Patents

Literature

139 results about "Automated optical inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

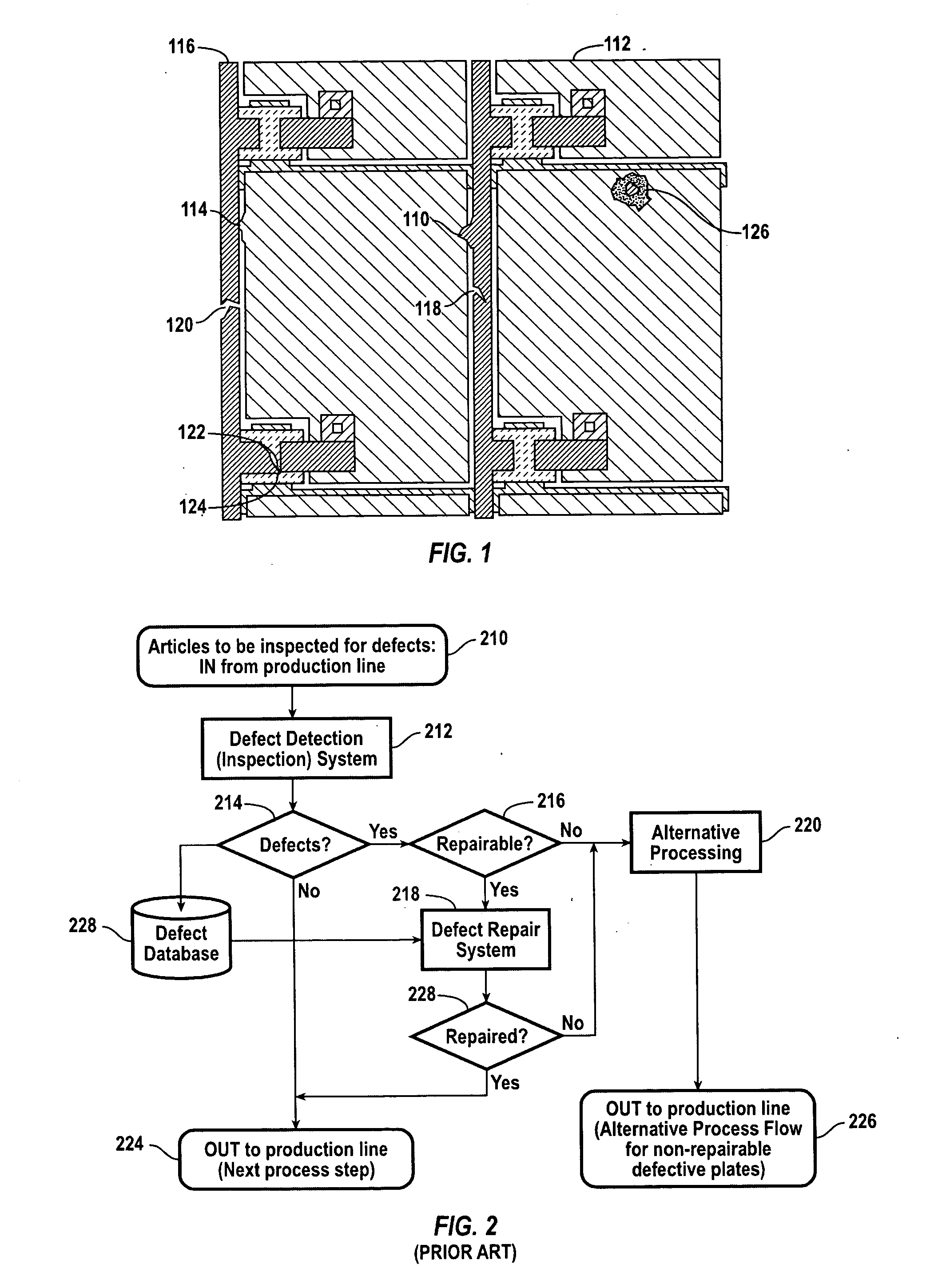

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-reflow as well as other stages.

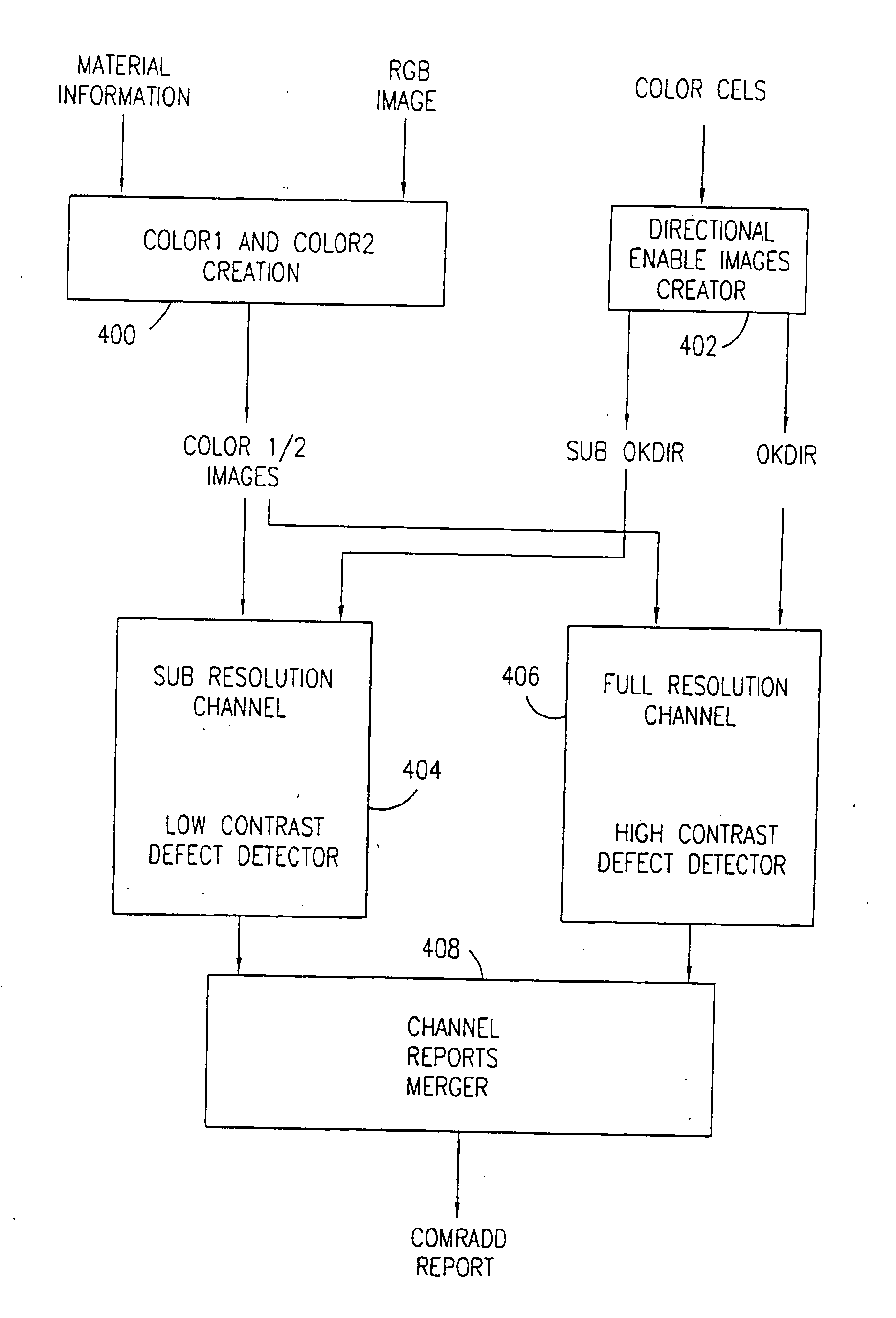

Detection of surface defects employing subsampled images

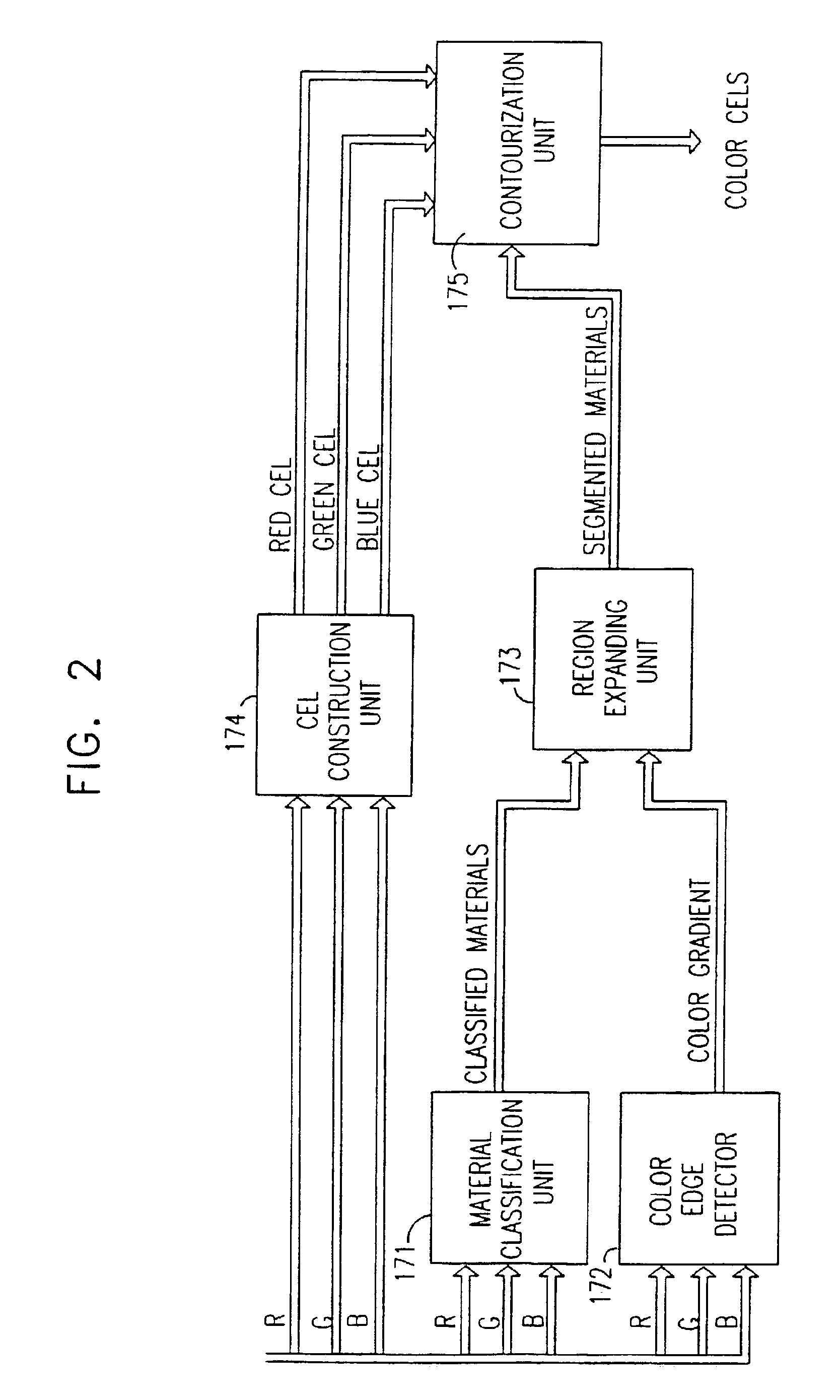

InactiveUS20070133862A1Function increaseIncrease diversityImage enhancementImage analysisColor imageAutomated optical inspection

A method for determining a location of a border in a color image, the image including at least two color populations, between a first color region associated with a first one of the two color populations and a second color region associated with a second one of the two color populations, both the first color region and the second color region being in the color image, the method includes identifying an approximate border location between the first color region and the second color region, determining a plurality of candidate border locations between the first color region and the second color region, each of the plurality of candidate border locations being determined by applying a corresponding border location method chosen from among a plurality of border location methods, choosing one method from among the plurality of border location methods as a preferred method, and determining a location of a border between the first color region and the second color region by designating one of the plurality of candidate border locations associated with the preferred method as the border. Also, an automated optical inspection device suitable for inspection of patterned articles.

Owner:ORBOTECH LTD

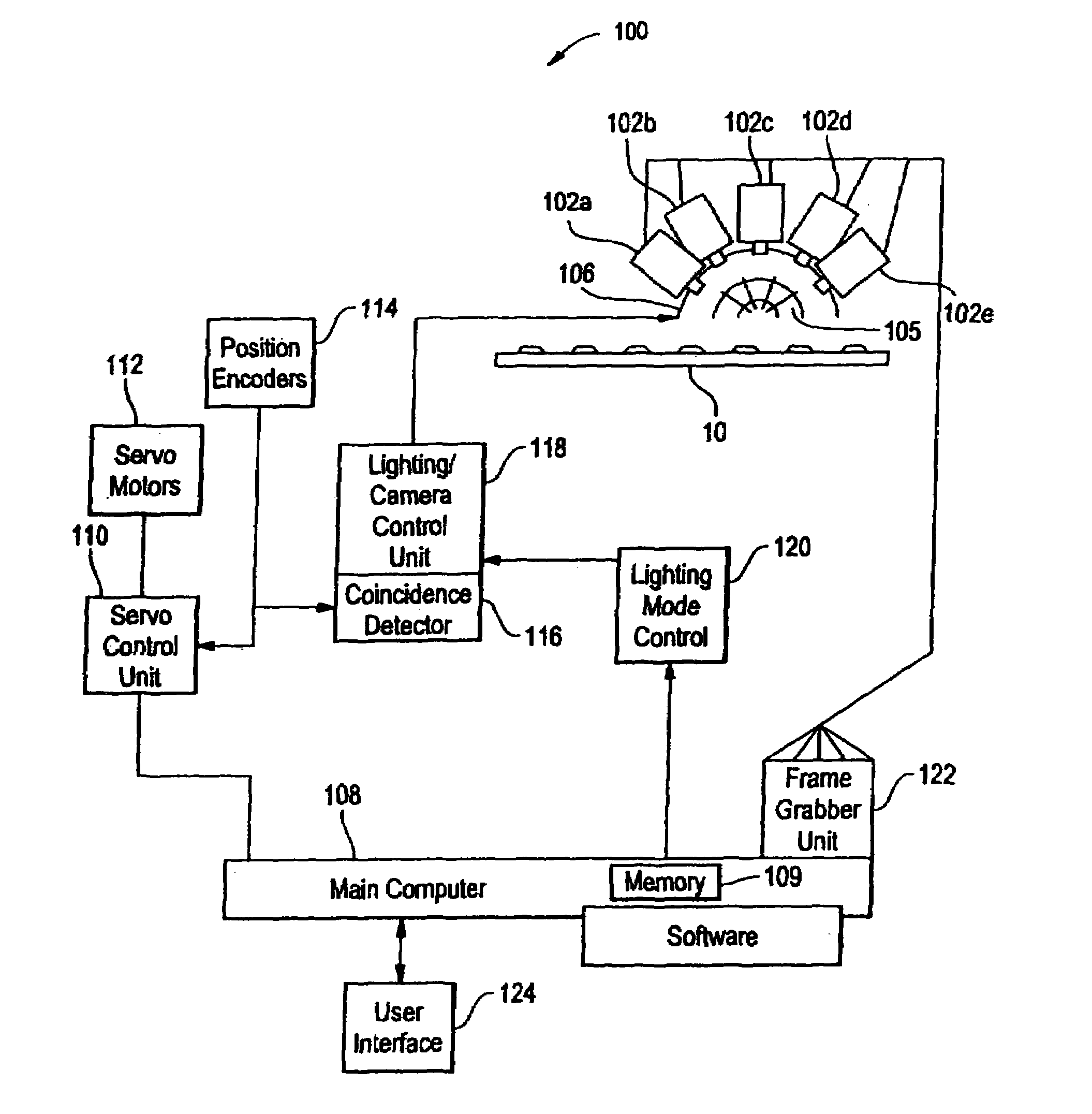

Optical inspection system

InactiveUS7075565B1Minimizing inspection timeMinimize timeMaterial analysis by optical meansColor television detailsComputer hardwareEffect light

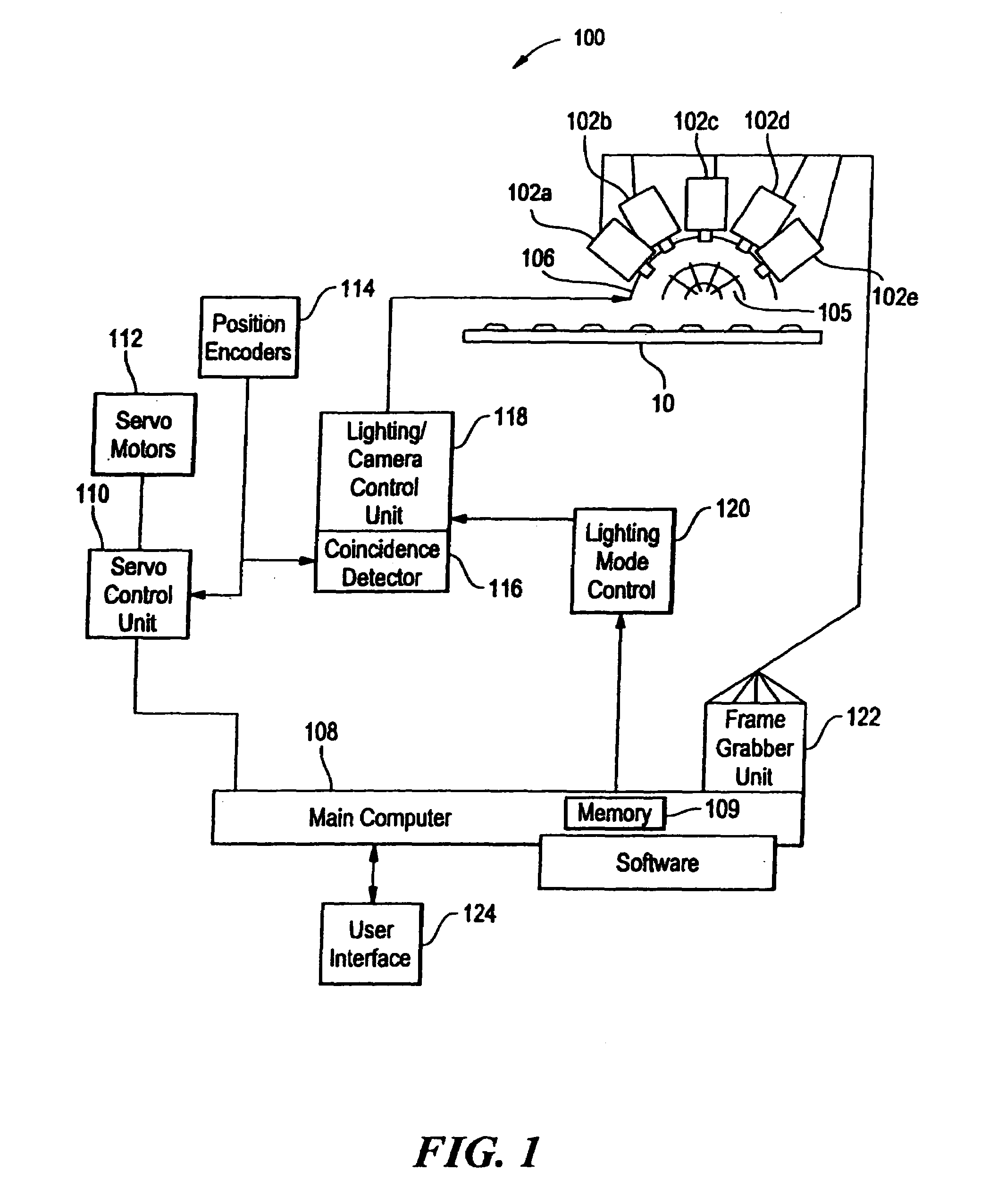

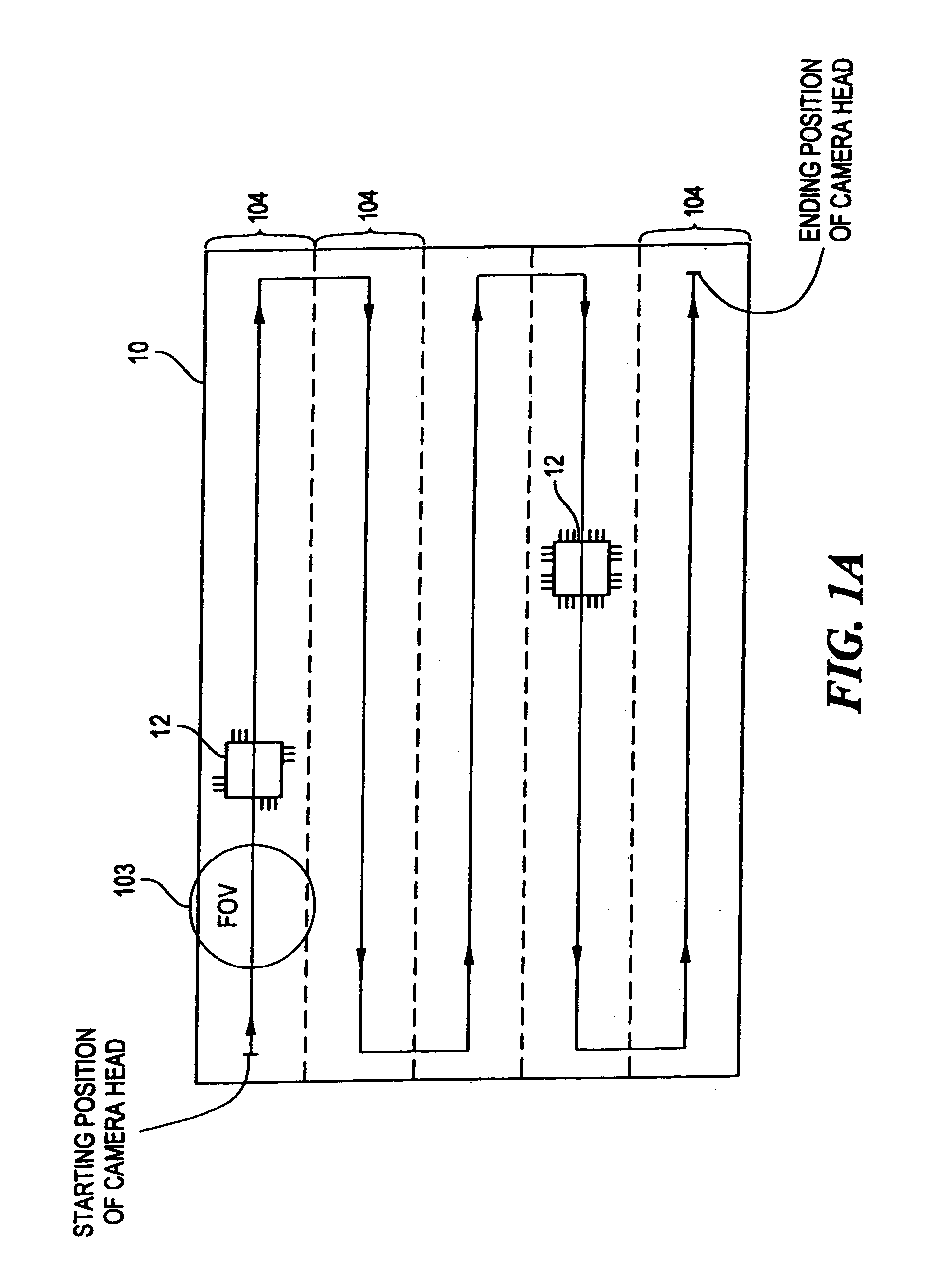

An automated optical inspection system includes a plurality of asynchronously triggerable cameras for providing image data of an object, such as a printed circuit board. The circuit board is divided into fields of view that are to be imaged in one or more cameras in one or more lighting modes. Each location on the board can be imaged by each camera in a plurality of lighting modes in a single pass across the board. The image data for each of the cameras can be concurrently transferred directly to main memory for opportunistic analysis by the main computer. The system allows the full bandwidth of the cameras to be utilized for reducing the inspection time of the board.

Owner:LANDREX TECH CO LTD

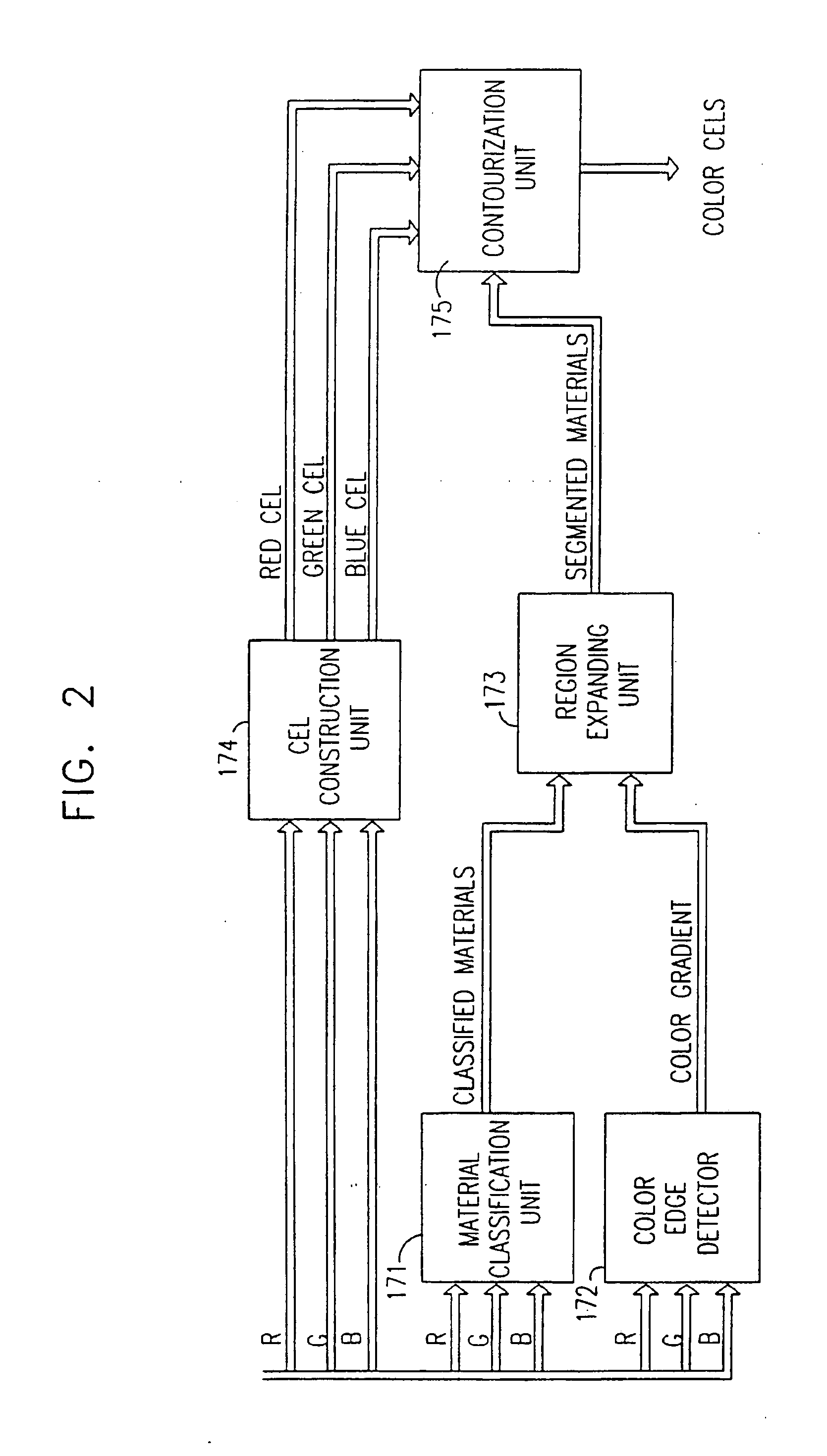

Optical inspection system

InactiveUS7200259B1Function increaseIncrease diversityImage enhancementImage analysisColor imageVisual inspection

This invention discloses a method for determining a location of a border in a color image, the image comprising at least two color populations, between a first color region associated with a first one of the two color populations and a second color region associated with a second one of the two color populations, both the first color region and the second color region being comprised in the color image, the method includes identifying an approximate border location between the first color region and the second color region, determining a plurality of candidate border locations between the first color region and the second color region, each of the plurality of candidate border locations being determined by applying a corresponding border location method chosen from among a plurality of border location methods, choosing one method from among the plurality of border location methods as a preferred method, and determining a location of a border between the first color region and the second color region by designating one of the plurality of candidate border locations associated with the preferred method as the border. An automated optical inspection device suitable for inspection of patterned articles is also disclosed.

