Patents

Literature

519 results about "Hydrated alumina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

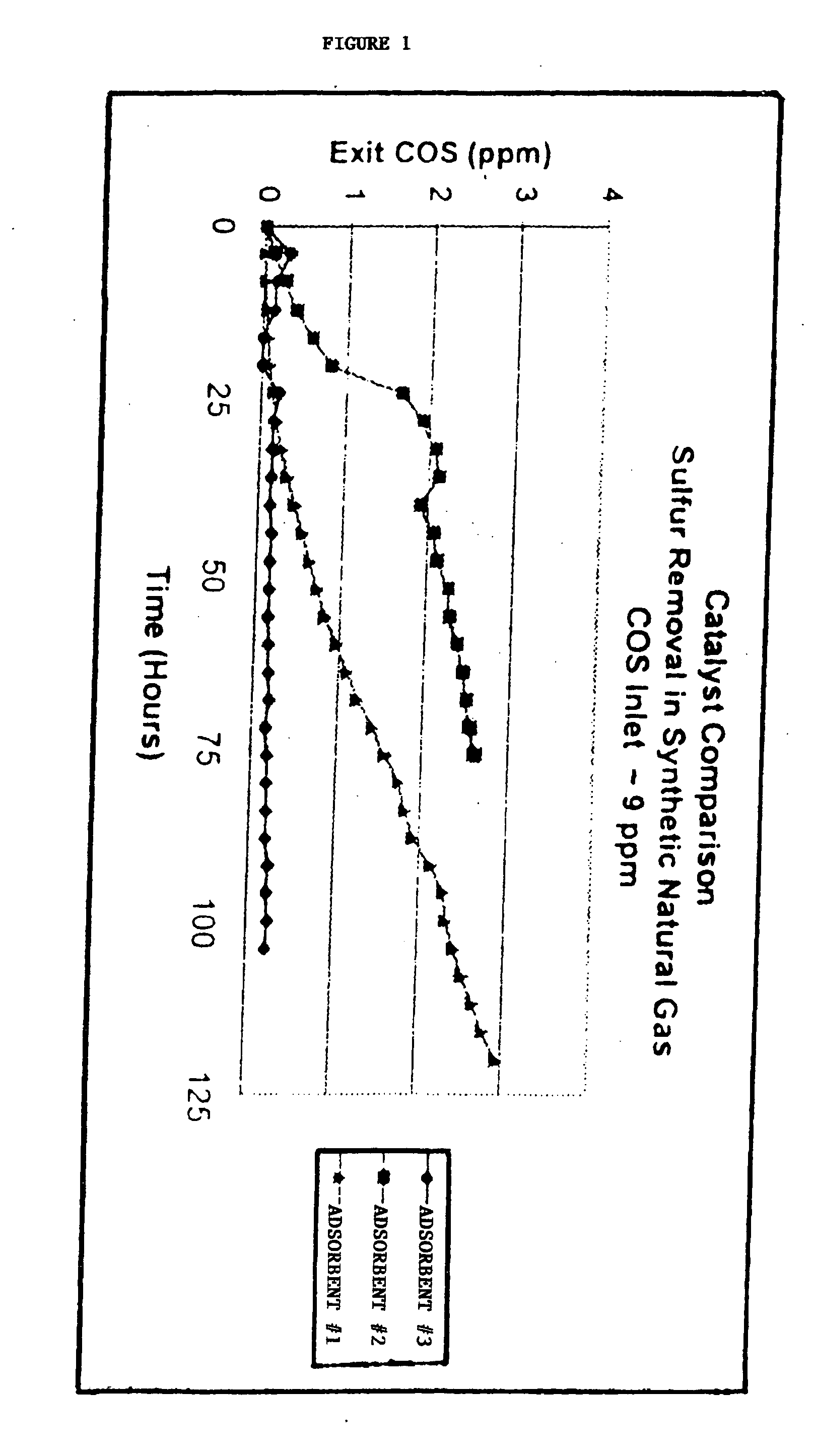

Desulfurization system and method for desulfurizing a fuel stream

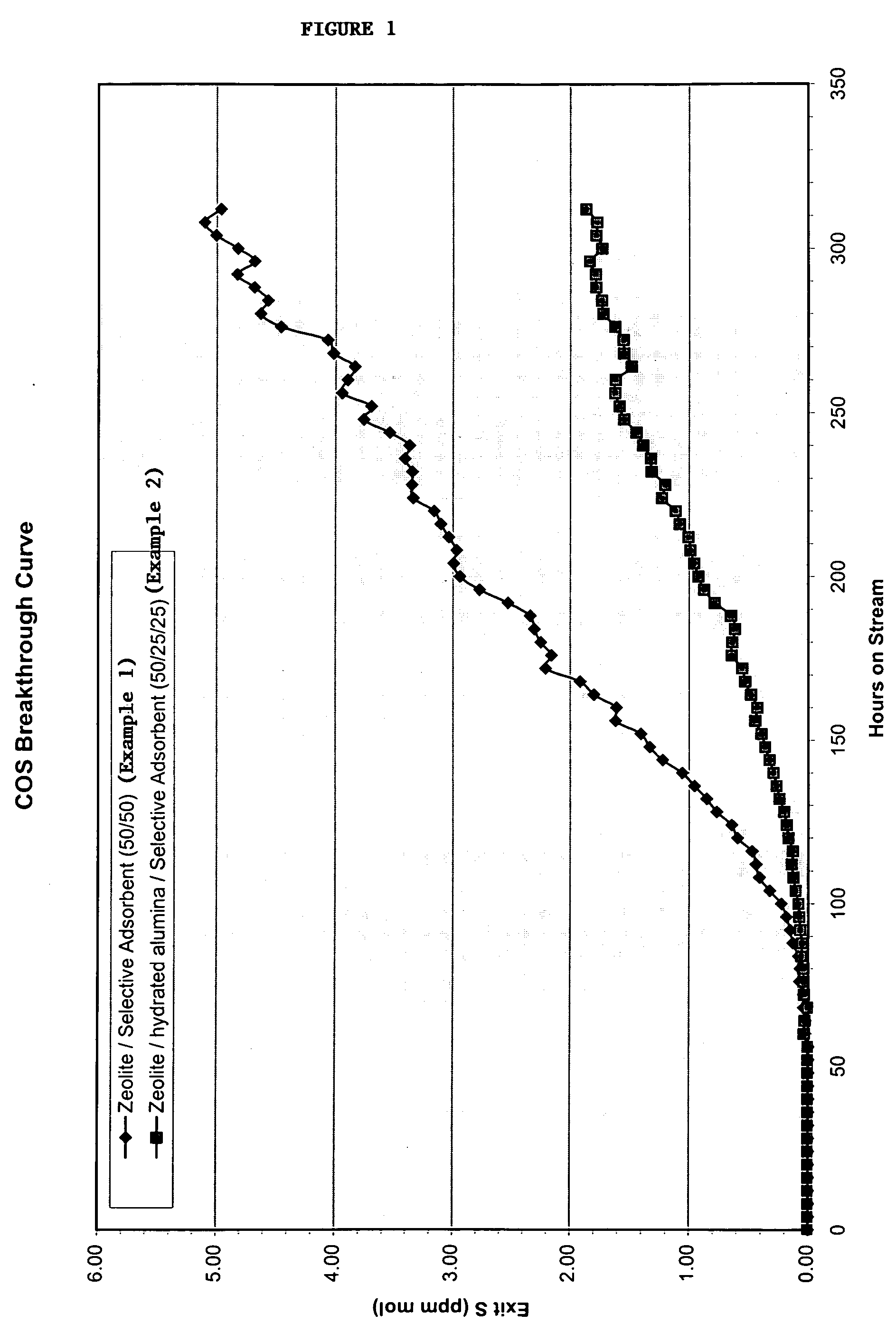

A method for producing a substantially desulfurized hydrocarbon fuel stream at temperatures less than 100° C. including providing a nondesulfurized fuel cell hydrocarbon fuel stream and passing the fuel stream through a sequential sulfur adsorbent system containing calcium exchanged zeolite, hydrated alumina and a selective sulfur adsorbent placed in sequence to produce a substantially desulfurized hydrocarbon fuel stream.

Owner:SUD CHEM INC

Preparation method for aluminum oxide by direct forming method

InactiveCN102923744AReduce drynessReduce stepsAluminium oxide/hydroxide preparationAluminium hydroxide preparationHydrated aluminaAluminium hydroxide

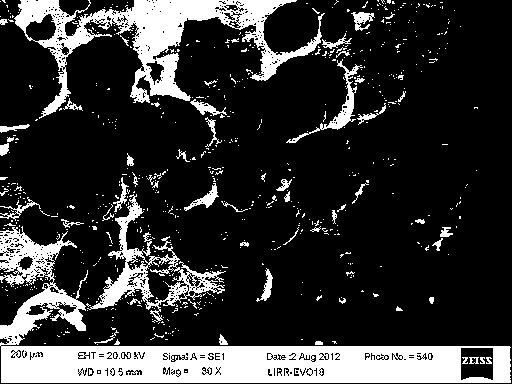

The invention discloses a preparation method for aluminum oxide by a direct forming method. The method is characterized in that the aluminum oxide is directly formed by a wet filter cake, wherein pore volume is 0.3-0.8ml / g; a specific surface area is 150-300 m<2> / g; and crushing strength is 30-120 N / particle; the preparation process comprises the steps: a) meta-aluminate containing aluminum or a strong acid salt compound is neutralized with a precipitator solution at a temperature of 30-80 DEG C and pH of 6-9; accessory ingredient is added in a neutralizing process; mixture is aged for at least 10min after neutralizing; b) prepared aluminium hydroxide gel is washed by de-ionized water for 4-10 times; dosage of the de-ionized water for each time is 10-40 times of mass of a dried substrate of prepared aluminium hydroxide; a hydrated alumina filter cake is obtained after washing and filtering; content of the aluminium hydroxide in the filter cake is controlled to be 5-50%; and c) the accessory ingredient is added into one or various liquid in the step a) and step b); the filter cake after washing is formed by a normal forming method; and the formed filter cake is dried at a temperature of 80-120 DEG C and calcined at a temperature of 450-1000 DEG C to obtain a finished product of the aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

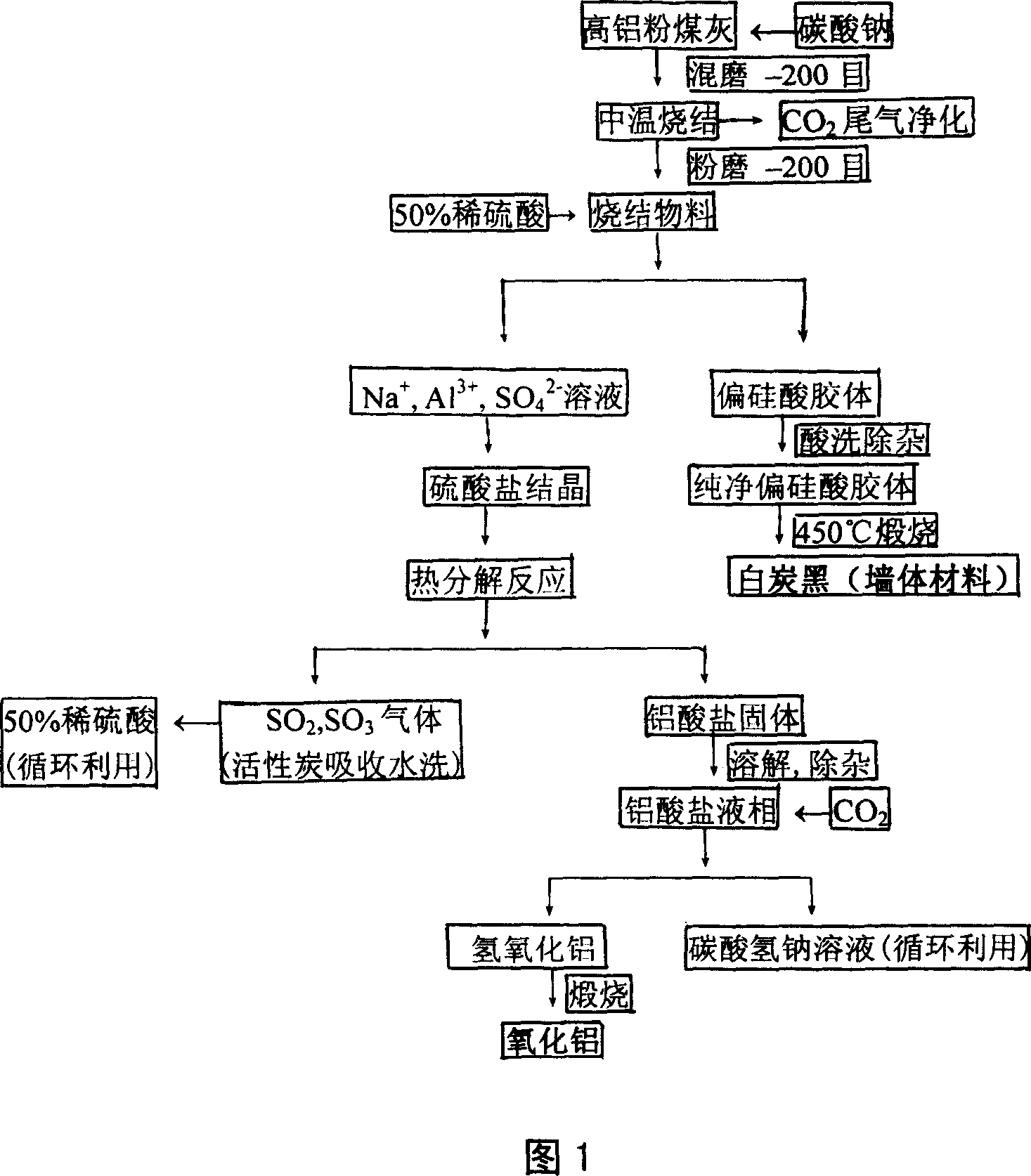

Clean production technique for preparation of aluminium oxide and white carbon black by using high-alumina coal ash

InactiveCN101041450ATake advantage ofWide variety of sourcesSilicon oxidesAluminium oxides/hydroxidesSodium bicarbonateSilica gel

