Patents

Literature

110results about How to "Easy pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

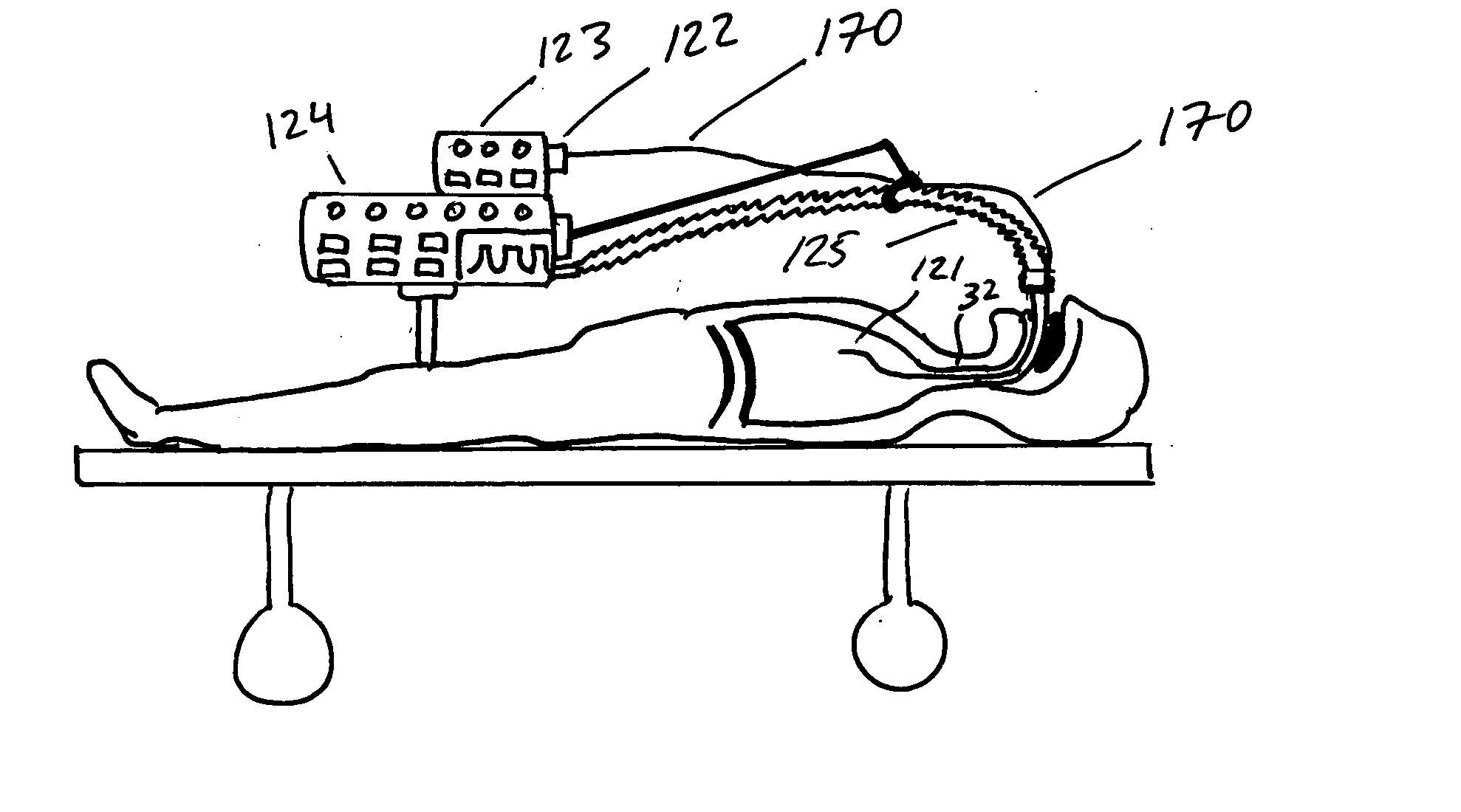

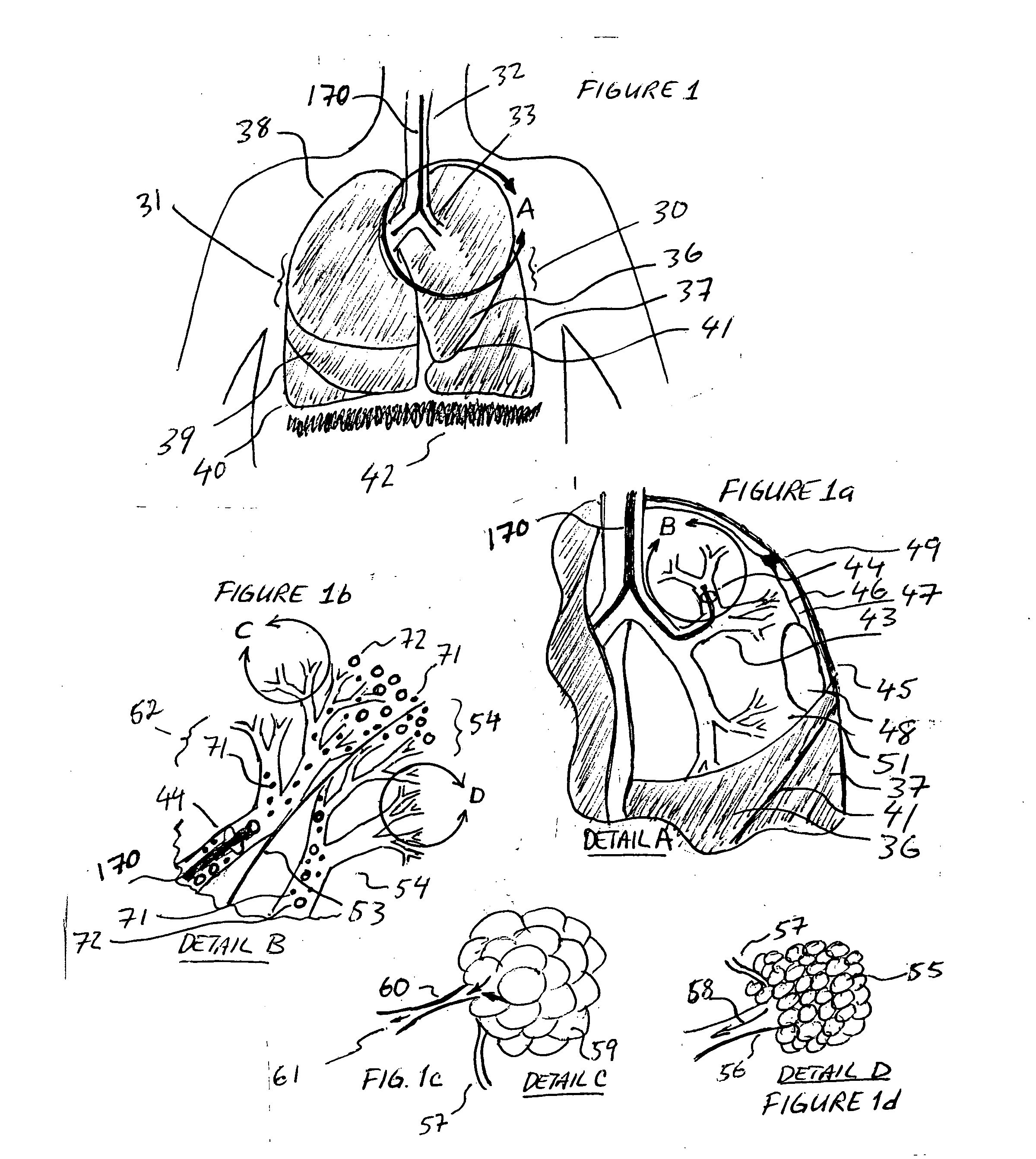

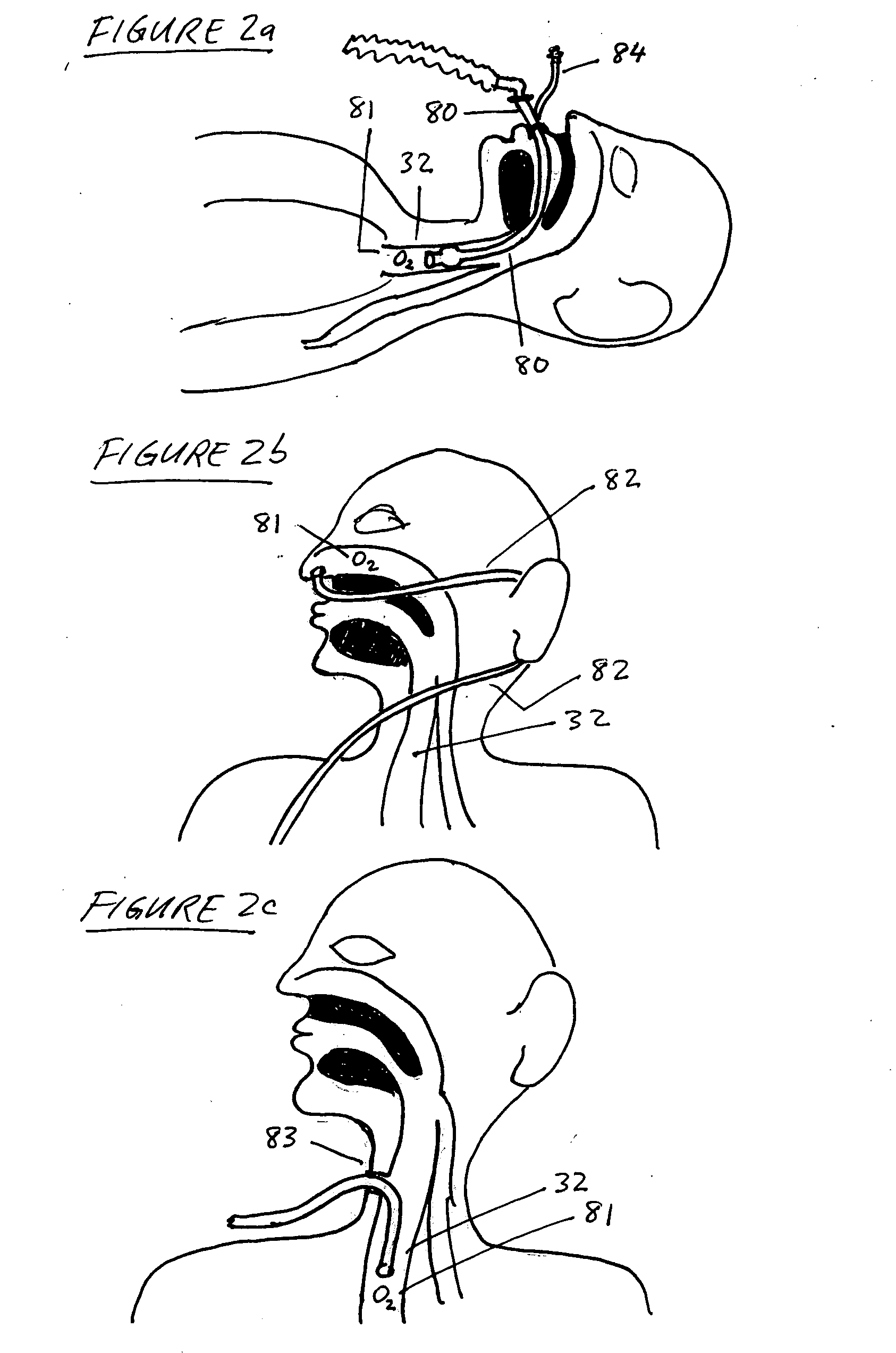

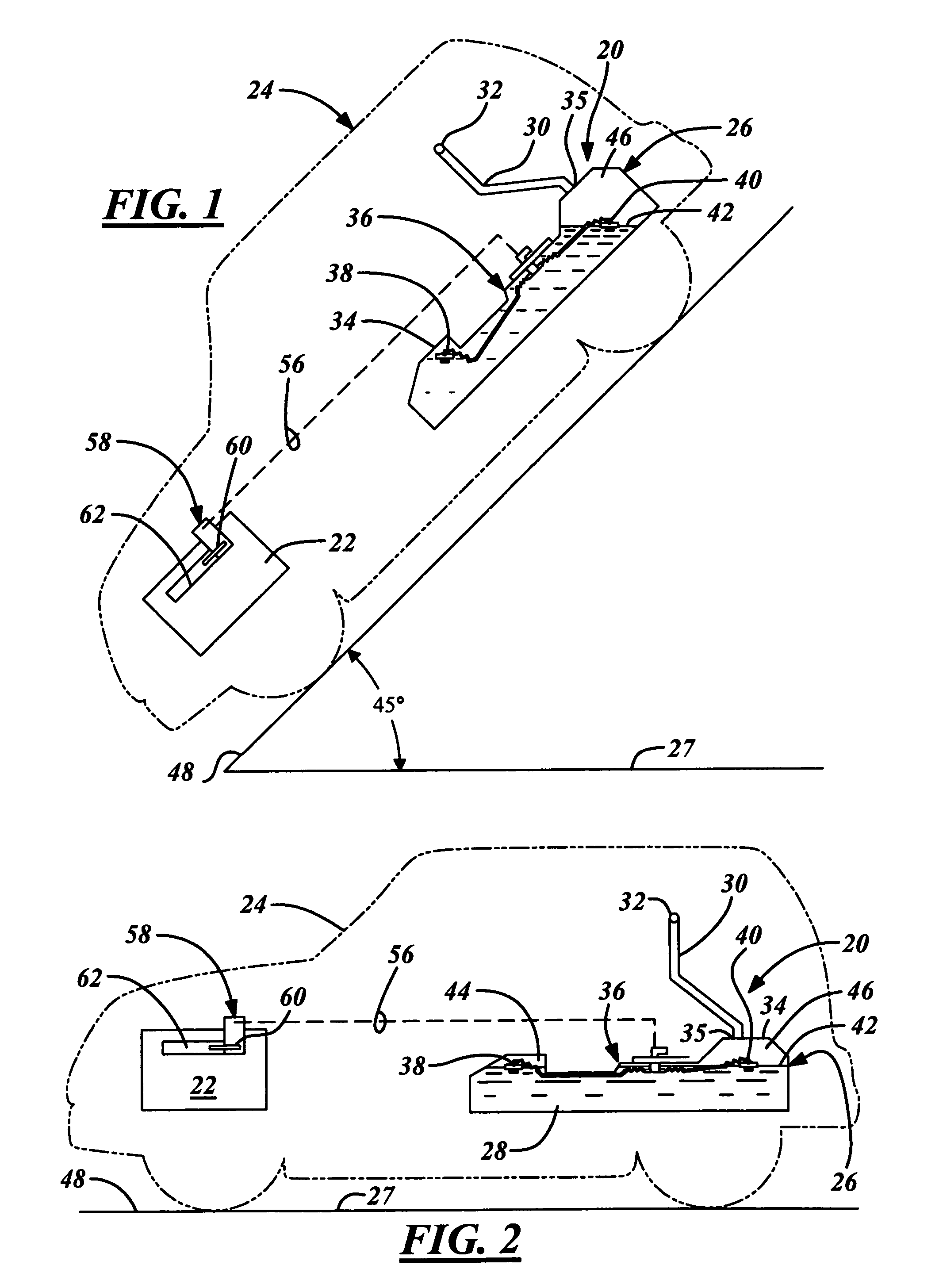

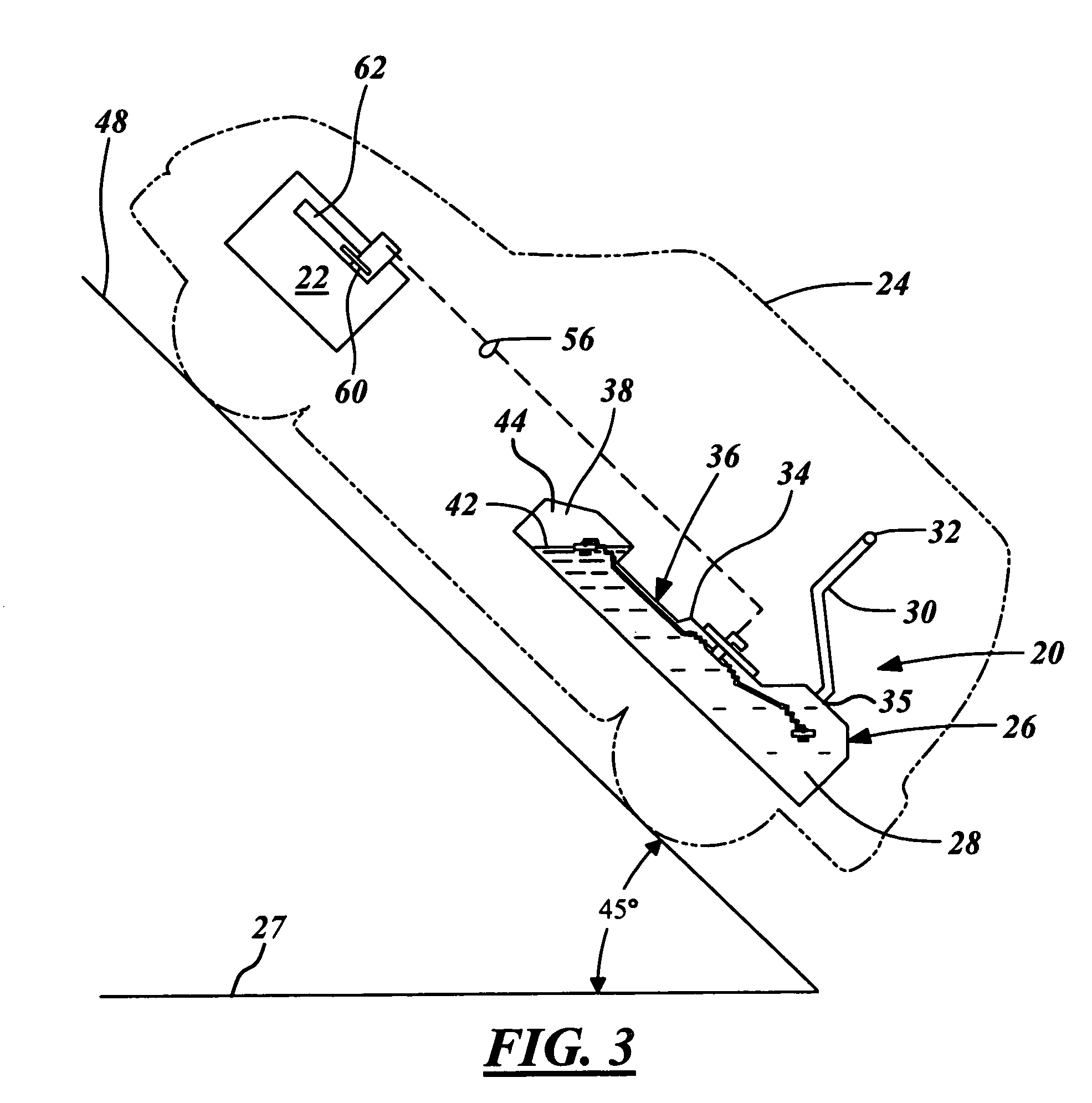

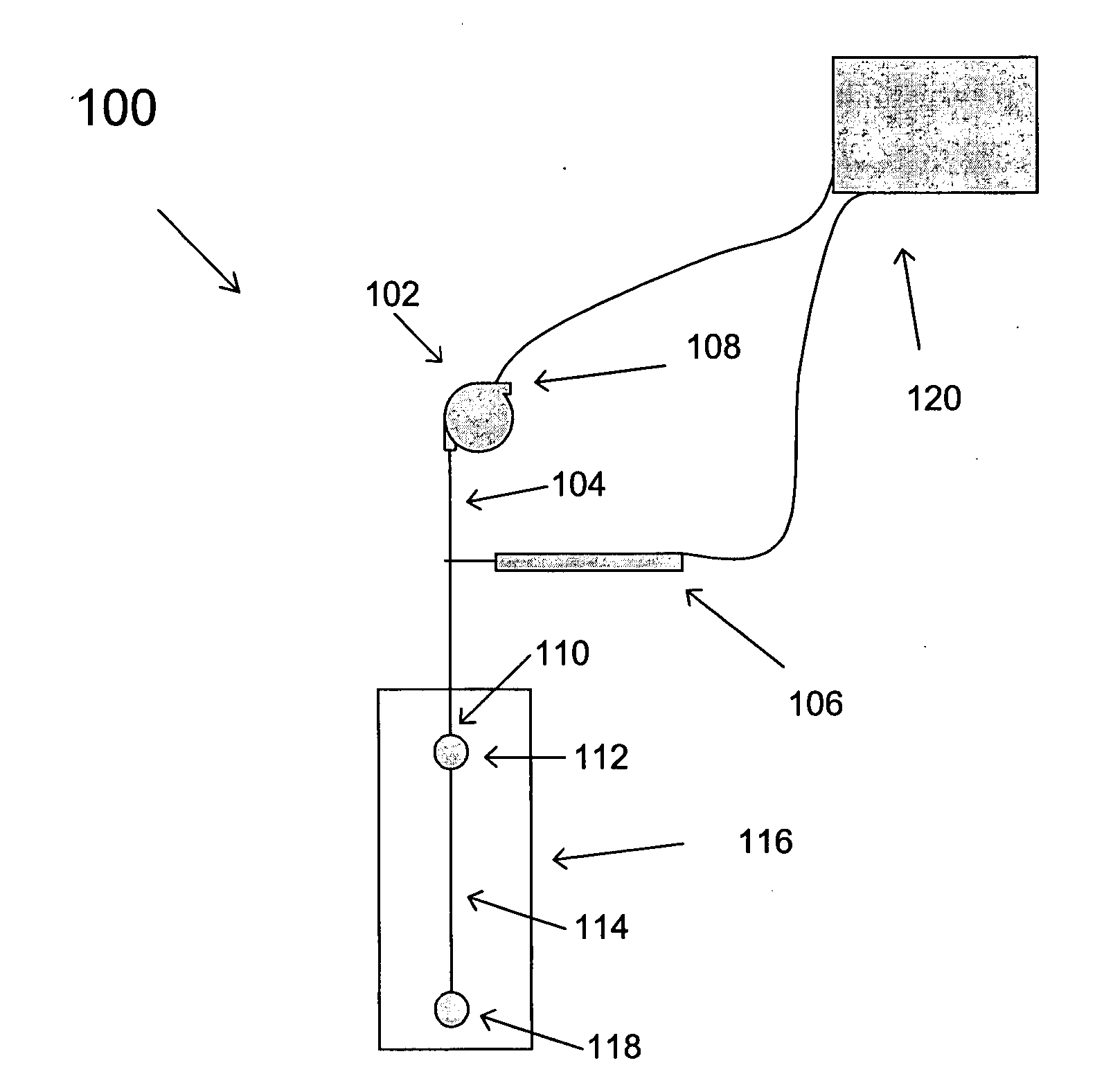

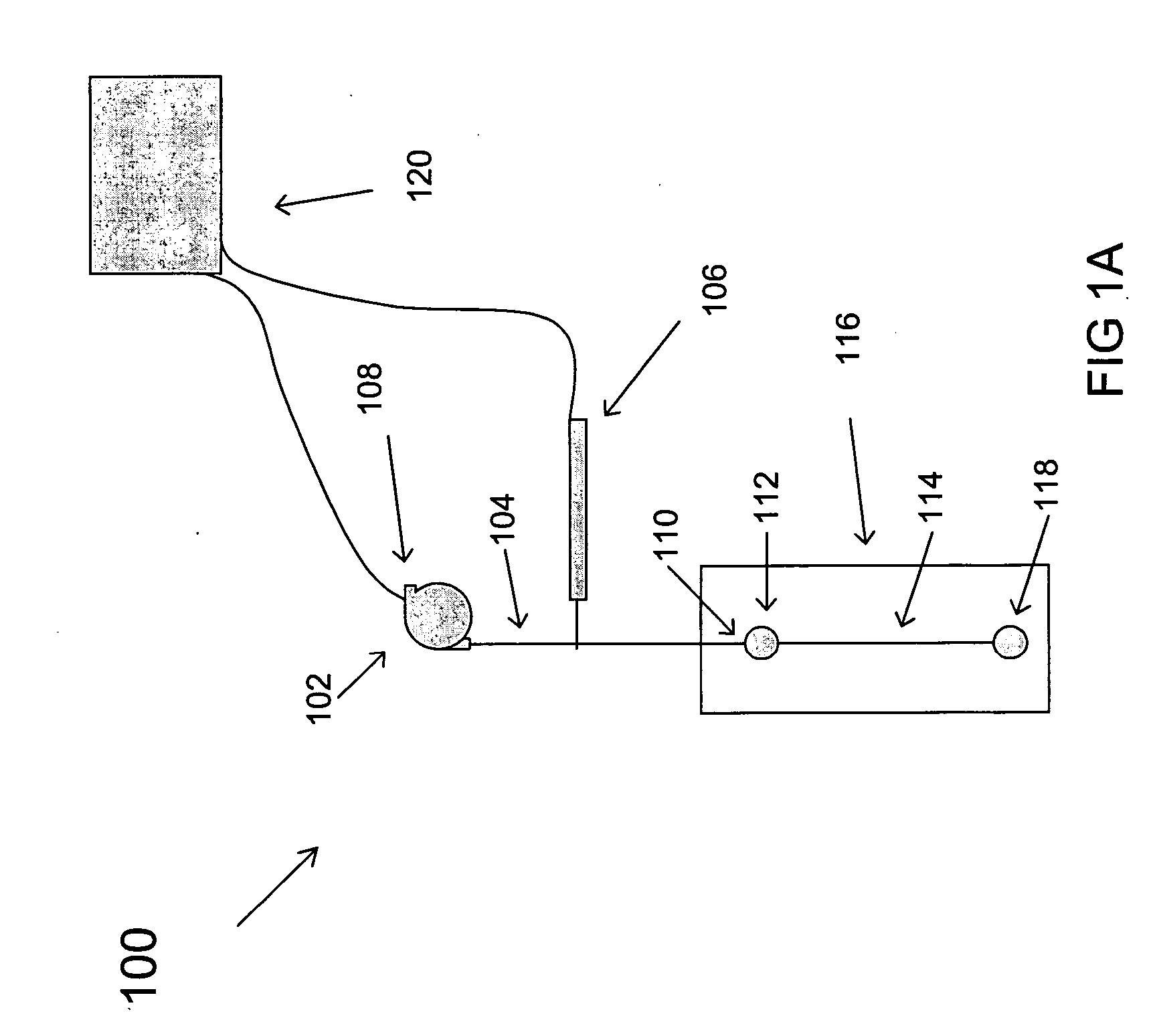

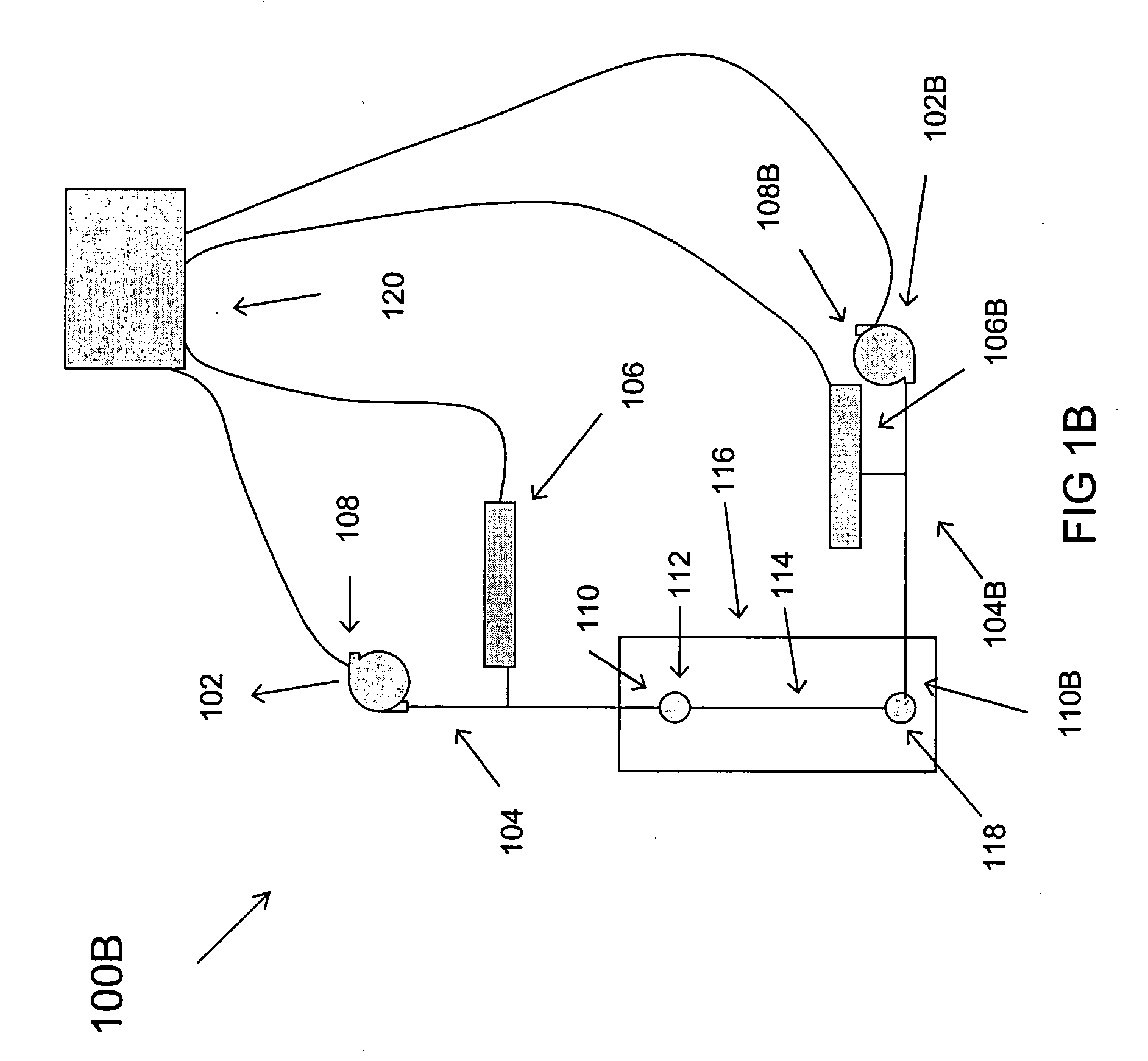

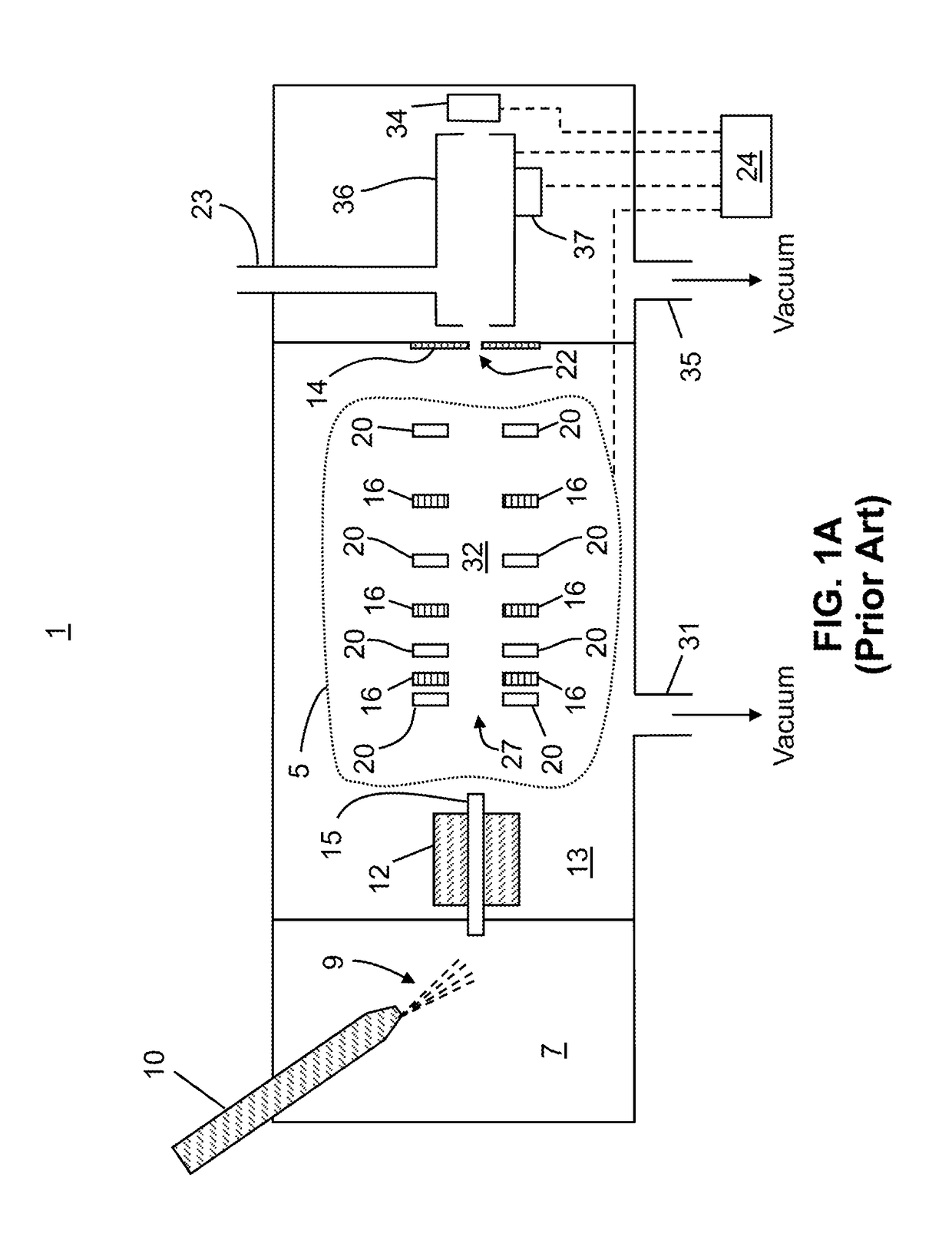

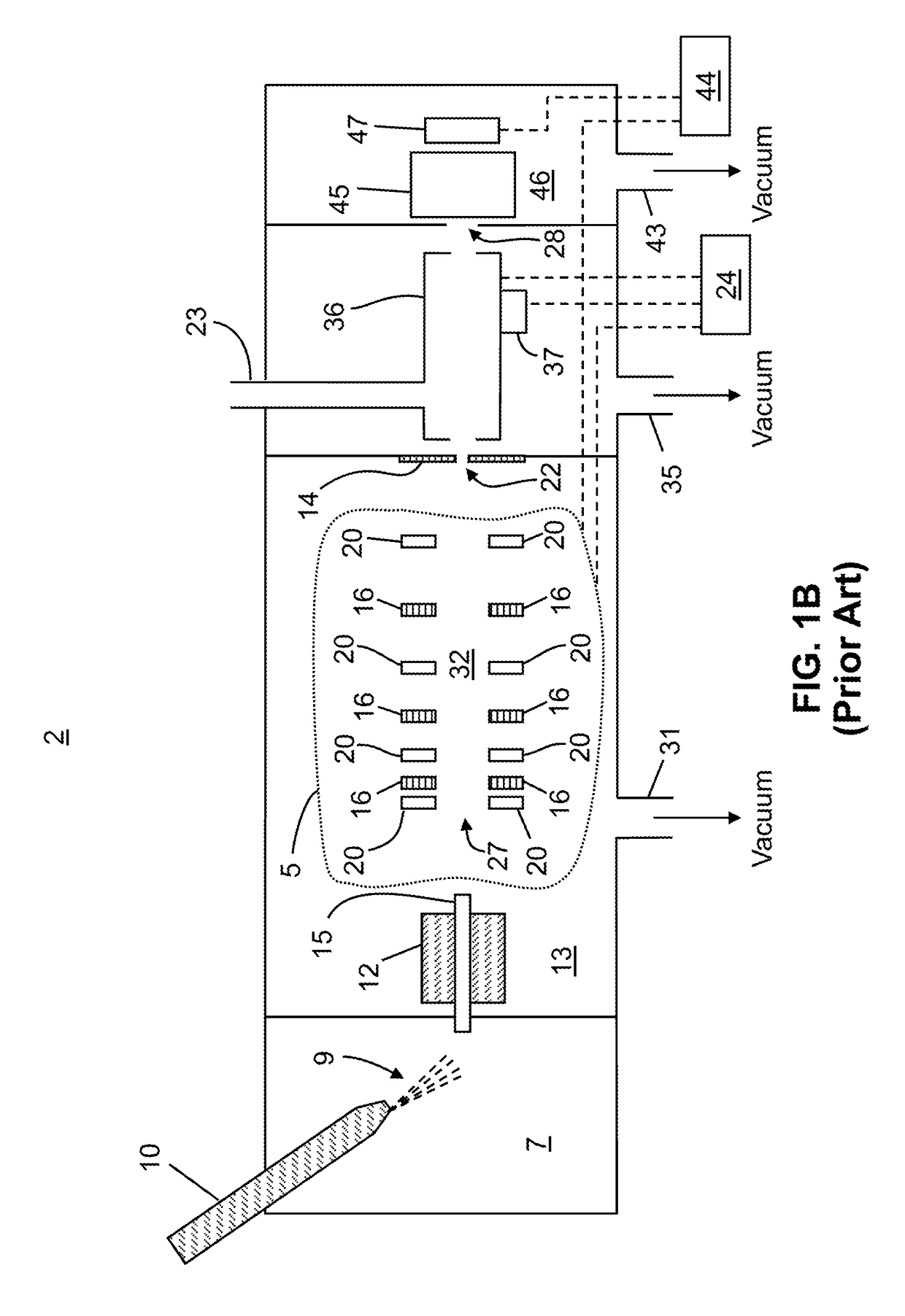

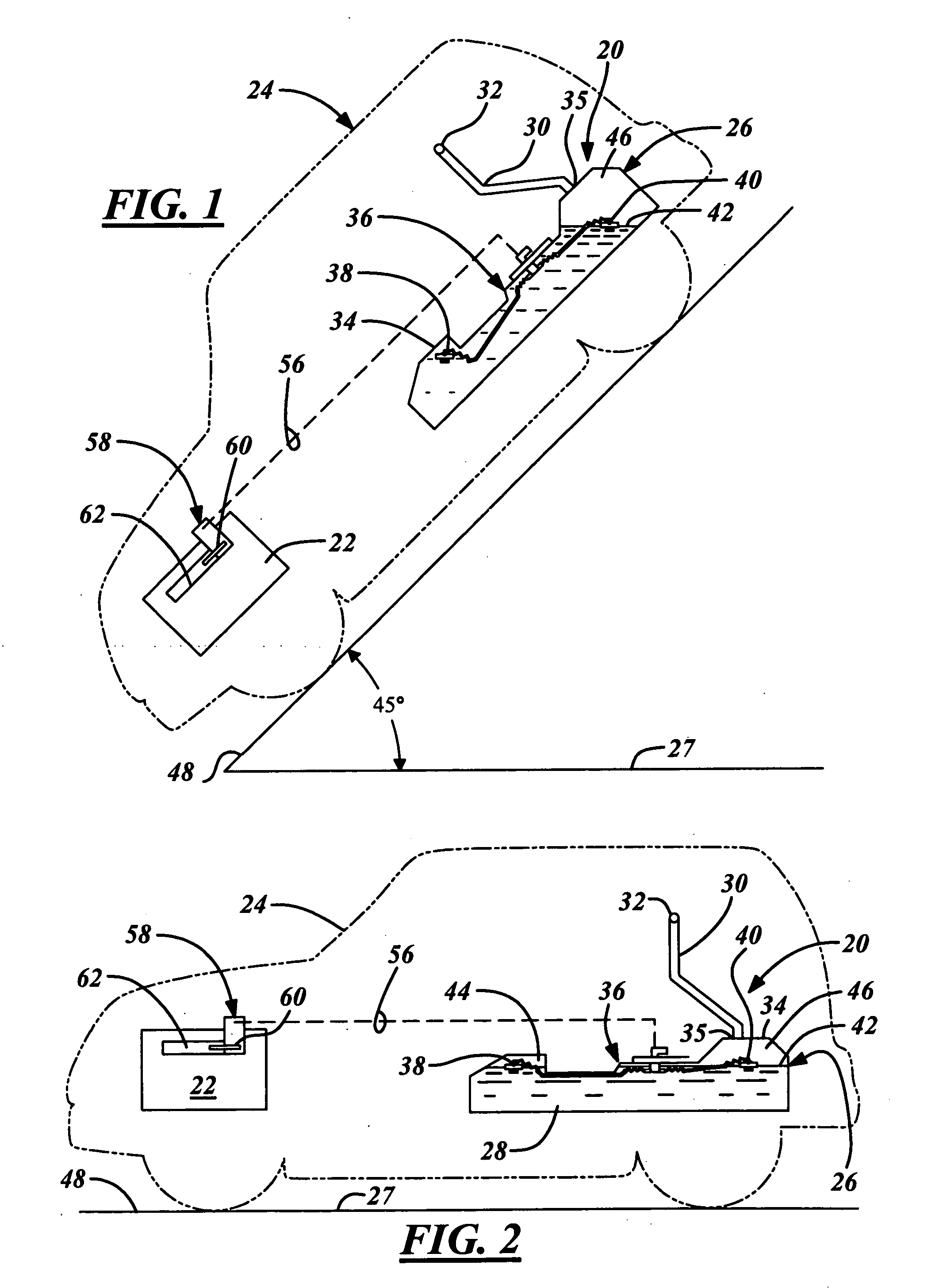

Methods, systems and devices for improving ventilation in a lung area

ActiveUS20050005936A1Facilitates of gas concentrationEasy pressure controlTracheal tubesOperating means/releasing devices for valvesDiseaseMechanical ventilation

Methods, systems and devices are described for new modes of ventilation in which specific lung areas are ventilated with an indwelling trans-tracheobronchial catheter for the purpose of improving ventilation and reducing hyperinflation in that specific lung area, and for redistributing inspired air to other healthier lung areas, for treating respiratory disorders such as COPD, ARDS, SARS, CF, and TB. Trans-Tracheobronchial Segmental Ventilation (TTSV) is performed on either a naturally breathing or a mechanical ventilated patient by placing a uniquely configured indwelling catheter into a bronchus of a poorly ventilated specific lung area and providing direct ventilation to that area. The catheter can be left in place for extended periods without clinician attendance or vigilance. Ventilation includes delivery of respiratory gases, therapuetic gases or agents and evacuation of stagnant gases, mixed gases or waste fluids. Typically the catheter's distal tip is anchored without occluding the bronchus but optionally may intermittently or continuously occlude the bronchus. TTSV is optionally performed by insufflation only of the area, or by application of vacuum to the area, can include elevating or reducing the pressure in the targeted area to facilitate stagnant gas removal, or can include blocking the area to divert inspired gas to better functioning areas.

