Patents

Literature

2507 results about "Acoustic emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustic emission (AE) is the phenomenon of radiation of acoustic (elastic) waves in solids that occurs when a material undergoes irreversible changes in its internal structure, for example as a result of crack formation or plastic deformation due to aging, temperature gradients or external mechanical forces. In particular, AE is occurring during the processes of mechanical loading of materials and structures accompanied by structural changes that generate local sources of elastic waves. This results in small surface displacements of a material produced by elastic or stress waves generated when the accumulated elastic energy in a material or on its surface is released rapidly. The waves generated by sources of AE are of practical interest in structural health monitoring (SHM), quality control, system feedback, process monitoring and other fields. In SHM applications, AE is typically used to detect, locate and characterise damage.

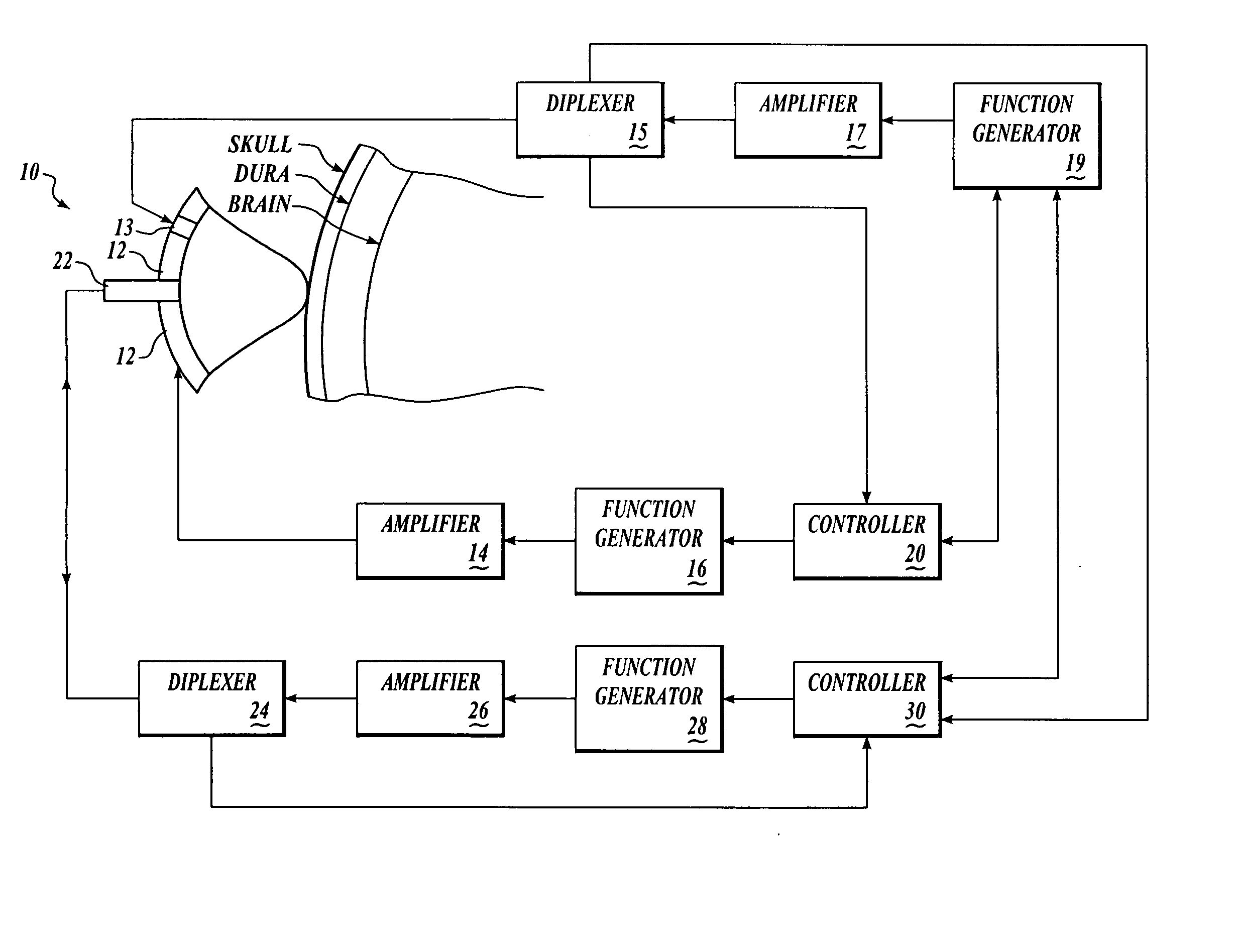

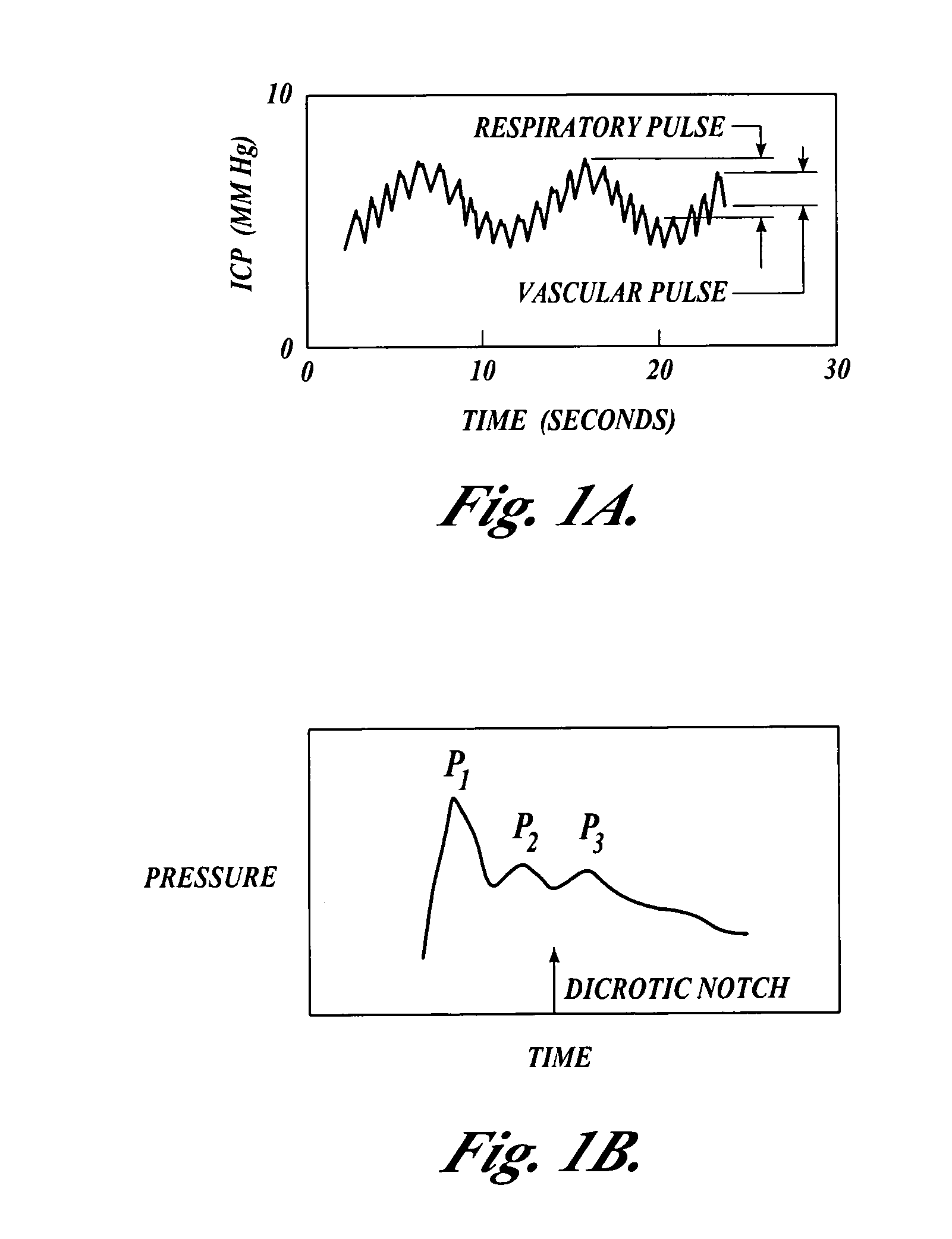

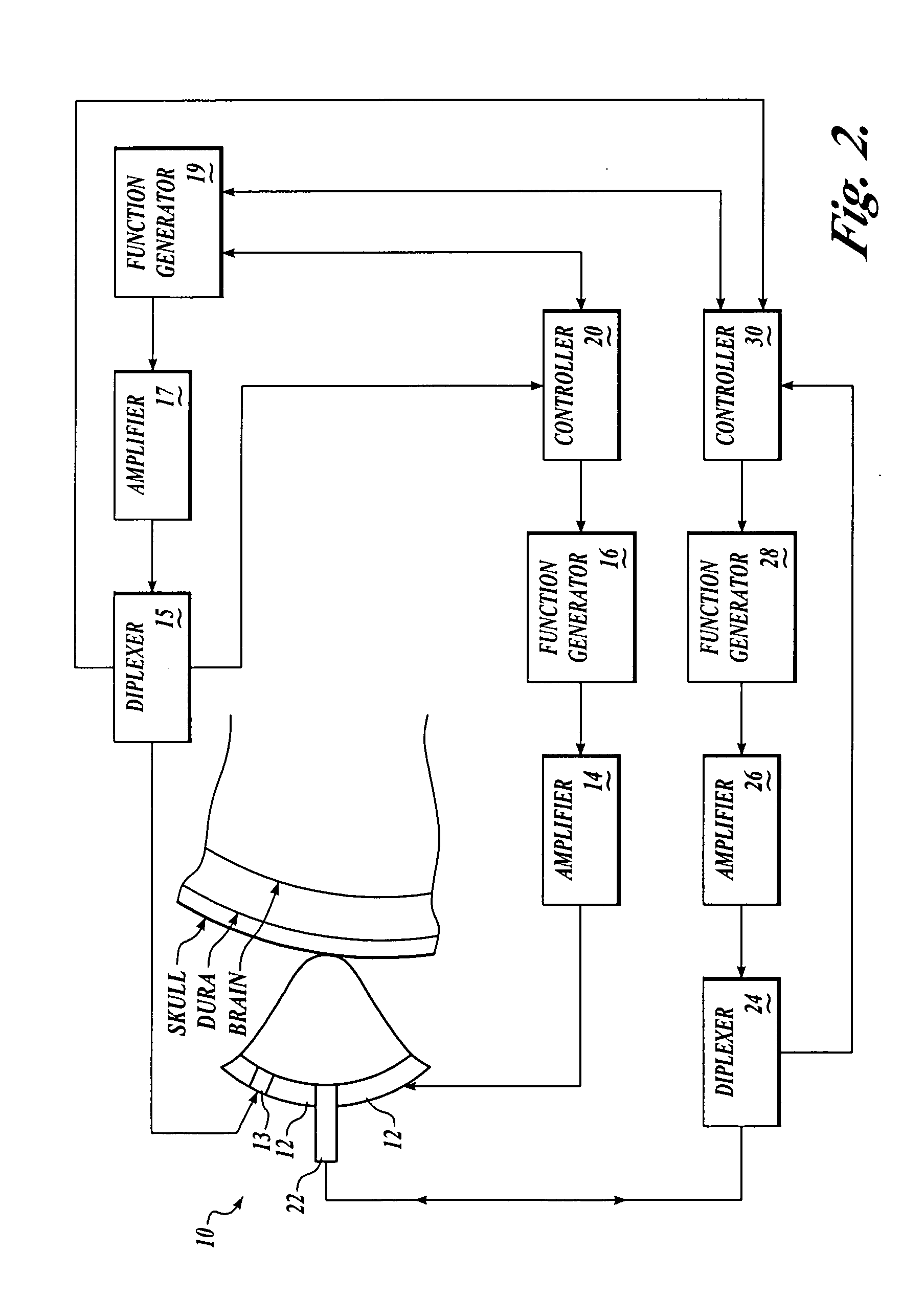

Systems and methods for making non-invasive physiological assessments by detecting induced acoustic emissions

InactiveUS20060079773A1Improve accuracyPositive diagnosisDiagnostics using vibrationsOrgan movement/changes detectionDiseaseNon invasive

Systems and methods for assessing a physiological parameter of a target tissue wherein a pulse of focused ultrasound is applied to a target tissue site thereby inducing oscillation of the target tissue. By these systems and methods, a property of an acoustic signal emitted from the oscillating target tissue is measured and related to a physiological property of the tissue. Specific applications for systems and methods of the present invention include the assessment and monitoring of intracranial pressure (ICP), arterial blood pressure (ABP), CNS autoregulation status, vasospasm, stroke, local edema, infection and vasculitus, as well as diagnosis and monitoring of diseases and conditions that are characterized by physical changes in tissue properties.

Owner:PHYSIOSONICS +1

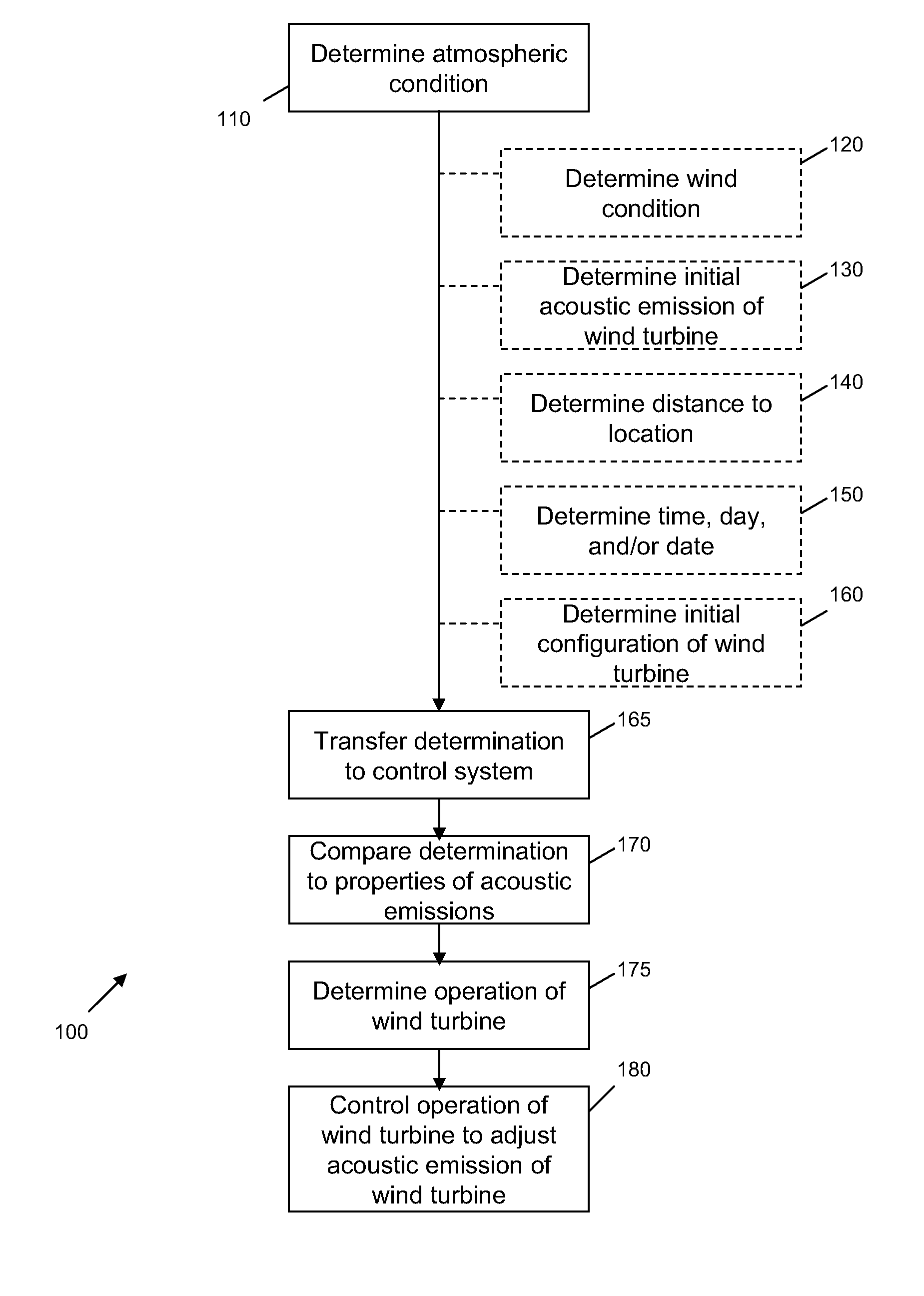

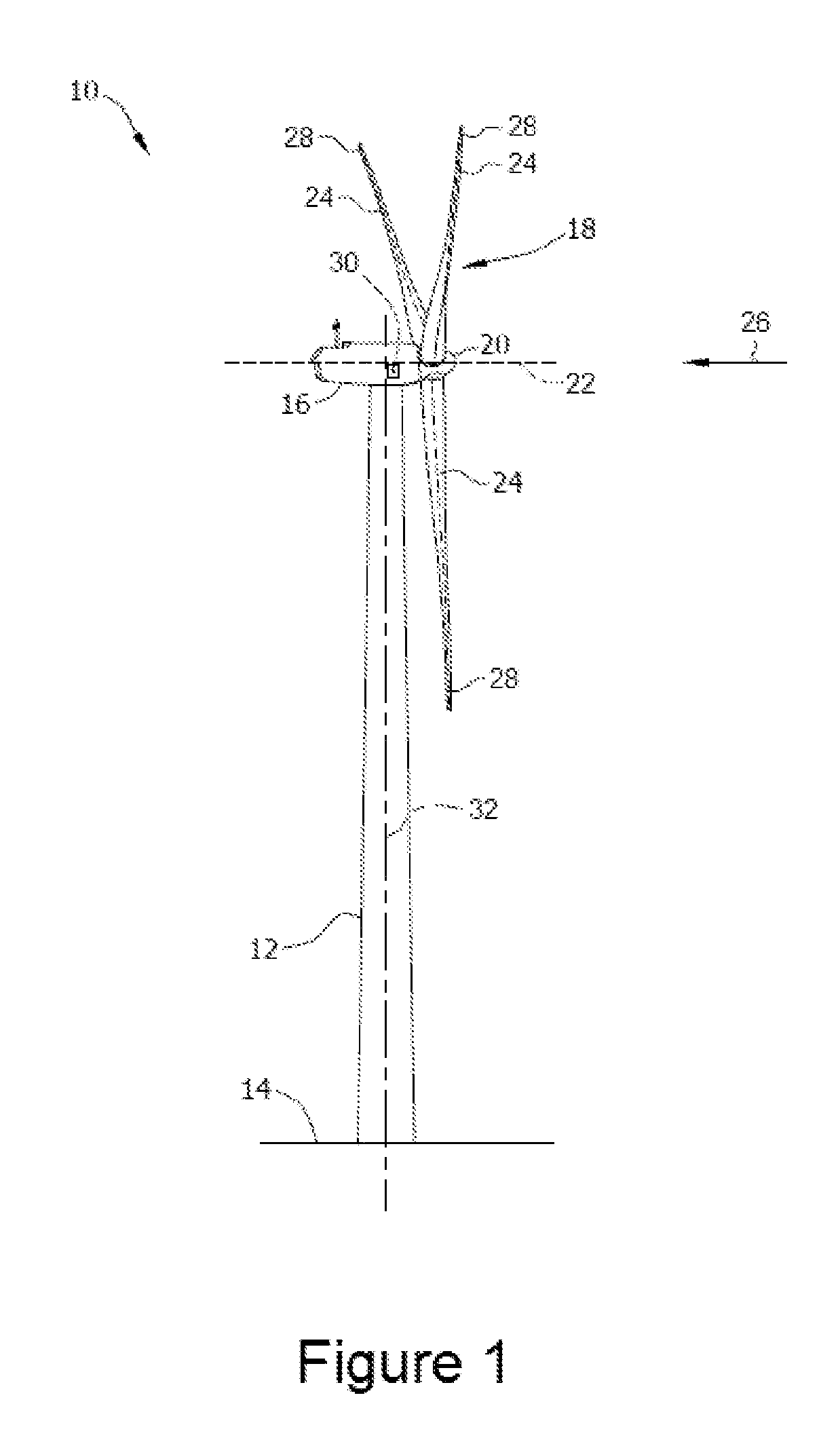

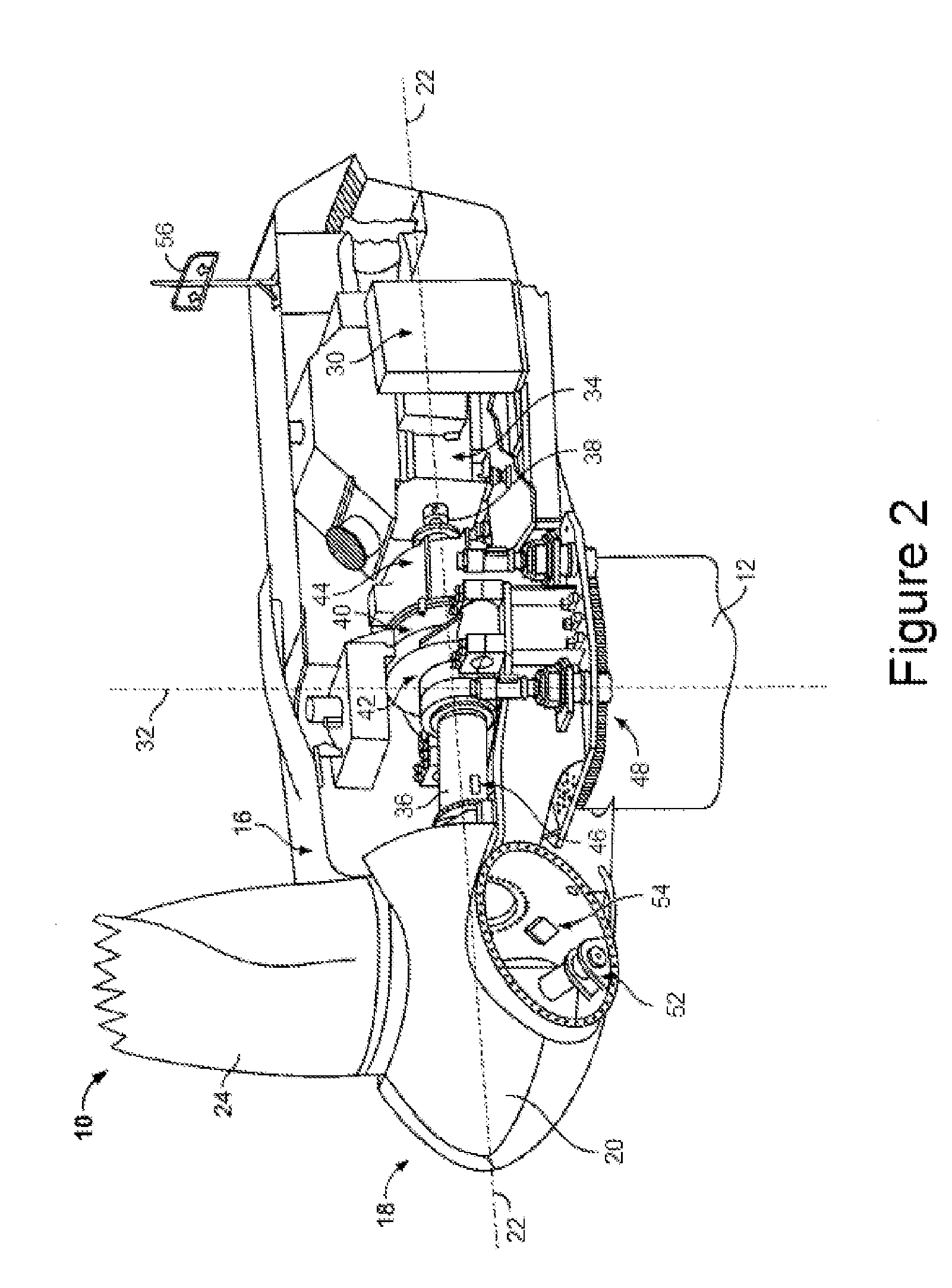

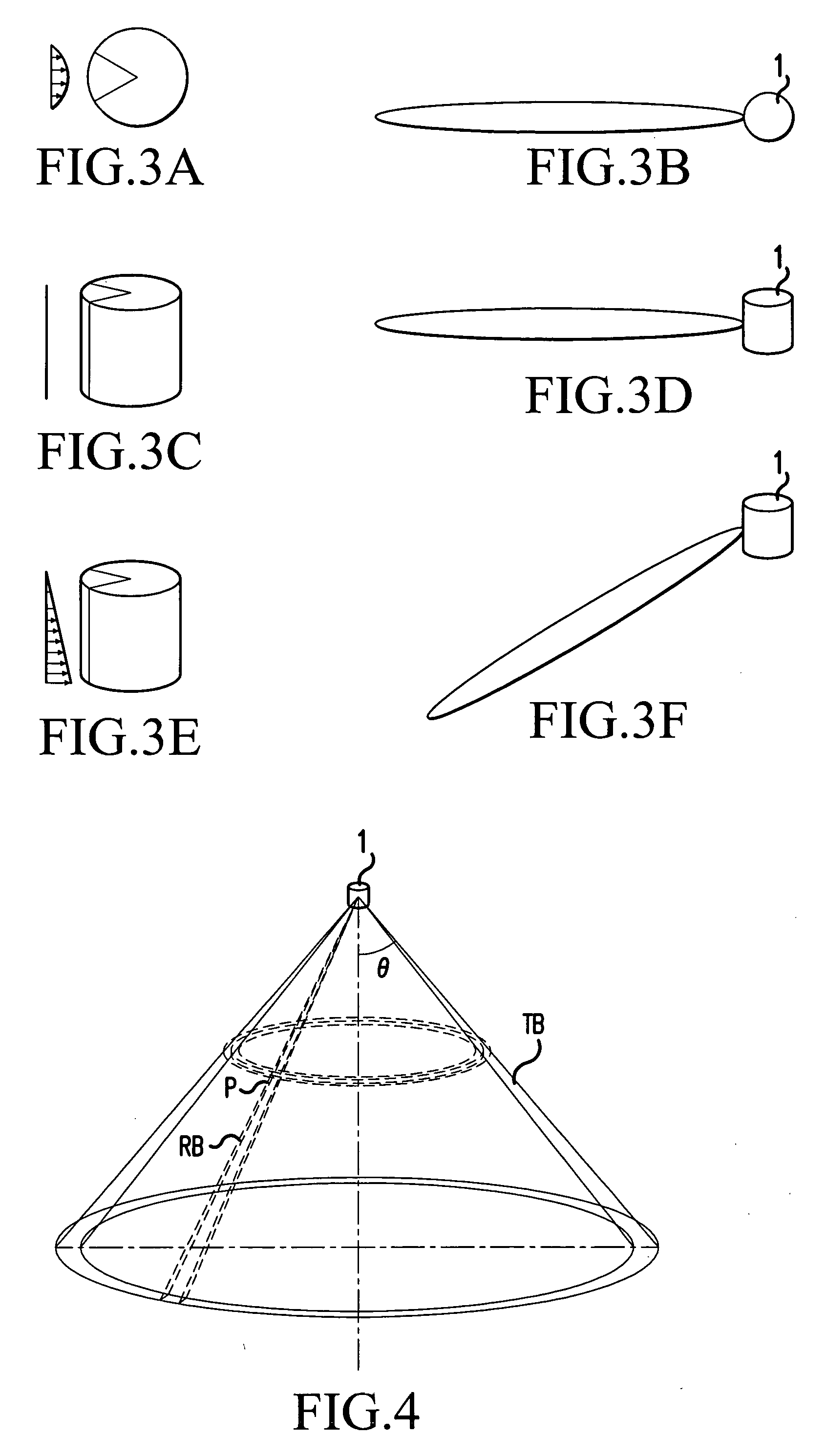

Method and apparatus for controlling acoustic emissions of a wind turbine

A method and an apparatus for monitoring an acoustic emission of a wind turbine that includes a rotor blade. The apparatus includes at least one sensor operatively coupled to the wind turbine. The sensor is configured to detect an atmospheric condition. A control system is communicatively coupled to the sensor, and configured to control operation of the wind turbine to adjust the acoustic emission of the wind turbine based on the atmospheric condition.