Owner:ORBOTECH LTD

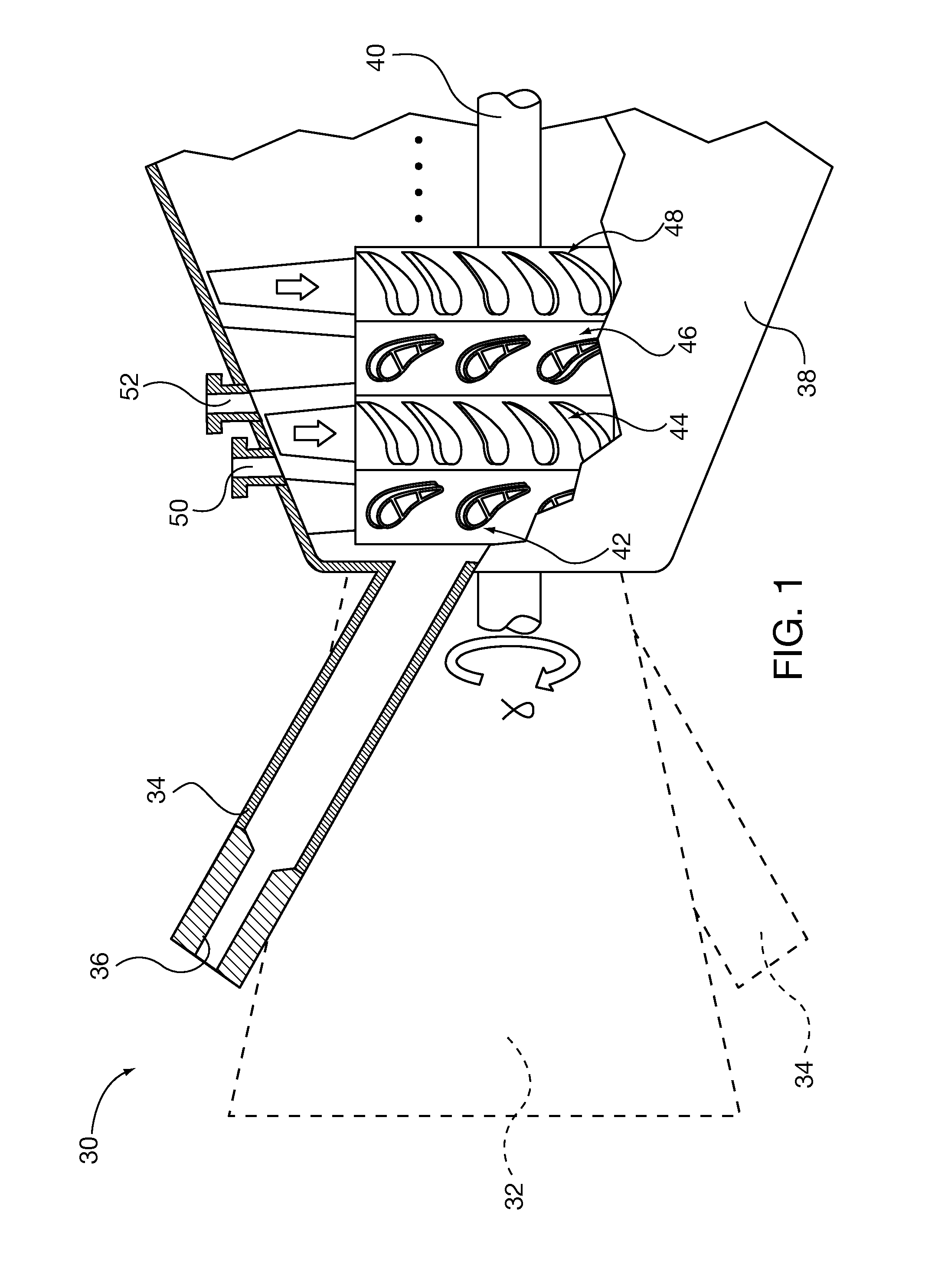

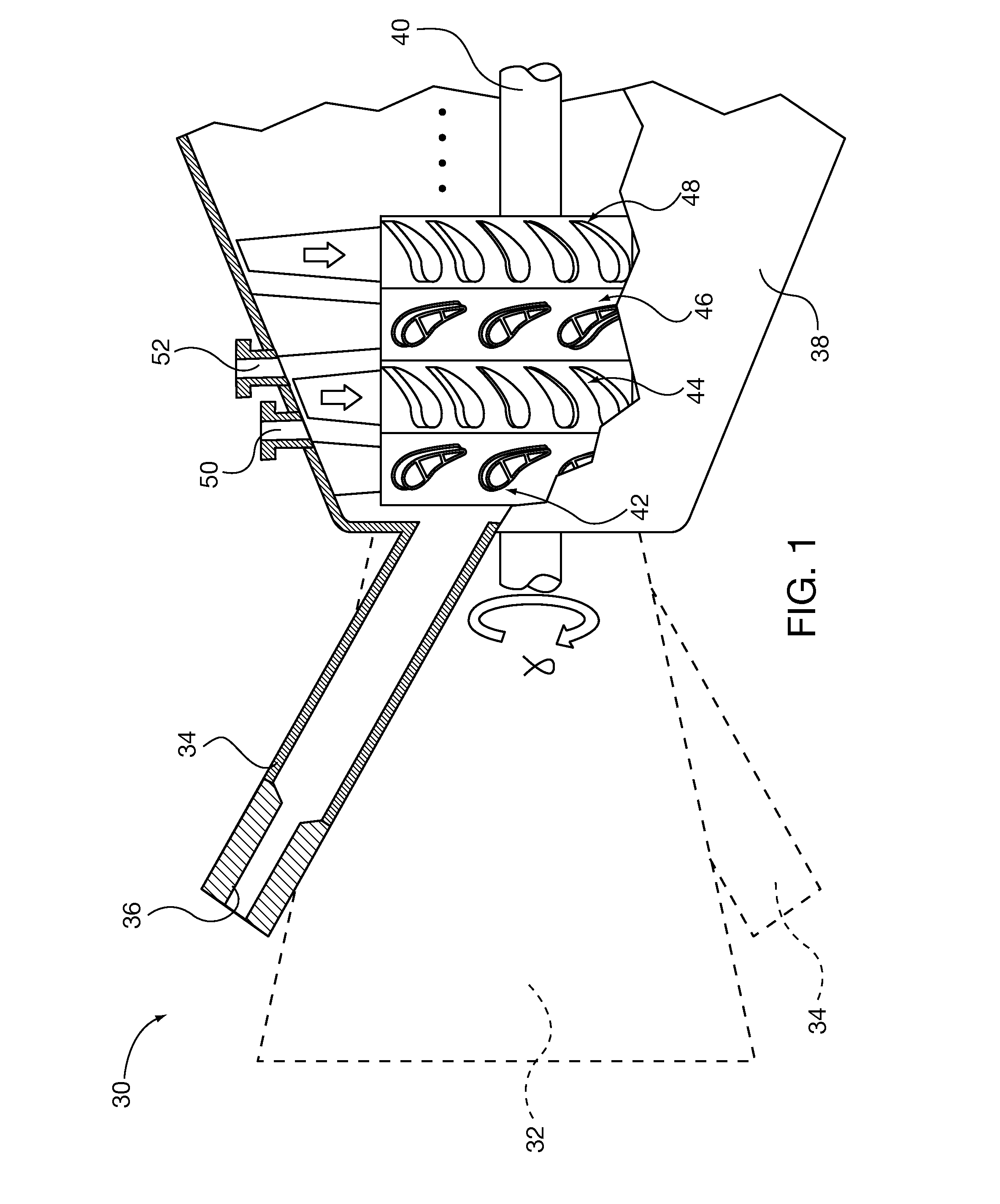

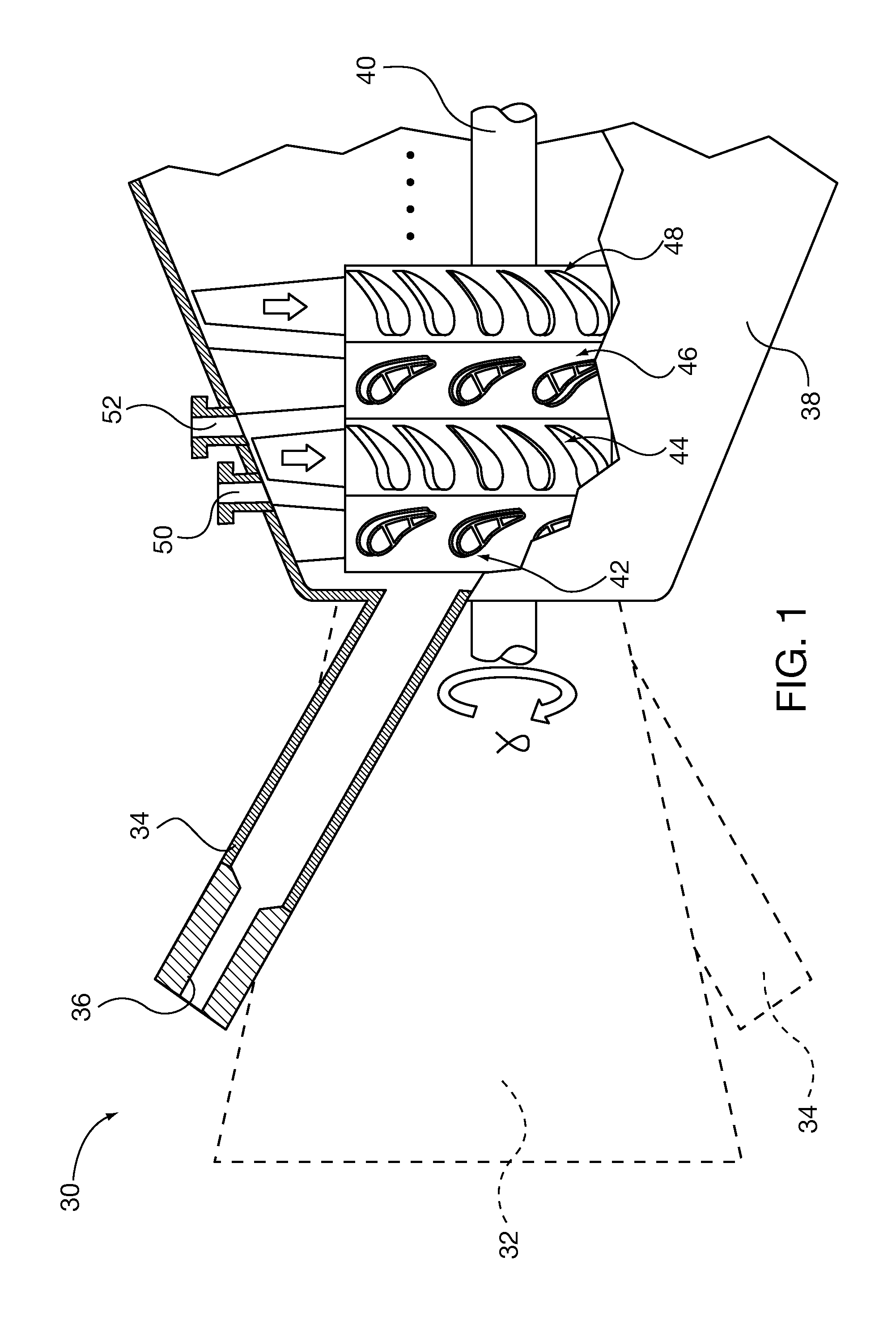

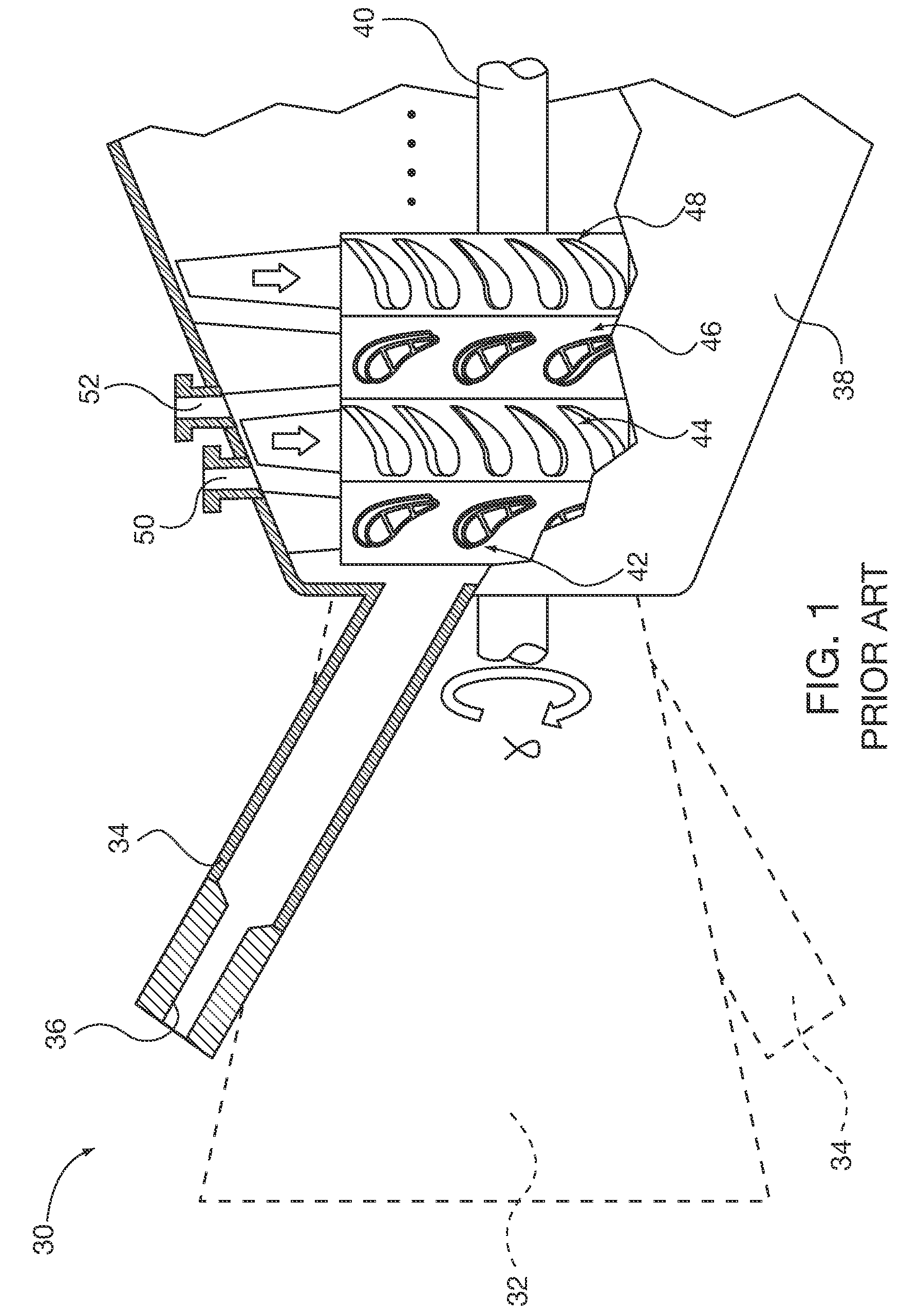

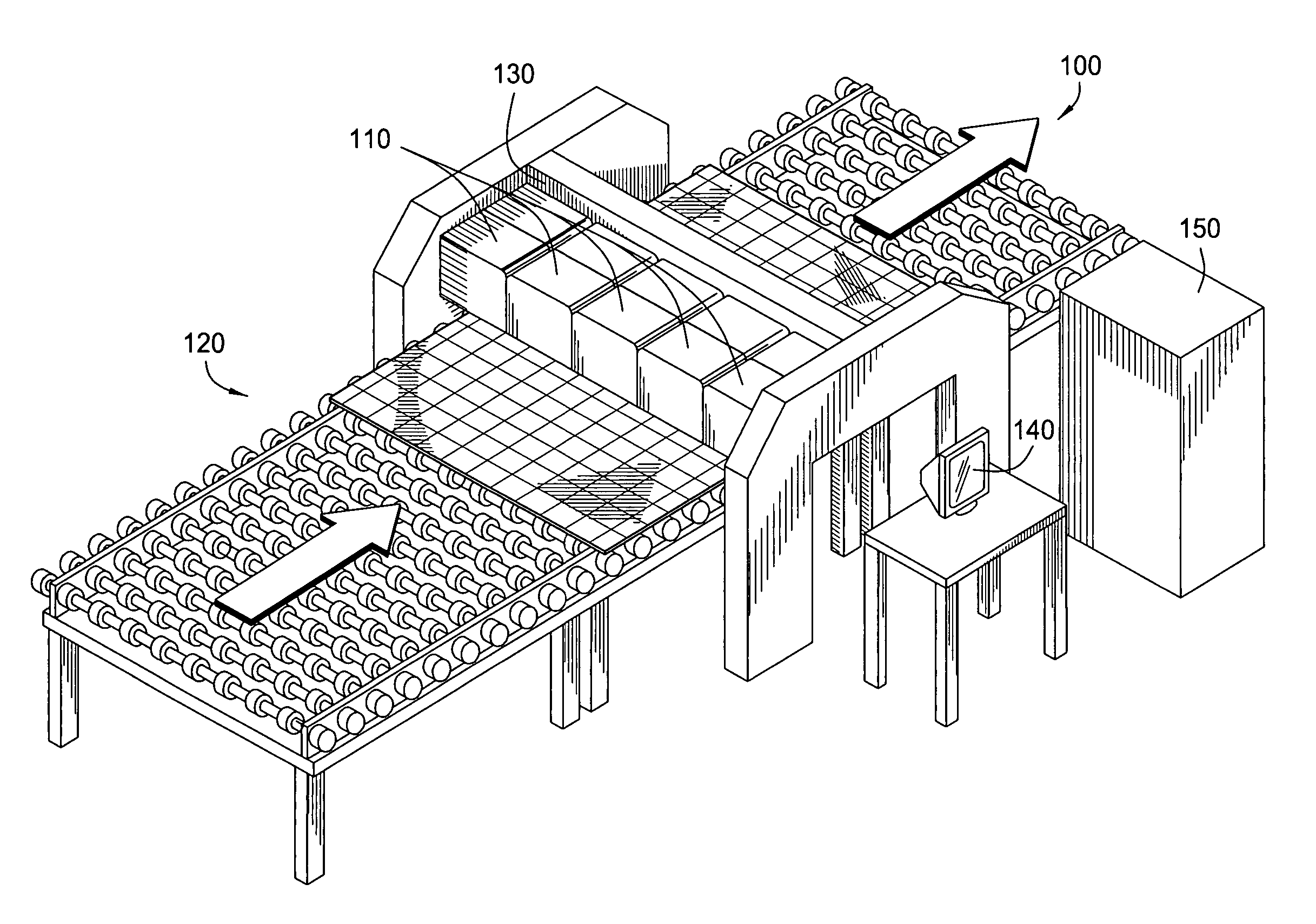

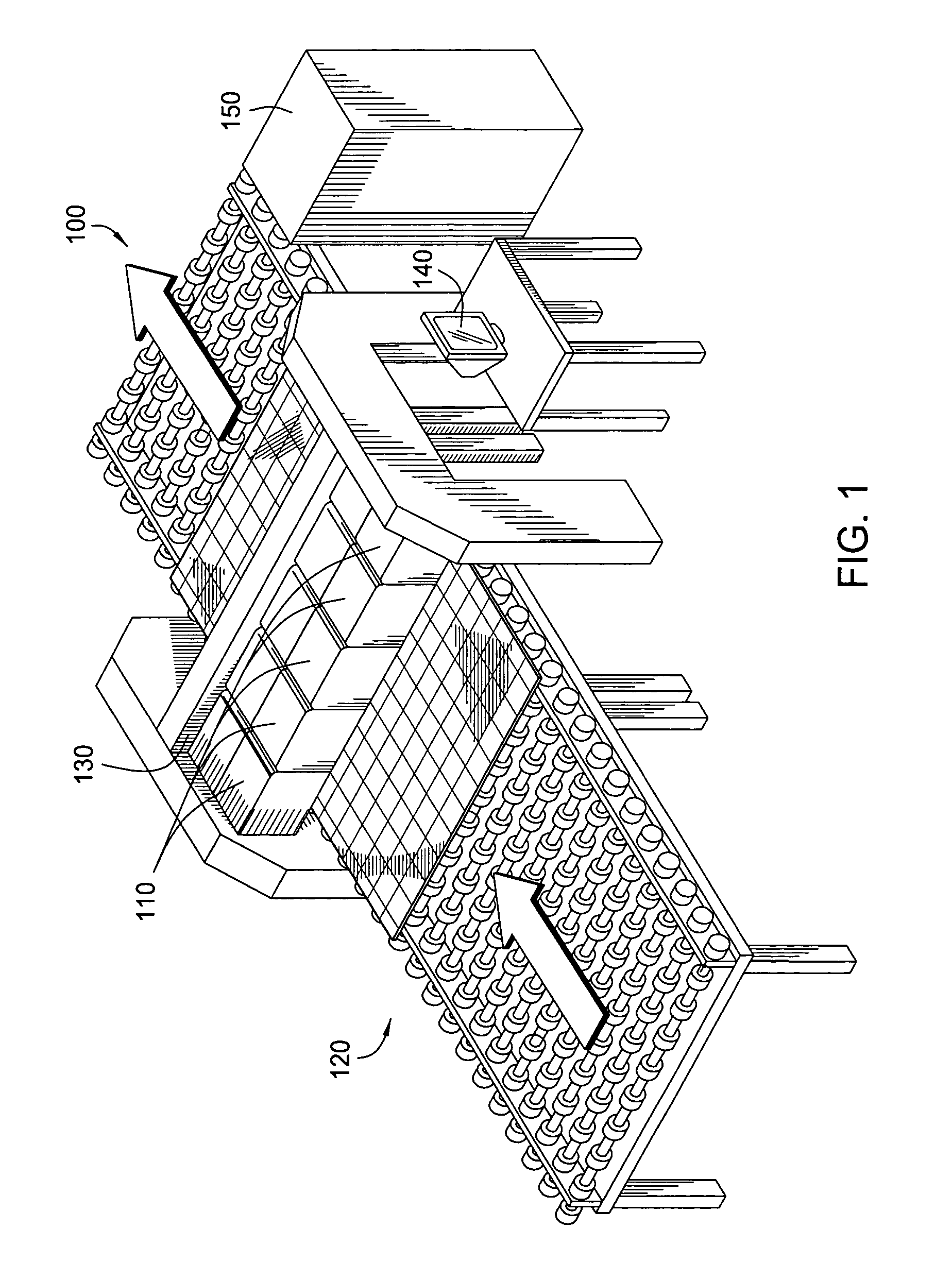

System and method for automated optical inspection of industrial gas turbines and other power generation machinery

ActiveUS20130194413A1Shorten the timeMore power generationTelevision system detailsMaterial analysis by optical meansIndustrial gasEngineering

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation.

