Patents

Literature

18421 results about "Mixed gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

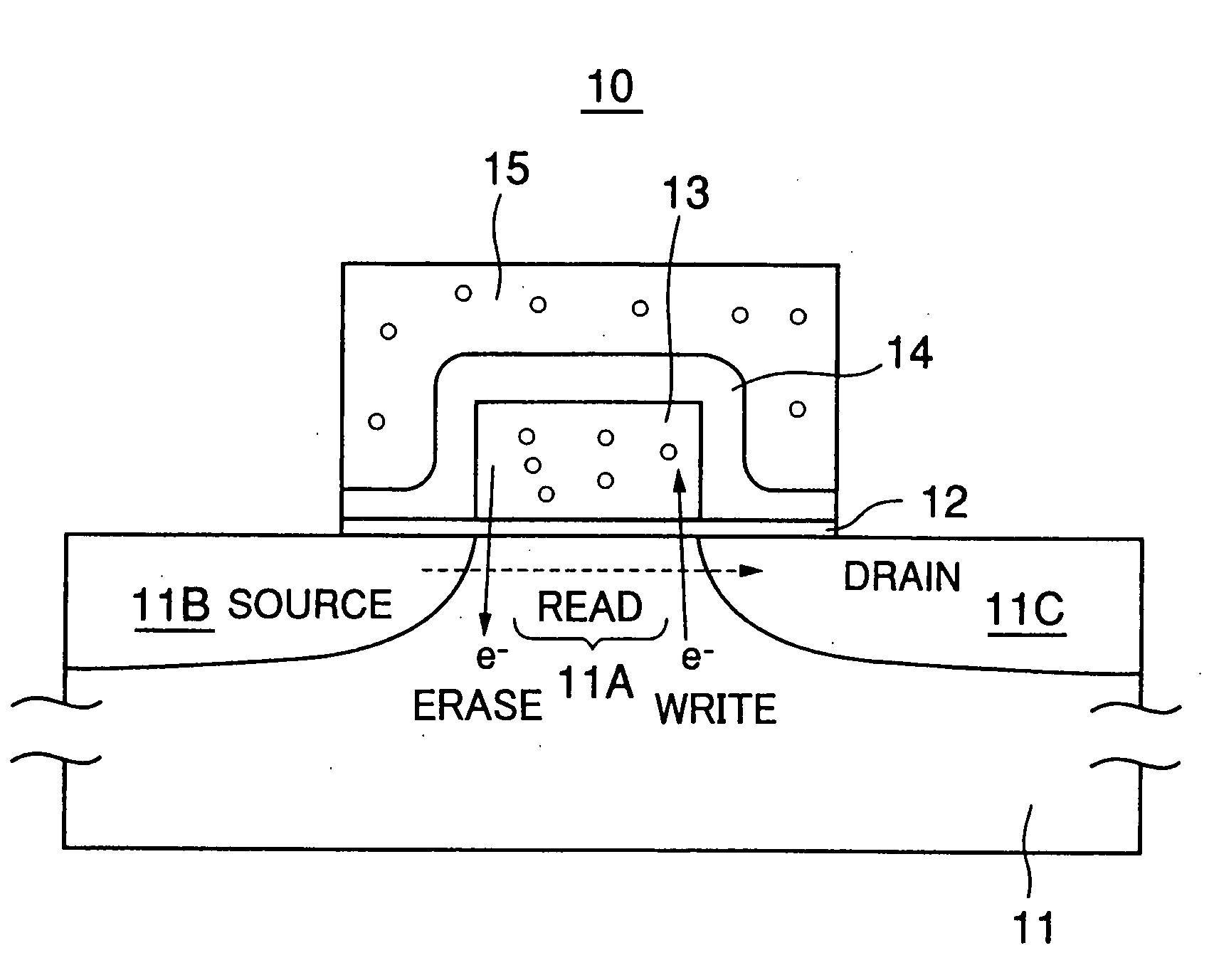

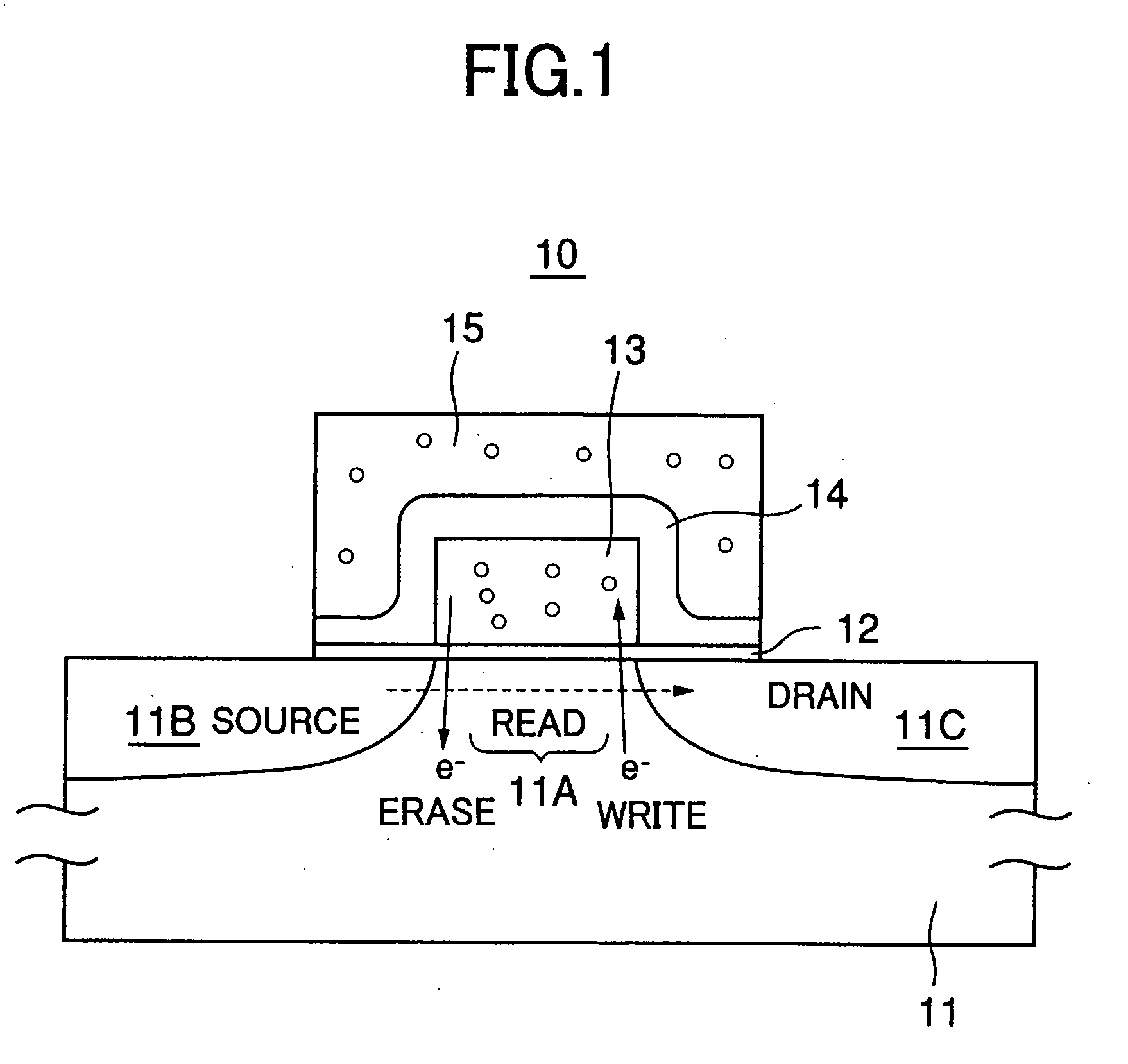

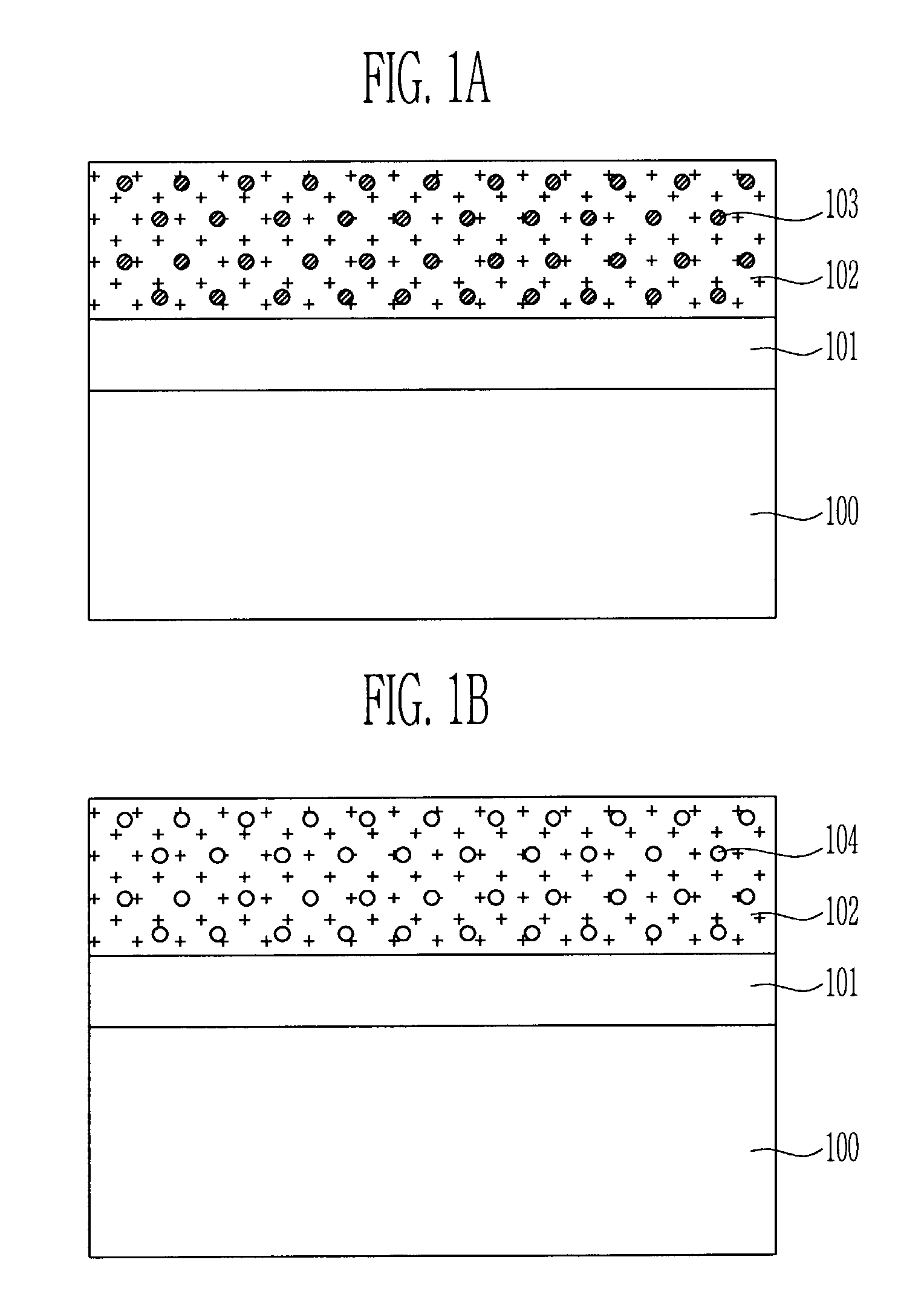

Dielectric film and formation method thereof, semiconductor device, non-volatile semiconductor memory device, and fabrication method for a semiconductor device

InactiveUS20080277715A1Improve wiring speedLow working voltageTransistorSemiconductor/solid-state device detailsDielectricHydrogen

Owner:FOUND FOR ADVANCEMENT OF INT SCI

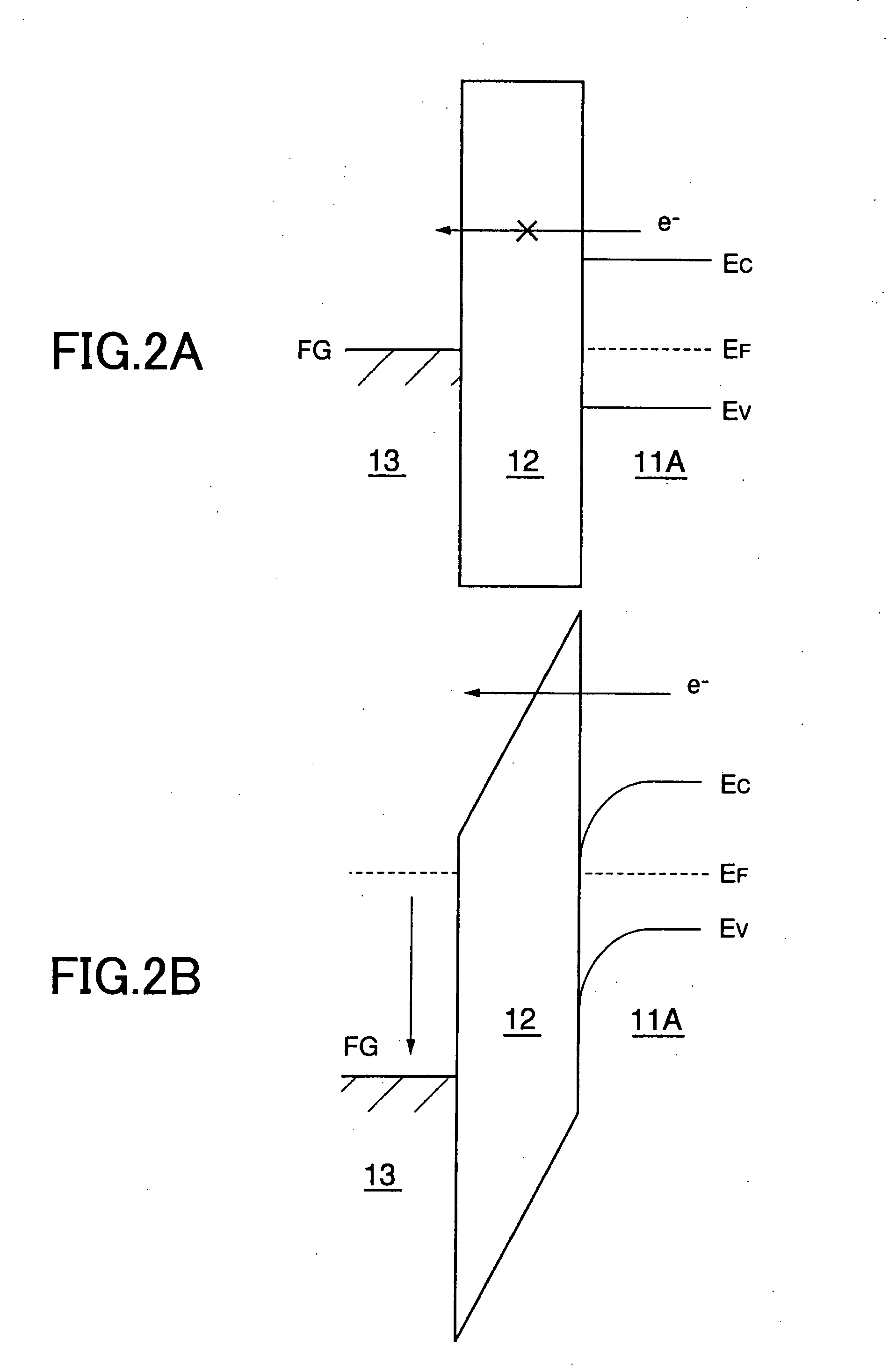

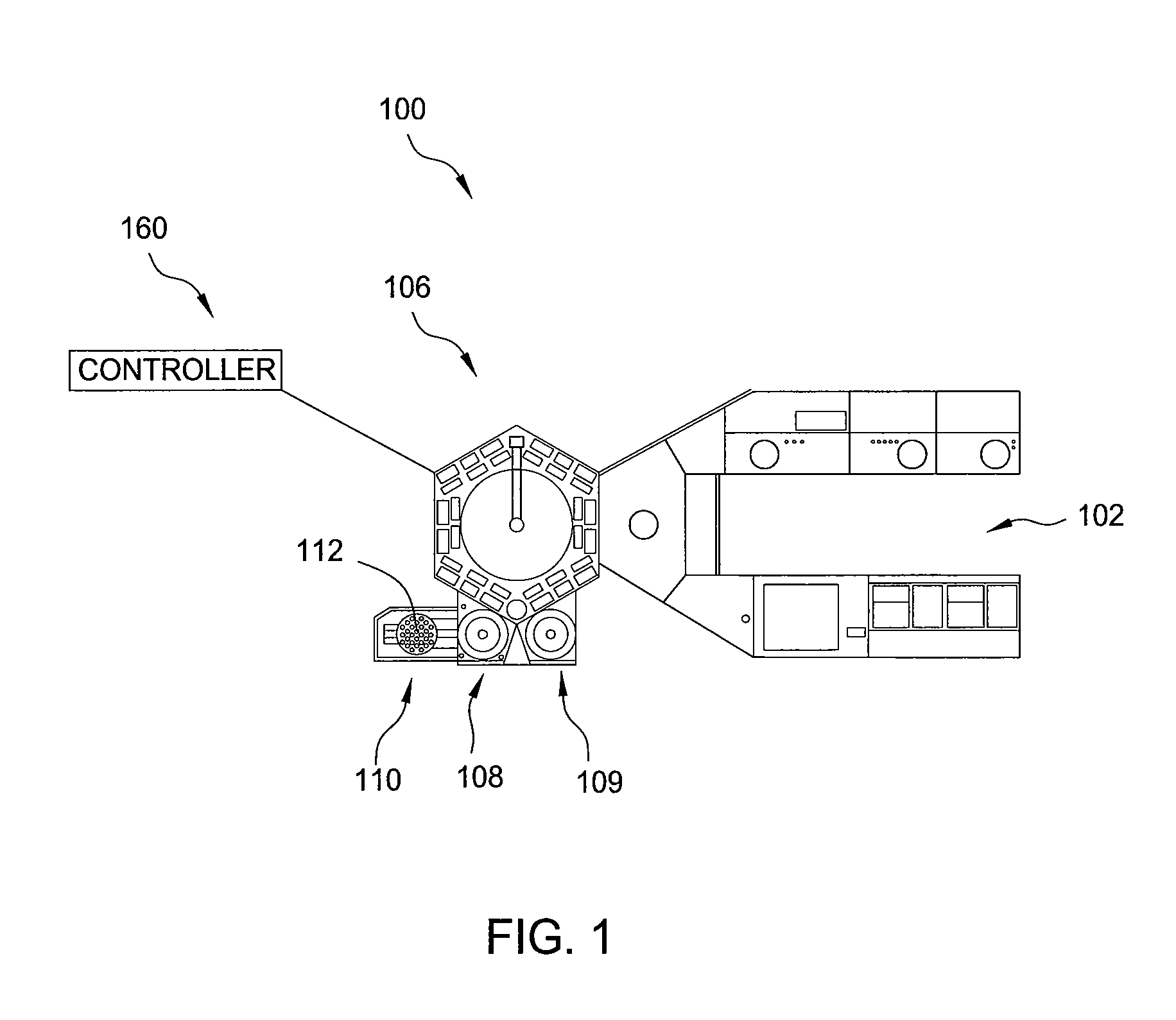

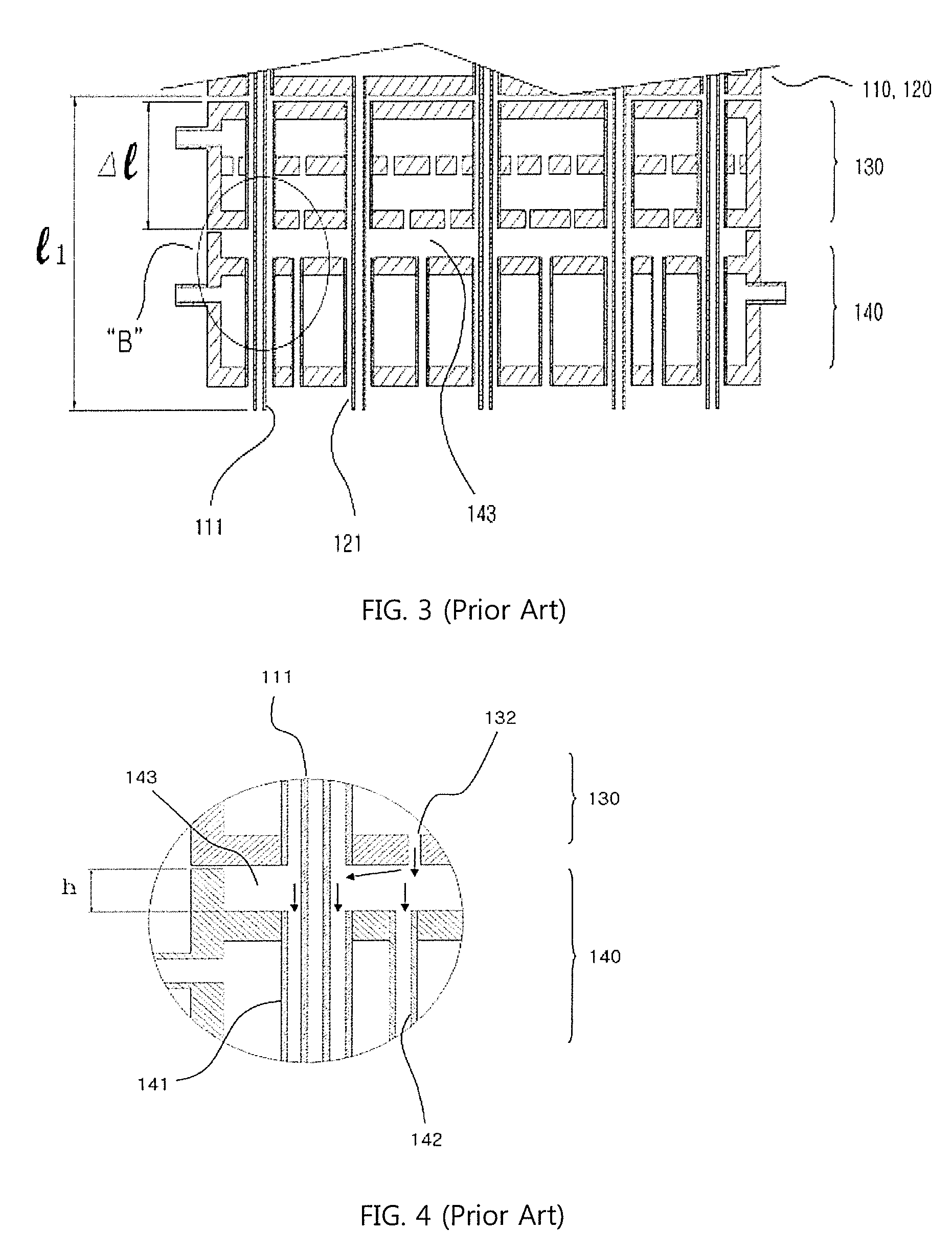

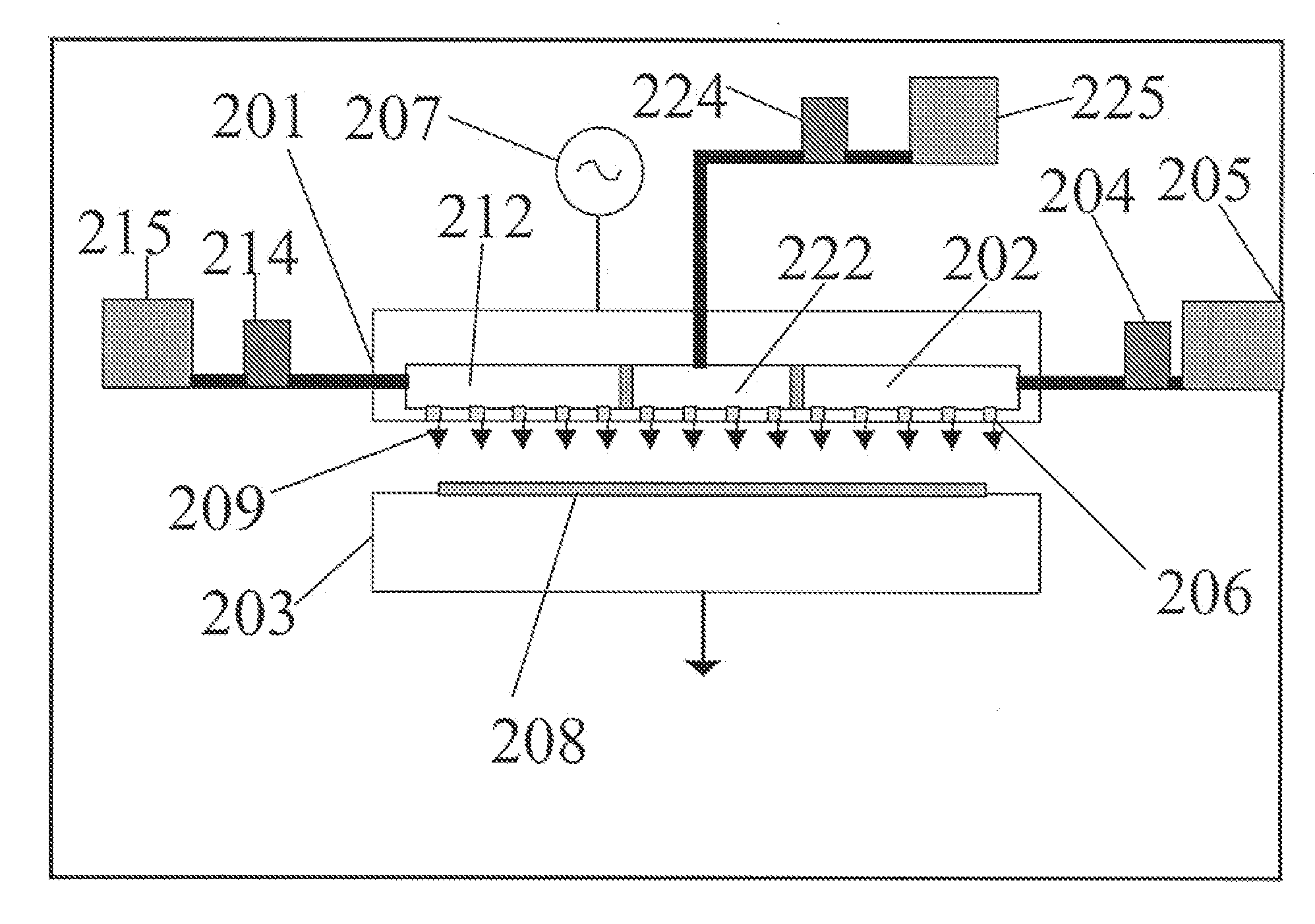

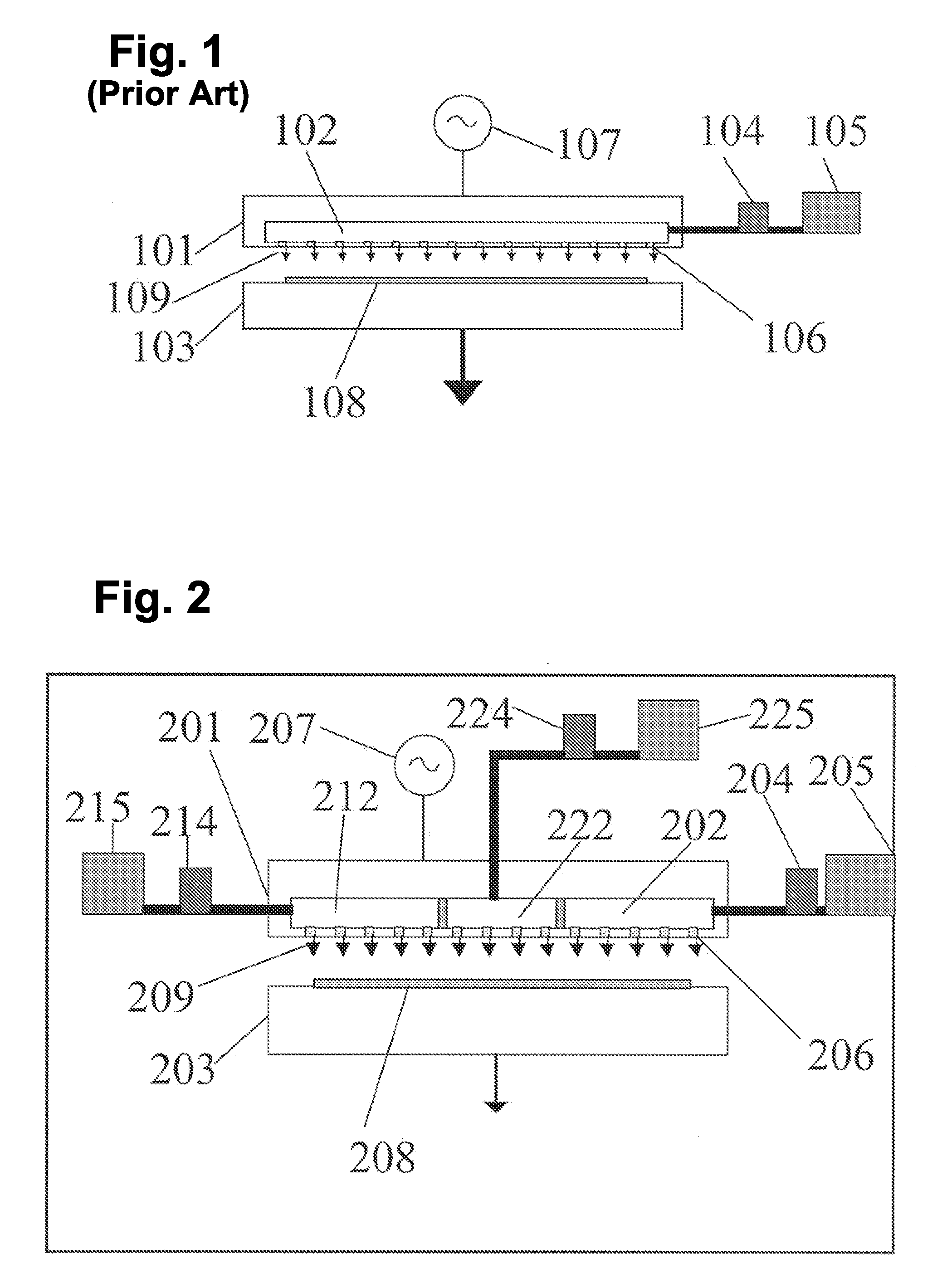

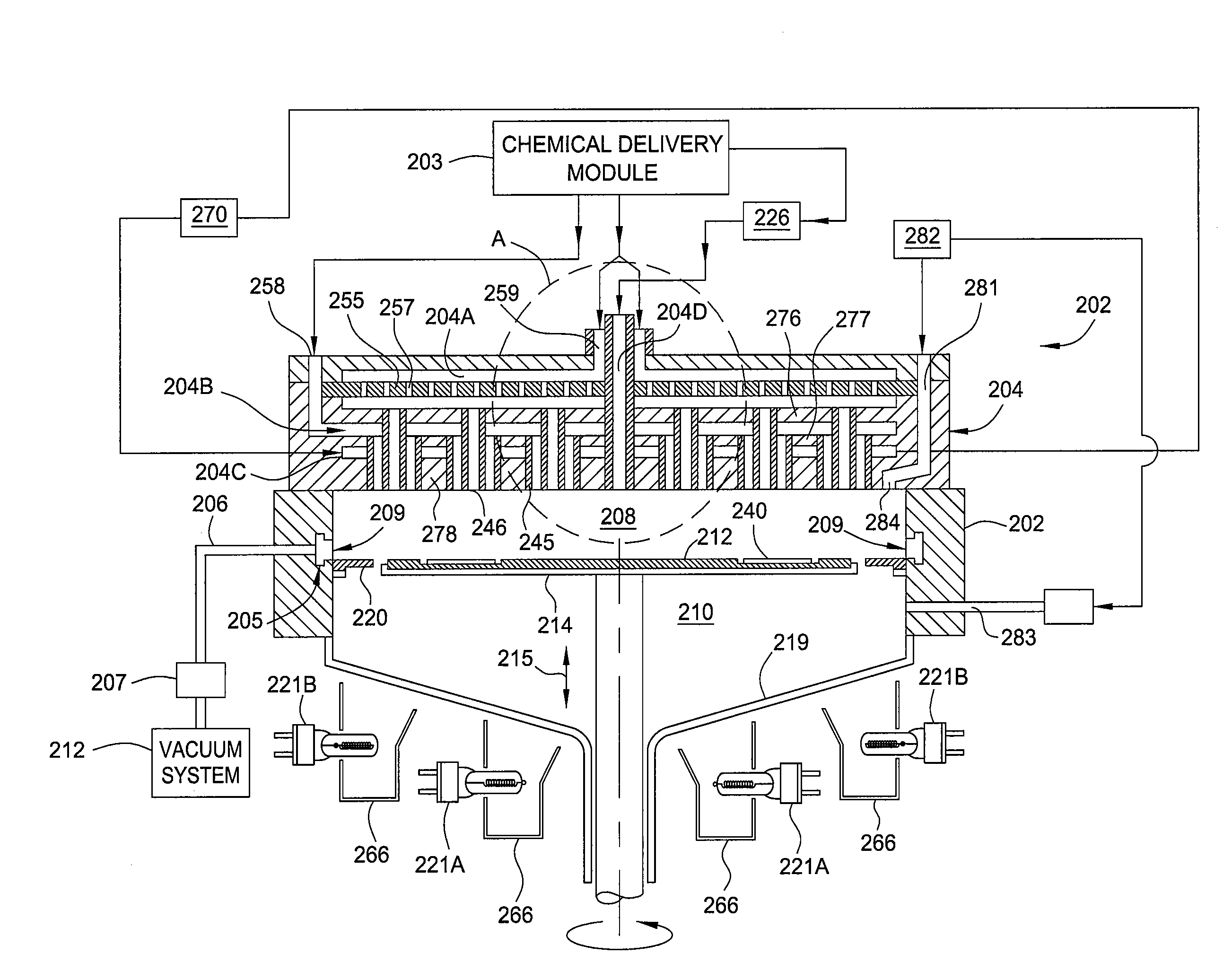

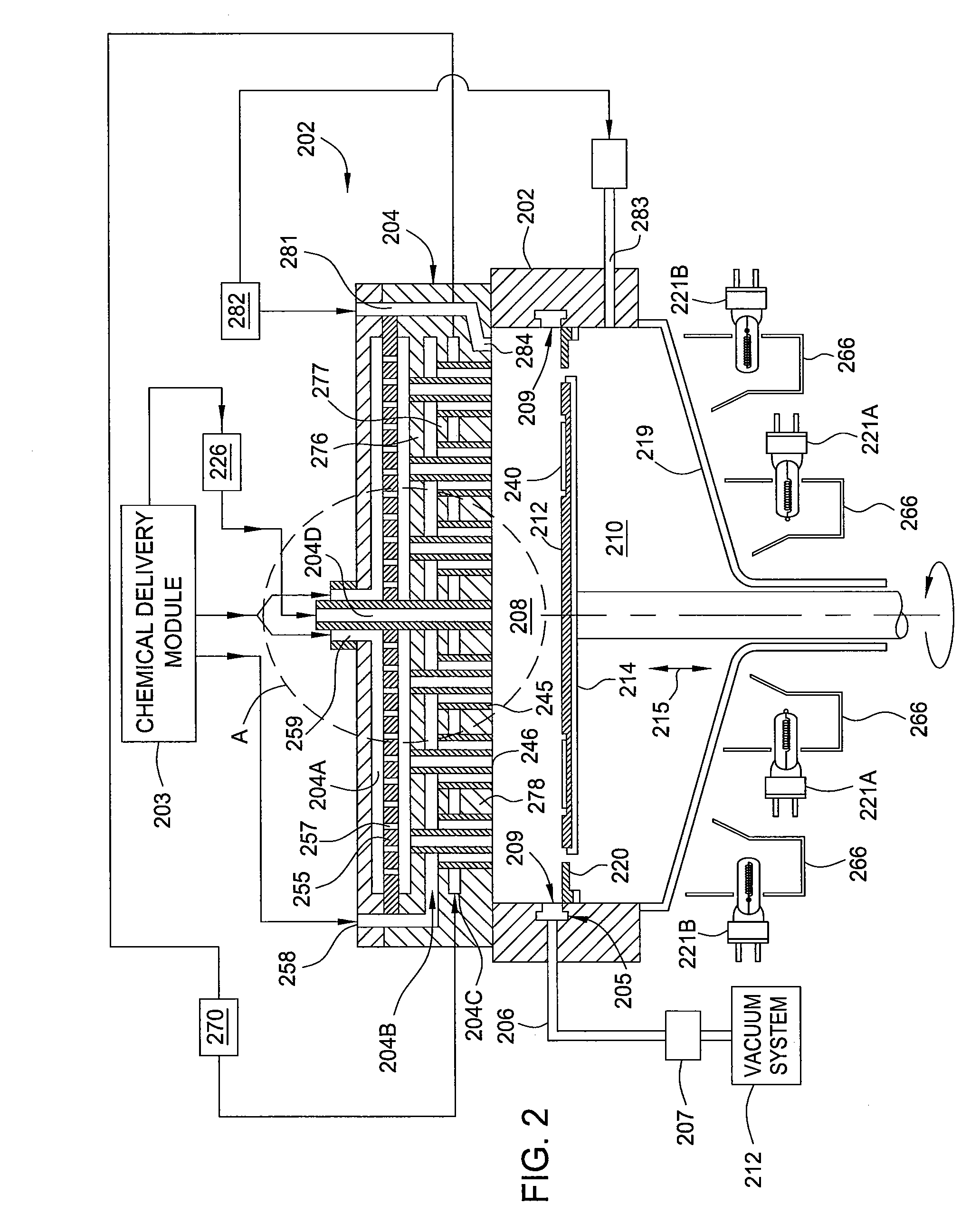

Showerhead assembly with metrology port purge

InactiveUS20110253044A1Avoid depositionLiquid surface applicatorsSpray nozzlesOptical measurementsChemical vapor deposition

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus is a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, the showerhead includes metrology ports with purge gas assemblies configured and positioned to deliver a purge gas to prevent deposition thereon. In one embodiment, the metrology port is configured to receive a temperature measurement device, and the purge gas assembly is a concentric tube configuration configured to prevent deposition on components of the temperature measurement device. In one embodiment, the metrology port has a sensor window and is configured to receive an optical measurement device, and the purge gas assembly and sensor window are configured to prevent deposition on the sensor window.