Owner:GENERAL ELECTRIC CO

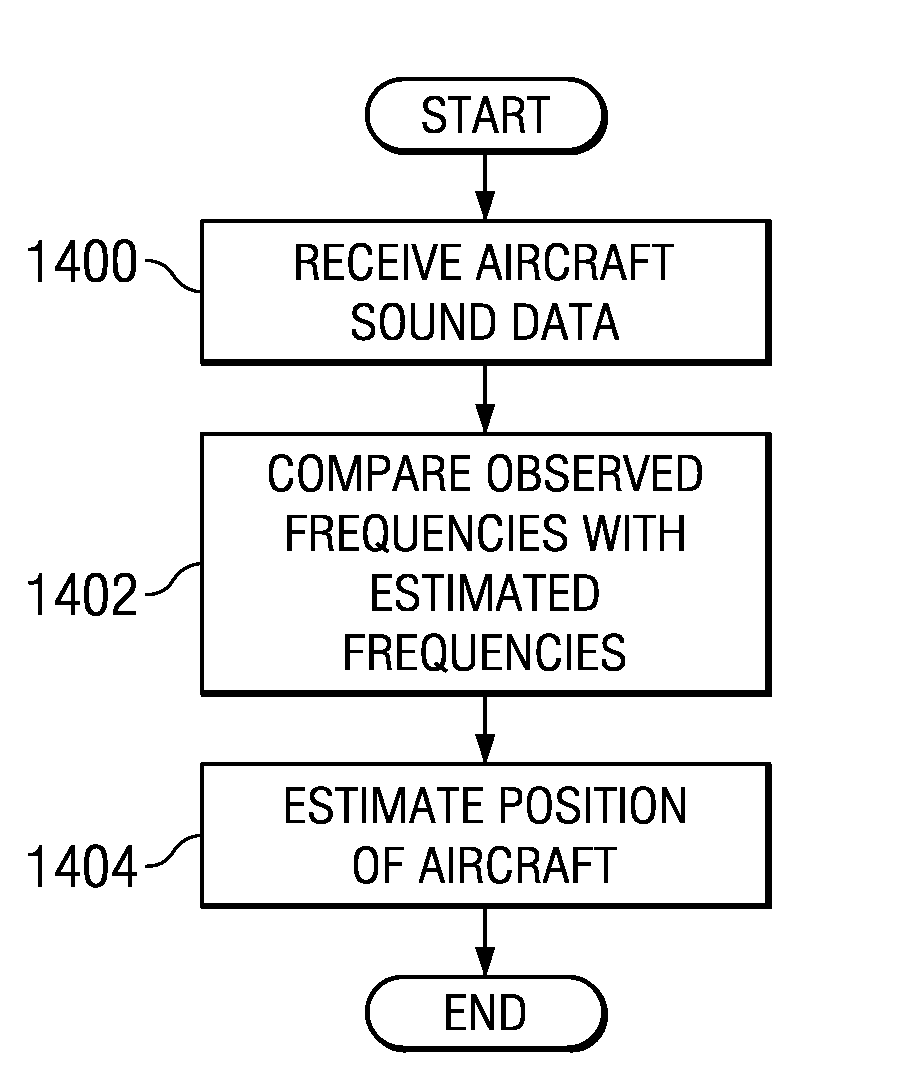

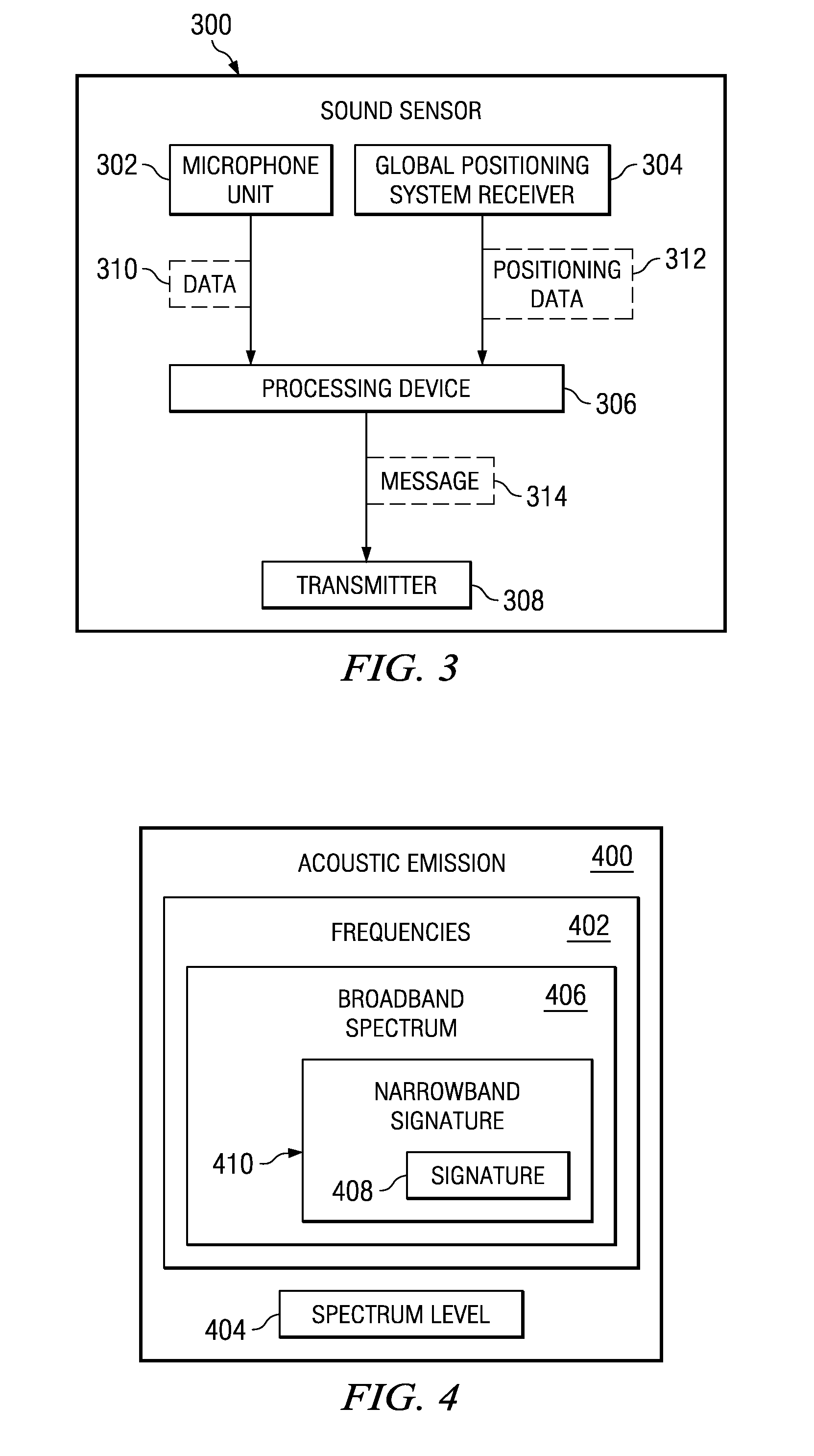

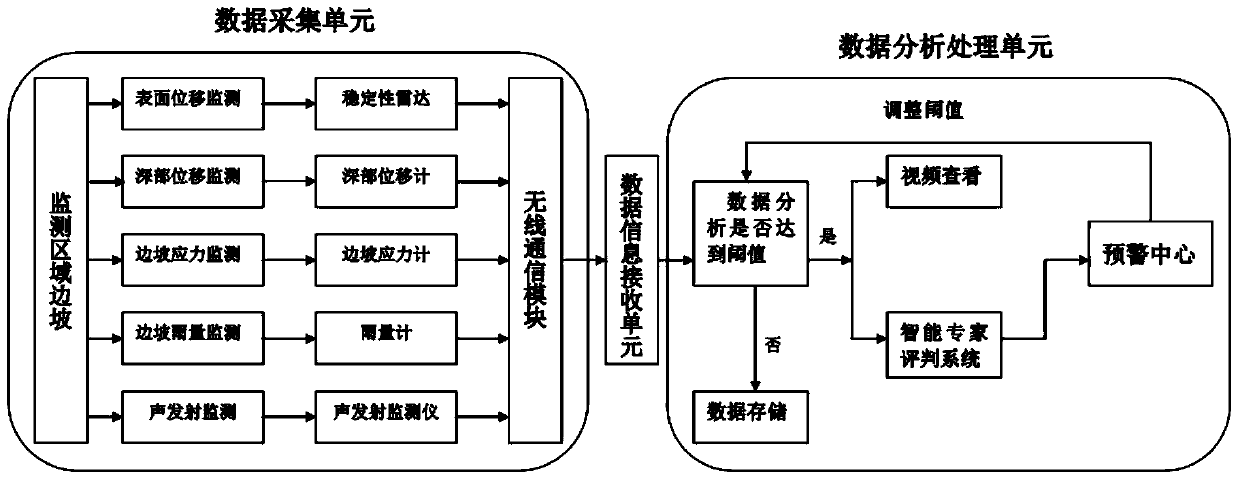

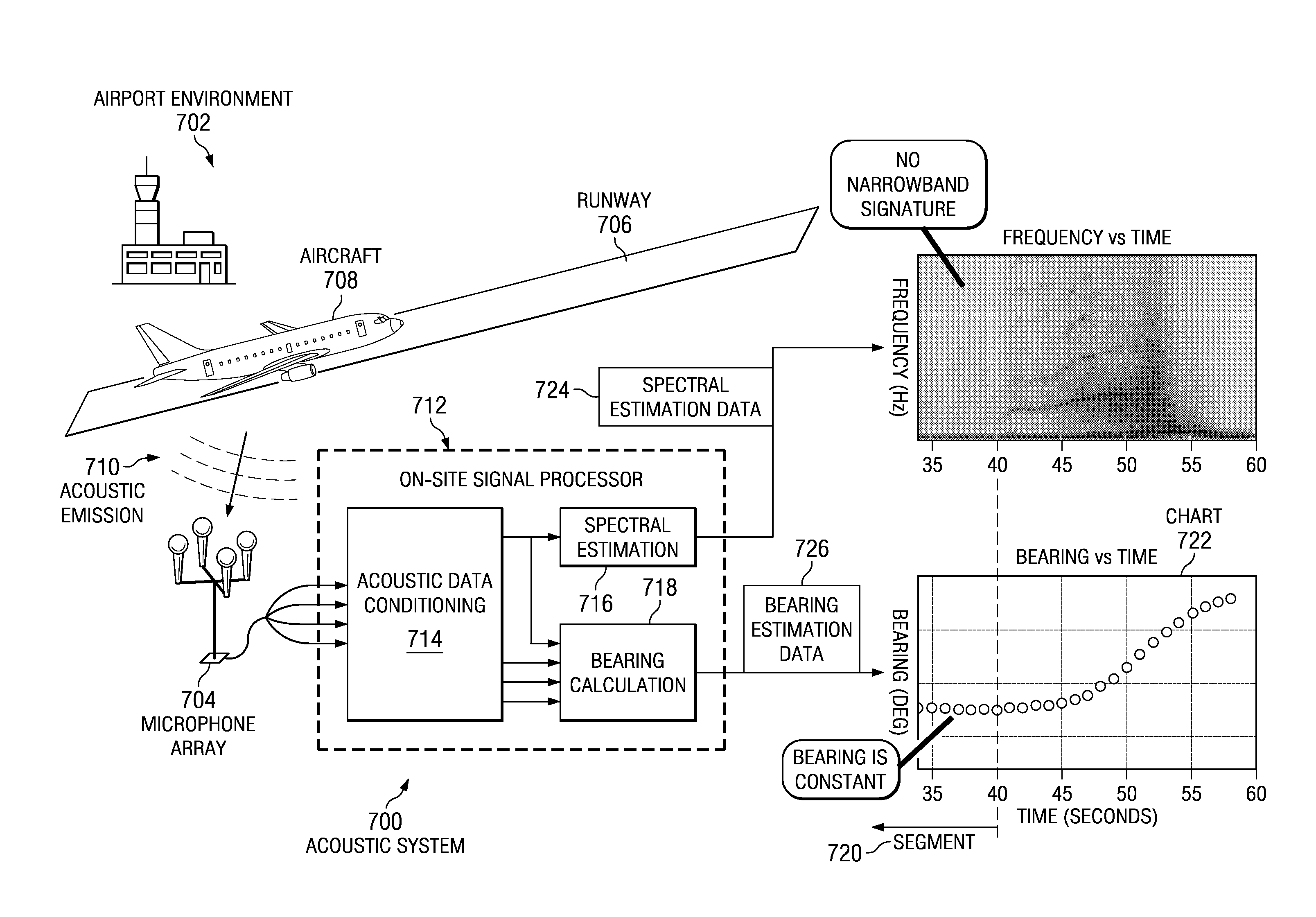

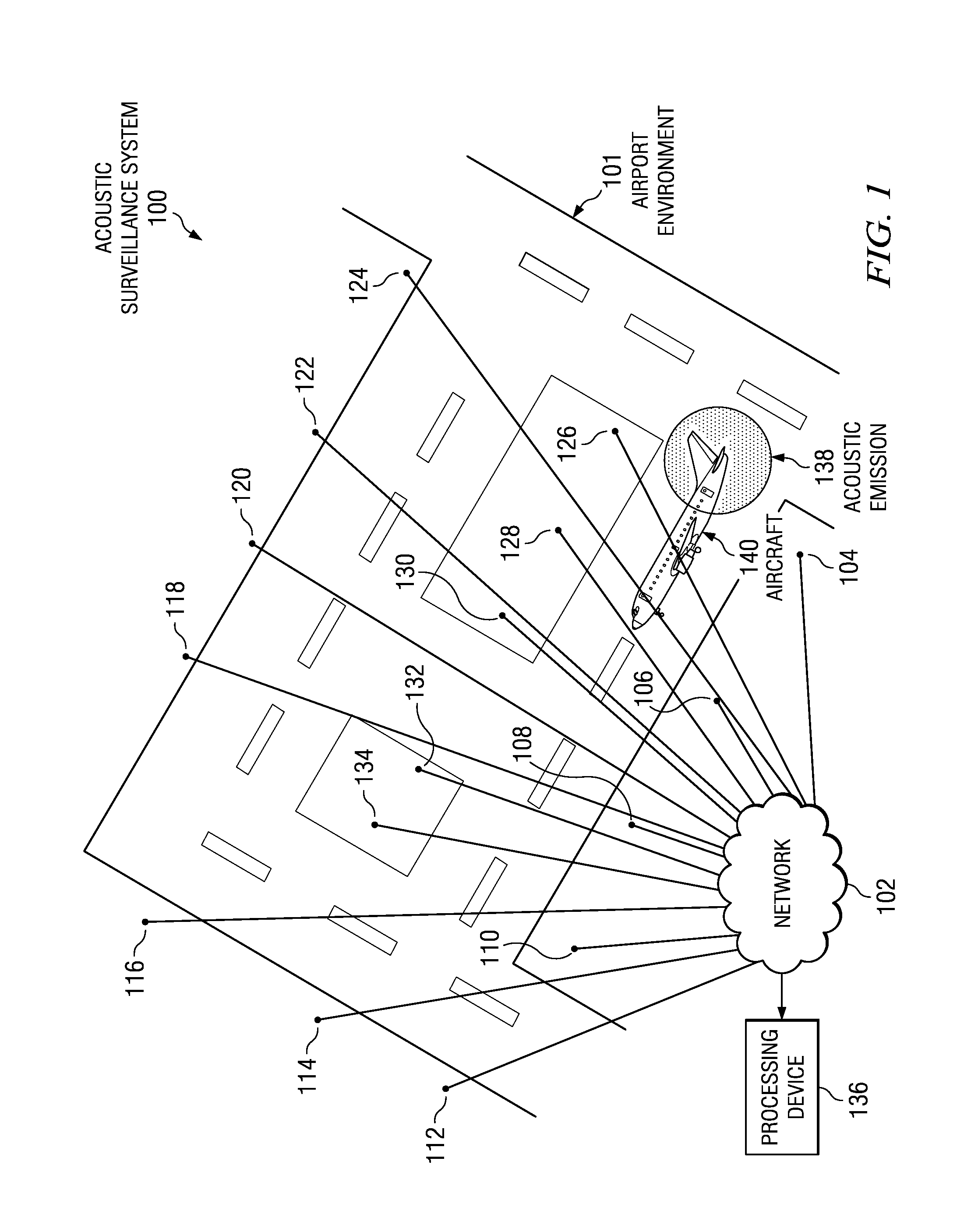

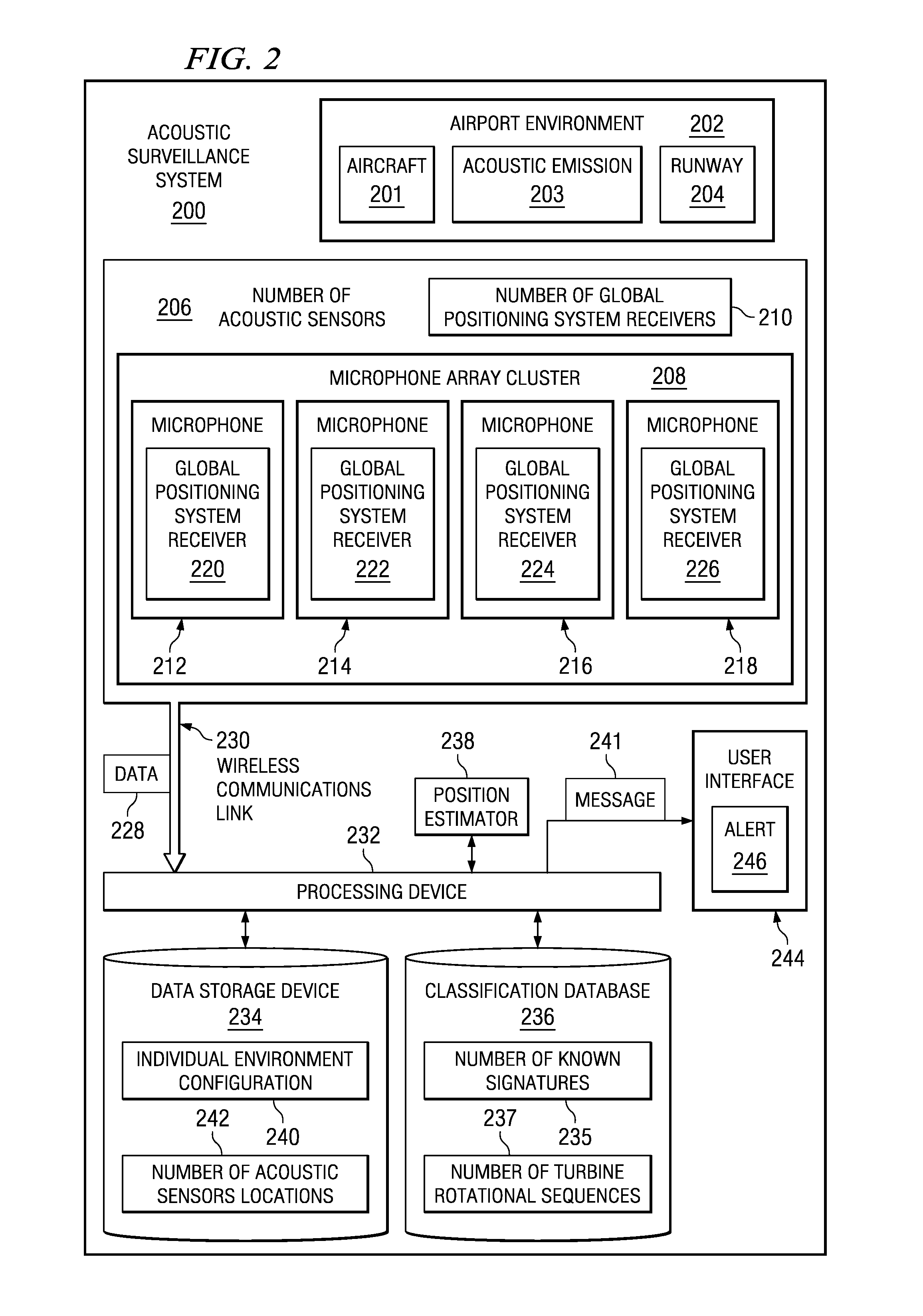

Acoustic wide area air surveillance system

ActiveUS20090257314A1Direction finders using ultrasonic/sonic/infrasonic wavesPosition fixationLocation detectionWide area

A method and apparatus for detecting an aircraft. The method is provided for wide area tracking of aircraft. An acoustic emission of the aircraft is detected from a plurality of locations. A position of the aircraft at a set of times is estimated by comparing a set of harmonically related Doppler shifted frequencies for the acoustic emission to an expected zero Doppler shifted frequency of the aircraft to form an estimated position. The position of the aircraft and a heading of the aircraft are tracked using the estimated position. The aircraft type is classified based on the corresponding set of zero Doppler frequencies at each acoustic sensor.

Owner:THE BOEING CO

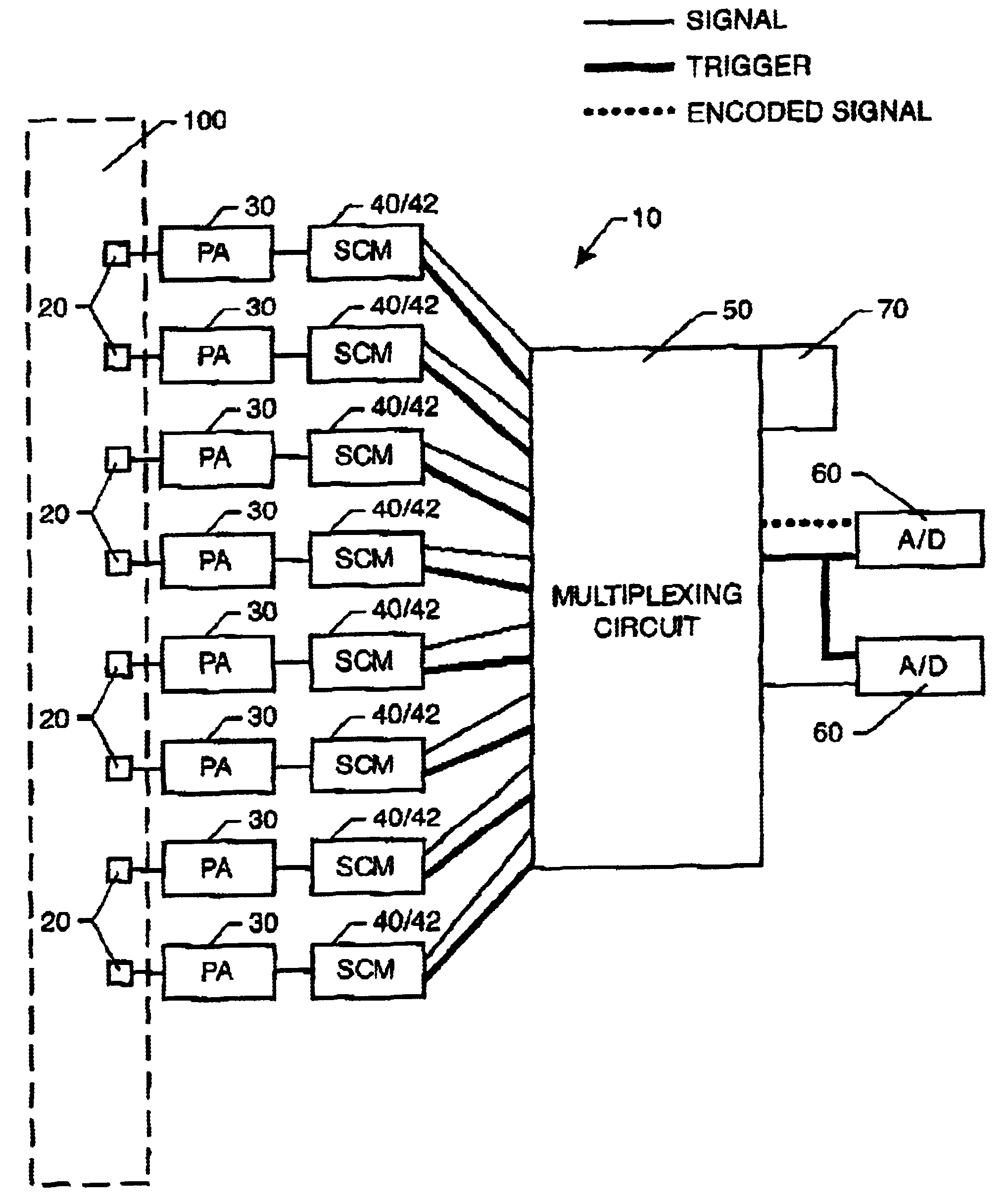

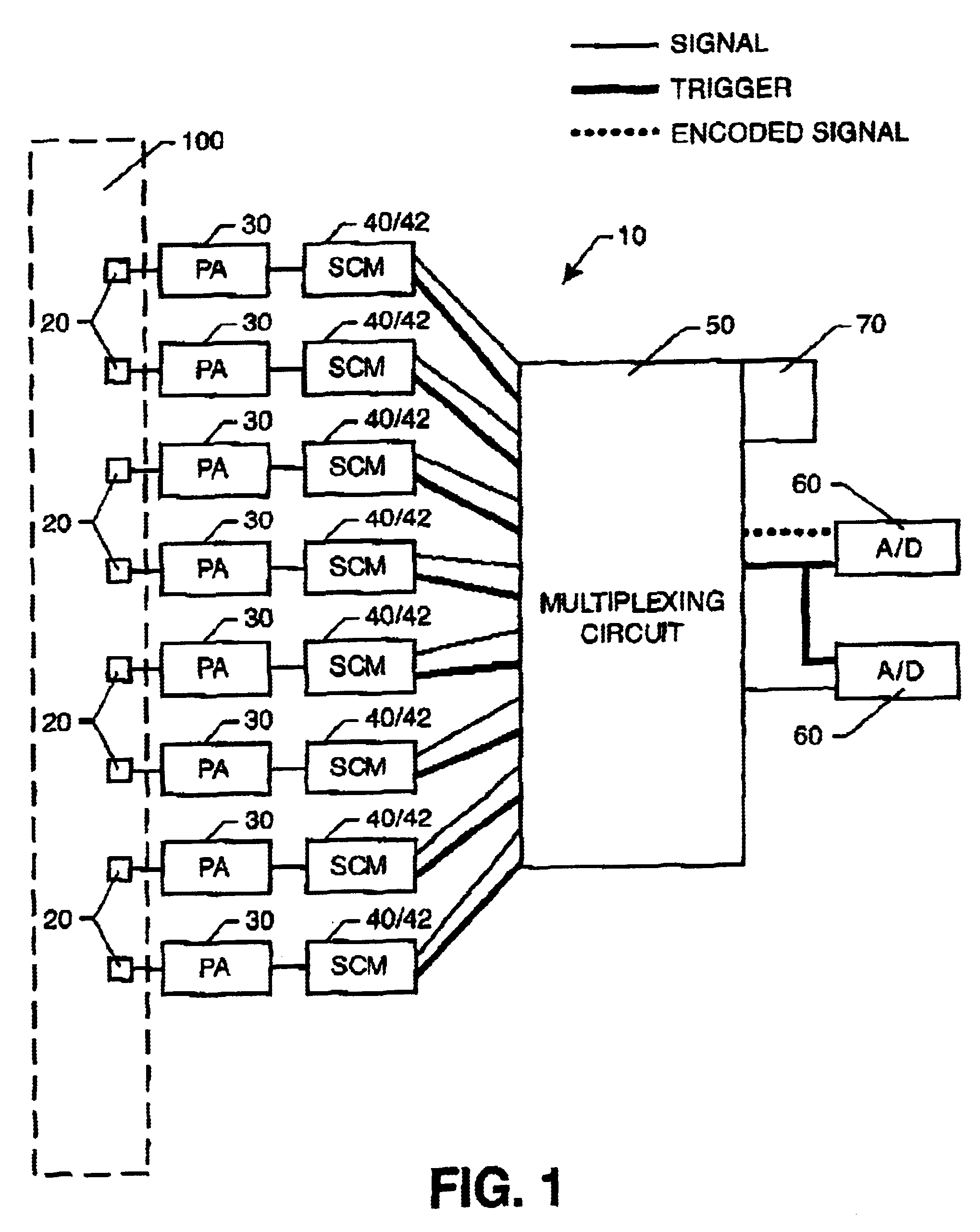

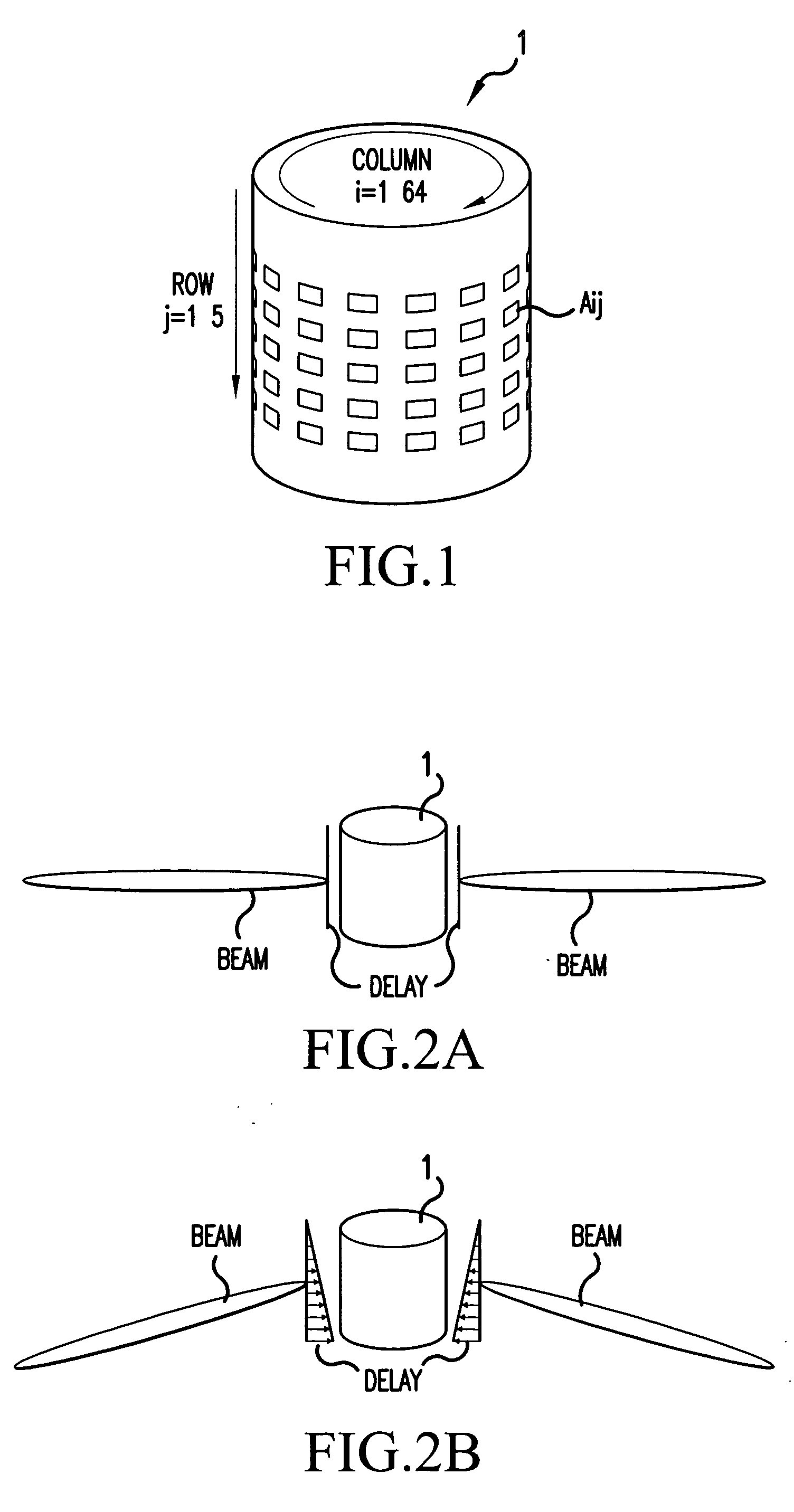

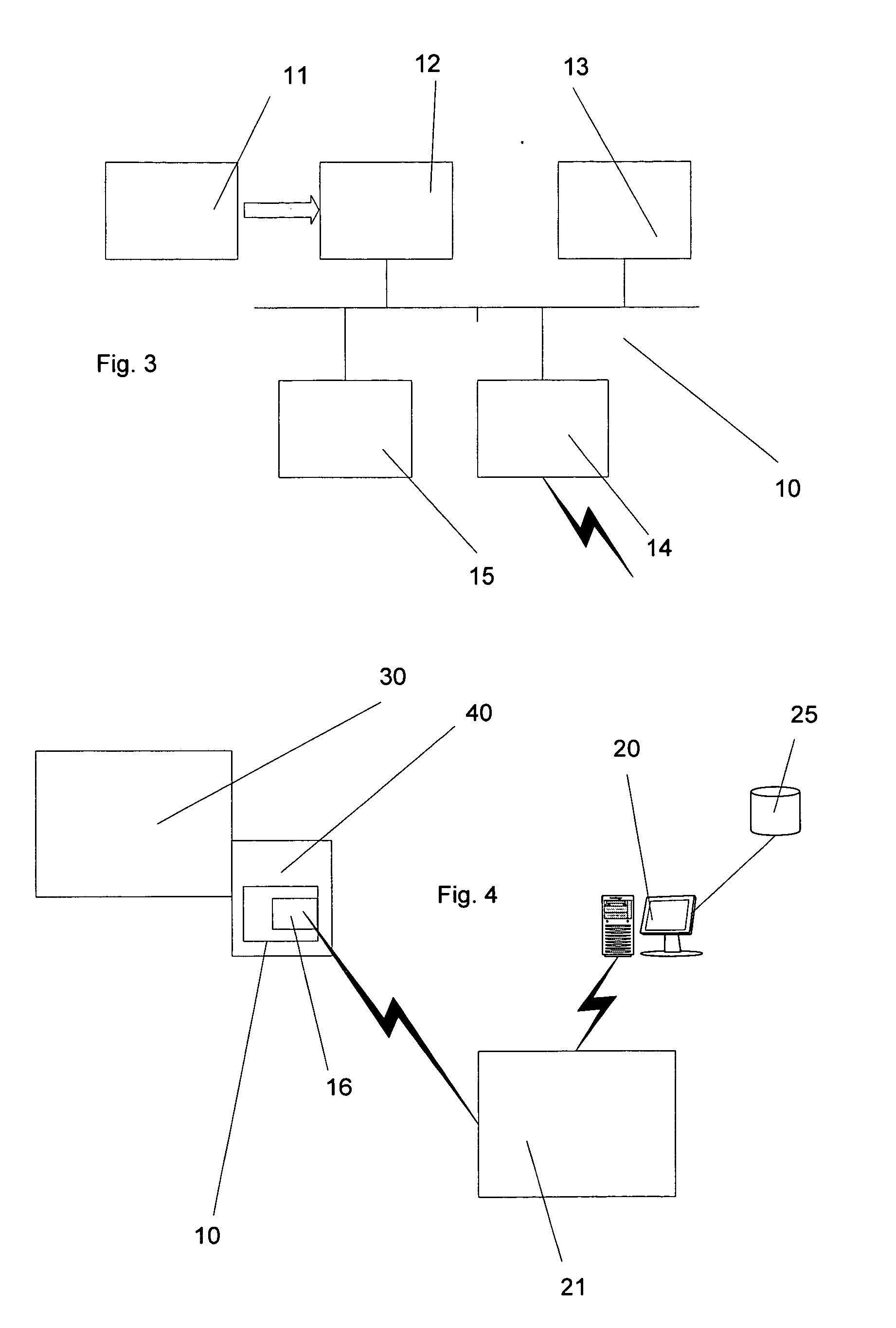

System for multiplexing acoustic emission (AE) instrumentation

InactiveUS6628567B1Vibration measurement in solidsMaterial analysis using acoustic emission techniquesMultiplexingAcoustic emission

An acoustic monitoring device has at least two acoustic sensors with a triggering mechanism and a multiplexing circuit. After the occurrence of a triggering event at a sensor, the multiplexing circuit allows a recording component to record acoustic emissions at adjacent sensors. The acoustic monitoring device is attached to a solid medium to detect the occurrence of damage.

Owner:DIGITAL WAVE CORP +1

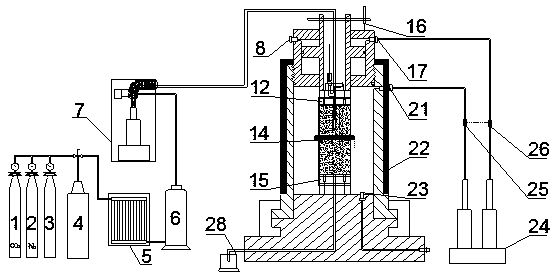

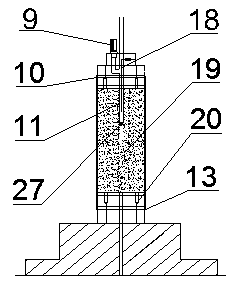

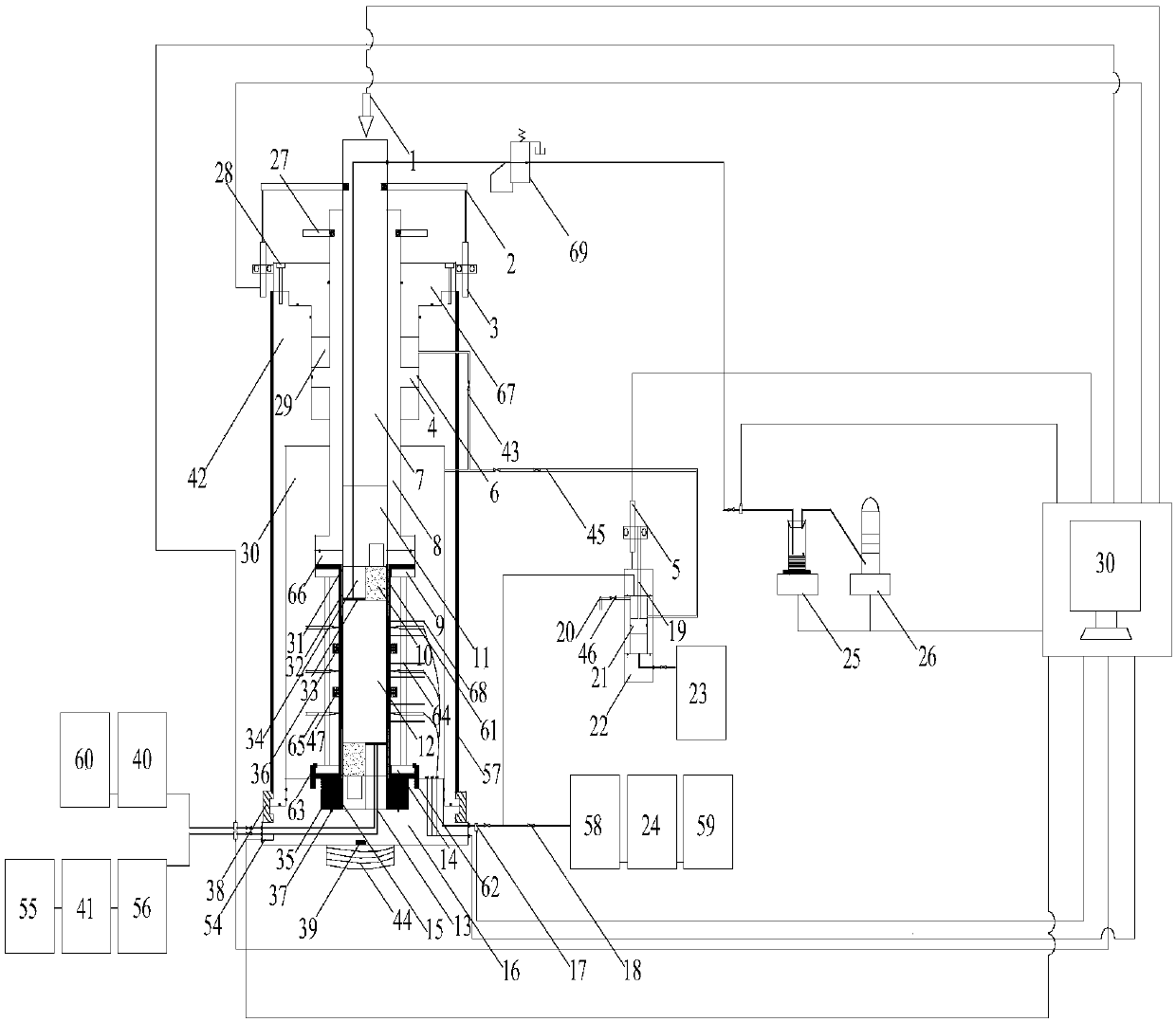

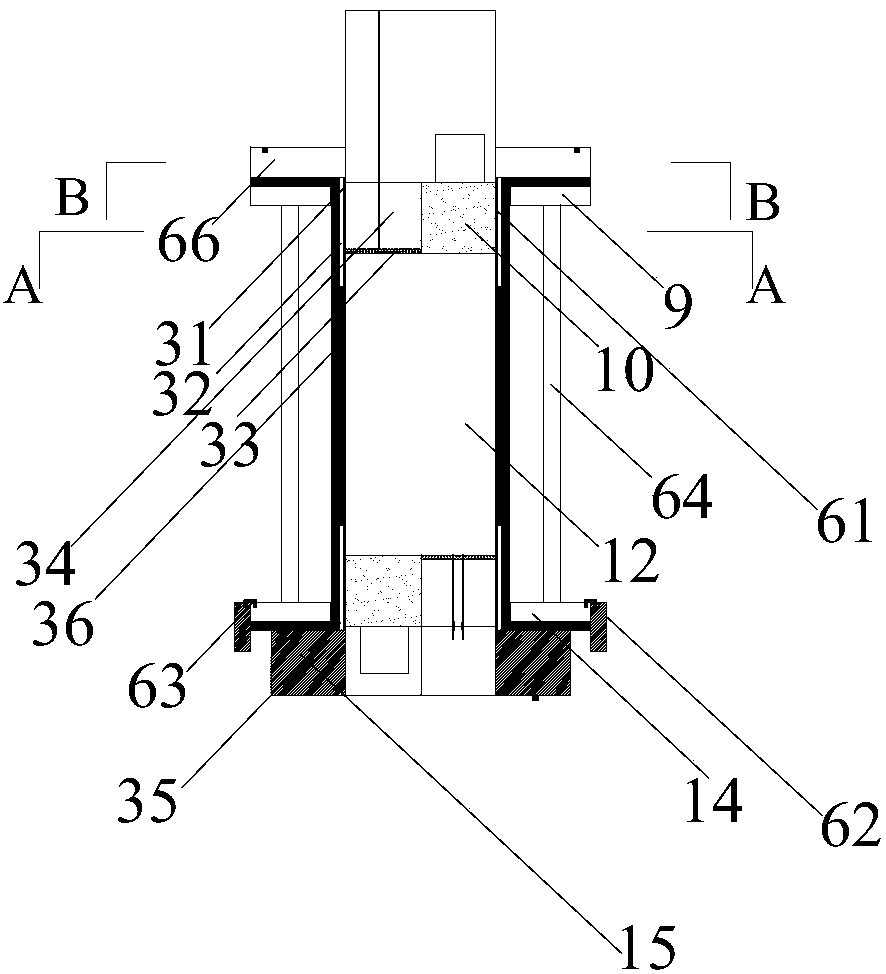

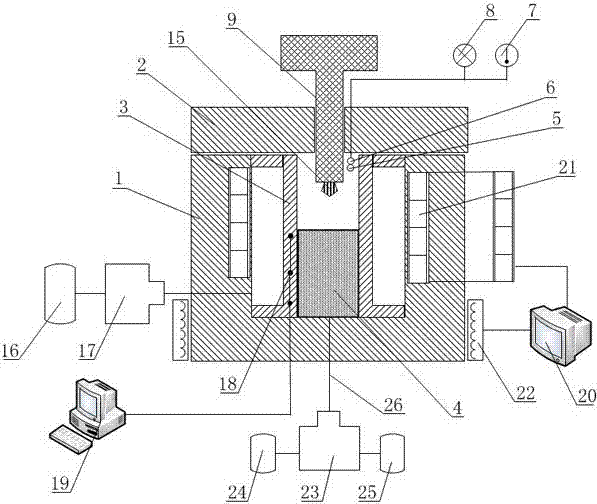

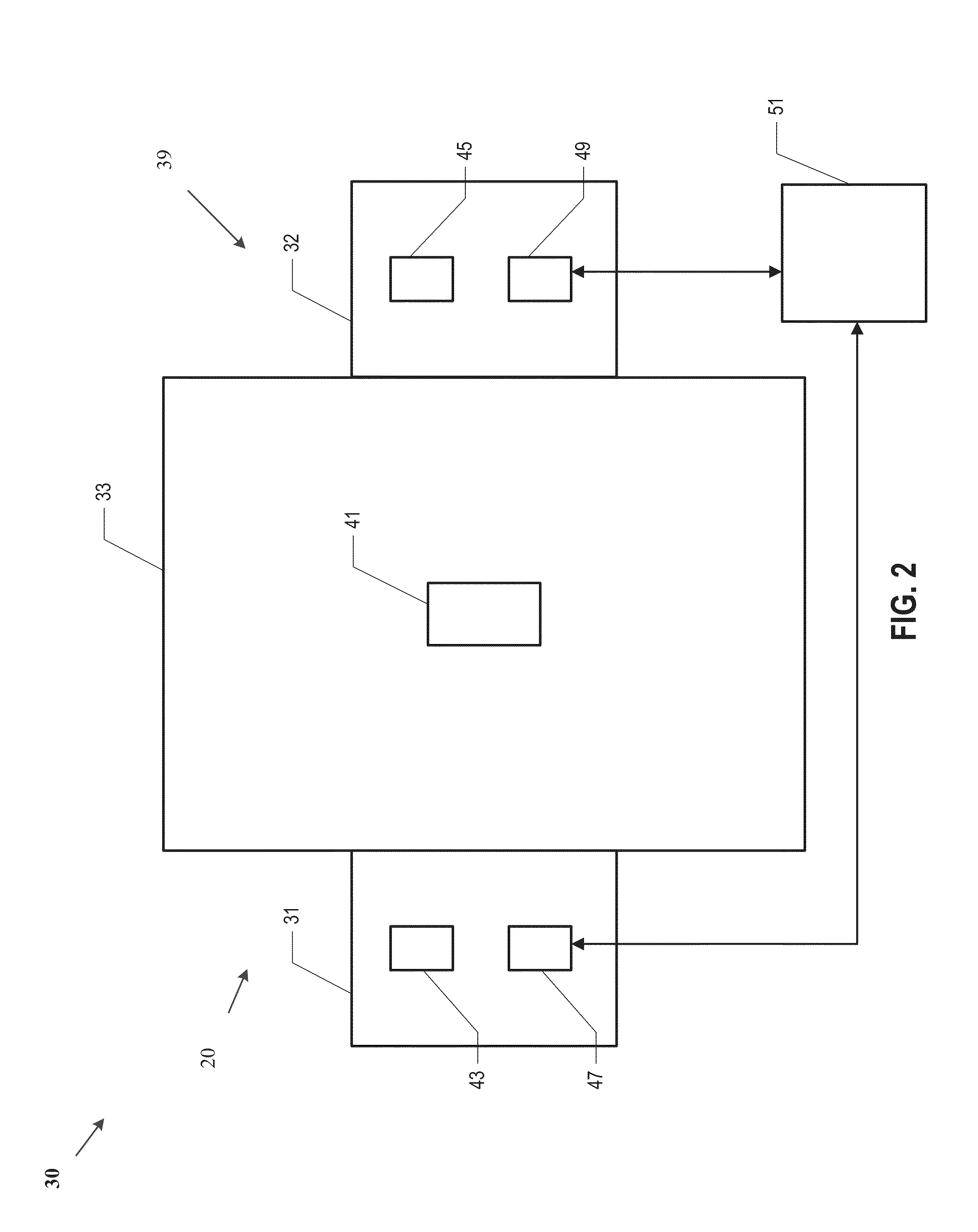

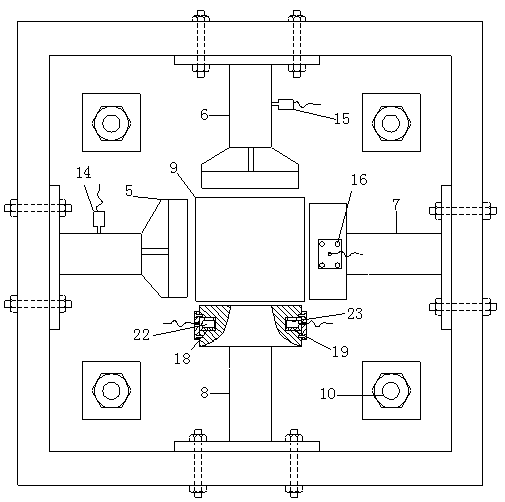

Coal petrography multiphase different fluid three-axis crushing test unit and method

ActiveCN105510142ARealize the effects of fracturingEnables research on the effects of fracturingMaterial strength using tensile/compressive forcesTest comparisonData acquisition

The invention discloses a coal petrography multiphase different fluid three-axis crushing test unit and method and belongs to the technical field of rock and rock mass mechanics and engineering. The unit is composed of a three-axis stress real-time loading system, a multiphase different fluid crushing system, a sealing system, a temperature control system, an acoustic emission monitoring system and a data acquisition system. Different fluid and multiphase crushing test comparison can be conducted on a coal petrography test piece, sensibility of parameters, such as fluid pressurization rate, fluid viscosity, fluid isothermal compressibility and fluid temperature, affecting crushing of the coal petrography test piece can be analyzed under multiple conditions, the change rule of the pressure and temperature of a crushing medium can be precisely recorded in a crushing experiment, acoustic emission events during test piece crushing can be recorded in real time through an assembled micro acoustic emission sensor, and multi-phase fluid seepage tests before and after crushing can also be conducted on the coal petrography test piece.

