Patents

Literature

177 results about "Gibbsite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gibbsite, Al(OH)₃, is one of the mineral forms of aluminium hydroxide. It is often designated as γ-Al(OH)₃ (but sometimes as α-Al(OH)₃.). It is also sometimes called hydrargillite (or hydrargyllite). Gibbsite is an important ore of aluminium in that it is one of three main phases that make up the rock bauxite.

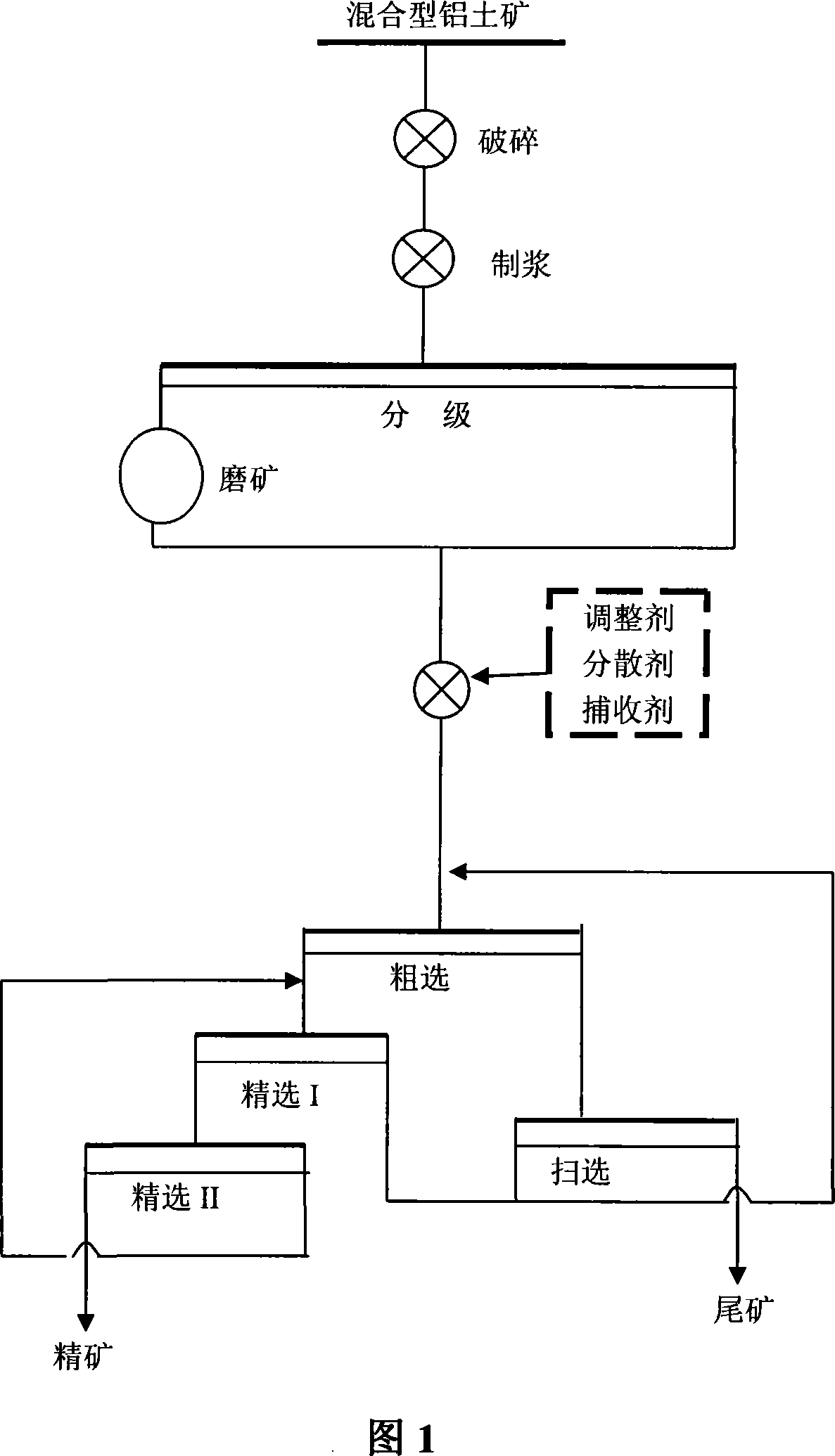

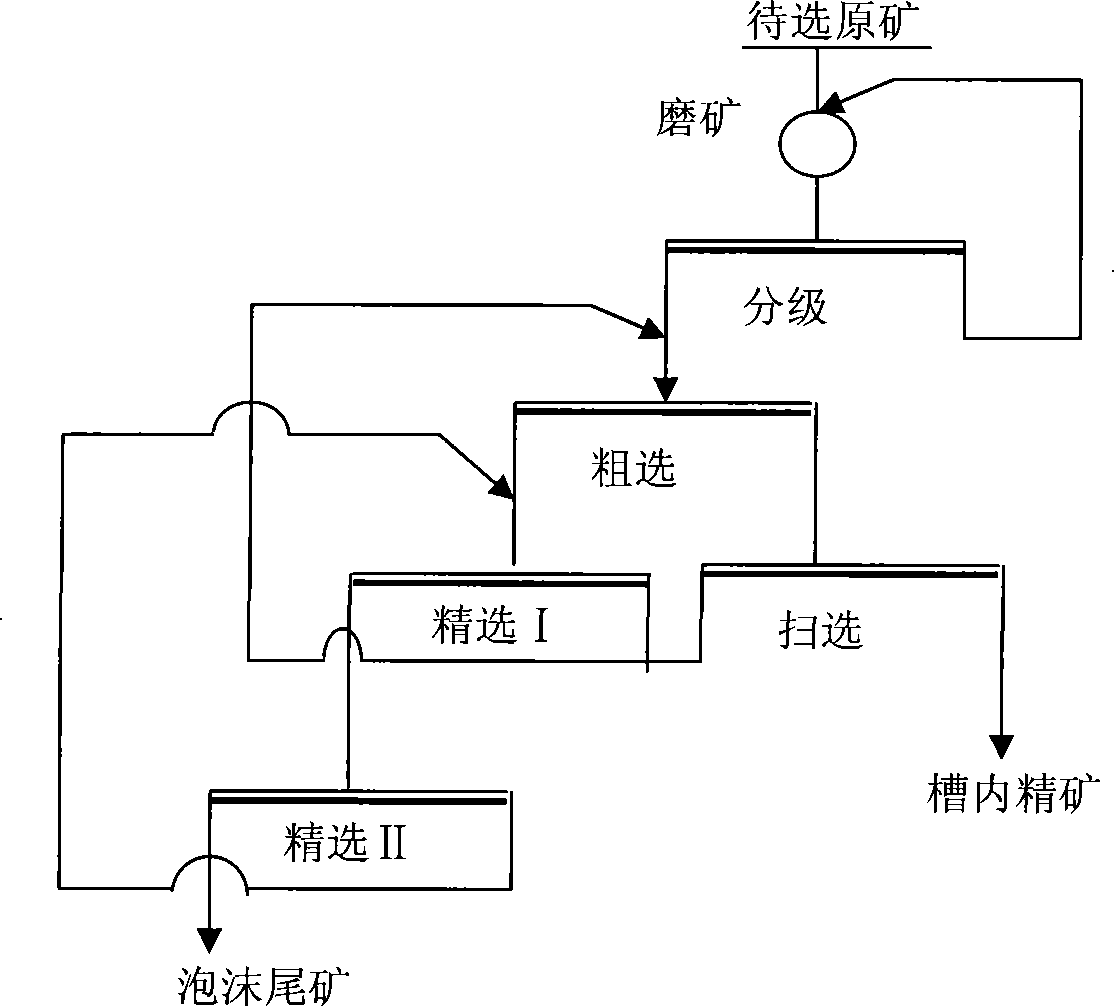

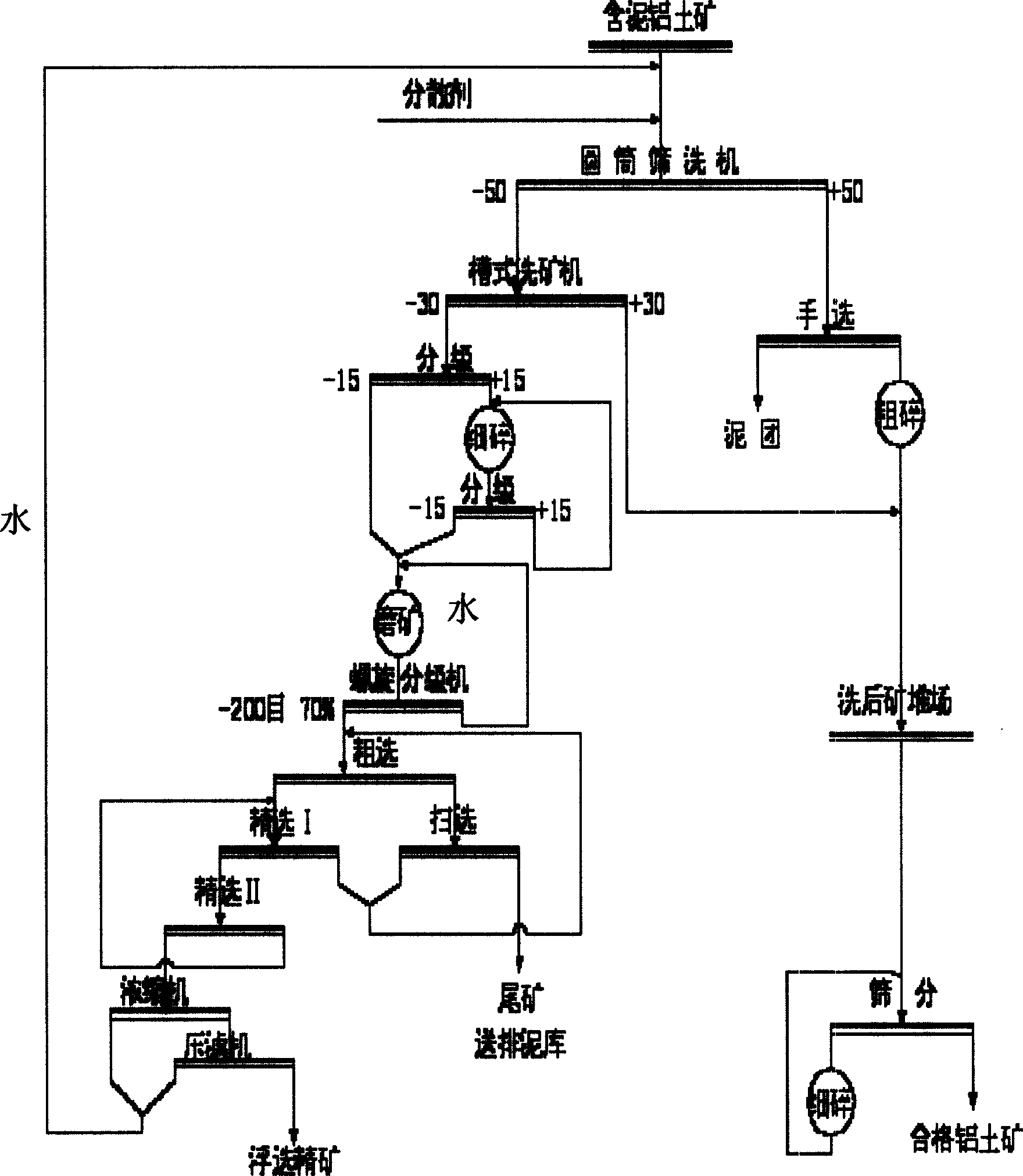

Method for ore dressing and desilicating mixed type bauxite

ActiveCN101176859ASolve the problem of beneficiation and desiliconizationSimple technical processFlotationWet separationHybrid typeSlurry

The invention relates to a mill run desiliconizing method for the mixed alumyte, in particular to a mill run desiliconizing method for the mixed alumyte with the gibbsite. The invention is characterized in that: smashing the mixed alumyte, adding the water to make slurry and make the ore smash, abstracting the coarse fraction mineral and the fine fraction mineral in the products by means of a screen separation craft or a grade craft, fine grinding the coarse fraction mineral which is abstracted, then mixing the milling grinding products and the fine fraction mineral which is abstracted by means of the screen separation craft or the grade craft, and carrying through a floatation. After the invention is carried into execution, the mill run desiliconization of the mixed alumyte with the gibbsite in middle or low grade is realized; the invention has a higher coefficient of recovery under the condition of guaranteeing A / S ratio of the ore concentrate. The invention has the advantages of simple and steady technological process, strong operability, capability of enlarging the resource supply of alumyte and providing a technical support for economy when the alumyte resources are needed, and important economic meaning and a social meaning for the sustainable development of the alumina industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

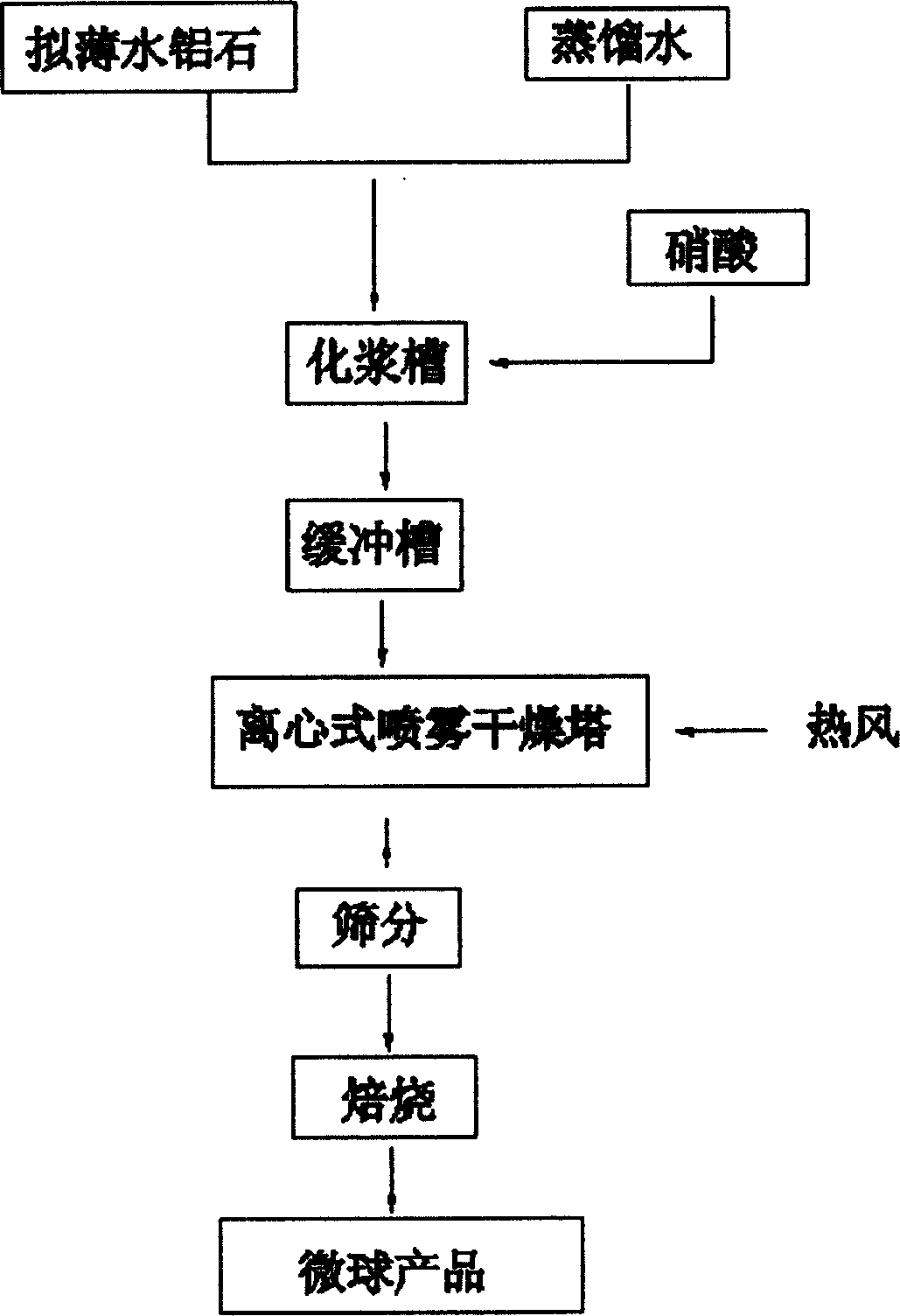

Process for producing gama-alumina microsphere

ActiveCN1631787ASimple production methodReduce manufacturing costAluminium oxide/hydroxide preparationGranularityMicrosphere

The invention relates to a method of producing ª†-alumina micro ball, using gibbsite and nitric acid to create into glue which is dried to be formed by centrifugal and then is produced by roasting. The method of producing ª†-alumina micro ball is simple and practical, with lost cost, increase the productive efficiency and productive capacity as well as satisfying the productive requirement ofª†-Al2O3 with different diameters, besides, it changes the volume, hard wearing of ª†-Al2O3 by adjust the quantity of gibbsite and acid, the products has good quality and it is benefit for spread and application in industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Chemical mechanical polishing composite of stainless steel surface polishing

InactiveCN101654599ASuppression of surface defectsFacilitates mechanical polishing capabilitiesPolishing compositions with abrasivesPseudoboehmiteHydrated alumina

The invention relates to a chemical mechanical polishing composite of stainless steel surface polishing; the polishing composite is composed of grinding material, oxidizer, polishing accelerant, metalchelator, penetrant, and surfactant; the invention is characterized in that: aluminum oxide sol, namely hydrated alumina dispersed in acidic aqueous solution in sol state, is added, the hydrated alumina can be boehmite, fake boehmite, diaspore or gibbsite.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Alpha-alumina carrier and preparation method thereof