Owner:APPLIED MATERIALS INC

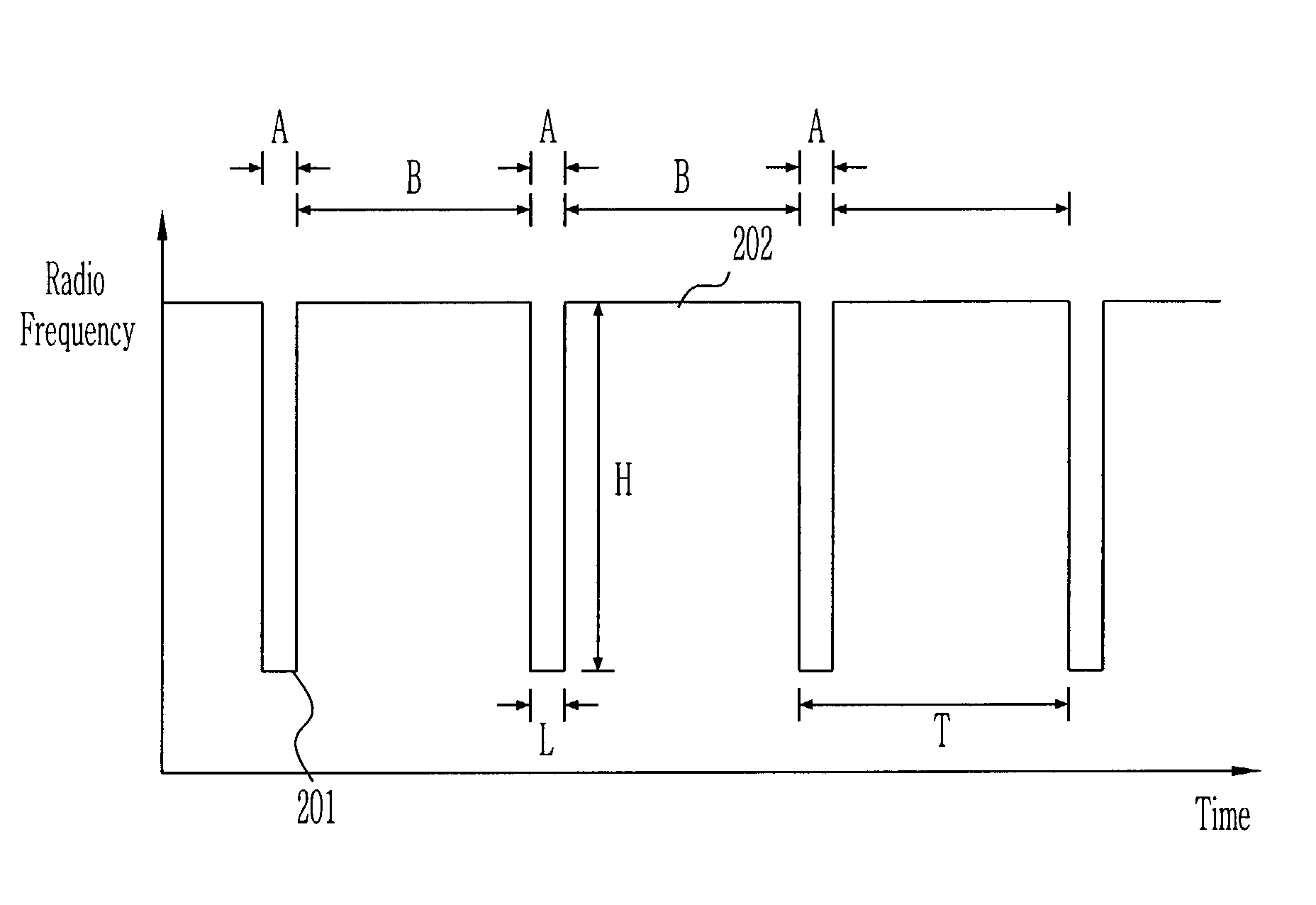

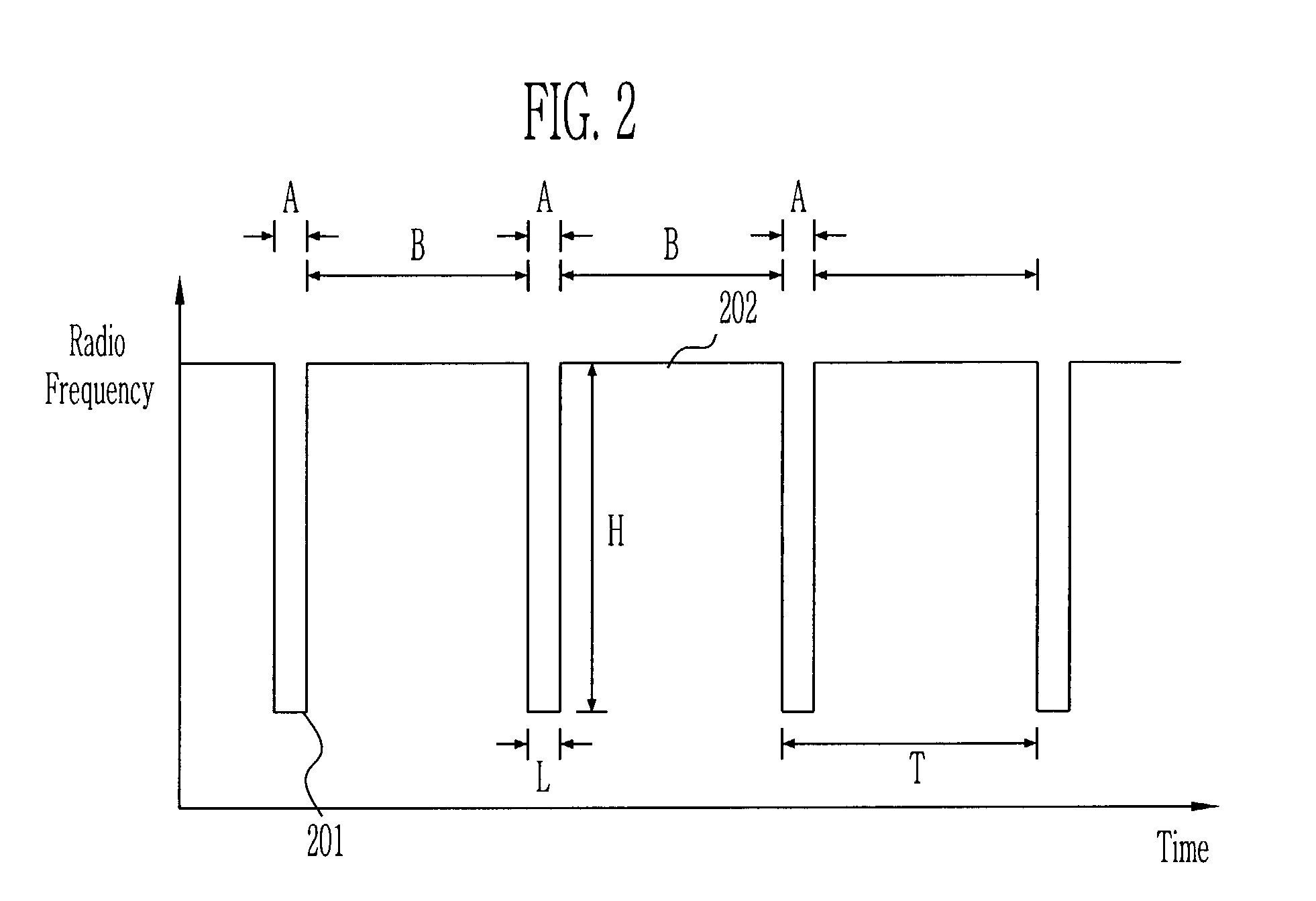

Method of forming insulating layer in semiconductor device

The present invention relates to a method of forming an insulating film in a semiconductor device. After a mixed gas of alkyl silane gas and N2O gas is supplied into the deposition equipment, a radio frequency power including a short pulse wave for causing incomplete reaction upon a gas phase reaction is applied to generate nano particle. The nano particle is then reacted to oxygen radical to form the insulating film including a plurality of nano voids. A low-dielectric insulating film that can be applied to the nano technology even in the existing LECVD equipment is formed.

Owner:SK HYNIX INC

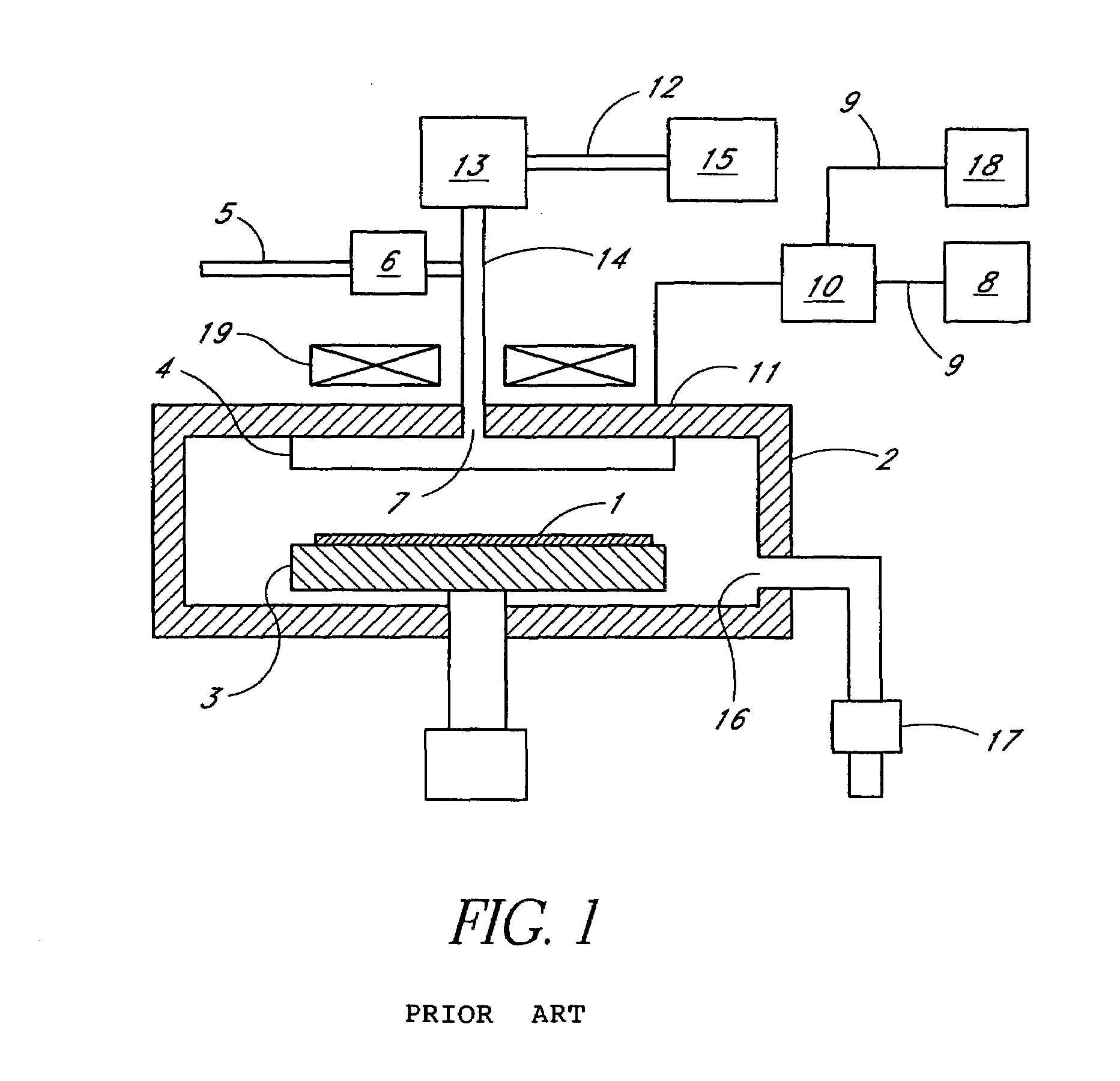

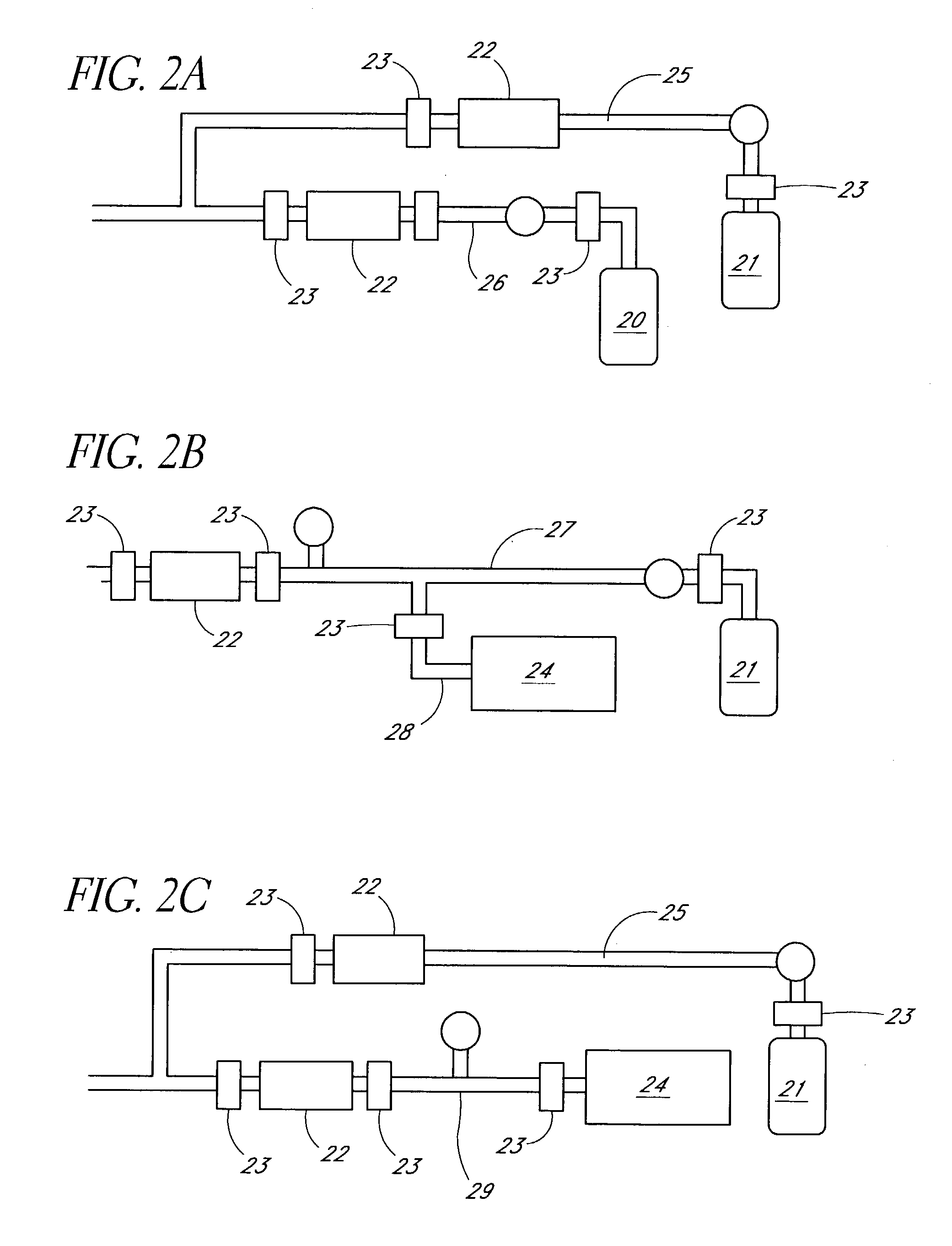

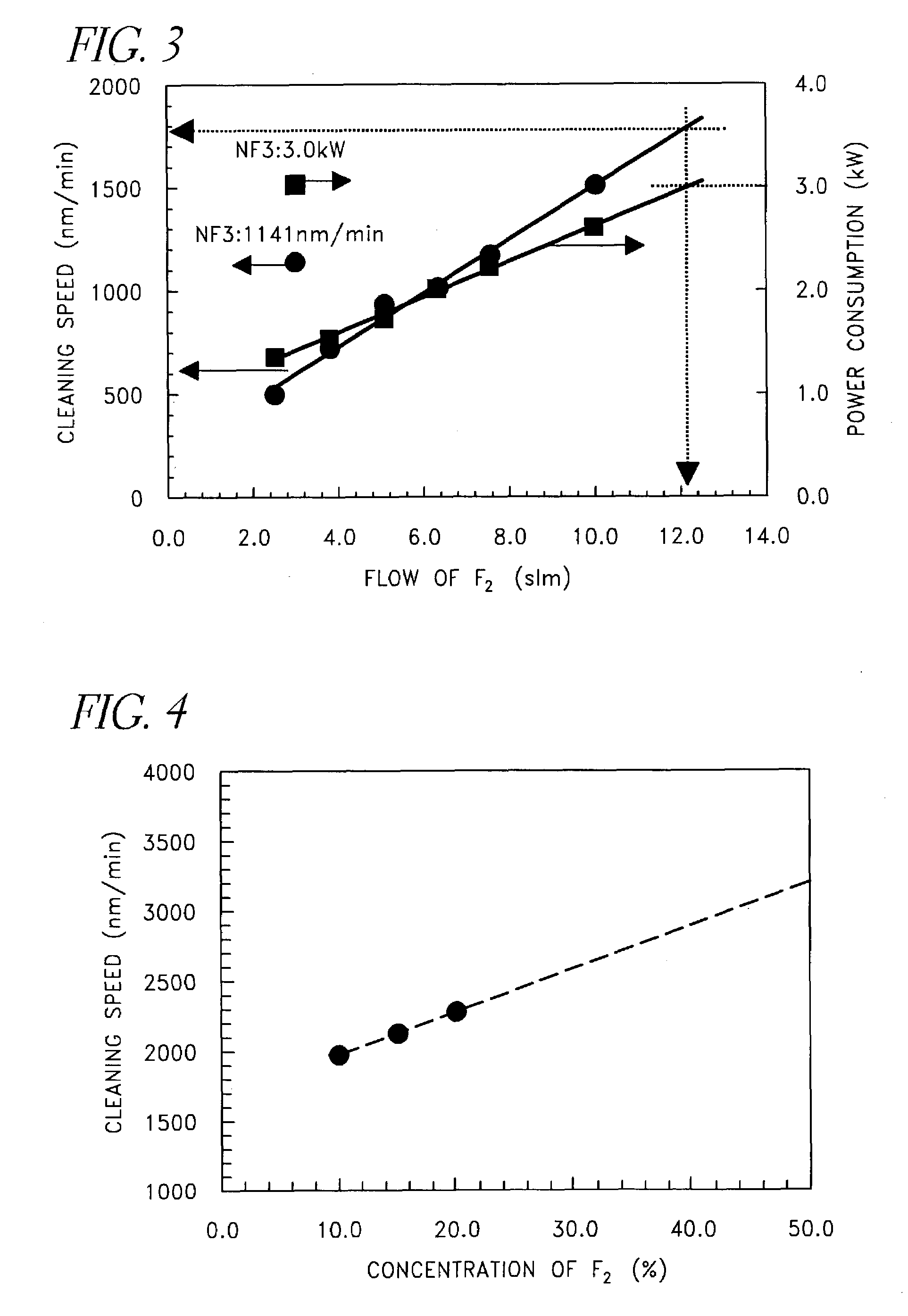

Method of cleaning CVD equipment processing chamber

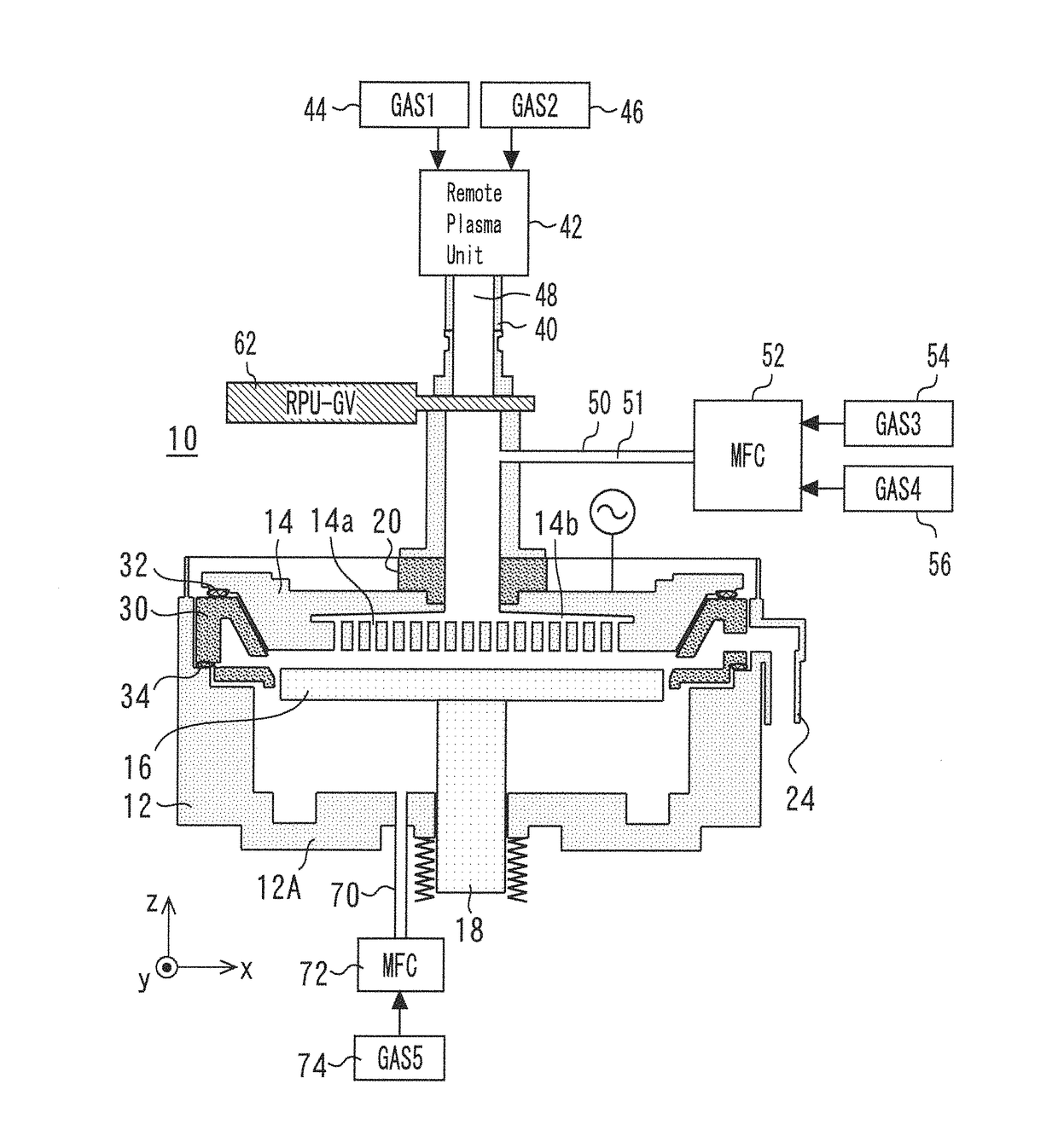

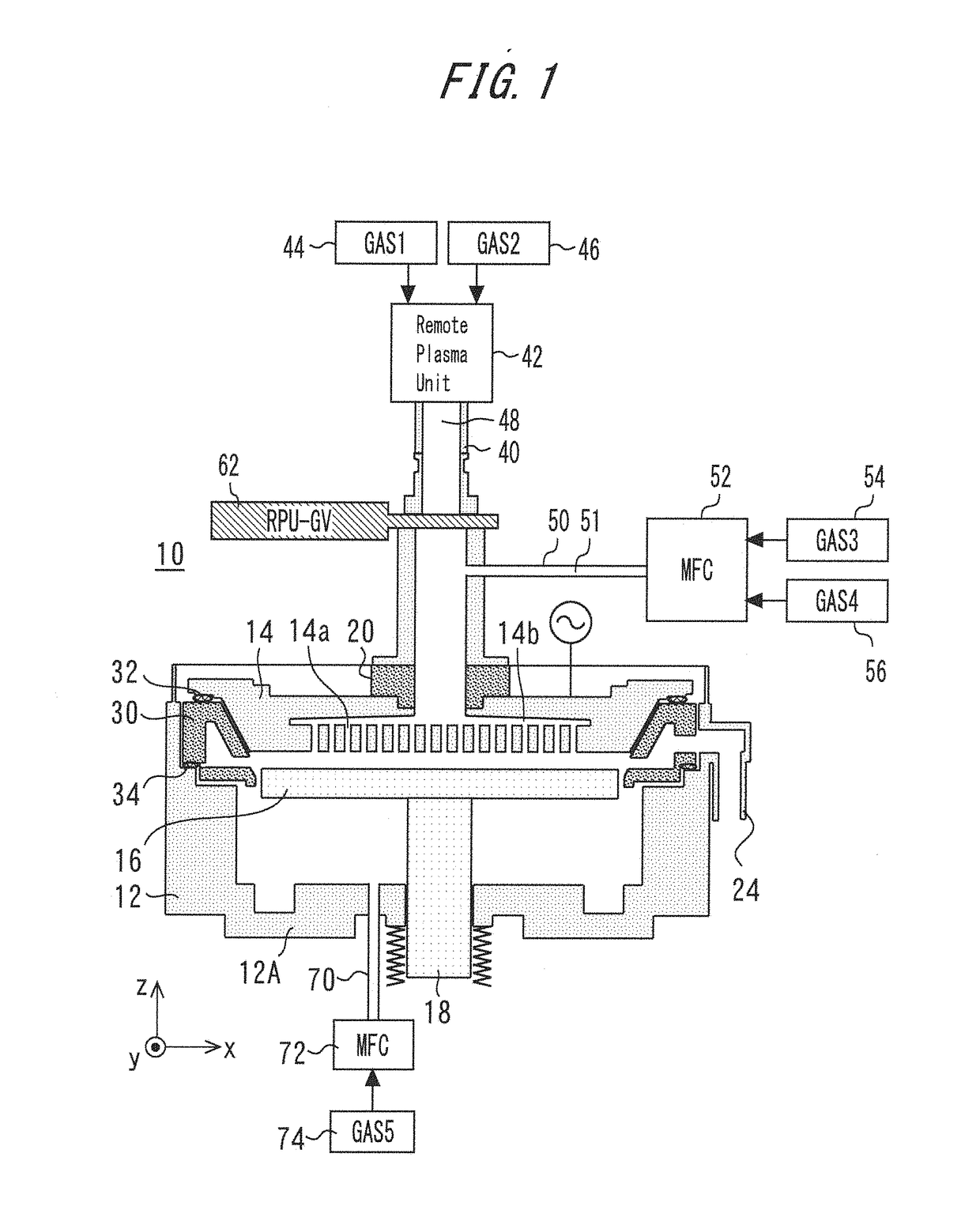

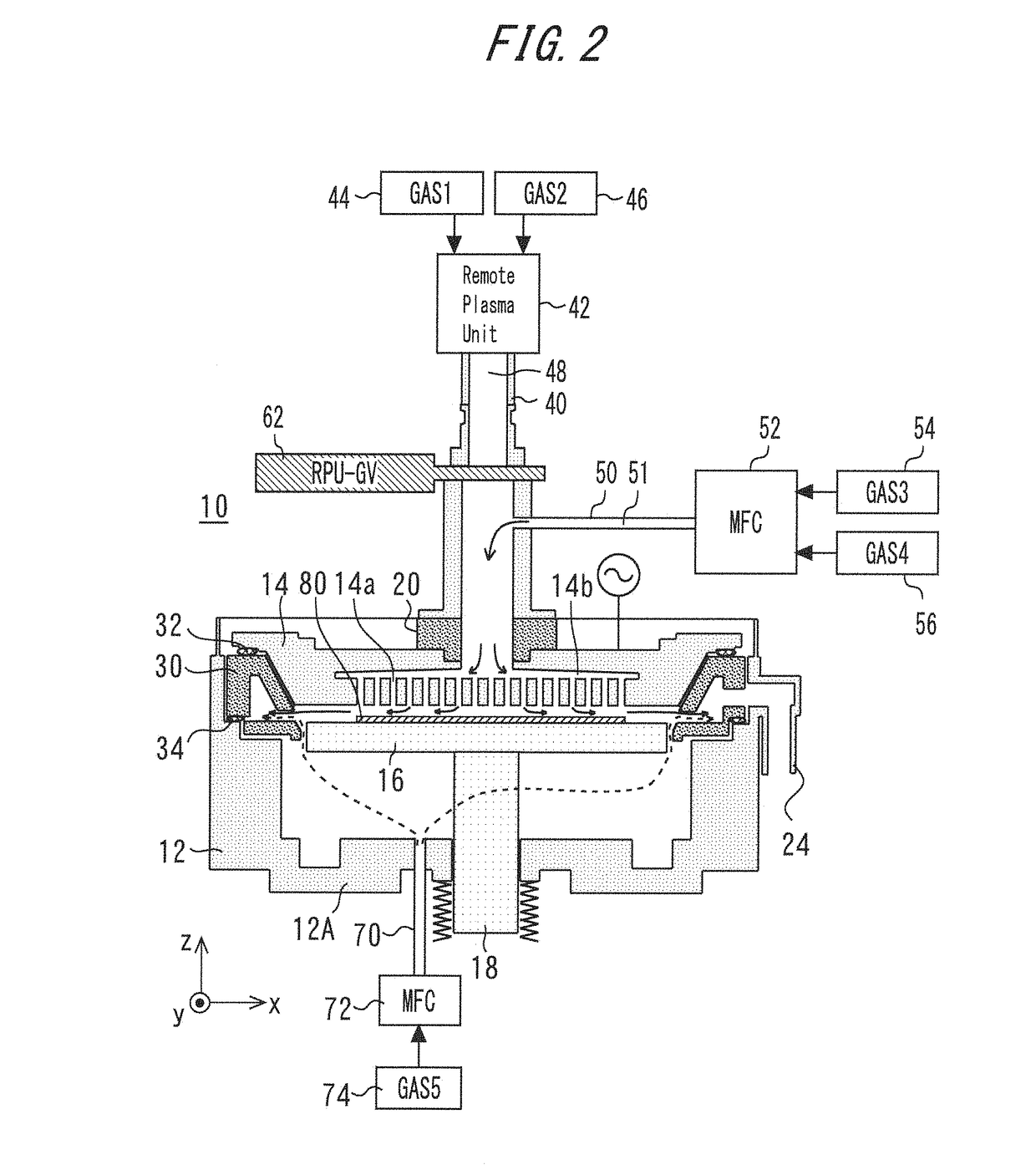

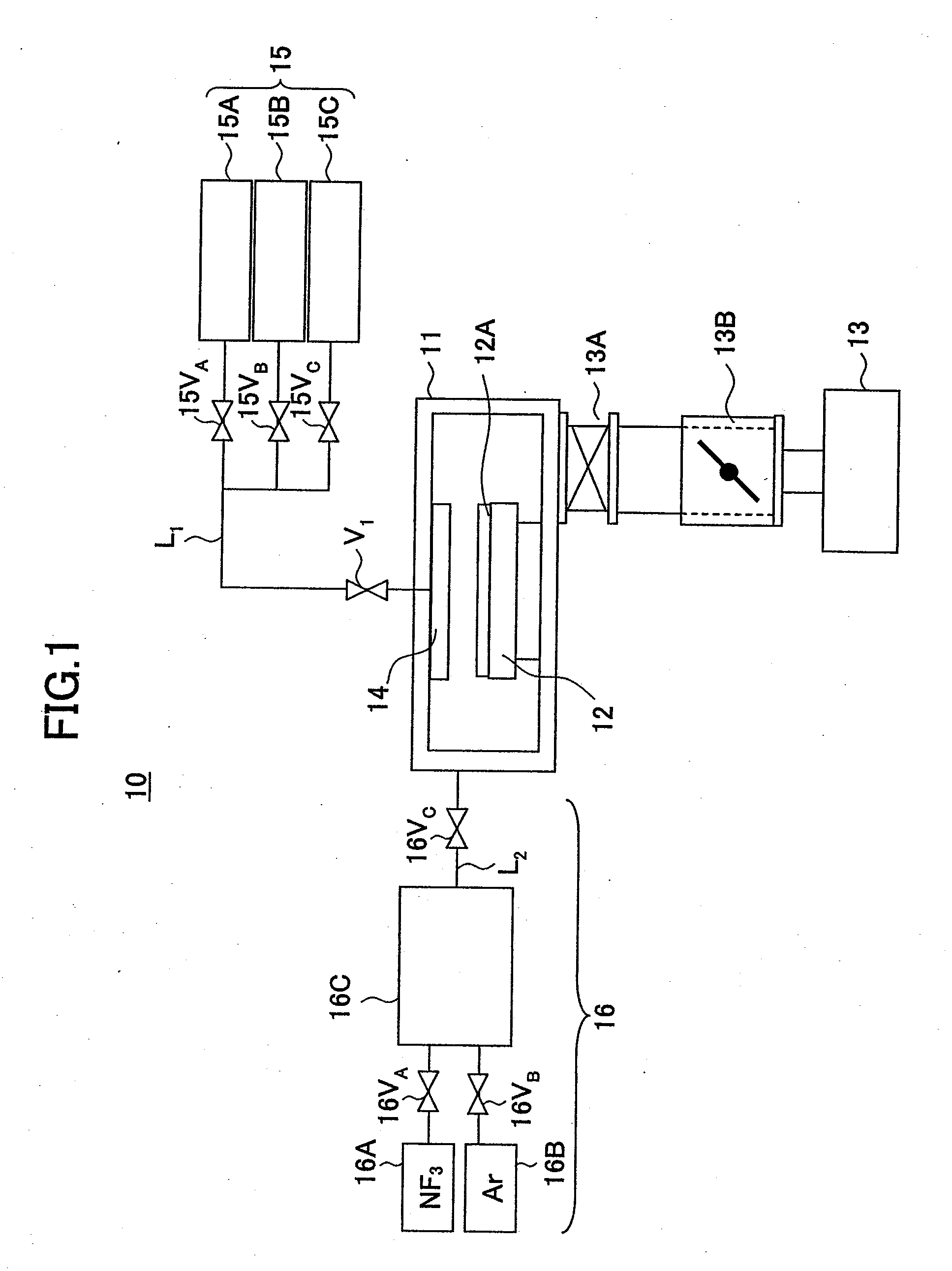

ActiveUS7234476B2Reduce operating costsImprove efficiencyElectric discharge tubesHollow article cleaningRemote plasmaOperational costs

A method of remote plasma cleaning a processing chamber of CVD equipment, which has high cleaning rates, low cleaning operational cost and high efficiency, is provided. The method comprises supplying cleaning gas to the remote plasma-discharge device; activating the cleaning gas inside the remote plasma-discharge device; and bringing the activated cleaning gas into the processing chamber and which is characterized in that a mixed gas of F2 gas and an inert gas are used as the cleaning gas. A concentration of the F2 gas is 10% or higher. The F2 gas, which is a cleaning gas, is supplied to the remote plasma-discharge device from an F2 gas cylinder by diluting F2 gas at a given concentration by an inert gas.

Owner:ASM JAPAN

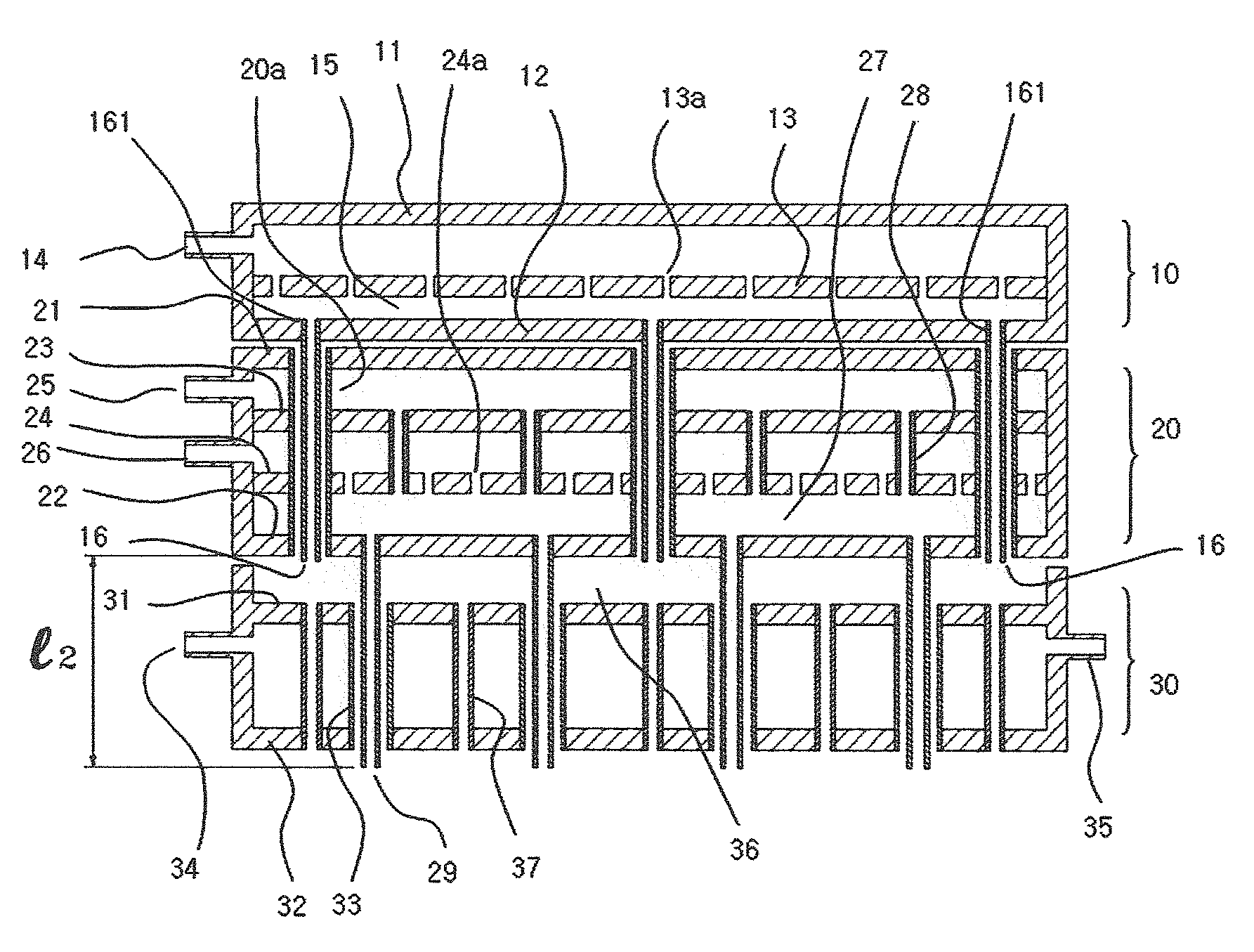

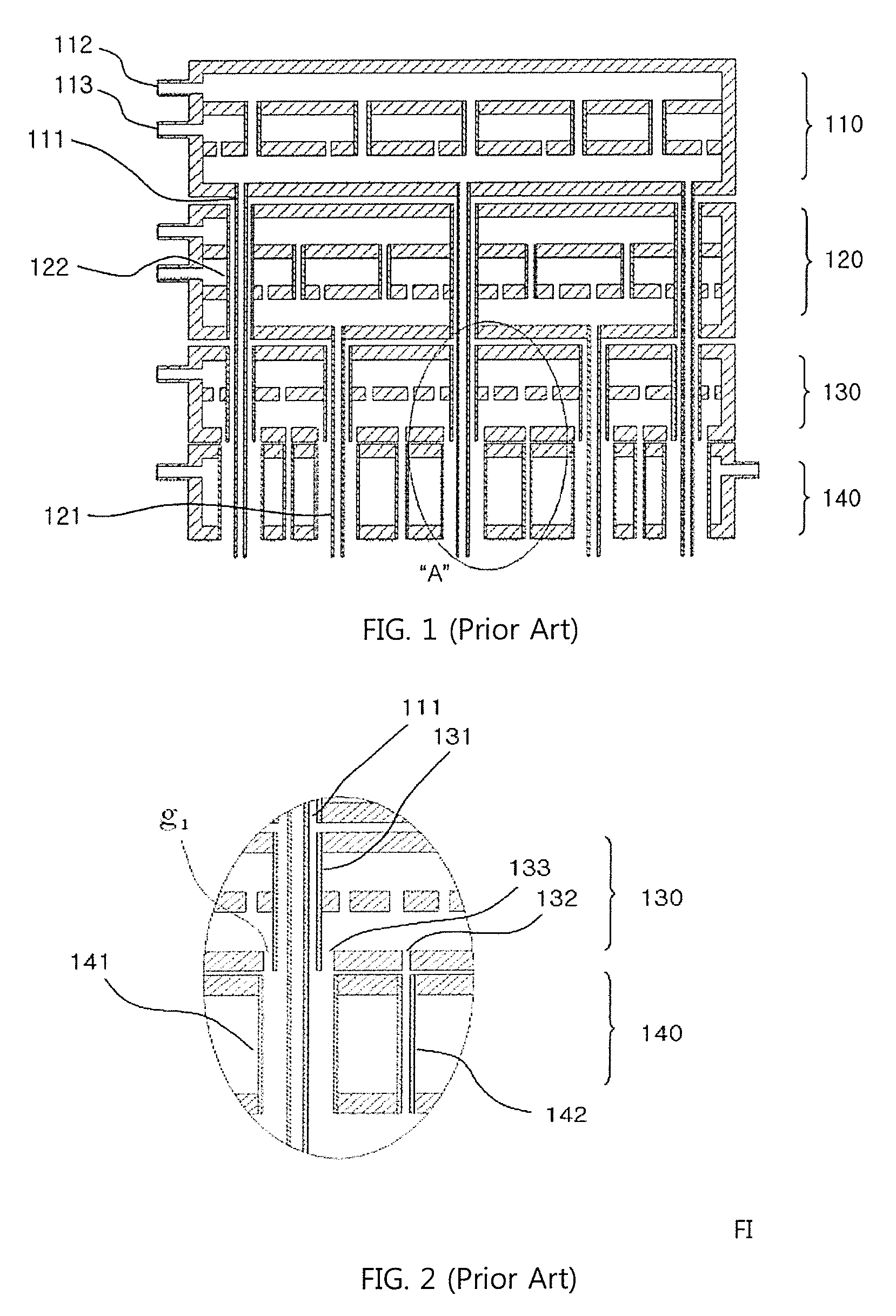

Showerhead for film depositing vacuum equipment

ActiveUS9315897B2Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasMixed gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

Etching Apparatus and Process with Thickness and Uniformity Control

InactiveUS20060191637A1Improve uniformityReduce unevennessElectric discharge tubesDecorative surface effectsEngineeringFilm material

Apparatus and process for etching semiconductor wafers and the like in which a substrate is supported by a pedestal within a chamber, and at least one gas capable of etching the substrate or a film material on the substrate is introduced into the chamber through a segmented gas injection element which is separated from the substrate by a distance approximately less than its size from which the distribution of the flow or mixture of gas can be altered spatially proximate to the substrate in a controlled and variable way, for each wafer or substrate if desired, by having a varying amount or mixture of gas flow to some or all of the segments such as to cause the etching rate distribution to vary across the substrate.

