Patents

Literature

354results about How to "Reduce air leakage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

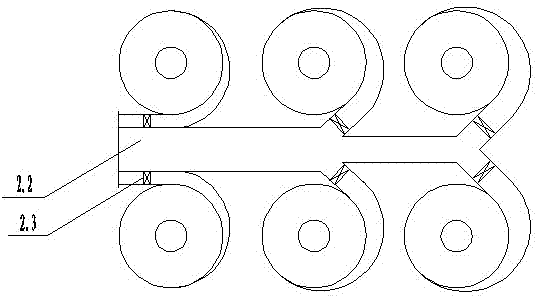

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

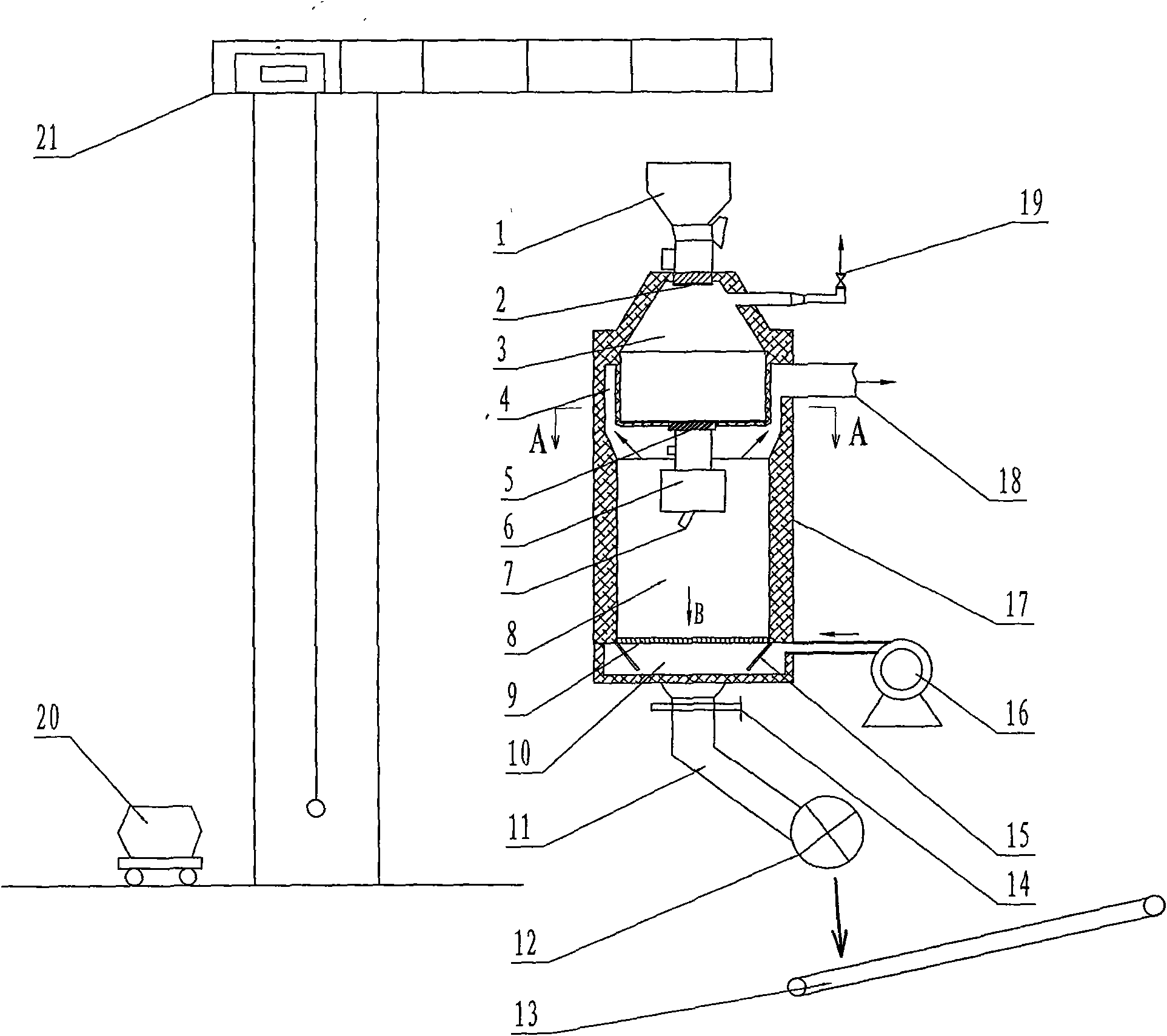

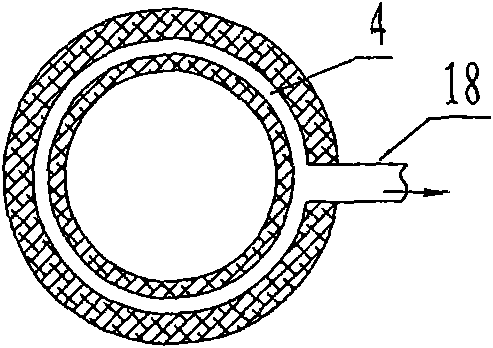

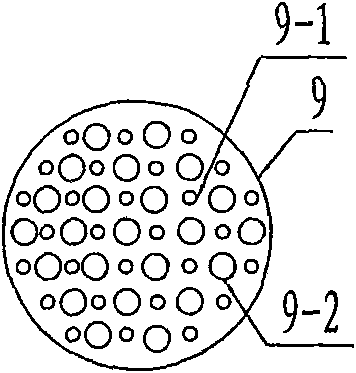

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

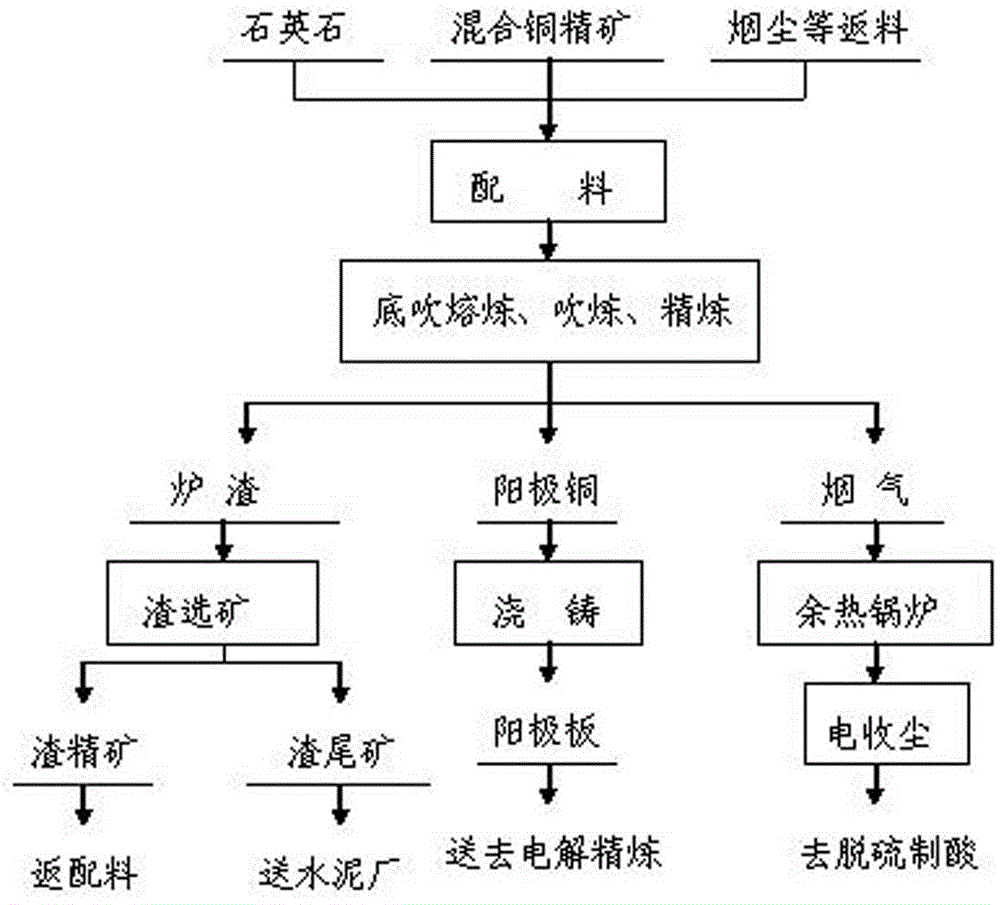

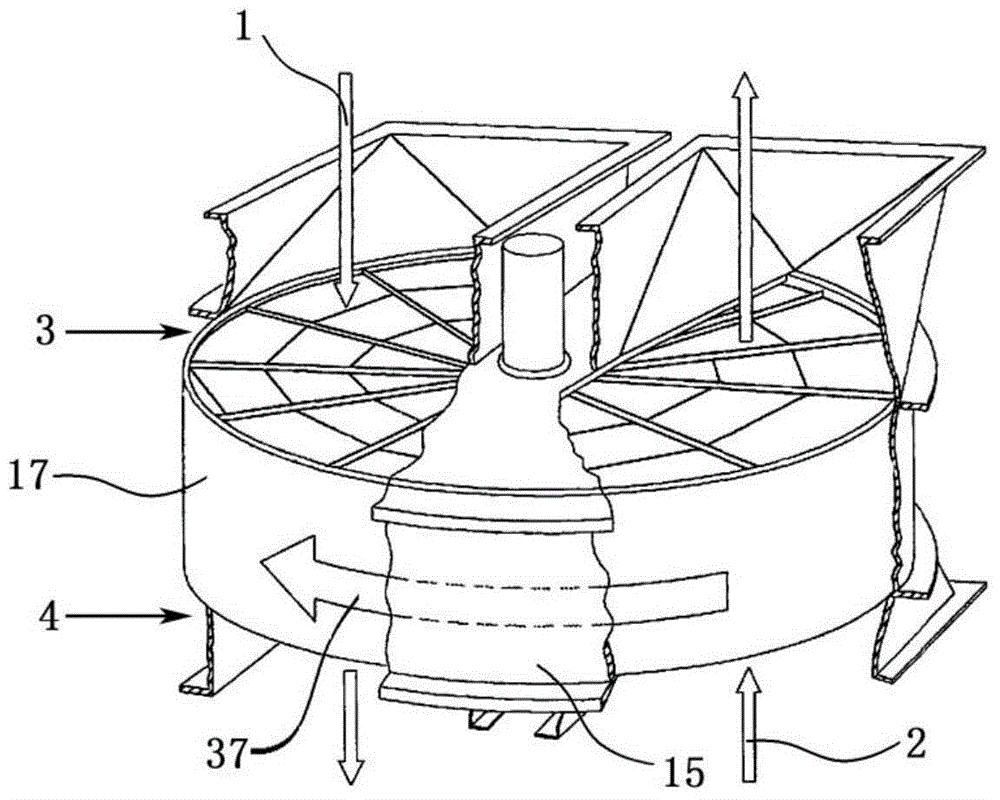

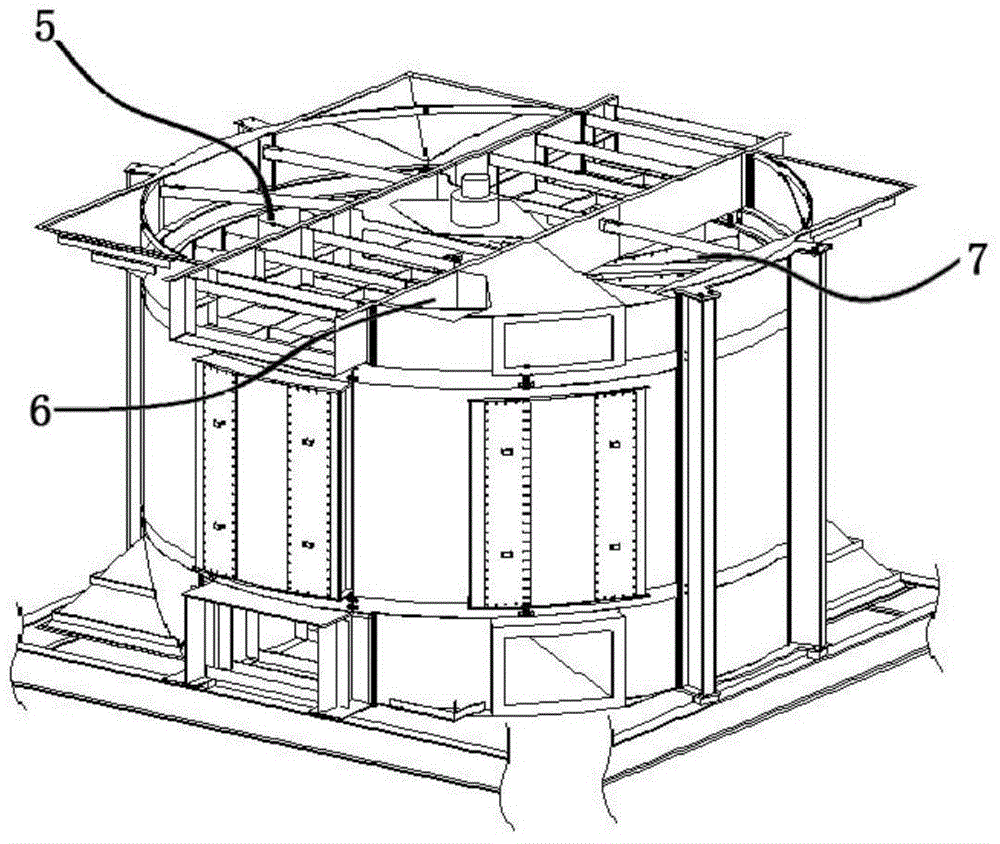

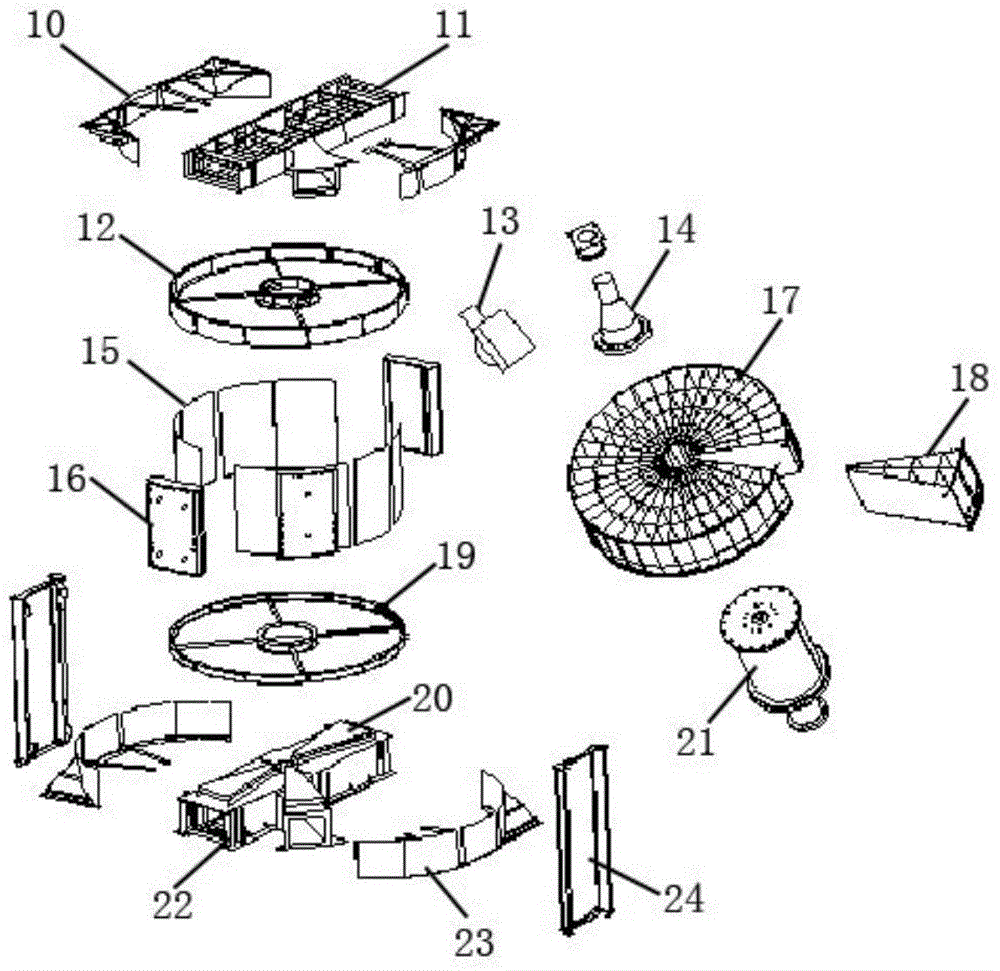

One-step copper smelting technology and device thereof

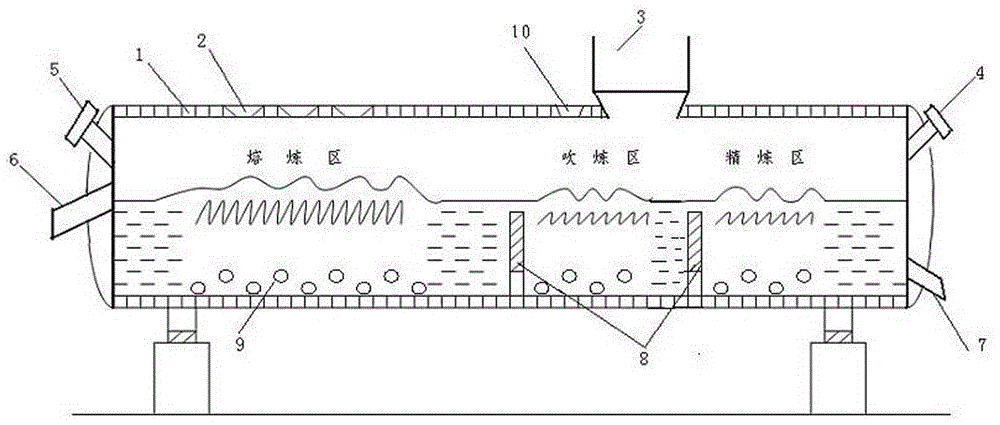

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

Rotary air preheater dust-blocking-prevention synergy sealing method and system

ActiveCN104949149AExtend your lifeEasy to implementCombustion processHeat exhanger sealing arrangementAir preheaterLiquid state

The invention discloses a rotary air preheater dust-blocking-prevention synergy sealing method and system. The dust-blocking-prevention synergy sealing method includes the steps that air leaked from the heat end is guided or extracted to the cold end from the heat end, and local heat exchange elements are purged and heated. The rotary air preheater dust-blocking-prevention synergy sealing system comprises a heat end primary air / smoke side sector sealing box, a heat end primary air / secondary air side sector sealing box and a cold end secondary air / smoke side sector sealing box, and further comprises a heat air leakage air flue; the heat end primary air / smoke side sector sealing box and the heat end primary air / secondary air side sector sealing box are each provided with an air inlet, one end of the heat air leakage air flue is in butt joint with the air inlets, and the other end of the heat air leakage air flue extends to a cold end secondary air highest-temperature module. By means of the rotary air preheater dust-blocking-prevention synergy sealing method and system, H2SO4 drops and liquid state NH4HSO4 are gasified while the air leaked from a preheater is reduced, and the aim of removing accumulated dust is achieved; the rotary air preheater dust-blocking-prevention synergy sealing method and system have the advantages of reducing the boiler smoke discharging temperature, restraining the accumulated dust of the preheater, reducing the air leakage rate, prolonging the service life of the heat exchange elements and the like.

