Patents

Literature

1601 results about "Leakage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of detecting leakage from geologic formations used to sequester CO2

InactiveUS7704746B1Low costLow detection limitDetection of fluid at leakage pointConstructionsGas phaseLeak detection

The invention provides methods for the measurement of carbon dioxide leakage from sequestration reservoirs. Tracer moieties are injected along with carbon dioxide into geological formations. Leakage is monitored by gas chromatographic analyses of absorbents. The invention also provides a process for the early leak detection of possible carbon dioxide leakage from sequestration reservoirs by measuring methane (CH4), ethane (C2H6), propane (C3H8), and / or radon (Rn) leakage rates from the reservoirs. The invention further provides a method for branding sequestered carbon dioxide using perfluorcarbon tracers (PFTs) to show ownership.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

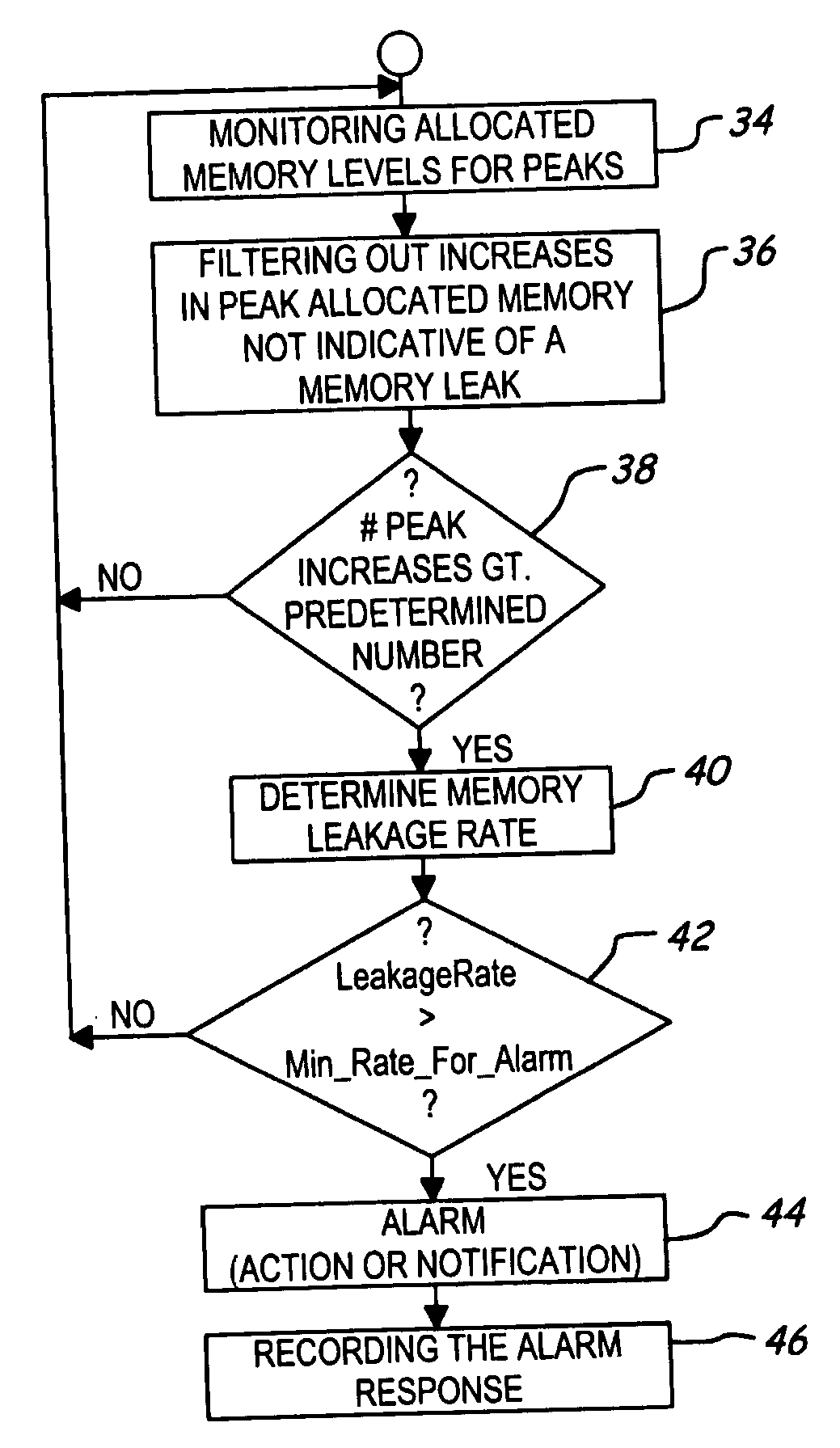

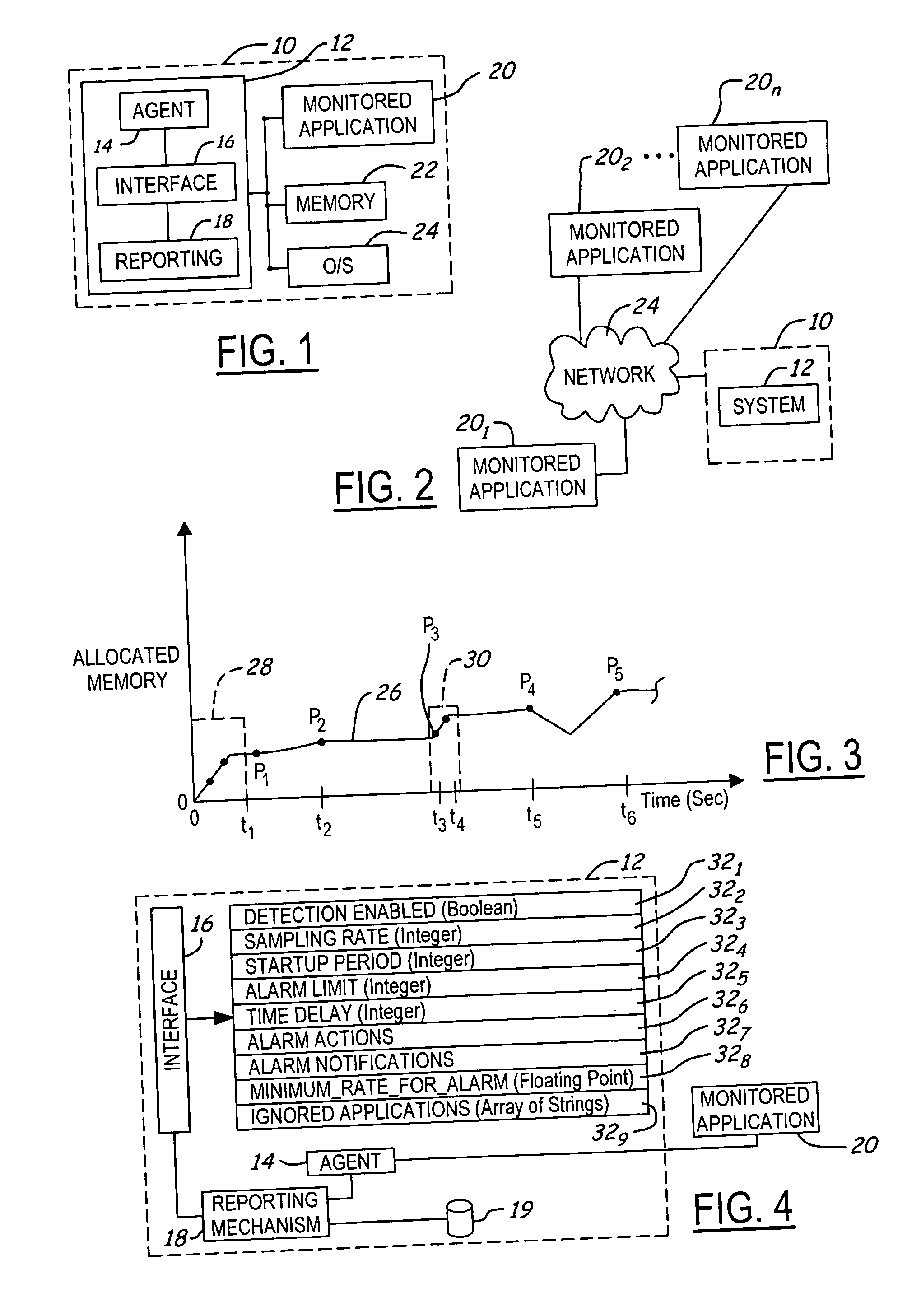

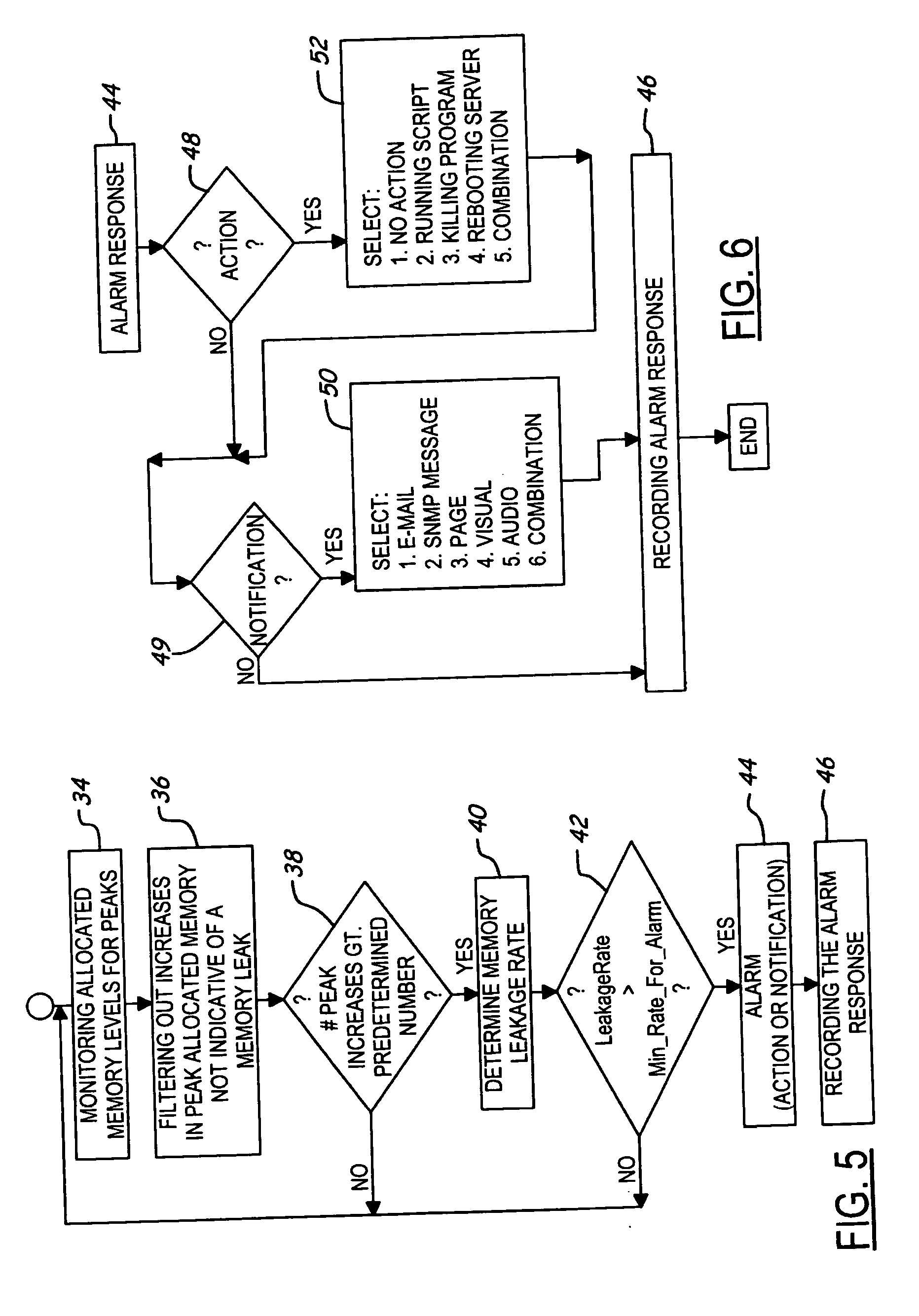

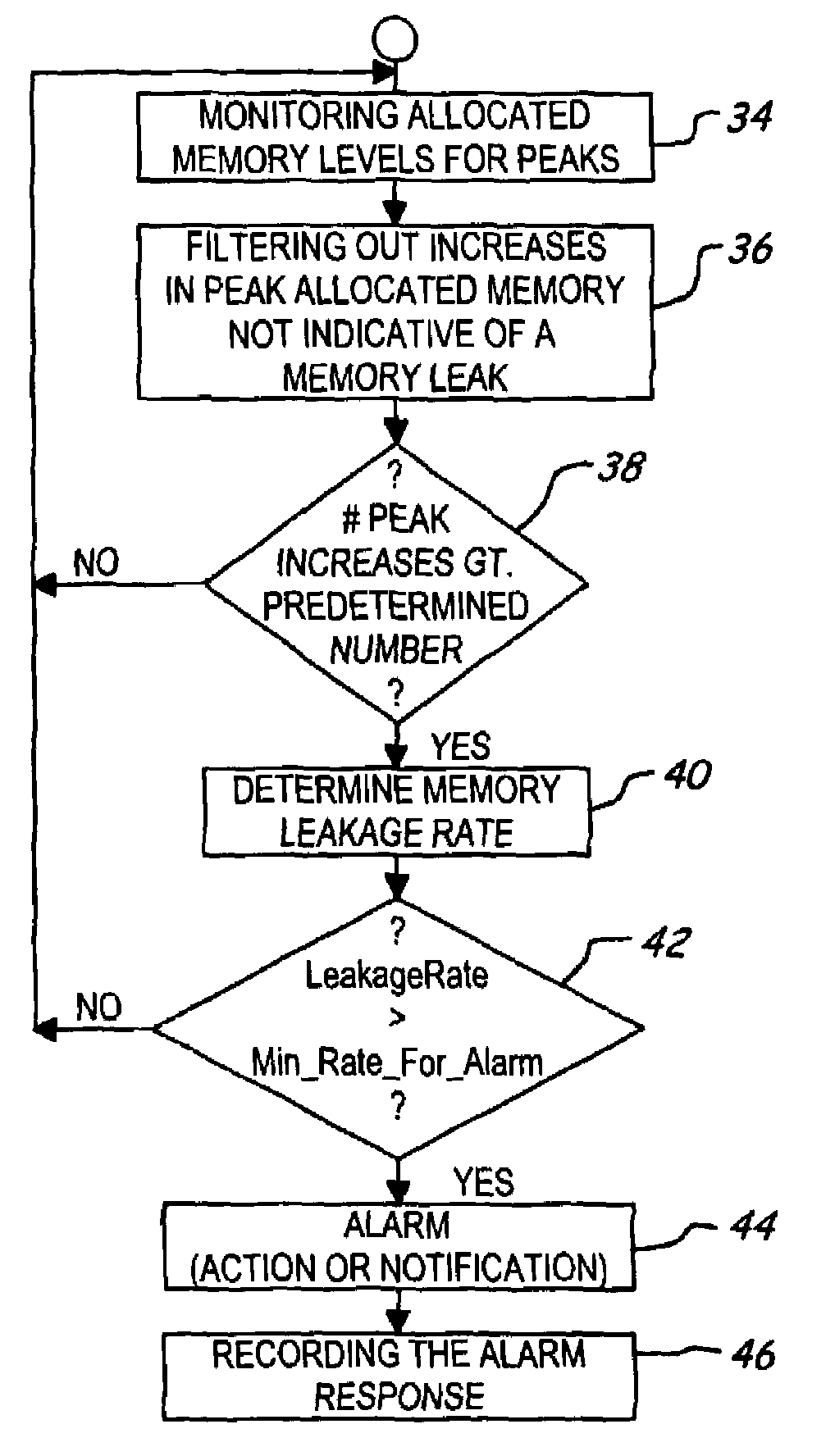

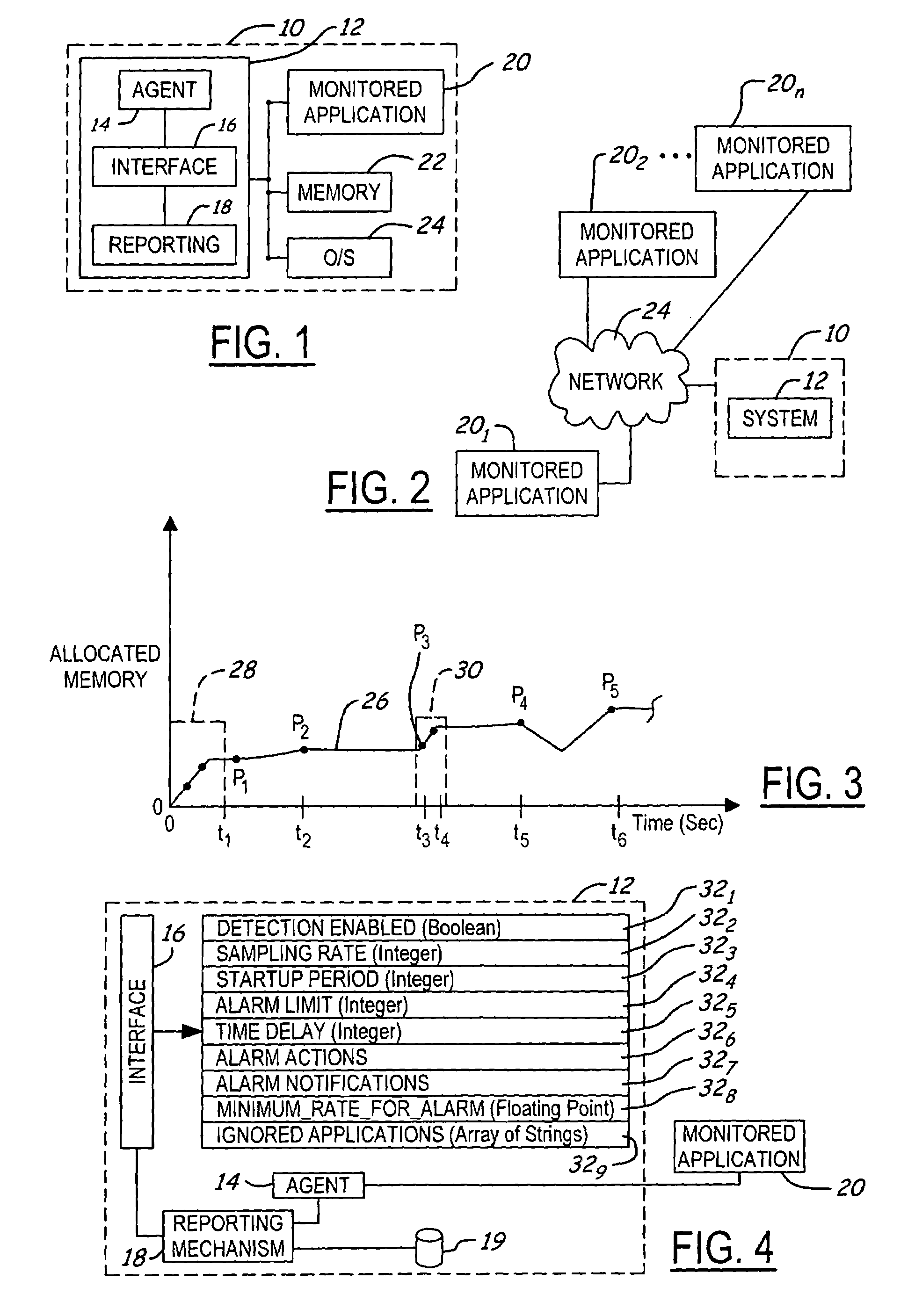

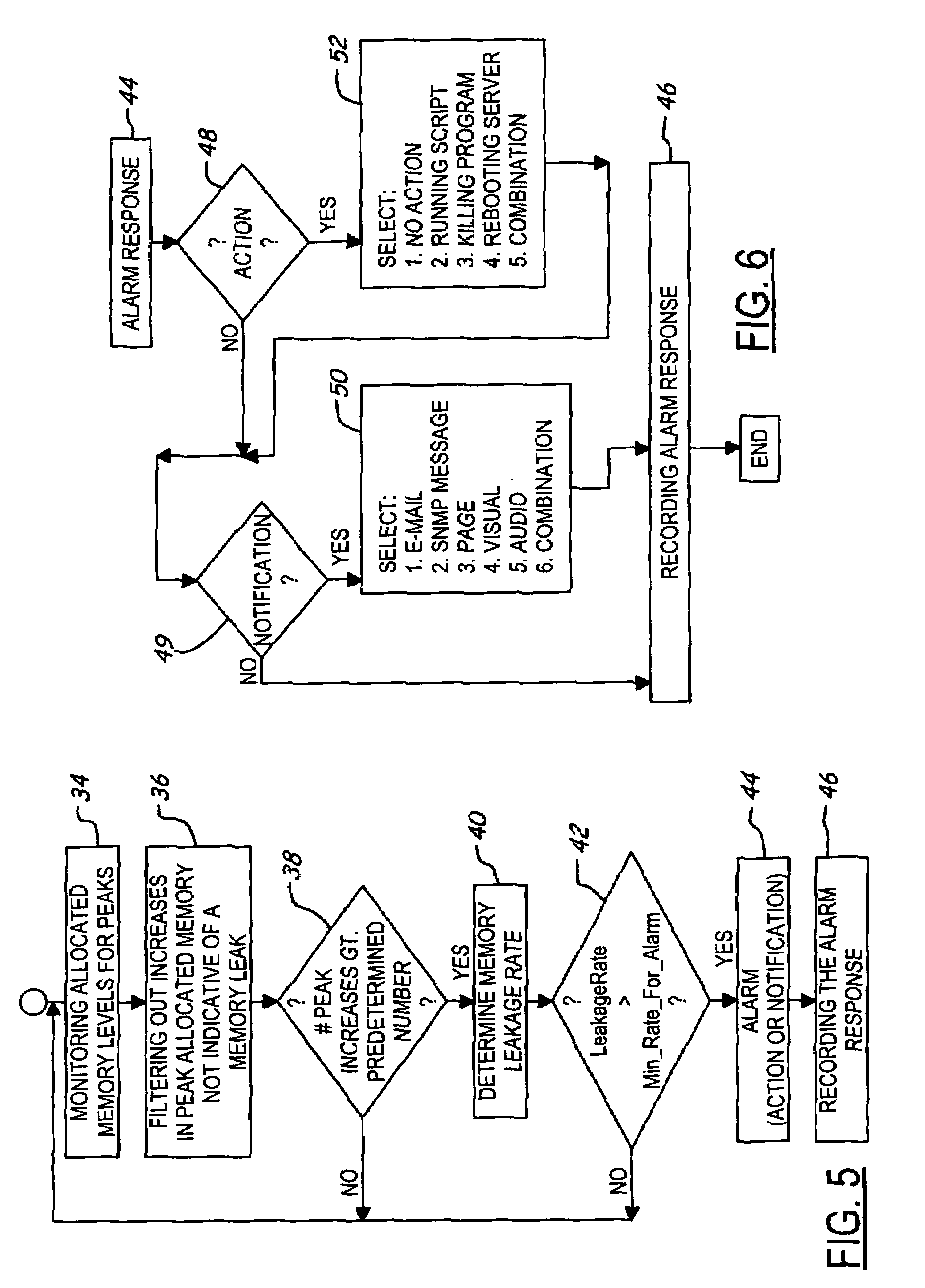

Apparatus and method for detecting memory leaks

A system and method for detecting memory leaks includes a monitoring agent, a user interface for configuring operating parameters and a reporting mechanism. The monitoring agent determines allocated memory levels of a monitored application at a sampling frequency and determines when a then-existing “peak” memory level has increased. The monitored application is determined to be leaking memory when a determined number of increases in the peak allocated memory level are detected. The determined number may be fixed ahead of time or may be calculated dynamically based on user specified parameters. When a given memory leakage rate is exceeded, an alarm response is taken, which may be either a specified notification of the alarm or an action. Certain increases in the peak allocated memory levels are ignored as not necessarily being indicative of a memory leak condition, such as during startup of the program or between rapidly, closely-occurring increases in the peak allocated memory level.

Owner:LAKESIDE SOFTWARE LLC

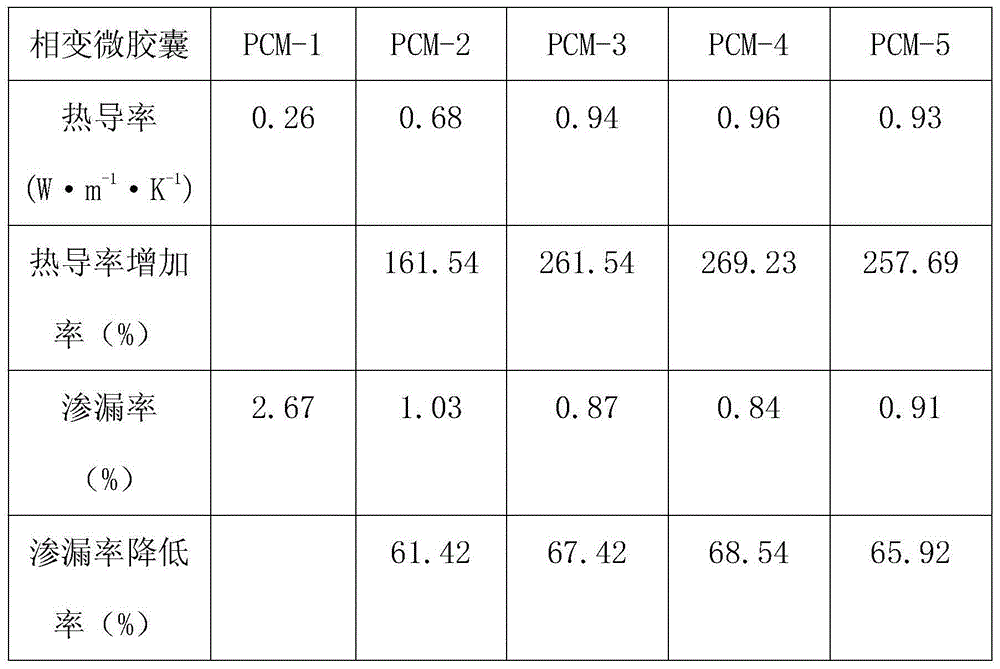

Preparation method of phase change microcapsule with graphene-modified wall material

InactiveCN104861934AImprove thermal conductivityReduce leak rateHeat-exchange elementsMicroballoon preparationState of artIn situ polymerization

The invention discloses a preparation method of a phase change microcapsule with a graphene-modified wall material. The preparation method comprises the following steps: preparing a graphene oxide solution; preparing a graphene-modified wall material pre-polymer; emulsifying a phase change material; preparing the phase change microcapsule with the graphene-modified wall material. A solid-liquid phase change material serves as a core material of the phase change microcapsule prepared by using an in-situ polymerization method, and a graphene-modified polymer serves as the wall material. Compared with the prior art in which graphene is not added for modification, the preparation method in which the graphene is added into the wall material has the advantages that the heat conductivity of the phase change microcapsule is improved, and the leakage rate is lower.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

