Patents

Literature

14170results about How to "Avoid scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

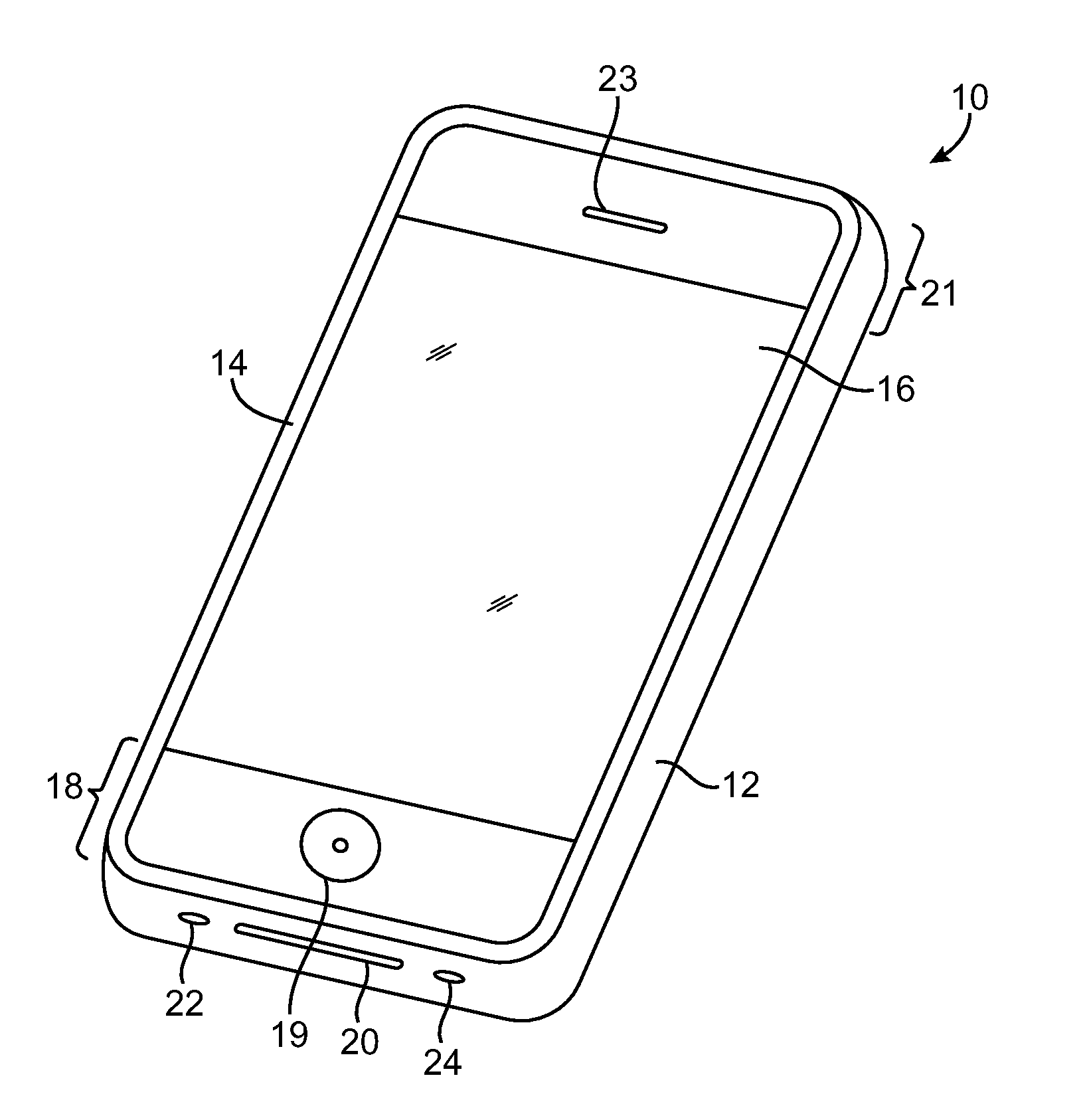

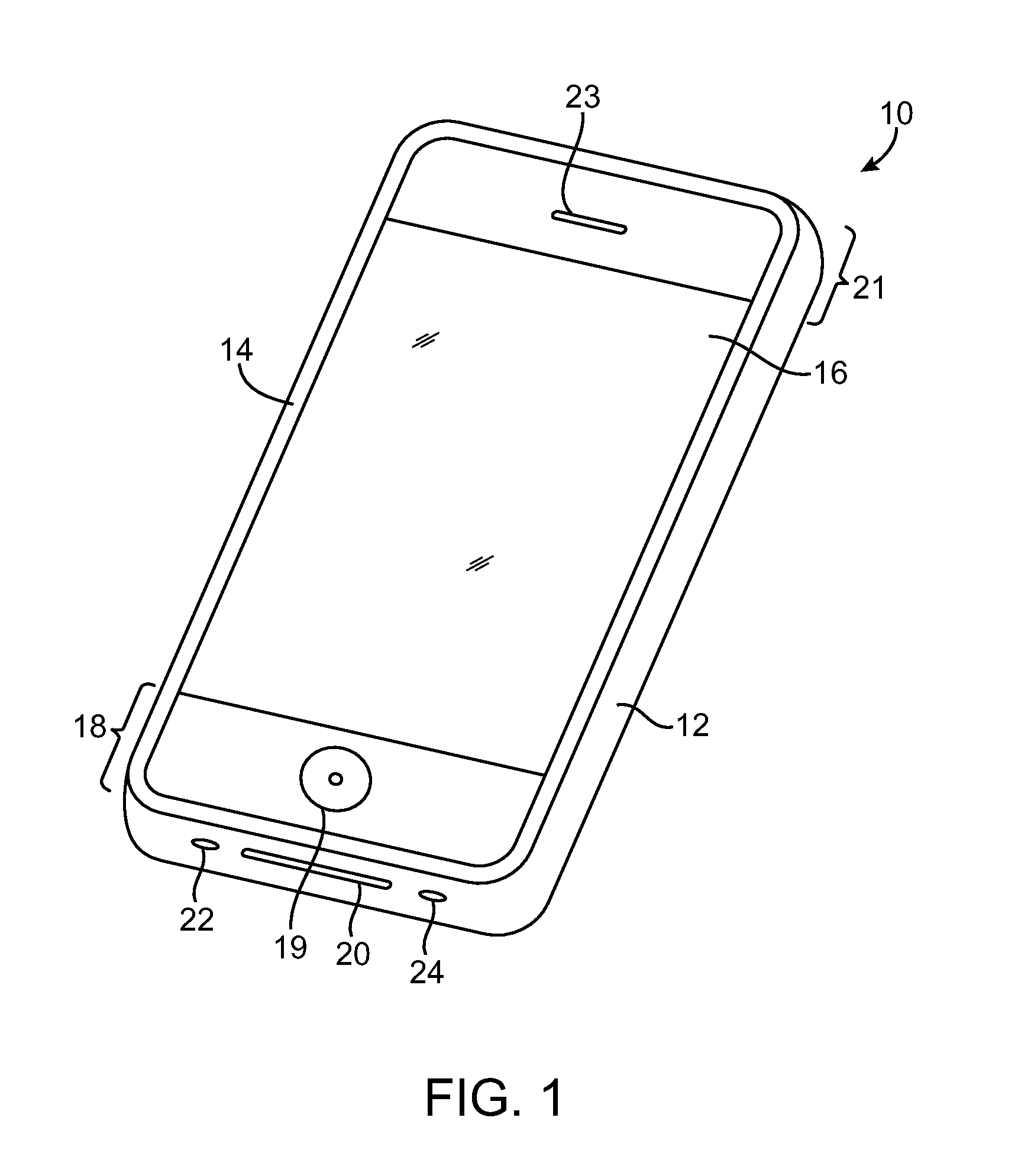

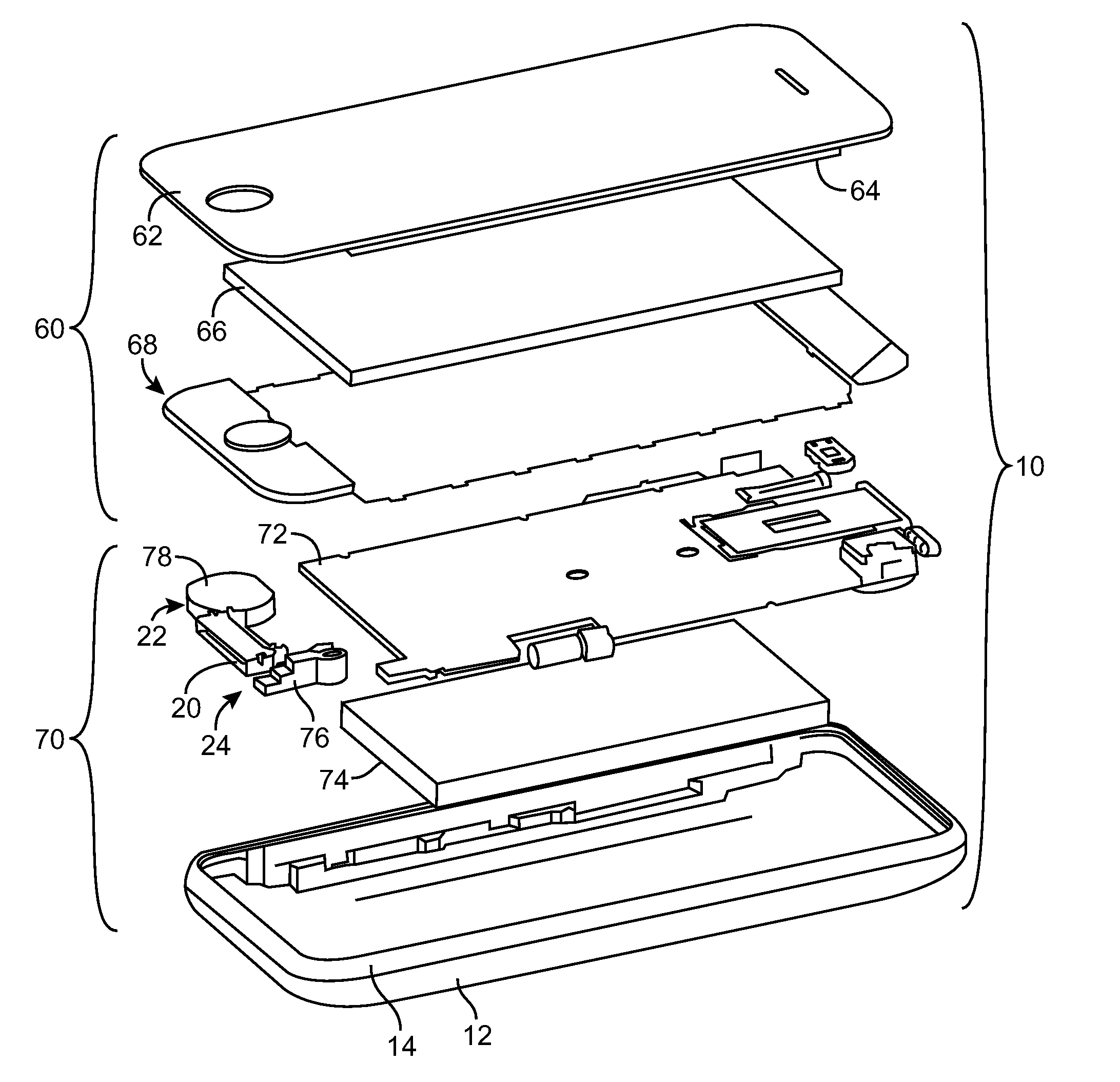

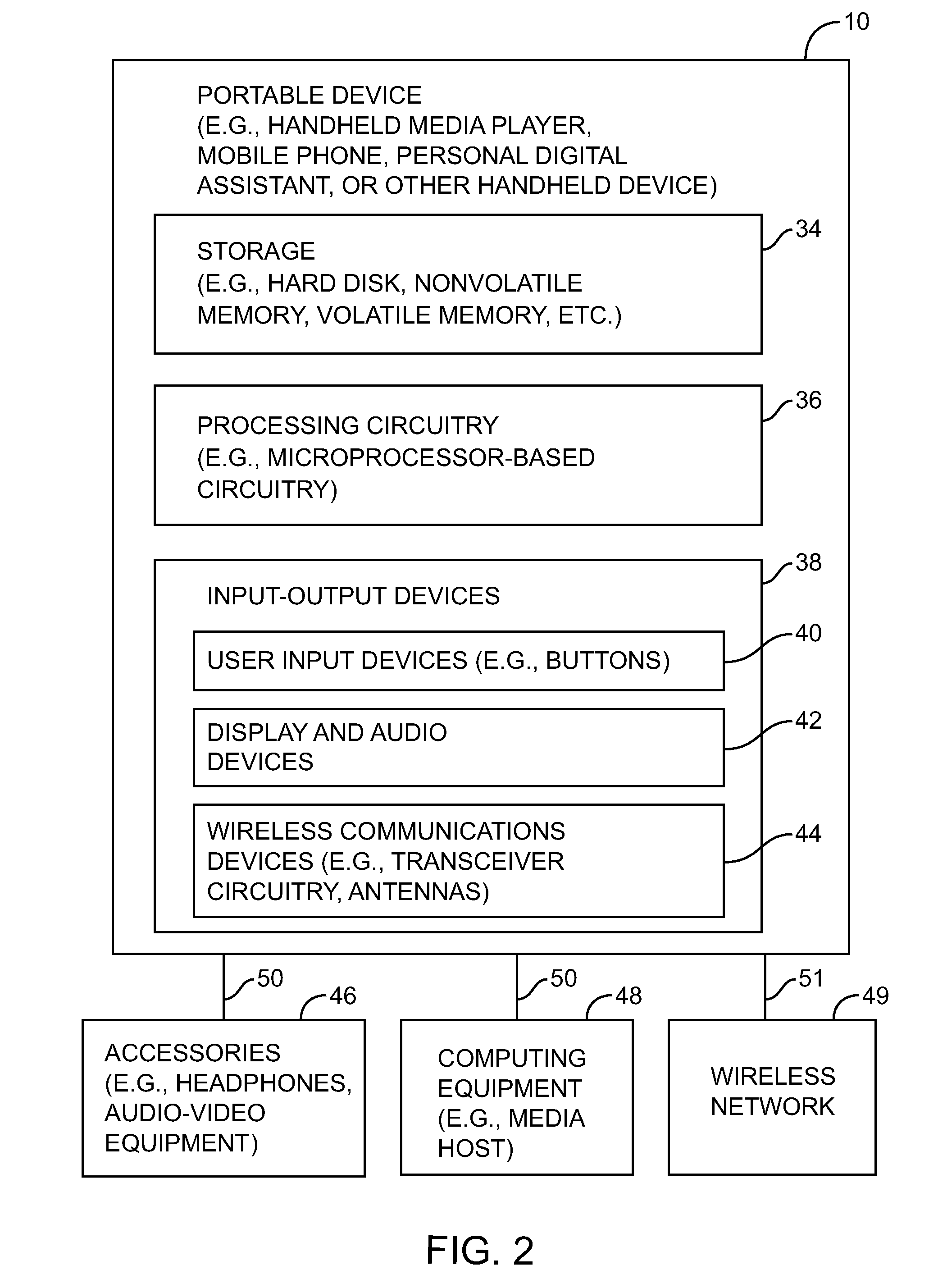

Portable electronic device with two-piece housing

ActiveUS20090257207A1Avoid scratchesDisassembled for rework or repair operationsWave amplification devicesMagnetic/electric field screeningDisplay deviceEngineering

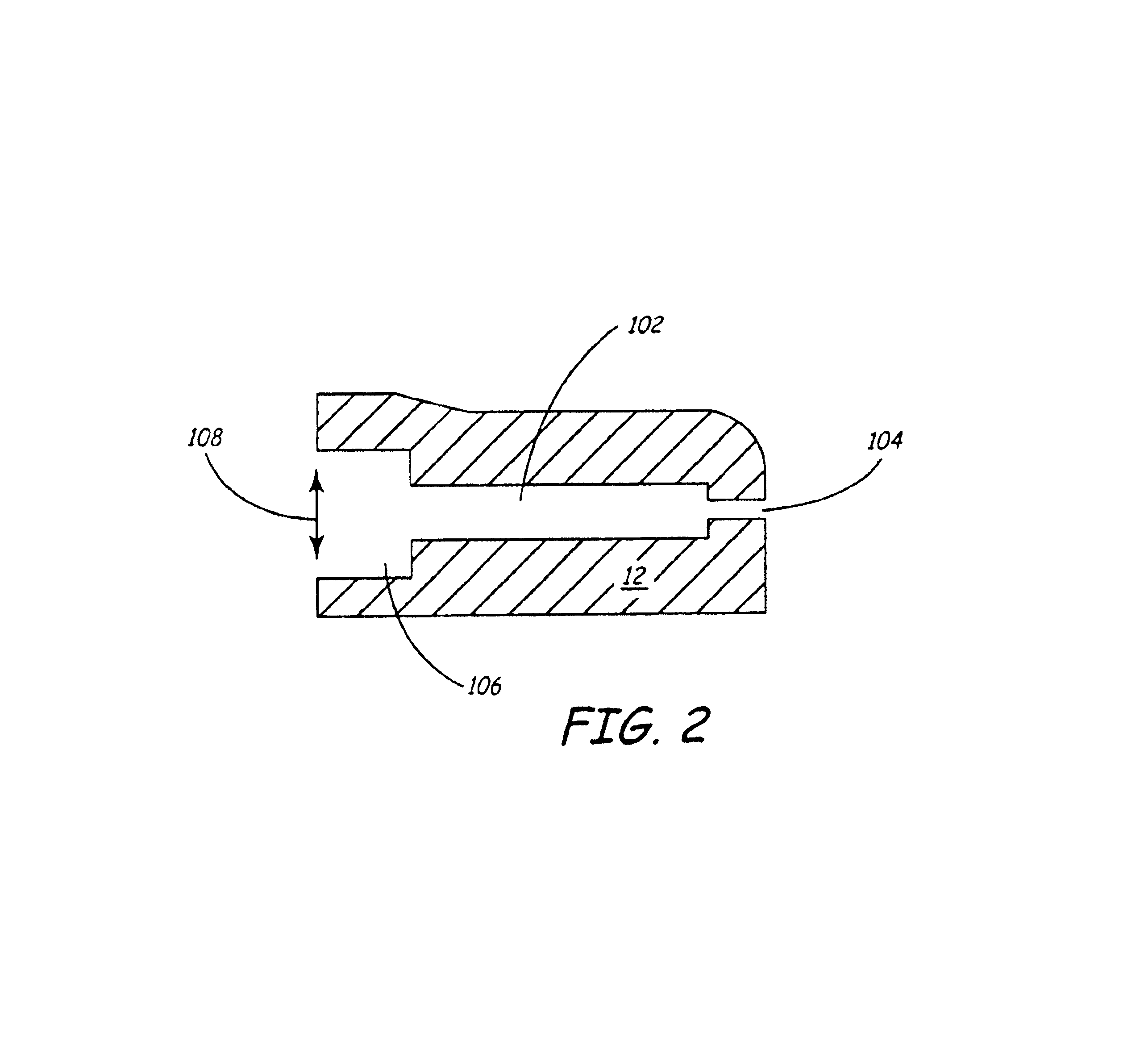

Portable electronic devices are provided. Each device may be formed from two parts. A first part may be provided with components such as a display, a touch screen, a cover glass, and a frame. A second part may be provided with a plastic housing, circuit boards containing electrical components, and a bezel. Engagement members may be connected to the first and second parts. The engagement members may be formed from metal clips with holes and springs with flexible spring prongs that mate with the holes in the clips. The metal clips may be welded to frame struts on the frame and the springs may be welded to the bezel. During assembly, the first part may be rotated into place within the second part. Retention clips attached to the frame may be used to secure the two parts together. Assembly instructions and associated connector numbers may be provided within the devices.

Owner:APPLE INC

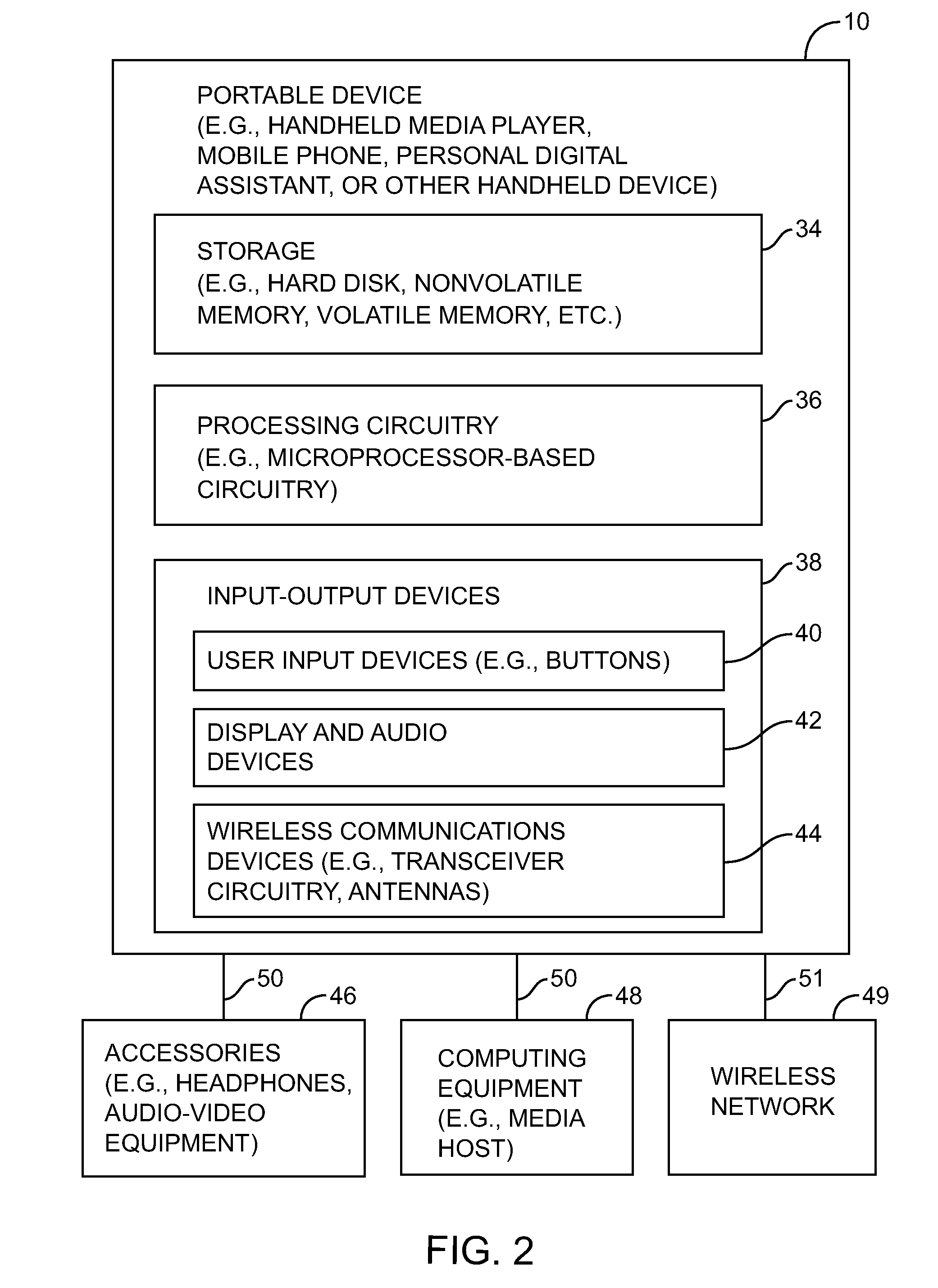

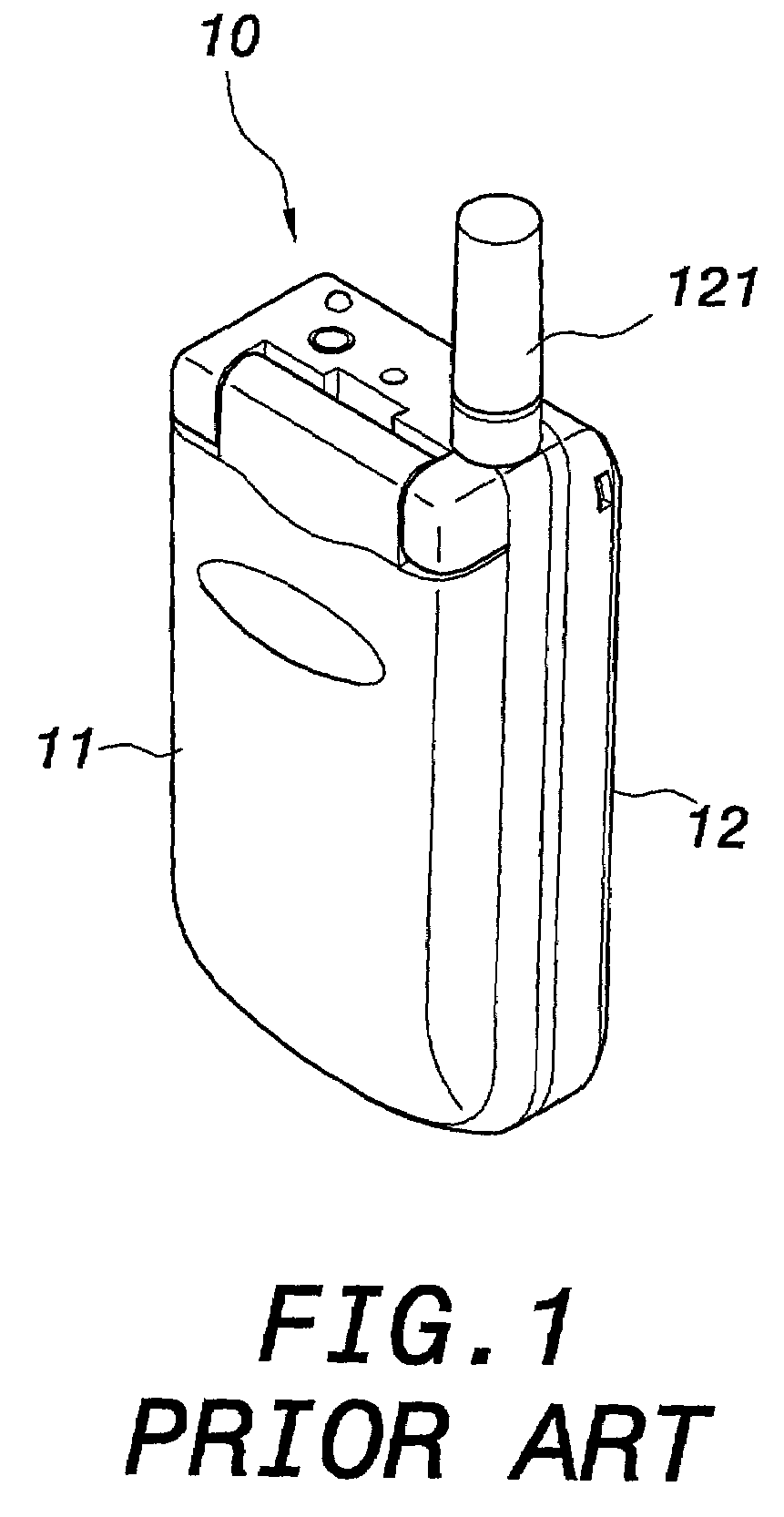

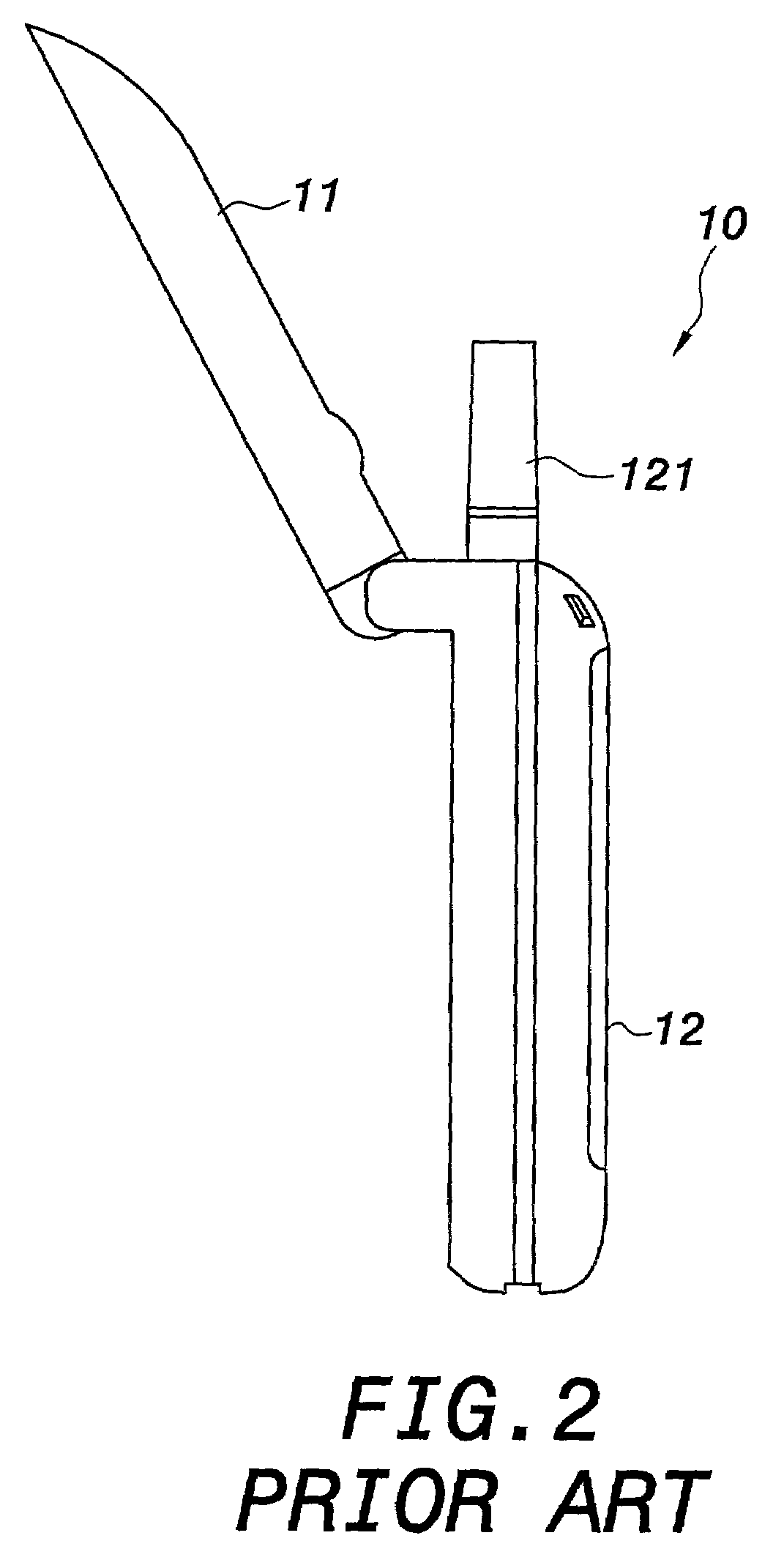

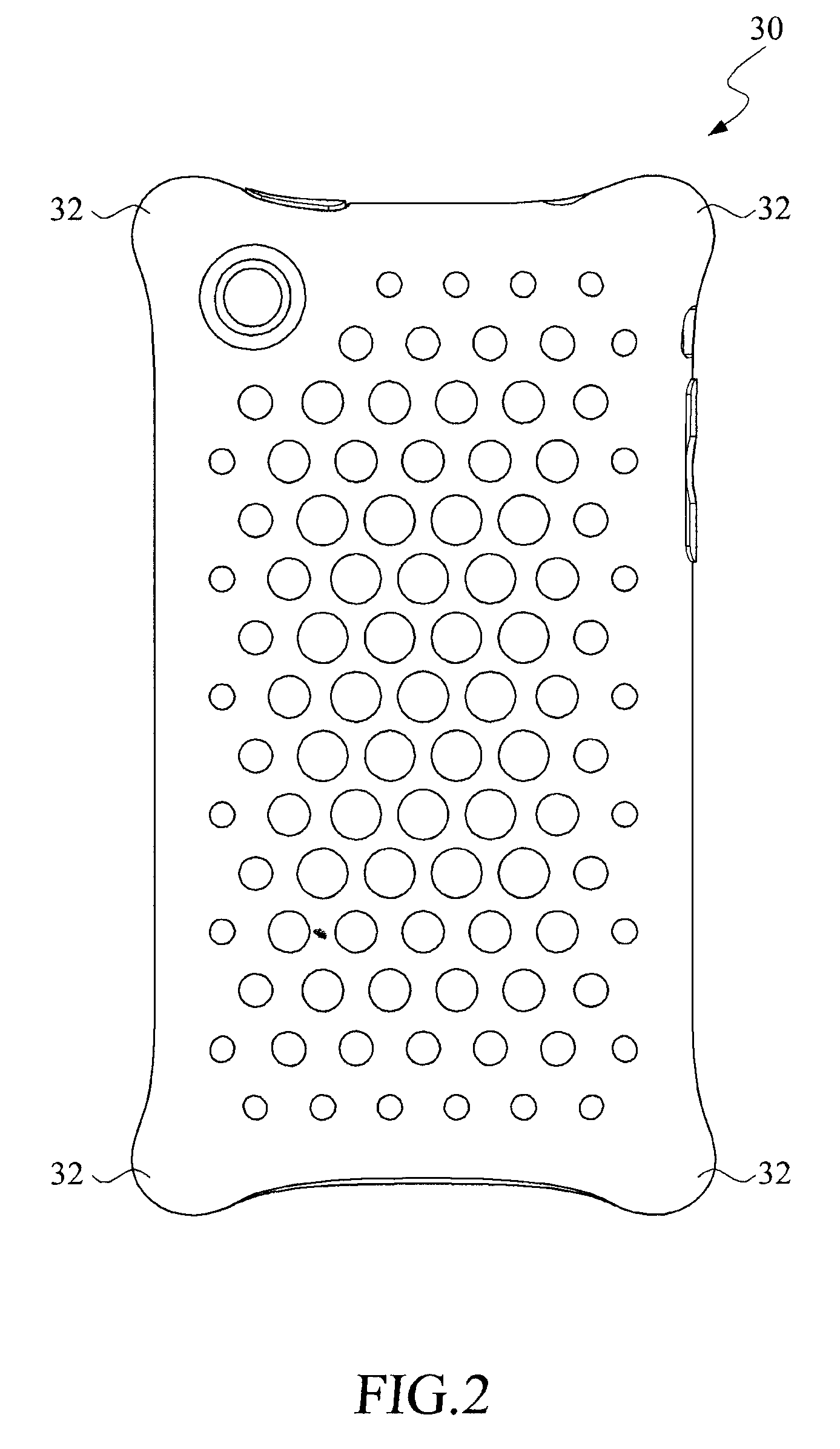

Protective mask of mobile phone

InactiveUS7194291B2Avoid scratchesPreventing ill-favored scars on the mobile phoneInterconnection arrangementsSubstation equipmentEngineeringCarelessness

The present invention relates to a protective mask of mobile phone comprising an upper cover body and a lower cover body. The upper and lower cover bodies can be joined with a front and a rear phone housings of a mobile phone, respectively, to effectively prevent abrasion of the mobile phone due to carelessness of a user, thereby preventing ill-favored scars on the mobile phone. Therefore, the deterioration of the quality of the mobile phone and the fall of its value can be avoided. Moreover, trend and fashion of the mobile phone can be achieved without the need of replacing the mobile phone. Therefore, waste of money can be avoided, and economic burden to the user can be lessened.