Owner:BREATHE TECHNOLOGIES INC

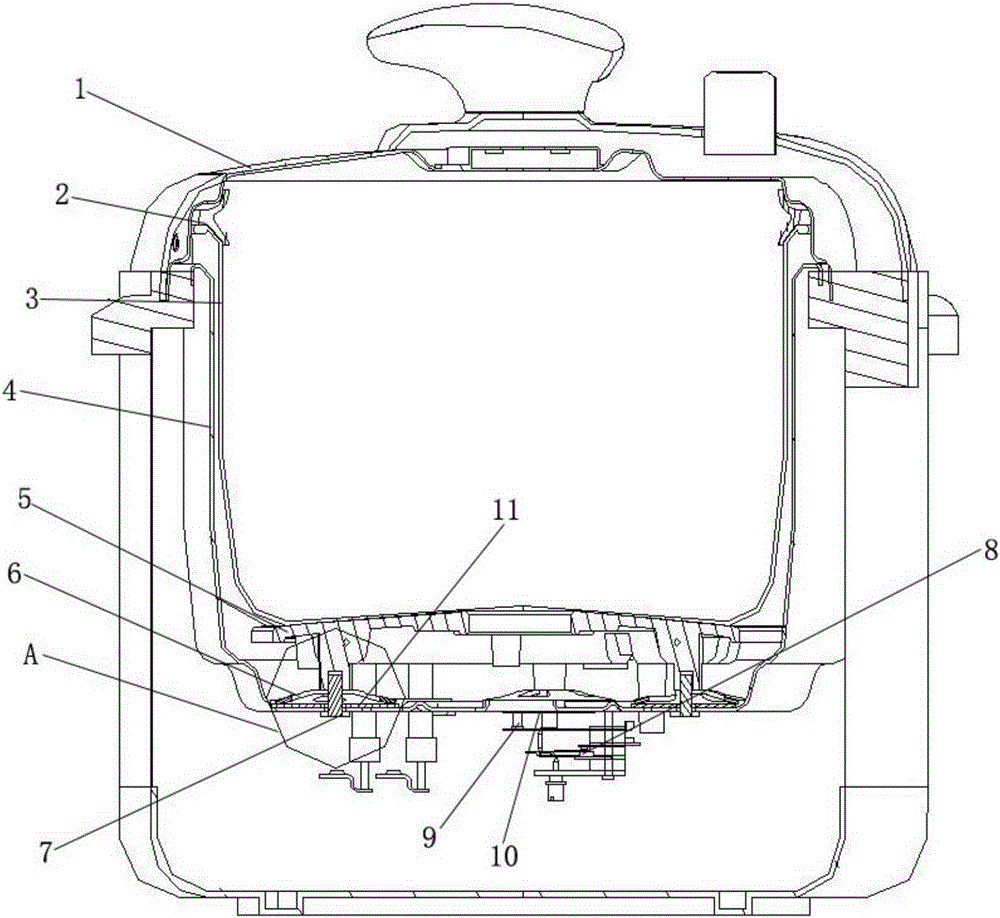

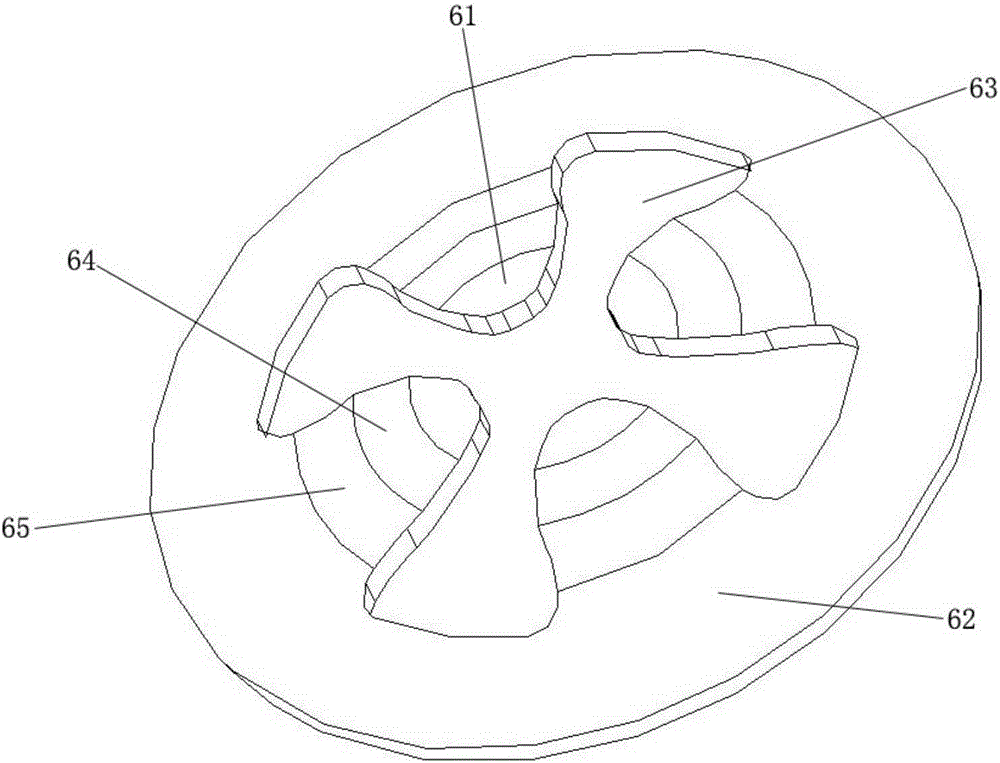

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

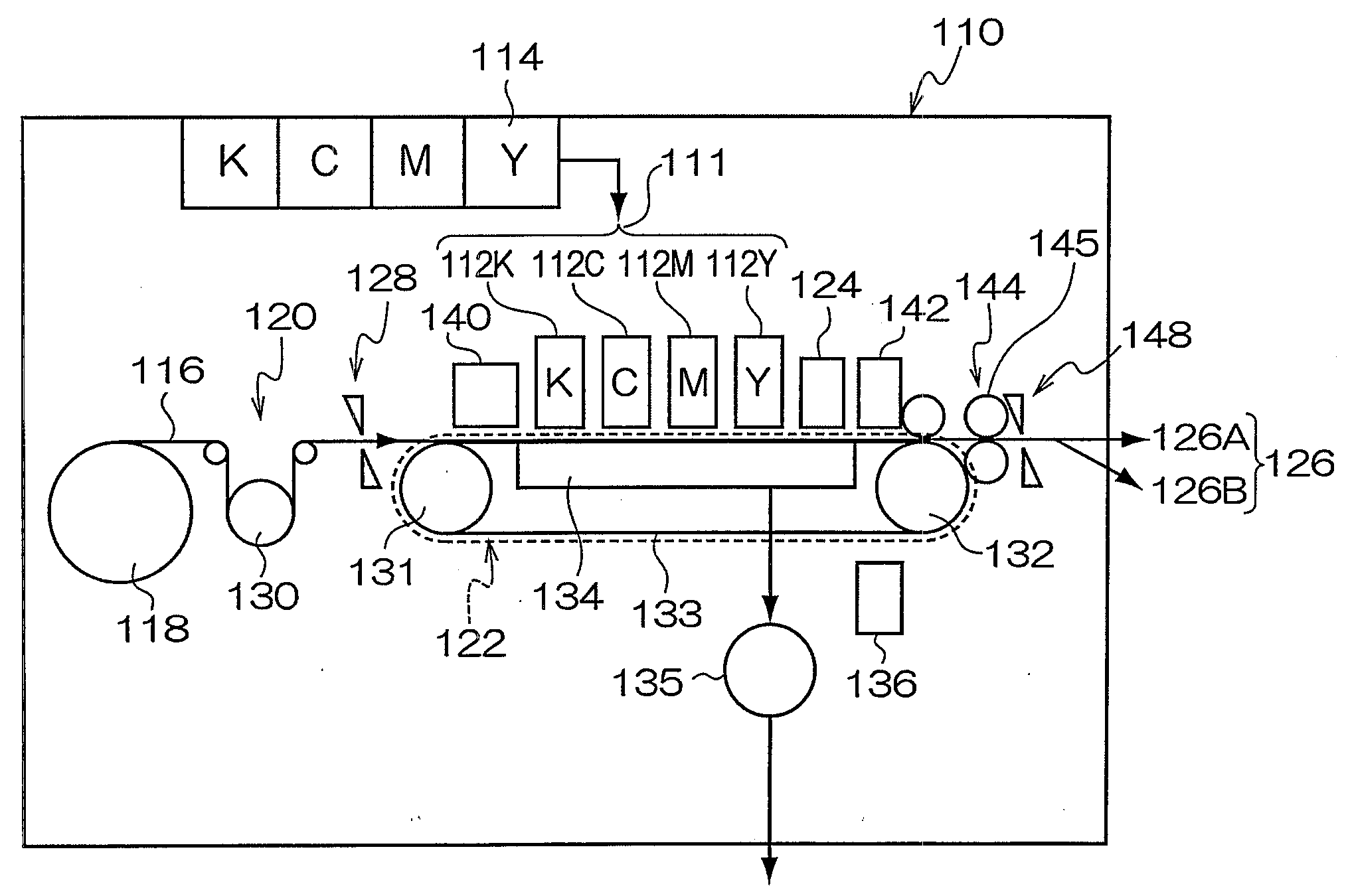

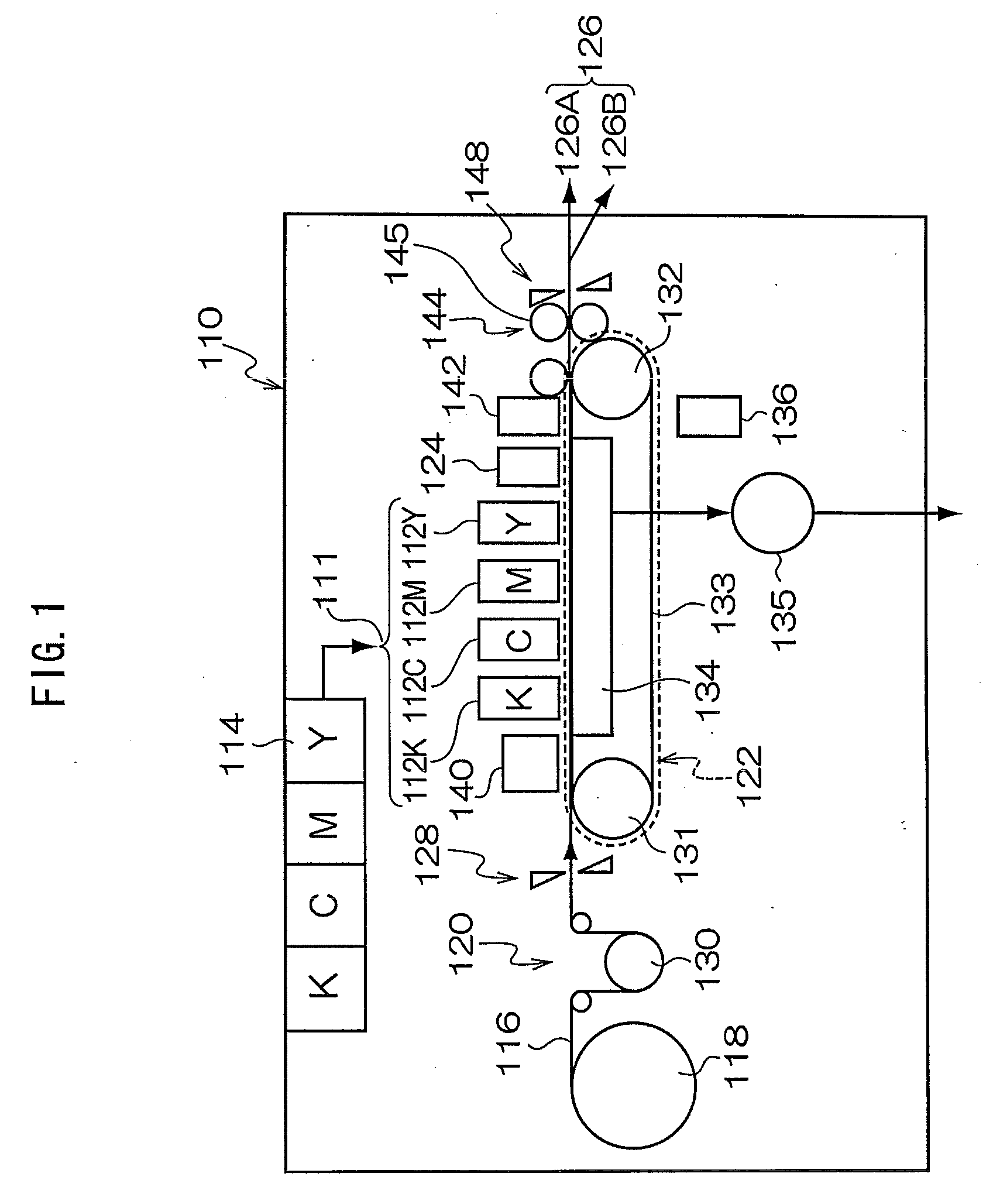

Liquid ejecting device

InactiveUS20090244226A1Excellent ability to remove air bubbleGood removal effectOther printing apparatusLiquid jetBuffer tank

Ink is supplied to a supply tank from a second buffer tank, and ink is pressure-fed from the supply tank to a head. Further, ink is supplied from the second buffer tank to a recovery tank, and ink is pressure-fed from the recovery tank to the head. In both pressure-feedings, ink containing air bubbles within the head is recovered at a first buffer tank. The ink, that contains the air bubbles and is recovered at the first buffer tank, is sent to the second buffer tank via an ink flow path. A degassing section is provided on the ink flow path, and a degassing process is carried out while ink is being fed.

Owner:FUJIFILM CORP

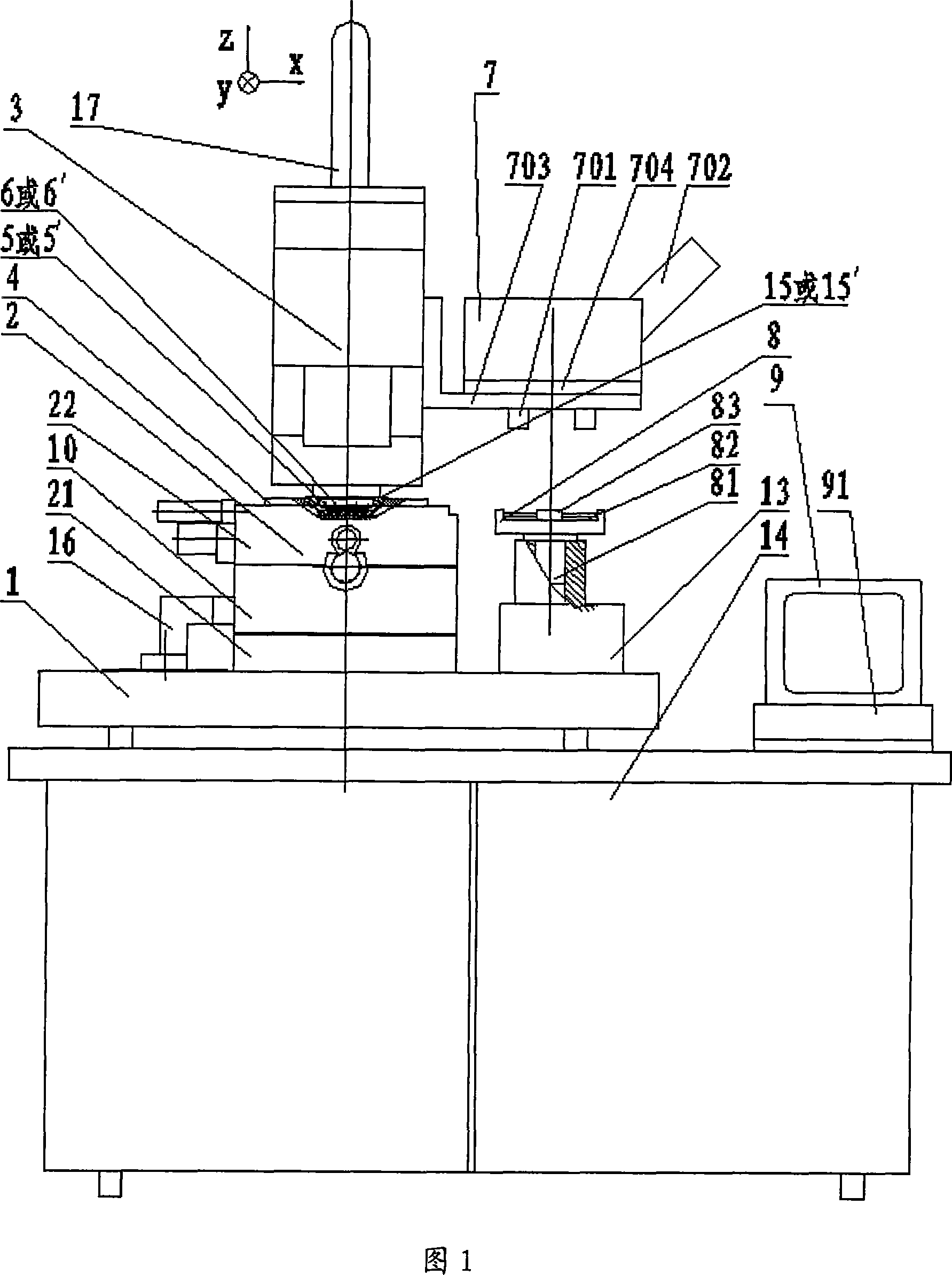

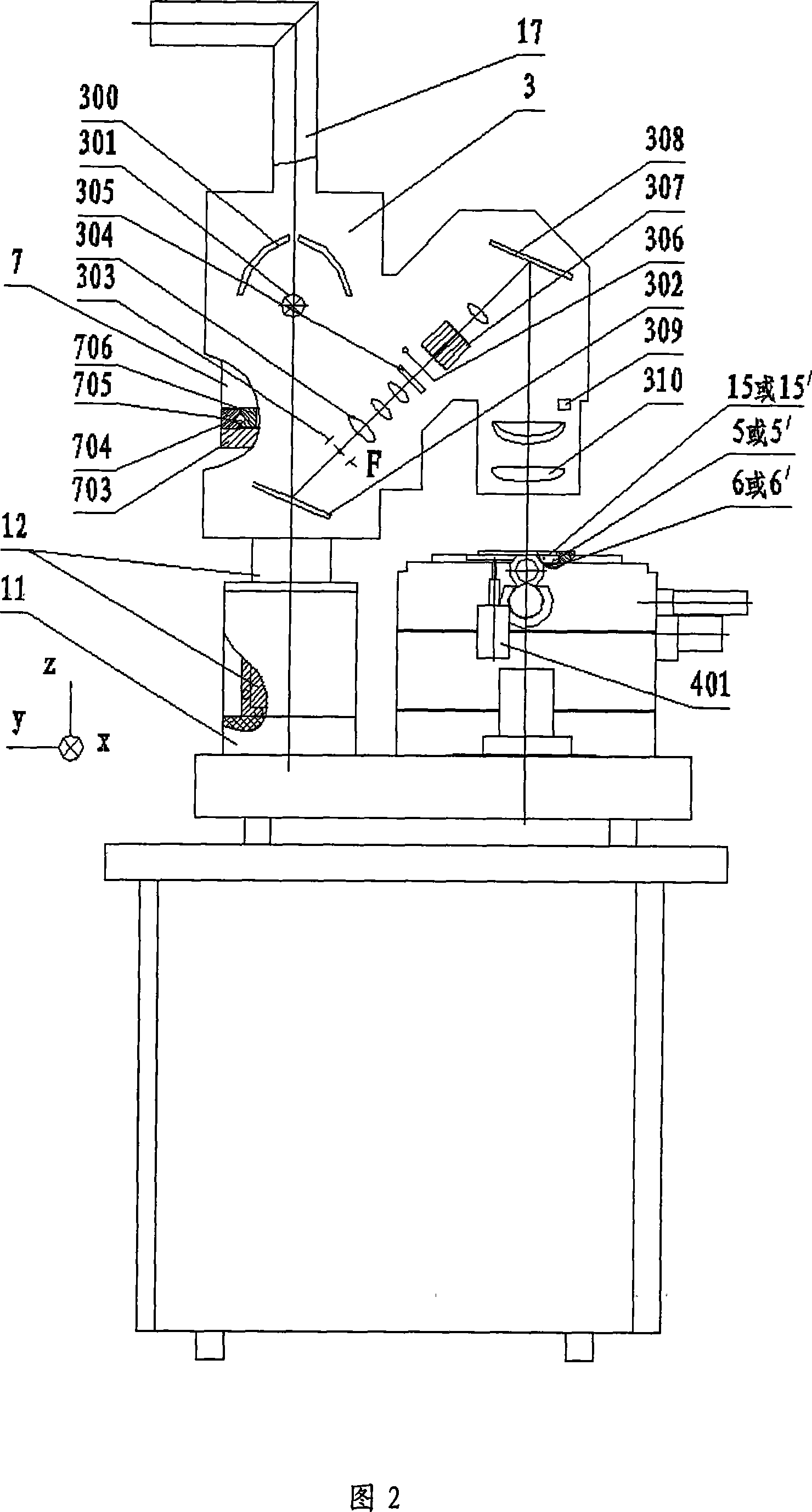

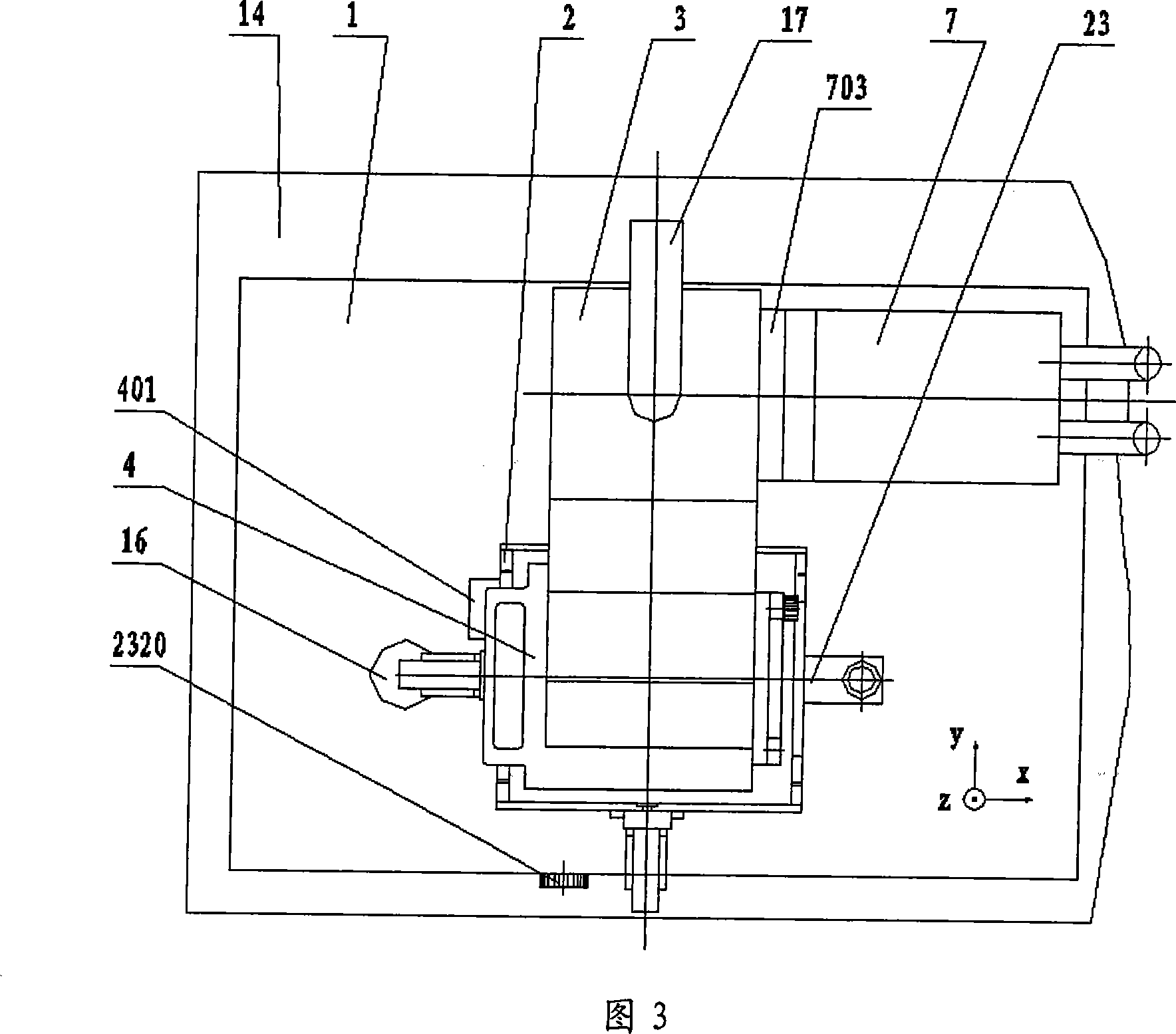

Dual-purpose copy arrangement for ultraviolet lighting micro-nano graph air pressure stamping and photolithography

ActiveCN101063810ASimple embossed structureQuality improvementSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMicro nanoUltraviolet

This invention relates to one ultraviolet nanometer gas pressure and etching copy device, which comprises the following parts: host large baseboard, pressure mobile bench system, even light system, pressure mode rack, mode and base slice and calibration system, lift system, load adjust bench system, prism lens and control system, wherein the host baseboard is fixed with pressure mode mobile bench system and other load adjust bench system; the XY pressure mode mobile bench is supported with pressure rack and prism lens added with pressure mask or mask film; the base slice or silicon slice are added onto adjust platform on pressure mode; the calibration system is connected to the one side of light system; the work bench system and light system output signals are output to control system.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

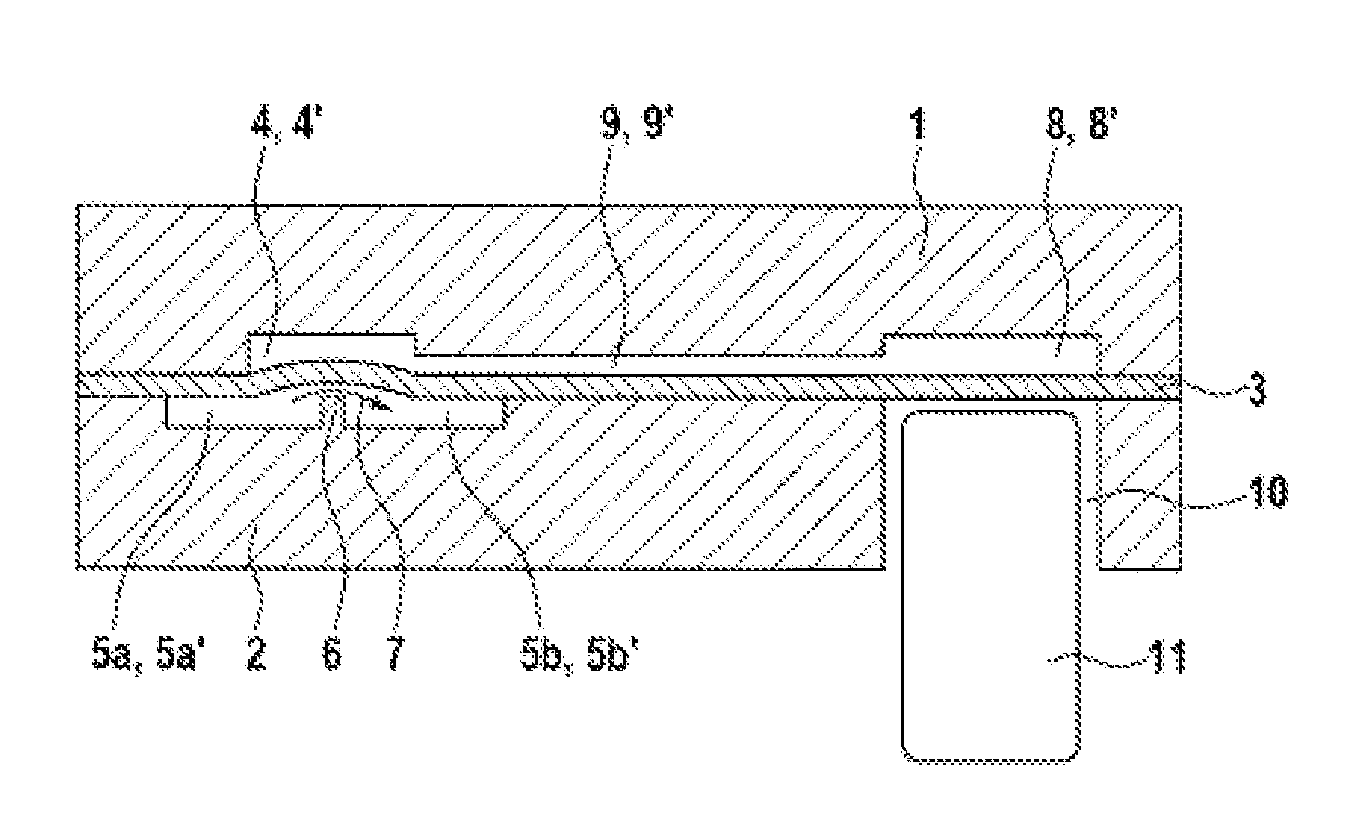

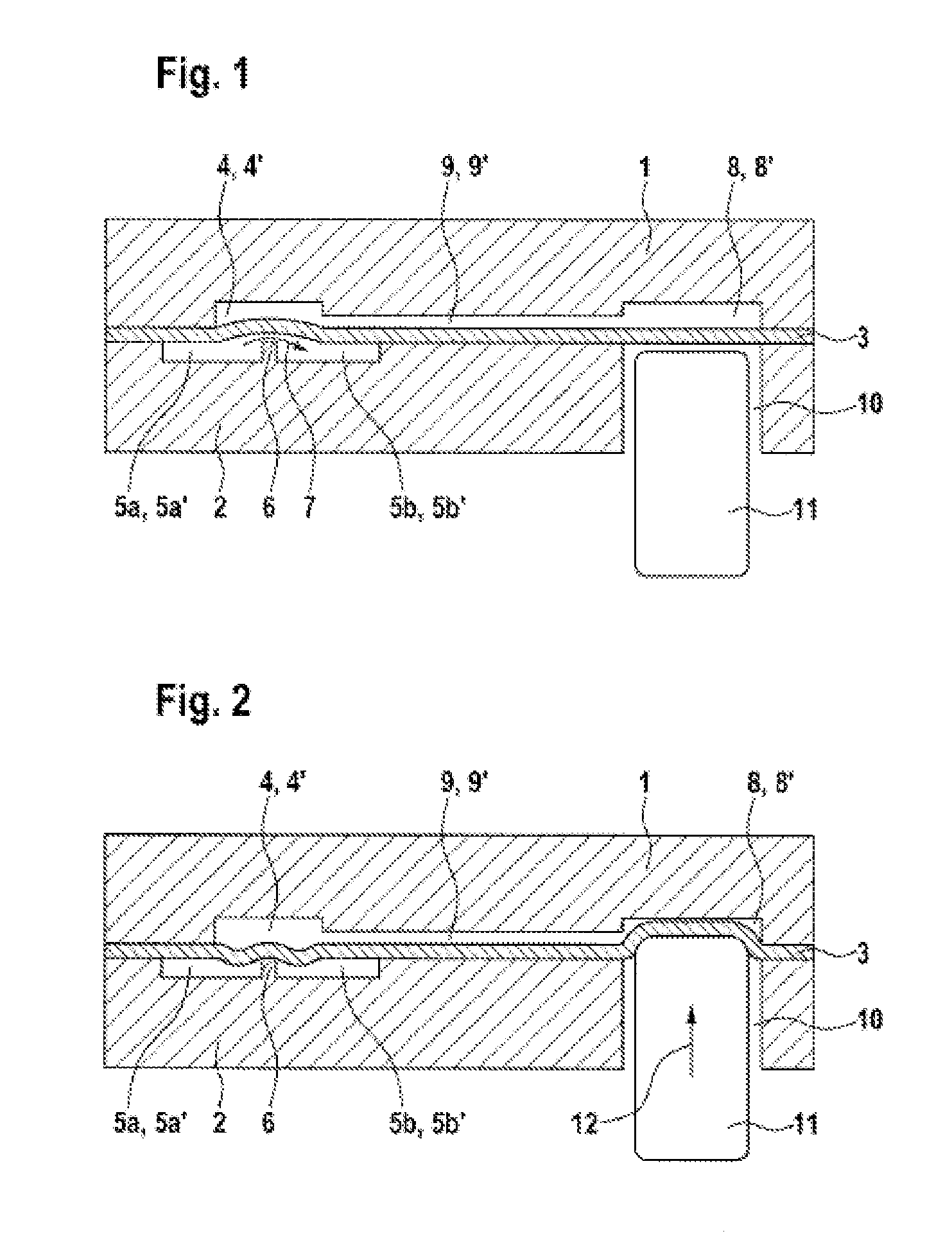

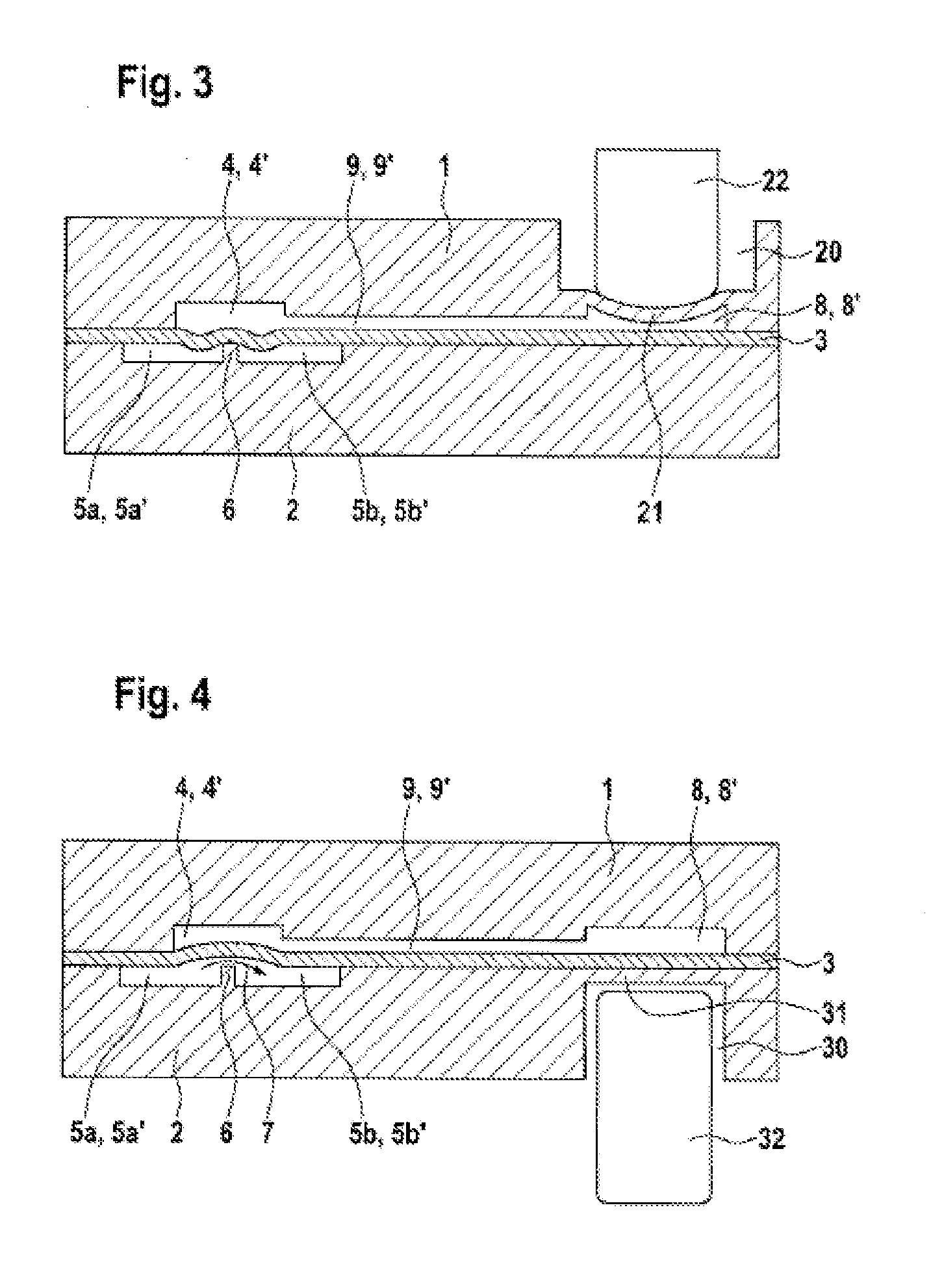

Microfluidic component for manipulating a fluid, and microfluidic chip

InactiveUS20120298233A1Control volumeEasy pressure controlValve arrangementsLaboratory glasswaresEngineeringActuator

A microfluidic component for manipulating a fluid includes a first substrate, a second substrate, and a third substrate that is configured from a resilient material and arranged between the first substrate and the second substrate. At least one first recess that forms a first control chamber is configured on the face of the first substrate facing the third substrate. At least one second recess that forms a fluid channel is configured on the face of the second substrate facing the third substrate. A second control chamber that is spatially separated from the first control chamber and a control channel that connects the first control chamber to the second control chamber are formed in the first substrate. At least one lateral wall of the second control chamber is configured from resilient material and is deformable by an actuator such that the inner volume of the second control chamber decreases.

