Patents

Literature

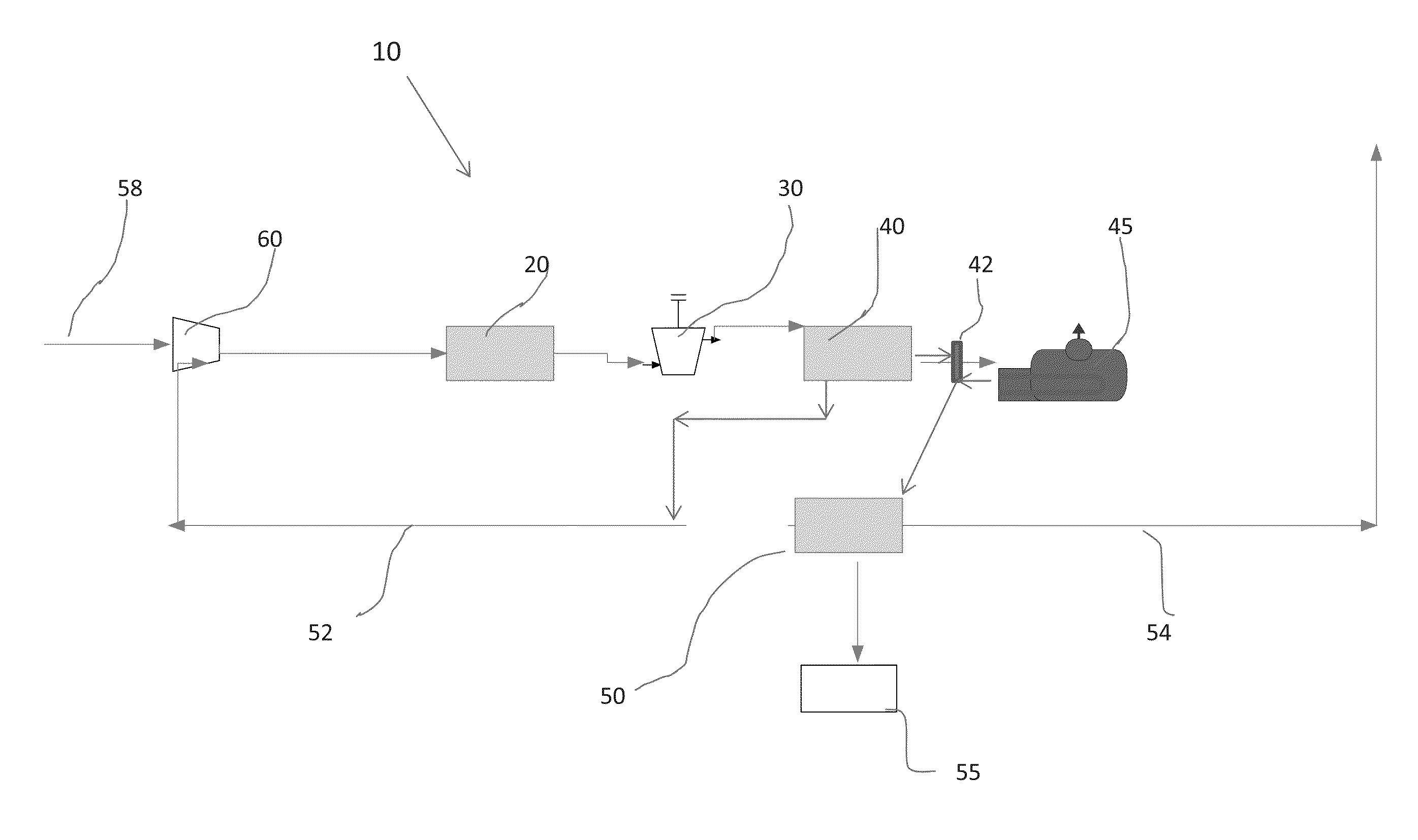

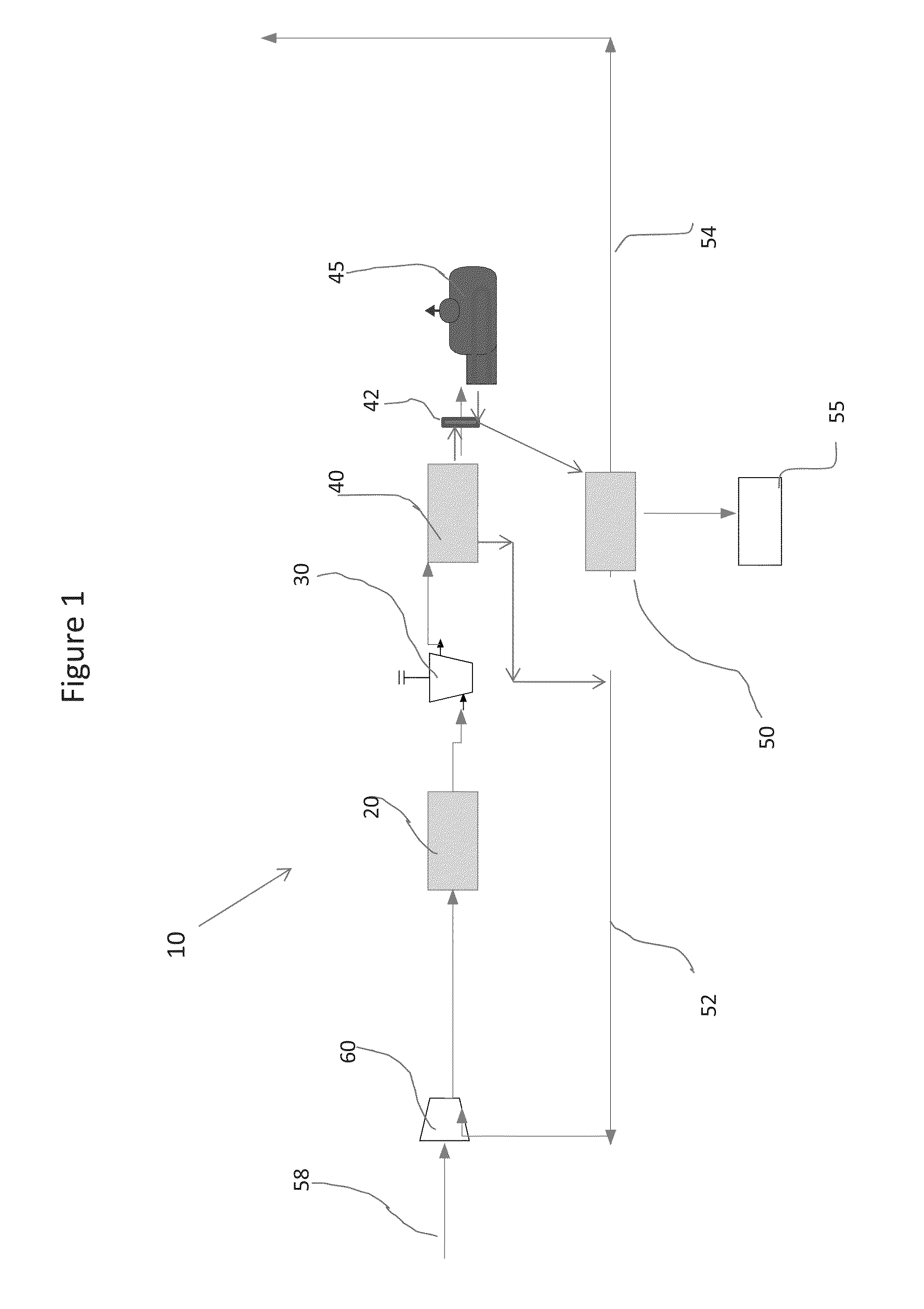

180results about How to "Prevent galvanic corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

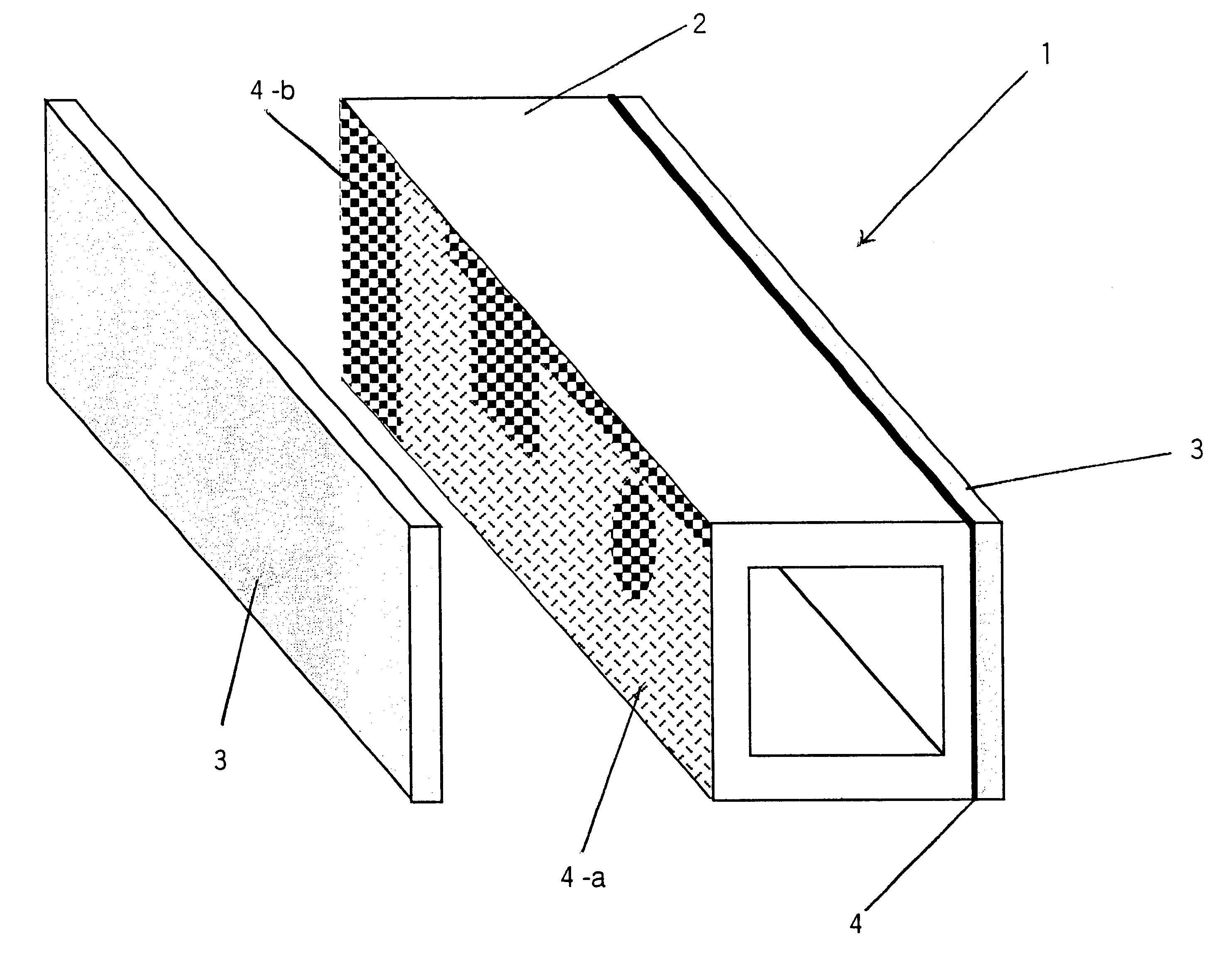

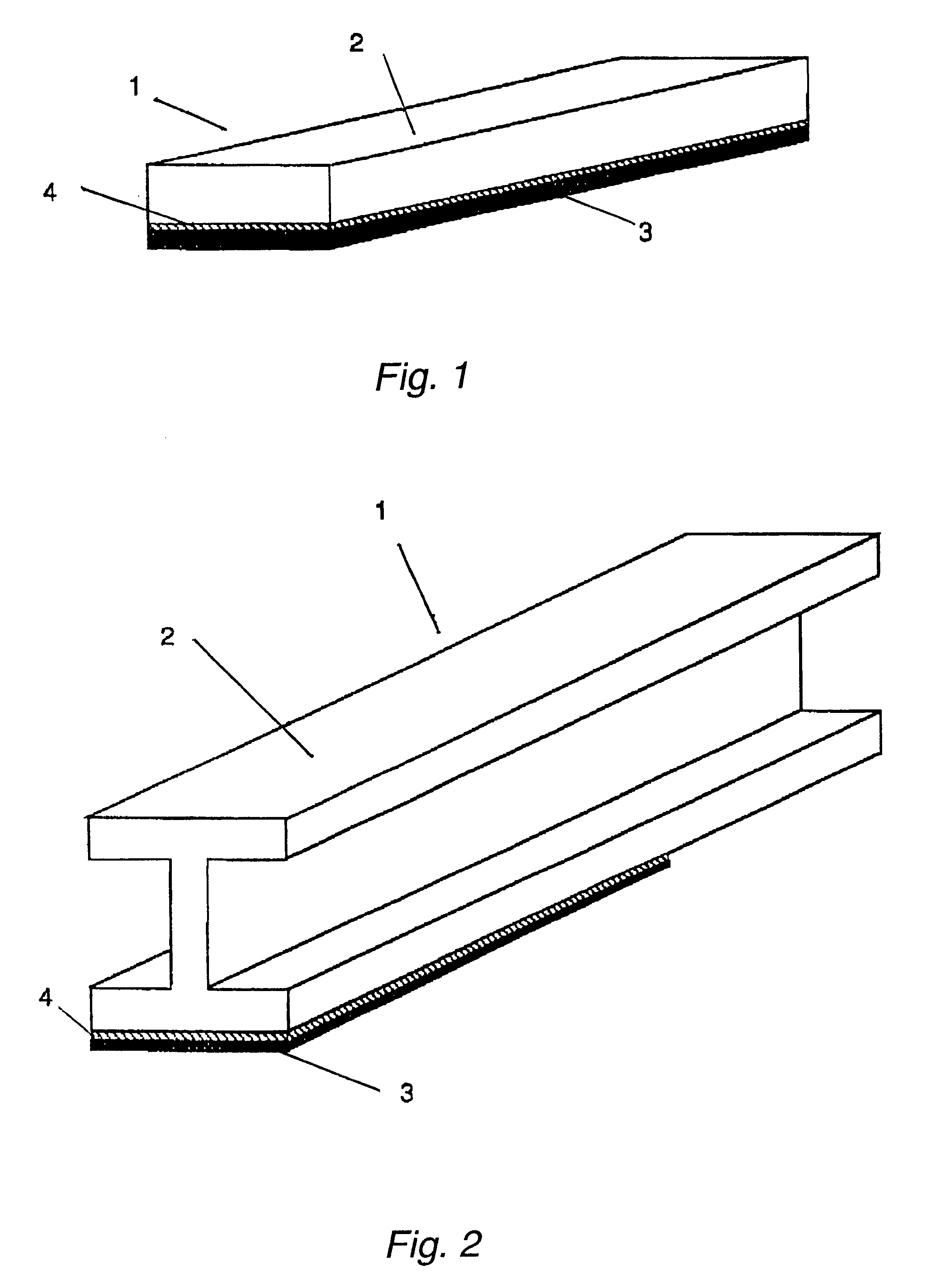

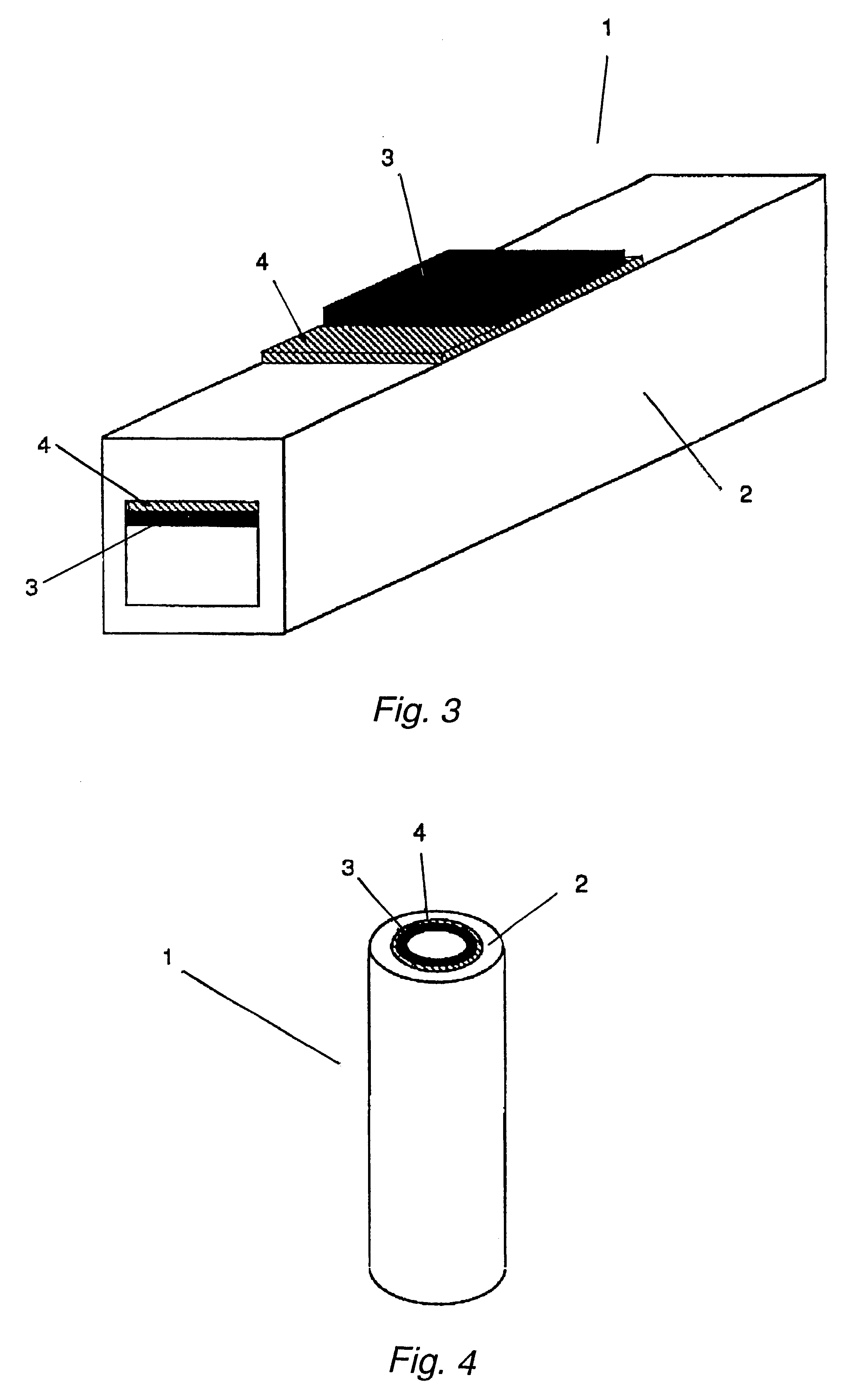

Light metal/CFRP structural member

InactiveUS6468613B1Prevent galvanic corrosionHigh structural reliabilitySynthetic resin layered productsCeramic shaping apparatusMetallic materialsRoom temperature

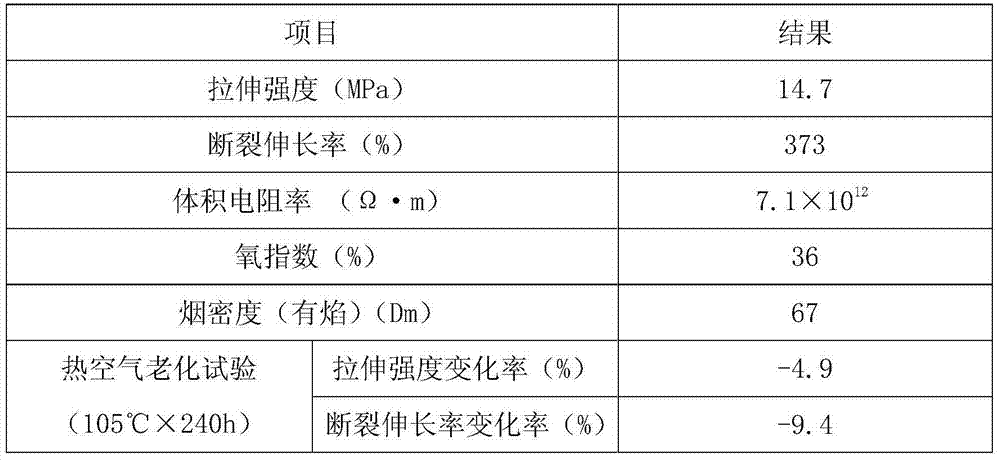

Light metal / CFRP-made structural members which are characterized in that they are structural materials in which a CFRP material is stuck to the surface of a light metal material via an adhesive agent layer of thickness at least 10 mum and up to 500 mum, and the volume resistivity of the adhesive agent layer between said metal material and said CFRP material is at least 1x1013 OMEGA.cm and, furthermore, the adhesive strength at room temperature is at least 15 MPa. In accordance with the present invention, since conventional light metal / CFRP structural materials can be made lighter and, furthermore, since the resistance to galvanic corrosion is outstanding and it is possible to markedly enhance the strength and the impact energy absorption performance, the development of applications and large-scale expansion into new fields becomes possible. Weight reduction and enhancing the durability and reliability of structures also makes a considerable contribution in terms of environmental protection.

Owner:TORAY IND INC

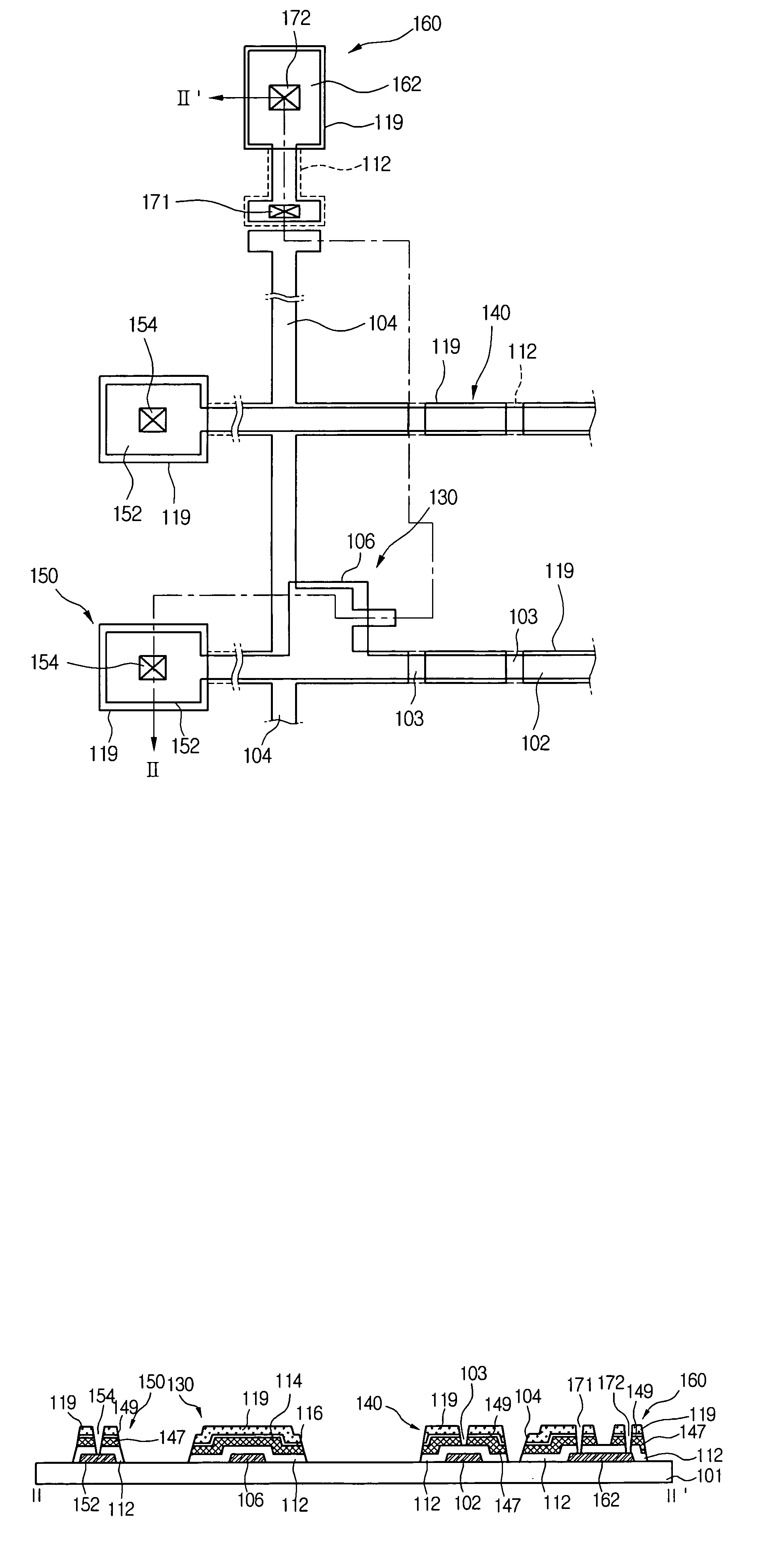

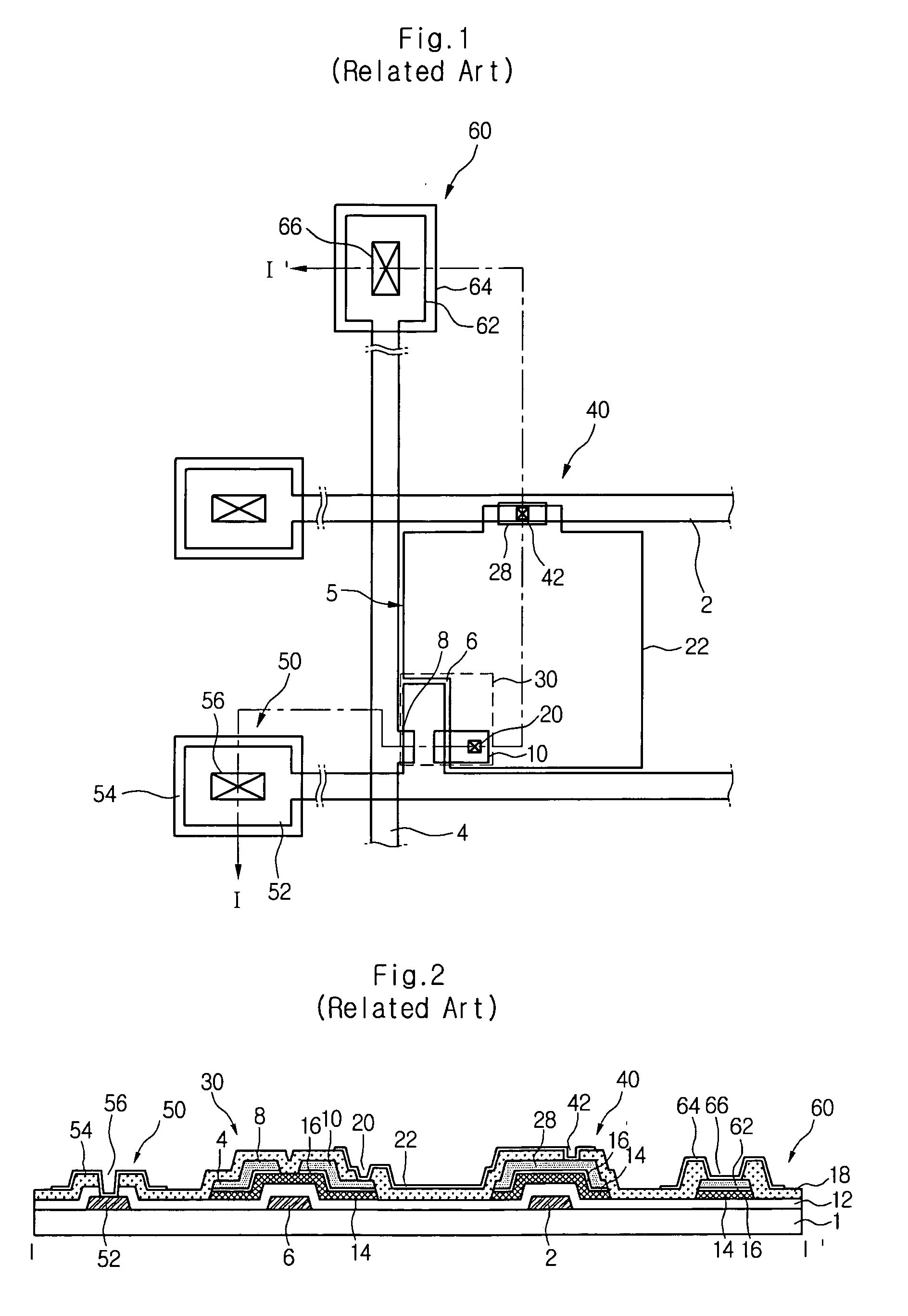

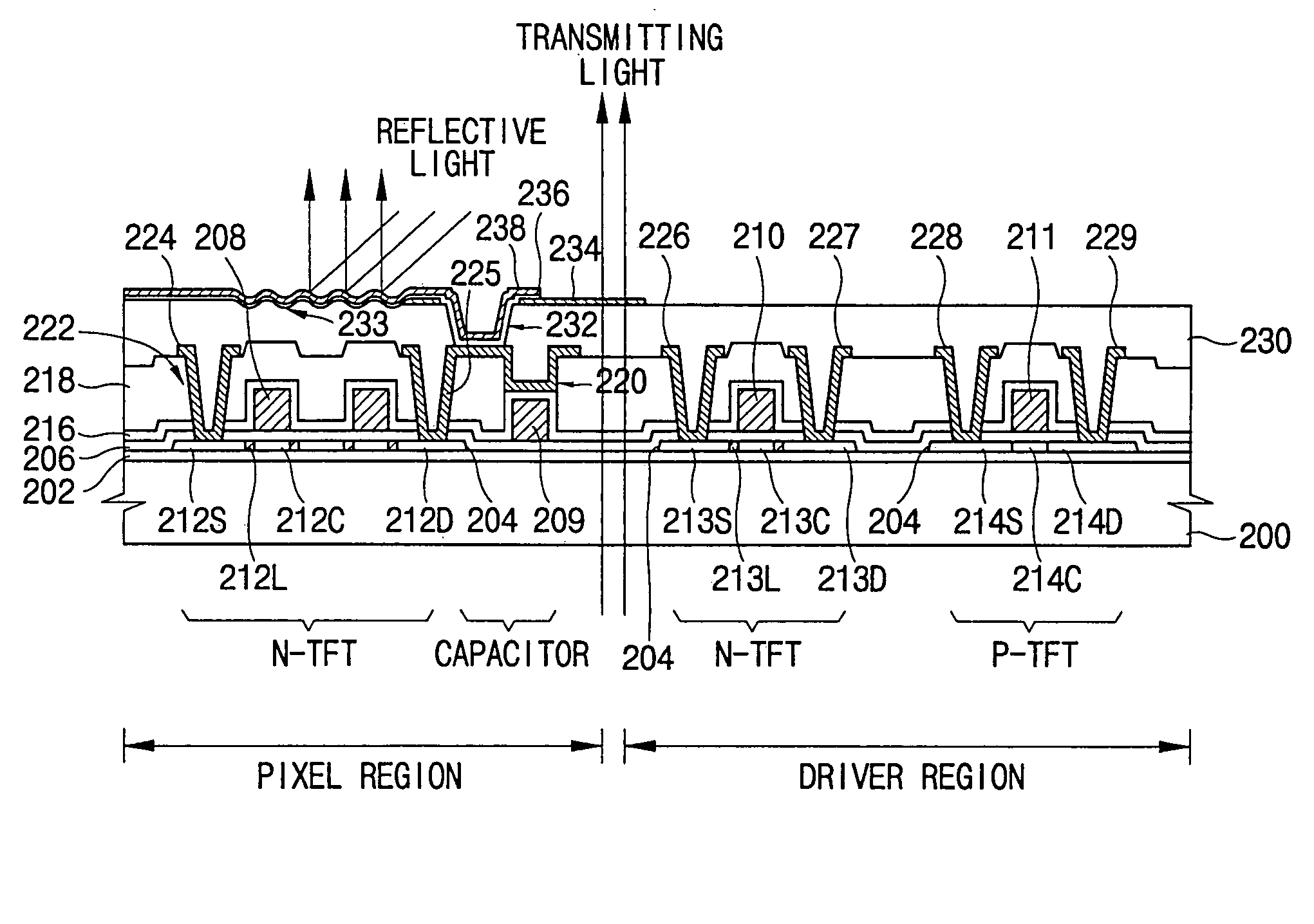

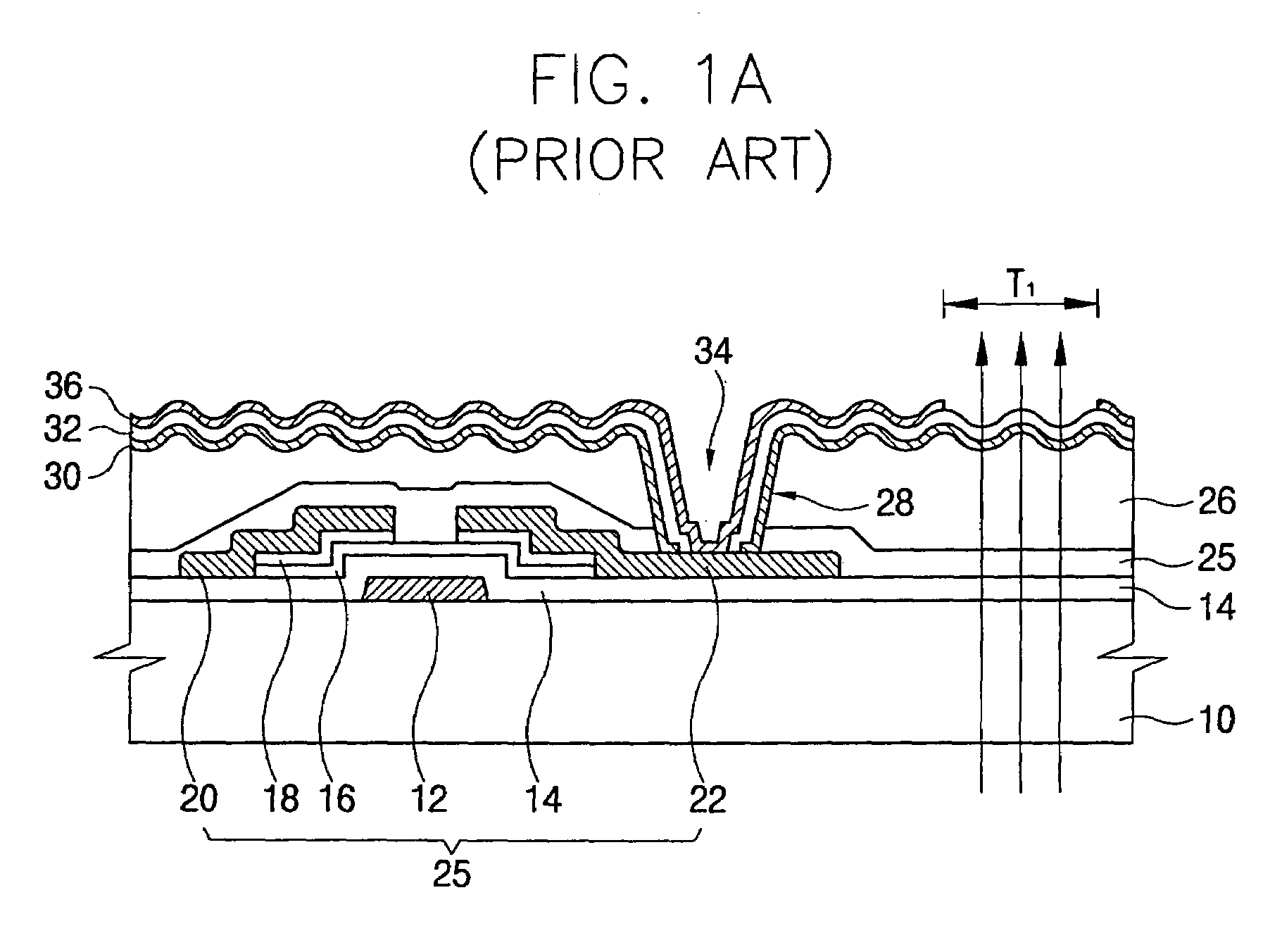

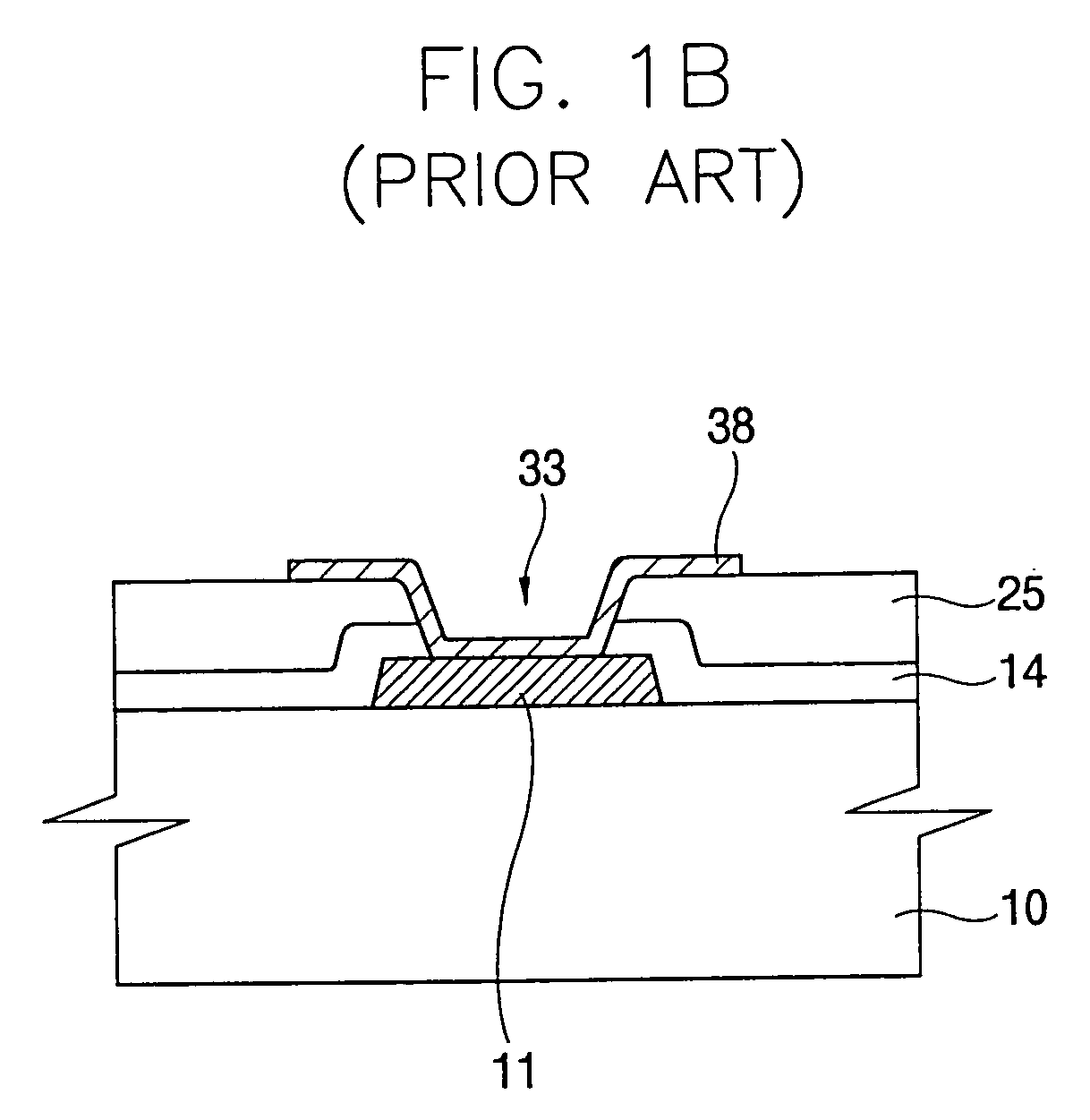

TFT array substrate and fabrication method thereof

InactiveUS20060145157A1Prevent corrosionReduce numberSolid-state devicesNon-linear opticsPhysicsData lines

A TFT array substrate is provided. The TFT array substrate includes a gate electrode connected to a gate line; a source electrode connected to a data line, the data line crossing the gate line to define a pixel region; a drain electrode facing the source electrode with a channel interposed therebetween; a semiconductor layer forming the channel between the source electrode and the drain electrode; a channel passivation layer formed on the channel to protect the semiconductor layer; a pixel electrode disposed in the pixel region to contact with the drain electrode; a storage capacitor including the pixel electrode extending over the gate line to form a storage area on a gate insulating layer on which a semiconductor layer pattern and a metal layer pattern are stacked; a gate pad extending from the gate line; and a data pad connected to the data line.