Owner:TAIYUAN UNIV OF TECH

Projecting simulator stand for coal and firedamp

InactiveCN101226183AAvoid influenceReach prominenceGeological measurementsMaterial analysisStress concentrationUltrasound attenuation

The invention relates to a coal-gas outburst simulation platform for processing coal-gas outburst simulation researches under different coal bed inclinations, different ground stresses and different gas pressures, and researching the transmission rule and attenuation character of acoustic emission signal in the outburst process. The invention uses a plurality of hydraulic jacks to axially jack coal sample, uses an aeration port to charge gas into the coal sample, and can simulate the protruded stress concentrated zone caused by underground coal face, to simulate the outburst condition of coal and gas. The protruded port of the device via a quick release device can realize mechanical automatic control, to quickly open the protruded port to instantly release pressure at the protruded end and eliminate the effect on the protruding energy by manually opening the protruded port, to simulate on-site protrusion actually.

Owner:CHONGQING UNIV

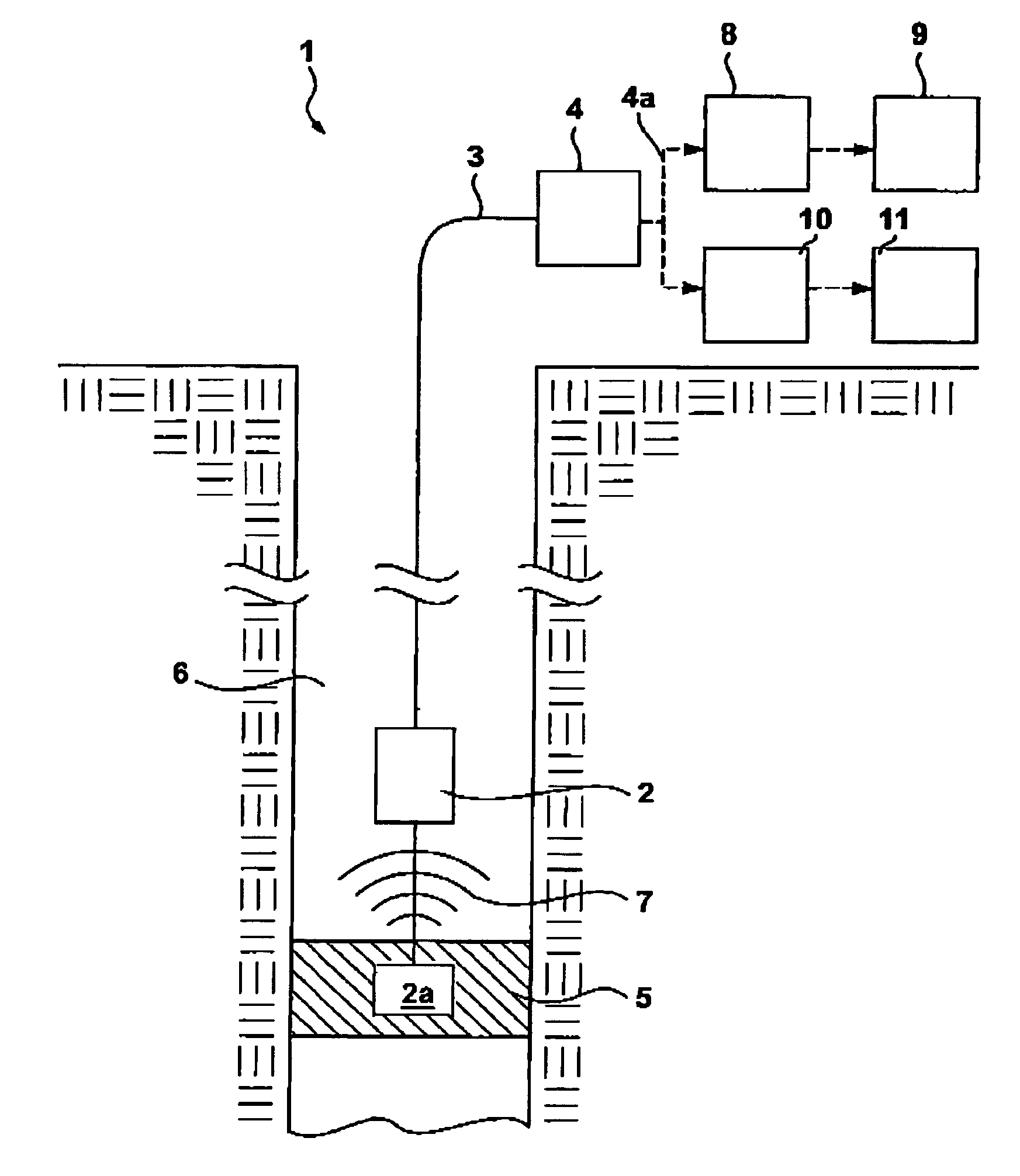

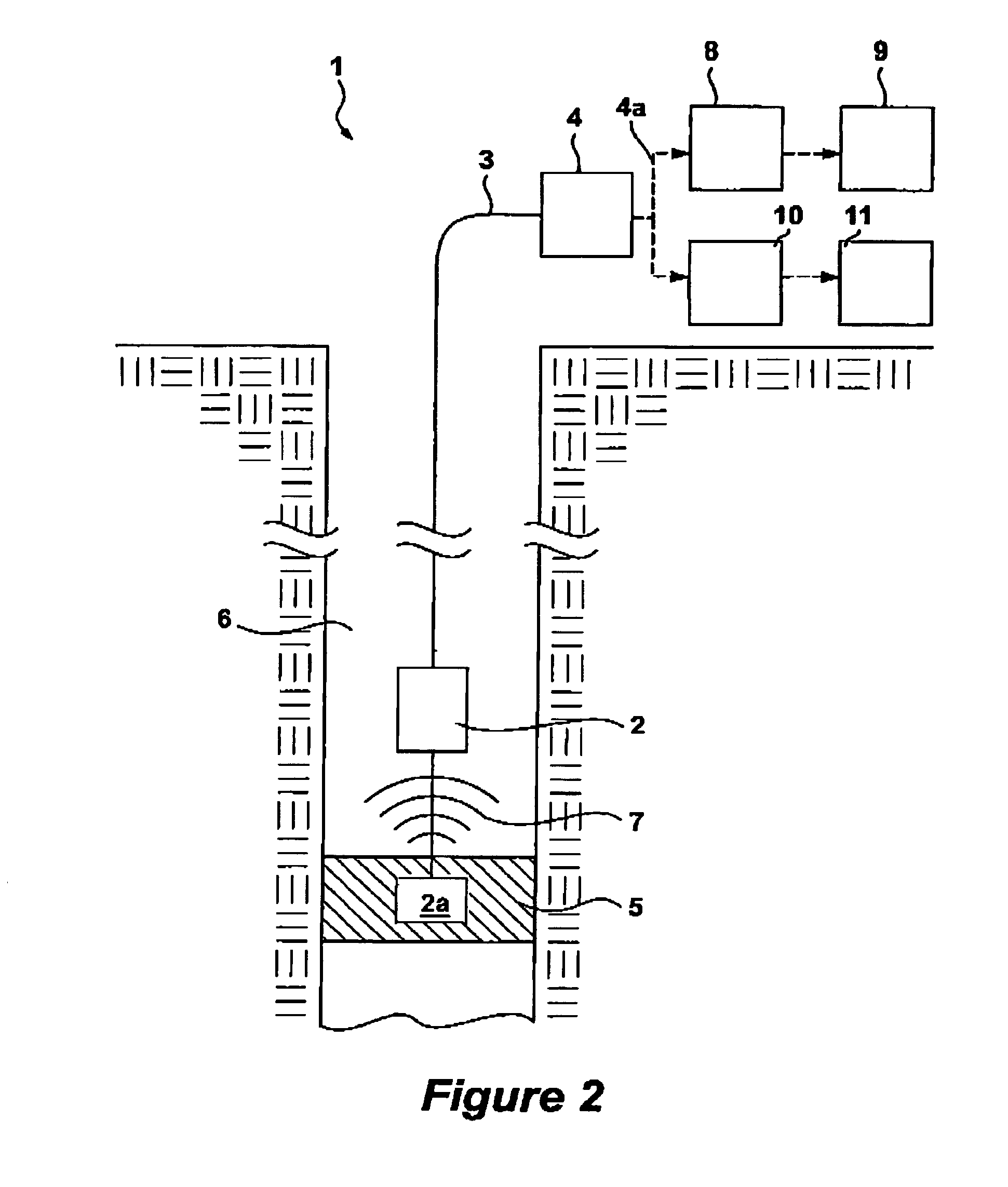

System and method for monitoring performance of downhole equipment using fiber optic based sensors

A method and system for monitoring the operation of downhole equipment, such as electrical submersible pumps, is disclosed. The method and system rely on the use of coiled fiber optic sensors, such as hydrophones, accelerometers, and / or flow meters. These sensors are either coupled to or placed in proximity to the equipment being monitored. As the sensor is perturbed by acoustic pressure disturbances emitted from the equipment, the length of the sensing coil changes, enabling the creation of a pressure versus time signal. This signal is converted into a frequency spectrum indicative of the acoustics emissions of the equipment, which can then be manually or automatedly monitored to see if the equipment is functioning normally or abnormally, and which allows the operator to take necessary corrective actions.

Owner:WEATHERFORD TECH HLDG LLC

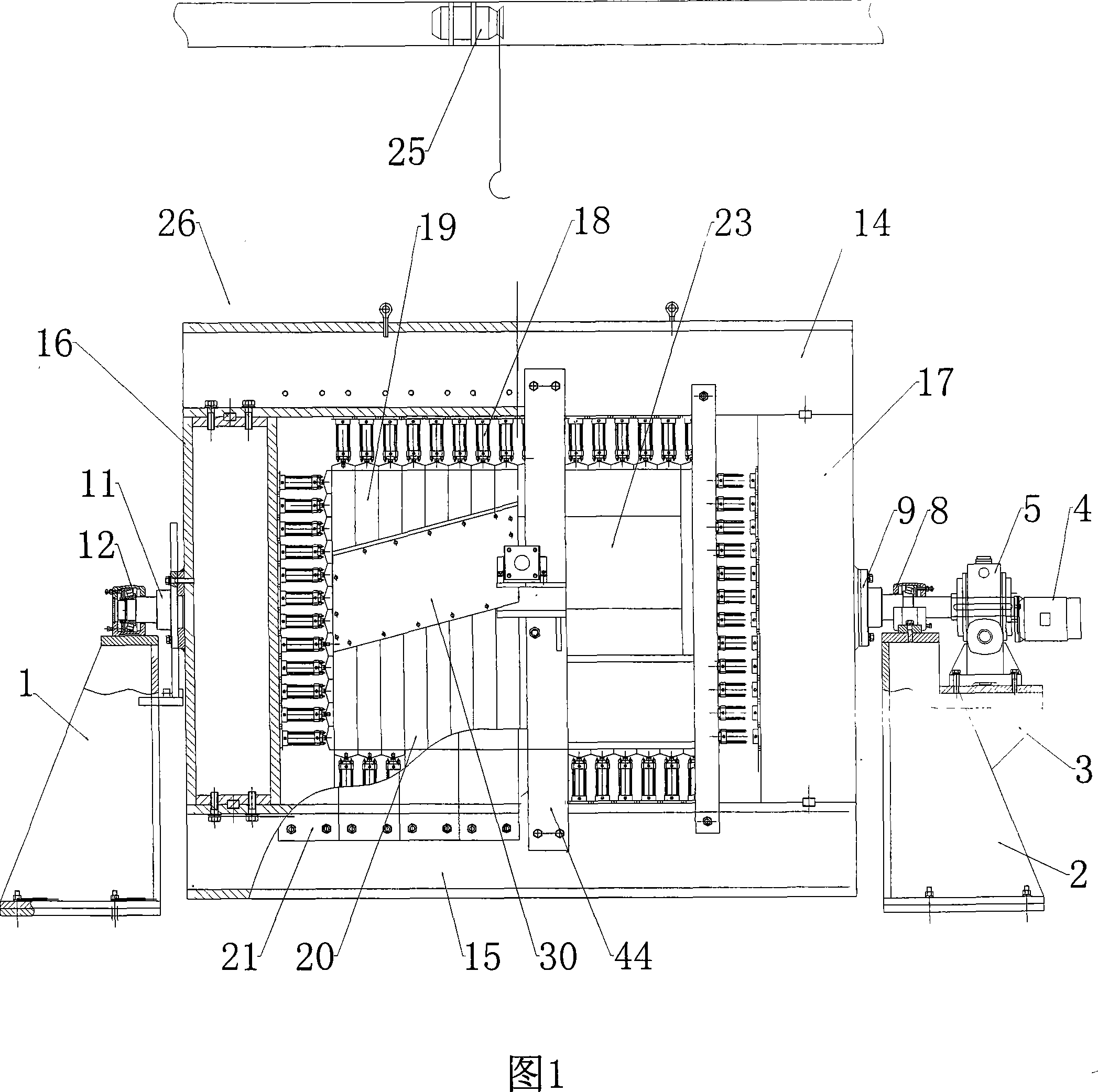

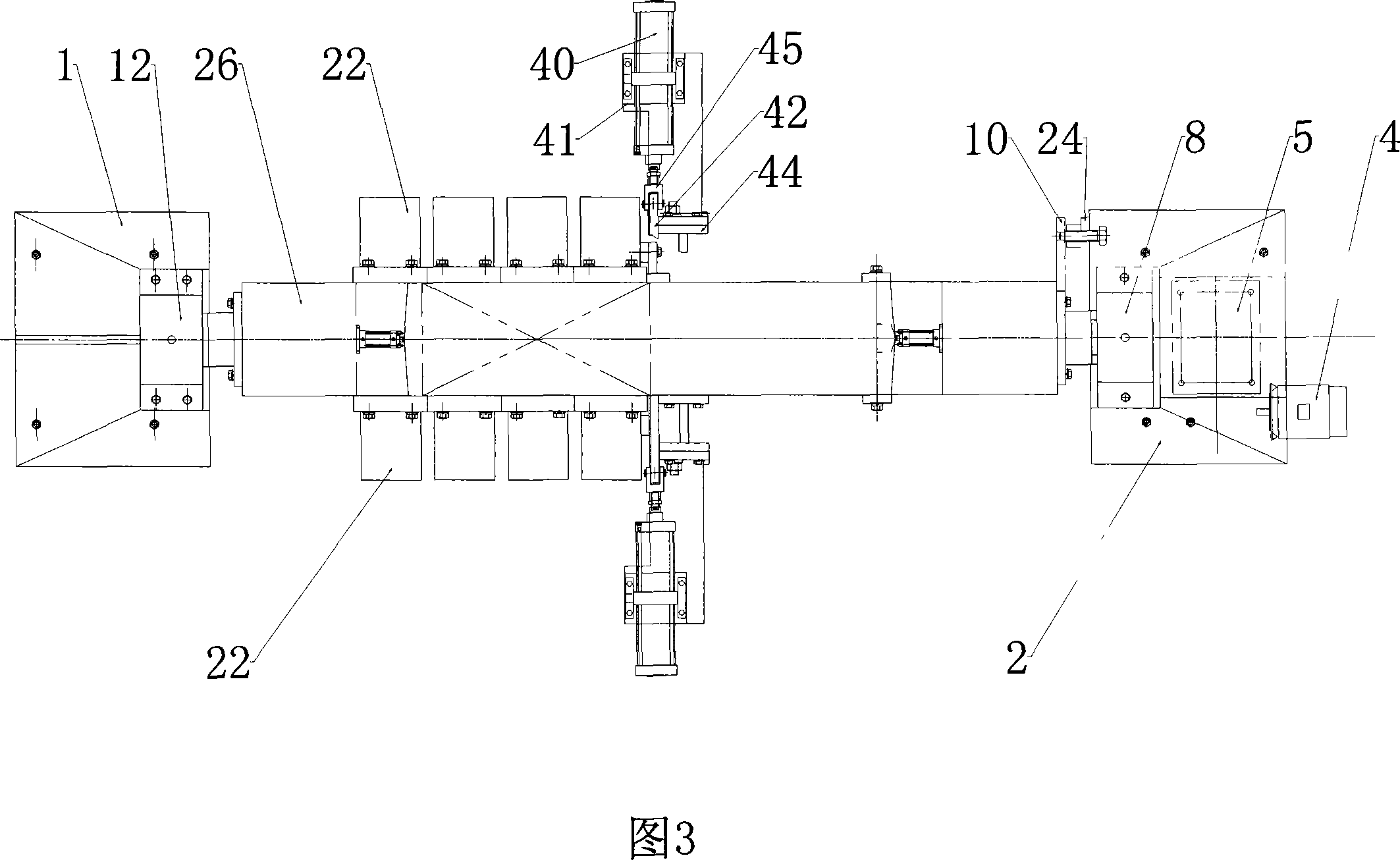

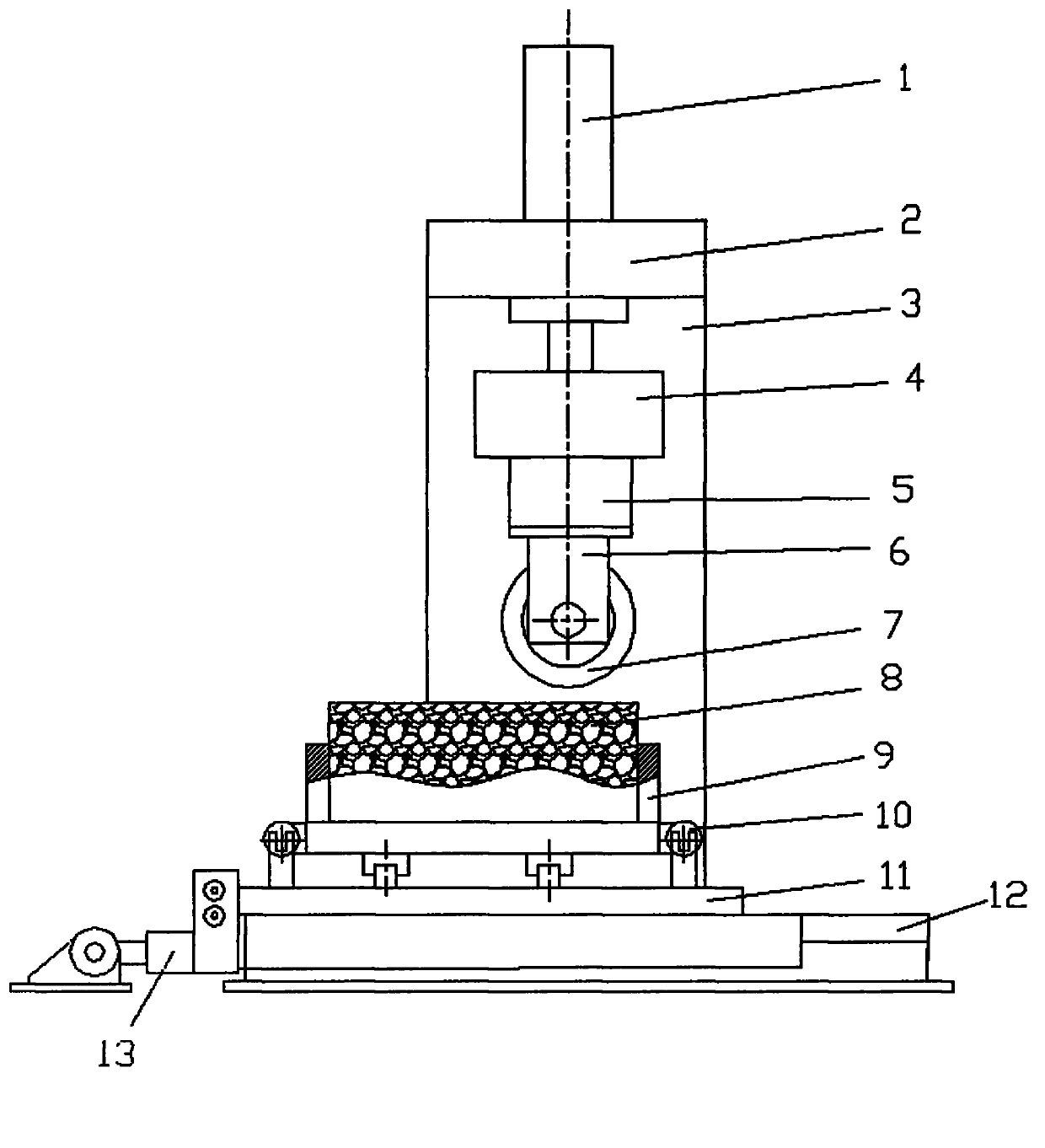

A hard rock hobbing cutter rock breaking characteristic testing device

InactiveCN103969141AObservable breakage featuresInvestigating abrasion/wear resistanceInvestigating machinabilityHobbingData acquisition

A hard rock hobbing cutter rock breaking characteristic testing device used in the field of tunnel engineering is provided. A rock silo supporting seat is positioned on a guide rail pair and realizes longitudinal motion by a longitudinal-moving hydraulic cylinder; a rock silo is positioned on the rock silo supporting seat and realizes lateral movement by lateral moving hydraulic cylindersfixed on the rock silo supporting seat; rock samples are positioned inside the rock silo. Two columns are vertically arranged at both sides of the rock silo, top ends of the columns are connected by a beam and thus a gantry structure is formed. A vertical hydraulic cylinder is fixed on the beam, and the lower part of the vertical hydraulic cylinder is connected with a walking beam. Under the walking beam, a hobbing cutter is installed to simulate the process of hobbing cutter rock breaking, or a similar hobbing cutter wearing module is installed to simulate the process of similar hobbing cutter wearing. An industrial computer, a data acquisition card, a three-axis force sensor, an acoustic emission device and a high-speed digital camera system are used to monitor the processes of hobbing cutter rock breaking and wearing. The device is capable of simulating the process of rolling-type rock breaking of the hobbing cutter, the process of rolling and impact-combined type rock breaking of the hobbing cutter and the process of similar hobbing cutter wearing.

Owner:CENT SOUTH UNIV

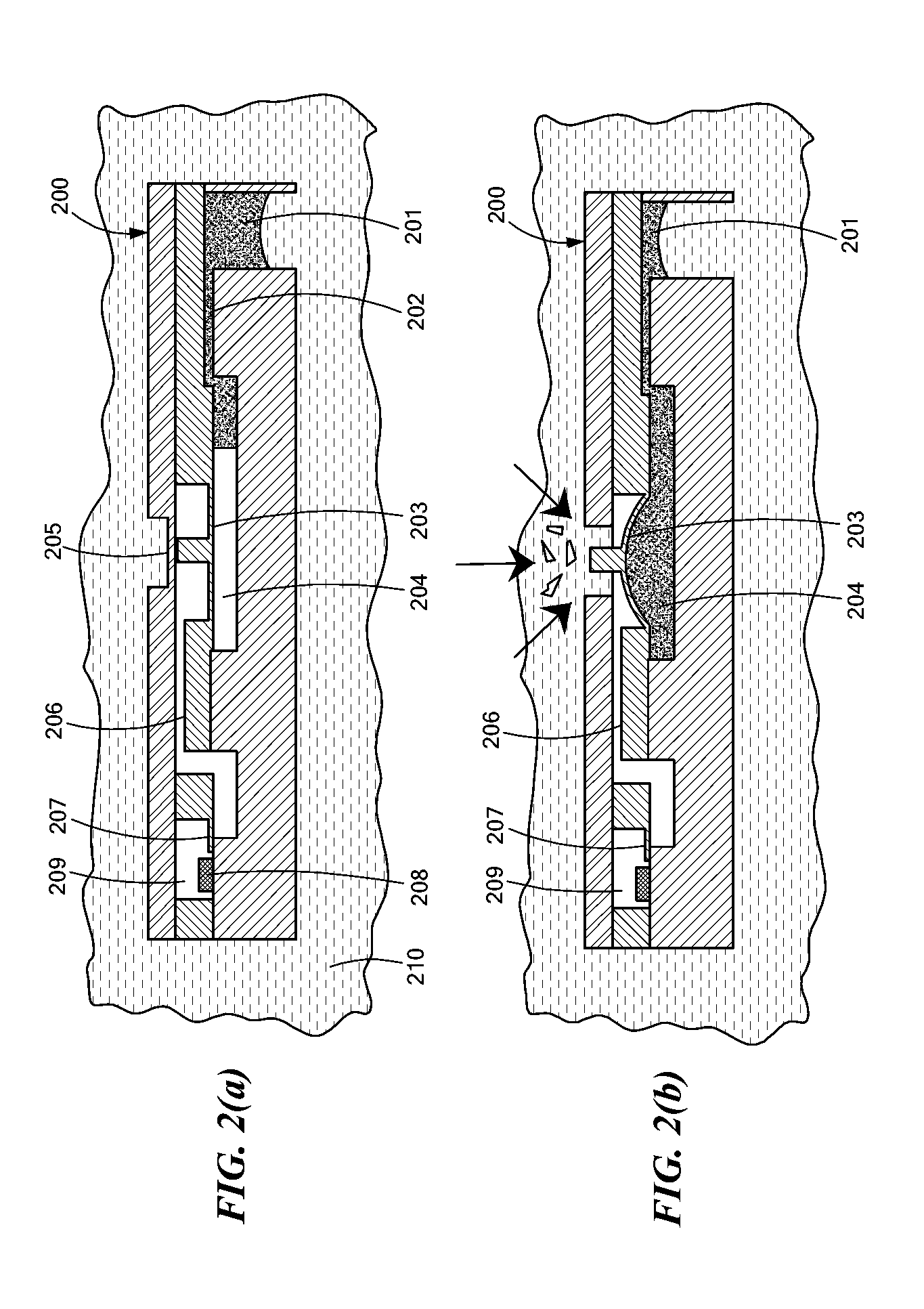

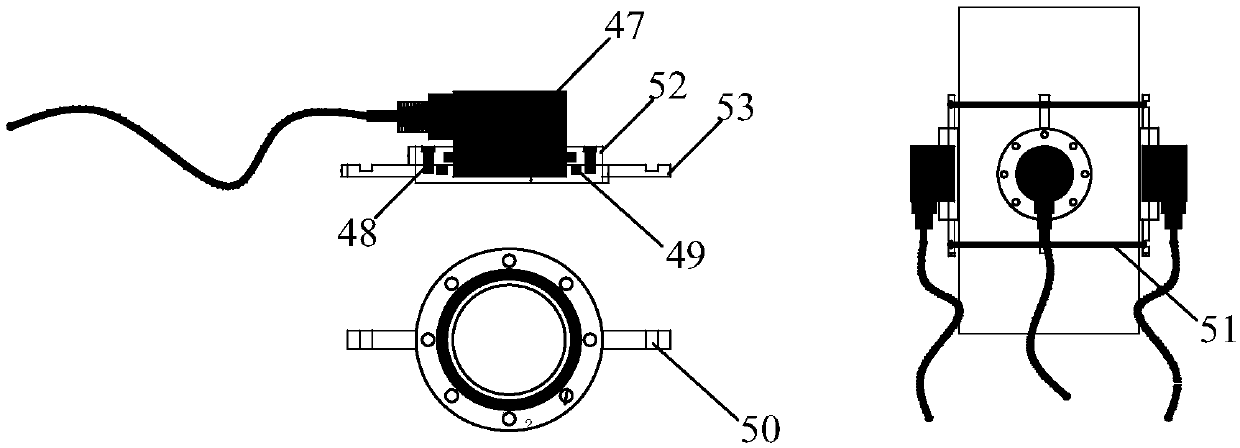

Passive Micro-vessel and Sensor

ActiveUS20140212986A1Short time intervalAccurate recordUltrasonic/sonic/infrasonic diagnosticsSurveyBiological bodyTriangulation

An electrically passive device and method for in-situ acoustic emission, and / or releasing, sampling and / or measuring of a fluid or various material(s) is provided. The device may provide a robust timing mechanism to release, sample and / or perform measurements on a predefined schedule, and, in various embodiments, emits an acoustic signal sequence(s) that may be used for triangulation of the device position within, for example, a hydrocarbon reservoir or a living body.

Owner:FLUIDION

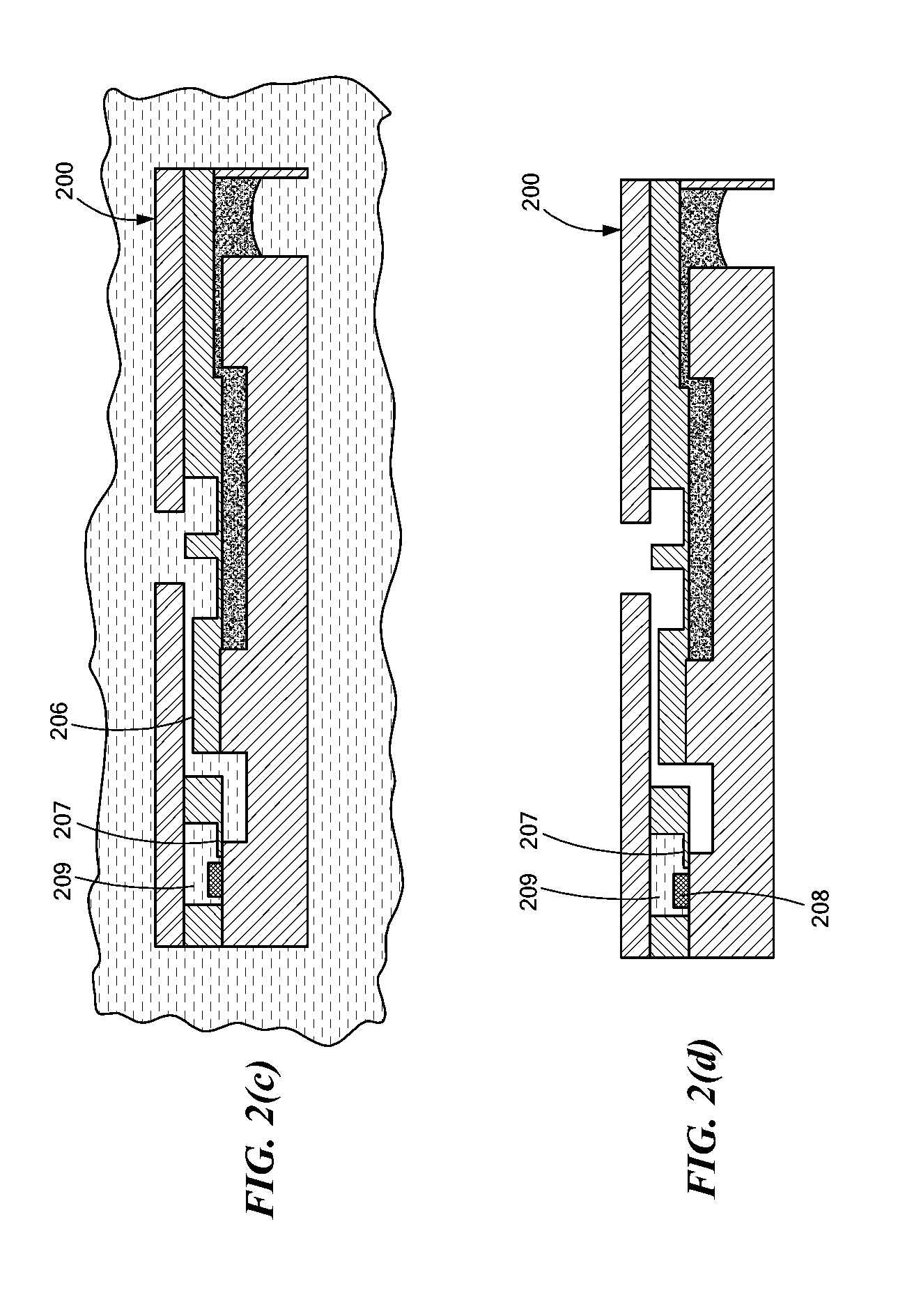

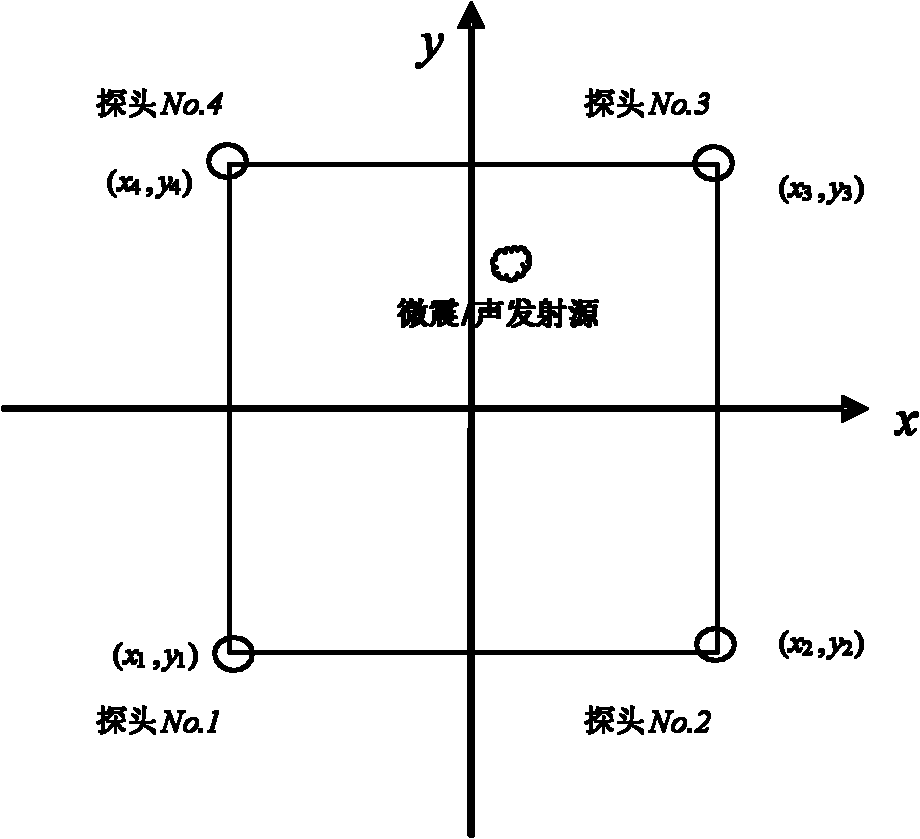

Method for positioning micro seismic source or acoustic emission source

The invention discloses a method for positioning a micro seismic source or an acoustic emission source, which comprises the following steps of: placing a plurality of acoustic emission transducers nearby an object to be detected, and solving position coordinates of the micro seismic source or the acoustic emission source by using a nonlinear least square regression method, such as a simplex acceleration method or a Marquardt method or the like, according to the coordinate values and the time difference of the positions of the known transducers and according to a distance operational formula. The acoustic emission positioning method disclosed by the invention does not need to measure or preset acoustic velocity, can avoid the influence of acoustic velocity measurement on positioning, improves the positioning precision, and is convenient and practical in practical engineering application compared with a traditional method.

