Laminate, metal-foil-clad laminate, circuit board, and circuit board for LED mounting

A laminate and base material technology, which is applied in the direction of circuit substrate materials, metal layered products, printed circuit components, etc., can solve problems such as insufficient heat dissipation of laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]

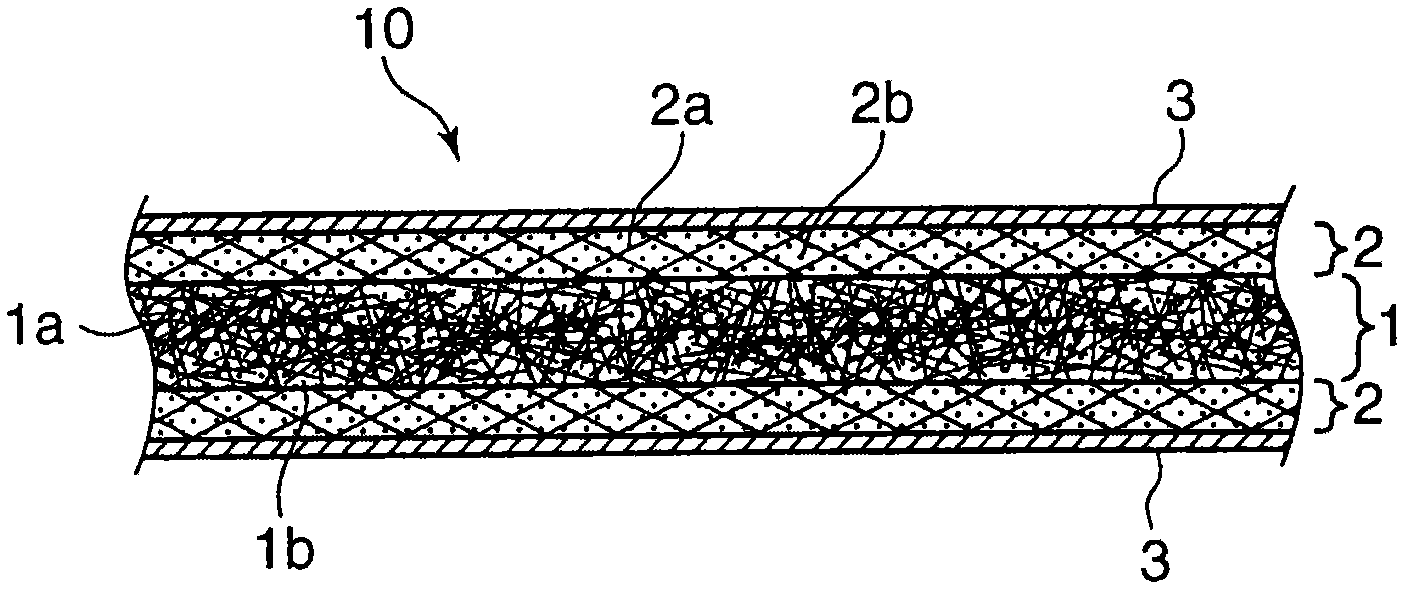

[0067] A gibbsite type aluminum hydroxide (Sumitomo Chemical ( Co., Ltd., D 50 : 5.4 μm) 35 parts by volume, gibbsite-type aluminum hydroxide (manufactured by Sumitomo Chemical Co., Ltd., D 50 : 12.6μm) 35 parts by volume, boehmite (D 50 : 5.5 μm) 15 parts by volume, and alumina (manufactured by Sumitomo Chemical Co., Ltd., D 50 : 0.76μ) 15 parts by volume to make them uniformly dispersed. Make the weight per unit area 60g / m 2 A glass nonwoven fabric (made by Baoling Co., Ltd.) with a thickness of 400 μm was impregnated with a resin varnish blended with a filler to obtain a core layer prepreg.

[0068] On the other hand, by making the weight per unit area 200g / m 2 A glass cloth (woven fabric) (7628 manufactured by Nittobo Co., Ltd.) having a thickness of 180 μm was impregnated with an epoxy resin varnish containing a hardener not mixed with a filler to obtain a surface layer prepreg.

[0069] Then, two core material layer prepregs were stacked, and one surface...