Owner:LG DISPLAY CO LTD

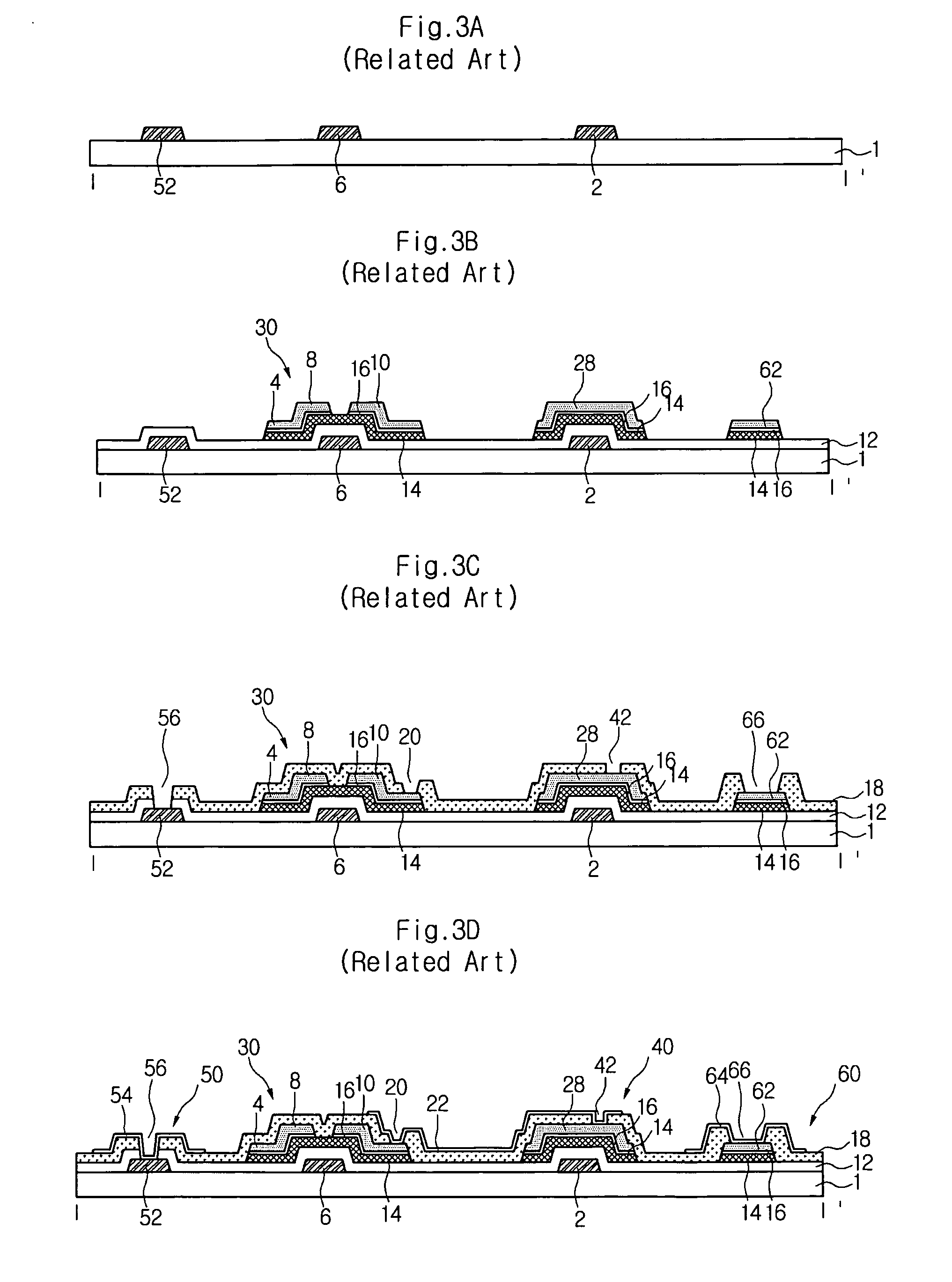

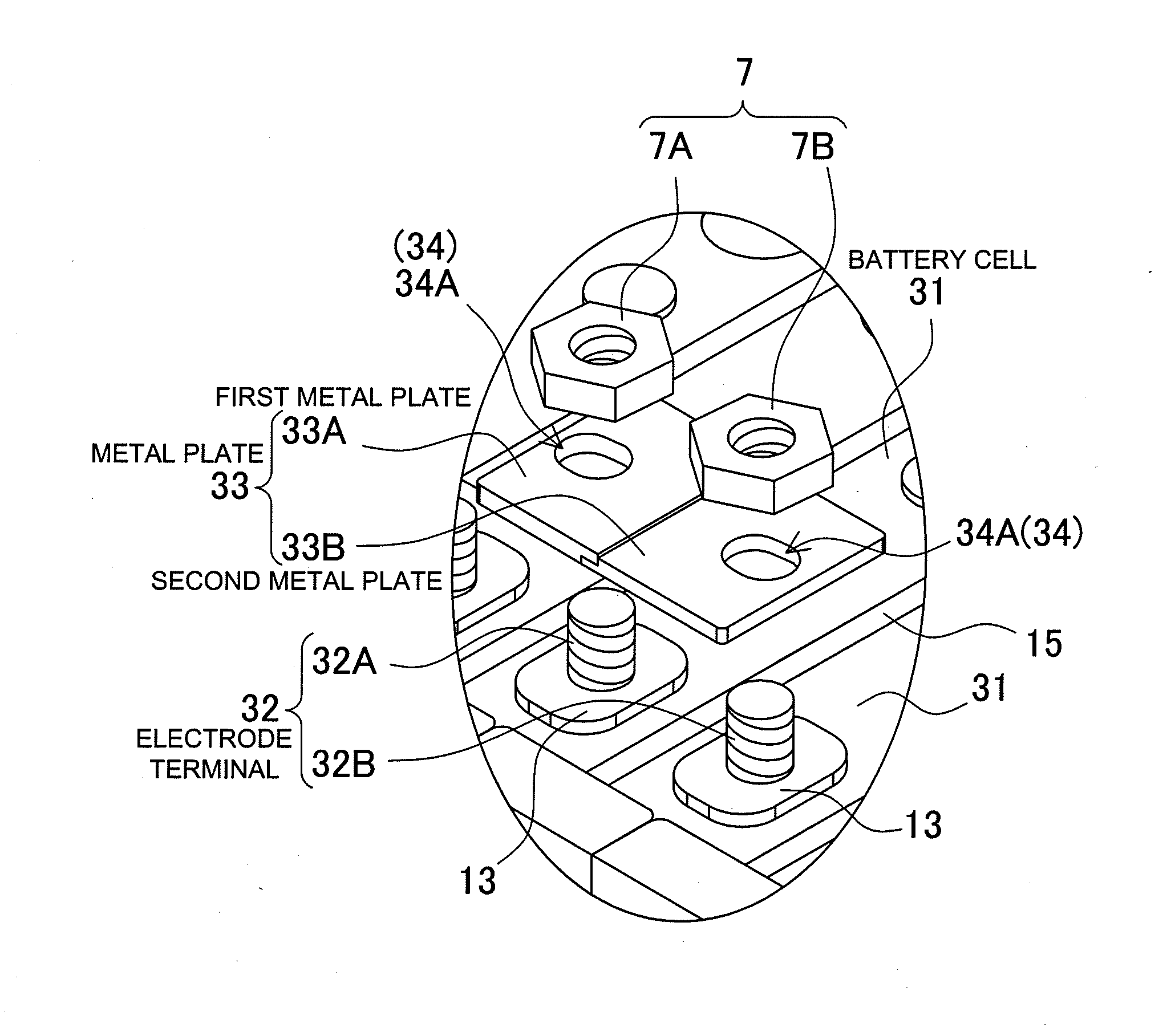

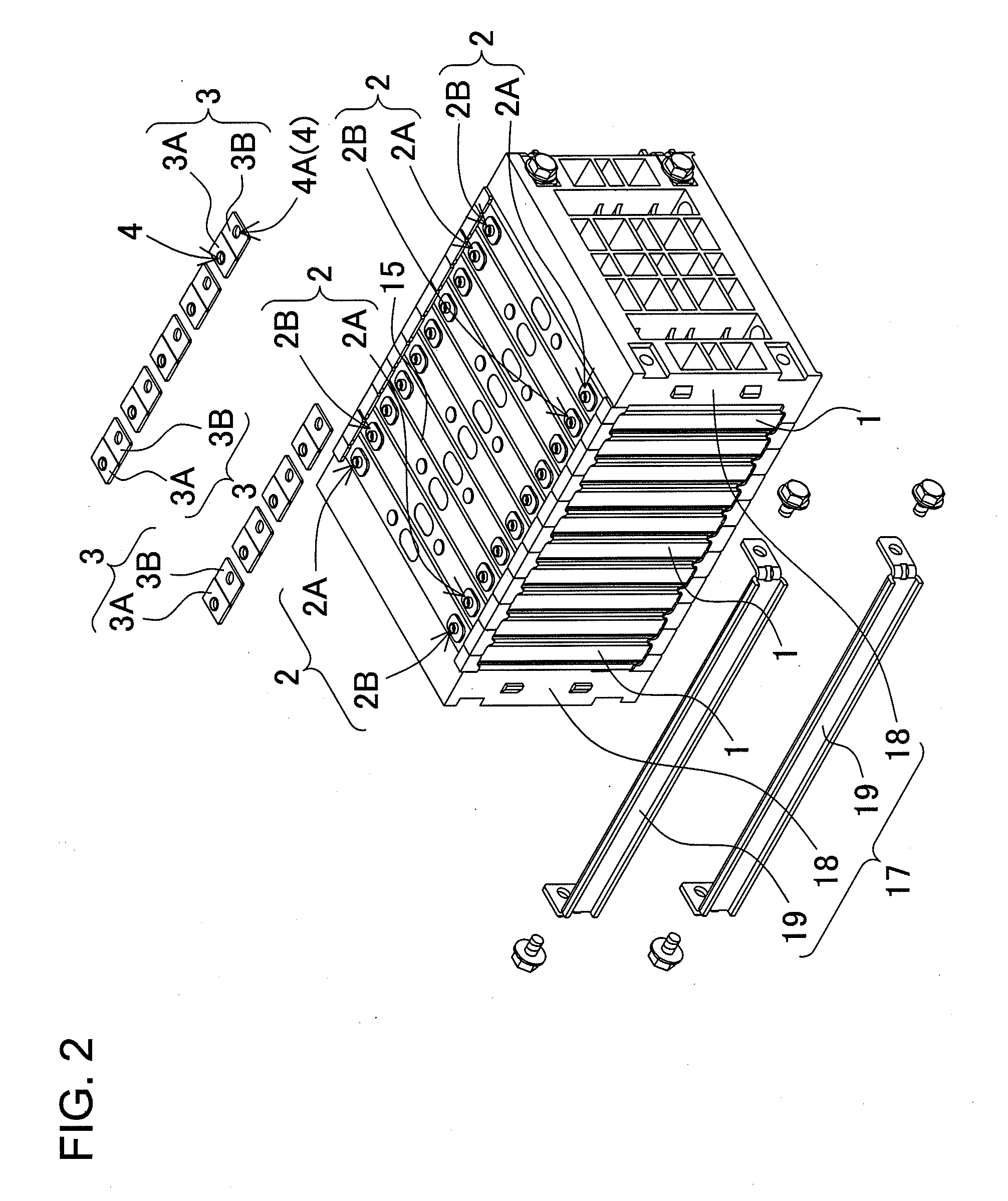

Battery array with reliable low-resistance connections

InactiveUS20110064993A1Reliable joiningIncrease charging and discharging capacityPrimary cell to battery groupingCell component detailsEngineeringElectrical and Electronics engineering

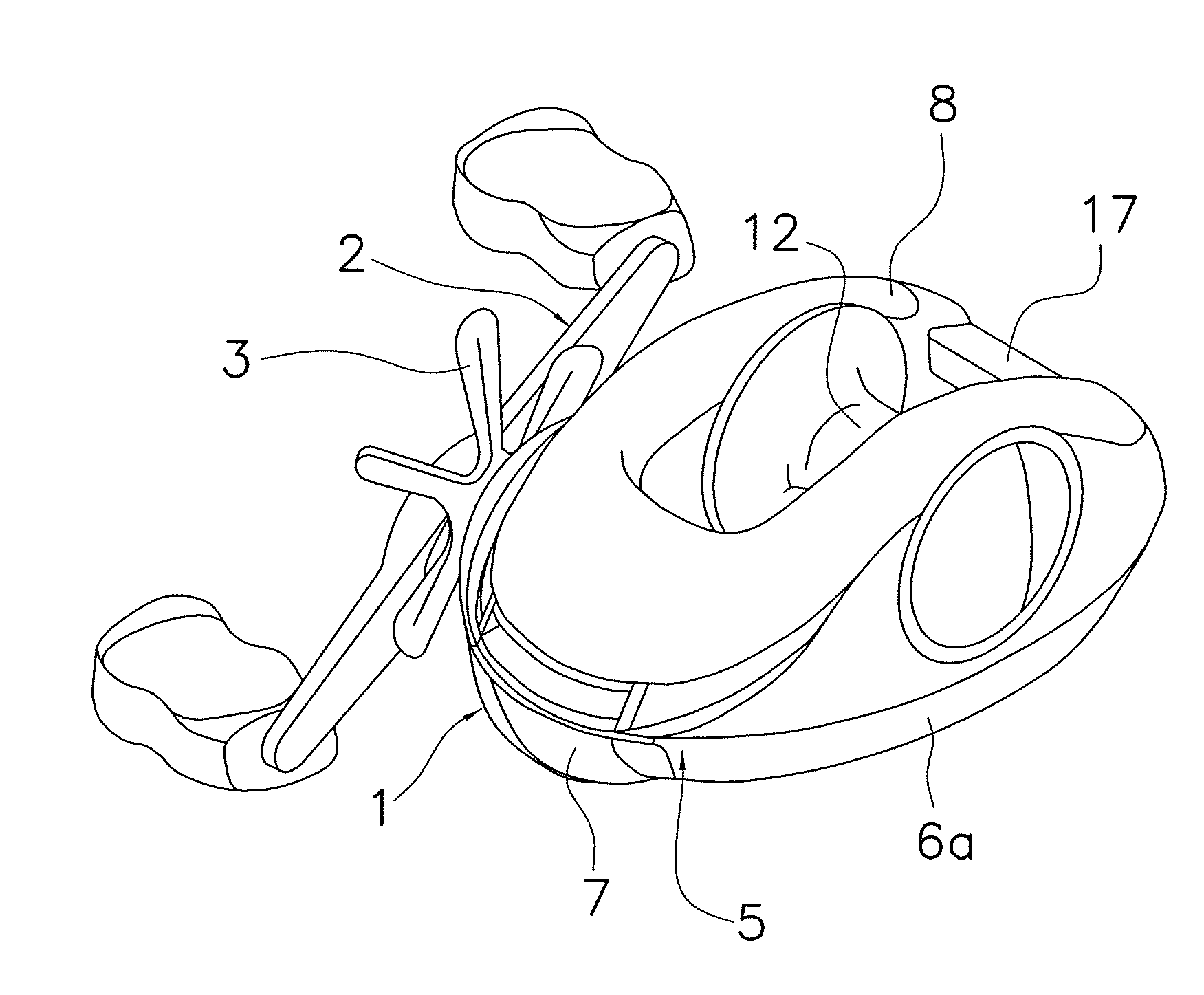

The battery array is provided with a plurality of battery cells 1 having positive and negative electrode terminals 2 that are different metals, and the positive and negative electrode terminals 2 of the battery cells 1 are connected by metal plates 3. Each metal plate 3 of the battery array is clad material having a first metal plate 3A that connects to one electrode terminal 2 of a battery cell 1 and a second metal plate 3B that connects to another electrode terminal 2. The clad material first metal plate 3A and second metal plate 3B are joined at a junction between positive and negative electrode terminal 2 connecting regions.

Owner:SANYO ELECTRIC CO LTD

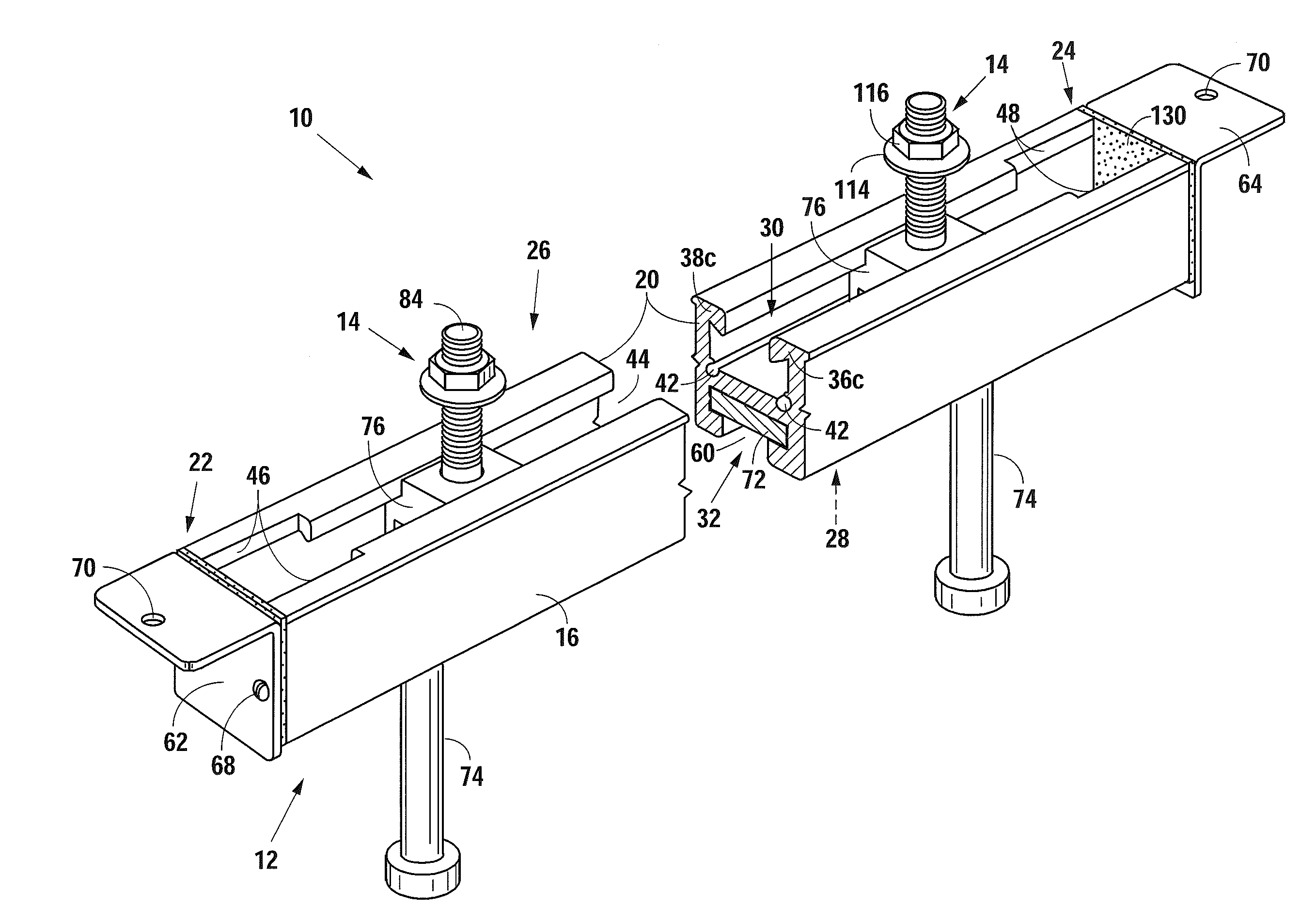

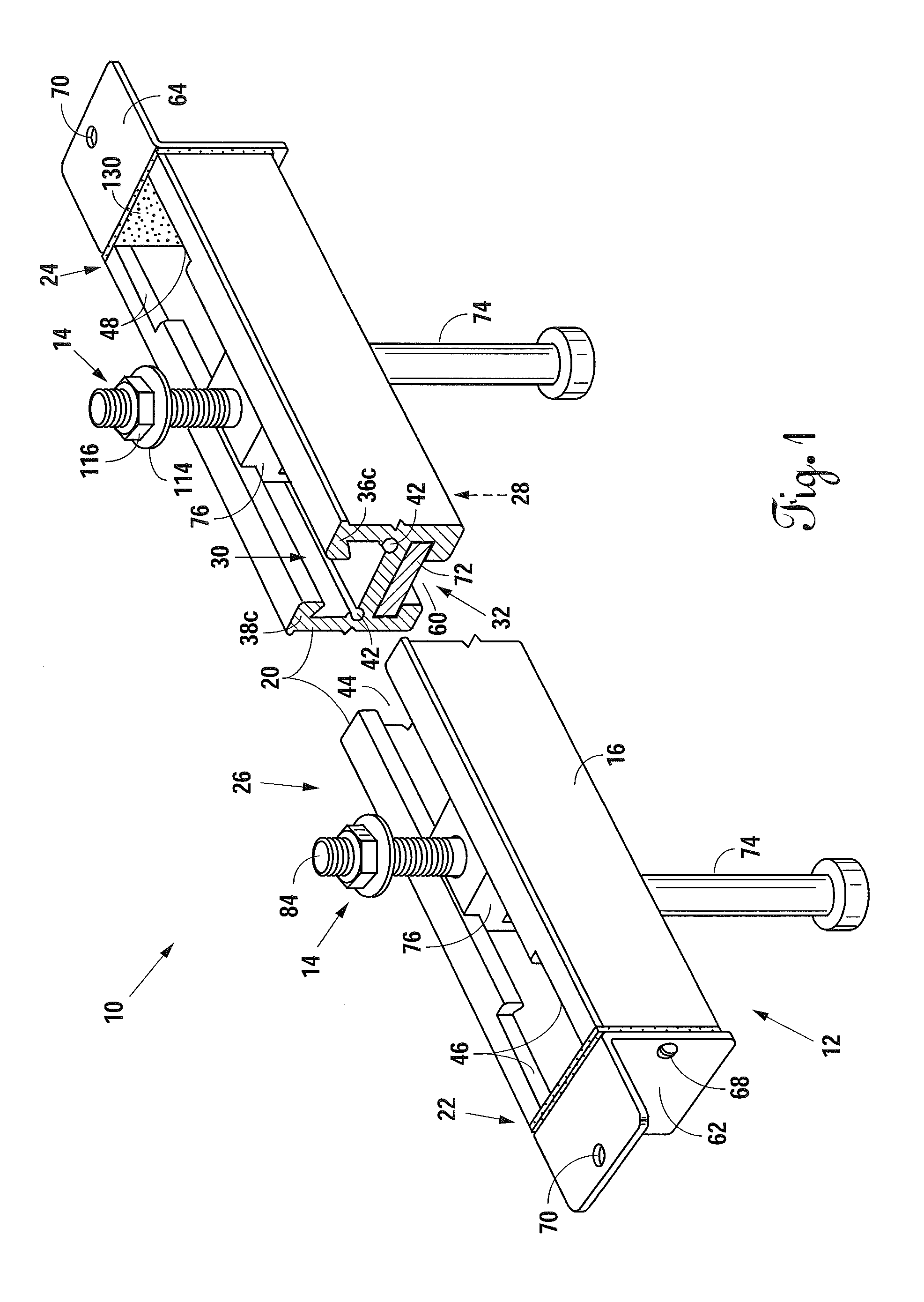

Cast-in anchor system

InactiveUS20140250825A1Connection securityManufacturing techniquePinsNutsMechanical engineeringIndustry standard

A cast-in anchor system for anchoring objects to concrete structures. The preferred system uses an extruded cast-in anchor and an extruded bolt retainer. The cast-in anchor is embedded within concrete with a face left exposed. The bolt retainer has a bolt inserted through it and is placed within an anchor channel on the exposed face of the cast-in anchor. The bolt retainer allows for use of an industry-standard bolt and prevents the bolt from rotating once the bolt-head is seated against it. The cast-in anchor and the bolt are positioned along the length of the anchor channel, with a threaded portion of the bolt extending out of the anchor channel. A workpiece is placed over the threaded portion of the bolt and a nut is tightened. Tightening the nut causes locking surfaces on the bolt retainer to engage with corresponding surfaces on the anchor channel which prevents the bolt retainer from exiting the anchor channel.