Owner:CENT SOUTH UNIV

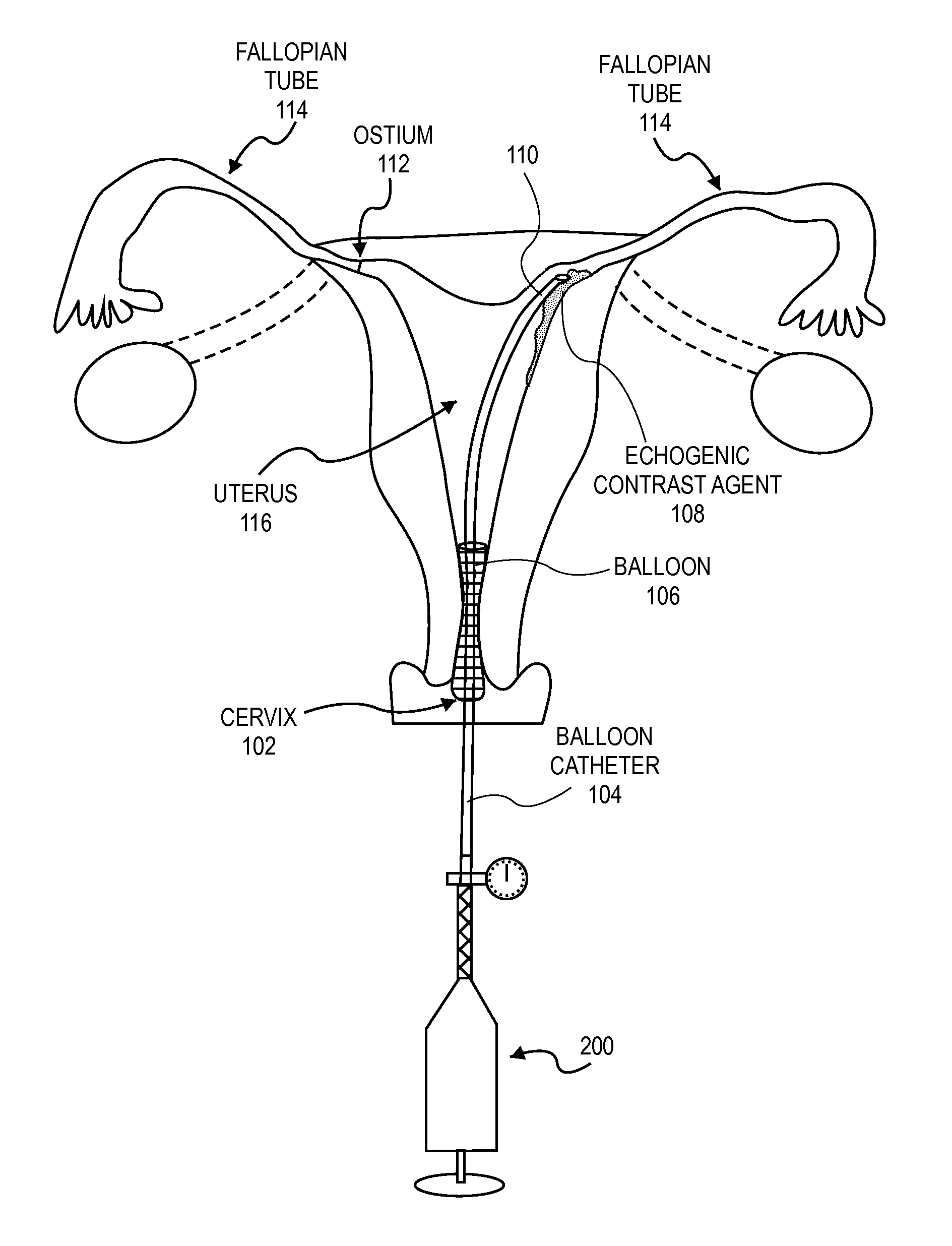

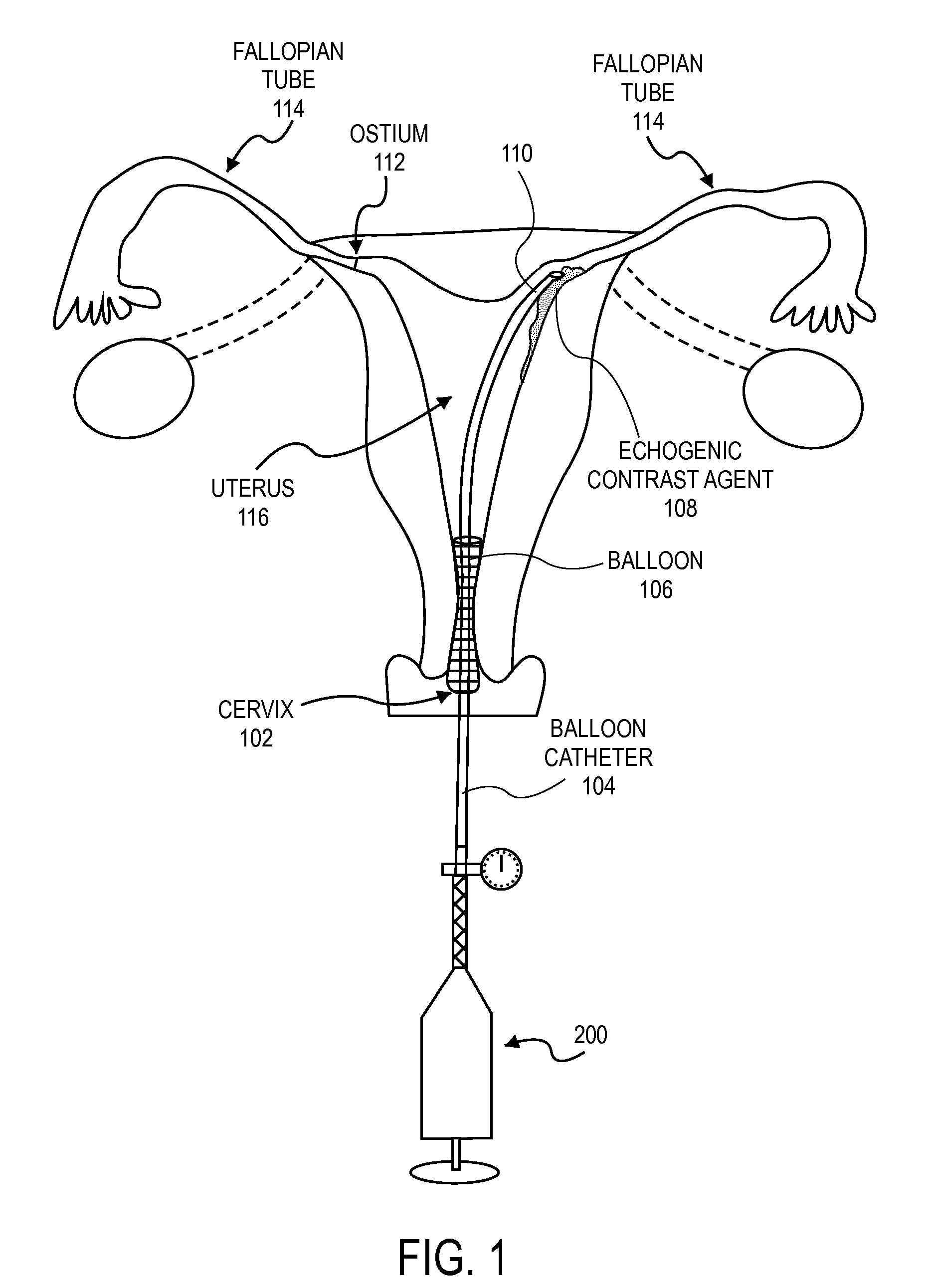

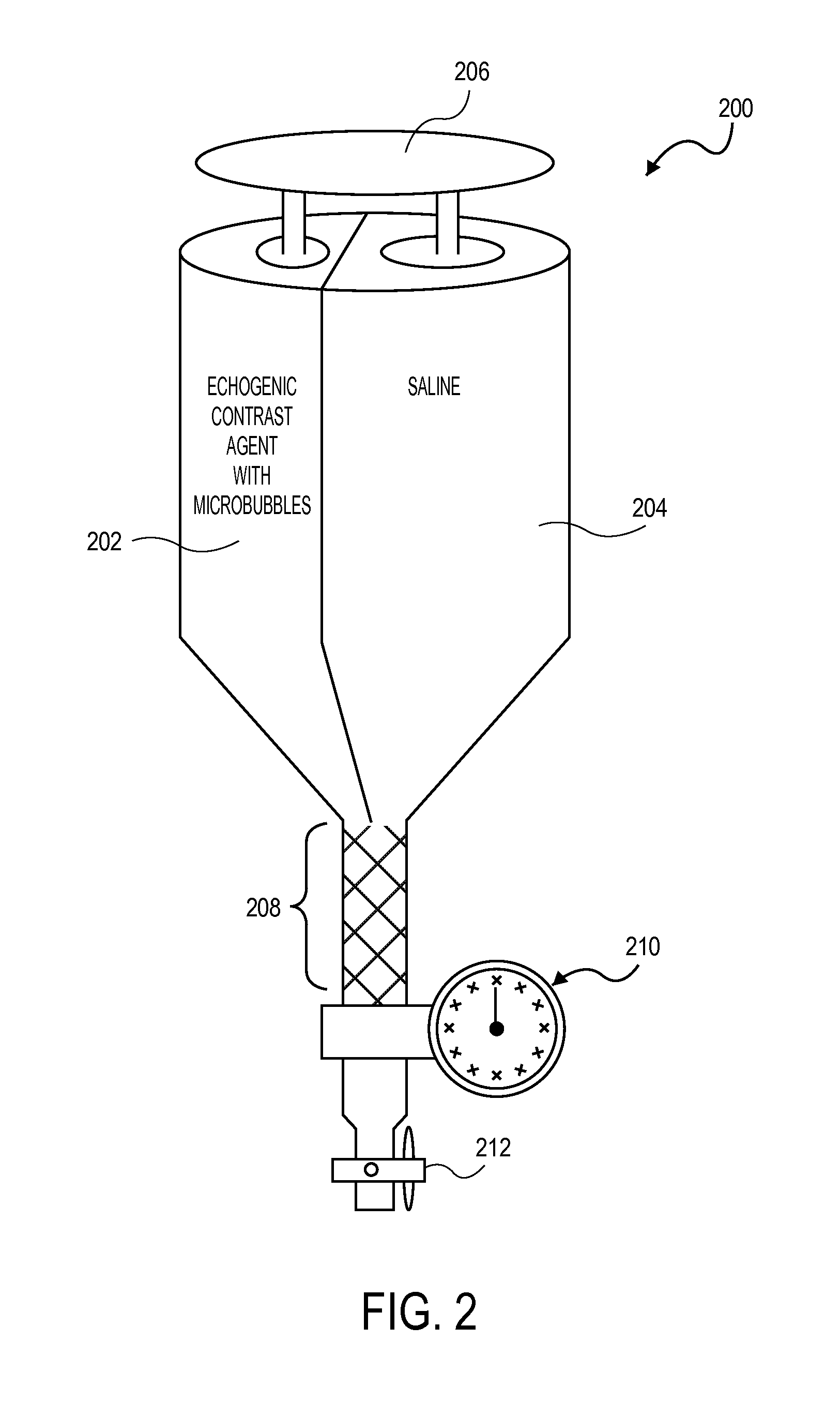

Methods and devices for determining lumen occlusion

InactiveUS20110137150A1Ultrasonic/sonic/infrasonic diagnosticsSurgeryMicrobubblesContrast enhance ultrasound

Embodiments of the present invention describe methods of determining the occlusion of body lumens and apparatuses for doing so. In one particular embodiment, the occlusion of the fallopian tubes by an intrafallopian contraceptive device may be confirmed by contrast enhanced ultrasonography (also known as stimulated acoustic emission hysterosalpingo-contrast sonography). In these embodiments a contrast agent containing microbubbles is used.

Owner:BAYER HEALTHCARE LLC

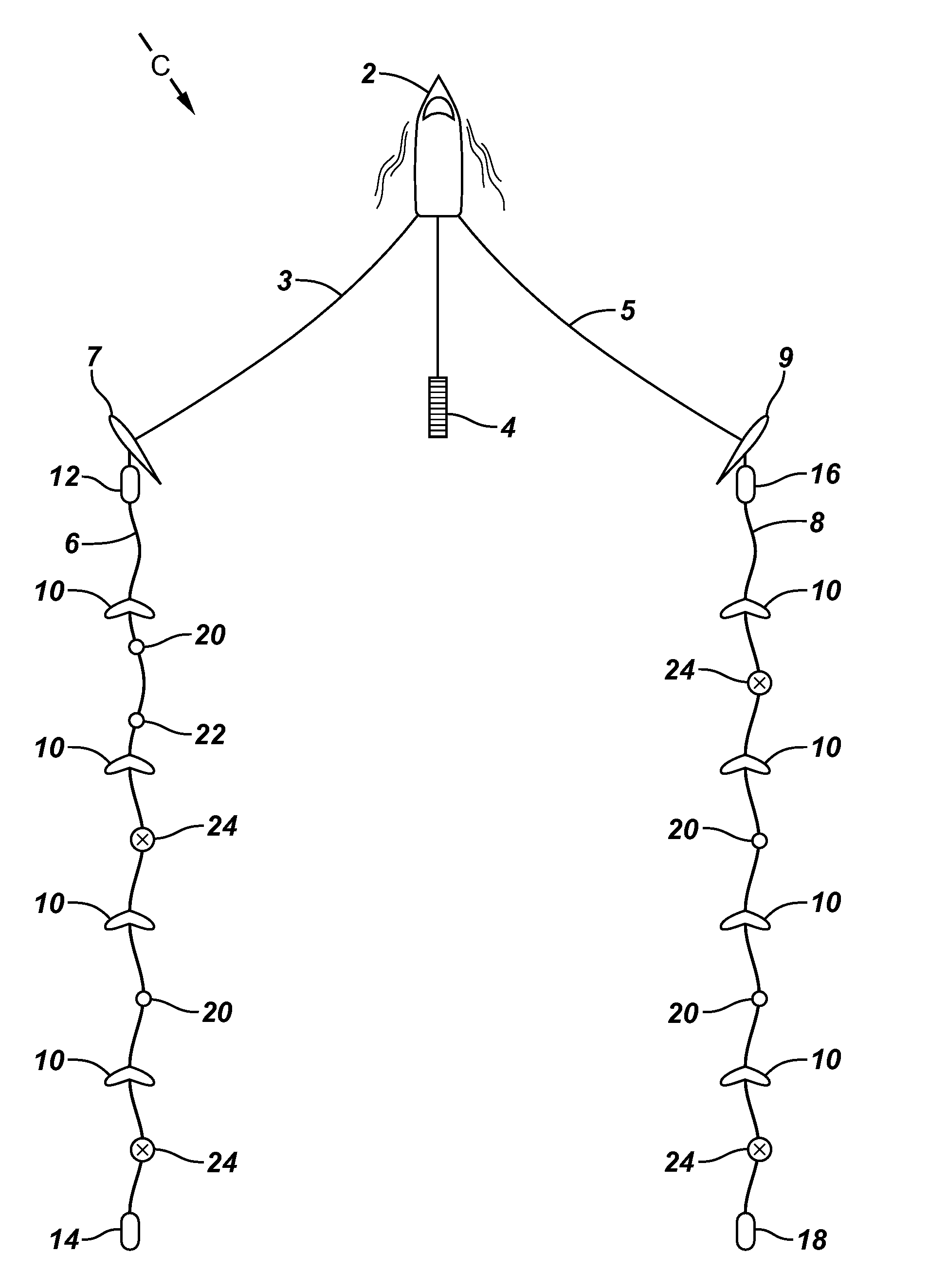

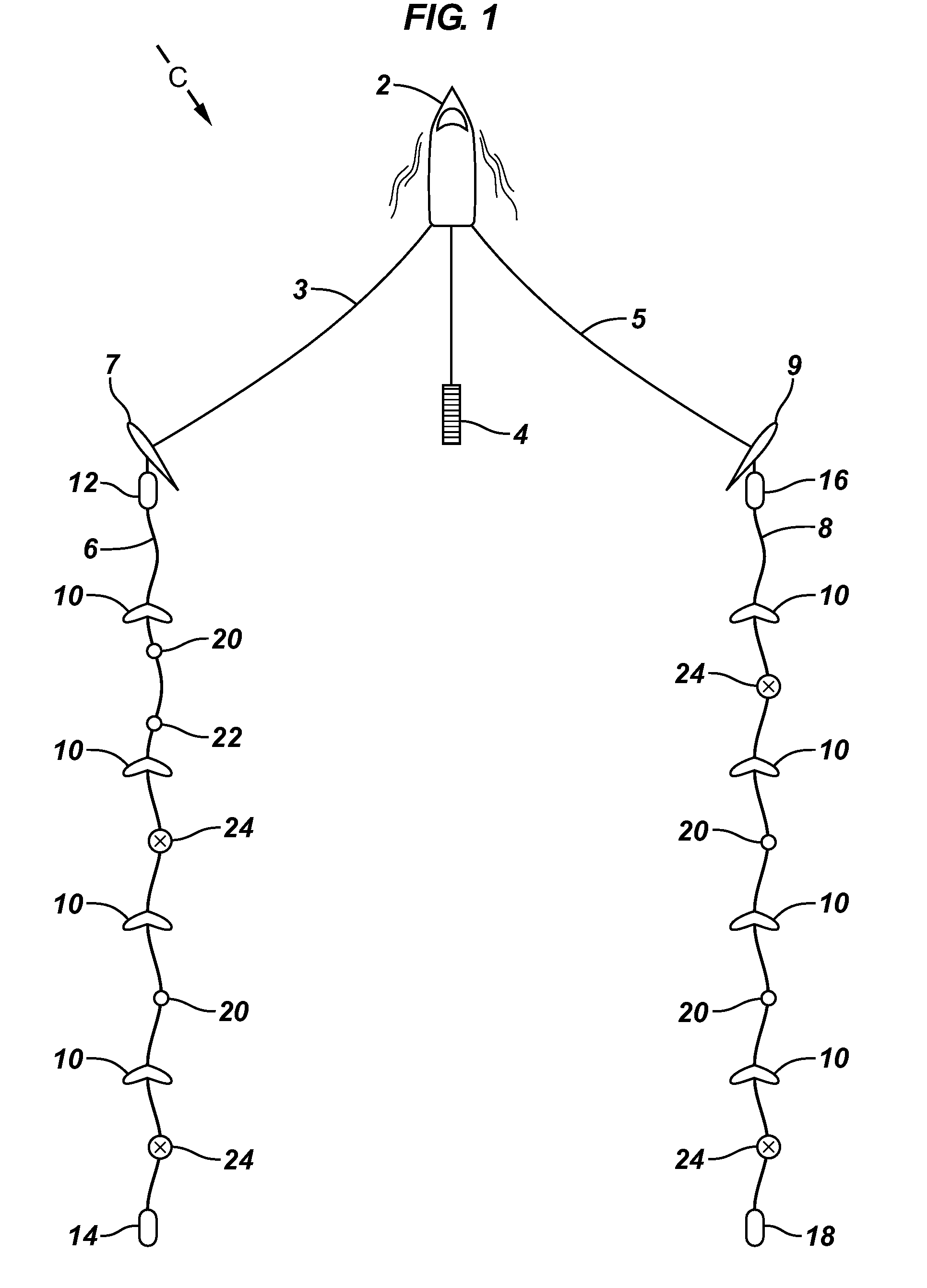

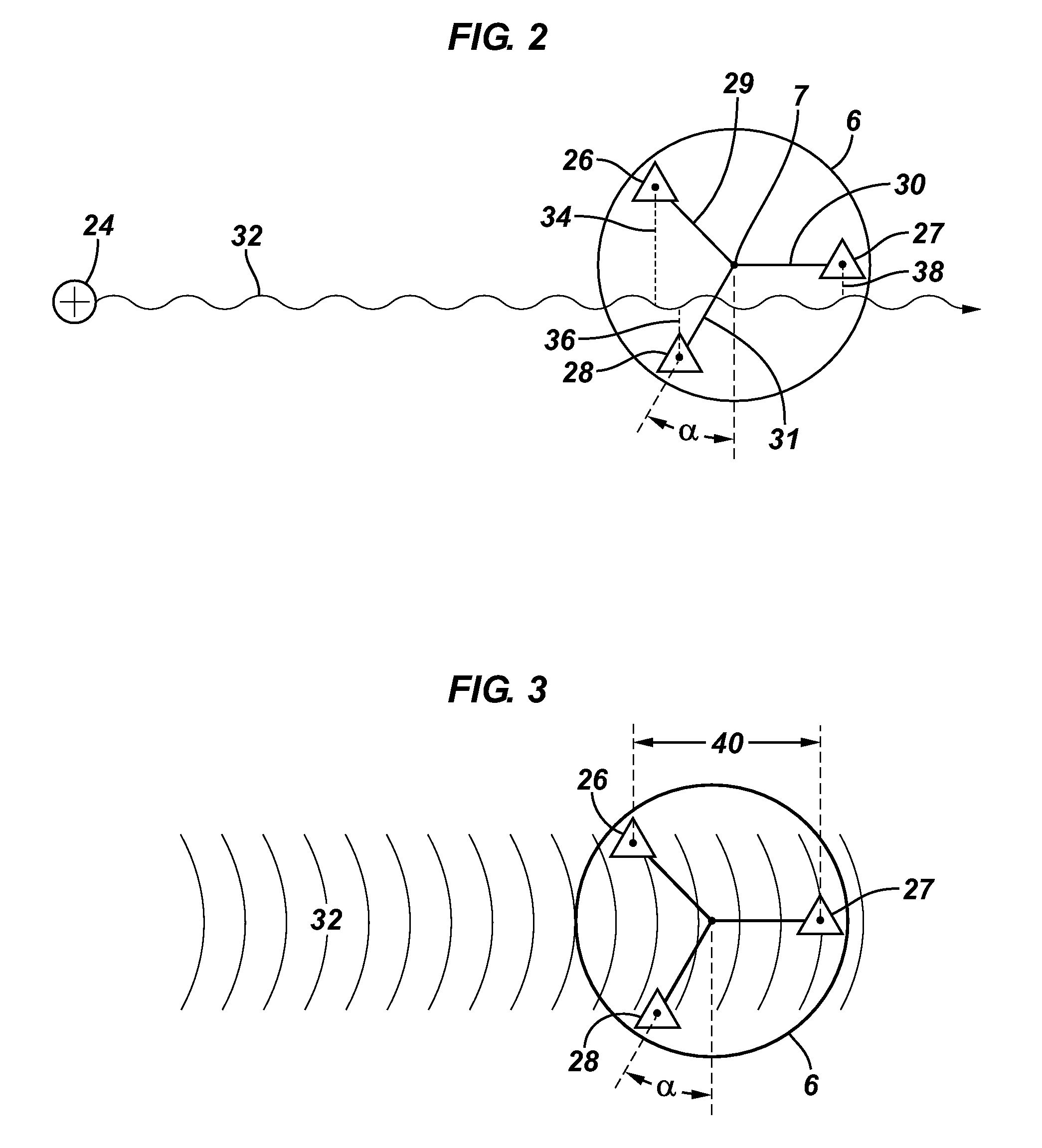

Methods and systems for determining orientation of seismic cable apparatus

InactiveUS20080025146A1Improve abilitiesImproved ghost separationDirection finders using ultrasonic/sonic/infrasonic wavesSeismology for water-covered areasSubject matterArrival time

Methods and systems for estimating one or more orientation parameters of a seismic apparatus are described. One method comprises initiating an acoustic signal from an acoustic transmitter in a marine seismic spread comprising a streamer, the streamer having at least two nodes separated by a fixed distance; measuring a first and a second difference in acoustic arrival times at the nodes for the acoustic signal; and using change in the second difference from the first difference to estimate orientation of the streamer. It is emphasized that this abstract is provided to comply with the rules requiring an abstract, which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:WESTERNGECO LLC

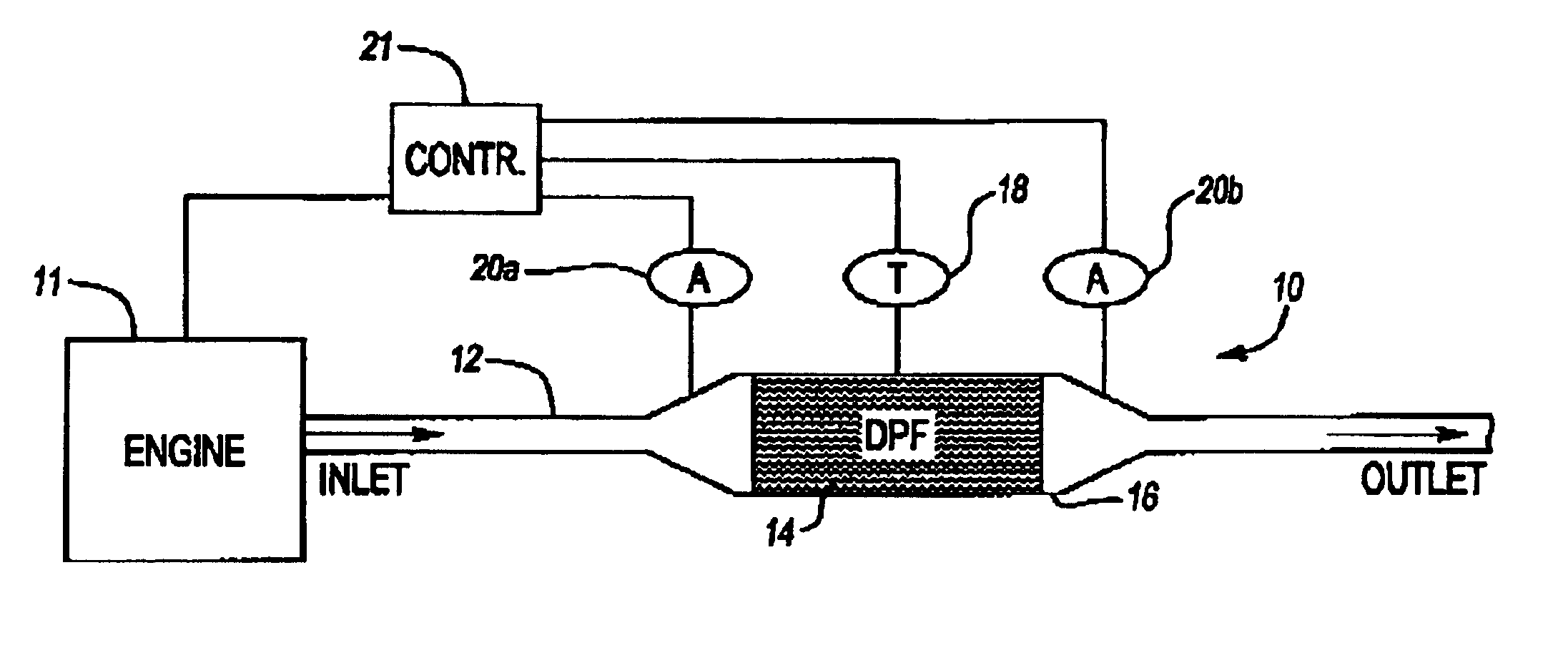

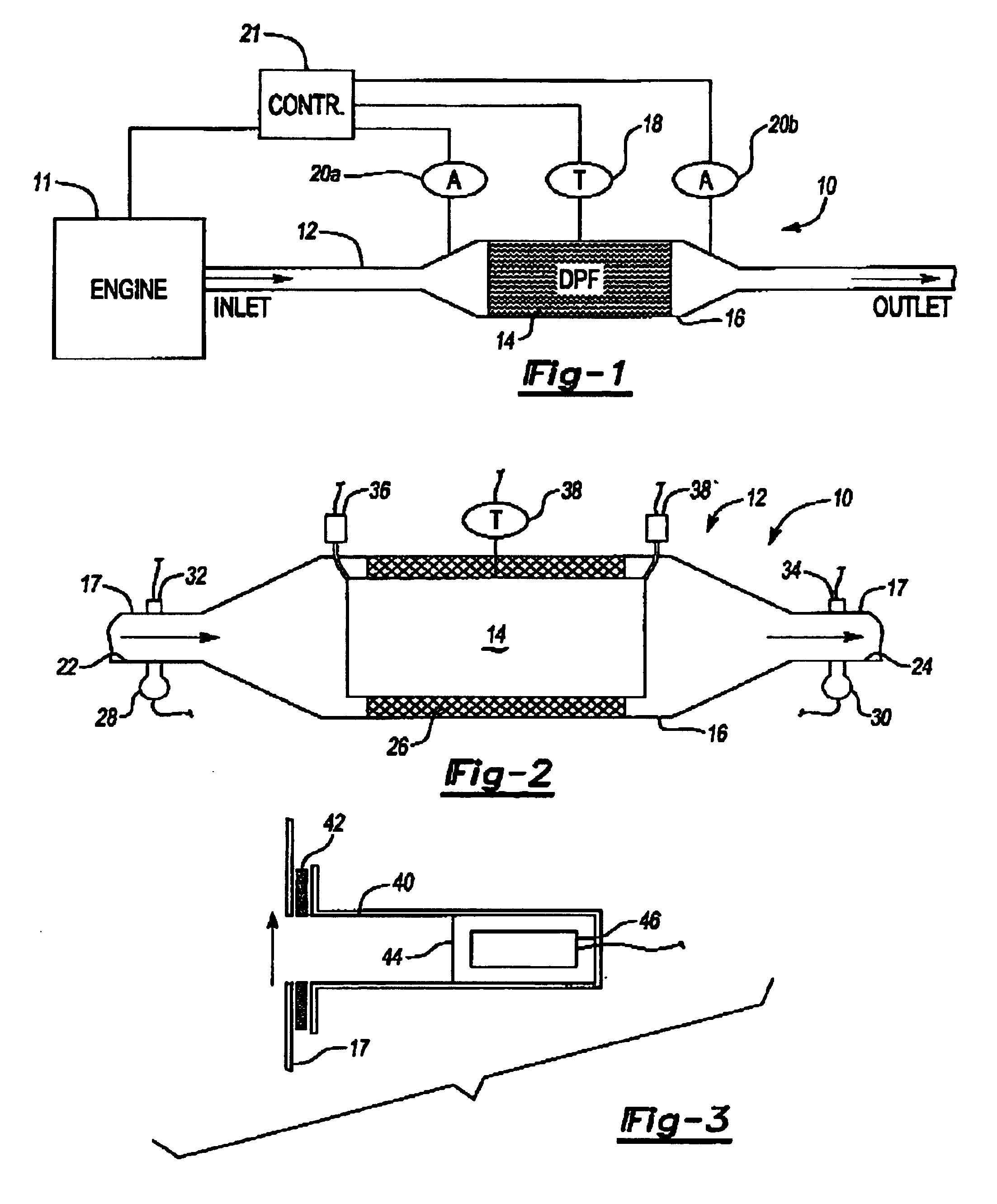

Diesel particulate filter monitoring using acoustic sensing

A particulate filter system is provided including an exhaust system transporting emissions from an engine. A filter such as a diesel particulate filter is disposed in the exhaust system. An acoustic sensor is associated with the exhaust system for detecting one or more frequencies passing through the filter. The frequency corresponds to a filter state indicative of a clean, full, loading, or failed filter. One or more acoustic sensors may fluidly or mechanically coupled to portions of the exhaust system to determine the frequency caused by the exhaust flow through the filter. The acoustic emissions from the filter may be used to compare to a known filter state to determine the present filter state. Alternatively, more sophisticated mathematical approaches may be used in which processed filter information is compared to a known filter state to determine the present filter state.

Owner:AVL NORTH AMERICA

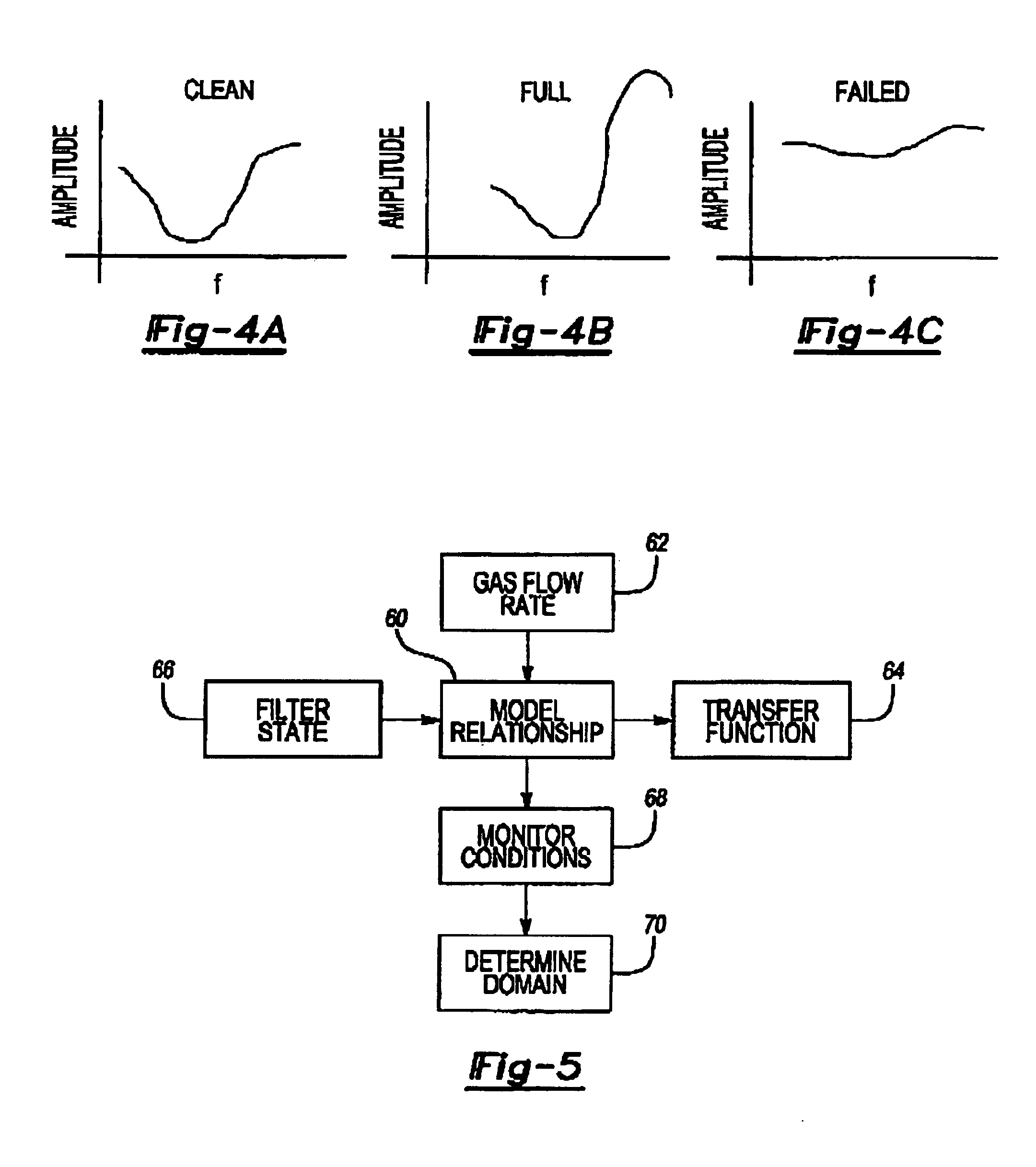

System for damage location using a single channel continuous acoustic emission sensor

InactiveUS7075424B1Material analysis using acoustic emission techniquesProcessing detected response signalSensor arrayElectricity

A sensor array for non-destructively monitoring a structure to detect a critical structural event. The sensor array includes a plurality of discrete sensor nodes, each of the discrete sensor nodes producing an electrical signal in response to a structural event. A signal adder is electrically connected to the plurality of discrete sensor nodes for receiving and combining the electrical signal from each of the discrete sensor nodes to form a single sensor array output signal. A signal processing module then receives and processes the single sensor output signal. In the preferred embodiment, the signal processing module uses the time interval between the electrical signals from each of the discrete sensor nodes formed into a single sensor array output signal to calculate the location of the critical structural event. Also, in the preferred embodiment, a data collection system is located downstream of the sensor processing module.

