Patents

Literature

995 results about "Light metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A light metal is any metal of relatively low density. More specific definitions have been proposed; none have obtained widespread acceptance. Magnesium, aluminium and titanium are light metals of significant commercial importance. Their densities of 1.7, 2.7 and 4.5 g/cm³ range from 19 to 56% of the densities of the older structural metals, iron (7.9) and copper (8.9).

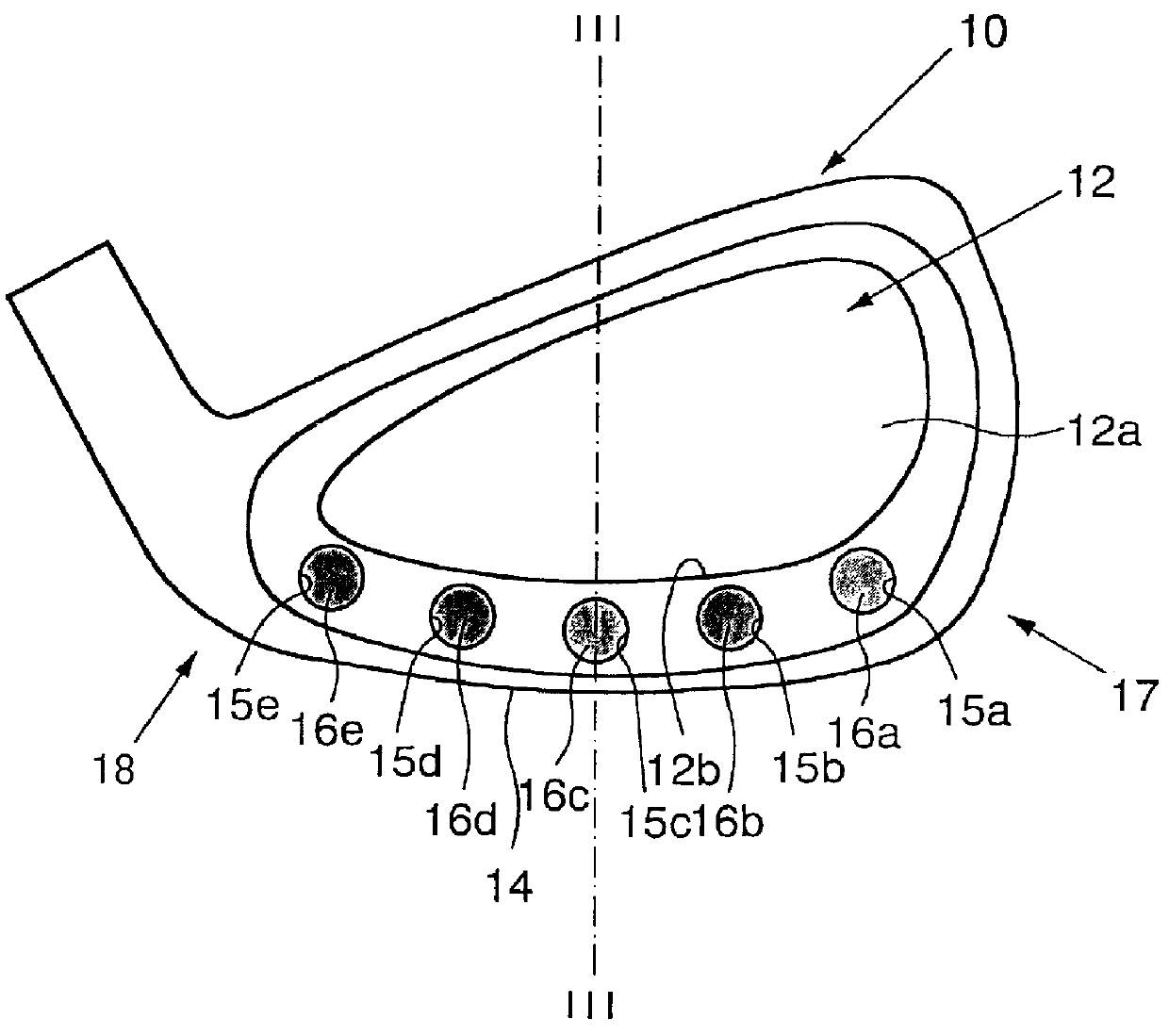

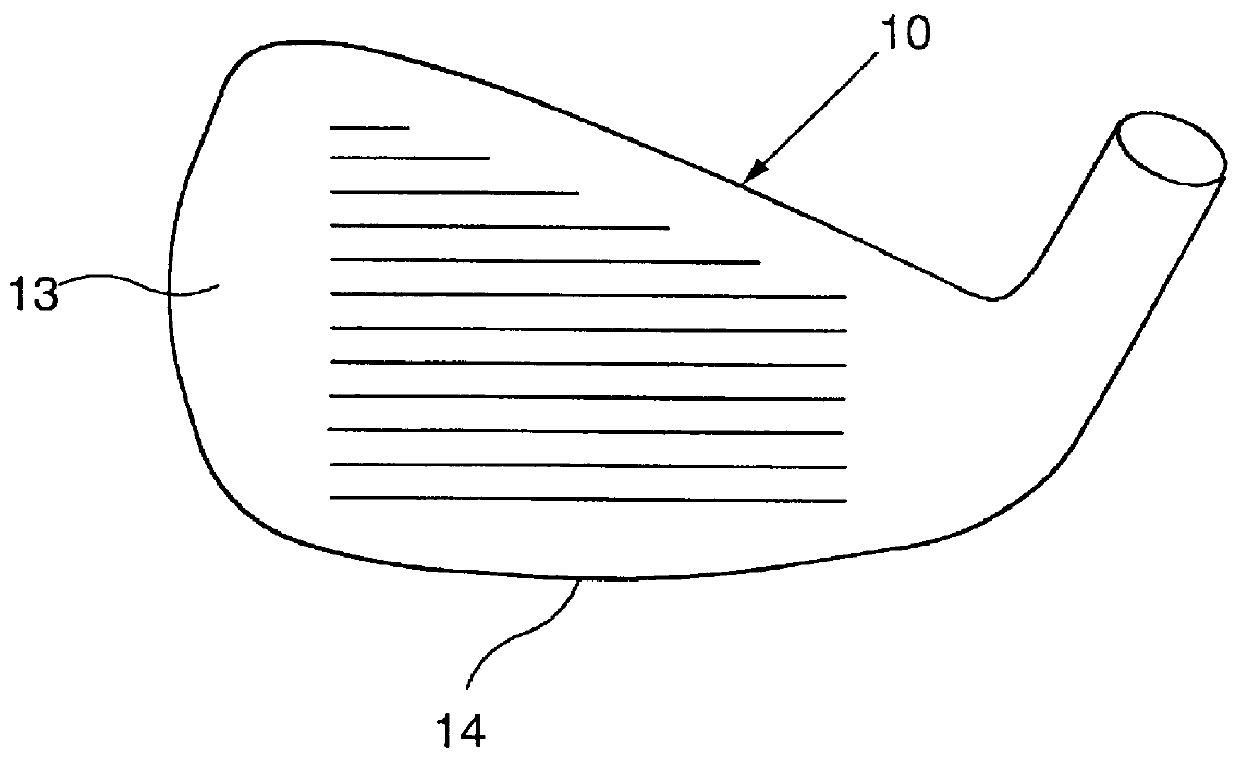

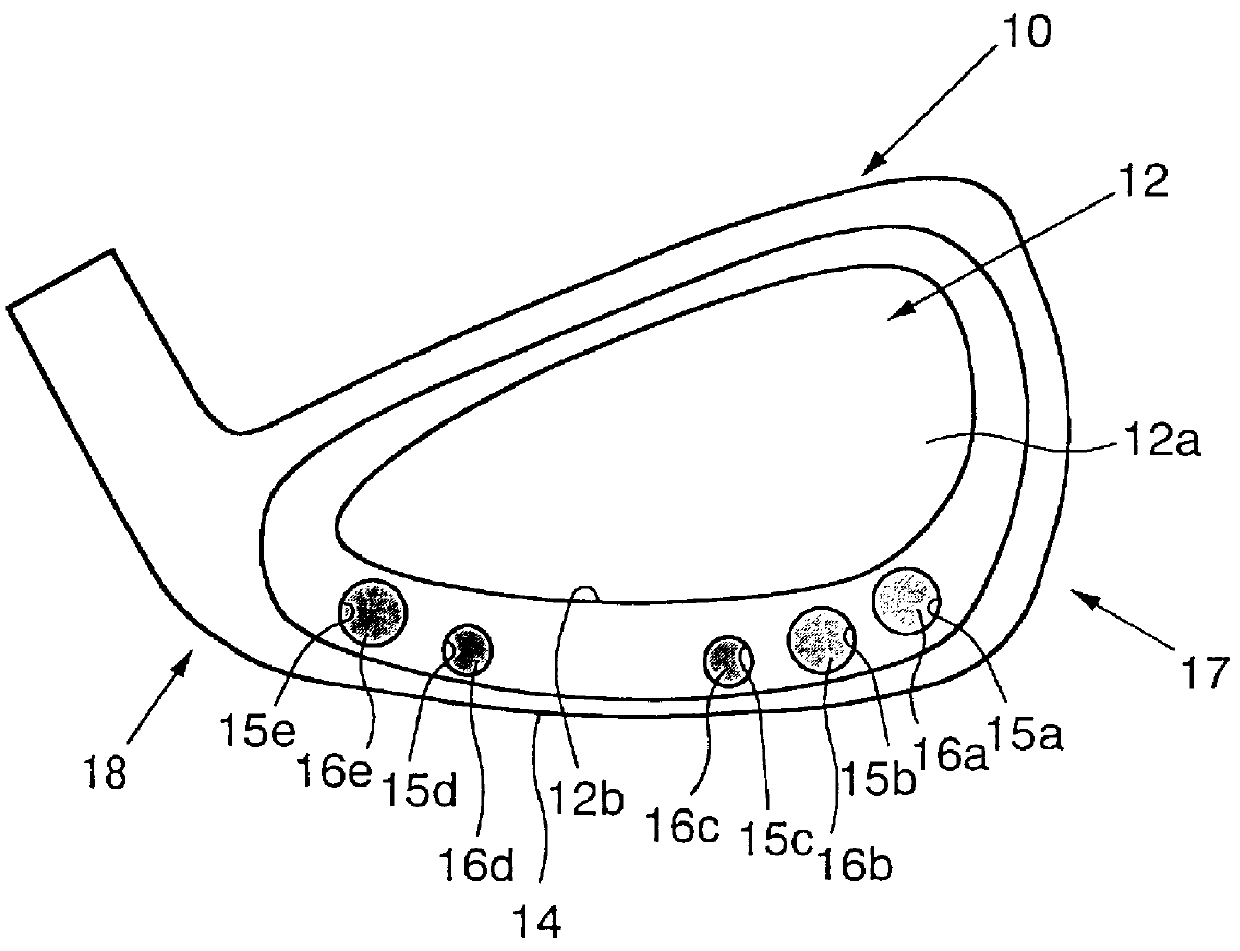

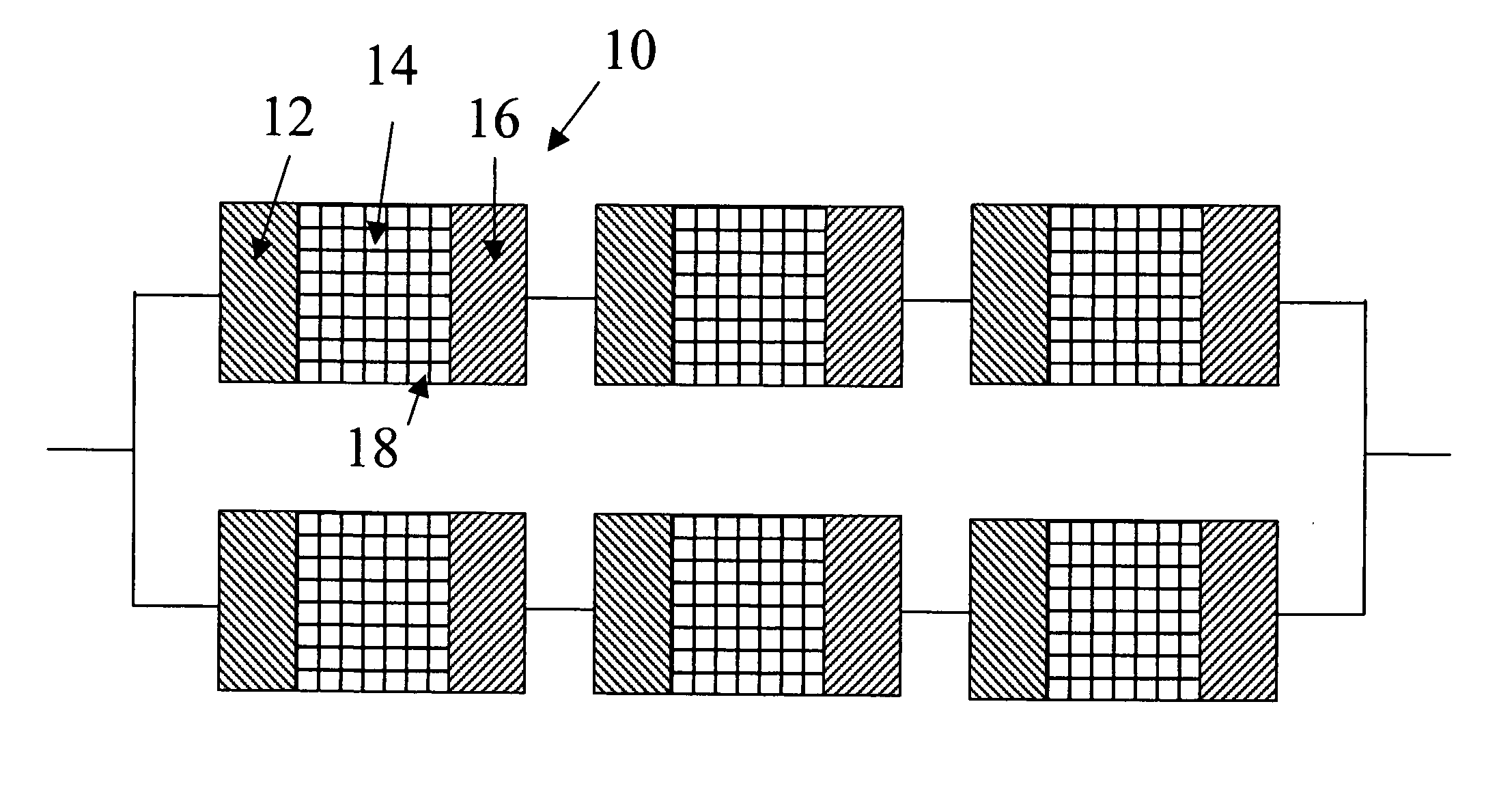

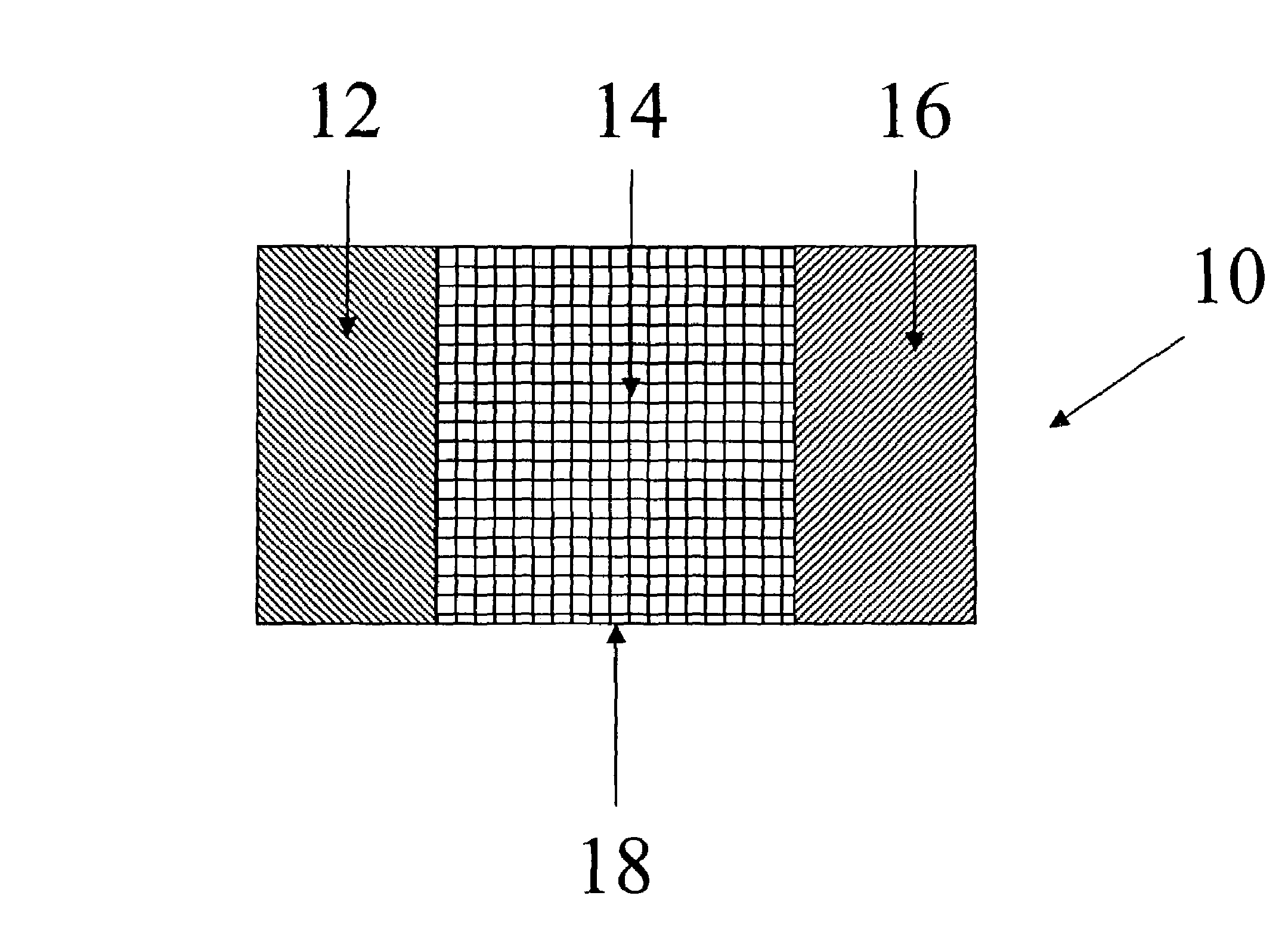

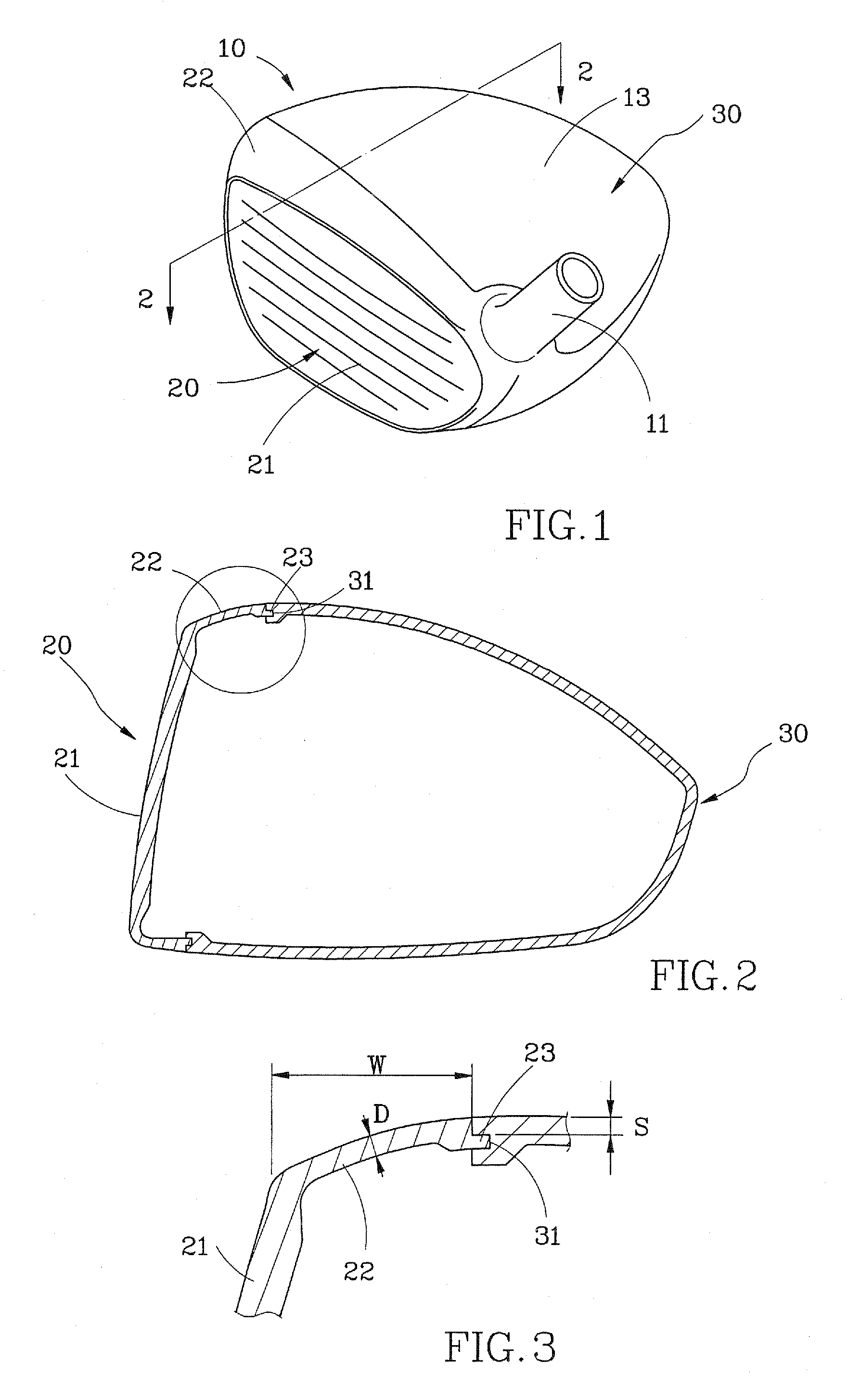

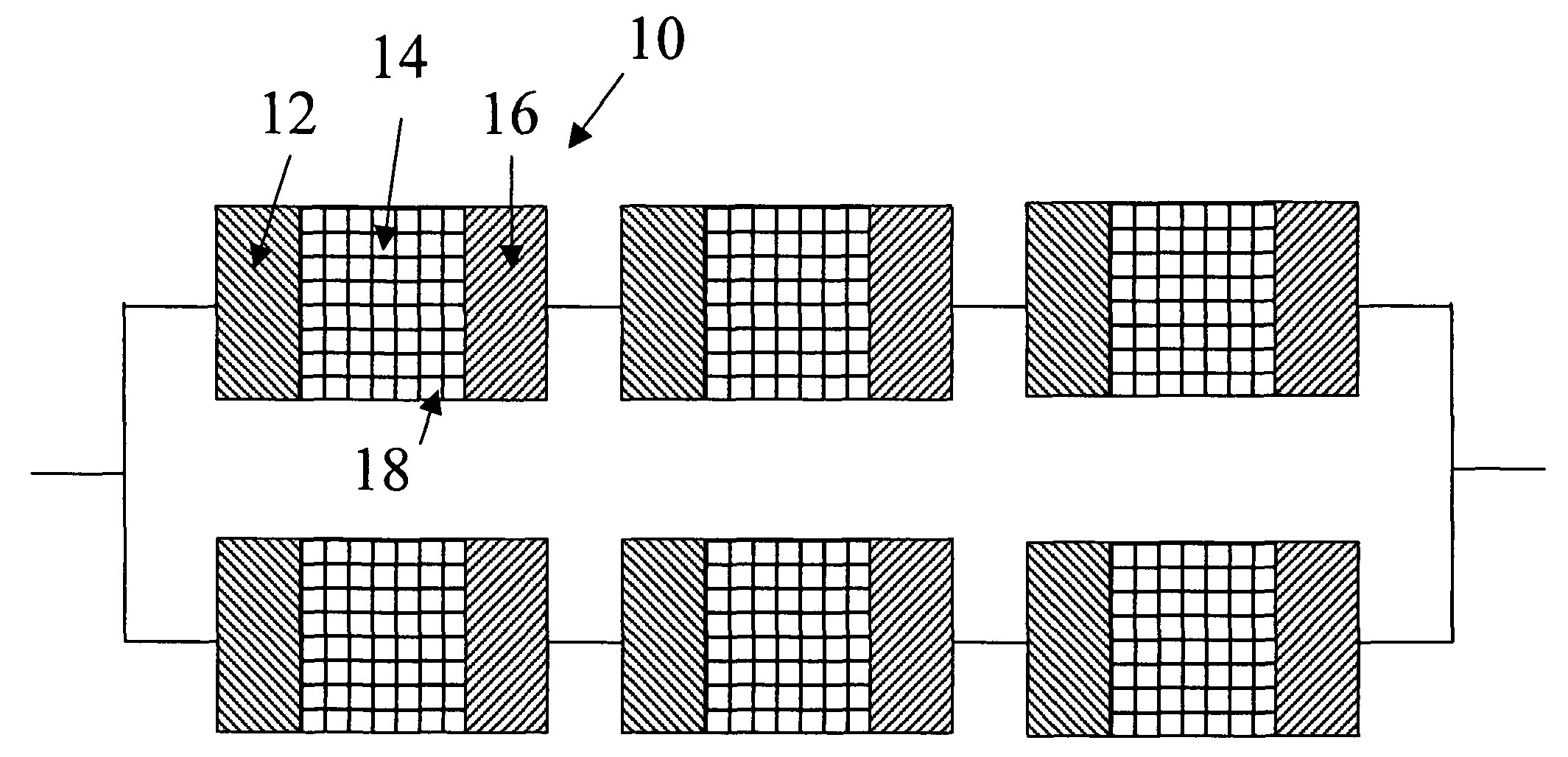

Iron golf club head including weight members for adjusting center of gravity thereof

An iron golf club head comprised of a head body 10 made of light metal such as titanium and containing a plurality of weight members 16. The head body 10 includes a front surface 13, a rear surface 13a, a cavity 12 disposed at the rear surface 13a, and a plurality of holes 15 disposed in the head body 10 at the rear surface 13a between a lower side wall 12b of the cavity 12 and a sole 14 of the head body 10 at predetermined intervals between a toe part 17 and a heel part 18. The center axis of each hole 15 is oriented substantially parallel to the sole 14 of the head body 10. The weight members 16 are press-inserted into the holes 15 in a direction going toward the front surface 13 of the head body 10 to a predetermined depth. Each weight member 16 is made of a material having a heavier specific weight than the light metal used for the aforesaid head body 10. Tungsten or tungsten alloy can be used as the material for the weight members 16. The combined weight of the weight members 16 does not exceed forty percent of the weight of the entire head.