Owner:ROBERT BOSCH GMBH

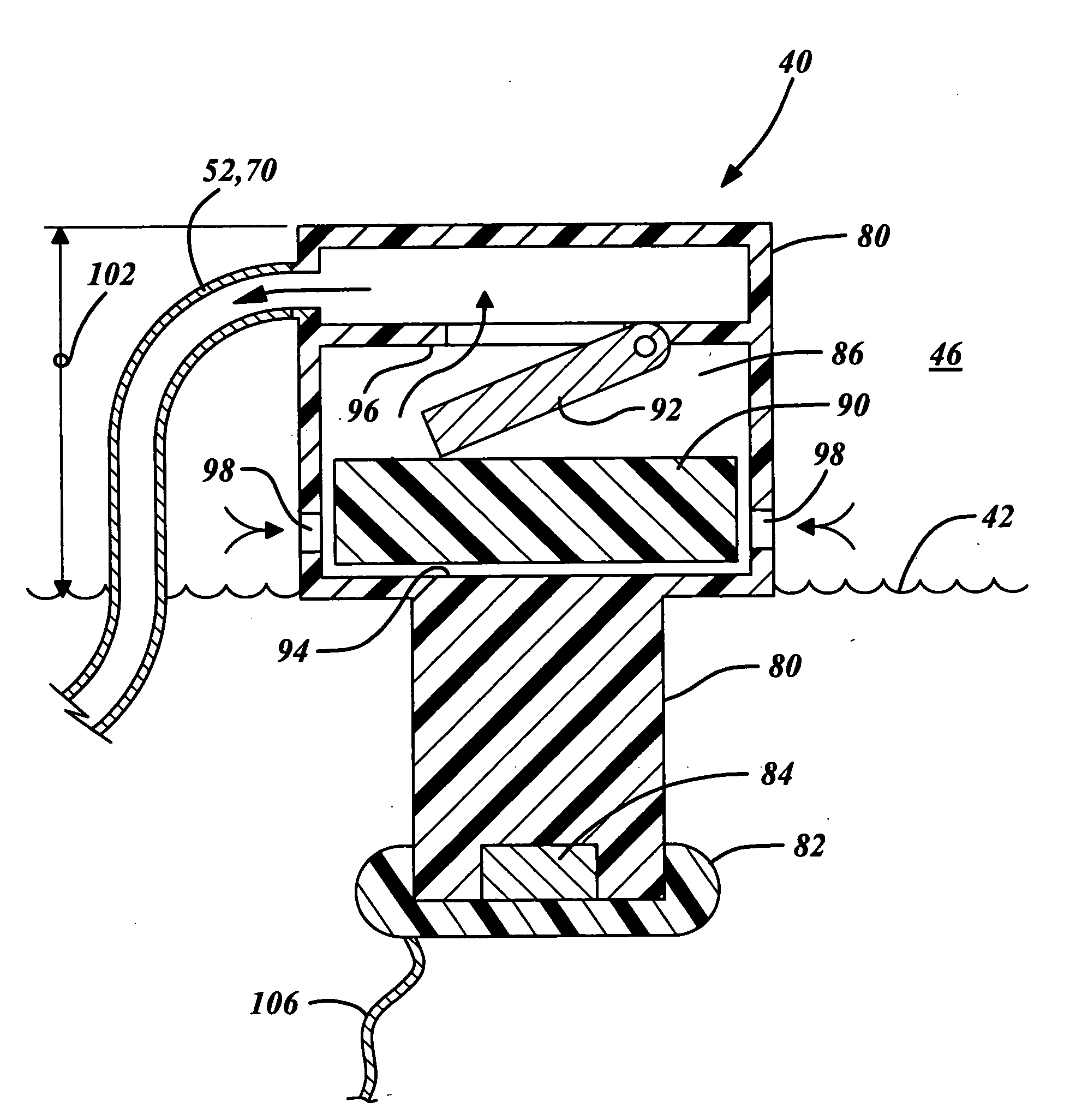

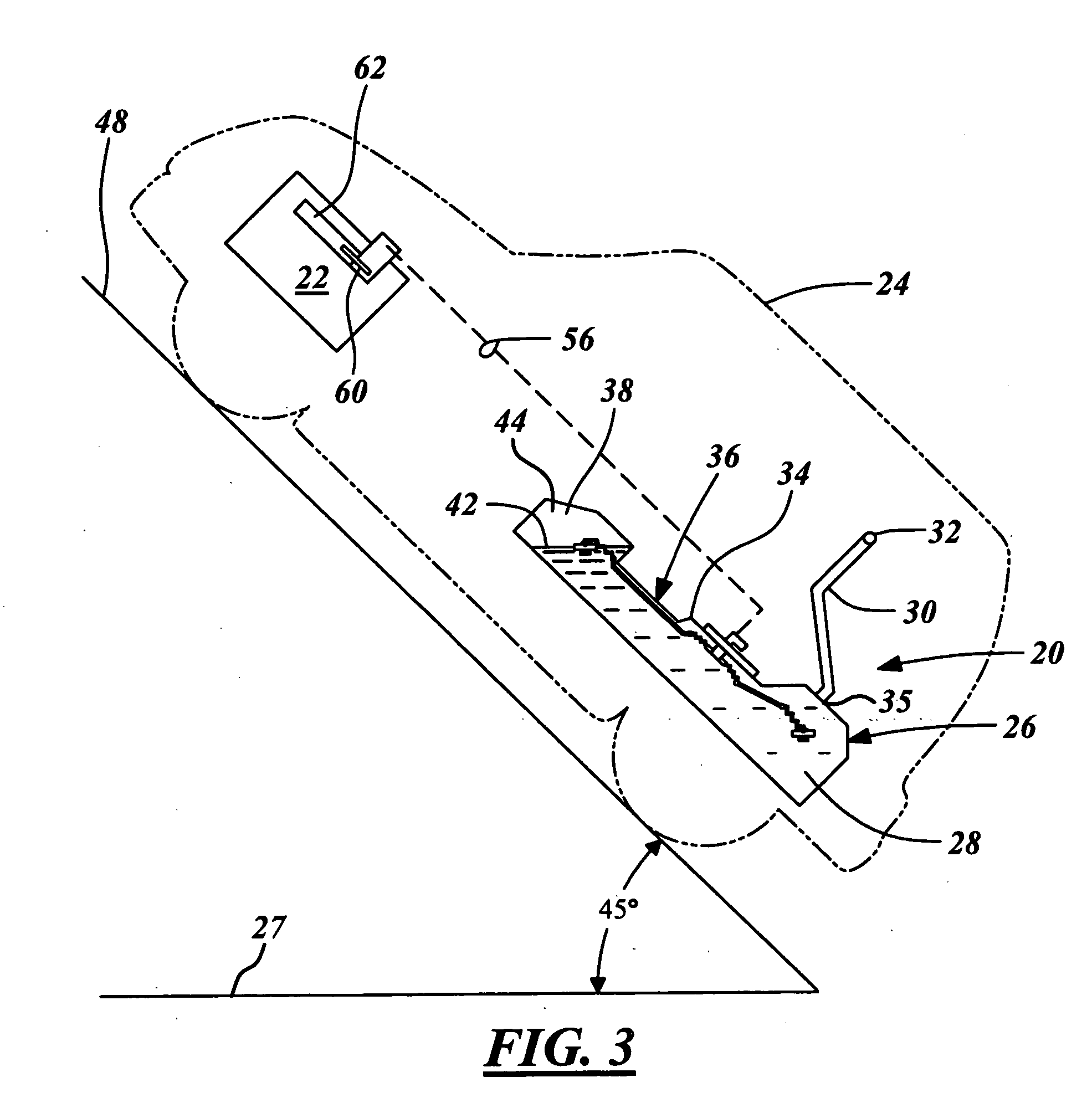

Fuel storage system for a vehicle

InactiveUS7520293B2Good flexibilityLight weightOperating means/releasing devices for valvesLarge containersExhaust valveSurface level

A fuel storage system for a transportation or recreational vehicle has a fuel tank that carries a vapor assembly that seeks out vapor pockets and controllably removes fuel vapor from the tank without releasing hydrocarbons to the surrounding environment. Preferably, a vent manifold attaches to a flange that sealably covers an access hole of the tank. At least one flexible tentacle extends from the manifold in the tank to a respective vapor vent valve that floats upon the surface of fuel at a vapor dome. When freely floating, the vent valve is open thus communicates the vapor dome through the tentacle and preferably with a filtering carbon canister. As fuel surface levels change or the vehicle tilts, changing the vapor dome size or location in the tank, the floating vapor vent valve is free to move generally with the vapor dome and as permitted by the flexibility of the trailing tentacle. With tank orientations where the vapor vent valve falls below the surface of fuel, the vent valve automatically closes to prevent flooding of the respective tentacle and remote vapor canister.

Owner:TI GRP AUTOMOTIVE SYST LLC

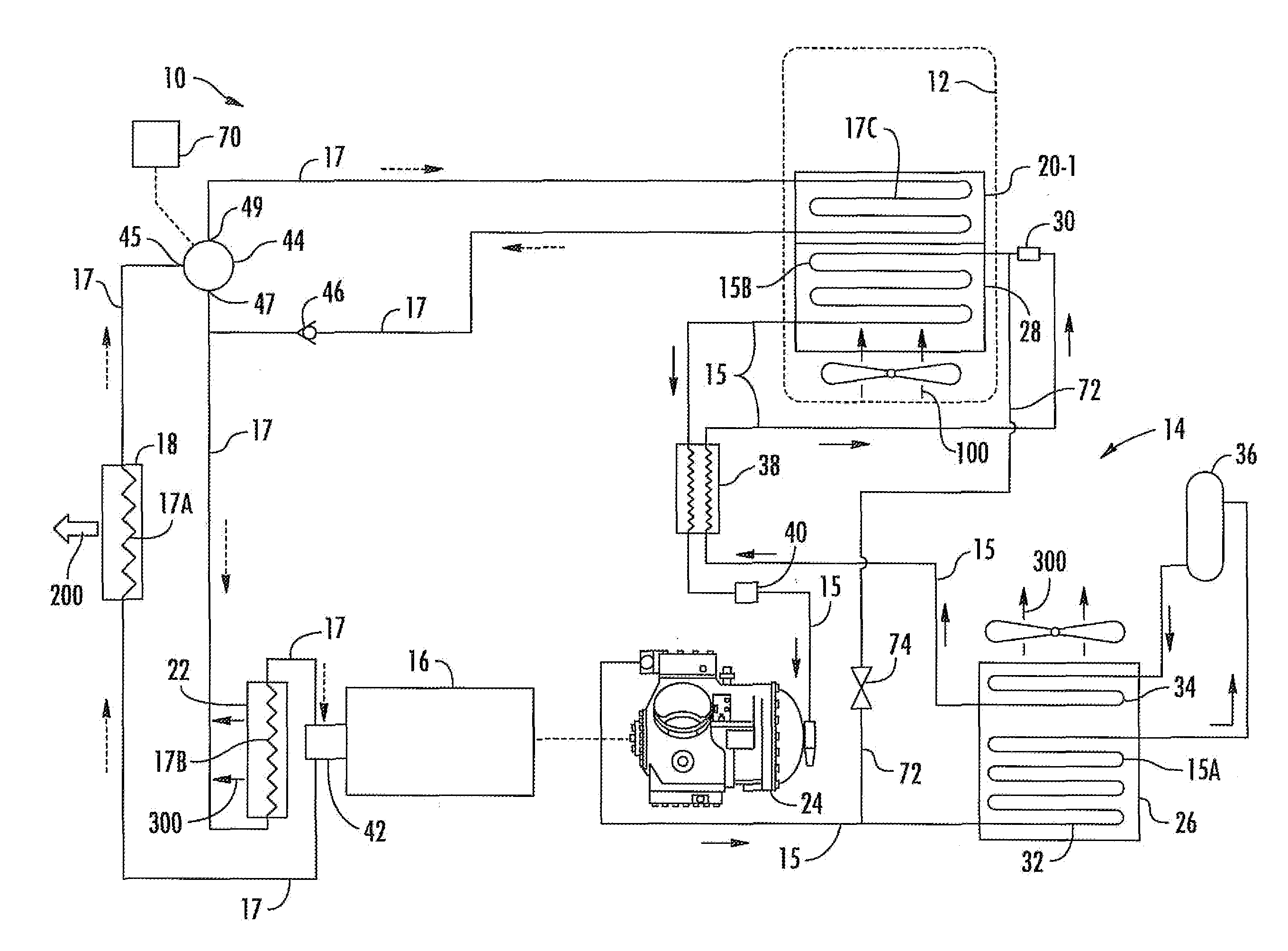

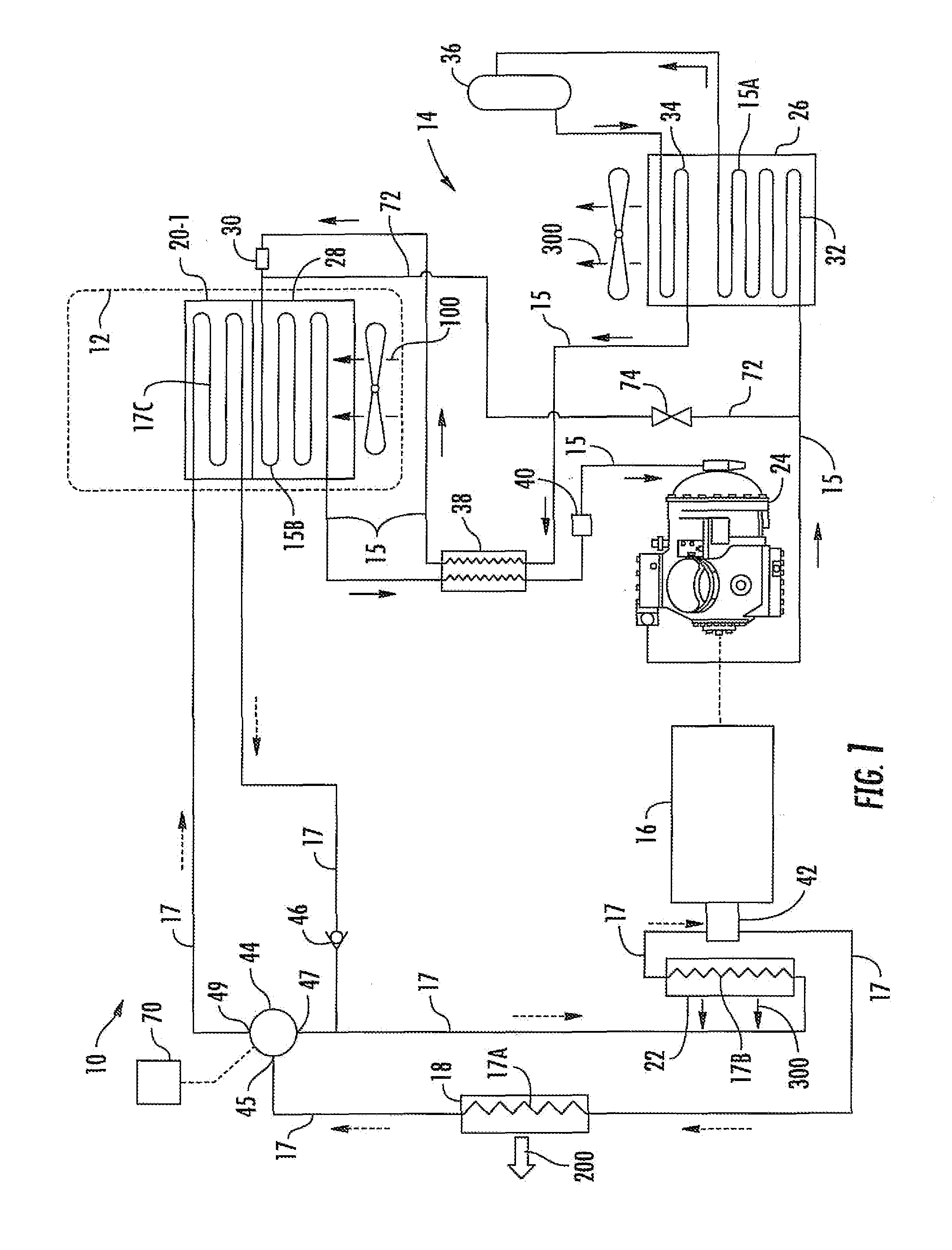

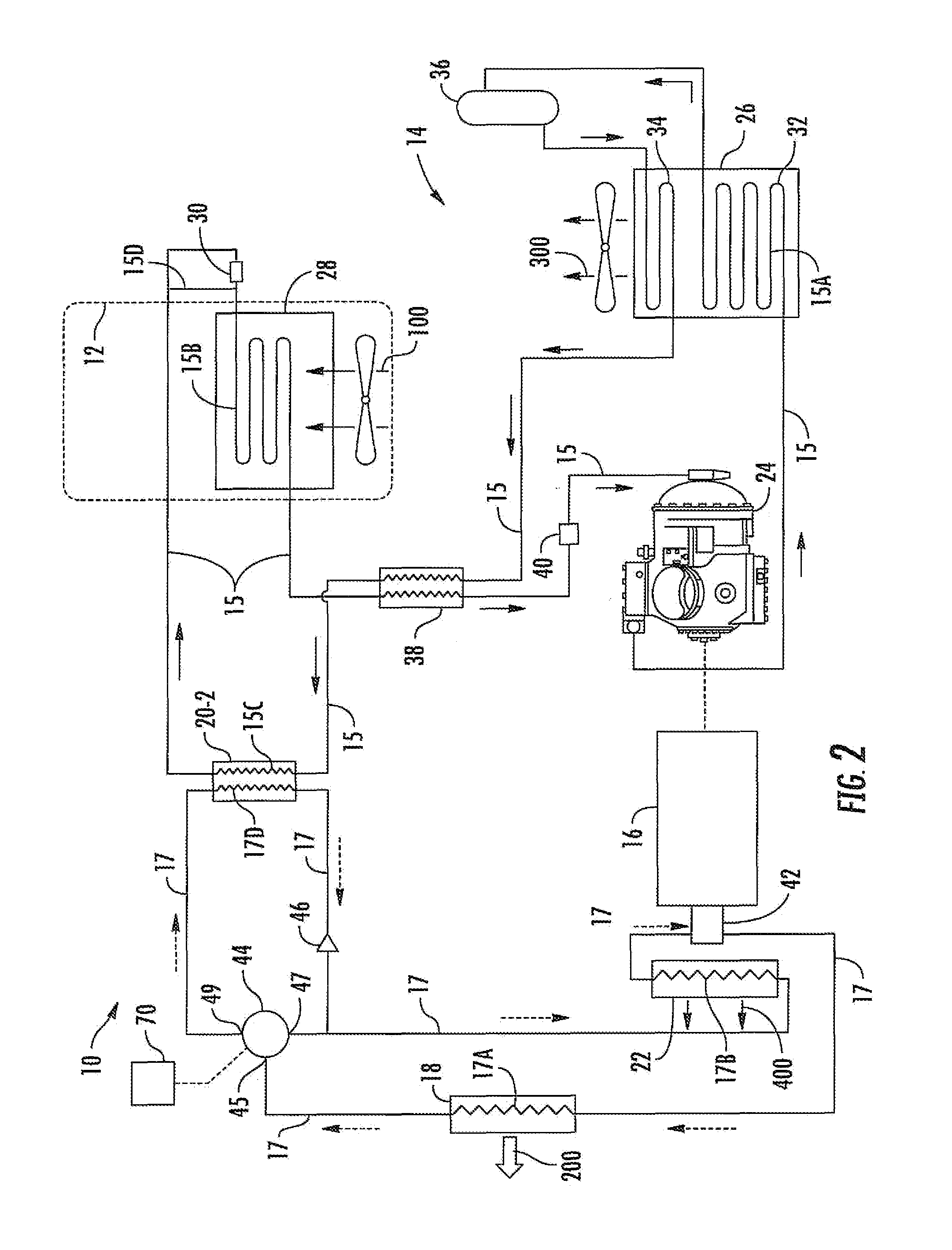

Transport Refrigeration System Utilizing Engine Waste Heat

ActiveUS20140223933A1Increase loadEasy pressure controlAir-treating devicesExhaust apparatusEngineeringRefrigerant

A transport refrigeration system includes a transport refrigeration unit having a refrigerant circuit through which a refrigerant is circulated in heat exchange relationship with air drawn from a cargo box, a fuel-fired engine for powering the refrigeration unit and having an exhaust system through which exhaust gases generated by the engine are discharged and an engine coolant circuit, an engine exhaust gases to engine coolant heat exchanger, and an engine coolant circuit to refrigeration unit heat exchanger.

Owner:CARRIER CORP

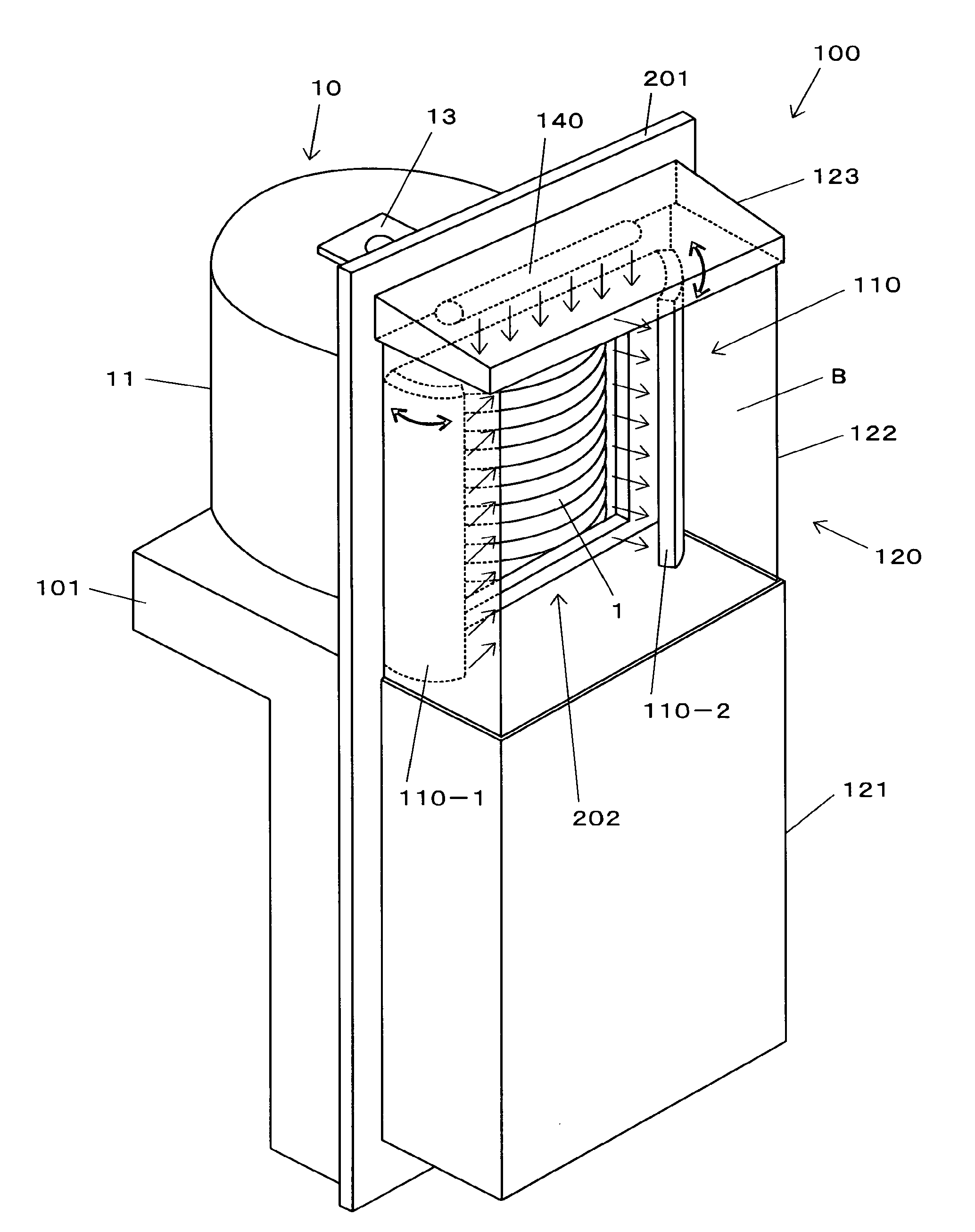

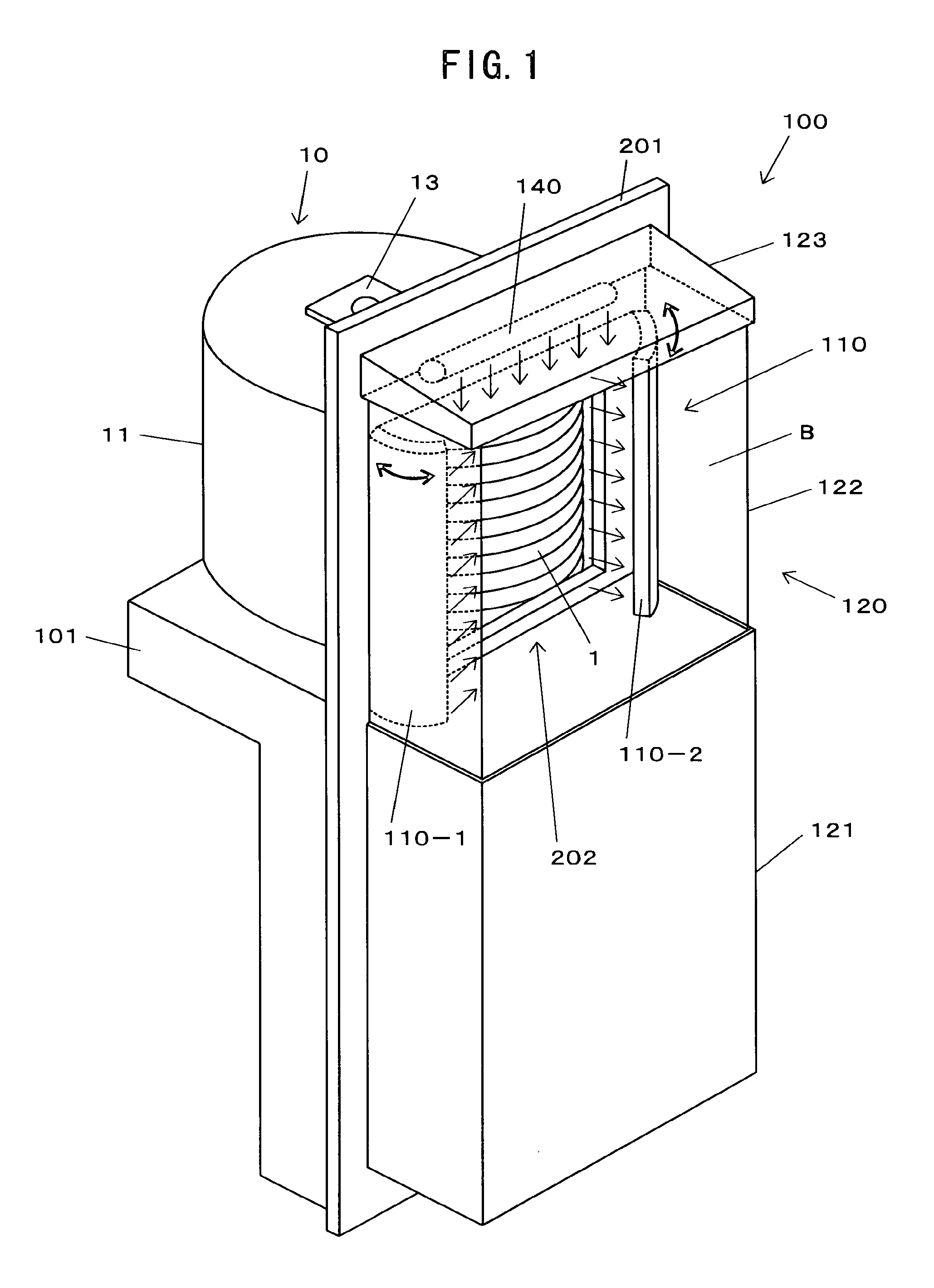

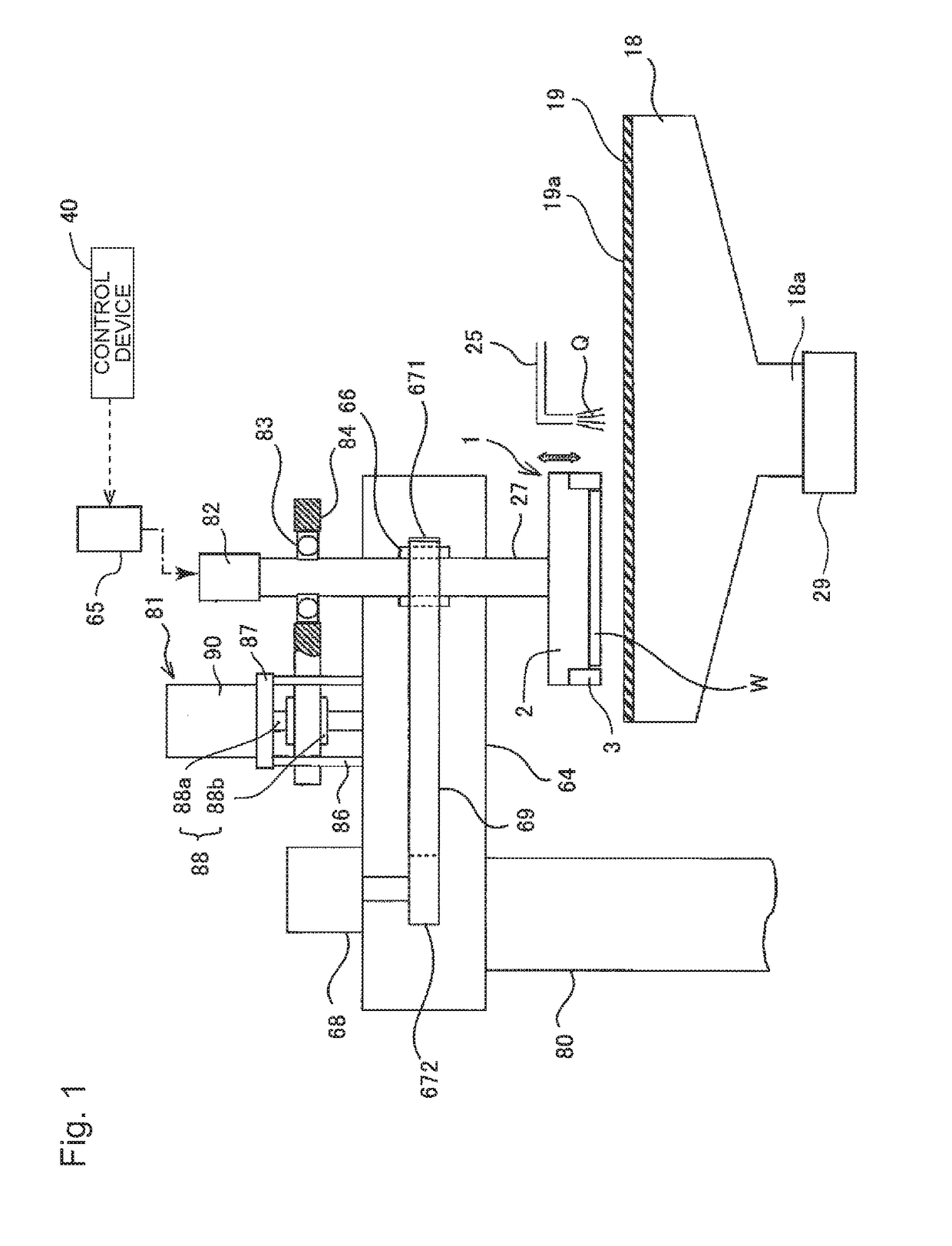

Load port

InactiveUS20130000757A1Shorten speedImprove efficiencyPipe supportsServomotor componentsEngineeringAtmosphere

A load part has a nozzle unit having outlets for generating outflow and / or inflow of gas used for replacing the atmosphere of a wafer storage container, in a direction approximately parallel to spaces between adjacent wafers being stored, are a driving unit for extending the nozzle unit to a door opening portion.

