Catalyst for preparing oxalate through CO gas phase synthesis and preparation method and application thereof

A gas-phase synthesis and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, carbon monoxide or formate reaction preparation, etc., can solve the problems of low activity and selectivity, poor stability, etc., and achieve high activity and selectivity performance-enhancing, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

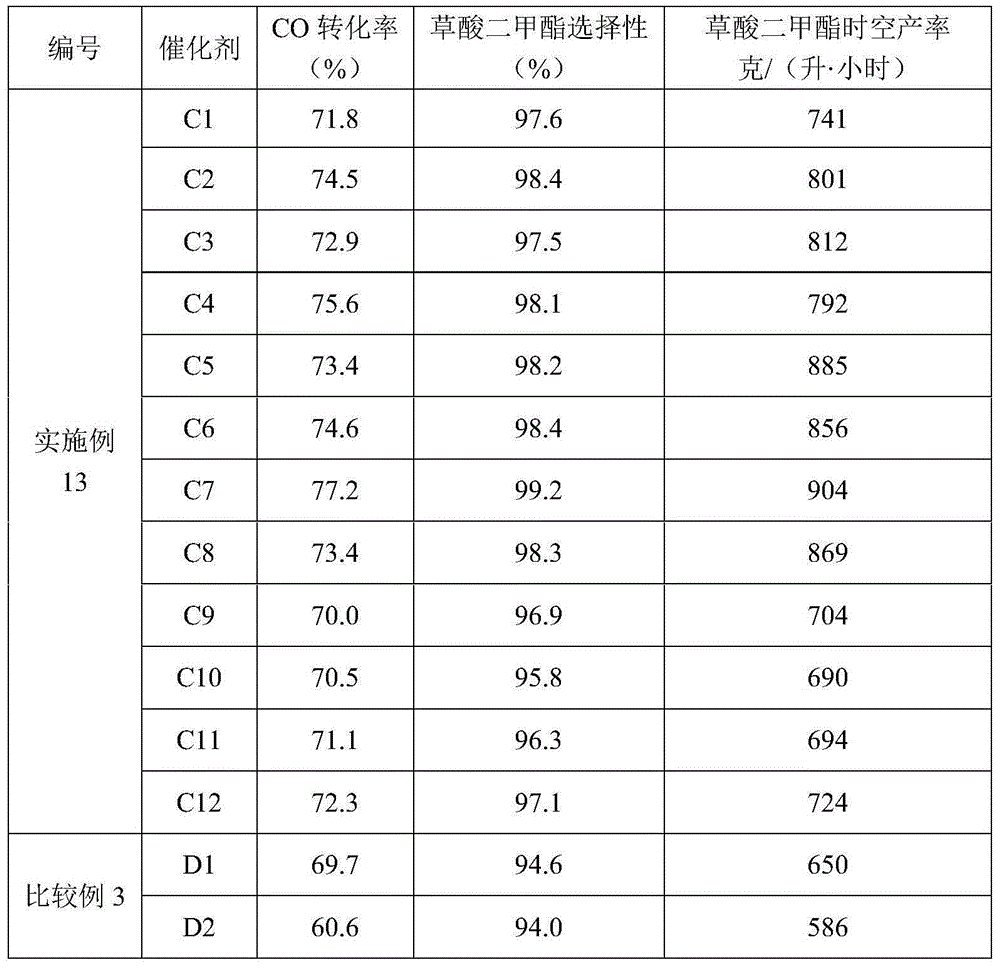

Examples

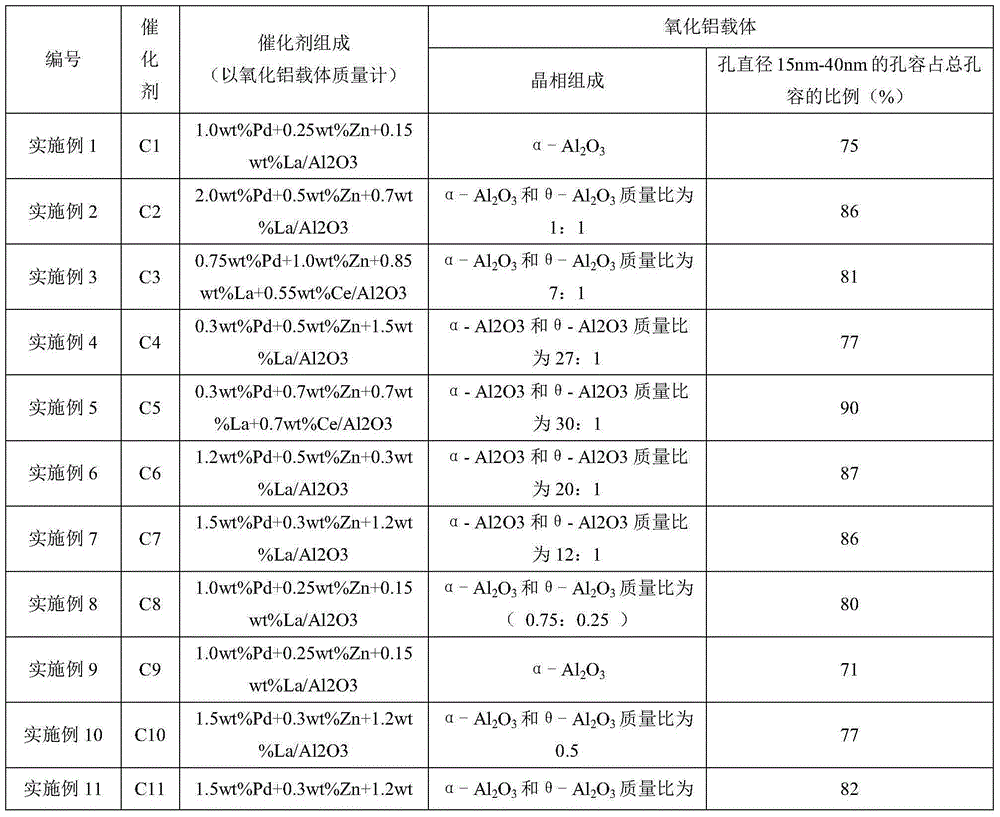

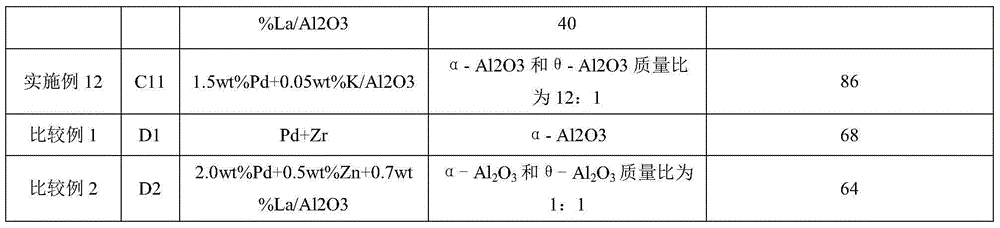

Embodiment 1

[0030] The formed pseudo-boehmite is treated with steam at 750°C for 6-8 hours, and then roasted at 1250°C for 3 hours to obtain α-Al 2 o 3 Alumina carrier. Weigh 100g of alumina support, based on metal element (the same below), according to 1.0wt%Pd+0.25wt%Zn+0.15wt%La / Al 2 o 3 content to prepare the catalyst, the specific steps are as follows: select lanthanum nitrate, prepare an impregnating solution according to the loading capacity, in order to control the modification of the surface of the support by rare earth metals, add succinic acid to the impregnating solution to make the solution pH=2, and then increase the specific surface area to 6.84 m 2 / g Al 2 o 3 Soak the carrier in the impregnating solution for 1 hour, then dry the solid at 110°C for 4 hours, and roast it at 400°C for 2 hours, then use palladium chloride and nitric acid as the carrier modified by rare earth according to the loading capacity of Pd and Zn. Pd-Zn-La / Al is prepared by preparing zinc into t...

Embodiment 2

