Patents

Literature

3516results about How to "Improve washing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

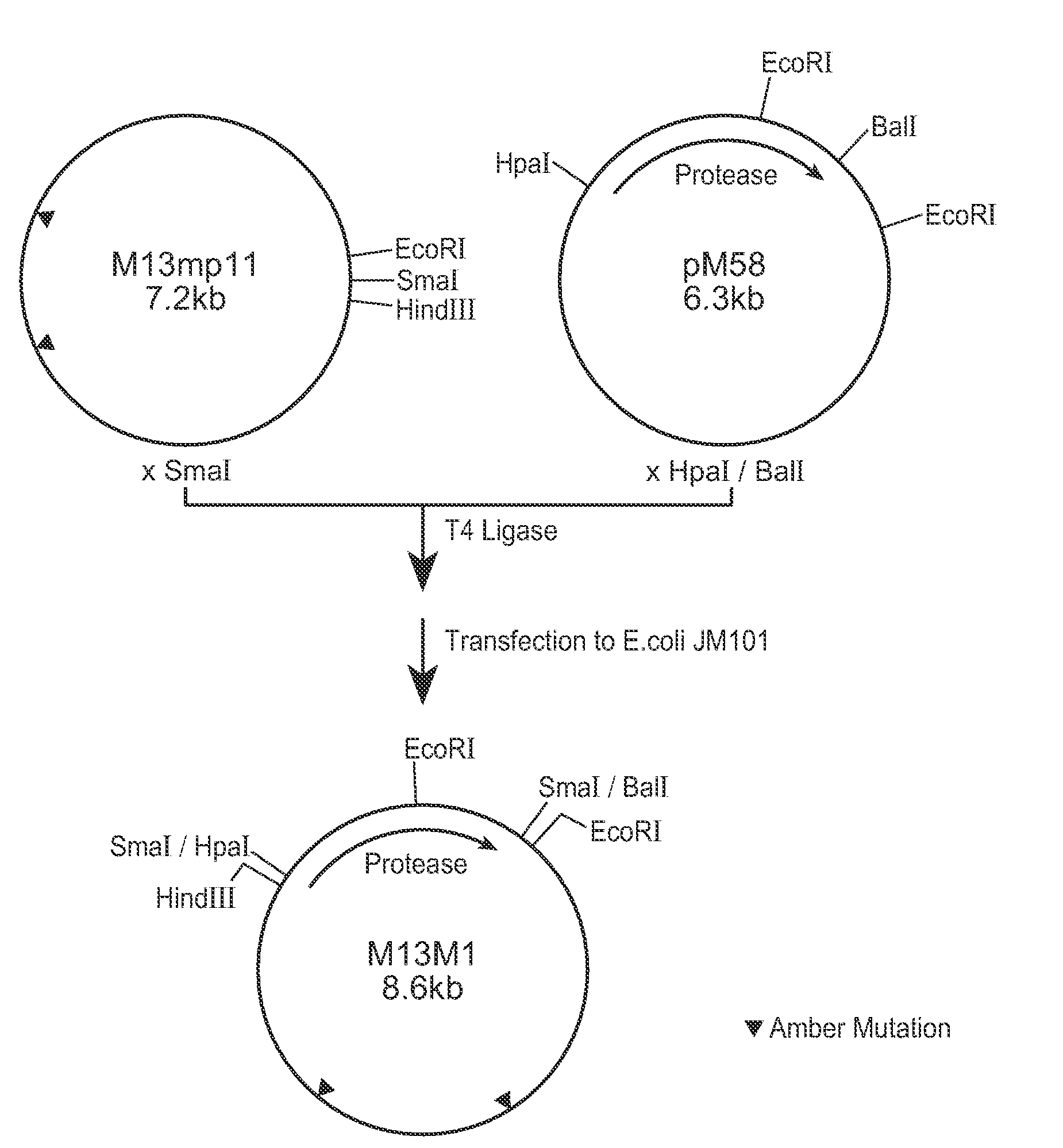

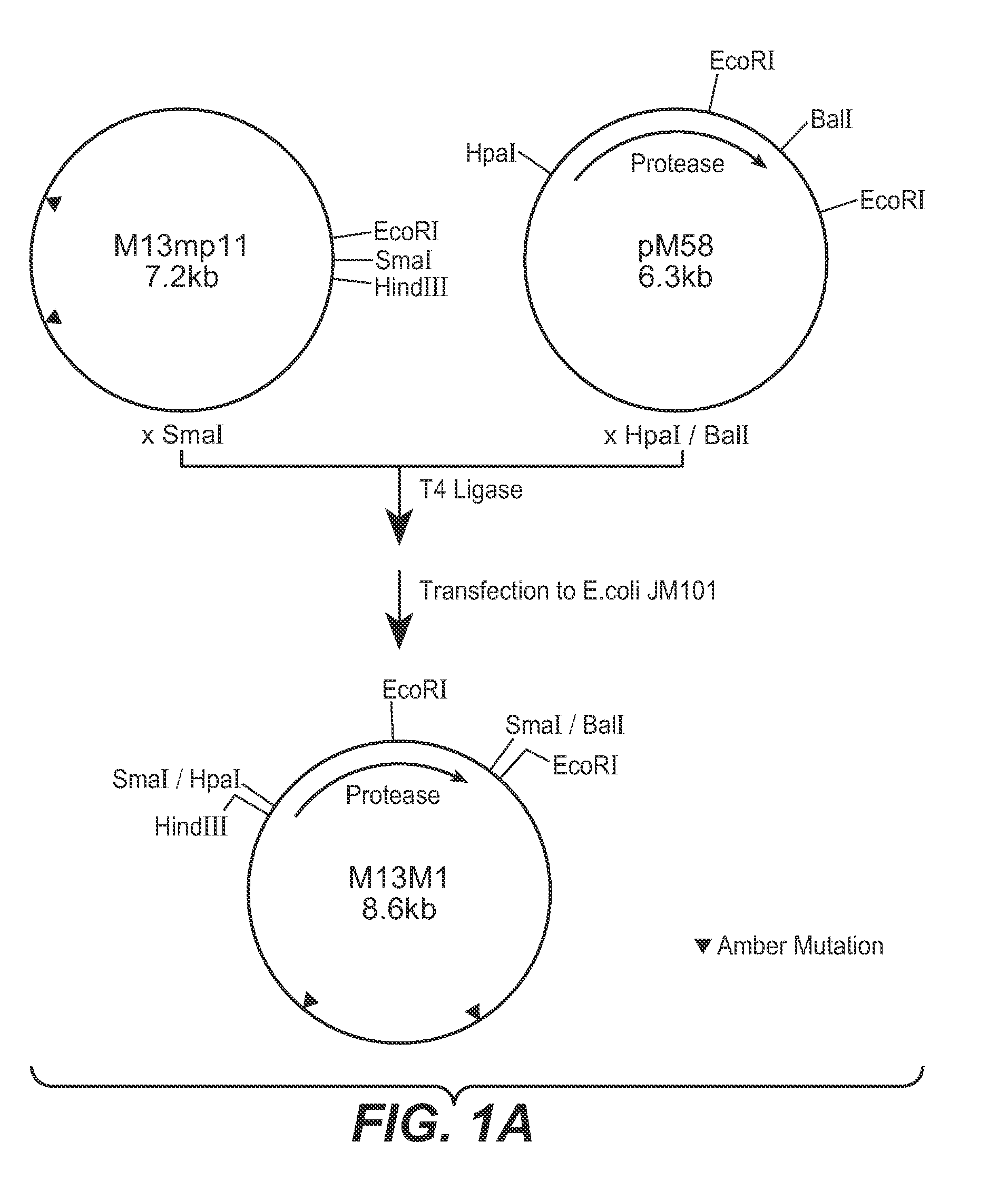

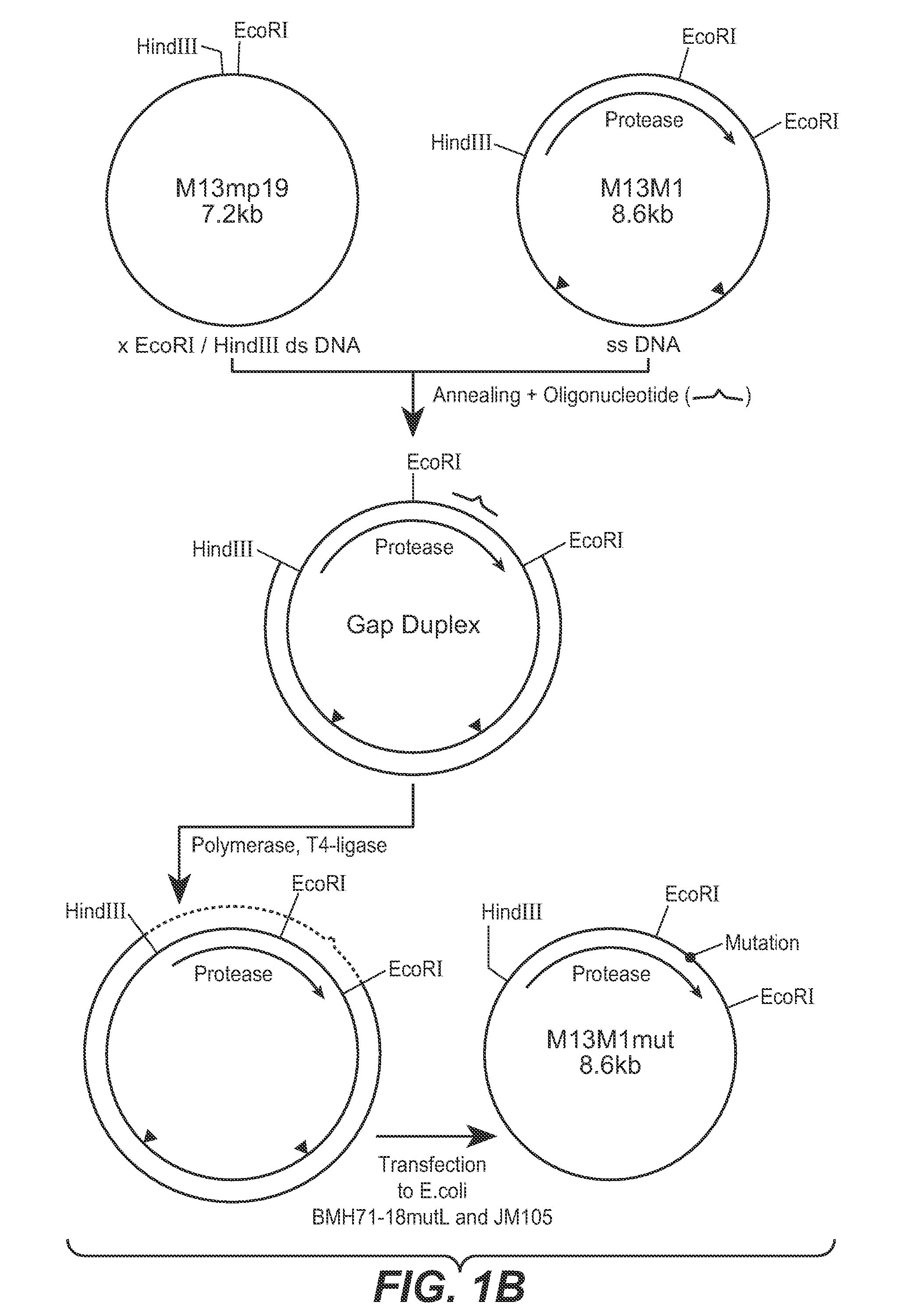

Protease variants active over a broad temperature range

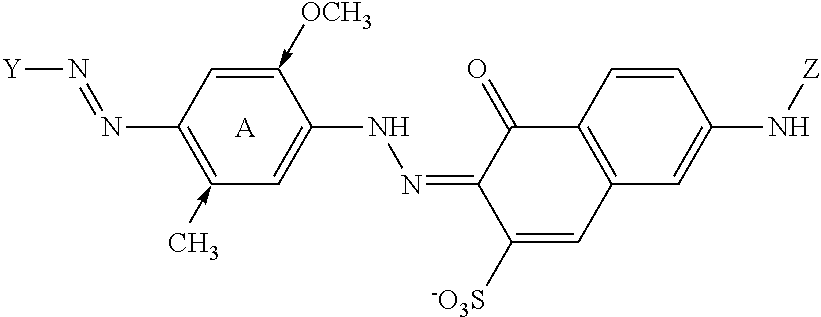

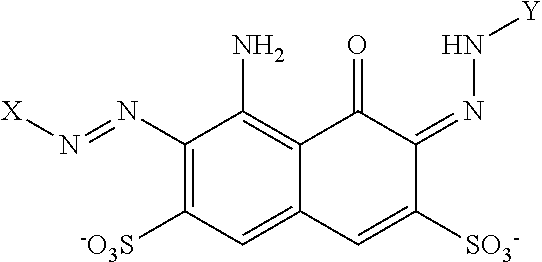

InactiveUS20080090747A1Improved propertyImprove washing performanceSugar derivativesHydrolasesProteaseProteinase activity

The present invention provides protease compositions particularly suited for dishwashing applications.