Owner:ZAJAC JOHN +1

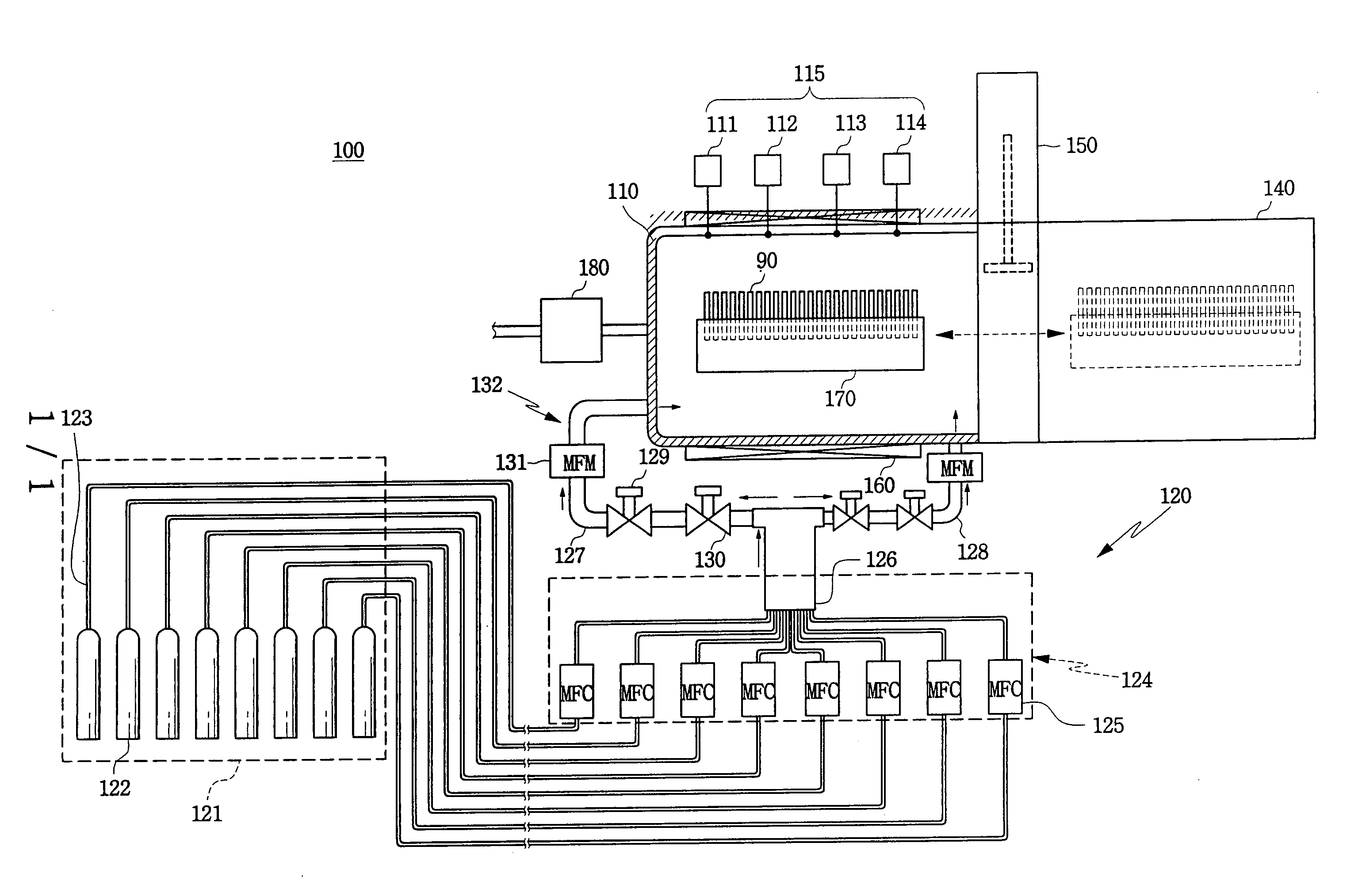

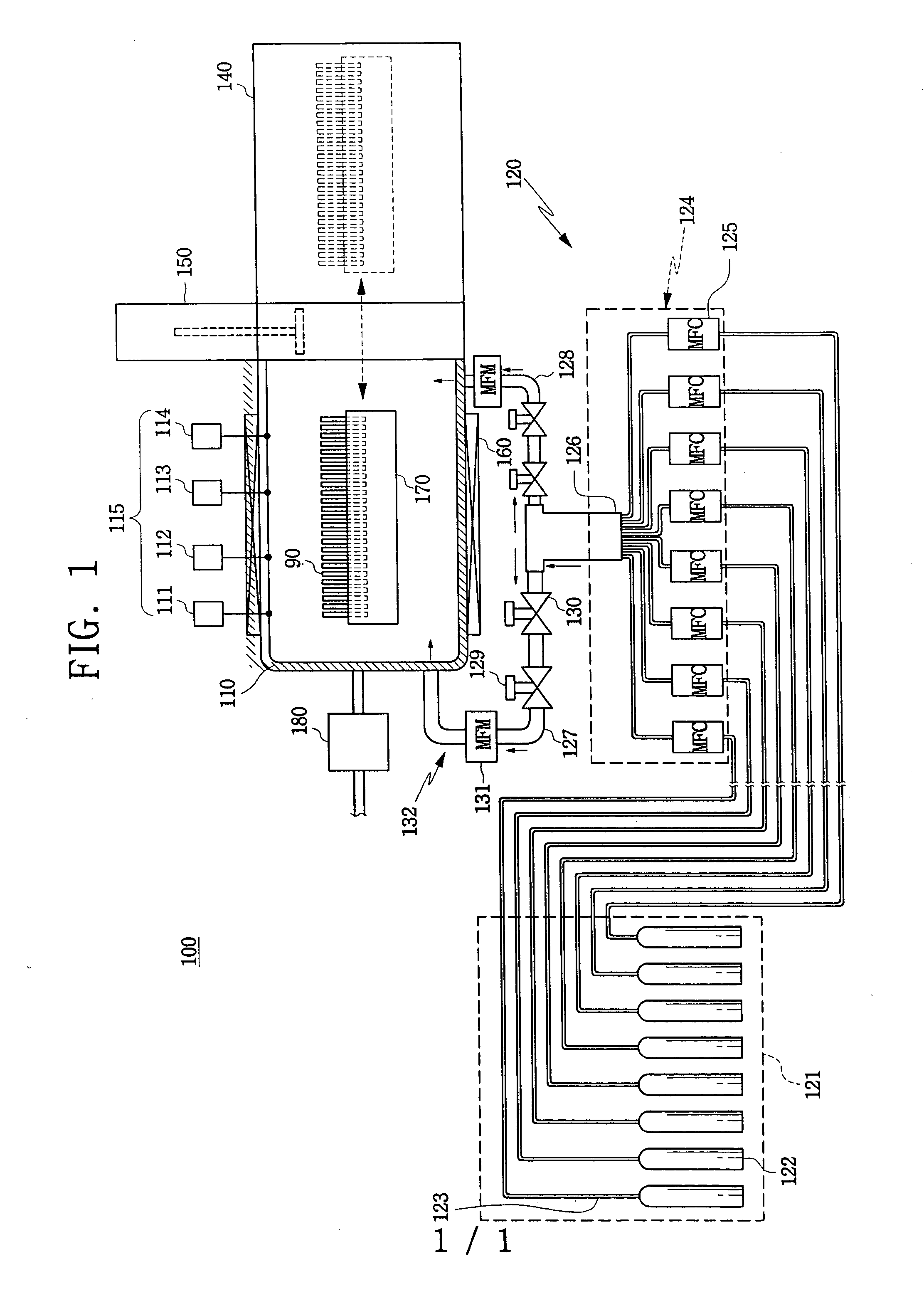

Film formation method and apparatus for semiconductor process

InactiveUS20060207504A1Improving inter-substrate uniformity in compositionUniform supplySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringEngineering

A film formation apparatus for a semiconductor process includes a process gas supply system configured to supply process gases. The process gas supply system includes a gas mixture tank configured to mix first and third process gases to form a mixture gas, a mixture gas supply line configured to supply the mixture gas from the gas mixture tank to a process field, a second process gas supply circuit having a second process gas supply line configured to supply a second process gas to the process field without passing through the gas mixture tank, and first and second switching valves disposed on the mixture gas supply line and the second process gas supply line, respectively. A control section controls the first and second switching valves to be opened and closed so as to alternately and pulse-wise supply the mixture gas and the second process gas to the process field.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus and method of processing substrate

PendingUS20180155836A1Avoid dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasProduct gas

A substrate processing apparatus includes a stage provided in a chamber, a shower head in which a plurality of slits are formed and which is opposed to the stage, a first gas supply part which supplies a first gas to a space between the stage and the shower head via the plurality of slits, and a second gas supply part which supplies a second gas which is not a noble gas to a region below the stage, wherein the second gas is the same gas as one of a plurality of kinds of gases constituting the first gas in a case where the first gas is a mixture gas constituted of the plurality of kinds of gases, and the second gas is the same gas as the first gas in a case where the first gas is a single kind of gas.

Owner:ASM IP HLDG BV

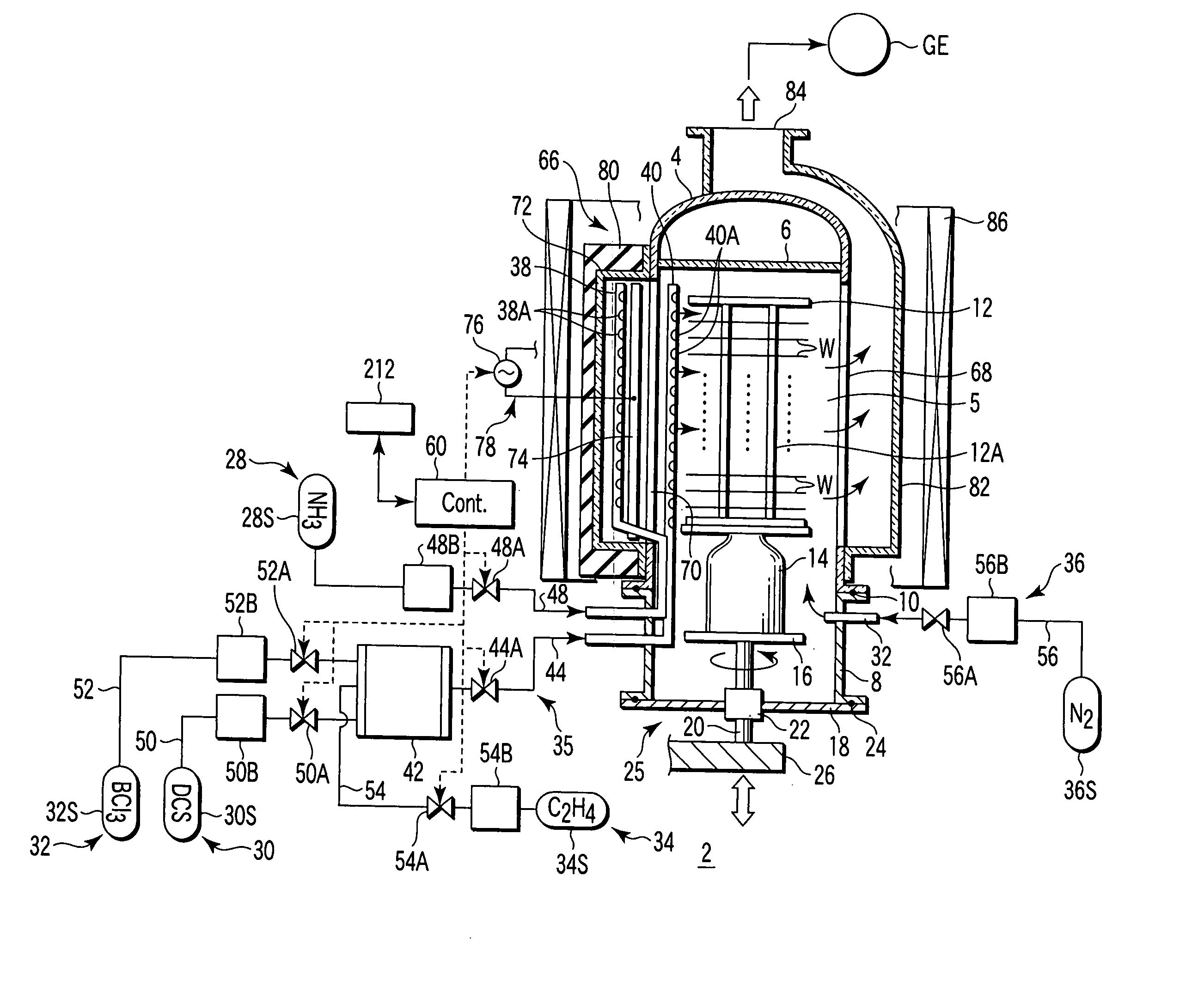

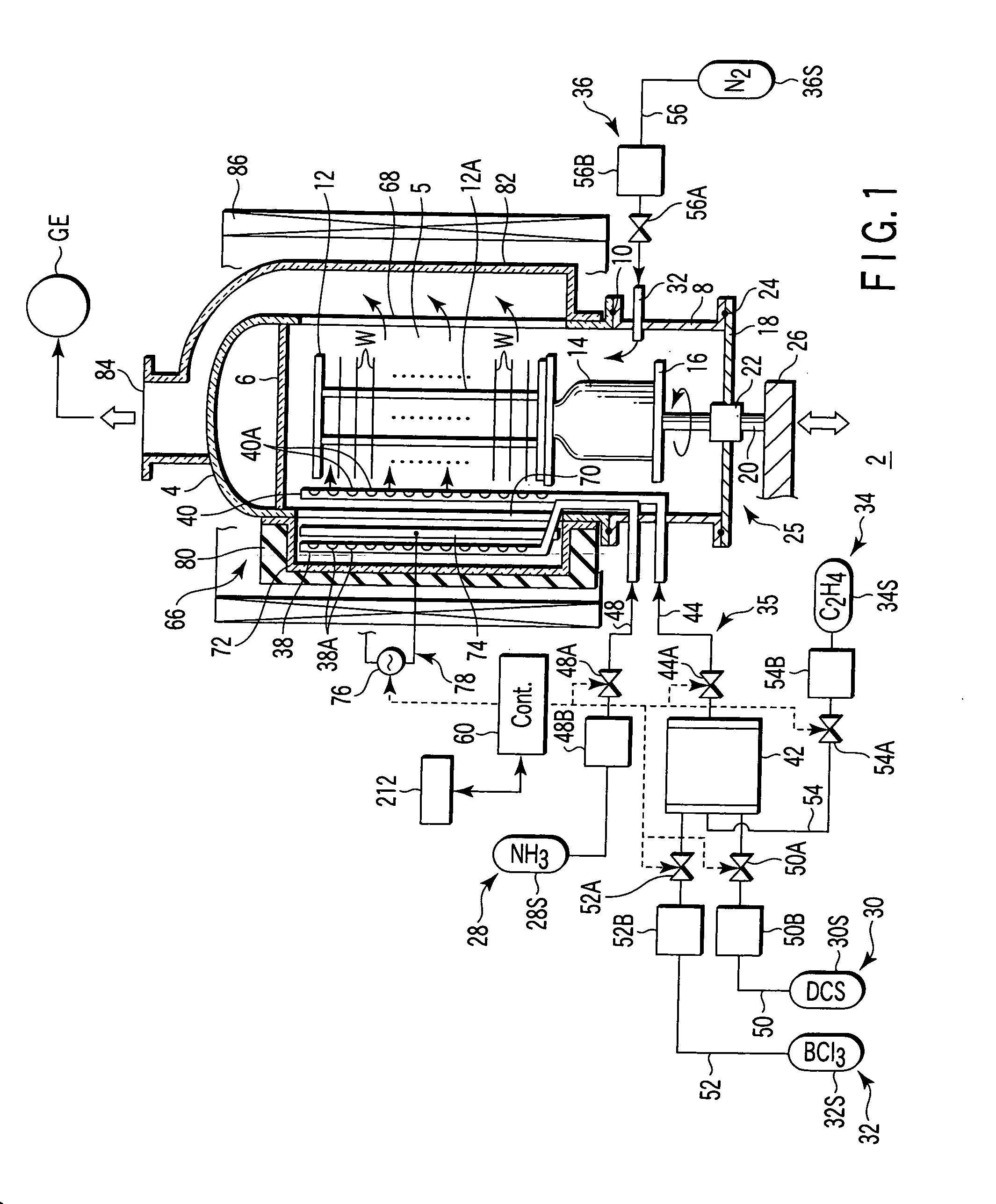

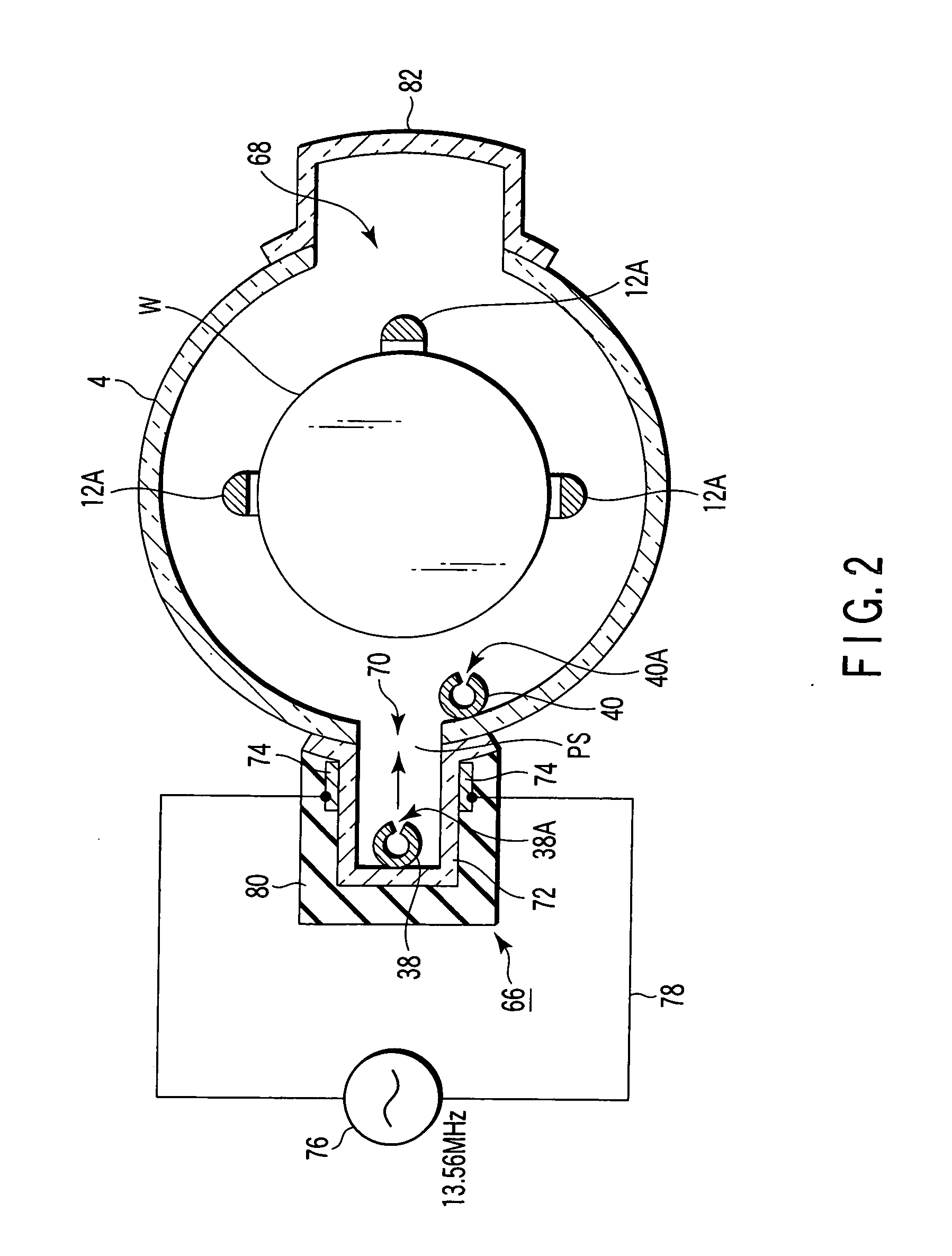

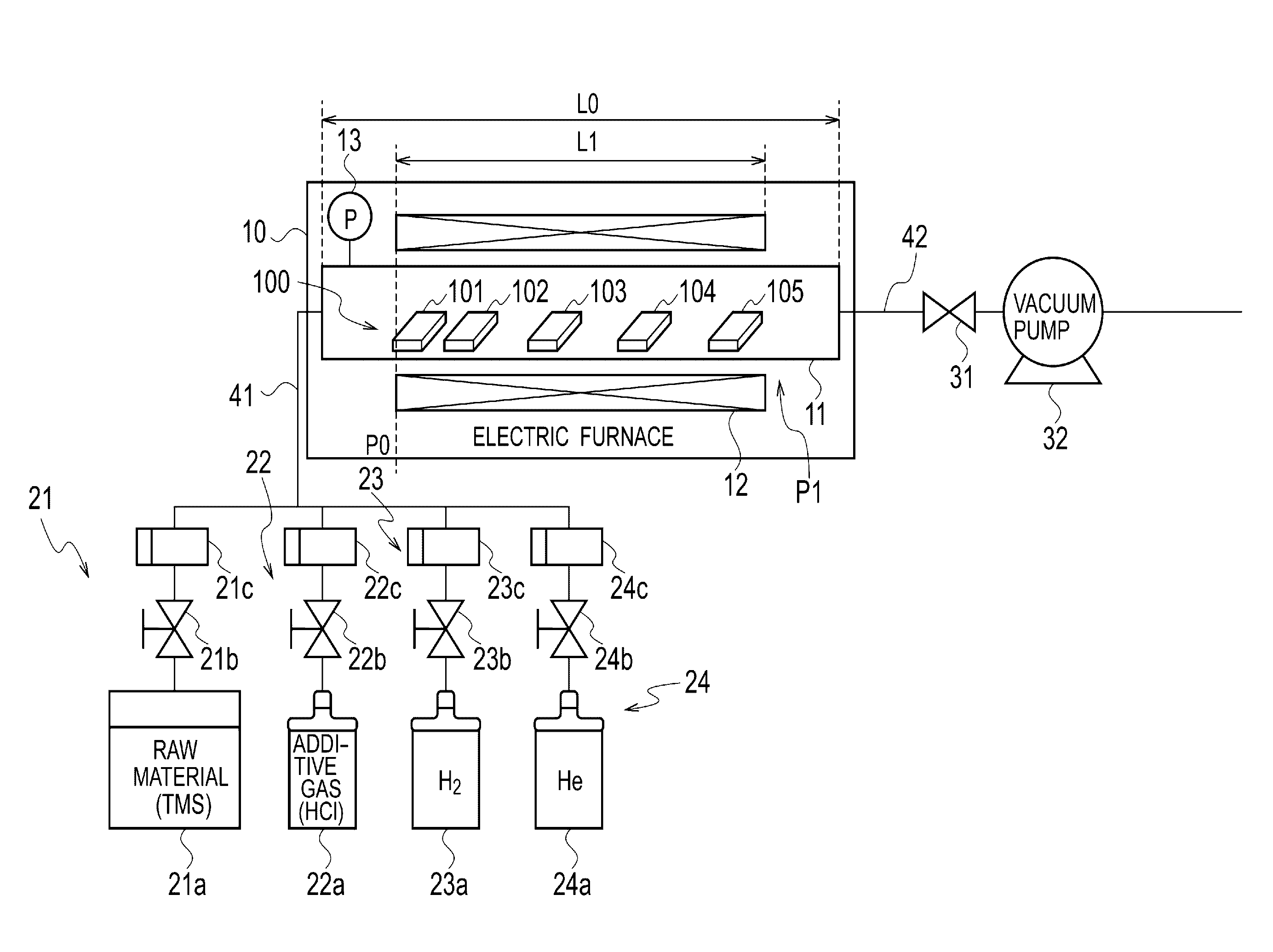

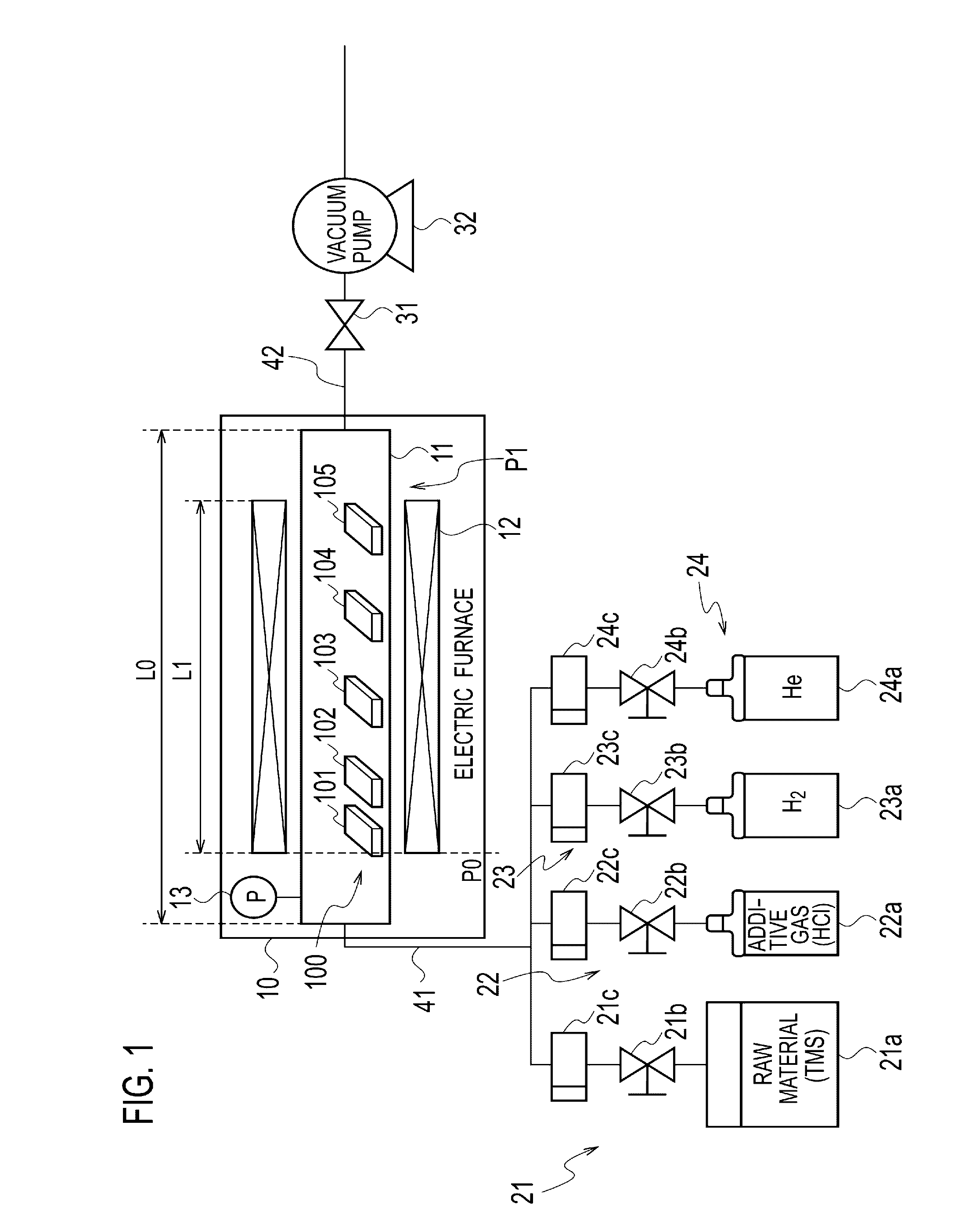

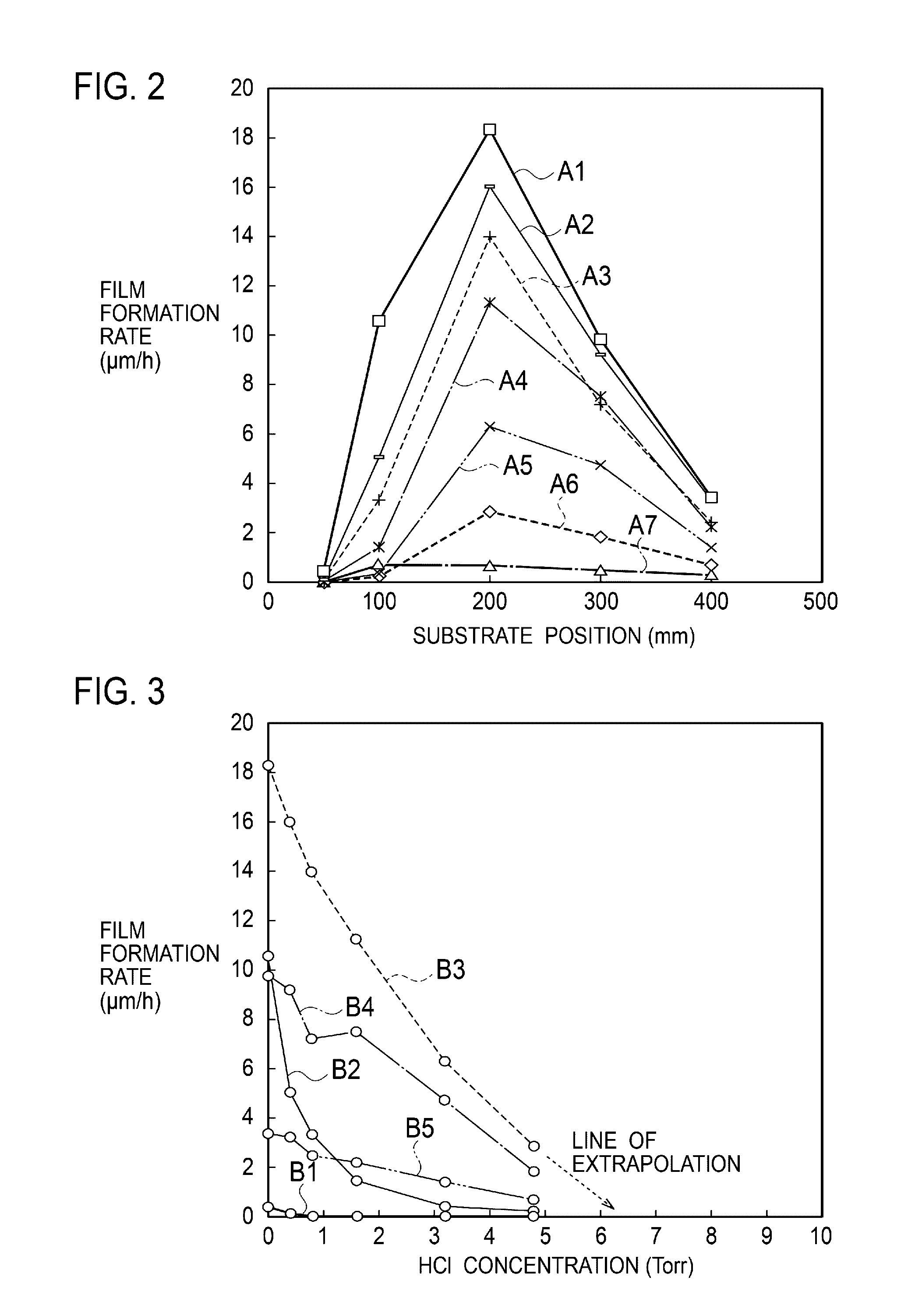

Heat-resistant composite material production method and production device

ActiveUS20160305015A1Reduce generationImprove mass productionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorideChemical vapor deposition

In the present embodiment, in the production of a heat-resistant composite material resulting from impregnating a ceramic fiber preform with silicon carbide, a mixed gas containing starting material gas, an additive gas, and a carrier gas is supplied to a substrate having a minute structure such as a preform stored in an electric furnace, silicon carbide is deposited to form a film by means of a chemical vapor deposition method or a chemical vapor infiltration method, and the film formation growth speed and embedding uniformity are controlled by means of the amount of additive gas added to the starting material gas, the starting material gas contains tetramethylsilane, and the additive gas contains a molecule containing chlorine such as methyl chloride or hydrogen chloride. The film formation growth speed and embedding uniformity of the silicon carbide are both achieved.

Owner:IHI CORP +1

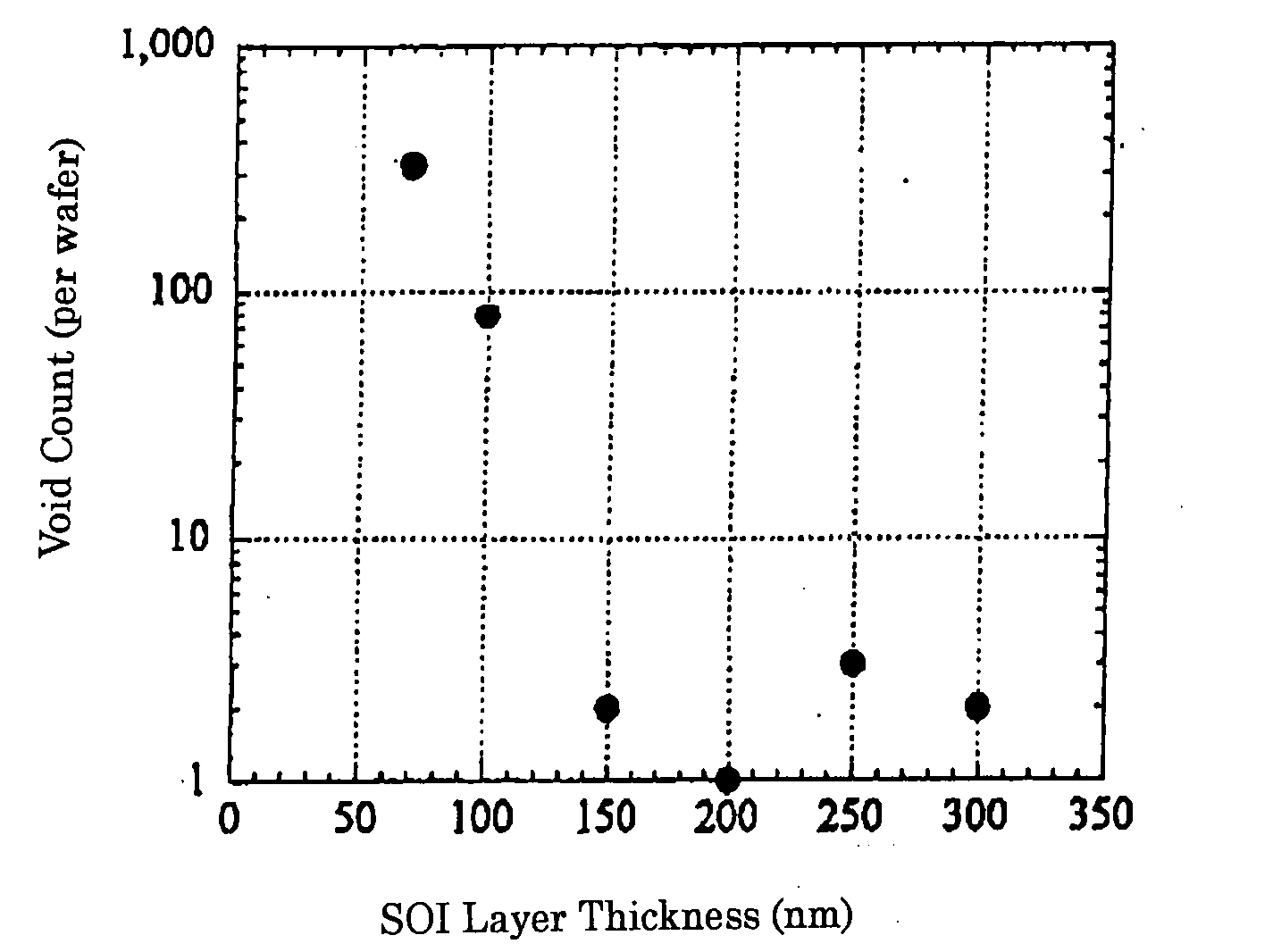

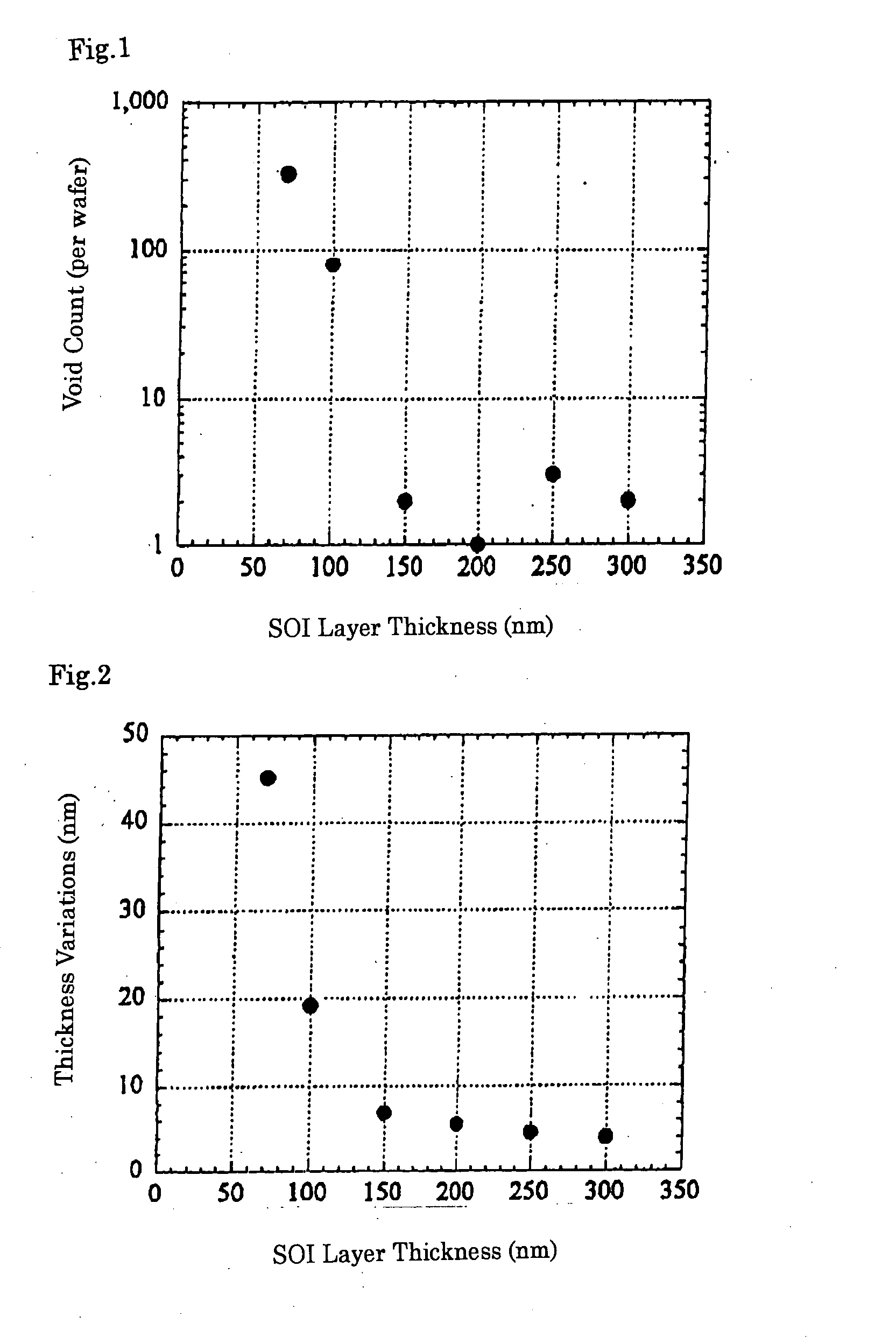

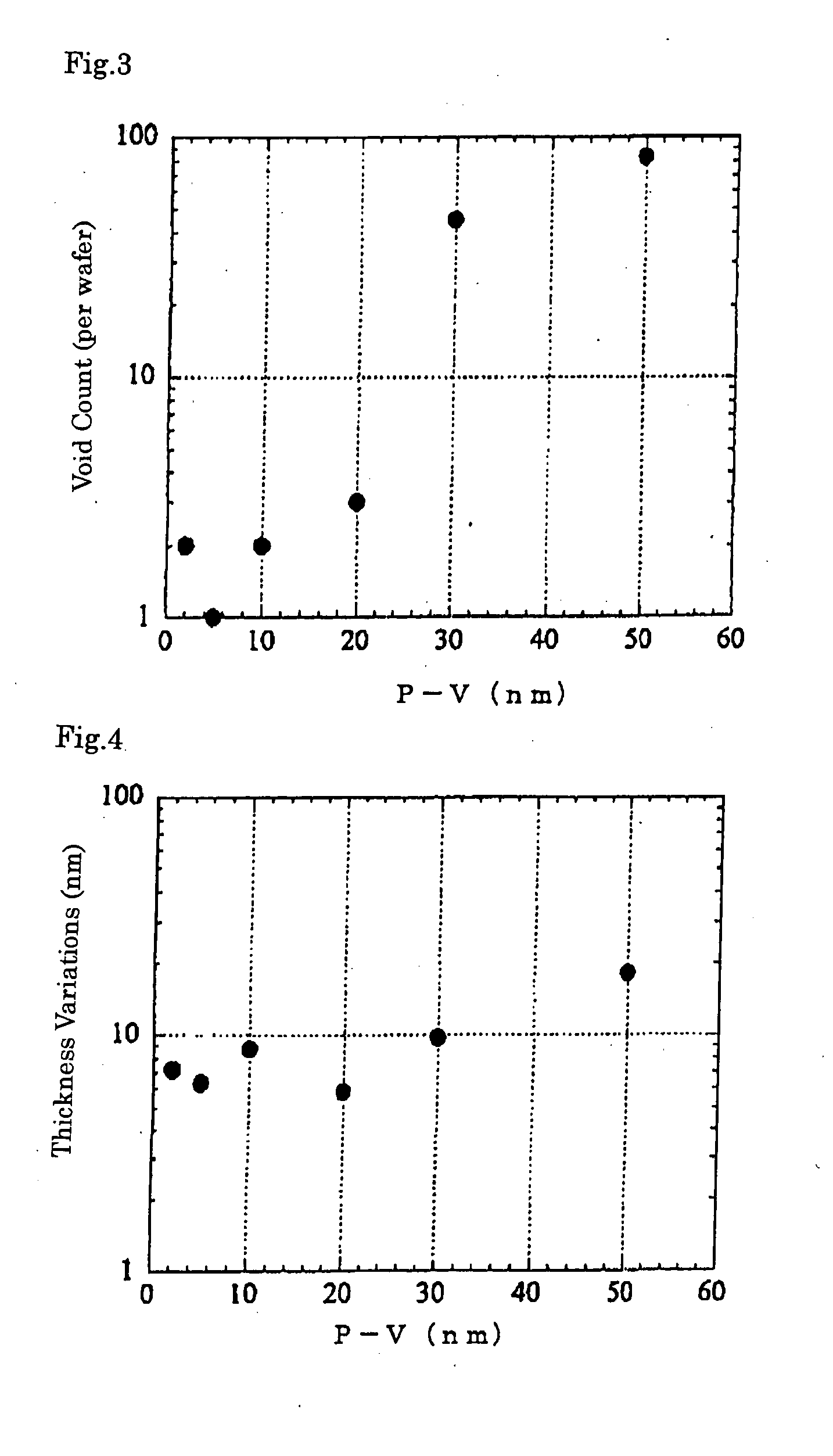

Method for Producing Direct Bonded Wafer and Direct Bonded Wafer

ActiveUS20080102603A1Reduce porosityReduce the generation of voidsSemiconductor/solid-state device manufacturingHydrogenWafering

A method for producing a direct bonded wafer comprising: forming a thermal oxide film or a CVD oxide film on a surface of at least one of a bond wafer and a base wafer, and bonding the wafer to the other wafer via the oxide film; subsequently thinning the bond wafer to prepare a bonded wafer; and thereafter conducting a process of annealing the bonded wafer under an atmosphere including any one of an inert gas, hydrogen and a mixed gas of an inert gas and hydrogen so that the oxide film between the bond wafer and the base wafer is removed to bond the bond wafer directly to the base wafer. Thereby, there is provided a method for producing a direct bonded wafer in which generation of voids is reduced, and a direct bonded wafer with a low void count.