Owner:YONEX CO LTD

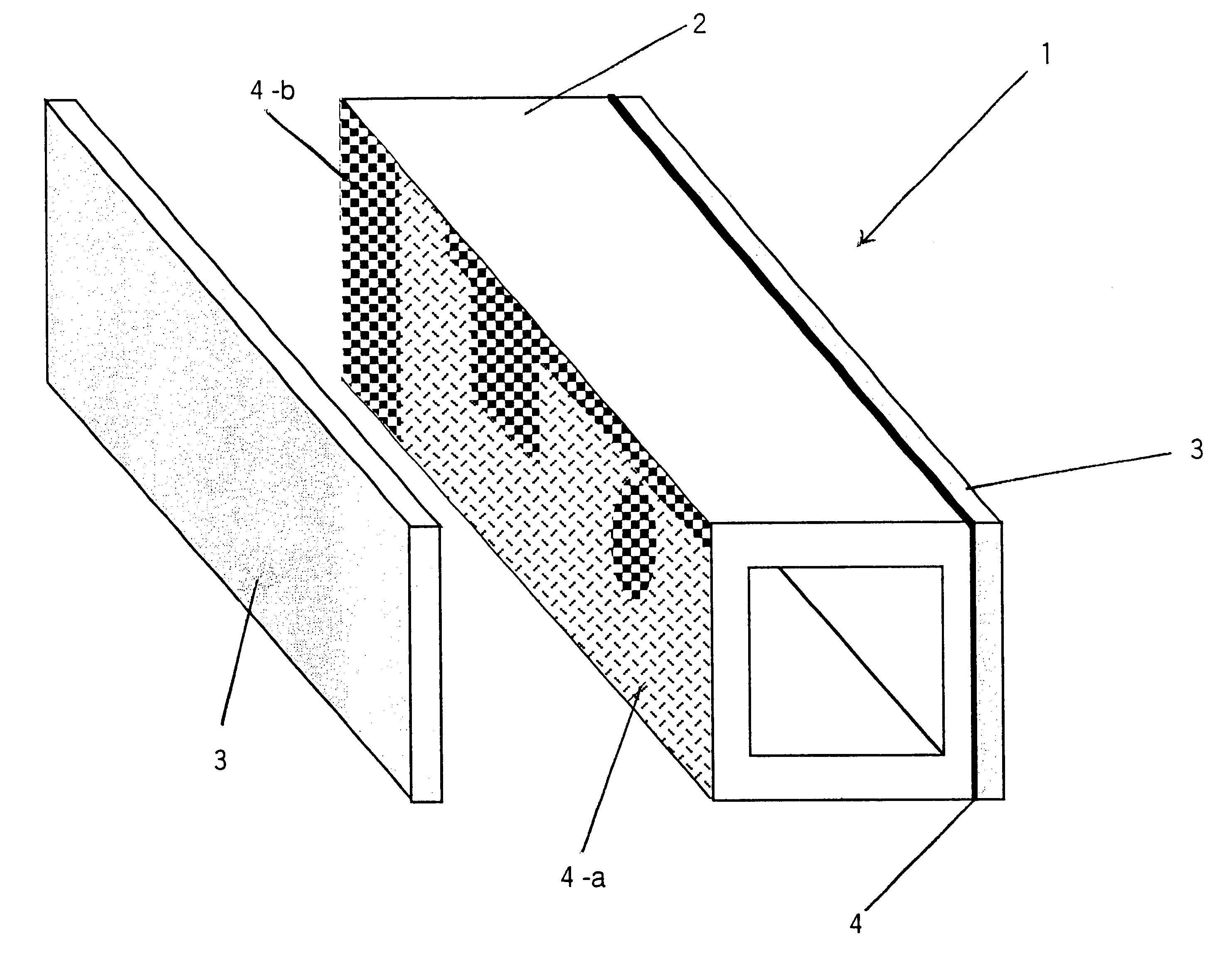

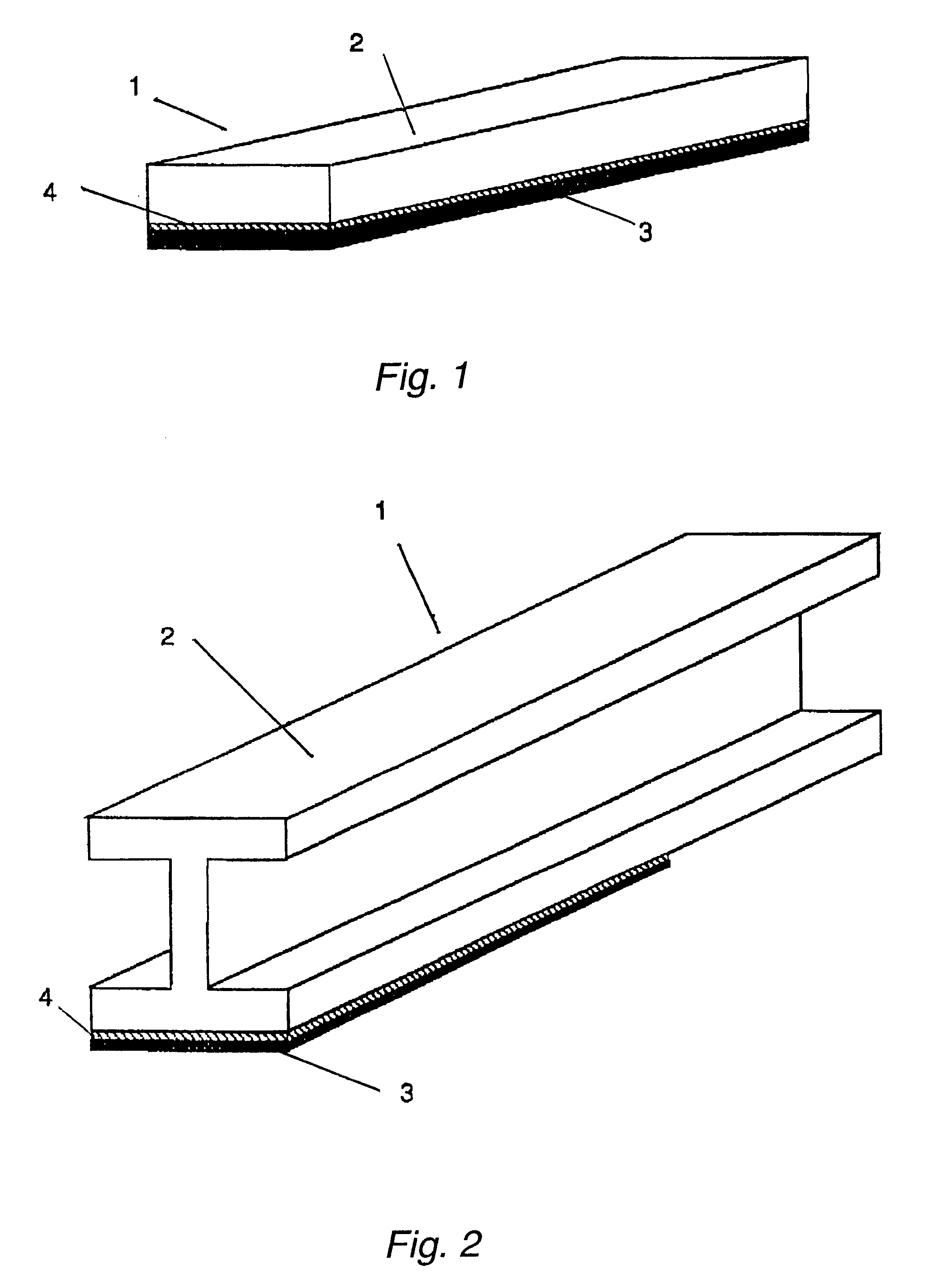

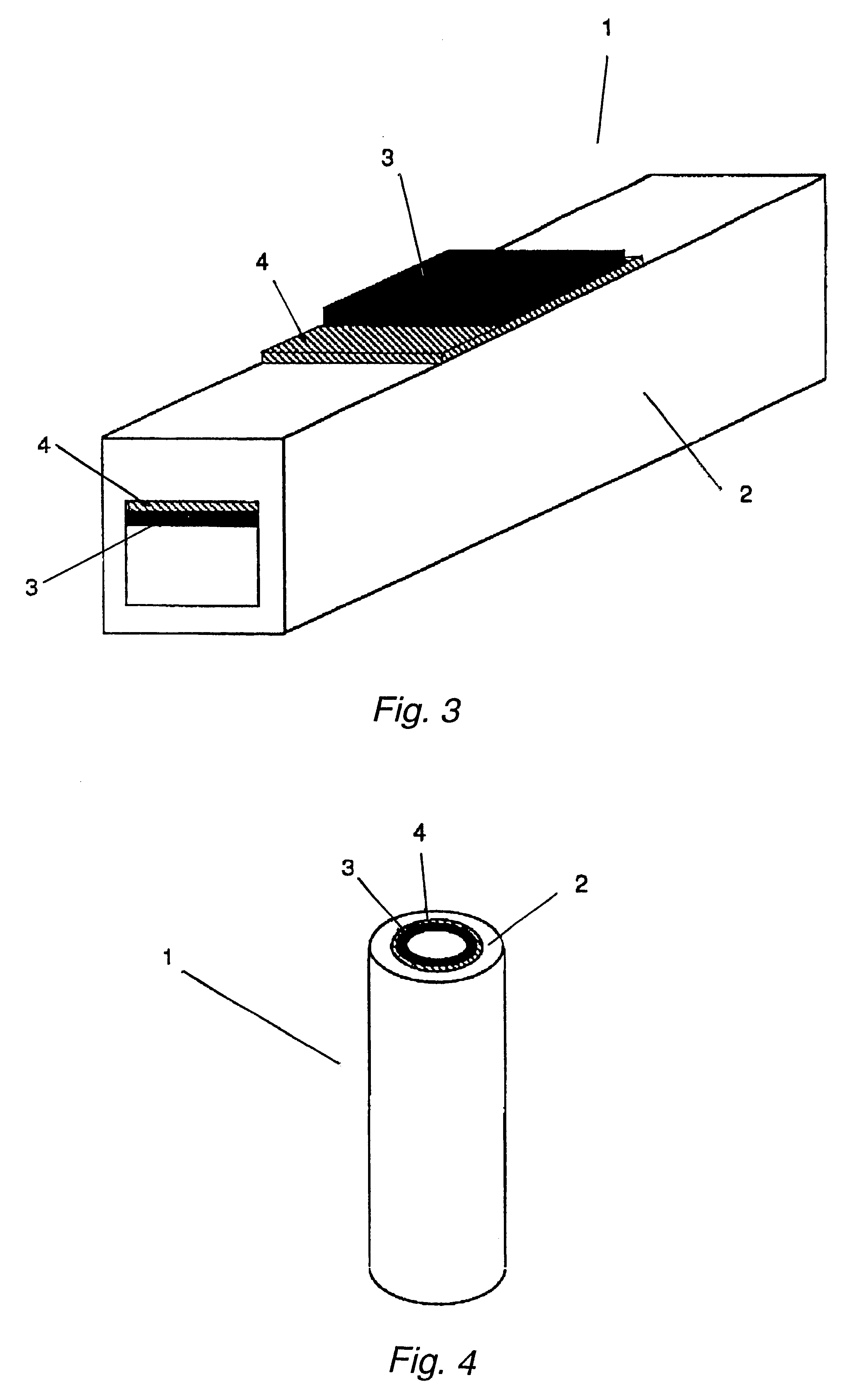

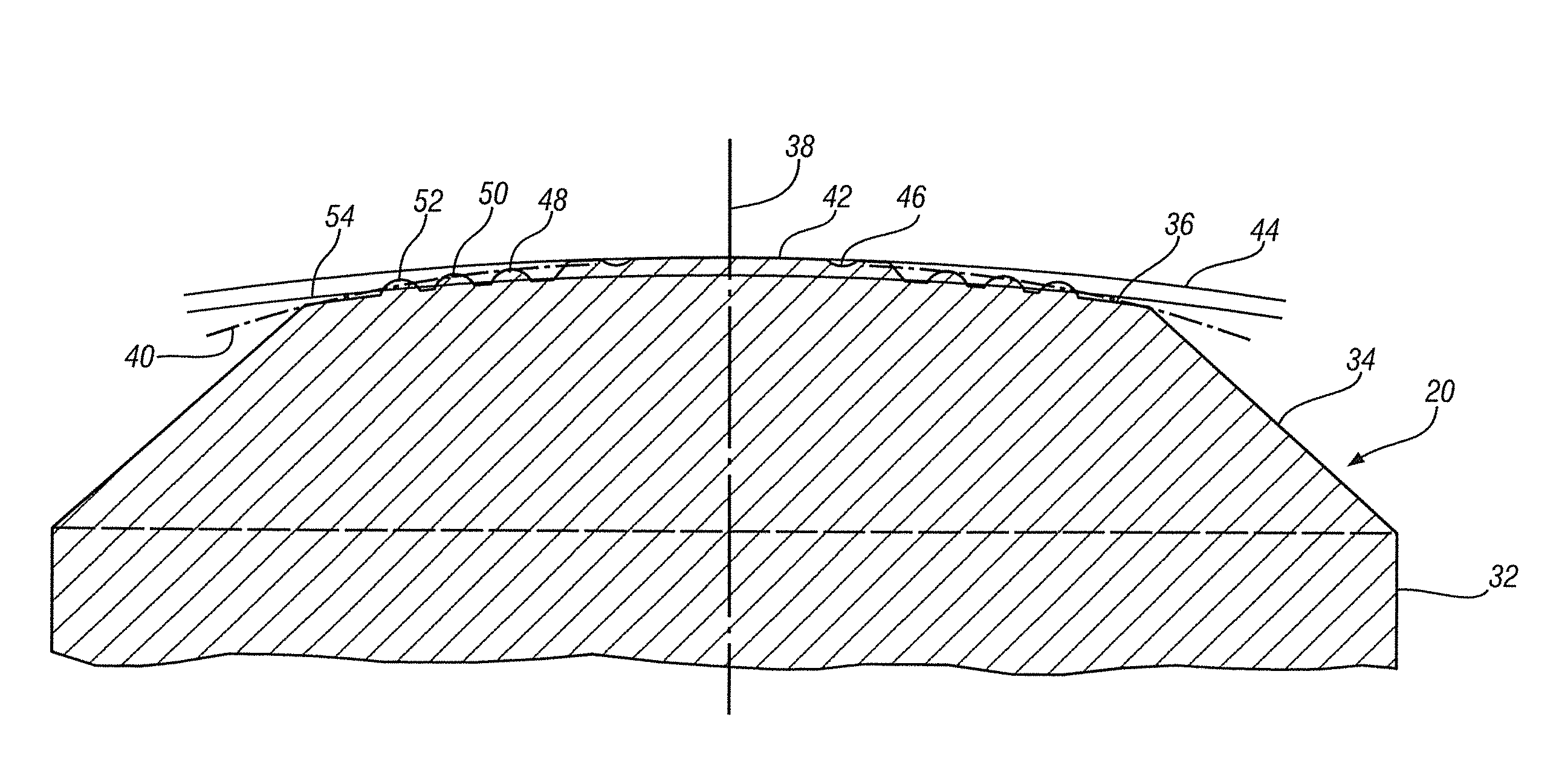

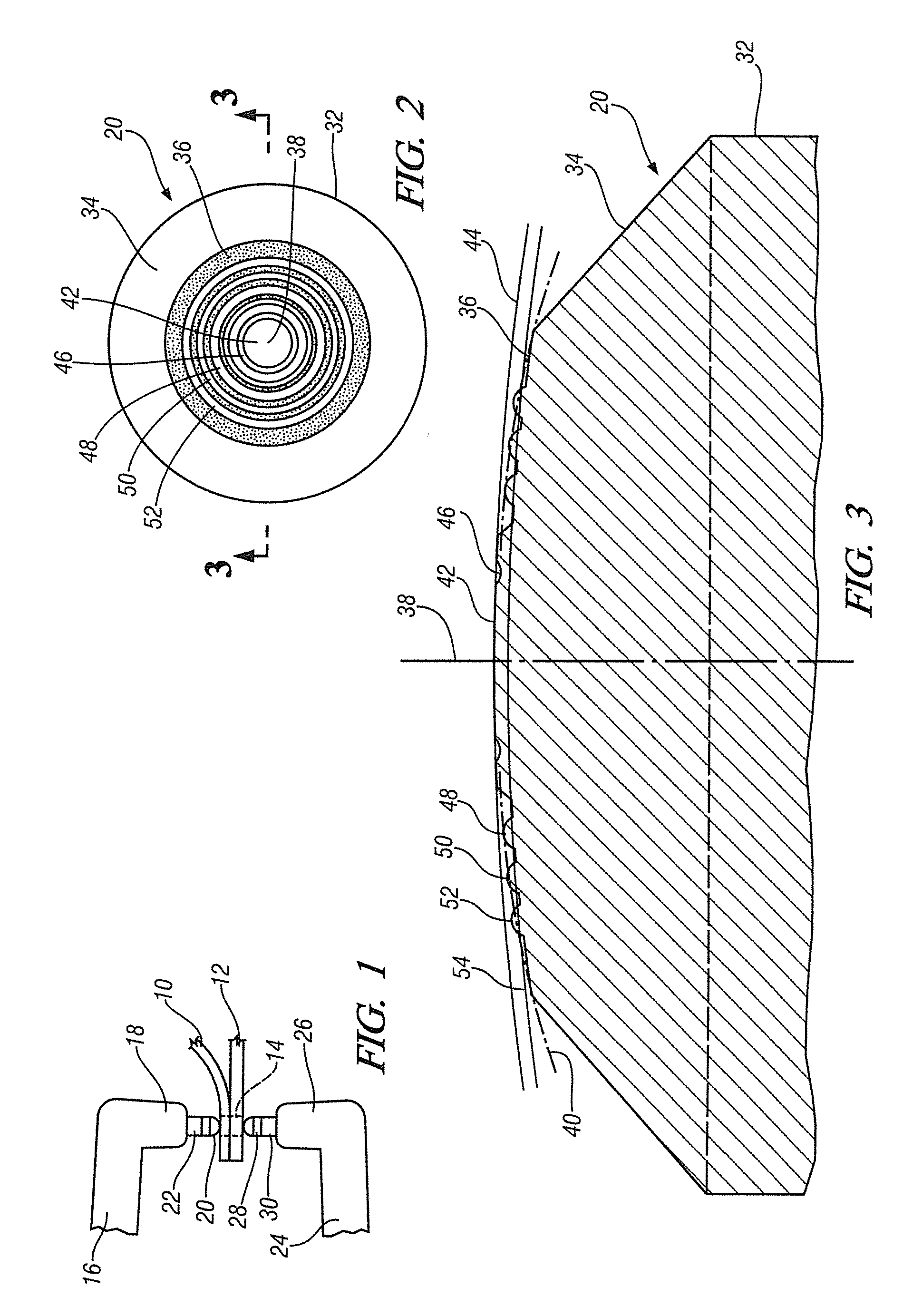

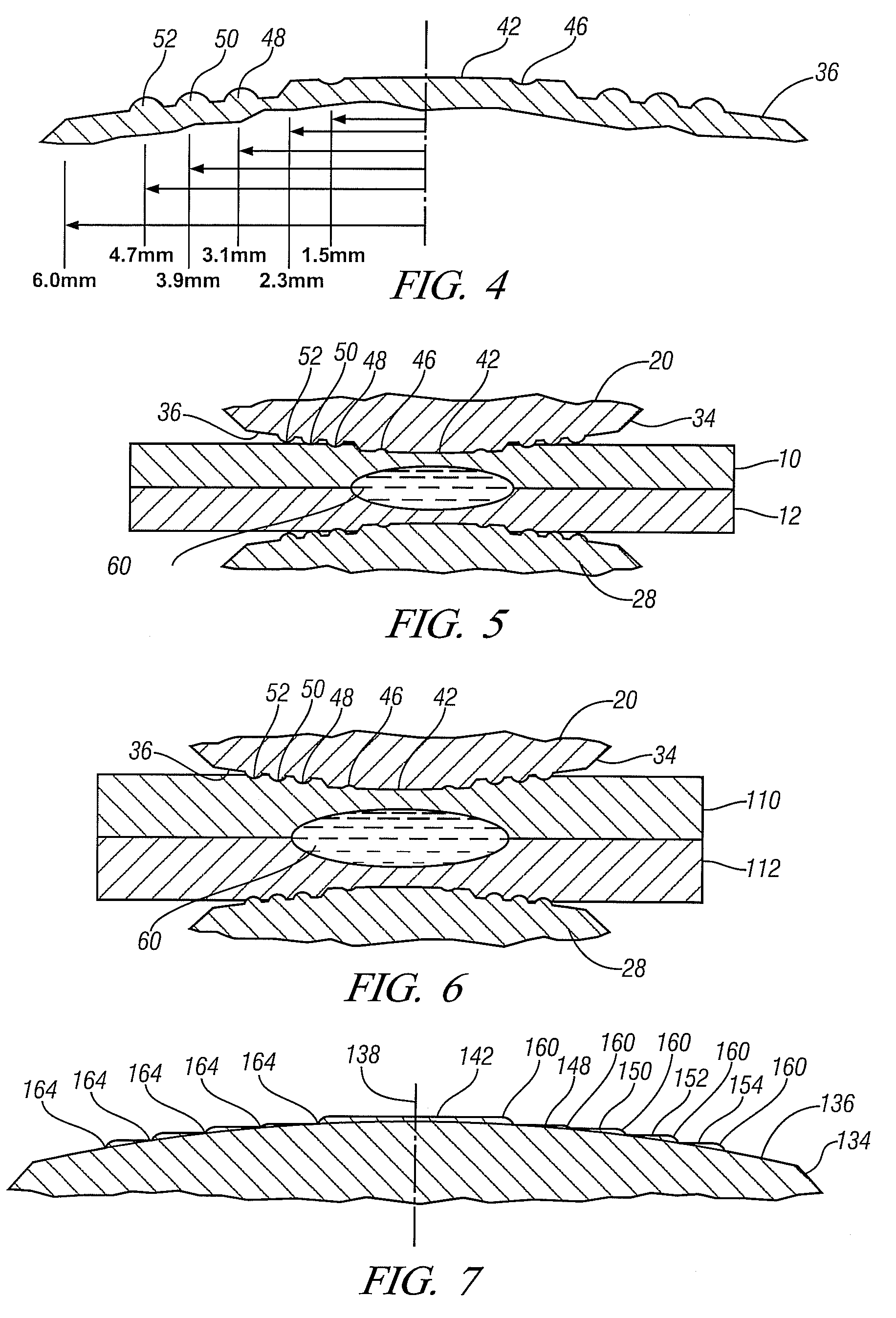

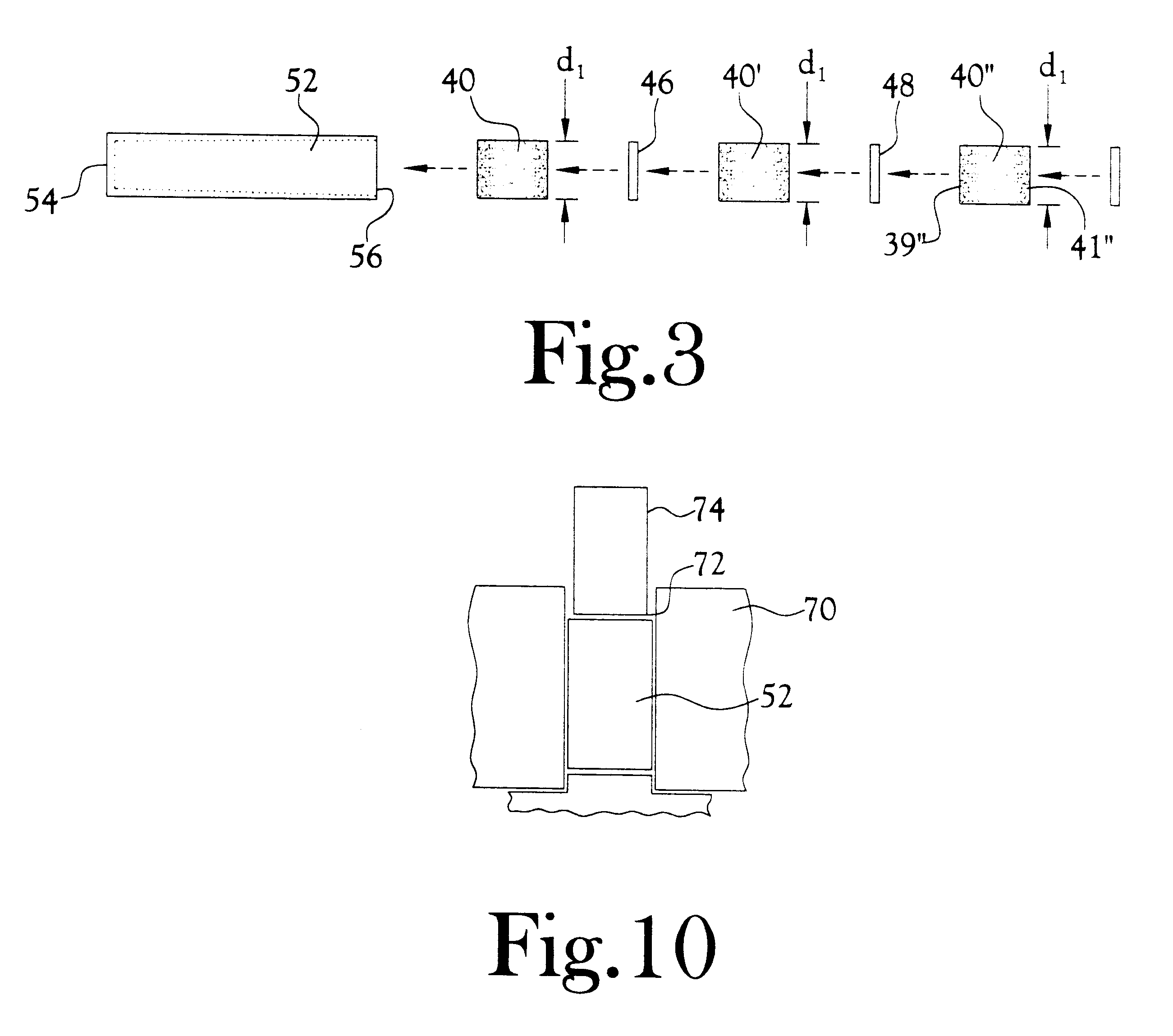

Light metal/CFRP structural member

InactiveUS6468613B1Prevent galvanic corrosionHigh structural reliabilitySynthetic resin layered productsCeramic shaping apparatusMetallic materialsRoom temperature

Light metal / CFRP-made structural members which are characterized in that they are structural materials in which a CFRP material is stuck to the surface of a light metal material via an adhesive agent layer of thickness at least 10 mum and up to 500 mum, and the volume resistivity of the adhesive agent layer between said metal material and said CFRP material is at least 1x1013 OMEGA.cm and, furthermore, the adhesive strength at room temperature is at least 15 MPa. In accordance with the present invention, since conventional light metal / CFRP structural materials can be made lighter and, furthermore, since the resistance to galvanic corrosion is outstanding and it is possible to markedly enhance the strength and the impact energy absorption performance, the development of applications and large-scale expansion into new fields becomes possible. Weight reduction and enhancing the durability and reliability of structures also makes a considerable contribution in terms of environmental protection.