Owner:DANISCO US INC

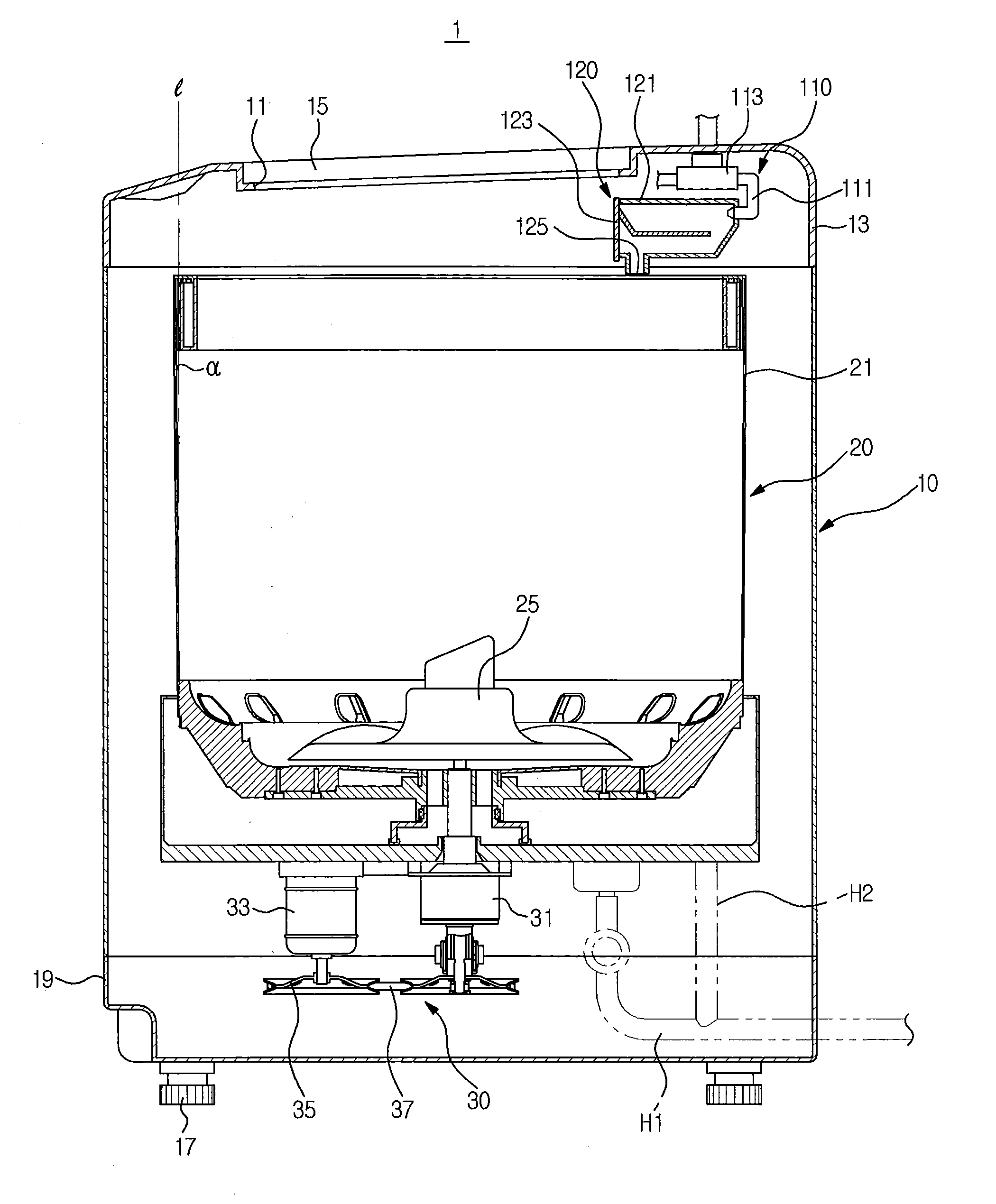

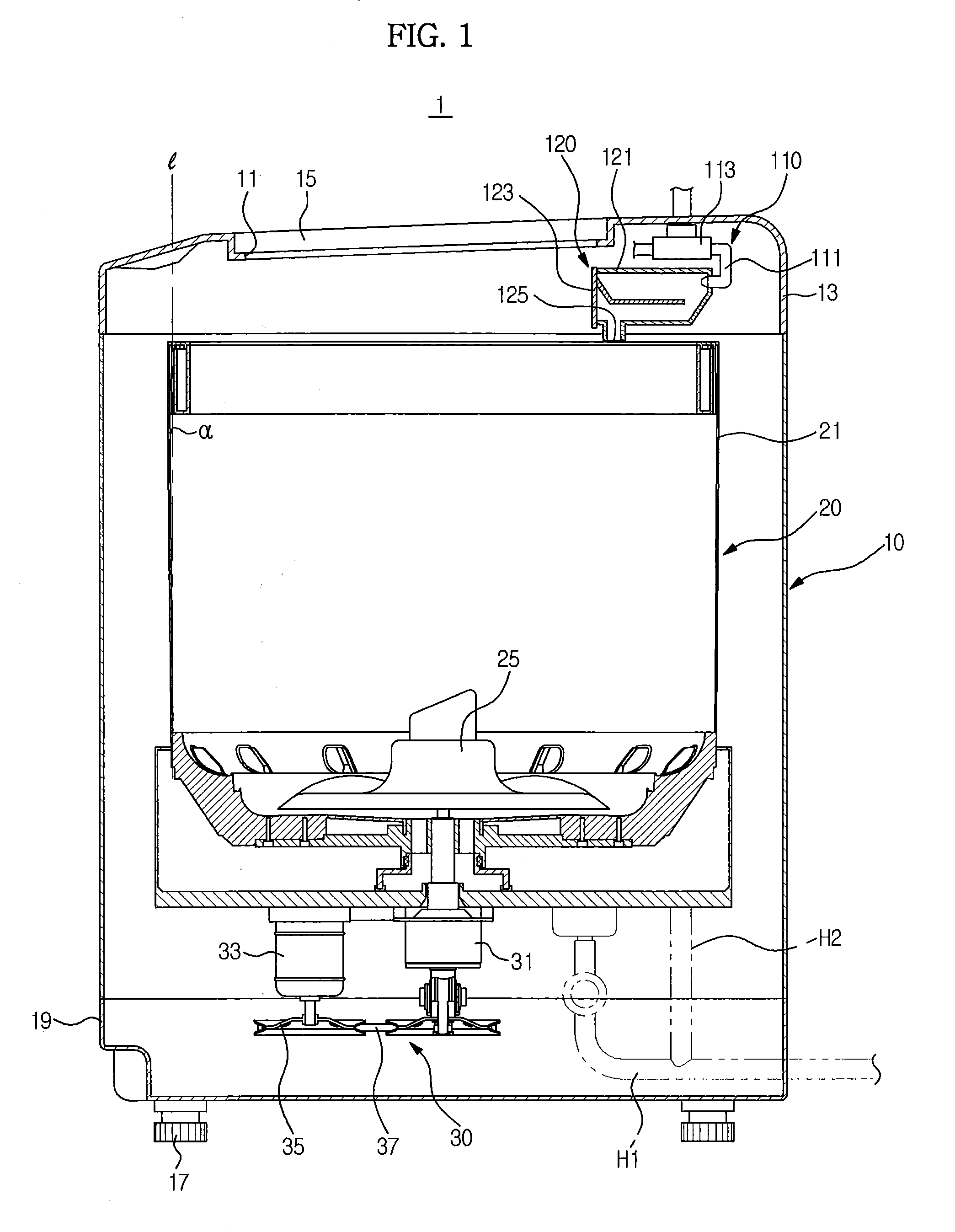

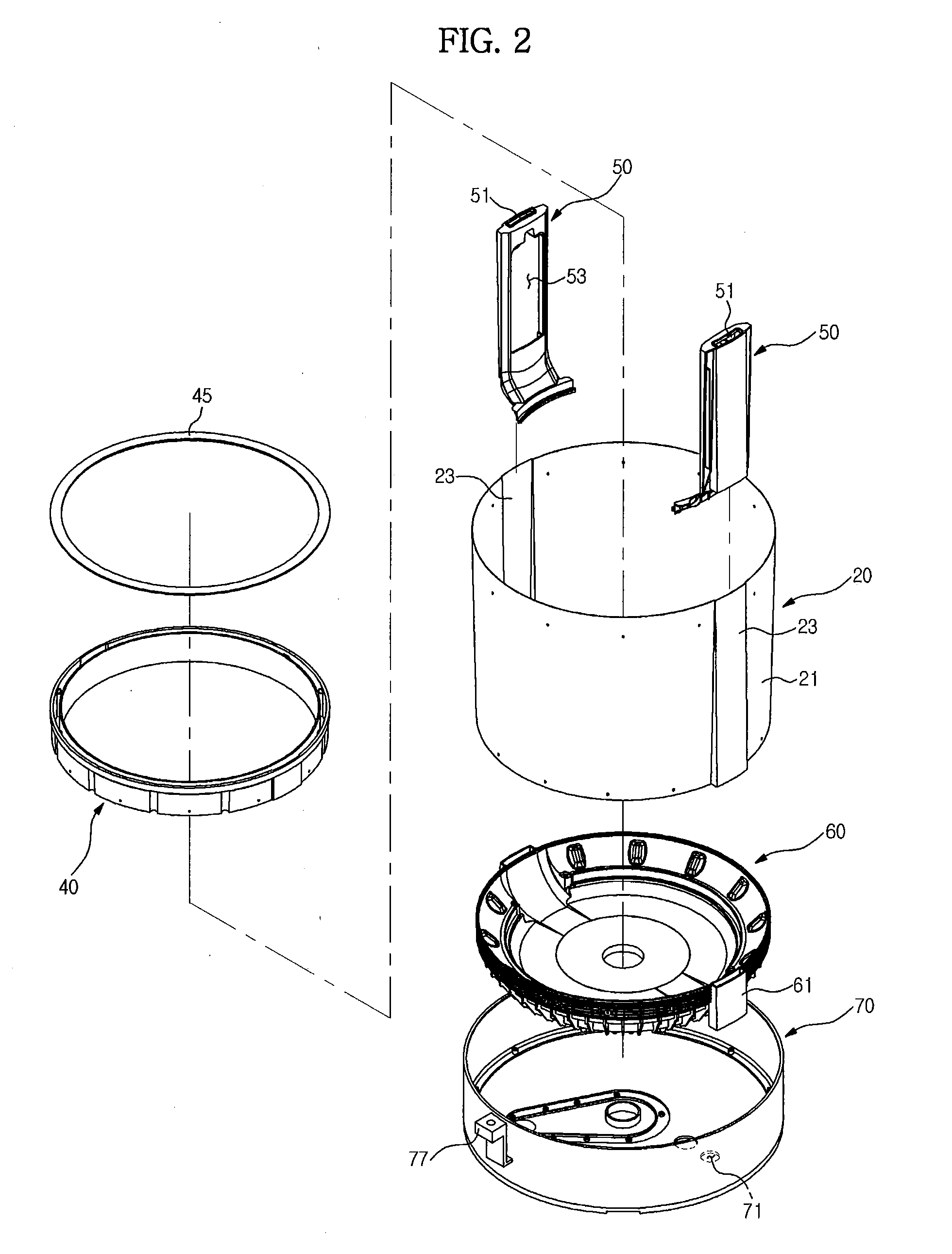

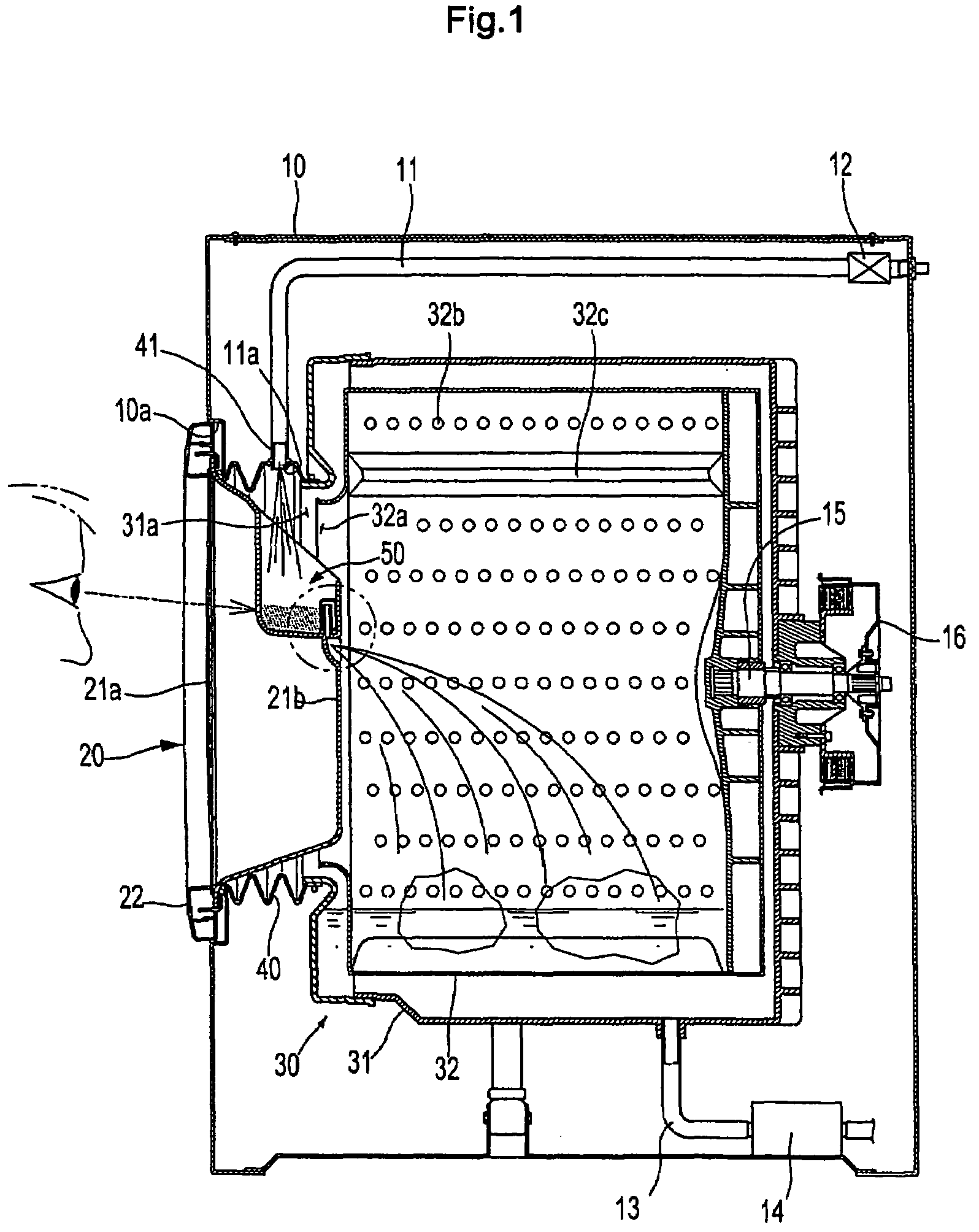

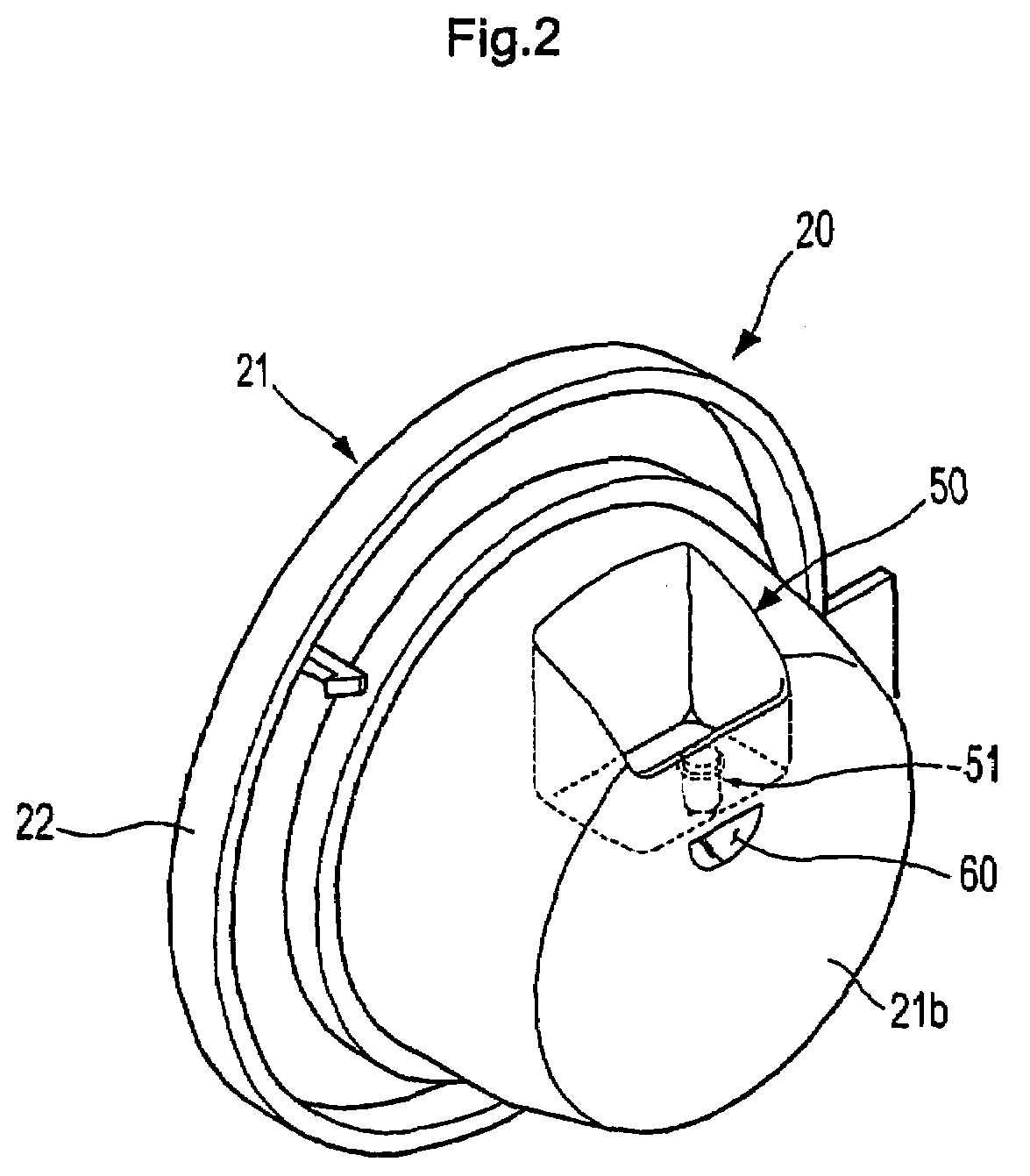

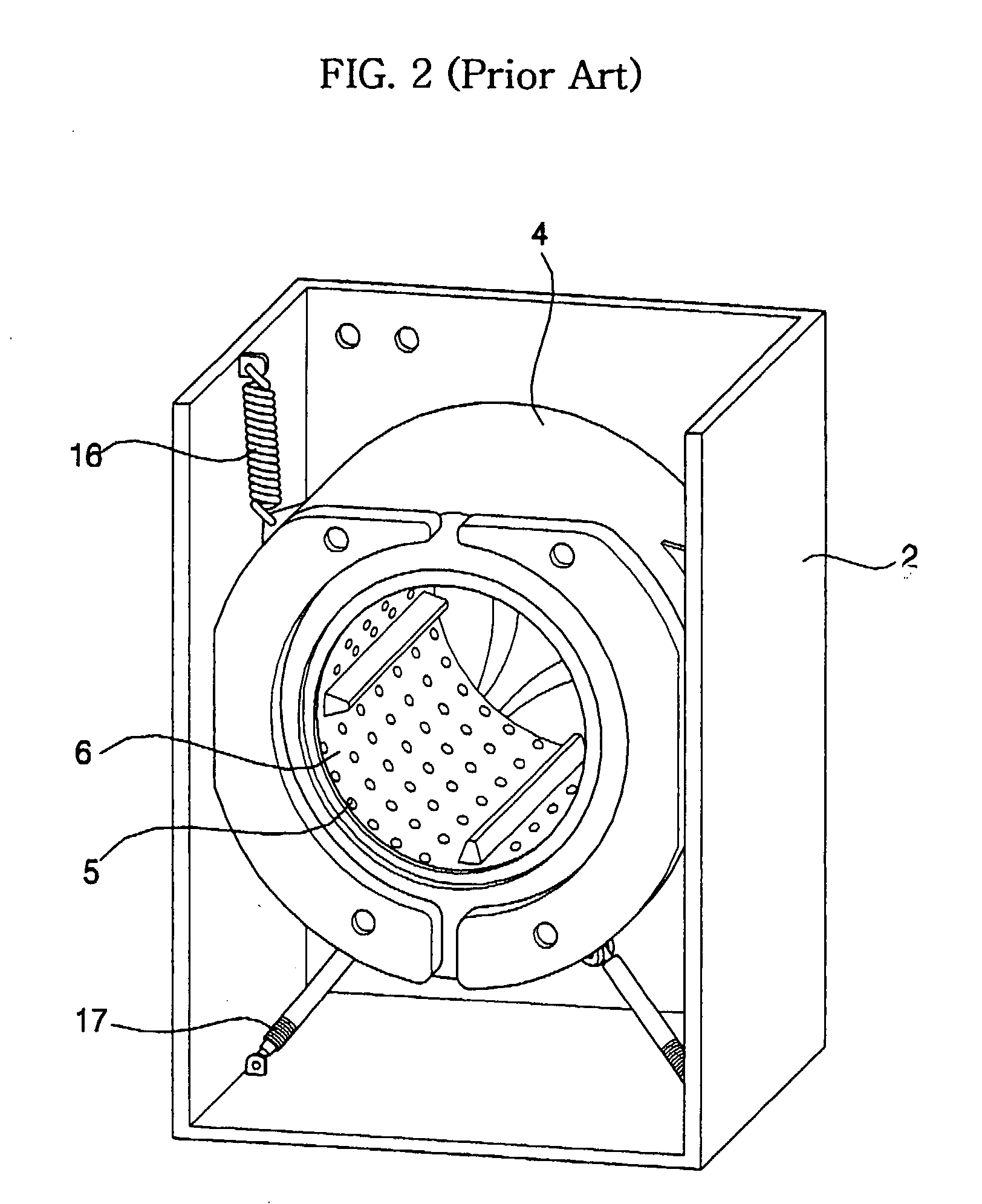

Washing machine

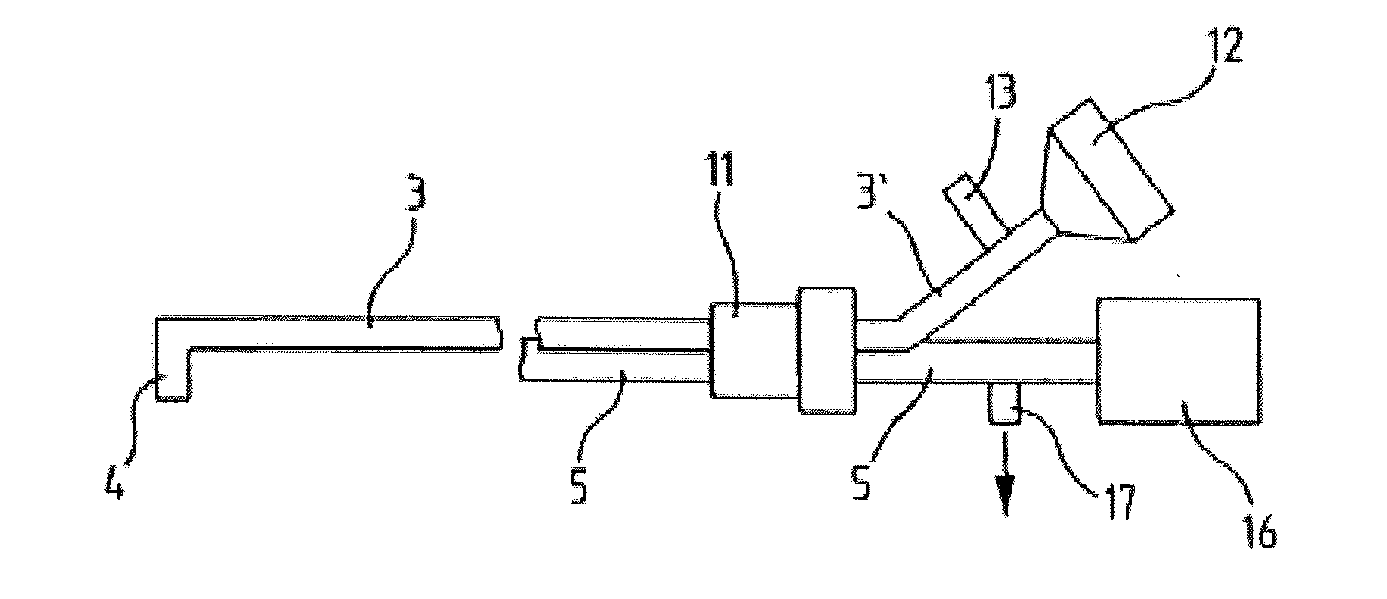

InactiveUS20130036776A1Reduce water consumptionImprove washing effectOther washing machinesInterengaging clutchesWater dischargeDrive shaft

A washing machine includes a cabinet forming an external appearance of the washing machine, a rotary tub disposed to rotate around a driving shaft vertically provided inside the cabinet and including a sidewall, which extends with inclination to have a diameter increasing from a lower side to an upper side of the washing machine, and at least one protrusion part, which protrudes from the sidewall with inclination to have a diameter increasing from an upper side to a lower side of the sidewall. A guide water filter is mounted on at least one protrusion part inside the rotary tub and provided at a rear surface thereof with a drain passage to discharge the washing water discharged from the balance ring to outside. A base is installed at the lower side of the rotary tub and includes a guide part and a support plate.

Owner:SAMSUNG ELECTRONICS CO LTD

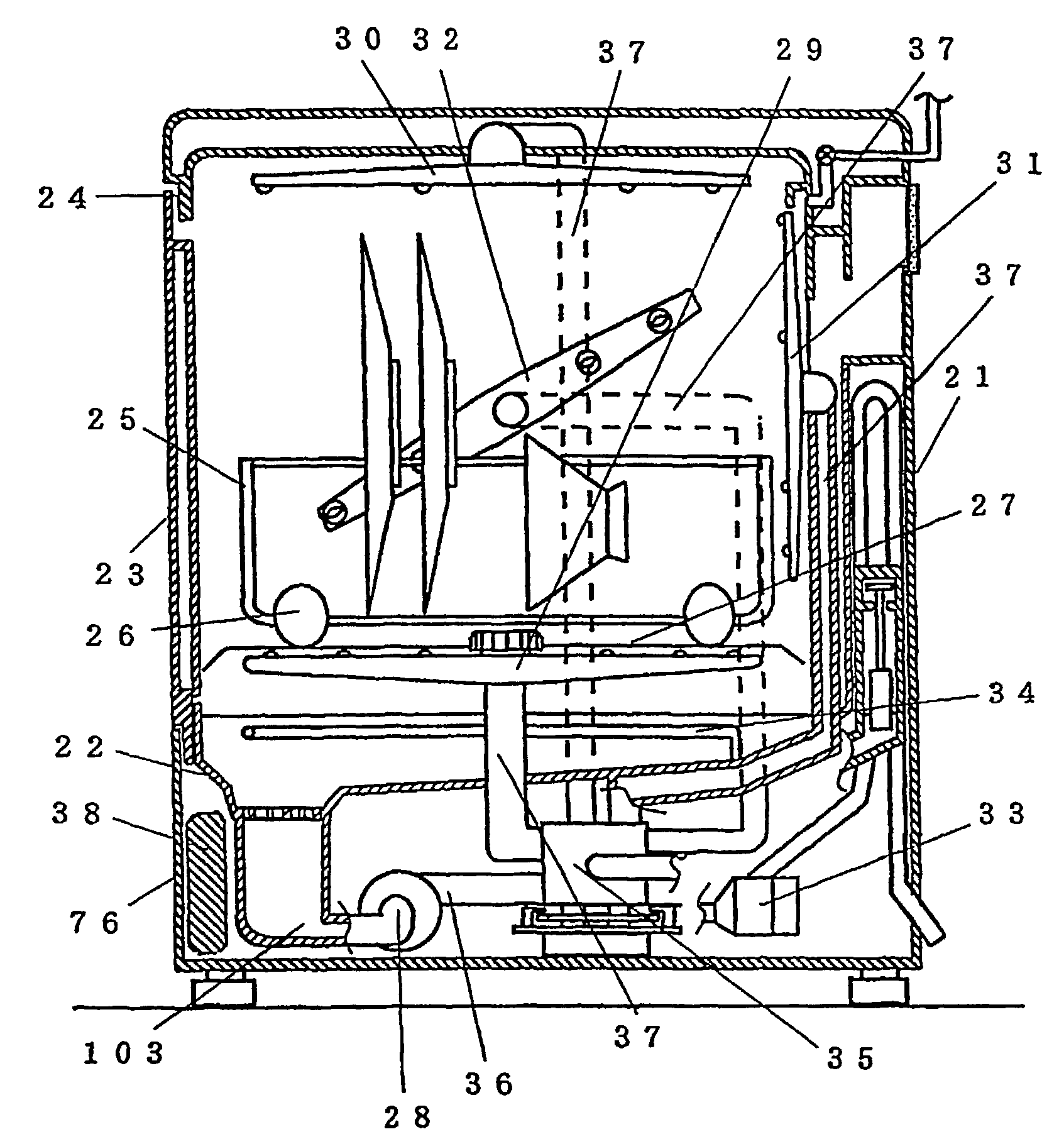

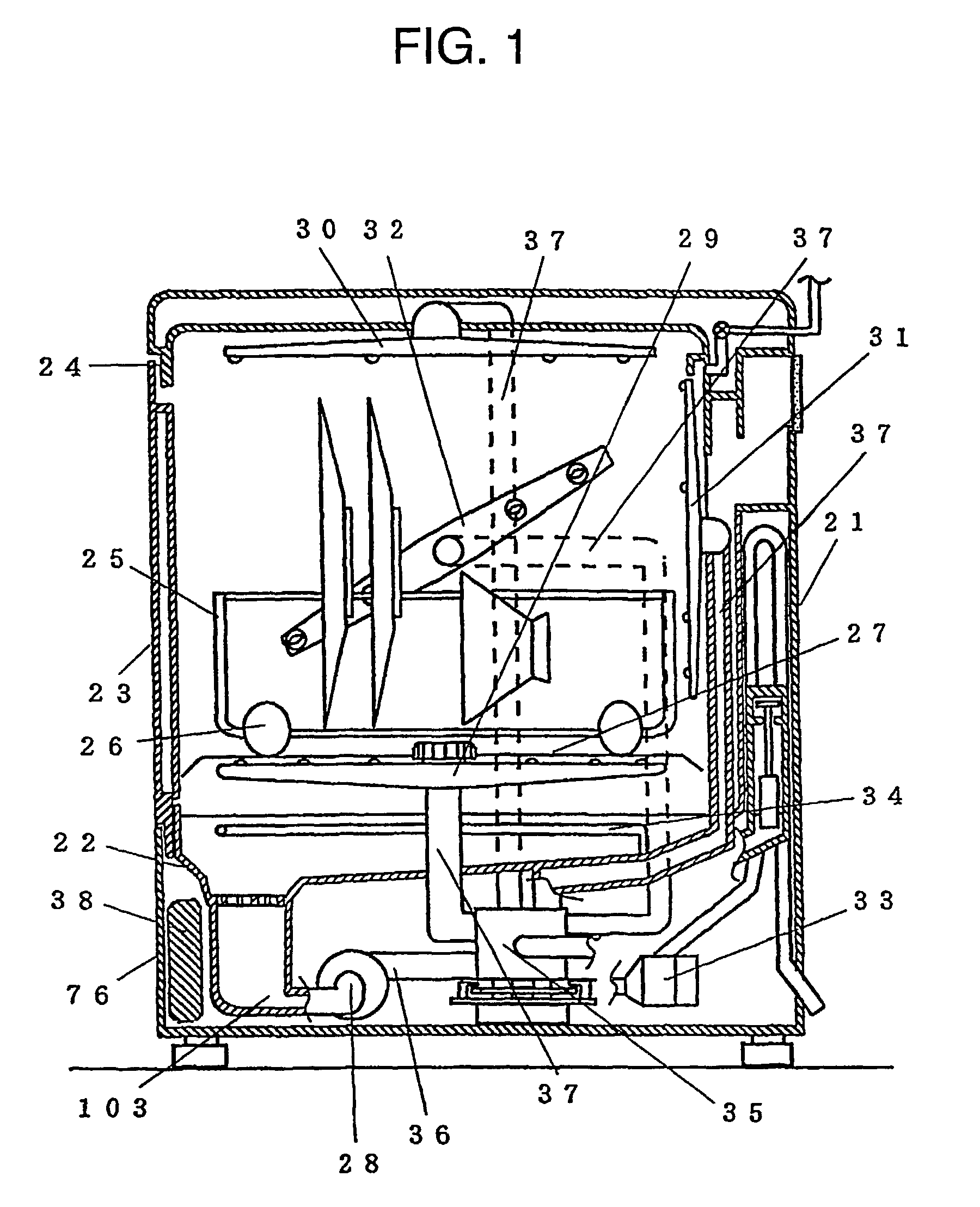

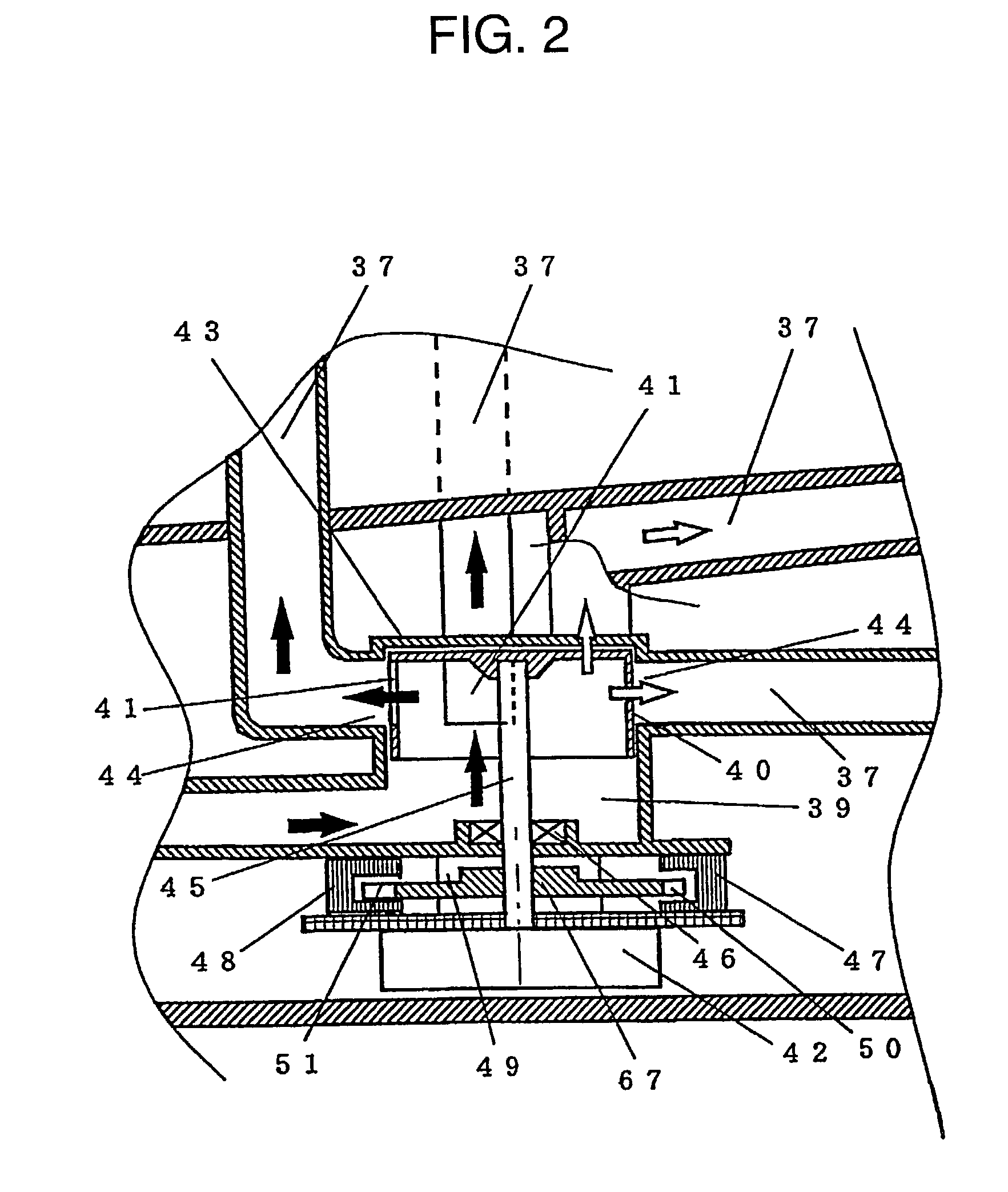

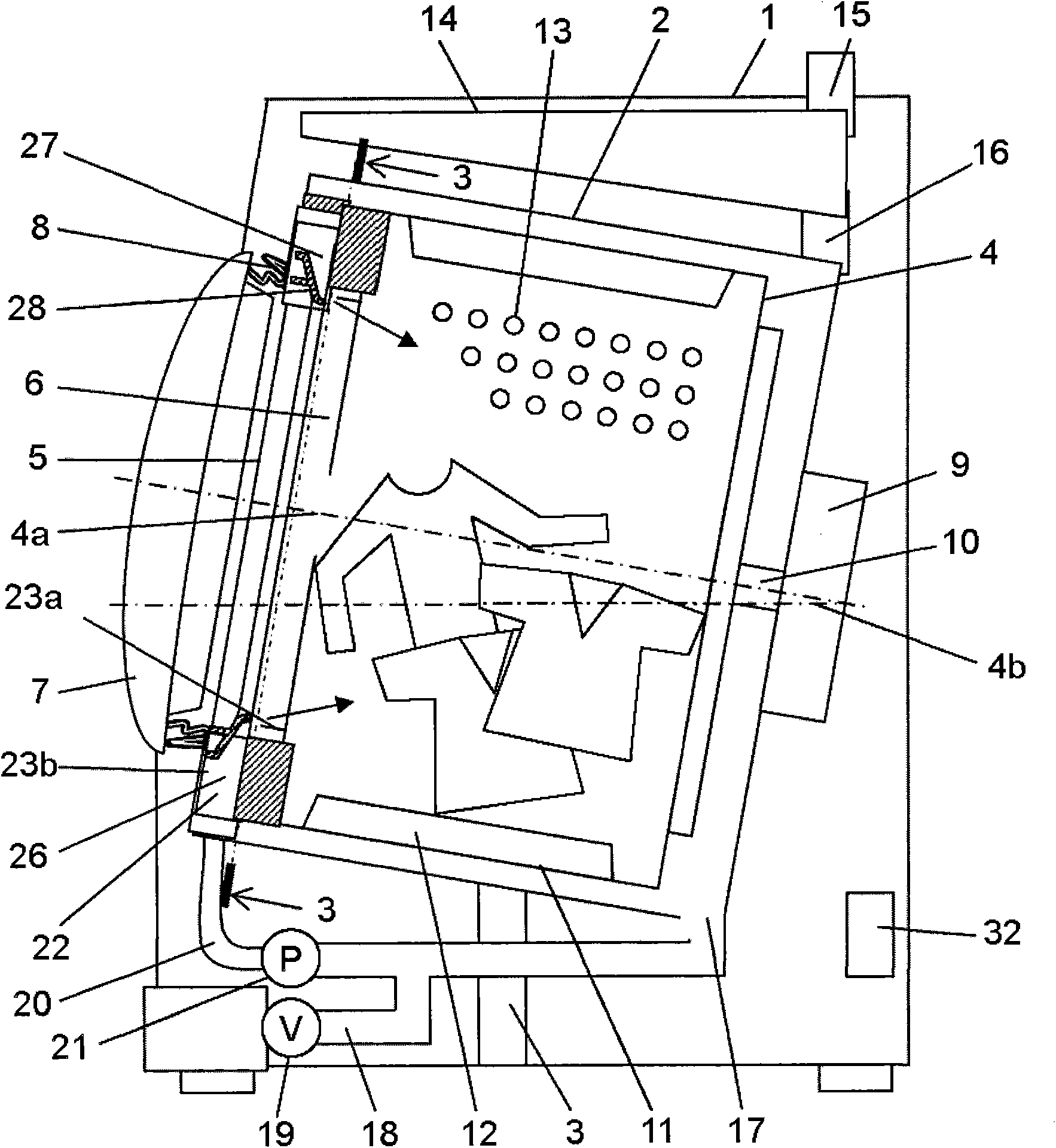

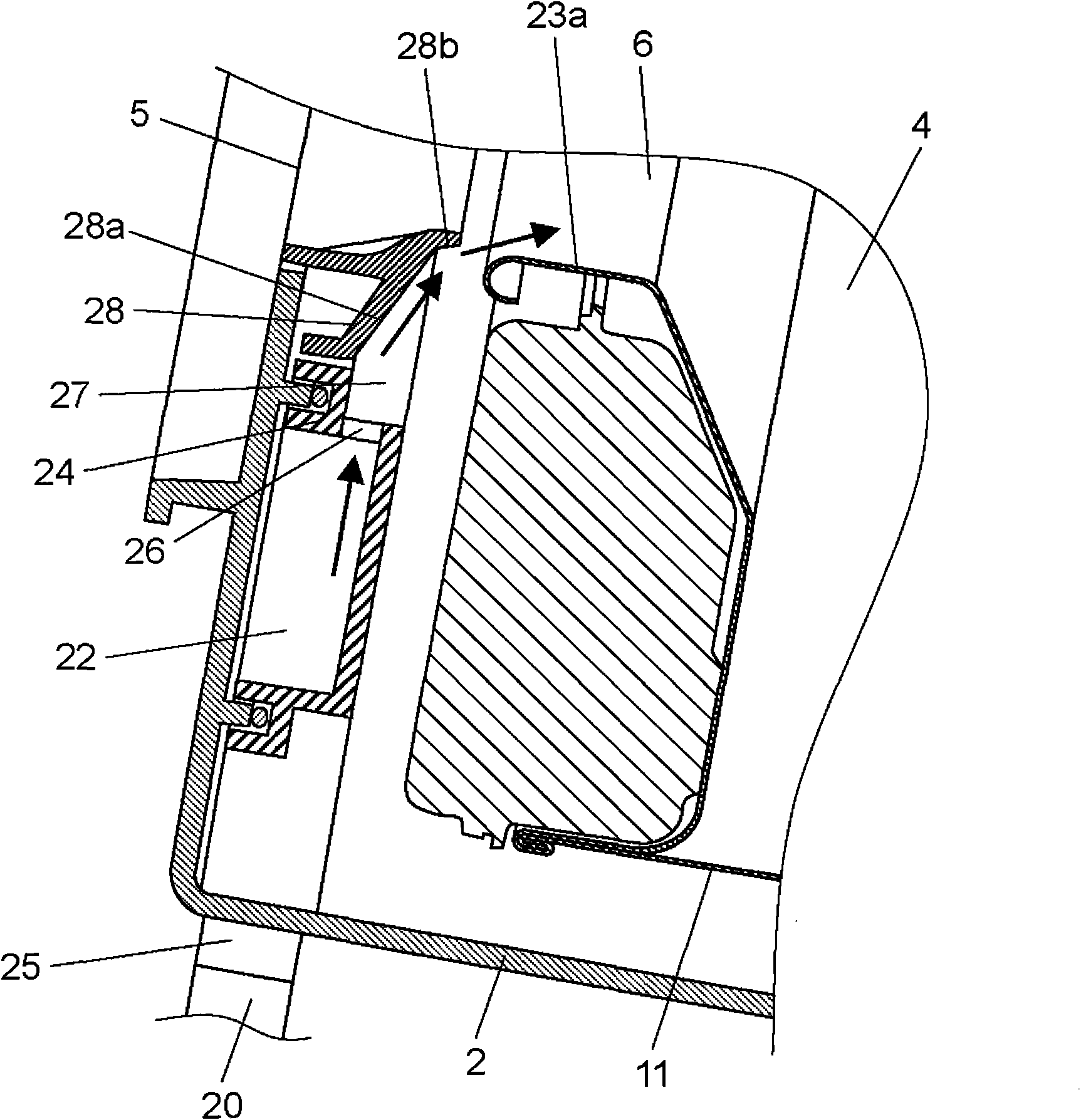

Washer

InactiveUS7270132B2Improve washing effectWash the eating utensils quicklyTableware washing/rinsing machine detailsElectrostatic cleaningWater savingEnergy analysis

A washer includes a plurality of washing devices for spraying washing water to an object to be washed from various directions of a washing tub, and a washing water feeding device for feeding the washing water. The washing water is sequentially sprayed from respective washing devices. Thus, the washing water can be sprayed to eating utensils from the various directions without increasing fed water, and a washing effect is improved. Speedy washing, energy saving, and water saving can be also achieved.

Owner:PANASONIC CORP

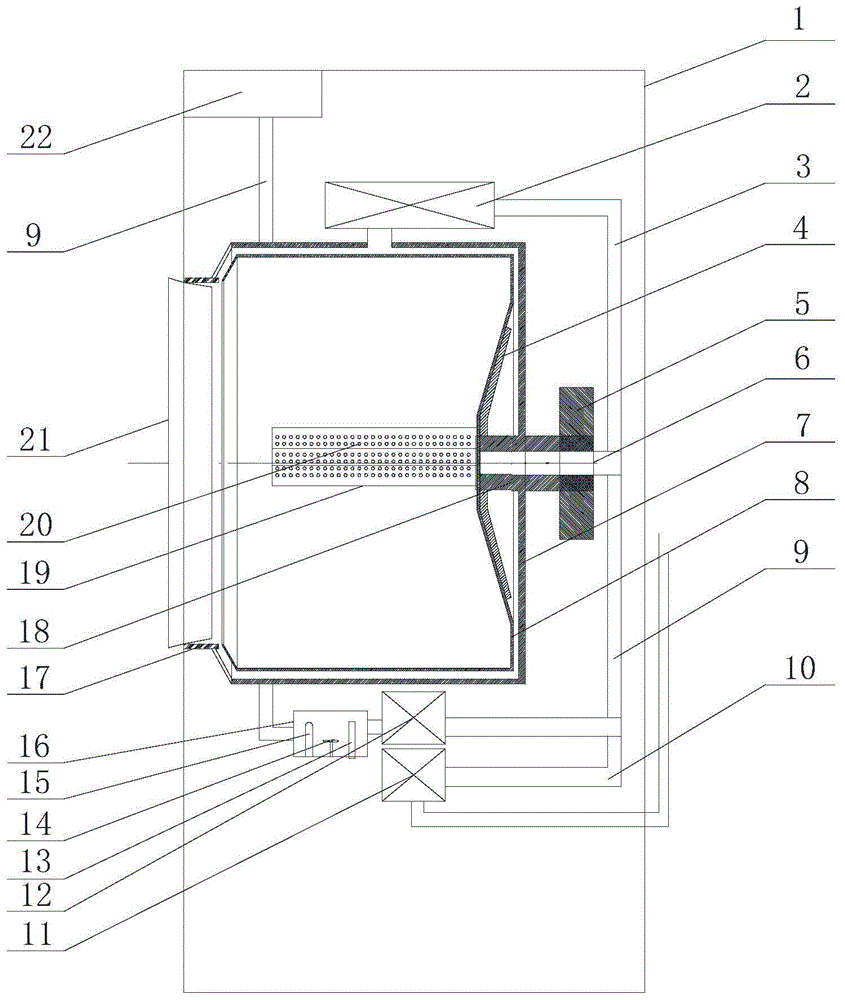

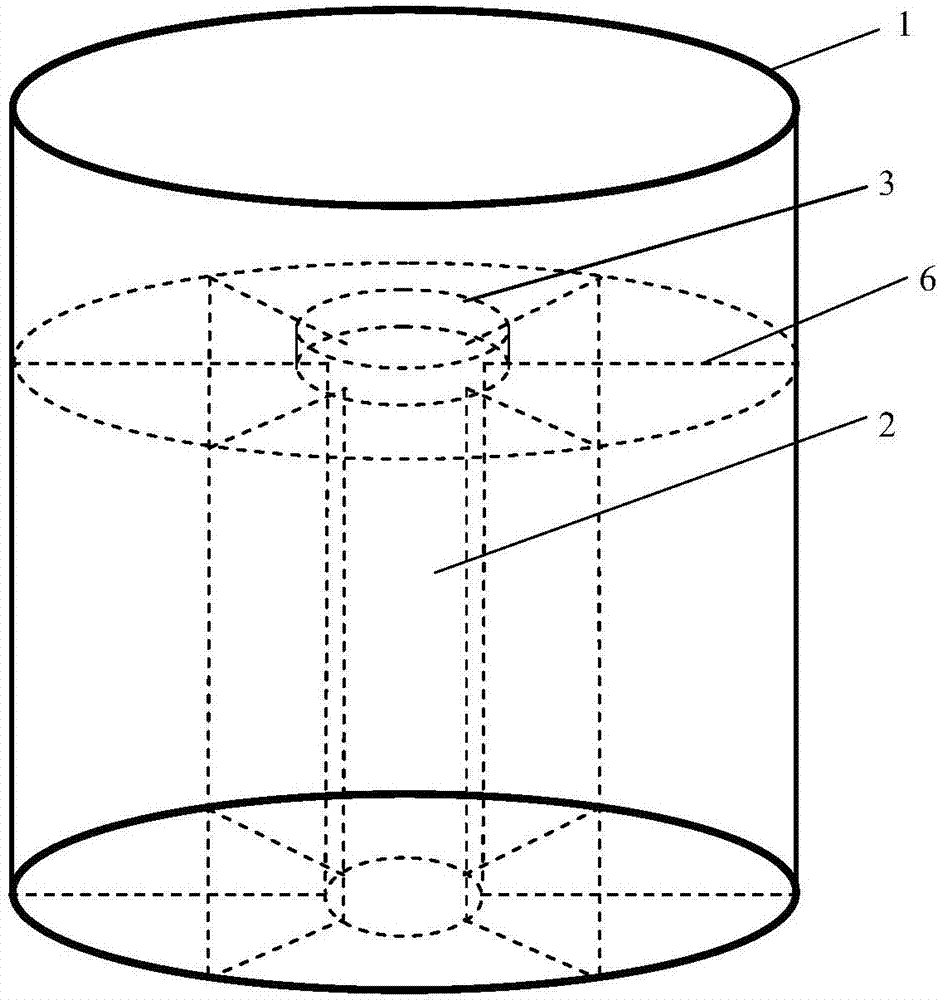

A water-saving drum washing machine

ActiveCN105696248AReduce the amount of waterRealize the purpose of saving waterOther washing machinesWashing machine with receptaclesWater savingMechanical engineering