The invention provides an alpha-alumina carrier. The most probable pore size of the alpha-alumina carrier is 3.00-9.50 microns, and the specific surface area is 0.15-1.20m<2> / g. The macroporous alpha-alumina carrier is used for catalyzing reaction, in particular for catalyzing epoxidation of ethylene to prepare ethylene oxide, and the heat produced in the catalysis process can be immediately transferred and evacuated so as to guarantee the stabilization of the catalyst and the stable operation of a reaction device. The invention further provides a method for preparing the alpha-alumina carrier. The method comprises the following steps: step A, uniformly mixing gibbsite, pseudo alumina monohydrate, a fluorine-containing compound and alkaline earth salt to obtain solid powder, and adding an adhesive and water to obtain a mixture; step B, kneading, forming, drying and roasting the mixture of the step A to obtain the alpha-alumina carrier, wherein the mass of the fluorine-containing compound is 5-15% of the solid powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

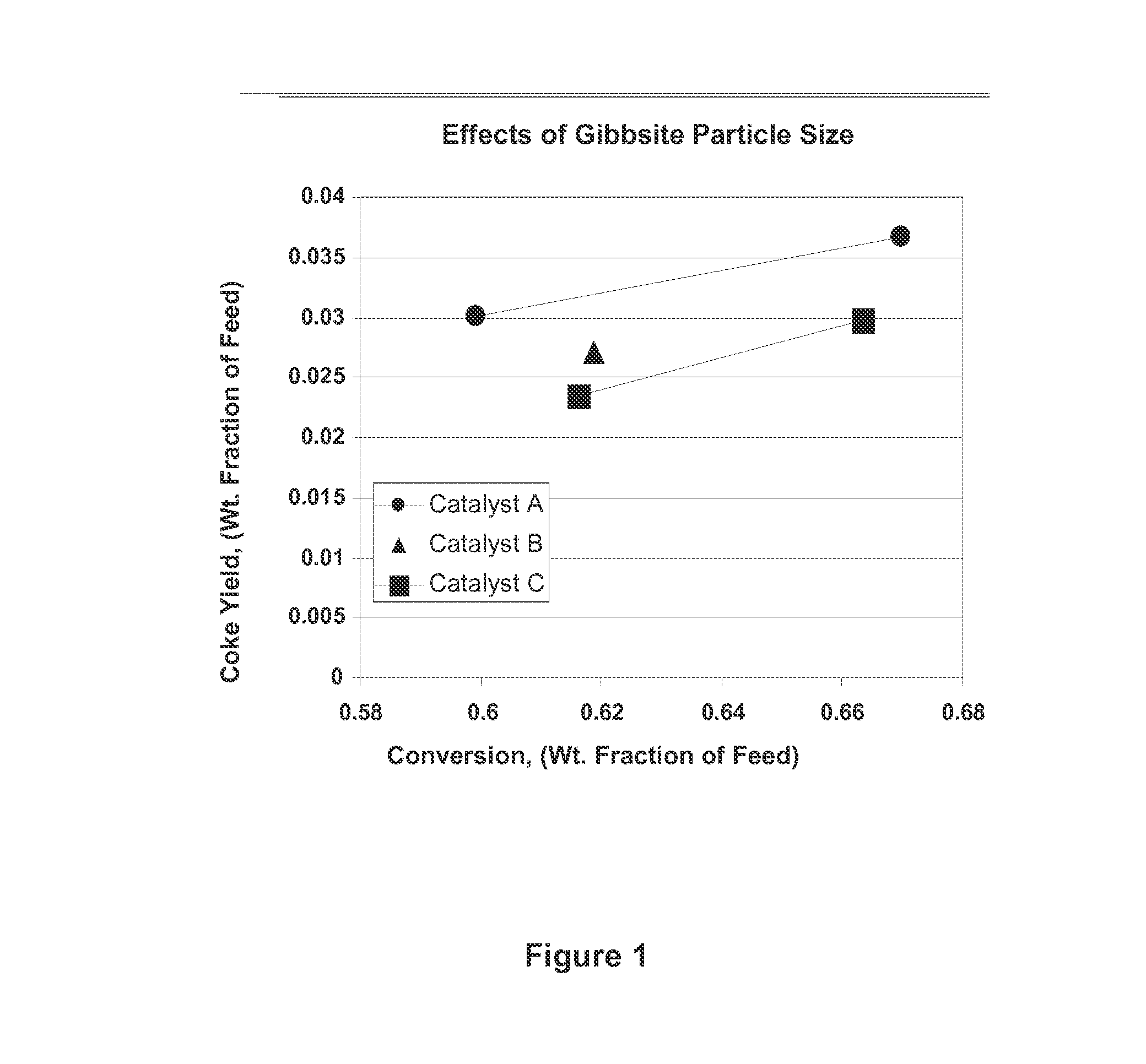

Gibbsite catalytic cracking catalyst

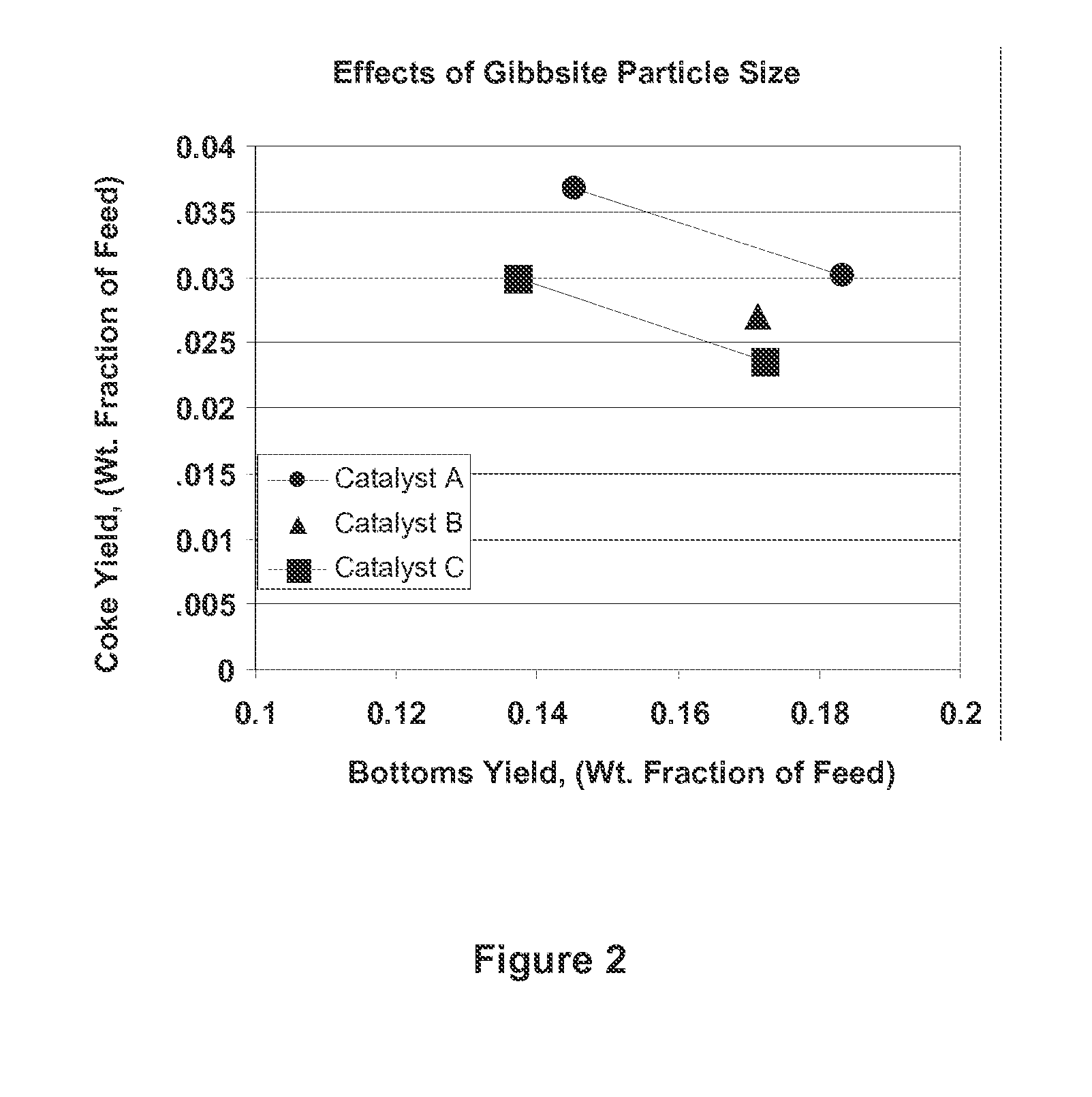

InactiveUS20130131419A1Reduce coke yieldCatalytic crackingMolecular sieve catalystsFaujasiteOrganic chemistry

A fluid catalytic cracking catalyst exhibiting reduced coke make comprises a zeolite cracking component in a matrix of gibbsite having a median particle size of not more than 0.4 microns and preferably not more than 0.3 microns. The zeolite cracking component will normally be a faujasite, with preference to zeolite Y in its various forms such as Y, HY, REY, REHY, USY, REUSY and secondary zeolite additives may be present, including ZSM-5.