Owner:RIGHT MFG

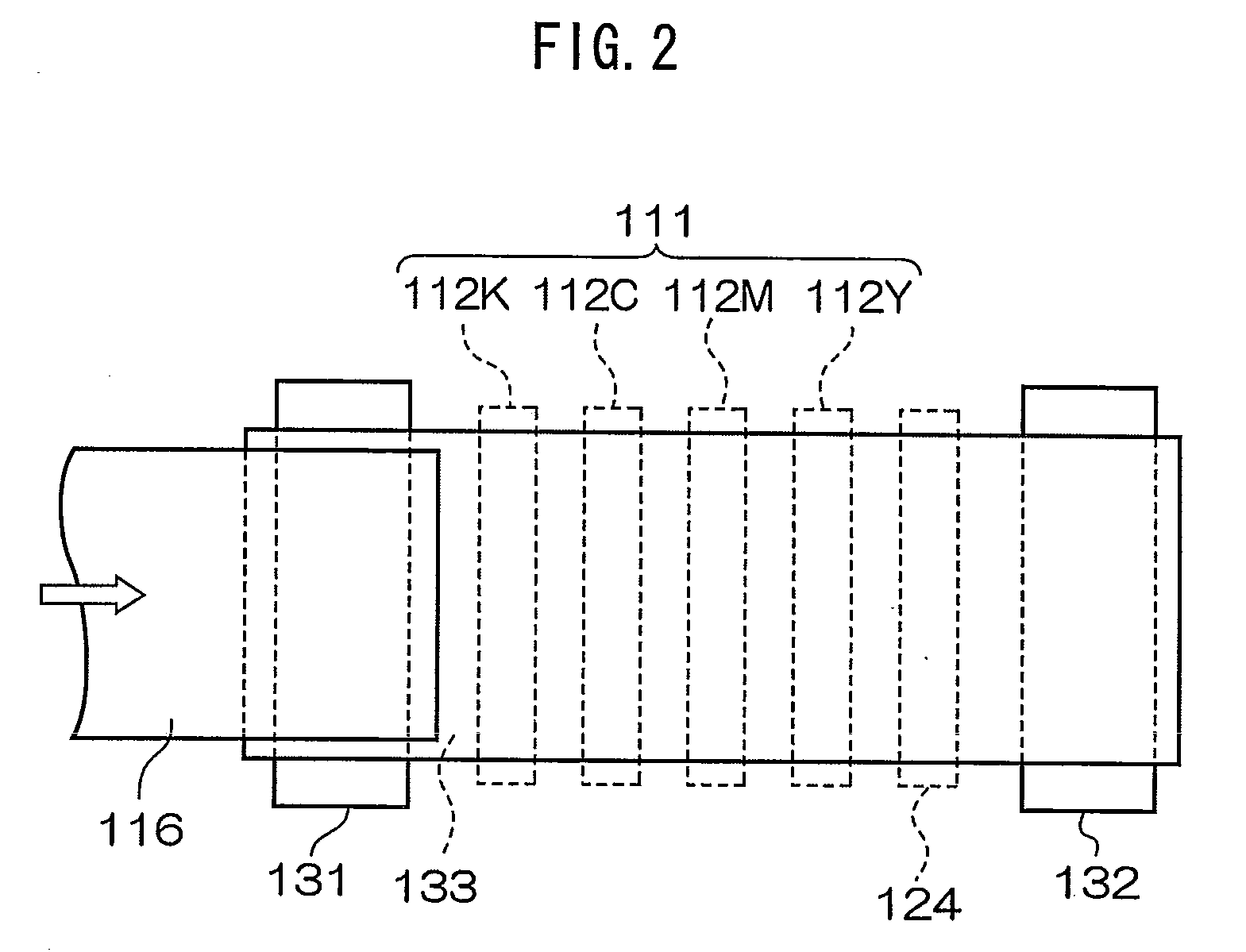

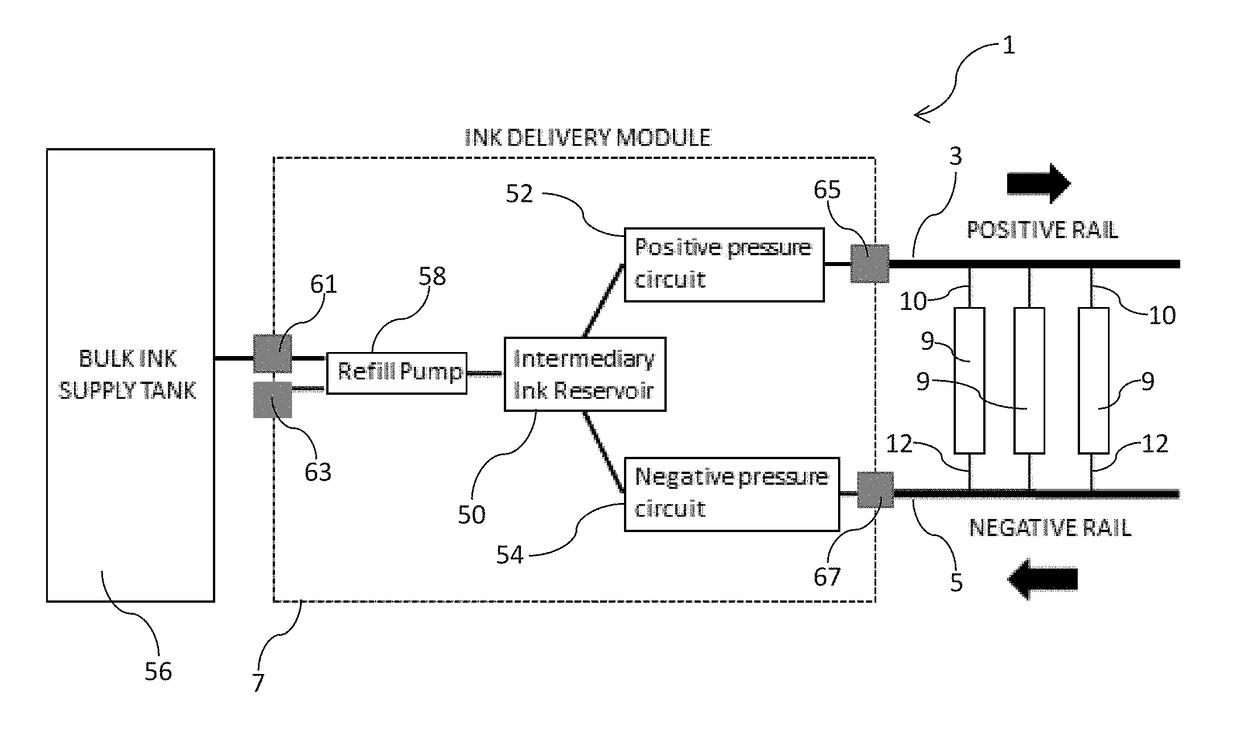

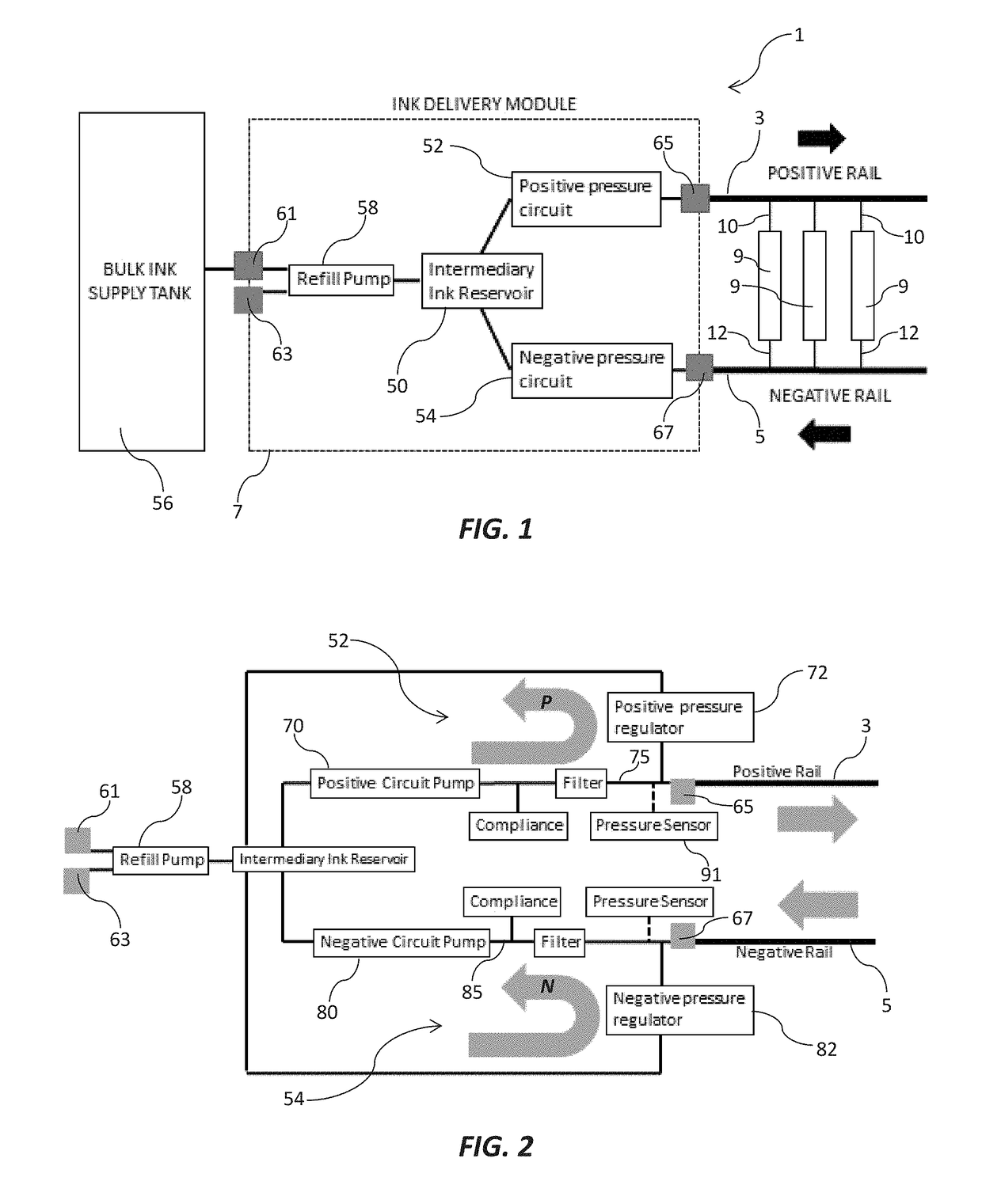

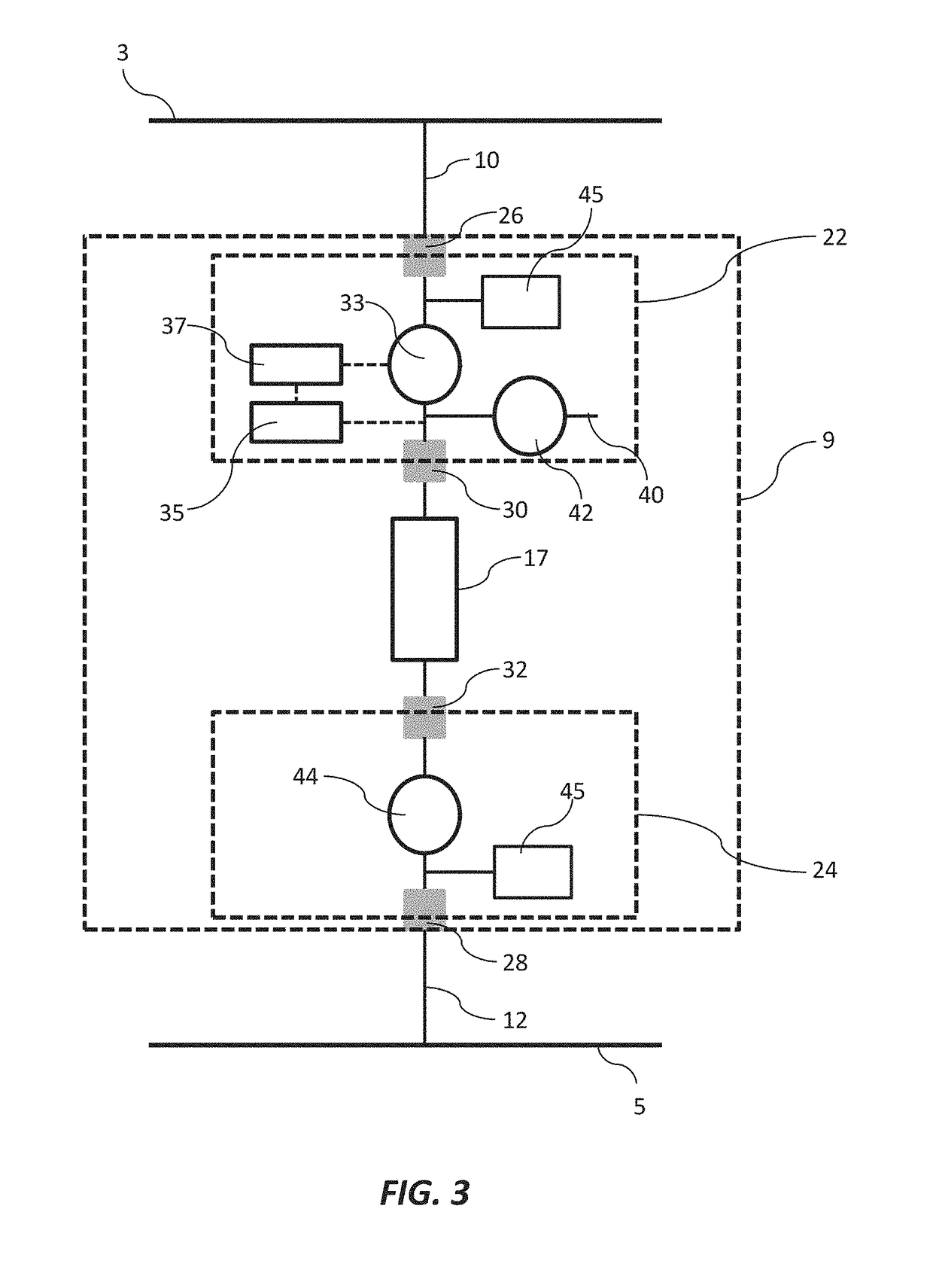

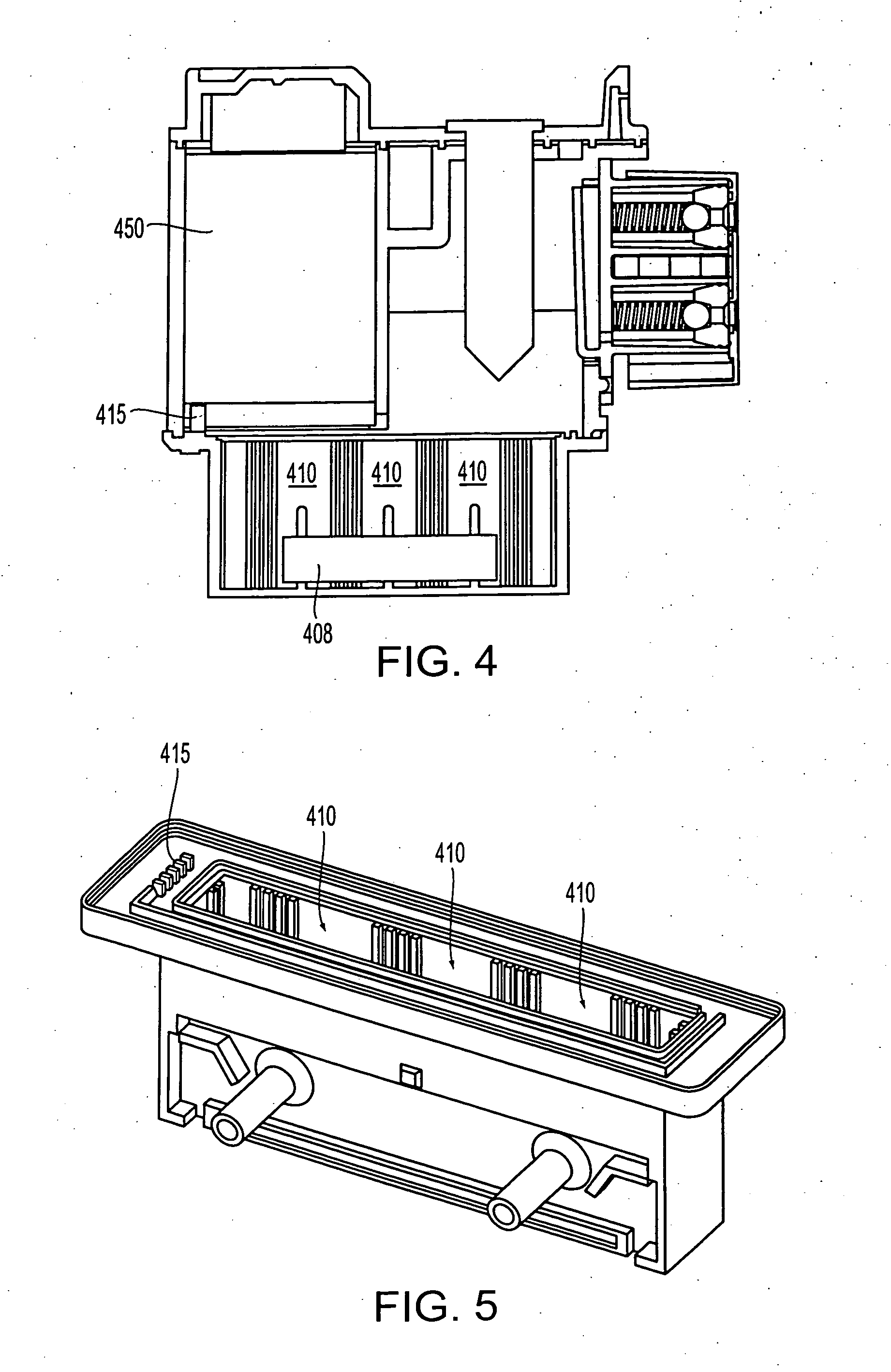

Ink delivery system for supplying ink to multiple printheads at constant pressure

An ink delivery system for an inkjet printer includes: a positive ink line; a negative ink line; and one or more print modules interconnected between the positive ink line and the negative ink line. Each print module includes: an inlet port; an outlet port; a printhead interconnected between the inlet port and the outlet port; a control valve positioned at the inlet port for controlling an ink pressure in the printhead; an ink pressure sensor for sensing an ink pressure in the print module; and a controller for receiving feedback from the pressure sensor and controlling the control valve. During printing, the ink pressure sensor, the controller and the control valve cooperate to control a backpressure in the printhead within a predetermined backpressure range.

Owner:MEMJET TECH LTD

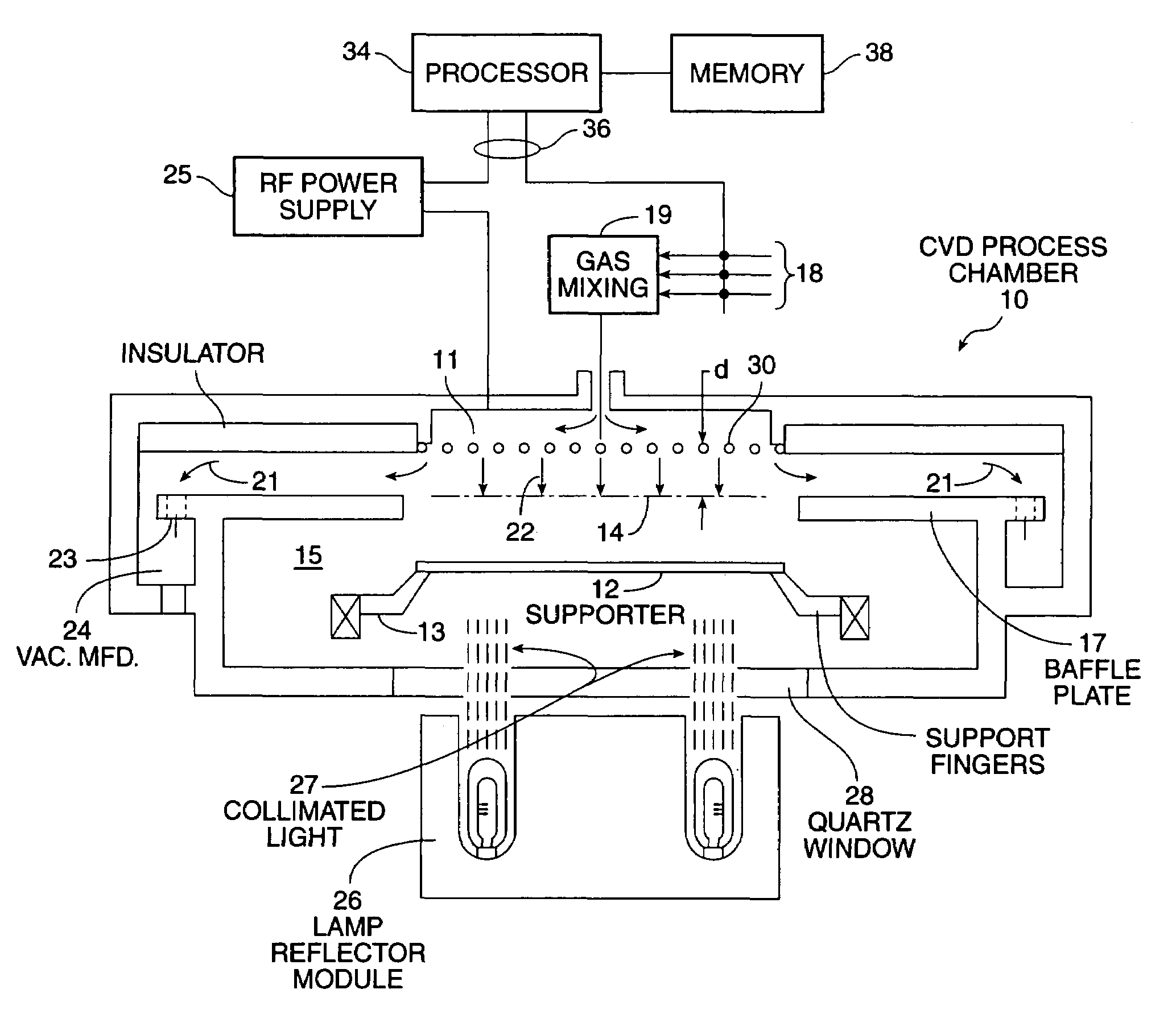

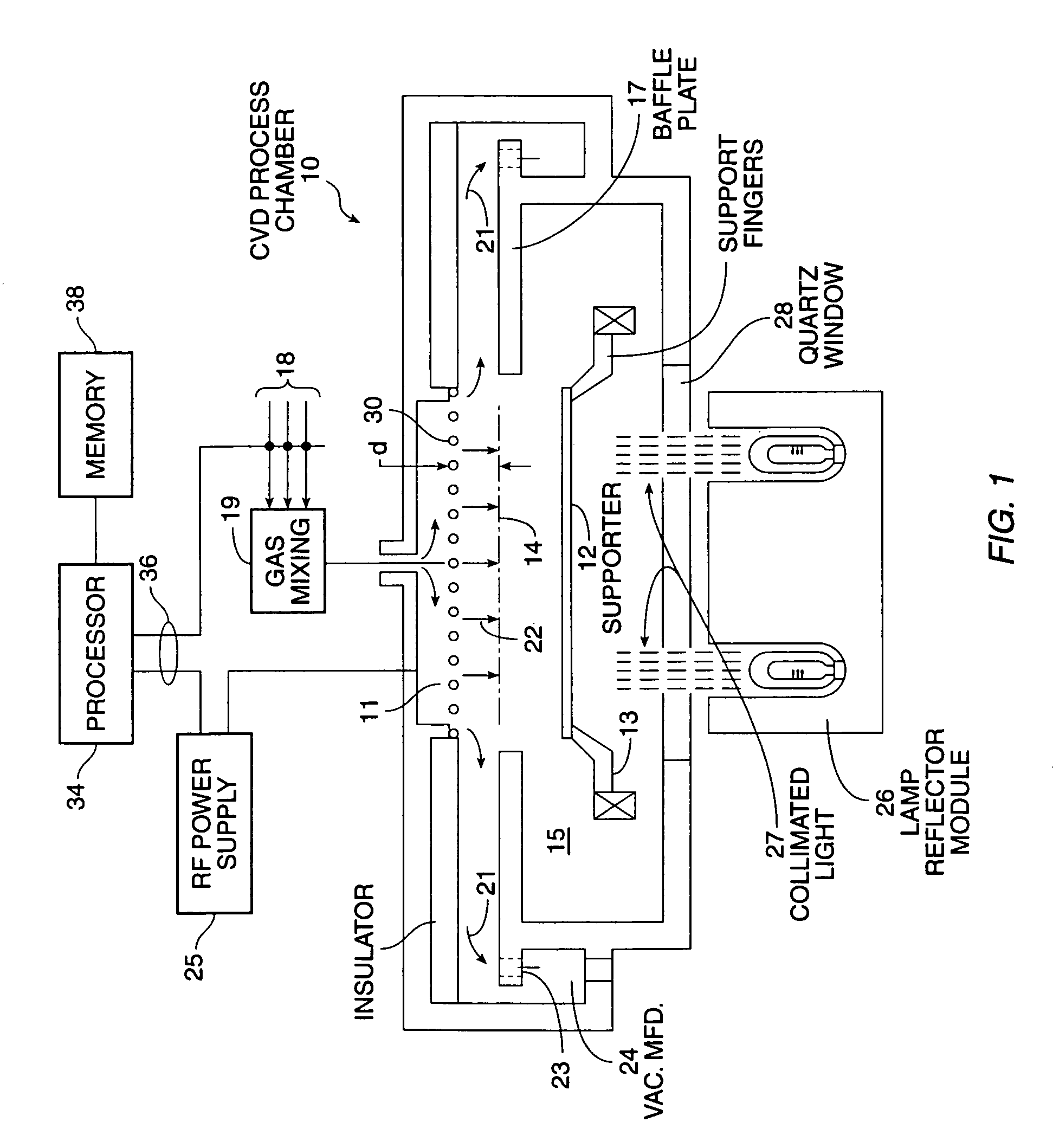

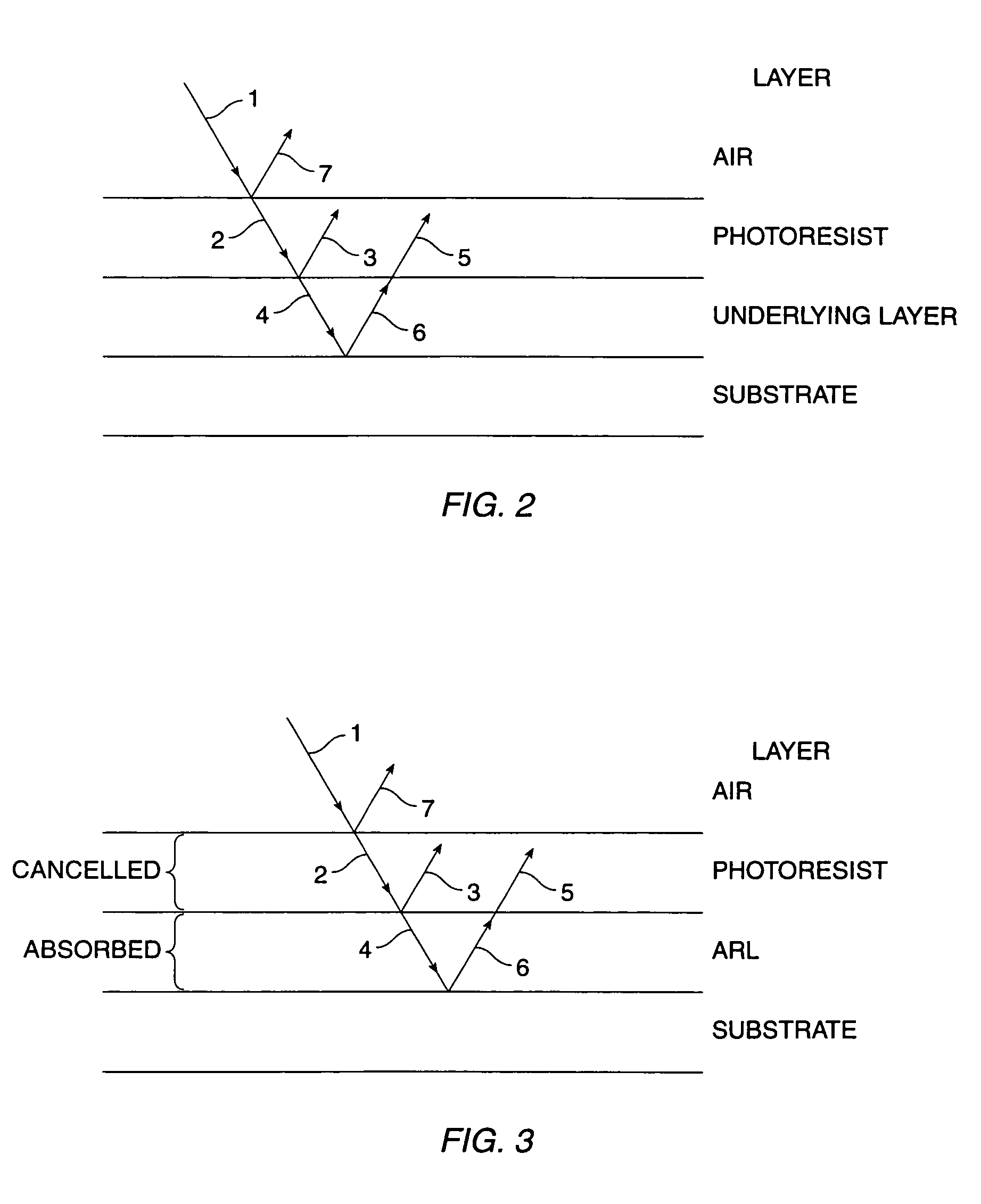

Method and apparatus for depositing antireflective coating

InactiveUS7070657B1Low deposition rateEasy to controlLiquid surface applicatorsSemiconductor/solid-state device manufacturingSilanesRefractive index

This invention provides a stable process for depositing an antireflective layer. Helium gas is used to lower the deposition rate of plasma-enhanced silane oxide, silane oxynitride, and silane nitride processes. Helium is also used to stabilize the process, so that different films can be deposited. The invention also provides conditions under which process parameters can be controlled to produce antireflective layers with varying optimum refractive index, absorptive index, and thickness for obtaining the desired optical behavior.

Owner:APPLIED MATERIALS INC

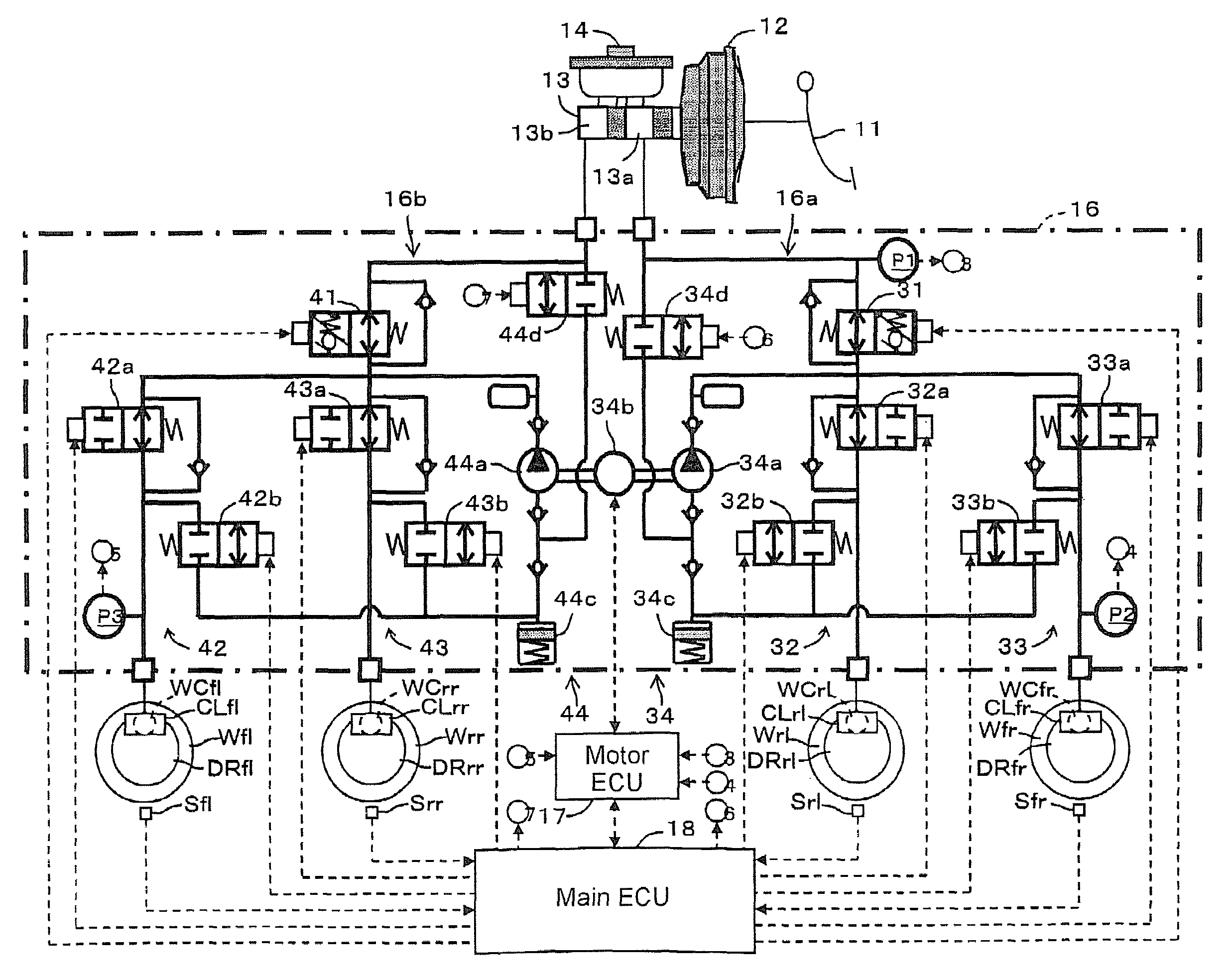

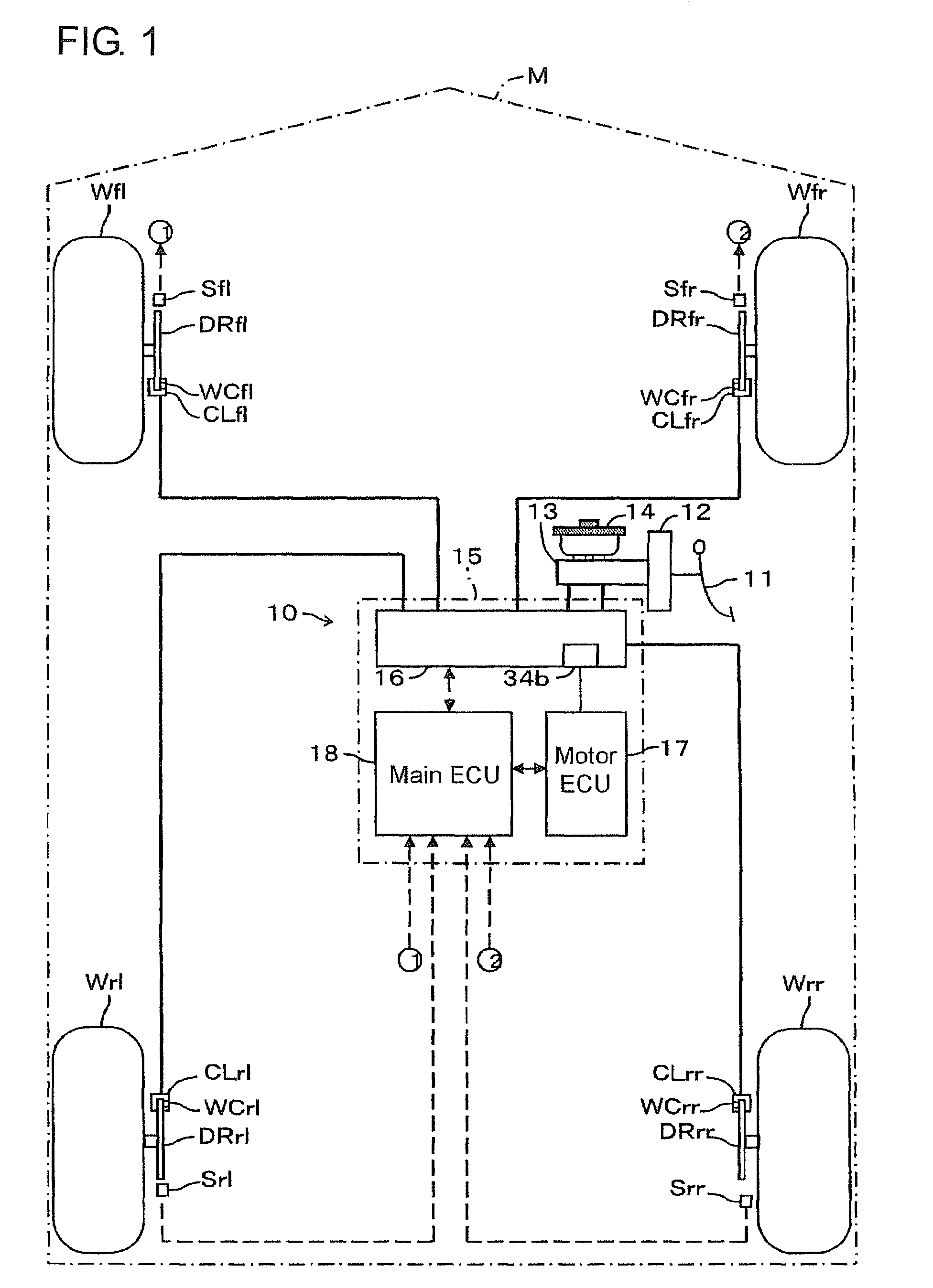

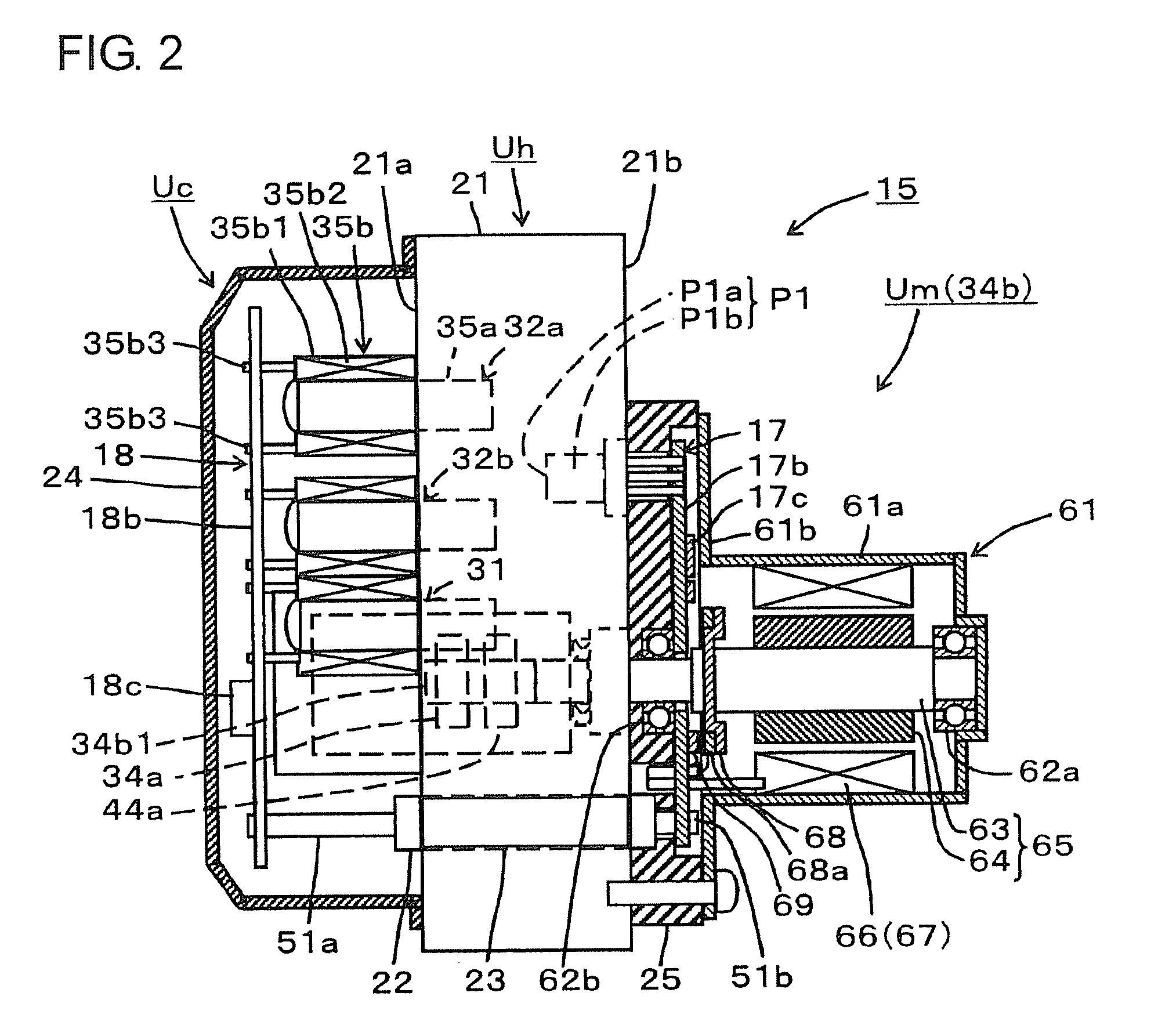

Brake hydraulic pressure control device

InactiveUS20090189440A1Reduce spacingReduce in quantitySingle motor speed/torque controlApplication and release valvesTransverterControl theory

In a brake hydraulic pressure control device, a main ECU is provided with a first converter for converting serial signals or parallel signals inputted thereto into parallel signals or serial signals to output the converted signals, while a motor ECU arranged away from the main ECU is provided with a second converter for converting serial signals or parallel signals inputted thereto into parallel signals or serial signals to output the converted signals. The first and second converters are electrically connected with each other through at least one conductive member capable of serial communication.

Owner:ADVICS CO LTD

Method and apparatus for controlling microfluidic flow

InactiveUS20060193730A1Easy to integrateThe price is rightFlexible member pumpsLaboratory glasswaresVoltage dividerVoltage sensor

An apparatus includes a pump; a gas pressure sensor; a microfluidic chip defining a microfluidic conduit; and a gas conduit providing fluid communication between the pump, the gas sensor and the microfluidic conduit; and a controller coupled to the pump and the gas pressure sensor, whereby the controller controls the pump, thereby controlling the gas pressure at the microfluidic conduit. An apparatus includes a microfluidic chip defining a microfluidic conduit extending from a microfluidic source electrode to a microfluidic ground electrode; a first resistor coupled to the microfluidic source electrode; a first and a second voltage divider, the first divider coupling a first power ground to a side of the first resistor opposite the microfluidic chip, the second divider coupling a second power ground to the lead between the first resistor and the microfluidic source electrode, and a first voltage sensor; and a second voltage sensor. Also included are methods of operating the apparatus.

Owner:BROWN UNIVERSITY

Two-stage hydrocarbon hydrogenation method with serial high-pressure parts

ActiveCN101892077AImprove work efficiencyImprove efficiencyTreatment with hydrotreatment processesHydrogenation reactionHigh pressure

The invention relates to a two-stage hydrocarbon hydrogenation method with serial high-pressure parts. First-stage hot high-pressure separator oil and a first-stage hot high-pressure separator gas are obtained from a first-stage hydrogenation reaction effluent by a first-stage high-pressure separation part; a first-stage cold high-pressure separator gas and first-stage cold high-pressure separator oil are obtained from the first-stage hot high-pressure separator gas by the first-stage cold high-pressure separation part; the first-stage hot high-pressure separator oil and the first-stage cold high-pressure separator gas enter a second-stage hydrogenation reaction part; a second-stage cold high-pressure gas and second-stage cold high-pressure separator oil are obtained from a second-stage hydrogenation reaction effluent by a second-stage cold high-pressure separation part; and at least part of the second-stage cold high-pressure separator gas is circularly returned to the first-stage hydrogenation reaction part. The method has the remarkable effects of reducing the total amount of recycle hydrogen, simplifying process and reducing investment, and is particularly suitable for the process of producing diesel oil from anthracene oil by a two-stage hydrocracking method.