The invention provides a water-saving drum washing machine comprising an outer drum, an inner drum disposed in the outer drum and a water inlet pipeline communicating with the inner drum. The inner drum and the outer drum are installed on a central shaft coaxially. The inner drum is a holeless inner drum. The inner wall of the inner drum is provided with a plurality of lifting devices; the central shaft is internally provided with a hollow structure; the water inlet pipeline and the lifting devices communicate with the hollow structure. The lifting devices are provided with a plurality of water outlets. The technical objective of saving water is mainly achieved by using the holeless inner drum and making the space between the inner drum and the outer drum free of water in a washing process. Since the holeless inner drum is used, the structure of the water-saving washing machine is redesigned for water feeding and water drainage of the washing machine; further a water feeding and drainage system, a washing and spinning system and an airing drying and drying system are improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

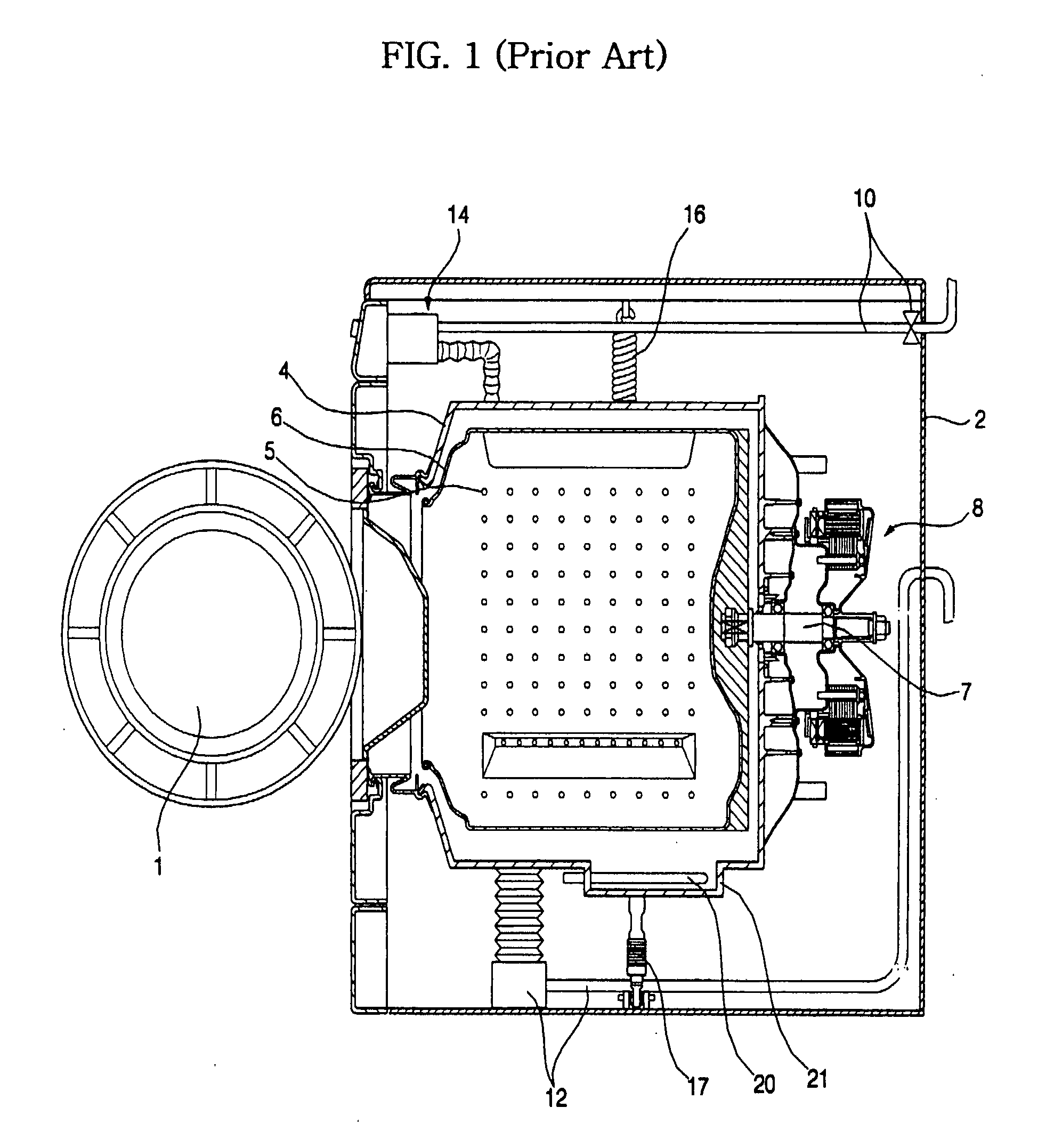

Washing machine and method for controlling the same

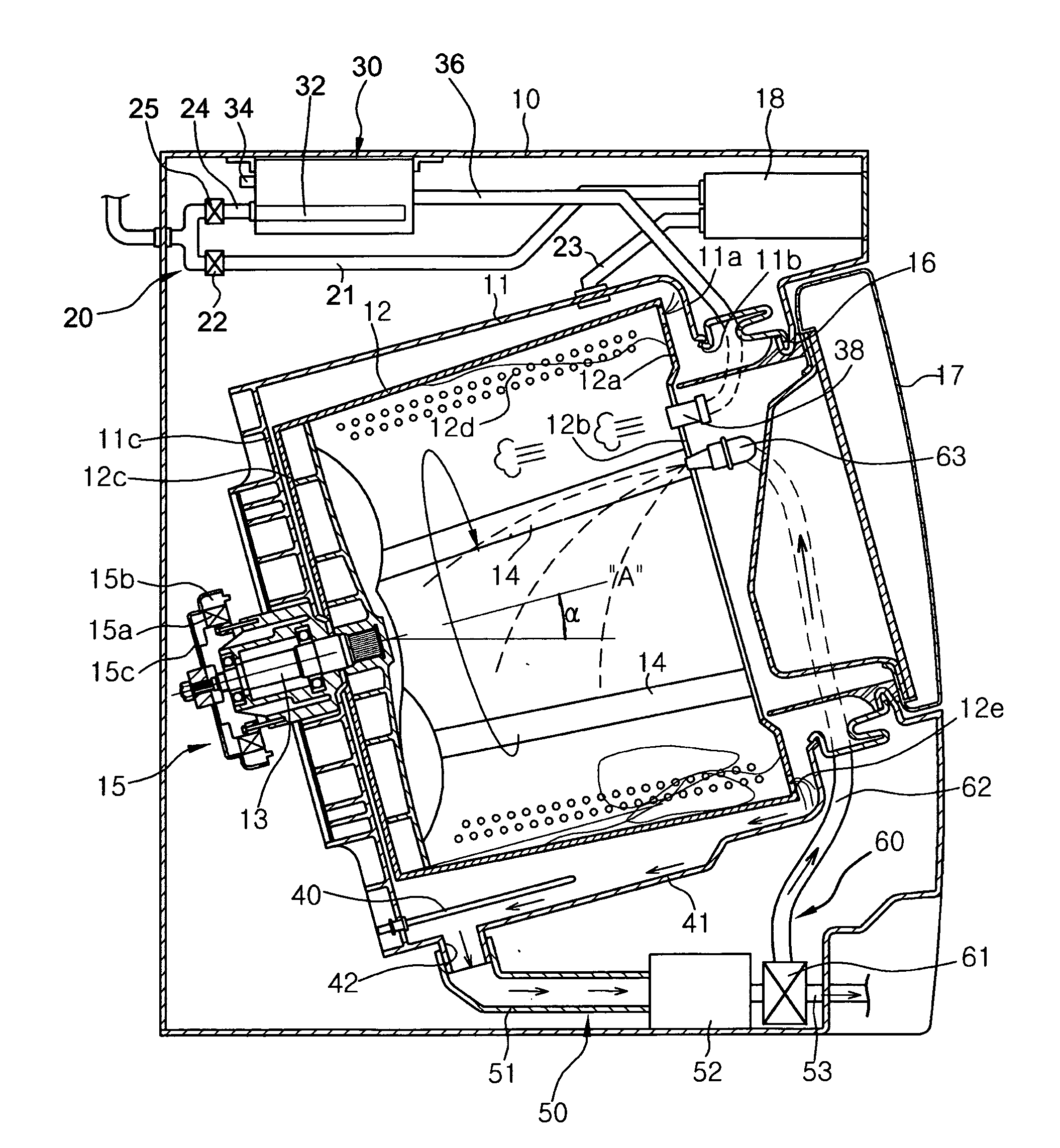

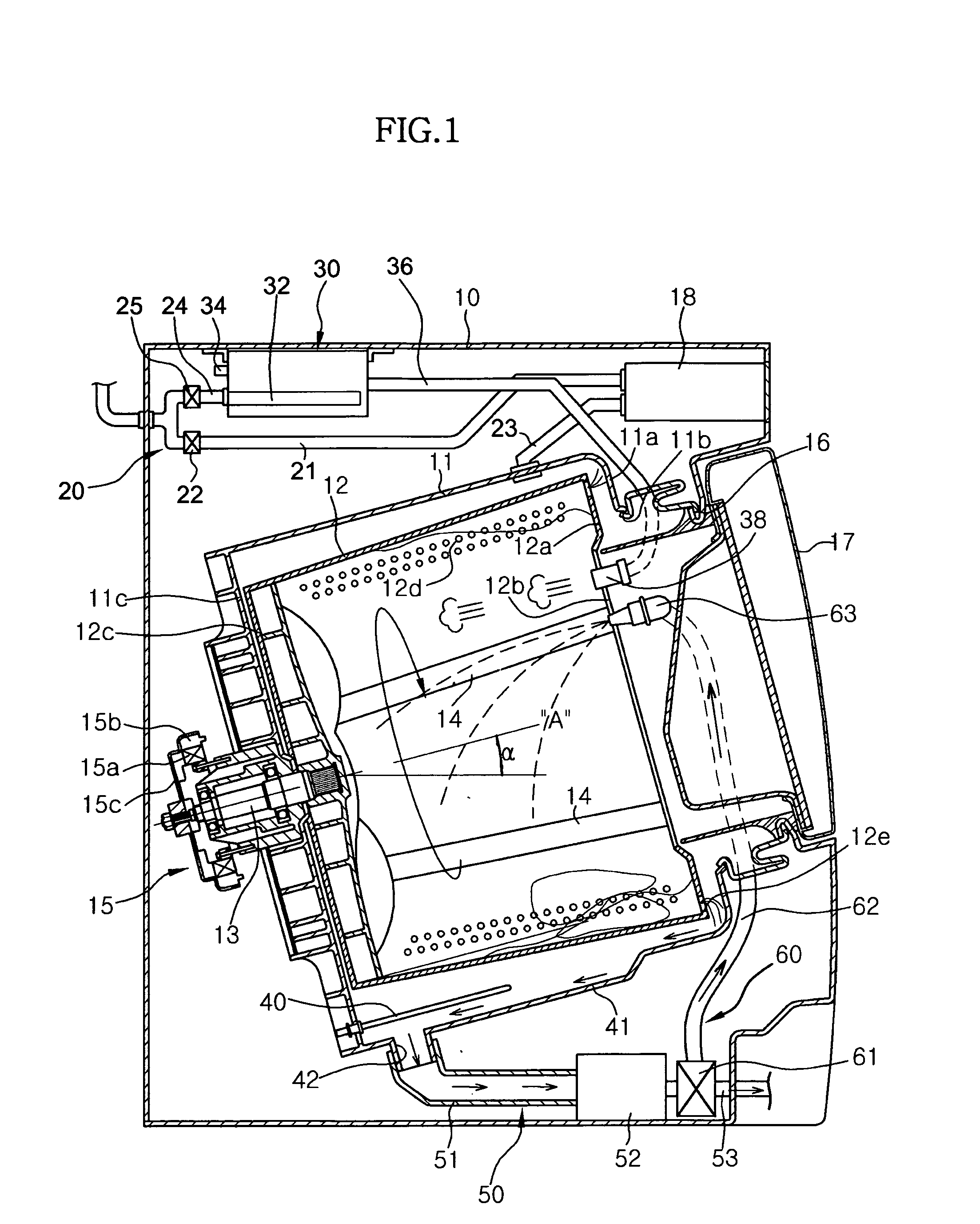

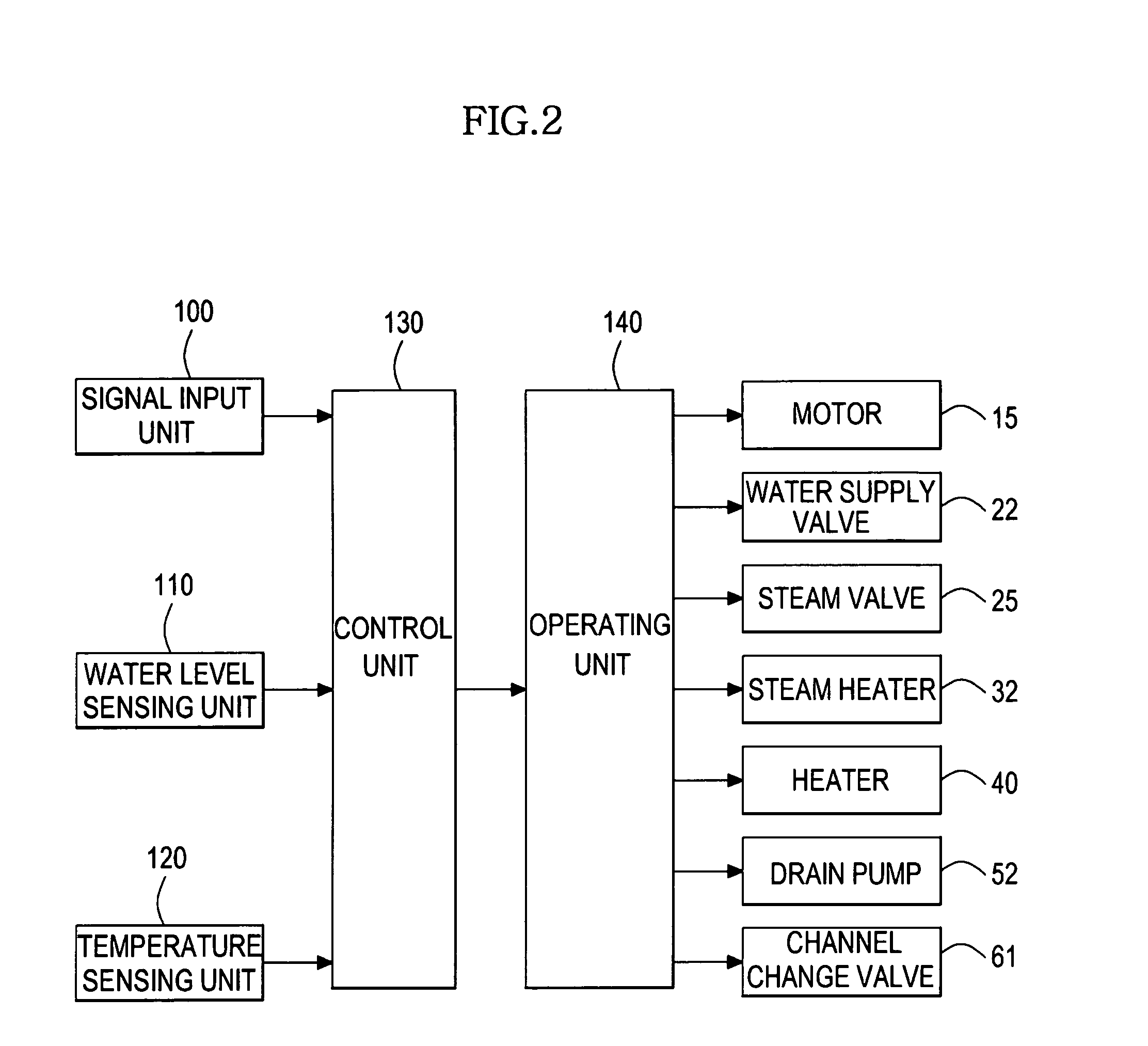

InactiveUS20060101586A1Shorten washing timeImprove washing effectOther washing machinesControl devices for washing apparatusProcess engineeringEnergy consumption

A washing machine having a steam generating device for directly heating wash water to generate optimum steam, and a method for controlling the same are provided. The method includes sensing a temperature of the steam generating device; controlling water supply means according to the temperature of the steam generating device such that wash water is supplied to the steam generating device; and controlling a quantity of wash water supplied from the water supply means. Further, the steam is supplied so as to rapidly soak laundry, thereby shortening overall washing time, and reducing energy consumption. Also, the steam is sprayed onto the laundry to provide sterilizing effects. Soaking effects of the laundry are improved, as well, so as to increase washing efficiency and eliminate wrinkling.

Owner:SAMSUNG ELECTRONICS CO LTD

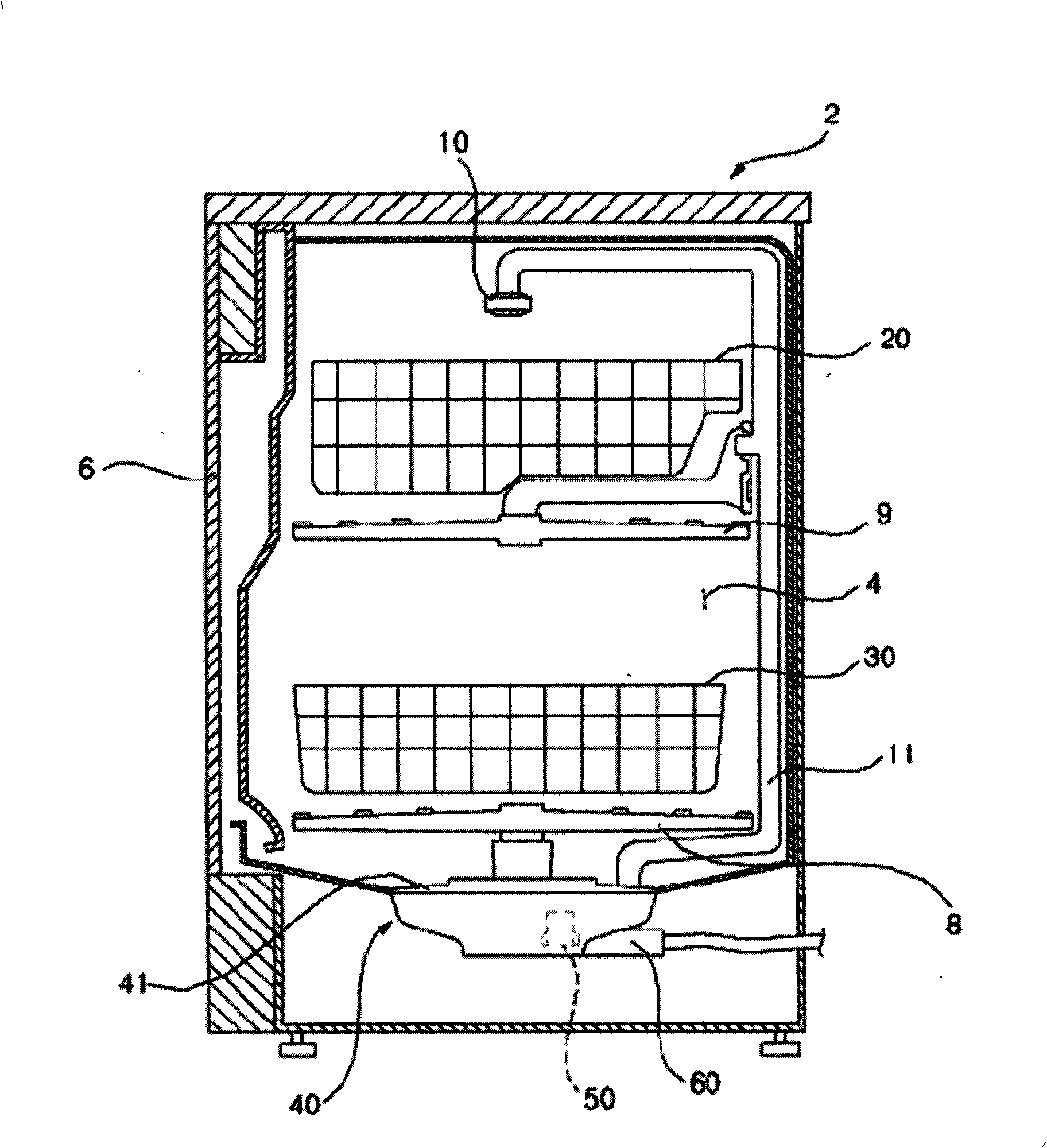

Drum washing machine with detergent supply device

InactiveUS20070240456A1Easy to manufactureLow production costOther washing machinesTextiles and paperSiphonWater level

A drum washing machine having a detergent supply device supplying water containing detergent to a washing tub. The detergent supply device is integrally formed with a door of the washing machine. The detergent supply device is provided with a discharge unit discharging detergent dissolved in the water to the washing tub when the level of the water supplied to the detergent supply device reaches a designated value. The discharge unit delays the discharge of the washing water supplied to the detergent supply device by a siphon, thus improving the solubility of the detergent.

Owner:SAMSUNG ELECTRONICS CO LTD

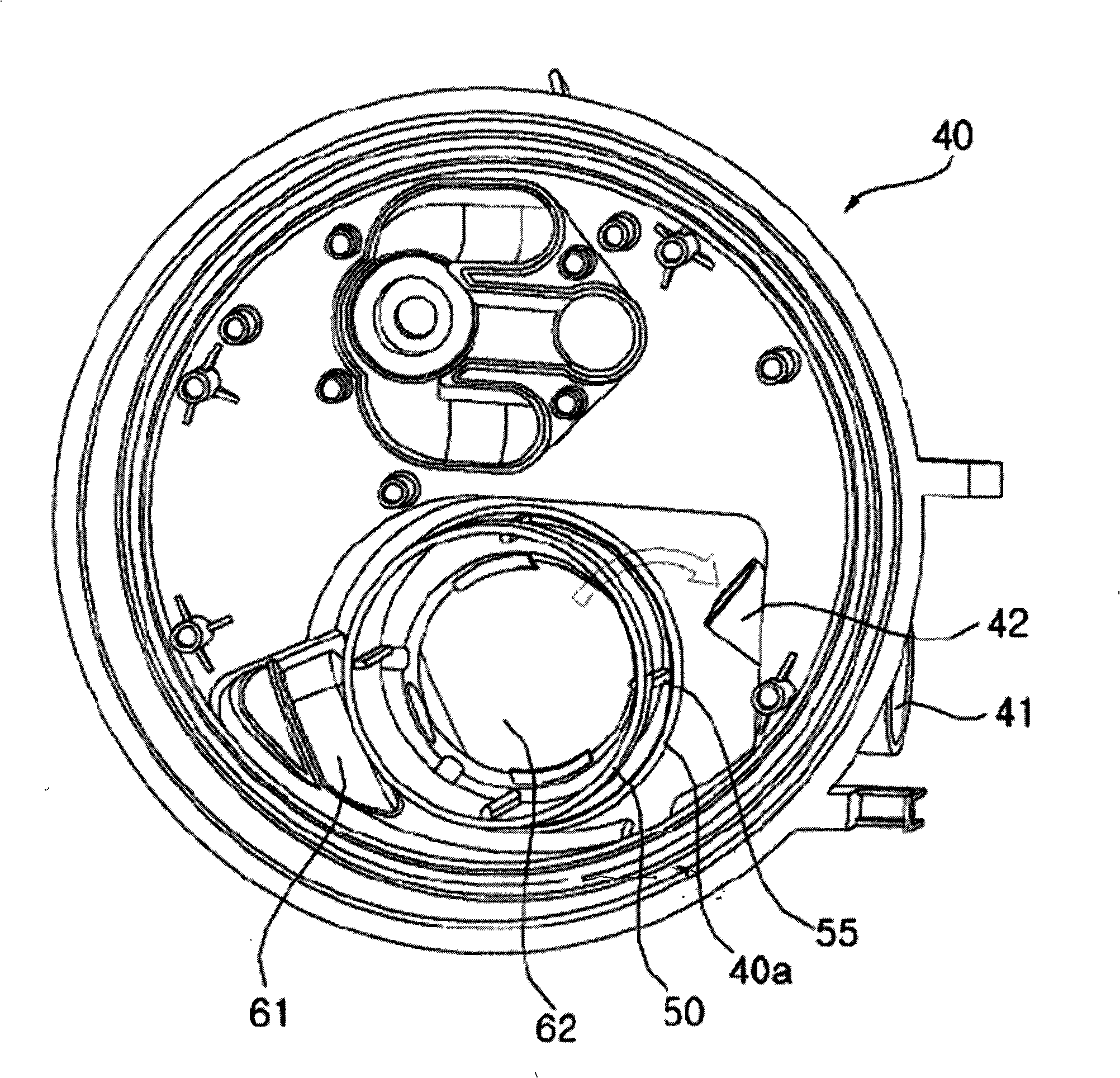

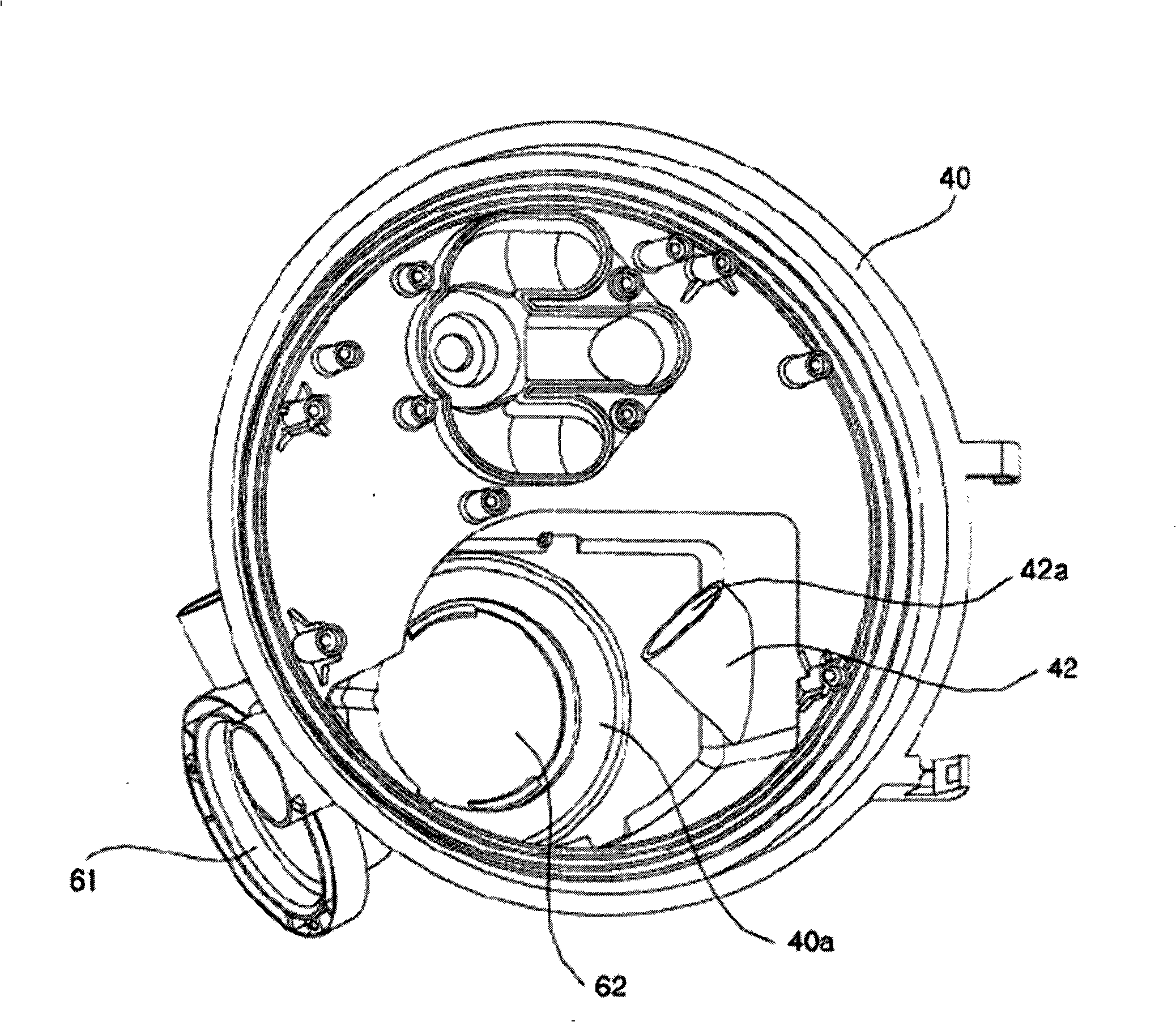

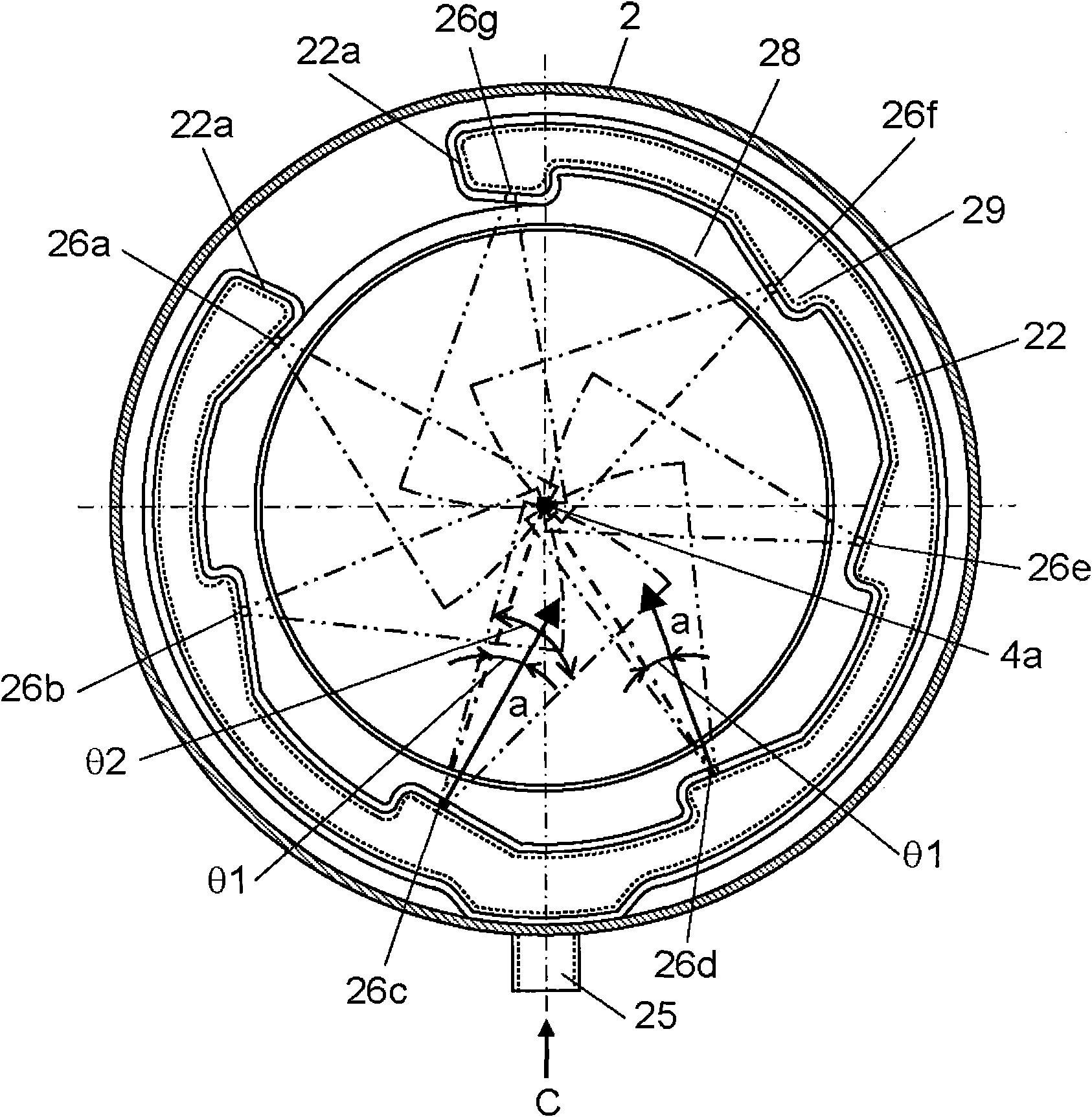

Dish washer

InactiveCN101406379AImprove washing effectSmooth circulationTableware washing/rinsing machine detailsWash waterEngineering

The invention discloses a dishwasher, which includes a filter rotarily provided for filtrating washing water, thereby minimizing the filter clogging phenomenon because that the dirt clings at part of the filter, so that the wash water can smoothly circulate and the washing performance of the dishwasher can be improved. And, when a washing pump is used to drive, the wash water for filtrating in the filter is sucked from a slope preset angle direction of the flank of the filter; and a rotary reinforcing rib rotating by the flowing of wash water produced when the washing pump is used to drive is formed in the filter, accordingly the invention has a simple structure and easy adoption.