Owner:SHIN-ETSU HANDOTAI CO LTD

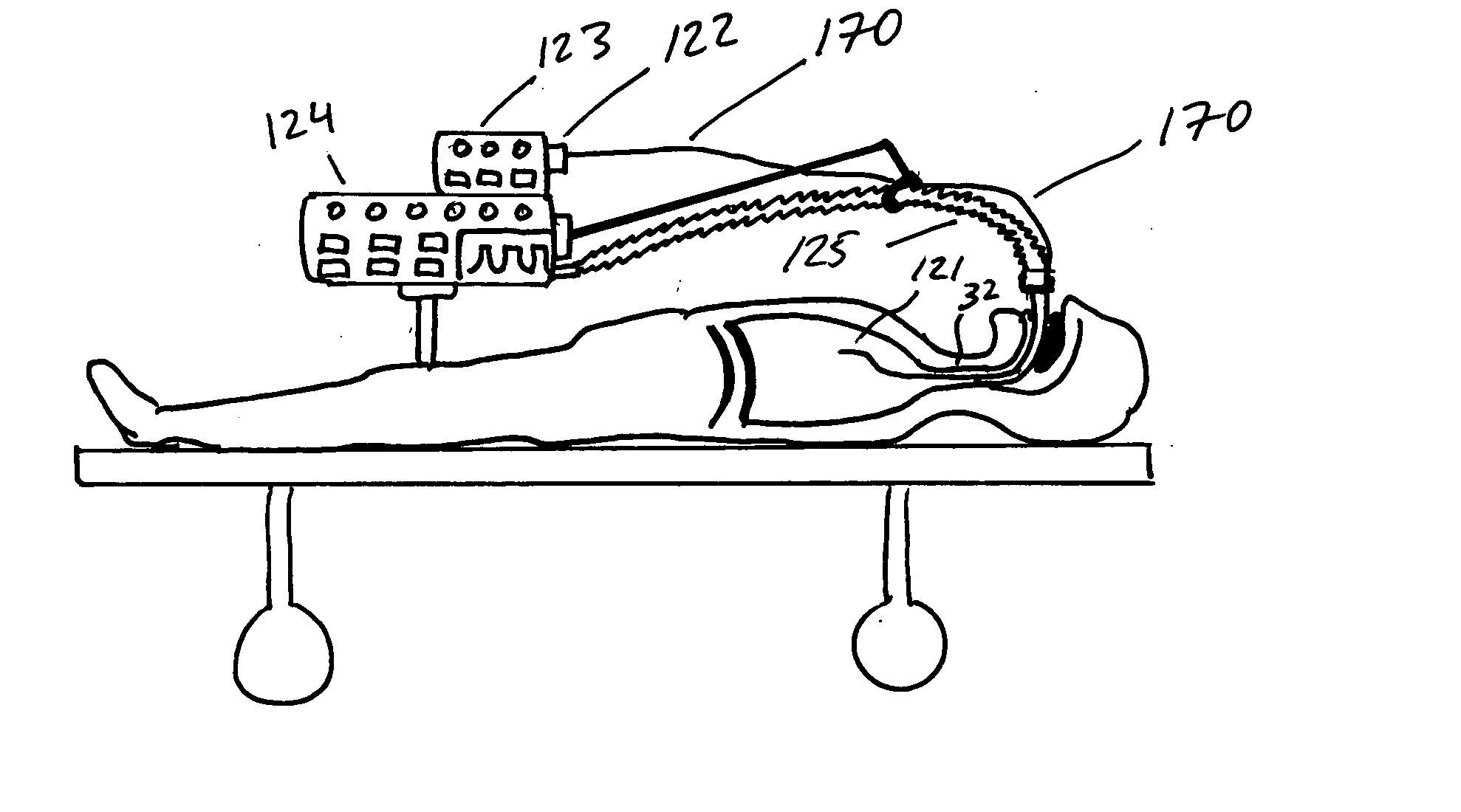

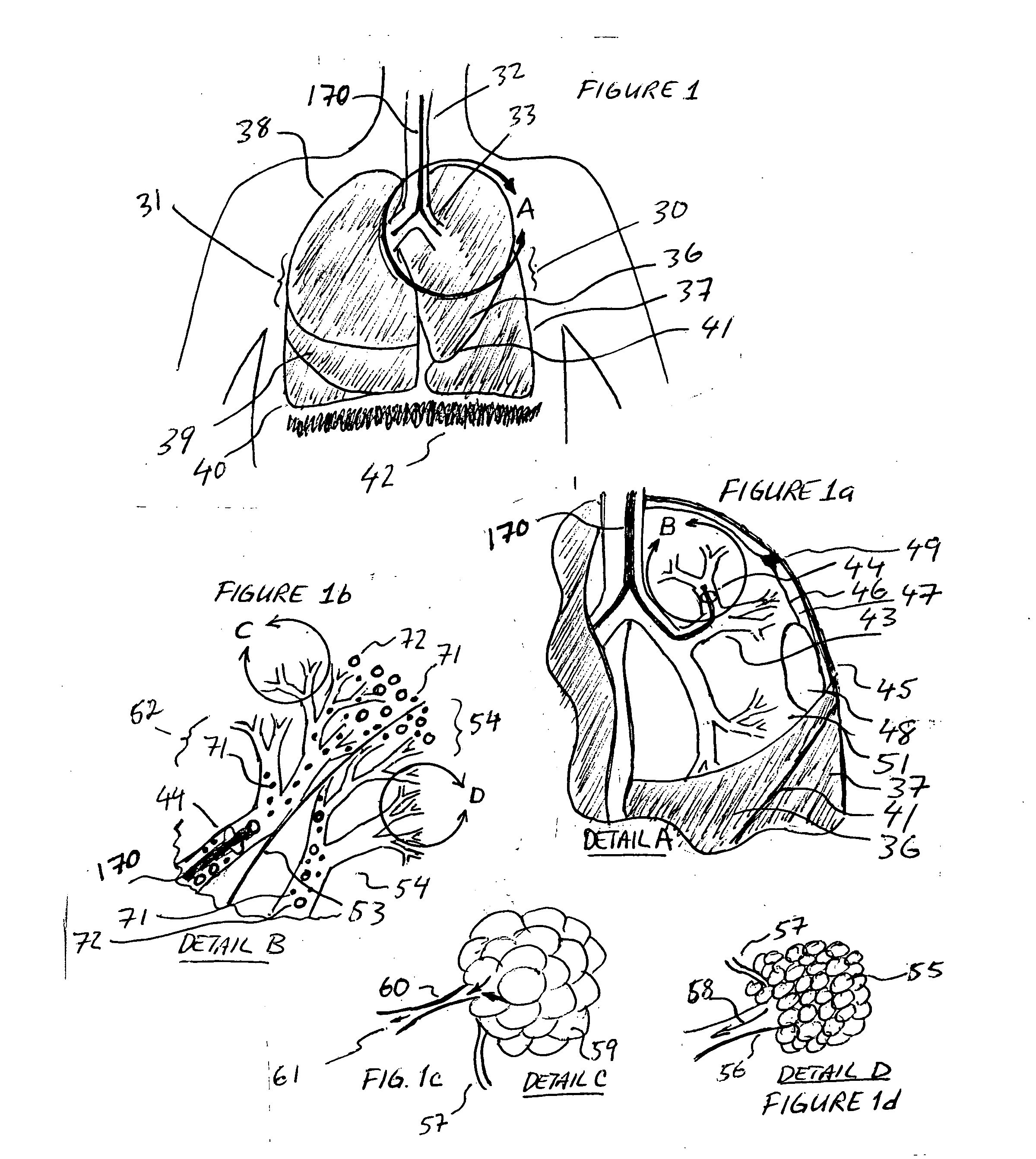

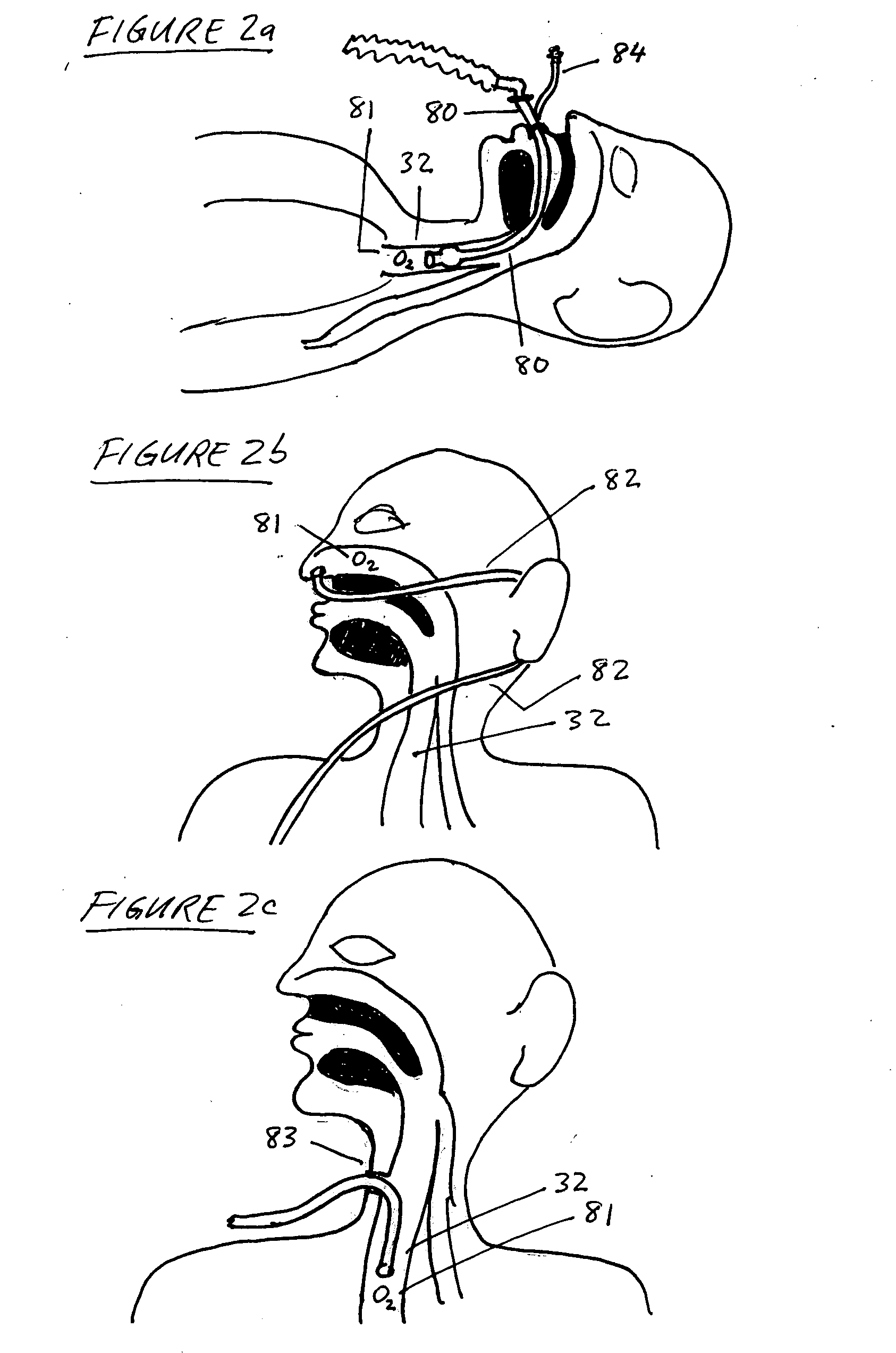

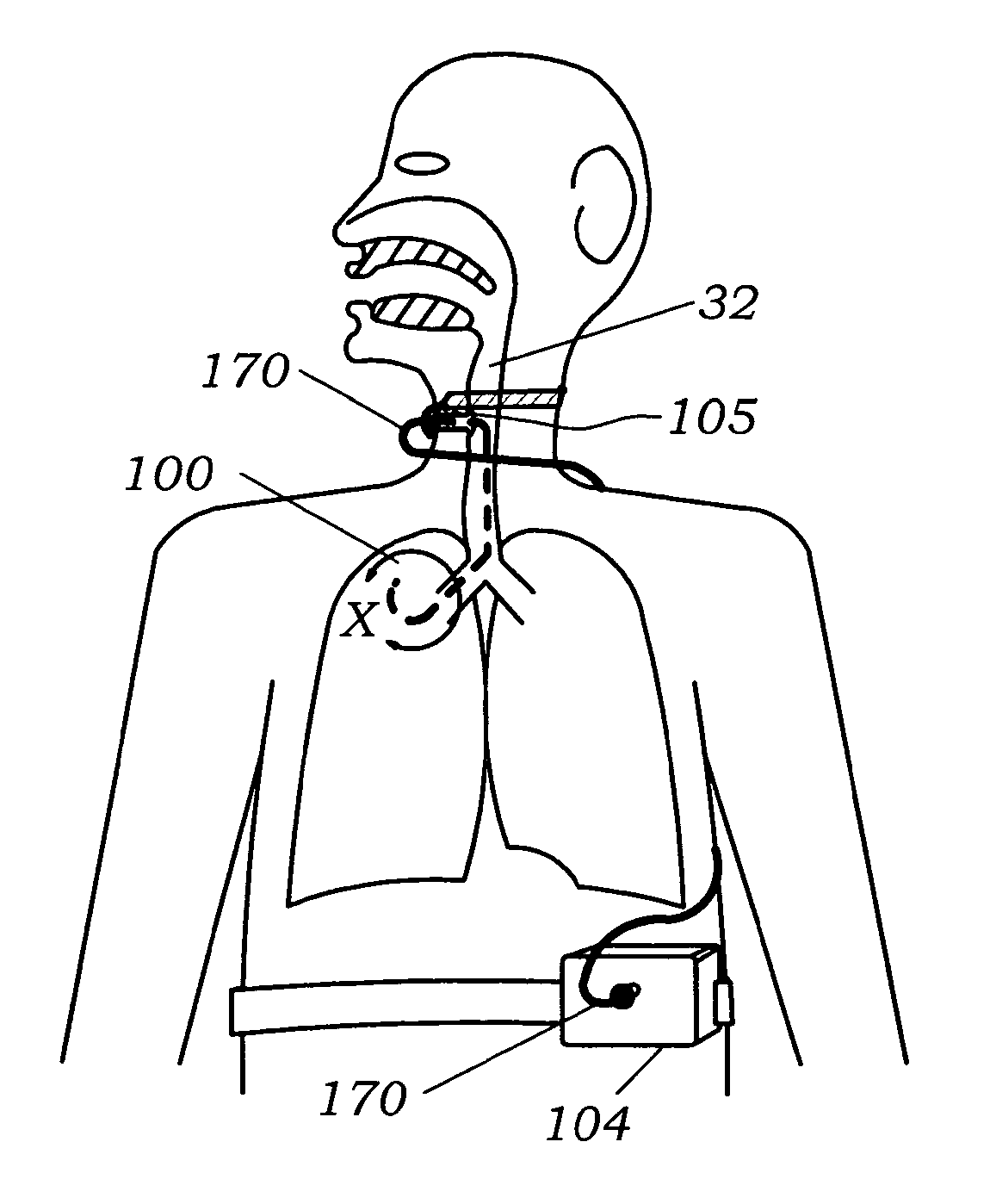

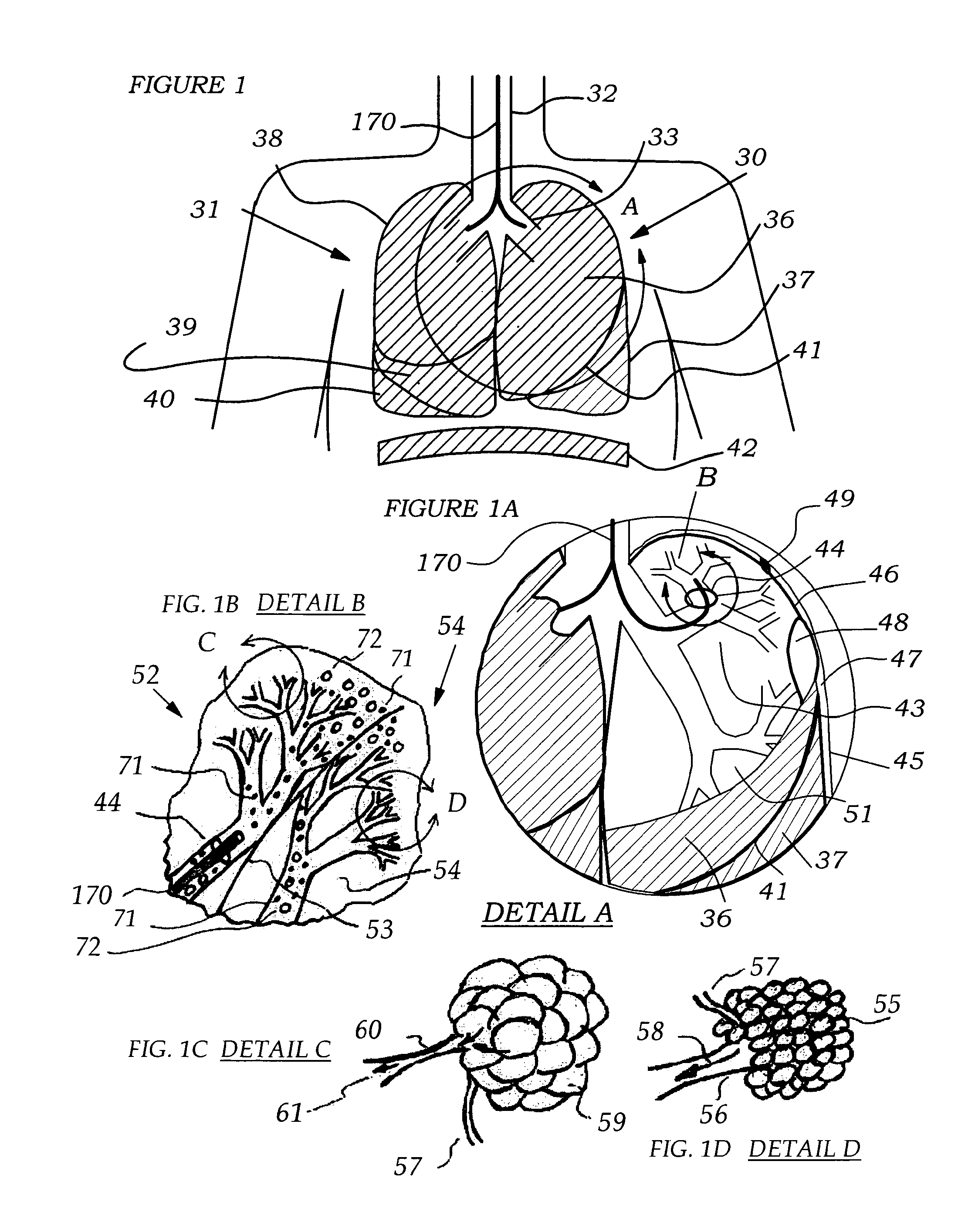

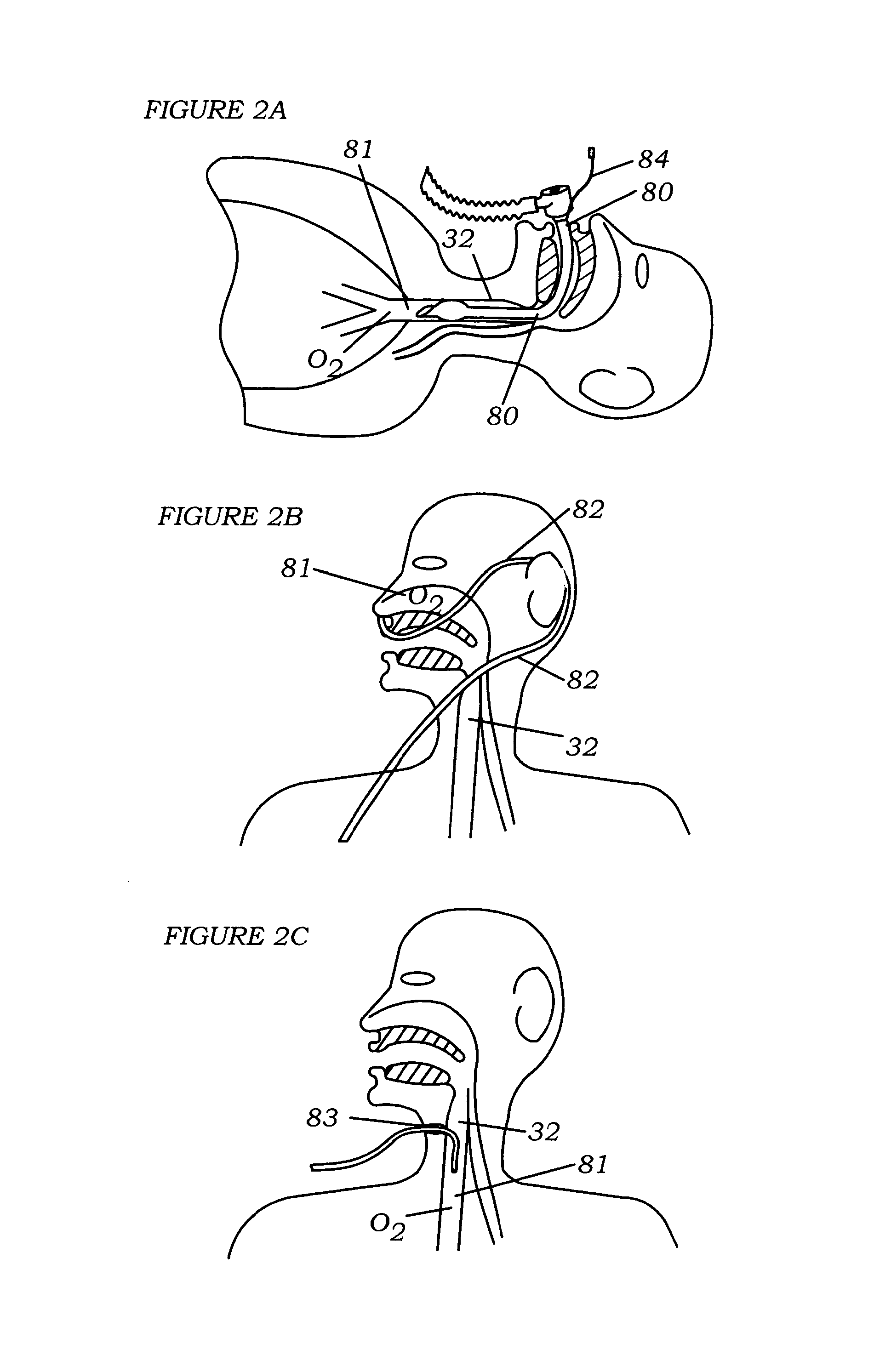

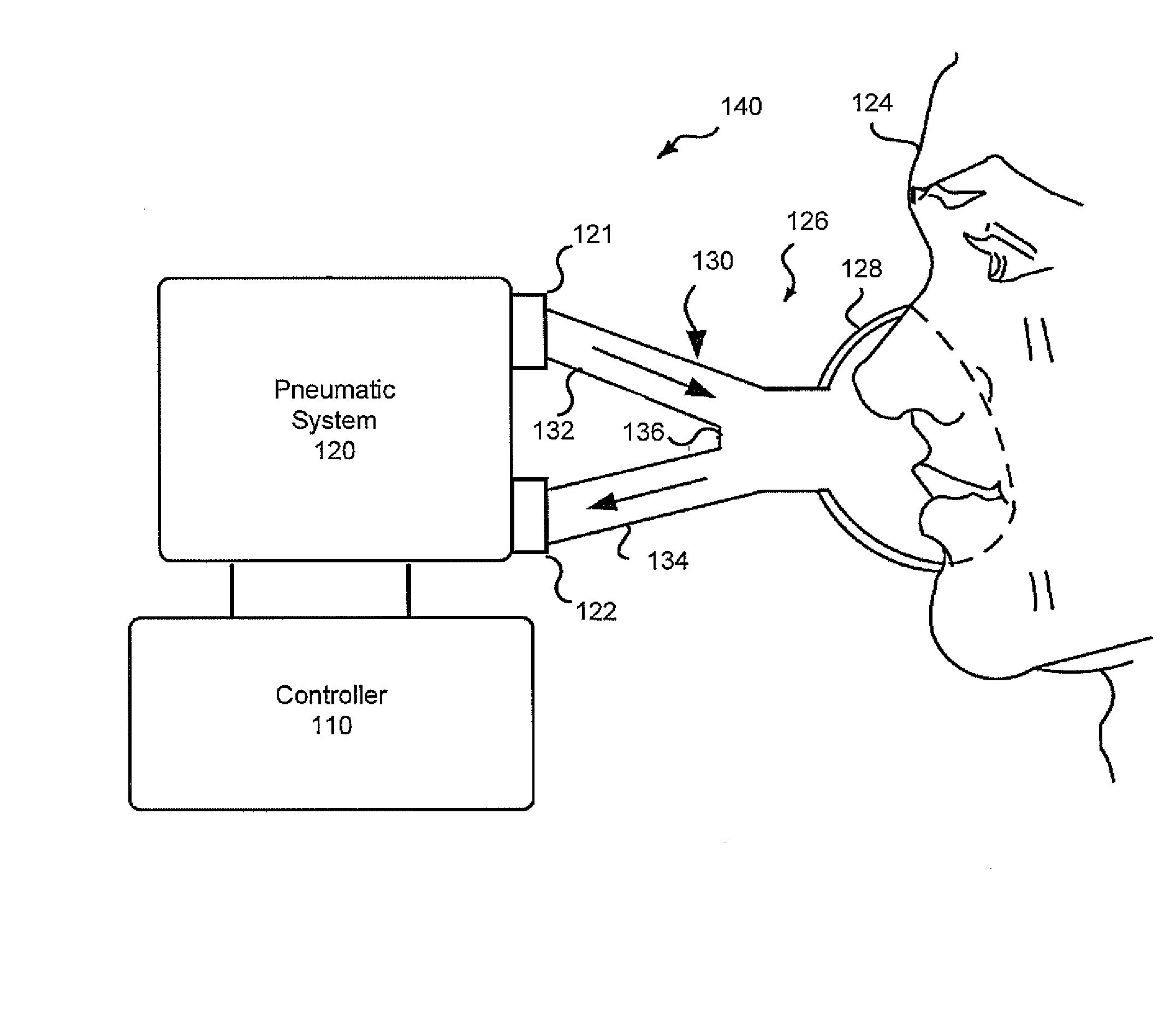

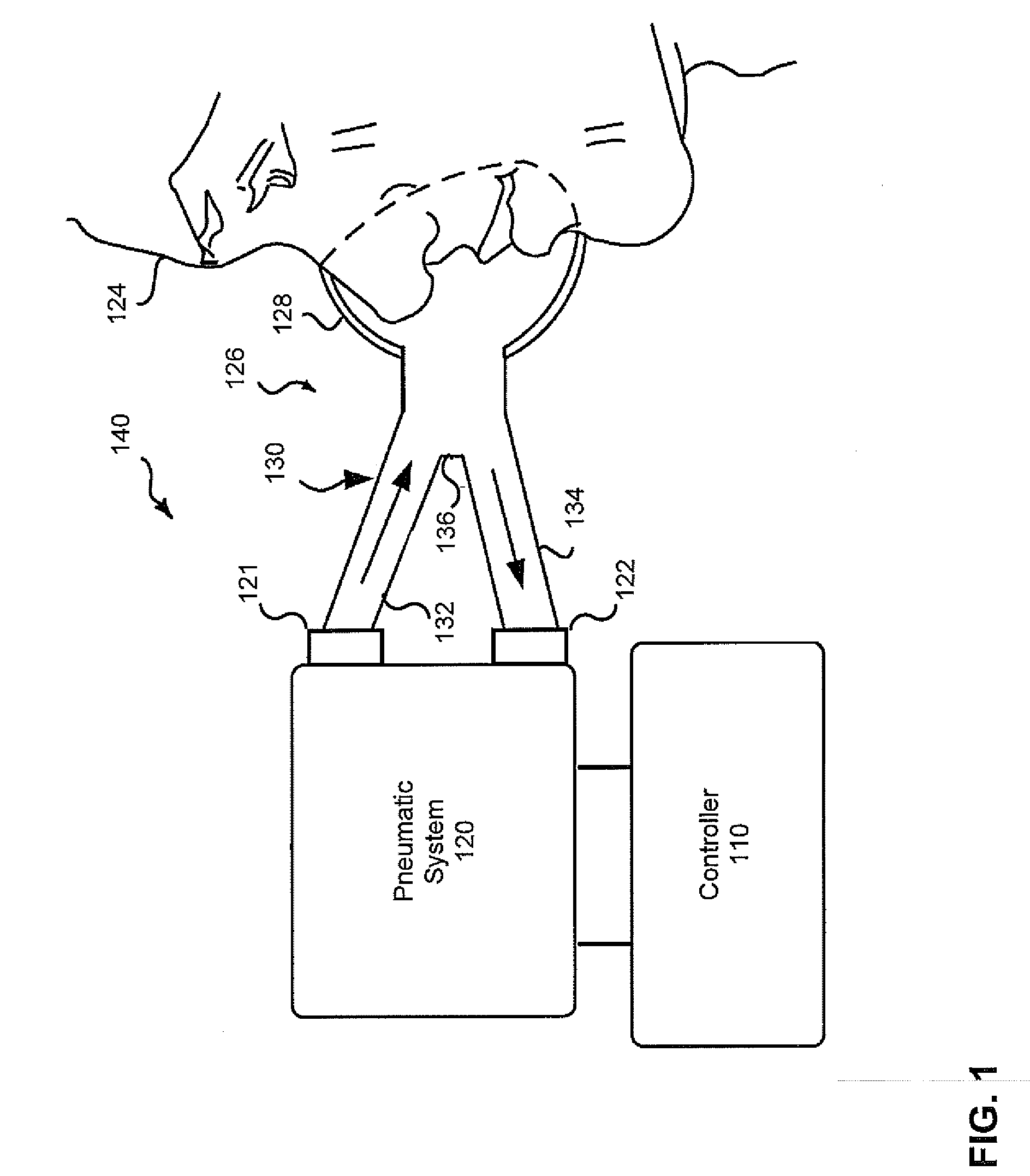

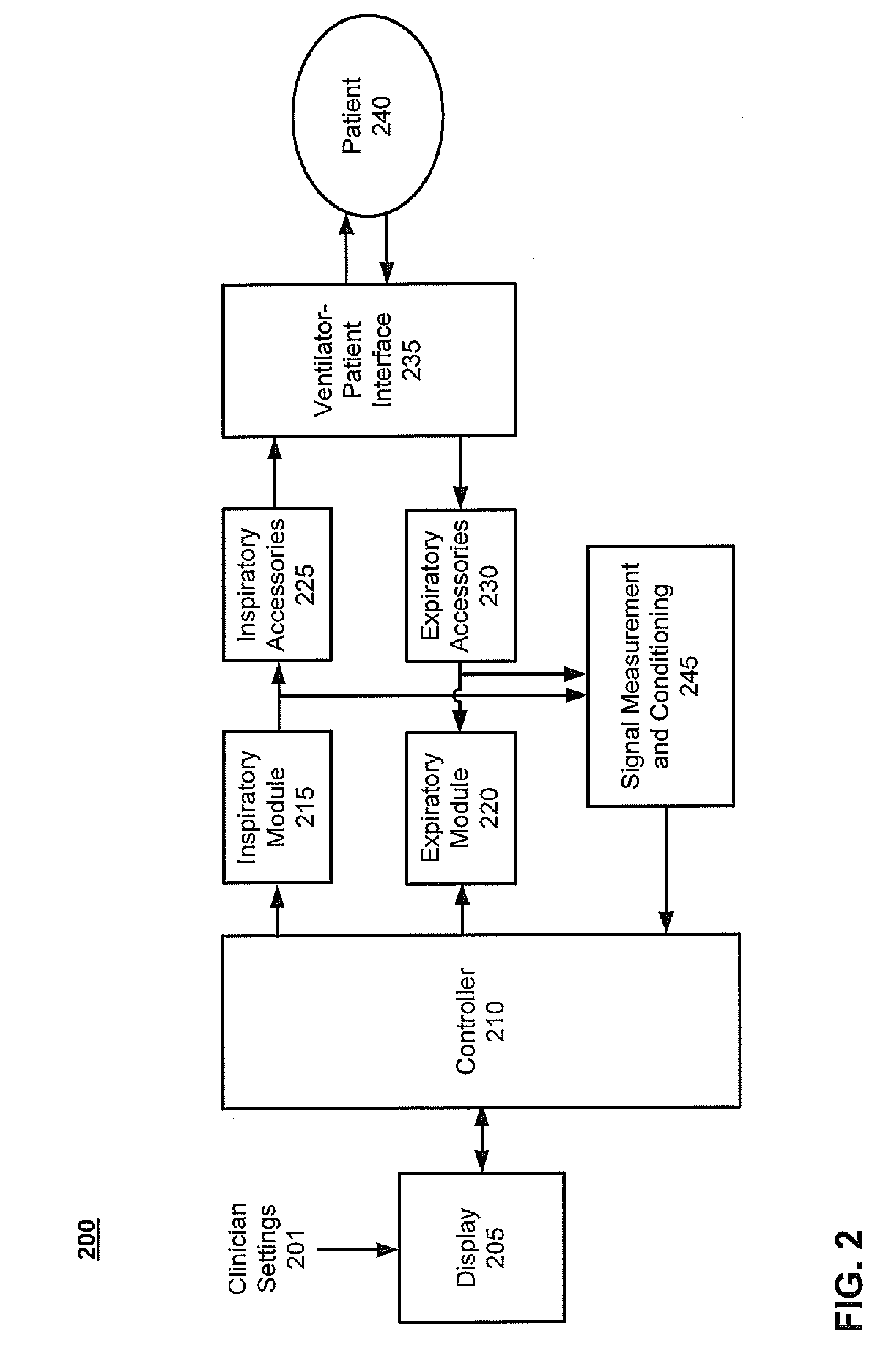

Methods, systems and devices for improving ventilation in a lung area

ActiveUS20050005936A1Facilitates of gas concentrationEasy pressure controlTracheal tubesOperating means/releasing devices for valvesDiseaseMechanical ventilation

Methods, systems and devices are described for new modes of ventilation in which specific lung areas are ventilated with an indwelling trans-tracheobronchial catheter for the purpose of improving ventilation and reducing hyperinflation in that specific lung area, and for redistributing inspired air to other healthier lung areas, for treating respiratory disorders such as COPD, ARDS, SARS, CF, and TB. Trans-Tracheobronchial Segmental Ventilation (TTSV) is performed on either a naturally breathing or a mechanical ventilated patient by placing a uniquely configured indwelling catheter into a bronchus of a poorly ventilated specific lung area and providing direct ventilation to that area. The catheter can be left in place for extended periods without clinician attendance or vigilance. Ventilation includes delivery of respiratory gases, therapuetic gases or agents and evacuation of stagnant gases, mixed gases or waste fluids. Typically the catheter's distal tip is anchored without occluding the bronchus but optionally may intermittently or continuously occlude the bronchus. TTSV is optionally performed by insufflation only of the area, or by application of vacuum to the area, can include elevating or reducing the pressure in the targeted area to facilitate stagnant gas removal, or can include blocking the area to divert inspired gas to better functioning areas.