The invention discloses a clean producing craft of aluminum oxide and white carbon black comprehensively with high-alumina coal ash, which comprises the following steps: making sodium carbonate as raw material; disintegrating high-alumina coal ash under medium-temperature; generating acid dissoluble aluminosilicate materials; using dilute sulphuric acid to acid dip; separating aluminum oxide and silica in the high-alumina coal ash; further treating aluminous liquid part; generating hydrated alumina deposition; finishing gamma-alumina or alpha- alumina product through calcining; washing, purifying, drying; calcining the silica gel part; getting white carbon black, silica aerogel, ultra-fine silica, porous silica and so on inorganic silicide.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Multiple element composite metal oxidate arsenic removal settling agent and use method thereof

The invention belongs to the material field for removing the arsenic in water by settlement, more particularly relates to polyelement composite metal oxide arsenic removal settlement agent and an application method thereof based on iron oxide, manganese oxide, and aluminum oxide. The invention uses an ectopic preparation method or situ preparation method for preparing and obtaining polyelement composite metal oxide arsenic removal settlement agent which comprises hydrated iron oxide, hydroxyl-hydrated ferric hydroxide, hydrated aluminum oxide, hydroxyl-hydrated alumina, hydrated manganese oxide and the like. The polyelement composite metal oxide arsenic removal settlement agent can be used for removing the arsenic pollutants in water bodies such as lakes, reservoirs, rivers, groundwater, drinking water, industrial waste water, and the like; in addition, the settlement agent can also be used for removing the heavy metals such as copper, chromium, cadmium, lead, and the like, and the pollutants such as iron, manganese, phosphates, and the like in water by settlement.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

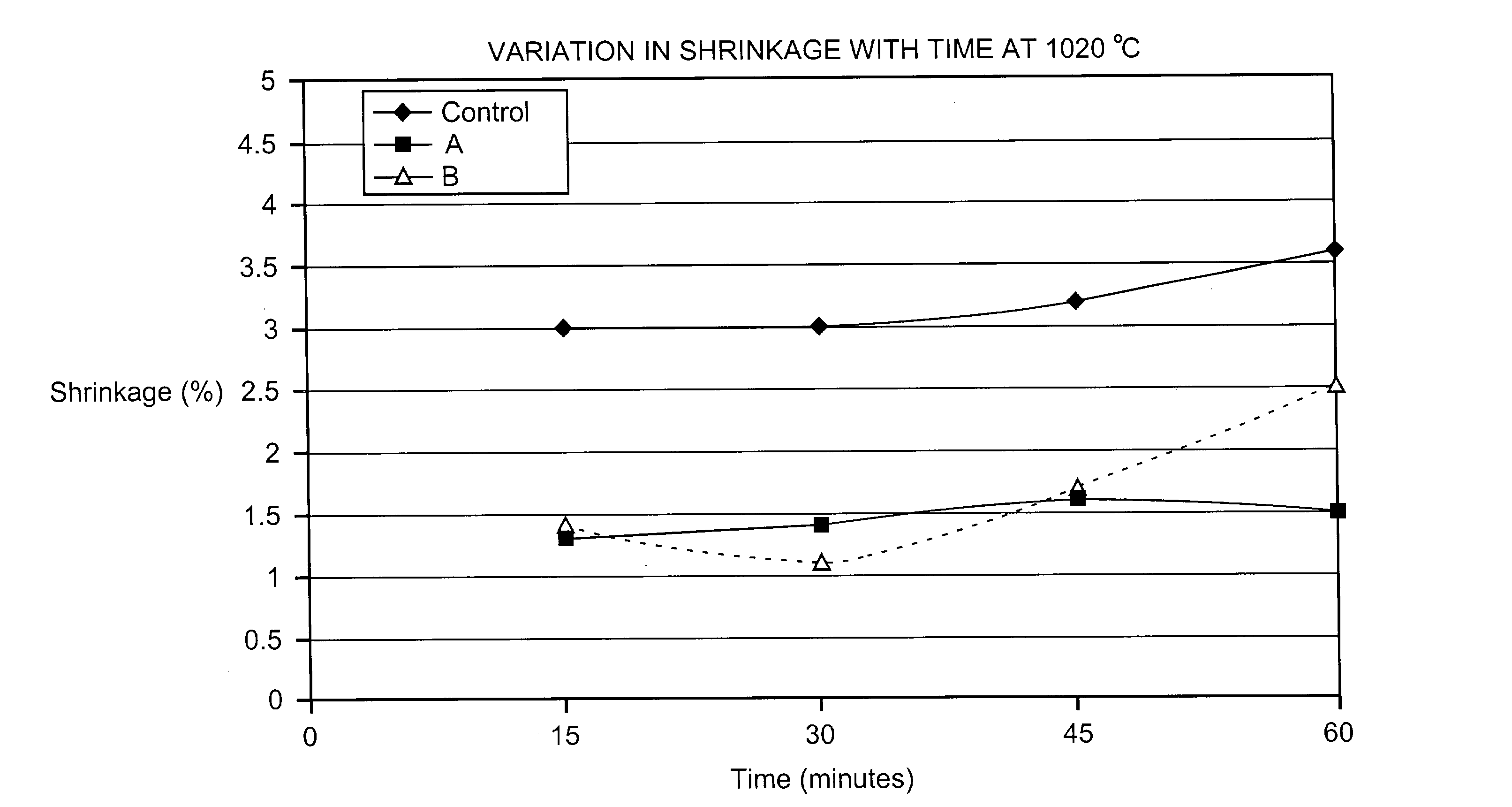

Plasterboard composition, preparation of this composition and manufacture of plasterboards

A plasterboard composition includes from 55 to 92% of hydratable calcium sulphate; from 0.1 to 5% of mineral and / or refractory fibres; from 3 to 25% of a mineral additive; from 1 to 5% of unexpanded vermiculite; and from 3 to 15% of hydrated alumina.

Owner:LAFARGE PALTRES SA

Titanium dioxide pigment and its preparing method

ActiveCN1775869AIncreased durabilityExcellent optical propertiesInorganic pigment treatmentOptical propertyHydrated alumina

The invention relates to titanium dioxide paint and the method to manufacture that belongs to the improvement of durability and optical properties for titanium dioxide. The titanium dioxide paint includes rutile type or anatase type titanium dioxide particle that includes zirconia, amorphous silica and hydrated alumina coating. Moreover, it has organic coating absorbed or bonding on it.

Owner:ANHUI JXTB GRP

Separators for electrochemical cells

ActiveUS8883354B2High strengthIncrease flexibilityPrimary cellsElectrode carriers/collectorsPseudoboehmiteHydrated alumina

Provided are separators for use in an electrochemical cell comprising (a) an inorganic oxide and (b) an organic polymer, wherein the inorganic oxide comprises organic substituents. Preferably, the inorganic oxide comprises an hydrated aluminum oxide of the formula Al2O3.xH2O, wherein x is less than 1.0, and wherein the hydrated aluminum oxide comprises organic substituents, preferably comprising a reaction product of a multifunctional monomer and / or organic carbonate with an aluminum oxide, such as pseudo-boehmite and an aluminum oxide. Also provided are electrochemical cells comprising such separators.