Owner:NANJING LG PANDA APPLIANCES

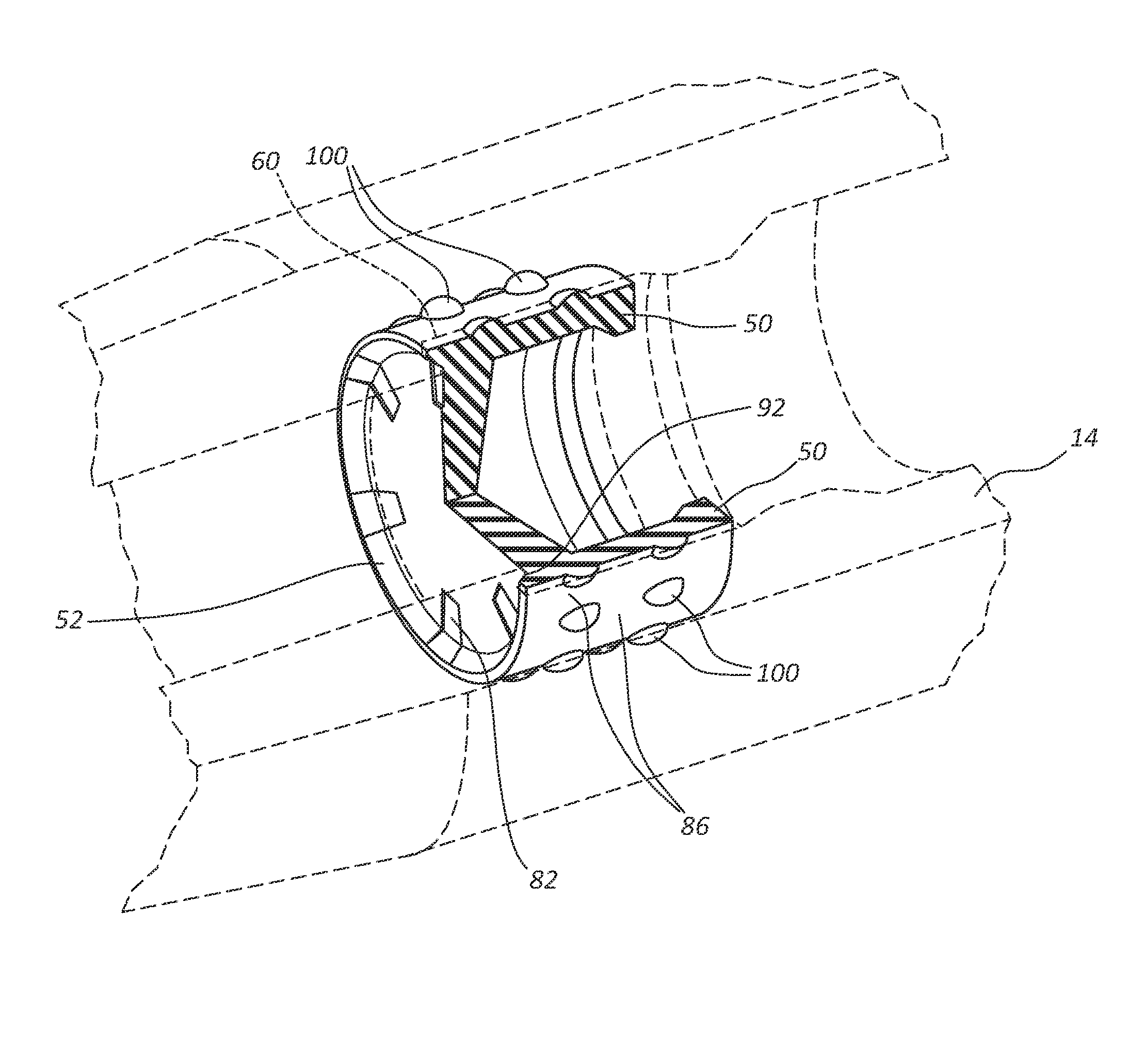

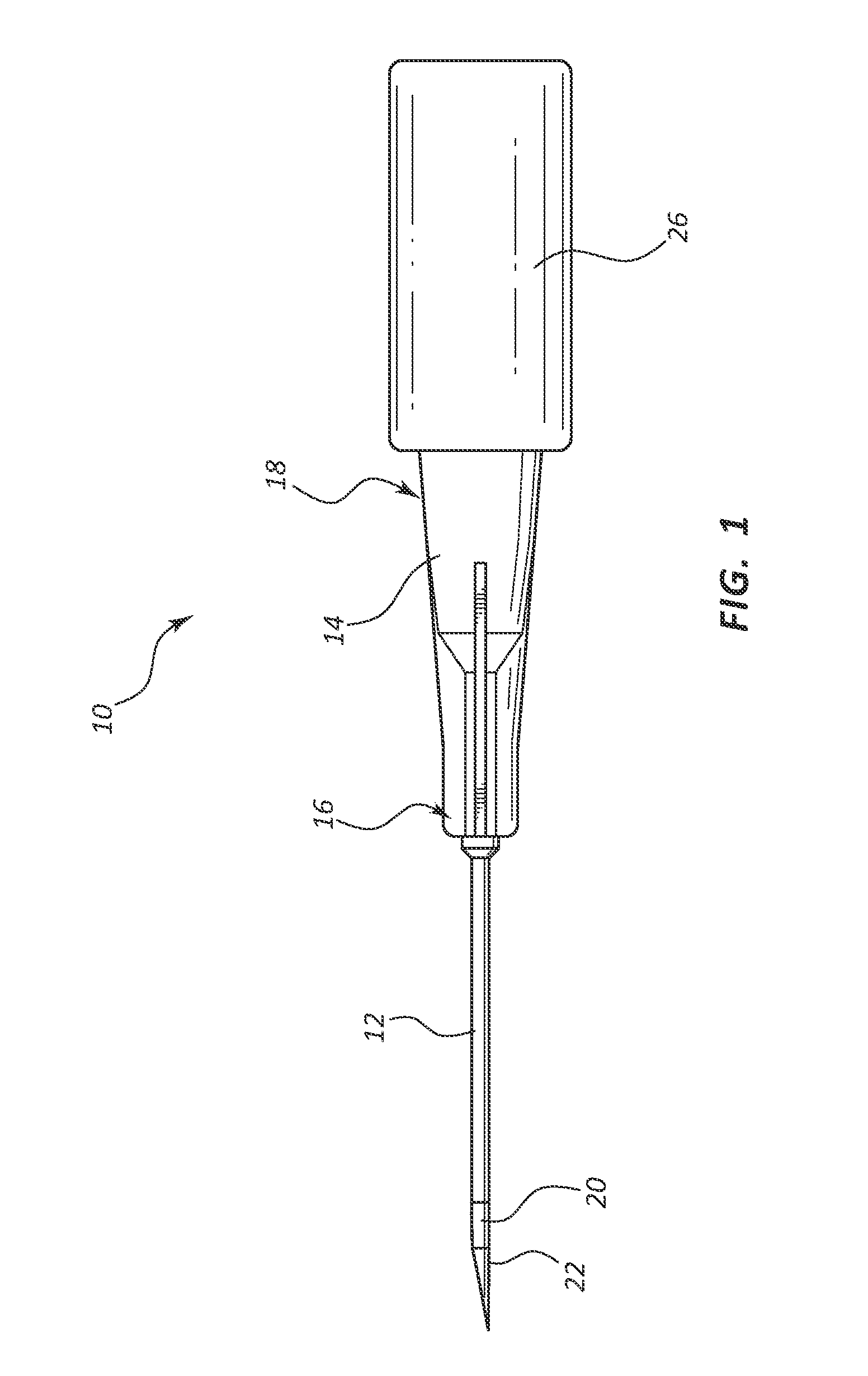

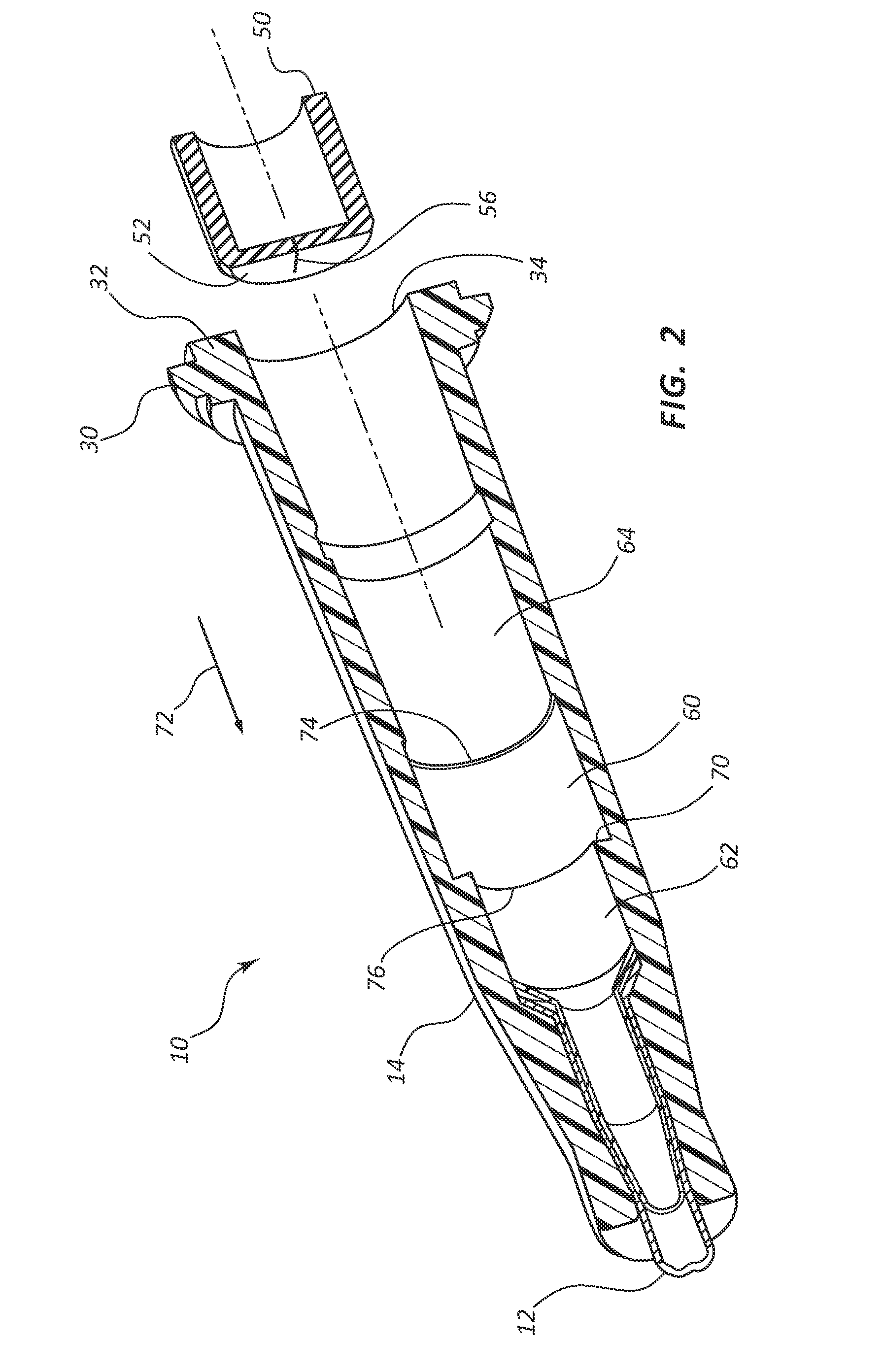

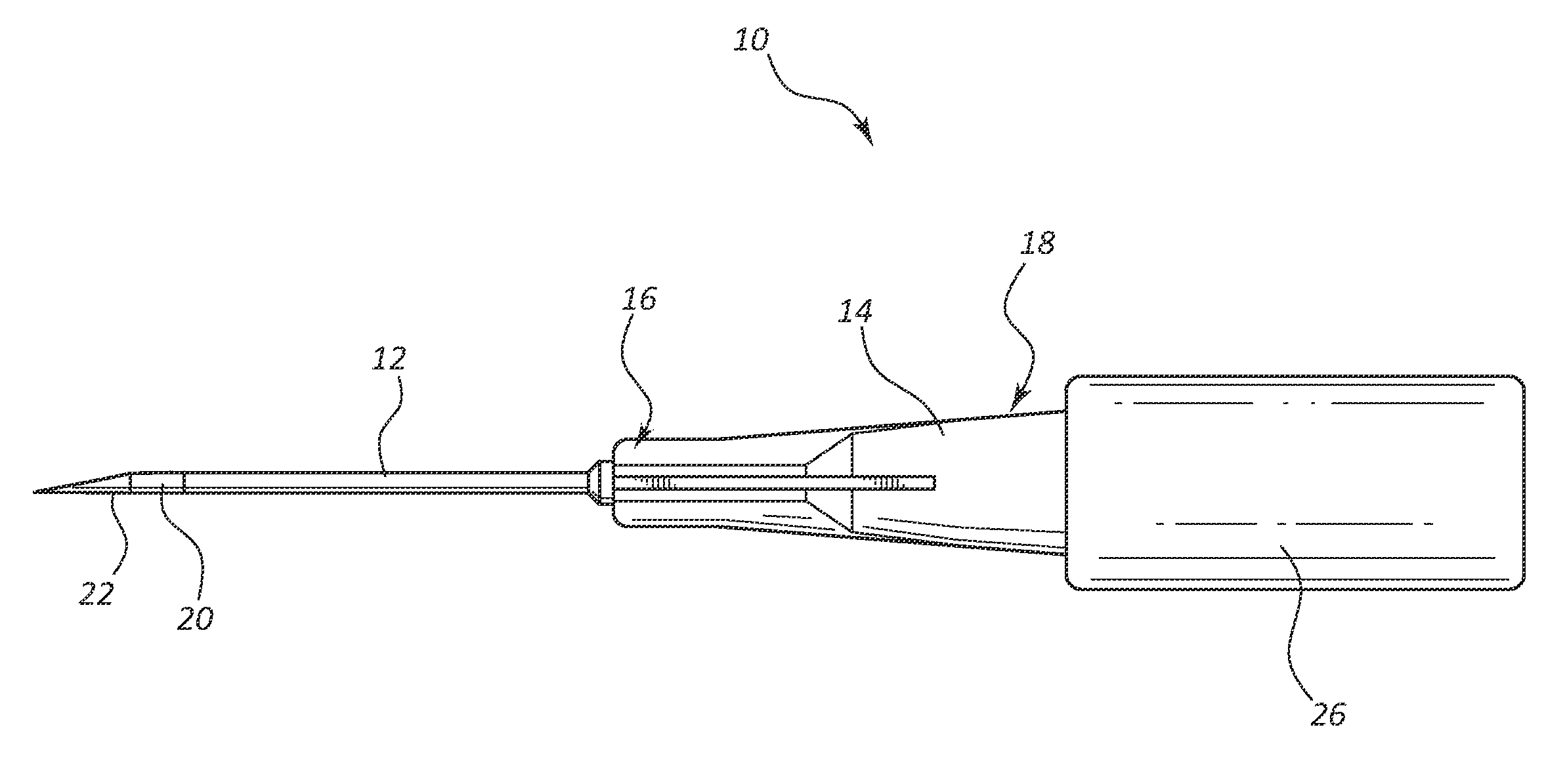

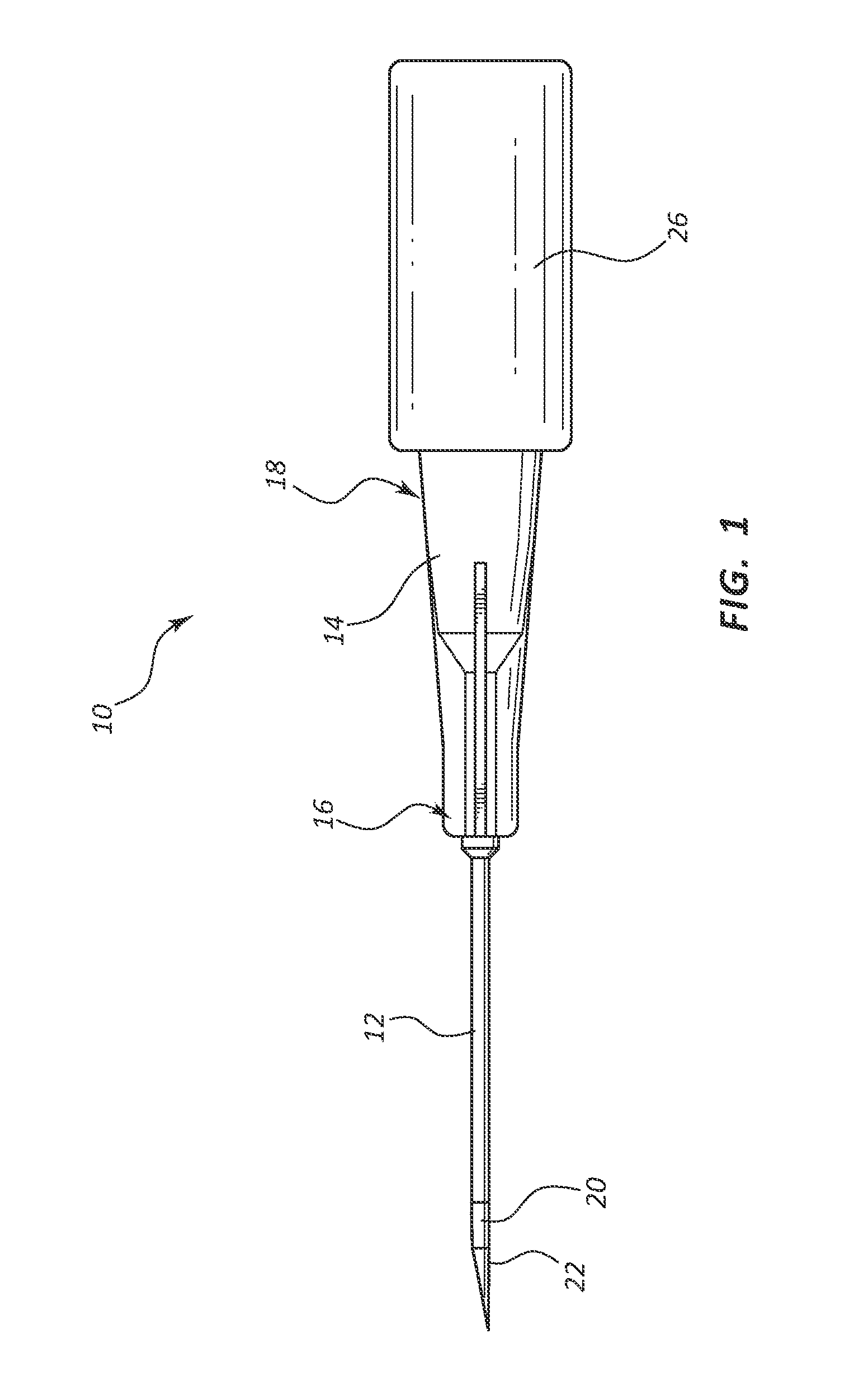

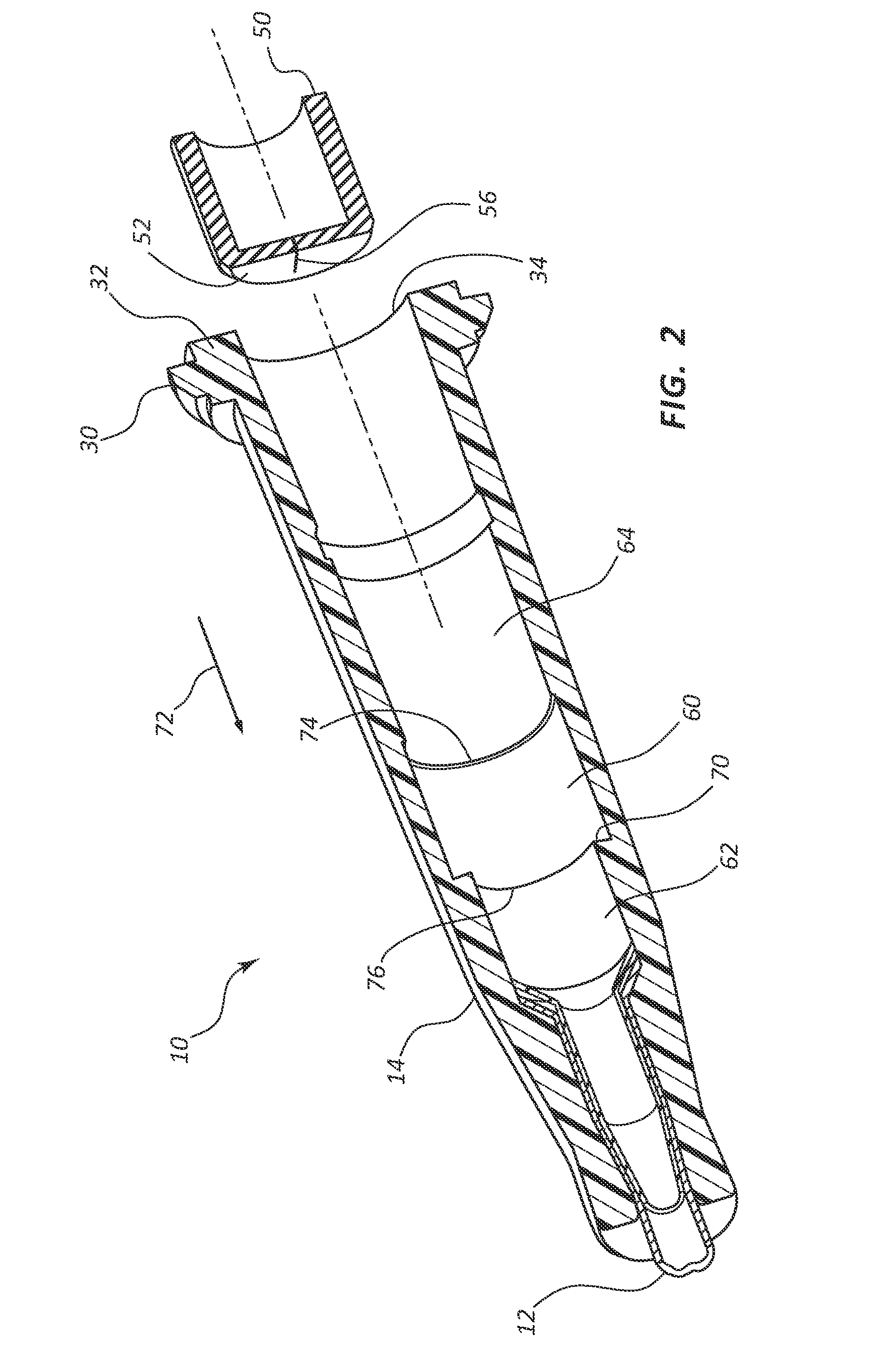

Systems and methods for sealing a septum within a catheter device

ActiveUS20130090608A1Good flush-abilityShorten actuatorInfusion devicesMedical devicesStop flowStopped flow

Systems and methods for sealing and venting a septum of an intravenous catheter device. Implementations of the present invention include a compact, molded septum that is retained within an inner lumen of a catheter adapter such that slowed or stopped flow of air and / or a fluid is permitted to pass between the compact septum and an inner wall surface of the catheter adapter via one or more fluid pathways. In some instances, a snap ring is provided to secure the position of the compact septum within the catheter adapter, a fluid pathway being provided through the snap ring.