Owner:SIEMENS ENERGY INC

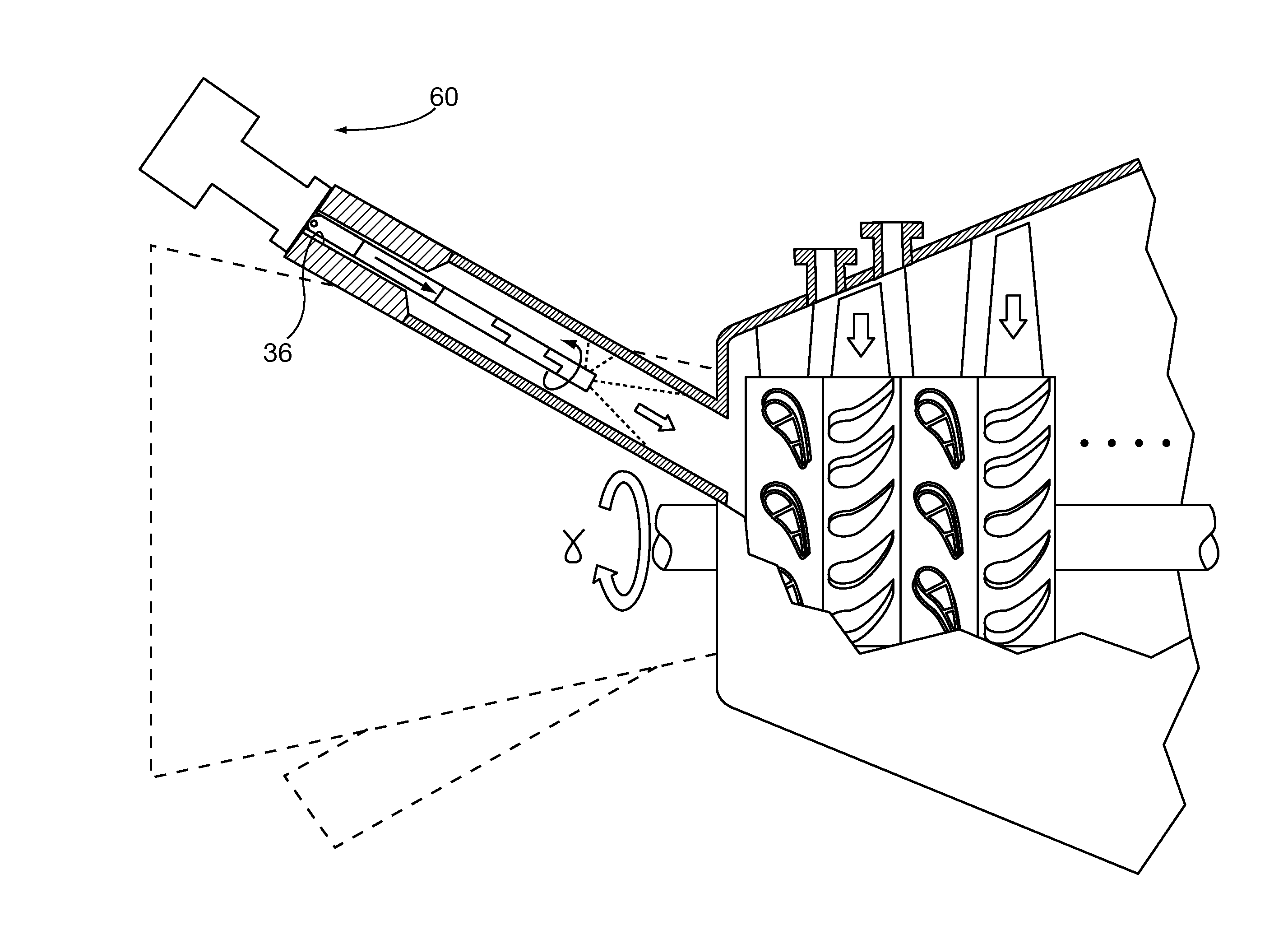

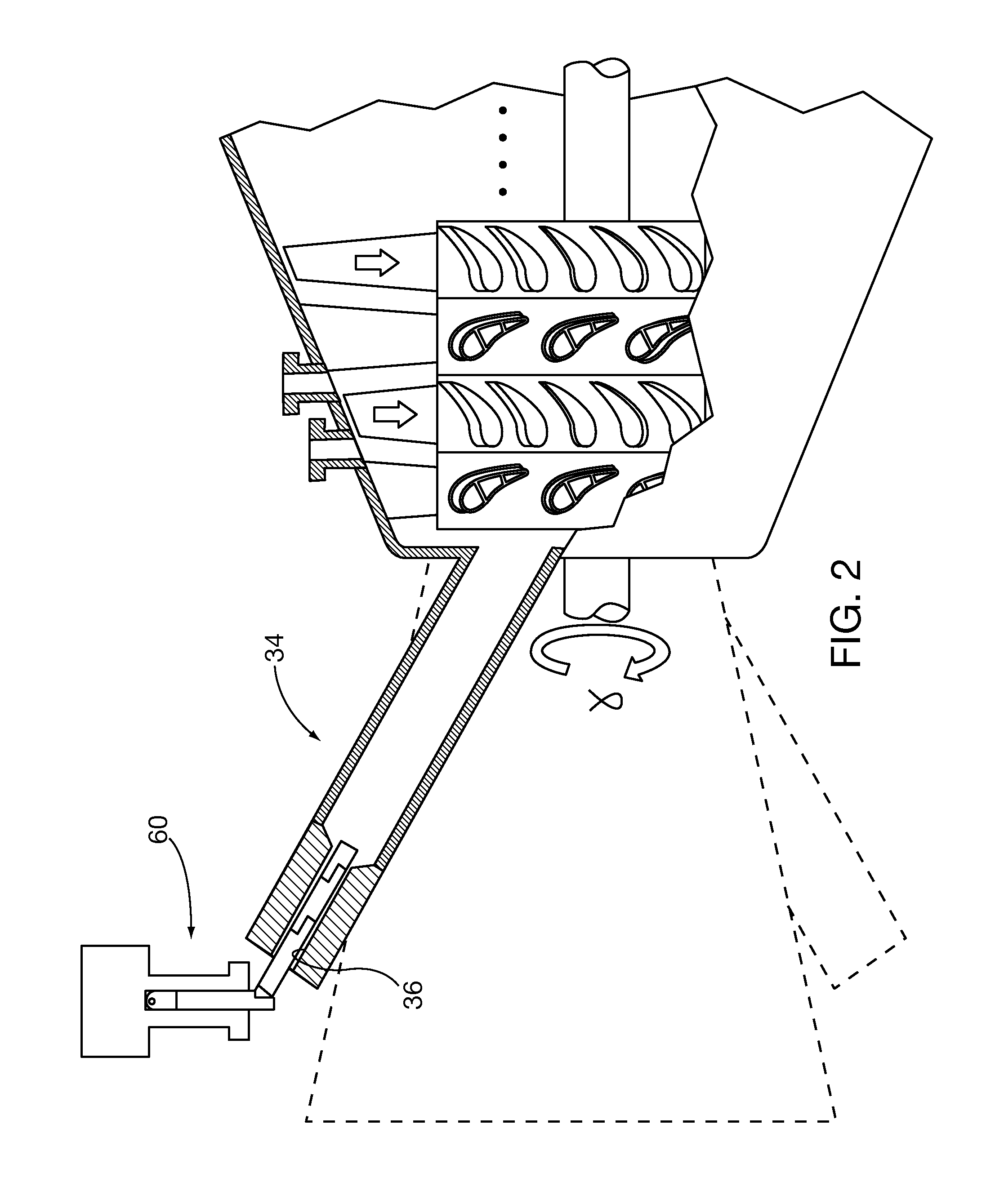

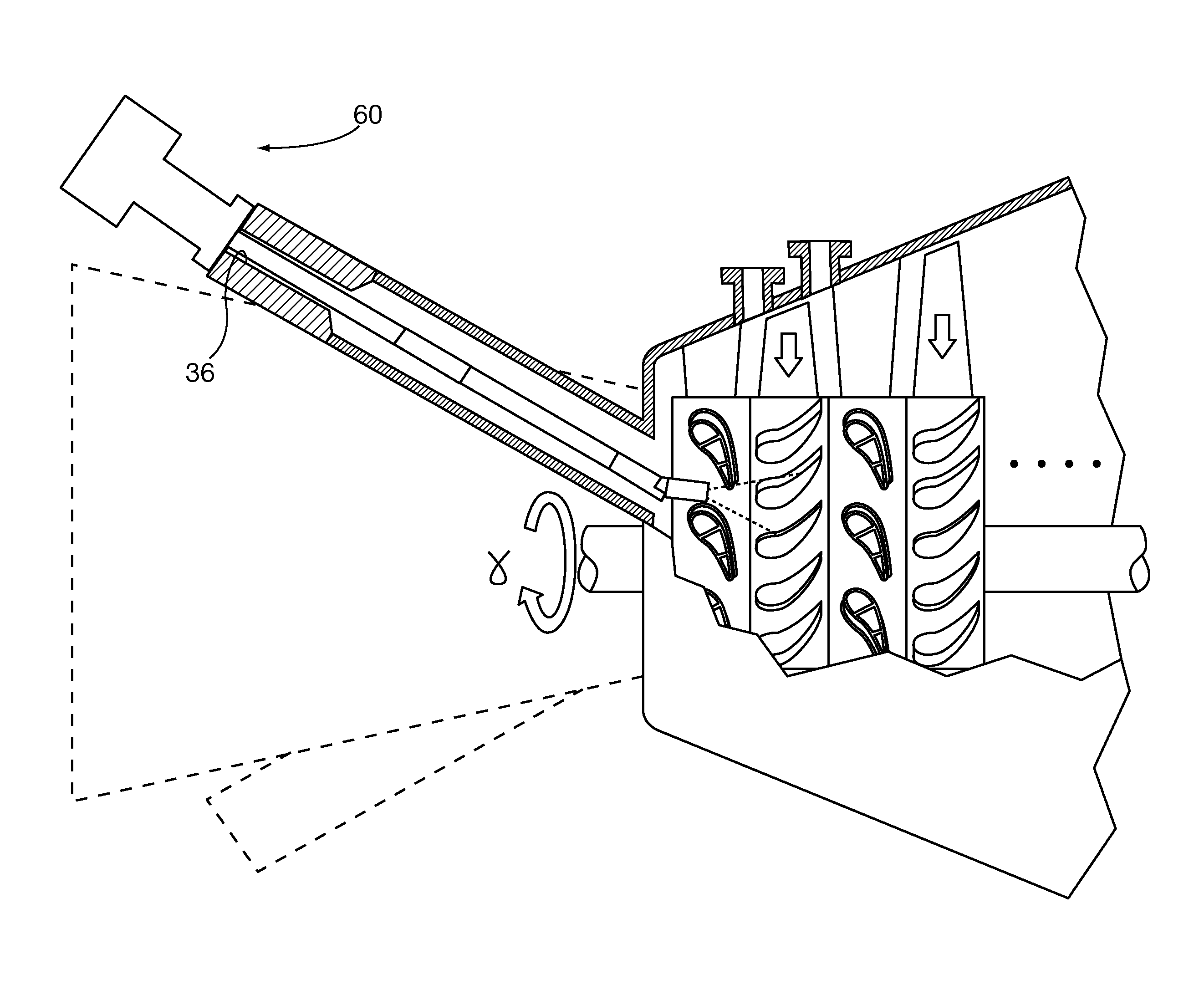

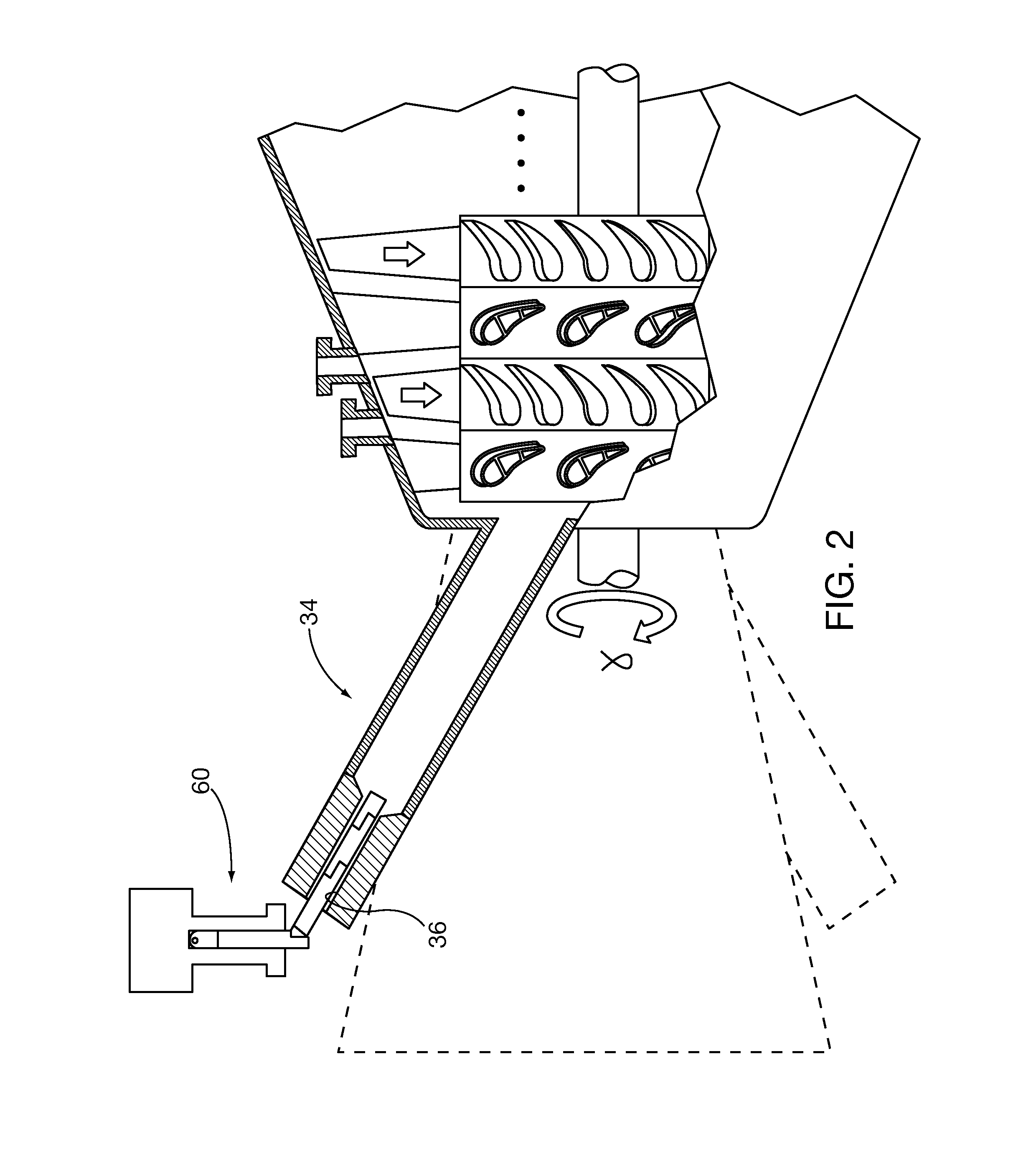

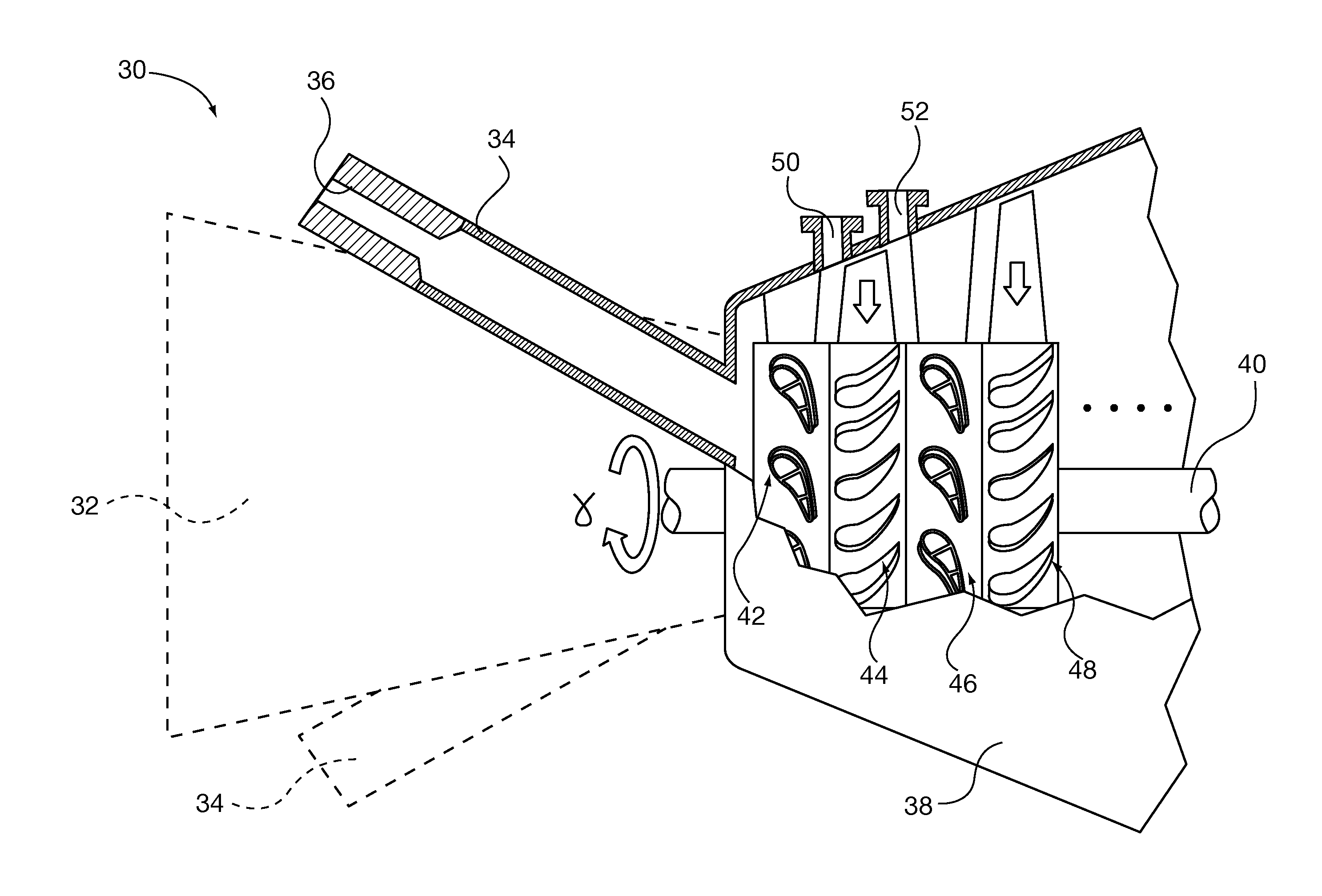

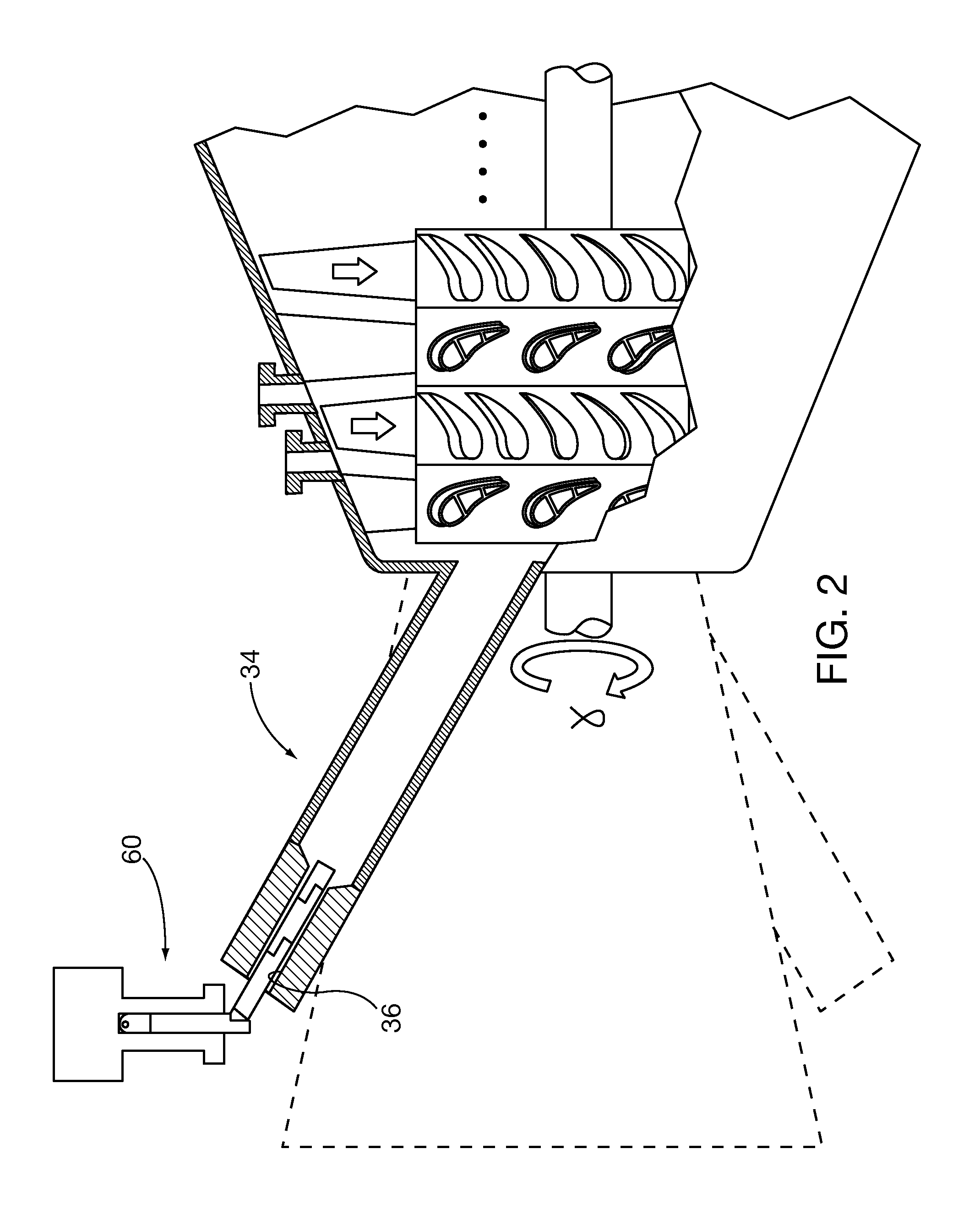

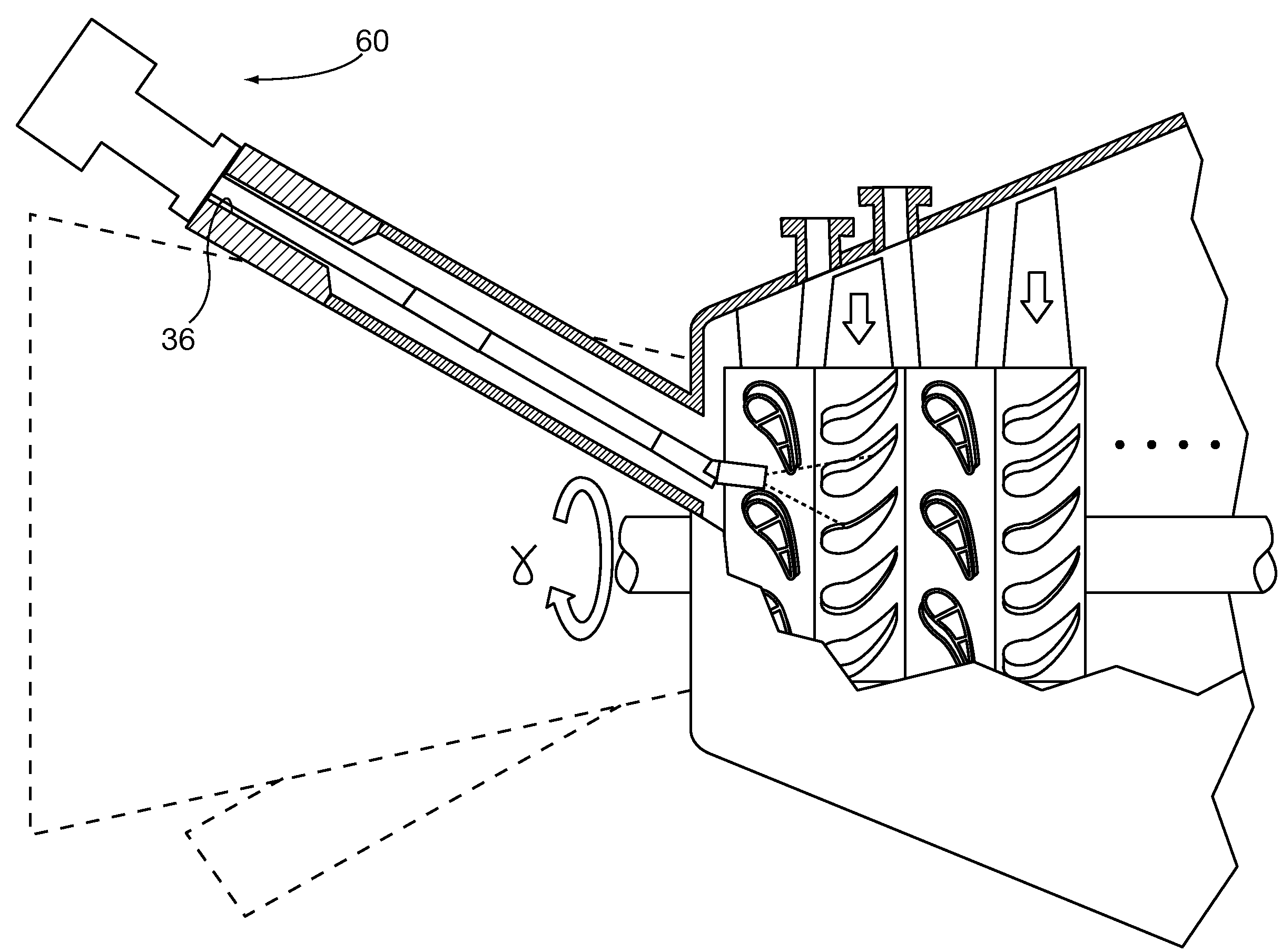

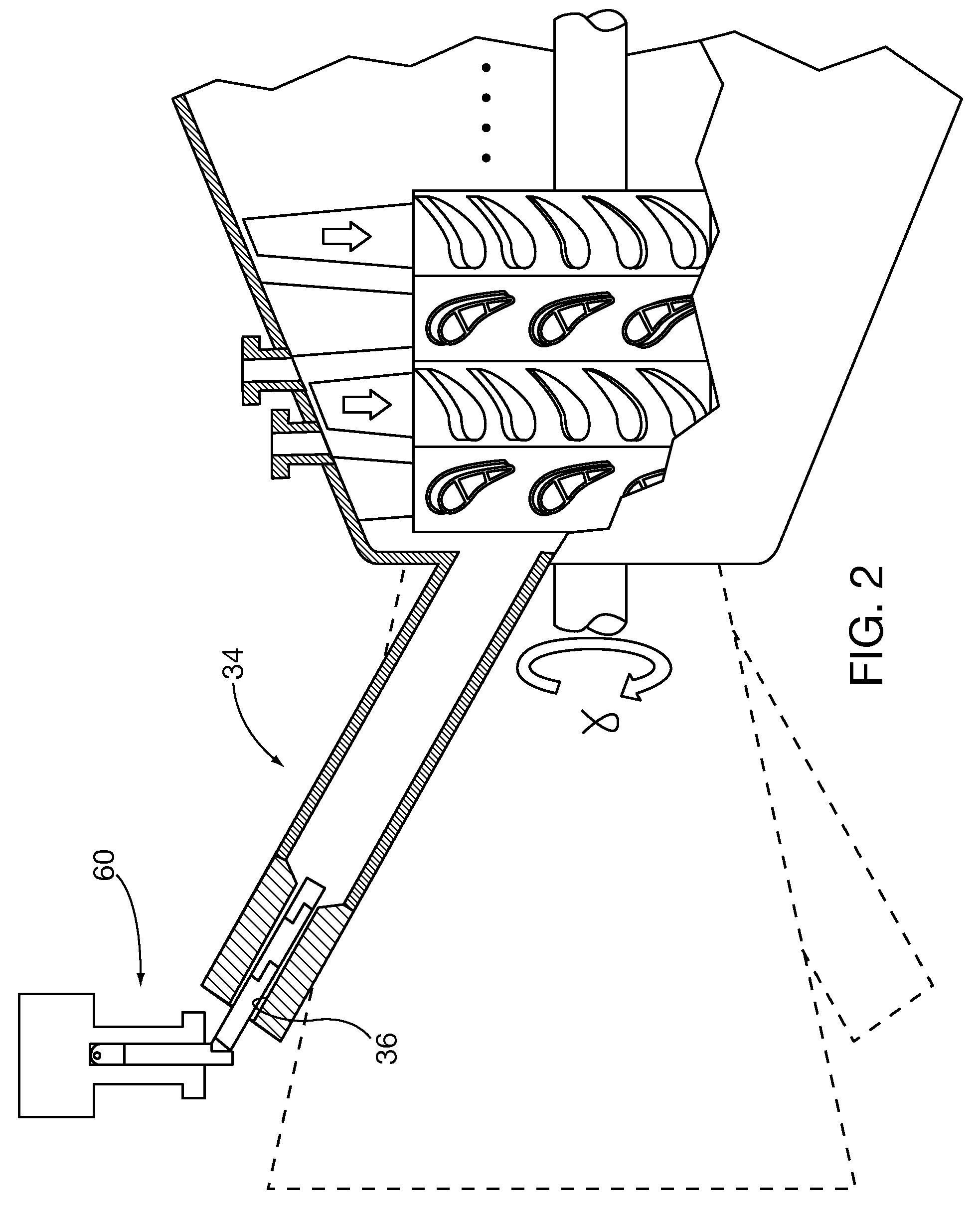

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with articulated multi-axis inspection scope

ActiveUS20130194412A1Minimize damageEqualize levelGas-turbine engine testingMaterial analysis by optical meansEngineeringVideo camera

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation. The inspection system includes an articulated multi-axis inspection scope.

Owner:SIEMENS ENERGY INC

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with multi-axis inspection scope

ActiveUS20130192353A1Shorten the timeMore power generationGas-turbine engine testingMaterial analysis by optical meansReceiptVideo camera

Owner:SIEMENS ENERGY INC

Step circuit board with gold-masking copper-plating hybrid surface process and manufacture method thereof

InactiveCN102946693ASolve the problem of burning boardThe plated area is stablePrinted circuit detailsPrinted circuit manufactureElectricityScreen printing

The invention discloses a manufacture method for a step circuit board with a gold-masking copper-plating hybrid surface process. The manufacture method comprises the steps of cutting materials, transferring an inner pattern, browning and pressing a plate, drilling, plating copper, electroplating the whole plate, adhering a thick gold dry film, achieving pattern transfer for the first time through exposing and developing, exposing a local electrical thick gold part, plating copper, nickel gold and electrical thick gold on the electrical thick gold part, removing the film, adhering a dry film, achieving pattern transfer for the second time through exposing and developing, exposing a part needing plating copper, plating copper, removing the film, silk-screen printing a wet film, achieving pattern transfer for the third time through exposing and developing, exposing a needed outer circuit, adhering a dry film to completely cover a PTH (Plated Through Hole) through exposing and developing, etching an outer circuit, removing the film, carrying out AOI (Automated Optical Inspection) to the outer layer, silk-screen printing and resistance-welding, lettering, forming, electrically testing, carrying out an OSP (Organic Solderability Preservatives) surface process, carrying out final inspection, packaging and shipping. The gold-masked copper-plated step circuit board manufactured by the method disclosed by the invention can achieve more compact assembling needs and a better adhering effect.

Owner:GUILIN UNIV OF ELECTRONIC TECH

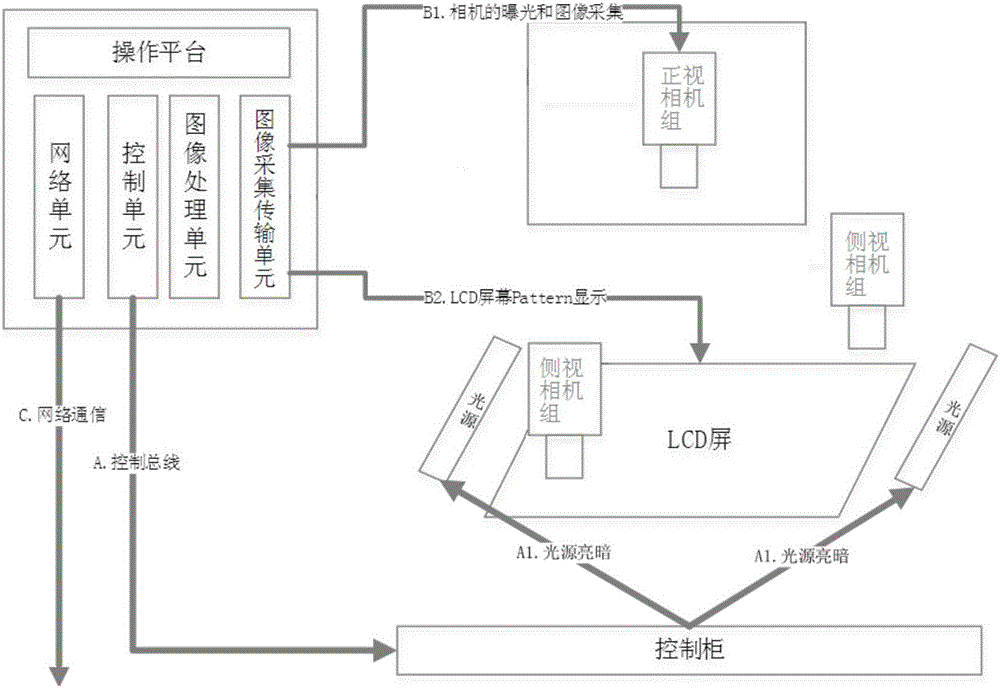

AOI (Automated Optical Inspection)-based macroscopic defect detection device and method

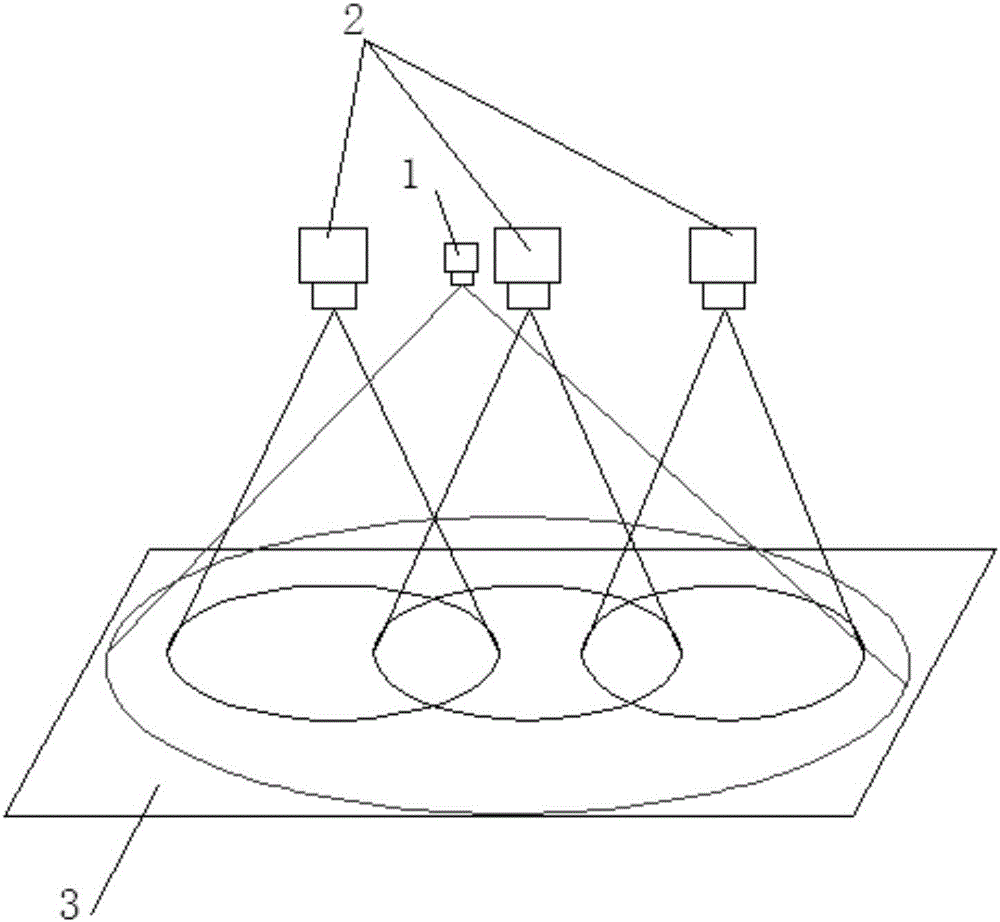

ActiveCN106770362ATroubleshoot unchecked issuesRich varietyOptically investigating flaws/contaminationView cameraFlat panel display

The invention provides an AOI (Automated Optical Inspection)-based macroscopic defect detection device used for detecting macroscopic display defects of a flat panel display module. The macroscopic defect detection device comprises a light source, a camera group, and an image acquisition and processing unit interacting with the camera group, and is characterized in that the camera group comprises at least one group of front view camera components and at least two groups of symmetrically arranged side view camera components, wherein the front view camera components and the side view camera components are positioned above a to-be-detected display panel and are used for photographing display images of the to-be-detected display panel; the photographing angle of the front view camera group is perpendicular to the to-be-detected display panel; an included angle exists between the photographing angle of the side view camera group and the to-be-detected display panel; and the to-be-detected display panel is positioned in a photographing range of the front view camera group and the side view camera group. According to the macroscopic defect detection device disclosed by the invention, the defects during defect detection by industrial front view cameras are overcome, and the type and capability of AOI defect detection are greatly enriched.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

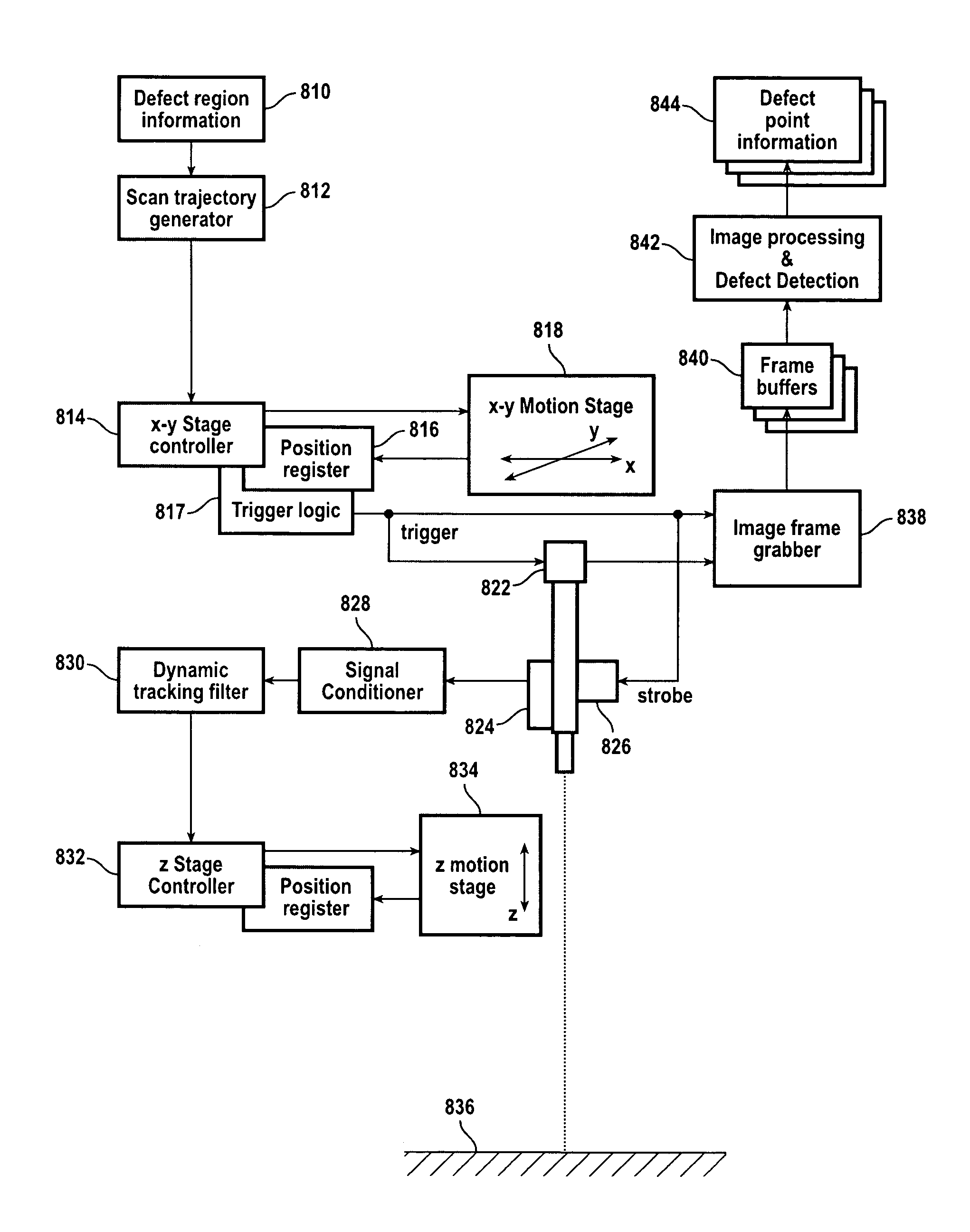

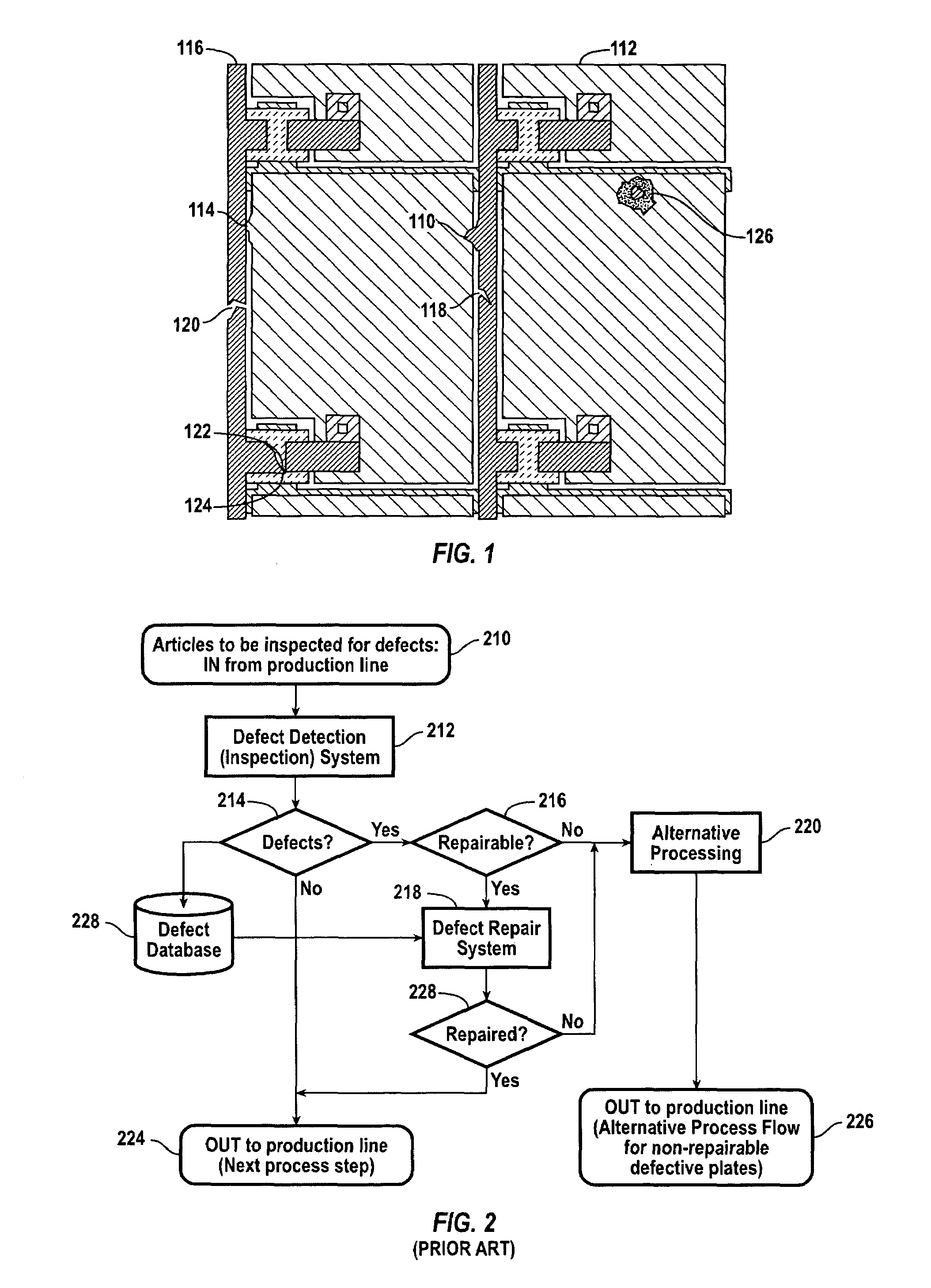

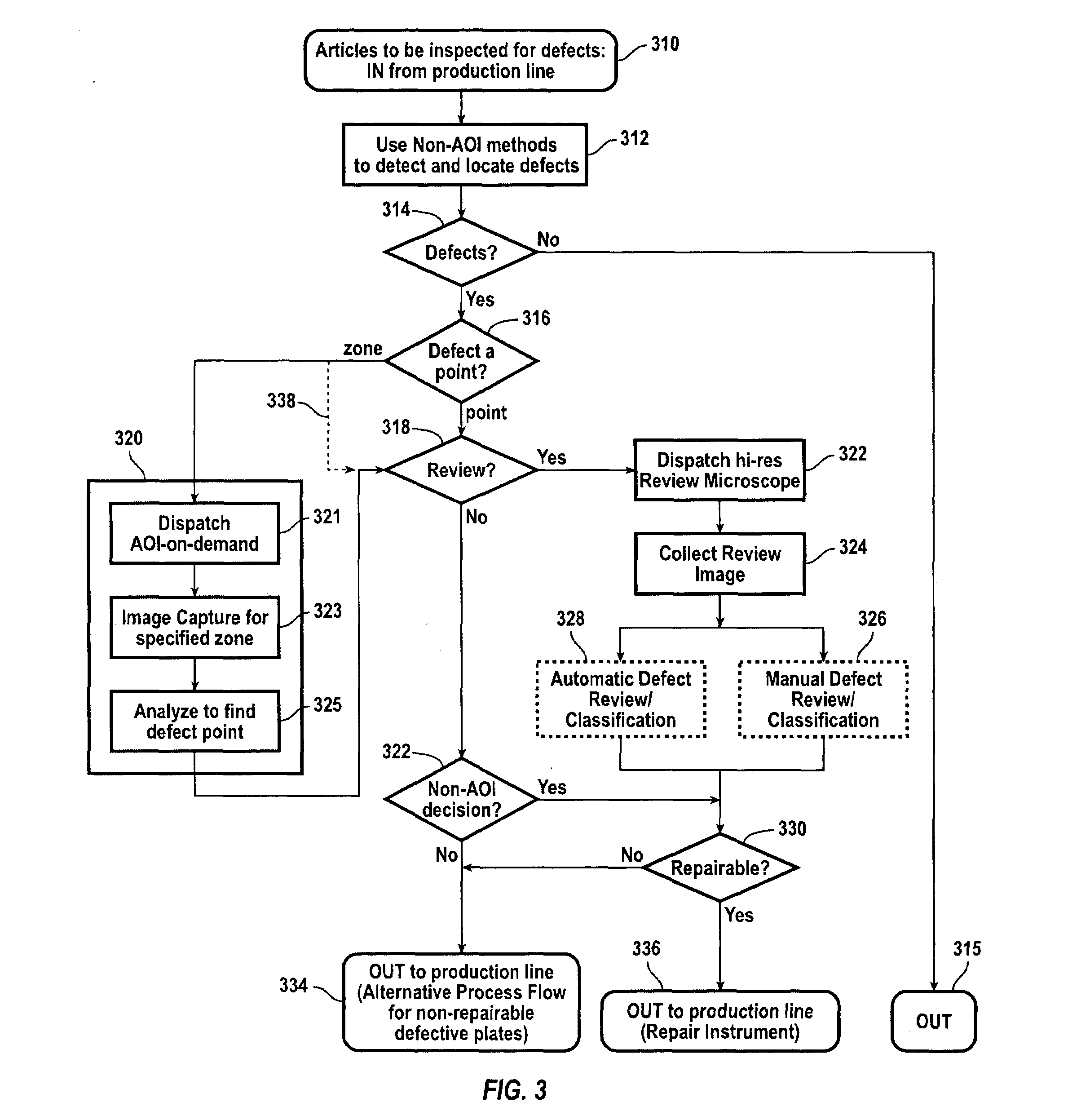

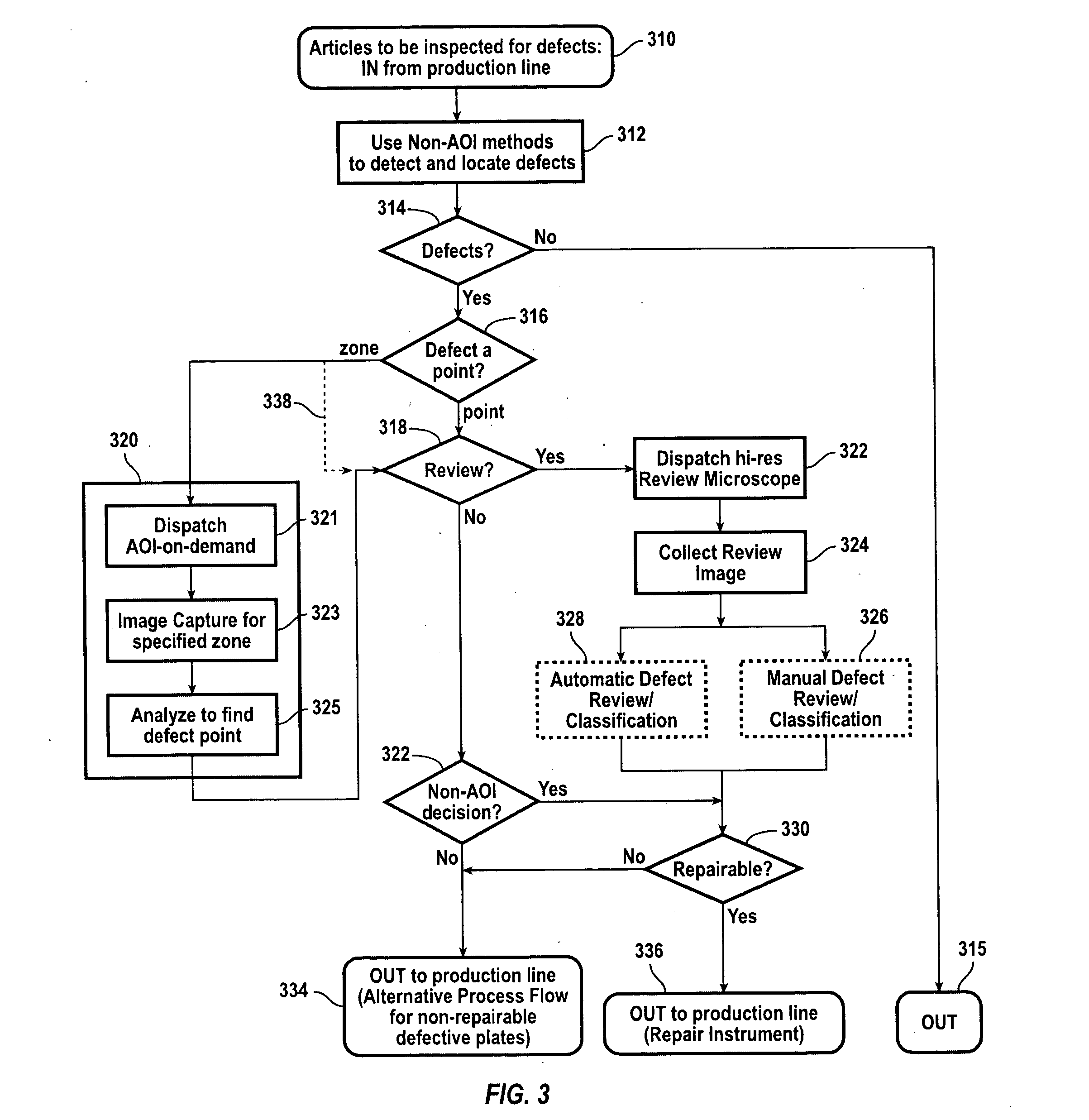

Inspection of TFT LCD panels using on-demand automated optical inspection sub-system

ActiveUS7084970B2Accurate locationEasy to checkOptically investigating flaws/contaminationNon-linear opticsContinuous scanningEngineering

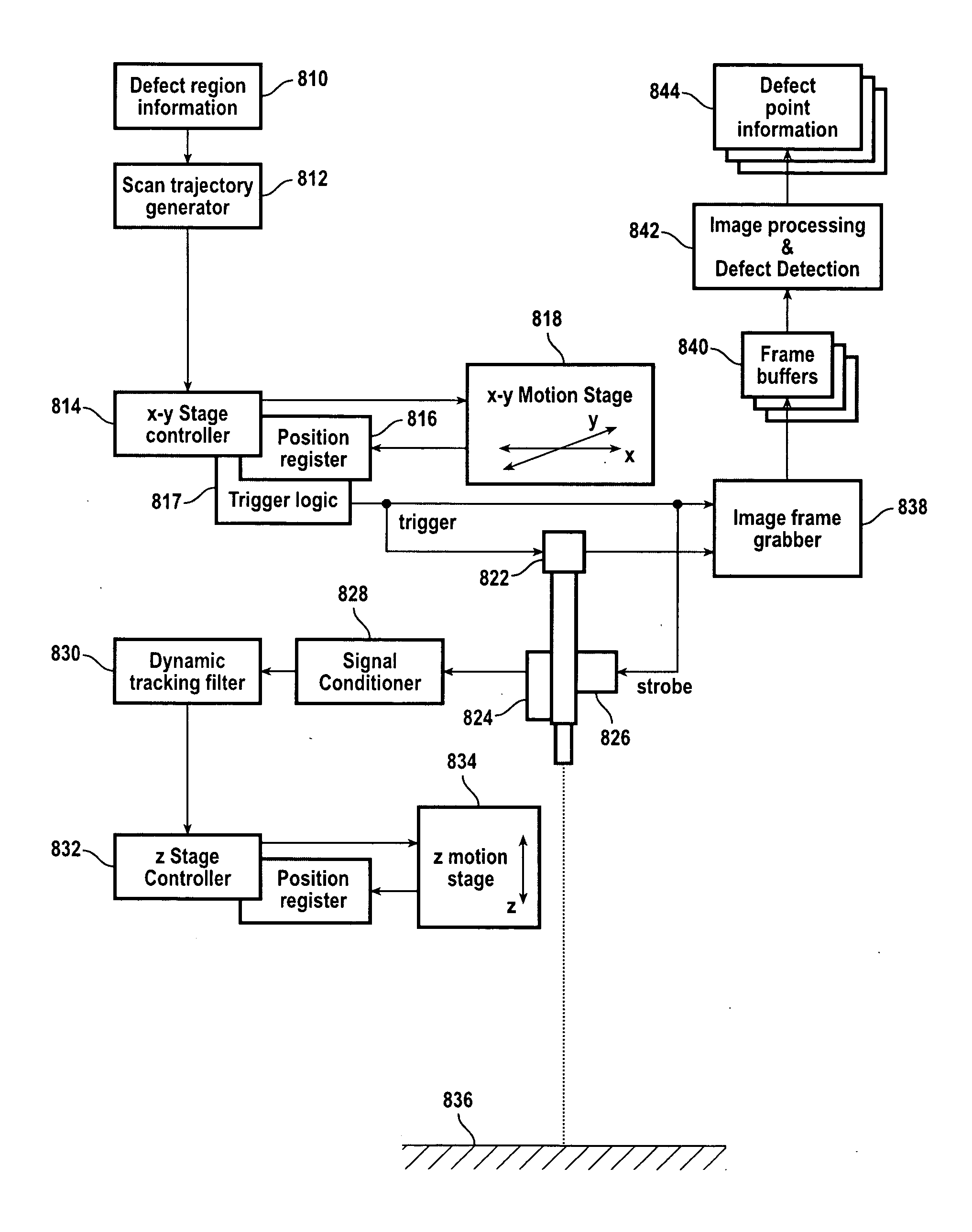

In an inspection system for electrical and electro-optical inspection of TFT-LCD panels, a fine resolution area imaging camera with a pulse illumination source disposed to scan the region and operative capture images of the region illuminated with pulses of short illumination and automatically maintained in focus while continuously scanning in order to resolve points of defects.