Owner:RICHARDSON DOUGLAS S

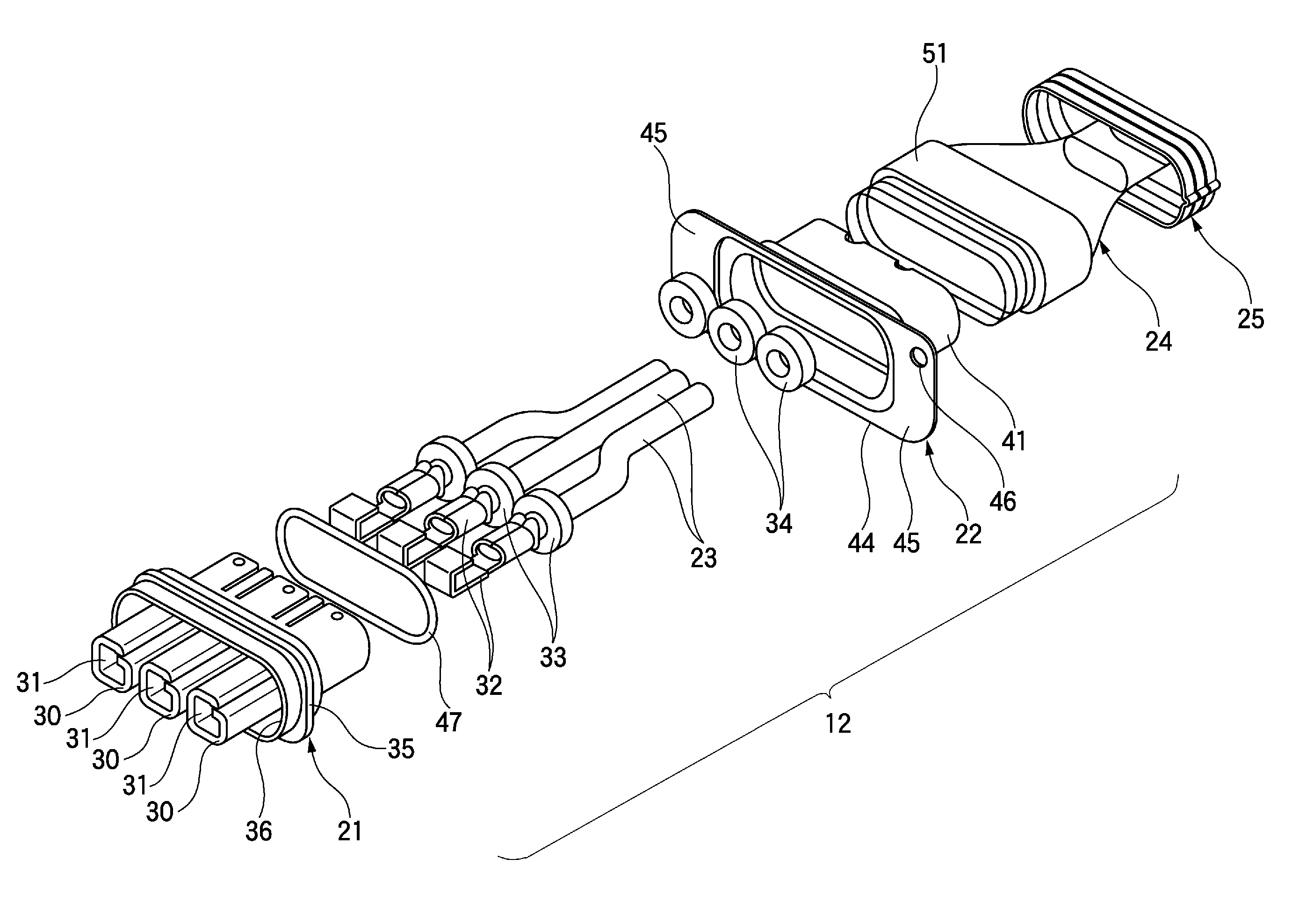

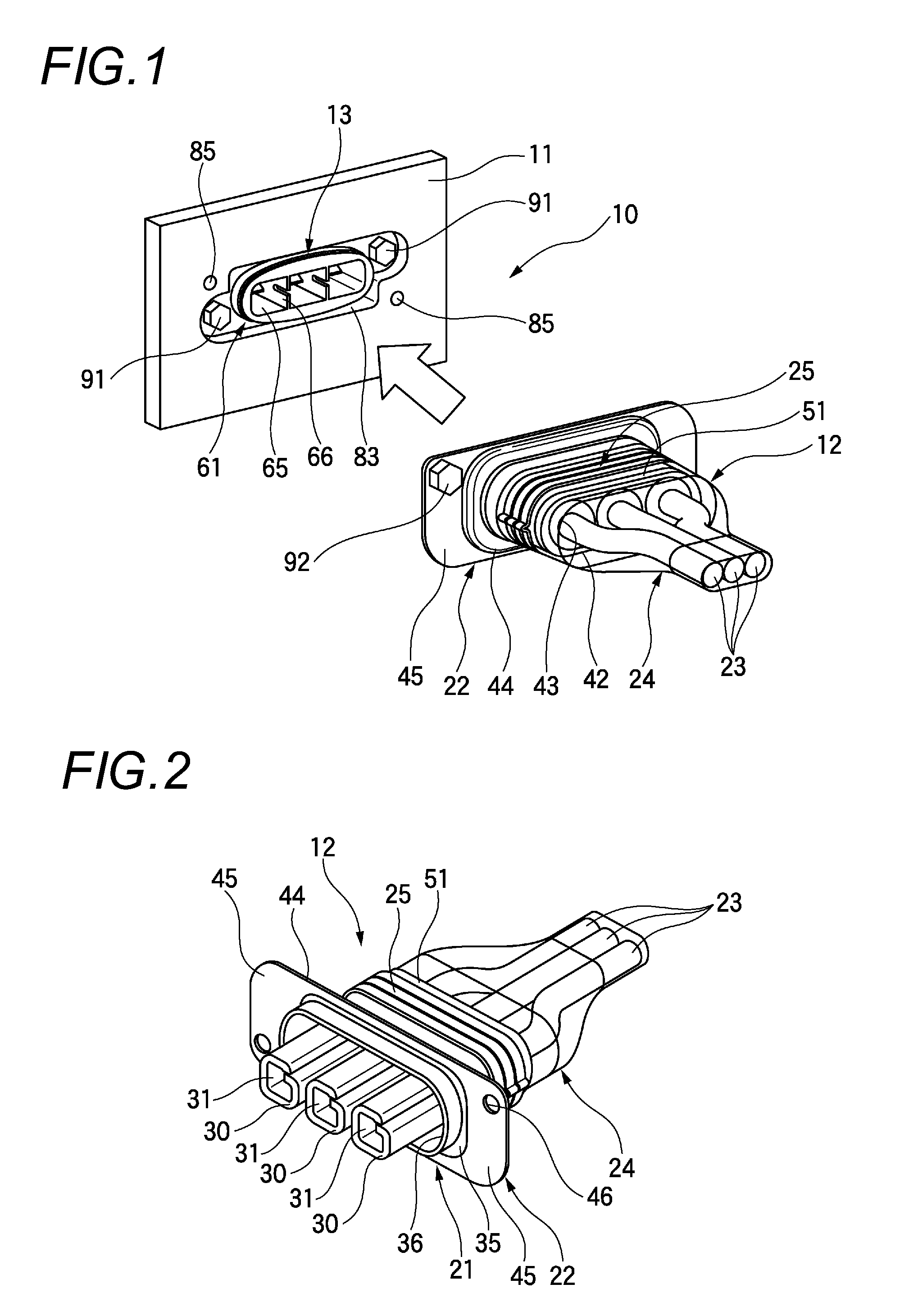

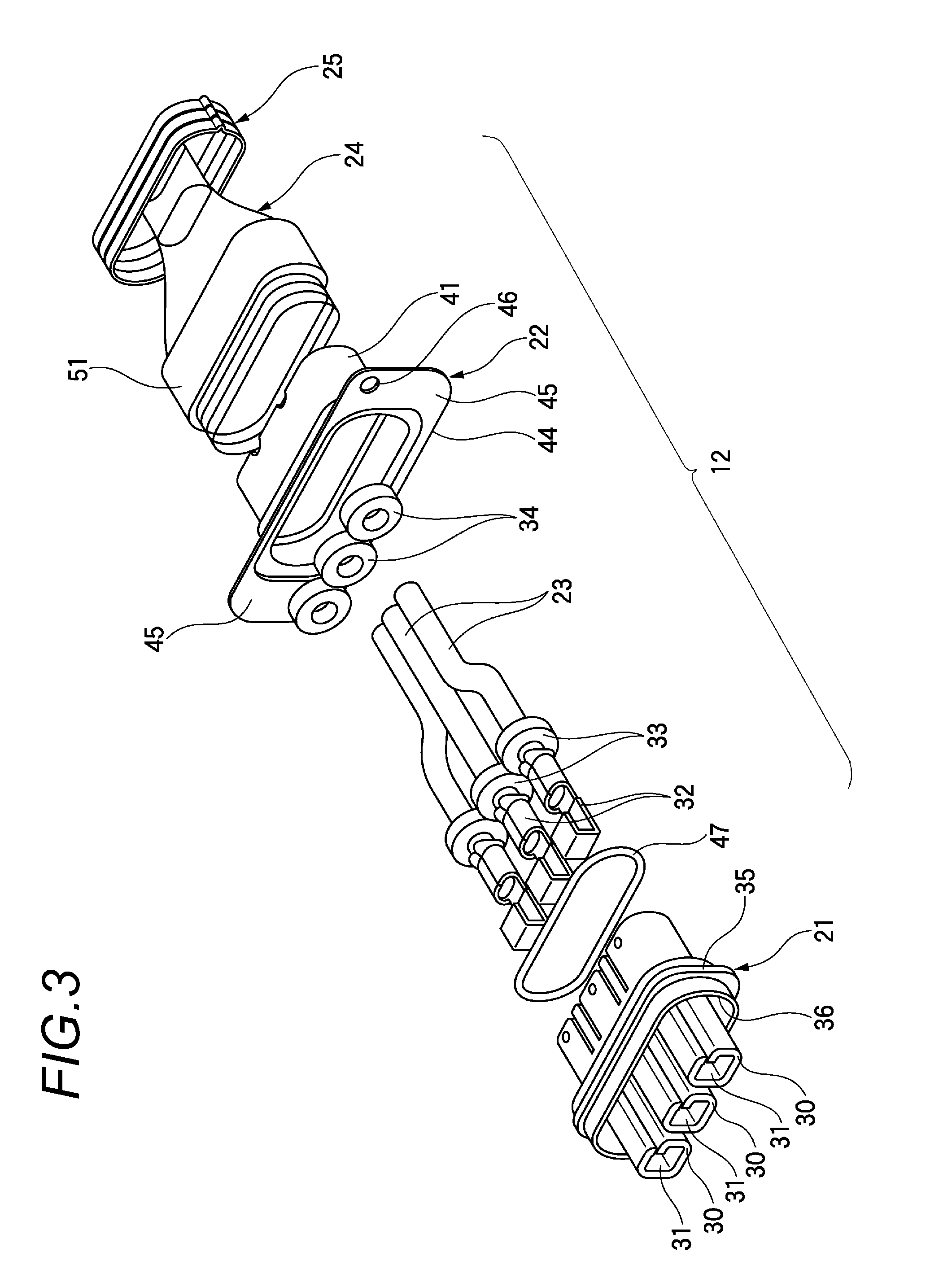

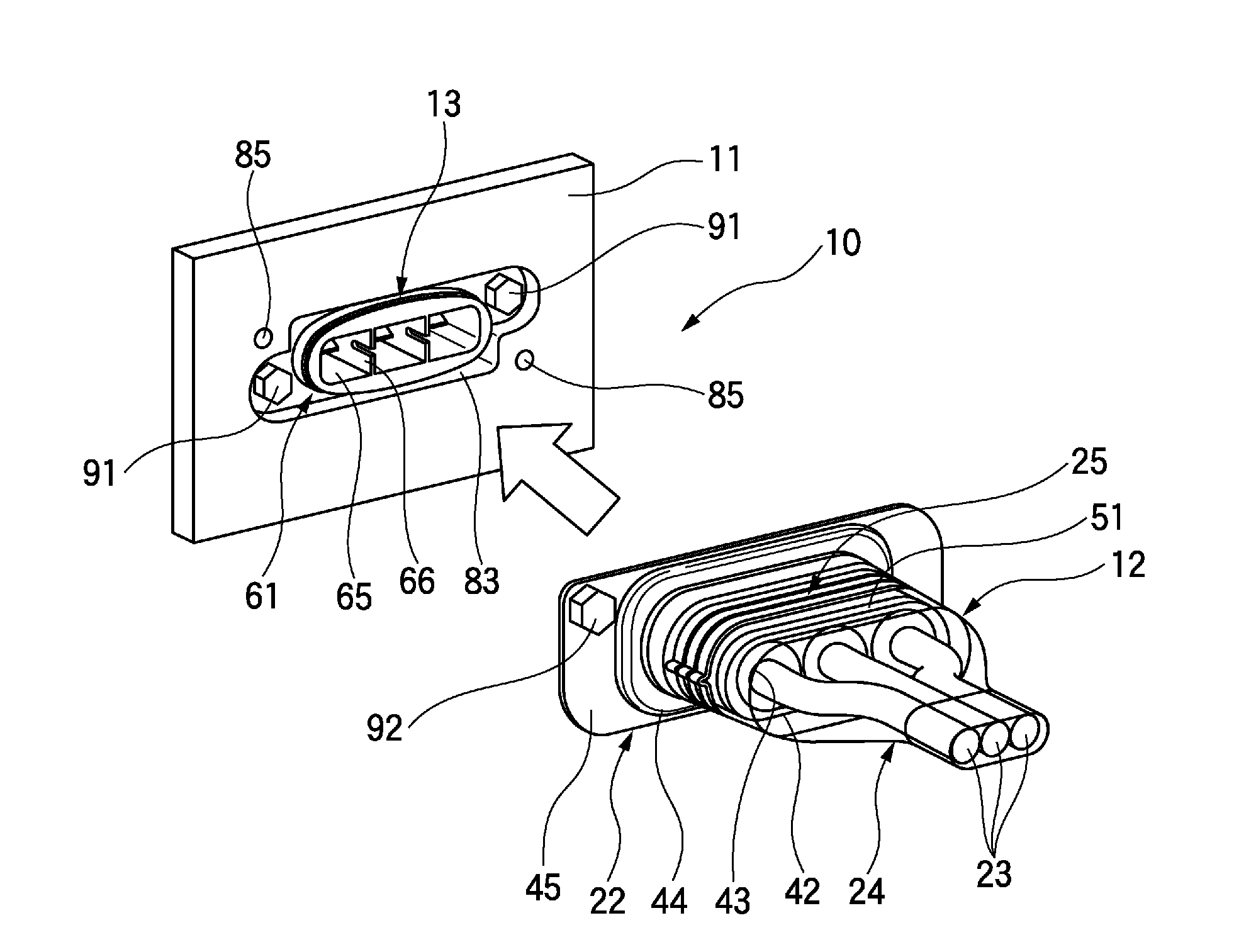

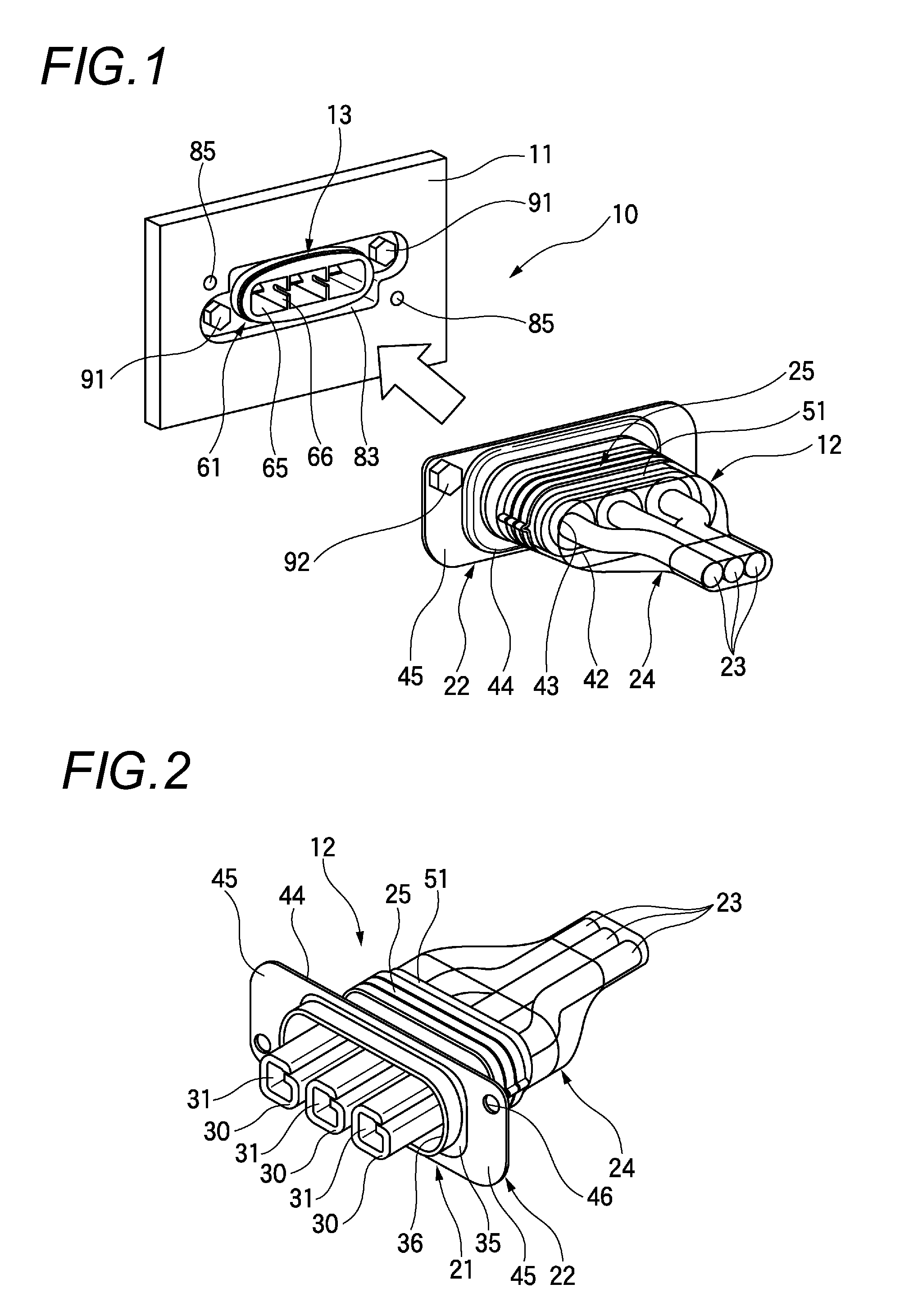

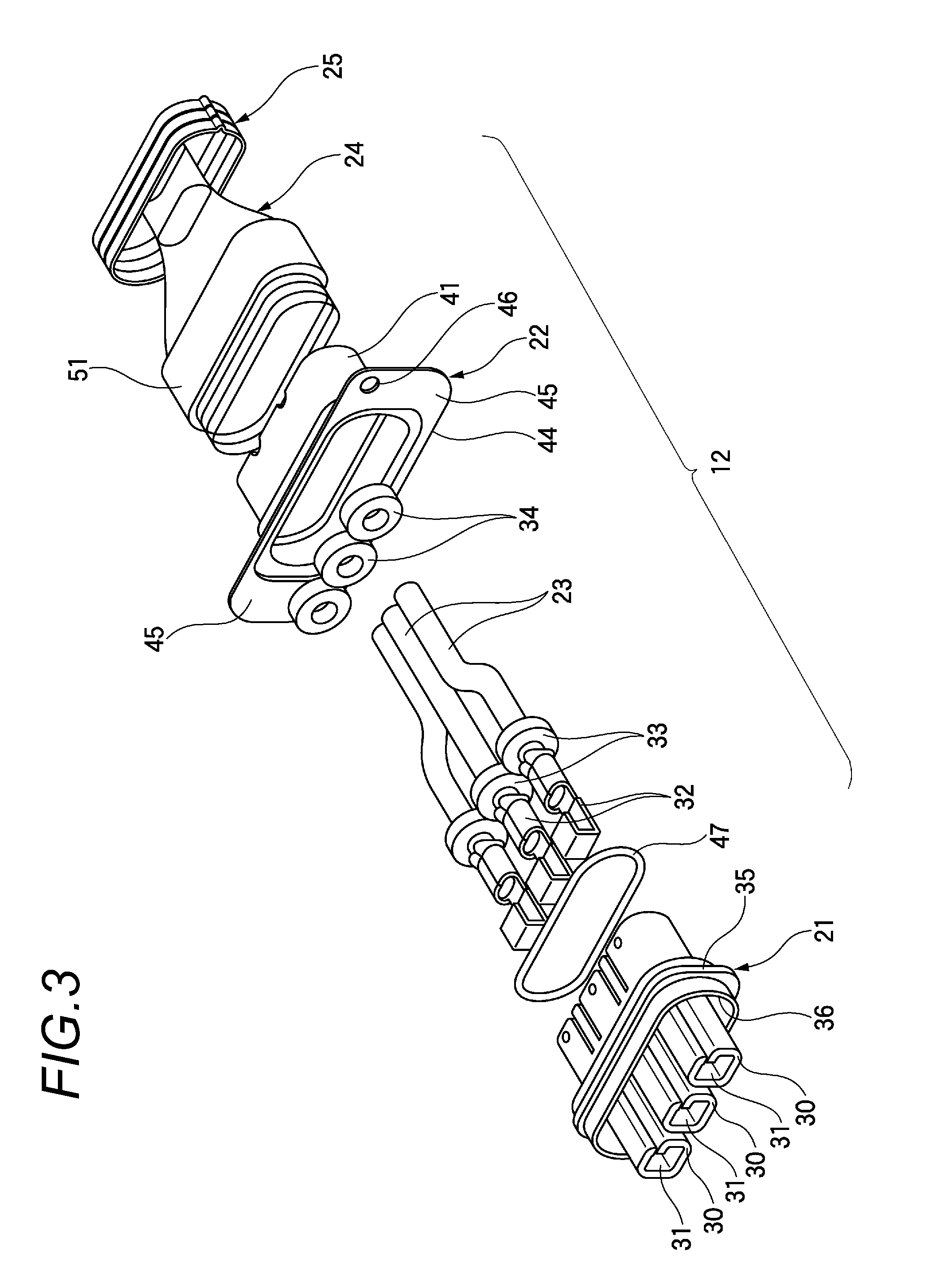

Shielded connector

ActiveUS9318849B2Improve shielding effectPrevent galvanic corrosionCouplings bases/casesCoupling parts mountingElectrical conductorInsulation layer

The male shielded connector of the invention includes terminals which are connected to end portions of electric wires, a housing which contains the terminals, a shield shell which covers the housing, a braided conductor which is externally provided to the wire and is covered on the shield shell, and a shield ring which is swaged to the outer circumference of the braided conductor to fix the braided conductor in a state that the braided conductor is electrically connected to the shield shell, the shield ring being made of a metal material. An insulation layer is provided between the braided conductor and the shield ring.

Owner:YAZAKI CORP

Reflection-transmission type liquid crystal display device and method for manufacturing the same

InactiveUS6980268B2Prevent galvanic corrosionSimple manufacturing processTransistorSolid-state devicesLiquid-crystal displayEngineering

Disclosed are a liquid crystal display (LCD) device and a method for manufacturing the LCD device. The LCD device has a substrate including a display region and a pad region located in a periphery of the display region, the display region having a transparent electrode, the pad region having a pad electrode. The transparent electrode and the pad electrode are formed from the same layer. A reflective electrode having a transmission window exposing a portion of the transparent electrode is formed on the transparent electrode. The manufacturing process can be simplified because the transparent electrode is directly connected to the reflective electrode. Since the pad electrode is formed of the same layer as the transparent electrode, no metal corrosion occurs to thereby increase the pad reliability during COG bonding.

Owner:SAMSUNG DISPLAY CO LTD

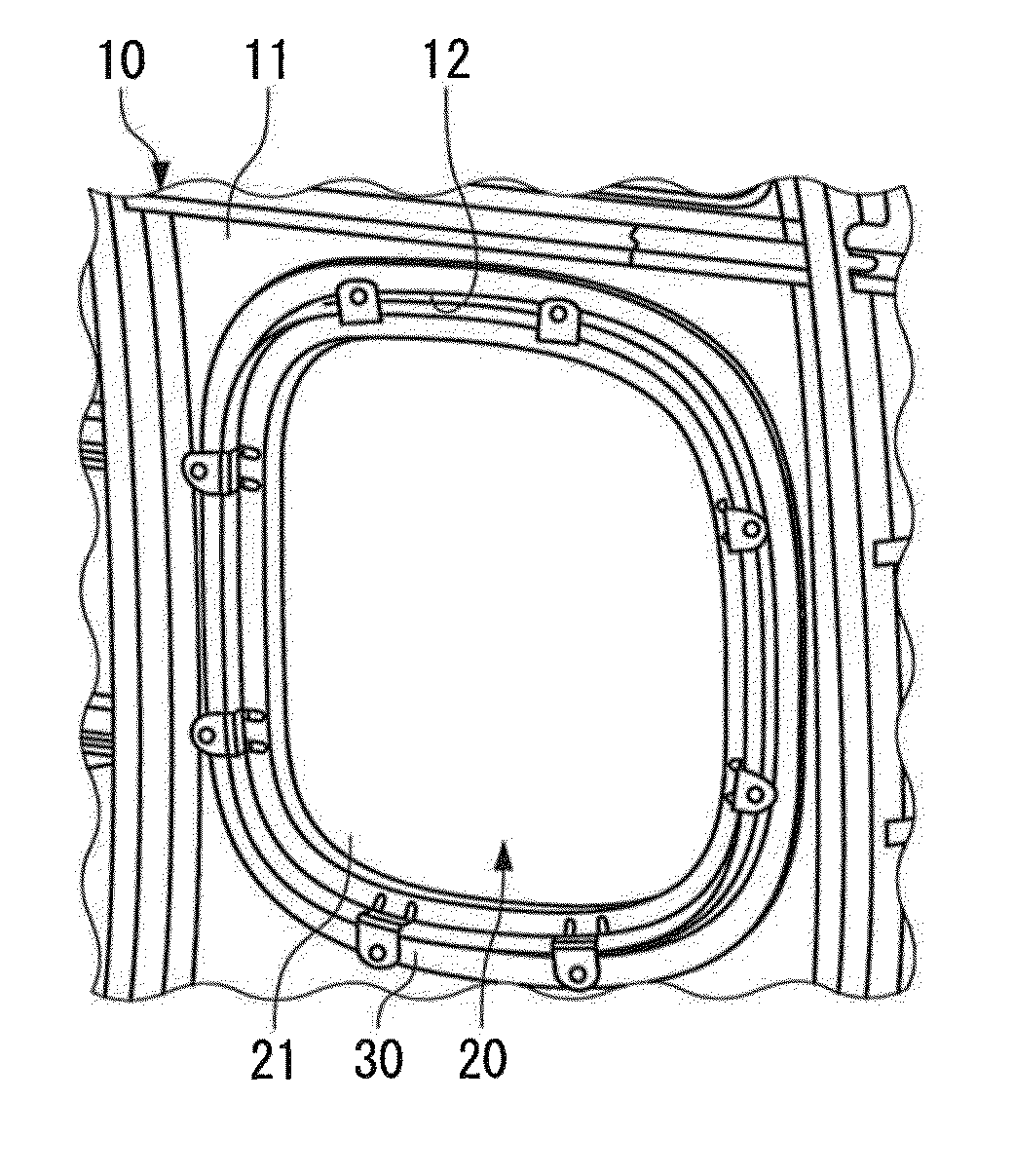

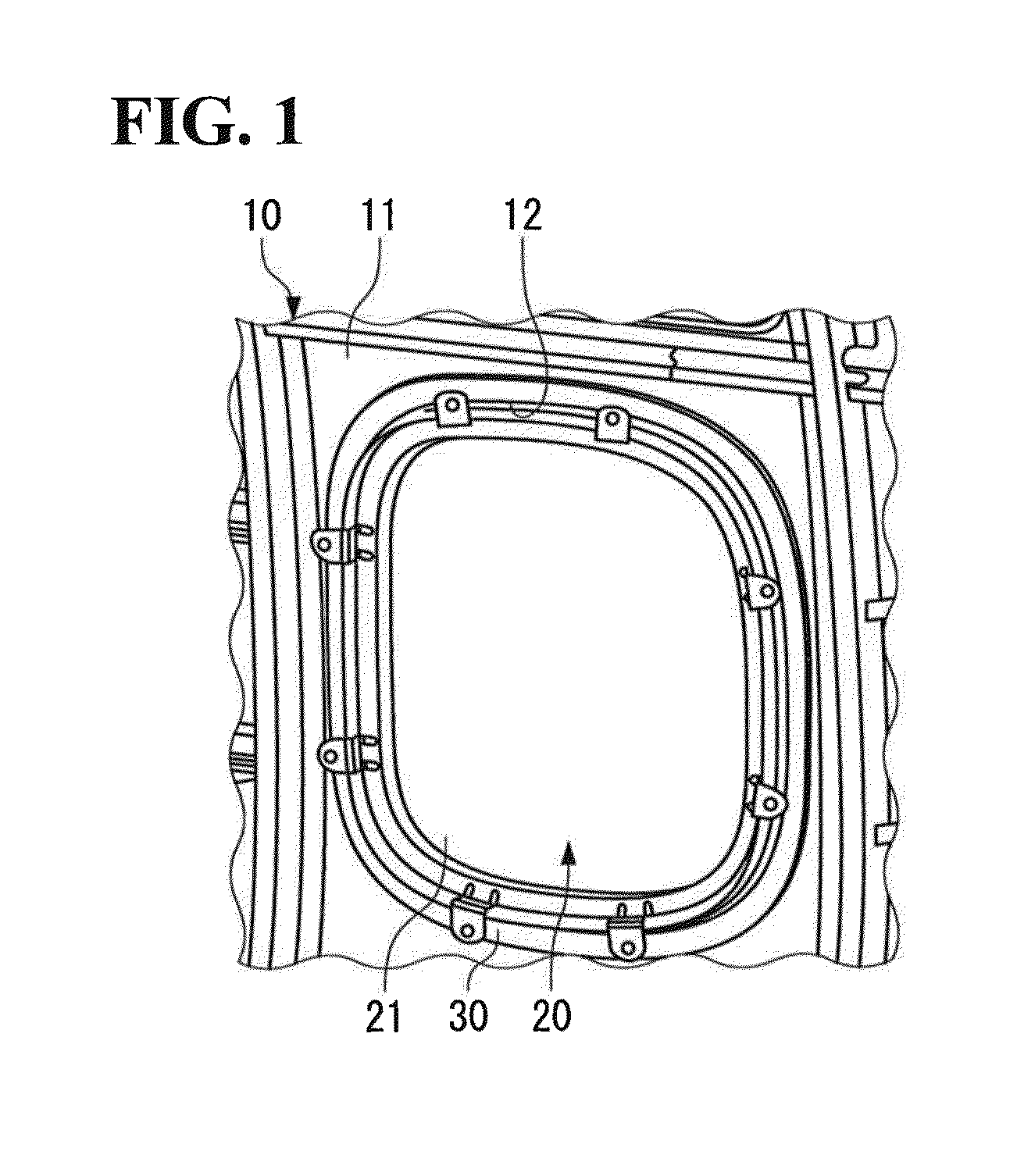

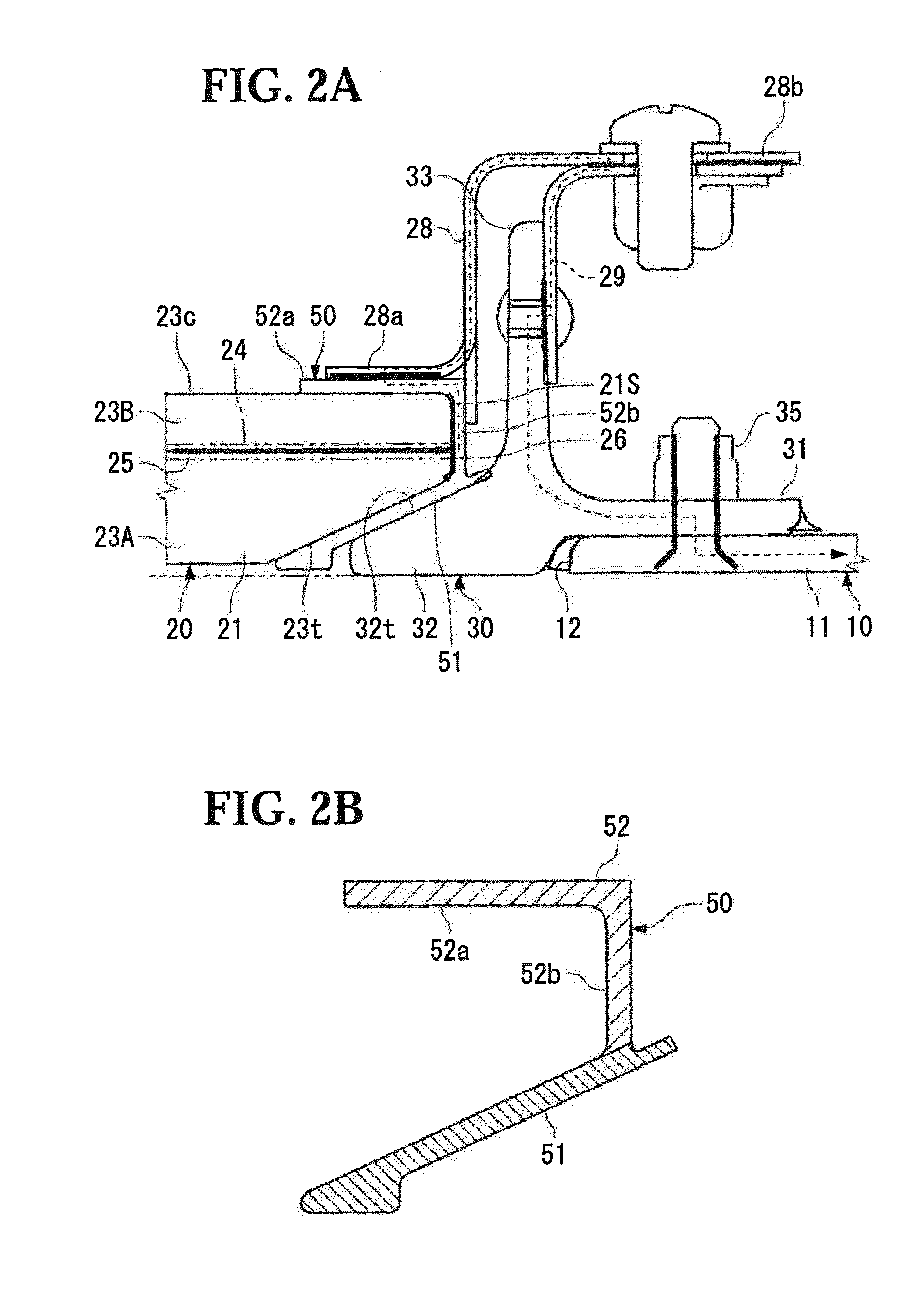

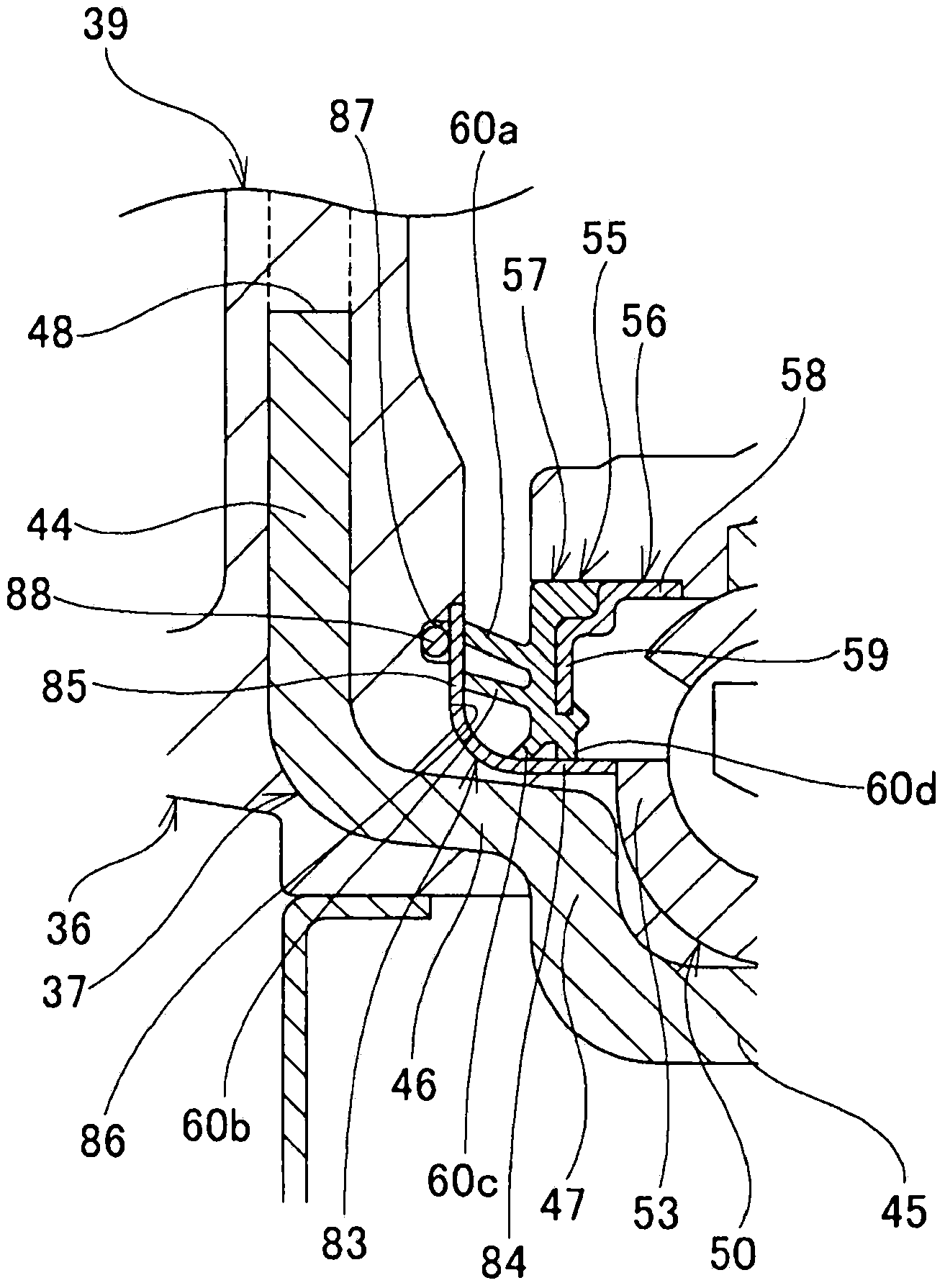

Window of aircraft, closing member for opening and gasket seal

ActiveUS20130062468A1Prevent invasion and leakagePrevent galvanic corrosionEngine sealsMagnetic/electric field screeningConductive materialsEngineering

An electromagnetic shield mesh 25 is provided on a window part 21, and a gasket seal 50 is provided between the electromagnetic shield mesh 25 and a window frame 30 made of a conductive material. The first seal part 51 of the gasket seal 50 has a low volume resistivity, and makes it possible to prevent electromagnetic noise from entering the inside of an airframe between the window part 21 and a window frame 30. Moreover, the second seal part 52 of the gasket seal 50, which is made in contact with the electromagnetic shield mesh 25 of the window part 21 on the outer perimeter side of window panels 23A and 23B, has a volume resistivity of, for example, 300 Ωcm or more, so that it becomes possible to prevent corrosion from occurring at contact portions with a clamp 28, a clip 29 or the like.

Owner:MITSUBISHI AIRCRAFT

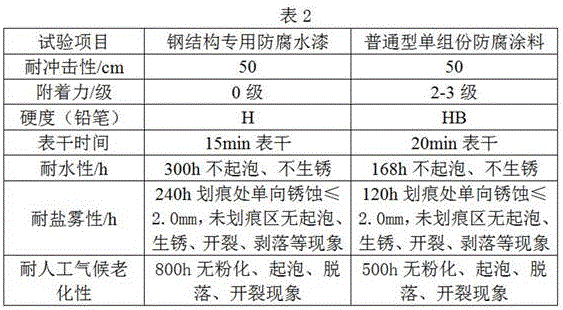

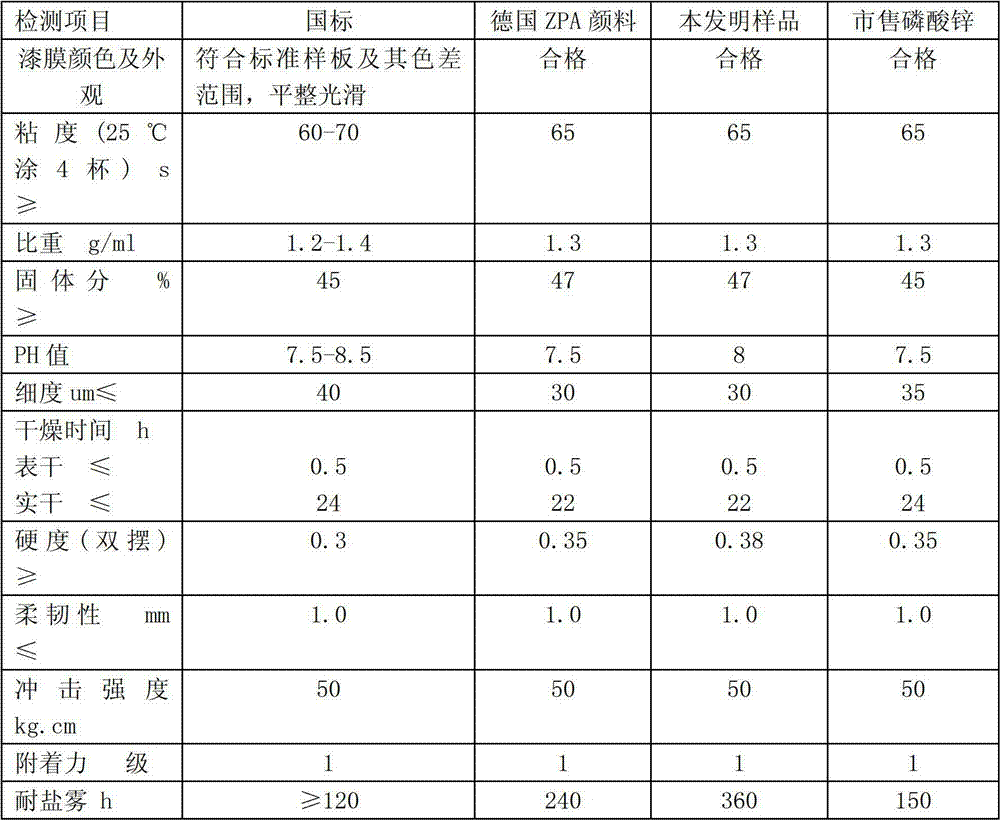

Special anticorrosion water paint for steel structure and preparation method thereof

ActiveCN106221458AReduce air permeabilityImprove anti-corrosion performanceAnti-corrosive paintsEpoxyOrganic solvent

The invention relates to the technical field of paint compositions, particularly relates to the technical field of waterborne antirust paint, and particularly discloses special anticorrosion water paint for a steel structure. The special anticorrosion water paint comprises a base material, an assistant and a pigment filler, wherein the base material is prepared by blending 30-40% of a waterborne epoxy modified acrylic emulsion and 10-15% of a waterborne one-component self-crosslinking fluorinated siloxane-acrylate emulsion in percentage by weight; the assistant comprises a neutralizer, deionized water, a wetting dispersant, a defoaming agent, a coalescing agent, an antiflash rusting agent, a thickener and an anti-settling agent. The invention further discloses a preparation method of the anticorrosion water paint, and the anticorrosion water paint is prepared by adding and blending the components step by step. The anticorrosion water paint does not use an organic solvent, does not contain toxic heavy metals, is non-toxic, has no pungent odor, is harmless to a human body, does not pollute the environment, and is also excellent in anticorrosive property, water fastness and water tolerance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Application of insulating coating

ActiveUS20080308678A1Prevent galvanic corrosionImprove adhesionWingsFuselage bulkheadsFiberCarbon fibers

Systems and methods for discontinuously applying an insulating primer to a carbon fiber reinforced plastic (CFRP) component are disclosed. In one embodiment, a method for mitigating electrical surface discharges from a CFRP component includes first applying an insulating primer to a metallic component. Next, an insulating primer is applied discontinuously to the CFRP component adjacent the metallic component. The discontinuous application of the insulating primer forms a primed portions and unprimed portions. The unprimed portions are configured to enable electrostatic dissipation.