Owner:LG ENERGY SOLUTION LTD

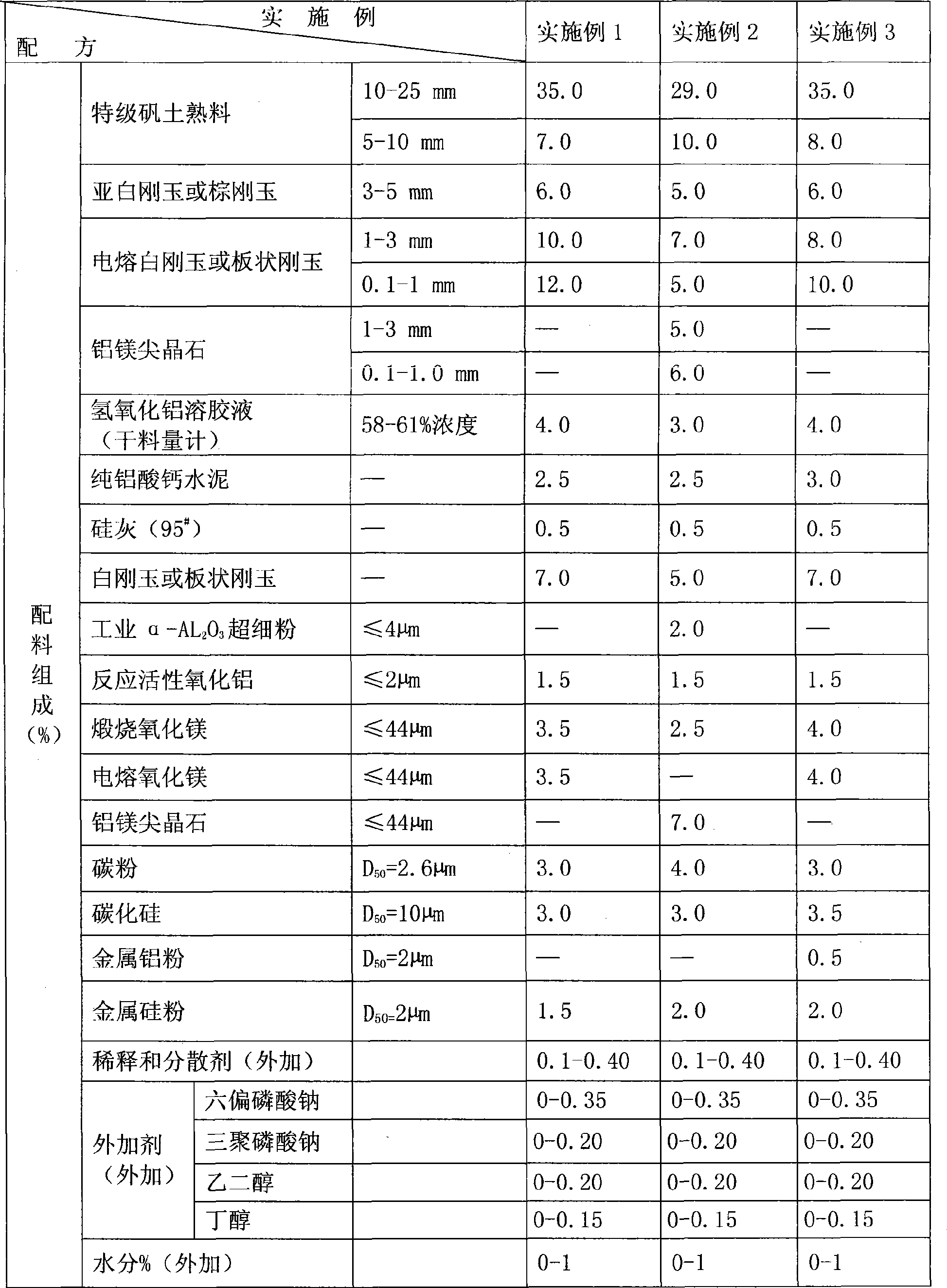

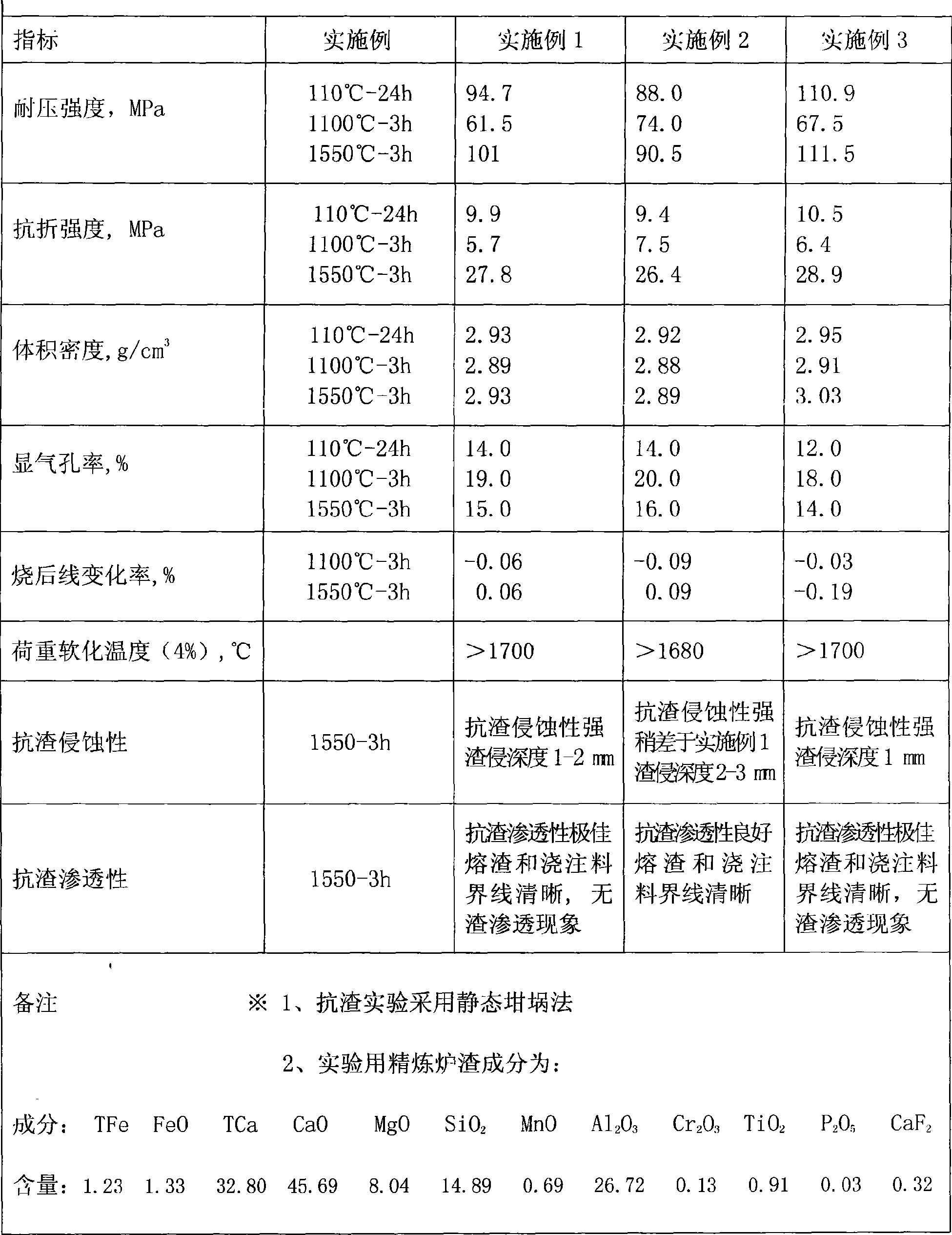

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

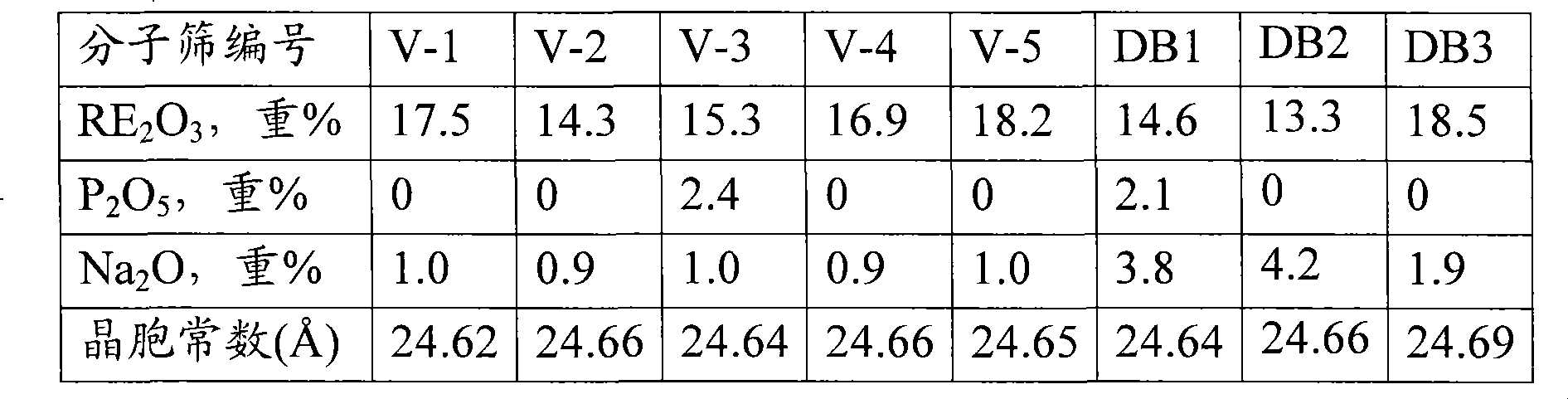

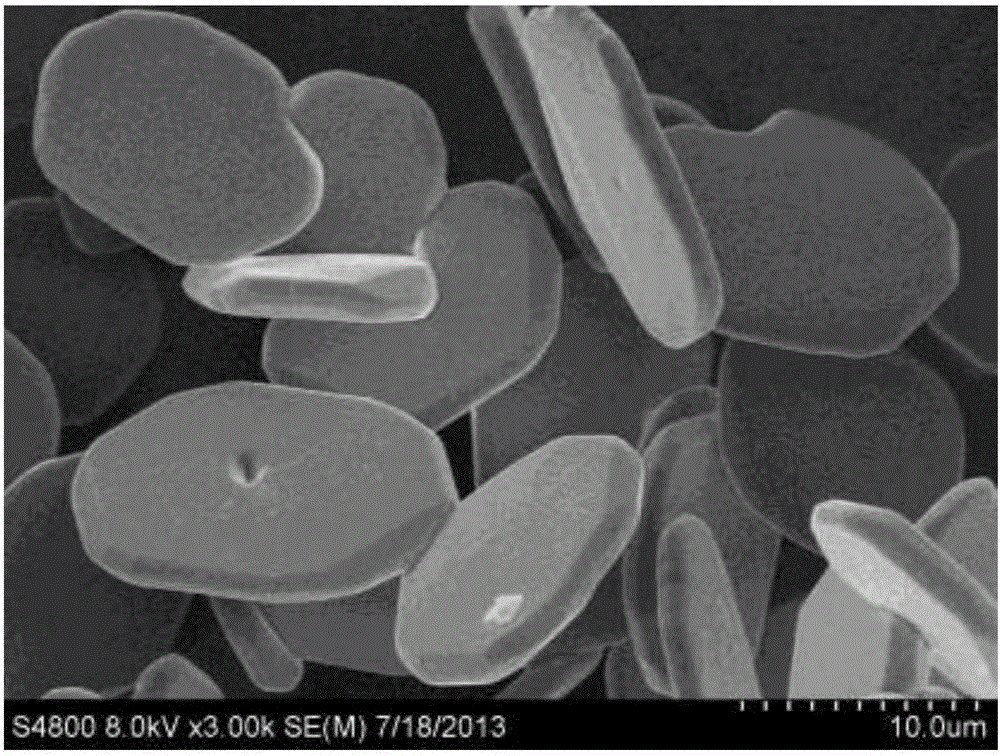

Hydrated alumina with structure of similar to thin diaspore of containing additive

ActiveCN1915486AHigh conversion capacity of heavy oilHigh yieldCatalyst activation/preparationAlkaline earth metalHydrated alumina

A hydrated alumina containing additive (0.5-40 Wt %) and with alpha-AlO (OH) structure for preparing the catalyst used for catalytic cracking reaction. Said additive is chosen from RE metal, La-family metal, Si, Ga, B and P. Its preparing process includes such steps as mixing alpha-AlO (OH) with H2O and acid while stirring, ageing, and mixing with additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pouring material for steel ladle

InactiveCN101891485AExtended service lifeImprove anti-stick performanceMelt-holding vesselsSlagSilicon dioxide

The invention discloses a pouring material for a steel ladle. The pouring material consists of the following components in part by weight: 40 to 75 parts of alumina-magnesia spinel (between 25 and 0.074 mm), 10 to 20 parts of alumina fine powder, 3 to 7 parts of magnesia powder of which the magnesia content is over 95 percent, 1 to 5 parts of pure calcium aluminate cement, 0.5 to 1.5 parts of silicon dioxide fine powder, 0.05 to 0.5 part of water reducing agent, 1 to 35 parts of corundum (between 25 and 0.074 mm) and 0.5 to 5 parts of hydrated alumina powder. The pouring material for the steel ladle has the advantages of extremely high molten steel corrosion resistance, slag corrosion resistance, slag penetration resistance, no pollution to molten steel when taken as a refractory material for the liner of a molten steel accommodating container for smelting pure steel, slag bonding resistance and very long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

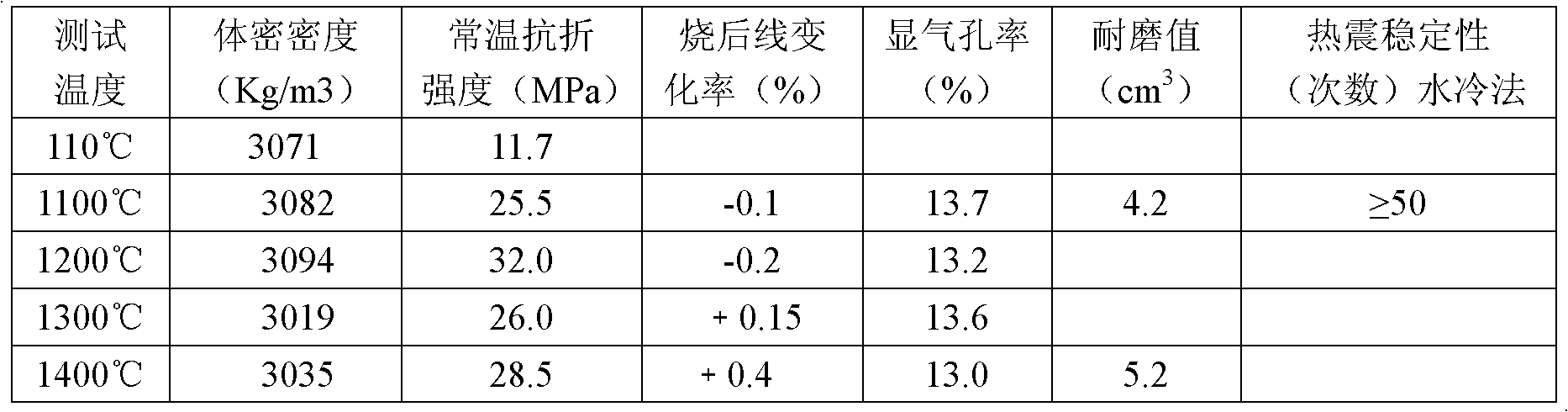

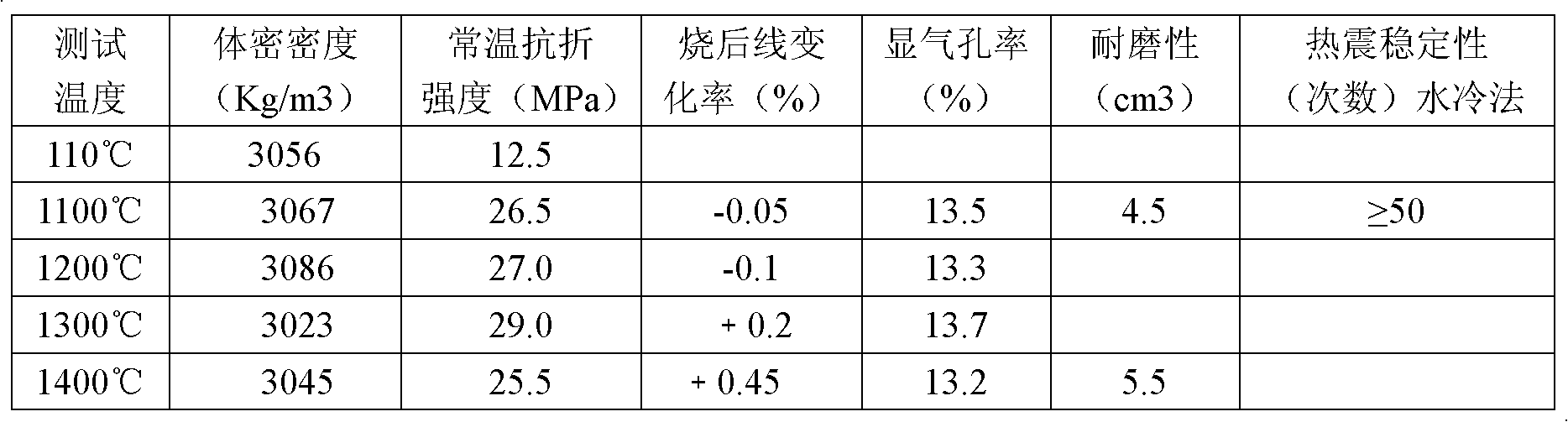

Preparation method for cement-free castable

The invention belongs to the technical field of refractory materials, in particular to a preparation method for cement-free castable which can be applied to a cement kiln coal injection pipe. In the castable, electrically-molten brown fused alumina, SiA and alpha-Al2O3 micro-powder are taken as main raw materials, hydrated alumina (rho-Al2O3) and MgO-SiO2-H2O are taken as a combined system, sodium tripolyphosphate is taken as a deflocculant, citric acid is taken as a retarding agent, and metal silicon powder and metal aluminum powder serving as antioxidants and anti-explosion fibers are contained. A large quantity of dichroite phases and a small quantity of spinel and mullite phases are generated by using a part of a substrate treated at a high temperature of the cement-free Al2O3-SiC refractory castable prepared with the method, so that the medium-temperature sintering performance of the Al2O3-SiC castable is improved, and the high-temperature mechanical property, oxidation resistance, wearing resistance, alkali resistance and thermal shock stability of the castable are enhanced. The adding amount of water is less than 4.5 percent, rupture strength at the using temperature of 1,100-1,400 DEG C is more than 25 MPa, apparent porosity is less than 14 percent, the wearing resistance value is less than 5cc, and the thermal shock stability is tested with a water cooling method for more than 50 times.