Owner:EXXON RES & ENG CO

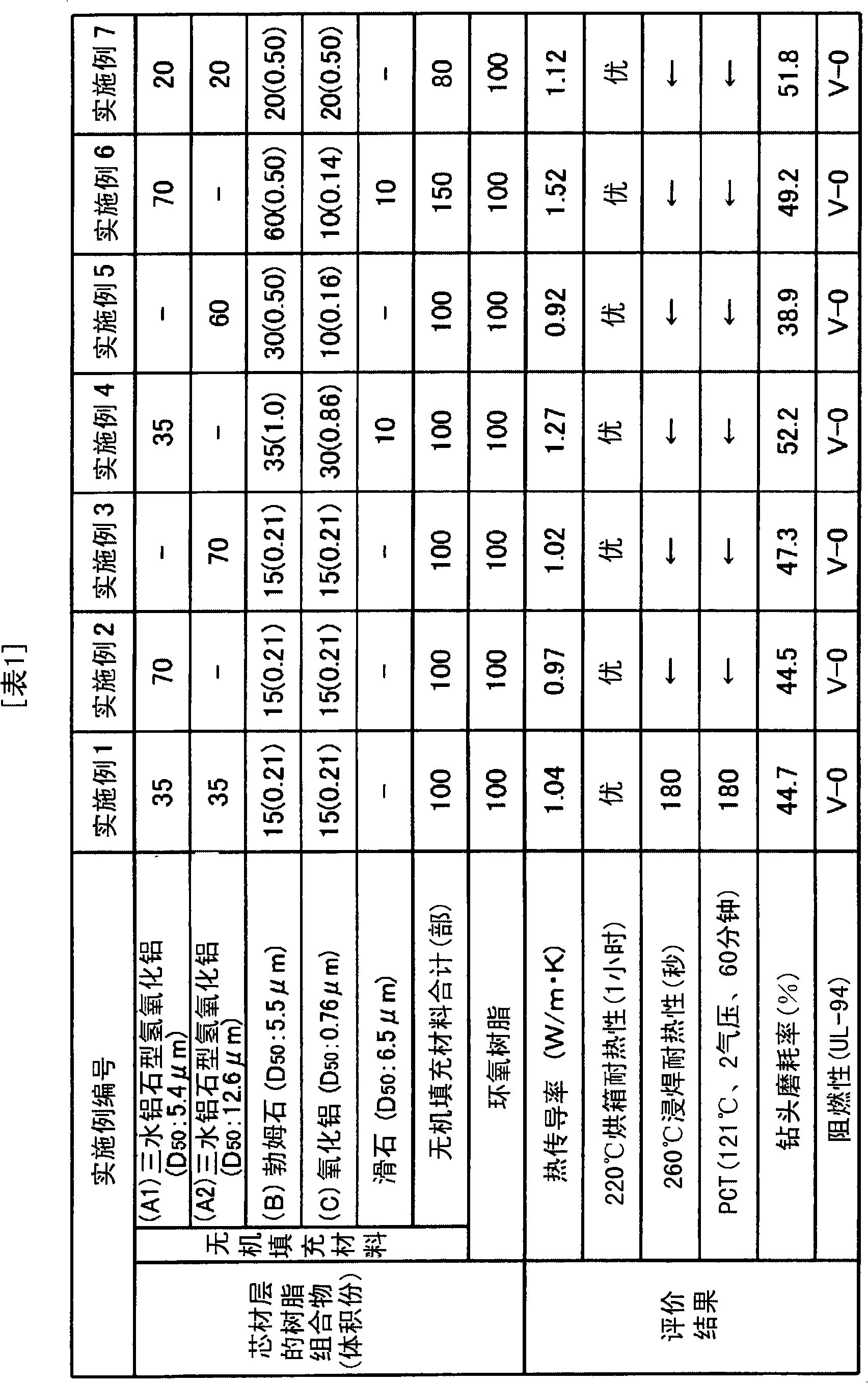

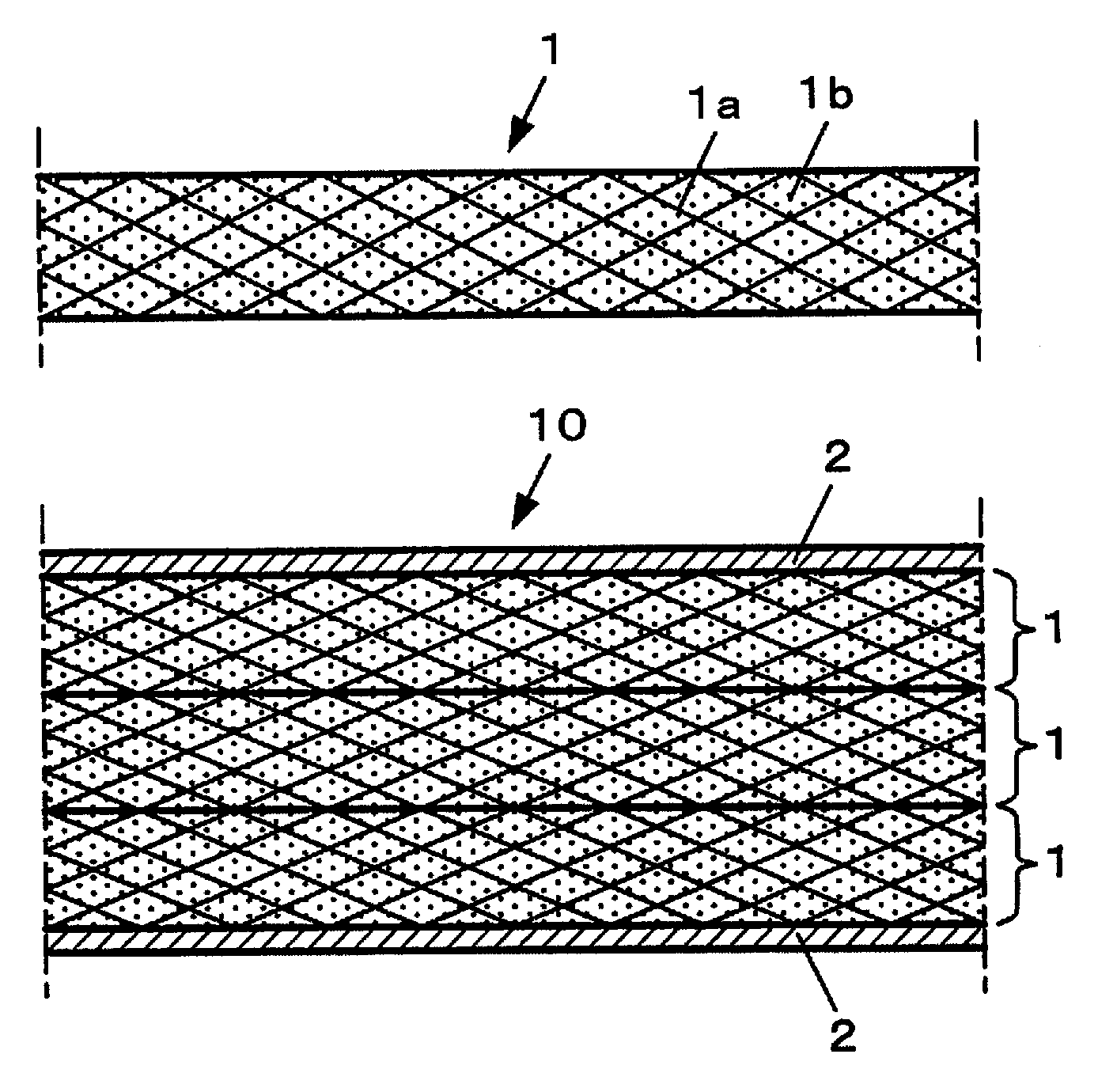

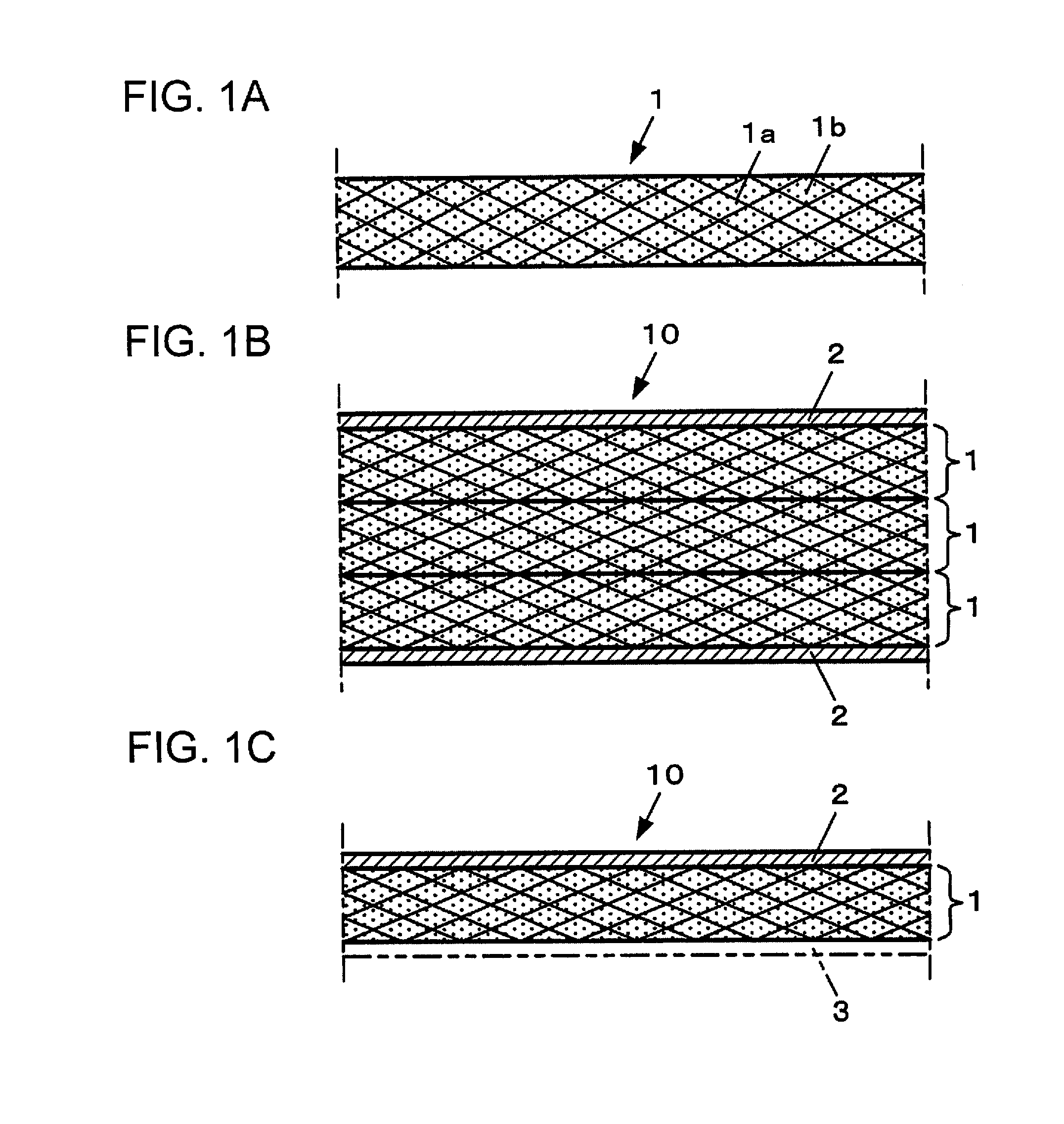

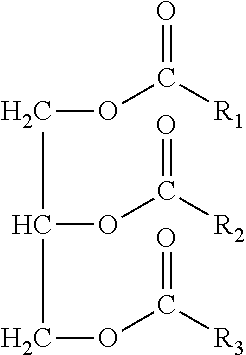

Thermosetting resin composition, prepreg, laminate, metal foil-clad laminate, and circuit board

ActiveUS20140087614A1Improve thermal conductivityImprove conductivityPrinted circuit aspectsElectrical equipmentMetal foilMaterials science

Provided is a thermosetting resin composition that contains 40 to 80 parts by volume of an inorganic filler with respect to 100 parts by volume of thermosetting resin solids and the inorganic filler. The inorganic filler contains (A) at least one type of particles selected from among gibbsite-type aluminum hydroxide particles and magnesium hydroxide particles having an average particle size (D50) of 1 to 15 μm; (B) aluminum oxide particles having an average particle size (D50) of 1.5 μm or less; and (C) a molybdenum compound, and the blending ratios (by volume) of the component (A), the component (B) and the component (C) with respect to 100% as the total amount of inorganic filler are component (A): 30 to 70%, component (B): 1 to 40%, and component (C): 1 to 10%.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Process for the production of alumina

A process for the production of alumina is performed by dissolving gibbsite Al2O3.3H2O in nitric acid to provide an acid solution containing aluminum nitrate; decomposing the acid solution at 300-700° C. with a free air supply to form alumina and Nox by spraying onto the inner surface of one or more rotary kilns, drying in a fluid bed, or drying in a steel belt conveyor furnace; regenerating the formed NOx into concentrated nitric acid and recycling the nitric acid to be used for the dissolving of gibbsite; and recovering the alumina formed upon decomposing the acid solution.

Owner:HALDOR TOPSOE AS

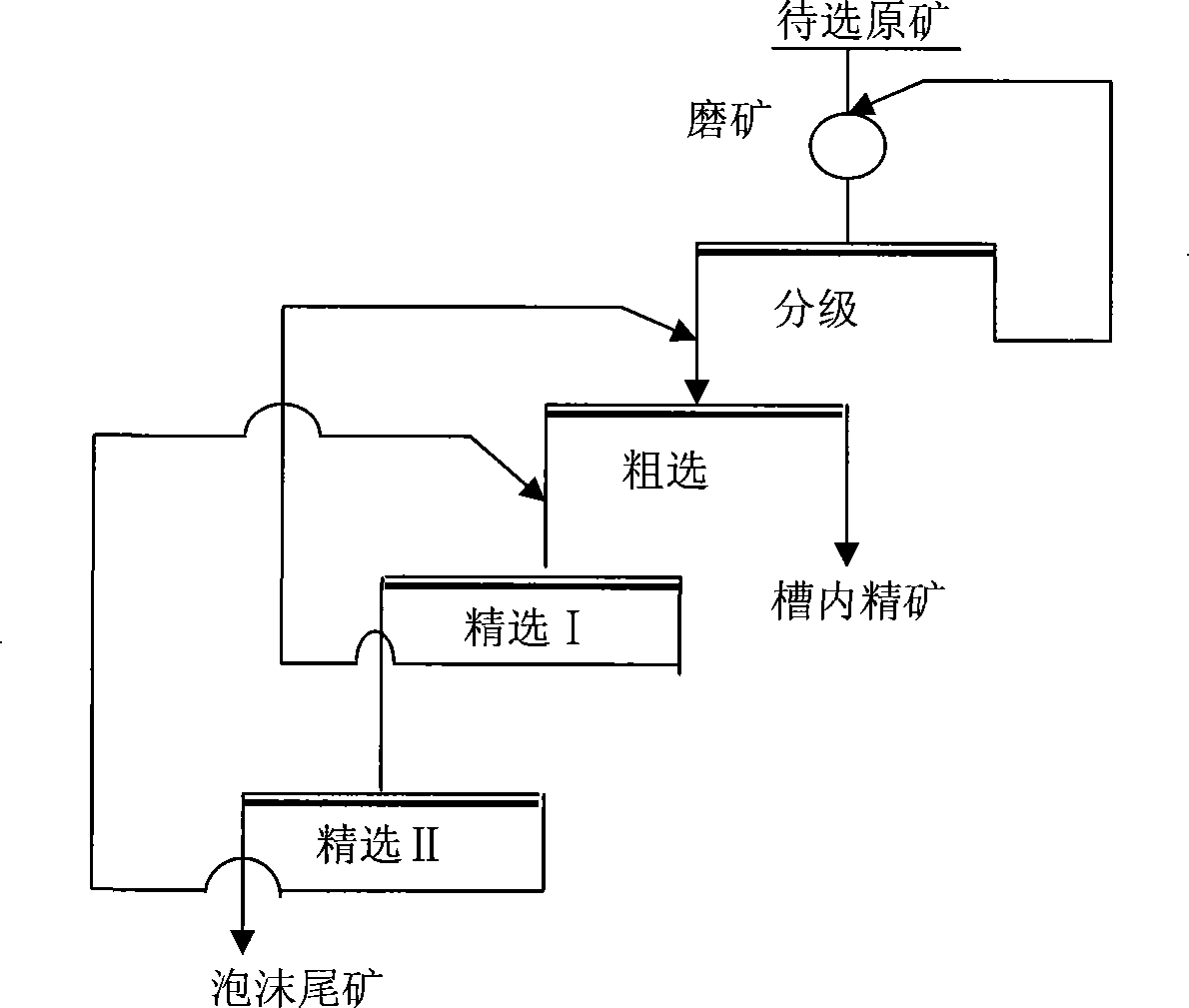

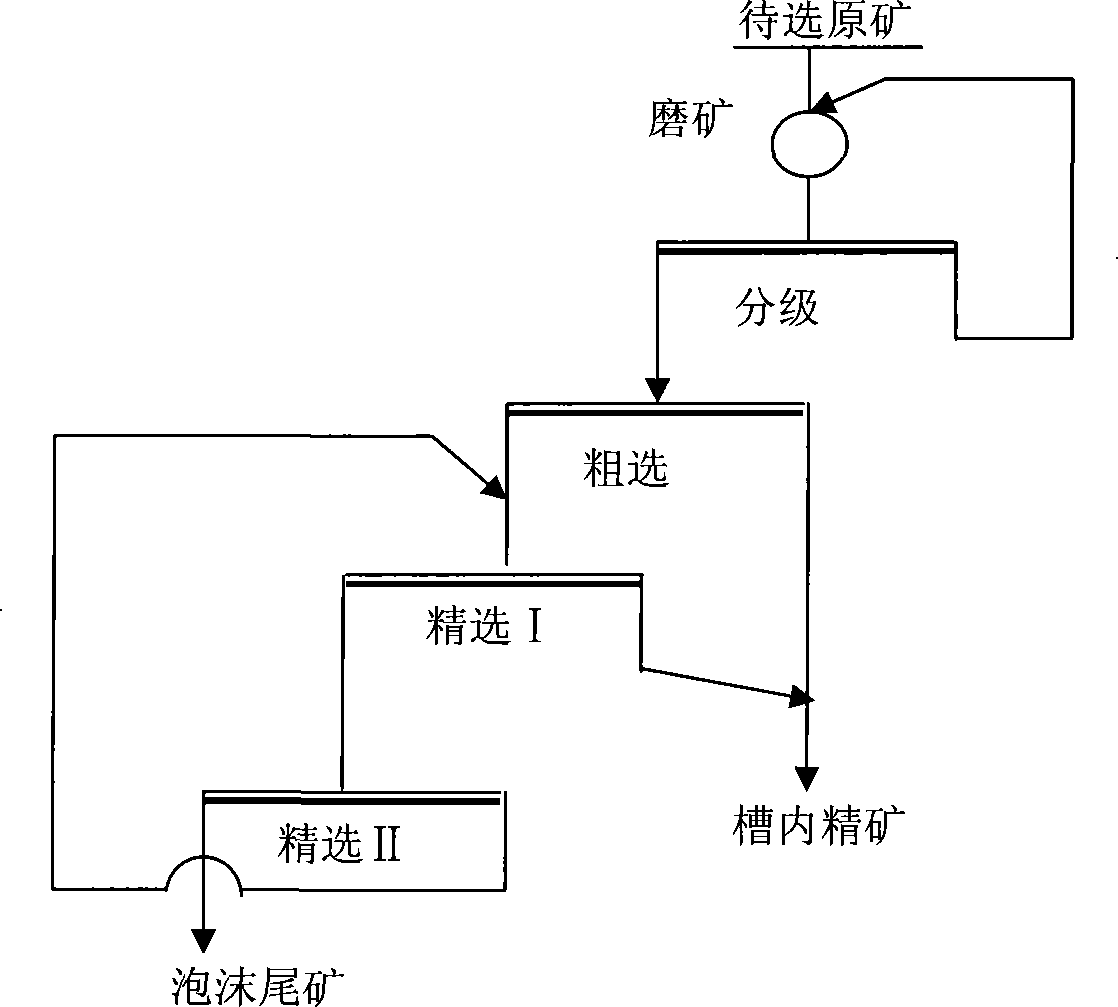

Method of alumyte flotation removing quartz

The invention relates to a flotation method for removing quartz from the bauxite, which is characterized by milling boehmite-containing gibbsite-type bauxite containing the quartz as impurity mineral, adding regulator and organic amine collector, adjusting the pH value of the ore pulp to 8.5-11.5, performing floatation while maintaining collector concentration in a floating system to obtain floated foams mainly containing quartz, and optionally grading to obtain coarse grains as tailings, wherein aluminum-containing mineral stayed in a floating tank is used as concentrate ore. The inventive method has the advantages of simple process, low cost, good concentrate ore particle size distribution, easy processing for tailings, etc. The method can float quartz impurity in the bauxite to widen economically-utilized bauxite resource; and has good application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

