Patents

Literature

39021results about How to "High selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing oxime

InactiveUS7161036B2Speed up the conversion processHigh selectivityOrganic compound preparationOrganic chemistry methodsKetoneAmmonia

A process for producing an oxime is provided, wherein the process comprises the step of reacting a ketone, hydrogen peroxide and ammonia in the presence of a crystalline titanosilicate having MWW structure under the condition that the ammonia concentration in the liquid portion of the reaction mixture is about 1% by weight or more. By the process, an ammoximation reaction of the ketone can be carried out with a high conversion of the ketone and a high selectivity to the oxime corresponding to the ketone, thereby producing the oxime with a high yield.

Owner:SUMITOMO CHEM CO LTD

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

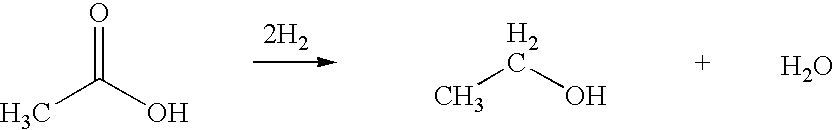

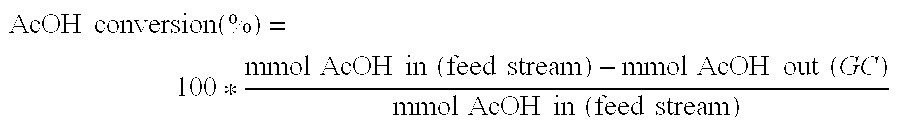

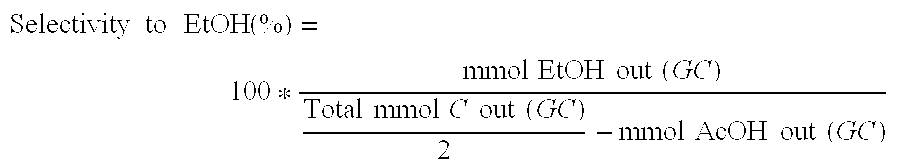

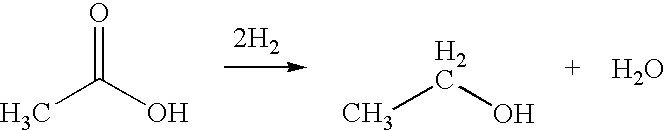

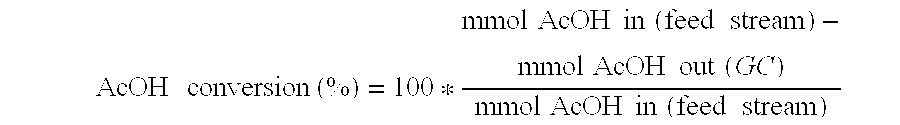

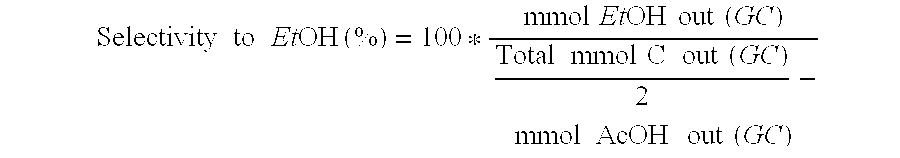

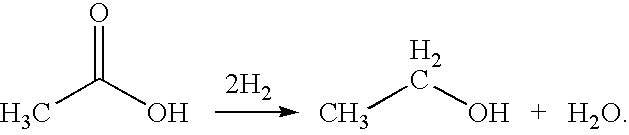

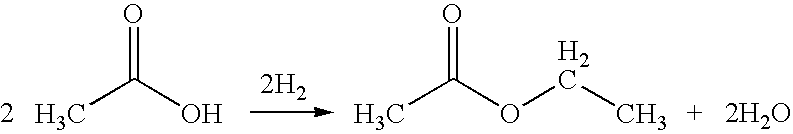

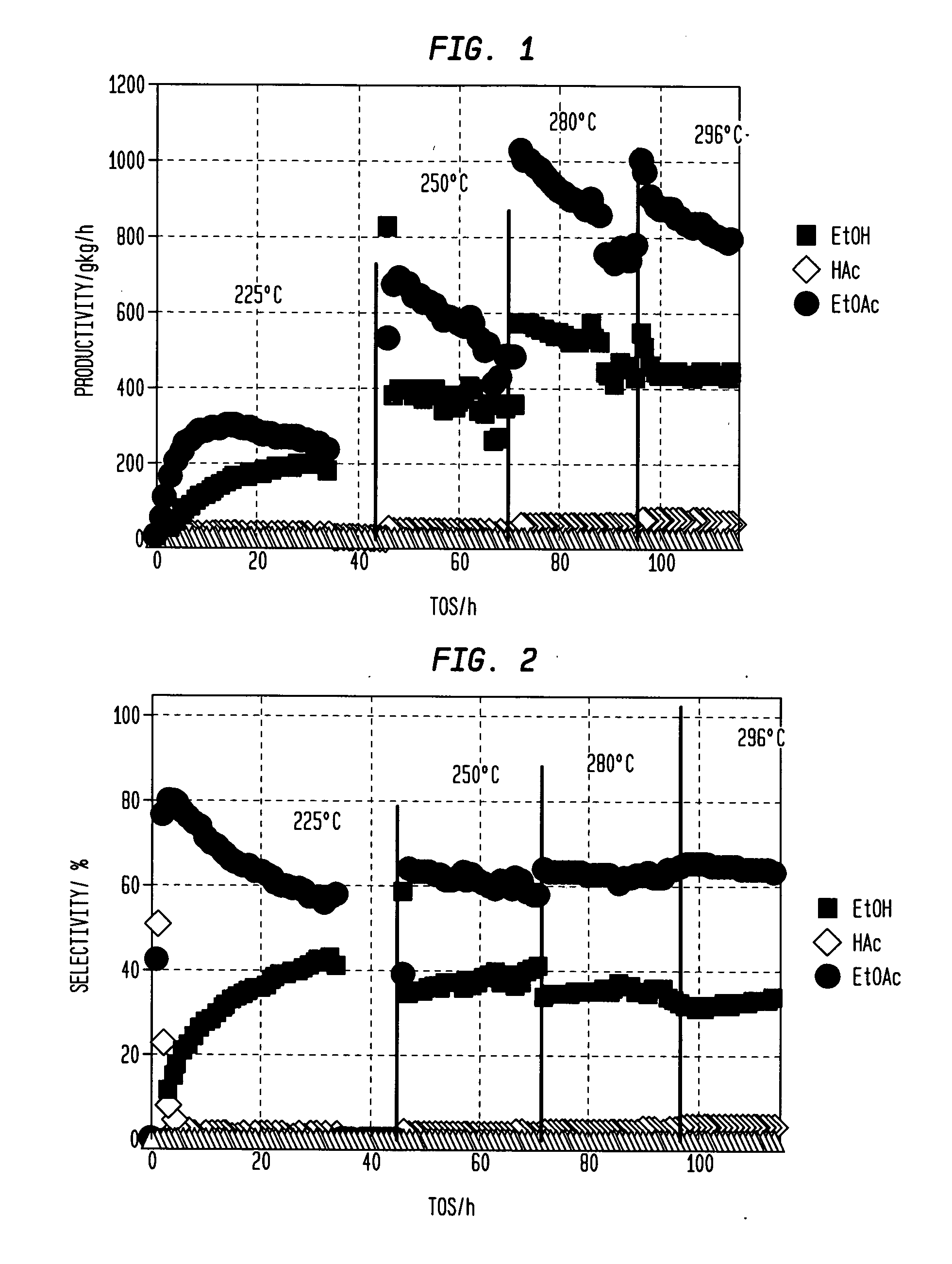

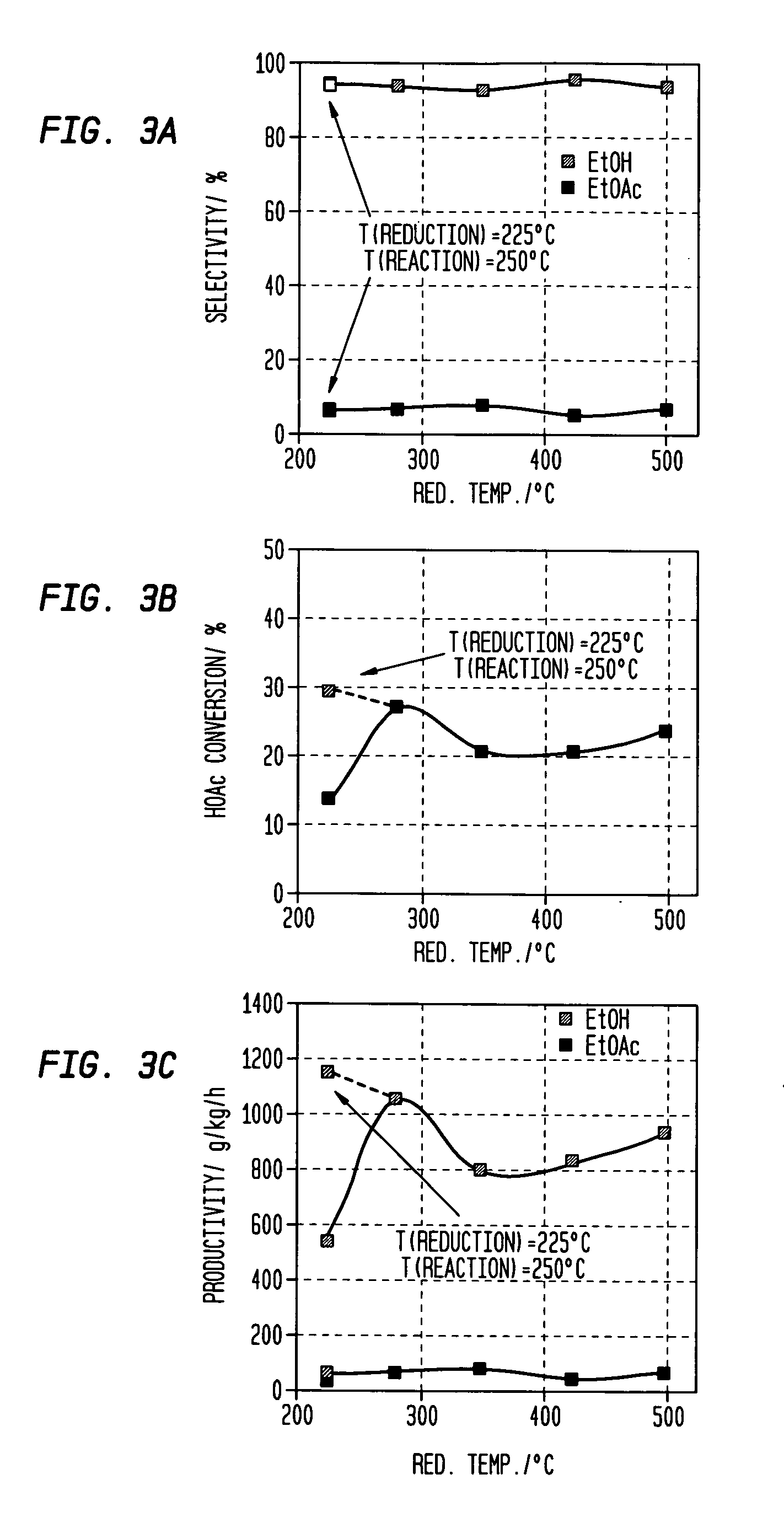

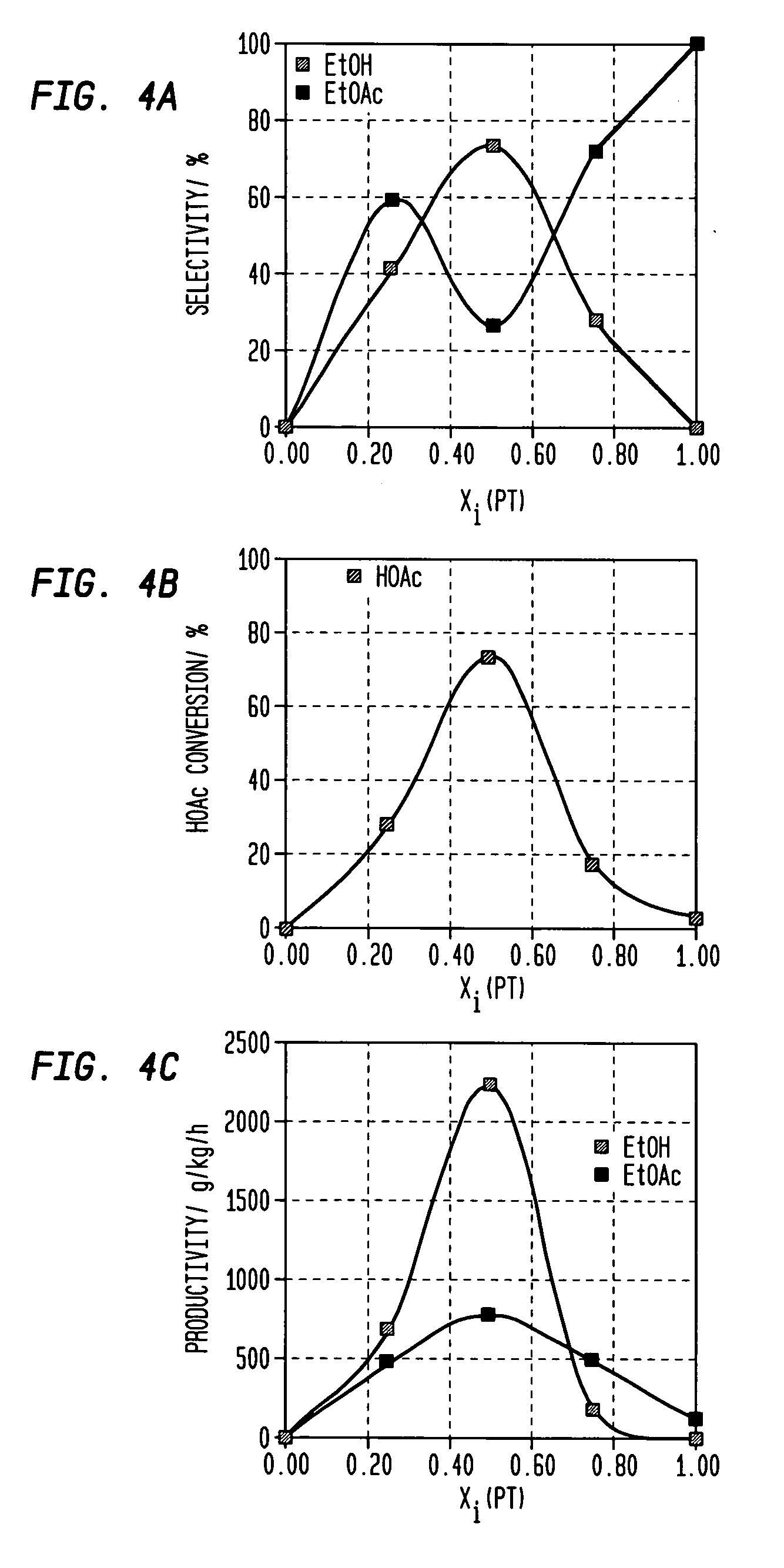

Ethanol production from acetic acid utilizing a cobalt catalyst

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

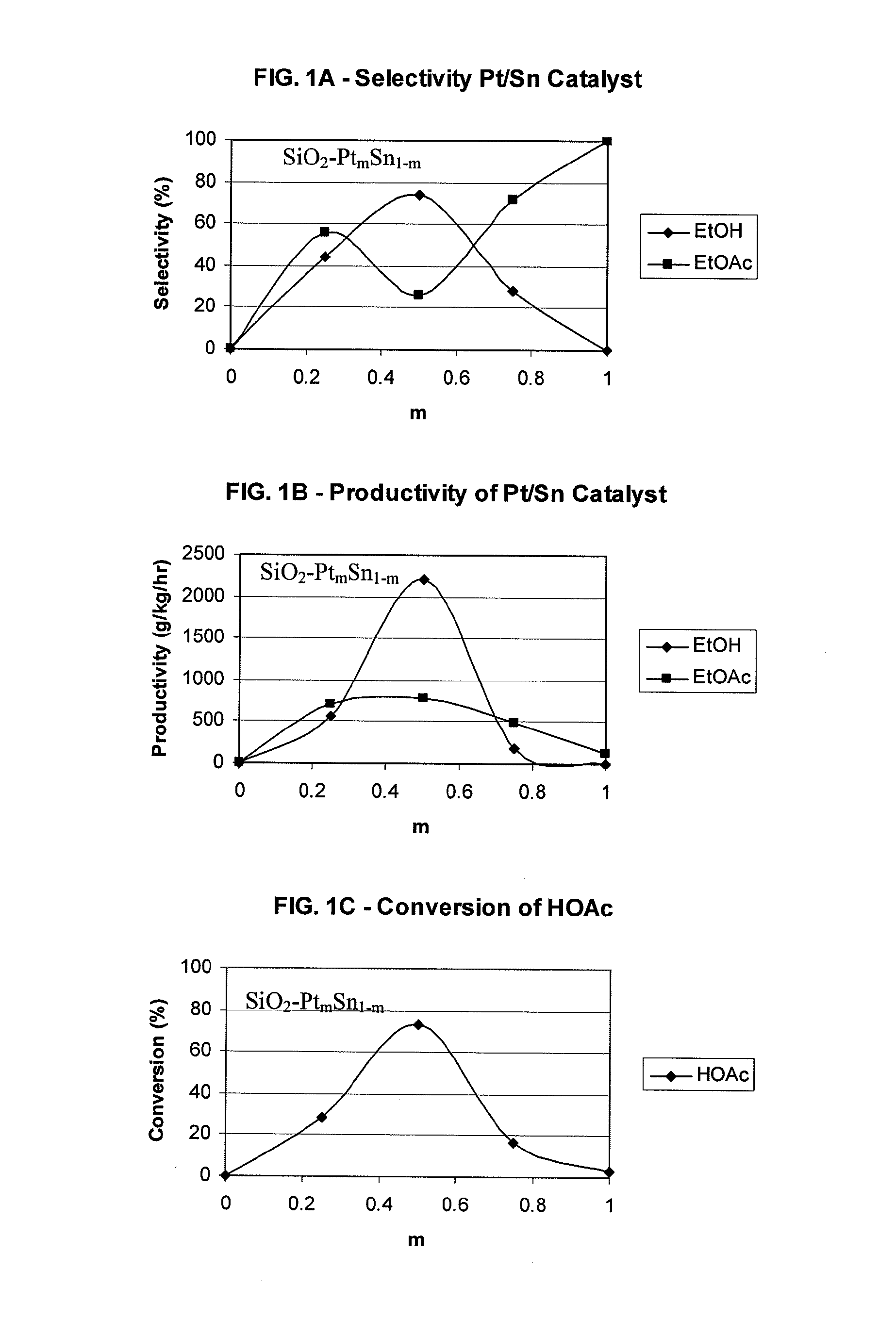

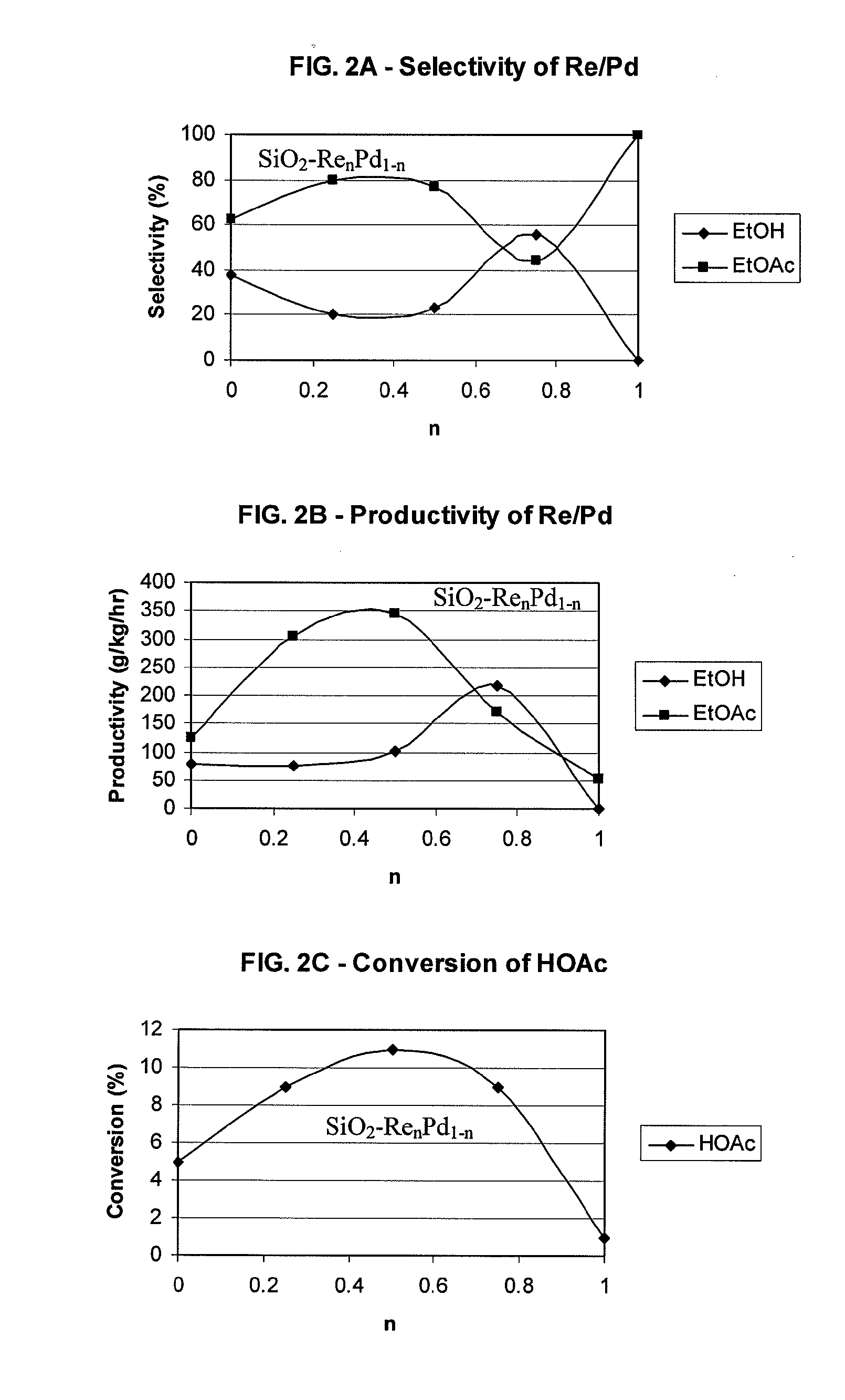

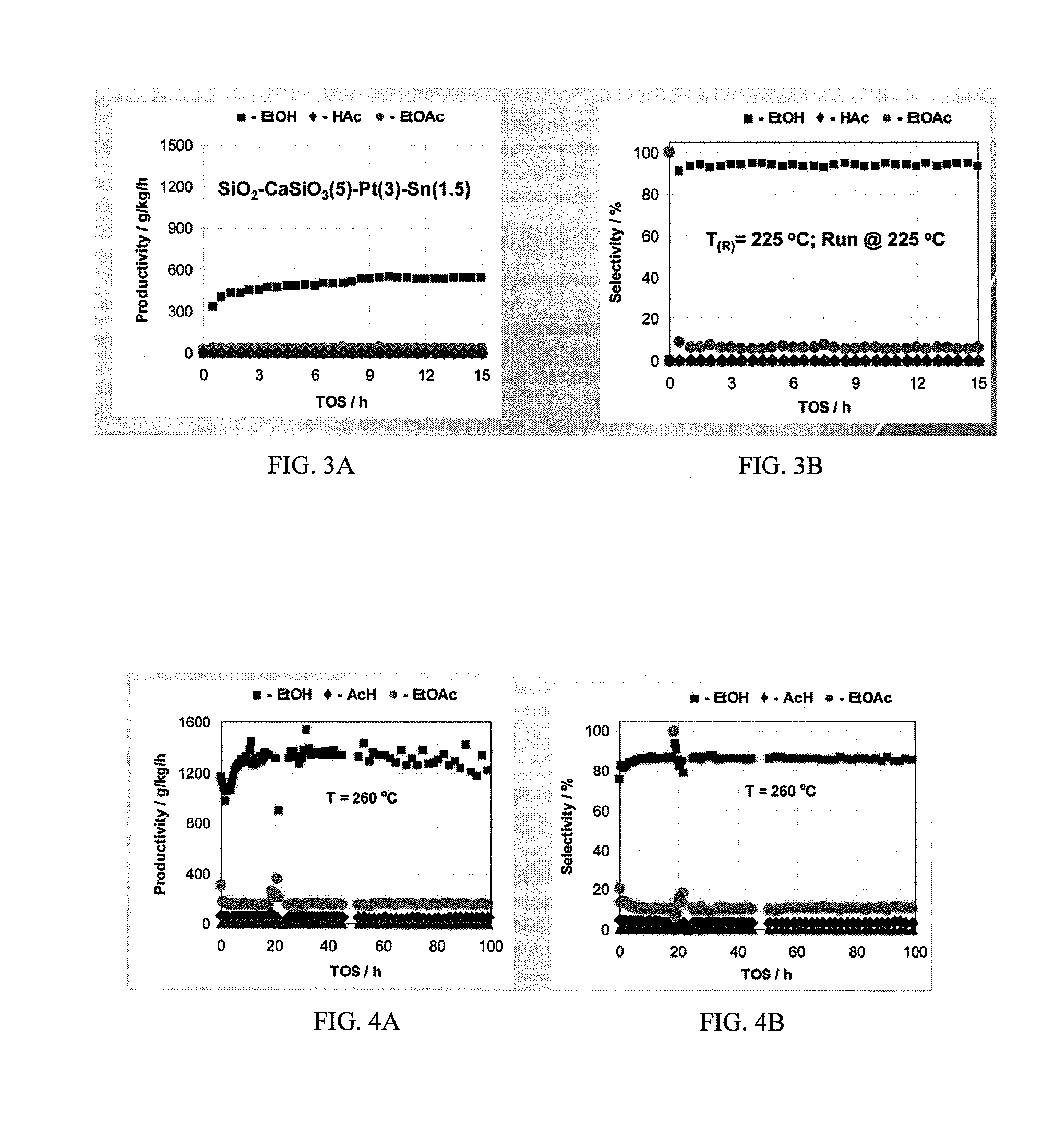

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

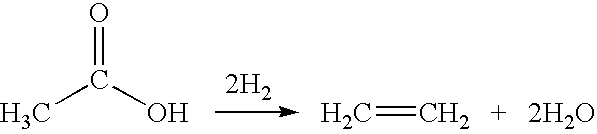

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

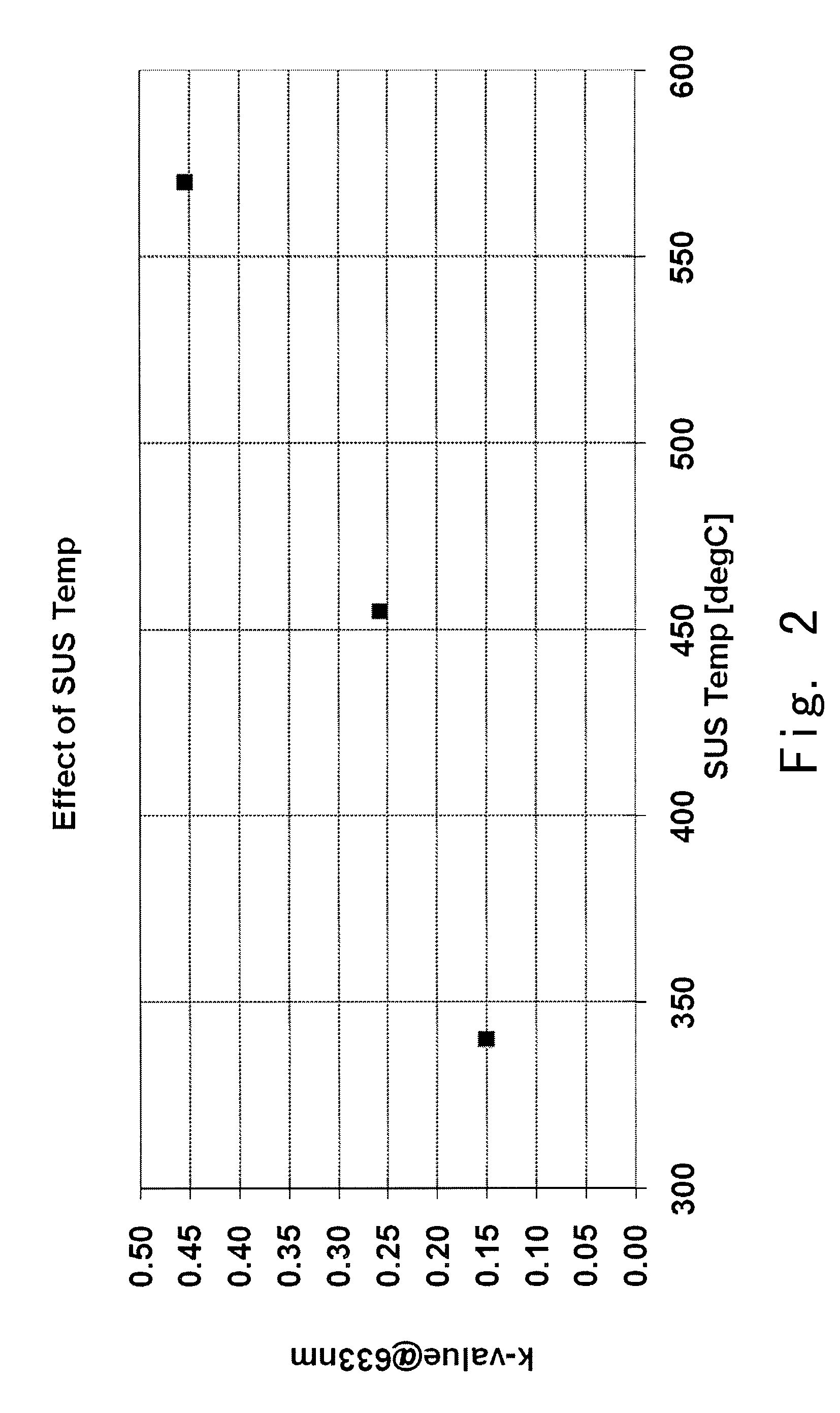

Method of forming a high transparent carbon film

ActiveUS7632549B2Improve featuresRich varietyLiquid surface applicatorsSemiconductor/solid-state device manufacturingCarbon filmProduct gas

A method of forming a transparent hydrocarbon-based polymer film on a substrate by plasma CVD includes: introducing a main gas consisting of a hydrocarbon gas (CαHβ, wherein α and β are natural numbers) and an inert gas at a flow ratio (R) of CαHβ / inert gas of 0.25 or less into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-based polymer film on the substrate by plasma polymerization of the gas at a processing temperature (T) wherein T≦(−800R+500).