Owner:BREATHE TECHNOLOGIES INC

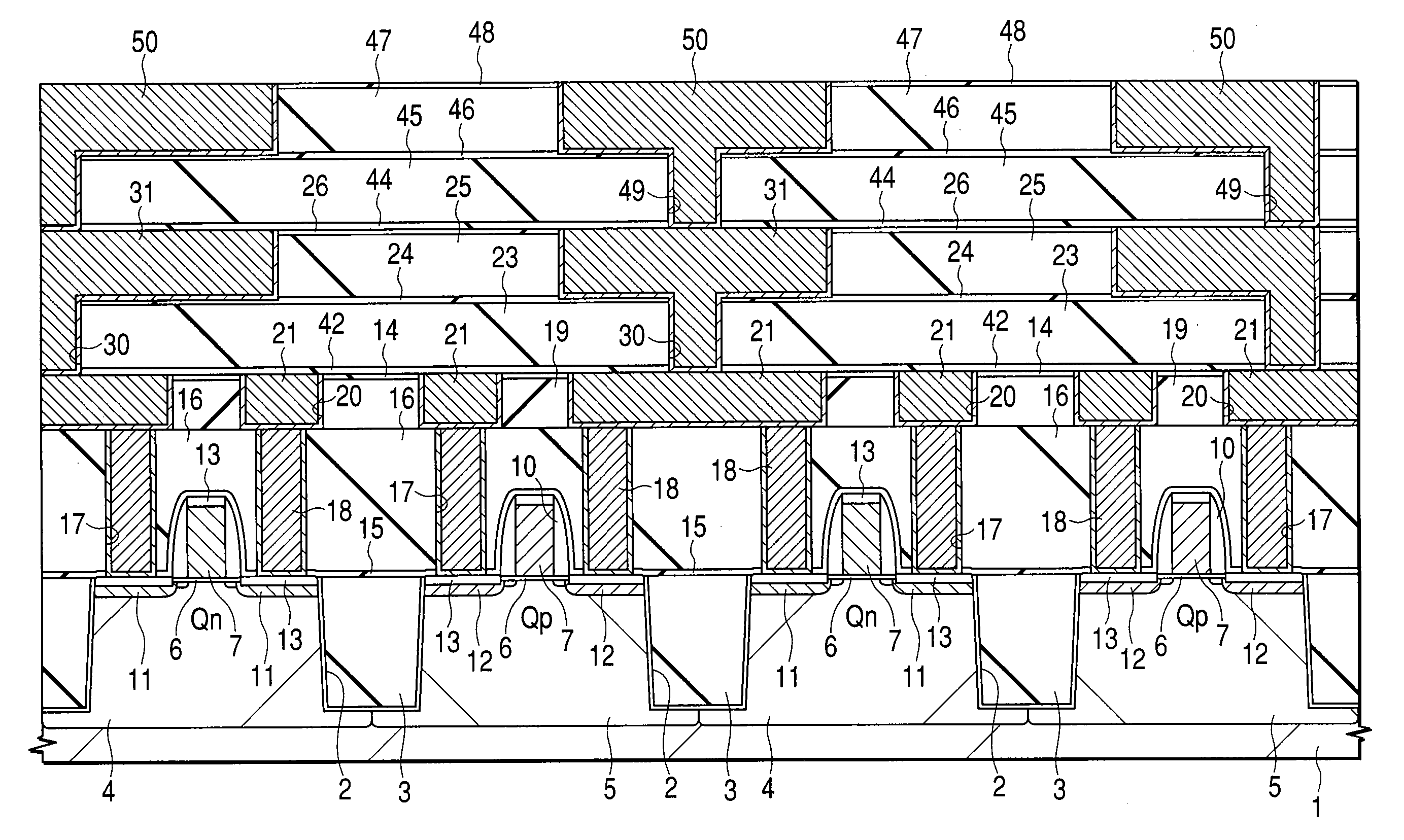

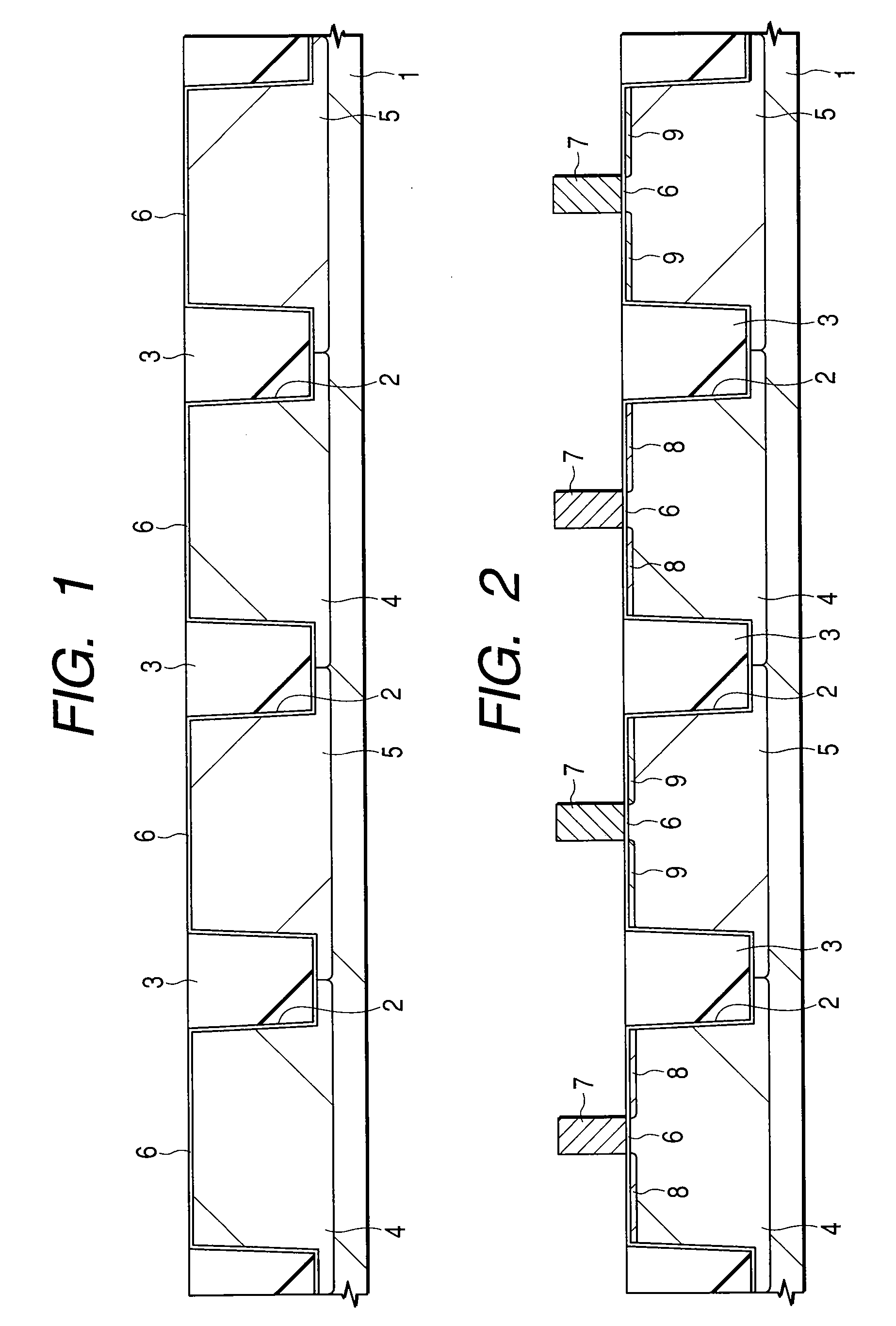

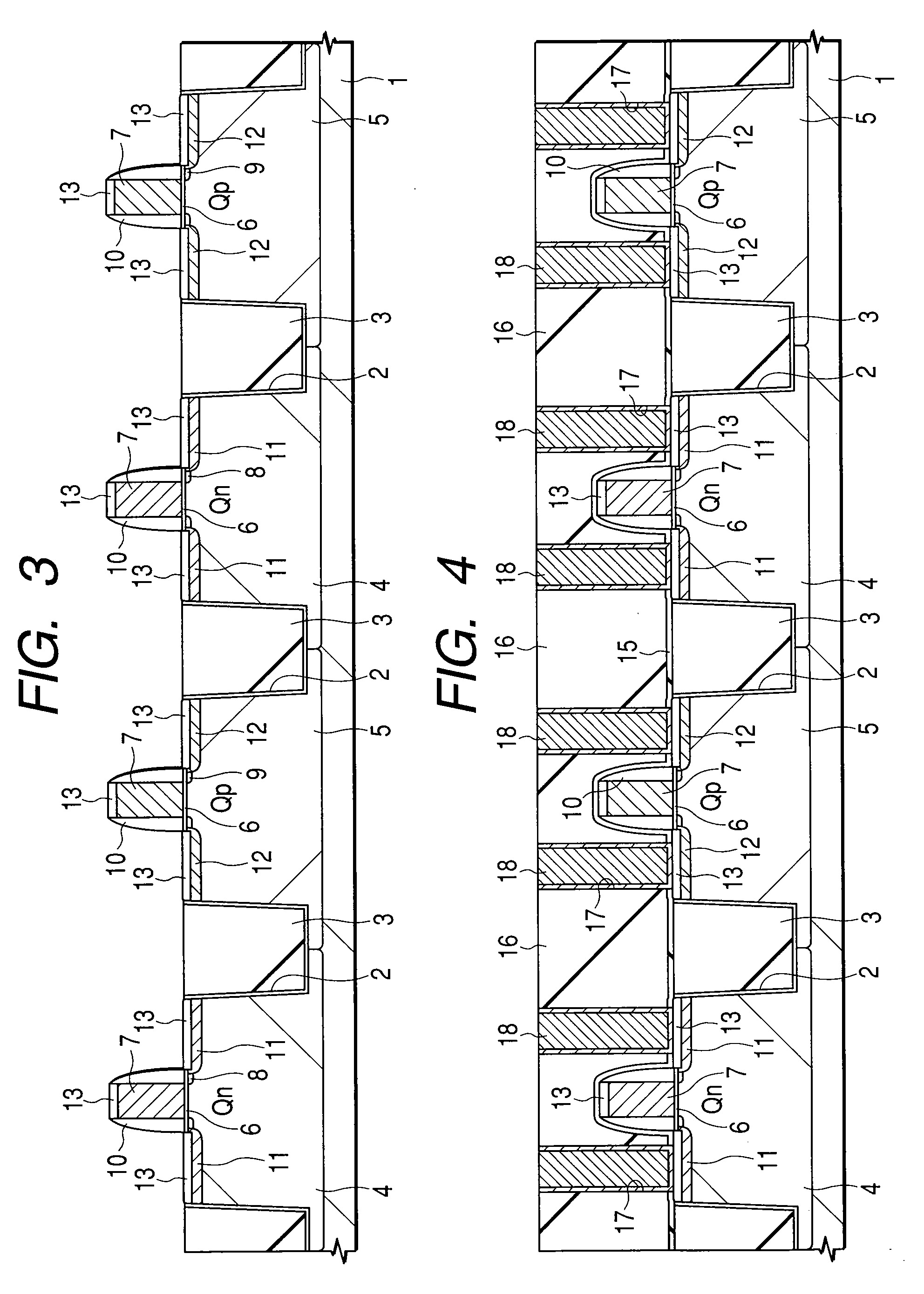

Fabrication Method of Semiconductor Integrated Circuit Device

The following defects are suppressed: when an interlayer insulating film including a silicon carbide film and an organic insulating film is dry-etched to form interconnection grooves over underlying Cu interconnections, an insulating reactant adheres to the surface of the underlying Cu interconnections exposed to the bottom of the interconnection grooves, or the silicon carbide film or the organic insulating film exposed to the side walls of the interconnection grooves are side-etched. When a lamination film made of a silicon oxide film, an organic insulating film, a silicon oxide film, an organic insulating film and a silicon carbide film is dry-etched to form interconnection grooves over Cu interconnections, a mixed gas of SF6 and NH3 is used as an etching gas for the silicon carbide film to work side walls of the interconnection grooves perpendicularly and further suppress defects that a deposit or a reactant adheres to the surface of the Cu interconnections exposed to the bottom of the interconnection grooves.