Owner:ORBOTECH LTD

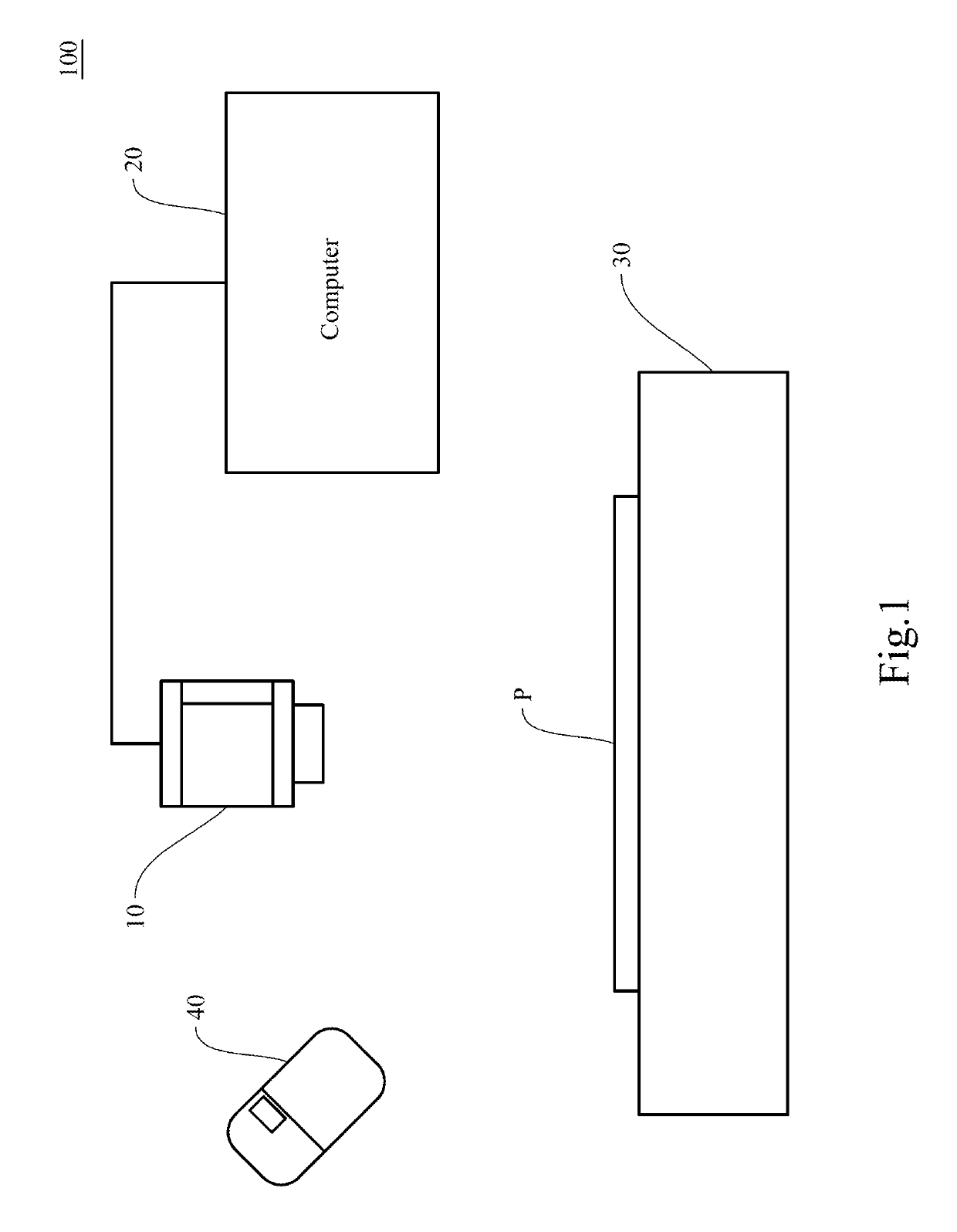

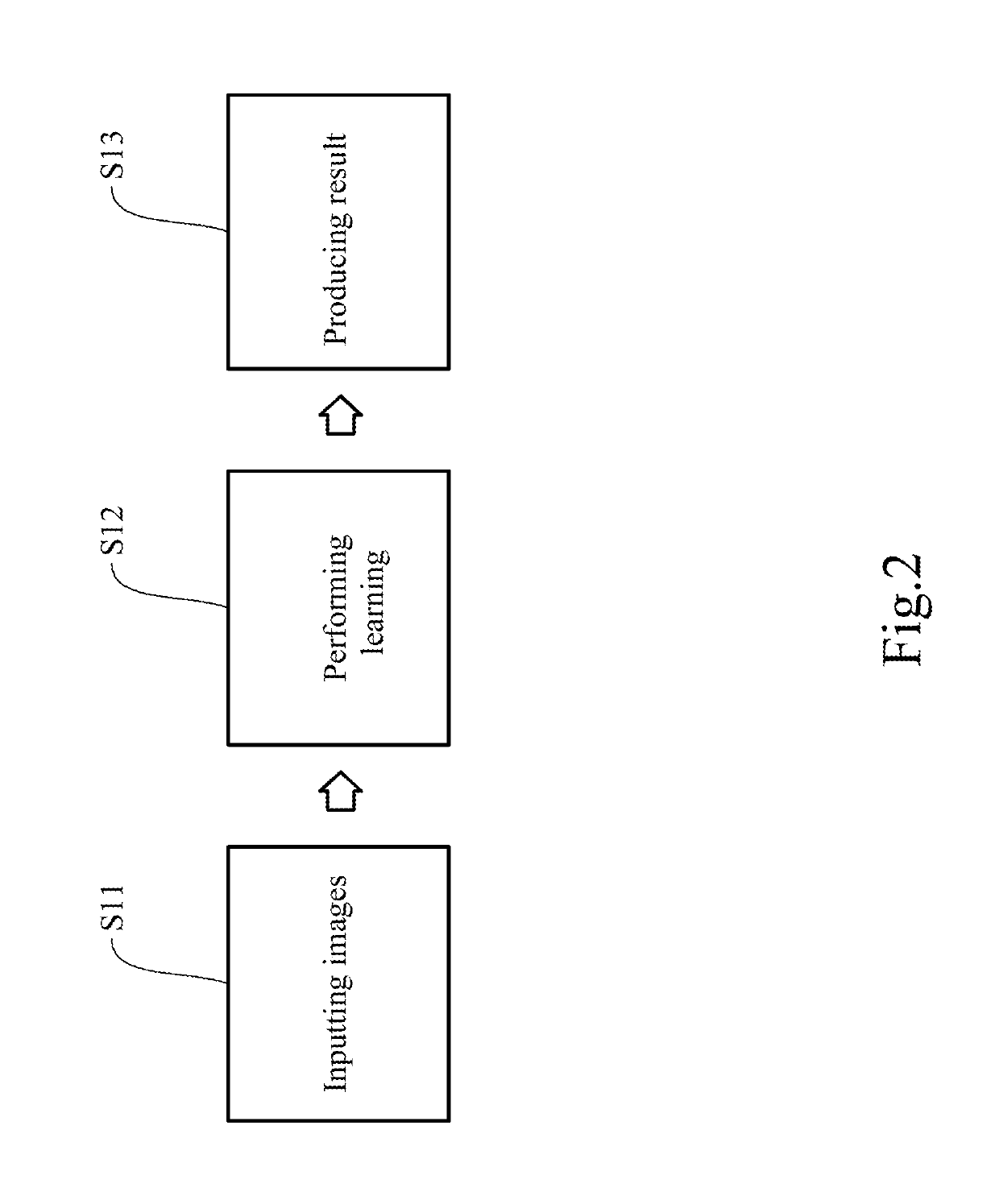

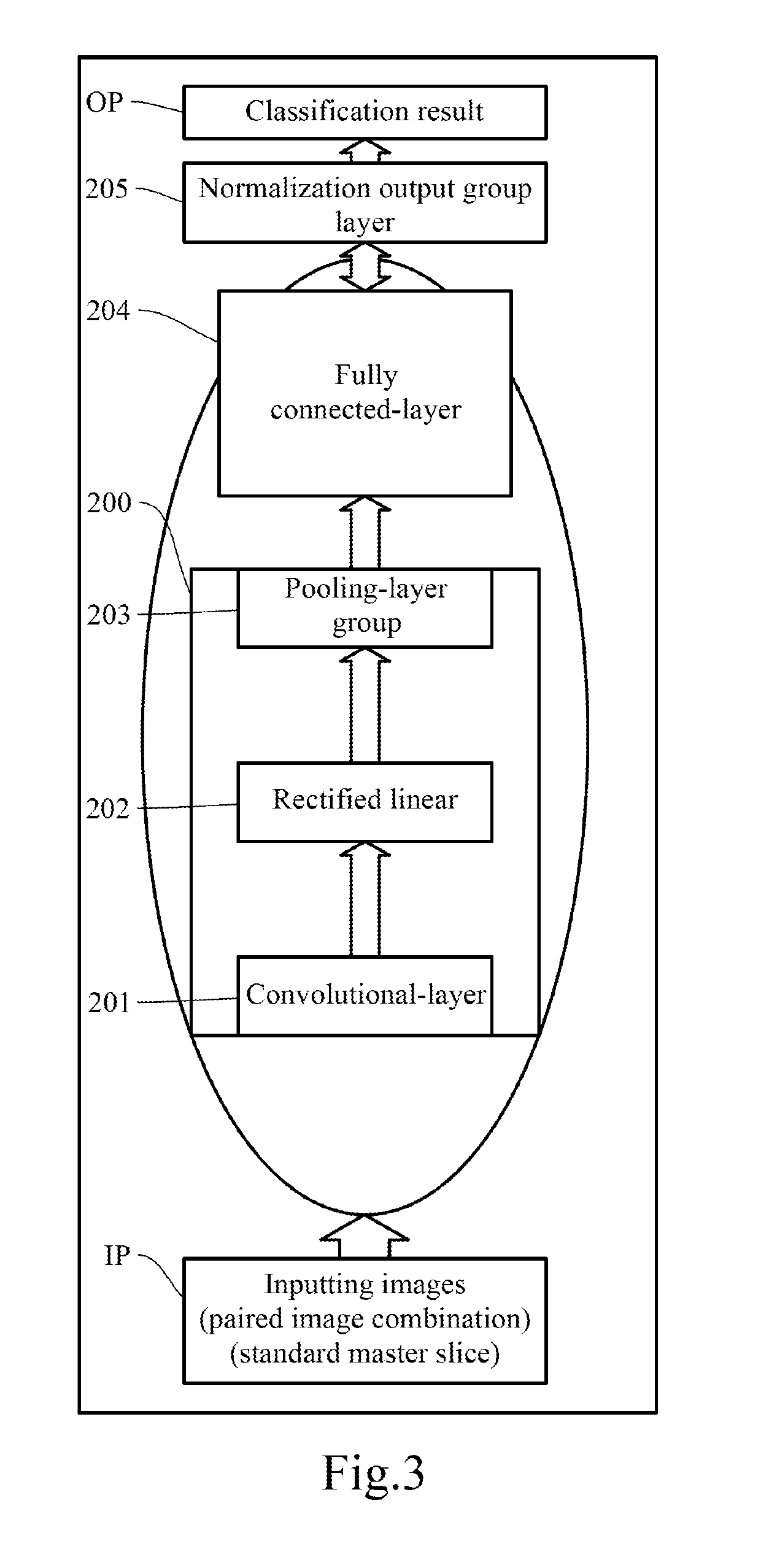

Automated optical inspection method using deep learning and apparatus, computer program for performing the method, computer-readable storage medium storing the computer program,and deep learning system thereof

ActiveUS20190197679A1Improve filtration rateReduce the number of samplesImage enhancementImage analysisAutomated optical inspectionBackpropagation

The present invention is an automated optical inspection method using deep learning, comprising the steps of: providing a plurality of paired image combinations, wherein each said paired image combination includes at least one defect-free image and at least one defect-containing image corresponding to the defect-free image; providing a convolutional neural network to start a training mode of the convolutional neural network; inputting the plurality of paired image combinations into the convolutional neural network, and adjusting a weight of at least one fully connected layer of the convolutional neural network through backpropagation to complete the training mode of the convolutional neural network; and performing an optical inspection process using the trained convolutional neural network.

Owner:UTECHZONE CO LTD

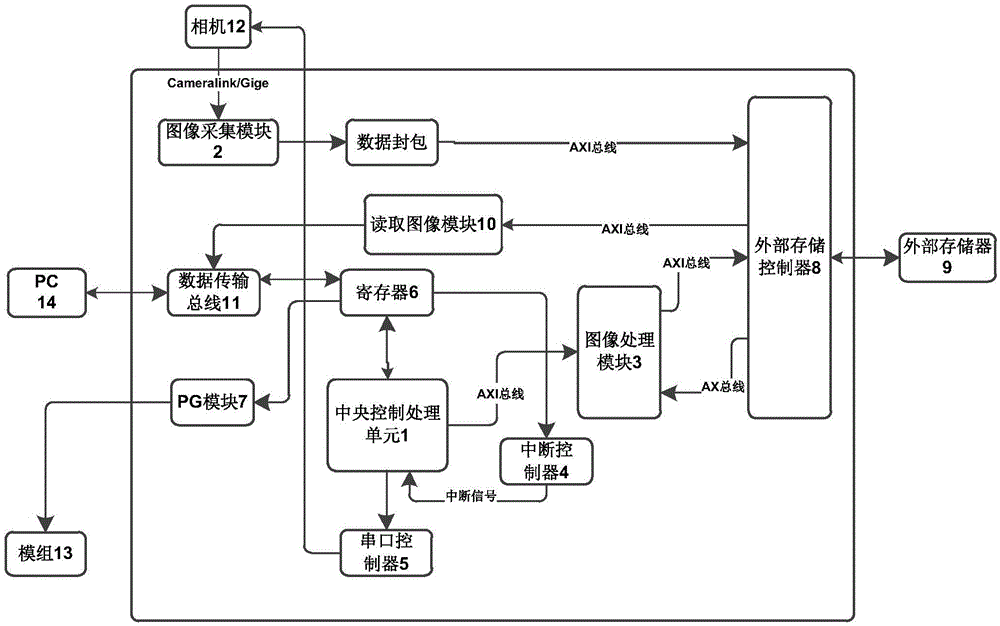

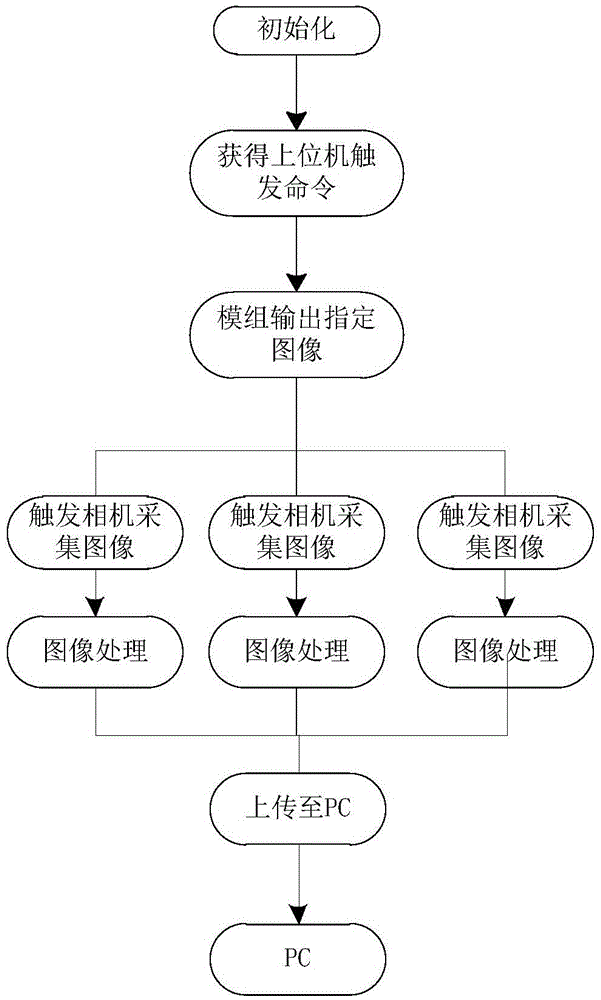

Automated optical inspection device and method for defect inspection of LCD (liquid crystal display) module

InactiveCN105607312ARealize automatic switchingEasy to detectStatic indicating devicesNon-linear opticsField-programmable gate arrayImaging data

The invention relates to the technical field of automated optical inspection of LCD (liquid crystal display) modules, in particular to an automated optical inspection device for defect inspection of an LCD module and an automated optical inspection method for the defect inspection of the LCD module. The device comprises a central control processing unit, an image acquisition module, an image processing module and a PG (Pattern Generate) module. The method comprises the following steps of receiving a PG configuration parameter and a camera configuration parameter, lighting up modules according to the PG configuration parameter, configuring a camera according to the camera configuration parameter, controlling the camera to shoot an module image and collect the shot image, performing image processing and defect inspection on the collected original image, and outputting a defect inspection result and processed image data. The device and the method provided by the invention have the advantages that the image acquisition module, the PG module and the image processing module are integrated on an FPGA (Field Programmable Gate Array), and the whole testing process is performed based on the FPGA, so that the system integration degree is improved, the interaction complexity is lowered, the real-time processing performance is improved, the defect inspection time is shortened, the system stability is greatly improved, the inspection time is shortened, and the factory production efficiency is improved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

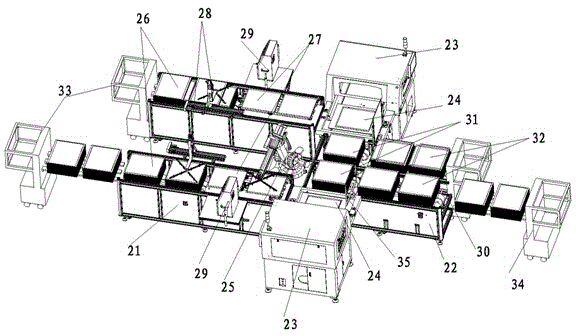

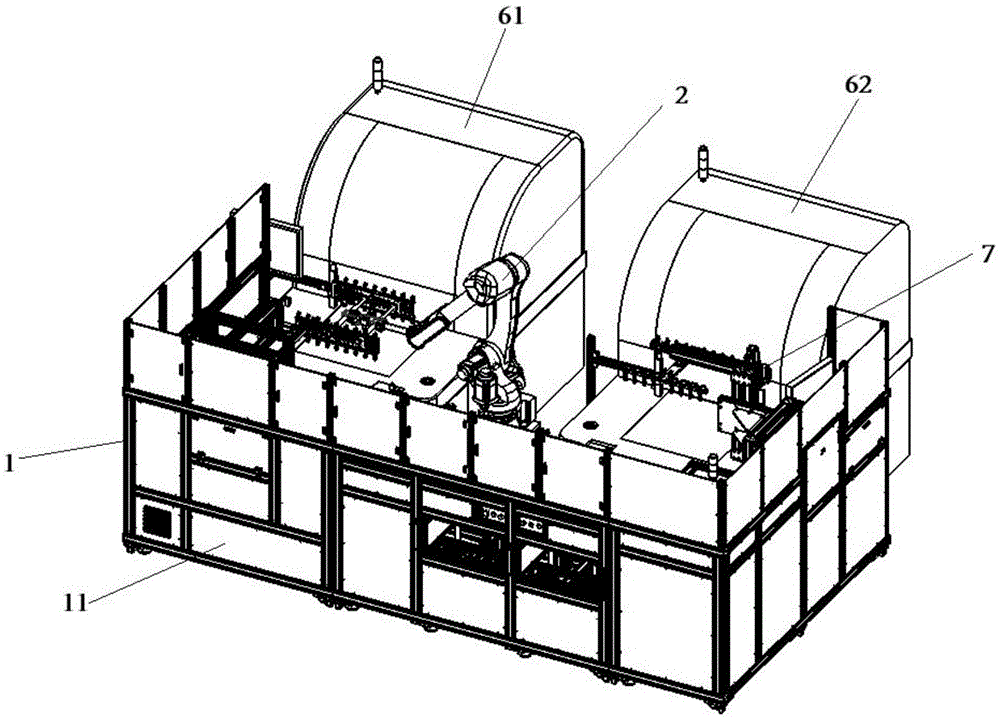

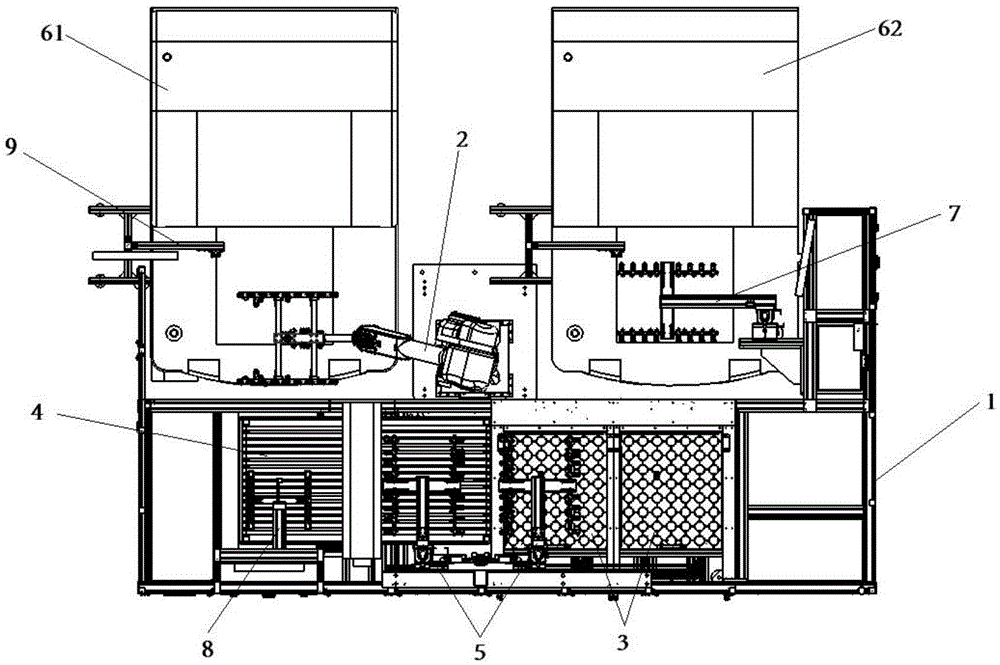

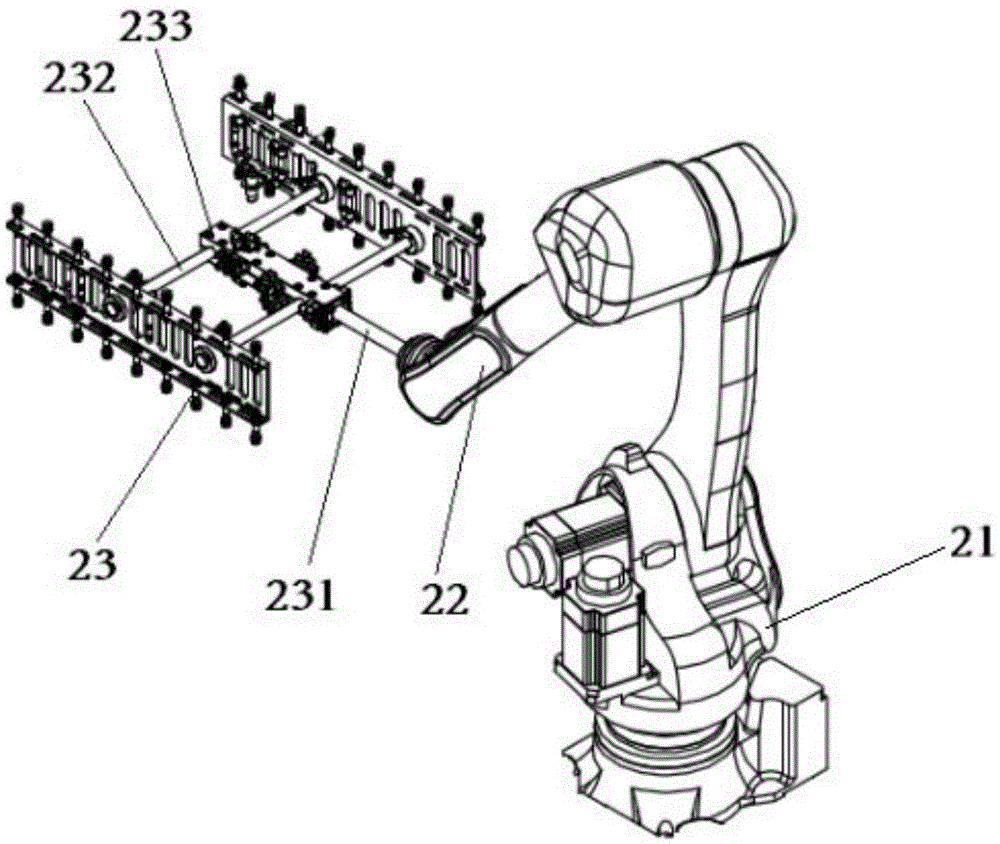

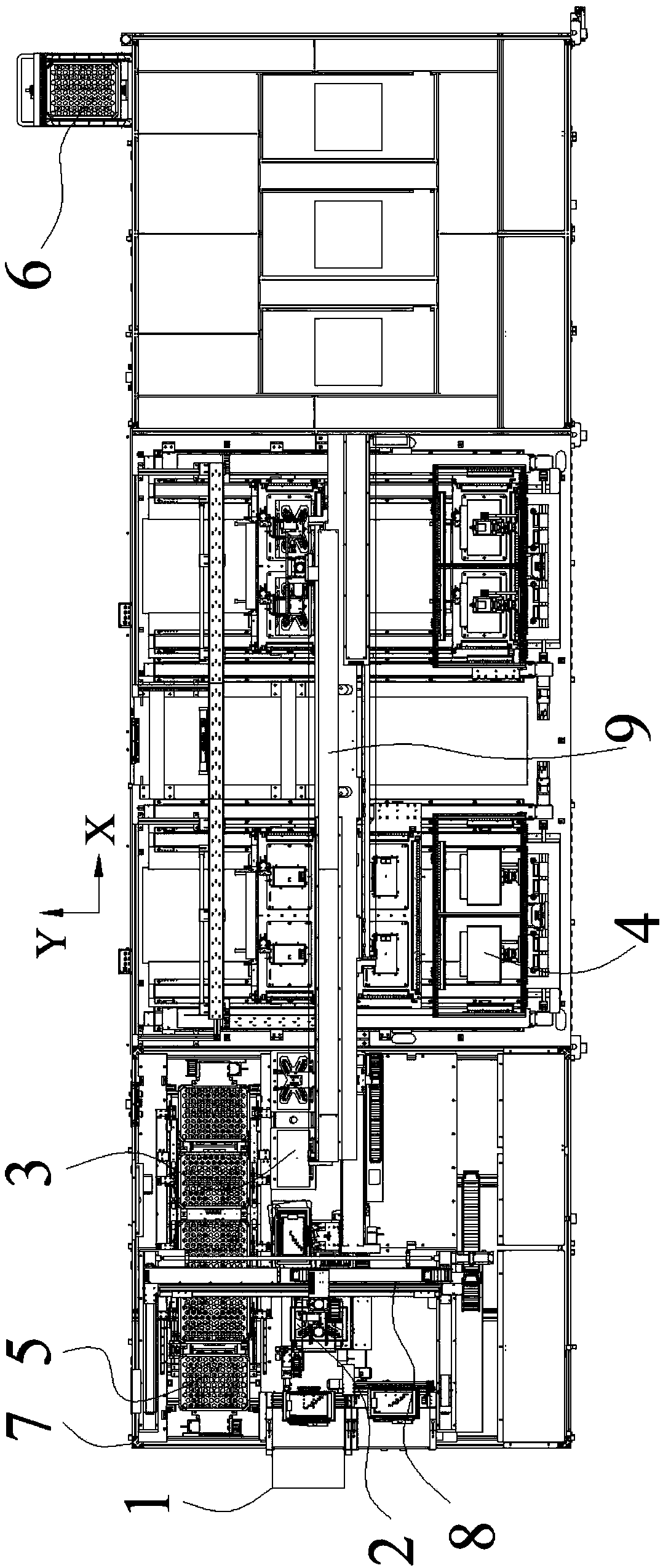

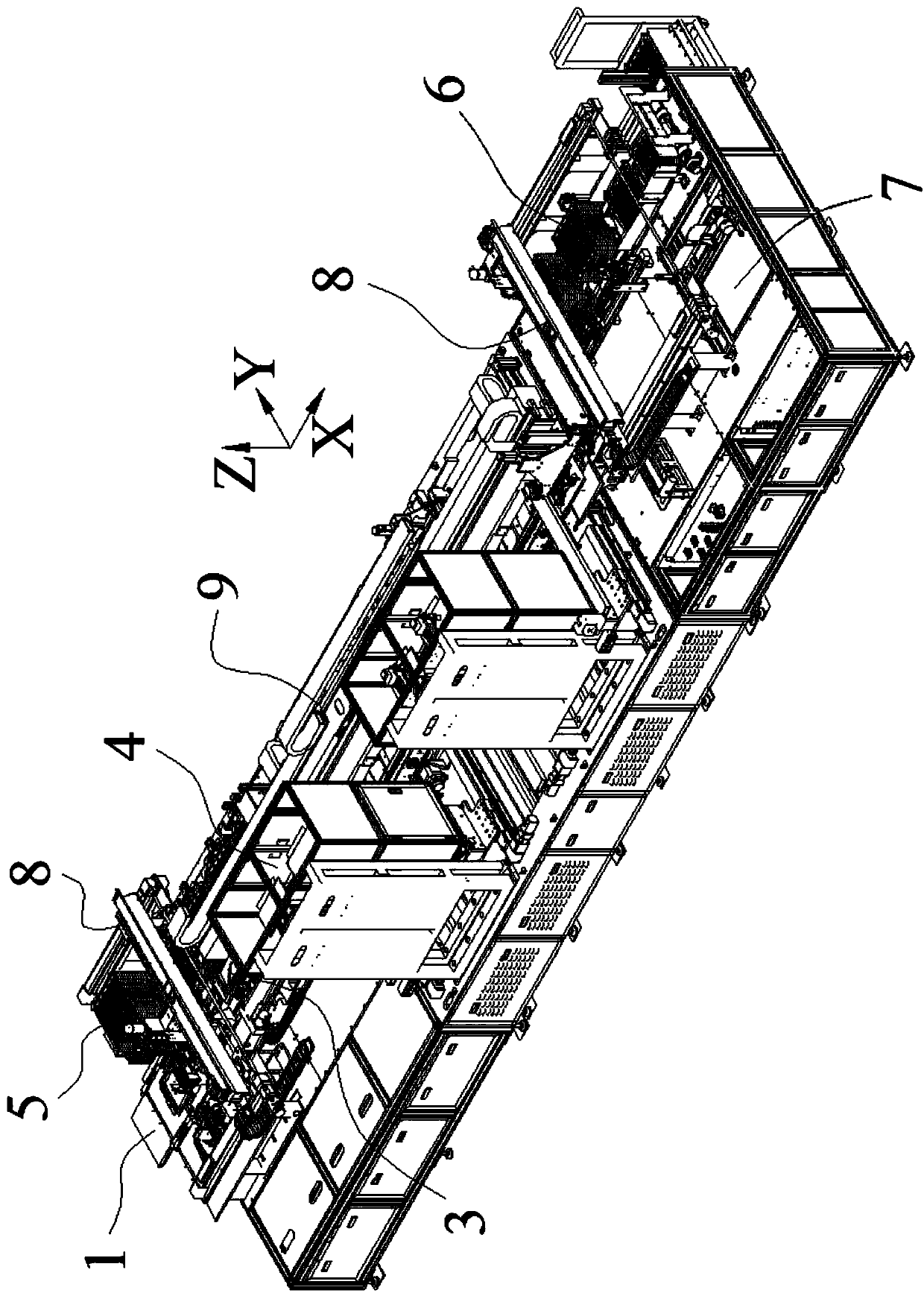

AOI (Automated Optical Inspection) station capable of conveying and automatically loading and unloading PCBs (Printed Circuit Board) in parallel by two lines

The invention discloses an AOI (Automated Optical Inspection) station capable of conveying and automatically loading and unloading PCBs (Printed Circuit Board) in parallel by two lines. The AOI station comprises two parallel PCB feeding conveyor line and a discharging conveyor line group, wherein an automated optical inspector is arranged on each of the two sides of the discharging conveyor line group; a horizontal table is arranged at a feed opening of each automated optical inspector; a discharge opening of one PCB feeding conveyor line is jointed to one horizontal table, and a discharge opening of the other PCB feeding conveyor line is jointed to the other horizontal table; a multi-joint carrying mechanical hand is arranged between the two PCB feeding conveyor lines. The AOI station is simple in structure, the PCBs are easily taken and placed, labor is reduced, and the machining efficiency of the PCBs is improved.