Owner:BECTON DICKINSON & CO

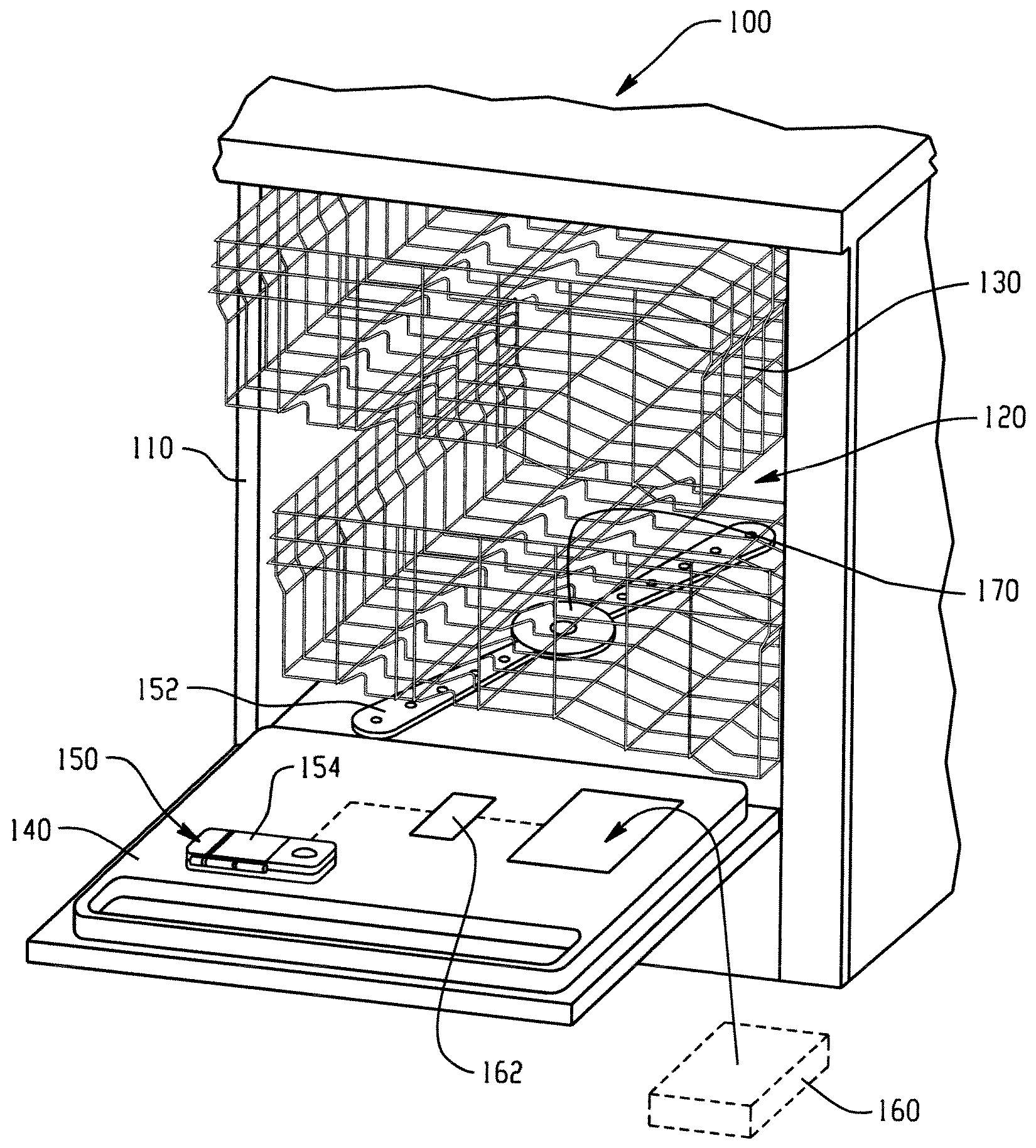

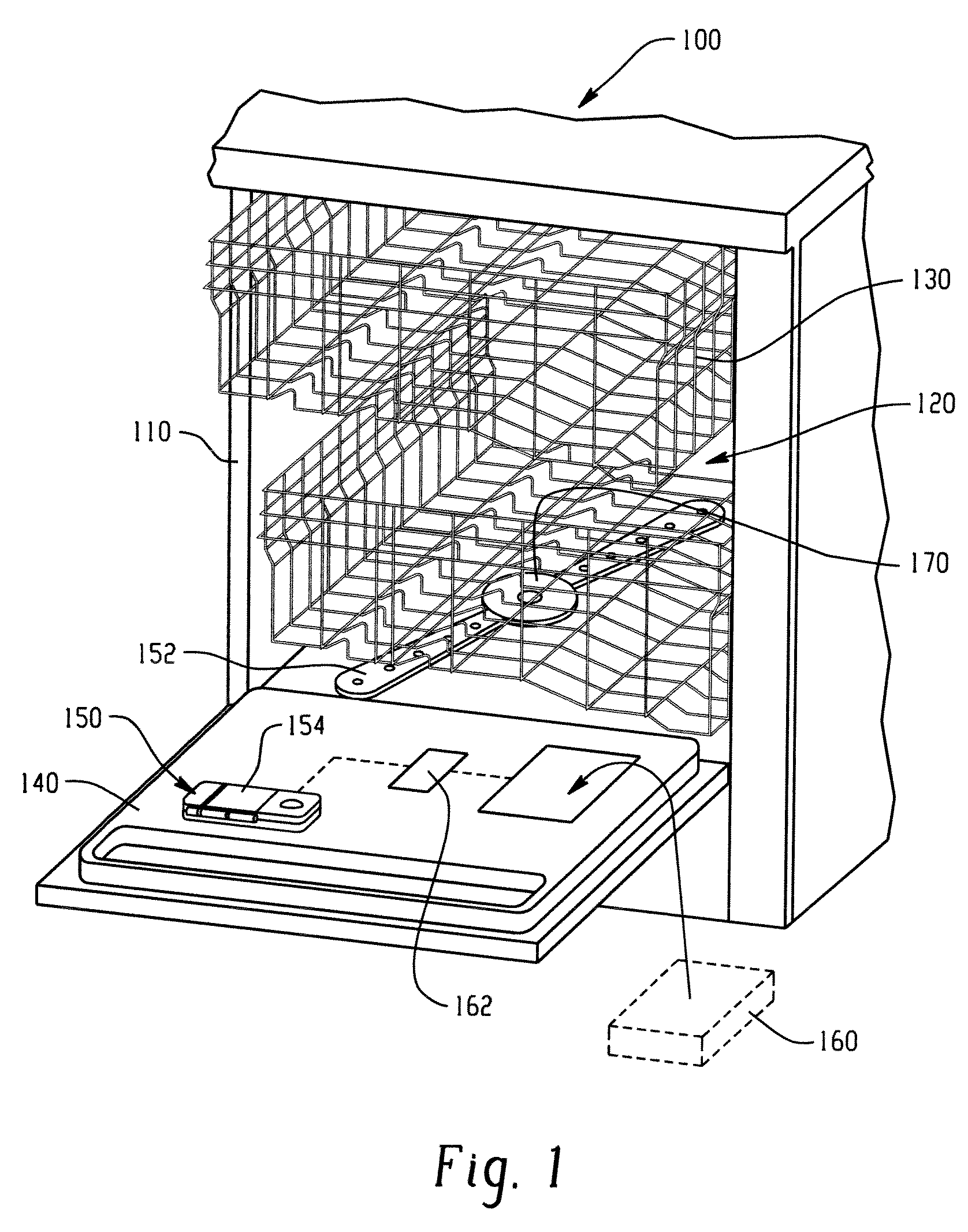

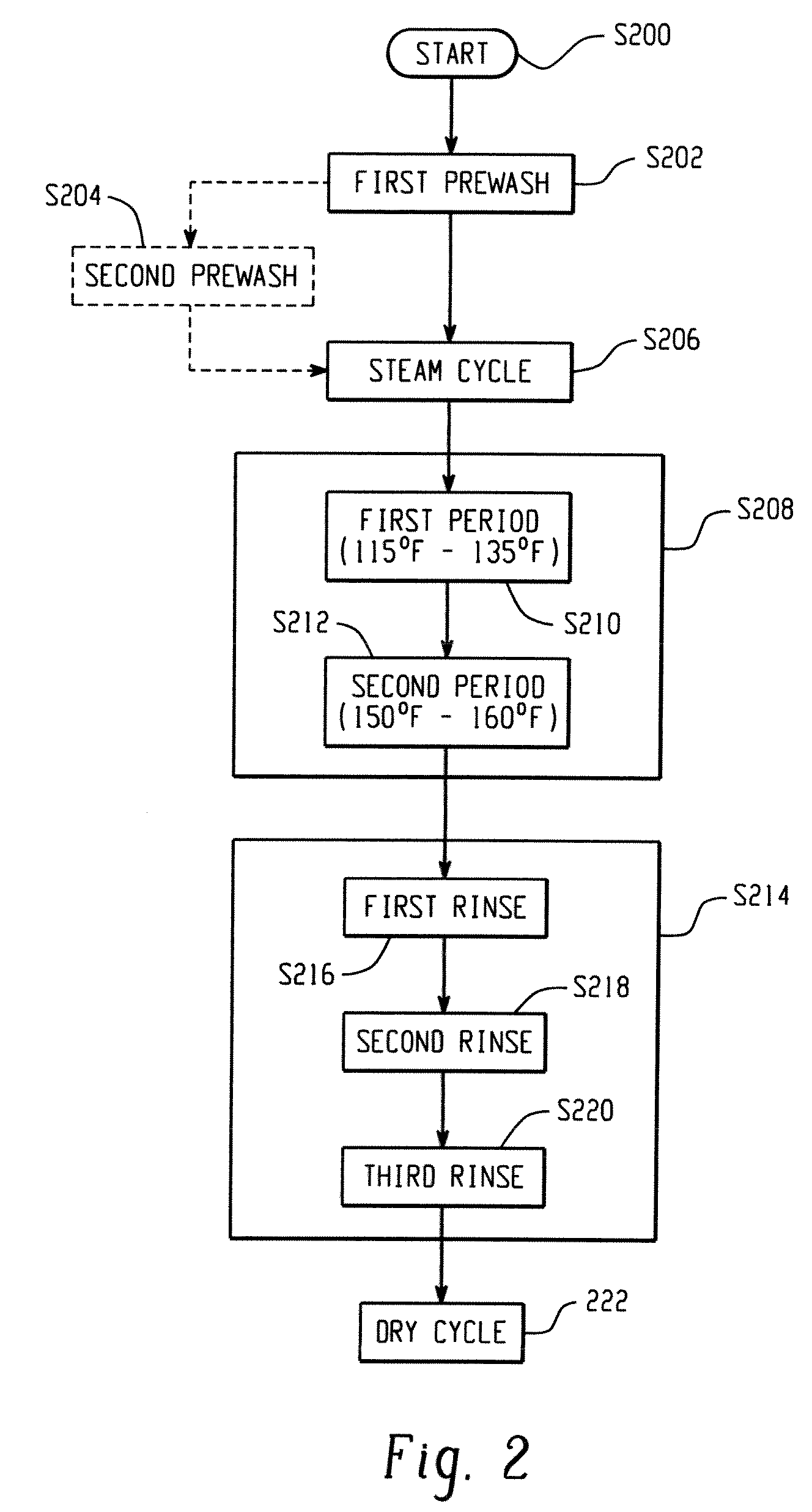

Deep clean cycle

InactiveUS20110000511A1Improve performanceSelectively energizing the heaterWashing processesAutomatic washing/rinsing machine detectionEngineeringEnzyme

A dishwasher includes a housing, a wash chamber in the housing that receives kitchenware therein, a detergent dispenser for introducing a detergent into the wash chamber, and a heater for raising temperature in the wash chamber. The dishwasher further includes a controller for selectively controlling water supply to and from the dish chamber. The controller establishes a temperature of the wash fluid circulating in the wash chamber during the first period in a range from about 115° F. (46° C.) to about 135° F. (58° C.) to enhance the wash performance of enzyme-based detergents and establishes a temperature of the wash fluid during a second period in the range from about 150° F. (65° C.) to about 160° F. (72° C.) to enhance wash performance of a chlorine-based detergent. A method of washing kitchenware contained in the dishwasher comprises (i) removing loose soil on the kitchenware in at least one pre-wash cycle, (ii) washing the kitchenware in a main wash cycle, and (iii) rinsing the kitchenware in at least one rinse cycle. The main wash cycle comprises the actions of (i) washing the kitchenware in a first temperature range for enzyme-based detergent for a first period and (ii) washing the kitchenware in a second temperature range for chlorine-based detergent for a second period.

Owner:GENERAL ELECTRIC CO

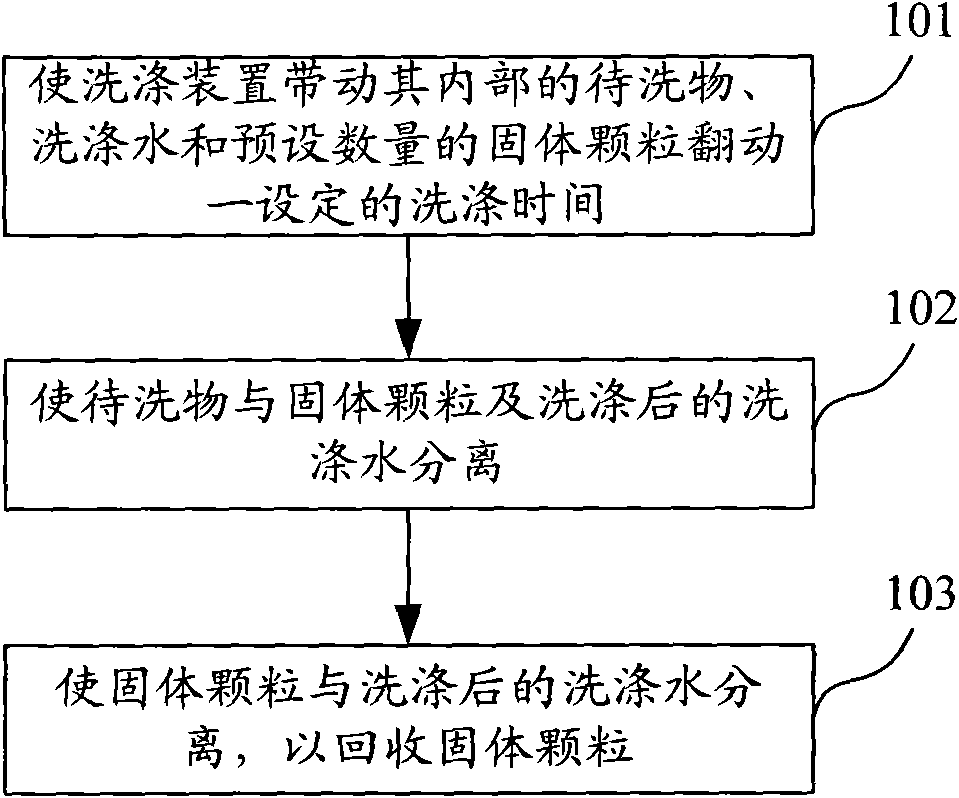

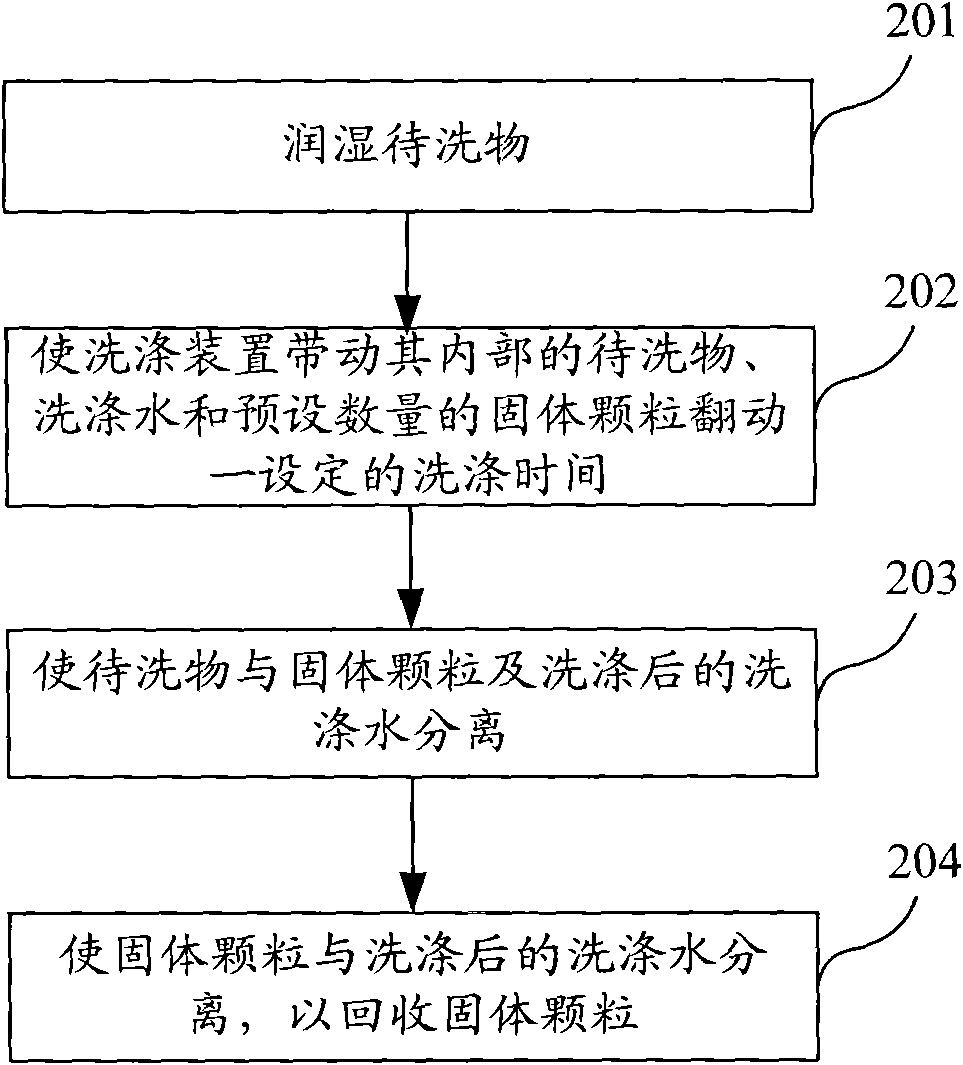

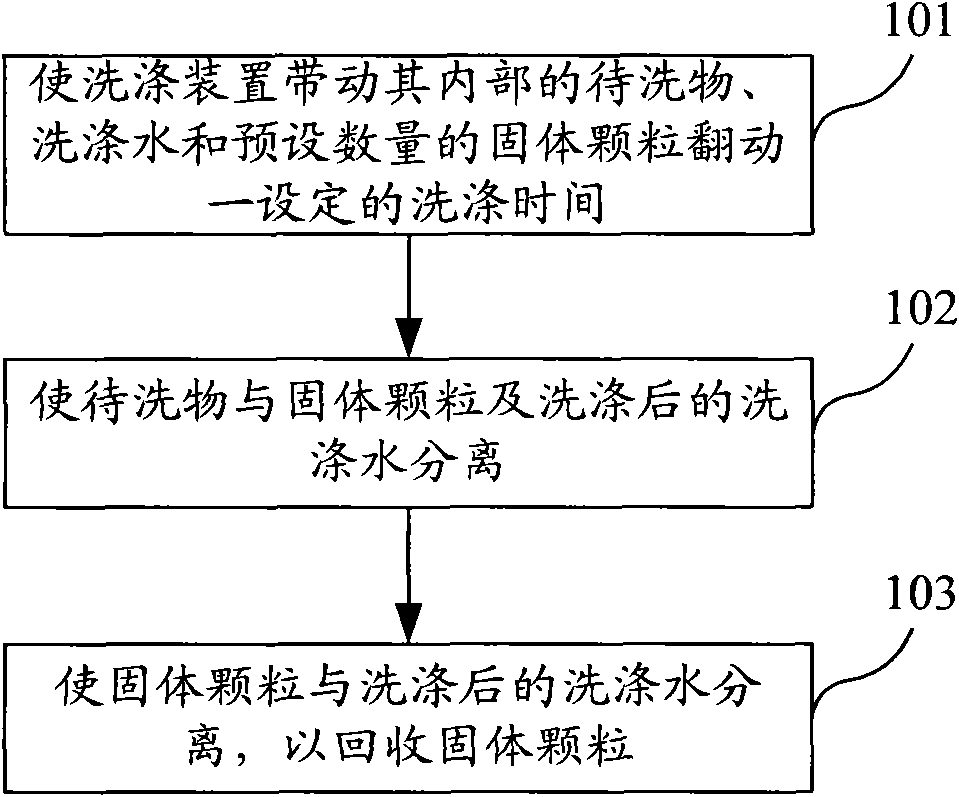

Washing method

InactiveCN101886321AReduce wearImprove washing effectOther washing machinesWashing machine with receptaclesSolid particleProcess engineering

The invention relates to a washing method. The method comprises the following steps: leading a washing device to drive objects to be washed in the washing device, washing water and a preset number of solid particles to flip for a set washing time; leading the objects to be washed to be separated from the solid particles and the washing water after washing; and leading the solid particles to be separated from the washing water after washing for recovering the solid particles. The washing method adopts the solid particles as washing media, thereby having good washing effect and saving water; and the solid particles are recovered after the washing is finished, thereby reducing the washing cost, leading the washing time to be short and causing small abrasion to clothes.

Owner:HAIER GRP CORP +1

Systems and methods for sealing a septum within a catheter device

Systems and methods for sealing and venting a septum of an intravenous catheter device. Implementations of the present invention include a compact, molded septum that is retained within an inner lumen of a catheter adapter such that slowed or stopped flow of air and / or a fluid is permitted to pass between the compact septum and an inner wall surface of the catheter adapter via one or more fluid pathways. In some instances, a snap ring is provided to secure the position of the compact septum within the catheter adapter, a fluid pathway being provided through the snap ring.

Owner:BECTON DICKINSON & CO

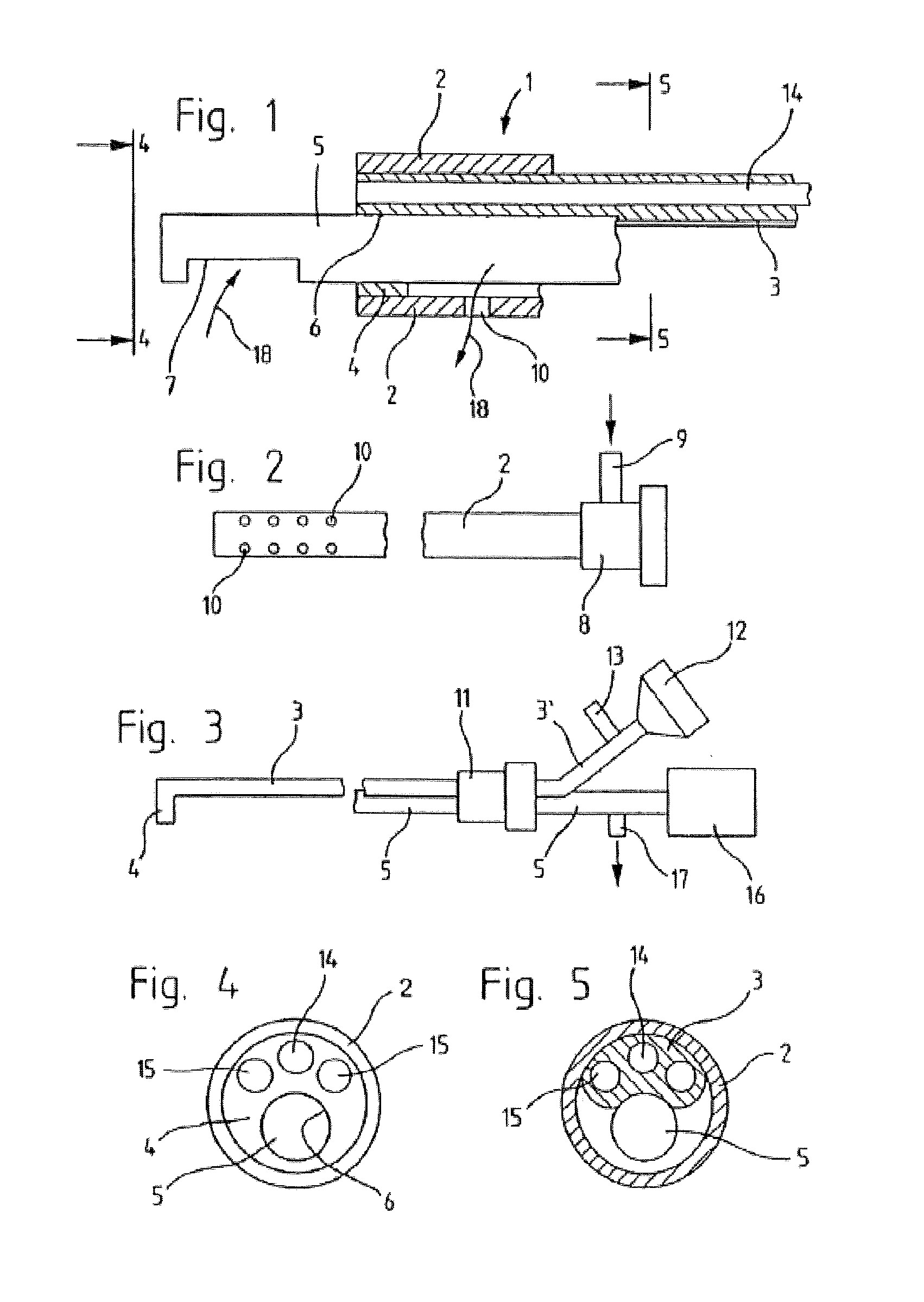

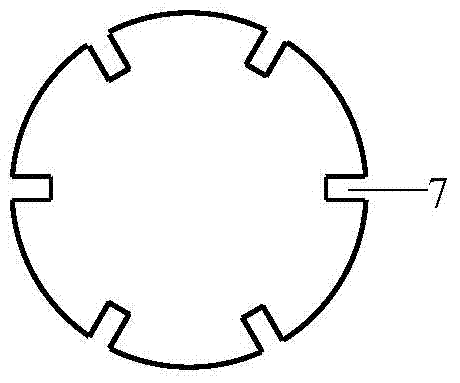

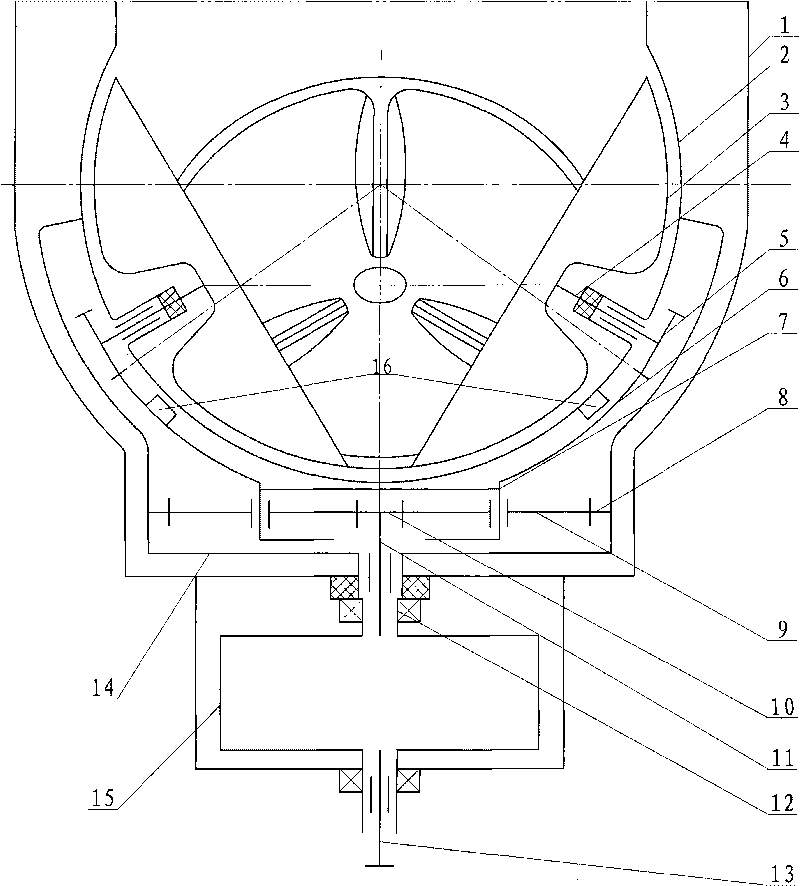

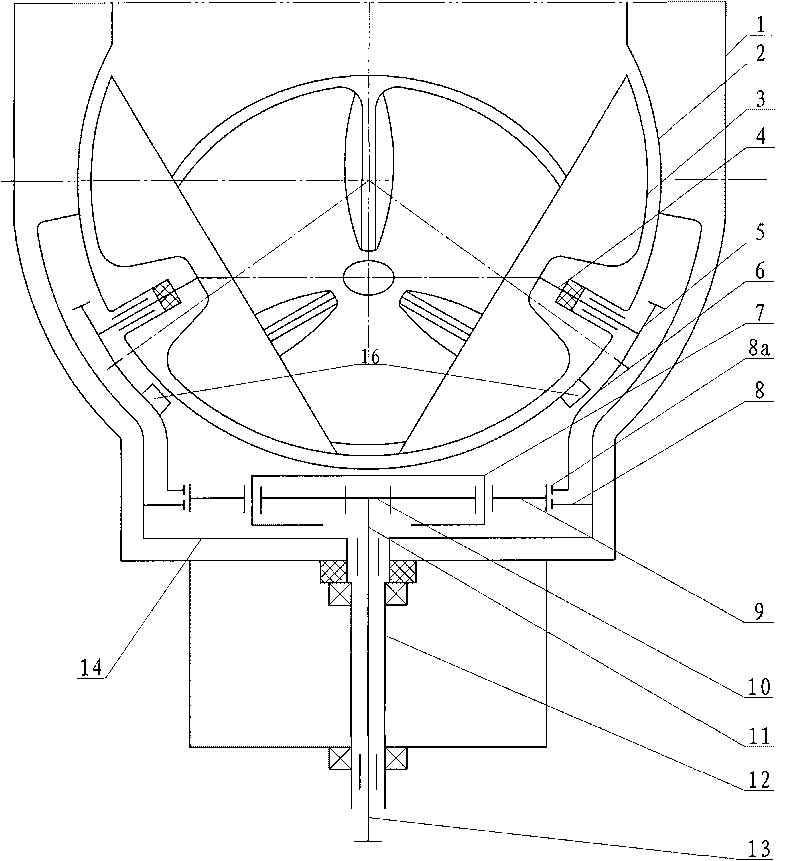

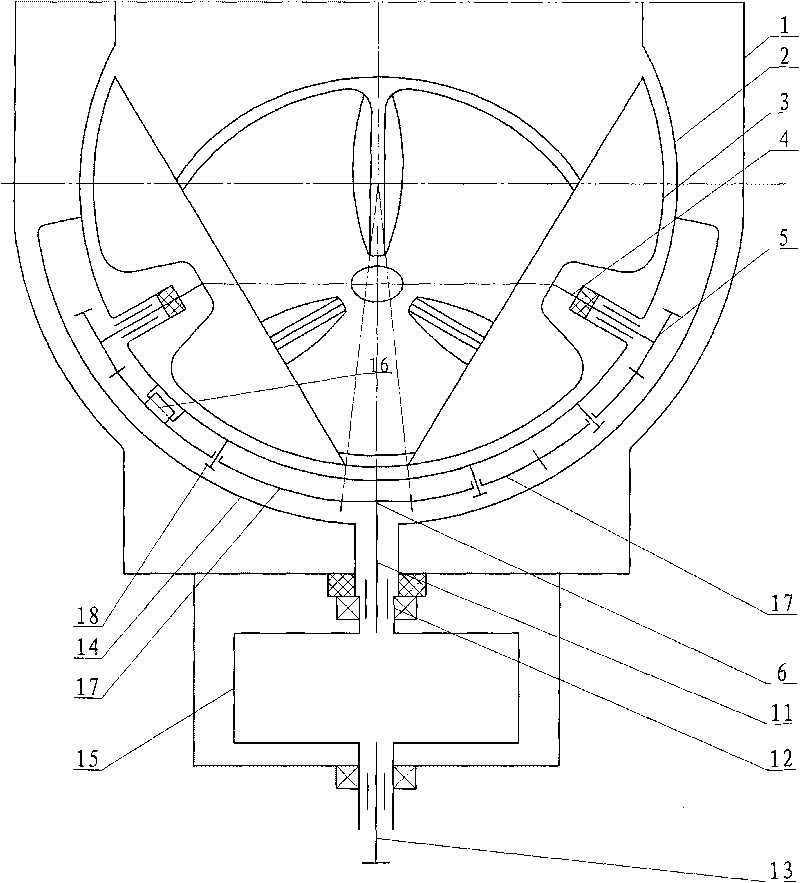

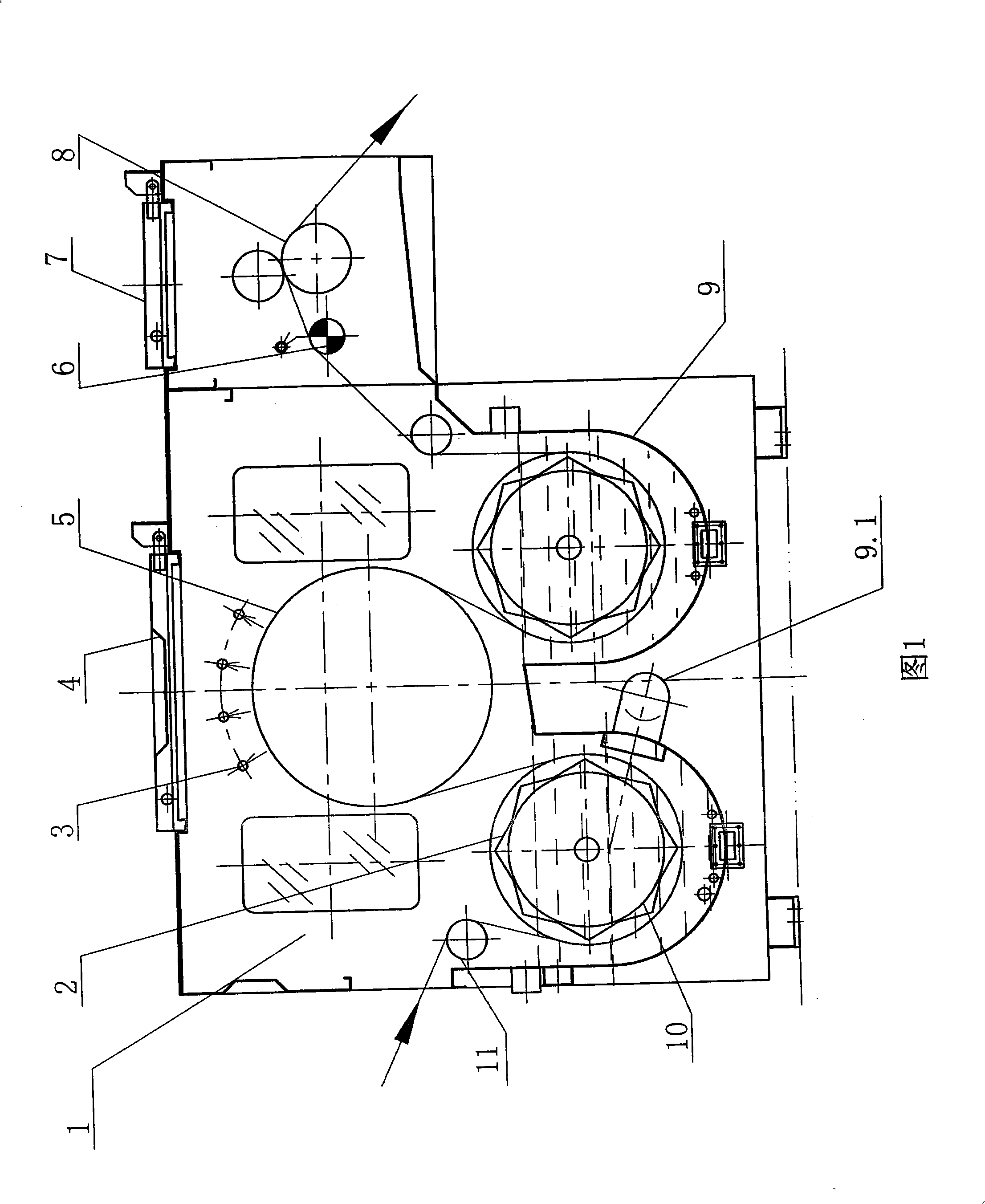

Multi-impeller washing machine and washing manner thereof

InactiveCN101191286AImprove washing effectToothed gearingsWashing machine with receptaclesImpellerLaundry washing machine

The invention relates to a multi-impeller washing machine which mainly comprises an outer barrel, an inner barrel, an input shaft, an input shaft sleeve and a reducing mechanism, wherein, the inner barrel can rotate in the fixed outer barrel; the input shaft can rotate in the input shaft sleeve; the reducing mechanism is arranged under impellers and above the input shaft and the input shaft sleeve; the impellers are three or four impellers which are evenly distributed at the bottom of the inner barrel and respectively connected with the reducing mechanism. One technical proposal of a washing method of the invention is that: during the washing process, the three or four impellers mutually rotate along the same direction or different directions in the inner barrel. The other technical proposal of the washing method of the invention is that: during the washing process, except that the three or four impellers rotate in the inner barrel, axle centers of the impellers revolute along a center line of the input shaft, and the inner barrel is braked or simultaneously driven to rotate. When the invention is used, complex netted whirling currents which are crisscrossed vertically and horizontally can be formed during the washing process, and washing effect can be greatly improved after clothes are rolled, stirred, impacted, extruded, slapped and kneaded.

