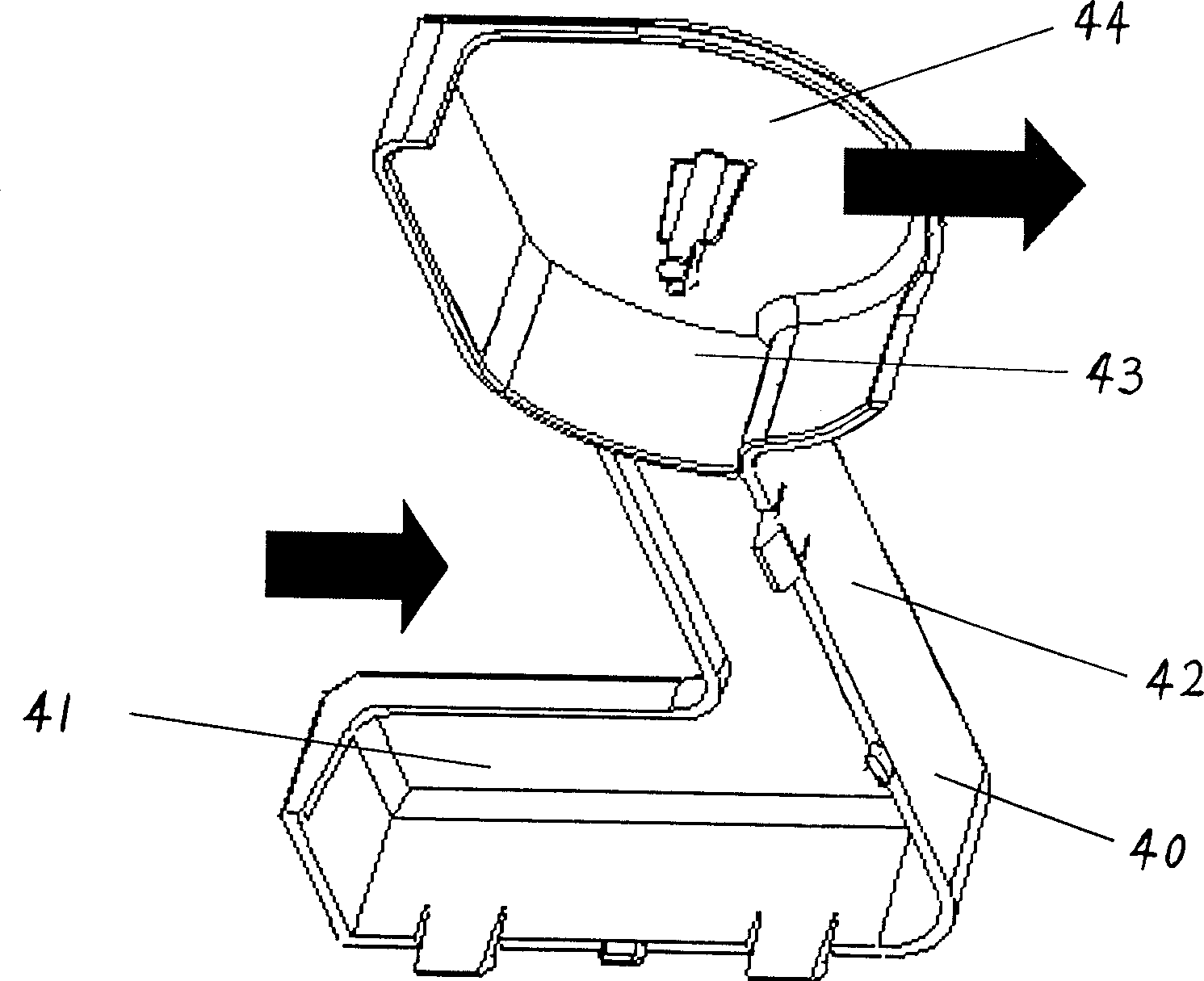

Air flow control system of table computer host machine

InactiveCN1414442AAddress cooling needsReasonable temperature distributionDigital data processing detailsFluteAir current

An air current pipe system includes a machine case and a system fan inside the air hole located on the rear backboard of the machine case. The characteristics of the invention are that there a guiding wind flute possessing the air inlet and at least one air outlet. The air inlet covers the system fan. The air outlet is installed above the CPU inside the machine case. The invention guarantees thatCPU with super-high primary frequency as well as the heating elements on the host board and the hard disks and the plug-in cards can operate under the safe temperature range.

Owner:LENOVO (BEIJING) LTD

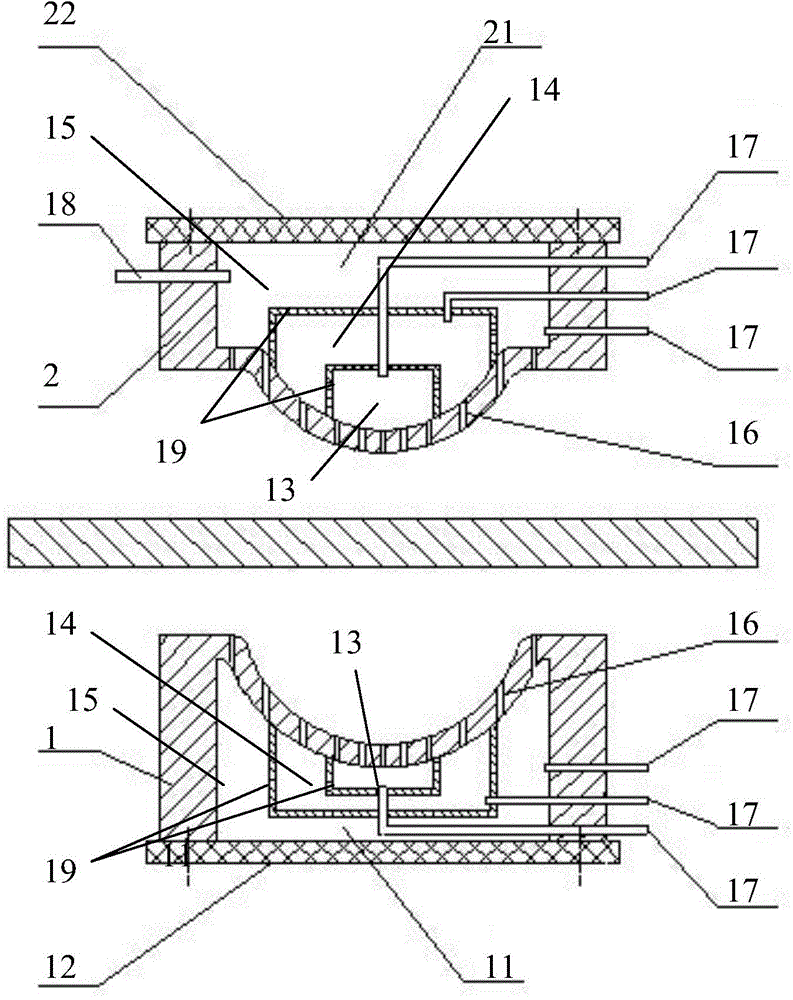

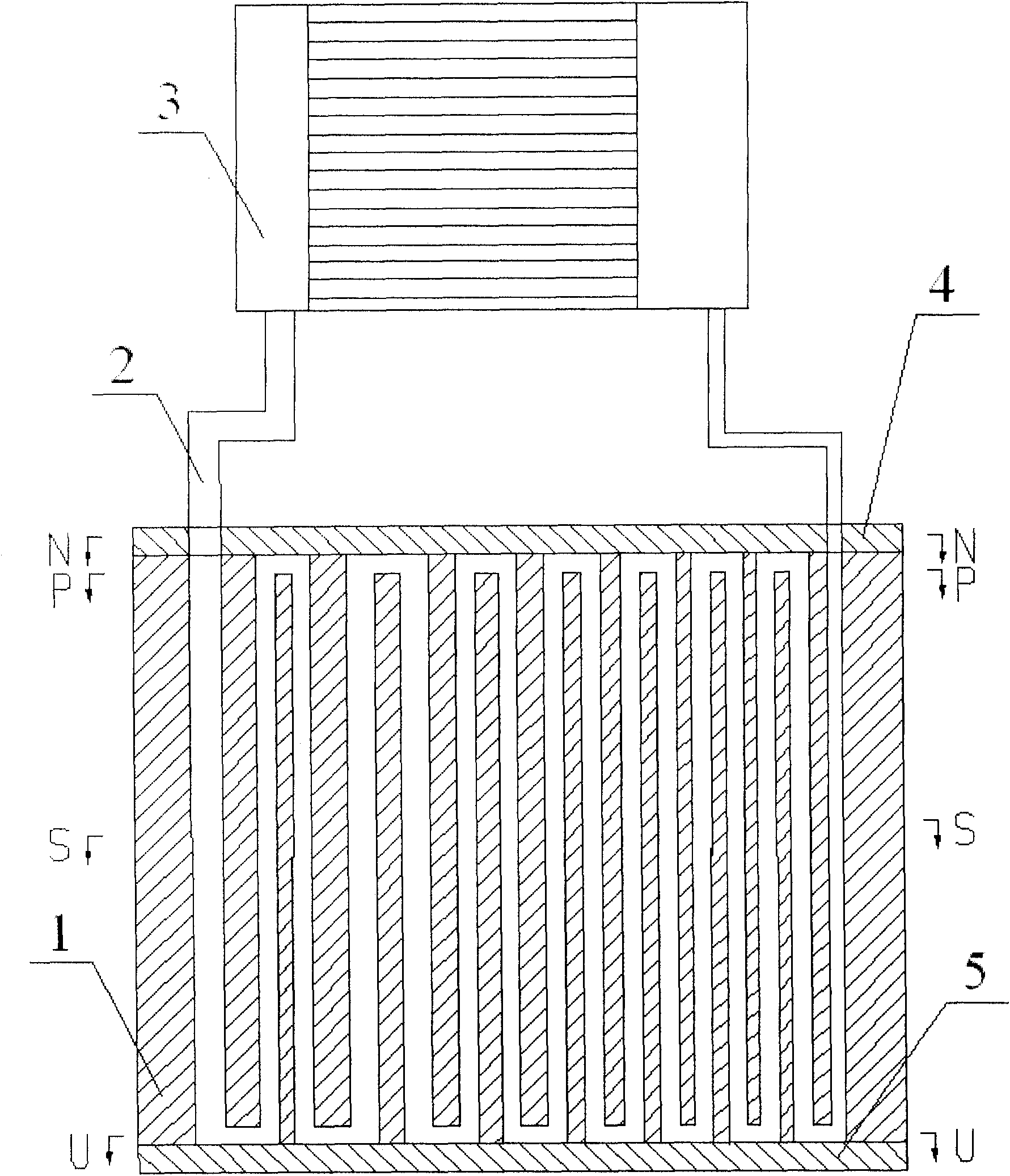

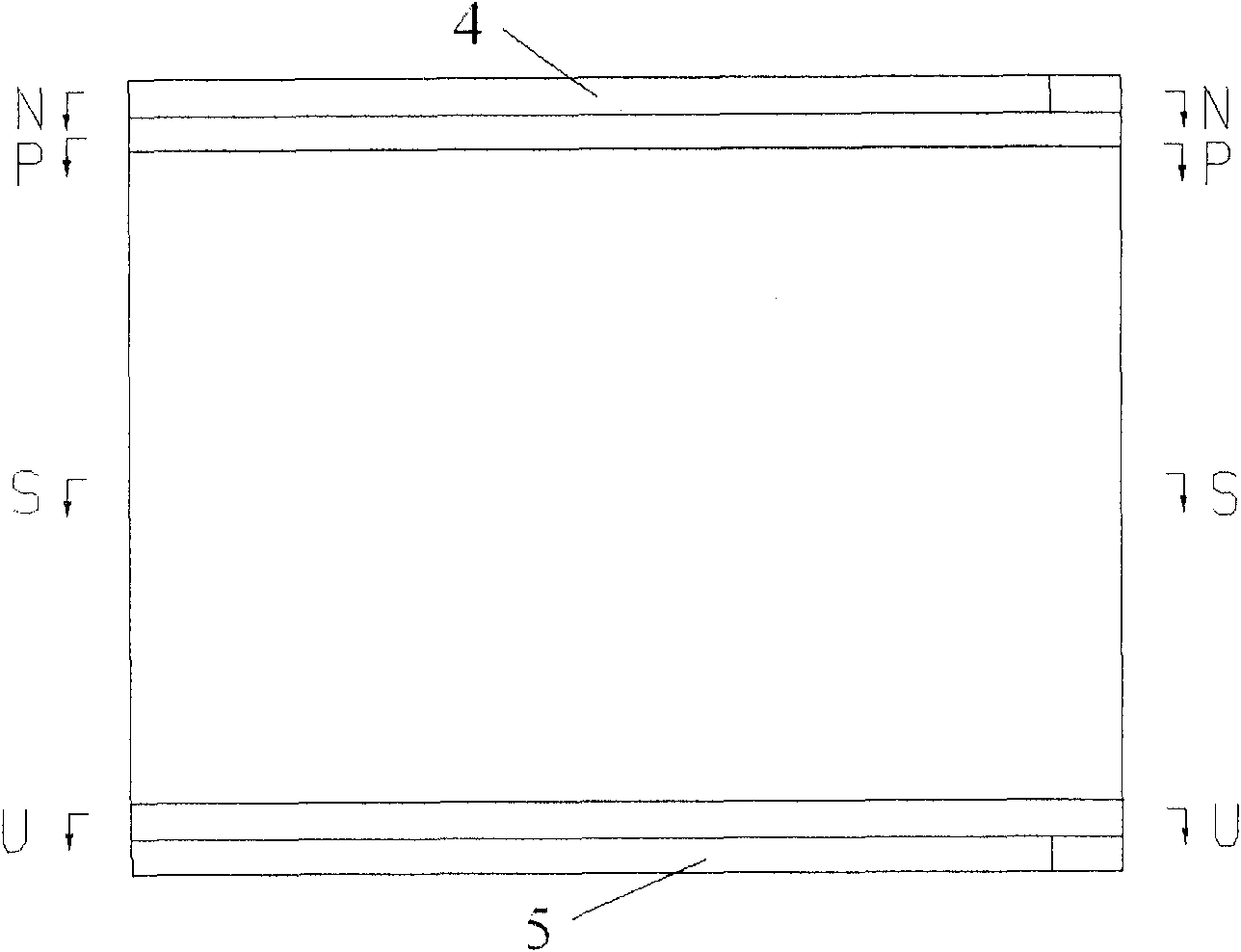

Underwear cup molding die and underwear molding method thereof

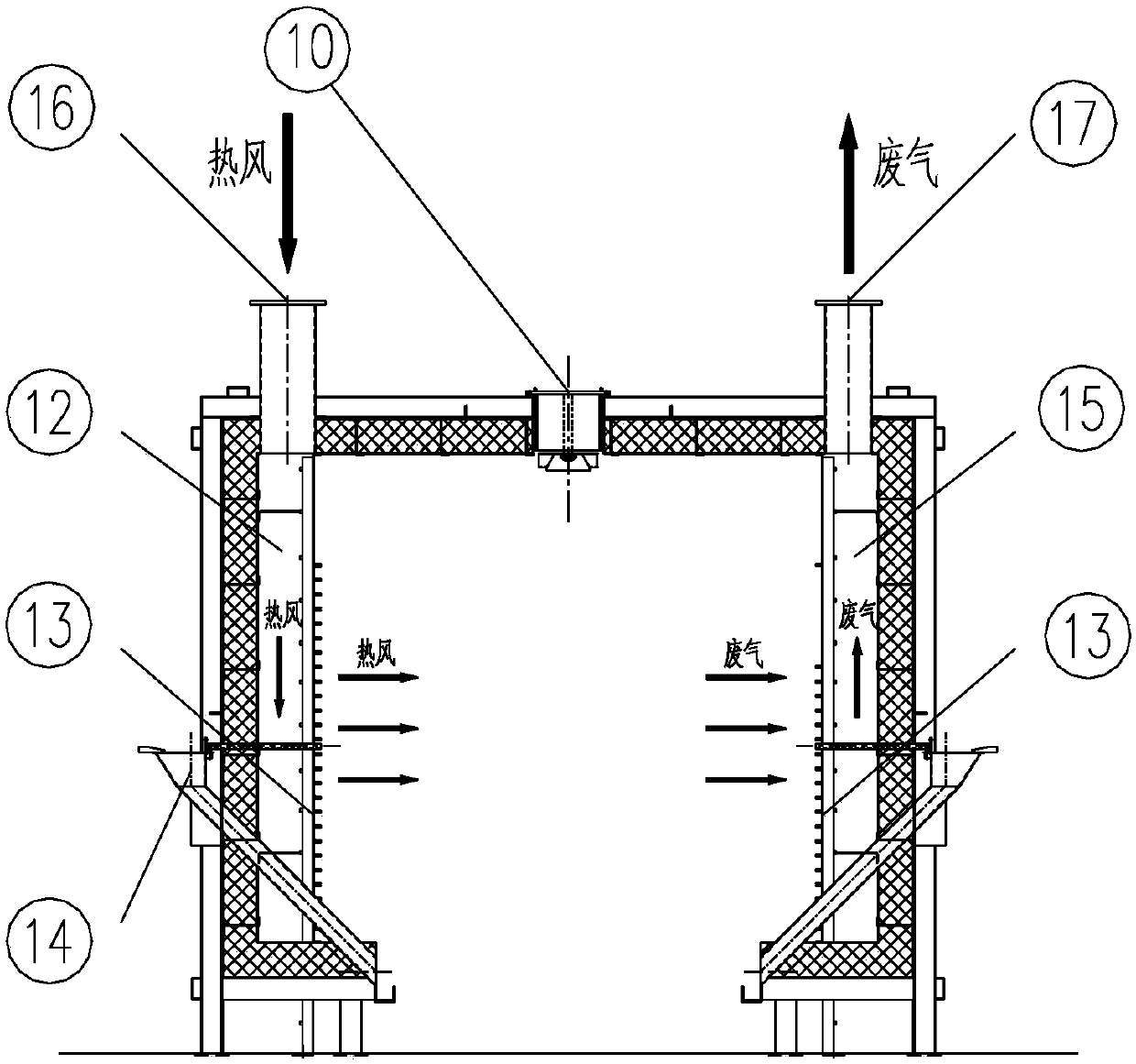

The invention discloses an underwear cup molding die. Cavities are formed in upper and lower dies, and superheated airflow is introduced into the cavities for heating, so that the die is rapidly preheated in a short time. The cavities are separated into multiple areas for respectively performing heating treatment at different temperatures, the condition that the temperature on the surface of the die is consistent with the temperature needed at each part of a mold pressing material is ensured, the heating effect of the cup material is improved, the problem caused by extremely high or low temperature is solved, the quality of the mold cup is improved, and the mold cup molding process is effectively perfected and improved. The molding die is suitable for molding modern three-dimensional cups of which the lower sides are thick and the upper sides are thin, so that the mold pressing temperature distribution on the die surface is reasonable, only the hot airflow is introduced into the first area of the lower die during mold pressing, so that the heating can be performed, the power consumption is reduced, the time is saved, the working efficiency is improved, the mold cup quality is improved, and the mold cup molding process is effectively perfected and improved.