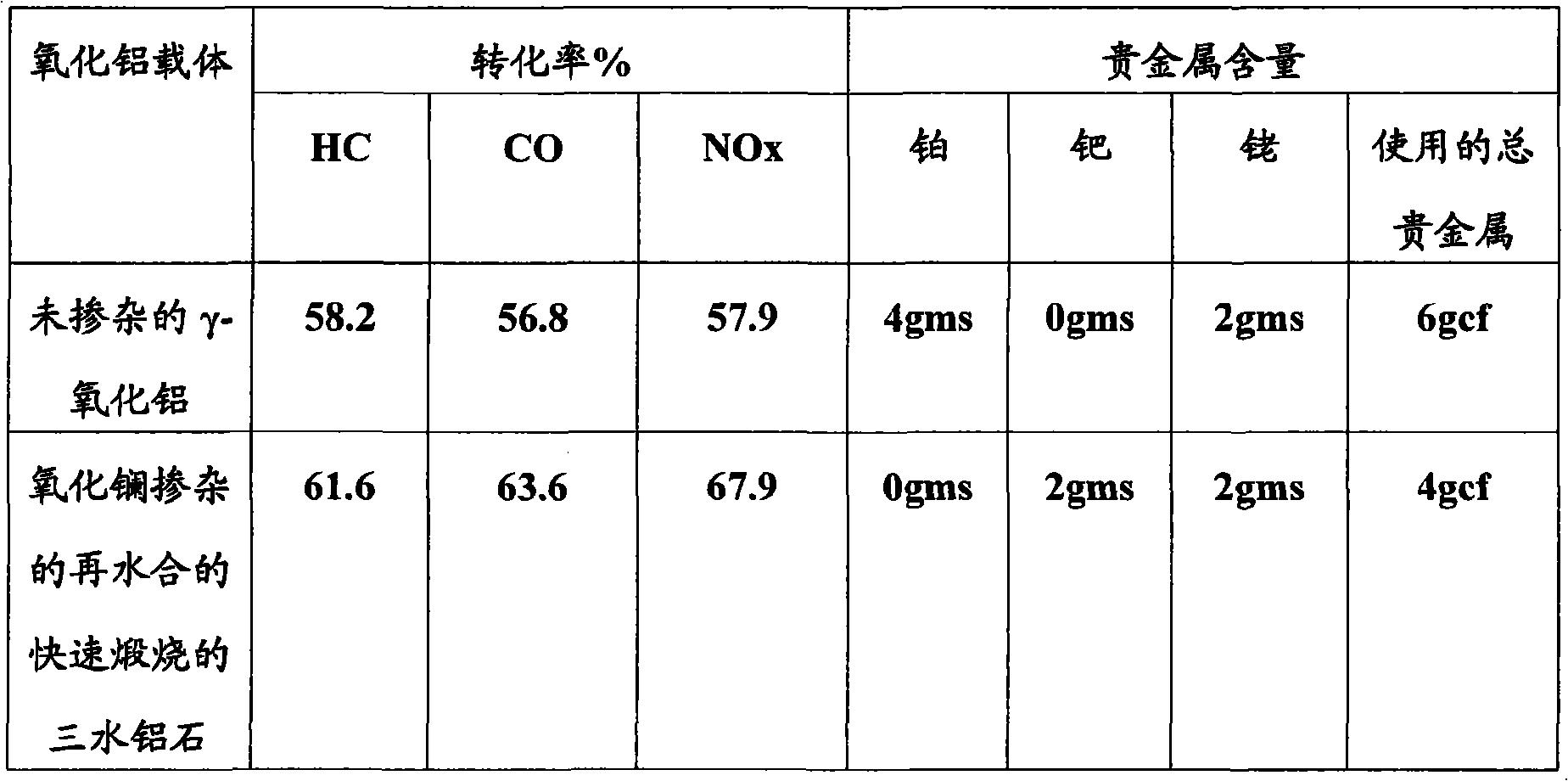

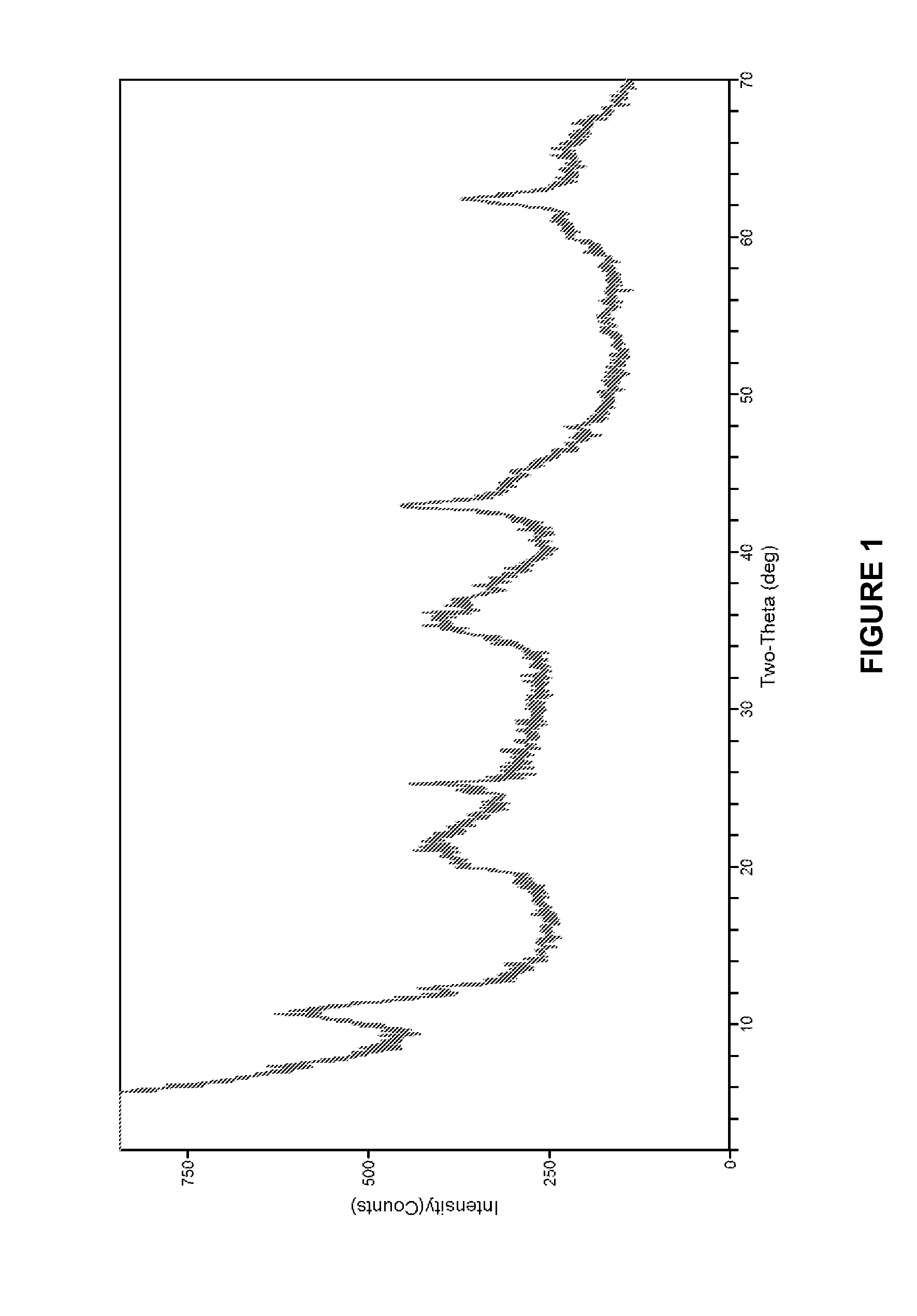

Stabilized flash calcined gibbsite as a catalyst support

InactiveUS20070098611A1Improve thermal stabilityLow costNitrogen compoundsInternal combustion piston enginesHigh sodiumChemical reaction

A low cost support useful in chemical reactions and automotive arts is formed by rehydrating a flash calcined gibbsite in an aqueous acidic solution. The rehydrated support can be subsequently stabilized by doping with a stabilizing metal such as lanthanum. The alumina support has excellent thermal stability, high sodium tolerance, high activity with low precious metal loading, and high pore volume and surface area.

Owner:ENGELHARD CORP

Activated alumina formed body and method for producing the same

InactiveUS6962684B2High bulk densityLarge pore volumeOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsAluminium hydroxideSorbent

An activated alumina formed body with a high bulk density and a large macro-pore volume is provided. The activated alumina formed body can be produced by a method comprising the steps of calcining a gibbsite-phase aluminum hydroxide having a median particle size of from about 10 μm to about 35 μm and a packed bulk density of from about 1.05 g / cm3 to about 1.3 g / cm3 to obtain an at least partially rehydratable alumina powder; forming the rehydratable alumina powder in the presence of water; maintaining the formed body in the presence of water to rehydrate the formed body; and calcining the rehydrated formed body to obtain an activated alumina formed body. The activated alumina formed body is usable as an adsorbent, a catalyst supporting precious metal or the like.

Owner:SUMITOMO CHEM CO LTD

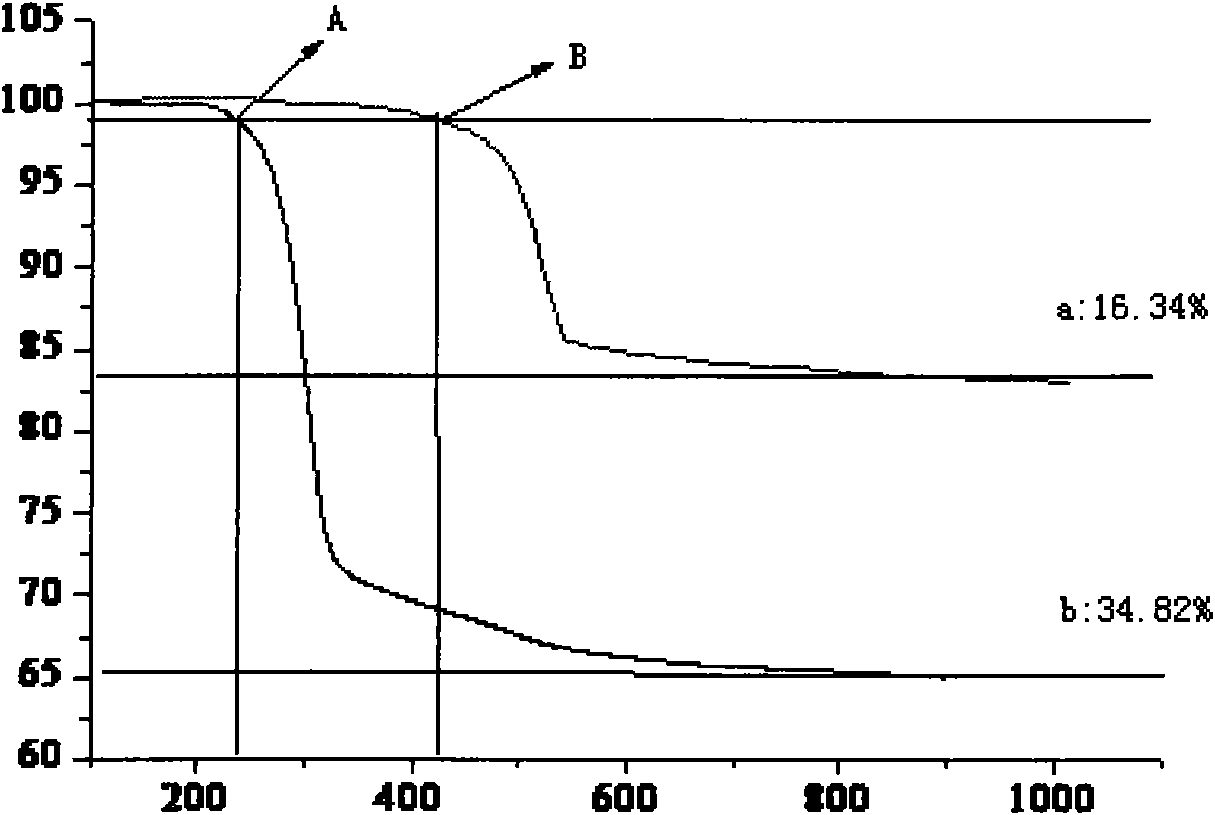

Dry preparation method for large-size boehmite

InactiveCN102249270AImprove heat resistanceHigh whitenessAluminium oxides/hydroxidesAluminium hydroxideGranularity

The invention discloses a dry preparation method for large-size boehmite. The method comprises the following steps of: at a temperature of 120-350DEG C and under a pressure intensity of more than or equal to 10kPa, converting the gibbsite crystal structure of aluminium hydroxide into boehmite; then grinding the boehmite till the granularity is of 1-4 micrometers, and scattering the boehmite particles into water uniformly by a wet high-speed stirring method, and conducting a nano-SiO2 coating treatment on the surface; and finally performing impurity removing, purification and drying, thus obtaining the product of large-size boehmite. The large-size boehmite prepared by a dry method of the invention has low impurity content, high boehmite conversion rate and controllable crystallization granularity. In addition, employing an inorganic modifier, the method provided in the invention can substantially reduce material oil absorption rate and improve liquidity, thus broadening the application of the method in the field of electronic materials.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

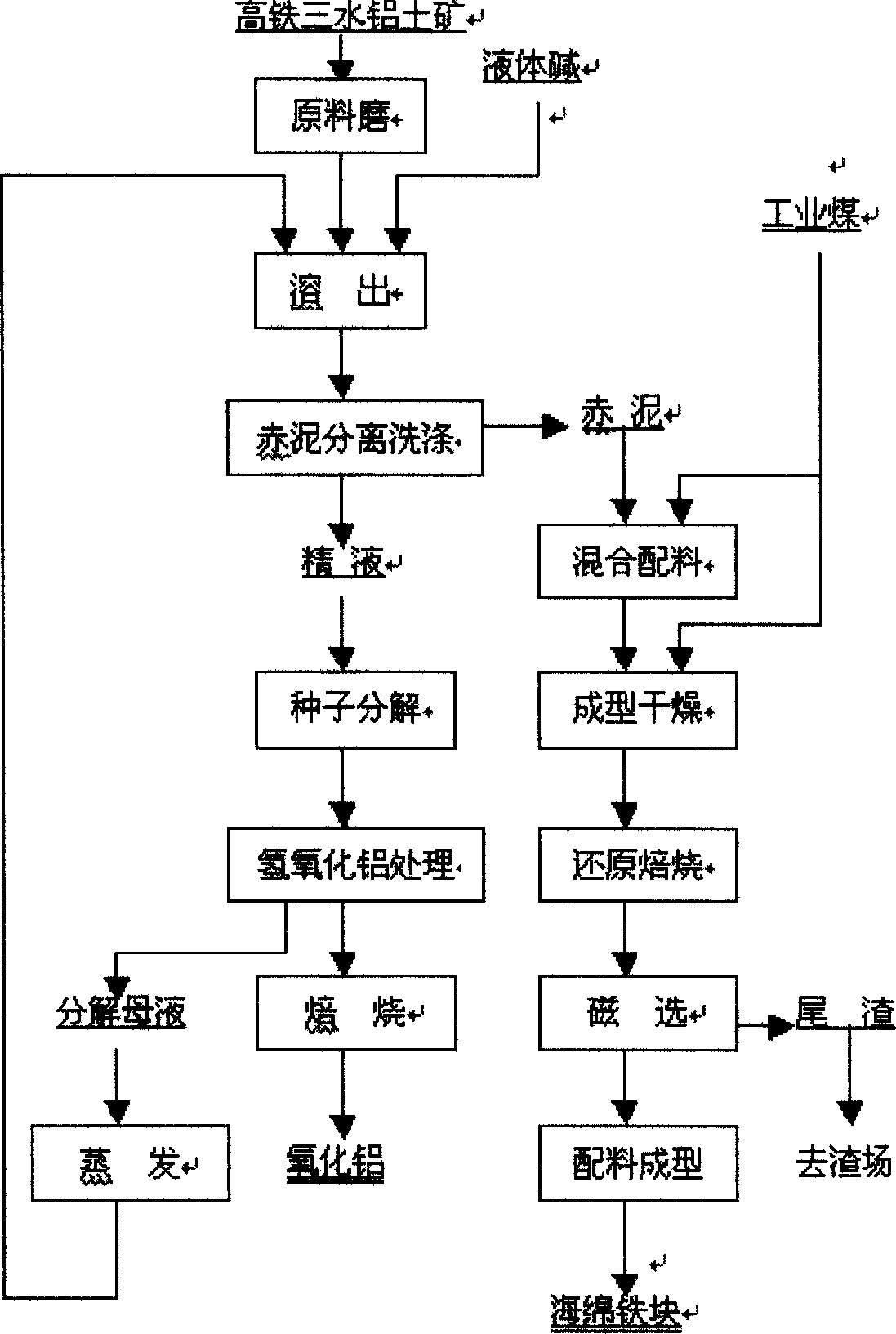

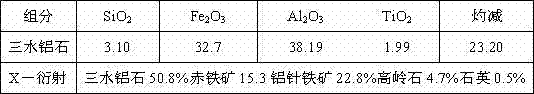

Method for extracting aluminium and iron from high-iron bauxite trihydrate

InactiveCN1743475ARealize comprehensive utilizationSimple processSolid separationRotary drum furnacesRed mudAluminium hydroxide

This invention provides a method for extracting Al and iron from a ferric gibbsite, which grinds and dissolves the ferric gibbsite then carries out rough and fine separation-washing to the red mud and sends the refined liquor to the resolving plant to separate AlOH and bake it to get A10. The red mud is matched with recovery coal and burning coal to be dried and baked then to be ground and selected magnetically to get sponge iron power to be filtered and matched with raw material, dried to get sponge iron balls.