Owner:潘雪珍

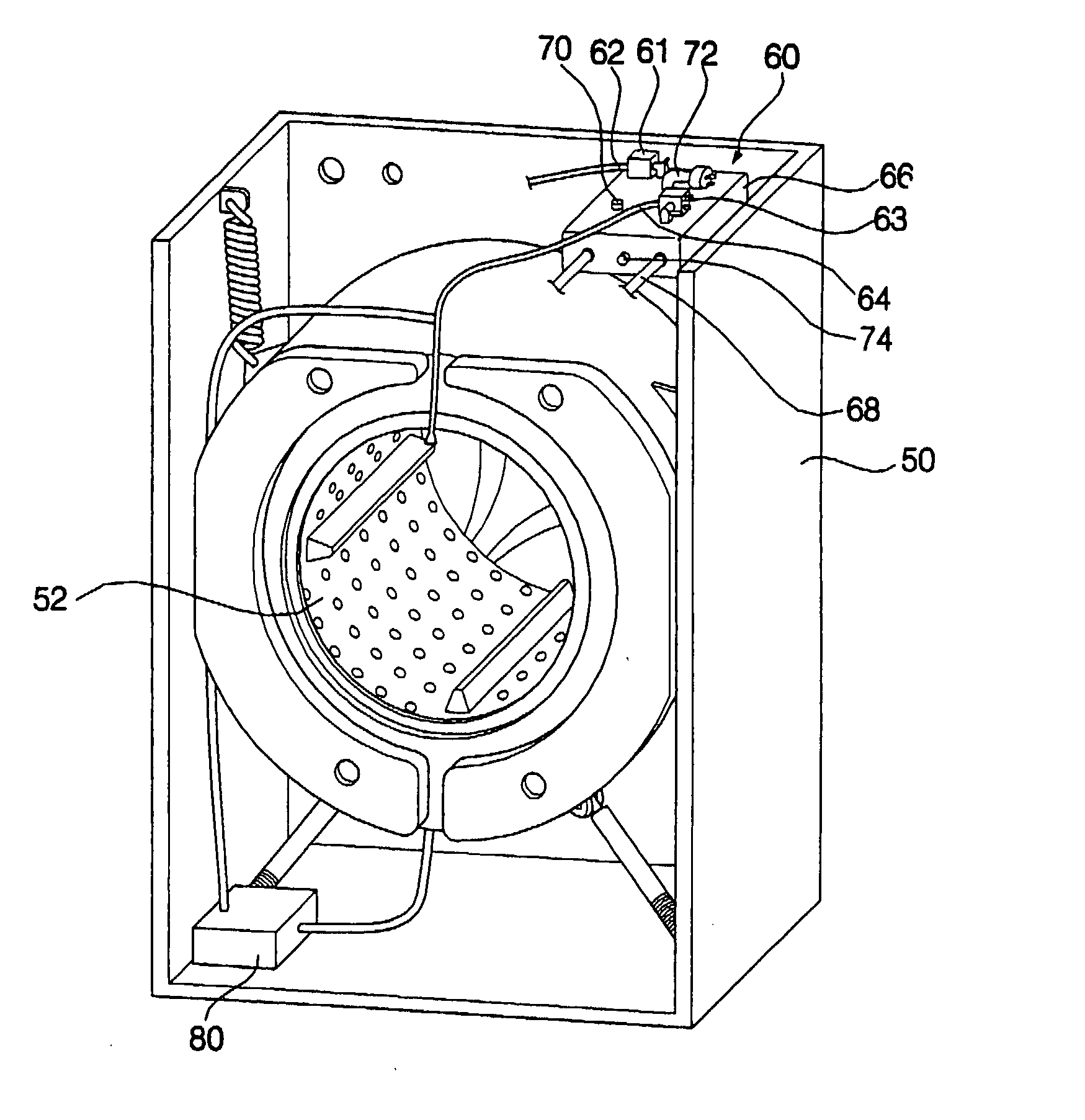

Washing machine

ActiveCN102121186AIncreases chances of spraying wash waterUniform supplyOther washing machinesWashing machine with receptaclesWash waterElectric motor

A drum-type washing machine includes a water tub for storing wash water, a rotary drum placed rotatably in the water tub and having an opening at the front, a motor for driving the rotary drum, a water circulating path for circulating the wash water stored in the water tub to the drum, a pump for conveying the wash water stored in the water tub to the water circulating path, multiple nozzles for jetting the wash water, conveyed to the nozzle water path by the pump, into the rotary drum, and a nozzle water path formed around a front face of the water tub for conveying the wash water from the water circulating path to the nozzles.

Owner:PANASONIC CORP

Endoscope having a shaft tube and optic

InactiveUS20110166419A1Facilitates cleaning for reuseReduce negative impactEndoscopesExcision instrumentsEngineeringEndoscope

A surgical endoscope having a shaft tube that can be connected at its proximal end area to a flushing water inlet and in the distal end area, has at least one lateral opening and having an optic extending through the shaft tube, said optic being designed with a smaller cross-section than the internal cross-section of the shaft tube, and through said optic an image guide extends along the length thereof, where a suction tube is arranged in the free internal cross-section of the shaft tube next to the optic, the suction opening of said suction tube being arranged distally in front of the shaft tube, said suction tube also being proximally connected to a suction device, and where in the distal end region of the shaft tube a locking element, locking the remaining free internal cross-section, thereof is disposed.

Owner:OLYMPUS WINTER & IBE

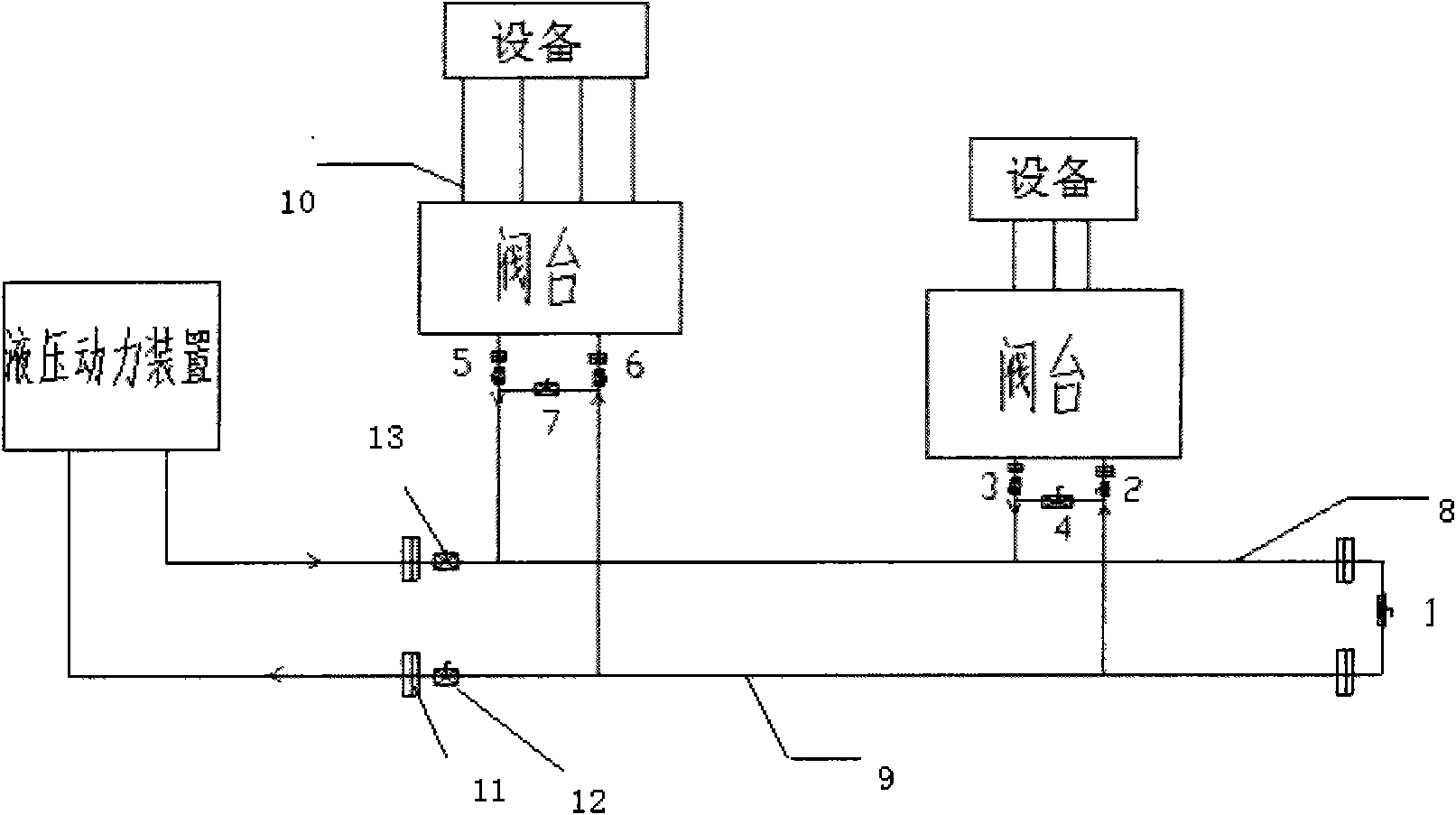

Pipeline cleaning method

ActiveCN101637768AWashed away wellCleaning time is shortHollow article cleaningIsolation valveEngineering

The invention relates to a pipeline cleaning method, which uses cleaning oil as medium and uses a pump to clean forcibly and circularly. The pipeline cleaning method comprises the following steps: 1)steps of processing and installing the pipeline: respectively installing a separating valve at a main pipeline, a branch pipeline and connecting part of bypass pipelines; 2) steps of installing a temporary cleaning device and disassembling the branch pipeline; 3) step of primary cleaning; 4) step of restoring the normal pipelines; and 5) step of secondary cleaning. Compared with the traditional construction process, the construction technique increases a control valve on the original basis, increases the step of reverse cleaning, uses the control of the bypass valve, has circular and thoroughcleaning, high cleanness, short time and low cost, avoids the defects that the dead angles are formed in cleaning and the like and has better technical effect and promotion value.

Owner:CHINA HUAYE GROUP

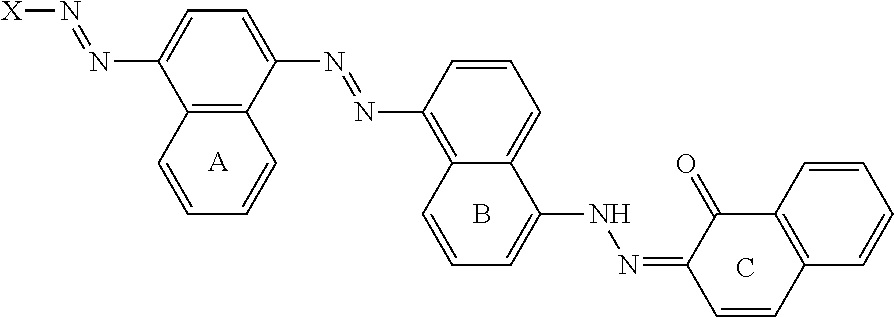

Cleaning composition comprising amylase variants with high stability in the presence of a chelating agent

ActiveUS20110212876A1Retained and increased wash performanceTowards stabilityOrganic detergent compounding agentsPolymeric surface-active compoundsAlpha-amylaseCleaning methods

Owner:THE PROCTER & GAMBLE COMPANY

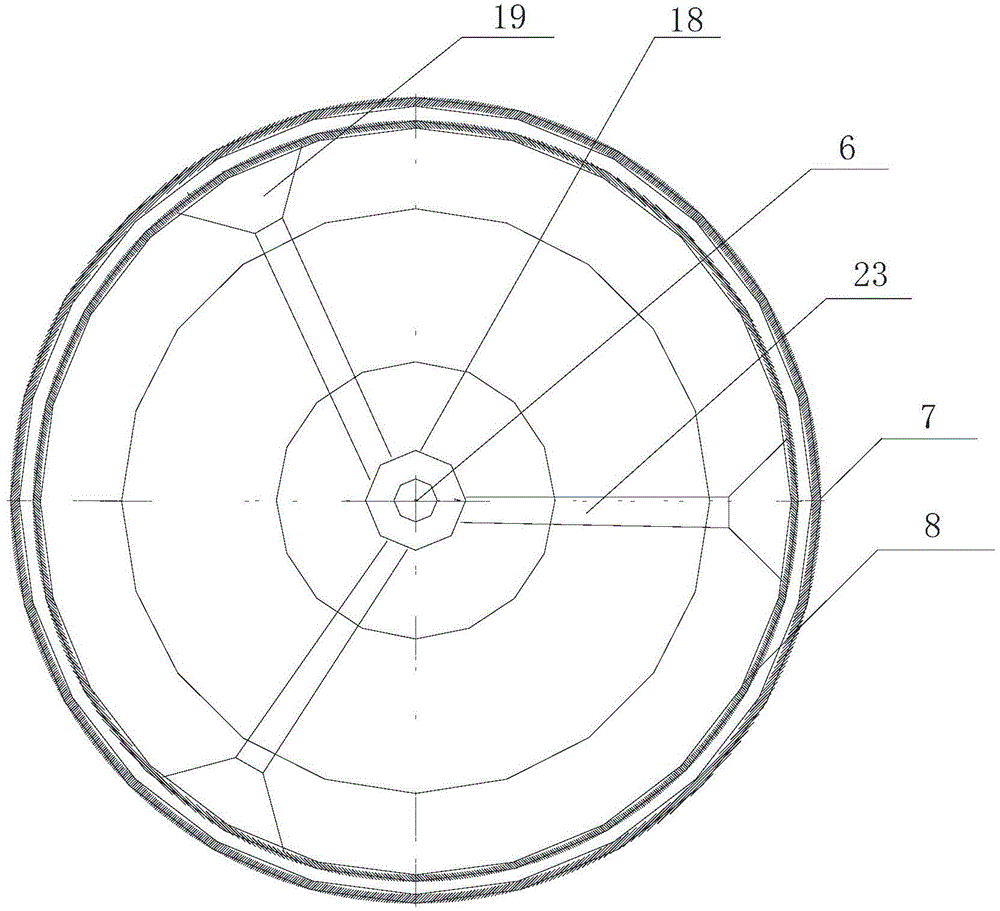

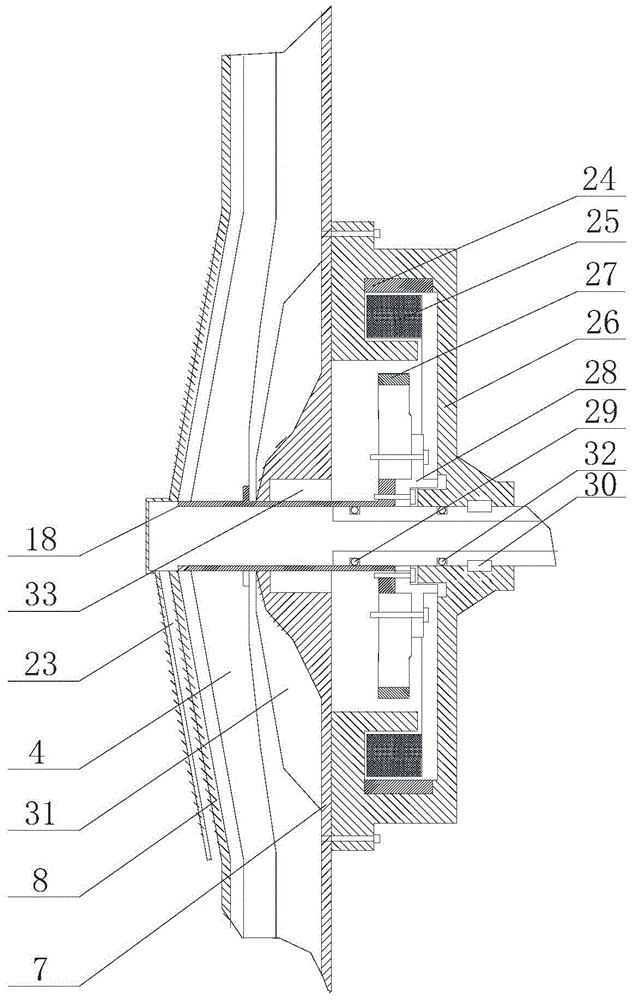

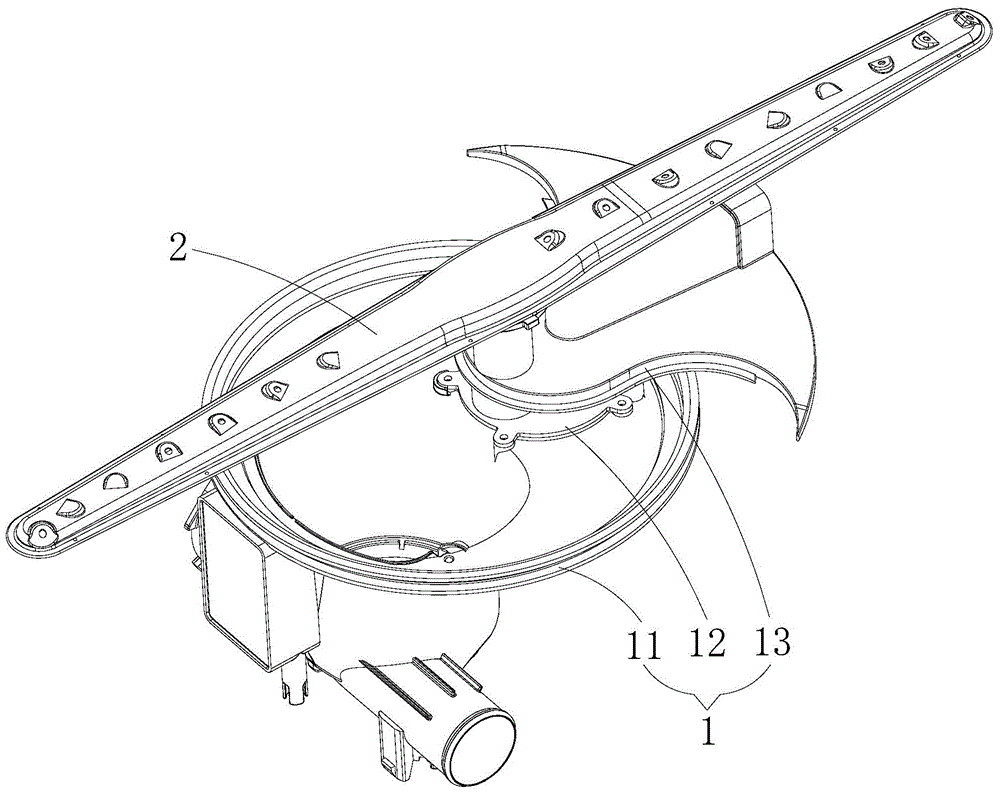

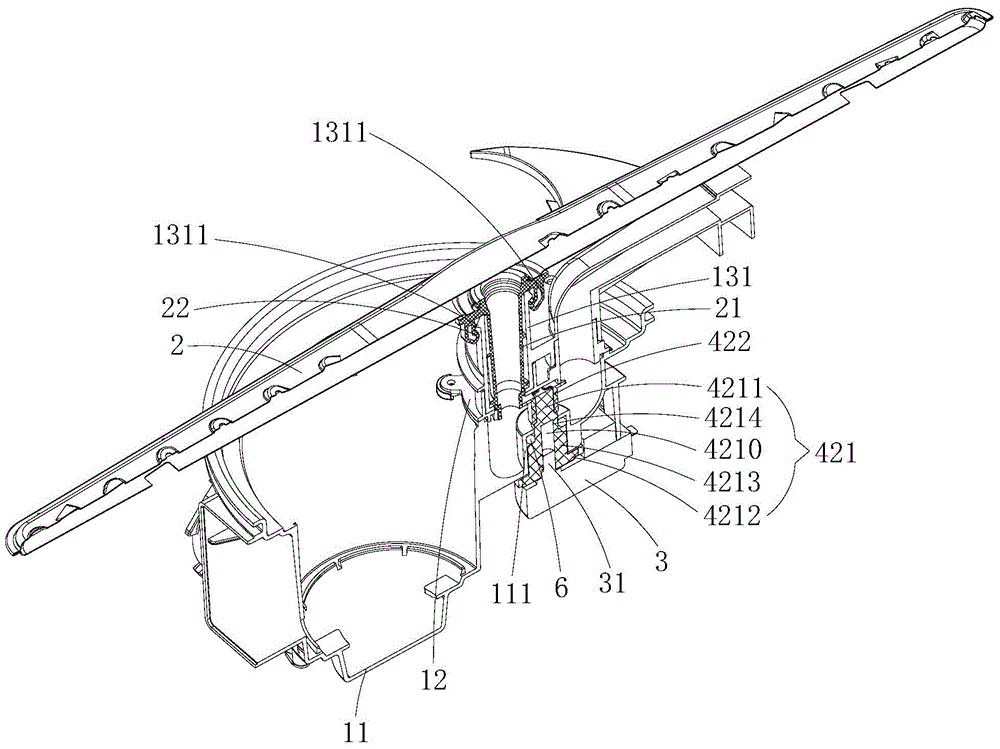

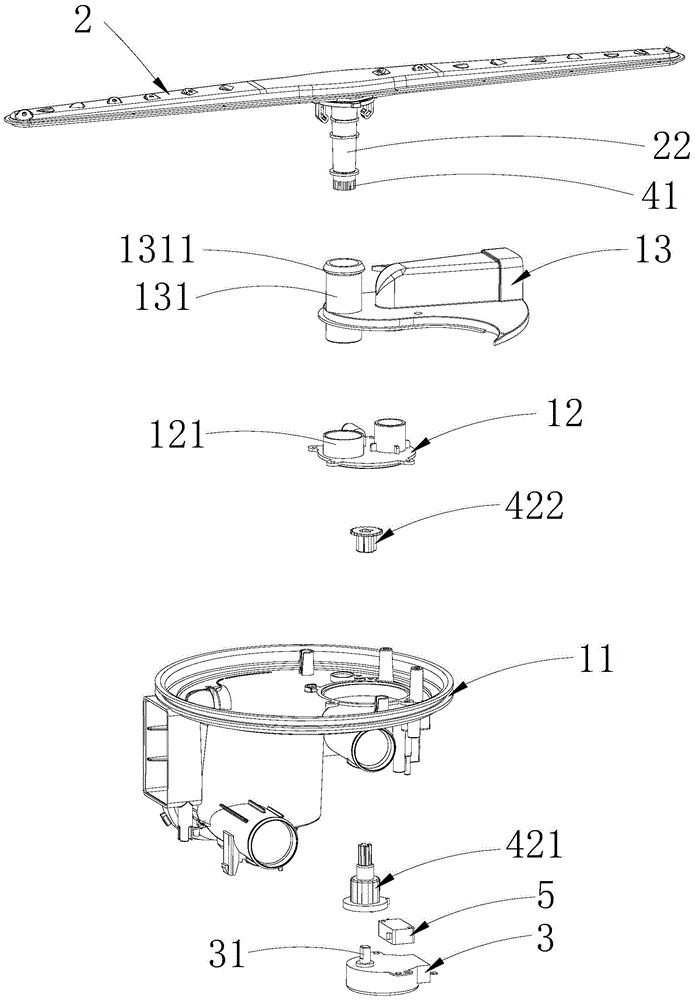

Spraying arm device and dish washing machine

ActiveCN104523208AGuaranteed stabilityImprove controllabilityTableware washing/rinsing machine detailsWater resourcesEngineering

The invention is applicable to the field of dish washing machines and discloses a spraying arm device and a dish washing machine. The spraying arm device comprises a spraying arm base assembly, a motor, a transmission structure and a spraying arm installed on the spraying arm base assembly, wherein a water cavity is formed in the spraying arm base assembly, a first connection pipe is arranged on the spraying arm in a protruding mode, penetrates through the spraying arm assembly and is communicated with the water cavity, the motor is installed on the spraying arm base assembly, and the transmission structure is connected between the first connection pipe and the motor in a transmission mode. Due to the fact that the motor and the transmission structure are matched to drive the spraying arm to rotate, the controllability of the rotational movement of the spraying arm is achieved, the spraying arm can stop at a certain position to perform reinforced washing by controlling starting and stop of the motor in the washing process, tableware which is high in fouling degree and difficult to clean can be subjected to independent prolonged washing, the washing efficiency and the washing effect of the tableware are improved, and electric energy and water resources can be saved easily; meanwhile, due to the fact that driving of the motor is stable, stability of rotation of the spraying arm is guaranteed.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

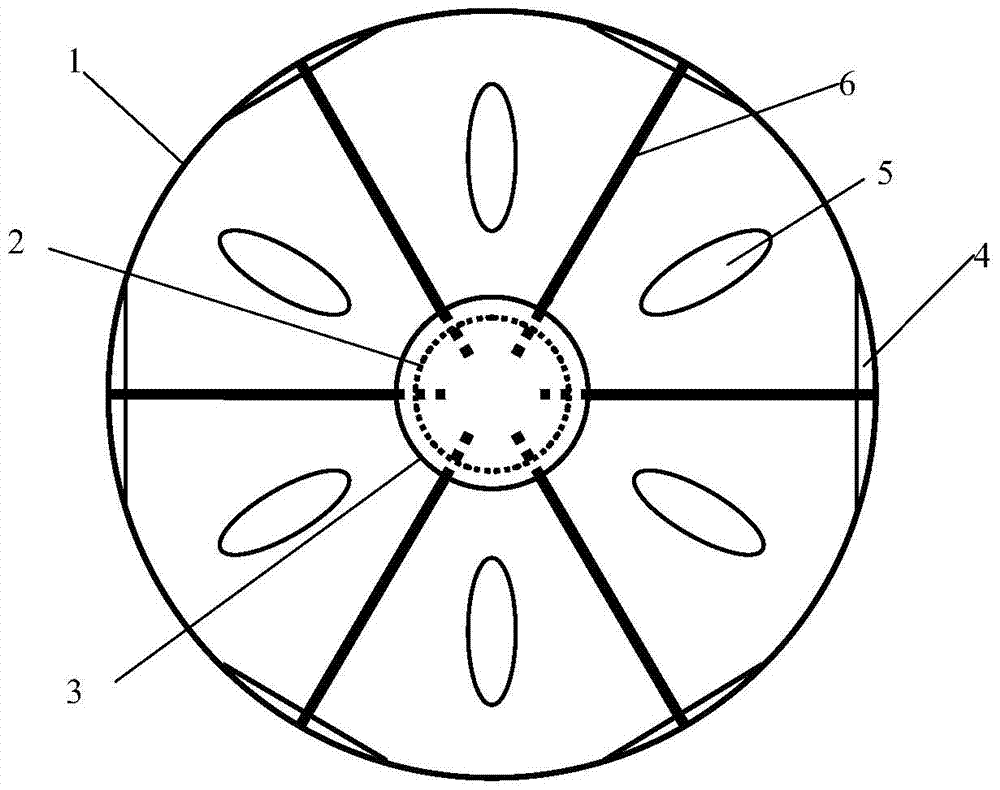

Flapping type washer preventing clothes from intertwining

InactiveCN104278476ACleaning rate and rinse improvementImprove washing effectOther washing machinesWashing machine with receptaclesImpellerMotor drive

The invention discloses a flapping type washer preventing clothes from intertwining and relates to the technical field of electric washer. The washer comprises a wash bucket which is vertically arranged and internally coaxially provided with a cylinder 2 in the fixed manner. A plurality of baffles 6 with holes are vertically arranged between the cylinder 2 and a wash bucket wall 1 along the diameter direction of the wash bucket. The wash bucket is divided into a plurality of wash chambers by the baffles. The clothes are separately placed in the different wash chambers. The inner wall or bottom of the wash bucket is provided with protruded ribs 5. During washing or rinsing, a motor drives the wash bucket to perform forward rotation, pause, reverse rotation and pause in a circulating manner. Thus, the baffles 6 constantly flap the clothes and drive the same to do forward rotation and reverse rotation in the water, and in this way, the clothes are washed cleanly. According to the arrangement, the traditional impeller structure is omitted, and the clothes are separately placed and washed and rinsed without vortex flow; the problem that the clothes are intertwined and extended is solved, and higher washing ratio and better rinsing effect are achieved.

Owner:陈爱文

Transmission mechanism of full-automatic multi-impeller washing machine and washing machine and washing mode thereof

InactiveCN101718030ASolution to short lifeImprove poor operating environmentOther washing machinesWashing machine with receptaclesImpellerVertical plane

The invention provides a transmission mechanism of a full-automatic multi-impeller washing machine and a washing machine and a washing mode thereof, relating to the technical field of washing machines, in particular to an full-automatic multi-impeller washing machine; the transmission mechanism of the full-automatic multi-impeller washing machine is mainly composed of a bevel gear part, all bevel gears of the bevel gear part run in the same spherical surface and are all arranged in a closed transmission box, so as to be separated from washing liquid; when in washing, only the impeller rotate, the shell of the transmission box does not rotate, and when in dehydration, the transmission box and an inner barrel rotate together; the rotating directions of the impellers, including forward rotation and reversal rotation, are different when being looked down from the center of the upper opening of the inner barrel, wherein at least one impeller rotate along the opposite direction with the other impellers; when in washing working condition, the clothes is thrown upwards to the great extent, and is rolled in a vertical plane, and the clothes rotate in a horizontal plane simultaneously; in addition, the different throwing phase positions are changed, so as not to lead the clothes to be twined, greatly improve the washing effect of the washing machine and the working efficiency and save the time and the water consumption.