Owner:SUZHOU UNIV

Heavy-hydrocarbon raw material hydrogenation treatment method

ActiveCN102443434AIncrease temperatureImprove distributionTreatment with hydrotreatment processesFractionationFixed bed

The invention discloses a heavy-hydrocarbon raw material hydrogenation treatment method, which comprises the following contents: an upper flow reactor (hereinafter referred to as UFR) is adopted and is connected in series with a lower flow type fixed bed reactor, heavy-hydrocarbon raw materials sequentially pass through the UFR and the lower flow type fixed bed reactor, reaction effluents are fractionated through a fractionation tower, a prepositive reactor is adopted, tower bottom oil of the fractionation tower partially circulates back to the prepositive reactor, and partial or all reaction effluents of the prepositive reactor are mixed with the UFR reaction effluents to enter the lower flow type fixed bed reactor. The method has the advantages that the upper flow type reactor, the lower flow type fixed bed reactor and the prepositive reactor are cooperated and matched through regulating the material distribution proportion, the flow process and the technical conditions, the cooperation matching effect of a combination flow process hydrogenation device is further improved, and further, the operation period can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

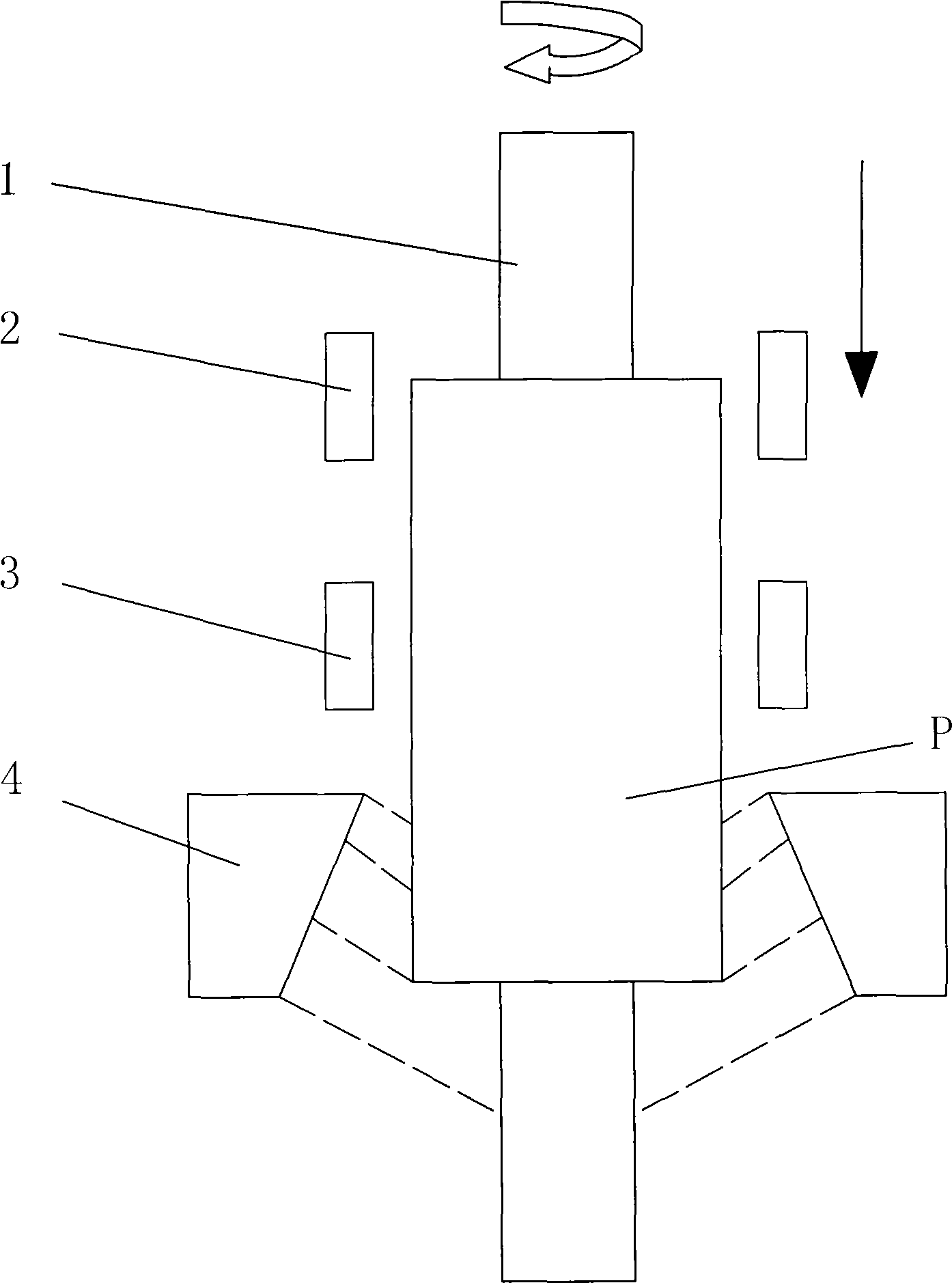

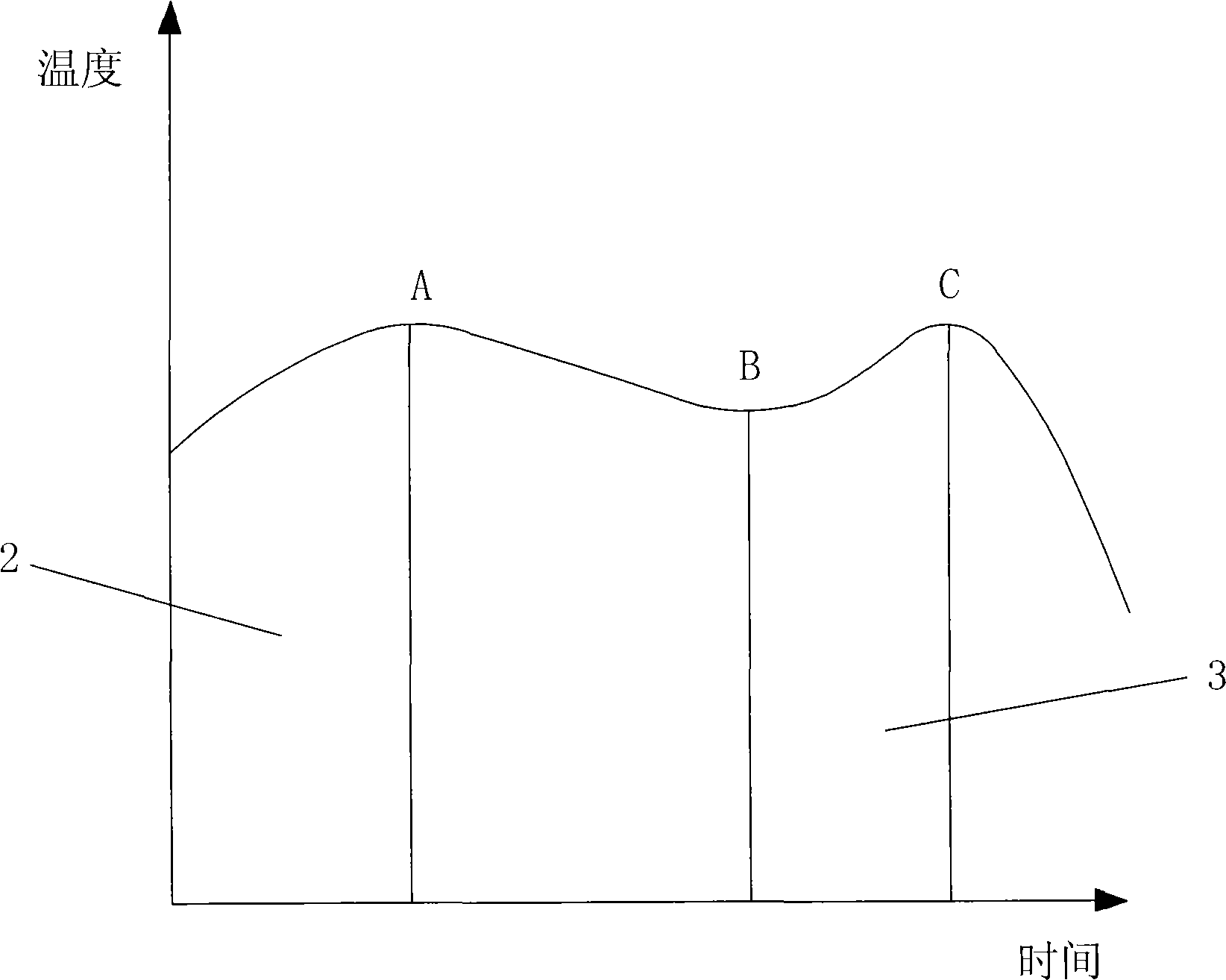

Improved roller double-frequently quenching process

InactiveCN101509054AReasonable temperature distributionFully austenitizedFurnace typesIncreasing energy efficiencyDeep levelDouble frequency

The invention discloses an improved roller double frequency quenching technique. A roller which is vertically hung on a quench machining tool sequentially passes through an upper sensor and a lower sensor from top to bottom; then, a sprinkler positioned under the sensor is used for quenching and cooling the roller; the heating-up temperature (TA) of the upper sensor is slightly higher than the heating-up temperature (TC) of the lower sensor, so that the temperature distribution tend to be reasonable, and the distance between the upper sensor and the lower sensor can be enlarged, thus being beneficial to full austenization and deep level heat permeating.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

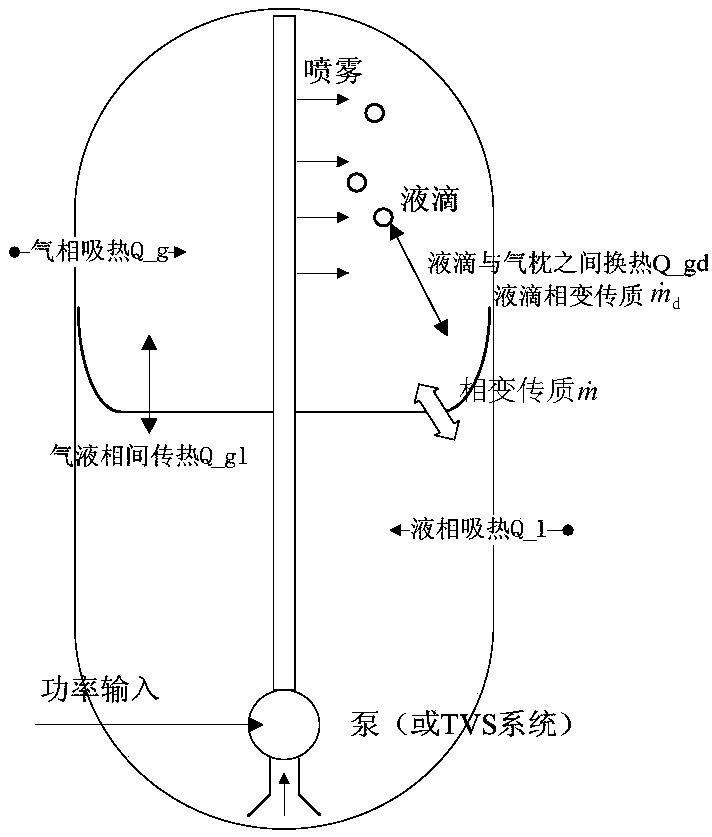

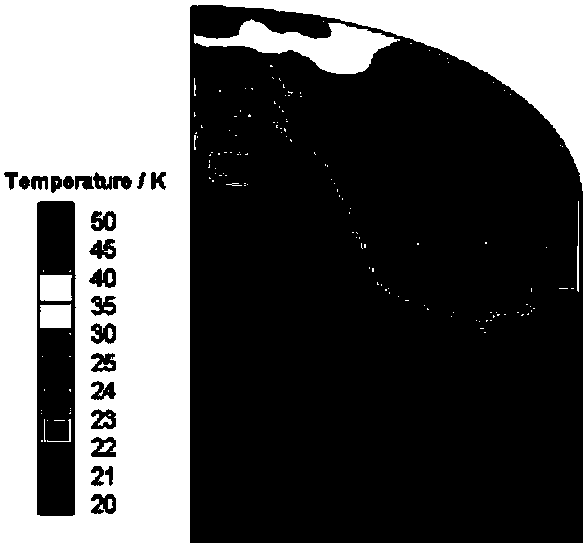

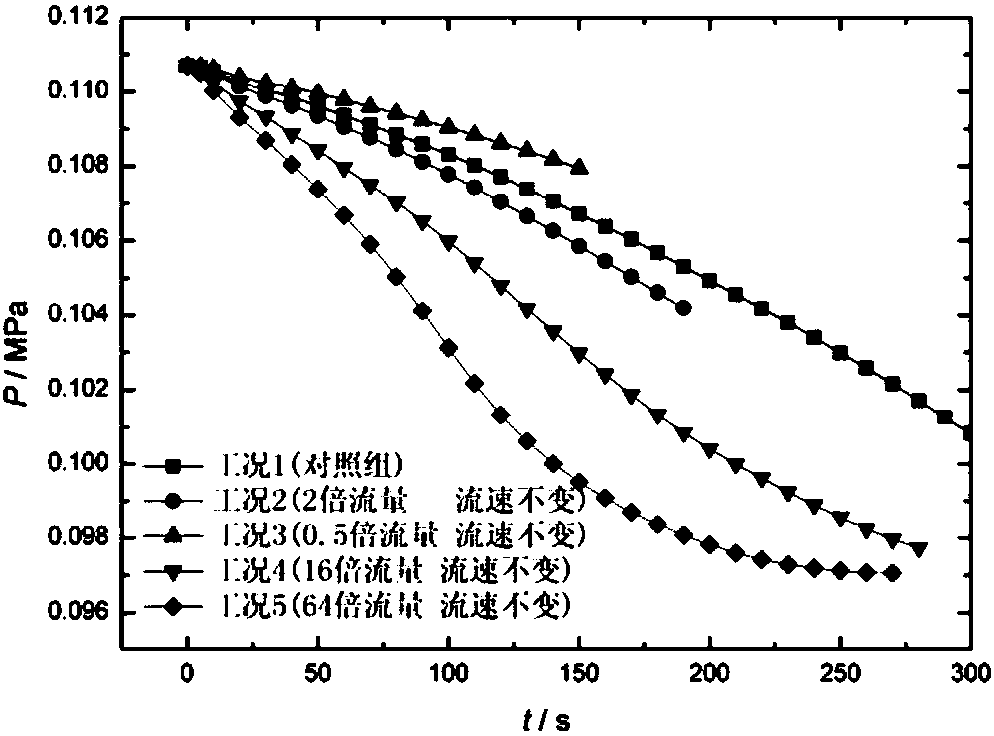

Method for simulating spray mixing in low-temperature propellant storage boxes

ActiveCN107871046AAccurate Pressure PredictionDetailed Fluid FormDesign optimisation/simulationSpecial data processing applicationsEvaporationCombined method

The invention relates to a method for simulating spray mixing in low-temperature propellant storage boxes, belongs to the field of space transportation overall design, has a background of carrying outlong-time in-orbit evaporation capacity control on low-temperature propellants, and mainly relates to a method for simulating long-time in-orbit storage box pressure control on low-temperature propellants by adoption of a spray mixing manner. For calculation of spray and two-phase flows, a dispersed phase and VOF combined method is adopted to establish a computational fluid mechanics simulation model for spray mixing in low-temperature propellant storage boxes; results obtained through the method is favorably identical with experiment results; compared with simple lumped parameter models, themethod is capable of predicting fluid forms, temperature changes and heat exchange trends in the storage boxes; and through the method, simulation design can be carried out on the spray mixing underdifferent flows, flow velocities and spouting temperatures, and a spray mixing optimization scheme is brought to make a contribution to improve long-time in-orbit low-temperature propellant storage box pressure ability and realizing a long-time in-orbit evaporation capacity control technology for engineering.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