Owner:NORTH CAROLINA AT&T STATE UNIV

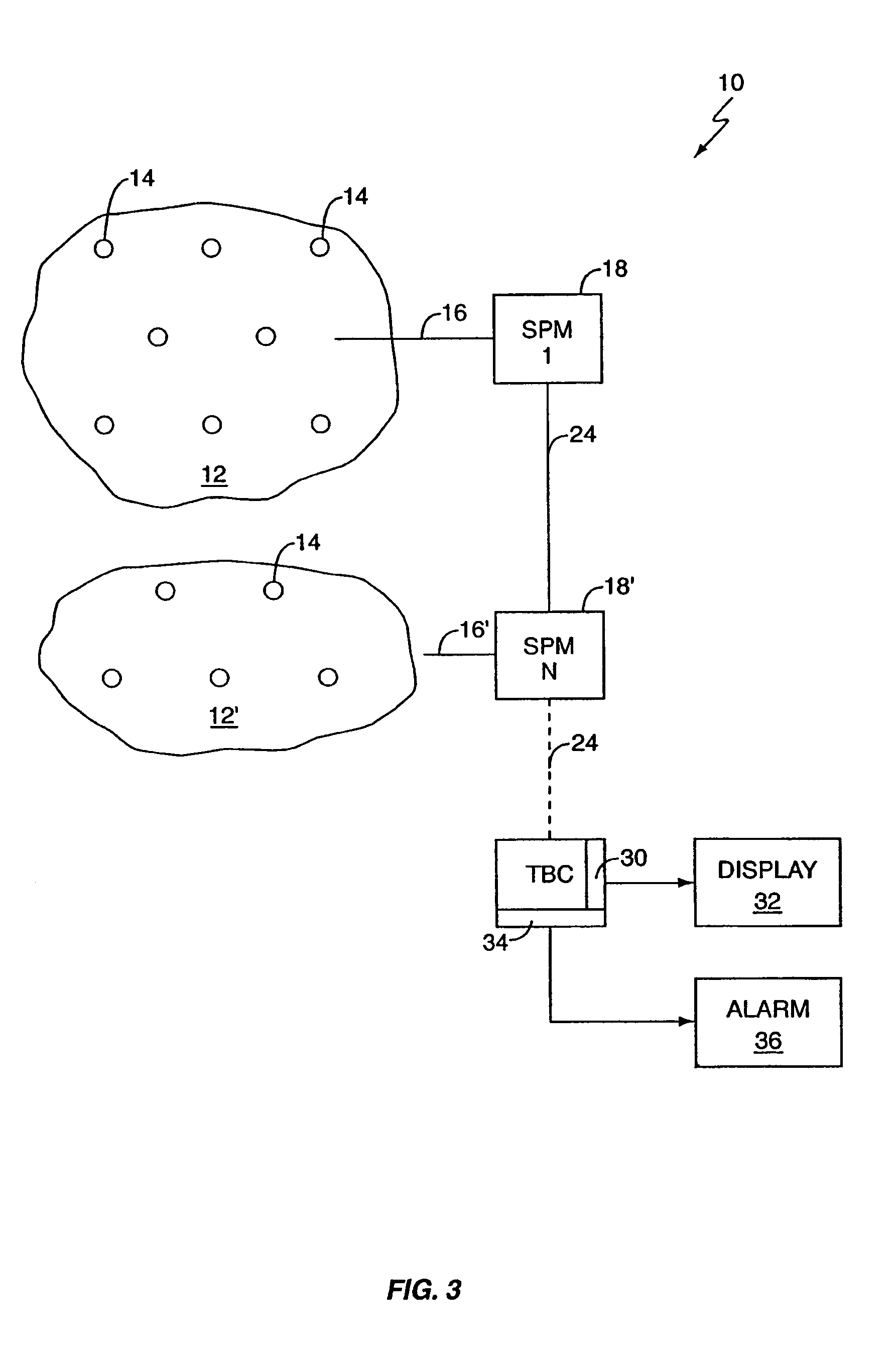

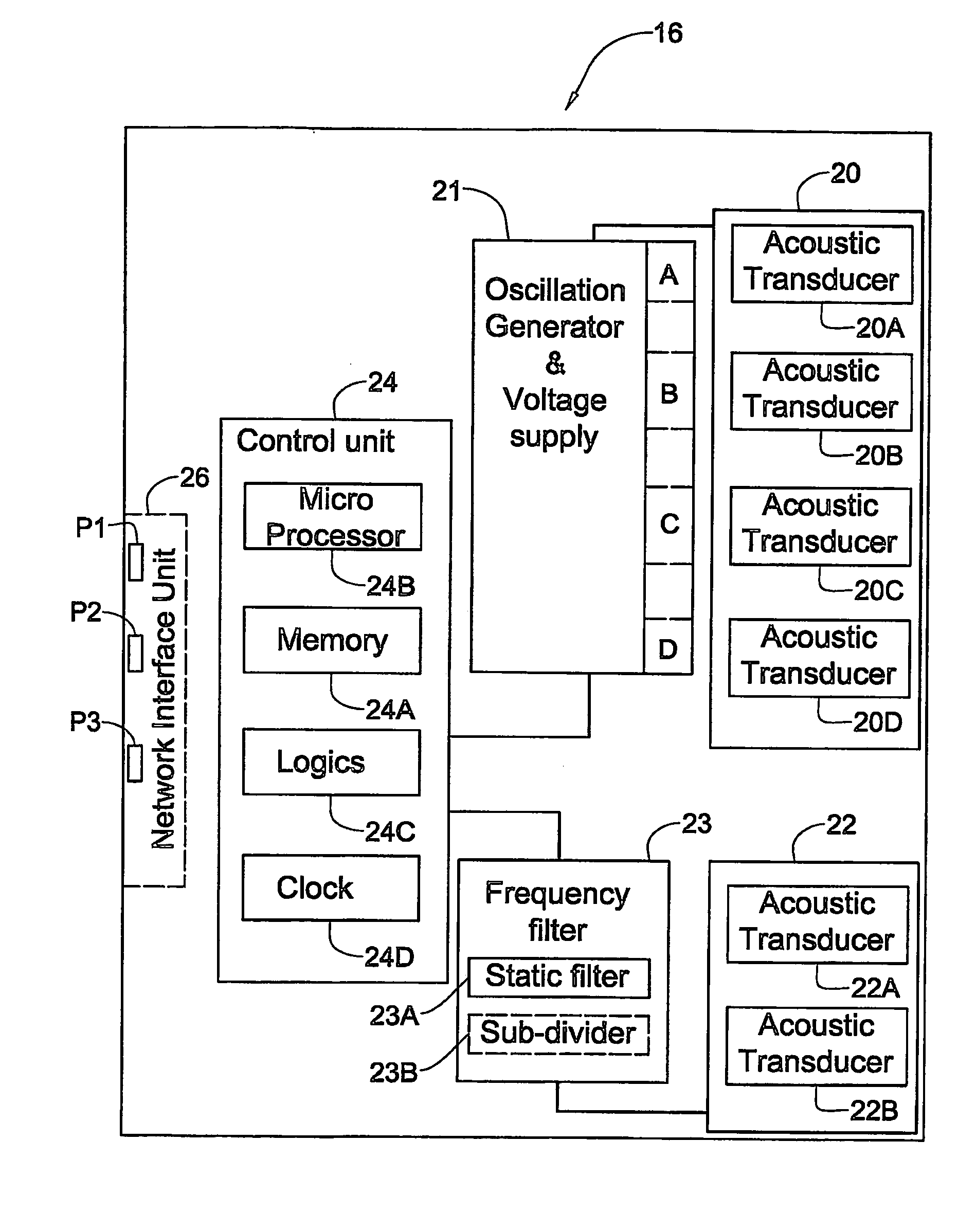

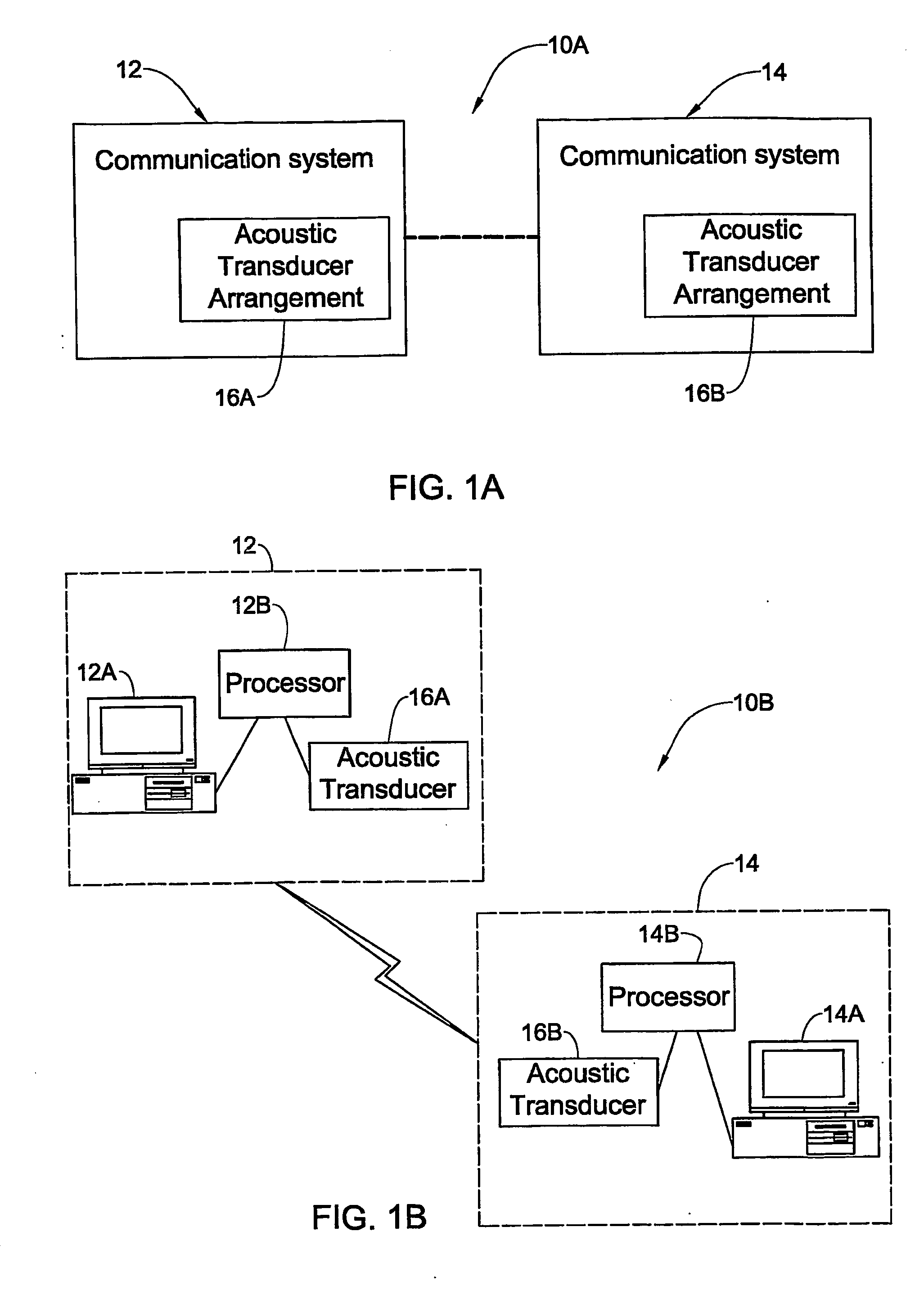

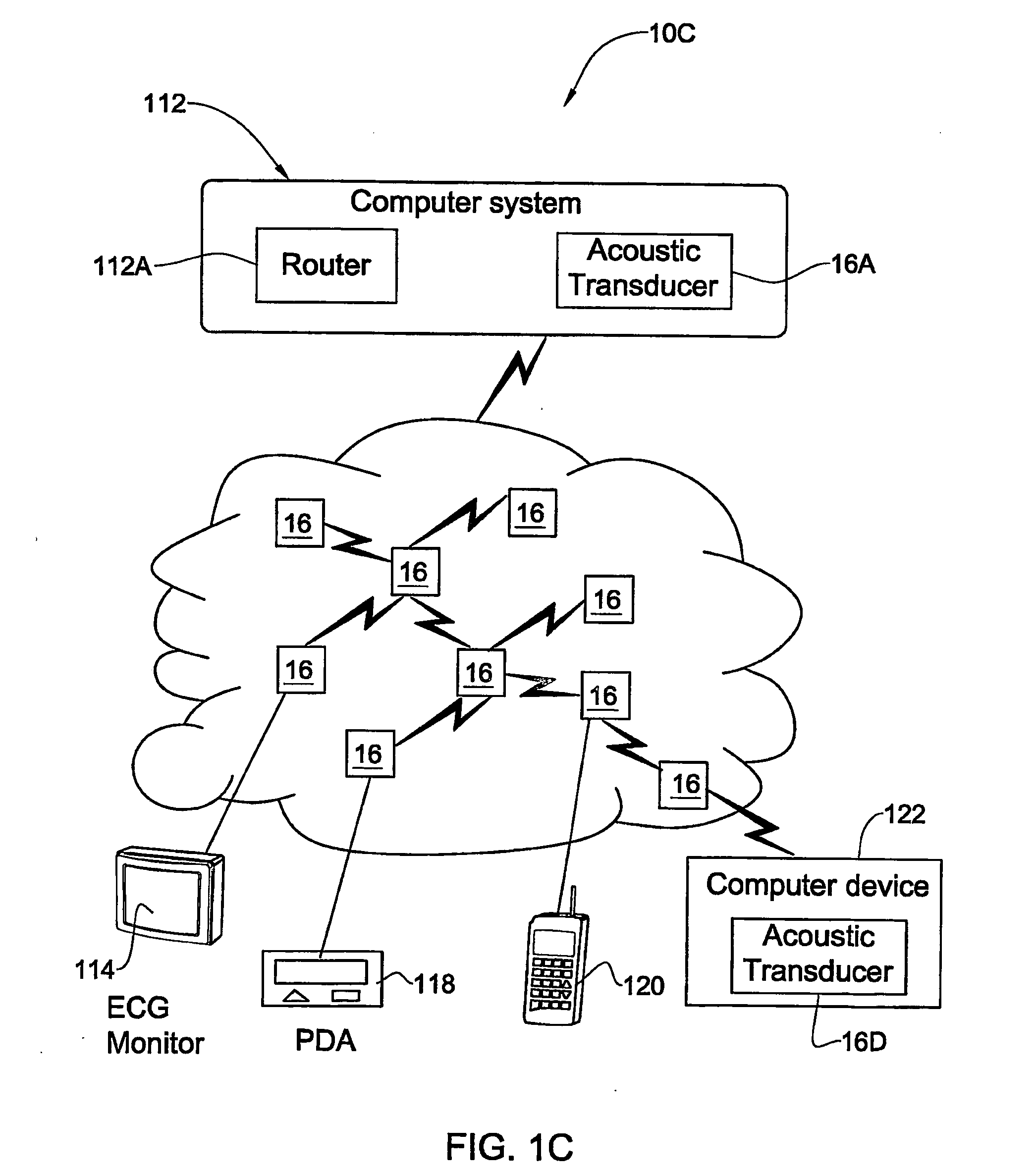

Method and system for acoustic communication

InactiveUS20060193270A1Facilitate communicationFast transferSonic/ultrasonic/infrasonic transmissionTime-division multiplexDigital dataData stream

An acoustic transducer arrangement and system and method utilizing the same are presented. The acoustic transducer arrangement includes: an acoustic transmitter assembly including an array of transmitter elements operable to generate together a multi-frequency acoustic signal; and a control unit preprogrammed to operate the acoustic transmitter assembly in accordance with digital data stream indicative of a received signal to generate the multi-frequency acoustic signal indicative of the received signal.

Owner:MEDIT MEDICAL INTERACTIVE TECH

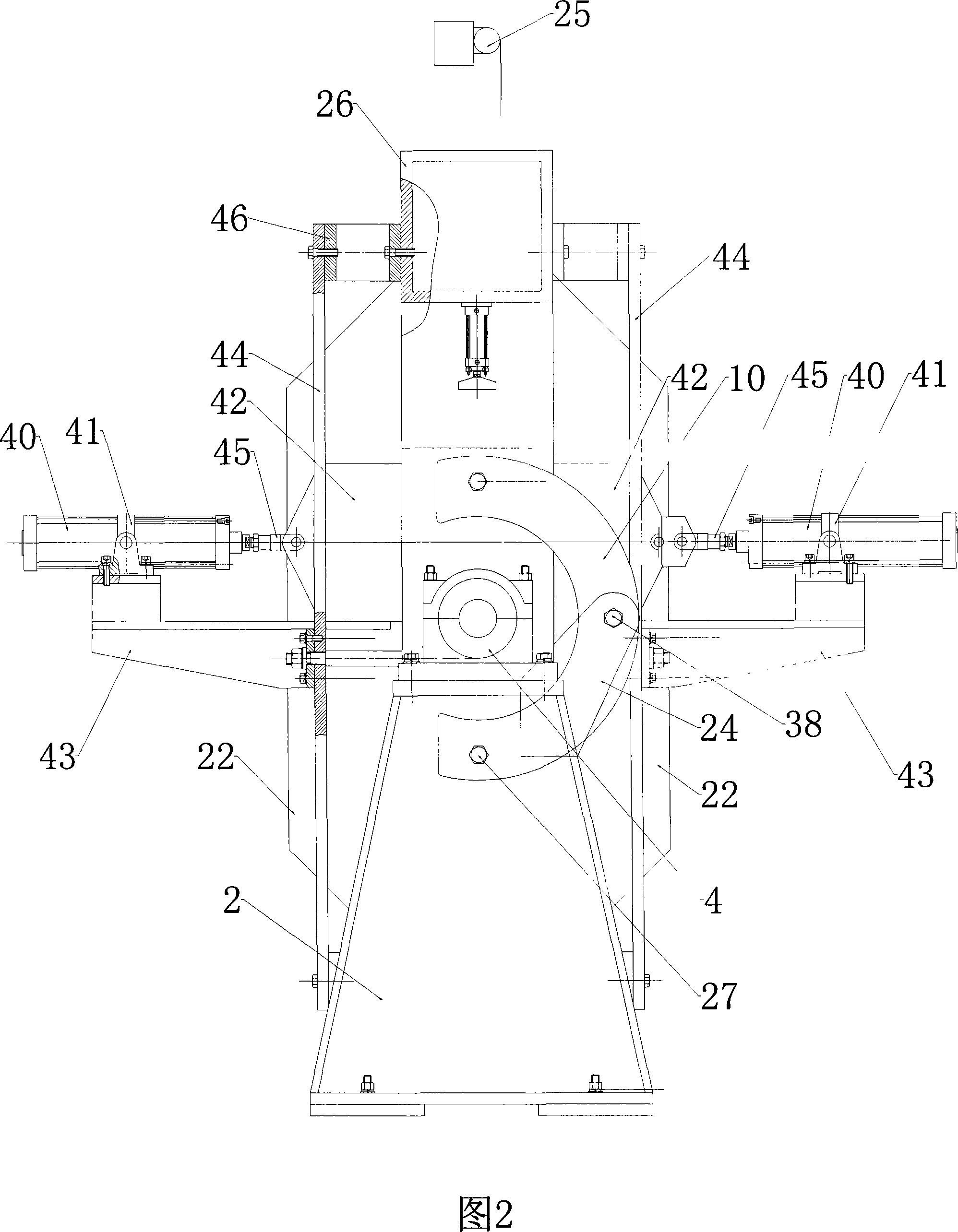

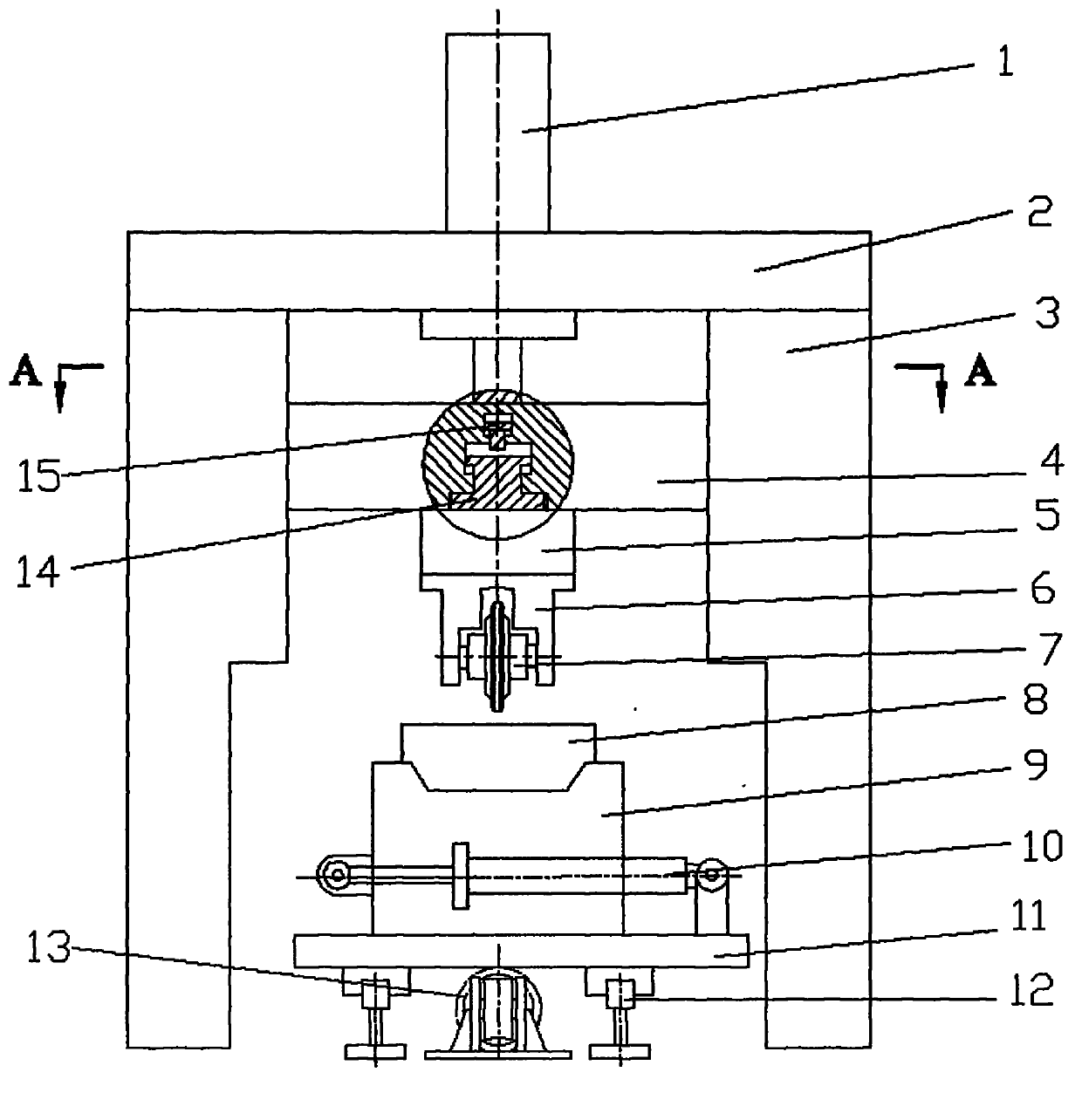

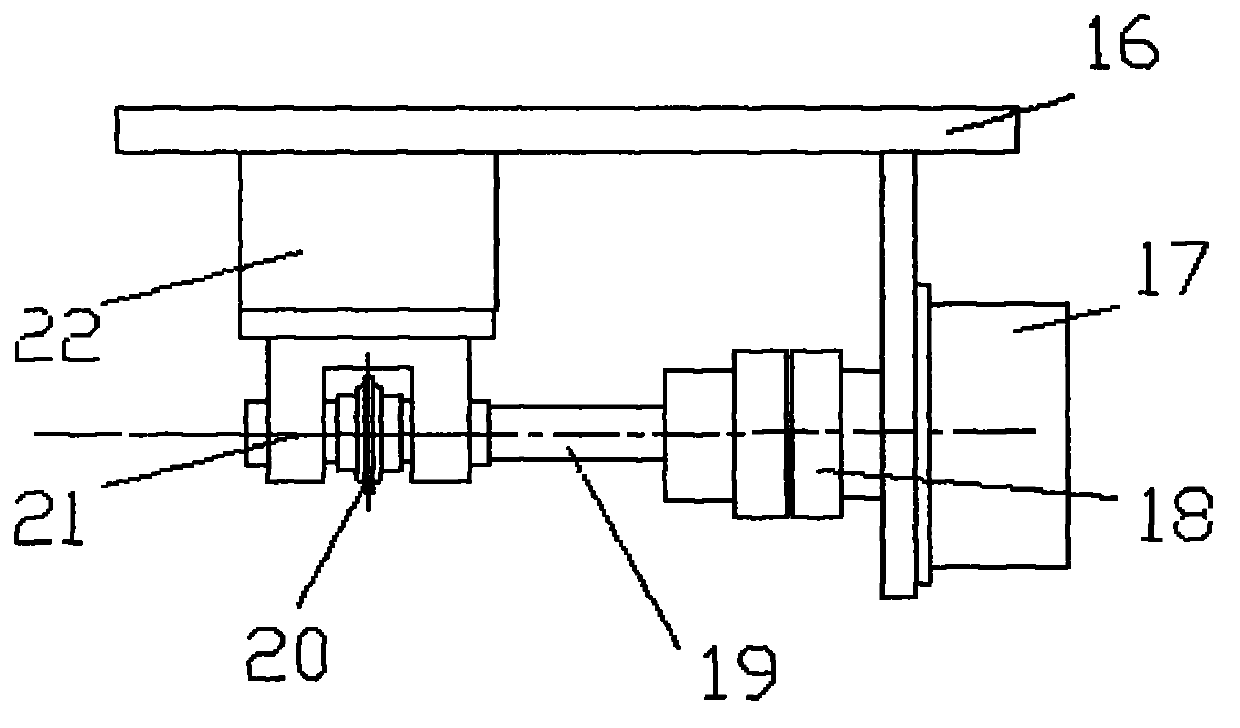

Microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method

ActiveCN107748110AOvercoming direct shear-seepageEasy to disassembleMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAxial pressureData acquisition

A microcomputer-controlled electro-hydraulic servo rock tri-axial dynamic shear-seepage coupling multifunctional test method belongs to the technical fields of rock mechanics and engineering technology and is characterized in that a test apparatus is composed of a loading system, a sealing system, a multiphase fluid injection system, an acoustic emission monitoring system, a deformation monitoringsystem and a data collection system. The test method not only solves technical problems that a tri-axial pressure chamber cannot be used for performing large displacement shear-seepage coupling of rocks under high confining pressure and high seepage pressure, and also can achieve various extended functions on the basis of the technology. The apparatus can achieve servo control loading of force, displacement and strain rate in shear direction and injection seepage of a multiphase fluid during dynamic shear. In addition, the apparatus is equipped with a temperature control system for performingconstant temperature control to the tri-axial pressure chamber at 0-200 DEG C; therefore, a series of extended experiments of dynamic shear-seepage coupling features of rocks under effect of temperature can be carried out.

Owner:TAIYUAN UNIV OF TECH

Ultrasonic transmitting/receiving apparatus and scanning sonar employing same

ActiveUS20060013066A1Avoid interferenceShorten the construction periodUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonarAcoustic emission

An ultrasonic apparatus is disclosed that includes a transducer having a plurality of transducer elements, a controller operatively connected to the transducer and driving the transducer elements to produce a first ultrasonic transmitting beam having a first frequency and a second ultrasonic transmitting beam having a second frequency; and a processor operatively connected to said transducer for forming and moving reception beams to receive echo signals and extracting frequency components corresponding to said first ultrasonic transmitting beam and said second ultrasonic transmitting beam.

Owner:FURUNO ELECTRIC CO LTD

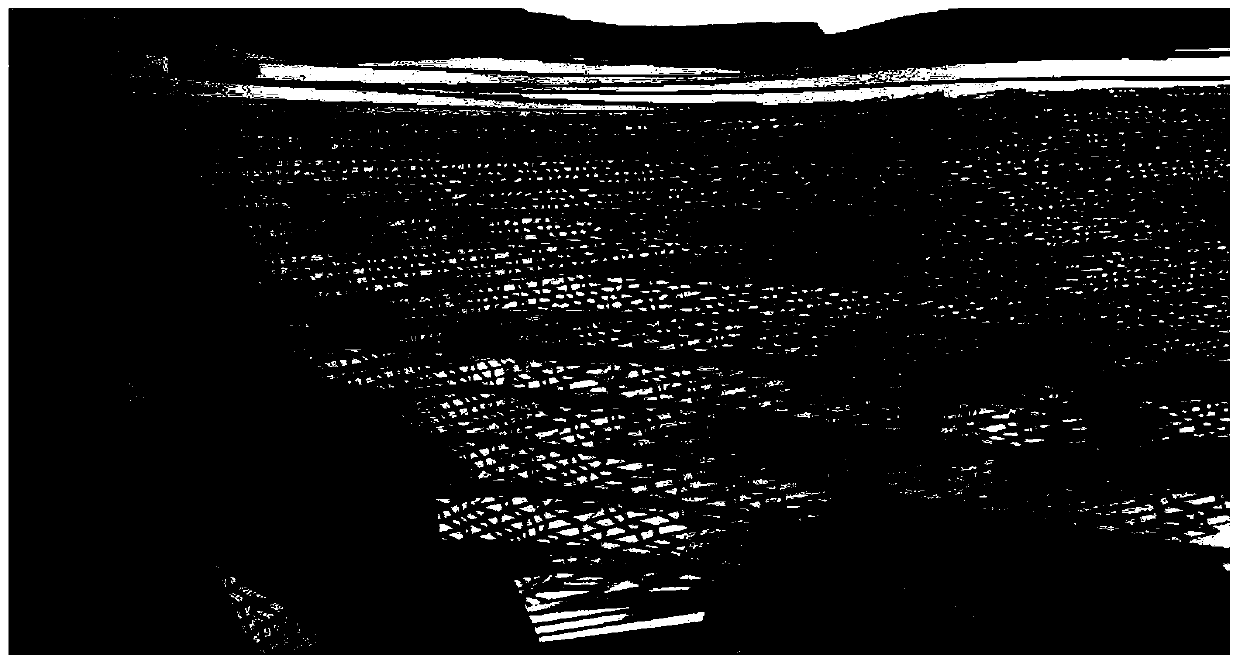

Multi-factor coupling on-line monitoring system and multi-factor coupling on-line monitoring system method for slope safety

The invention provides a multi-factor coupling on-line monitoring system and a multi-factor coupling on-line monitoring system method for slope safety. The monitoring system comprises a data acquisition unit, a wireless communication module, a data information receiving unit and a data analysis and processing unit. The data analysis and processing unit comprises a threshold value analysis unit, a data storage unit, a video viewing unit, an intelligent expert judgment system and an early warning unit. Multi-information coupling analysis and processing is performed by the intelligent expert judgment system. According to the system and the method provided by the invention, a rainfall, displacement and stress monitoring method and an acoustic emission method for monitoring internal damage of a slope are organically combined to dynamically monitor the whole process of slope instability from different angles, and comprehensive judgment is performed through the intelligent expert judgment system, and therefore, the monitoring accuracy of the slope safety is greatly improved.