Owner:何巨堂

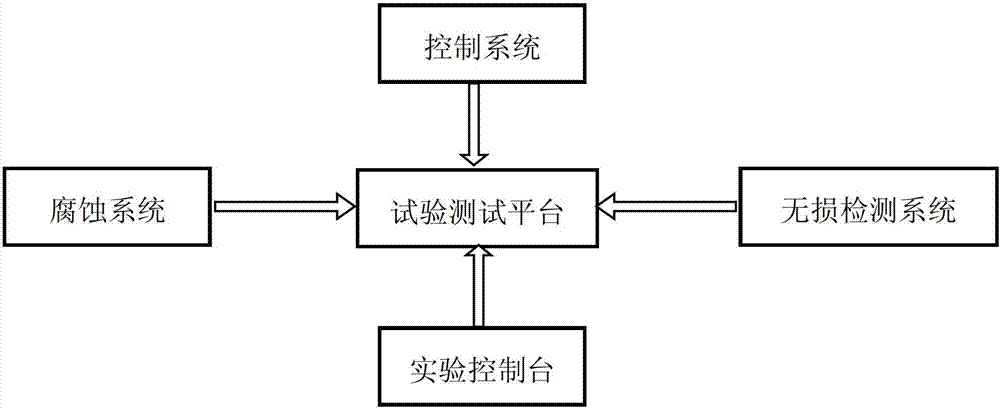

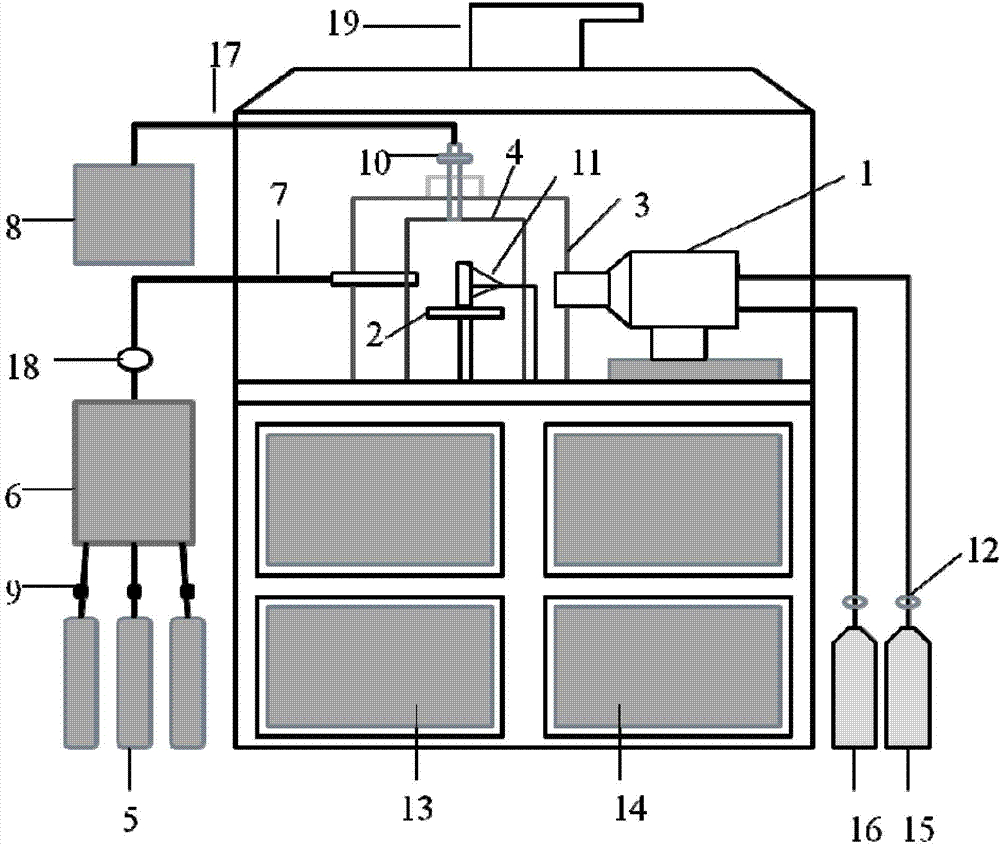

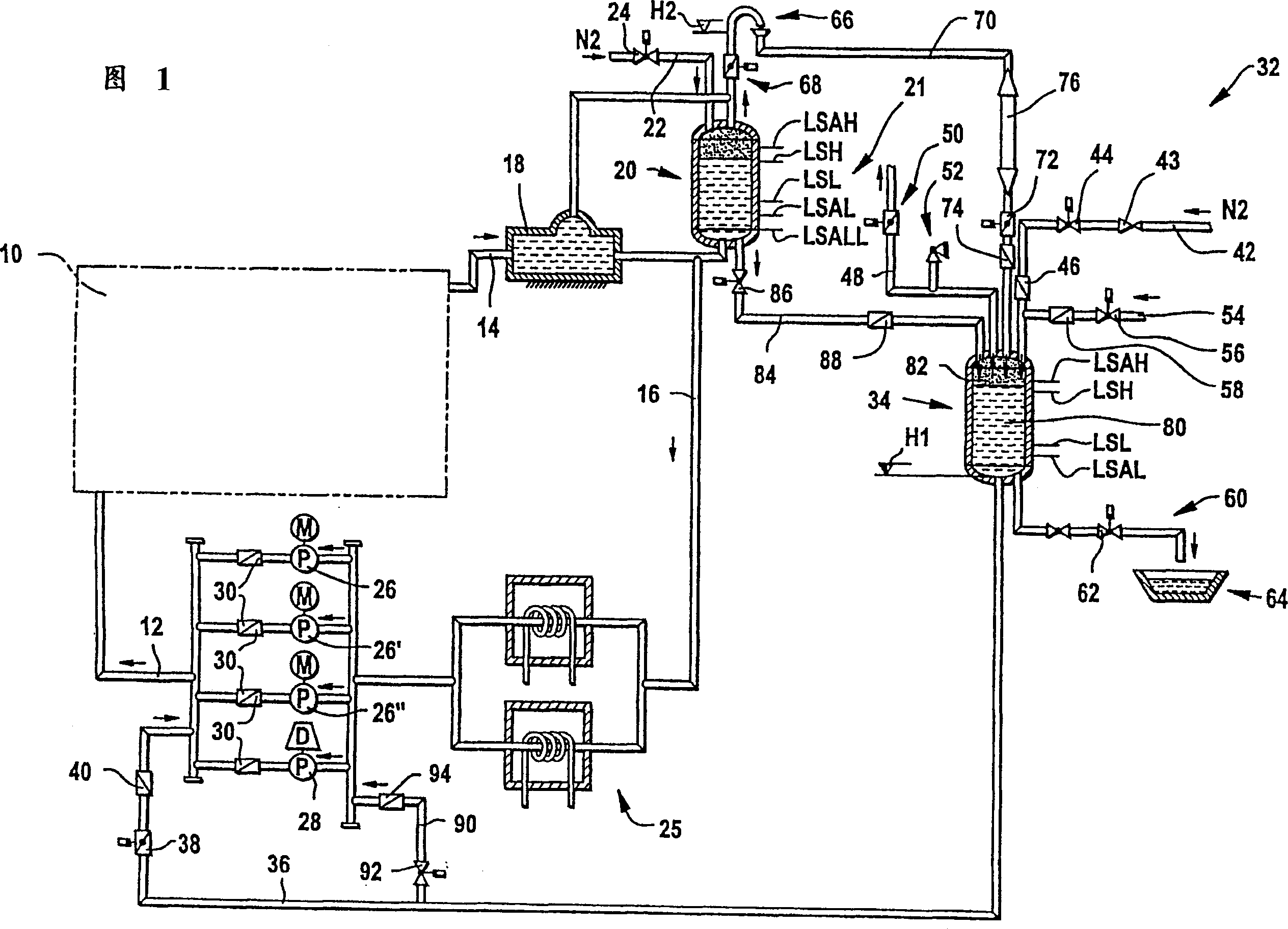

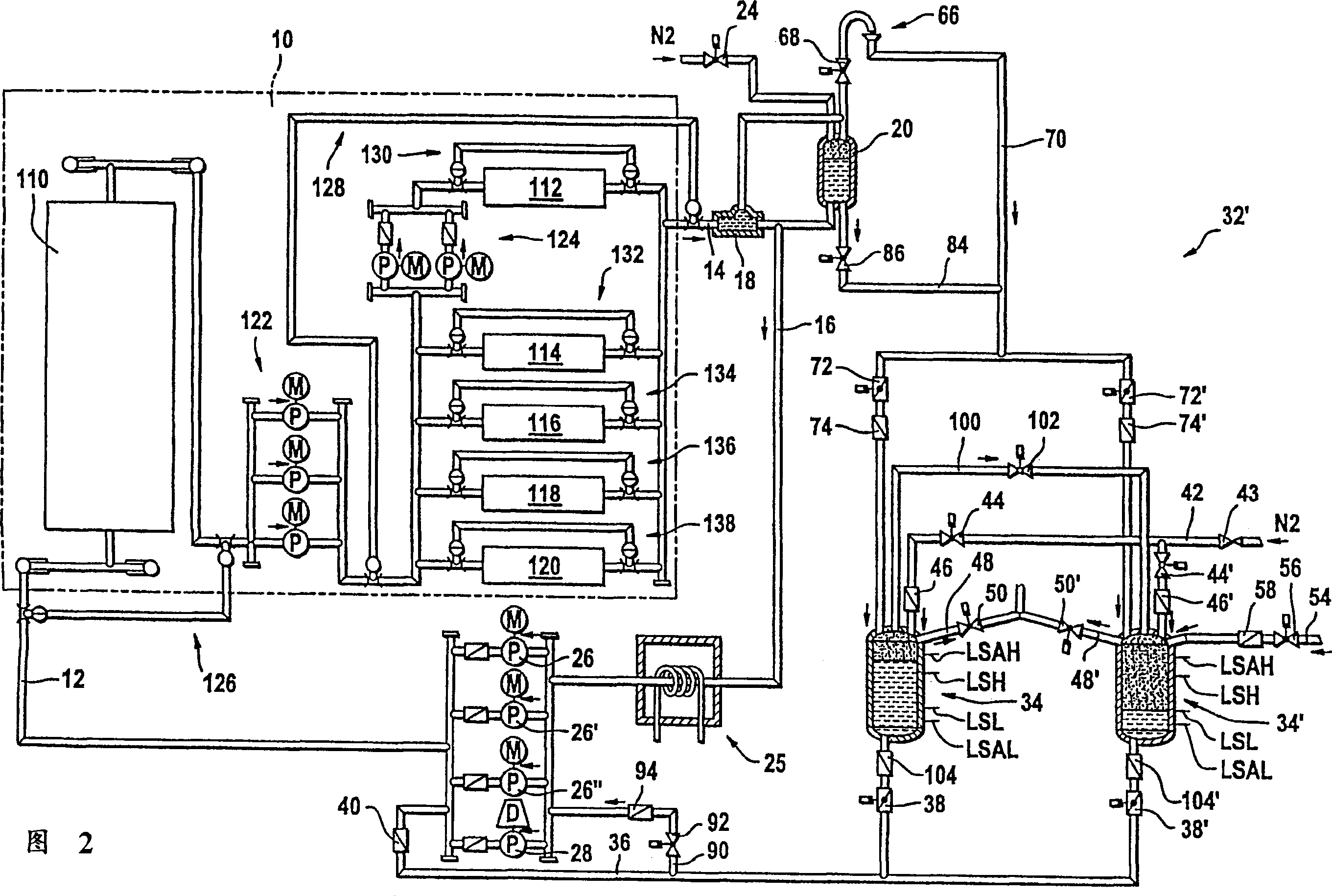

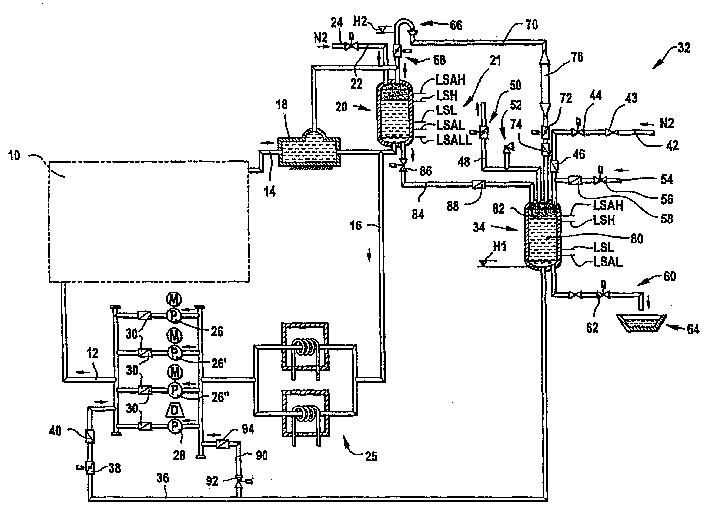

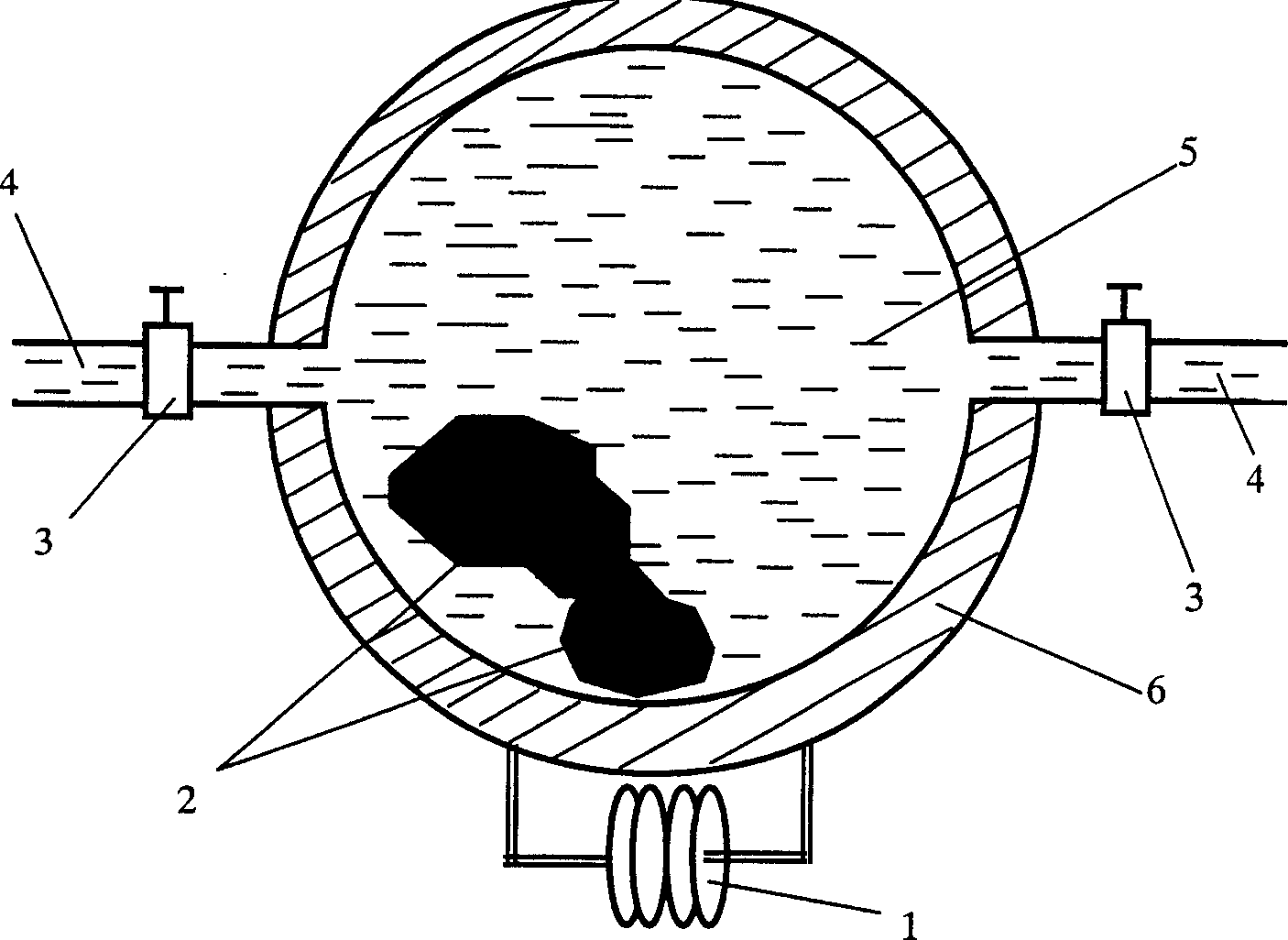

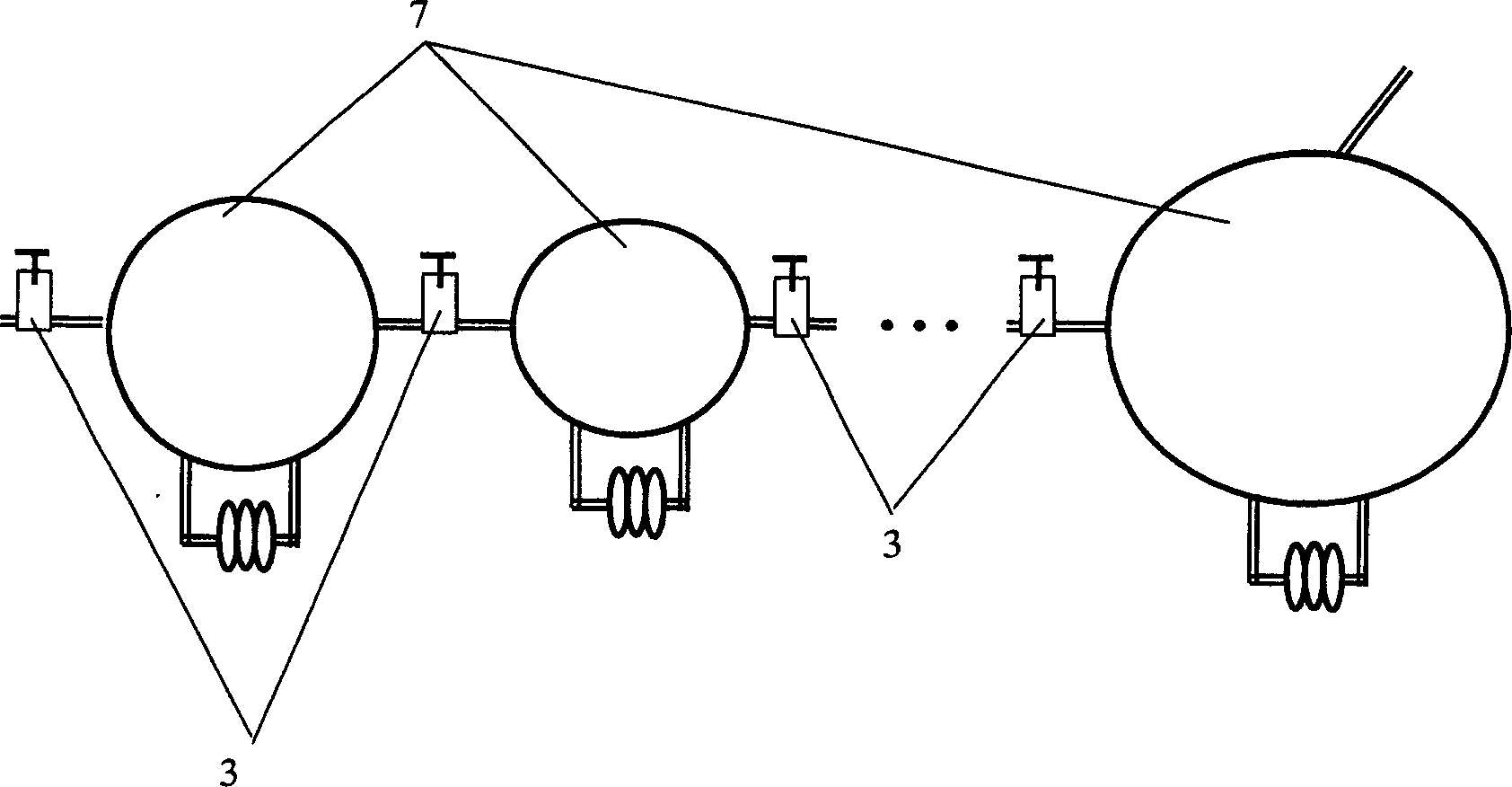

Tester for simulation and real-time test of gaseous corrosion failure of thermal barrier coating

InactiveCN103091239AIncrease concentrationEasy pressure controlWeather/light/corrosion resistanceCorrosionTurbine blade

The invention discloses a tester for simulation and real-time test of a gaseous corrosion failure of a thermal barrier coating, belonging to the field of testers of high-temperature coating materials. The tester comprises a test platform, a corrosive gas loading system, a nondestructive testing system, a control system and the like, wherein the test platform is provided with a test sample clamping device and a sample chamber, the corrosive gas loading system is fixed on the test platform, and the nondestructive testing system and the control system are arranged below the test platform. The tester disclosed by the invention can be used to simulate a high-temperature corrosive service environment of the thermal barrier coating of aeroengine turbine blades, simulate a gas corrosion failure process when the coating takes service by means of controlling the type (such as H2S, SO2 and steam), pressure, corrosion temperature and other parameters of the corrosive gas, periodically detect the changes of coating impedance and damage acoustic emission signals during corrosion of the test sample through a complex impedance spectrometry system and an acoustic emission detection system, and analyze the evolution conditions of interface shapes and damages in the corrosion process of the test sample, thereby providing an important test platform for effectively evaluating the failure process and failure mechanism of the thermal barrier coating in the high-temperature gas corrosion environment.

Owner:XIANGTAN UNIV

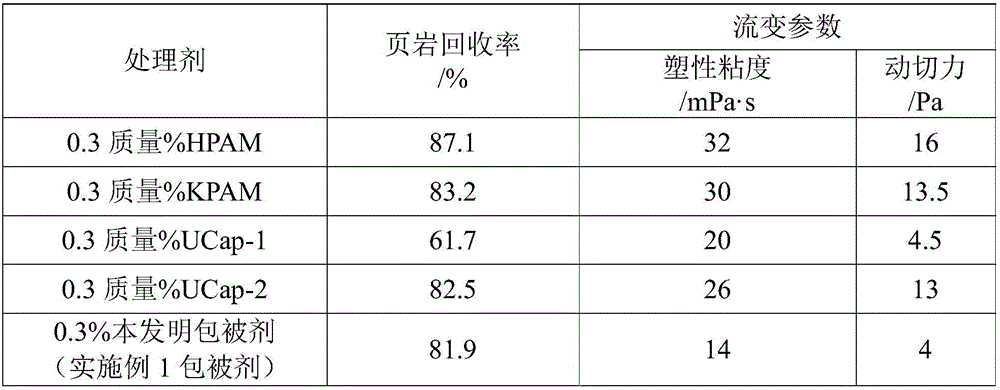

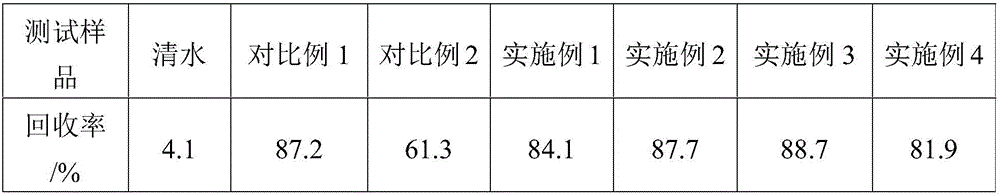

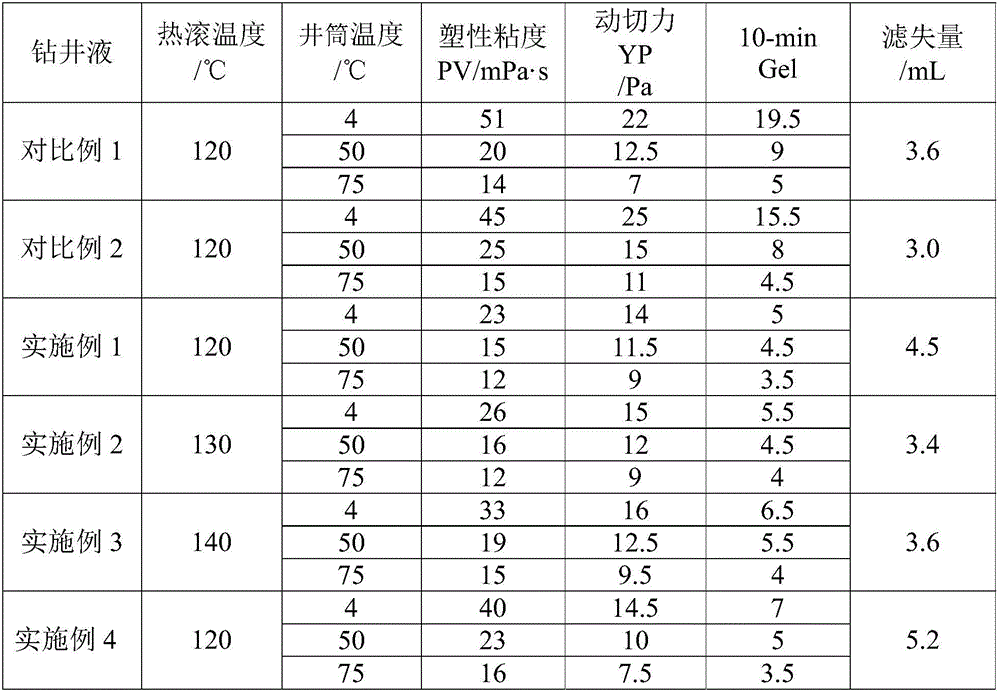

Coating agent and preparation method and application and drilling fluid used for petroleum drilling

ActiveCN106554462AAvoid instabilityAvoid severe viscosity build-up problems at low temperaturesDrilling compositionWell drillingPetroleum

The invention relates to the field of petroleum drilling, and concretely provides a coating agent and a preparation method and an application thereof and drilling fluid, the coating agent contains an acrylamide monomer structural unit shown as a formula (I), an anti-temperature monomer structural unit shown as a formula (II), and a cation monomer structural unit shown as a formula (III), wherein, R1 and R2 are respectively independent as H, C1-C15 straight chain or branched chain alkyl, and R3 is H or C1-C5 straight chain or branched chain alkyl. The drilling fluid has strong inhibition performance and stable rheological property.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