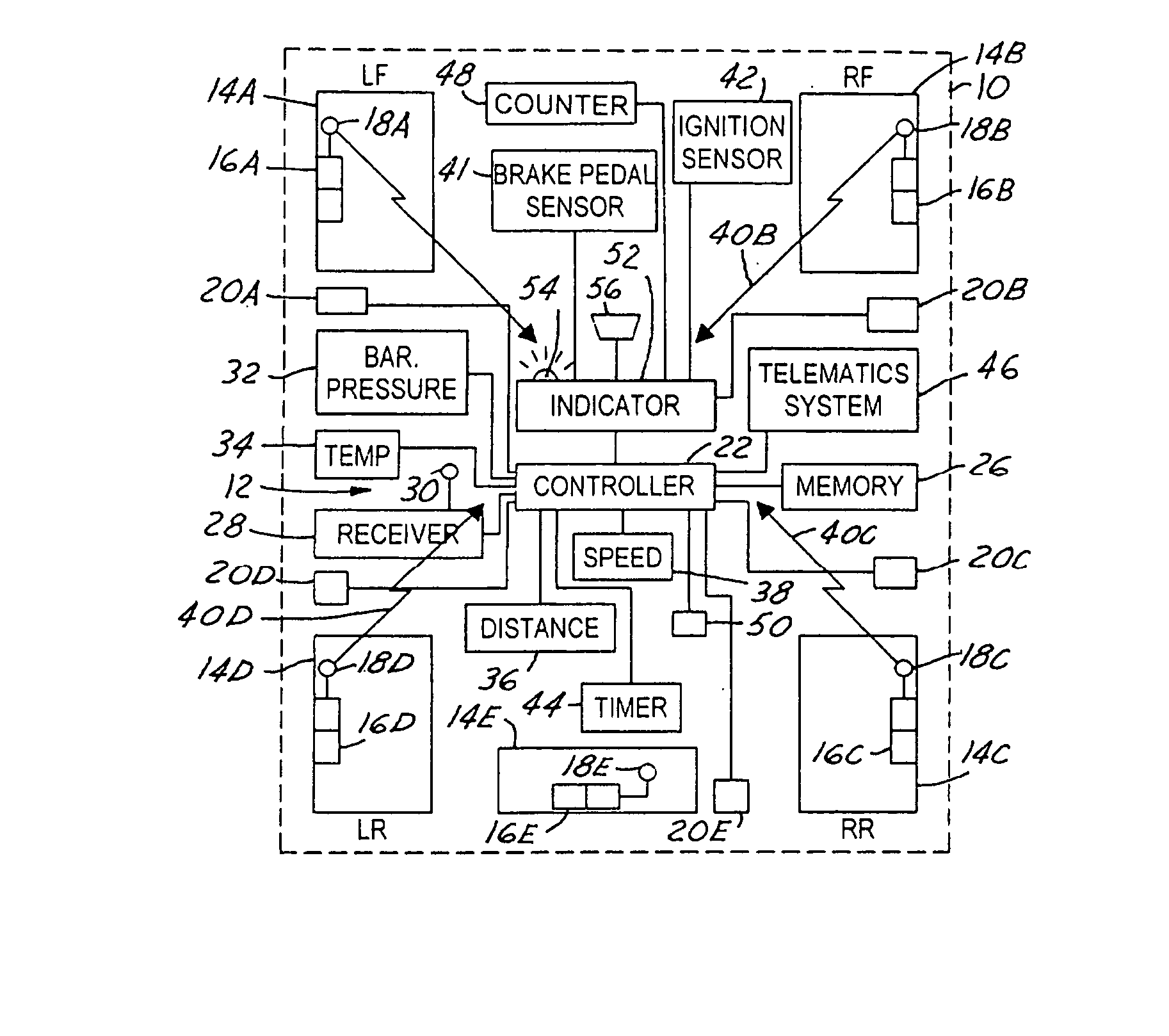

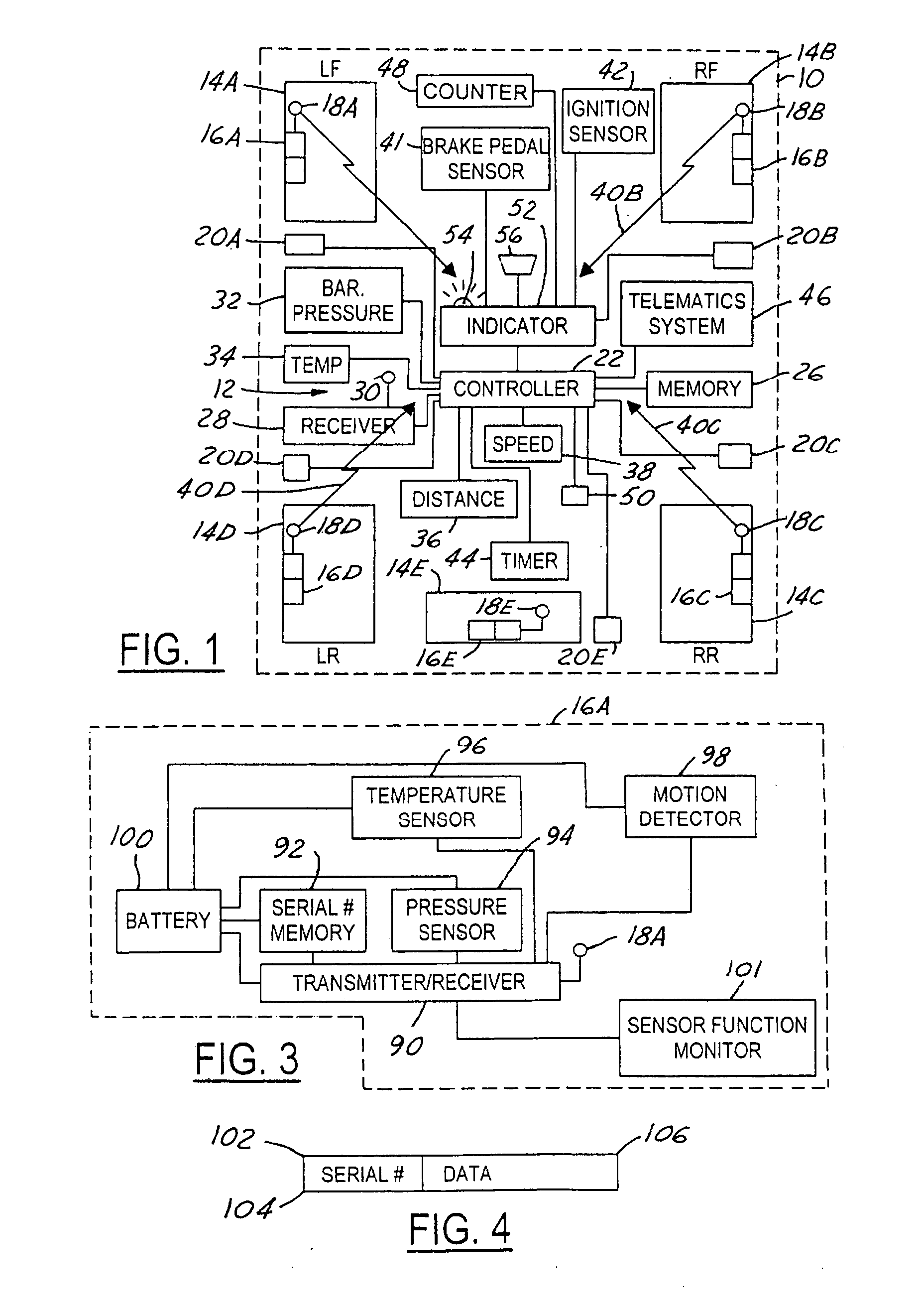

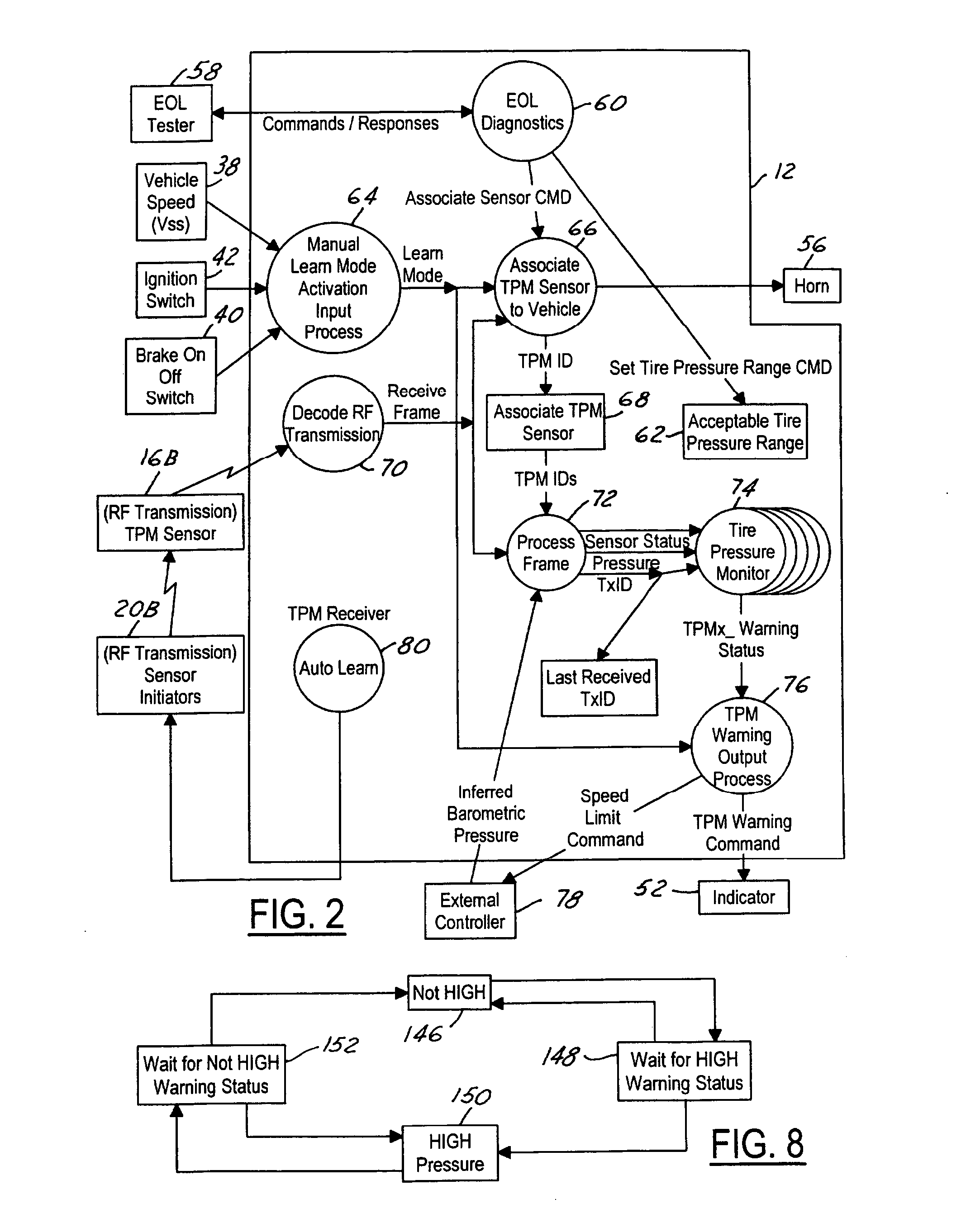

Method and apparatus for detecting leakage rate in a tire pressure monitoring system

InactiveUS20060010961A1Quickly alertedDetection of fluid at leakage pointTyre measurementsEngineeringTire-pressure monitoring system

A tire pressure monitoring system for a vehicle has been disclosed that can detect an excessive leakage rate of a tire. The system utilizes the starting pressure and starting temperature of a tire and the current pressure and current temperature of that tire with the time lapsed to determine the leakage rate of the tire. This leakage rate is compared to a leakage rate threshold. If the leakage rate is greater than the leakage rate threshold, an excessive leakage rate alert is generated.

Owner:FORD GLOBAL TECH LLC

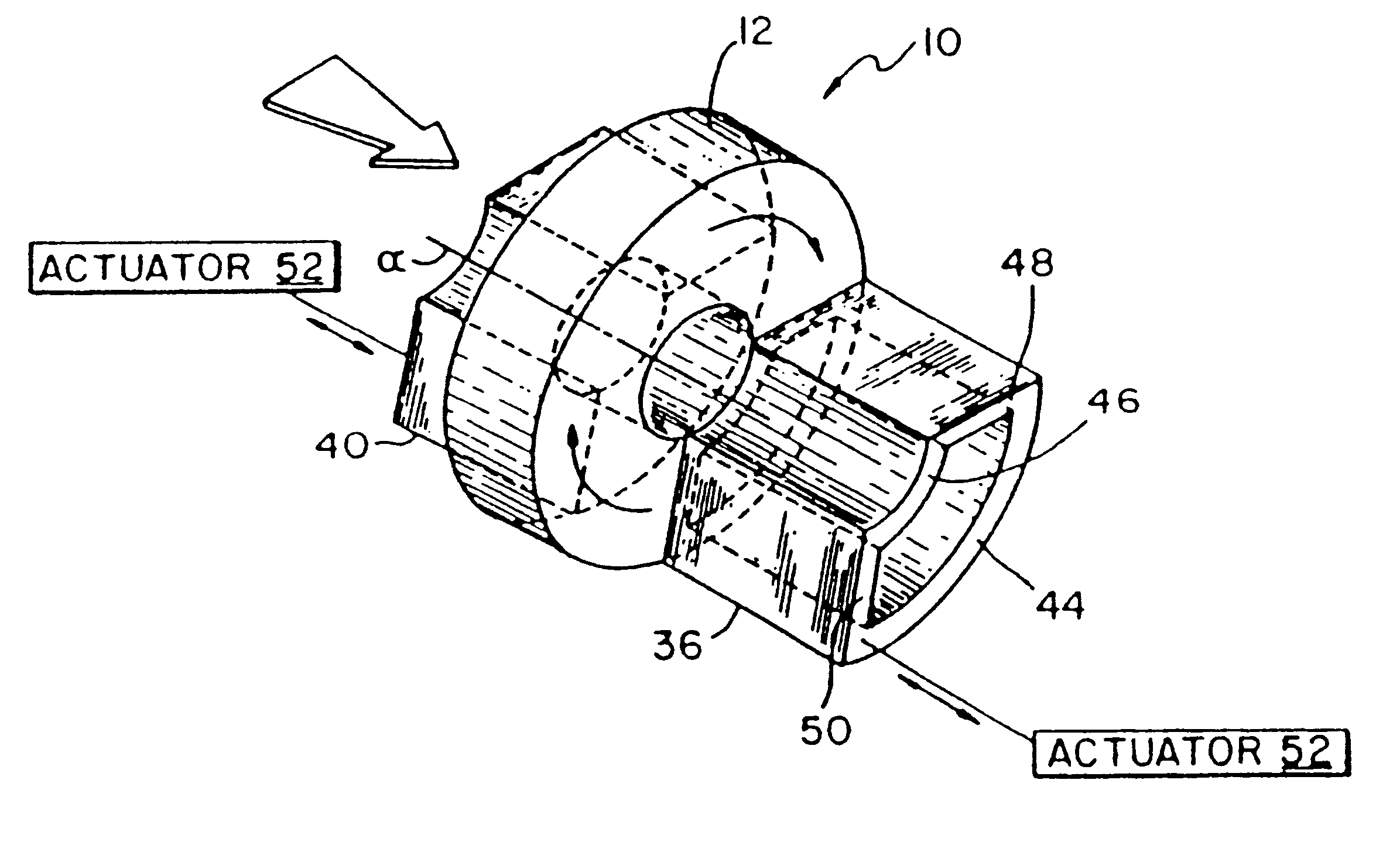

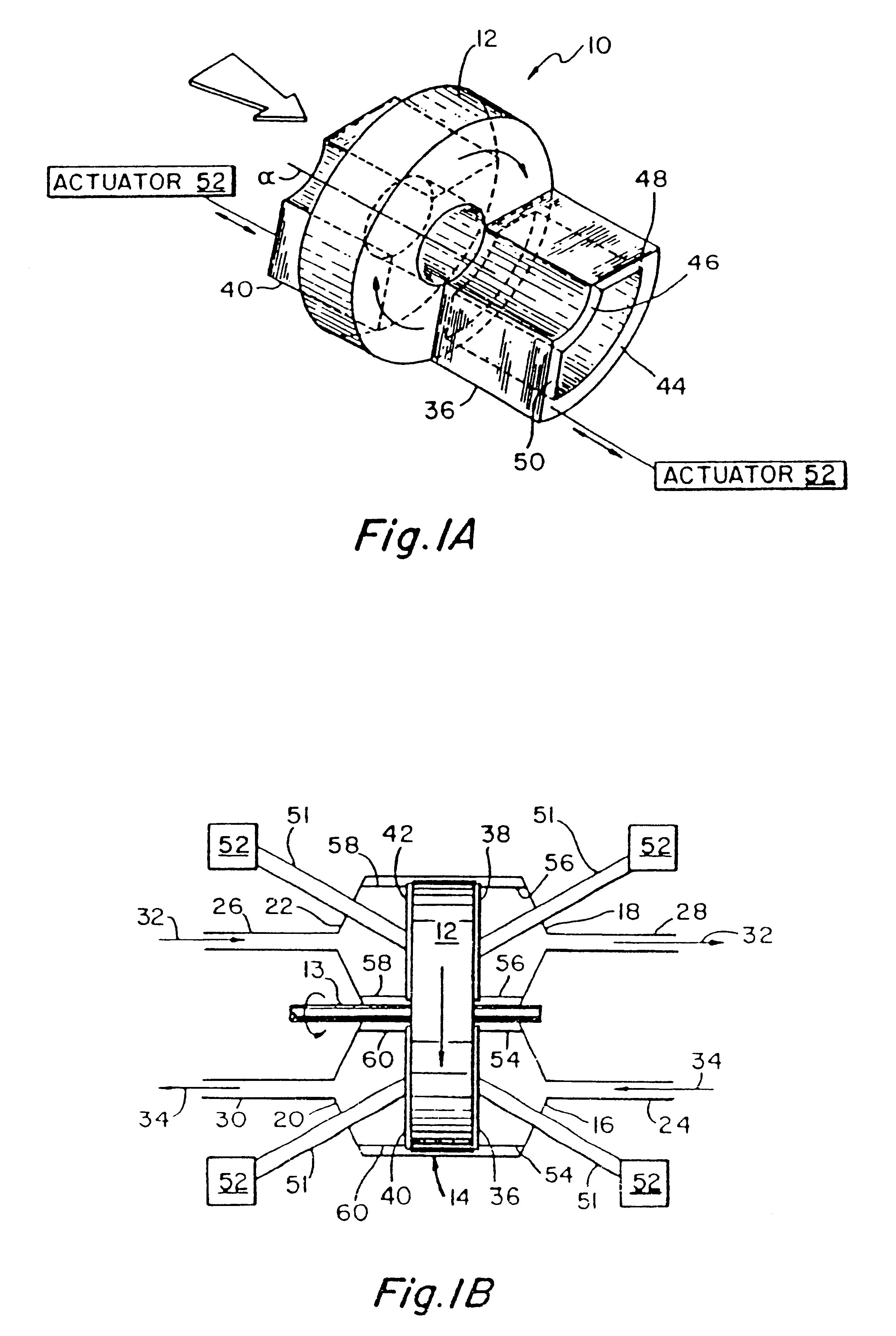

Heat exchanger containing a component capable of discontinuous movement

InactiveUSRE37134E1Reduced Seal LeakageReduce leak rateCombustion processRegenerative heat exchangersEngineeringMicro heat exchanger

Owner:MASSACHUSETTS INST OF TECH

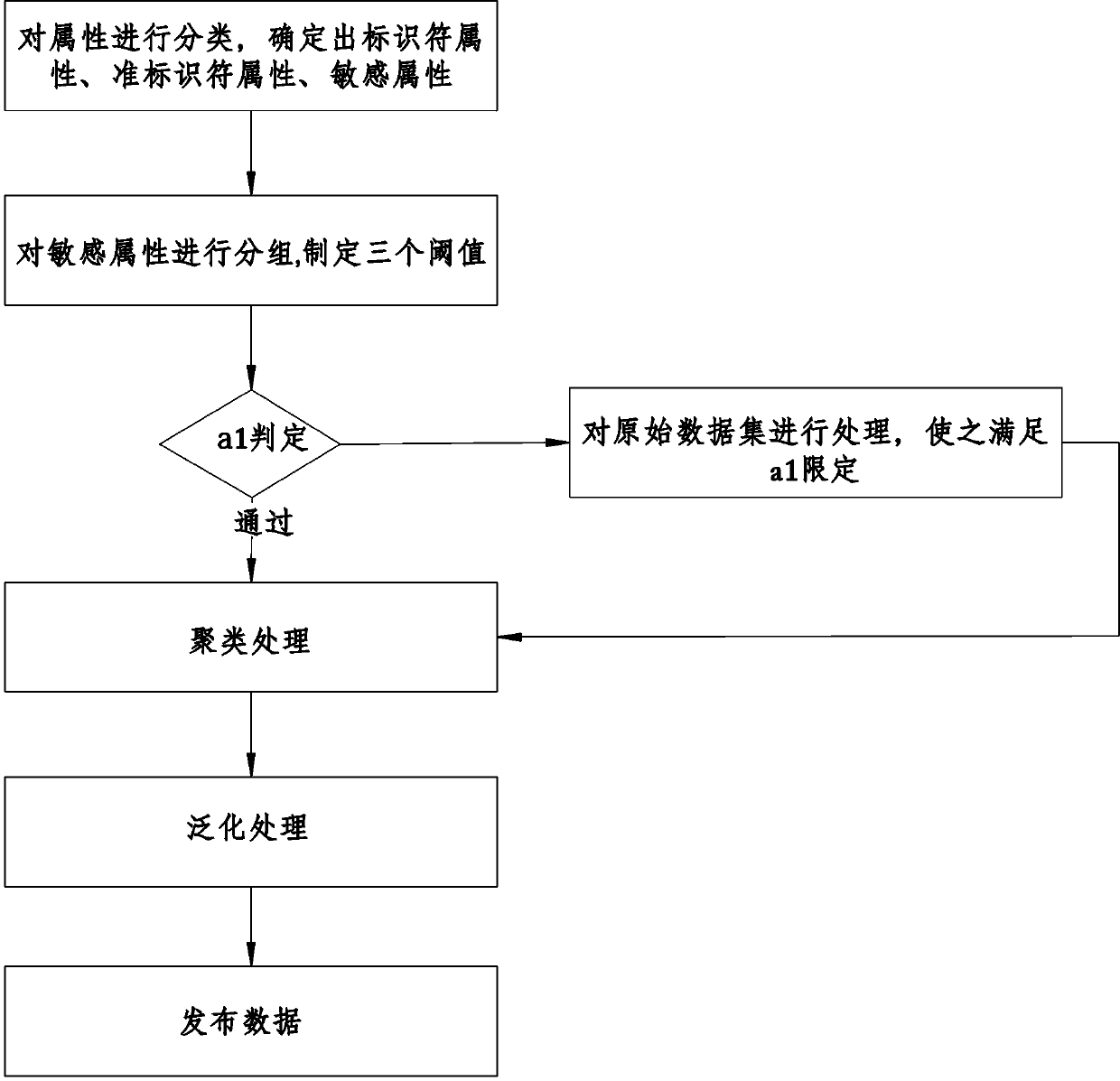

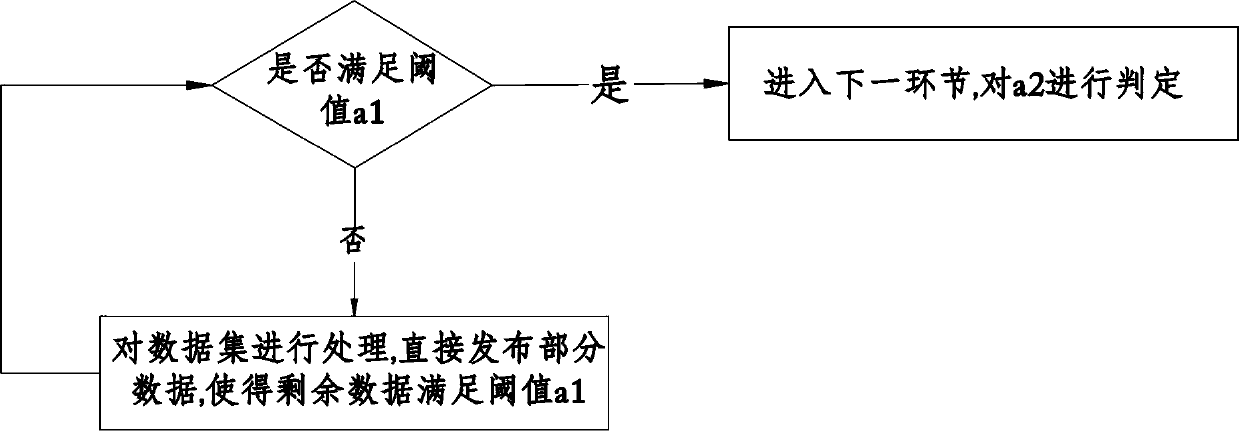

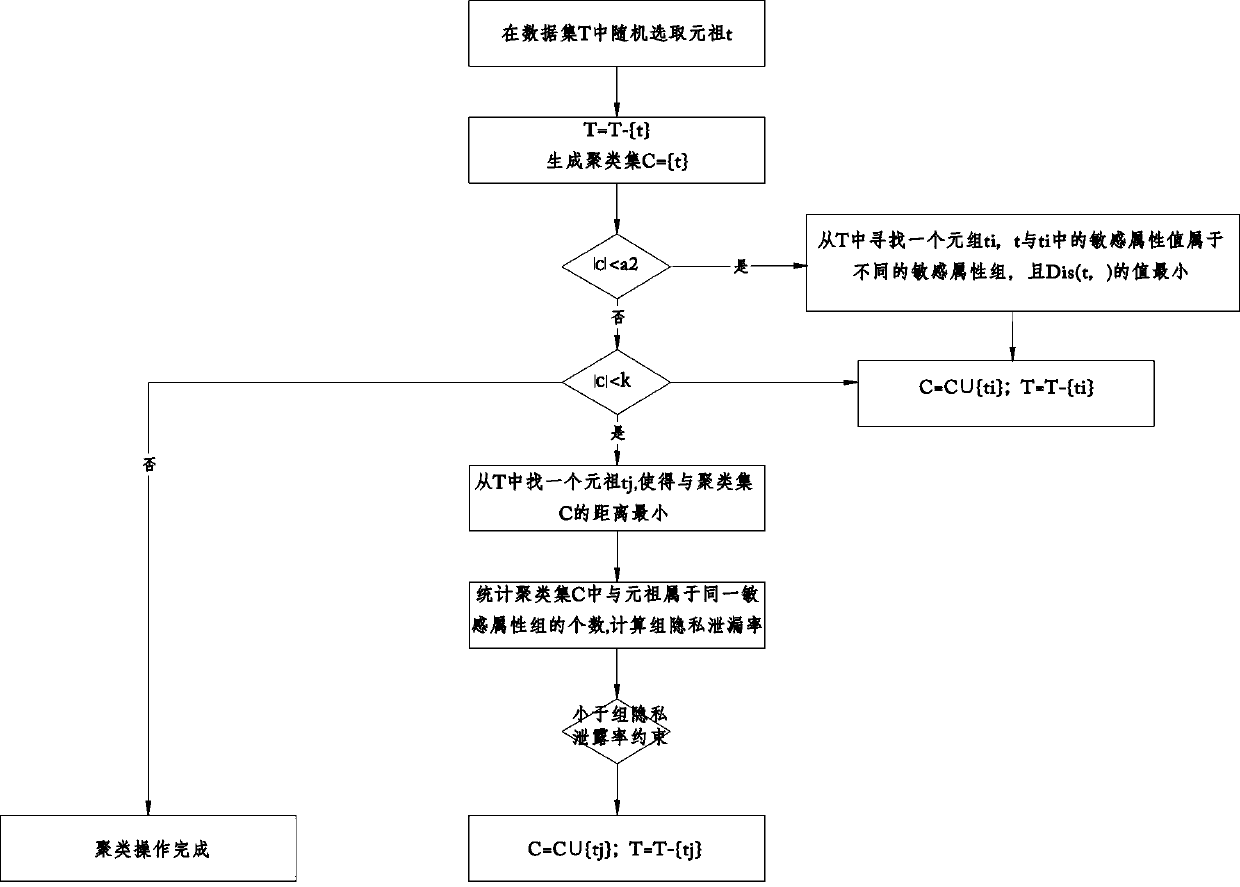

Health data privacy protection method based on K-anonymity

ActiveCN105512566APrevent Consistency AttacksFlexible handling of anonymityDigital data protectionData setK-anonymity

The invention relates to a health data privacy protection method based on the K-anonymity. The health data privacy protection method comprises that (1) sensitive information is divided into groups, the privacy leakage rate of each group is set for restraint; (2) statistics is carried out to the tuple number of different sensitive attribute values in the data set; (3) whether clustering operation is directly carried out to data or only part of the data is processed is judged in dependence on a threshold a1; (4) whether the number of the sensitive attribute values is larger than a2 is judged, if the number of the sensitive attribute values is larger than a2, the next step is executed, otherwise the process is stopped; (5) clustering processing is carried out to the data; and (6) generalization processing is carried out to the data. According to the invention, K-anonymity processing is carried out to the data, and therefore the processed data can resist linking attack, and consistency attack can be effectively prevented.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