Owner:MAANSHAN NANSHAN DEV +1

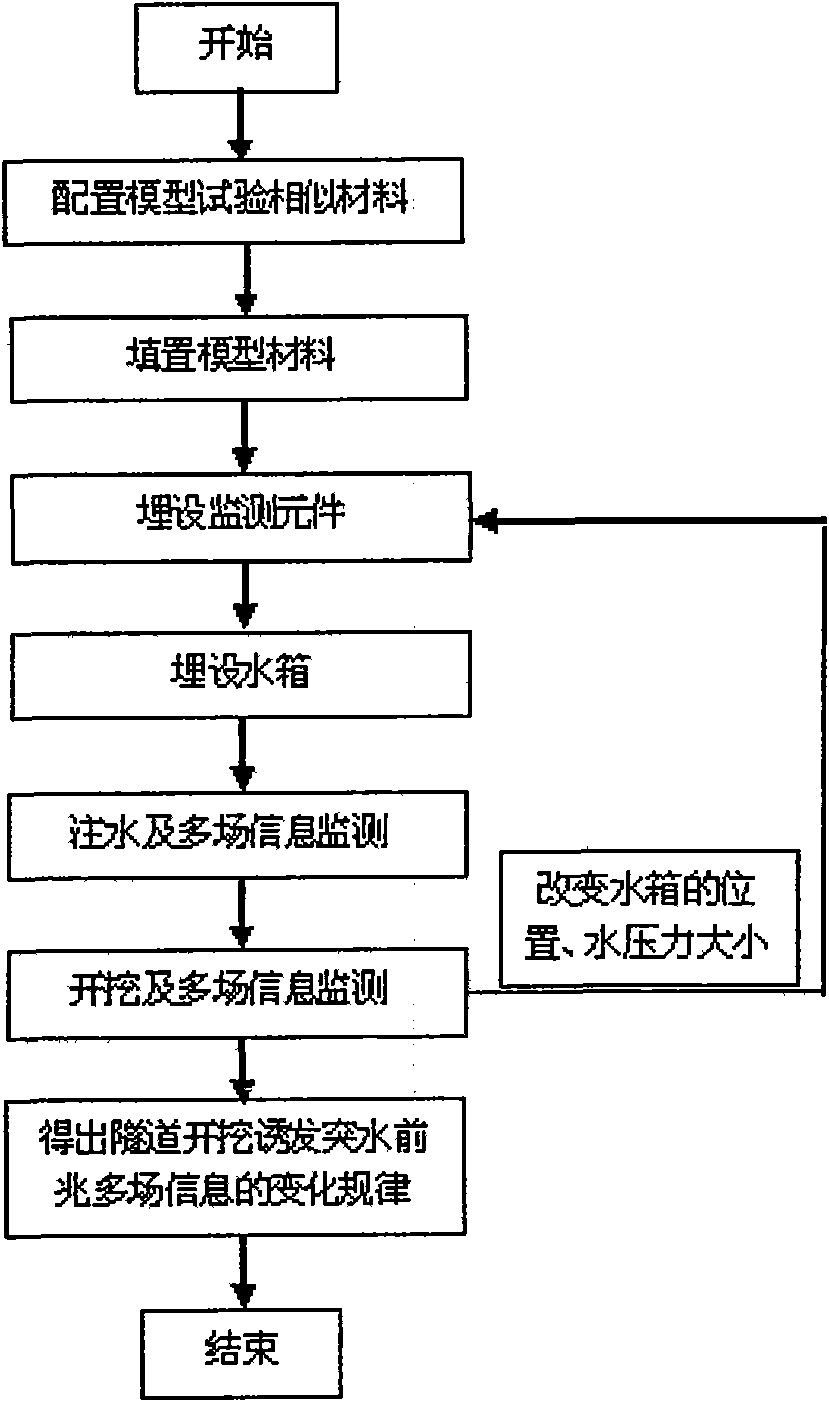

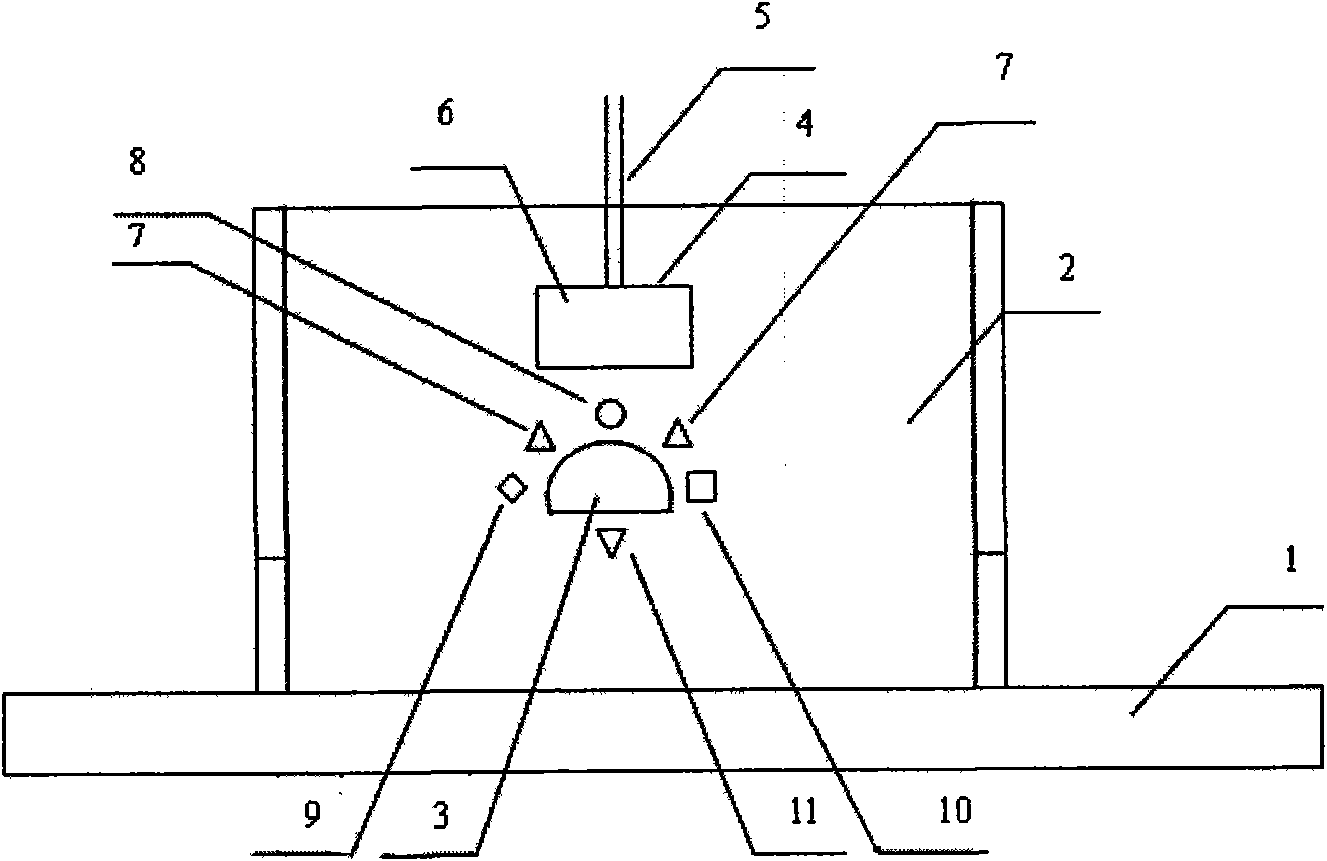

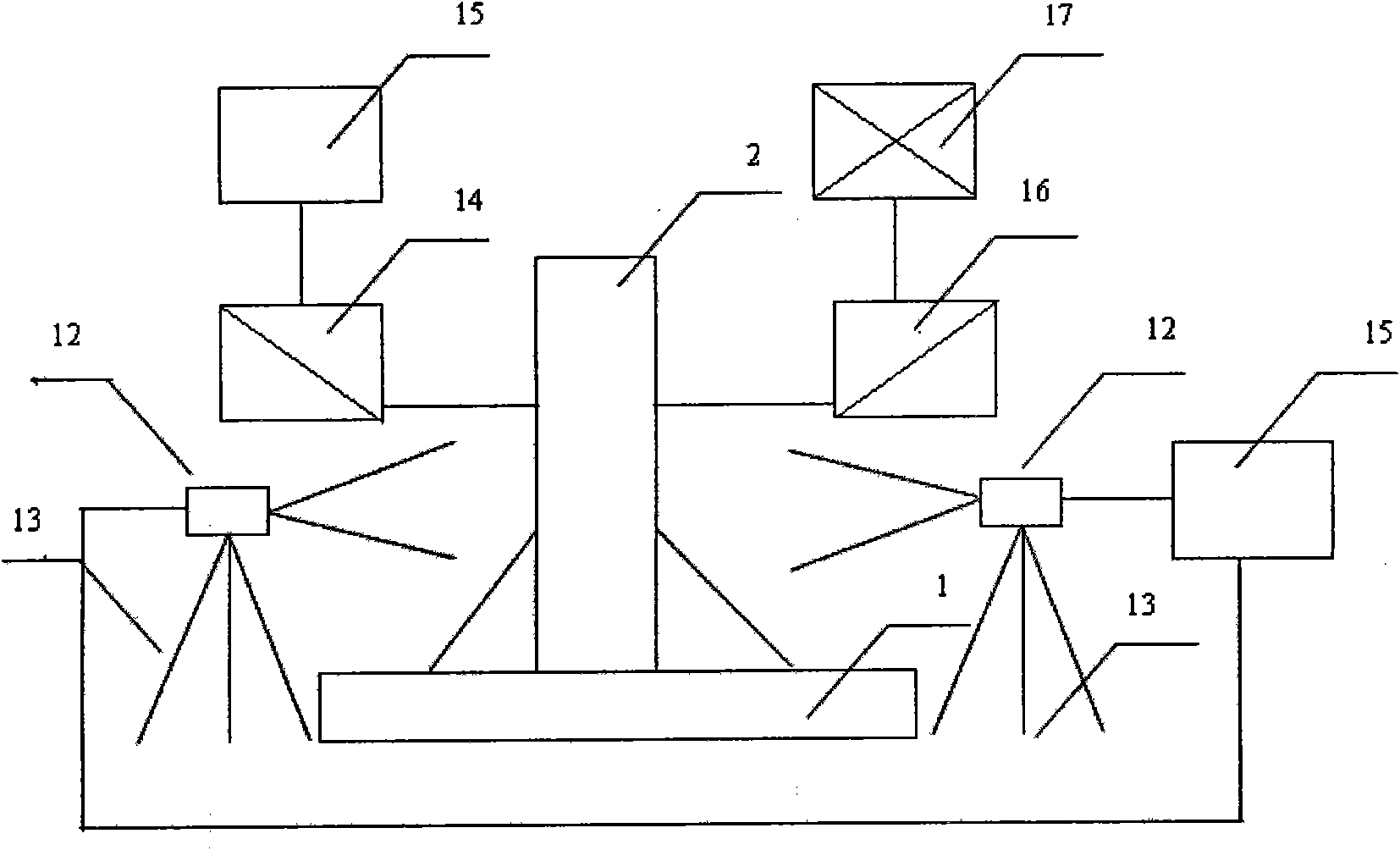

Test method of karst water burst when tunneling and monitor device thereof

InactiveCN101625352ARealize real-time monitoringComprehensive collection of dataMaterial analysisFiberMulti field

The invention discloses a test method of karst water burst when tunneling, comprising the following steps of: preparing materials; filling materials; embedding elements; embedding a water tank; injecting water and monitoring, tunneling and monitoring, etc. The invention further discloses a monitor device used for the test method of the karst water burst when tunneling, comprising a module frame fixed on a base, a preset water tank, a water pressure loading mechanism, a stress field monitoring mechanism, a deformation field monitoring mechanism, a temperature field monitoring mechanism, a seepage field monitoring mechanism, an acoustic emission field monitoring mechanism, a module surface displacement deformation observing mechanism, a module deformation and water burst observing mechanismin tunnels after tunneling, a fiber demodulation device and a computer. The invention simultaneously can research the change regularity of premonitory multi field information which induces the water burst when tunneling at different water body containing positions and under different water pressure conditions, has wide application, high reliability, abundant collecting data, high test precision, etc.

Owner:SHANDONG UNIV

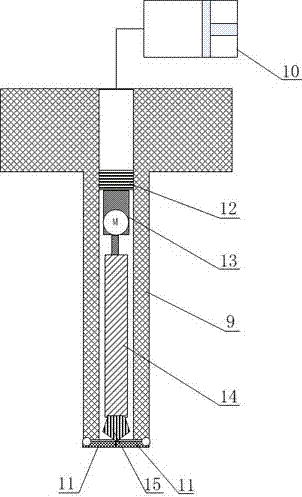

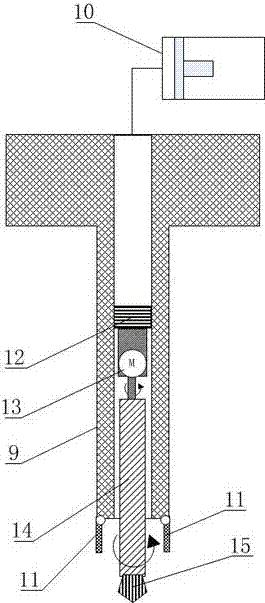

Multifunctional drill bit rock breaking experiment device and method capable of testing triaxial strength parameter of rock

ActiveCN107505207AIncrease profitShort timeMaterial strength using tensile/compressive forcesStress–strain curveRock sample

The invention discloses a multifunctional drill bit rock breaking experiment device capable of testing the triaxial strength parameter of rock. The device comprises a main body device, a pressure head structure, a confining pressure system, an acoustic emission system, a temperature control system and a pore material injection system. The device has the benefits as follows: the real temperature, crustal stress and pore pressure of a stratum can be simulated in a closed environment, a triaxial mechanical test and a drill bit rock breaking test can be completed simultaneously, a stress-strain curve of a rock sample, dynamic vibration of a drill bit and a drill column, bit pressure and influences of footage on the rock sample can be determined, an experiment basis is provided for research of mechanical properties of complex oil and gas reservoirs and drill bit rock breakage under multiple conditions, a rock breaking experiment can be conducted while conventional mechanical properties of the rock are tested, two experiments can be completed once after the designed temperature and pressure conditions are met, the total time consumption is reduced, and the utilization rate of underground rock cores can be effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

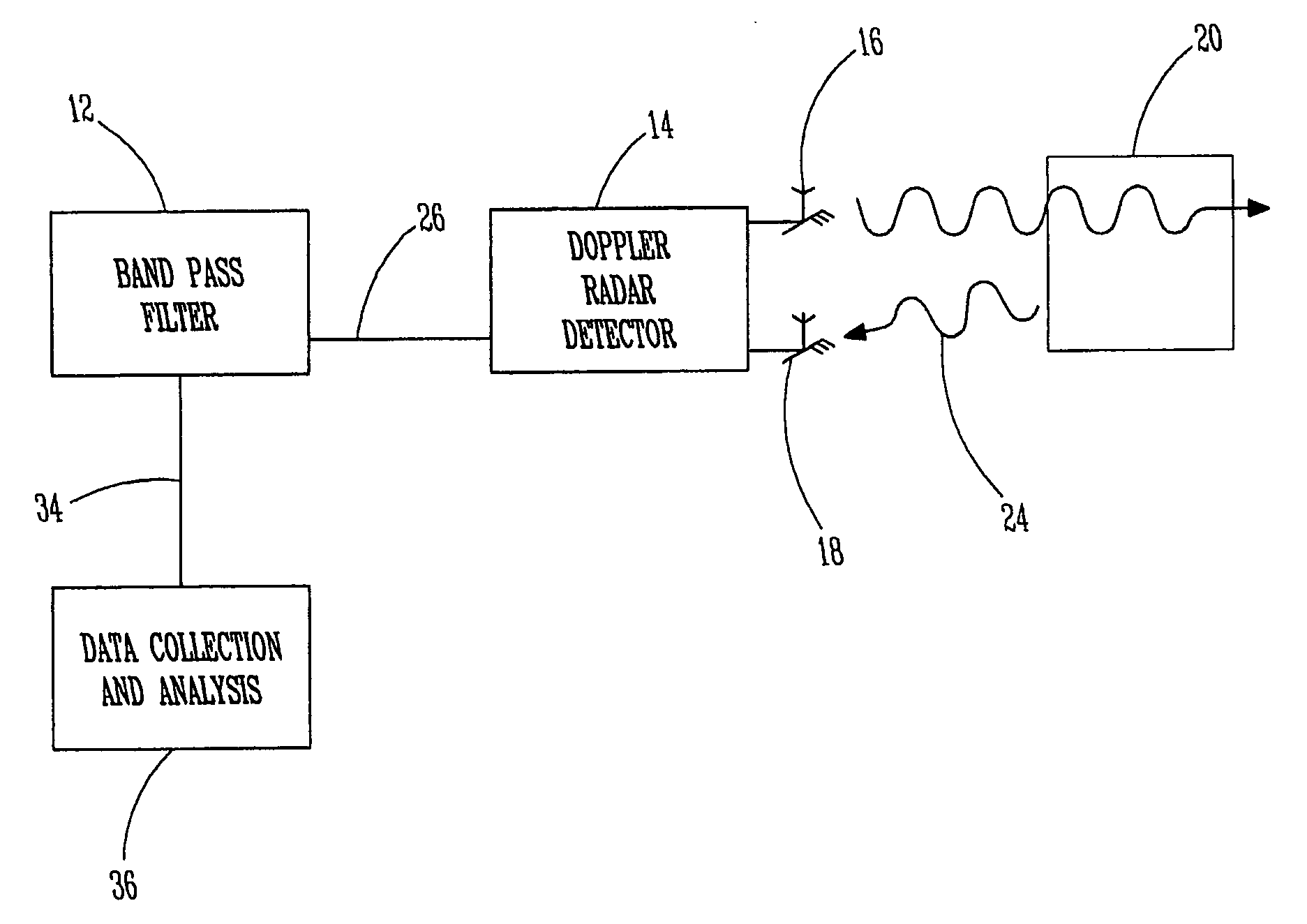

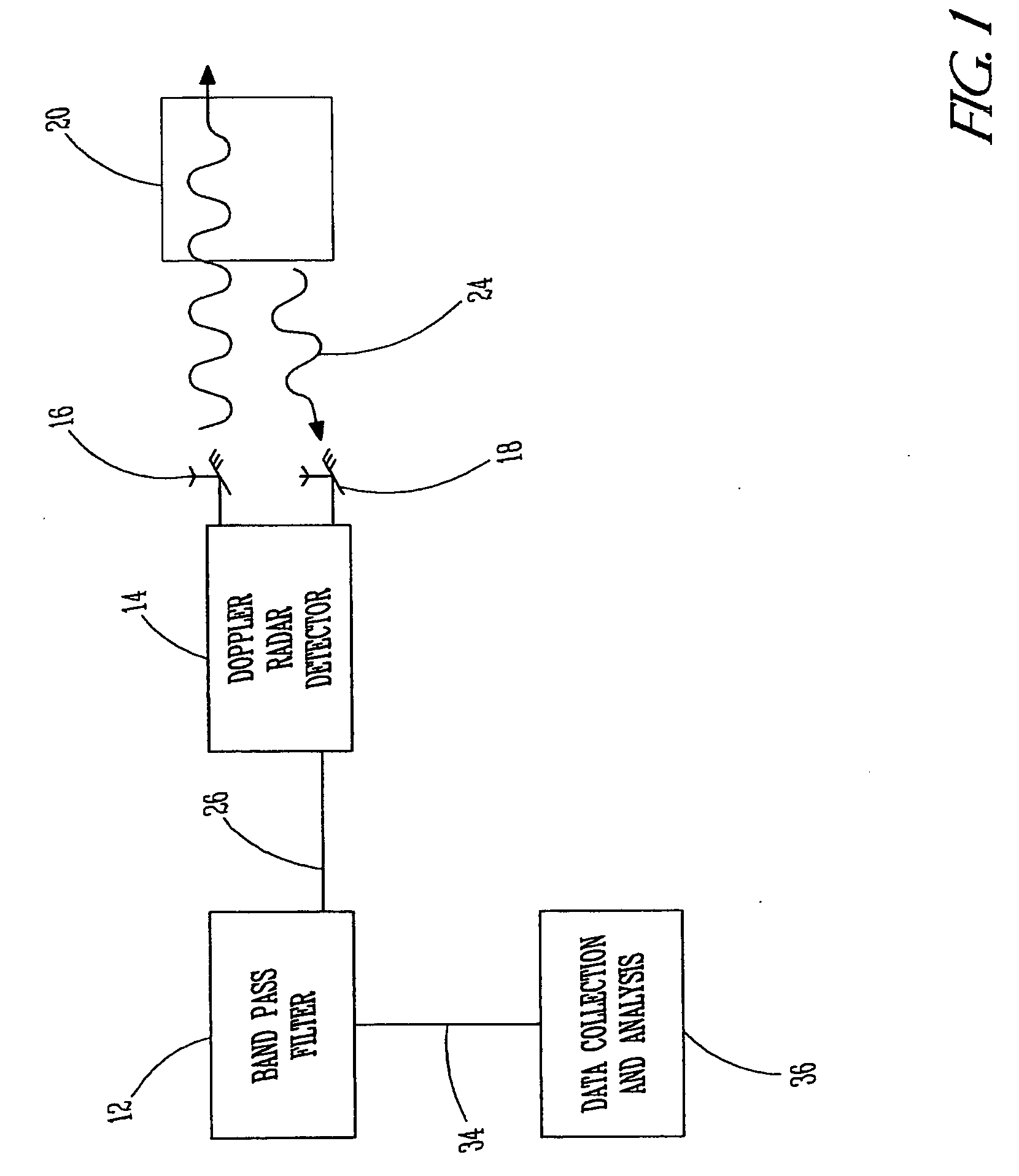

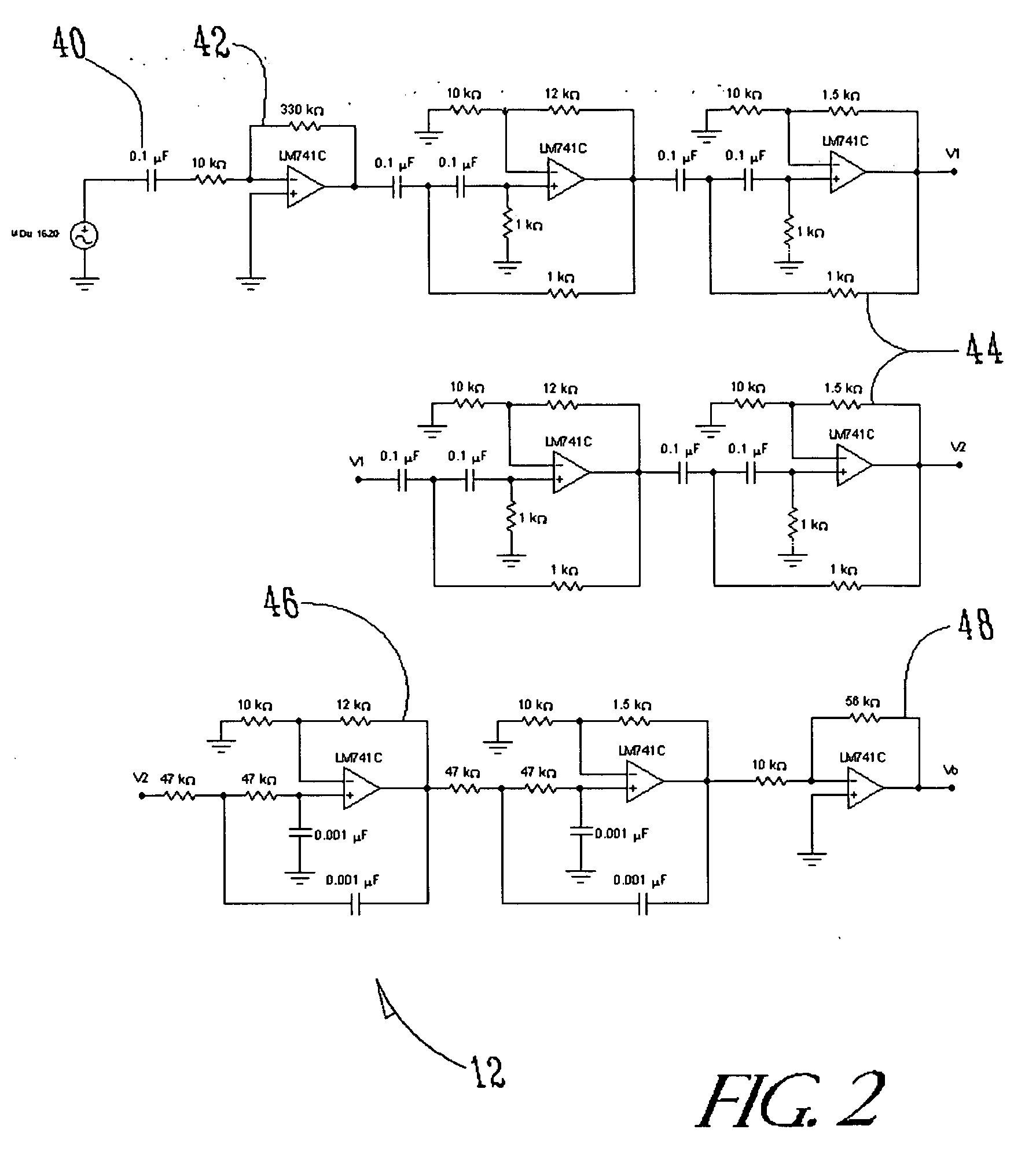

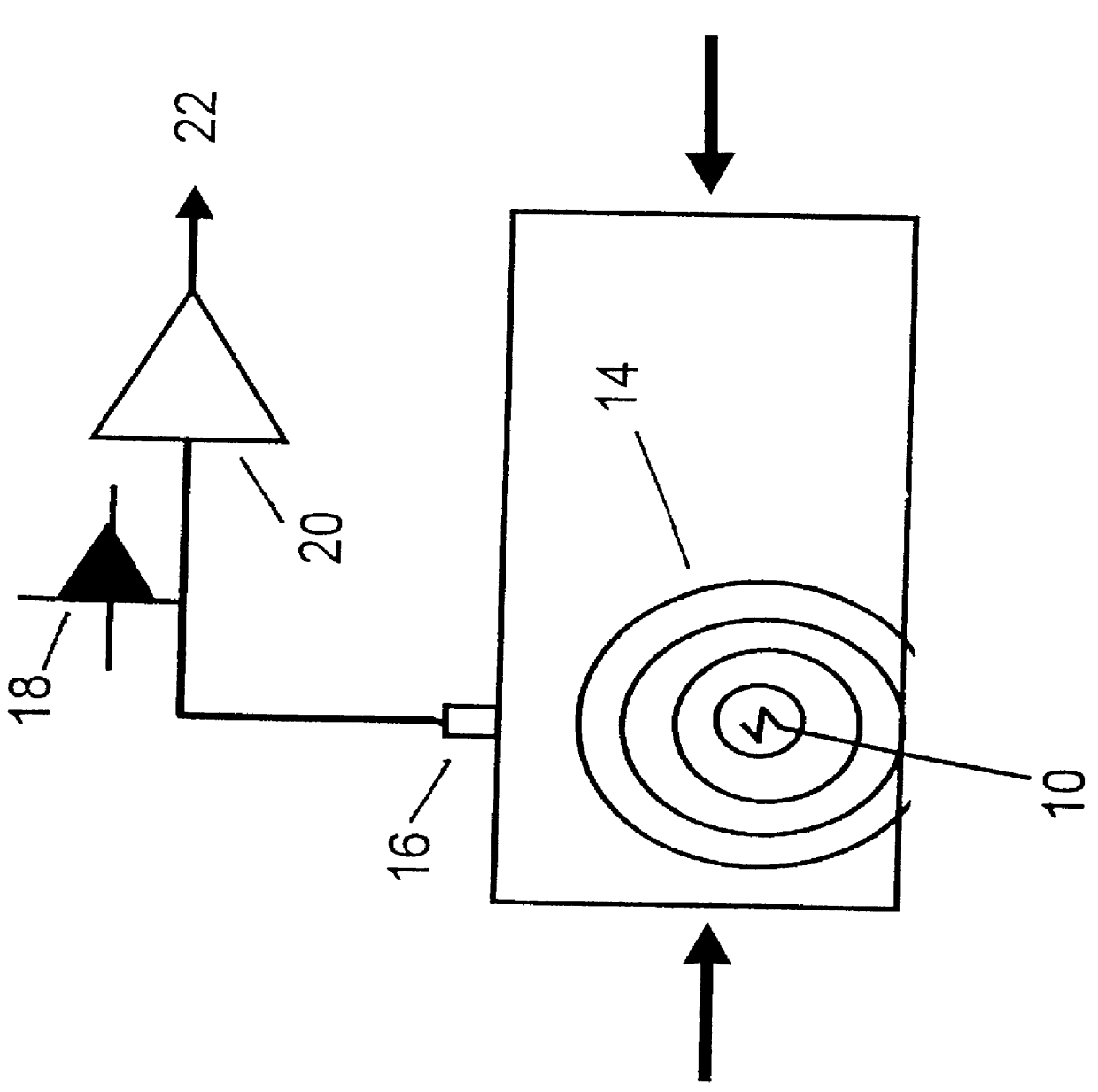

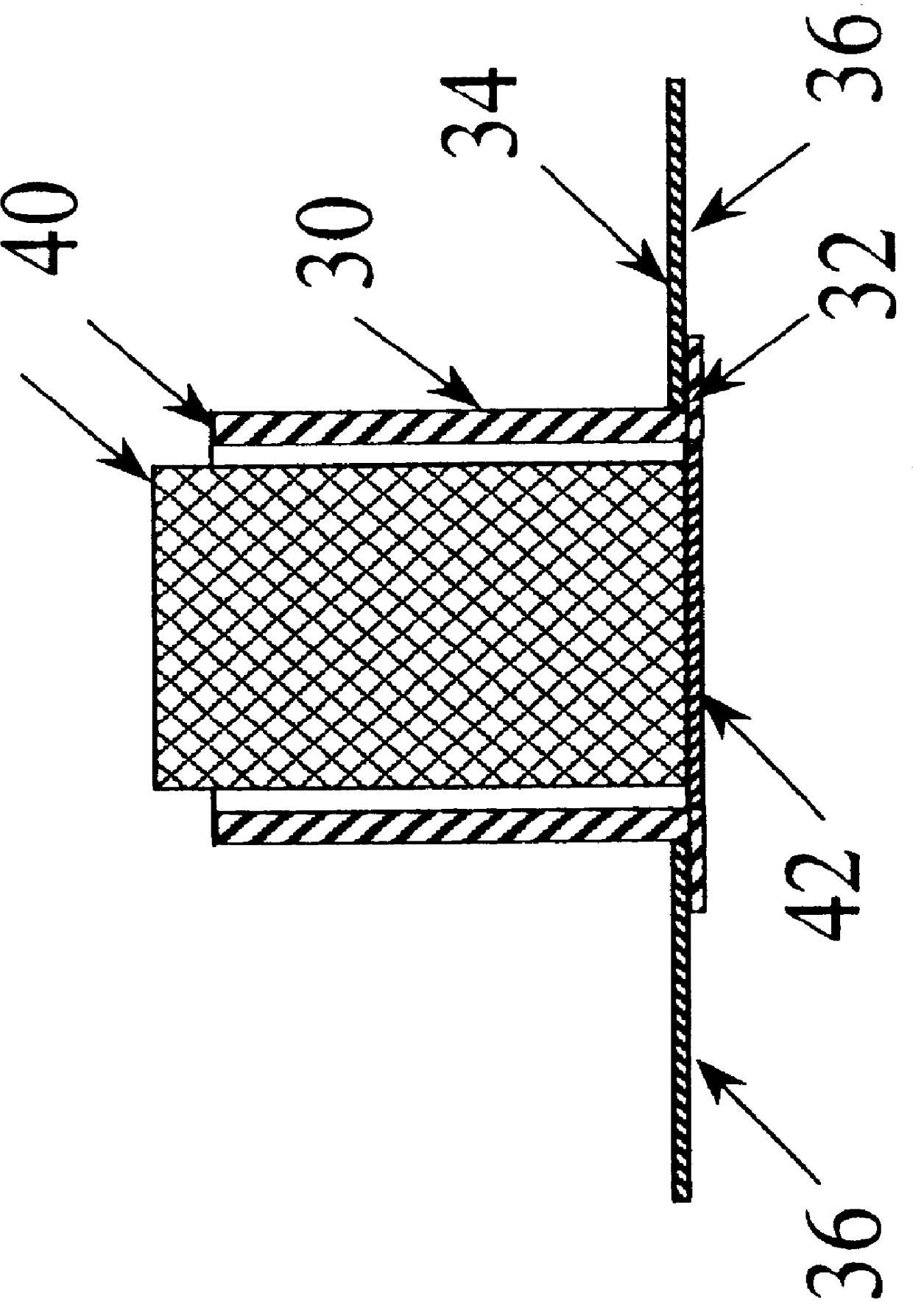

Method for detecting acoustic emission using a microwave doppler radar detector

InactiveUS20050265124A1Overcome limitationsGood conditionVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesIntermediate frequencyAcoustic emission

Acoustic emissions are detected by reflecting microwave radar signals off of an object, receiving reflected radar signals, generating an intermediate frequency, and filtering the intermediate frequency to remove low frequency signals associated with object movement and not acoustic emissions. A microwave Doppler radar detector provides the signals, a band-pass filter filters the intermediate frequency signal, and resulting signal is collected and analyzed to establish a relationship between the acoustic emission and the filtered signal. One application described is detecting tool wear using a microwave Doppler-based acoustic emission sensor and predicting tool wear based on the detected acoustic emission.

Owner:SMITH GREGORY C

Diagnosis of osteoporosis using acoustic emissions

InactiveUS6024711AInexpensive and simple to usePromote disseminationOrgan movement/changes detectionPerson identificationAcoustic emissionMedicine

Osteoporosis may be detected in-vivo by applying an acoustic sensor in contact with the skin of the patient while subjecting the patient to stress, for example, by lifting light weights and measuring the acoustic emissions sensed by the acoustic sensor to provide an indication of the degree of osteoporosis damage incurred by the bones of the patient being diagnosed.