Owner:TORAY IND INC

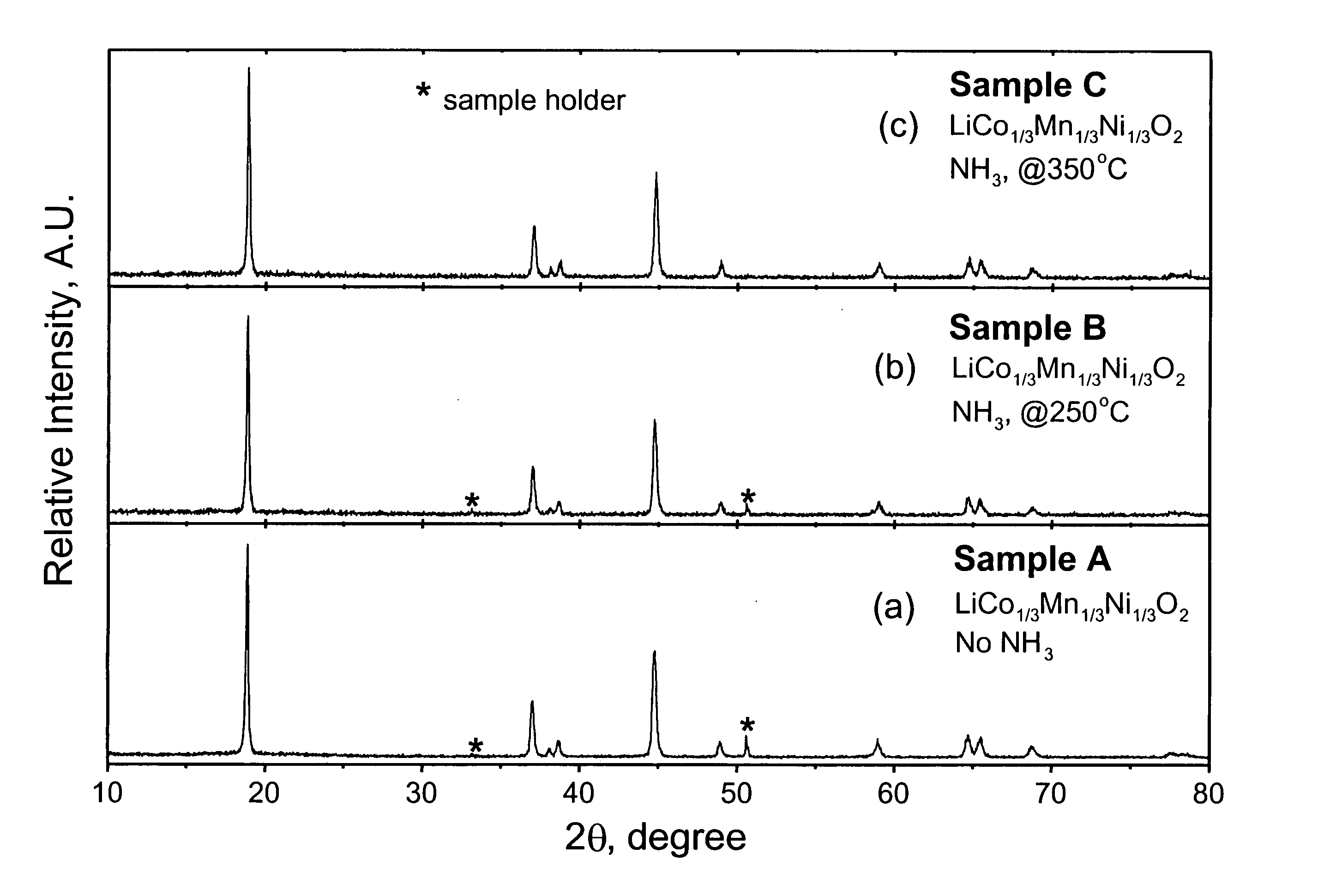

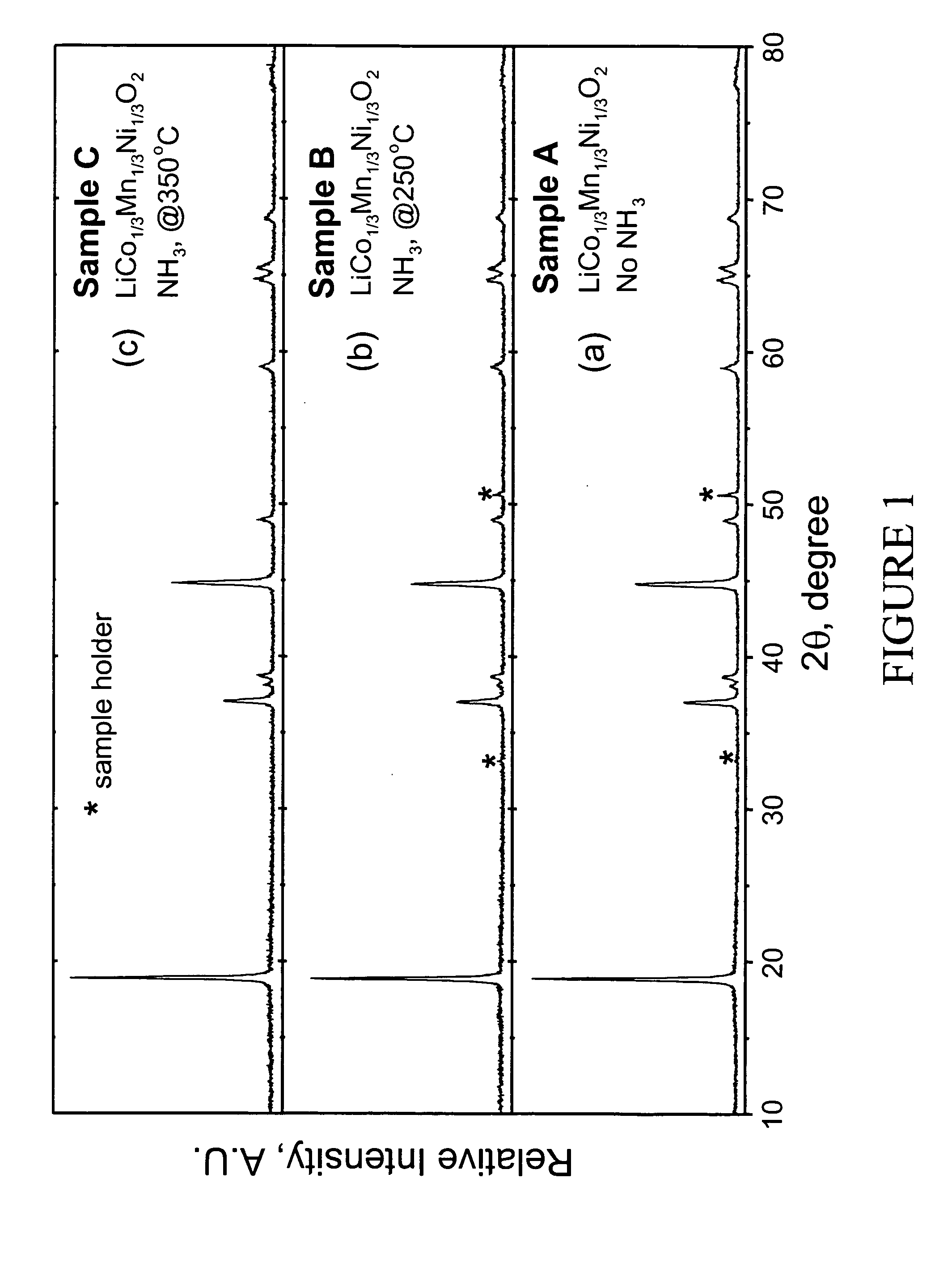

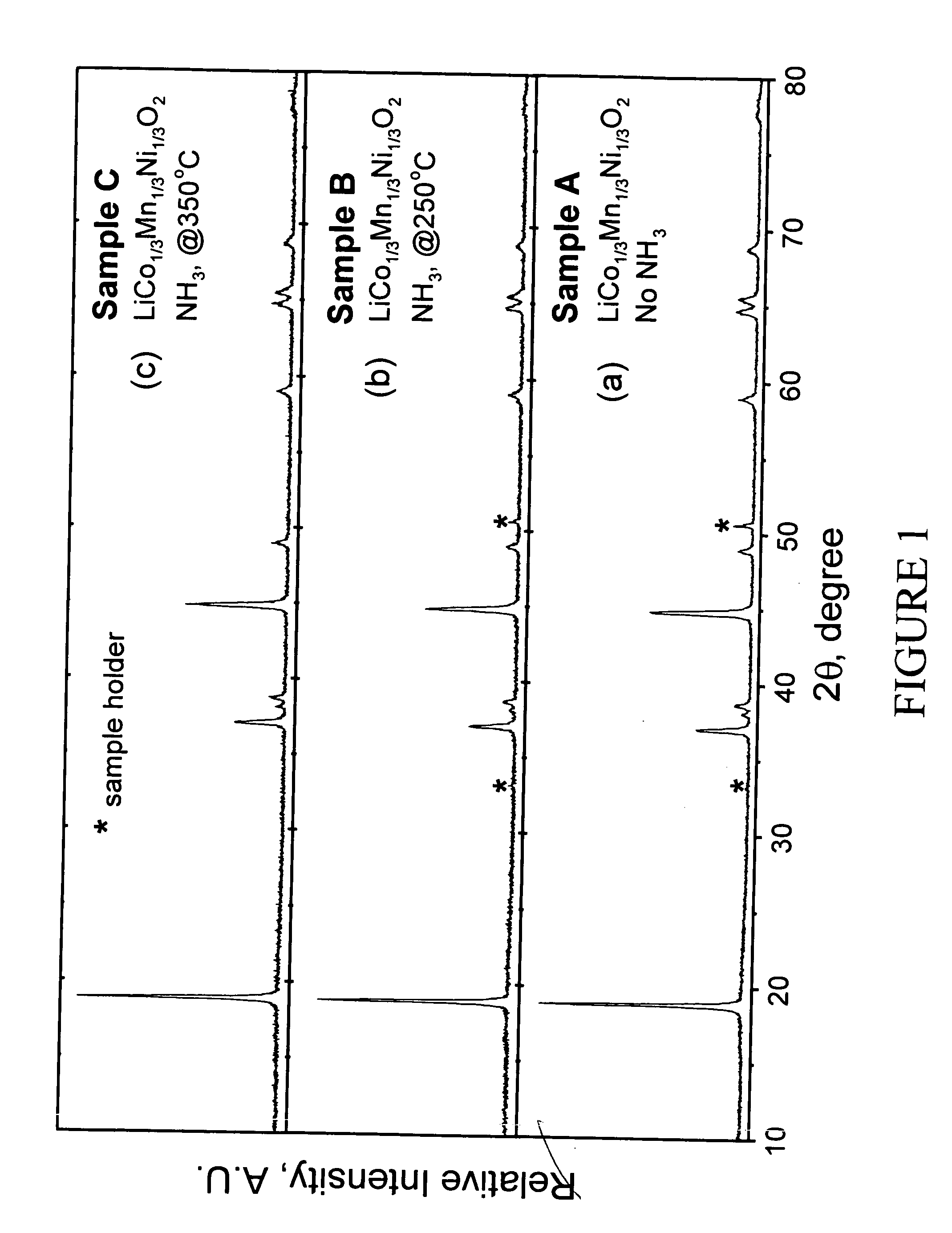

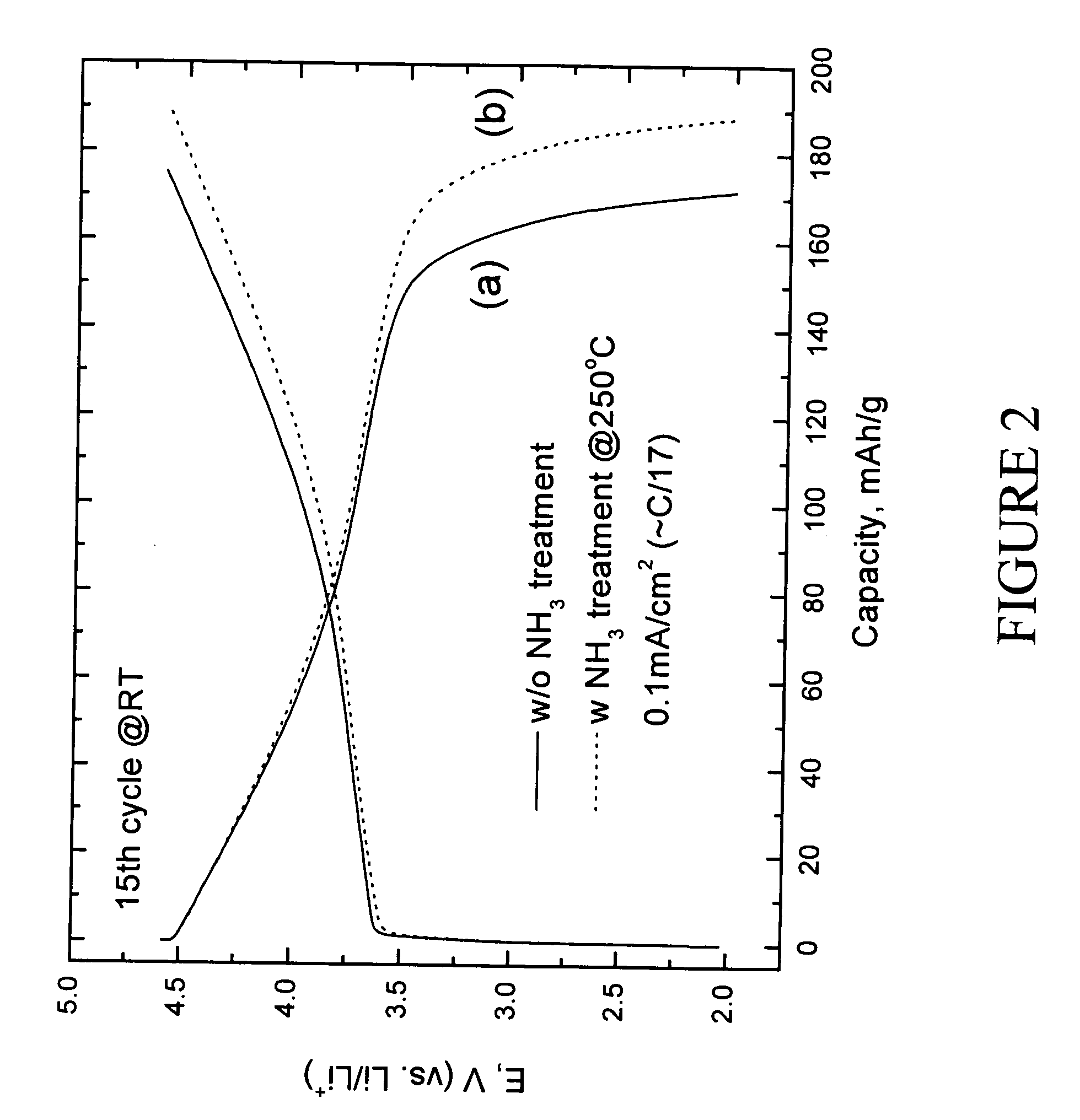

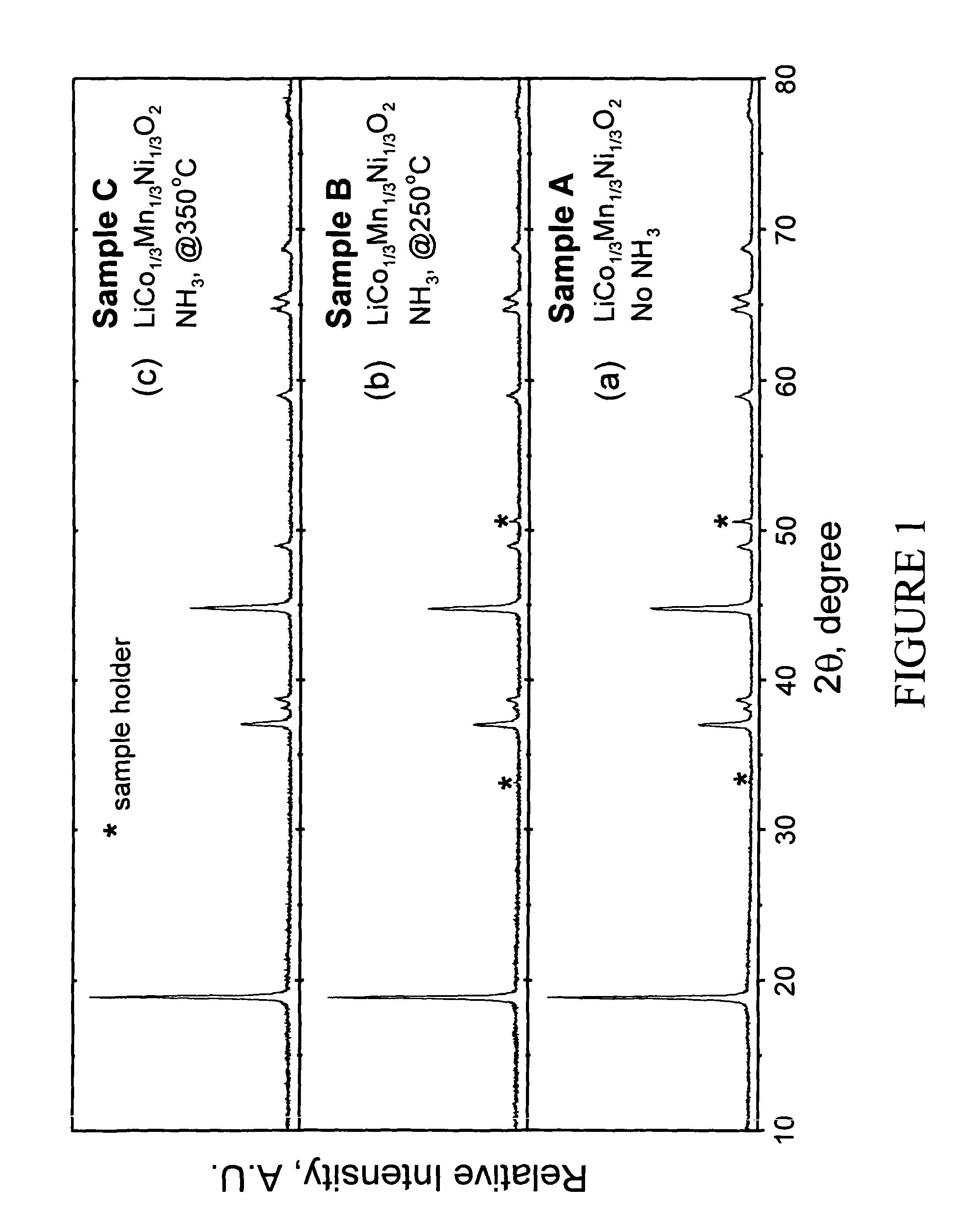

Lithium metal oxide electrodes for lithium batteries

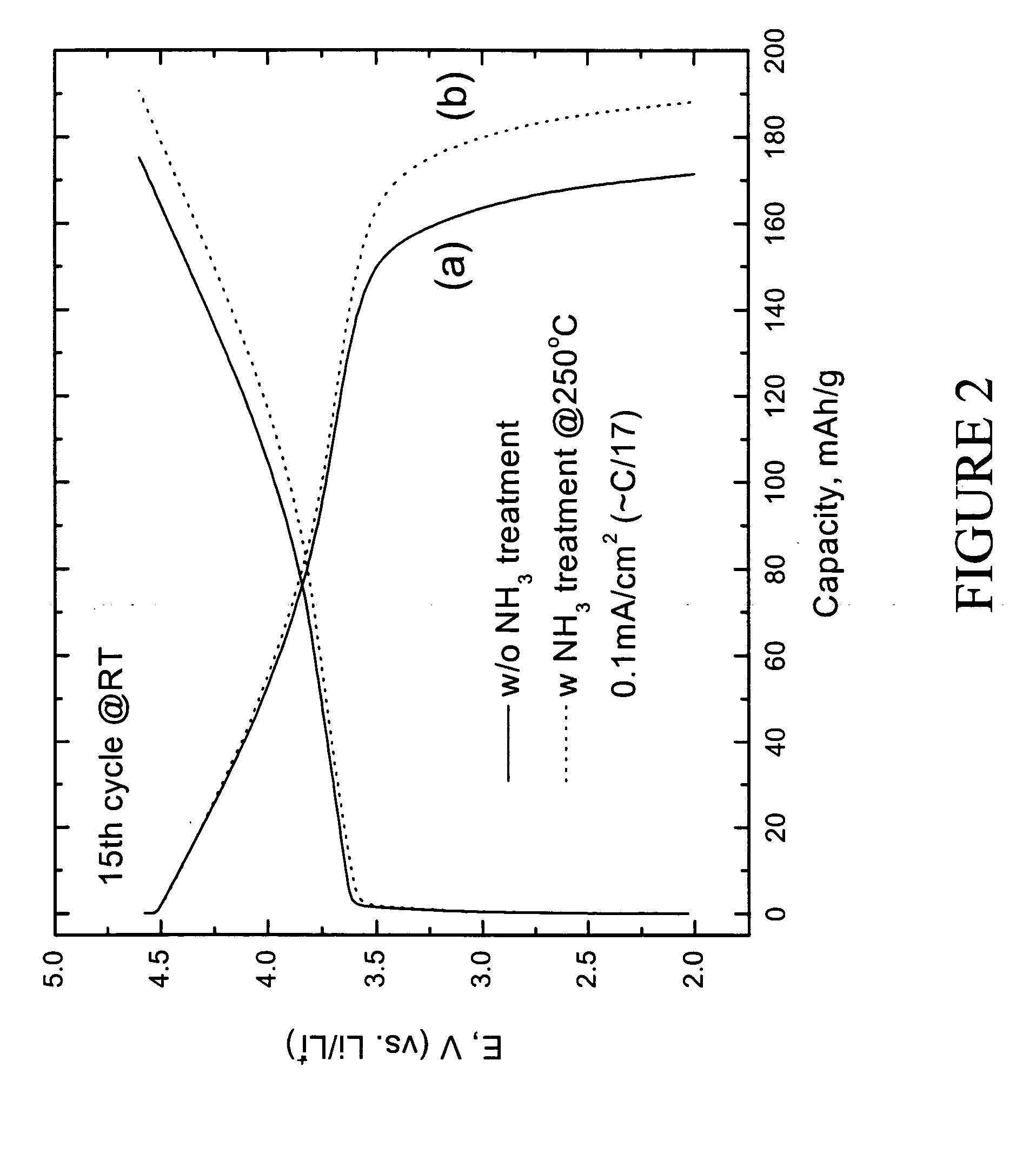

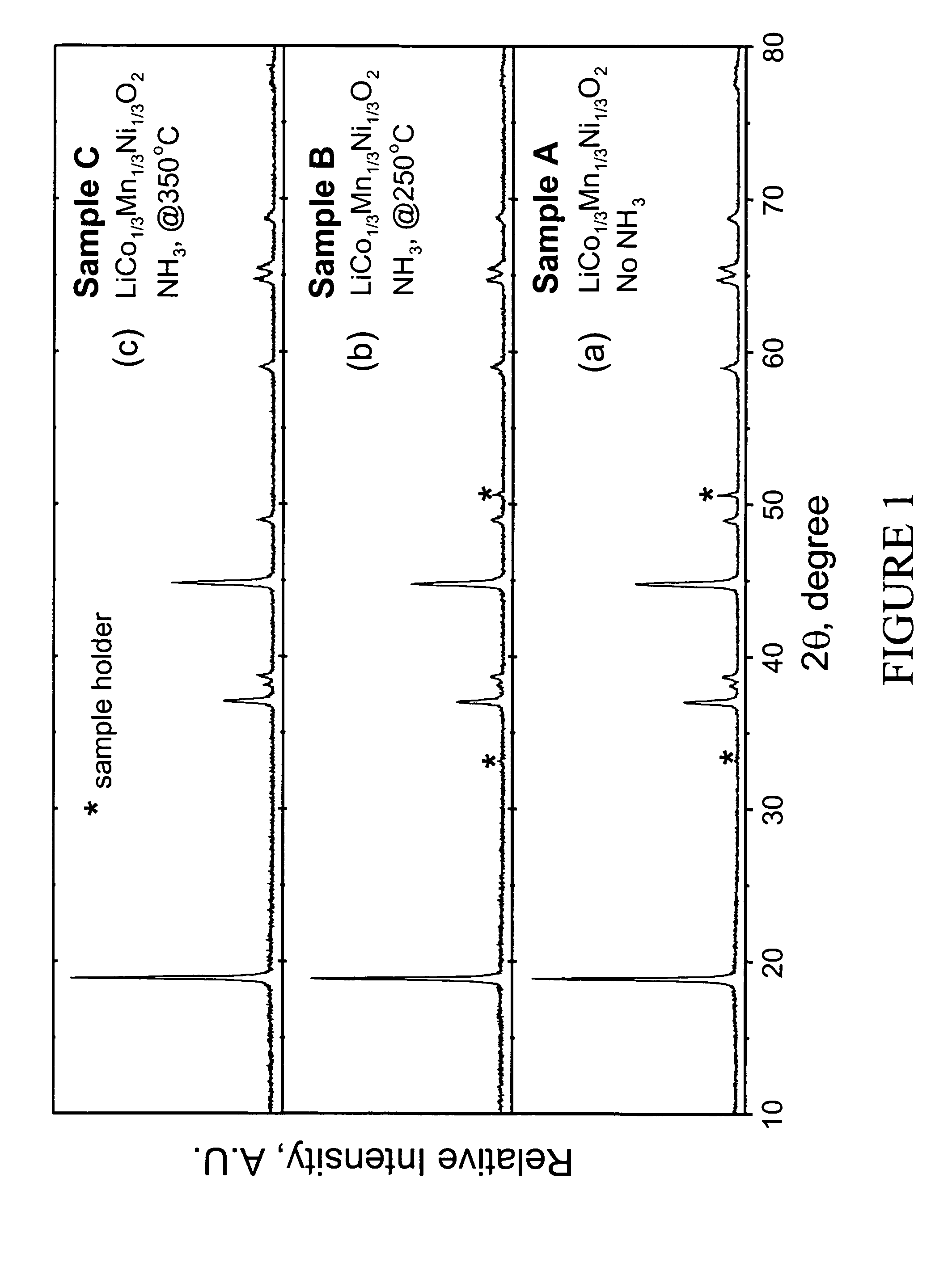

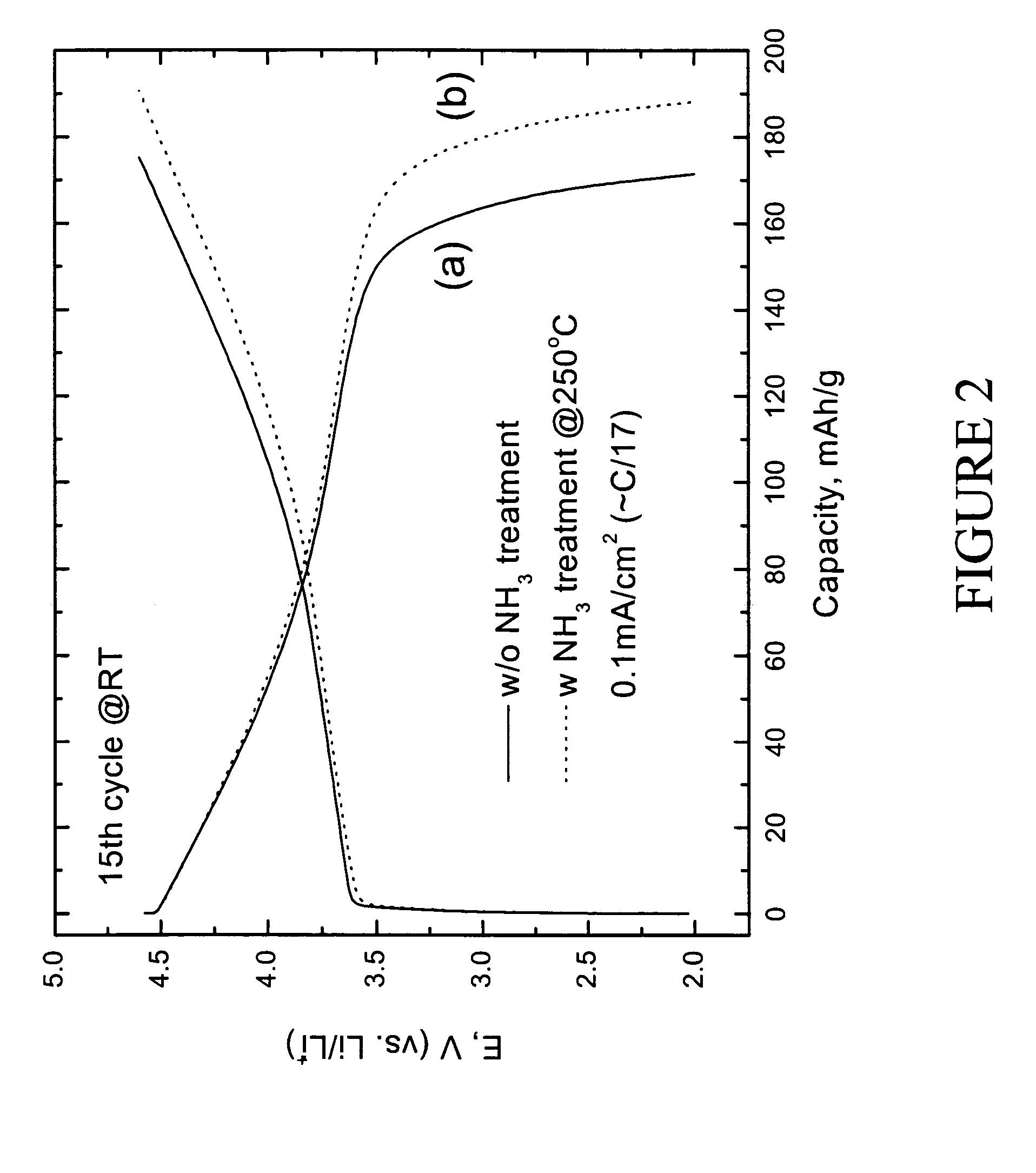

ActiveUS20050026040A1Increase capacityImprove cycle stabilityCellsElectrode thermal treatmentLithium metalOxidation state

An uncycled electrode for a non-aqueous lithium electrochemical cell including a lithium metal oxide having the formula Li(2+2x) / (2+x)M′2x / (2+x)M(2-2x) / (2+x)O2-δ, in which 0≦x<1 and δ is less than 0.2, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more of the first row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first and second row transition metal elements and Sn. Methods of preconditioning the electrodes are disclosed as are electrochemical cells and batteries containing the electrodes.

Owner:UCHICAGO ARGONNE LLC

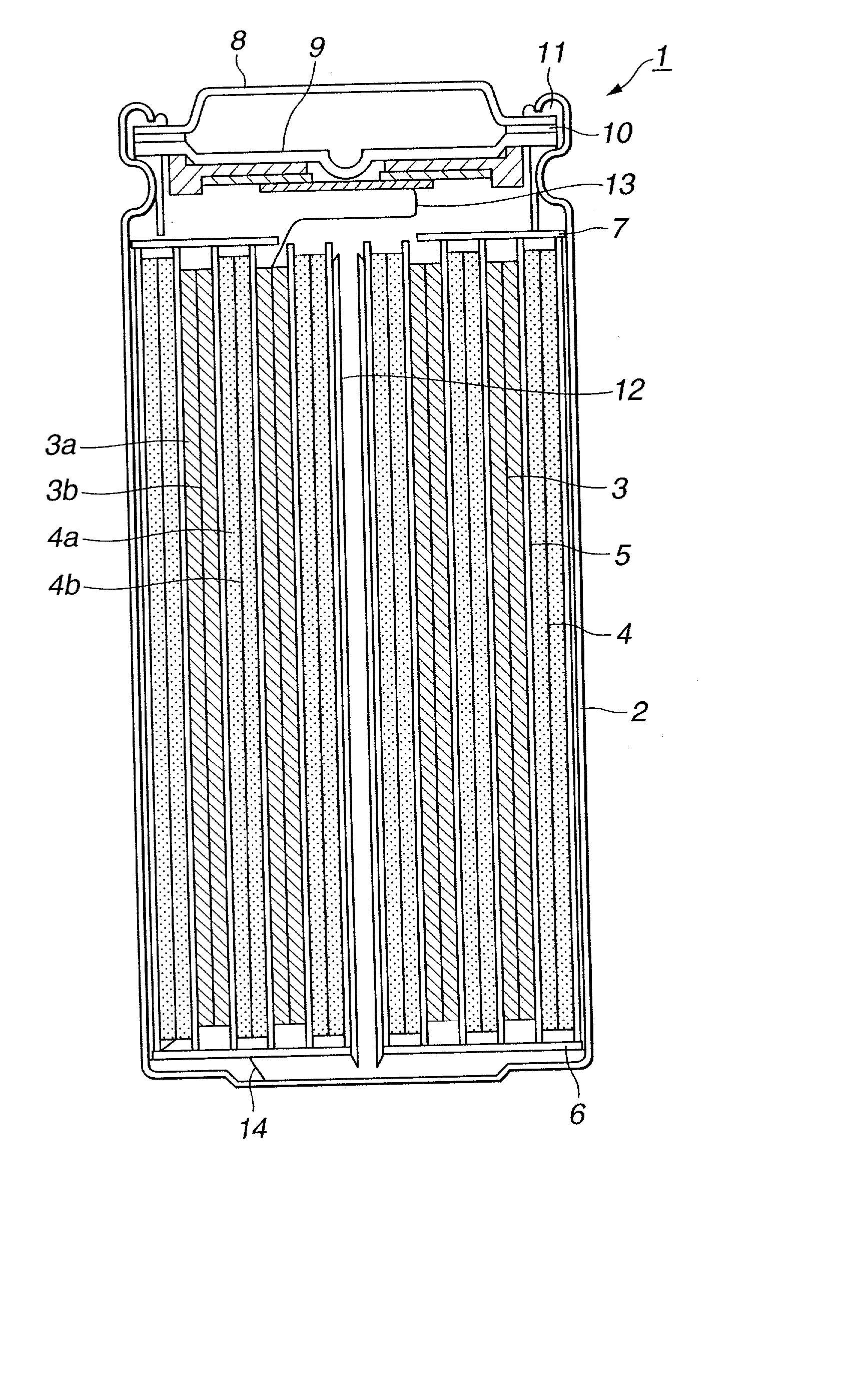

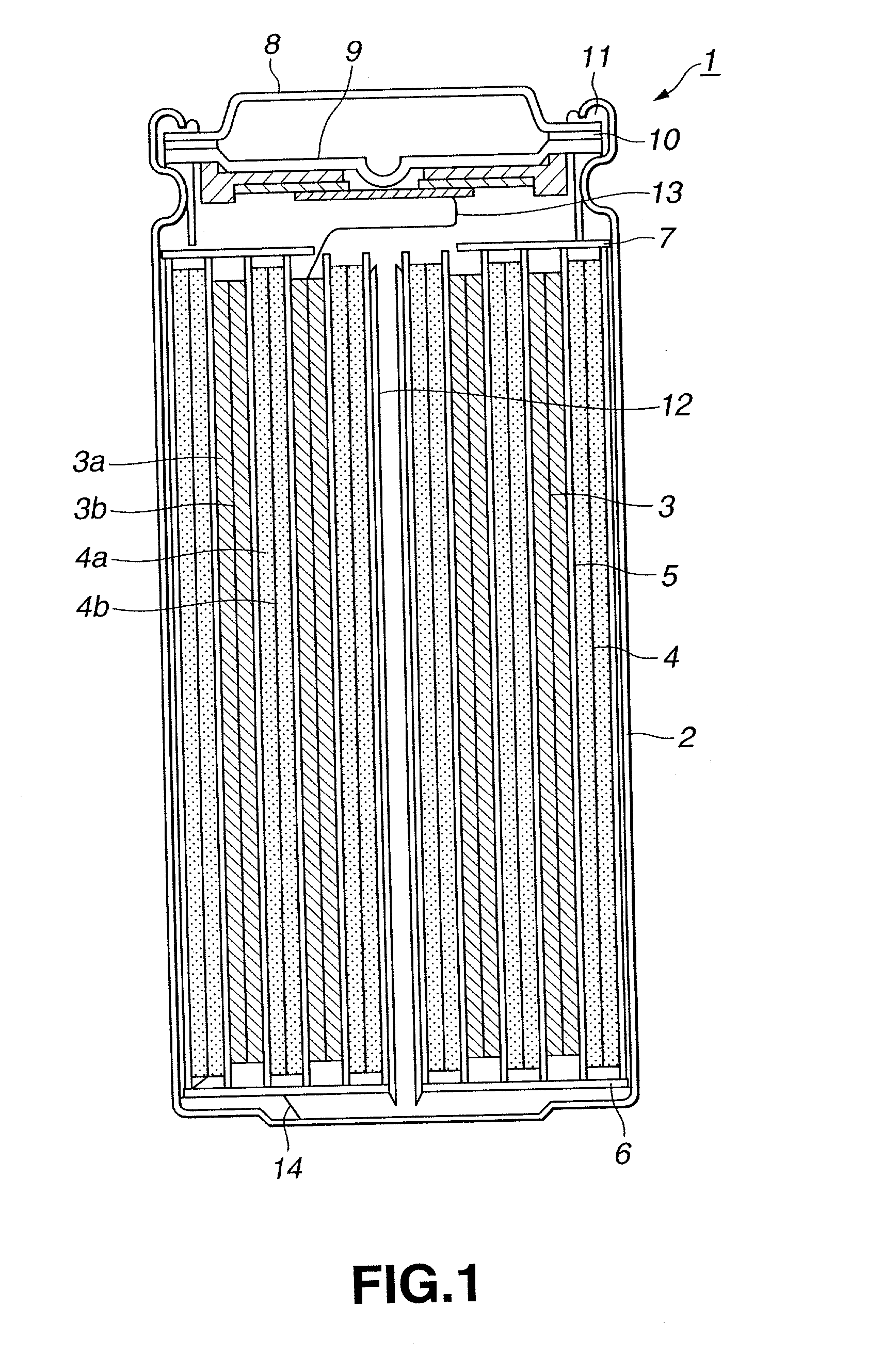

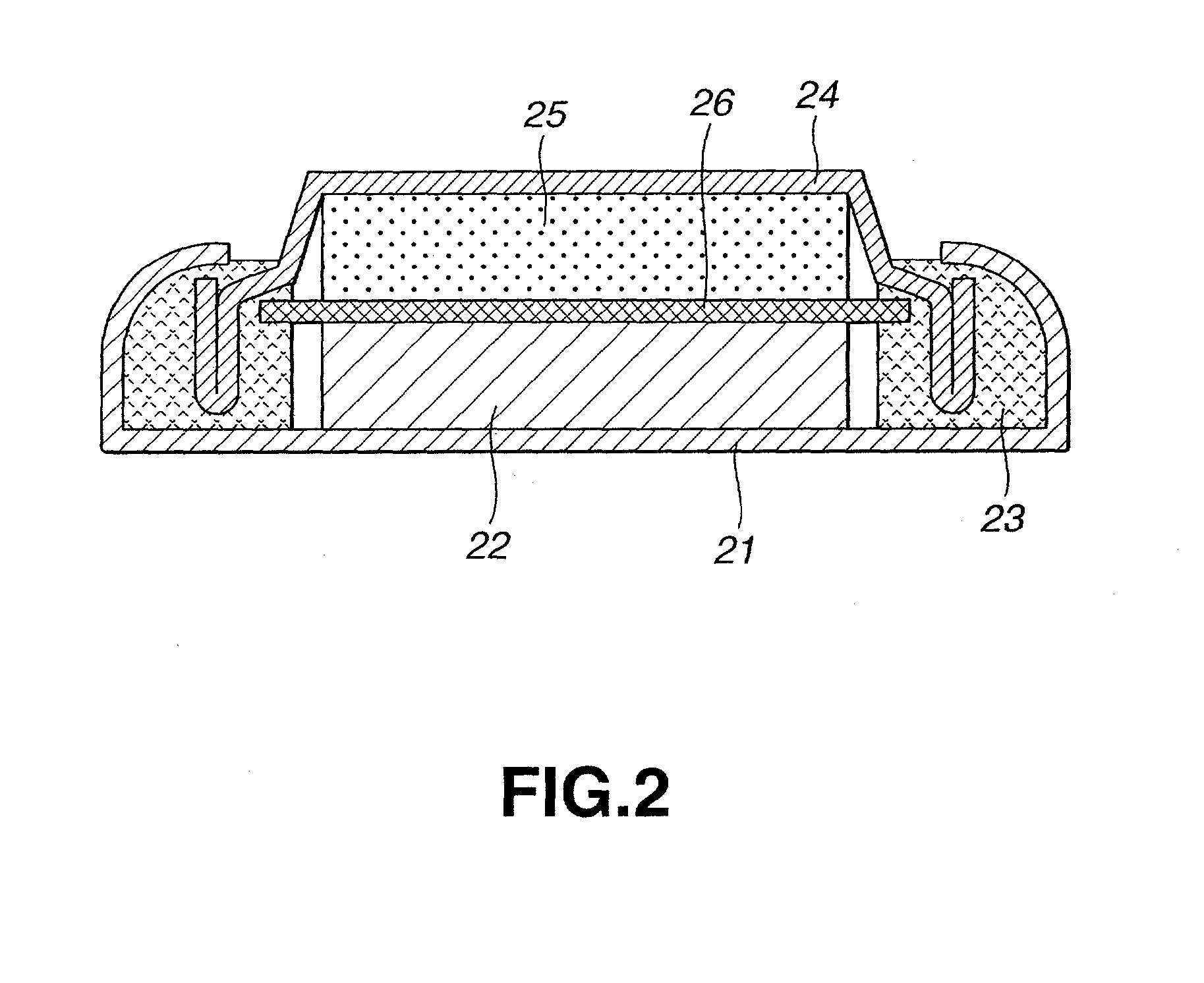

Anode active material and nonaqueous electrolyte secondary battery

InactiveUS20030008212A1Chemical deterioration of a nonaqueous electrolyte material is preventedAvoid destructionElectrode manufacturing processesPrimary cell maintainance/servicingFiberMaterials science

The present invention relates to an anode material excellent in its charging and discharging characteristics and a secondary battery excellent in its charging and discharging cyclic characteristics. An anode active material is used for a nonaqueous electrolyte secondary battery including an anode having the anode active material, a cathode having a cathode active material and a nonaqueous electrolyte. The capacity of the anode is expressed by the sum of a capacity component obtained when light metal is doped and dedoped in an ionic state and a capacity component obtained when the light metal is deposited and dissolved. The light metal includes an anode base material capable of doping and dedoping the light metal in an ionic state and a fibrous material having an electric conductivity.

Owner:SONY CORP

Lithium metal oxide electrodes for lithium batteries

InactiveUS20060188781A1Increase capacityImprove cycle stabilityActive material electrodesAlkali metal oxidesLithium metalOxidation state

An uncycled preconditioned electrode for a non-aqueous lithium electrochemical cell including a lithium metal oxide having the formula Li(2+2x) / (2+x)M′2x / (2+x)M(2−2x) / (2+x)O2−δ, in which 0≦x<1 and δ is less than 0.2, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more of the first row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first and second row transition metal elements and Sn, and an uncycled electrode of the formula xLi2M′O3.(1−x)LiMO2, in which 0≦x<1, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more first-row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first- and second-row transition metal elements and Sn, the electrode being preconditioned in a proton-containing medium with a pH<7.0. Methods of preconditioning the electrodes are disclosed as are electrochemical cells and batteries containing the electrodes.

Owner:UCHICAGO ARGONNE LLC +1

Lithium metal oxide electrodes for lithium batteries

InactiveUS7314682B2Electrode thermal treatmentActive material electrodesLithium metalOxidation state

An uncycled electrode for a non-aqueous lithium electrochemical cell including a lithium metal oxide having the formula Li(2+2x) / (2+x)M′2x / (2+x)M(2−2x) / (2+x)O2−δ, in which 0≦x<1 and δ is less than 0.2, and in which M is a non-lithium metal ion with an average trivalent oxidation state selected from two or more of the first row transition metals or lighter metal elements in the periodic table, and M′ is one or more ions with an average tetravalent oxidation state selected from the first and second row transition metal elements and Sn. Methods of preconditioning the electrodes are disclosed as are electrochemical cells and batteries containing the electrodes.

Owner:UCHICAGO ARGONNE LLC

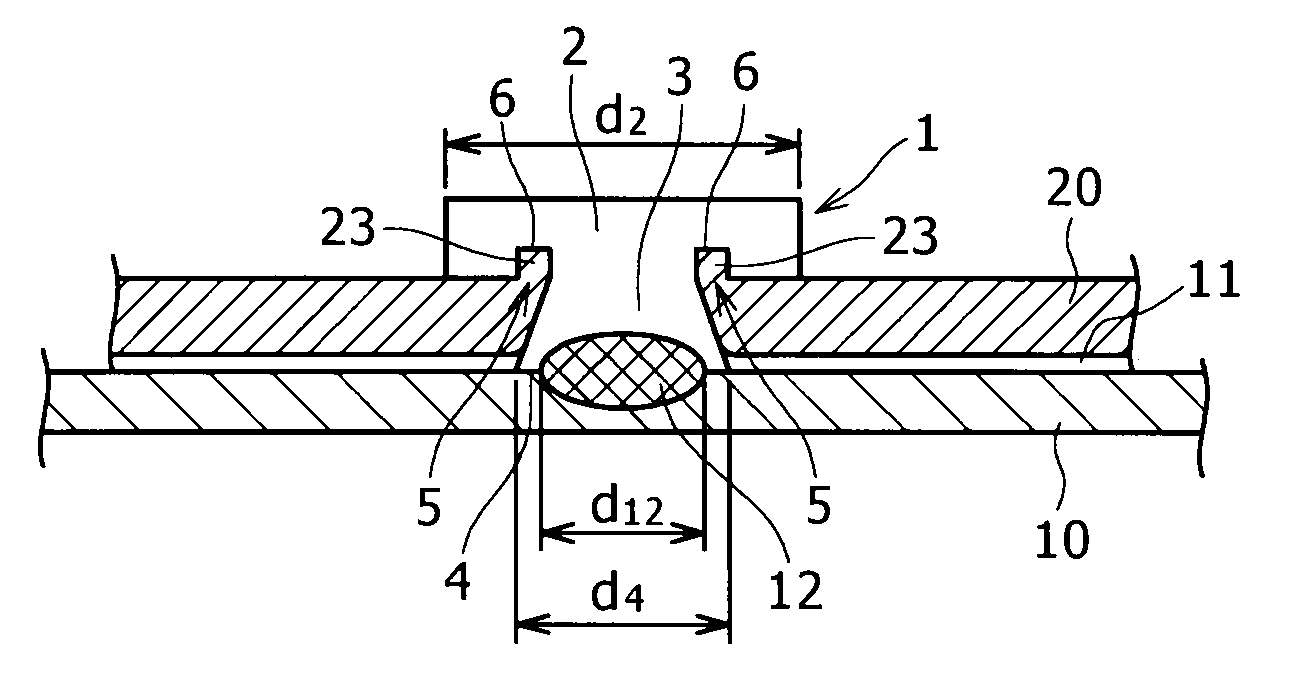

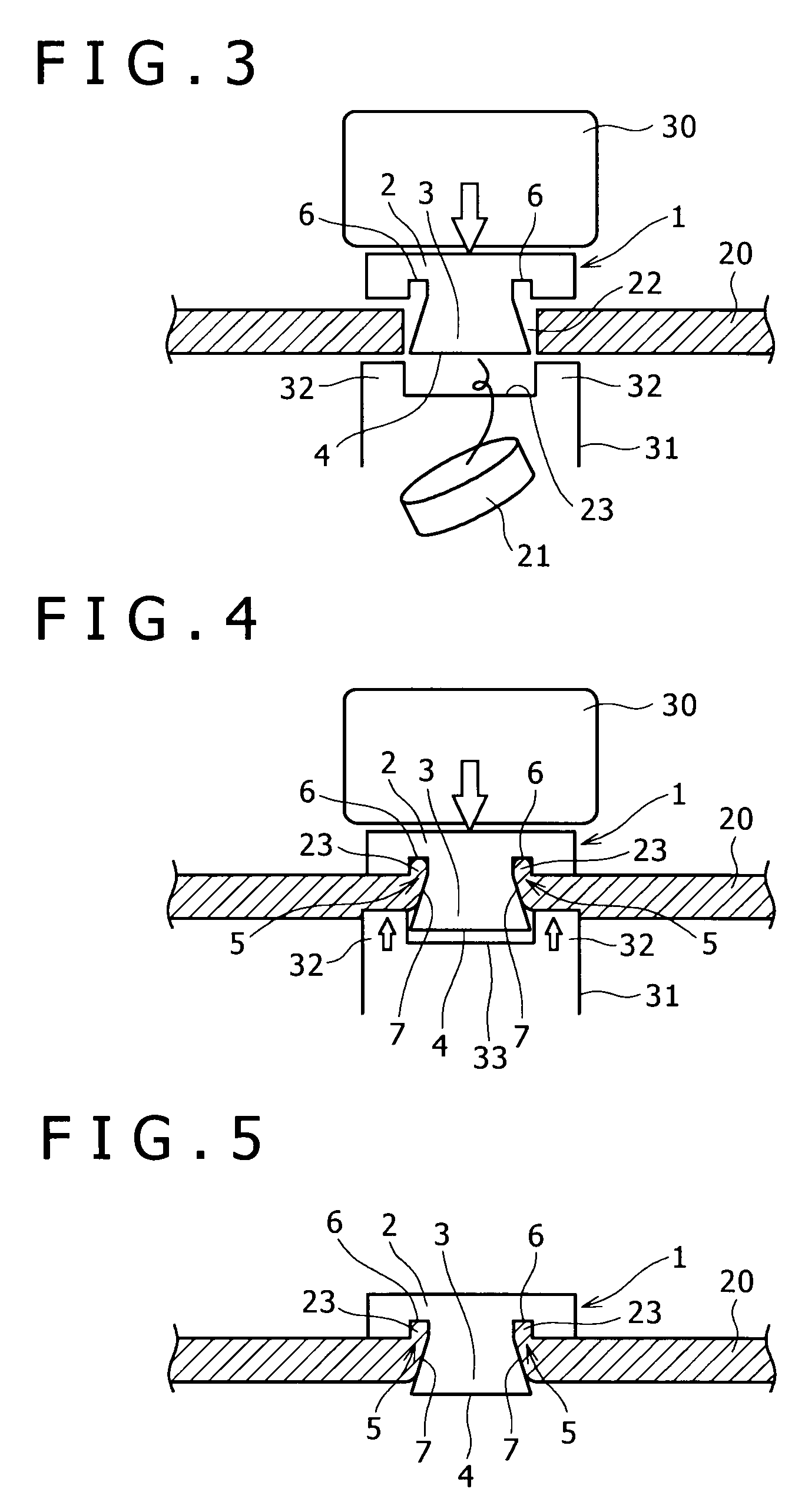

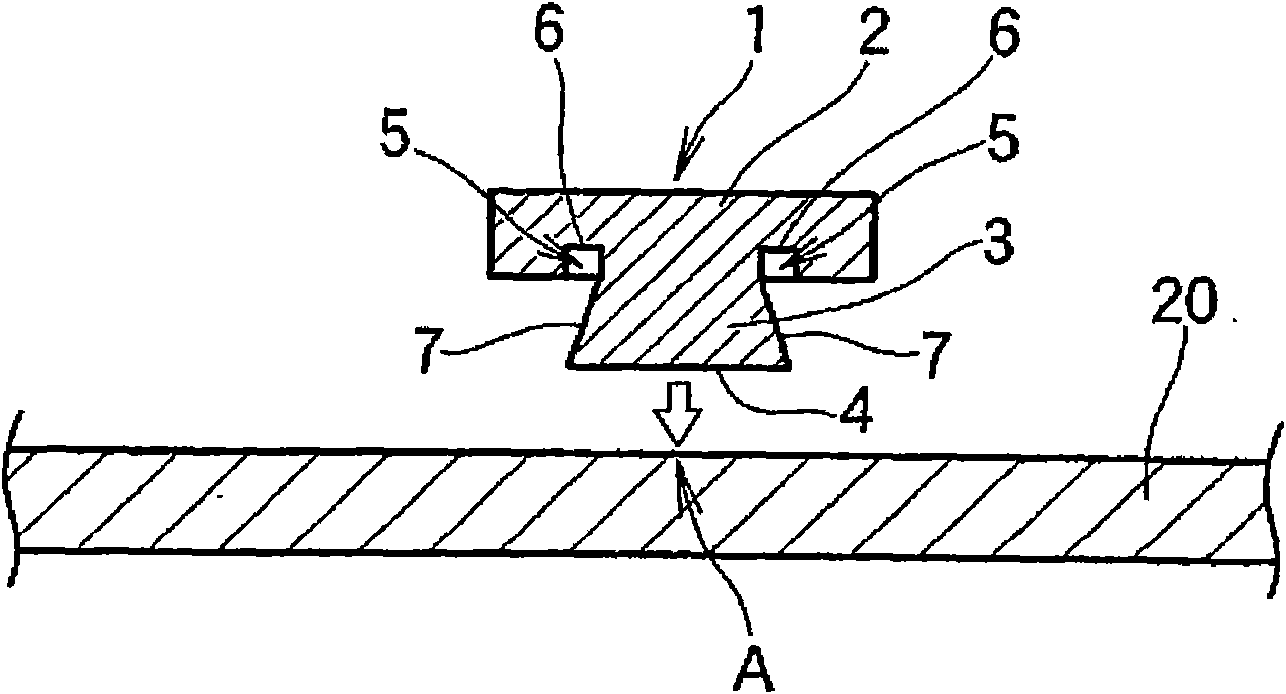

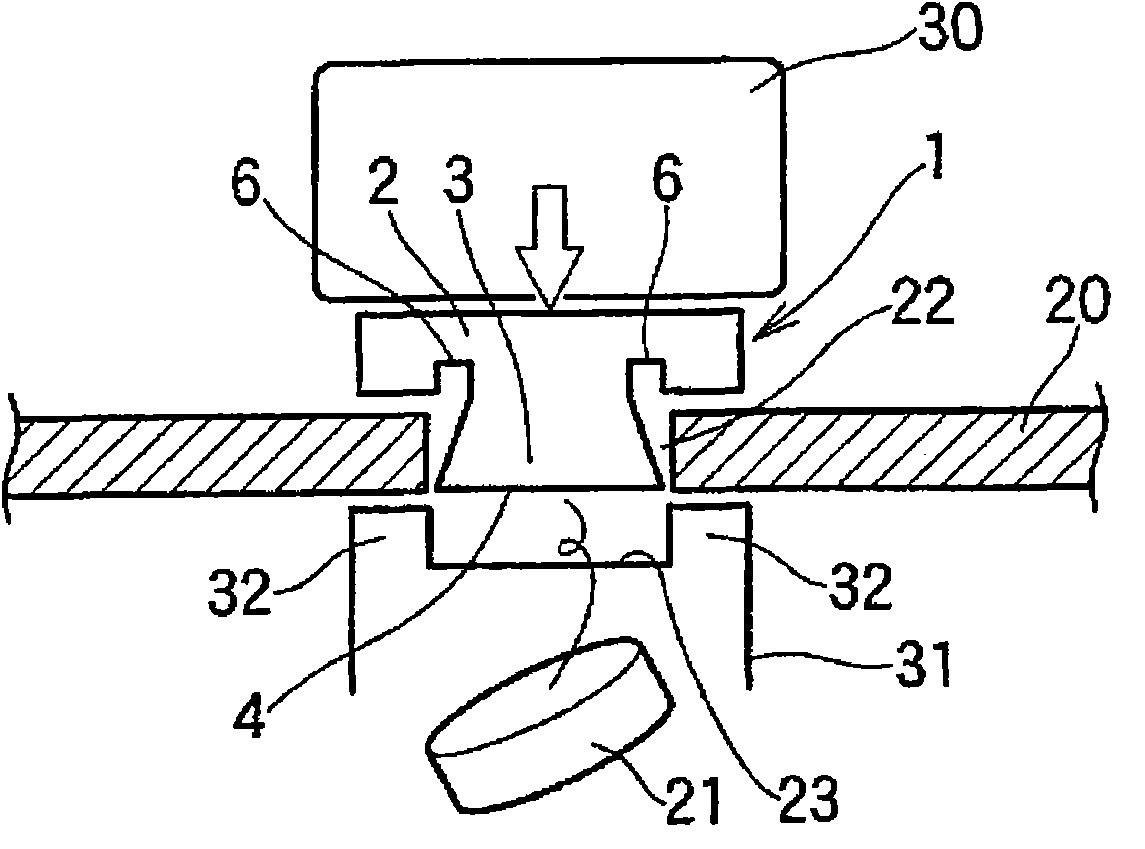

Method for joining dissimilar metals of steel product and light metal product with each other