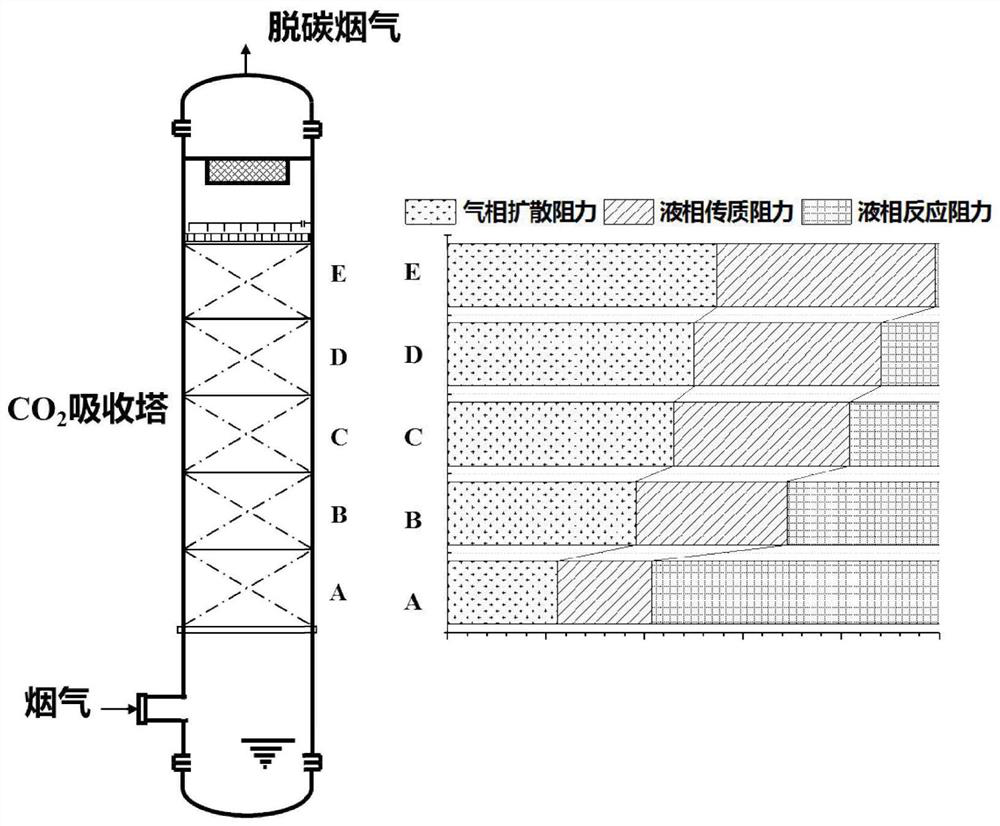

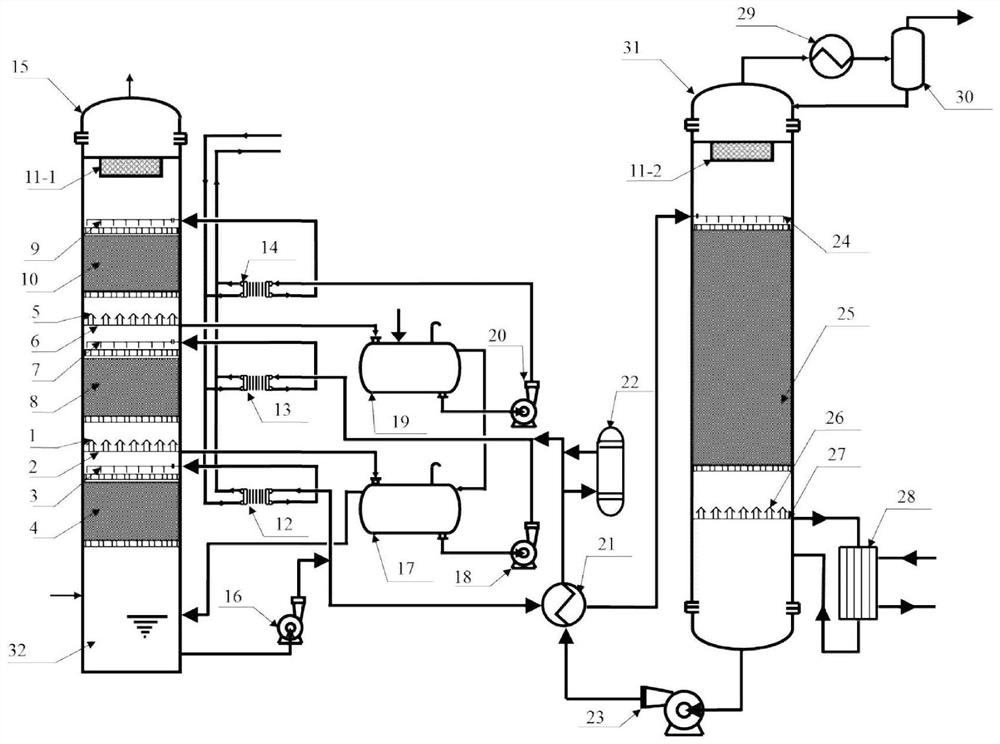

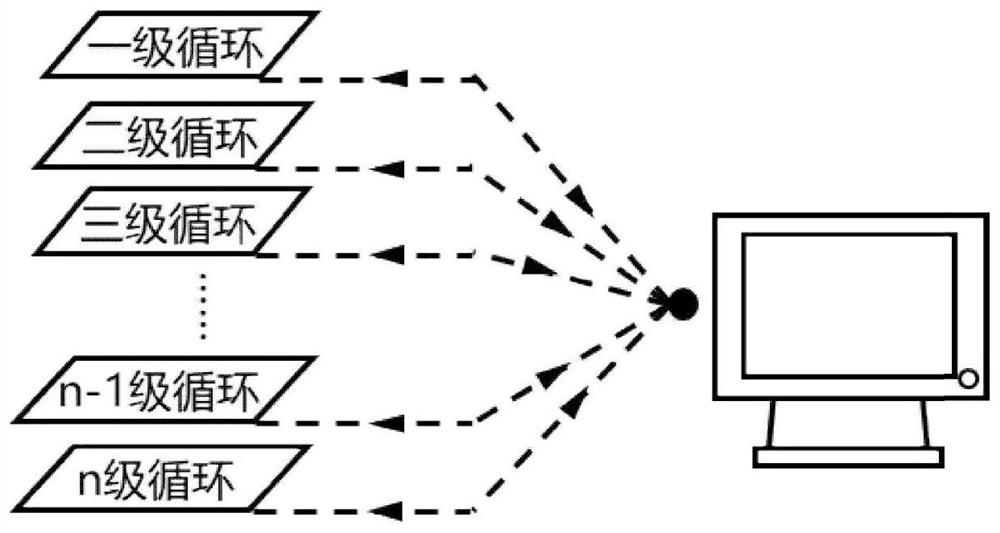

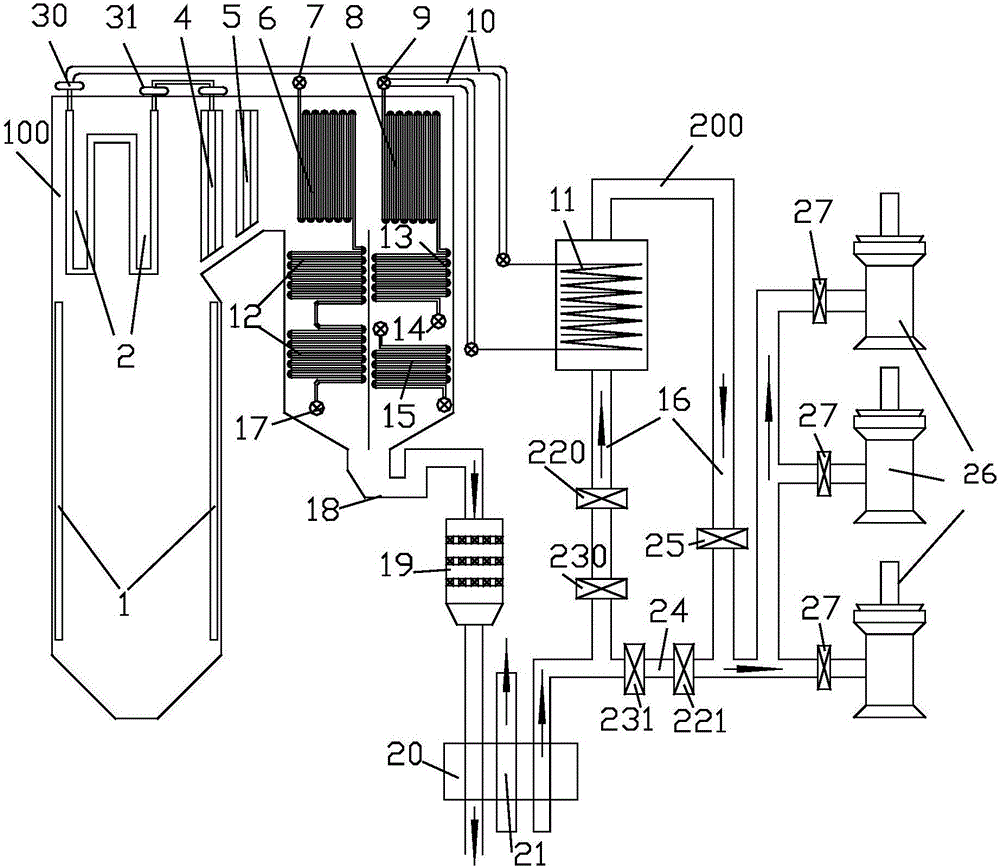

Partitioned multi-stage circulating CO2 trapping and concentrating method based on mass transfer-reaction regulation and control

PendingCN113521966AImprove capture efficiencyReduce desorption energy consumptionHuman health protectionProductsProcess engineeringSlurry

The invention relates to a partitioned multi-stage circulating CO2 trapping and concentrating method based on mass transfer-reaction regulation and control. The method adopts multi-element means such as multi-stage cycle absorption, intelligent multi-factor regulation, pre-washing cooling, inter-stage cooling, post-stage water washing, slurry cleaning, cooling water waste heat utilization, small-particle-size high-density spraying and the like. The method takes low cost, low energy consumption, stability and high efficiency as optimization targets, the generation of secondary pollutants is effectively inhibited while CO2 is efficiently trapped, and high-efficiency trapping, low-energy-consumption desorption and high-purity concentration of CO2 are realized. Aerosol removal is sequentially carried out from top to bottom through multi-stage circulation, the carbon capture efficiency is improved, the absorption rate and rich solution concentration are maintained, and the carbon emission reduction cost is reduced.

Owner:ZHEJIANG UNIV

Bubble fluidised bed combustion device and method for burning-used biologic mass fuel

InactiveCN1928430AImprove combustion efficiencyImprove burn rateFluidized bed combustionApparatus for fluidised bed combustionFlueSuperheater

The invention relates to a bubble fluidized bed combustor with biomass fuel and the method. The combustor comprising higher furnace chamber, binary flue duct and the heating surface such as overheater connected with the binary flue duct. It also contains tail flue, collector, induced fan, chimney and fly-ash return device set on the lower end of binary flue duct where the collecting fly-ashes are delivered into combustion dense phase of furnace so as to improve burnout rate of fly-ash. Said furnace dense phase is various cross-sections. Biomass fuel is delivered into furnace chamber assisted by wind after preprocessed by crushing equipment through the feed port at the front of boiler in parallel, here soft straws is crushed under 10cm and is delivered into boiler. Mature and stable fluidized combustion technology is applied in combusting straws and stalks biomass and it is provided with wide application for stock, high combusting efficiency and efficiently solve the problem of alkali metals during the combusting process of high alkali biomass.