Owner:ASM JAPAN

Catalysts for making ethanol from acetic acid

InactiveUS20100197485A1High selectivitySuitable for useMolecular sieve catalystsOrganic compound preparationTungstenIridium

Catalysts and processes for forming catalysts for use in hydrogenating acetic acid to form ethanol. In one embodiment, the catalyst comprises a first metal, a silicaceous support, and at least one metasilicate support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

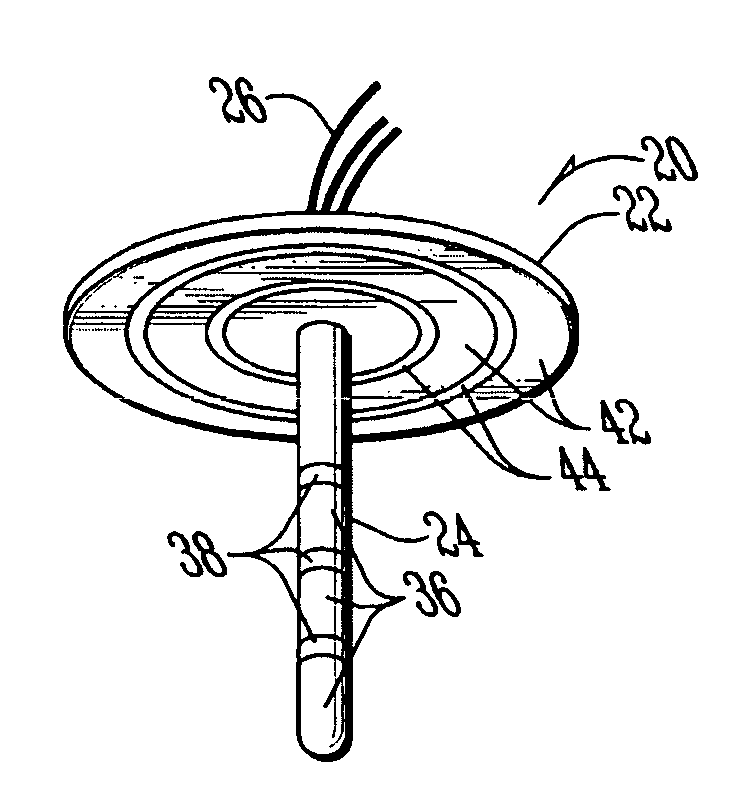

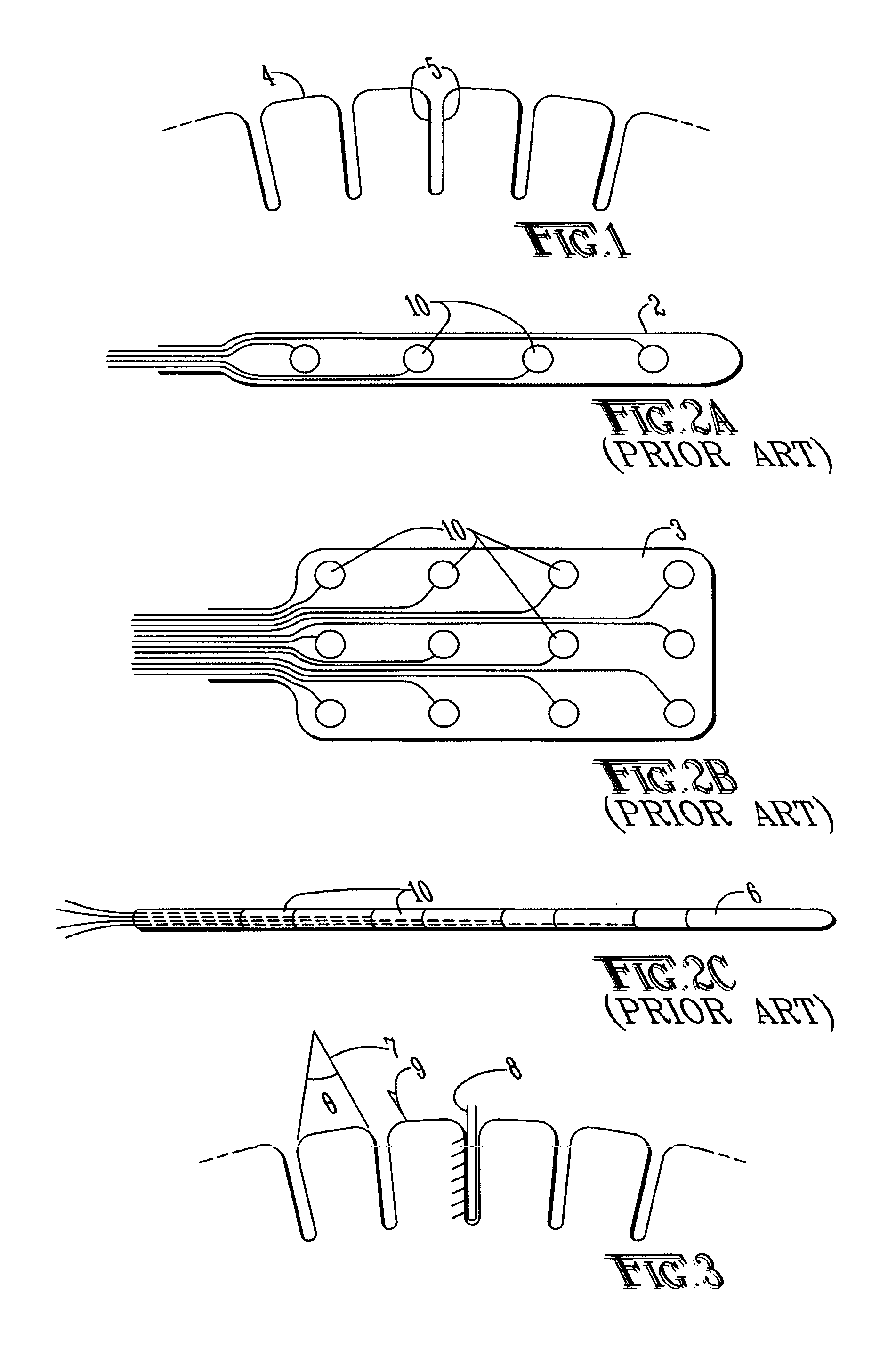

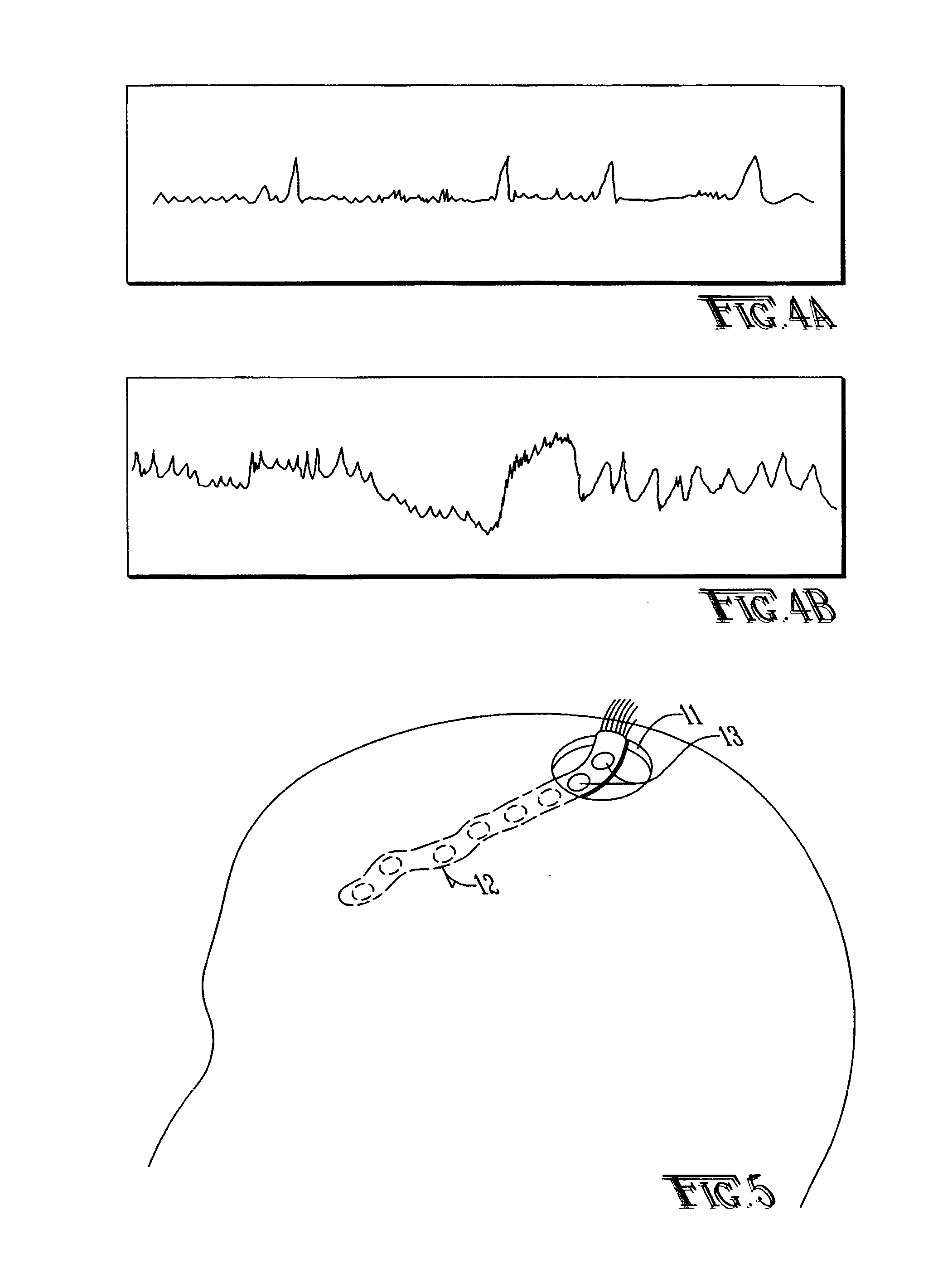

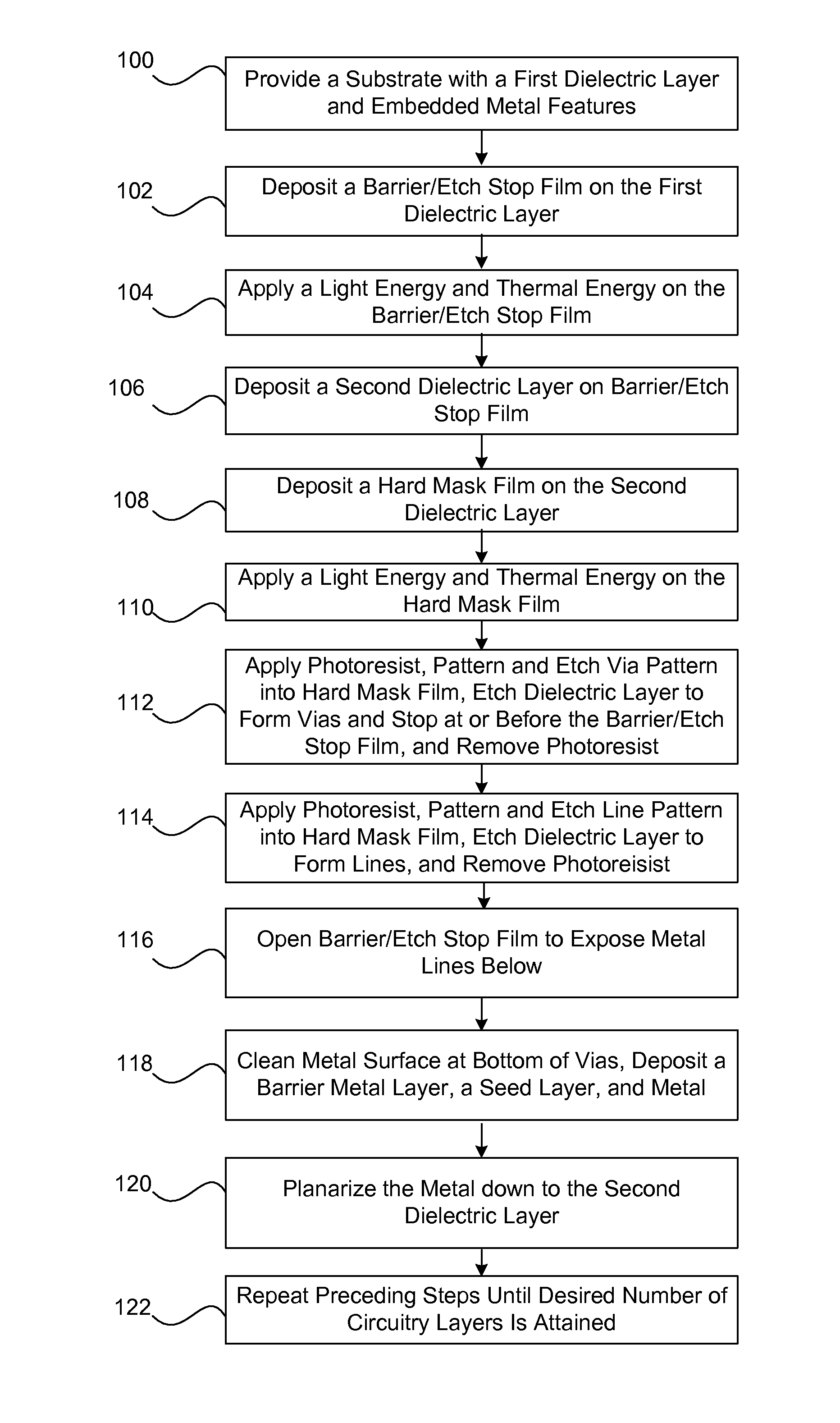

Unitized electrode with three-dimensional multi-site, multi-modal capabilities for detection and control of brain state changes

ActiveUS7006859B1Reduce noiseDisplacement minimizationElectroencephalographyHead electrodesMulti siteElectrical conductor

An electrode with three-dimensional capabilities for detection and control of brain state changes of a subject. The electrode includes a disk portion having an upper surface and a lower surface, and a shaft portion secured to and extending perpendicularly outwardly from the lower surface of the disk portion; the shaft portion having an outer surface. The disk portion and shaft portion may include one or more recording or stimulating contact surfaces structured to operatively interact with the brain of a subject. Insulating material isolates each of the recording or stimulating contact surfaces from each other. At least one conductor operatively and separately connect each of the recording or stimulating contact surfaces in communication with external apparatus. The disk portion and shaft portion are structured relative to each other to operatively provide support and anchoring for each other while providing three-dimensional capabilities for detection and control of brain state changes of a subject. Modified embodiments include insertible / retractable electrode wires, both contained in channels and sheathed in axially displaceable cannulae; activating mechanisms for inserting / retracting the electrode wires and / or cannulae; and multiple shaft portions.

Owner:FLINT HILLS SCI L L C

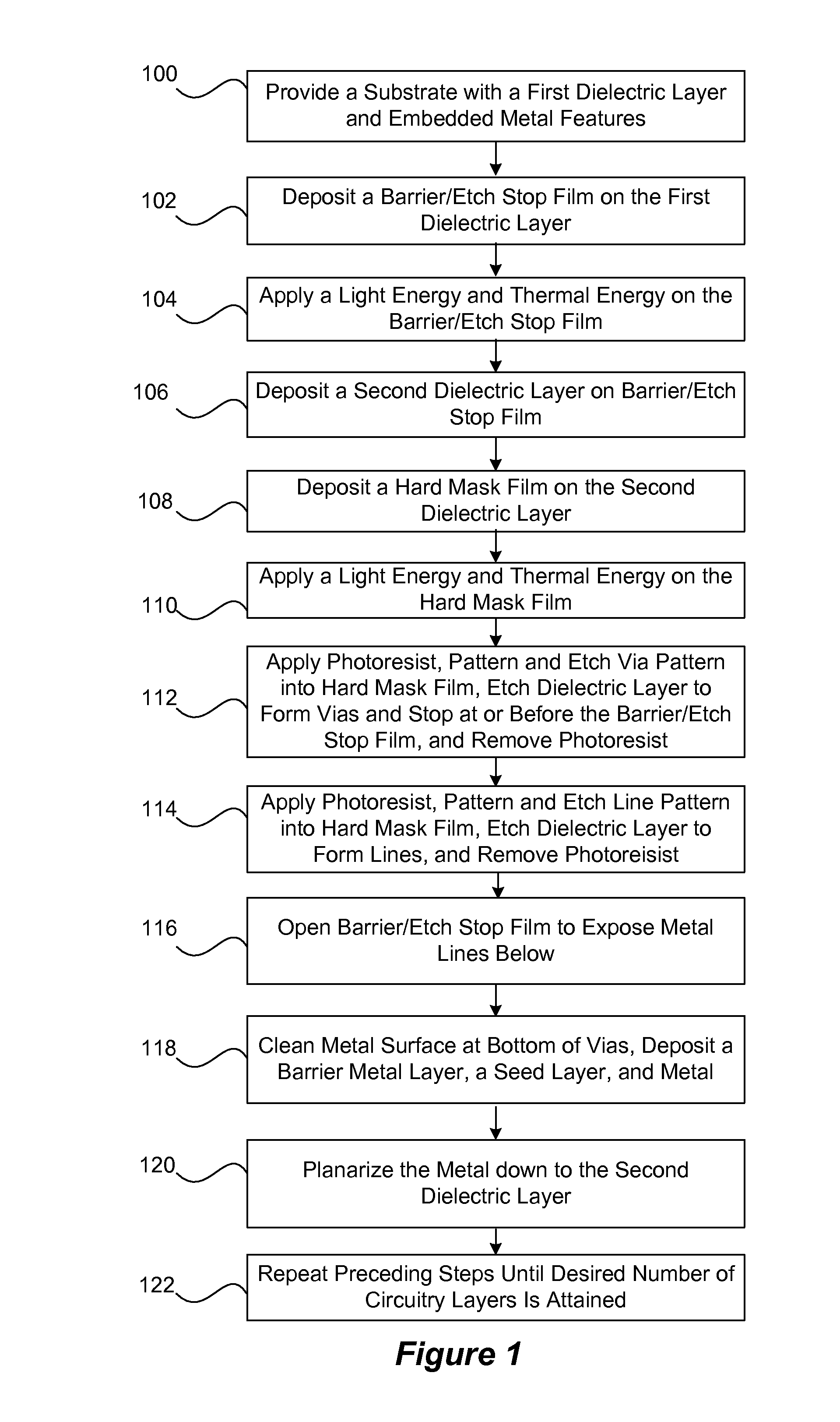

UV treatment of etch stop and hard mask films for selectivity and hermeticity enhancement

ActiveUS8242028B1Increase hermeticityHigh selectivitySemiconductor/solid-state device manufacturingThermal energyHydrogen

A method for the ultraviolet (UV) treatment of etch stop and hard mask film increases etch selectivity and hermeticity by removing hydrogen, cross-linking, and increasing density. The method is particularly applicable in the context of damascene processing. A method provides for forming a semiconductor device by depositing an etch stop film or a hard mask film on a substrate and exposing the film to UV radiation and optionally thermal energy. The UV exposure may be direct or through another dielectric layer.