Owner:南京博沃科技发展有限公司

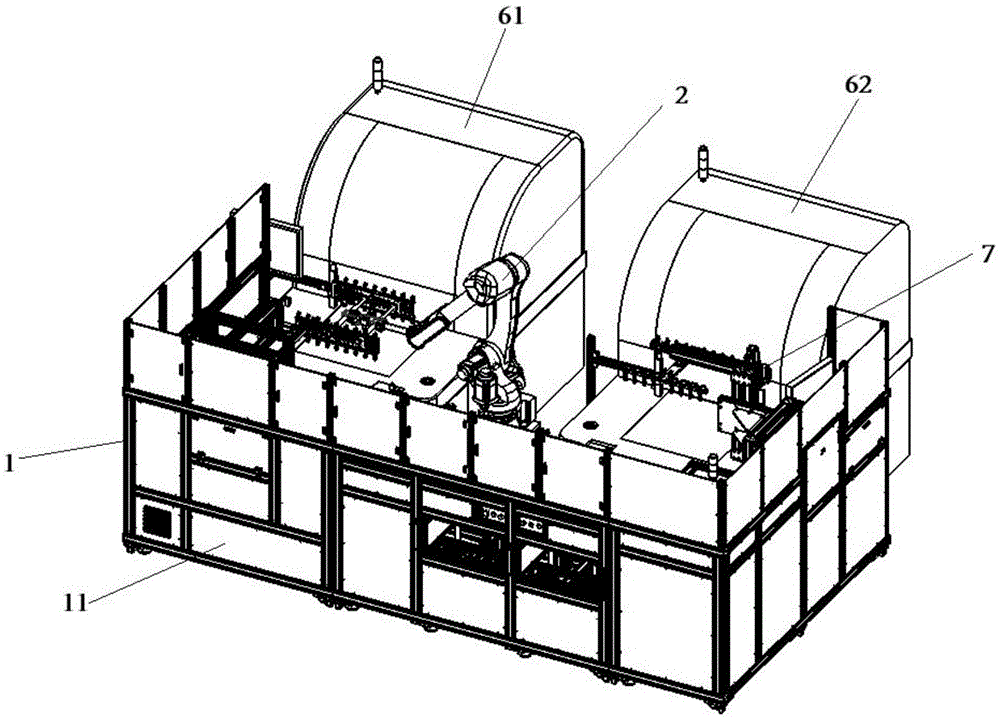

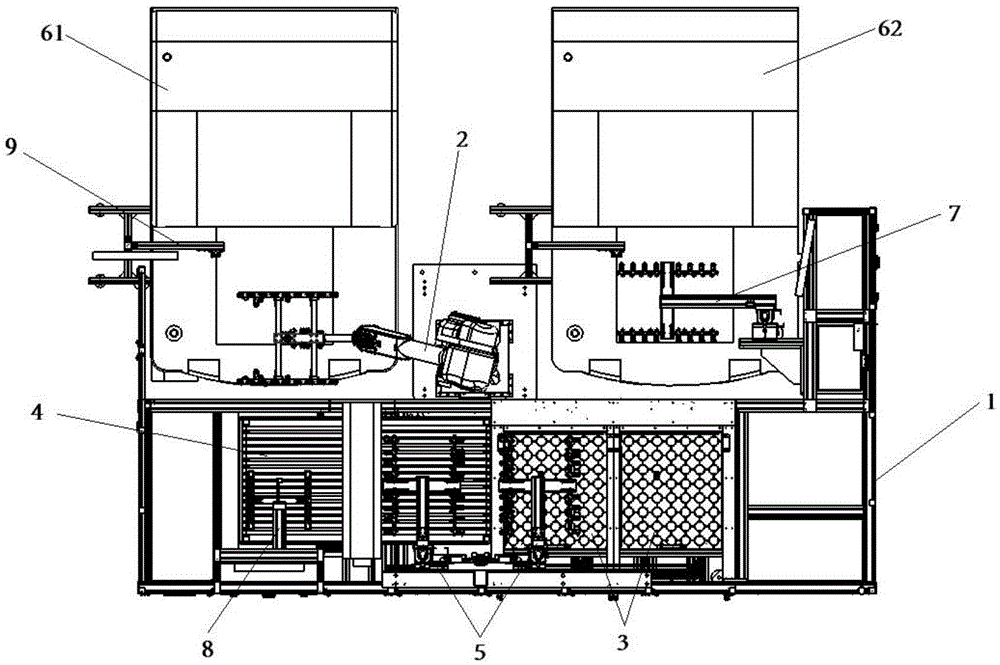

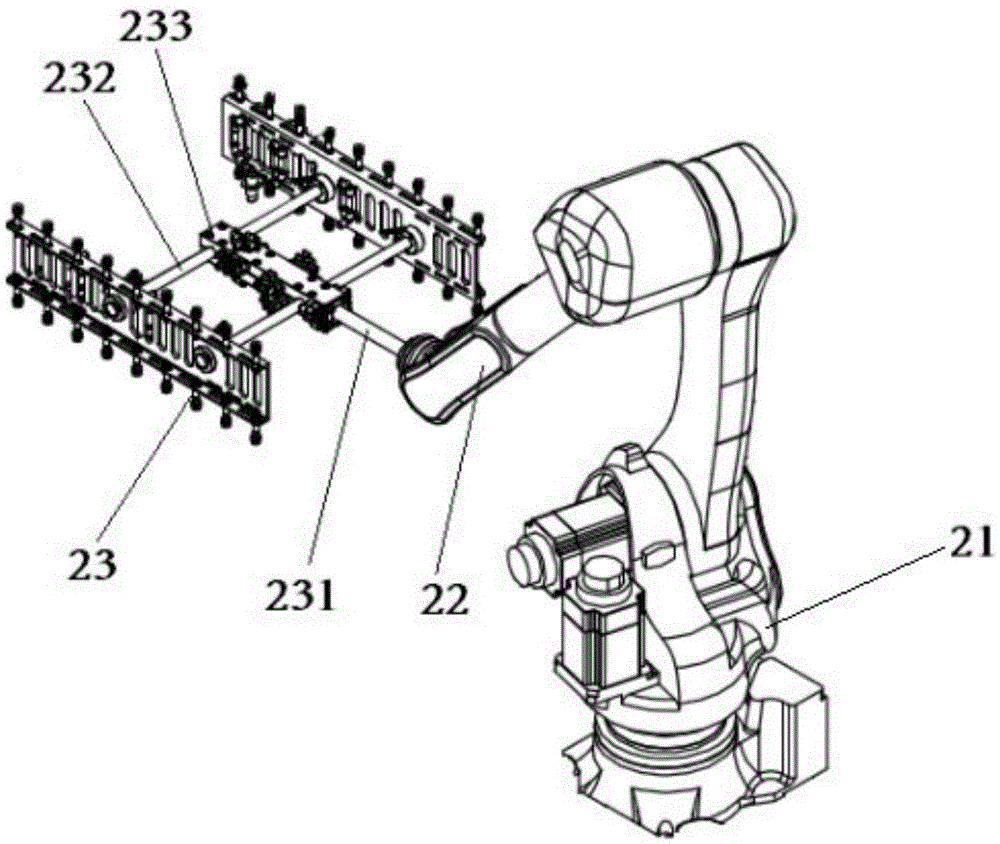

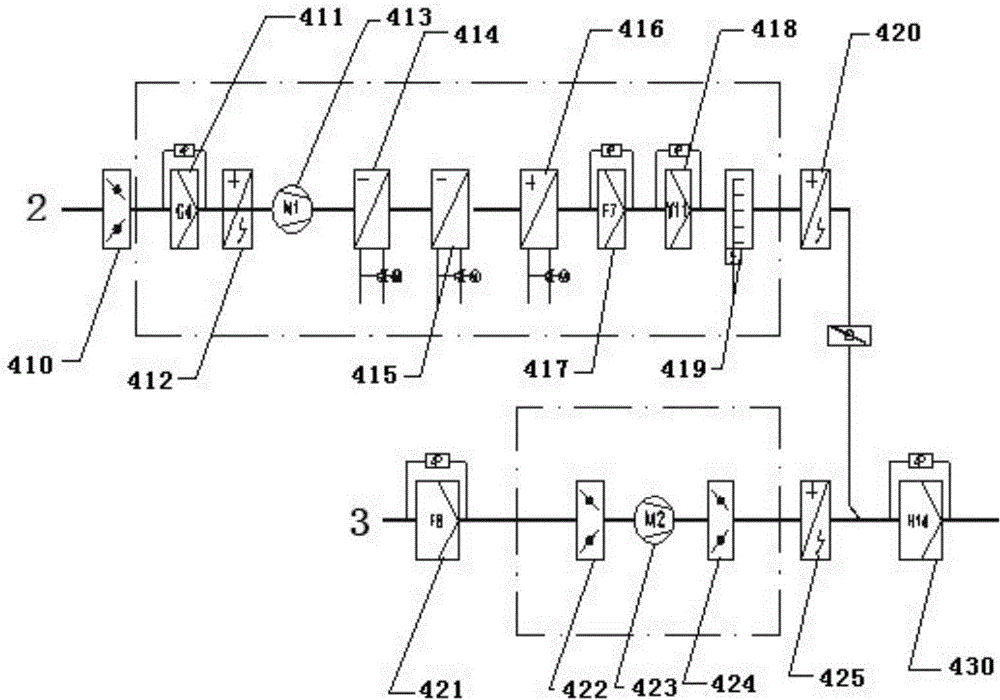

Automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of circuit board and technological process of automatic plate feeding and discharging system

The invention discloses an automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of a circuit board. The automatic plate feeding and discharging system comprises a robot device, a feeding and discharging device, a double-faced dust sticking machine, a transferring device, an AOI machine, a butt joint device and a general control system for controlling the equipment to work, wherein the robot device is provided with robot mechanical arms; the double-faced dust sticking machine is located beside the feeding and discharging device; the transferring device is arranged above the feeding and discharging device and the double-faced dust sticking machine; the AOI machine comprises a face A detection and a face B detection machine; detection openings of the face A detection and the face B detection machine are opposite to the feeding and discharging device and the double-faced dust sticking machine; the robot device is located between the face A detection and the face B detection machine; and the butt joint device is located on one side of the face B detection machine and can be in up-down butt joint with the robot mechanical arms. The butt joint device can be in up-down butt joint with the robot mechanical arms so that time consumed by a plate overturning procedure is saved, and furthermore, a whole production process has relatively rapid efficiency; and the structure is compact so that the occupied area of equipment is reduced.

Owner:GUANGZHOU TAILI ELECTRICAL & MECHANICAL EQUIP CO LTD

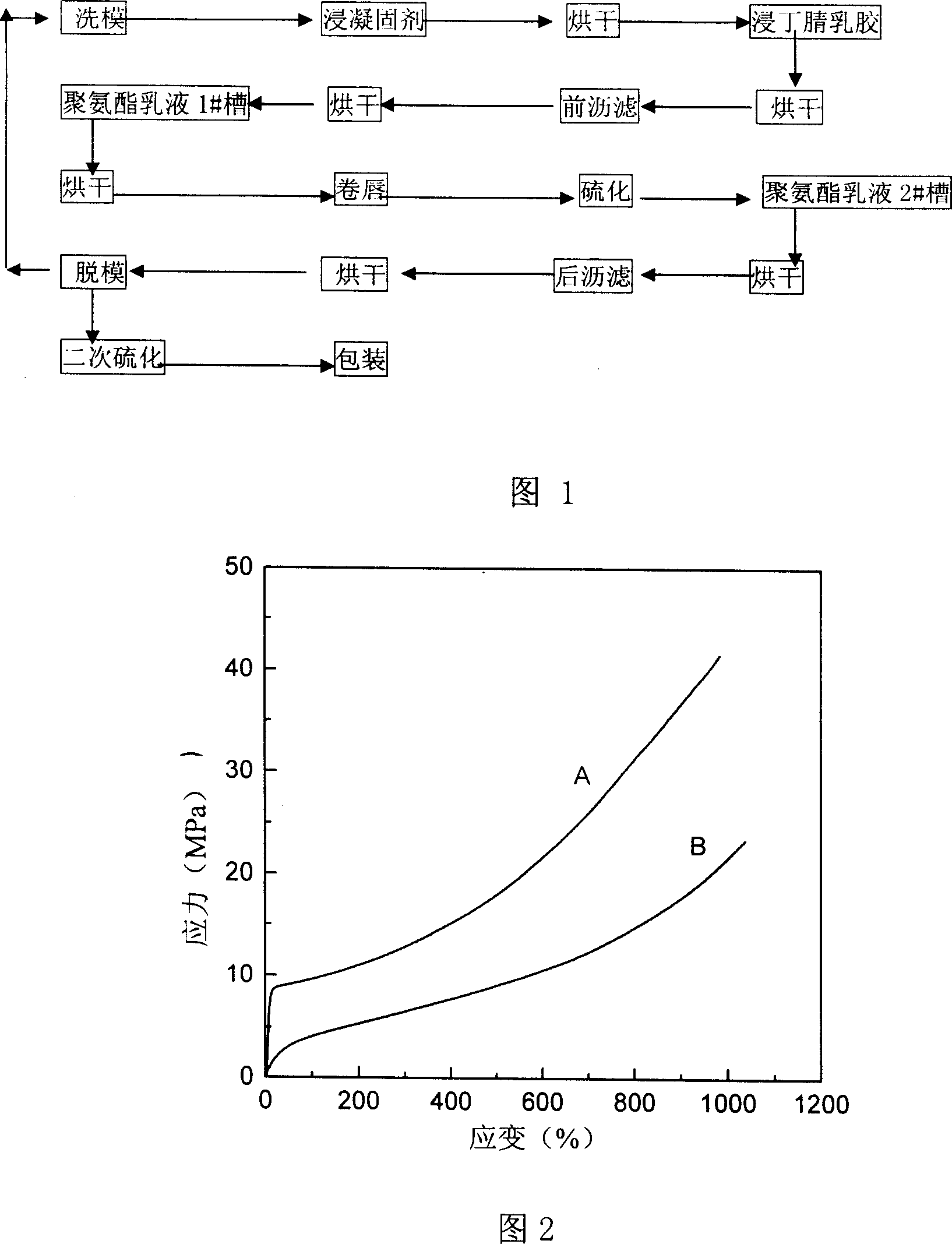

Method for fabricating one-off composite glove of nitrile butadiene rubber polyurethane

InactiveCN101003165AGood breathability and moisture permeabilityImprove wearing comfortDiagnosticsGlovesHigh resistanceEmulsion

A process for preparing the expendable composite nitrile rubber-polyurethane glove includes generating a layer of nitrile rubber film on a mould, and dipping it in aquatic polyurethane emulsion. The resultant glove has high resistance to oil and bacterial osmosis, high weatherability, and high air and moisture permeability.

Owner:TIANJIN GREENCOAT POLYMER MATERIAL TECH CO

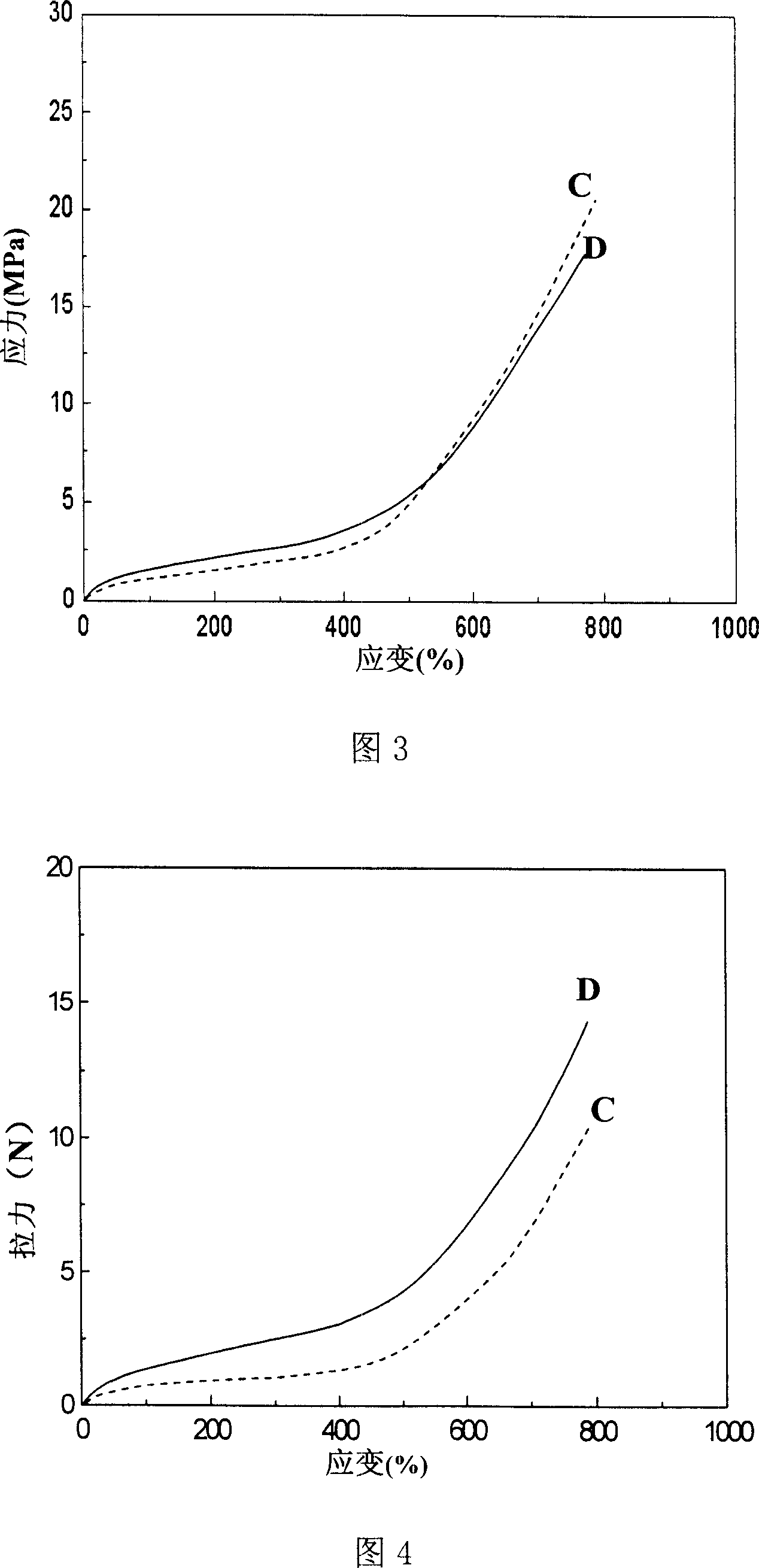

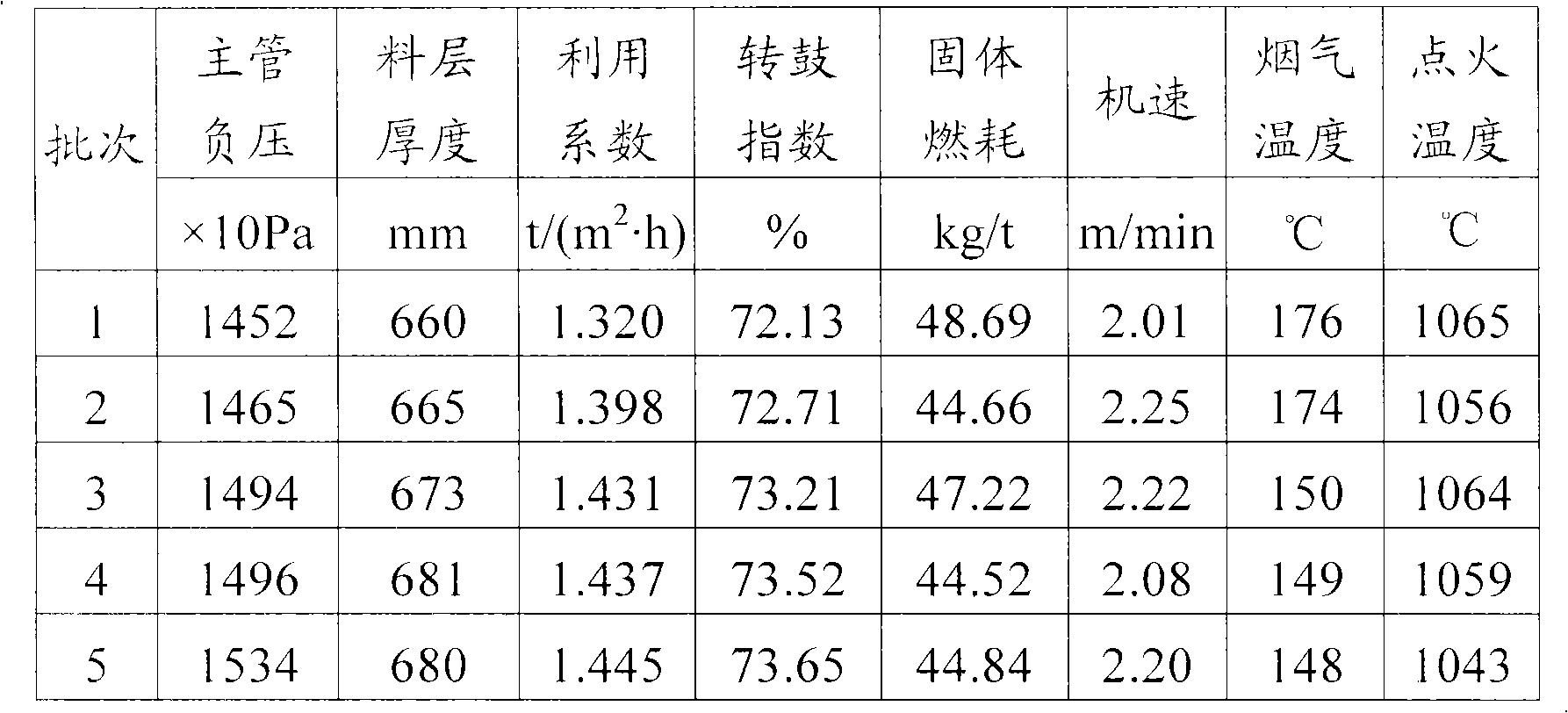

Method for sintering vanadium-titanium magnetite concentrate at high negative pressure and high air quantity

ActiveCN102251100AReduce air leakage rateIncrease productionProcess efficiency improvementAir volumeTitanium

The invention discloses a method for sintering vanadium-titanium magnetite concentrate at high negative pressure and high air quantity, comprising preparing, mixing, distributing, igniting and sintering, thermally breaking, cooling and screening, wherein the sintering is carried out under the conditions of the negative pressure of over 13500a and the unit area air quantity of a sintering machine of 100-110m<3>(m<2>.min); and the low negative-pressure ignition and full-wind sintering are adopted in the igniting and sintering process. According to the method for sintering vanadium-titanium magnetite concentrate at high negative pressure and high air quantity, which is disclosed by the invention, the yield can be improved and vanadium-titanium sintering ore with high quality can be prepared at high efficiency.

