Automated optical inspection device and method for defect inspection of LCD (liquid crystal display) module

An optical automatic detection and defect detection technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of parallel image processing, complicated equipment interaction, and long detection time, so as to achieve versatility and reduce interaction complexity , the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples. Obviously, the examples are only some examples of the present invention, not all examples, so the examples should not be construed as limiting the present invention.

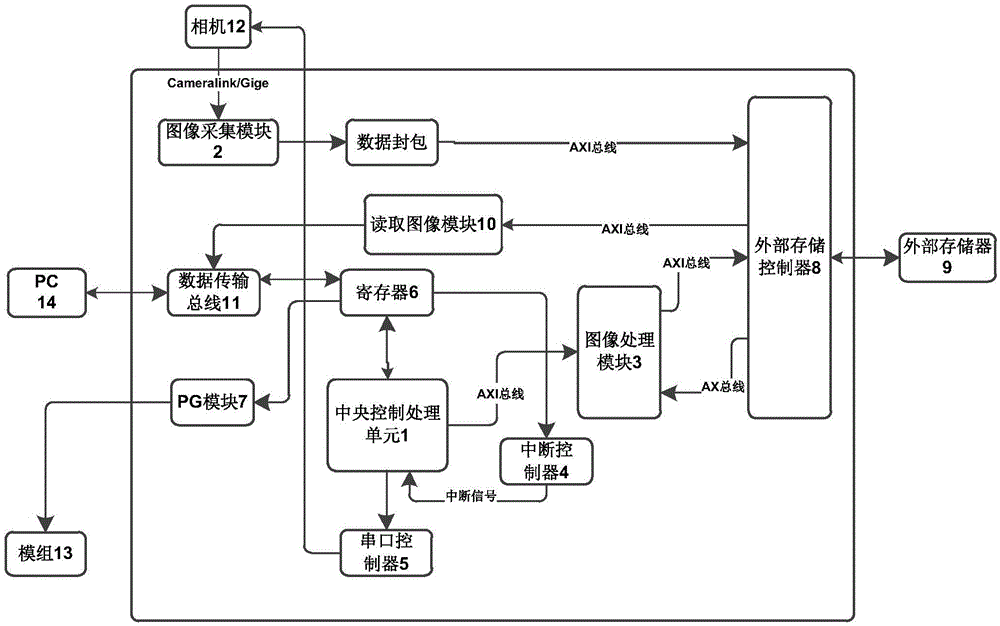

[0027] Such as figure 1 As shown, the optical automatic detection device used for LCD liquid crystal module defect detection in the present invention includes: a central control processing unit 1 integrated in the FPGA, an image acquisition module 2, an image processing module 3, an interrupt controller 4, and a serial port controller 5 , register 6, PG module 7, external storage controller 8, read image module 10, data transmission bus 11 and external storage module 9 outside FPGA, camera 12, module 13 and PC personal computer 14. Wherein, the data transmission bus 11 adopts a PCIE bus.

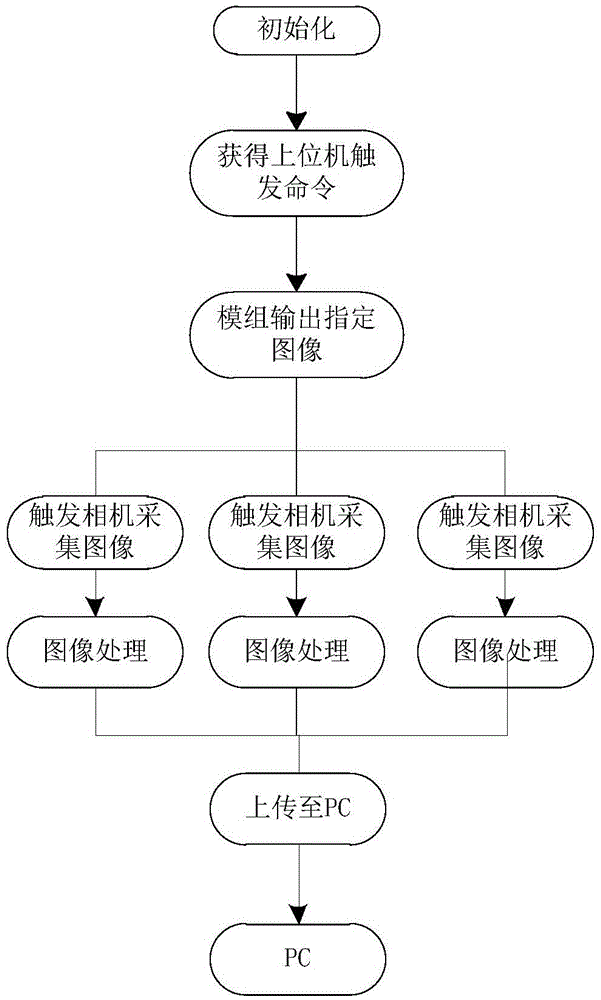

[0028] Such as figure 2 Be the optical automatic detection method that the present invention is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com