Owner:广东金昇智能数控有限公司

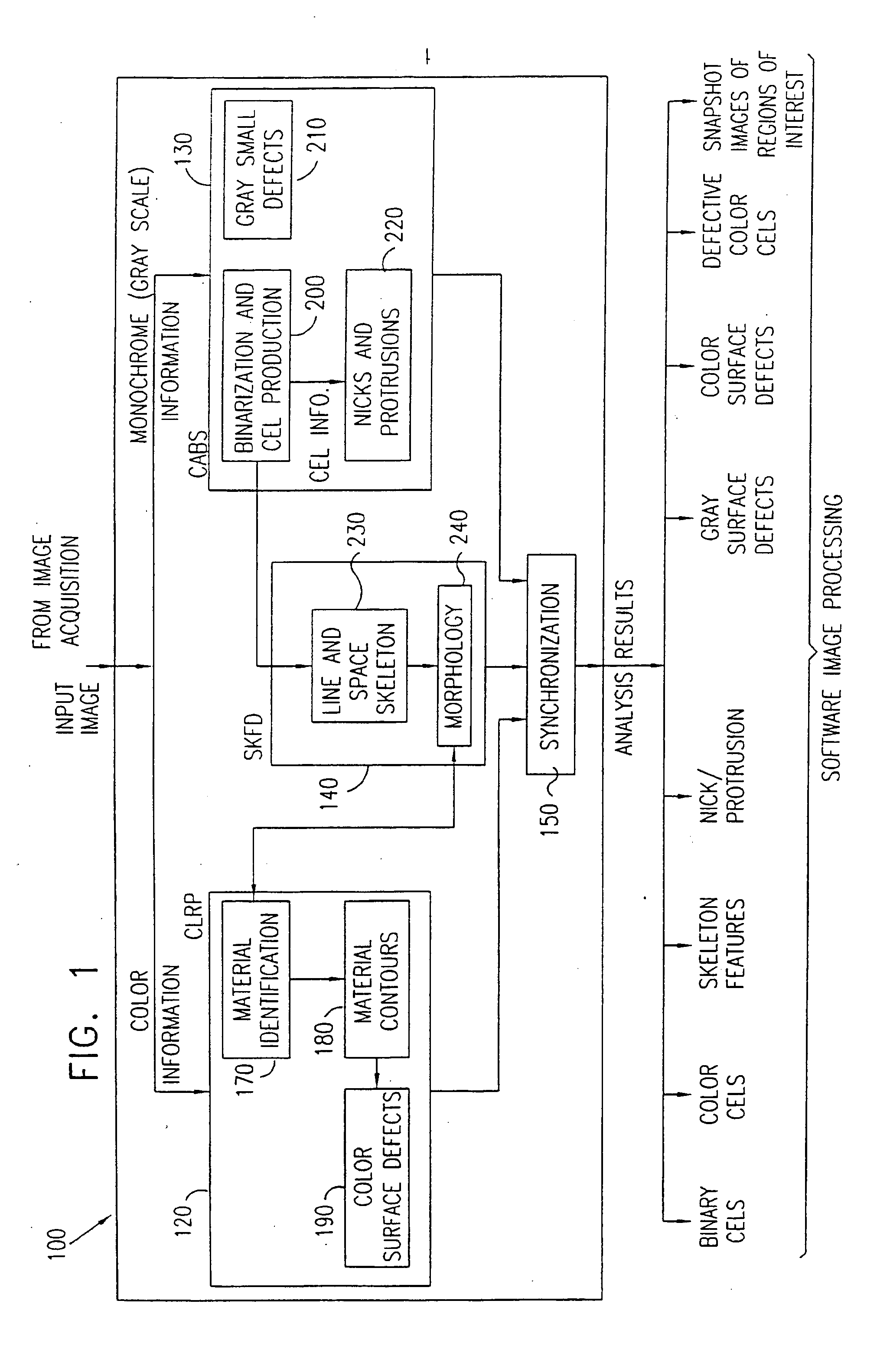

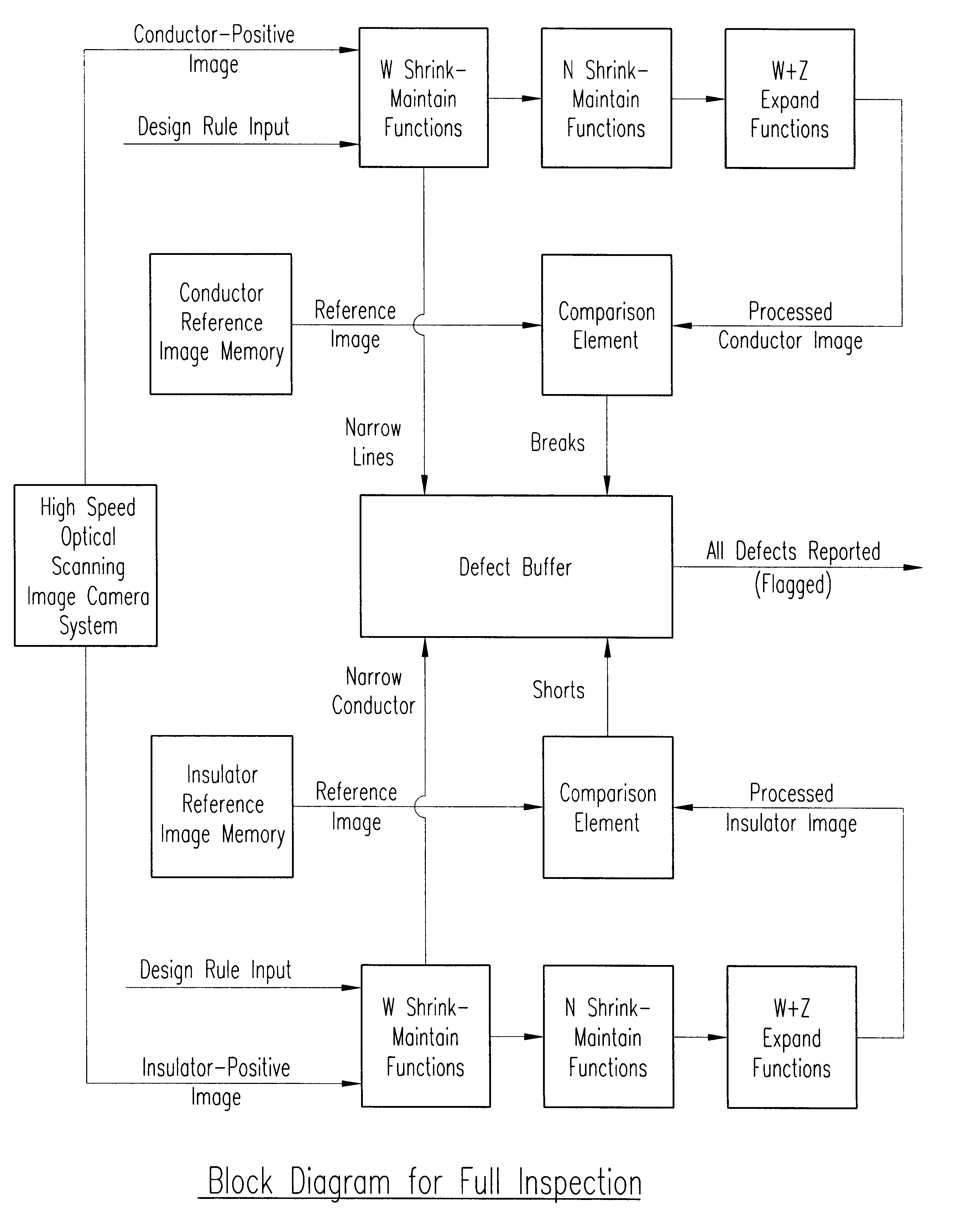

Apparatus for and method of automatic optical inspection of electronic circuit boards, wafers and the like for defects, using skeletal reference inspection and separately programmable alignment tolerance and detection parameters

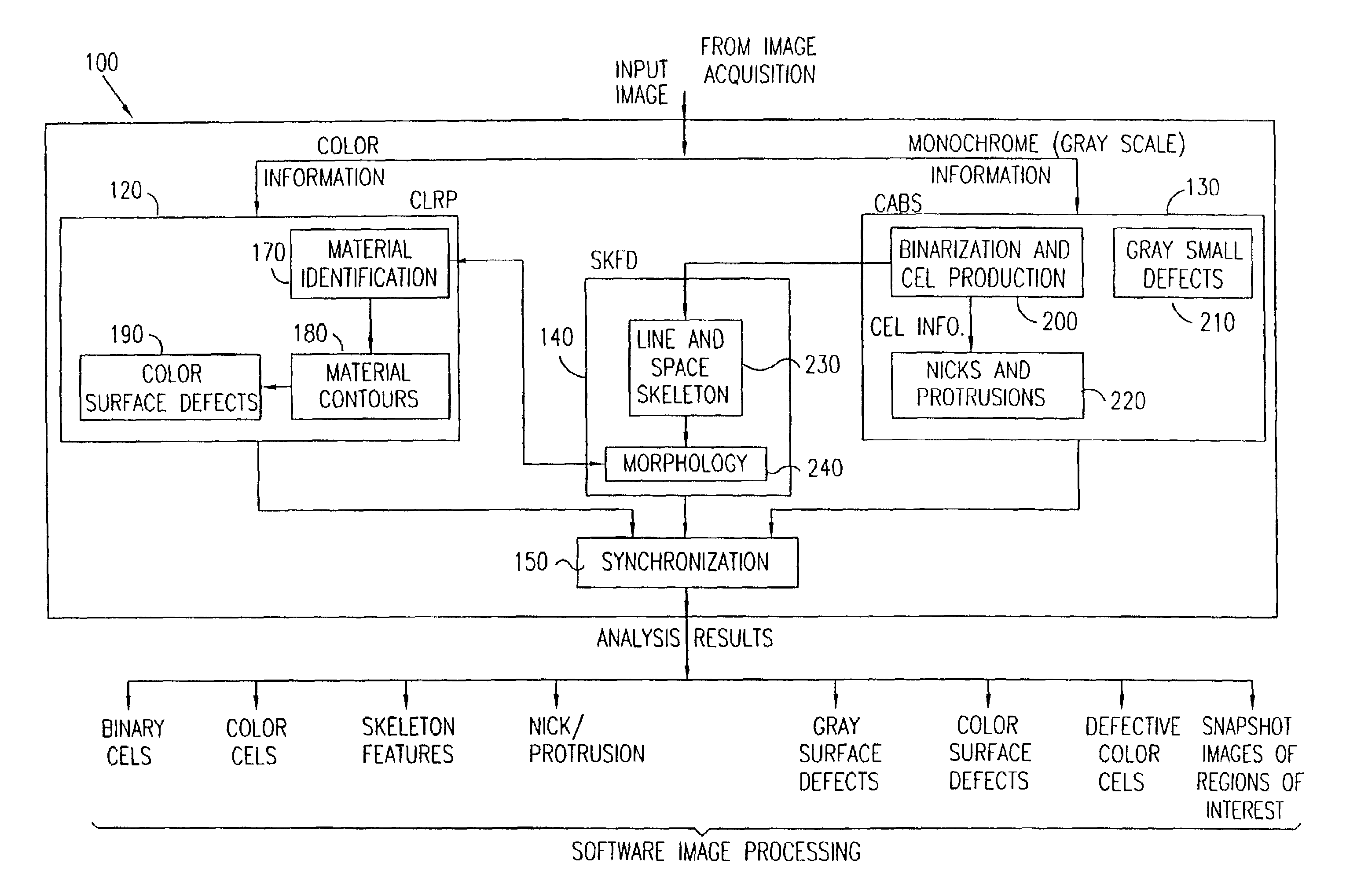

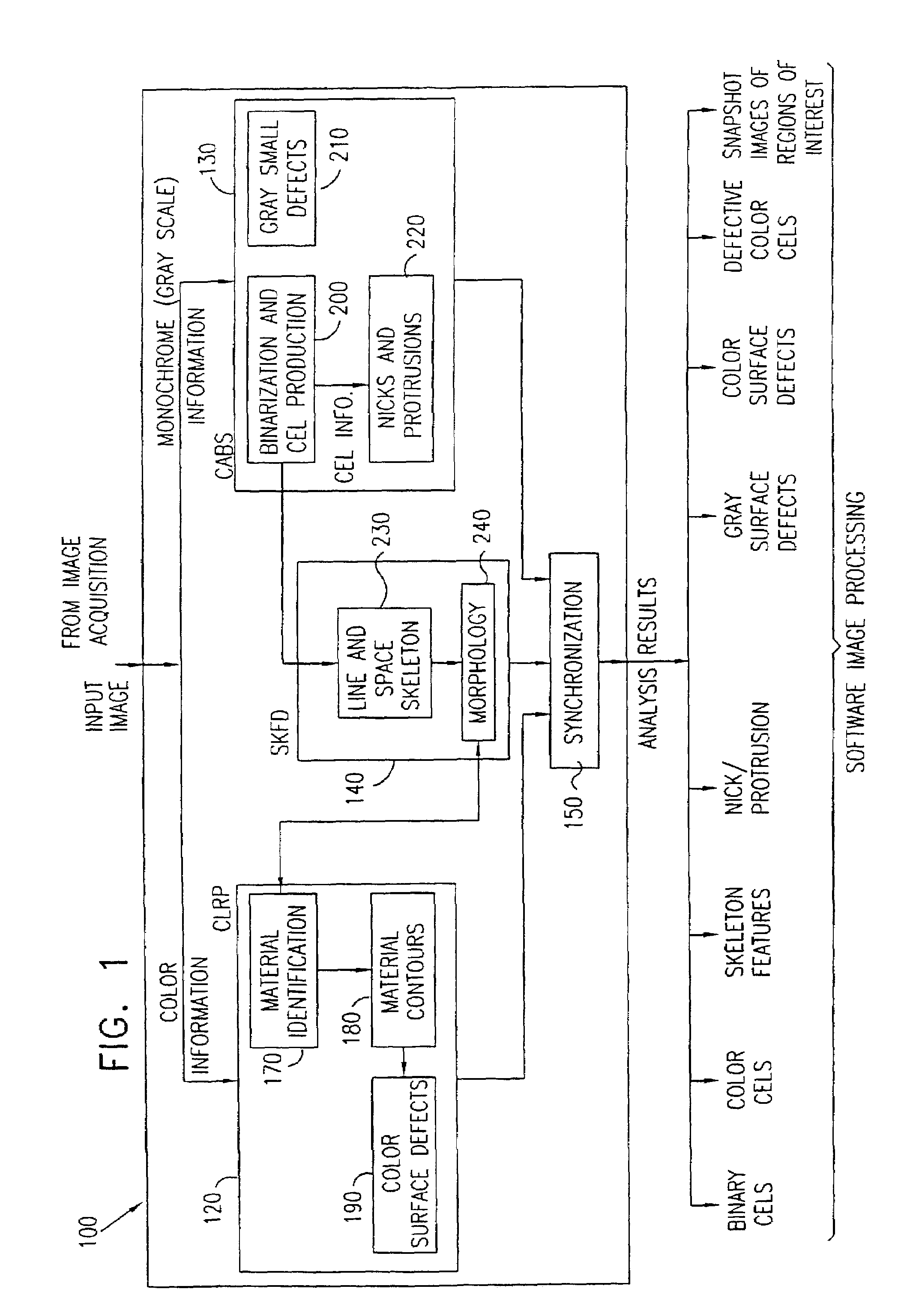

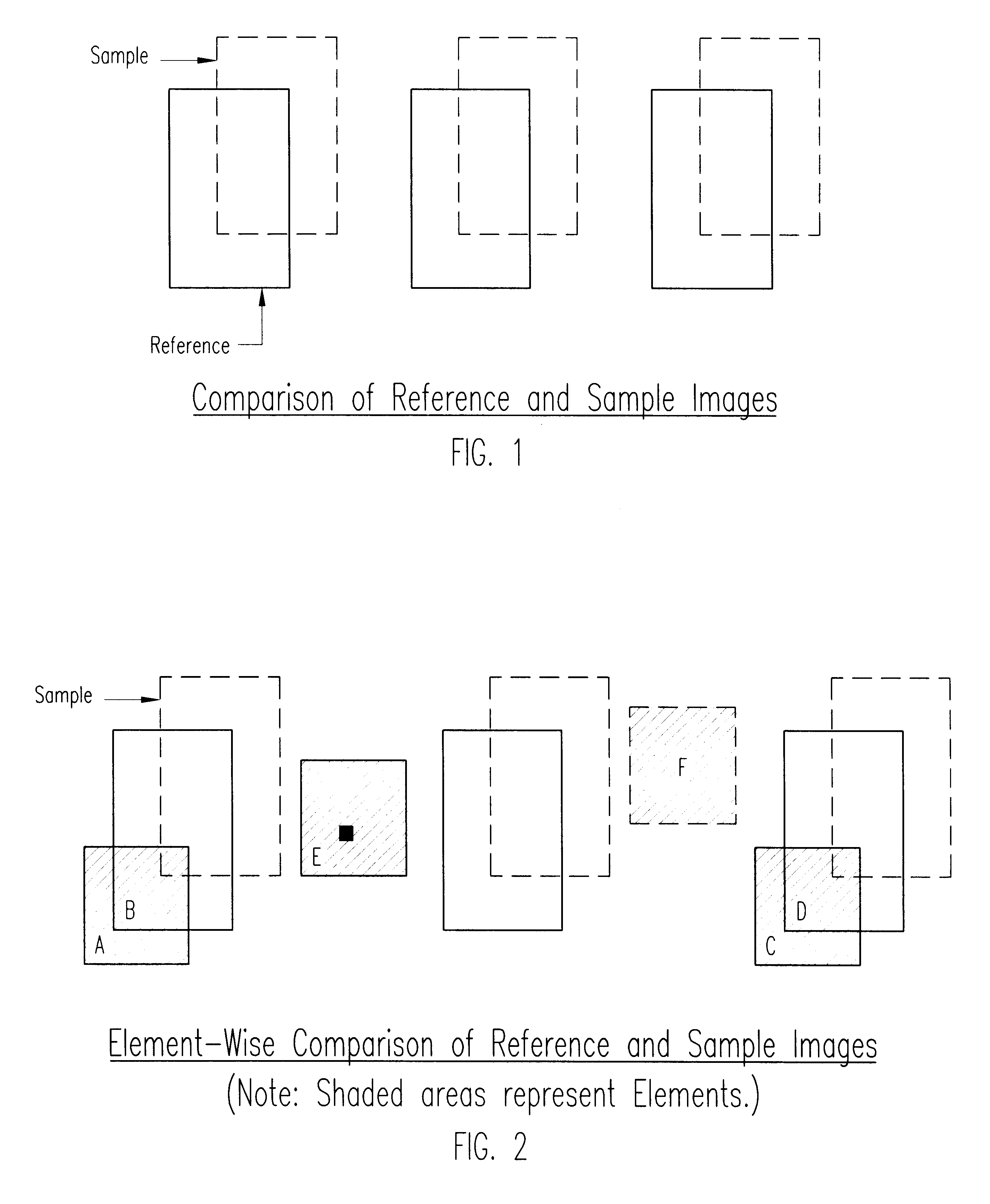

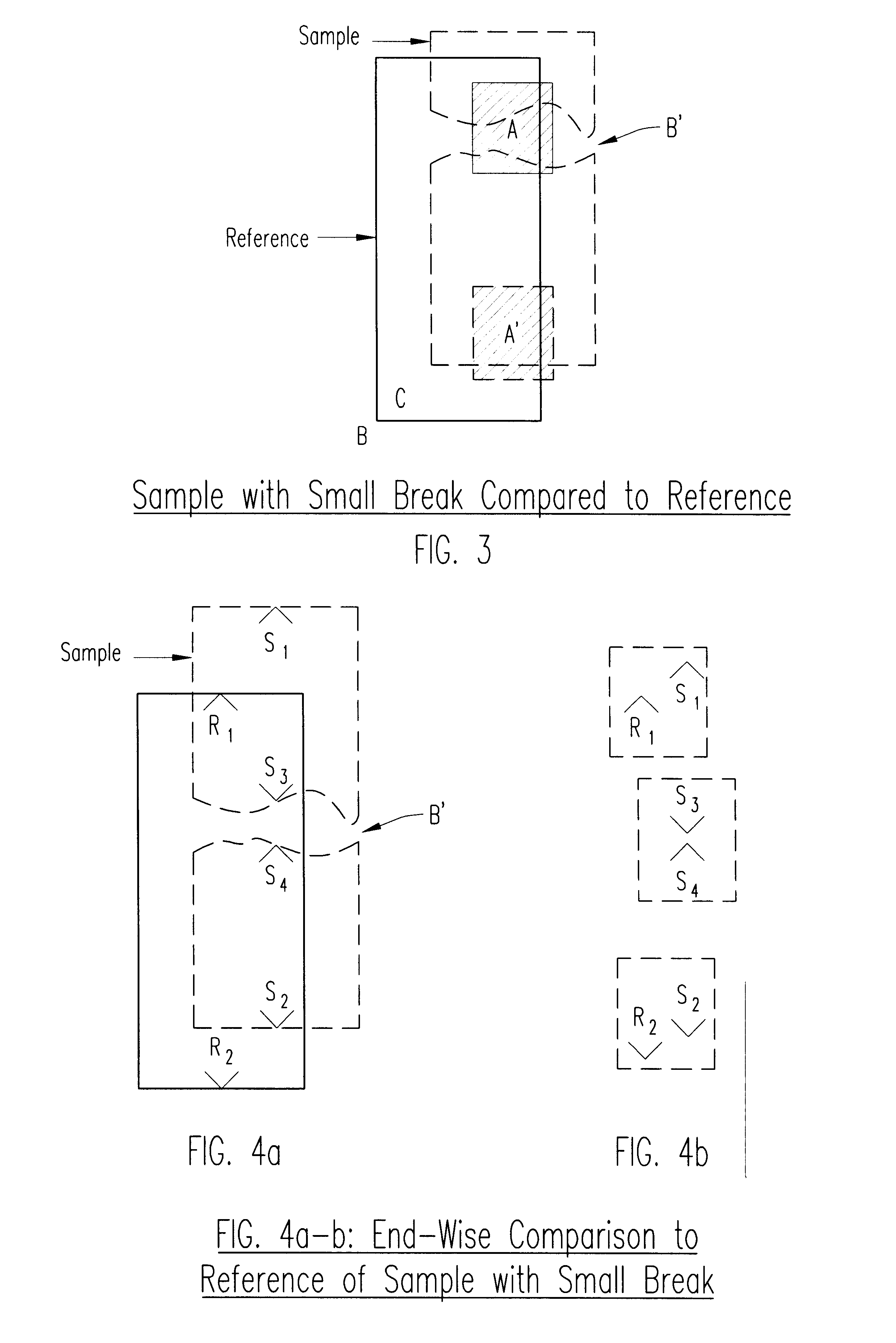

A novel wafer or circuit board automatic scanning optical inspection system and technique using the reference comparison principle for finding defects in scanned sample images, that enables a new degree of universality in finding all defects including very small single pixel conductor breaks and shorts and defects of irregular shapes, and together with simultaneous design rule processing, through the use of processed skeletal reference images and with separately programmable alignment tolerance and detection parameters.

Owner:BELTRONICS

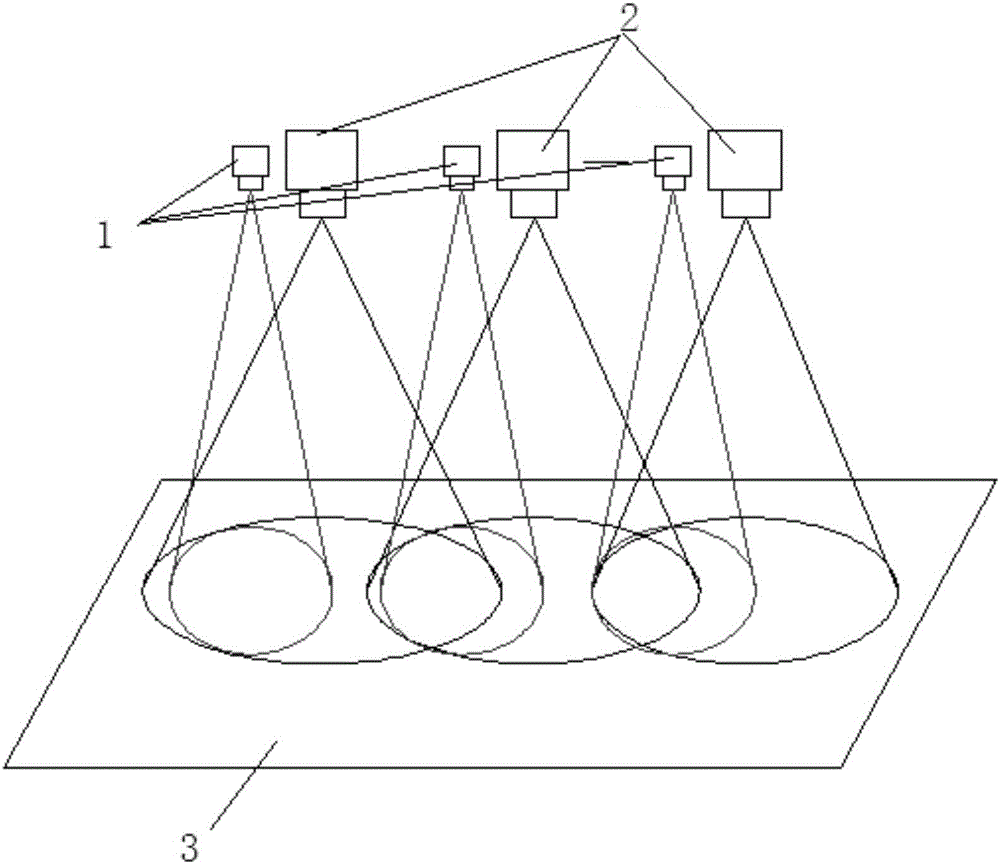

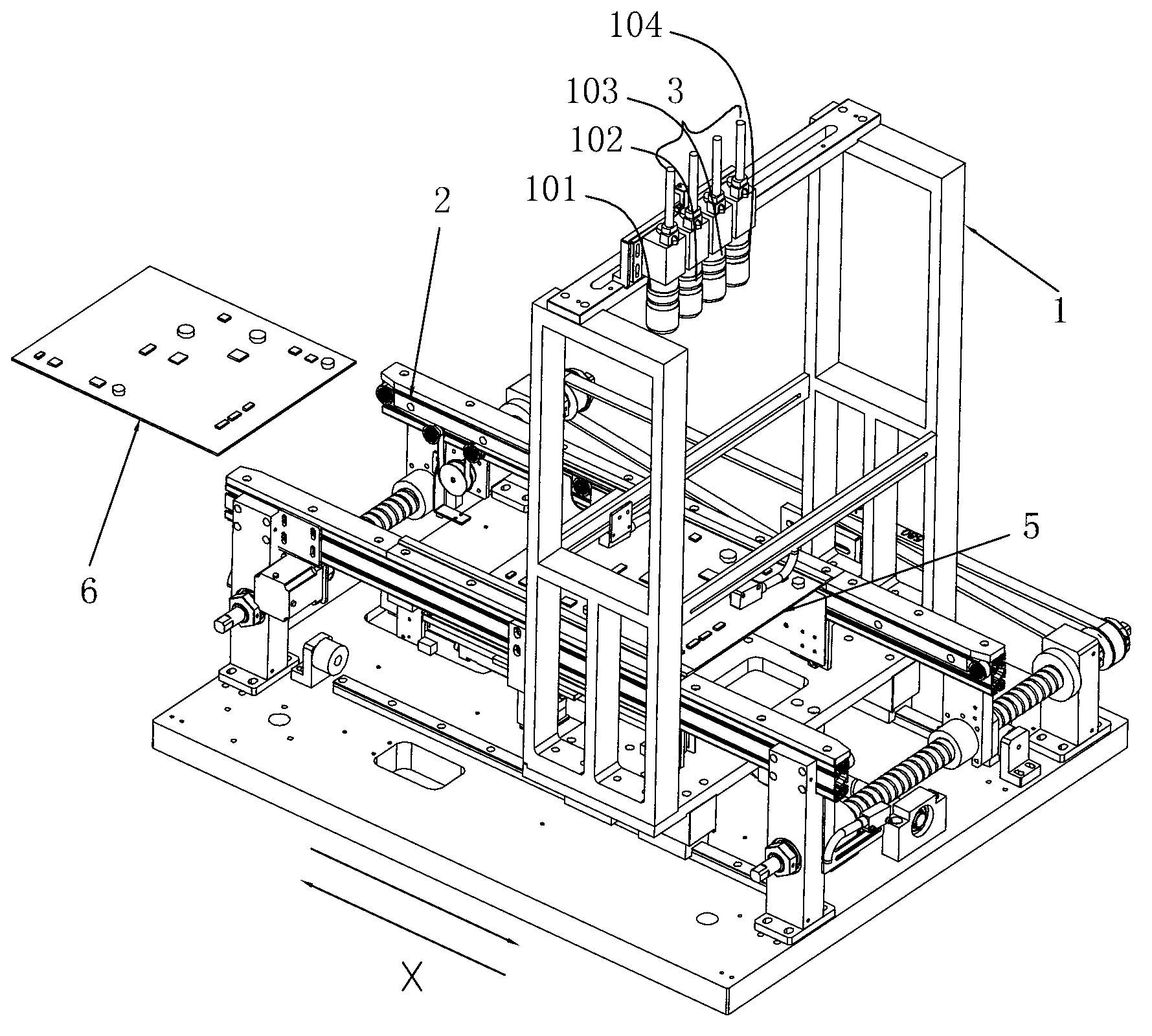

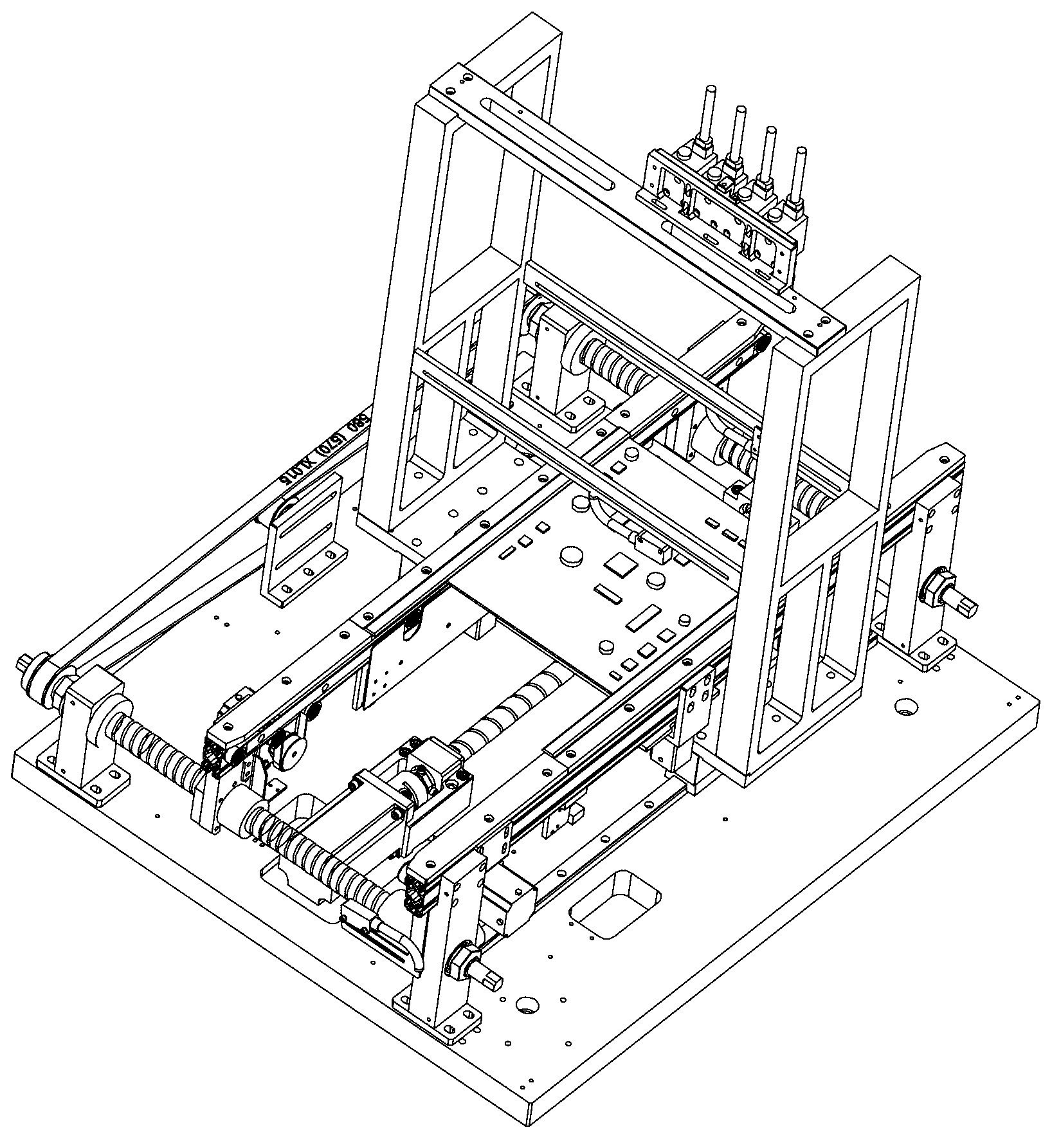

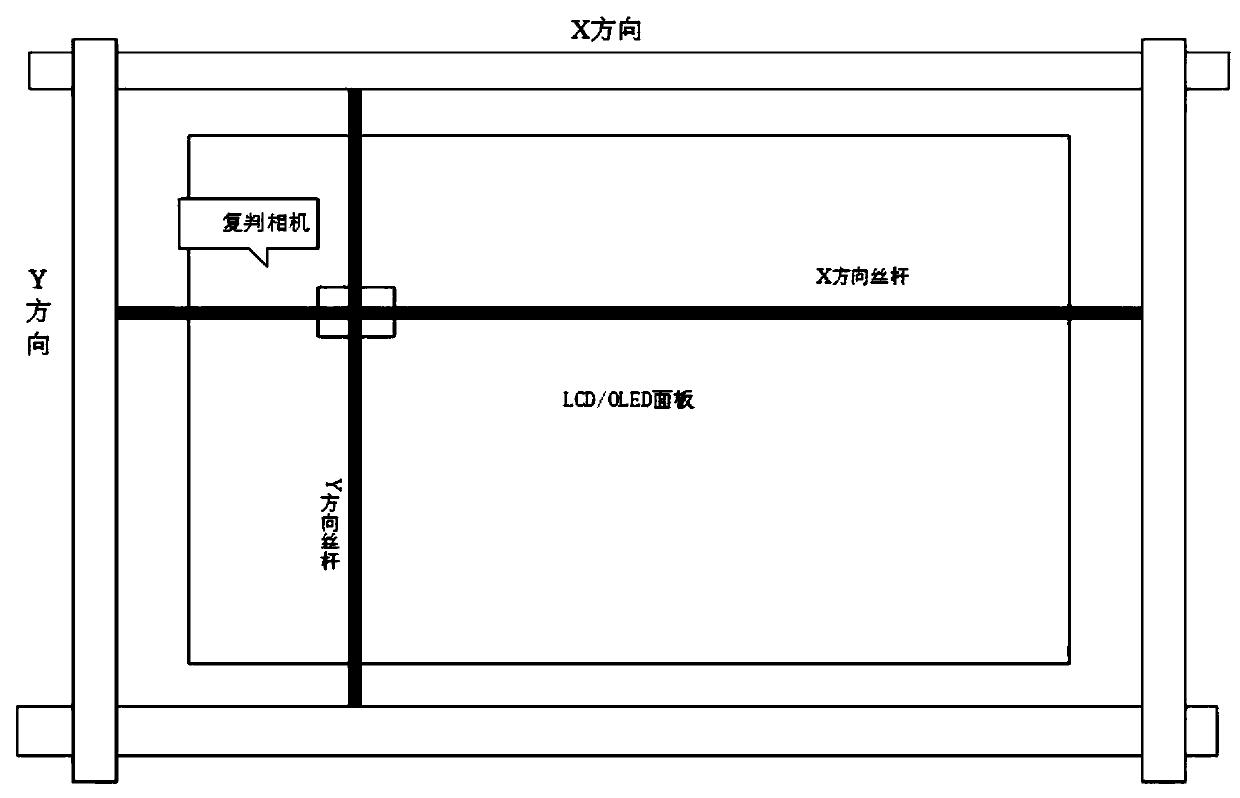

AOI (automated optical inspection) device with multiple area-array cameras and image shooting method thereof

InactiveCN103076330AImprove efficiencyShorten the timeMaterial analysis by optical meansUsing optical meansVisual inspectionShooting method

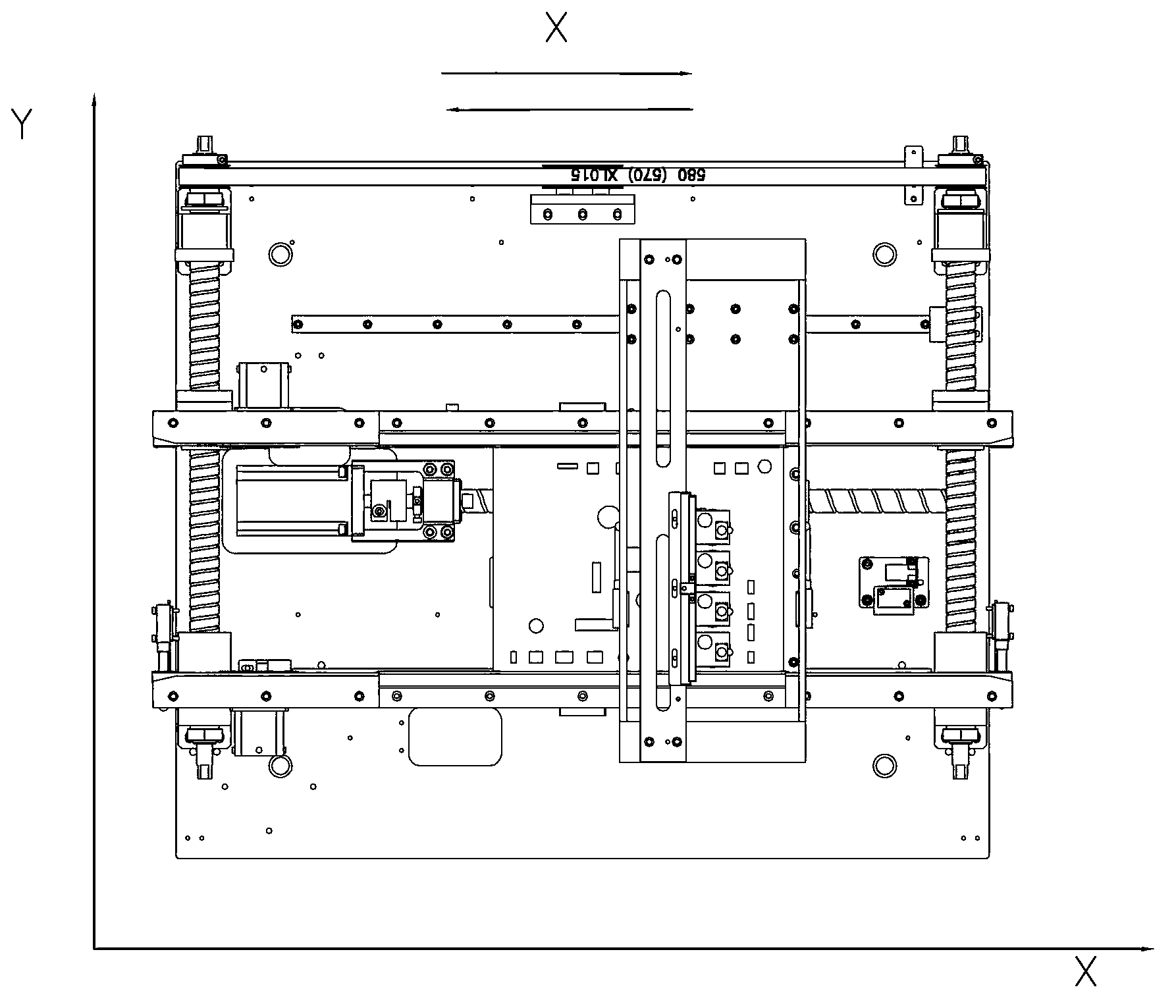

The invention discloses an AOI device with multiple area-array cameras. The AOI device comprises a camera frame capable of moving in the X axis of the device, and a conveying mechanism for conveying PCBs (printed circuit boards) for a working stage, wherein the camera frame is provided with a camera array formed by at least two area-array cameras; the shooting directions of each area-array camera is the same; FOV (fields of view) of two adjacent area-array cameras are provided with overlapping regions; and the device further comprises a controller used for controlling each area-array camera to shoot images of a PCB simultaneously, and a processor used for splicing the images shot by each camera into one image. The AOI device enables the images shot by a plurality of cameras to be spliced into a complete image through arranging the plurality of area-array cameras side by side in the Y axis. The invention further discloses an image shooting method of the device. Compared with the prior art, motor moving time and camera moving time are reduced, and the scanning speed for shooting is high, so that the efficiency of the AOI device is improved remarkably, and time and cost are saved.

