Thin-wall sliding sleeve disassembling fixture

A technology for dismantling tooling and sliding sleeves, applied in manufacturing tools, hand-held tools, etc., can solve the problem of difficult disassembly of thin-walled sliding sleeves, and achieve the effects of avoiding deformation and scratching of the hole wall, smooth movement, and safe and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

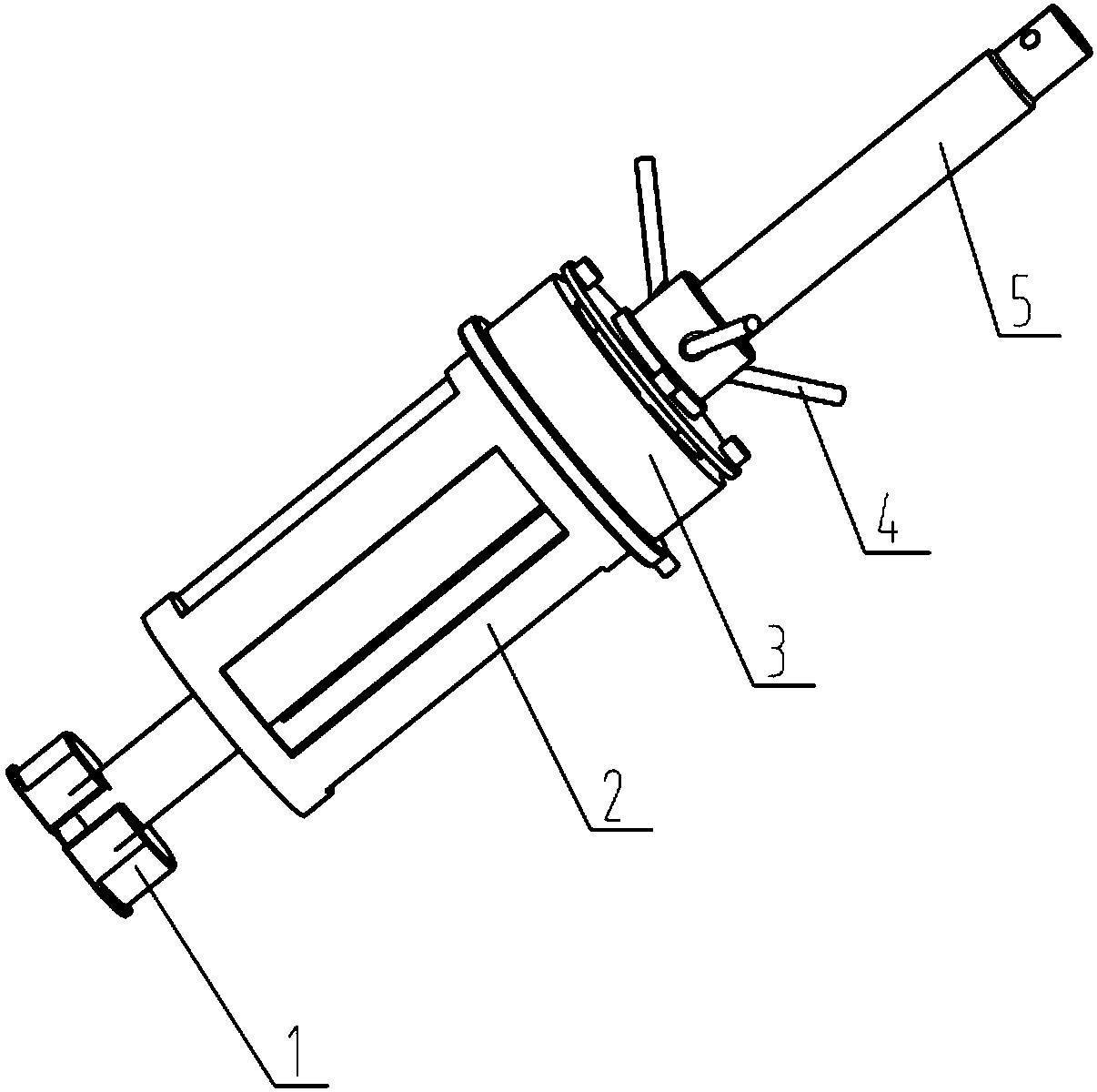

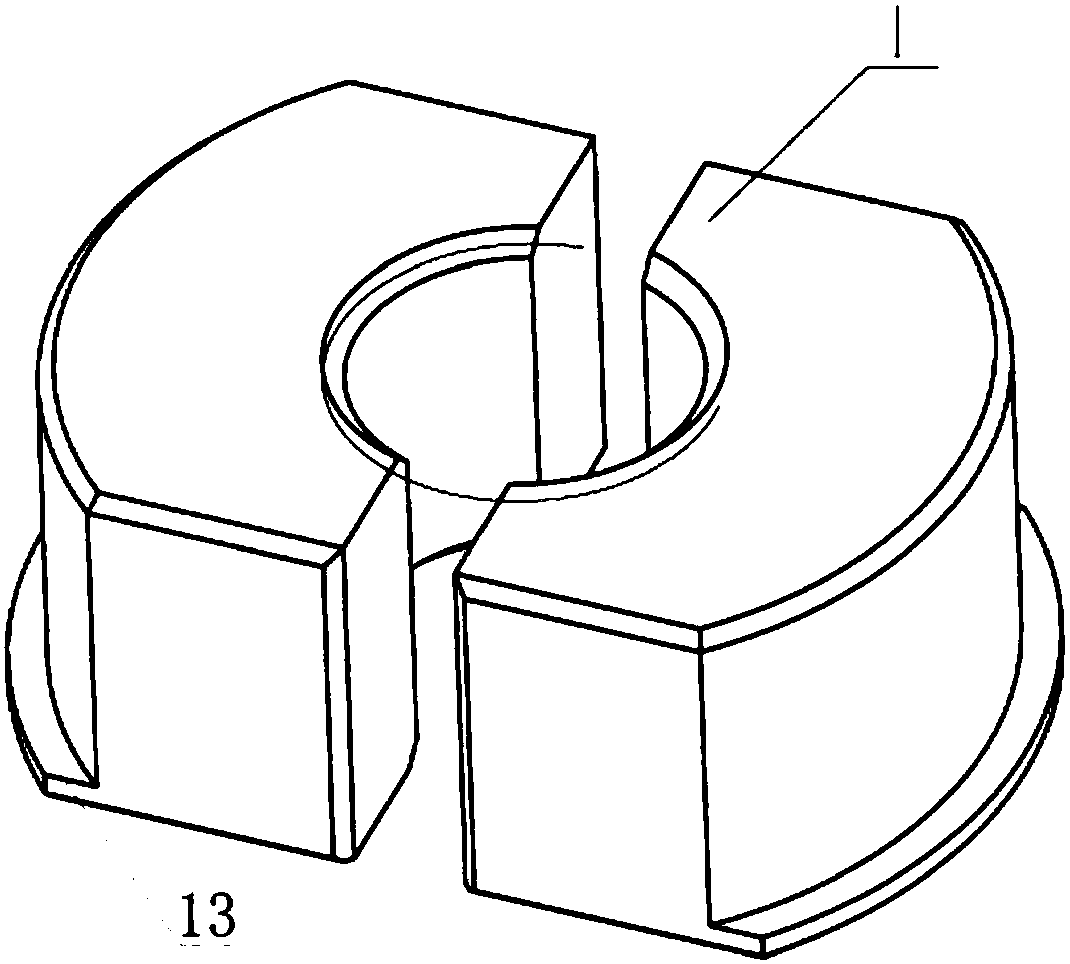

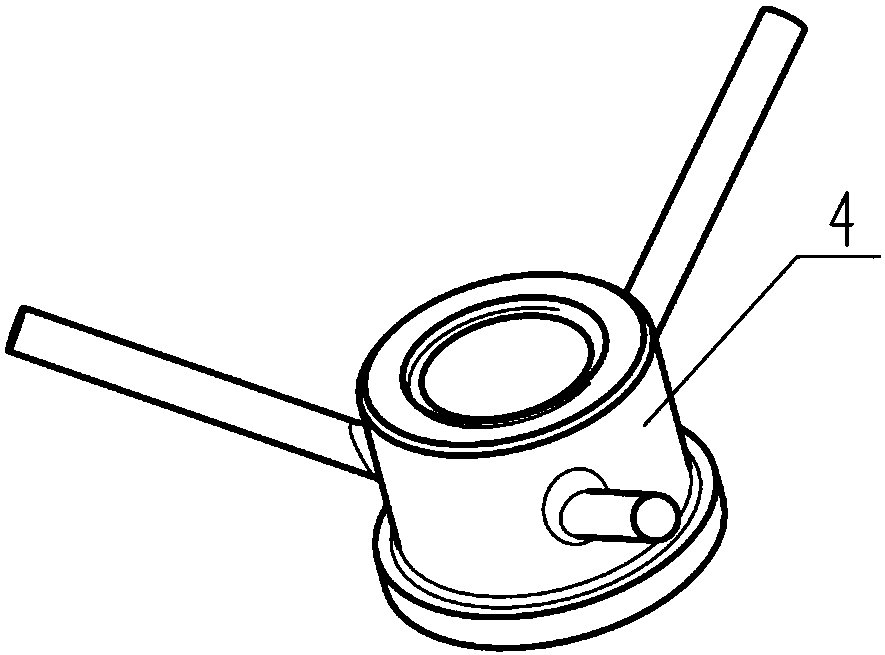

[0024] Examples such as Figures 1 to 7 As shown, a thin-walled sliding sleeve disassembly tooling includes a puller nut 4 and a puller screw 5, the puller screw 5 is threaded with the puller nut 4, and one end of the puller screw 5 is provided with Claw 1, puller screw 5 is threadedly connected with claw 1, bracket 2 and hydraulic system 3 are arranged between puller nut 4 and claw 1, bracket 2 and hydraulic system 3 are set on the puller screw 5, the bracket 2 is close to the claw 1, the hydraulic system 3 is close to the puller nut 4, the claw 1 is a two-body type, and the outer circumference of the bottom of the claw 1 is provided with a step 13, and the surface of the step can contact the end surface of the thin-walled sliding sleeve 6, The inner peripheral surface of the claw 1 away from the end of the step 13 is provided with an internal thread, the hydraulic system 3 includes a hydraulic base 8, the hydraulic base 8 is set with a hydraulic cylinder 11, the outer circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com