Owner:THE UNIV OF BRITISH COLUMBIA

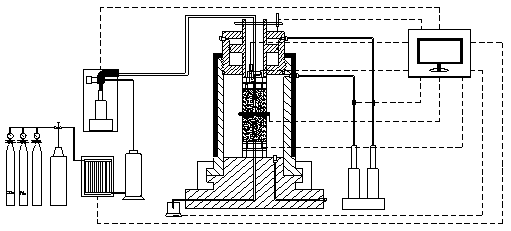

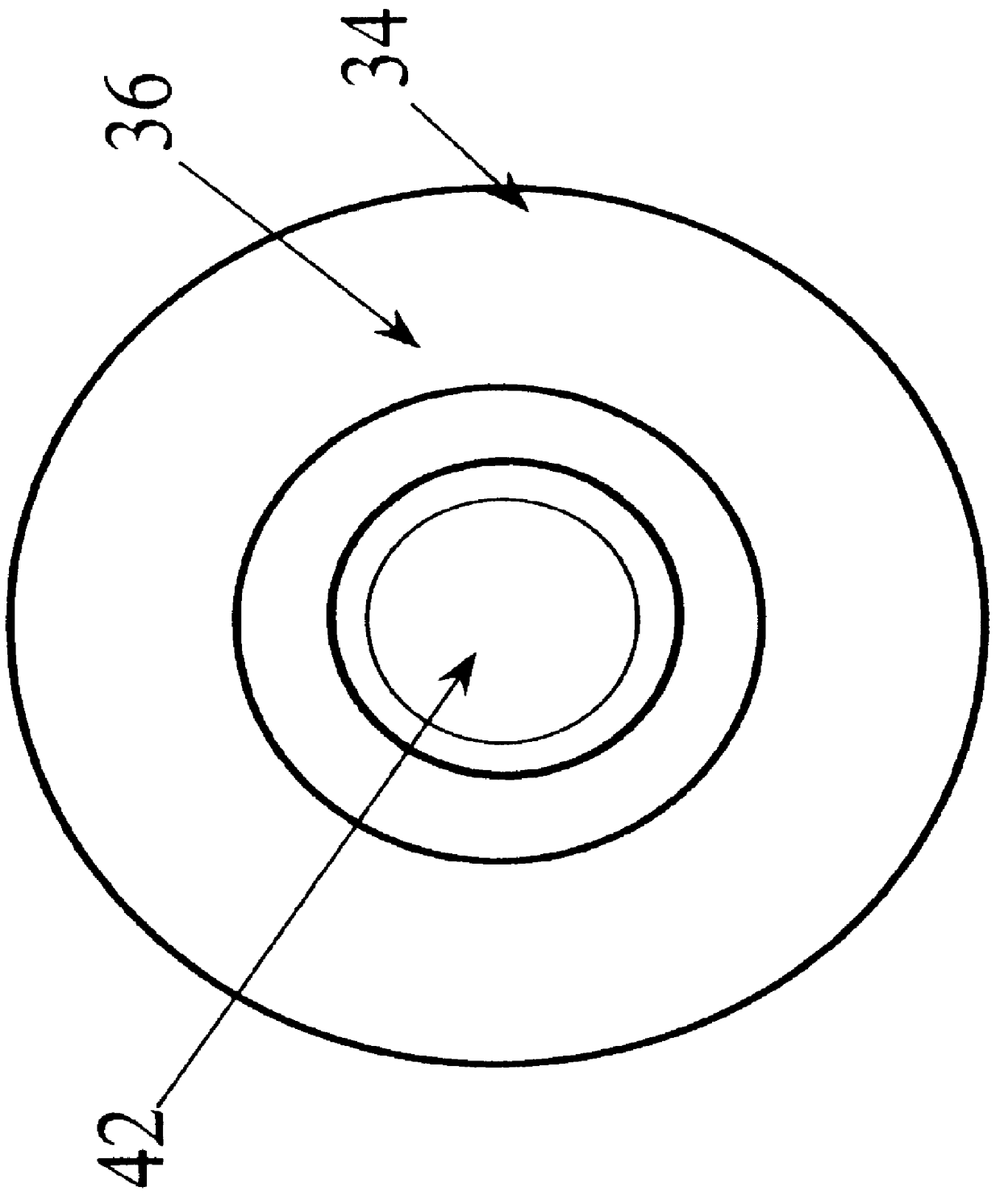

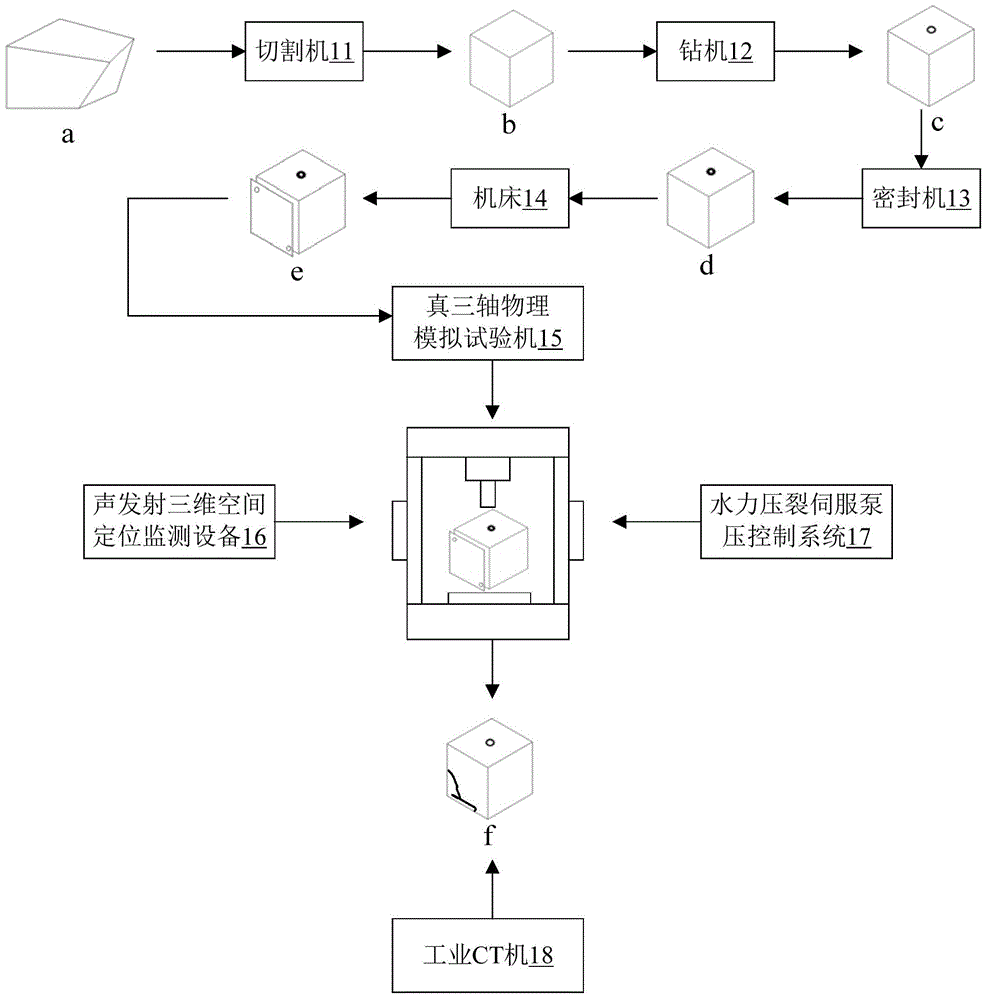

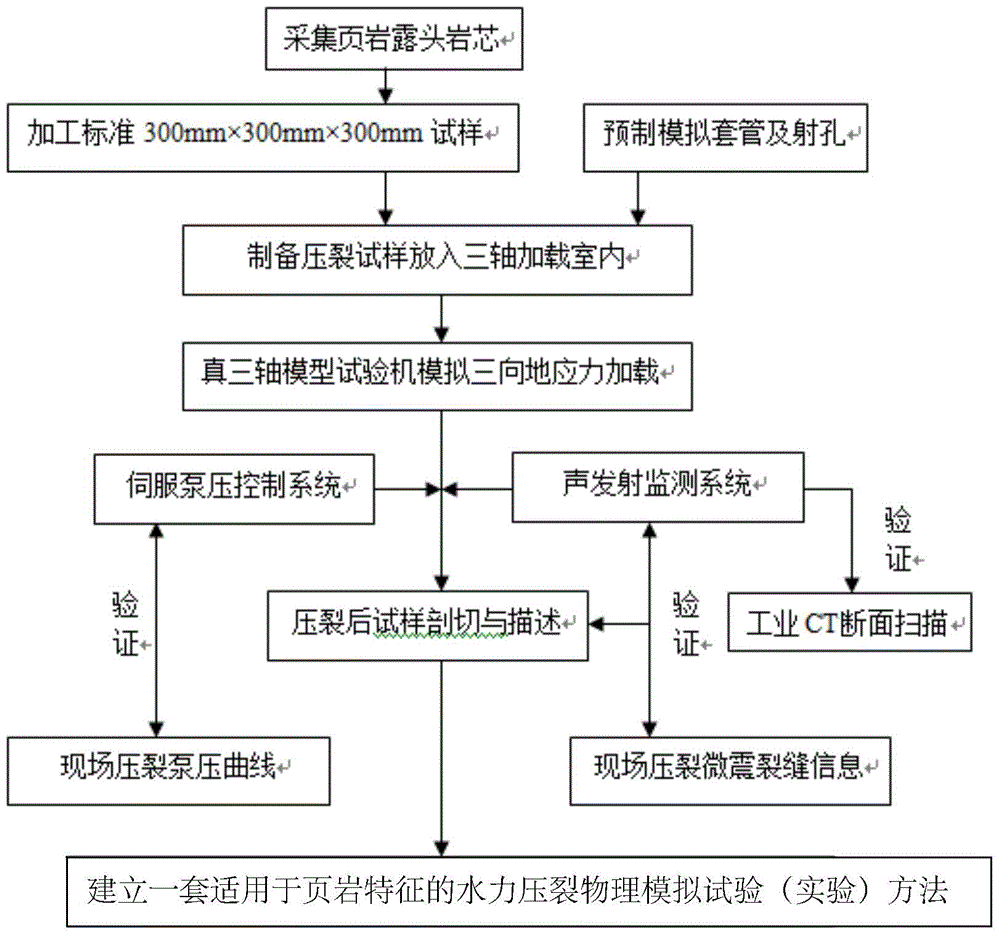

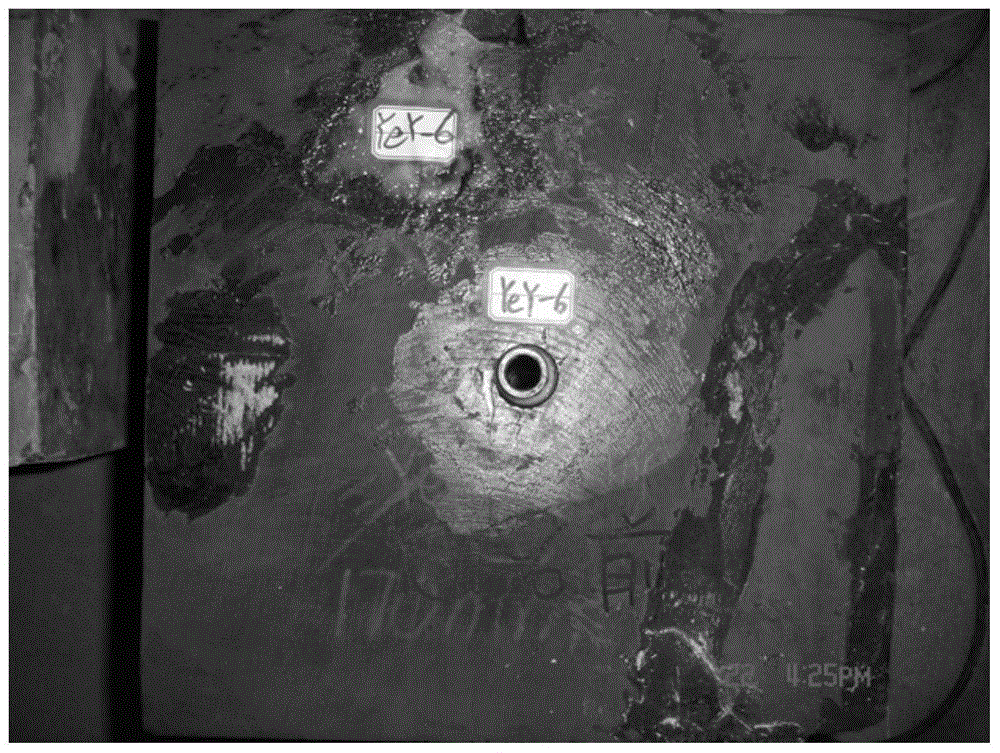

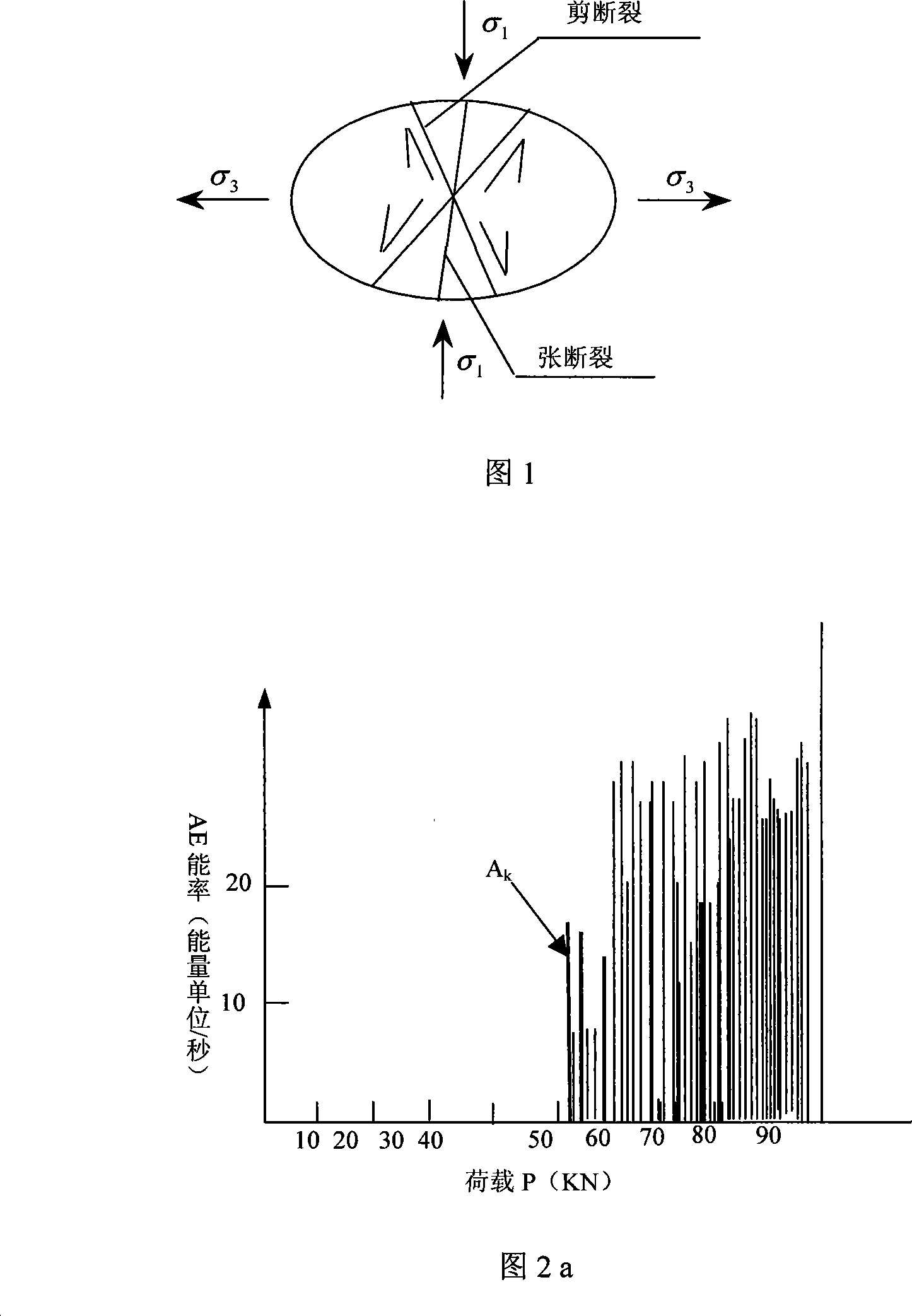

Physical simulation system and method for fracture propagation in shale

InactiveCN105756645AAccurate discriminationTo achieve the purpose of increasing productionFluid removalFracturing fluidHydraulic fracturing

The invention discloses a physical simulation system and method for fracture propagation in shale. The system comprises a drilling rig, a sealing machine, a machine tool, a true triaxial physical simulation testing machine, a hydraulic fracturing servo pump pressure control system, acoustic emission three-dimensional space location monitoring equipment and an industrial CT (computed tomography) machine, wherein the drilling rig, the sealing machine and the machine tool are jointly used for processing acquired shale into a fracturing sample; the true triaxial physical simulation testing machine is used for loading simulated three-dimensional ground stress to the fracturing sample; the hydraulic fracturing servo pump pressure control system is used for providing a fracturing fluid for the fracturing sample, so that a hydraulic fracturing process can be simulated; the acoustic emission three-dimensional space location monitoring equipment is used for monitoring the simulated hydraulic fracturing process in real time; the industrial CT machine is used for preforming tomography scanning on the fracturing sample before and after hydraulic fracturing. The physical simulation system for fracture propagation in the shale can be used for researching fracture initiation, expansion and extension laws of anisotropic shale in the hydraulic fracturing process, so that fracture information can be distinguished more accurately, high-precision basic data are provided for fracturing construction design, technical support is provided for site fracturing construction, and the yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

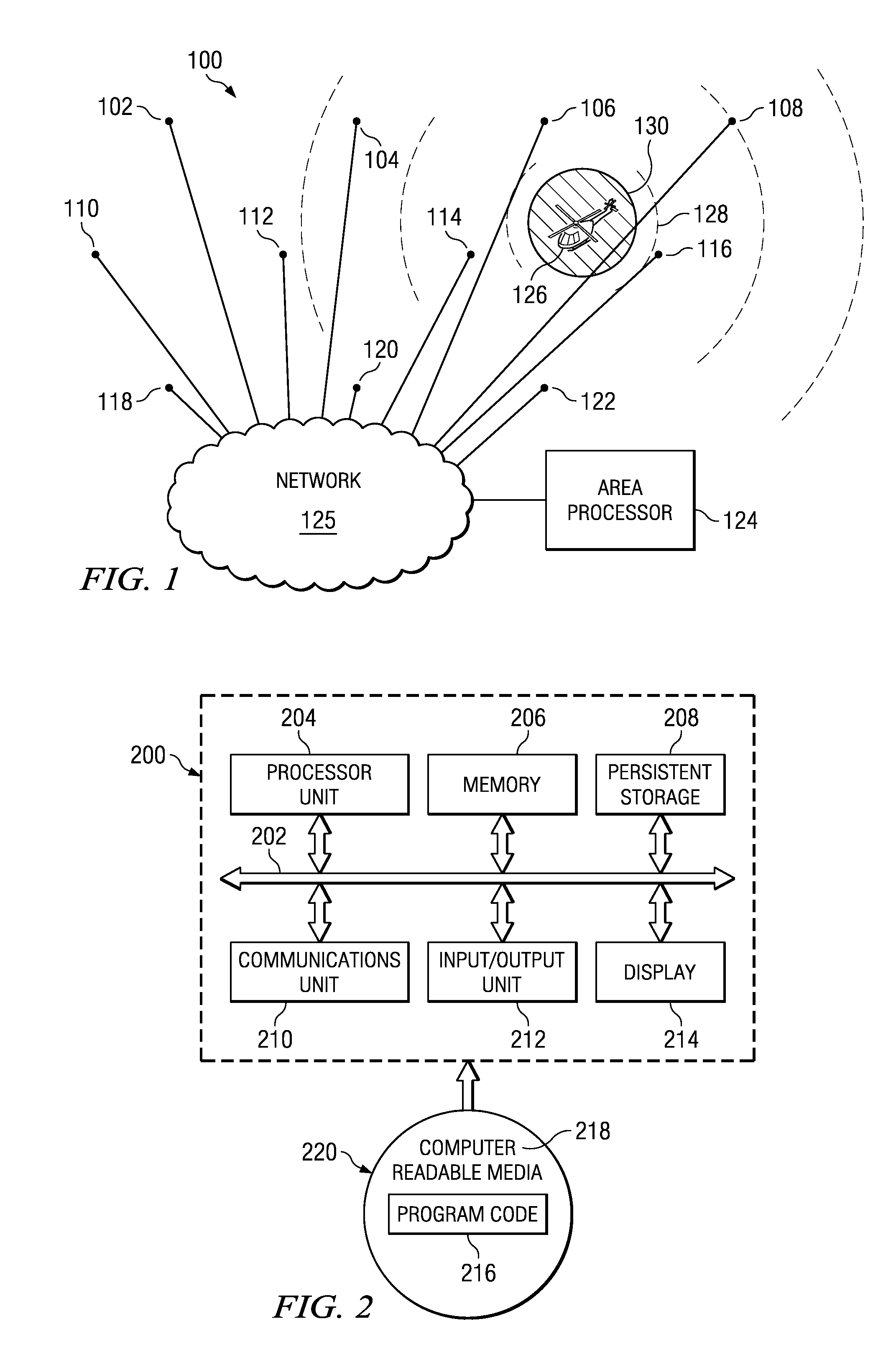

Acoustic airport surveillance system

ActiveUS8059489B1Material analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionMonitoring system

The different advantageous embodiments provide a method and apparatus for detecting an aircraft. The different advantageous embodiments may provide a method for detecting an acoustic emission emitted by the aircraft using a number of acoustic sensors to form a detected acoustic emission. The aircraft may be identified from the detected acoustic emission to form an identified aircraft. A bearing may be estimated for the identified aircraft using the detected acoustic emission.

Owner:THE BOEING CO

Method for measuring ground stress

InactiveCN101162177ALow costEasy and fast measurementForce measurement by measuring frquency variationsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic emissionRock sample

The present invention relates to a ground stress measuring method which comprises the following procedures: 1) the occurrence of joint and faultage are determined; the nearest sequent subjoint and fissure in the same sequence are drawn on a stereographic projection drawing; 2) a terrane lay uses the strike line as a rotating axis and rotates to the horizontal position towards the dip direction; the rotary angle is equal to a dip angle of the lay, and the strike line of the joint and fissure winding lay rotates to the horizontal state to find a conjugated X-shaped joint; then the conjugated X-shaped joint and lay in the horizontal state rotate to the original state; three directions of the ground stress are determined on the stereographic projection drawing; 3) samples are drilled along three directions of the ground stress and 5 to 7 samples are drilled along each direction; 4) the acoustic emission experiment of a rock sample is done indoors to have a Db4 small wave analysis on the acoustic emission signals of rock, thereby determining the acoustic emission Kaiser point of rock; the size of the ground stress is determined according to the acoustic emission Kaiser point of rock. The invention is small in sample quantity, low in cost, rapid in measuring progress of the ground stress, and accordingly more convenient and rapid in measurement of the ground stress.

Owner:南京银茂铅锌矿业有限公司

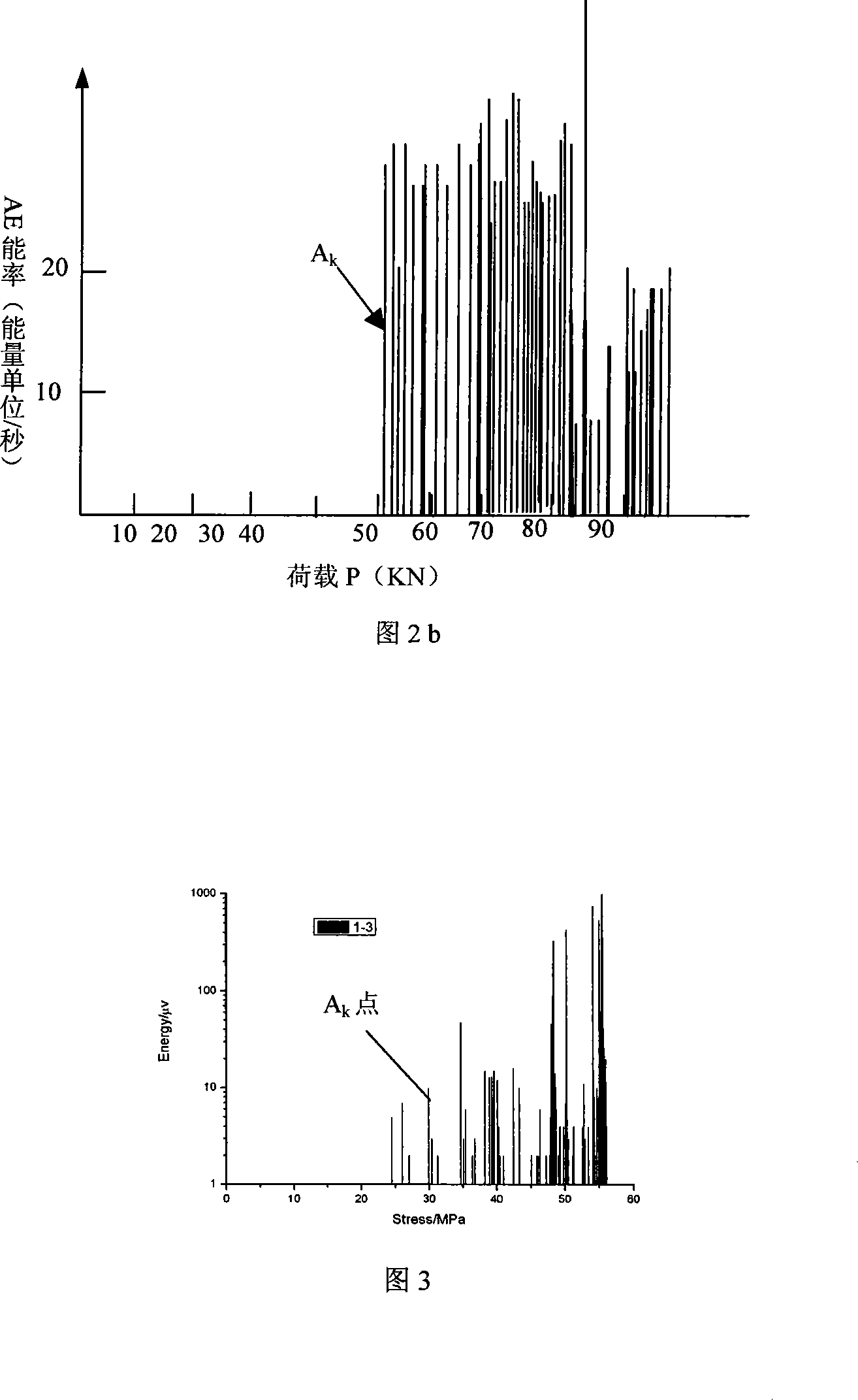

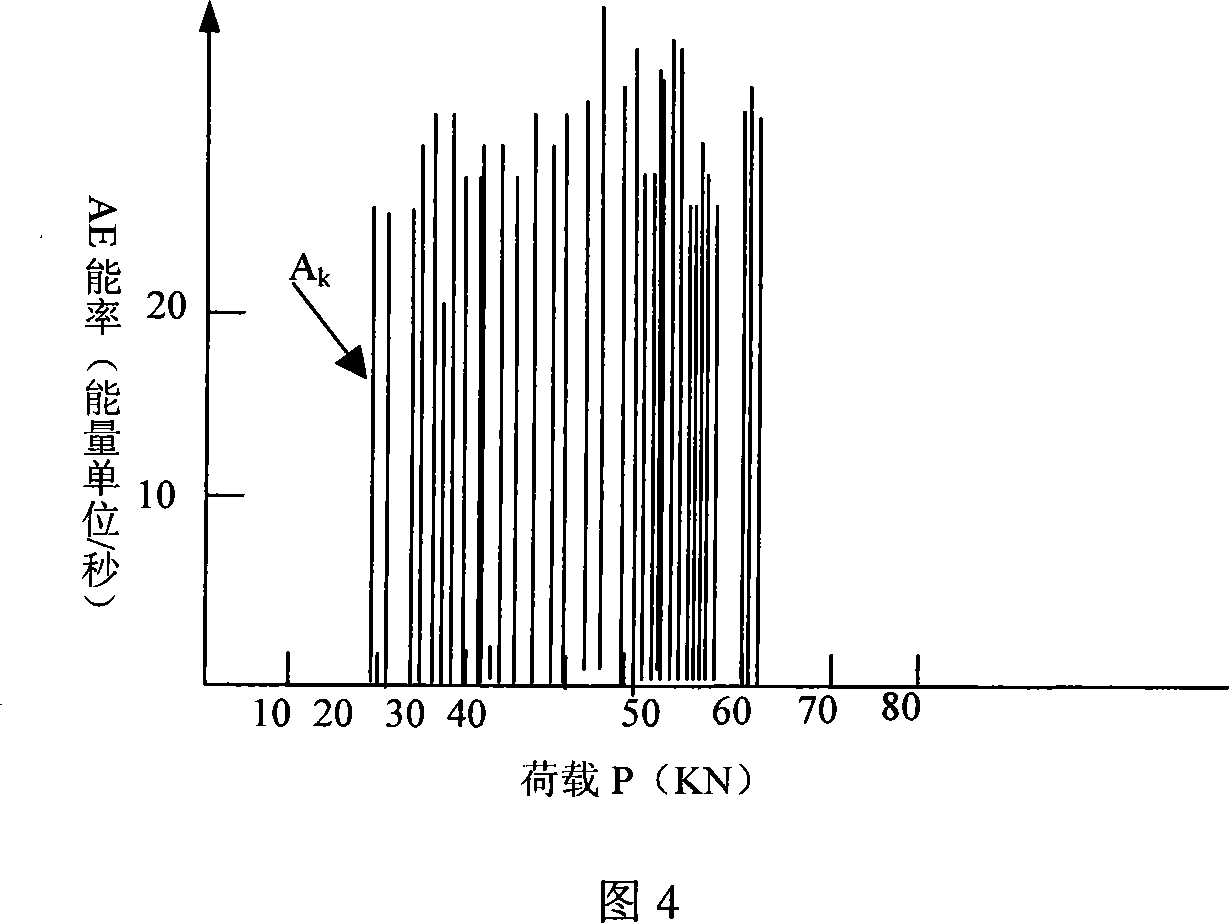

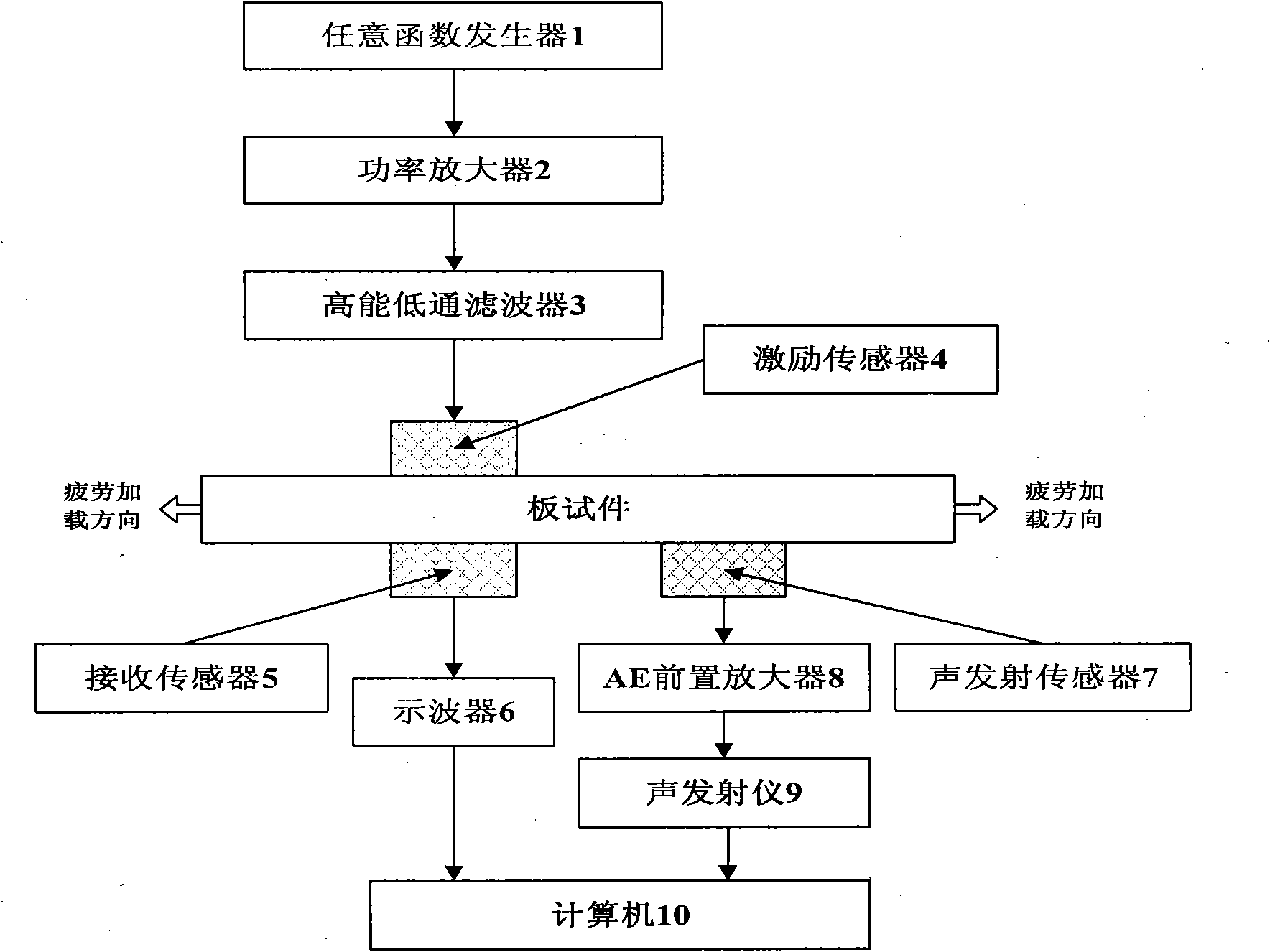

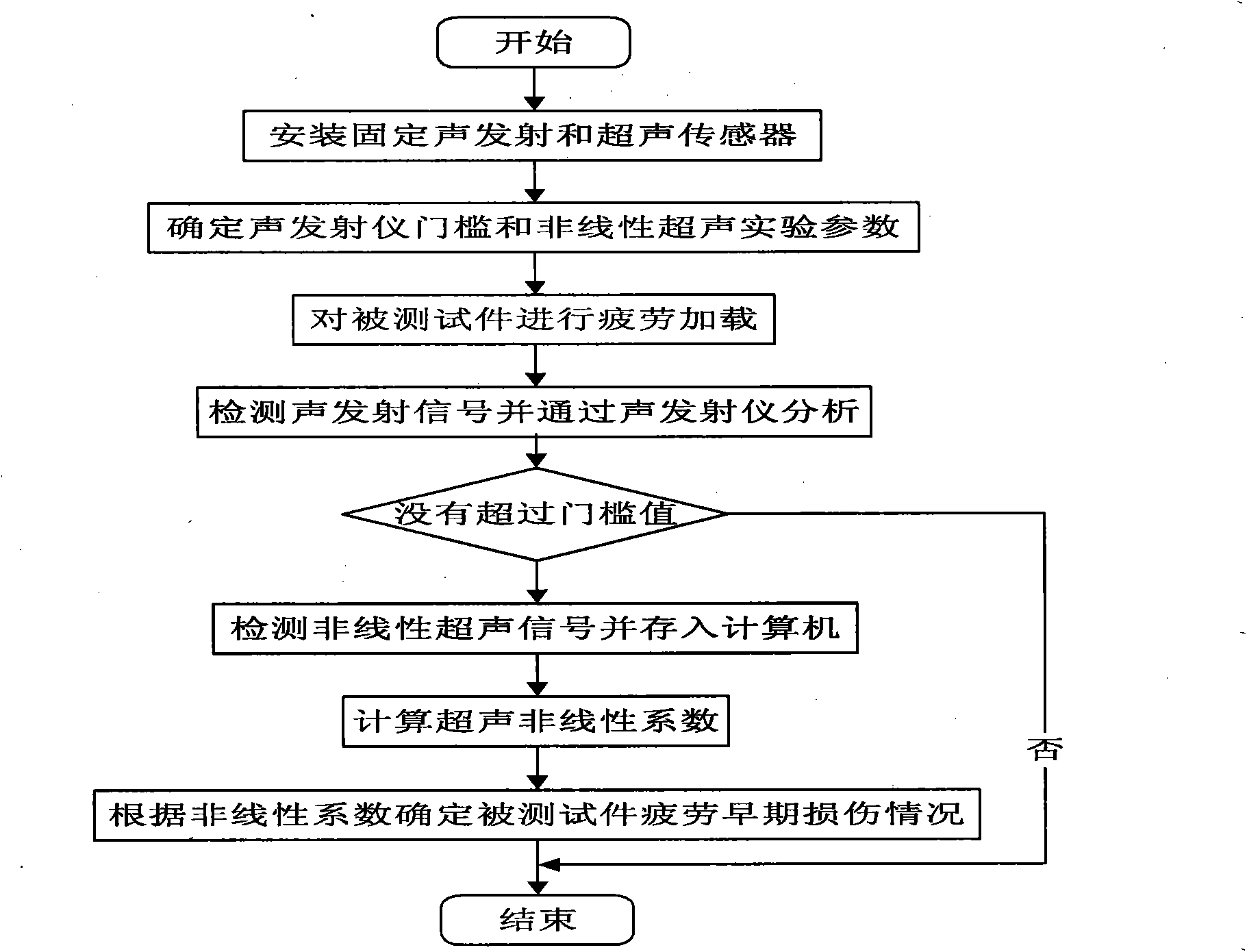

Method for non-linear ultrasonic online detection of early fatigue damage to metal material

InactiveCN101806778ARealize the whole process of fatigue detectionSolve misjudgmentMaterial analysis using acoustic emission techniquesFatigue damageSonification

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more than the empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