Owner:NINGGUO JULONG IND

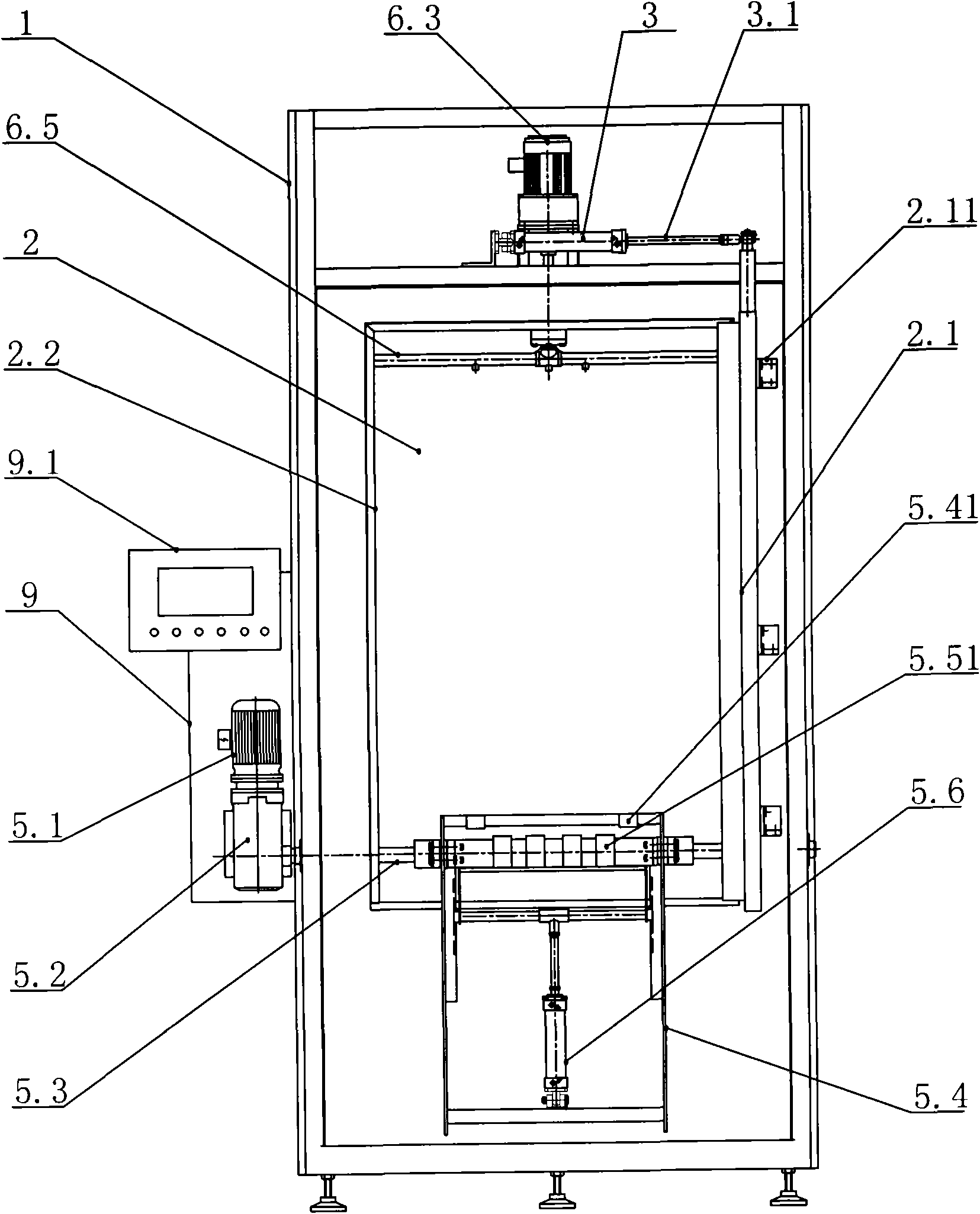

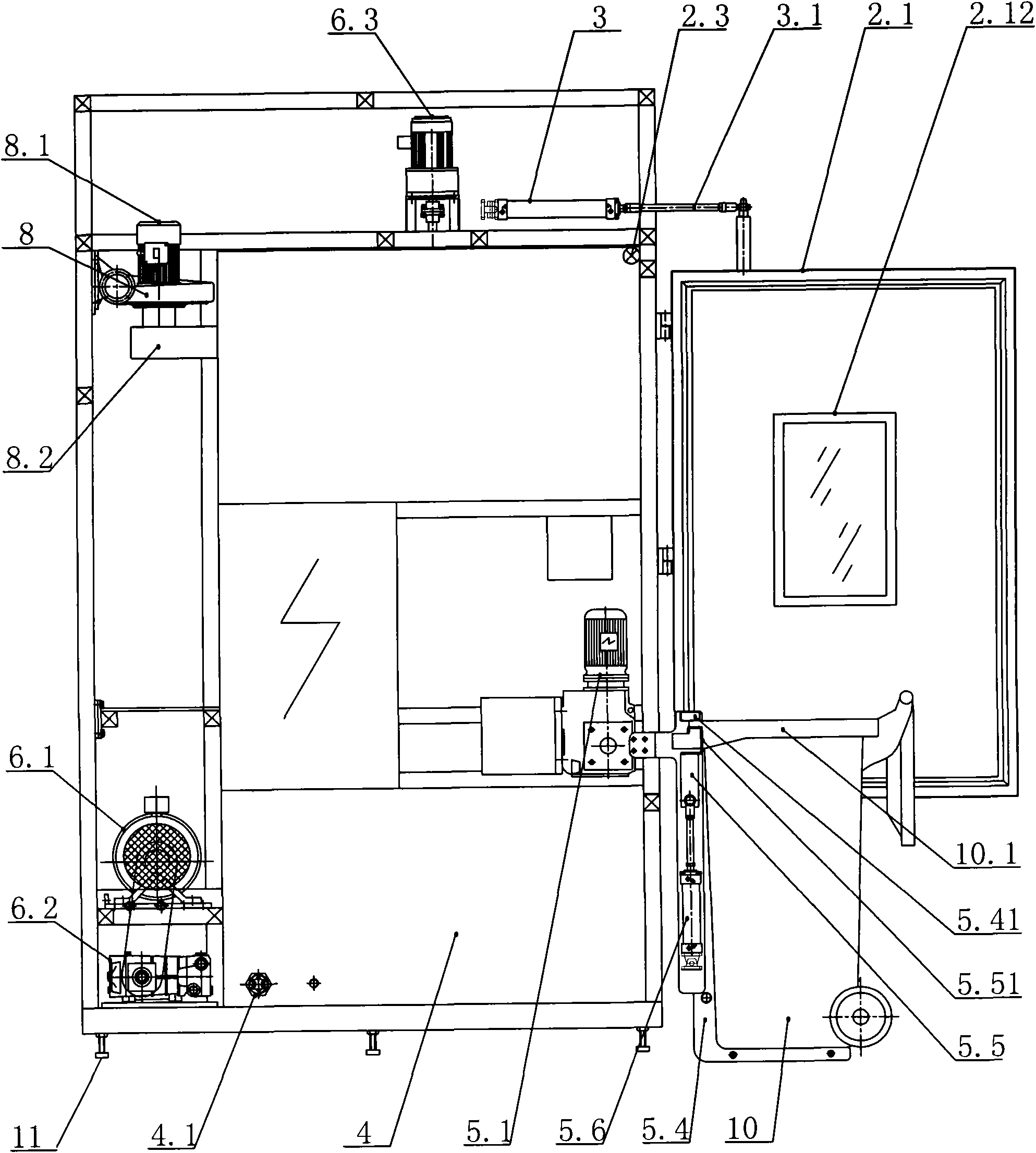

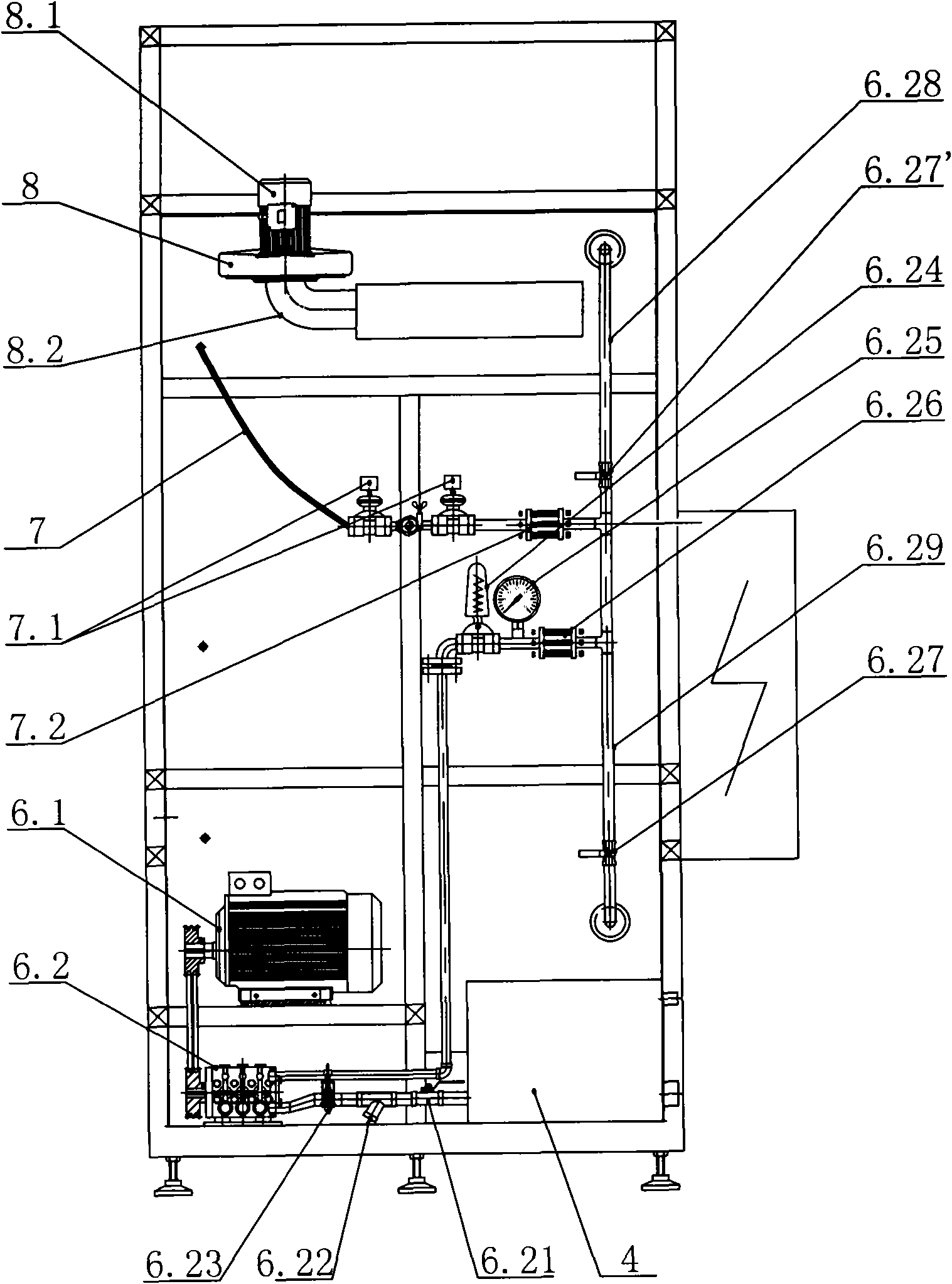

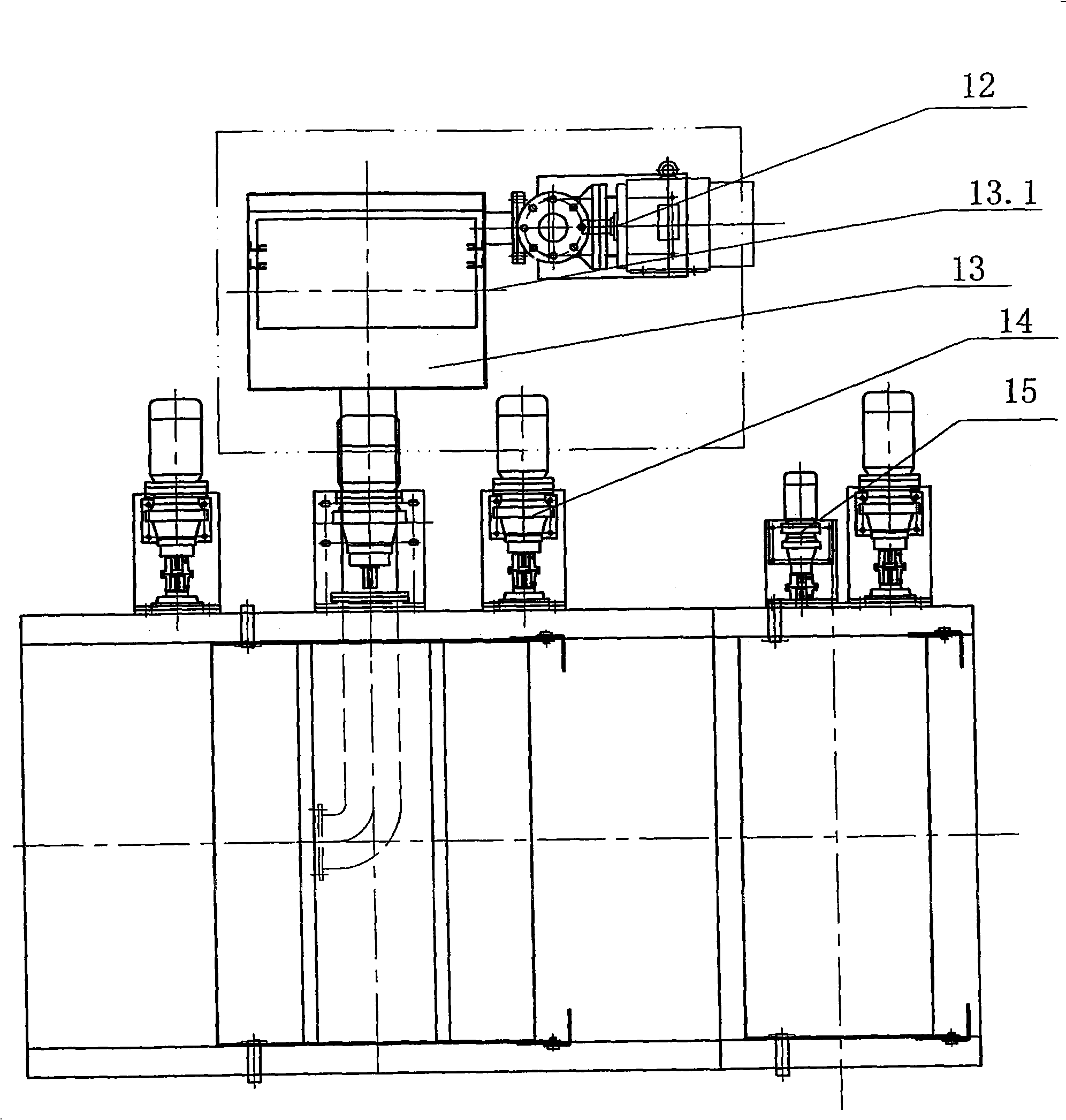

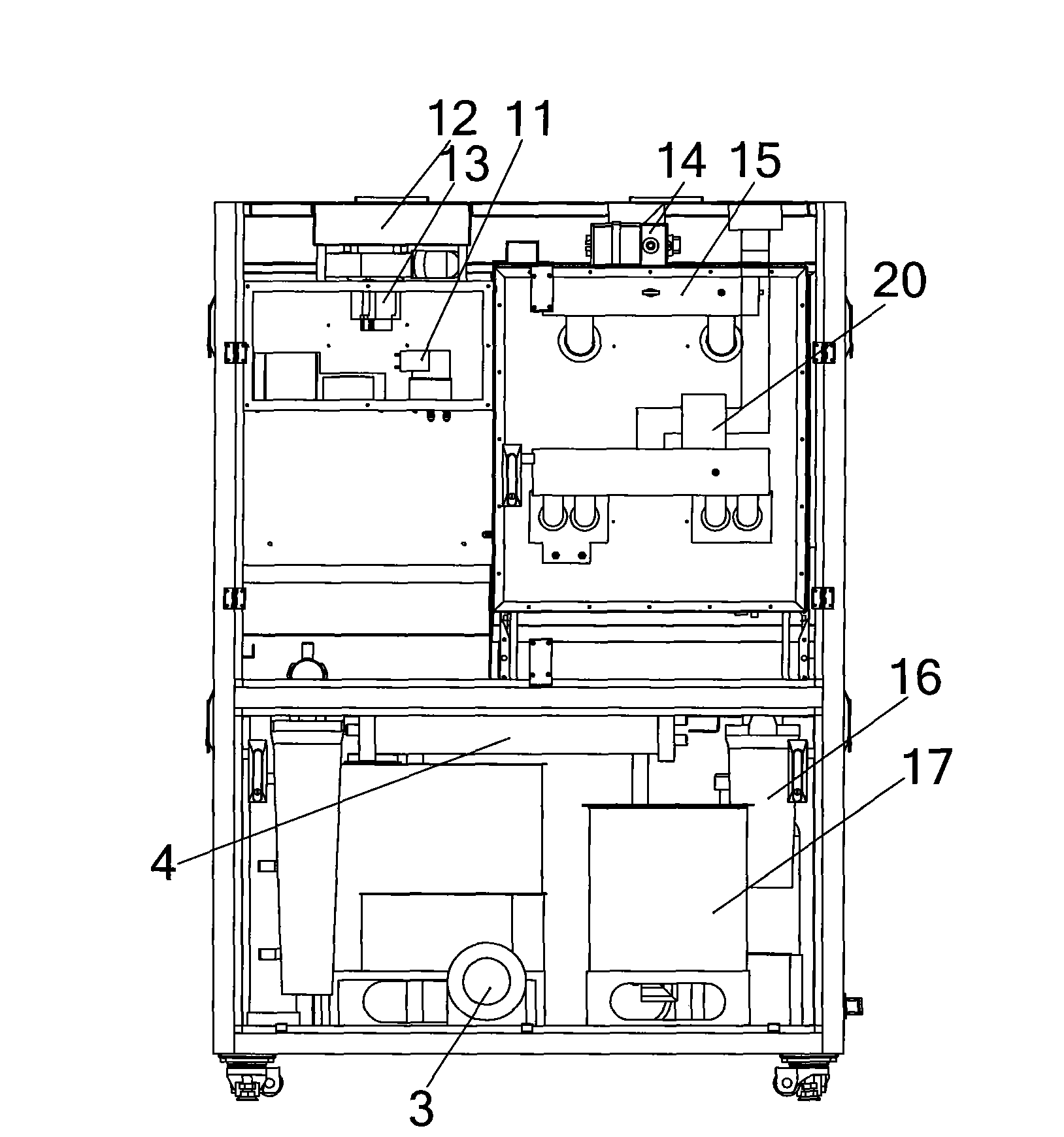

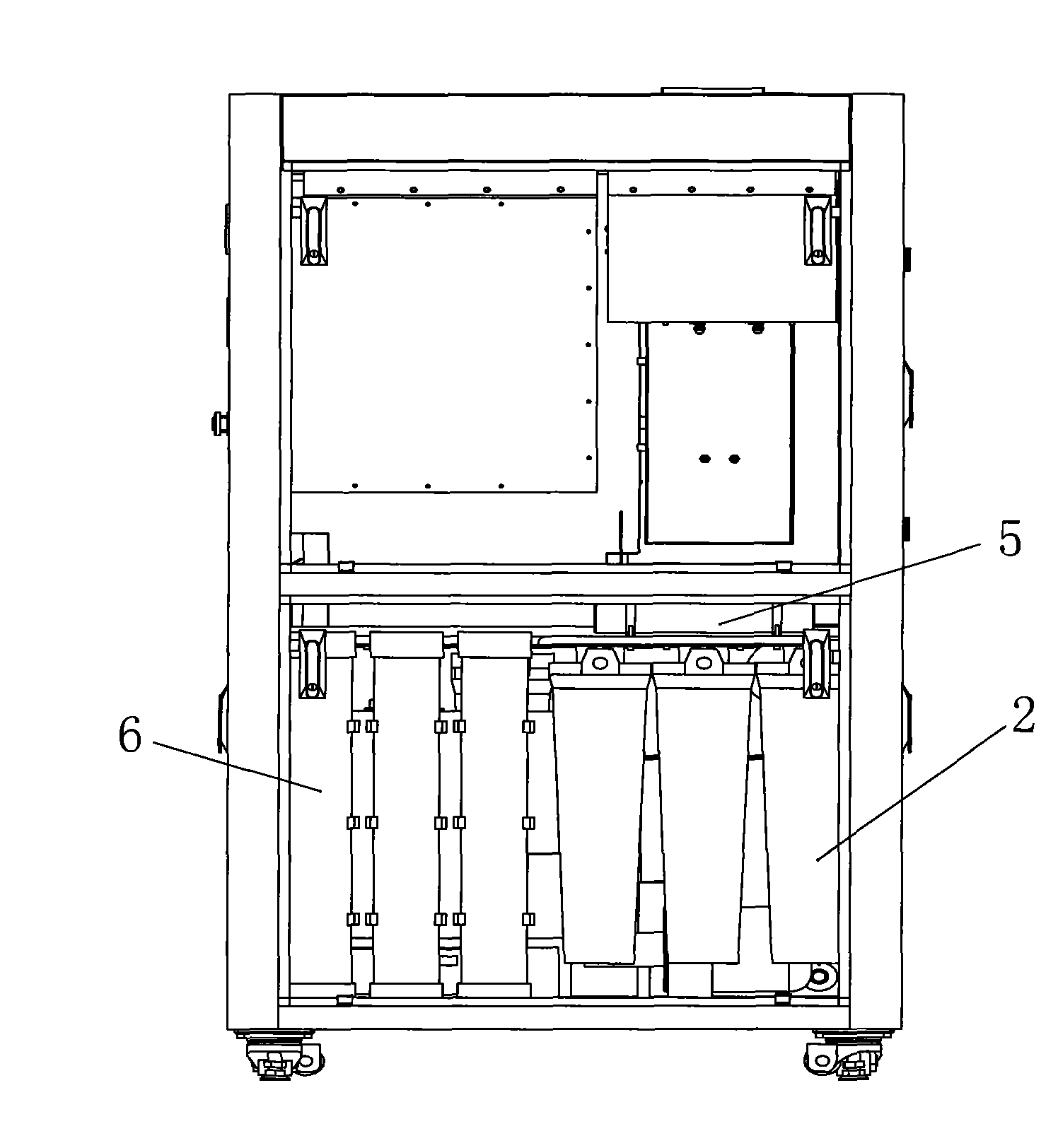

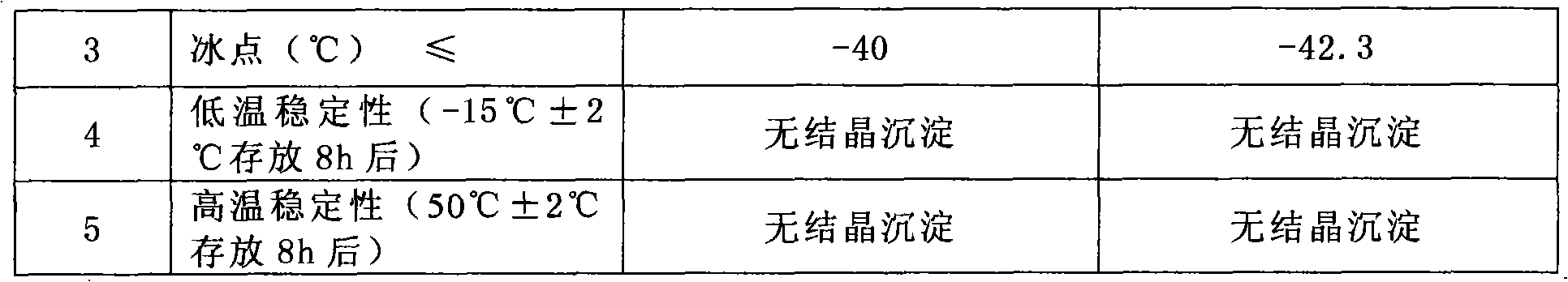

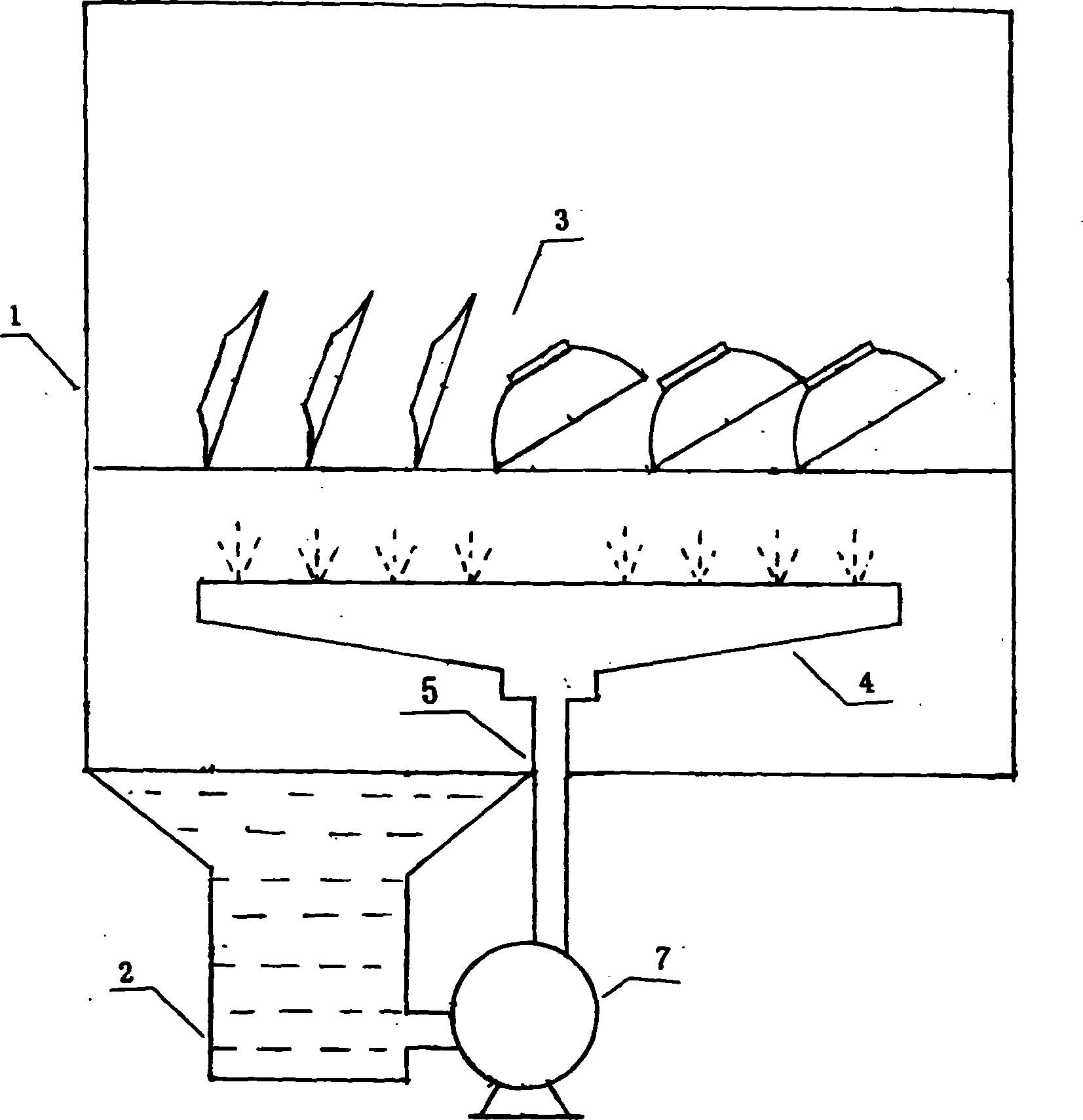

Full-automatic environment-friendly collecting box high-pressure cleaning machine

ActiveCN101972762AReduce lossesImprove washing effectHollow article cleaningSolenoid valveEngineering

The invention discloses a full-automatic environment-friendly collecting box high-pressure cleaning machine and belongs to the technical field of environment-friendly device. The machine comprises a box and a washing chamber, an environment-friendly collecting box holding turning mechanism and a spraying mechanism for cleaning the environment-friendly collecting box which are arranged in the box, wherein the upper part of the box is provided with a mist extracting fan; a sealing door is arranged on the front wall of the washing chamber and a water tank is arranged under the washing chamber; an electric heater and a liquid level controller are mounted in the water tank; an insulating layer is arranged on the outer wall of the water tank; a base plate of the washing chamber is provided with a clean water collecting port; a filter screen is arranged at the clean water collecting port; in the spraying mechanism, a water inlet of a high-pressure plunger pump is connected to the water tank; a water outlet is connected to an upper spraying mechanism and a lower spraying mechanism through a high pressure water pipe; an air inlet pipe communicated with an air supply is arranged in the box; and the air inlet pipe is connected to a water outlet pipe of a water outlet one-way valve after being serially connected to a solenoid valve and an air pipe one-way valve. The high-pressure cleaning machine has good washing effect and low labor intensity and can reuse the clean water.

Owner:HYVA MECHANICS (CHINA) CO LTD

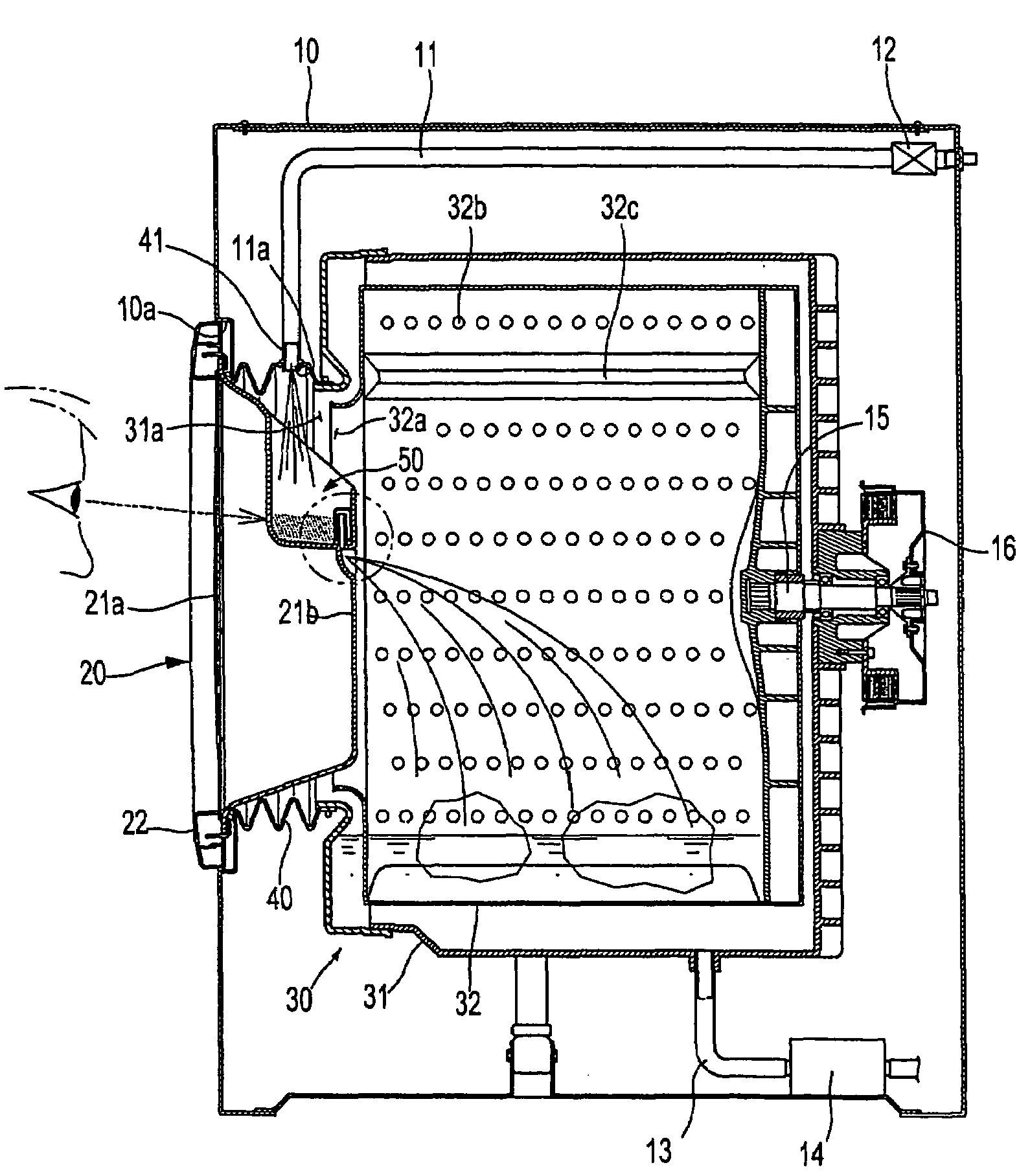

Washing method in steam injection type washing machine

ActiveUS20070169280A1Improve washing effectIncrease temperatureSteam generation heating methodsWashing receptaclesWash waterProcess engineering

A washing method in a steam injection type washing machine in which wash water is heated to generate high temperature and high-pressure steam while passing through the steam supply unit in the wash or rinse cycle, and the generated steam is injected into the wash tub at the top of the wash tub. Accordingly, it is possible to rapidly achieve the wetting of clothes with wash water while achieving an enhancement in sterilization and washing performances. In addition, consumption of water and electrical energy can be reduced.

Owner:LG ELECTRONICS INC

Laundry multi-compartment pouch composition

InactiveUS20100190677A1Improve stabilityImprove bleaching effectOrganic/inorganic per-compounds compounding agentsDetergent materialsSolid componentWater soluble

Laundry multi-compartment pouch made from a water-soluble film and having at least two compartments. The pouch of the present invention comprises a composition containing a solid component and a liquid component, wherein the solid component contains a peroxide source and a mixture of specific polymer.