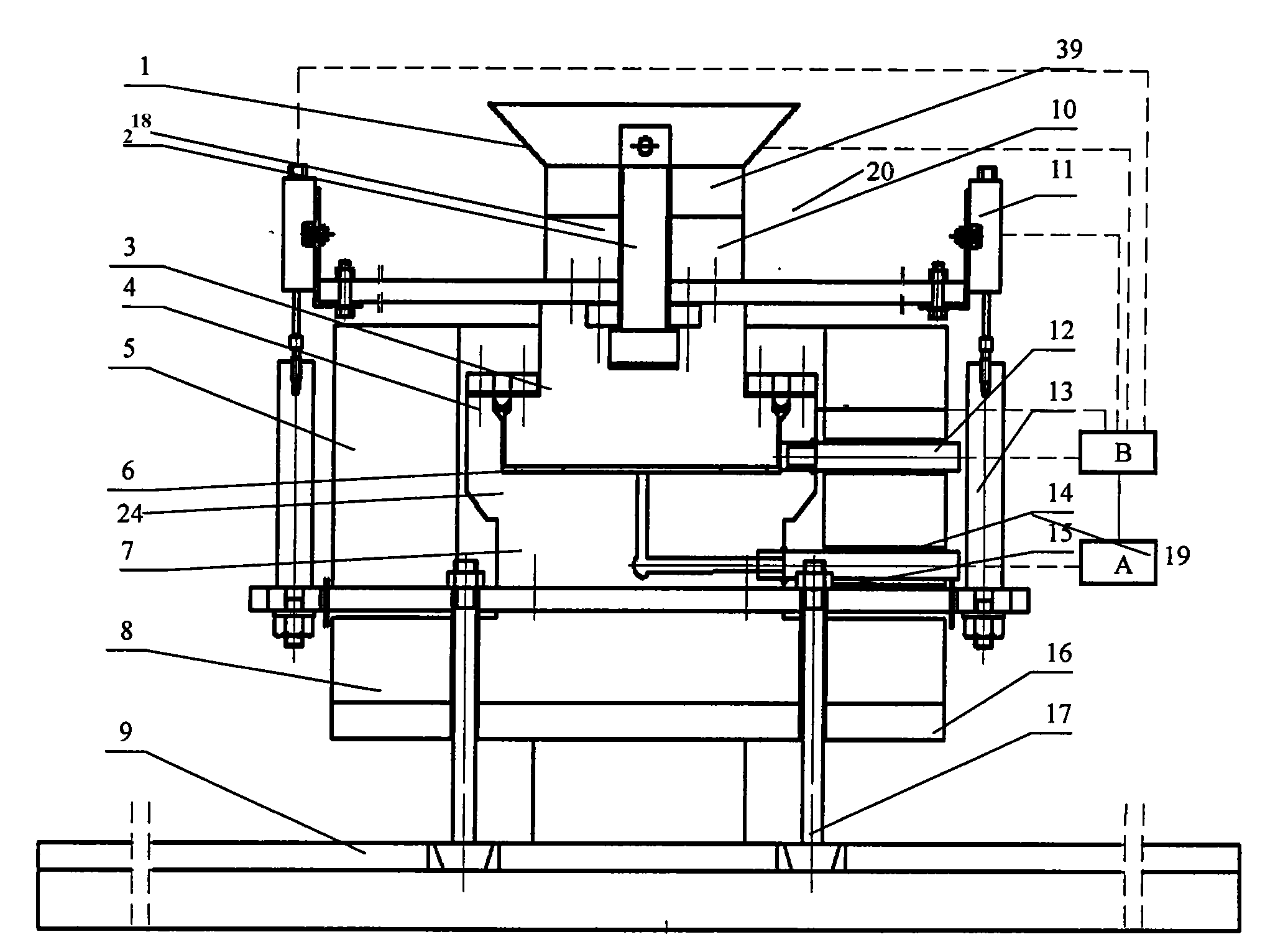

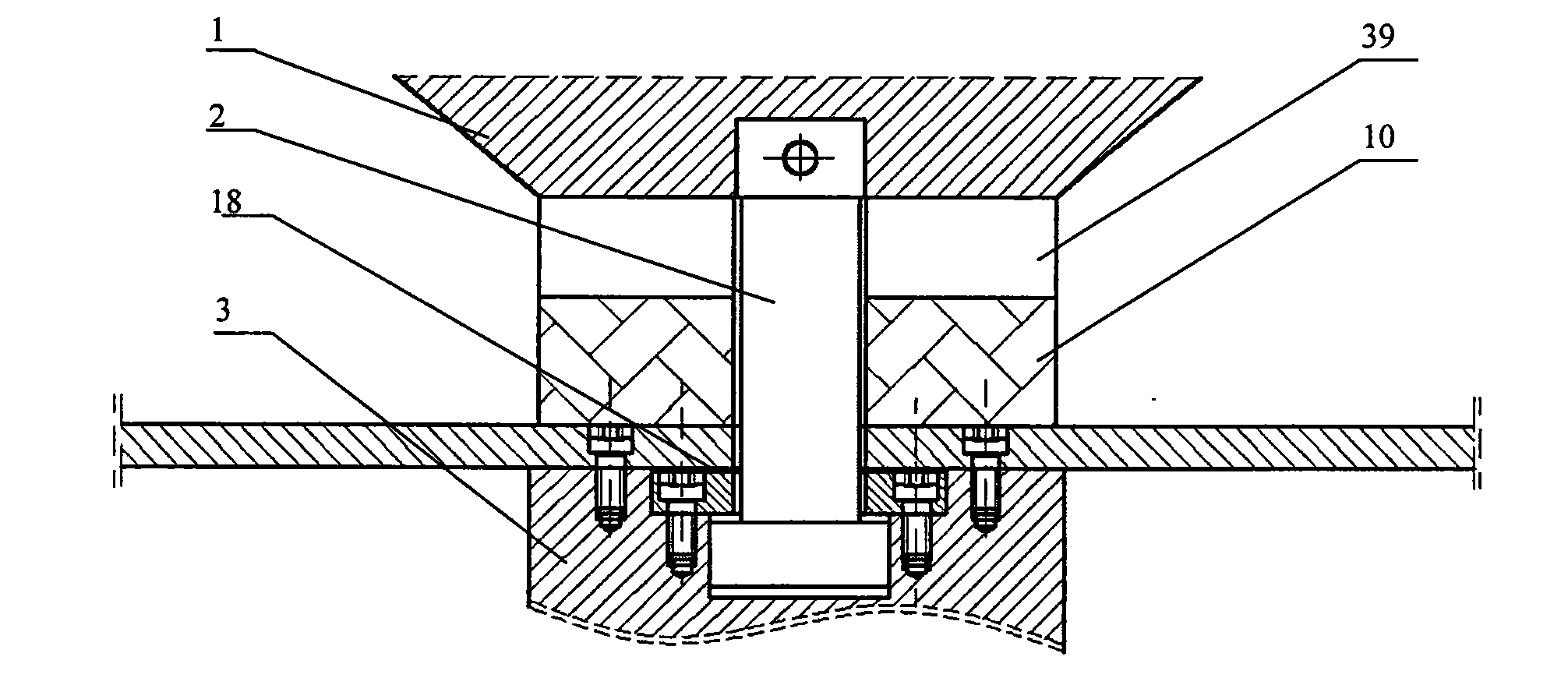

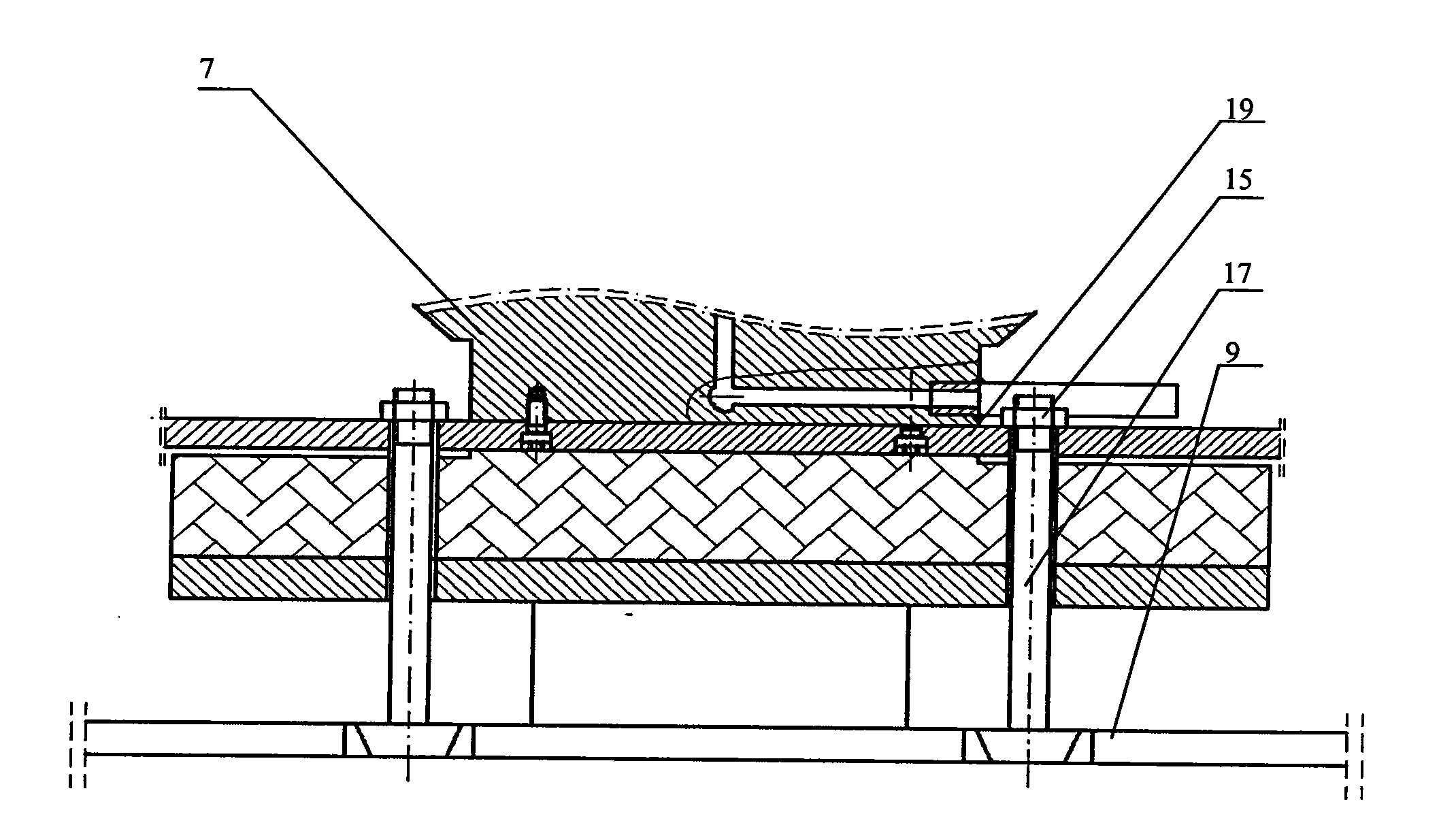

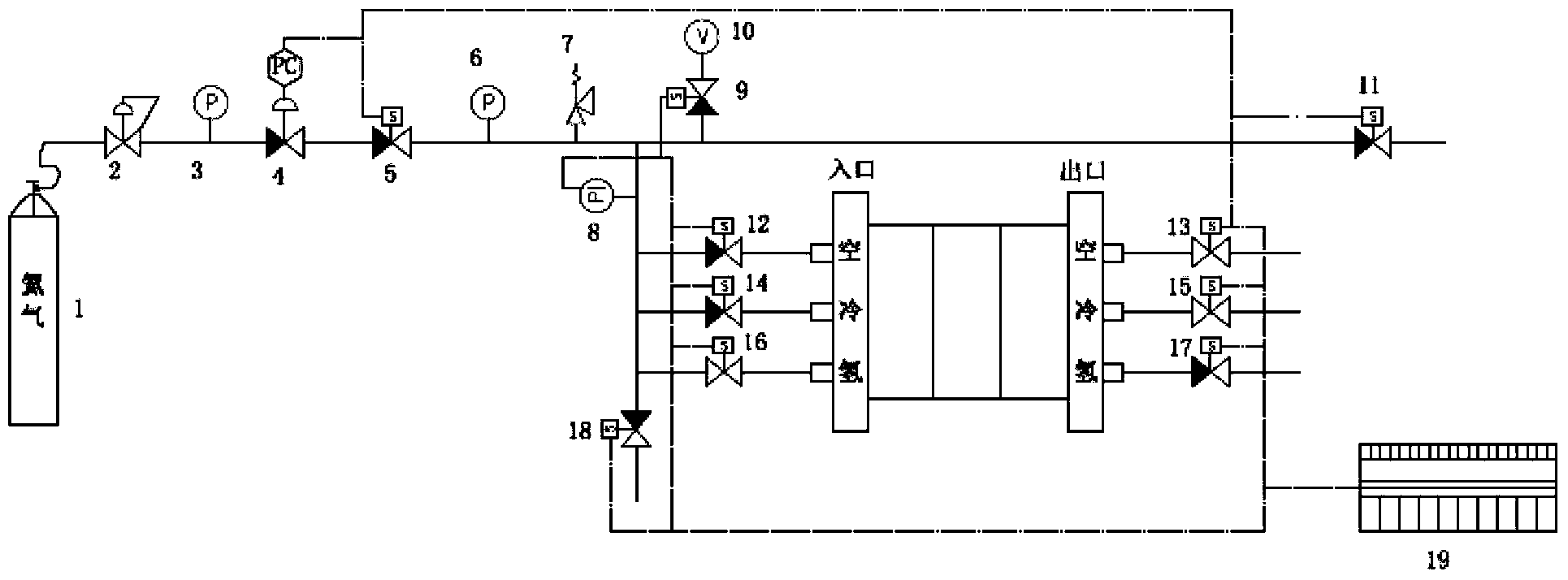

High-temperature comprehensive property evaluation experimental device of sealing spacer

InactiveCN101655437AAchieve high temperature compression reboundAchieve resilienceMeasurement of fluid loss/gain rateInvestigating material ductilityData acquisitionSmall footprint

The invention relates to a high-temperature comprehensive property evaluation experimental device of a sealing spacer, comprising a spacer loading system, a flange lifting separation system, a spacerdeformation measuring system, a heating and temperature control measuring system, a cooling heat insulation system, a medium setting system, a medium sealing and leakage rate measuring system and a data acquisition system. The invention has the advantages of high parameter, convenient experiment, compact structure of a whole experimental machine, small occupying area, and the like, takes a low-pressure area as a leakage measuring cavity, enhances the measuring precision of the pressure of the leakage measuring cavity and also effectively avoids the problem of pipeline leakage caused by takinga high-pressure area as a leakage cavity so that the measurement of the sealing property of the spacer is more accurate; and in addition, the flange lifting separation system can solve the problem ofthe difficult bonding and separation of the high-temperature experimental spacer and a flange.

Owner:NANJING UNIV OF TECH

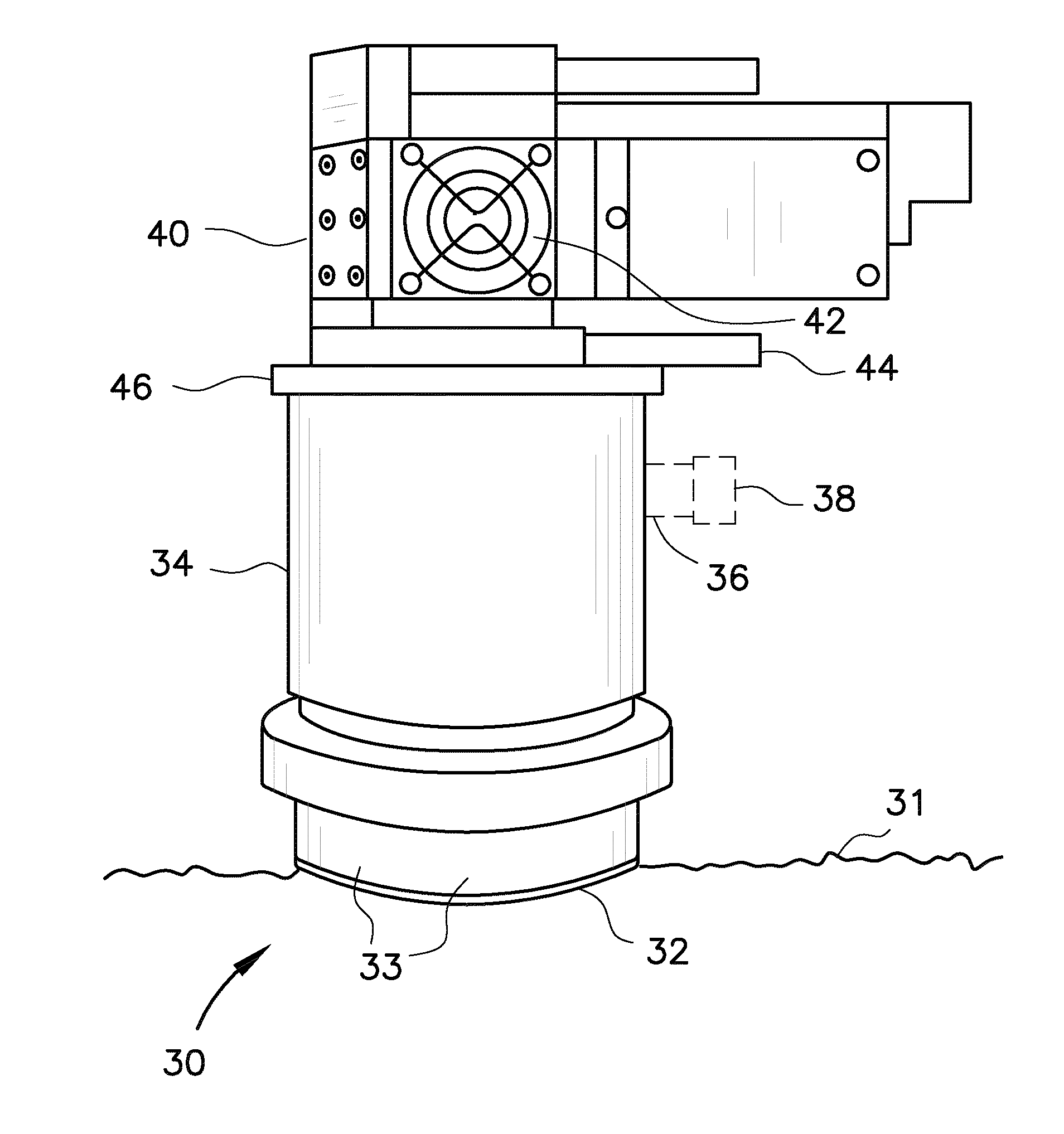

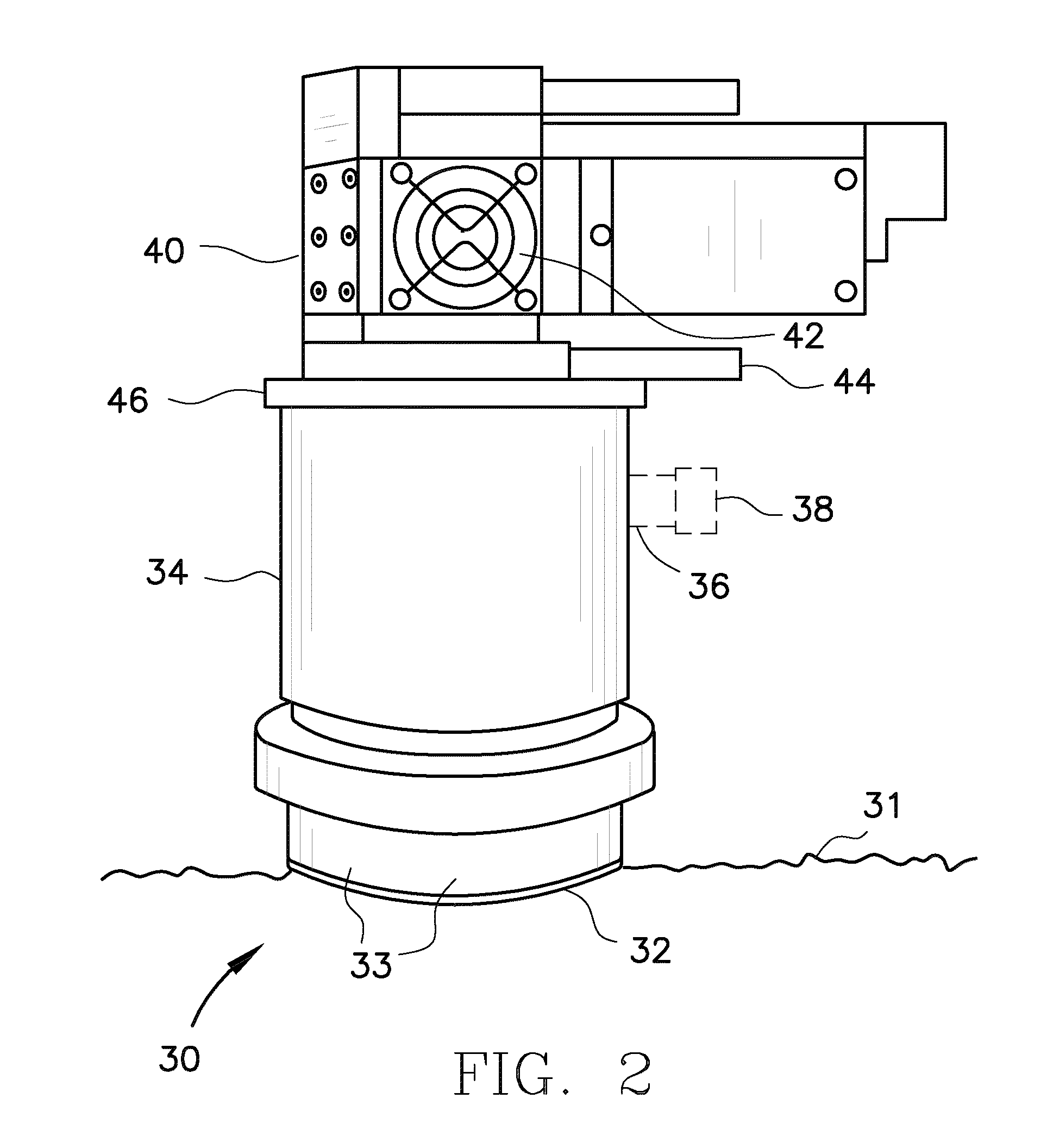

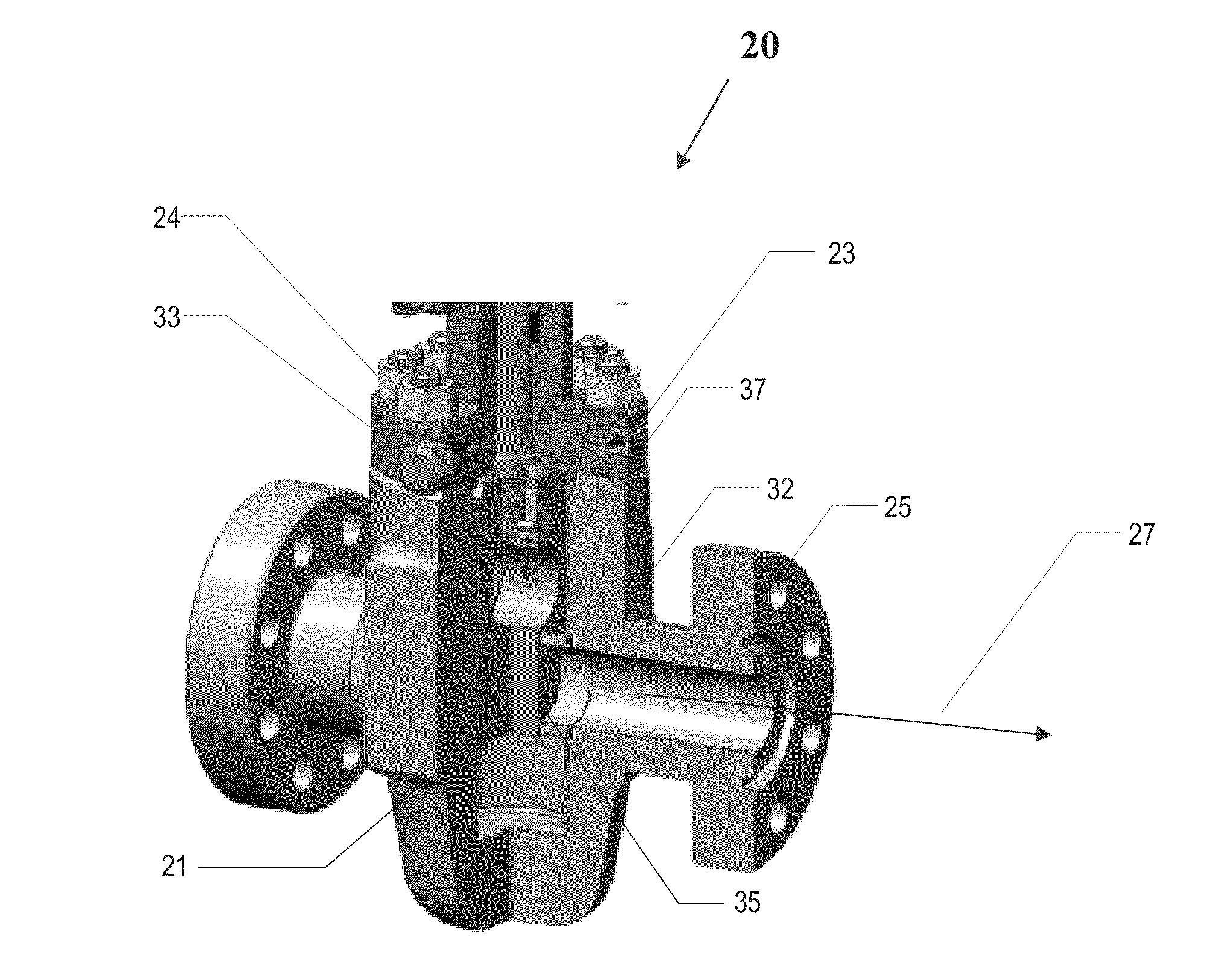

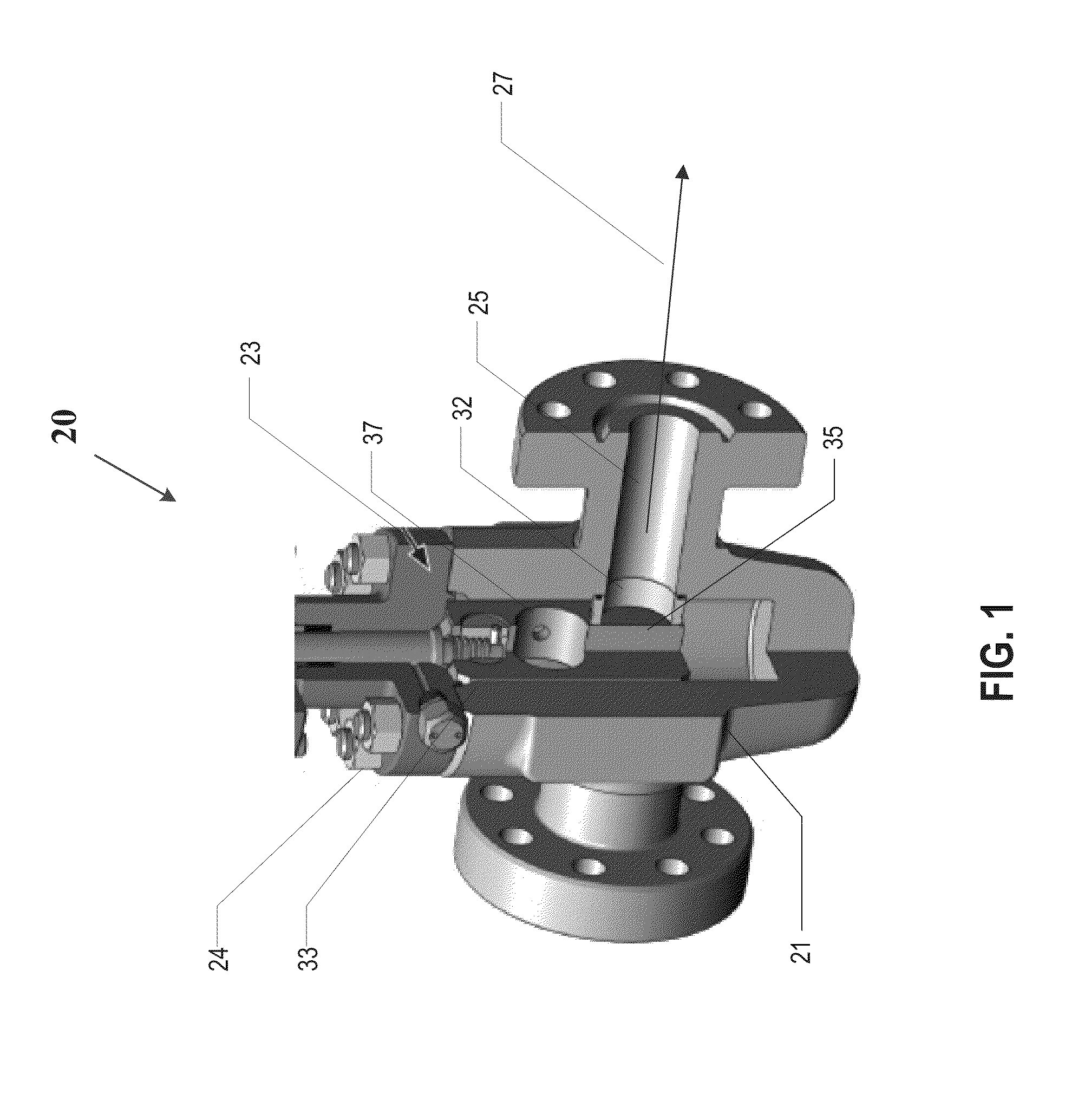

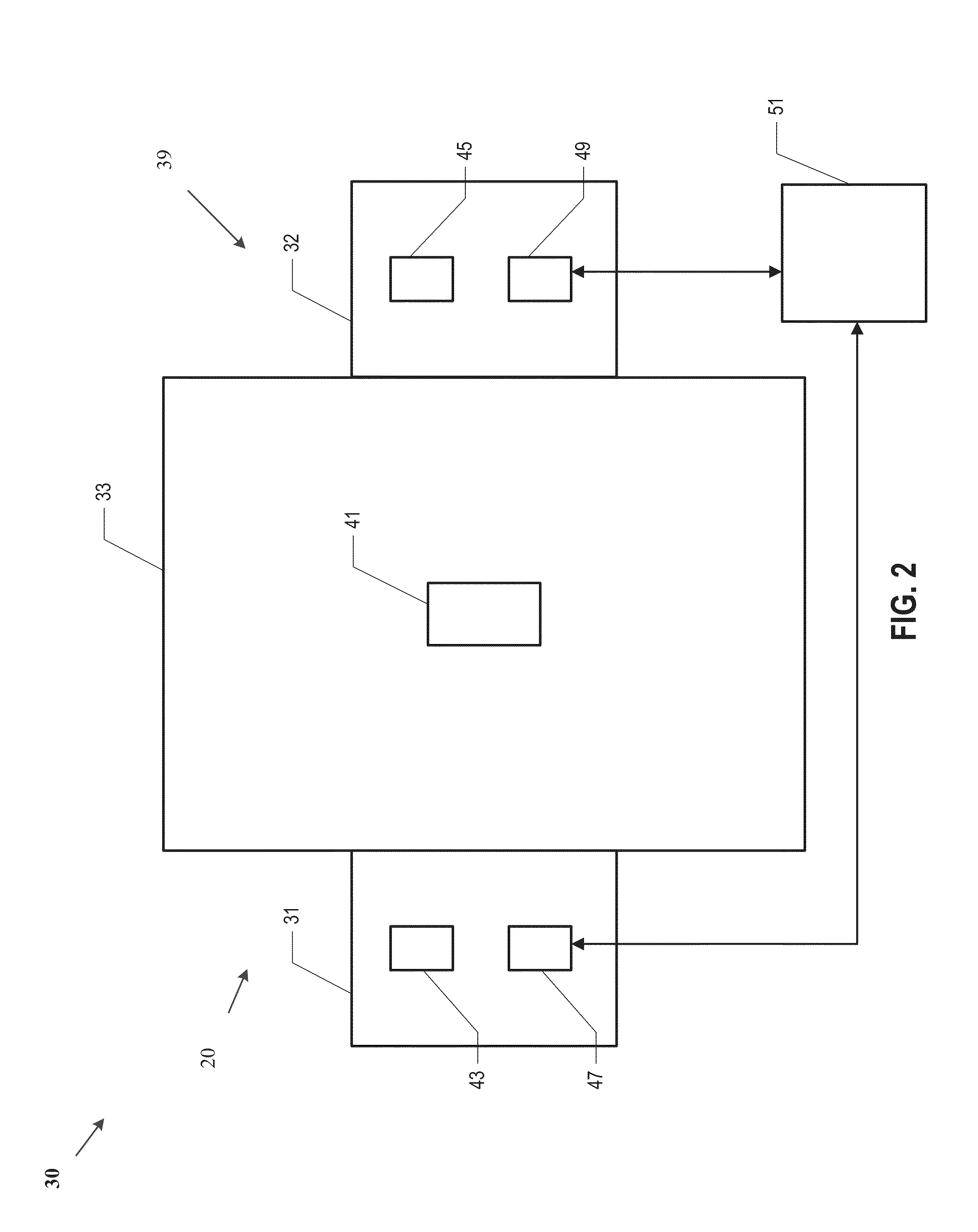

Gate Valve Real Time Health Monitoring System, Apparatus, Program Code and Related Methods

ActiveUS20140182381A1Eliminating and reducing downtimeEliminating and reducing and human interventionVibration measurement in solidsProgramme controlAcoustic emissionEngineering

Systems, apparatus, and program code, and methods for monitoring the health and other conditions of the valve, are provided. An exemplary system for monitoring the condition of the gate valve includes a logic module configured to perform the operations of receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface. An exemplary method for monitoring the condition of the gate valve includes receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface.