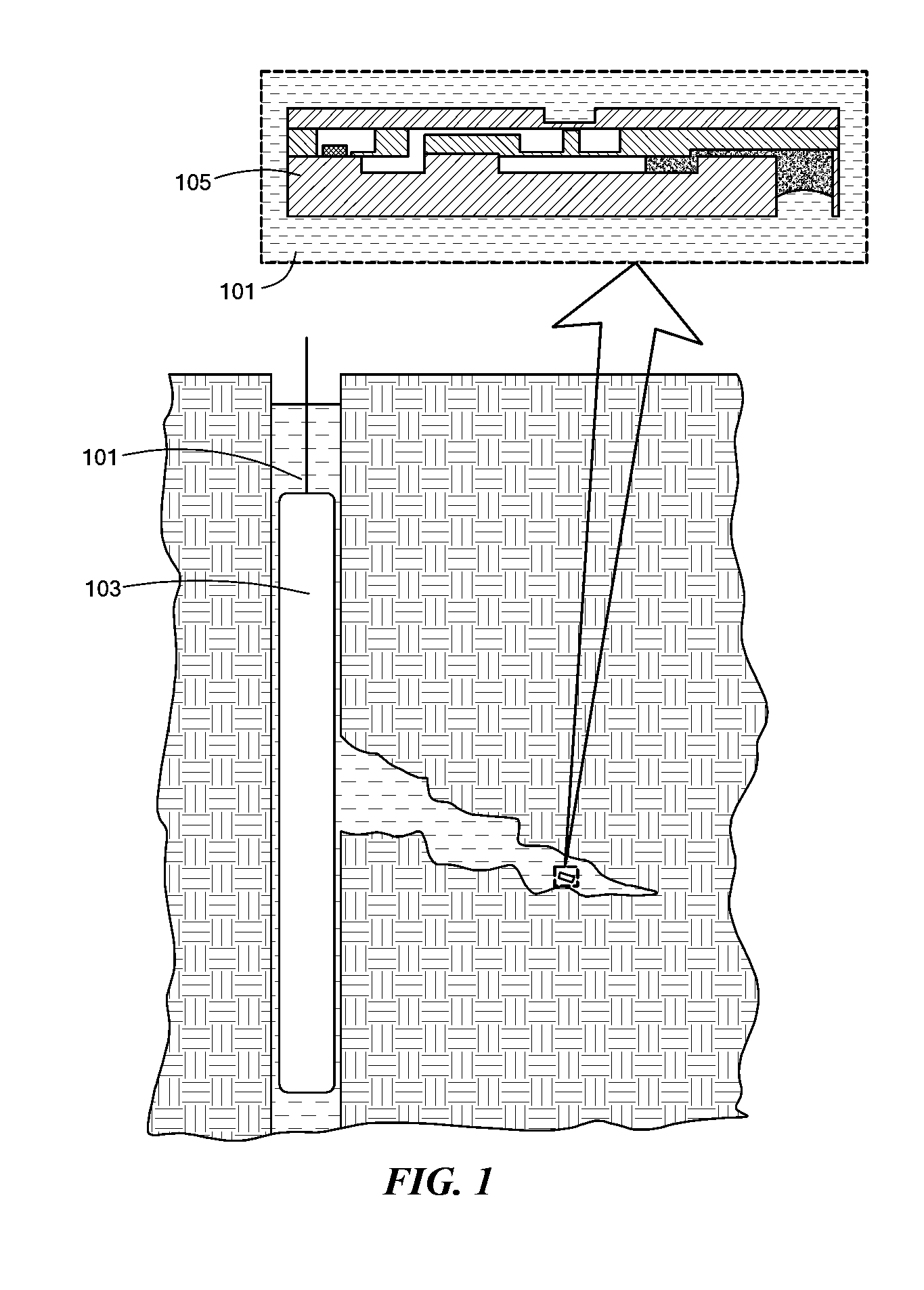

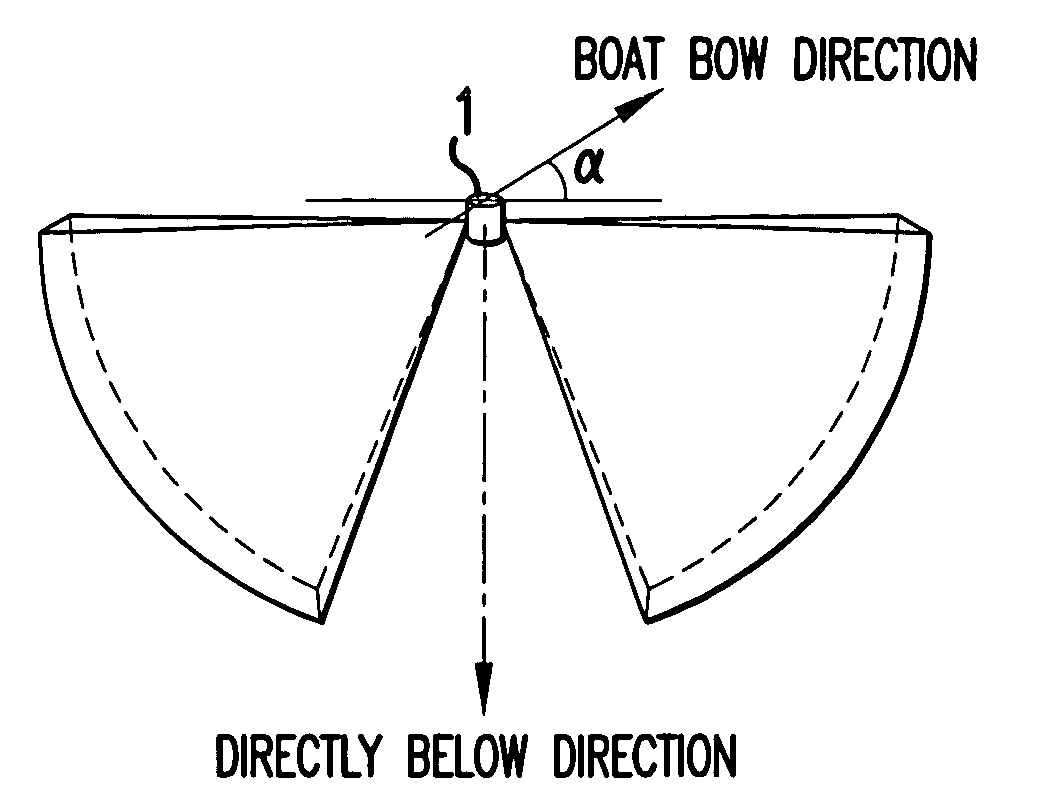

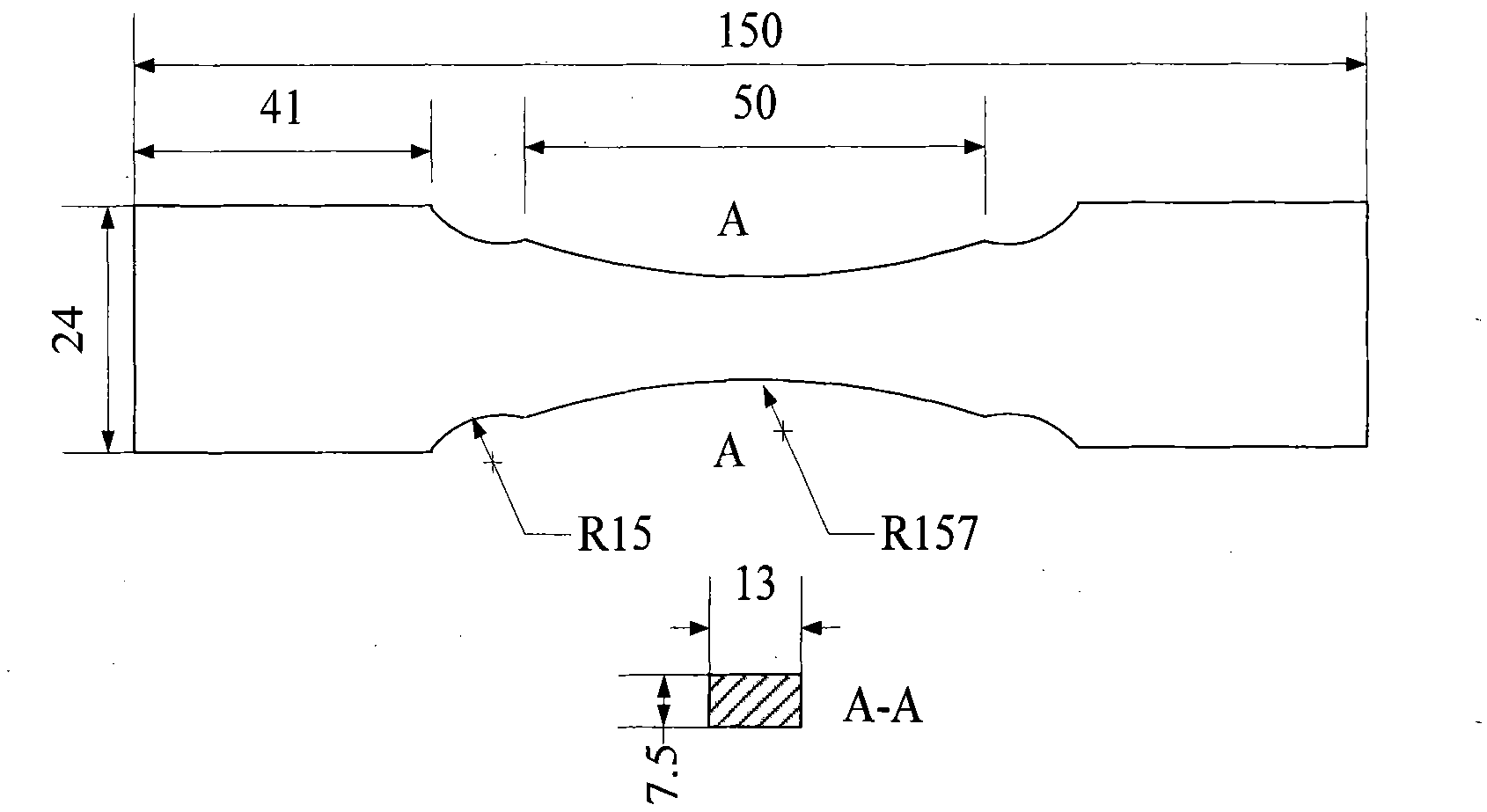

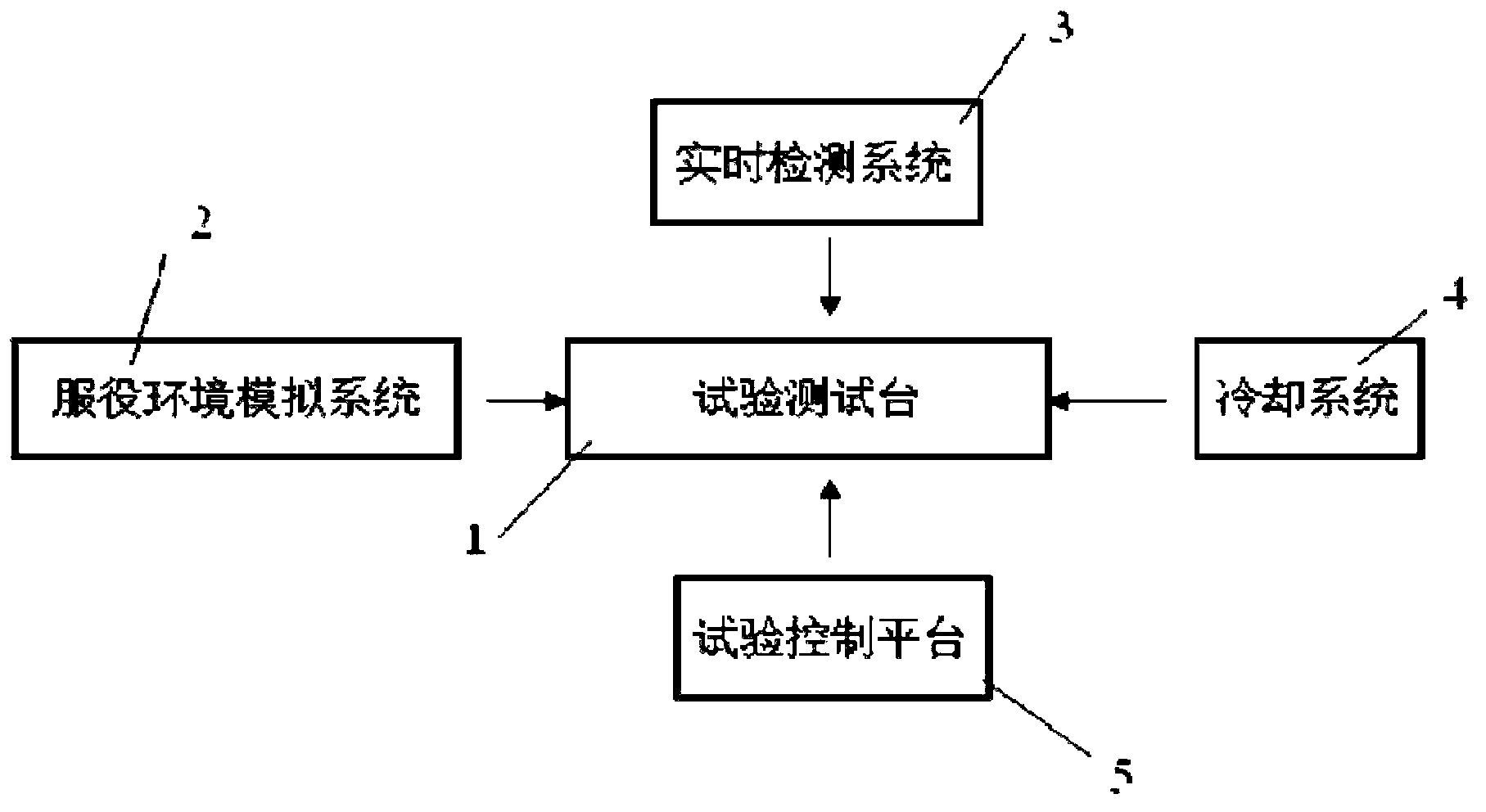

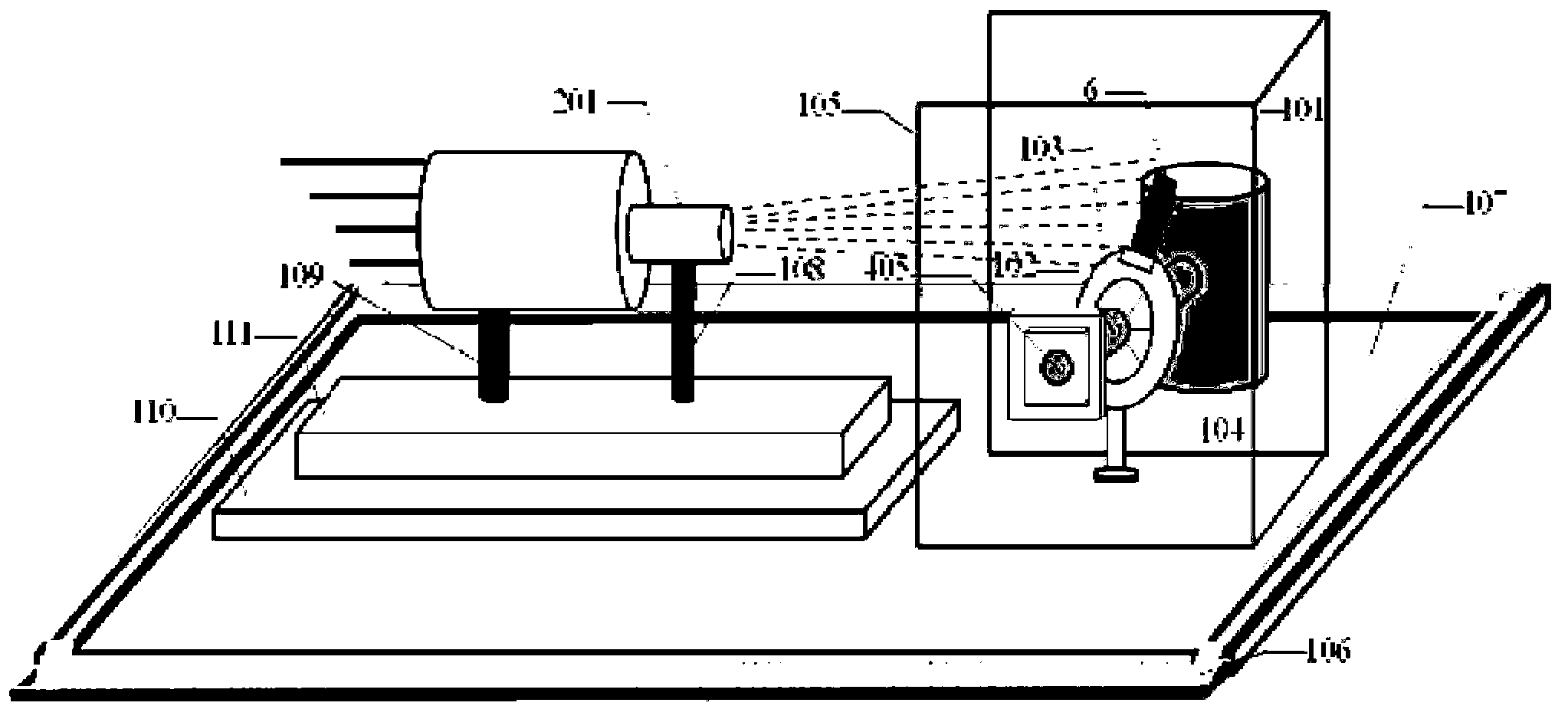

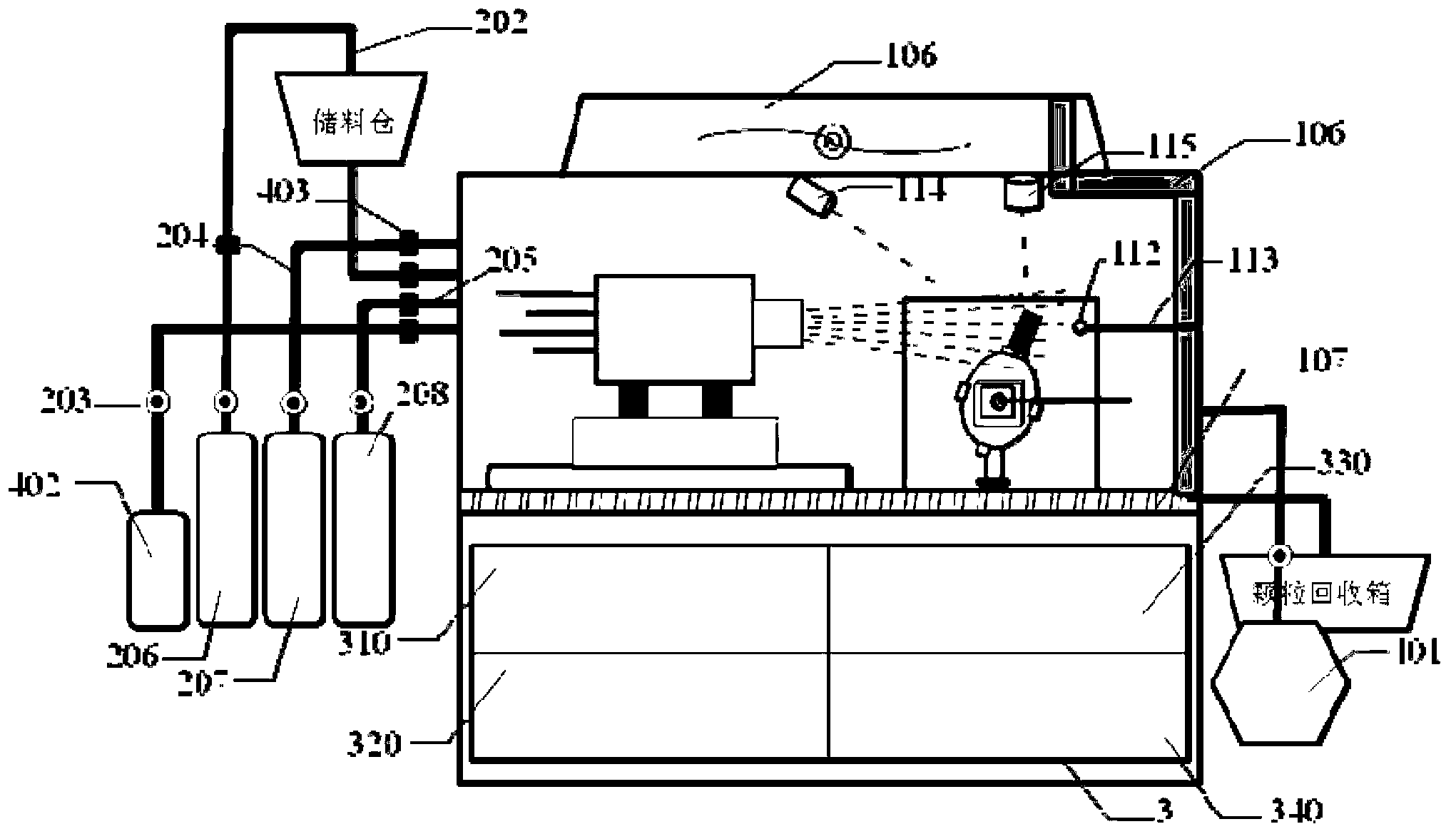

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

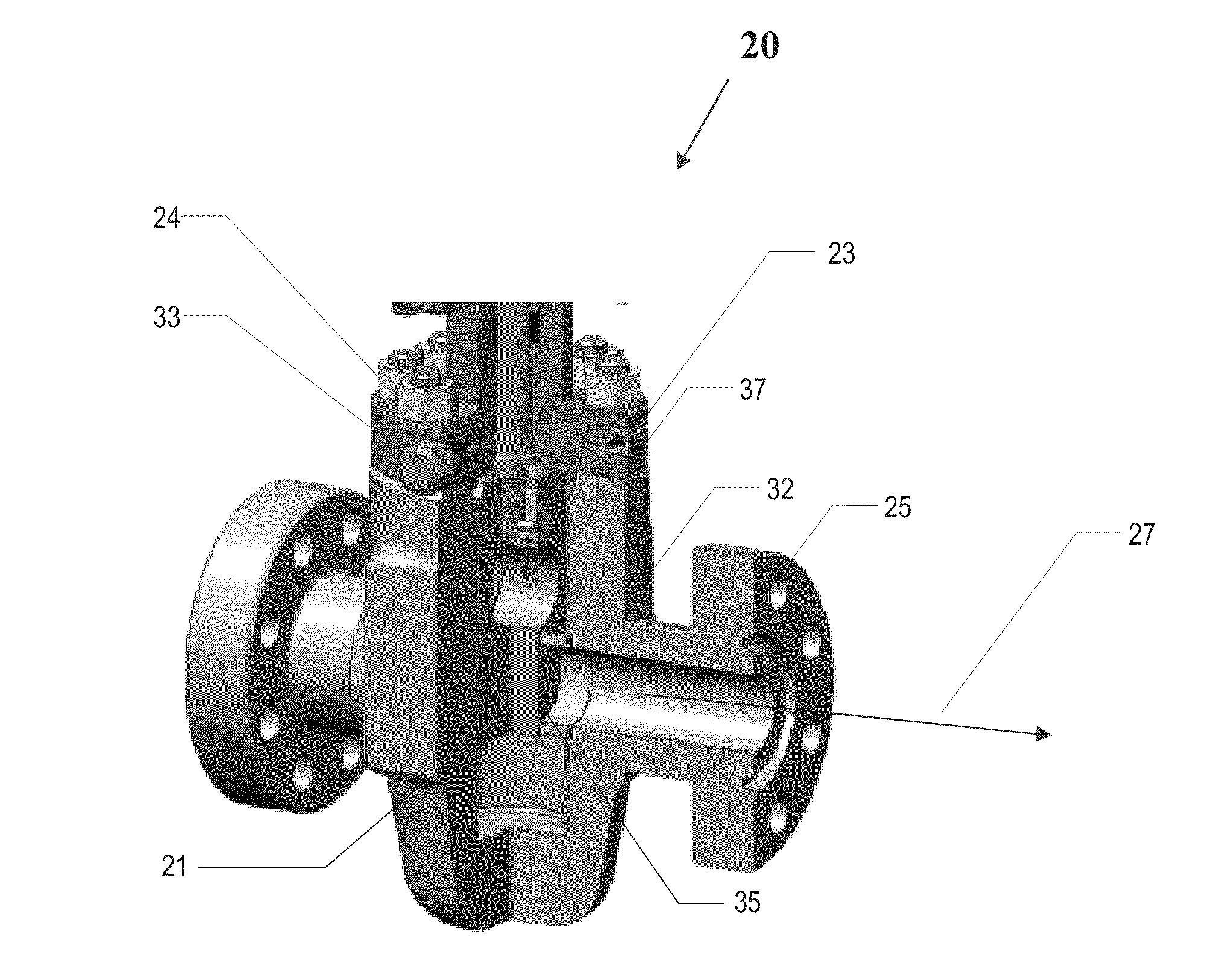

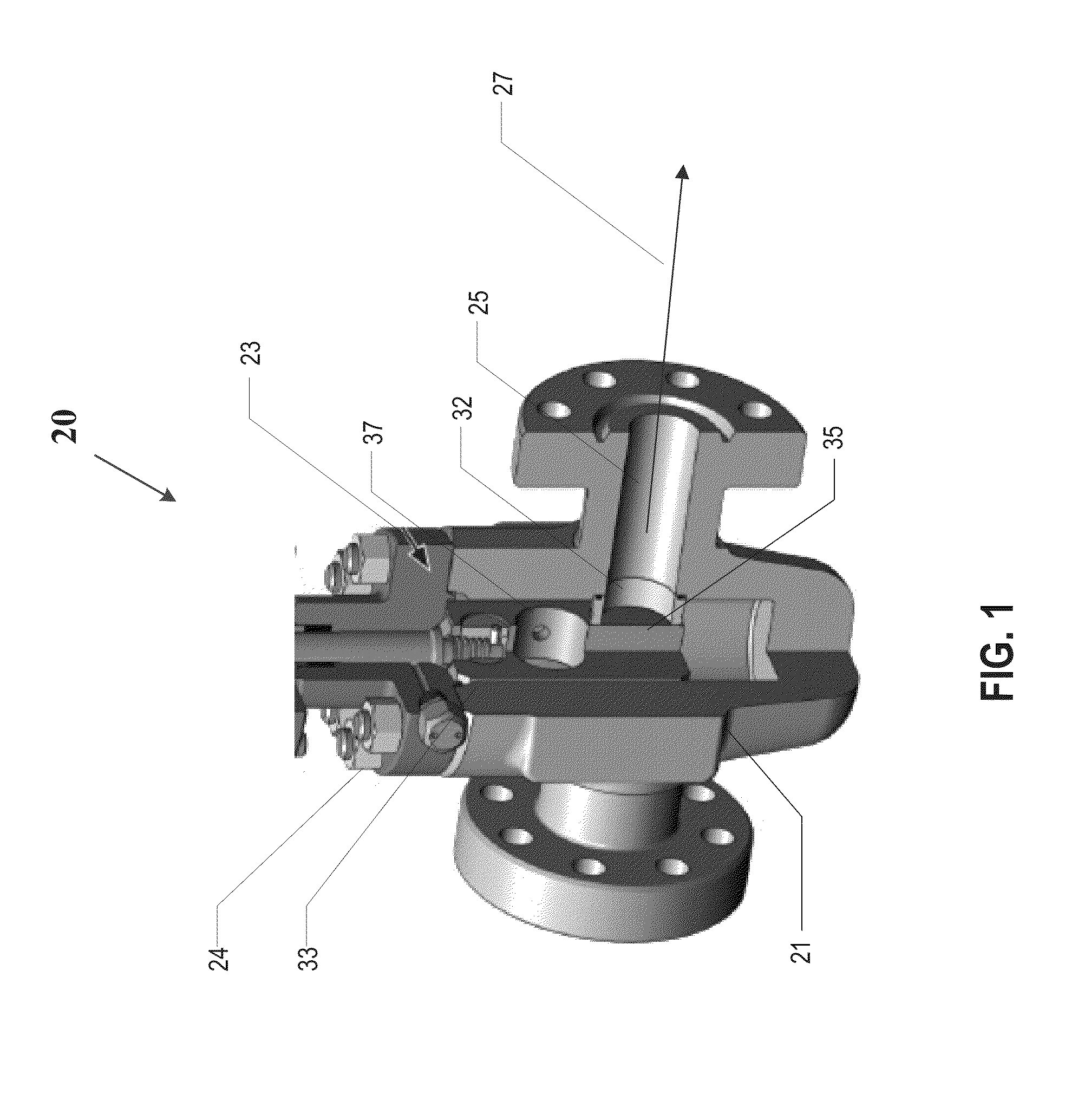

Gate Valve Real Time Health Monitoring System, Apparatus, Program Code and Related Methods

ActiveUS20140182381A1Eliminating and reducing downtimeEliminating and reducing and human interventionVibration measurement in solidsProgramme controlAcoustic emissionEngineering

Systems, apparatus, and program code, and methods for monitoring the health and other conditions of the valve, are provided. An exemplary system for monitoring the condition of the gate valve includes a logic module configured to perform the operations of receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface. An exemplary method for monitoring the condition of the gate valve includes receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface.

Owner:VETCO GRAY LLC

Indoor pull-out test apparatus for anchor rod

InactiveCN103398901ASolve the problem that the expansion shell bolt pull-out test cannot be carried outOvercoming the limitations of inconvenient monitoring of anchor mechanical responseMaterial strength using tensile/compressive forcesAcoustic emissionGeotechnical engineering

The invention relates to an indoor pull-out test apparatus for an anchor rod, which belongs to the technical field of geotechnical engineering. The apparatus comprises a horizontal loading system, a vertical loading system, an anchor rod pulling system, a box, support columns and a bearing plate. The test apparatus can realize loading of a sample at two horizontal directions and a vertical direction and overcomes the problem that a traditional indoor pull-out test apparatus for an anchor rod cannot carry out pull-out test under loading conditions; the test apparatus is provided with an acoustic emission sensor, can realize whole-course monitoring of damage, breakage and generation and expansion of cracks in the sample during pull-out test of the anchor rod and overcomes the limitation that mechanical response of an anchoring body cannot be conveniently monitored in traditional indoor pull-out test. The test apparatus provided by the invention can be applied in pull-out experimental study of mechanical behaviors of an expansion shell anchor rod and a corresponding anchoring body in geotechnical engineering so as to provide scientific experimental bases for test of anchoring performance of the expansion shell anchor rod and can also be applied in pull-out experimental study of a bond-type anchor rod.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

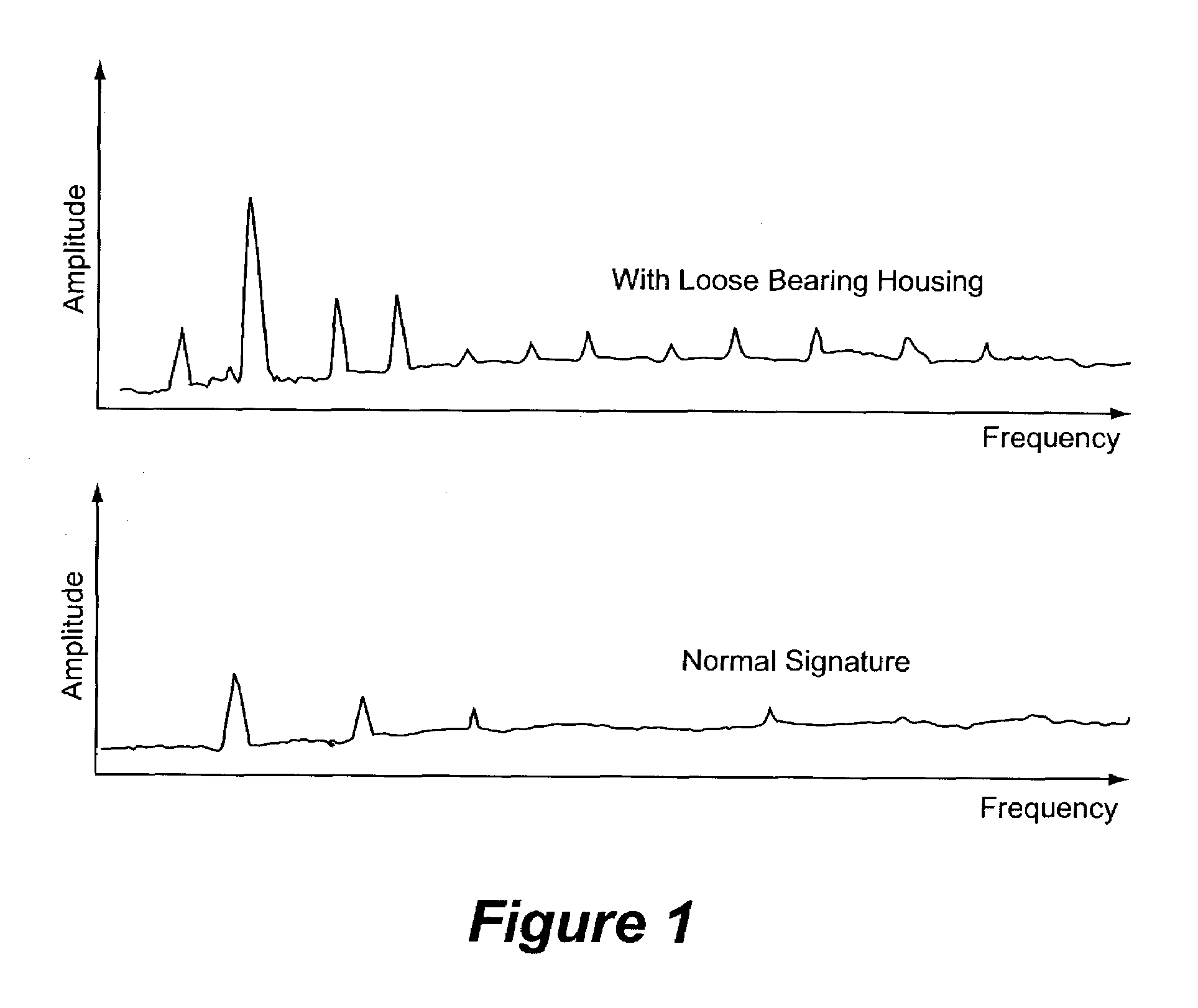

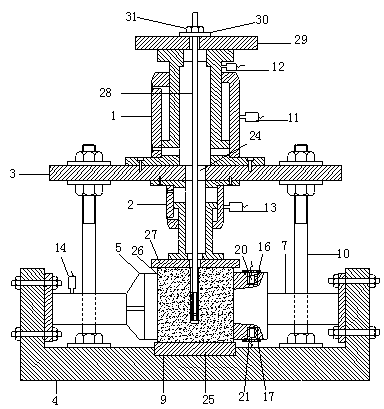

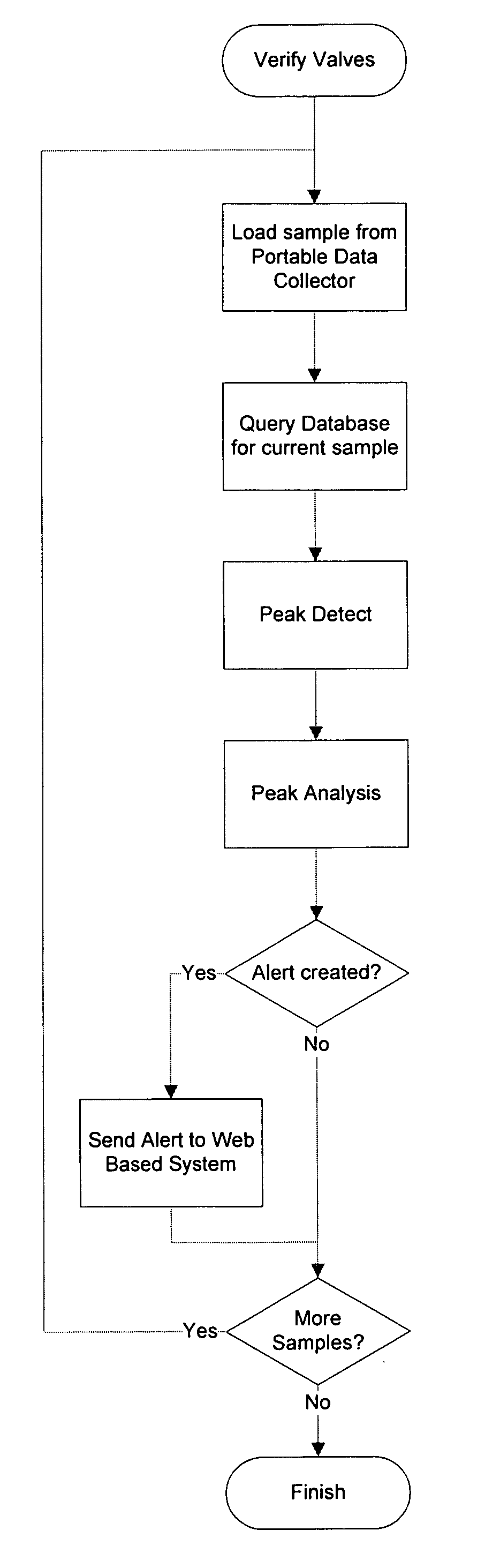

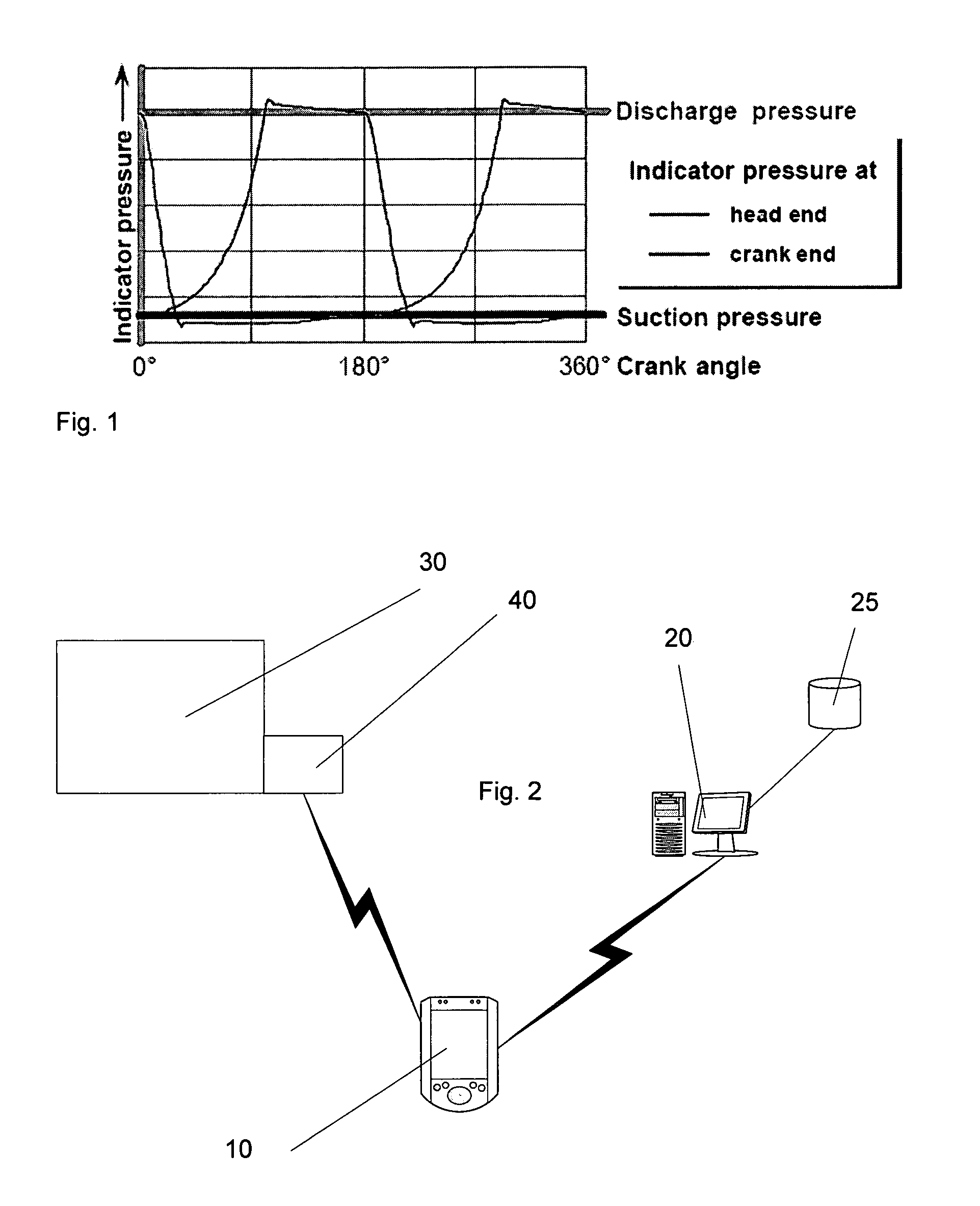

Valve monitoring system and method

ActiveUS20050257618A1Simplified and cost-effectiveImprove availabilityVibration measurement in solidsVibration measurement in fluidAcoustic emissionMonitoring system

A valve monitoring system includes an alert generation system and a memory. The memory encodes baseline acoustic emission data on the valve for a predetermined period of operation. The alert generation system is arranged to receive acoustic emission data for the valve, compare the received acoustic emission data for the valve with the baseline acoustic emission data encoded in the memory and identify valve anomalies in dependence on differences in the received acoustic emission data and the baseline acoustic emission data.

Owner:COMPRESSOR PROD INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com