Owner:NOVELLUS SYSTEMS

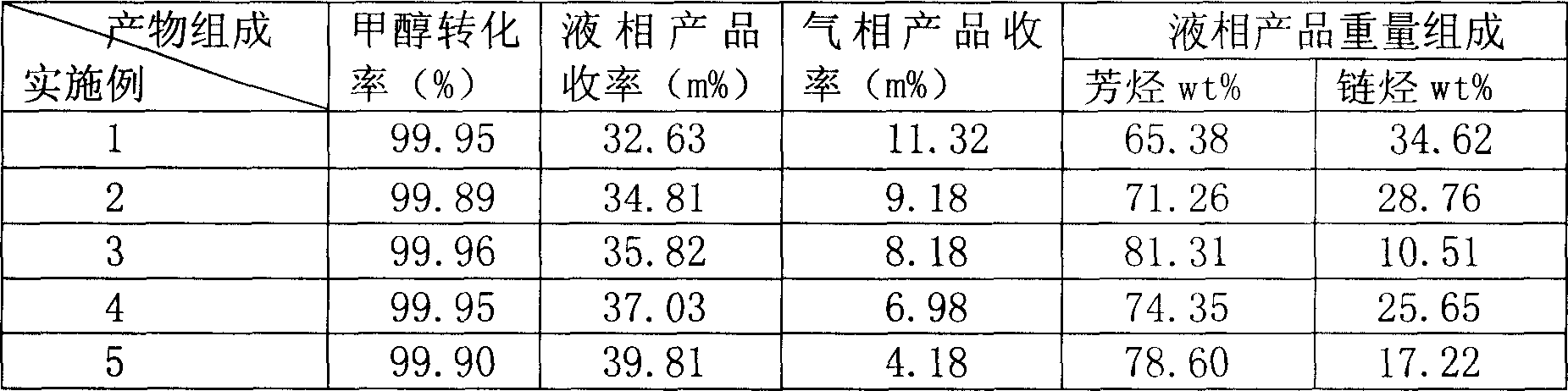

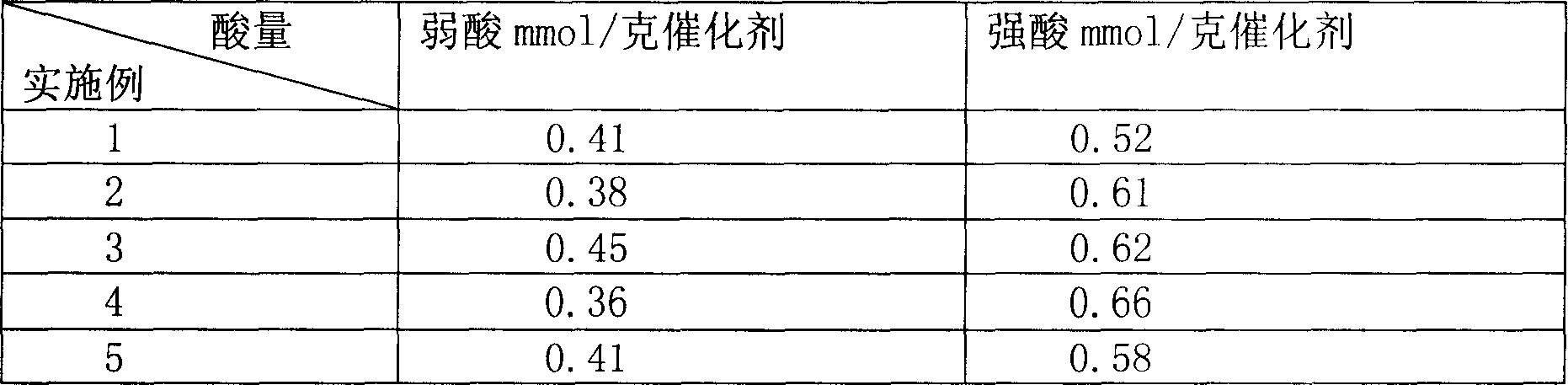

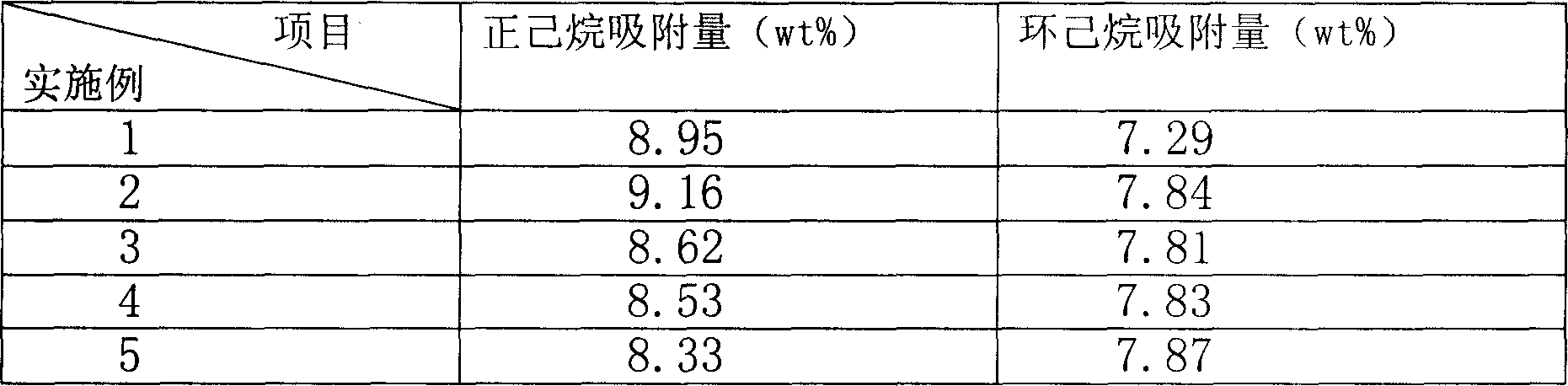

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

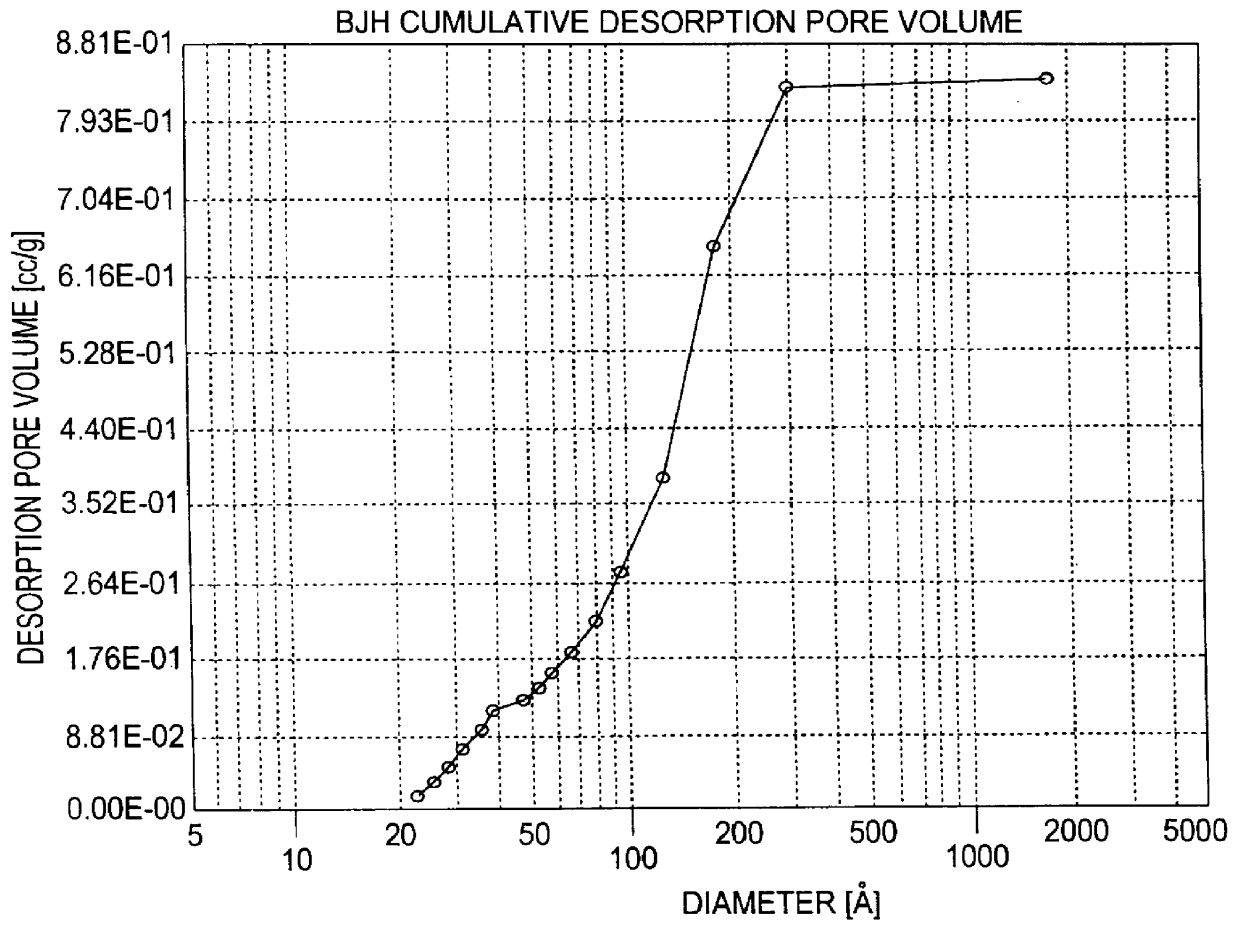

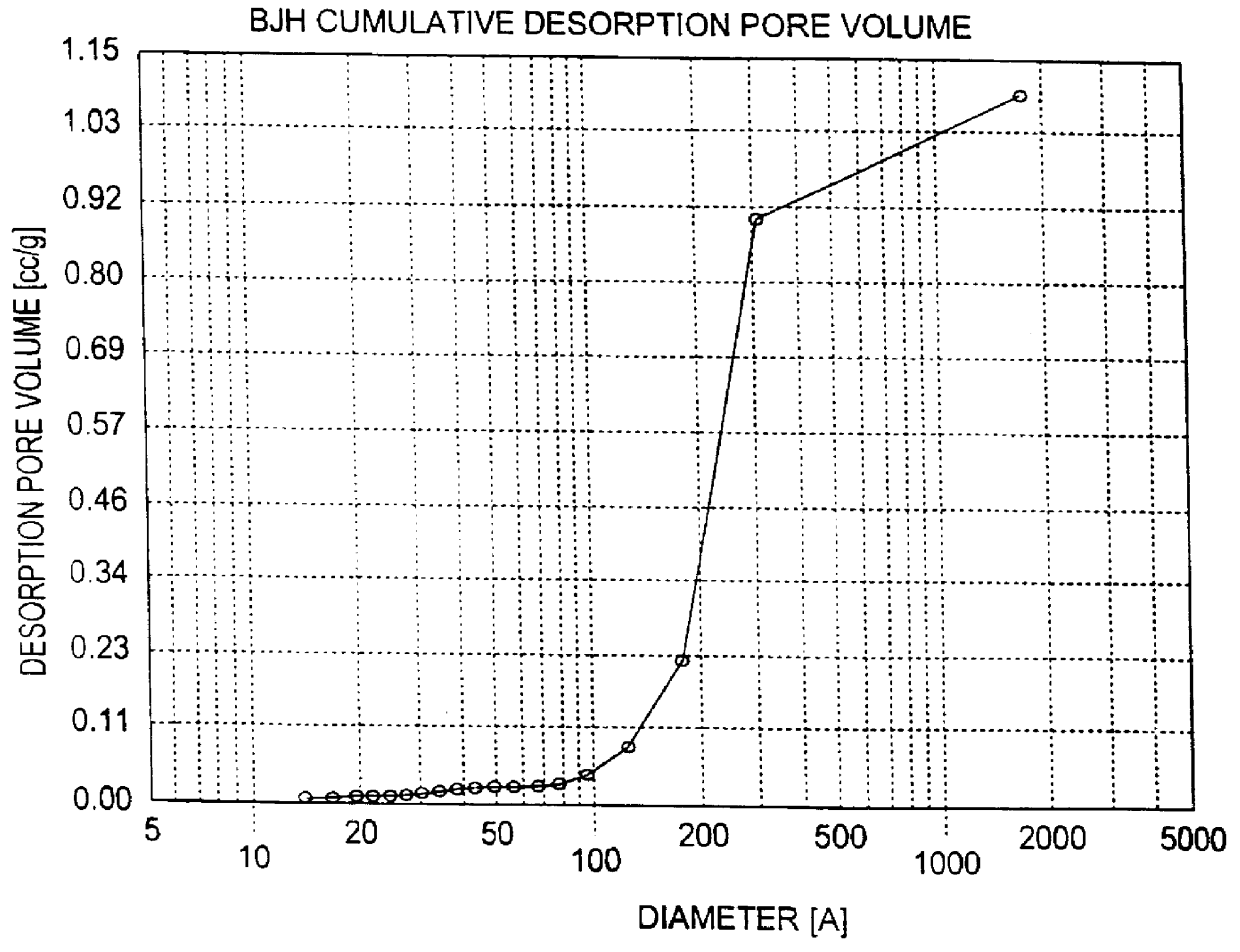

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

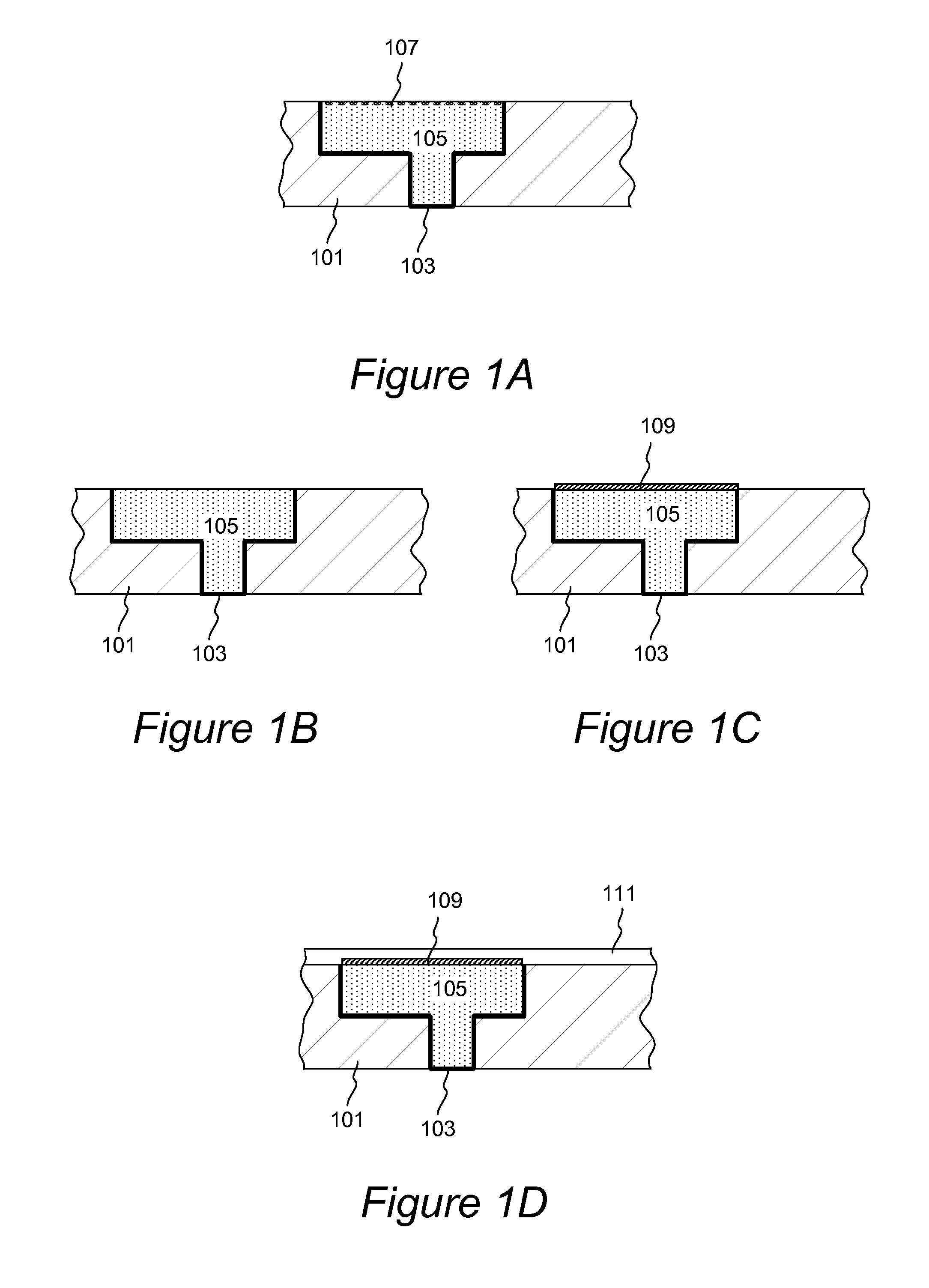

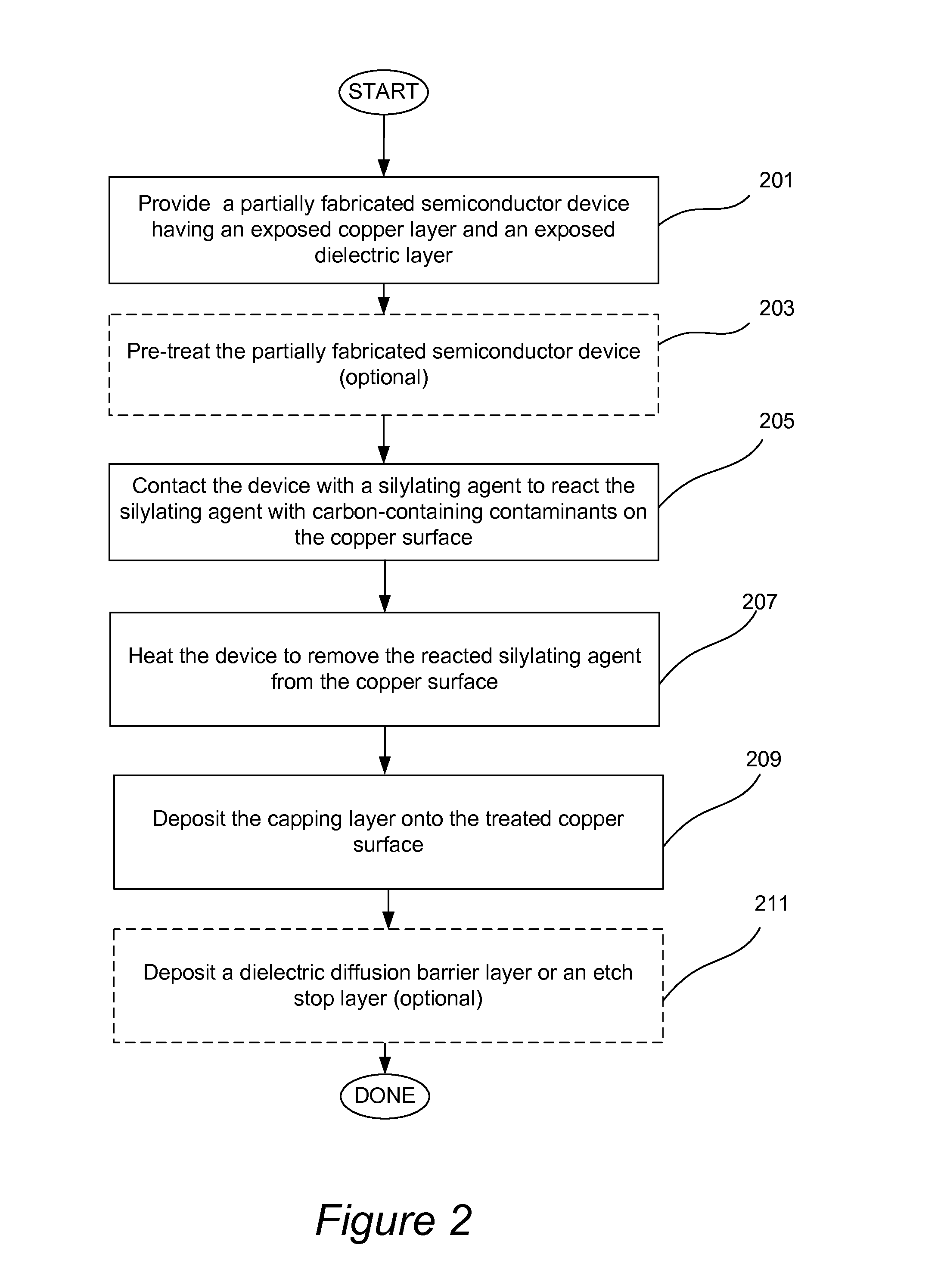

Cleaning of carbon-based contaminants in metal interconnects for interconnect capping applications

InactiveUS20150380296A1Avoid depositionLow deposition rateLiquid surface applicatorsSemiconductor/solid-state device manufacturingMetal interconnectSilylation

Protective caps residing at an interface between copper lines and dielectric diffusion barrier layers are used to improve various performance characteristics of interconnects. The caps, such as cobalt-containing caps or manganese-containing caps, are selectively deposited onto exposed copper lines in a presence of exposed dielectric using CVD or ALD methods. The deposition of the capping material is affected by the presence of carbon-containing contaminants on the surface of copper, which may lead to poor or uneven growth of the capping layer. A method of removing carbon-containing contaminants from the copper surface prior to deposition of caps involves contacting the substrate containing the exposed copper surface with a silylating agent at a first temperature to form a layer of reacted silylating agent on the copper surface, followed by heating the substrate at a higher temperature to release the reacted silylating agent from the copper surface.

Owner:LAM RES CORP

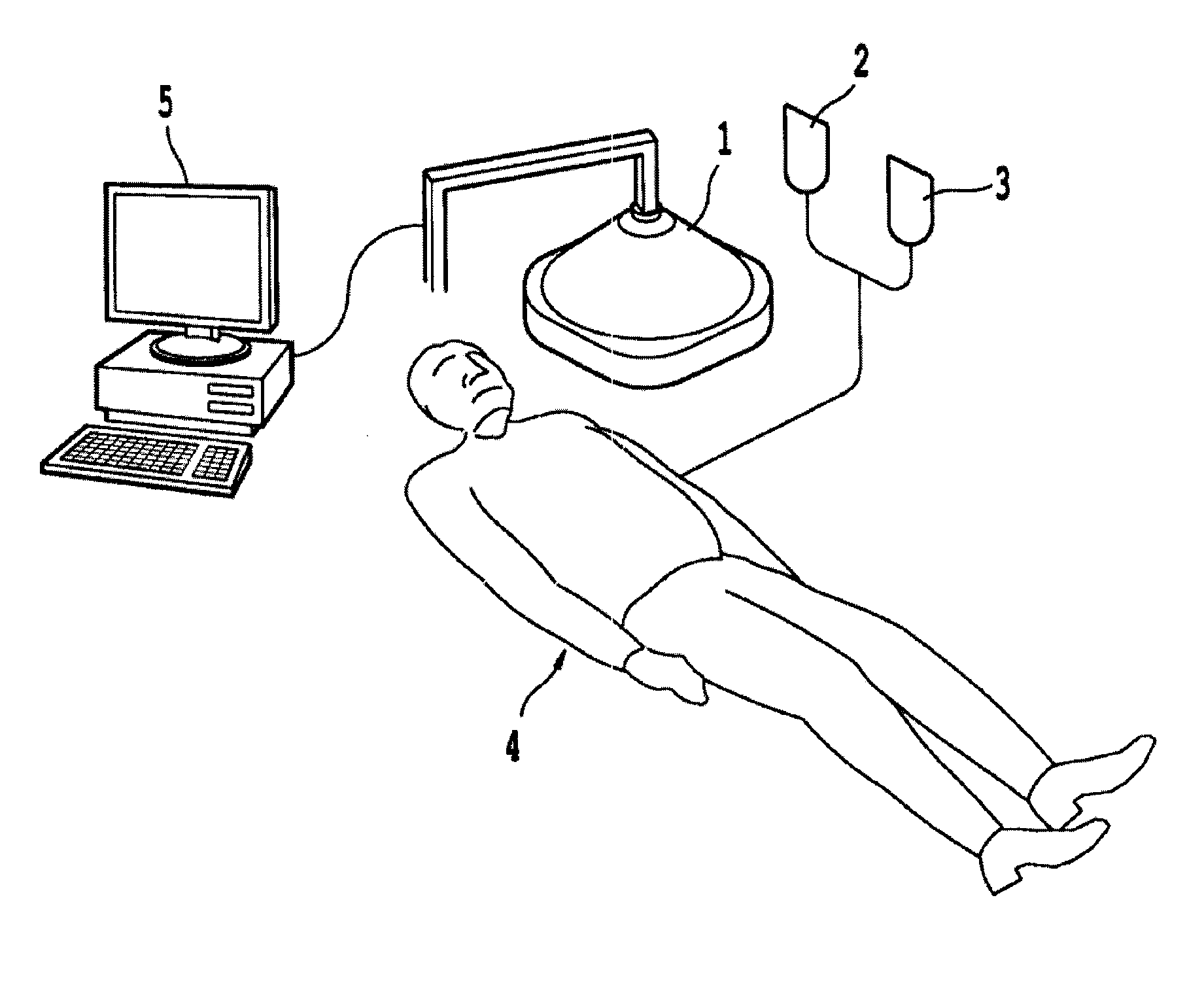

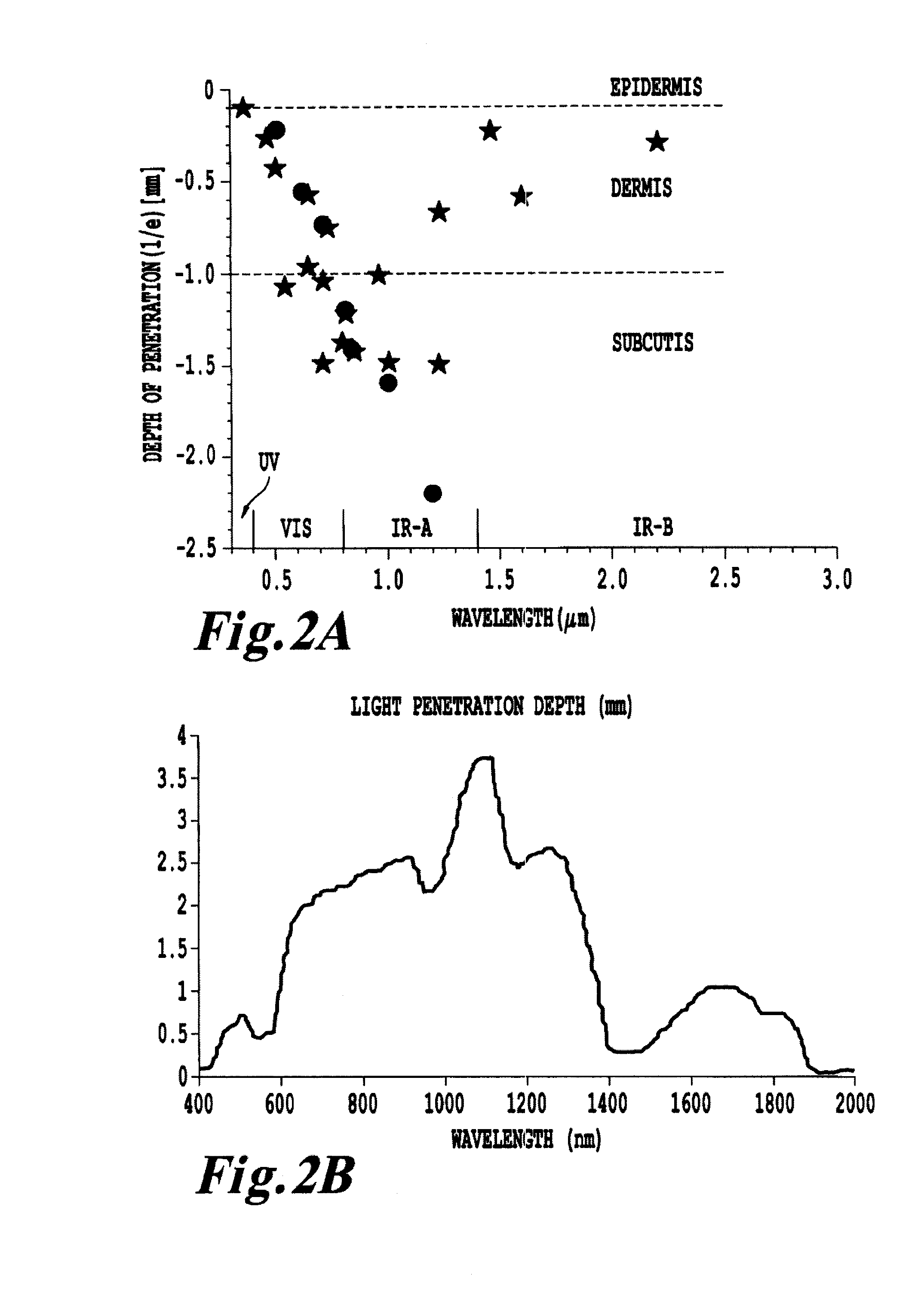

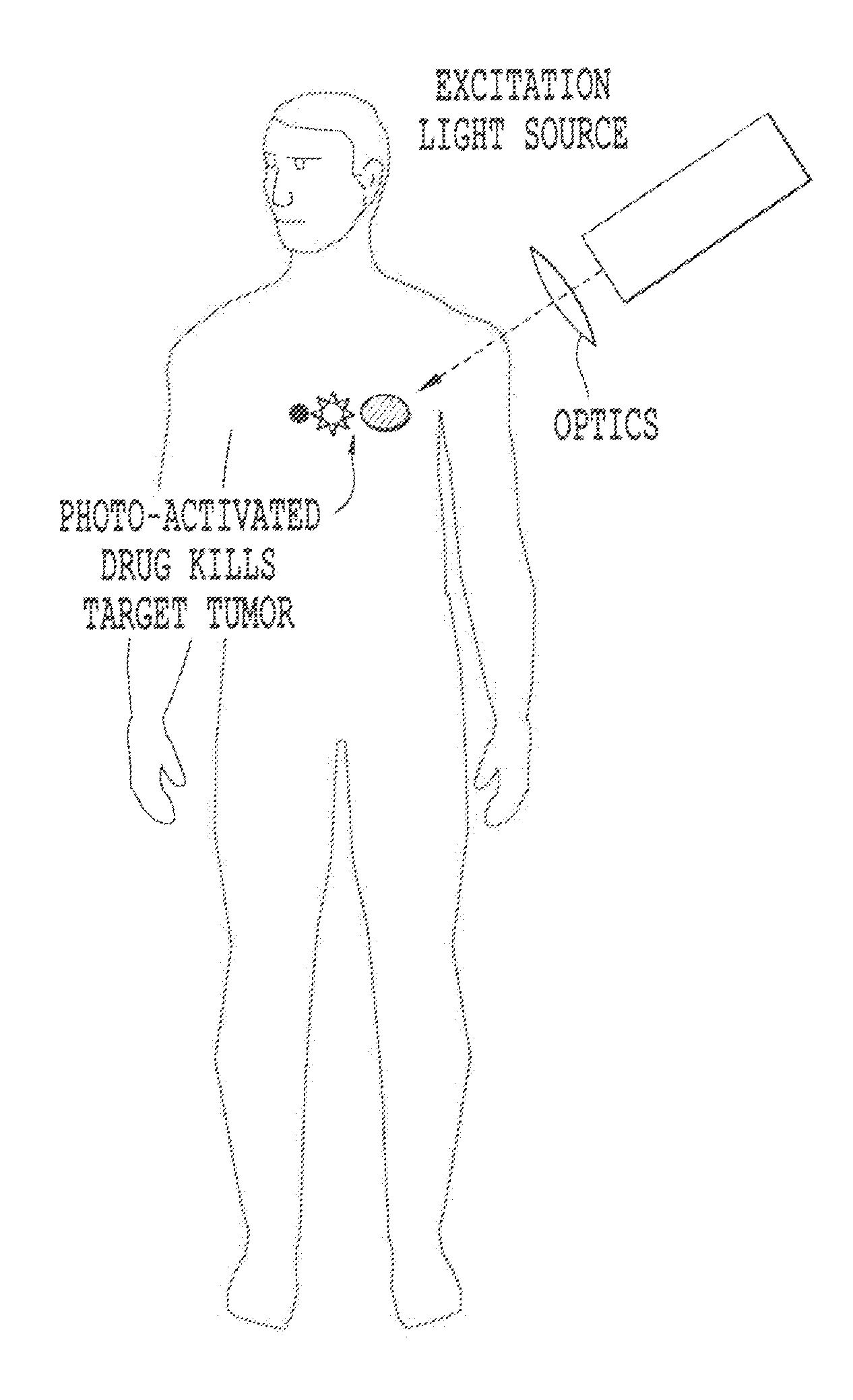

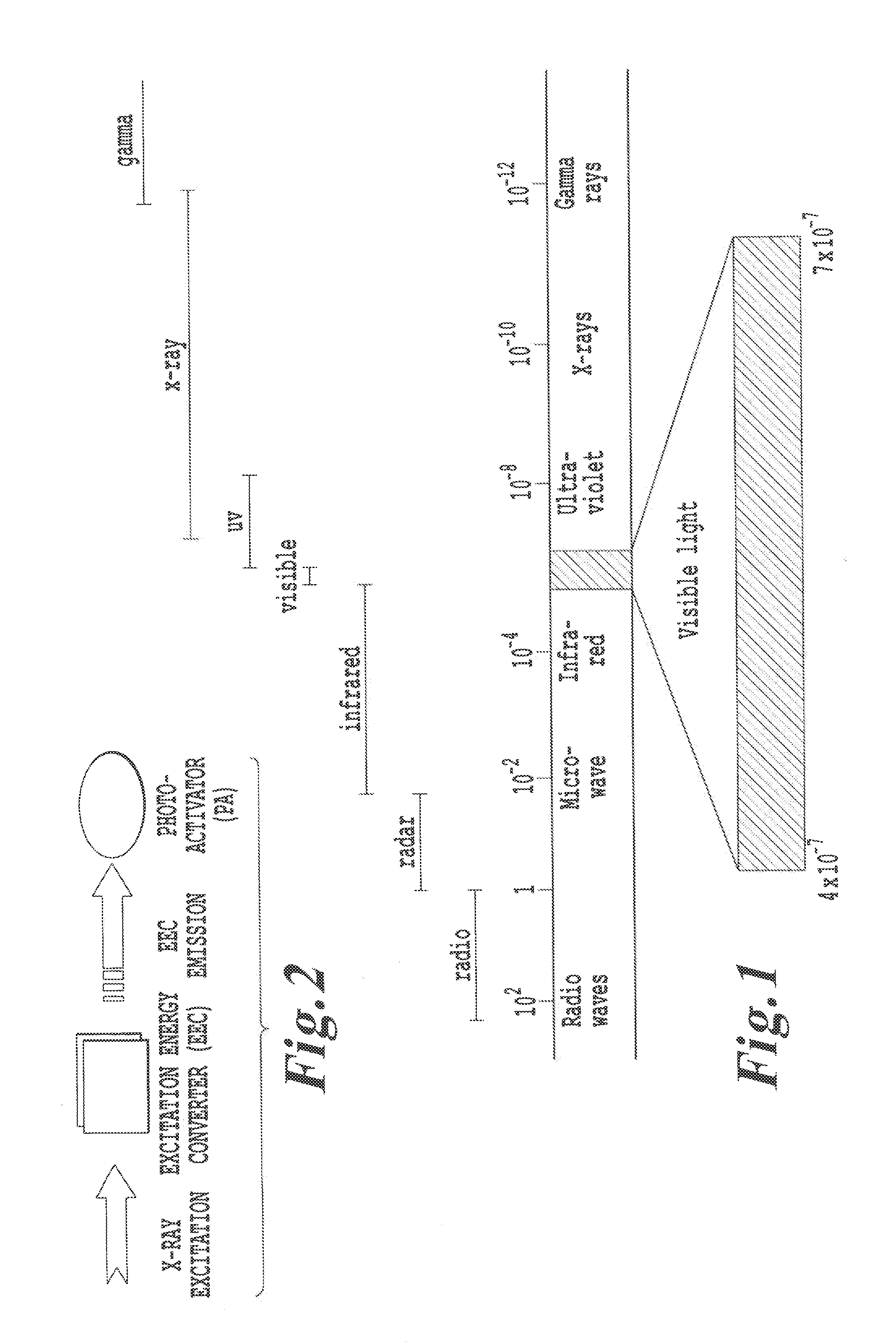

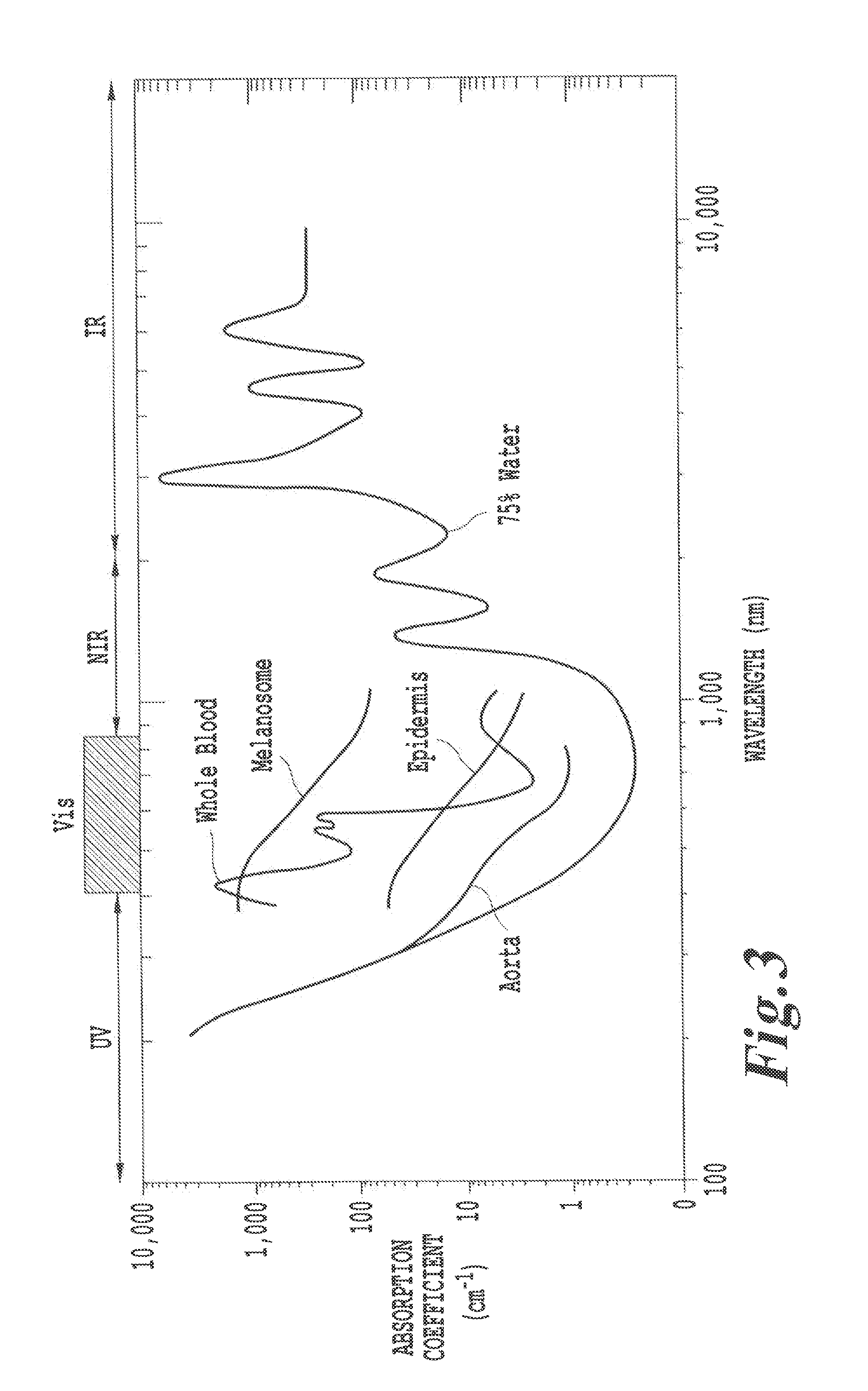

Non-invasive systems and methods for in-situ photobiomodulation

InactiveUS20100016783A1High selectivityAntibacterial agentsPowder deliveryDiseaseBiological regulation

Products, compositions, systems, and methods for modifying a target structure which mediates or is associated with a biological activity, including treatment of conditions, disorders, or diseases mediated by or associated with a target structure, such as a virus, cell, subcellular structure or extracellular structure. The methods may be performed in situ in a non-invasive manner by application of an initiation energy to a subject thus producing an effect on or change to the target structure directly or via a modulation agent. The methods may further be performed by application of an initiation energy to a subject in situ to activate a pharmaceutical agent directly or via an energy modulation agent, optionally in the presence of one or more plasmonics active agents, thus producing an effect on or change to the target structure. Kits containing products or compositions formulated or configured and systems for use in practicing these methods.

Owner:DUKE UNIV +1

Organically-functionalized monodisperse nanocrystals of metals

InactiveUS6103868AHigh selectivityAvoid problemsPolycrystalline material growthLiquid surface applicatorsNanocrystalReducing agent

PCT No. PCT / US96 / 20402 Sec. 371 Date Jun. 18, 1998 Sec. 102(e) Date Jun. 18, 1998 PCT Filed Dec. 27, 1996 PCT Pub. No. WO97 / 24224 PCT Pub. Date Jul. 10, 1997Organically functionalized metal nanoparticles are produced by mixing a metal precursor with an organic surface passivant and reacting the resulting mixture with a reducing agent to generate free metal while binding the passivant to the surface of the free metal to produce organically functionalized metal particles.

Owner:RGT UNIV OF CALIFORNIA

Tunable catalyst gas phase hydrogenation of carboxylic acids

InactiveUS20100121114A1High selectivityExcessive loss of activityOrganic compound preparationHeterogenous catalyst chemical elementsPlatinumAcetic acid

A process for selective formation of ethanol from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with catalyst comprising platinum and tin on a high surface area silica promoted with calcium metasilicate. Selectivities to ethanol of over 85% are achieved at 280° C. with catalyst life in the hundreds of hours.