Owner:ENOMOTO HIROYUKI +2

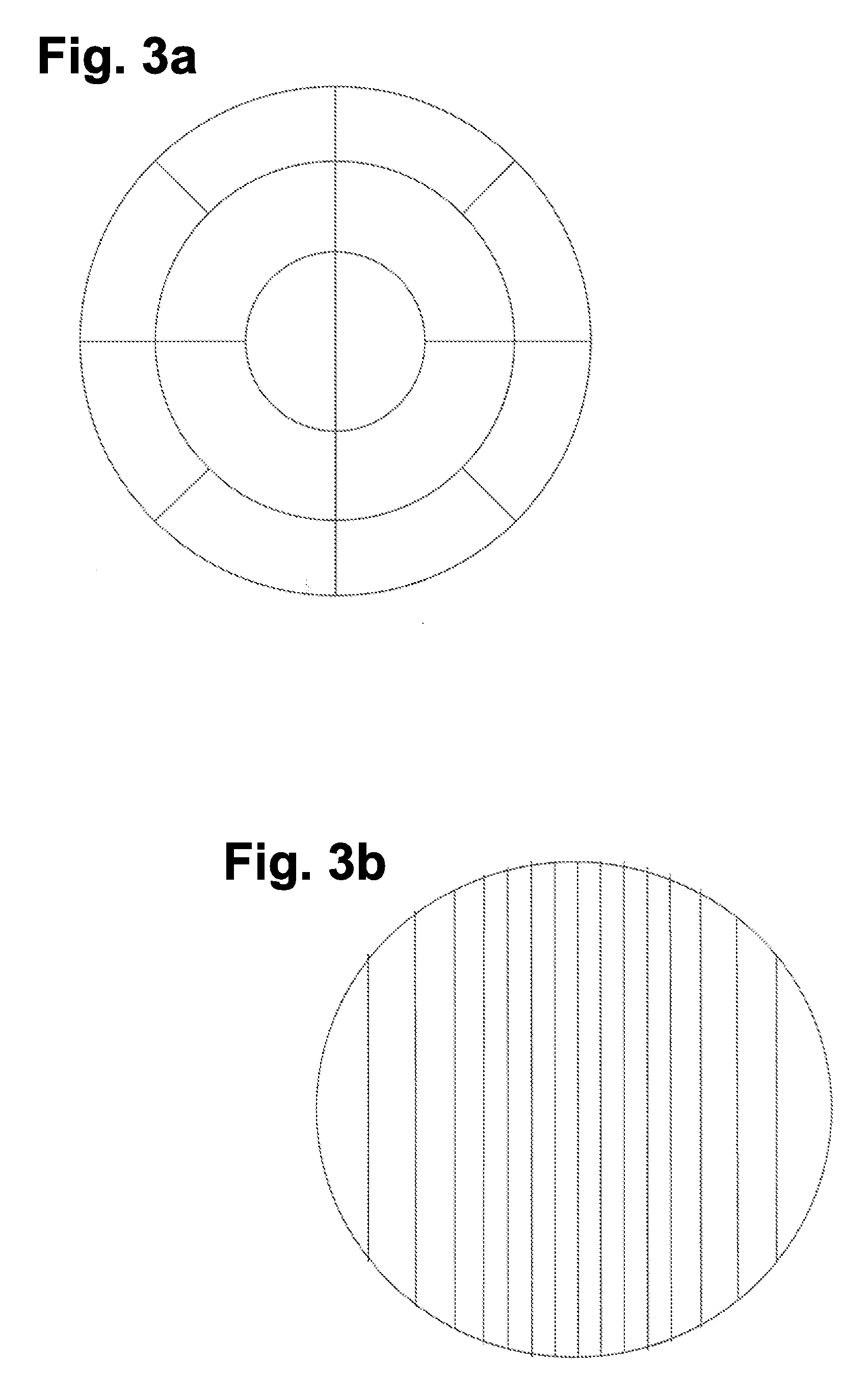

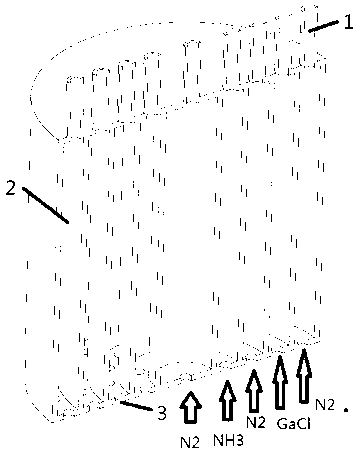

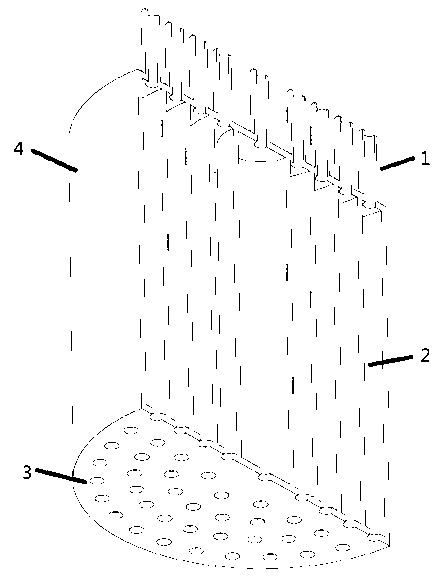

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

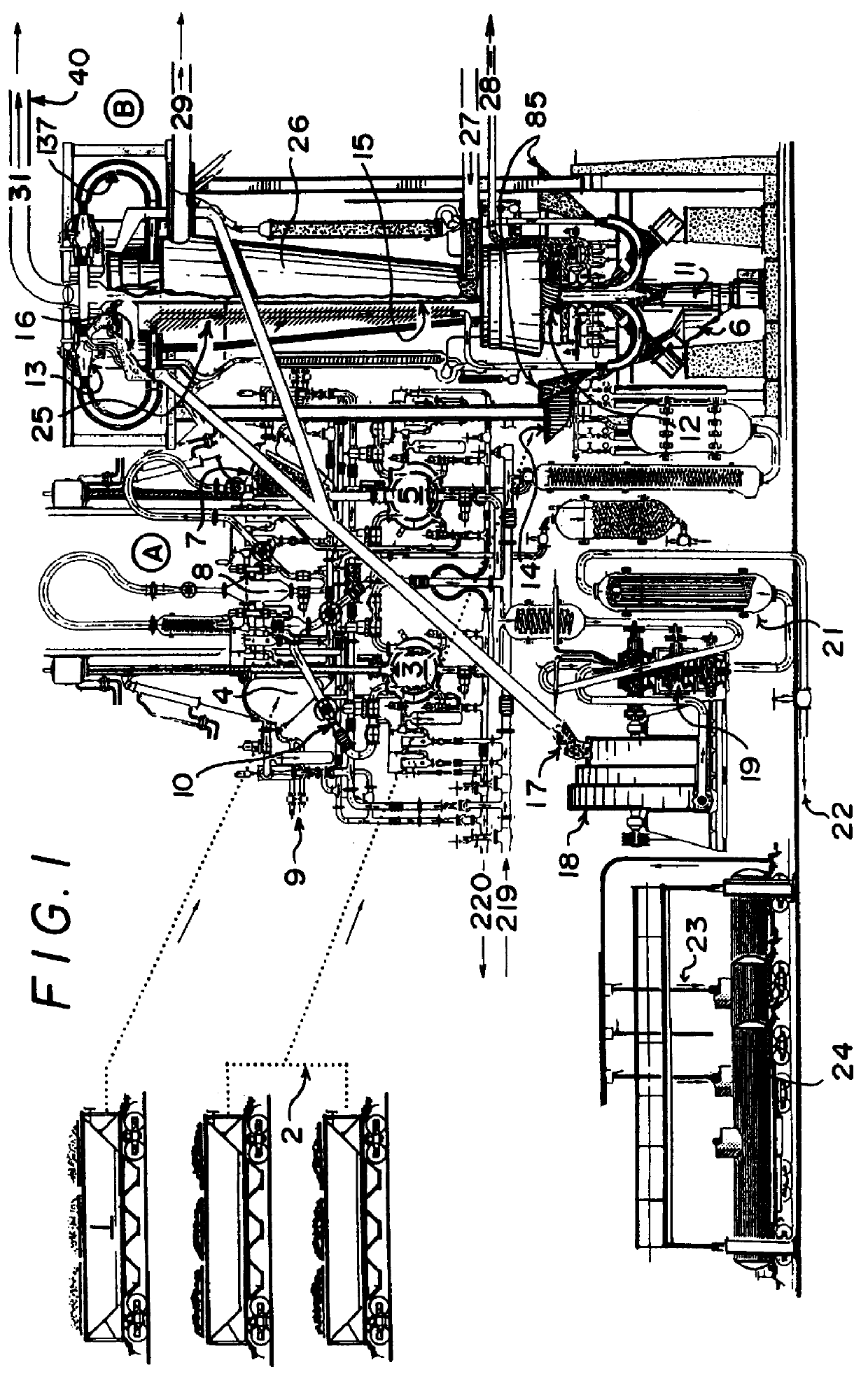

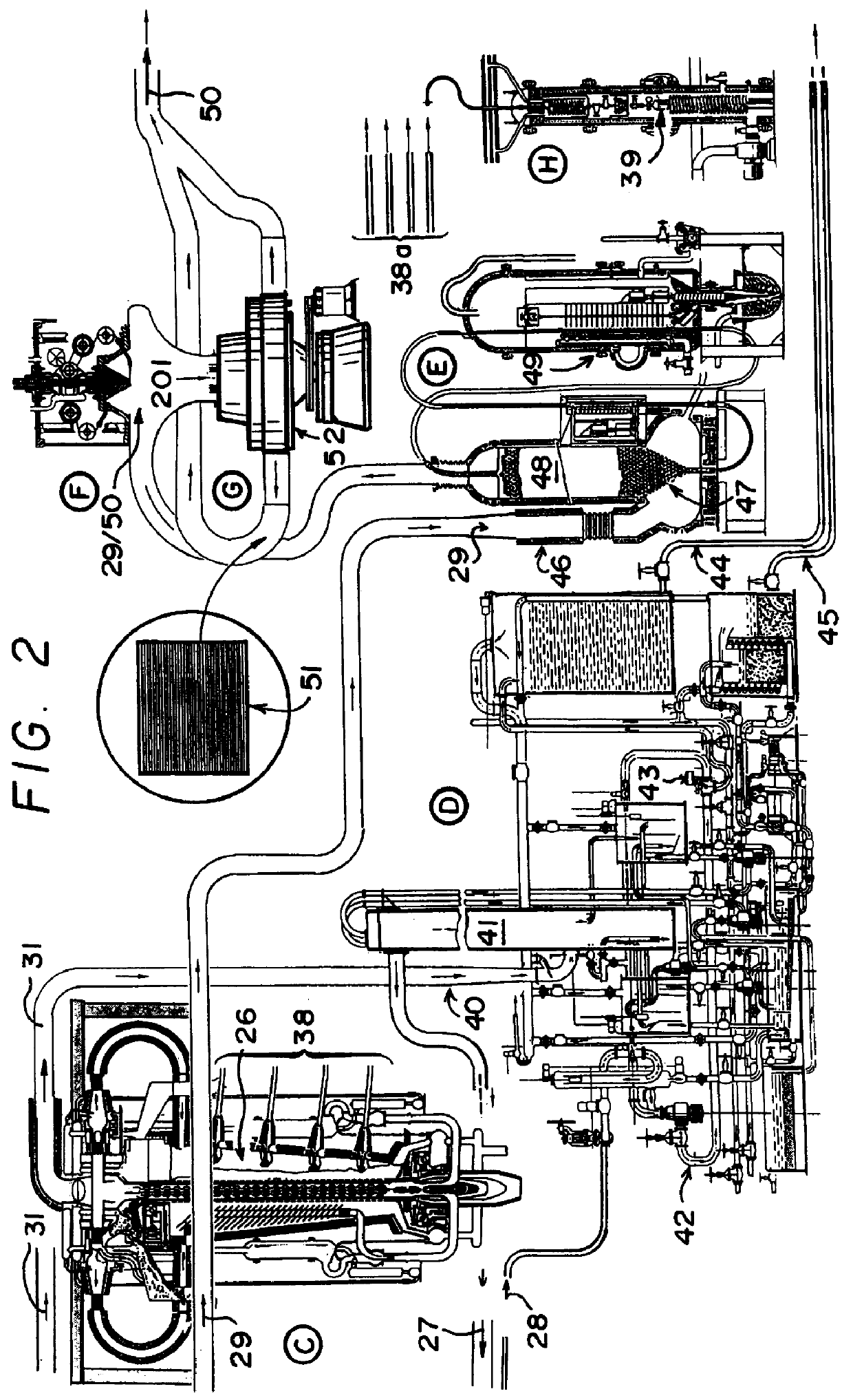

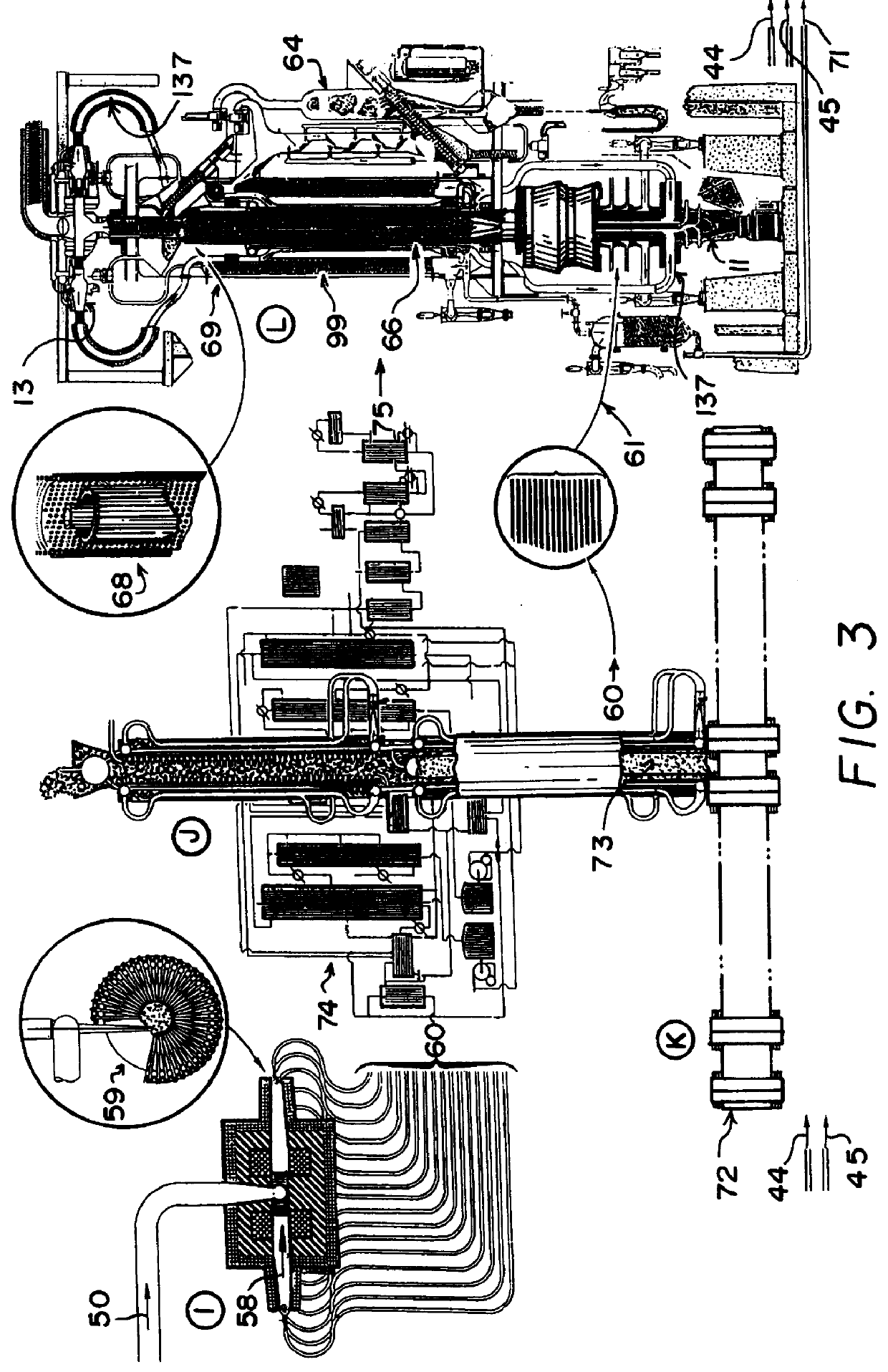

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

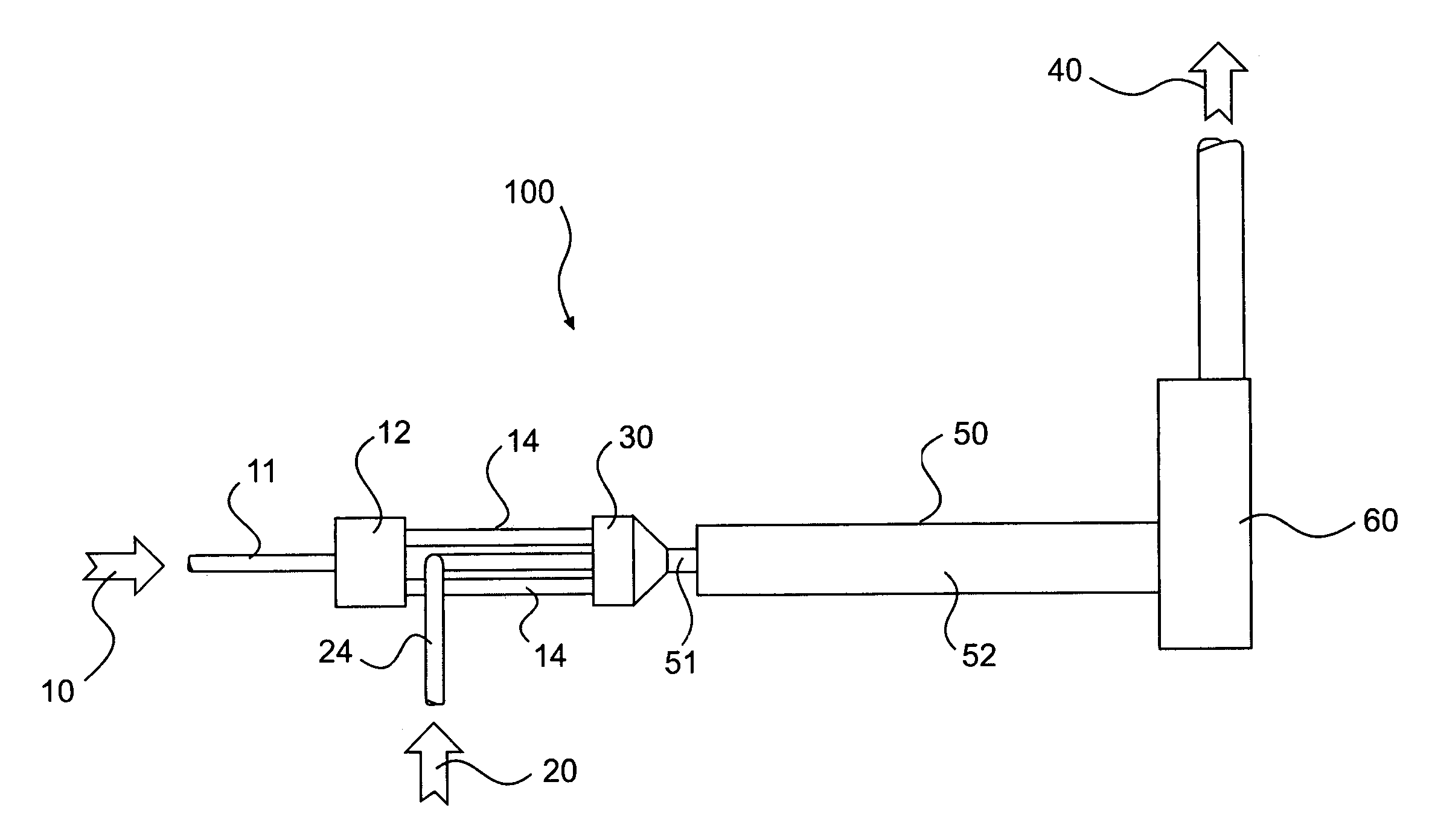

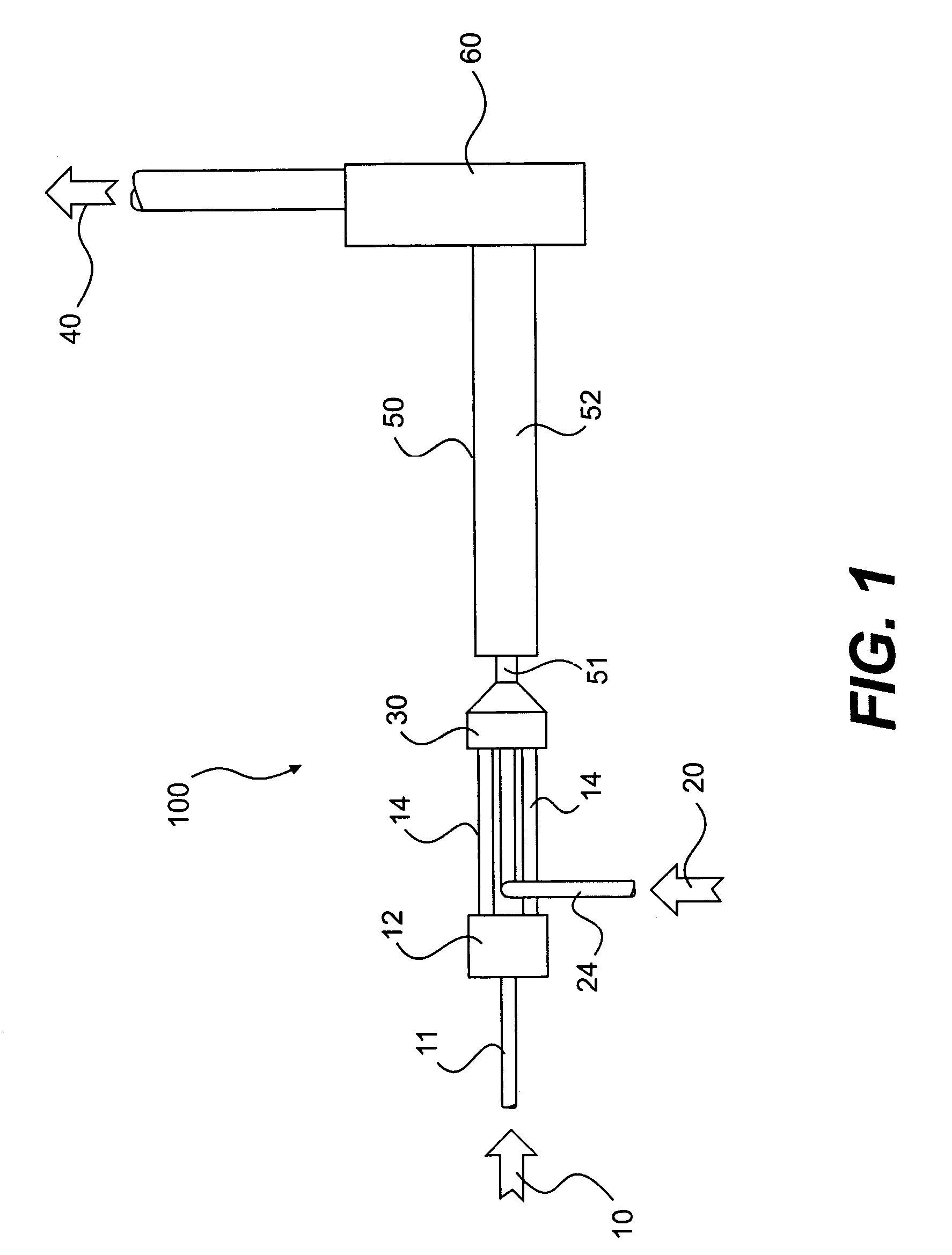

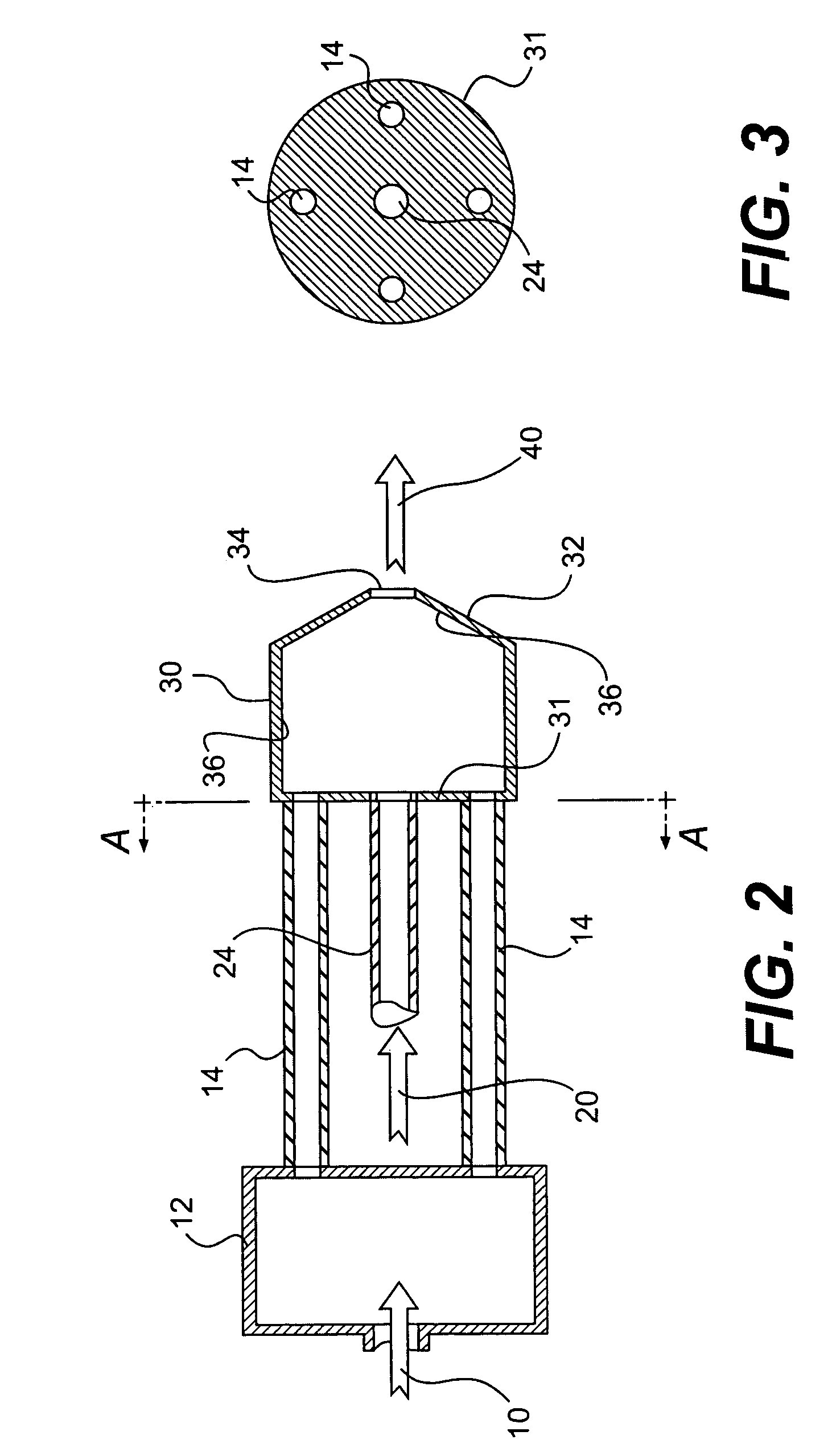

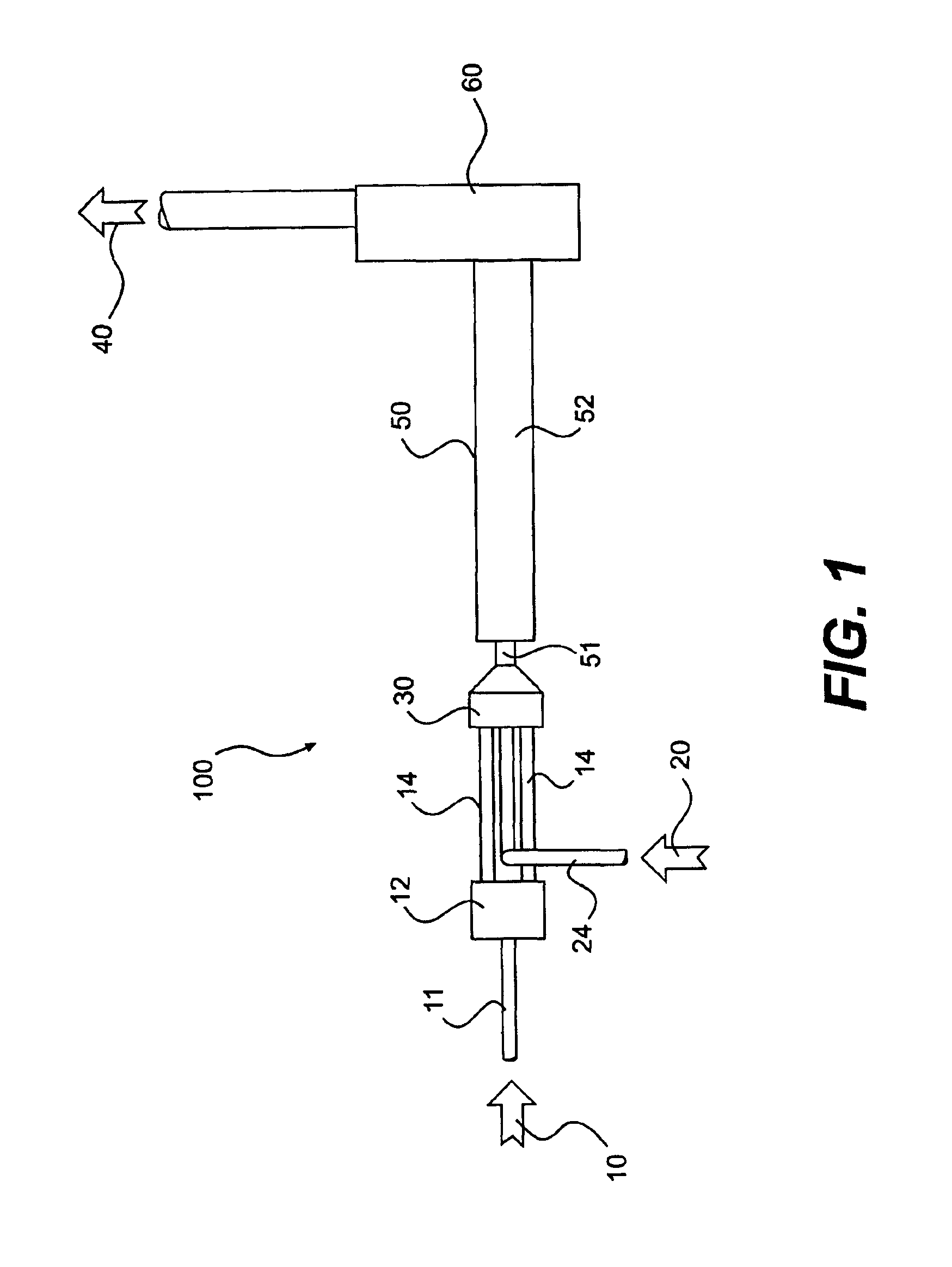

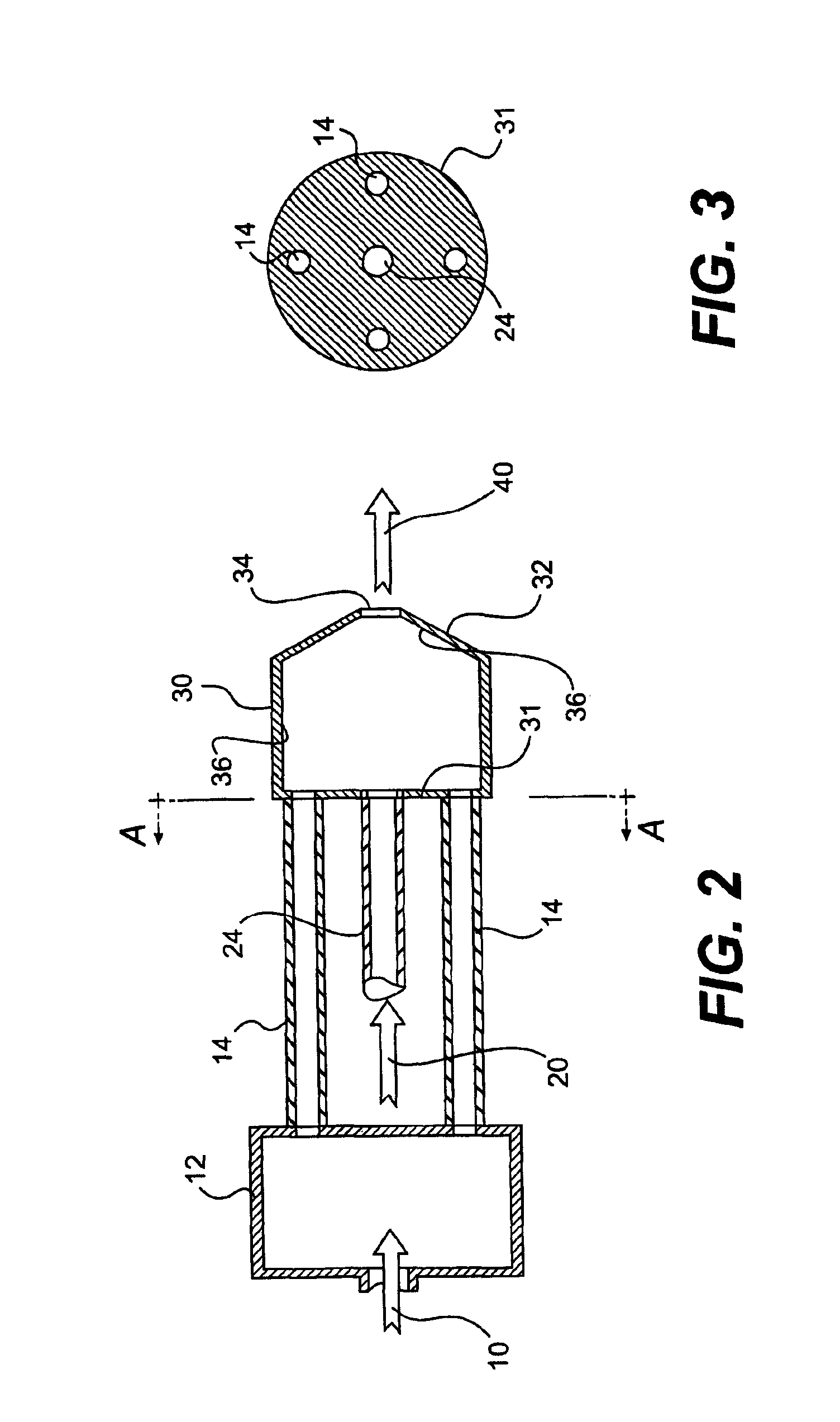

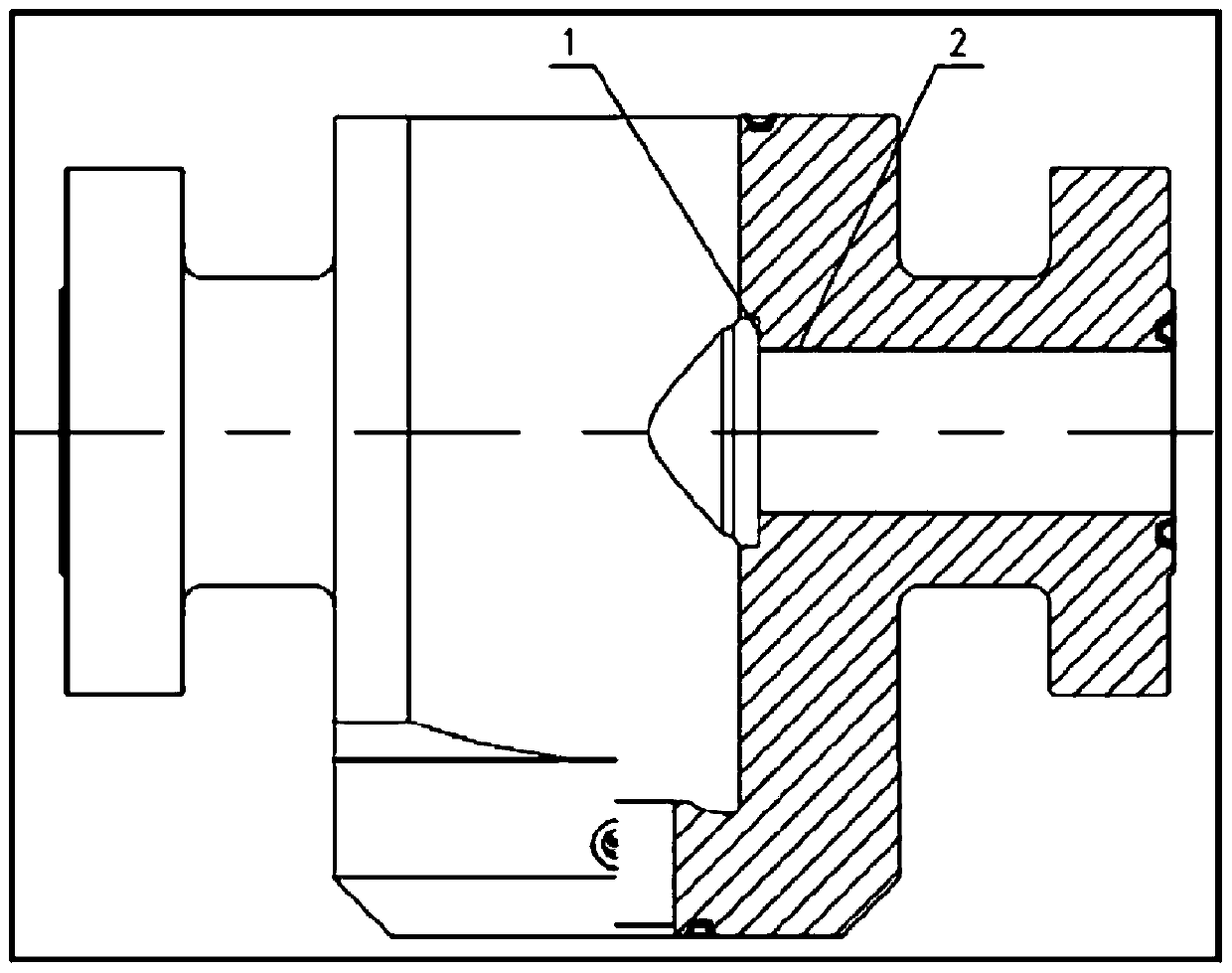

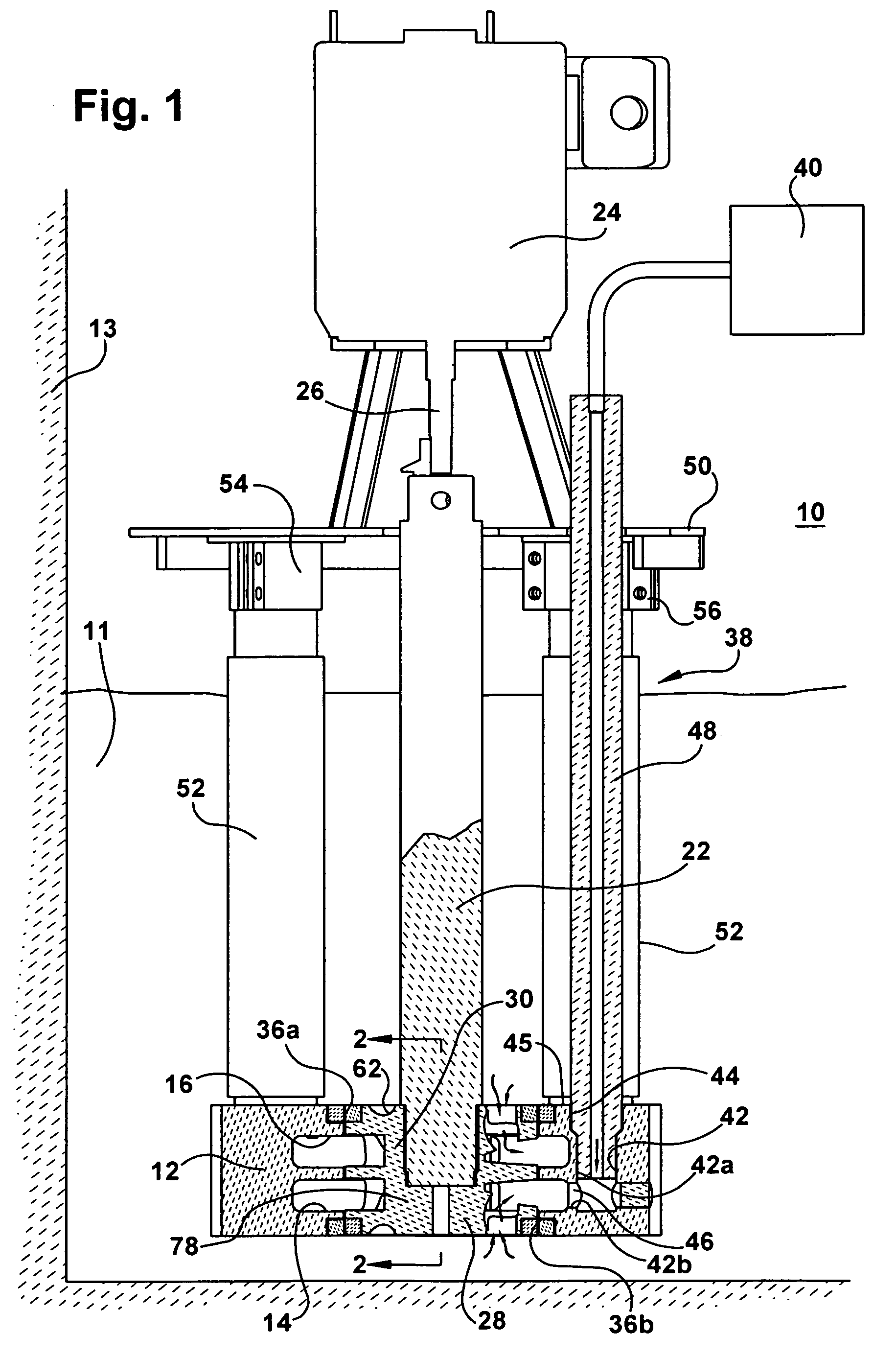

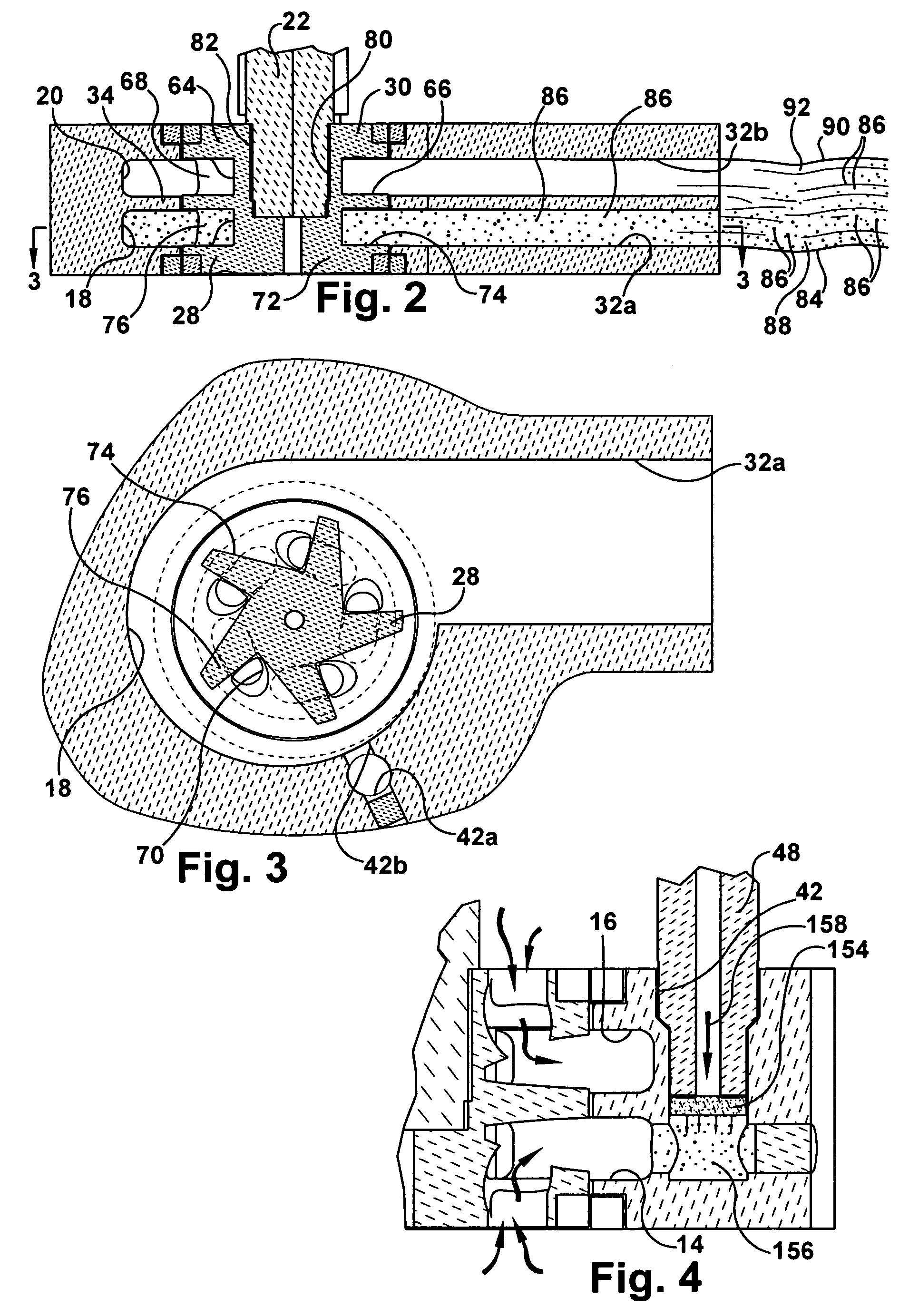

Method and apparatus for mixing gases

A method and apparatus for mixing a first stream of gas with a second stream of gas is provided. The method includes introducing a first stream of gas into a first stream manifold and directing the first stream from the first stream manifold into a mixing chamber via a plurality of first stream passages flow coupled to the mixing chamber. A second stream of gas is directed into the mixing chamber via at least one second stream passage flow coupled to a first end of the mixing chamber. A combined stream is formed from the first and second streams, gradually converged, and discharged from the mixing chamber through a mixing chamber exit port.

Owner:CATERPILLAR INC

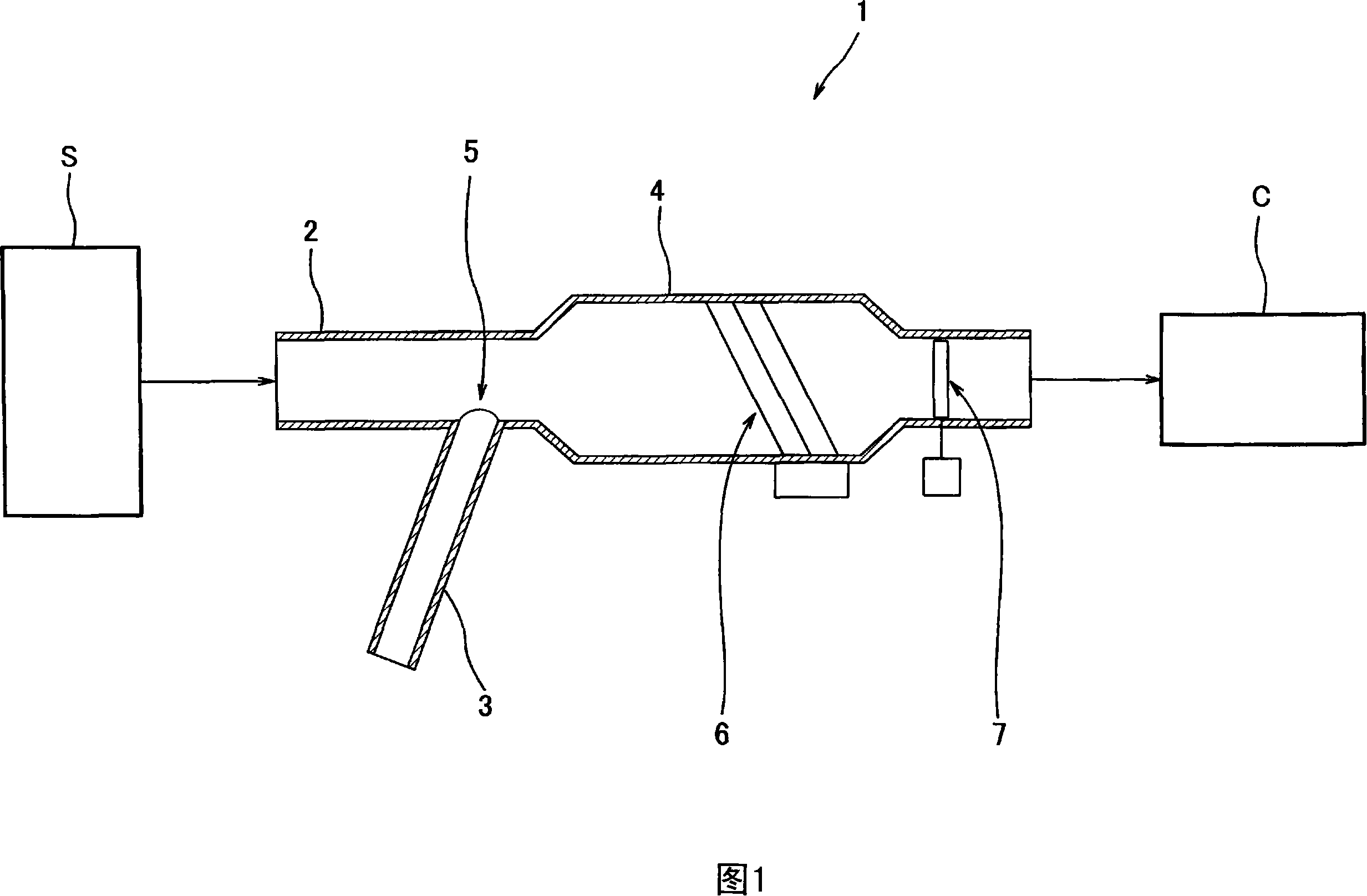

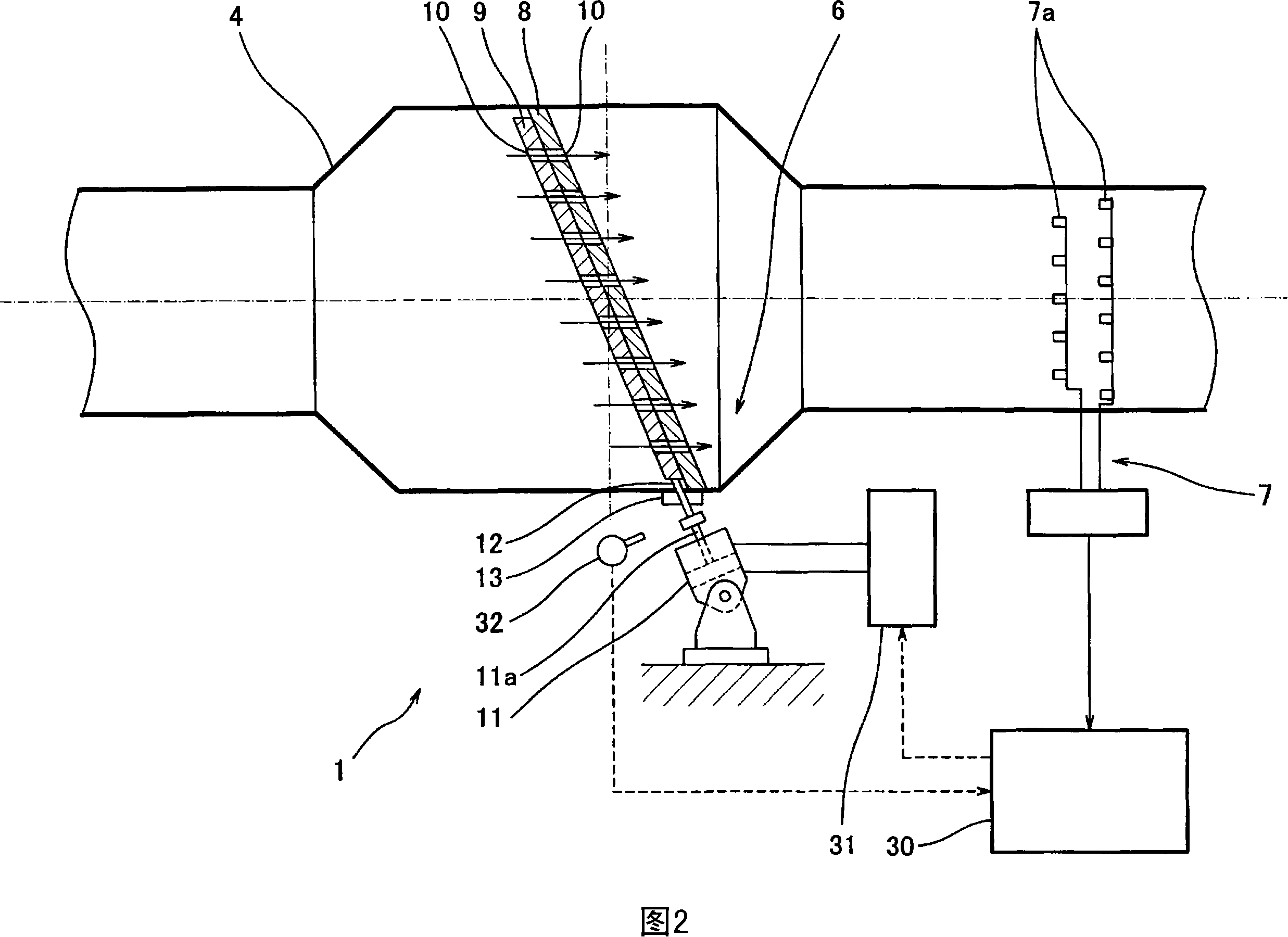

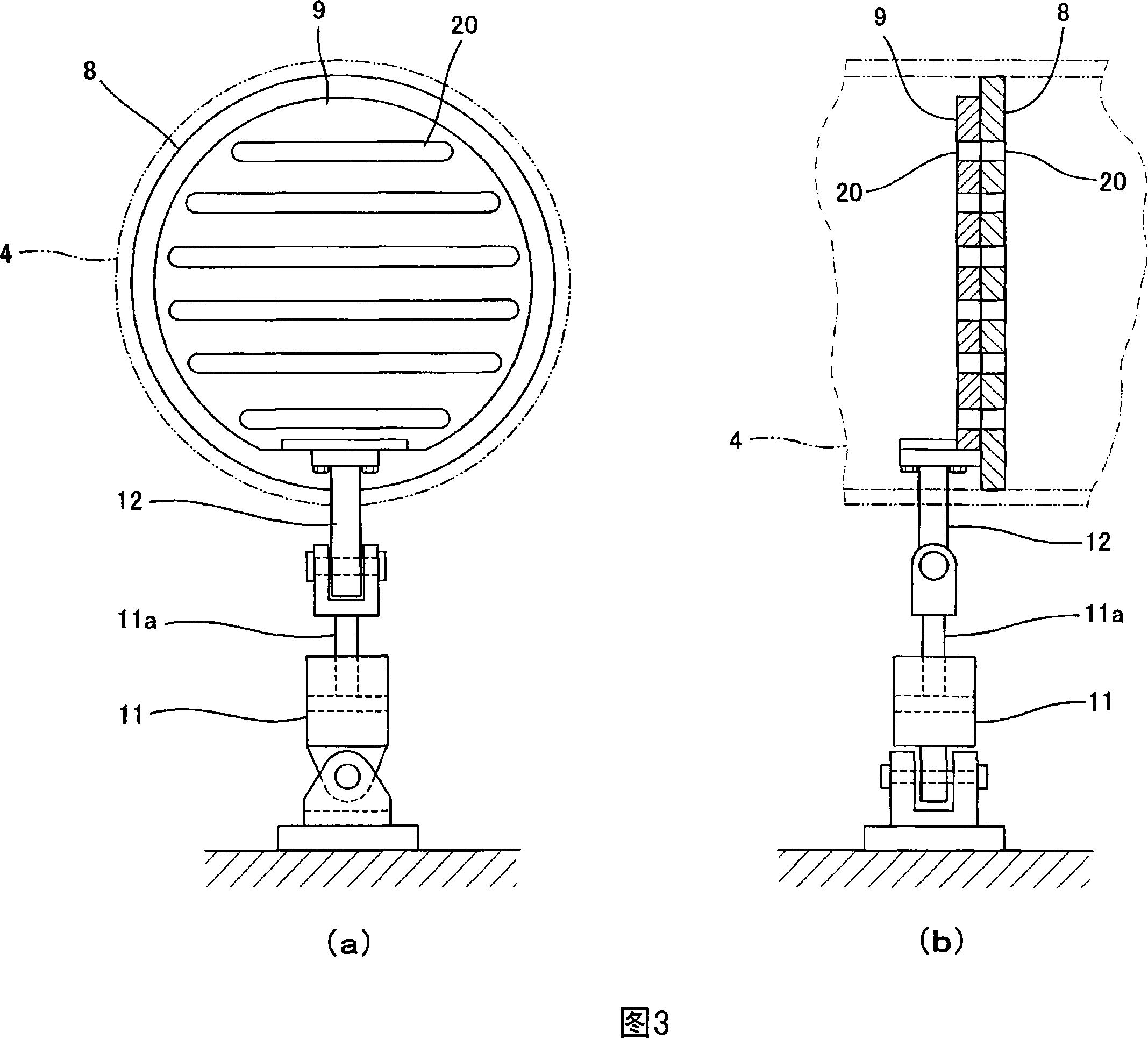

Mixed fluid uniformization device and mixed fluid feeding apparatus

InactiveCN101142012AImprove uniformityFlow mixersTransportation and packagingMixed statesEngineering

Owner:KAWASAKI HEAVY IND LTD

Method and apparatus for mixing gases

A method and apparatus for mixing a first stream of gas with a second stream of gas is provided. The method includes introducing a first stream of gas into a first stream manifold and directing the first stream from the first stream manifold into a mixing chamber via a plurality of first stream passages flow coupled to the mixing chamber. A second stream of gas is directed into the mixing chamber via at least one second stream passage flow coupled to a first end of the mixing chamber. A combined stream is formed from the first and second streams, gradually converged, and discharged from the mixing chamber through a mixing chamber exit port.