Owner:THE BOEING CO

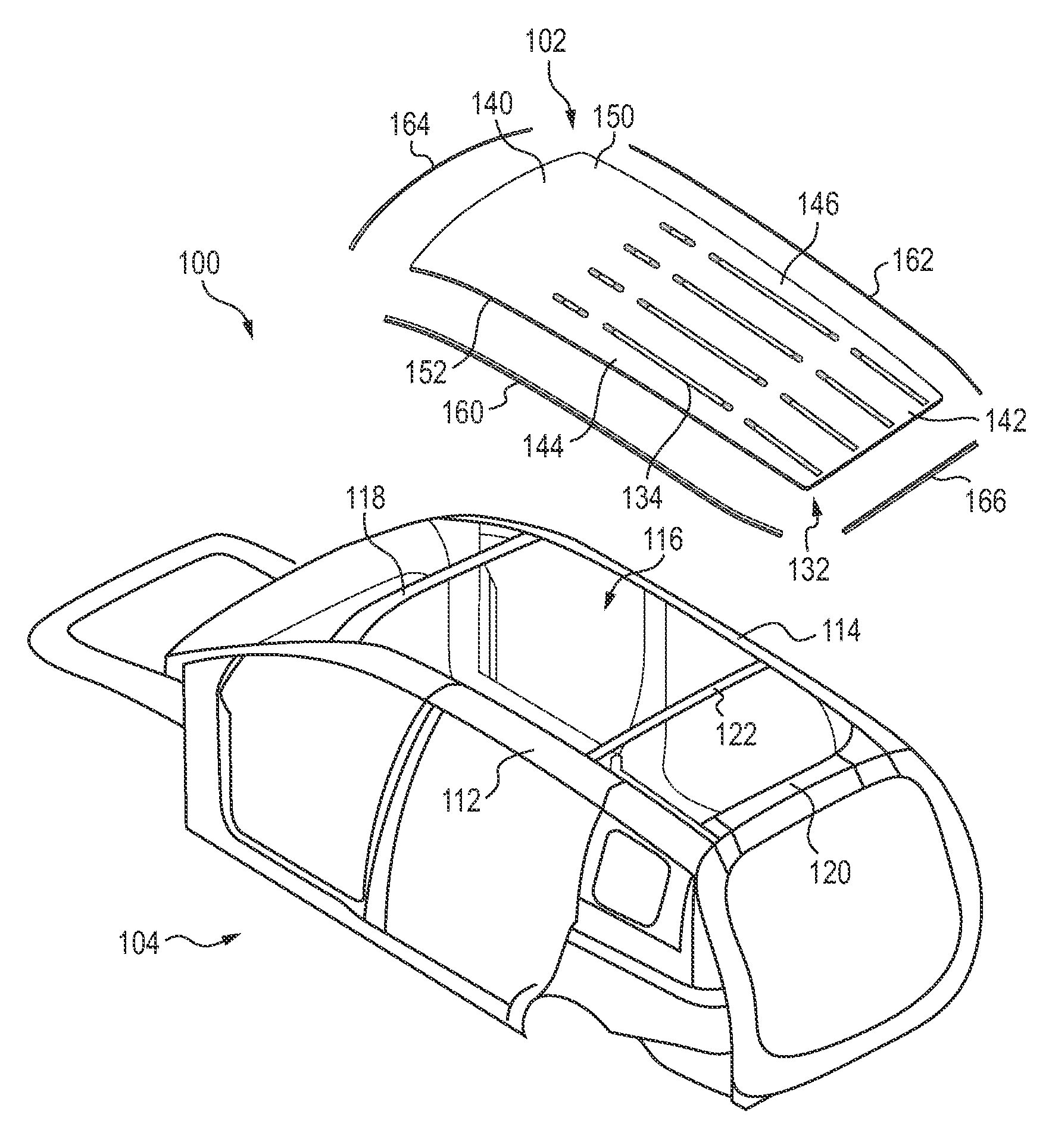

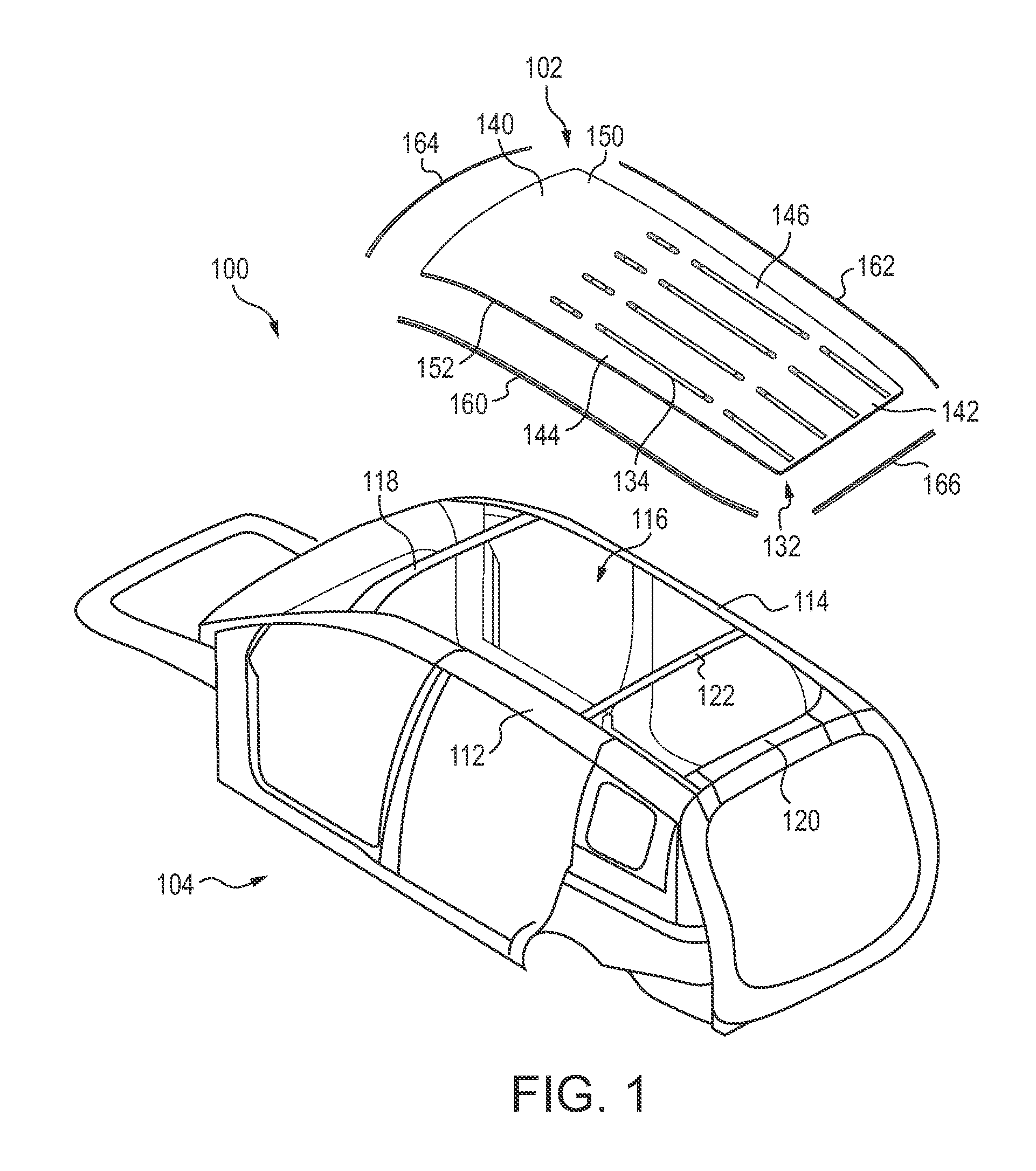

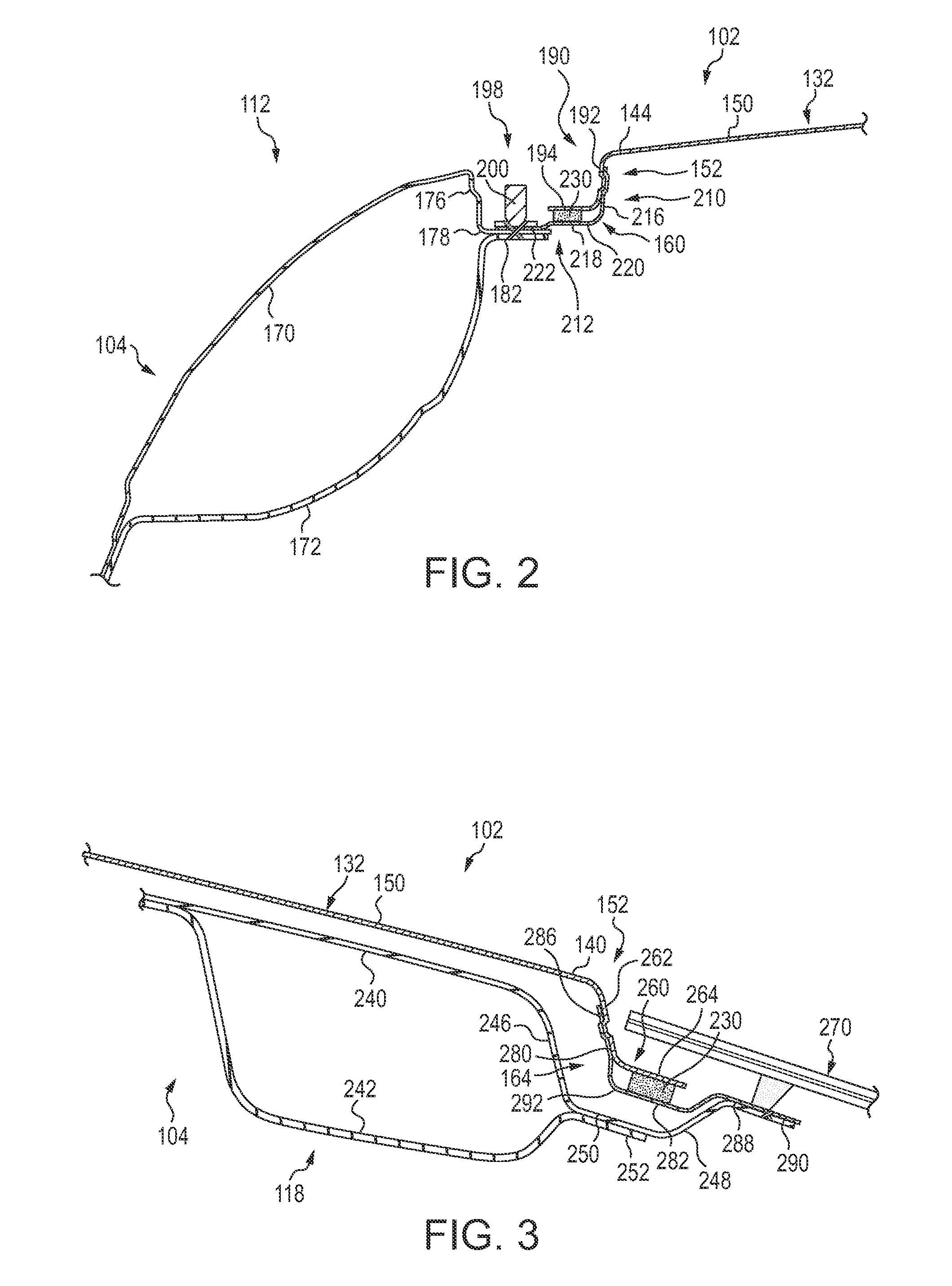

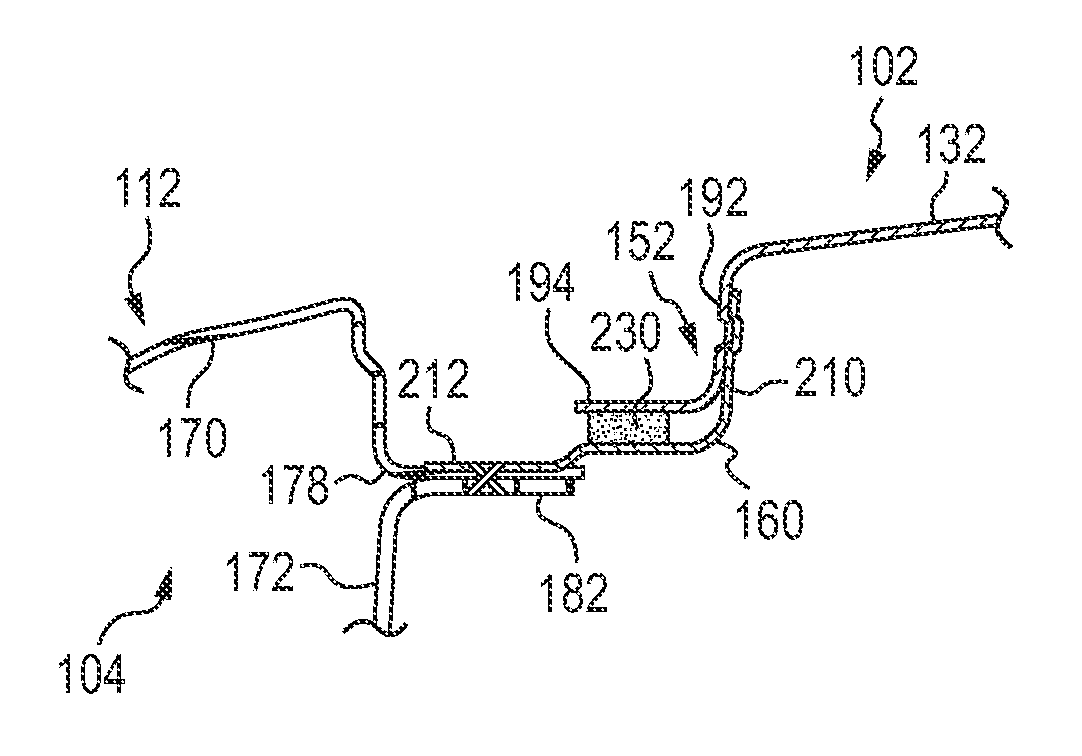

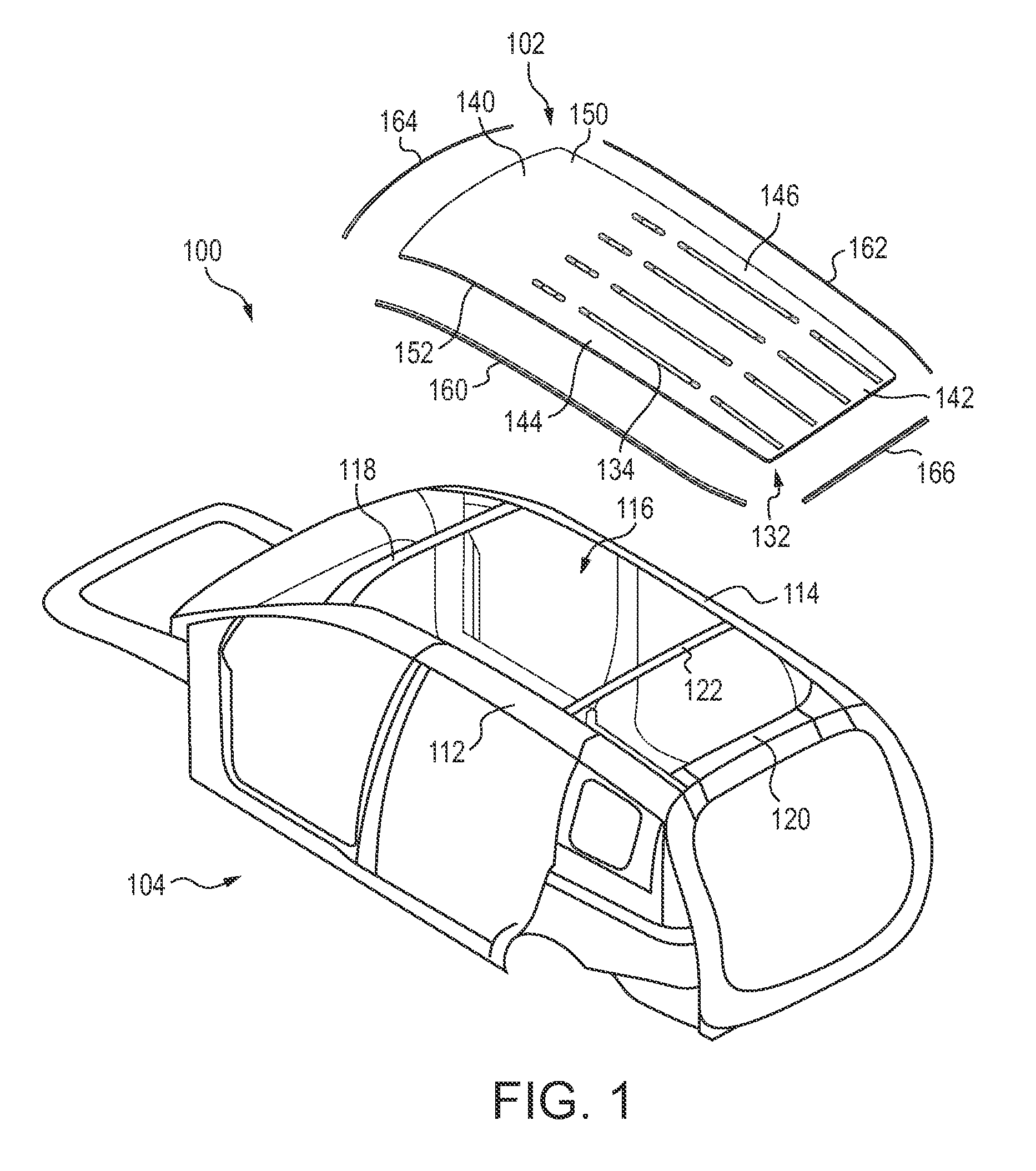

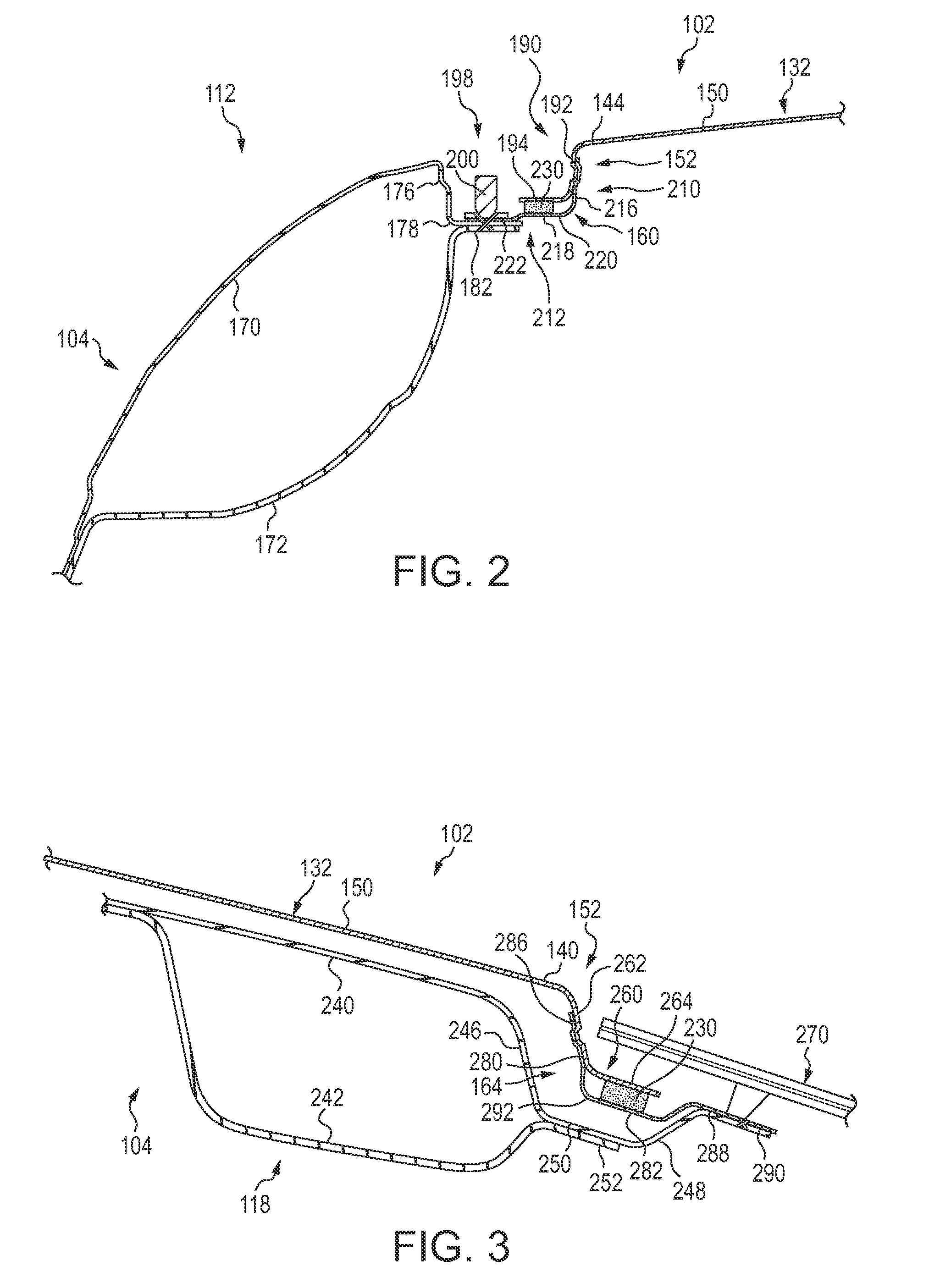

Vehicle roof structure

InactiveUS20150217812A1Prevent galvanic corrosionReduce thermal deformationSoldering apparatusSuperstructure subunitsAdhesiveAlloy

A vehicle assembly includes a roof structure having a roof panel formed of aluminum or an aluminum-based alloy and a vehicle body formed of steel or a steel alloy supporting the roof structure. The vehicle body includes a pair of laterally spaced side panels, a front roof rail and a rear roof rail. A bracket formed of steel or a steel alloy secures the roof structure to the vehicle body. The bracket has a first portion fastened to the roof panel and a second portion extending away from the roof structure and welded to the vehicle body. An adhesive located inward of the connection of the vehicle body and second portion of the bracket bonds the second portion to the vehicle body. The adhesive seals the connection of the roof panel and bracket first portion and reduces thermal distortion of the attached roof panel relative to the vehicle body.

Owner:HONDA MOTOR CO LTD

Shielded connector

ActiveUS20140370753A1Improve shielding effectPrevent galvanic corrosionElectrically conductive connectionsCoupling device detailsElectrical conductorInsulation layer

The male shielded connector of the invention includes terminals which are connected to end portions of electric wires, a housing which contains the terminals, a shield shell which covers the housing, a braided conductor which is externally provided to the wire and is covered on the shield shell, and a shield ring which is swaged to the outer circumference of the braided conductor to fix the braided conductor in a state that the braided conductor is electrically connected to the shield shell, the shield ring being made of a metal material. An insulation layer is provided between the braided conductor and the shield ring.

Owner:YAZAKI CORP

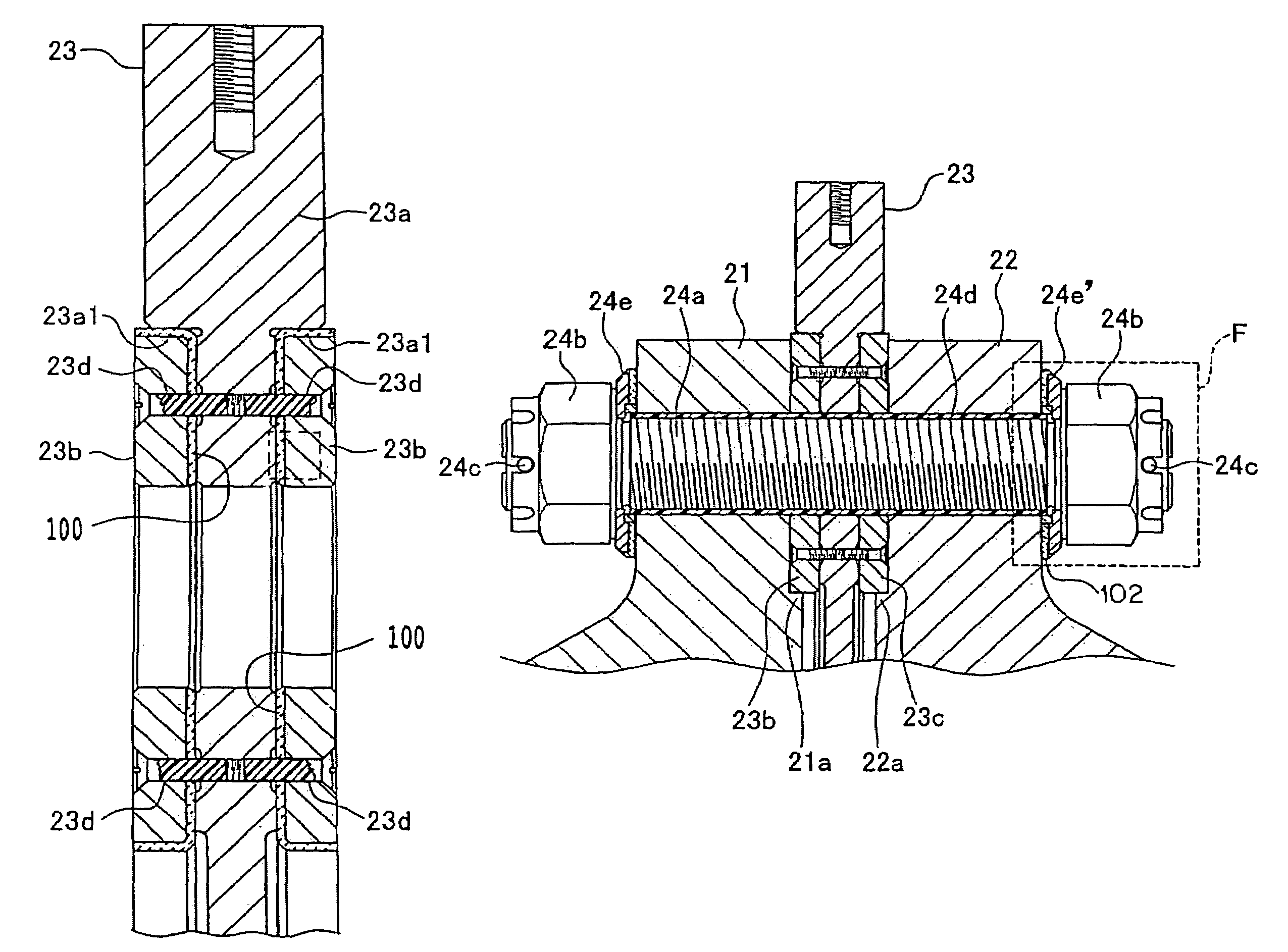

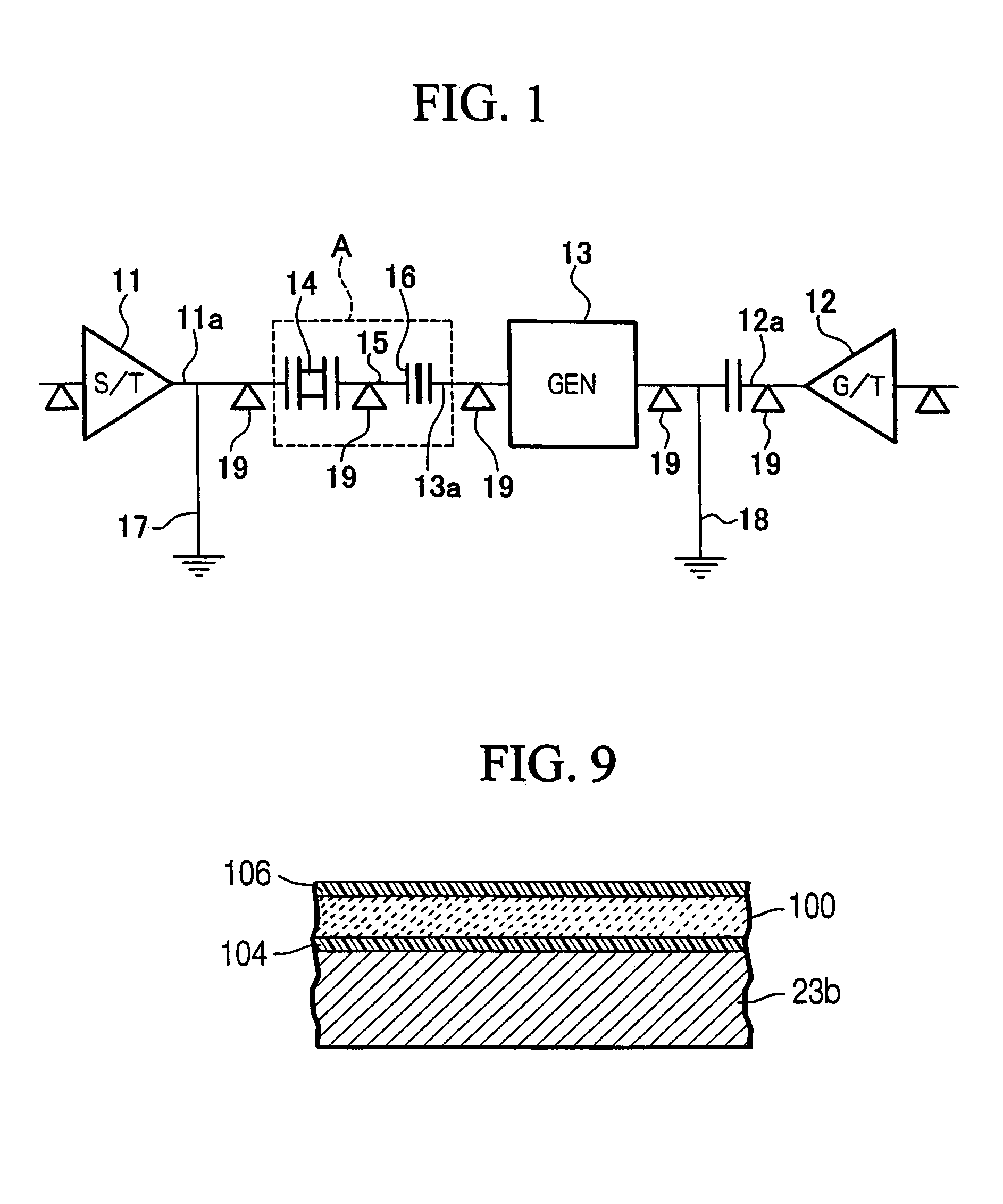

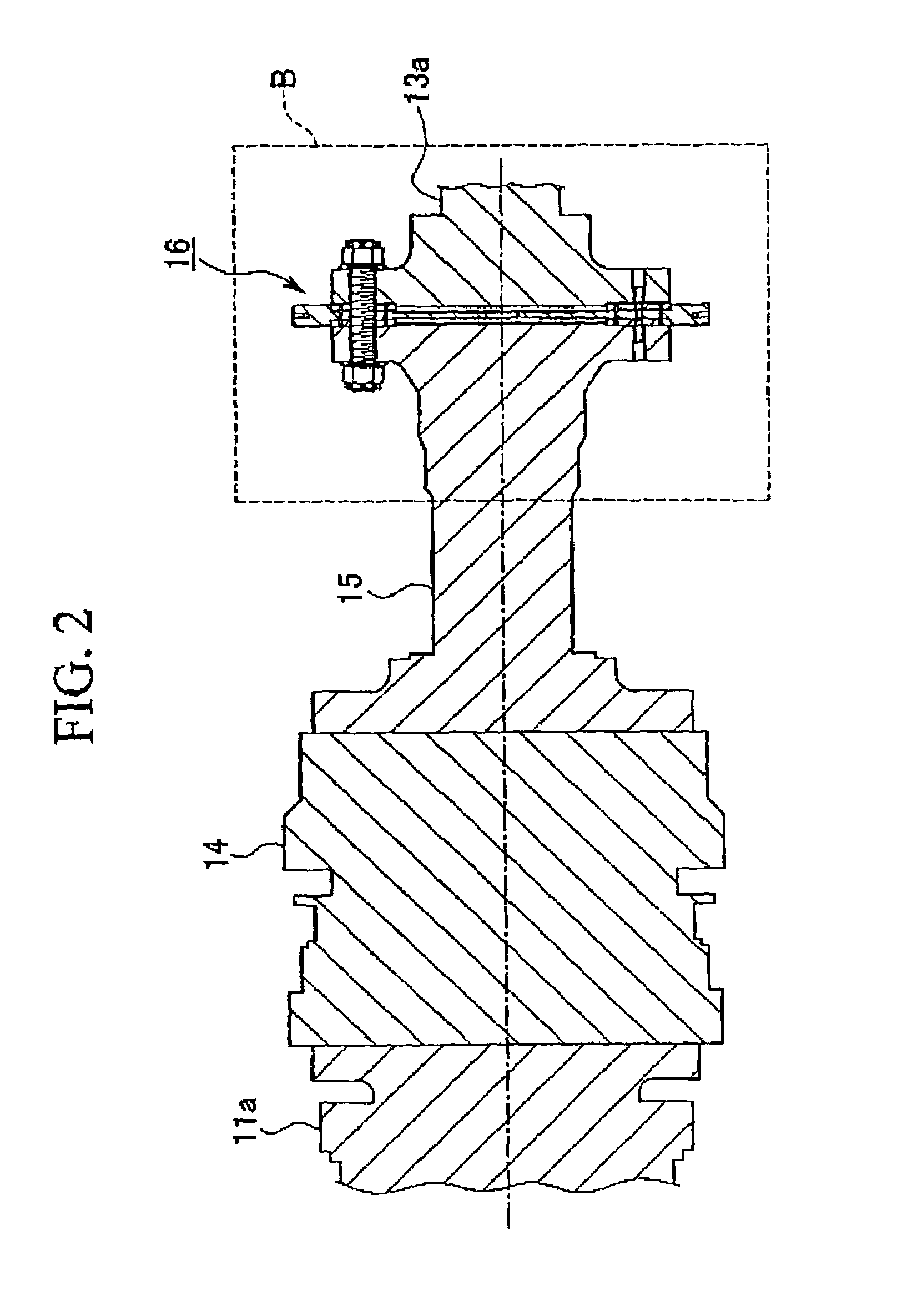

Rotor coupling having insulated structure

InactiveUS7530757B2Prevent galvanic corrosionPotential of each rotor can be reducedMolten spray coatingCombination enginesElectricityCoupling

A rotor coupling having insulated structure which can assuredly prevent galvanic corrosion of beating members, rotors and the like which is caused by shaft voltage, is provided in a shaft system that requires insulation. A generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine. The rotor coupling having insulated structure is employed in power generating equipment in which a generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine, a generator rotor and a rotating machinery rotor are connected, a first grounding electrode is provided to the steam turbine rotor, and a second grounding electrode is provided to the generator rotor, wherein both the rotors between the generator and the steam turbine are connected in an electrically insulated state.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