Owner:GUIYANG AL-MG DESIGN & RES INST

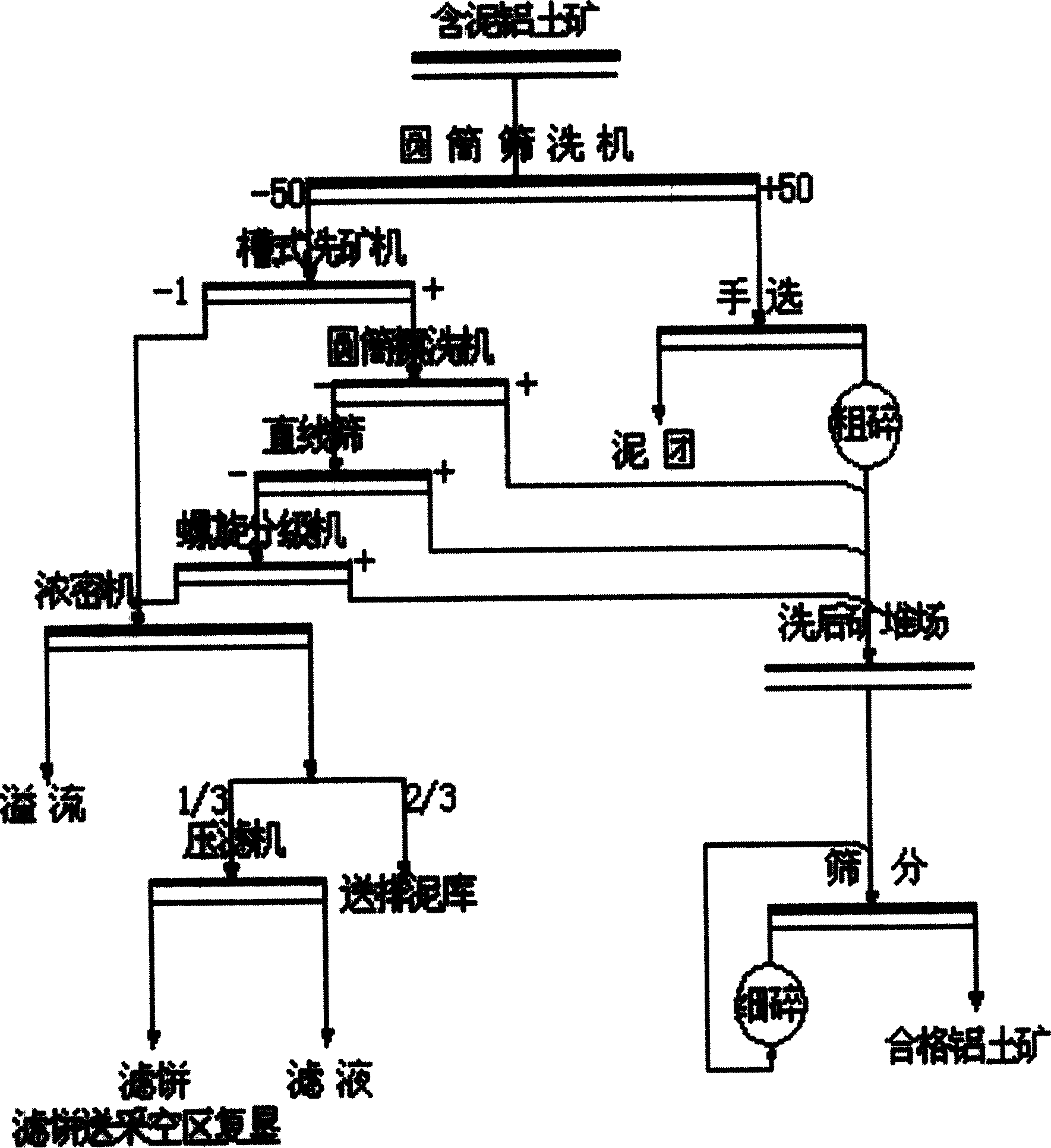

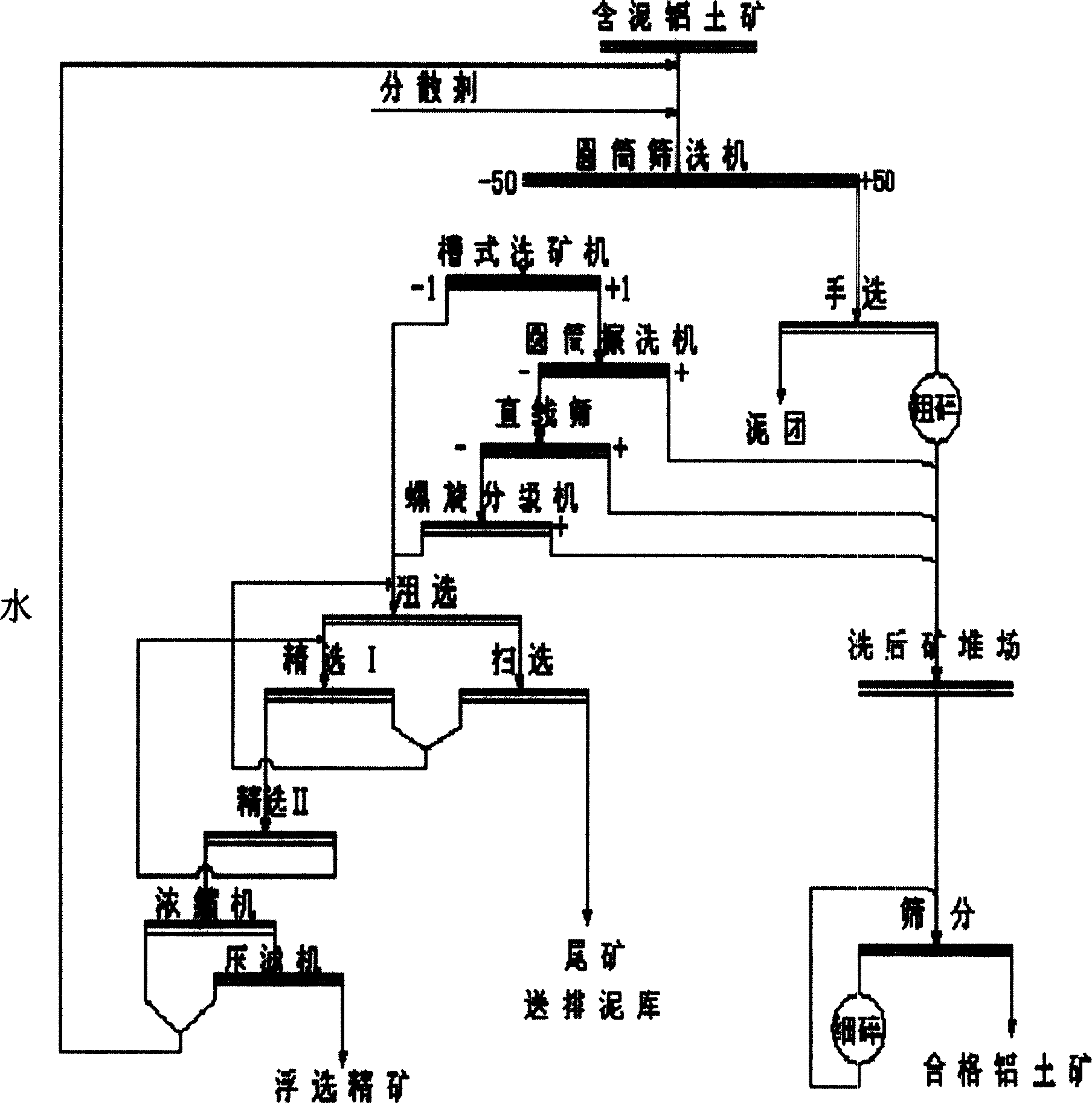

Washup-flotation process for stacked bauxite

The invention discloses a mill run technology of bauxite, especially relates to a ore wash-floatation technology of cumulate bauxite. For cumulate bauxite, changing the single ore wash technology into ore wash and appending dispersant, and floatation to the gangue. The invention can increase the quality of wash-concentrate and decrease the mud ratio of wash-concentrate; by floatation, a number of gibbsite, diasporite, bodhmite can be reclaimed, achieve the intention of using bauxite.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

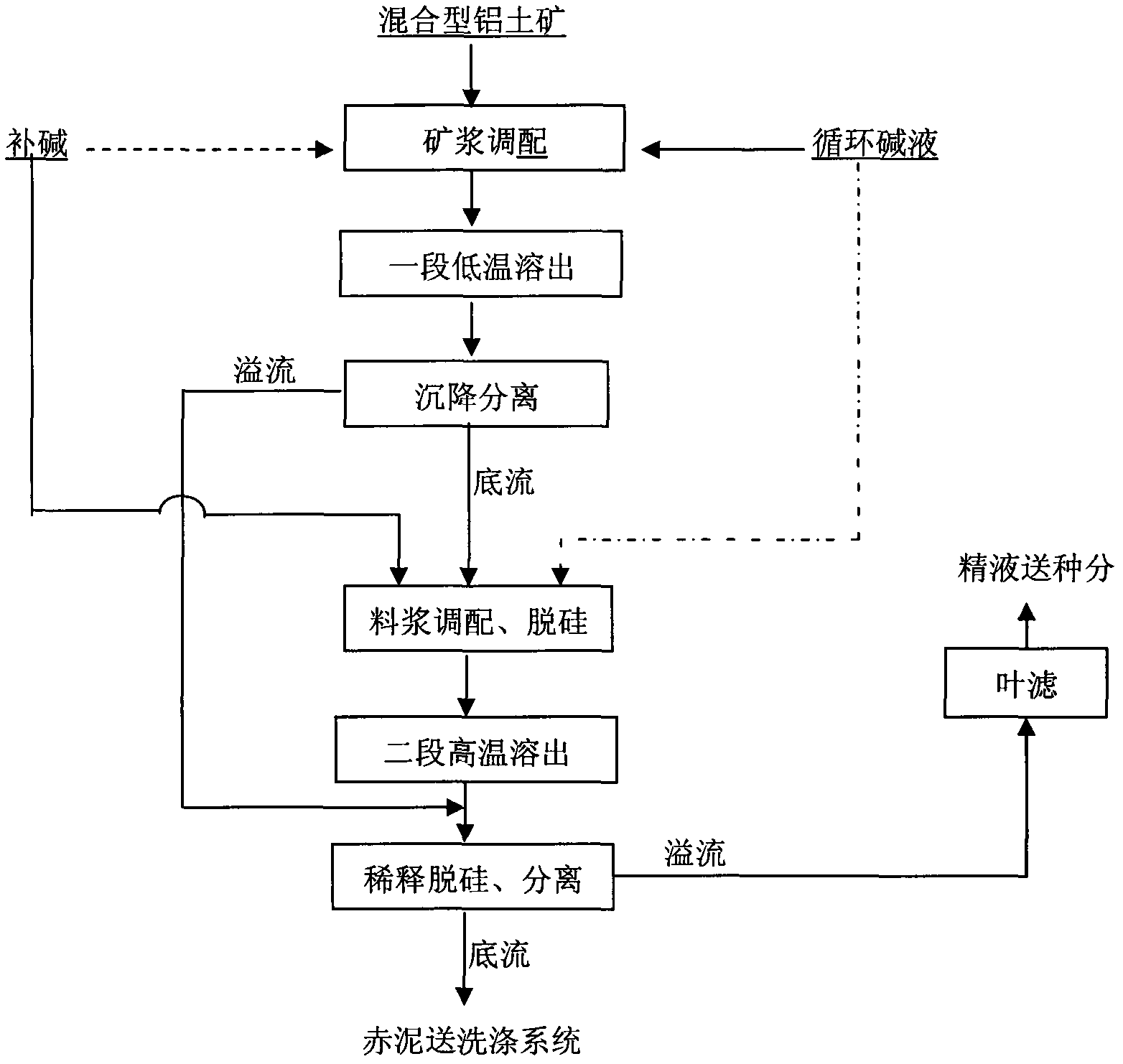

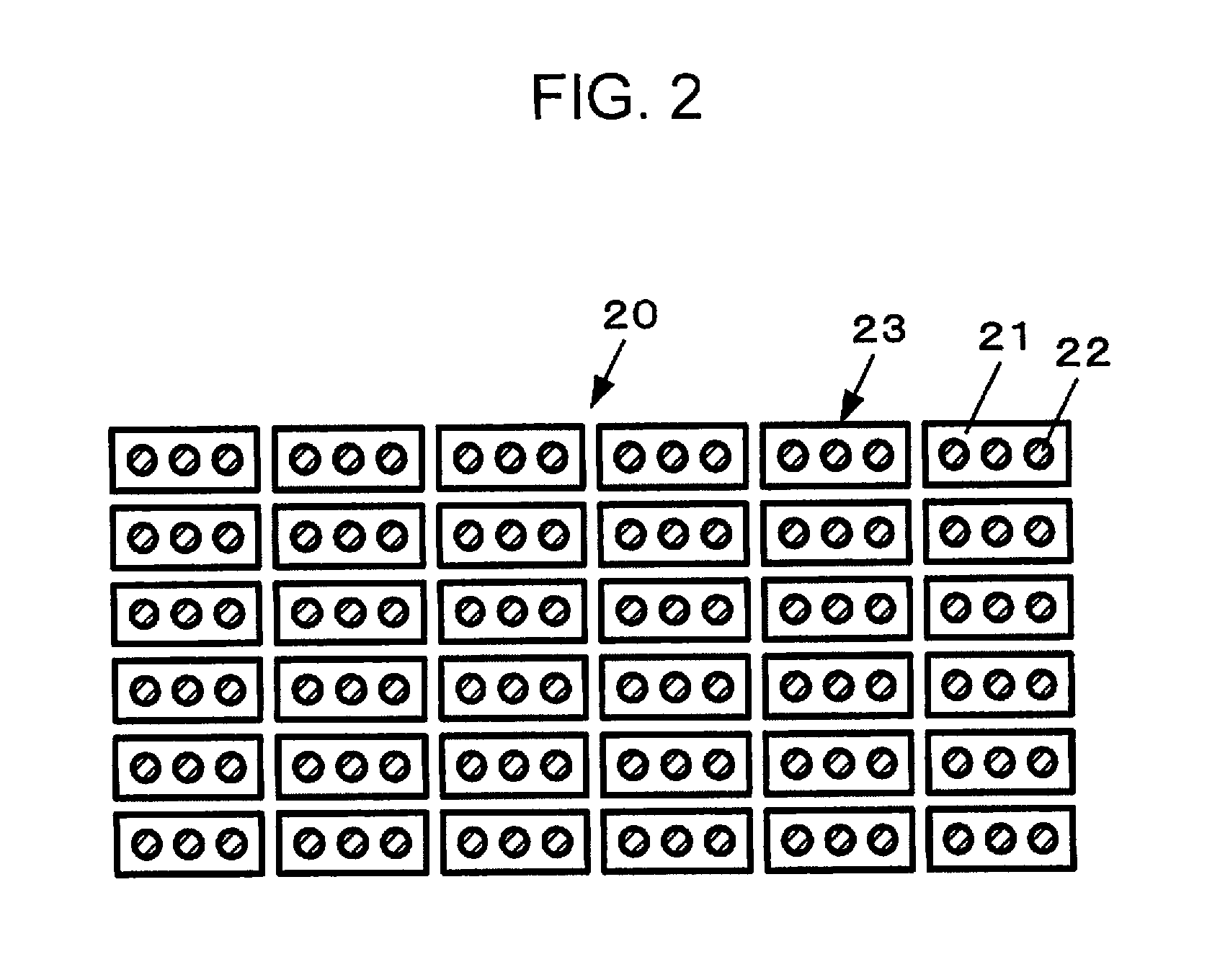

Two-stage digestion process of boehmite-gibbsite hybrid bauxite

InactiveCN102826577AOptimize process systemReduce material flowAluminium oxides/hydroxidesRed mudFull recovery

The invention relates to a two-stage digestion process of boehmite-gibbsite hybrid bauxite. The process is characterized in that soluble gibbsite of the boehmite-gibbsite hybrid bauxite is dissolved under a normal pressure and in short time without adding lime during the digestion process; and that insoluble boehmite is treated by a high temperature. The method can not only ensure full recovery of alumina but also reduce energy consumption of the digestion greatly. By performing predesilicification of ore pulp under a condition of high solid content after a first bottom flow is added to a systemized supplement with alkali, heating surface scar of a second high-temperature digestion slows down; and pulp liquid volume of predesilicification can be reduced. Loss of alumina and red mud amount can be reduced because no lime is added in the digestion process. With the two-stage digestion process of the boehmite-gibbsite hybrid bauxite, problems of low alumina recovery rate or large investment, high energy consumption and the like existing in a process of Bayer digestion process of the boehmite-gibbsite hybrid bauxite can be solved; and objects of economically producing alumina with the two-stage digestion process by employing the boehmite-gibbsite hybrid bauxite as raw materials are realized.

Owner:长沙瑞德新材料科技发展有限公司 +1

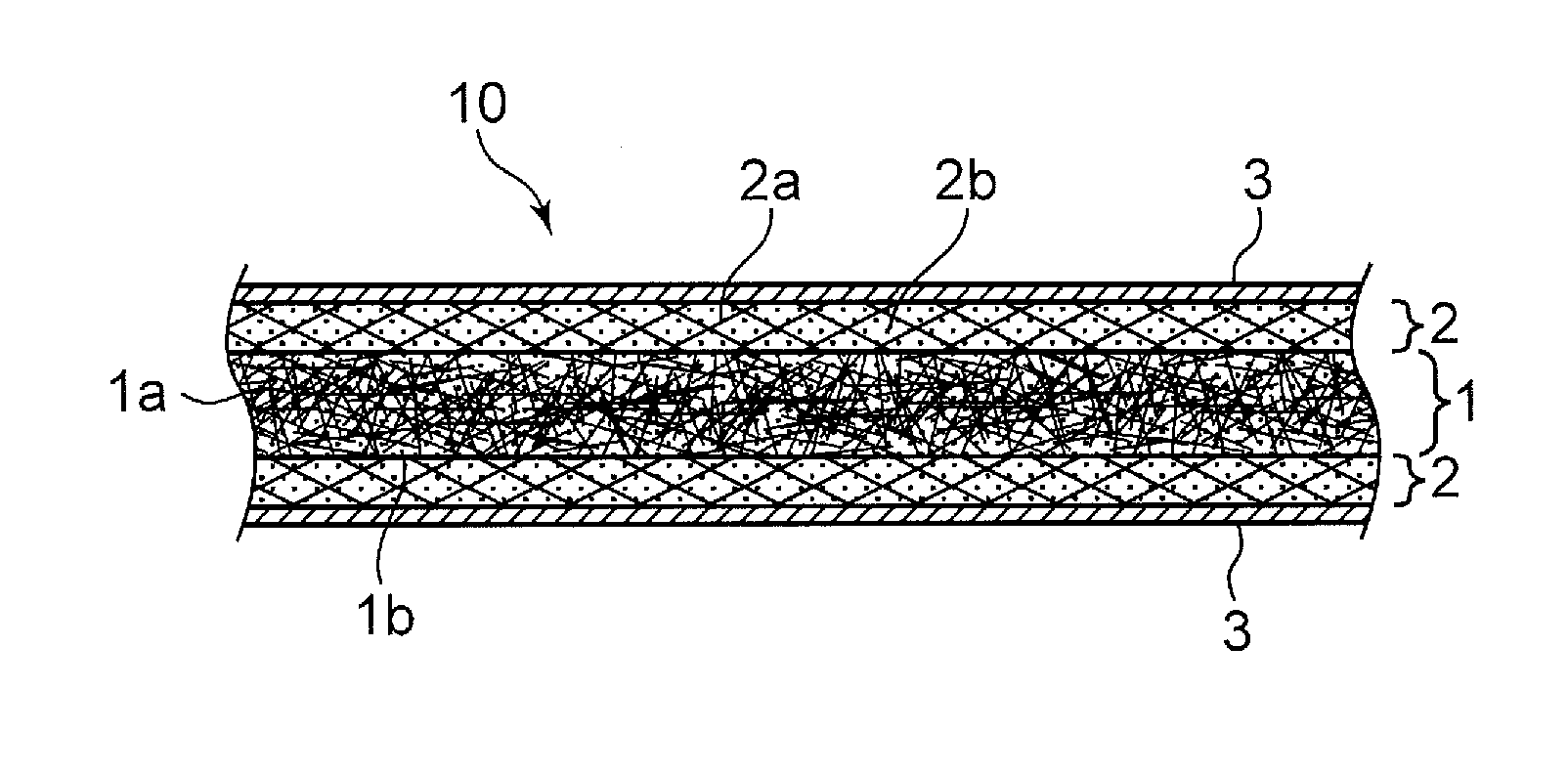

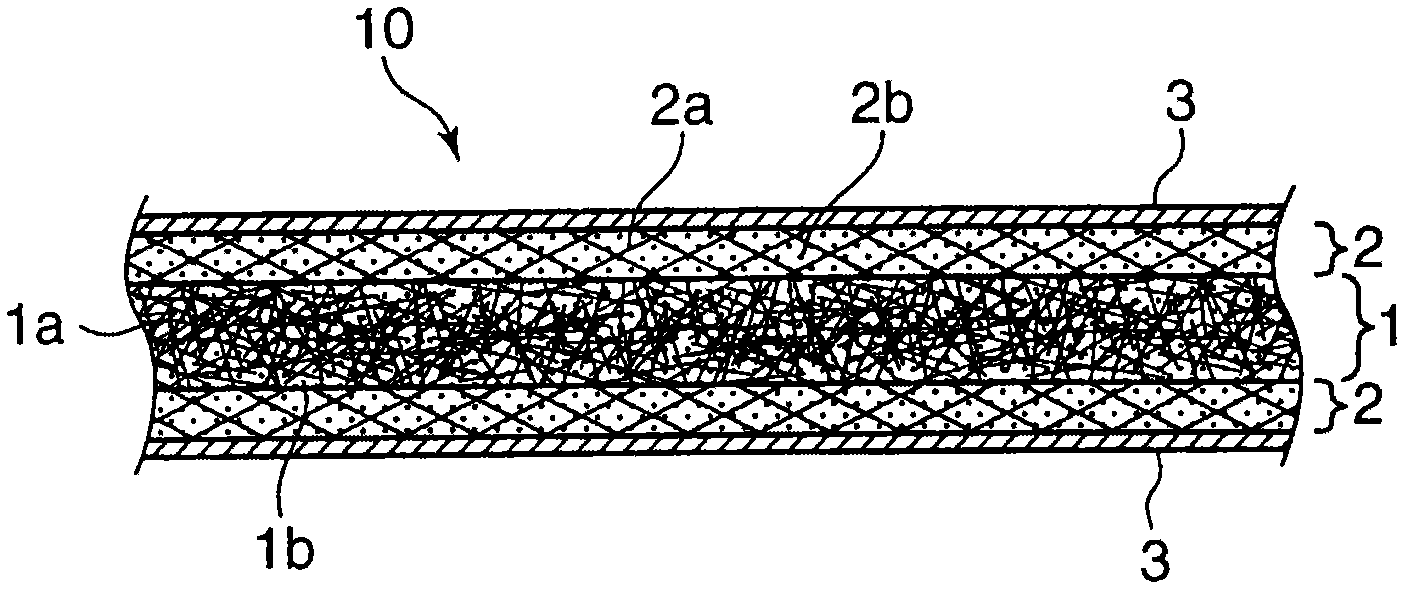

Laminate, metal-foil-clad laminate, circuit board, and circuit board for LED mounting

ActiveCN102036815AWith a clear purposeClear featuresSynthetic resin layered productsCircuit susbtrate materialsInorganic particleAluminium hydroxide

A laminate which comprises: a core material layer obtained by impregnating a nonwoven fibrous base with a thermosetting resin composition; and surface material layers respectively laminated to both surfaces of the core material layer. The thermosetting resin composition comprises 100 parts by volume of a thermosetting resin and 80-150 parts by volume of an inorganic filler. The inorganic filler comprises (A) gibbsite-form aluminum hydroxide particles having an average particle diameter (D50) of 2-15 [mu]m, (B) at least one inorganic ingredient selected from a group consisting of boehmite particles having an average particle diameter (D50) of 2-15 [mu]m and inorganic particles which have an average particle diameter (D50) of 2-15 [mu]m and which contain crystal water having a release initiation temperature of 400 DEG C or higher or contain no crystal water, and (C) aluminum oxide particles having an average particle diameter (D50) of 1.5 [mu]m or smaller, the proportion of (A) the gibbsite-form aluminum hydroxide particles to (B) the at least one inorganic ingredient selected from a group consisting of the boehmite particles and the inorganic particles to (C) the aluminum oxide particles (ratio by volume) being 1:(0.1-1):(0.1-1).