Owner:BELAIR ELECTRONICS INC

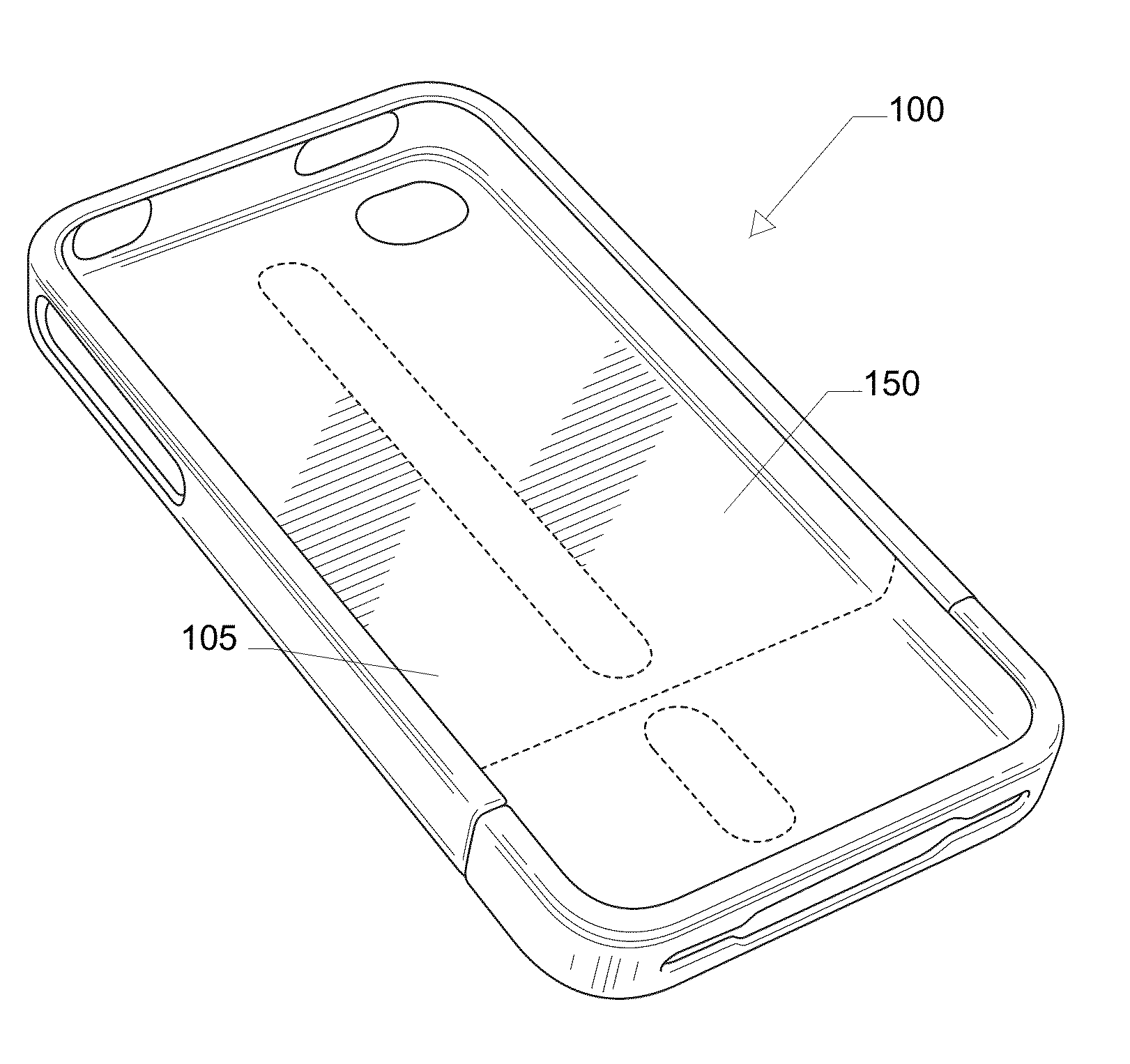

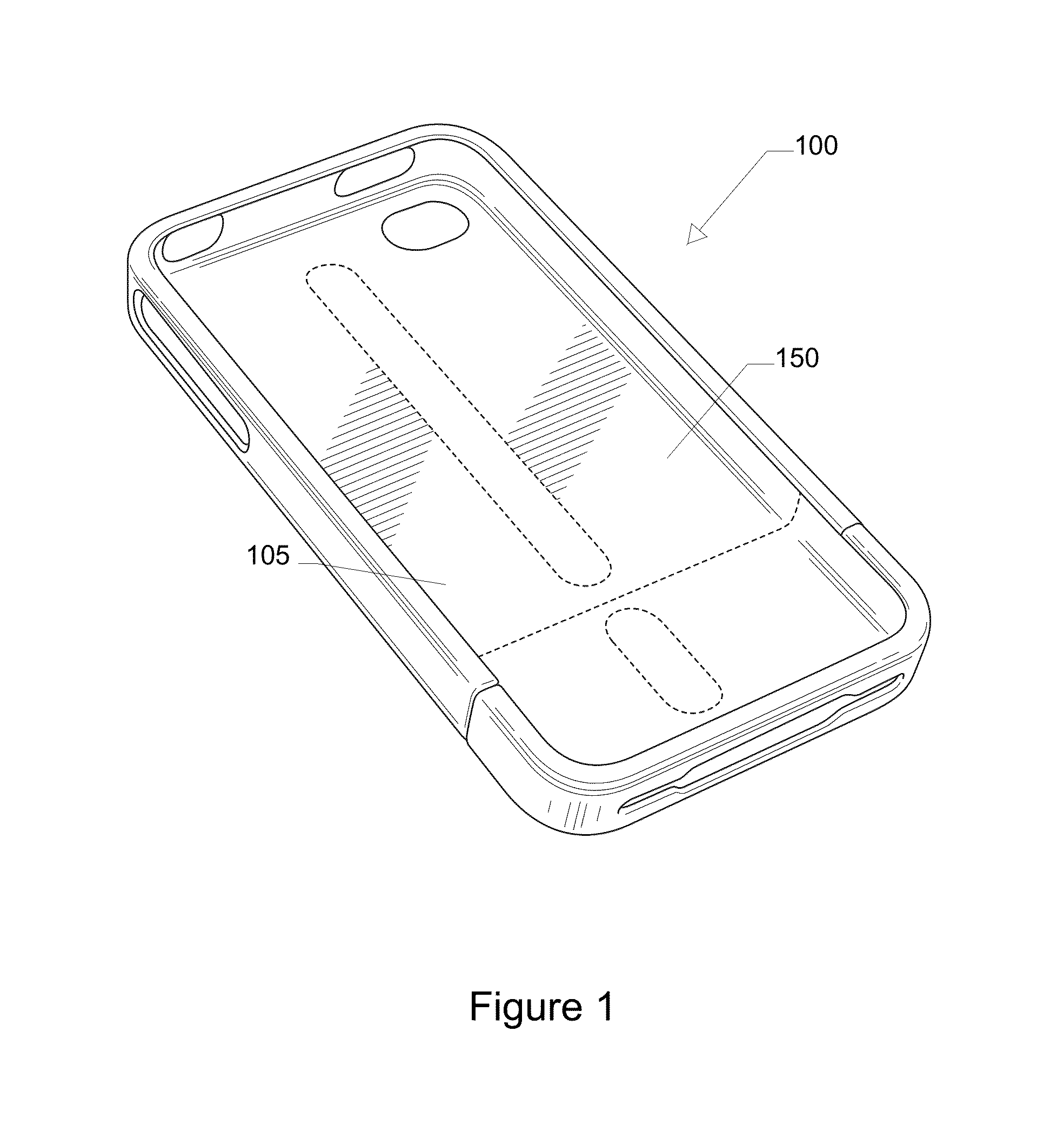

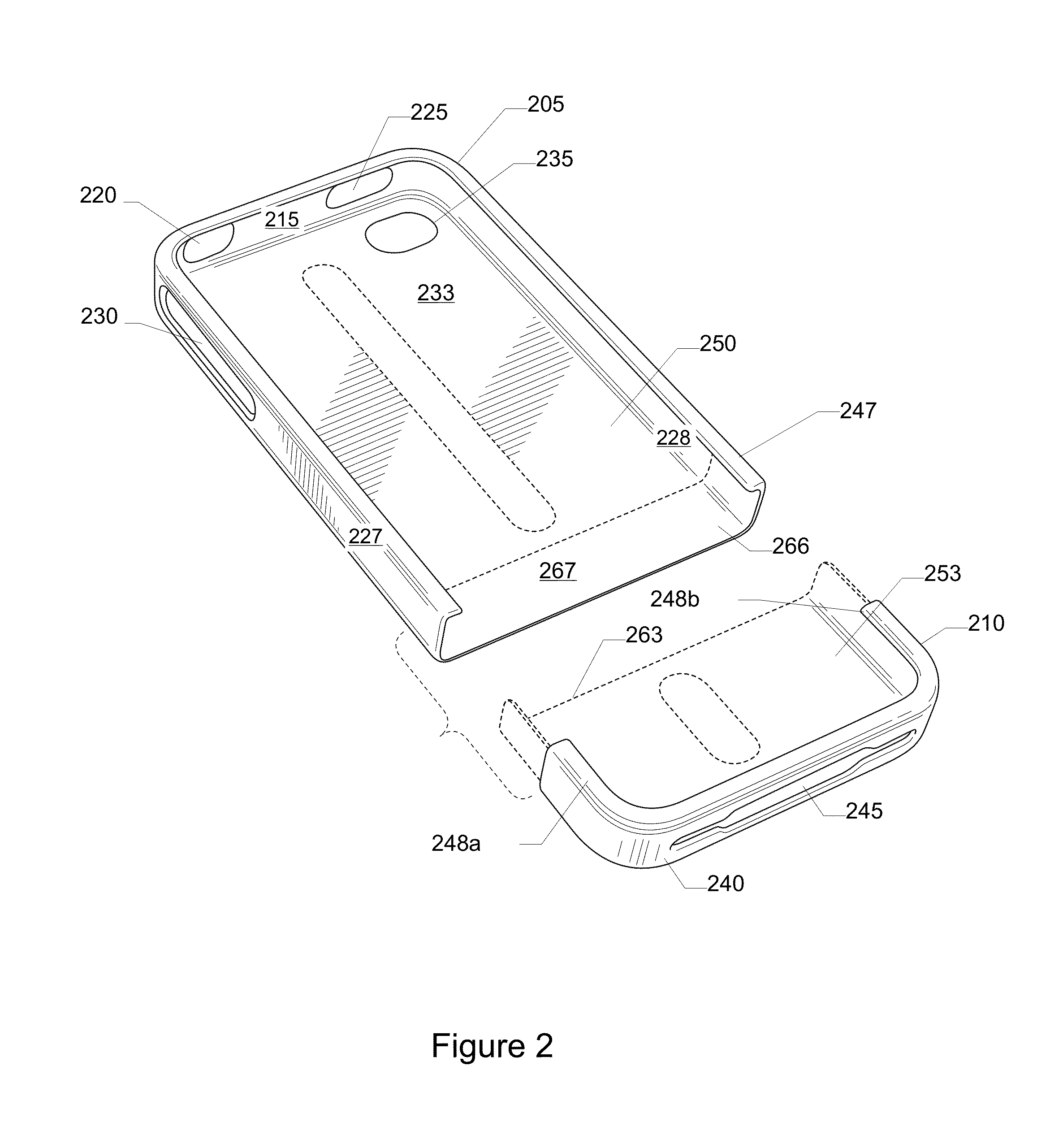

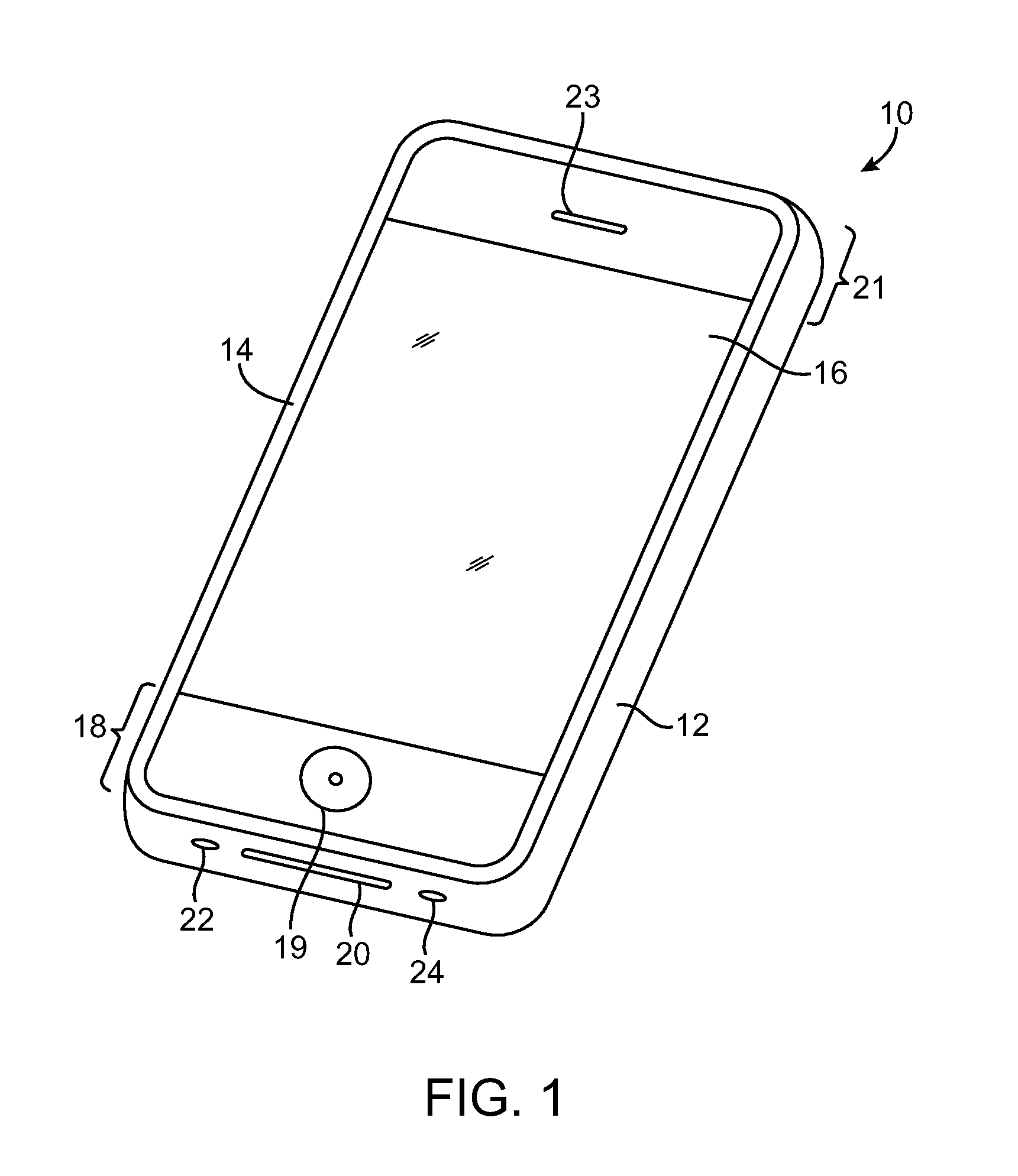

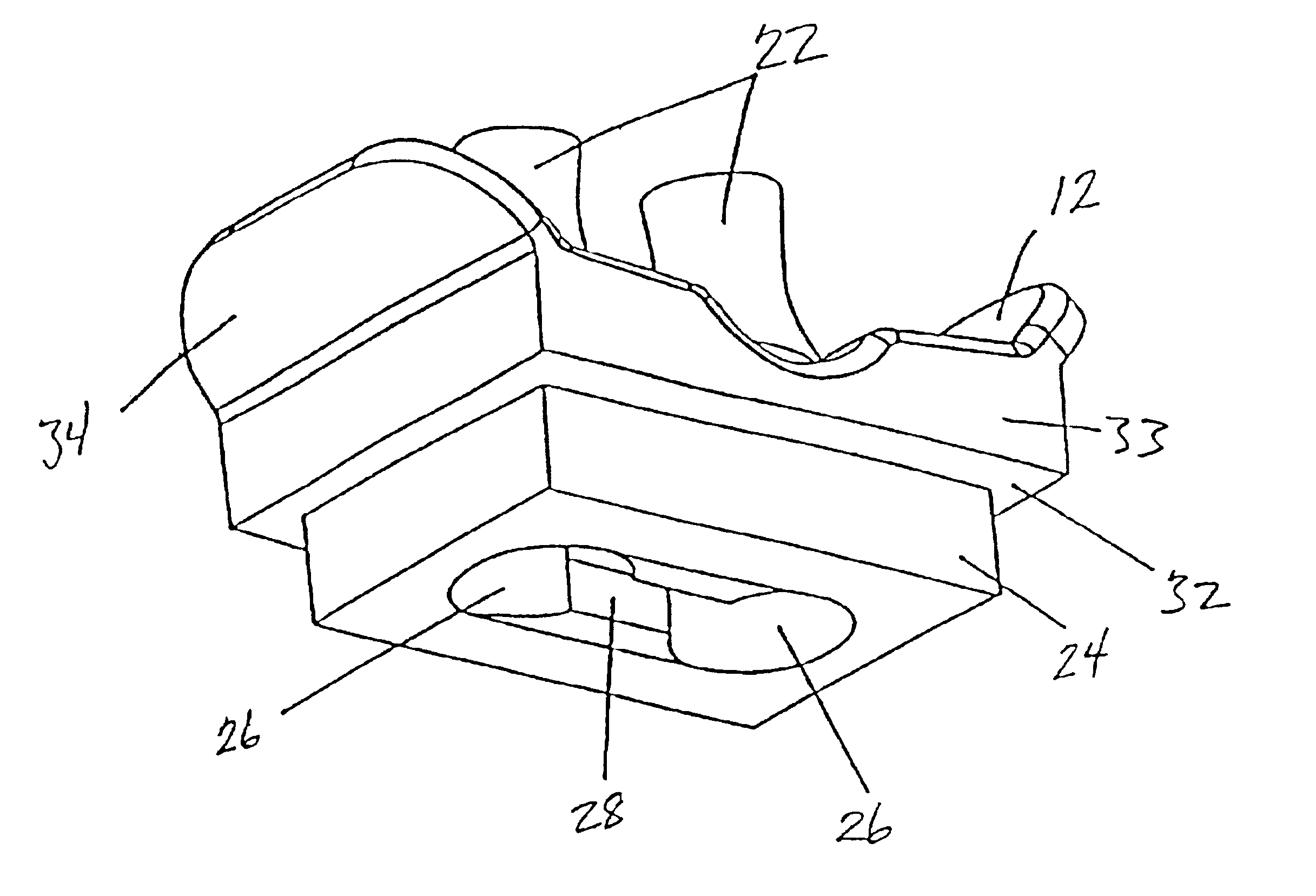

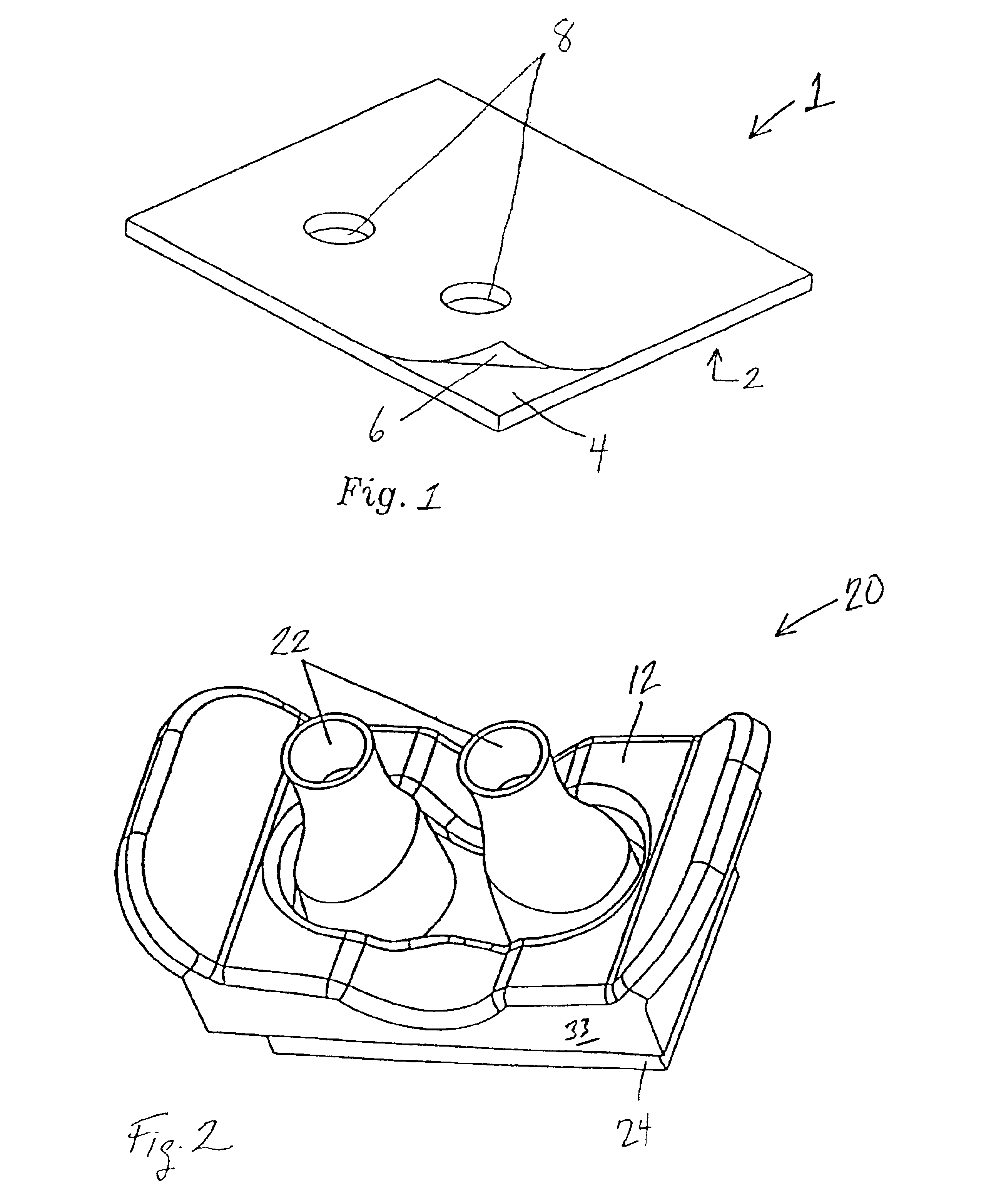

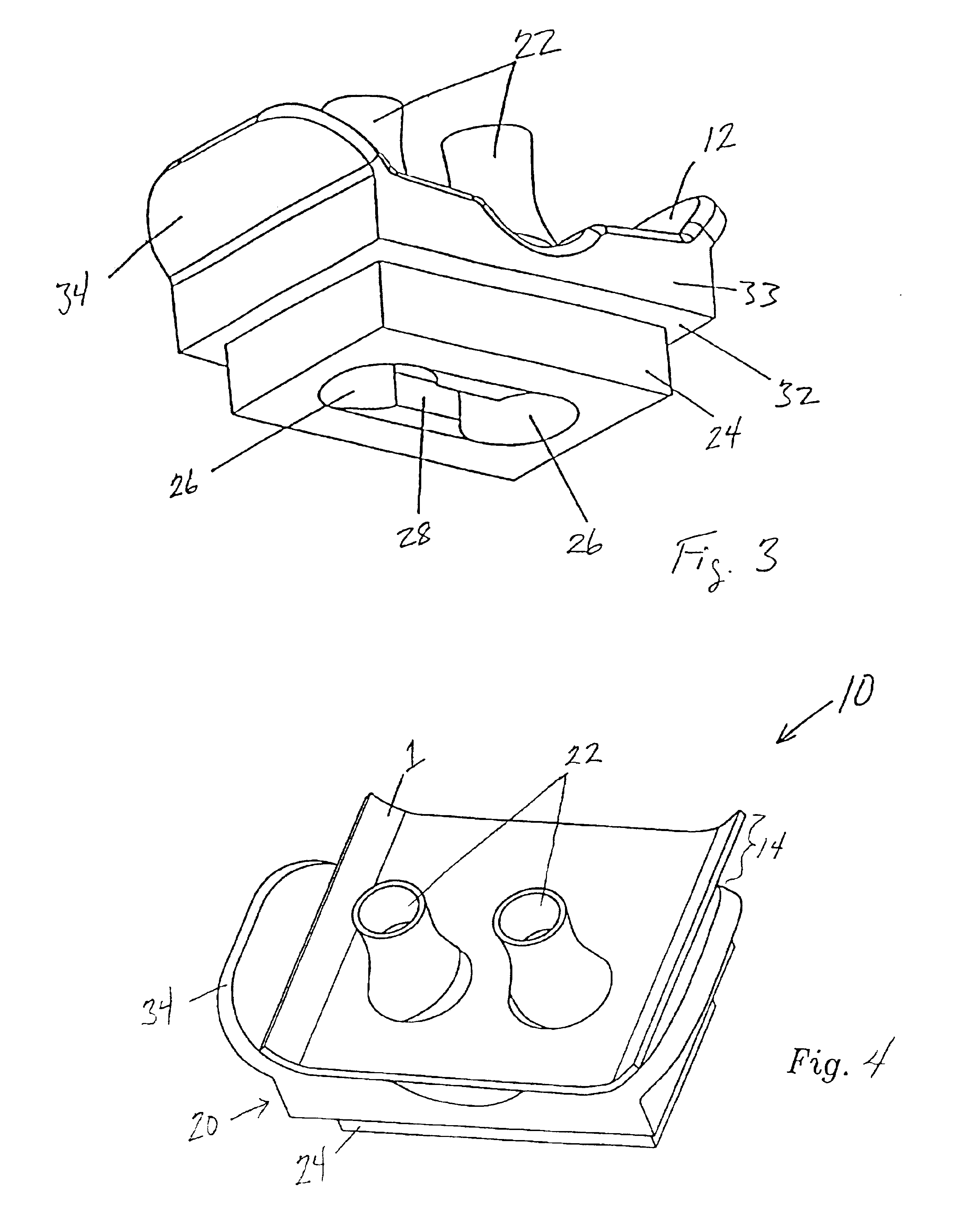

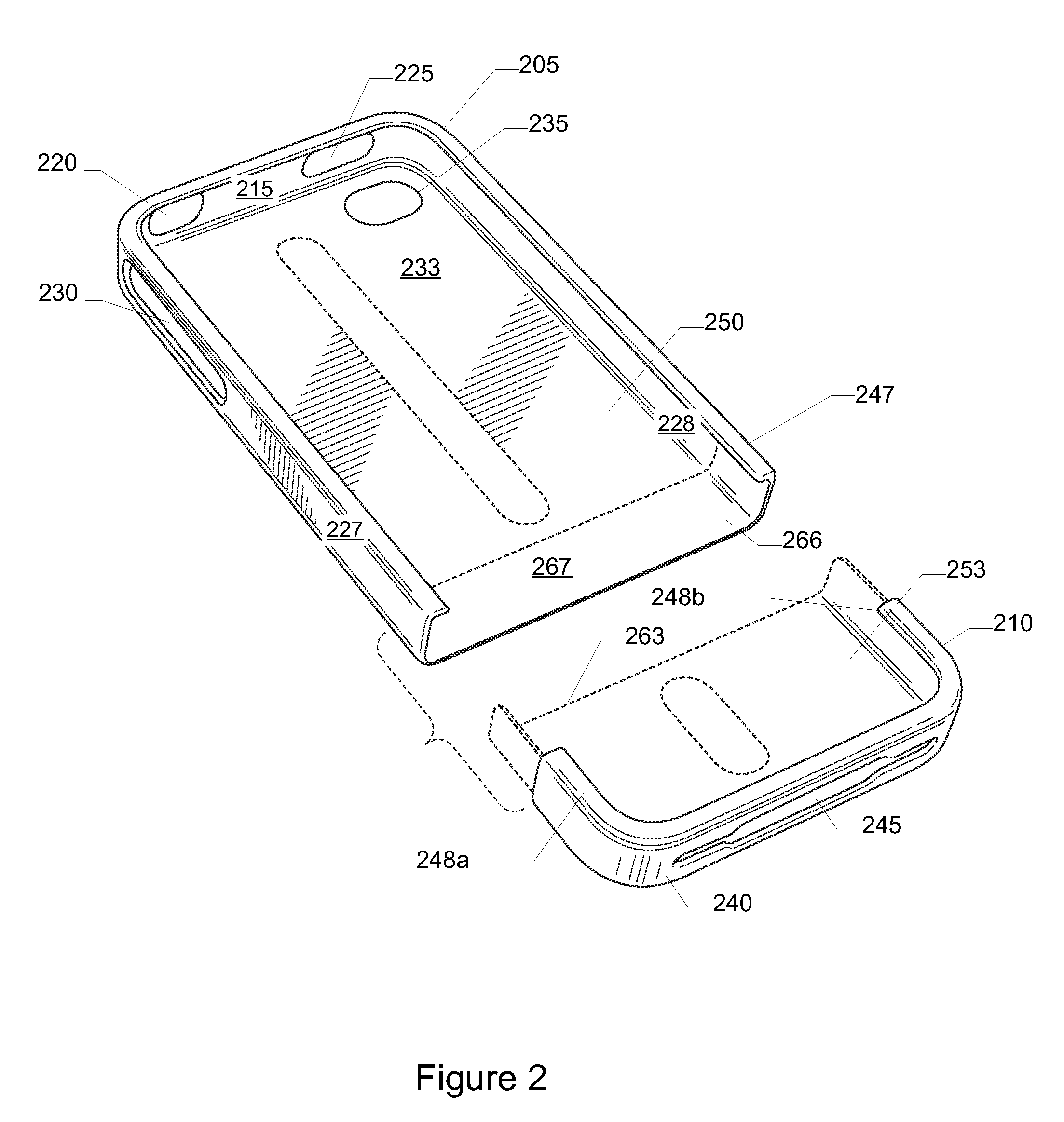

Case for portable electronic device

InactiveUS8457701B2Avoid scratchesConnection securityAdditive manufacturing apparatusDigital data processing detailsCamera lensEngineering

A case for an electronic device protects the electronic device. The case has a lower case portion and an upper case portion, which assemble together to protect the electronic device. A back of the case can include a back opening to expose a camera lens and flash of the electronic device or first and second back openings. The first back opening exposes the camera lens. The second back opening exposes the flash.

Owner:VINCI BRANDS LLC

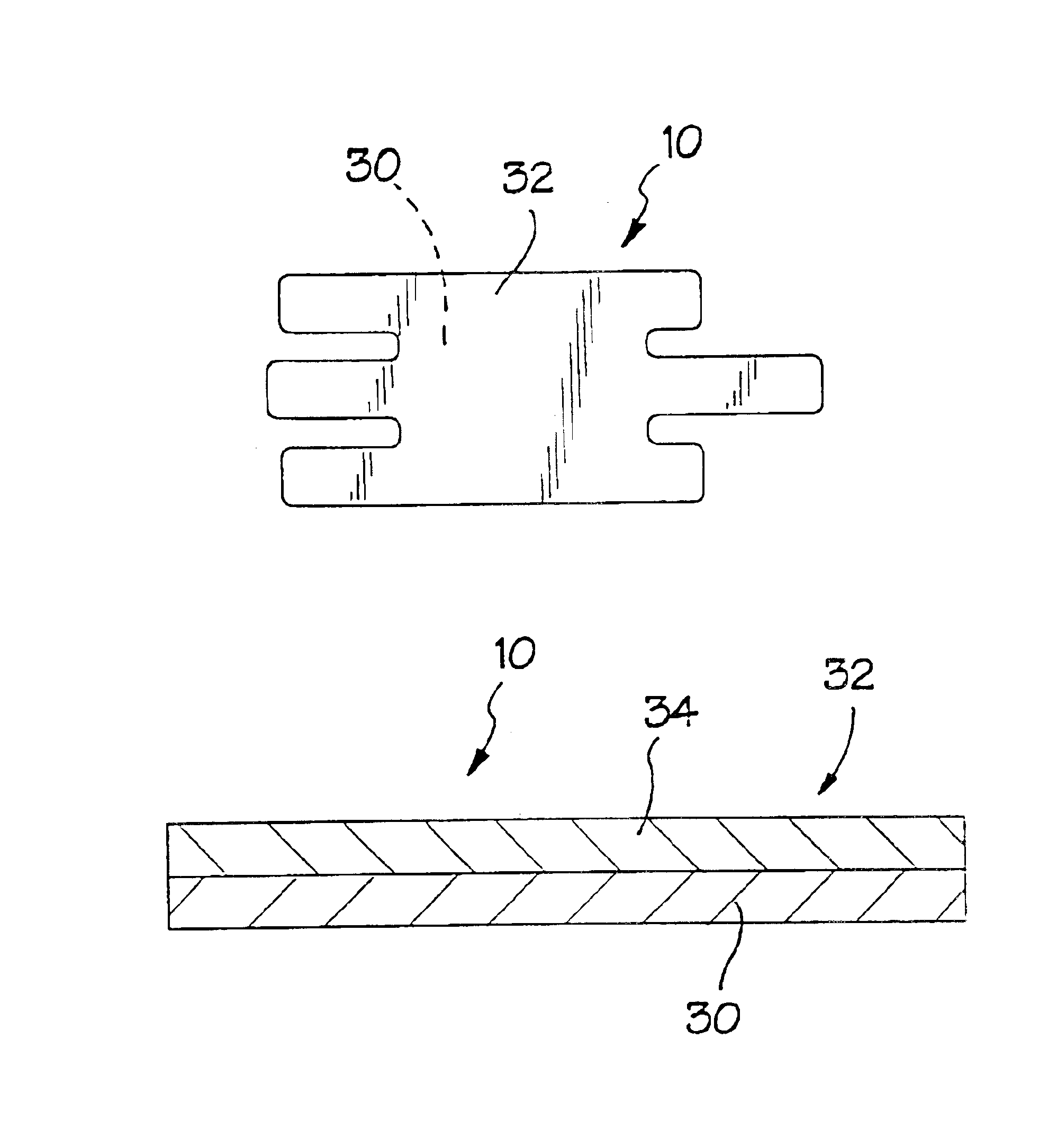

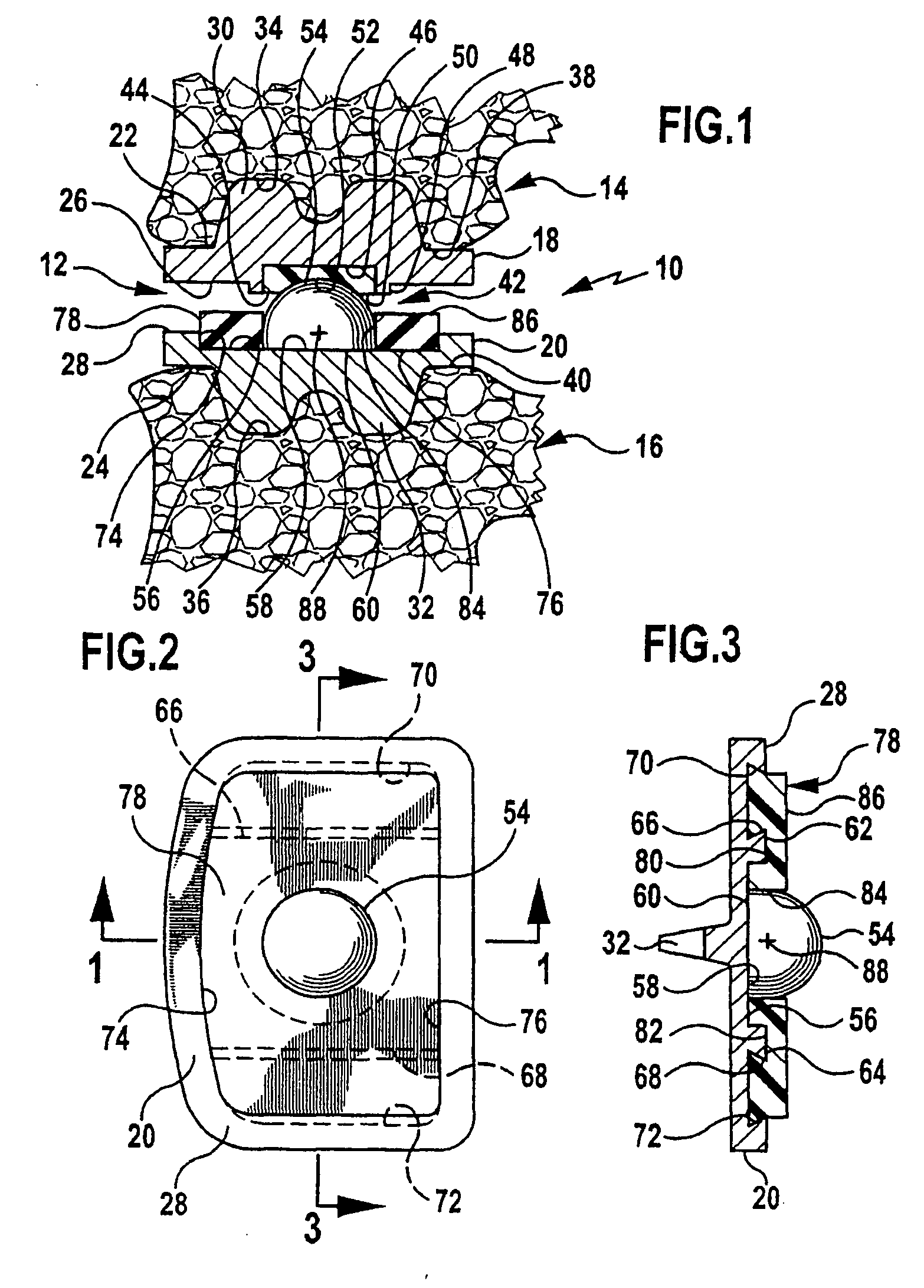

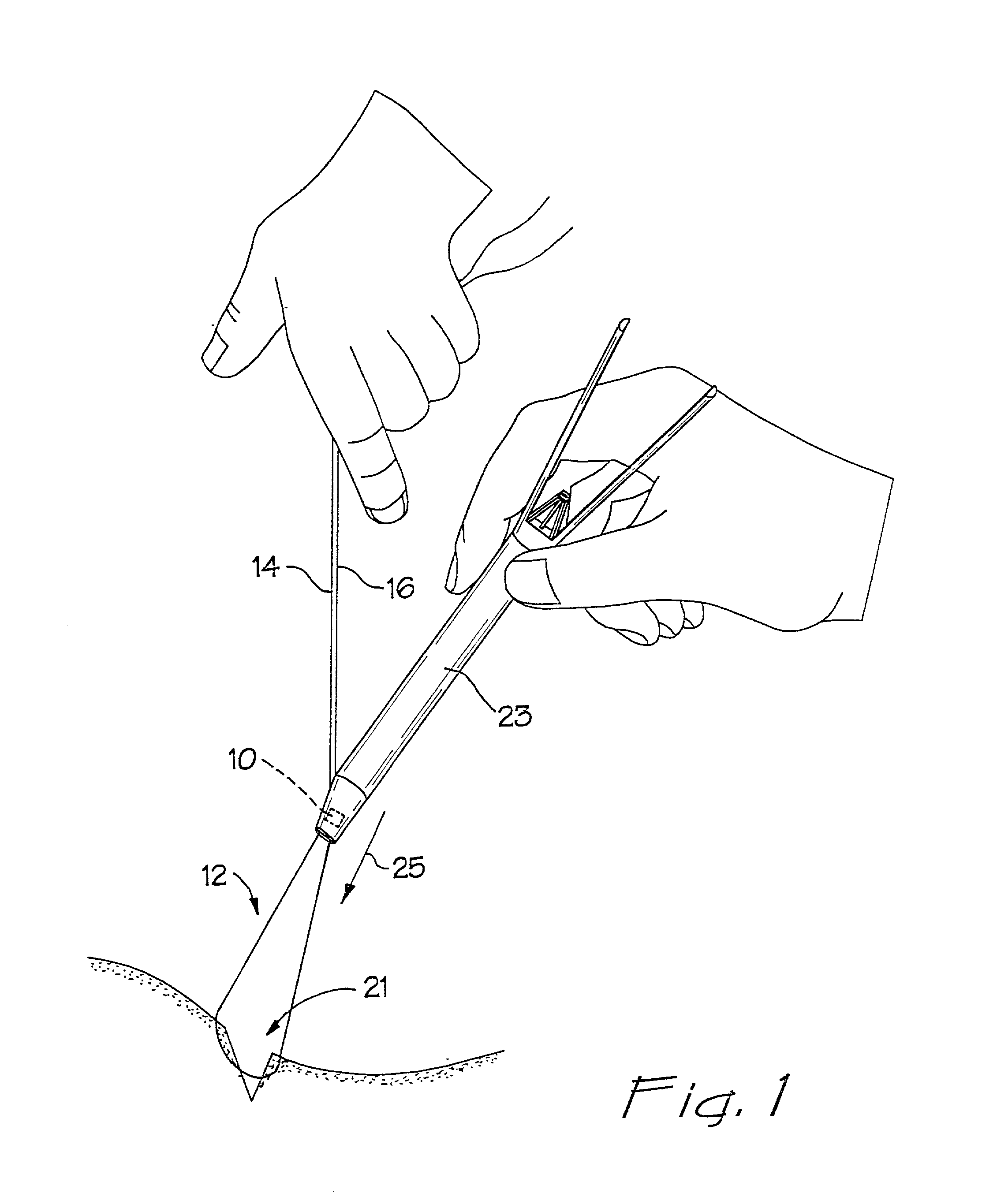

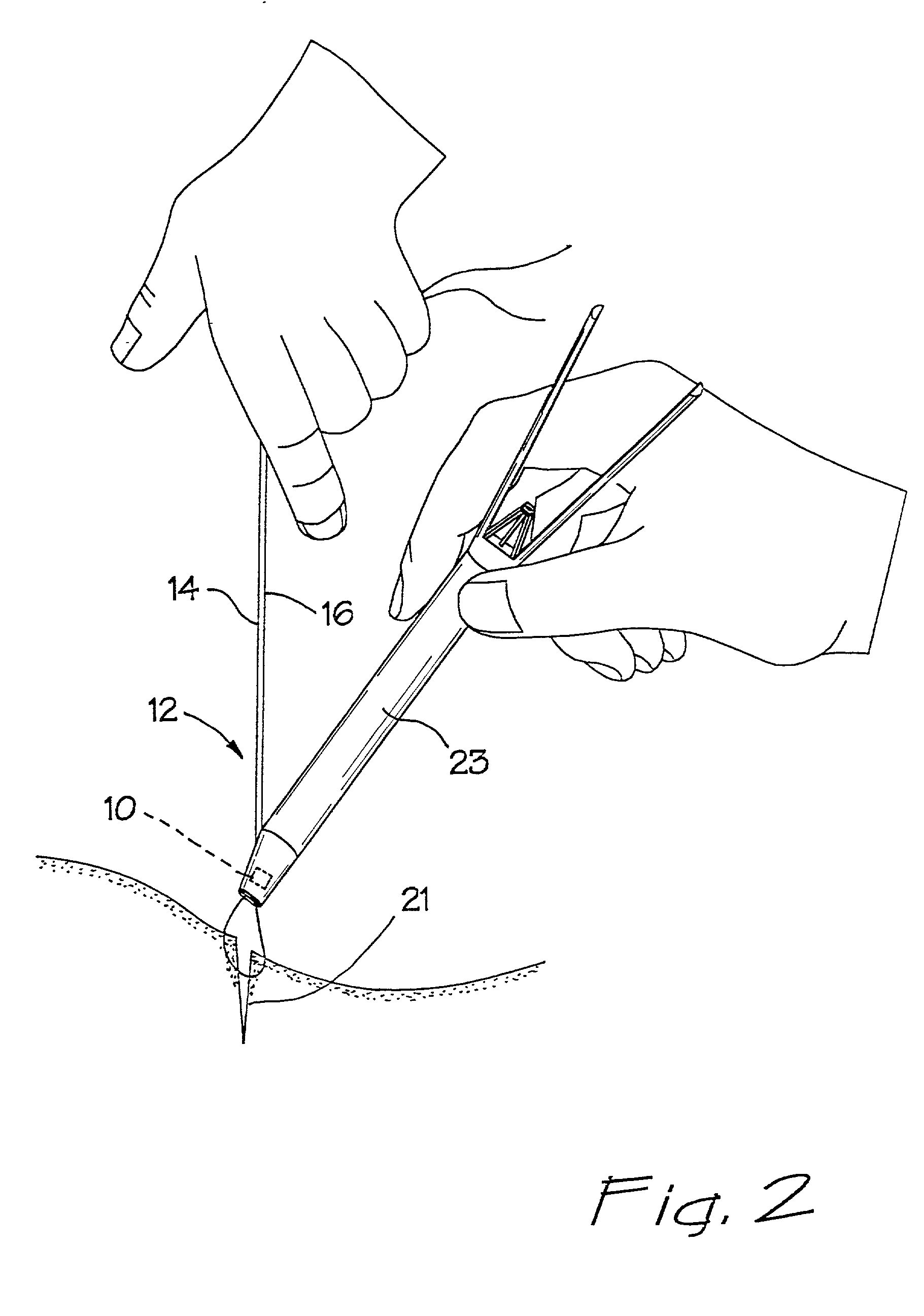

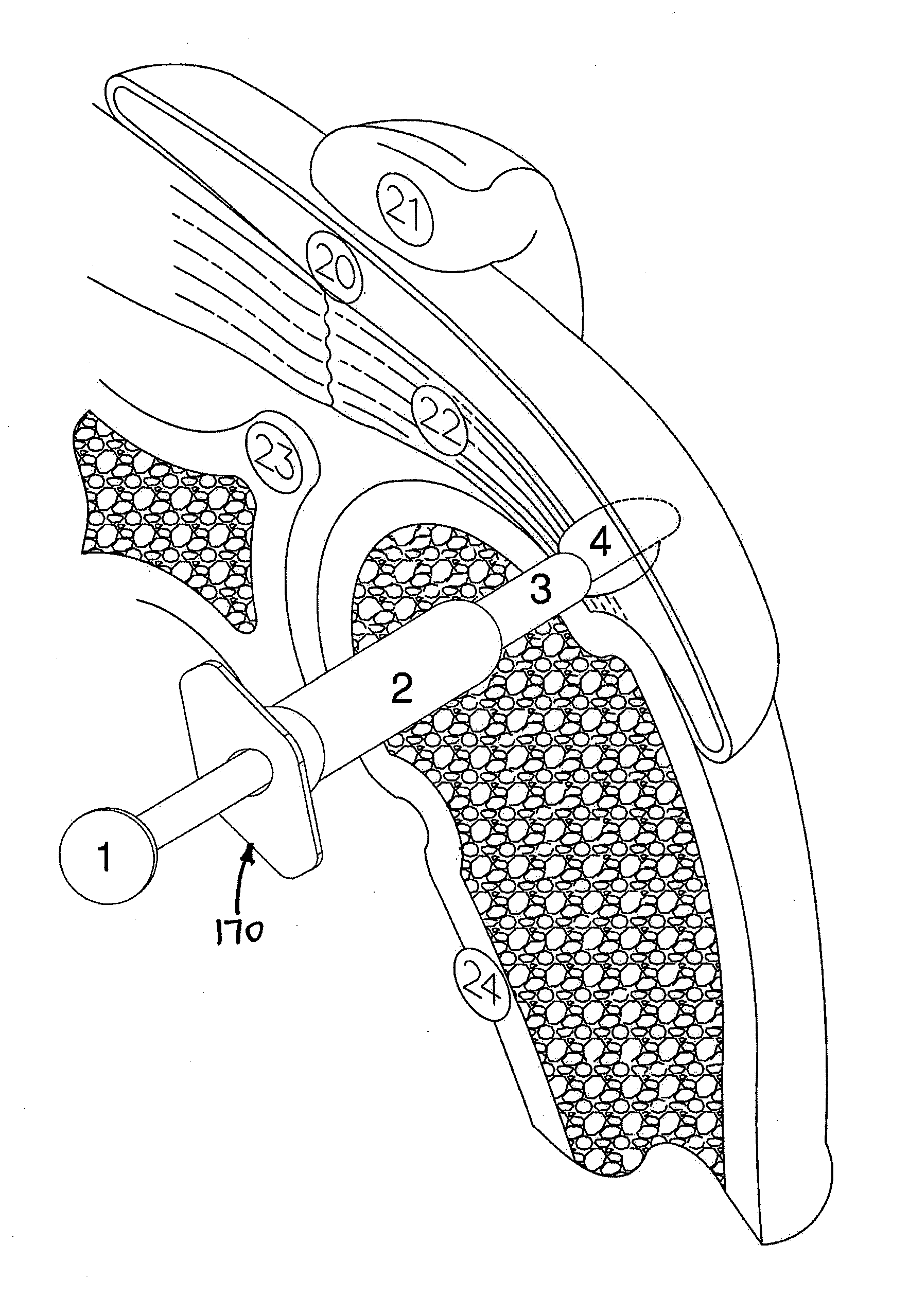

Surgical clip

InactiveUS6818009B2Increase frictionIncrease contact areaSuture equipmentsWound clampsSurgical ClipsSurgical department

A surgical clip having a sliding state and a crimped state is adapted for use in a surgical procedure initially to slide along suture ends to an operative position and ultimately to crimp the suture ends at the operative position. A substrate, bendable between the sliding state and the crimped state carries at least one coating having either lubricious or traction enhancing properties. A second coating can be added to form a coating laminate with the outer coating having lubricious properties facilitating the sliding state and the inner coating having traction enhancing properties facilitating thee crimped state.