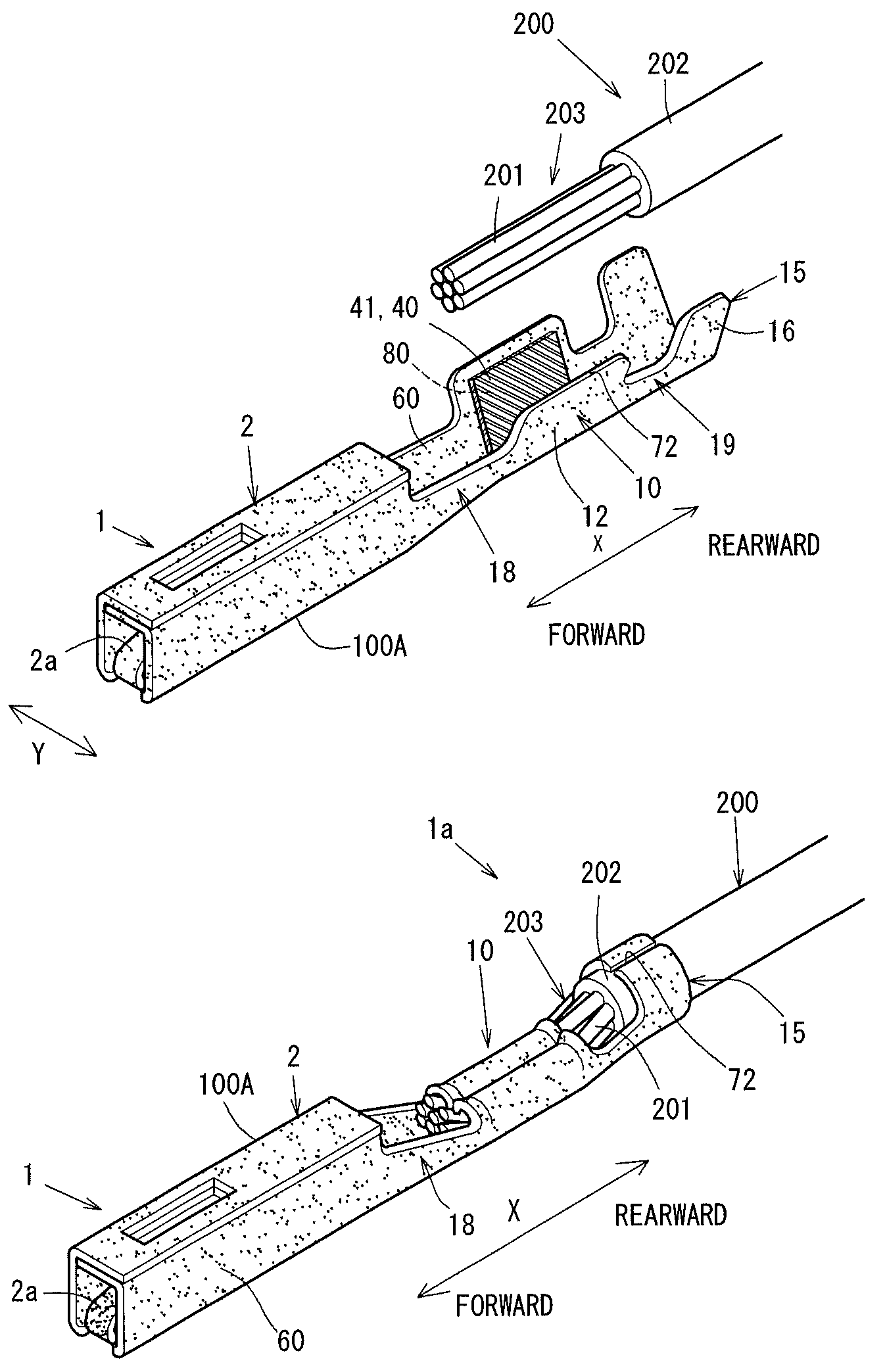

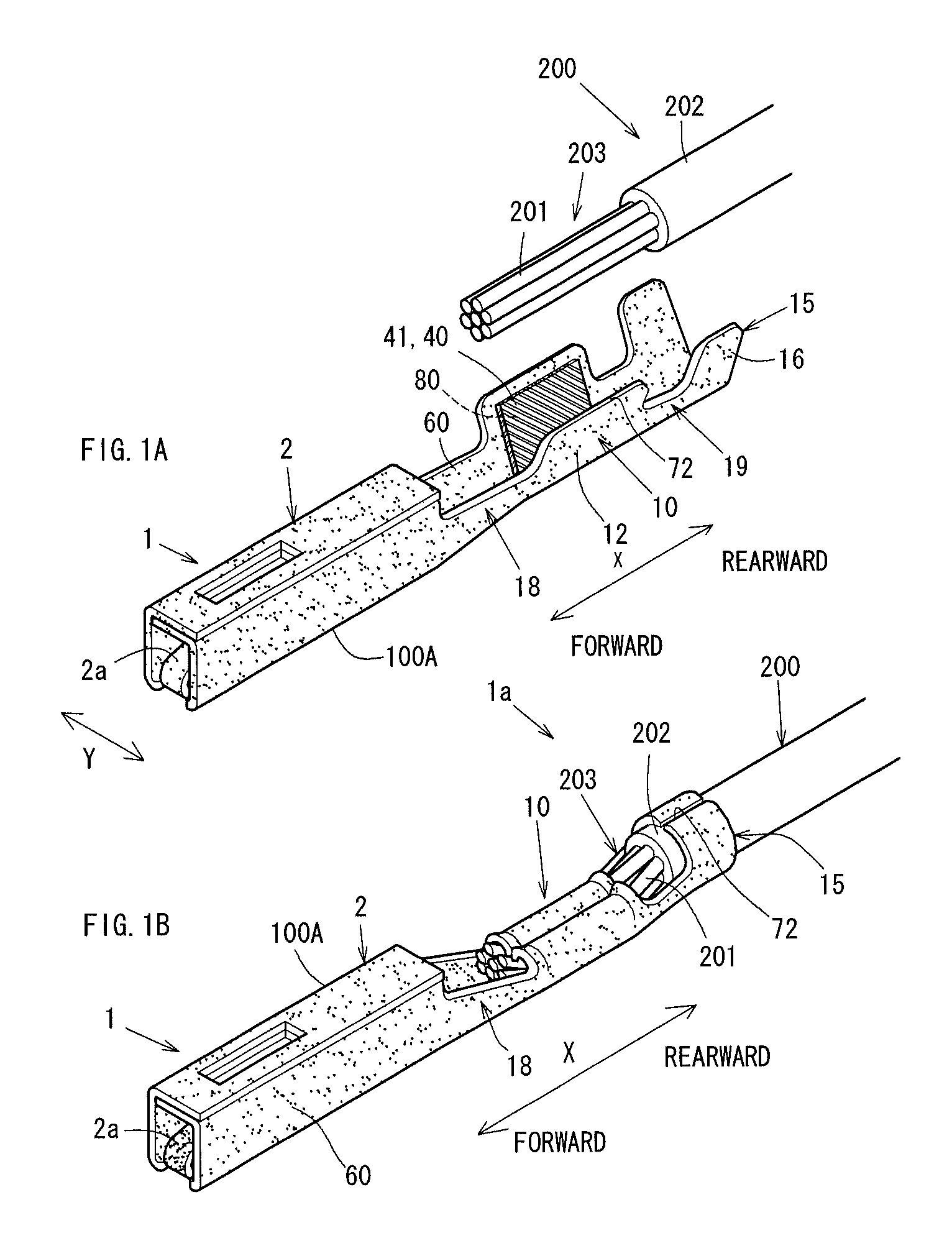

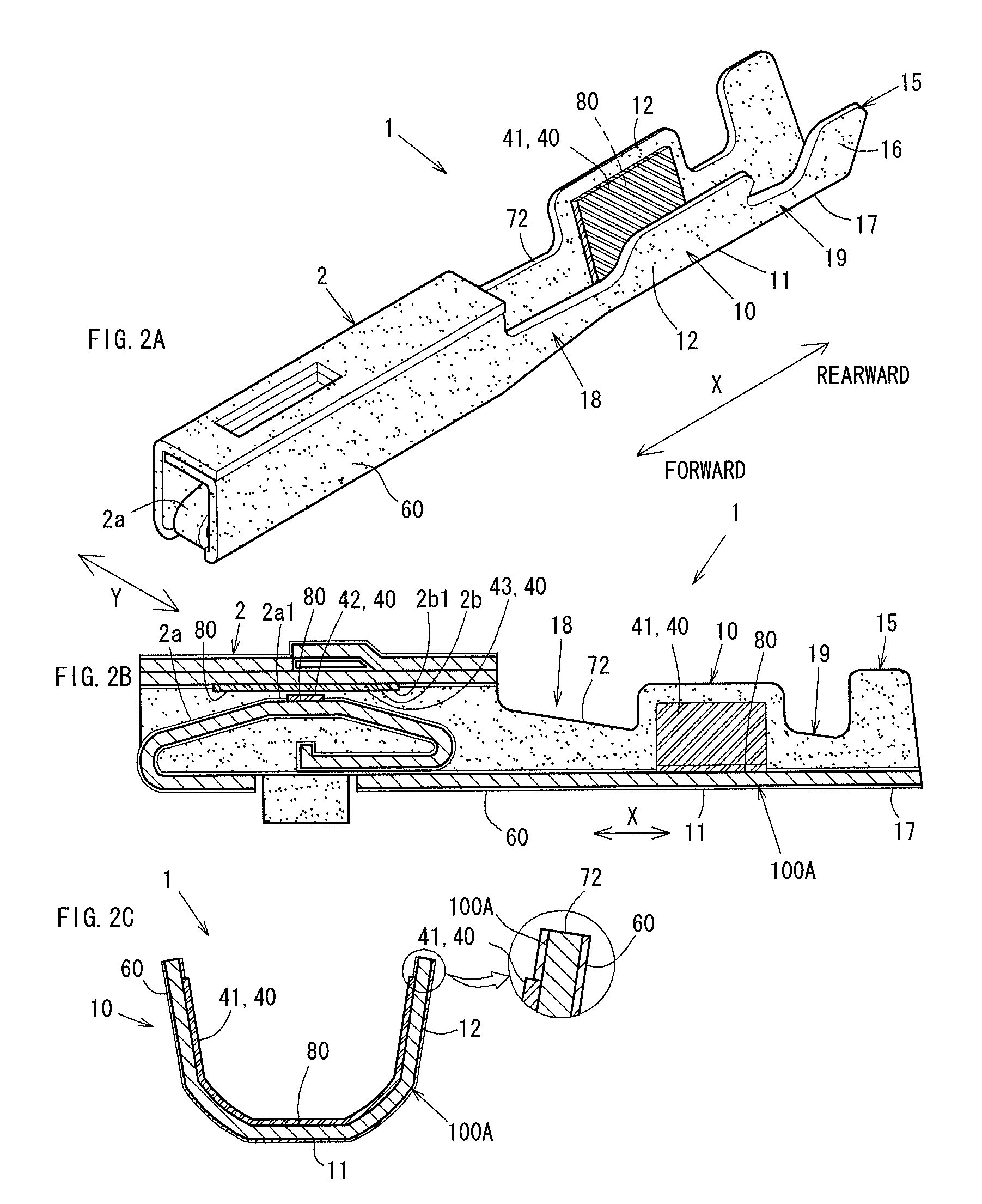

Crimp terminal, connection structural body and method for producing the same

ActiveUS9318815B2Prevent galvanic corrosionImprove conductivityAnodisationContact member manufacturingMetallic materialsAluminium

Owner:FURUKAWA ELECTRIC CO LTD +1

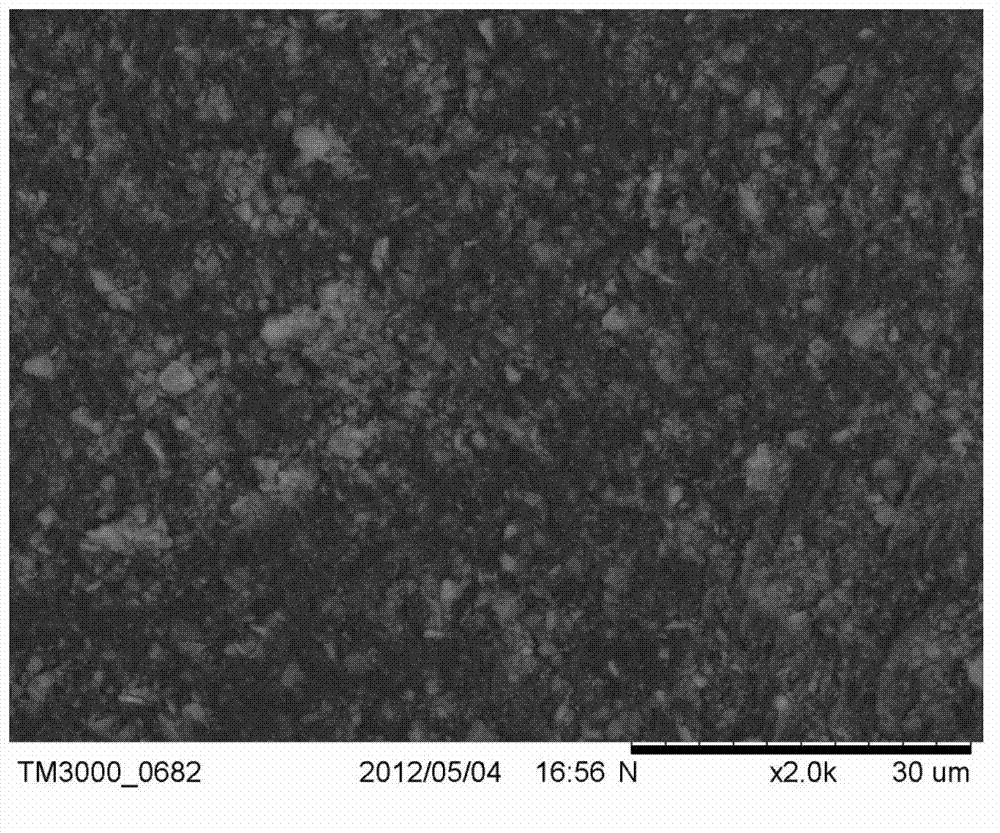

Nanometer oxide coated phosphate rust resisting pigment and preparation method thereof

InactiveCN102775833ALow costImprove aging resistanceInorganic pigment treatmentAnti-corrosive paintsEmulsionChemistry

The invention discloses a nanometer oxide coated phosphate rust resisting pigment which is a composite rust resisting pigment formed by coating a nanometer-scale oxide on micron-scale phosphate, wherein the weight ratio of the nanometer-scale oxide to the micron-scale phosphate is (1-10):100. The preparation of the nanometer oxide coated phosphate rust resisting pigment comprises the following steps of: A, preparing calcium phosphate through carrying out liquid phase reaction on a calcium-containing compound and phosphoric acid; B, adding a titanyl sulfate or zinc sulfate solution into a calcium phosphate solution, mixing evenly, then stirring and slowly dripping calcium hydroxide emulsion into the mixture to generate nanometer titanium dioxide or nanometer zinc oxide which is coated on the surface of the calcium phosphate; and C, filtering the reaction solution and drying and roasting a filter cake to obtain the nanometer oxide coated phosphate rust resisting pigment. The rust resisting pigment provided by the invention has the advantages of excellent metal rust resisting property and very low cost.

Owner:HEBEI UNIVERSITY

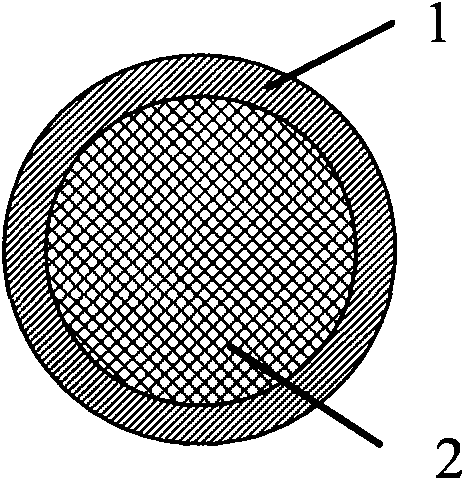

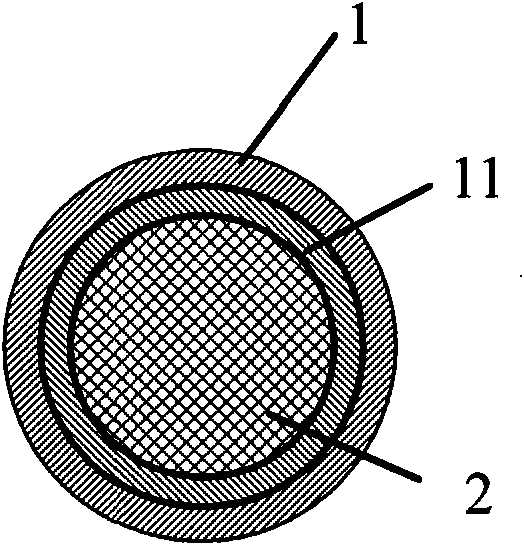

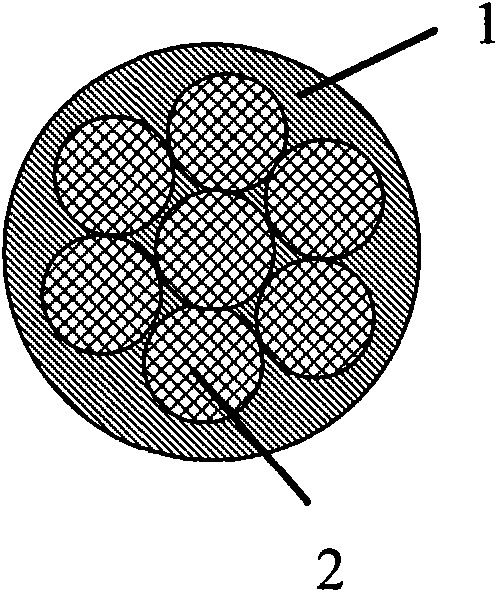

Reinforced cable core and manufacturing method thereof

InactiveCN101727998AExtended service lifePrevent Galvanic CorrosionNon-insulated conductorsConductive materialCarrying capacityElectrical conductor

The invention discloses a reinforced cable core and a manufacturing method thereof. The reinforced cable core comprises a fiber reinforced core and a metallic sheath, wherein the fiber reinforced core is coated by the metallic sheath. The reinforced cable core of the invention not only has the advantages of low density, low expansion coefficient, high tensile strength and the like, but also has the functions of improving the current carrying capacity of a cable, shielding an inner fiber composite structure to avoid the electrical erosion between a fiber and an aluminum conductor, protecting the surface of a fiber composite material and reducing the mechanical performance loss caused by surface damage. Compared with reinforced cable cores with other structures, which are formed by only fiber composite cores, the reinforced cable core of the invention not only plays a role of bearing but also can further improve the current carrying capacity of the cable.

Owner:SHANGHAI ELECTRIC CABLE RES INST

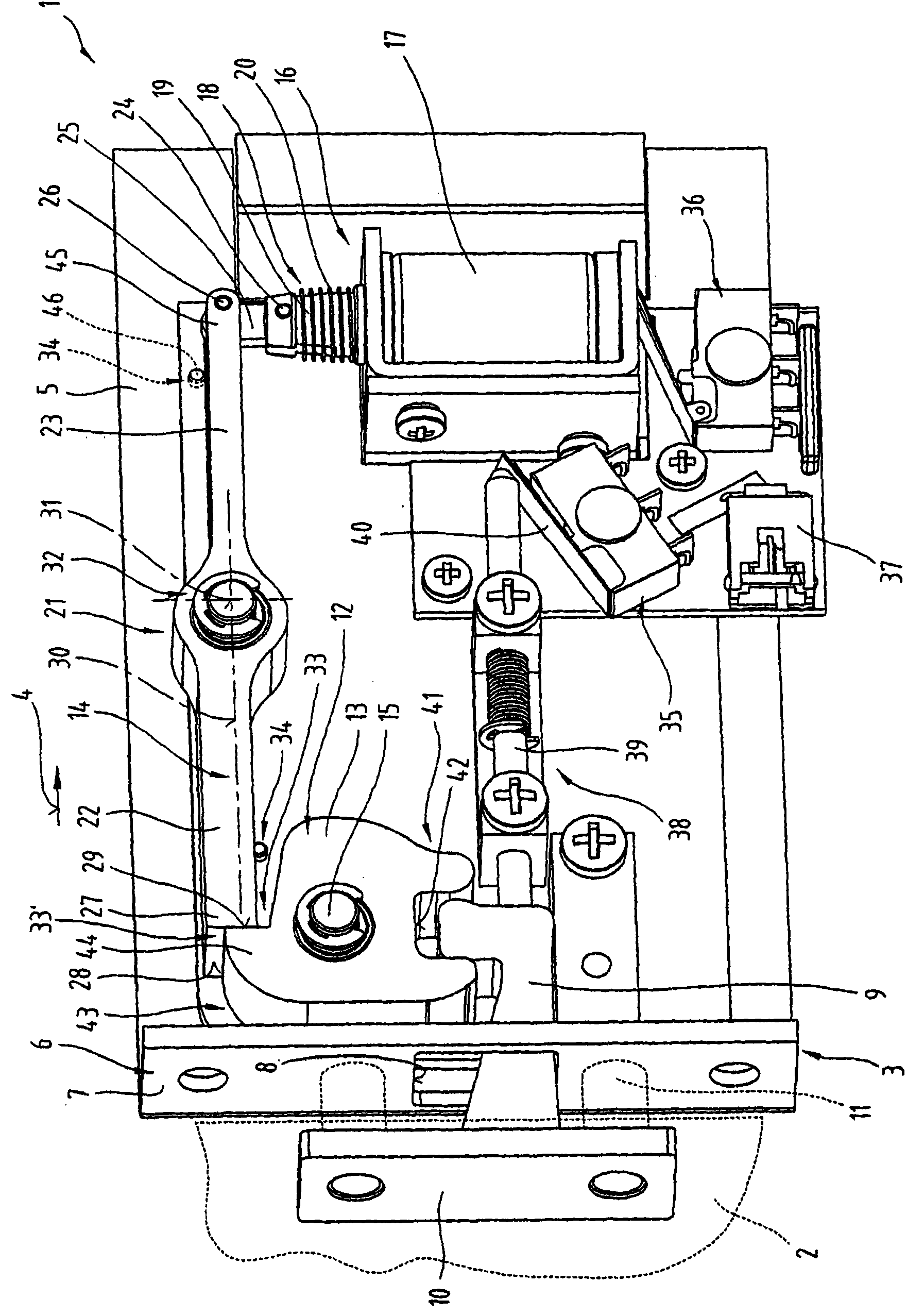

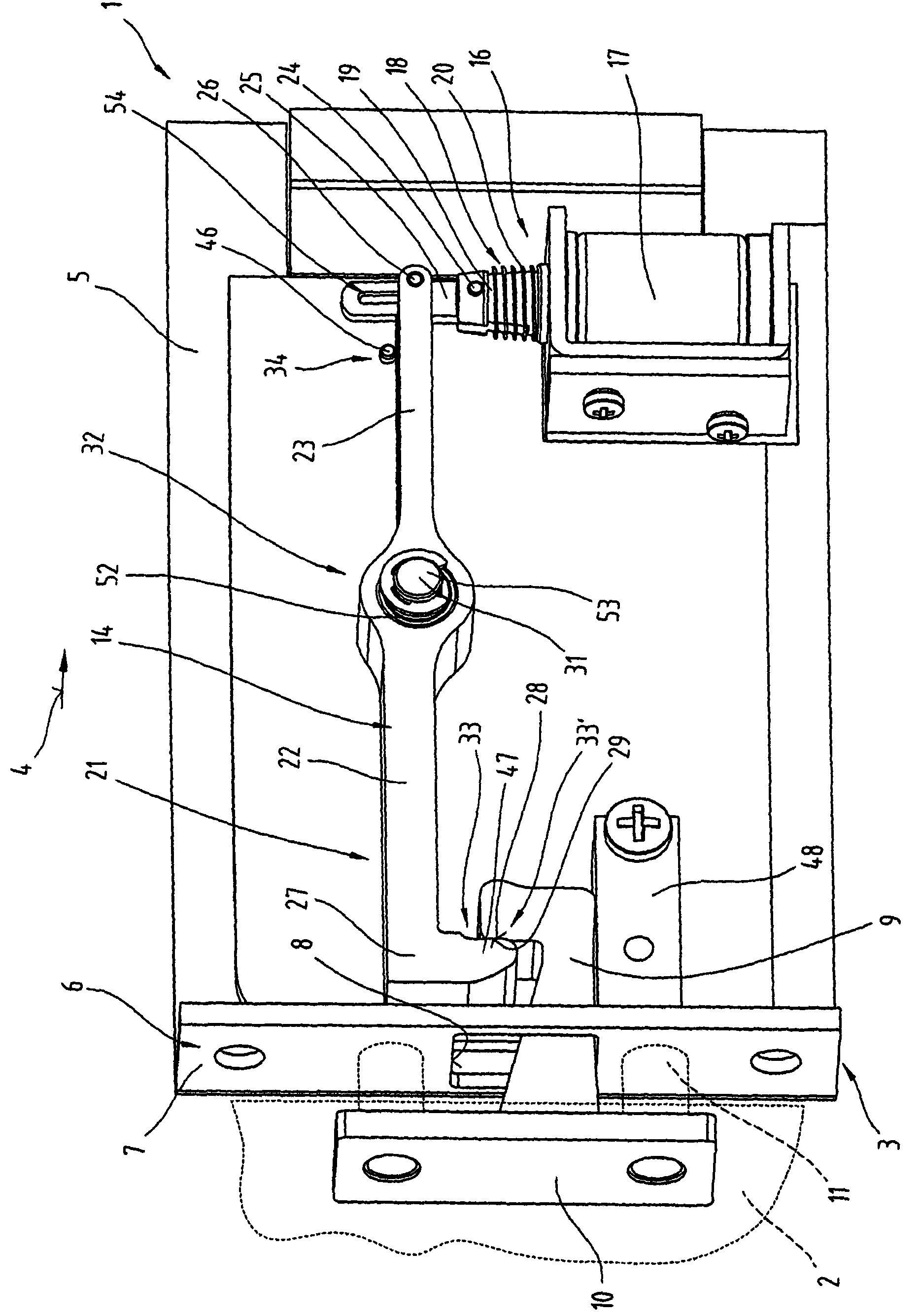

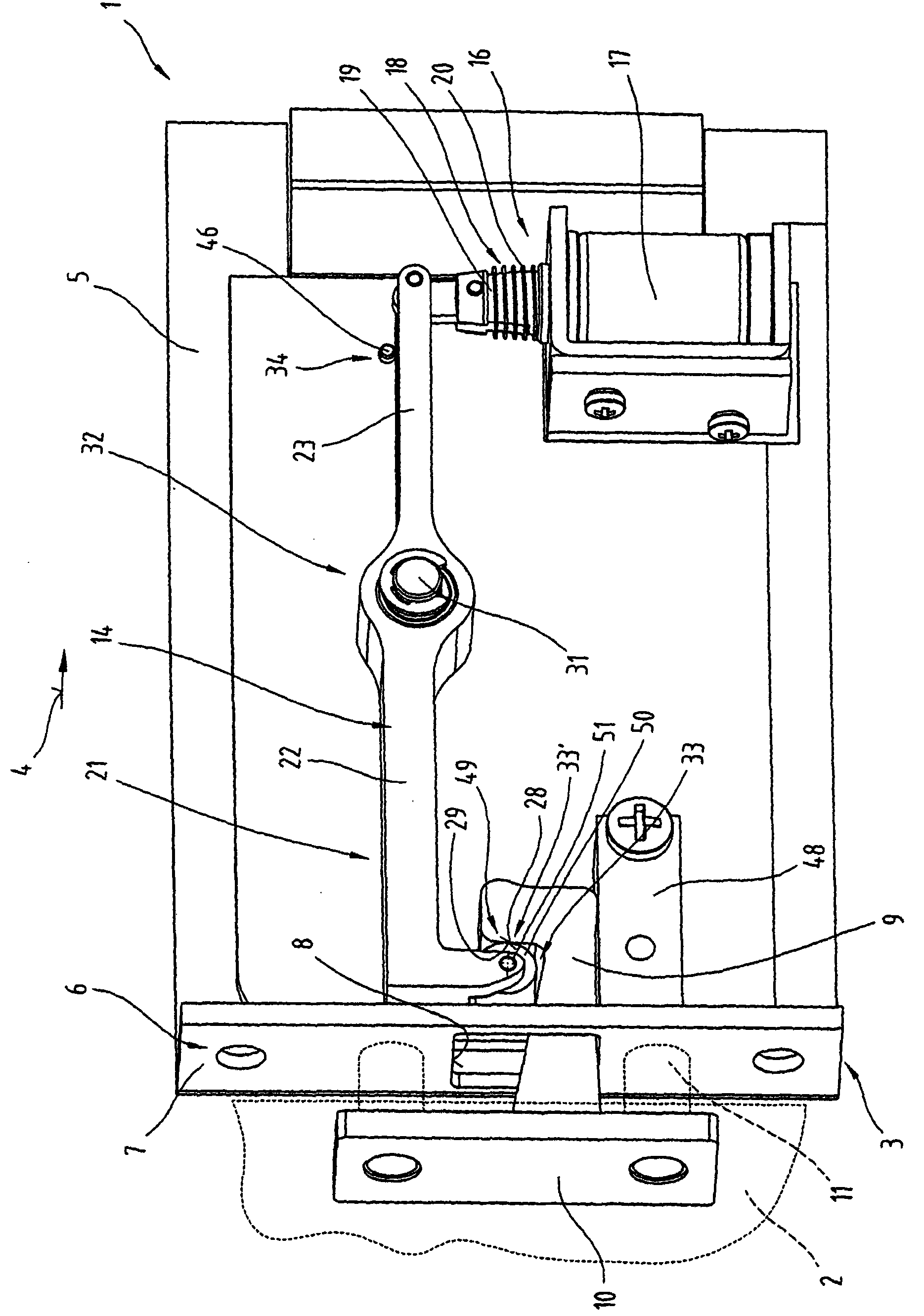

Lock which can be unlocked in an electrically automated manner, in particular for storage systems like lockers

ActiveCN101802328AReduce torsionImprove automationNon-mechanical controlsElectrical locking actuatorsElectricityCoupling

The invention relates to a lock (1) which can be unlocked in an electrically automated manner, in particular for use for storage systems like lockers. In this case, a blocking element (9) is provided which can be inserted into the lock (1), can be blocked in the lock (1) and in this case holds a locker door (2), which is firmly connected to the blocking element (9), in the closed position. Furthermore, a blocking catch (14) is provided which can be moved rotationally in a limited manner and which, on assuming its blocking position, engages either directly or indirectly via at least one coupling element (12), which is mounted such that it can move, with the blocking element (9). The essential feature in this case is that the section of a force introduction point (33') for the blocking force into the blocking catch (14) is designed such that force and impulse introduction, which are dependent on an interlock on the installation, from the blocking element (9) or from an intermediate coupling element (12), which may be provided, to the blocking catch (14) occurs directed virtually exclusively radially with respect to the pivoting axis (31) thereof, and any tangential force or impulse components which may occur can be transmitted virtually exclusively by friction forces to the force introduction point (33'). This achieves increased security against external manipulatory actions.