Owner:ZHEJIANG UNIV

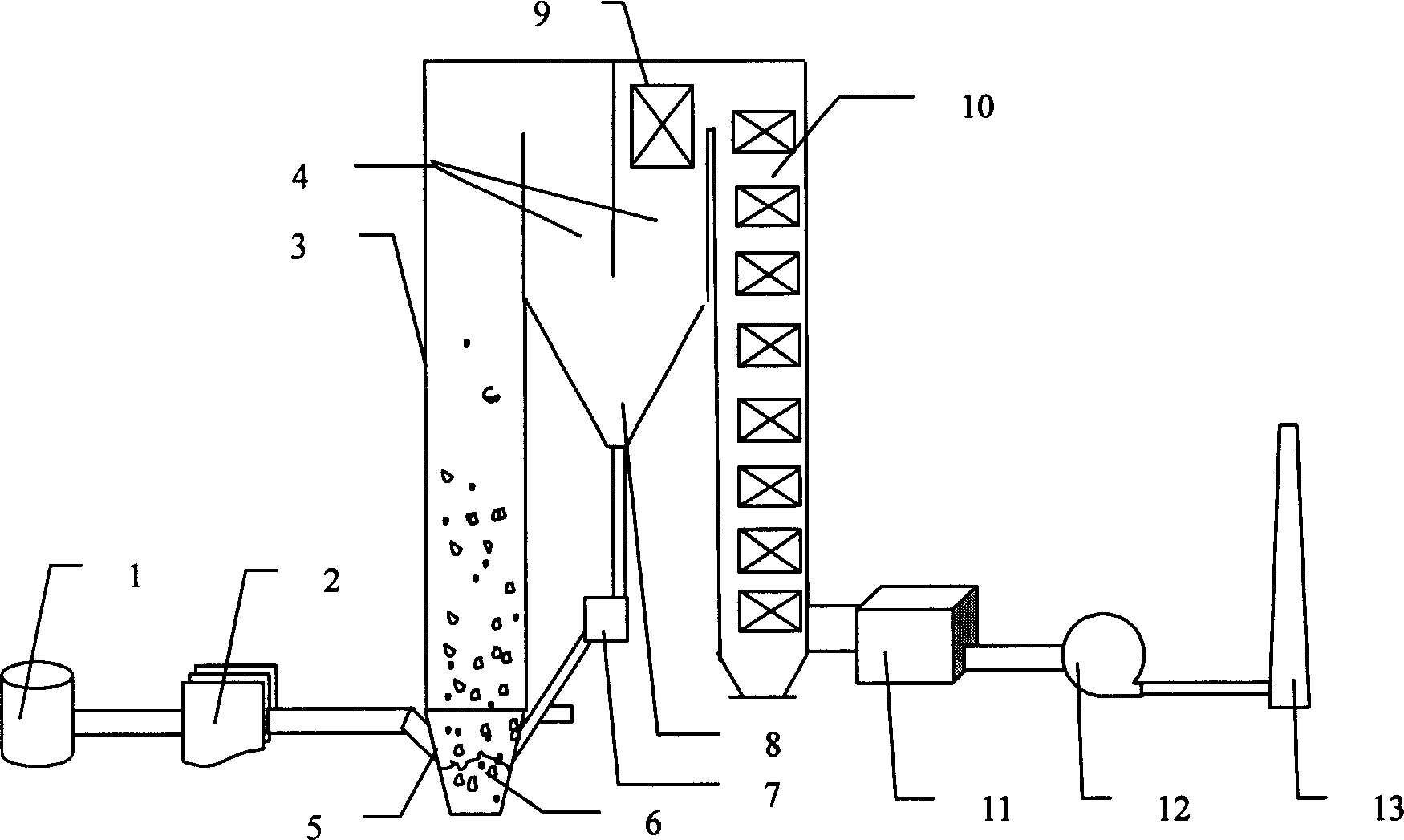

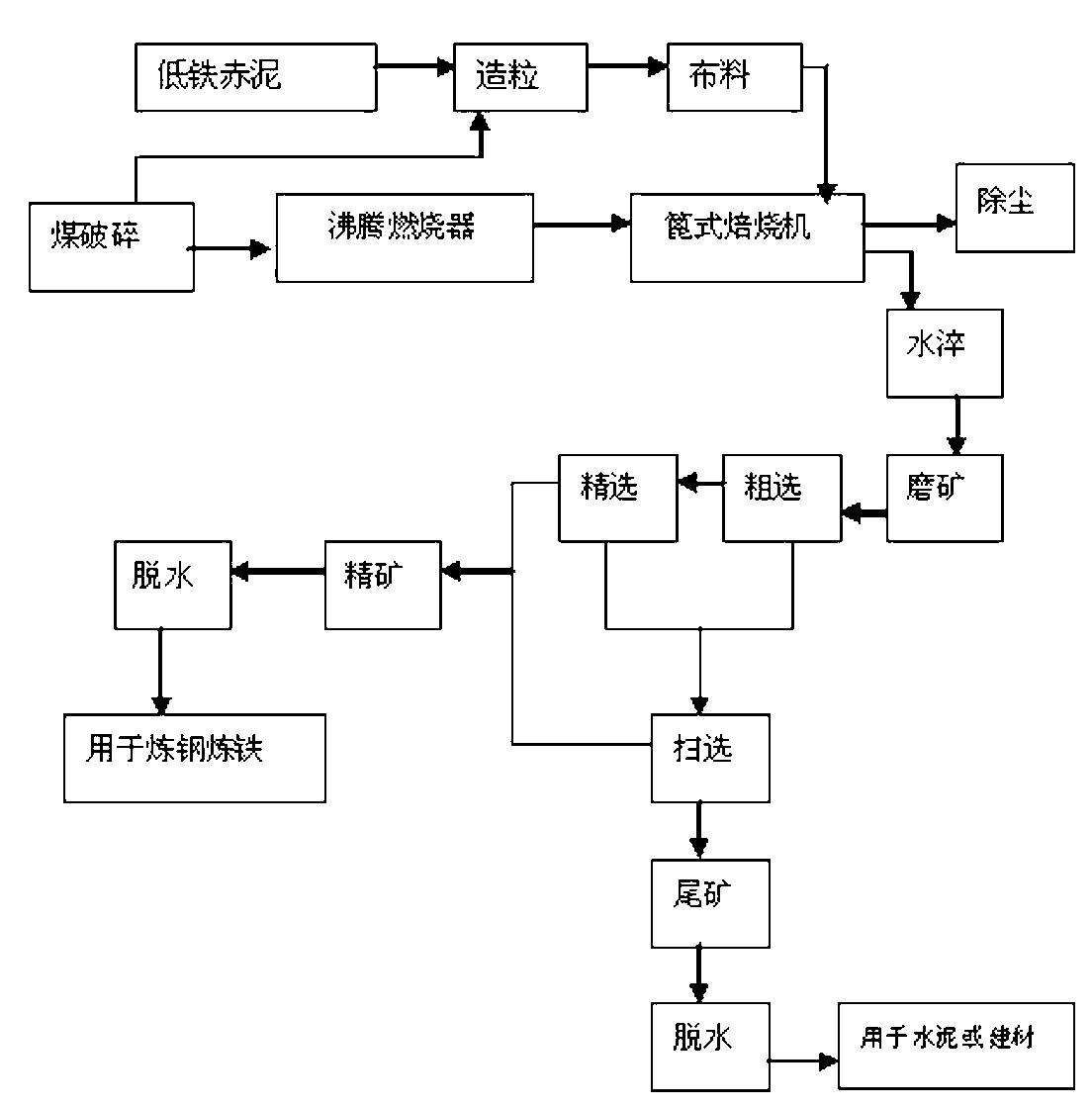

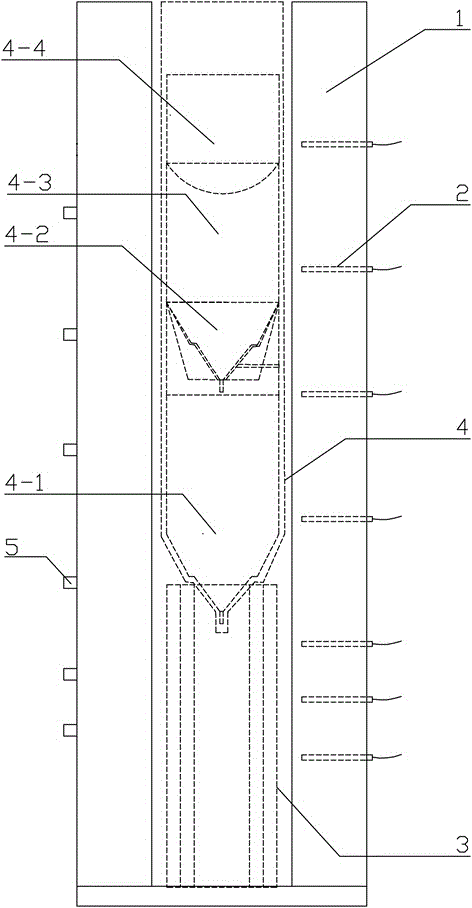

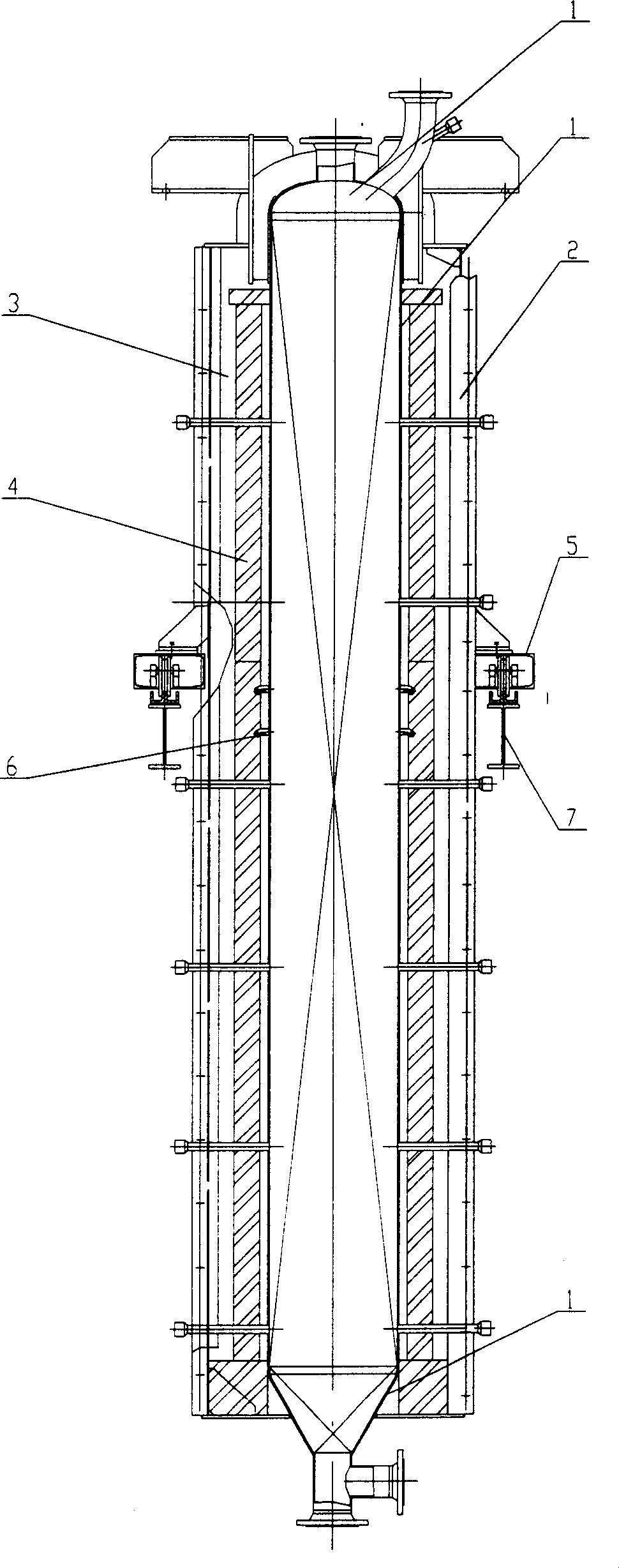

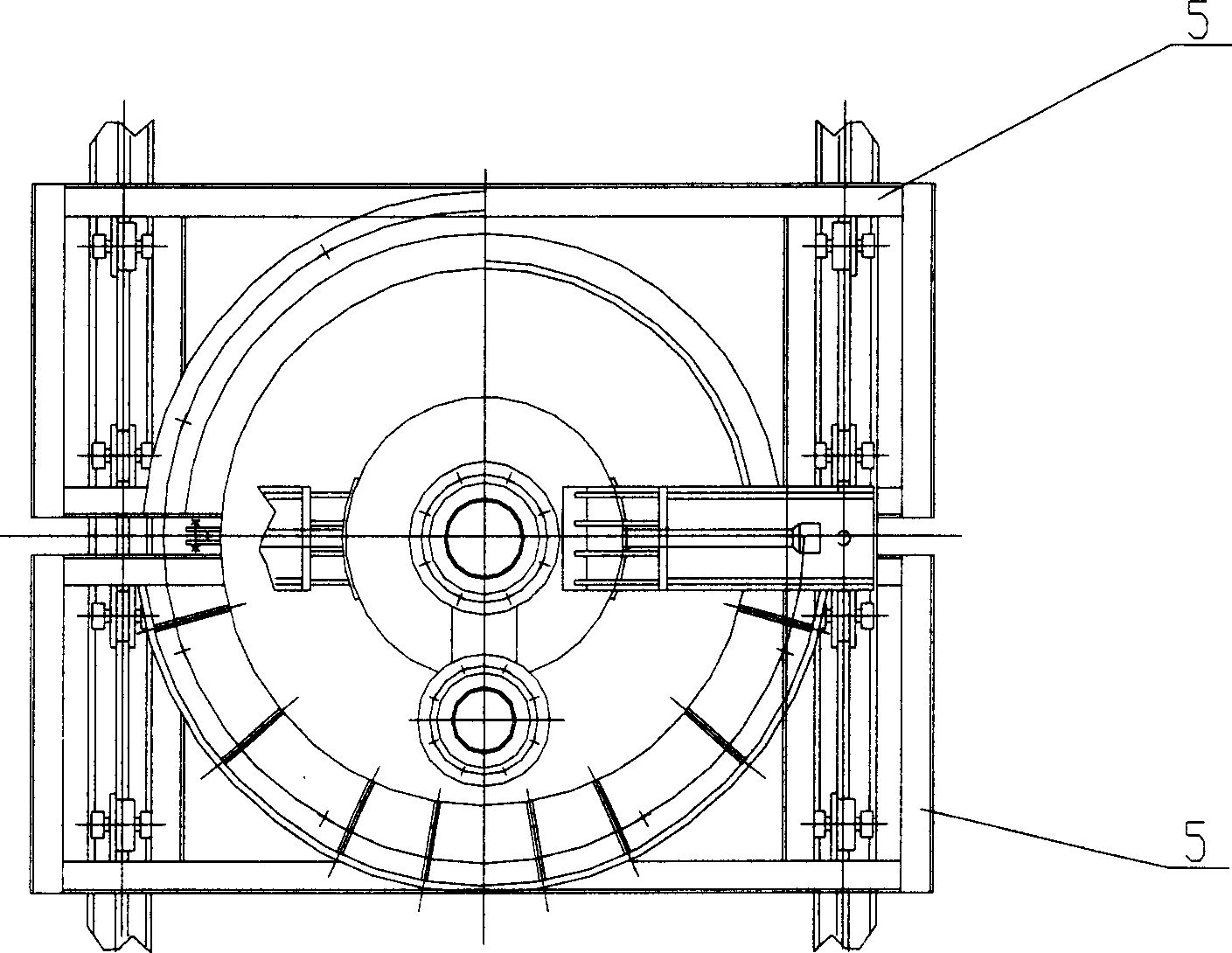

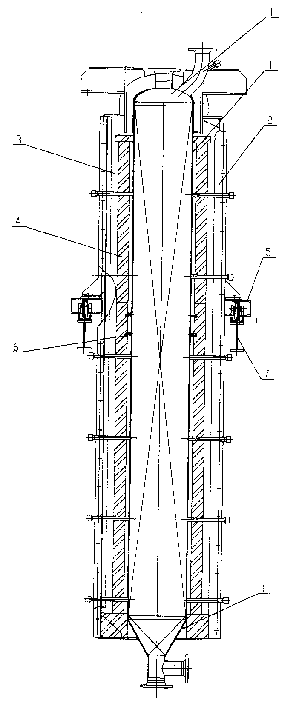

Method and device for preparing powdered iron through magnetizing low-iron red mud

The invention discloses a method and a device for preparing powdered iron through magnetizing low-iron red mud, and belongs to the field of red mud processing process and equipment. The device is characterized by comprising a grate type roasting machine consisting of a roasting section, a preheating section and a drying section, and retaining walls are arranged among the three sections; the roasting section and the preheating section are connected with an air collecting pipe through an air passage; the air collecting pipe is communicated with a drying section through a fan and a blower pipeline; and a convey grate of the grate type roasting machine penetrates the roasting section, the preheating section and the drying section. According to the invention, a grate type low-temperature weak-reduction magnetizing roasting-wet-type weak-magnetic separation method is adopted for purifying low-iron red mud, and compared with the prior art, the method and the device have the advantages of being more energy-saving and economical, stable and high in production.

Owner:SHANDONG LUMING HIGH TEMPERATURE MATERIAL TECH

Germanium single crystal growth furnace and germanium single crystal growth temperature control method based on growth furnace

InactiveCN105951170APrecise temperature controlBreak the blockadePolycrystalline material growthFrom frozen solutionsSupporting systemTemperature control

The invention relates to the technical field of preparation of new materials, in particular to a germanium single crystal growth furnace and a germanium single crystal growth temperature control method based on the growth furnace. The germanium single crystal growth furnace is fixed on a base vertically and is characterized in that the growth furnace adopts a cylindrical stainless steel furnace body; several heating electrodes are arranged on the side wall of the furnace body from bottom to top; annular thermal insulation materials are arranged inside the furnace body; a support system is arranged at the bottom of a central shaft of the furnace body; a special-shaped quartz tube is erected on the support system; a lower crucible, a middle ring, an upper crucible and a sealing cap are sequentially arranged in the special-shaped quartz tube from bottom to top; quartz wool covers the special-shaped quartz tube. The growth furnace specific to the growth characteristics of 8-inch germanium single crystals is exquisite in structure and reasonable in design of temperature area.

Owner:云南中科鑫圆晶体材料有限公司 +2

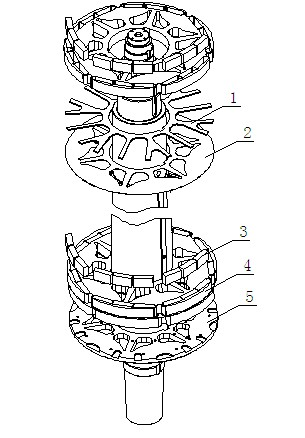

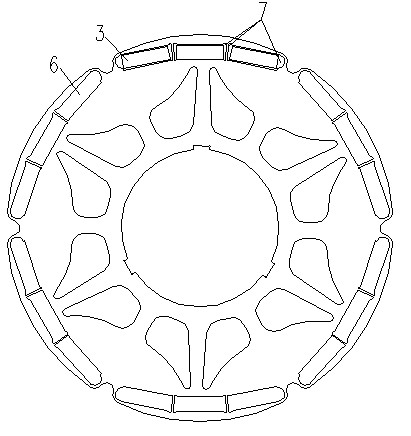

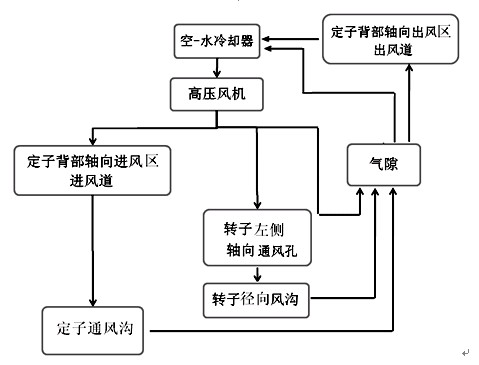

Megawatt-grade permanent magnet generator

ActiveCN102005839AReasonable distributionReasonable temperature distributionMagnetic circuit rotating partsMagnetic circuit stationary partsFastenerRotor magnets

The invention discloses a megawatt-grade permanent magnet generator relating to the technical field of permanent magnet generators. The megawatt permanent magnet generator comprises a rotor magnet steel fixing structure, a rotor magnet steel mounting tool, a motor ventilation structure and the like, wherein the rotor magnet steel fixing structure comprises a plurality of rotor core plates which are fixed on a rotating shaft trough square keys, every two adjacent core plates are separated by a stainless steel ventilating duct plate to form a radial rotor ventilating duct, stainless steel rotorcore pressing plates are respectively arranged at both ends of a rotating shaft core, and a plurality of magnetic steel slots are arranged on a core punching sheet close to the excircle of either core plate, matched with magnetic steel to be assembled in shape, and uniformly distributed on the circumference. The rotor has very simple structure and can be easily and conveniently assembled, the magnetic steel can be rapidly mounted, additional magnetic steel fasteners or other complicated fixing modes are not needed, the magnetic steel can be prevented from loosening or falling off, and the long-term, normal, reliable and safe operation of the motor is ensured.

Owner:DONGFANG ELECTRIC MACHINERY

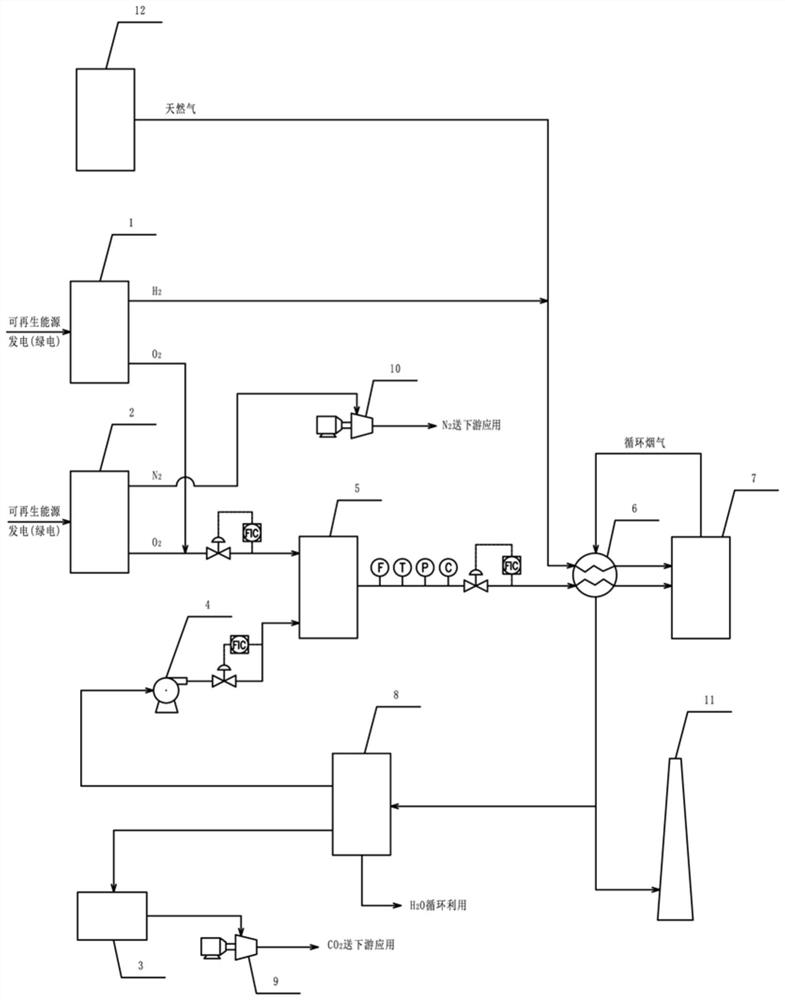

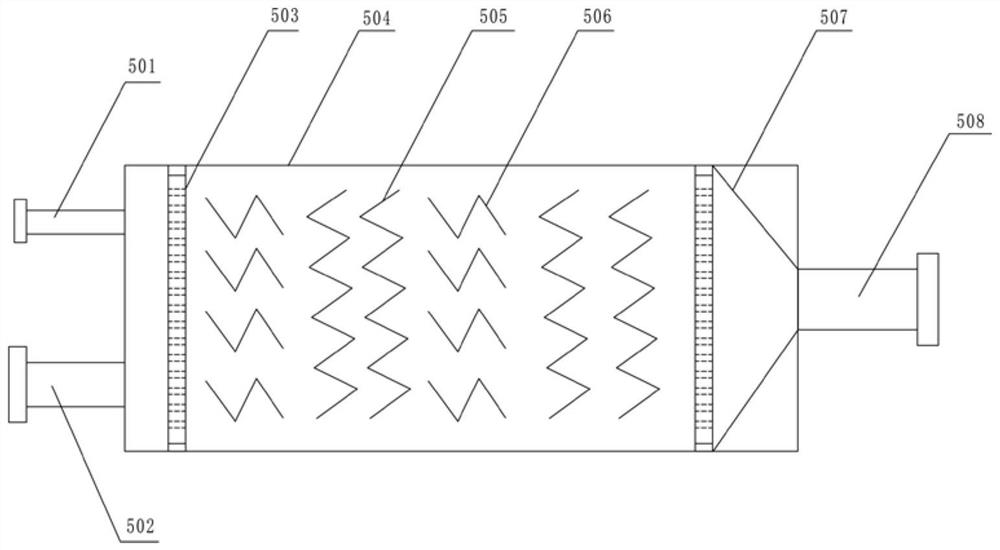

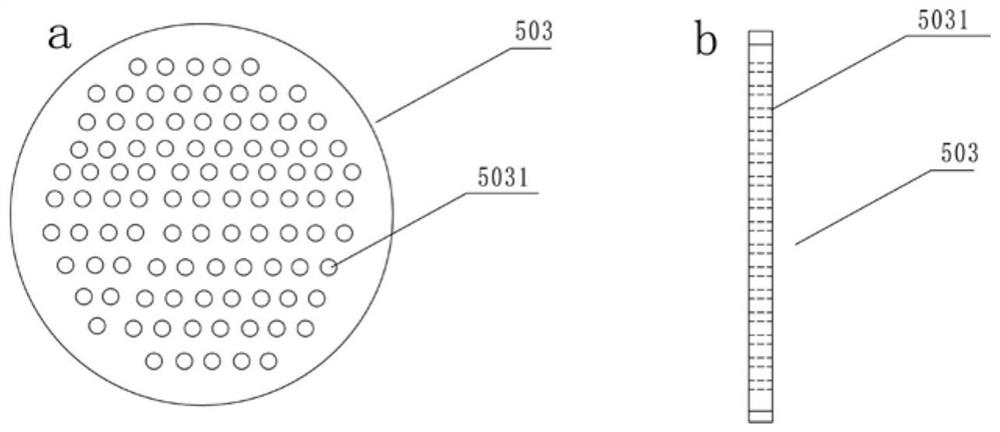

Nitrogen-insulating combustion and CO2 capture and utilization process for gas-fired boiler

The invention discloses a gas-fired boiler nitrogen-insulating combustion and CO2 capture and utilization process. A system required by the process comprises a natural gas supply device, a water electrolysis hydrogen production device, an oxygen preparation device, a nitrogen compressor, a carbon-based nitrogen-insulating gas mixer, a gas heat exchanger, a gas-fired boiler, a chimney, a flue gas dehydration device, an air blower, a CO2 recovery device and a CO2 compressor. The method has excellent performance in the aspects of yield increase, energy conservation and emission reduction, the unit consumption of per ton of steam and natural gas can be reduced by 10% or above, the yield can be improved by 10% or above, the flue gas emission is reduced, and ultralow emission of NOx is achieved.