Owner:王锦峰

Inspection of TFT LCD panels using on-demand automated optical inspection sub-system

ActiveUS20050254045A1Accurate locationEasy to checkOptically investigating flaws/contaminationNon-linear opticsEngineeringAutomated optical inspection

In an inspection system for electrical and electro-optical inspection of TFT-LCD panels, a fine resolution area imaging camera with a pulse illumination source disposed to scan the region and operative capture images of the region illuminated with pulses of short illumination and automatically maintained in focus while continuously scanning in order to resolve points of defects.

Owner:ORBOTECH LTD

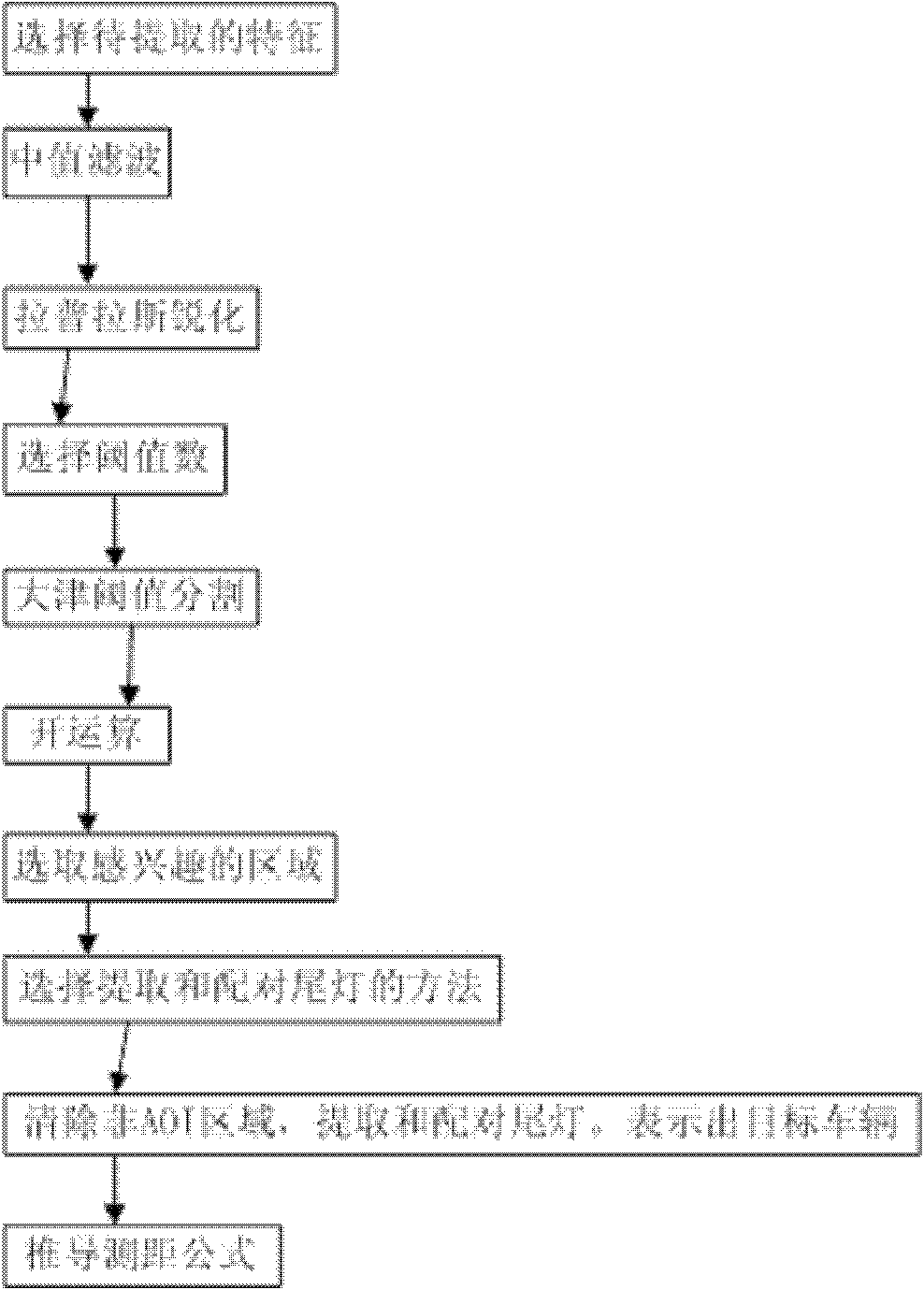

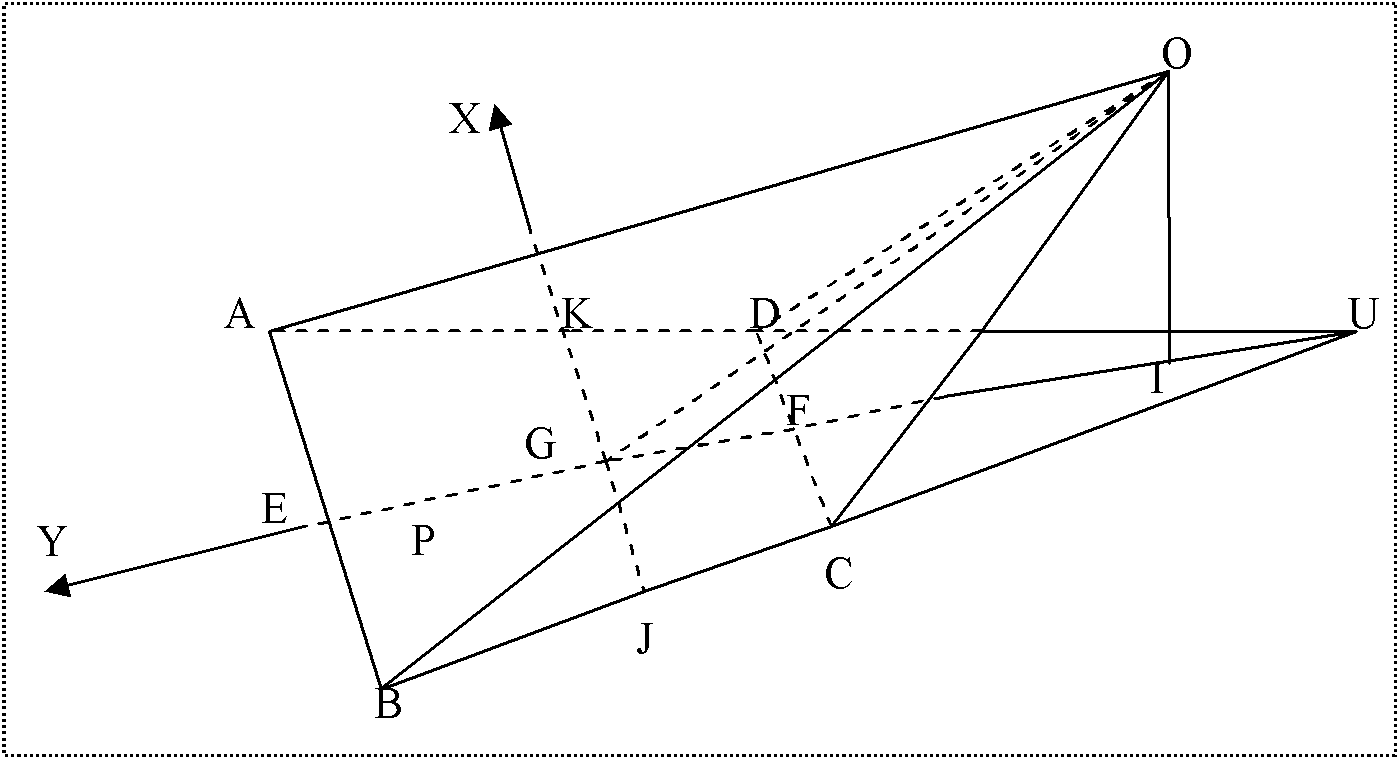

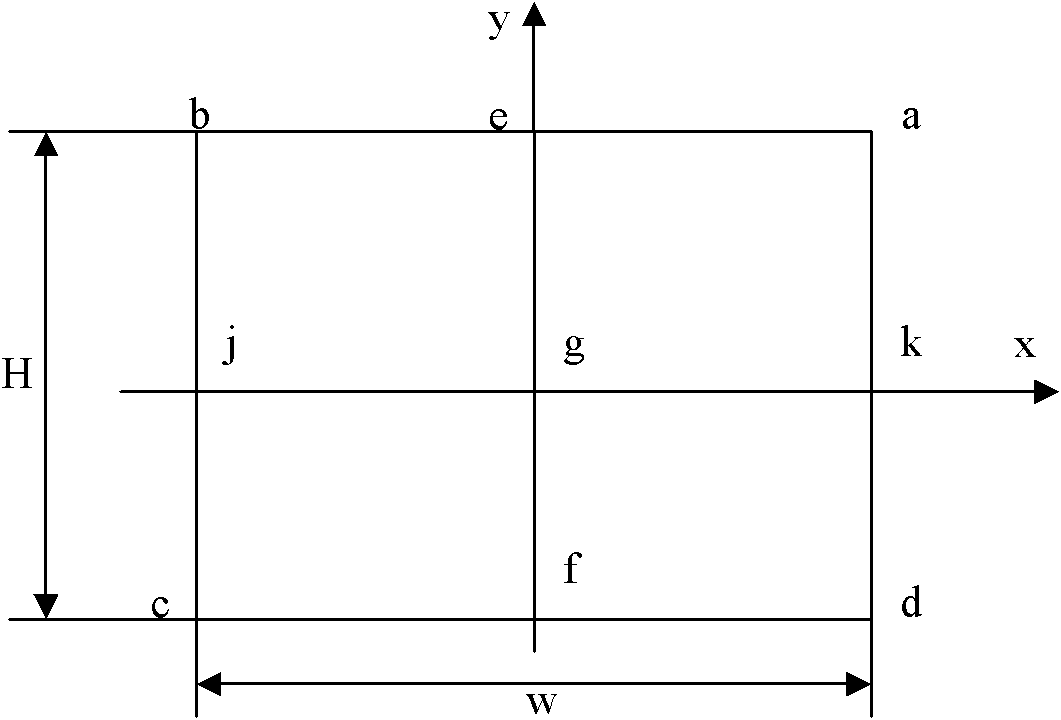

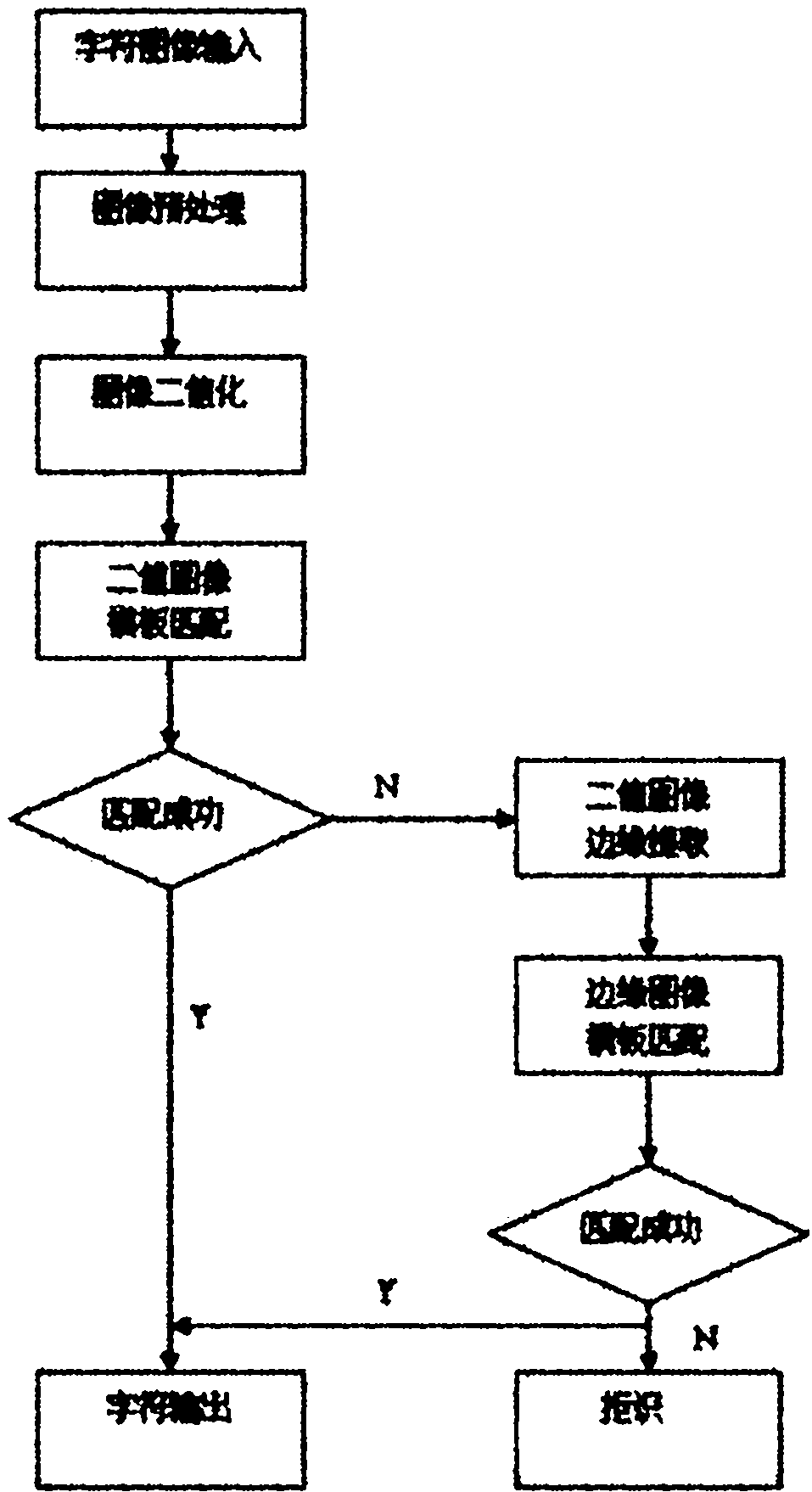

Night image characteristic extraction method in intelligent vehicle-mounted anti-collision pre-warning system

InactiveCN103020948AReduce distractionsReduce noiseImage enhancementImage analysisImaging processingFeature extraction

The invention belongs to the field of a photoelectric technology, and specifically discloses a night image characteristic extraction method in an intelligent vehicle-mounted anti-collision pre-warning system. The night image characteristic extraction method comprises the following steps of: selecting an automobile tail light as characteristics to be extracted, and then canceling noises of images, carrying out image edge clearness, selecting threshold value and carrying out threshold segmentation by using a series of image processing methods; and selecting an interested region AOI (Automated Optical Inspection) when the characteristics of the automobile tail light are extracted and paired, and expressing a target automobile by a rectangular frame and deducing a distance measuring formula through modeling and a series of transformations after extracting and paring the characteristics of the automobile tail light. According to the night image characteristic extraction method, the characteristics of the automobile tail light are highlighted, extracted and paired by a series of image processing methods so as to locate the special location of a front automobile in a lane and provide reliable data for the intelligent vehicle-mounted anti-collision pre-warning system which calculates the distance between the front automobile and the automobile.

Owner:中国航天科工集团第二研究院二〇七所

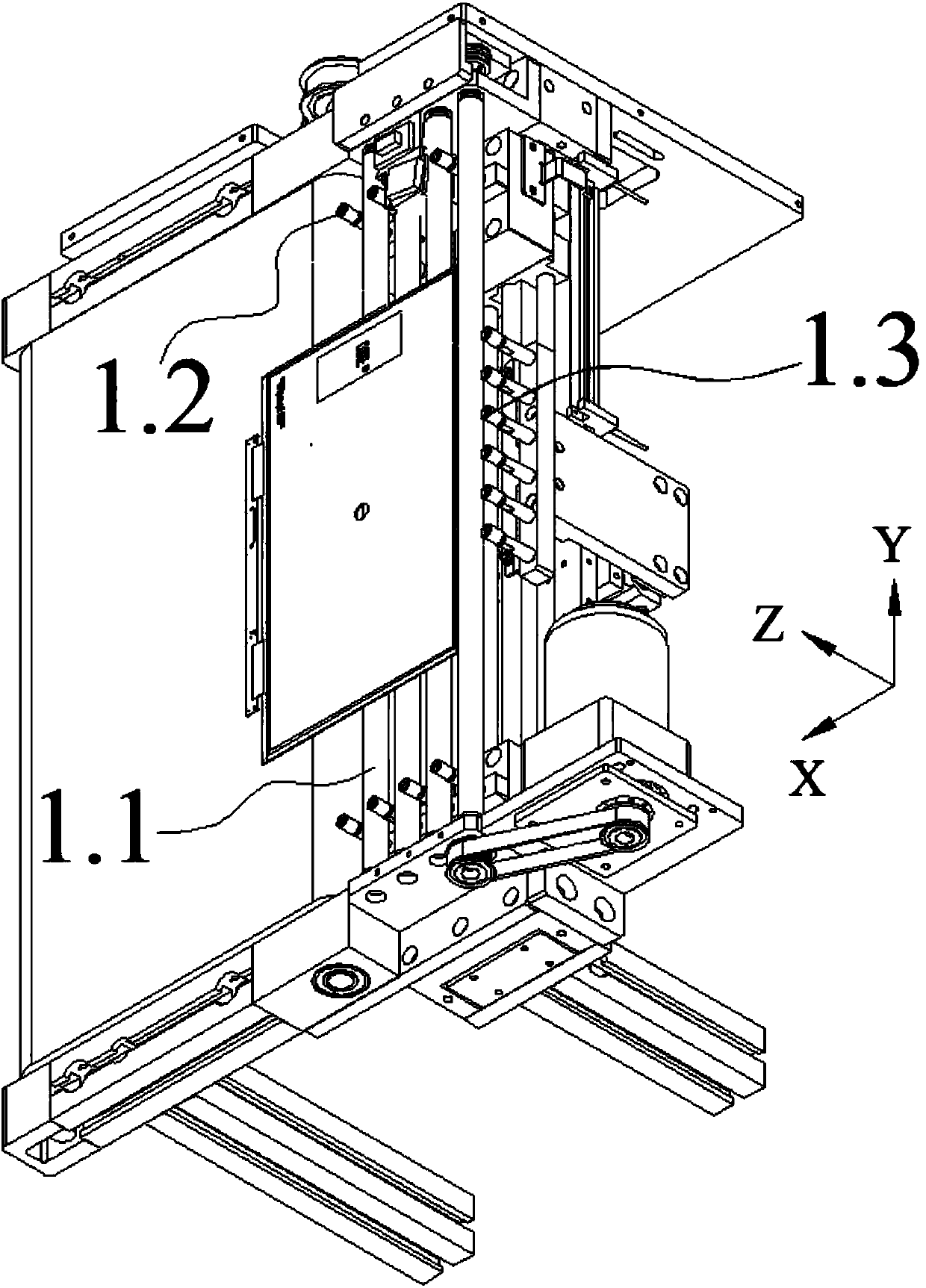

Automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of circuit board and technological process of automatic plate feeding and discharging system

The invention discloses an automatic plate feeding and discharging system for double-faced AOI (Automated Optical Inspection) of a circuit board. The automatic plate feeding and discharging system comprises a robot device, a feeding and discharging device, a double-faced dust sticking machine, a transferring device, an AOI machine, a butt joint device and a general control system for controlling the equipment to work, wherein the robot device is provided with robot mechanical arms; the double-faced dust sticking machine is located beside the feeding and discharging device; the transferring device is arranged above the feeding and discharging device and the double-faced dust sticking machine; the AOI machine comprises a face A detection and a face B detection machine; detection openings of the face A detection and the face B detection machine are opposite to the feeding and discharging device and the double-faced dust sticking machine; the robot device is located between the face A detection and the face B detection machine; and the butt joint device is located on one side of the face B detection machine and can be in up-down butt joint with the robot mechanical arms. The butt joint device can be in up-down butt joint with the robot mechanical arms so that time consumed by a plate overturning procedure is saved, and furthermore, a whole production process has relatively rapid efficiency; and the structure is compact so that the occupied area of equipment is reduced.

Owner:GUANGZHOU TAILI ELECTRICAL & MECHANICAL EQUIP CO LTD

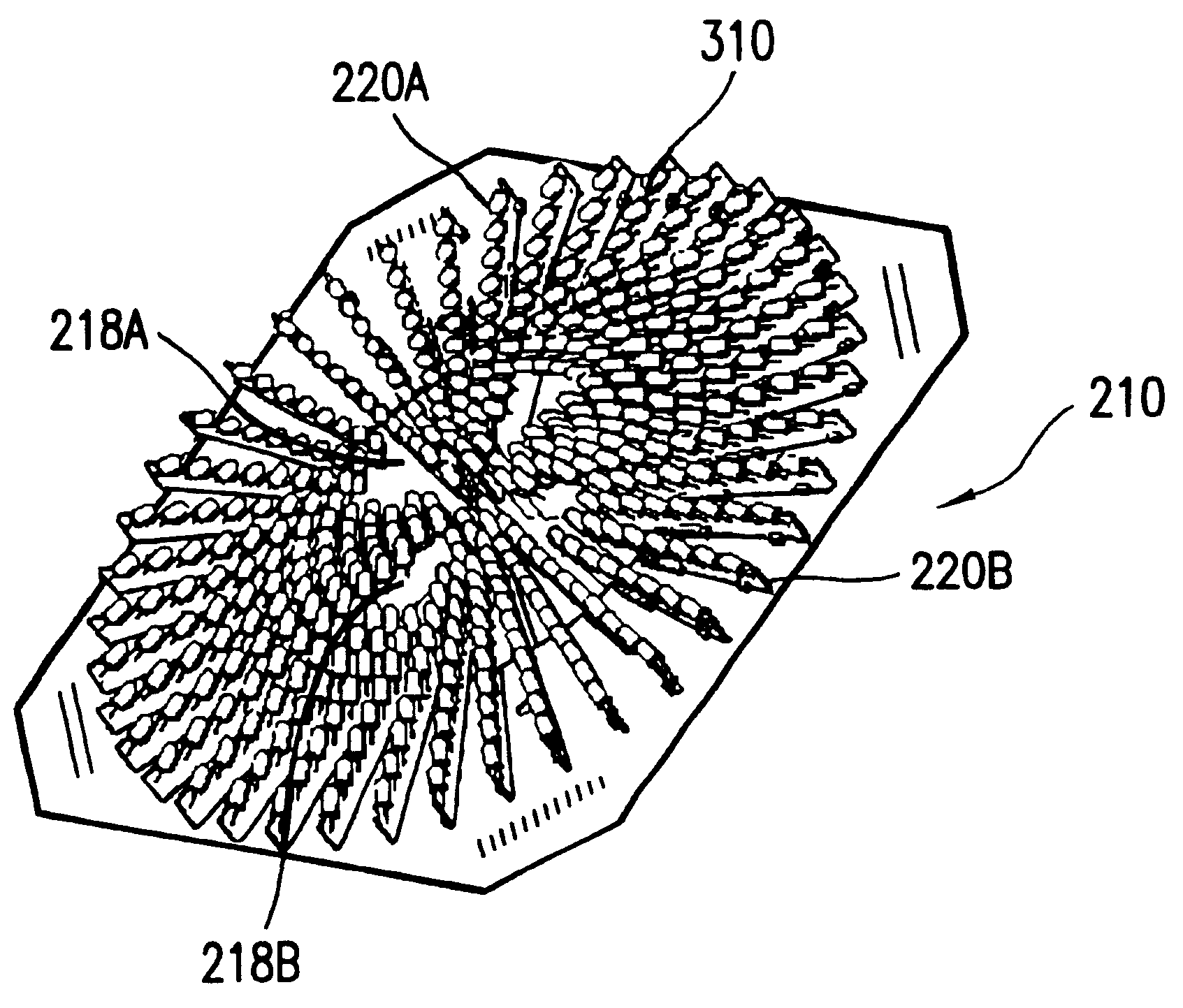

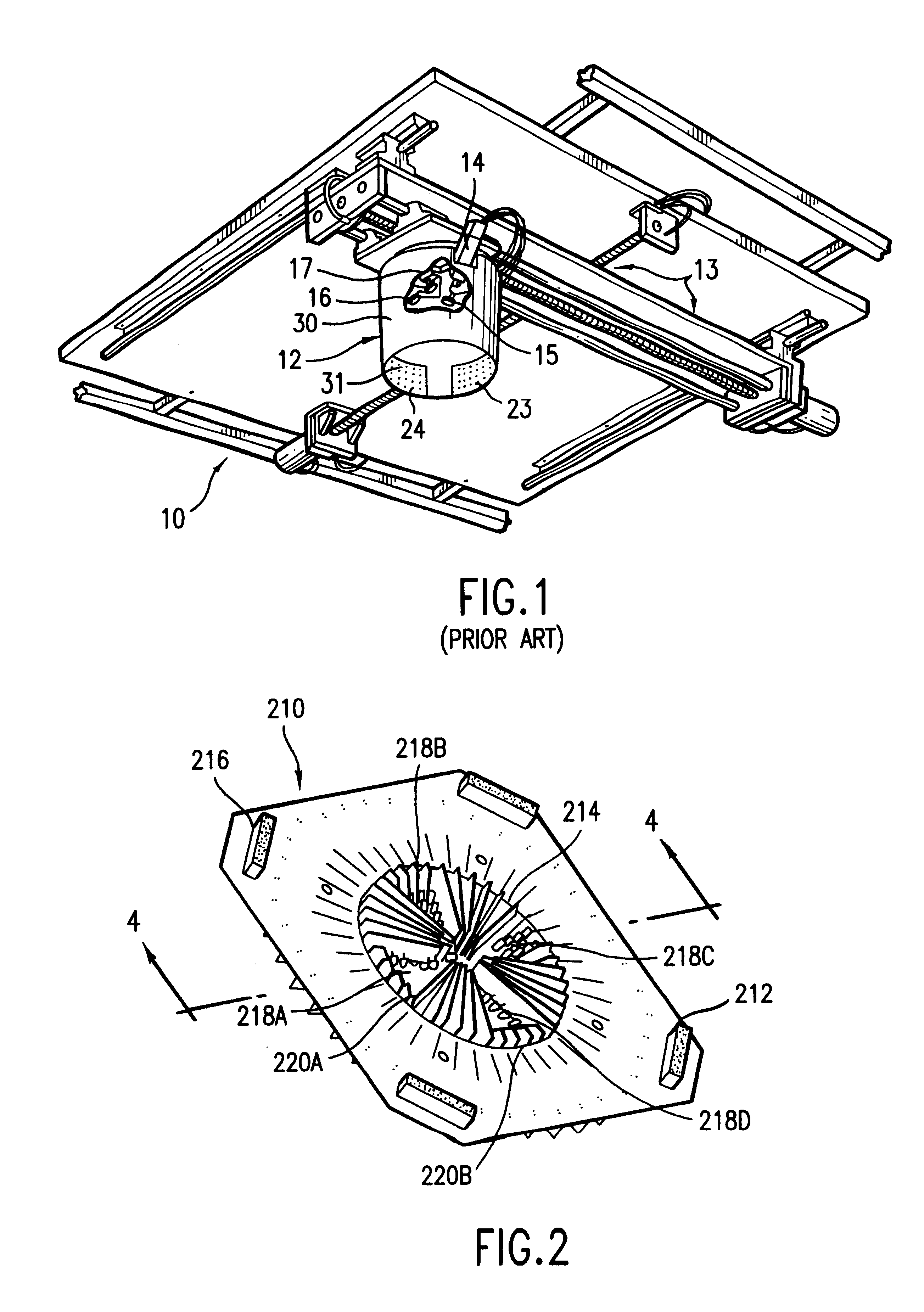

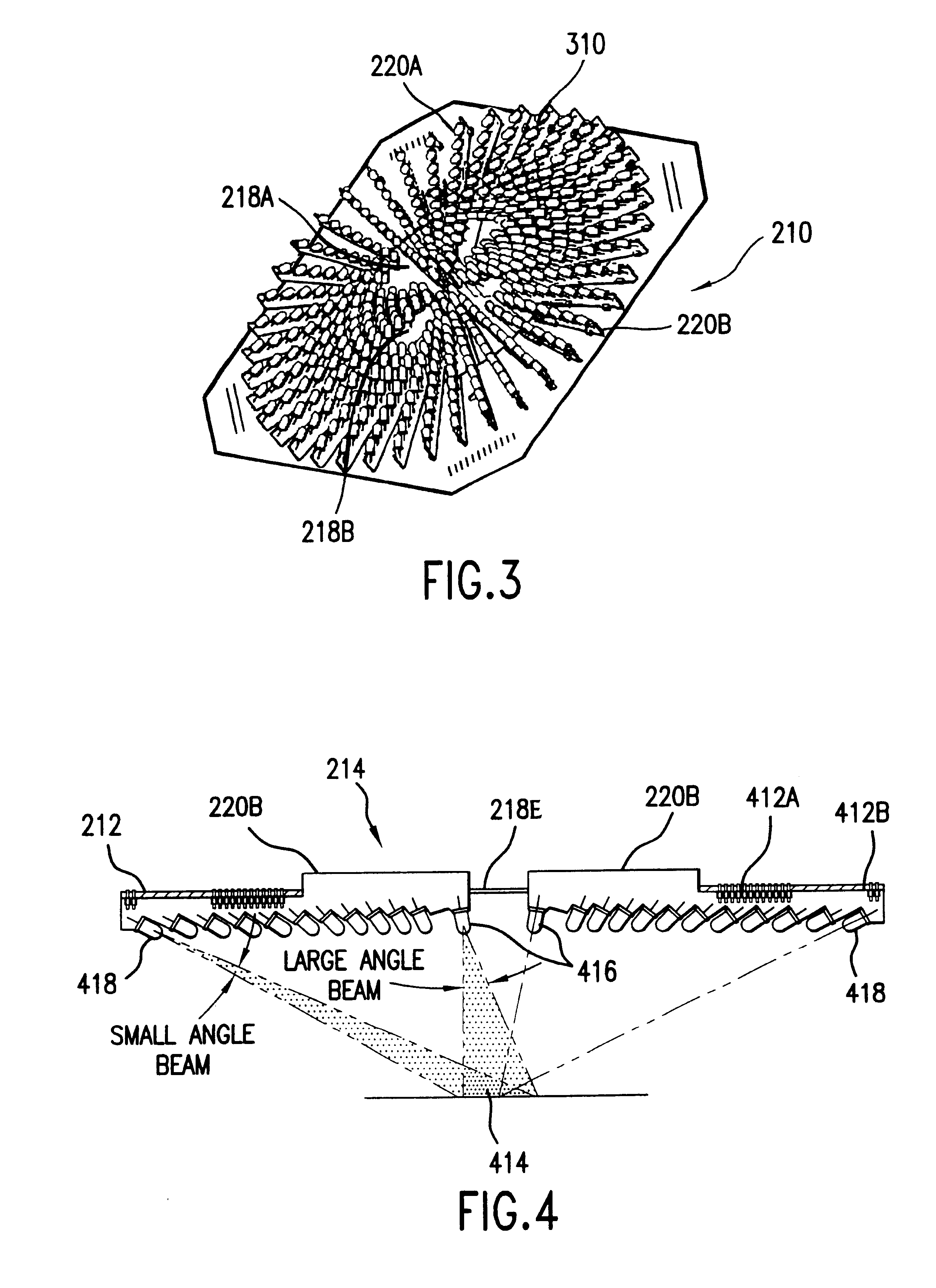

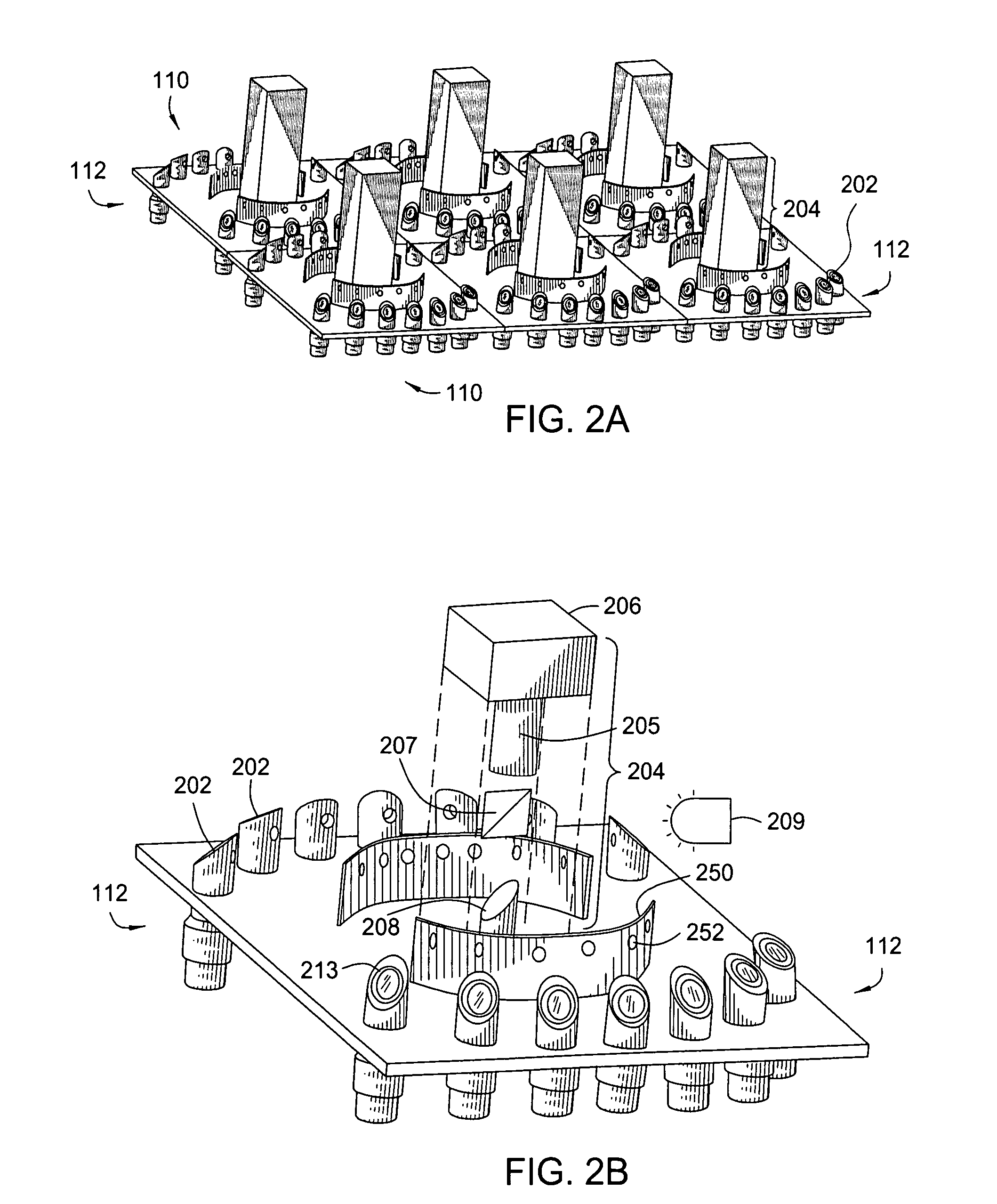

Lighting arrangement for automated optical inspection system

InactiveUS6850637B1Reduce variationImprove uniformityInvestigating moving sheetsCharacter and pattern recognitionElevation angleVisual inspection

An optical inspection system with an improved illumination system. The improved illumination system used to illustrate the invention has a base formed from a printed circuit board. Substrates for mounting lighting elements, which are exemplified by light emitting diodes, are formed also on printed circuit boards. These circuit boards have serrated edges and the diodes are mounted to the serrations. This configuration allows the light emitting elements to be focused on the focal point. Also in the exemplary illumination system, the light emitting elements have different beam widths so that variations in the illumination intensity as a function of elevation angle are reduced.