Owner:KEBA HANDOVER AUTOMATION GMBH

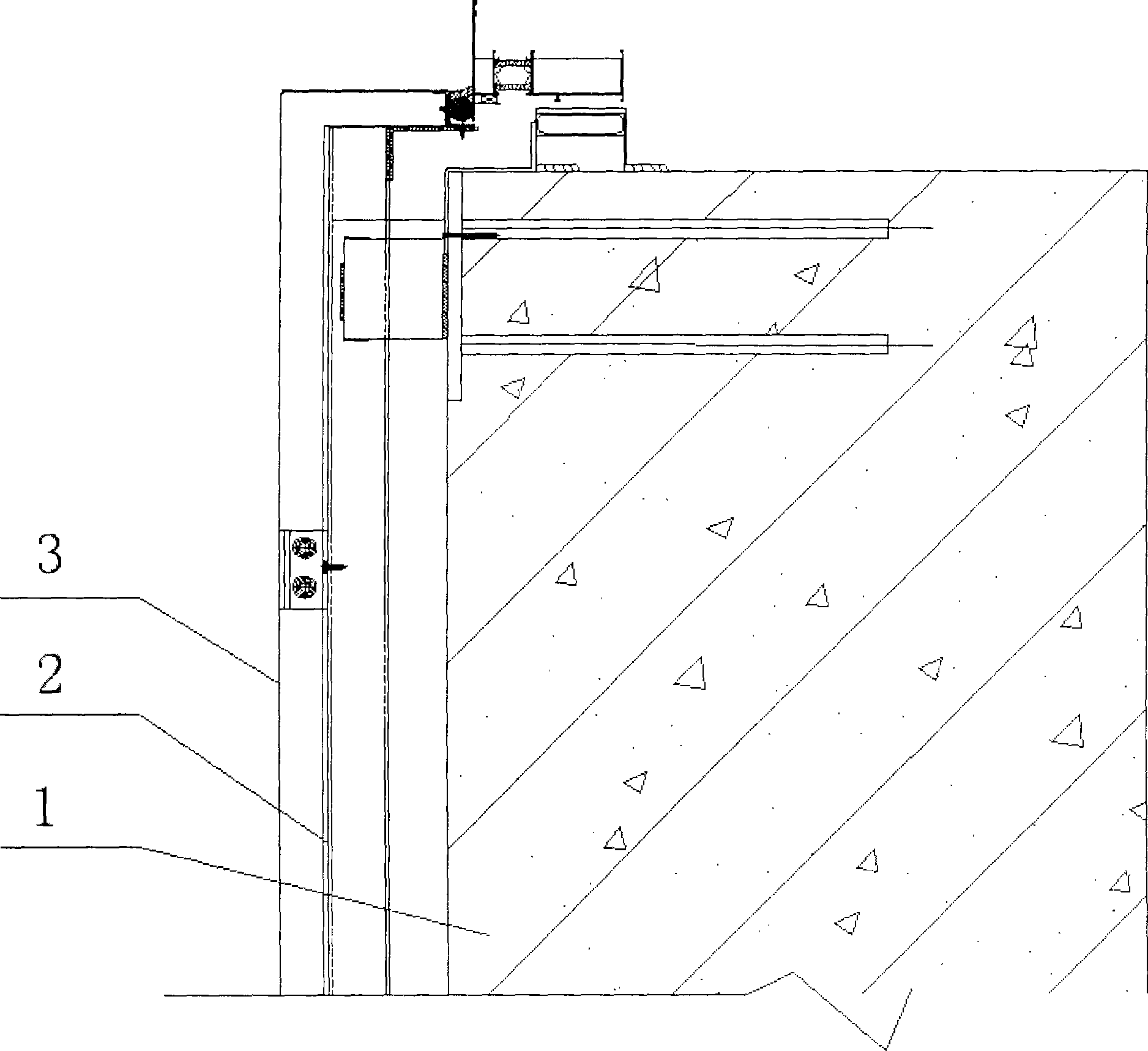

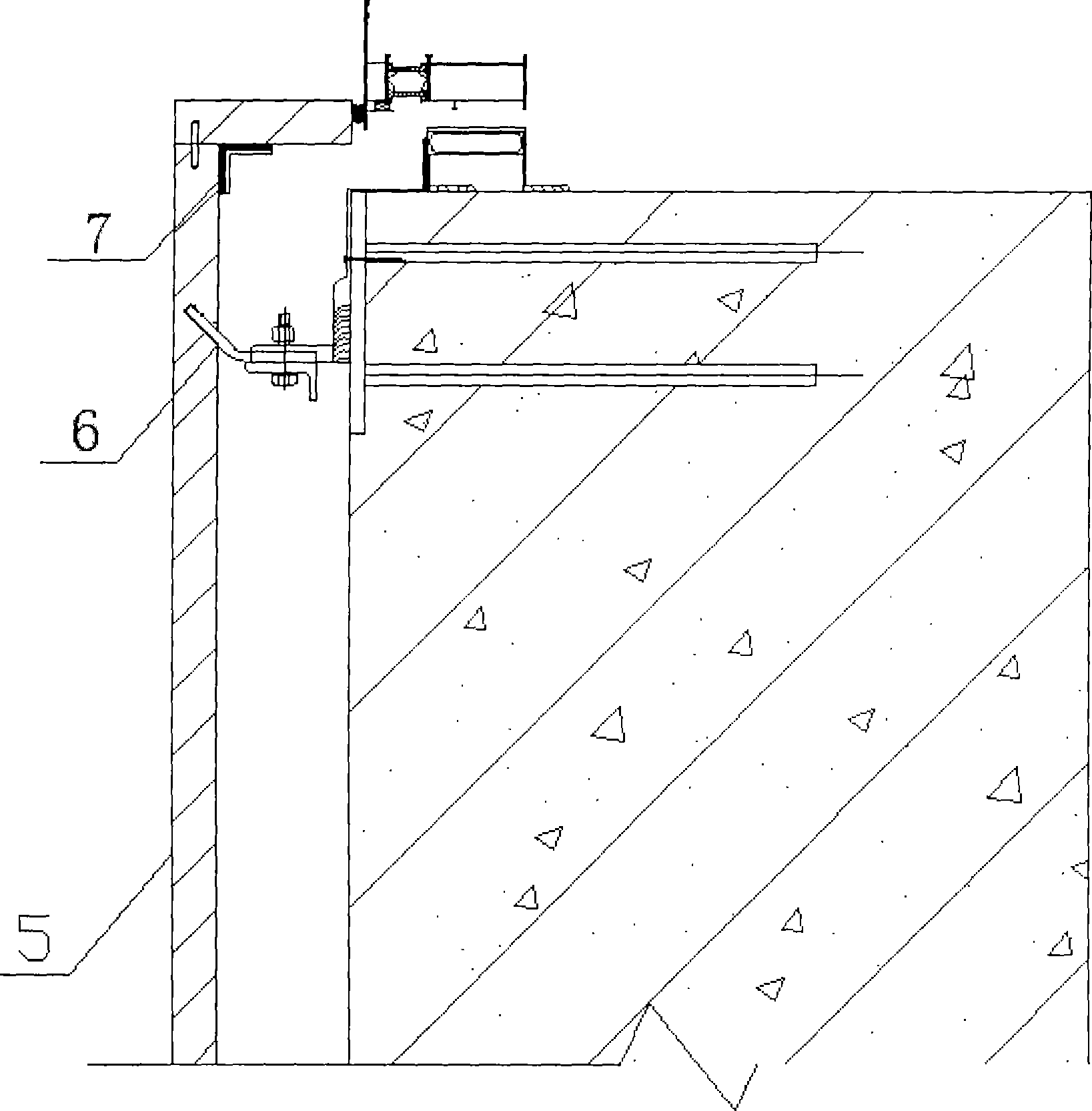

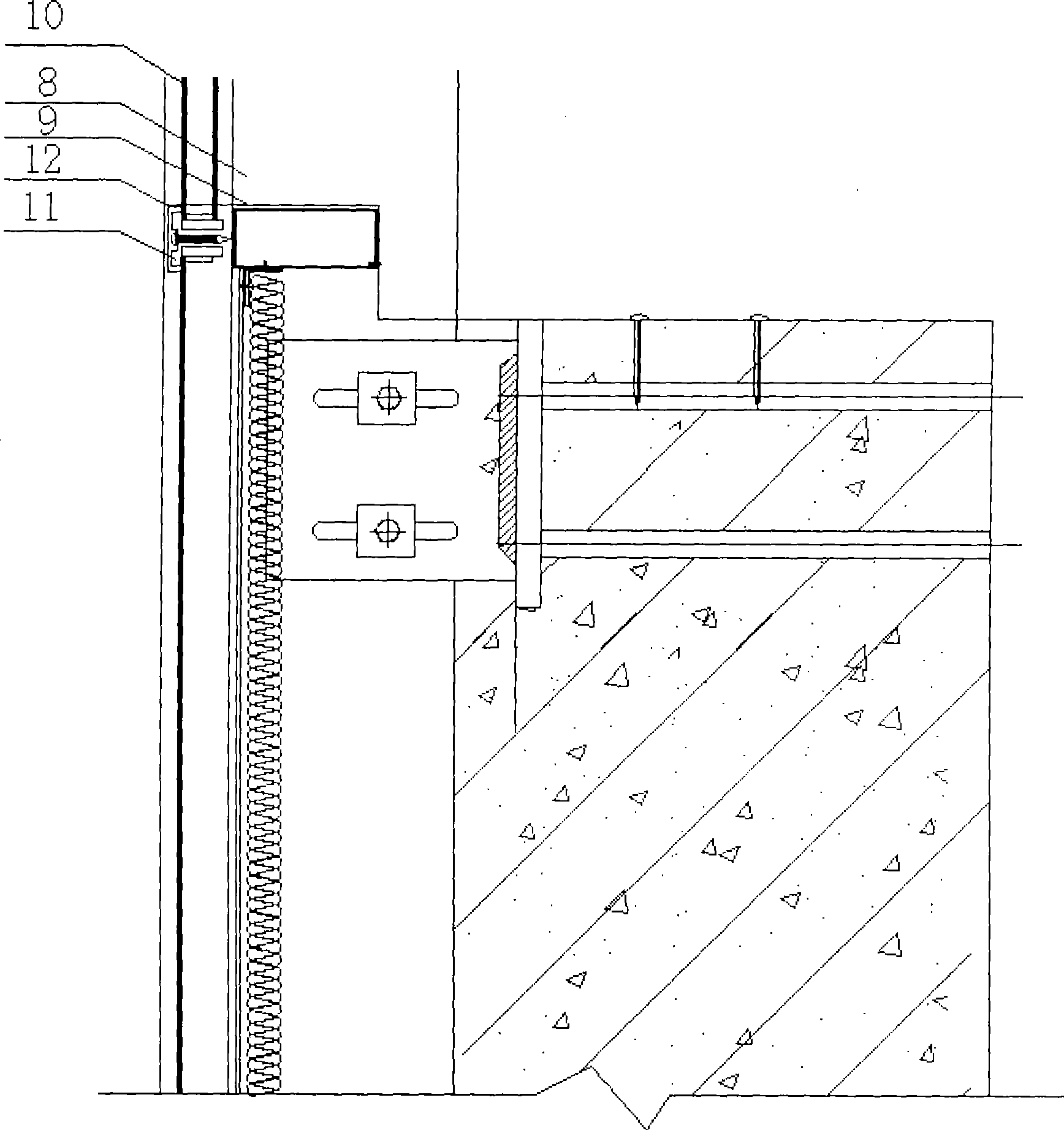

Combined curtain wall

The invention relates to a combined curtain wall which is characterized by comprising an aluminum single veneer curtain wall, a heat-insulated transparent frame glass curtain wall, a stone curtain wall, a steel plate structure and aluminum alloy doors and windows. The aluminum single veneer curtain wall is positioned at the aluminum plate part between a porch and the windows and a large area of shearing wall parts; the stone curtain wall is positioned on a solid wall on the lower part; and the rest part of the combined curtain wall is the heat-insulated transparent frame glass curtain wall. The combined curtain wall can effectively prevent the electric erosion and the earthquake while strengthening the viewing effect, reduce the precision requirement of the construction and better achieve the effects of heat preservation and insulation.

Owner:葛汉明

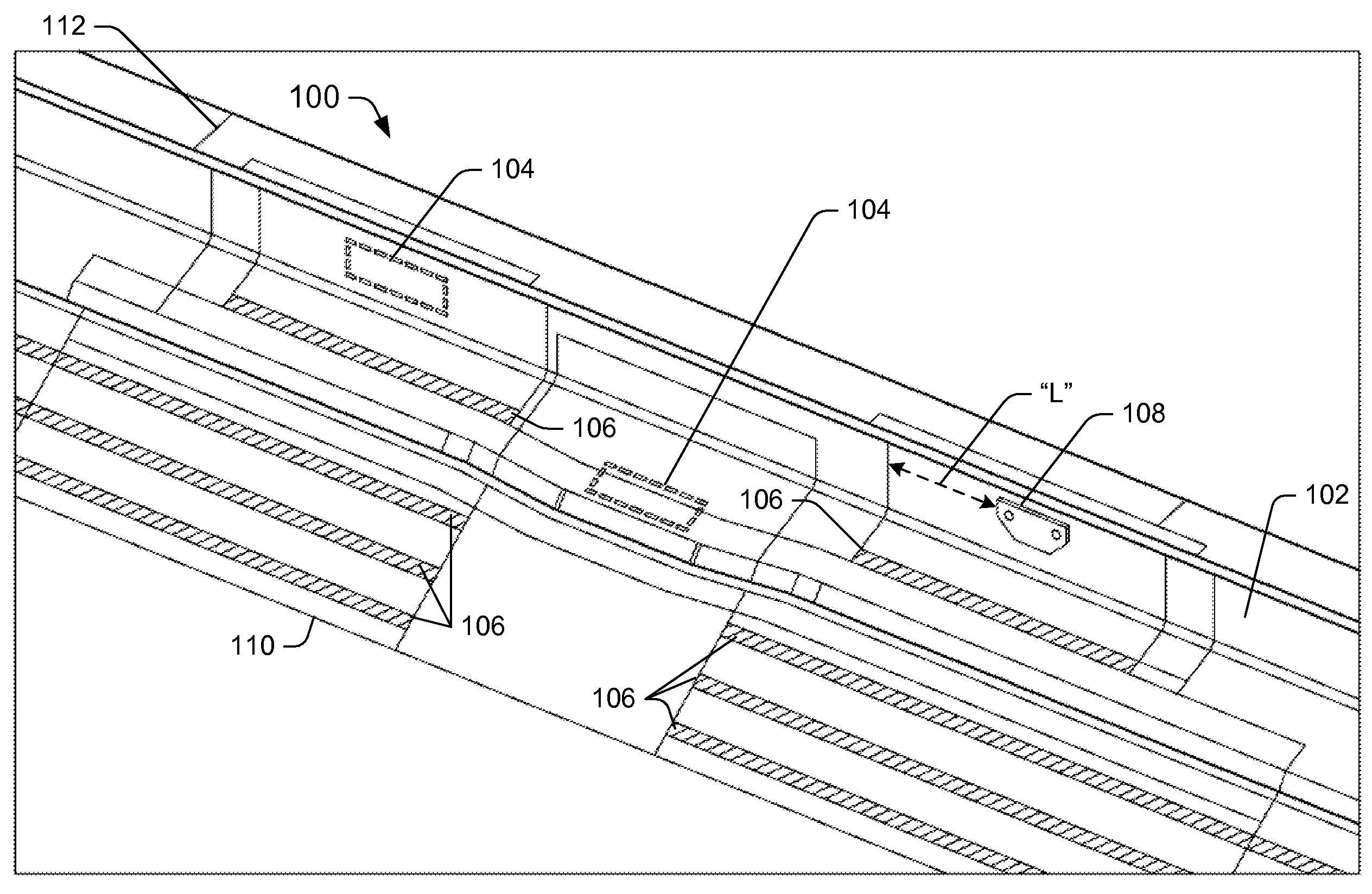

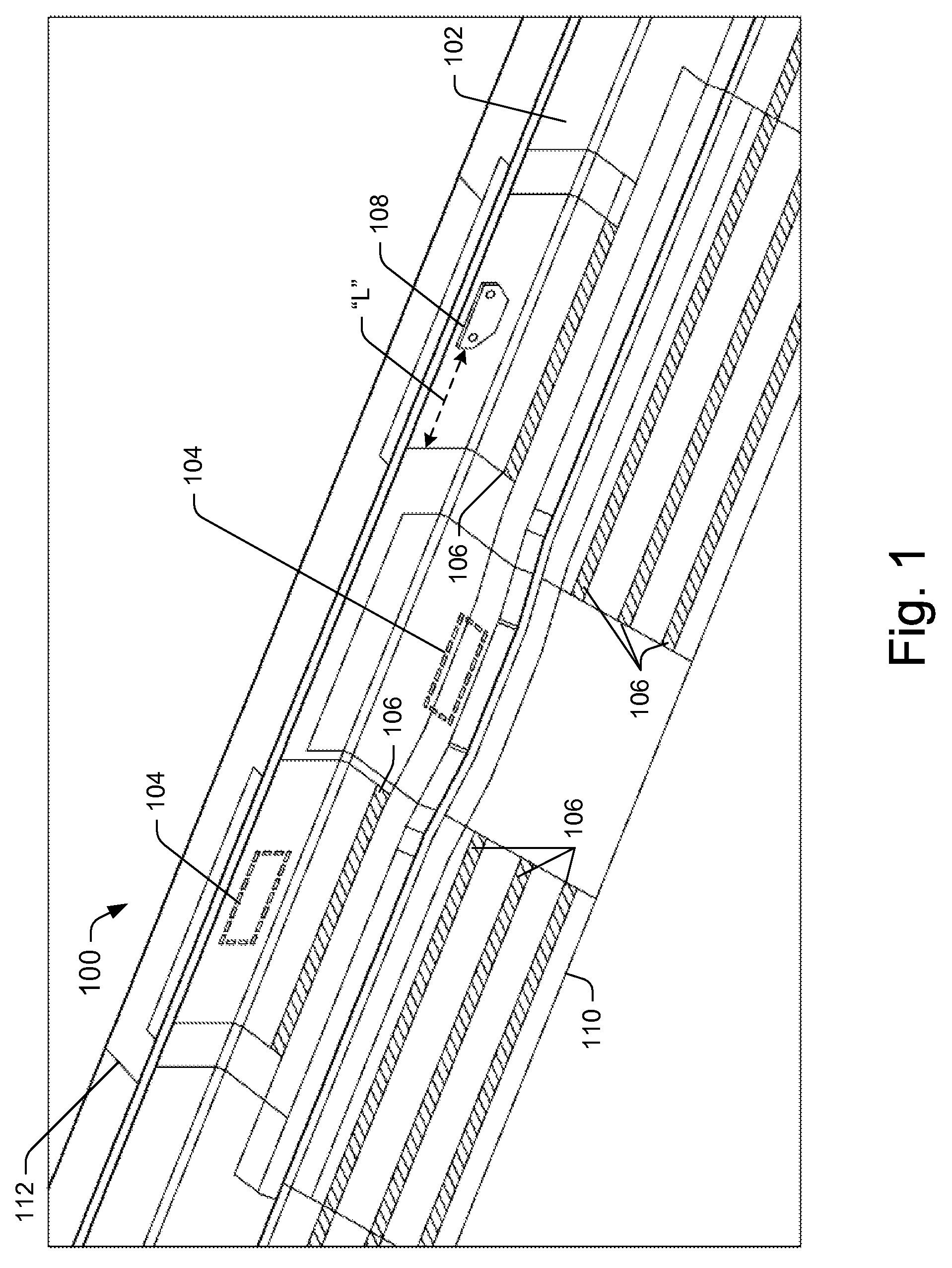

Vehicle roof structure

InactiveUS9114836B1Prevent galvanic corrosionReduce thermal deformationSuperstructure subunitsSuperstructure connectionsAdhesiveAlloy

A vehicle assembly includes a roof structure having a roof panel formed of aluminum or an aluminum-based alloy and a vehicle body formed of steel or a steel alloy supporting the roof structure. The vehicle body includes a pair of laterally spaced side panels, a front roof rail and a rear roof rail. A bracket formed of steel or a steel alloy secures the roof structure to the vehicle body. The bracket has a first portion fastened to the roof panel and a second portion extending away from the roof structure and welded to the vehicle body. An adhesive located inward of the connection of the vehicle body and second portion of the bracket bonds the second portion to the vehicle body. The adhesive seals the connection of the roof panel and bracket first portion and reduces thermal distortion of the attached roof panel relative to the vehicle body.

Owner:HONDA MOTOR CO LTD

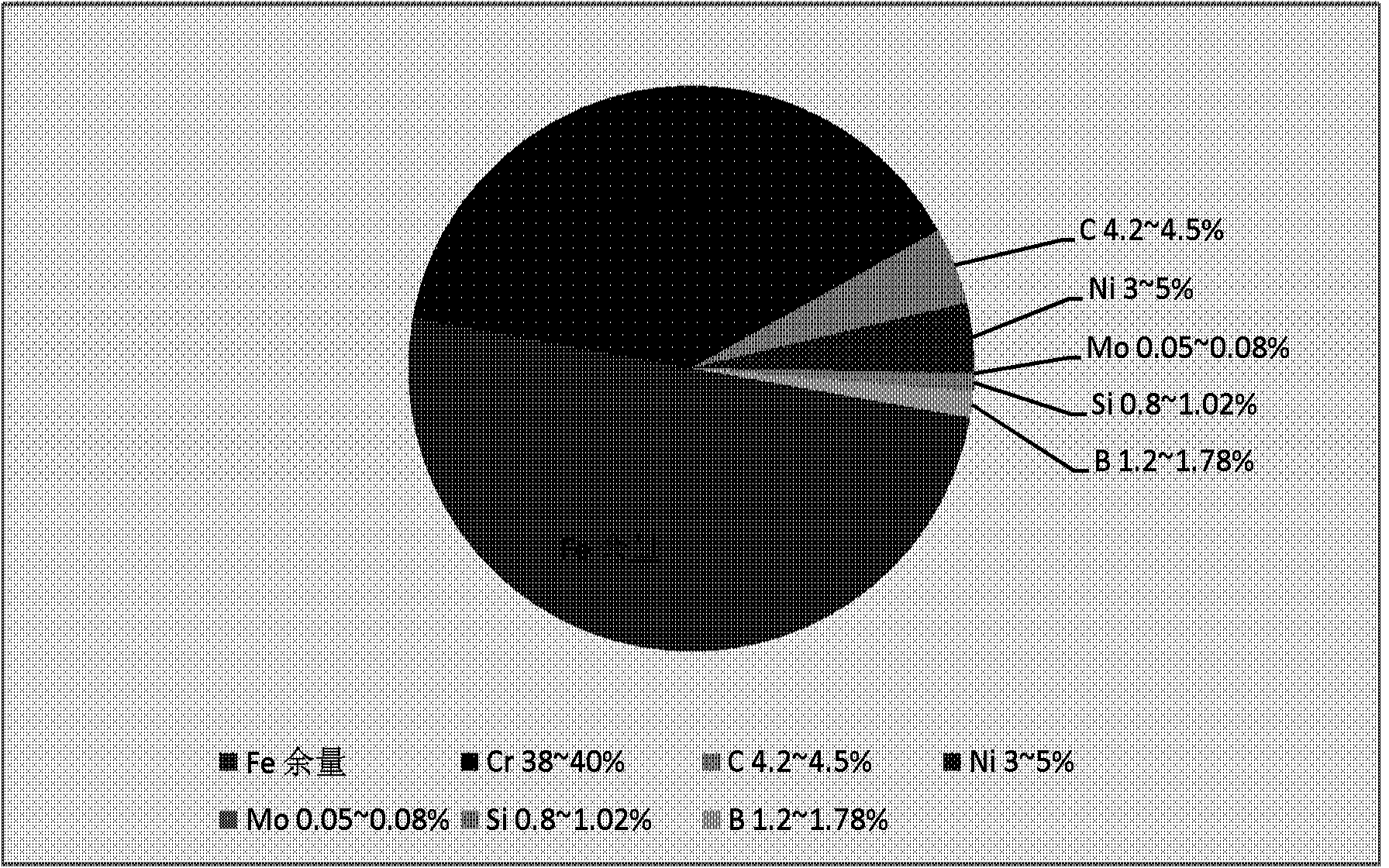

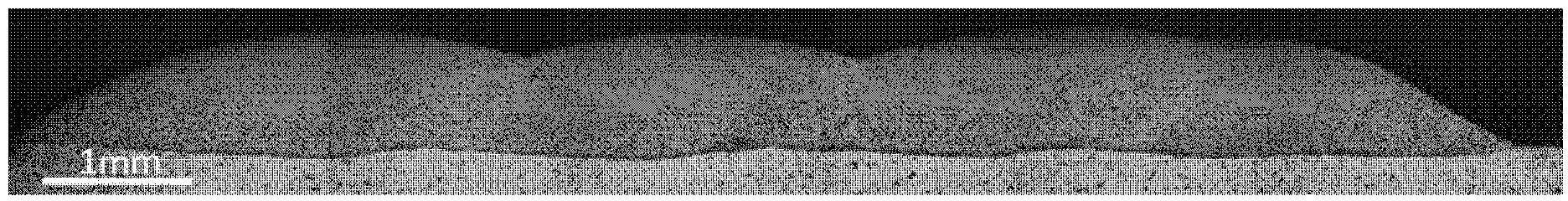

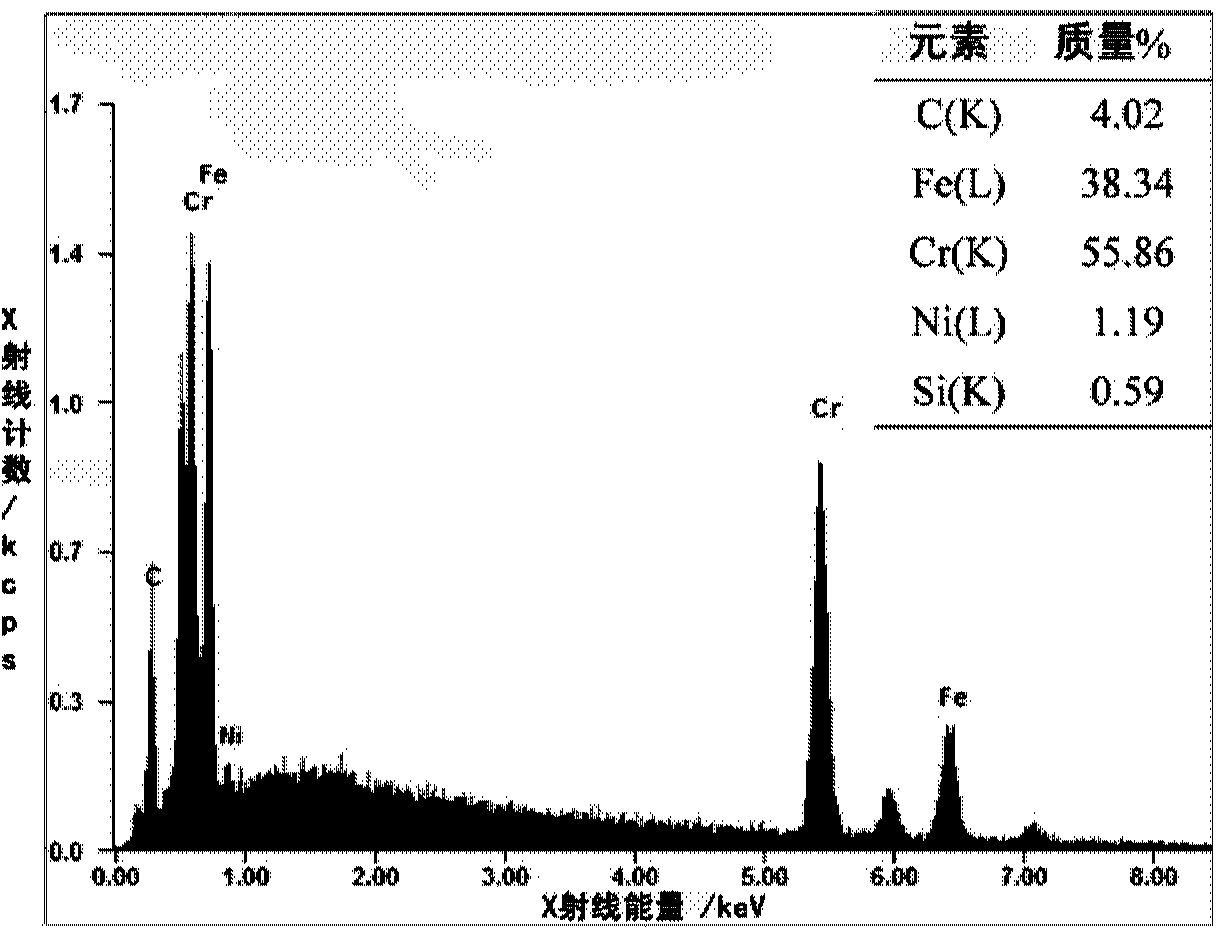

Iron-based composite powder high in chromium content for laser cladding

ActiveCN103752818AHigh hardnessImprove wear resistanceMetallic material coating processesCrack freeHardness

The invention discloses iron-based composite powder high in chromium content for laser cladding. The iron-based composite powder high in chromium content for laser cladding is composed of the chemical compound of Cr3C2, Cr and Fe, Ni, Mo, Si and B. The iron-based composite powder high in chromium content for laser cladding comprises, by mass, 38%-40% of Cr, 4.2%-4.5% of C, 3%-5% of Ni, 0.05%-0.08% of Mo, 0.8%-1.02% of Si, 1.2%-1.78% of B and the balance Fe. The particle size of the iron-based composite powder is between +140 meshes and -325 meshes. The iron-based composite powder is high in carbon content and chromium content, the hardness of a coating can be effectively improved, requirements of the laser cladding technology of iron-based base materials such as carbon steel and stainless steel can be met, a cladding layer of a sample of the iron-based composite powder is free of cracks and macroscopic pores, all the components are distributed evenly, the hardness of the iron-based composite powder can reach HV0.21000 and is five times that of a base body, the corrosion resistance of the iron-based composite powder cladding layer is improved due to the high chromium content, and the iron-based composite powder is suitable for normal temperature, high temperature, abrasion resistance and corrosion resistance working conditions.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

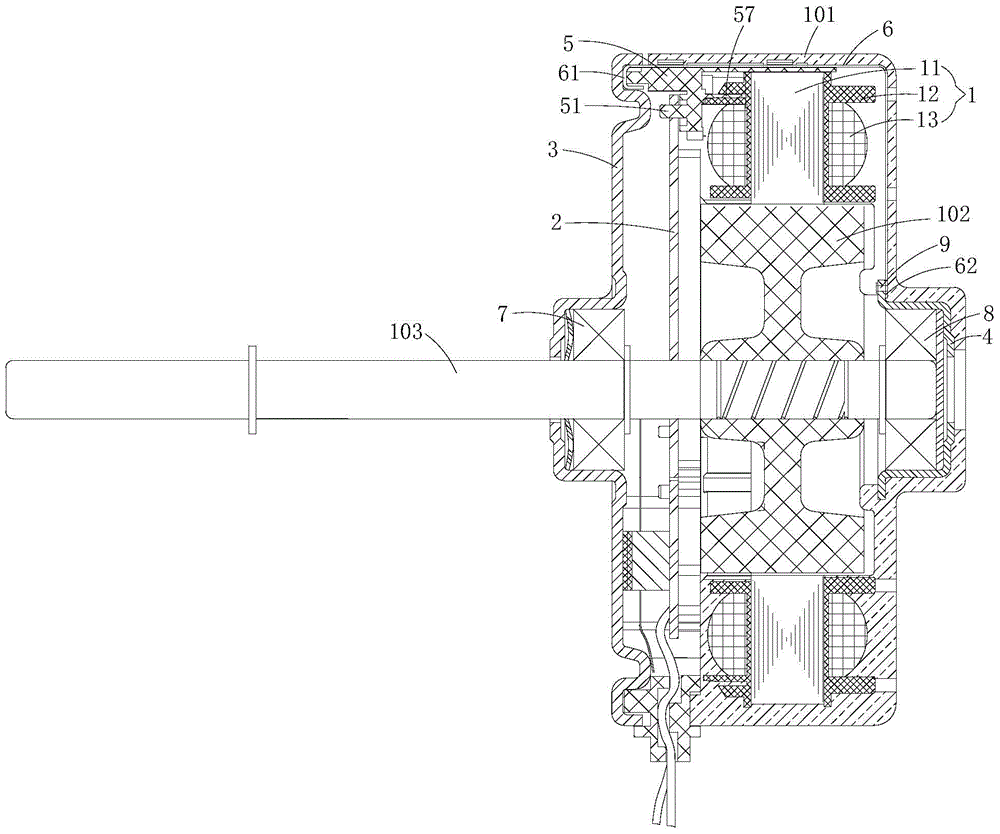

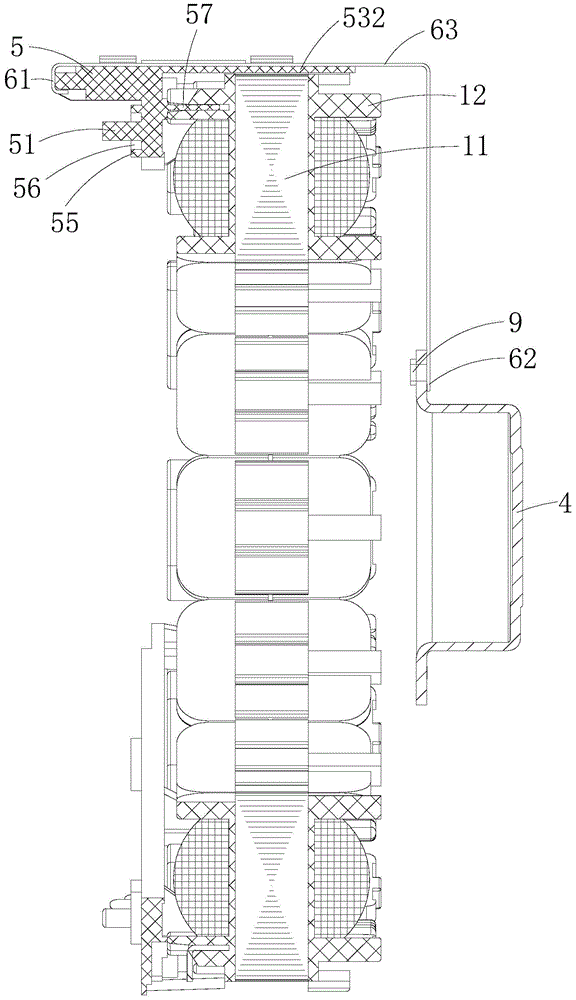

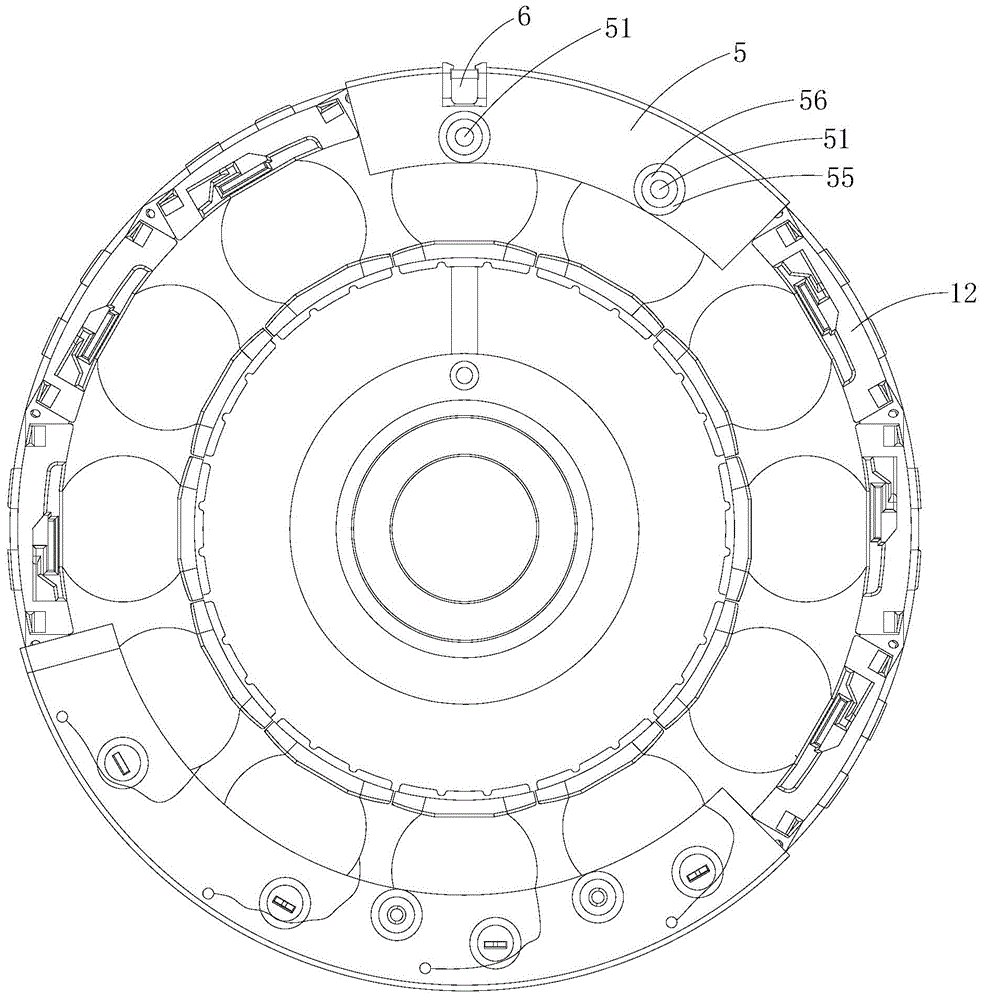

Motor

ActiveCN104467294APrevent bearing corrosionGood conductivity and stabilityAssociation with grounding devicesMechanical energy handlingStatorElectrical connection

The invention is applicable to the motor filed and discloses a motor. The motor comprises a stator assembly, a circuit board, a first bearing rack and a second bearing rack as well as an insulation support and a metal conductive component, wherein the first bearing rack and the second bearing rack are arranged on two sides of the stator assembly respectively; the insulation support is mounted on the stator assembly, the metal conductive component is fixed on the insulation support, two ends of the metal conductive component are electrically connected with the first bearing rack and the second bearing rack respectively, a positioning column is arranged on the insulation support, a positioning hole is formed in the circuit board, the circuit board is supported on the insulation support, and the positioning column penetrates through the positioning hole. According to the motor, electrical connection between the first bearing rack and the second bearing rack is realized by the aid of the arranged metal conductive component, and the longtime effectiveness of the electrical connection between the first bearing rack and the second bearing rack is guaranteed; meanwhile, lock fixing of the metal conductive component can be realized by the aid of the arranged insulation support, the circuit board can be supported and positioned, and the used parts of the motor are reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