Owner:PANASONIC CORP

Stabilized flash calcined gibbsite as a catalyst support

InactiveCN101321584AEasy to carryIncrease surface areaInternal combustion piston enginesDispersed particle separationHigh sodiumChemical reaction

Owner:BASF CATALYSTS LLC

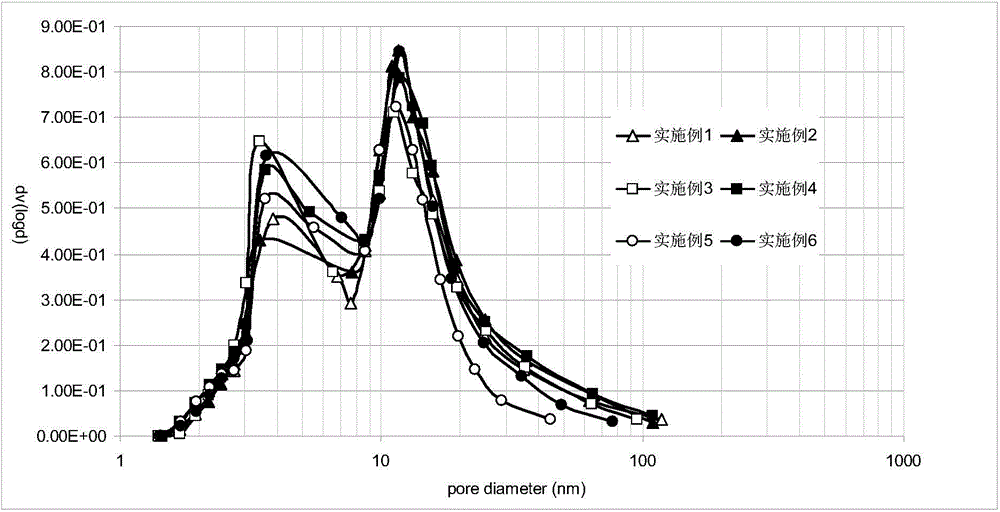

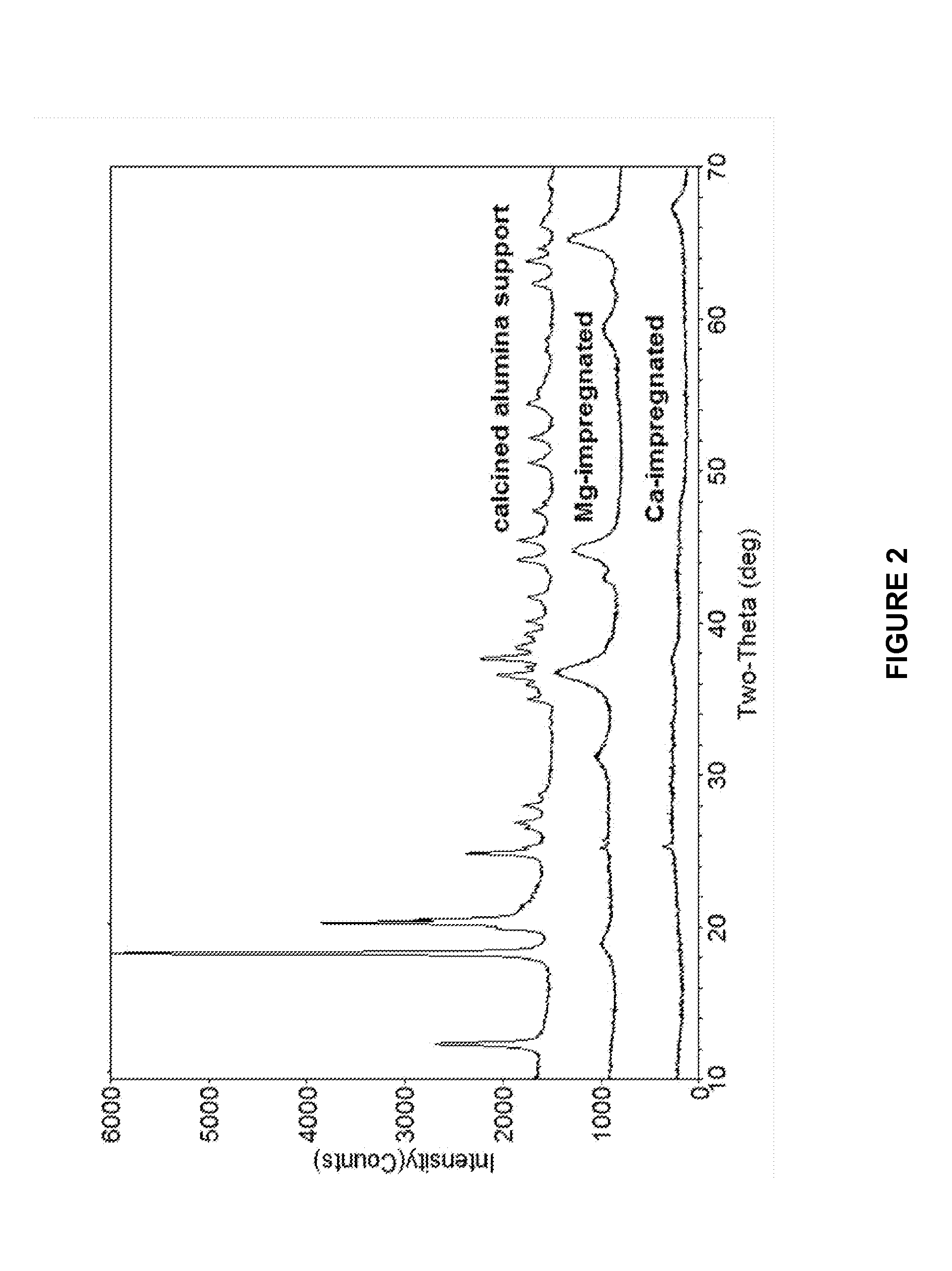

Composite oxide carrier with bimodal mesopores, as well as preparation method and application of composite oxide carrier

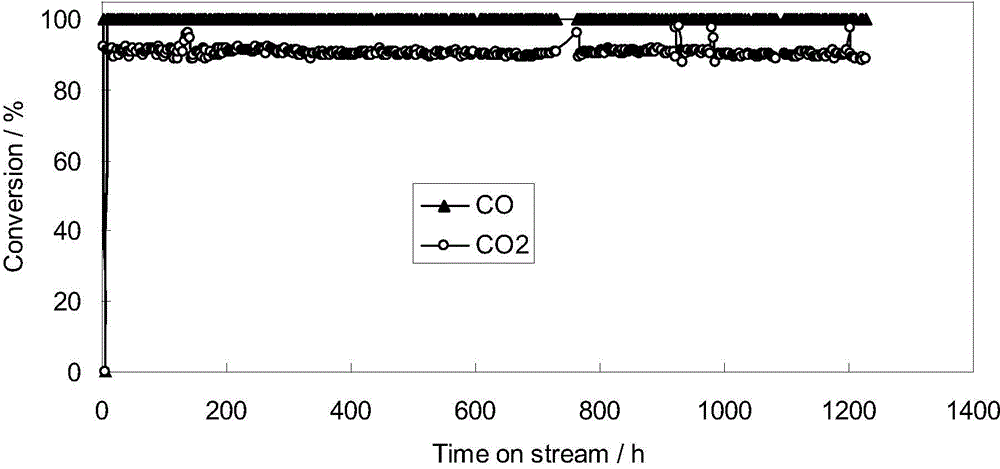

ActiveCN105618157AHigh activityImprove stabilityCatalyst carriersGaseous fuelsAlkaline earth metalMethanation

The invention discloses a composite oxide carrier with bimodal mesopores as well as a preparation method and application of the composite oxide carrier. An oxide carrier is used for an immersion type CO2 methanation catalyst, and comprises a basic carrier gamma-Al2O3 and structure stabilizing additives. A composite oxide carrier comprises a mixture of gamma-Al2O3, pseudo bohemite (Al2O3.H2O) and gibbsite (Al2O3.3H2O). The composite oxide carrier is prepared by adding the structure stabilizing additives such as alkaline-earth metal, transition metal, rare-earth metal and the like, a pore former and a binder in a process including impregnation, mixing, granulation, forming and calcination. The composite oxide carrier provided by the invention has relatively large specific surface area and a bimodal distributed mesoporous structure, and has the advantages of high carrier water absorption rate, stable structure and good mechanical strength; the preparation process facilitates enlarged production. A supported Ni-based CO2 methanation catalyst prepared by adopting the carrier disclosed by the invention has relatively good low-temperature catalysis activity and long-time operation stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

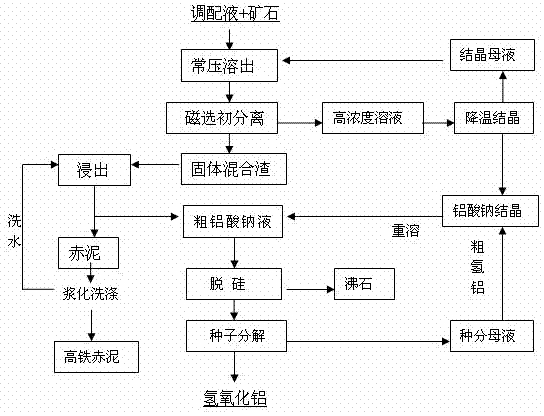

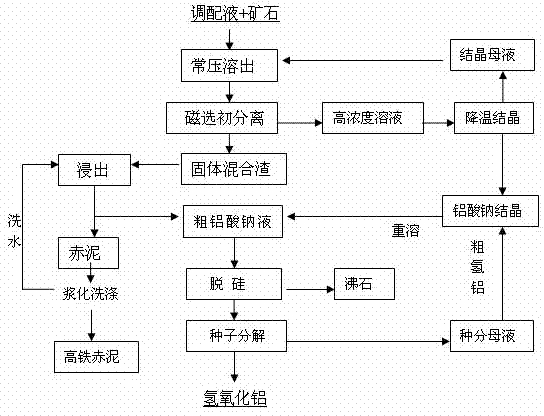

Method for treating gibbsite by using high-concentration alkali liquor under normal pressure

ActiveCN102502733AImprove cycle efficiencyAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention discloses a method for treating gibbsite by using high-concentration alkali liquor under normal pressure. The method comprises the following steps of: stirring and uniformly mixing a high-concentration NaOH solution and high-iron gibbsite in an alkali-resistant reactor, heating to the temperature of between 110 and 140 DEG C under normal pressure, and performing primary separation on digestion slurry by using a magnetic separation grader; leaching the obtained solid slag at the temperature of 65 DEG C by using a small amount of water, and performing further liquid-solid separation to obtain high-iron red mud; performing cooling crystallization on a solution obtained after magnetic separation, returning a mother solution to the digestion process, adding a sodium aluminate crystal into a seed decomposition mother solution, redissolving to obtain a sodium aluminate solution, adding Bayer process red mud, lime and the like into the sodium aluminate solution, and performing desilication twice to obtain a sodium aluminate fine solution with the aluminum-to-silicon ratio of 145 to 180 and the molar ratio alphaK of sodium oxide to aluminum oxide of 1.45 to 1.55; and decomposing the fine solution by a Bayer process under the conventional conditions, and performing liquid-solid separation to obtain aluminum hydroxide particles and the seed decomposition mother solution. The seed decomposition mother solution is not evaporated and is returned to the process after aluminum salt and coarse hydrogen and aluminum are dissolved in the seed decomposition mother solution, so that the defect of large water evaporation amount caused by a large concentration difference is overcome.

Owner:中铝山东有限公司

Catalyst carrier, and preparation method and application thereof

InactiveCN103041867AEnhanced mass transferImprove heat transfer performanceCatalyst carriersOther chemical processesReaction rateAlkali metal oxide

The invention relates to a catalyst carrier used for generating gas pulse in a reactor. The outer shape of the catalyst carrier is in a circular cake shape (flying saucer shape). The catalyst carrier is composed of a plurality of unit holes. The structure of each unit hole is that two ends of unit hole are prismoids and the middle portion of the unit hole is a hollow neck (weir groove), wherein the prismoids are preferably triple prismoids, quadruple prismoids or pentagonal prismoids, hexagonal prismoids, regular circular truncated cones, etc. The catalyst carrier is made of chemical ceramic materials. The chemical ceramic materials comprise the following raw materials of, by weight, gibbsite, 25-35 parts of kaolin, 10-20 parts of Guizhou soil, 5-10 parts of talcum, 8-12 parts of feldspar and 8-12 parts of alkali metal oxide. The catalyst carrier is suitable for being used as a carrier for the catalyst of the field of petroleum chemistry or as filling materials in the reactor. The carrier with the structure enhances a mass transfer effect and a heat transfer effect between gas and liquid, and further increases catalytic effect of the catalyst and reaction rate. The catalyst carrier has high hardness, high strength, large specific surface area, good high temperature resistance and good acid and alkali resistance.

Owner:刘一序

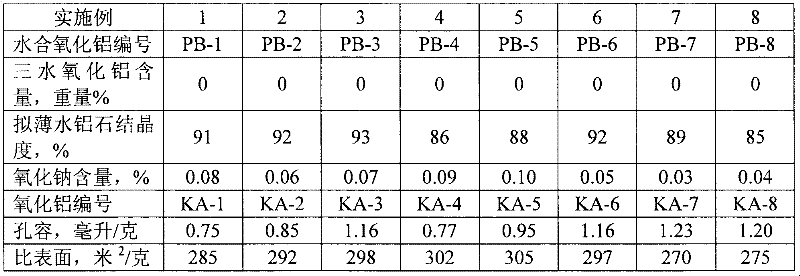

Preparation method of pseudo-boehmite

ActiveCN102442689AFacilitate synthesis reactionEasy to operateAluminium oxides/hydroxidesReaction temperatureDawsonite

The invention provides a preparation method of pseudo-boehmite. The preparation method, which comprises a gel formation reaction which is carried out on a sodium aluminate solution and an acidic gas, is characterized in that: the acidic gas is a mixed gas containing CO2 and at least one gas with the pressure of less than 6.38kPa; the gel formation reaction temperature is 10-100DEG C; and the amount of the acidic gas and the ratio of CO2 to the gas with the pressure of less than 6.38kPa in the acidic gas make the pH value of the gel formation reaction be 3-7. Compared with the prior art, the method provided by the invention, which ensures that contents of gibbsite and dawsonite in the obtained pseudo-boehmite are zero or very small, allows the synthetic reaction of pseudo-boehmite to be convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