Owner:APPL MEDICAL RESOURCES CORP

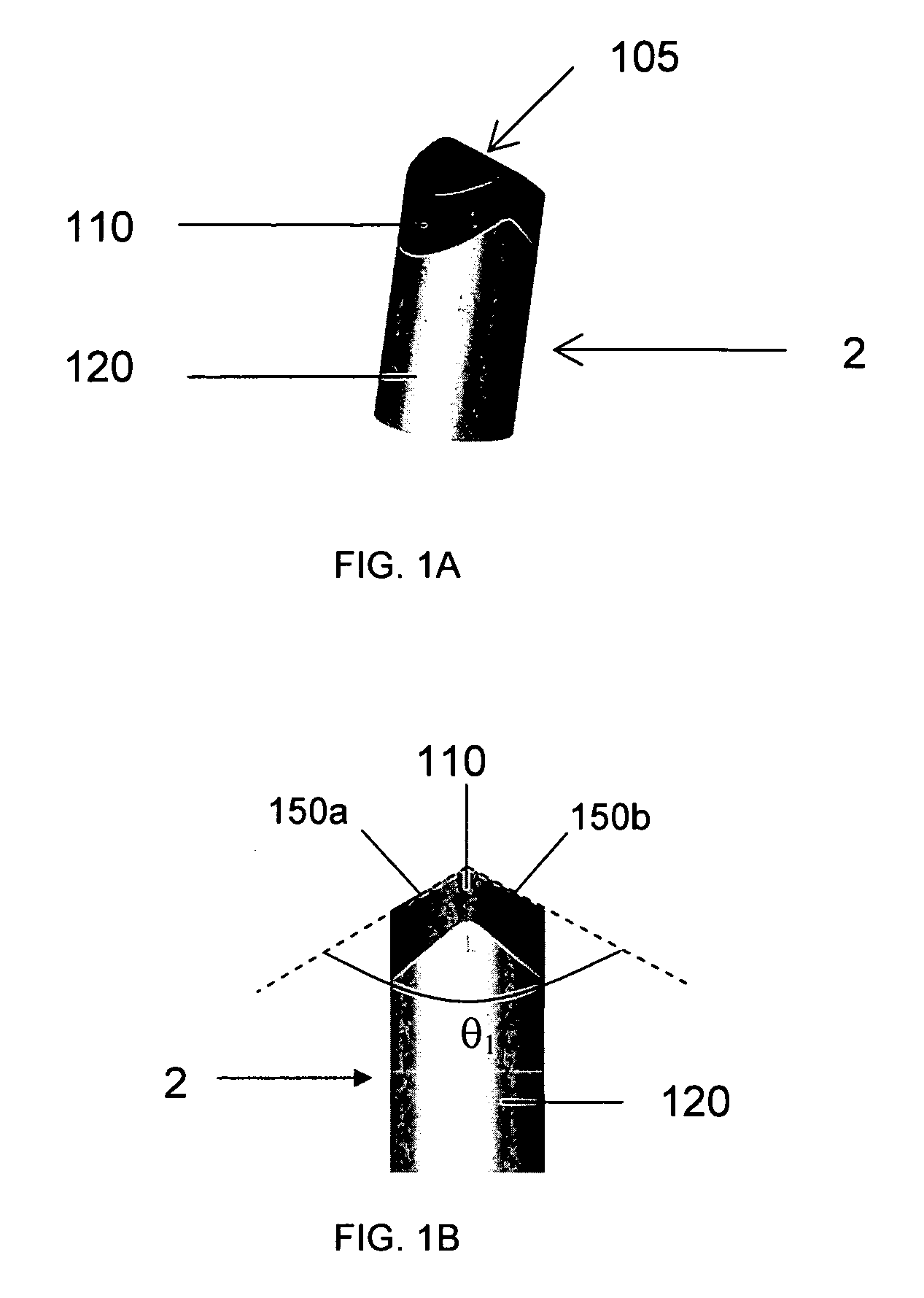

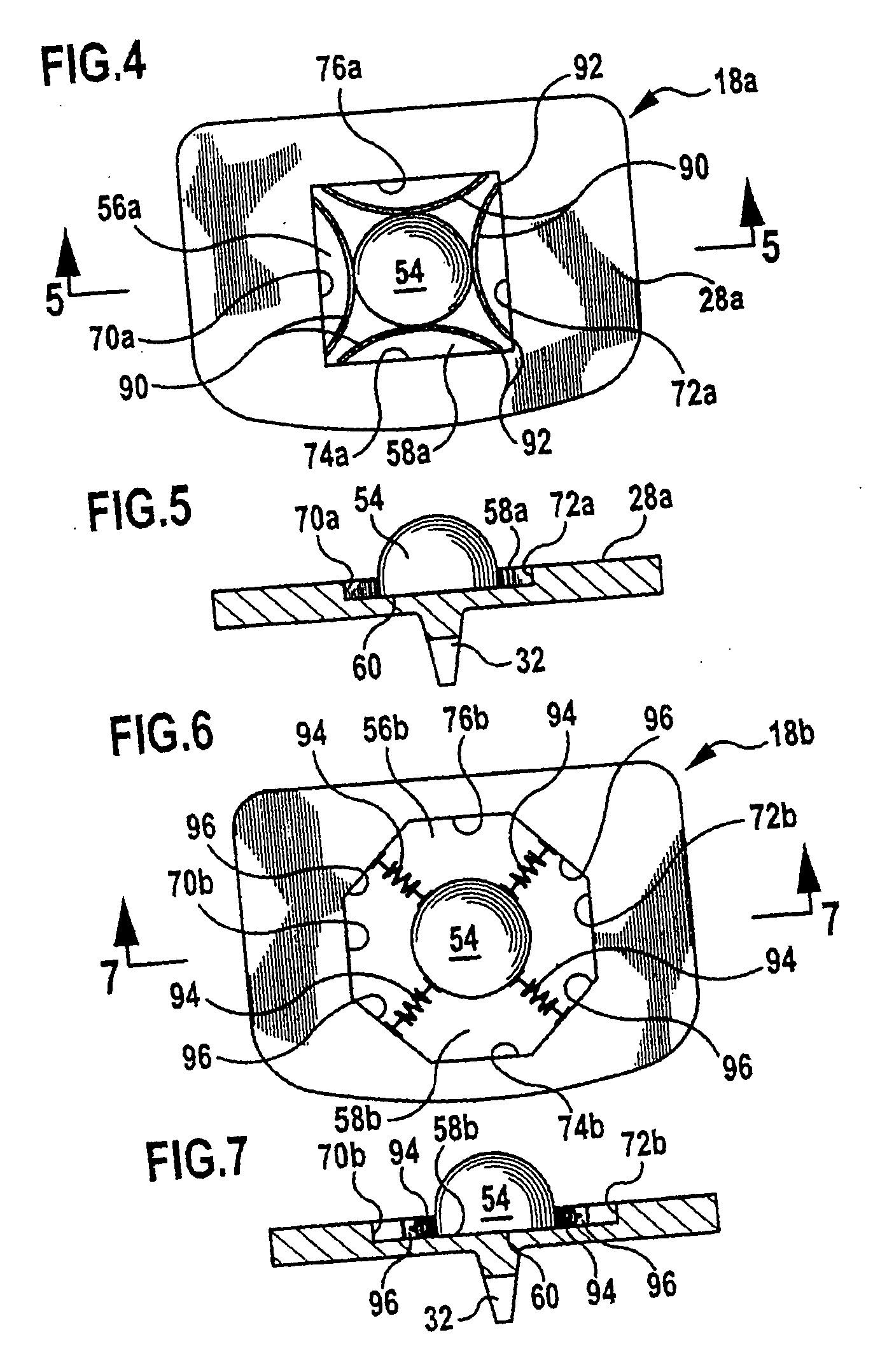

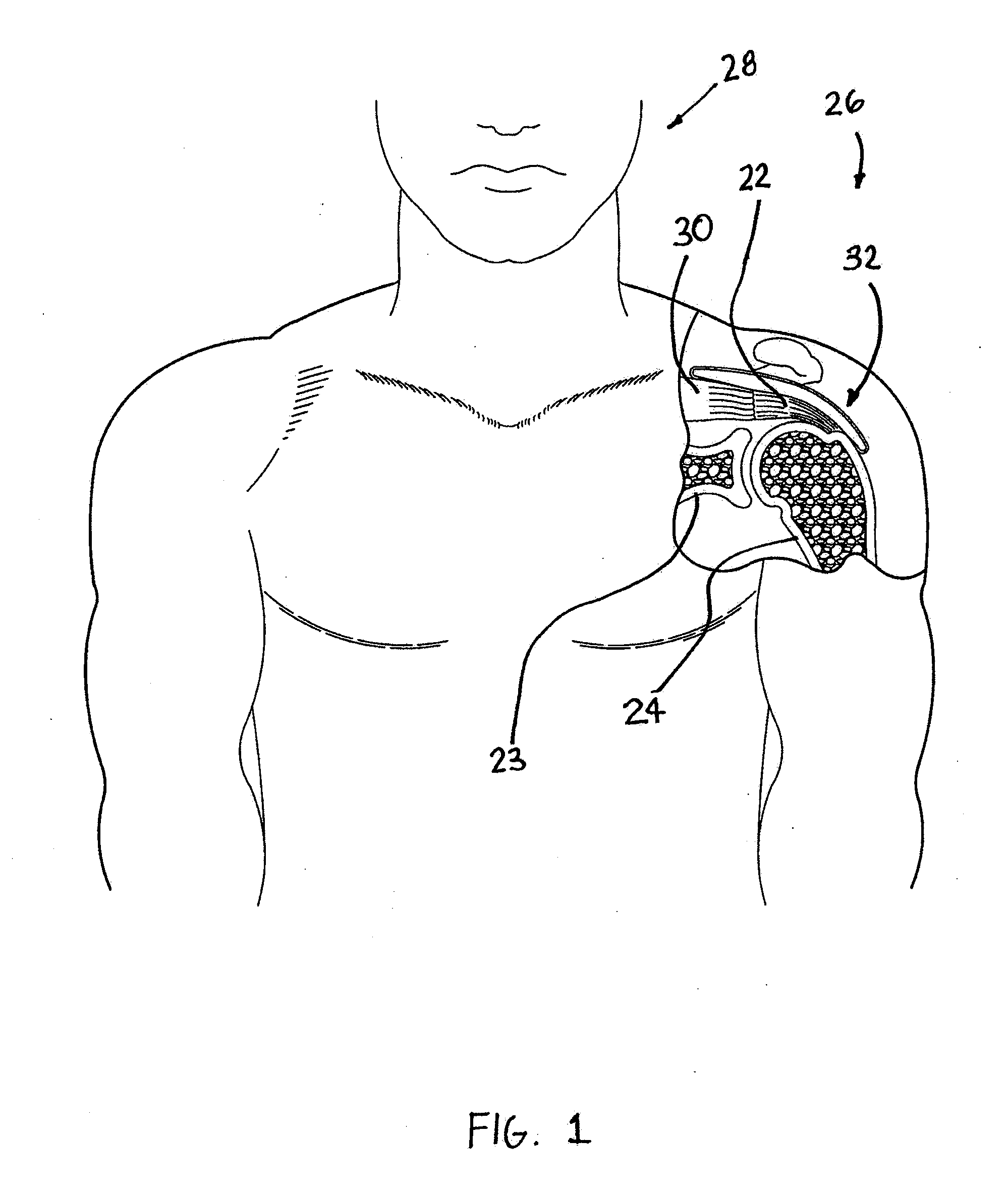

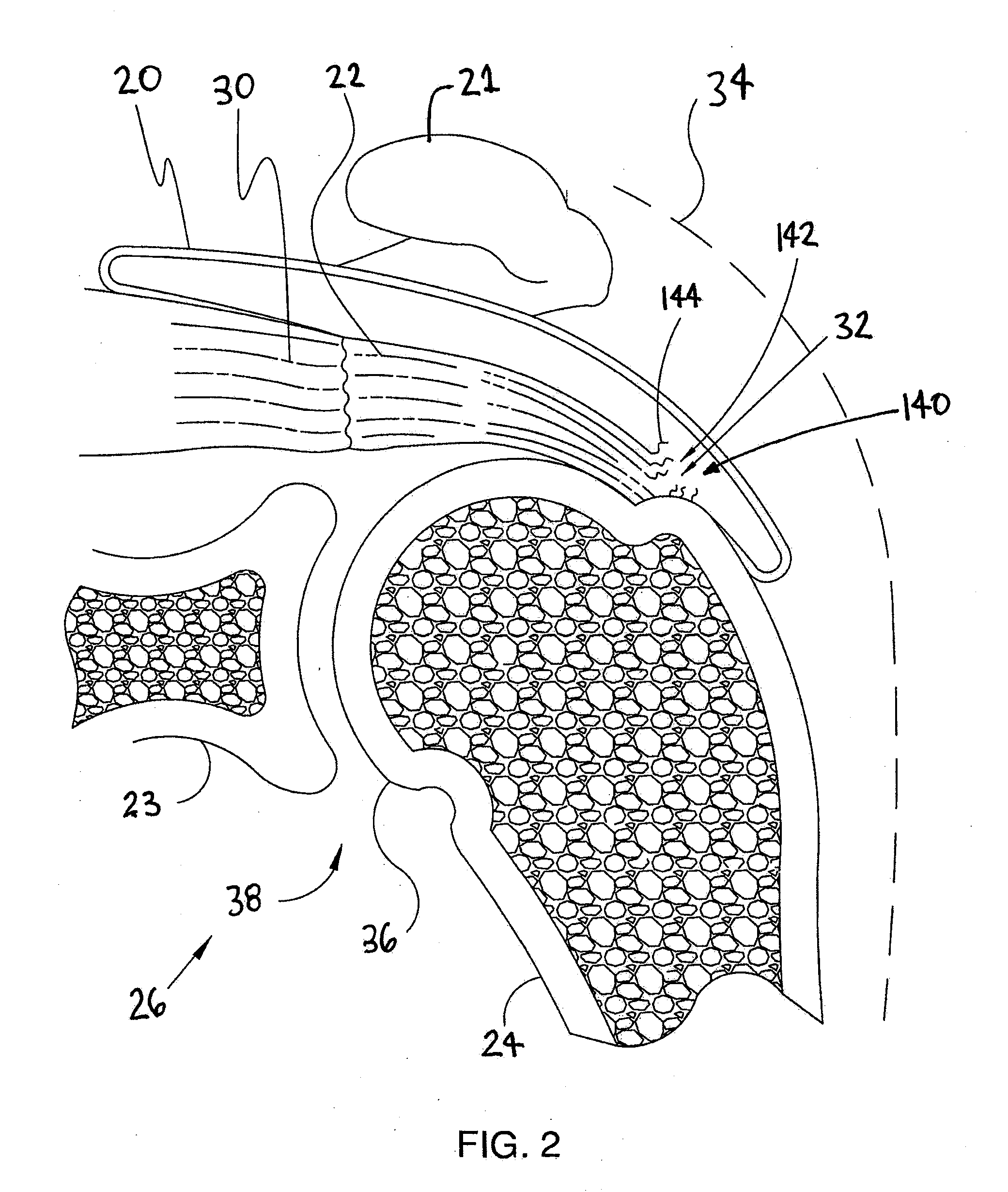

Implants and delivery system for treating defects in articulating surfaces

InactiveUS20060178748A1Precise positioningPrevent rotationDiagnosticsBone implantArticular surfacesTissue defect

The invention provides implant plugs having a complex clinically acceptable proximal surface. The invention also provides multi-phase implant plugs which have a nonplanar proximal surface. Suitable implant proximal surface shapes include, but are not limited to, concave surfaces, convex surfaces, faceted domes and angled surfaces formed by the convergence of two facets. The implants of the invention are suitable for repair of tissue defects in articulating surfaces. The invention also provides delivery devices and methods for delivering the implants of the invention. The invention also provides methods for creating defects suitable for use with the implants of the invention.

Owner:OSTEOBIOLOGICS

Intervertebral implant

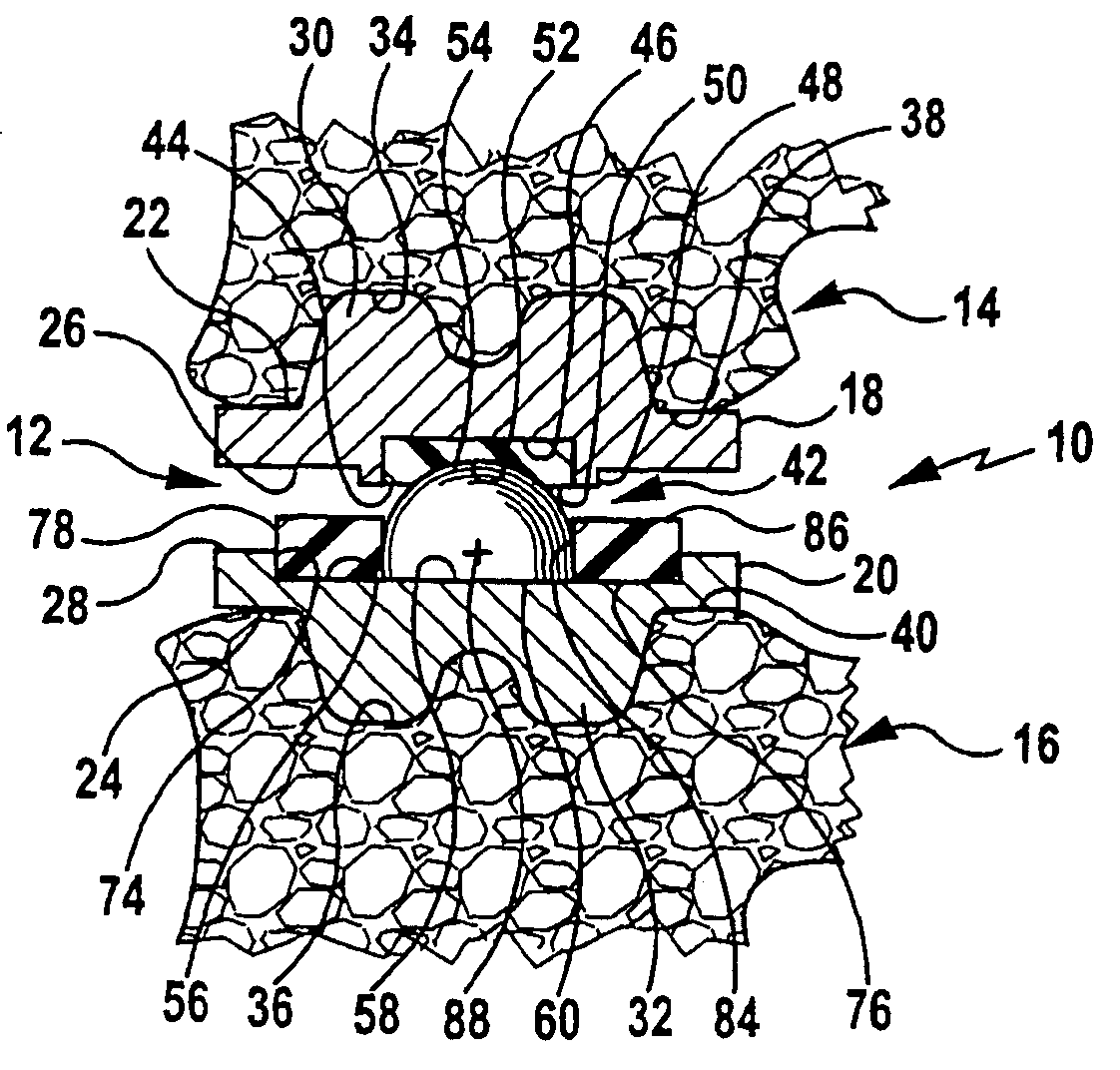

InactiveUS20050080488A1Excellent abrasion resistanceImprove stabilityJoint implantsSpinal implantsIntervertebral spaceSacroiliac joint

An intervertebral implant is provided for insertion between a first vertebral body and a second vertebral body defining an intervertebral space. The implant includes a first anchoring part for anchoring at the first vertebral body, a second anchoring part for anchoring at the second vertebral body, and a joint configured to connect the first and second anchoring parts together. The joint includes a first joint part carried by the first anchoring part, and a second joint part carried by the second anchoring part. The implant further includes at least one restoring device adapted to exert a restoring force on the first or second joint part. The restoring force of the at least one restoring device transfers the first or second joint part from a deflected position back to a normal position and / or limits movement of the first or second joint part away from the normal position.

Owner:AESCULAP AG

Portable electronic device with two-piece housing

ActiveUS7933123B2Avoid scratchesDisassembled for rework or repair operationsDigital data processing detailsSubstation equipmentEngineeringCover glass

Owner:APPLE INC

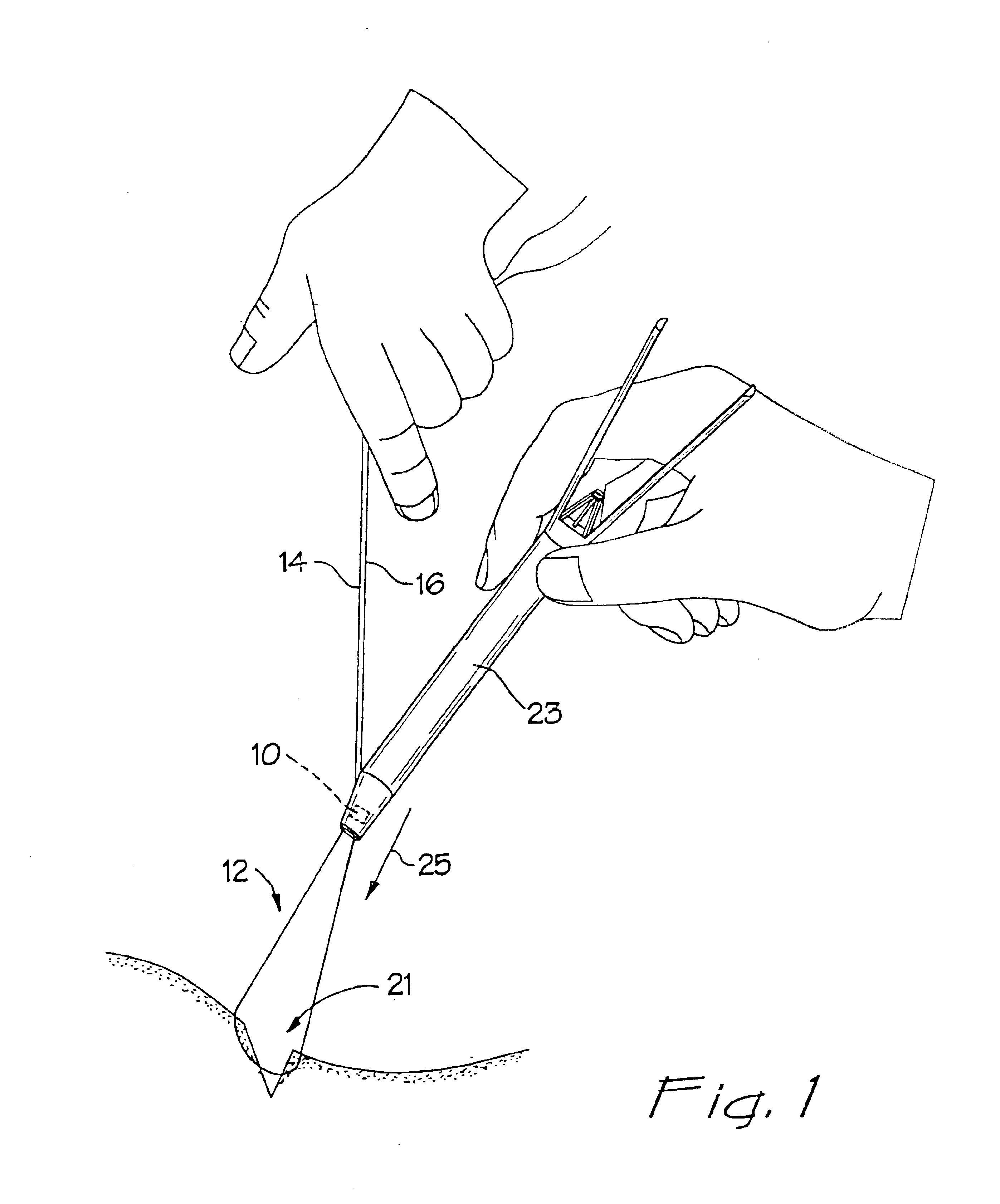

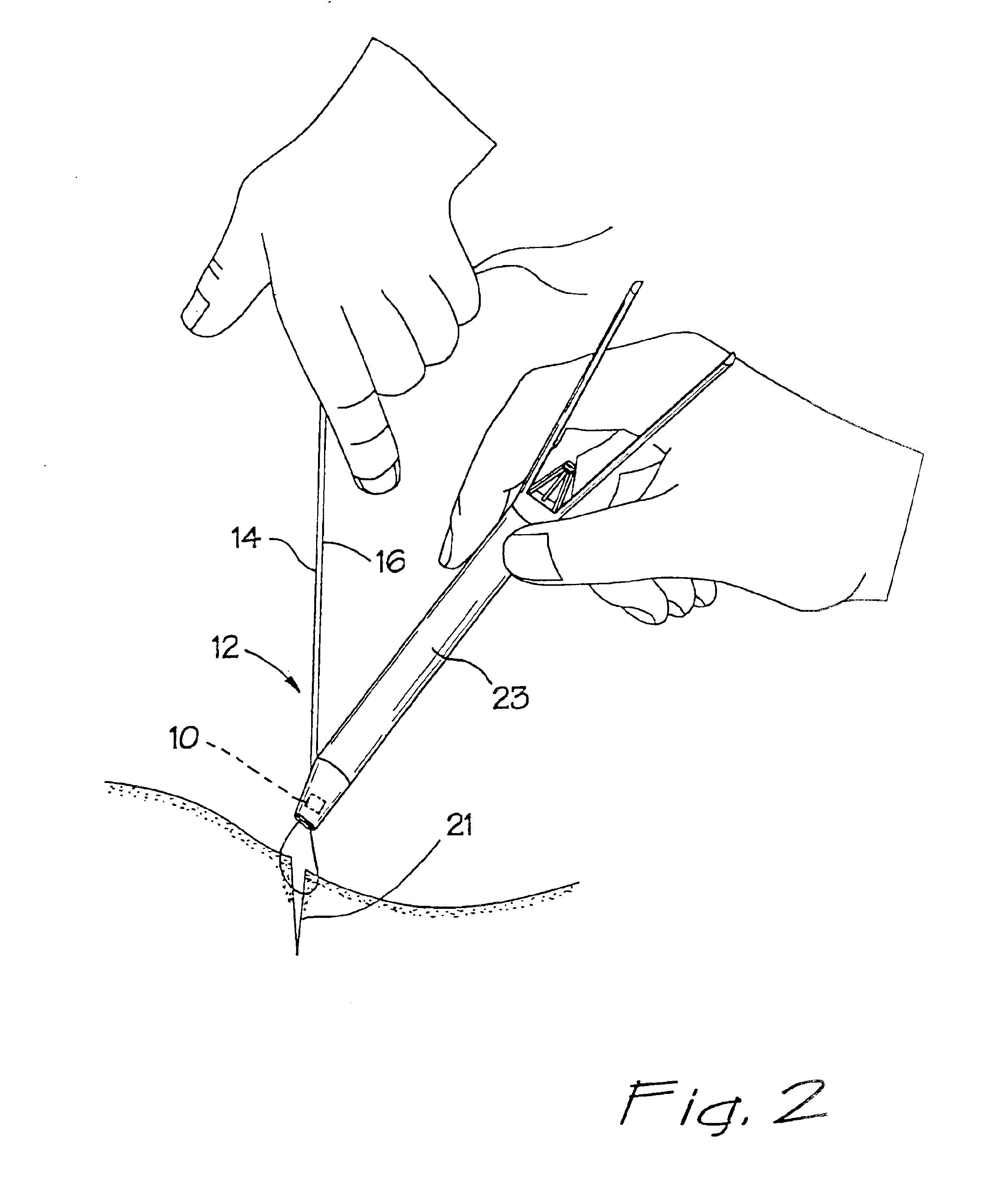

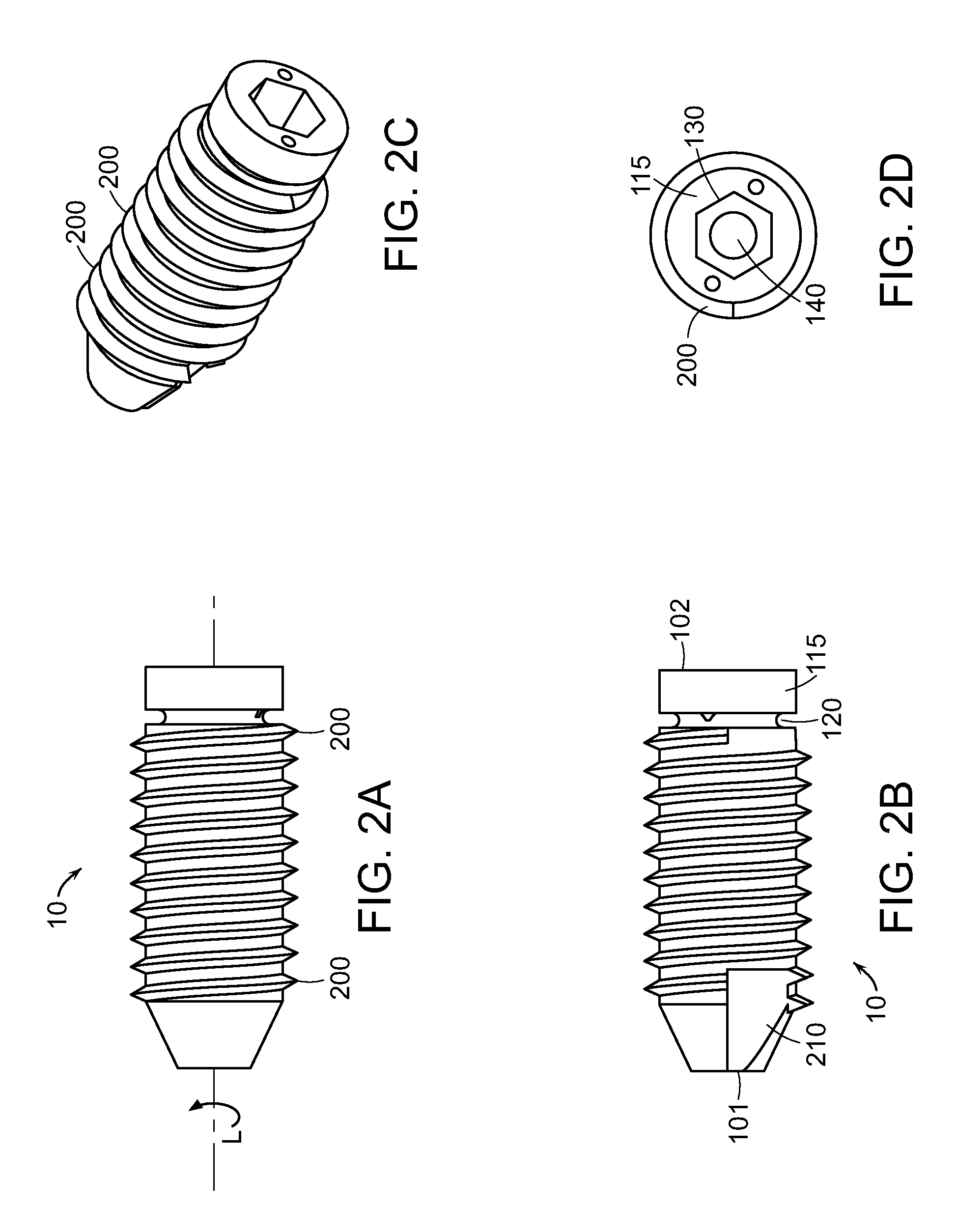

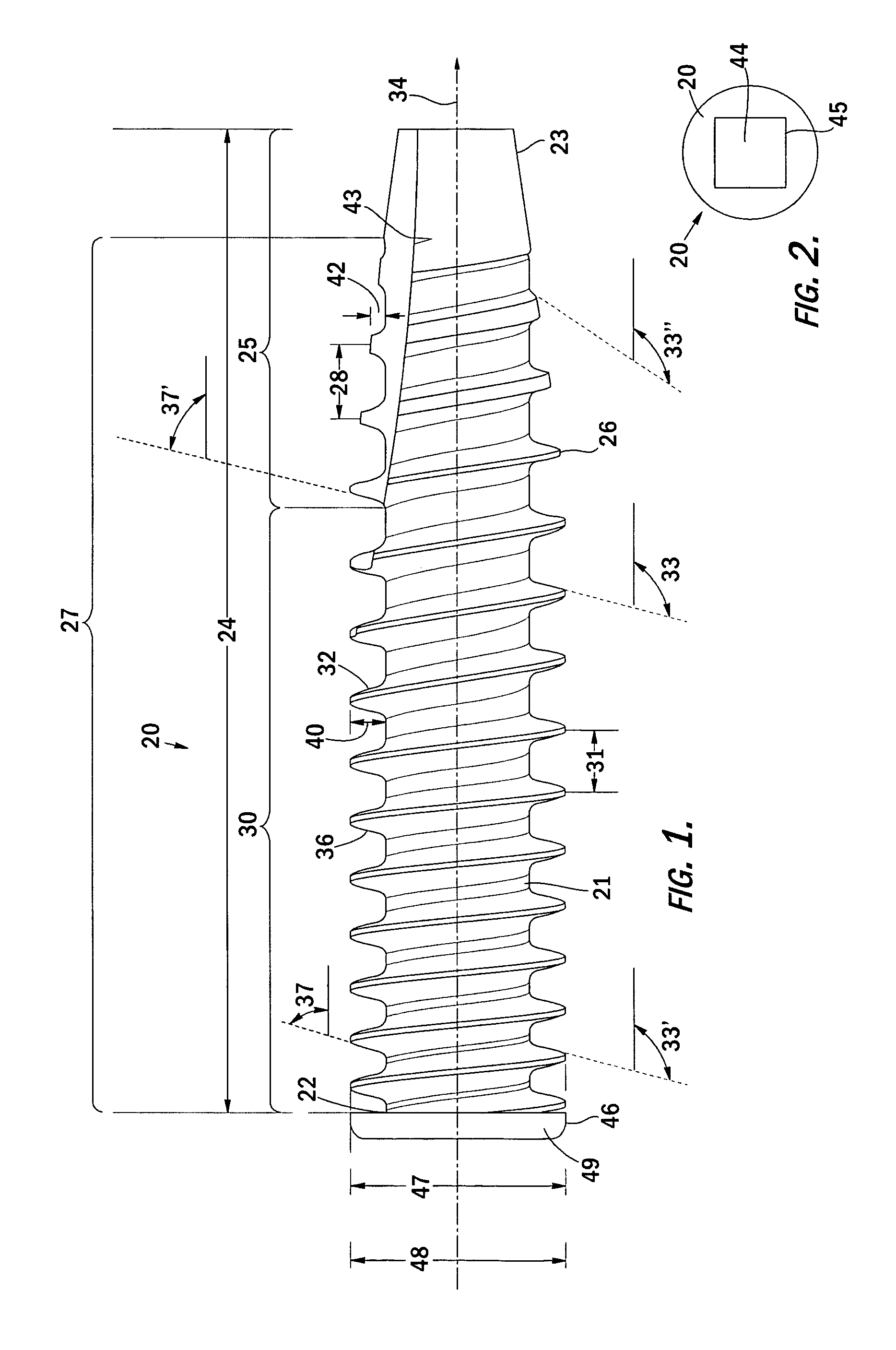

Cannulated anchor and system

ActiveUS20100076499A1Maximize accuracyMinimal damageSuture equipmentsLigamentsEngineeringGuide wires

Cannulated anchors are provided that may be optimally forced in, press fit, screwed in or otherwise installed into tissue with minimal damage to the flexible members or sutures attached thereto. Systems for installing at least one flexible member into tissue include the cannulated anchor, the at least one flexible member capable of being received by the cannulated anchor; and an installer with a driver head insertable into the cannulation of the anchor proximate the trailing end and with an essentially longitudinal cannulation centrally disposed along the axis and sized to accept a guidewire therethrough. Movement of the installer about the longitudinal axis causes corresponding movement of the cannulated anchor such that the outer surface of the cannulated anchor is capable of effecting anchoring into the tissue.

Owner:ALASKA HAND RES

Method and apparatus for non-abrasive cushioning seal of assisted breathing devices

A method and apparatus for preventing abrasion on an infant's nose and adjacent areas when used in conjunction with respiratory administration devices.