Owner:PANZHIHUA IRON AND STEEL +1

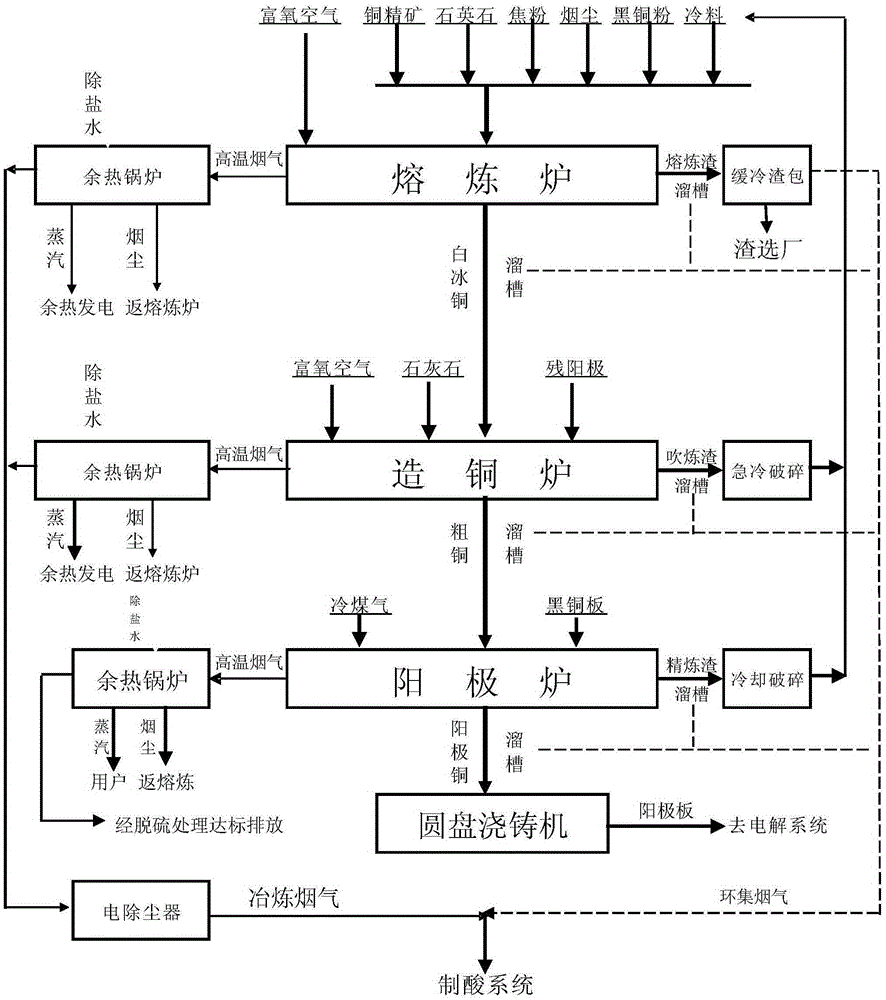

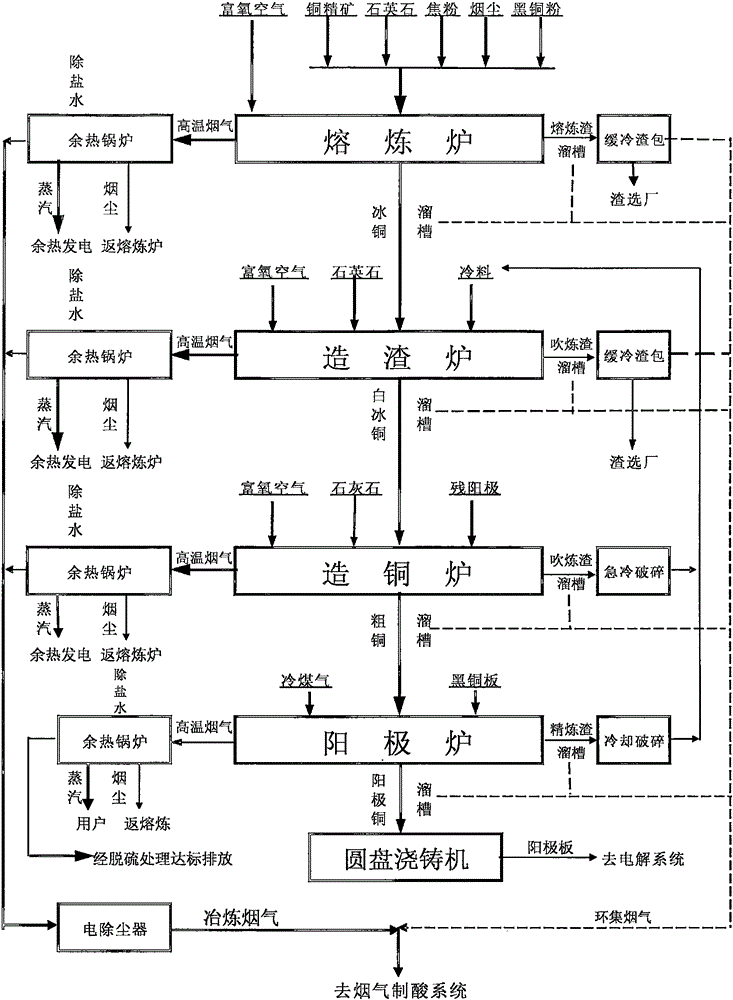

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

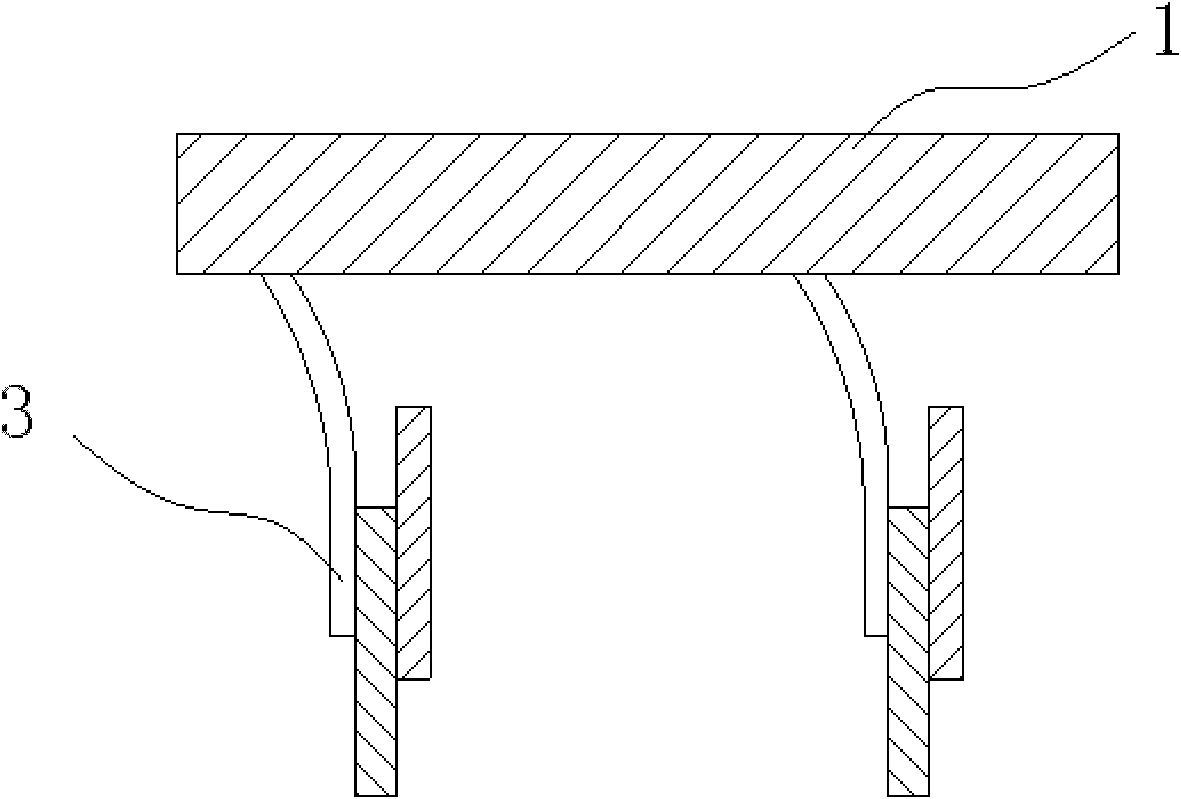

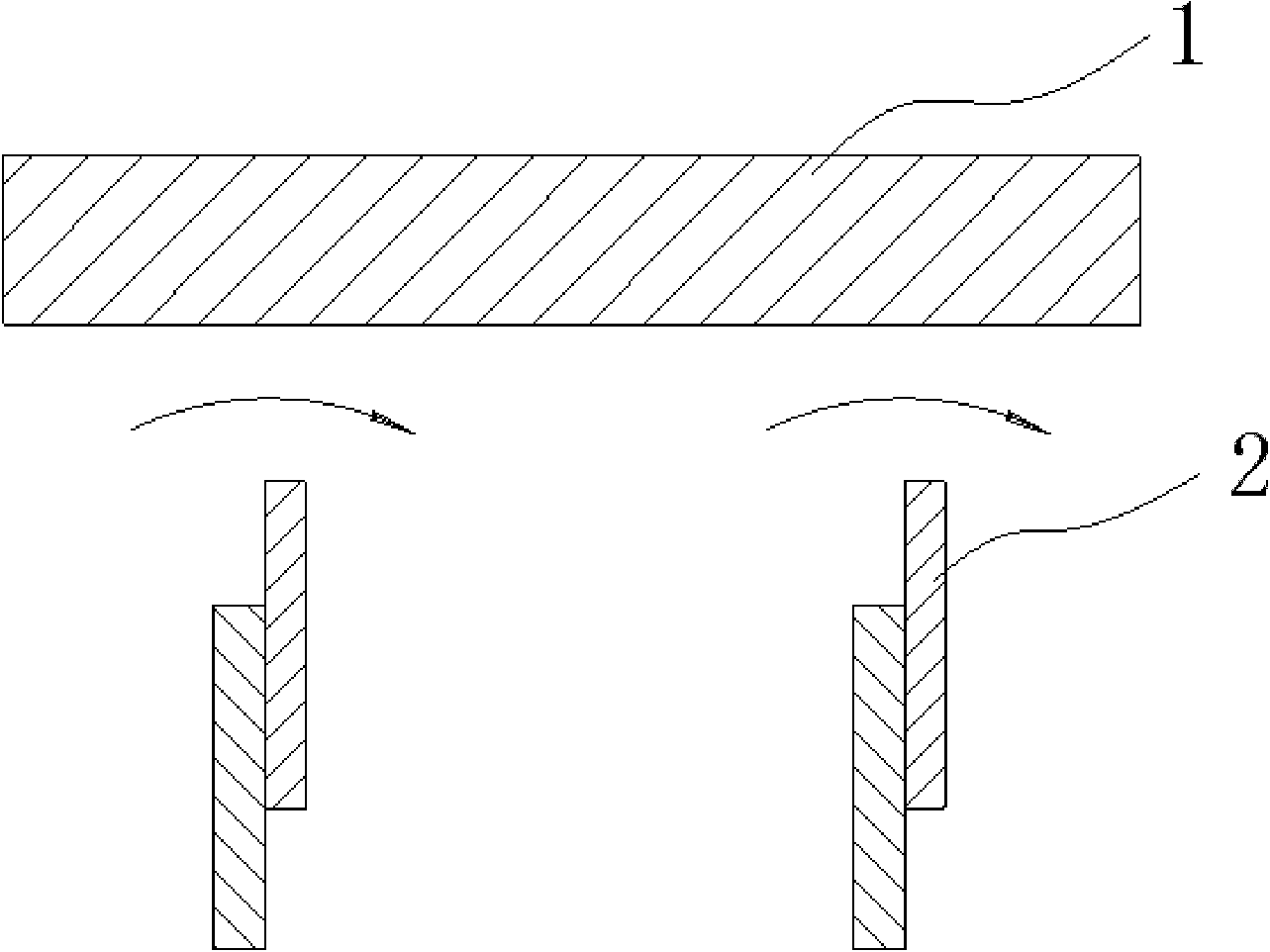

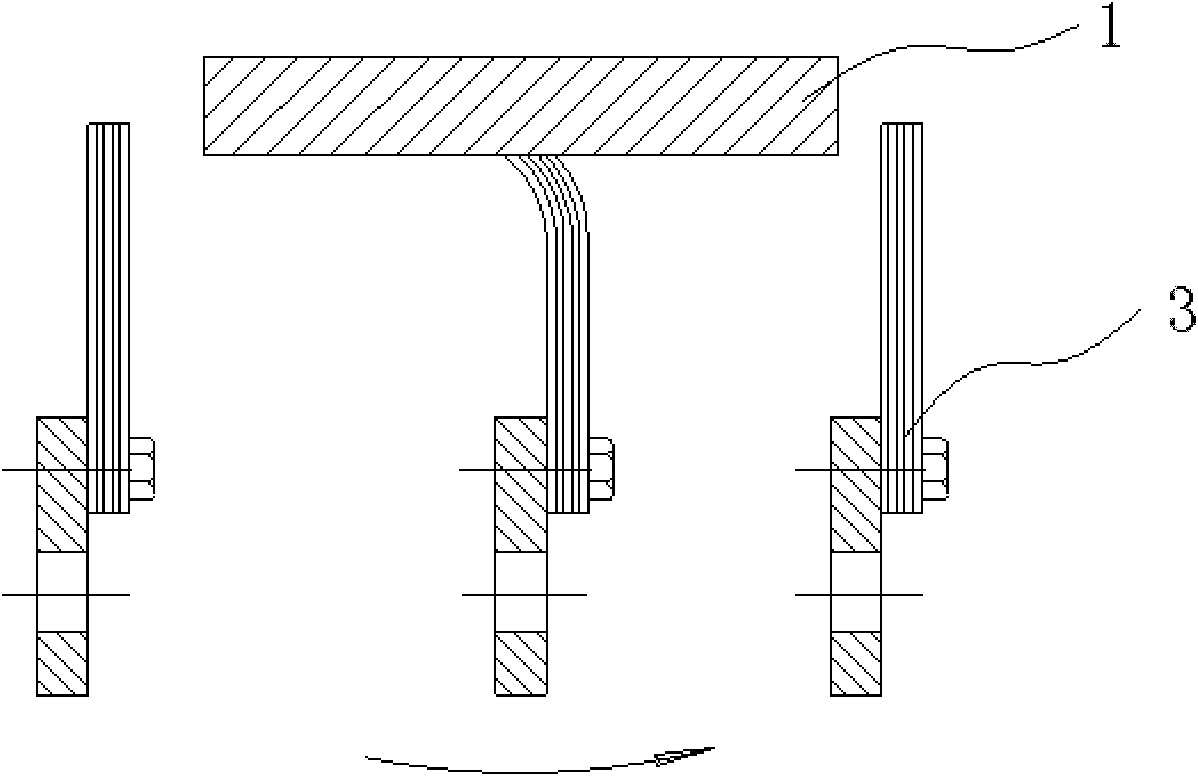

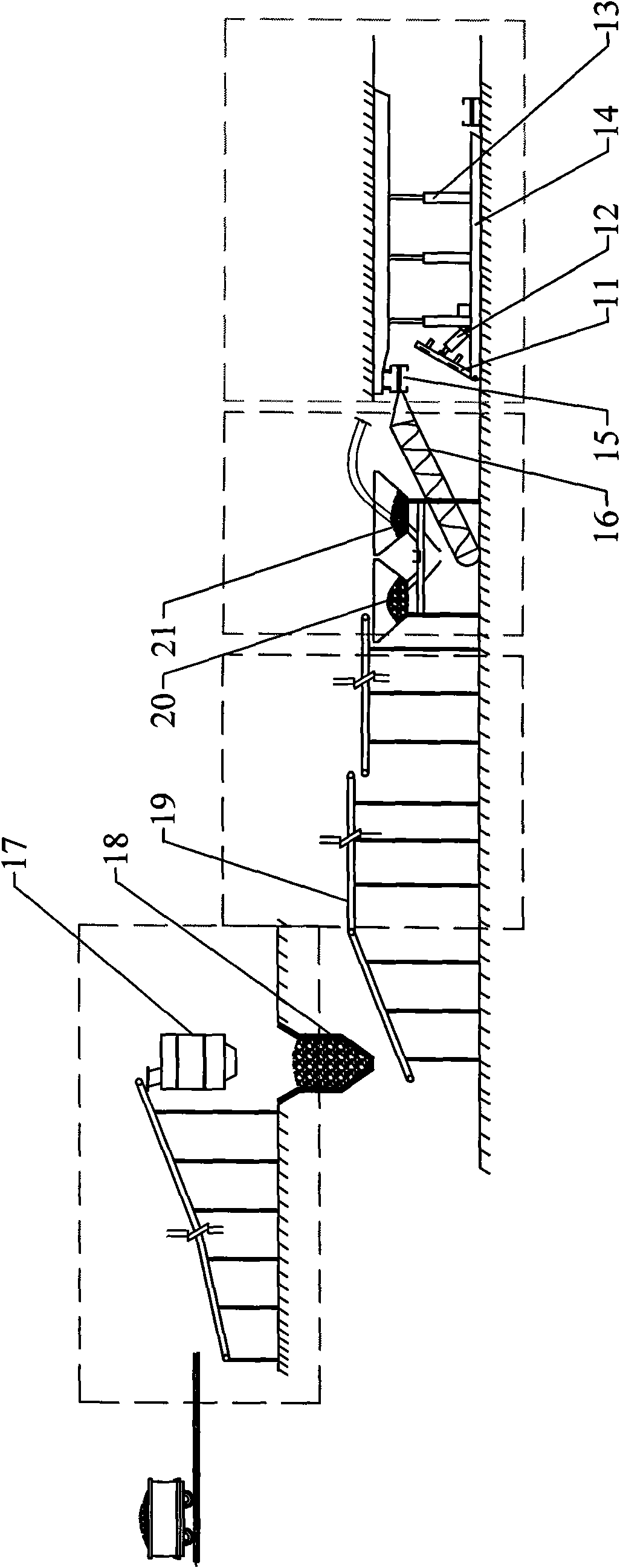

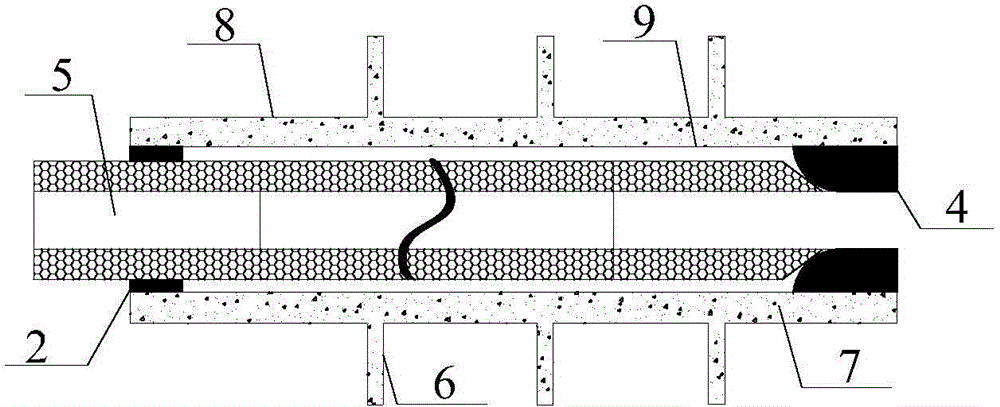

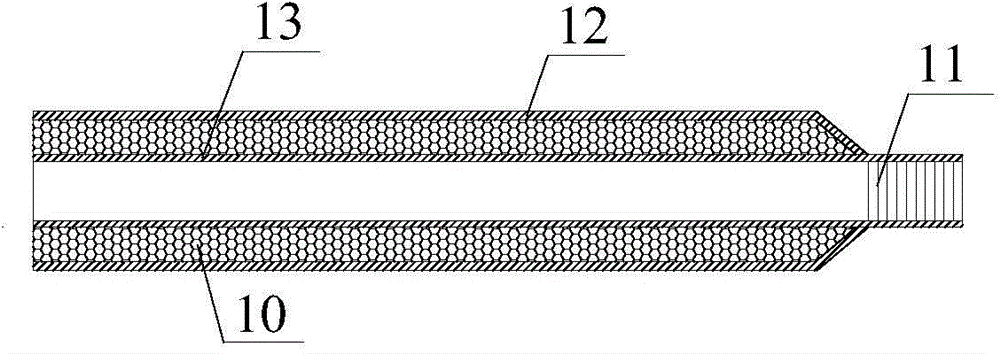

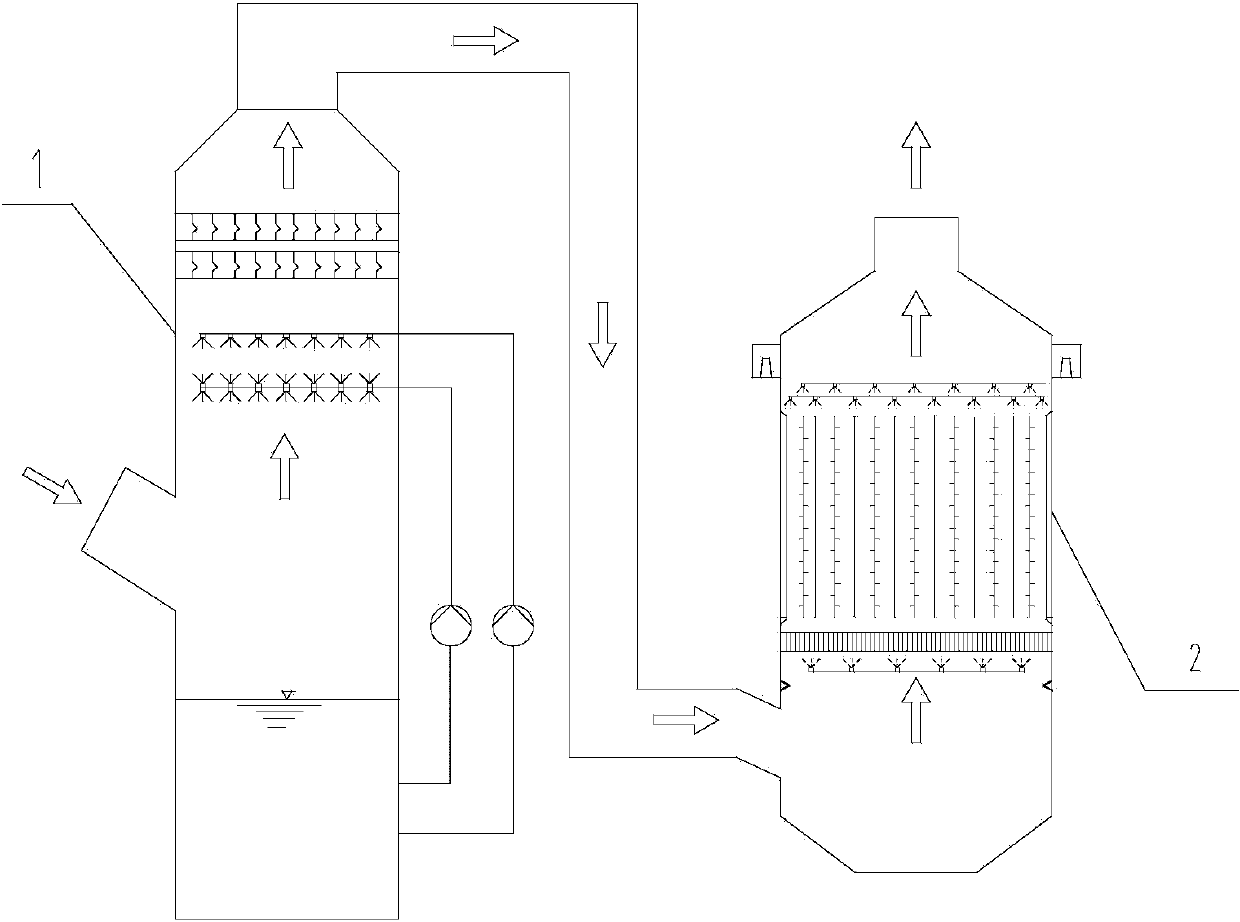

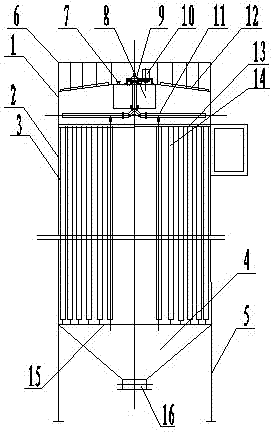

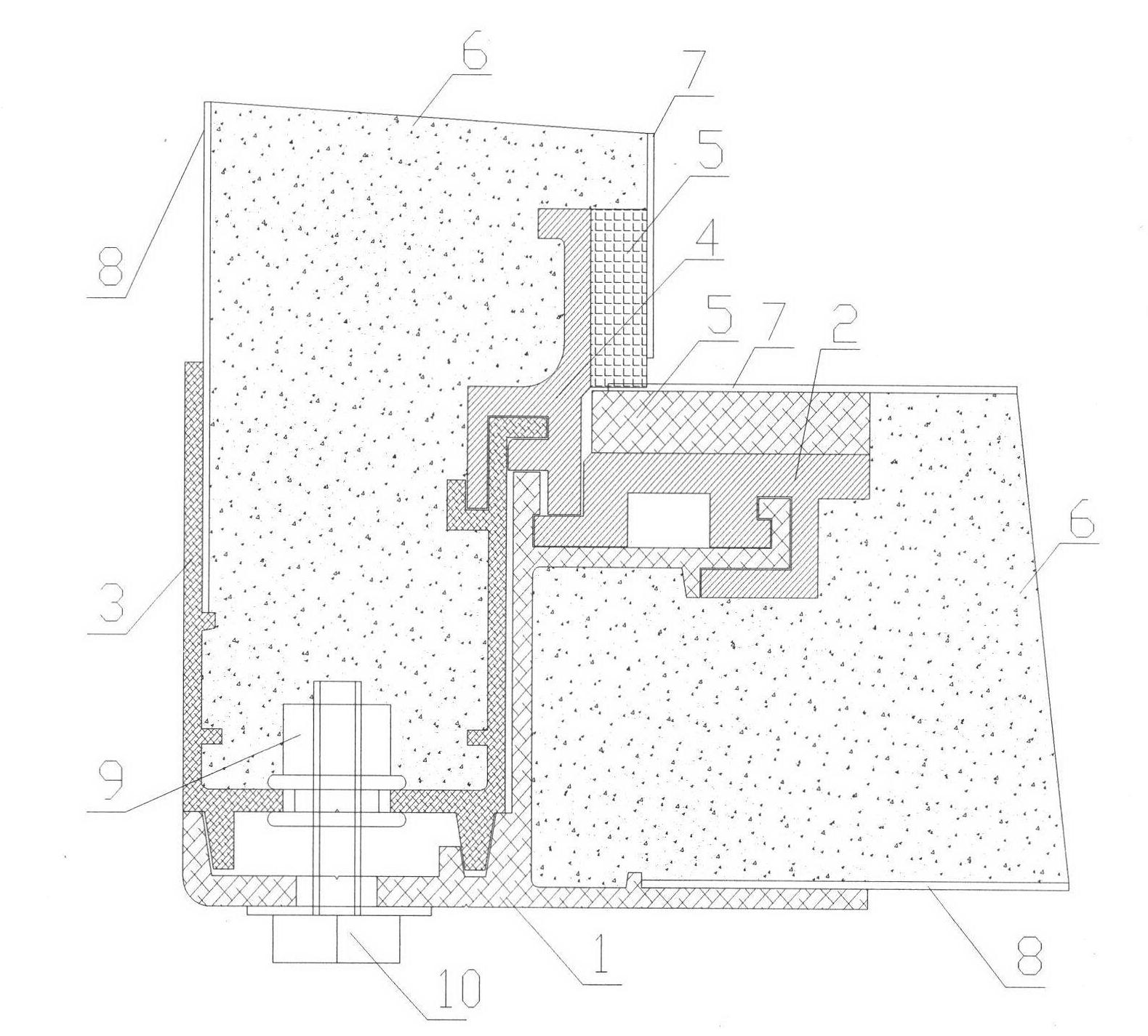

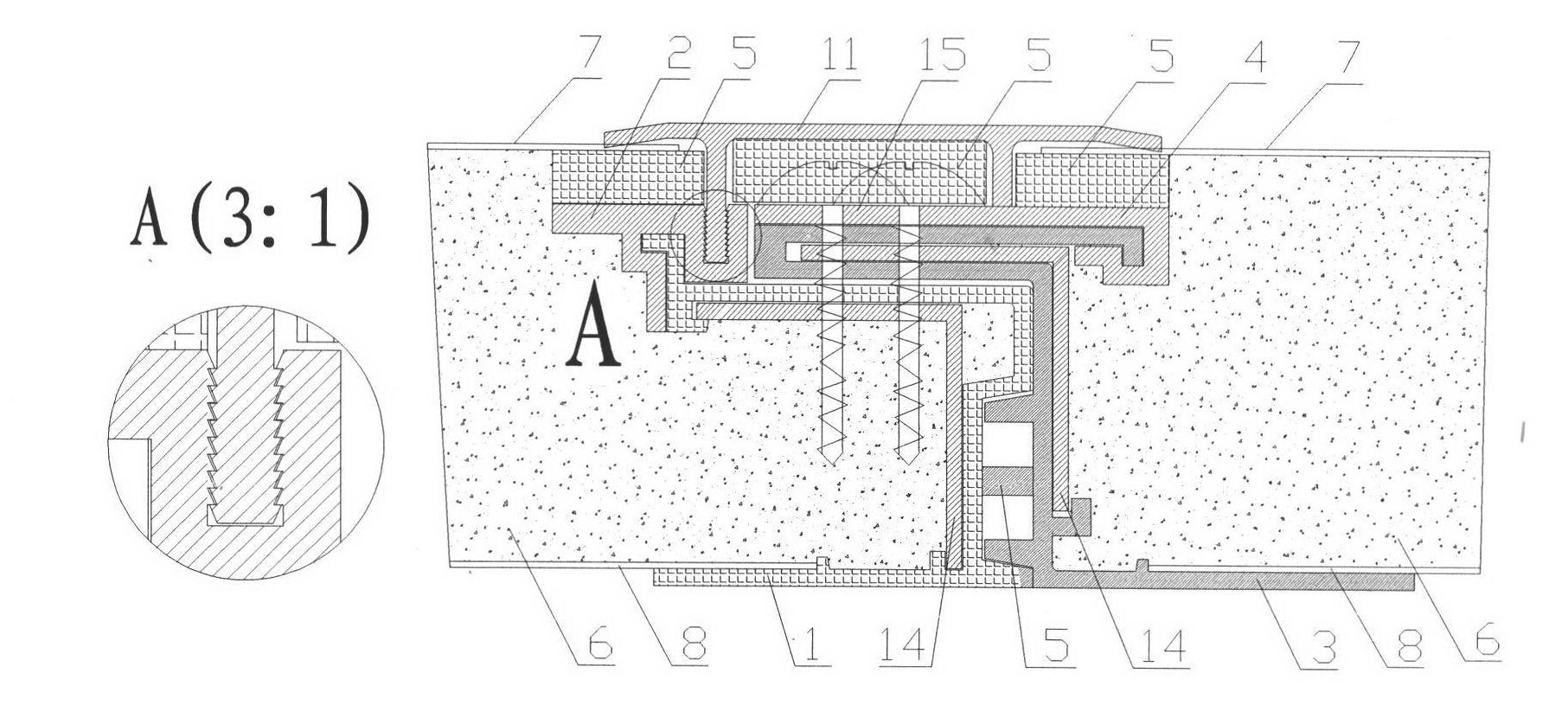

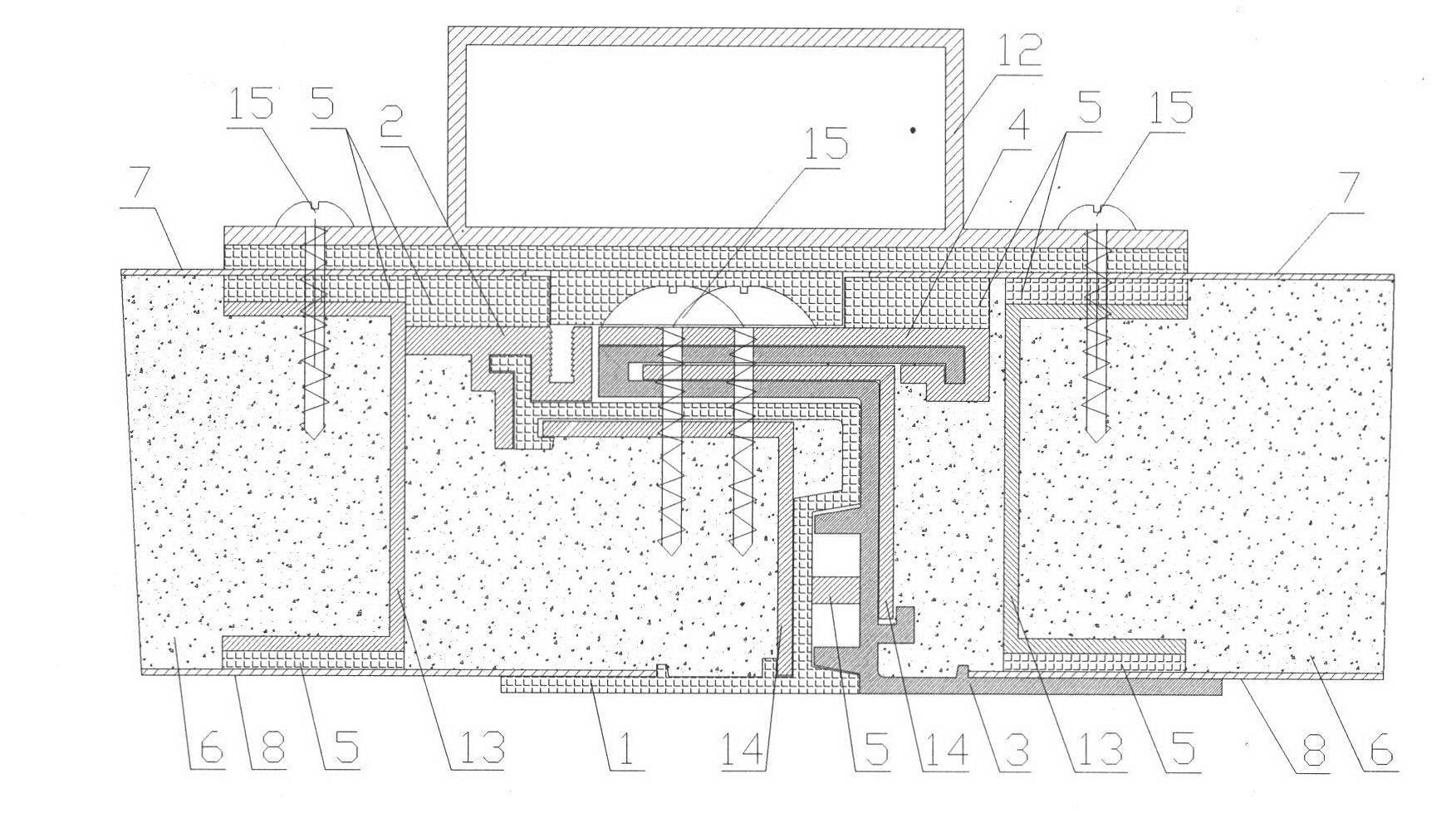

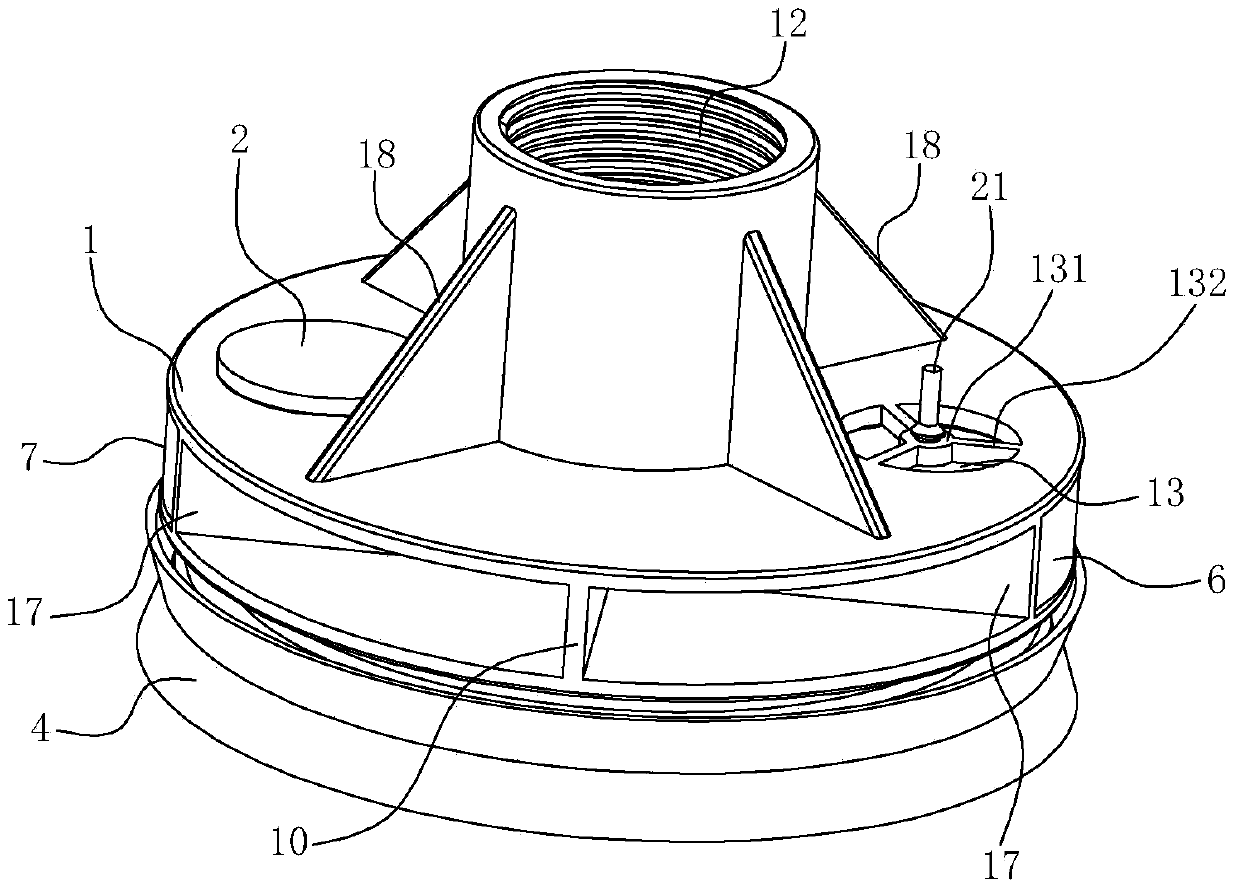

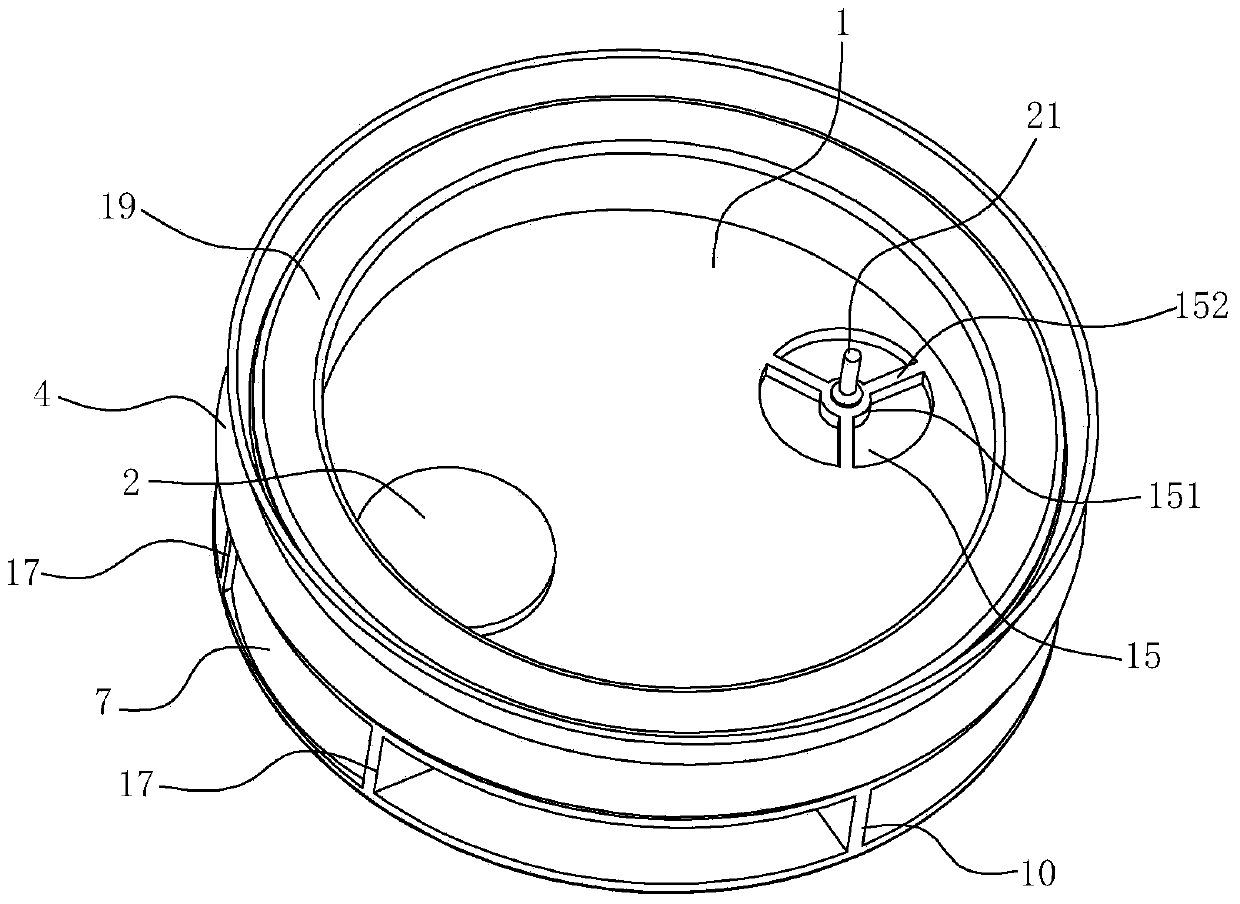

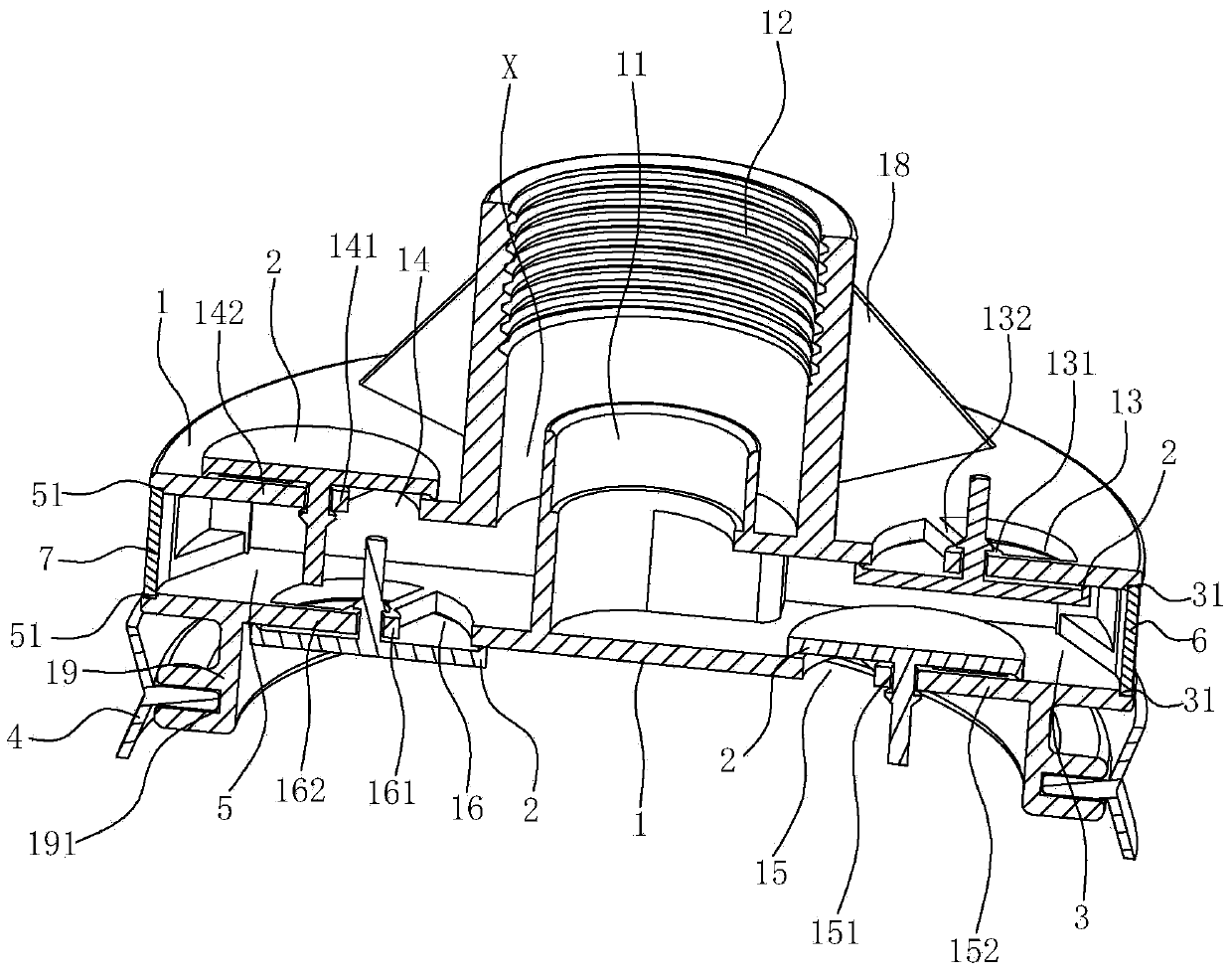

Vertical adverse current waste heat recycling device and method for sintering ore

ActiveCN106091707AGuaranteed uptimeReduce air leakage rateIncreasing energy efficiencyWaste heat treatmentSlagResource utilization

Provided are a vertical adverse current waste heat recycling device and method for sintering ore. The device comprises a top feed bin, a vertical adverse current recycling device body, a splay distributor, a cooling air redistribution device, a center air distributor, a crossed beam, a first annular air distribution pipe, a second annular air distribution pipe, a vibration feeder and a lower collection bin, all of which are connected with one another. The method comprises the steps that the high-temperature sintering ore enters the top feed bin after being smashed and then enters the vertical adverse current recycling device body via five discharging pipes; in the descending process, materials descend uniformly due to the splay distributor and the crossed beam; the materials are discharged out from seven discharging outlets in the lower portion of the vertical adverse current recycling device body; and after being discharged out of the seven discharging outlets, the materials are gathered in the lower collection bin, and the materials are discharged out at a certain speed after being mixed. The