Owner:TONGDA REFRACTORY TECH CO LTD

Flame retardant polymer compositions comprising a particulate clay mineral

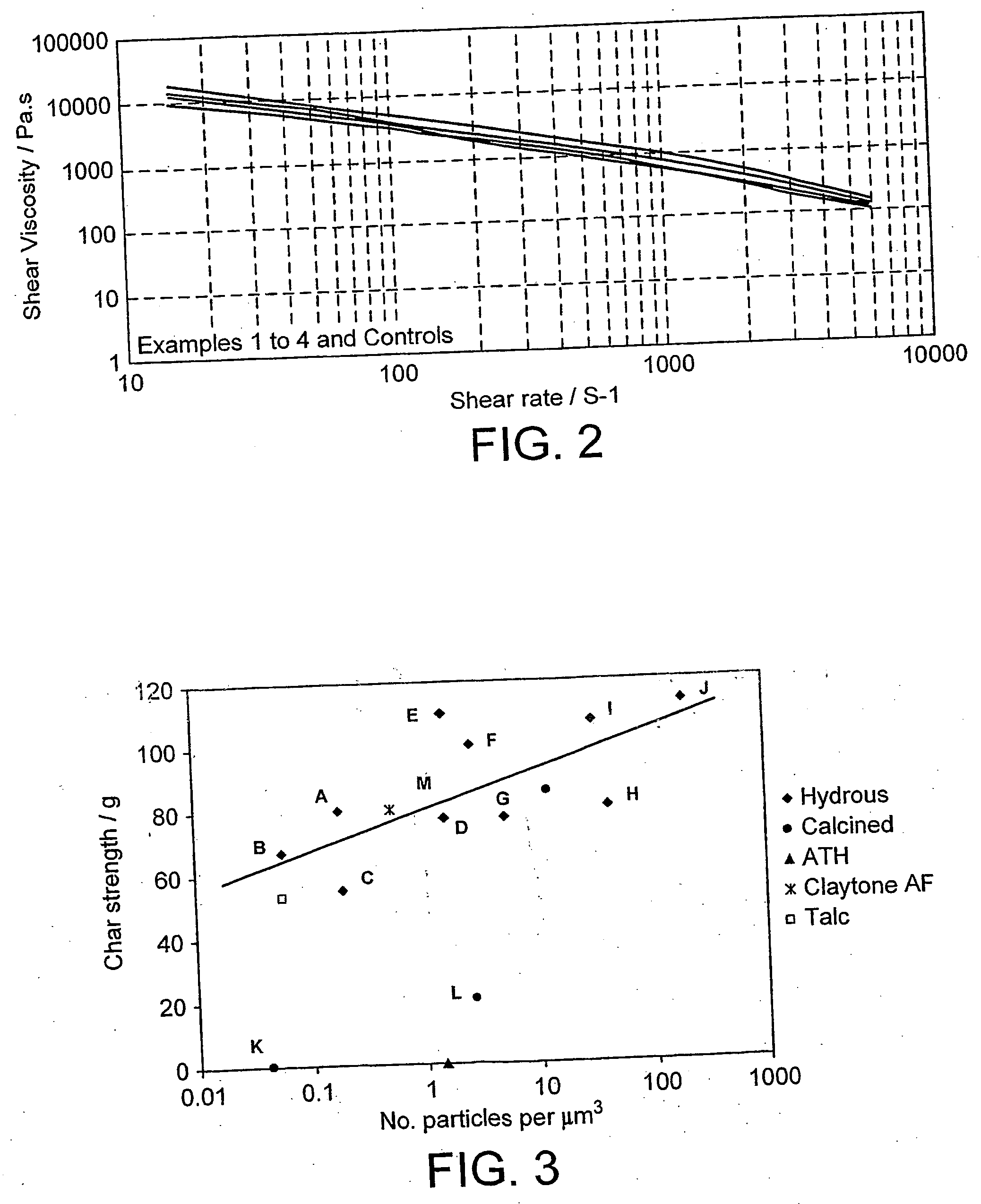

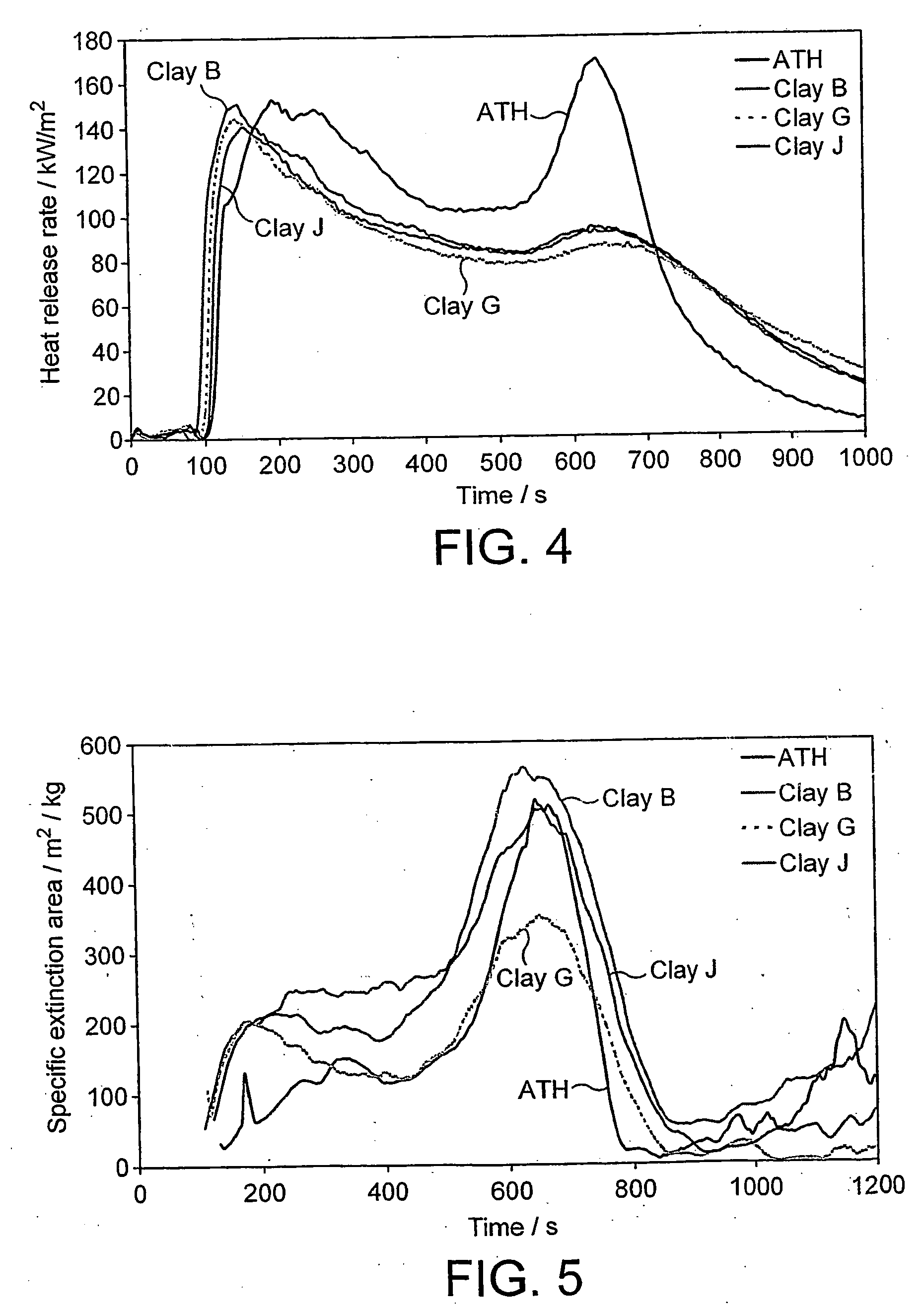

A flame retardant polymer composition having acceptable char strength and optionally also drip resistance comprises a polymer and a particulate clay mineral distributed in the polymer composition at a particle number per unit volume of at least about 1 particle per 100 μm3, provided that the clay mineral present at the said particle number per unit volume is not an organomontmorillonite. The composition preferably further contains alumina trihydrate (ATH) and / or another flame retardant.

Owner:GOODMAN HOWARD +1

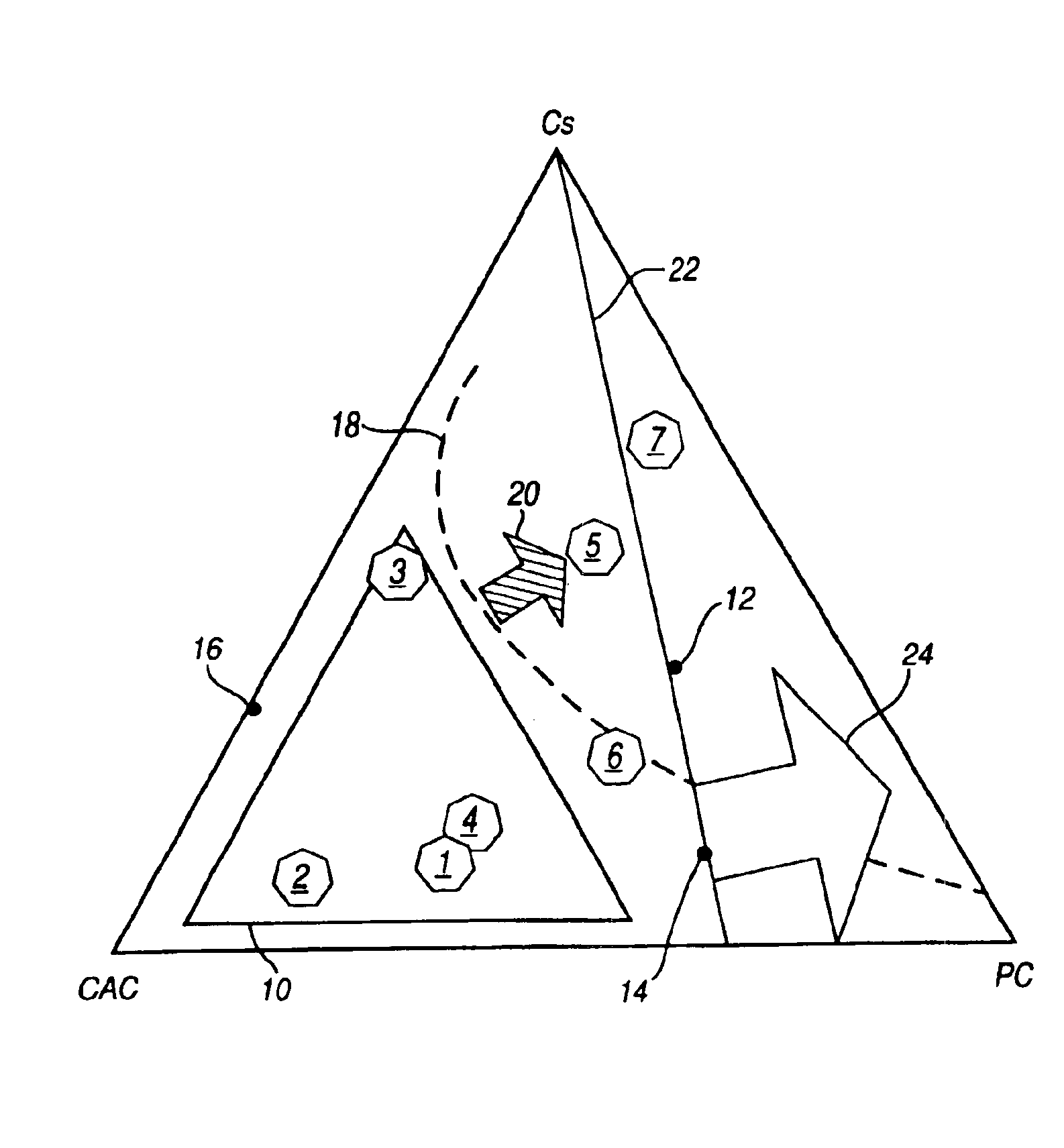

Non-efflorescing cementitious bodies

InactiveUS6923857B2Satisfactory physical propertyReduce weatheringSolid waste managementPretreated surfacesCalcium silicateHydrated alumina

A non-efflorescing cementitious body is formed from sources of calcium aluminate, calcium silicate, calcium sulphate and reactive silica, these ingredients being present in such relative proportions that, upon hydration, both monosulphate (C3A.CŜ.12H) and hydrated alumina (AH3) are formed. Also disclosed is a hydraulic binder and a paste from which such bodies can be formed and a method for forming such bodies. In addition to exhibiting low efflorescence, these bodies retain satisfactory physical properties, especially good durability to natural weathering conditions.

Owner:LAFARGE ALUMINATES

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

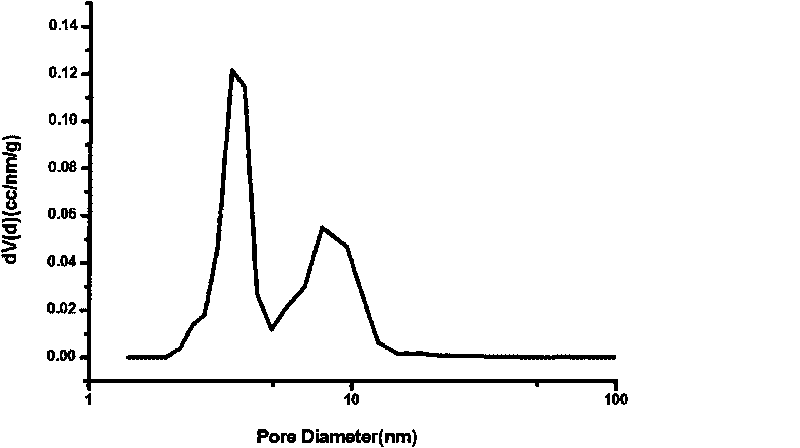

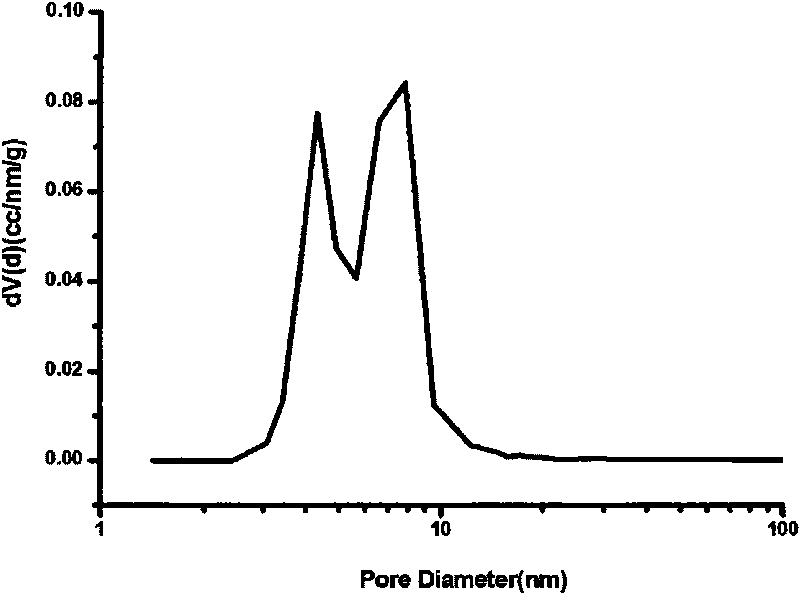

Method for preparing aluminum oxide with bimodal pore distribution

InactiveCN101704537AEasy to shapeEasy to operateCatalyst carriersCatalyst activation/preparationPore distributionHydrated alumina

The invention relates to a method for preparing aluminum oxide with bimodal pore distribution, which comprises the following steps of: preparing two types of hydrated alumina raw materials under different process conditions; and then mixing, molding and calcinating the two hydrated alumina raw materials in a ratio of 1:0.5-4, wherein the calcination temperature is between 450 and 1,000 DEG C, and the calcination time is between 1 and 12 hours. The aluminum oxide provided by the invention has the bimodal pore distribution, has no pore-forming agent in the preparation process, has the pore diameter smaller than the pore volume of pores and not more than 5 percent of the total pore volume, and can be used as a catalyst and a carrier or an adsorbent thereof.