Owner:VETCO GRAY LLC

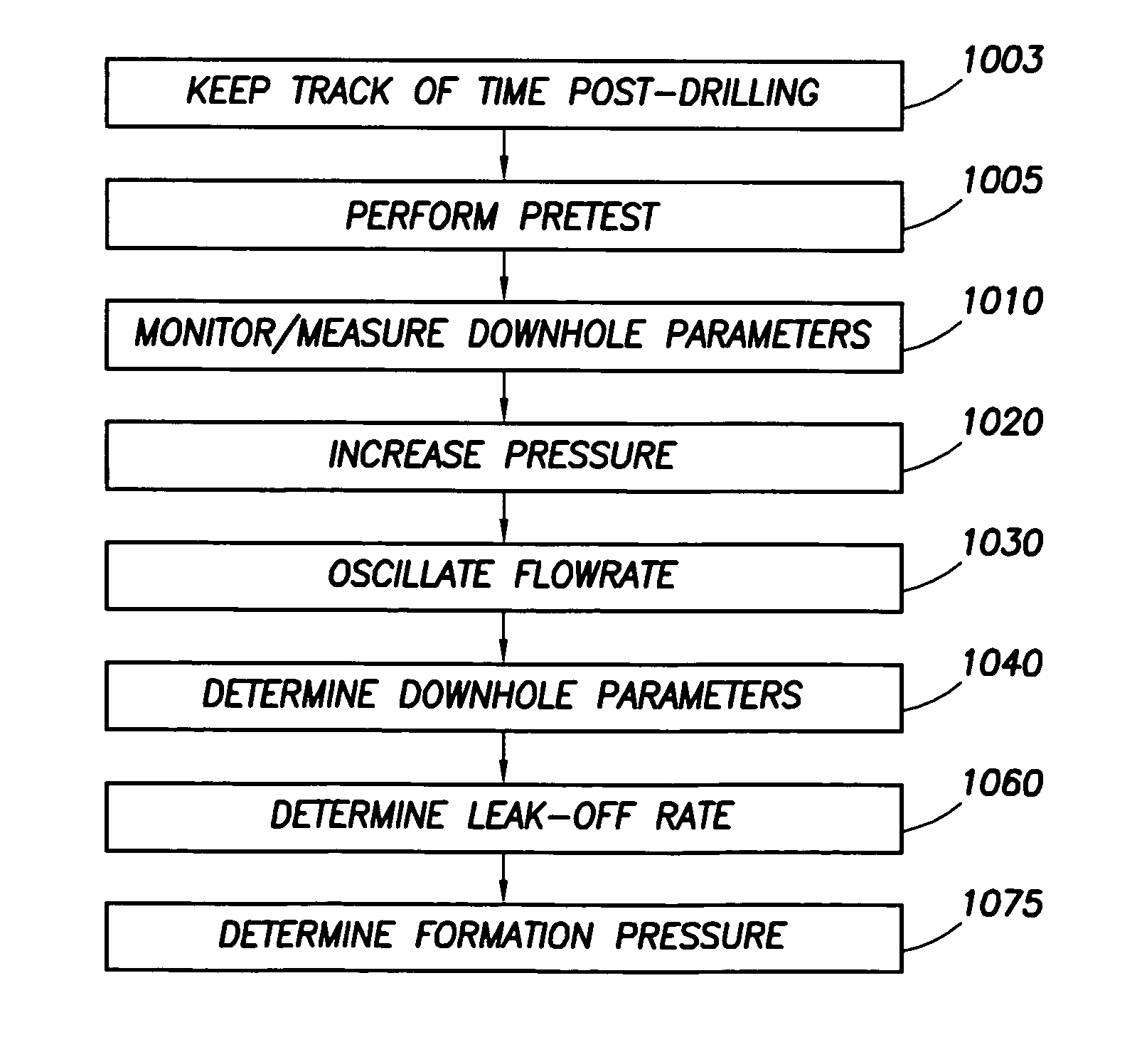

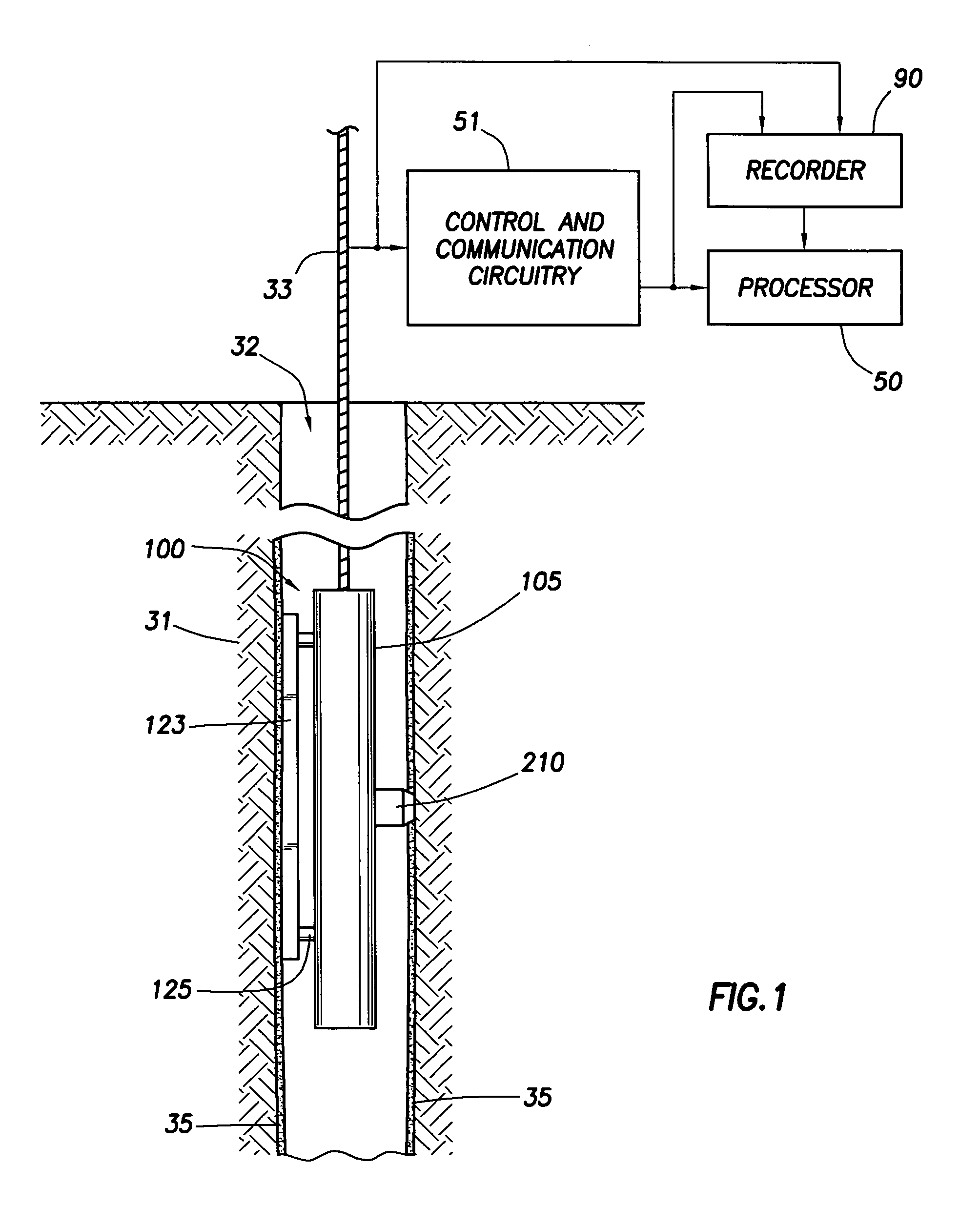

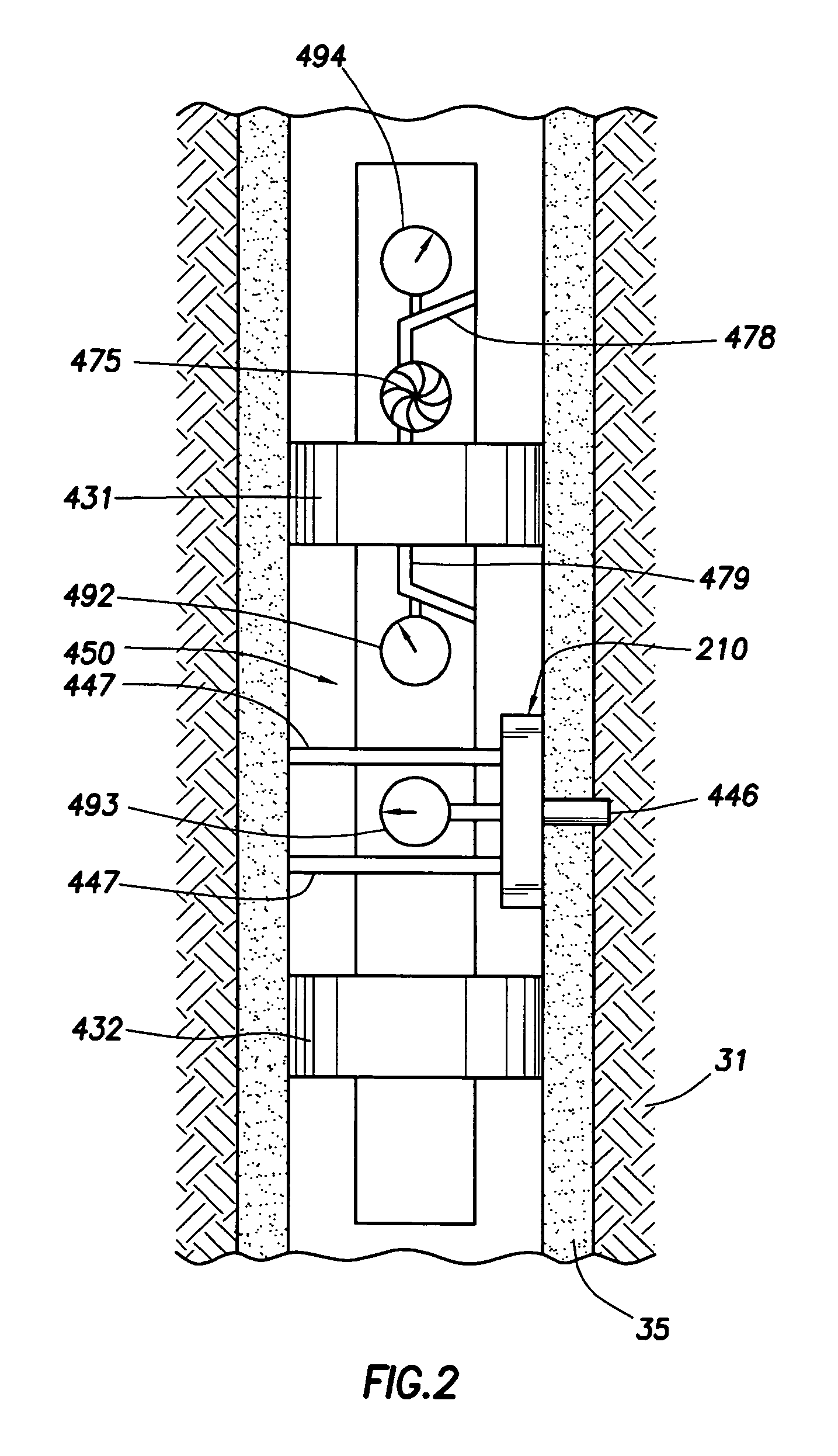

Method for determining pressure of earth formations

A method for determining formation pressure at a depth region of formations surrounding a borehole, including: keeping track of the time since cessation of drilling at the depth region; deriving formation permeability at the depth region; causing wellbore pressure to vary periodically in time and determining, at the depth region, the periodic and non-periodic component of pressure measured in the formations; determining, using the time, the periodic component and the permeability, the formation pressure diffusivity and transmissibility and an estimate of the size of the pressure build-up zone around the wellbore at the depth region; determining, using the time, the formation pressure diffusivity and transmissibility, and the non-periodic component, the leak-off rate of the mudcake at the depth region; determining, using the leak-off rate, the pressure gradient at the depth region; and extrapolating, using the pressure gradient and the size of the build-up zone, to determine the formation pressure.

Owner:SCHLUMBERGER TECH CORP

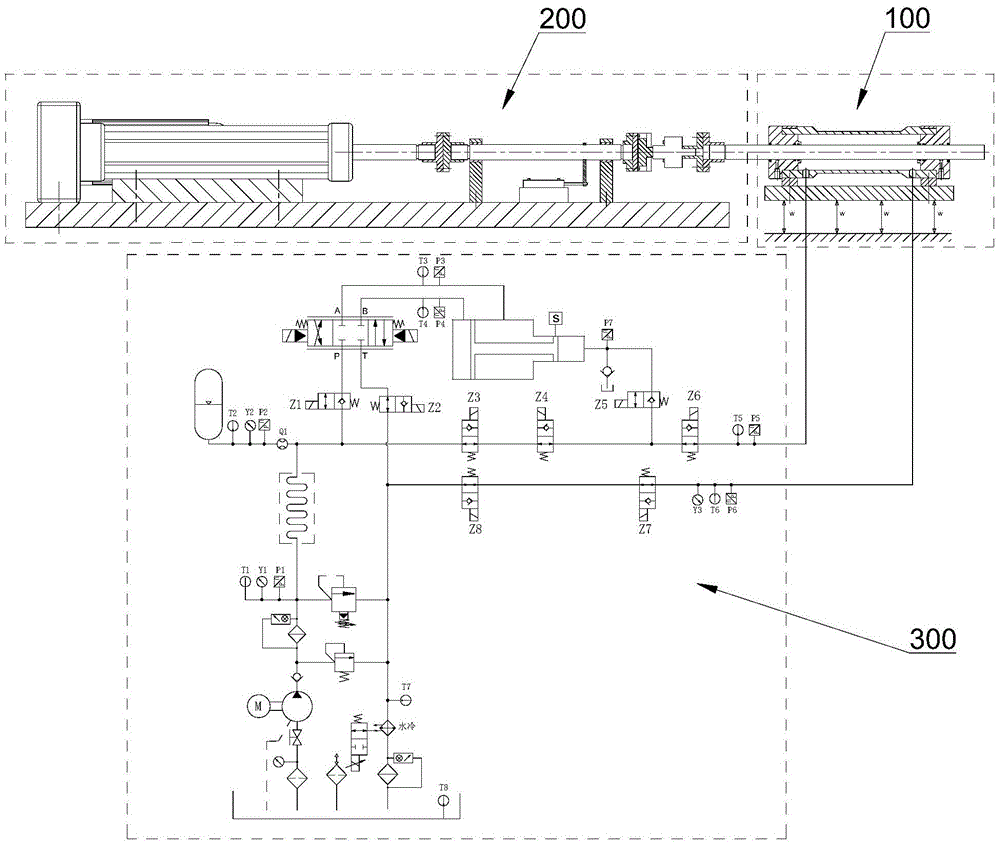

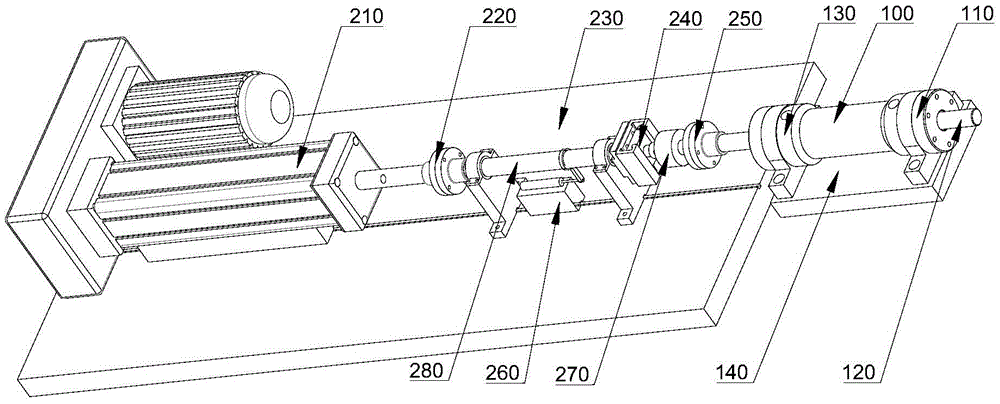

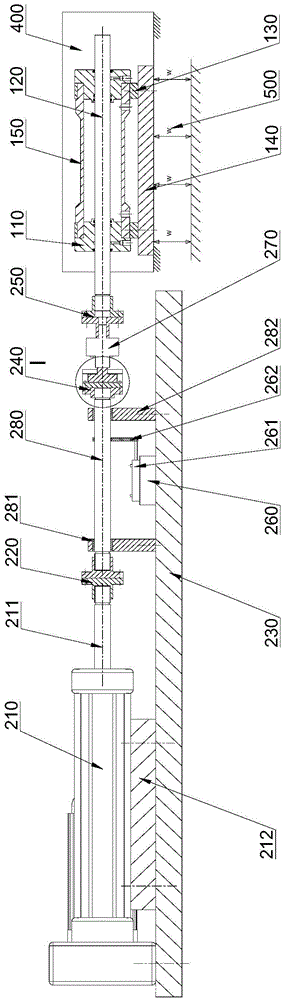

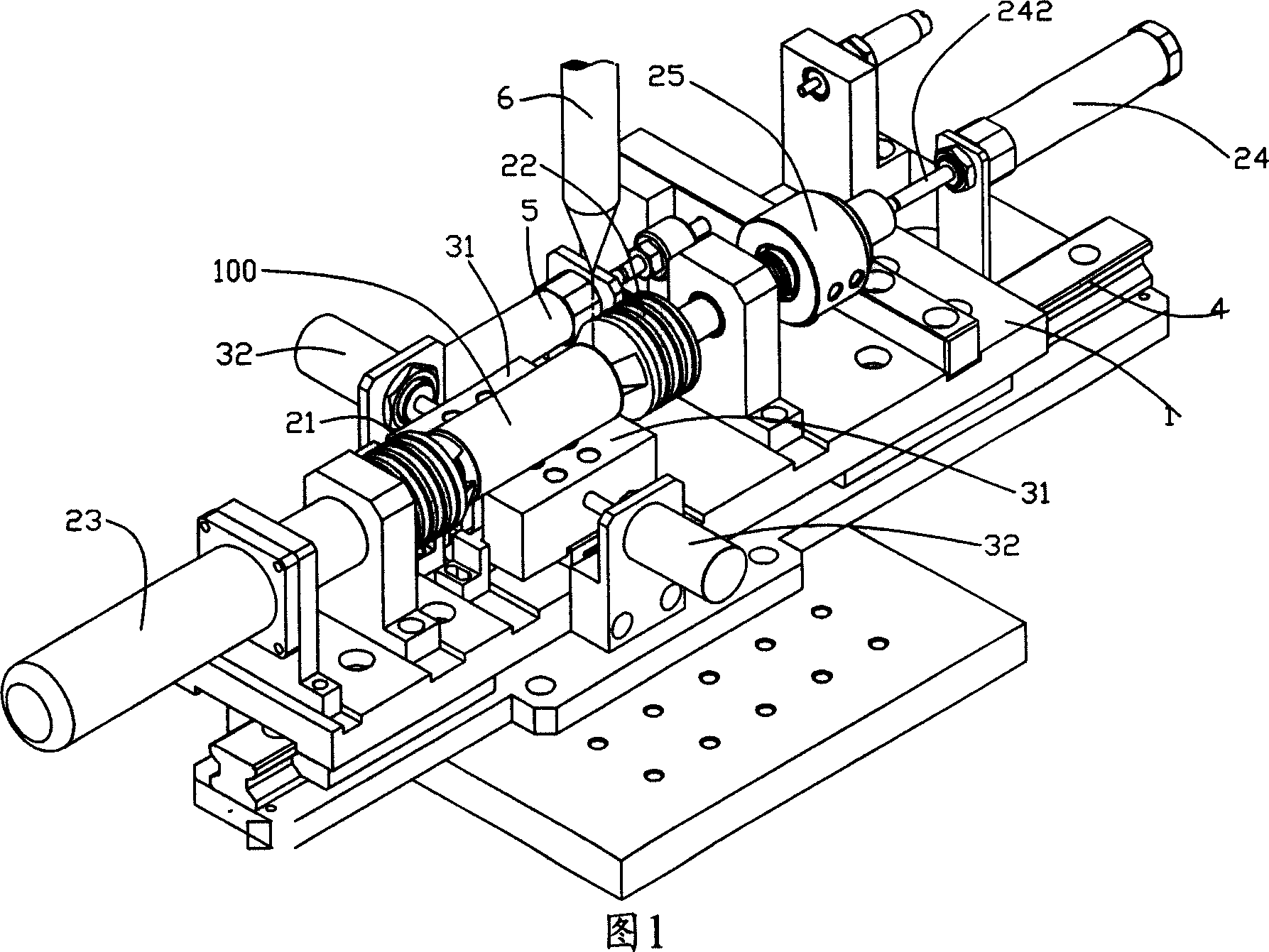

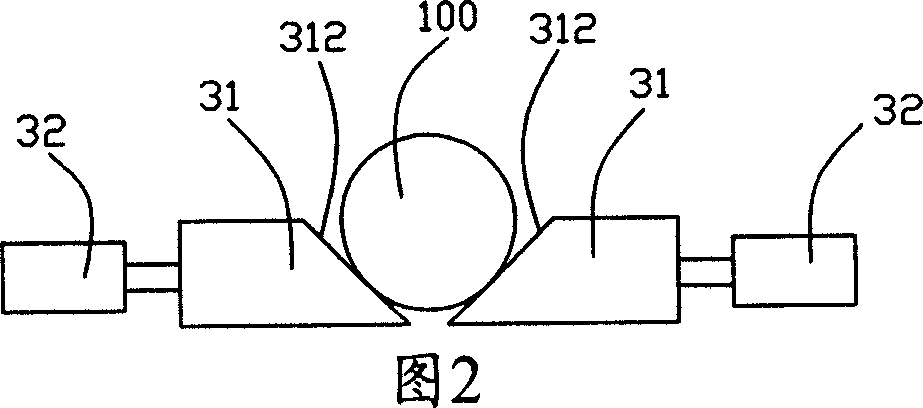

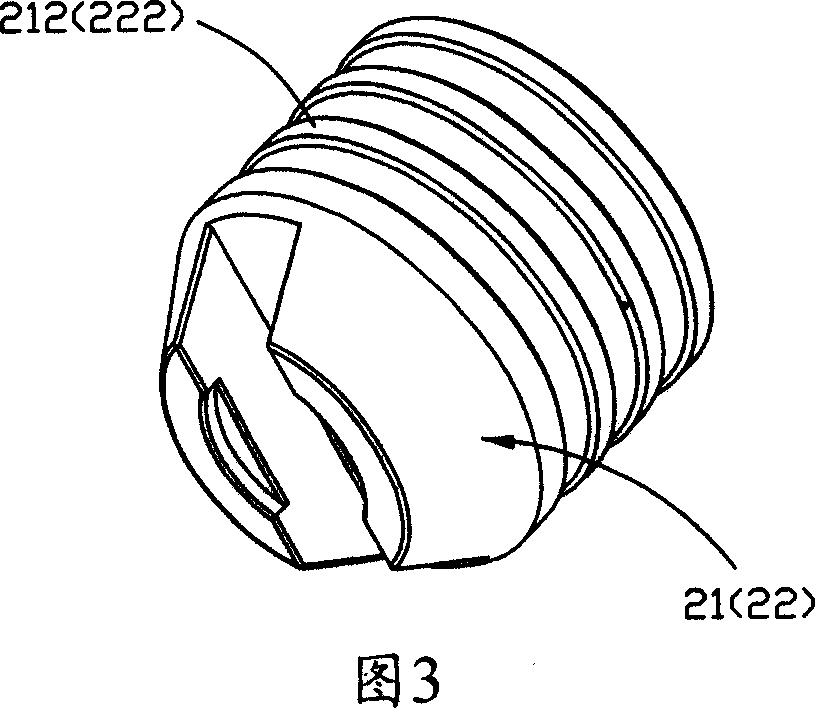

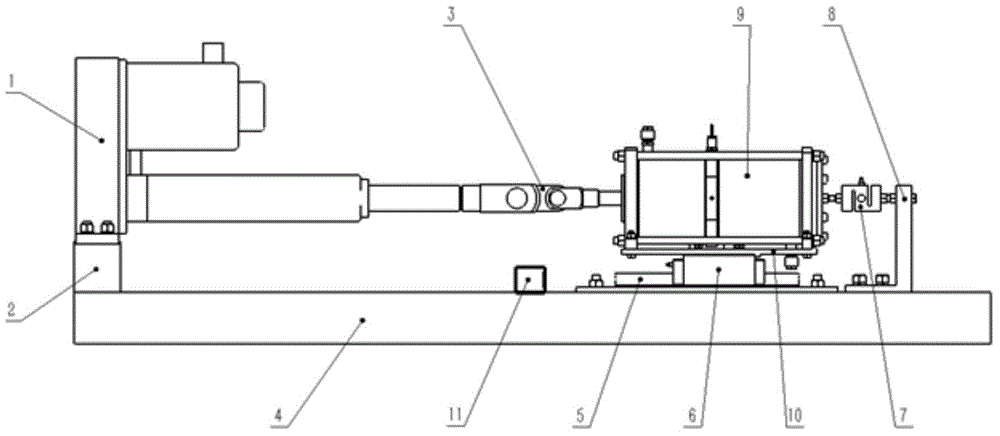

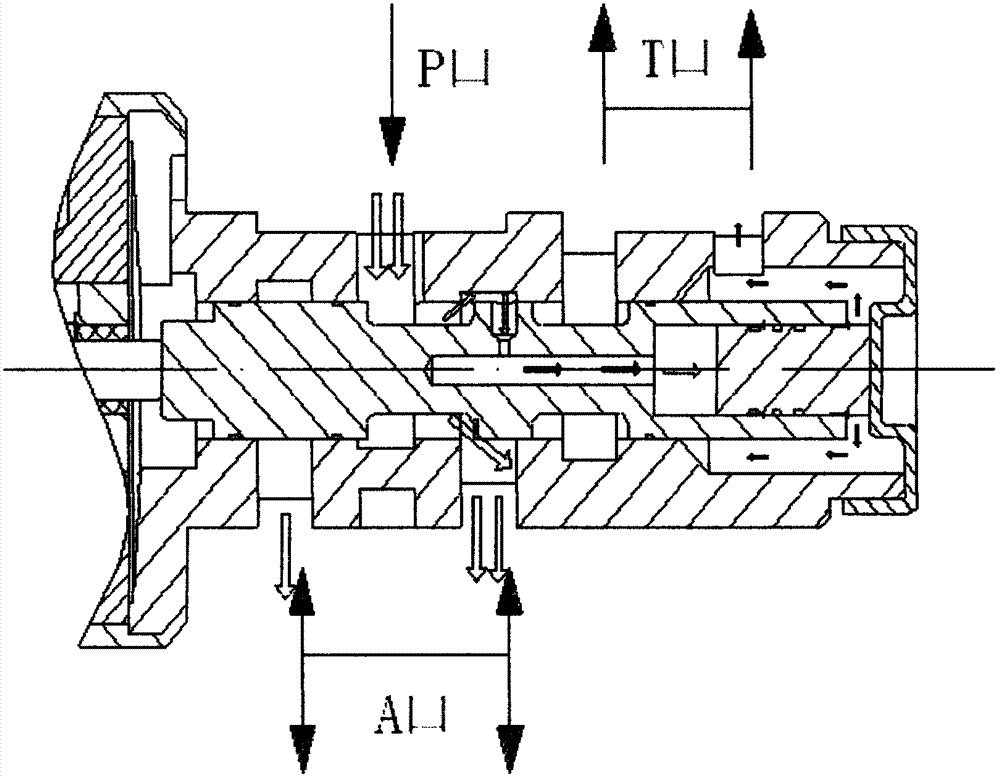

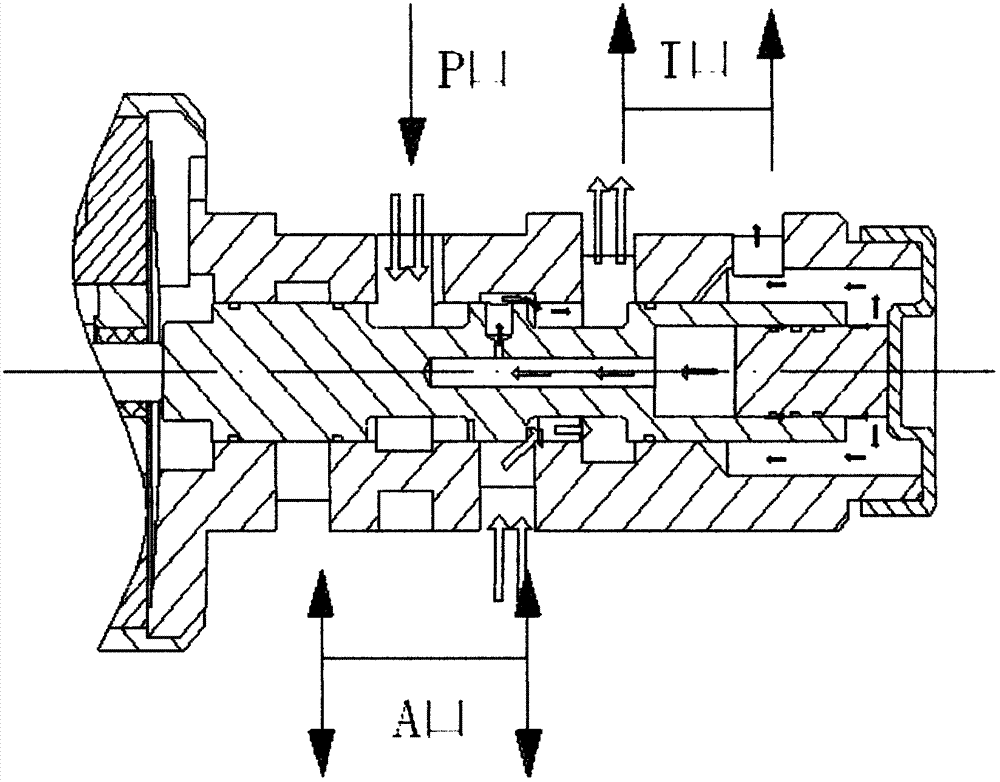

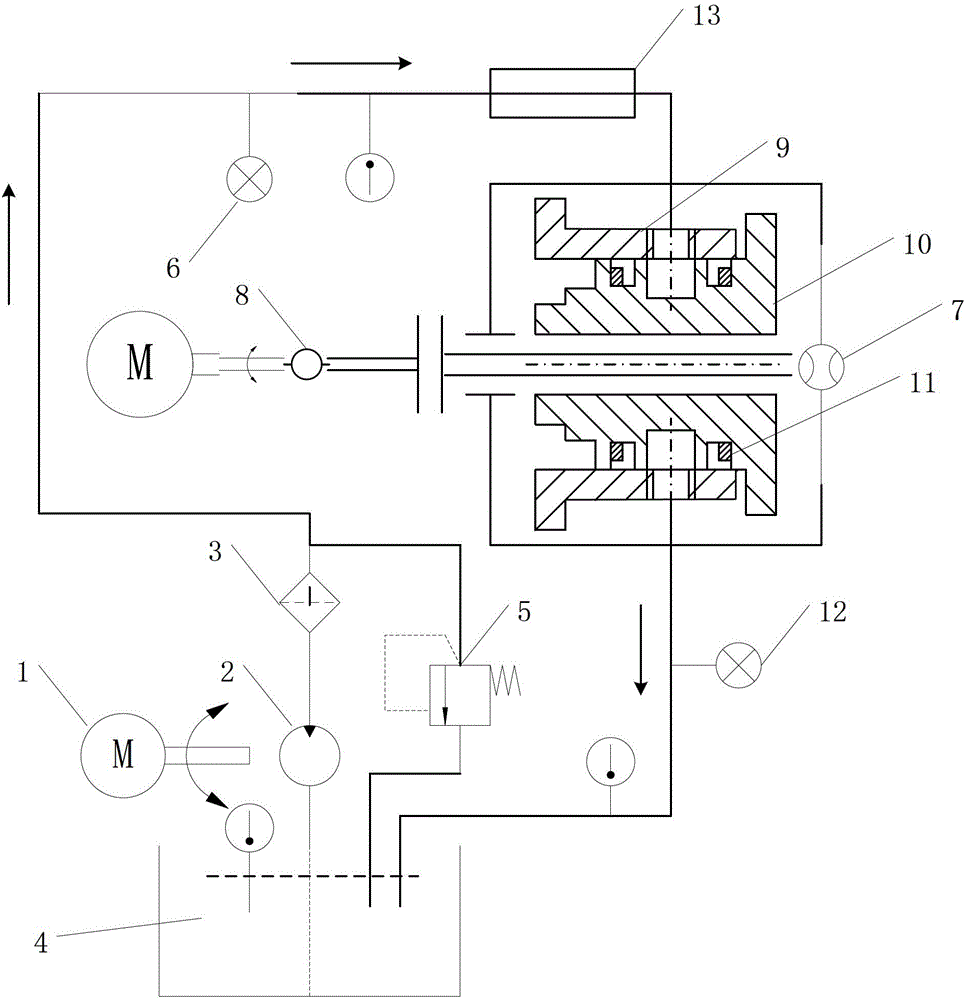

Multi-working-condition comprehensive simulation test system for reciprocating seal of aviation actuator

ActiveCN105673621AIsolation impactExtend your lifeFluid-pressure actuator testingAviationPilot system

The invention discloses a multi-working-condition comprehensive simulation test system for reciprocating seal of an aviation actuator. The multi-working-condition comprehensive simulation test system comprises a test actuator, a reciprocating driving loading system and a hydraulic system, wherein the reciprocating driving loading system is connected with a piston rod of the test actuator; the hydraulic system is connected to an oil inlet / outlet of a cylinder body; the test actuator comprises an end cover, the piston rod and the cylinder body; the reciprocating driving loading system comprises an electric cylinder, a transmission shaft, a transmission vibration isolating device, a force sensor and an LVDT sensor, and the transmission shaft is connected with the force sensor through the transmission vibration isolating device; and the hydraulic system comprises a pump source module, a pressurization module, a pressure maintaining module and a pipeline heater. By using the multi-working-condition comprehensive simulation test system, multi-working-condition comprehensive conditions such as high pressure, wide temperature range, variable speed and airborne vibration of the aviation actuator can be effectively simulated, and the friction force character of multi-type shaft seal of single piston rod and the leakage rate obtained after repeated reciprocation can be accurately measured under various working conditions; and the multi-working-condition comprehensive simulation test system has the characteristics of convenience in use, operation stability, test accuracy, long service life and the like.