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

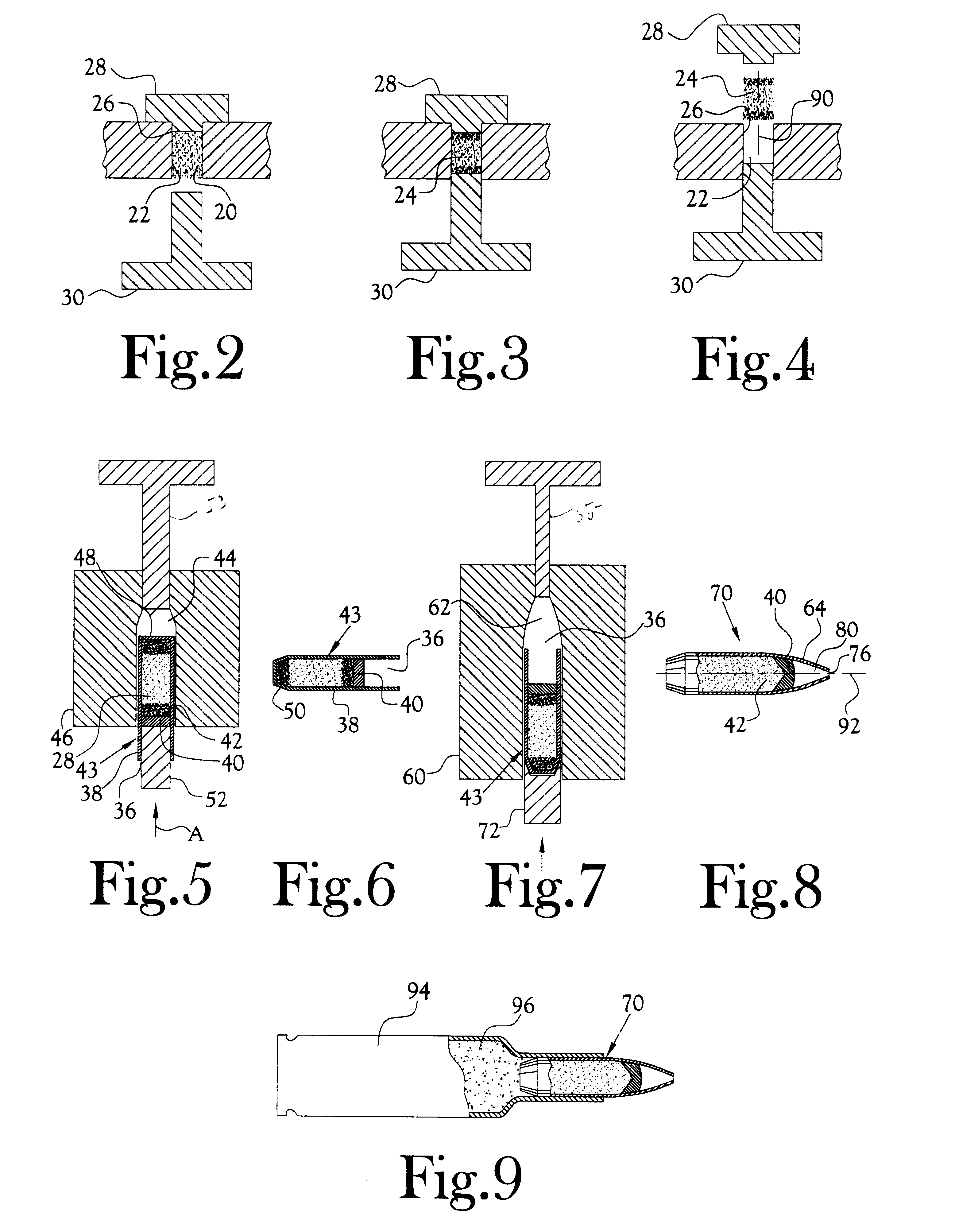

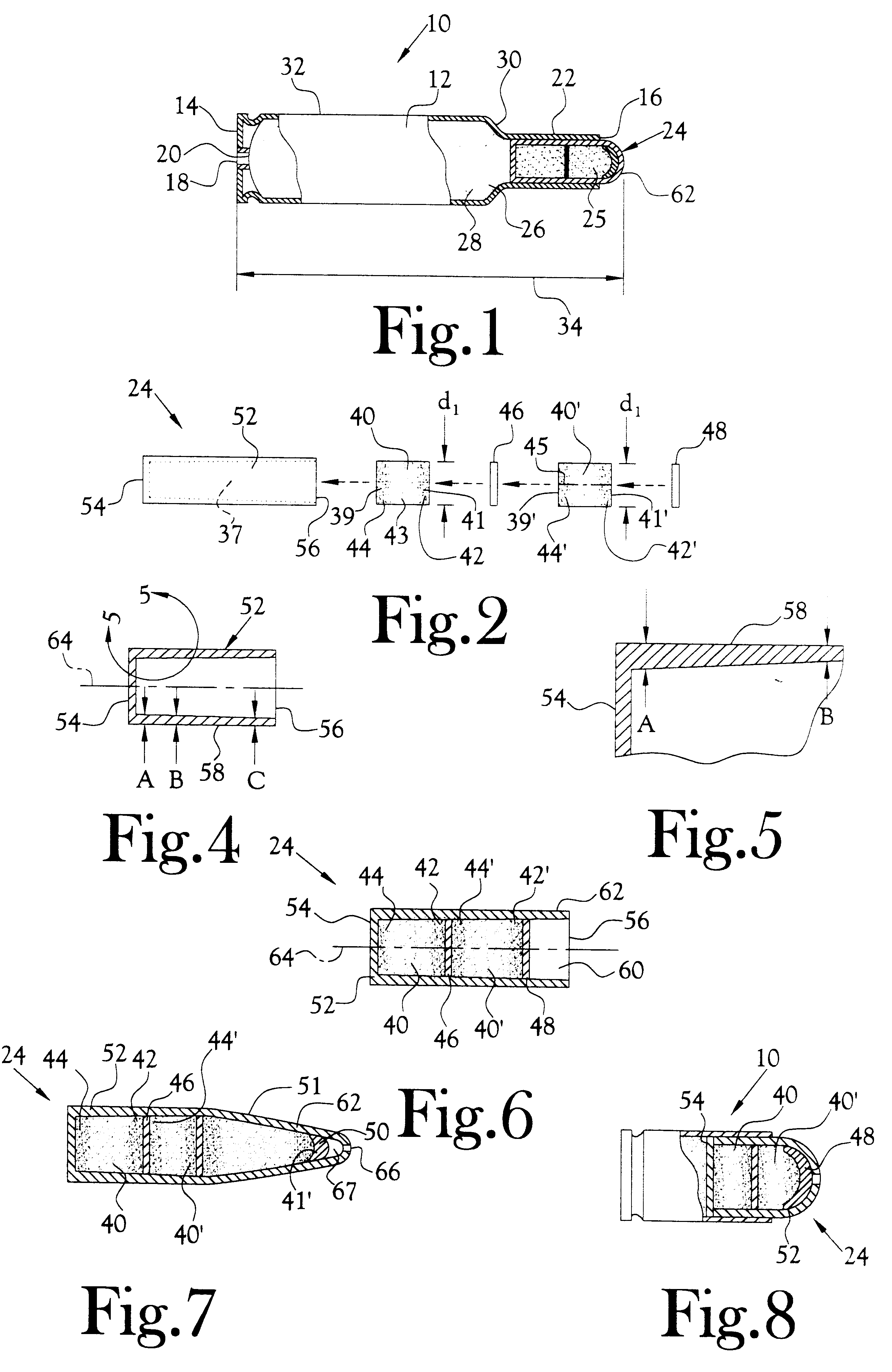

Method for the manufacture of a frangible nonsintered powder-based projectile for use in gun ammunition and product obtained thereby

InactiveUS6457417B1Easy and inexpensive to manufactureAmmunition projectilesTraining ammunitionSemi solidRicochet

A method for the manufacture of heavy metal powder-based frangible projectiles which are relatively easy and inexpensive to manufacture and which exhibit a selectable variety of desirable physical and / or performance properties. The projectiles of the present invention are powder-based, preferably including predominately tungsten powder as a heavy metal, particularly a tungsten powder which includes a predominate portion of finely sized particles. Lighter metal powders, also preferably having a predominate portion of finely sized particles, may be employed in combination with the tungsten to achieve certain desired results. Importantly, the present inventor has found that inclusion of a non-metal matrix powder, also of finely sized particles, in a mixture of a heavy metal powder, such as tungsten powder, and a light metal powder, may be employed in a variety of combinations to produce a projectile which is fully frangible upon striking a target (no ricochet), or which is frangible after either partial or full penetration of a selected target, either a semi-solid (e.g., a gel block) or a solid (e.g., a ¼ inch thick cold rolled steel plate at an angle of about 90 degrees).

Owner:COVE CORP +1

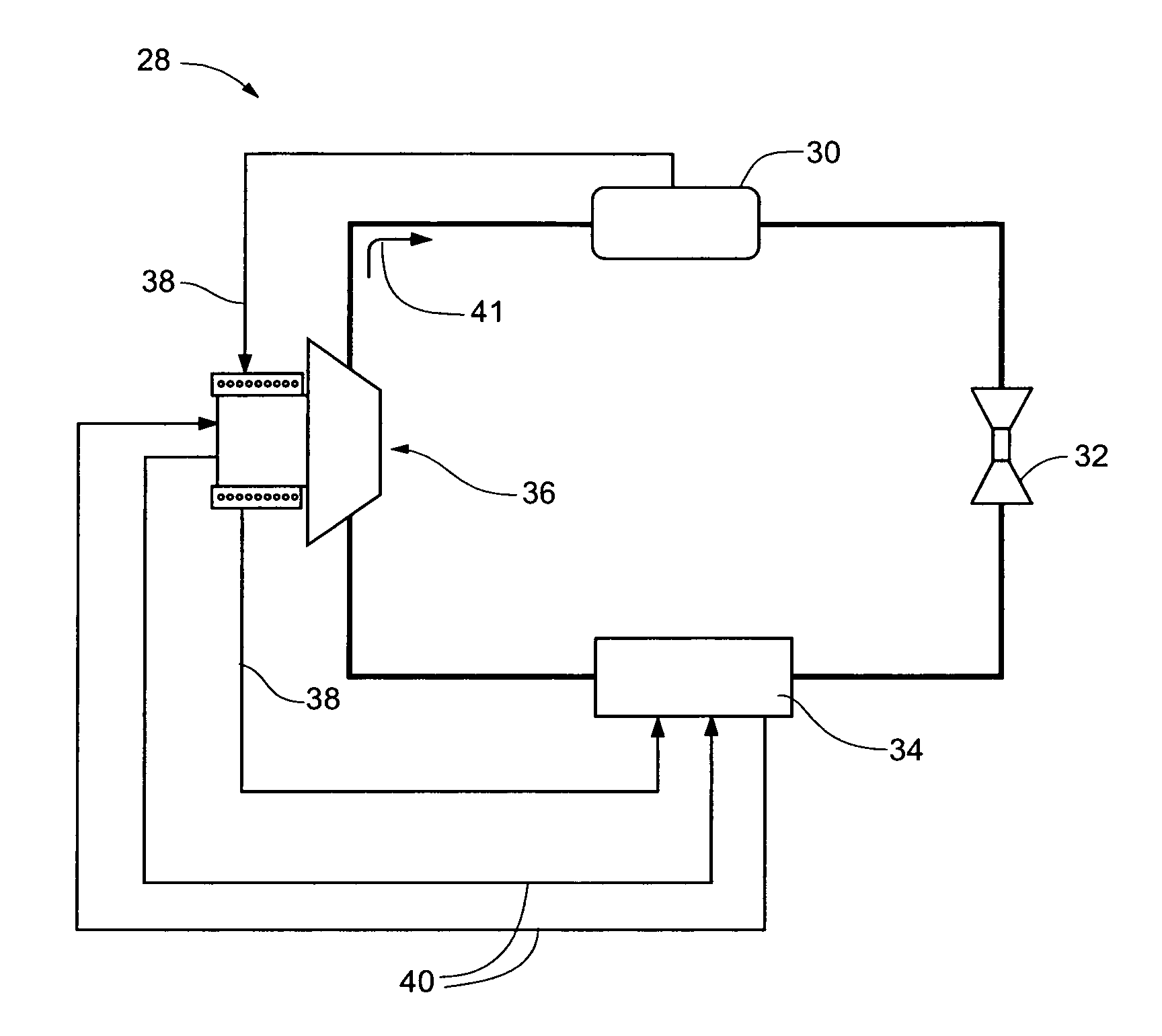

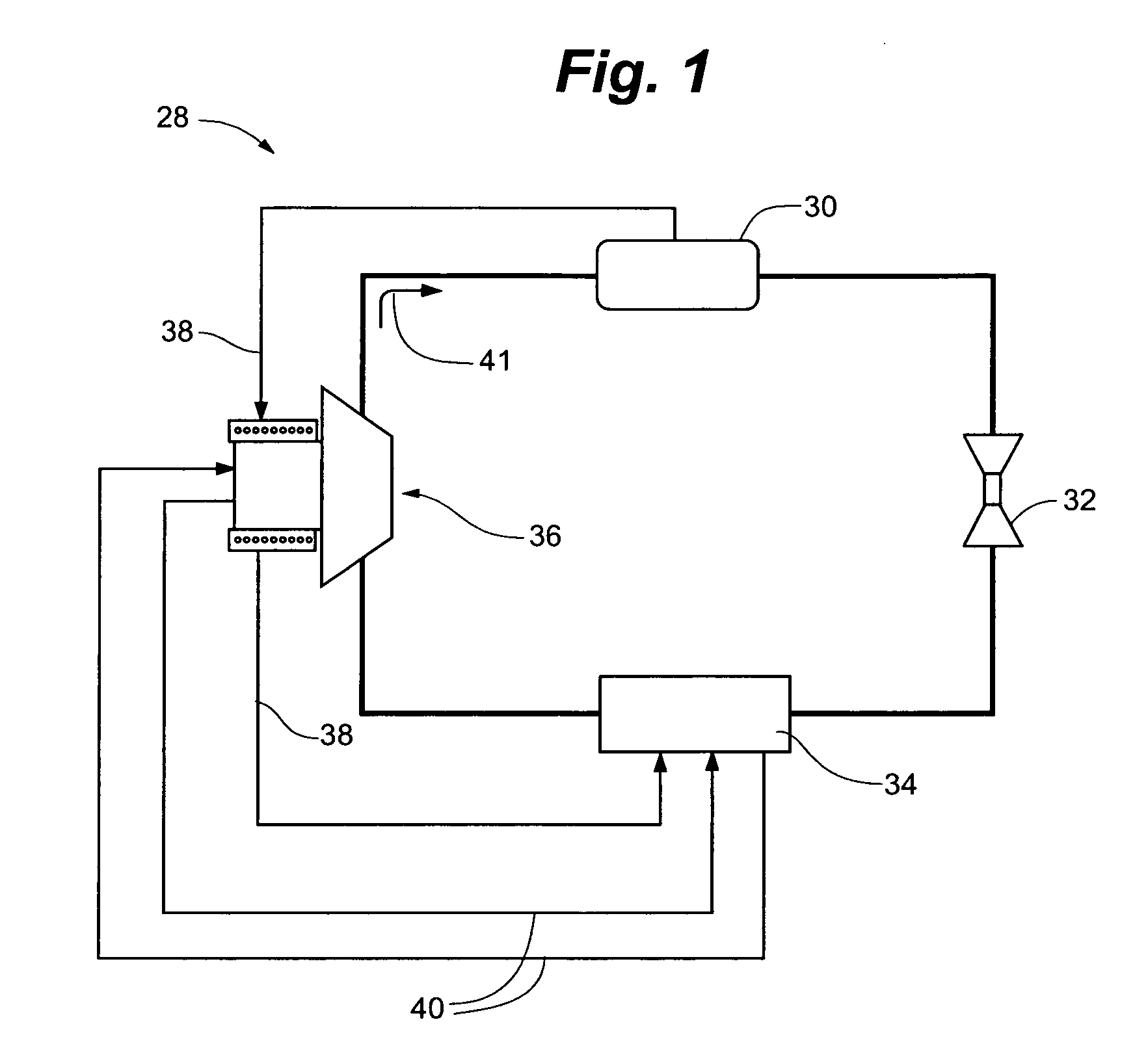

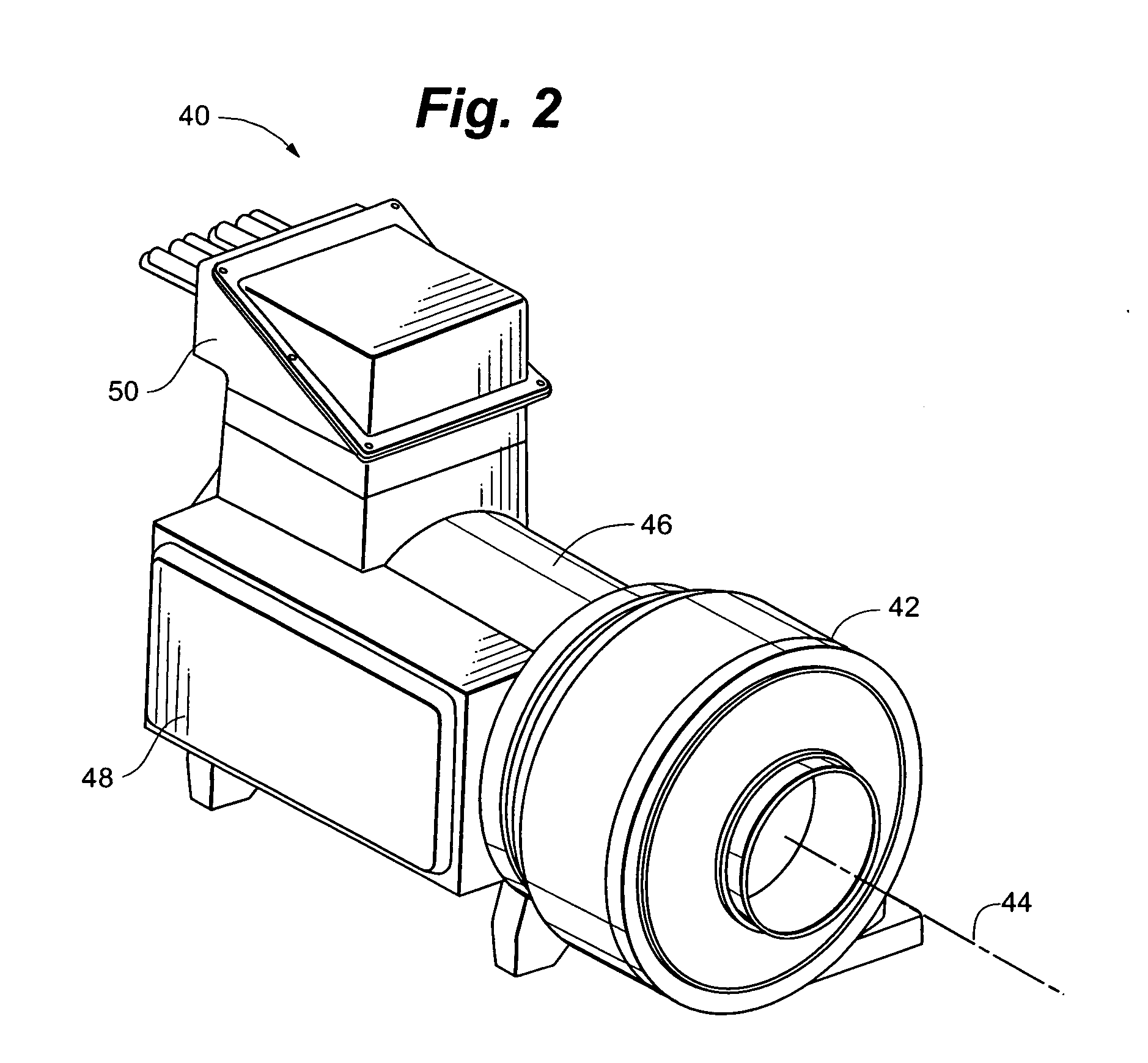

High capacity chiller compressor

ActiveUS20080115527A1Improve efficiencyIncrease power outputWind motor controlEfficient regulation technologiesMagnetic bearingEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

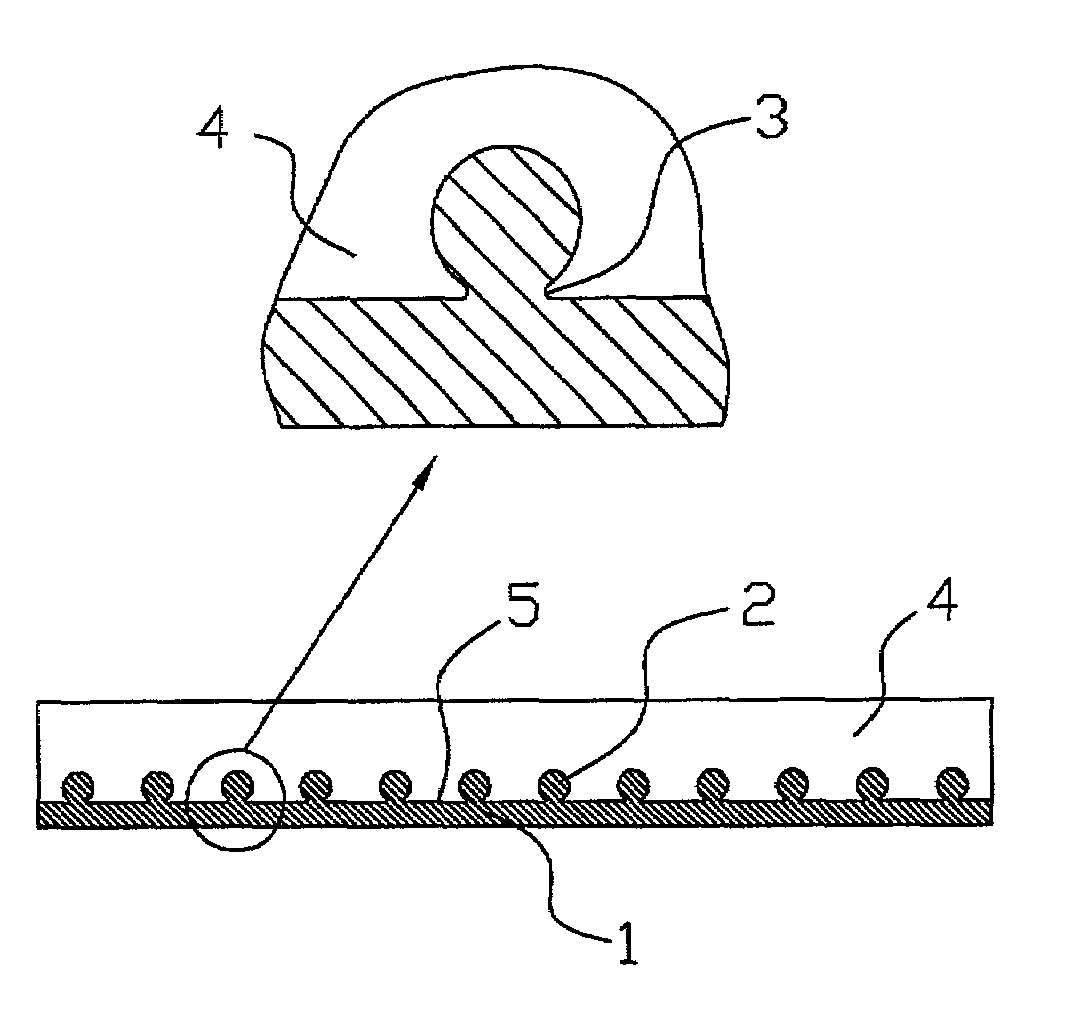

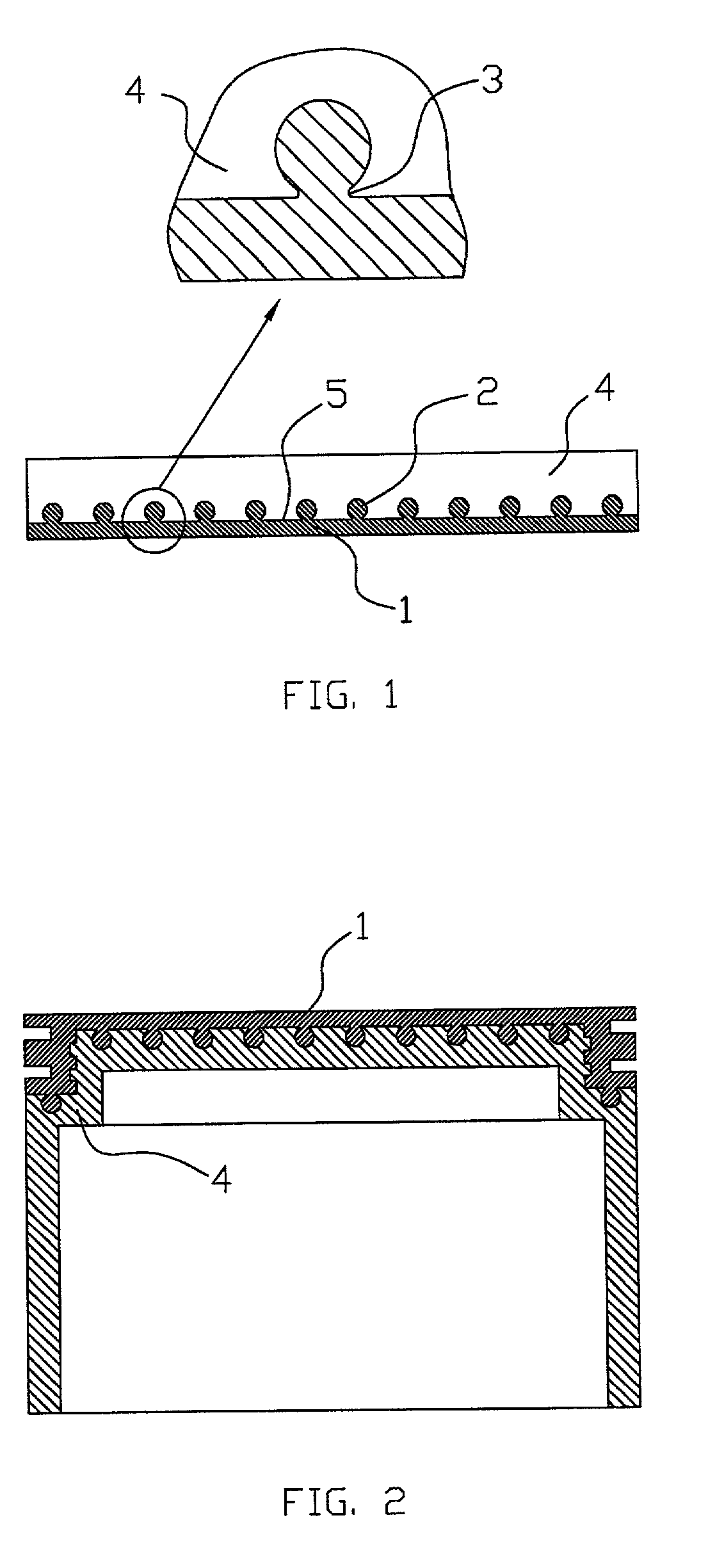

Method for manufacturing clad components

A method for manufacturing a clad component in which a cladding workpiece having a section comprising a first metal onto which a number of metal beads are rigidly bonded is inserted into a mold. A molten second metal is poured into the mold, where it flows about and covers the beads and is then permitted to cool. This process forms an article made of the second metal, which is mechanically interlocked to the beads, clad by the first metal. Typically the first metal is a high-melting point strong metal, such as steel, and the second metal is a lower-melting point, weaker, but lighter metal, such as aluminum.

Owner:NANOMETAL

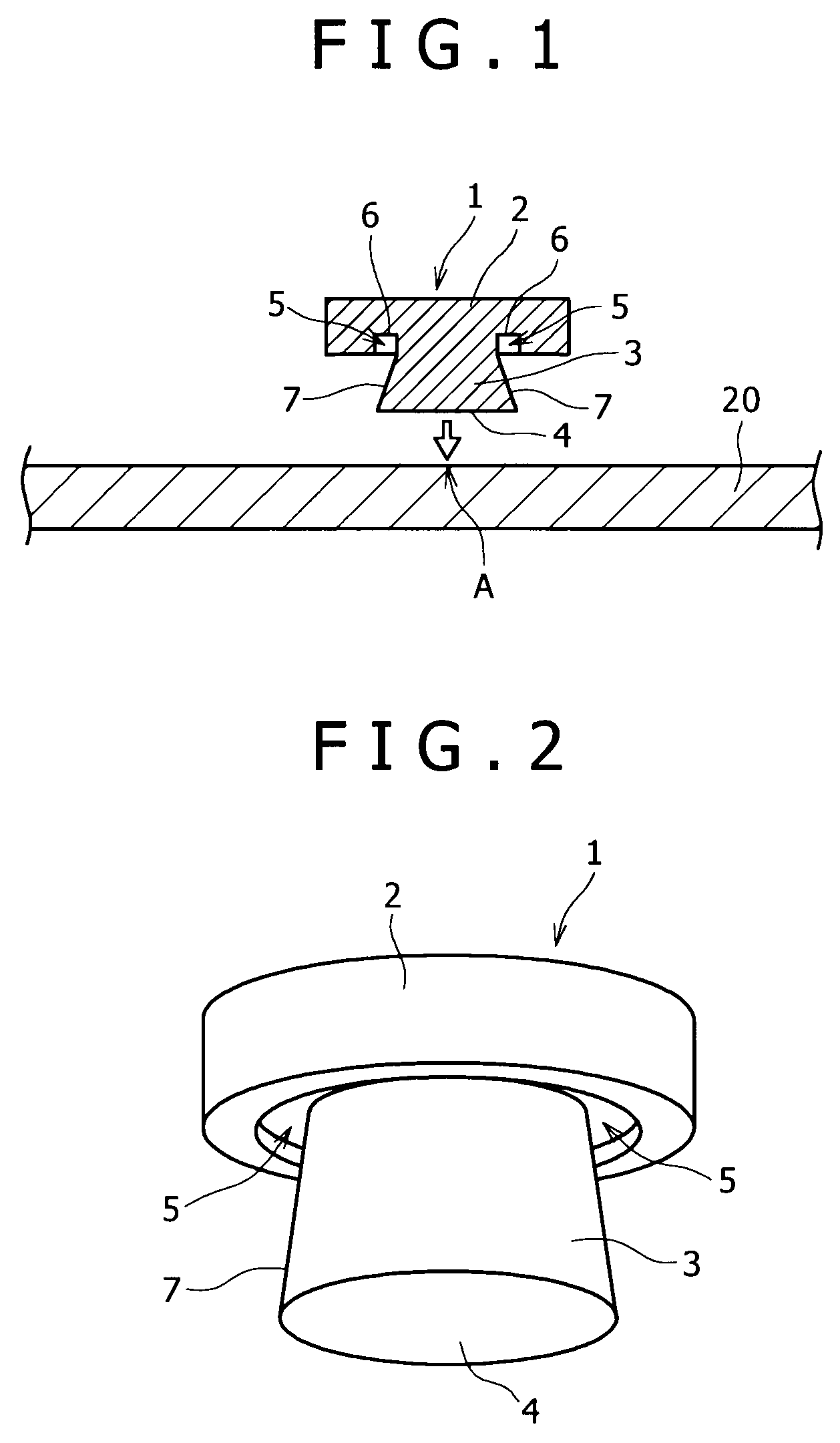

Electrode for spot welding

ActiveUS8525066B2Readily re-shapedOhmic-resistance electrodesWelding/cutting media/materialsSheet steelSpot welding