Owner:SHANGHAI YUANHAN ENERGY&CHEM TECH CO LTD +1

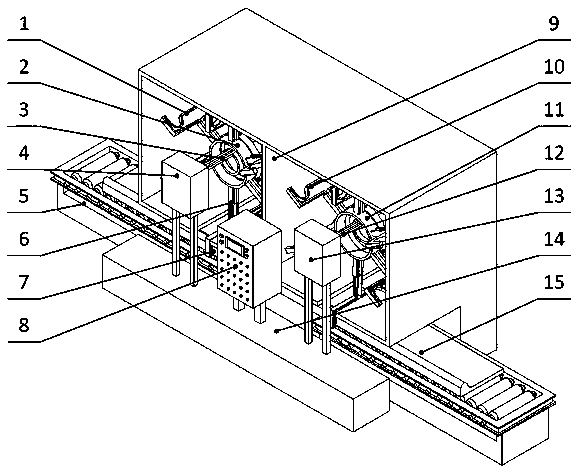

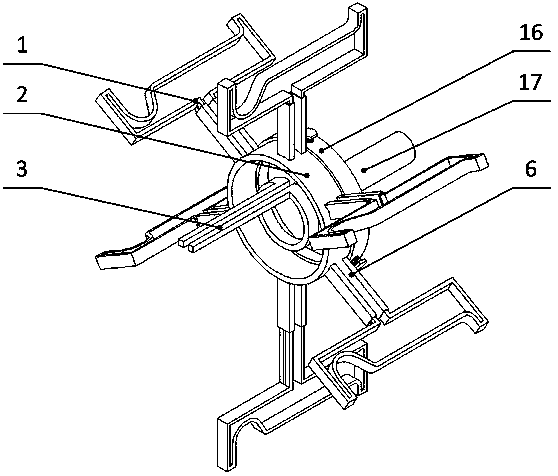

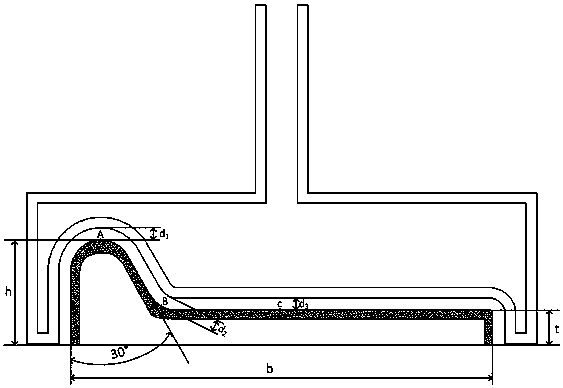

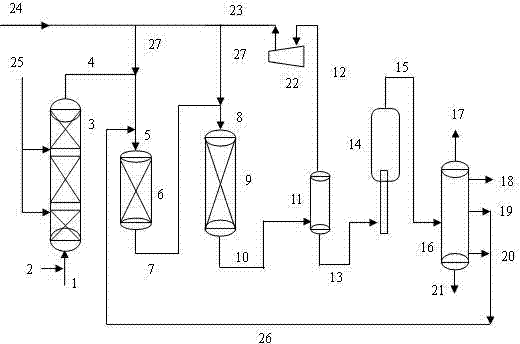

Marine flat-bulb steel squirrel-cage type induction heating device and marine flat-bulb steel squirrel-cage type induction heating process

ActiveCN110791626AAchieve continuous quenchingReasonable temperature distributionIncreasing energy efficiencyFurnace typesEngineeringHeating effect

The invention relates to a marine flat-bulb steel squirrel-cage type induction heating device and a marine flat-bulb steel squirrel-cage type induction heating process and belongs to the technical field of metallurgical thermal treatment processes. Continuous quenching is achieved by way of preheating and heating the marine flat-bulb steel by using copy coils of a preheating coil group and a heating coil group as the marine flat-bulb steel is driven by a roller conveyor belt to move at a uniform speed. A reasonable temperature distribution is obtained on the surface of a workpiece by means ofheat conduction, and an ideal heating effect is obtained by way of secondary heating. The surface temperature of the preheated marine flat-bulb steel is detected in real time through an infrared temperature measuring camera and the copy coils are matched with different shape parameters of the marine flat-bulb steel on line in the heating process, so that a phenomenon of an excessive local temperature difference caused by a sharp corner effect is reduced and the performance of the marine flat-bulb steel after induction heating quenching and the uniformity of a hardening layer are improved.

Owner:YANSHAN UNIV

Method and mechanism for increasing temperature of primary air of boiler pulverizing system

InactiveCN106402915AWithout Compromising Safety and ReliabilityReduce distractionsSolid fuel pretreatmentIndirect carbon-dioxide mitigationAir preheaterCombustion

The invention discloses a method for increasing the temperature of primary air of a boiler pulverizing system. The primary air is further heated by utilizing superheated steam of a boiler, so that the drying capability of the primary air is increased. On a pipeline from a low-temperature superheater outlet header to a next superheater header, a steam-gas heat exchanger is added, and a part of or all primary air from an outlet of an air preheater is heated by using steam. The invention further provides a mechanism used by the method. According to the method and the mechanism which are disclosed by the invention, the temperature of the primary air can be independently controlled, so that the requirement of drying capacity is satisfied, and the pulverizing system is safely and reliably operated; the temperature of the primary air is increased, so that the problem of serious imbalance of the primary air and secondary air can be preferably solved, and the proportion of the primary air to the secondary air is kept within a reasonable design range; and the interference of unreasonable distribution of the primary air and the secondary air on a combustion organization is reduced, so that the problems of unreasonable distribution of furnace box temperature, overtemperature of furnace outlet gas and ultrahigh exhaust gas temperature are solved at the same time.

Owner:SHANGHAI JIAO TONG UNIV +2

Valvular electrically heated furnace and application in catalyst carrier decomposition thereof

ActiveCN1603732AReasonable temperature distributionHeating temperature is easy to controlElectric heating for furnacesThermal insulationDecomposition

The invention provides a kind of resolution type heating furnace, involves an electric heating stove and its decomposes on in the catalyst carrier the application. Including inner liner, stove tile, outside stove tile thermal insulation material, furnace shell; The stove tile divides into at least two petals in the circumference direction, each petal stove tile alone is loaded with the electric heating part, the thermal insulation material, each petal stove tile joint on a pulley, the pulley may slippery leave along the track outside the tube body, enables around the tube body each petal stove tile to be allowed to separate with the furnace body, is advantageous for controls warm, overhaul. The invention may use in each kind to need to control the temperature the heating furnace, specially takes the catalyst carrier decomposing furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