vertical adverse current waste heat recycling device and method for the sintering ore have the advantages that operation is stable and reliable, the air leakage rate is low, dust pollution is low, the rate of residual heat resource utilization is high, the device and the method can be used for recycling waste heat of steel slag blocks, red hot iron alloy ingot bars, ferronickel slag and the like, and the recycled high-temperature waste heat can be used for power generation, heating in winter and the like.

Owner:北京中冶设备研究设计总院有限公司

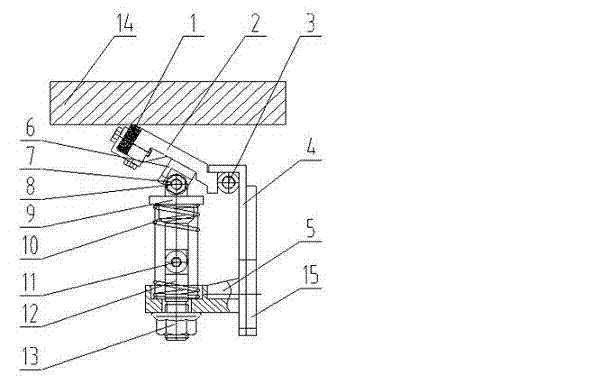

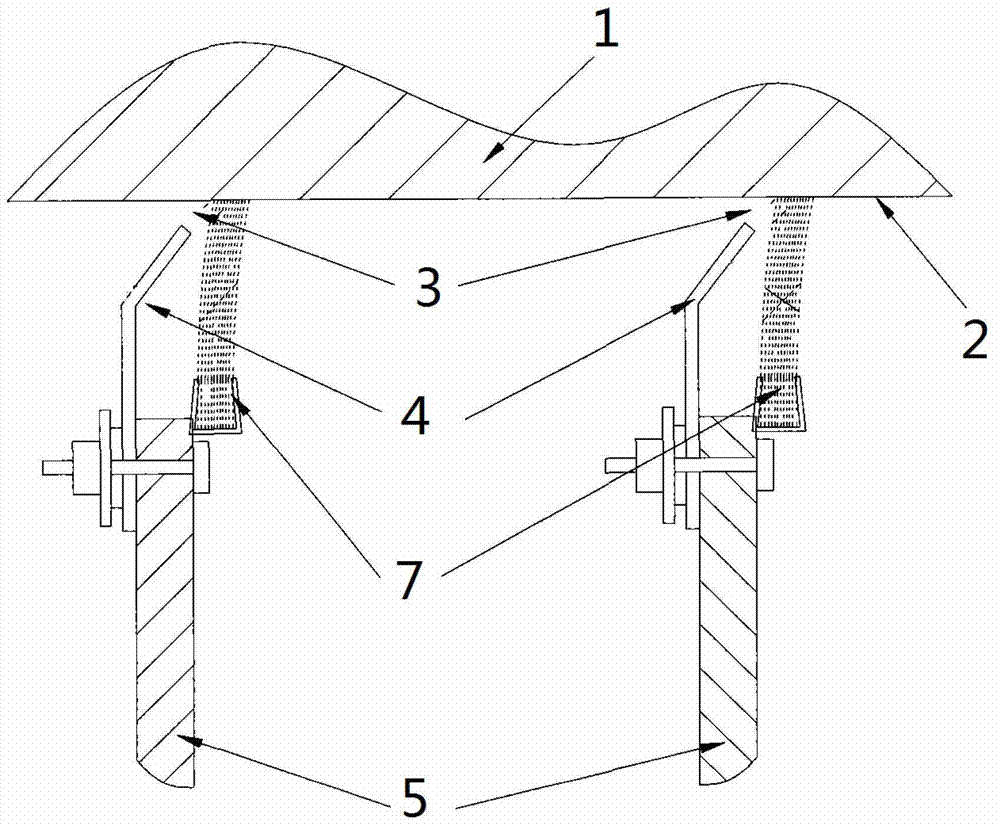

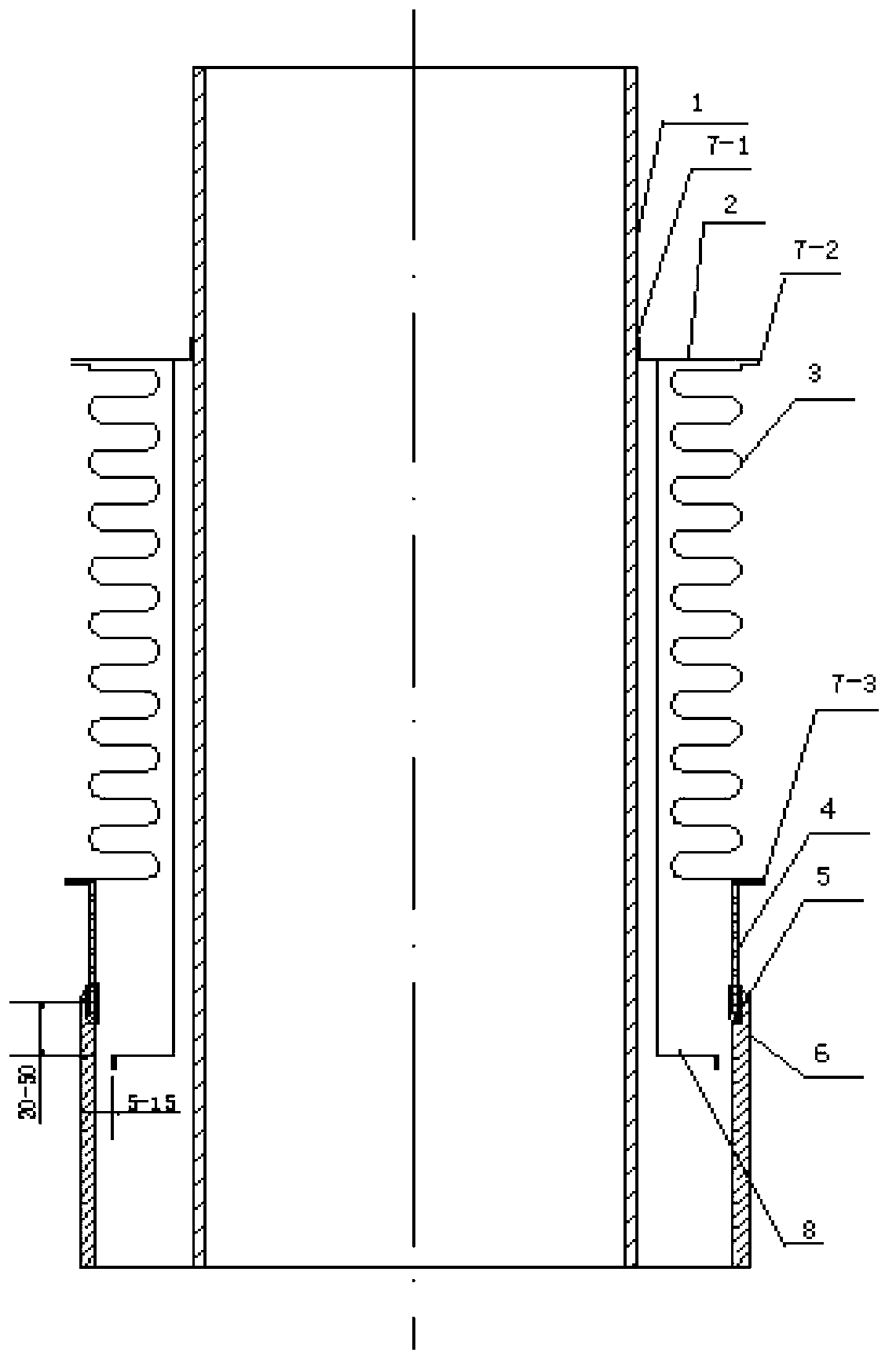

Elastic sheet contact type sealing device of rotary air preheater

InactiveCN101788154ADoes not form a sealing gapReduce coefficient of frictionEngine sealsCombustion processAir preheaterEngineering

The invention relates to the technical field of device sealing, in particular to an elastic sheet contact type sealing device of a rotary air preheater, solving the problems of unreasonable sealing structure and large air leakage rate of a traditional rotary air preheater. The elastic sheet contact type sealing device comprises a sector plate, a radial partition plate and an axial curved plate. Sealing devices are arranged at the cold end and the hot end of a rotor of the rotary air preheater; the sealing devices comprise a plurality of sealing elements; the elements comprise element installation main plates and a plurality of layer of elastic sheets arranged on the element installation main plate; protection sheets are arranged between every two layers of adjacent elastic sheets; the working end of the elastic sheets is 5 to 20 mm higher than the sealing end face of the sector plate; and when the air preheater is rotated, the sealing elements rotate to the position below the radial sector plate of the rotary air preheater and the position of the axial curved sealing plate, and the elastic sheets, one end face of the sector plate and the axial curved sealing plate are sealed in the elastic contact mode.