Owner:GM GLOBAL TECH OPERATIONS LLC

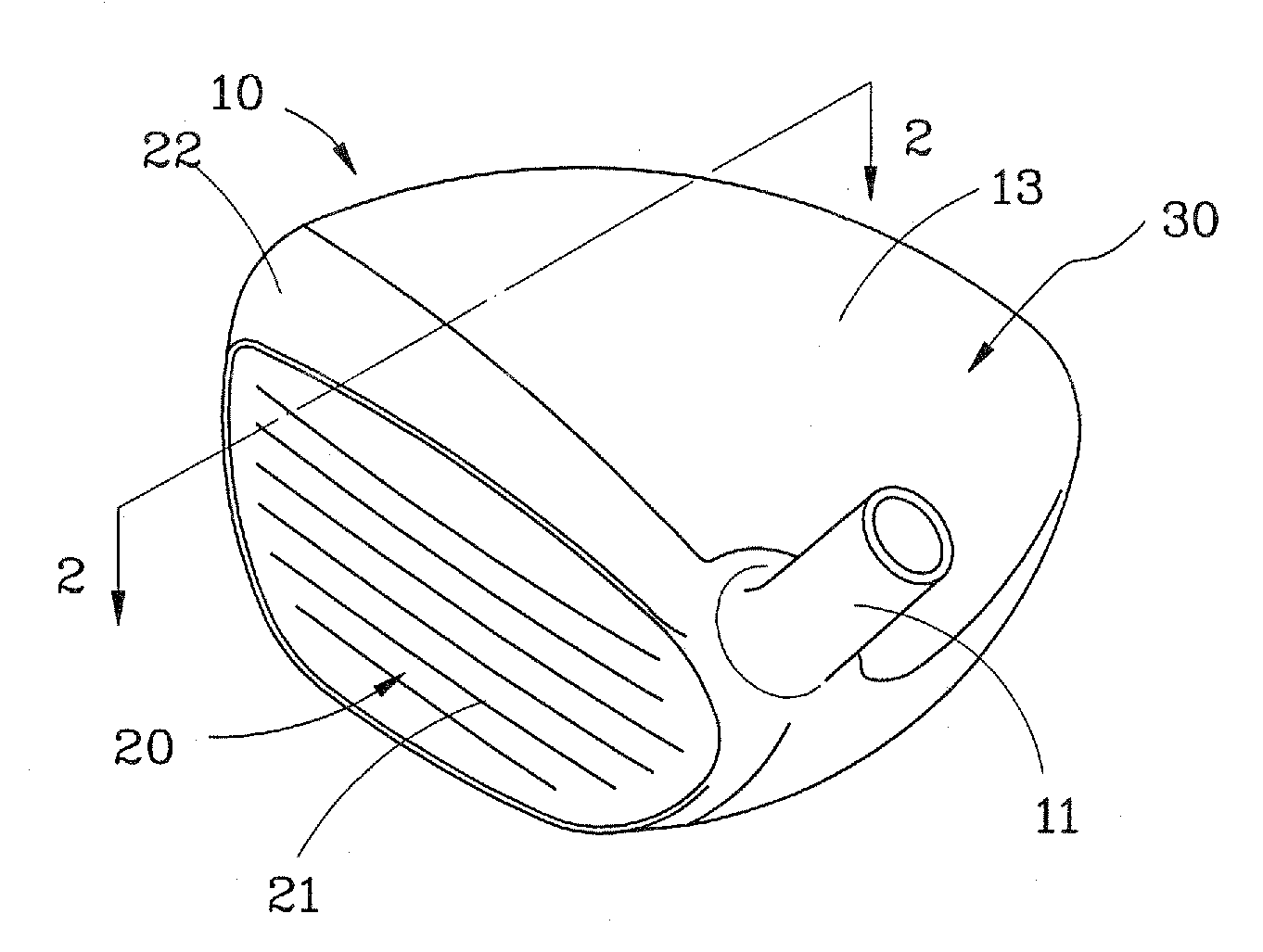

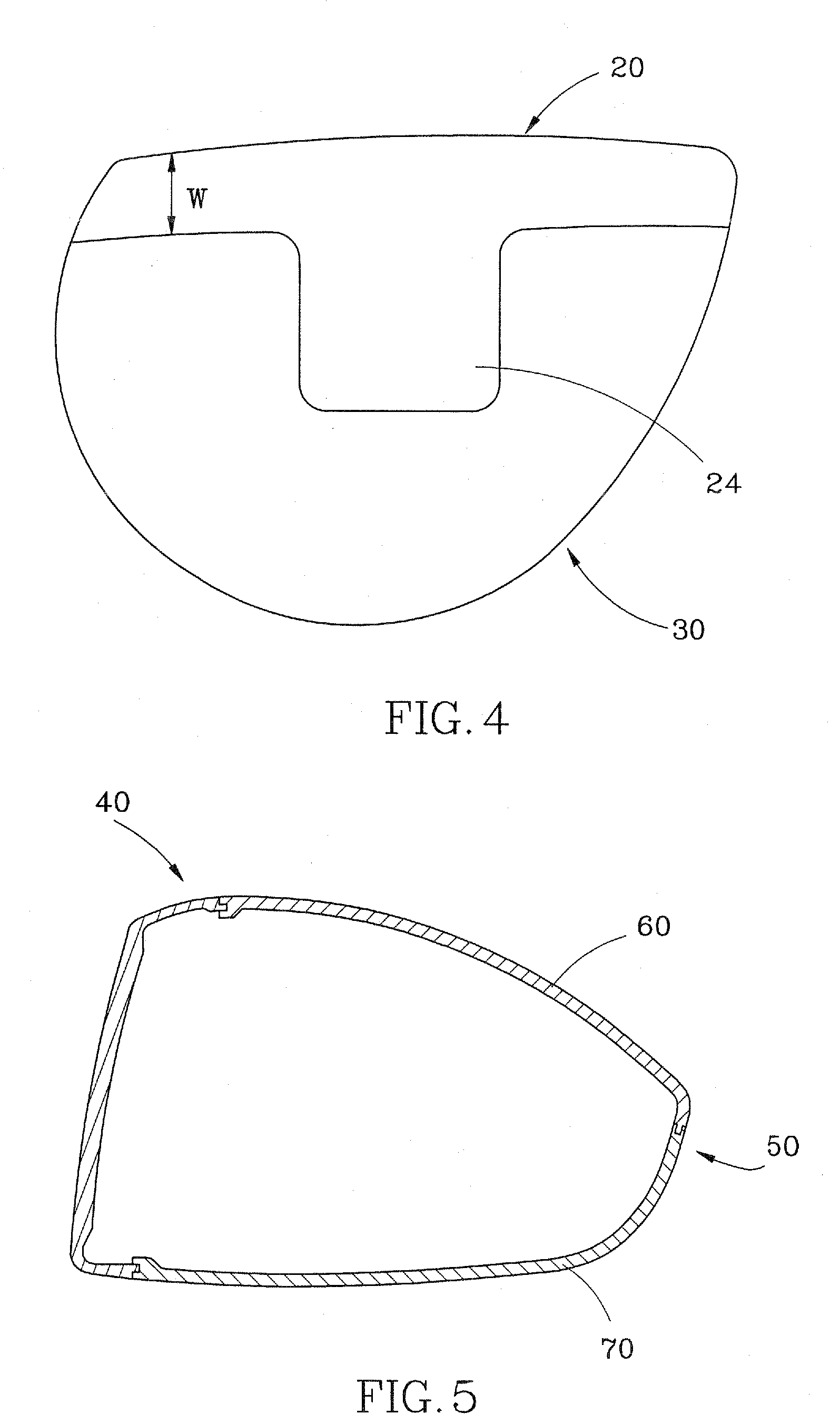

Golf club head

A golf club head includes a front member, a rear member and a neck connected together to form a housing. The front member, which is made of a flexible material, such as aluminum alloy, stainless or Maraging steel, has a face and an annular wall projected from a back of the face to form a cup-like member, wherein the wall has a connecting portion at a distal end thereof, and a length of the wall is identical to or greater than 8 mm and a thickness of the wall is identical to or less than 2 mm. The rear member, which is made of a light metal, such as magnesium alloy or aluminum alloy, has a connecting portion to engage the connecting portion of the front member. The neck is fixed on the rear member.

Owner:CHEN ARCHER C C

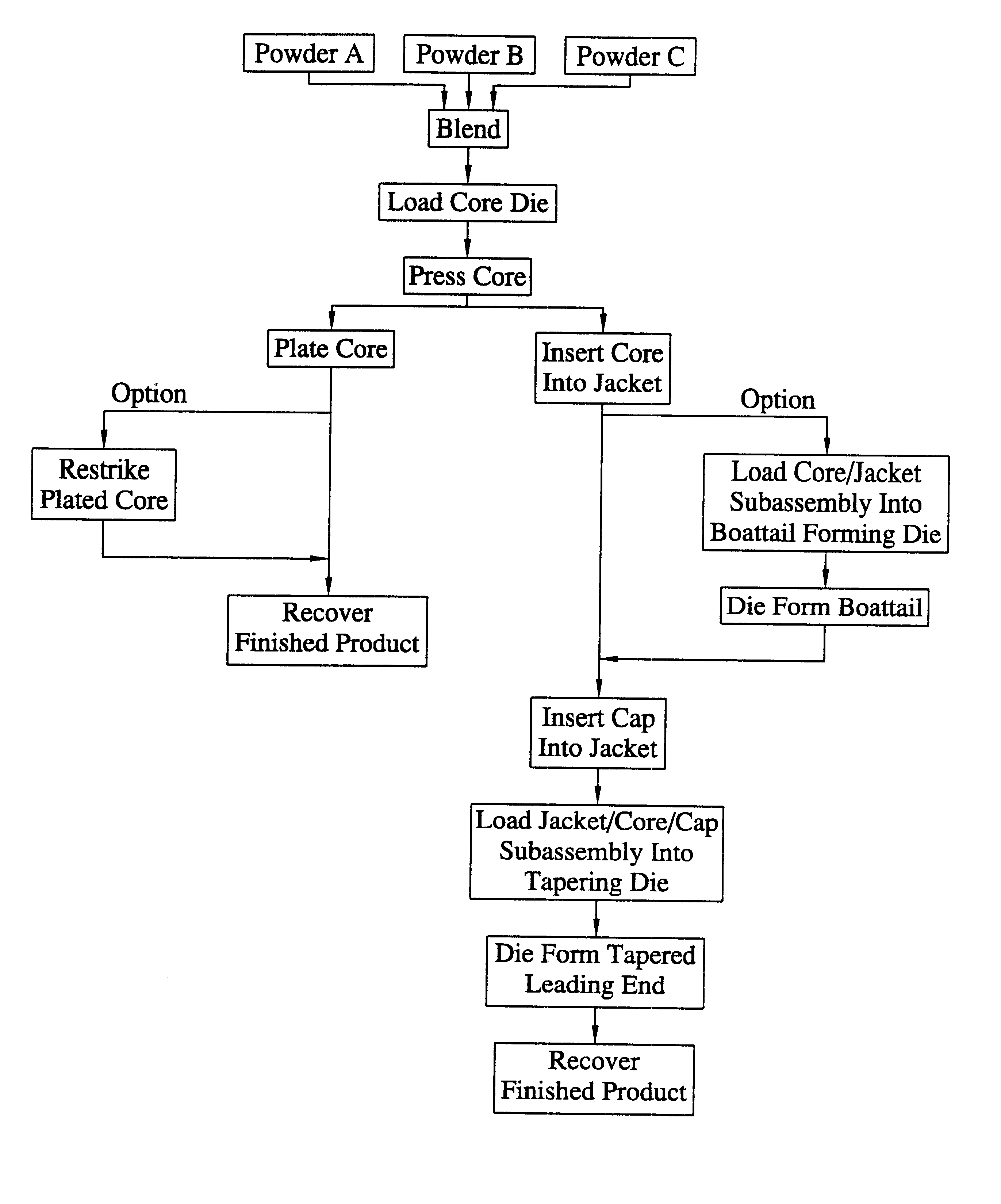

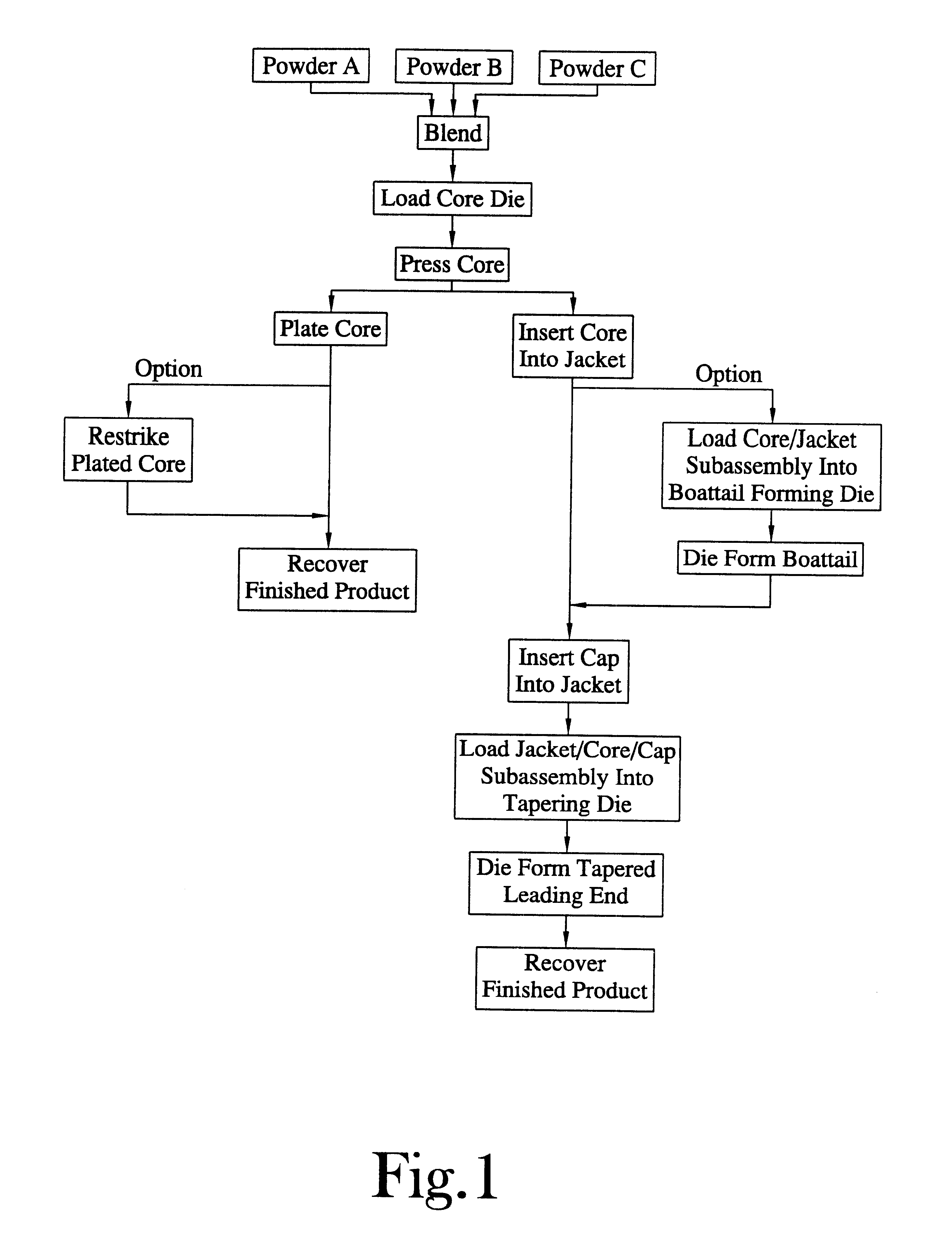

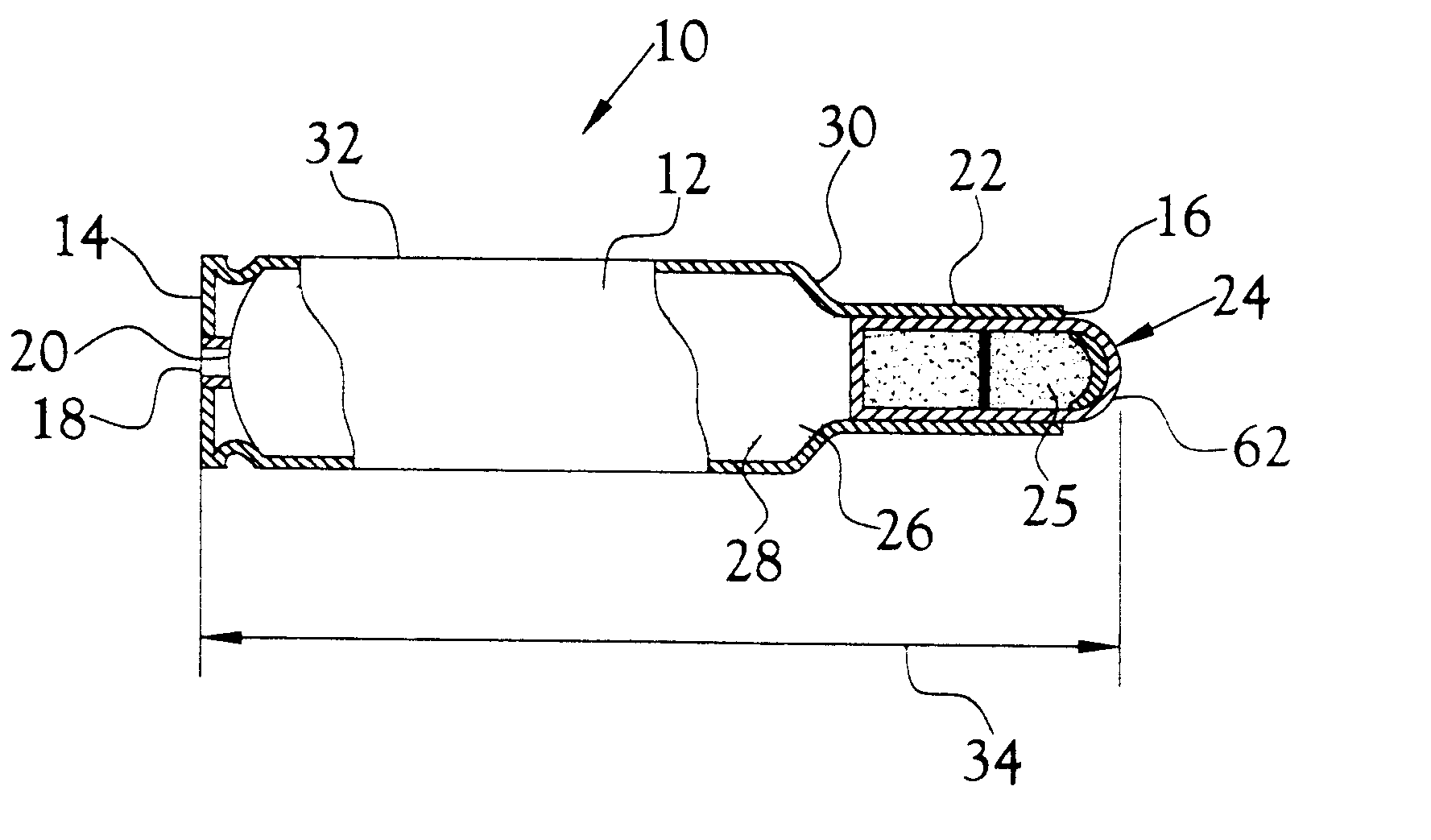

Method for the manufacture of a multi-part projectile for gun ammunition and product produced thereby

InactiveUS6317946B1Maximize weightImprove accuracyAmmunition projectilesHollow articlesRoom temperatureMaterials science

A method for the manufacture of a projectile for small-bore weapons ammunition comprising the steps of producing a plurality of compacts from a mixture of a heavy metal powder and a light metal powder at room temperature, and without further treatment of the compacts, introducing the compacts into a metal jacket one at a time, including pressing each compact into the jacket with a pressure sufficient to ensure substantially complete filling of a respective portion of the jacket by each compact before introducing a further compact into the jacket. The compacts fill less that the entire volume of the jacket, leaving a portion of the jacket void of compacts. Prior to the pressing of the last of the compacts introduced into the jacket, a disc having an outer diameter substantially equal to the internal diameter of said jacket adjacent the open end thereof is introduced into the jacket. Following pressing the last introduced compact and the separator dics, that portion of the jacket adjacent its open end is infolded toward the longitudinal centerline of the jacket to at least substantially close the open end of the jacket.A unique projectile and a round of ammunition formed with the projectile are disclosed.

Owner:MEALS LLC

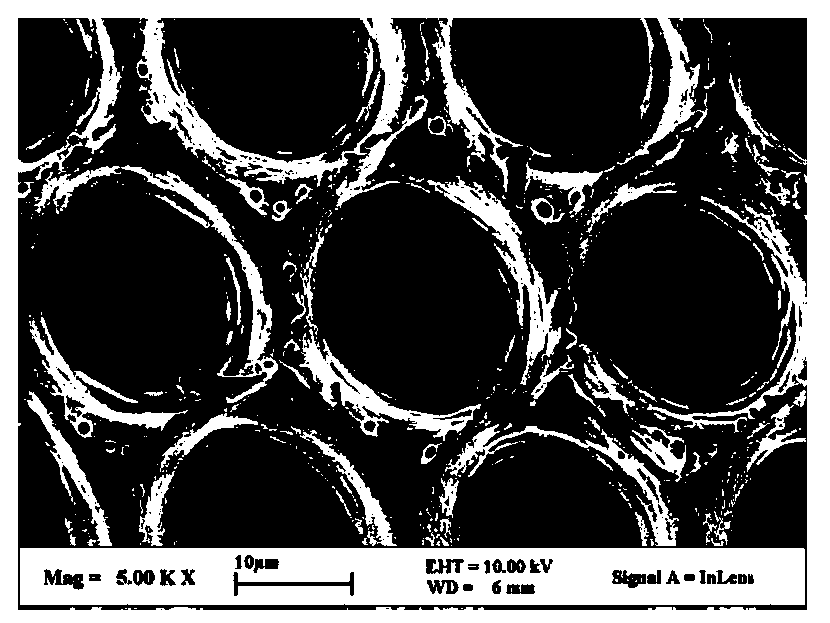

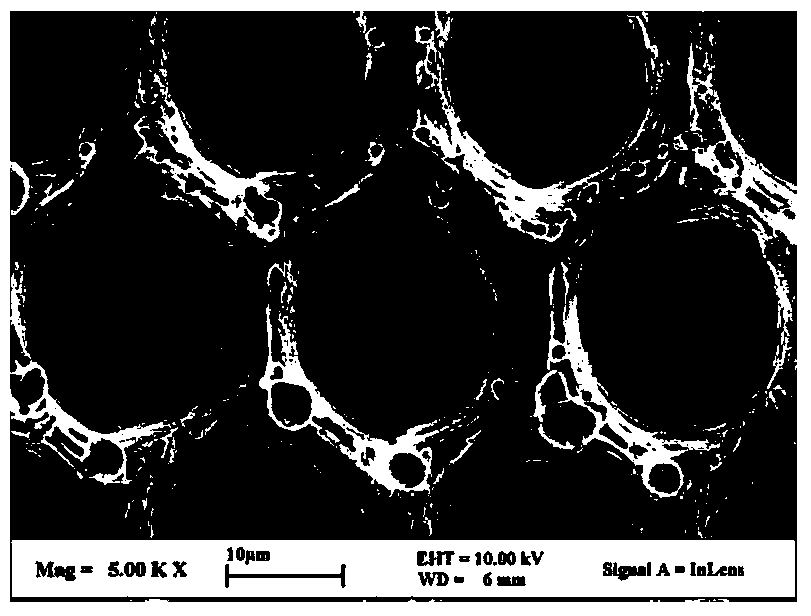

Method for preparing light metal super-hydrophobic surface

InactiveCN101423945AExcellent superhydrophobic propertiesWear-resistantAnodisationOther chemical processesLow temperature plasmaWear resistance

The invention relates to a preparation method for a light metal superhydrophobic surface, in particular to a light metal surface with a superhydrophobic property and corrosion and wear resistance. The preparation method comprises the following steps: a layer of porous oxidation film is formed on the surface through anodic oxidation of the light metal surface first; the surface is modified by a low-temperature plasma treatment technique; and at last, the superhydrophobic surface is formed on the surface of the oxidation film through chemical modification. The method does not require complex and expense equipment and has a simple process, good repetitiveness, a contact angle of the surface and water up to 153 to 170 degrees as well as good corrosion and wear resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

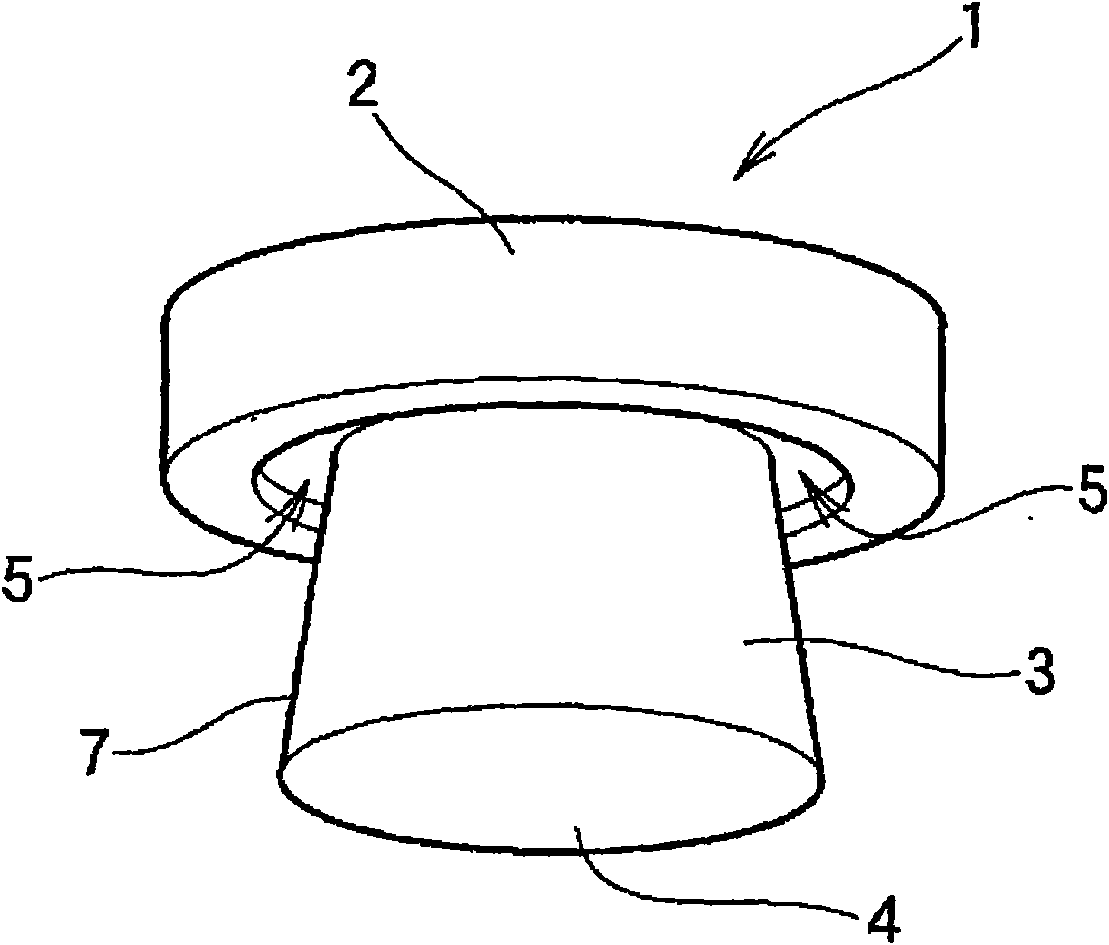

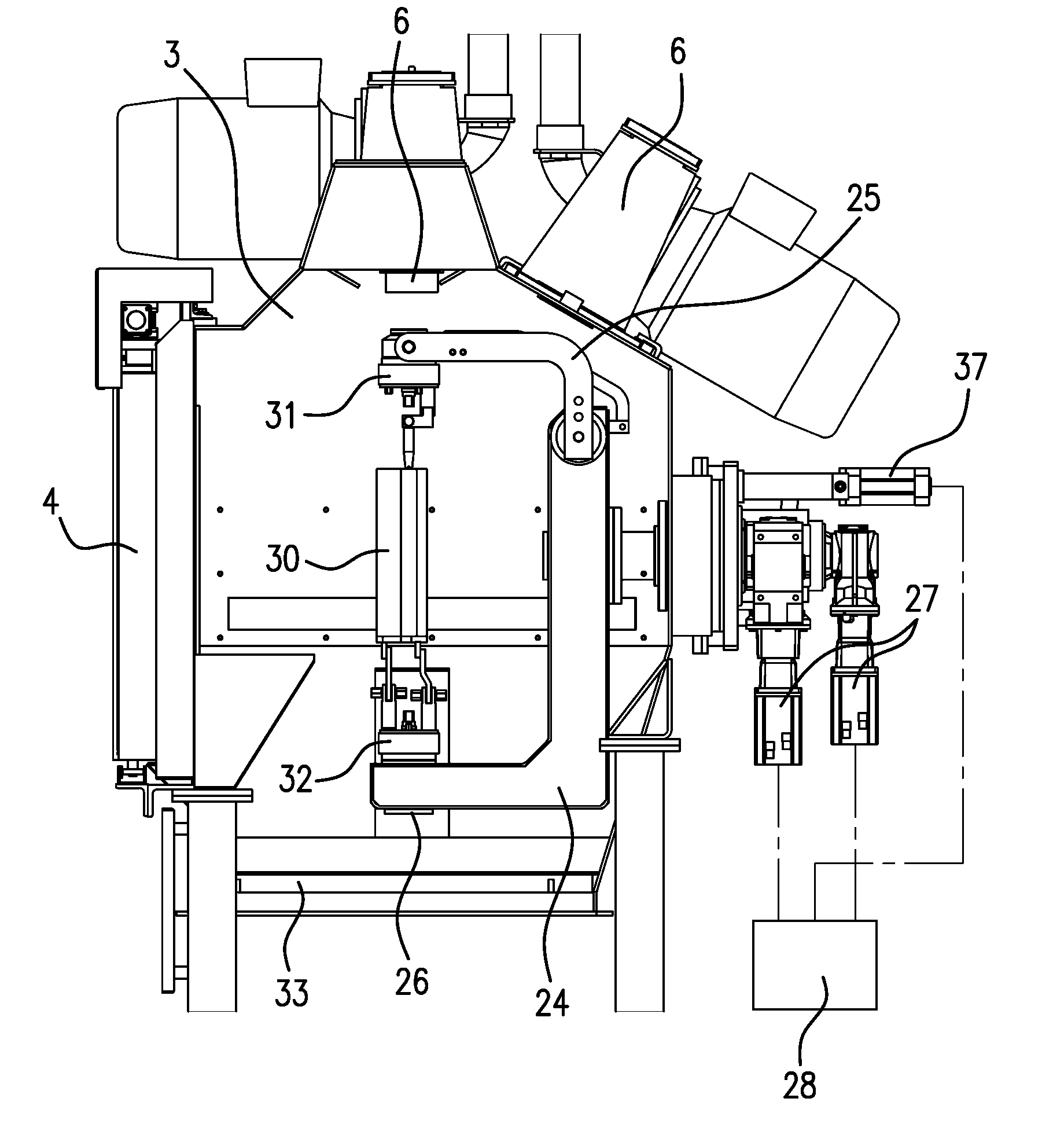

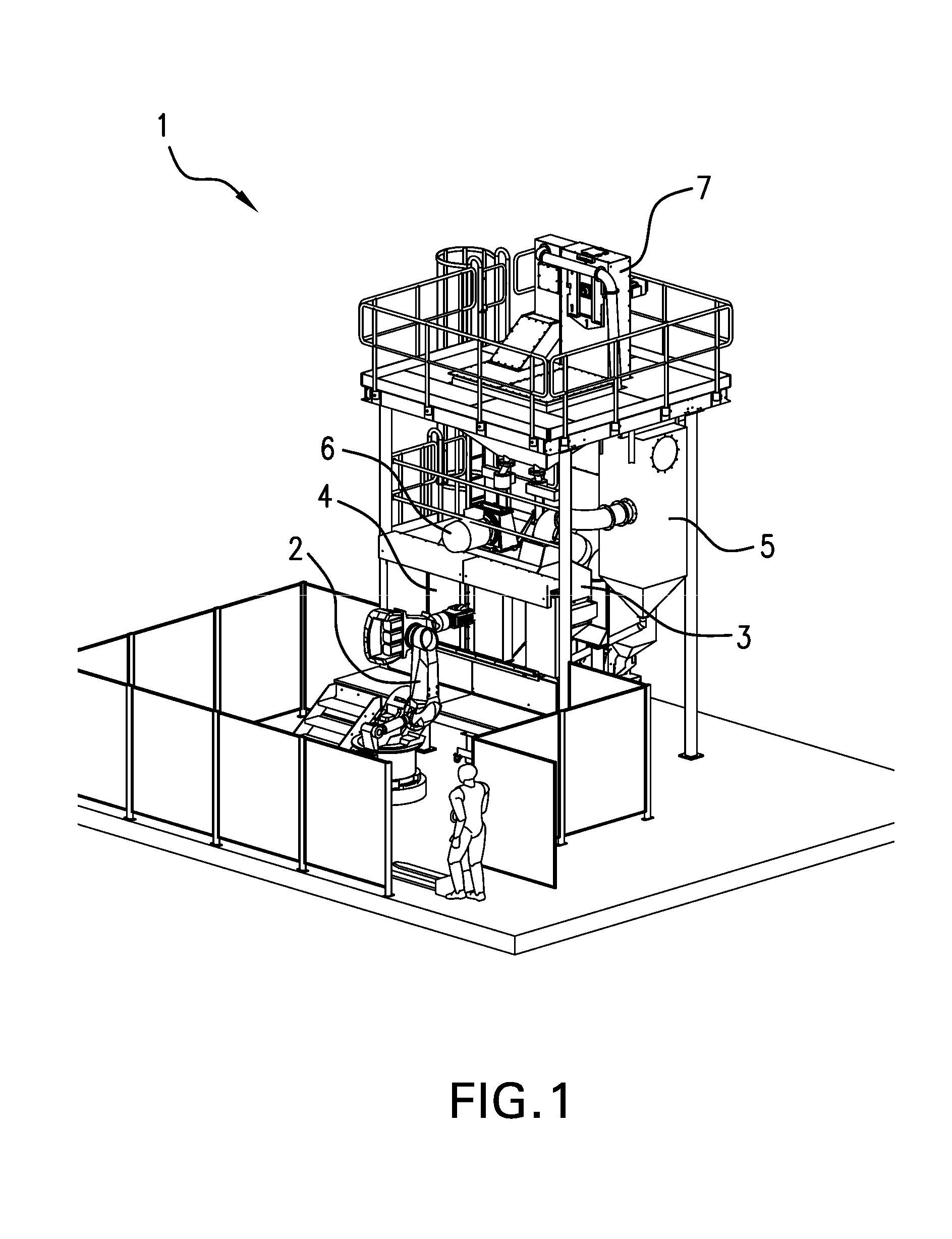

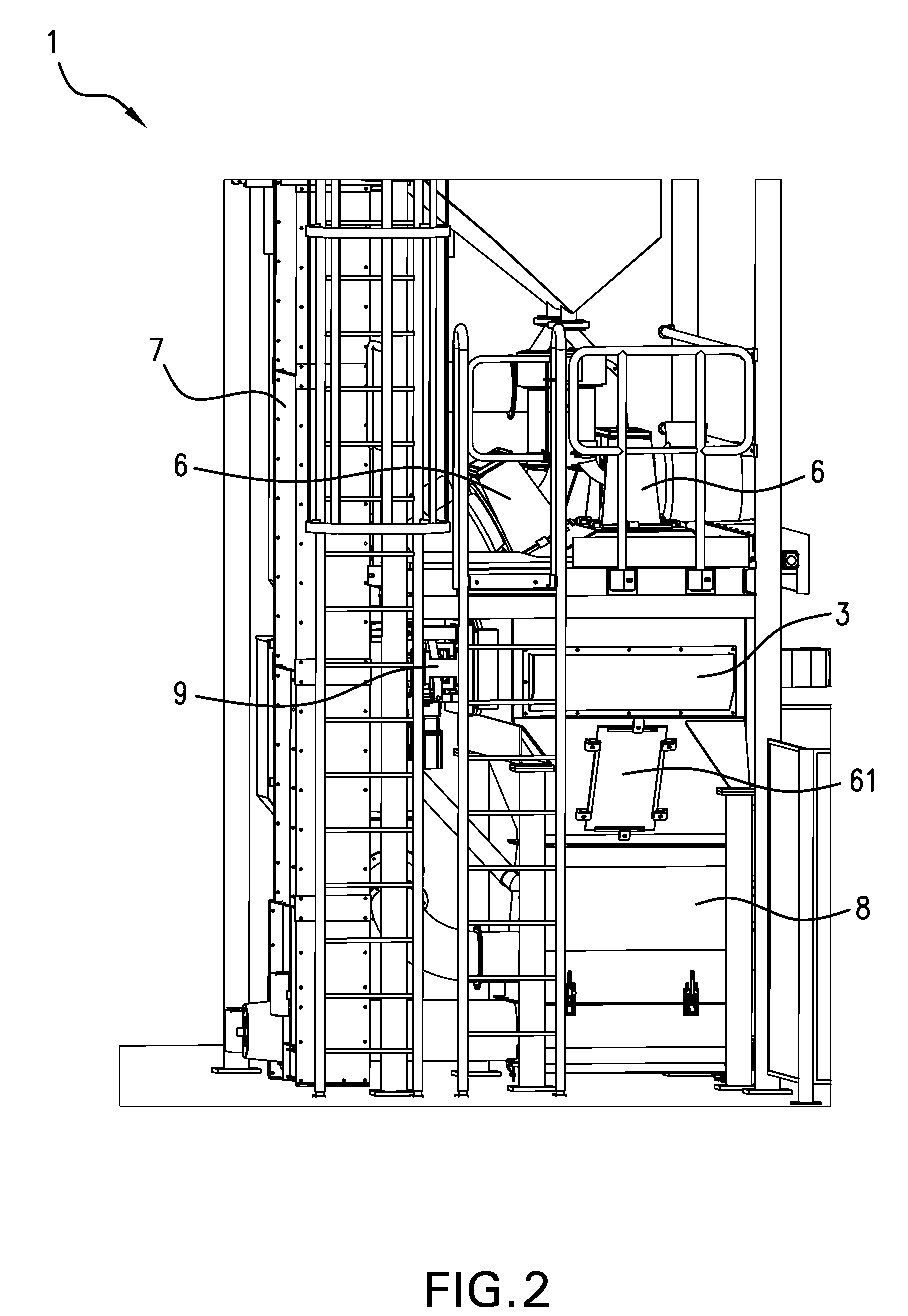

Shot-blasting installation for blasting work pieces made from light metal alloys

InactiveUS7421872B2Promote accumulationValve arrangementsFluid-tightness measurementAbrasive blastingEngineering

A shot-blasting installation (1) for blasting work pieces (30) made from light metal alloys, comprising at least one blasting chamber (3) for receiving the work pieces that are to be blasted, at least two blasting wheels (6) arranged in walls of the blasting chamber for introducing a blasting agent into the blasting chamber, and a separator (8) for separating the mixture of blasting agent and material that has been removed by blasting, wherein the separator (8) is arranged directly beneath the blasting chamber (3), and wherein a manipulator (10) for handling the cast work piece (30) during blasting is arranged in the blasting chamber (3).