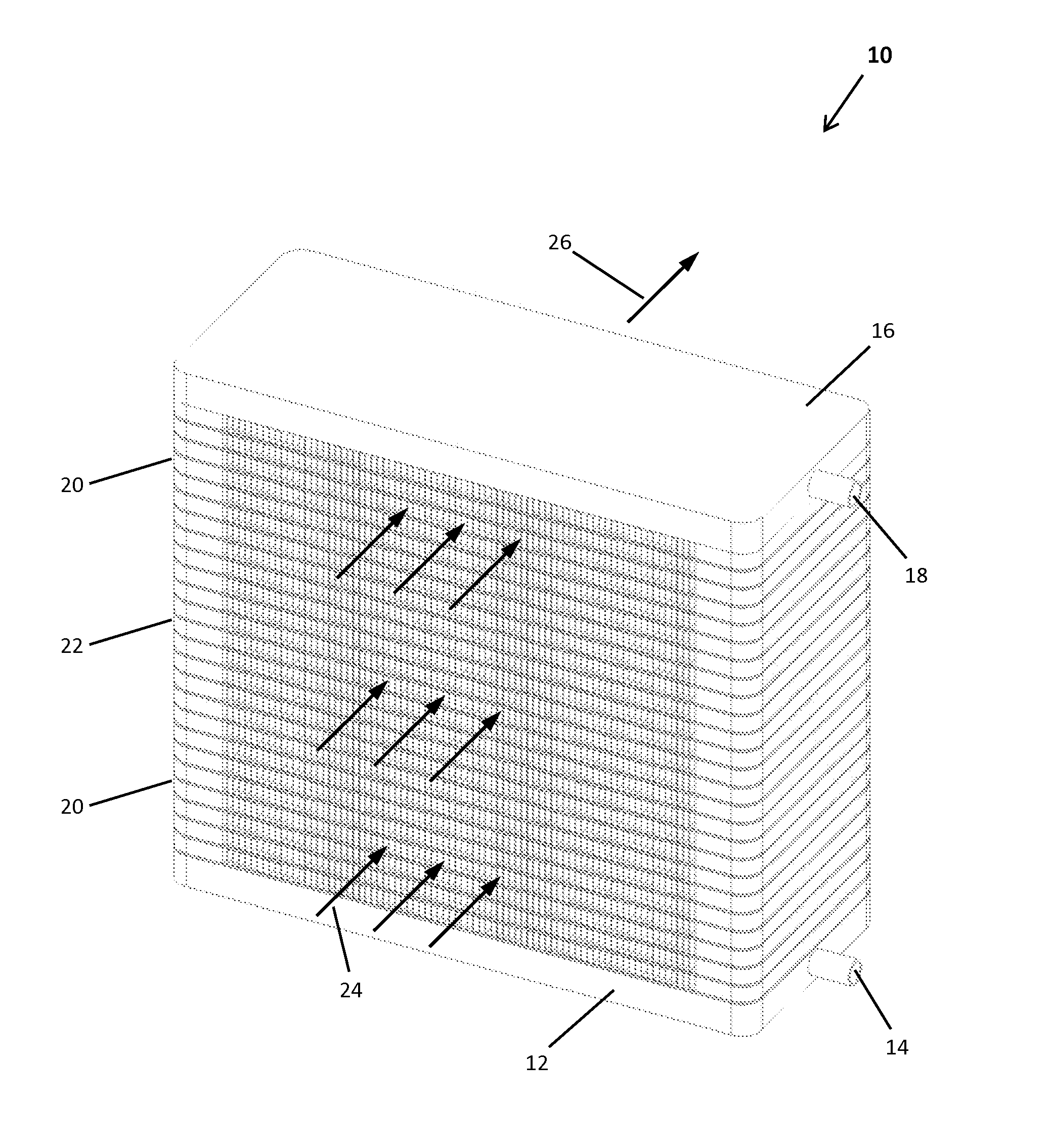

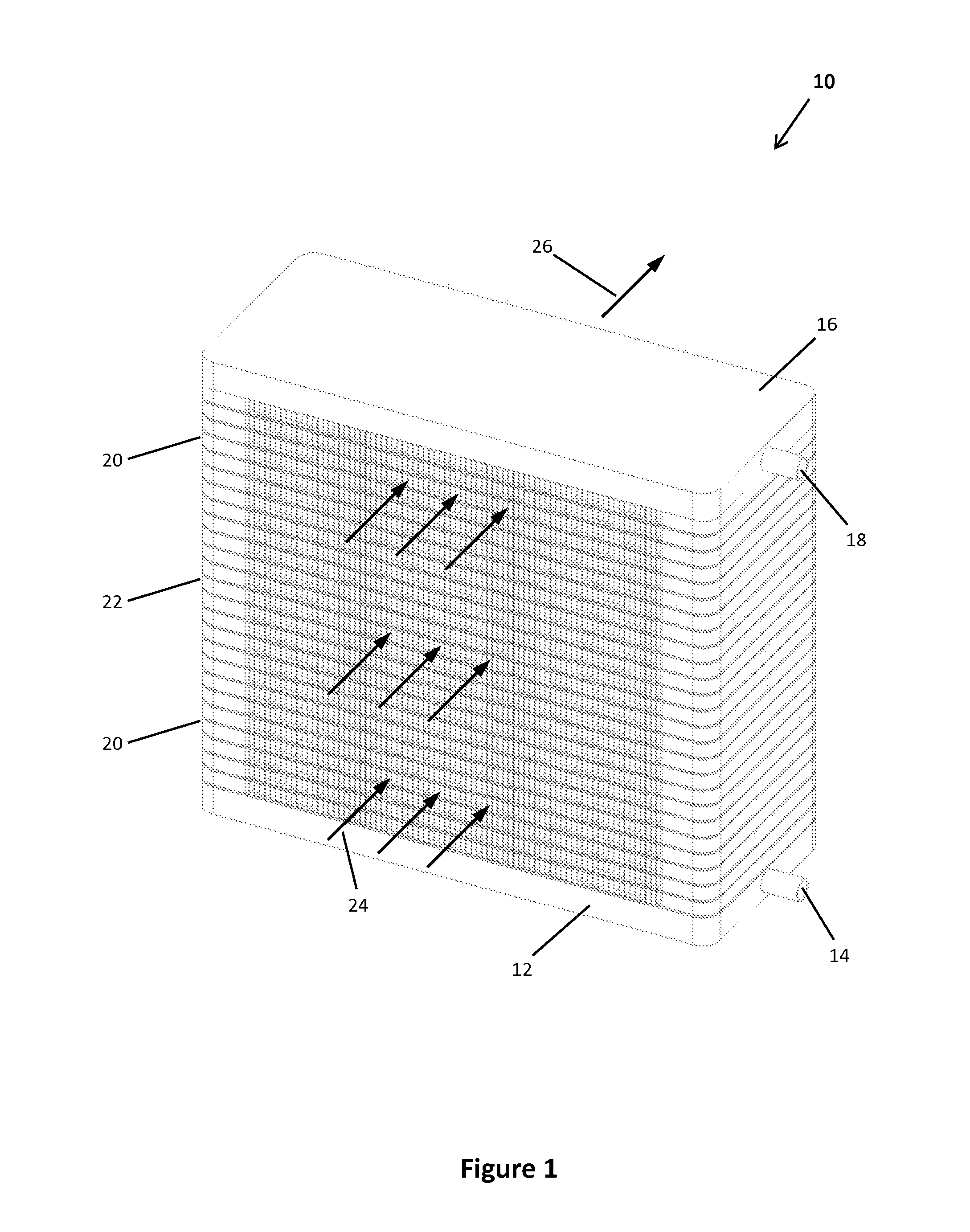

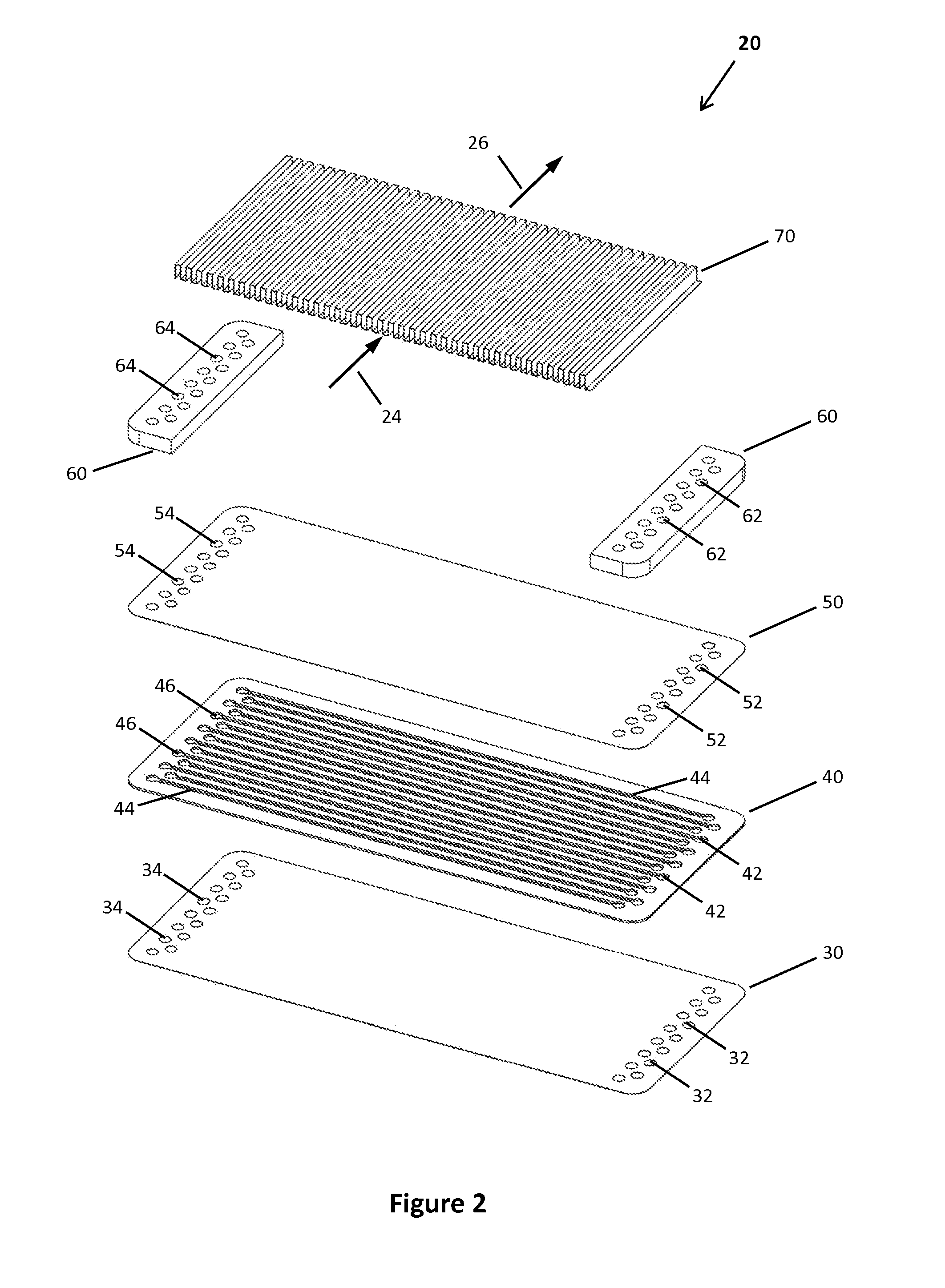

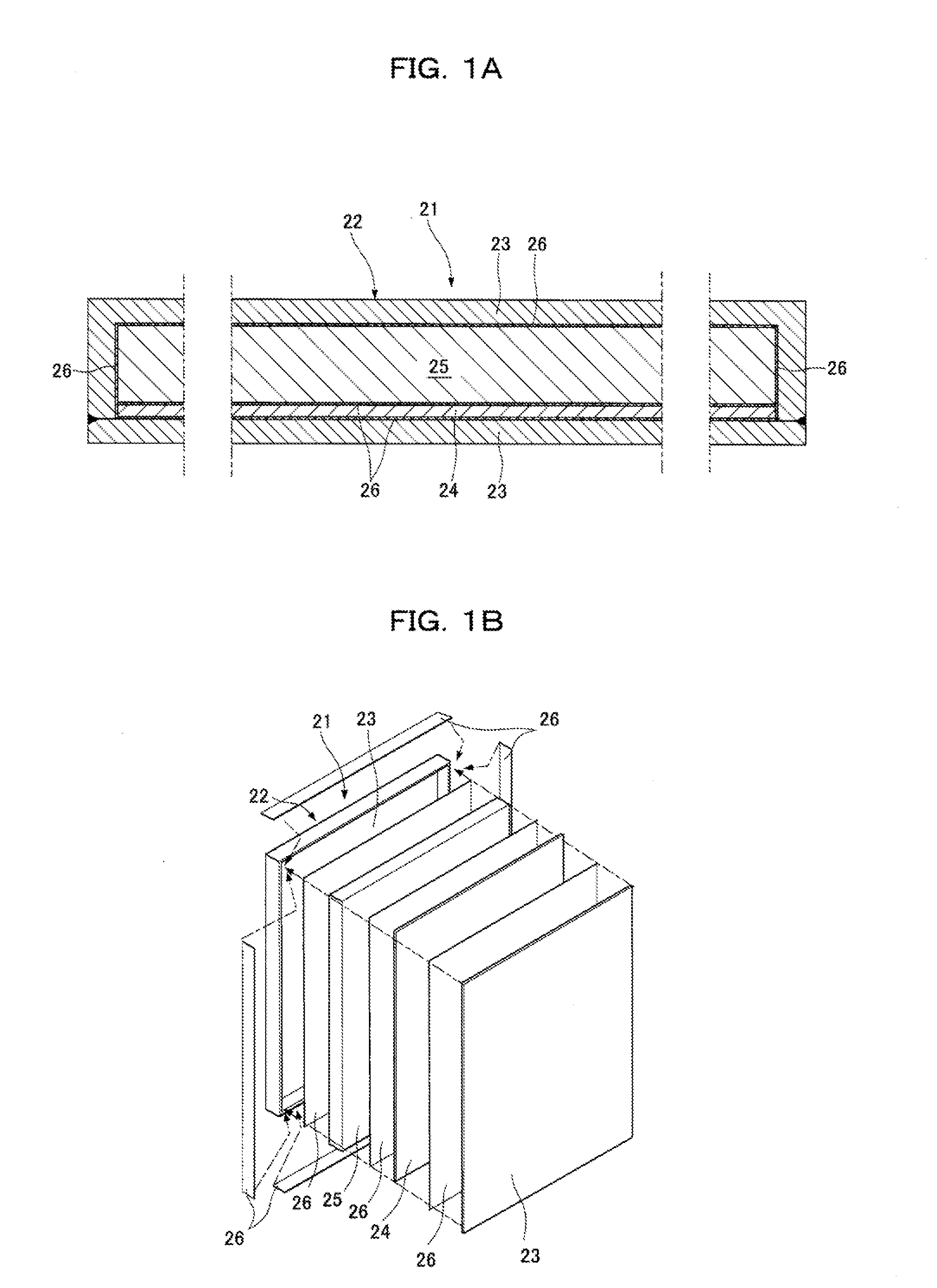

Plate fin heat exchangers and methods for manufacturing same

InactiveUS20160238323A1Low costImprove efficiencyStationary conduit assembliesHeat transfer modificationEngineeringMechanical engineering

Disclosed herein is a plate fin heat exchanger subassembly. The subassembly includes three plates in intimate contact with each other. The first plate is sandwiched between the second and third plates. Each of the plates has a first at least one fluid opening and a second at least one fluid opening located at the ends of each plate. The first plate has at least one elongate fluid channel extending between the first and second fluid openings. One fluid passageway for a first heat exchanger fluid extends through the first and second fluid openings in each plate and along the elongate channel in the first plate. At least one fin has two thermal transfer surfaces. The first thermal transfer surface is in intimate contact with the second plate. The other fluid passageways for a second heat exchanger fluid are located on each side of the fin.

Owner:ENERGYOR TECH

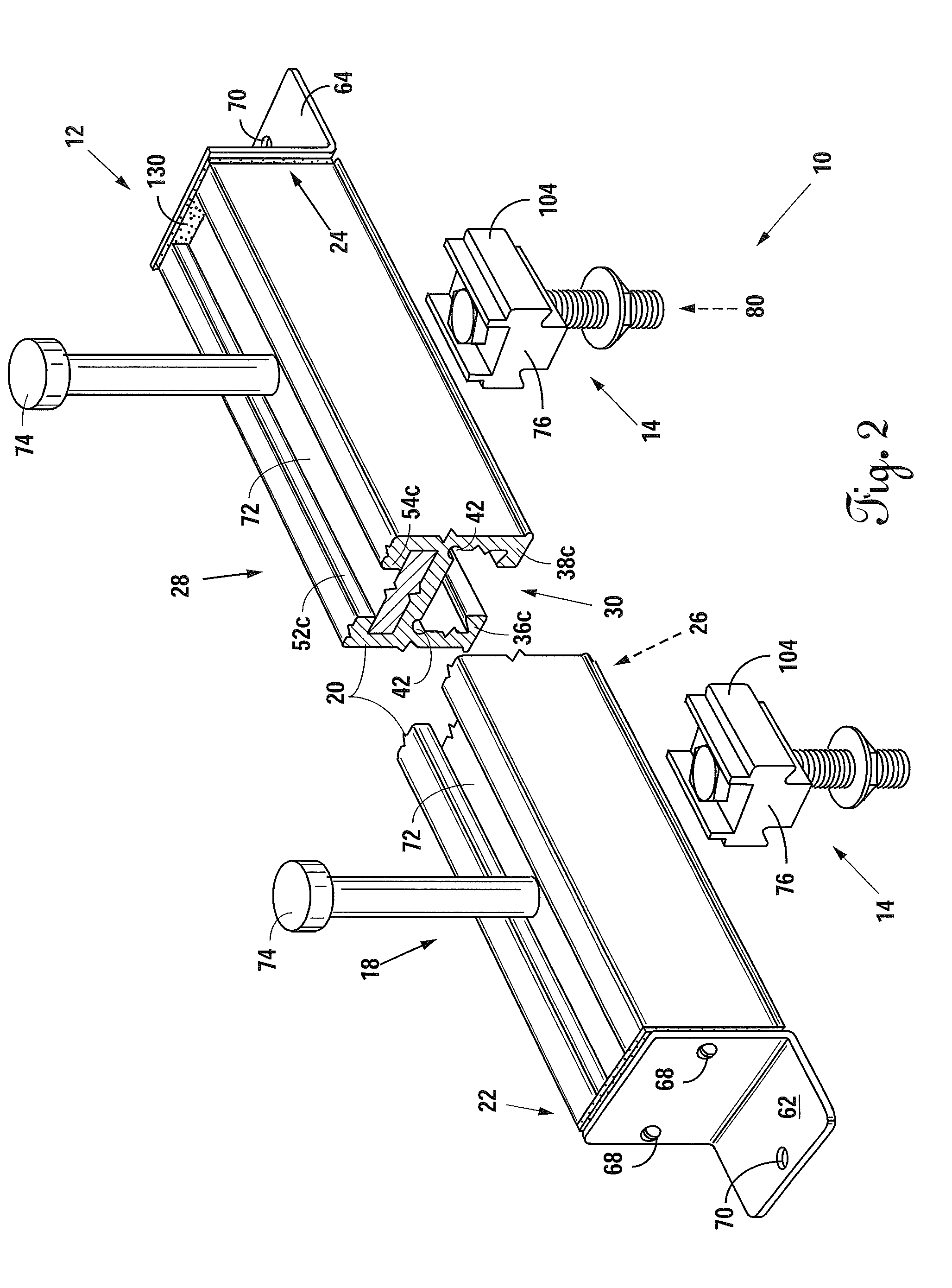

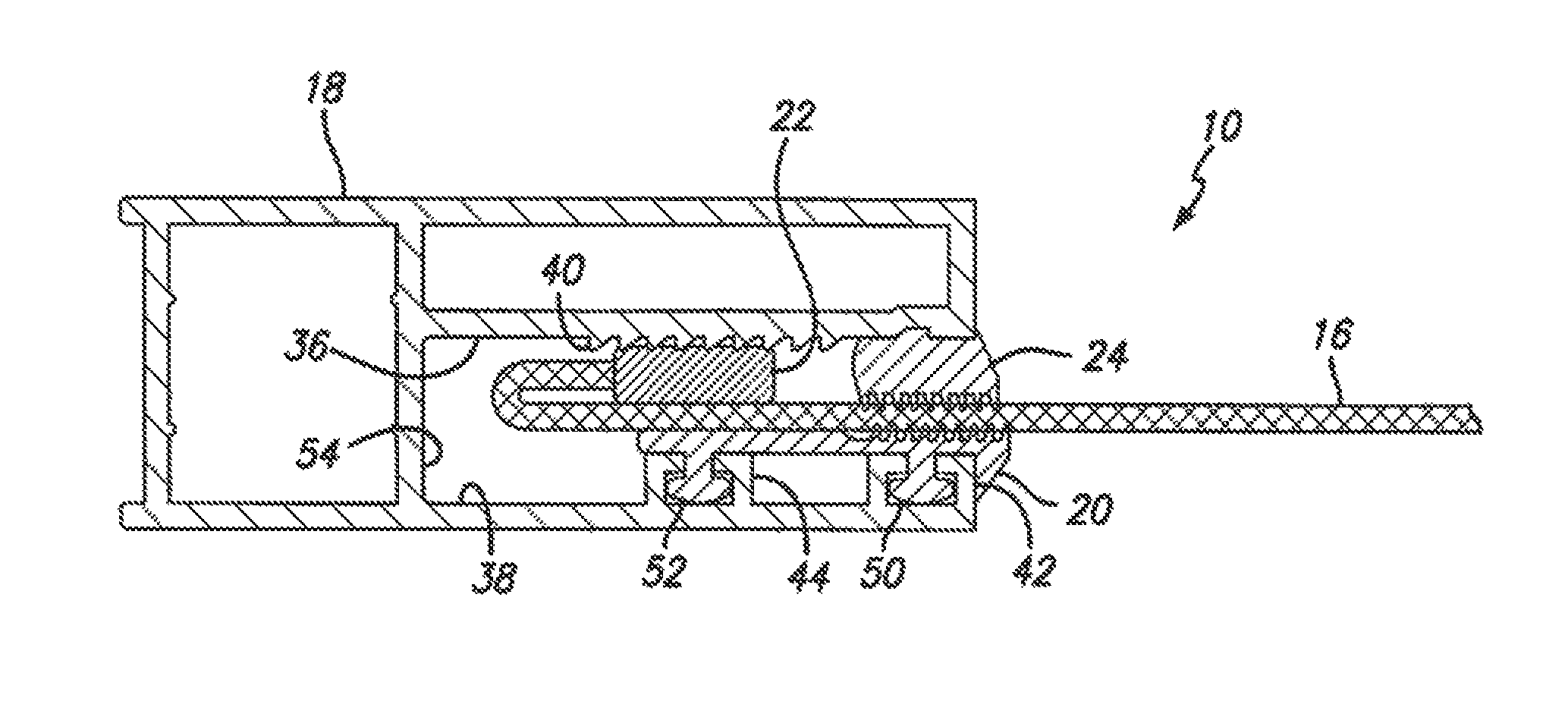

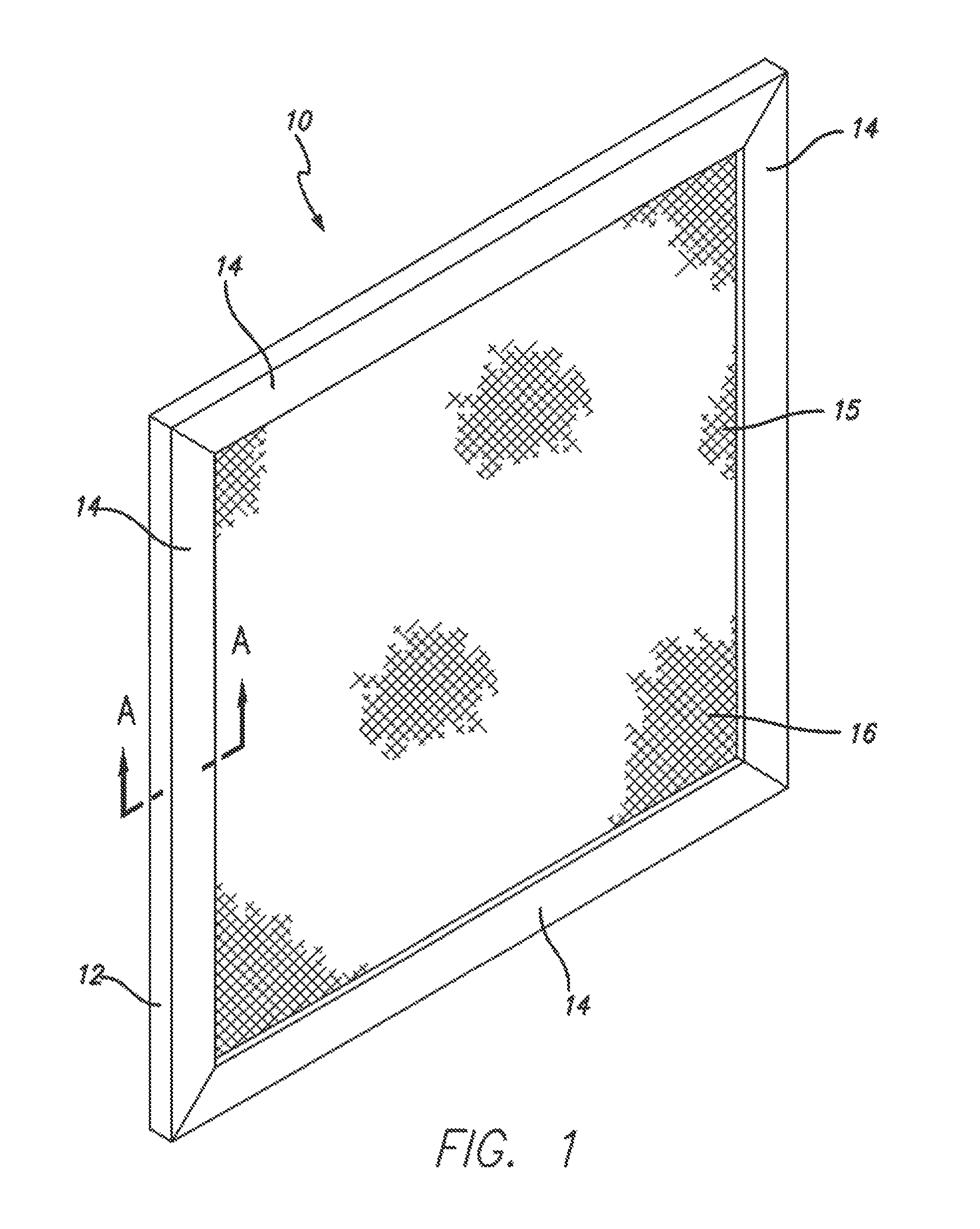

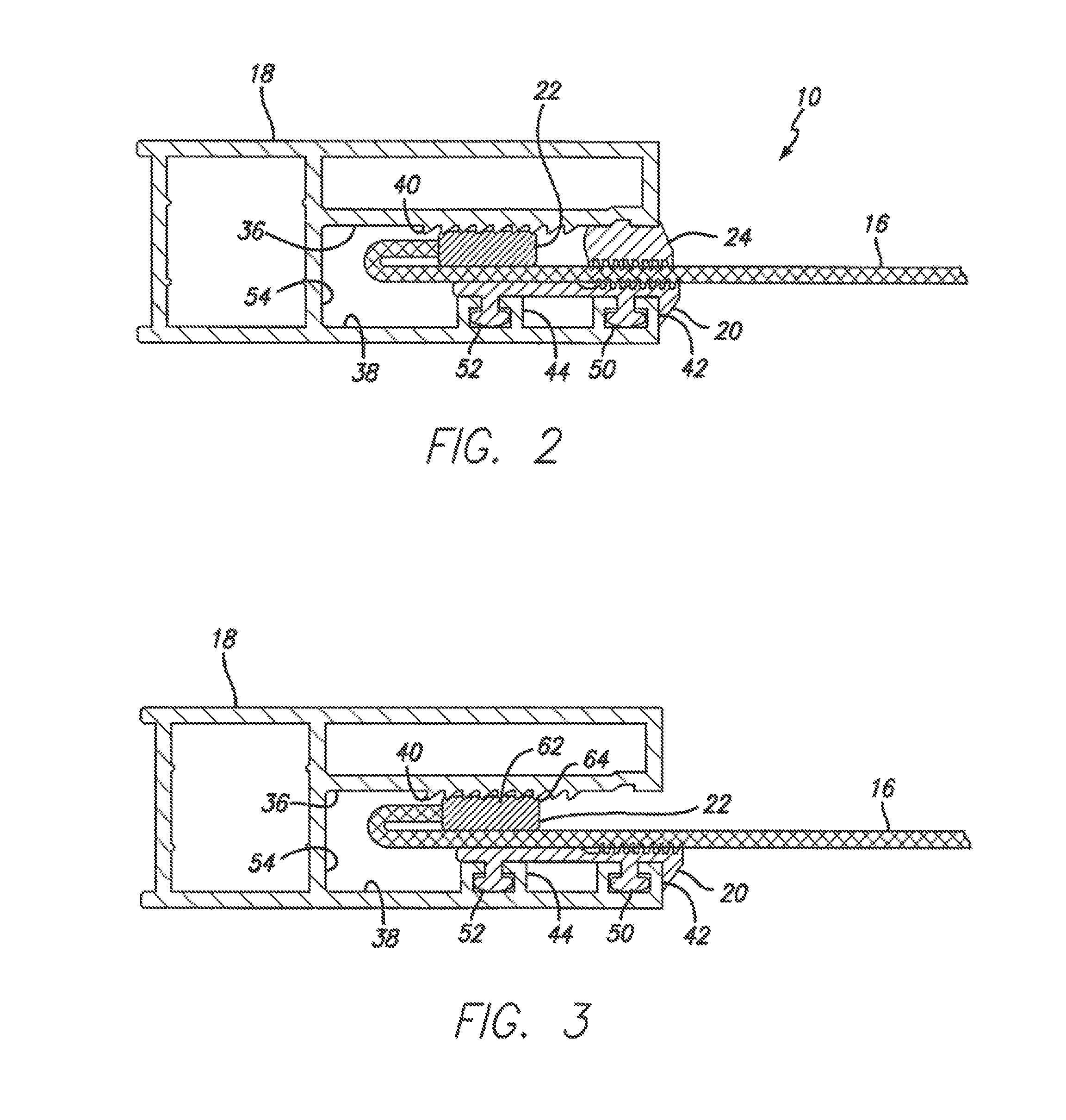

Adjustable screen tensioning system

ActiveUS9284770B2Improve the immunityPrevent galvanic corrosionInsect protectionLight protection screensFree edgeLock screen

An adjustable screen re don system is presented. The present invention screen retention system comprises a mesh Of perforate screen retained within a frame composed of frame members have channel cross sections. The screen is formed with a rolled or U-shaped edge hem. The edge hem having a free edge that folds inwardly over the inner face of the screen and is parallel to, and spaced above, the inner face of the screen. The framing members are channel section extrusions which contain features for retaining, tensioning and locking the screen. The adjustable screen retention system herein presented improves upon the prior art by providing a more secure attachment of the screen within the channel of the frame members thereby providing increased resistance to screen impact loading. The new system also provides for a broader range of screen of tensioning adjustment than has heretofore been available and further electrically isolates the screen from the walls of the channel.

Owner:C R LAURENCE

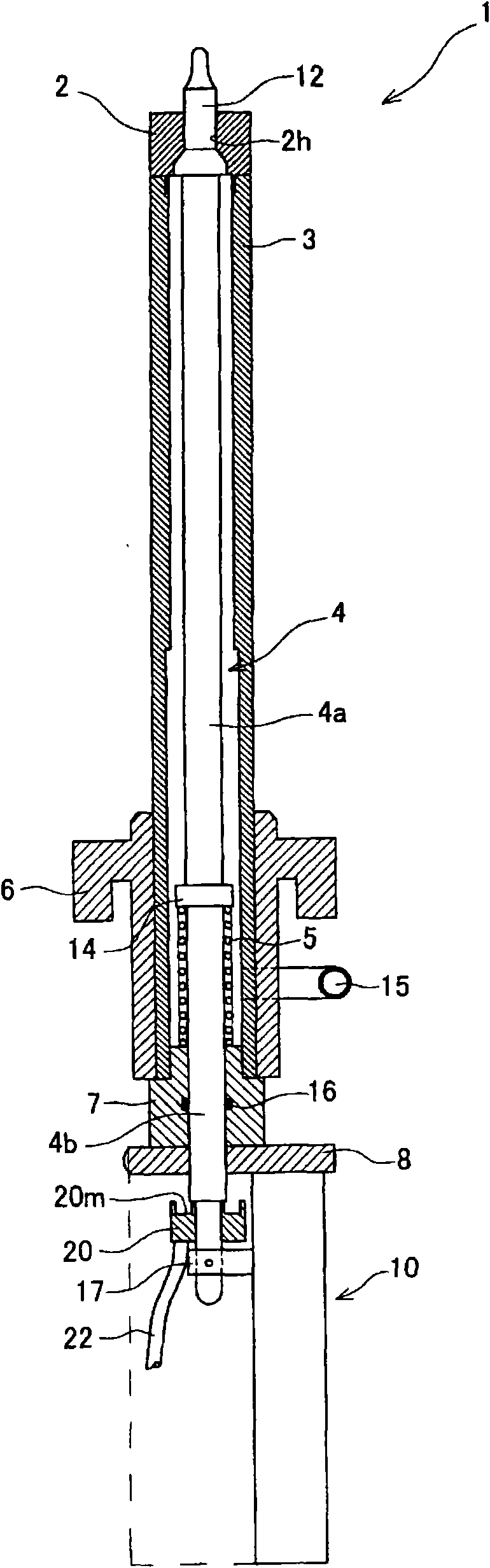

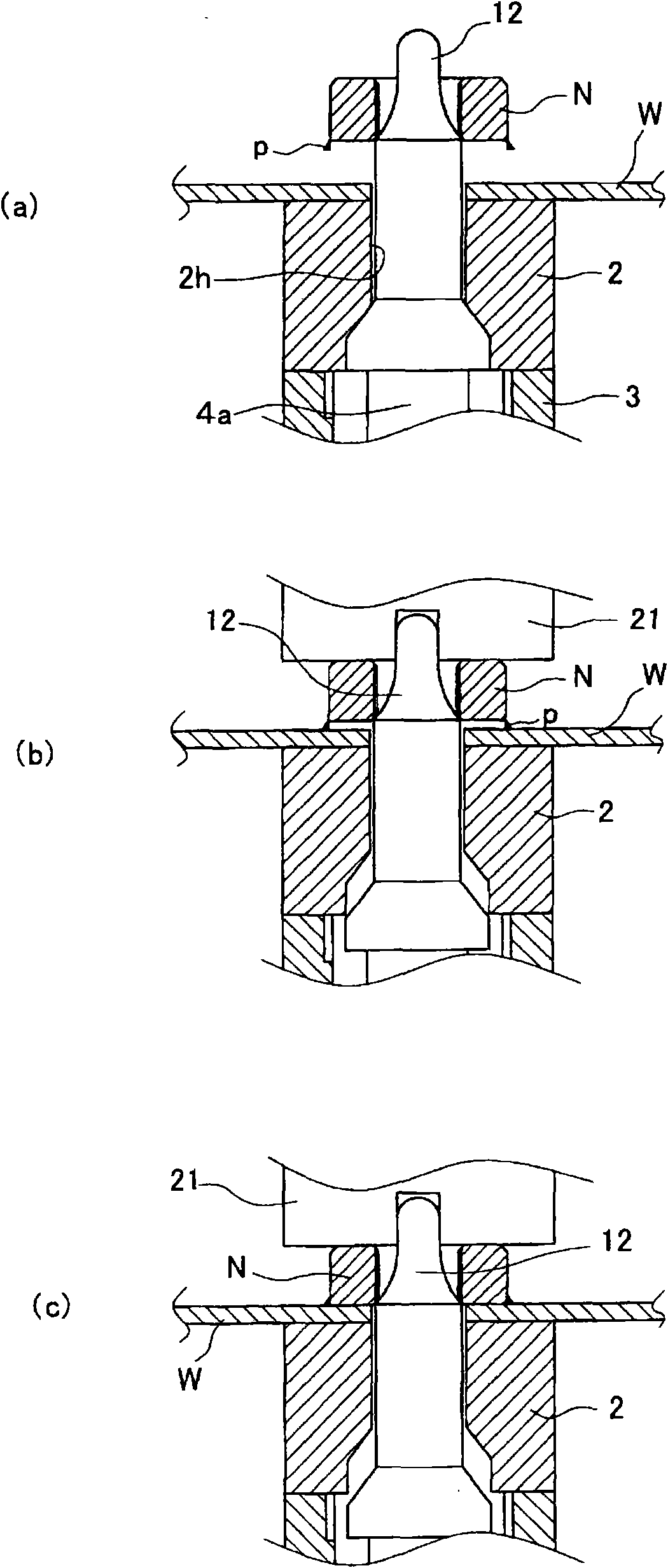

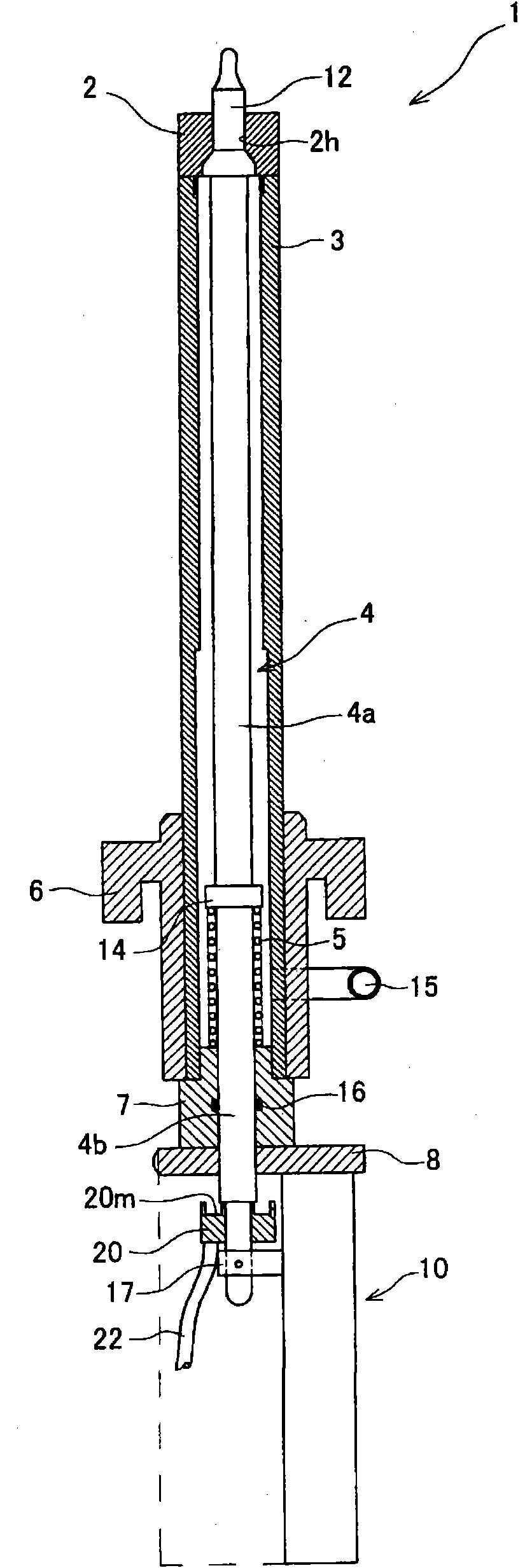

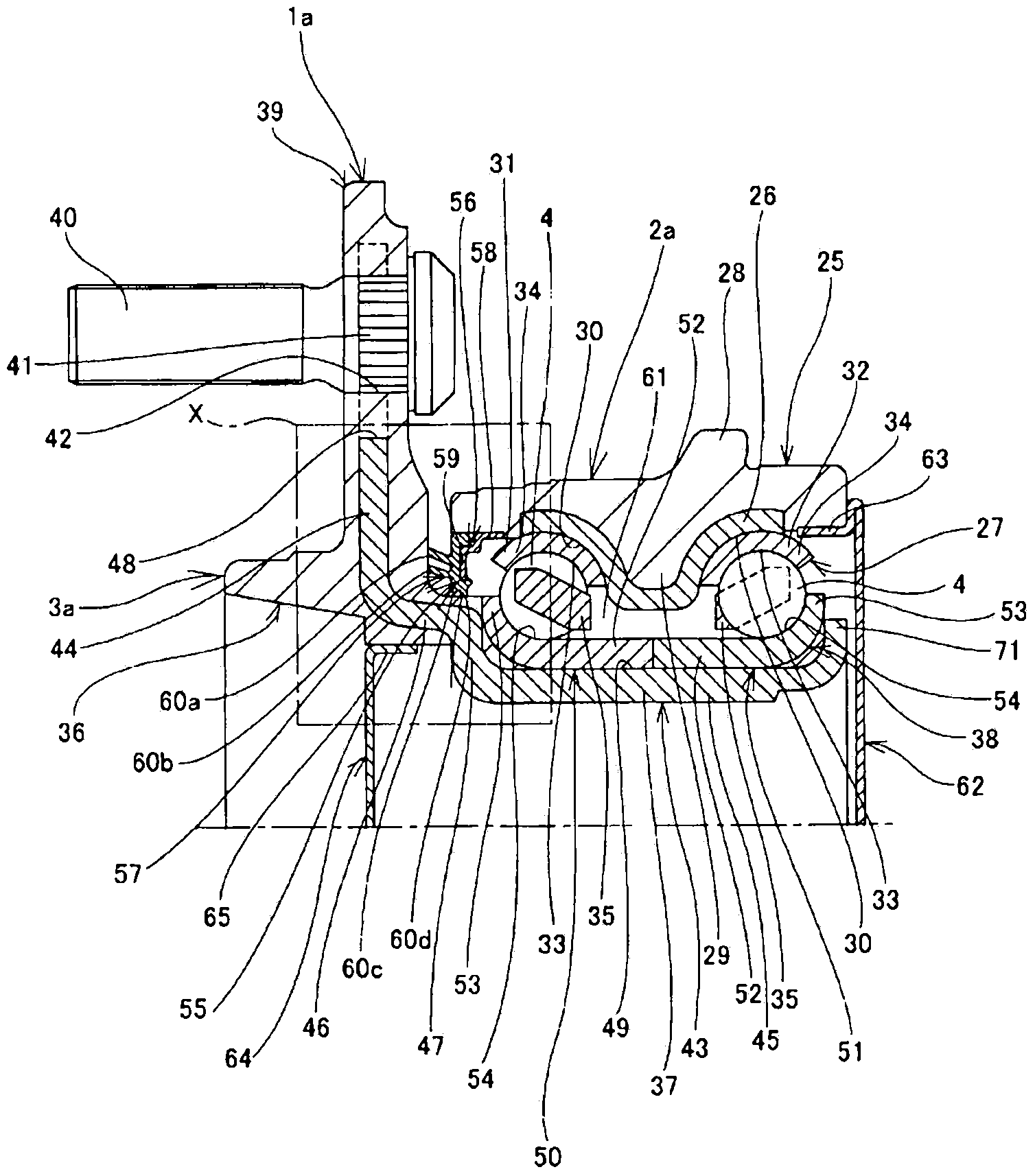

Welding lower electrode device

InactiveCN101862920AIncreased durabilityReduce adverse effectsWelding/cutting media/materialsSoldering mediaMechanical engineeringElectrode

An object of the present invention is to reduce the size of an entire device by simplifying a device configuration, and also accurately measure the stroke position of a rod. A lower electrode 2 is mounted on an upper portion of an electrode holder tube 3. A rod 4 that is vertically movable within the electrode holder tube 3 is divided into a first rod 4a and a second rod 4b. The rod 4 is urged upward by a compressed spring 5 that is interposed between a spring receiving seat 14 fixed to the upper end surface of the second rod 4b and an insulating adapter 7. Pressurized air supplied from a pressurized air supply pipe 15 to assist the urging force is received by a pressure receiving portion on the lower surface of the spring receiving seat 14, thereby assisting the spring 5 to urge the rod 4 upward. A magnetic sensor 10 is disposed below the second rod 4b, and a lower end portion of the second rod 4b is directly connected to a detector 17 of the magnetic sensor 10.