Owner:CELANESE INT CORP

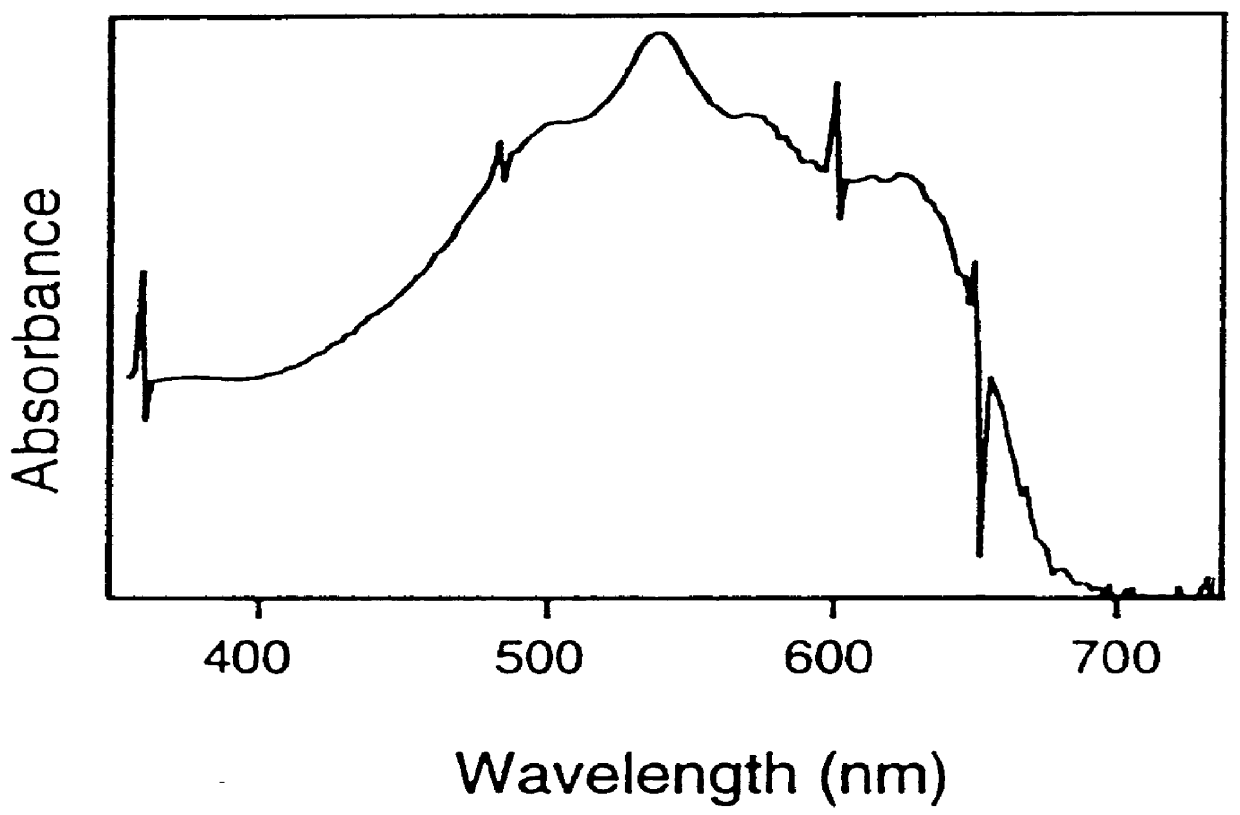

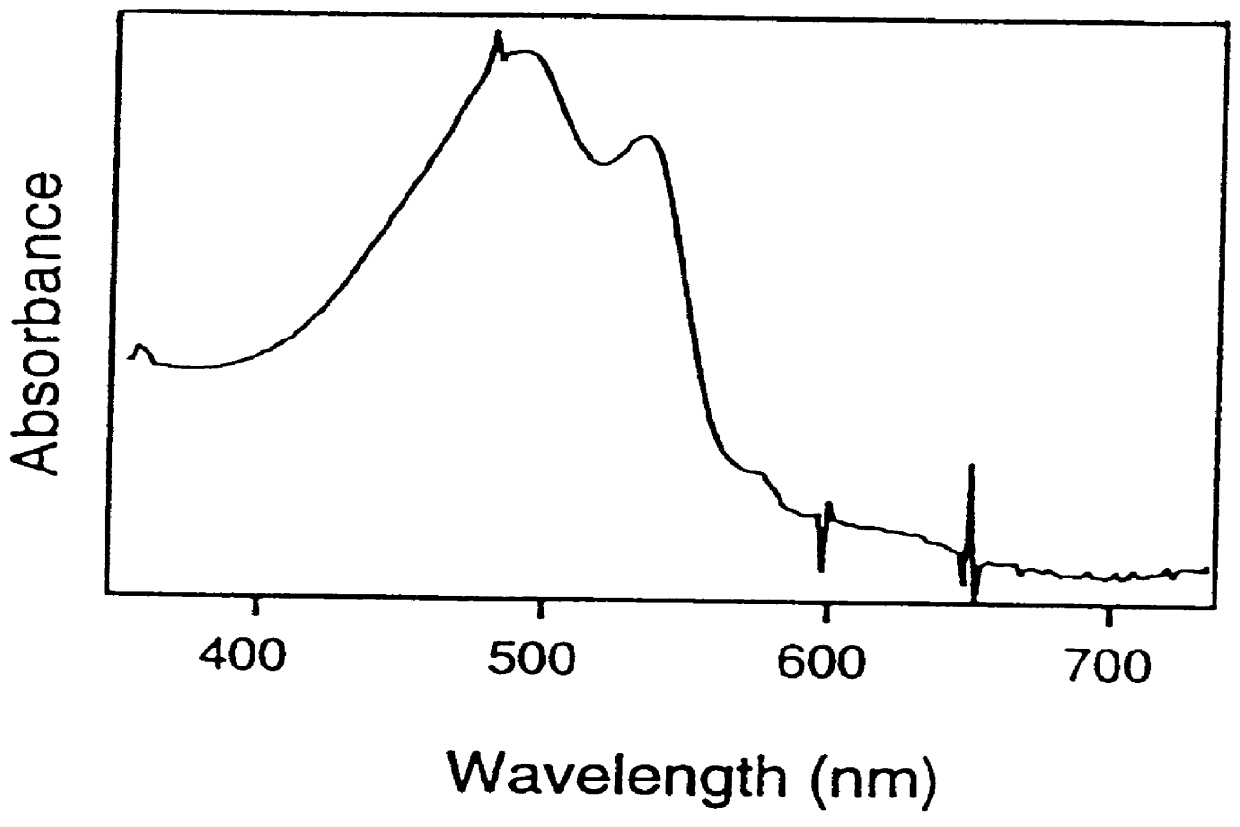

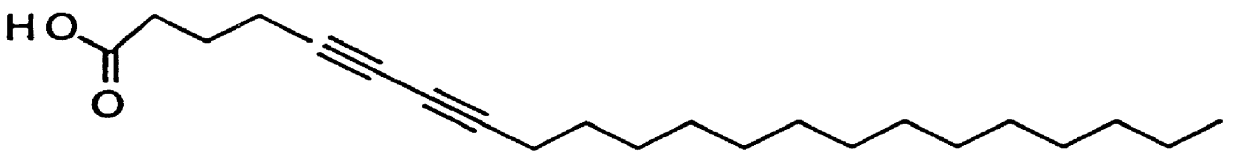

Sol-gel matrices for direct colorimetric detection of analytes

InactiveUS6022748AEasily associated with transducing deviceRobust and stableMaterial nanotechnologyBiological testingAnalyteBiopolymer

The present invention relates to methods and compositions for the direct detection of analytes using color changes that occur in immobilized biopolymeric material in response to selective binding of analytes to their surface. In particular, the present invention provides methods and compositions related to the encapsulation of biopolymeric material into metal oxide glass using the sol-gel method.

Owner:SANDIA +1

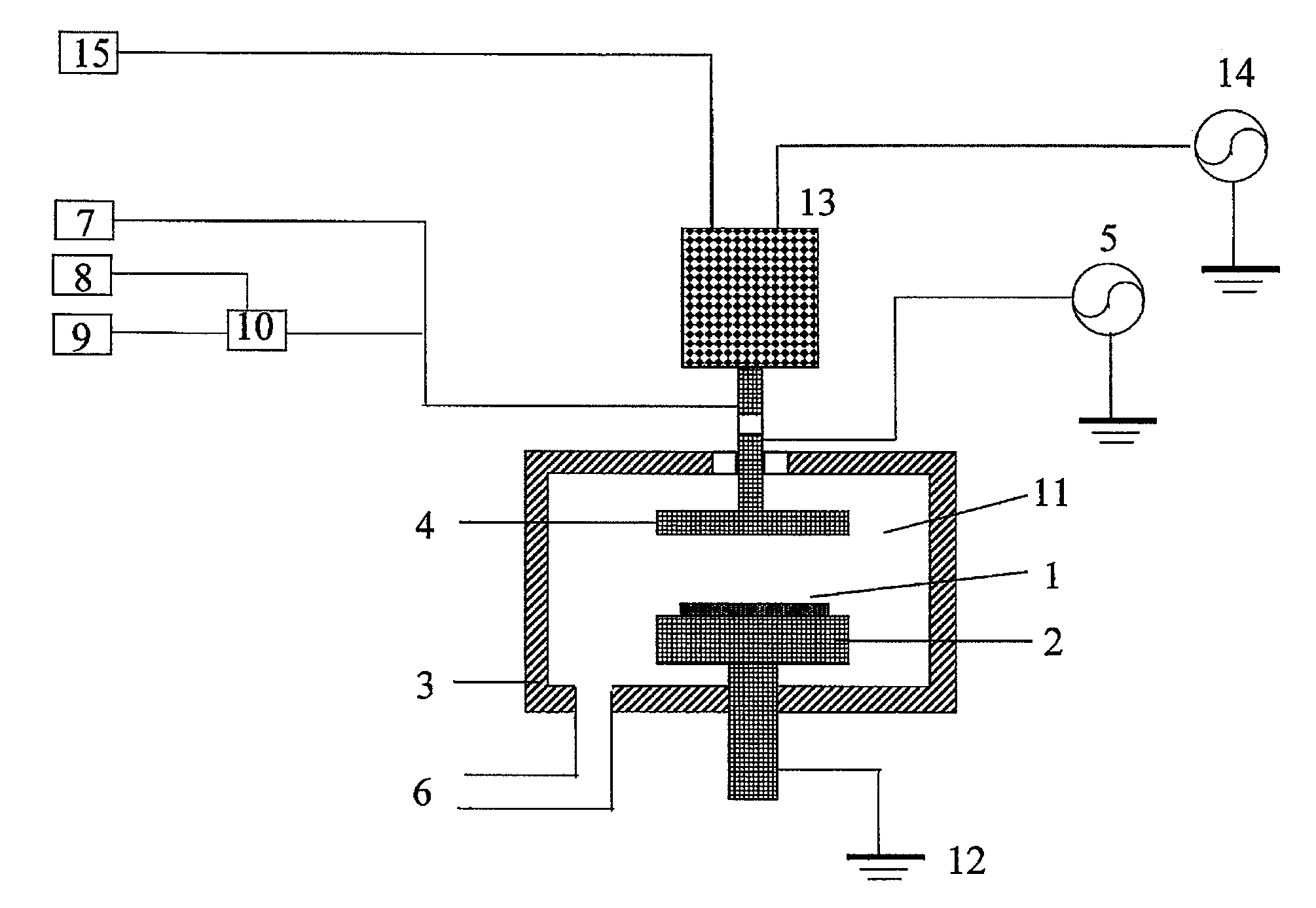

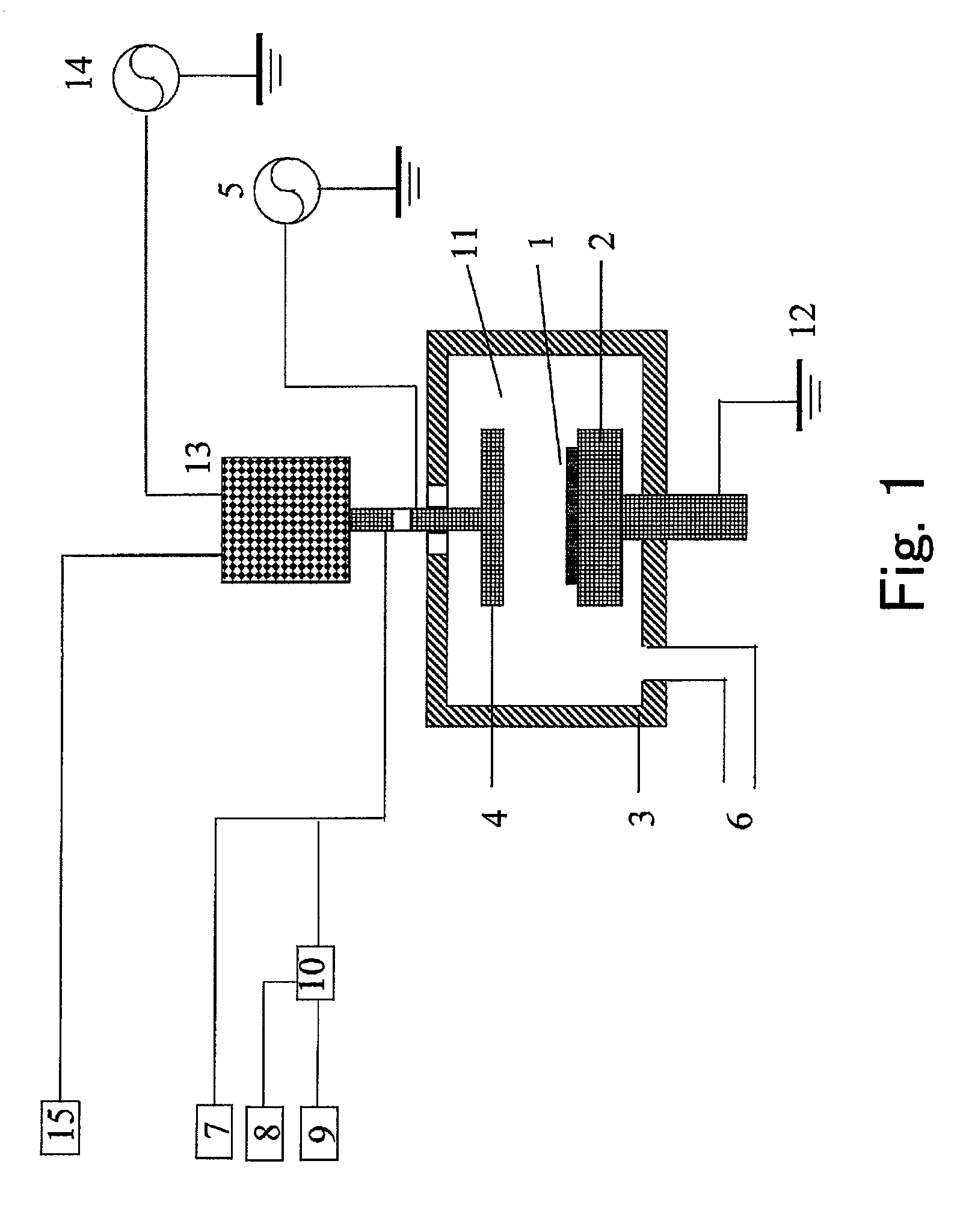

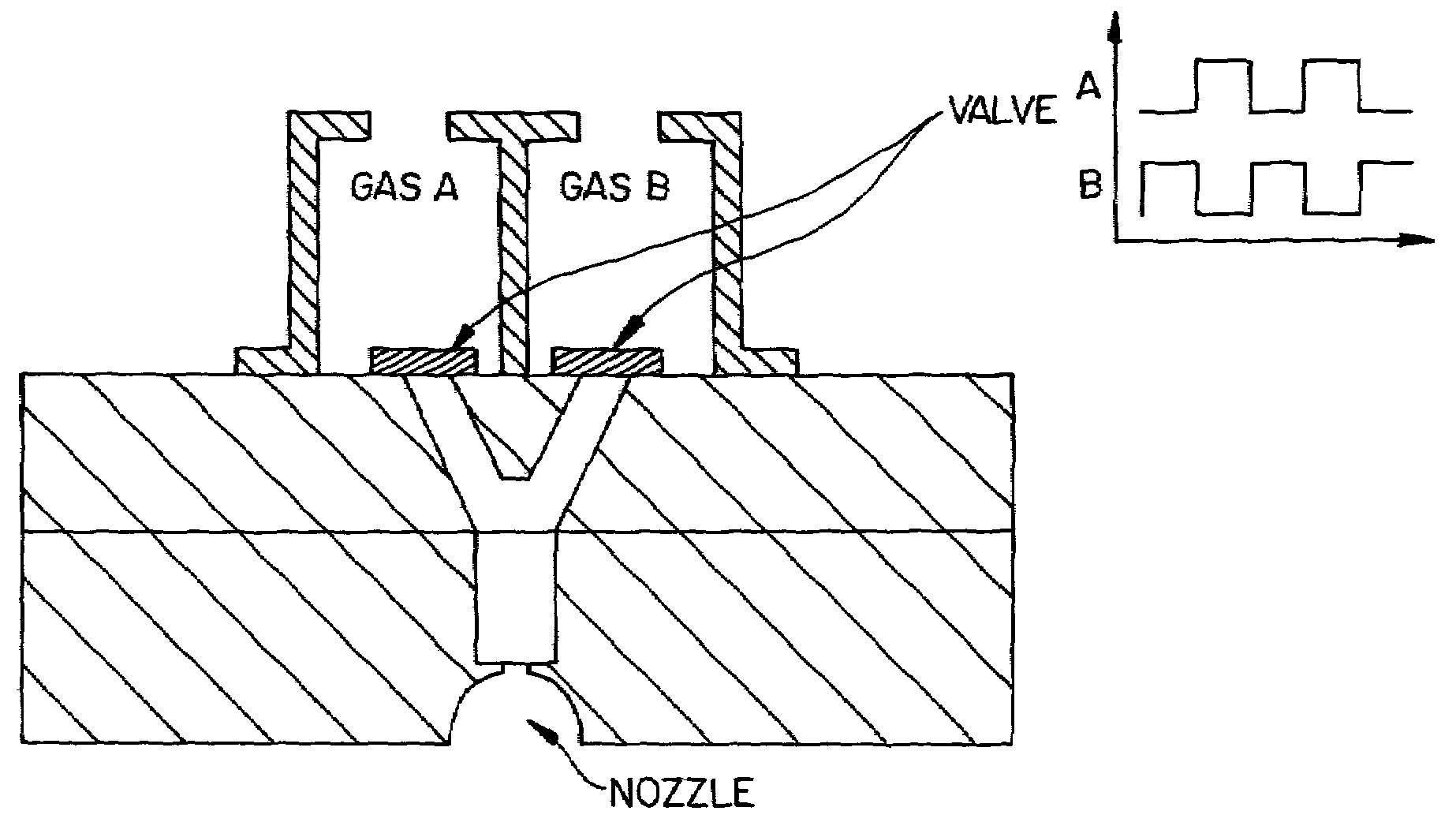

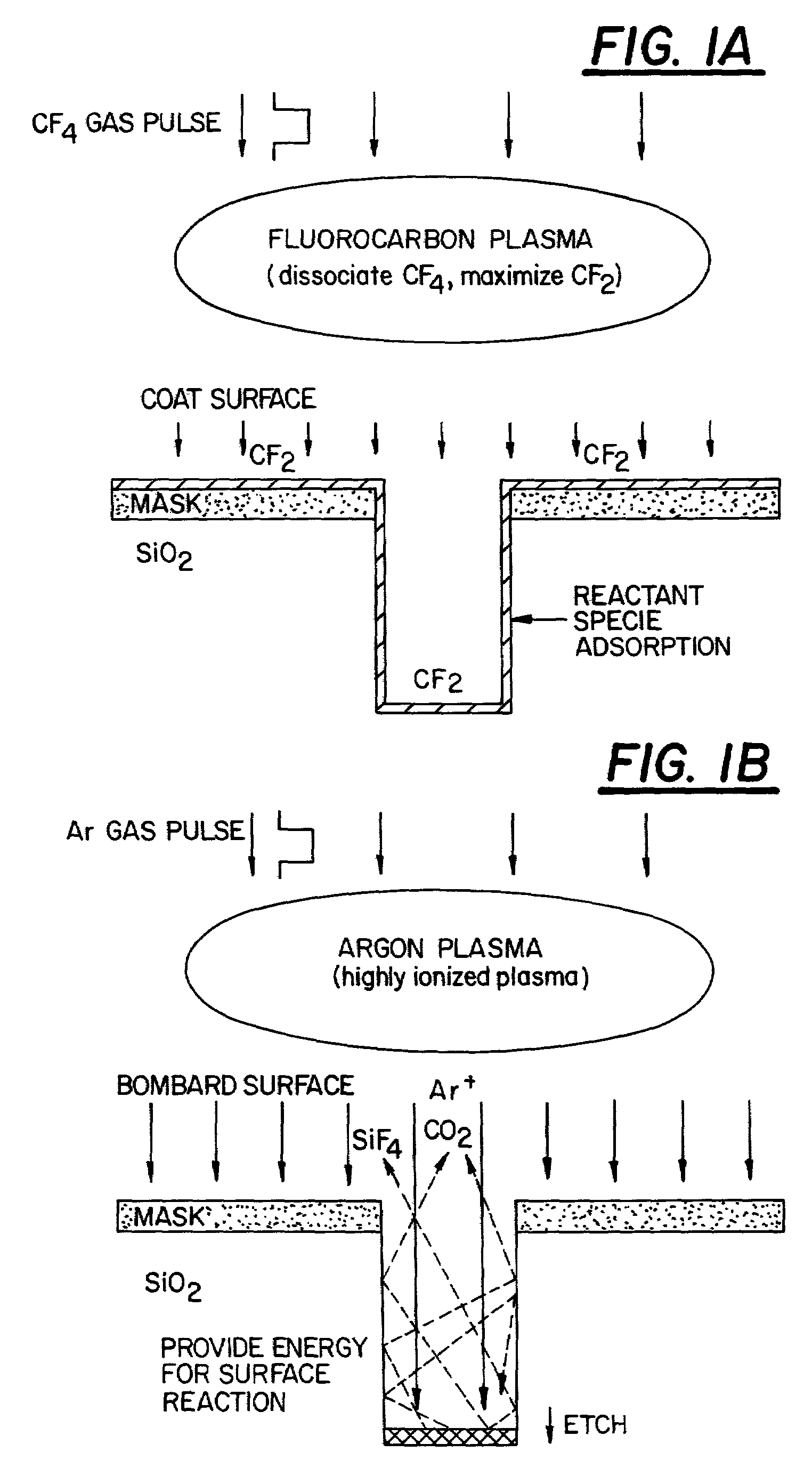

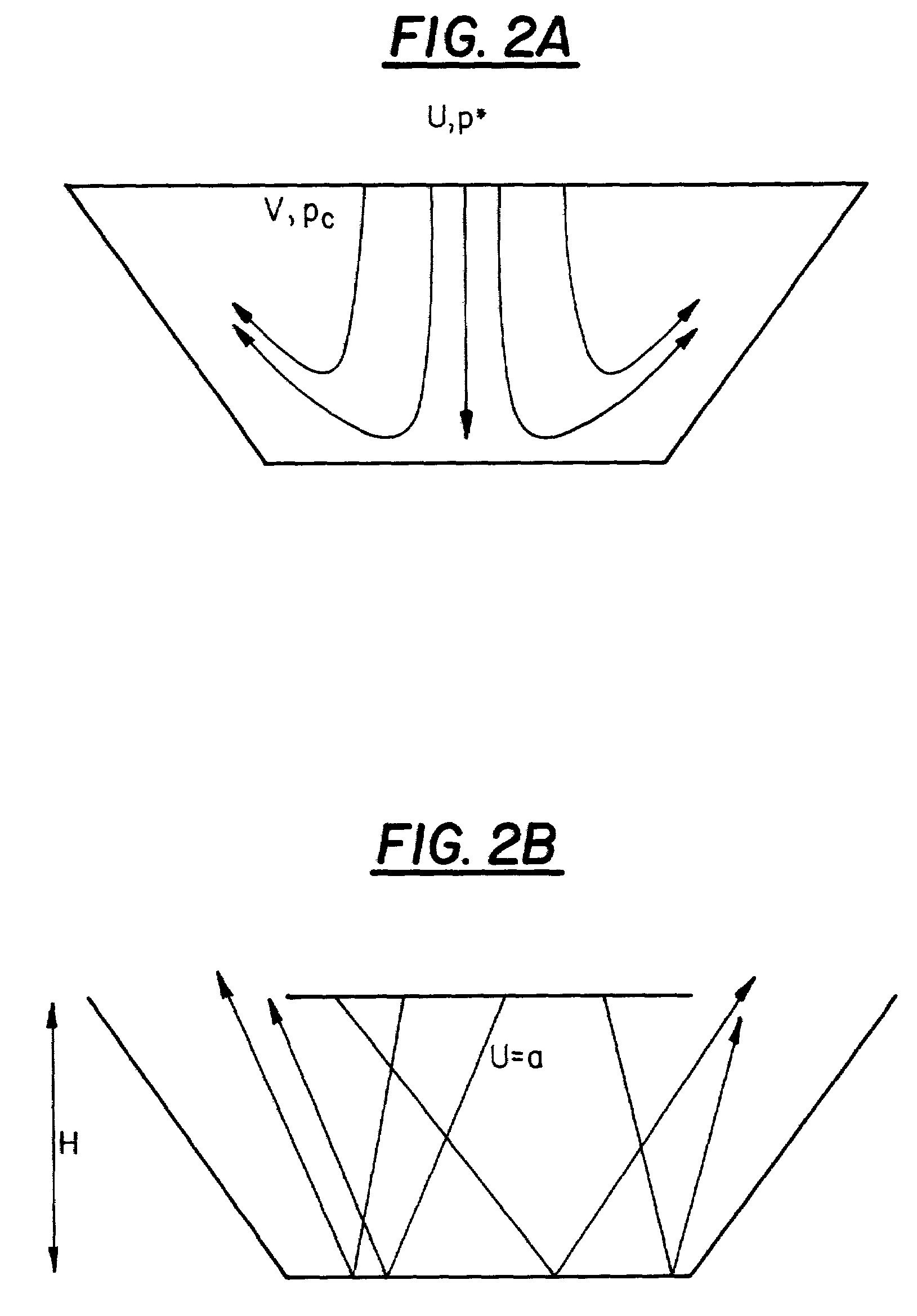

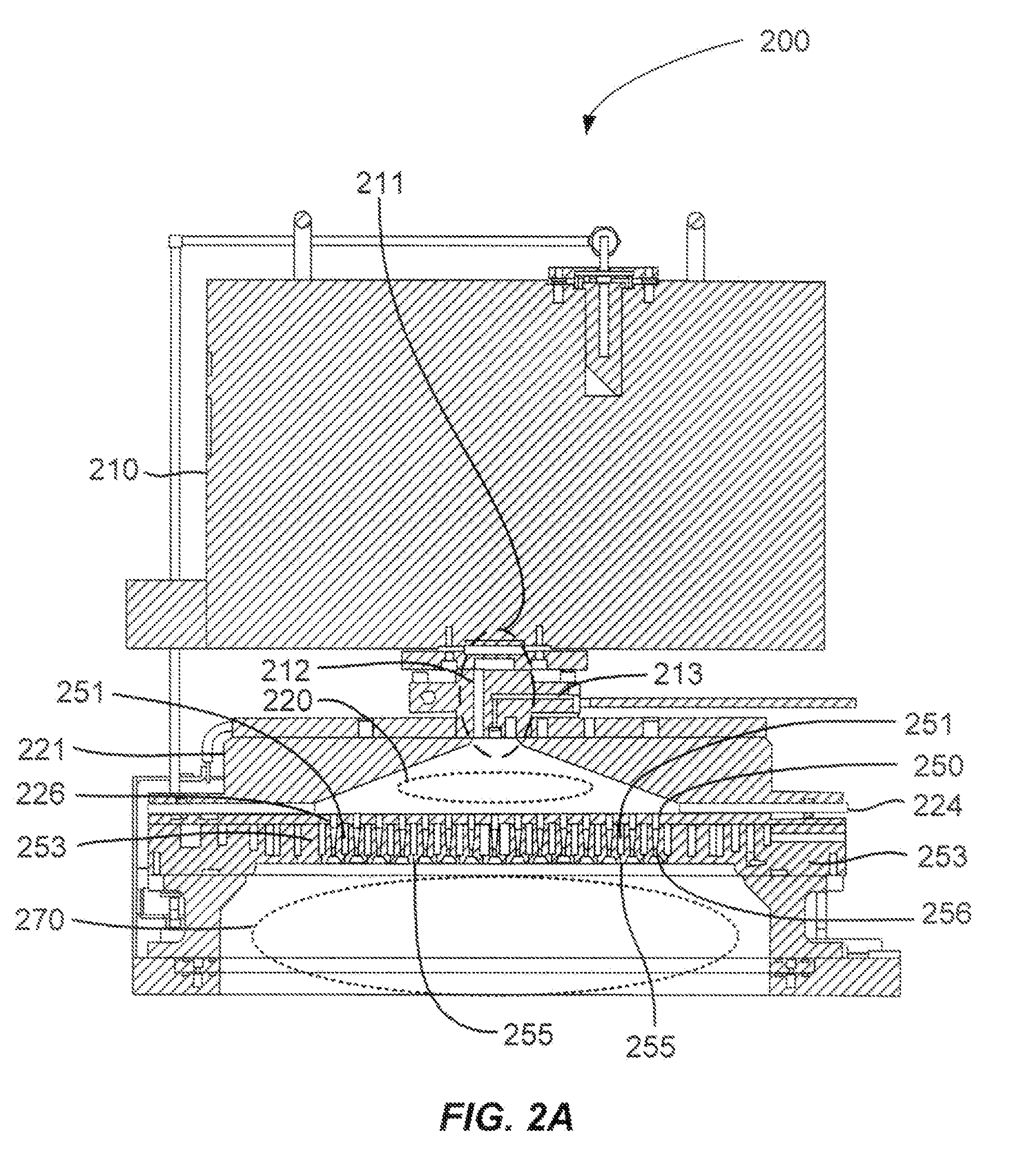

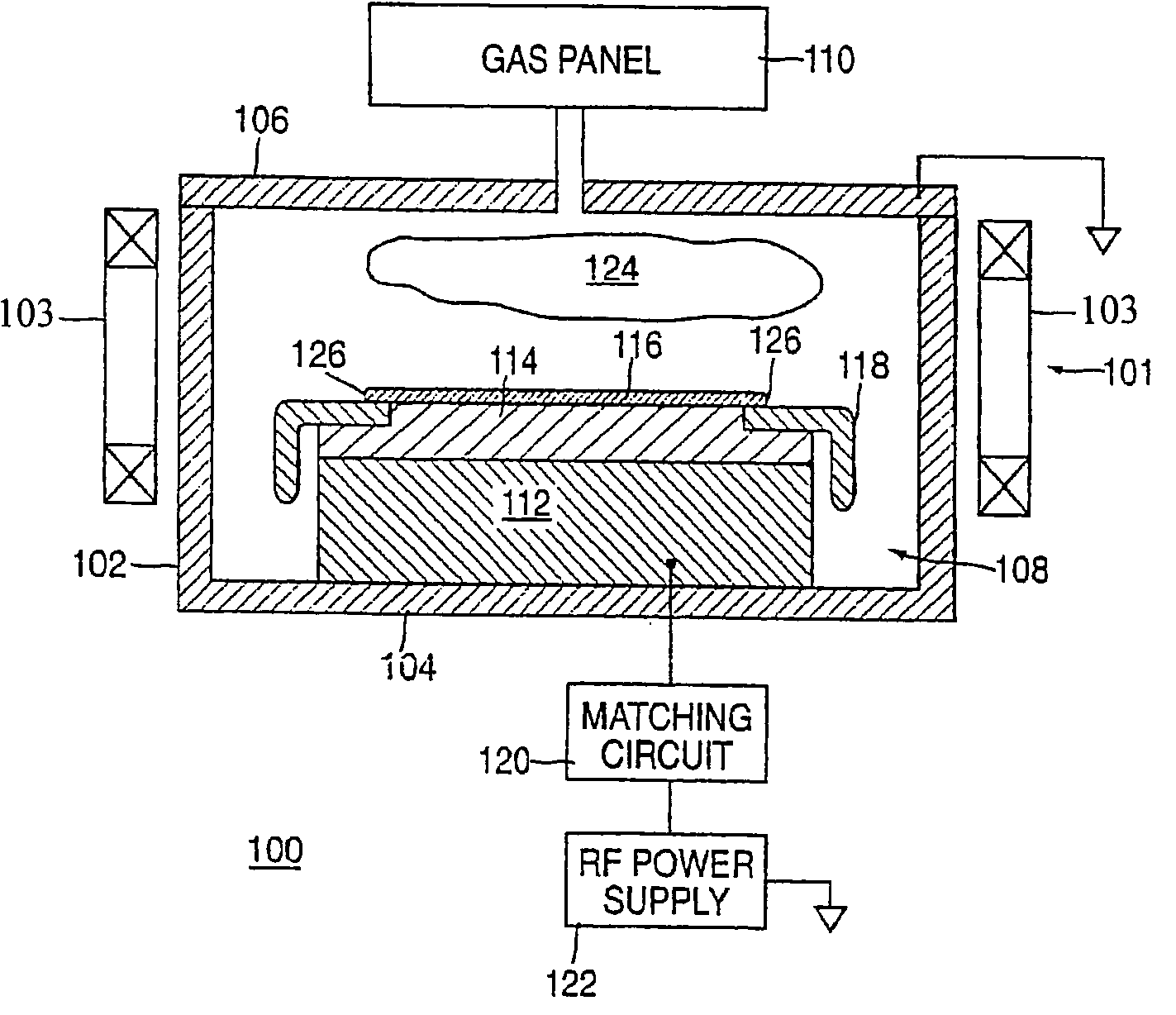

Pulsed plasma processing method and apparatus

InactiveUS7166233B2Remove restrictionsImproved profileDecorative surface effectsVacuum evaporation coatingEngineeringPlasma processing

In a method for performing a plasma-assisted treatment on a substrate in a reactor chamber by: introducing at least one process gas into the reactor chamber; and creating a plasma within the reactor chamber by establishing an RF electromagnetic field within the chamber and allowing the field to interact with the process gas, the electromagnetic field is controlled to have an energy level which varies cyclically between at least two values each sufficient to maintain the plasma, such that each energy level value is associated with performance of a respectively different treatment process on the substrate.

