Patents

Literature

80 results about "Crimp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crimping is joining two or more pieces of metal or other ductile material by deforming one or both of them to hold the other. The bend or deformity is called the crimp.

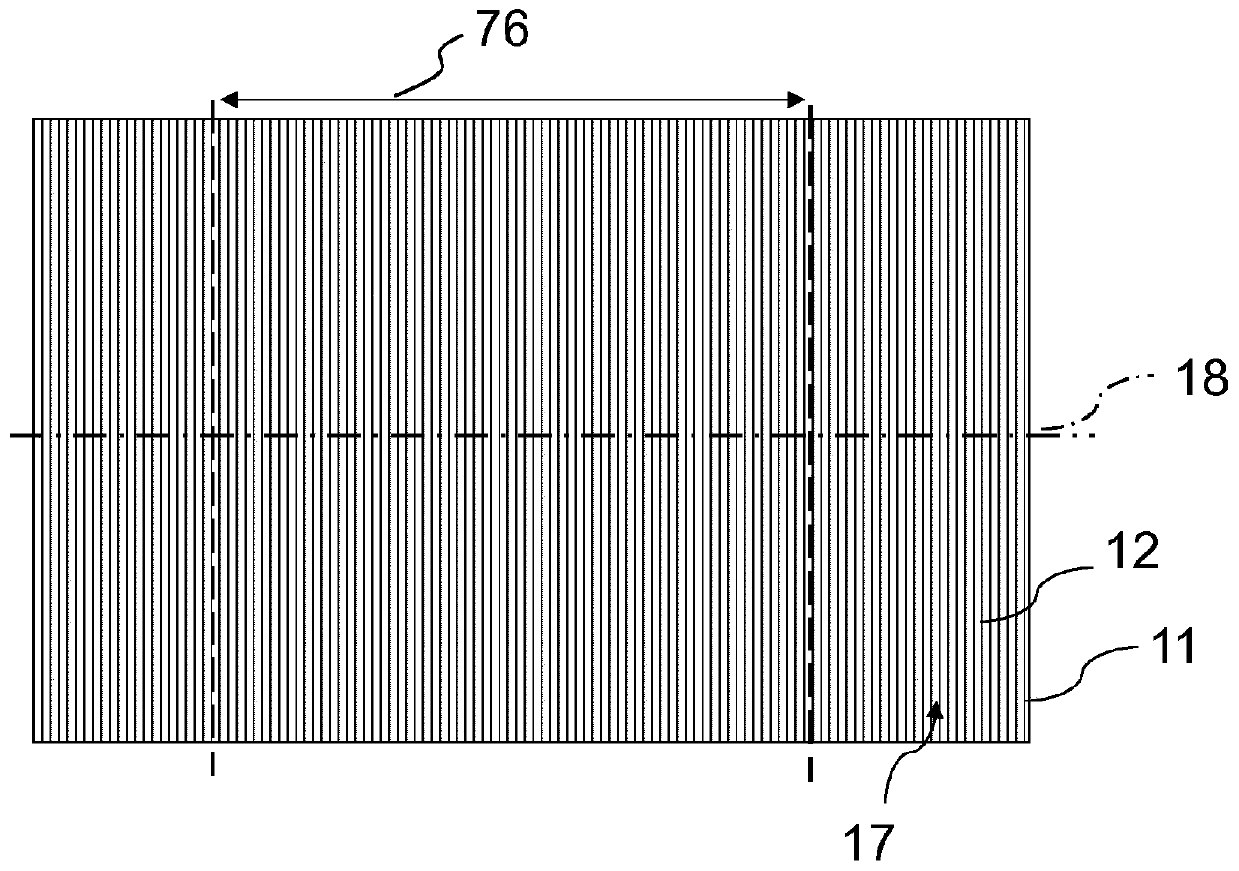

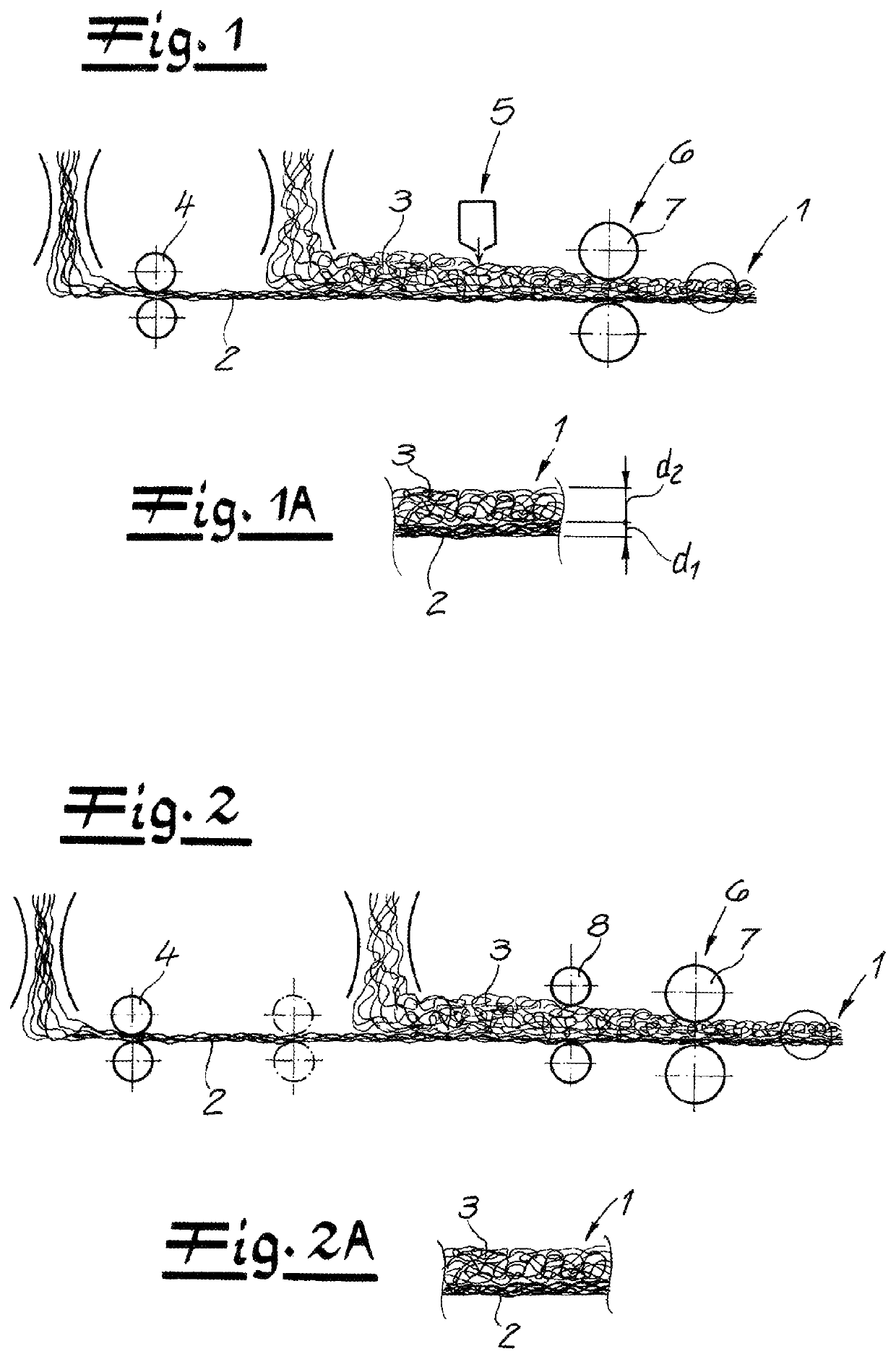

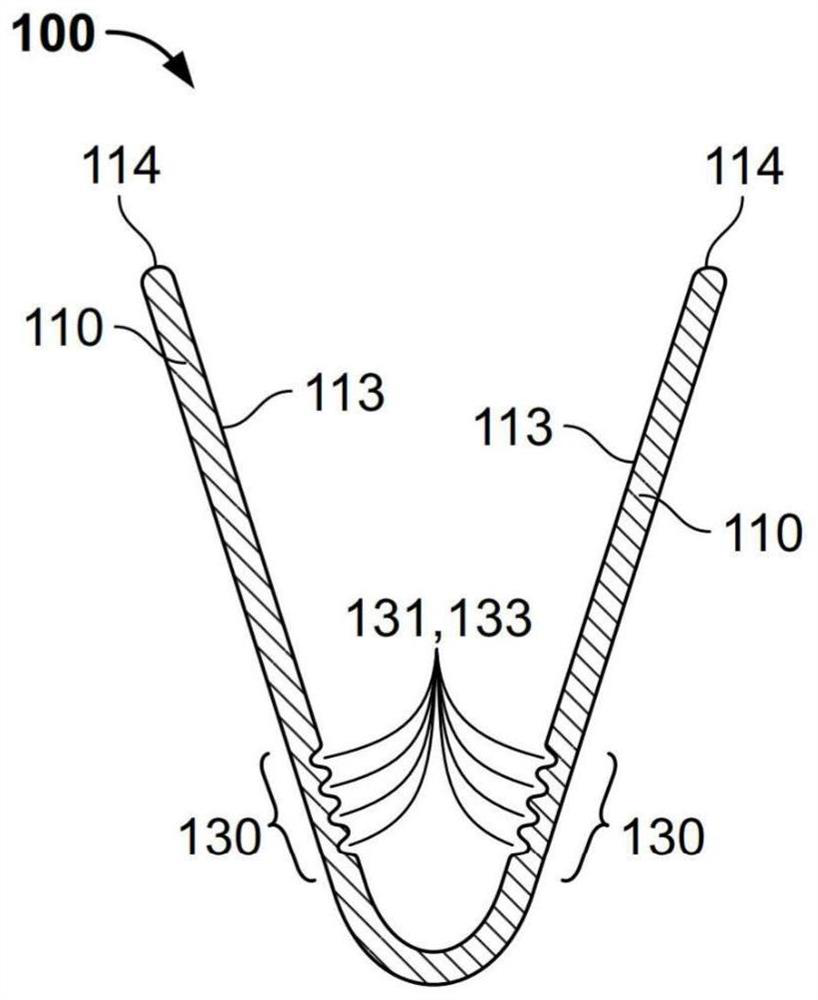

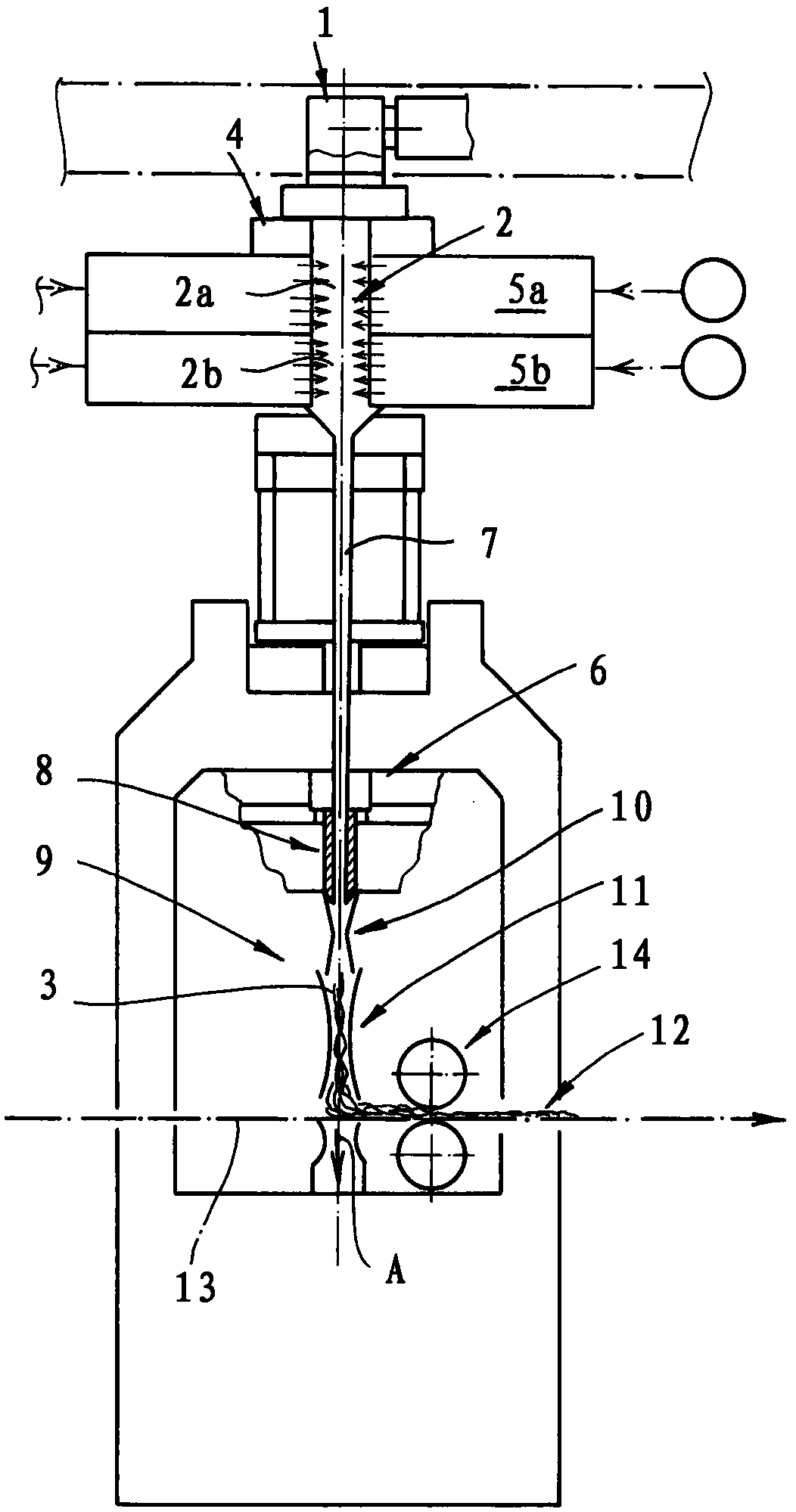

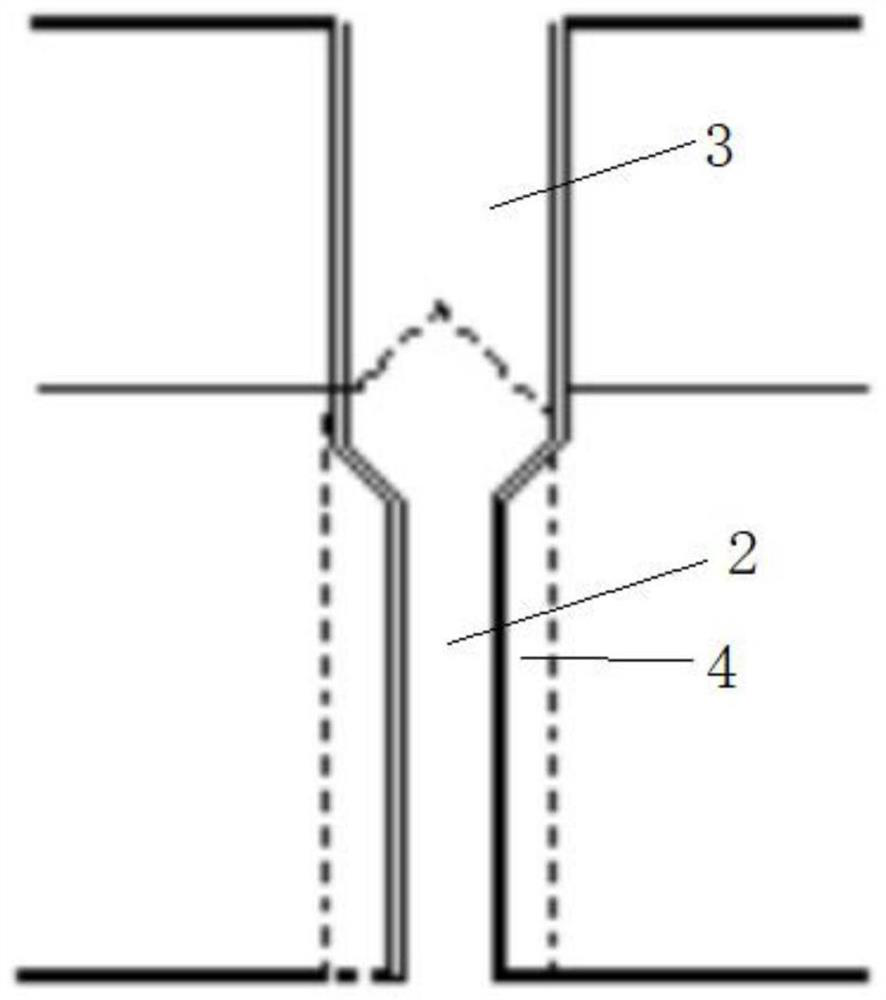