Owner:ZHEJIANG UNIV

Device and method for detecting sealing property of sealing component

ActiveCN101799349AEasy to measureAccurate measurementFluid-tightness measurement using fluid/vacuumControl systemEngineering

The invention relates to a device and a method for detecting the sealing property of a sealing component. The device of the invention comprises a steam generator, an autoclave and a control system, wherein the steam generator is used for heating a medium to generate steam and pressure; the autoclave is provided with an inner cavity, and comprises an upper mold plate, a lower mold plate, a sealing component to be detected and an auxiliary seal ring, wherein the sealing component to be detected is loaded between the upper mold plate and the lower mold plate; the auxiliary seal ring is positioned outside the sealing component to be detected; a leak detecting cavity is enclosed between the sealing component to be detected and the auxiliary seal ring; the inner cavity of the steam generator is communicated with the inner cavity of the autoclave through a steam supply pipeline; the detecting device also comprises a detecting gas passage communicated with the leak detecting cavity and a working gas supply system communicated with the detecting gas passage; and a hygroscope positioned at downstream of the leak detecting cavity is arranged on the detecting gas passage. In the invention, dry working gas takes the steam leaked in the leak detecting cavity away, and the instant and average leakage rates of the sealing component are computed by measuring the moisture change of the working gas before and after passing through the leak detecting cavity.

Owner:SUZHOU BMC SEALING TECH CO LTD

Cylinder battery casing laser welding fixture

ActiveCN1990163ASmall amount of round runoutReduce air leakage rateWelding/cutting auxillary devicesAuxillary welding devicesWorkstationSupport surface

The invention involves a cylindrical battery shell laser welding fixture which includes workstation, clamping device and support device; said clamping device is equipped on the workstation which is used for clamping two clamping heads of two ends of clamping batteries and the first driver device for driving the second clamping head rotating using its shaft line as rotating axle; said support device is equipped on said workstation and is equipped with support surface matching or arranged with the cylinder face of battery. The support surface of support device can ensure the battery axis is coincidence with the rotation axis of welding fixture using said devices when clamping battery, the round jumping amount of battery is small when the clamping head rotating to improving the laser welding quality and reducing the leakage rate of battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

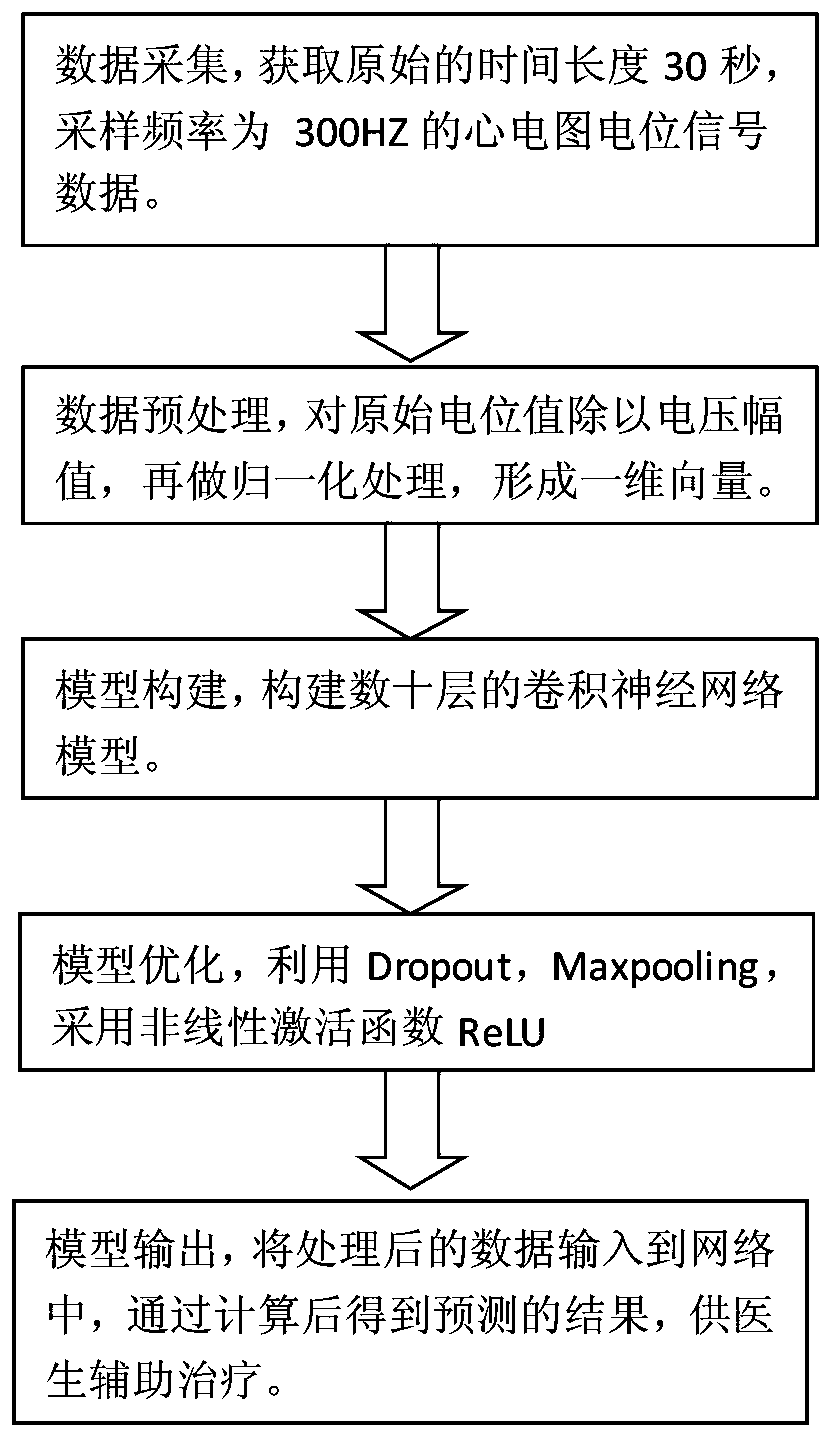

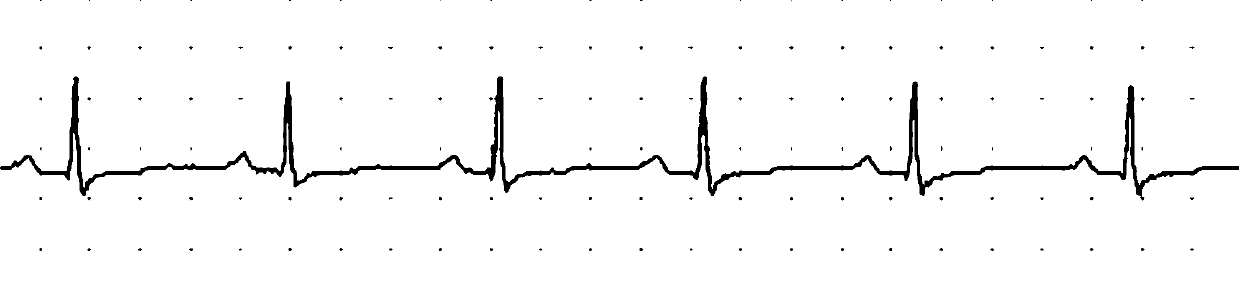

Electrocardiogram classification method based on deep learning model

InactiveCN107657318ASolve balance problemsSolve problems such as high missed diagnosis rateDiagnostic recording/measuringSensorsClassification methodsData treatment

The invention discloses an electrocardiogram classification method based on a deep learning model, and the method is characterized in that the method comprises the steps: data obtaining, data processing, model construction, algorithm optimization, and model training. A technical problem to be solved in the invention is to carry out the discrimination of arrhythmia through electrocardiogram data, to provide assistance and reference for a doctor, and to solve problems that doctors are not sufficient in some places and the wrong diagnosis and diagnosis leakage rate are higher. According to the embodiment of the invention, the invention has the following beneficial effects that the method employs the deep learning method, and achieves the discrimination of arrhythmia in the electrocardiogram information through the building of a large-scale convolution neural network. Compared with the conventional model, the method saves the cost, and is higher in accuracy.

Owner:成都蓝景信息技术有限公司

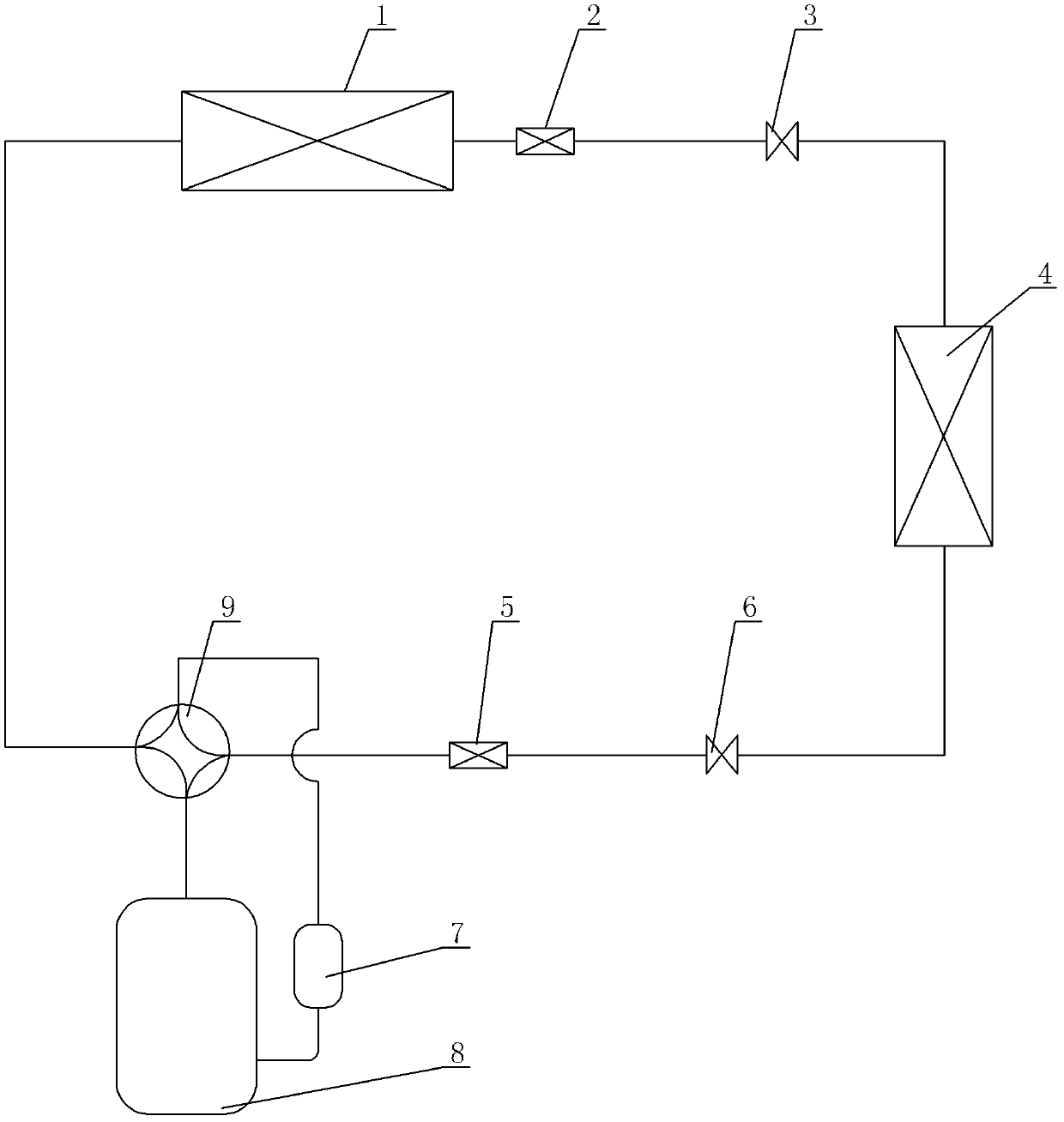

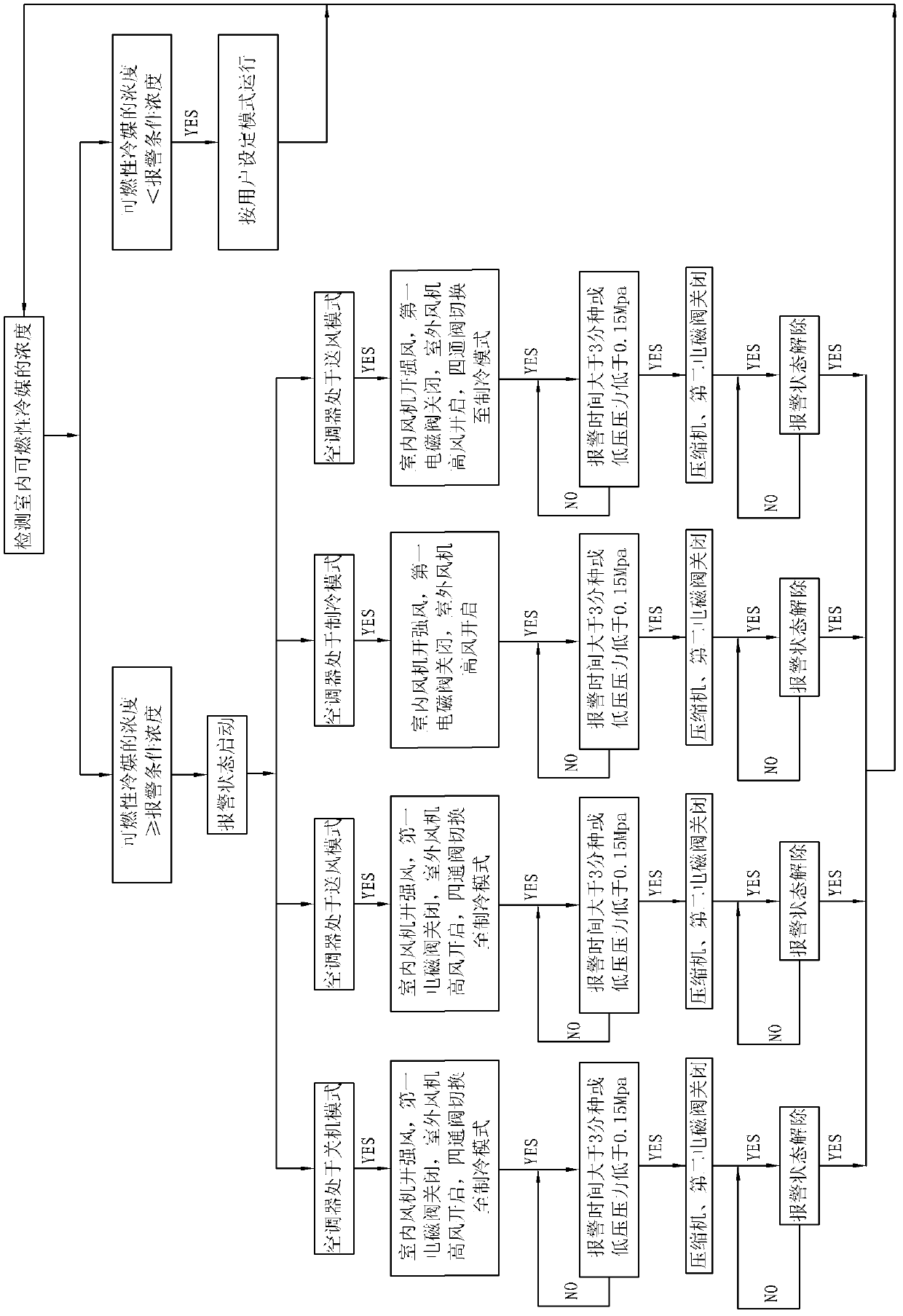

Safety control method for conditioner utilizing flammable refrigerants

ActiveCN103322641AReduce leakageReduce the risk of explosionSpace heating and ventilation safety systemsLighting and heating apparatusMagnetic valveSafety control

A safety control method for a conditioner utilizing flammable refrigerants comprises the following steps: a detecting the density of the indoor flammable refrigerants by a sensor in the indoor side of the conditioner; b entering into step c when the density of the indoor flammable refrigerants detected by the conditioner is greater than or equals to a warning condition density, and otherwise, the conditioner runs in a user set model continuingly; c starting a warning state, opening an indoor air blower and an outdoor air blower of the conditioner and recycling the flammable refrigerants in the indoor side to the outdoor side; d closing a compressor and a second magnetic valve when the warning time is greater than n minutes or the low-pressure pressure is lower than p MPa; and e closing the indoor air blower and the outdoor air blower of the conditioner when the density of the indoor flammable refrigerants detected by the conditioner is lower than the warning condition density and the warning state is relieved, and entering into step a. The conditioner can recycle the flammable refrigerants in the indoor side to the outdoor side when the situation of refrigerant leaking happens, reduces the leakage rate of the refrigerants in a room to the greatest extent, lowers the risks of flaming in the room and exploding of the compressor, and therefore, ensures the personnel safety of a user to the greatest extent and avoids unnecessary property loss.

Owner:GUANGDONG MEIZHI PRECISION MFG

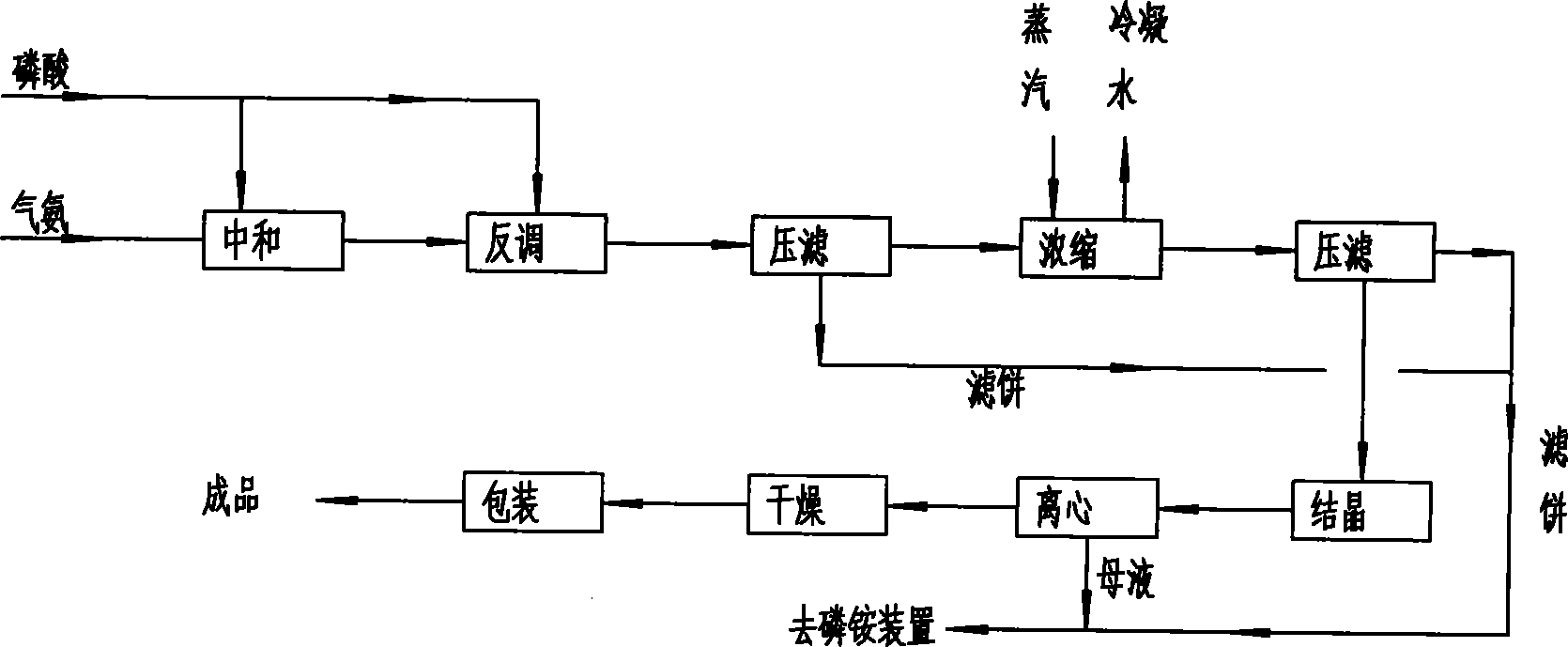

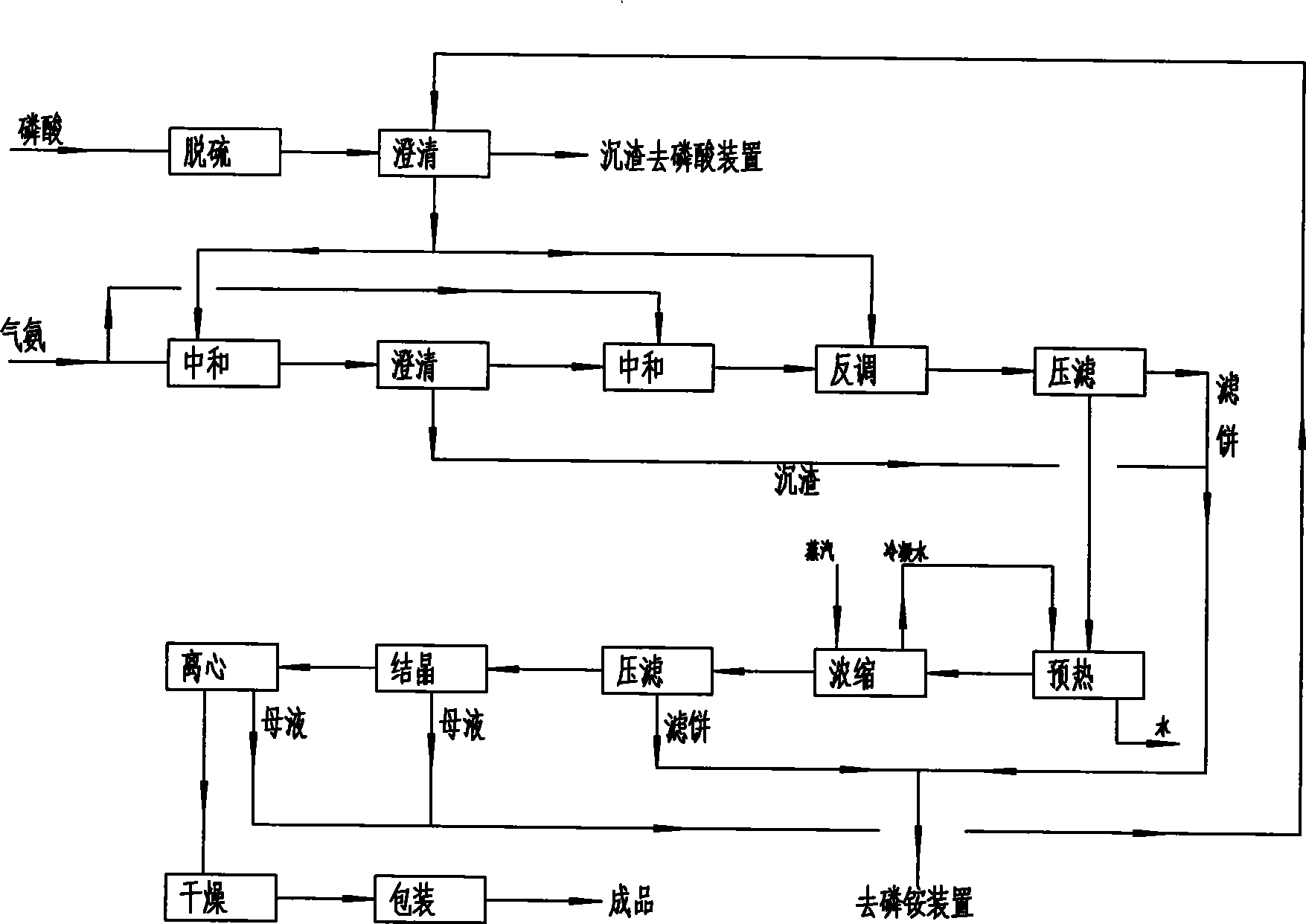

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

ActiveCN101367512AReduce labor intensityReduced pressure filter loadPhosphatesPhosphatePhosphoric acid

The invention relates to a craftwork for producing the industrial-level monoammonium phosphate consecutively with the phosphoric acid by wet process, which adopts the following steps: 1) phosphoric acid and phosphorite pulp are desulfurized to get the desulfurized phosphoric acid; 2) the acid is undertaken the first neutralization action to get a neutralized material pulp clarifying solution; 3) after the second neutralization reaction, the solution is reacted with the desulfrized phosphoric acid to get a secondary neutralized material pulp with the pH value being adjusted; 4) the secondary neutralized material pulp with the pH value being adjusted is primarily filtered to get a primary filtering solution and a primary filtering mass; 5) the primary filtering solution is secondarily concentrated and press filtered to get the secondary filtering solution; 6) the obtained secondary filtering solution is dissolved through the grain refining, is cooled down in vacuum, is crystallized, is centrifugally separated and dried to get the finished product of the industrial-level monoammonium phosphate. The invention has the advantages that the operation during the production process is consecutive; the labor intensity of the worker is reduced; the leakage rate of the ammonia is low and the loss is small; the secondary neutralized raw material solution is clear solution, so that the viscosity is low and the loss of the ammonia is small; the neutralization and the press filtering load is reduced; the crystallization production capacity is large; the heat energy is adequately used, thereby reducing the consumption of the vapor.

Owner:HUBEI XIANGYUN GROUP CHEM

Multifunctional pneumatic reciprocating sealing performance test bench

InactiveCN104132805AInterchangeableEasy to controlMachine part testingMeasurement of fluid loss/gain rateEngineeringFriction force

A multifunctional pneumatic reciprocating sealing performance test bench comprises a servo electric cylinder. The servo electric cylinder is installed on a workbench through a positioning cushion block. A servo electric cylinder drive rod is connected to a piston rod of a test air cylinder through a hinge. The test air cylinder is installed on a pair of precise ball sliding blocks through a fixing plate. The precise ball sliding blocks are installed on a precise guide rail fixed to the workbench. The other end of the test air cylinder is connected with one end of a tension and pressure sensor through a flange, the other end of the tension and pressure sensor is fixed to the workbench through a first supporting piece, and a grating scale displacement sensor is installed on the workbench below the tested piston rod. According to the multifunctional pneumatic reciprocating sealing performance test bench, friction force and the leakage rate of pneumatic sealing can be comprehensively measured, and the multifunctional pneumatic reciprocating sealing performance test bench has the advantages of being simple in structure, easy and convenient to mount and dismount, accurate in measurement, various in test function and the like, the air cylinders are convenient to control, and different structures of sealing rings can be changed.