Owner:TOKYO ELECTRON LTD

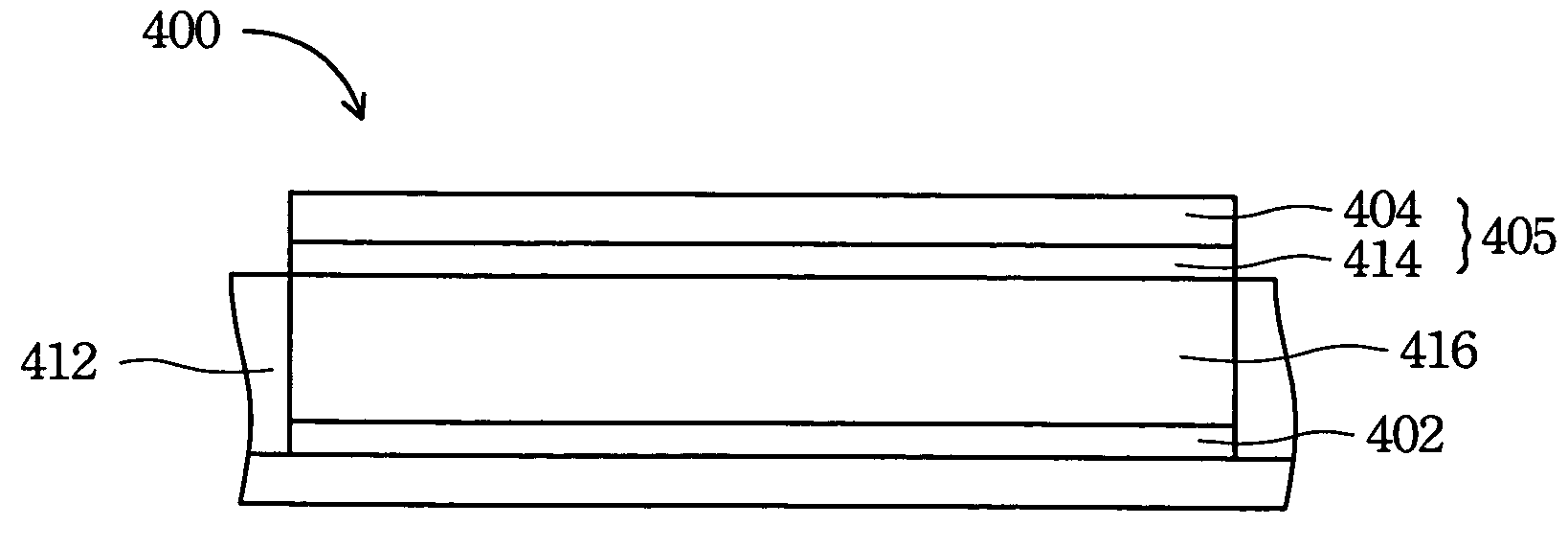

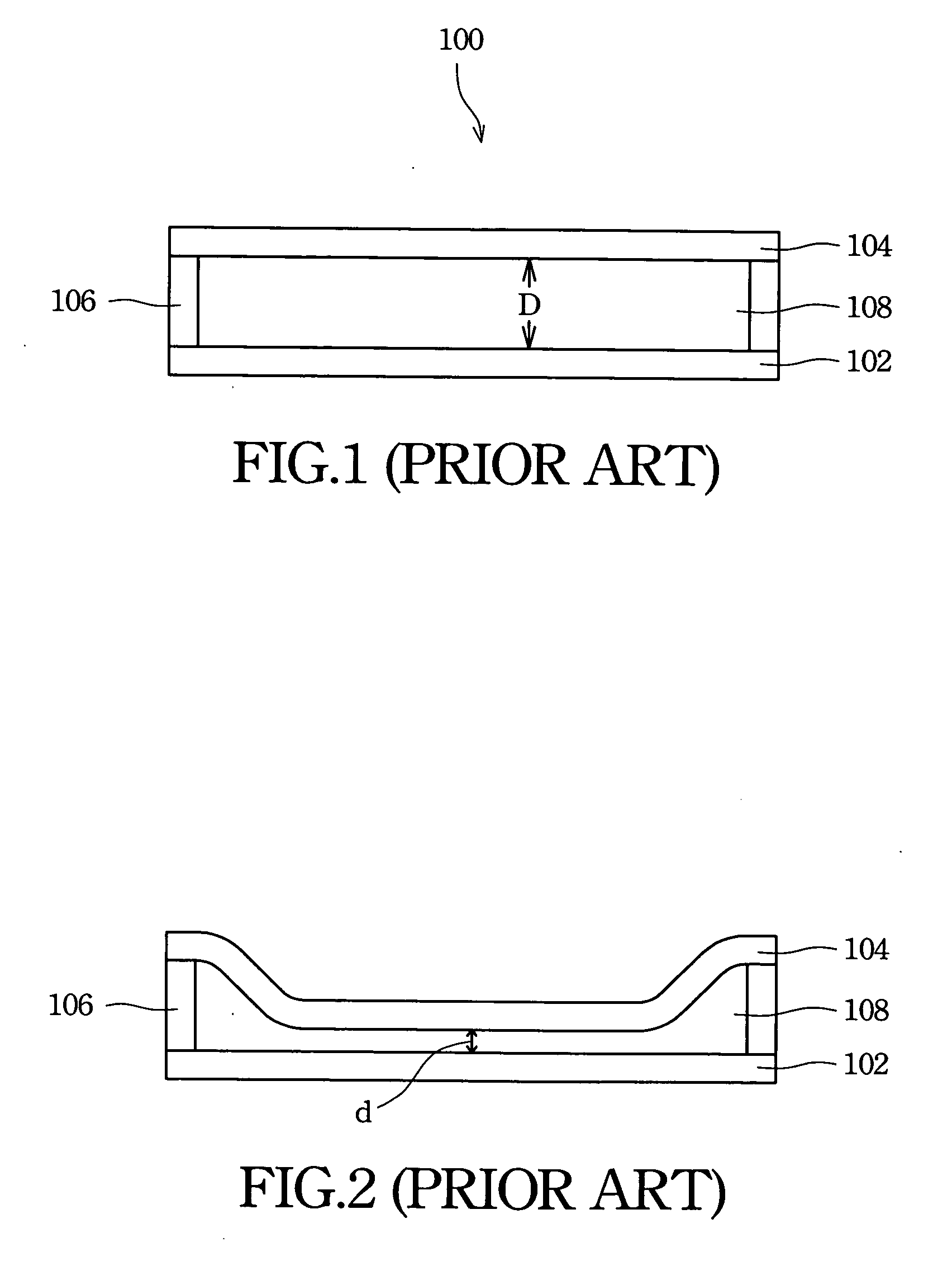

Structure of a micro electro mechanical system and the manufacturing method thereof

InactiveUS20050078348A1Improve etch selectivityHigh selectivityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical system

A structure of a micro electro mechanical system and a manufacturing method are provided, the structure and manufacturing method is adapted for an optical interference display cell. The structure of the optical interference display cell includes a first electrode, a second electrode and posts. The second electrode comprises a conductive layer covered by a material layer and is arranged about parallel with the first electrode. The support is located between the first plate and the second plate and a cavity is formed. In the release etch process of manufacturing the structure, the material layer protects the conductive layer from the damage by an etching reagent. The material layer also protects the conductive layer from the damage from the oxygen and moisture in the air.

Owner:SNAPTRACK

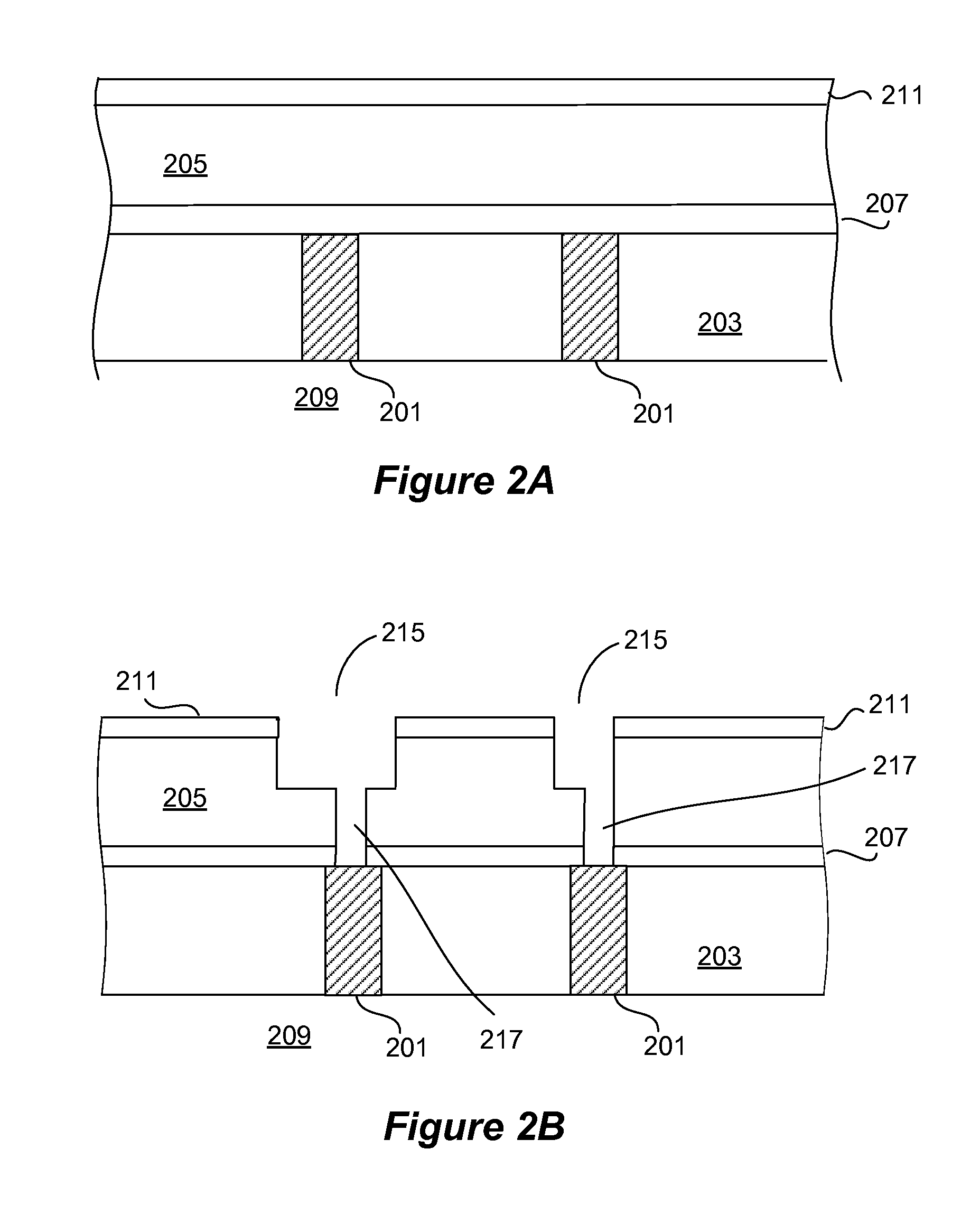

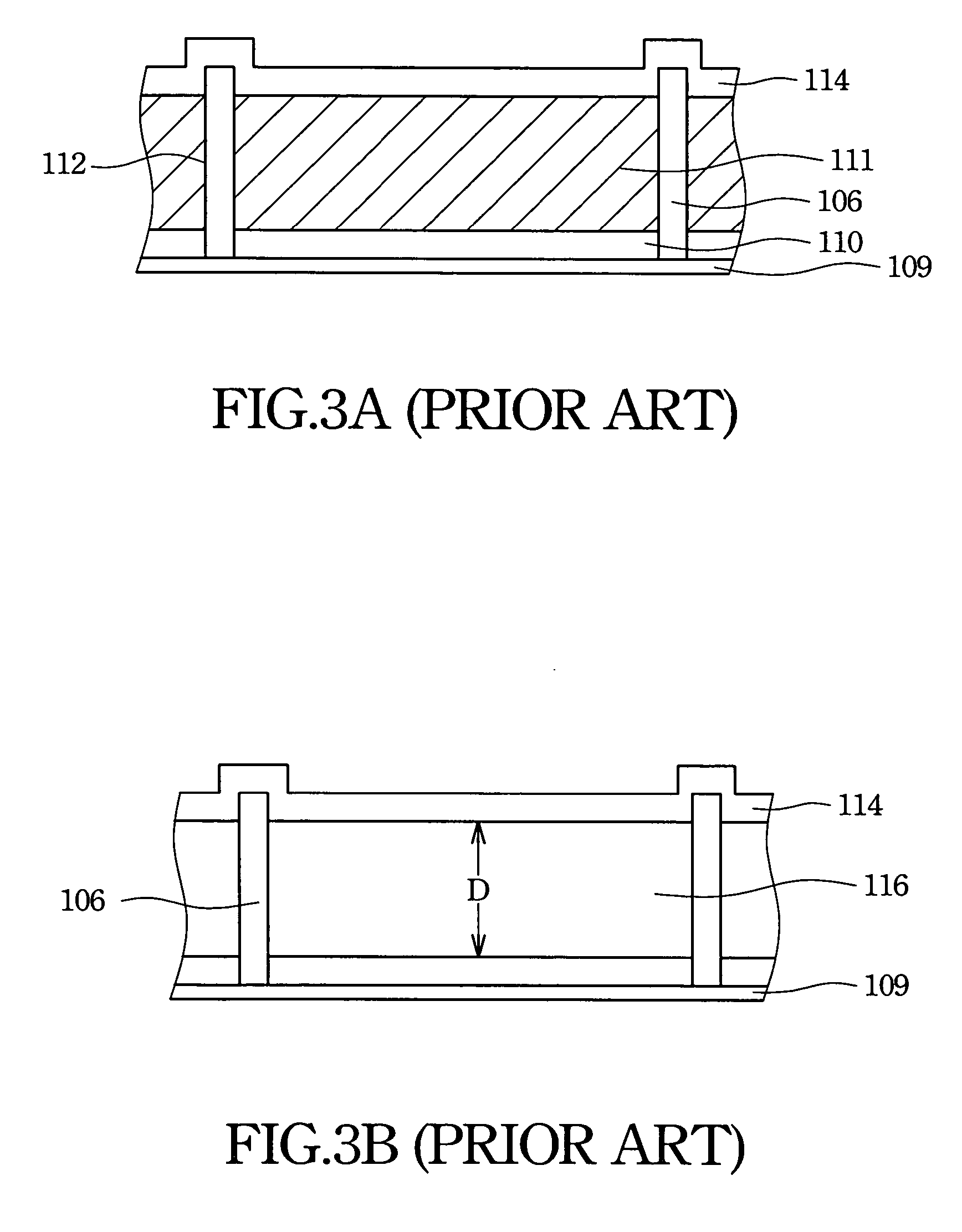

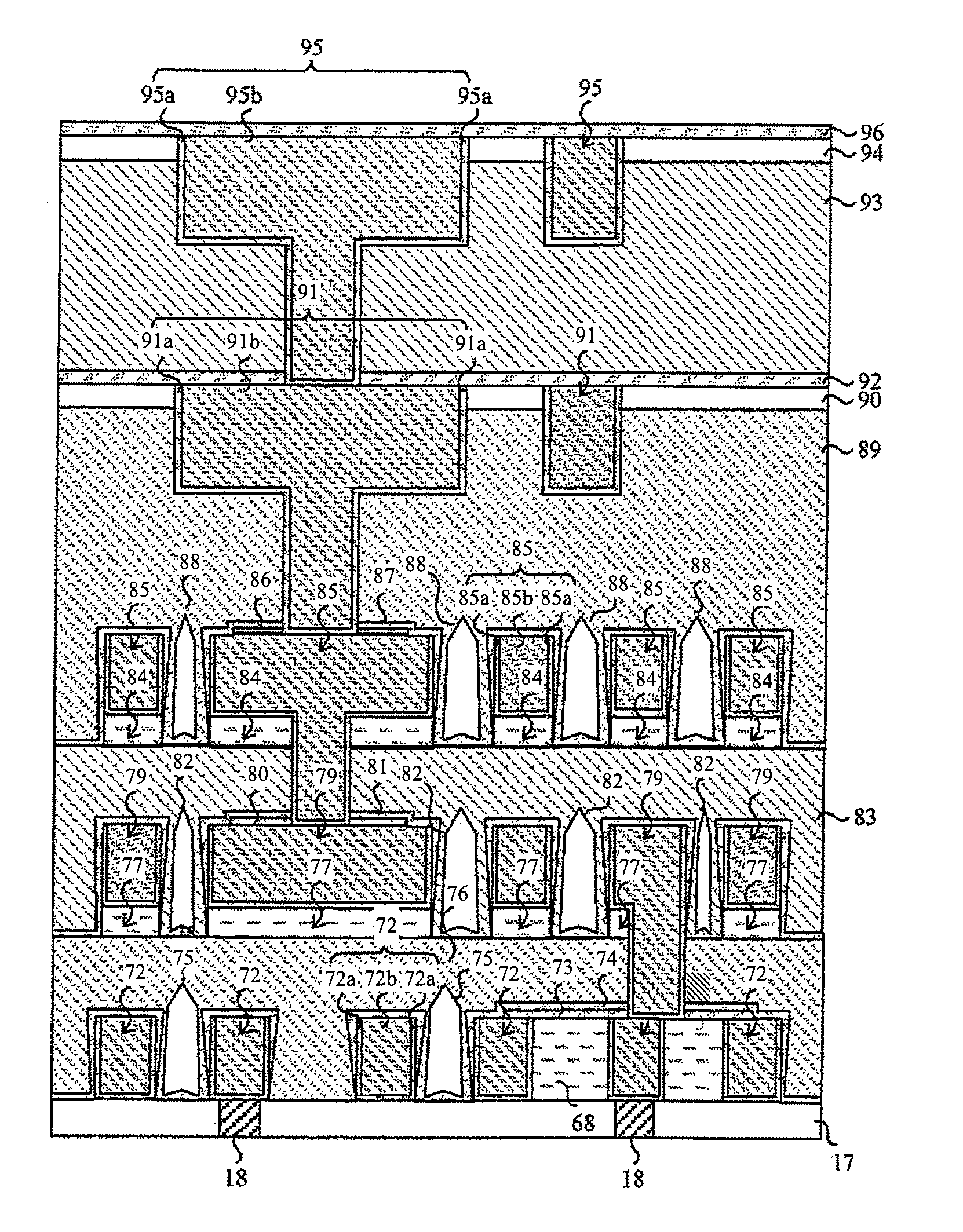

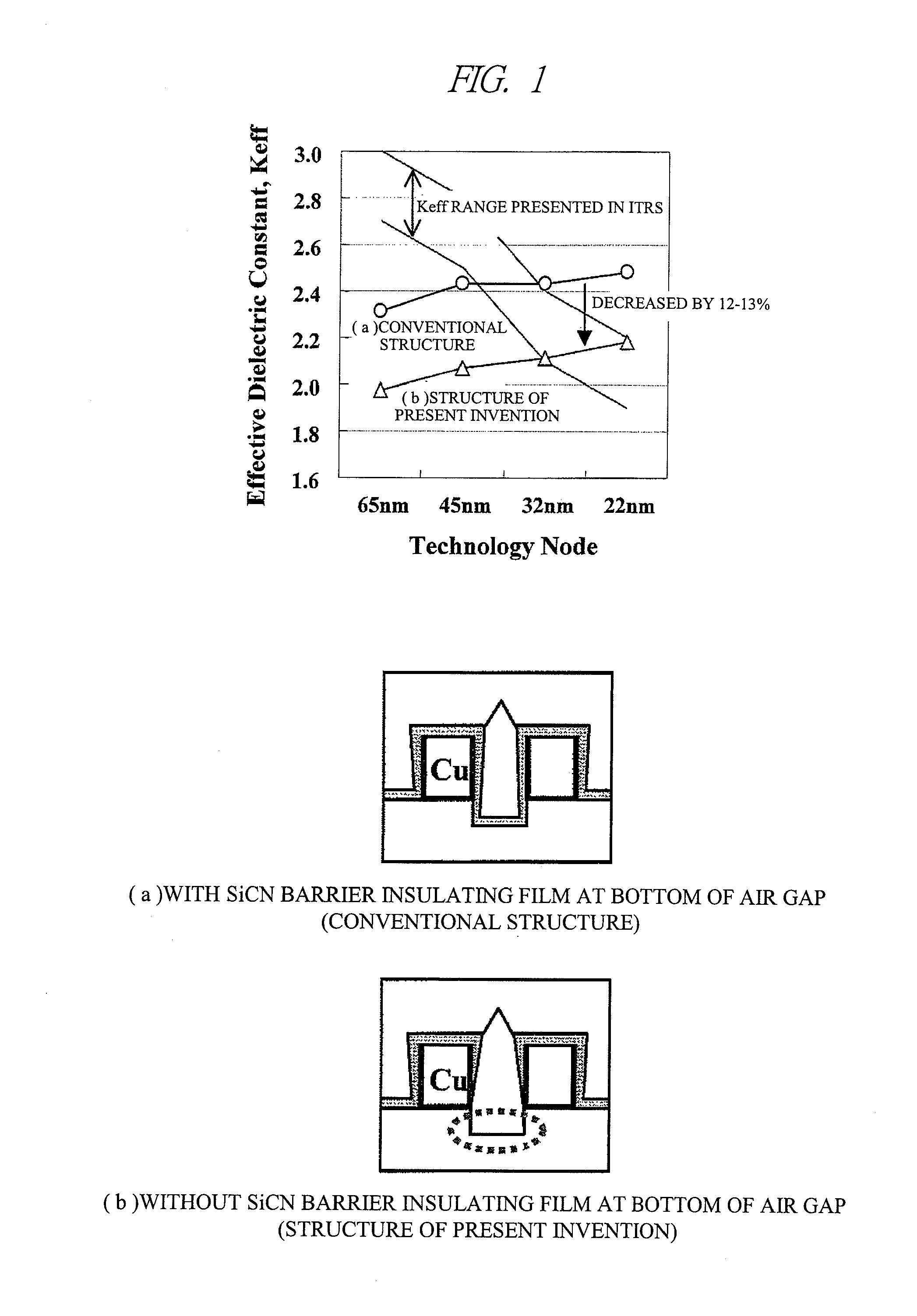

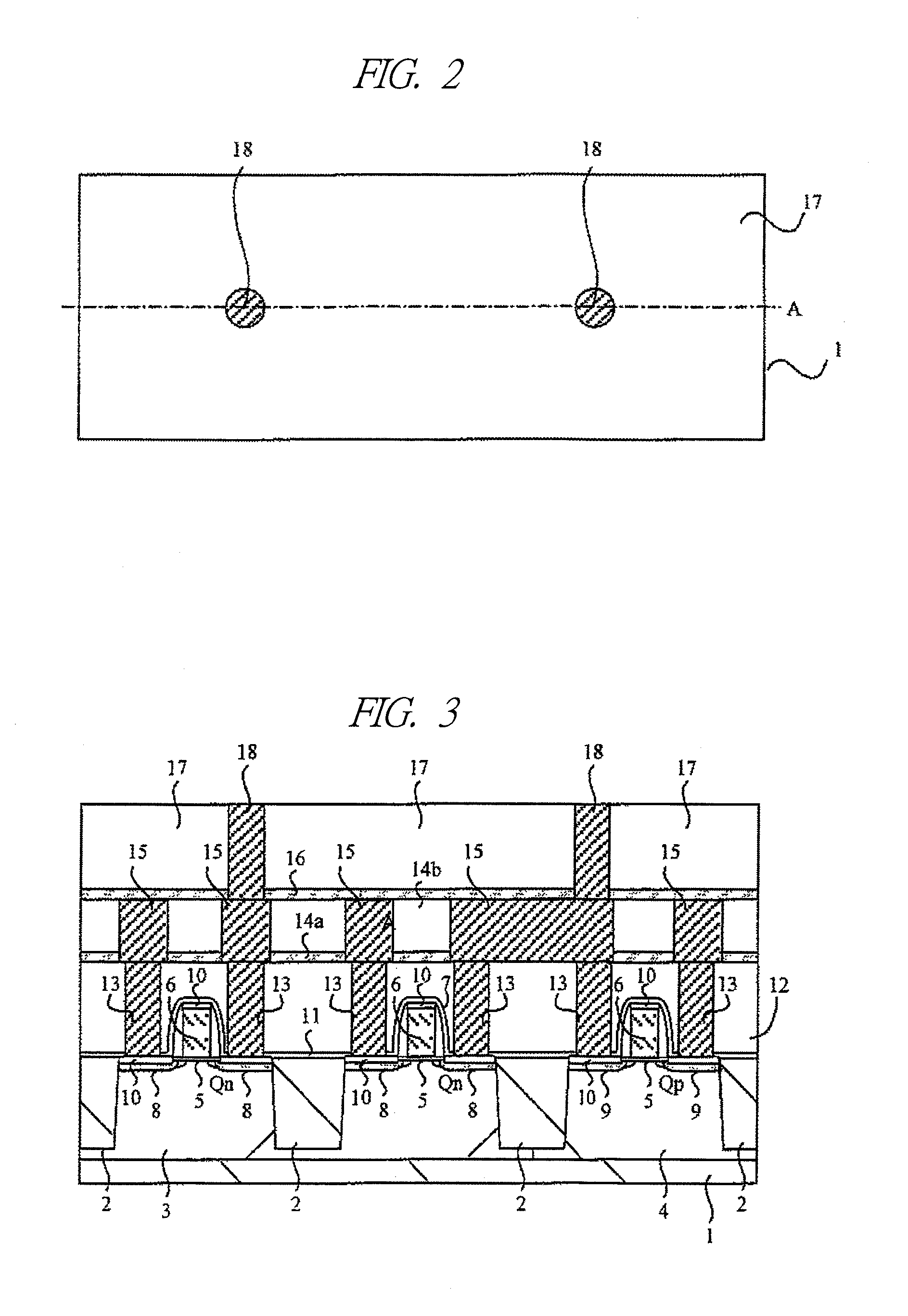

Semiconductor device and manufacturing method thereof

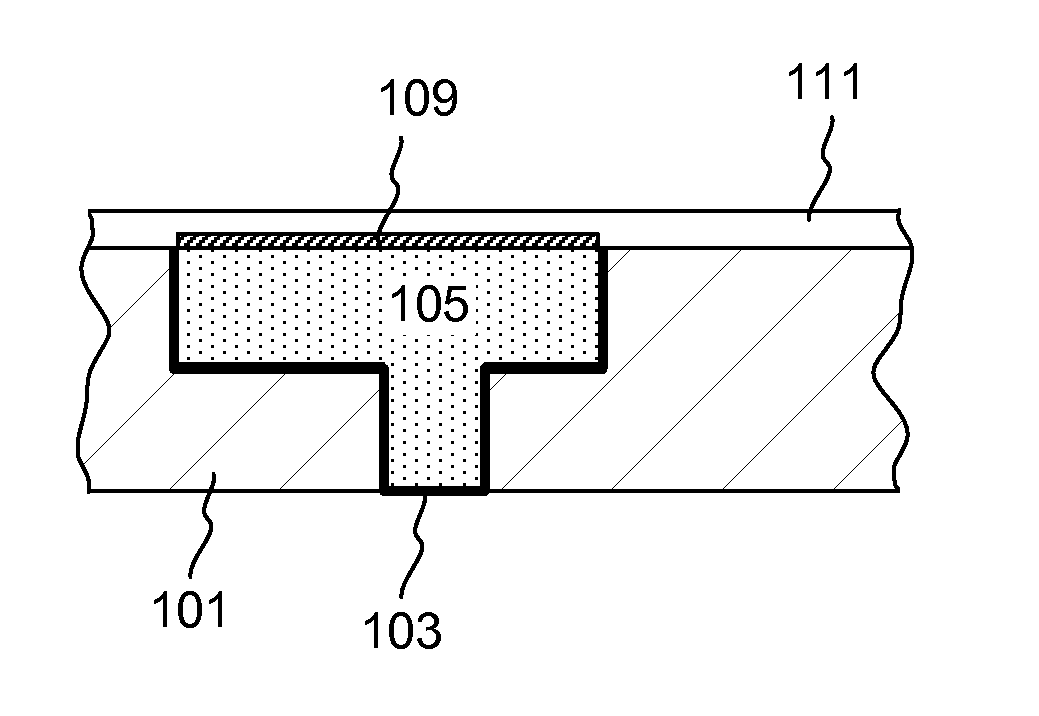

ActiveUS20100130001A1Reduce capacitanceEffective dielectric constantSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCopper

Wirings mainly containing copper are formed on an insulating film on a substrate. Then, after forming insulating films for reservoir pattern and a barrier insulating film, an insulating film for suppressing or preventing diffusion of copper is formed on upper and side surfaces of the wirings, the insulating film on the substrate, and the barrier insulating film. Here, thickness of the insulating film for suppressing or preventing diffusion of copper at the bottom of a narrow inter-wiring space is made smaller than that on the wirings, thereby efficiently reducing wiring capacitance of narrow-line pitches. Then, first and second low dielectric constant insulating films are formed. Here, a deposition rate of the first insulating film at an upper portion of the side surfaces of facing wirings is made higher than that at a lower portion thereof, thereby forming air gaps. Finally, the second insulating film is planarized by interlayer CMP.