Owner:DISA IND

Lithium metal oxide electrodes for lithium batteries

Owner:UCHICAGO ARGONNE LLC +1

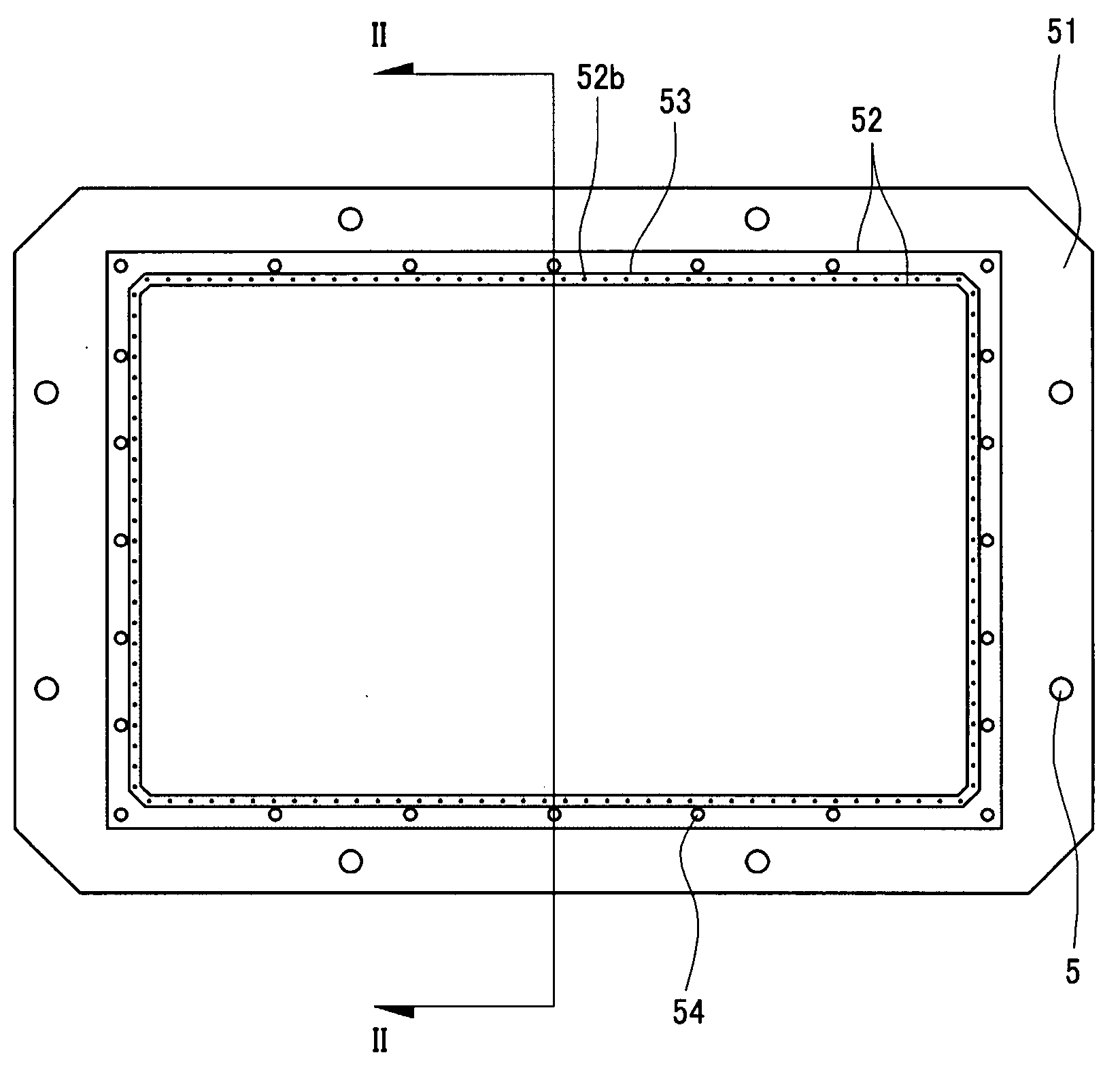

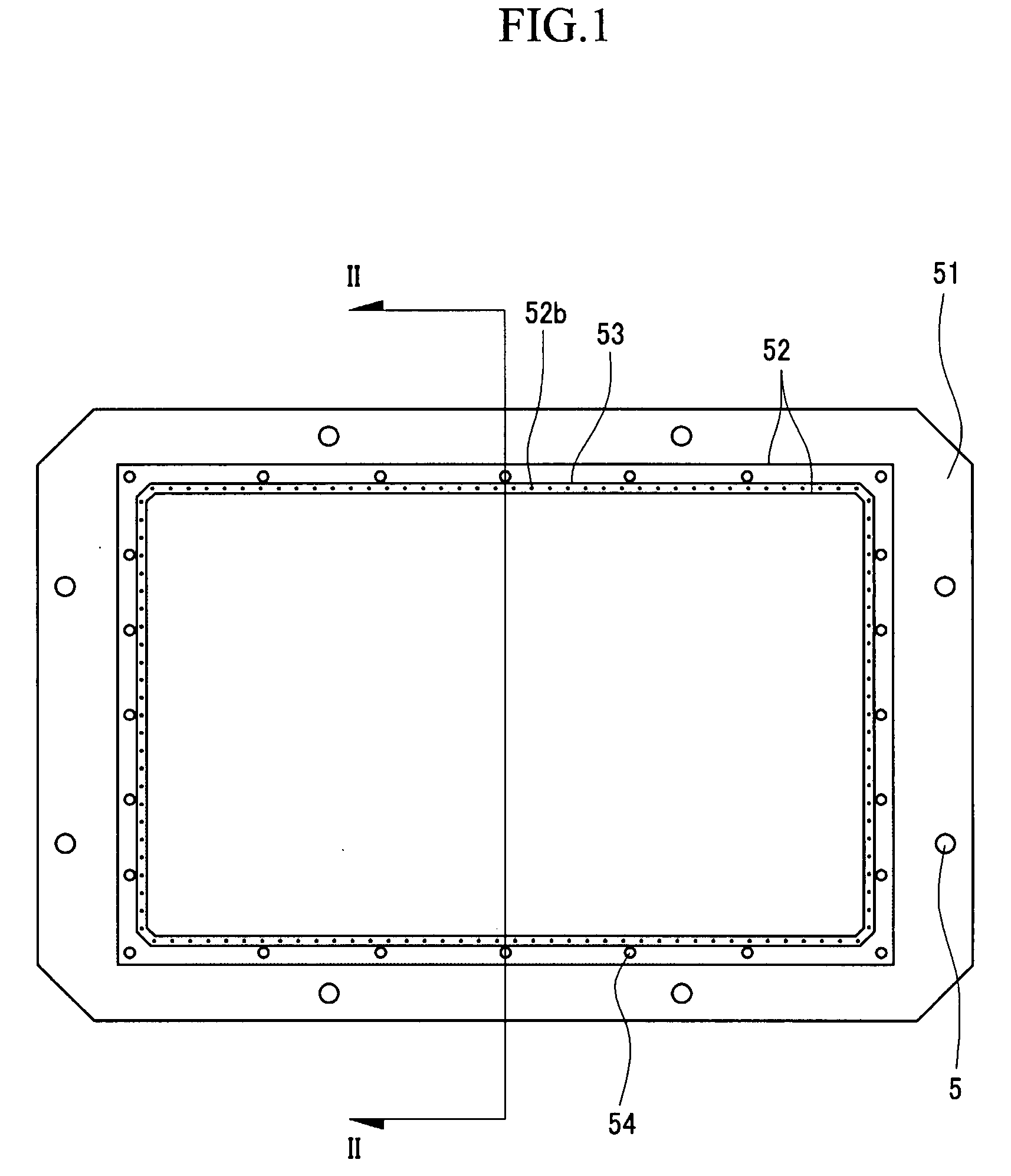

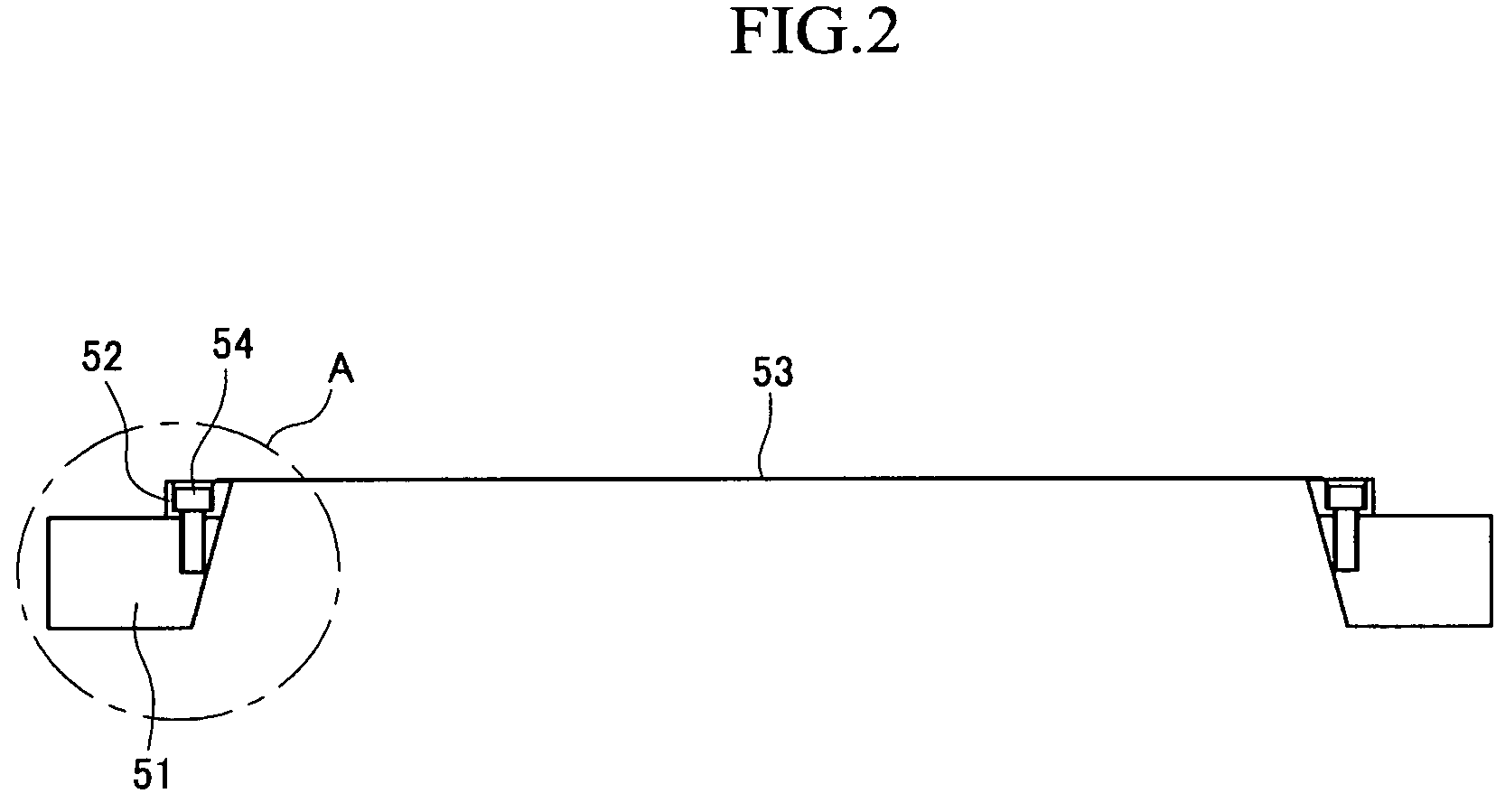

Mask and method of manufacturing the same

InactiveUS20070190889A1Electroluminescent light sourcesVacuum evaporation coatingEngineeringShadow mask

A mask that facilitates OLED processing and is capable of being made cost-effectively is presented. The mask includes a mask frame, a connection frame fastened to the mask frame, a mask plate welded to the connection frame, and a plurality of fastening members that fasten the connection frame to the mask frame. The connection frame, which is capable of being welded to the mask plate, is interposed between the mask plate and the mask frame to create a tension in the mask plate. Thus, it is possible to manufacture a shadow mask that does not sag. The mask frame may be formed with a light metal such as aluminum.

Owner:SAMSUNG ELECTRONICS CO LTD

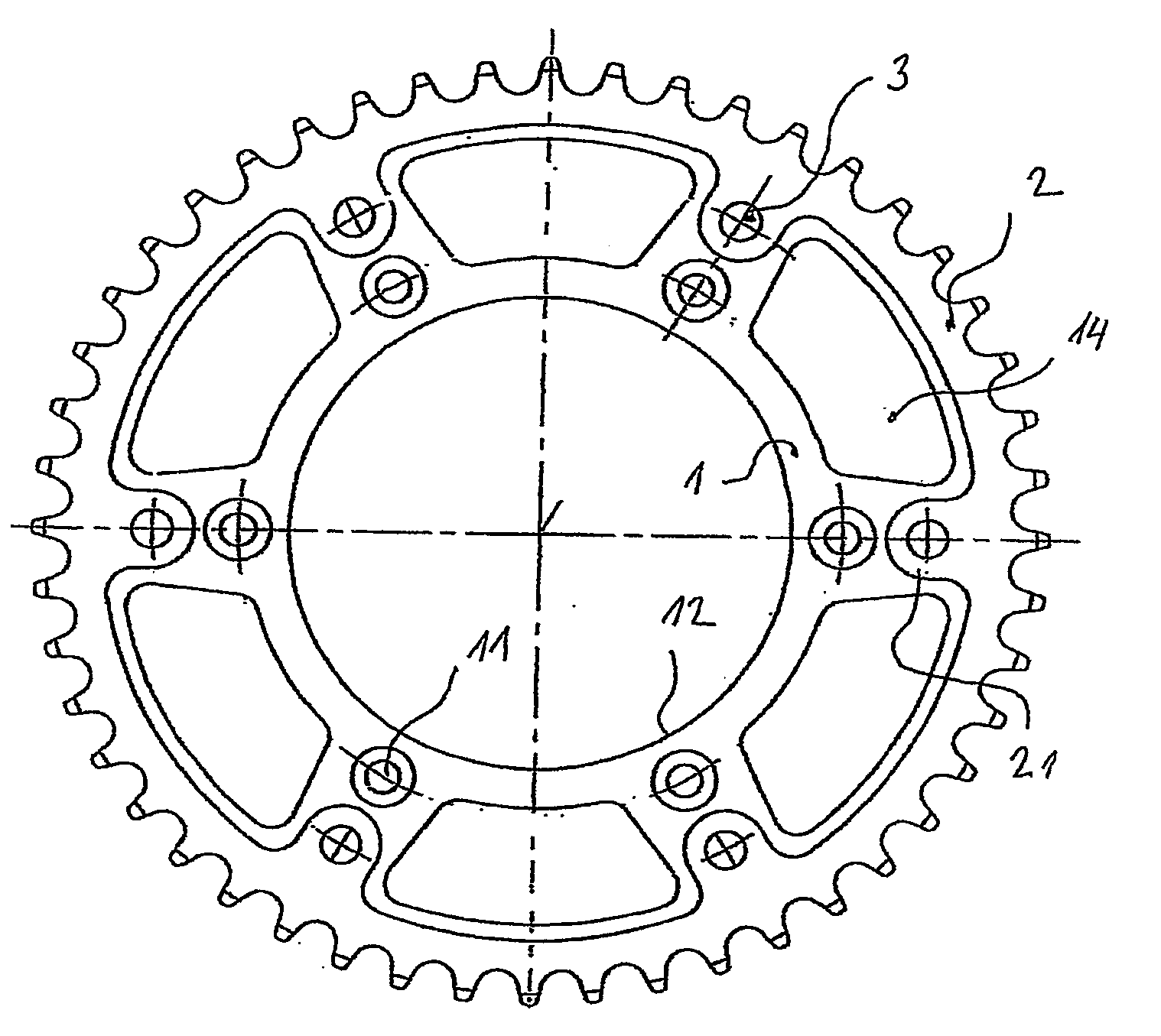

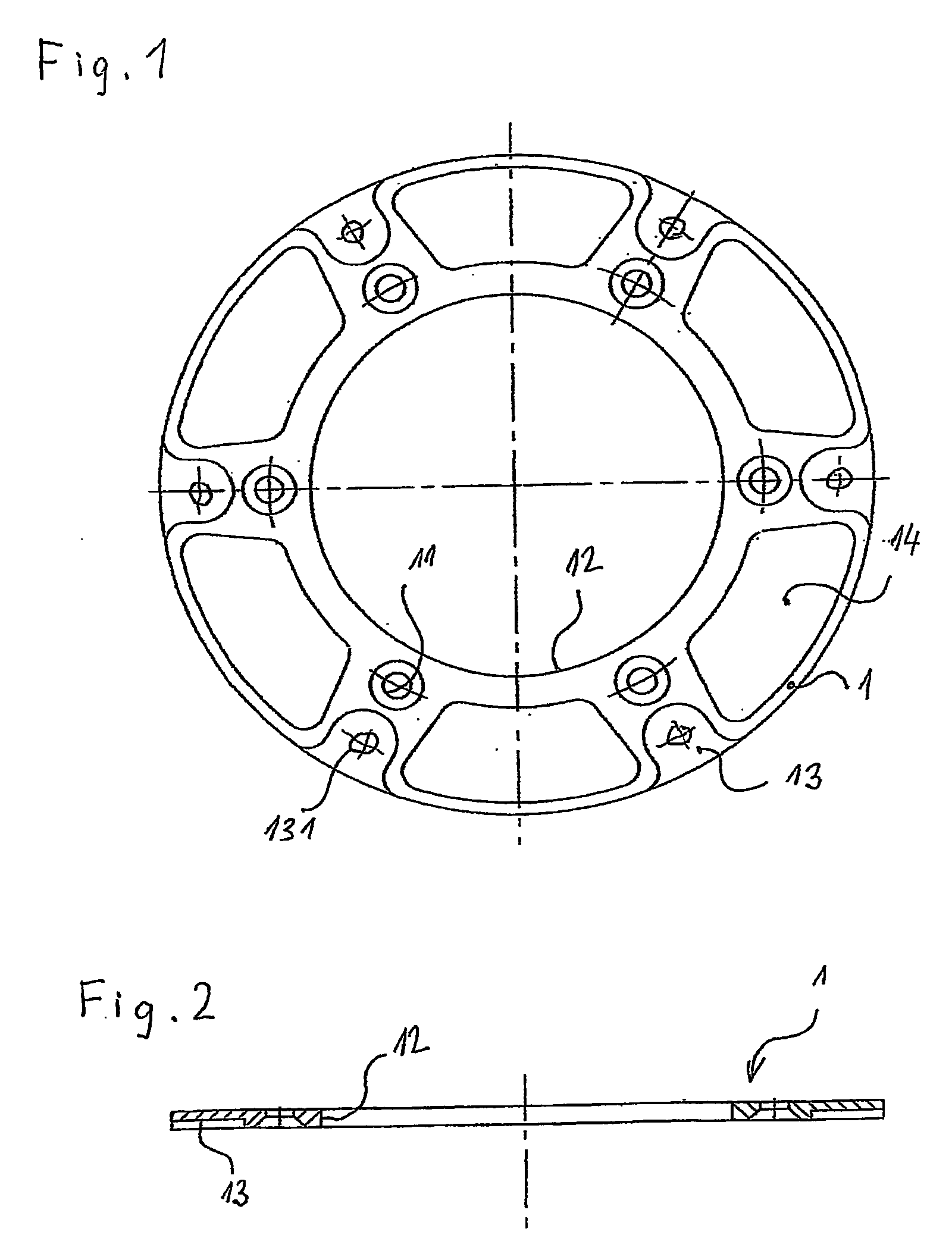

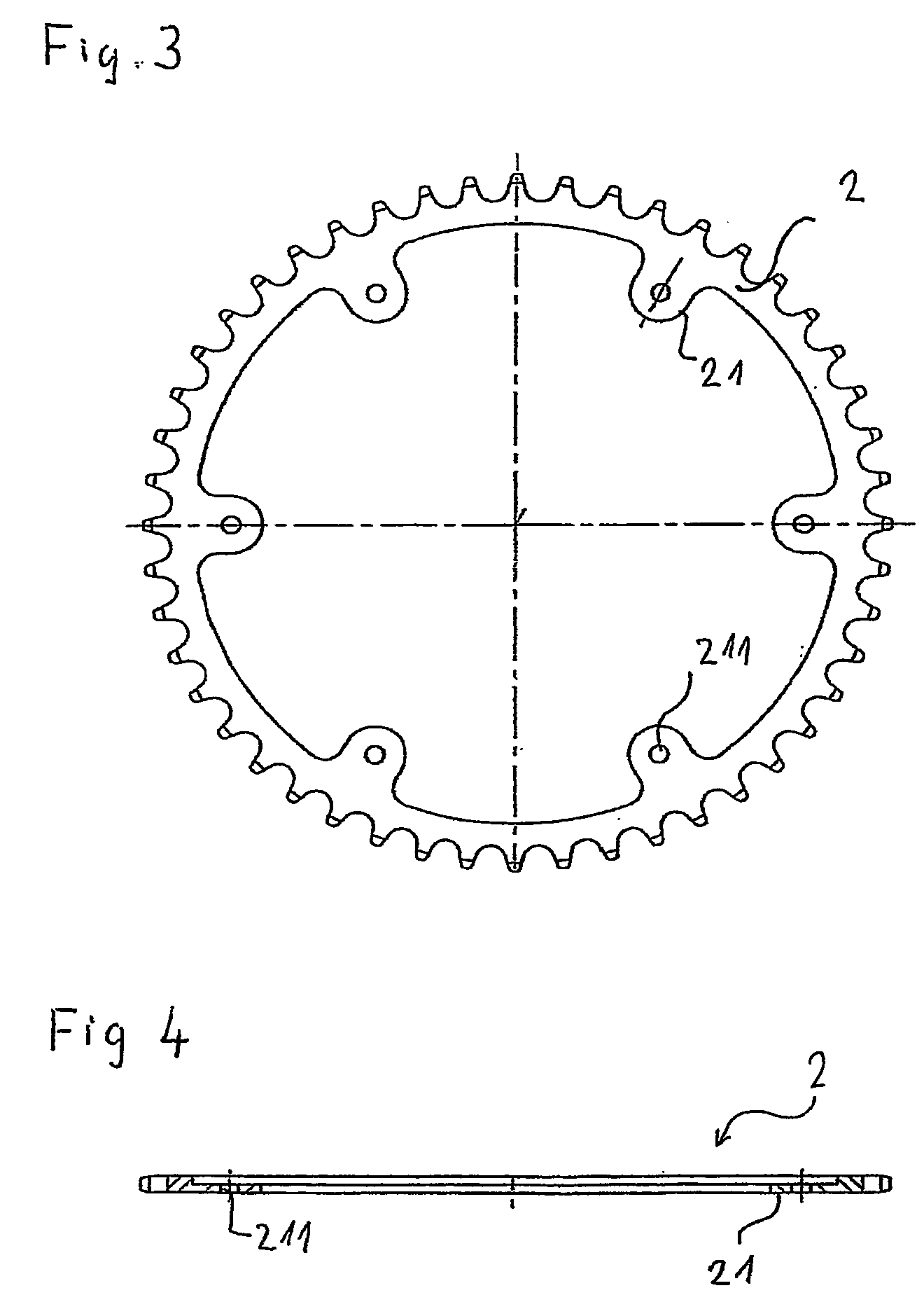

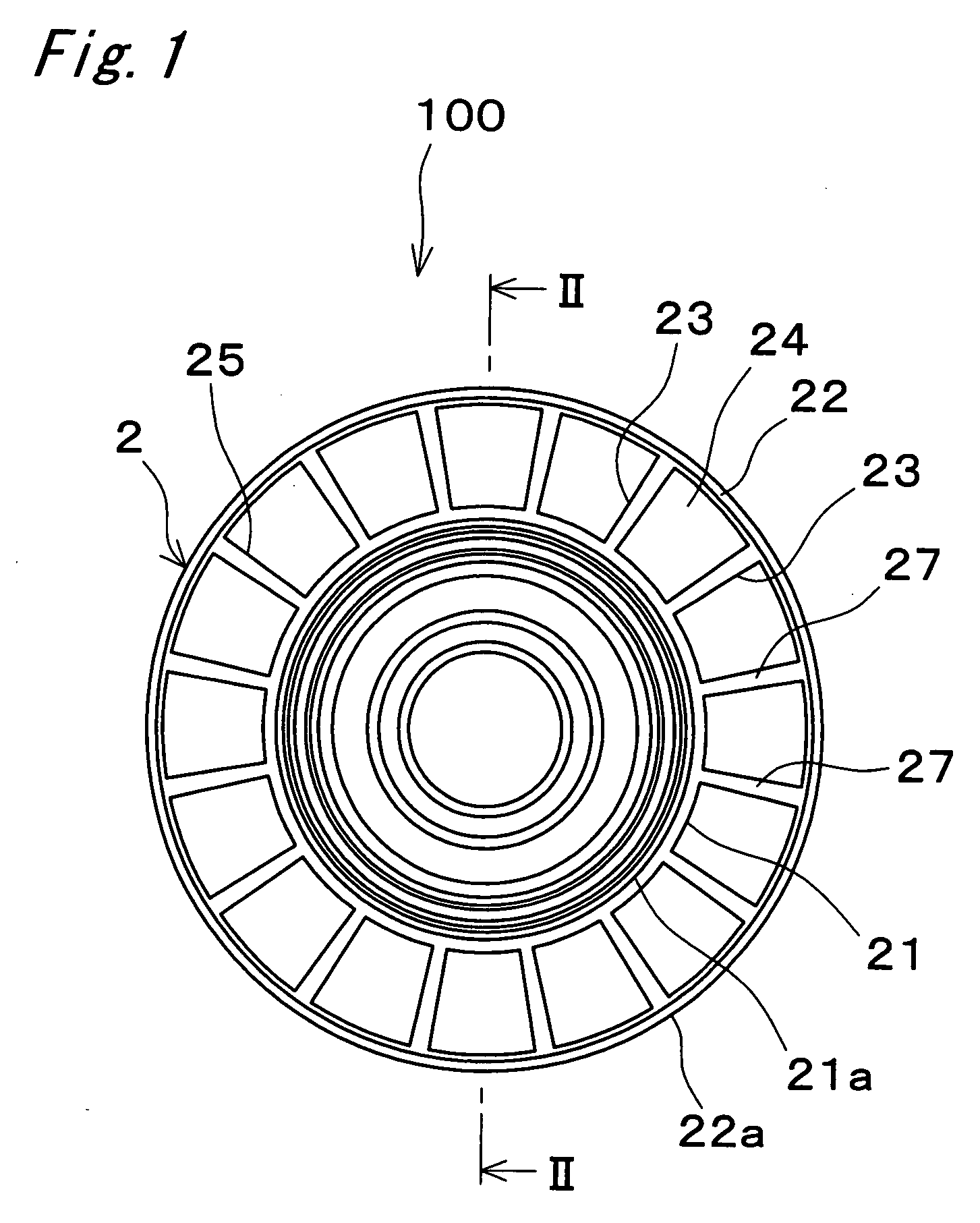

Lightweight sprocket

ActiveUS20050233850A1Lightweight and economical in construction and operationExtended service lifeV-beltsChain/belt transmissionSprocketEngineering

The present invention relates to lightweight sprocket, consisting of a central portion (1) made from light metal alloy, to which a peripheral toothed portion (2) made from ferrous alloy is joined, using rivets (3) for joining said portions (1,2), where said joining is created between radial beams (21) of the peripheral toothed portion (2) and pocket-like recess (13) in the central portion (1), radial beams (21) being overlapped across bottoms of pocket-like recesses (13), and where a thickness of radial beams (21), at least over the joining area, is decreased by 10 to 60%, in relation to full thickness of said toothed peripheral portion (2), and a thickness of a bottom of the pocket-like recess (13) in the central portion (1) is decreased by 20 to 70%, in relation to full thickness of the central portion (1) of the sprocket.

Owner:SUPERSPROX

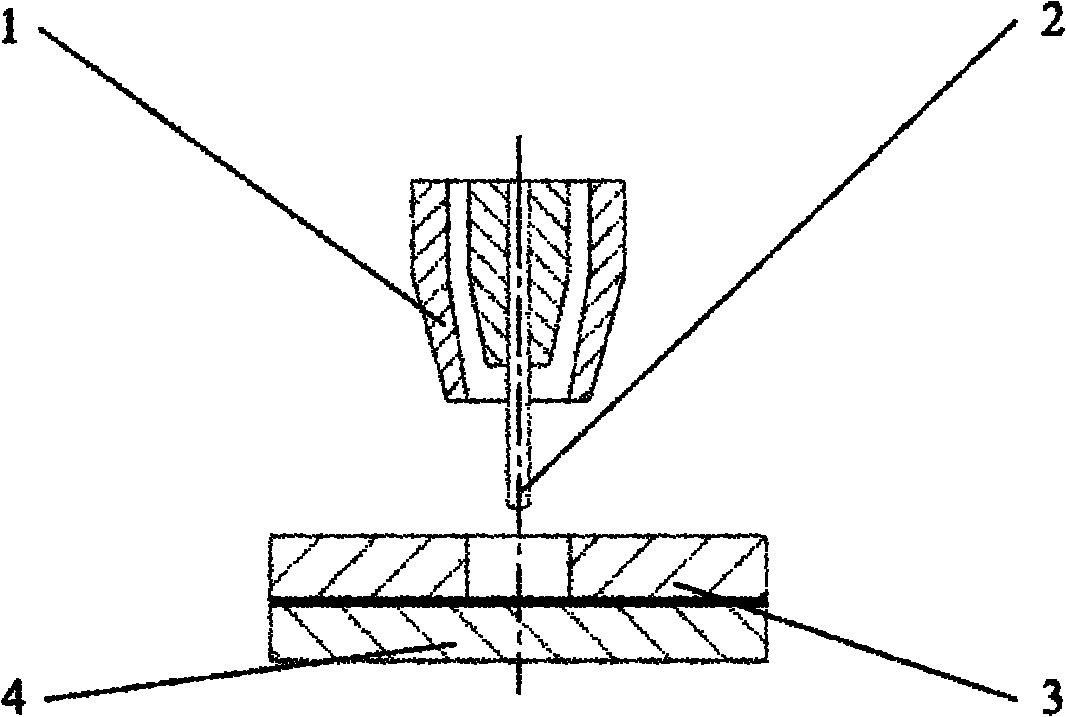

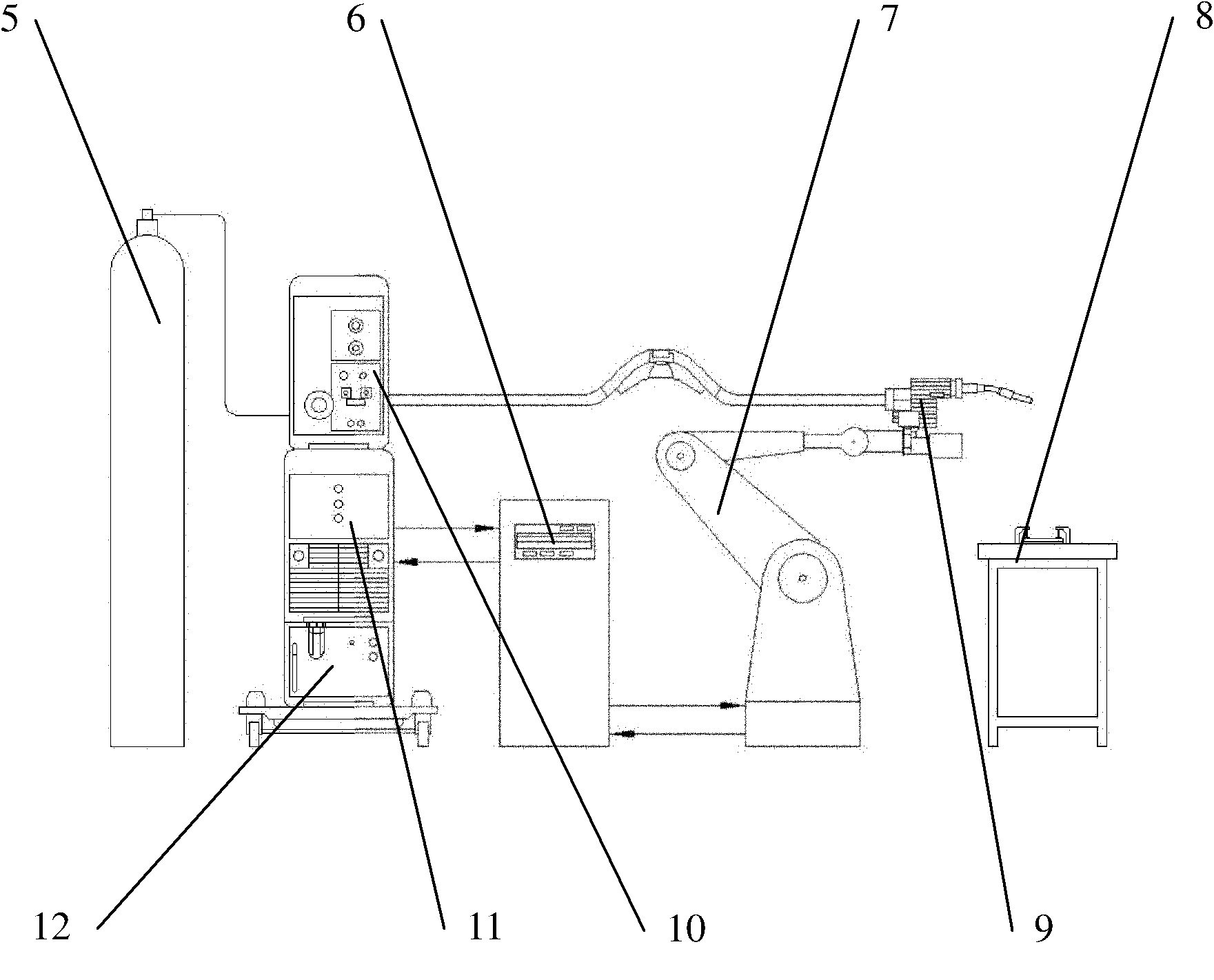

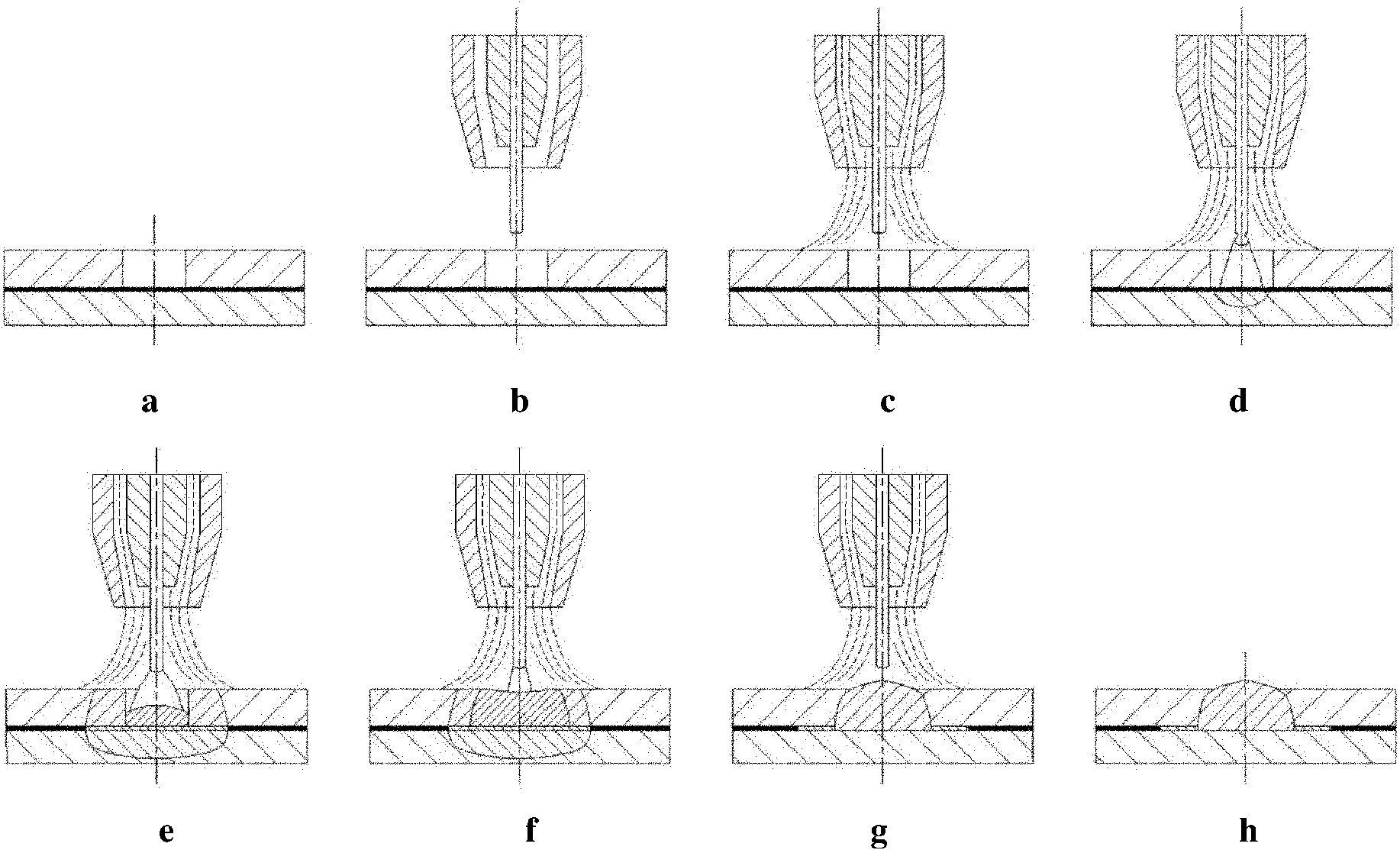

Dissimilar metal spot welding system of light metal and coated steel and welding method thereof