Owner:TSINGHUA UNIV

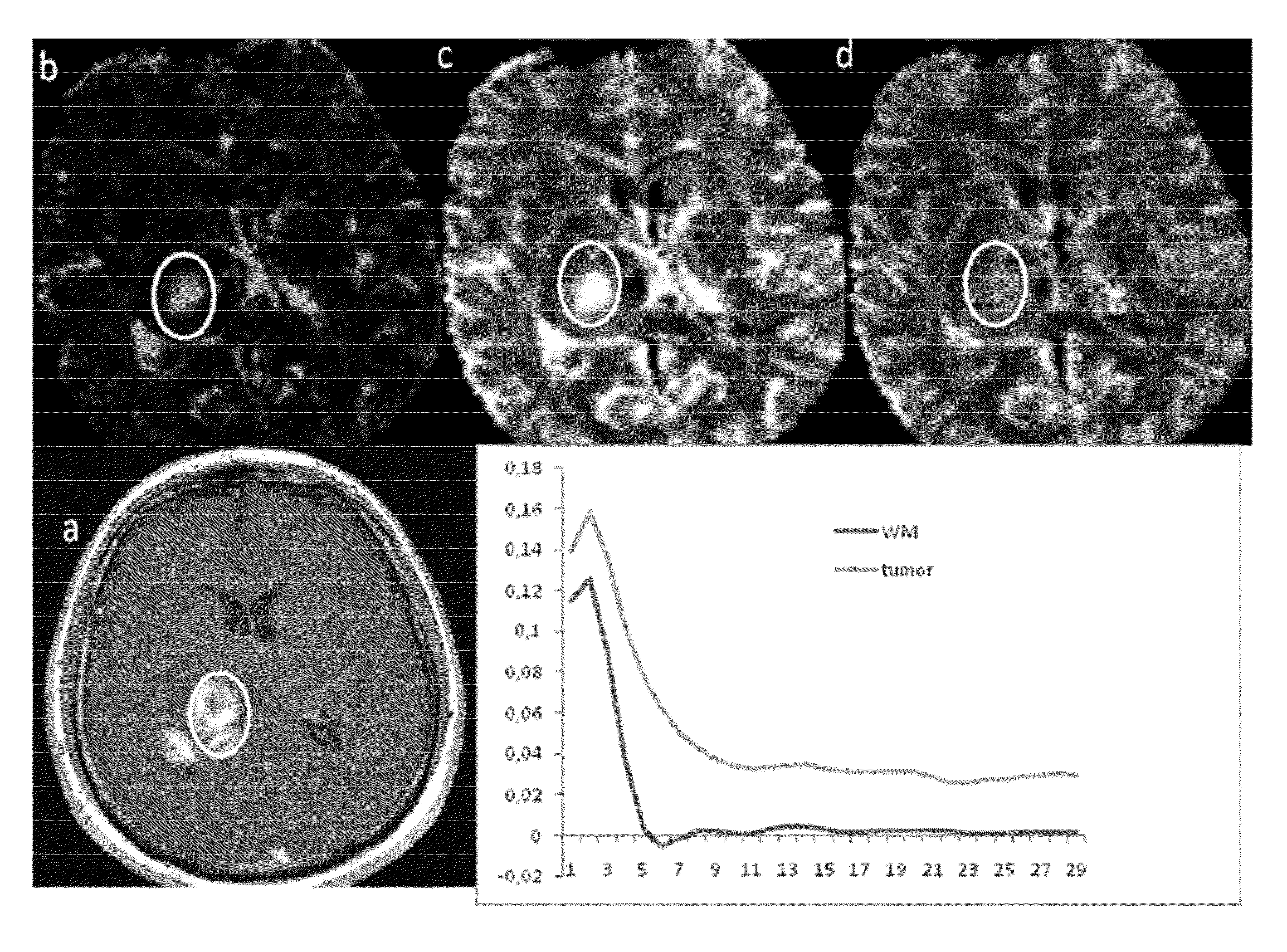

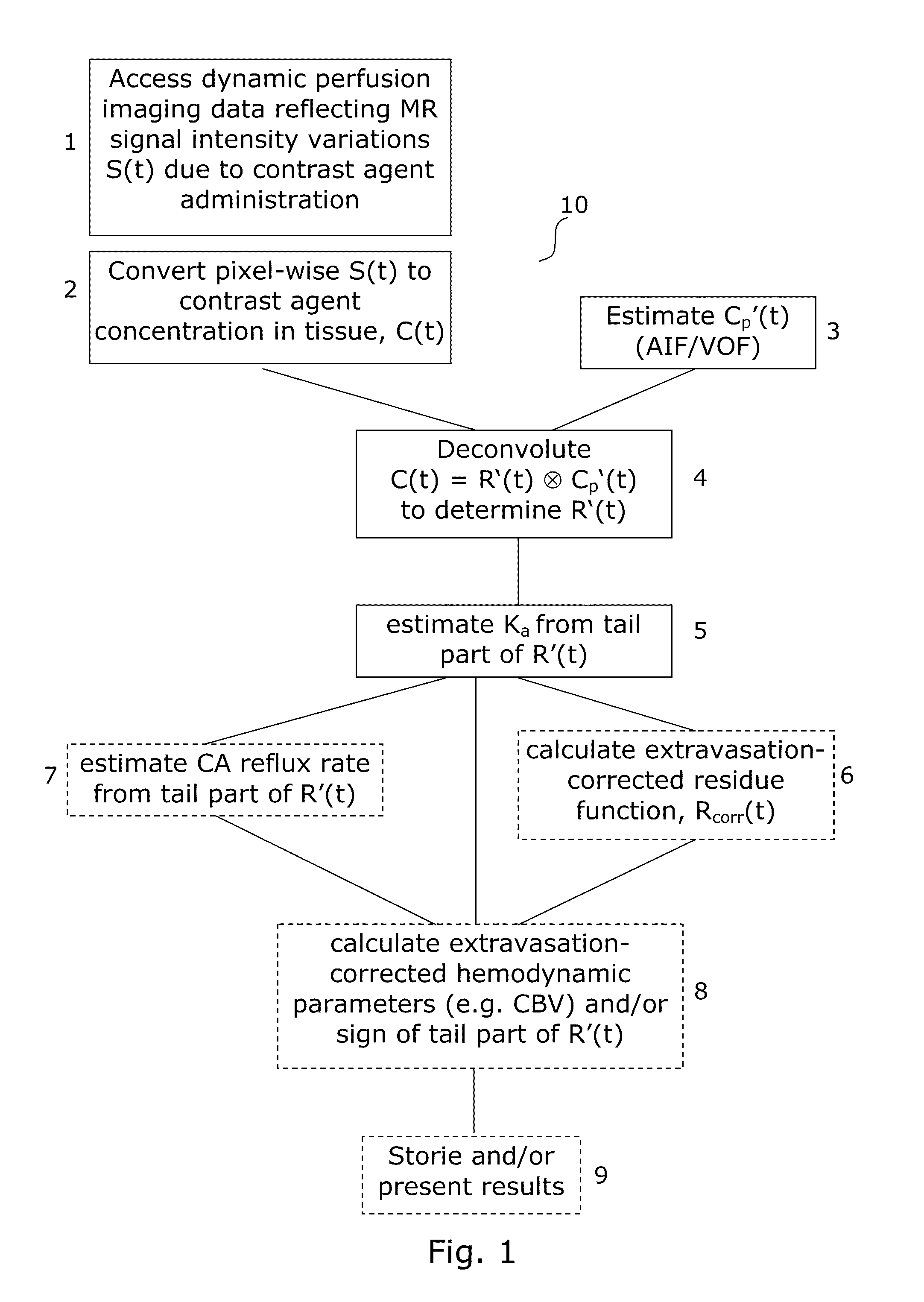

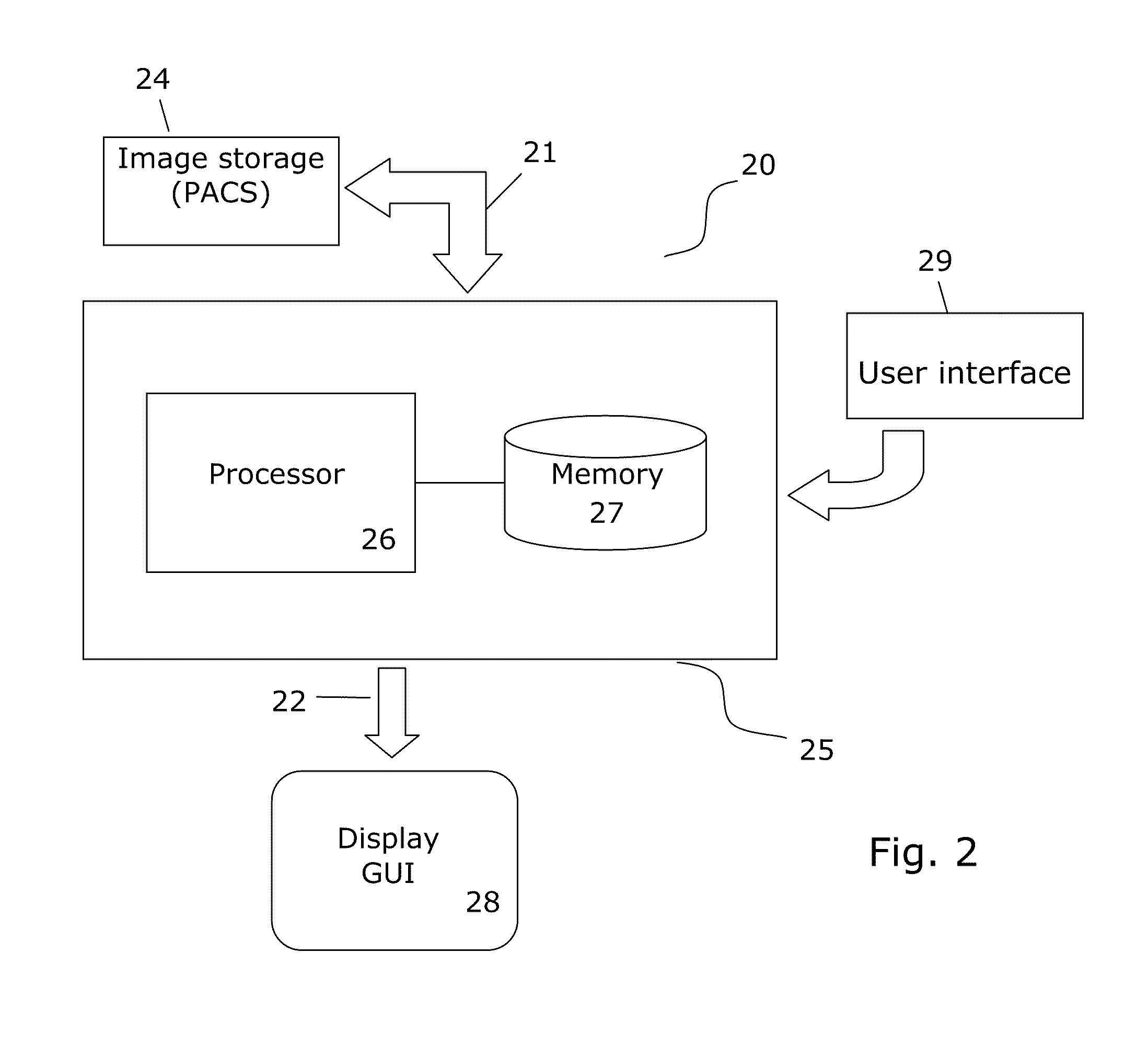

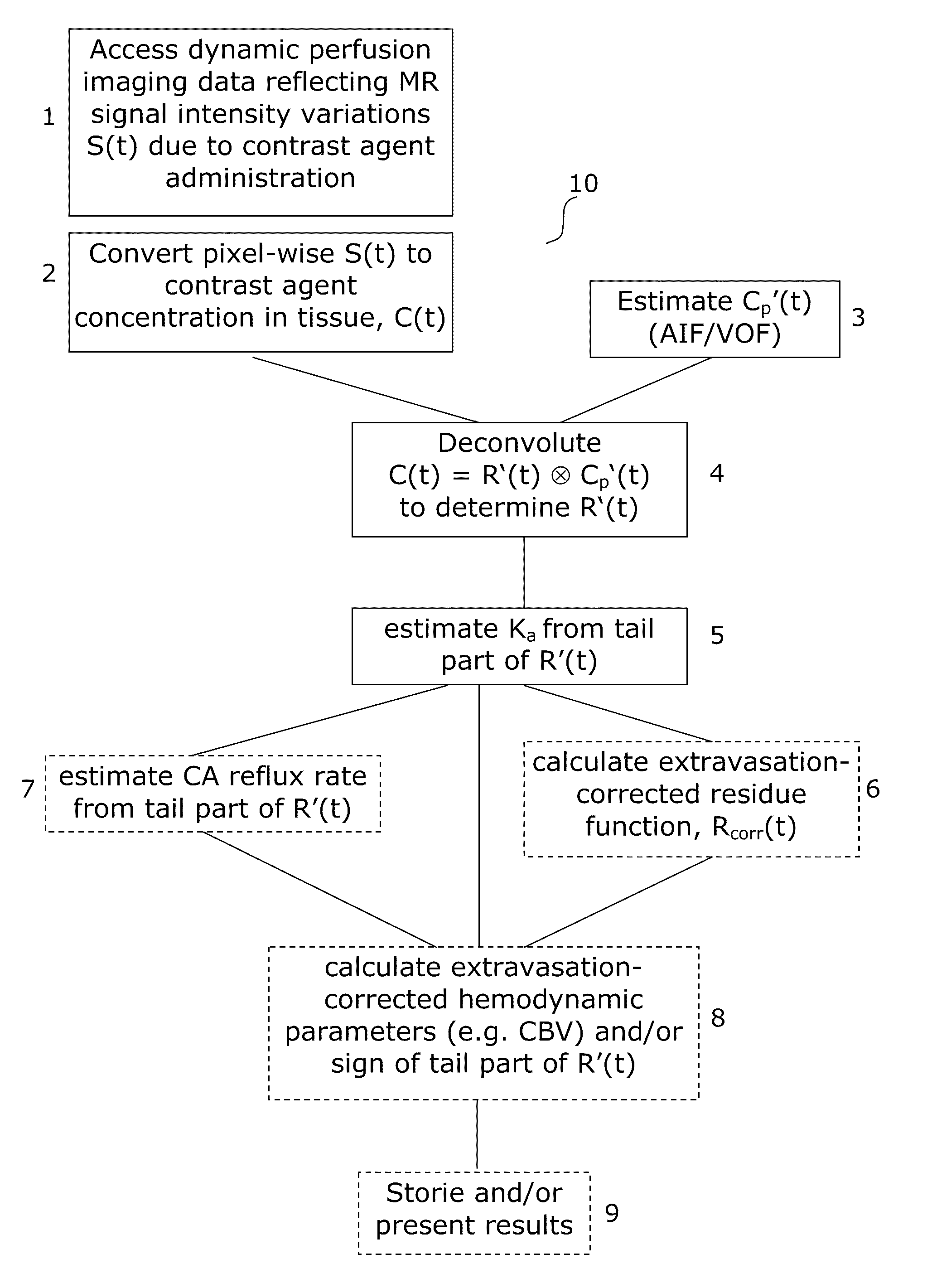

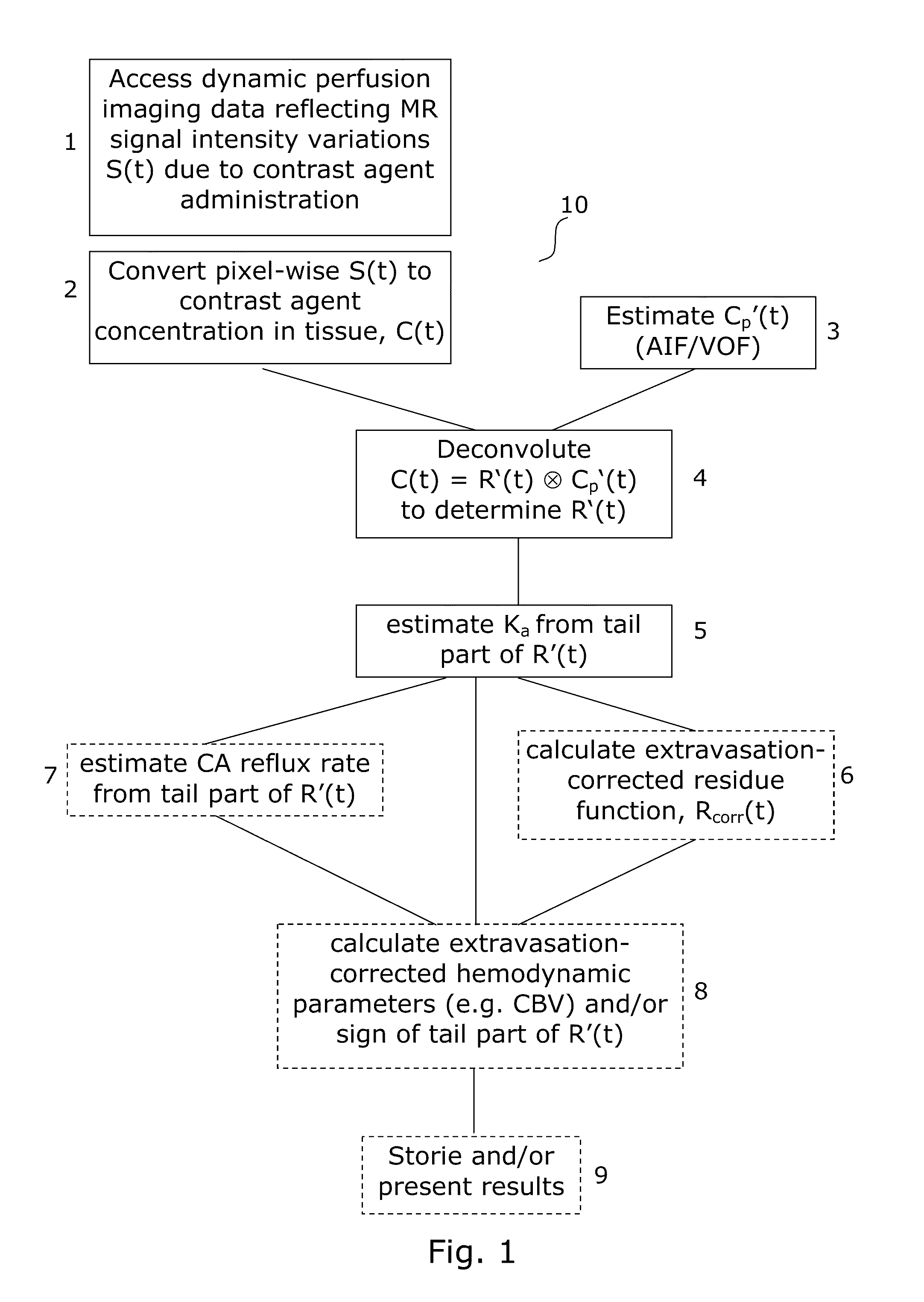

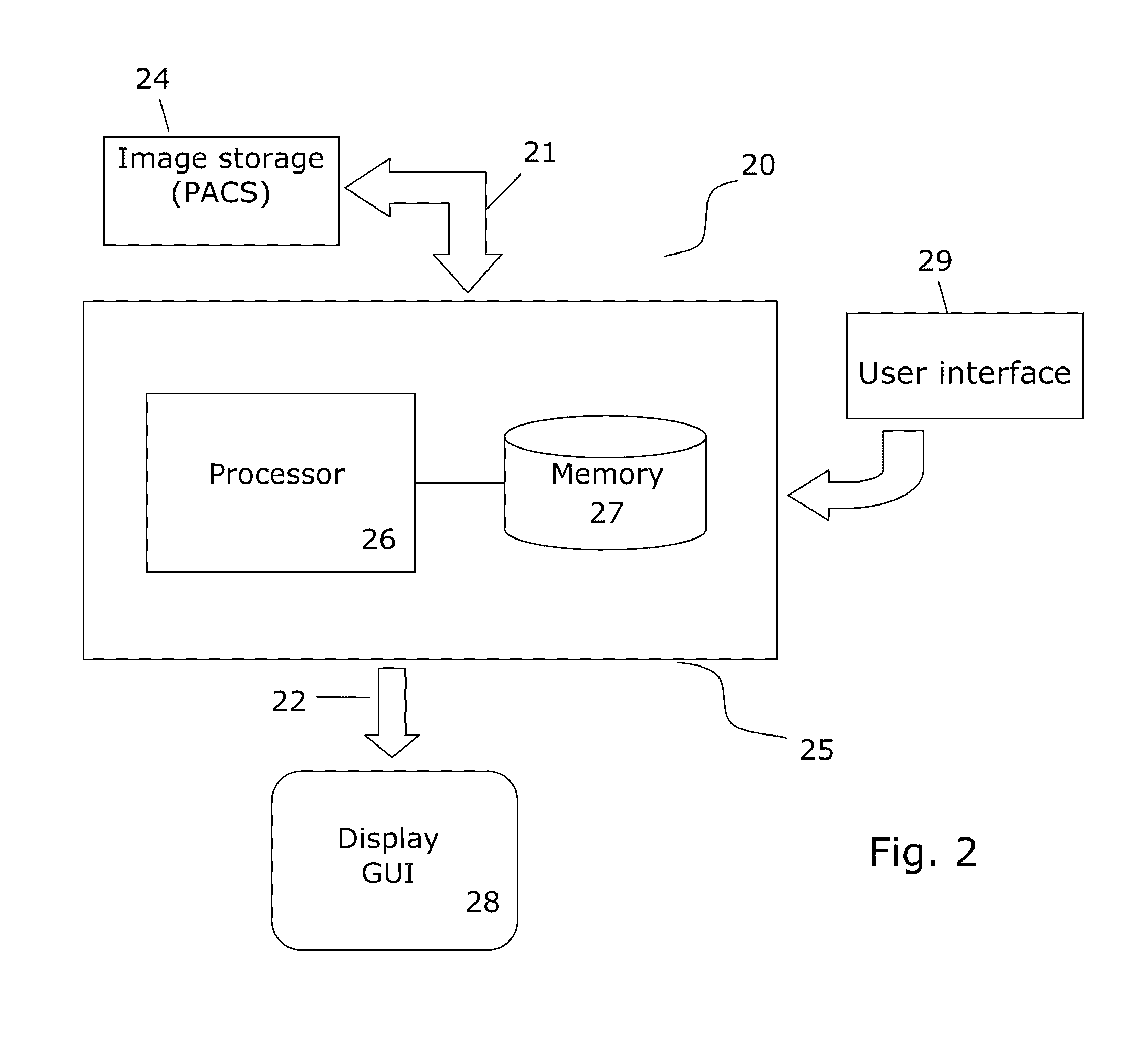

Estimating and correcting for contrast agent extravasation in tissue perfusion imaging

ActiveUS20110257519A1Good estimateRobust estimationImage enhancementImage analysisDynamic contrastArterial input function

The invention provides a method, an image analysis software product, and a system for medical imaging analysis for estimating contrast agent extravasation in contrast agent based perfusion imaging such as MRI dynamic contrast enhanced (DCE) imaging, and in particular correction, compensation, or visualization of extravascular leakage of contrast agent in tumors. According to the invention, the effect of extravasation is directly manifested in the tail part of an observed, apparent residue function, R′(t), obtained directly by de-convoluting the expression C(t)=R′(t)Cp′(t) with the arterial input function (AIF). A leakage rate or extravasation constant is determined directly from the tail part of the determined apparent residue function. The invention also relates to distinguishing between T1-dominant and T2*-dominant extravasation effects in perfusion imaging to from the sign of the tail part of the determined apparent residue function and to an automated method for DSC-MRI involving correction for contrast agent extravasation and partial volume effects.

Owner:UNIV OSLO HF

Oil sleeve joint sealing and detecting device

ActiveCN102455244AImprove reliabilityEasy to useMeasurement of fluid loss/gain rateInternal pressureTest sample