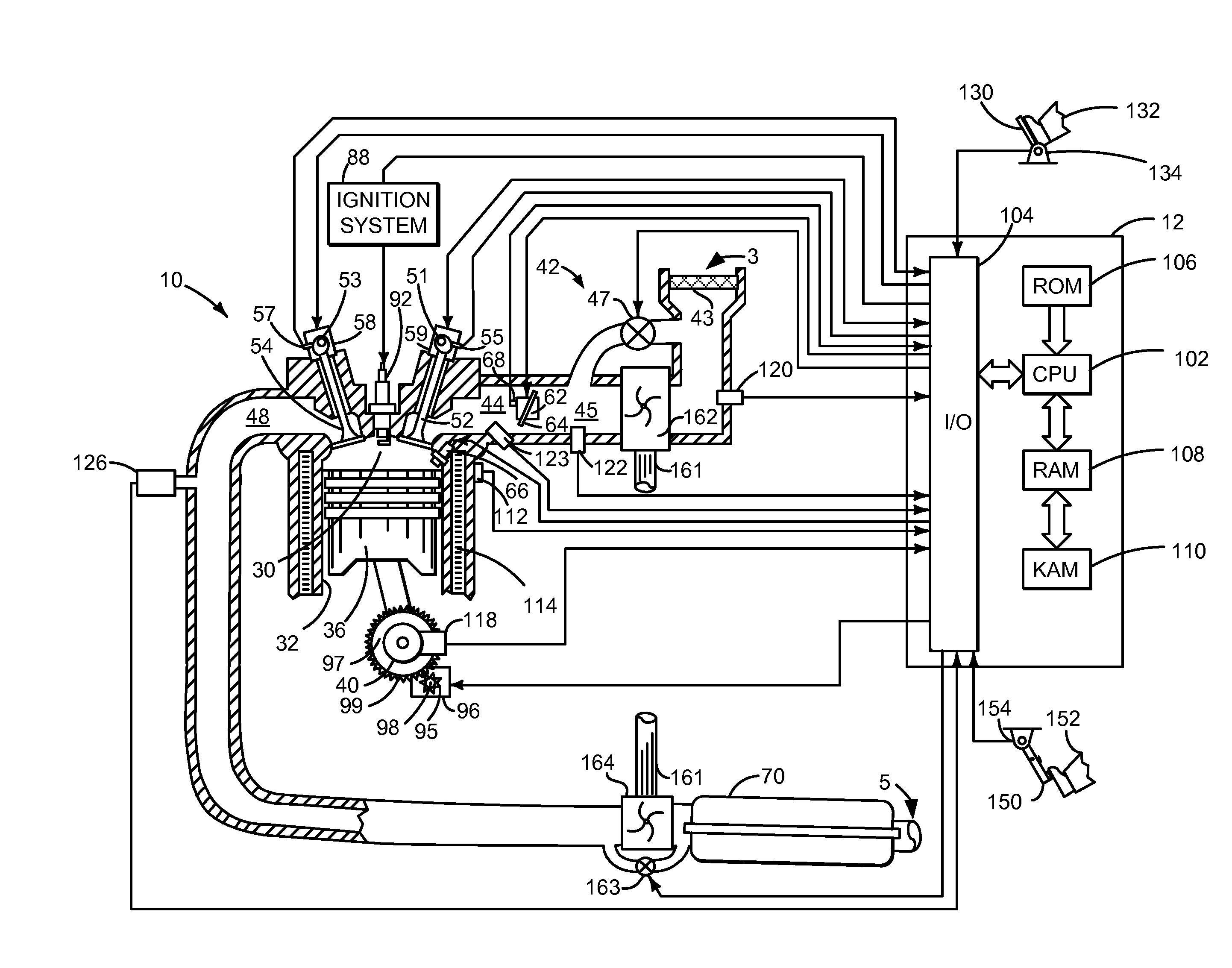

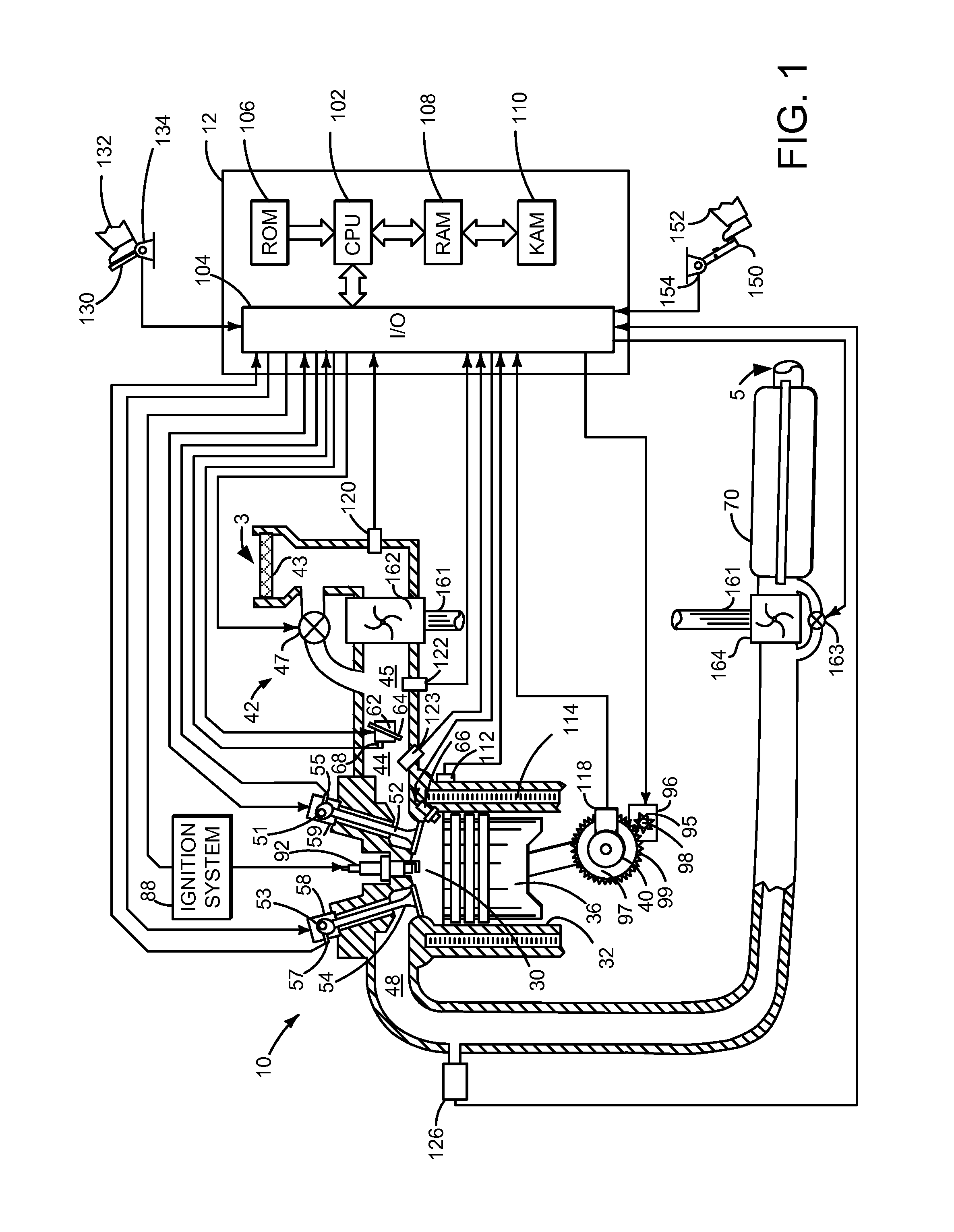

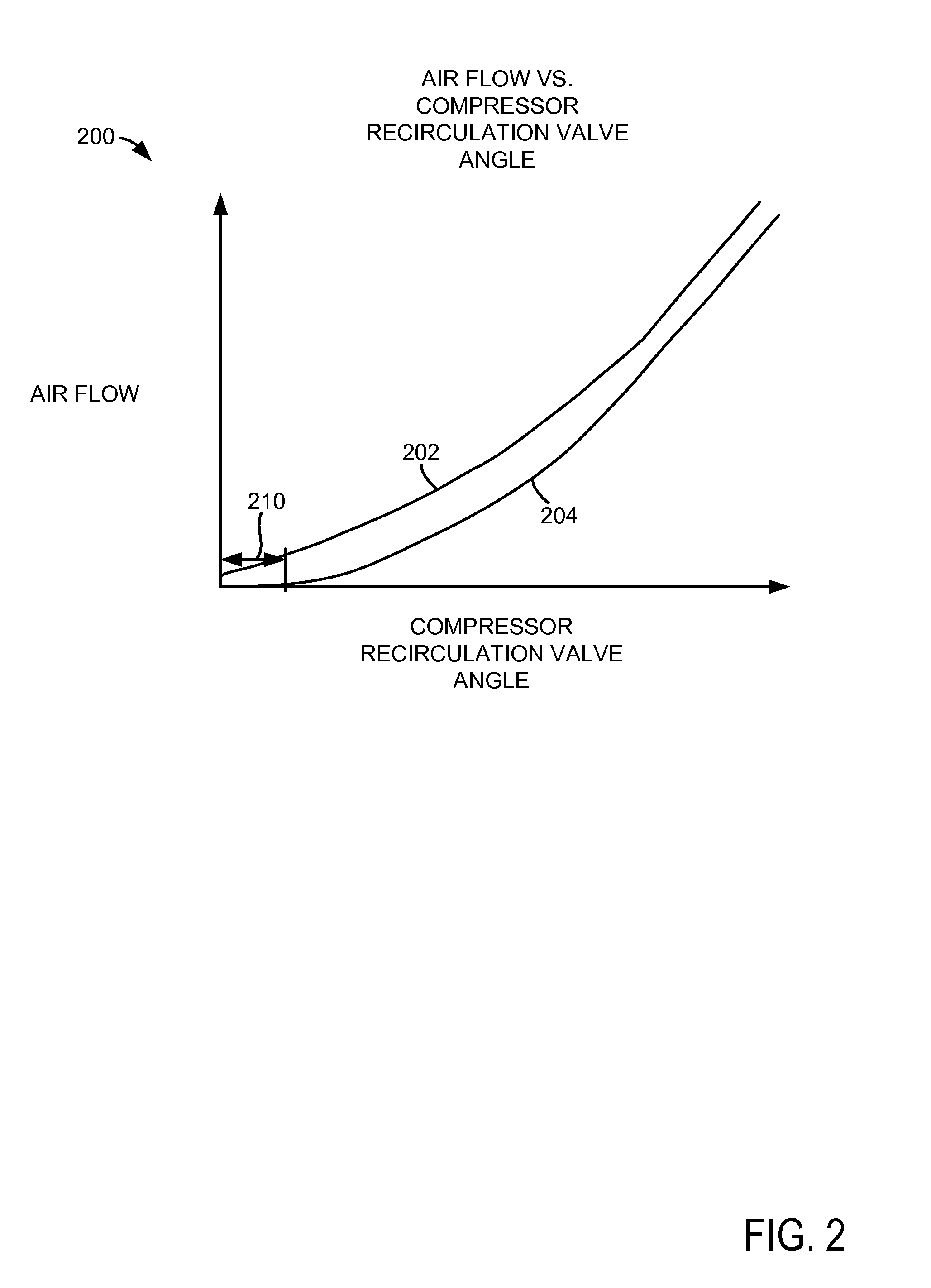

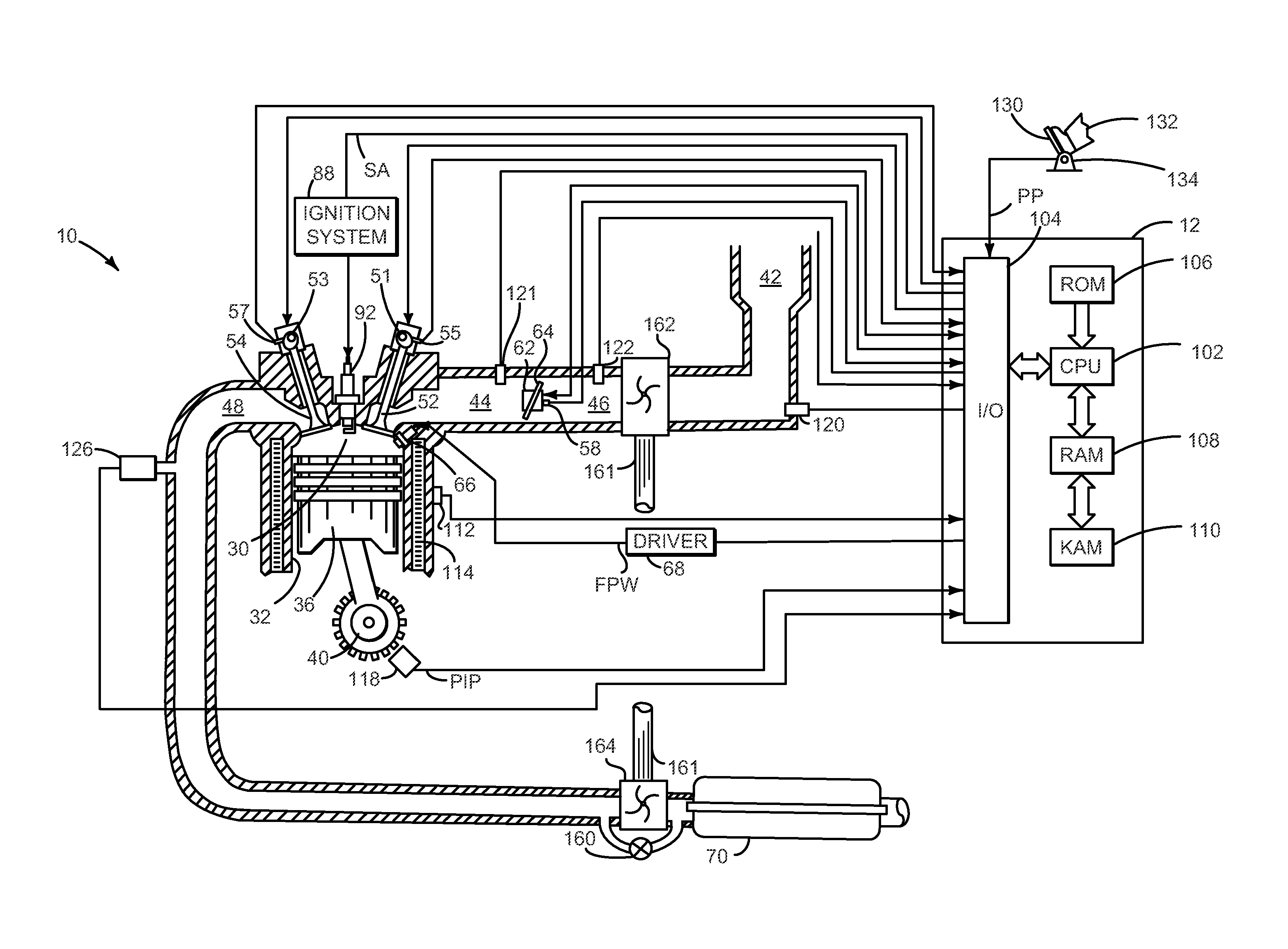

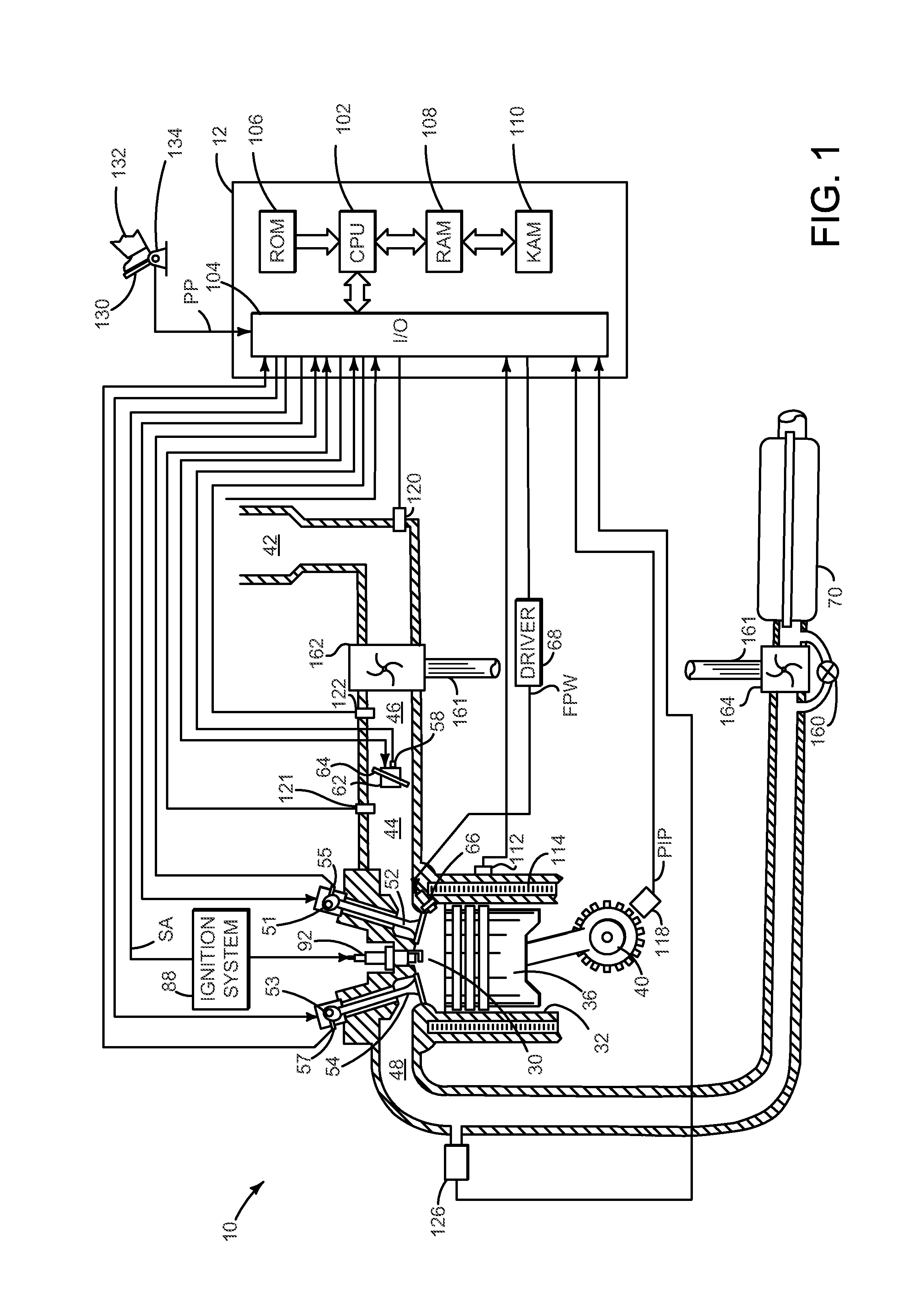

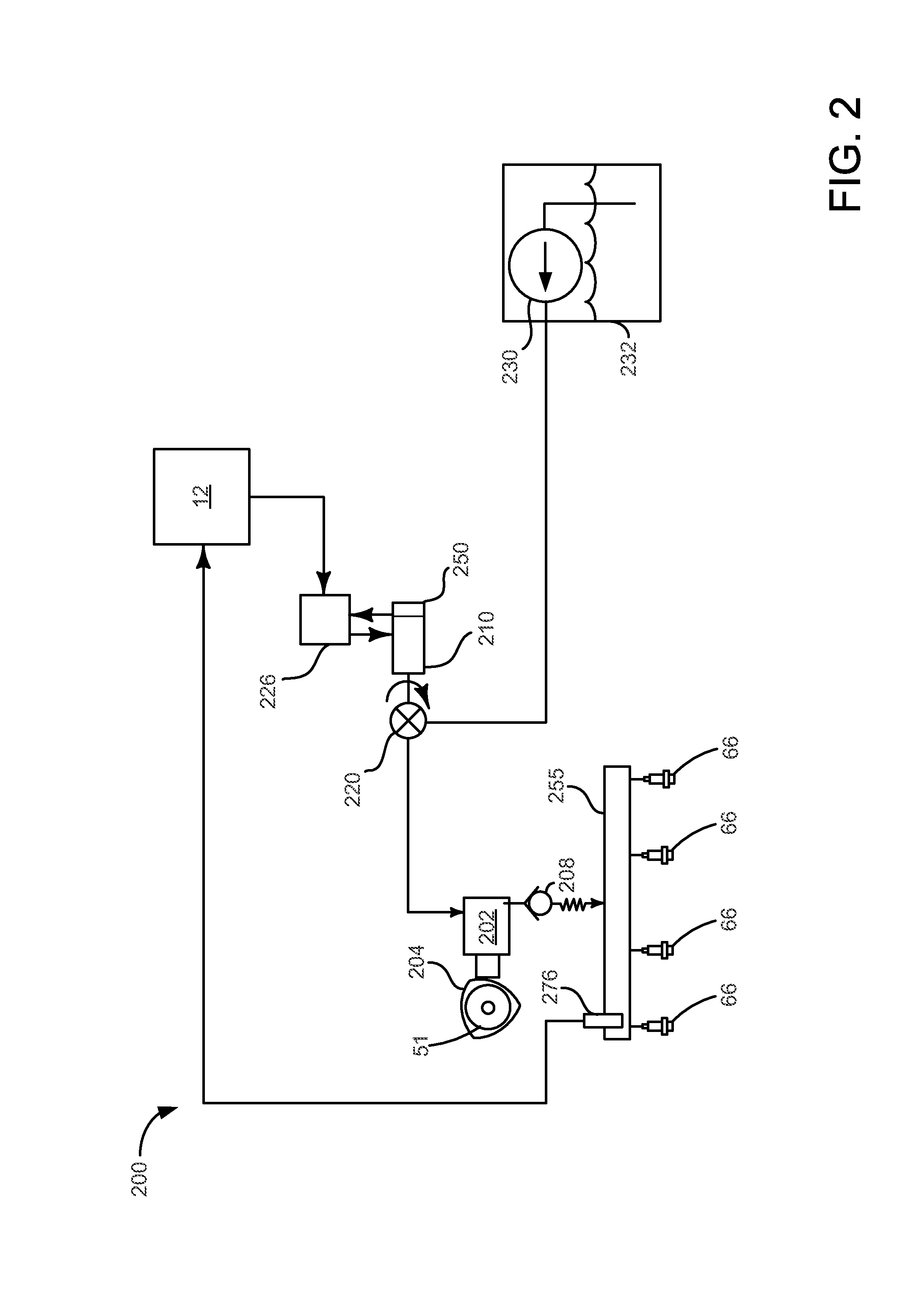

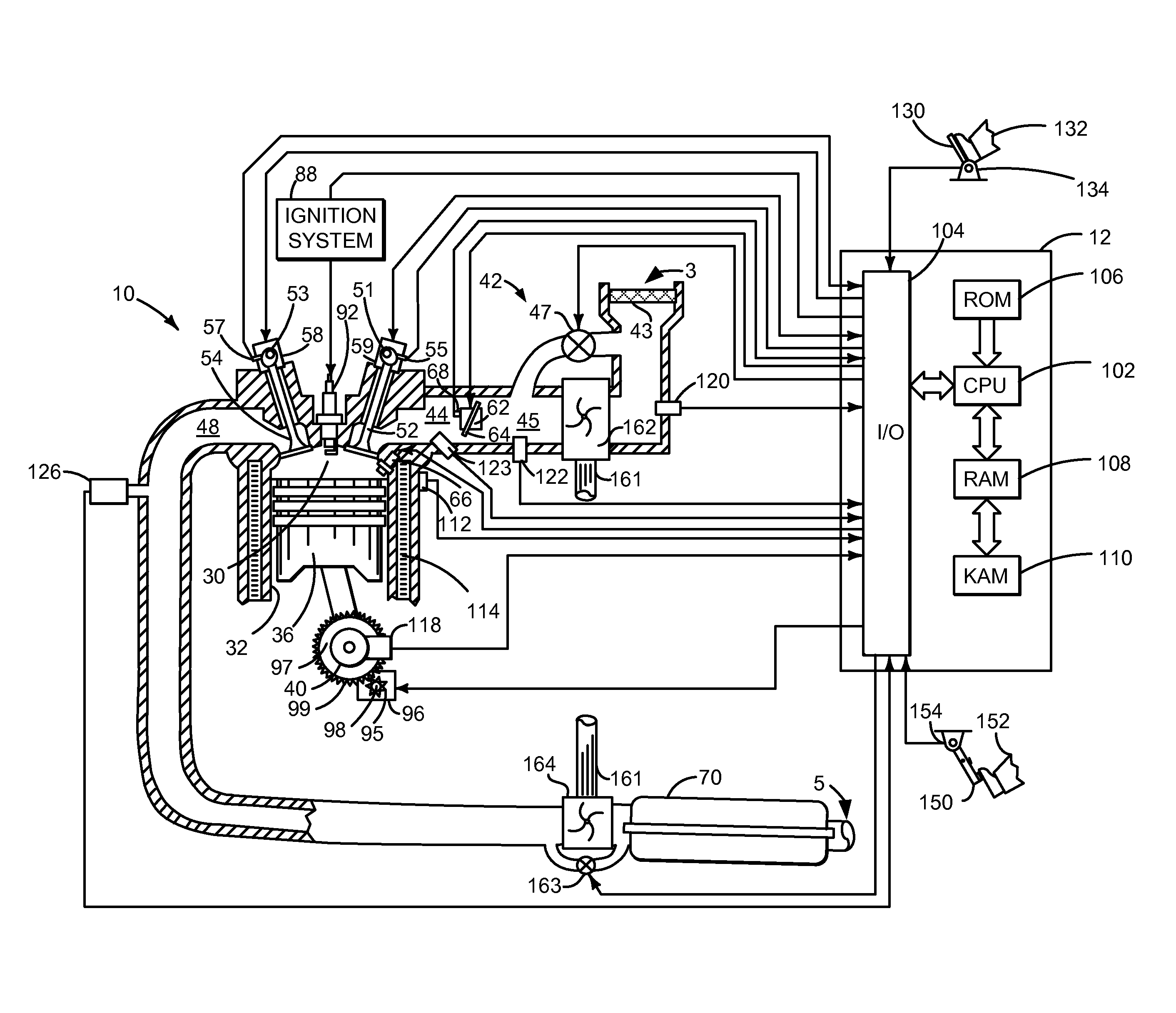

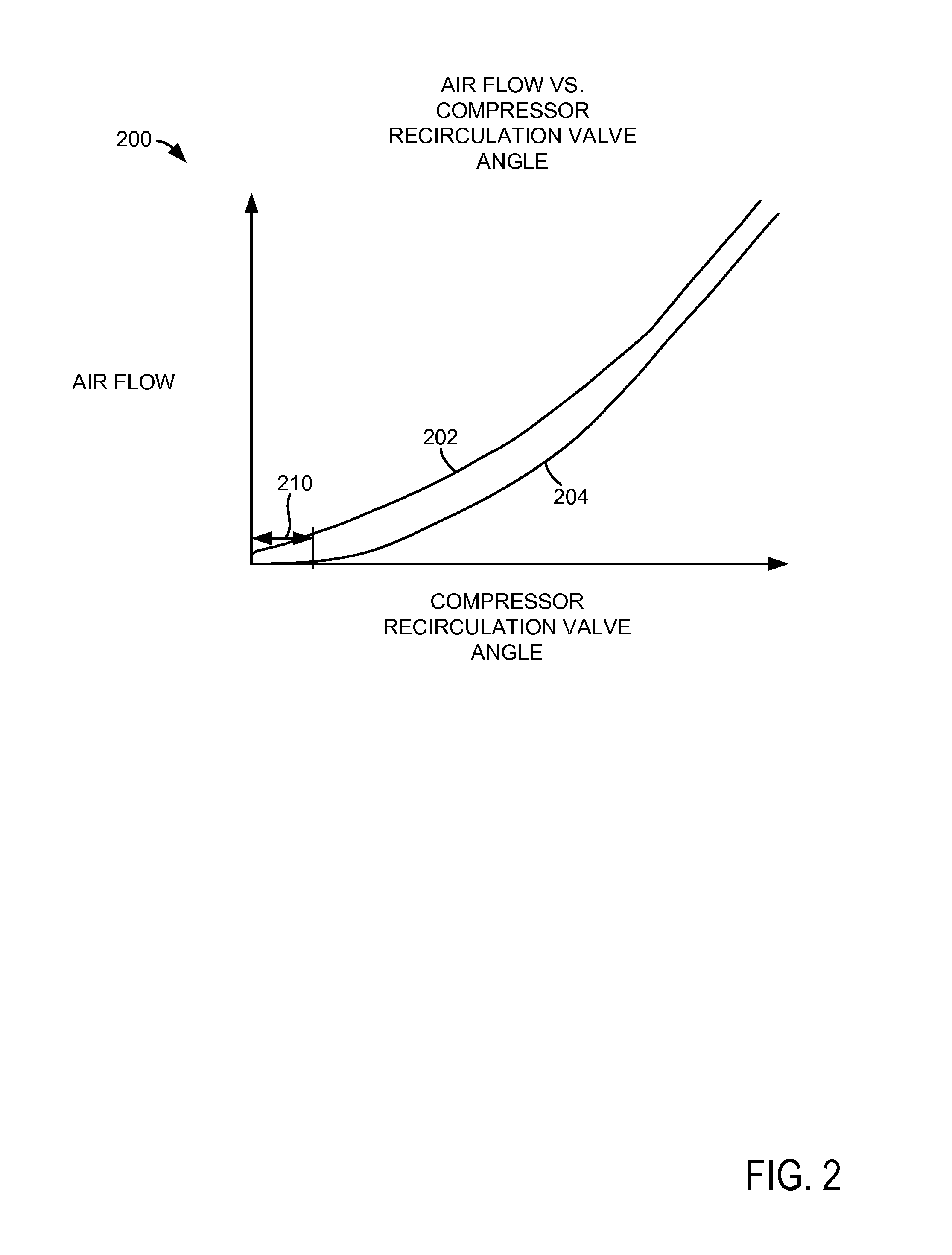

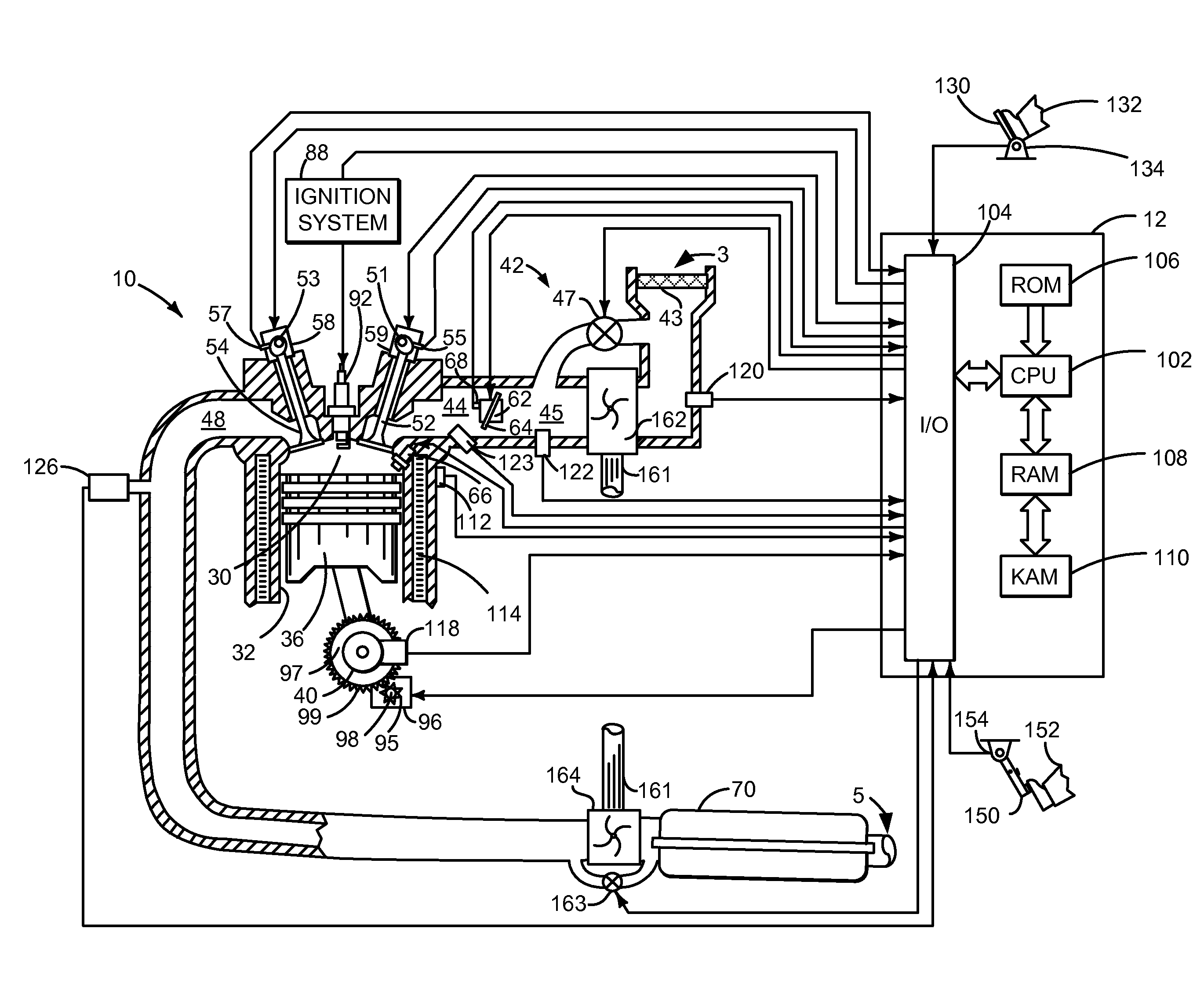

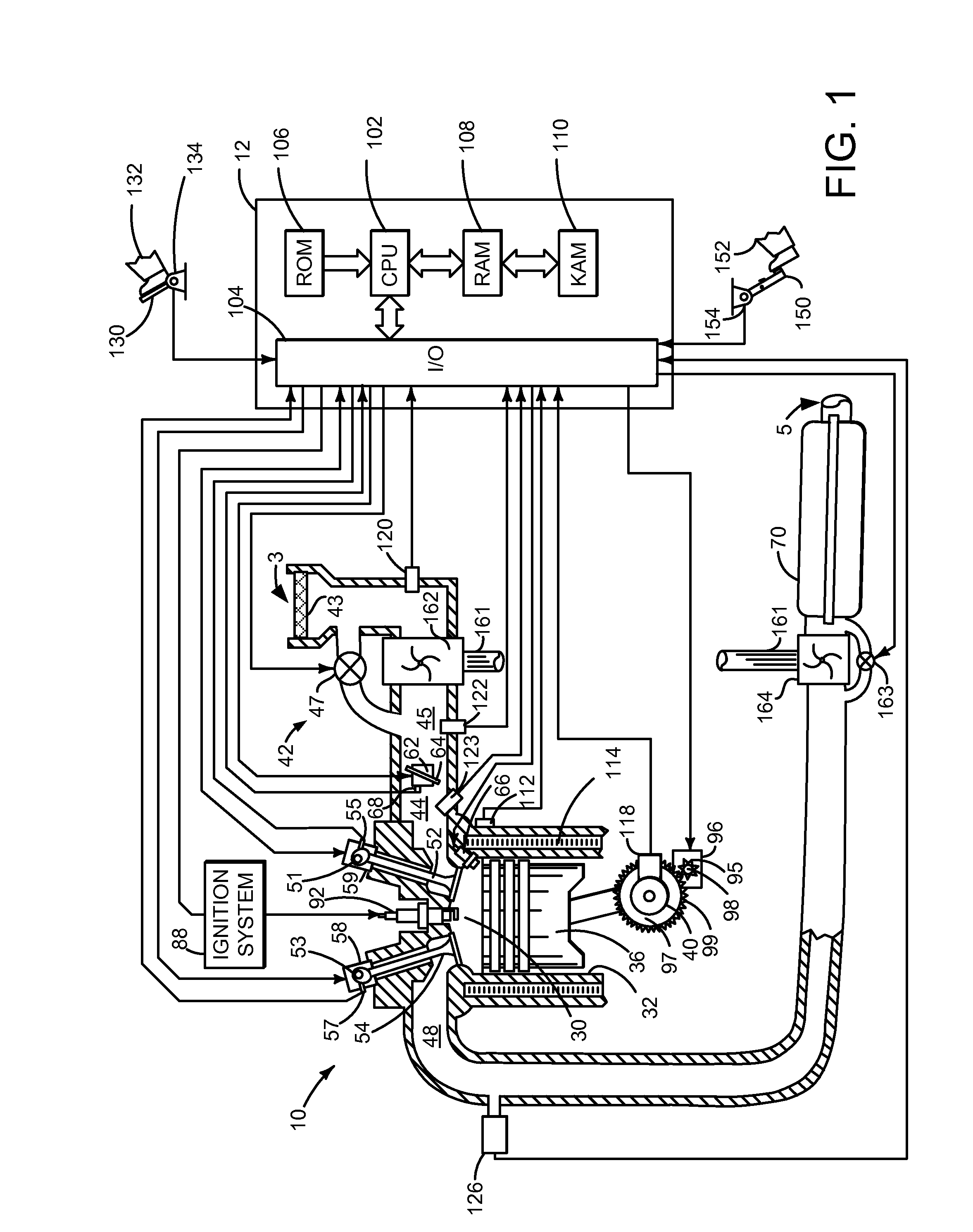

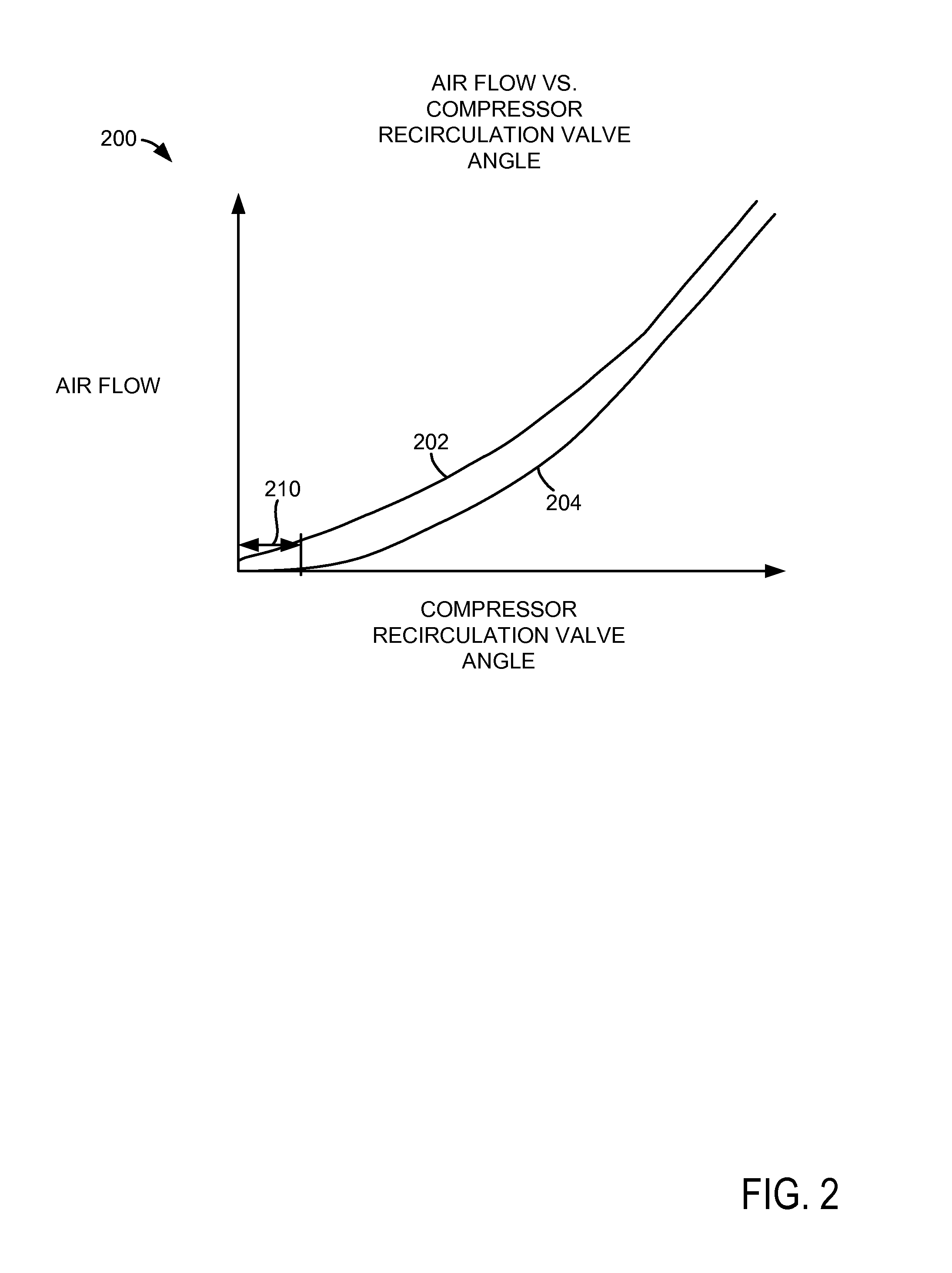

Methods and system for improving compressor recirculation valve operation

ActiveUS20160169089A1Improve engine airflow controlImproved air-fuel ratio controlElectrical controlInternal combustion piston enginesClosed loopInlet pressure

Systems and methods for improving compressor recirculation valve operation of an engine that includes a compressor are presented. The systems and methods adjust a position of a waste gate while the compressor recirculation valve is operated in a closed loop mode to maintain engine intake manifold throttle inlet pressure during a diagnostic mode to adapt operation of the compressor recirculation valve.

Owner:FORD GLOBAL TECH LLC

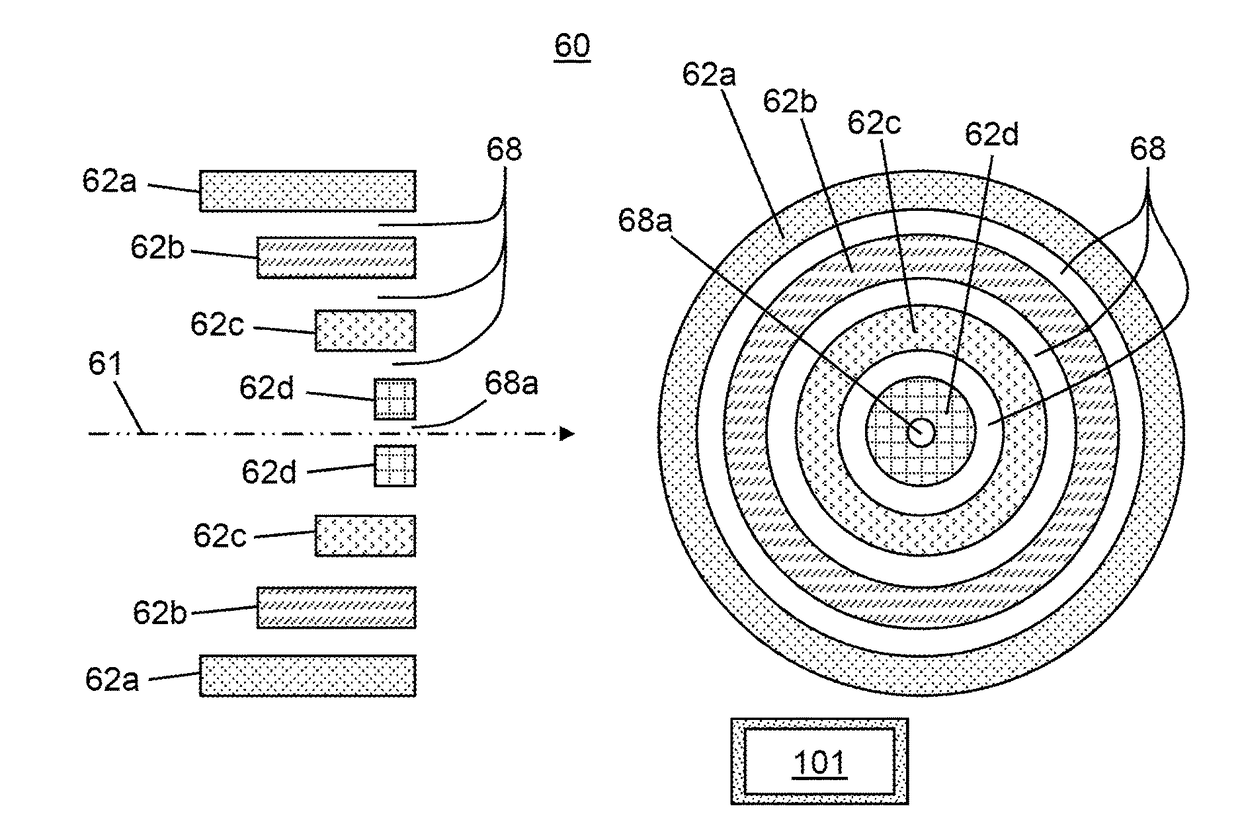

System for transferring ions in a mass spectrometer

ActiveUS9761427B2Easy pressure controlEfficient pumpingElectron/ion optical arrangementsIon transferMass analyzer

Owner:THERMO FINNIGAN

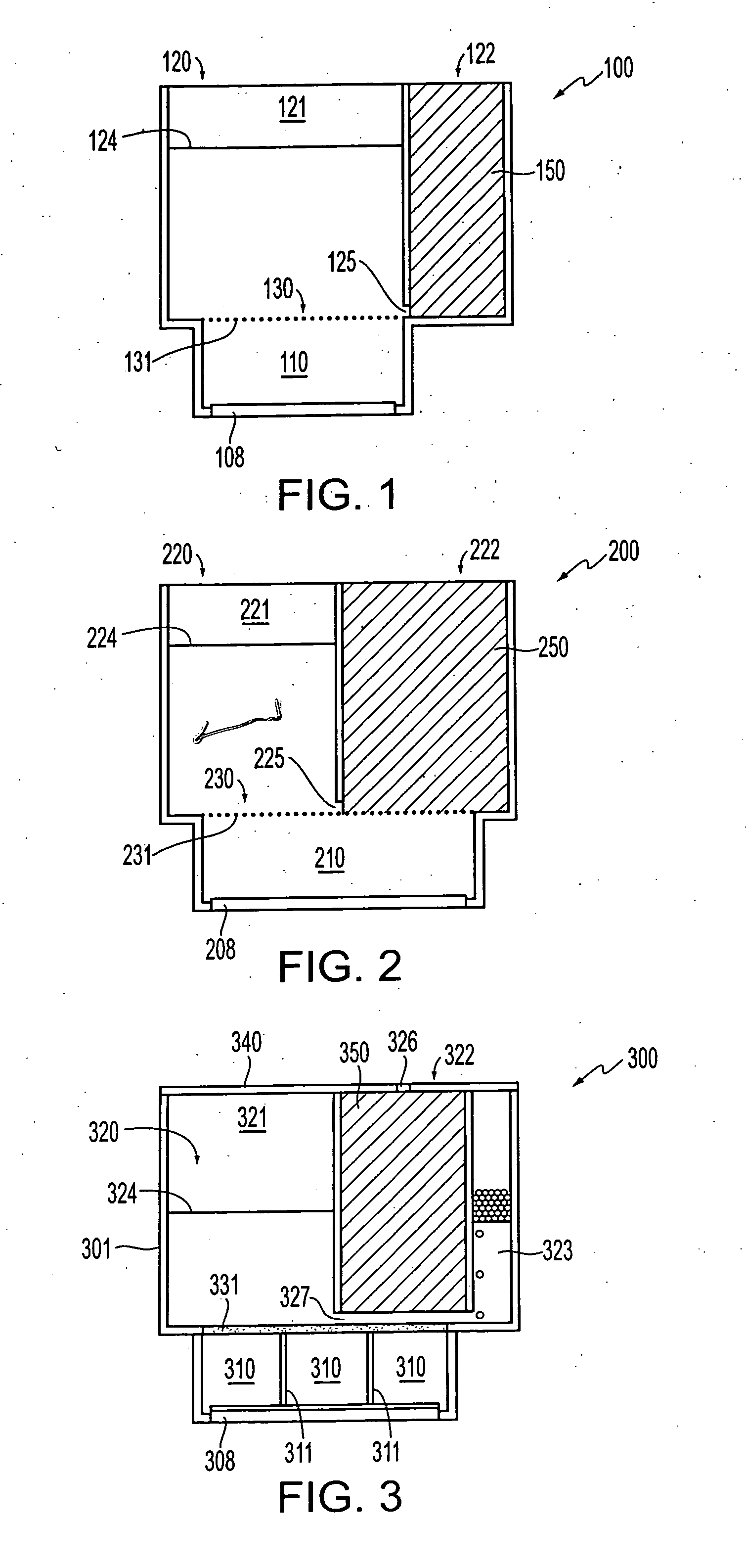

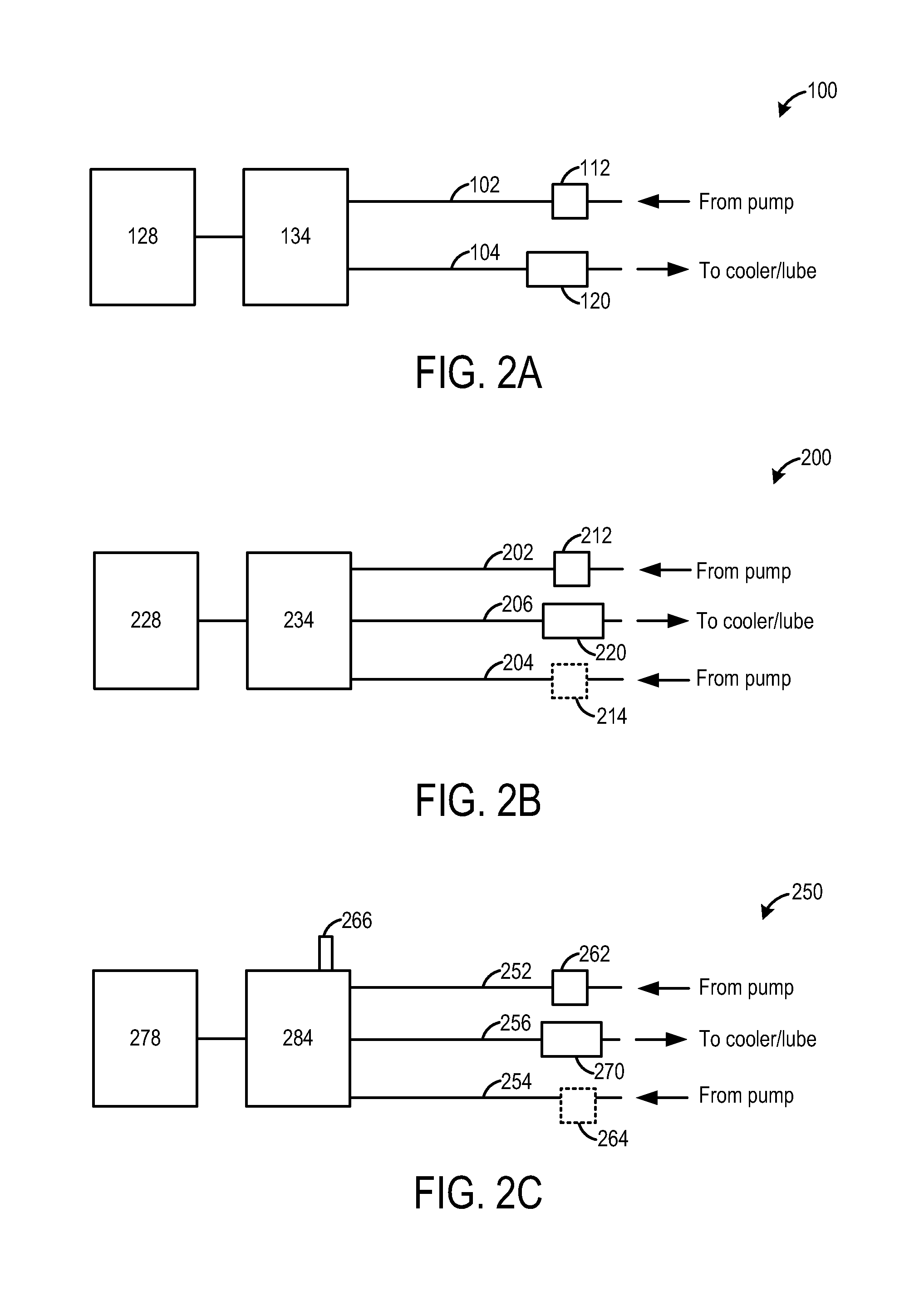

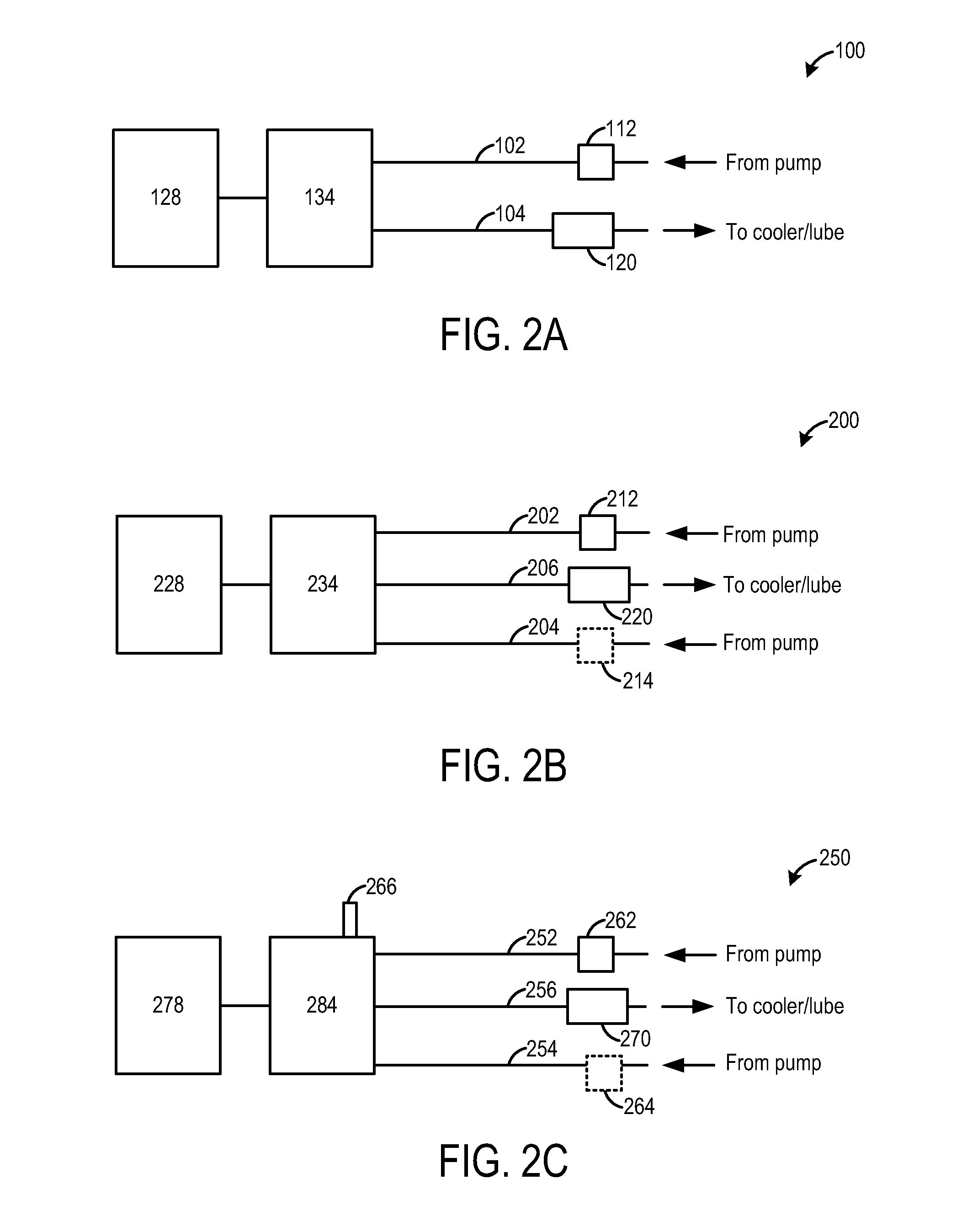

Print head pressure control architectures

InactiveUS20050157129A1Improve robustnessReduce decreaseLiquid surface applicatorsCoatingsFiberEngineering

A fluid container, such as, for example, an inkjet print head cartridge, architecture uses a relatively large filter that is located below a negative pressure material chamber and a free ink chamber in a side-by-side relationship. The negative pressure material volume relative to a free ink chamber value can me made to be approximately one to one. Both chambers overlie an ink manifold / delivery port and are separated from the delivery port by a filter. Flow impedance of the cartridge is reduced, as a result, in any orientation of the cartridge. The filter may be separated from, or in contact with a negative pressure material. A cartridge lid is provided with a negative pressure material chamber which is suspended into the cartridge. A negative pressure material having a fiber felt construction is provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

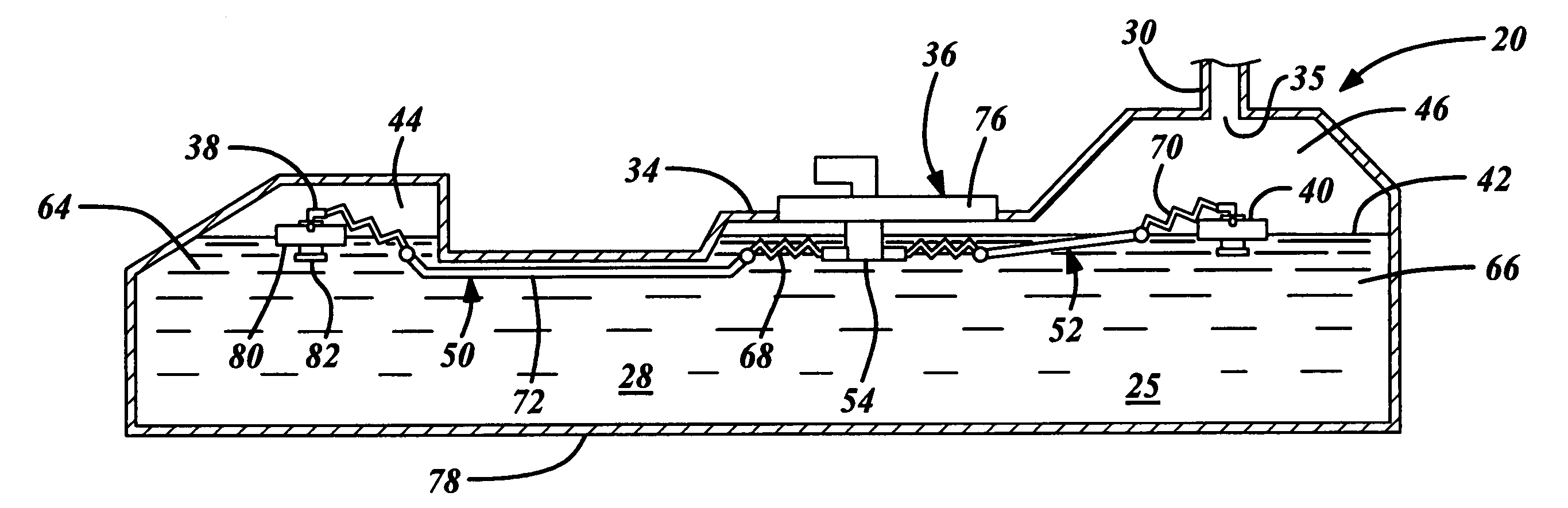

Fuel storage system for a vehicle

InactiveUS20070186976A1Good flexibilityImproved fuel tank pressure controlLarge containersPipeline systemsHydrocotyle bowlesioidesSurface level

A fuel storage system for a transportation or recreational vehicle has a fuel tank that carries a vapor assembly that seeks out vapor pockets and controllably removes fuel vapor from the tank without releasing hydrocarbons to the surrounding environment. Preferably, a vent manifold attaches to a flange that sealably covers an access hole of the tank. At least one flexible tentacle extends from the manifold in the tank to a respective vapor vent valve that floats upon the surface of fuel at a vapor dome. When freely floating, the vent valve is open thus communicates the vapor dome through the tentacle and preferably with a filtering carbon canister. As fuel surface levels change or the vehicle tilts, changing the vapor dome size or location in the tank, the floating vapor vent valve is free to move generally with the vapor dome and as permitted by the flexibility of the trailing tentacle. With tank orientations where the vapor vent valve falls below the surface of fuel, the vent valve automatically closes to prevent flooding of the respective tentacle and remote vapor canister.