Owner:CATERPILLAR INC

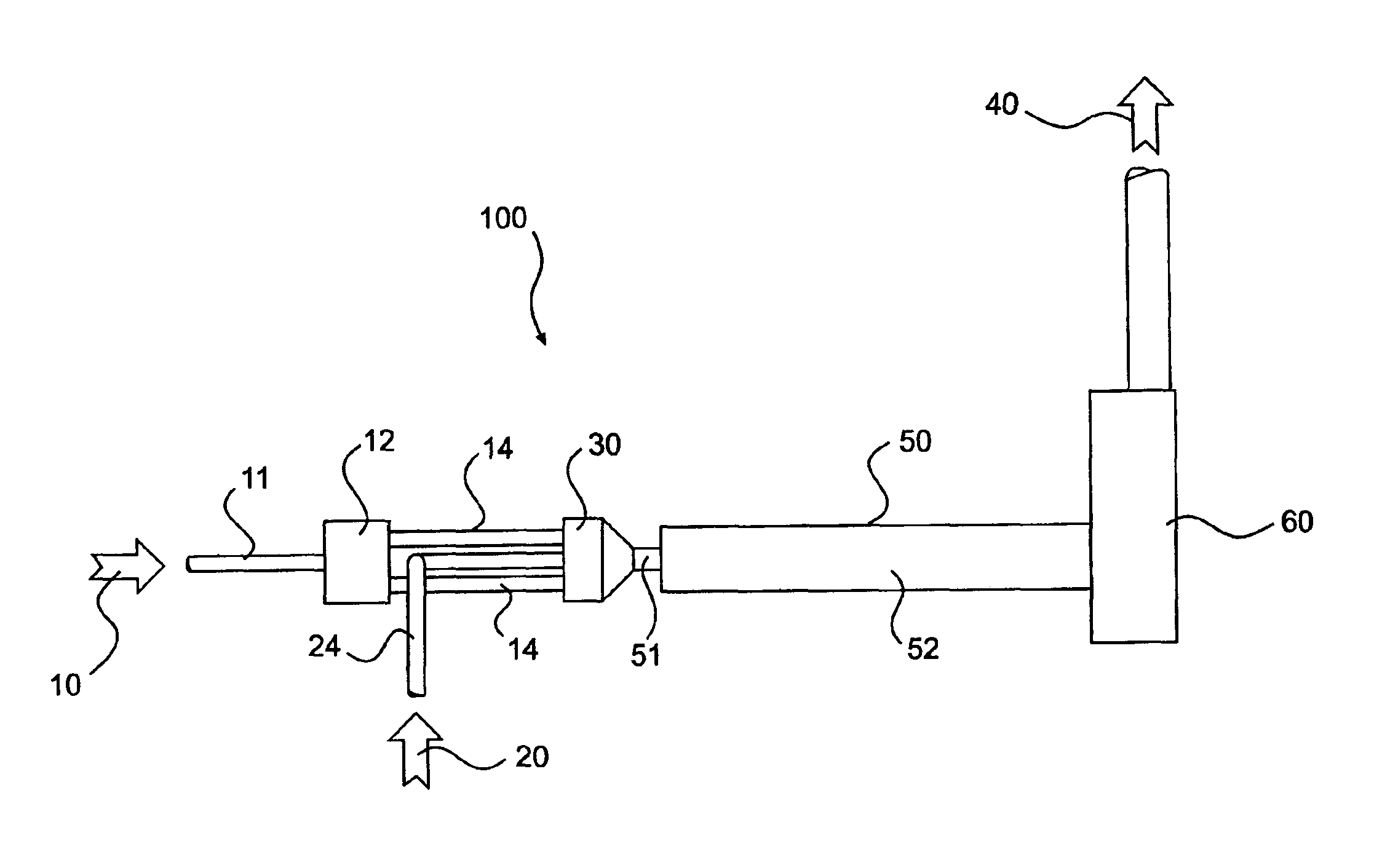

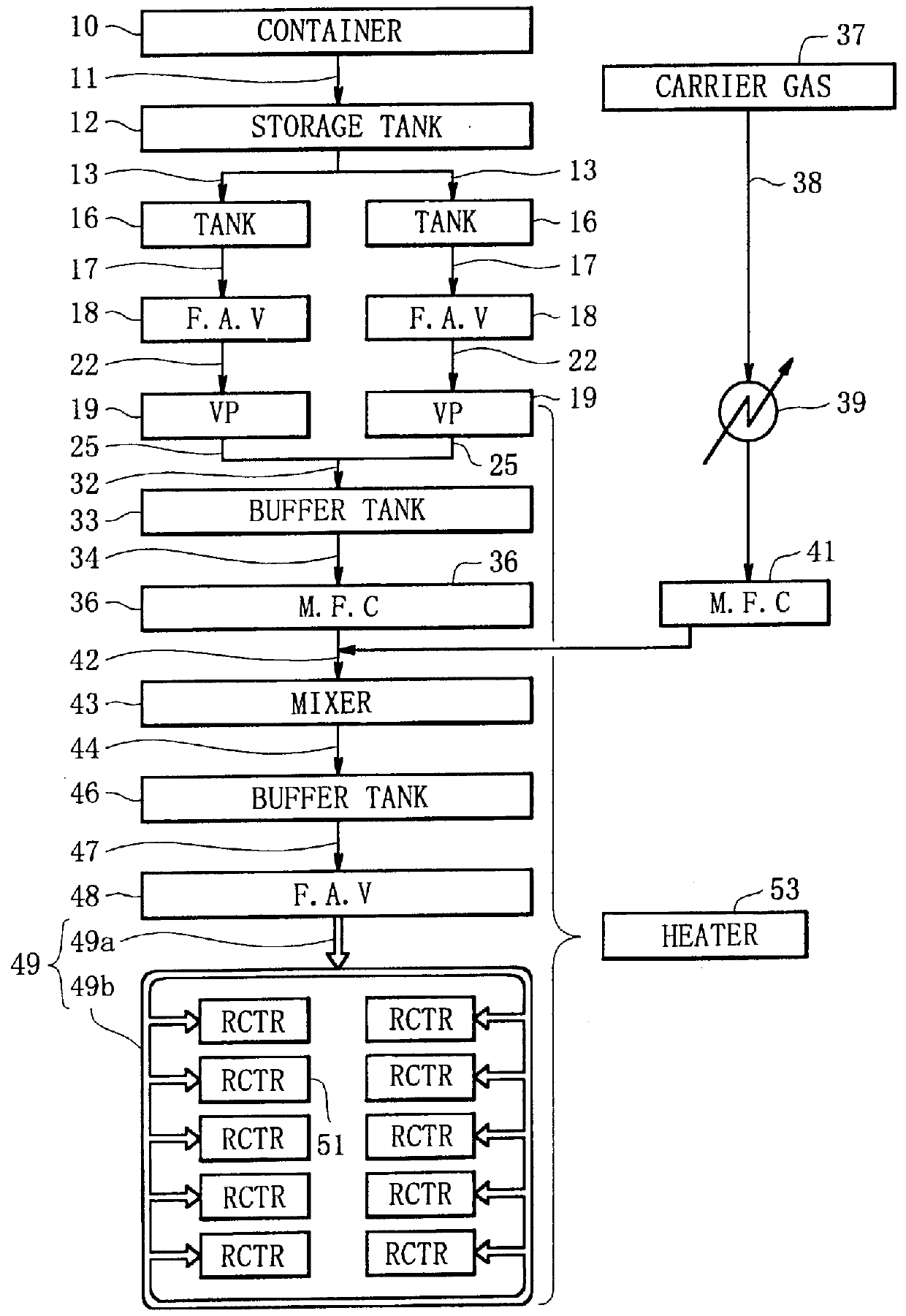

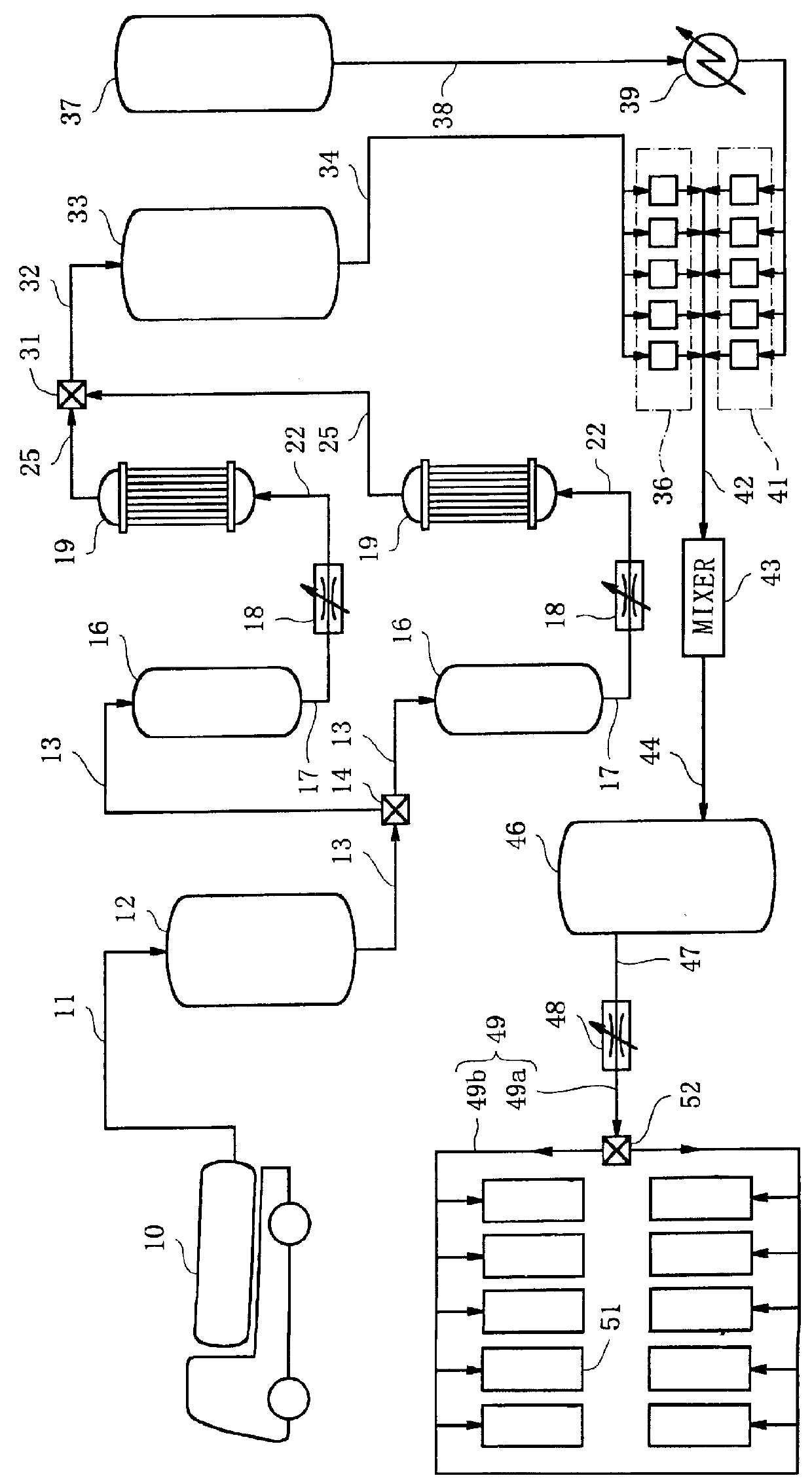

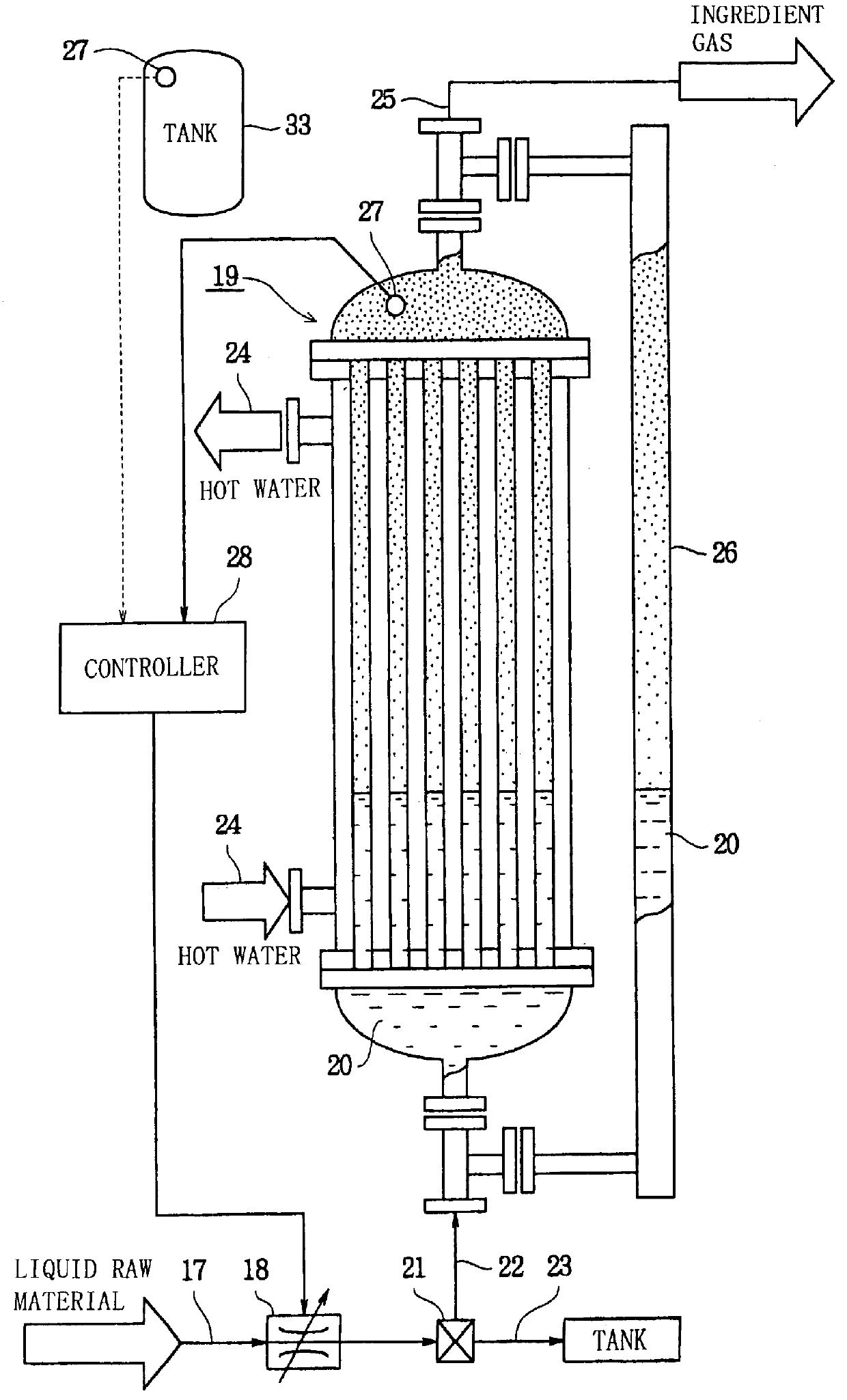

Method and apparatus for feeding a gas for epitaxial growth

InactiveUS6039809APolycrystalline material growthTransportation and packagingBoiling pointProduct gas

A liquid raw material is heated to its boiling point or higher at a vaporizer to mix the vaporized ingredient gas and a carrier gas at a mixer at predetermined concentrations. The flow of the mixed gas is adjusted while the mixed gas is heated to over its condensing point and the temperature thereof is kept. Subsequently, the mixed gas is fed to a reactor for epitaxial growth while the mixed gas is heated to over its condensing point and the temperature thereof is kept. When the temperature of a heating medium is kept constant at the vaporizer to vaporize the liquid raw material and the feeding amount of the liquid into the vaporizer is adjusted by the pressure of the gas inside the vaporizer, the liquid surface level can be controlled to be constant.

Owner:MITSUBISHI MATERIALS CORP

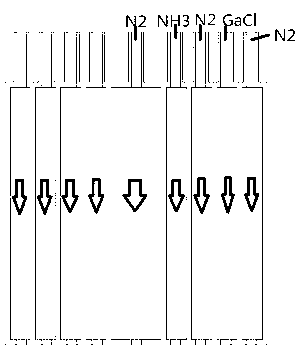

Multiple precursor concentric delivery showerhead

InactiveUS20110256692A1Simple methodSpray nozzlesSemiconductor/solid-state device manufacturingChemical vapor depositionVapor phase

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus provides a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, a plurality of concentric tube assemblies are disposed within the showerhead to separately deliver a first gas from a first gas channel and a second gas from a second gas channel into the processing volume of the chamber. In one embodiment, the showerhead further includes a heat exchanging channel through which the plurality of concentric tube assemblies is disposed.

Owner:APPLIED MATERIALS INC

Methods, systems and devices for improving ventilation in a lung area

ActiveUS7588033B2Effective and direct cannulationIncrease hyperinflationTracheal tubesOperating means/releasing devices for valvesDiseasePrimary bronchus

Methods, systems and devices are described for new modes of ventilation in which specific lung areas are ventilated with an indwelling trans-tracheobronchial catheter for the purpose of improving ventilation and reducing hyperinflation in that specific lung area, and for redistributing inspired air to other healthier lung areas, for treating respiratory disorders such as COPD, ARDS, SARS, CF, and TB. Trans-Tracheobronchial Segmental Ventilation (TTSV) is performed on either a naturally breathing or a mechanical ventilated patient by placing a uniquely configured indwelling catheter into a bronchus of a poorly ventilated specific lung area and providing direct ventilation to that area. The catheter can be left in place for extended periods without clinician attendance or vigilance. Ventilation includes delivery of respiratory gases, therapeutic gases or agents and evacuation of stagnant gases, mixed gases or waste fluids. Typically the catheter's distal tip is anchored without occluding the bronchus but optionally may intermittently or continuously occlude the bronchus. TTSV is optionally performed by insufflation only of the area, or by application of vacuum to the area, can include elevating or reducing the pressure in the targeted area to facilitate stagnant gas removal, or can include blocking the area to divert inspired gas to better functioning areas.

Owner:BREATHE TECHNOLOGIES INC

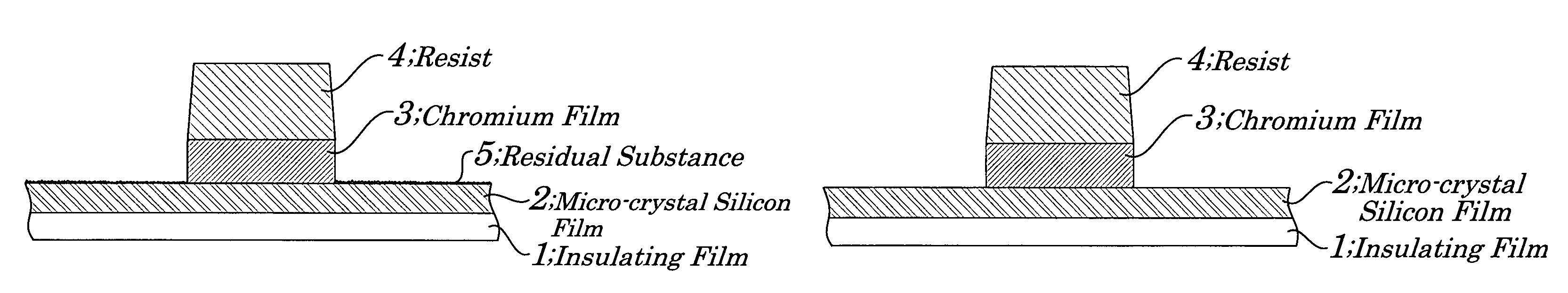

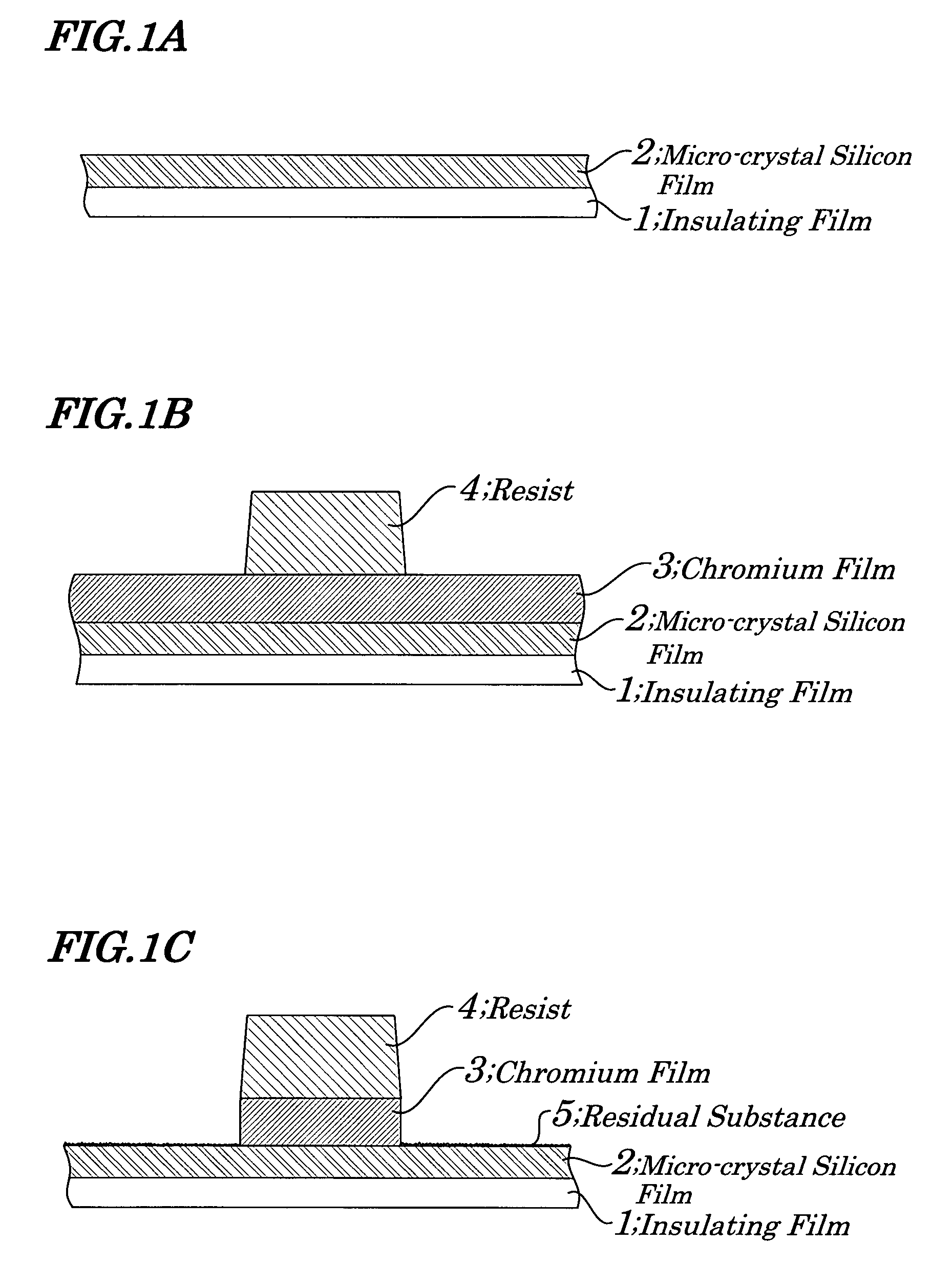

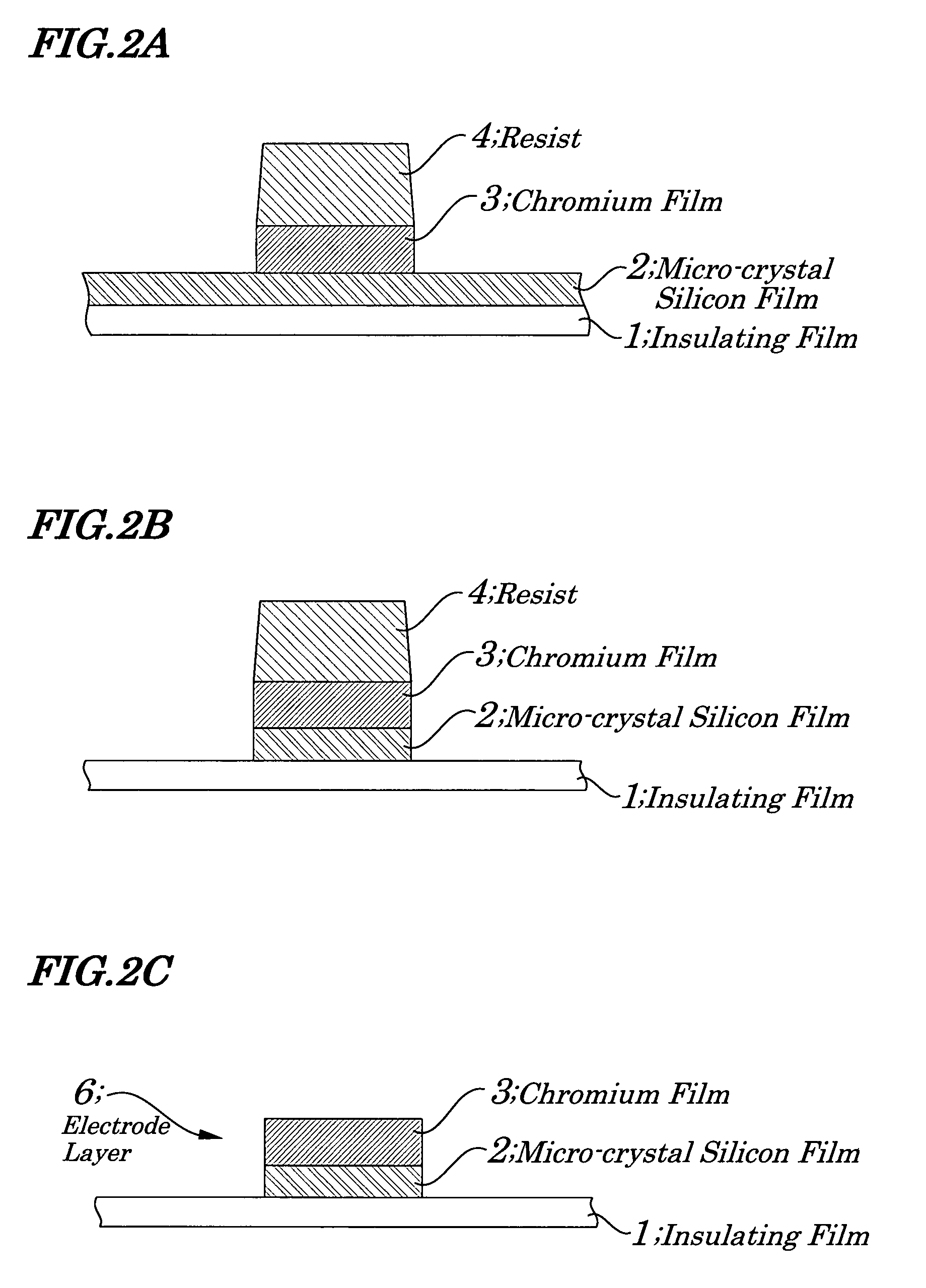

Stacked film patterning method and gate electrode forming method

InactiveUS7723221B2Improve uniformityAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesResistMixed gas

A stacked film patterning method is provided which is capable of reliably removing residual substances remaining after etching of a metal film, improving etching uniformity of a silicon film, and preventing an occurrence of etching residues. A micro-crystal film and a chromium film are sequentially formed on an insulating film serving as a front-end film and the chromium film is etched to be patterned by using a resist as a mask. Next, a micro-crystal silicon film on which the residual substances exist is exposed to plasma of a mixed gas including chlorine gas and oxygen gas to selectively etch the residual substances on a surface of the micro-crystal silicon film. After that, the micro-crystal silicon film is dry etched.

Owner:NEC LCD TECH CORP

Flow rate compensation for transient thermal response of hot-wire anemometers

ActiveUS20100218765A1Operating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringOxygen

Systems and methods are described for application of a transitory corrective modification to a hot-wire anemometer flow voltage and / or calculated flow rate to compensate for transient thermal response of the anemometer during a change in mixture of a mixed gas being measured. According to one embodiment a method of applying the transitory corrective modification is provided. An output signal of an exhalation flow sensor of a medical ventilator is received. The flow sensor includes a hot-wire anemometer. The output signal is indicative of a rate of flow of expired gas by a patient. Transient thermal response of the hot-wire anemometer is compensated for by applying a corrective modification to the output signal or a value based thereon. The corrective modification is based at least in part on a fraction of inspired oxygen (FiO2) being supplied by the medical ventilator to the patient.

Owner:TYCO HEALTHCARE GRP LP

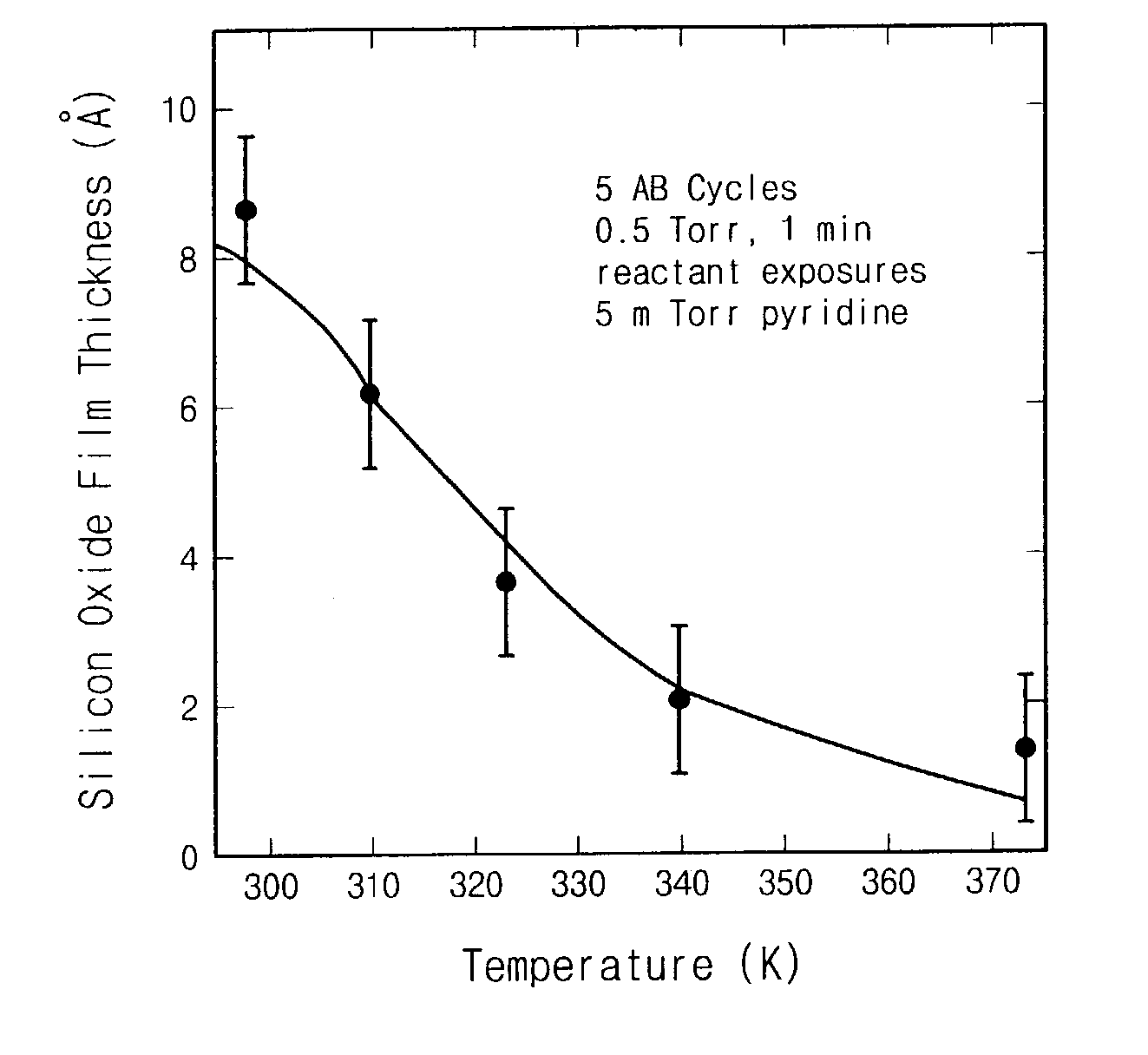

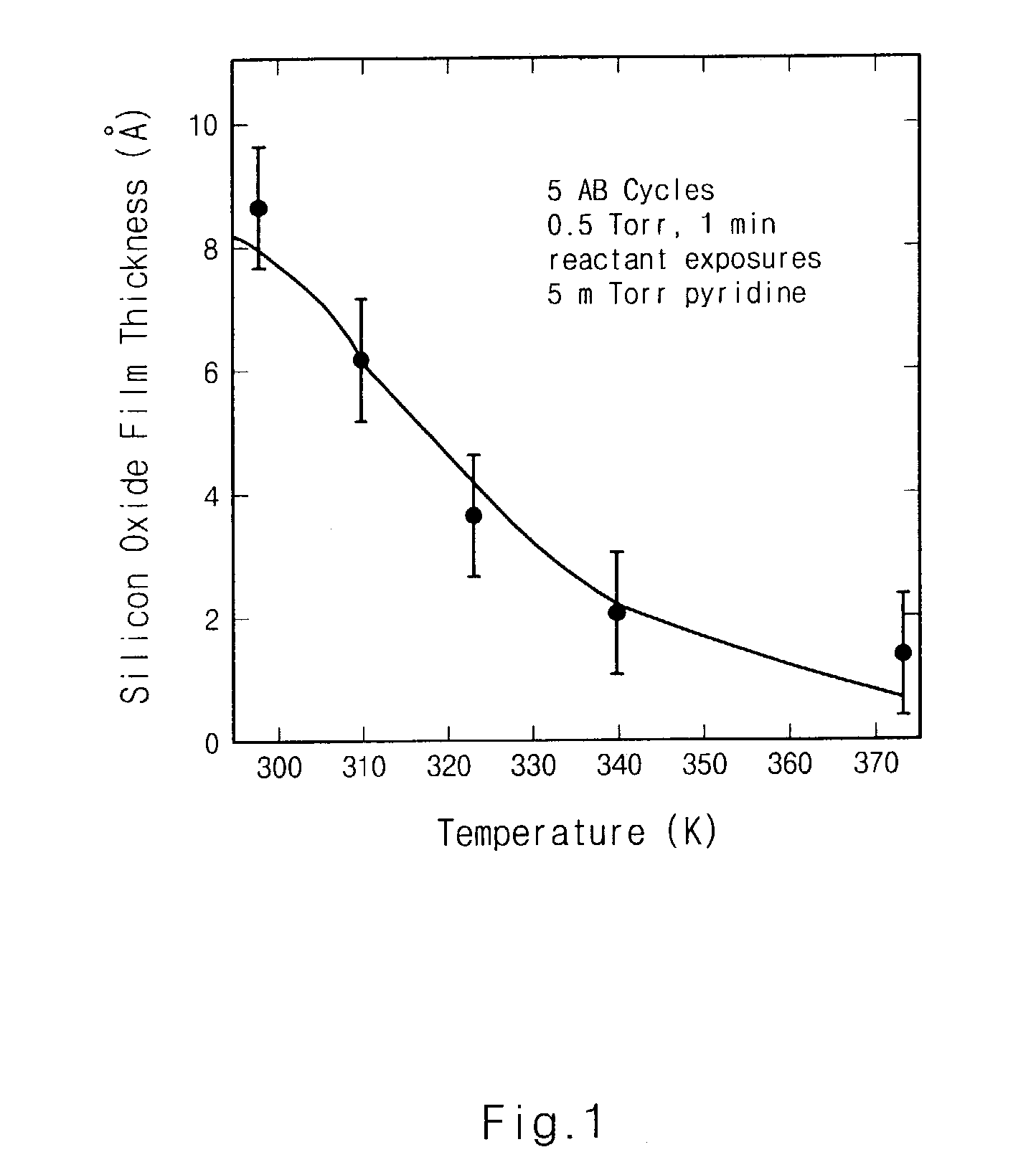

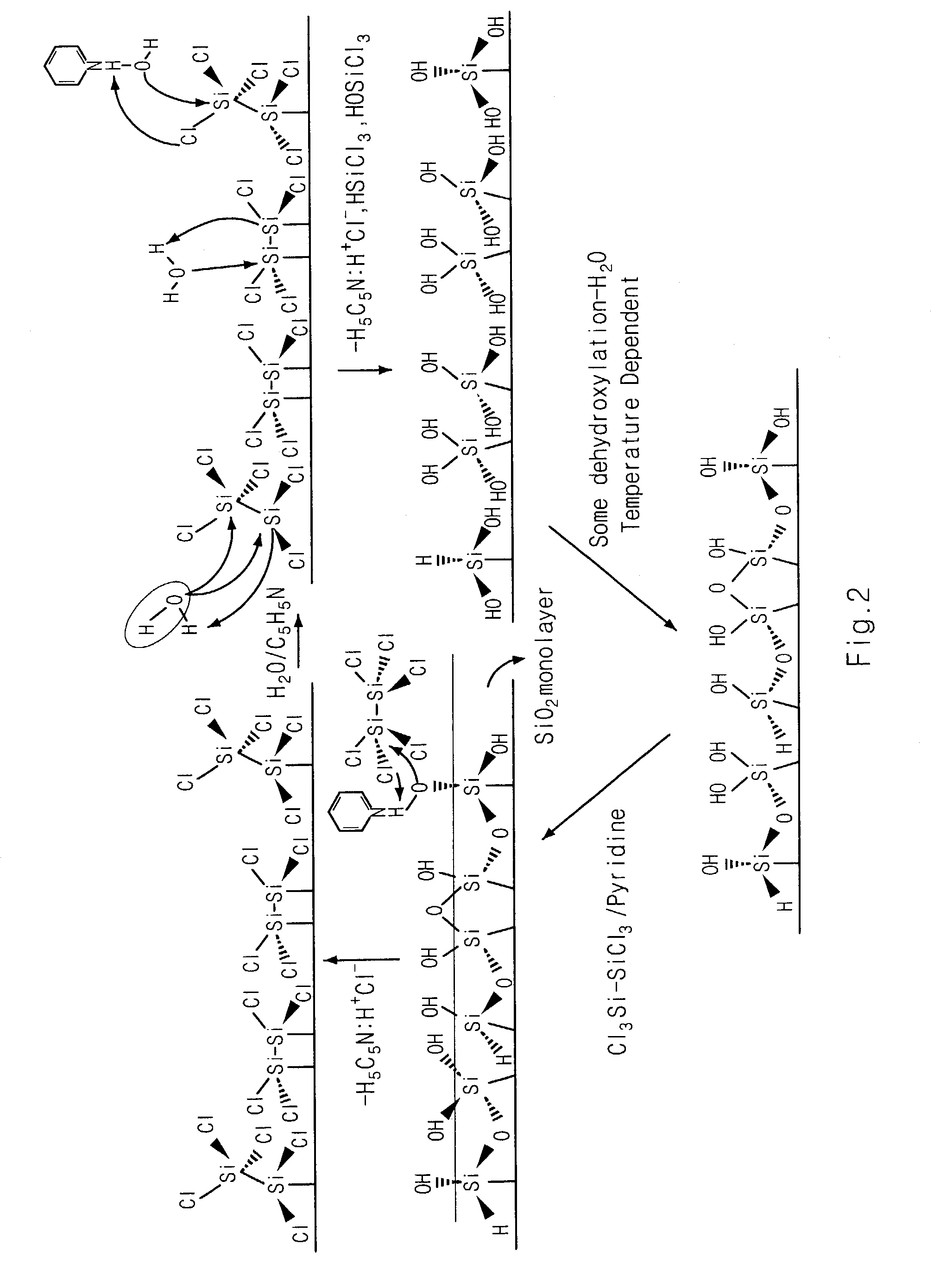

Method for atomic layer deposition (ALD) of silicon oxide film

InactiveUS7077904B2Increase deposition rateReduce the temperaturePolycrystalline material growthFrom chemically reactive gasesSilicon oxideAtomic layer deposition

The present invention relates to a method for forming silicon oxide films on substrates using an atomic layer deposition process. Specifically, the silicon oxide films are formed at low temperature and high deposition rate via the atomic layer deposition process using a Si2Cl6 source unlike a conventional atomic layer deposition process using a SiCl4 source. The atomic layer deposition apparatus used in the above process can be in-situ cleaned effectively at low temperature using a HF gas or a mixture gas of HF gas and gas containing —OH group.

Owner:SAMSUNG ELECTRONICS CO LTD

Gas supply unit and semiconductor device manufacturing apparatus using the same

InactiveUS20050016452A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialManufactured apparatus

A semiconductor device manufacturing apparatus is provided. The semiconductor device manufacturing apparatus comprises a furnace having a closed predetermined space for seating a wafer, a loading device located at one side of the furnace to load the wafer on which a prior process may have been performed, a gate valve interposed between the furnace and the loading device to selectively open / close a pathway between the furnace and the loading device, a heater for heating an interior of the furnace, a vacuum pump for maintaining the interior of the furnace with a suitable pressure necessary to the process, a gas reservoir for storing individually various kinds of reaction gases supplied from an exterior of the space, a gas mixing device connected to the gas reservoir to mix the various kinds of reaction gases supplied from the gas reservoir with an even mixing ratio, at least two mixed gases supply pipes connected to the gas mixing device to supply the reaction gases mixed in the gas mixing device to each direction of the furnace, and a mixed gases flow control unit installed at the mixed gases supply pipe to control the flow of the reaction gases supplied through the mixed gases supply pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

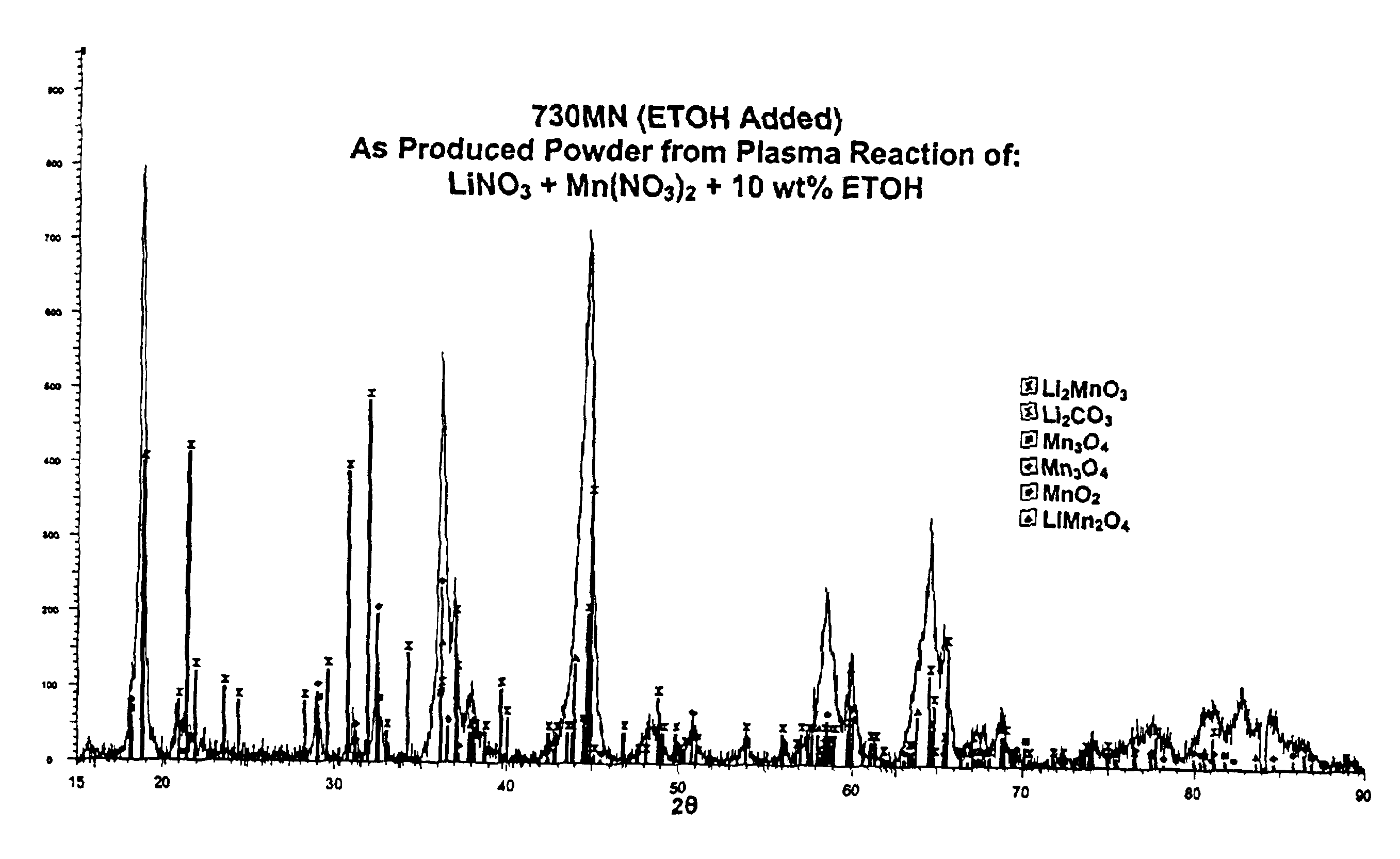

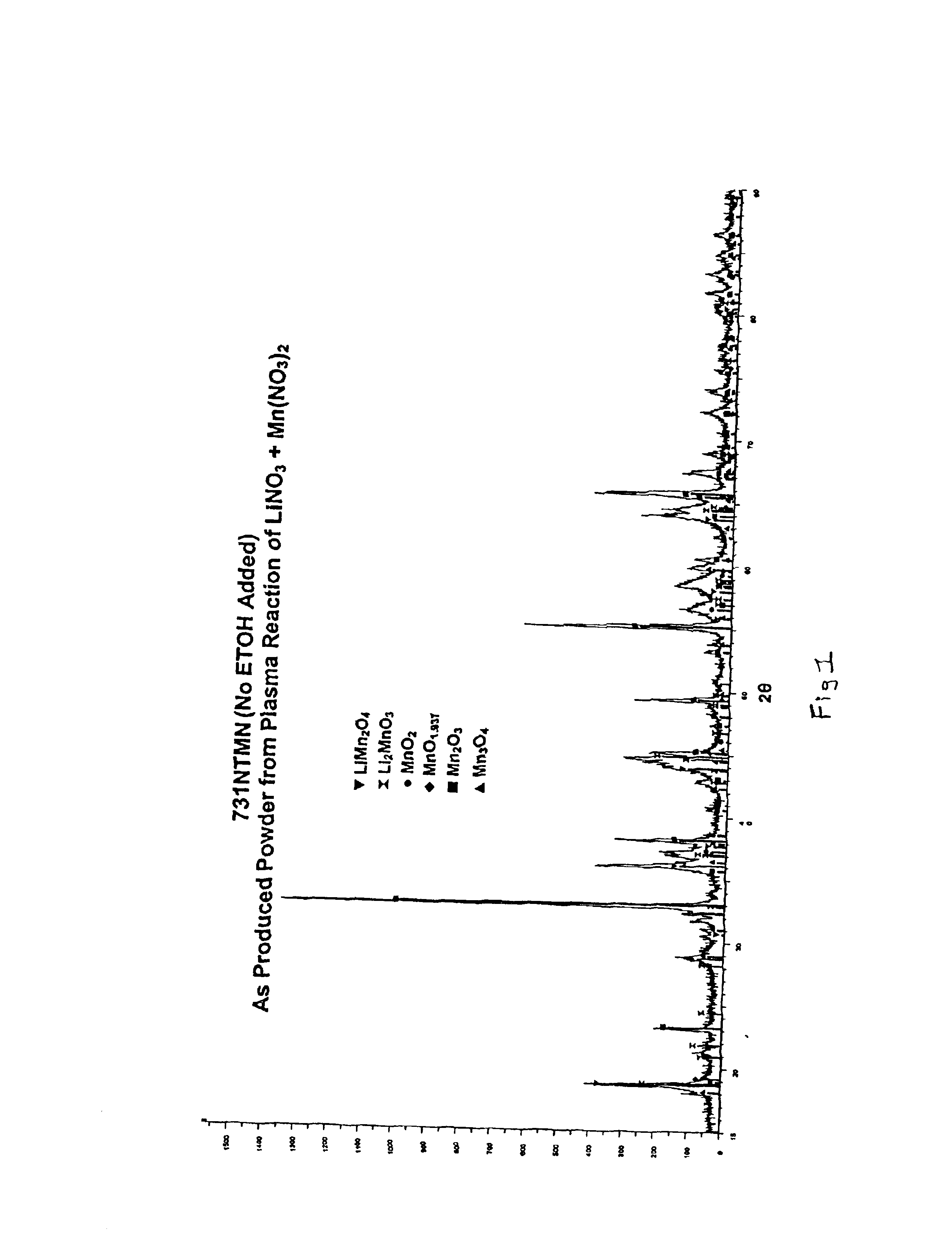

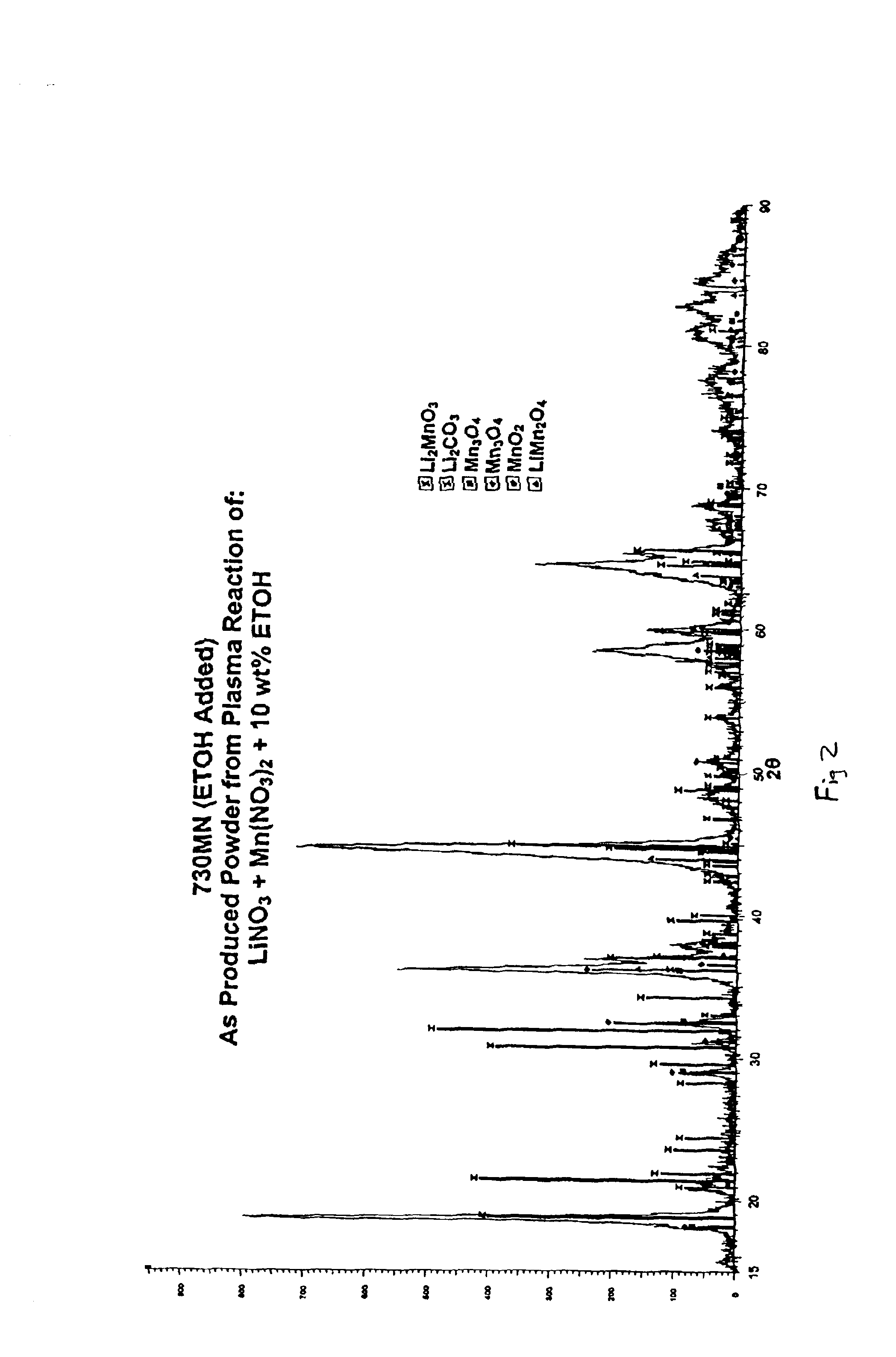

Plasma synthesis of lithium based intercalation powders for solid polymer electrolyte batteries