Owner:THE PROCTER & GAMBLE COMPANY

Ceramic particle with adsorption, ion exchange and negative ion generating functions and preparation method thereof

InactiveCN101885605AMicropores are small and denseGood sintering strengthIon exchangeCeramic particle

The invention discloses a ceramic particle with adsorption, ion exchange and negative ion generating functions. The ceramic particle is prepared by the following raw materials by weight percentage content: 15-35% of natural adsorption material, 10-25% of ion exchange material, 20-45% of natural negative ion releasing material, 1-15% of rare earth material, 0.05-1.5% of radioactivity material, 5-25% of binding material and 2-12% of water. The invention also discloses a preparation method of the ceramic particle. The ceramic particle of the invention has strong adsorption property, good ion exchange property and high negative ion releasing quantity and has good washing, cleaning and purifying capabilities.

Owner:深圳市成为生物科技有限公司

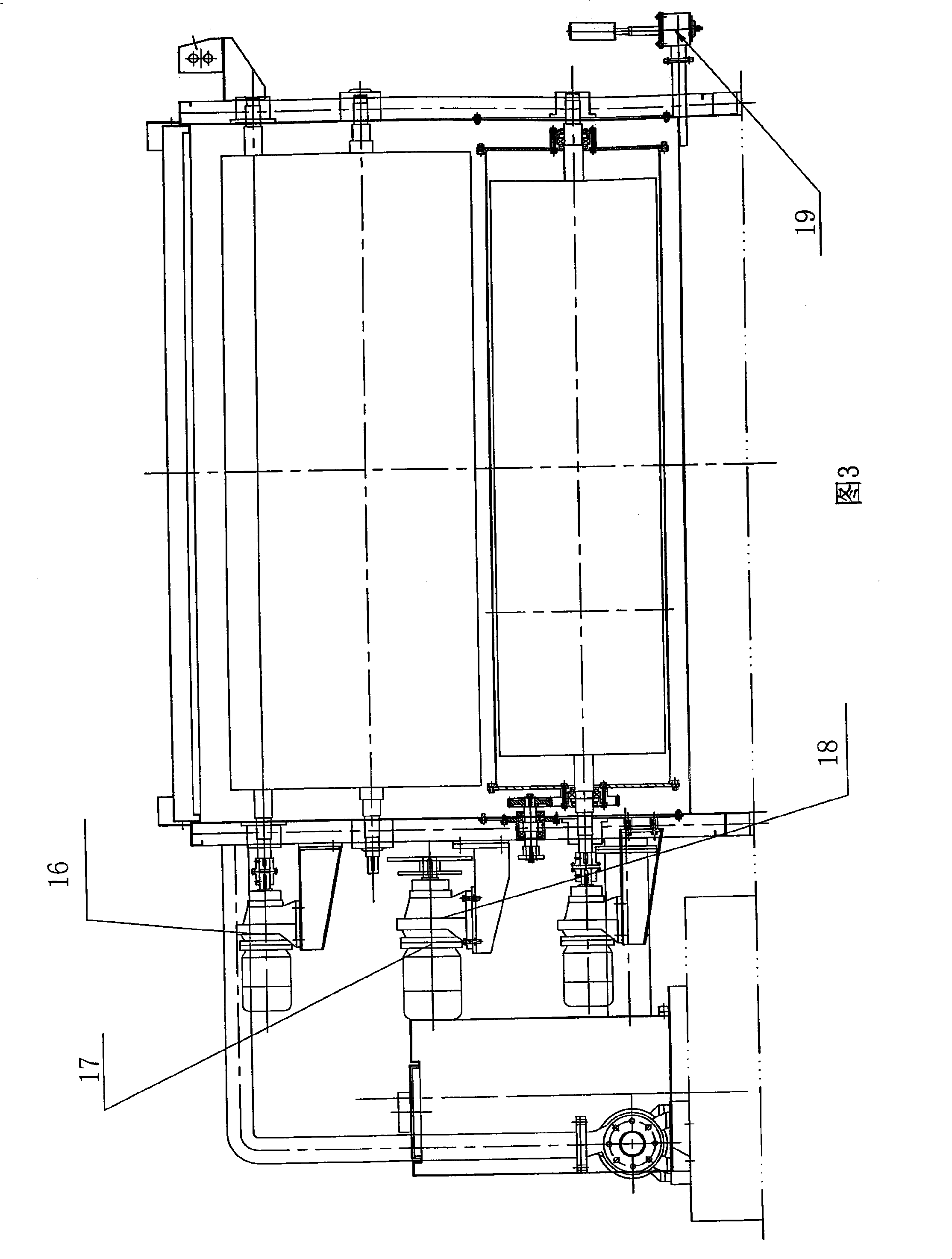

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Printed circuit board cleaning machine

InactiveCN101583246AImprove washing efficiencyGood washing effectWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisElectricityWater saving

The embodiment of the invention provides a printed circuit board cleaning machine, belonging to the technical field of printed circuit cleaning. The cleaning machine comprises a chassis, a master control system, a backing water treatment system, a cleaning system, a drying system, a waste water treatment system and a water detection system; the systems are all arranged in the chassis, the main control system is electrically connected with other systems and controls the operation of other systems; wherein, a water inlet and a water outlet are arranged on the backing water treatment system, the water outlet of the backing water treatment system is connected with the cleaning system, and the water outlet of the cleaning system is connected with the waste water treatment system; the drying system is connected with an air inlet of the cleaning system; the detection ends of the water detection system are respectively arranged on the water outlet ends of the backing water treatment system and the cleaning system, which are used for detecting the effluent water of the backing water treatment system and the cleaning system. The cleaning machine has the advantages of high cleaning efficiency, good cleaning effects, cleaning water saving and environmental protection.

Owner:常州至易环保科技有限公司

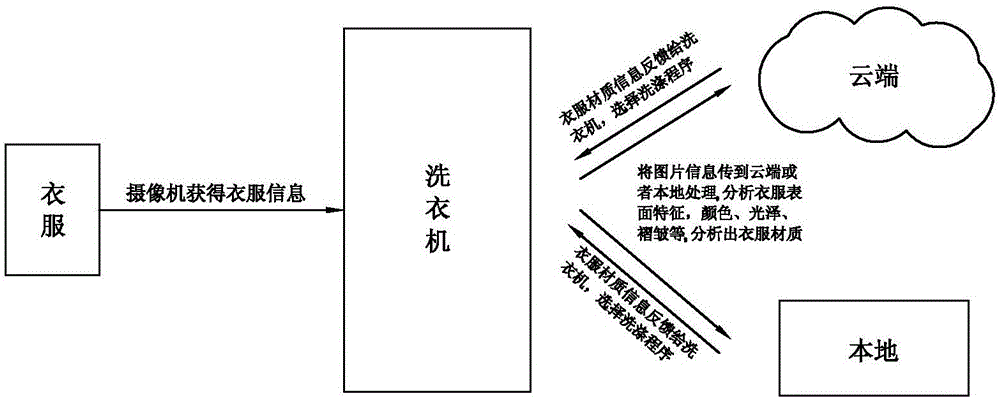

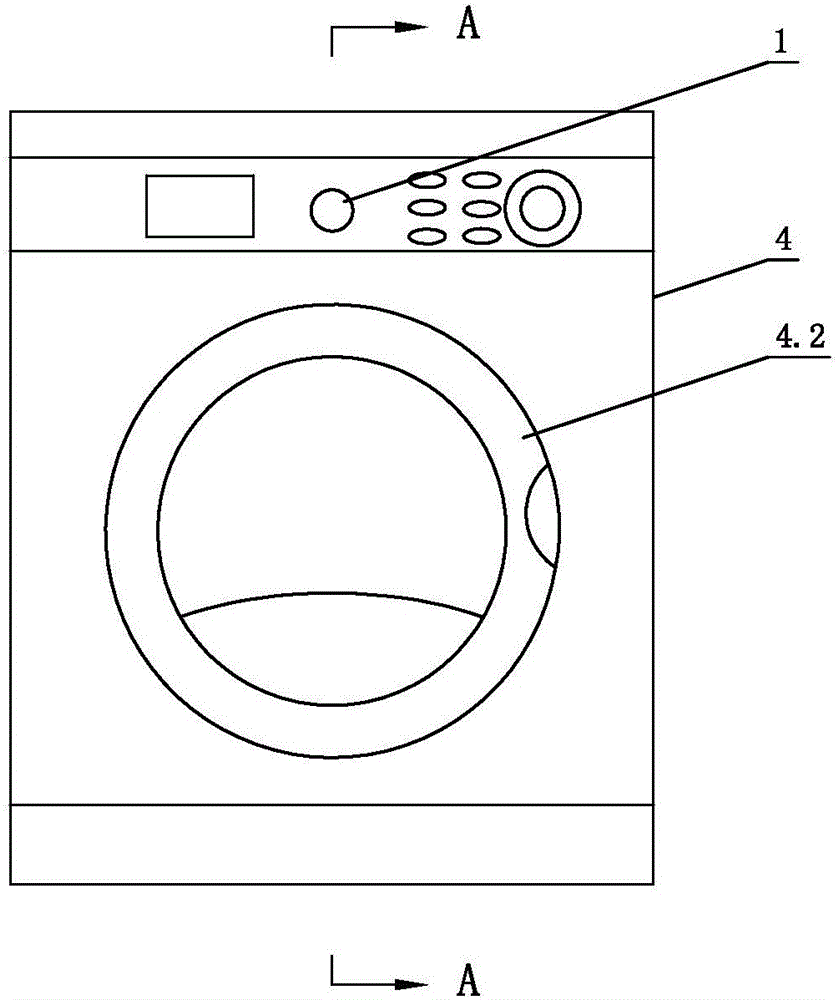

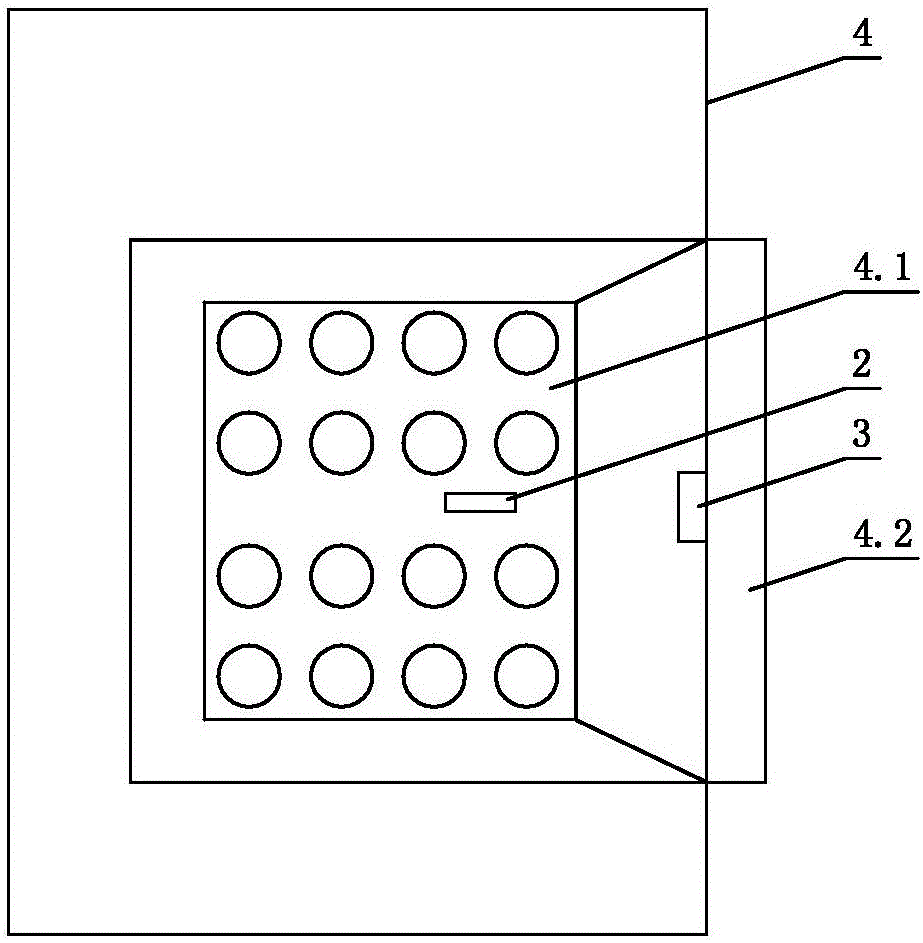

Washing machine having cloth material identification function and control method thereof

InactiveCN106567220AEasy to operateImprove washing effectOther washing machinesControl devices for washing apparatusComputer scienceCloud server

The invention provides a washing machine having a cloth material identification function. The washing machine comprises a host. A camera part used for shooting clothes is arranged on the host. The camera part is connected with a cloud server and / or a local server. A cloth database is arranged on the cloud server and / or a local server. Cloth materials are identified through image recognition, and a voice module is arranged on the host. According to the invention, the camera part is arranged to shoot clothes; materials of the clothes are analyzed through the image recognition technology; and whether the clothes can be washed together is determined and an optimal washing procedure for washing is automatically selected. Compared with a traditional washing machine, the provided washing machine is characterized in that the washing machine is quite convenient to operate without selecting washing procedures by itself, is quite convenient, practical and has good washing effects.

Owner:GUANGDONG GALANZ GRP CO LTD +1

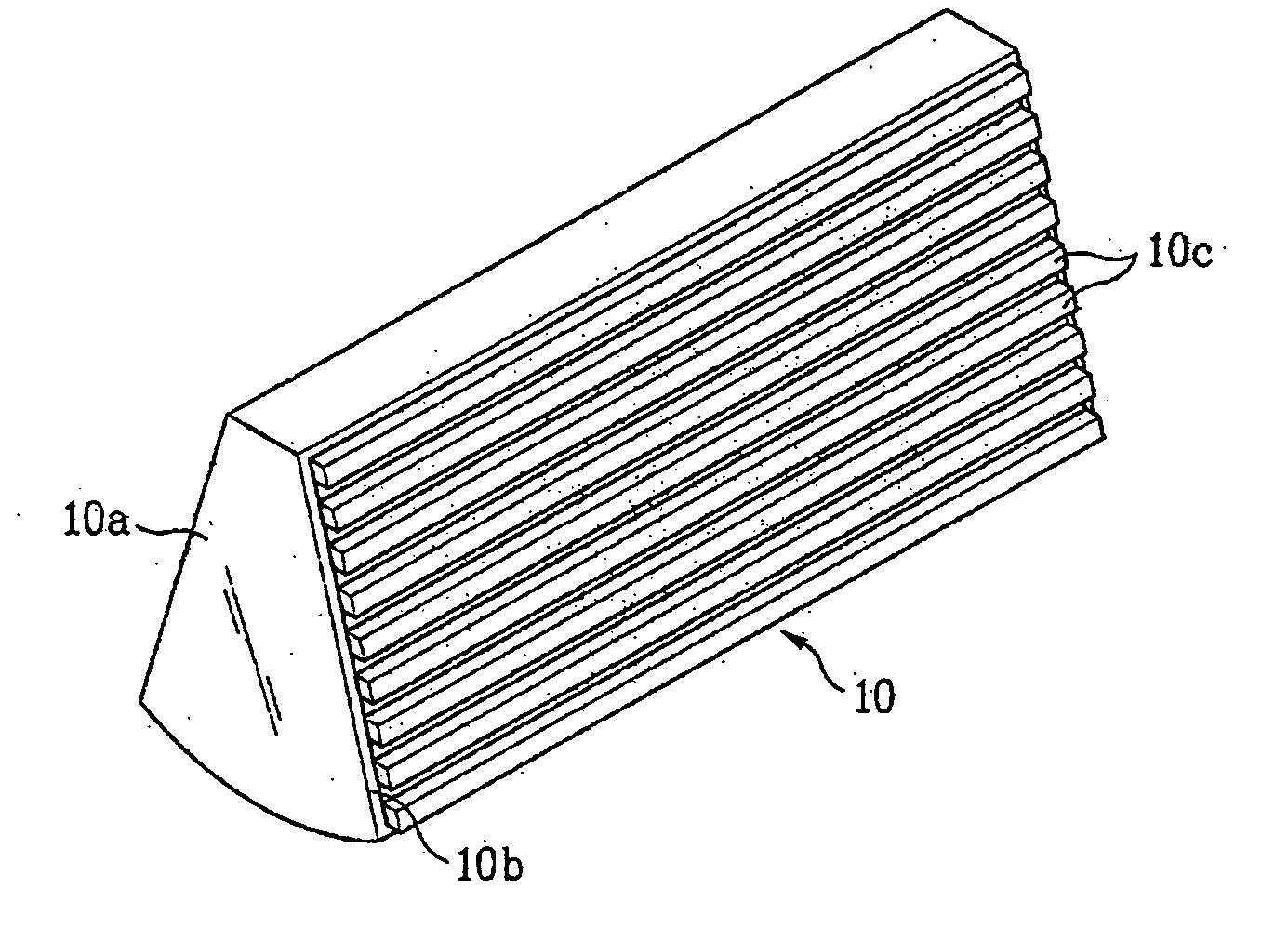

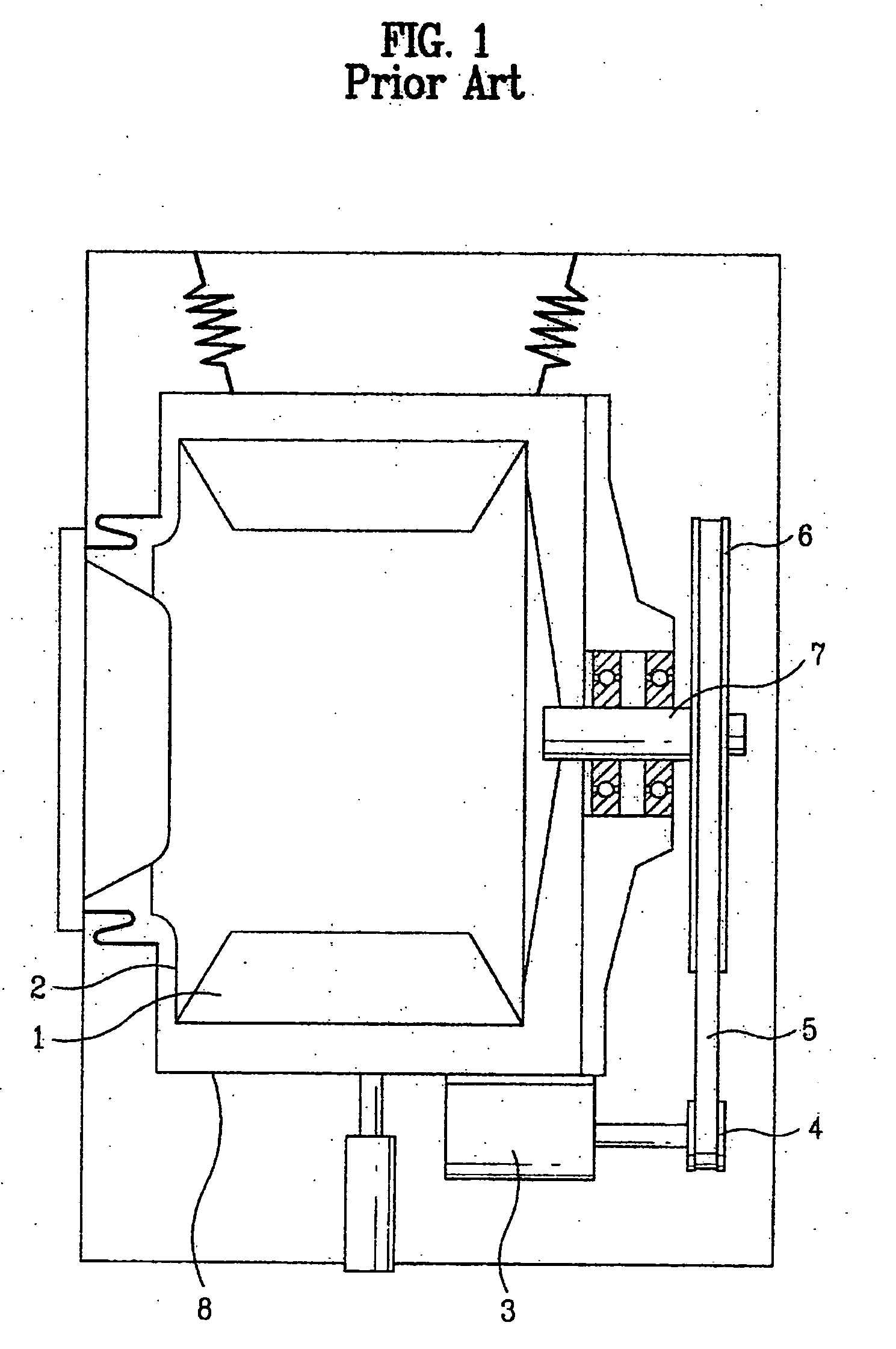

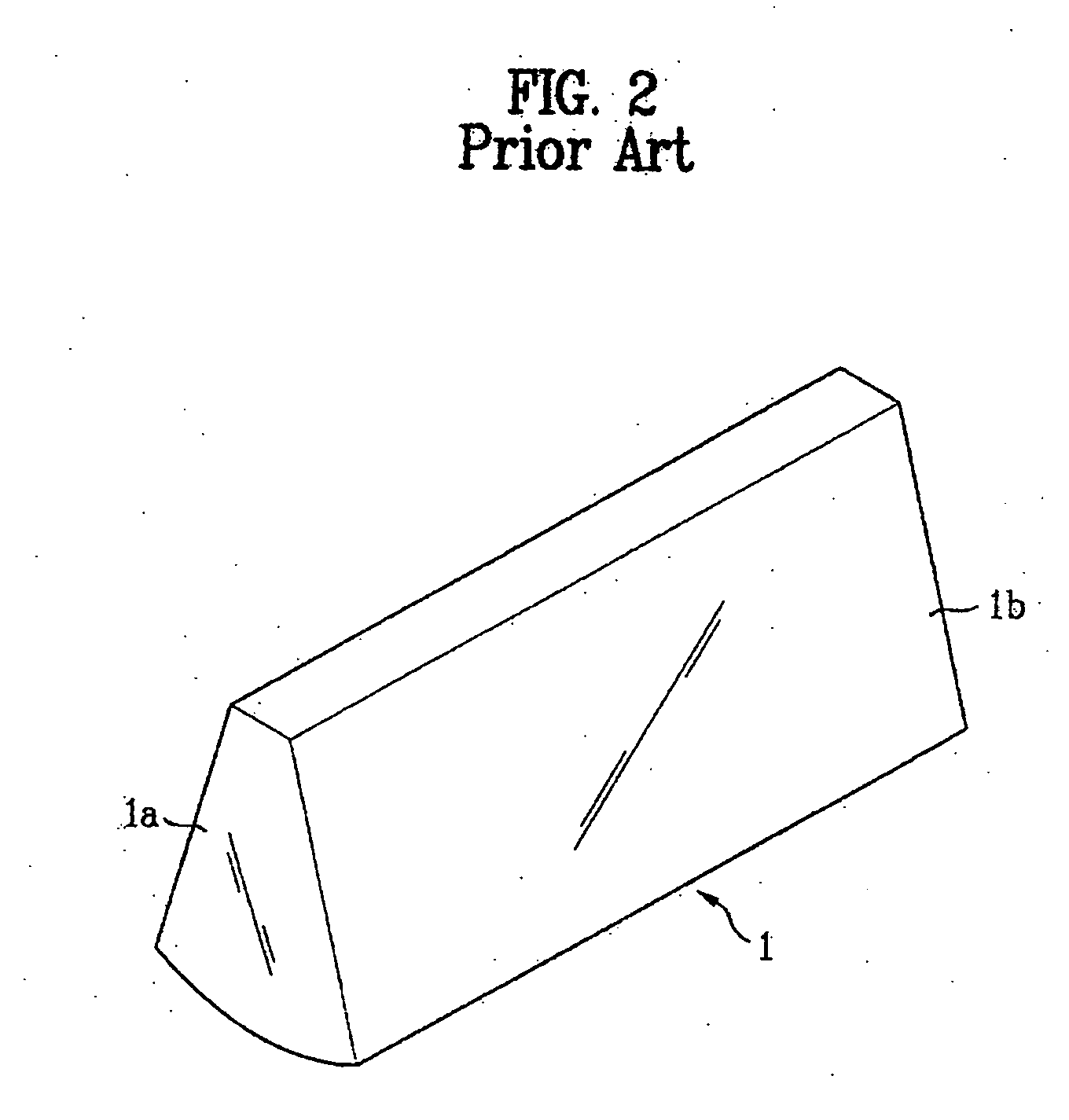

Drum-type washing machine

InactiveUS20050204783A1Increase friction forceImprove washing effectOther washing machinesWashing machine with receptaclesThumb oppositionEngineering

A drum-type washing machine, having a plurality of lifts installed on an inner circumferential surface of a drum, enables improved washing performance by providing friction plates on the inclined sides of each lift to increase a frictional force between the lift and laundry. Each lift includes a pair of inclined sides, disposed in opposition to each other to form a shape having a regular trapezoidal cross-section, for lifting laundry; and a pair of friction plates, consisting of a pair of opposing surfaces respectively provided on each inclined side and having a multitude of protuberances formed on both faces, to increase a frictional force with respect to the laundry.

Owner:LG ELECTRONICS INC

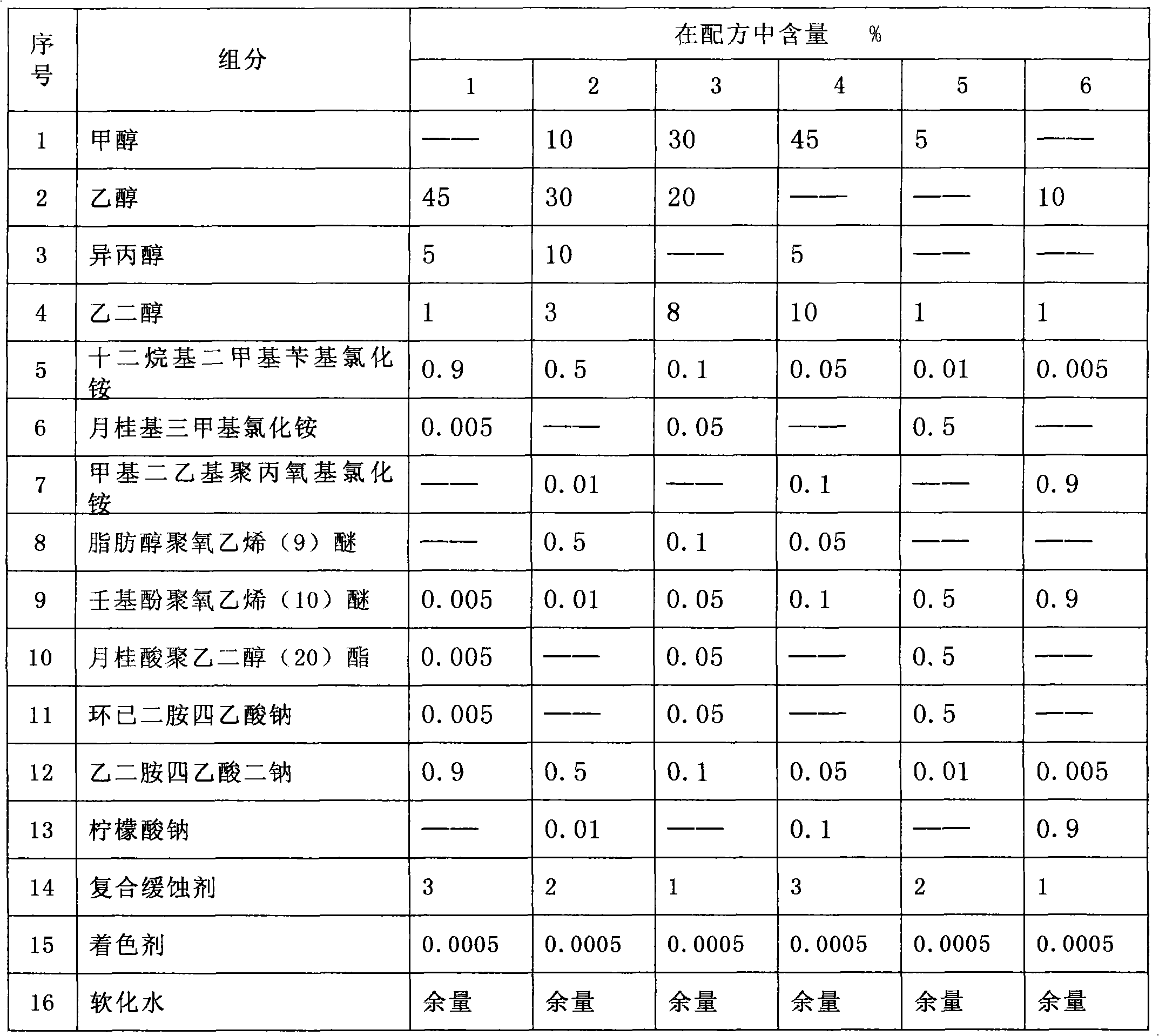

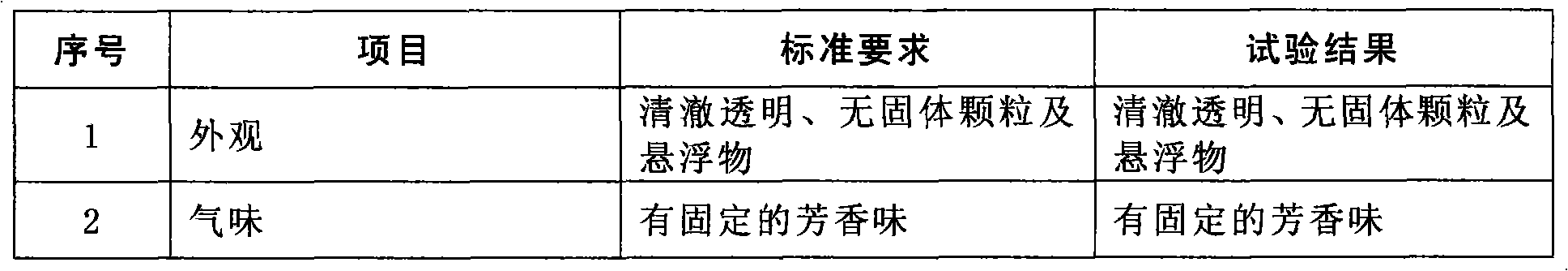

Cleaning agent for automobile windshield

ActiveCN101831360ALow volatilityImprove washing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryNonionic surfactant

The invention relates to a cleaning agent for an automobile windshield, which consists of the following components in percentage by weight: 1 to 50 percent of monobasic alcohol, 1 to 10 percent of ethylene glycol, 0.005 to 0.1 percent of complexing agent, 0.005 to 0.1 percent of cationic surfactant, 0.005 to 0.1 percent of nonionic surfactant, 0.1 to 3 percent of composite corrosion inhibitor, 0.005 to 0.1 percent of colorant and the balance of water. The cleaning agent has cleaning, anti-freezing, anti-fog, anti-corrosion, anti-static, lubricating properties, can effectively remove dust, dirt, spray mark, gum, lac and the like on the windshield, and has high stability of high and low temperature and no damage to the automobile windshield.

Owner:北京蓝星清洗有限公司

A cleaning unit of dish washer

InactiveCN1879547AWidely distributedEven and fast sprayTableware washing/rinsing machinesInjection armEngineering

The invention relates to a washing unit for dish-washing machine. The compressed water by water pump is ejected out through injection nozzle of injection arm to wash dinner service. The air inlet pipe for air compression extends to top of hollow rotation shaft through lower part of hollow rotation shaft. The compressed air enters into air inlet pipe through magnetic valve and is discharged from top of hollow rotation shaft, compressed water confluent at this place and generates a large amount of air bubble. The water mingled with air bubble is ejected out through injection nozzle and spread in fog water at faster speed to wash dinner service. The rotation of injection arm is speeded up, and the washing with fog water is more evenly. Thus the washing effect is improved.

Owner:张英华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com