Embodiment 2~7、 and comparative example 1~14

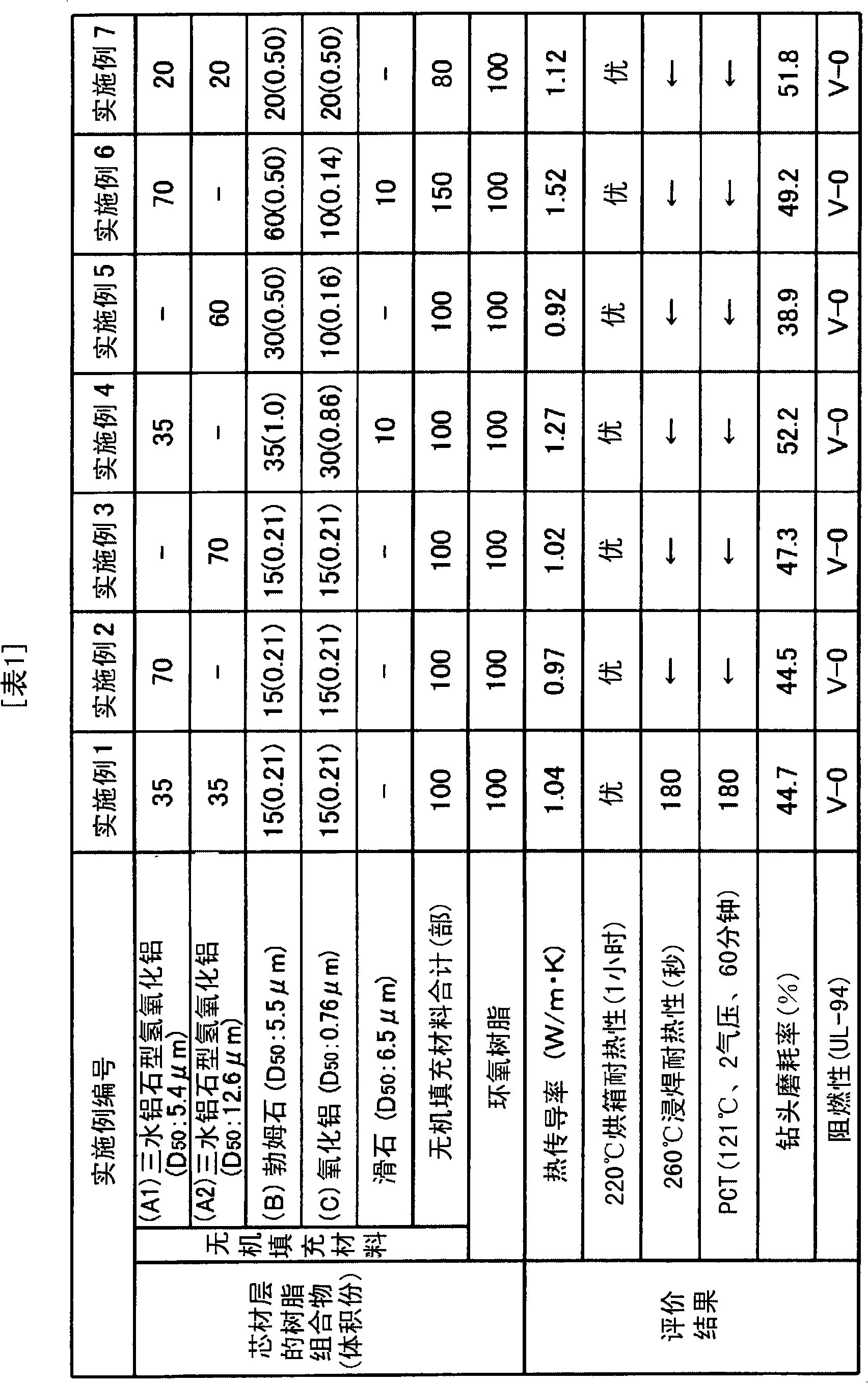

[0084] In the manufacture of the core material layer prepreg, except having changed the composition of the resin composition as shown in Table 1 or Table 2, it carried out similarly to Example 1, and obtained the laminated body, and evaluated it. Table 1 shows the results of Example 1 and Examples 2-7, and Table 2 shows the results of Comparative Examples 1-14.

[0085] In addition, in Example 4 and Example 6, the average particle diameter (D 50 ) talc (manufactured by Fuji Talc Industry Co., Ltd.)) of 6.5 μm, the average particle diameter (D 50 ) 0.76 μm alumina (manufactured by Sumitomo Chemical Co., Ltd.).

[0086]

[0087]

[0088] According to the results shown in Table 1 and Table 2, the copper-clad composite laminates of Examples 1 to 7 of the present invention all have high thermal conductivity above 0.97 W / m K, heat resistance, drill wear resistance, resistance The flammability is relatively high. On the other hand, compared with the copper-clad composite lam...

Embodiment 8~16、 and comparative example 15~27

[0090] In the manufacture of the core material layer prepreg, except having changed the composition of the resin composition like Table 3 or Table 4, it carried out similarly to Example 1, and obtained the laminated body, and evaluated it. Table 3 shows the results of Examples 8-16, and Table 4 shows the results of Comparative Examples 15-27.

[0091] In addition, in Example 14, the average particle diameter (D 50 ) 6.5 μm of crystalline silica, in Example 15 using the average particle size (D 50 ) magnesia of 6.5 μm (manufactured by Nippon Light Metal Co., Ltd.), the average particle diameter (D 50 ) Aluminum nitride (manufactured by Furukawa Electronics Co., Ltd.) of 6.6 μm, the average particle diameter (D 50 ) 4 μm alumina (manufactured by Sumitomo Chemical Co., Ltd.).

[0092]

[0093]

[0094] According to the results in Table 3, the thermal conductivity of the laminates of Examples 8 to 16 of the present invention are all high, and the oven heat resistance and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com