Owner:LANDREX TECH CO LTD

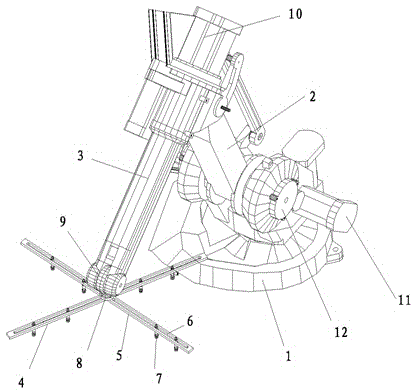

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with multi-axis inspection scope

ActiveUS8713999B2Minimize damageEqualize levelGas-turbine engine testingMaterial analysis by optical meansIndustrial gasVisual inspection

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation. The inspection system includes a multi-axis inspection scope suitable for inspection within the turbine section of a gas turbine.

Owner:SIEMENS ENERGY INC

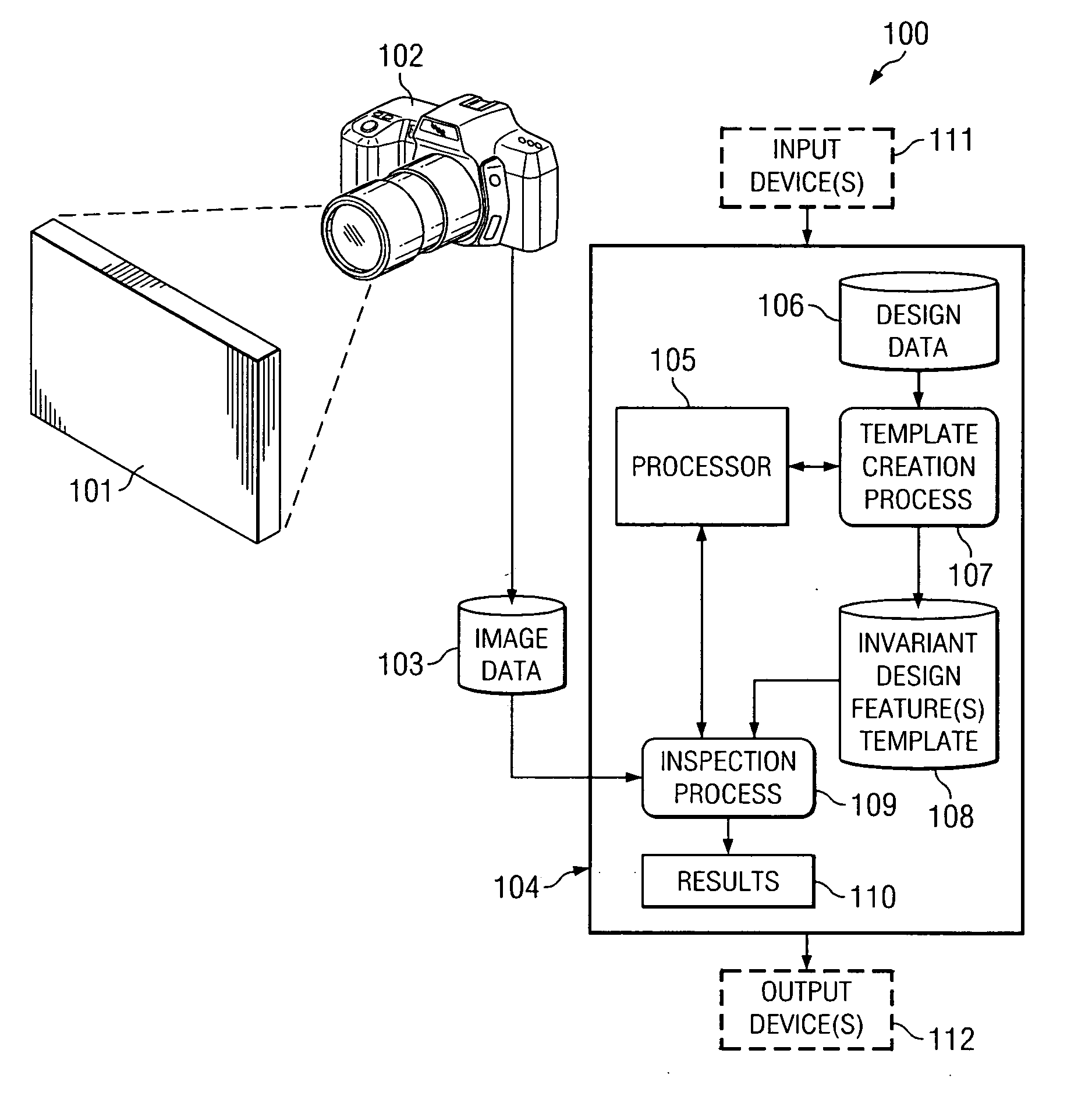

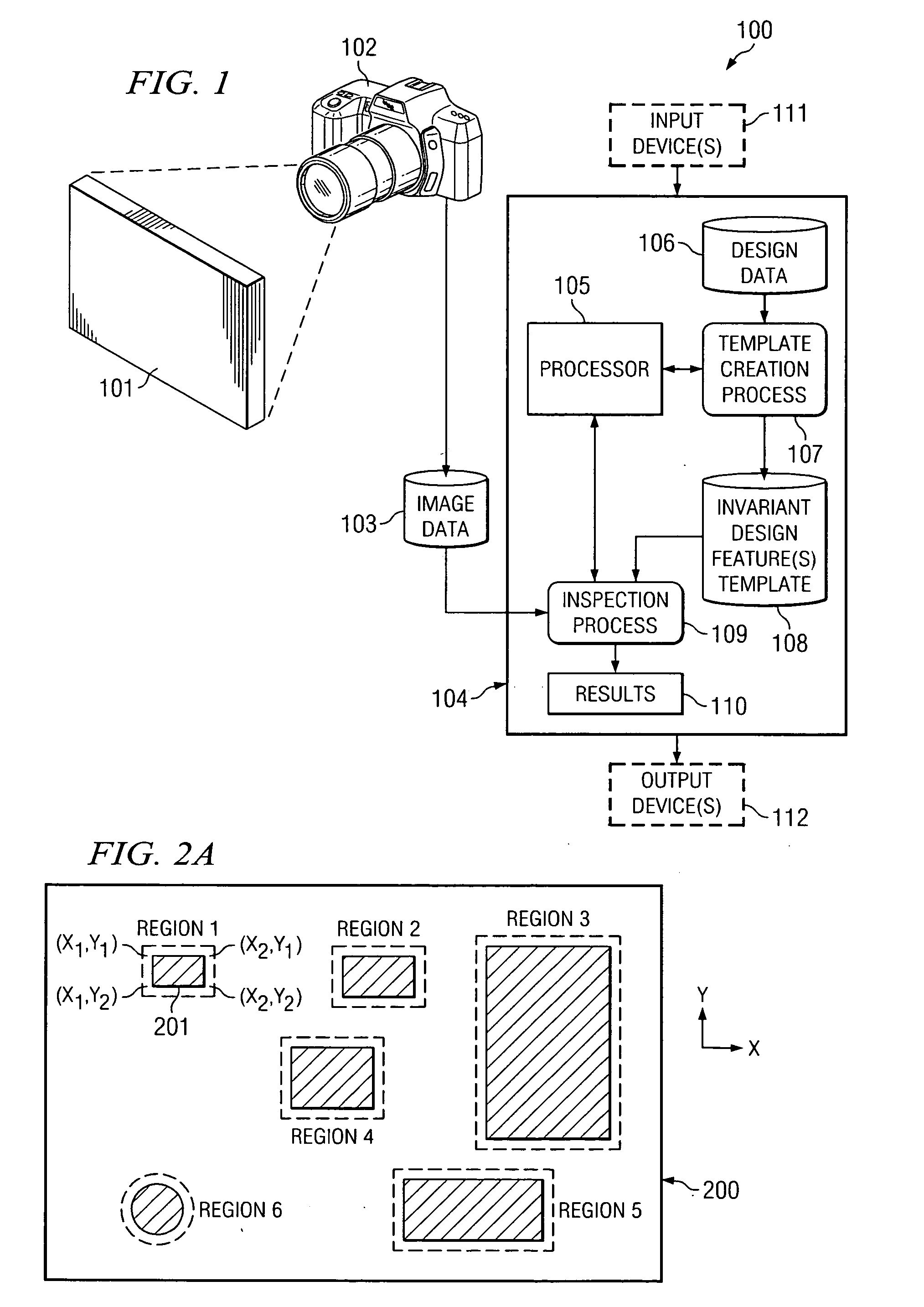

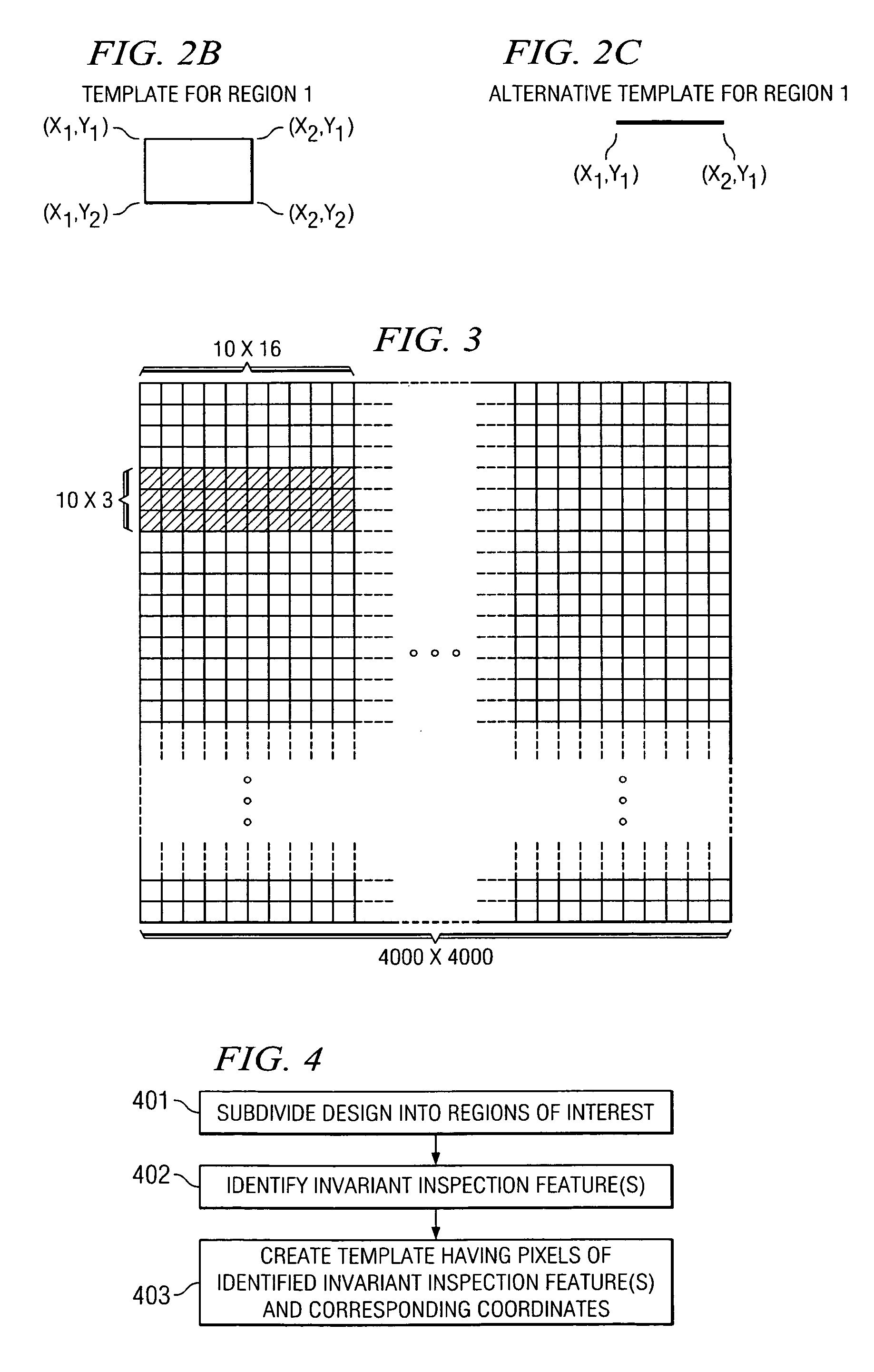

System and method for performing automated optical inspection of objects

InactiveUS20050281452A1Improve efficiencyReduce in quantityImage enhancementImage analysisBrightness perceptionAutomated optical inspection

A system and method for performing optical inspection are provided. At least one “invariant feature” of an object design is determined, and such invariant feature is used in inspecting objects having the corresponding design. An “invariant feature” is a feature that is invariant certain transformations occurring in a captured image of an object under inspection, such as brightness, color, and / or other transformations in the captured image. Accordingly, an inspection template may comprise information corresponding to at least one pre-selected invariant feature of an object's design. In certain embodiments, the template is a shape description of a feature that provides an intrinsic invariance to a specified set of basic transformations. Accordingly, the amount of pixel values stored in a template may be minimized, which minimizes the number of pixel comparisons made between a captured image of the object under inspection and the inspection template during the inspection analysis.

Owner:AGILENT TECH INC

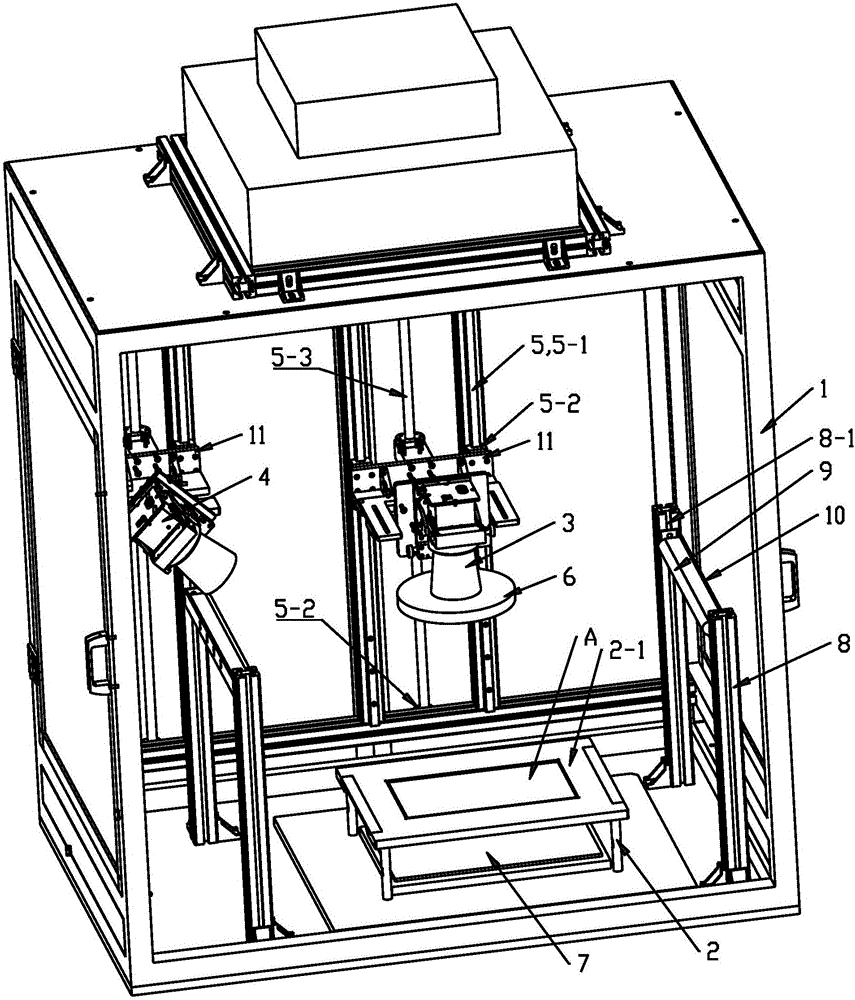

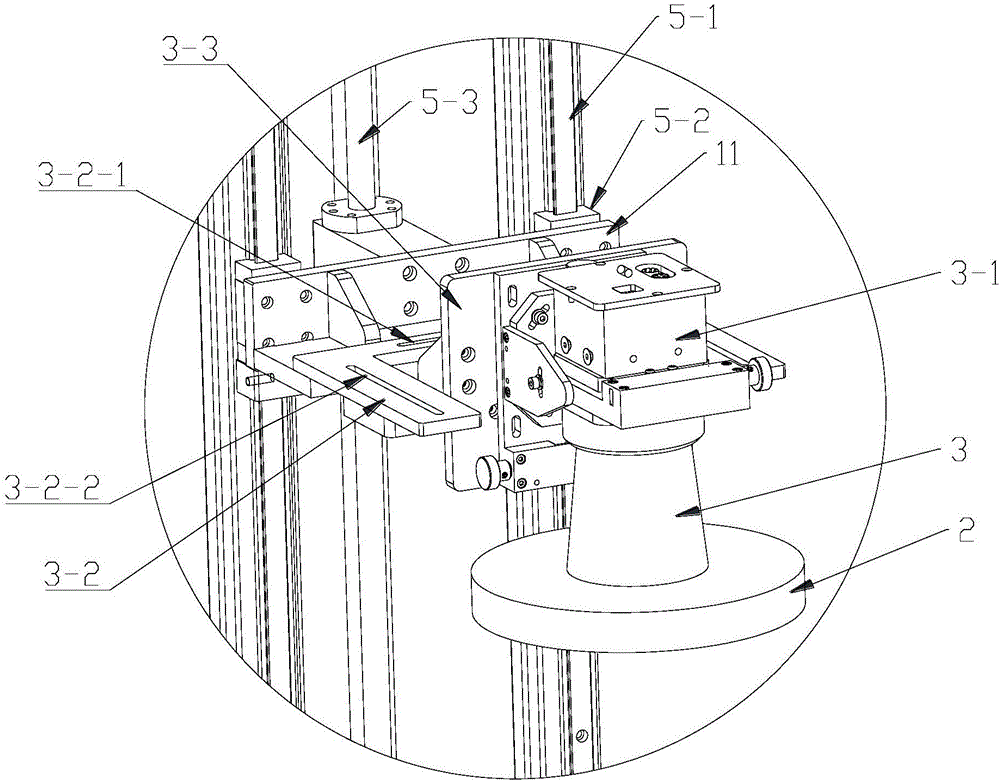

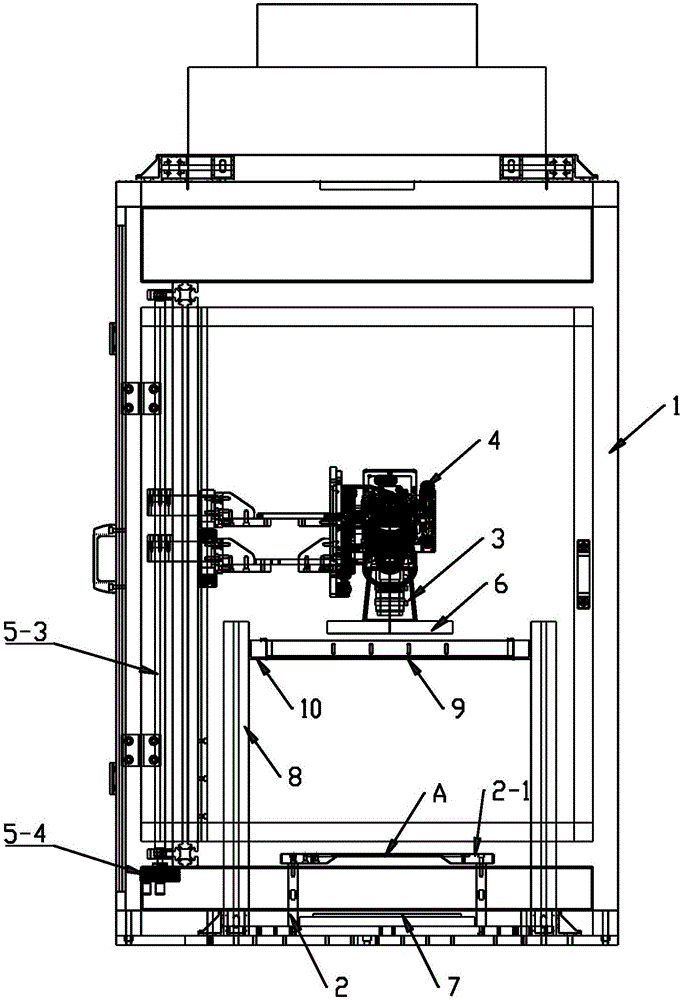

Panel inspection device

PendingCN107826745AImprove the efficiency of optical inspectionReduce human inputConveyor partsEngineeringTest platform

The invention relates to the technical field of panel optical inspection devices, in particular to a panel inspection device. The panel inspection device comprises a base, and is characterized in thata sheet allocating device, an automatic optical inspection device, a discharging device and a storing device are sequentially arranged in the conveying direction of a panel on the base. The sheet allocating device is used for bearing a to-be-inspected panel to be transferred to an inspection platform on the automatic inspection device. The automatic optical inspection device is used for performing optical inspection on the to-be-inspected panel on the inspection platform. The discharging device is used for transferring the panel which is identified as a finished product by the automatic optical inspection device. The storing device is used for storing the panel which is identified as an NG product by the automatic optical inspection device. The panel inspection device is reasonable in structural layout, is high in panel inspection efficiency, improves the panel inspection efficiency greatly, and has a great popularization value.

Owner:KUSN JINGXUN ELECTRONICS TECH

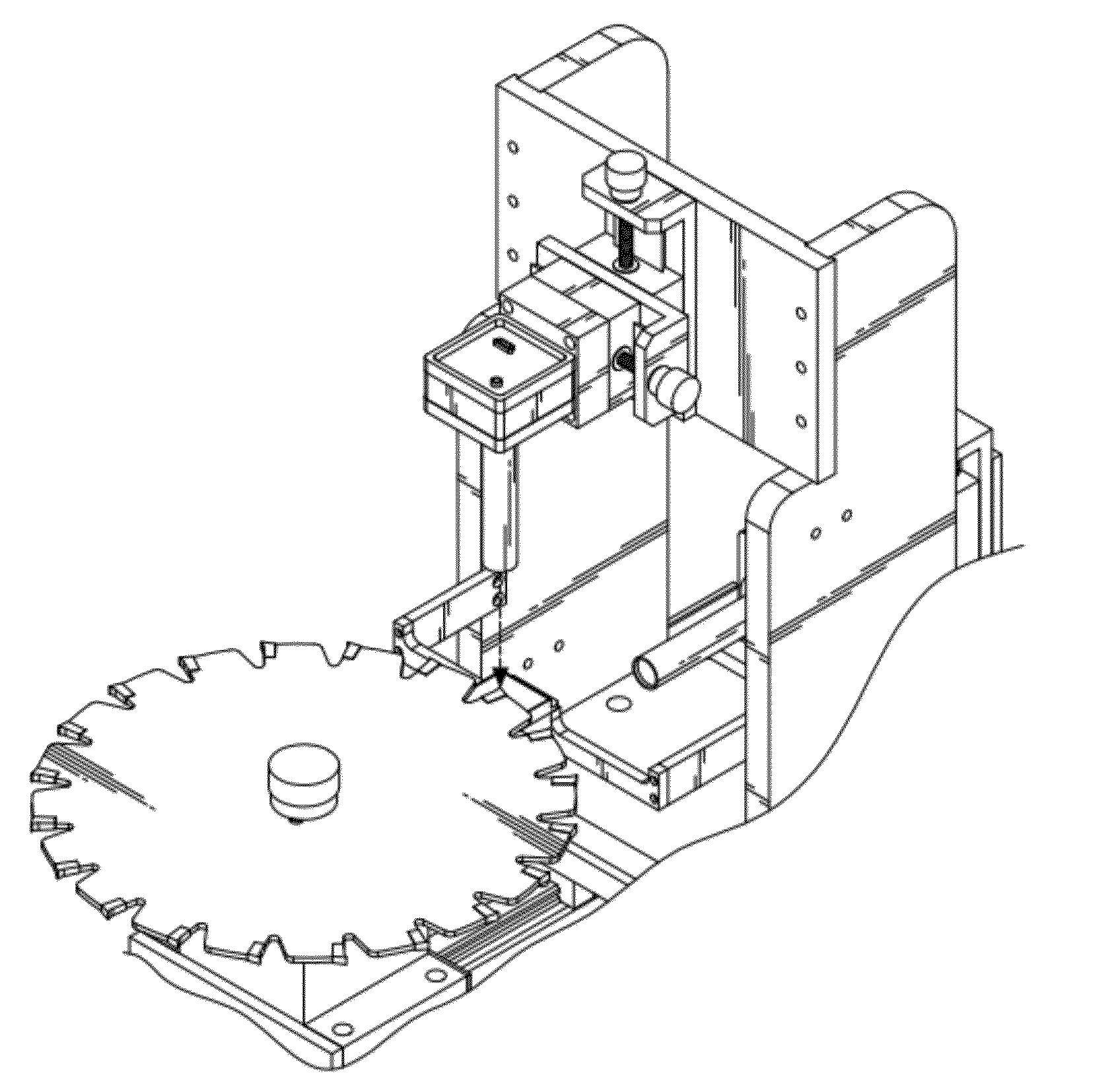

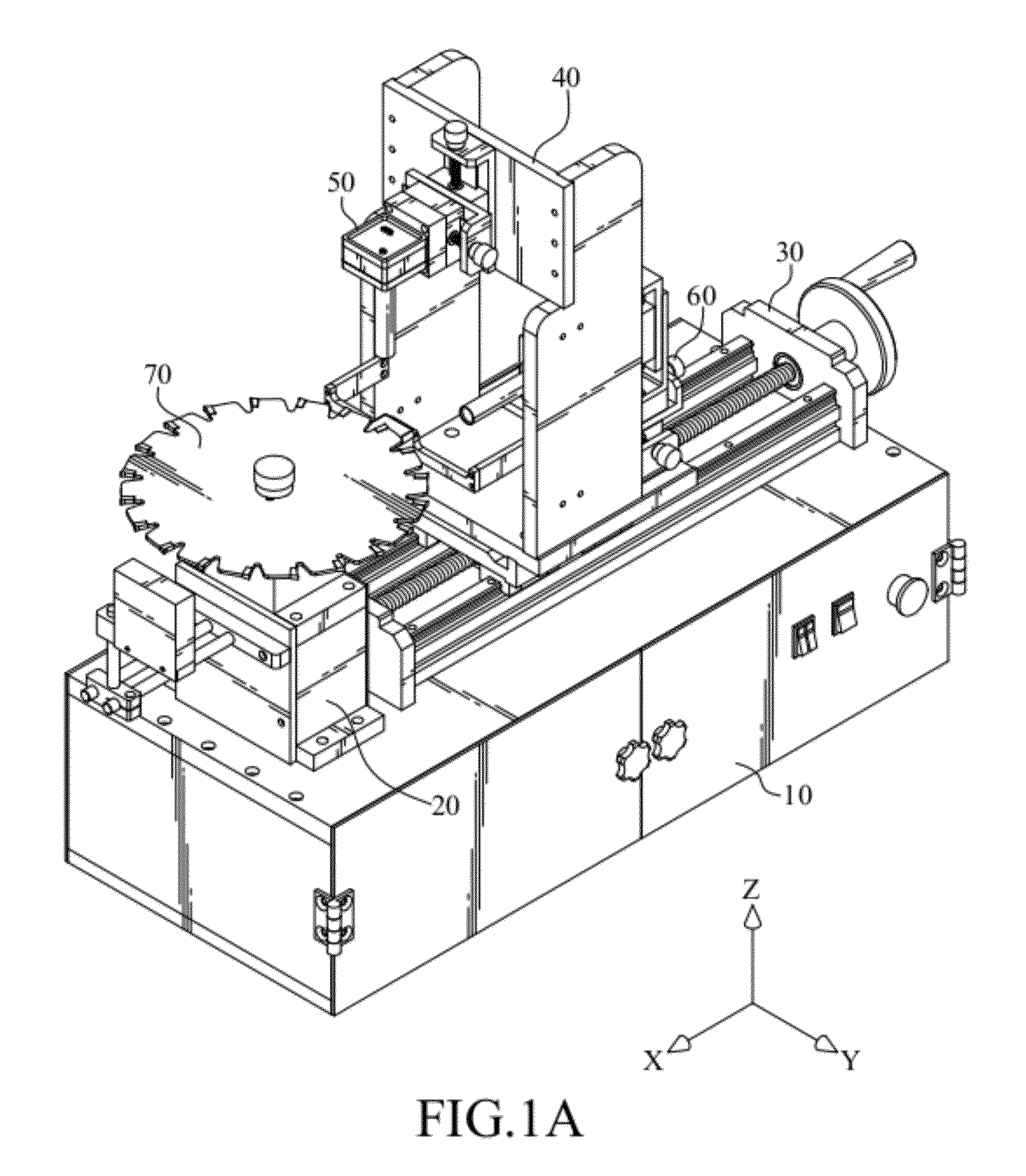

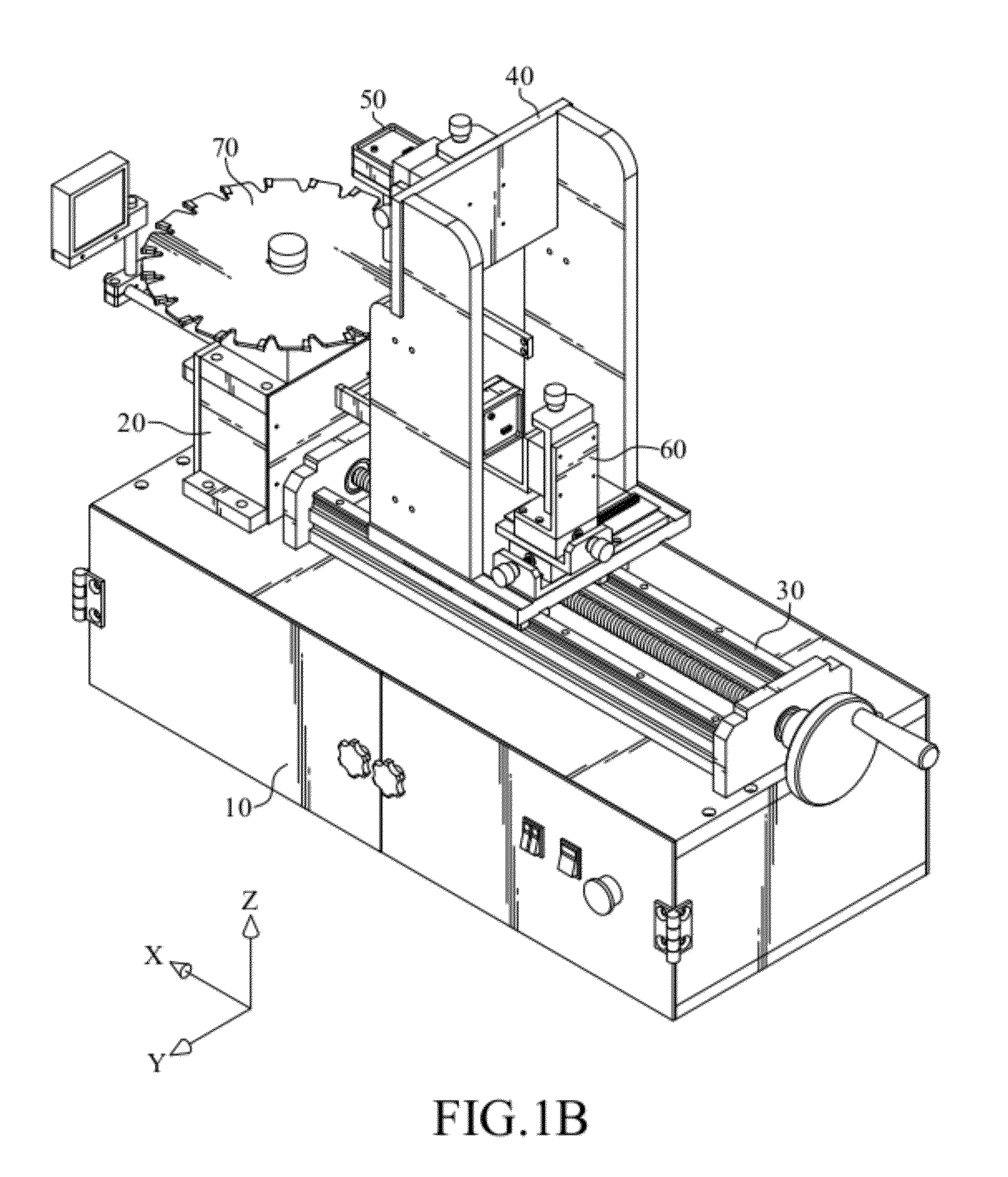

Automated optical inspection system for the runout tolerance of circular saw blades

InactiveUS20120242827A1Eliminate disadvantagesColor television detailsClosed circuit television systemsRadial positionComputer module

An automated optical inspection system for the runout tolerance of circular saw blades comprises a rotating device, a first and a second optical inspection module, and a computing device. The rotating device is used to rotate a circular saw blade. The circular saw blade includes multiple teeth, and each tooth has a side and a back. The first / second optical inspection module is used to capture a side / back image of the tooth. The computing device activates the rotating device to rotate the circular saw blade, and activates the first and the second optical inspection module to capture the side image and the back image of each tooth upon rotation of the circular saw blade. The computing device performs a radial-position-calculating procedure according to the side images, to obtain an amount of radial runout, and performs an axial-position-calculating procedure according to the back images, to obtain an amount of axial runout.