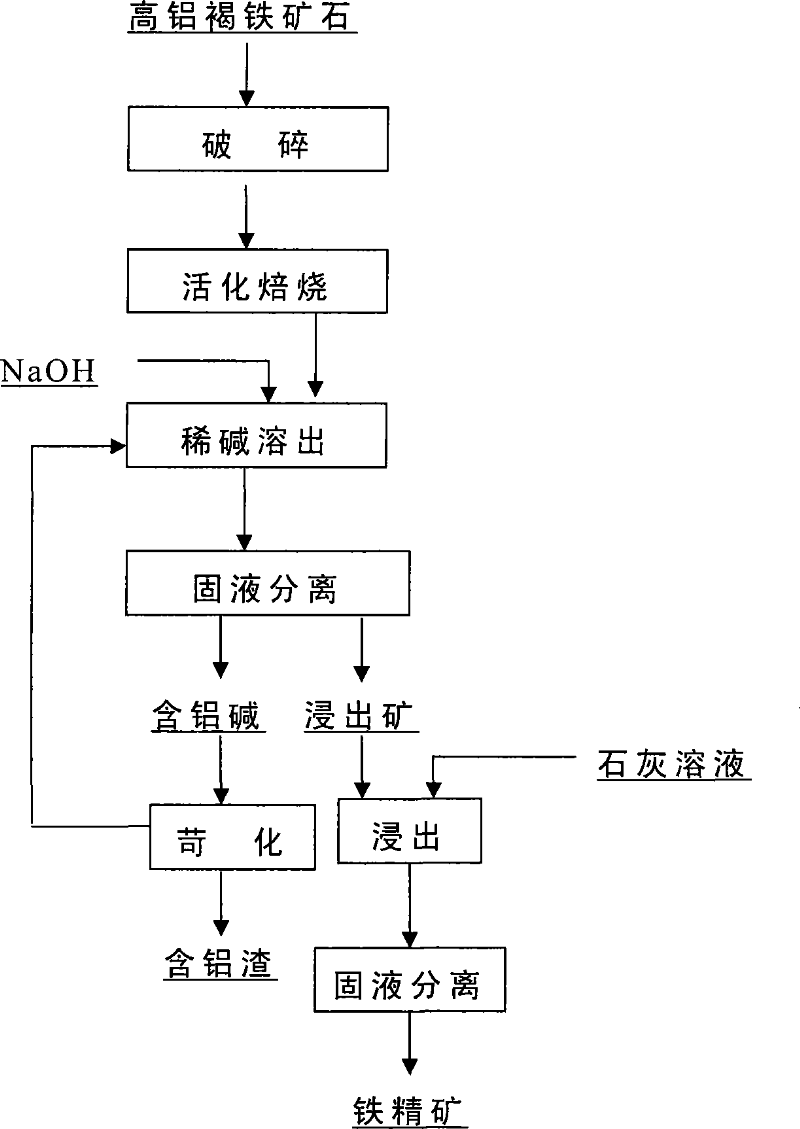

Ion-aluminum separation technique of high-alumina brown iron ore

InactiveCN101037721ARaise the gradeFacilitate the dissolution reactionProcess efficiency improvementRational useMaterials science

The invention discloses a process for separating iron and aluminium from high aluminium brown iron ore, wherein brown iron ore is broken to the granularity of less than 1.0mm, and is actived and braked for 10-20 minutes at the temperature of 400-500 DEG C, then placed in the reactor to have a stripping dealuminzation by 100-150 g / l NaOH solution at the temperature of 120-150 DEG C based on the quality liquid-solid rate of 3 / 1 -6 / 1, the time of stripping is 20-45 minutes, the filtrate can be causticized and be back to reuse after solid-liquid separation, and the filter cake is reacted with lime solution at the temperature of 100- 140 DEG C for 30-50 minutes and then solid-liquid separation, accordingly Al2O3 content can be reduced to 3.0%, and Na2O content can be less than 0.25% in the iron ore concentrate, while iron ore concentrate grade can be greatly improved. The invention is usable for the iron and aluminium separation of brown iron ore with higher-content aluminium oxide in the form of gibbsite of aluminium mineral with good dealuminzation and low process cost, the content of Al2O3 and Na2O in ore concentrate satisfies the requirement of blast furnace ironmaking materials, provided a powerful technical support for the rational use of existing rich high aluminium brown iron ore.

Owner:CENT SOUTH UNIV

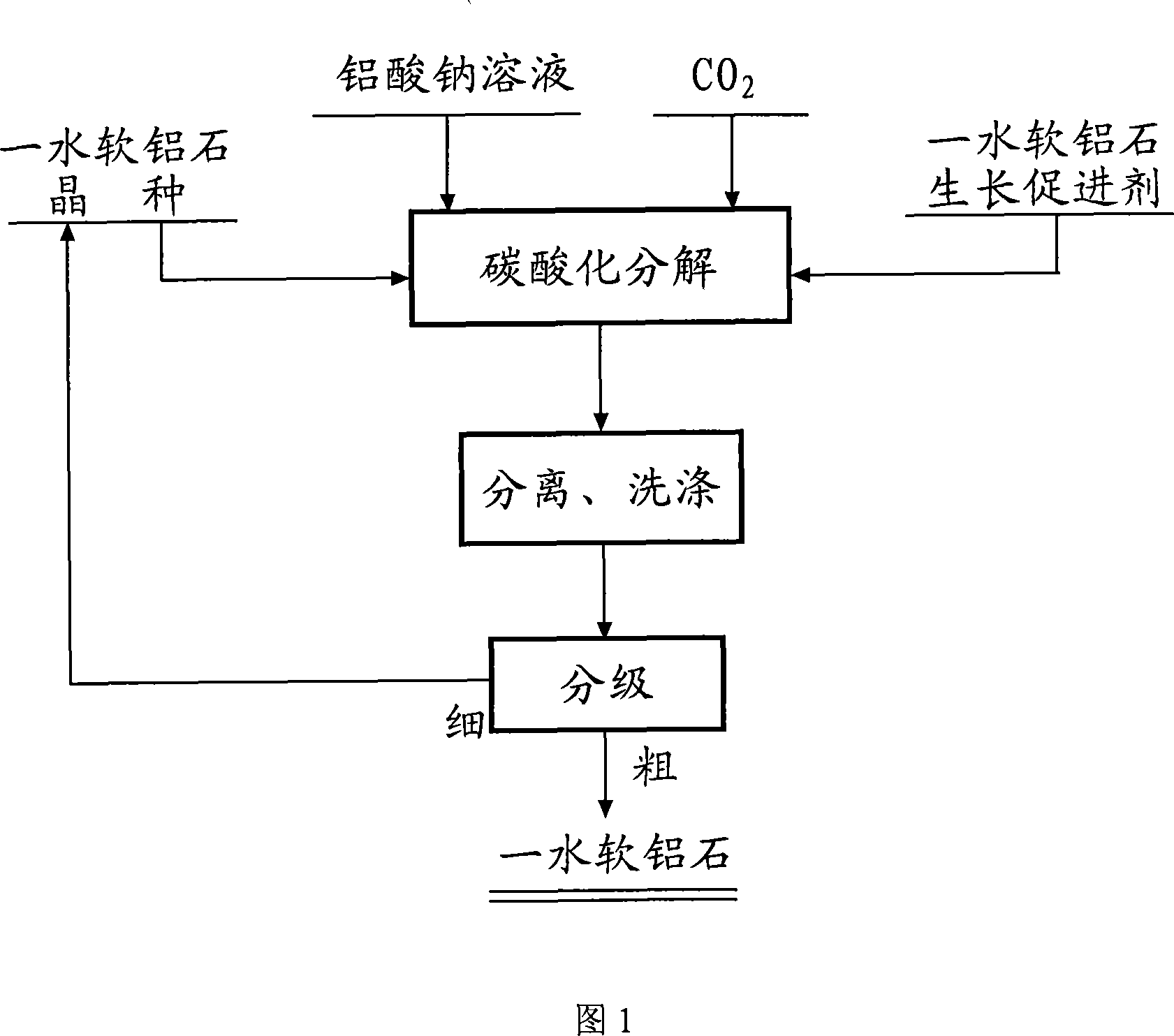

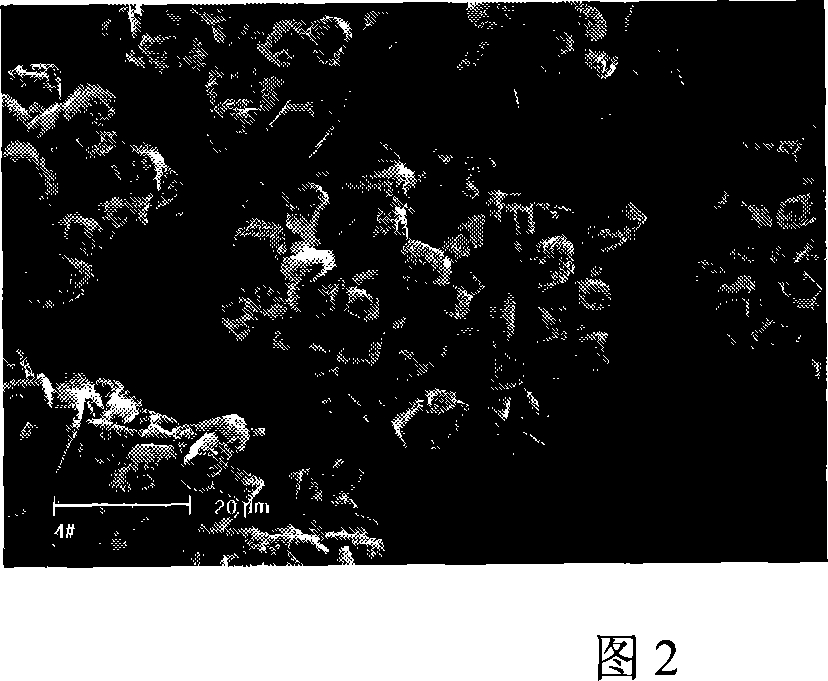

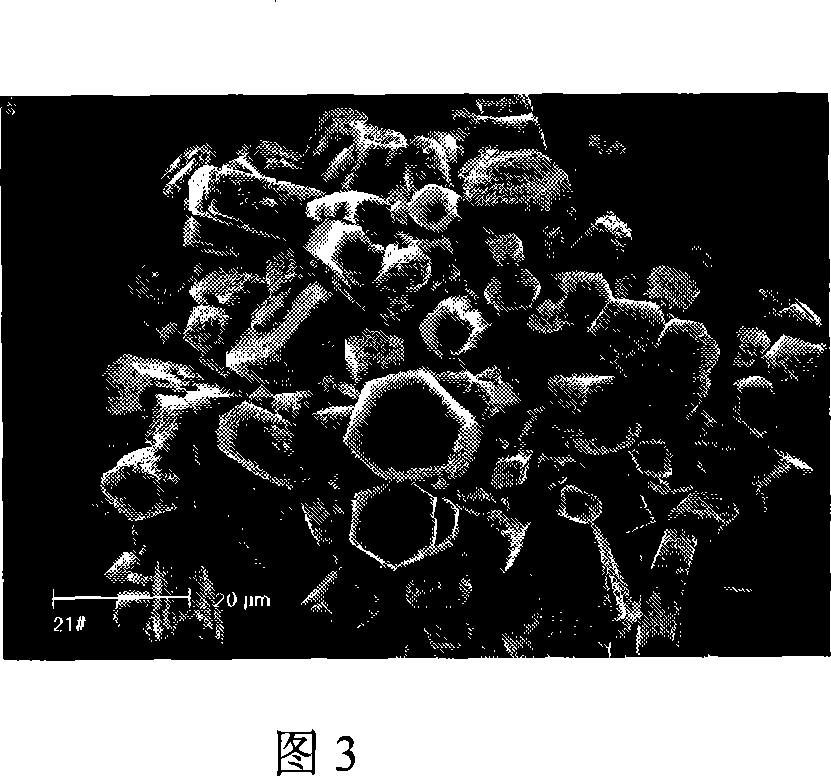

Method for preparing water softening aluminium stone of sodium aluminate solution carbonation resolving

InactiveCN101045542ANo costNo complexityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationWater softeningDecomposition

A process for preparing the boehmite by carbonating decomposition of sodium aluminate solution features that the crystal seeds of boehmite are added, the speed of filling CO2 is controlled for suppressing the educing out of gibbsite, and the crystal growth promoter is used. Its decomposing conditions are also disclosed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

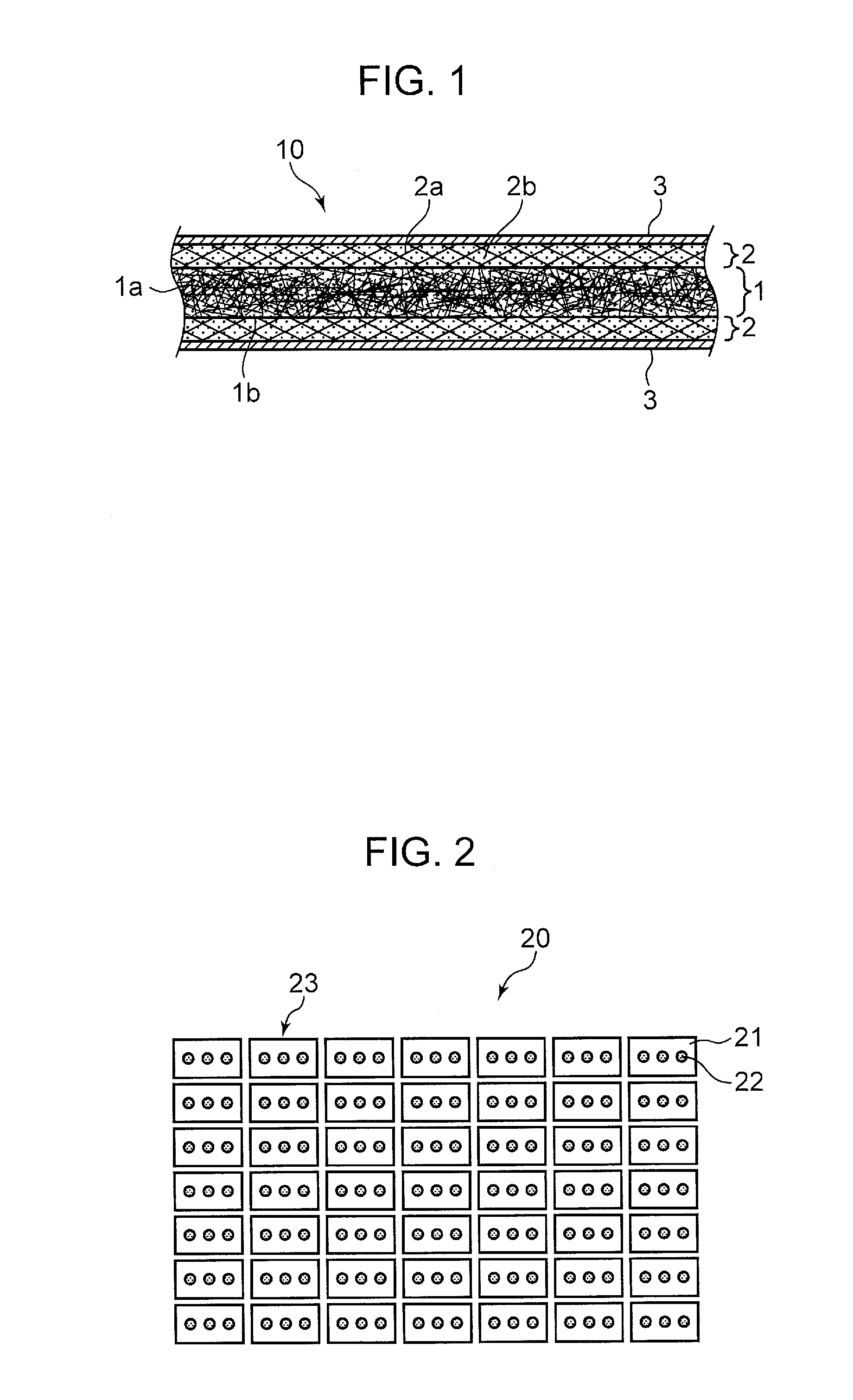

Prepreg, laminate, metal-foil-clad laminate, circuit board, and circuit board for LED mounting

ActiveUS20120228010A1Synthetic resin layered productsPrinted circuit aspectsMetal foilAluminium hydroxide

Disclosed is a prepreg obtained by impregnating a woven fabric base with a thermosetting resin composition, wherein the thermosetting resin composition contains 80 to 200 volume parts of an inorganic filler per 100 volume parts of a thermosetting resin, and the inorganic filler contains (A) gibbsite aluminum hydroxide particles having an average particle diameter (D50) of 2 to 15 μm, (B) at least one inorganic component selected from the group consisting of boehmite particles having an average particle diameter (D50) of 2 to 15 μm and inorganic particles that have an average particle diameter (D50) of 2 to 15 μm and that contain crystal water having a release initiation temperature of 400° C. or higher or contain no crystal water, and (C) aluminum oxide particles having an average particle diameter (D50) of 1.5 μm or smaller, the compounded ratio (volume ratio) of the gibbsite aluminum hydroxide particles (A), the at least one inorganic component (B) selected from the group consisting of the boehmite particles and the inorganic particles, and the aluminum oxide particles (C) being 1:0.1 to 2.5:0.1 to 1.

Owner:PANASONIC CORP

Method for preparing unformed aluminium hydroxide

InactiveCN1843924AAvoid or suppress generationReduce volumeProductsReagentsHigh concentrationAluminium hydroxide

The invention discloses a method for preparing non-shaped aluminum hydroxide, relating to an aluminum hydroxide, especially relating to a method for preparing aluminum hydroxide with high acid dissolubility and low density. The method comprises following steps: preparing strong sodium metaaluminate with gibbsite and sodium-hydroxide to control solution caustic ratio; diluting with deioned water and adding hole enlarging agent; adding deioned water into autoclave firstly, got solution of raw material and carbon dioxide flows into autoclave to control glue forming temperature; regulating feeding flow rate and filtering, washing and drying slurry and getting said product. The invention employs continous feeding and carbon dioxide of high concentration for glue forming to fasten neutralizing reaction and shorten glue forming time, and thus prevents diaspore generation, saves cooling device, increases device usage or reduces autoclave volumn. The product can dissolve into hydrogene nitrate of 20% completely and the bulk density is less than or equal to 0.4 g / ml.