Owner:宁波市镇海福尔迅电梯部件厂

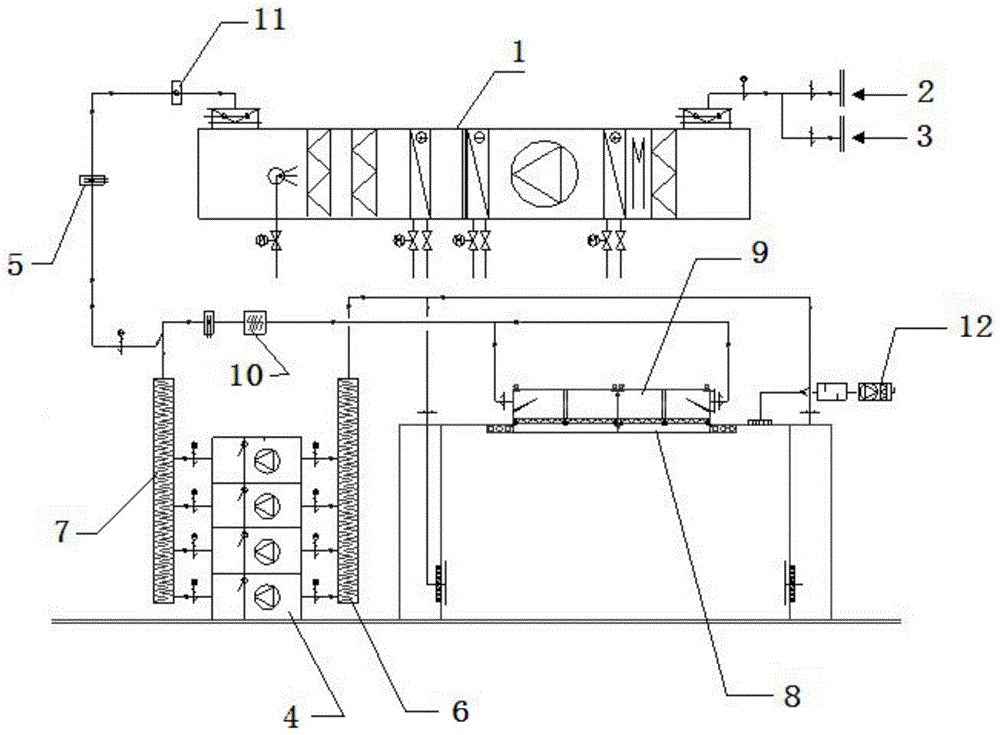

Intelligent energy-saving air handling system for operation room

InactiveCN104819521AReal-time air volume adjustmentReduce power consumptionDucting arrangementsMechanical apparatusFresh airEngineering

The invention discloses an intelligent energy-saving air handling system for an operation room. The intelligent energy-saving air handling system comprises an air handling unit (1), an electric heating unit (5) and a noise elimination static pressure tank group which are sequentially connected through an air pipe, the air handling unit (1) is used for filtering outdoor fresh air (2) and indoor fresh air (3), the electric heating unit (5) is an air duct type electric heater and arranged on an outlet air output pipeline of the air handling unit (1) and used for electrically heating outputted air, the noise elimination static pressure tank group includes a first noise elimination static pressure tank (6) and a second noise elimination static pressure tank (7) which are connected by a plurality of circulating fan (4) parallel pipelines, and the electrically heated fresh air and return air subjected to noise elimination by the noise elimination static pressure tank group are mixed by a three-way valve, heated, sterilized and inputted to the operation room through an air supply static pressure tank (9) arranged at the top of the intelligent operation room. According to the intelligent energy-saving air handling system for the operation room, energy is saved by more than 50%.

Owner:殷晓冬

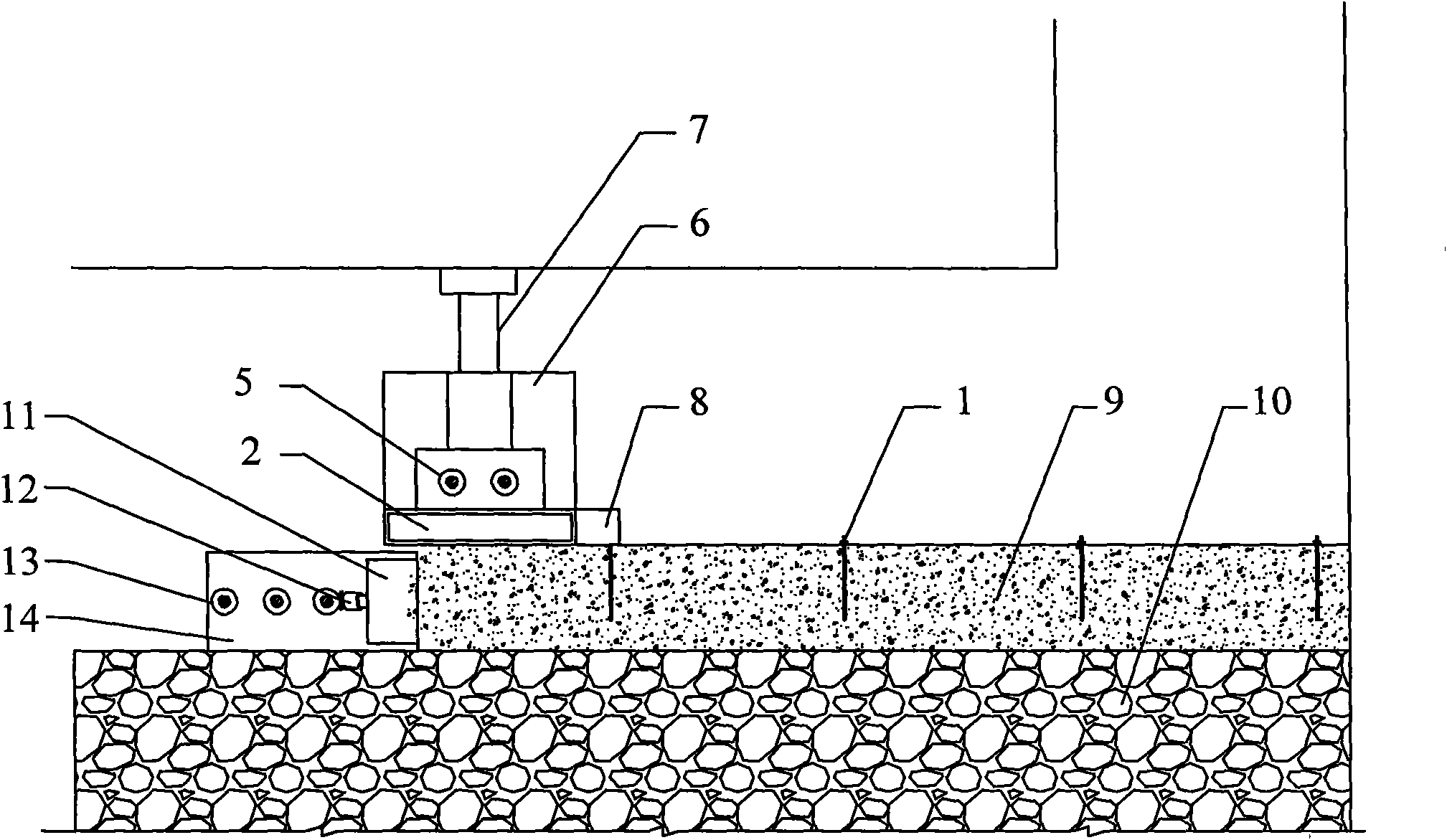

Road retained method for extrusion molding of waste rock

InactiveCN101858215AIncrease widthScientific and reasonable structureUnderground miningSurface miningInfillEngineering

The invention relates to a road retained method for extrusion molding of waste rock, belonging to the technical field of mine exploitation and comprising the following steps of: (1) fixing a template beside the road to be retained, wherein the template is placed vertically and parallel to the road, faces to a goaf, and a certain distance is maintained between the template and the goaf to form an area to be filled; (2) smashing the waste rock into granules, adding cementitous materials to stir uniformly to form filler; (3) filling the filler in the area to be filled to form an infill; and (4) removing the template and moving the template along the work surface, and then entering the next filling circle. The invention realizes a retained road by using the waste rock as raw materials, changes waste material into things of value, and reduces discharging pollutants of waste rock; a rock bolt is added beside the road so that the stability of the retained road is increased; comprehensive mechanic operation is adopted, thereby the labor intensity is reduced and the efficiency is improved; opened operation is adopted, therefore, the problems of pipe blocking and the like are avoided and better reliability are achieved; the extraction and support for the retained road are free from cross interference and in great safe condition; and the obtained infill has great width, reasonable structure, low air leakage ratio and great reliability.

Owner:HENAN POLYTECHNIC UNIV

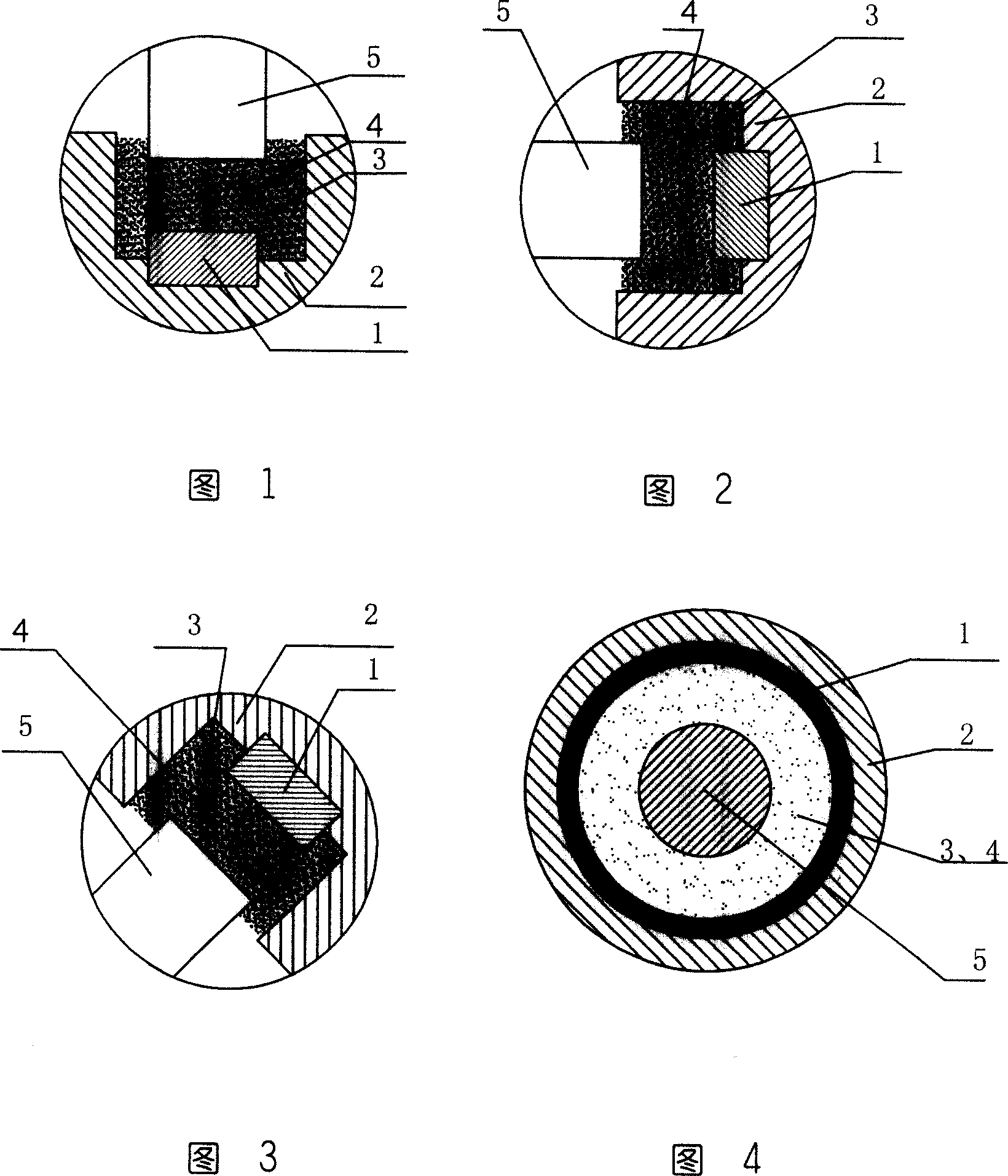

Pneumatic tire

ActiveUS20100186866A1Reduce air leakage rateIncreased durabilityWithout separate inflatable insertsWith separate inflatable insertsPolymer scienceAdhesive

A pneumatic tire comprising an air permeation preventive layer comprising a film of a thermoplastic resin composition containing a polyvinyl alcohol or ethylene vinyl alcohol copolymer, to which a protective film of a rubber composition containing an ethylene propylene rubber (EPM) or ethylene propylene diene rubber (EPDM) is, directly or via an adhesive, placed adjacent thereto, as one layer in at least one side thereof, whereby both a further reduction in the air leakage rate of the pneumatic tire and a good durability can be achieved and furthermore a reduction in the weight of the tire can be achieved.

Owner:YOKOHAMA RUBBER CO LTD

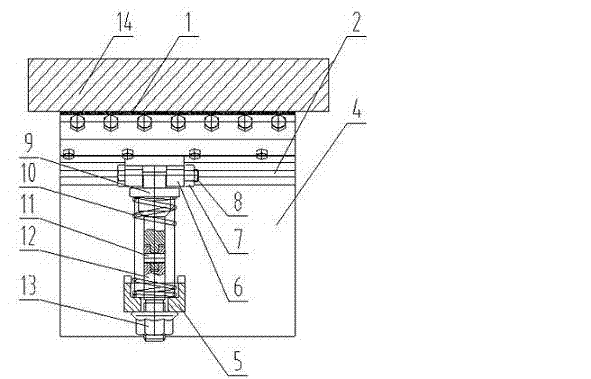

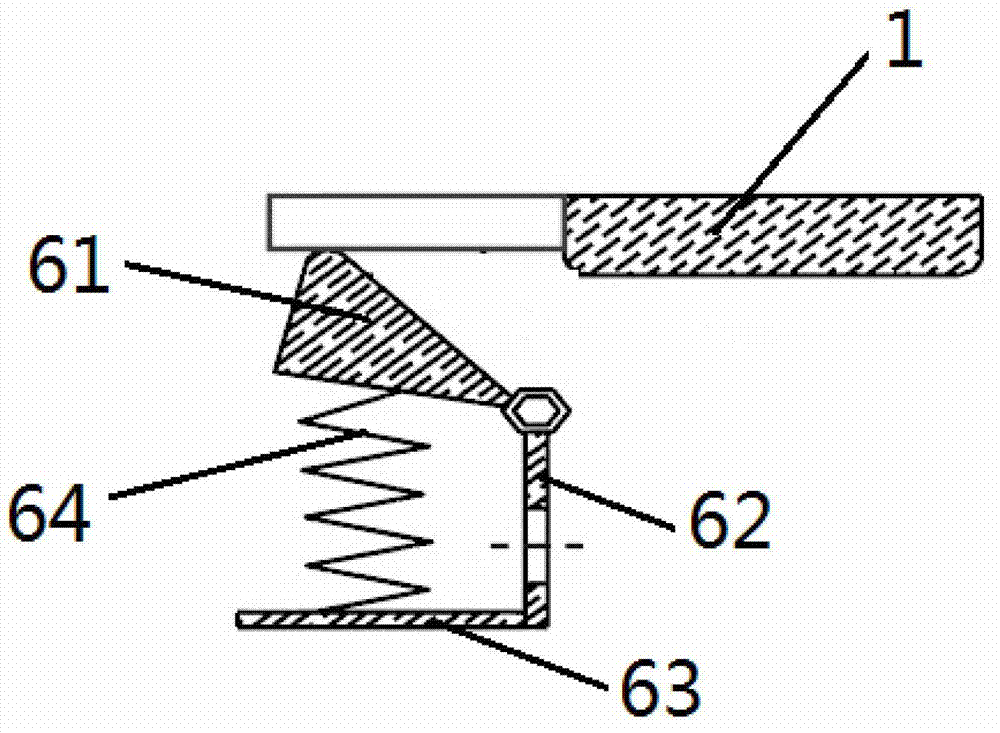

Multi-arm ceramic sealing device of air preheater

ActiveCN102777603AAchieving a radial sealDoes not interfere with free movementEngine sealsCombustion processAir preheaterWear resistant

The invention relates to a multi-arm ceramic sealing device of an air preheater, and the device comprises an inclined wear-resistant sealing plate, a fixed plate and a joint type spring guide regulating device, wherein the joint type spring guide regulating device comprises a rotating part, a regulating stem, a compression spring, a supporting seat and a regulating nut, the regulating stem is composed of a regulating stem I and a regulating stem II, the upper end of the regulating stem I is arranged on the back surface of the inclined wear-resistant sealing plate through the rotating part, the lower end of the regulating stem II is provided with a screw thread and connected with the regulating nut after passing through a round hole arranged in the front end of the supporting seat, the compression spring is sleeved on the regulating stem, and the rear end of the supporting seat is fixedly arranged on the fixed plate on a corresponding position. Wear-resistant ceramic blocks on the wear-resistant sealing plate can be in contact with a sector plate of the air preheater in the whole rotating process, so that the multi-arm ceramic sealing device has the advantages of good sealing effect, excellent wear resistance property, long service life, suitability for modular production, convenience for field installation, short construction period and the like. The multi-arm ceramic sealing device is most suitable for radially sealing a rotary air preheater of a large boiler.

Owner:江苏鑫信润科技股份有限公司

Underground coal mine drilling, heat injection and hole sealing integration method

The invention provides an underground coal mine drilling, heat injection and hole sealing integration method suitable for drilling, high-pressure heat injection and hole sealing. The method is characterized in that multiple disc-shaped slots are cut in a bottom plate rock stratum through high-pressure jet flow; a plastic sleeve is fed into a drilled hole, and grout is injected into the portion between the wall of the drilled hole and the outer wall of the plastic sleeve; after the grout is condensed, a heat injection pipe is fed into the sleeve for heat injection; after heat injection is finished, the heat injection pipe is withdrawn, two polyurethane reaction bags are arranged at the end, close to a coal bed, of the drilled hole, and the portion between the two bags is filled with a heat insulating material; grout is injected into the opening end of the drilled hole, and then hole sealing is finished. The method has the advantages of being capable of insulating heat, resistant to high pressure, high in sealing degree and the like, the problems that hole sealing fails and gas leaks from hole wall cracks due to heat loss and high pressure in the heat injection process can be effectively solved, the heat injection pipe can be recycled, and heat injection cost is low.

Owner:CHINA UNIV OF MINING & TECH

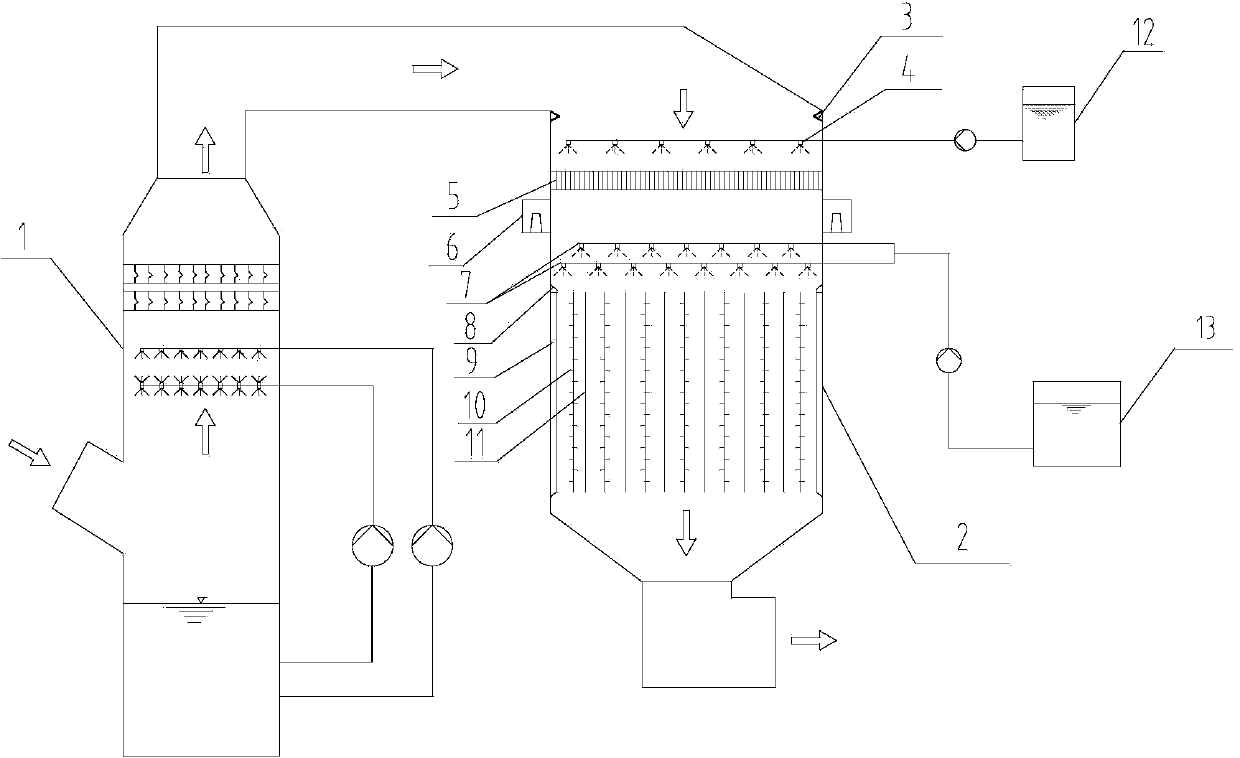

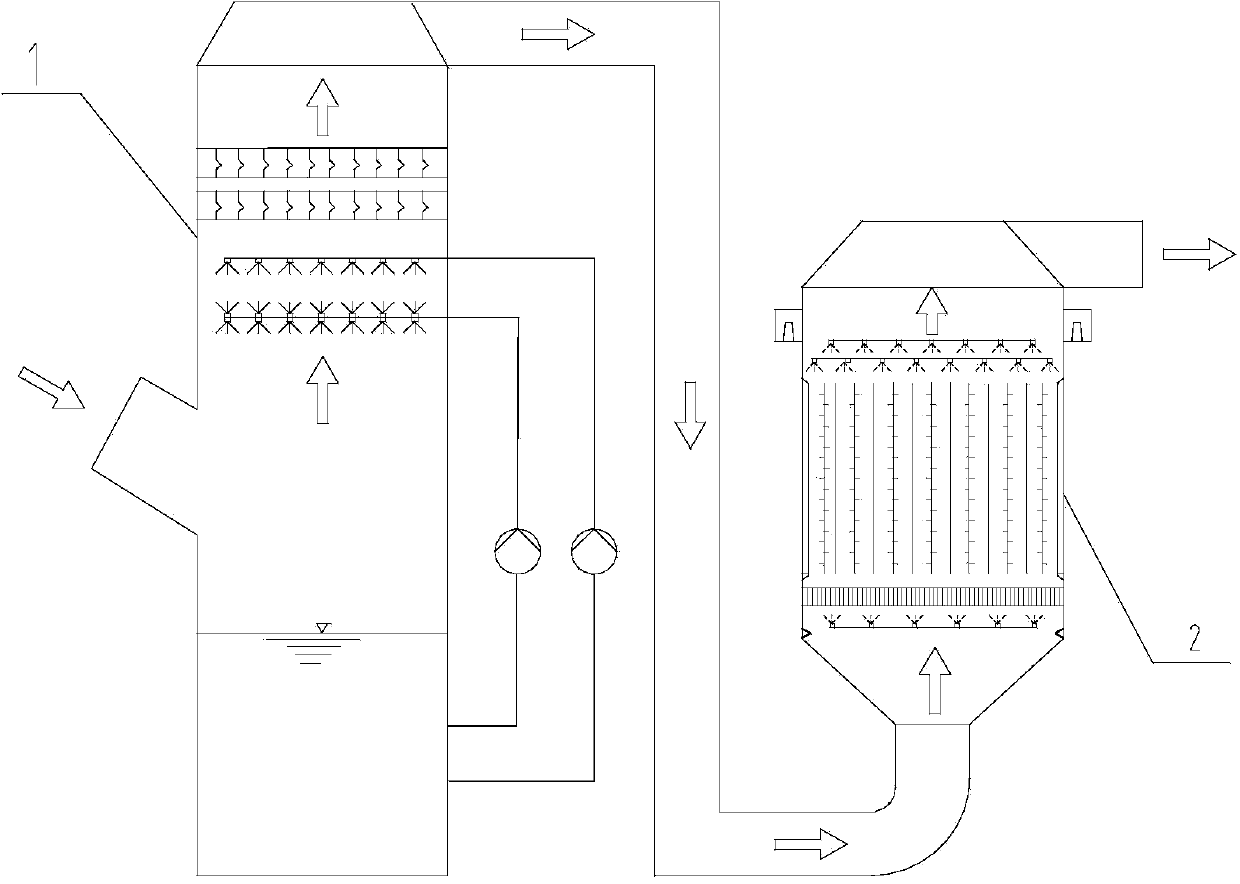

Vertical flow wet-type electric precipitator and wet electric precipitation method