Owner:CHINA NAT OFFSHORE OIL CORP +1

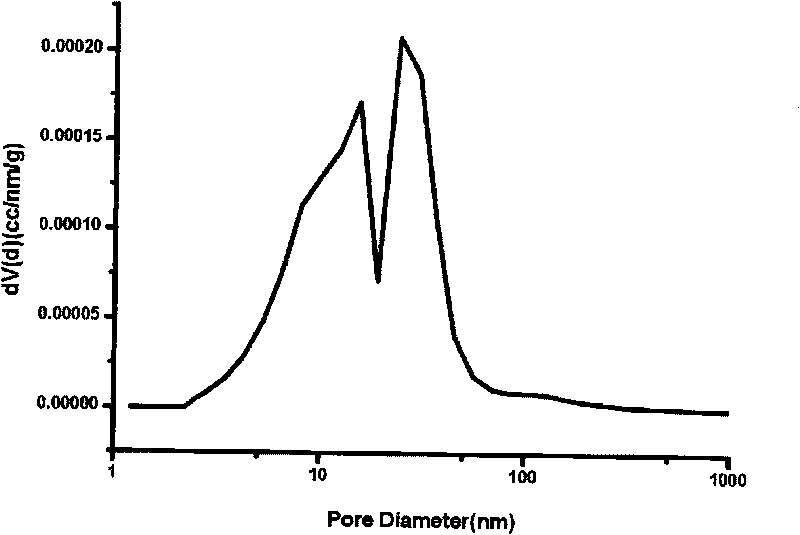

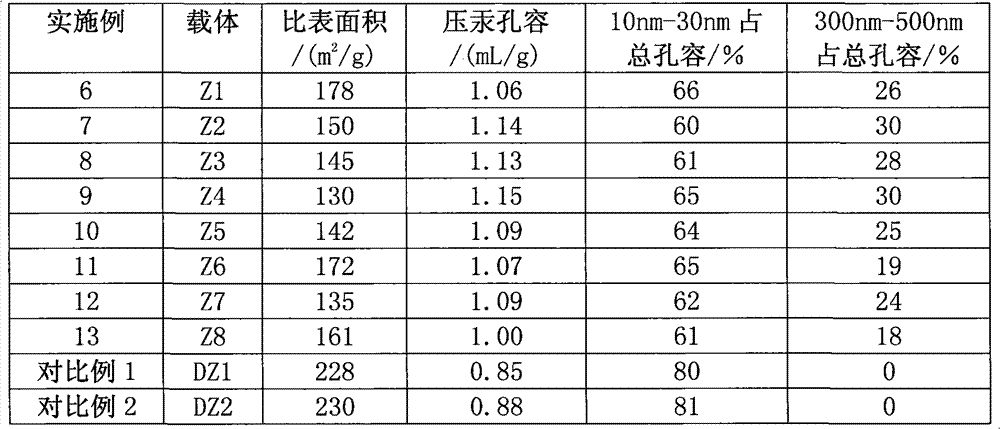

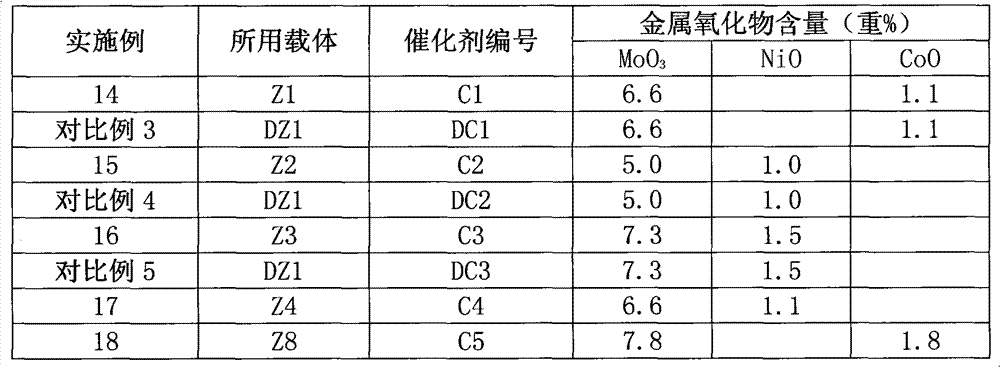

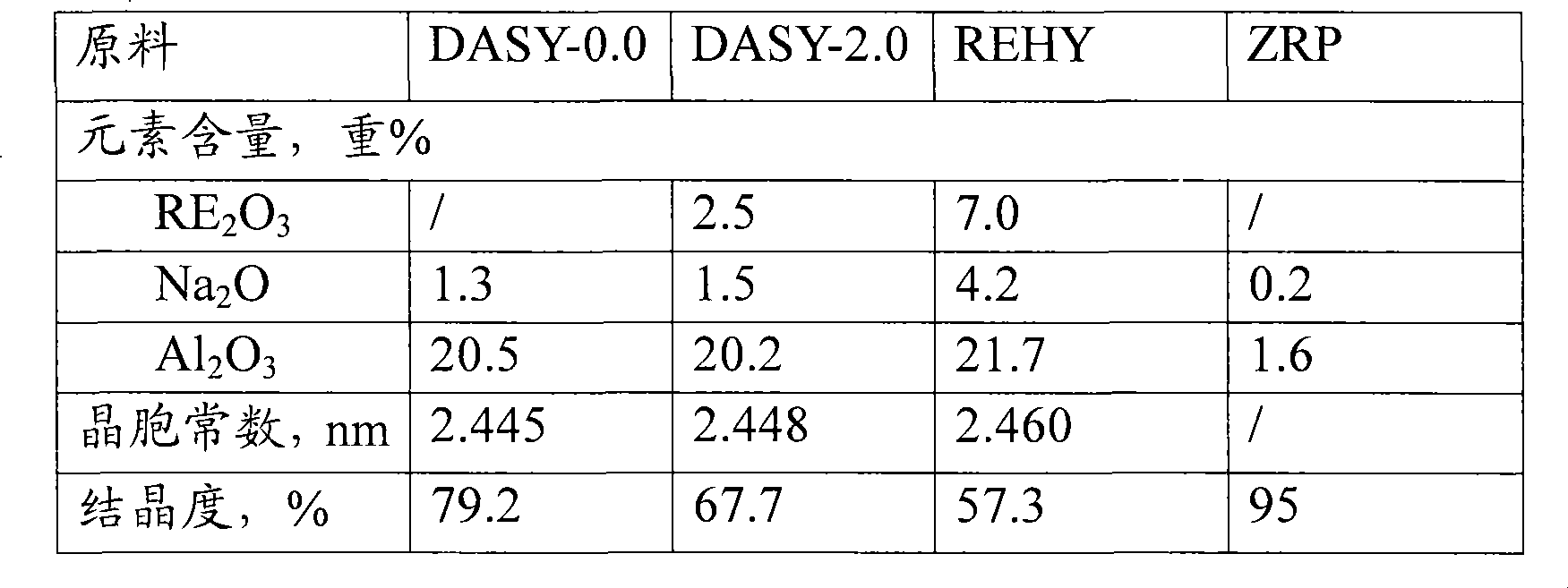

Heavy-petroleum hydrogenating deasphaltenizing catalyst and preparation and application thereof

ActiveCN103357445ACatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsHydrated aluminaResidual oil

The invention provides a hydrogenating deasphaltenizing catalyst and preparation and application thereof. The hydrogenating deasphaltenizing catalyst comprises a supporter and a hydrogenating active metallic compound, wherein the supporter is a doublet-hole alumina supporter which has the pore volume of 0.9 to 1.2ml / g and specific surface area of 50 to 300m<2> / g under the representation in a mercury intrusion method, and the pore volume of a hole being 10 to 30nm in diameter accounts for 55 to 80% of the total pore volume, and the pore volume of a hole being 300 to 500nm in diameter accounts for 10 to 35% of the total pore volume. The preparation method of the supporter comprises the following steps of: mixing, molding, drying and roasting hydrated alumina P1 containing pseudo-boehmite and a modifying substance P2 of the P1, wherein the mixing ratio in weight of the P1 to P2 is (20-95): (5-80; ); the k value of P2 ranges from 0 to 0.9, and the k is DI2 / DI1, wherein DI1 represents the acid peptizing index of the hydrated alumina P1 containing the pseudo-boehmite; and DI2 represents the acid peptizing index of the modifying substance P2 of the P1. Compared with the prior art, the catalyst provided by the invention shows greater performance on hydrogenating deasphaltenizing and demetalizing after being applied to hydroprocessing of residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

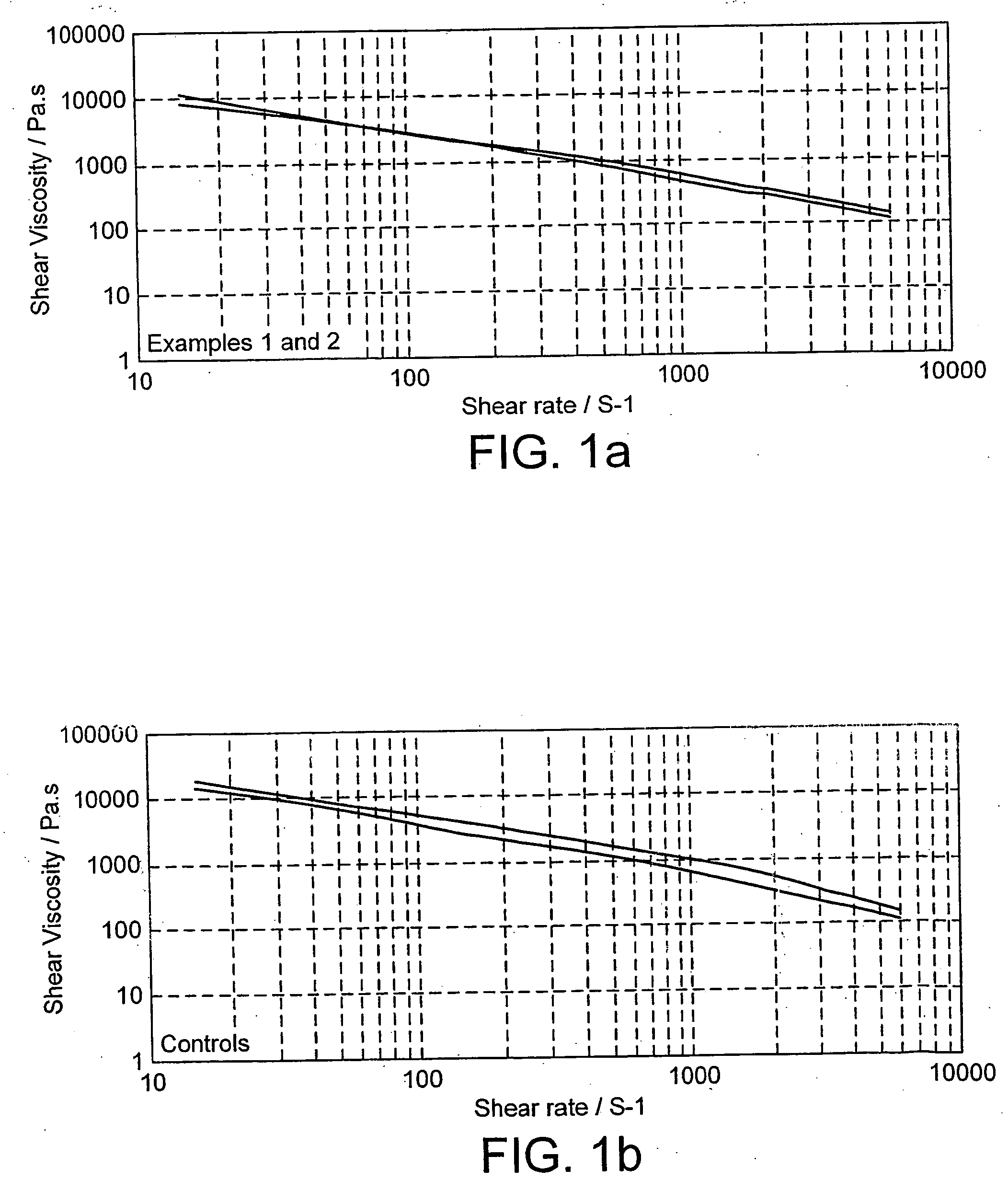

Sulfur adsorbent, desulfurization system and method for desulfurizing

ActiveUS20070131589A1Efficient desulfurizationHydrogenOther chemical processesFuel cellsHydrated alumina

A method for producing a substantially desulfurized hydrocarbon fuel stream at temperatures less than 100° C. including providing a nondesulfurized fuel cell hydrocarbon fuel stream and passing the fuel stream through a sulfur adsorbent system containing a specialized sulfur adsorbent containing hydrated alumina to produce a substantially desulfurized hydrocarbon fuel stream.

Owner:CLARIANT INT LTD

Method for preparing hydrated alumina

ActiveCN103043694AIncrease spawn rateSmall particle sizeAluminium hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateHydrated alumina

The invention discloses a method for preparing hydrated alumina. The method comprises the following process that: (1) bottom water is added into a neutralization reactor and is heated to 50-95 DEG C, an acid aluminium salt water solution is added at the same time so as to control the pH value between 2 and 4, and the pH value is stabilized for a while; (2) the acid aluminium salt water solution and alkali metal aluminate (or alkaline precipitator) solution to regulate the pH value between 6 and 8, and the pH value is stabilized for a while; the alkaline precipitator solution (or the alkaline precipitator solution) is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; (4) the acid aluminium salt water solution is added to regulate the pH value to be between 2 and 4, and the pH value is stabilized for a while; (5) the alkaline precipitator solution or the alkaline precipitator solution is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; the steps (4) and (5) are repeated for 1-4 times; (7) after gelatinizing is completed, aging, filtering, washing and drying are carried out to obtain the hydrated alumina; and the steps (1)-(3) are carried out under the action of ultrasonic waves, and the frequencies of the ultrasonic waves are10-80 kHZ. The hydrated alumina which is prepared through the method is distributed in a centralized manner and has high crystallinity and large pore volumes and pore diameters.