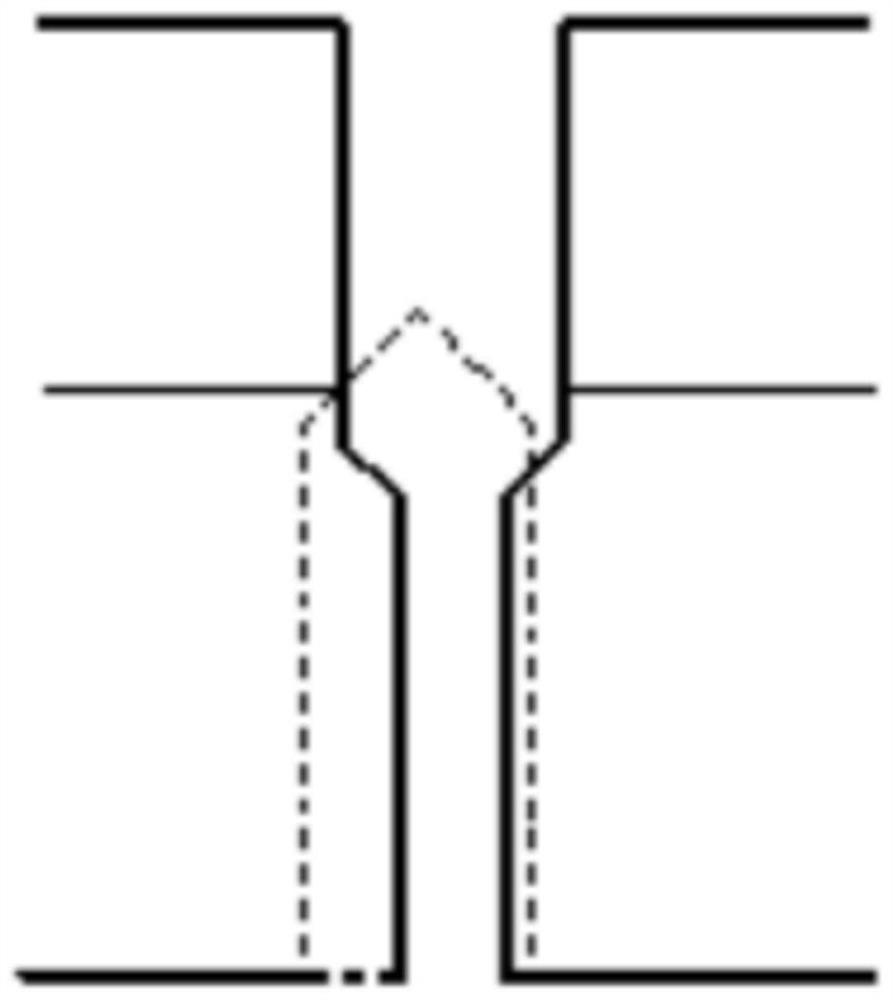

Monofilament metal saw wire

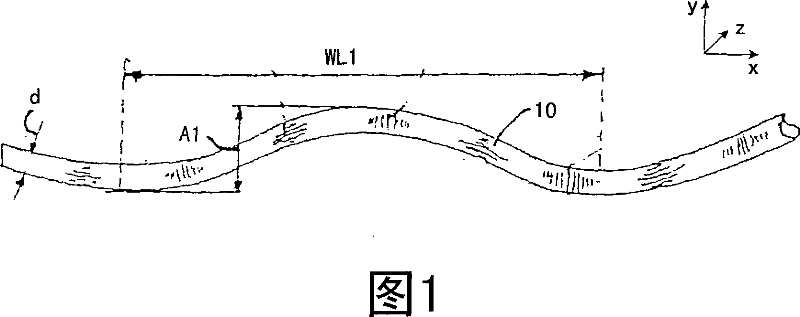

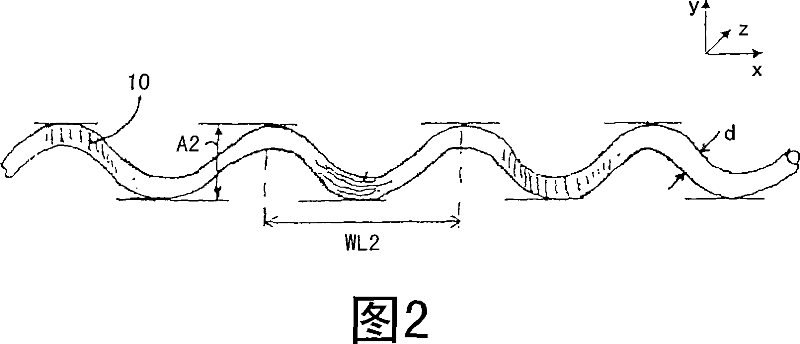

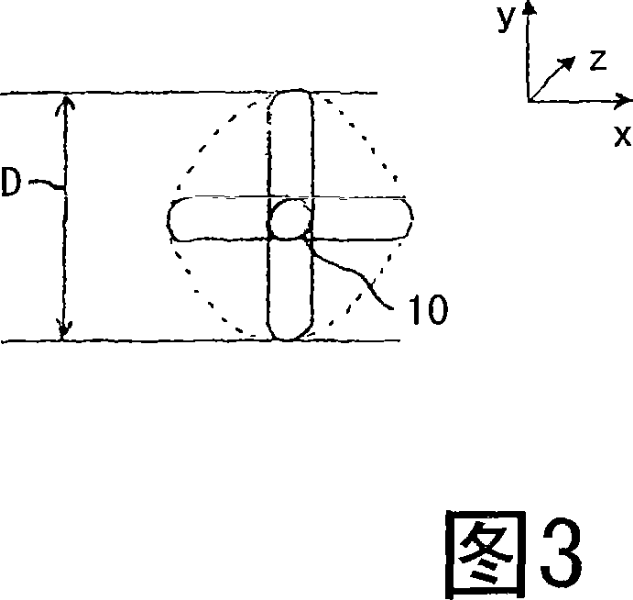

ActiveCN101039771AEasy to manufactureImproved entrainment characteristicsMetal sawing devicesMetal sawing toolsMicrometerCrimp

Monofilament metal saw wire for a wire saw, wherein the saw wire being provided with a plurality of crimps. The crimps are arranged in at least two different planes, such that, when measured, between measuring rods of a micrometer, over a length comprising crimps in at least two different planes, a circumscribed enveloping D diameter of the saw wire is between 1.05 and 1.50 times a diameter d of the saw wire itself.