Owner:KEIFER ELIZABETH ANNE

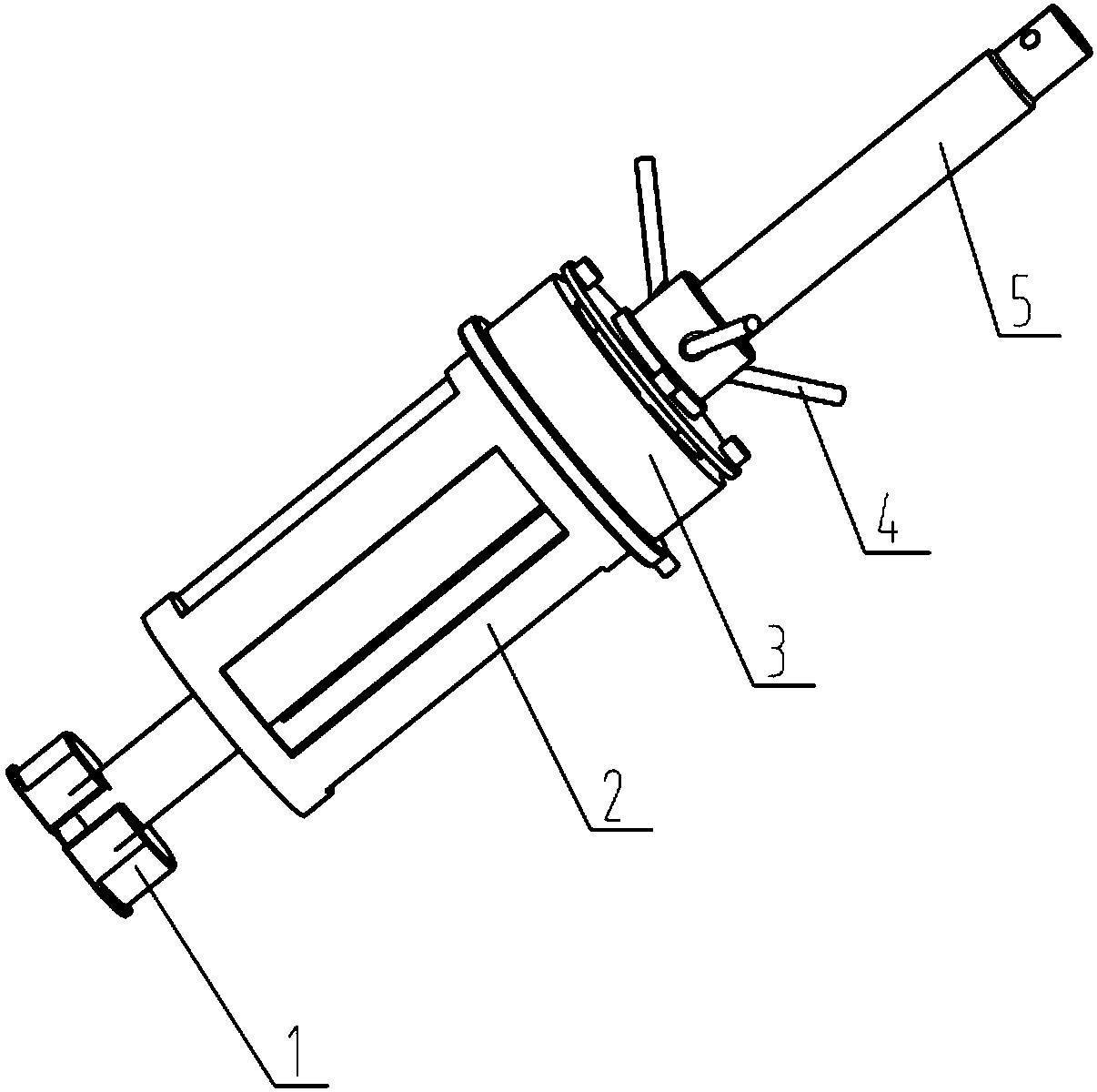

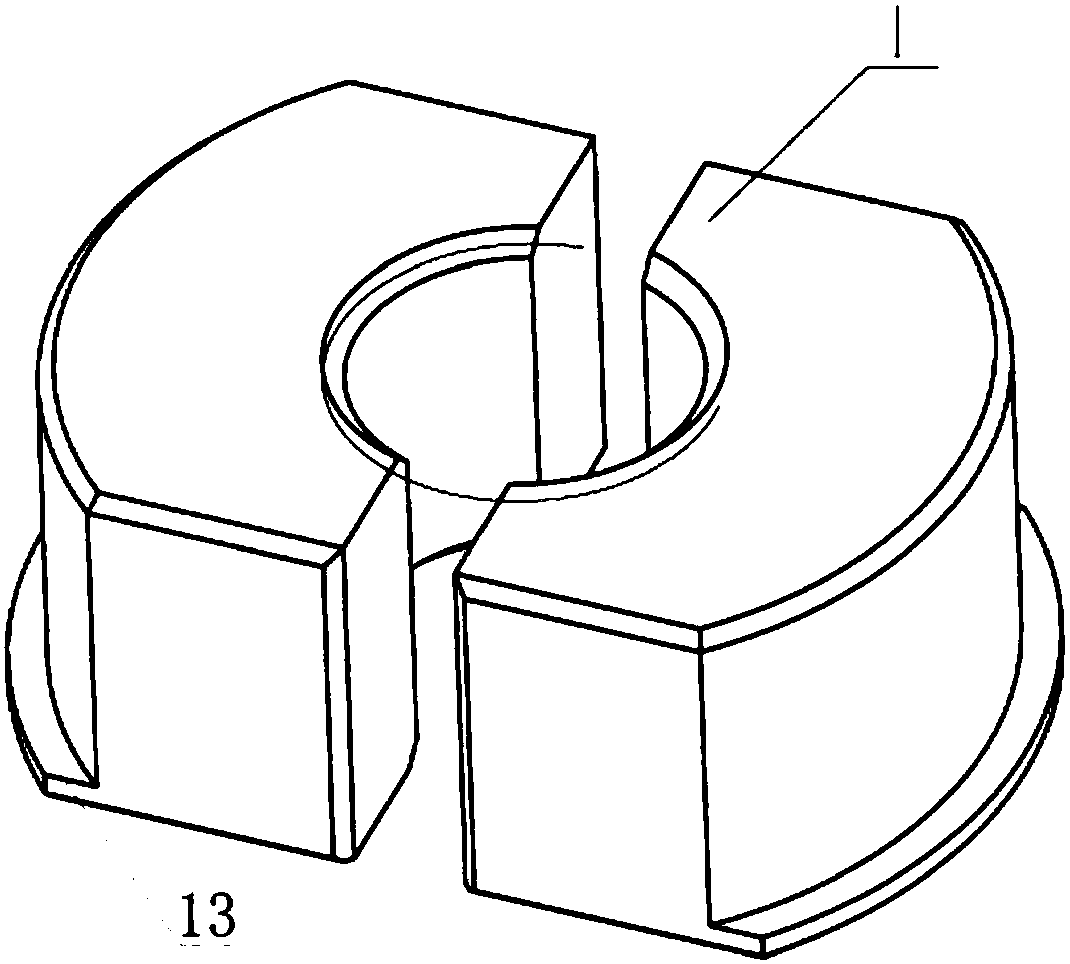

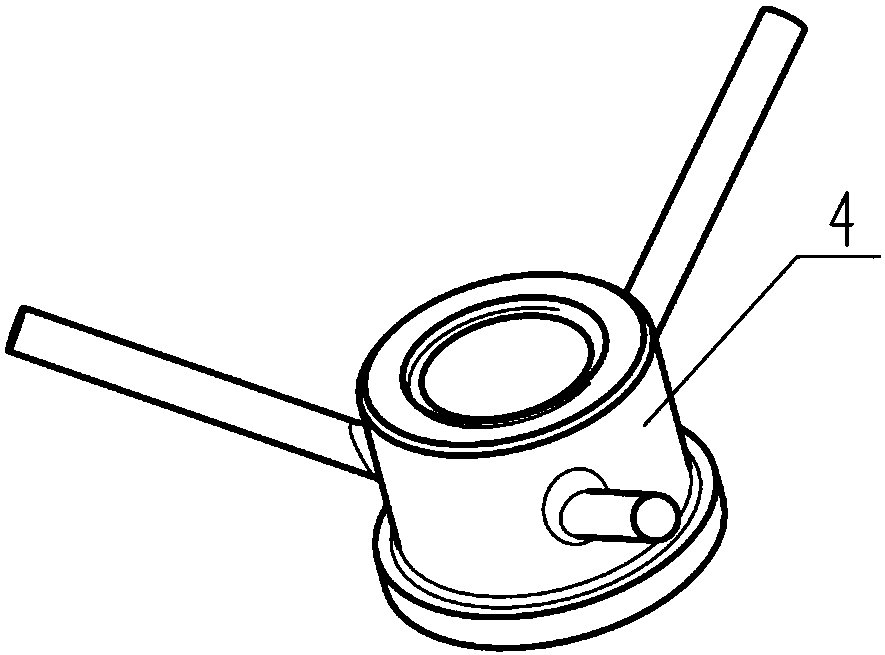

Thin-wall sliding sleeve disassembling fixture

PendingCN108555826AEasy loadingGuaranteed fitMetal-working hand toolsEngineeringMechanical engineering

The invention provides a thin-wall sliding sleeve disassembling fixture. The thin-wall sliding sleeve disassembling fixture comprises a puller nut and a puller screw. The puller screw is in threaded connection with the puller nut. One end of the puller screw is provided with a clamping jaw. The puller screw is in threaded connection with the clamping jaw. A bracket and a hydraulic system are installed between the puller nut and the clamping jaw. The bracket and the hydraulic system are sheathed on the puller screw. The bracket is adjacent to the clamping jaw. The hydraulic system is adjacent to the puller nut. Through controlling the hydraulic system to boost pressure and reduce pressure, the disassembly of a thin-wall sliding sleeve can be realized. The thin-wall sliding sleeve disassembling fixture is small in volume, light in weight, smooth and steady in movement, and safe and convenient in operation, and capable of preventing the deformation of the thin-wall sliding sleeve and thescratching of a hole wall in an disassembling process.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

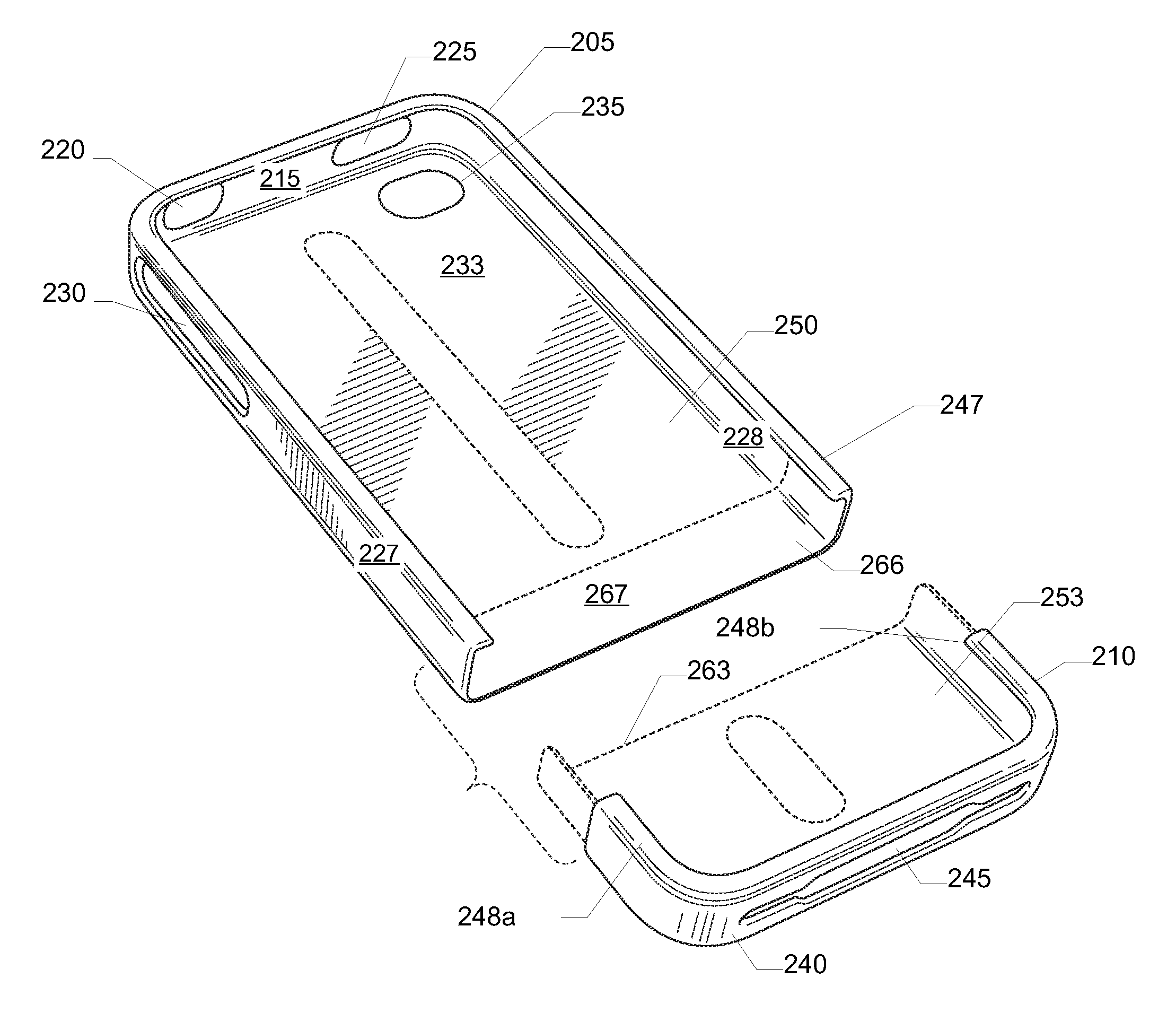

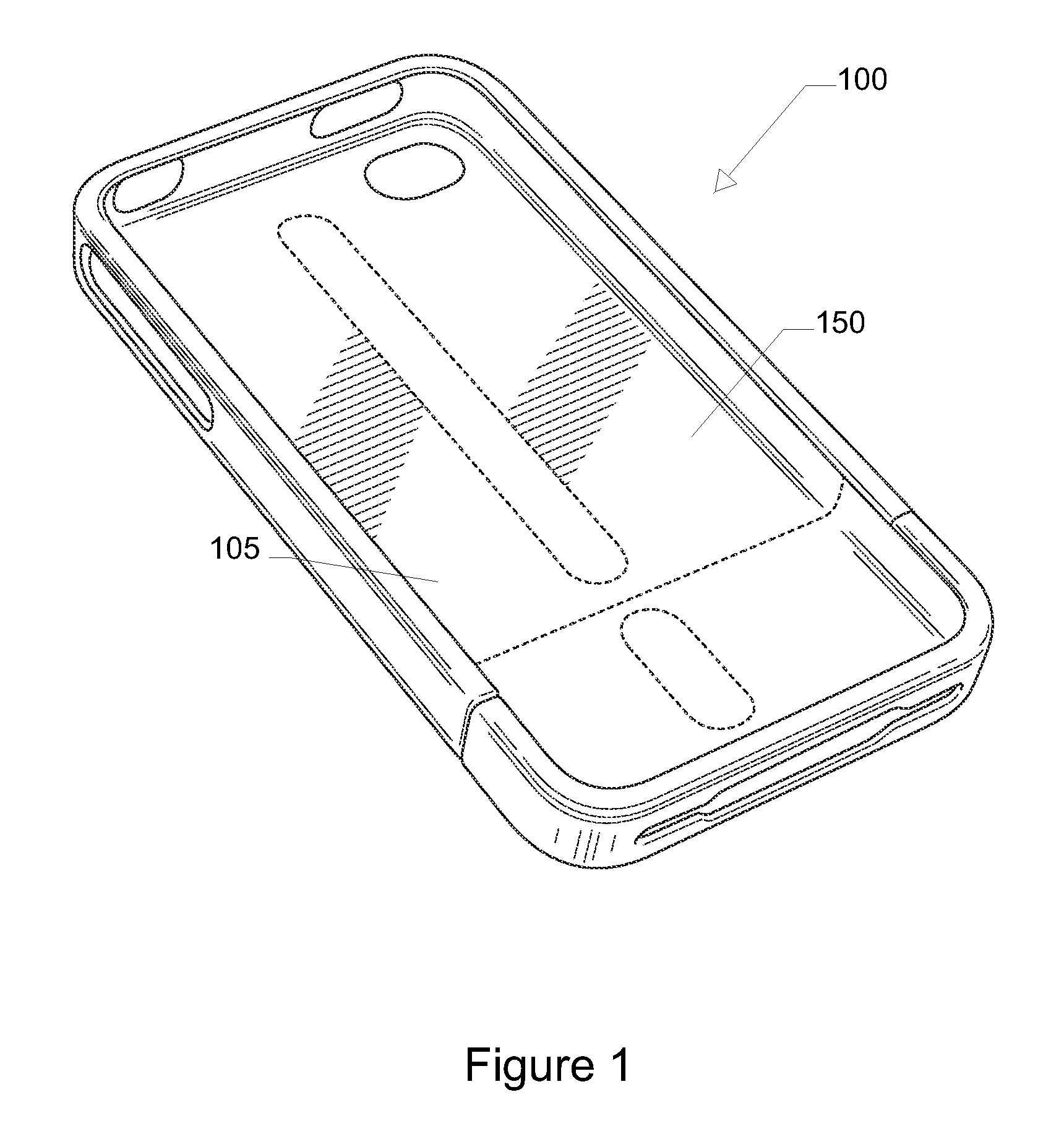

Case for Portable Electronic Device

InactiveUS20110309728A1Avoid scratchesConnection securityShow cabinetsAdditive manufacturing apparatusCamera lensEngineering

A case for an electronic device protects the electronic device. The case has a lower case portion and an upper case portion, which assemble together to protect the electronic device. A back of the case can include a back opening to expose a camera lens and flash of the electronic device or first and second back openings. The first back opening exposes the camera lens. The second back opening exposes the flash.

Owner:VINCI BRANDS LLC

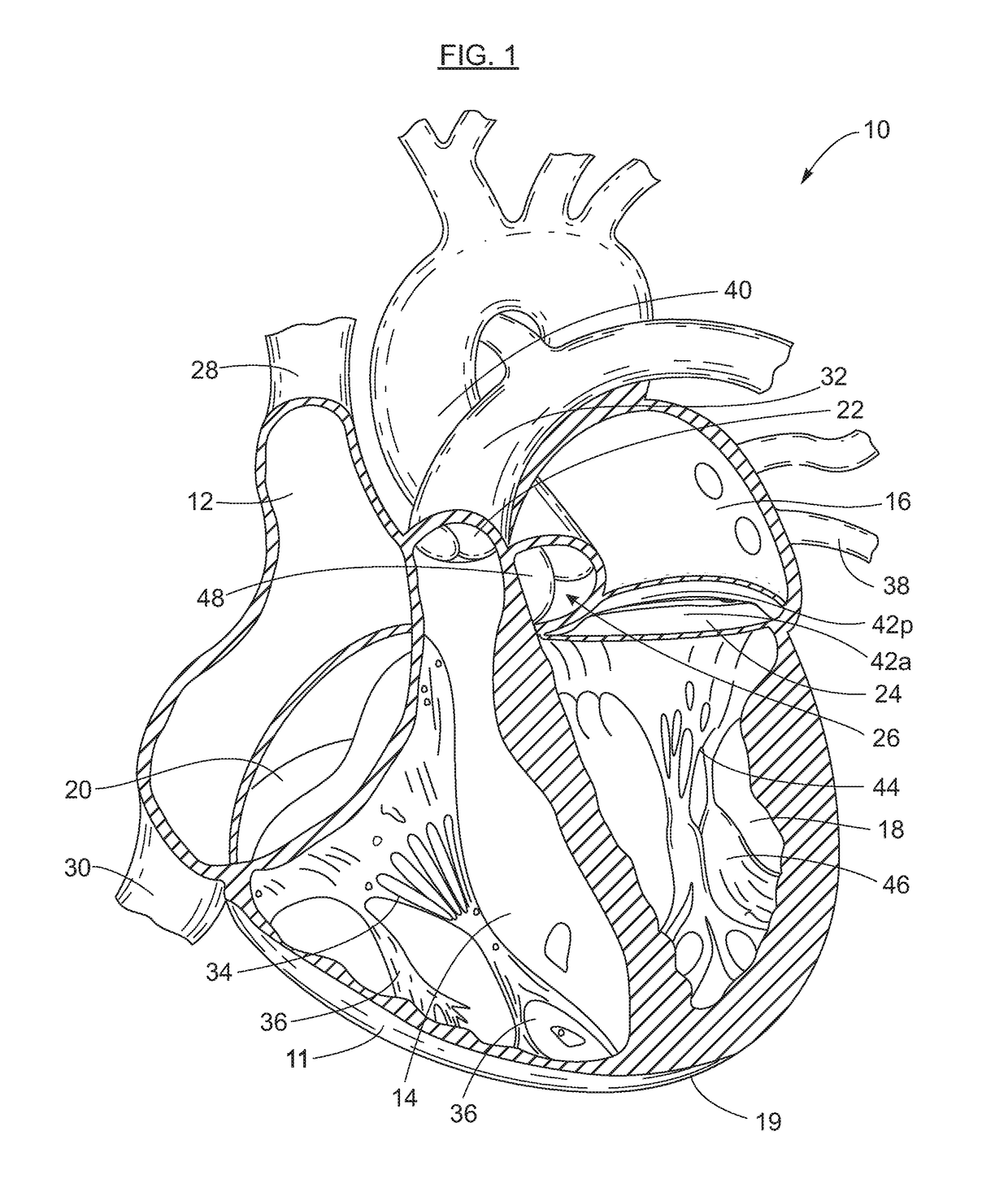

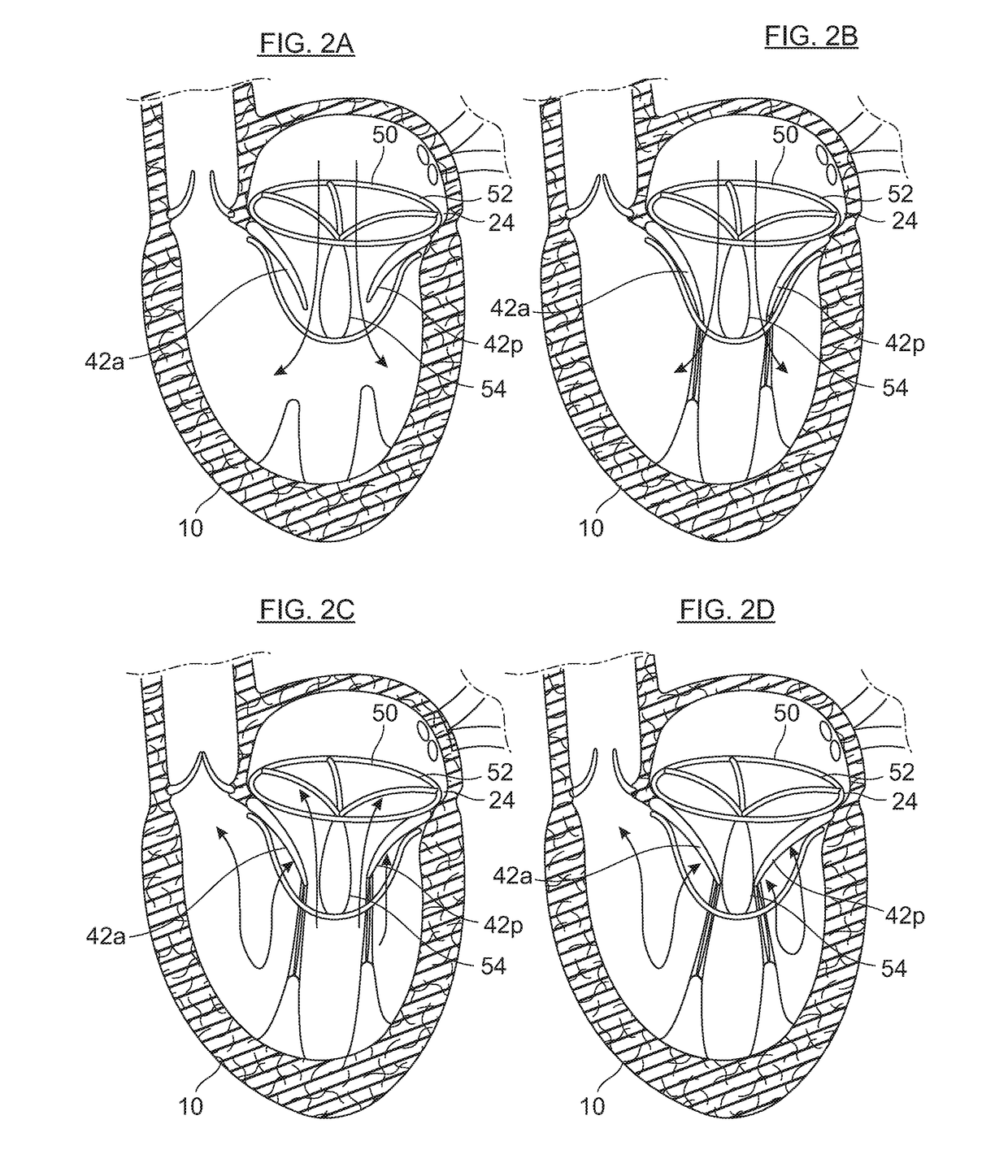

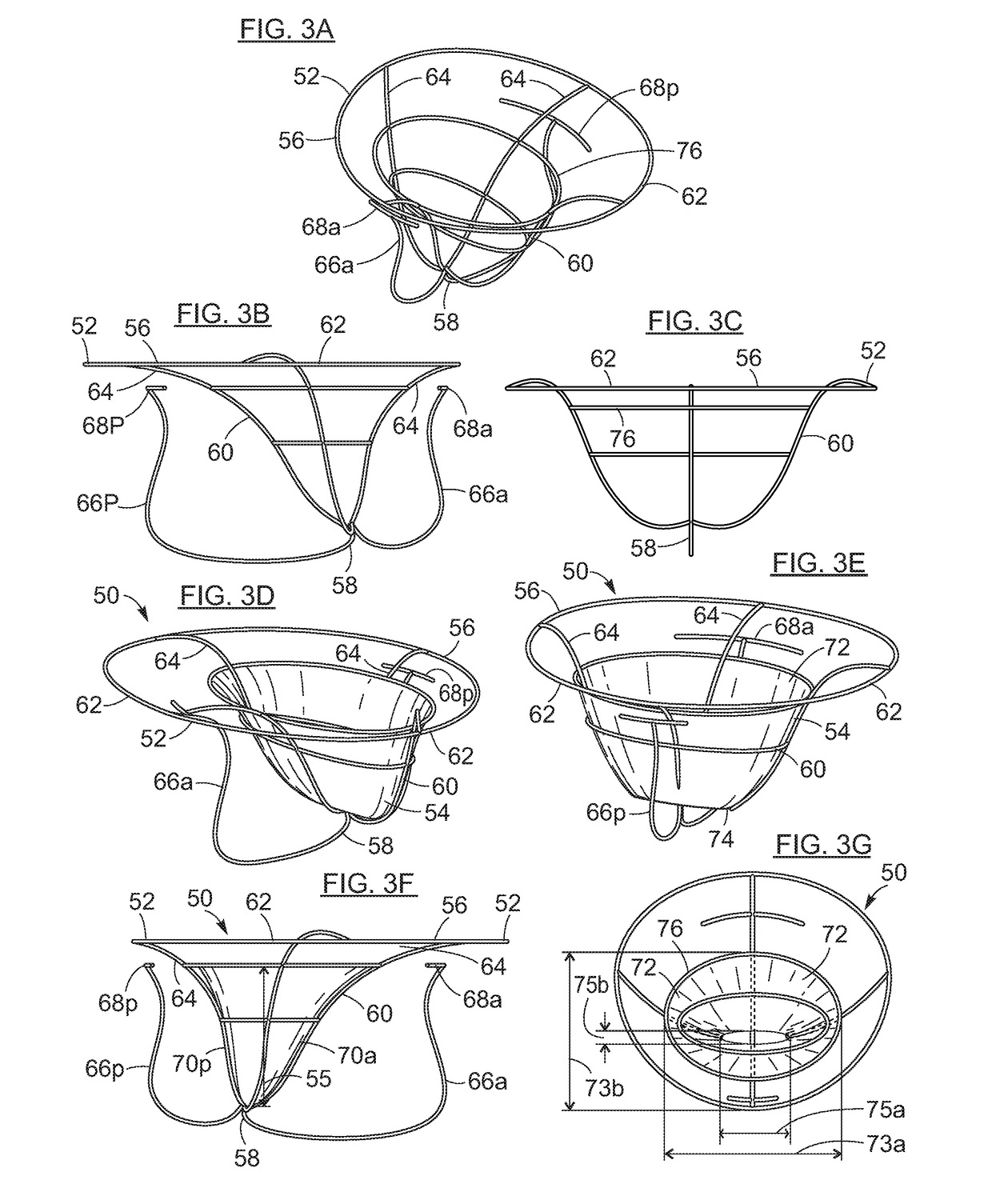

Transcatheter device for treating mitral regurgitation

ActiveUS20190060072A1Improve valve functionReduce and eliminate valve regurgitationAnnuloplasty ringsMitral valve functionHeart chamber

The invention is a prosthetic device for improving function of a mitral valve. The device includes a sealing member configured for positioning between mitral valve leaflets. The device also includes an expandable anchor frame configured to be positioned within one or more heart chambers, for maintaining the sealing member at a desired position between valve leaflets. The sealing member reduces mitral regurgitation be filling the gap that can occur between opposing leaflets of a damaged mitral valve, thus restoring proper mitral valve closure.