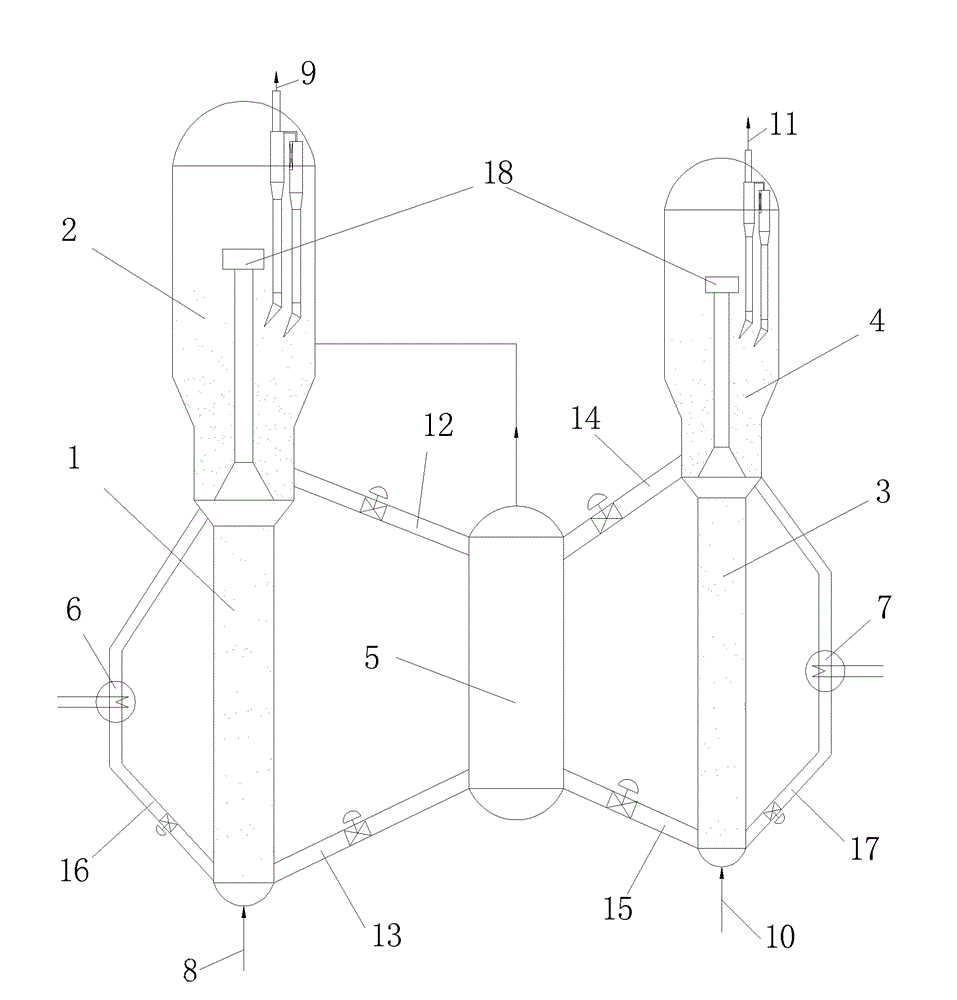

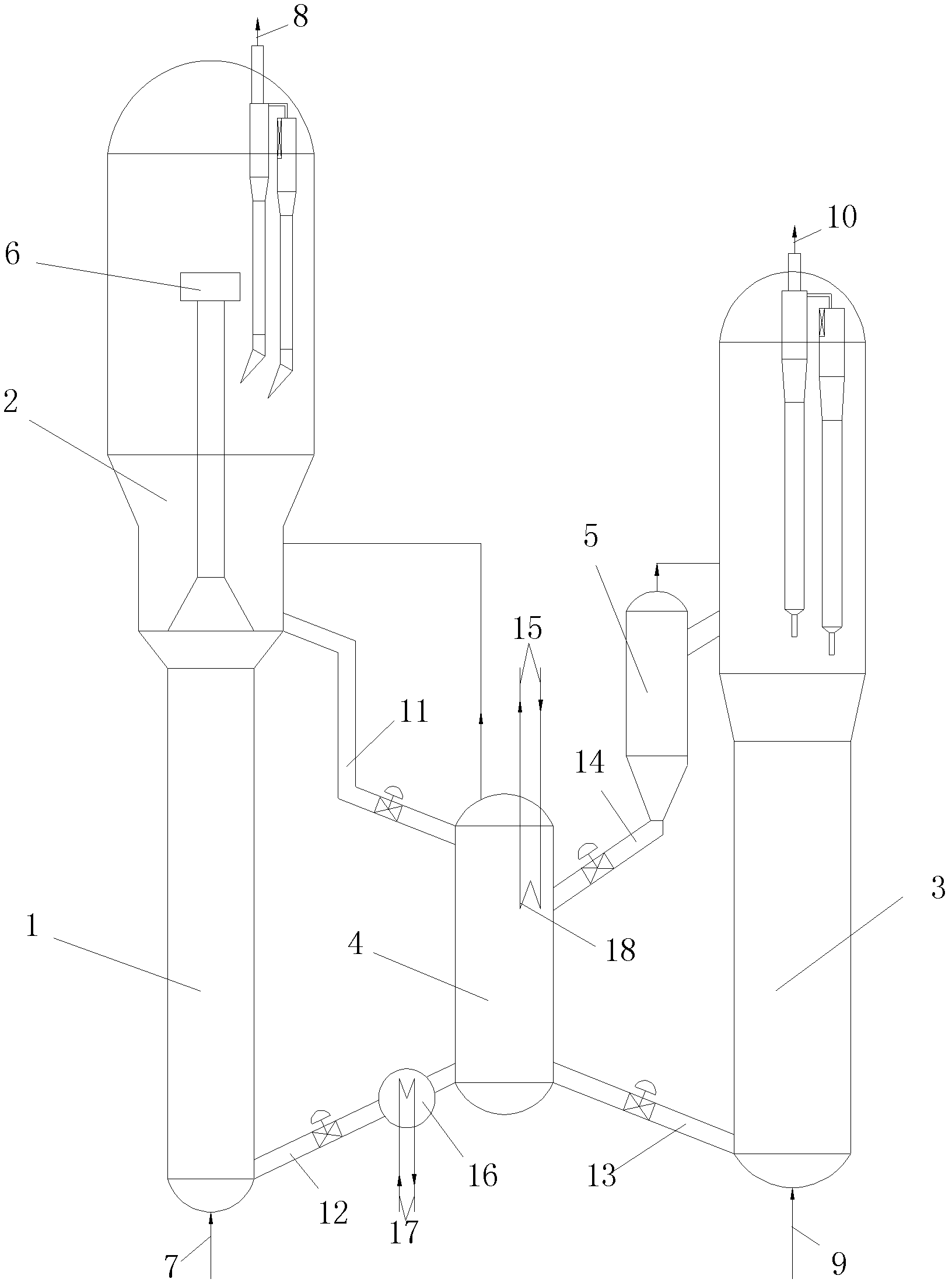

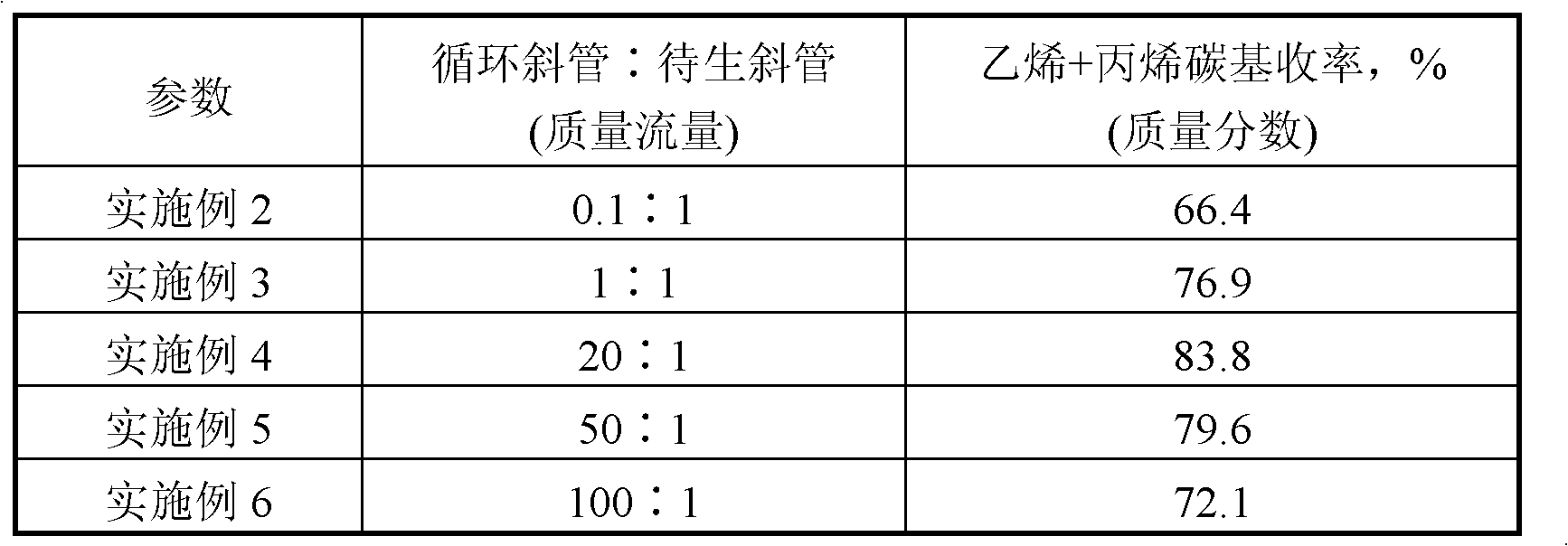

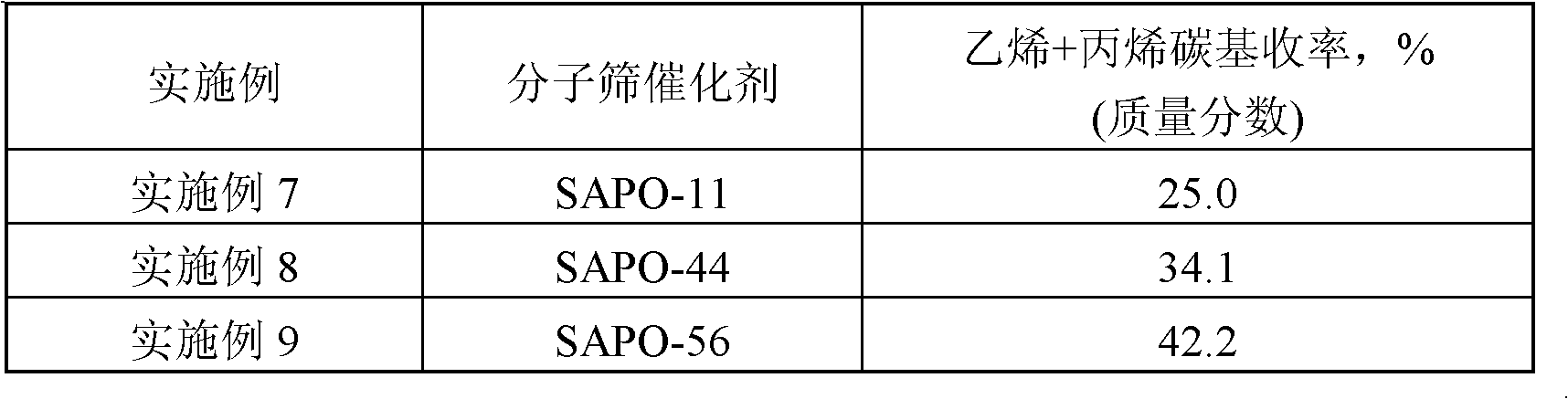

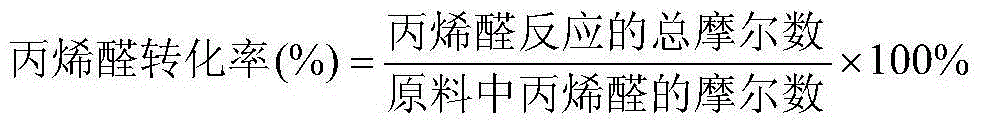

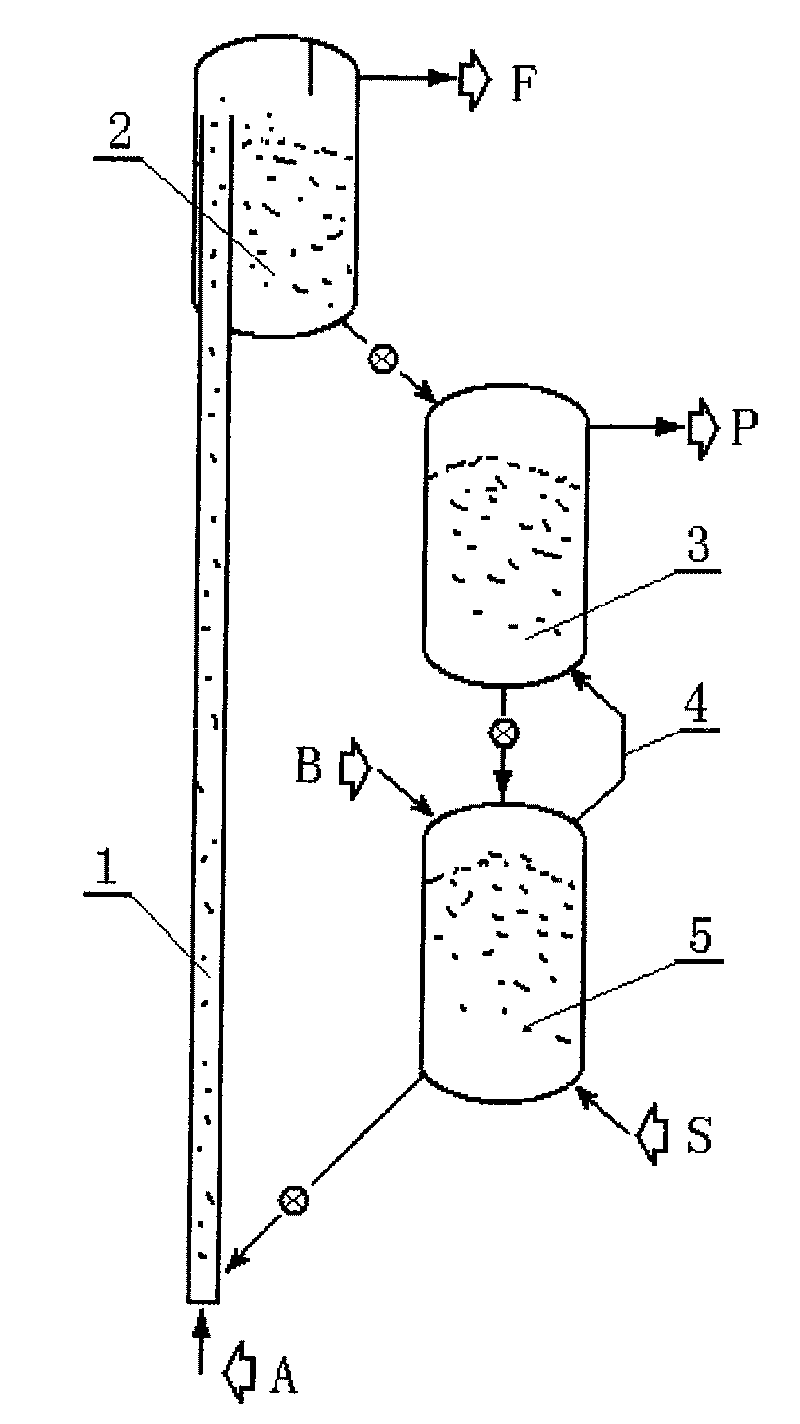

Method for producing low-carbon olefins by converting oxygen-containing compounds

ActiveCN103121901BUniform carbon distributionReasonable temperature distributionHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveFluidized bed

The invention relates to a method for converting oxygenated chemicals to generate low-carbon olefins, and mainly solves problems of undermixing catalysts and low-yield low-carbon olefins in a reaction zone in the prior art. The method for converting the oxygenated chemicals to generate the low-carbon olefins includes that the oxygenated chemicals are contacted with molecular sieve catalysts in a fluidized bed reactor, generated gaseous products with low-carbon olefins flow out of the fluidized bed reactor, and to-be-generated catalysts which are already generated enter into a reaction settler; the to-be-generated catalysts in the reacting settler enter a blender and the reactor after steam stripping, and the catalysts in the blender are divided into two parts after being blended and then enter the reactor and a regenerator; and the catalysts in the regenerator are contacted with a regenerated medium to form regenerated catalysts, and the regenerated catalysts enter a regenerated settler, and the regenerated catalysts are divided into two parts and respectively enter the blender and the reactor after steam stripping. According to the technical scheme, the method solves the problem effectively and is adaptable to industrial manufacture for converting the oxygenated chemicals to generate the low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

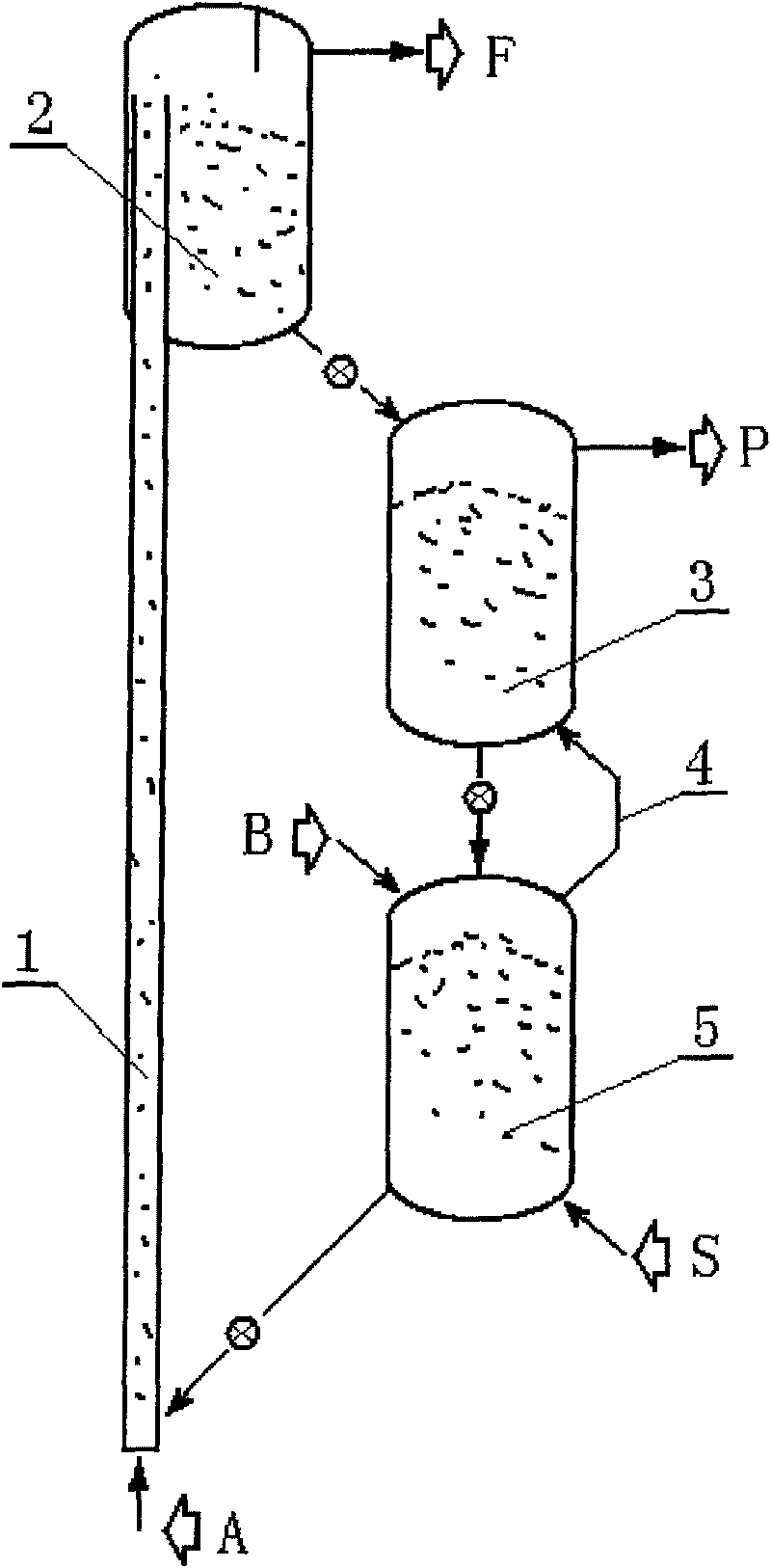

Method for producing low carbon olefin with oxygen compound

ActiveCN103121890BUniform carbon distributionReasonable temperature distributionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

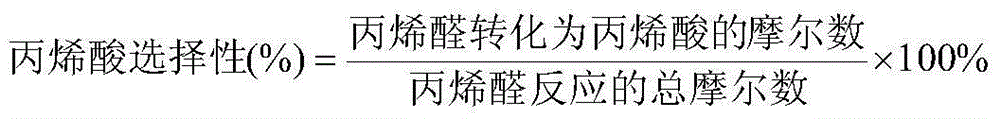

Method for preparing unsaturated acid from unsaturated aldehyde

ActiveCN104649885AEasy to operateHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsWater vaporFixed bed

The invention relates to a method for preparing unsaturated acid from unsaturated aldehyde. A fixed bed reactor is employed in the method. Reaction raw materials are preheated through a pre-heater to higher than 160 DEG C and then are fed into the reactor, wherein a salt bath is employed for heating the raw materials at a salt bath temperature of 240-265 DEG C and at a space velocity of 800-2200 / h. The reaction raw materials comprise following components, by volume, 8-12% of acraldehyde or methyl acraldehyde, 11-17% of water steam, 9-17% of oxygen and 60-72% of nitrogen. The fixed bed reactor is filled with an oxidizing catalyst, which contains elements of molybdenum, vanadium, copper and antimony. Main composition of the catalyst is represented as the following general formula: MoVCu<c>Sb<d>Sr<e>Si<f>M<g>N<h>O<x> (I). The catalyst also contains magnesium-based lanthanum hexaaluminate. The catalyst is prepared by: mixing the compound represented containing the molybdenum and the vanadium as the formula (I) with the magnesium-based lanthanum hexaaluminate respectively according to mass percentage ratios of 91-98% and 0.5-10%; kneading the raw materials of the catalyst; moulding the catalyst; and drying and roasting the catalyst. The method can produce acrylic acid stably for a long period.

Owner:PETROCHINA CO LTD

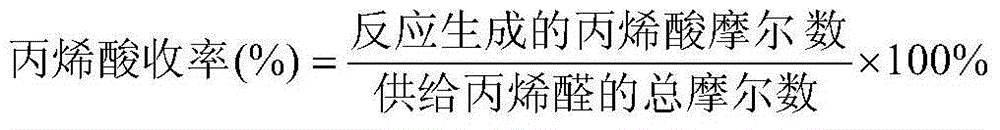

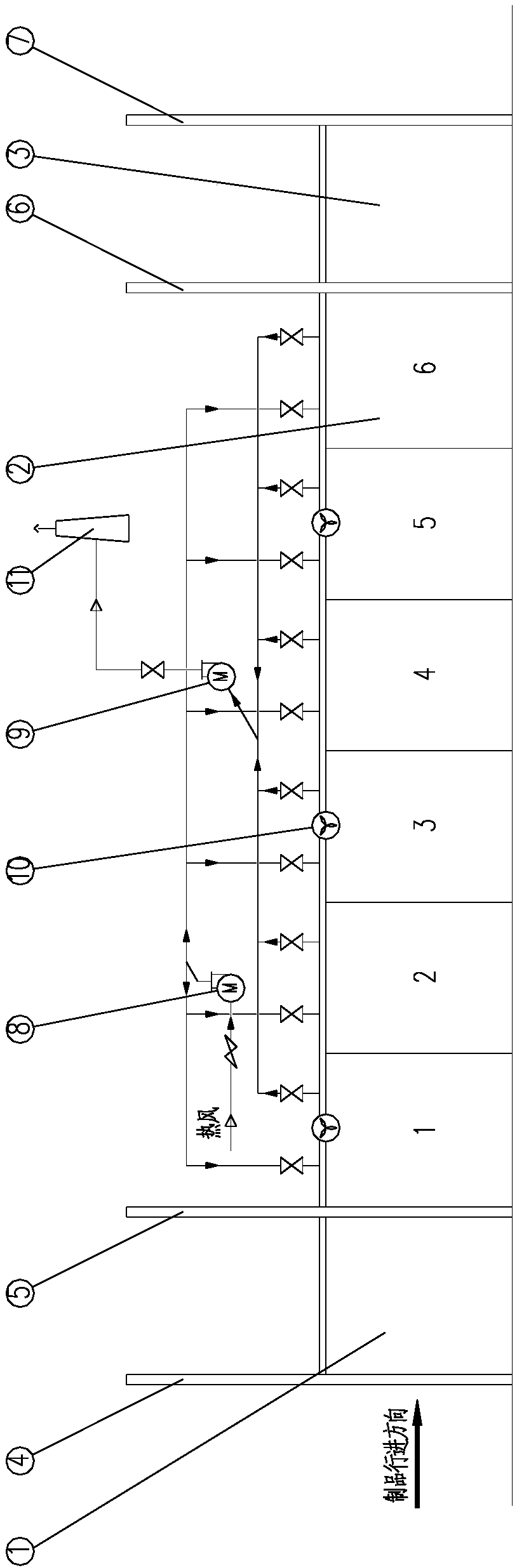

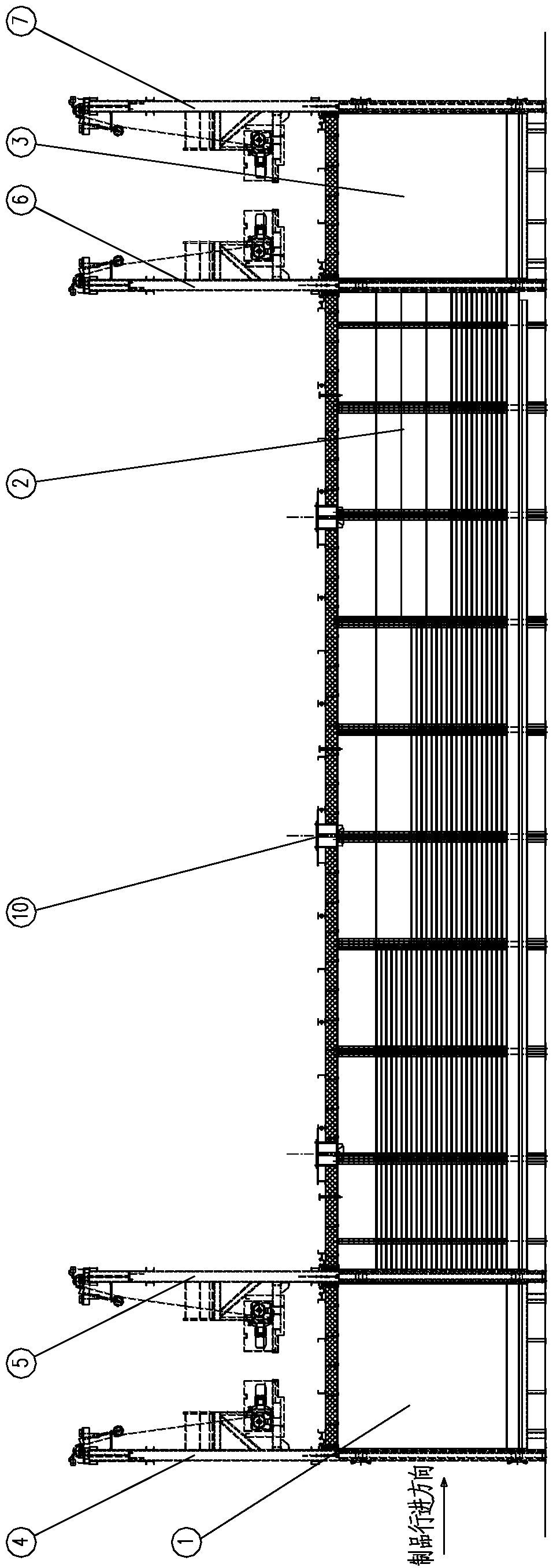

Tunnel type magnesian refractory brick salt immersing heat treatment kiln and technology