Owner:SMK CO LTD

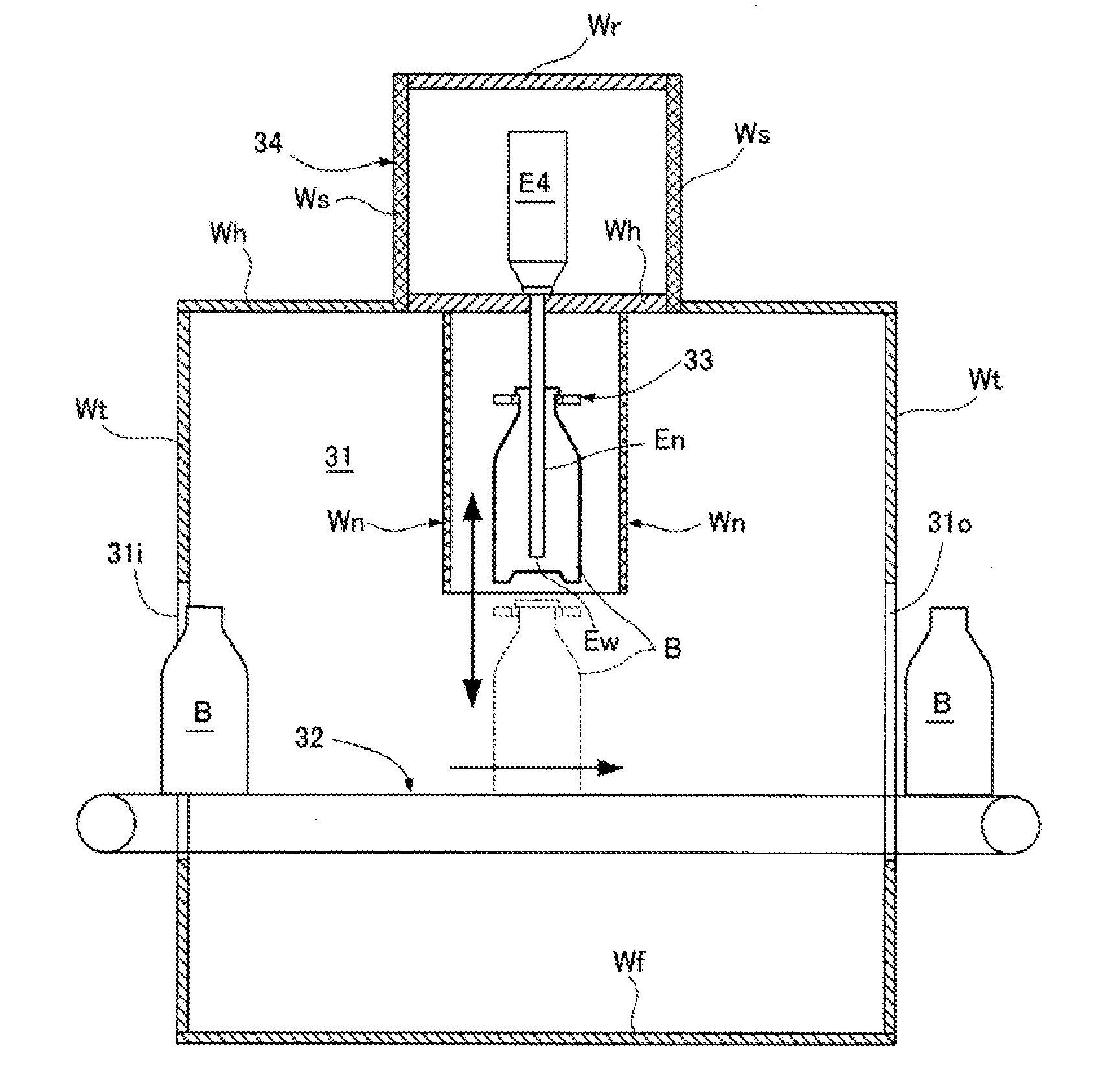

Shield and electron beam container sterilization equipment

ActiveUS20160083131A1Prevent corrosionEffectively attenuatePackage sterilisationMaterial analysis by optical meansCorrosion resistantEngineering

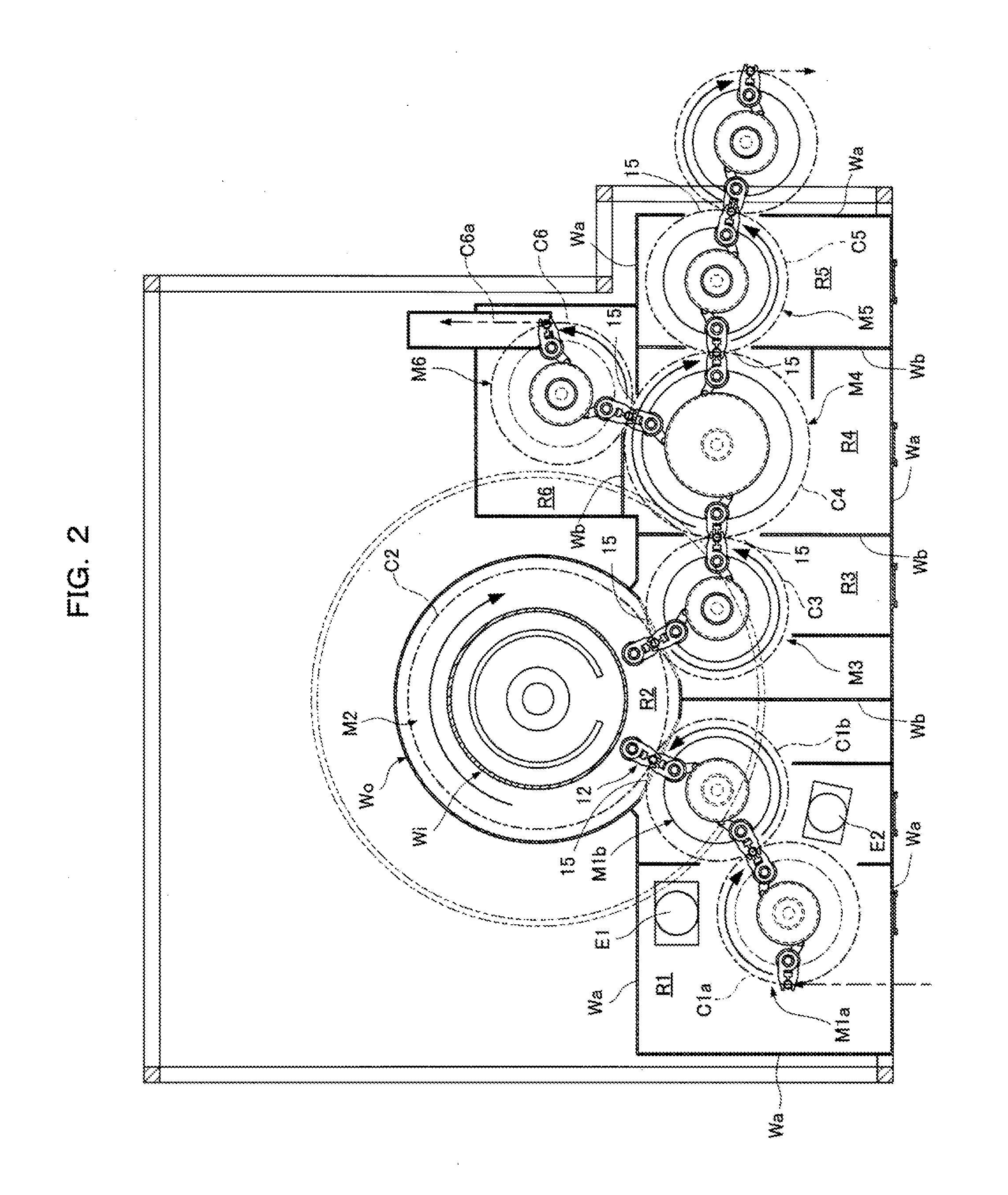

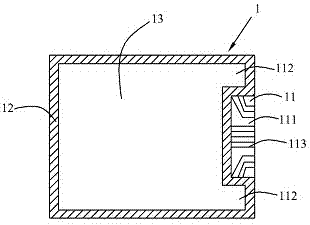

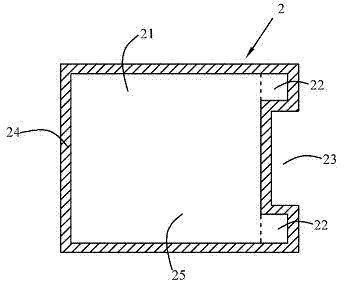

Provided is a shield used for container sterilization equipment that inserts, from the mouth of a container (B), an irradiation nozzle (En) having an exit window (Ew) on the distal end of the irradiation nozzle (En) and sterilizes the inner surface of the container (B), the irradiation nozzle (En) being surrounded by composite shields (Wi, Wo). A composite shield block (21) forming the composite shields (Wi, Wo) includes a magnetic shield (24) and an X-ray shield (25) that are disposed in the hollow section of a board-shaped shell (22) made of a corrosion resistant material, and an insulating layer (26) that is interposed between one surface of the board-shaped shell (22) and the magnetic shield (24), between the magnetic shield (24) and the X-ray shield (25), and between the X-ray shield (25) and one surface of the board-shaped shell (22).

Owner:HITACHI ZOSEN CORP

OLED (organic light emitting devices) screen body capable of preventing lead corrosion and OLED screen body packaging method

ActiveCN102244088AExtended service lifePrevent Galvanic CorrosionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceOrganic layer

The invention provides a method for packaging an OLED (organic light emitting diode) screen body comprising the following steps: a) preparing packaging sheets, arranging a plurality of through holes on the packaging sheets, forming a plurality of packaging holes; b) dispensing on the packaging sheets, dispensing zone being arranged at one side of the through hole which is housed by a notch; c) preparing the substrate, preparing an anode layer, an organic layer and a cathode layer on the substrate; d) under the inert gas or vacuum environment, packaging the packaging sheets on the substrate by using a packaging glue; and e) incising along an edge of the through hole of the packaging sheet far away from a packaging pit, and obtaining the OLED screen body. By using the OLED screen body with the packaging structure, liquid oxygen can be effectively prevented to be sealed in a corresponding space in a packaging process, thus leads are prevented from electrocorrosion, and the service life of the screen body is prolonged.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Erosion and corrosion resistant coatings for exhaust gas recirculation based gas turbines

ActiveUS20130340403A1Prevent galvanic corrosionBlade accessoriesEfficient propulsion technologiesMartensitic stainless steelExhaust fumes

A compressor blade for use in a compressor section of a gas turbine engine, comprising: a martensitic stainless steel compressor blade and an abrasive coating having an anodic component. The compressor blade has a blade portion, a dovetail portion and a platform portion intermediate the blade portion and the dovetail portion, the blade portion terminating in a tip opposite the dovetail portion. A cobalt-based coating overlies at least the blade portion of the compressor blade. The cobalt-based coating comprises a cobalt based material that includes precipitates of tungsten carbide that provide erosion resistance and particles of a sacrificial metal-based material distributed through the cobalt-based coating that provide galvanic corrosion resistance to the system.

Owner:GENERAL ELECTRIC CO

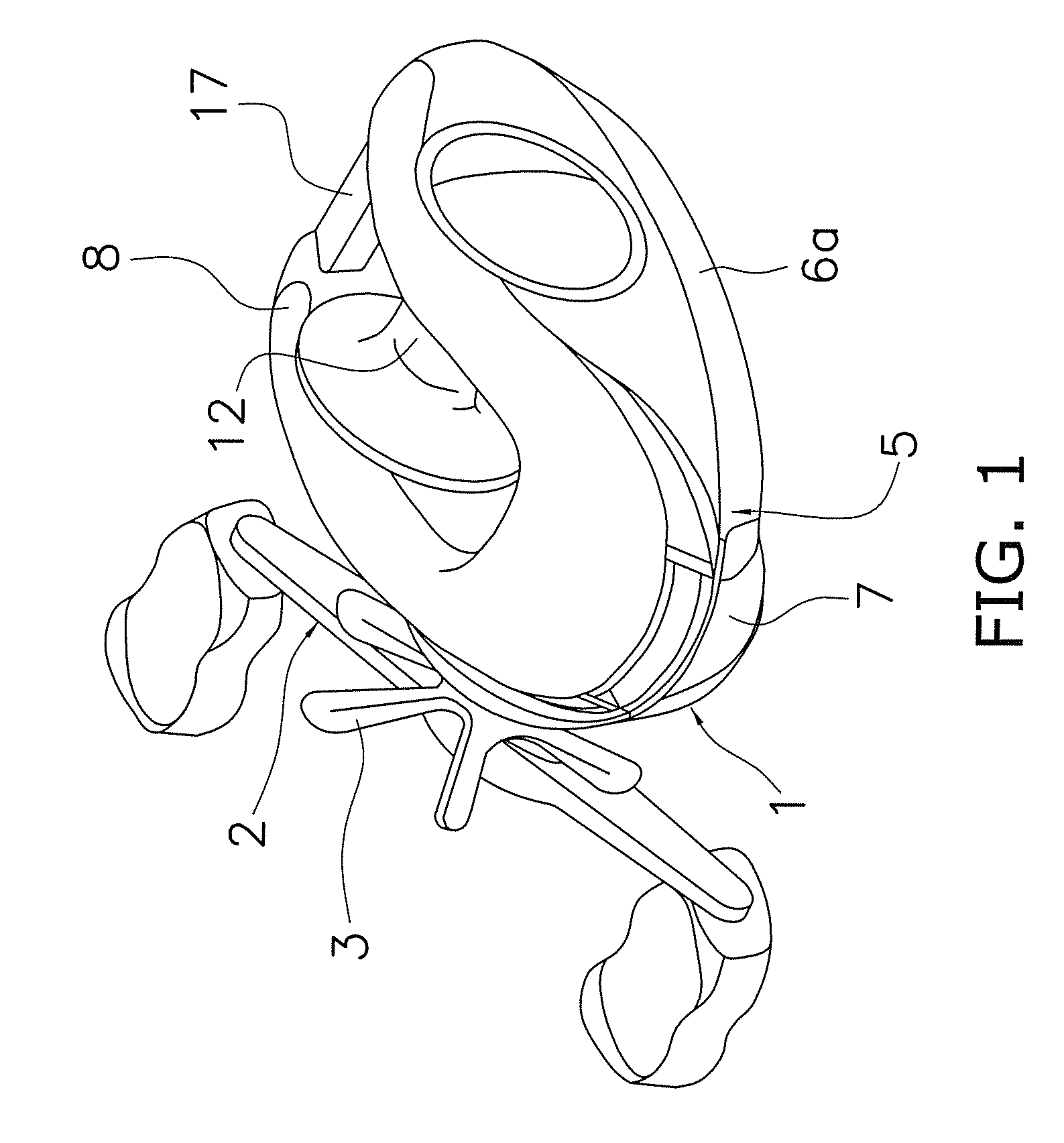

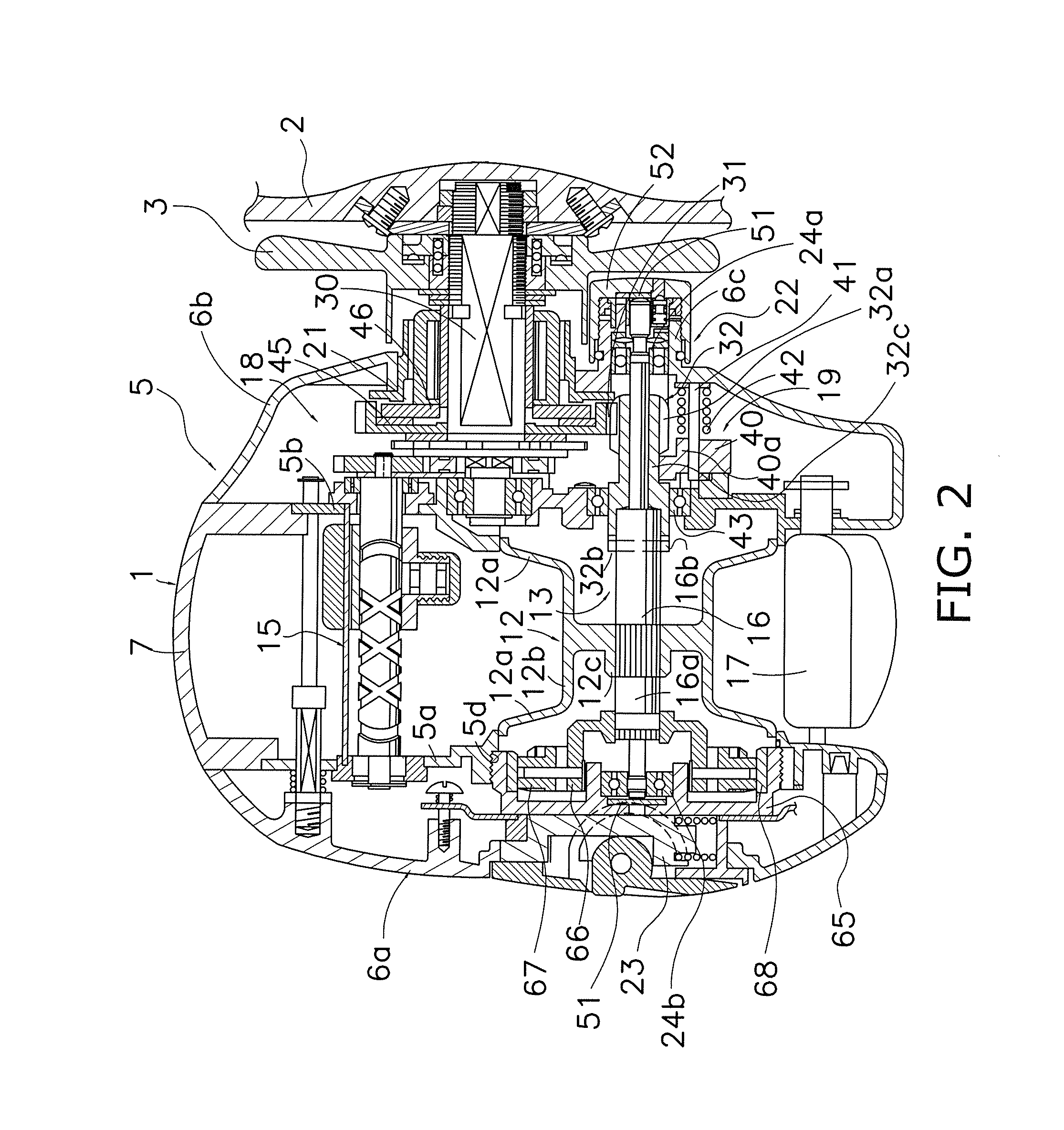

Fishing reel

ActiveUS20120223173A1Excellent abrasion resistanceReduce frictional resistanceReelsSurface layerMechanical engineering

A fishing reel for winding and releasing a fishing line includes a tubular spool being configured to wind the fishing line onto an outer periphery thereof, a spool shaft made of metal, the spool shaft being attached to an inner periphery of the spool, and a Diamond Like Carbon (DLC) layer being formed on a surface layer side of the spool shaft.

Owner:SHIMANO INC

Tracking-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540000AExcellent tracking resistanceGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesGas releaseMechanical property

The invention discloses a tracking-resistant polyethylene sheath material for a power wire and a preparation method thereof. The tracking-resistant polyethylene sheath material for the power wire is prepared from the following substances in parts by weight: 50-70 parts of high-density polyethylene, 30-40 parts of linear low-density polyethylene, 15-25 parts of ethylene-propylene-diene monomer, 3-6 parts of polytrifluoropropyl methylsiloxane, 10-15 parts of nano wollastonite, 20-25 parts of sediment white carbon black, 5-10 parts of nano-montmorillonite, 4-6 parts of ferrocene, 10-15 parts of magnesium hydroxide, 8-12 parts of methyl phenyl silicone oil, 2-3 parts of dibutyltin dilaurate, 3-5 parts of phosphoguanidine and 5-10 parts of borax. The sheath material is excellent in tracking resistance, so that the electric erosion phenomenon on the surface of the power wire in extra-high voltage can be solved; meanwhile, the sheath material is good in physical and mechanical properties, electrical insulation property, environmental stress crack resistance, ageing resistance and heat resistance, durable in use, long-term in operation in outdoor severe environment without failure, good in flame retardant effect, low in smoke during combusting without harmful gas release, free of environmental pollution, safe and environment-friendly.

Owner:天长市富达电子科技股份有限公司

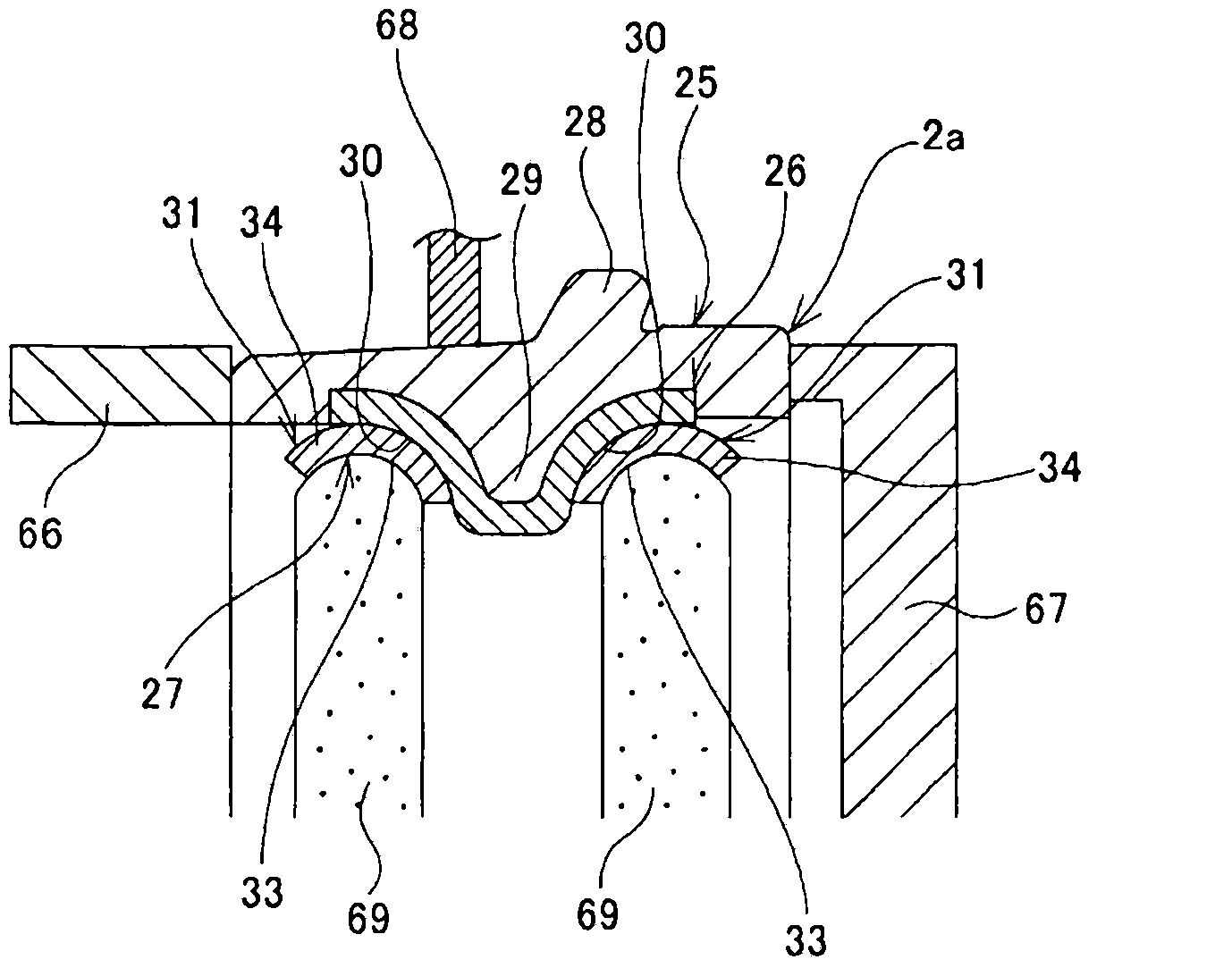

Roller bearing unit

ActiveCN103703262AAchieve lightweightIncreased durabilityRolling contact bearingsHubsFiberRolling-element bearing

The invention provides a roller bearing unit for which the weight can be decreased and the durability can be improved. An outer ring core metal (26) that is manufactured from an iron alloy and forms an outer ring (2a) is molded to an outer ring main body (25) manufactured from a synthetic resin containing reinforced fibers or from an aluminum alloy. At the inner circumferential surface of the outer ring core metal (26), outer ring raceway members (27) are fitted into and affixed to mating concave surfaces (30), which are the portions of the inner circumferential surface of the outer ring core metal (26) that are exposed from the outer ring main body (25). A hub core metal (37) that is manufactured from an iron alloy and forms a hub (3a) is molded to a hub main body (36) manufactured from a synthetic resin containing reinforced fibers or from an aluminum alloy. At the outer circumferential surface of the hub core metal (37), inner ring raceway members (38) are fitted onto and affixed to a mating surface (49), which is the portion of the outer circumferential surface of the hub core metal (37) that is exposed from the hub main body (36).

Owner:NSK LTD

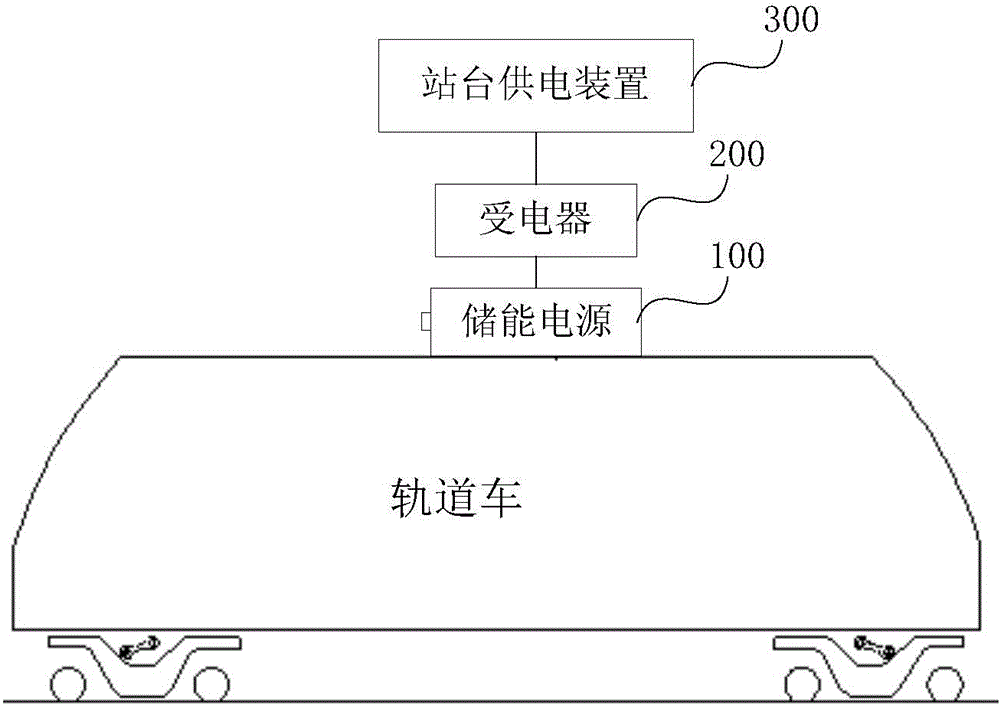

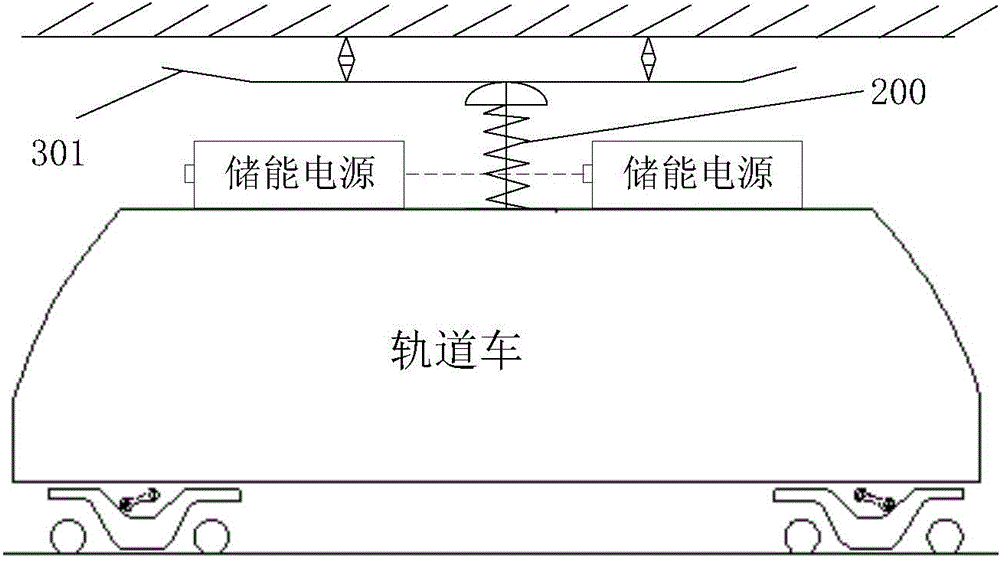

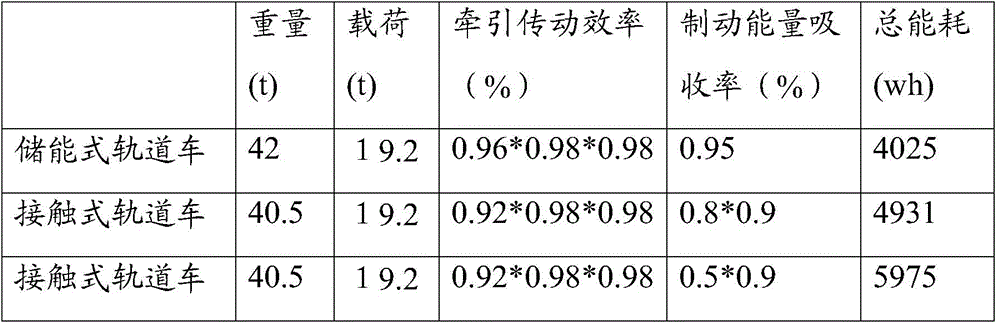

Traction power supply system of track car

InactiveCN104149630AGuaranteed uptimeSimple structurePower current collectorsElectricityTraction power supply

The invention provides a traction power supply system of a track car. When the track car enters a station, a station power supply device arranged on the track car station will make contact with a current collector on the track car, so that energy storage power sources connected with the current collector are charged, and then the energy storage power sources provide traction power for the track car to guarantee that the track car normally operates without arranging an overhead line system; in this way, the structure of the power supply system is simplified, and when the track car brakes, all generated braking energy will be recovered by the energy storage power sources, so that the utilization rate of energy is greatly increased, and heat discharged into the environment is reduced; moreover, because steel rails in the power supply system are only used as walking rails, reflowing is not borne any more, and electro-corrosion on roadside facilities is avoided.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com