The invention provides a vertical flow wet-type electric precipitator and wet electric precipitation method. The vertical flow wet-type electric precipitator comprises an annular plate, a spray humidifying layer, a flue gas uniform distribution device, a dust removing electric field area, washing and spraying layers, a plurality of insulator boxes, an atomization water tank and a process water tank, wherein the spray humidifying layer comprises a fine atomizing nozzle and a spray pipeline; flue gas sequentially passes through the annular plate, the spray humidifying layer and the flue gas uniform distribution device; the dust removing electric field area is used for blocking a baffle board of a flue gas blind area; the washing and spraying layers are arranged above the dust removing electric field area; the wet electric precipitation method comprises the following steps: a continuous manner is adopted to conduct atomization and humidification on inlet flue gas and conduct uniformly distributed optimization treatment on the flue gas; an intermittent or continuous manner is adopted to conduct sprinkling and cleaning on a dust-collecting electrode and a discharge electrode; a method of hot air sweeping is adopted to ensure insulation. The vertical flow wet-type electric precipitator and the wet electric precipitation method can effectively ensure the high-efficient and stable operation of the vertical flow wet-type electric precipitator, optimize the fluid field, and strengthen turbulence and atomization of the flue gas; local micro-mixing, and collision as well as crash coagulation of fine particles are promoted; the dust removal efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Preparation method of integral-type vacuum heat insulation and temperature preservation plate

InactiveCN102635171AHas a leak rateReduce air leakage rateClimate change adaptationInsulation improvementInorganic materialsGetter

The invention discloses a preparation method of an integral-type vacuum heat insulation and temperature preservation plate, and belongs to the technical field of an outer temperature preservation material for building outer walls. The technical scheme to be solved is that a preparation method of a vacuum heat insulation and temperature preservation plate which has a plate-type core material, has good integrity, is low in air leakage rate, and prevents cold and hot bridge is provided. According to the technical scheme, the preparation method comprises the following steps of: step one, manufacturing a core material plate; step two, loading the core material plate, and step three, vacuumizing and packaging. According to the invention, different from the prior art that the core material is in a powder shape, the plate provided by the invention has the advantages that an inorganic material is synthesized into the plate material, and a special bonding material is adopted for bonding the core material and the packaging layer together, thus the temperature preservation plate has the integrity; the core material plate is adopted and drilled for holding an air absorption agent, the quantity and position are distributed scientifically, and the long-lasting vacuum degree is ensured; and the air leakage rate is lowered by a dual-seal mode.

Owner:陈宏宇

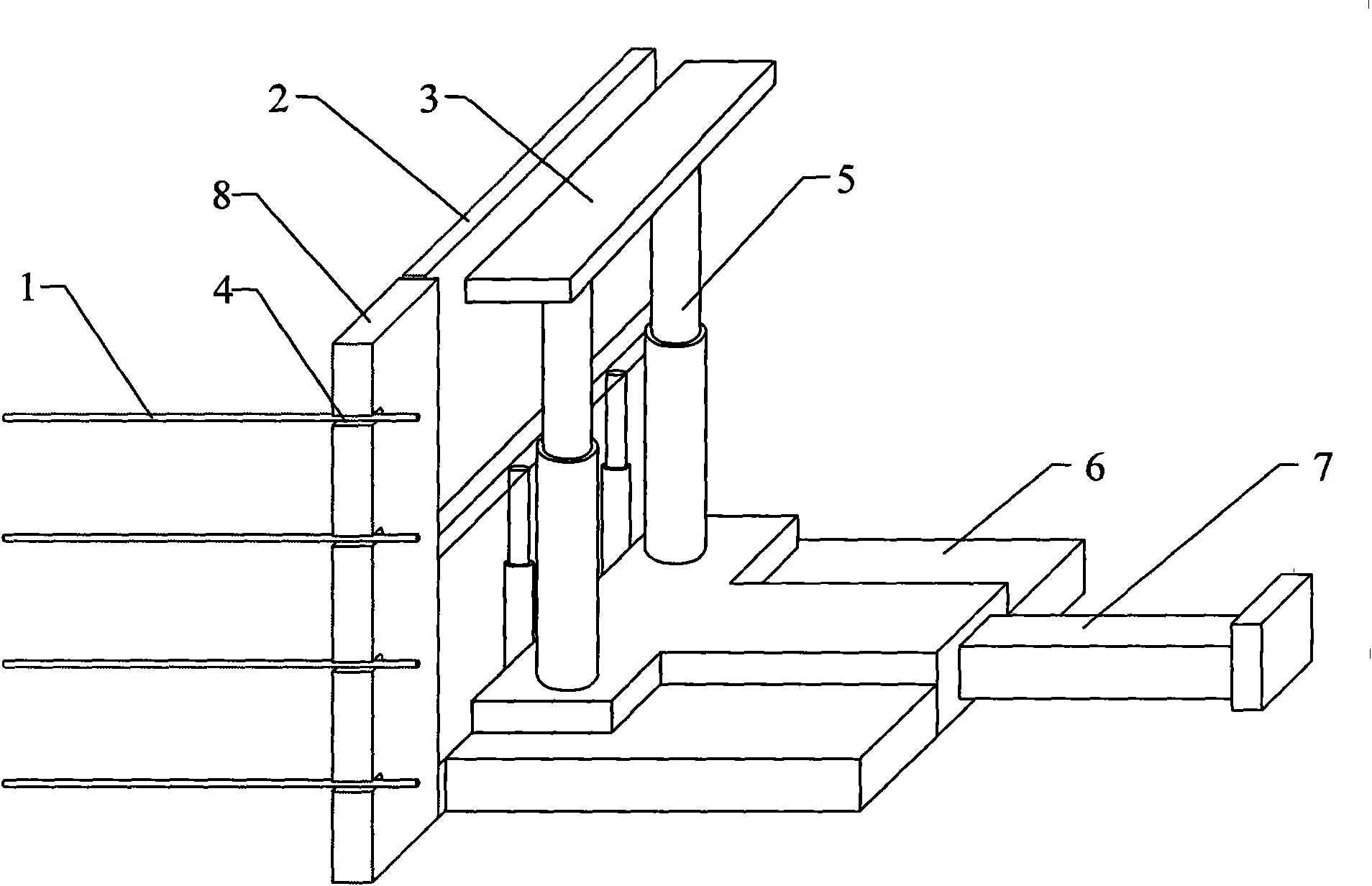

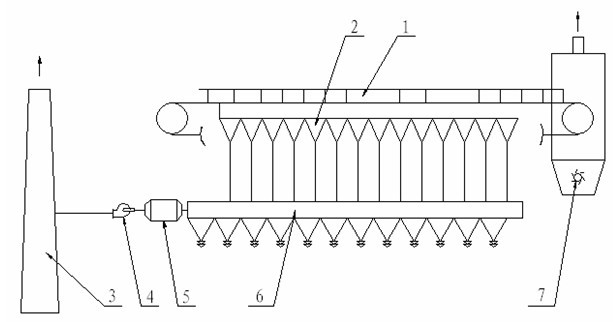

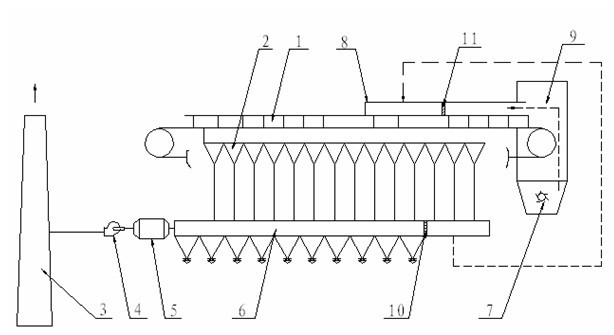

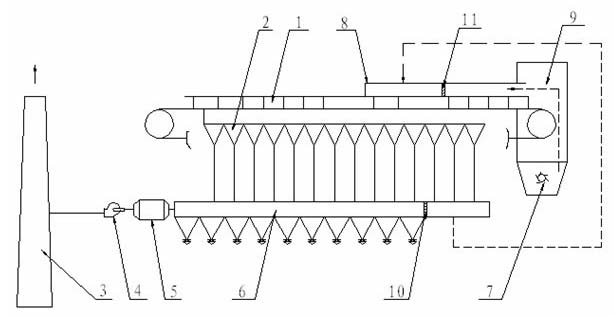

Self-cyclic utilization device for sinter machine tail smoke and tail wind box smoke

InactiveCN102022914AReduce air leakage rateReduce rapid cooling pulverizationFurnace typesWaste heat treatmentEngineeringFlue

The invention relates to a self-cyclic utilization device for sinter machine tail smoke and tail wind box smoke. The self-cyclic utilization device comprises a trolley (1), wherein a seal cover (8) is arranged above the trolley (1); the tail of the trolley (1) is provided with a dust-removing cover (9); a plurality of wind box (2) are connected below the trolley (1); a large gas flue (6) is arranged below the air bellows (2); and all the air bellows (2) are communicated with the large gas flue (6). The self-cyclic utilization device is characterized in that the top of the dust-removing cover (9) is closed; the seal cover (8) is internally provided with a clapboard II (11); the seal cover (8) is divided into front and back sections by the clapboard II (11), the front section of the seal cover (8) is closed, and the back section of the seal cover (8) is communicated with the dust-removing cover (9); and a clapboard I (10) is arranged inside the large gas flue (6) and divides the large gas flue (6) into the front and back sections, the front section of the large gas flue (6) is sequentially connected with a dust remover (5), a main draft fan (4) and a chimney (3), and the back section of the large gas flue (6) is connected to the front section of the seal cover (8) through a pipeline.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

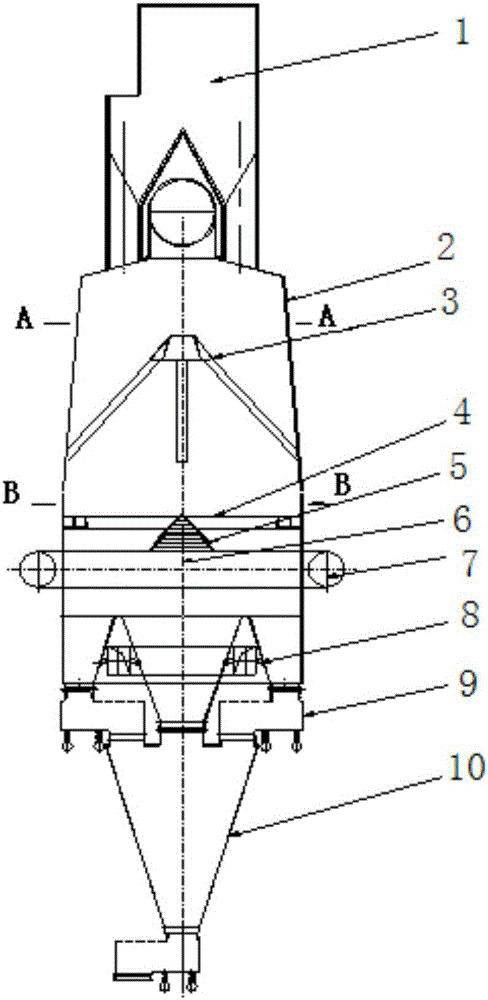

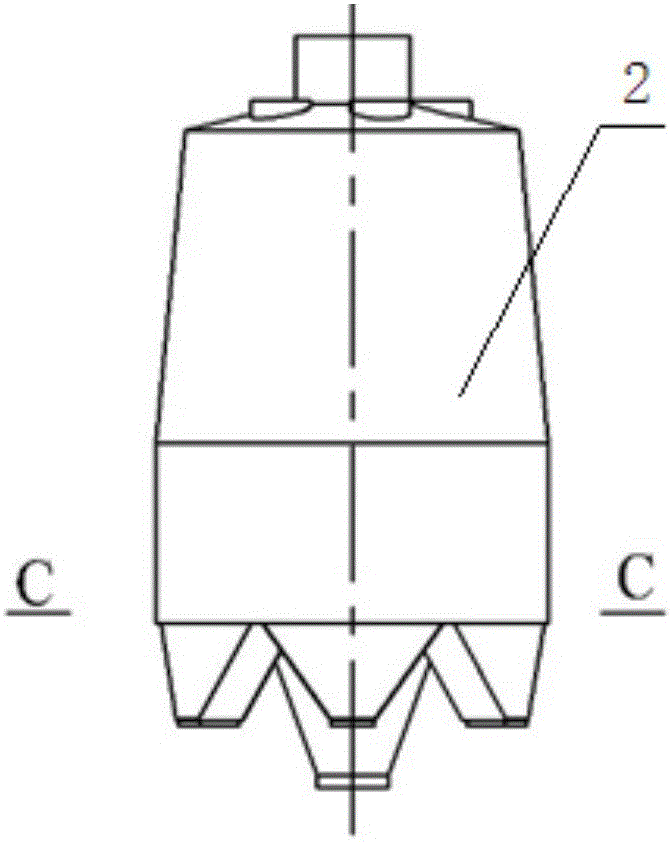

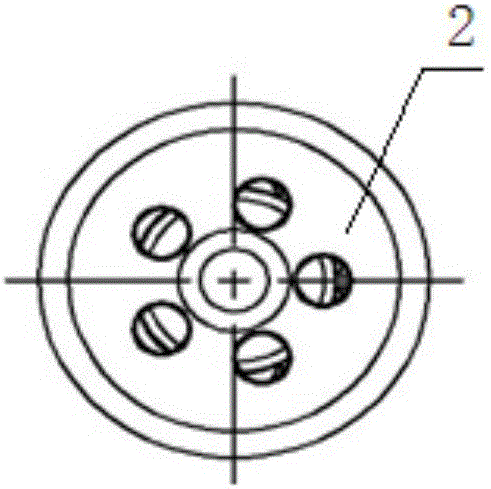

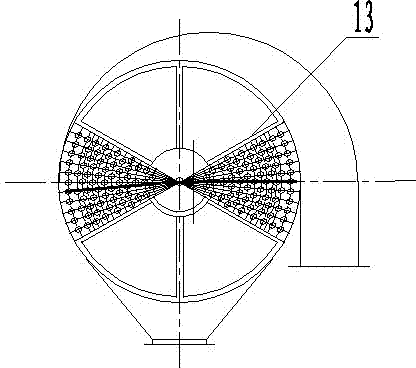

Large stepping type rotating pulse desuter

InactiveCN102755791ASolve the problem of unequal service lifeAccelerate the realization of localizationDispersed particle filtrationCycloneEngineering

A large stepping type rotating pulse desuter is composed of an upper barrel (with an air outlet), a volute, a middle barrel, an ash hopper, a support, a top guardrail, a compressed air inlet pipe, an air bag, a pulse valve, a stepping motor, a speed shifting mechanism, spray-blow pipes, a top cover, a tube nest, a filter bag assembly, a guide grid and an ash discharging valve. The large stepping type rotating pulse desuter is of a round structure and is simple in structure, convenient to construct and high in compression strength. A filter bag is a round special denting-preventing device. The tube nest is specially arranged. Filter area of one deduster reaches 2540 square meters, and one deduster is only provided with one pulse valve, two to three spray-blow pipes and one air bag arranged in an air purifying chamber and rotating to be balanced. An air inlet is arranged on the upper portion of the middle barrel and is a tangential cyclone inlet. A module type structure is adopted so that processing and transporting are facilitated. A plurality of large stepping type rotating pulse desuters can form a super large pulse desuter which has the advantages of being low in investment and operation expanse and wide in adaptive range.

Owner:ZUNYI CITY GUI KE TECH

Magnetic field method for sealing air gap

InactiveCN101004220ASimple structureEasy maintenanceEngine sealsFurnace typesEngineeringElectrical and Electronics engineering

The present invention provides a magnetic field sealing method of air-gap. It is characterized by that on the air-gap of fixed body to be sealed a sealing groove correspondent to contact surface of mobile body is set, in the sealing groove bottom portion a magnetic field source is set, the groove interior is filled up with magnetic sealing medium to form magnetic field. The invented magnetic field flexible sealing theory is characterized by that in the air-gap to be sealed a magnetic field is created, the contact surface of said air-gap is filled up with magnetic sealing medium, under the action of magnetic field in the air-gap said magnetic sealing medium can be stably stored in the sealed air-gap, so that said sealed portion can obtain 'zero' leakage.

Owner:SHIJIAZHUANG RAILWAY INST

Quartz-crystal resonator and packaging technology of quartz-crystal resonator

ActiveCN104270115AGood performance resistanceImprove stabilityImpedence networksQuartz crystal resonatorEngineering

The invention discloses a quartz-crystal resonator. The quartz-crystal resonator comprises an outer shell, a wafer and a pin. The outer shell is composed of a substrate and an upper shell body. The base plate comprises a substrate body and a boss, wherein the substrate body protrudes to form the boss. A step face is formed on the outer side of the boss, and an annular groove is formed in the step face and filled with sealing gum. The upper shell body comprises a cover with the closed upper end, an opening is formed in the lower end of the cover, the lower end of the cover is inserted into the annular groove, and a gap between the inner surface of the annular groove and the outer surface of the lower end of the cover is sealed through sealing gum. The wafer is fixedly installed on the boss of the substrate. The pin is fixed to the substrate through an insulator and electrically connected with the wafer. The invention further discloses a packaging technology of the quartz-crystal resonator. By means of the quartz-crystal resonator and the packaging technology, the good sealing effect can be played, air leakage and the like can be avoided, the vacuum degree can be greatly improved, the air leakage rate can be lowered, and meanwhile stability and firmness are better.