PendingCN107940990ASolve the problem of easy product hydrationSolve the problem of hydrationFurnace typesControl devices for furnacesAir volumeBrick

The invention discloses a tunnel type magnesian refractory brick salt immersing heat treatment kiln and a technology. The heat treatment kiln comprises a heat treatment kiln body, an outlet preparation chamber and an inlet preparation chamber; the inlet preparation chamber and the outlet preparation chamber are arranged at an inlet and an outlet of the heat treatment kiln body correspondingly, theinlet and the outlet of the heat treatment kiln body are separated from the external atmosphere, and kiln doors are arranged between the heat treatment kiln body and the inlet preparation chamber aswell as between the heat treatment kiln body and the outlet preparation chamber correspondingly, and an inlet of the inlet preparation chamber and an outlet of the preparation chamber are also provided with kiln doors; and the heat treatment kiln body is divided into a plurality of areas, and the heat supply air volume of each area is independently adjusted. Compared with the prior art, the tunneltype magnesian refractory brick salt immersing heat treatment kiln and the technology have the beneficial effect that through arrangement of the inlet preparation chamber and the outlet preparation chamber, the air volume partitioning control mode, arrangement of hot air circulation devices and the like, the thermal regulation required by the treatment technology of the heat treatment kiln is ensured.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

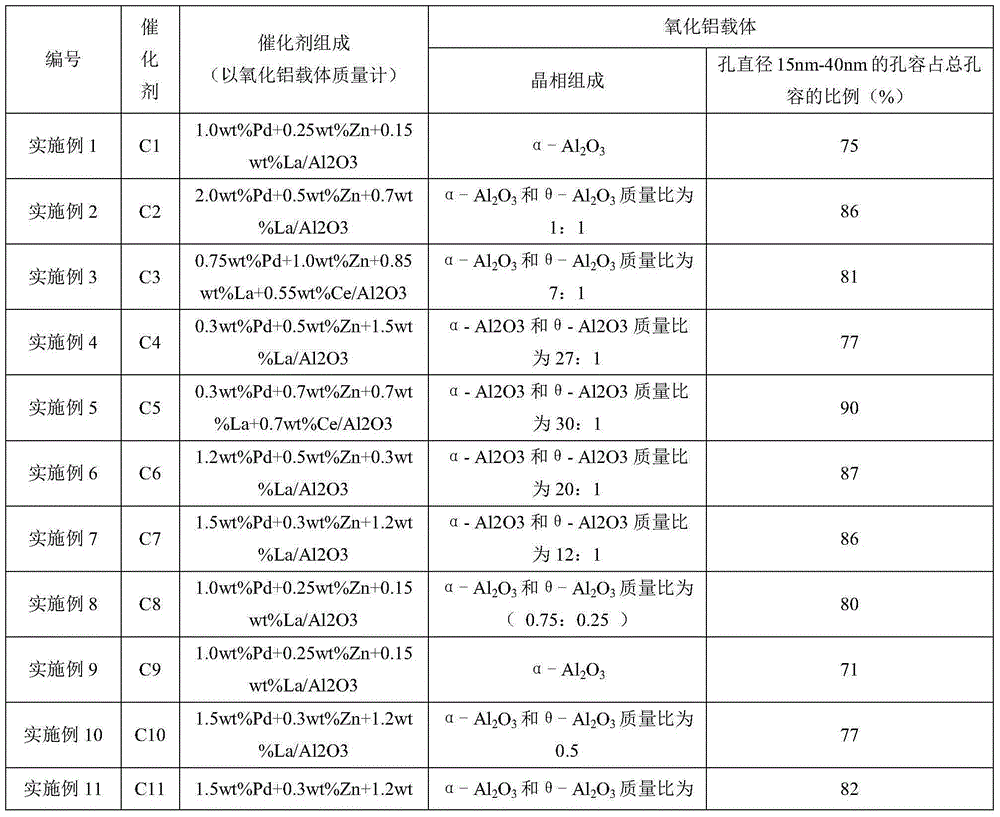

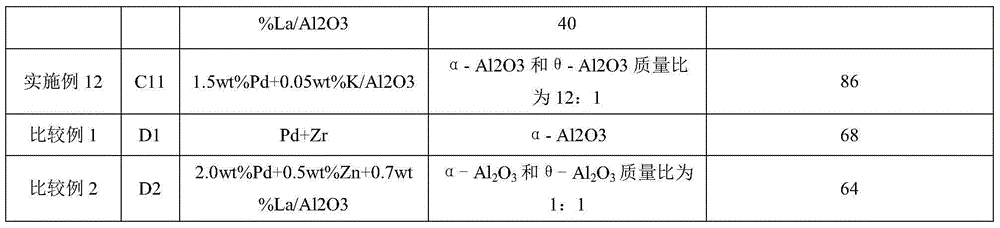

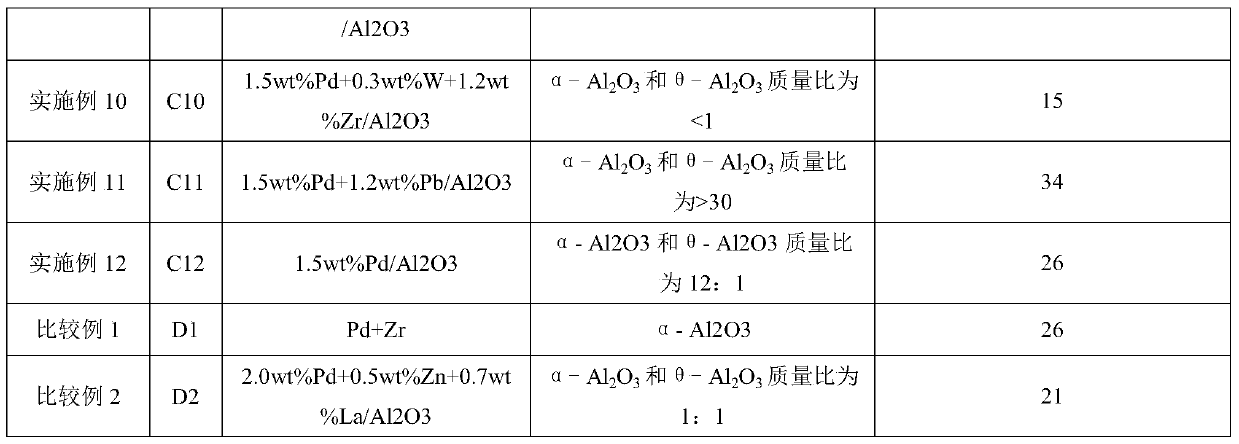

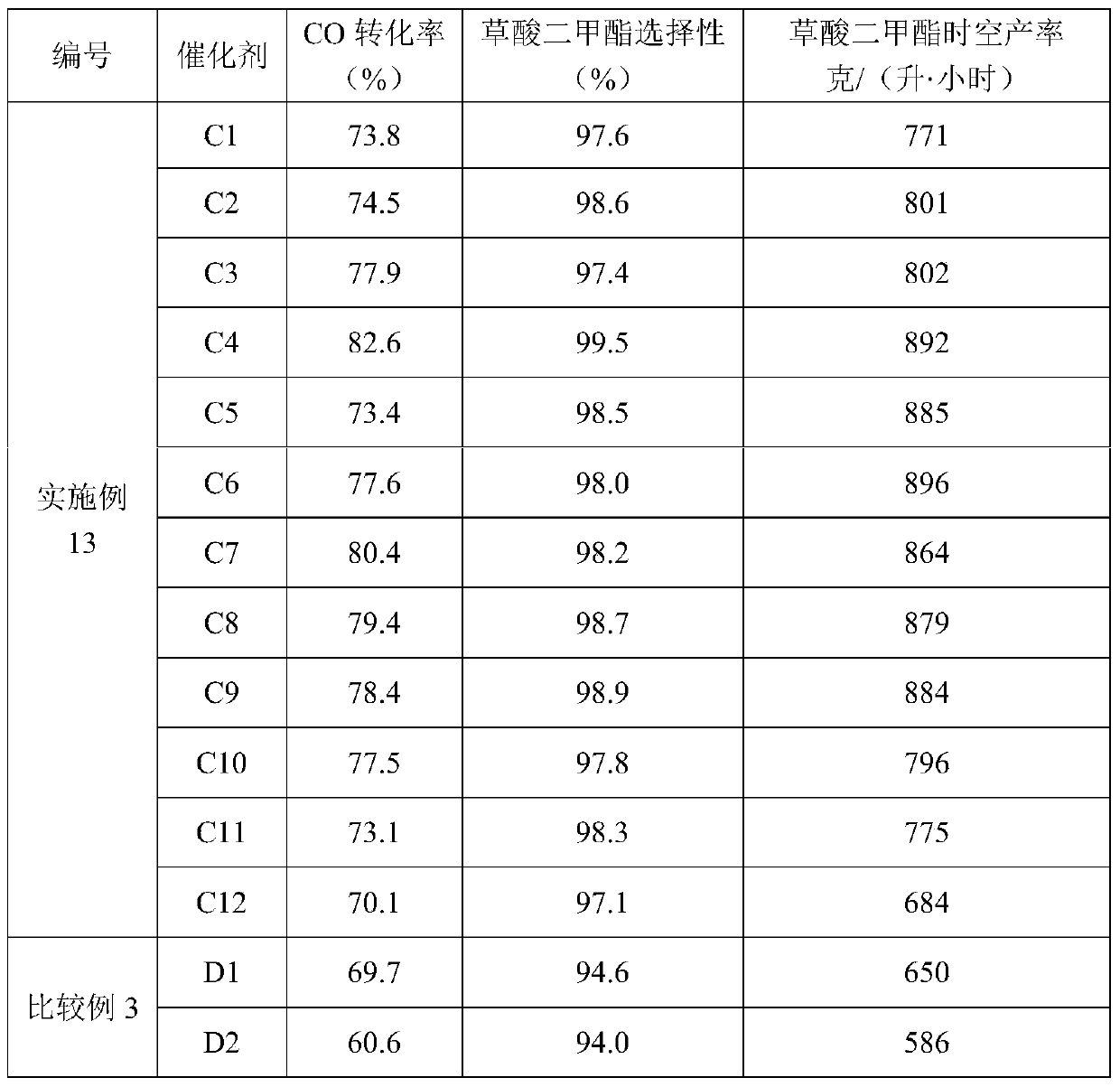

Catalyst for preparing oxalate through CO gas phase synthesis and preparation method and application thereof

ActiveCN106607024AHigh activityHigh selectivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsOxalateRare-earth element

Owner:CHINA PETROLEUM & CHEM CORP +1

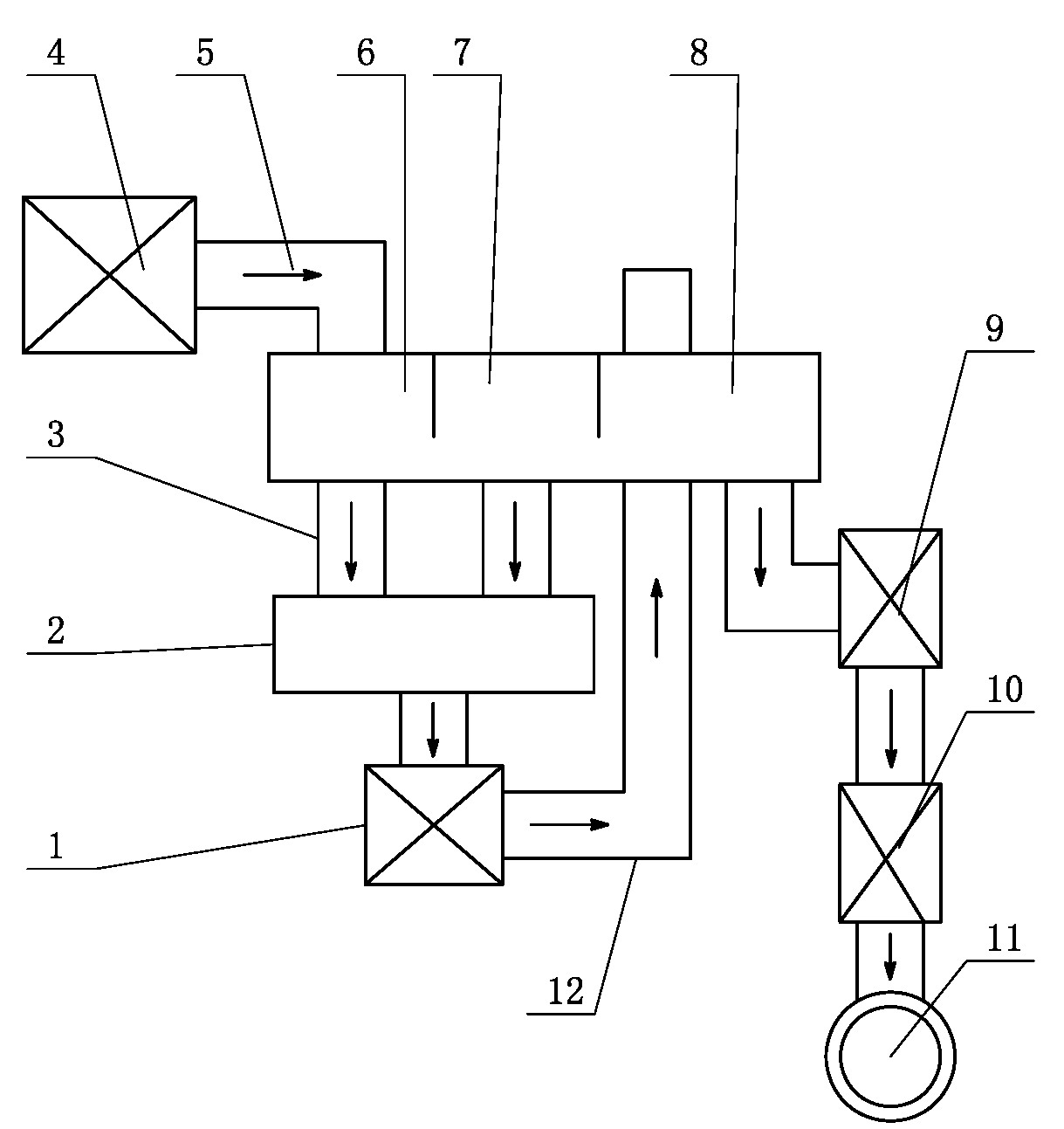

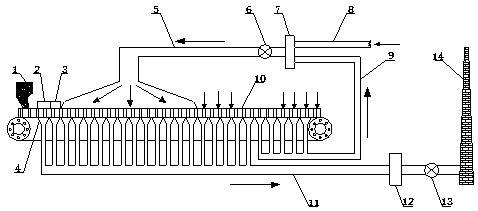

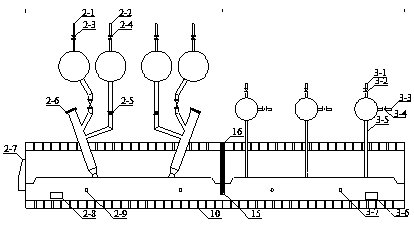

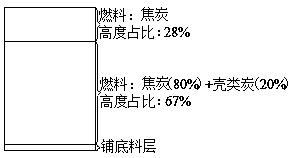

Iron ore sintering device and method with coke replaced with biomass charcoal based on fuel layering and flue gas circulating

PendingCN109443002AReasonable temperature distributionReduce upper underburnCharge manipulationFurnace cooling arrangementsIron ore sinteringMixing tank

The invention relates to an iron ore sintering device and method with coke replaced with biomass charcoal based on fuel layering and flue gas circulating, and belongs to the technical field of the iron and steel industry. The iron ore sintering device with the coke replaced with the biomass charcoal based on fuel layering and flue gas circulating comprises a sintering machine body, a mixing tank,an ignition furnace, a holding furnace, air bellows, a mixed flue gas circulating pipeline, a mixed flue gas circulating fan, a mixed flue gas dust removal device, a sintered ore cooling waste gas pipeline, a circulating flue gas pipeline, a sintering trolley, a large flue, a large flue dust removal desulfurizer, a large flue fan, a chimney and a sintering furnace. By means of the device and method, the biomass charcoal is adopted for replacing the coke, and reduction of fossil fuel consumption, utilization of flue gas waste heat, enrichment of SO2 in flue gas and reduction of the flue gas discharge amount can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