Owner:XIAMEN UNIV

Sintering method red mud and Bayer method red mud mixed dam building method

ActiveCN101164925AIncrease stack heightImprove processing efficiencySludge treatmentAluminium oxides/hydroxidesVertical tubeBrick

This invention discloses a method for damming by using mixed mud from sintering process and Bayer process. In this invention, the gibbsite Bayer process and sintering process red mud are mixed in the ratio of (0.43-2.33):1(dried mud) are used for the damming. Bricks are used for building cofferdam columns, in which are placed the vertical tubes which are then connecting filtration tubes and water-drainage ditch. There are permeating holes on the walls of the tubes. Between the column and its tube filled is fine sands. Due to the material of the dam is the same as the material decking-up, it makes simple building process and saving area for decking up Bayer process red mud. Advantages are low cost and saving raw materials.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

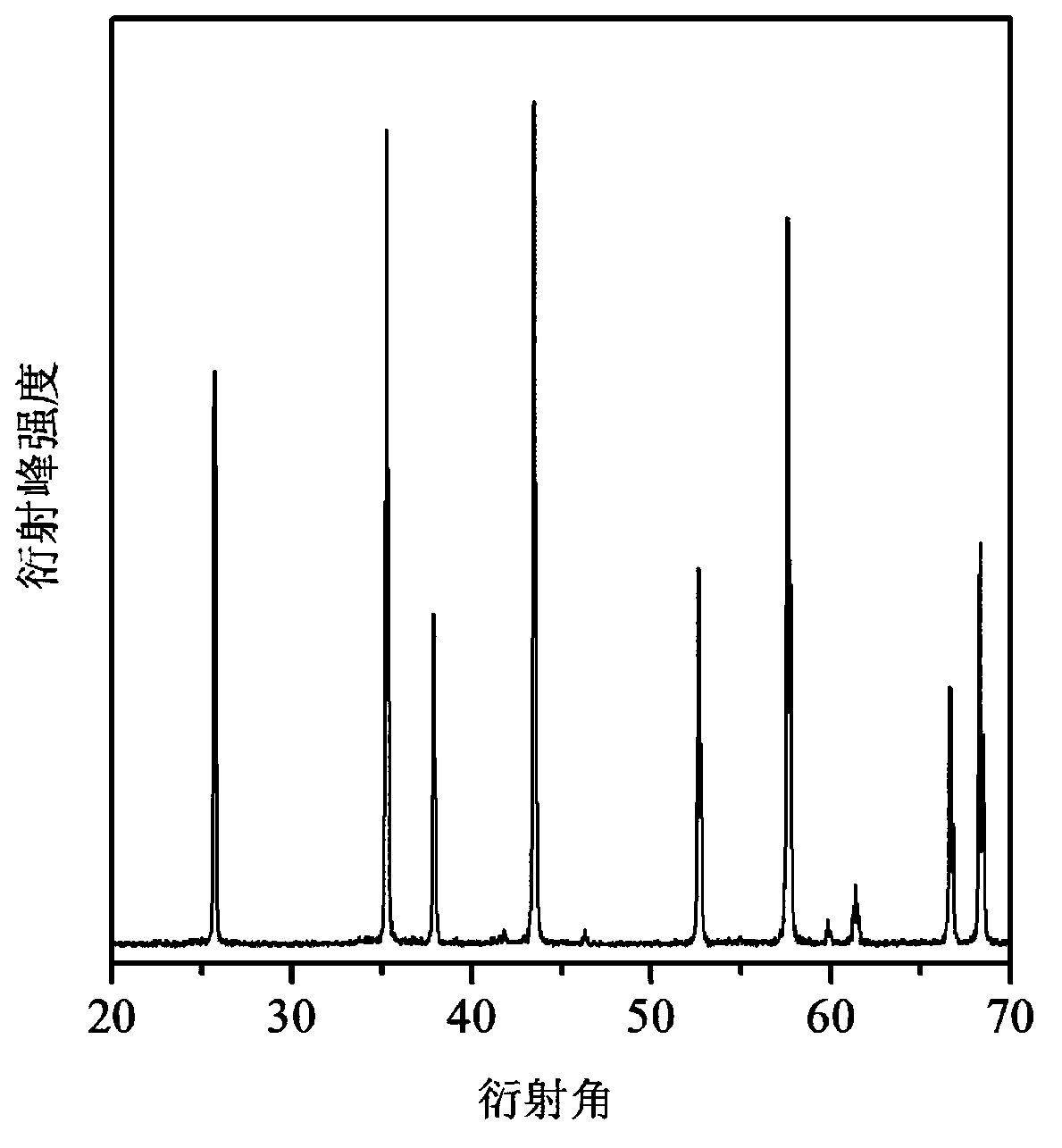

Aluminum hydroxide micropowder used as resin filler and method for producing the same

InactiveCN102317211APigmenting treatmentPrinted circuit aspectsAluminium hydroxidePhysical chemistry

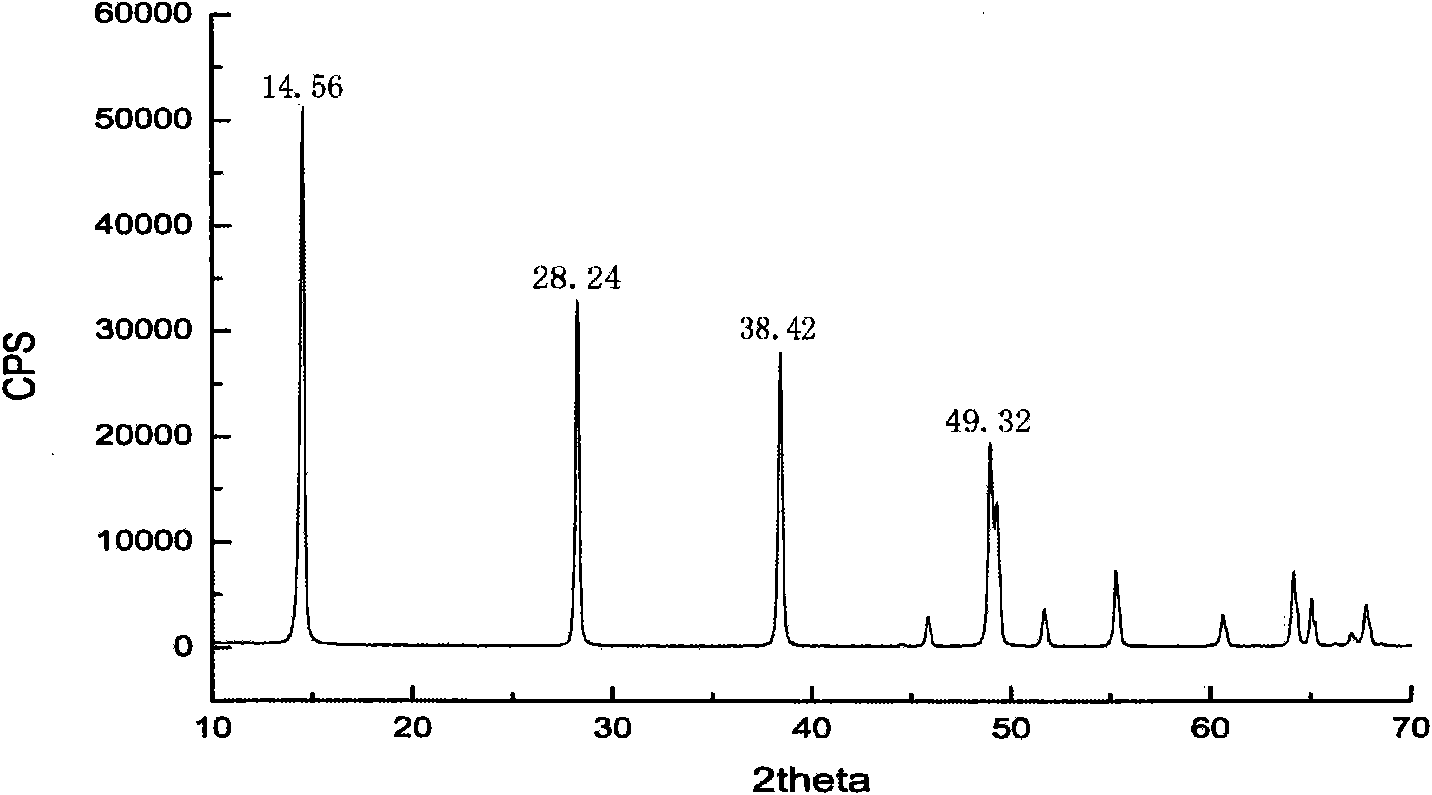

Provided is an aluminum hydroxide powder used as a resin filler having excellent resin filling properties. Also provided is a method for producing the same. The aluminum hydroxide powder used as a resin filler has a gibbsite crystal structure; the average grain diameter in the grain diameter distribution as determined by laser scattering is between 2.0 and 4.0 [mu]m; the ratio D90 / D10 of secondary grain diameter D10, which is the diameter of 10% of the cumulative mass from the microparticle portion, and the secondary grain diameter D90, which is the diameter of 90% of the cumulative mass from the microparticle portion, is between 4.0 and 6.0; D2 and D1 satisfy formula (1) 2xD1 = D2 = 4xD1 (1) when there are two or more frequency maximums within a grain diameter range I that is between 0.5 and 5.0 [mu]m, with D2 being the maximum grain diameter of the frequency maximum having the largest maximum grain diameter of the frequency maximums within the grain diameter range I and D1 being the maximum grain diameter of the frequency maximum showing the smallest maximum grain diameter; the intensity ratio I (110) / I (002) of the peak at crystal faces (110) and (002) as determined by powder X-ray diffraction is between 0.30 and 0.45; and the total sodium content is 0.10 wt% or less in terms of Na2O.

Owner:SUMITOMO CHEM CO LTD

Catalytic cracking process for biofeeds

InactiveUS20140163285A1High distillate selectivityCatalytic crackingCatalyst activation/preparationVegetable oilOxygen

Owner:EXXON RES & ENG CO

Preparation method of high heat-resistant boehmite

InactiveCN101830491AHigh heat resistanceChemical stability does not changeAluminium oxides/hydroxidesGranularityAluminium hydroxide

The invention discloses a preparation method of high heat-resistant boehmite. The method comprises the following steps: firstly converting aluminium hydroxide with the crystalline structure of gibbsite to boehmite under the condition that the temperature is not less than 350 DEG C and the pressure is not less than 10kPa; secondly grinding boehmite to 50-400nm (particle size), then dispersing boehmite particles evenly in water, adopting wet high-speed mixing method to disperse boehmite, performing surface nano-SiO2 coating; and finally removing impurities, purifying, and drying to obtain the boehmite product. Boehmite which is prepared by the dry heat method adopted by the invention has low content of impurities, the boehmite conversion rate is high, and the grain size is controllable. In addition, the invention uses the inorganic modifier, thus significantly reducing oil adsorption of material, increasing liquidity and broadening the application of boehmite in the field of electronic materials.

Owner:上海百图高新材料科技有限公司

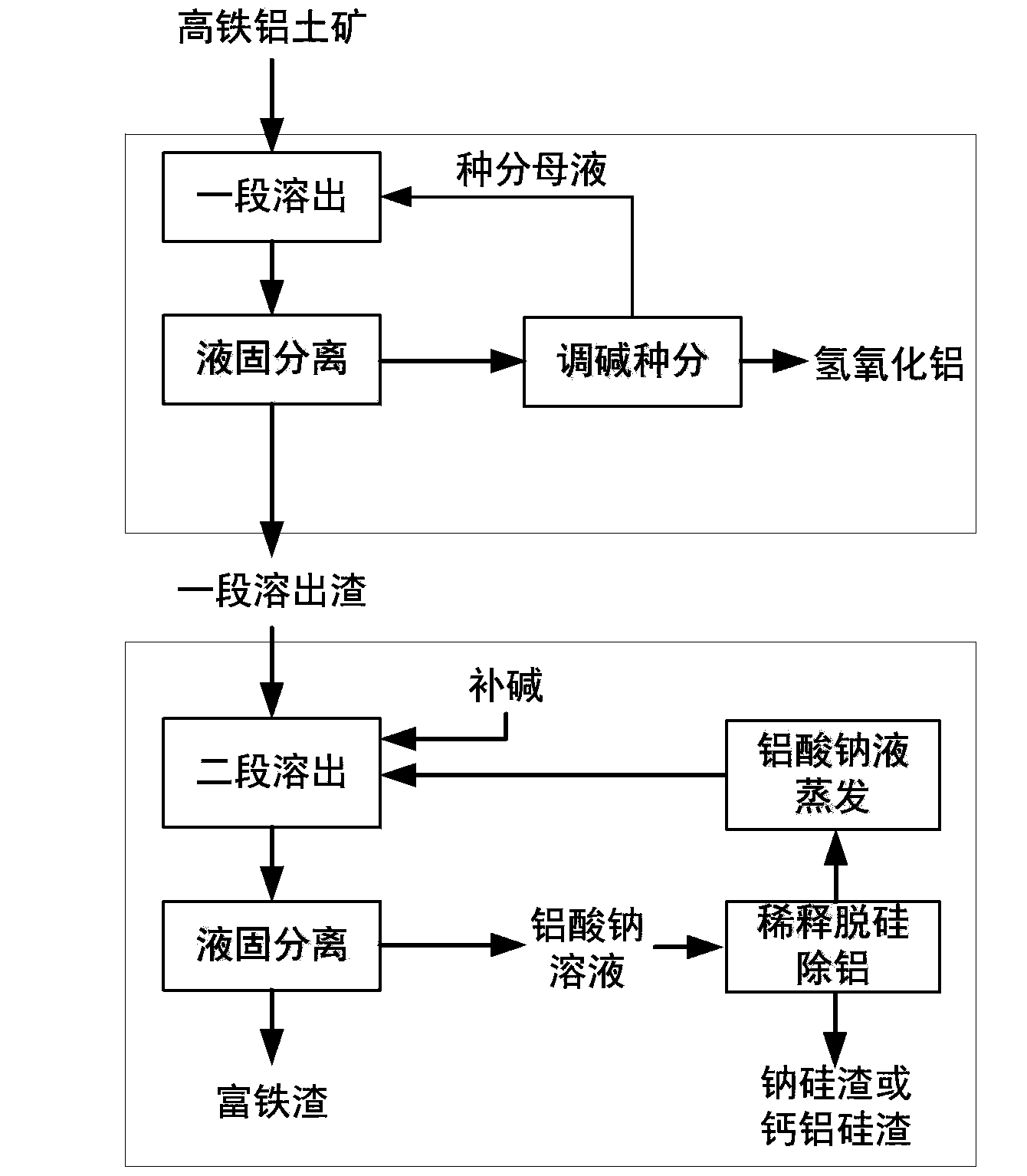

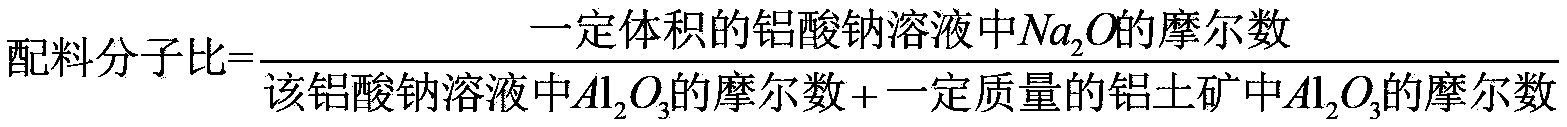

Method for extracting aluminum and iron from high iron gibbsite-type bauxite

The invention relates to a method for separating and extracting aluminum and iron in bauxite by treating high iron gibbsite-type bauxite by using an alkali medium two-stage wet dissolution process. The primary dissolution of the method comprises the following steps: dissolving out easily dissoluble aluminum component in the high iron gibbsite-type bauxite at low temperature by using a sodium aluminate solution in low alkali concentration, separating liquid from solid, seed-precipitating the primary dissolved solution to obtain an aluminum hydroxide product, and returning the seed-precipitating mother solution for dissolving out the bauxite; the secondary dissolution comprises the following steps: treating primary dissolved slag at a high temperature high-alkaline condition by using an alkali liquor in high molecular ratio or low molecular ratio, feeding aluminum and silicon in the slag into a liquid phase, separating liquid from solid to obtain iron-enriched slag, returning the liquid phase for treating the primary dissolves slag after diluting and removing aluminum and silicone, evaporating and concentrating. The process flow of the method is simple, the separating effect of the iron and the aluminum is obvious so as to respectively obtain aluminum oxide and iron-enriched slag, the iron-enriched slag can be directly used as iron making raw material, and an efficient method for utilizing the high iron bauxite resource in China.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for determining effective aluminum and activated silicon in gibbsite bauxite

ActiveCN106769300AThe method is simple, fast and efficientPreparing sample for investigationAnalysis by thermal excitationDigestionVolumetric flask

The invention relates to a method for determining effective aluminum and activated silicon in gibbsite bauxite. The method comprises the following steps of putting a weighed sample into a digestion tank of a closed microwave digestion instrument, adding a sodium hydroxide solution for digestion, transferring a digestion solution into a beaker containing hydrochloric acid after digestion is completed, heating the breaker to micro-boil and dissolve hydrated sodium aluminosolicate therein, transferring the solution to a volumetric flask for constant volume after cooling, mixing evenly, clarifying and absorbing 10mL of solution to a 100Ml volumetric flask; and adding 10mL of 6mol / L HCl, diluting the HCl to constant volume by using distilled water, mixing evenly, determining the content of distilled aluminum and activated silicon by using an inductively coupled plasma atomic emission spectrometry at the same time, and calculating the effective aluminum content according to the contents of the distilled aluminum and the activated silicon based on a calculation formula: effective aluminum (%)=dissolved aluminum (%)- k*activated silicon (%), wherein the contents of the effective aluminum and the dissolved aluminum are based on Al2O3, the content of the activated silicon is based on SiO2, the value range of k is 0.90-1.10 and the optimal value is 1.006. The method provided by the invention is simple, fast and efficient, can be widely applied to exploration evaluation of the gibbsite bauxite, and is of guiding significance in adjustment of a production technology.

Owner:南通铂莱德节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com