Owner:TI GRP AUTOMOTIVE SYST LLC

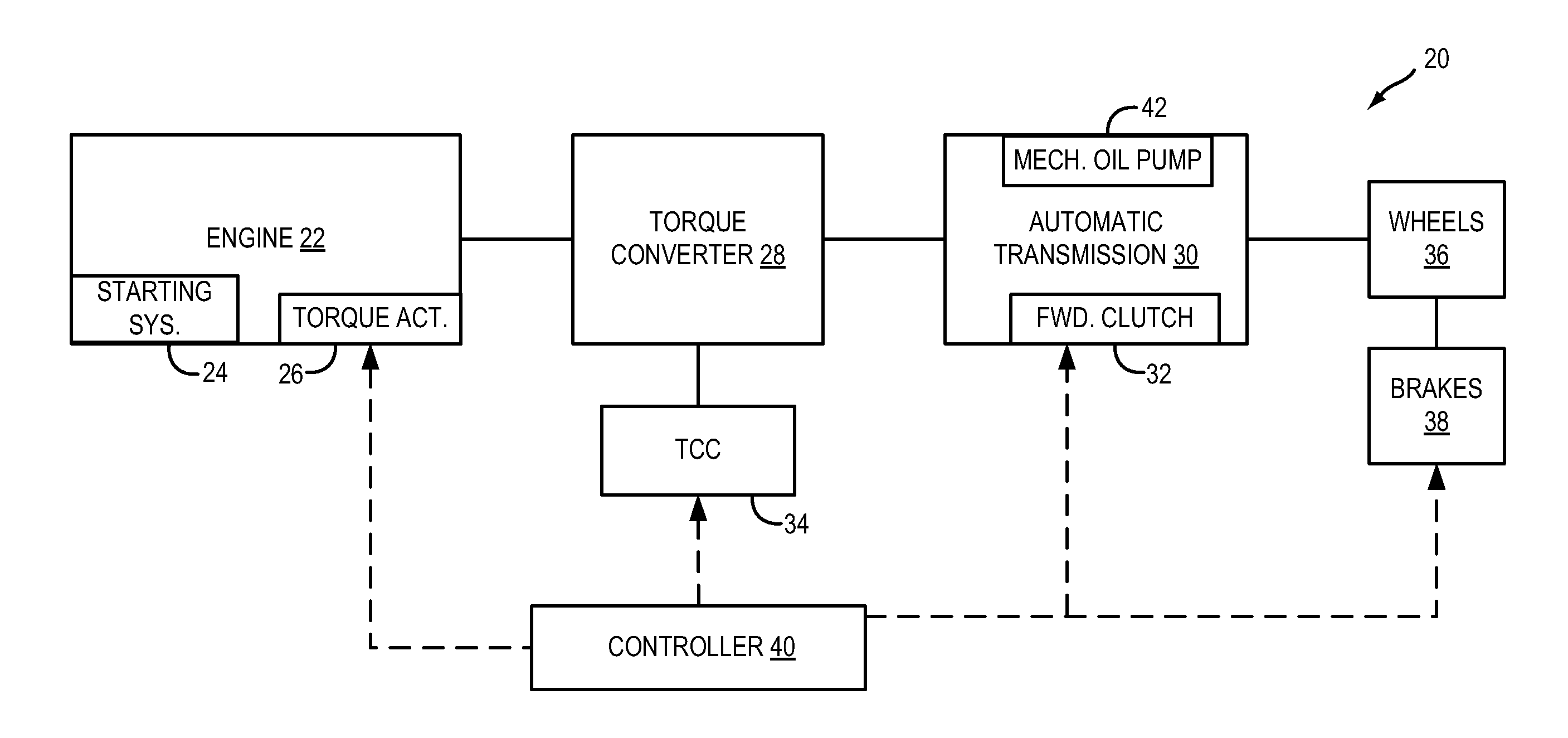

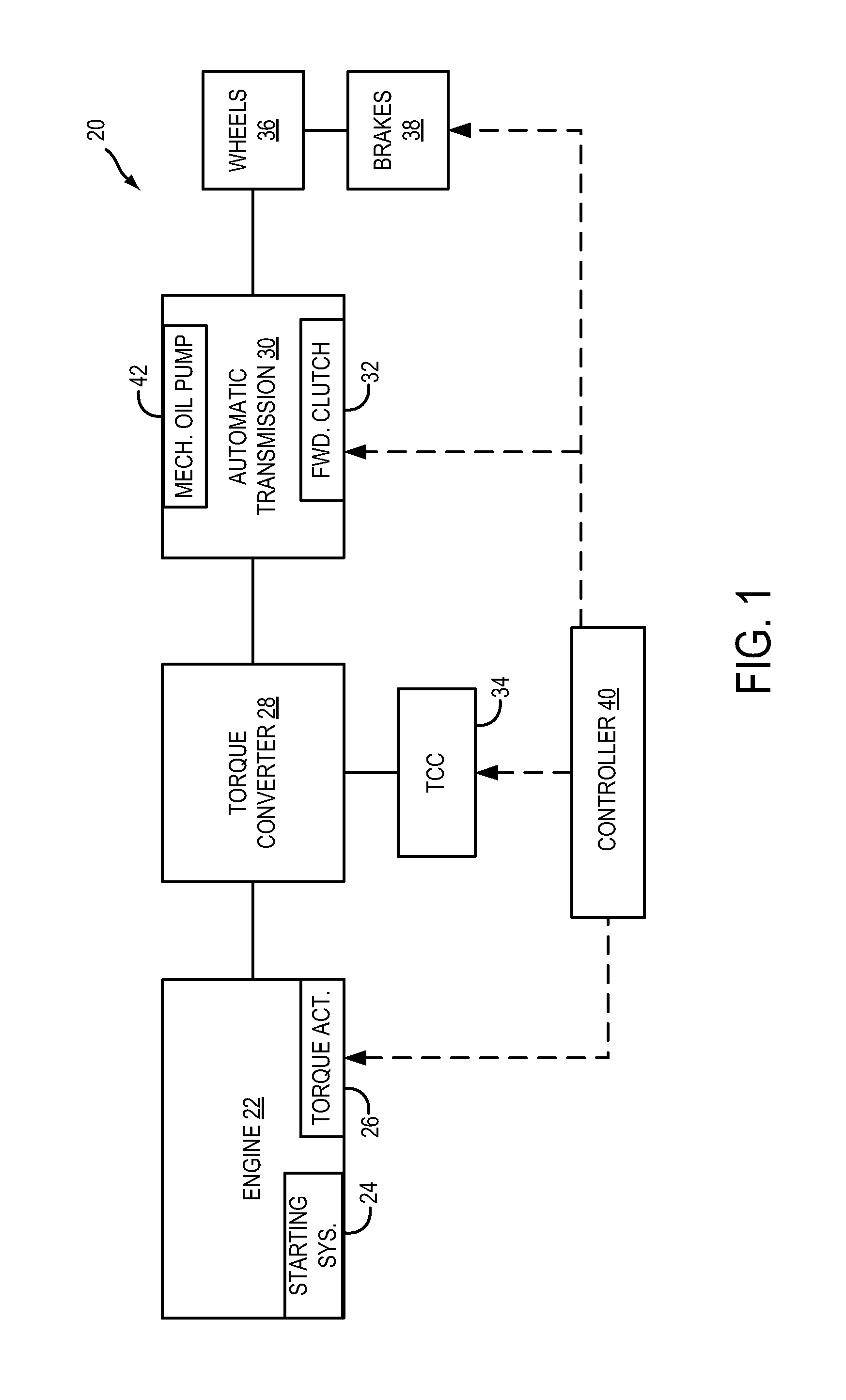

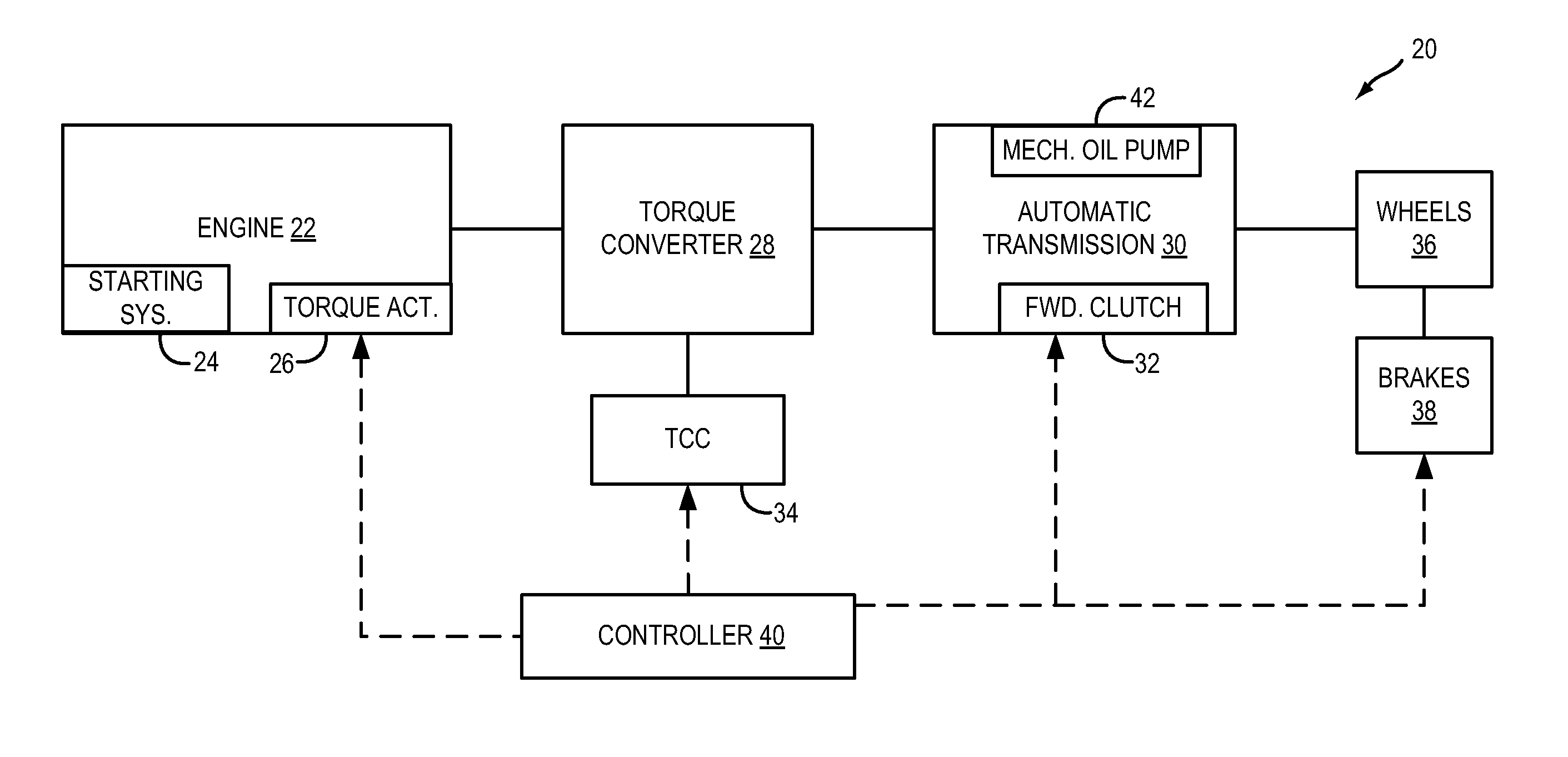

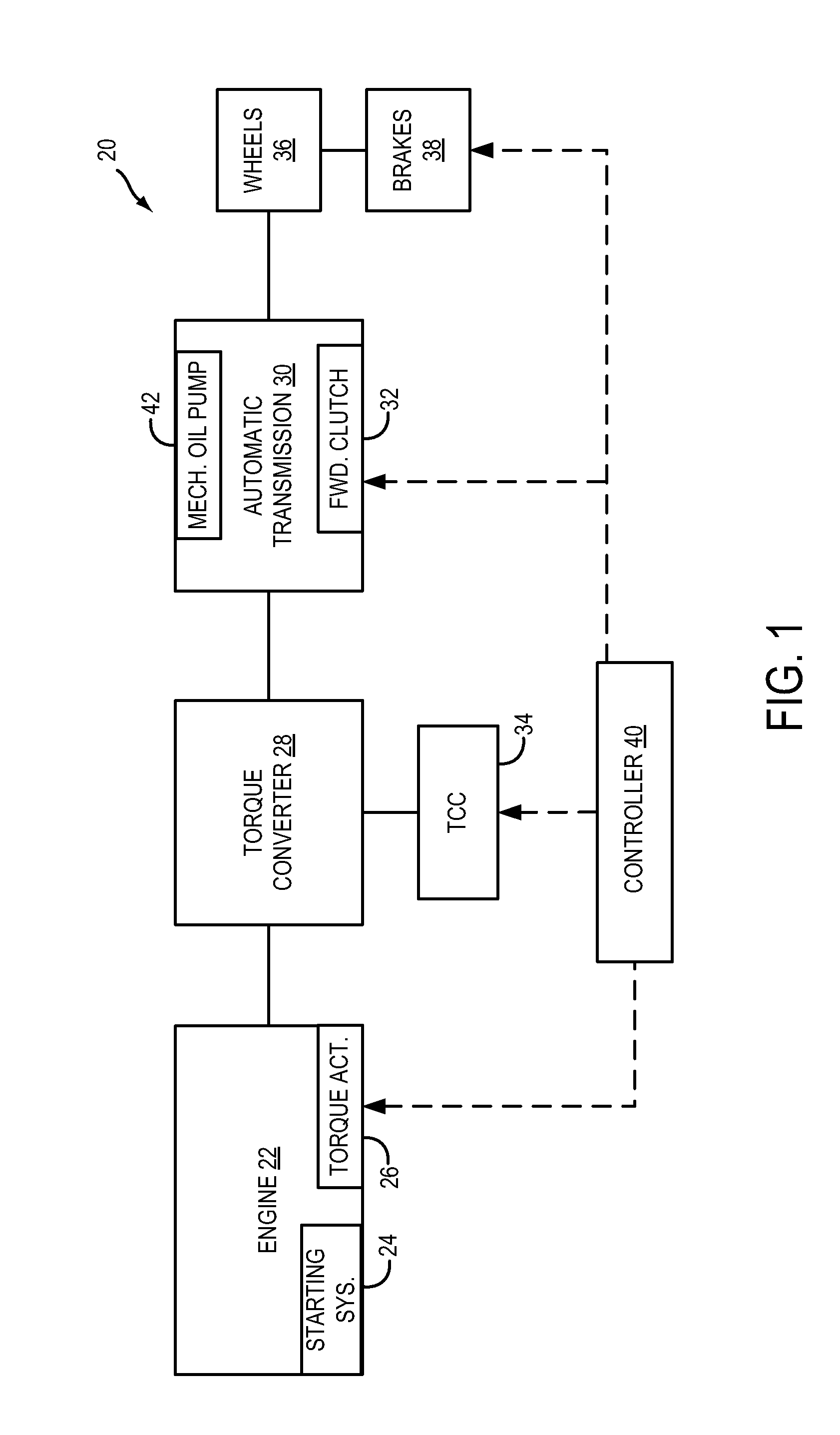

Methods and systems for assisted direct start control

ActiveUS20140094343A1Save fuelReduce exhaust emissionsElectrical controlGearing controlDrag torqueDirect torque control

Methods and systems are provided for controlling a vehicle system including a selectively shut-down engine, a torque converter and a torque converter lock-up clutch. One example method comprises, during an idle-stop engine shut-down, restricting flow of transmission fluid out of the torque converter, and adjusting engagement of the torque converter lock-up clutch to adjust a drag torque on the engine to stop the engine.

Owner:FORD GLOBAL TECH LLC

Fuel pump with quiet cam operated suction valve

InactiveUS20130213359A1Reduce impact velocityLittle noiseNoise reducing fuel injectionMachines/enginesCamHigh pressure

Owner:FORD GLOBAL TECH LLC

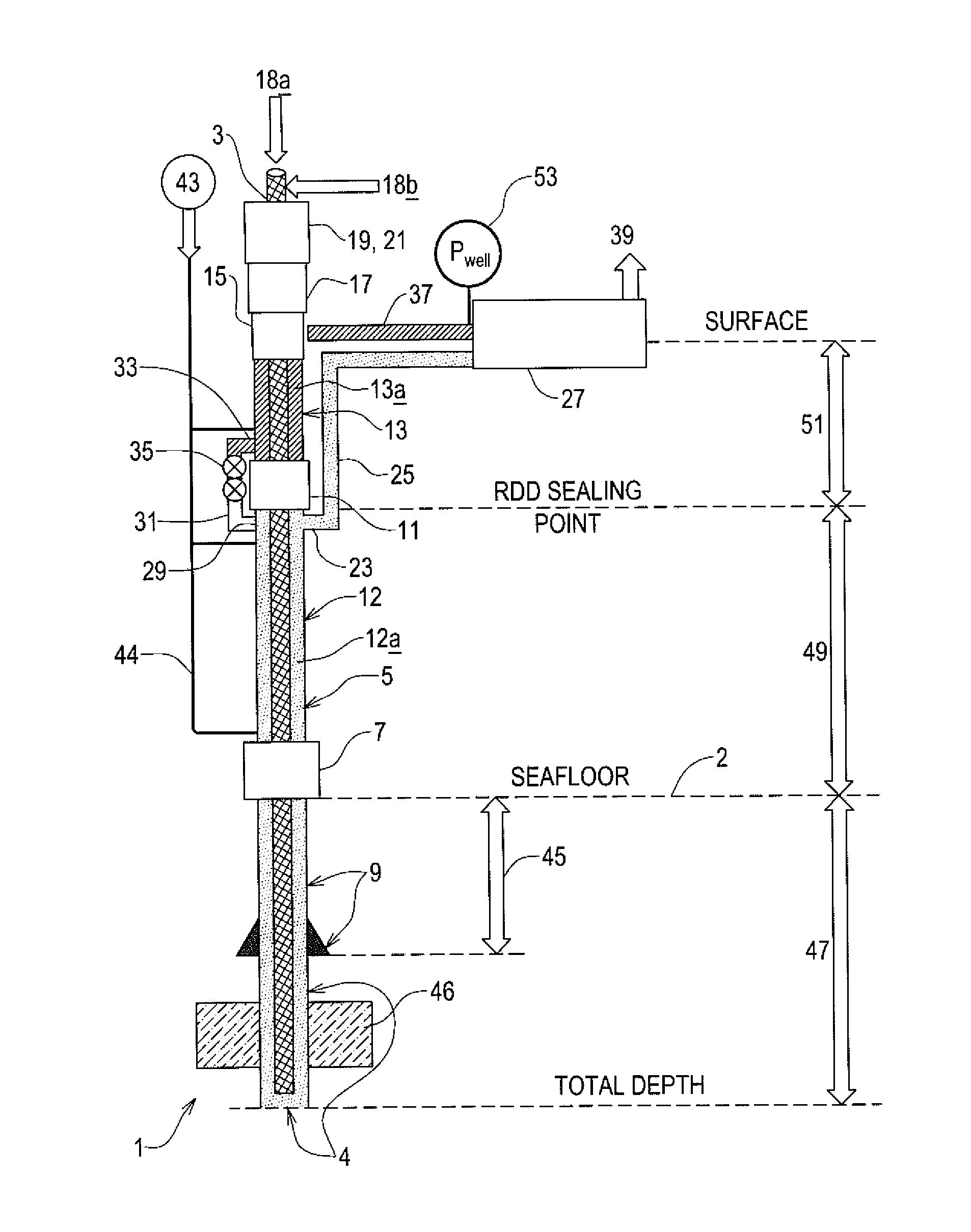

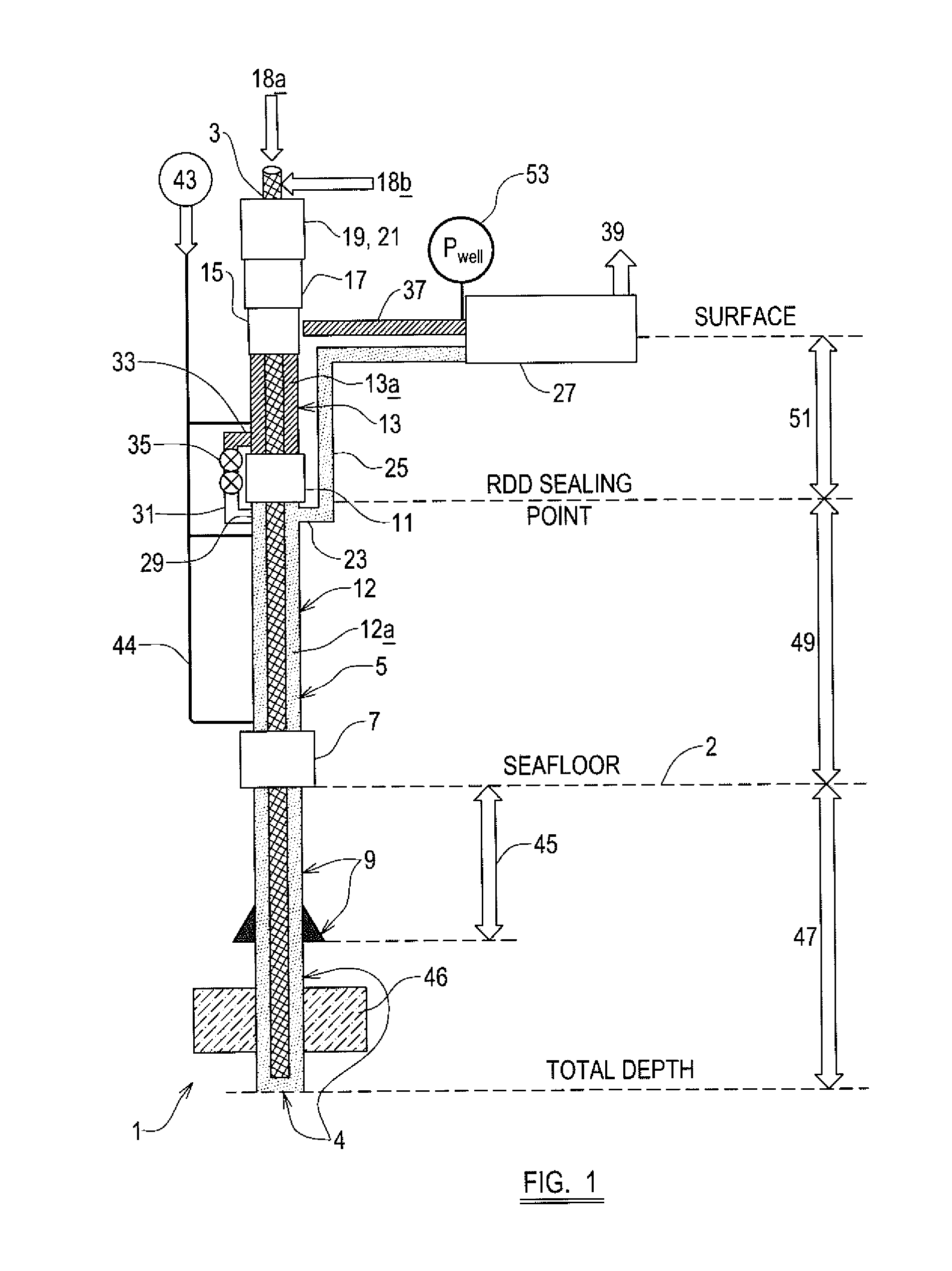

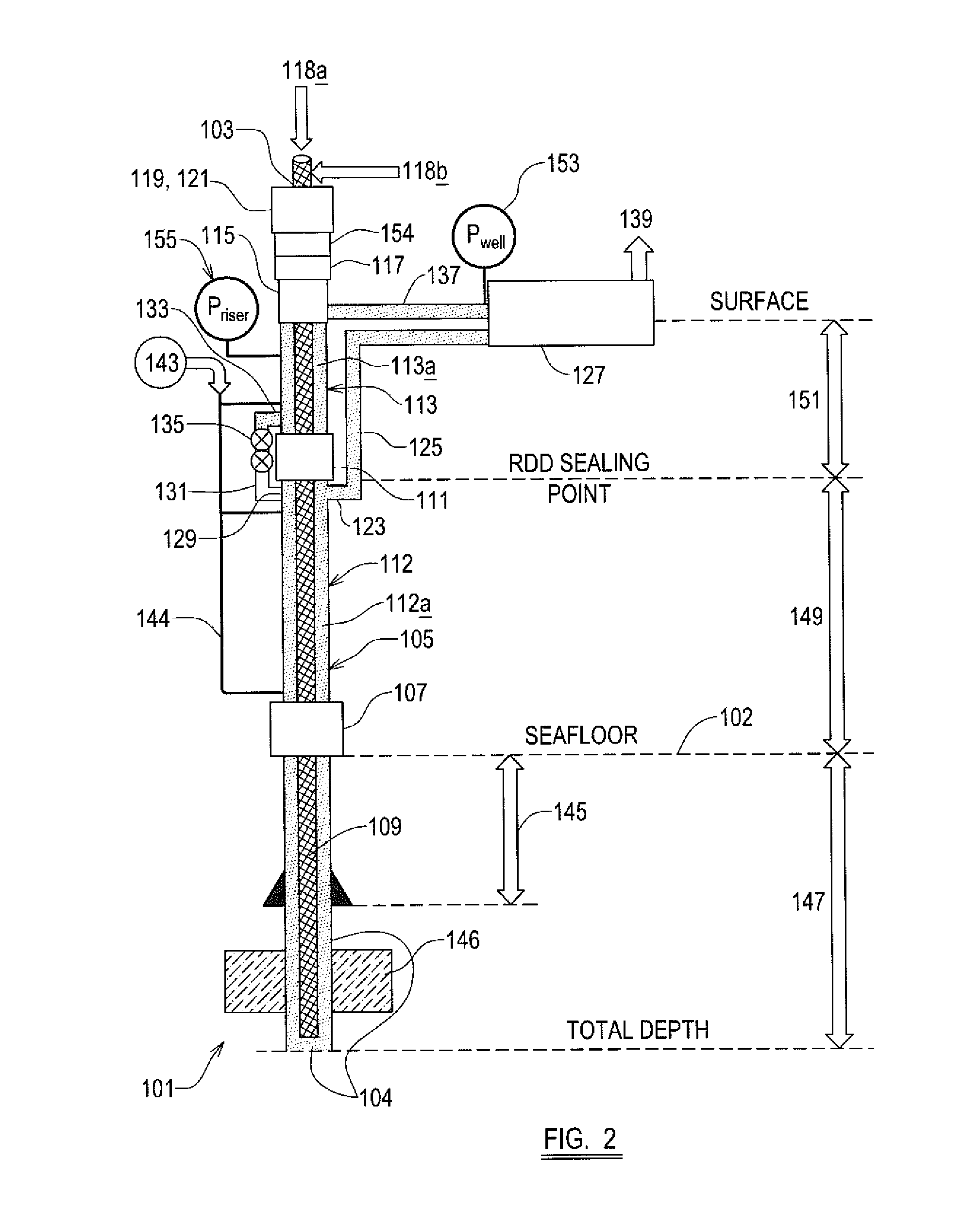

Drilling method for drilling a subterranean borehole

A method of drilling a subterranean wellbore using a drill string including the steps of estimating or determining a reduced static density of a drilling fluid based on the equivalent circulating density of the drilling fluid in a section of the wellbore, providing a drilling fluid having substantially that reduced static density, introducing the drilling fluid having said reduced static density into the wellbore, and removing the drilling fluid from the wellbore via a return line.

Owner:GRANT PRIDECO LP

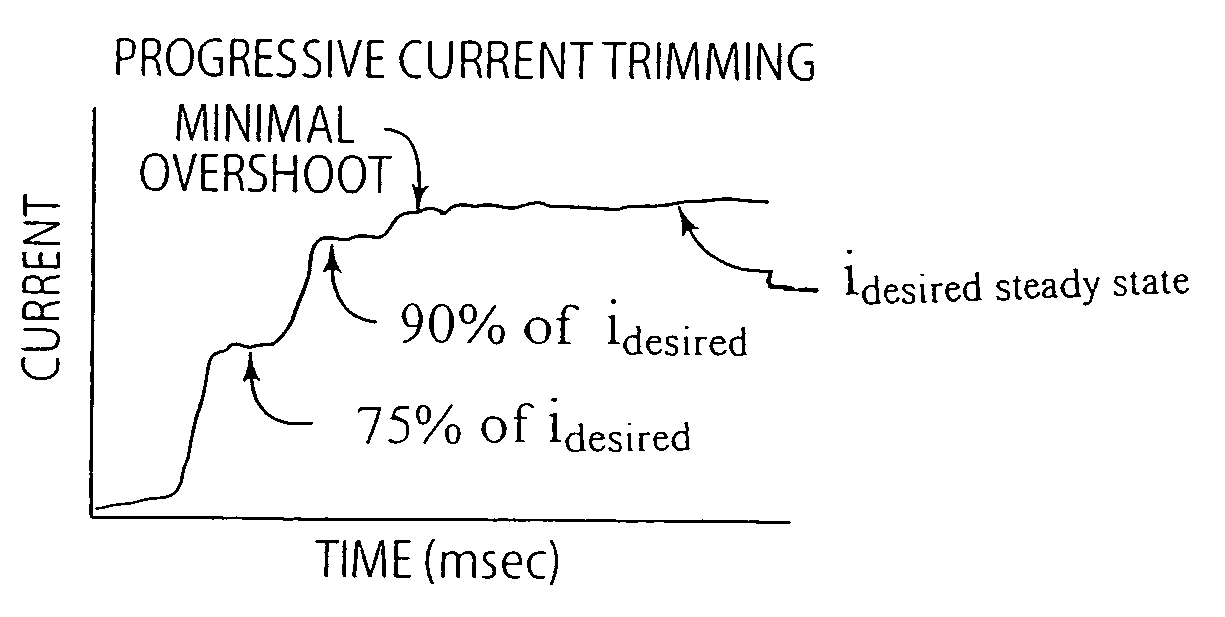

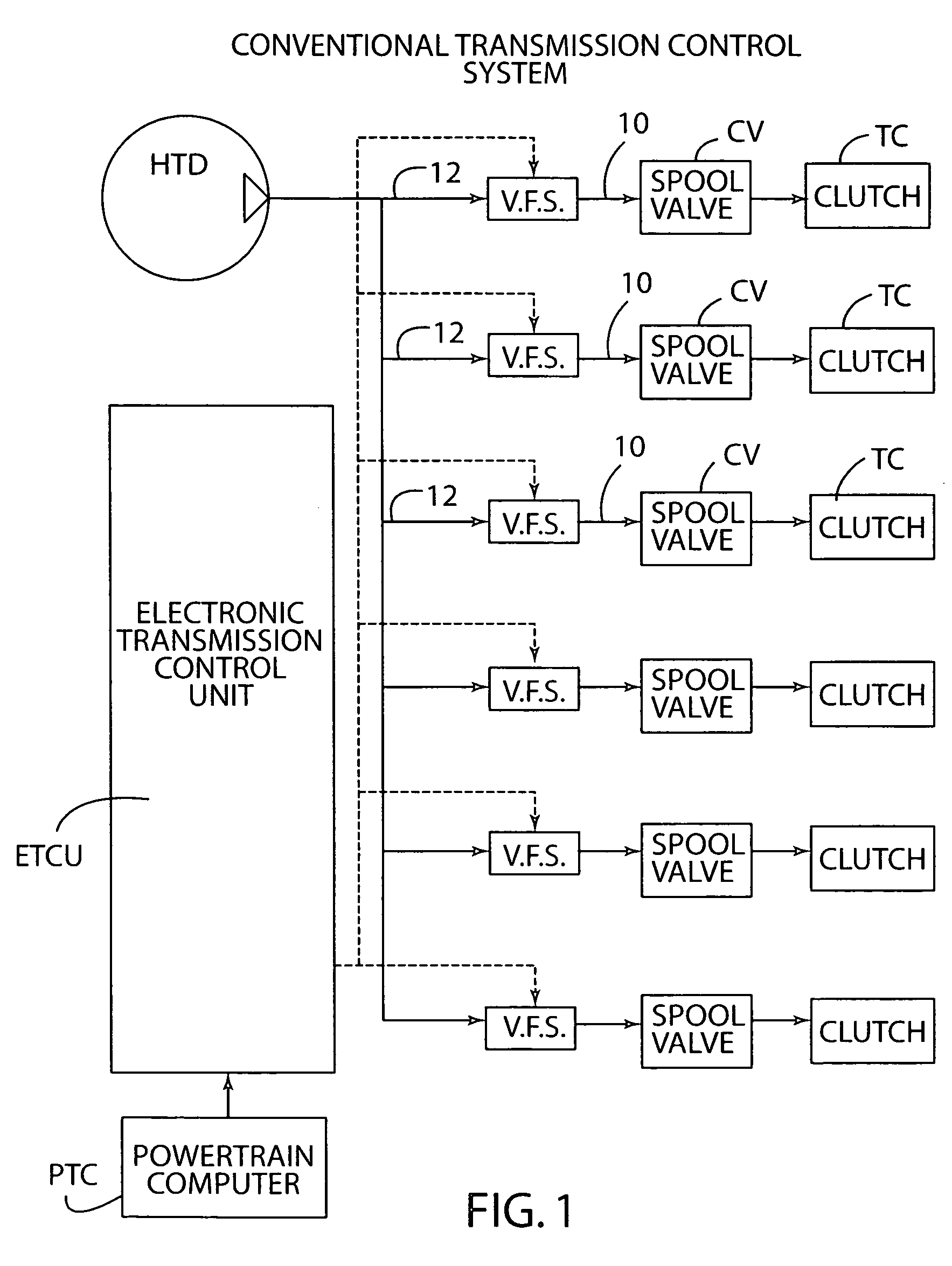

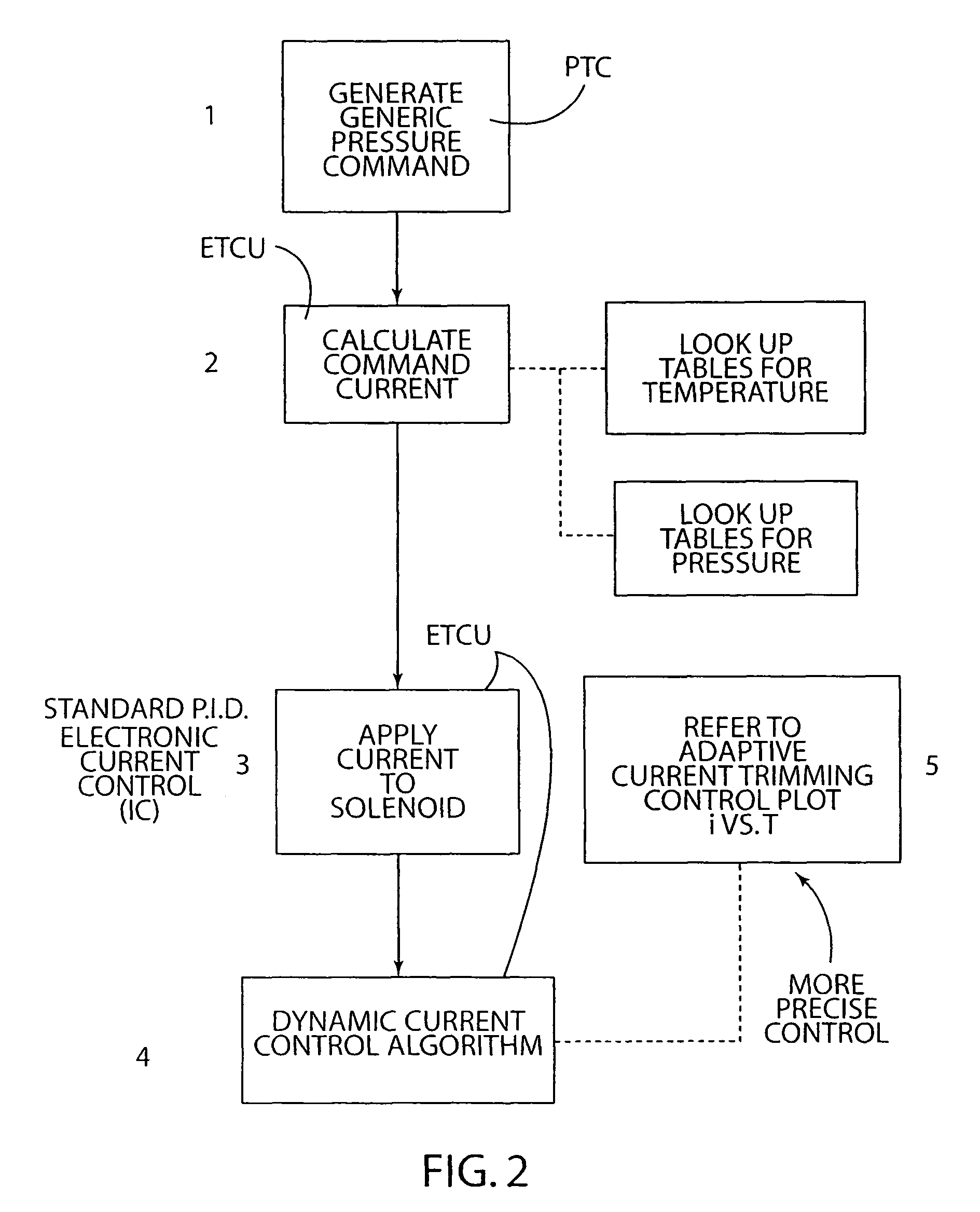

Dynamic pressure control system with solenoid valve command current trimming

ActiveUS8172060B2Improve controlImprove responseDigital data processing detailsFluid actuated clutchesSolenoid valveControl system