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

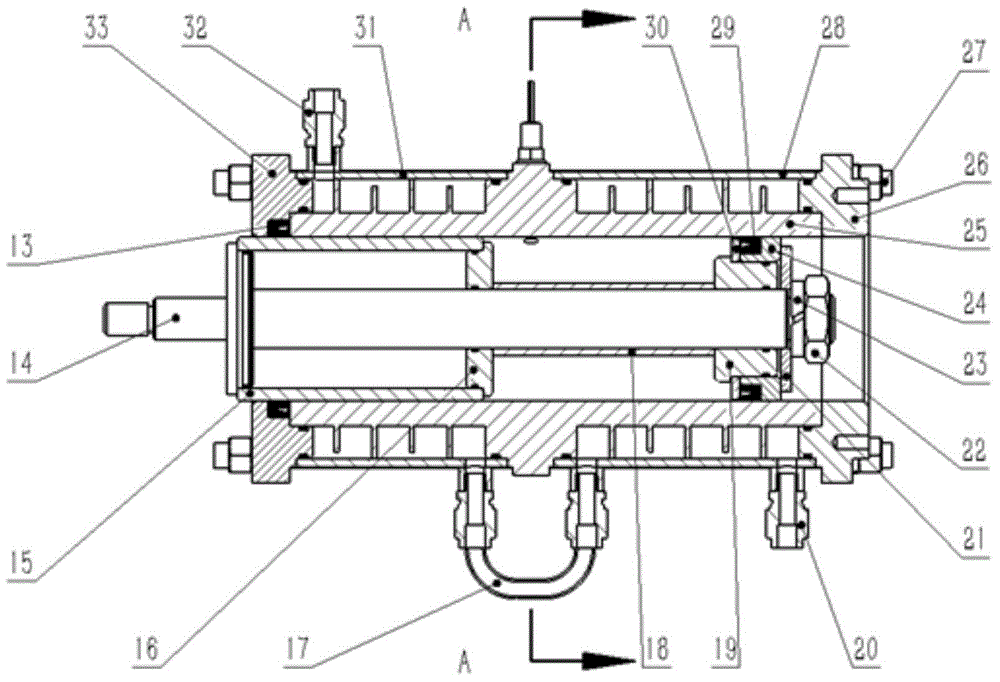

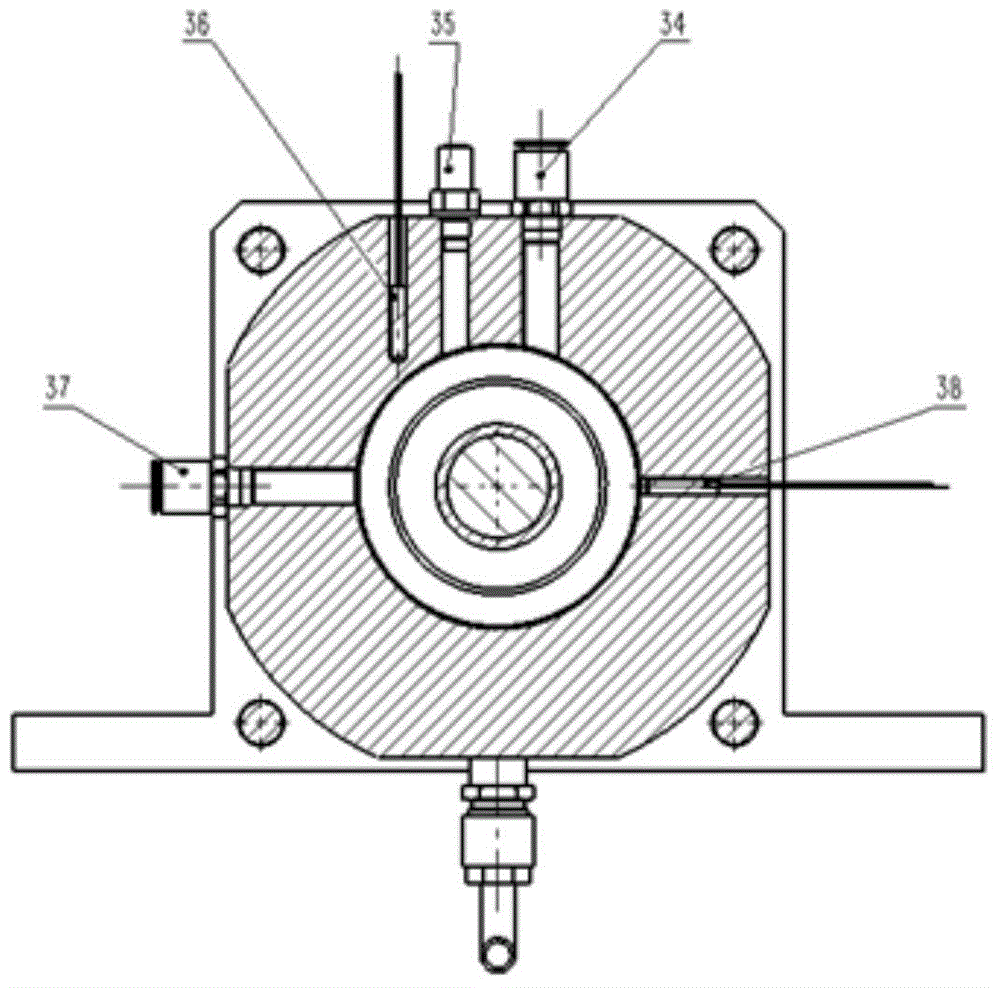

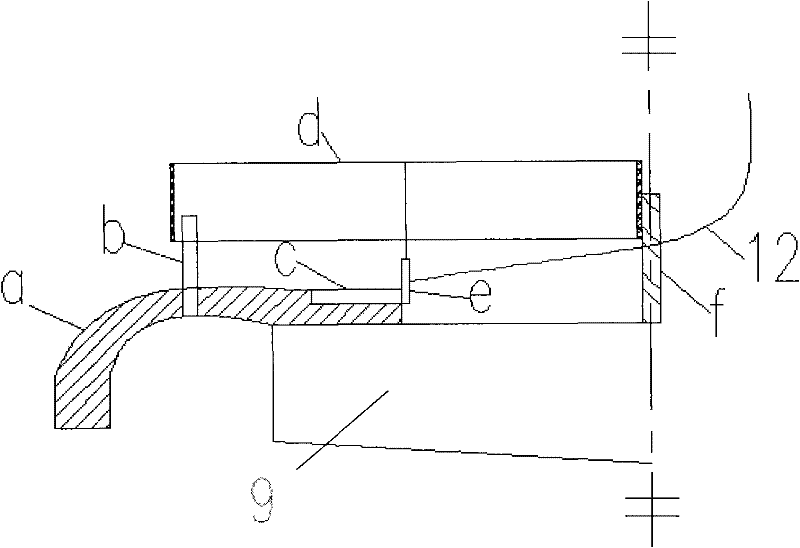

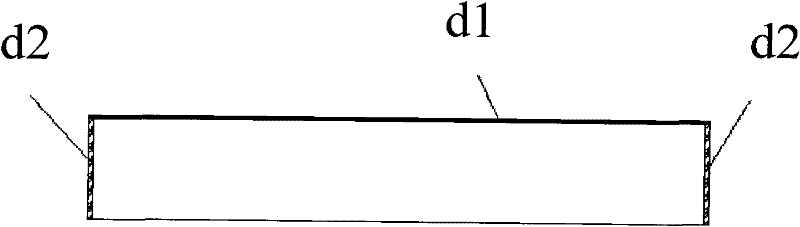

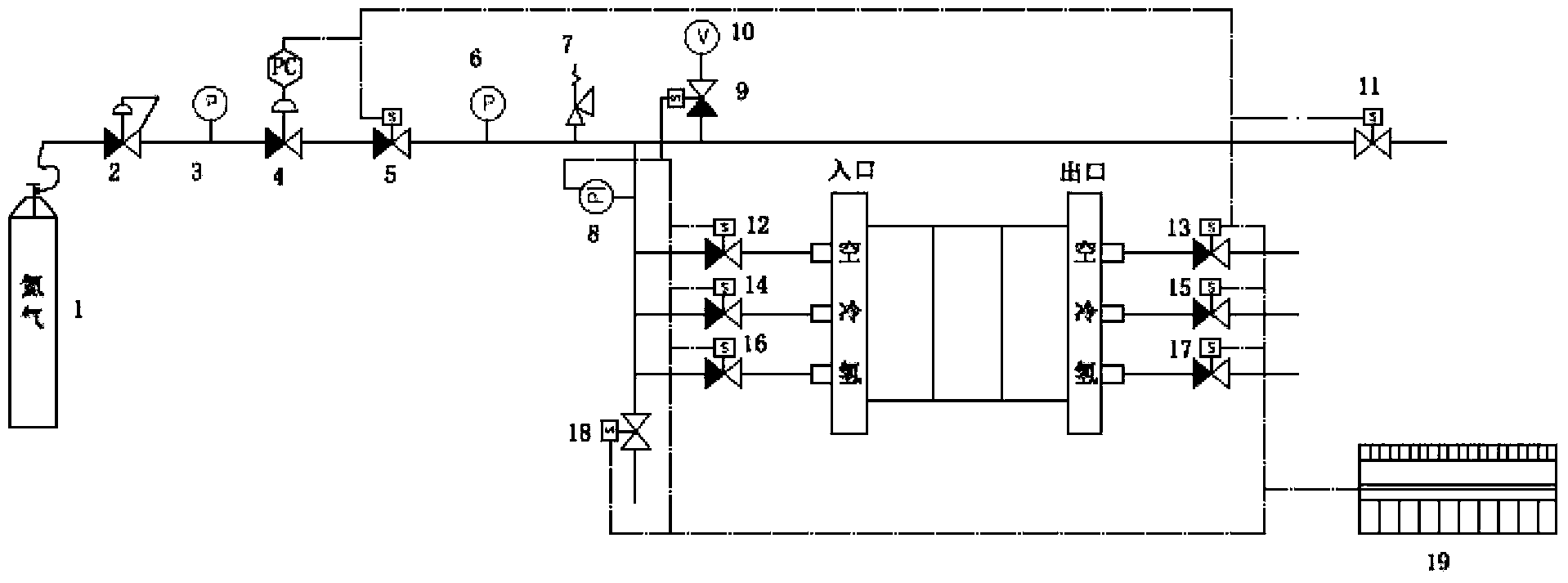

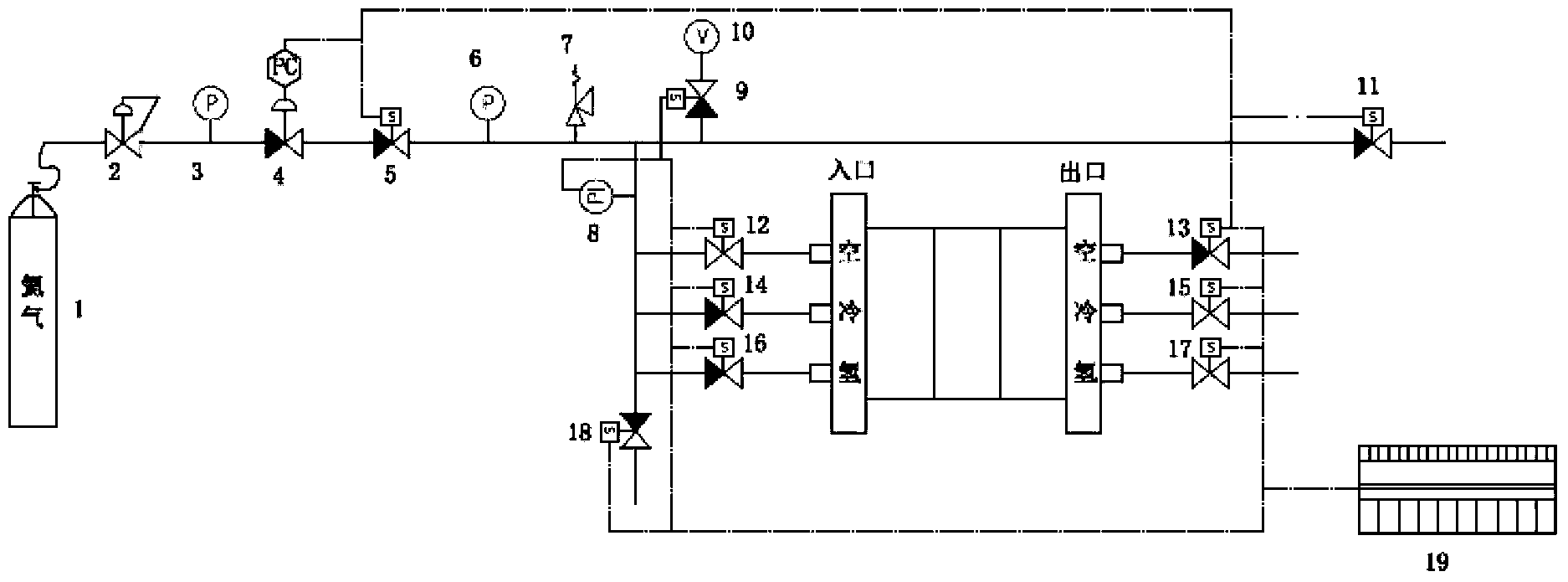

Device and method for testing fuel cell stack leakage rate

ActiveCN104180958AGuaranteed reliabilityGuaranteed reproducibilityMeasurement of fluid loss/gain rateFuel cellsHydrogen

The invention relates to a device and method for testing the fuel cell stack leakage rate. The device comprises a helium tank and an intake manifold and further comprises eleven electromagnetic valves, a precise pressure sensor, a proportional pressure regulating valve, a safety valve, a fixed container, a corresponding pressure meter and pipelines. Compared with the prior art, a gas pressure maintaining test can be conducted, the leakage rates can be automatically and accurately measured in the inner leakage and outer leakage processes of an electric stack, and safety interlocking and automatic discharging are achieved. The volumes of a hydrogen cavity, an air cavity and a cooling liquid cavity of any electric stack are calibrated respectively, and eight types of common gas leakage rates of total leakage of the air cavity, total leakage of the hydrogen cavity, outer leakage of the air cavity, outer leakage of the hydrogen cavity, outer leakage of the cooling liquid cavity, leakage between the hydrogen cavity and the air cavity, leakage between the hydrogen cavity and the cooling liquid cavity and leakage between the air cavity and the cooling liquid cavity can be automatically calculated.

Owner:河南豫氢装备有限公司

Apparatus and method for detecting memory leaks

A system and method for detecting memory leaks includes a monitoring agent, a user interface for configuring operating parameters and a reporting mechanism. The monitoring agent determines allocated memory levels of a monitored application at a sampling frequency and determines when a then-existing “peak” memory level has increased. The monitored application is determined to be leaking memory when a determined number of increases in the peak allocated memory level are detected. The determined number may be fixed ahead of time or may be calculated dynamically based on user specified parameters. When a given memory leakage rate is exceeded, an alarm response is taken, which may be either a specified notification of the alarm or an action. Certain increases in the peak allocated memory levels are ignored as not necessarily being indicative of a memory leak condition, such as during startup of the program or between rapidly, closely-occurring increases in the peak allocated memory level.

Owner:LAKESIDE SOFTWARE LLC

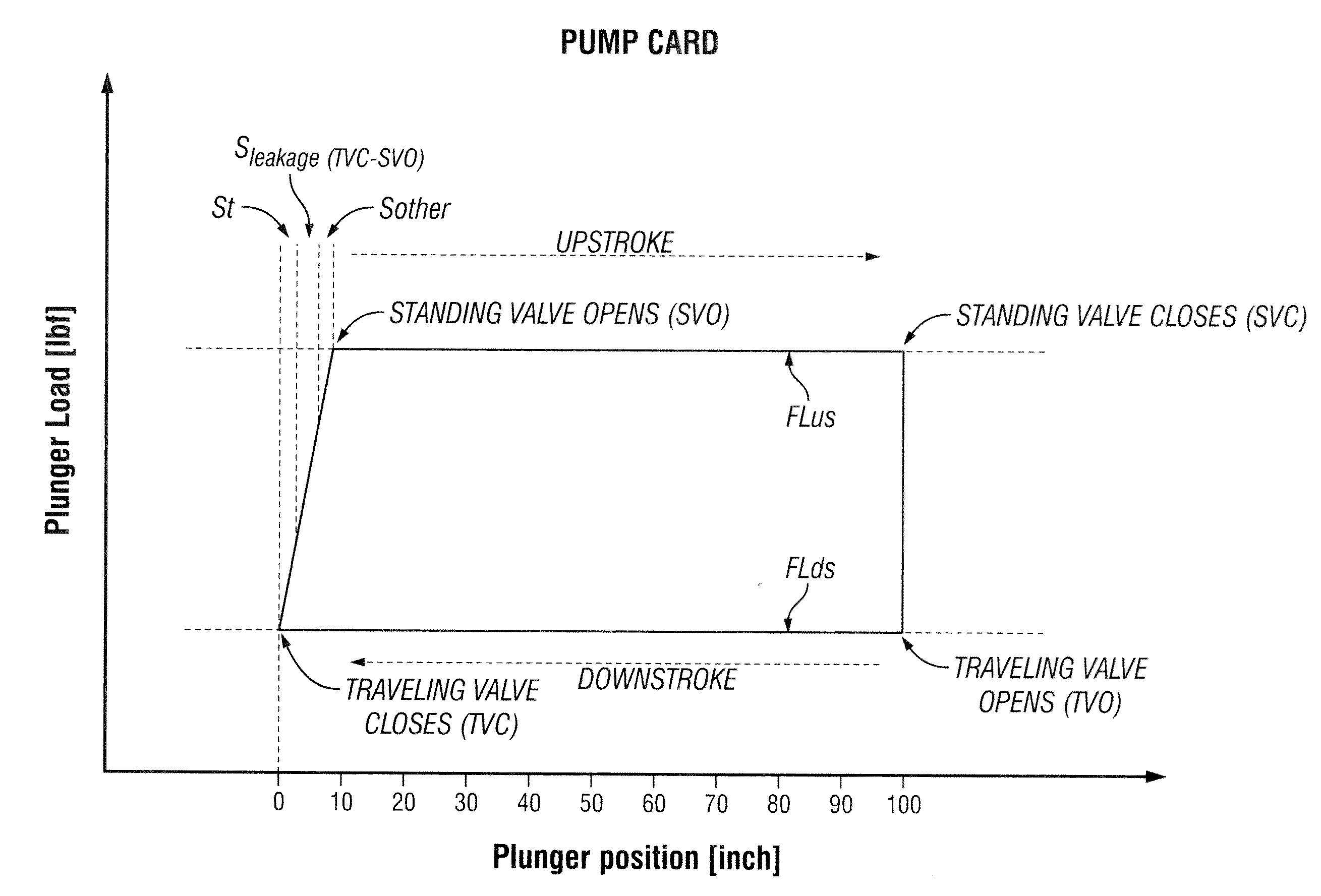

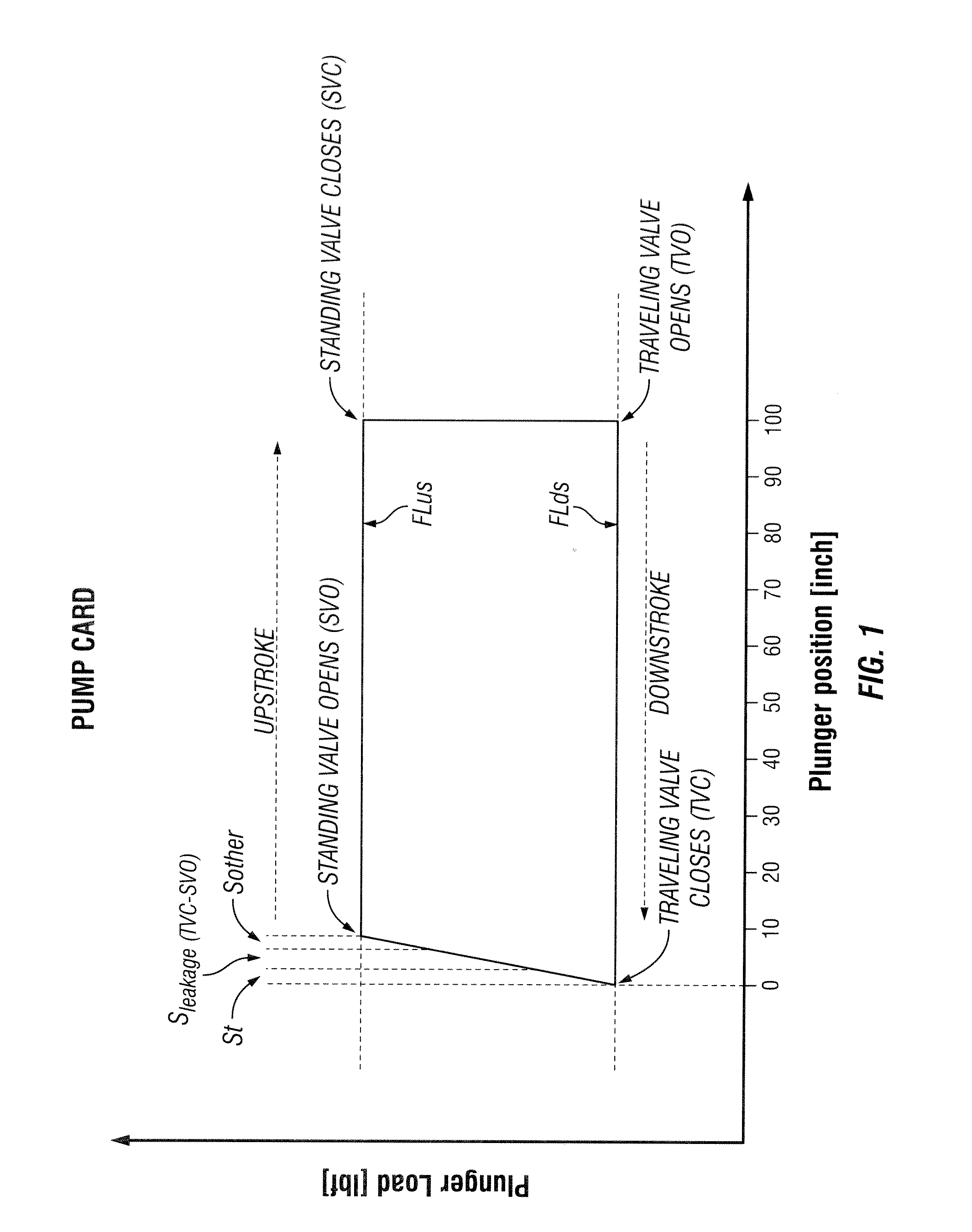

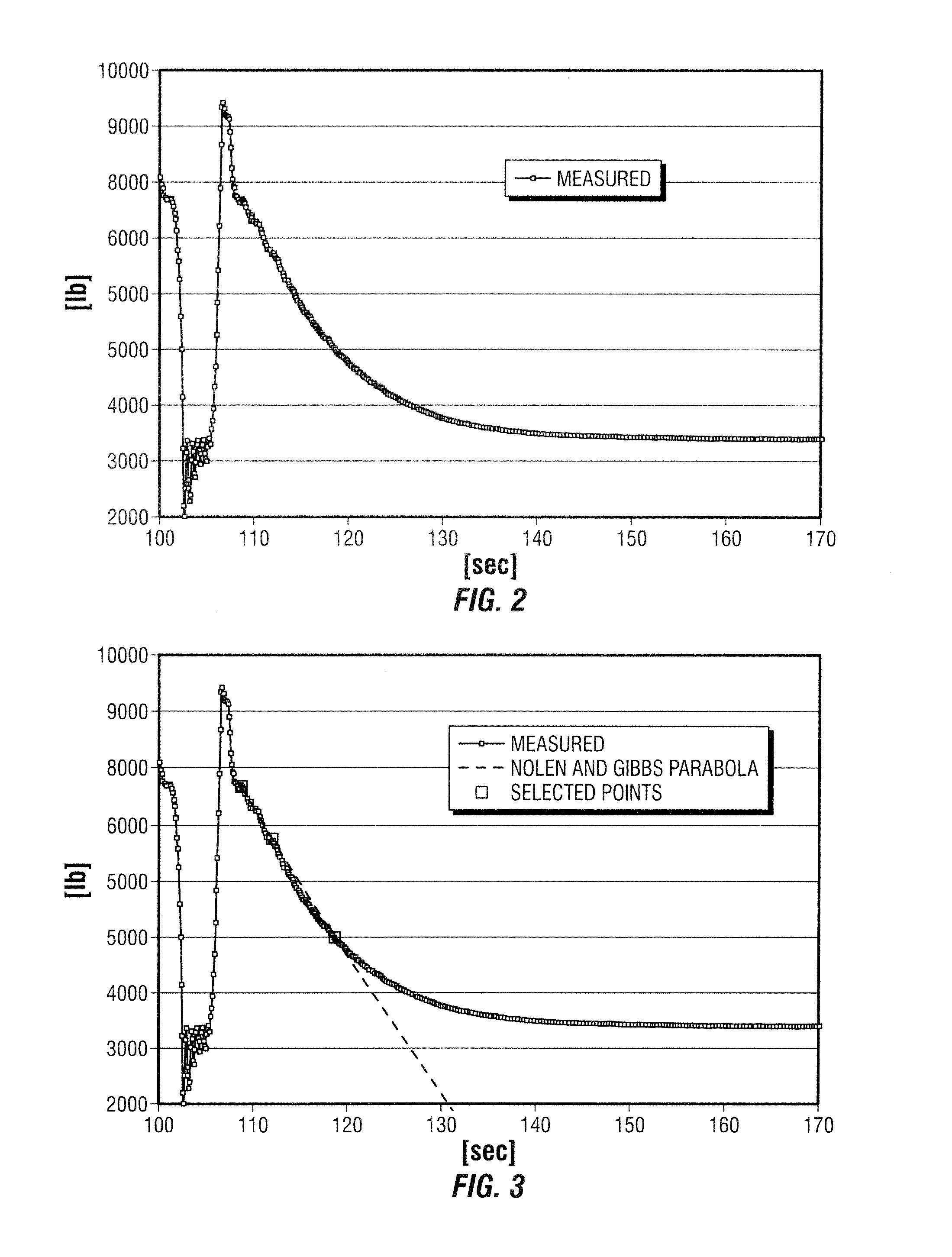

Methods for measuring leakage rate and inferring production rate of an oilfield downhole pump

ActiveUS20130024138A1Improve accuracyAccurately determineSurveyConstructionsProduction rateEngineering

Methods for measuring the leakage rate of a downhole pump using either measured axial load information from the drive rod string or using measured production data. The invention is for methods of applying the leakage rate to a downhole dynamometer card, for a reciprocating rod pump, for determining well production.

Owner:RAVDOS HLDG INC

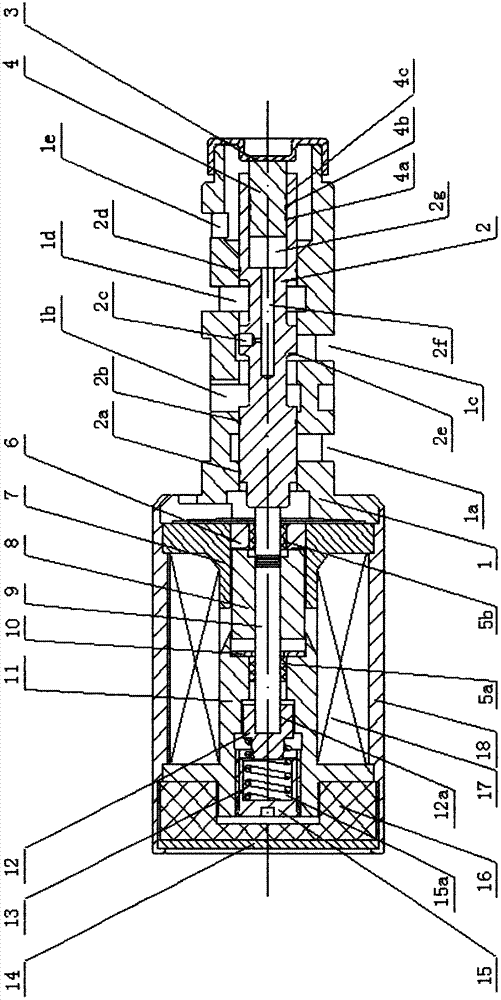

Two-position three-way inverse proportion decompression electromagnetic valve for AT (Automatic Transmission)

InactiveCN103032619ALight in massQuick responseOperating means/releasing devices for valvesMultiple way valvesAutomatic transmissionEngineering

The invention relates to a two-position three-way inverse proportion decompression electromagnetic valve for an AT (Automatic Transmission). The two-position three-way inverse proportion decompression electromagnetic valve is mainly formed by a main valve and a proportion electromagnet, wherein the main valve is formed by a valve body, a valve core which is positioned at the inner part of the valve body, a valve seat which is sleeved on the valve body and an inner valve core which is positioned at the inner part of the valve core and close to one side of the valve seat, and the proportion electromagnet is formed by a sliding bearing, a bearing seat, a pole shoe, an armature, a top rod, a stroke gasket, a stop iron, a spring seat, a regulating spring, a baffle plate, a regulating screw, a baffle plate cushion, a coil and a yoke iron. According to the two-position three-way inverse proportion decompression electromagnetic valve disclosed by the invention, the problems such as lower response speed, larger pressure fluctuation, short service life, large leakage rate and high manufacturing cost of an existing inverse proportion decompression electromagnetic valve for the AT are solved, and the two-position three-way inverse proportion decompression electromagnetic valve disclosed by the invention has the advantages of high response speed, small pressure fluctuation, long service life , small leakage rate, lower manufacturing cost and the like.

Owner:兰溪市中元贸易有限公司

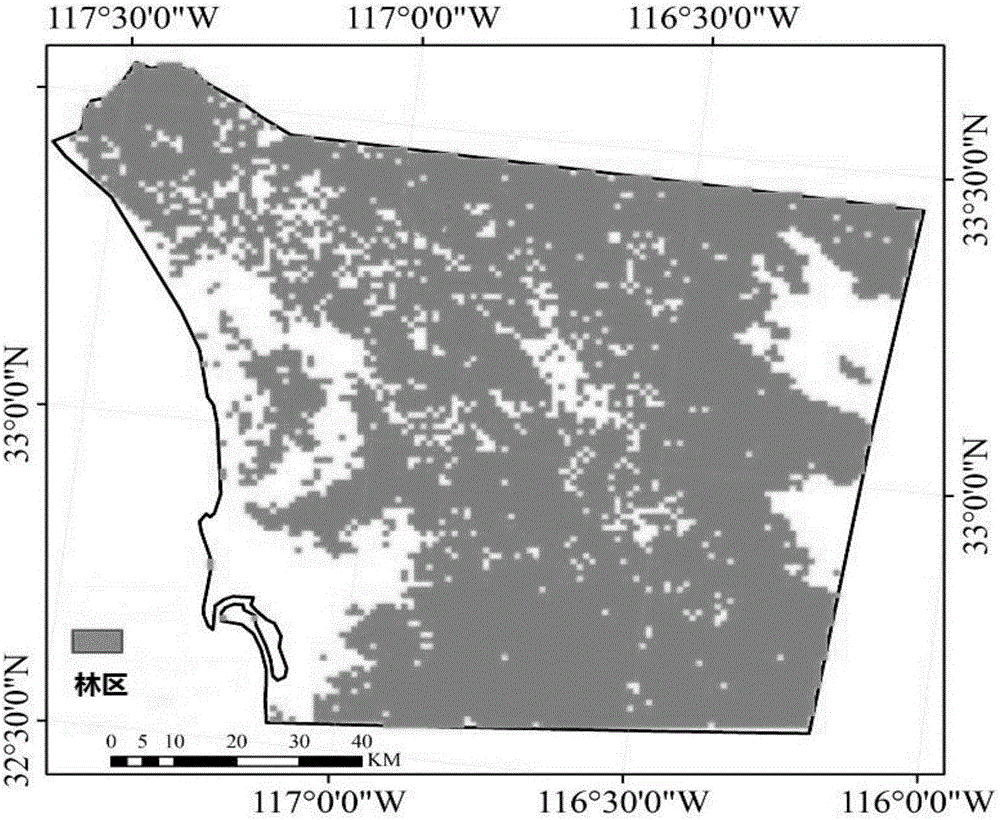

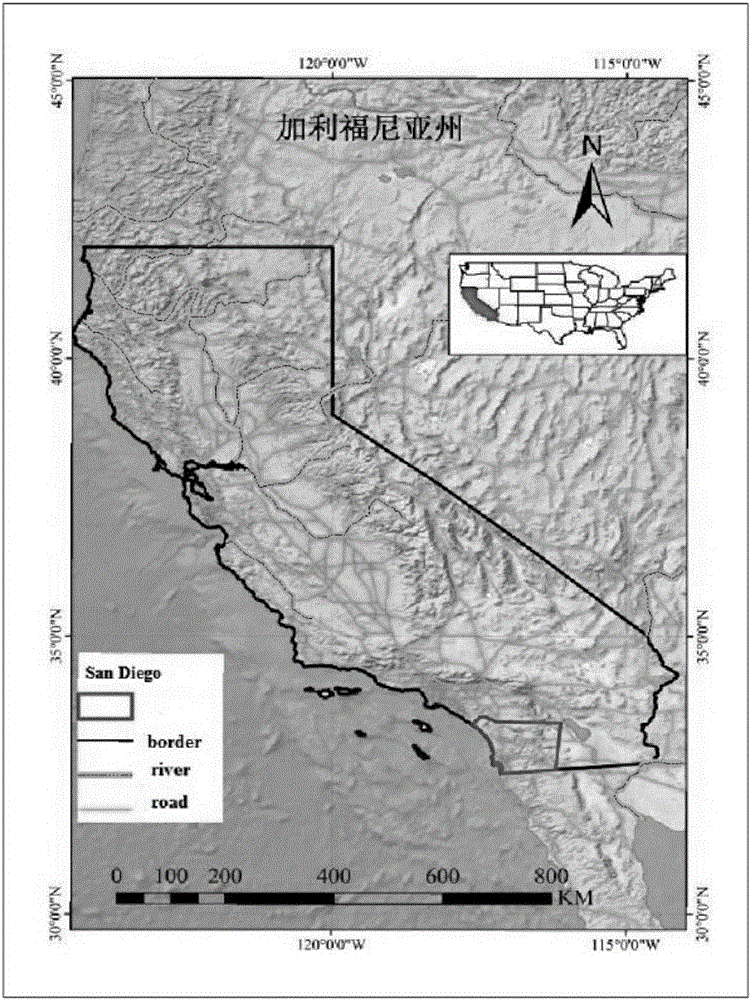

Forest fire fire point detection method based on MODIS

InactiveCN106840409AImprove the correct rateAdaptableSensing radiation from gases/flamesPyrometry for hot spots detectionBrightness temperatureRecognition algorithm

The invention discloses a forest fire fire point detection method based on an MODIS. Firstly, time sequence data is established for multiple days of MOD02 and MOD03 data from the MODIS, time sequence daily value data of multiple days of NDVI and brightness temperature is obtained, break points in the time sequence daily value data of the NDVI and brightness temperature are recognized through a time sequence break point recognition algorithm, and the recognized break points serve as potential fire points; relative fire points are distinguished from the potential fire points through a space context analysis method; real fire points are extracted from autonomous modular sensor data, the relative fire points are compared with the real fire points, and the correctness and leakage rate of the relative fire points are verified. The potential fire points are distinguished through the method that the time sequence data break points are detected through the BFAST algorithm without determining the potential fire points through fixed threshold values, therefore the algorithm has higher adaptability and flexibility for fire point distinguishing, the defects that the regional difference cannot be met by distinguishing the potential fire points through the fixed threshold values is overcome, and the fire point correctly discriminating rate is increased.

Owner:BEIJING NORMAL UNIVERSITY

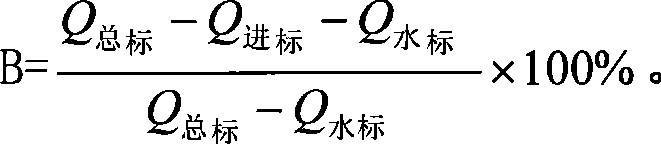

Air leakage rate measuring method of sintering machine system

InactiveCN101435711ASolve the large measurement errorReduce contentFurnace typesIndirect mass flowmetersObservational errorGas analysis

The invention relates to a method for measuring system air leakage rate of a sintering machine in metallurgy. The invention discloses a method for measuring the system air leakage rate of the sintering machine. The method comprises the following steps: firstly, by measuring charge level air speeds at different parts of a machine pallet of the sintering machine, the effective air quantity(Q[inlet]) entering a sinter layer is worked out, by measuring the air speed in a main duct in front of an electrostatic dust collector, the total air quality(Q[total]) pumped in the main duct by an air exhauster is worked out, and by the water content in mixing material, the content of the air converted into vapor is worked out; secondly, the air qualities(Q[total standard], Q[inlet standard] and Q[water standard]) at the standard state are converted all together; and finally, the air leakage rate(B) is worked out according to the formula. The measuring method has strong operability and can overcome the defects of inconvenient measurement, big measurement error and complex air analysis existing in daily production and the defect existing in prior art that the local air leakage rate can only be measured by the air leakage point air speed measuring method. In a word, the method has the advantages of easy operation, accurate measurement and good use effect.