InactiveUS6838072B1Less timeLower costAluminium compoundsOxide/hydroxide preparationSingle phasePlasma reactor

The invention relates to a process for preparing lithium intercalation compounds by plasma reaction comprising the steps of: forming a feed solution by mixing lithium nitrate or lithium hydroxide or lithium oxide and the required metal nitrate or metal hydroxide or metal oxide and between 10-50% alcohol by weight; mixing the feed solution with O2 gas wherein the O2 gas atomizes the feed solution into fine reactant droplets, inserting the atomized feed solution into a plasma reactor to form an intercalation powder; and if desired, heating the resulting powder to from a very pure single phase product.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

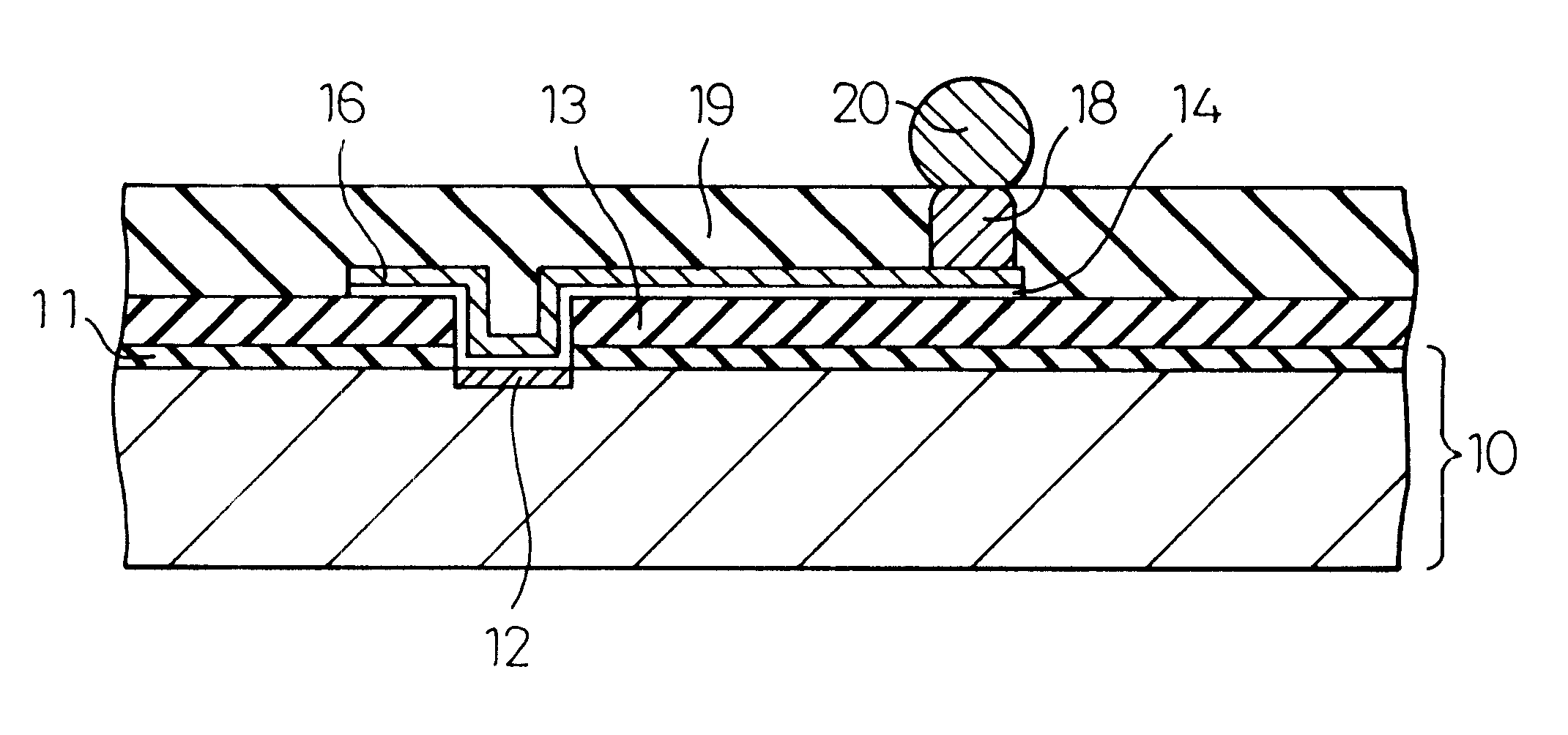

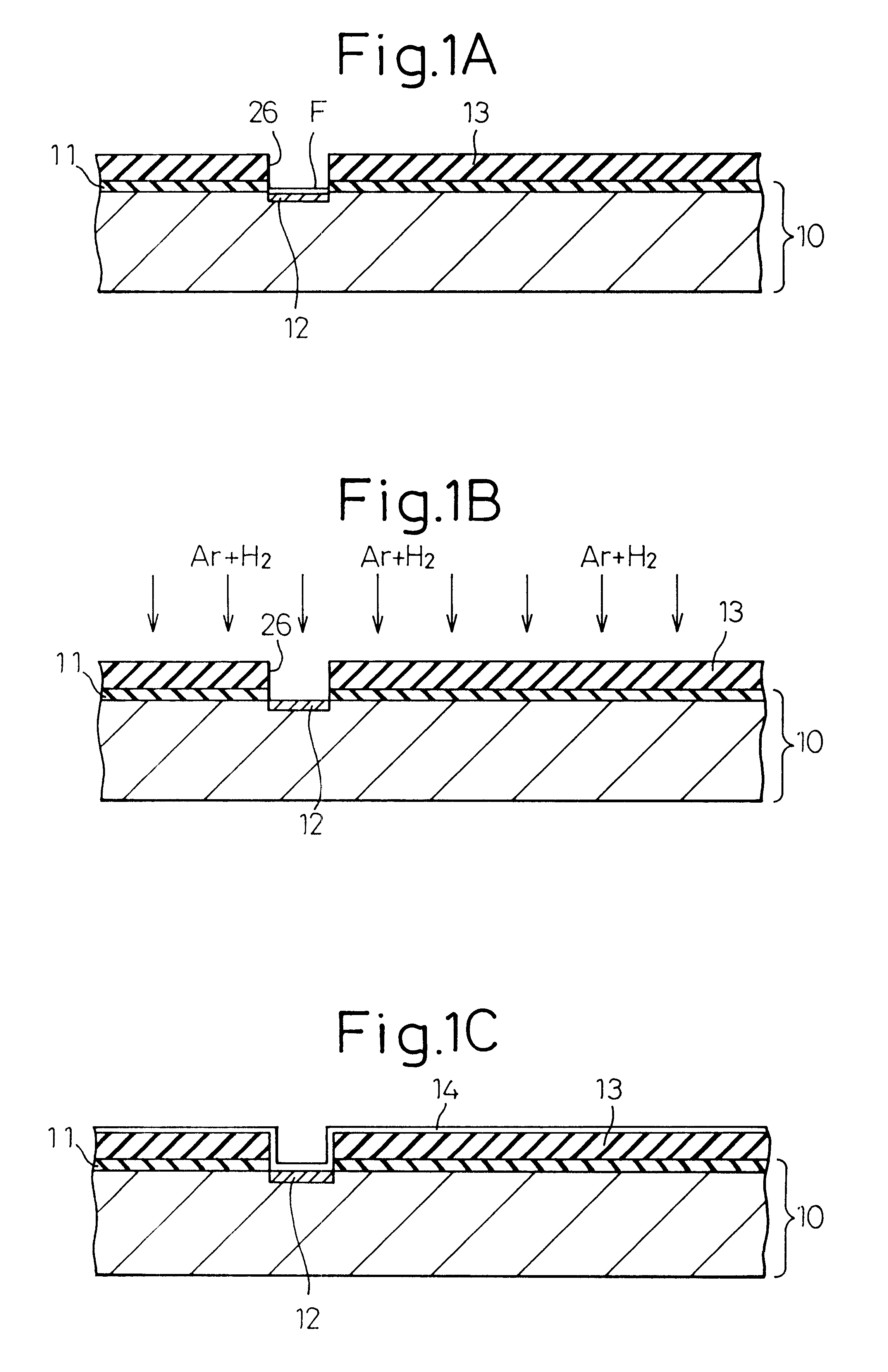

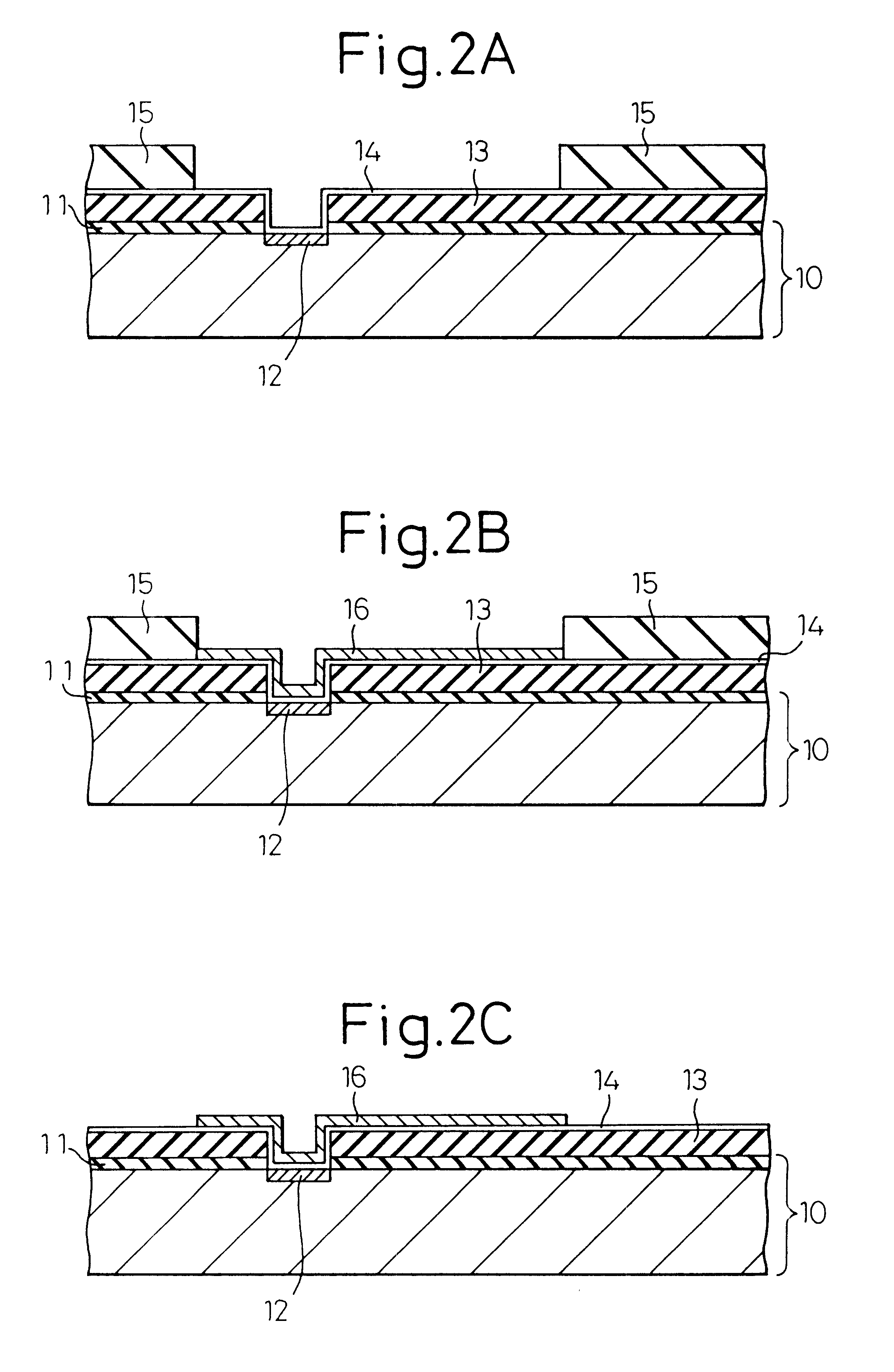

Method of producing semiconductor device comprising insulation layer having improved resistance and semiconductor device produced thereby

InactiveUS6200888B1Satisfactory electrical connectionReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

Owner:SHINKO ELECTRIC IND CO LTD

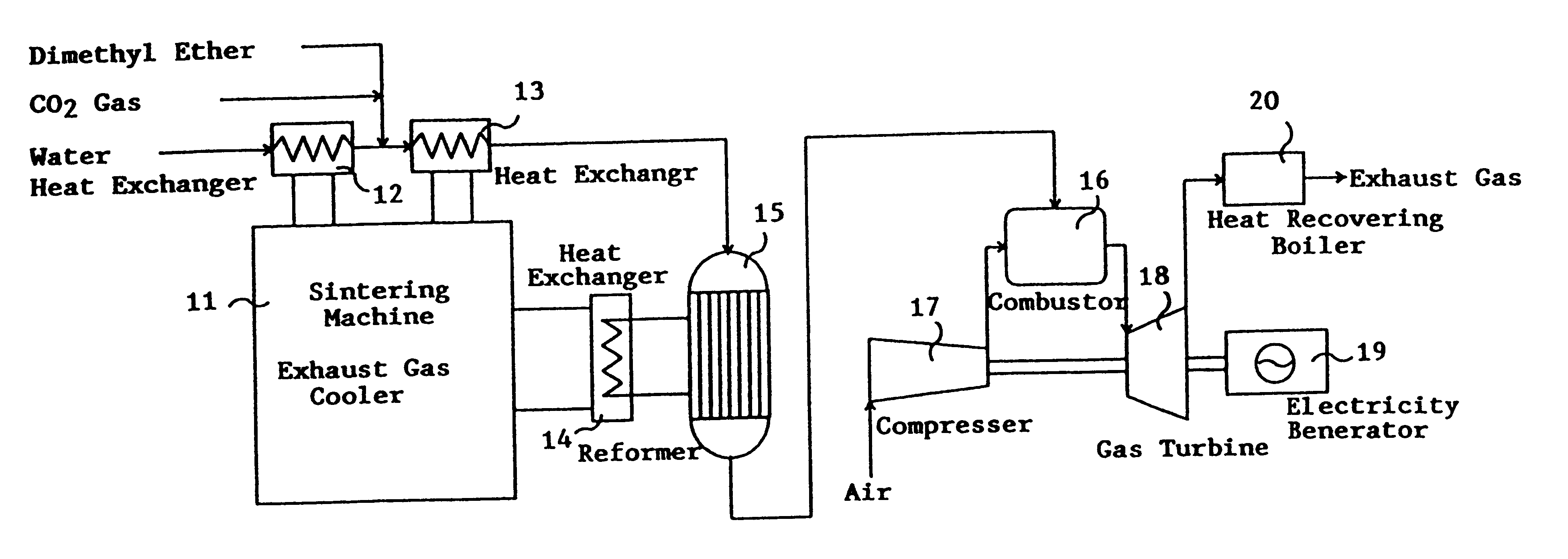

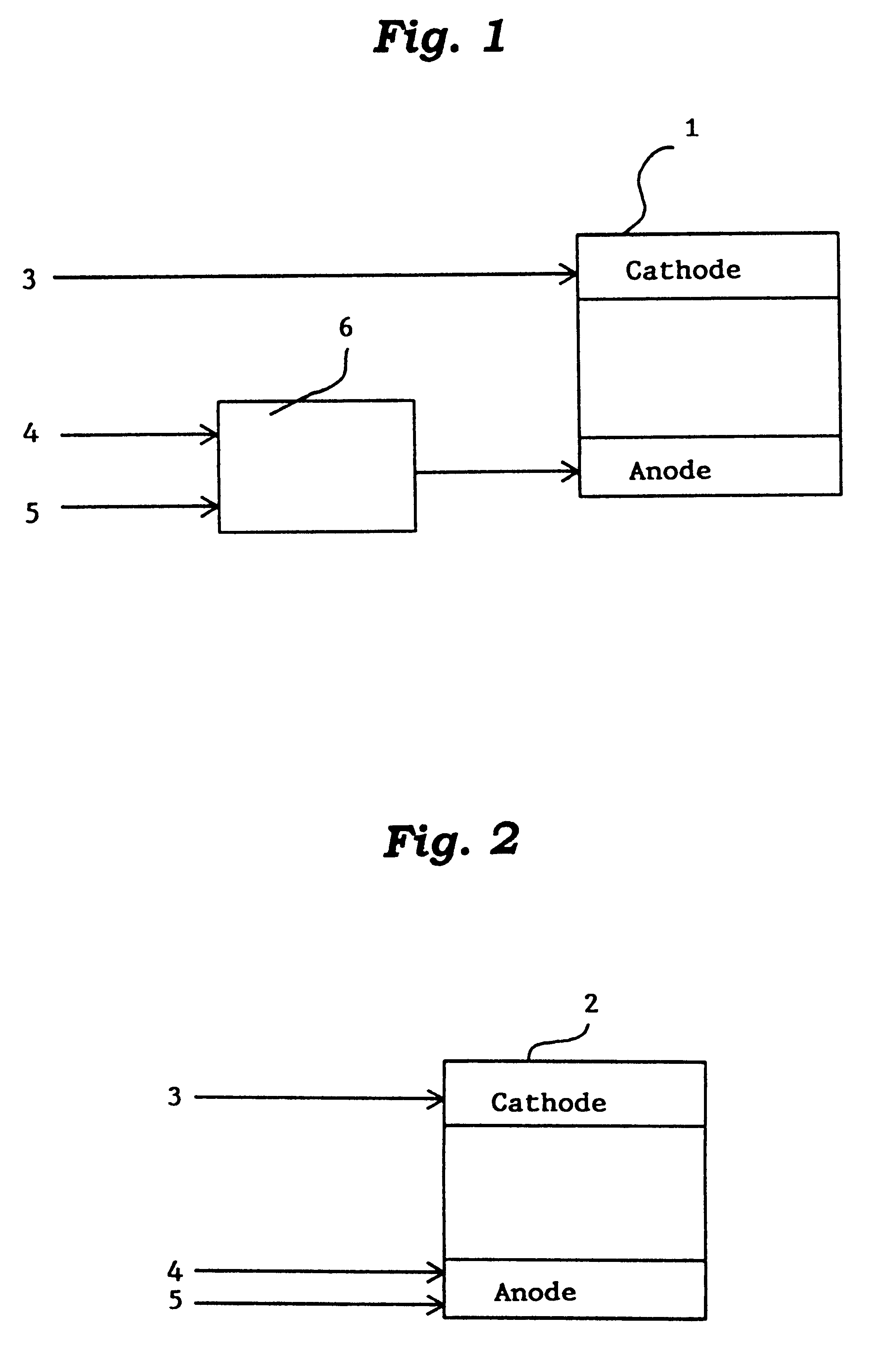

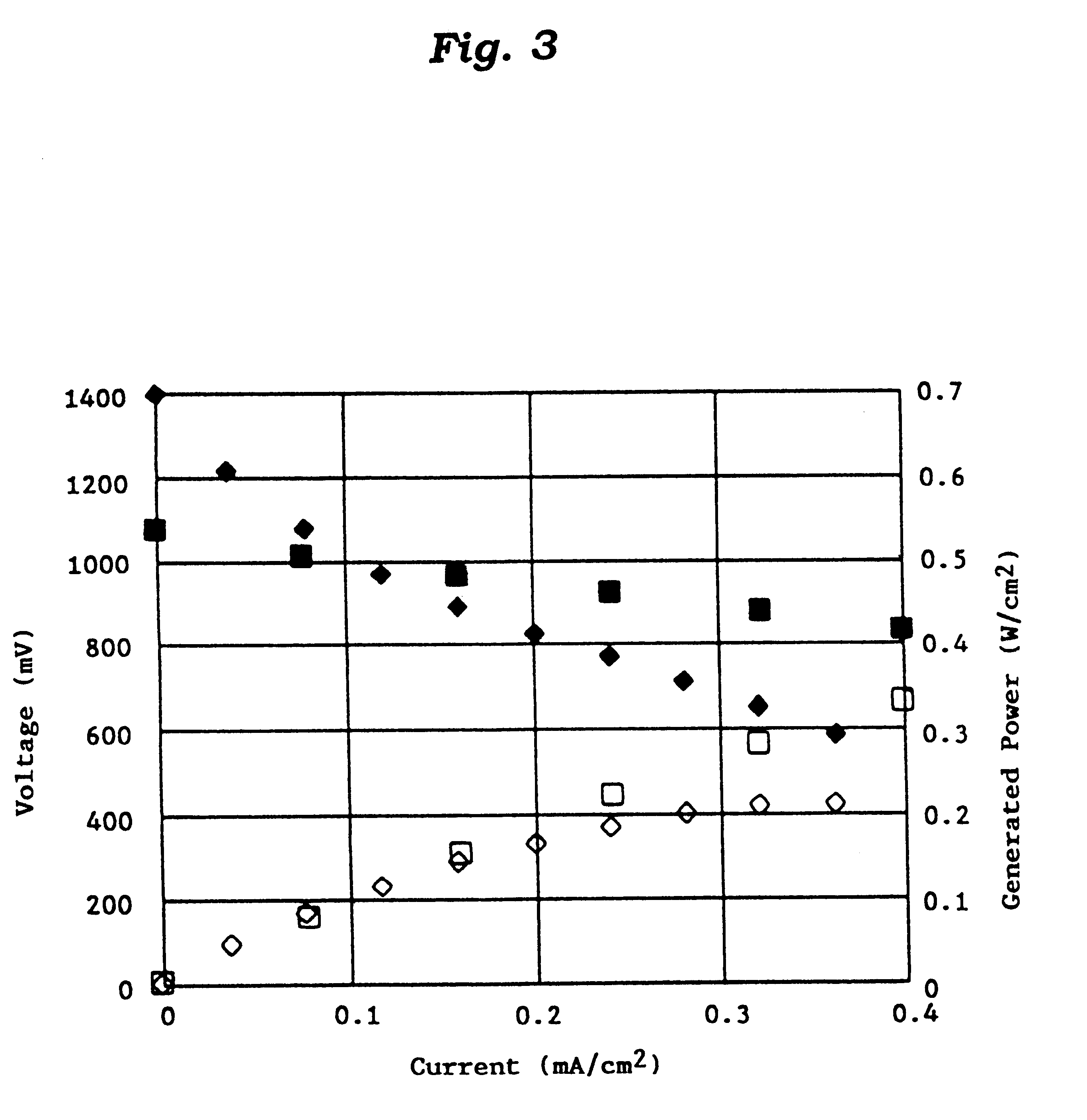

Catalyst for manufacturing hydrogen or synthesis gas and manufacturing method of hydrogen or synthesis gas

InactiveUS6361757B1Produce hydrogenEfficient productionIron compoundsCobalt compoundsIridiumForming gas

This invention provides a catalyst for producing hydrogen gas from a mixed gas comprising dimethyl ether and water vapor or carbon dioxide gas, which comprises copper, iron, cobalt, palladium, iridium, platinum, rhodium, or nickel as an active component, and a method of producing synthesis gas or hydrogen gas in a high yield at a low temperature. By using the catalyst, a fuel cell, electricity generation, reduction of iron ore and the like can be carried out.

Owner:NIPPON KOKAN KK

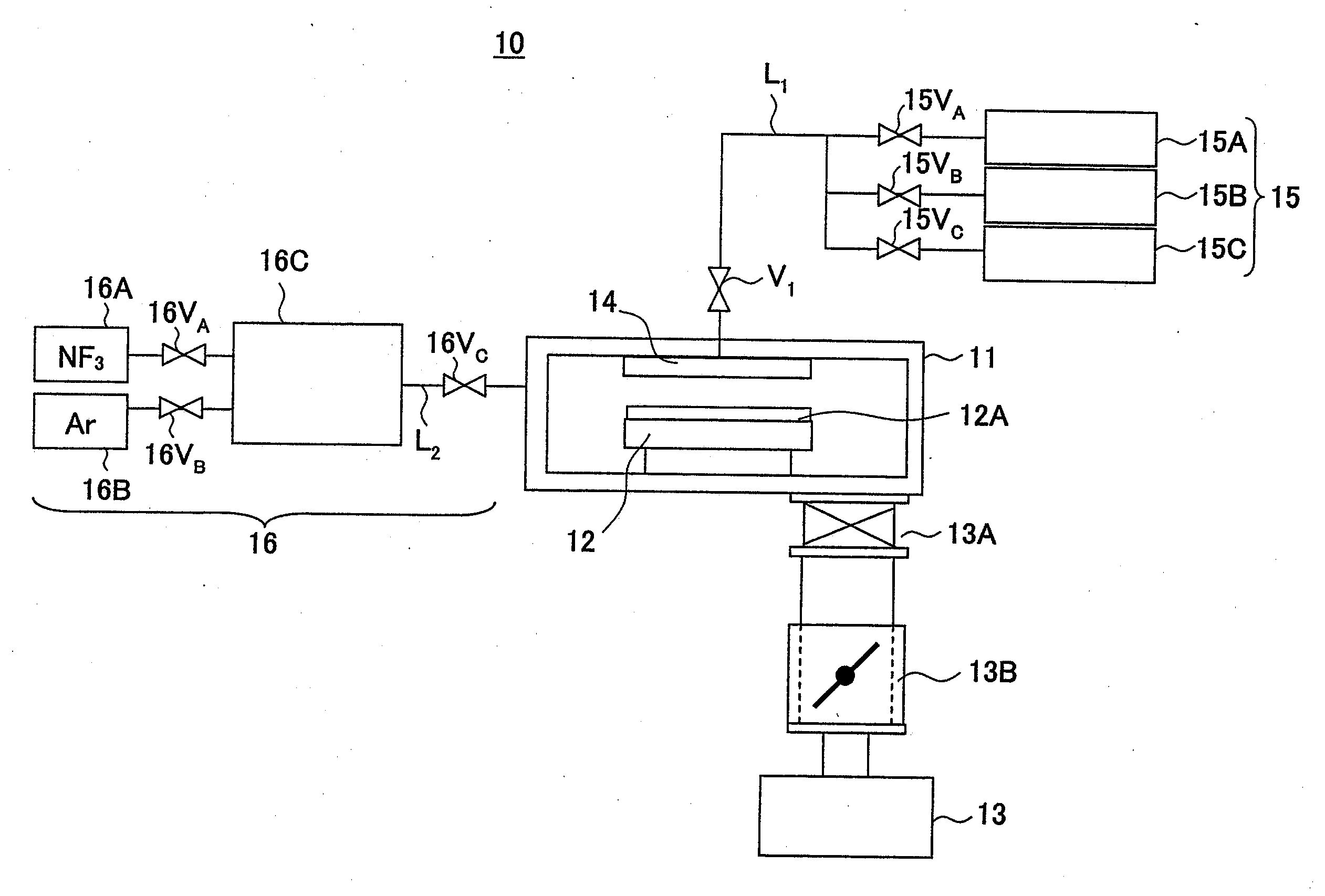

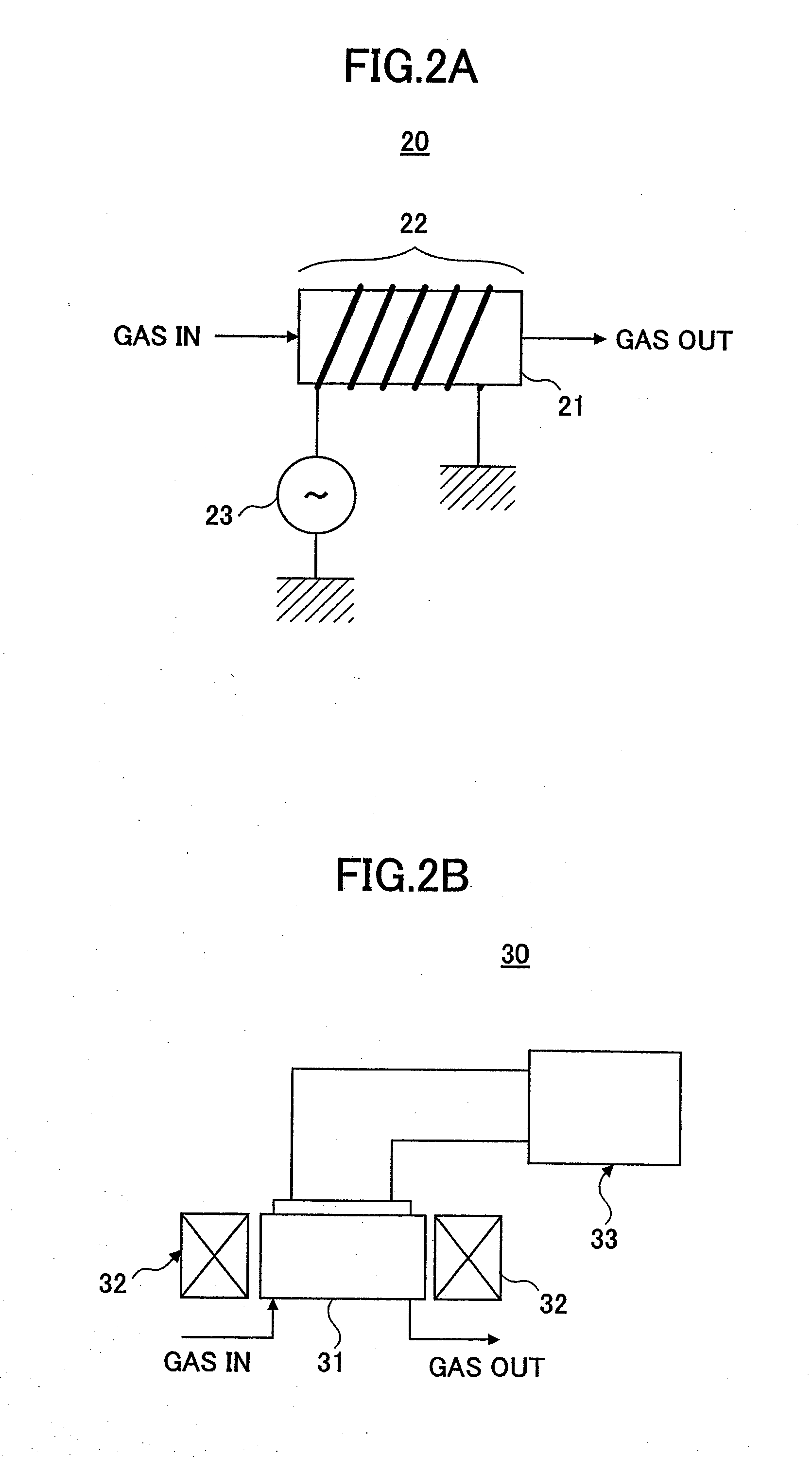

Plasma Generation Method, Cleaning Method, and Substrate Processing Method

InactiveUS20100252068A1Improve throughputAvoid it happening againElectric discharge tubesDecorative surface effectsHigh frequency powerPlasma generator

A plasma generation method in a toroidal plasma generator that includes a gas passage having a gas entrance and a gas outlet and forming a circuitous path and a coil wound around a part of the gas passage includes the steps of supplying a mixed gas of an Ar gas and an NF3 gas containing at least 5% of NF3 and igniting plasma by driving the coil with a high-frequency power, wherein the plasma ignition step is conducted under a total pressure of 6.65-66.5 Pa.

Owner:TOKYO ELECTRON LTD

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

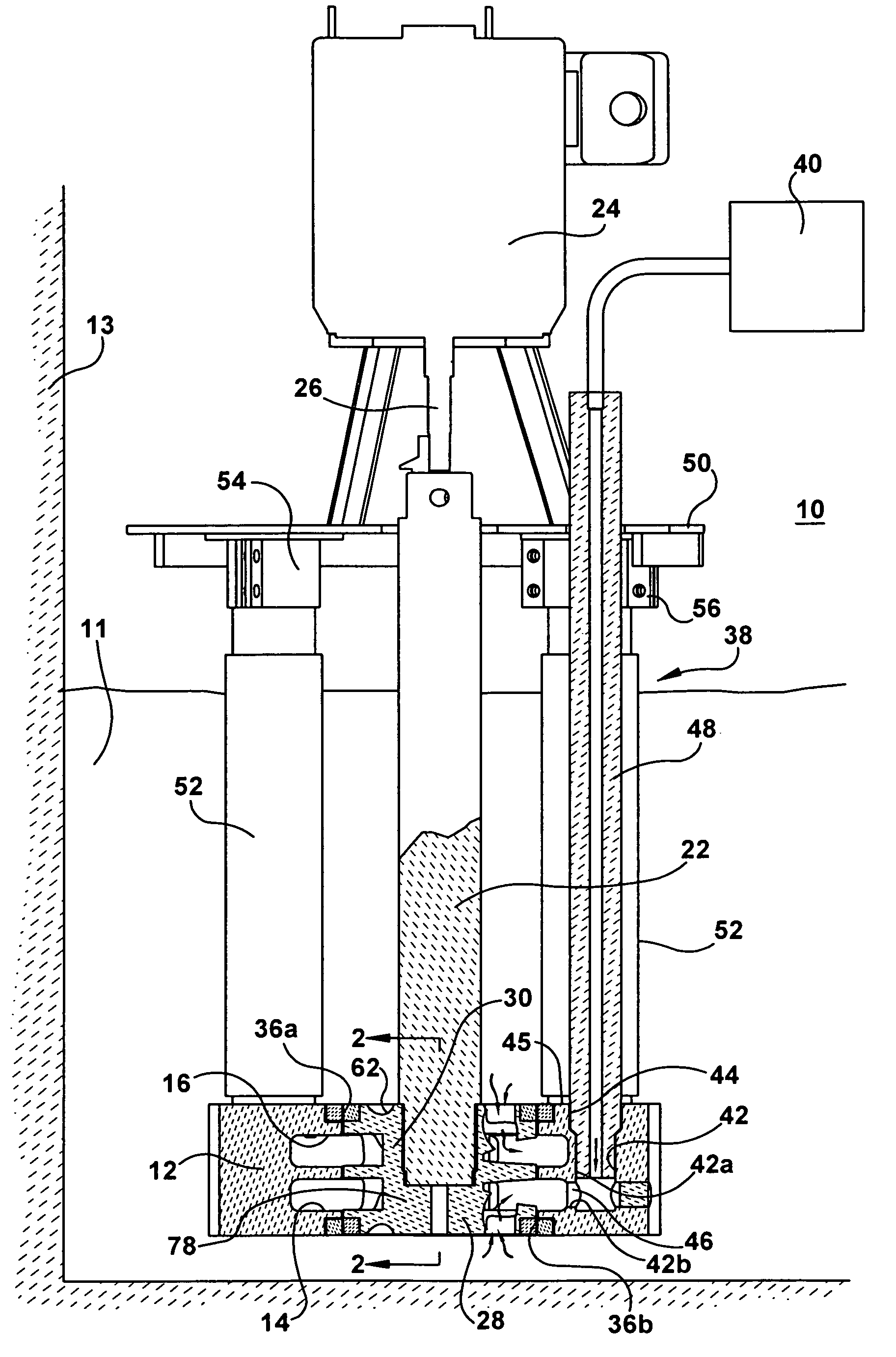

Gas mixing and dispersement in pumps for pumping molten metal

InactiveUS7476357B2Well mixedEfficient pumpingMelt-holding vesselsCharge manipulationImpellerPump chamber

A molten metal pump including a pump base with an inlet and outlet, a mixing impeller chamber for mixing gas and molten metal, a pumping impeller chamber for pumping molten metal. First and second impeller members supported by a shaft are adapted to rotate in mixing and pumping chambers respectively. The impeller members may be integrally formed of a single impeller or separate impellers on one or more shafts. A gas passageway extends from a gas source to the mixing chamber in the base. A gas dispersement pump includes a base with an impeller chamber and inlet and an outlet. An impeller is mounted to a shaft and adapted to be rotated in the impeller chamber. A gas passageway extends from a gas source to a gas outlet proximate to the impeller chamber. A gas dispersement member of porous refractory material is adapted to disperse gas from the gas passageway. In a gas dispersement and gas / molten metal mixing pump, the dispersement member disperses the gas stream entering the mixing chamber where the gas is mixed with molten metal. Molten metal is pumped in the pumping chamber. A gas / molten metal mixture is discharged from the mixing chamber and molten metal is discharged from the pumping chamber.

Owner:THUT BRUNO H

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com