Owner:EDWARDS LIFESCIENCES CORP

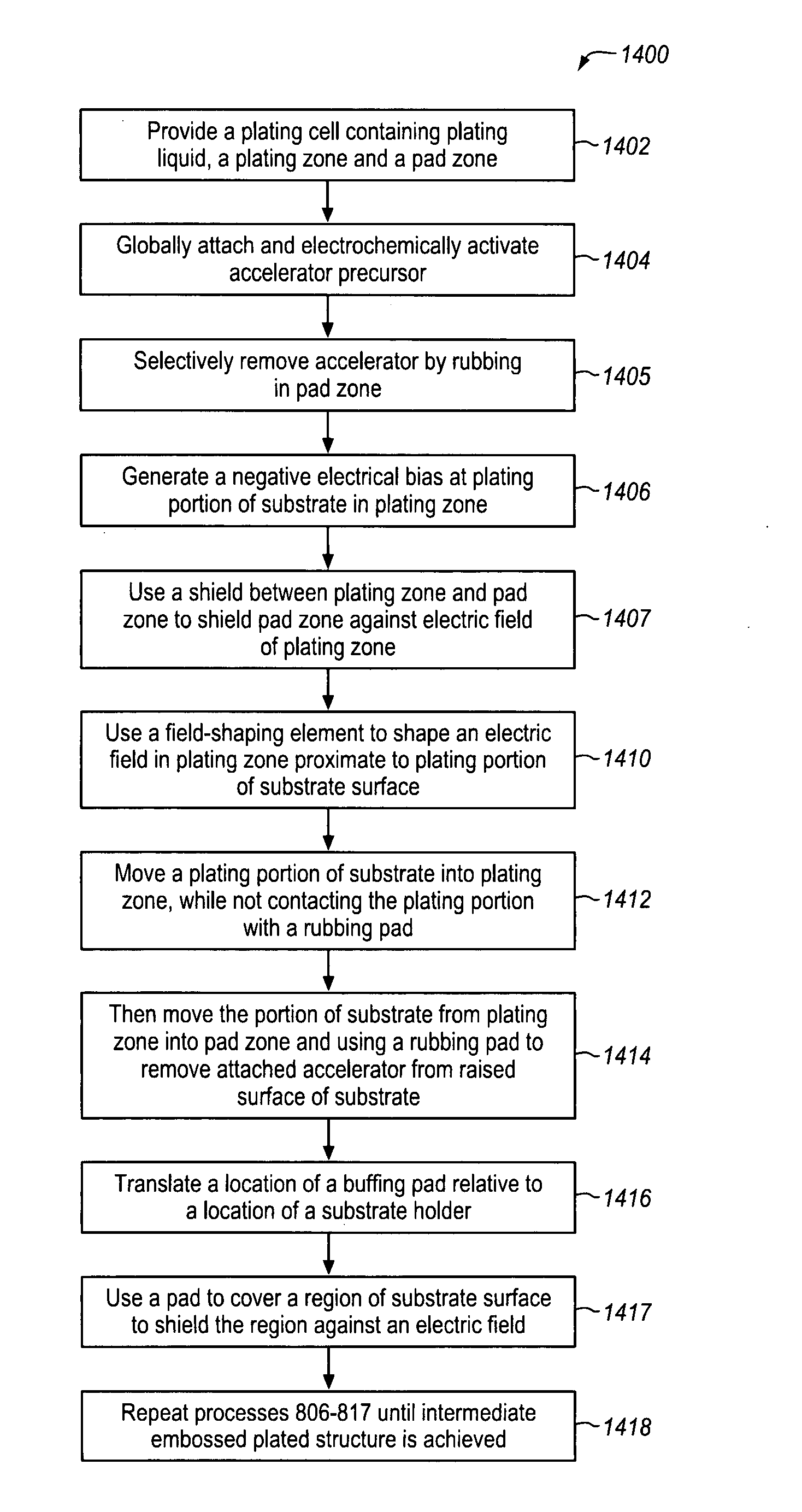

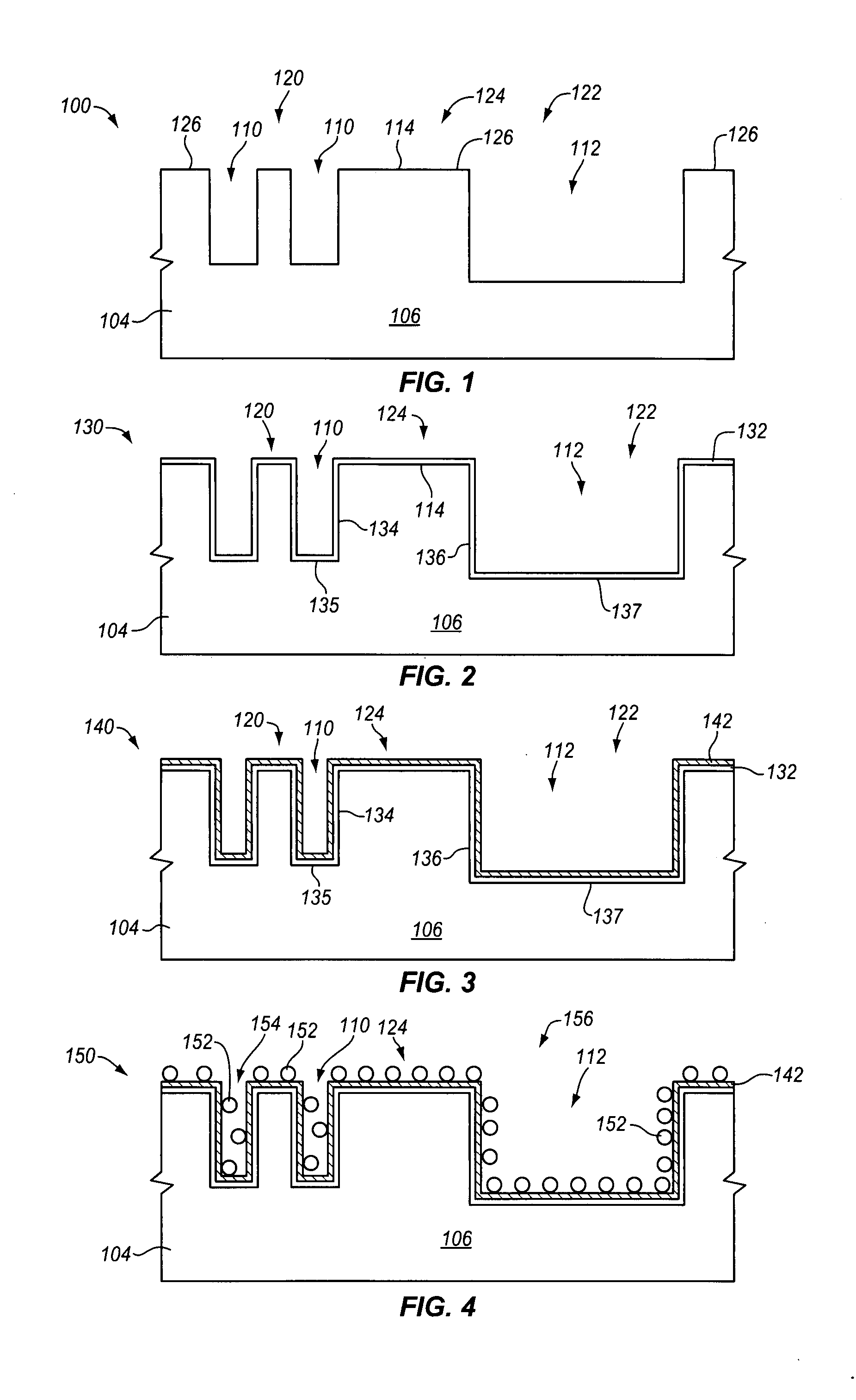

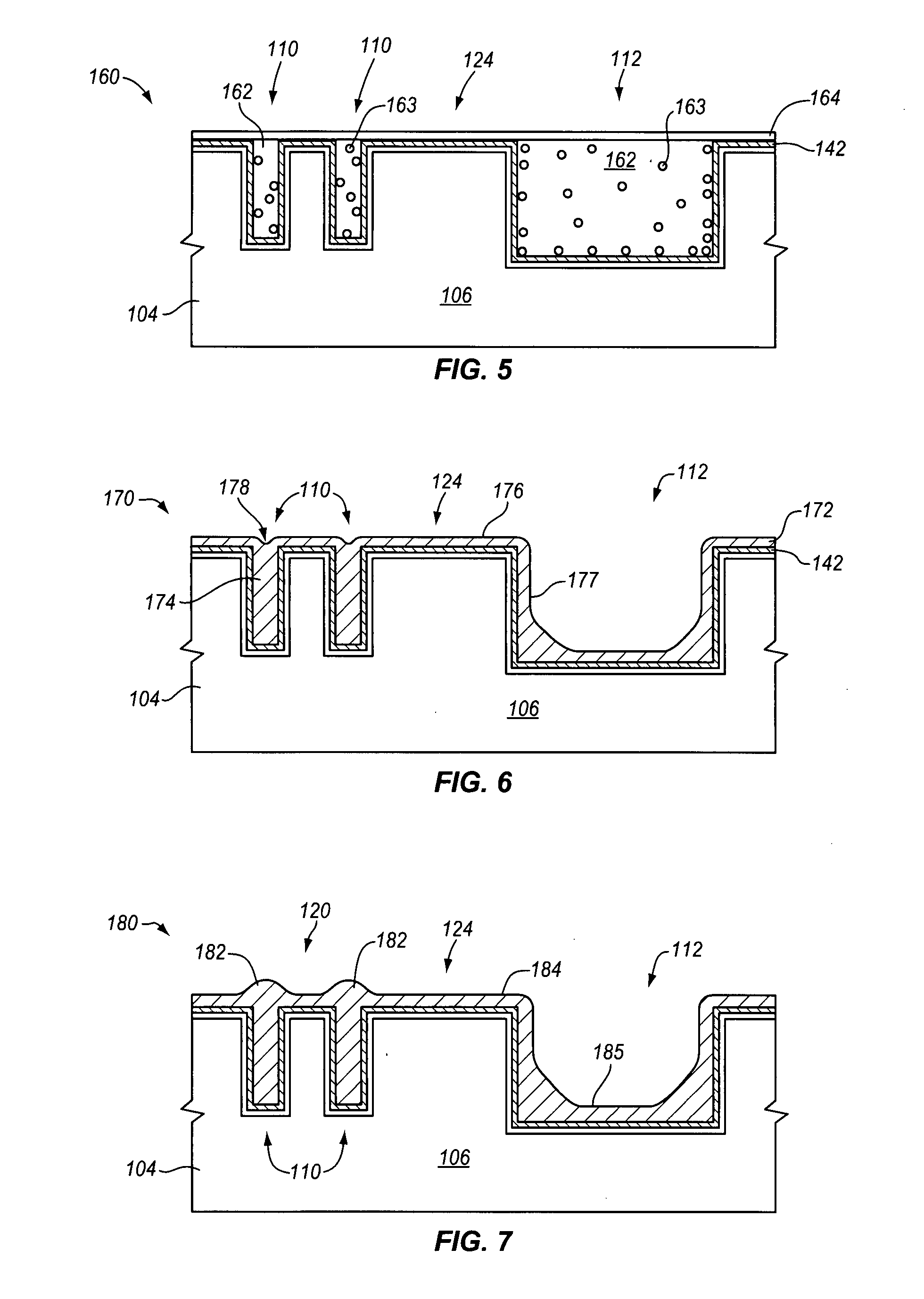

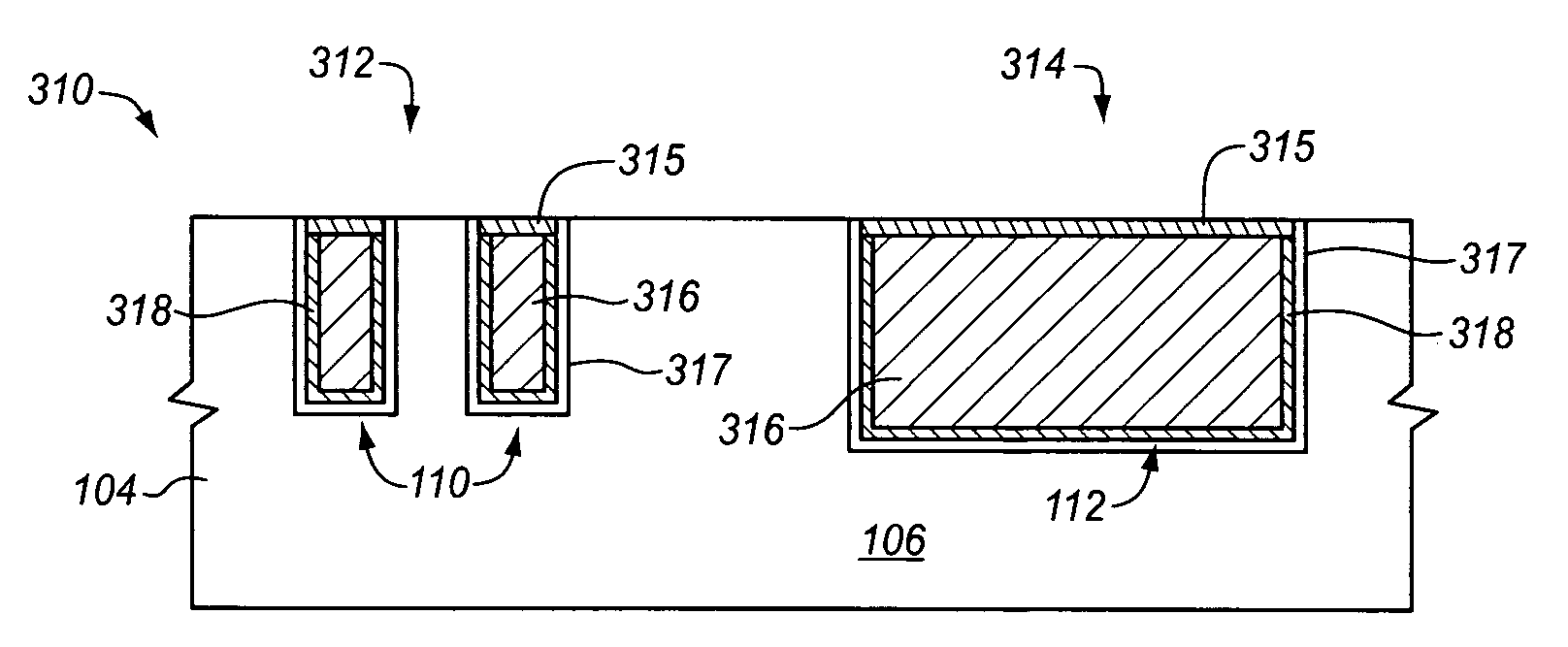

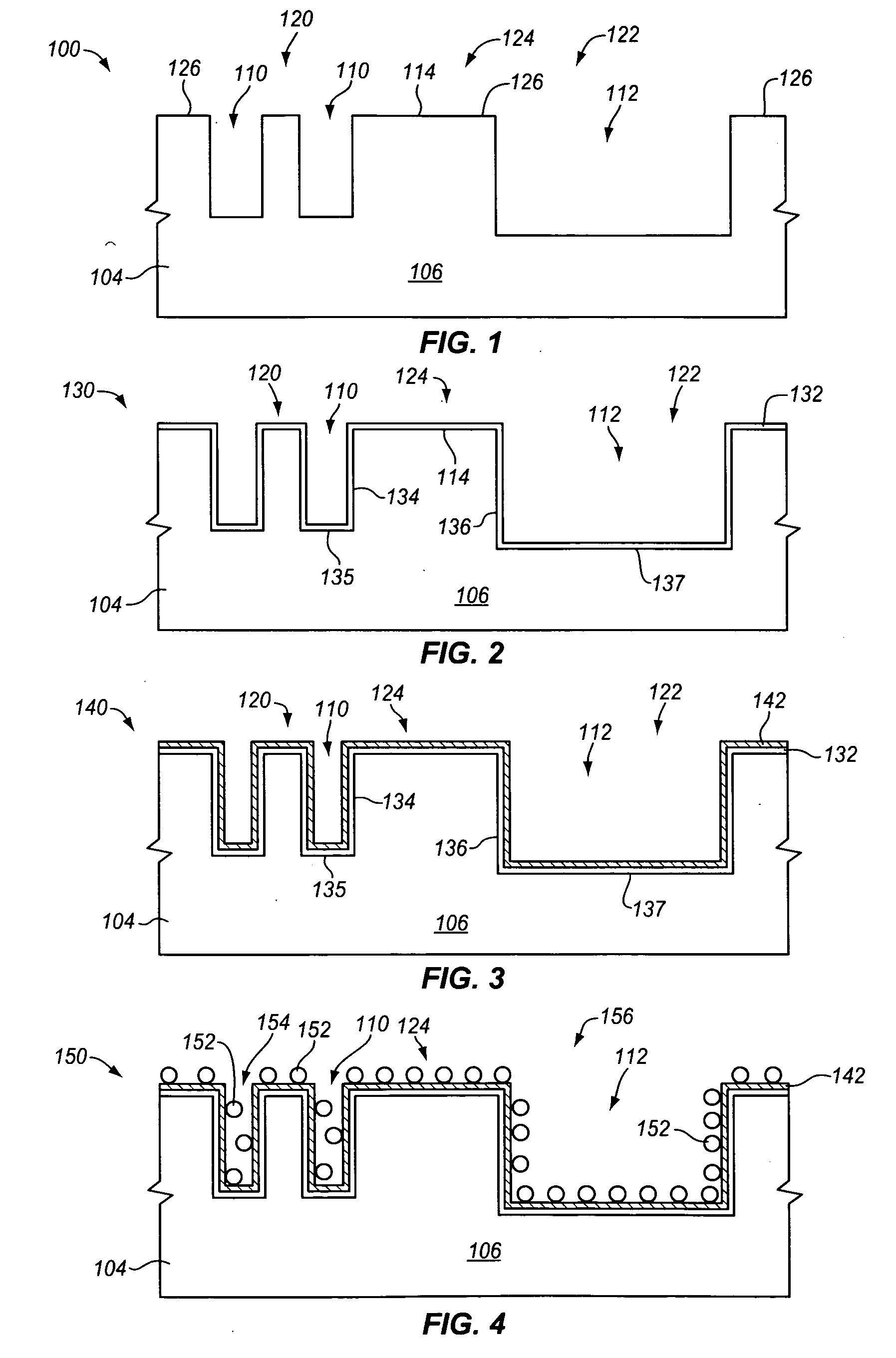

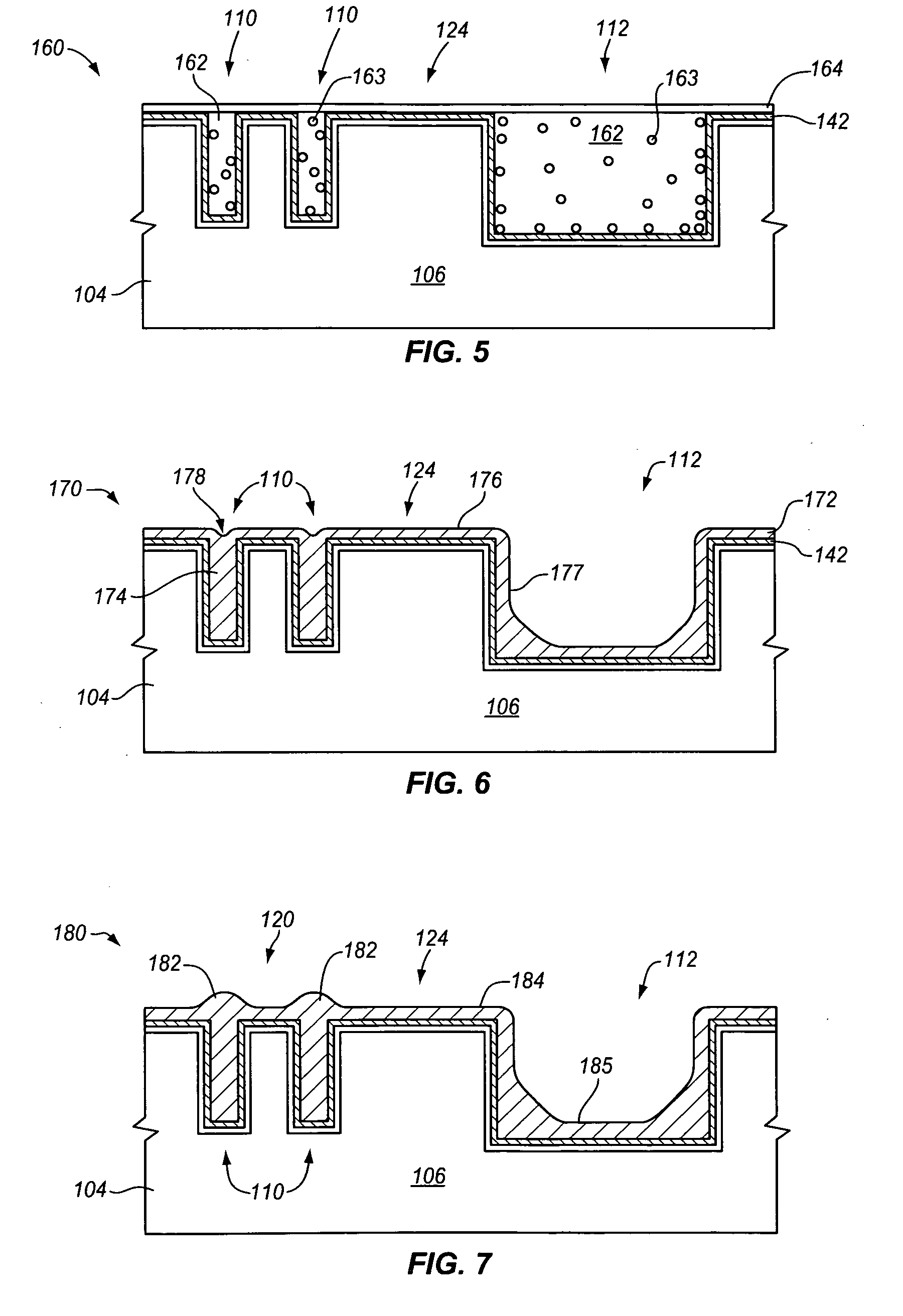

Topography reduction and control by selective accelerator removal

ActiveUS20090280649A1Improve throughputLow costCellsDecorative surface effectsMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

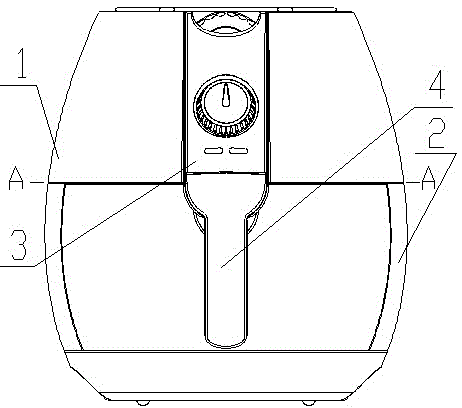

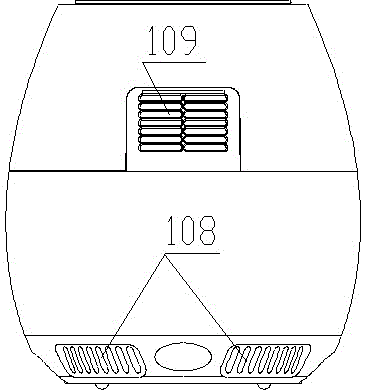

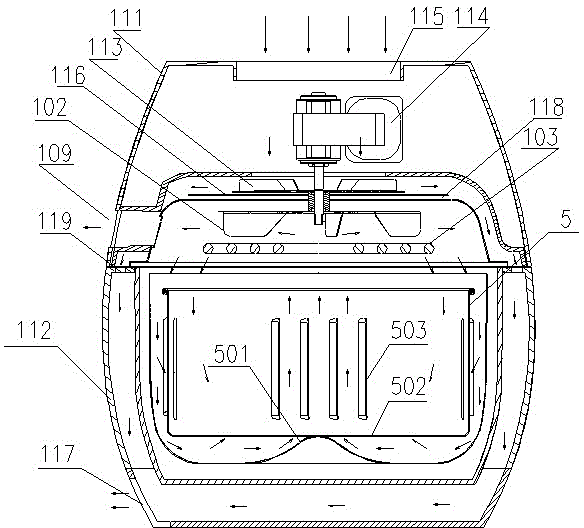

Smokeless air fryer

The invention relates to a smokeless air fryer which finishes the cooking of foods and does not exhaust smoke by utilizing the high-speed hot air circulation technology. The smokeless air fryer comprises an air fryer fixed body and an air fryer movable body, wherein a top-driven power supply switch is arranged on one side of the lower end surface of a boss part at the front part of the air fryer fixed body, and a timer is arranged at the boss part; a top-driven boss is arranged on one side of the upper end surface of a handle of the air fryer movable body, and the handle is in locking and opening matching with an object containing mesh basket; the top-driven boss is in top-driven opening and closing matching with the top-driven power supply switch on one side of the lower end surface of the boss part of the air fryer fixed body; a planer screw type electric heating tube is arranged below hot air blades of the air fryer fixed body, a power supply joint of the planer screw type electric heating tube is connected with the inner wall of the air fryer fixed body through a connection assembly, and a tube body of the planer screw type electric heating tube is elastically connected with the inner wall of the air fryer fixed body through a tension spring; and the center of the bottom of an oil collecting backflow pot of the air fryer movable body is in an arc bulge shape, and the wall circumference and the bottom of the oil collecting backflow pot are in an arc shape.

Owner:NINGBO CARELINE ELECTRIC APPLIANCE CO LTD

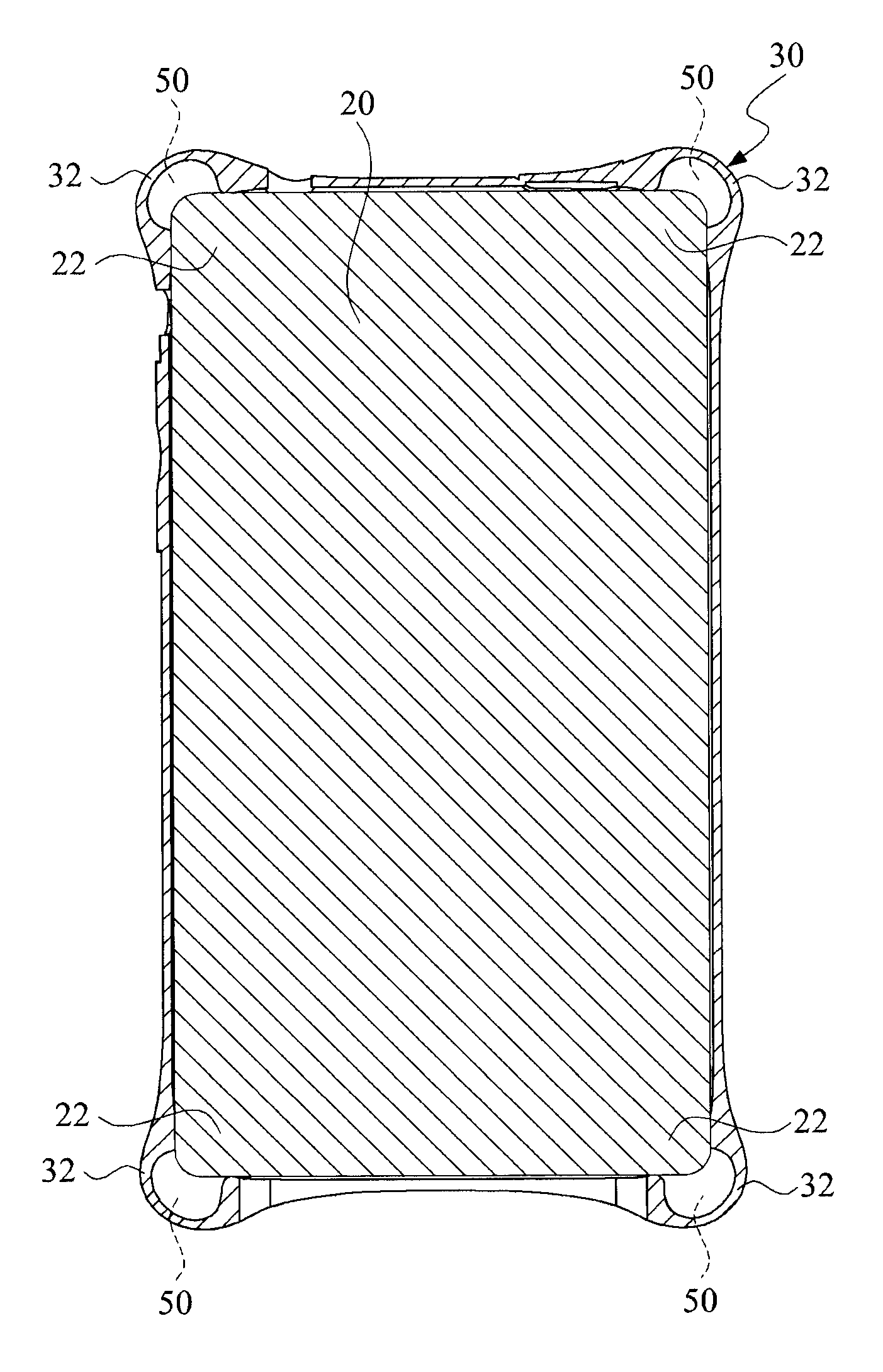

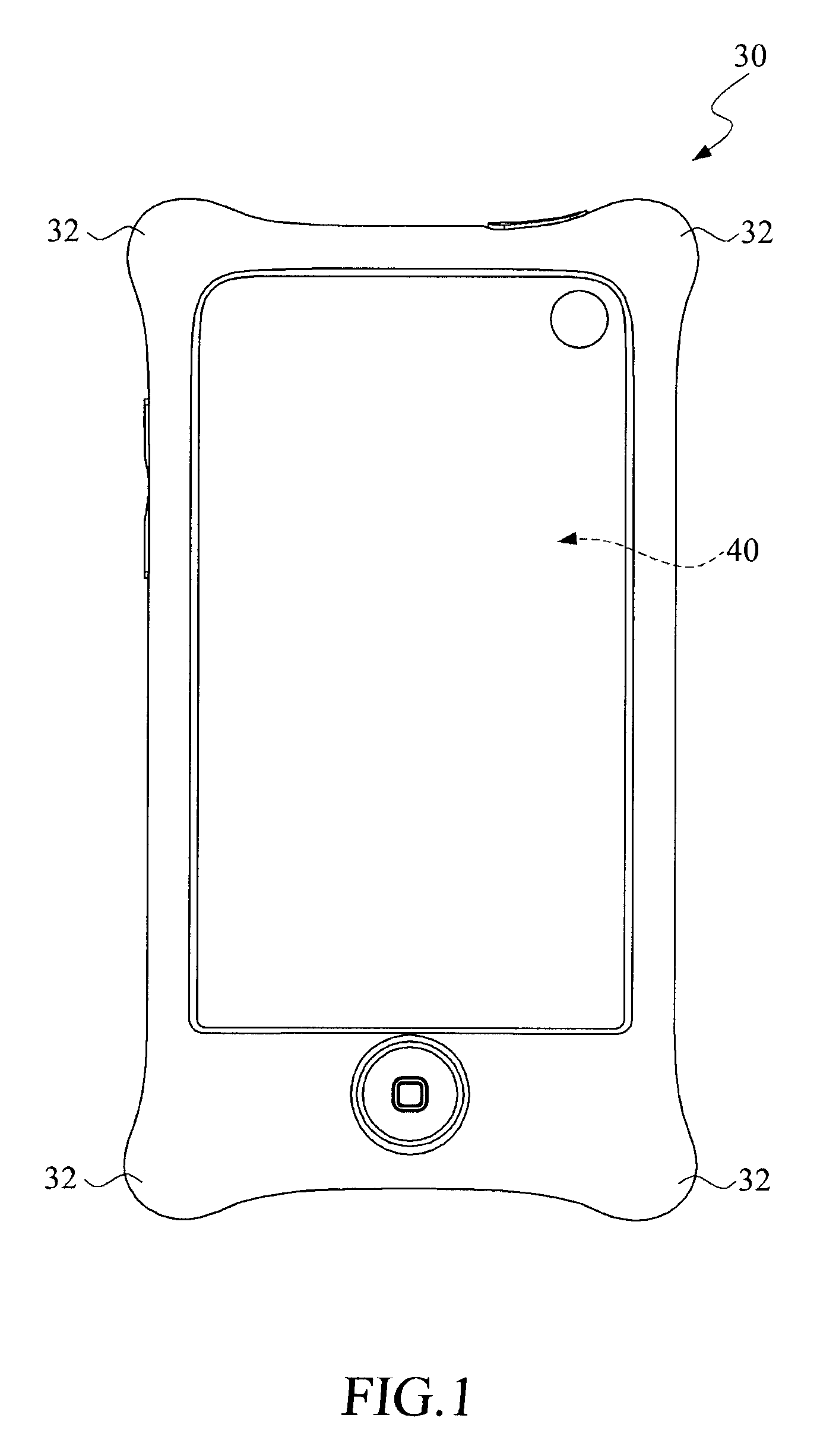

Shock-absorbing protection cover for a portable product

InactiveUS7938260B2Reduce risk of damageAvoid scratchesPortable framesSubstation equipmentEngineeringInternal zone

A protection cover is used for sleeving over a portable product so as to help protect the product from being scratched. The protection cover includes a shock-absorbing structure for shielding and concealing a corner of the portable product. The shock-absorbing structure is formed with an air chamber bulging outwardly from the corner of the portable product. The shock-absorbing structure further has an inner region that defines an opening for access into the air chamber and that abuts tightly and sealingly against the corner of the portable product so as to convert the air chamber into an air-trapped chamber when the protection cover is sleeved over the portable product.

Owner:FRUITSHOP INT

Topography reduction and control by selective accelerator removal

ActiveUS20090277867A1Improve throughputLow costDecorative surface effectsSemiconductor/solid-state device manufacturingMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

Surgical clip

InactiveUS20020065536A1Increase frictionIncrease contact areaSuture equipmentsWound clampsSurgical ClipsSurgical department

a surgical clip having a sliding state and a crimped state is adapted for use in a surgical procedure initially to slide along suture ends to an operative position and ultimately to crimp the suture ends at the operative position. a sub straight, bendable between the sliding state and the crimped state carries at least one coating having either lubricious or traction enhancing properties. A second coating can be added to form a coating laminate with the outer coating having lubricious properties facilitating the sliding state and the inner coating having traction enhancing properties facilitating thee crimped state.

Owner:APPL MEDICAL RESOURCES CORP

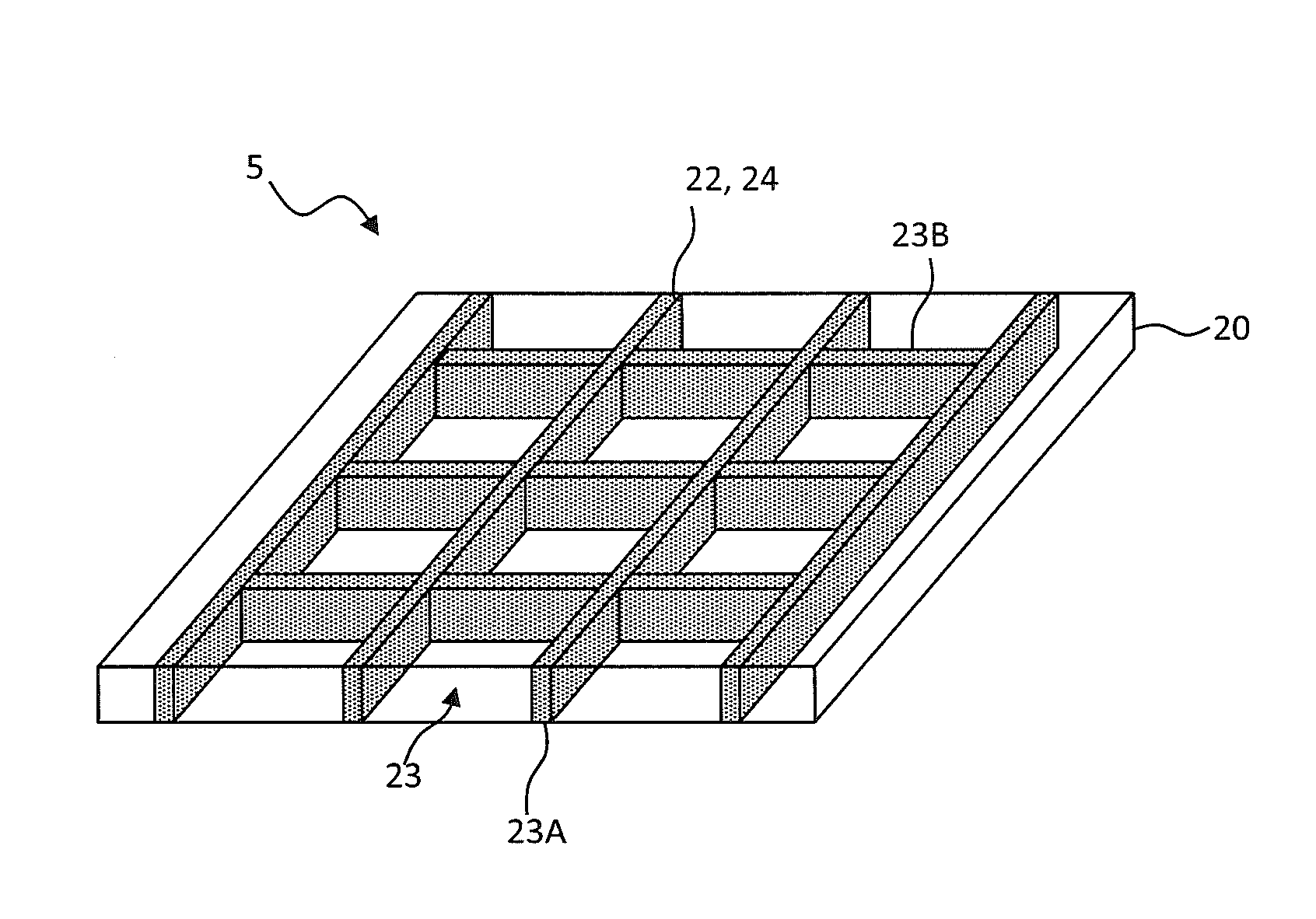

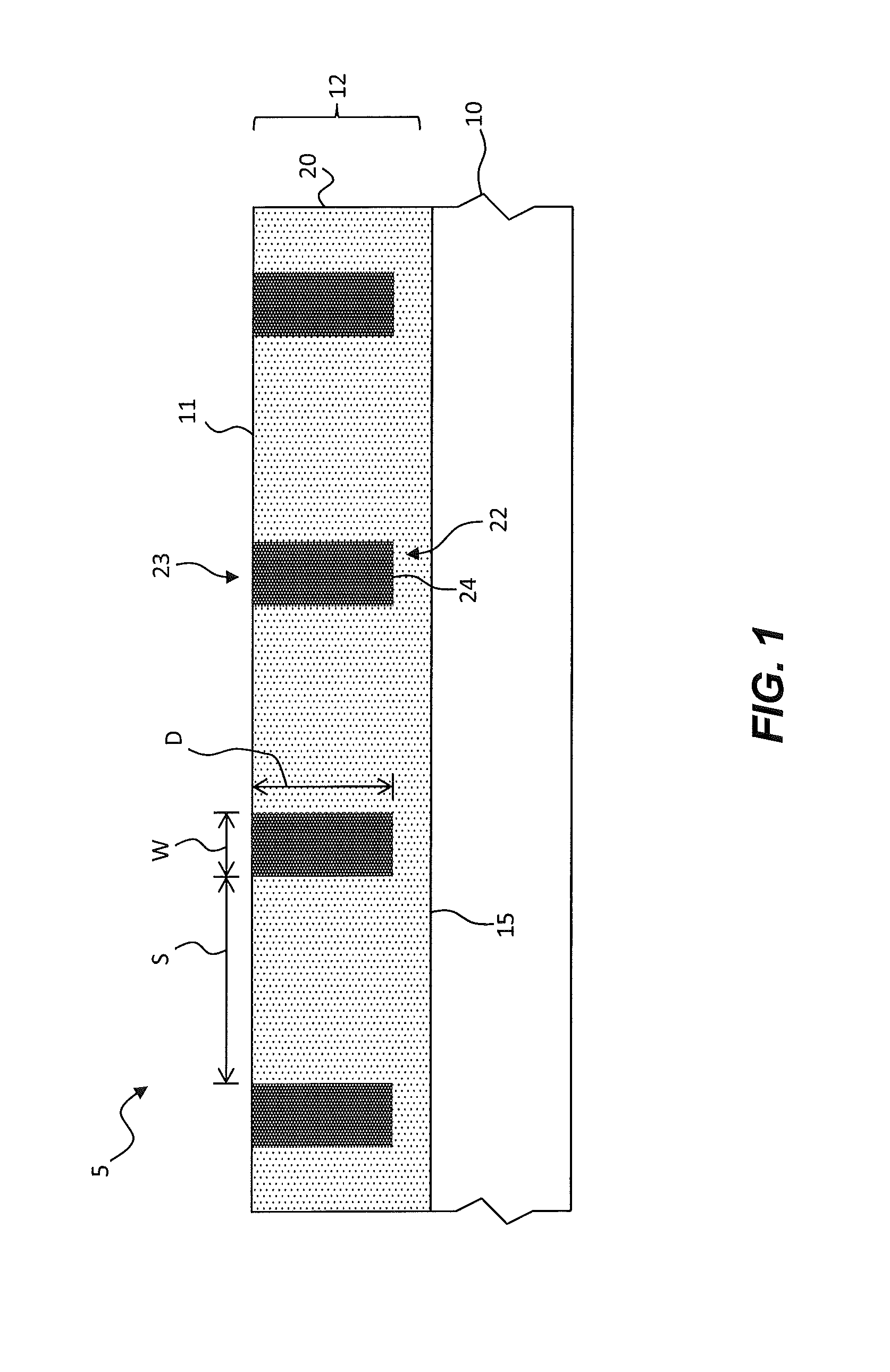

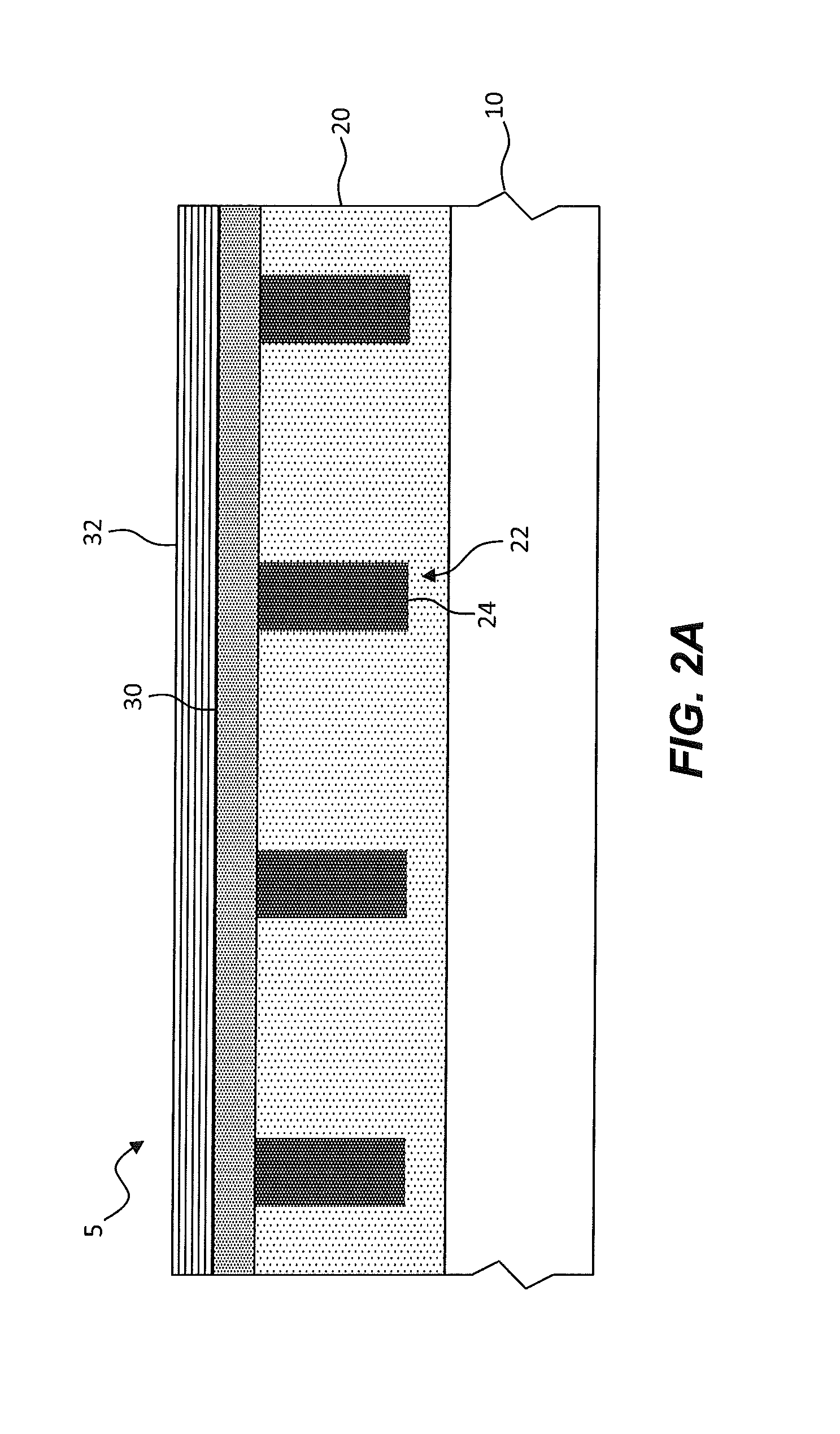

Imprinted micro-louver structure method

InactiveUS20140110040A1High transparencyLow costSemiconductor/solid-state device manufacturingPretreated surfacesLouverChemistry

A method of making a micro-louver structure includes coating a curable layer on a surface and imprinting a pattern of micro-channels in the curable layer. The micro-channels have a greater depth than width and are spaced apart by a separation distance greater than the width. The curable layer is at least partially cured to form a cured layer. A light-absorbing material is coated over the cured layer and in the micro-channels and at least a portion of the light-absorbing material removed from the surface of the cured layer leaving at least a portion of the light-absorbing material in the micro-channels. The light-absorbing material is cured to form a light-absorbing structure in each micro-channel.

Owner:EASTMAN KODAK CO

Implantable tendon protection systems and related kits and methods

ActiveUS20130158661A1Promote tissue growthEasy to packLigamentsMusclesSurgical procedure kitAdhesive

An implantable tendon protection system includes a body adapted to be implanted within a bursa overlying a tendon of a patient to protect the tendon. The body may be fixed to the tendon with adhesive, sutures, staples, and / or anchors. A surgical kit is provided with such a tendon protection system and an insertion cannula. Methods of protecting a tendon of a patient are also disclosed.