Owner:KOKUSA ELECTRIC CO LTD

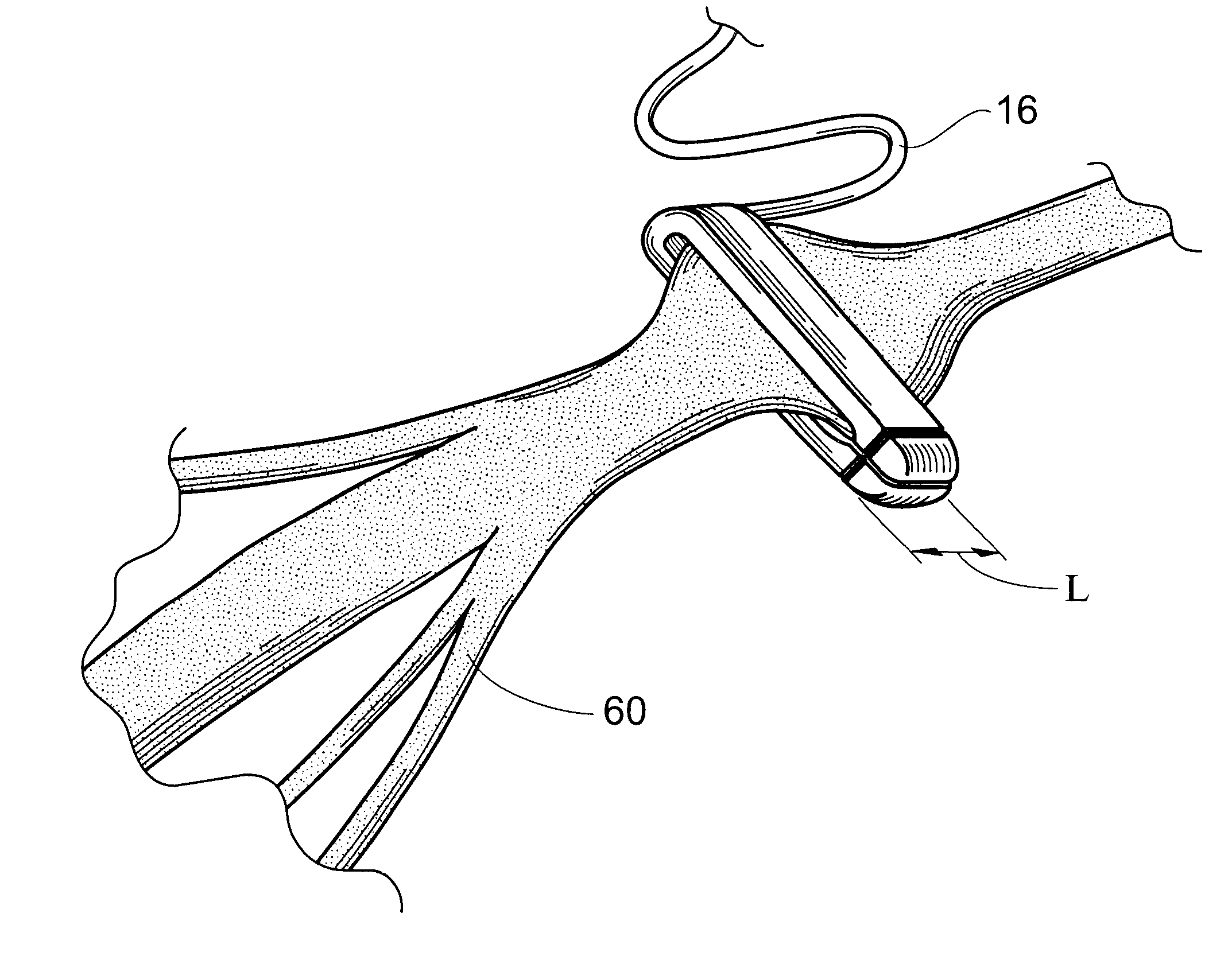

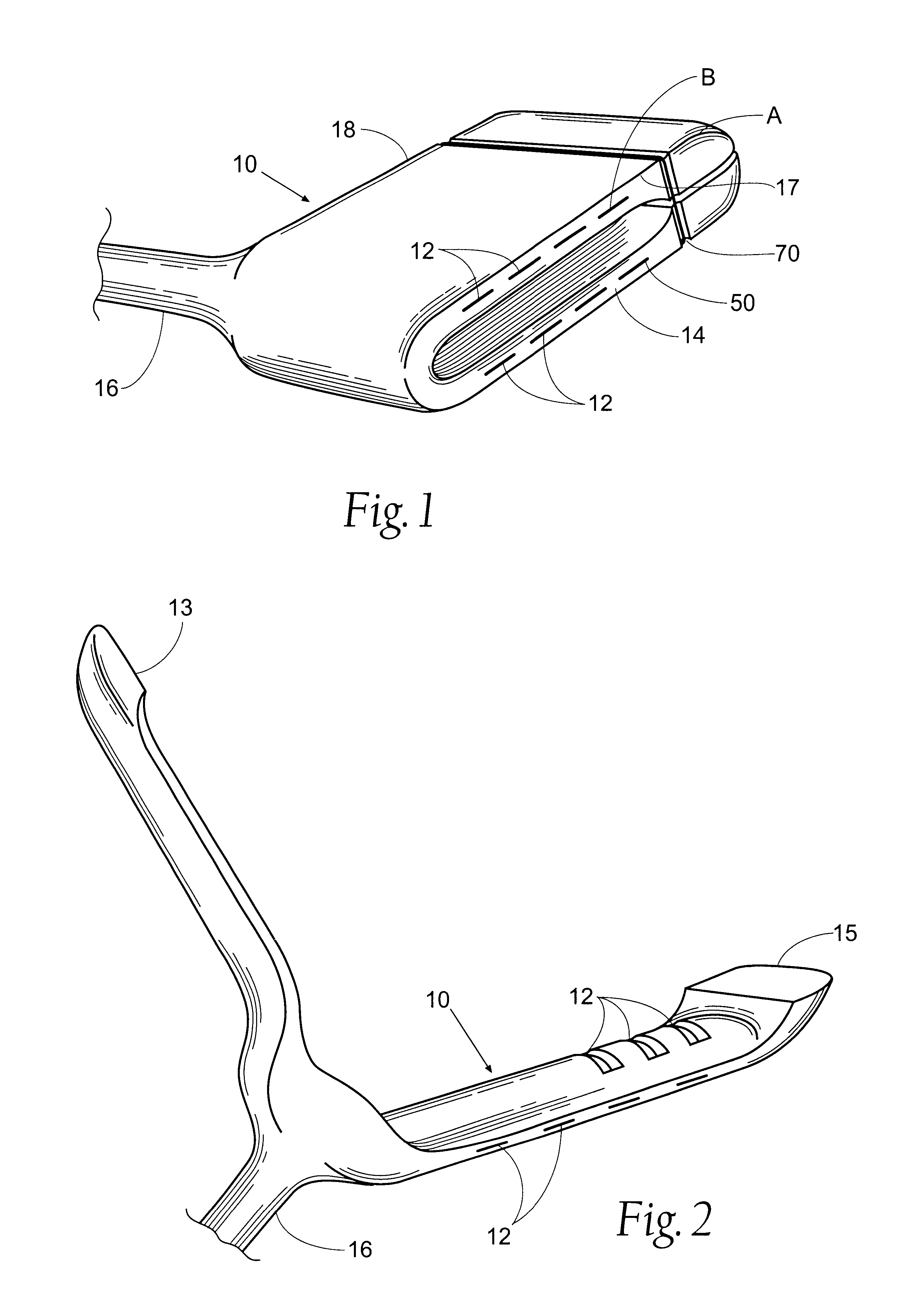

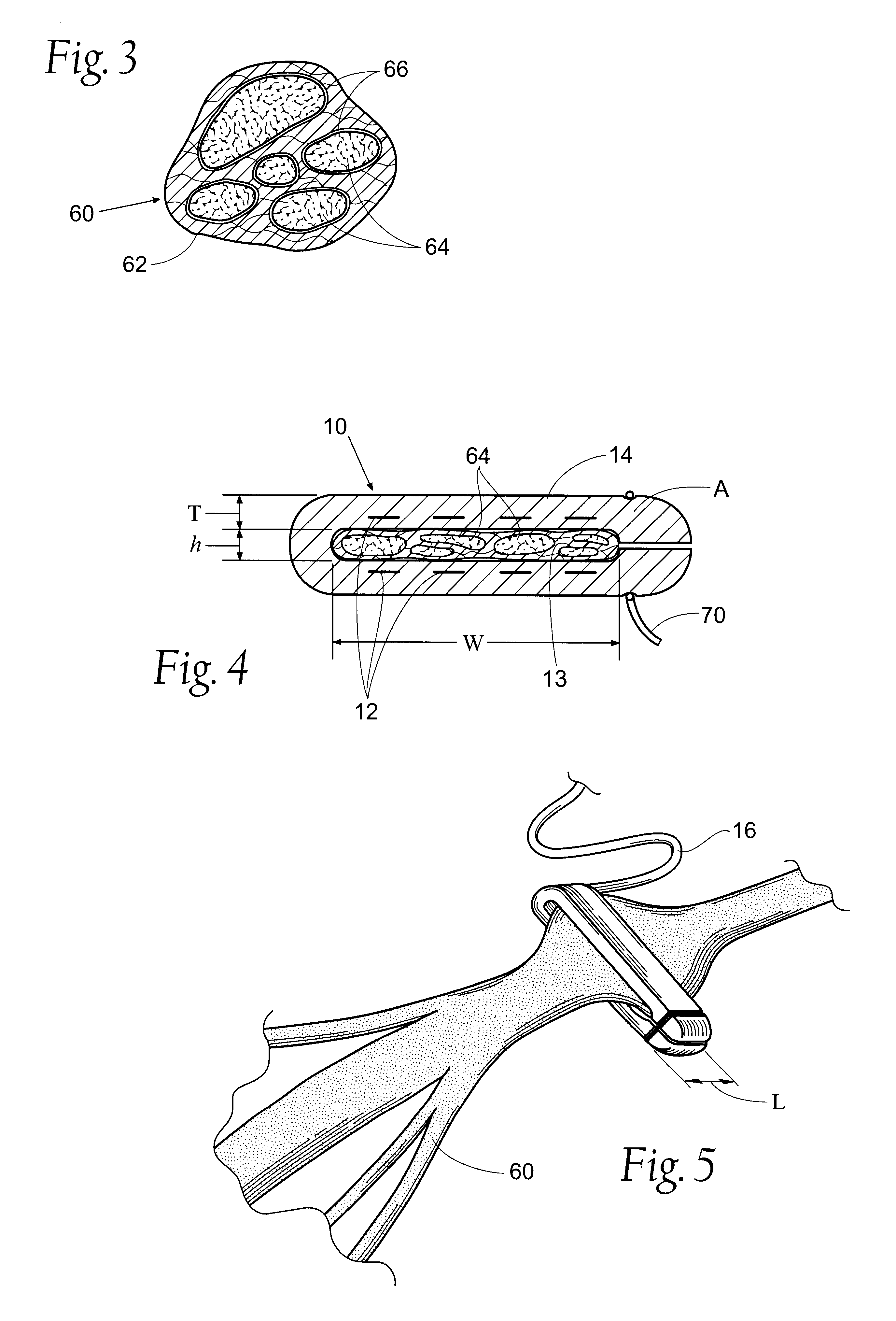

Flat interface nerve electrode and a method for use

A flat interface nerve electrode is provided along with a method for its use. The electrode provides a plurality of conductive elements embedded in a non-conductive cuff structure, which acts to gently and non-evasively redefine the geometry of a nerve through the application of a force so as to apply pressure to a nerve in a defined range, namely from 2 to 40 mmHG and more preferably from 15 to 30 mmHG and most preferably from 15 mmHG to 20 MMHG. This range is selected to minimize the reduction of blood flow within the tissue, which preferably is at least 70% of the initial value, more preferably 90% of the initial value. The cuff has an opening, which is elongated relative to the diameter of the nerve to which it is applied. Preferably, the cuff is constructed from an elastic bio-compatible material having top and bottom beam members configured to define a nerve opening. The cuff is open at one side and has a connection at the other side which results in a spring force being applied through the surfaces of the nerve opening to the subject nerve. During implantation the open sides of the cuff are closed so as to capture the nerve in the cuff. As the nerve is reshaped, specific nerve axons become more easily addressed through the epineurium by the embedded conductive elements.