Owner:FLEXTRONICS AUTOMOTIVE USA

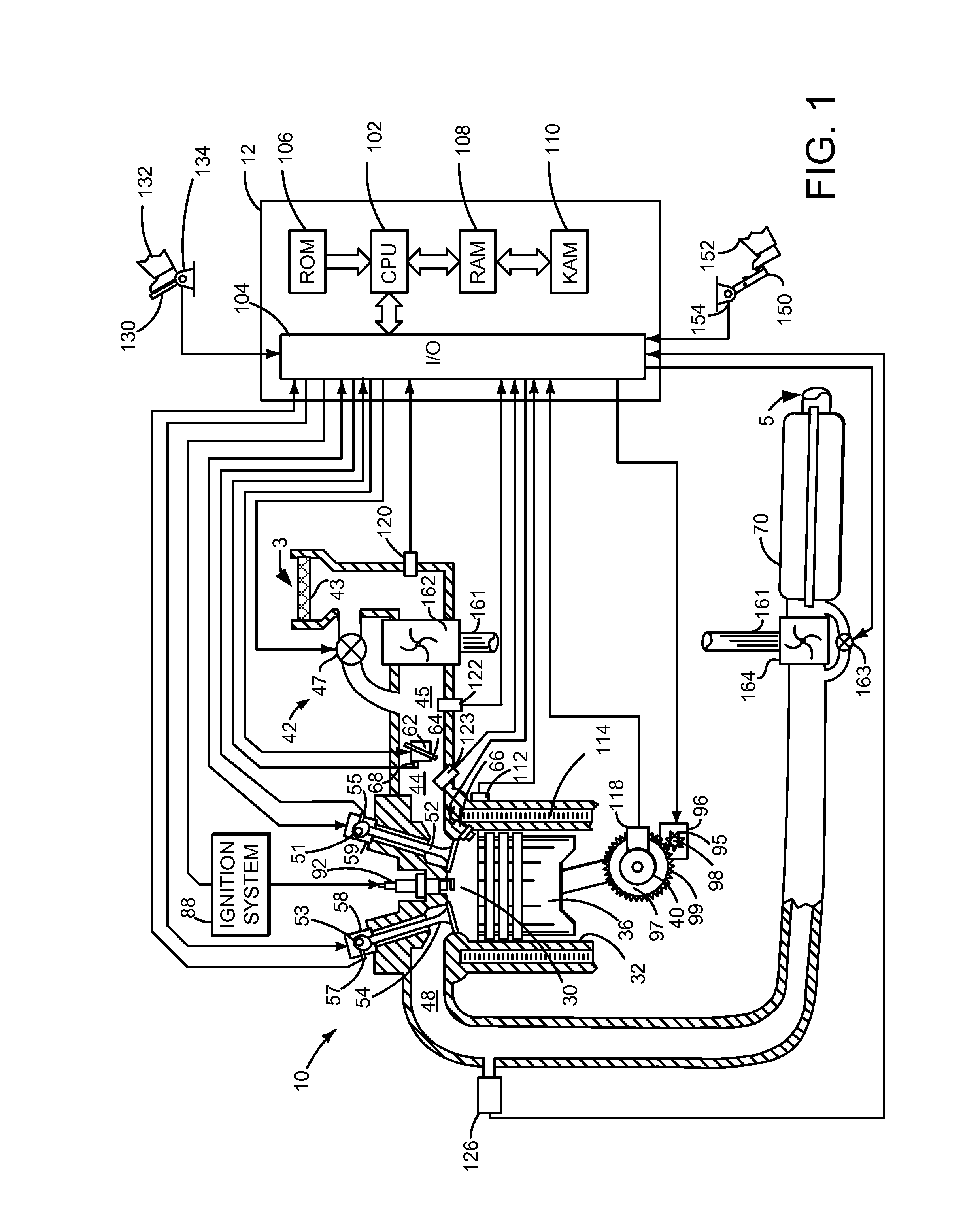

Methods and system for compensating compressor recirculation sludge

ActiveUS20160169091A1Increase air volumeReduce air pressureElectrical controlInternal combustion piston enginesTurbochargerSludge

Systems and methods for compensating for deposits that may accumulate within a compressor recirculation valve positioned in parallel with a turbocharger compressor are presented. The systems and methods adjust actuators to maintain engine operation such that it may be more difficult for a driver to become aware that a compressor recirculation valve diagnostic is being executed.

Owner:FORD GLOBAL TECH LLC

Cooling system for a metallurgical furnace

InactiveCN1401008ALow costEasy pressure controlCooling devicesWater flowAtmospheric pressure discharge

A cooling system for a blast furnace includes a cooling circuit closed by a return line and at least one circulation pump for circulating cooling water through the closed cooling circuit. An emergency feed line with an emergency feed valve, which opens in case of a power failure, is connected to the cooling circuit. An emergency overflow valve is located at the highest point of the closed cooling circuit. This emergency overflow valve opens in case of a power failure, so that the closed cooling circuit becomes an open cooling circuit with an atmospheric pressure discharge at its highest point. A pressure vessel, which is connected to the emergency feed line, contains a certain volume of emergency water which is pressurised by a gas, so that, in case of a power failure, an emergency water flow establishes through the open cooling circuit.

Owner:PAUL WURTH SA

Methods and systems for assisted direct start control

ActiveUS20110130245A1Reduce exhaust emissionsSave fuelElectrical controlRotary clutchesDrag torqueDirect torque control

Methods and systems are provided for controlling a vehicle system including a selectively shut-down engine, a torque converter and a torque converter lock-up clutch. One example method comprises, during an idle-stop engine shut-down, restricting flow of transmission fluid out of the torque converter, and adjusting engagement of the torque converter lock-up clutch to adjust a drag torque on the engine to stop the engine.

Owner:FORD GLOBAL TECH LLC

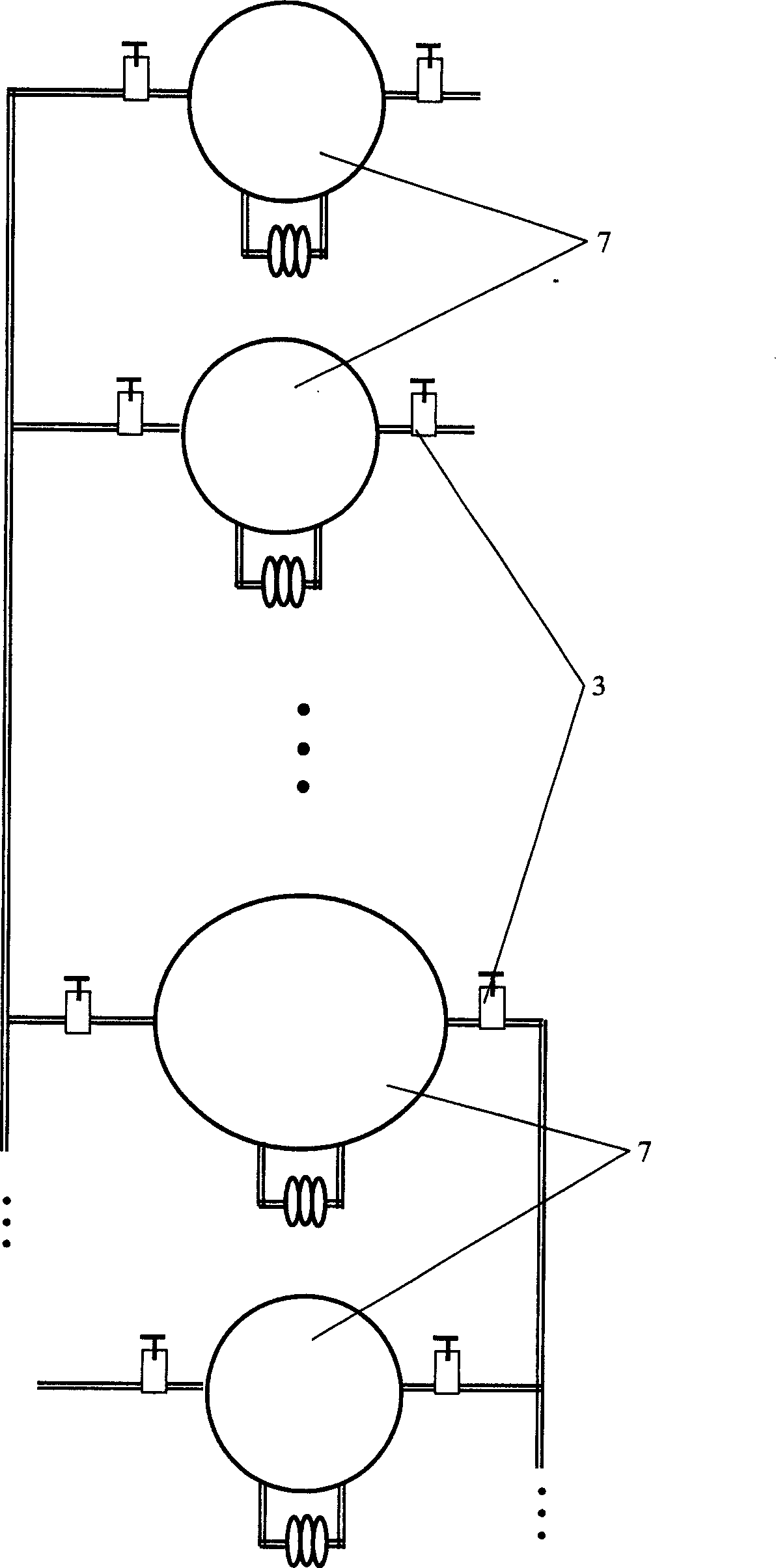

Pressure and ultrahigh pressure generating method and device

InactiveCN1776284AReduced Possibility of ContaminationHighly integratedPipeline systemsPressure vesselsEngineeringHigh pressure

The invention is suitable for preparing artificial diamond, high pressure forming, plastic working, food processing under hyperpressure, autoclaving and machining etc. After procedure of phase change, volume of resultant of phase change is increased so as to extrude matter of phase change to produce pressure and hyperpressure. Pressure container is airtight. Starting and stopping phase change is controlled by phase change control device. The unit of generating pressure is composed of phase change control device, resultant of phase change, control valve, connection pipe, matter of phase change and pressure container. The said unit can be connected in cascaded, parallel and mixed connection modes. Advantages are: no pulsant pressure, long holdup time, transferable to other energy form to make work to outside.

Owner:许宏

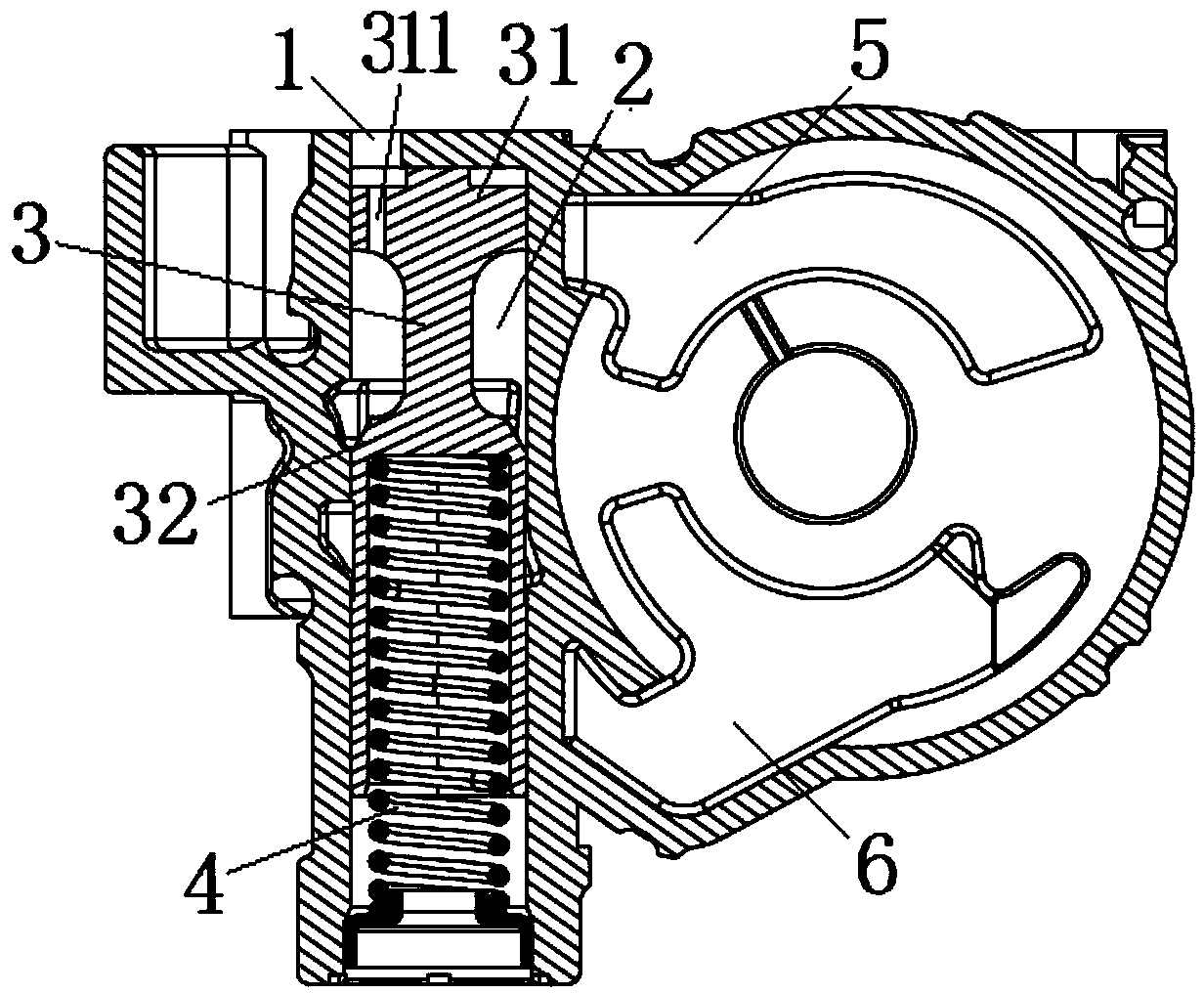

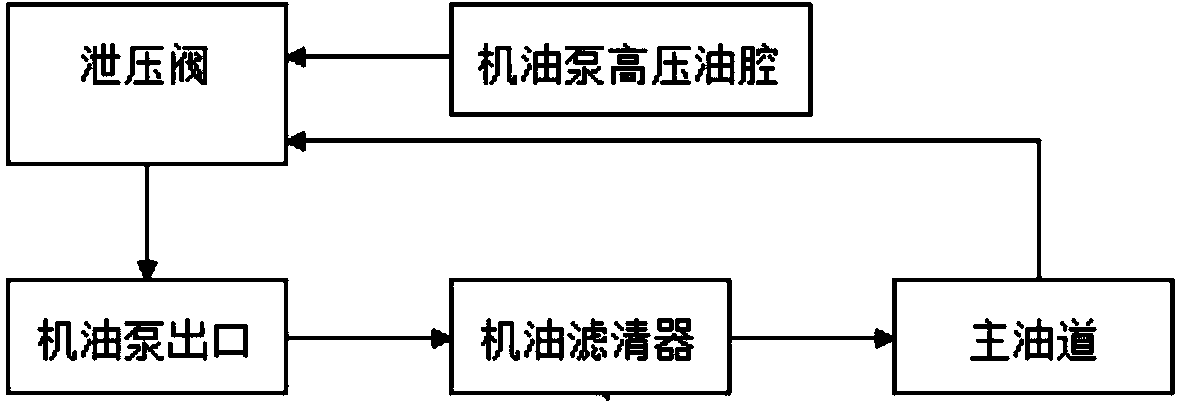

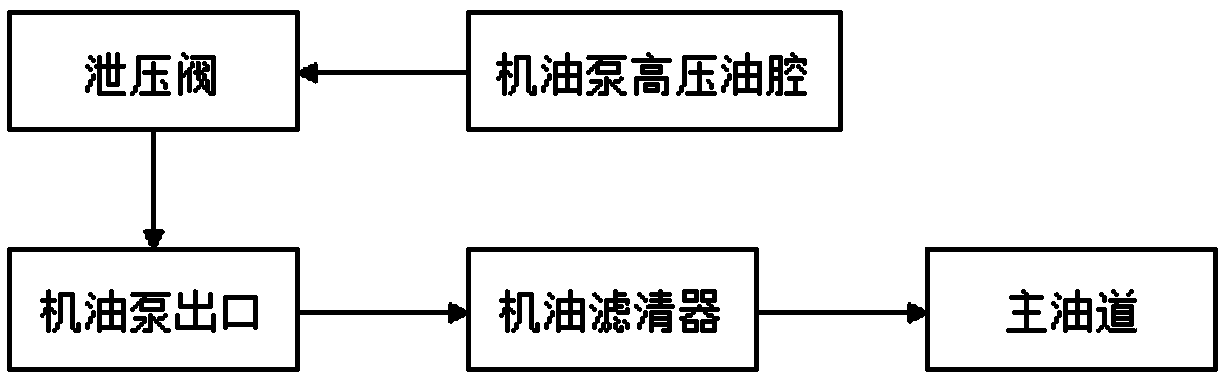

Oil pump and control method of engine lubrication system of oil pump

ActiveCN103806976AShort reaction timeEasy pressure controlPressure lubrication with lubrication pumpLubrication pressure controlHigh pressurePressure controlled ventilation

The invention discloses an oil pump and a control method of an engine lubrication system of the oil pump. The oil pump comprises an oil pump high-pressure oil cavity, an oil pump low-pressure oil cavity, a plunger cavity connected with the oil pump high-pressure oil cavity and a feedback oil way connected with an oil filter rear main way oil way, a plunger and a spring are arranged in the plunger cavity, the feedback oil way is communicated with the plunger cavity, one end of the plunger is a first plunger head, the other end of the plunger is a second plunger head, the first plunger head separates the feedback oil way from the oil pump high-pressure oil cavity, the second plunger head is connected with the spring, and the first plunger head is provided with a plunger hole used for enabling the feedback oil way and the oil pump high-pressure oil cavity to be communicated. The control method comprises the following steps that a pressure relief valve of the oil pump is controlled to work jointly by the pressure of the oil pump high-pressure oil cavity and the pressure fed back by the oil filter rear main way oil way. According to the oil pump and the control method of the engine lubrication system of the oil pump, pressure control of the whole engine lubrication system is improved, the pressure of oil of the engine can be accurately controlled, and the pulsation of the pressure of the oil is reduced.

Owner:CHERY AUTOMOBILE CO LTD

Methods and system for determining compressor recirculation valve sludge

ActiveUS20160169092A1Improving engine air intake pressure controlReduce the possibilityElectrical controlInternal combustion piston enginesDriver/operatorSludge

Systems and methods for determining the presence or absence of deposits that may accumulate within a compressor recirculation valve positioned in parallel with a turbocharger compressor are presented. The systems and methods adjust actuators to maintain engine operation such that it may be more difficult for a driver to become aware that a compressor recirculation valve diagnostic is being executed.

Owner:FORD GLOBAL TECH LLC

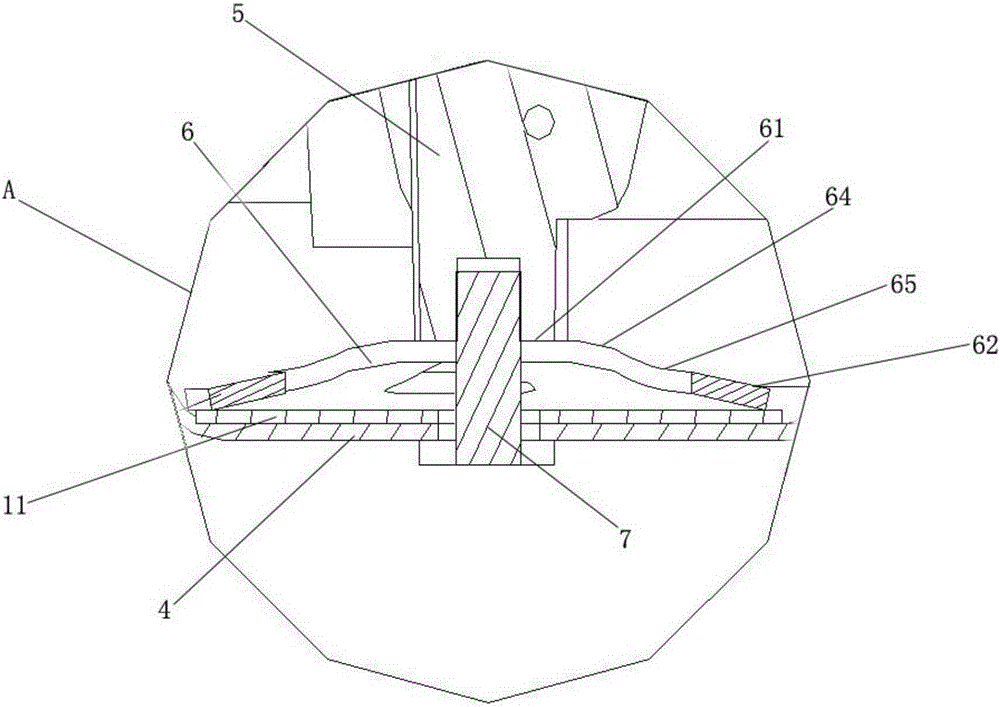

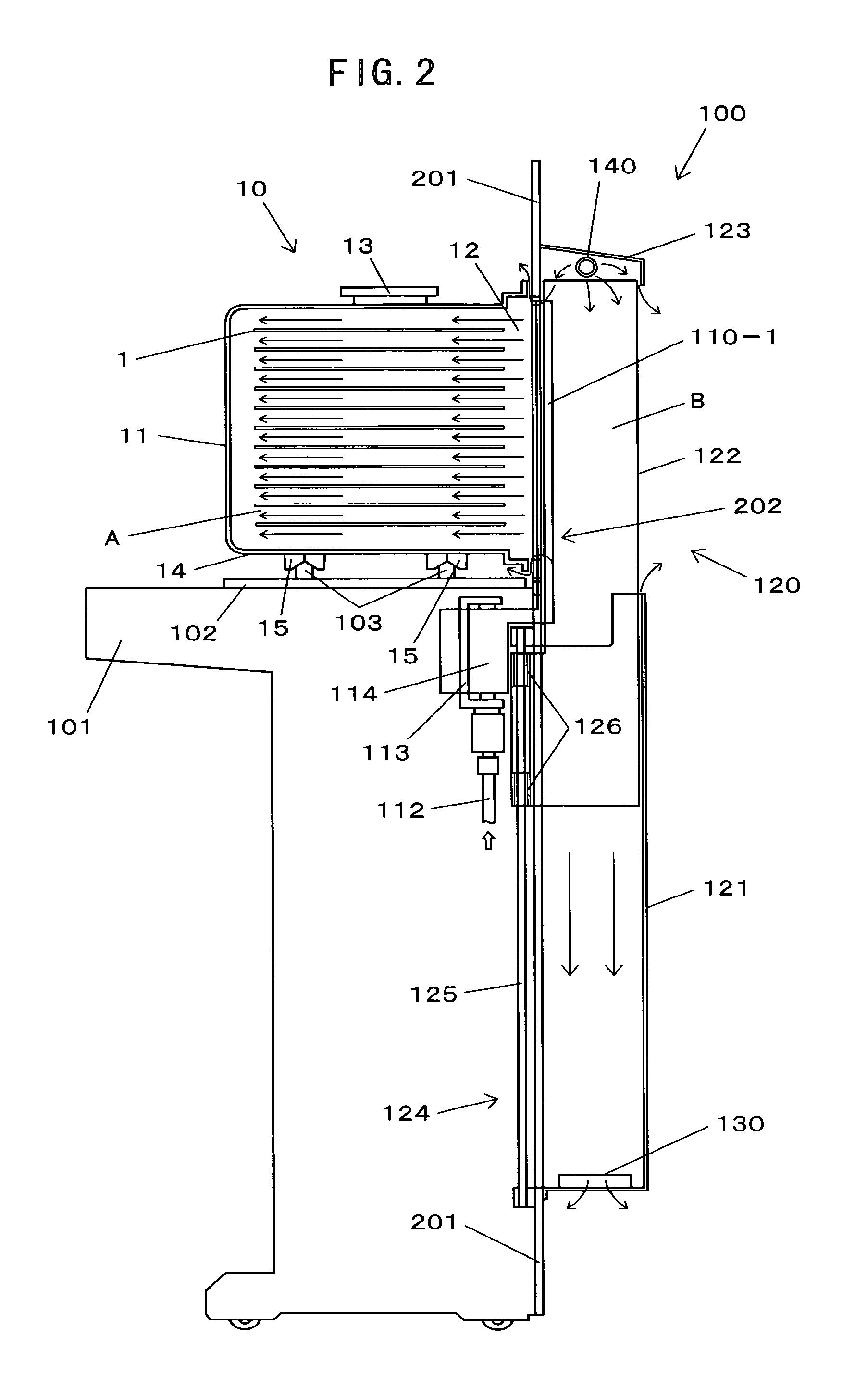

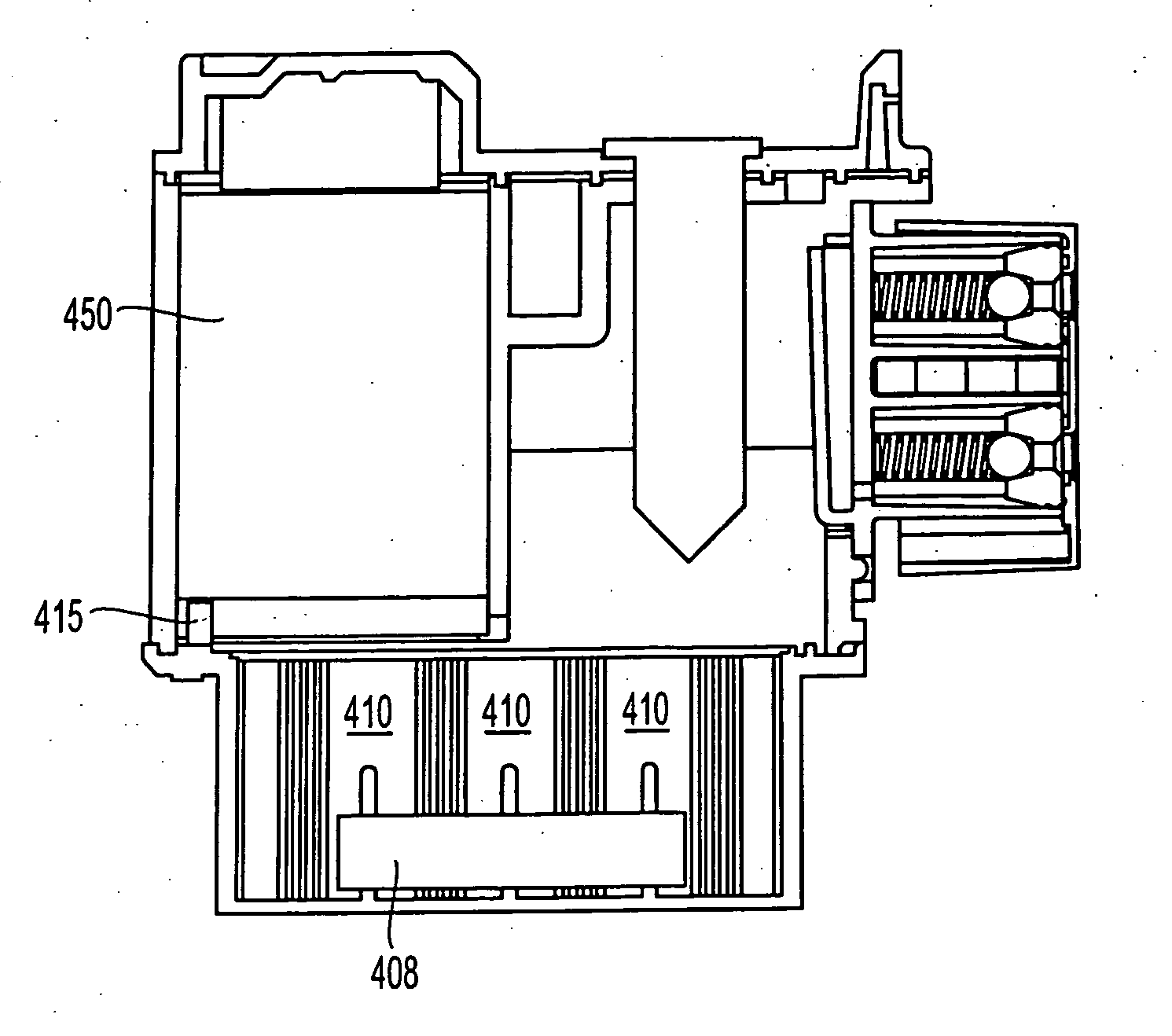

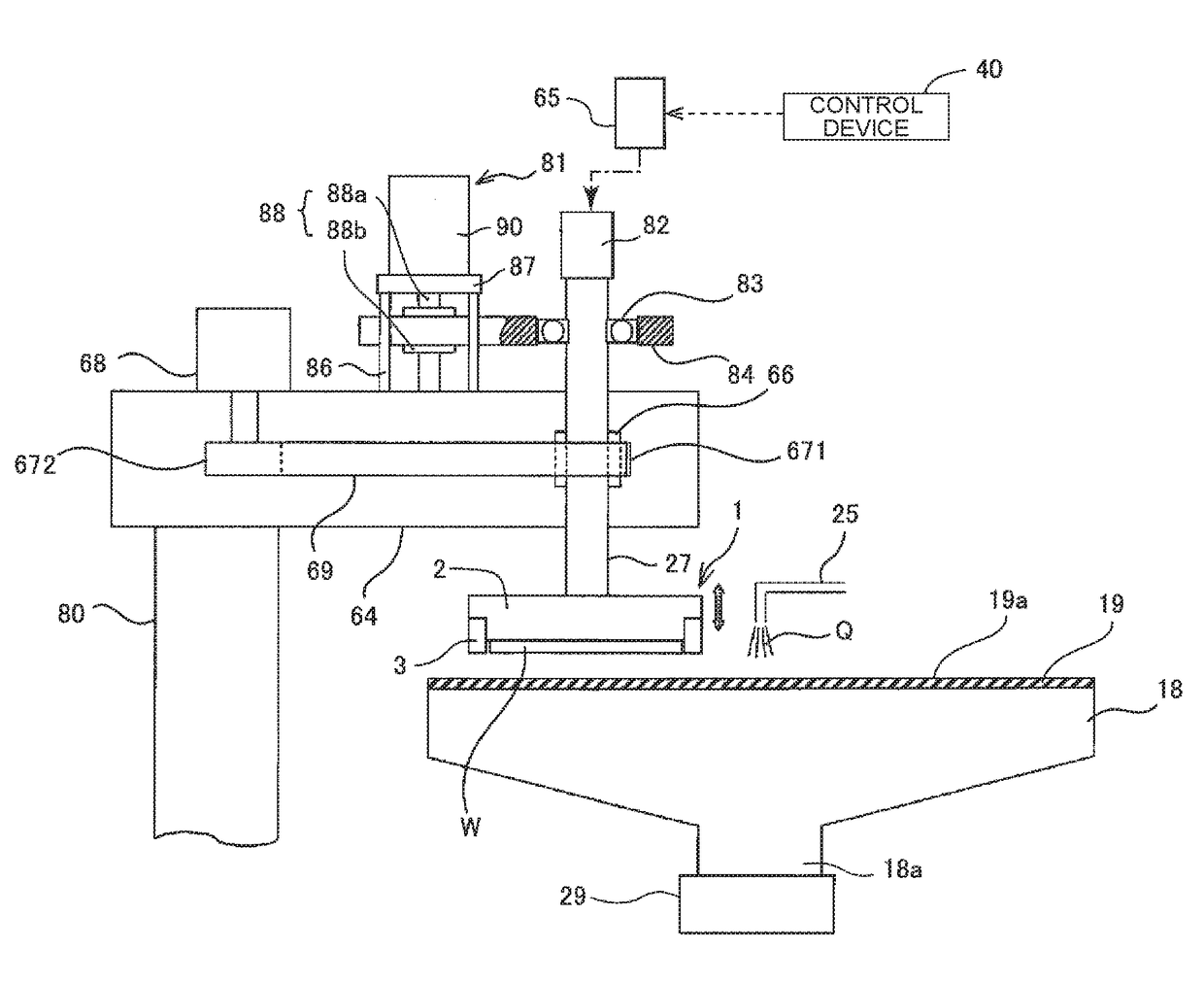

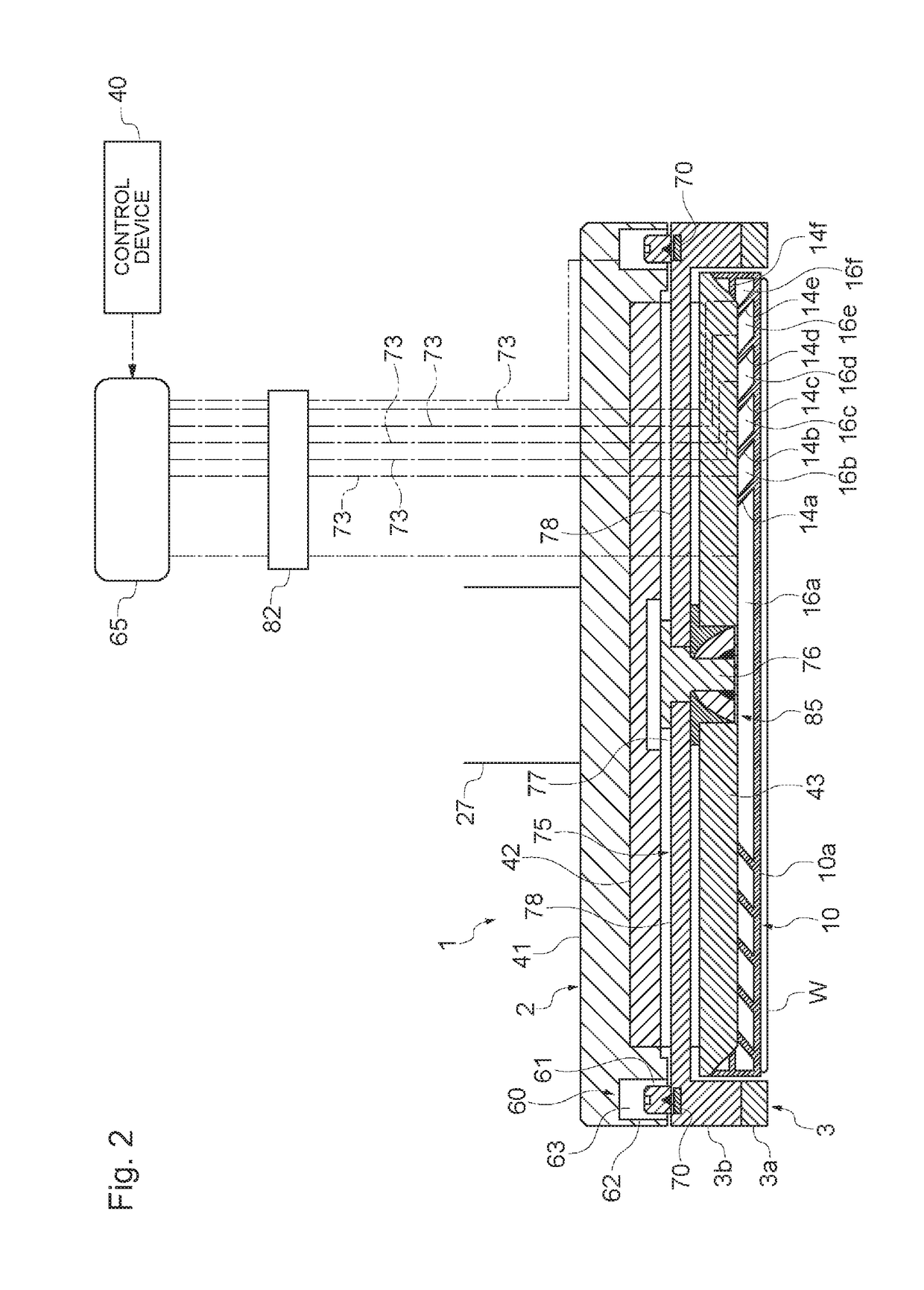

Elastic membrane, substrate holding device, and polishing apparatus

ActiveUS20180301367A1Easy pressure controlExpansion can be suppressedSemiconductor/solid-state device manufacturingLapping machinesMechanical engineering

An elastic membrane to be used for a polishing head includes a contact portion configured to come into contact with a wafer, an annular side wall provided to stand on an outer peripheral end of the contact portion, a first partition wall linearly extending inward in a radial direction in sectional view from the side wall, and a second partition wall linearly extending inward and upward in the radial direction in sectional view from an outer peripheral end portion of the contact portion, wherein the first partition wall, the second partition wall, and the side wall constitute an edge pressure chamber for pressing an edge of the wafer.

Owner:EBARA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com