Owner:CHINA PETROLEUM & CHEM CORP +1

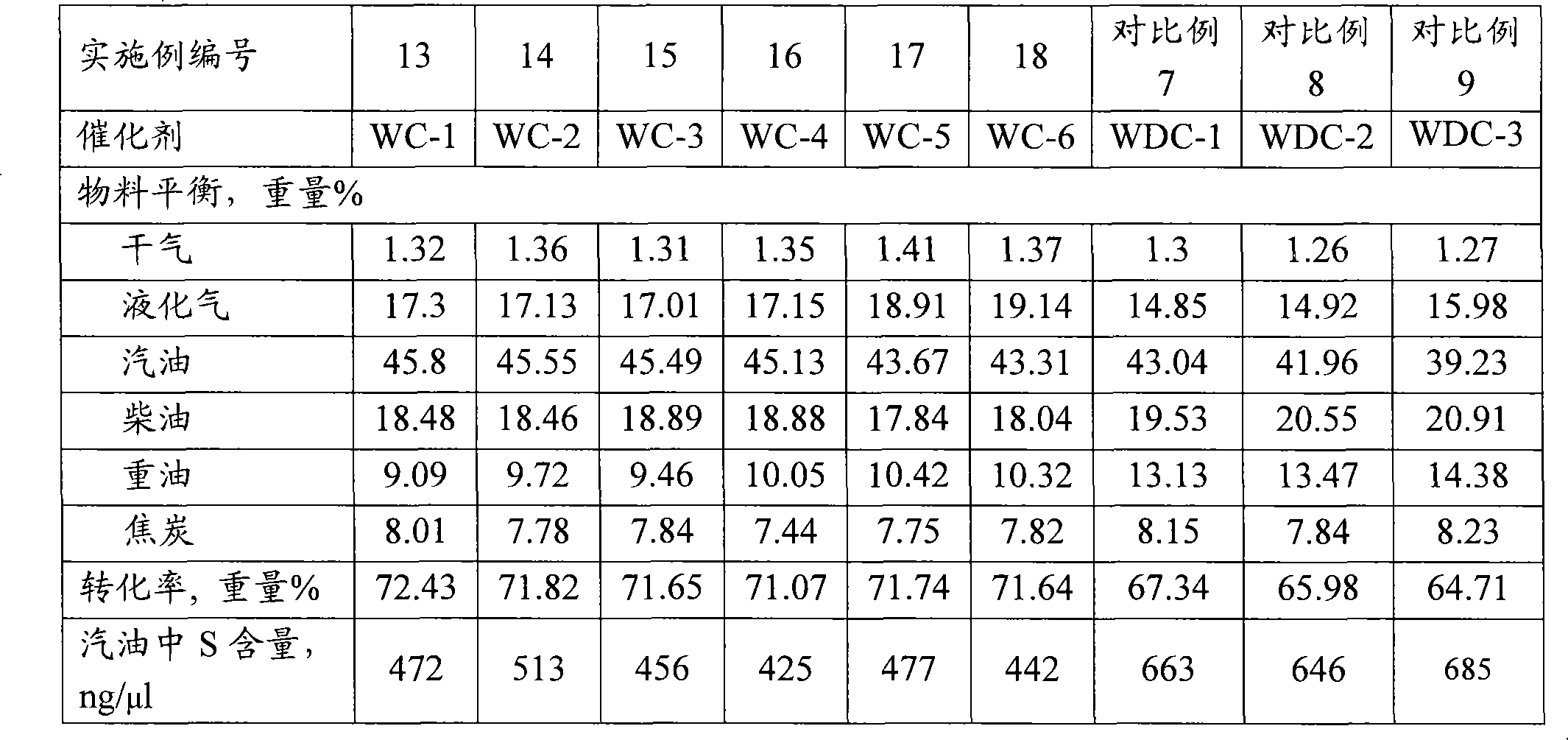

Catalyst for heavy oil catalytic cracking and preparation method thereof

ActiveCN101451074AGood hydrothermal stabilityImprove conversion abilityCatalytic crackingAluminum IonHeat treated

The invention provides a catalytic cracking catalyst and a method for preparing the same. The catalyst comprises an REY molecular sieve with effective quantity and a substrate. The invention is characterized in that the method for preparing the REY molecular sieve comprises: after a NaY molecular sieve is contacted with an aqueous solution containing rare-earth ions, or is contacted with the aqueous solution containing rare-earth ions and a solution containing aluminum ions or colloid, the solution is contacted with an additional precipitator so that part of rare earth is precipitated on the molecular sieve; the solution is subjected to hydrothermal treatment and is finally contacted with an aqueous ammonium salt solution; the substrate contains hydrated alumina modified by transition metal oxide; and the catalyst is prepared by the pulping, spraying and drying of the REY molecular sieve and the substrate. The catalyst is used for cracking the heavy oil, has strong capacity for cracking the heavy oil, high gasoline yield, low sulphur content in the gasoline and strong capacity for resisting vanadium pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano Al2O3 film encapsulated carbon-aluminum spinelle refractory castable and preparation method thereof

InactiveCN101417884APerformance indicators improved and enhancedDense tissue structureHydration reactionManufacturing technology

The invention relates to a carbon-aluminum spinel refractory castable material wrapped up by a nano AL2O3 film and a preparation method thereof. The preparation method of the carbon containing castable material firstly puts the mixture of hydrated alumina, carbon powders and water in a high speed impact mixing-stirring mill for coating processing treatment, the materials impact and collide with each other after high-speed impact treatment, thus forming a composite sol suspension liquid of carbon and aluminum hydroxide and causing the aluminum hydroxide to be strongly absorbed on the surface of the carbon, therefore, the manufacture technology for coating carbon powders by using aluminum hydroxide is realized, then the composite sol suspension liquid is directly added to the mixed materials for preparing alumina gel coatings by controlling the conversion process from the aluminum hydroxide to the gel, and hence the whole-covered, crack-free and high-strength compact alumina wrapping layer is formed; and during the mixing and stirring process of the castable material, magnesium hydroxide sols are generated by the hydration reaction of magnesia powders and mixed water in matrix powders, then the nanostructure matrix of carbon-aluminum-spinel is generated by the in-situ synthesized reaction of the magnesium hydroxide sol and aluminum hydroxide sol suspension liquid, and finally the carbon-aluminum refractory castable material is prepared.

Owner:高树森

Preparation method of titanium dioxide pigment with high covering power, weather resistance and whiteness

ActiveCN106497147AHigh whitenessGood average particle sizeCoatingsPigment physical treatmentFiltrationSlurry

The invention provides a preparation method of a titanium dioxide pigment with high covering power, weather resistance and whiteness. The preparation method includes: adopting a titanium dioxide primary product, beating in water to prepare slurry, adding water-soluble silicate solution as a dispersant, and performing curing prior to grinding treatment; heating up the slurry, adding in the water-soluble silicate solution, adopting mineral acid to regulate pH value, and performing curing prior to forming a dense, hydrated and unformed silica membrane; adding the water-soluble silicate solution again, maintaining the pH value of the slurry with an acidic aluminium compound, and performing curing prior to forming a loose and porous membrane layer taking aluminium hydrosilicate as a main ingredient so as to assure high covering power and whiteness; wrapping the loose hydrated alumina membrane to assure excellent dispersibility; performing filtration washing, drying, gasification and pulverization, and recovering with a bag filter to obtain the finished product. The preparation method has the advantages that the titanium dioxide pigment prepared with the method has high weather resistance and whiteness besides excellet covering power, is high in production cost, and can be widely applied to the fields of flat and matt building coatings, printing ink and the like with requirements on high dry covering power.

Owner:中信钛业股份有限公司

Method for preparing high water dispersibility titanium dioxide

ActiveCN103965659AAdjust pHGood dispersionInorganic pigment treatmentWater dispersibleHydrated alumina

The invention discloses a method for preparing a high water dispersibility titanium dioxide. The method comprises the following steps sequentially: a, adding a dispersing agent into a titanium dioxide slurry, and stirring uniformly; b, adding a phosphorus-containing solution, and curing; c, adding an aluminum sulfate solution to control the pH value of the titanium dioxide slurry to be 1.5 to 4.5, and curing; d, adding a sodium metaaluminate solution to control the pH value of the titanium dioxide slurry to be 8.5 to 10.5, and curing; e, adjusting the pH value of the titanium dioxide slurry to be 7.0 to 7.8, and curing; f, filtering, washing, drying, and pulverizing to obtain the high water dispersibility titanium dioxide. According to the method, before coating, the dispersing agent is added to improve a dispersing condition of the titanium dioxide slurry, then the phosphorus-containing solution and the aluminum-containing solution are used as a coating agent, and then the coating agent is deposited on the surface of titanium dioxide in forms of aluminum phosphate and hydrated alumina, so that the water dispersibility of a product is effectively improved, and the titanium dioxide product with the high water dispersibility is obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

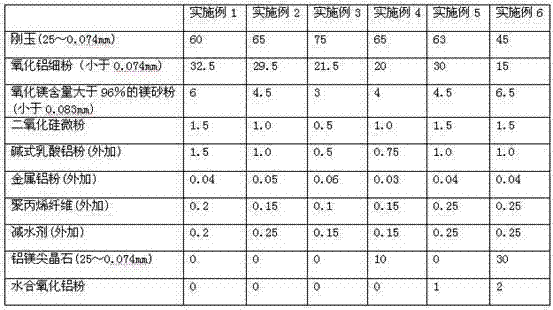

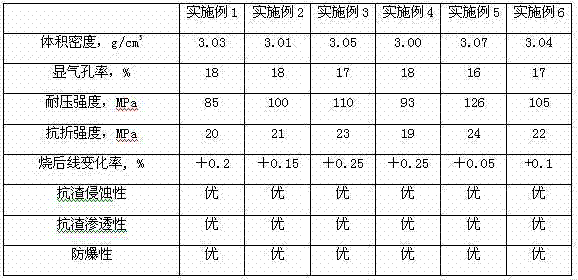

Cement-free aluminum-magnesium castable for rapidly baking ladle

InactiveCN102452836AExtended service lifeOvercoming the inadequacy of not being able to achieve fast bakingCooking & bakingSilicon dioxide

The invention discloses a cement-free aluminum-magnesium castable for rapidly baking a ladle. The castable consists of the following components in percentage by mass: 45-75 percent of corundum (granularity of 25-0.074 millimeters), 15-35 percent of fine alumina powder, 3-7 percent of magnesia powder of which the magnesite content is over 96 percent, 0.5-1.5 percent of alkaline aluminum lactate powder, 0.02-0.06 percent of metal aluminum powder, 0.1-0.3 percent of polypropylene fibers of which the melting point is lower than 200 DEG C, 0.5-1.5 percent of micro silicon dioxide powder, 0.1-0.3 percent of a water reducing agent, 5-35 percent of aluminum-magnesium spinel (granularity of 25-0.074 millimeters) and 0.5-3 percent of hydrated alumina powder. The castable disclosed by the invention has the advantages of difficulty in cracking during quick baking, superior molten steel erosion, residue erosion resistance and residue permeation resistance; and the castable does not pollute molten steel when taken as a refractory material of an inner lining of a container for accommodating the molten steel during smelting of pure steel, and has relatively long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Silicon nitride bonded corundum permeable brick and preparation method

InactiveCN102276273AHigh blowing success rateExcellent thermal peeling resistanceBrickHydrated alumina

The invention discloses silicon nitride and corundum combined breathable bricks and a preparation method. The silicon nitride and corundum combined breathable bricks are characterized by being prepared by the following steps: adding water into corundum particles and fine powder, hydrated alumina, alumina micro powder and monomer silicon powder, which serve as raw materials, mixing to obtain a sludge material; pouring in molds to form breathable brick bodies; demolding, curing and drying; removing pre-buried organic burning-out material by pre-burning to form slits; and preparing by high-temperature nitridation treatment. The bricks comprise: 70 to 80 parts of corundum particles and fine powder, 3 to 12 parts of active alumina micro powder, 1 to 6 parts of hydrated alumina, 4 to 15 parts of monomer silicon powder and organic water reducer serving as a dispersant in an amount which is 0.05 to 0.30 percent based on the total weight parts of the previous raw materials. The bricks overcomethe drawbacks of low thermal-shock resistance and low stripping resistance of the conventional corundum-spinel breathable brick material, are expected to replace conventional chromium corundum and corundum-spinel breathable brick materials for making steel and have the characteristics of high blow-off rate, high stripping resistance, long service life and the like.