Owner:武汉市杰精精密电子有限公司

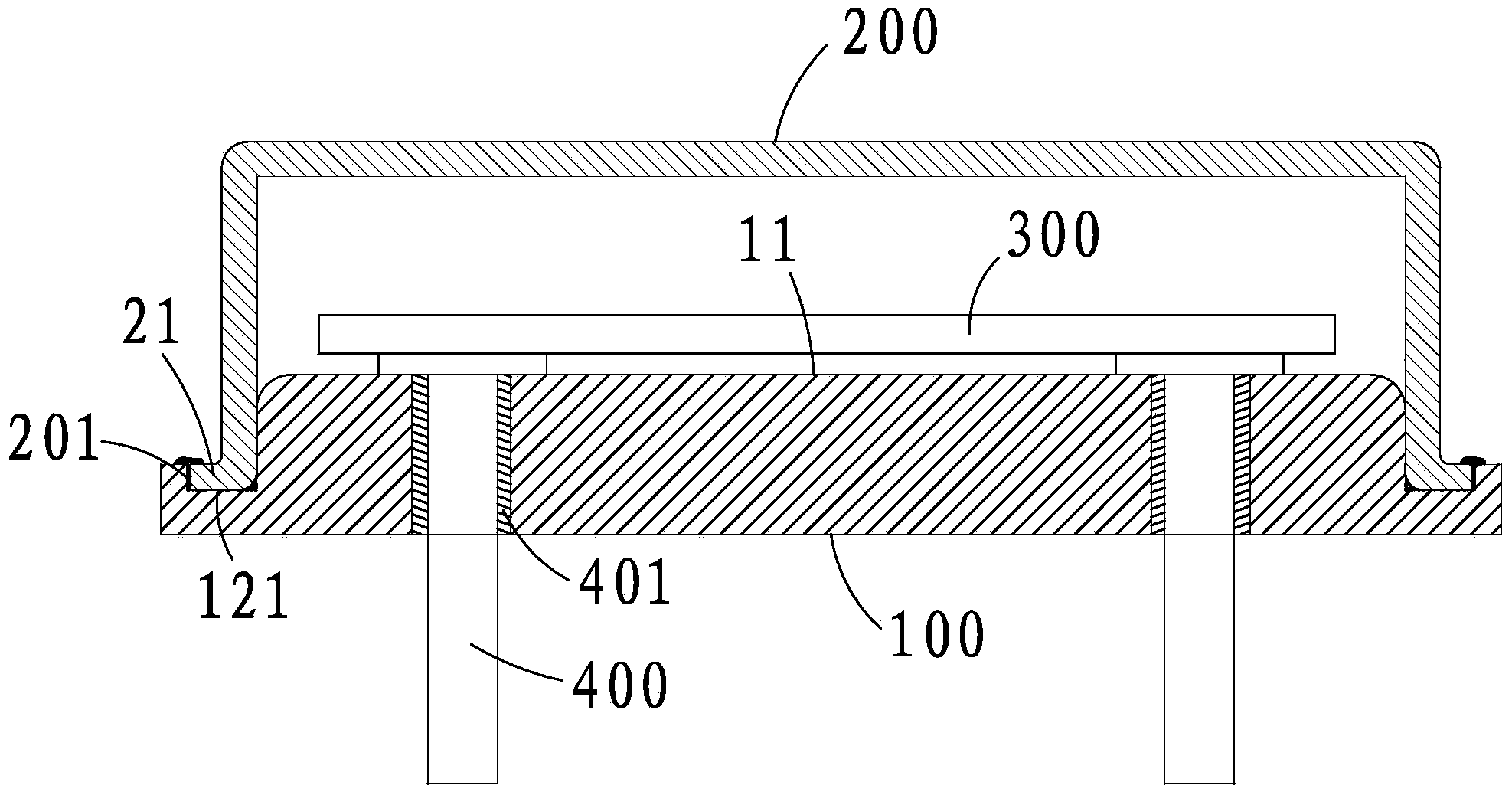

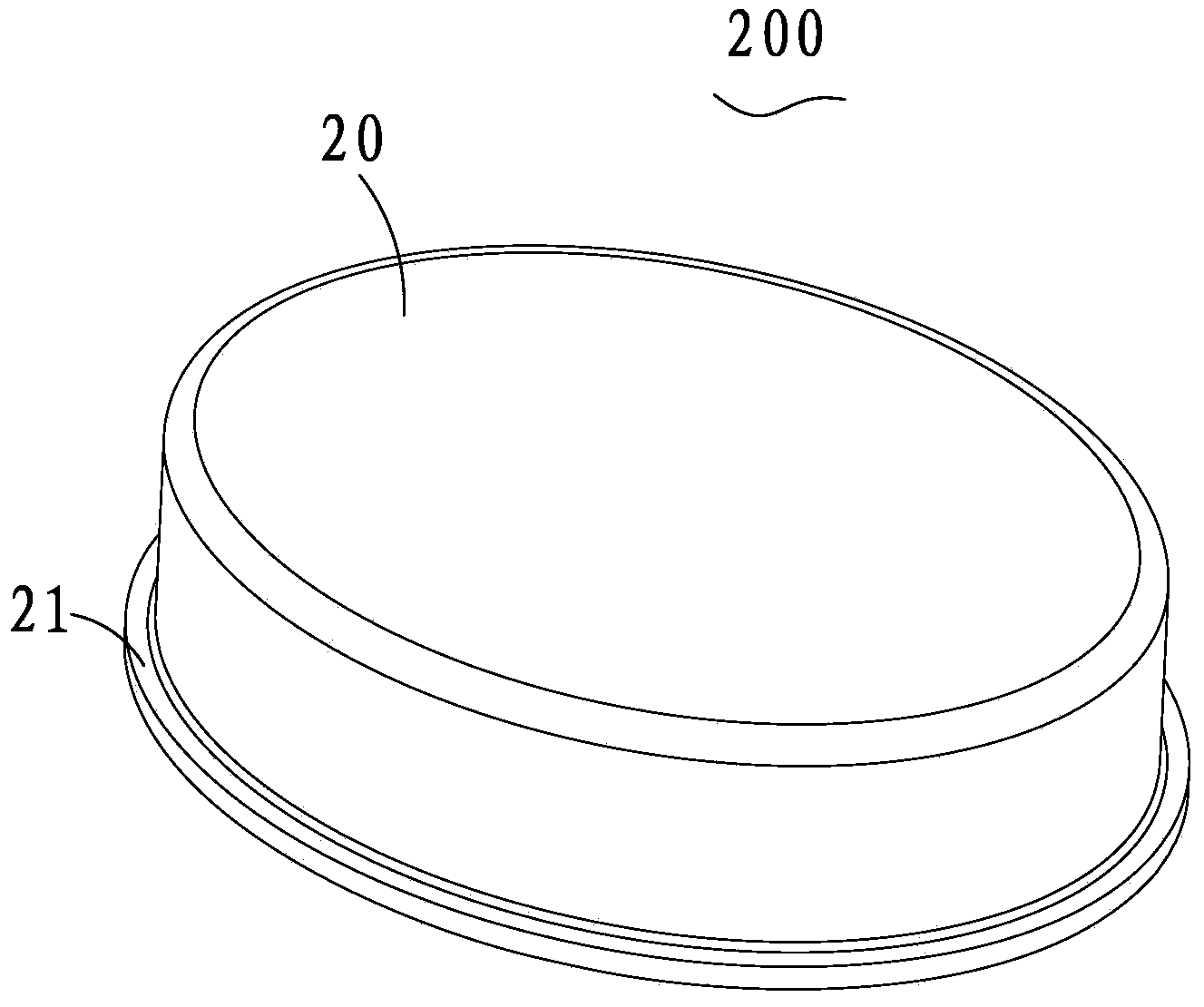

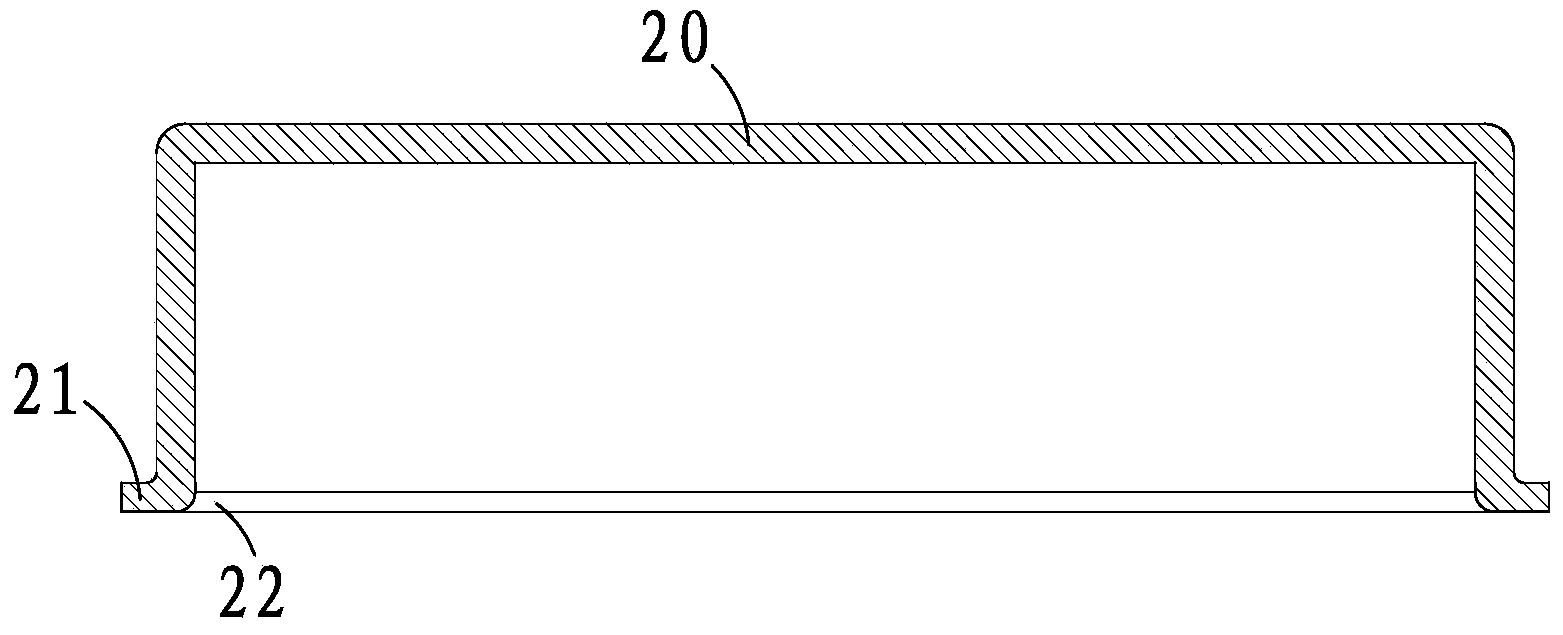

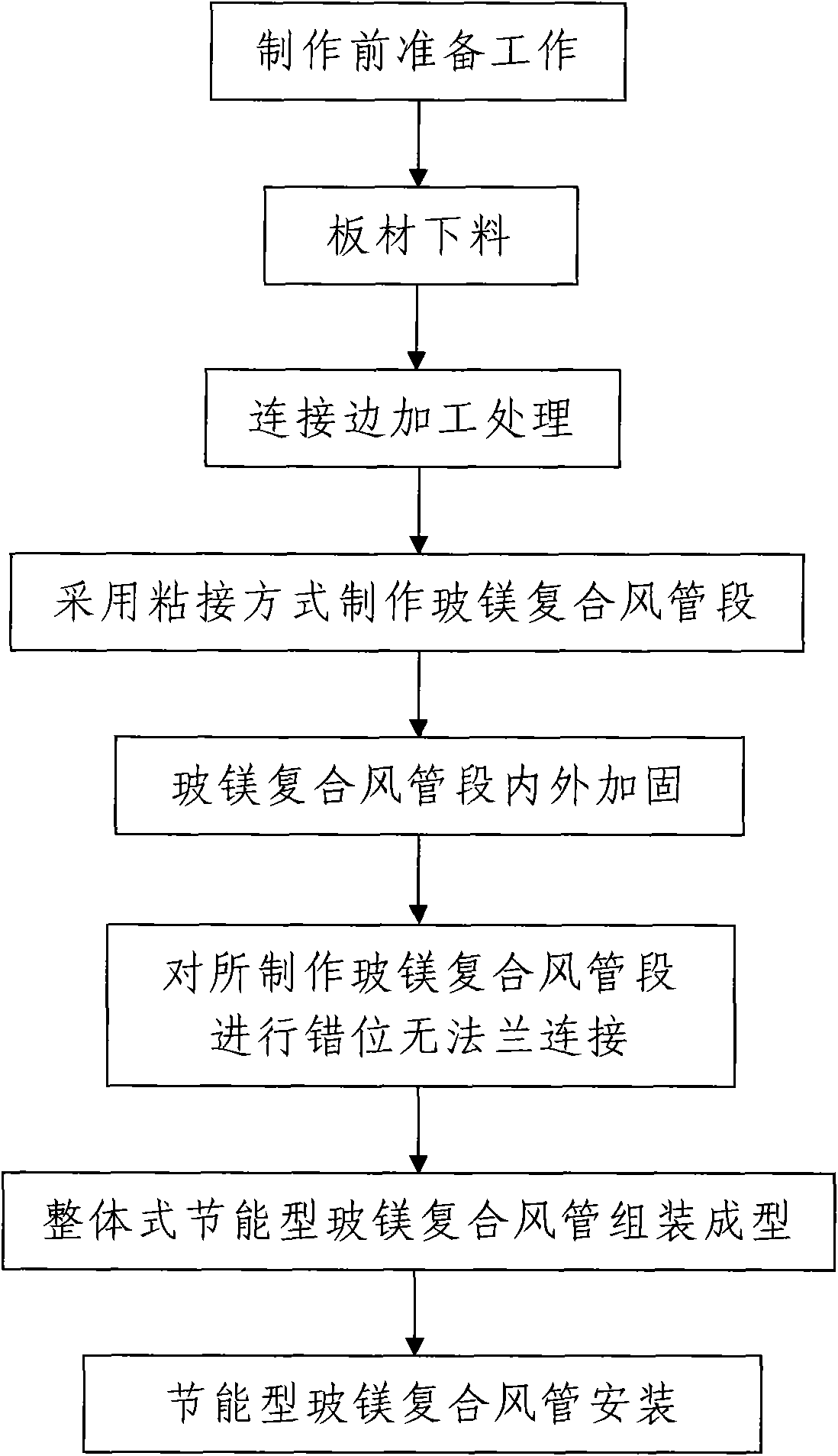

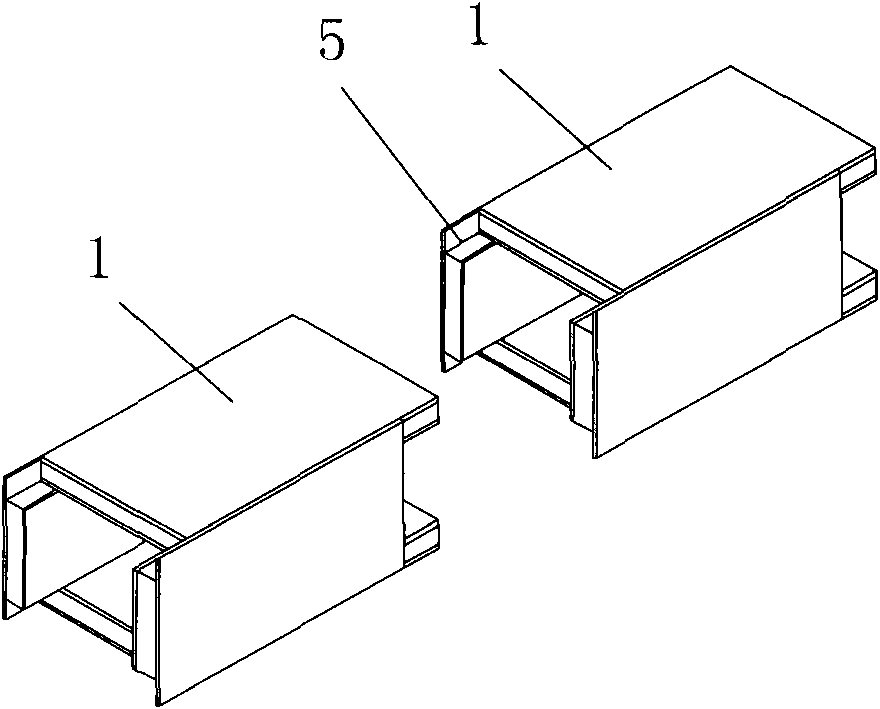

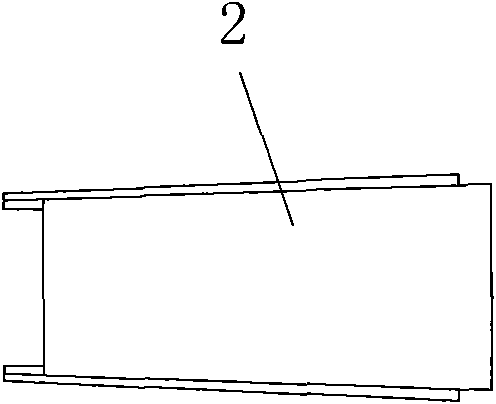

Energy-saving glass fiber and magnesium composite air duct manufacture and installation method

The invention discloses an energy-saving glass fiber and magnesium composite air duct manufacture and installation method. An energy-saving glass fiber and magnesium composite air duct is manufactured by assembling a plurality of sections of glass fiber and magnesium composite air duct sections. The method comprises the following steps of: 1, preparing before manufacturing; 2, manufacturing glass fiber and magnesium composite air duct sections, manufacturing a plurality of sections of glass fiber and magnesium composite air ducts in which upper plates and lower plates as well as left plates and right plates are malposed by adopting the glass fiber and magnesium composite air ducts and adhering glue; and 3, assembling and installing the energy-saving glass fiber and magnesium composite air duct: assembling all finished glass fiber and magnesium composite air duct sections and obtaining the integral energy-saving glass fiber and magnesium composite air duct. The invention has the advantages of simple manufacture process, convenient construction, low labor intensity and high construction speed; and the manufactured energy-saving glass fiber and magnesium composite air duct has the advantages of reliable connection among all members and easy insurance of quality. Meanwhile, the investment of used machinery equipment during the construction is less, the cost input is low, the manufacture process greatly reduces adverse factors of noise, vibration, and the like, thus the method can be used for manufacturing various shapes and structures of glass fiber and magnesium composite air ducts.

Owner:SHAANXI CONSTR ENG GRP CO LTD THE FIRST BUILDING

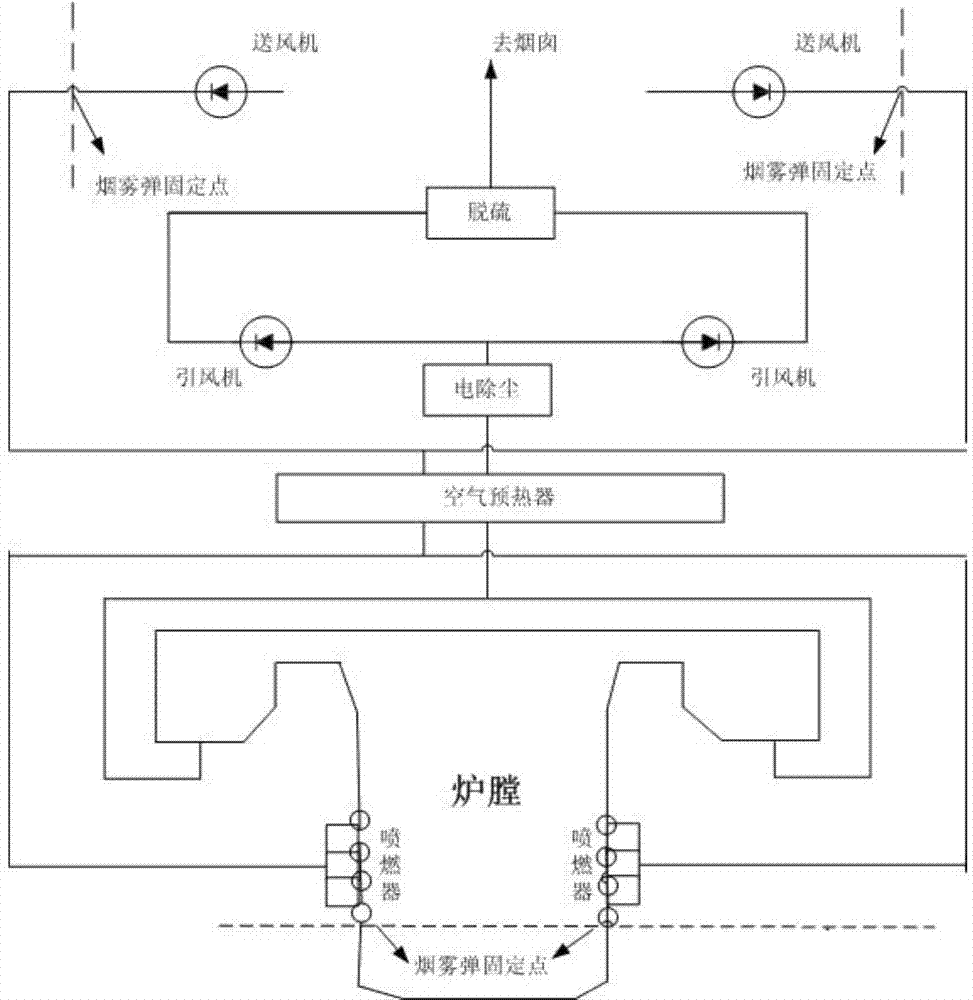

Method for detecting leakproofness of boiler

InactiveCN103487216AReduce air leakage rateReduce pollutionDetection of fluid at leakage pointCombustion systemBoiler furnace

The invention discloses a method for detecting the leakproofness of a boiler. The boiler comprises a boiler furnace, a rear smoke channel, a blower and a fuel nozzle. An outlet of the blower and an outlet of the fuel nozzle are communicated with the boiler furnace. The method comprises the steps that at least one of the boiler furnace, the outlet of the blower and the outlet of the fuel nozzle is provided with a color smoke shell, the pressure in the boiler furnace is increased to enable the pressure in the boiler furnace to be higher than the pressure outside the boiler, and then the color smoke shell is ignited. The emission points of color smoke outside the boiler are checked and marked, namely, air leak points of the boiler furnace and the rear smoke channel are found, the air leak rate of the boiler furnace and the rear smoke channel can be greatly reduced by patching the air leak points timely, on-site environmental pollution is alleviated, the use efficiency of fuel in a burning system in a large-capacity boiler is improved, and energy conservation and environmental protection are facilitated.

Owner:CHINA SHENHUA ENERGY CO LTD +2

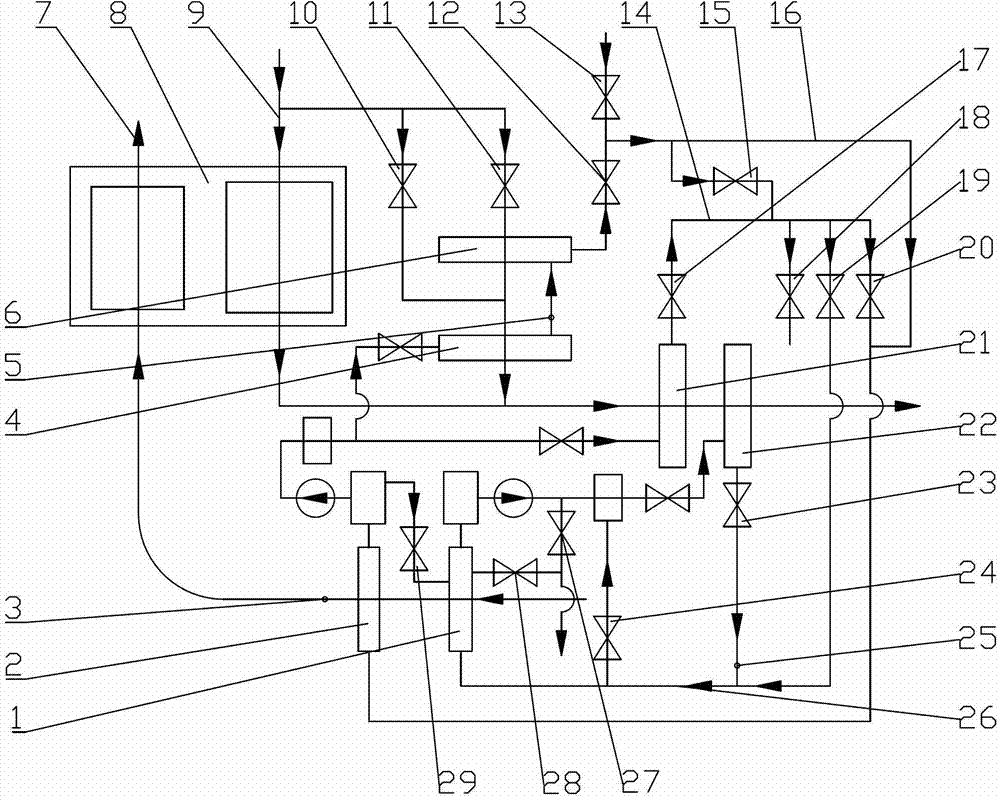

Part control phase change air preheating system and air preheating method

InactiveCN103115377AImprove securityImprove adaptabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a part control phase change air preheating system and an air preheating method. The part control phase change air preheating system and the air preheating method well solve the coupling problem of traditional air preheater low temperature corrosion and heat efficiency, an operating method of the air preheating system can be timely adjusted according to actual operation parameters, adjusting capability is greatly increased, and not only is economy and high efficiency of a thermal circulation system guaranteed, but also security and adaptability of the air preheating system can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