Owner:武钢集团有限公司

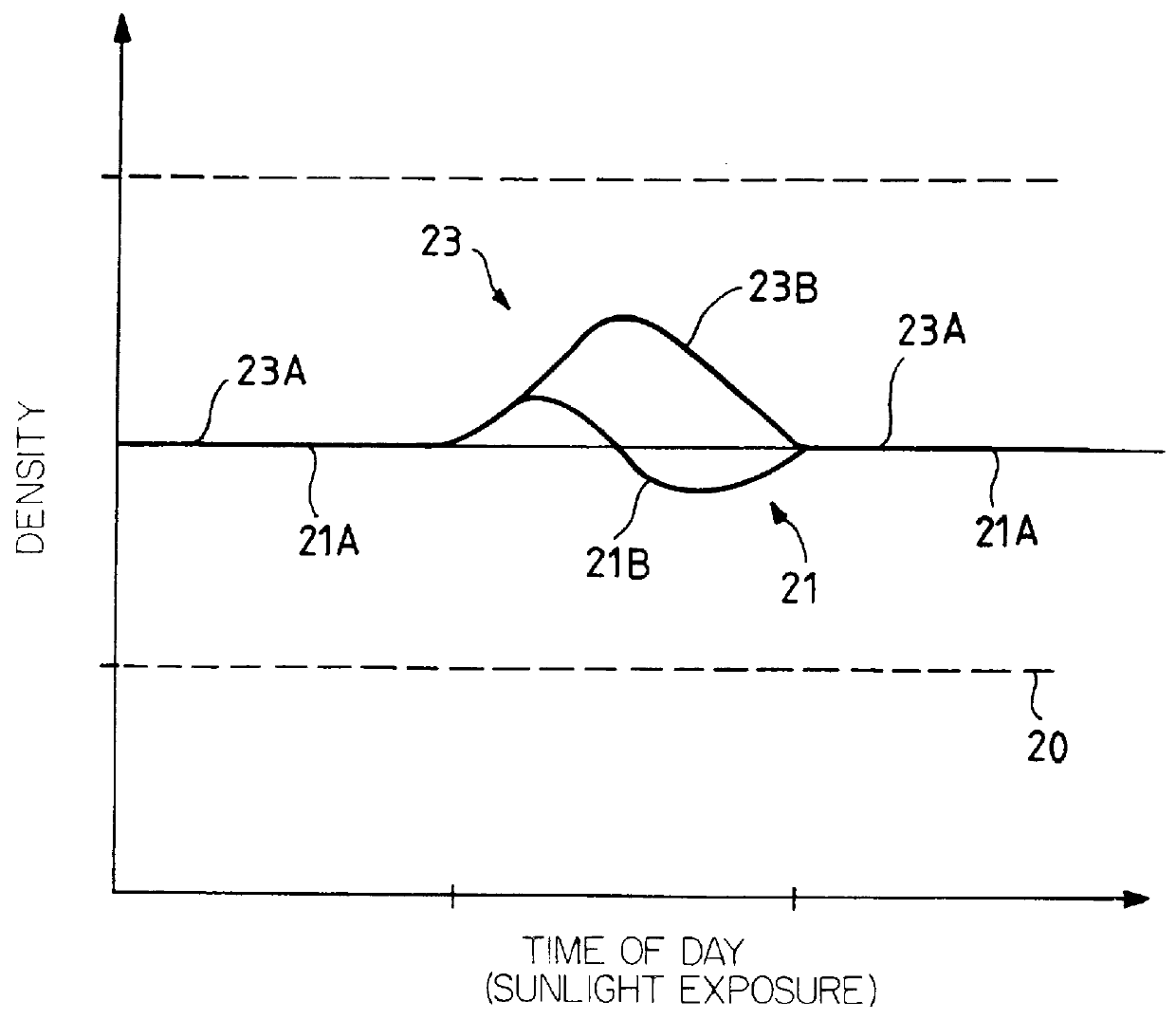

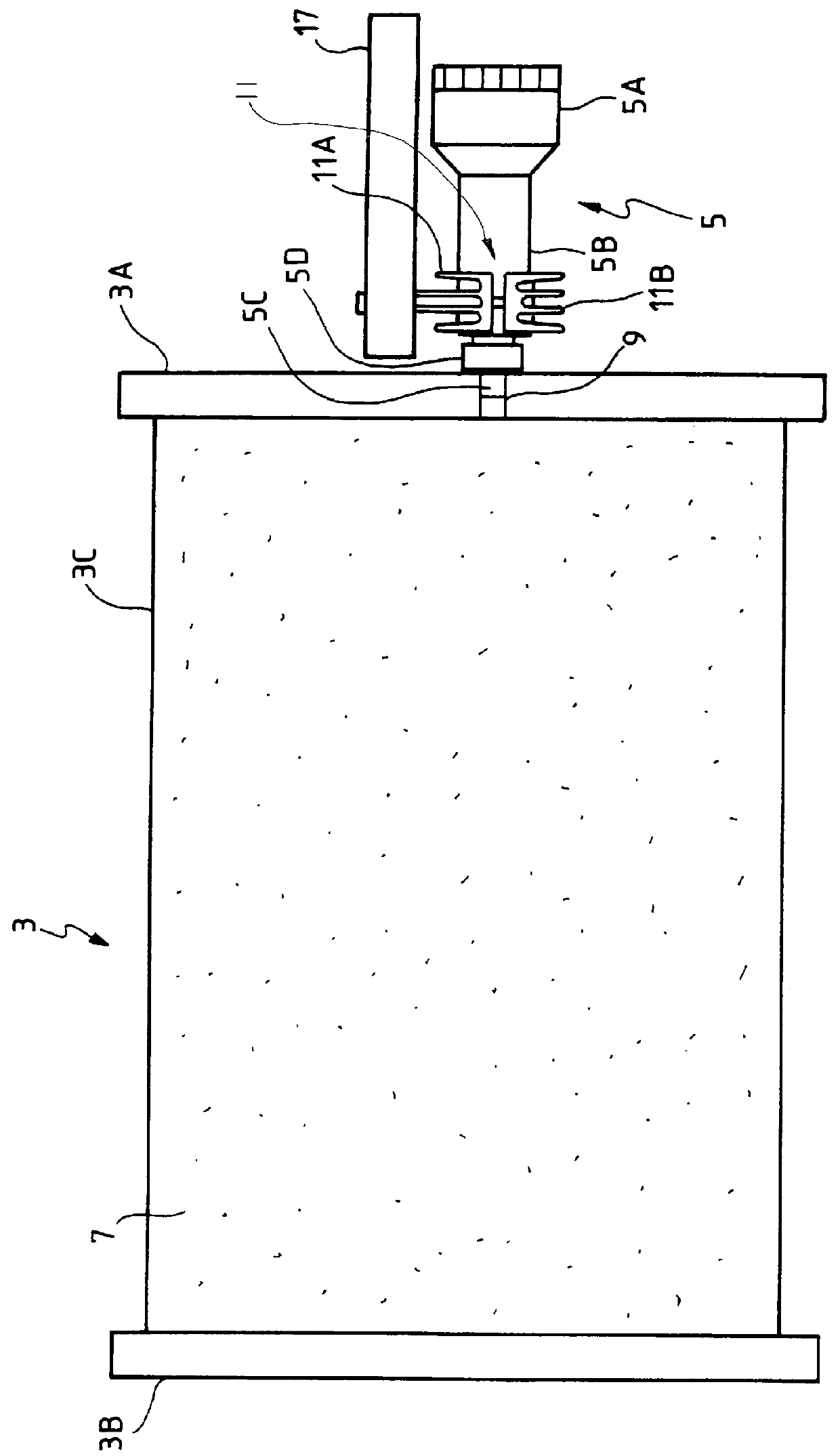

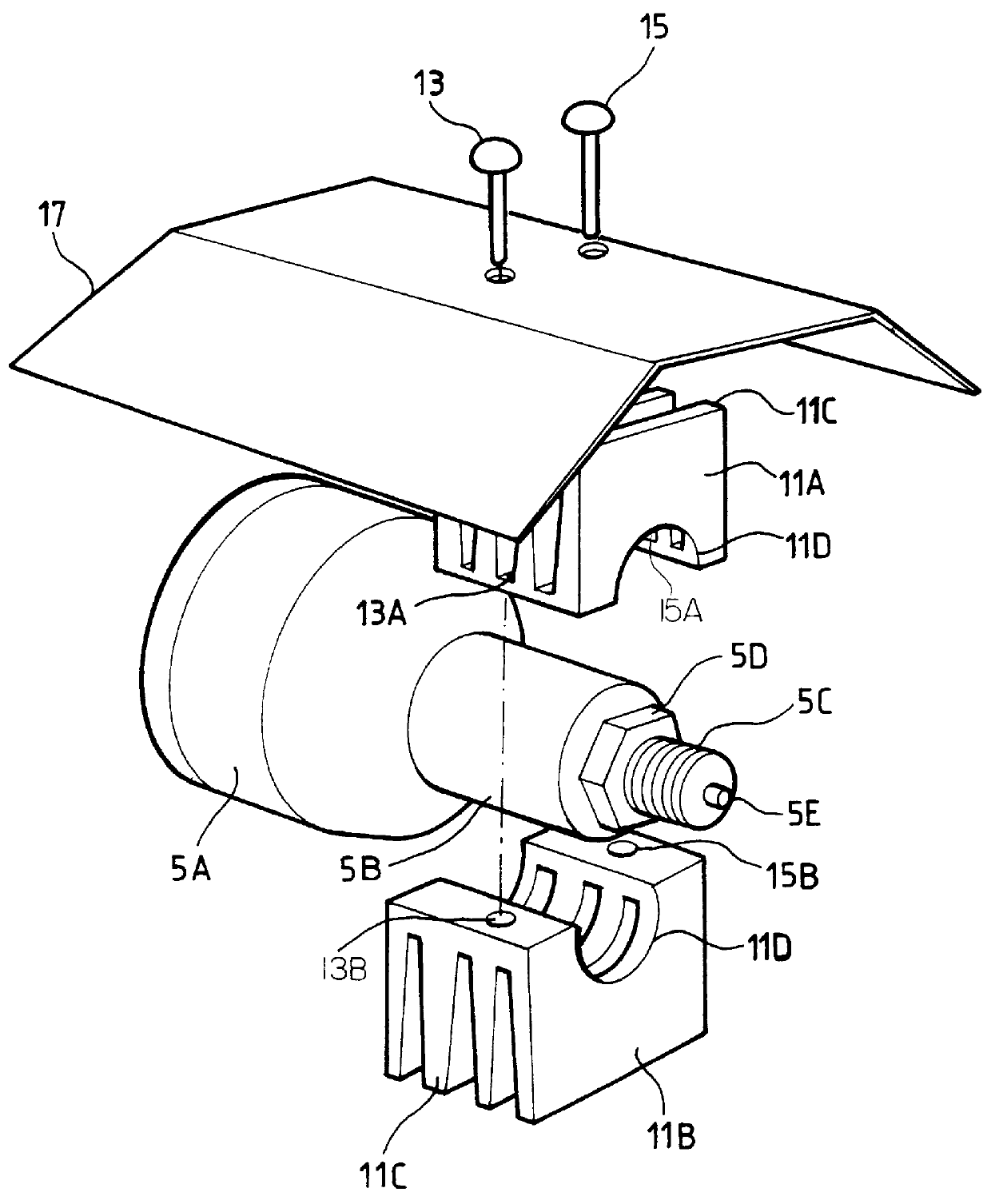

Density sensor for monitoring the rate of leakage from a switchgear case with improved reliability

InactiveUS6125692AImprove reliabilityThermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringSwitchgear

A density sensor for monitoring a rate of leakage from the case of electrical switchgear filled with dielectric gas under pressure, the sensor comprising a fixing support mounted from the outside in the thickness of the case and communicating with the dielectric gas. A radiator is placed around the fixing support of the density sensor, thereby enabling a measurement artifact that is due to the exposure of the case and of the sensor to solar radiation to be transformed in such a manner that any risk of untimely crossing of a low density threshold is eliminated.

Owner:GEC ALSTHOM T & D SA +1

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

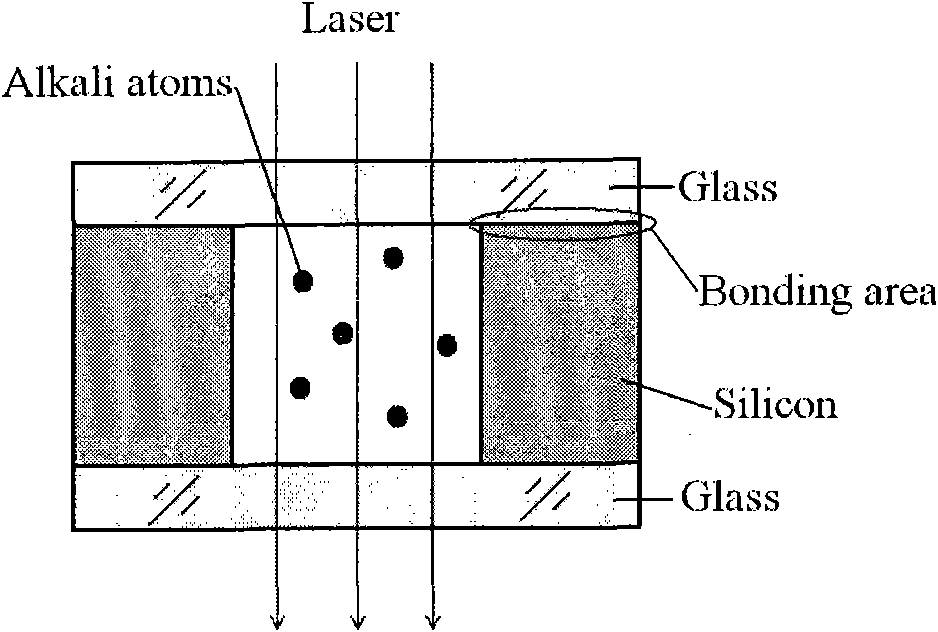

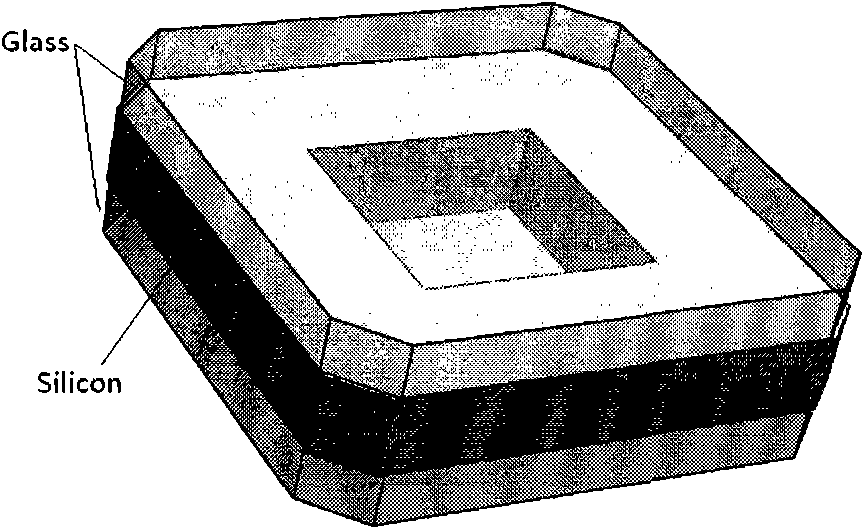

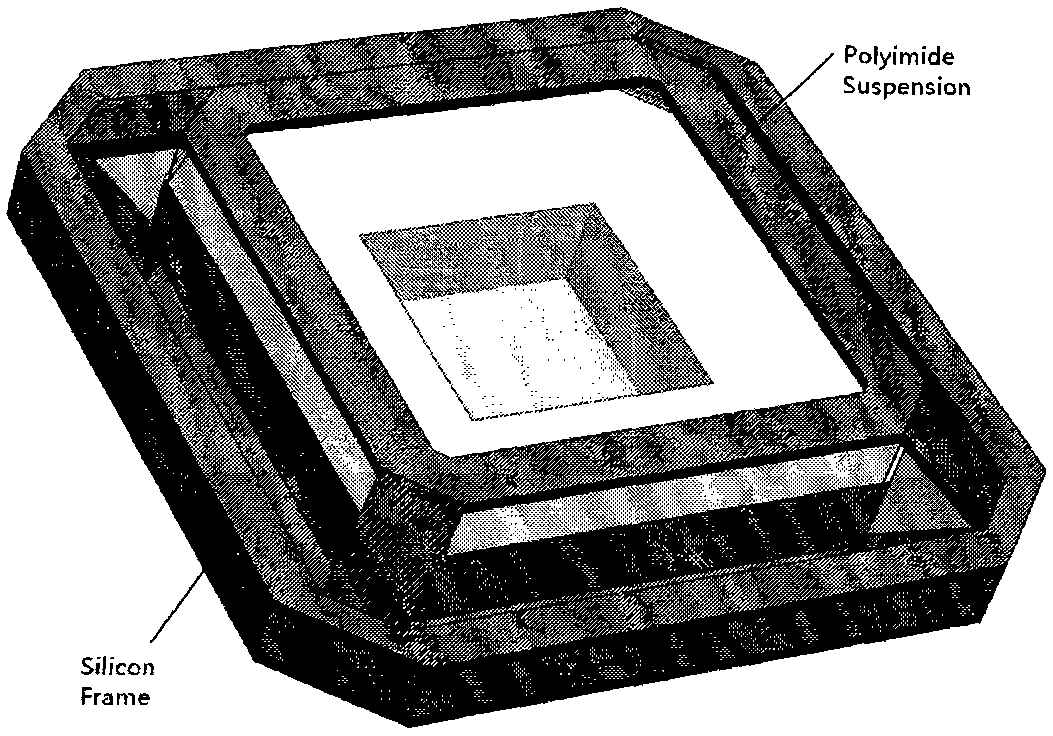

Micro electro mechanical system (MEMS) process-based micro atomic cavity device air tightness package and method

InactiveCN102205941ASimple structural designSimple processDecorative surface effectsSolid-state devicesGyroscopeEngineering

The invention relates to a micro electro mechanical system (MEMS) manufacturing process-based micro atomic cavity air tightness package structure and a method. The structure and the method are characterized in that: a micro atomic cavity which is manufactured by the MEMS process is arranged in a glass or metal seal buffer cavity through a supporting structure, and the air tightness of the micro atomic cavity is improved, so that the service life of devices such as a micro atomic clock and the like based on the micro atomic cavity is prolonged, and the stability of the devices is improved. The structure and the method have a key point that: in the glass or metal buffer cavity structure, the inside of the buffer cavity is vacuumized or filled with buffer gas of which the components and the pressure are approximate to those of gas in the micro atomic cavity, and a leading wire of the micro atomic cavity passes through the buffer cavity to realize air tightness lead. By the package structure and the method, the leakage rate of the micro atomic cavity and outside can be effectively reduced, and the technical problem of short service life of micro atomic cavity devices is solved. The air tightness package structure is particularly suitable for the micro atomic cavity devices such as micro atomic clocks, micro atom magnetometers, micro atom gyroscopes and the like with low power consumption and small volumes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

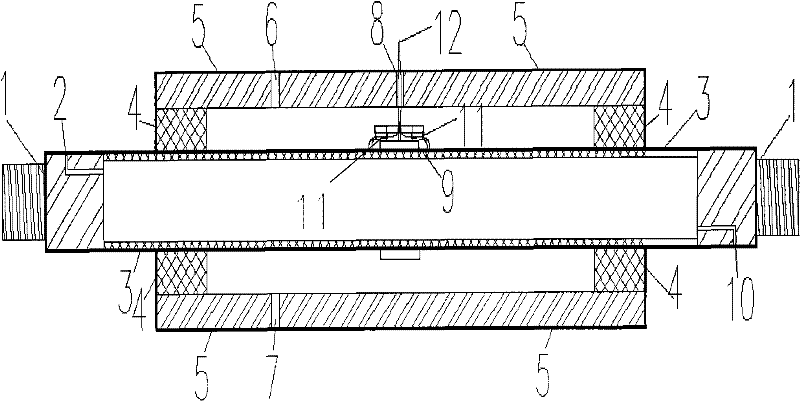

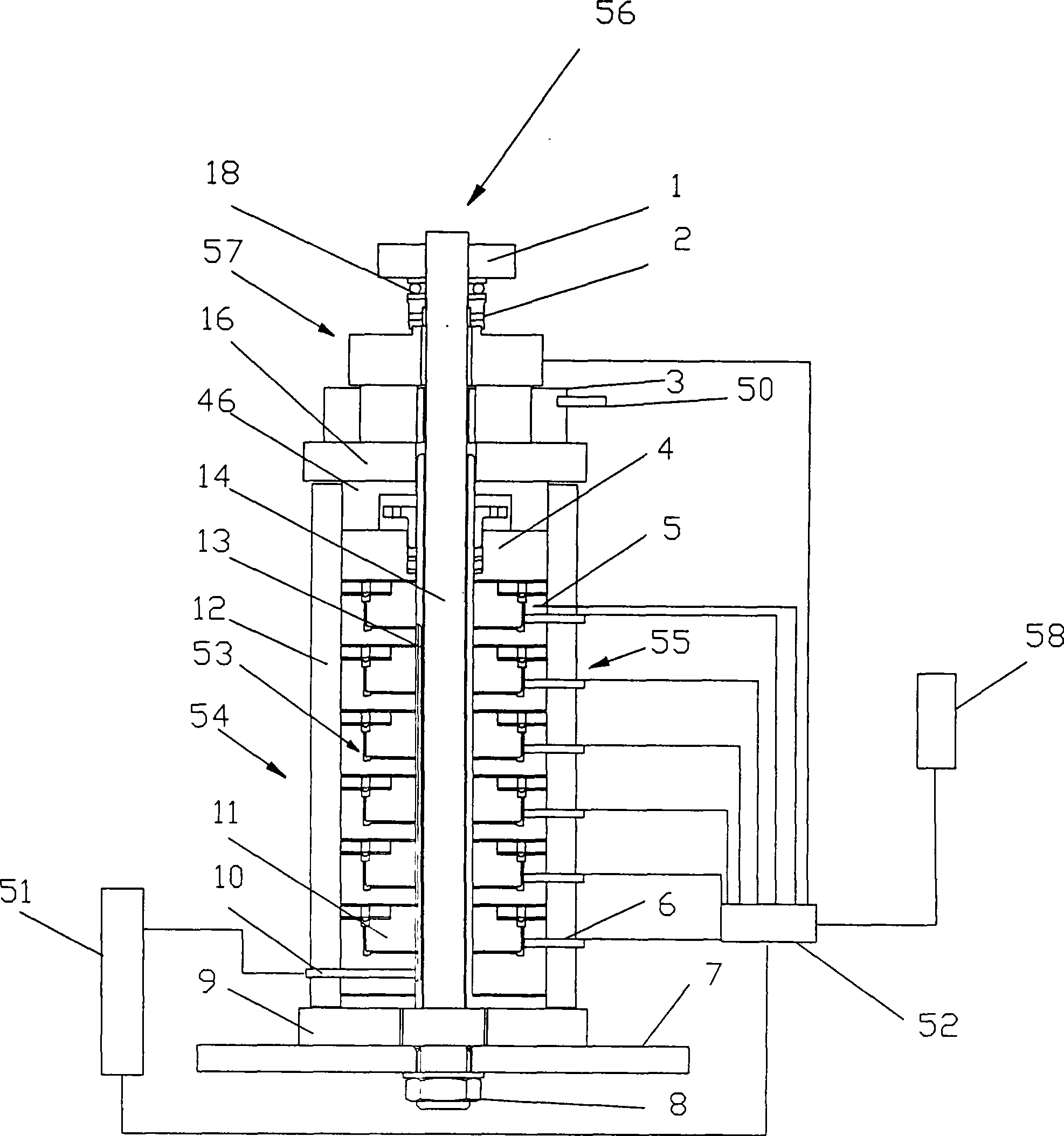

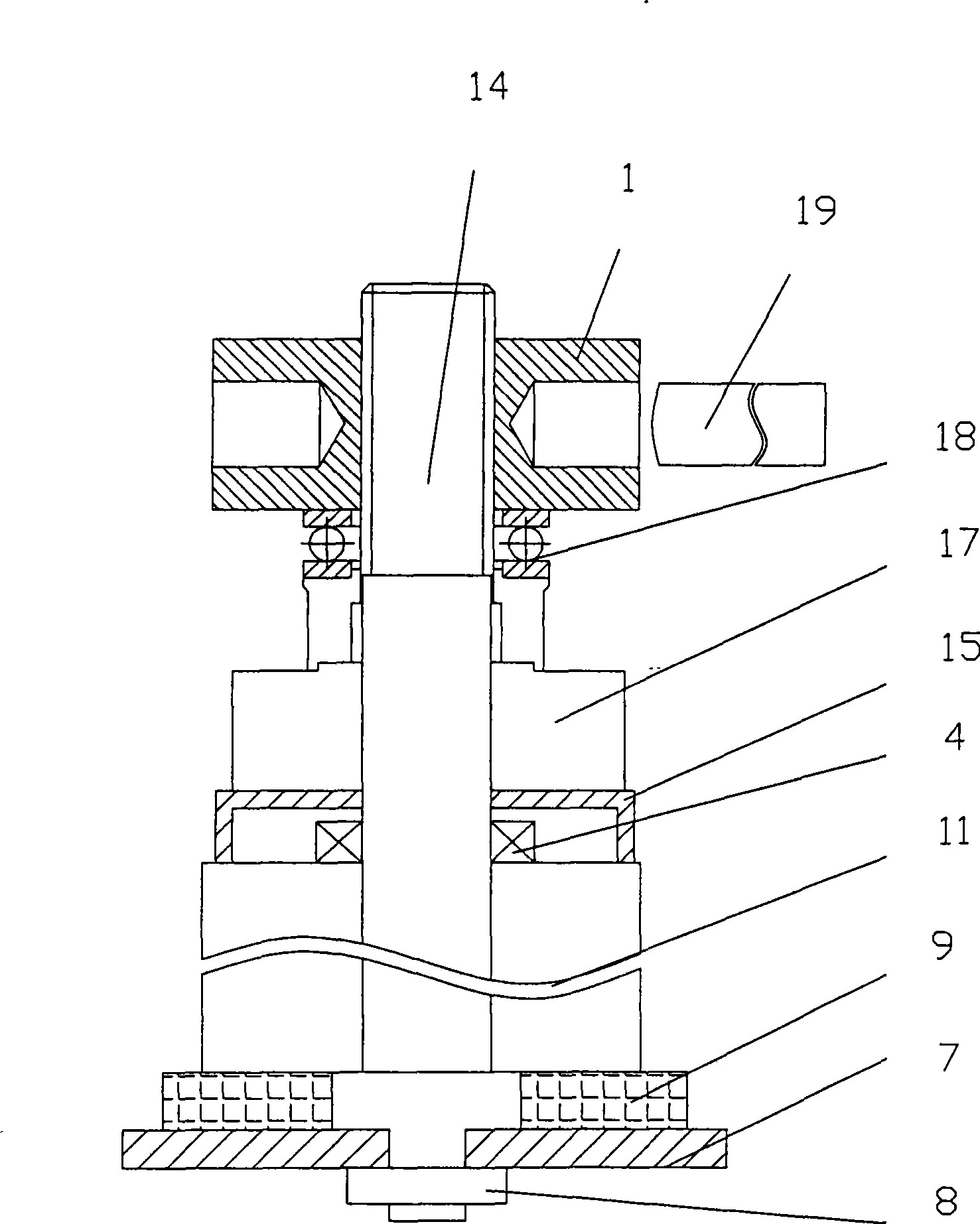

Multi-functional multi-specimen sealing gasket service life evaluation testing apparatus

InactiveCN101446510ARealize measurementEasy to controlMachine part testingFluid-tightness measurement using fluid/vacuumTemperature controlControl system

The invention relates to a multi-functional multi-specimen sealing gasket service life evaluation testing apparatus which comprises a gasket loading and load measuring system (56) and a medium given system (51). The apparatus is characterized in that the air given end of the medium given system (51) is connected with the air inlet end of a medium sealing system (53), the medium sealing system (53) is positioned inside of a temperature controlling and measuring system (54), a cooling thermal insulation system (57) is placed above the medium sealing system (53), and a leakage rate measuring system (55) is positioned on one side of the temperature controlling and measuring system (54); the medium sealing system (53), the temperature controlling and measuring system (54) and the cooling thermal insulation system (57) are connected respectively through stress bolts (14) of the gasket loading and load measuring system (56); and a data acquisition and control system (52) is respectively and electrically connected with the medium given system (51), the medium sealing system (53), the temperature controlling and measuring system (54), the leakage rate measuring system (55) and the cooling thermal insulation system (57).

Owner:NANJING TECH UNIV

Estimating and correcting for contrast agent extravasation in tissue perfusion imaging

ActiveUS8718747B2Robust estimationAccurately determineImage enhancementImage analysisDynamic contrastArterial input function

The invention provides a method, an image analysis software product, and a system for medical imaging analysis for estimating contrast agent extravasation in contrast agent based perfusion imaging such as MRI dynamic contrast enhanced (DCE) imaging, and in particular correction, compensation, or visualization of extravascular leakage of contrast agent in tumors. According to the invention, the effect of extravasation is directly manifested in the tail part of an observed, apparent residue function, R′(t), obtained directly by de-convoluting the expression C(t)=R′(t)Cp′(t) with the arterial input function (AIF). A leakage rate or extravasation constant is determined directly from the tail part of the determined apparent residue function. The invention also relates to distinguishing between T1-dominant and T2*-dominant extravasation effects in perfusion imaging to from the sign of the tail part of the determined apparent residue function and to an automated method for DSC-MRI involving correction for contrast agent extravasation and partial volume effects.

Owner:UNIV OSLO HF

Automotive rotary sealing ring testing device

ActiveCN103148998AStable jobAccurately Measure LeakageMachine part testingMeasurement of fluid loss/gain rateWorking environmentDrive motor

The invention belongs to the field of sealing engineering of automobile transmission devices, and particularly relates to a testing device used for estimating and testing the performance of an automotive rotary sealing ring. The technical scheme of an automotive rotary sealing ring testing device includes that the automotive rotary sealing ring testing device is used for testing the performance of the sealing ring and comprises a driving motor, a pump, a filter, an oil tank, an overflow valve, a pressure sensor A, a flowmeter, a torque sensor, a variable frequency driving motor, an oil inlet sleeve, an oil distribution sleeve, a pressure sensor B, a temperature sensor, a heat-sink cooling device and a box body used for fixing the oil inlet sleeve. The automotive rotary sealing ring testing device can be used for real simulation of a real working environment of the rotary sealing ring, a plurality of different working conditions can be provided by means of speed regulation, pressure regulation, temperature controlling and the like, and the performance of the sealing ring can be estimated by means of testing of a leakage rate and abrasion at the same time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com