Owner:ROTATION MEDICAL

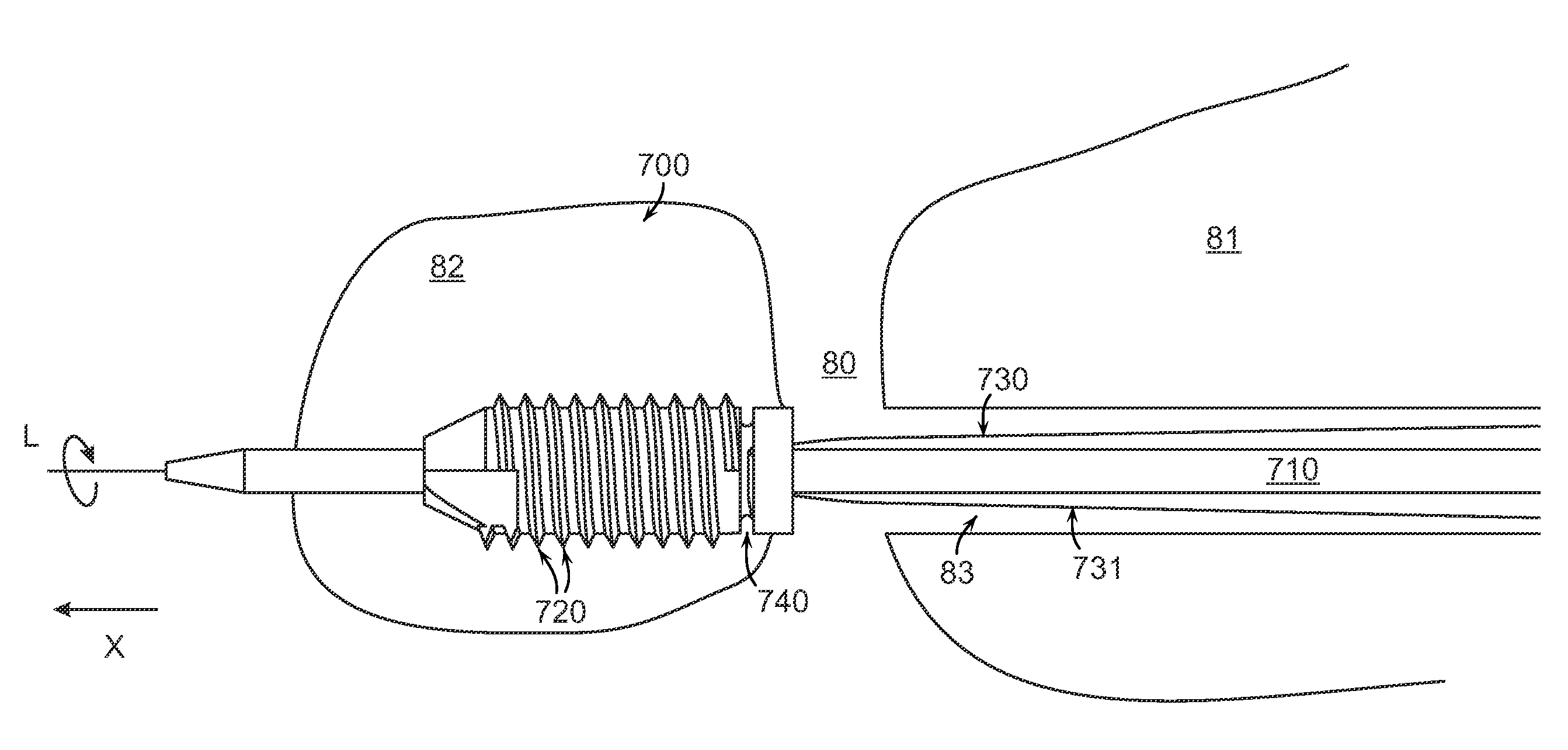

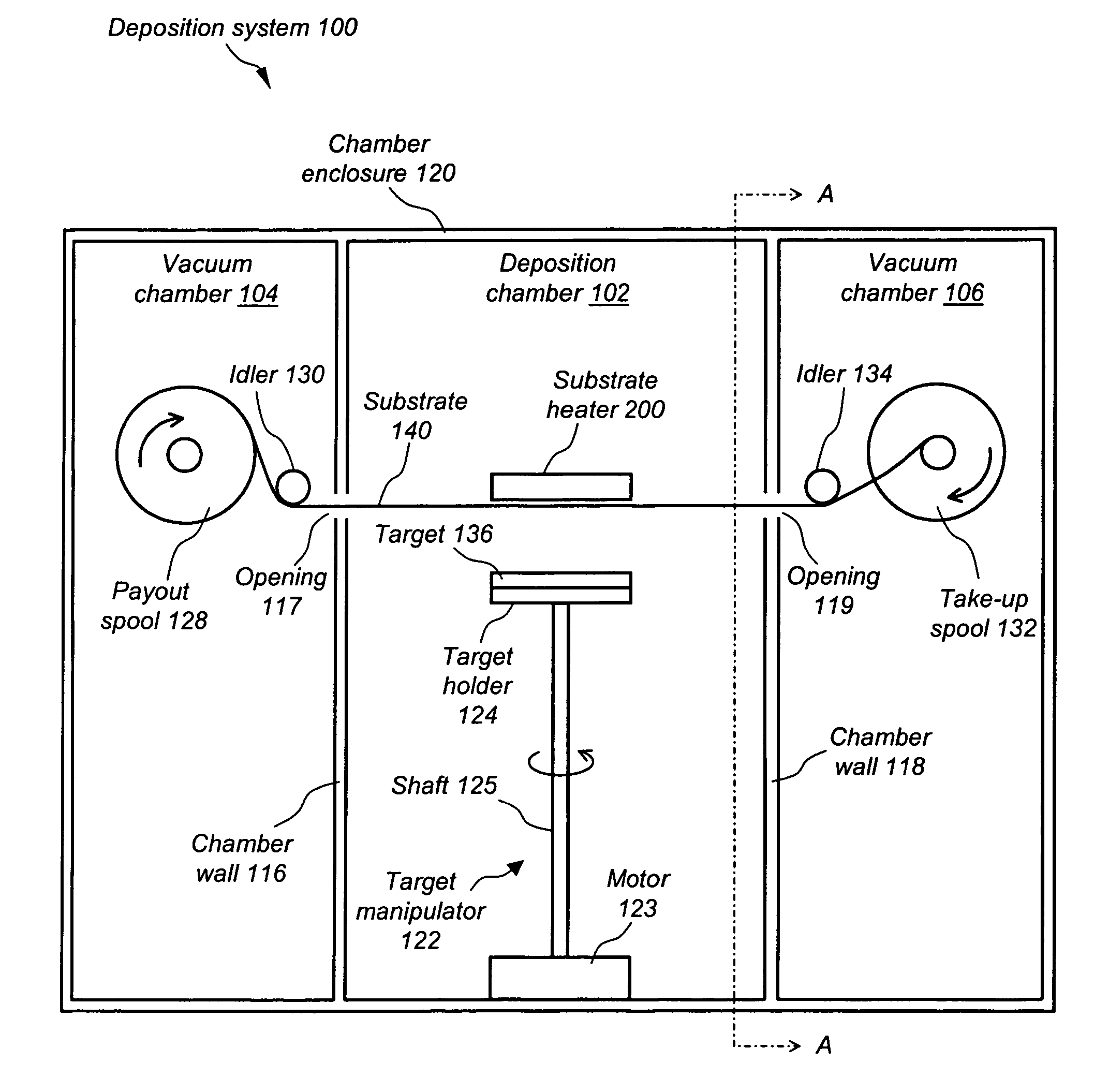

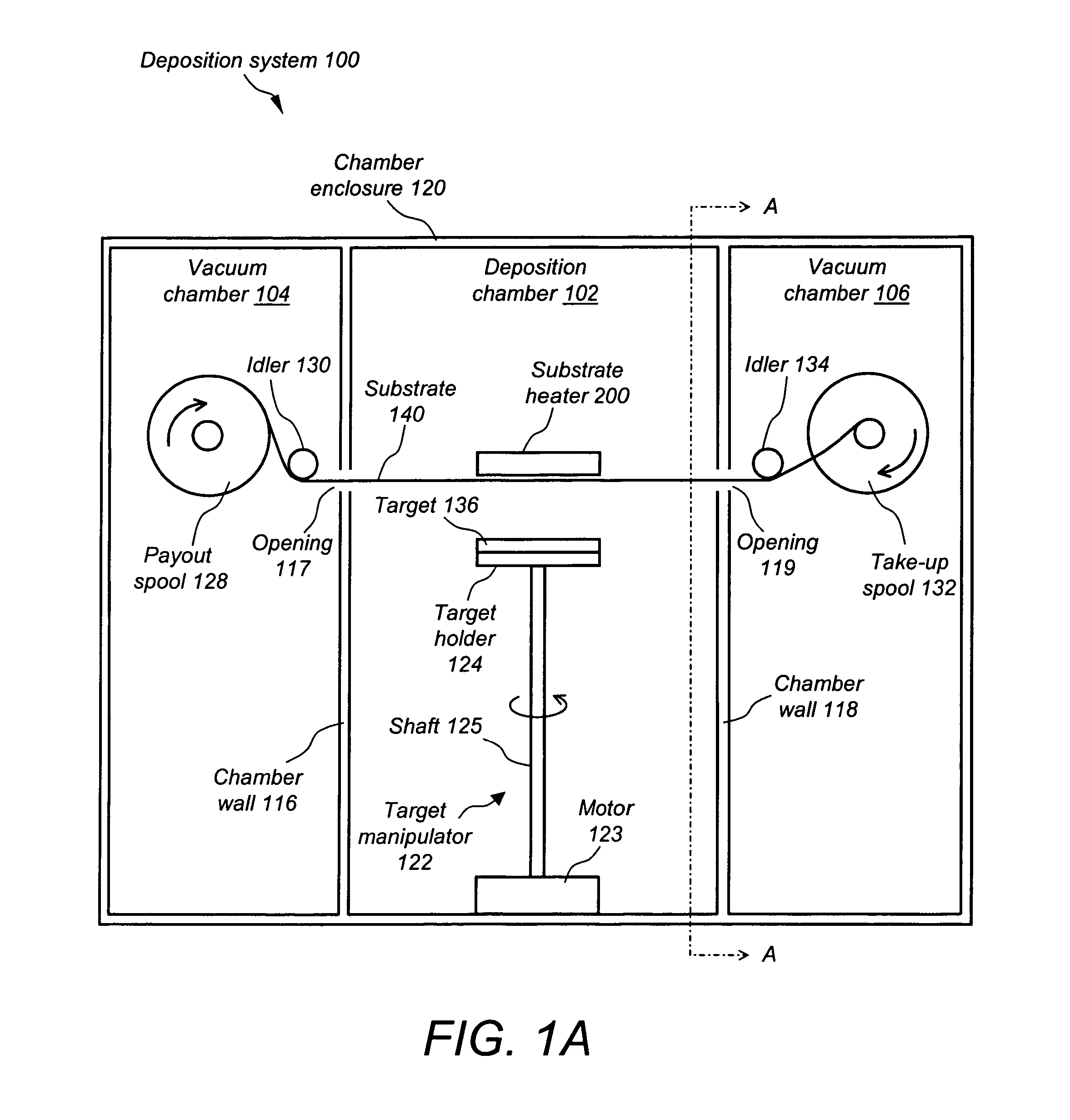

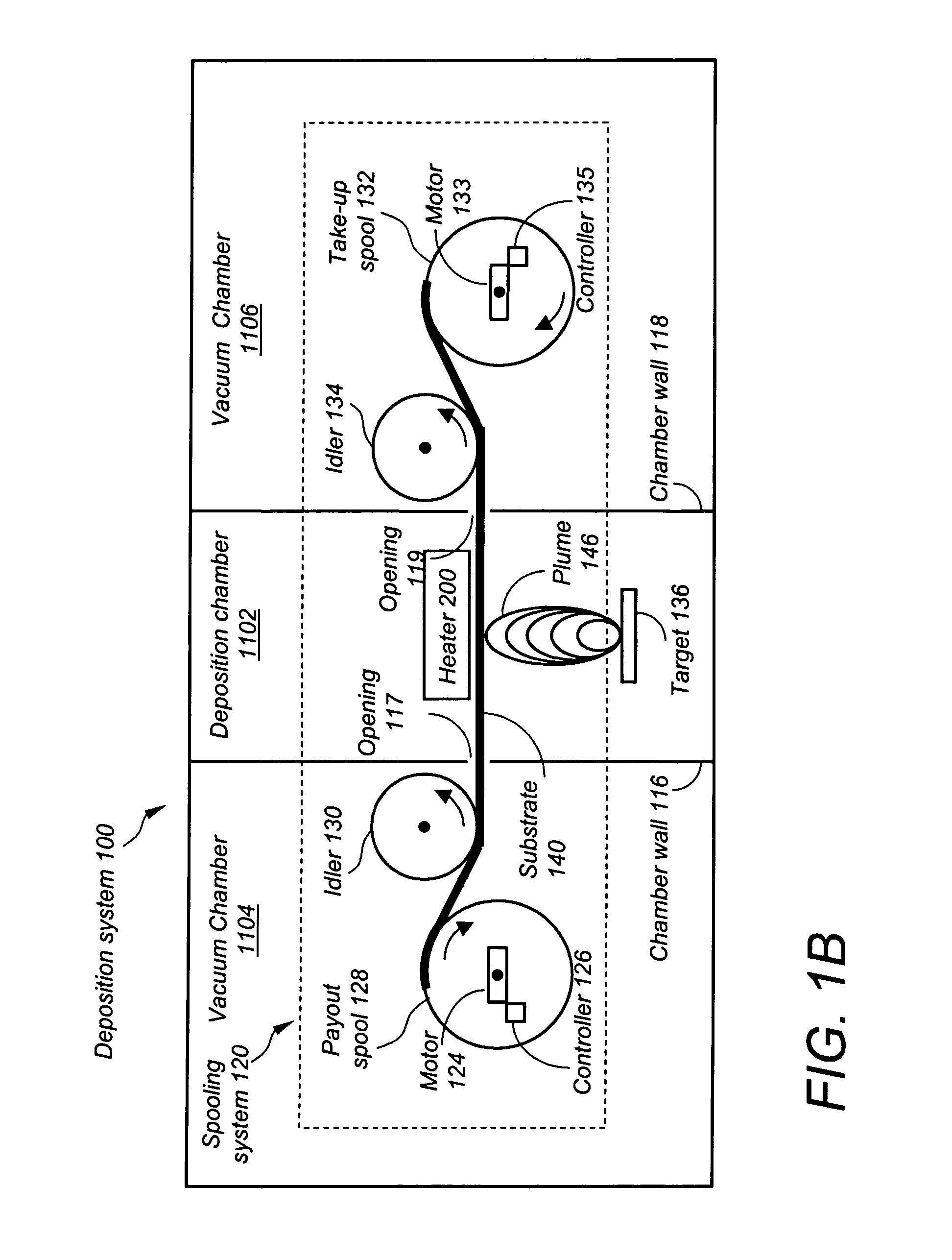

High throughput continuous pulsed laser deposition process and apparatus

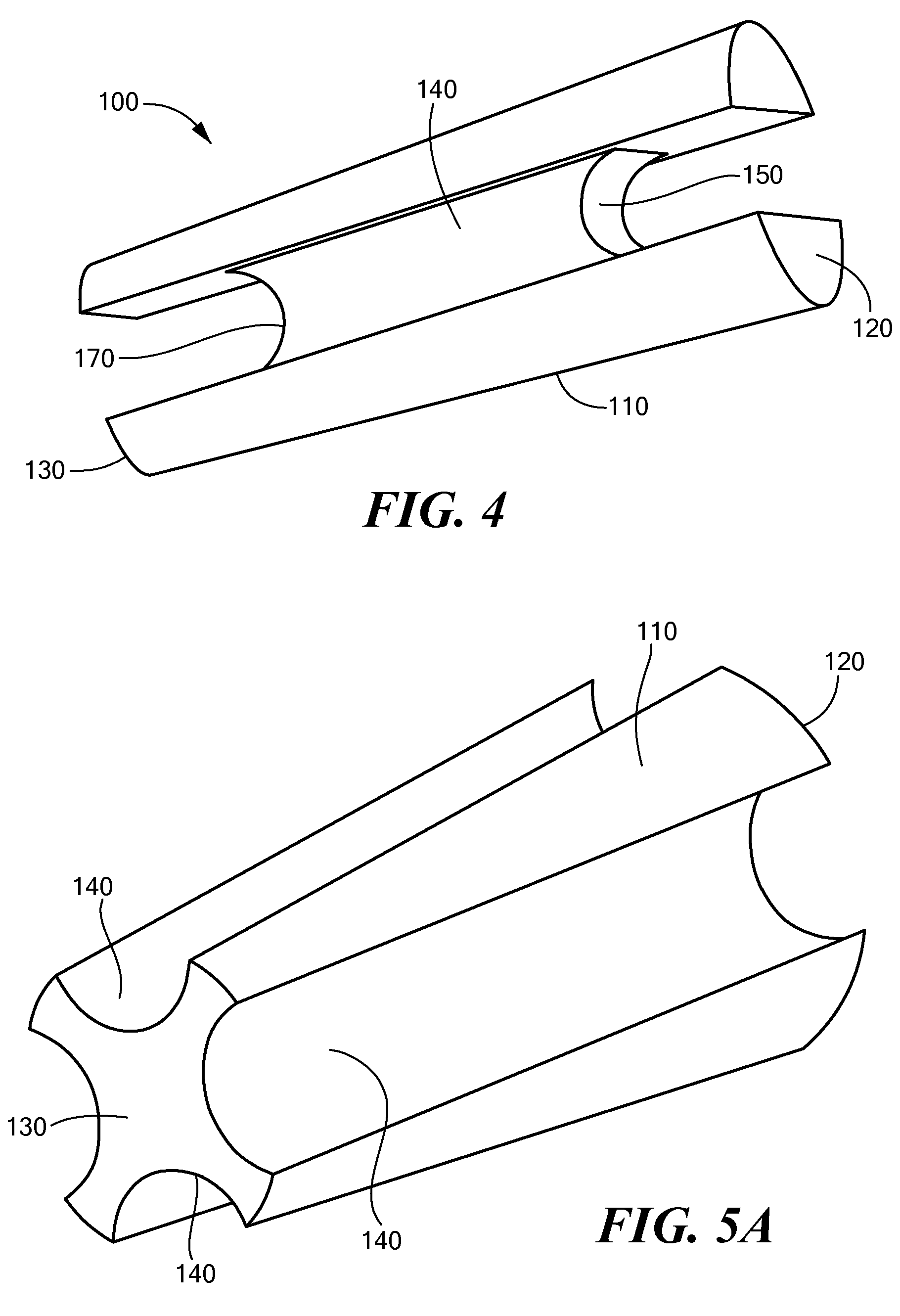

InactiveUS20050005846A1Ensure uniformityAvoid scratchesVacuum evaporation coatingSputtering coatingYttrium barium copper oxideHigh flux

The present invention relates to an apparatus and method for forming a high-temperature superconducting film on a long tape substrate at speeds suitable for large-scale production. The method includes a spooling system for use in a high-throughput, continuous pulsed laser deposition (PLD) process in which a superconducting layer, such as yttrium-barium-copper-oxide (YBCO), is deposited atop a buffered metal substrate tape that is translated through one or more deposition chambers via the action of a reel-to-reel spooling system and a conductive-radiant multi-zone substrate heater. It also optionally includes a multi-target manipulator apparatus and multiple laser beams in which multiple targets are impinged upon simultaneously.

Owner:SUPERPOWER INC

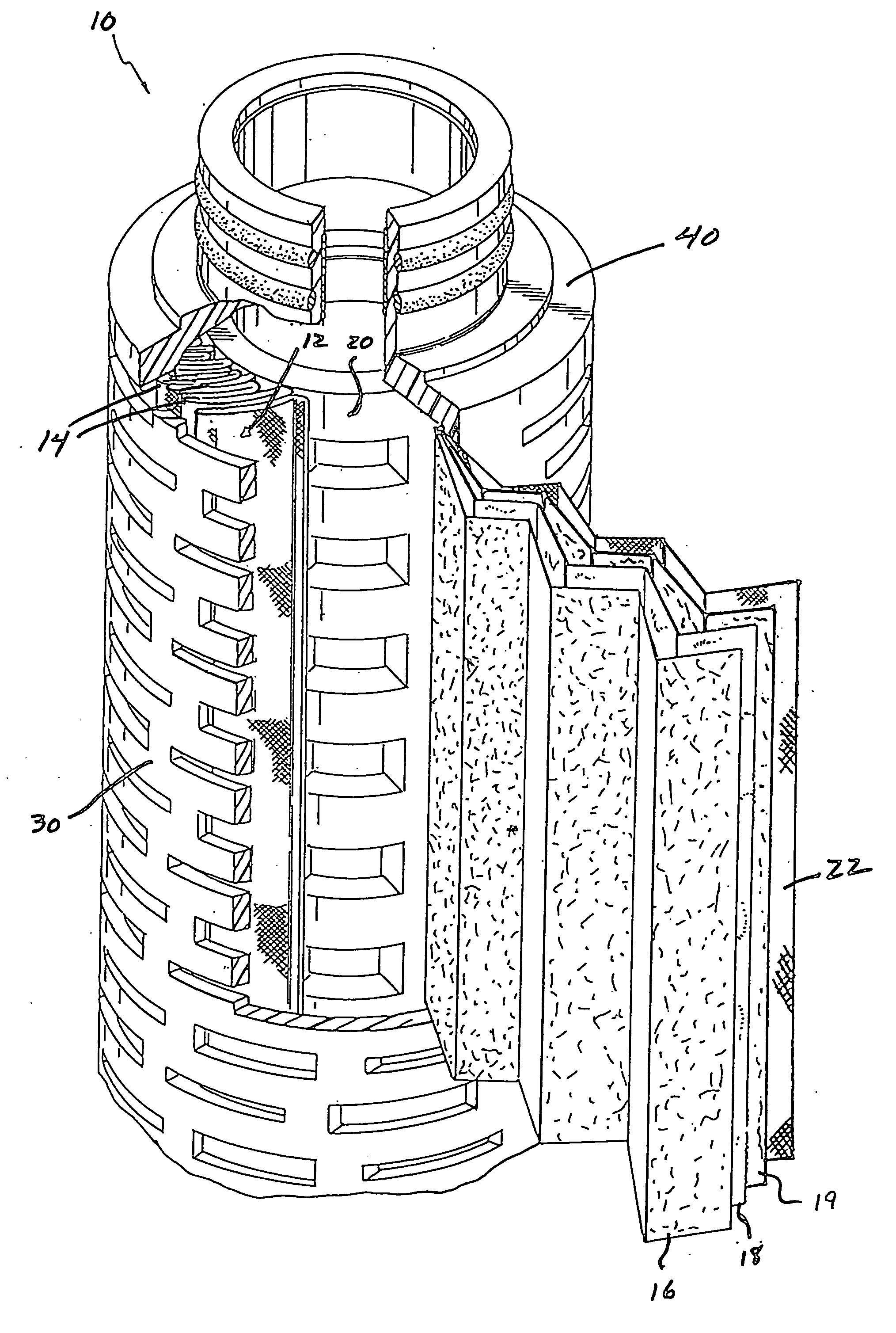

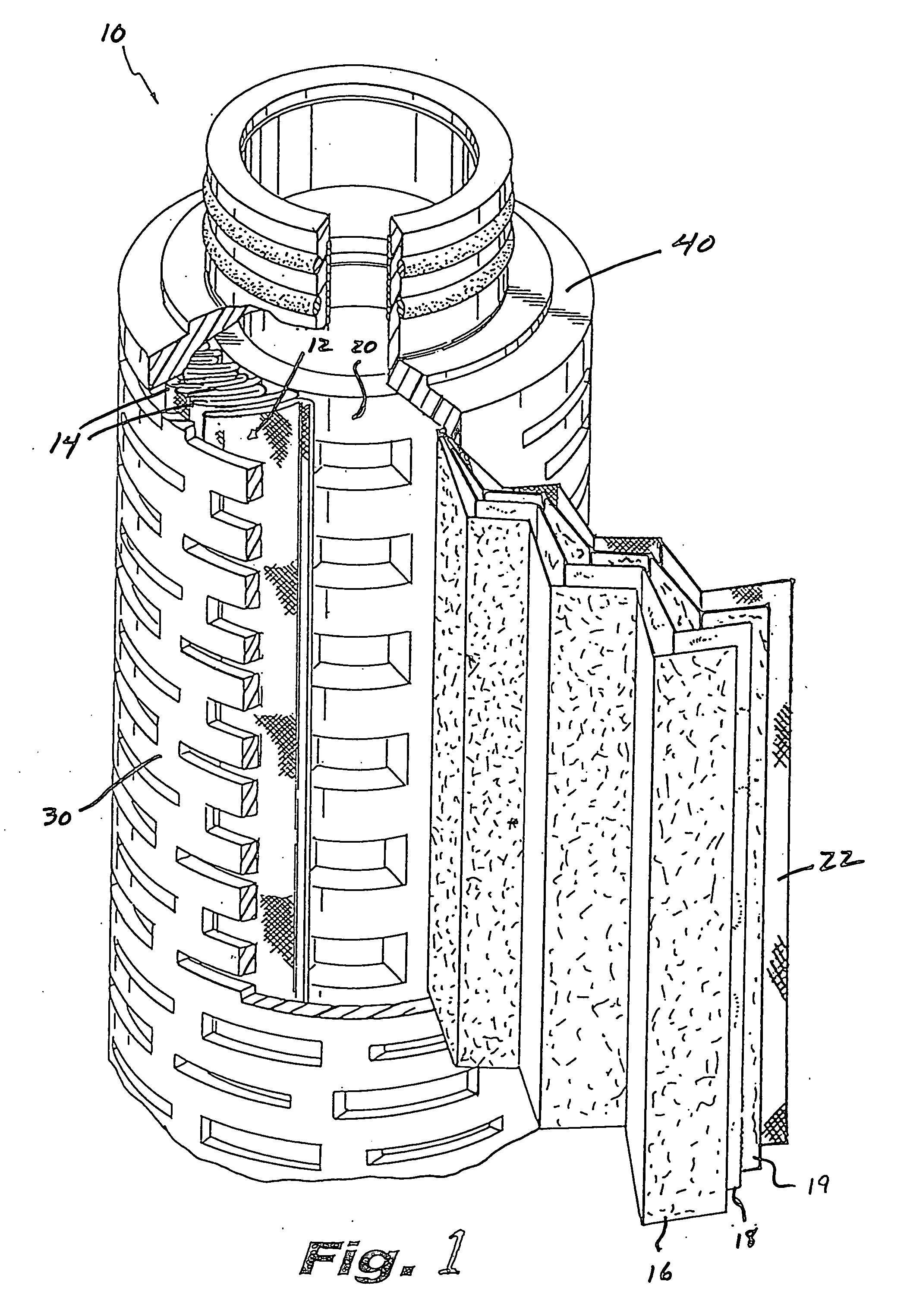

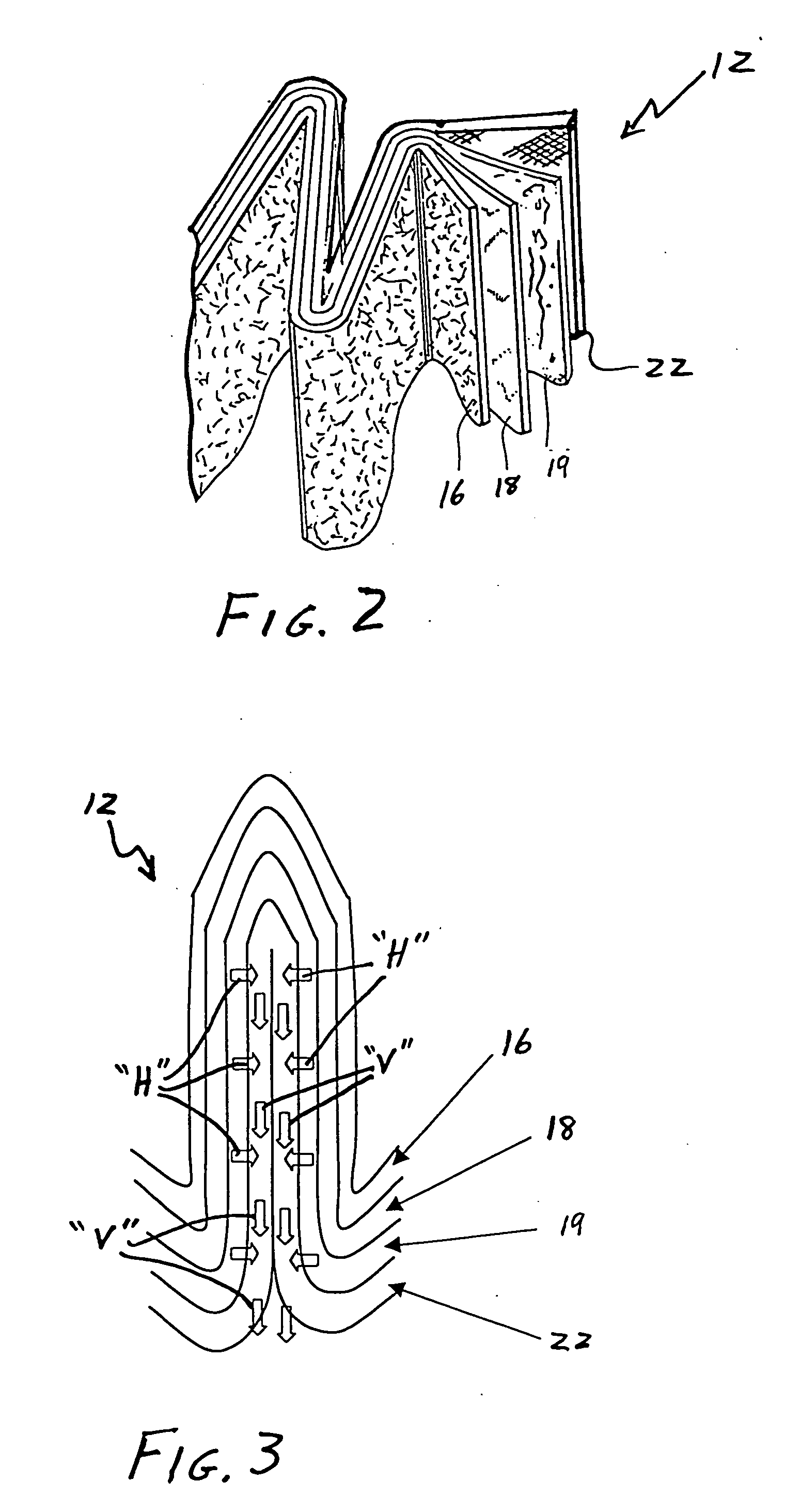

Multi-layer pleat support filter construction

InactiveUS20040060858A1Superior filtration performanceImprove flowSemi-permeable membranesMembrane filtersEngineeringStreamflow

A filter element is disclosed that includes a filtration media, an upstream pleat support and a multi-layer downstream pleat support. The multi-layer downstream support includes a first downstream support layer and a second downstream support layer. The first downstream support layer is in contact with the filtration media and is interposed between the filtration media and the second downstream layer. The first downstream support layer is fabricated so as to minimize points of surface contact with the filtration media, thereby enhancing fluid flow away from the filtration media. The second downstream support layer is in contact with the first downstream support layer and is fabricated so as to facilitate lateral fluid flow relative to the multi-layer downstream pleat support. The disclosed filter element may be utilized in filter cartridges of various designs to provide enhanced filtration performance, e.g., by way of increased media area and improved flow / throughput.

Owner:3M INNOVATIVE PROPERTIES CO

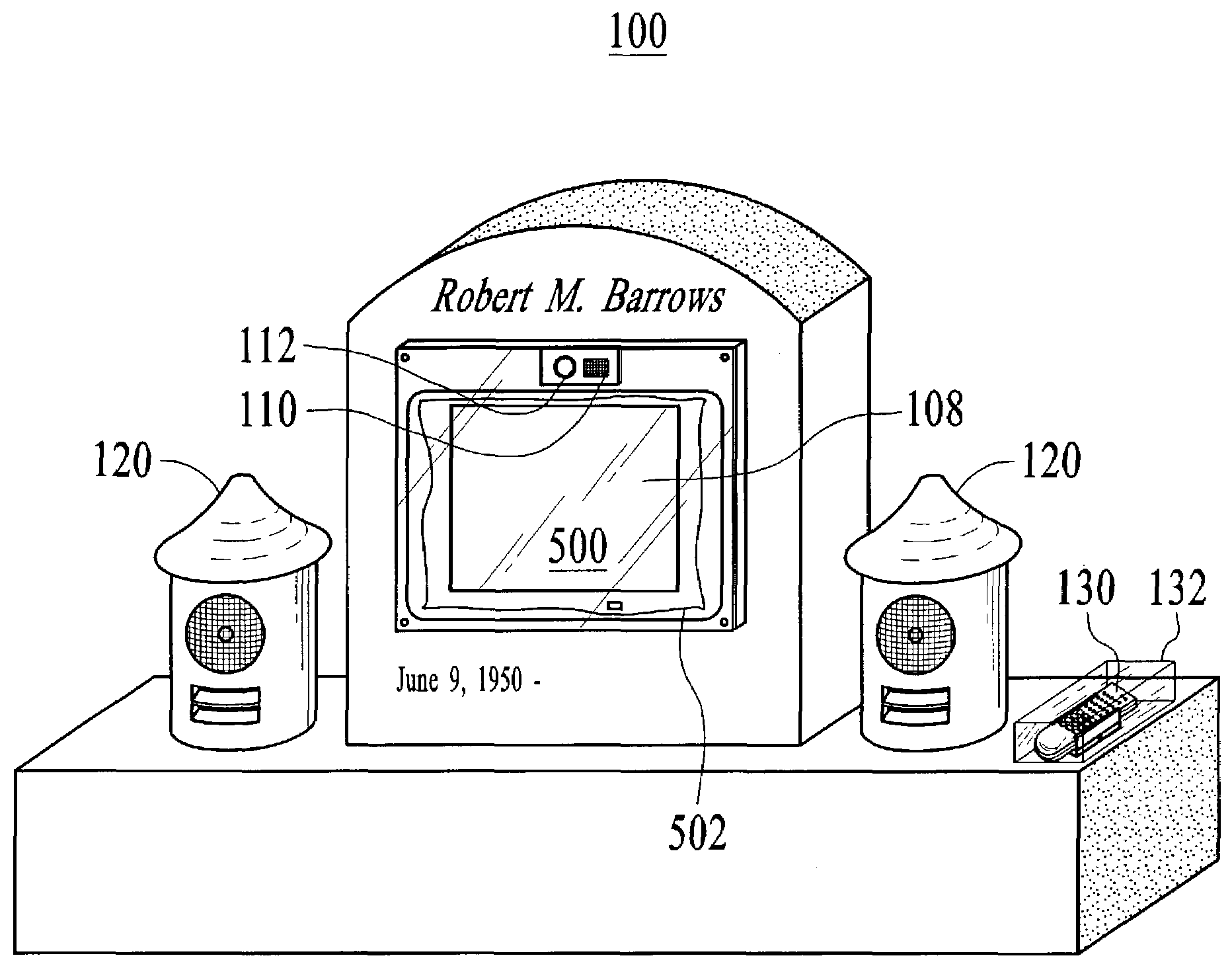

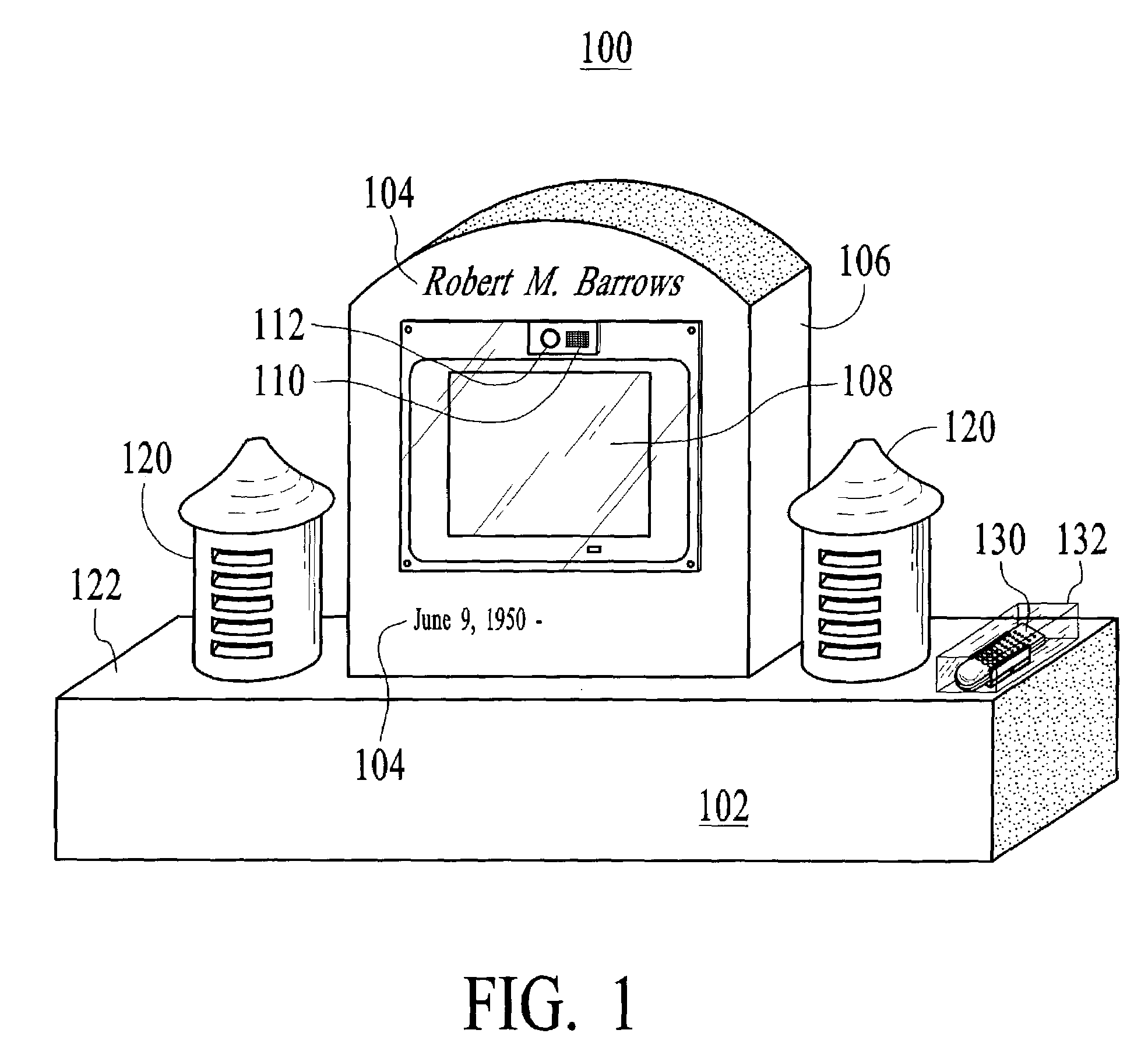

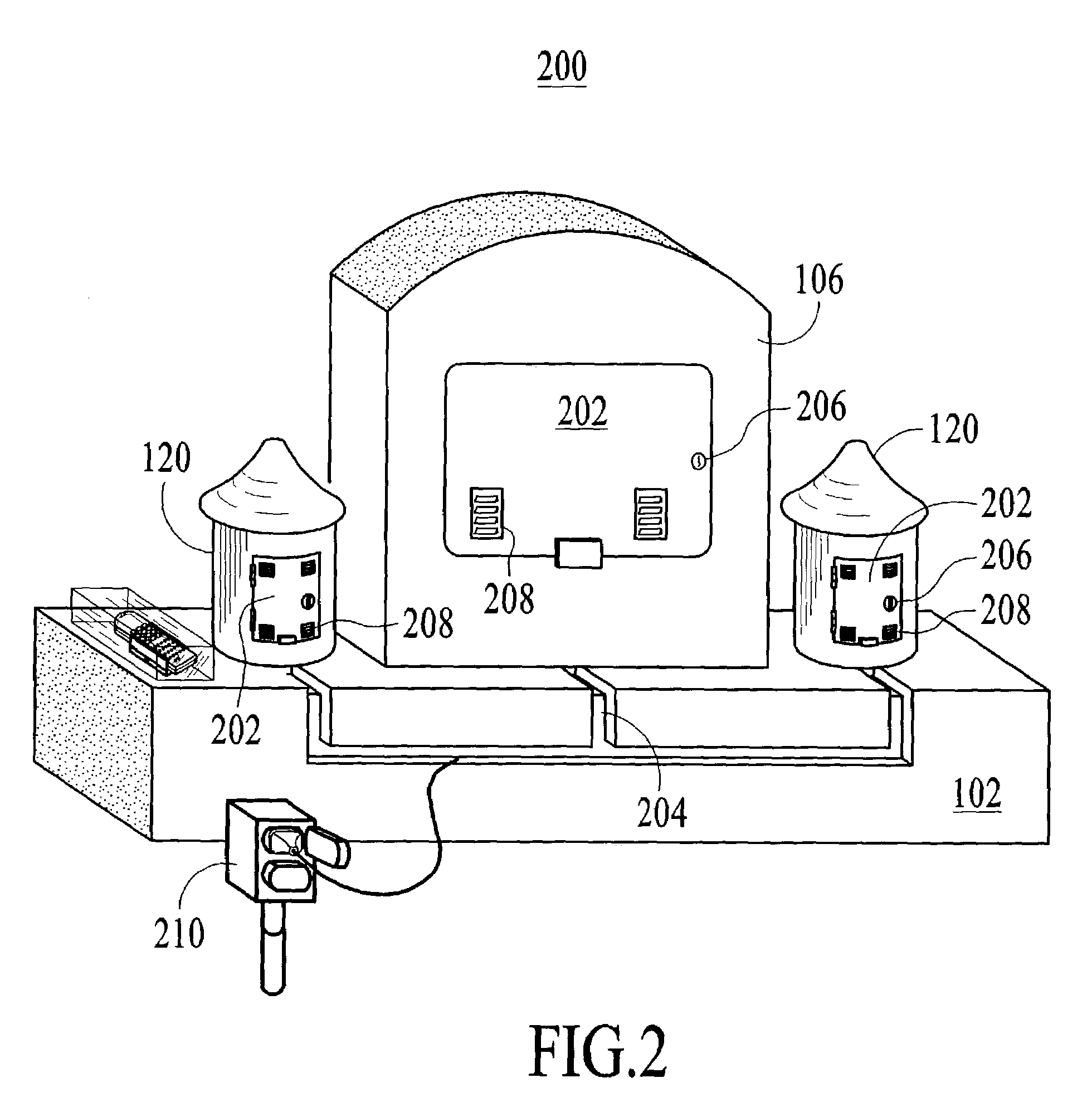

Video enhanced gravemarker

InactiveUS7089495B2Easy to installEasy to removeTelevision system detailsRecord information storageAcoustic waveData storing

A tombstone for communicating audio and visual data related to the deceased from the tombstone to a user, the tombstone comprising an indicia bearing and viewing portion, a visual display, an audio transmitter for communicating sound waves to a user, data related to the deceased, the data comprising audio and visual images of the deceased, the data stored within storage media, and means for reproducing the audio and visual images of the deceased from the data related to the deceased utilizing one or more players, readers or drivers for the one or more of the storage media.

Owner:R M BARROWS

Method and Device for Stabilizing Joints With Limited Axial Movement

ActiveUS20080269743A1Broaden applicationImprove concentrationSuture equipmentsInternal osteosythesisSuture anchorsRelative motion

An apparatus for stabilizing a joint with low relative motion during orthopedic surgery. The apparatus includes a press-fit fastener body and a coupler. The press-fit fastener body has a proximal end and a distal end and is configured to be press-fit into a tunnel in a first bone member. The coupler is located on or is part of the press-fit fastener body and is configured to receive at least one flexible element trailing from at least one suture anchor. At least a portion of the suture anchors are located within a second bone member.

Owner:ALASKA HAND RES

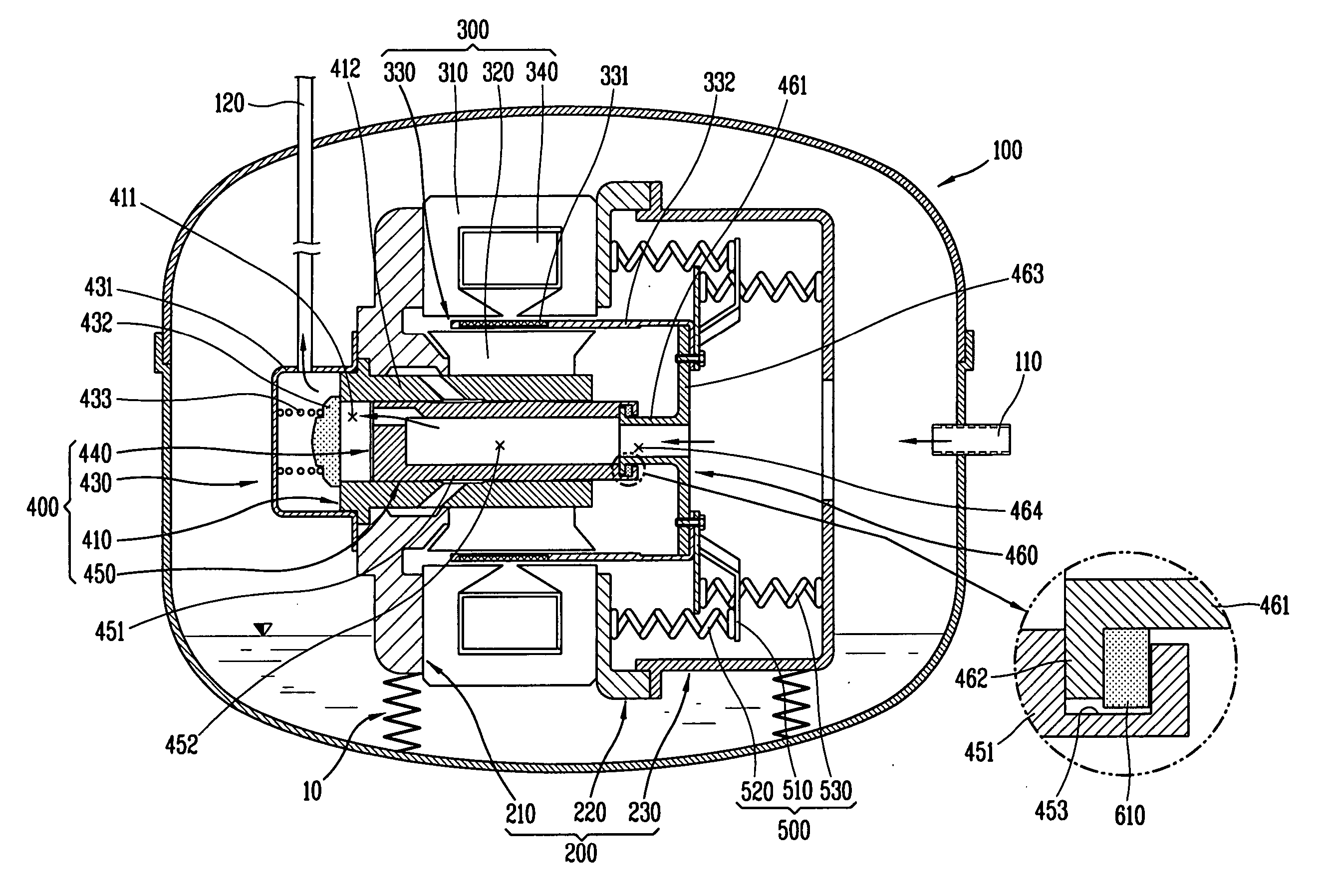

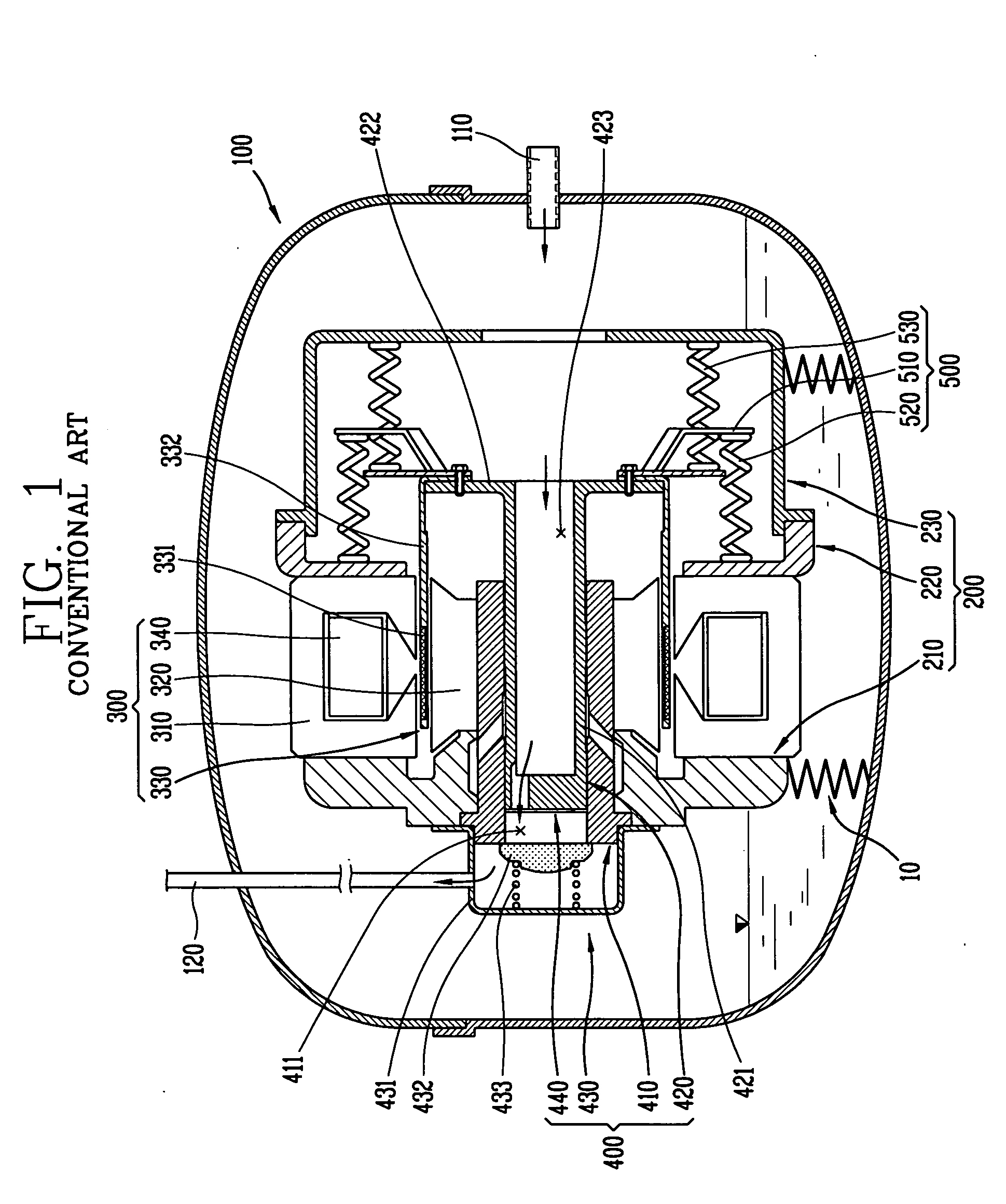

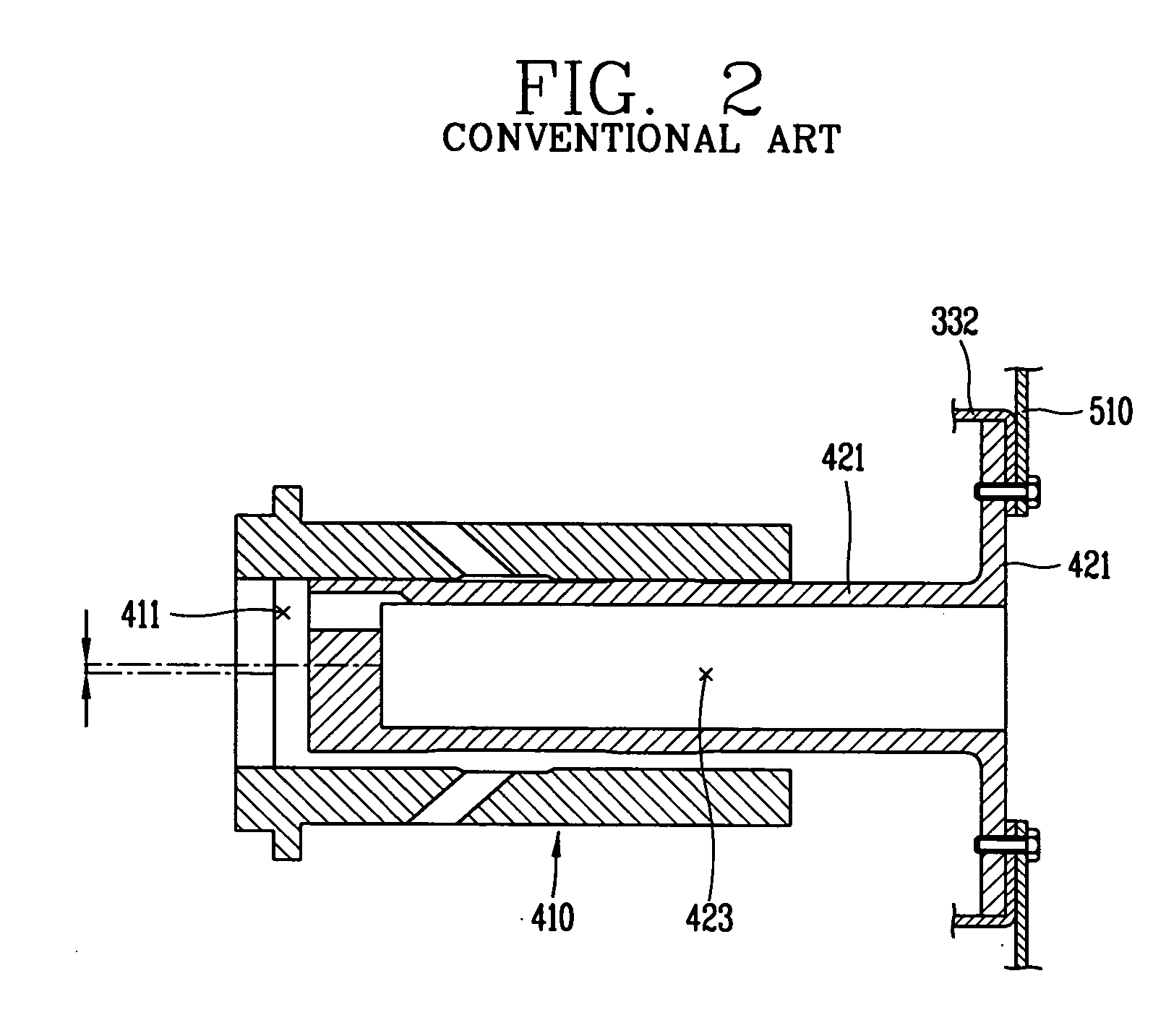

Apparatus for preventing abrasion in reciprocal compressor

InactiveUS20050142007A1Avoid scratchesPositive displacement pump componentsPlungersInterior spaceRelative motion

The present invention discloses an apparatus for preventing abrasion in a reciprocal compressor, including a cylinder, a reciprocal motor having a stator and a mover, and generating a linear reciprocation driving force, a piston inserted into an inside space of the cylinder to be linearly movable, a piston rod coupled to the piston to be movable in the radial direction of the piston, and coupled to the mover of the reciprocal motor, for transmitting the linear reciprocation driving force of the reciprocal motor to the piston, and a concentricity control means coupled to a junction between the piston and the piston rod, for fixing the piston and the piston rod in the axial direction, and allowing a relative motion thereof in the radial direction. The apparatus for preventing abrasion in the reciprocal compressor prevents abrasion from being generated between the cylinder and the piston due to processing errors and assembly errors of components of the reciprocal compressor.