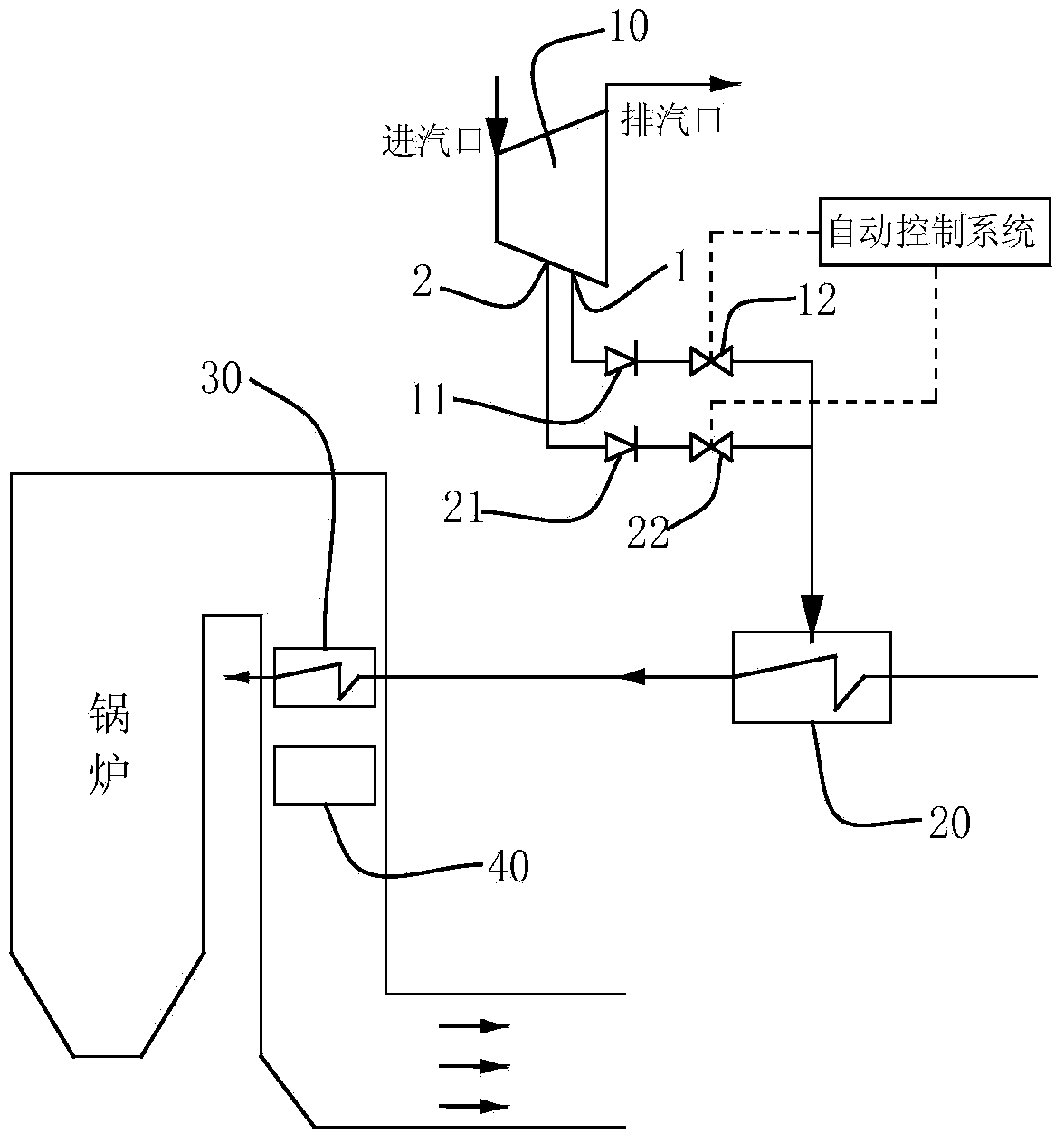

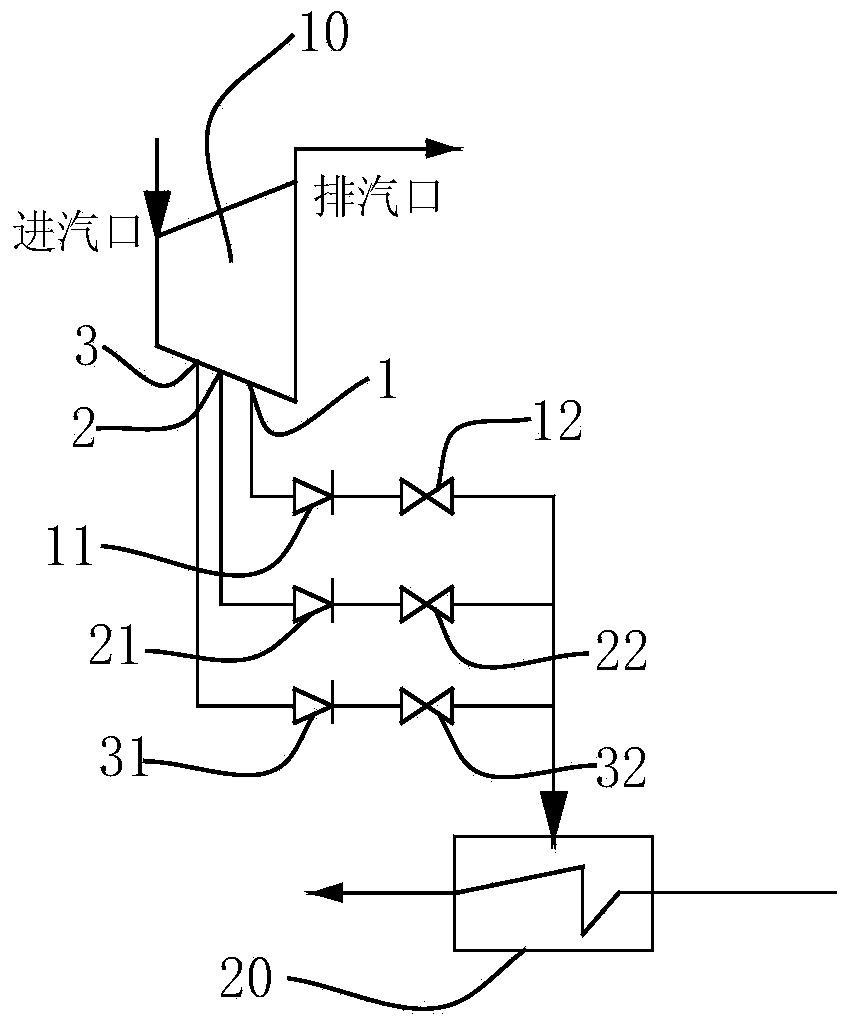

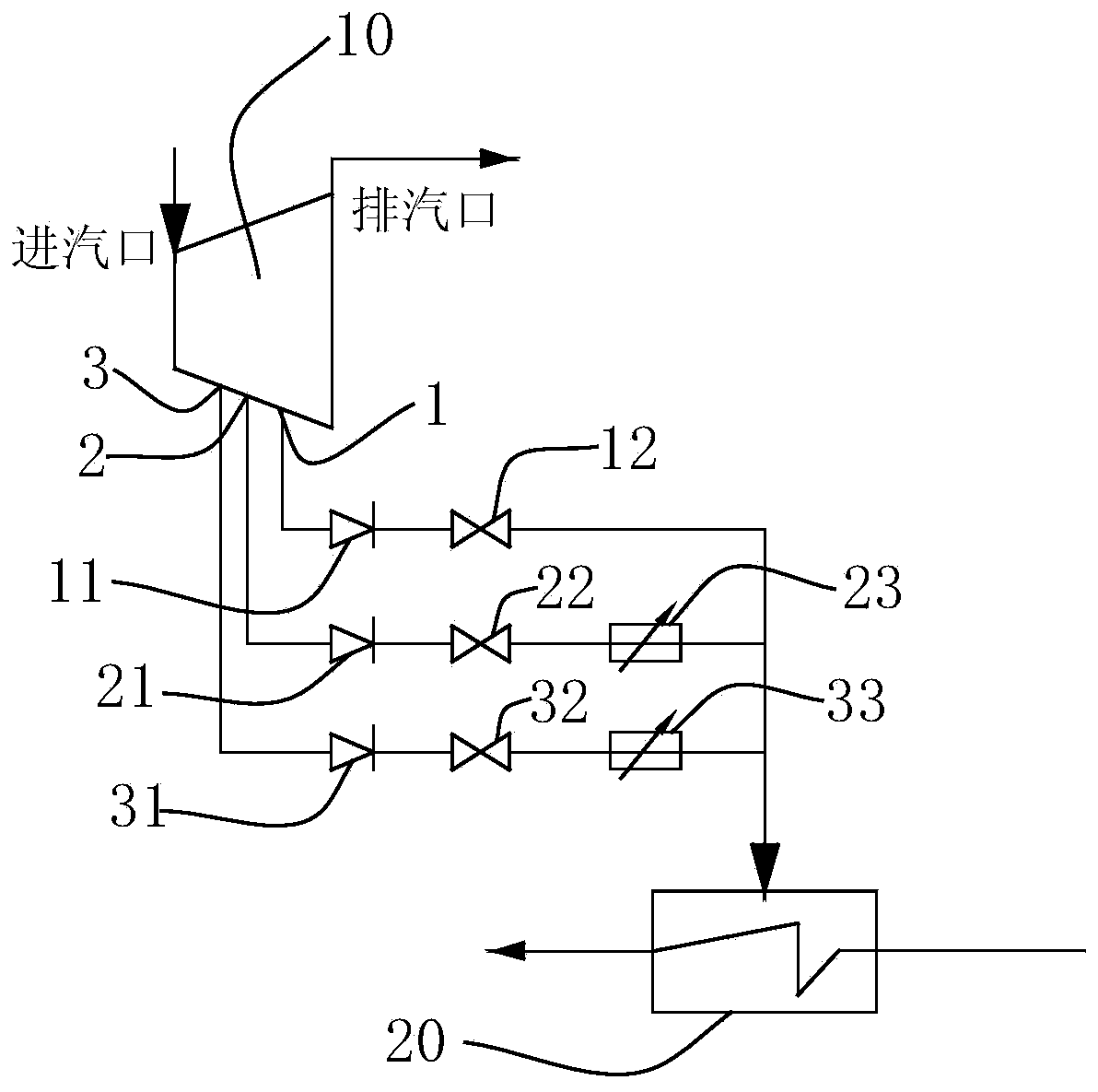

Regenerative system of turbogenerator unit and operation method thereof

ActiveCN103644005ASolve environmental problems that cannot be put into operationIncrease feed water temperatureSteam useFeed-water heatersEngineeringHigh pressure

The invention discloses a regenerative system of a turbogenerator unit and an operation method thereof. The system comprises a high-pressure cylinder and a high-pressure heater, wherein an steam exhaust port and a plurality of high-pressure steam extraction ports whose steam extraction pressure is increased sequentially are formed in the high-pressure cylinder, the high-pressure steam extraction ports are connected with the same high-pressure heater through high-pressure steam extraction pipelines, and an extraction check valve and an isolated valve are arranged on each high-pressure steam extraction pipeline. When the turbogenerator unit operates at a rated load, a first high-pressure steam extraction port with the lowest steam extraction pressure supplies steam for the high-pressure heater, and the steam extraction pressure at the time is set to be P0; when the turbogenerator unit operates in a state lower than the rated load, a high-pressure steam extraction port with steam extraction pressure less than or equal to P0 or closer to P0 is selected to supply steam for the high-pressure heater, and the isolated valves on other high-pressure steam extraction pipelines are switched off. According to the regenerative system of the turbogenerator unit and the operation method thereof, a denitration system can operate normally when the unit operates at a low load, the boiler feeding temperature is increased, and the thermodynamic cycle efficiency of the unit is improved accordingly.

Owner:王振宇

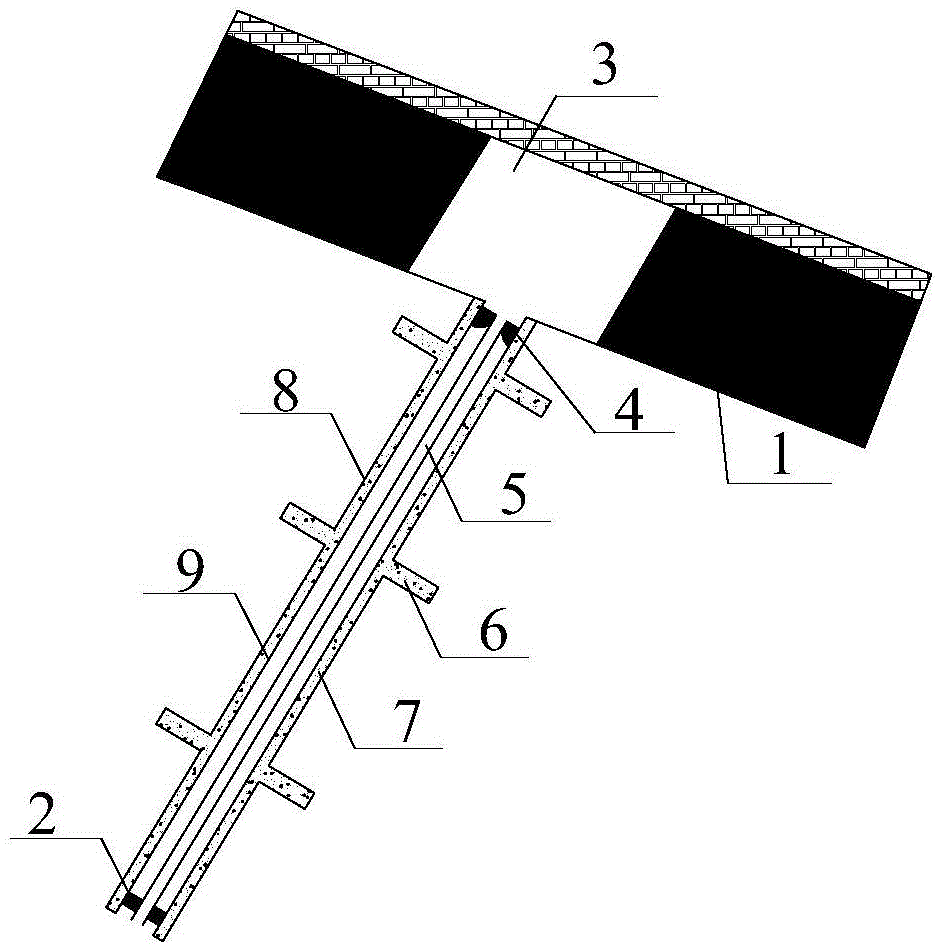

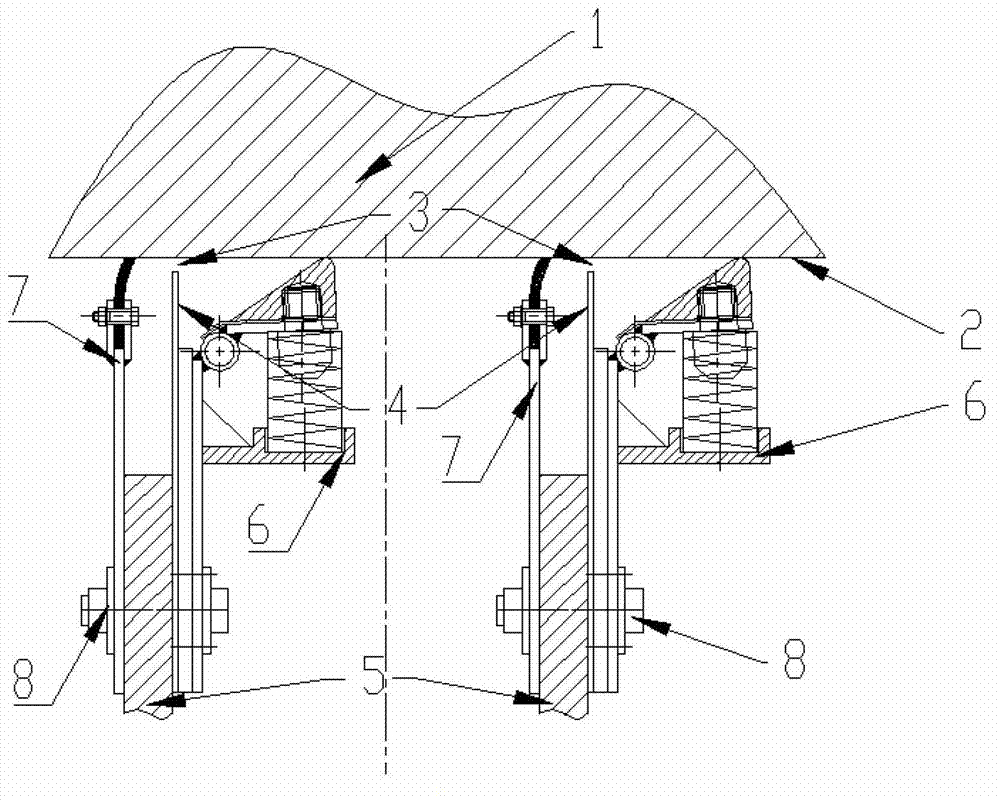

Flexible sealing structure of rotary air pre-heater

ActiveCN102901118AGuarantees a stable sealGood sealing effectEngine sealsCombustion processEngineeringMechanical engineering

The invention discloses a flexible sealing structure of a rotary air pre-heater. The flexible sealing structure is a contact type sealing device and comprises a sealing sliding block, a regulation supporting seat and a supporting fixing plate; the sealing sliding block is rotatablely connected with the supporting fixing plate; the supporting fixing plate is relatively arranged on a radial baffle plate of the air pre-heater fixedly; the regulation supporting seat is fixedly connected with the supporting fixing plate; a compression spring is arranged between the regulation supporting seat and the sealing sliding block; the sealing sliding block is in contact with a fan-shaped plate or an axial arc-shaped plate of the air pre-heater; a reset regulation device is arranged between the sealing sliding block and the regulation supporting seat; two ends of the reset regulation device are respectively connected with the sealing sliding block and the regulation supporting seat; and the reset regulation device is used for regulating the maximal resilience modulus of the compression spring positioned between the sealing sliding block and the regulation supporting seat. By using the flexible sealing structure, through regulating the reset regulation device, the regulation of sealing acting force between a moving component and a stationary component in the air pre-heater is realized; the wear of a sealing surface is decreased; and the service life of a quick-wear part is prolonged.

Owner:南京通用电气装备有限公司

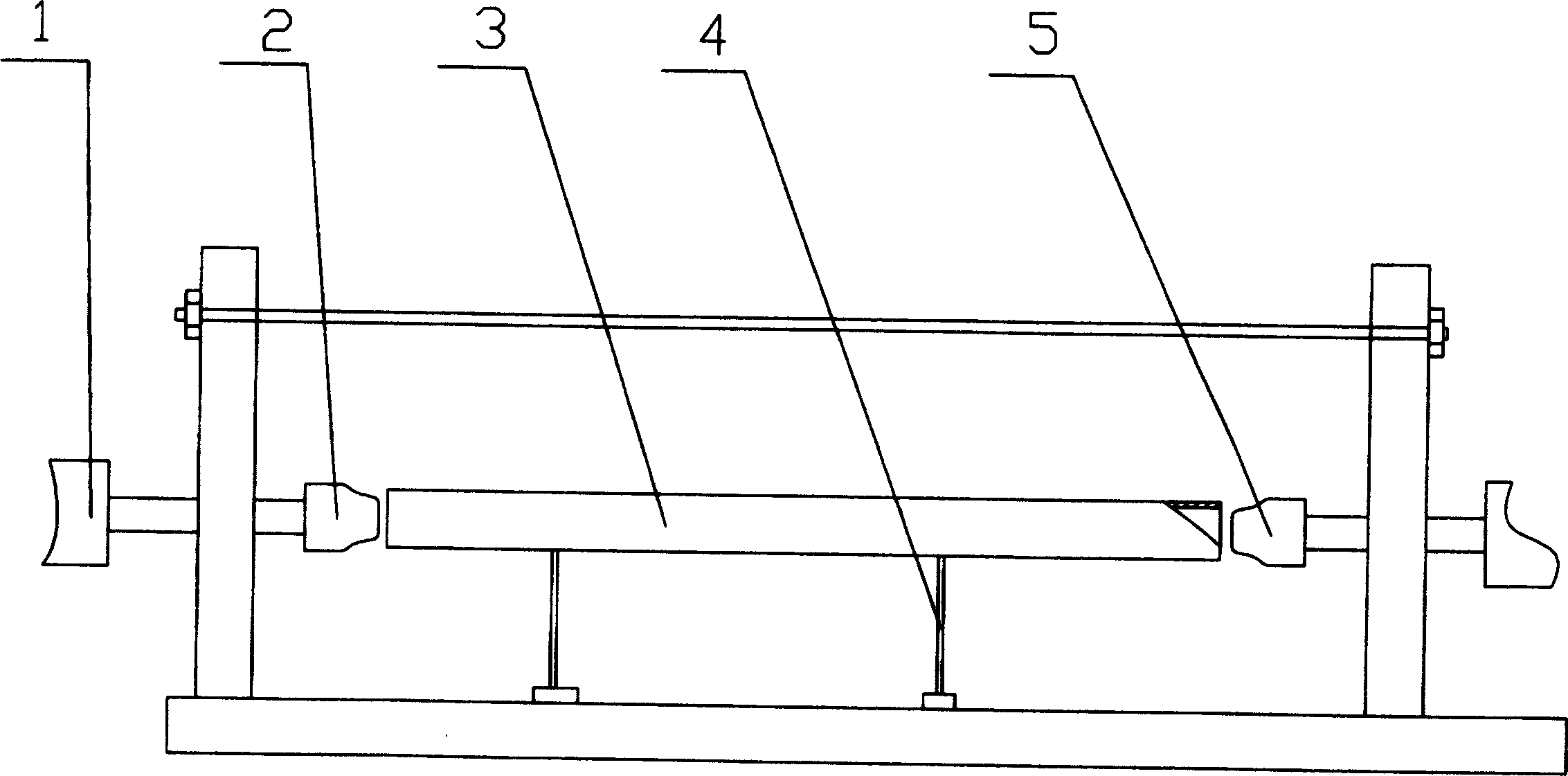

Method for expanding bus pipe

The present invention discloses bus pipe flaring process, and relates to large caliber aluminum alloy pipe flaring process. The present invention completes bus pipe flaring in a flaring apparatus with two coaxial die heads and one power source connected to one or two of the die heads. The bus pipe flaring process includes the following steps: heating the ends of the straight pipe to 280-330 deg.c; pushing the ends of the straight pipe separately to two die heads coaxially; feeding the die heads until reaching the set stroke; and restoring the die heads to obtain the flared bus pipe. The present invention can produce bus pipe with high integrity, high precision, high strength and capacity of ensuring the reliability of combined switch.

Owner:张道勇

Process for producing anode copper by adoption of four connected furnaces

InactiveCN105002371AAchieve separationInto continuous stabilityRotary drum furnacesCrucible furnacesSlagSlow cooling

The invention provides a process for producing anode copper by adoption of four connected furnaces. The process is particularly characterized in that a smelting furnace, a slagging furnace, a copper preparation furnace and an anode furnace are connected in series from front to back and are connected through chutes. The process mainly comprises the steps that copper concentrate and flux enter the smelting furnace to react with oxygen-enriched air to generate smelting slag and copper matte, and the smelting slag continuously overflows and is put into a slow cooling slag bag through the corresponding chute; the copper matte is siphoned to continuously flow into the slagging furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, white matte and high-temperature smoke; the converting slag continuously overflows and is put into the slow cooling slag bag through the corresponding chute; the white matte is siphoned to continuously flow into the copper preparation furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, crude copper and high-temperature smoke; copper preparation slag is discharged regularly and is quenched and broken to return to the slagging furnace; crude copper is siphoned and continuously or discontinuously flows into the anode furnace through the corresponding chute, the anode furnace operates alternately, and anode copper is obtained through oxidation and reduction. The process achieves continuous operation of the crude copper production process.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

Composite type labyrinth compression resistant air-conditioning cabinet

InactiveCN102221257ASolve the deformation rateSolve the strength problemHeating and ventilation casings/coversFoam rubberEngineering

The invention relates to a composite type labyrinth compression resistant air-conditioning cabinet. In the air-conditioning cabinet, a No.1 frame aluminum section and a No.2 frame plastic section are buckled to form an integrated section, and form one air-conditioning cabinet board together with an outer panel, an inner panel, foaming polyurethane and foaming rubber; a No.3 frame aluminum section and a No.4 frame plastic section are buckled to form an integrated section, and form the other air-conditioning cabinet board together with the outer panel, the inner panel, the foaming polyurethane and the foaming rubber; and the two air-conditioning cabinet boards are locked by bolts and nuts. The composite type labyrinth compression resistant air-conditioning cabinet overcomes the defects of insufficient stiffness, low static pressure, high deformation rate, poor heat-insulating and heat-preserving effects and incapability of eliminating cold bridges in the prior art. In addition, due to the adoption of a labyrinth leakproof structure with a tenon, the air leak rate is reduced, the cold bridges are eliminated, and deformed steel is inserted into the sections to enhance the stiffness of the sections greatly and make the sections capable of resisting positive and negative pressure; and after the sections are spliced oppositely, an aluminum alloy cover plate can be inserted without screw exposure, so the application of high-end purification is facilitated, and the problems of the air leak rate and the deformation rate and strength of a cabinet body are solved in one step.

Owner:南京平欧空调设备有限公司

External expansion joint type glass-metal sealing-in end socket structure with internal shielding cover

ActiveCN102840702AReduce the temperatureReduce air leakage rateSolar heat devicesSolar thermal energy generationEngineeringAlloy

The invention provides an external expansion joint type glass-metal sealing-in end socket structure with an internal shielding cover. The external expansion joint type glass-metal sealing-in end socket structure is particularly suitable for a groove type photo-thermal high-temperature heat collecting pipe. The structure is mainly characterized in that a metal shielding cover (8) is connected to a metal end cover (2), and is arranged between a metal pipe (1) and an external expansion joint (3), so that the heat of the medium in a metal pipe (1) can be preventing from being transmitted to the outside; the shielding cover (8) is used for shielding a glass-metal sealing-in part, thus, the temperature of the sealing-in part is reduced, and an effect of thermal shock protection can be achieved; and the sealing-in part comprises a kovar alloy ring (4), a piece of transition glass (5) wrapped on the kovar alloy ring (4), and a glass pipe (6) connected with the piece of transition glass, so that protection for the sealing-in part is finally favorably achieved, air tightness in sealing is improved, and service life of the heat collecting pipe is prolonged.

Owner:BEIJING UNIV OF TECH

Bi-directional hand inflator piston

ActiveCN104196697AEasy to assembleLow costPositive displacement pump componentsPumpsPistonAir chamber

The invention relates to a bi-directional hand inflator piston. The piston comprises a piston body. An inner bore and an outer bore are formed in the central position of the piston body, characterized in that: a plurality of radially arranged separators is mounted between an upper surface and a lower surface of the piston body. By using the separators, the space between the upper surface and the lower surface is divided into both air intake and air outlet guide chambers. The air intake and air outlet guide chambers are not communicated to each other. The air intake guide chamber is communicated to a space within the inner bore. The air outlet guide chamber is communicated to a space between the outer bore and the inner bore. A first cover plate is fixed at an outer end opening between two separators dividing to form the air intake guide chamber, for covering the outer end opening. A second cover plate is fixed at an outer end opening between two separators dividing to form the air outlet guide chamber, for covering the outer end opening. Only two cover plate components of the whole piston need to be additionally fixed by adhesion, so that the assembling is more convenient, the cost is low, and the air leakage possibility due to unstable adhesion is reduced.

Owner:GRI LEISURE & SPORT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com