Owner:ARCELORMITTAL BIESEN & BERTENBERG +1

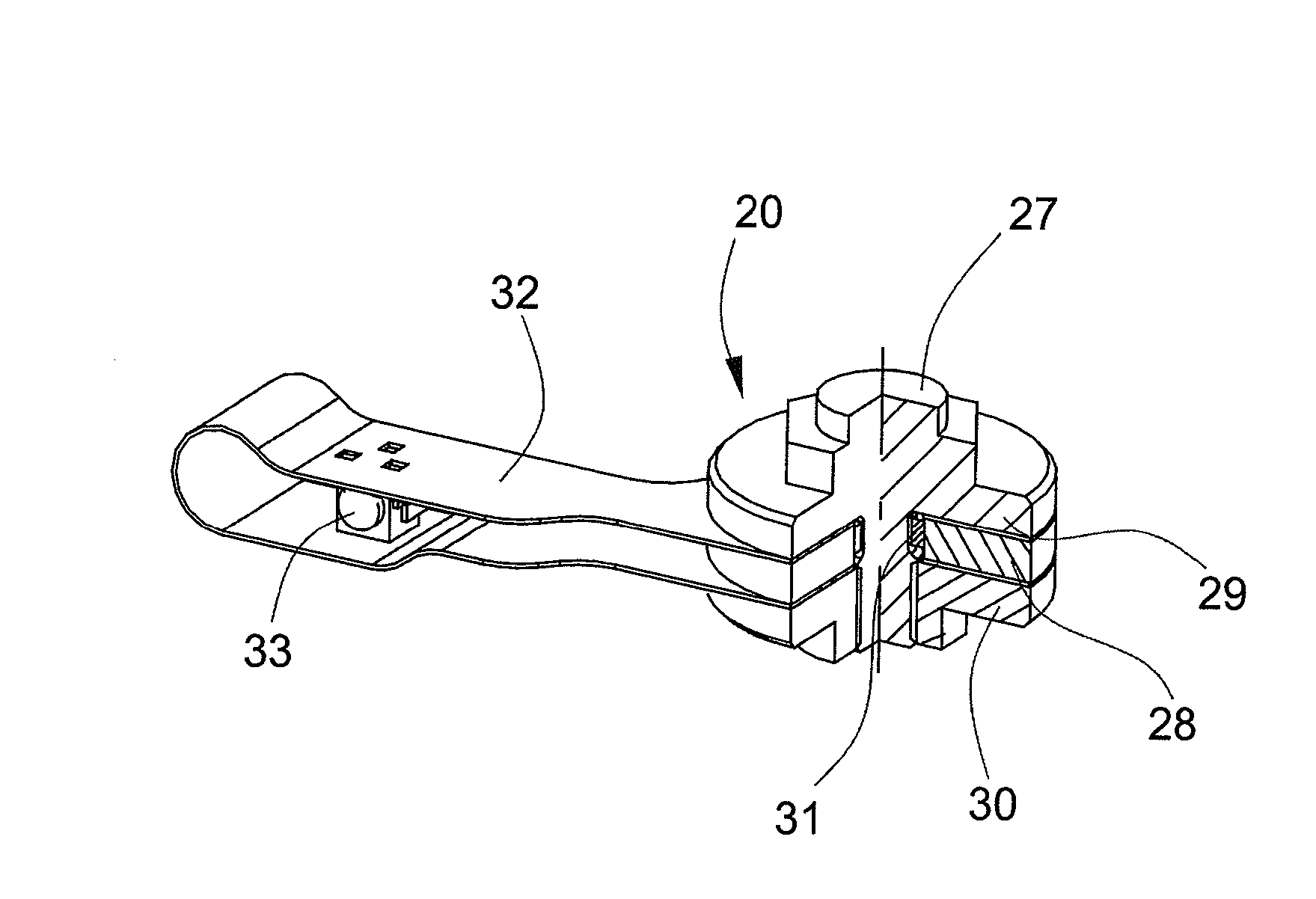

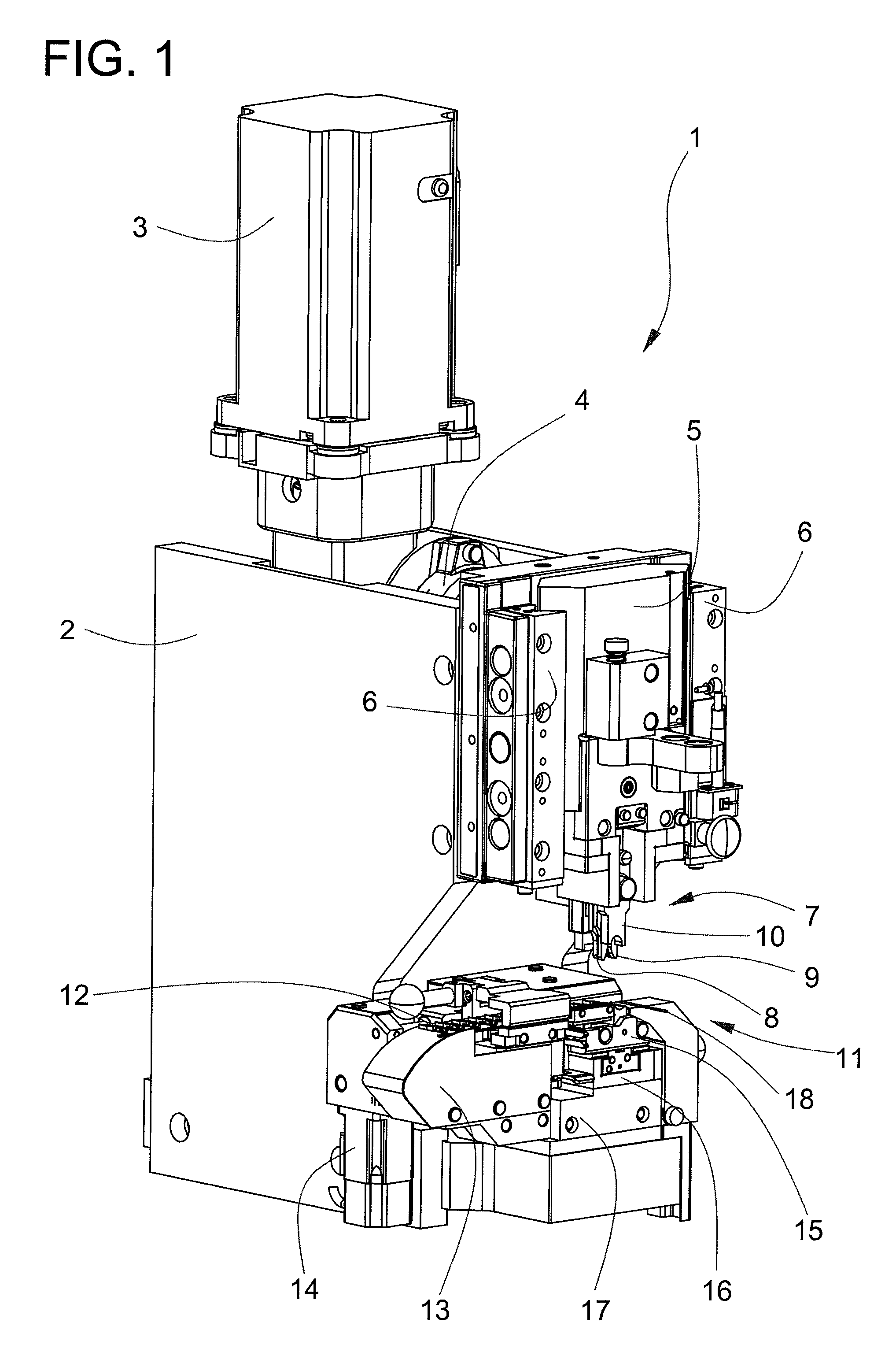

Crimping device

InactiveUS7587918B2Accurate measurementLine/current collector detailsShaping safety devicesElectrical conductorEngineering

A crimping device has for each crimper an anvil including a conductor anvil provided with a force sensor on which the force that arises in the conductor anvil during the crimping operation acts. The conductor anvil rests on a sensor body which in turn rests on a supporting part of the crimping device. The force sensor measures the force that is required to manufacture the conductor crimp, the quality of the crimped fastening being assessable by reference to the force curve generated by the force sensor.