Owner:ZHENGZHOU UNIV +1

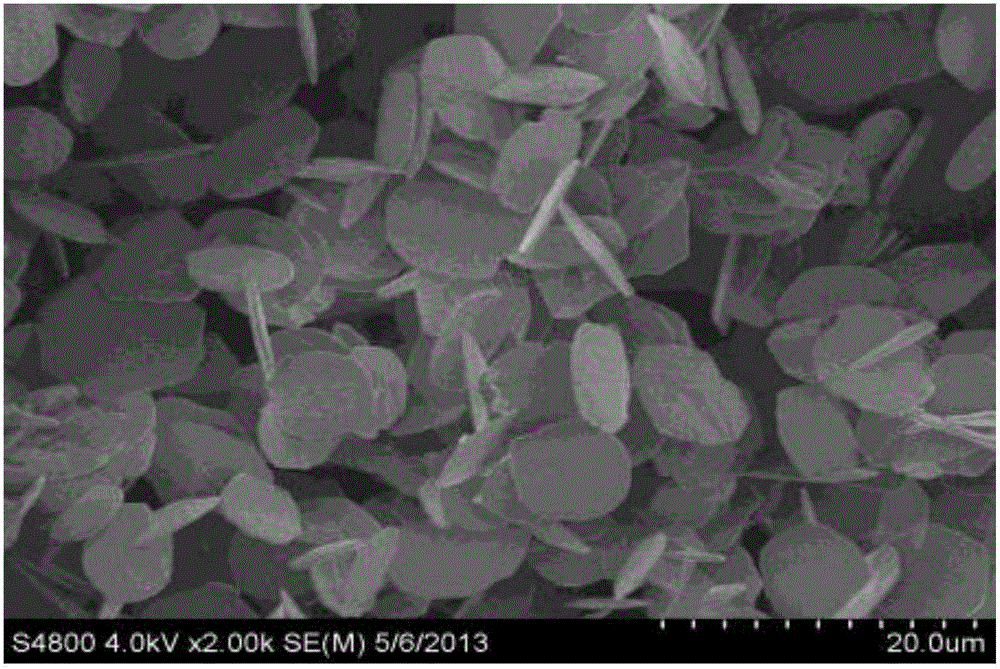

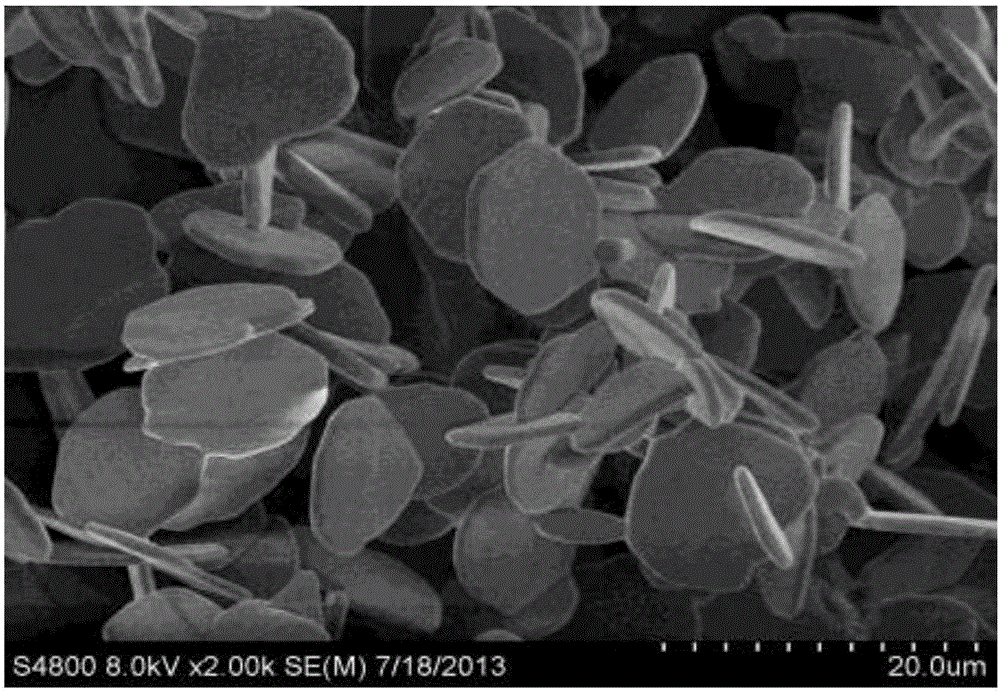

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

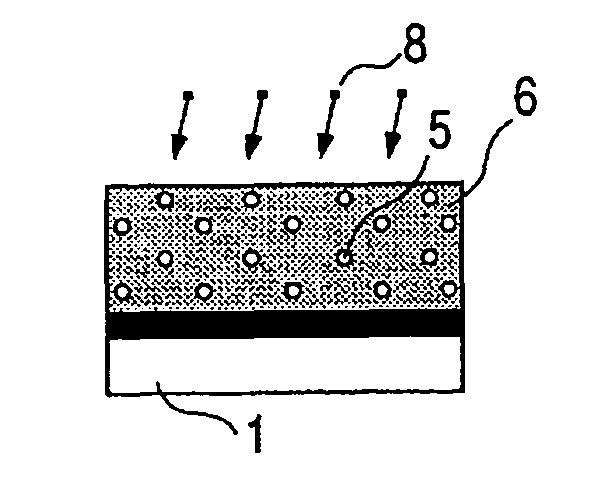

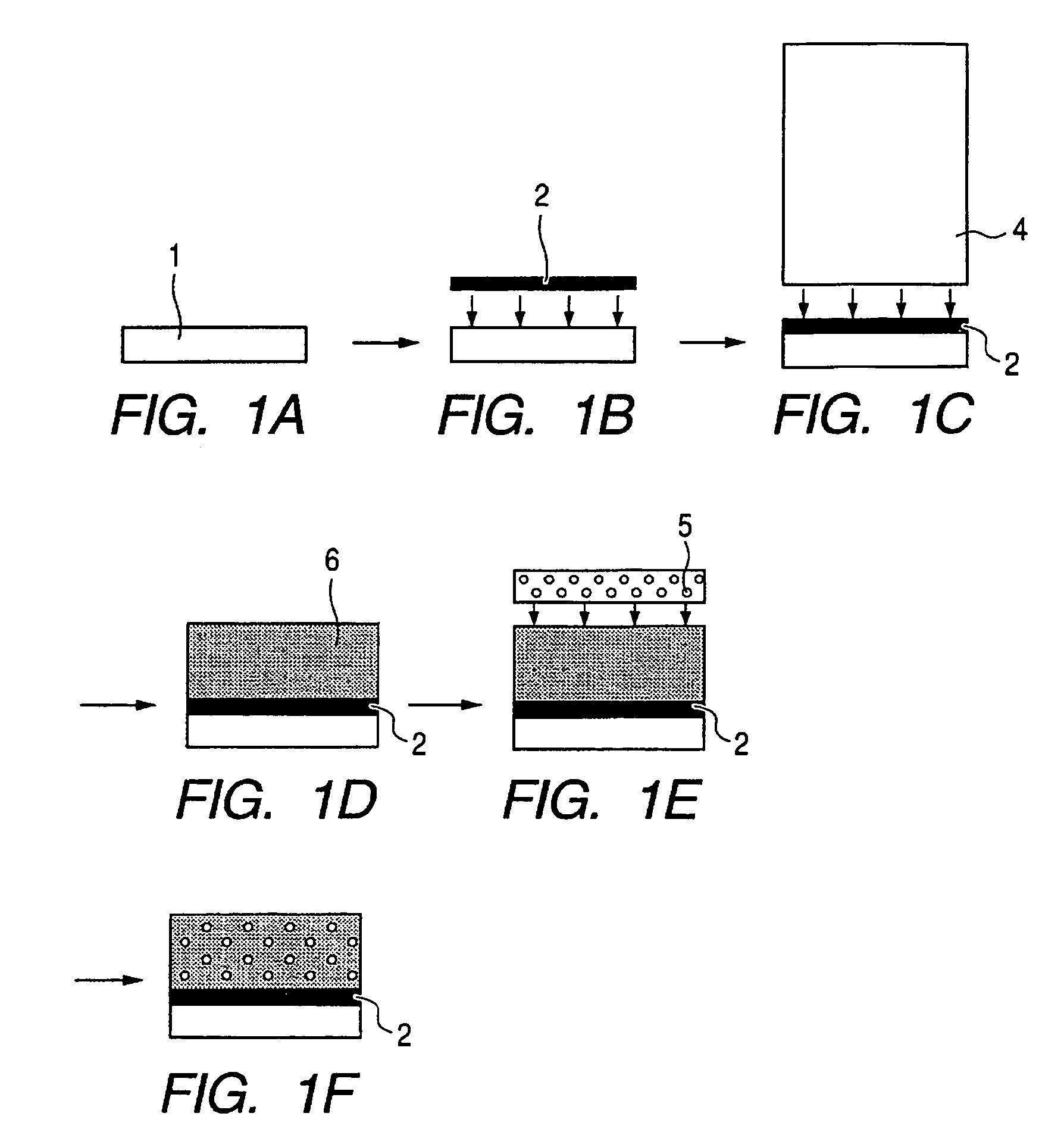

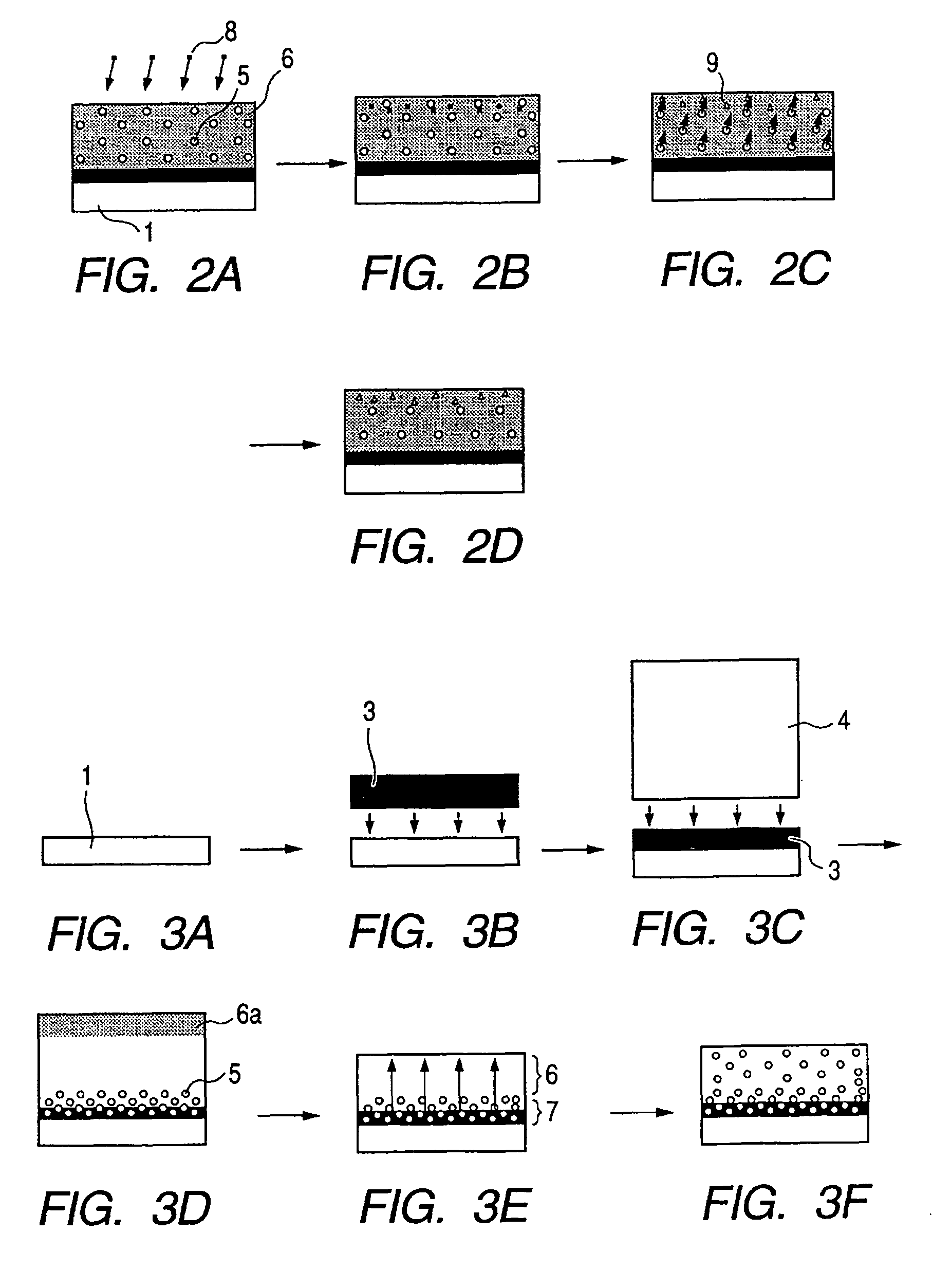

Article having microporous body part, production method of ink medium, diffusion method of sulfur-containing organic acid into microporous layer, production method of article having meicroporous body part, and inkjet recording medium produced therefrom

InactiveUS7867586B2Eliminate yellowingGood prevention effectCoatingsThermographyDiffusion methodsOrganic acid

Provided is an inkjet recording medium in which hydrated alumina and a sulfinic acid compound or thiosulfonic acid compound coexist in a pigment in an ink receiving layer, and which can prevent white-background yellowing during storage in a resin file holder or the like and ensure printing quality at the same time. The ink receiving layer of the inkjet recording medium contains the sulfinic acid compound or thiosulfonic acid compound, which functions to prevent yellowing, in a salt form or in a free form so as to be diffusible.