[0032] Calcining pseudo-boehmite powder at 1250°C for 4 hours to obtain 2 o 3 powder, then mixed with pseudo-boehmite powder at a mass ratio of 1:1, treated with steam at 750°C for 2 hours, and then calcined at 900°C for 4 hours to obtain α-Al 2 o 3 and θ-Al 2 o 3 Mixed crystal alumina carrier. Weigh 100g of alumina carrier, based on metal element (the same below), according to 2.0wt%Pd+0.5wt%Zn+0.7wt%La / Al 2 o 3 content to prepare the catalyst, the specific steps are as follows: select lanthanum acetate, prepare an impregnating solution according to the loading capacity, in order to control the modification of the surface of the carrier by rare earth metals, add succinic acid to the impregnating solution to make the solution pH=2, and then increase the specific surface area to 8.74 m 2 / g Al 2 o 3 Soak the carrier in the impregnating solution for 1 hour, then dry the solid at 110°C for 4 hours, and roast it at 400°C for 2 hours, then use palladium chloride and nitric...

Embodiment 3

[0034] Calcining pseudo-boehmite powder at 1250°C for 4 hours to obtain 2 o 3 powder, mixed with pseudo-boehmite powder at a mass ratio of 7:1, treated with steam at 750°C for 3 hours, and then calcined at 850°C for 5 hours to obtain α-Al 2 o 3 and θ-Al 2 o 3 Mixed crystal alumina carrier. Weigh 100g of alumina carrier, based on metal element (the same below), according to 0.75wt%Pd+1.0wt%Zn+0.85wt%La+0.55wt%Ce / Al 2 o 3 content to prepare the catalyst, the specific steps are as follows: select lanthanum nitrate and cerium sulfate, and prepare an impregnation solution according to the loading capacity, in order to control the modification of the surface of the carrier by rare earth metals, add terephthalic acid to the impregnation solution to make the solution pH=1, and then The specific surface area is 8.79m 2 / g Al 2 o 3 Soak the carrier in the impregnating solution for 3 hours, then dry the solid at 80°C for 4 hours, and bake it at 450°C for 3 hours, then use pallad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com