The invention provides a dissimilar metal spot welding system of light metal and coated steel and a welding method thereof, wherein the system comprises a CMT (cold metal transfer) arc welding system, an air bottle, a robot control module, a robot and a clamping device; the arc welding system is connected to the robot control module and used for transmitting a welding control signal; the air bottle is communicated with the CMT arc welding system; the robot control module is connected to the robot for transmitting a control signal of the movement of the robot. In the invention, a spot melting soldering joint is formed between light metal and coated steel to realize the spot connection of the light metal and the coated steel; the serious deformation of the joint during continuous seam welding is solved while the connecting quality of dissimilar metal is ensured; traditional vehicle body part joints primarily using resistance spot welding process are not influenced; and the design and manufacture costs of vehicle bodies are greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

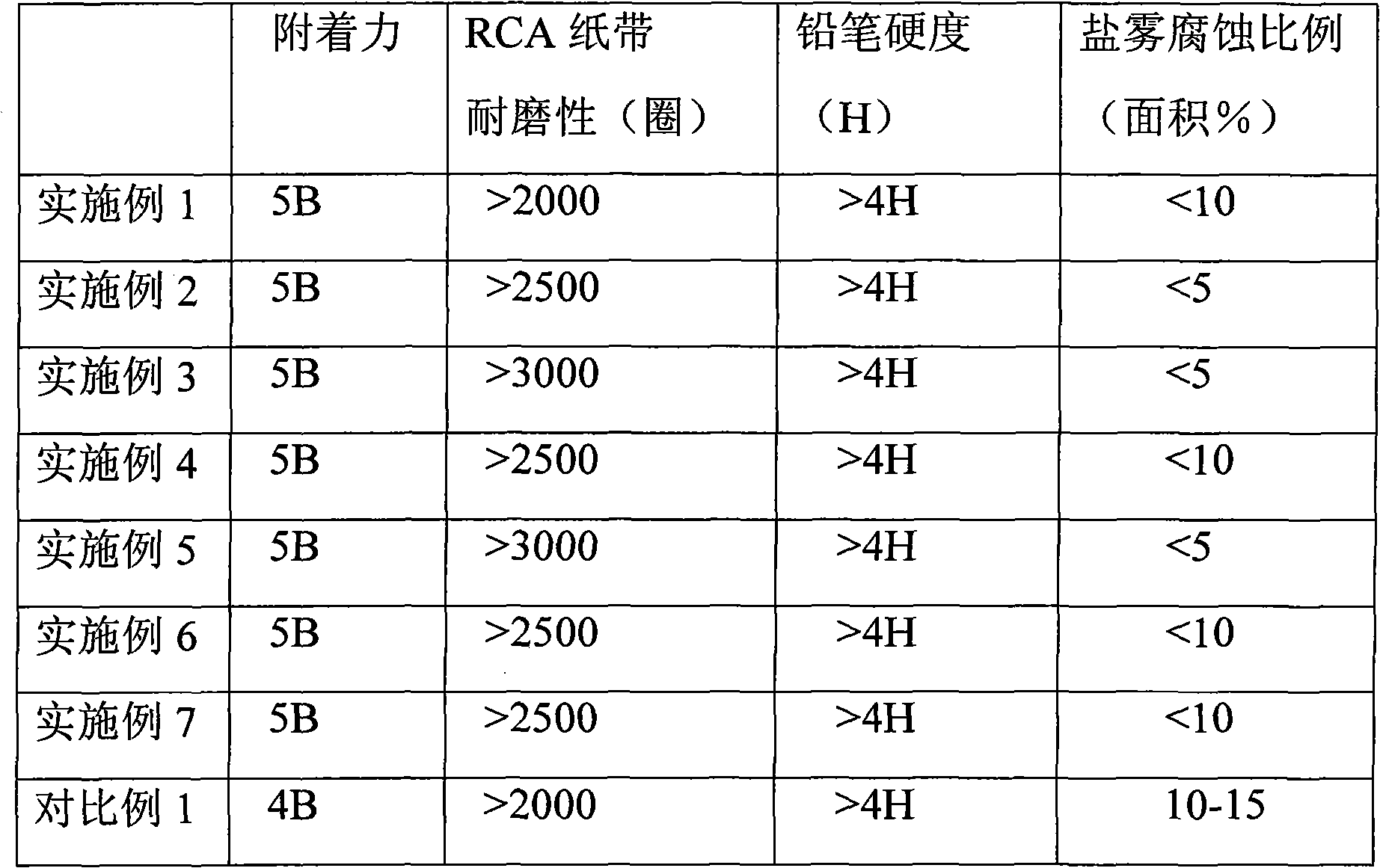

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101985768AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the field of micro-arc oxidation, and relates to micro-arc oxidation electrolyte. The electrolyte comprises the aqueous solution of film former and toner, and has the pH value of 6.0 to 12, wherein the film former is phosphate and / or silicate; the toner is a titanium compound; and the film former content is 5 to 50 g / L, and the toner content is 5 to 30 g / L. When used for performing micro-arc oxidation on light metals, the micro-arc oxidation electrolyte provided by the invention can form blue ceramic films on the surfaces of the light metals so as to break the limitation of the conventional micro-arc oxidation technology to colors, expand grey-black and grey-white tones to colorful fields with uniform colors and achieve the decoration effect of a light-metallic product. Moreover, by the invention, the erosion resistance, the pollution resistance and the compactability of the micro-arc oxidized film are enhanced, and the surface of the micro-arc oxidized film has a ceramic texture. The invention further discloses a micro-arc oxidation method.

Owner:BYD CO LTD

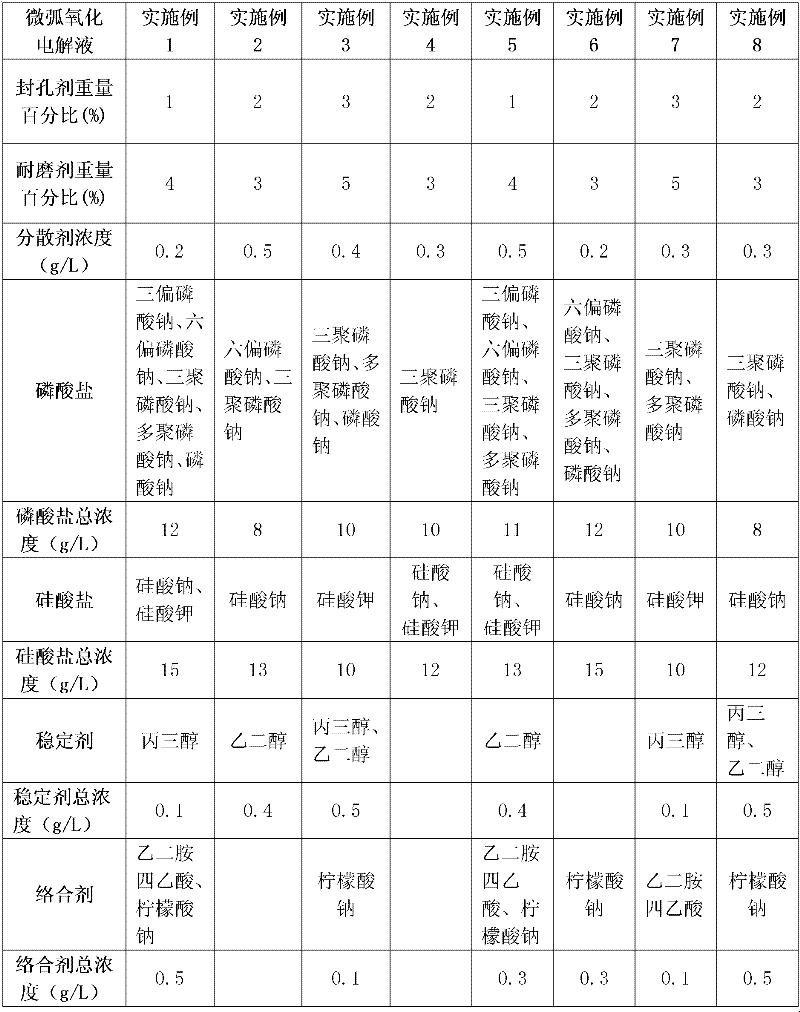

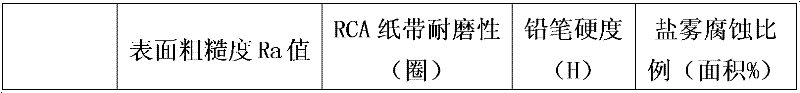

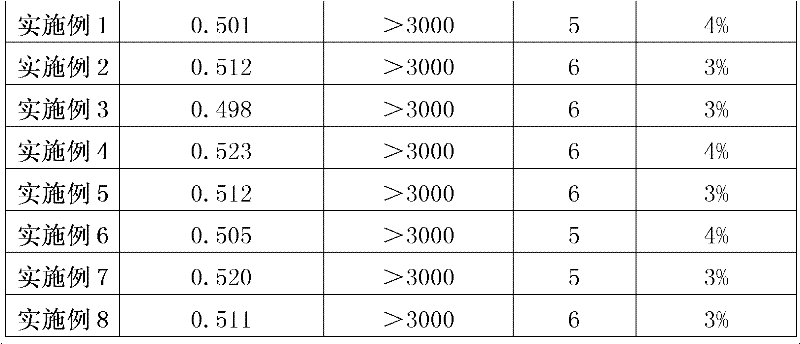

Micro-arc oxidation electrolyte and micro-arc oxidation method

ActiveCN102560591ASimple compositionEasy to controlAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a micro-arc oxidation electrolyte and a micro-arc oxidation method. The micro-arc oxidation electrolyte comprises the following components: a basic solution, a wear-resisting agent, a pore sealing agent and a dispersing agent, wherein the basic solution is phosphate and silicate aqueous solution of pH 8-12, the wear-resisting agent is graphite powder, the pore sealing agent is silica powder or alumina powder, and the dispersing agent is polyoxyethylenealkylphenol ether. The micro-arc oxidation electrolyte of the invention is simple in composition, and easy in control. Light metal parts to be plated are subjected to micro-arc oxidation using the micro-arc oxidation electrolyte of the invention, and are directly subjected to pore sealing treatment in the micro-arc oxidation process without after-treatment. The process of the invention is simple, and obtained micro-arc oxide film layer is high in hardness, and is good in abrasion resistance and corrosion resistance.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

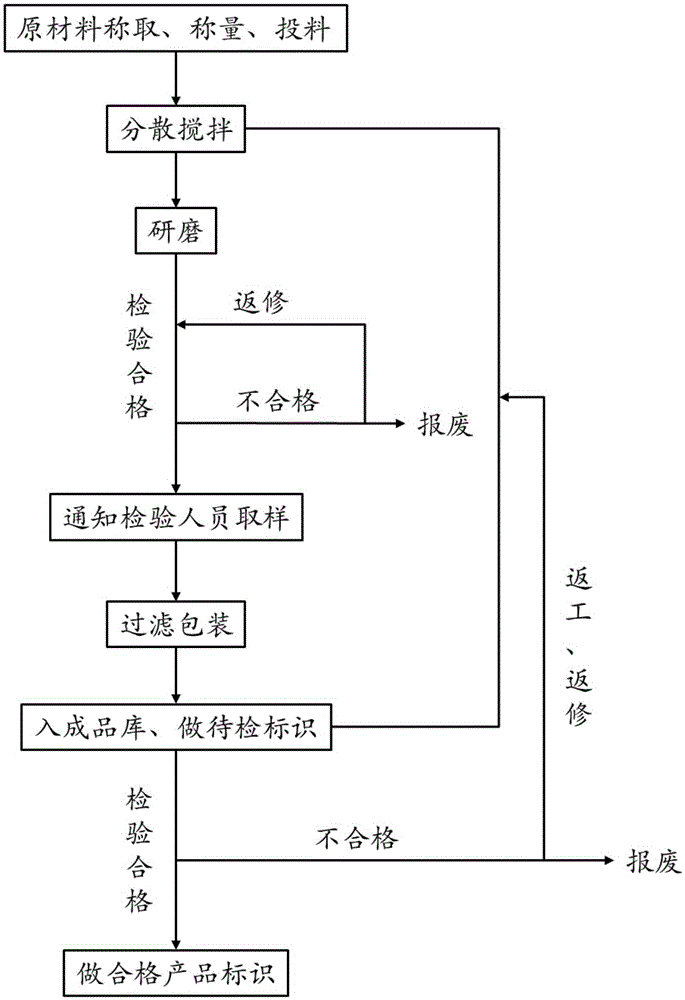

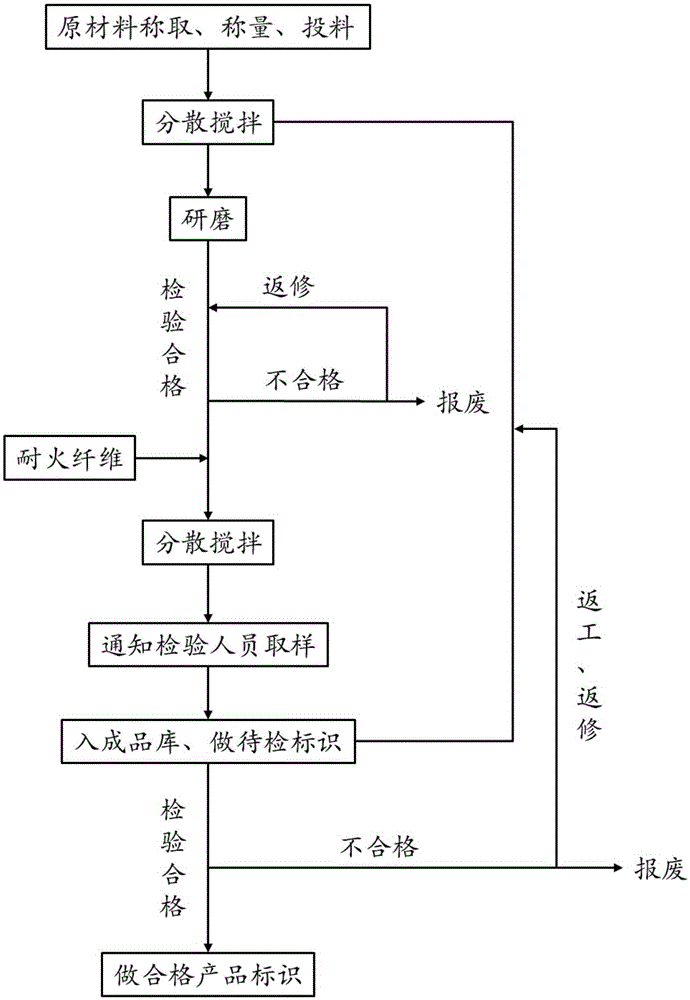

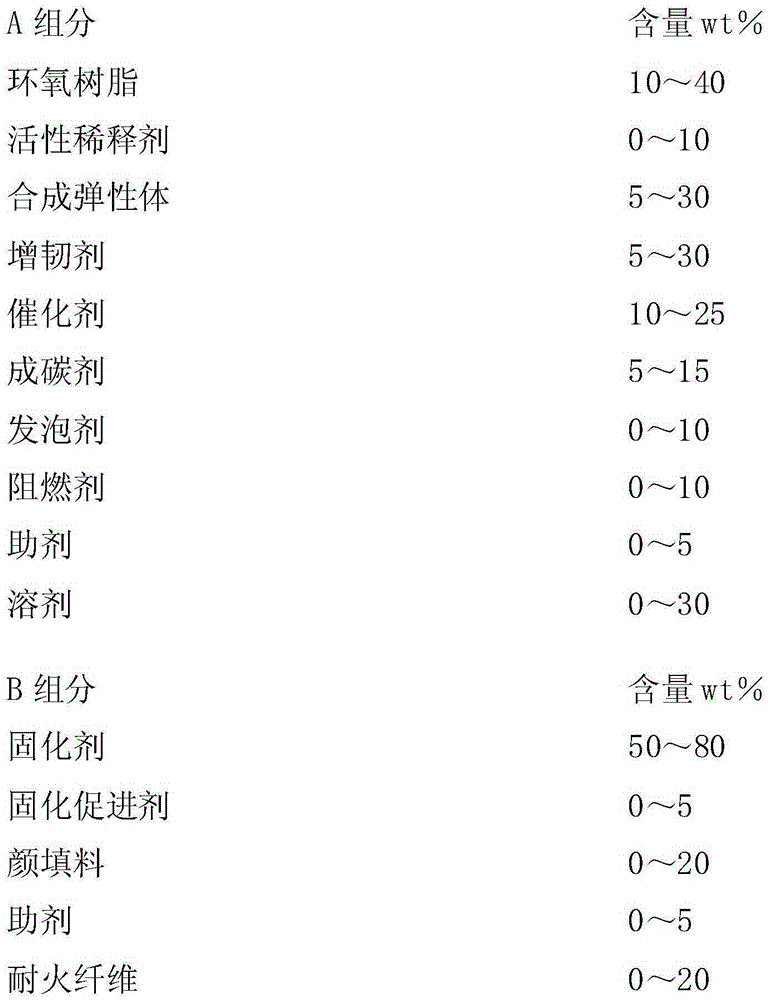

Flexible epoxy intumescence fire-retardant coating and preparation method thereof

InactiveCN105238221AImprove water resistanceExcellent medium resistanceFireproof paintsEpoxy resin coatingsElastomerFiber

The invention relates to a flexible intumescence fire-retardant coating and a preparation method thereof, and belongs to the field of functional coatings. The flexible intumescence fire-retardant coating is composed of a component A and a component B. The component A is prepared from epoxy resin, reactive diluent, synthetic elastomer, flexibilizer, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent. The component B is prepared from a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. The flexible epoxy intumescence fire-retardant coating prepared through the method has certain flexibility, and is particularly suitable for fire-retardant protection of the surface of a flexibility or deformation base material and the surface of a shapeless base material or the surface of light metal. In addition, the flexible epoxy intumescence fire-retardant coating prepared through the method has excellent water resistance, medium resistance, ageing resistance and salt-fog resistance and is suitable for fire-retardant protection of hydrocarbon fire potential risk areas in the ship, airplane and ocean environment and the petrochemical industry.

Owner:MARINE CHEM RES INST CO LTD

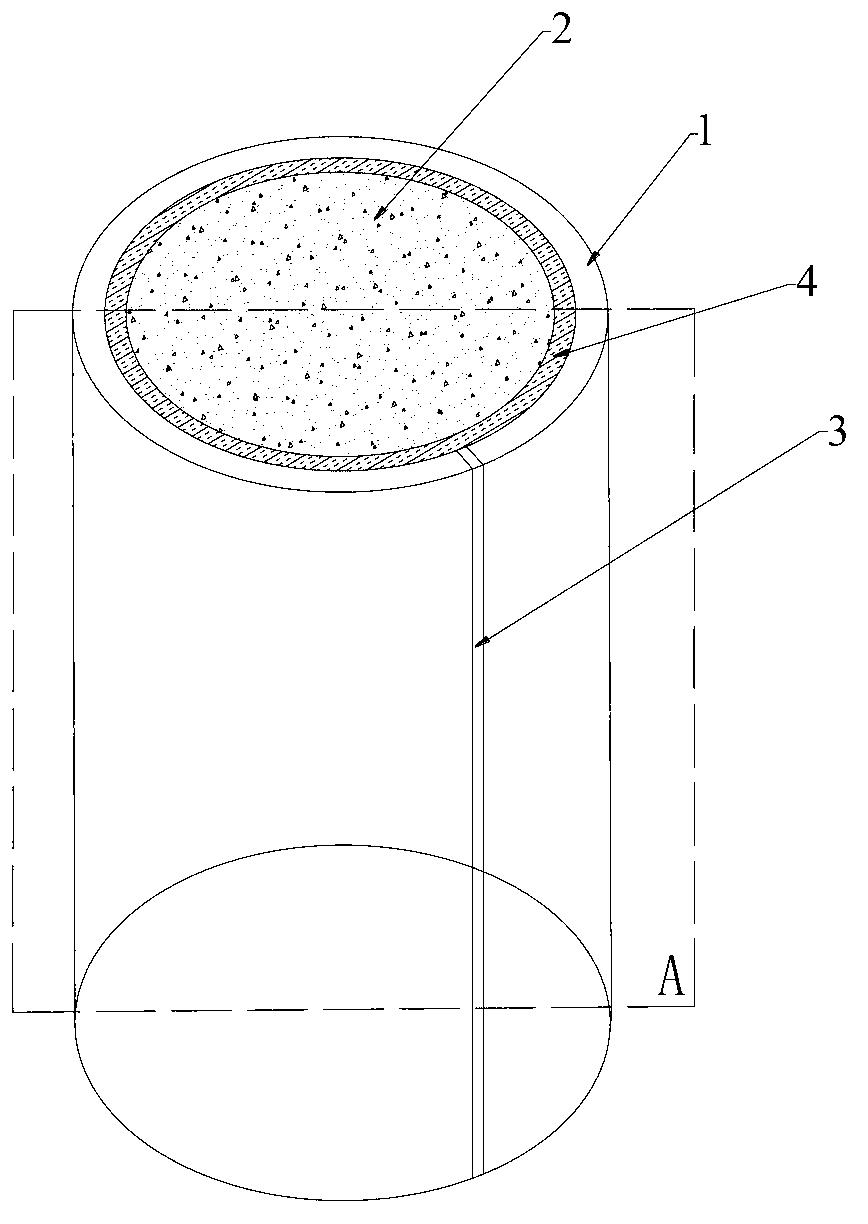

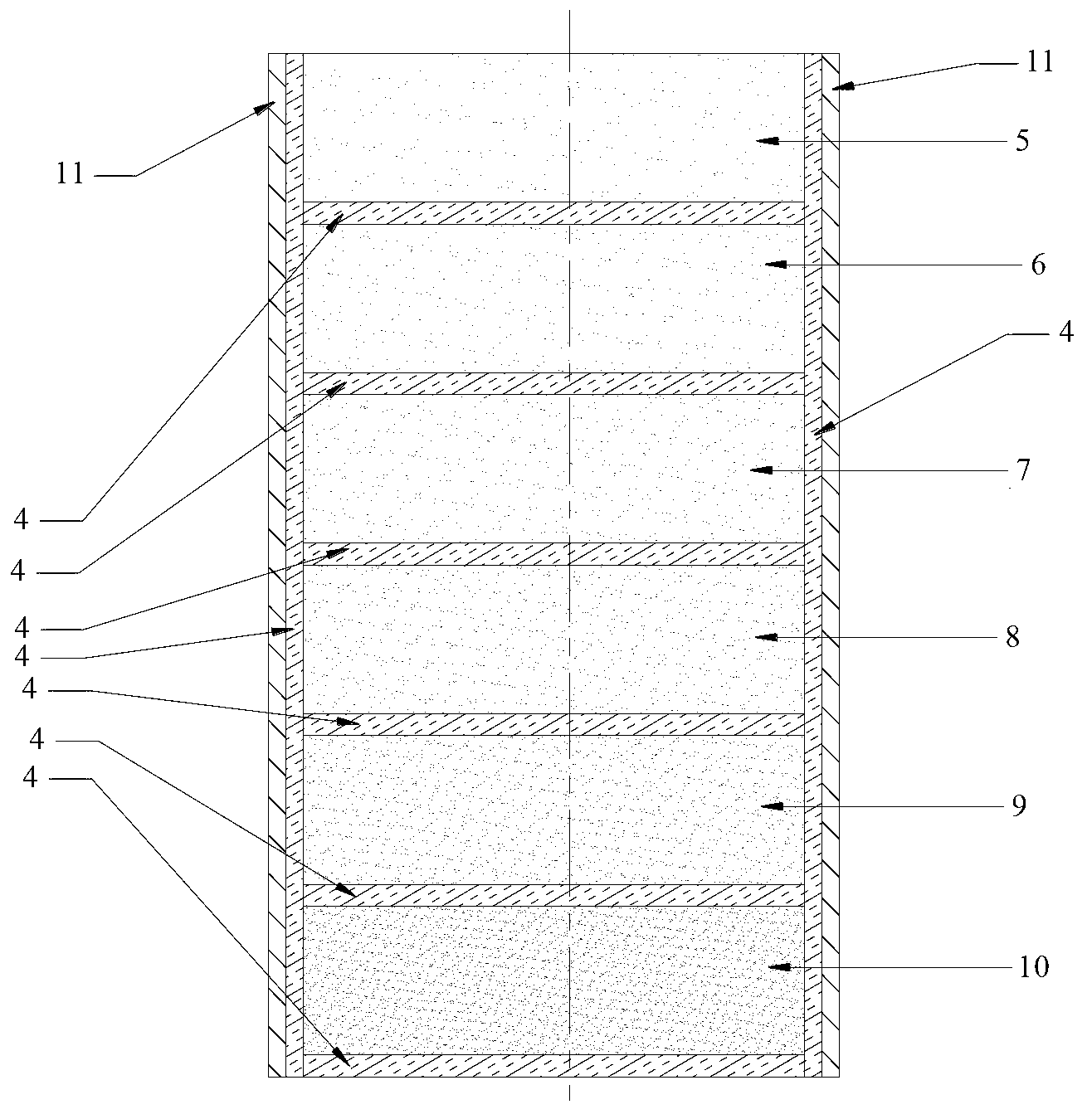

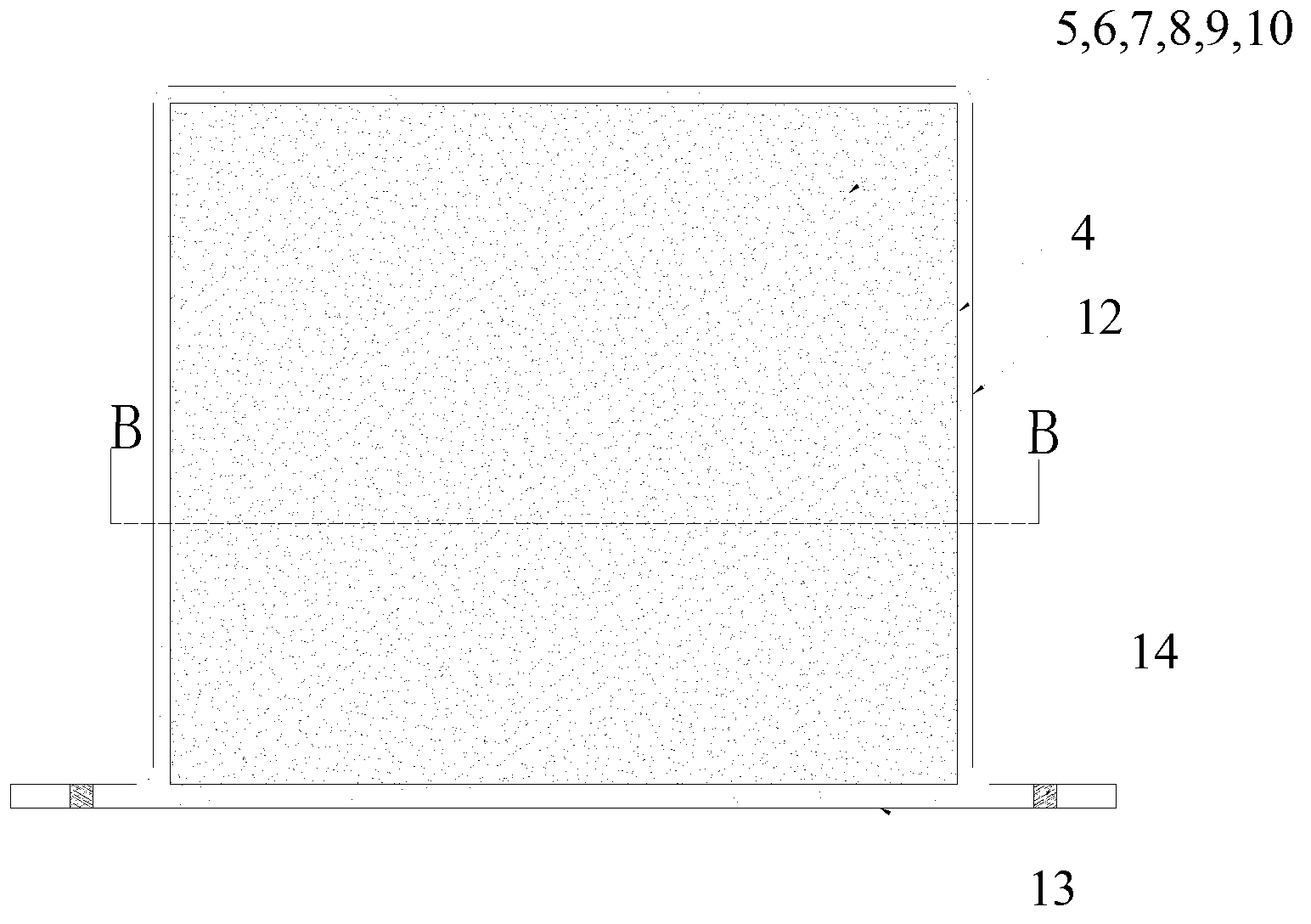

Buffering energy-absorbing structure

The invention discloses a buffering energy-absorbing structure which comprises a hollow metal thin-wall structure, wherein a light metal foam material or metal cellular material is filled in the hollow metal thin-wall structure; the hollow metal thin-wall structure is fixedly connected with the filled light metal cellular material through binding or brazing, thereby forming the complete buffering energy-absorbing structure; the density of the filled metal foam material along the longitudinal direction is changed in a gradient form; and an aperture size or cellular wall thickness of the filled metal cellular material along the longitudinal direction is changed in the gradient form. Compared with the traditional energy-absorbing structure, the buffering energy-absorbing structure has the advantages that the deformation mode is more stable, the energy-absorbing efficiency is higher, the weight of the energy-absorbing structure is effectively reduced, the impact force during the whole energy-absorbing process is stable and the crashing safety of the energy-absorbing structure is greatly increased. The buffering energy-absorbing structure served as a direct impact energy-absorbing structure of an automobile can greatly increase the direct impact safety of the automobile and can reduce the casualties.