Owner:LG ELECTRONICS INC

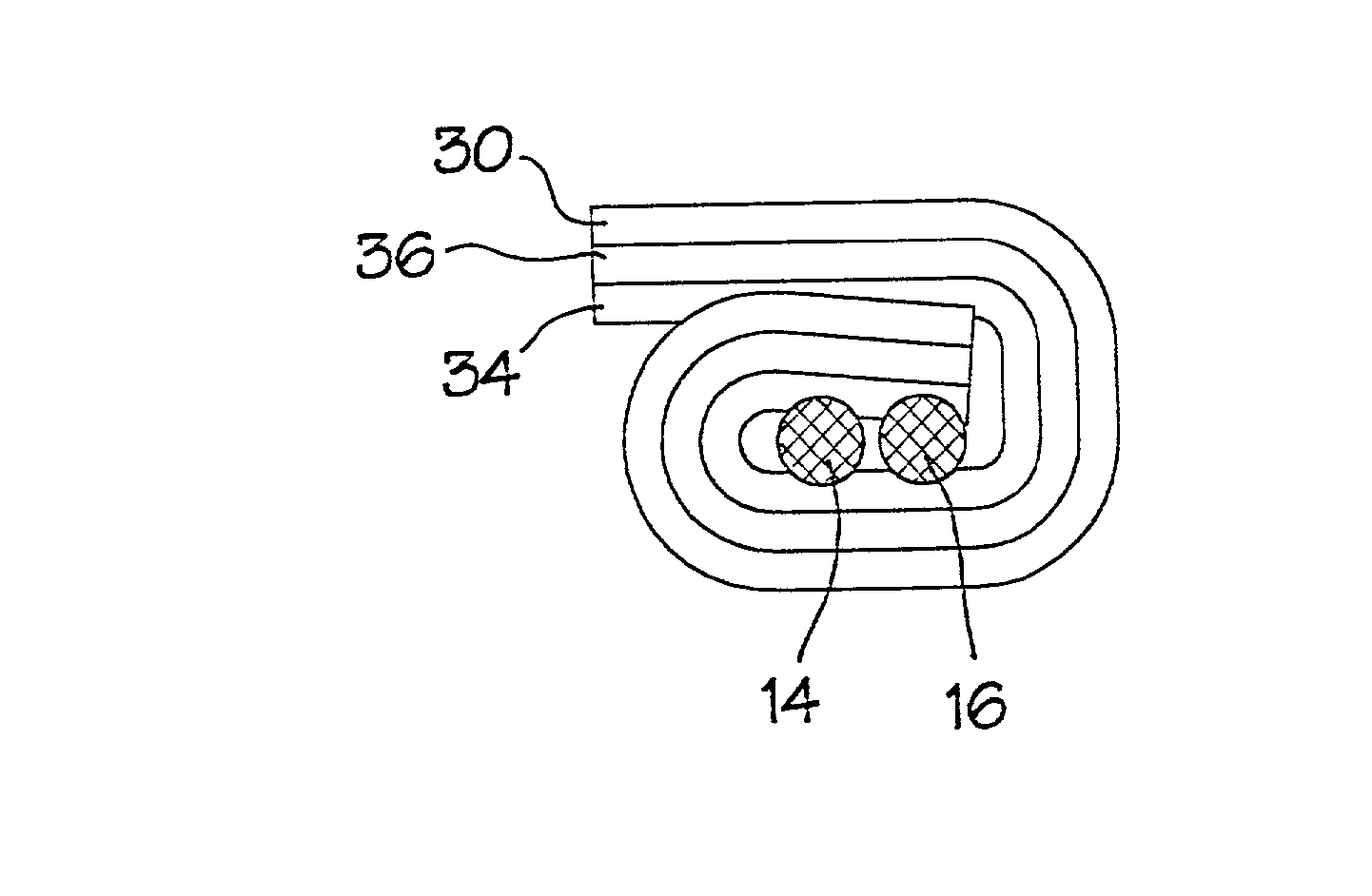

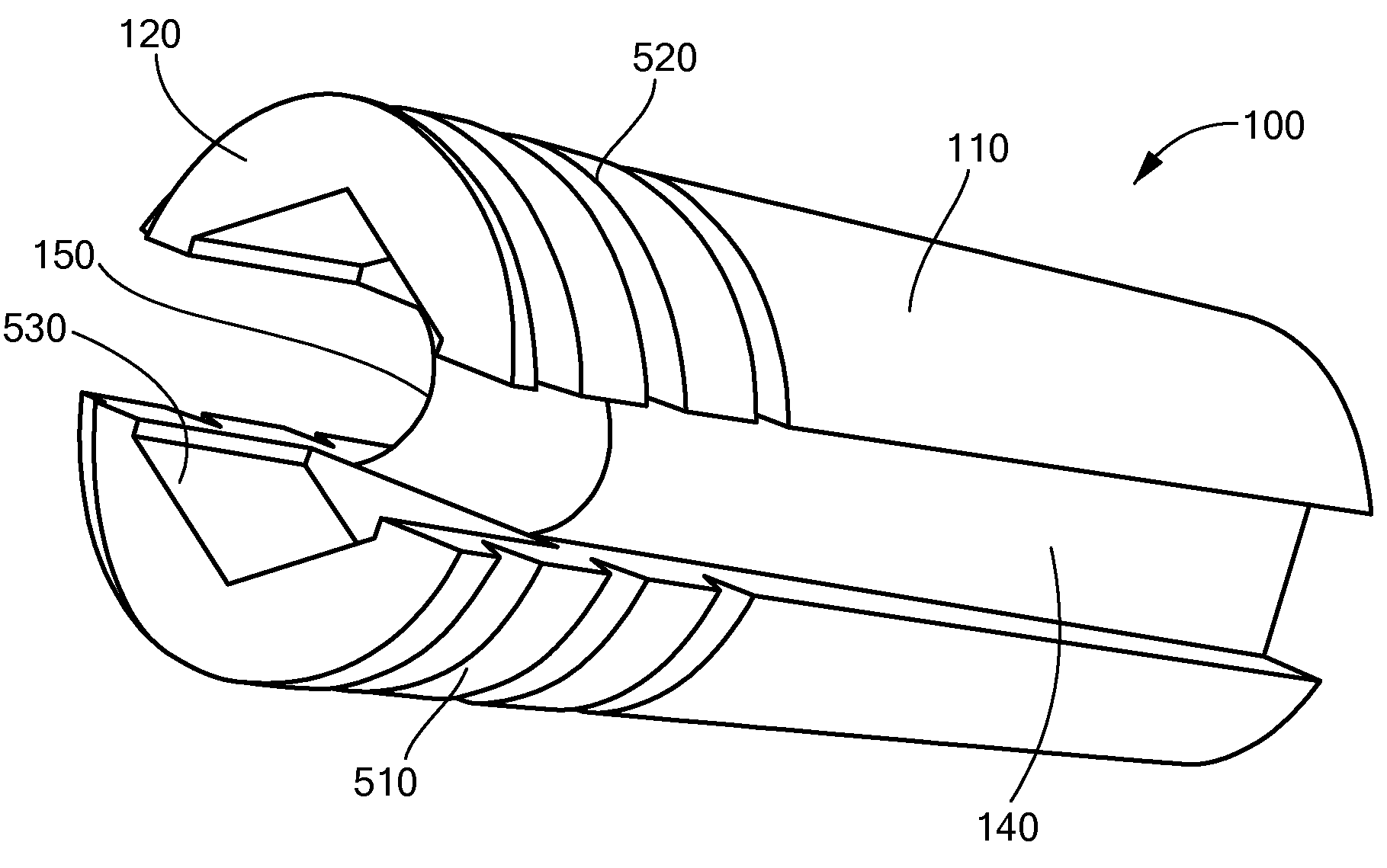

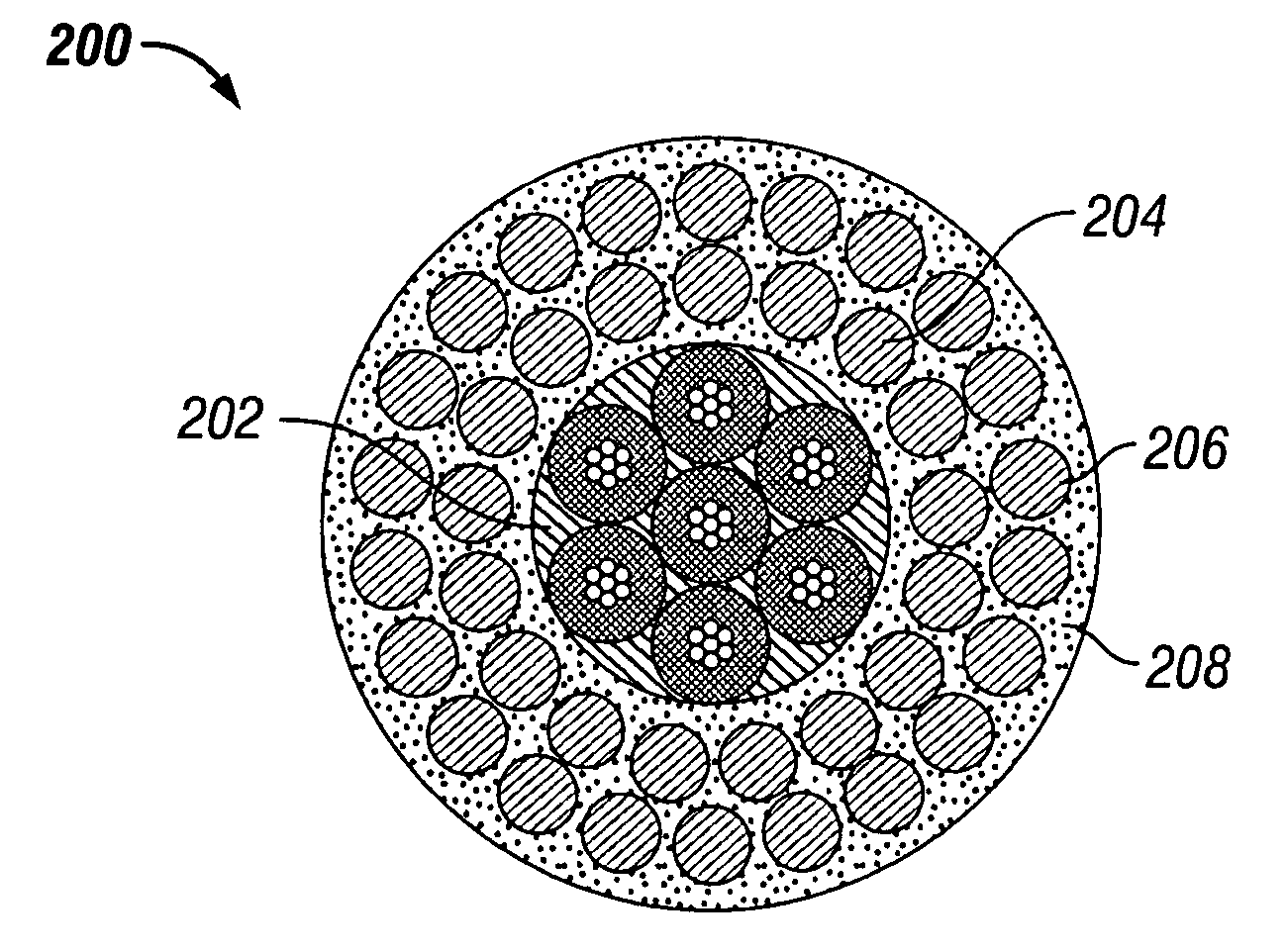

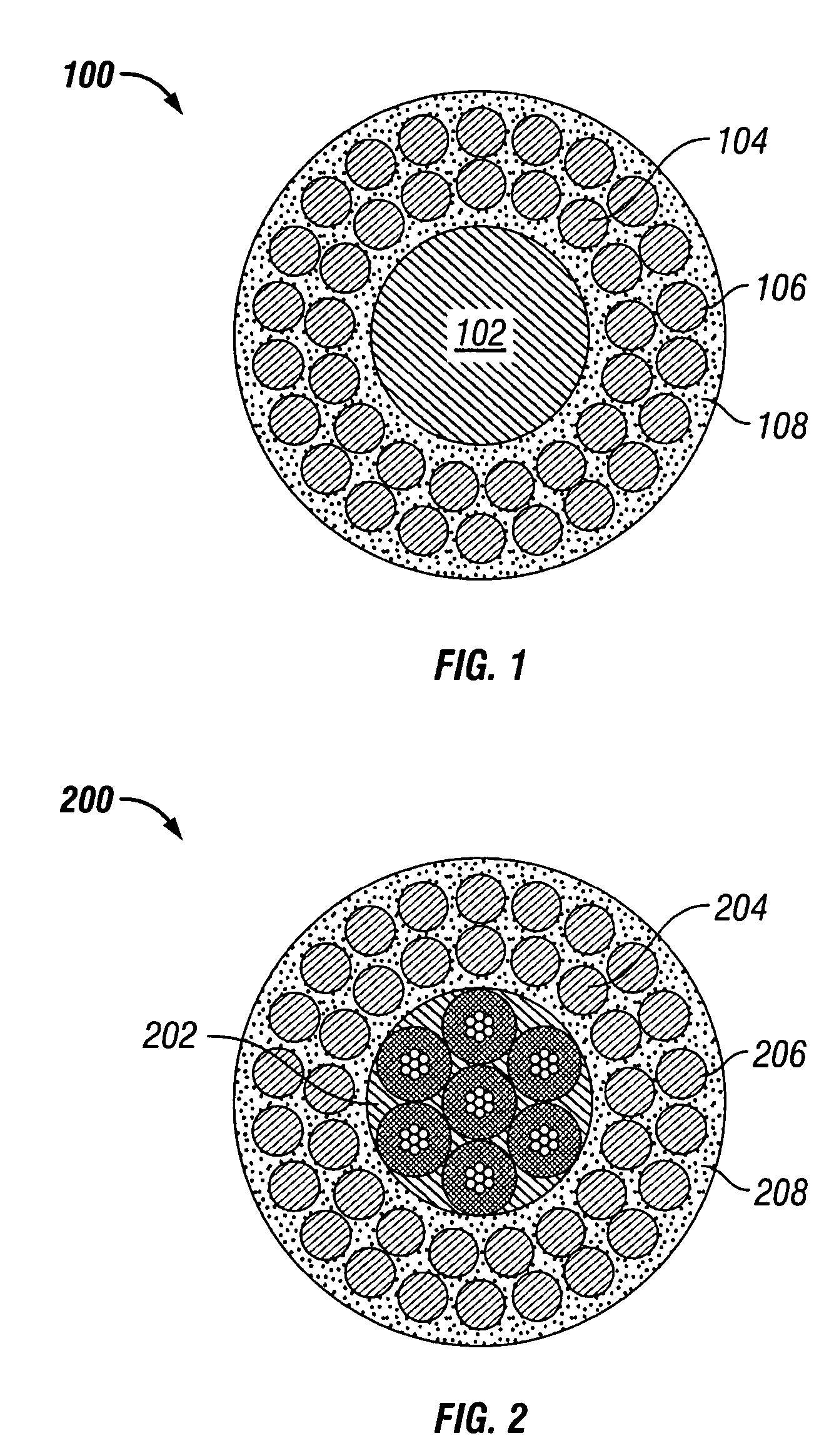

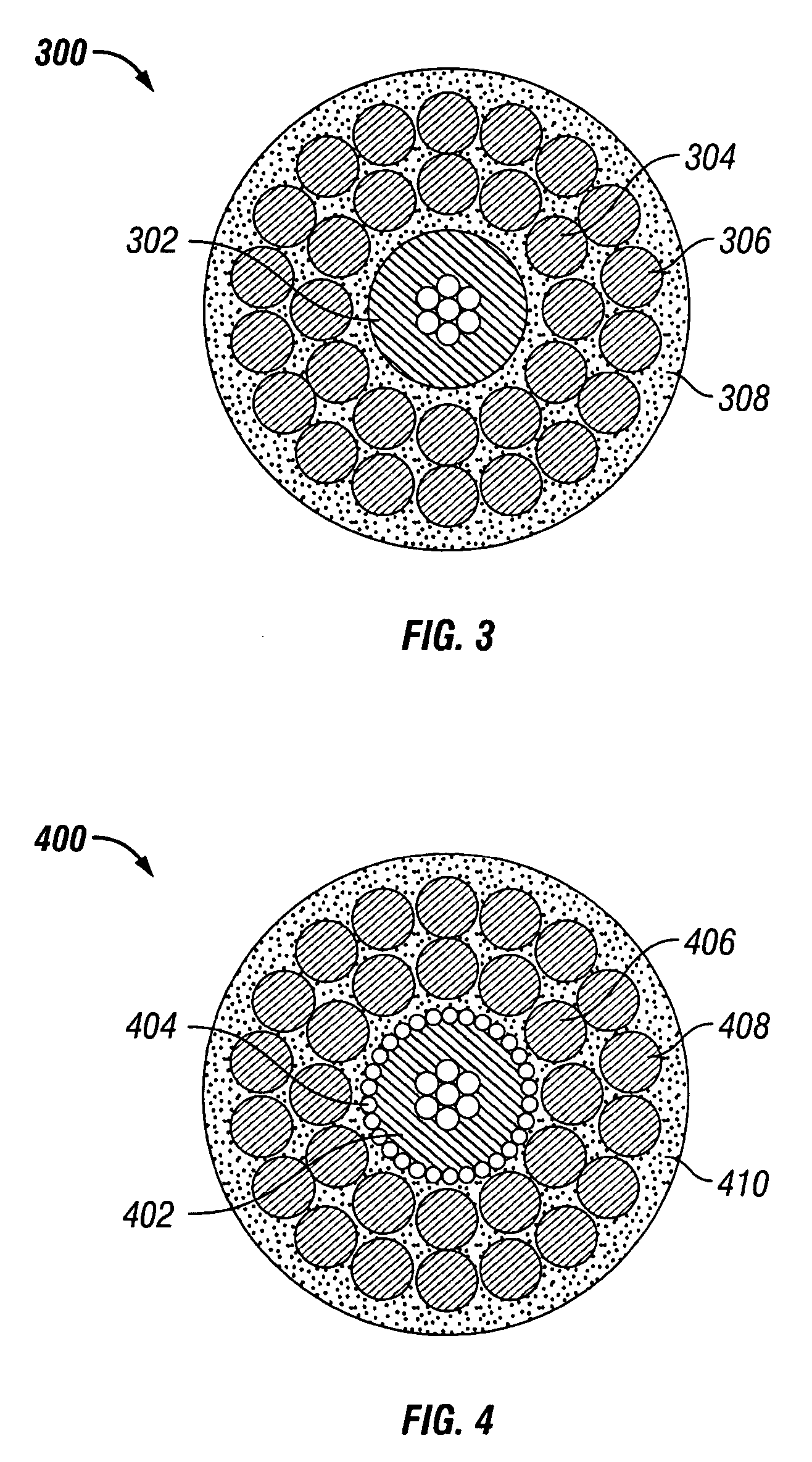

Enhanced electrical cables

ActiveUS7170007B2Avoid scratchesReduce resistancePower cables with screens/conductive layersInsulated cablesFiberElectrical conductor

Wellbore electrical cables according to the invention include at least one insulated conductor, at least one layer of armor wires surrounding the insulated conductor, and a polymeric material disposed in the interstitial spaces formed between armor wires and interstitial spaces formed between the armor wire layer and insulated conductor which may further include wear resistance particles or even short fibers, and the polymeric material may further form a polymeric jacket around an outer, layer of armor wires. The insulated conductor is formed from a plurality of metallic conductors encased in an insulated jacket. The invention also discloses a method of preparing a cable by extruding first layer of polymeric material upon at least one insulated conductor; serving a first layer of armor wires upon the polymeric material; softening the polymeric material to partially embed armor wires; extruding a second layer of polymeric material over the armor wires; serving a second layer outer armor wires thereupon; softening the polymeric material to partially embed the second armor wire layer; and optionally extruding a third layer of polymeric material over the outer armor wires embedded in the second layer of polymeric material. Further disclosed are methods of using the cables of the invention in seismic and wellbore operations, including logging operations.

Owner:SCHLUMBERGER TECH CORP

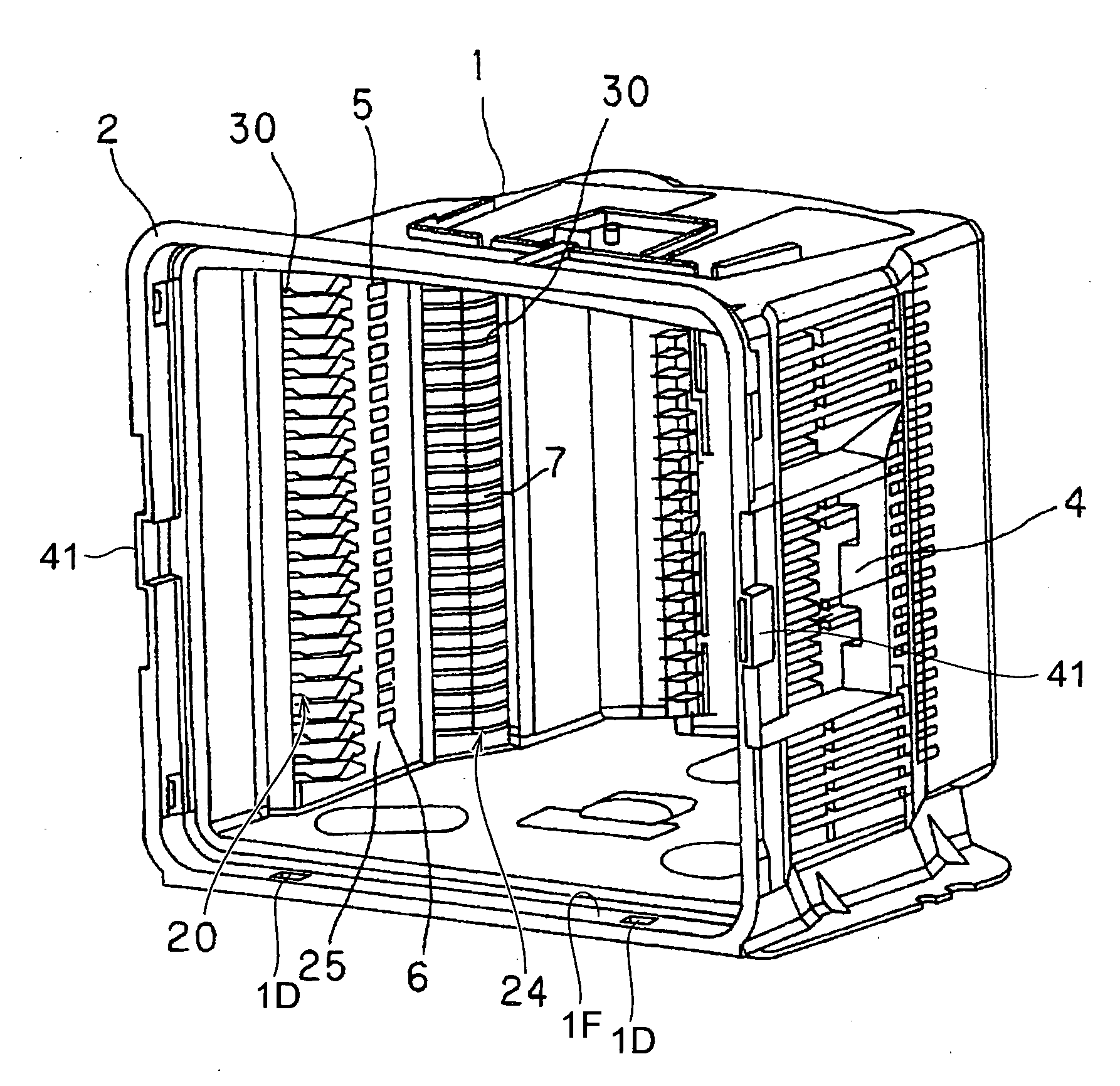

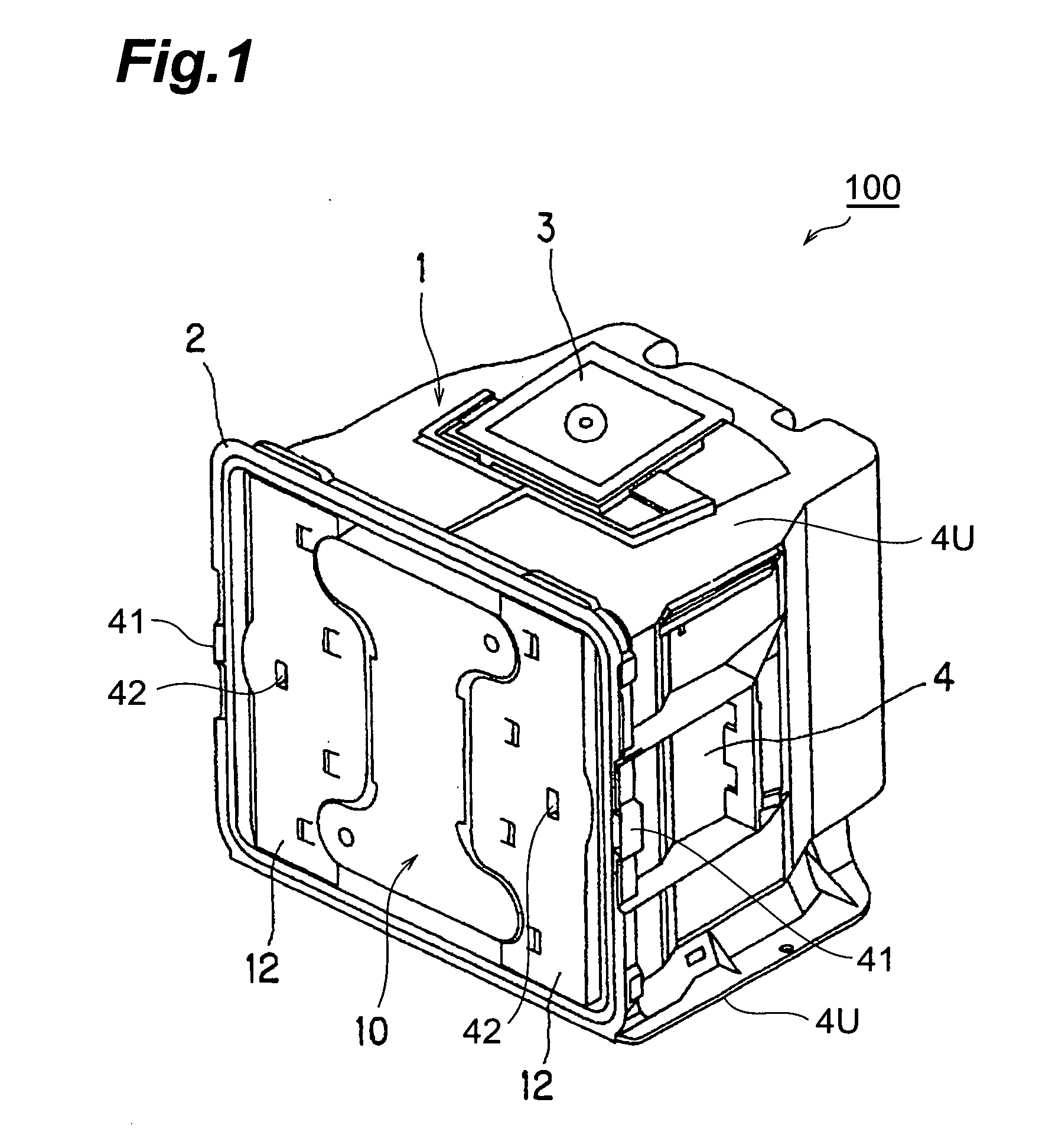

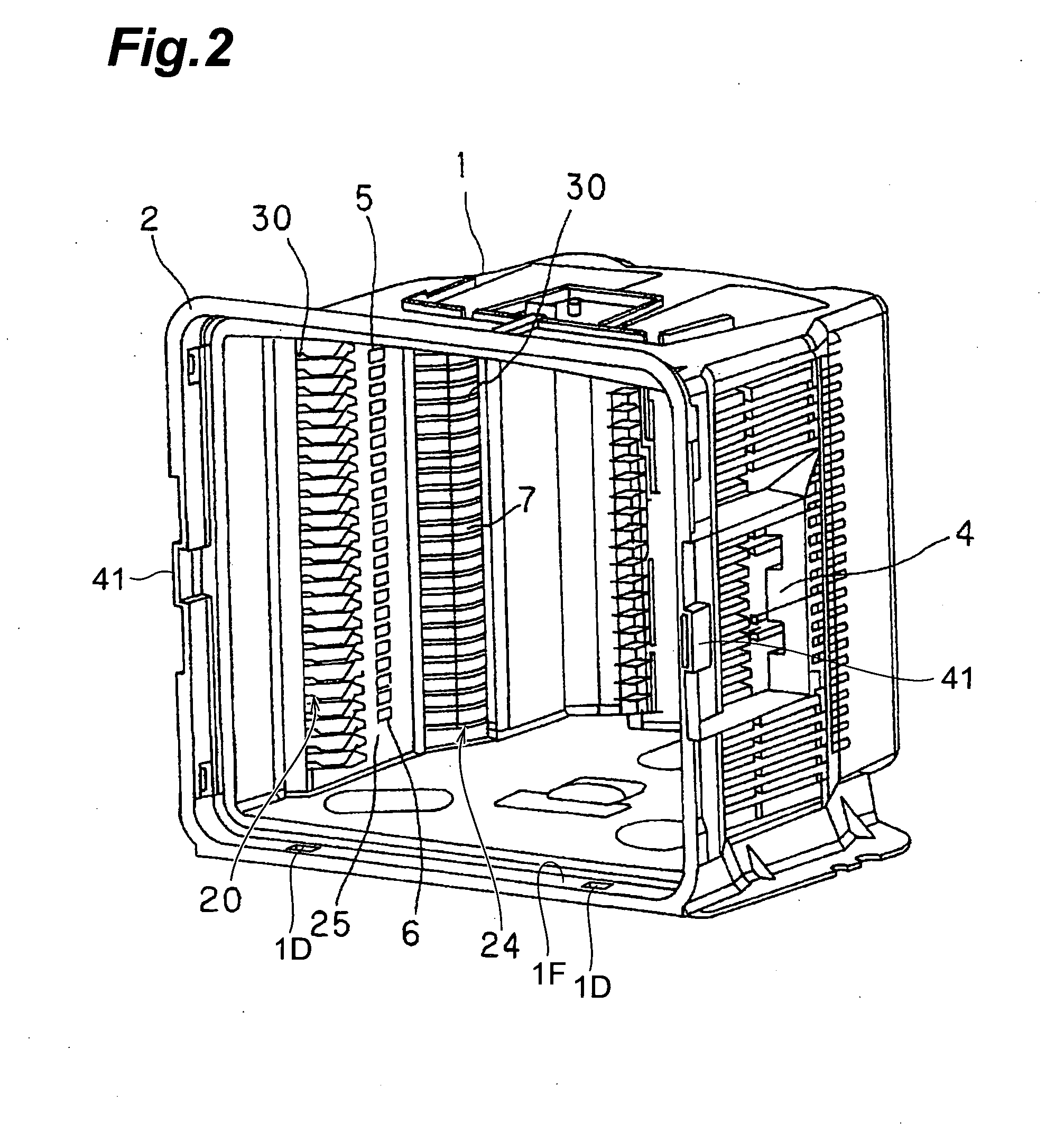

Substrate storage container and method for manufacturing the same

InactiveUS20060283774A1Prevent contamination and scratchingFine pitchSemiconductor/solid-state device manufacturingOther accessoriesEngineeringMechanical engineering

A substrate storage container includes a container main body, first supporting parts and second supporting parts. The container main body includes a back wall and a pair of side walls in order to store a substrate between the side walls. The first supporting parts are opposingly disposed on each side wall in order to support a peripheral edge part of the substrate. The second supporting parts are opposingly disposed on each side wall in order to support the peripheral edge part of the substrate and positioned between the back wall and the first supporting parts. The first supporting parts and the second supporting parts are covered with a resin layer having a lower frictional property than that of the container main body.

Owner:SHIN-ETSU POLYMER CO LTD

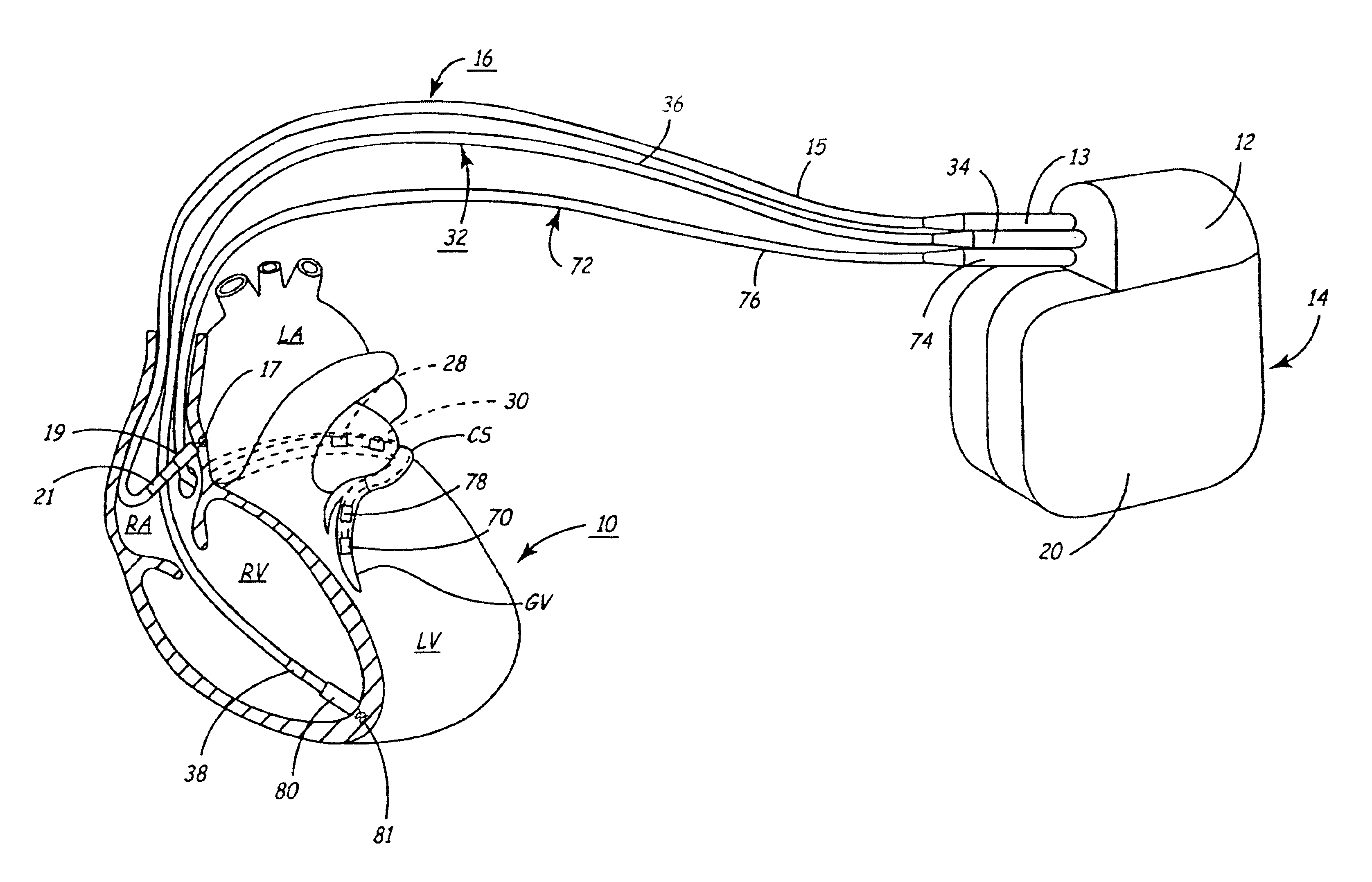

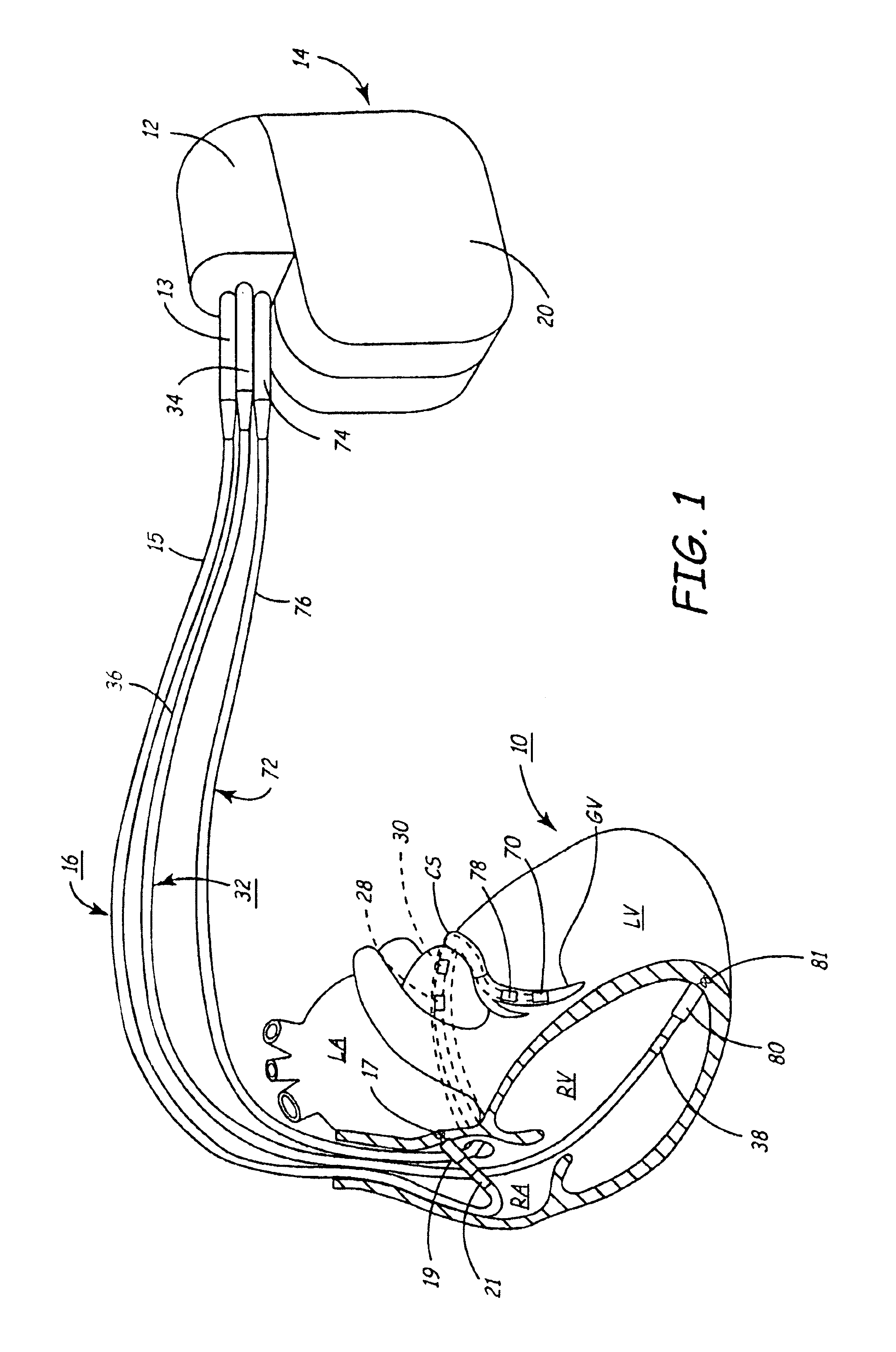

Enhanced method and apparatus to identify and connect a small diameter lead with a low profile lead connector

InactiveUS6968235B2Prevent intrusionAvoid scratchesTransvascular endocardial electrodesHeart defibrillatorsElectricityElectrical connection

The present invention provides a practical, multi-polar, in-line connector system for use in connecting implantable medical devices (IMD) and associated non-standard, low profile medical electrical leads. In addition, the present invention provides a system that uses tool less, frictional, sealed, compressive electrical connections for most or all of the electrical interconnections between an IMD and a low profile lead. A protective sleeve seals the lead connector to the non-standard port to prevent intrusion of body fluids therein. In addition, optional microchip-based circuitry coupled to the sleeve enables wireless communication and remote programming for diverse IMDs. Memory associated with the circuitry can store, update and reprogram a wide variety of information relevant to the IMD, the patient, and the attending physician, among others. For example, the microchip may be used to identify the lead type and characteristics, as well as other useful data.