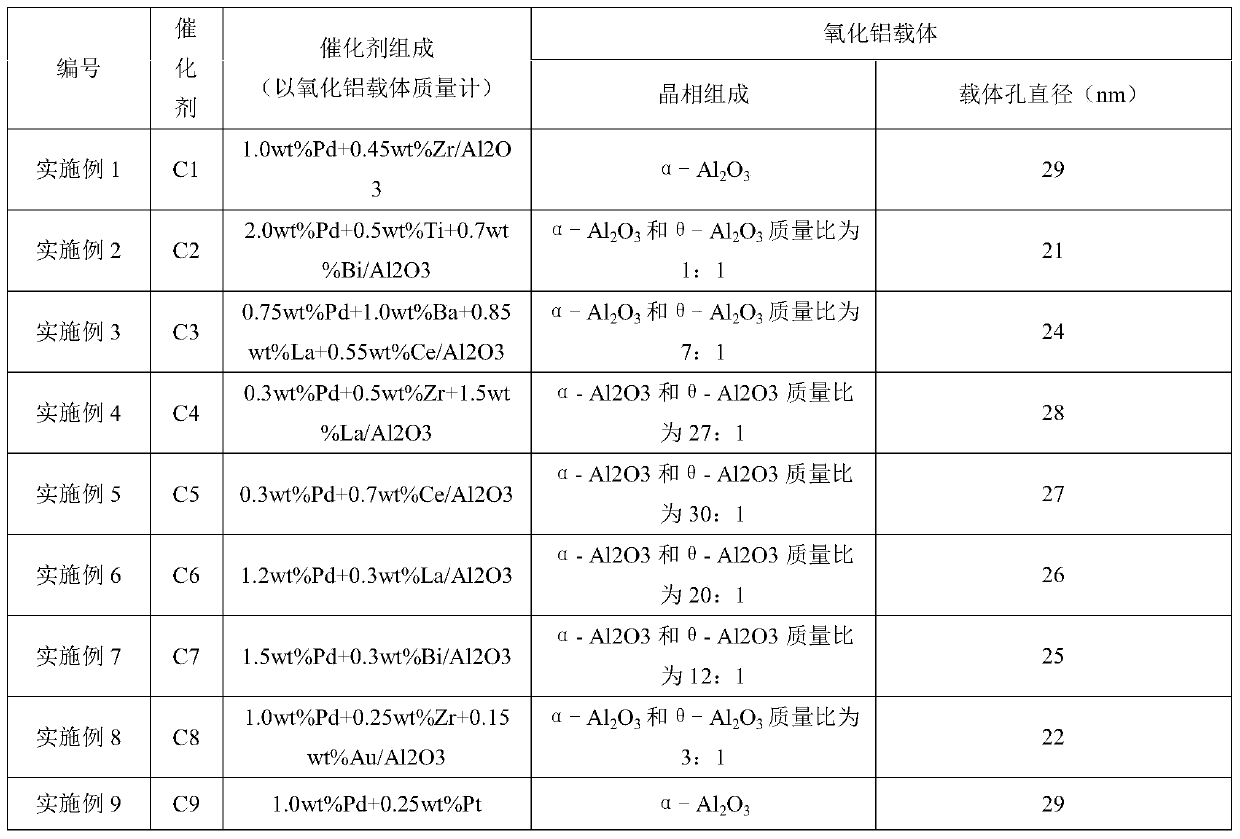

Catalyst, preparation method and application of co gas phase synthesis of oxalate

ActiveCN106824177BHigh activityHigh selectivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseAdditive ingredient

The invention relates to a CO gaseous-phase synthetic oxalic ester catalyst, a preparation method and application. The CO gaseous-phase synthetic oxalic ester catalyst mainly solves the technical problems of low activity and selectivity and low stability existing in the prior art. The catalyst is prepared from the following components in percentages by weight: a) using palladium as an active component, wherein the dosage of the active component is 0.1% to 4.0% of the weight of a carrier; b) using at least one element of IV B family or the sixth period in the periodic table of elements as an accessory ingredient, wherein the dosage of the accessory ingredient is 0.05% to 4.0% of the weight of the carrier; and c) using aluminum oxide as the carrier, wherein the specific surface area of the aluminum oxide carrier is 3 to 30 square meters per gram, and the average pore diameter of the aluminum oxide carrier is 15 to 40 nm. The catalyst can be used in industrial production of CO gaseous-phase synthetic oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

ActiveCN102876377BReduce the amount of mixed hydrogenStable temperatureTreatment with hydrotreatment processesFluid phaseHydrogenation reaction

The invention discloses a hydrotreatment and catalytic cracking combined method of a heavy hydrocarbon raw material. According to the invention, an upflow reactor is at least connected in series with a downflow fixed bed reactor. The heavy hydrocarbon raw material passes through UFR and is mixed with a catalytic cracking heavy fraction, and the mixture enters the downflow fixed bed reactor. A hydrogenation reaction effluent is separated so as to obtain a liquid phase, and the liquid phase is subjected to catalytic cracking. The obtained catalytic cracking heavy fraction returns to an inlet of the downflow fixed bed reactor. According to the method, the catalytic cracking heavy distillate oil, which is introduced into the inlet of the fixed bed reactor, is beneficial to hydrogenation reaction and can significantly improve temperature rising of the bed when used as cutback oil and can minimize the amount of hydrogen injected through the inlet when used as a hydrogen donor, thus further raising cooperative effect of combined flow equipment and prolonging the running period as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zero cooling air consumption super-strength cooling device for aircraft engine turbine blade

InactiveCN102146844AReduce processing stepsAvoid complexityTurbine/propulsion engine coolingAviationTurbine blade

The invention discloses a zero cooling air consumption super-strength cooling device for a turbine blade of an aircraft engine and relates to the cooling technology of turbine blades. A plurality of round hole channels are transversely processed inside the turbine blade from the front edge to the tail edge of the blade; the adjacent round hole channels are mutually communicated into a channel end to end; head and tail round holes nearby the front edge and the rear edge of the turbine blade are respectively communicated with an inlet and an outlet of a heat radiator through two conduits to form closely-communicated internal cooling channels; and high-pressure fluid is filled in the internal cooling channels. When the turbine blade feels high-temperature gas, the high-pressure fluid in the internal cooling channels forms inner circulation under the heat drive of the high-temperature gas, and the heat in the circular flow of the high-pressure fluid is taken away by the heat radiator, so that the super-strength cooling to the turbine blade is realized under the situation that the cooling air is not required. The zero cooling air consumption super-strength cooling device can improve the cooling the turbine blade under the situation that cooling air is not required and increase the inlet temperature of a turbine, thereby increasing the thrust-weight ratio of the aircraft engine and reducing the manufacturing cost of the aircraft engine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for preparing hydrogen-riched gas by solid fuel catalytic gasification

InactiveCN101045524BReasonable temperature distributionReduce the temperatureDirect heating destructive distillationHydrogen productionCatalytic reformingSyngas

A process for preparing the H2-enriched gas by catalytic gasification of solid fuel features that the solid catalyst used also as the heat carrier is circulating through riser combustion reactor, solid catalyst storage tank, catalytic reforming reactor and pyrolyzing reactor. In said pyrolyzing reactor, the biomass or coal and the solid heat carrier (catalyst) take part in fast pyrolytic reaction.Its resultant and the water steam take part in catalytic decomposing and reforming reaction to generate H2-enriched gas or synthetic gas.

Owner:DALIAN UNIV OF TECH

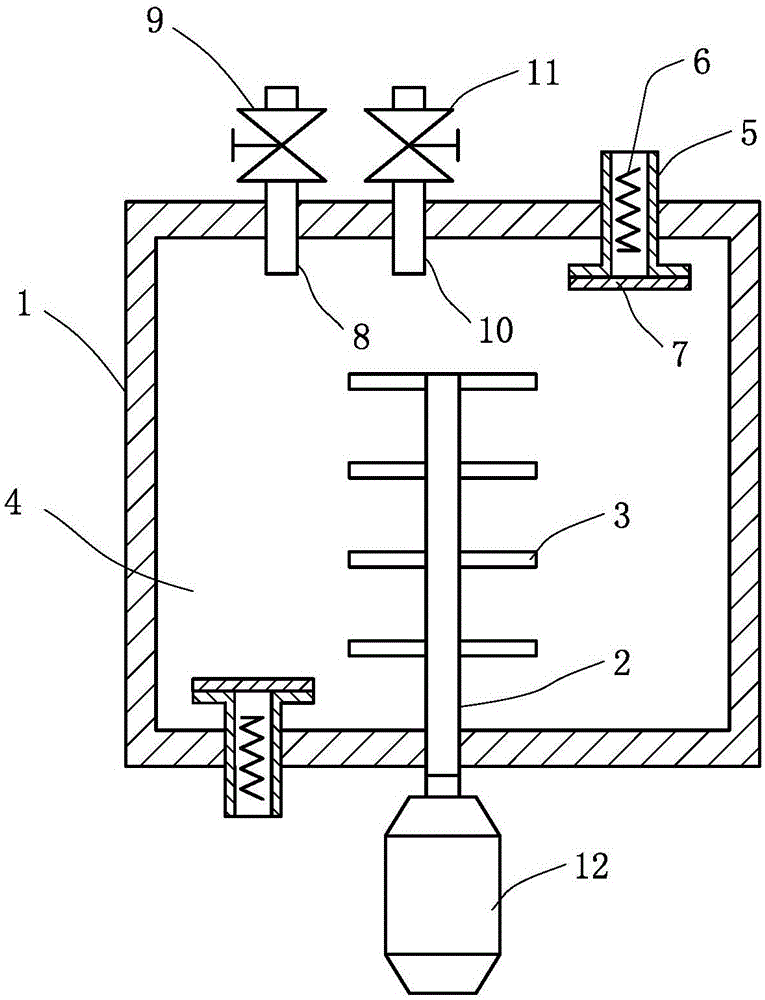

Food sterilizing device and sterilizing method

The present invention discloses a food sterilizing device belonging to the technical field of sterilization equipment. The food sterilizing device includes a pressure vessel. The pressure vessel includes a sealed sterilizing chamber and is characterized in that the pressure vessel is provided with non-contact temperature heating mechanisms which can be used to boost the temperature of the sterilizing chamber. An air inlet pipe and an air outlet pipe are arranged at the pressure vessel, an air outlet valve is provided on the air outlet pipe, an air outlet valve is provided on the air inlet pipe, and the air inlet pipe and air outlet pipe both stretch into the sterilizing chamber. A transmission shaft driven by a power unit is rotably mounted on the pressure vessel, pluralities of trays are arranged on the transmission shaft, and the trays are located in the sterilizing chamber. The present invention also discloses a food sterilizing method that can quickly heat up in a short time, shorten the sterilization time, reduce energy consumption, and maintain the taste of food, and can be widely used in food production.

Owner:王昆

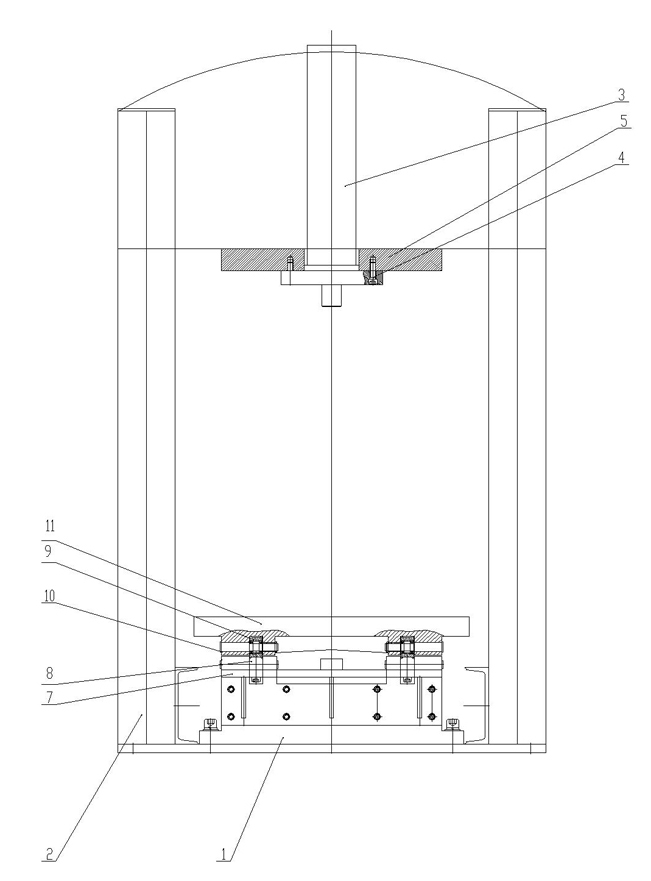

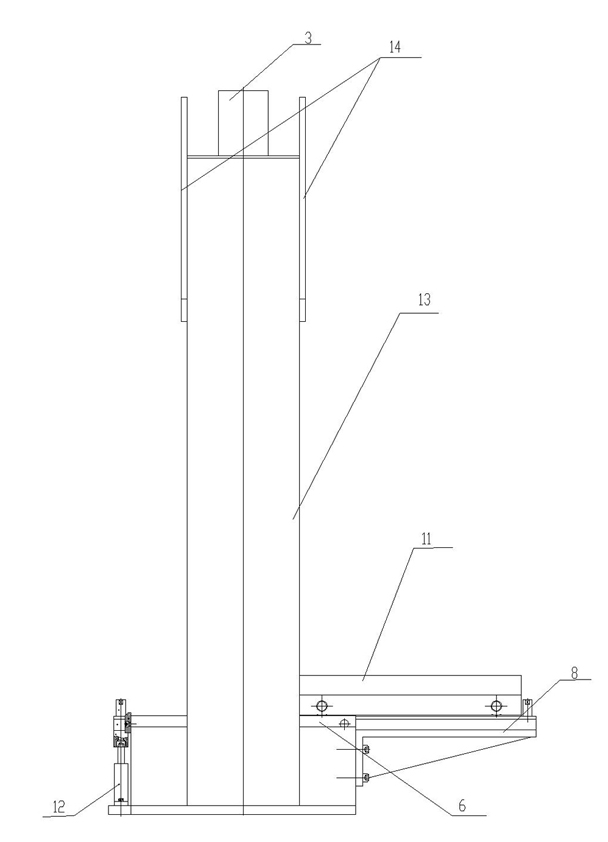

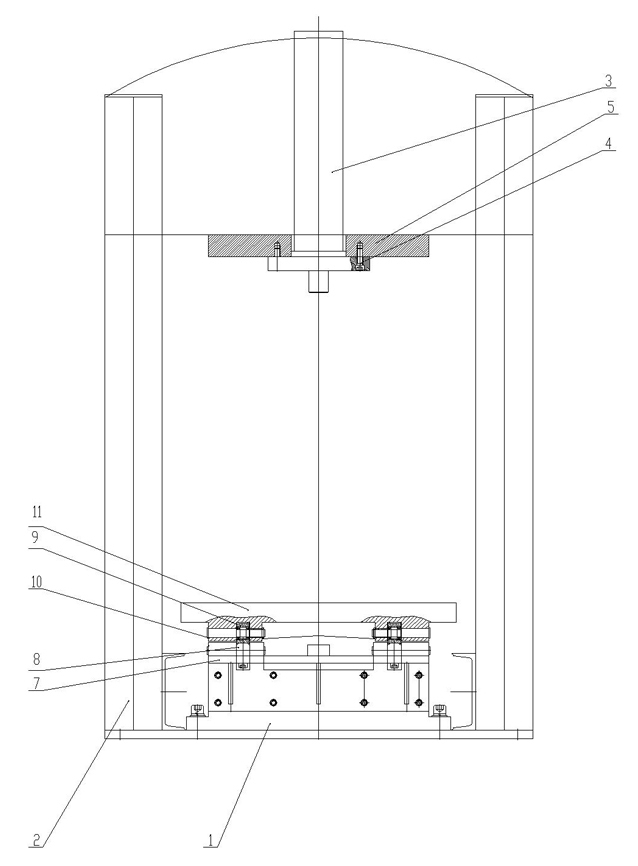

Hydraulic type portal frame

InactiveCN102009910ALight weightImprove corrosion resistanceBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderEngineering

The invention discloses a hydraulic type portal frame which comprises a base and a rack installed on the base, wherein a difunctional hydraulic cylinder is installed on the top of the rack, the bottom of the difunctional hydraulic cylinder is provided with a work platform through a screw, the base is provided with a bracket, a support plate is installed on one side of the bracket, and a guide rail is installed on the support plate, extends into the bracket, and is fixedly connected with the bracket; a guide wheel is movably installed on the guide rail, the guide wheel is provided with a guide wheel shaft, and the guide wheel shaft is installed in a chute on the lower end of a work sliding table; and a single acting hydraulic cylinder is installed on of the base at the other side of the work sliding table. The invention provides a hydraulic machine which has the advantages of reasonable structure and lower production cost, and is lighter and more convenient.

Owner:SHAOXING UNIVERSITY +2

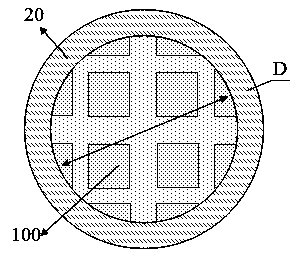

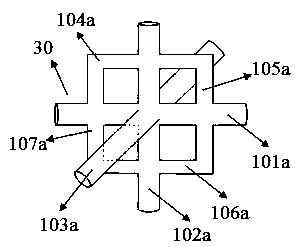

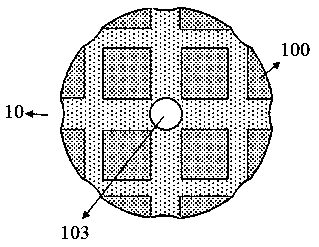

Hydrotreating method of heavy hydrocarbon raw material

InactiveCN111100693AReasonable temperature distributionIncrease profitTreatment with hydrotreatment processesChemical/physical processesPtru catalystFixed bed

The invention discloses a hydrotreating method of a heavy hydrocarbon raw material. The method comprises the following steps: at least one up-flow reactor and at least one down-flow fixed bed reactorare connected in series, a heavy hydrocarbon raw material is sequentially enable to pass through the up-flow reactor and the down-flow fixed bed reactor, and effluent of the down-flow fixed bed reactor is separated to obtain products; wherein the up-flow reactor is at least filled with a hydrotreating catalyst provided by the invention, a hydrotreating catalyst carrier at least comprises seven channels penetrating through the carrier; the first channel, the second channel and the third channel penetrate through the sphere center of the catalyst carrier and are communicated with one another, every two channels are perpendicular to each other, the fourth channel, the fifth channel, the sixth channel and the seventh channel are connected end to end and communicated, and the total volume of the channels accounts for 20%-60% of the volume of the spherical carrier. According to the method, the overall performance of the catalyst can be improved, the catalytic performance synchronization of the up-flow catalyst and the fixed bed catalyst is realized, the catalytic activity is improved, and the operation period is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com