Owner:CANON KK

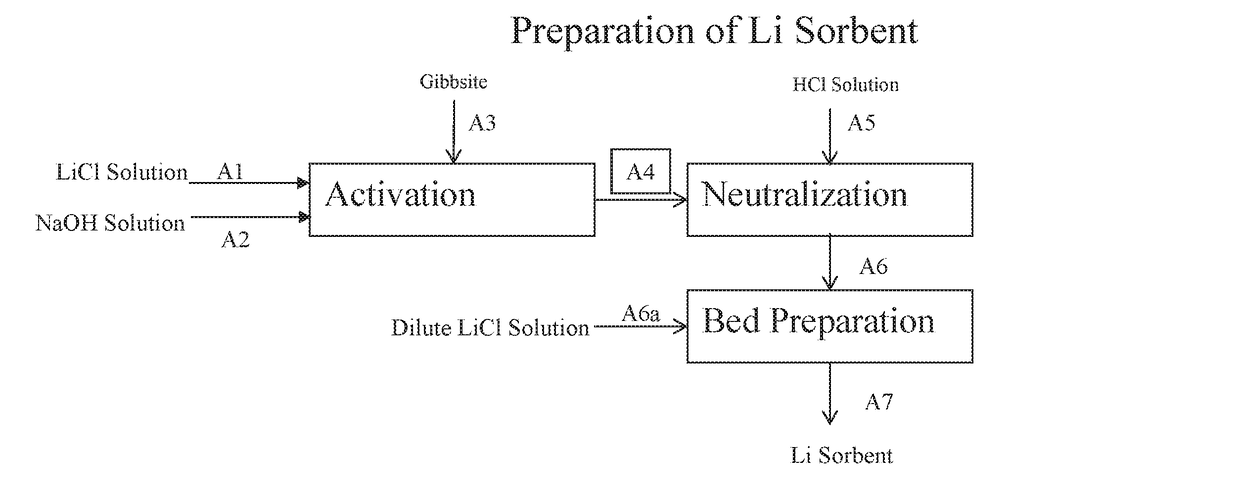

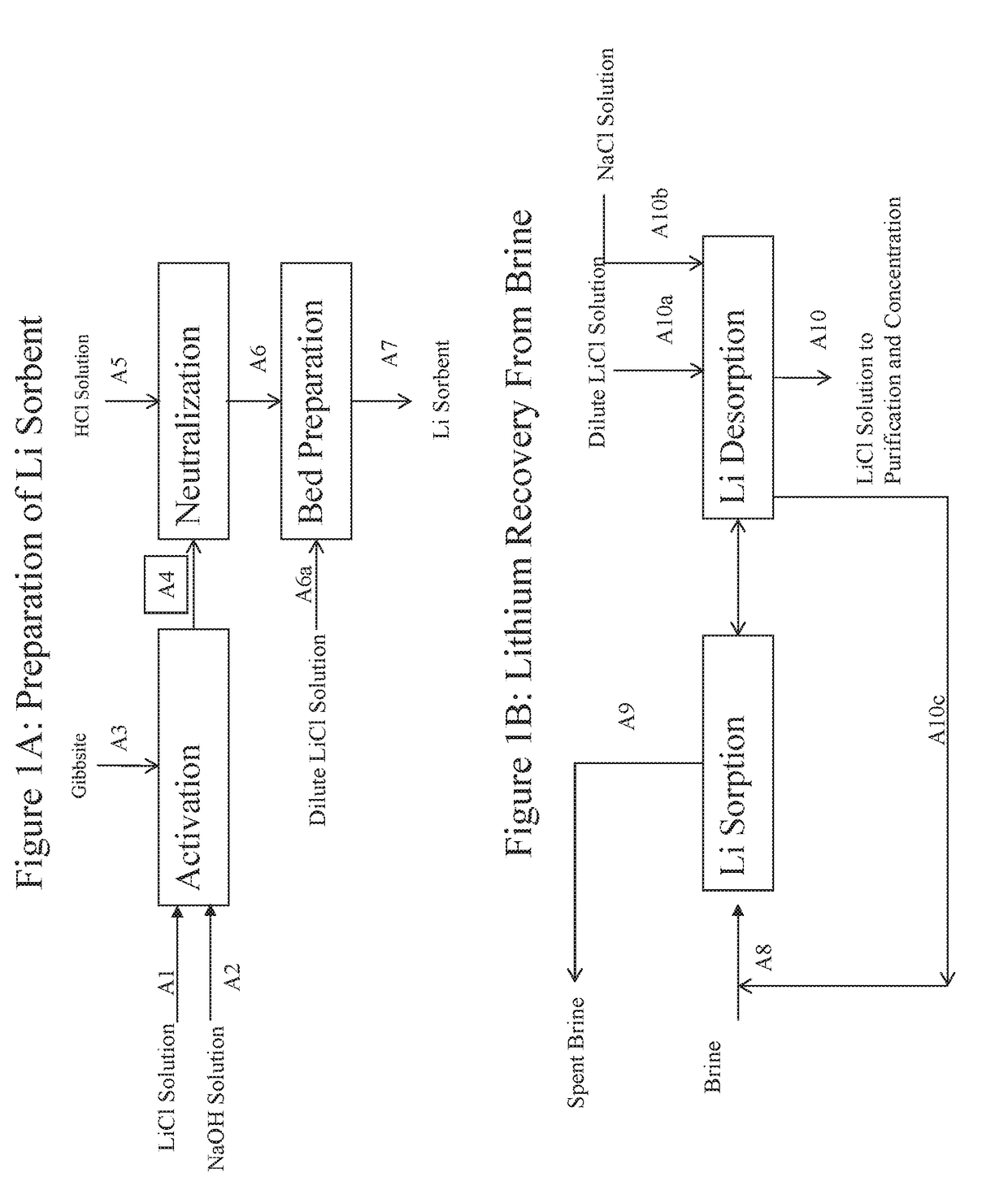

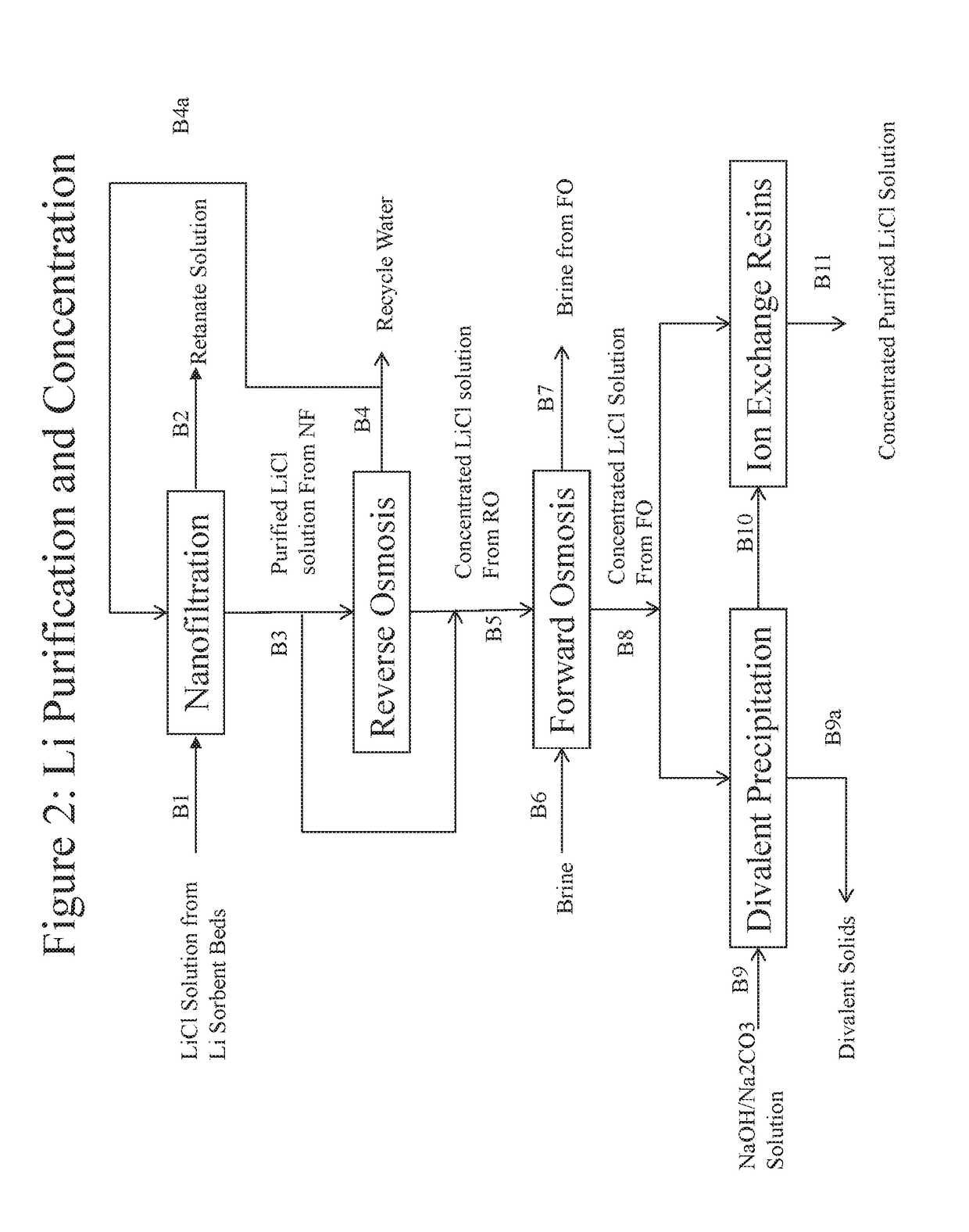

Processes for recovering lithium values from lithium-containing brines

ActiveUS20180245180A1High purityHigh yieldOther chemical processesEnergy based wastewater treatmentLithiumHydrated alumina

Producing high purity lithium solution from a lithium source containing dissolved Na+, Ca2+, and Mg2+, by: passing the source into and out of a bed of sorbent composed of hydrated alumina intercalated with LiX, preferably LiCl, to extract lithium from the lithium source into the sorbent; washing the bed of sorbent with dilute aqueous LiCl to remove lithium from the sorbent to obtain a lithium eluent of increased Li+ concentration; subjecting this eluent to nanofiltration to produce a lithium permeate from which Ca2+, Mg2+, and other nanofilterable components are concurrently removed, yielding a permeate solution with 25% or less, and a retentate solution with 75% or more Ca2+ and Mg2+, as compared to the eluent from washing; and subjecting the permeate solution to a particular forward osmosis yielding a solution having 13,000-25,000 ppm dissolved lithium. Specified optional steps and new features can be used to increase lithium concentrations and purity.

Owner:ALBEMARLE CORP

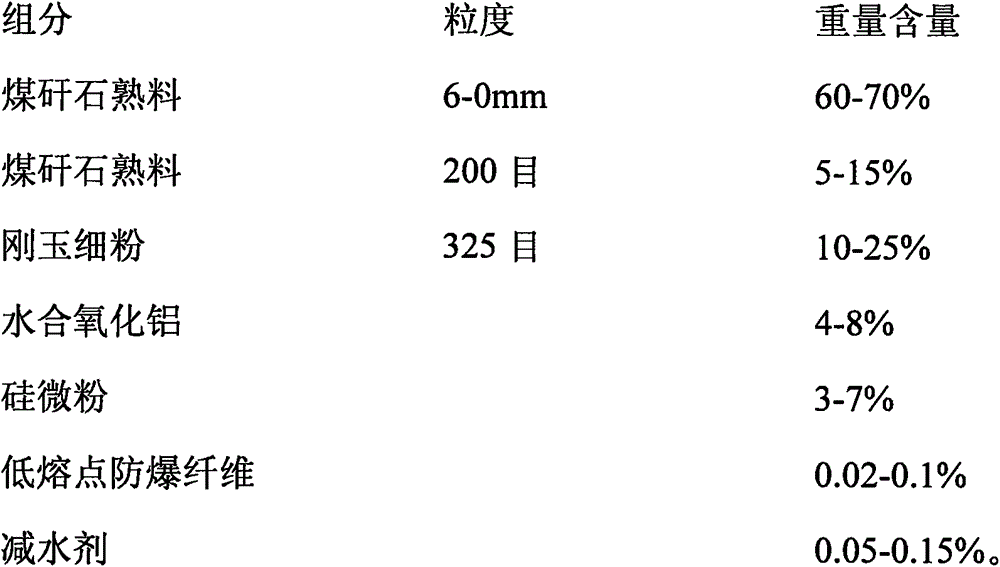

Molten salt furnace pouring material and preparation method thereof

The present invention particularly relates to a molten salt furnace pouring material and a preparation method thereof. The technical scheme comprises: adopting low iron, a coal gangue clinker being subjected to an iron reducing treatment and a corundum material as main raw materials, adopting hydrated alumina as a binding agent, and carrying out inspection, crushing, iron removing, material matching, mixing, random inspection and other steps to prepare the low iron and high anti-thermal shock molten salt furnace pouring material. According to the present invention, the pouring material has strong CO erosion resistance, such that the condition that the furnace hearth lining body become abnormal loose can be effectively avoided; the pouring material does not contain cement, has high high-temperature strength and excellent thermal shock resistance, and can bear strong erosion of high temperature flue gas and coal ash and sharp fluctuation of the furnace hearth temperature; and with the iron reducing and the high thermal shock resistance of the molten salt furnace pouring material, the service life of the furnace hearth lining body can be significantly improved, and the long service life and the high reliability of the molten salt furnace lining can be achieved.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

Magnesium aluminate spinel light refractory castable and production method thereof

The invention relates to a magnesium aluminate spinel light refractory castable and a production method thereof. According to the magnesium aluminate spinel light refractory castable and the production method thereof, the purpose of improving the porosity of the refractory castable is achieved by using magnesium aluminate spinel light aggregate and introducing air bubbles during the production of the castable. According to the magnesium aluminate spinel light refractory castable and the production method thereof, a foaming method and castable are combined, not only is the characteristic of large raw critical particle size in the castable ensured but also the porosity of the castable is improved. According to the magnesium aluminate spinel light refractory castable and the production method thereof, 50-65 wt% of light magnesium aluminate spinel particles which serve as the aggregate and 10-15 wt% of sintered magnesium aluminate spinel fine powder, 10-15 wt% of aluminum oxide micro powder and one of 15-20 wt% of pure calcium aluminate cement or hydrated alumina which serve as the matrix are mixed; and a water reducing agent, a foaming agent and a foam stabilizer are added. The magnesium aluminate spinel light refractory castable produced according to the method provided by the invention has high porosity, low thermal conductivity and good thermal shock resistance, and the serviceability temperature reaches 1700 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

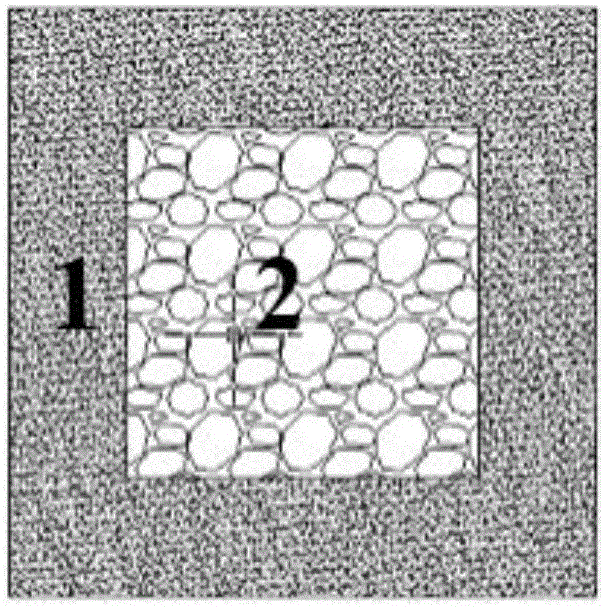

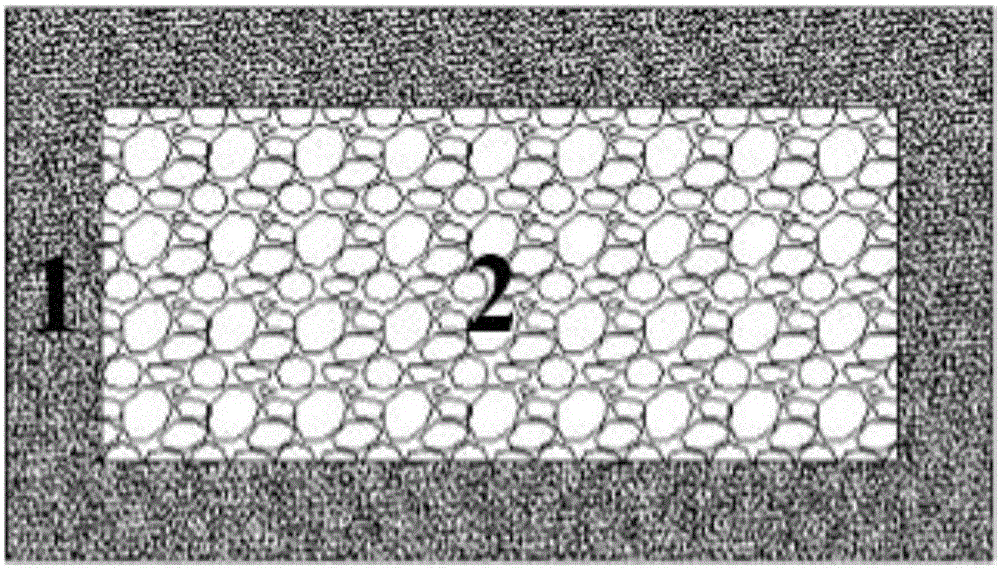

Heat-resistant and high-strength concrete having gradient enclosing structure, and preparation method thereof

ActiveCN106116333AHigh bonding strengthIncrease internal effective humiditySolid waste managementFiberAluminate

The present invention discloses a heat-resistant and high-strength concrete having a gradient enclosing structure. The heat-resistant and high-strength concrete comprises an inner layer high-strength and heat-resistant concrete and an outer layer high heat-resistant concrete from inside to outside, wherein the inner layer high-strength and heat-resistant concrete adopts a silicate-based cement, fly ash, mineral powder, river sand, basalt graded gravel, toughening fiber, a polycarboxylic acid water reducing agent, an inner curing light aggregate and water as raw materials, and the outer layer high heat-resistant concrete adopts an aluminum-based cement, aluminum sand, aluminum stone, hollow fiber, a polycarboxylic acid water reducing agent, an inner curing light aggregate and water as raw materials. According to the present invention, the gradient enclosing structure is designed, such that the generated calcium aluminate and the generated dicalcium aluminate in the outer layer high heat-resistant concrete in the high temperature environment can be converted into the non-hydrated alumina ceramic phase at the high temperature, and the non-hydrated alumina ceramic phase is firmly bonded with the aluminum stone, the aluminum sand and the like so as to significantly increase the high-temperature resistance; and the large doping amount of the fly ash and the mineral powder are used in the inner layer high-strength and heat-resistant concrete, such that the durability is ensured, and the disadvantages of rapid strength loss in the high temperature environment and the like of the existing ordinary silicate heat-resistant concrete can be effectively solved.

Owner:HUBEI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com