Owner:CASE WESTERN RESERVE UNIV

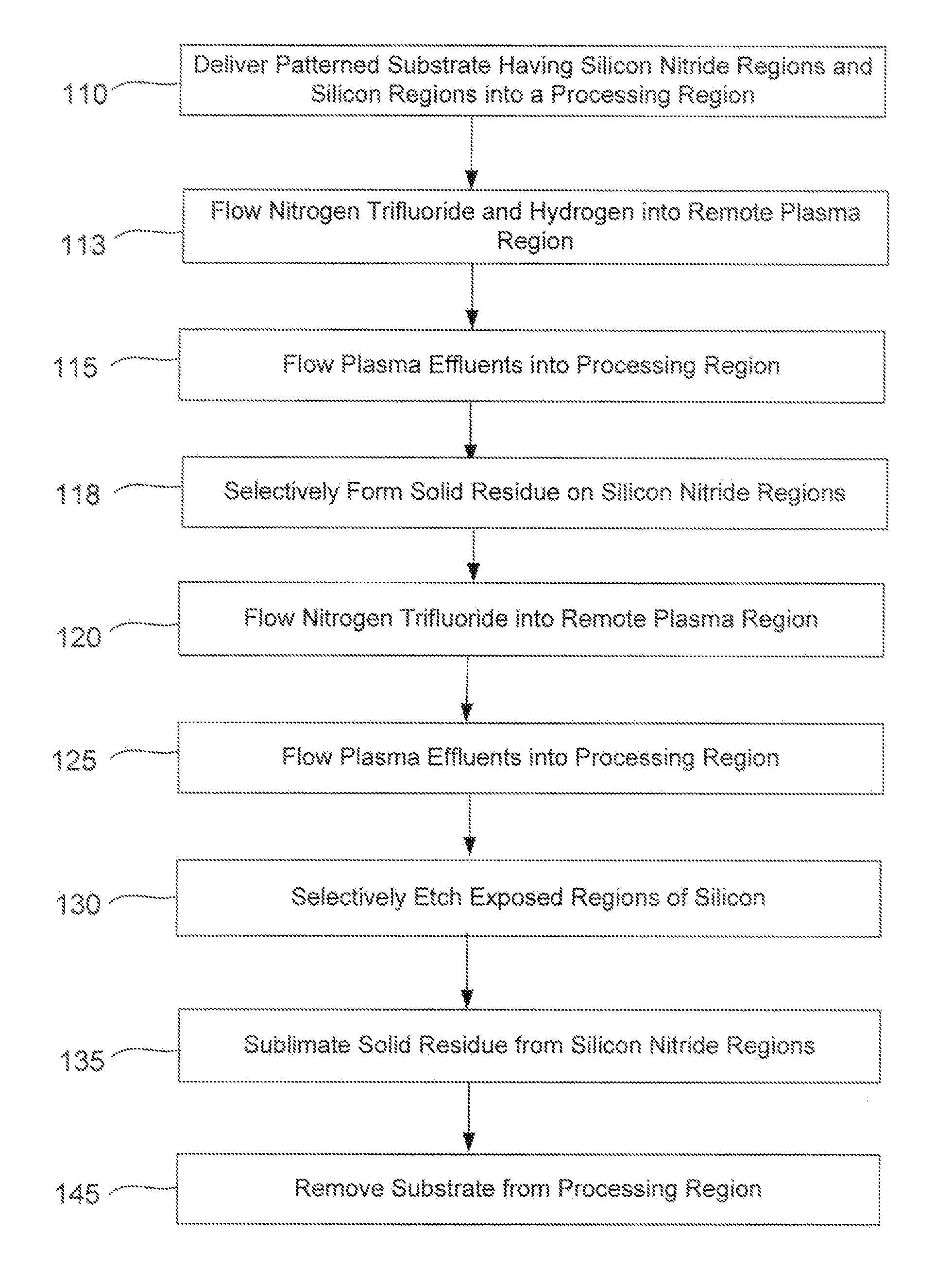

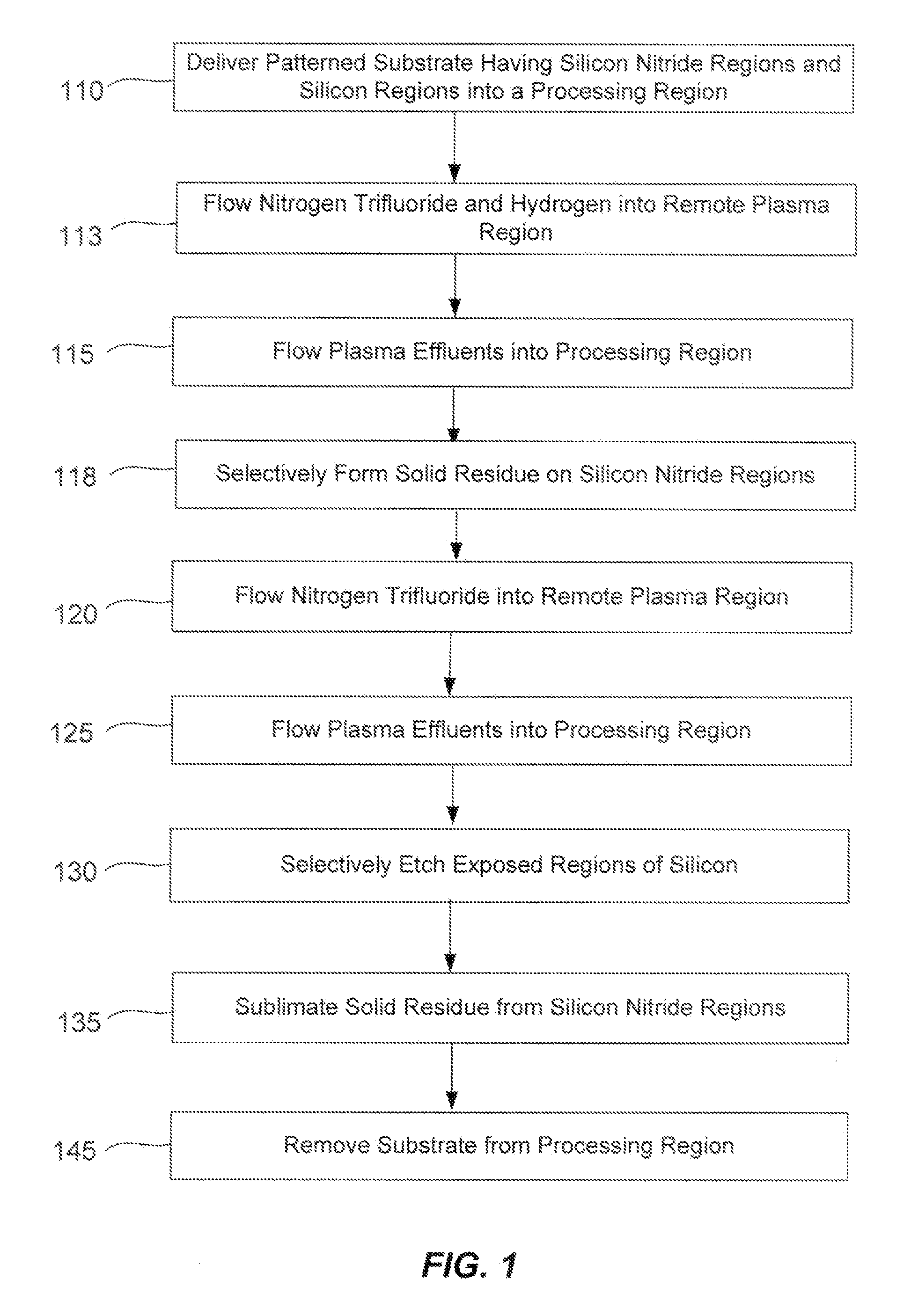

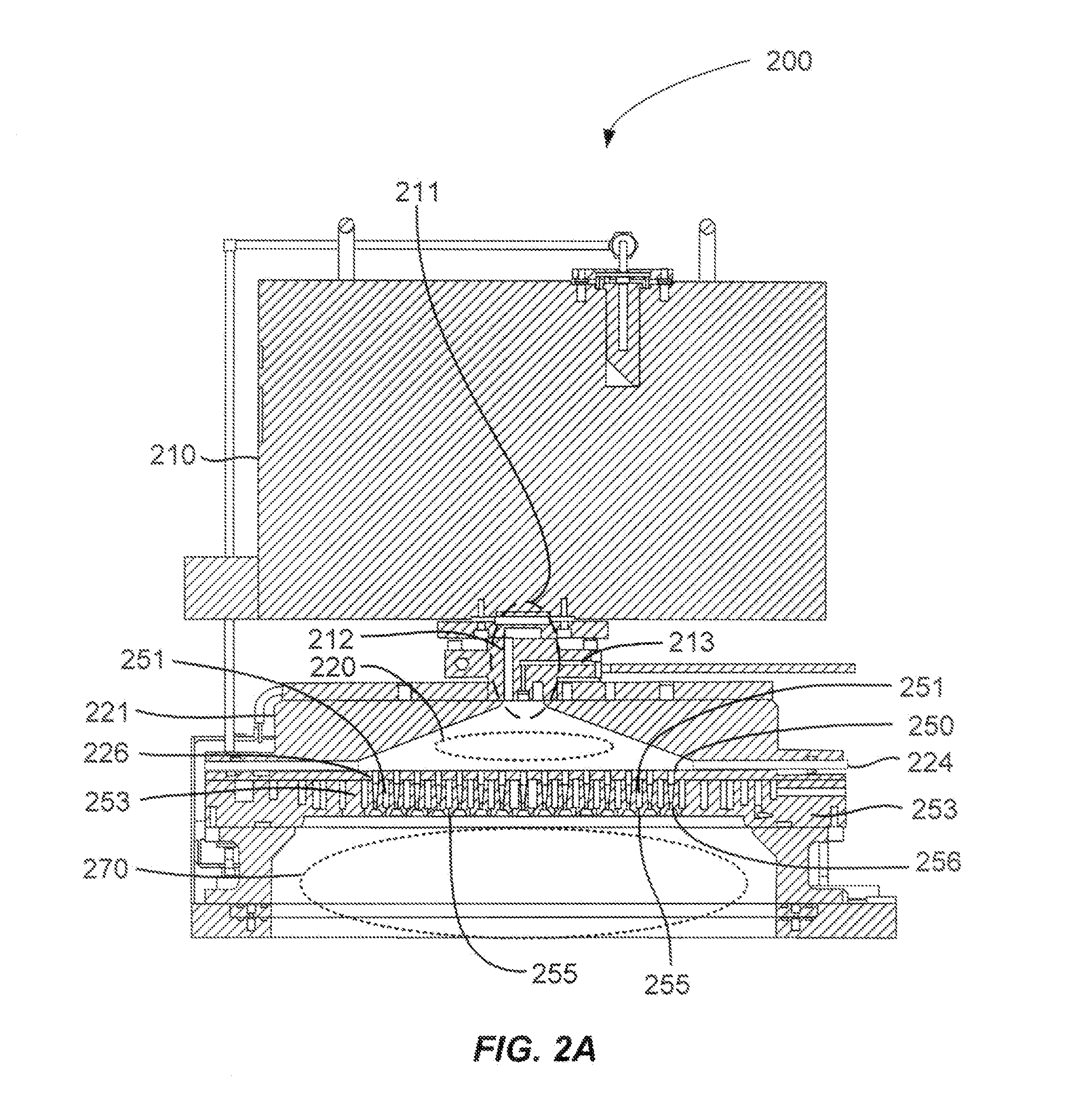

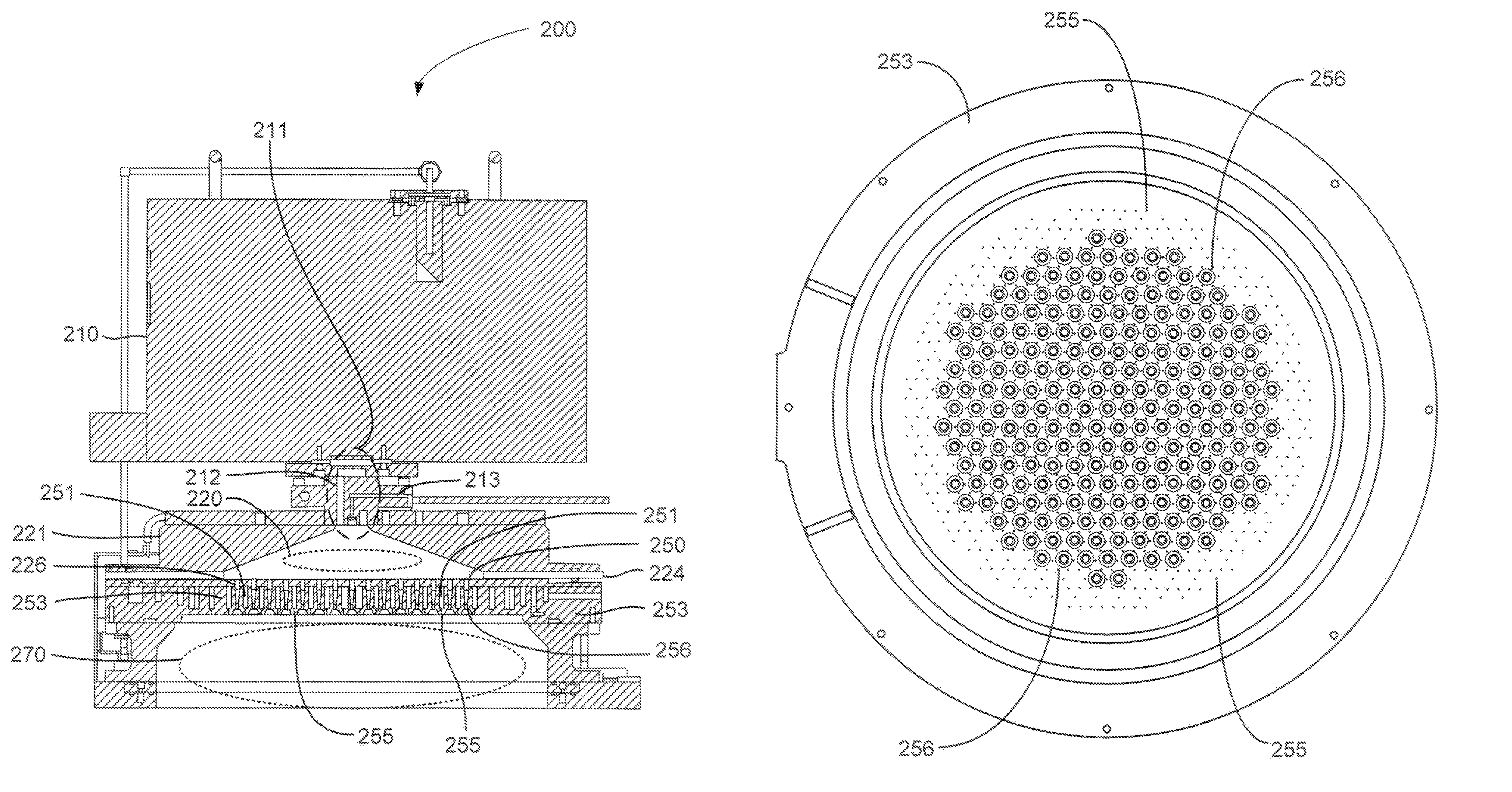

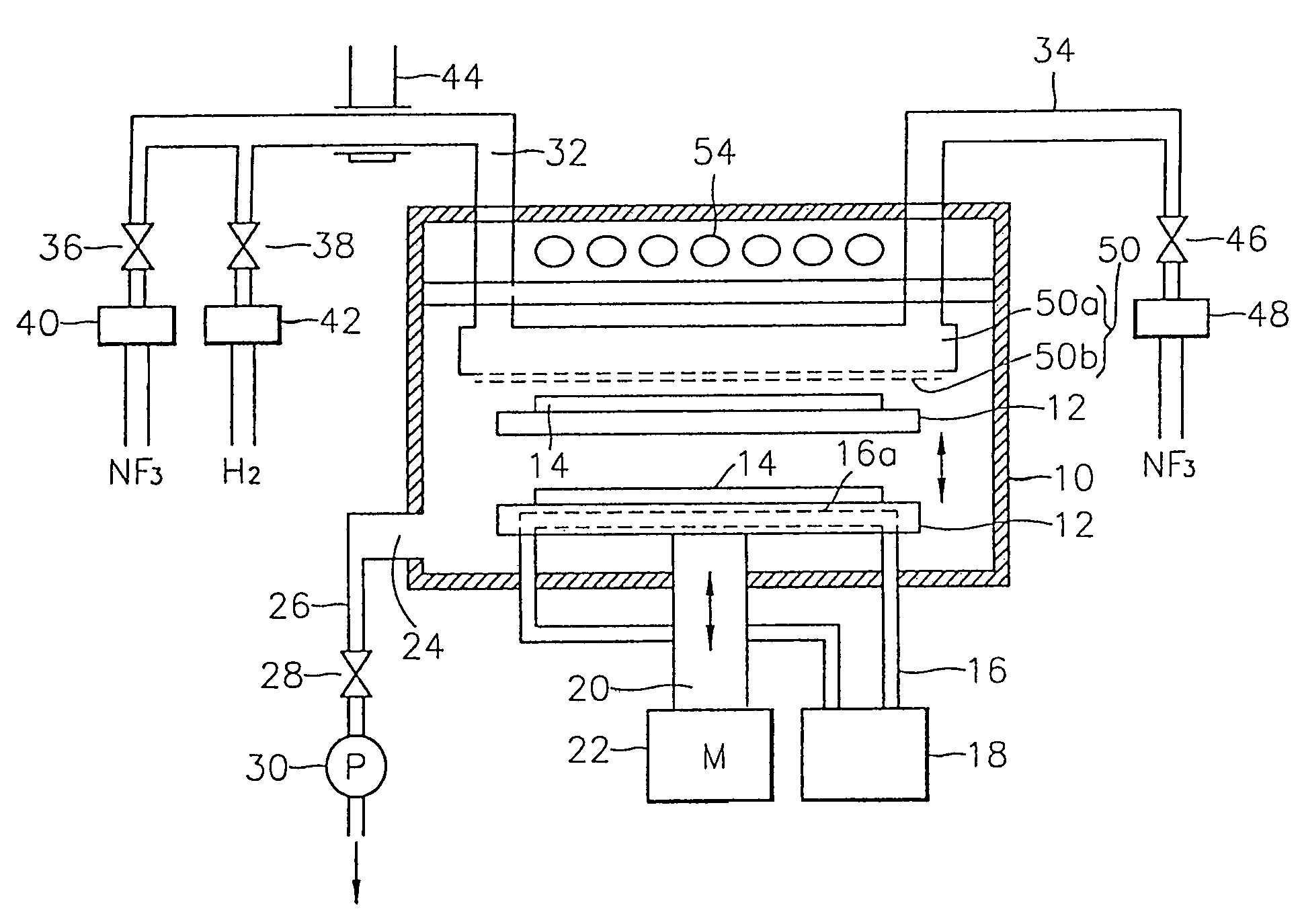

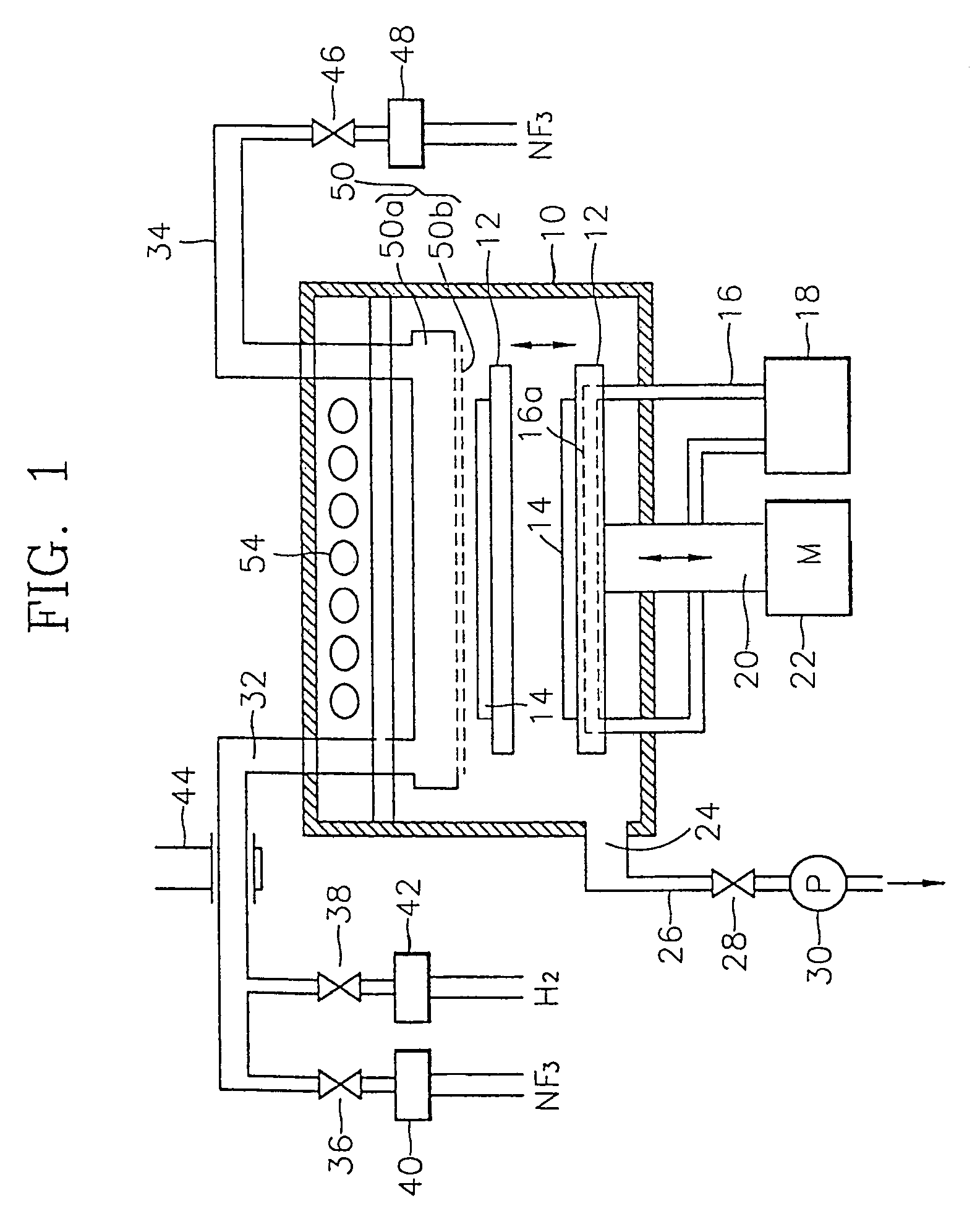

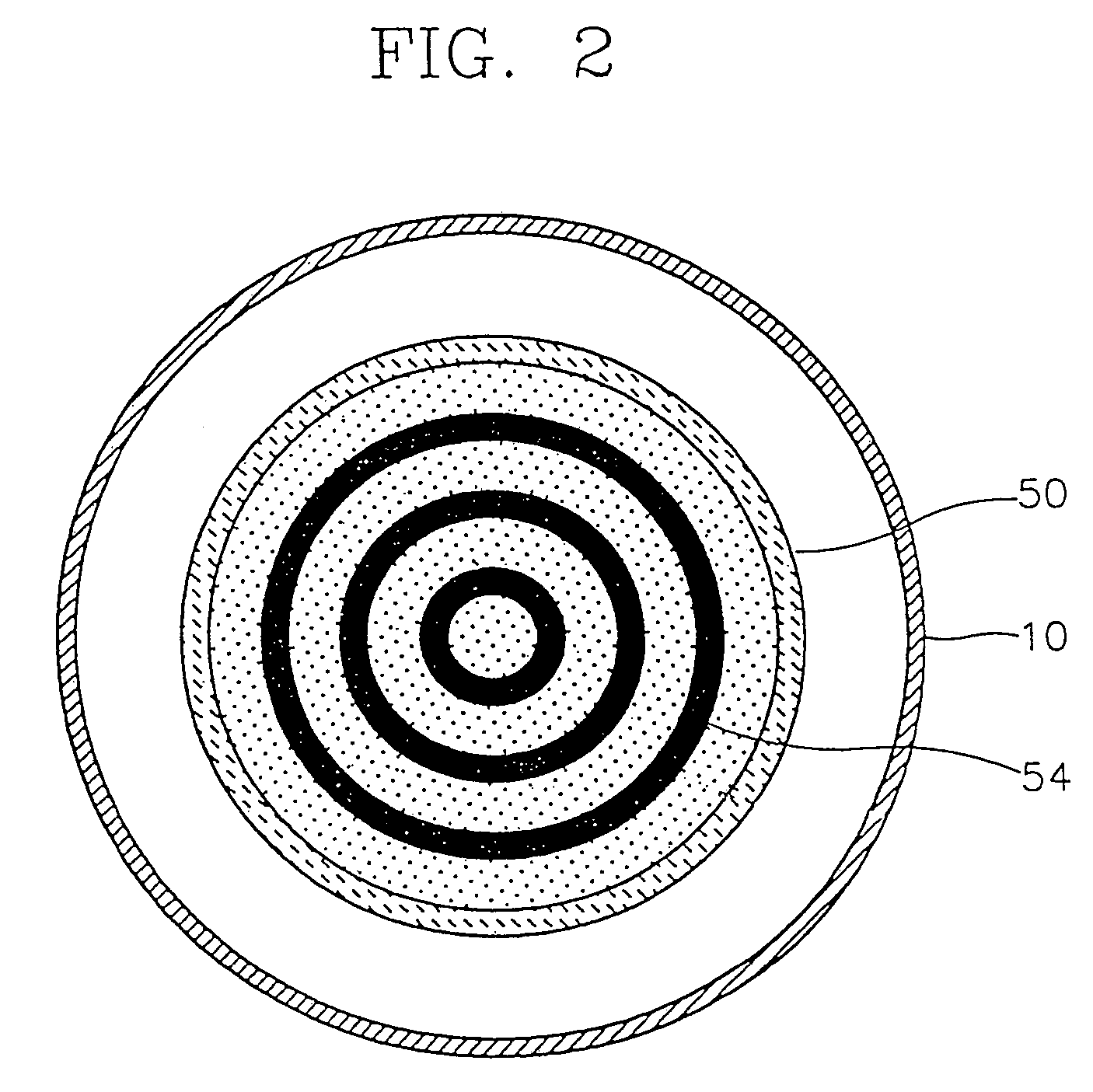

Selective suppression of dry-etch rate of materials containing both silicon and nitrogen

InactiveUS20130059440A1Inhibit etch rateImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

A method of suppressing the etch rate for exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. The etch selectivity of silicon relative to silicon nitride and other silicon-and-nitrogen-containing material is increased using the method. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-nitrogen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including nitrogen trifluoride and hydrogen (H2). The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

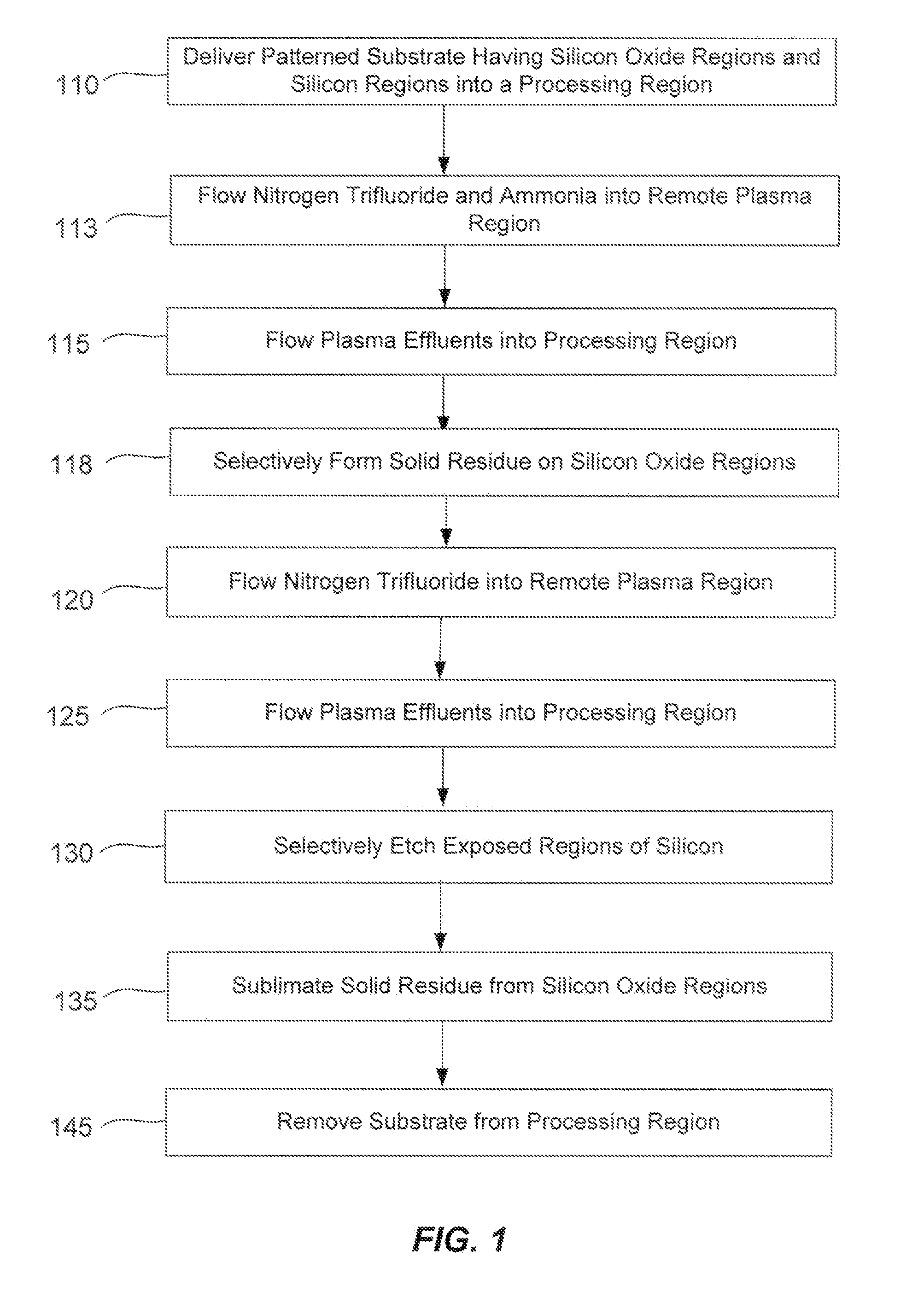

Selective suppression of dry-etch rate of materials containing both silicon and oxygen

InactiveUS20130052827A1Inhibit etch rateHigh selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaHydrogen

A method of suppressing the etch rate for exposed silicon-and-oxygen-containing material on patterned heterogeneous structures is described and includes a two stage remote plasma etch. Examples of materials whose selectivity is increased using this technique include silicon nitride and silicon. The first stage of the remote plasma etch reacts plasma effluents with the patterned heterogeneous structures to form protective solid by-product on the silicon-and-oxygen-containing material. The plasma effluents of the first stage are formed from a remote plasma of a combination of precursors, including a nitrogen-containing precursor and a hydrogen-containing precursor. The second stage of the remote plasma etch also reacts plasma effluents with the patterned heterogeneous structures to selectively remove material which lacks the protective solid by-product. The plasma effluents of the second stage are formed from a remote plasma of a fluorine-containing precursor.

Owner:APPLIED MATERIALS INC

Enhanced herbicide composition

An herbicide composition comprising a PSI inhibitor and a salicylate or another SAR inducer and methods of use for said composition is disclosed.

Owner:VALENT BIOSCIENCES CORP

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS7488688B2High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

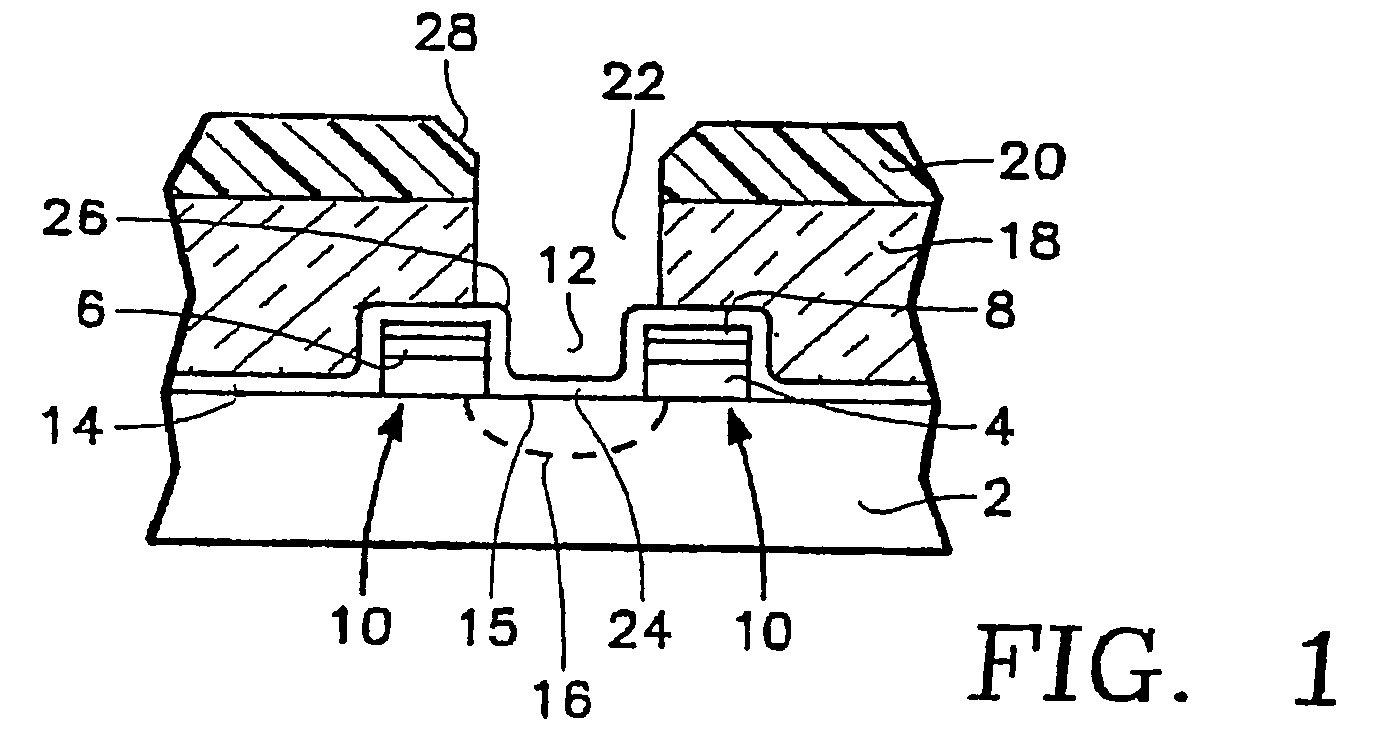

Self-aligned contact etch with high sensitivity to nitride shoulder

InactiveUS20060051968A1Reliable controlHigh selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingMedium densityDielectric substrate

A method and apparatus are provided for etching semiconductor and dielectric substrates through the use of plasmas based on mixtures of a first gas having the formula CaFb, and a second gas having the formula CxHyFz, wherein a / b≧⅔, and wherein x / z≧½. The mixtures may be used in low or medium density plasmas sustained in a magnetically enhanced reactive ion chamber to provide a process that exhibits excellent corner layer selectivity, photo resist selectivity, under layer selectivity, and profile and bottom CD control. The percentages of the first and second gas may be varied during etching to provide a plasma that etches undoped oxide films or to provide an etch stop on such films.

Owner:APPLIED MATERIALS INC

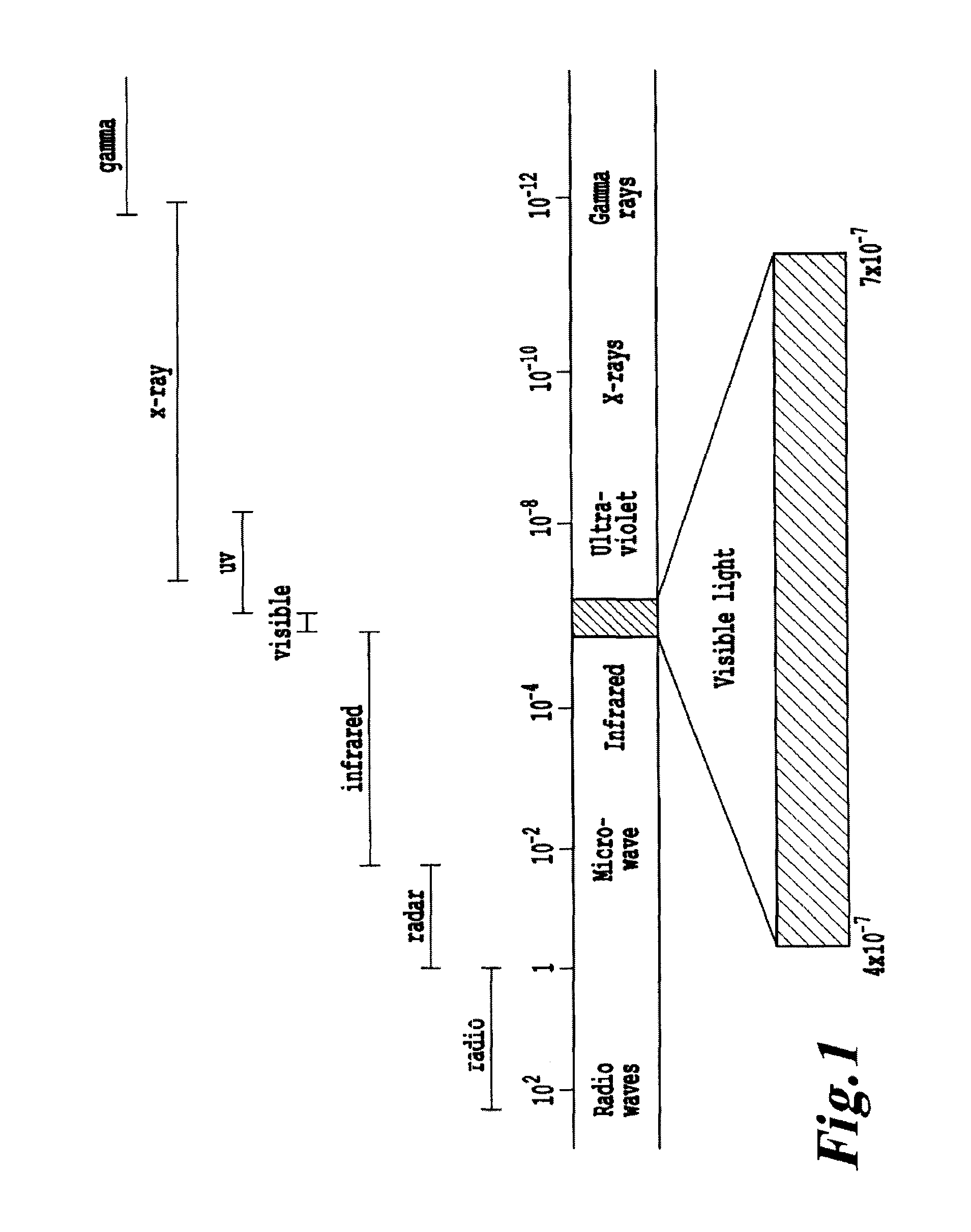

Non-invasive energy upconversion methods and systems for in-situ photobiomodulation

ActiveUS20110021970A1High selectivityAvoid the needAntibacterial agentsSenses disorderDiseaseHigh energy

Products, compositions, systems, and methods for modifying a target structure which mediates or is associated with a biological activity, including treatment of conditions, disorders, or diseases mediated by or associated with a target structure, such as a virus, cell, subcellular structure or extracellular structure. The methods may be performed in situ in a non-invasive manner by placing a nanoparticle having a metallic shell on at least a fraction of a surface in a vicinity of a target structure in a subject and applying an initiation energy to a subject thus producing an effect on or change to the target structure directly or via a modulation agent. The nanoparticle is configured, upon exposure to a first wavelength λ1, to generate a second wavelength λ2 of radiation having a higher energy than the first wavelength λ1. The methods may further be performed by application of an initiation energy to a subject in situ to activate a pharmaceutical agent directly or via an energy modulation agent, optionally in the presence of one or more plasmonics active agents, thus producing an effect on or change to the target structure. Kits containing products or compositions formulated or configured and systems for use in practicing these methods.