Owner:NAT TAIWAN UNIV OF SCI & TECH

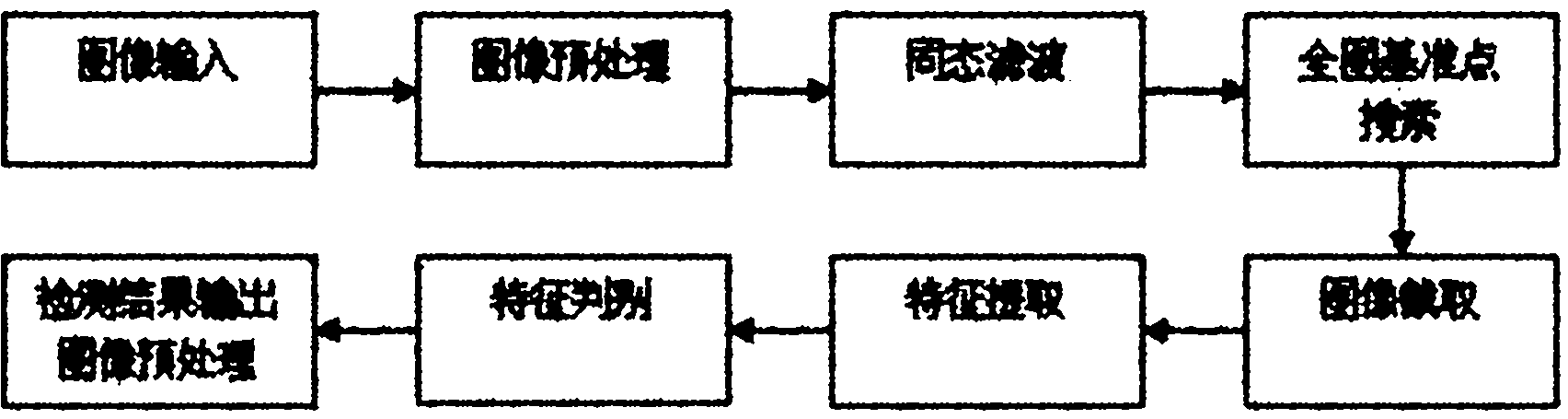

Automated optical inspection (AOI)-based bullet apparent defect detection method

InactiveCN104122271AAchieve complete detectionAccurate and comprehensive image acquisitionImage analysisOptically investigating flaws/contaminationImaging processingFeature extraction

The invention discloses an automated optical inspection (AOI)-based bullet apparent defect detection method including (1) using a CCD (charge coupled device) linear array camera to shoot the bullet surface to obtain a bullet surface initial gray level image; (2) sequentially denoising, enhancing and segmenting the initial gray level image for pretreatment to obtain a binaryzation image; (3) performing connected domain labeling processing on the binaryzation image to obtain a pixel dot set of all defects on the bullet surface; (4) respectively extracting the characteristics of each defective area; and (5) comparing the extracted characteristic values with preset defect standard features to determine the type of each defect. The method is based on the automatic optical inspection, designs a whole set of bullet apparent defect detection programs, and through the precision comprehensive image acquisition, fast image processing algorithm and convenient and accurate feature extraction and recognition, complete bullet apparent defect detection can be efficiently and accurately implemented.

Owner:NINGBO MOSHI OPTOELECTRONICS TECH

Automatic optical inspection using multiple objectives

ActiveUS20060170910A1Material analysis using wave/particle radiationSolid-state devicesComputer scienceAutomated optical inspection

Apparatus and techniques for automated optical inspection (AOI) utilizing image scanning modules with multiple objectives for each camera are provided. A scanning mechanism includes optical components to sequentially steer optical signals from each of the multiple objectives to the corresponding camera.

Owner:APPL MATERIALS ISRAEL LTD

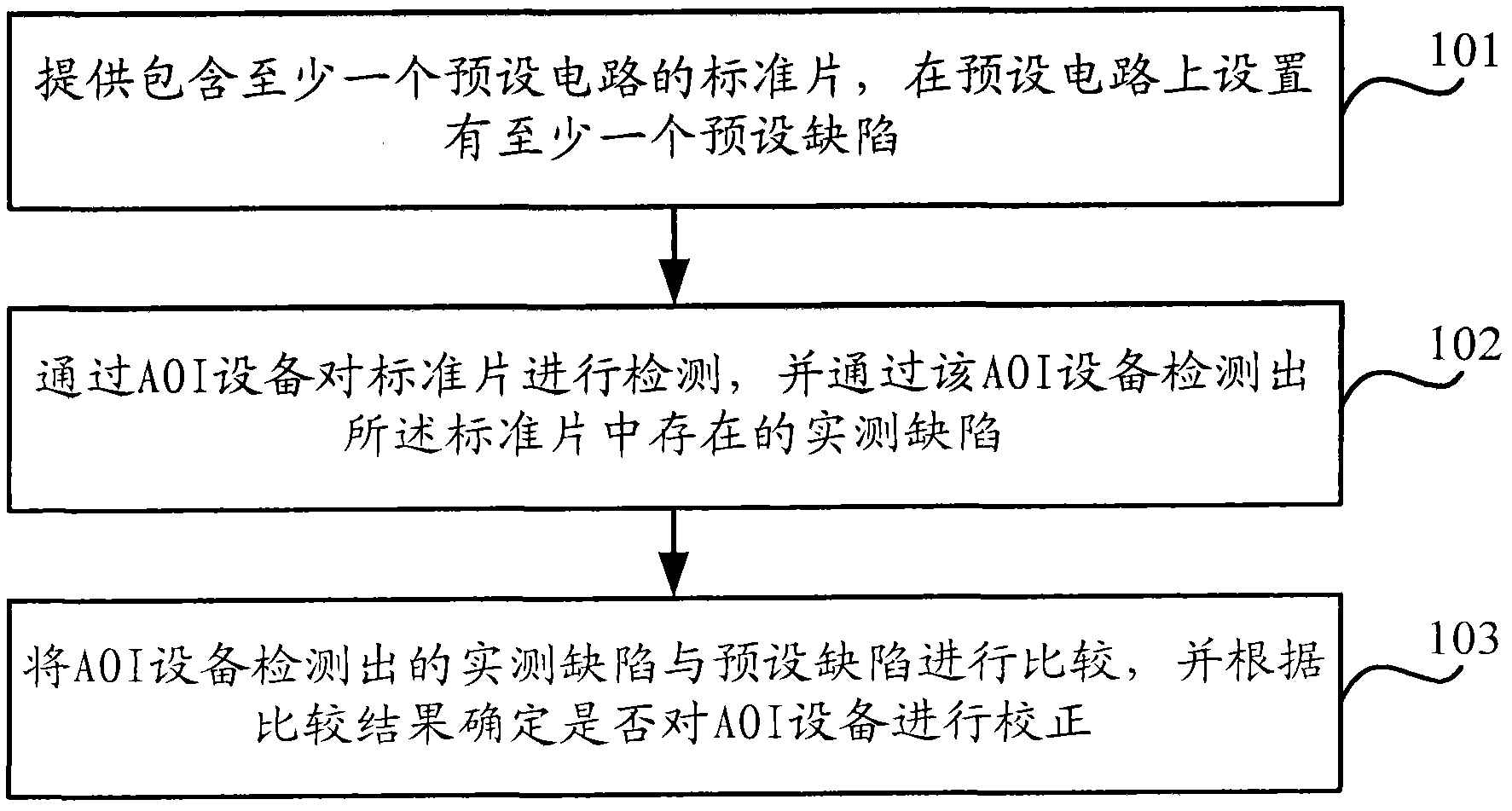

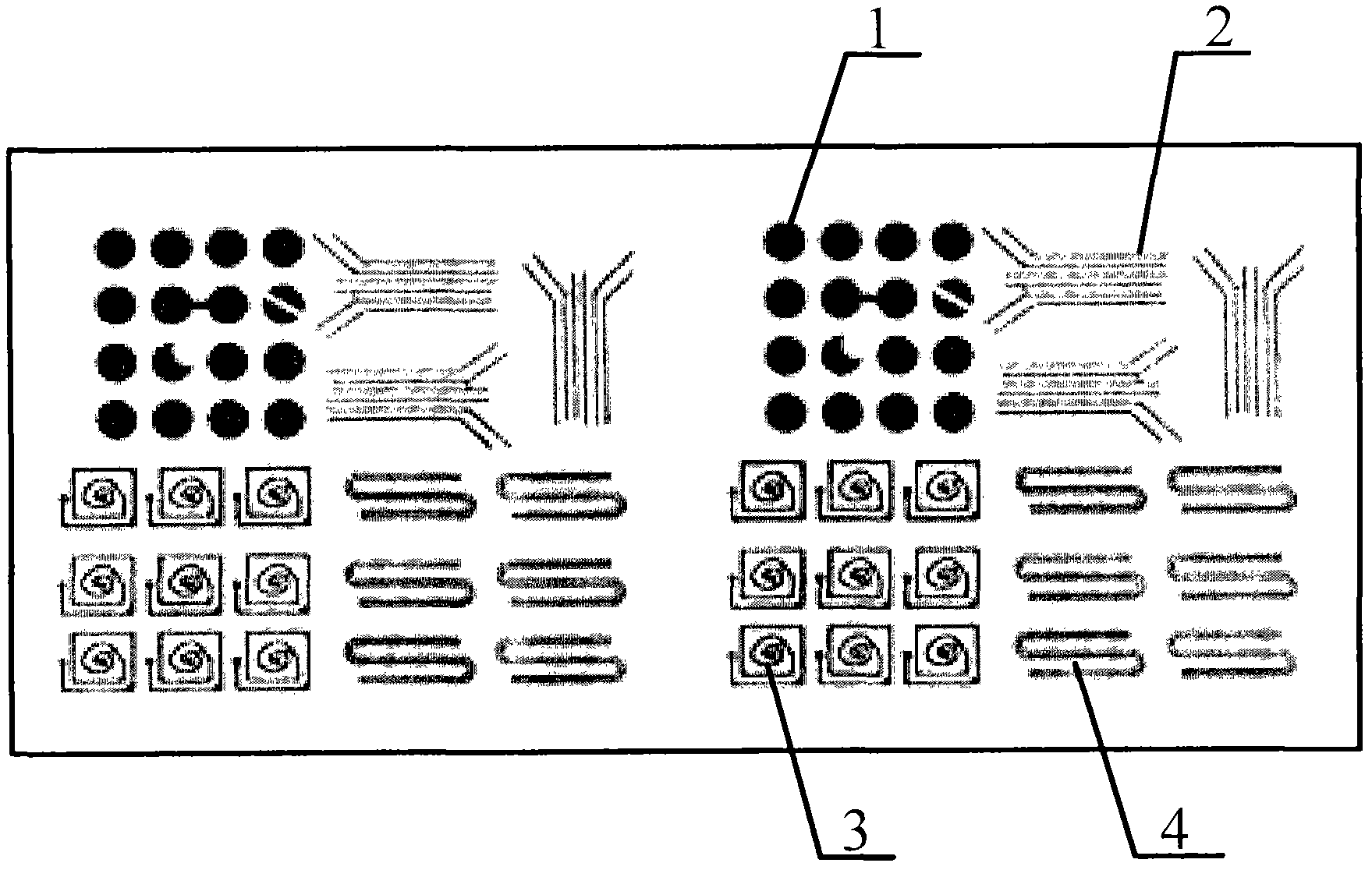

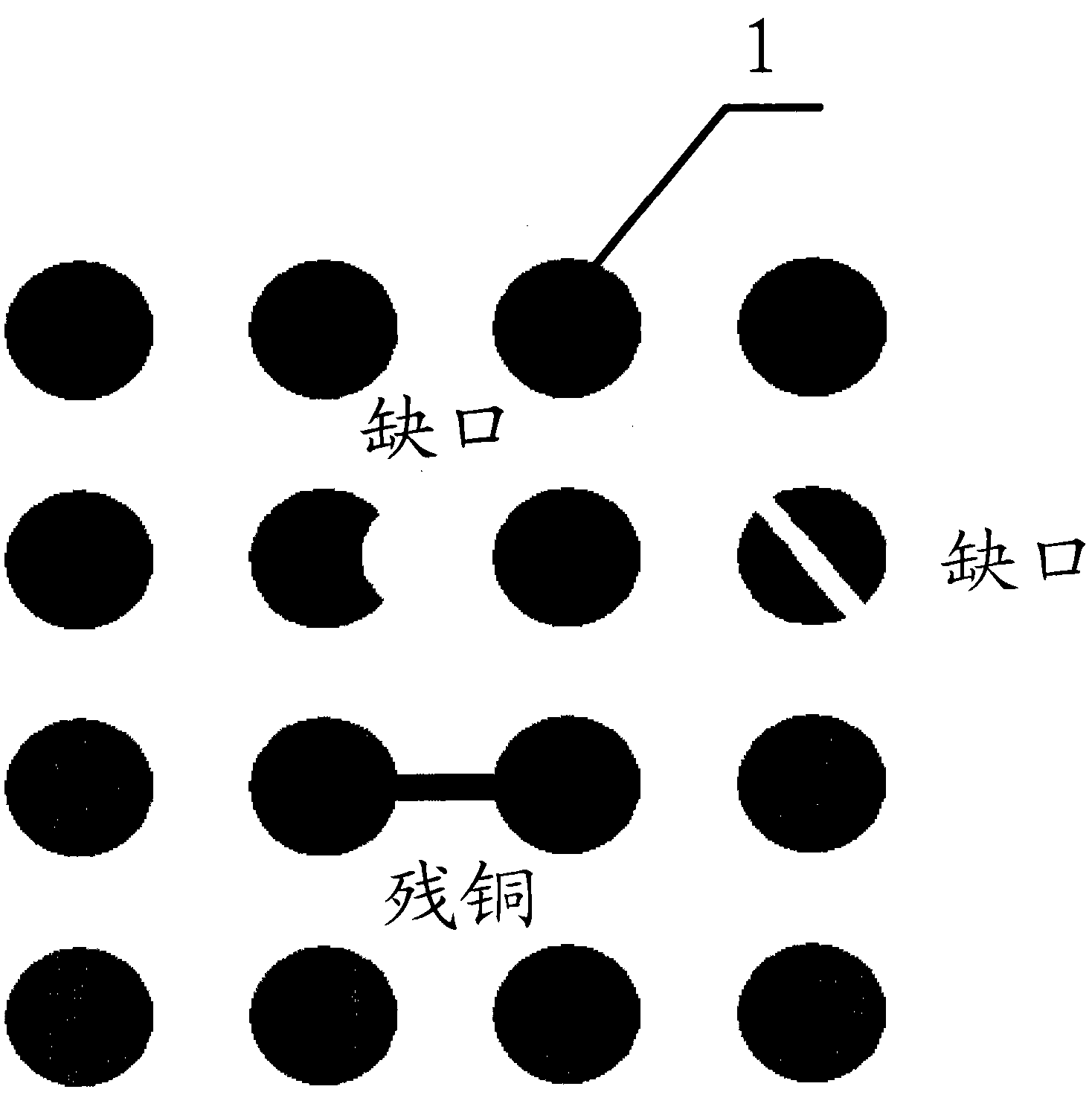

Method for determining performance of automatic optical detection equipment and standard film

InactiveCN102033073AEasy to detectImprove accuracyMaterial analysis by optical meansPrinted circuit manufacturePrinted circuit boardAutomated optical inspection

The invention discloses a method for determining the performance of automatic optical detection equipment and a standard film, which are used for enhancing the inspection correctness of a printed circuit board (PCB). The method comprises the following steps of: providing the standard film which comprises at least one preset circuit, wherein at least one preset defect is formed on the preset circuit; inspecting the standard film through automated optical inspection (AOI) equipment and determining an actual measurement defect existing in the standard film through the AOI equipment; and comparing the actual measurement defect inspected by the AOI equipment with the preset defect and determining whether the AOI equipment should be corrected or not according to a comparison result. Due to the adoption of the technical scheme, the inspection correctness and stability of the AOI equipment are ensured and the inspection correctness of the PCB is enhanced.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

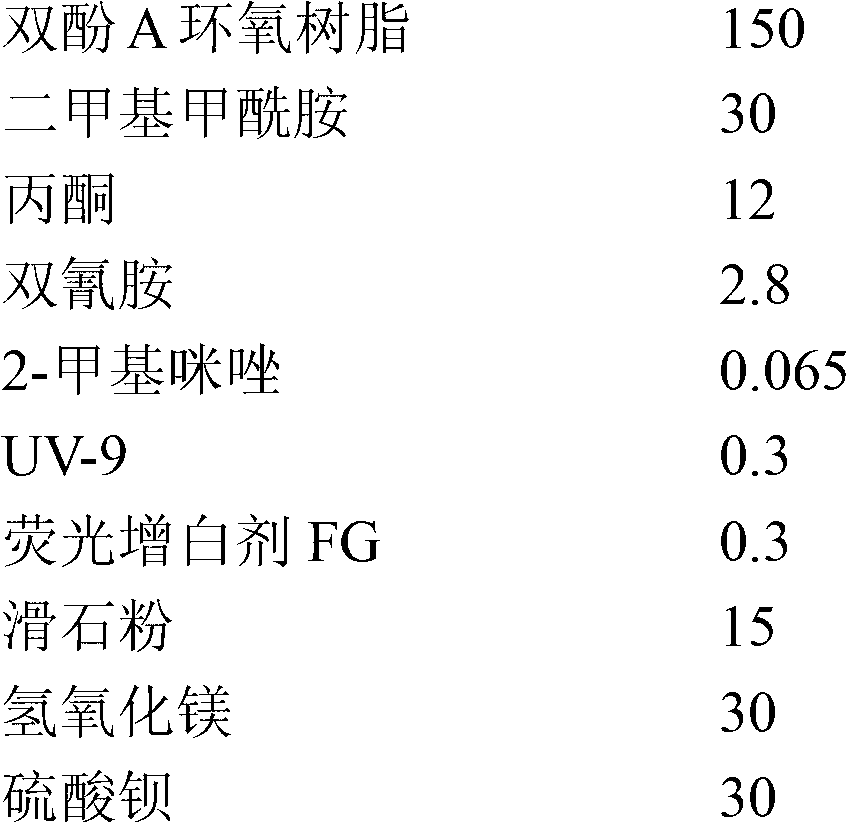

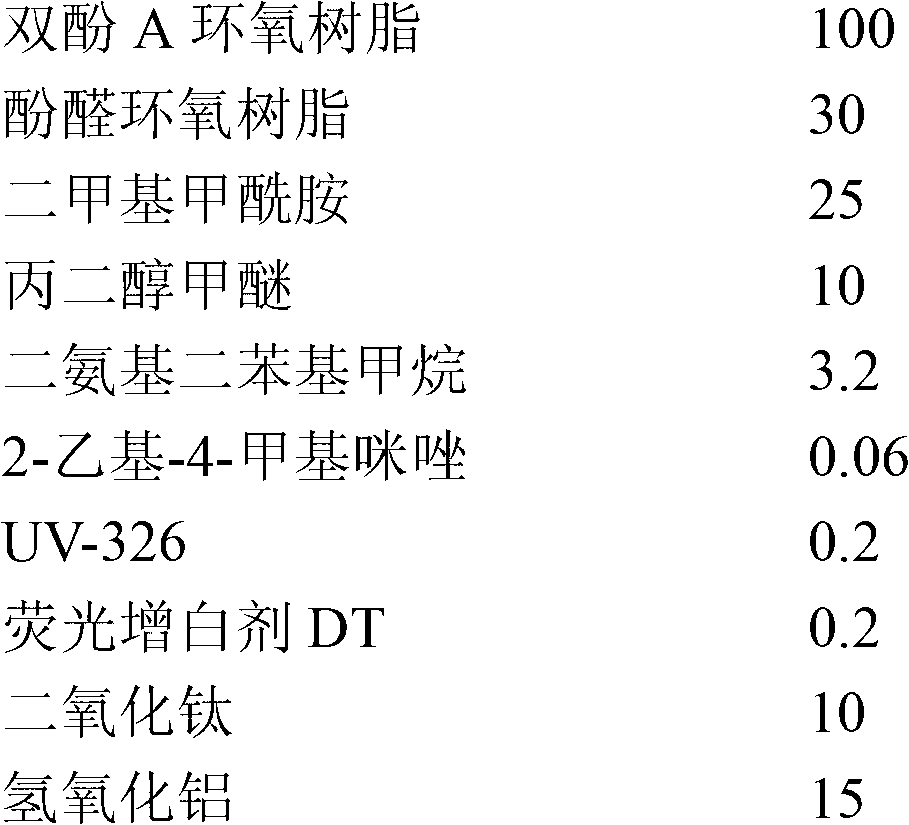

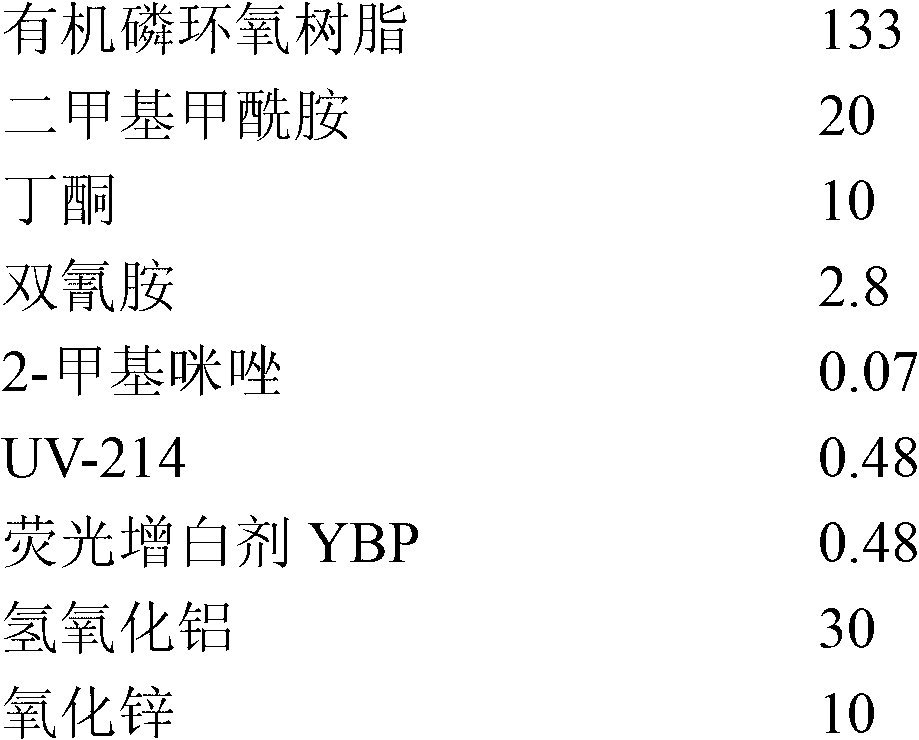

Copper foil clad laminated board with UV shielding function, adhesive and preparation methods thereof

ActiveCN102796478AMeet the variety of choicesFunction increaseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveWhitening Agents

The invention discloses a copper foil clad laminated board with UV shielding function and a preparation method thereof, and a copper foil clad laminated board adhesive and a preparation method thereof. The copper foil clad laminated board adhesive disclosed by the invention comprises the following components in parts by mass: 125-150 parts of resin, 25-42 parts of solvent, 2.1-3.6 parts of curing agent, 0.2-1.0 part of UV absorbent, 0.2-1.0 part of fluorescent whitening agent and 25-75 parts of auxiliary packing. The copper foil clad laminated board disclosed by the invention has various natural colors, and can satisfy diversified options for high-performance UV-shielding copper foil clad laminated boards; and meanwhile, the copper foil clad laminated board has excellent UV shielding function (the UV absorptivity exceeds 99.99%) and weather resistance, and is completely suitable for the development process of the PCB (printed circuit board) processing procedure and the AOI (automated optical inspection) detection technique of high-density integrated circuits. The preparation method of the copper foil clad laminated board has the characteristics of simple technique, favorable controllability, cost saving and the like.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

Detection mechanism with side light source configured for annular light source and backlight source for AOI (Automated Optical Inspection) visual inspection

PendingCN106680207ASolve insufficient lightingAddressing inhomogeneityMaterial analysis by optical meansCamera lensEffect light

The invention discloses a detection mechanism with a side light source configured for an annular light source and a backlight source for AOI (Automated Optical Inspection) visual inspection. The detection mechanism comprises a stand and a CCD (Charge Coupled Device) camera. The stand is provided with a support frame, wherein the top of the stand is provided with a mounting rack for fixing a product to be detected, the backlight source is arranged under the product to be detected relative to the stand, the CCD camera comprises a central view CCD camera positioned right above a detection area and a side view CCD camera positioned on the side surface of the detection area, the annular light source is fixedly installed below a camera lens of the center view CCD camera, the stand is provided with high-angle strip-shaped light sources for lighting towards the detection area respectively above the left and right sides of the support frame, and the heights of the center view CCD camera and the side view CCD camera can be adjusted up and down relative to the stand through a corresponding up-and-down sliding mechanism. The detection mechanism can solve the problem that the lighting is insufficient and uneven during AOI visual inspection.

Owner:苏州富鑫林光电科技有限公司

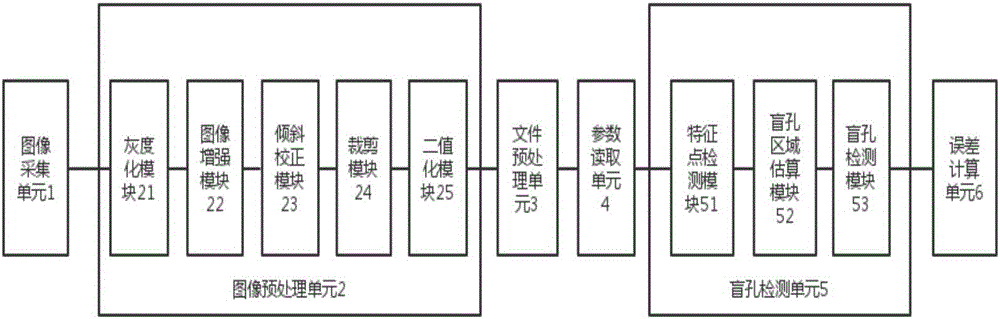

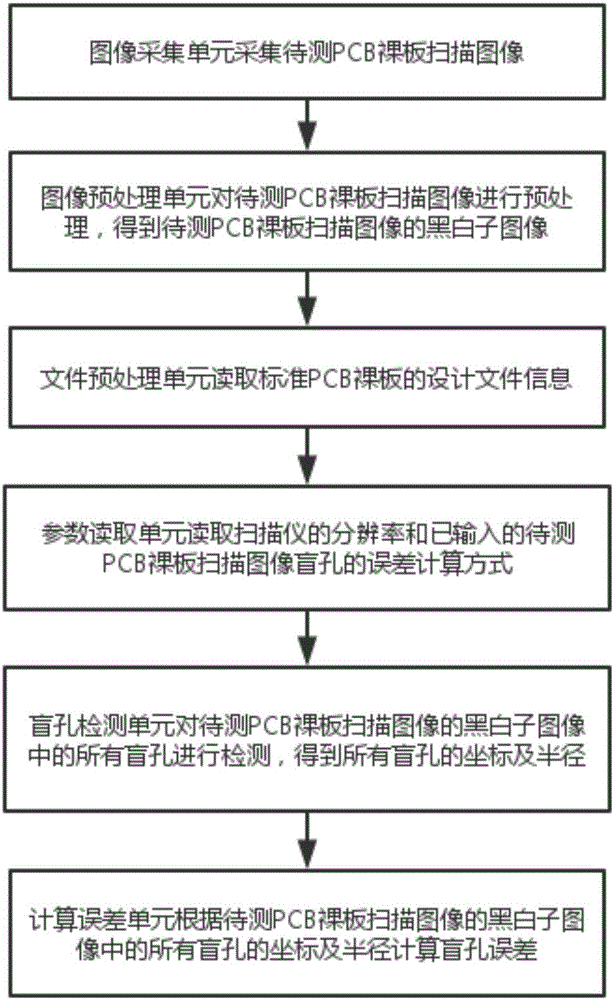

System and method for detecting defects of blind holes in PCB (Printed Circuit Board) bare board based on AOI (Automated Optical Inspection)

ActiveCN106327496AImprove accuracyReduce noise interferenceImage enhancementImage analysisPrinted circuit boardAutomated optical inspection

Owner:XIDIAN UNIV

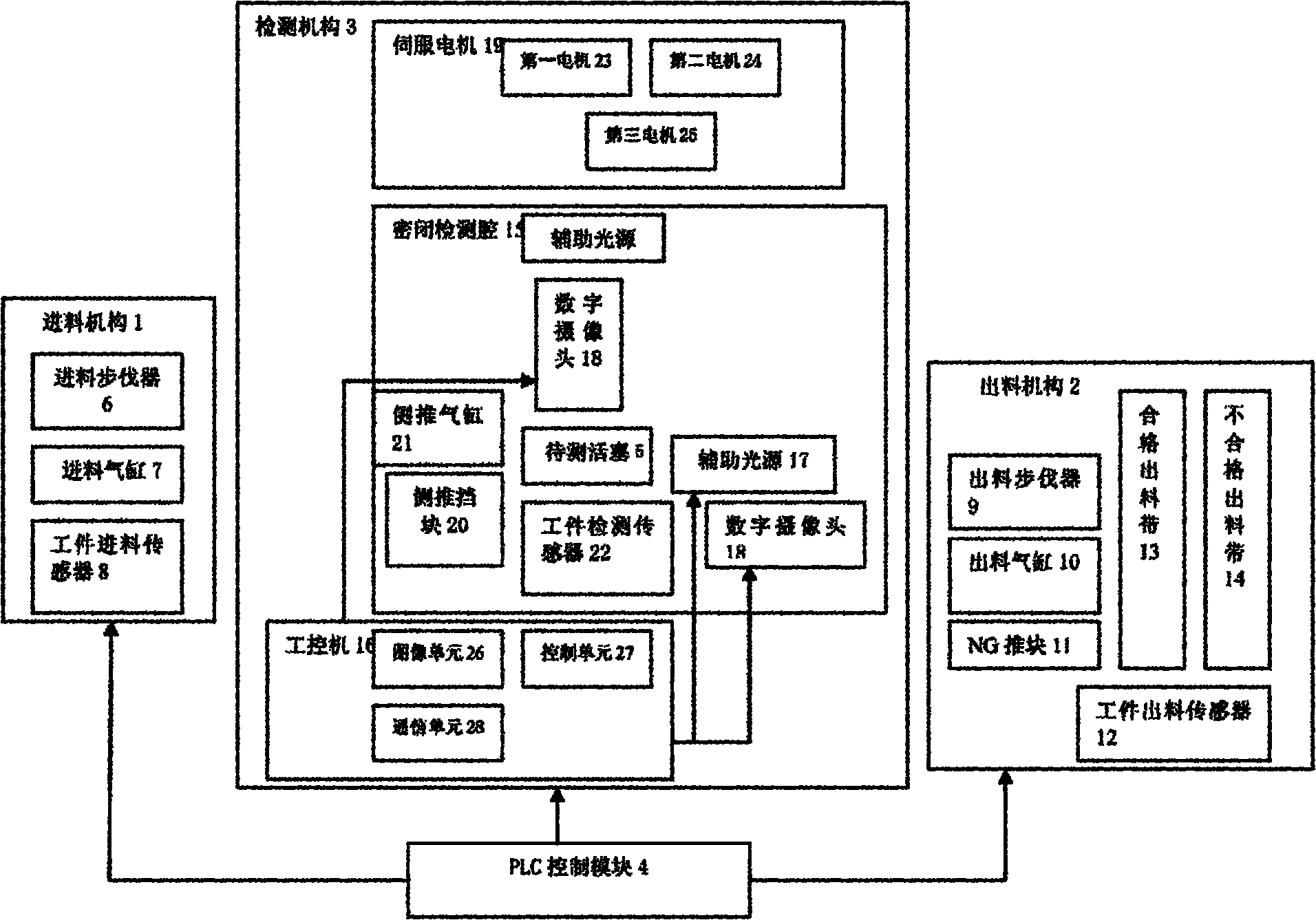

Visual inspection system for automobile piston assembly quality

InactiveCN102072910AReduce reflectionDistinctive featuresOptically investigating flaws/contaminationPiston ringVisual inspection

The present invention relates to a visual inspection system for automotive piston assembly quality, which belongs to the technical field of automated optical inspection. The visual inspection system comprises a piston feeding mechanism, a piston discharging mechanism, a piston detection mechanism and a PLC (programmable logical controller) control module, the PLC control module is connected with the piston feeding mechanism and the piston discharging mechanism through communication lines of an I / O (input / output) port and is used for outputting control commands and receiving work piece in-place signals, and the piston detection mechanism is arranged between the piston feeding mechanism and the piston discharging mechanism and just faces to a piston to be detected, is also connected with the PLC control module and is used for transmitting detection information. The visual inspection system can realize one-step automatic visual inspection of characters on the top surface of the automotive piston, the assembly of a piston ring, the integrity of a graphite layer and the like based on digital images.

Owner:SHANGHAI JIAO TONG UNIV

AOI (Automated Optical Inspection)-based display panel micro defect judgment method and device

InactiveCN109856156AAccurate classificationClass correct downgradeOptically investigating flaws/contaminationComputer scienceAutomated optical inspection

The invention belongs to the technical field of display defect detection and discloses an AOI (Automated Optical Inspection)-based display panel micro defect judgment method and device. According to the method and device of the invention, the position of a micro defect is detected through a large camera; secondary image acquisition is performed on the micro defect through a small camera; analysisprocessing is performed; and finally a defect type is outputted. With the method and device of the invention adopted, small defects can be accurately classified, and the correct degradation classification of panels can be realized.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com