Owner:HUNAN UNIV

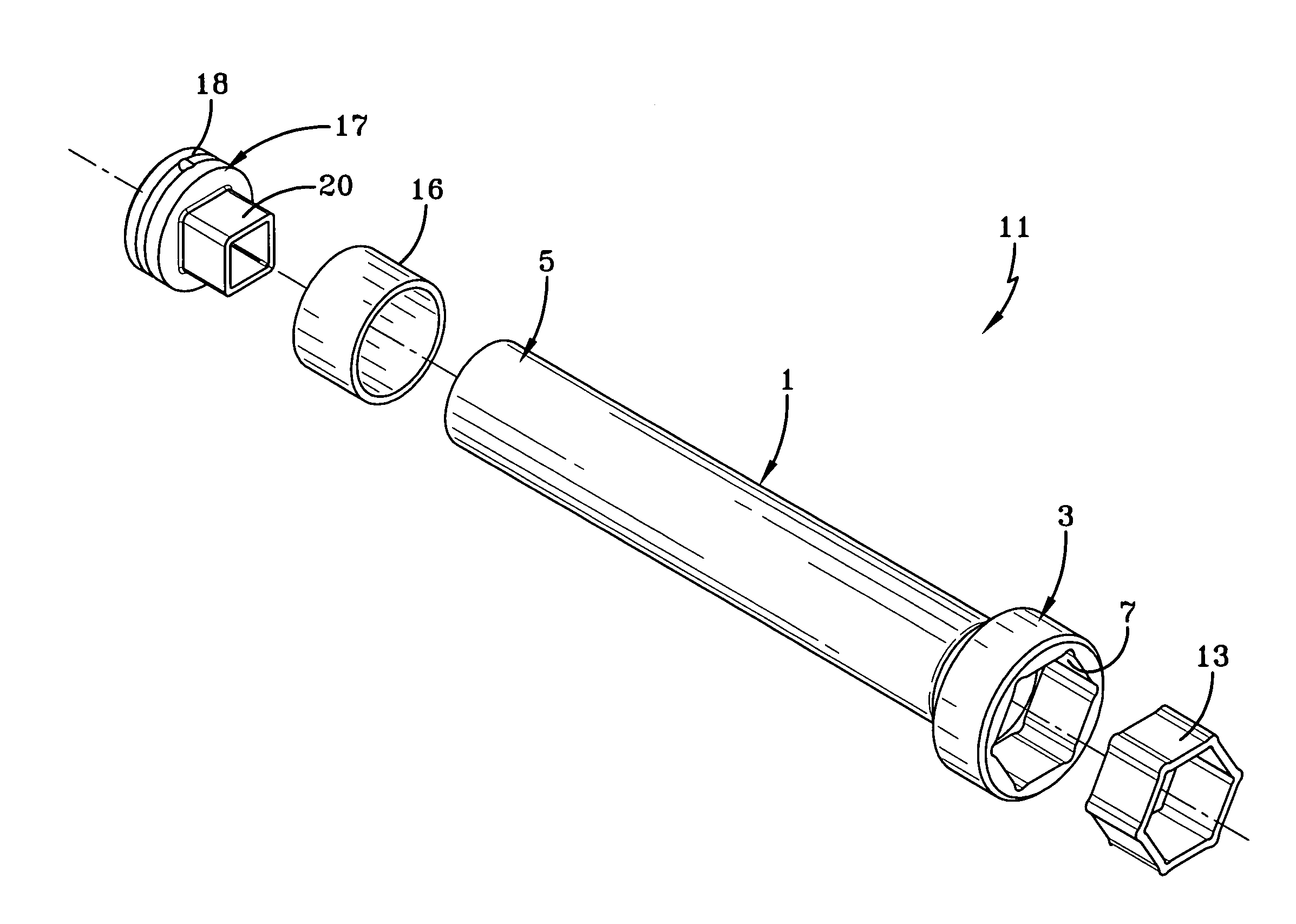

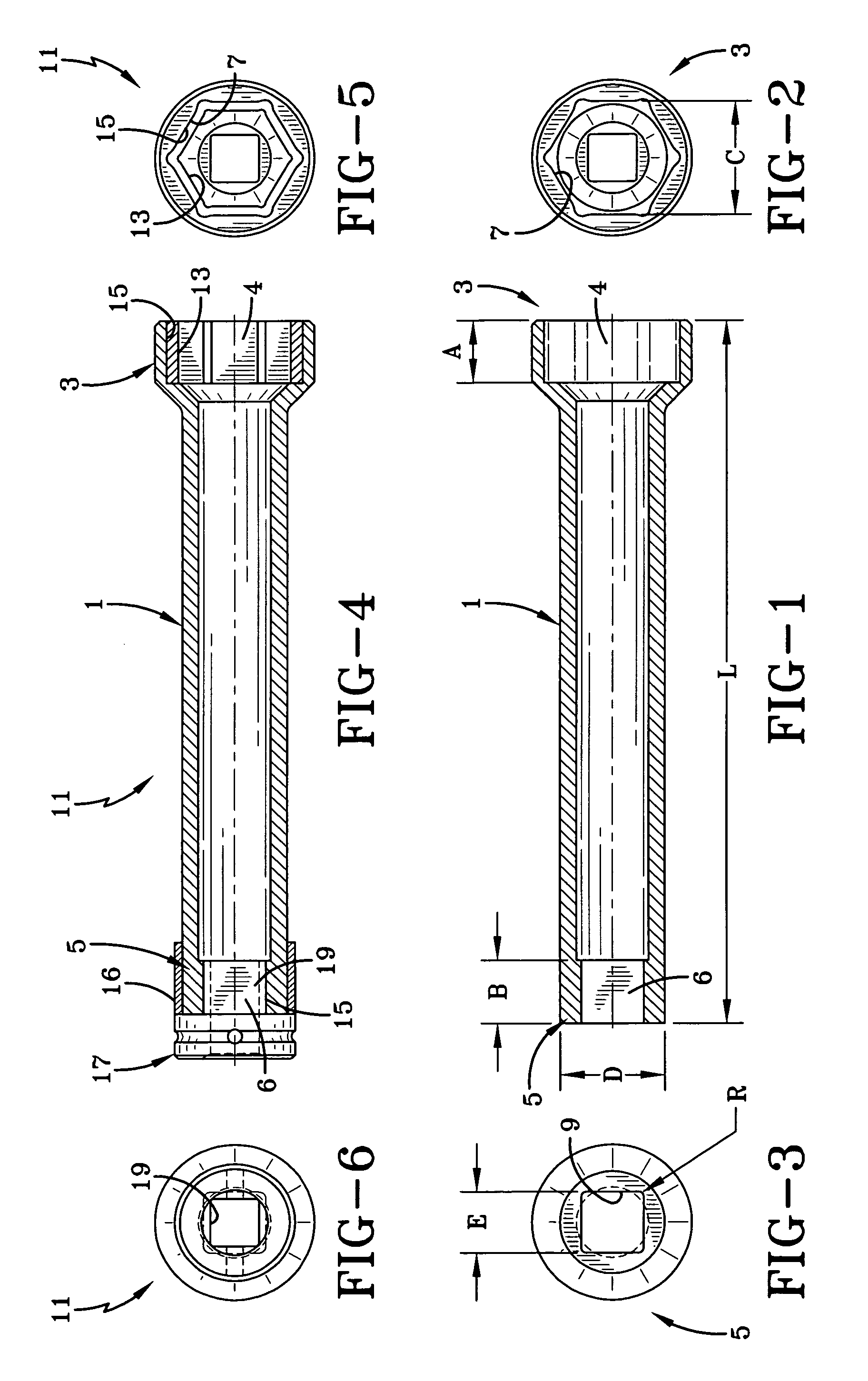

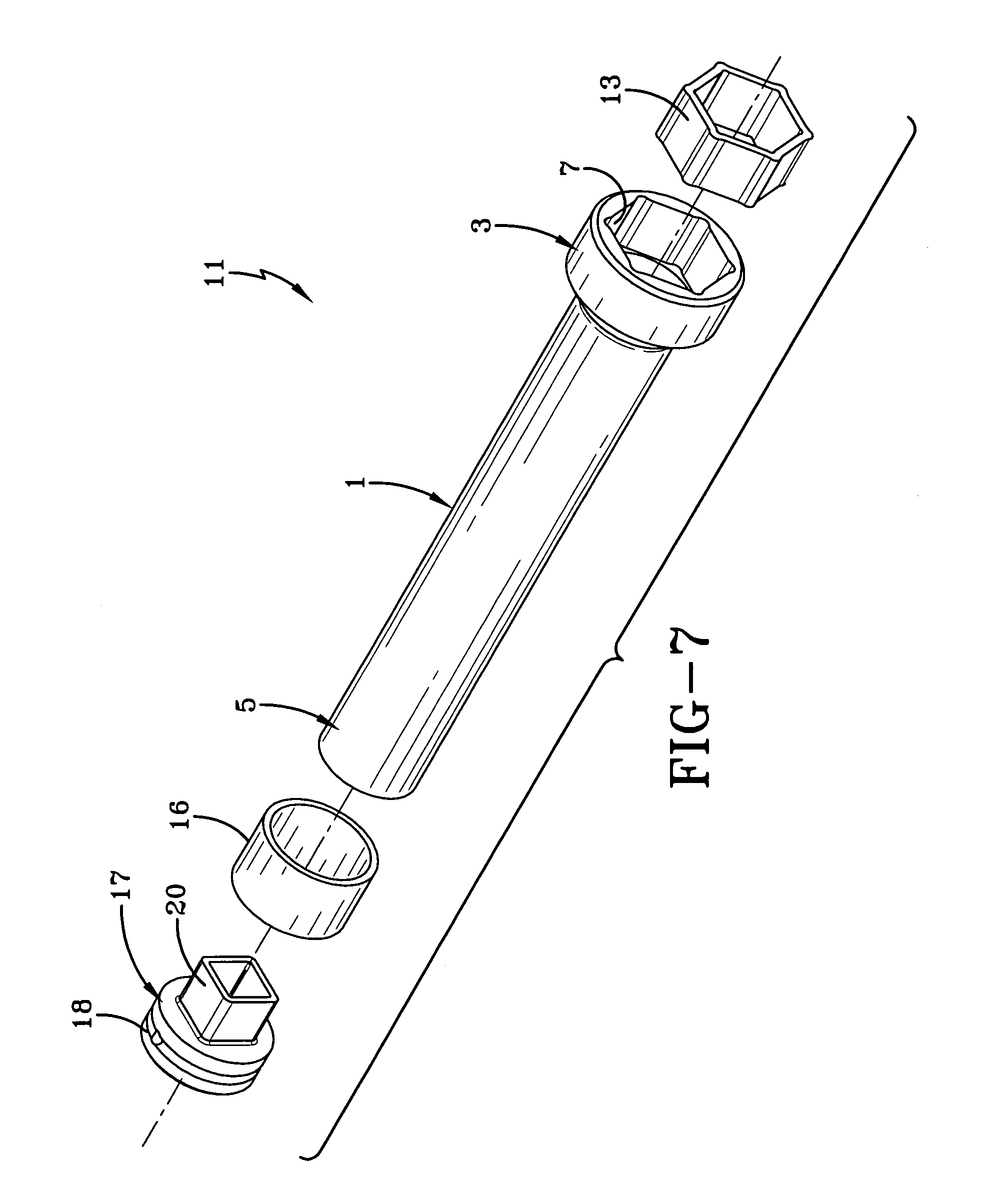

Reinforced impact socket

ActiveUS7841261B2Solution to short lifeHigh strengthSpannersWrenchesHigh intensityUltimate tensile strength

The present invention is a lightweight impact socket having an aluminum or other light metal blank having a fastener end and a drive end. A high strength, heat-treated steel alloy insert is inserted into the fastener end of the blank and glued in place to yield a highly effective impact socket. A drive end insert can be inserted into the bore at the drive end to add strength to the drive end of the impact socket. A high strength, heat-treated steel alloy sleeve can be adhered to the outside of the lightweight blank to add further strength to the drive end of the impact socket.

Owner:WRIGHT TOOL

Metal die for coining super-hydrophobic micro-nanometer surface and laser manufacturing method thereof

ActiveCN103521929AHigh structural fidelityIncrease flexibilityNanotechnologyLaser beam welding apparatusPicosecond laserOptoelectronics

The invention discloses a metal die for coining a super-hydrophobic micro-nanometer surface and a laser manufacturing method thereof. The laser manufacturing method comprises the following steps that an ultra-short pulse laser is used for ablating a metal base material, a symmetrical negative structure of a lotus leaf micro-nanometer structure is obtained on the surface of the metal base material through laser ablating removing, and then the metal die is obtained; the symmetrical negative structure of the lotus leaf micro-nanometer structure is a micrometer-level pit and a nanometer-level substructure on the inner surface of the micrometer-level pit. The invention provides the micro-nanometer coining metal die for coining a non-metal material or a light-metal material so as to form the lotus leaf micro-nanometer structure with the surface being super hydrophobic and the laser manufacturing method of the metal die, and particularly relates to the micro-nanometer coining metal die which is manufactured efficiently in a large area by the utilization of high-power picosecond lasers and the manufacturing method of the metal die. The metal die for coining the super-hydrophobic micro-nanometer surface and the laser manufacturing method of the metal die have the comprehensive advantages that the manufacturing efficiency is high, the micro-nanometer coining die is high in temperature resistance, high in pressure resistance and wide in coning material range, the micro-nanometer structure is precise and adjustable in parameter and the lotus structure is vivid. Moreover, the manufacturing method is far superior than other methods.

Owner:TSINGHUA UNIV

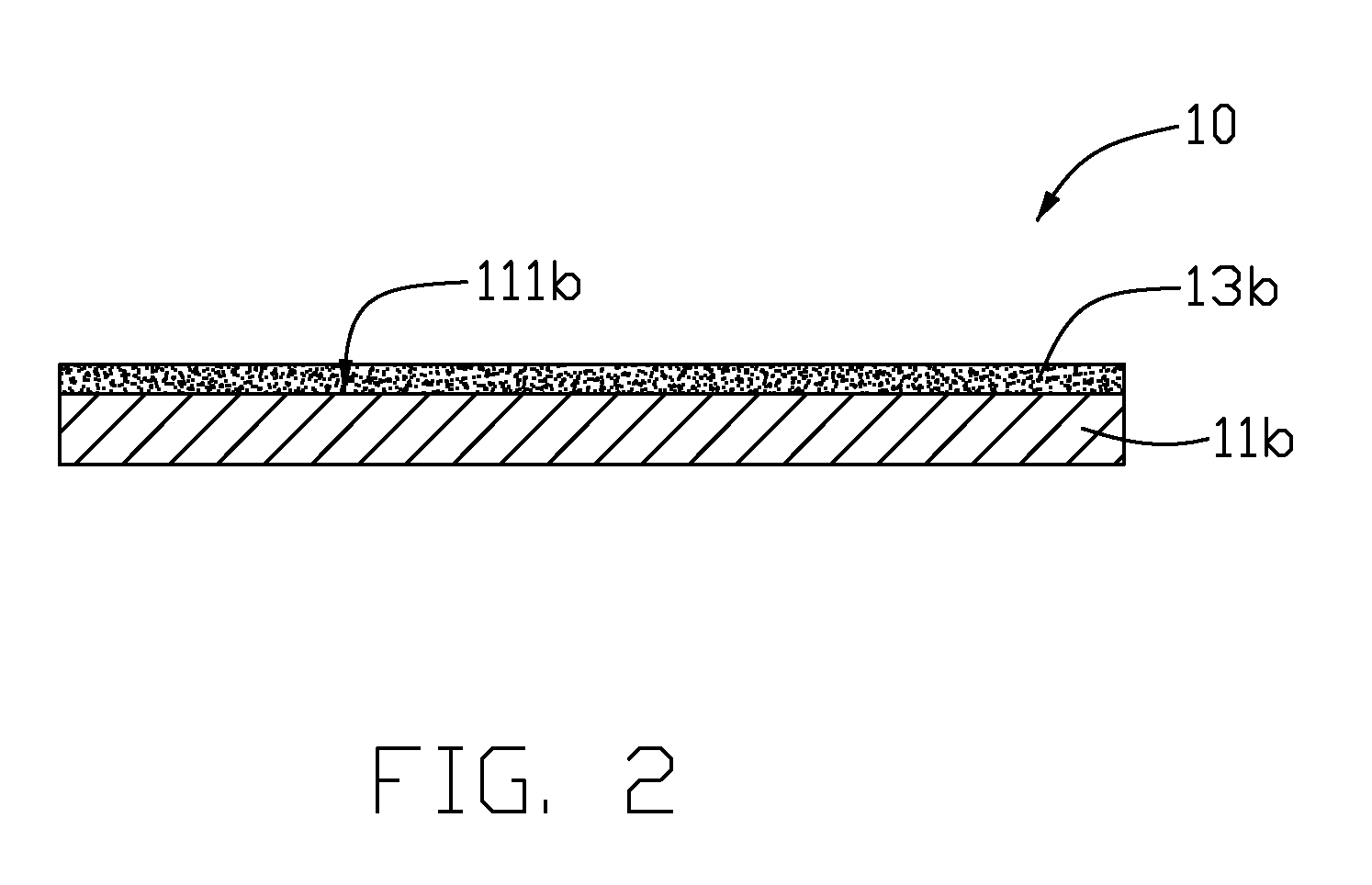

Housing for electronic device and method for making the same

An exemplary housing includes a light metal base and a ceramic film. The light metal base has an outer surface. The ceramic film is formed on the outer surface of the light metal base by micro-arc oxidation process. A method for making the present housing is also provided.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

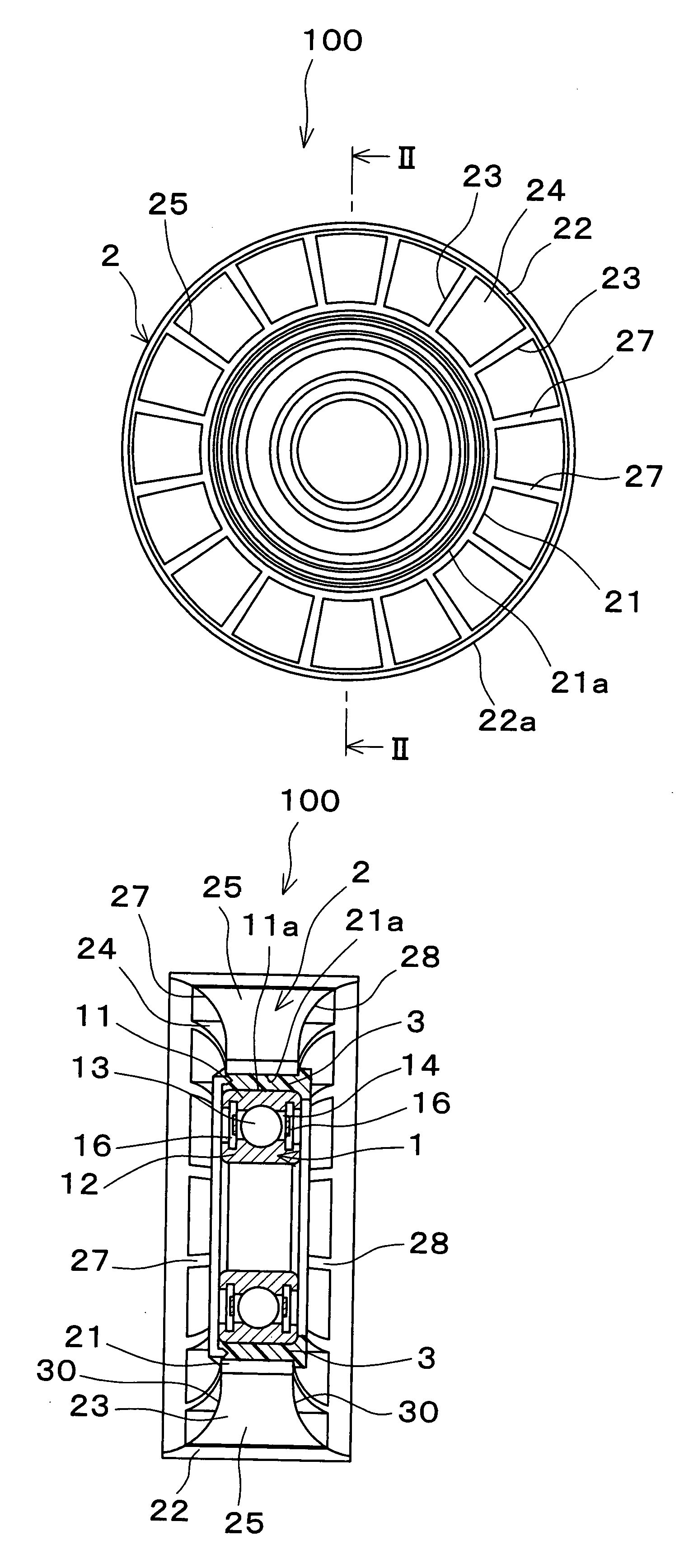

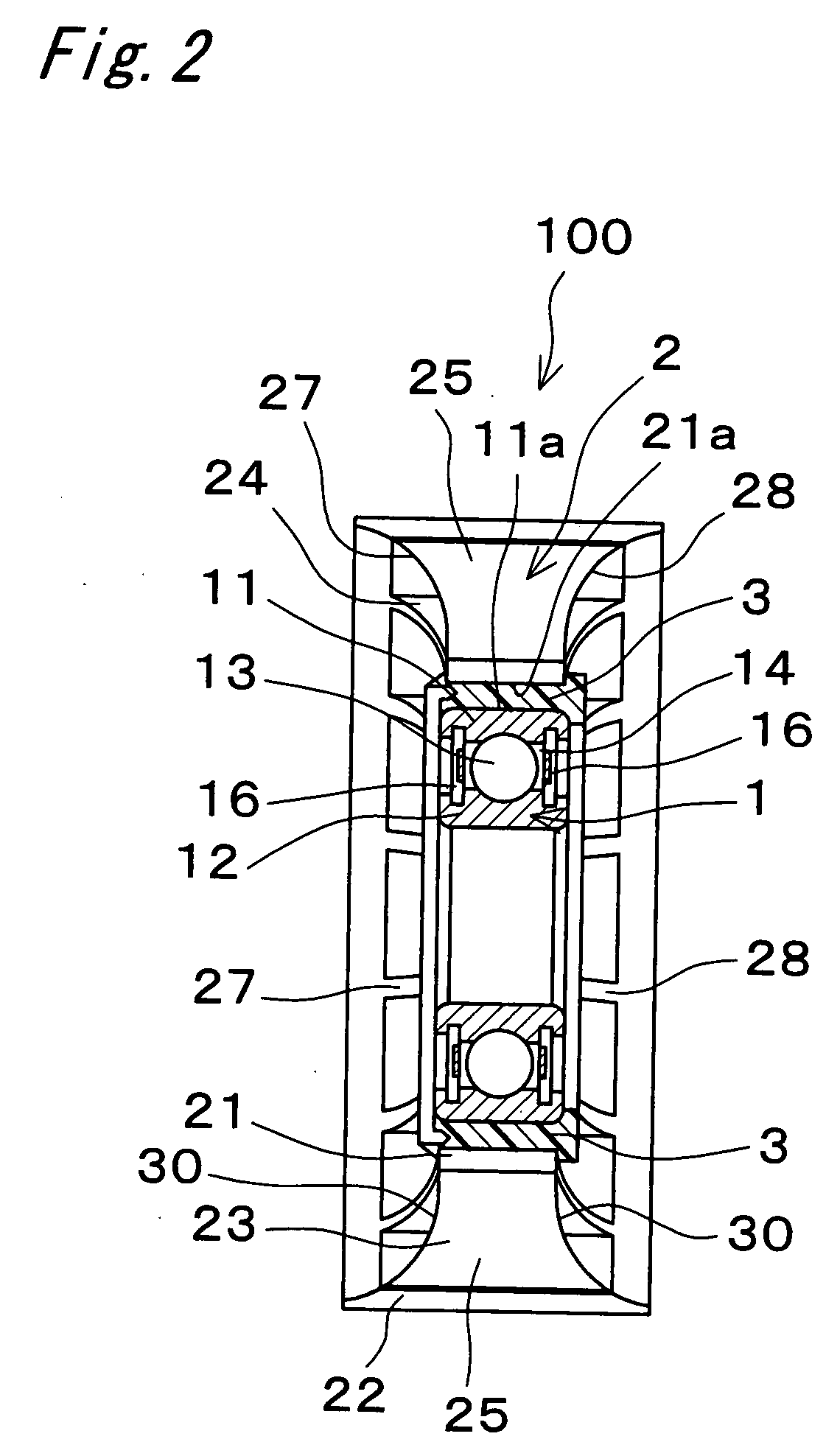

Pulley assembly and pulley usable therefor

InactiveUS20070232427A1Wind noise is generatedReduce generationGearingPortable liftingThermal expansionSpoke

In a pulley assembly, an annular joint member made of a high polymer material is disposed between an outer ring of a bearing and a light metal pulley. The joint member has a coefficient of thermal expansion larger than that of the pulley. The outer ring has a coefficient of thermal expansion smaller than that of the pulley. The pulley has an annular boss, an annular rim, and a plurality of spokes which have side faces each consisting of a surface parallel to an axial direction of the pulley. Front faces of the spokes are positioned on one identical imaginary surface of revolution, and rear faces of the spokes are also positioned on one identical imaginary surface of revolution.

Owner:JTEKT CORP

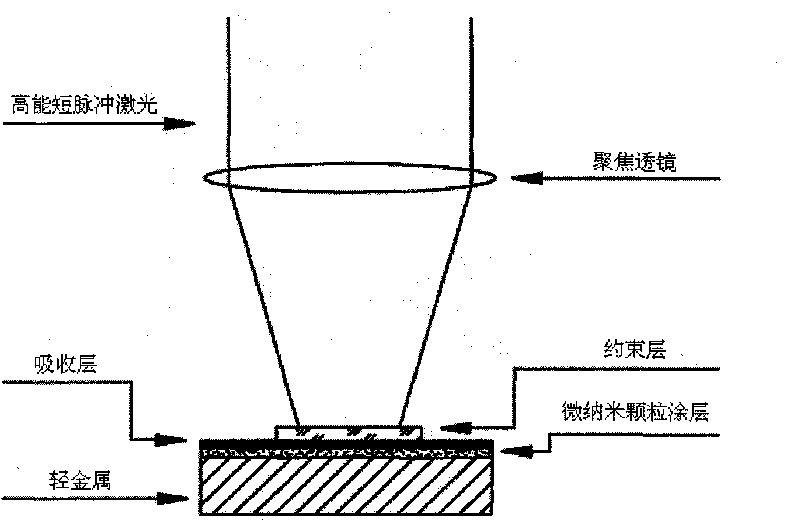

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

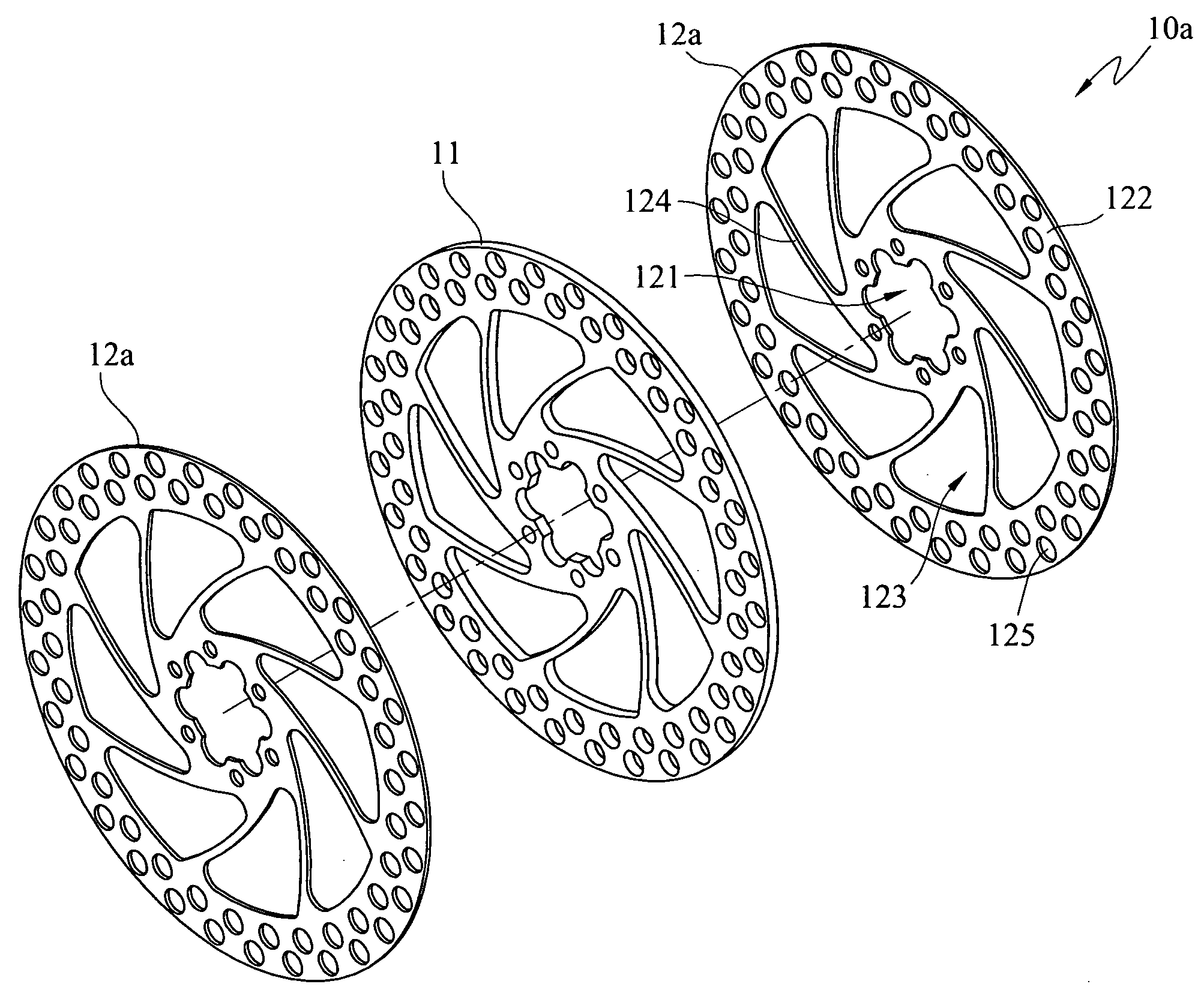

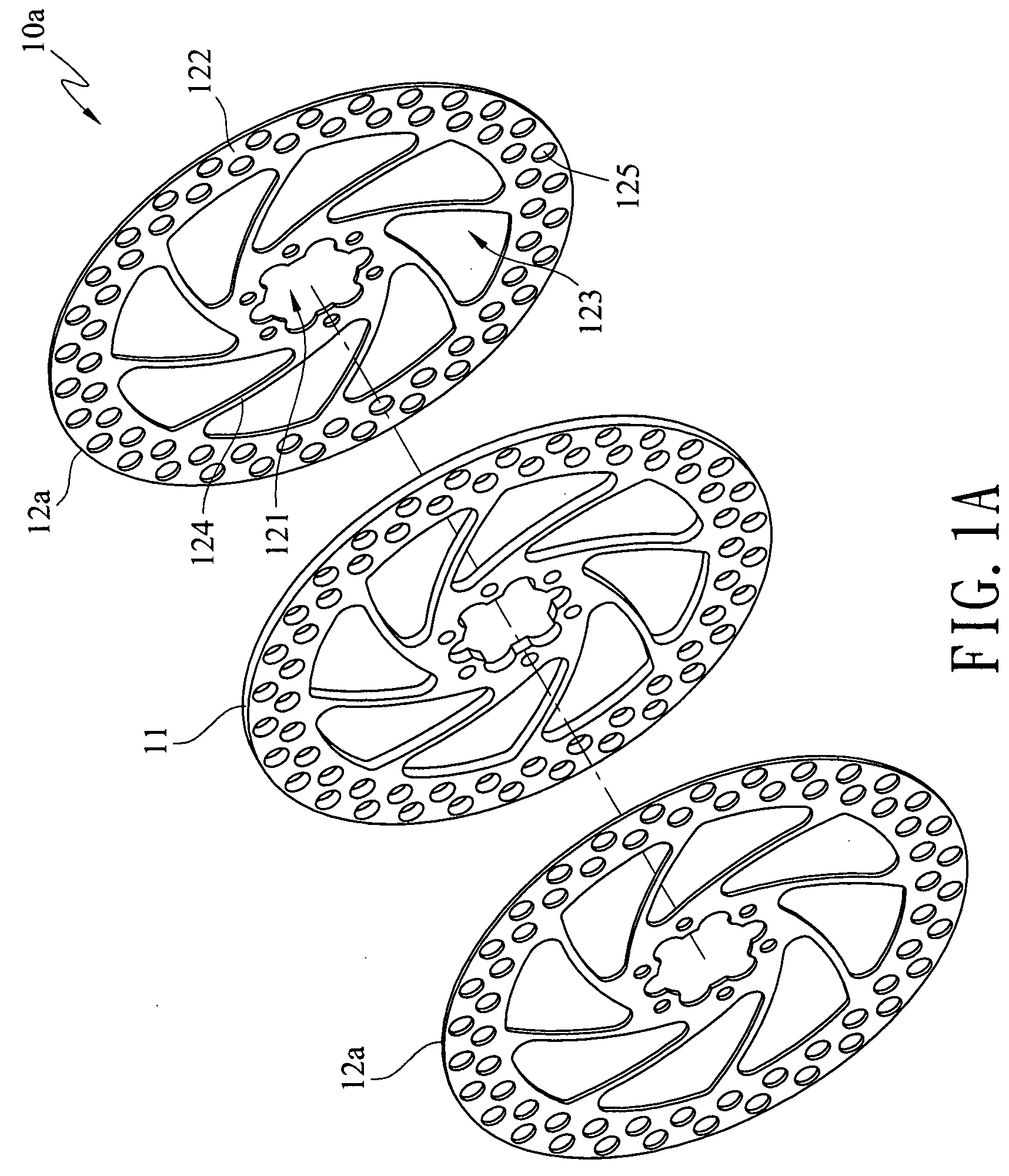

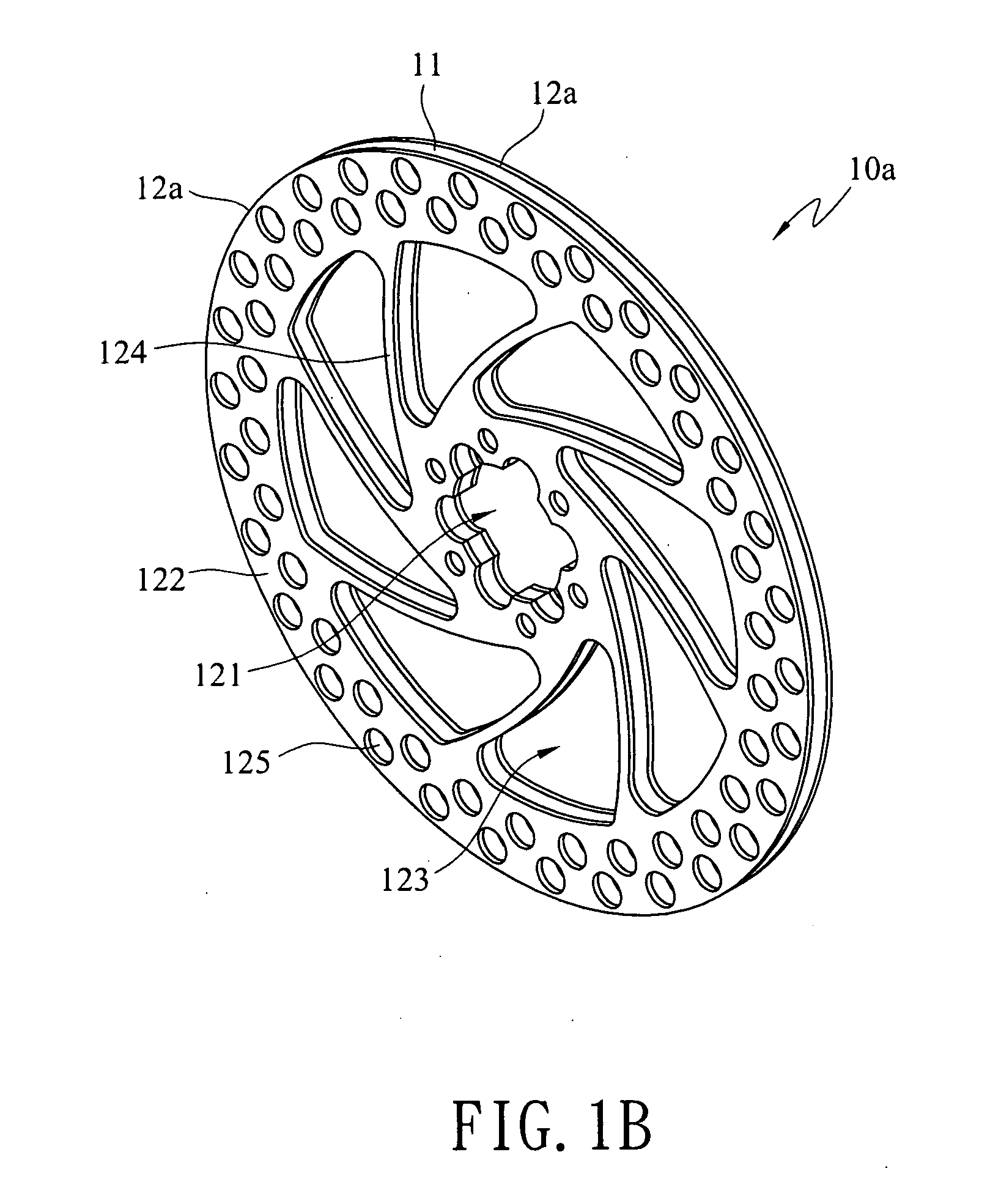

Brake disc structure with composite materials

InactiveUS20080060891A1Reduce manufacturing costMeet the requirementsBraking discsActuatorsEngineeringWear resistance

A brake disc structure with composite materials is provided, which includes a disc-shaped inner disk made of a light metal material, and at least two outer disks respectively stacked and combined with the upper and lower surfaces of the inner disk through a metallurgical reaction process. The outer disks are disc-shaped and made of a ferrous metal material. Moreover, an axle hole is opened in the center of each outer disk for being fitted on a hub and penetrates the inner disk, thereby constituting the brake disc structure of composite materials having properties of abrasion resistance and light weight.

Owner:METAL INDS RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com