Owner:MEDTRONIC INC

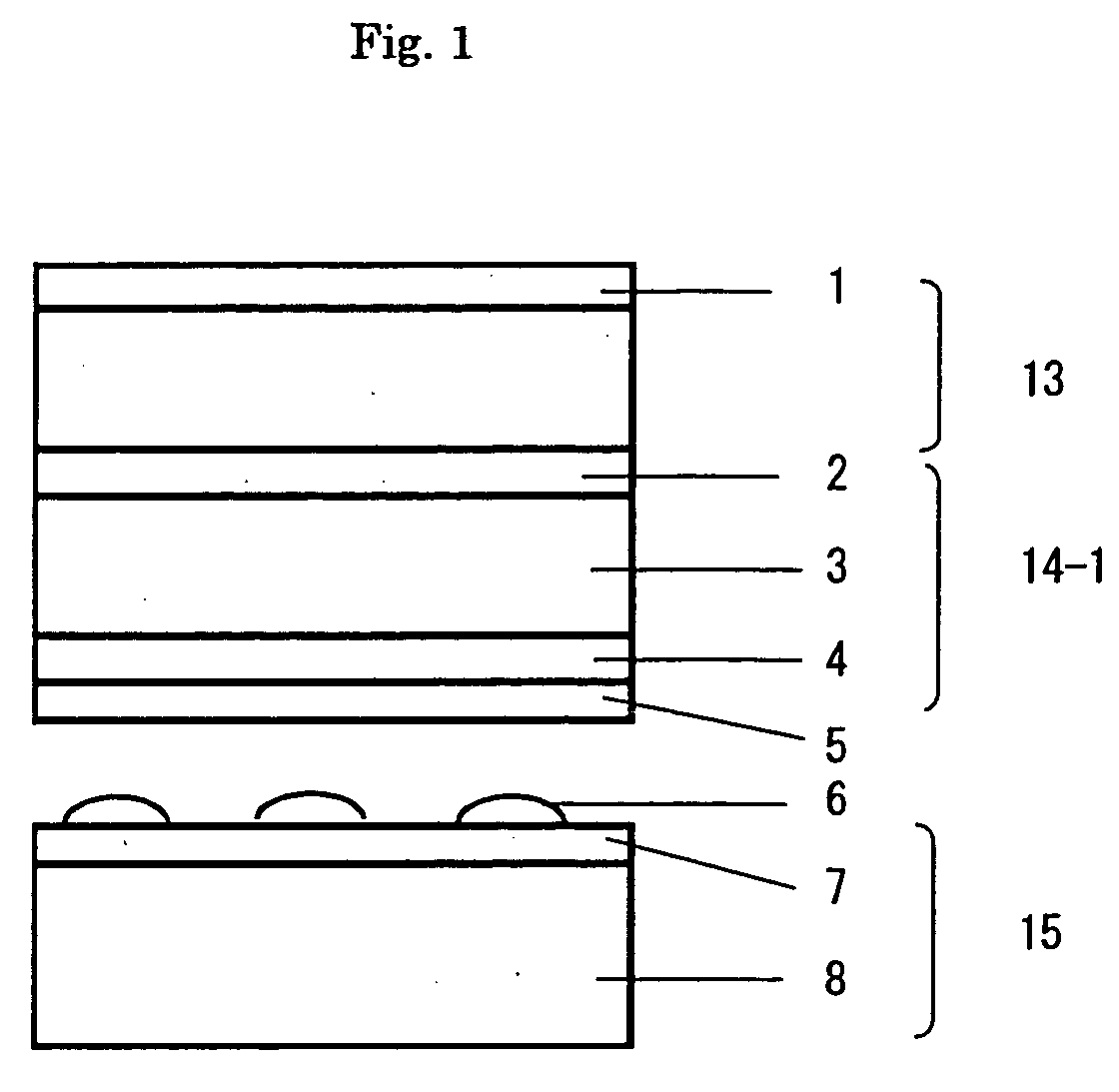

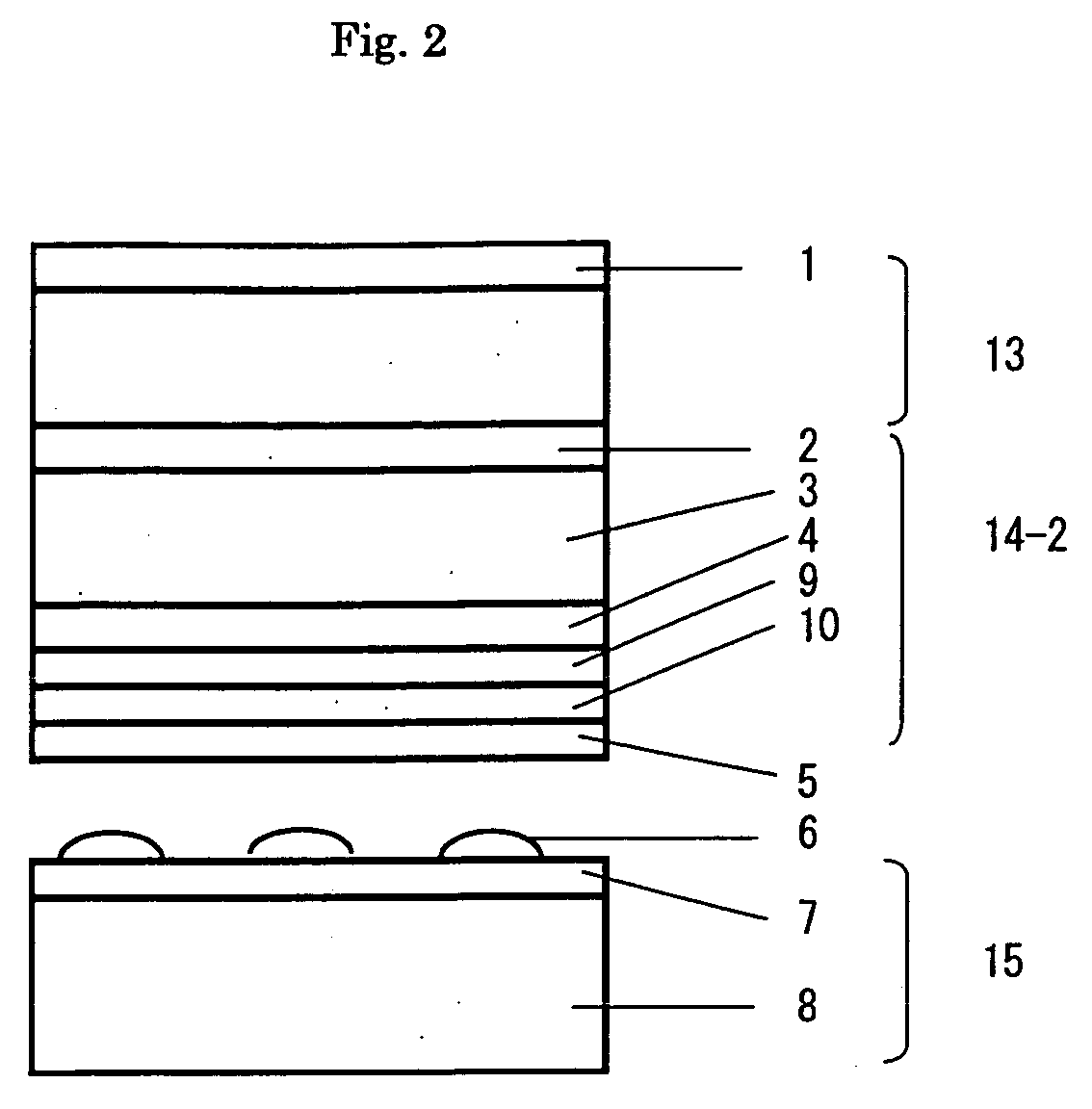

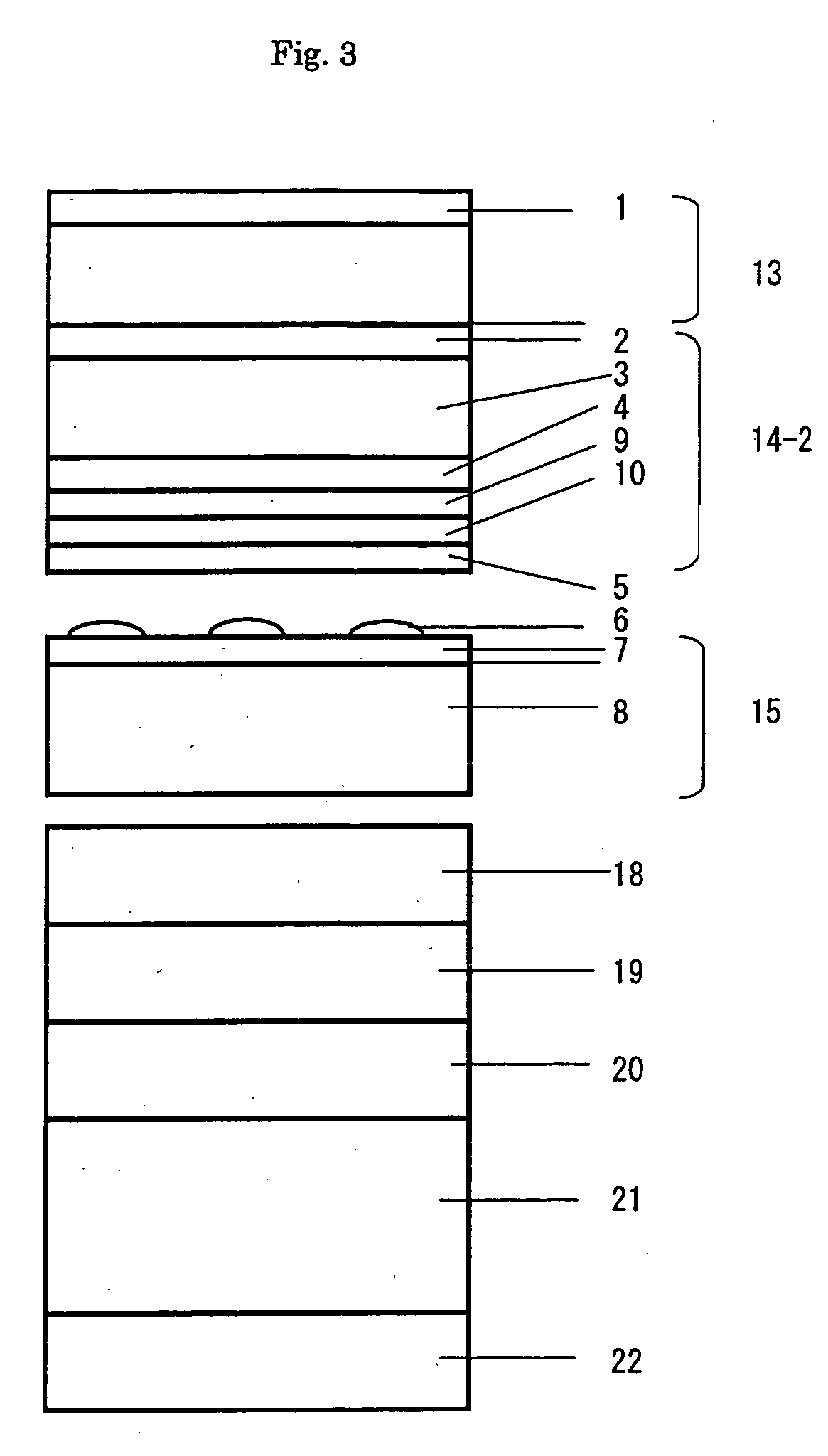

Transparent conductive laminate, touch panel and liquid crystal display unit with touch panel

InactiveUS20060013967A1Improve cohesionPreventing scratches of the polymer filmLiquid crystal compositionsStatic indicating devicesVisibilityLiquid-crystal display

The transparent conductive laminate of the invention is a laminate comprising a film made of a polymer with a photoelastic constant of no greater than 70×10−12 Pa−1, a light-scattering layer with a haze value in the range of 0.2-1.4% formed on one side thereof, and a transparent conductive layer formed on the other side thereof, wherein the laminate exhibits an overall retardation of λ / 4. By using the laminate it is possible to provide touch panels with reduced light reflection, no coloration, excellent visibility and high reliability for outdoor use, as well as touch panel-equipped liquid crystal displays employing them.

Owner:TEIJIN LTD

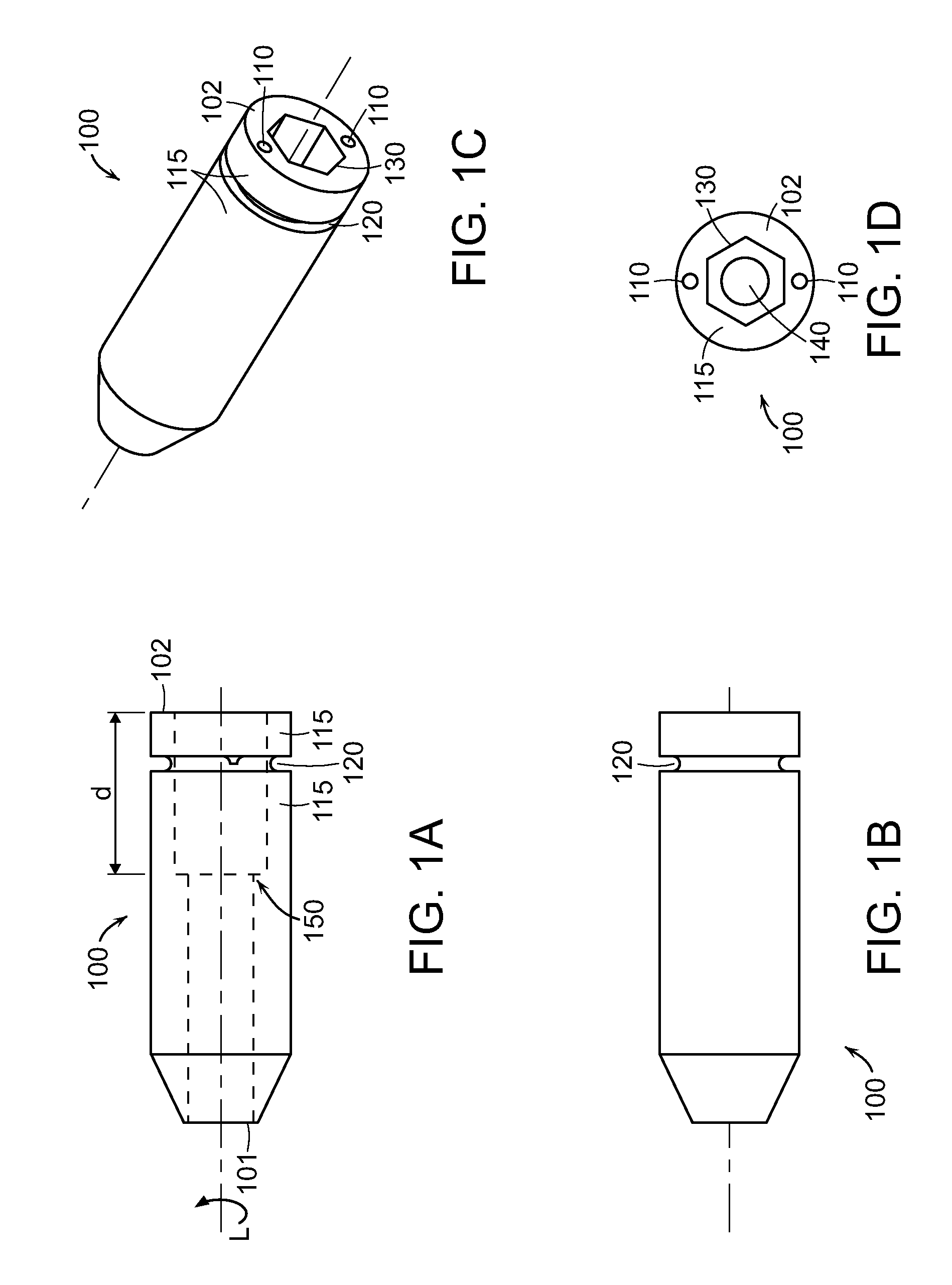

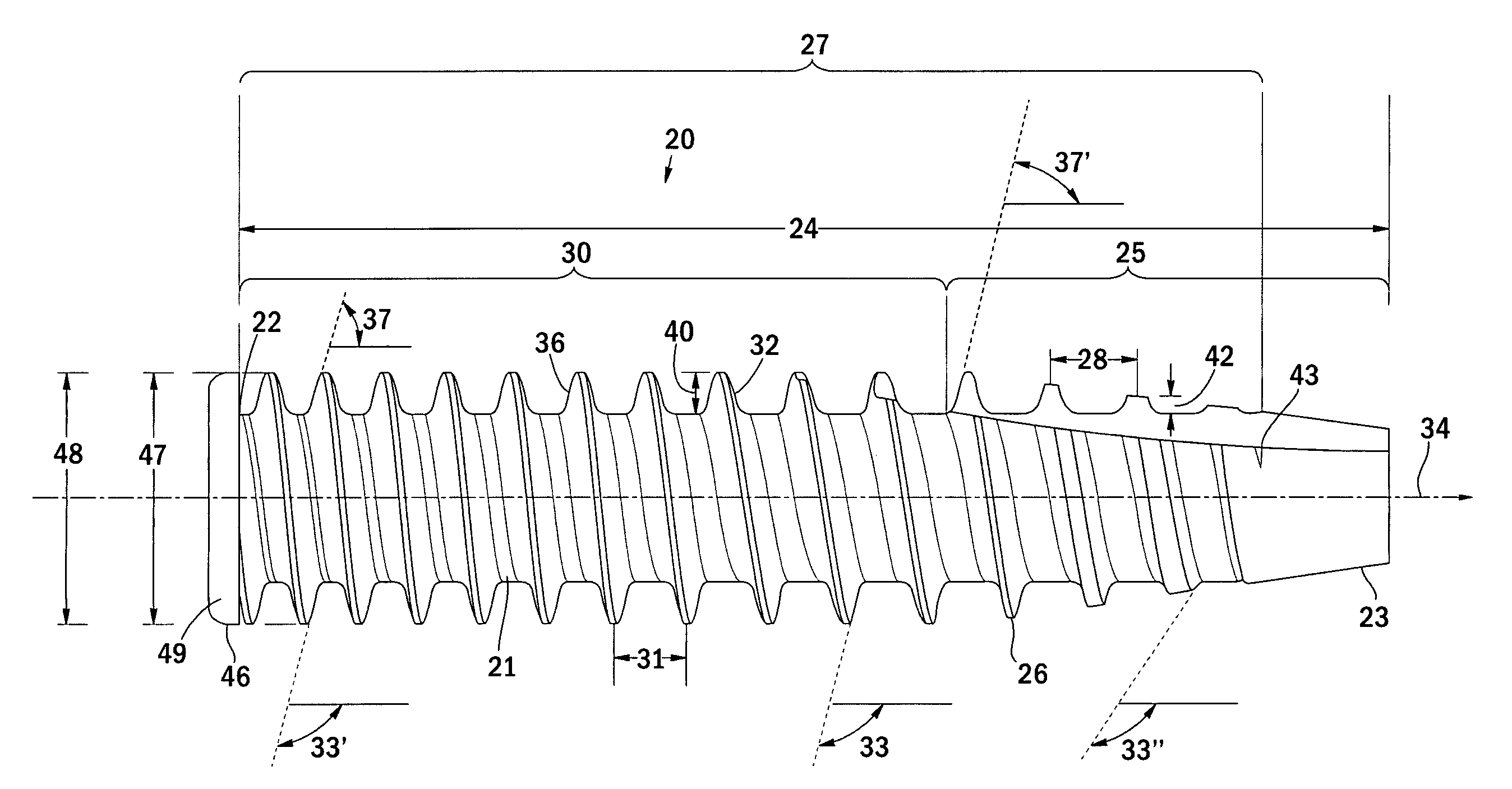

Orthopedic screw and method

InactiveUS7578836B2Avoid scratchesMaintain structural integritySuture equipmentsNutsMeniscal tearsIliac screw

A screw, driving device, and method are provided for repairing a tissue injury of a patient, such as a meniscal tear in a knee or osteochondritis dissecans. The screw has a root, a distal section having a narrowing cross section toward the distal end, and a thread along at least a portion of the root between the proximal end and the distal end. Along a leading section extending from the distal end, the helical pitch is substantially constant; along a trailing section between the leading section and the root's proximal end, the helical pitch decreases. The substantially constant pitch along the leading section assists in preventing a stripping of the helical section. At the proximal end is a head having a diameter greater than a major root diameter of the central section. The head is for improving the tissue retention characteristics of the screw.

Owner:DEPUY MITEK INC

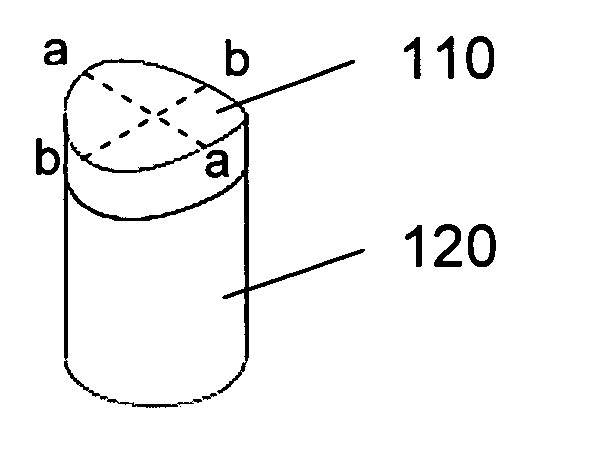

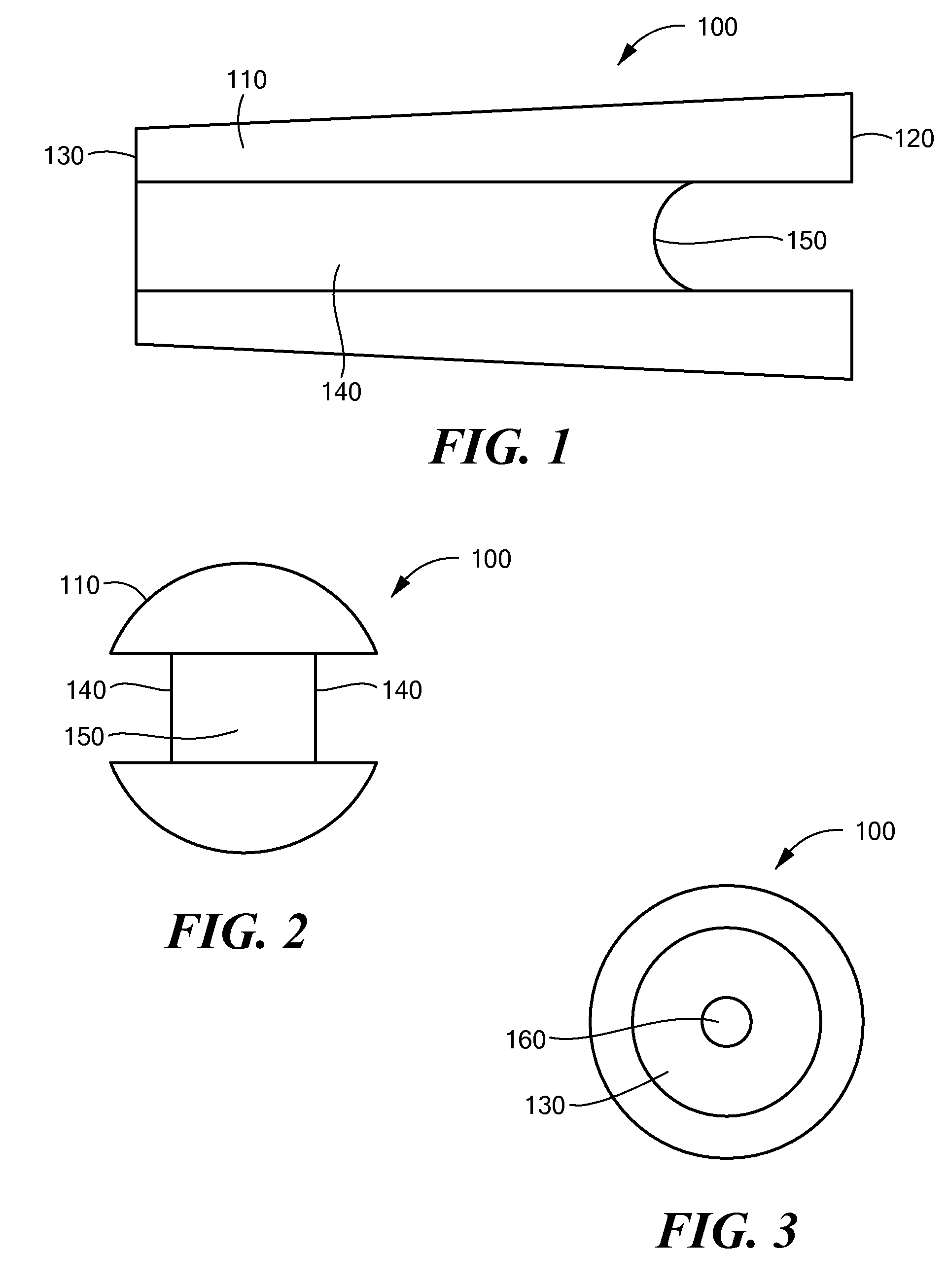

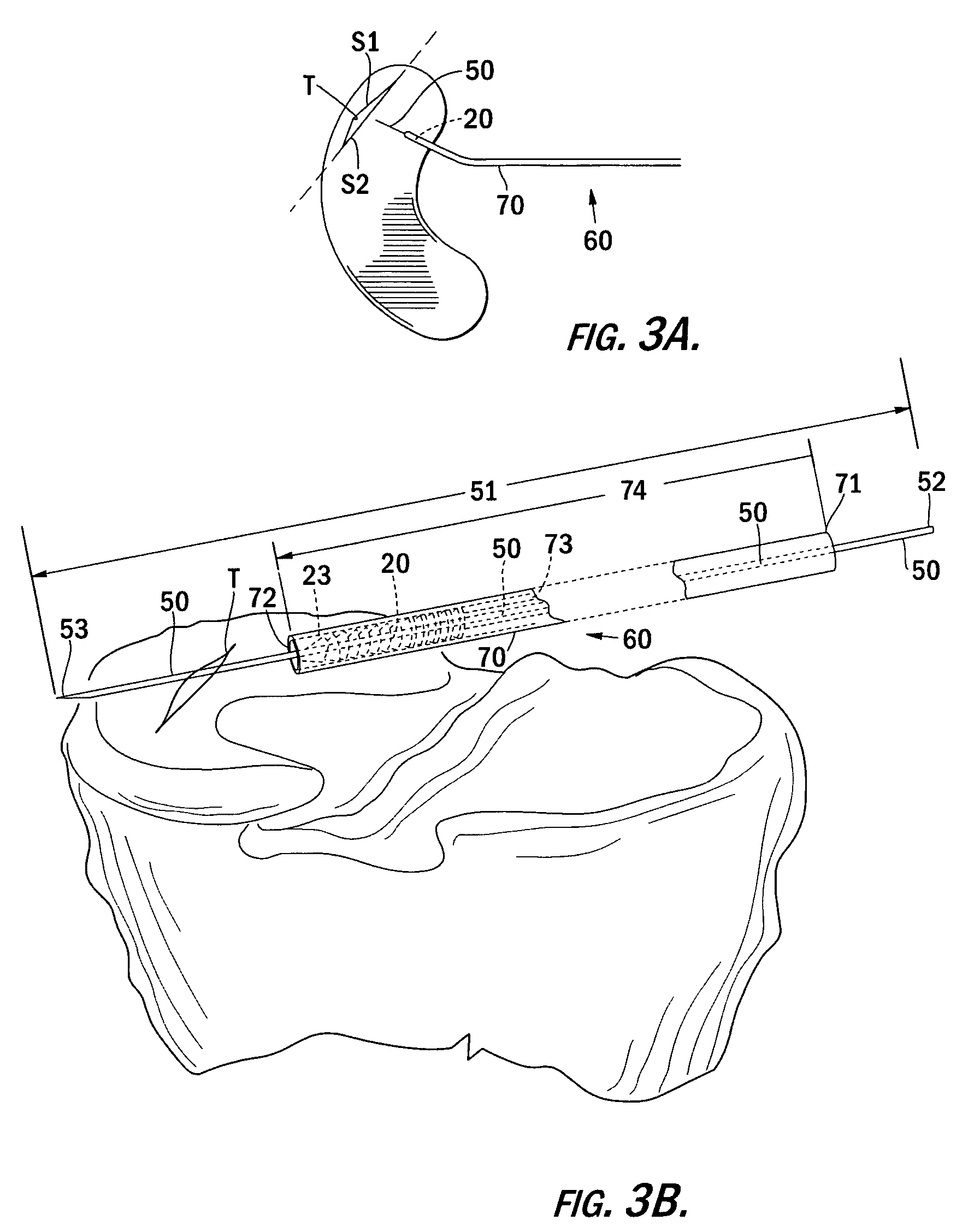

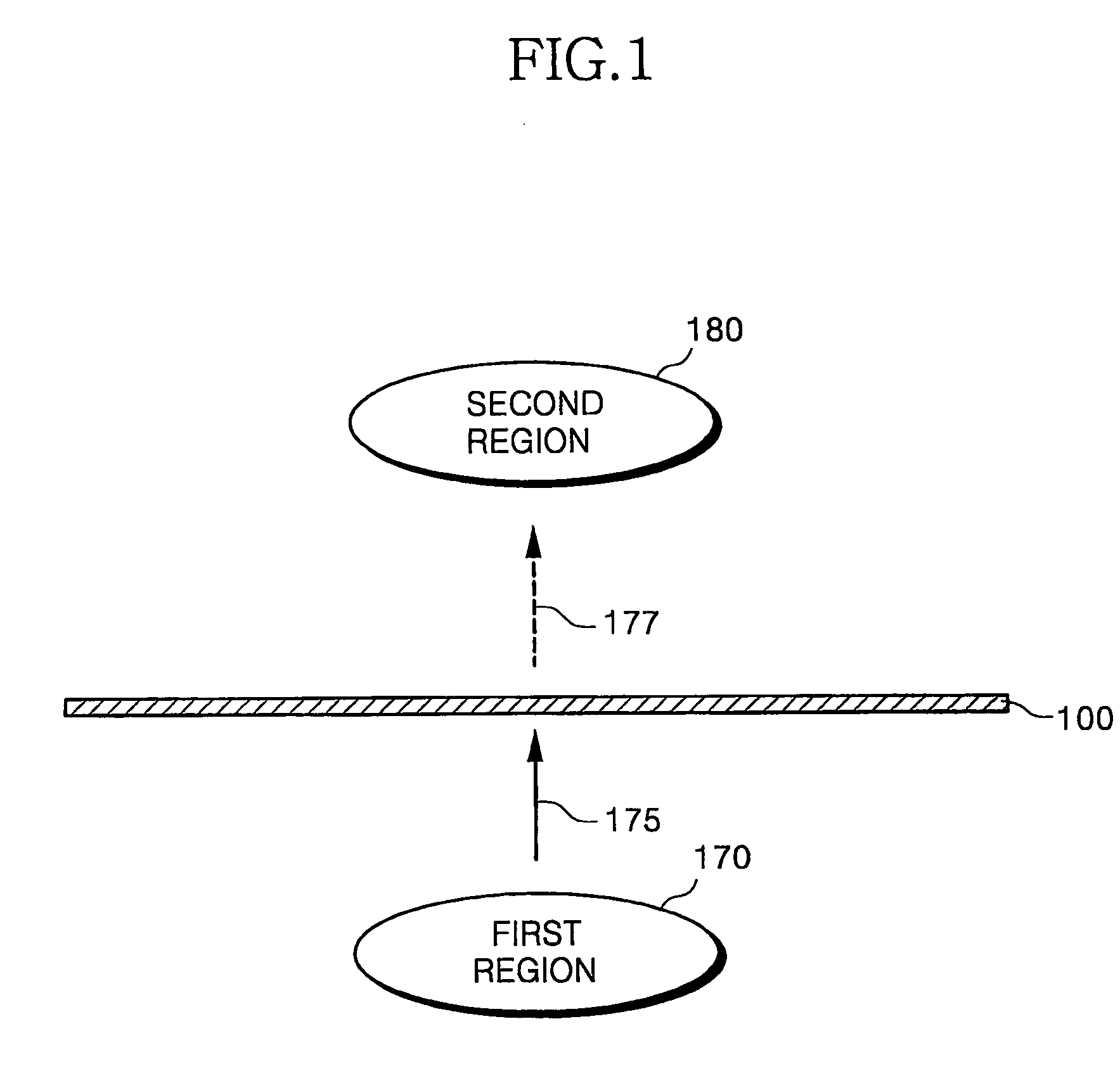

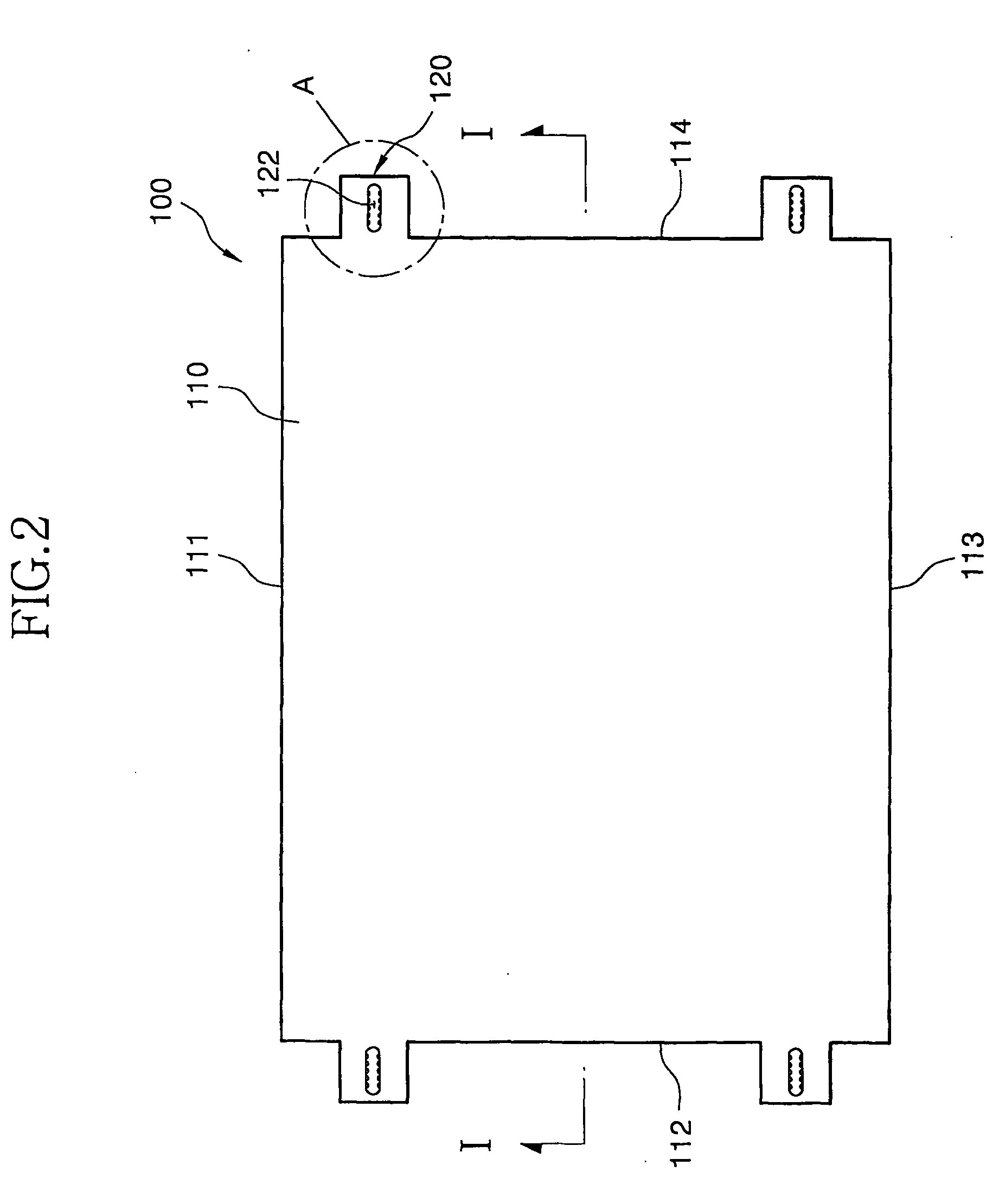

Optical member, backlight assembly and liquid crystal display device using the same

InactiveUS20060007367A1Avoid separationQuality improvementShow cabinetsImpedence networksWrinkleLiquid-crystal display

Disclosed are an optical member (100), a backlight assembly (500) and a liquid crystal display device (800) using the optical member. The optical member (100) includes an optical body (110) and a first fixing part (120). The optical body varies optical characteristic of first light incident into thereto to exit a second light. The first fixing part (120) is protruded from at least one side face of the optical body (110), and including a fixing hole (122) and a vibration attenuating means (124). The fixing hole (122) is elongated in a main expansion direction of the optical body (110), and the vibration attenuating means (124) is formed on an inner of the fixing hole to attenuate external vibration applied to the optical body (110). The fixing hole (122) allows movement of the optical member (100) in accordance with expansion of the optical member (100) caused by heat, thereby preventing wrinkles from being created on the optical body. The vibration attenuating member (124) prevents the optical body from being scratched.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com