Owner:DUKE UNIV +1

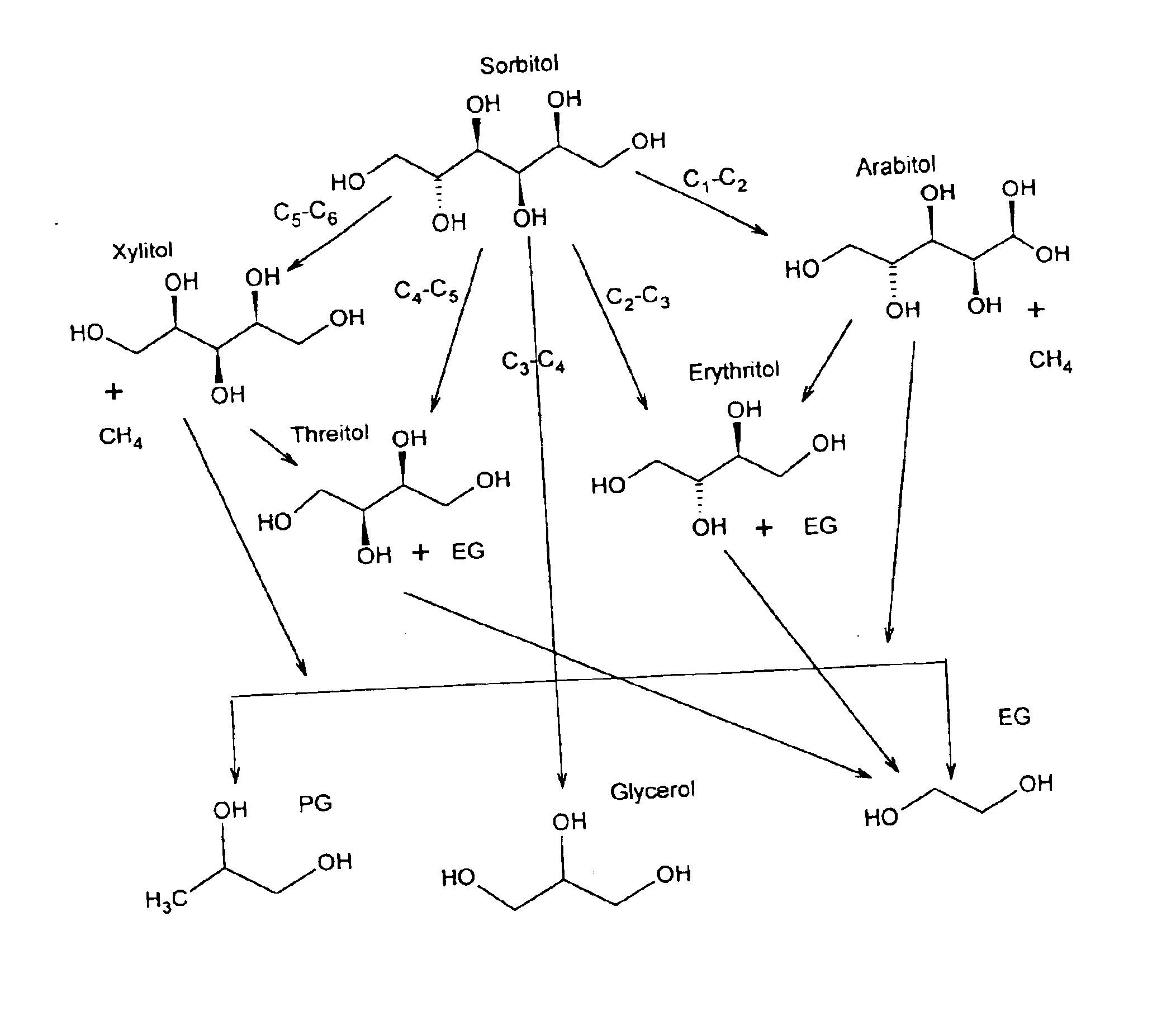

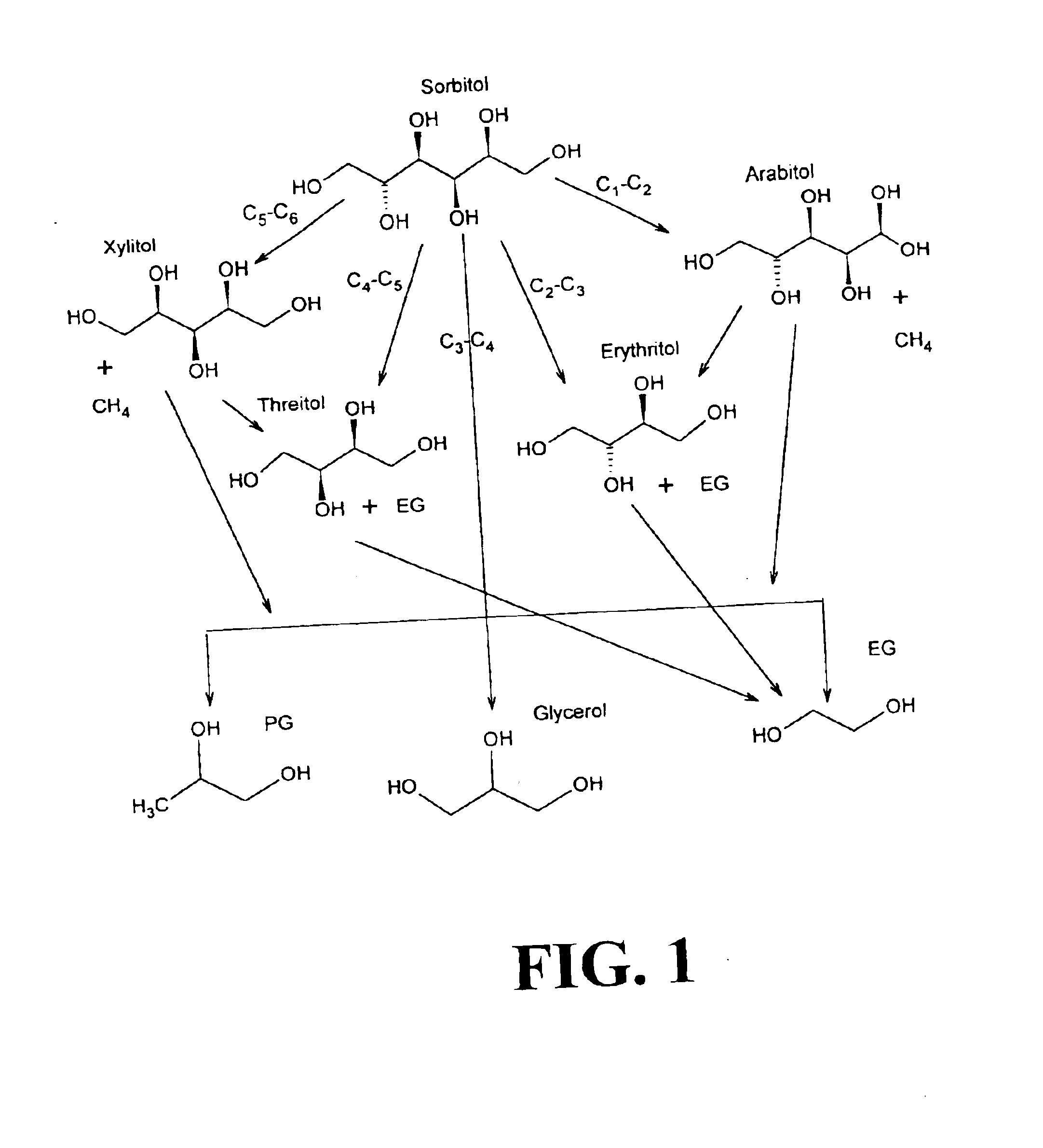

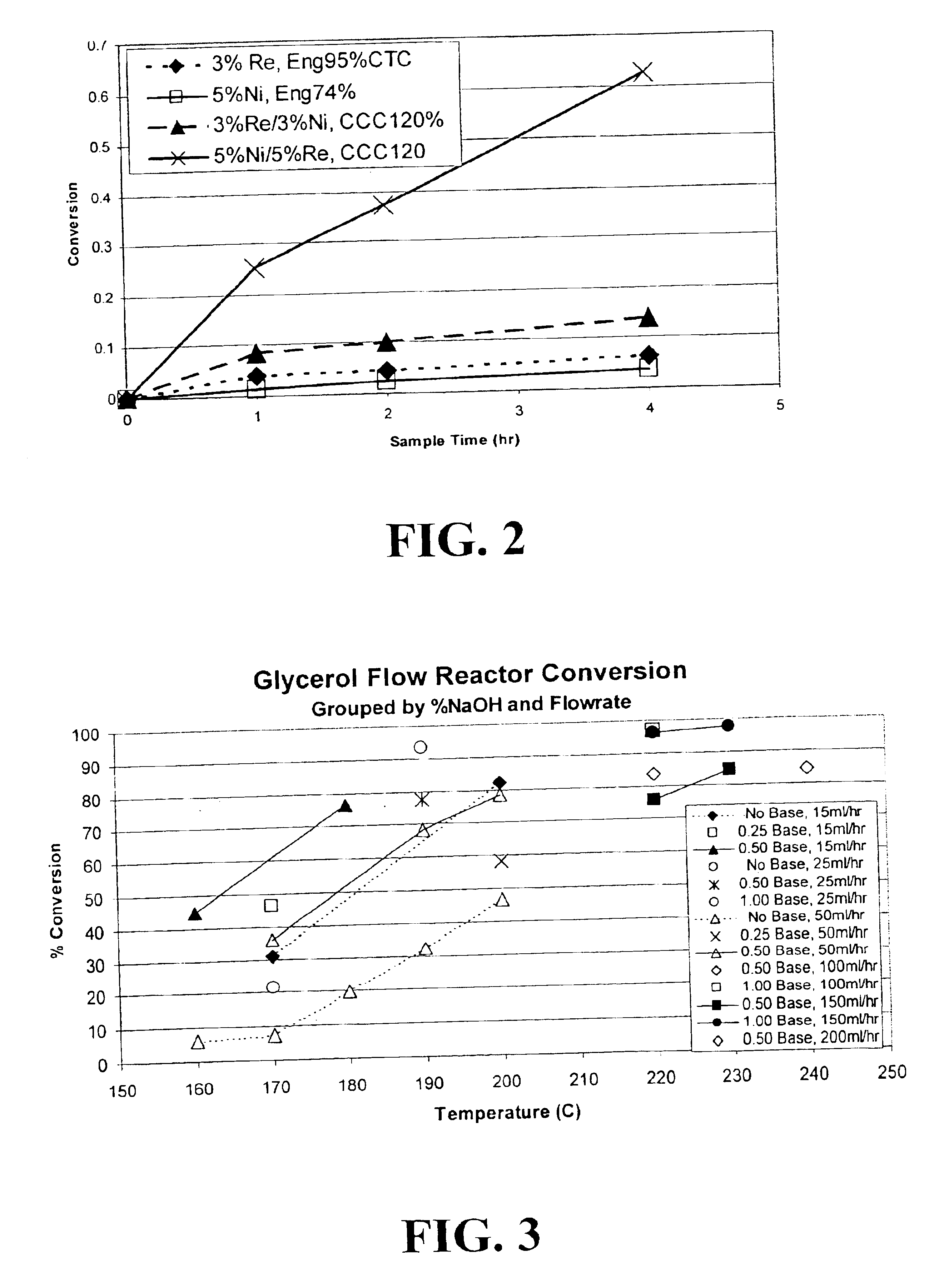

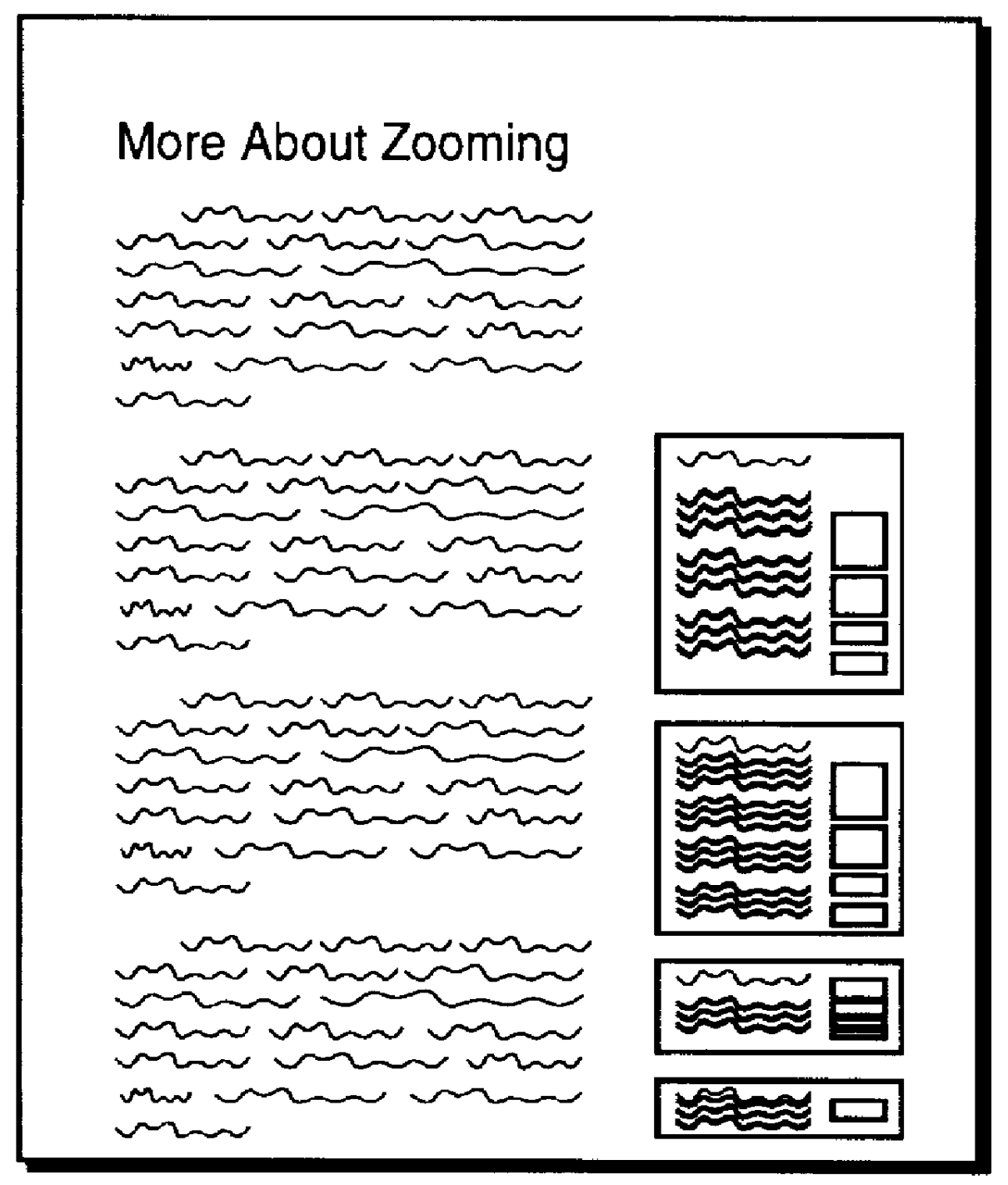

Hydrogenolysis of 6-carbon sugars and other organic compounds

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

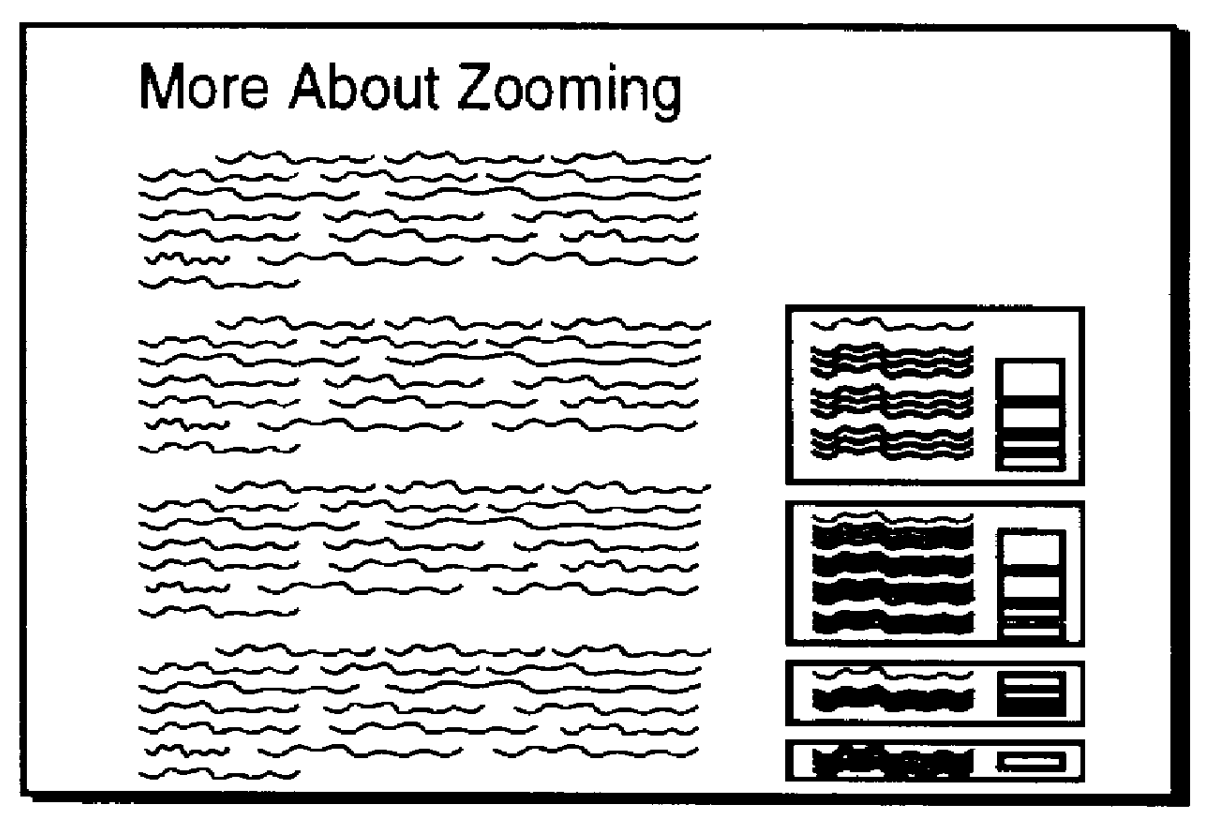

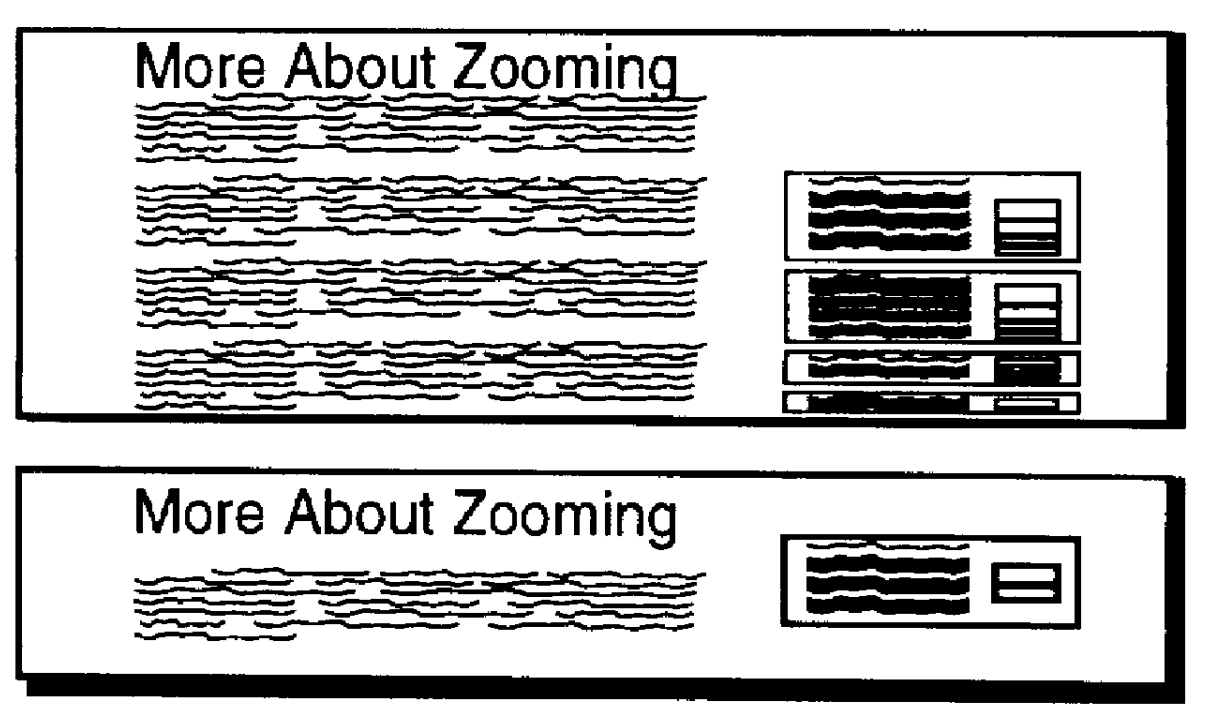

Zooming controller

InactiveUS6061062ACost effectiveIncrease speedInput/output processes for data processingProportional controlImage resolution

A method and device for accessing a broad data field having a fine resolution. The user selects a scale which can be varied. The scale controls a range within the data field. By moving the range to encompass different portions of the data field, the user can scan that portion of the data field. The present invention allows the user to simultaneously select the scale while moving the range over different portions of the data field. Thus, the user can "zoom in" and "zoom out" of different portions of the data field. In one embodiment of the present invention, a particular piece of data within the broad data field can be accessed. First, the scale is selectively varied, thereby controlling a range within the data field. Then, the range is moved to encompass portions of the data field in which the piece of data resides. Next, the scale is successively decreased while, simultaneously, points successively closer to the location are kept with the range. The scale is decreased (i.e., increasing the range's resolution) and the range is moved in this manner until the piece of data is actually accessed.

Owner:APPLE INC

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

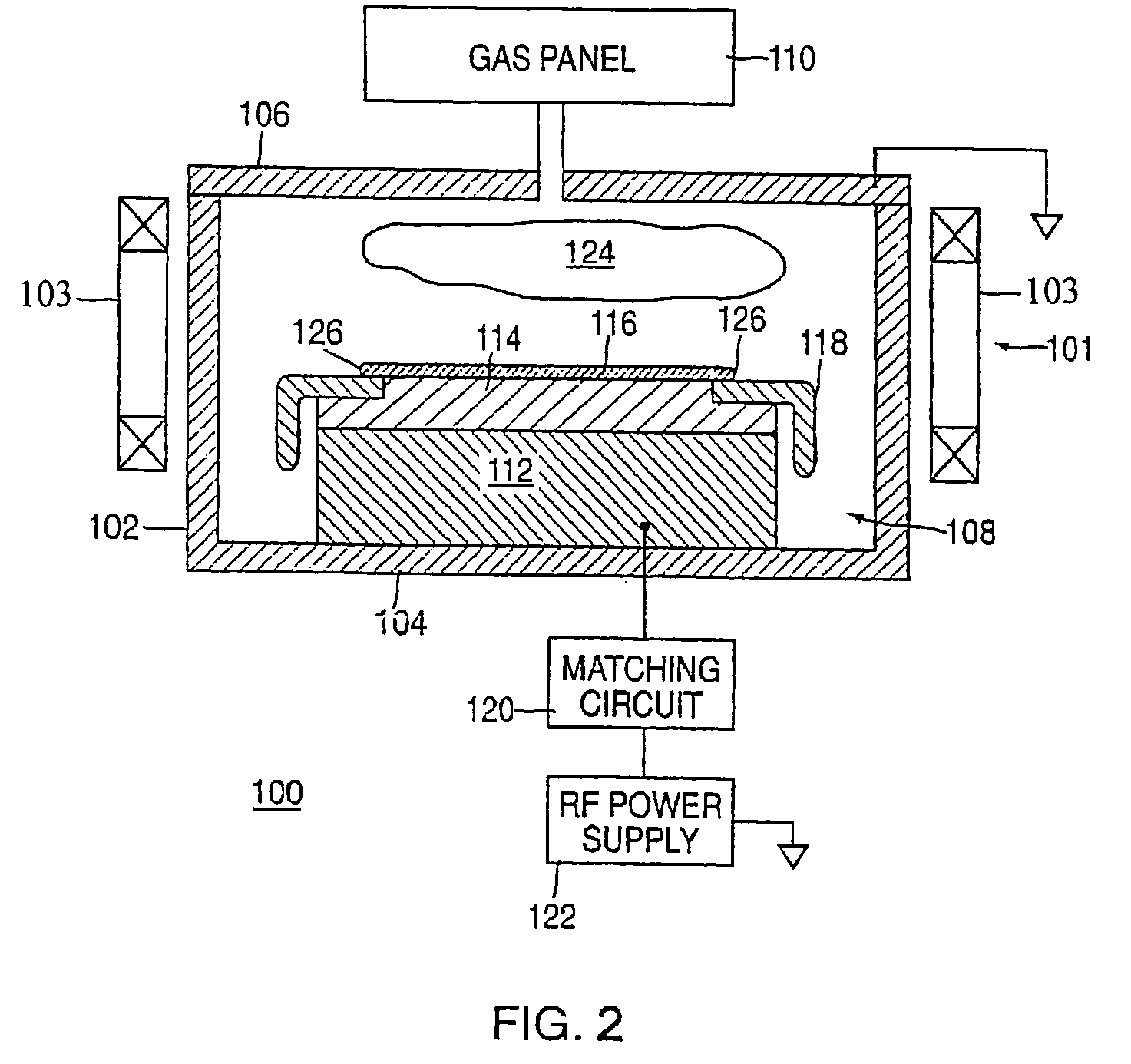

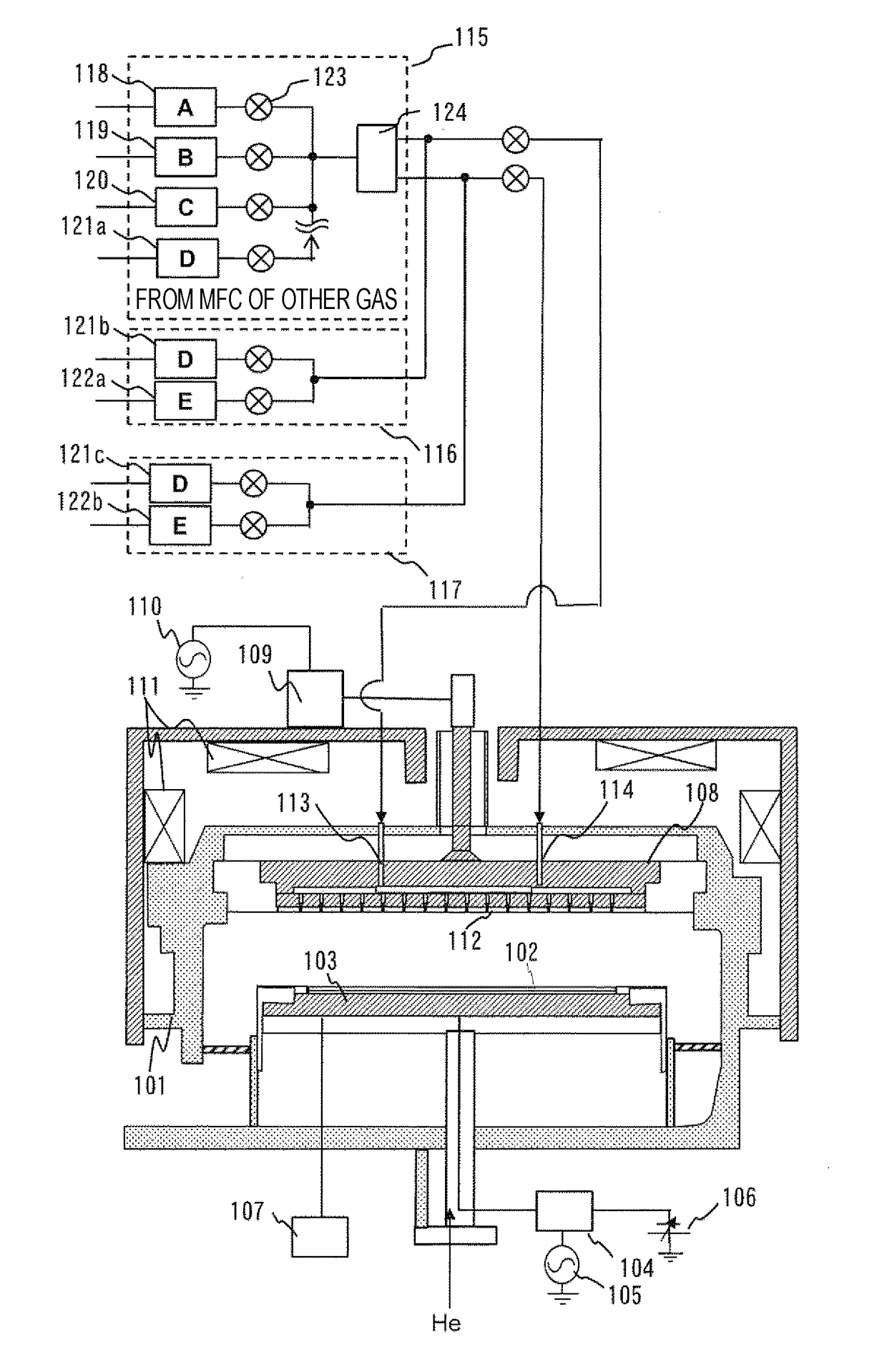

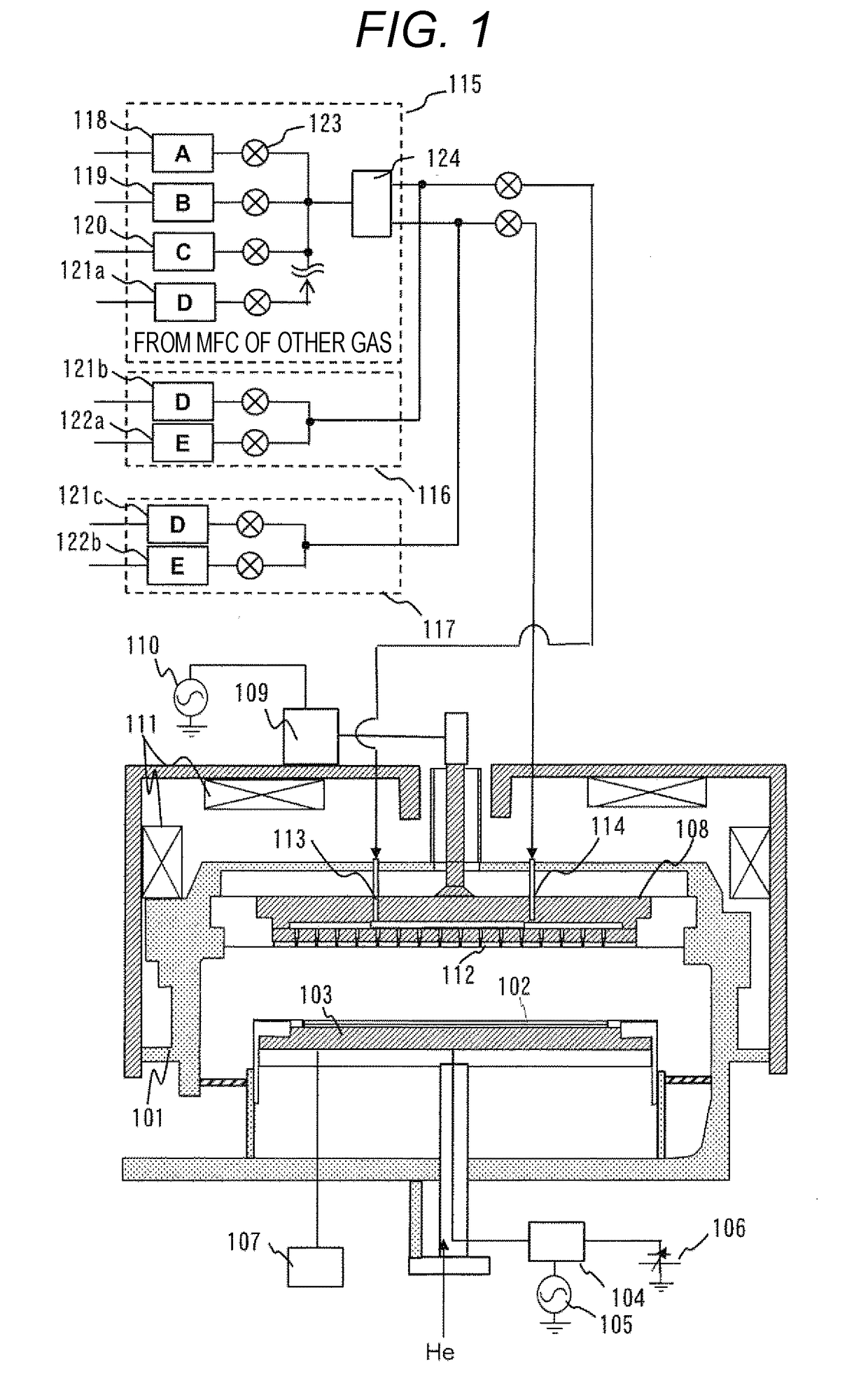

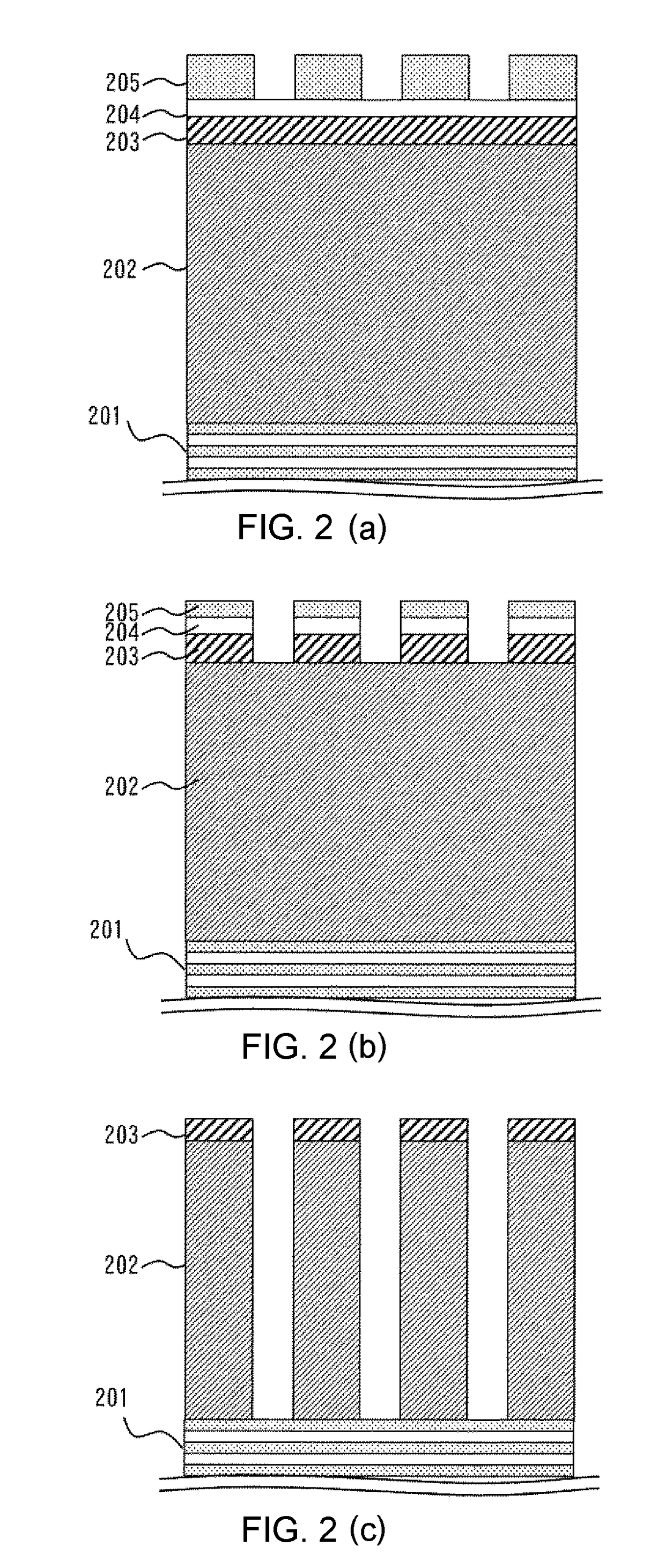

Plasma processing method and plasma processing apparatus

ActiveUS20180068862A1High etch rateHigh selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma treatmentControllability

The present invention provides a plasma processing method and a plasma processing apparatus. The plasma processing method enables consistent processing by realizing a high selectivity and a high etching rate when etching a laminated film using a boron-containing amorphous carbon film, realizes high throughput including prior and post processes by simplifying a mask forming process, and has shape controllability of vertical processing. In the present invention, in a plasma processing method for forming a mask by plasma-etching a laminated film including an amorphous carbon film containing boron, the boron-containing amorphous carbon film is plasma-etched by using a mixed gas of an oxygen gas, a fluorine-containing gas, a halogen gas, and a silicon tetrafluoride gas, or a mixed gas of an oxygen gas, a fluorine-containing gas, a halogen gas, and a silicon tetrachloride gas.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com