Owner:KOMAX HOLDING

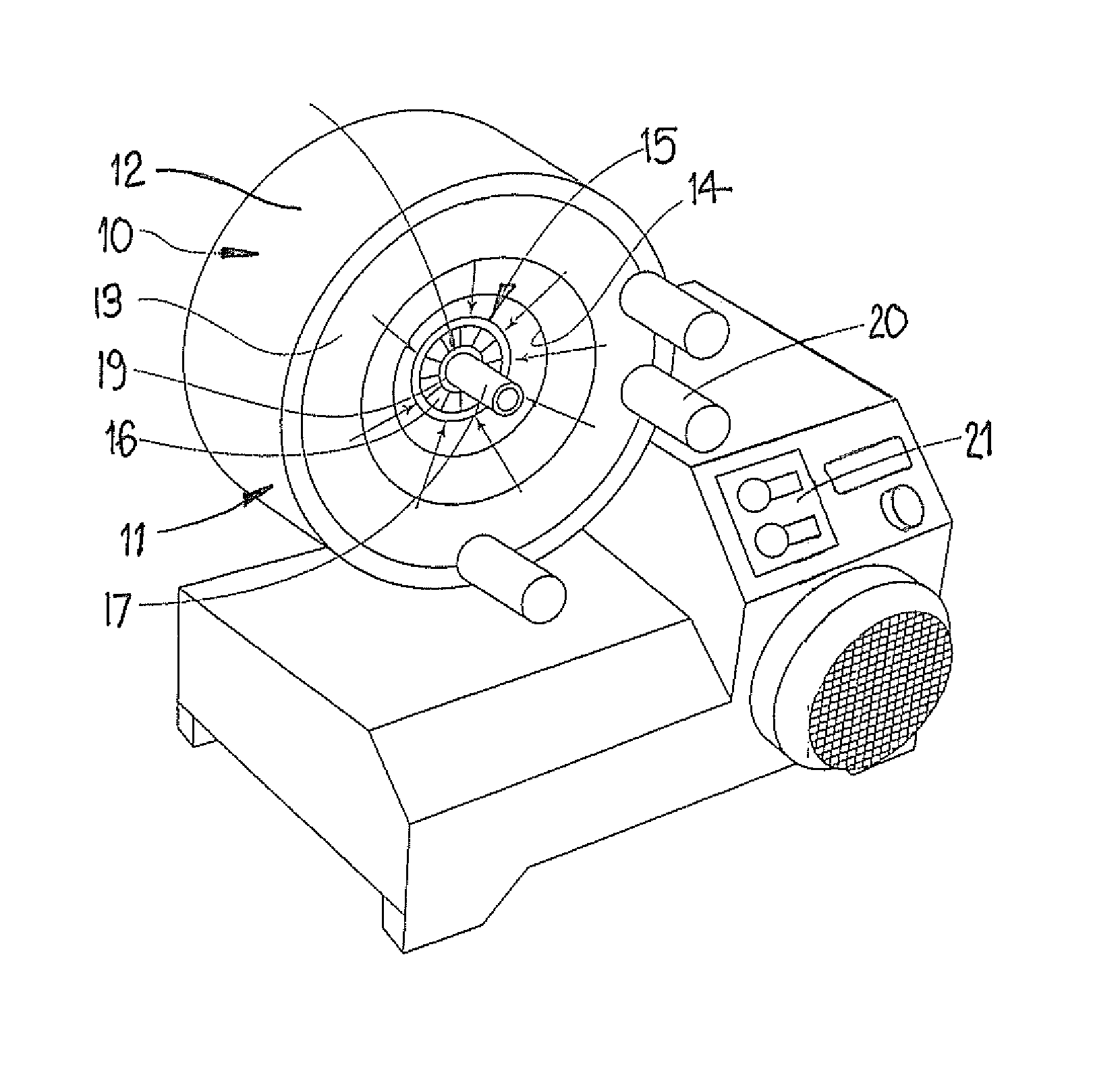

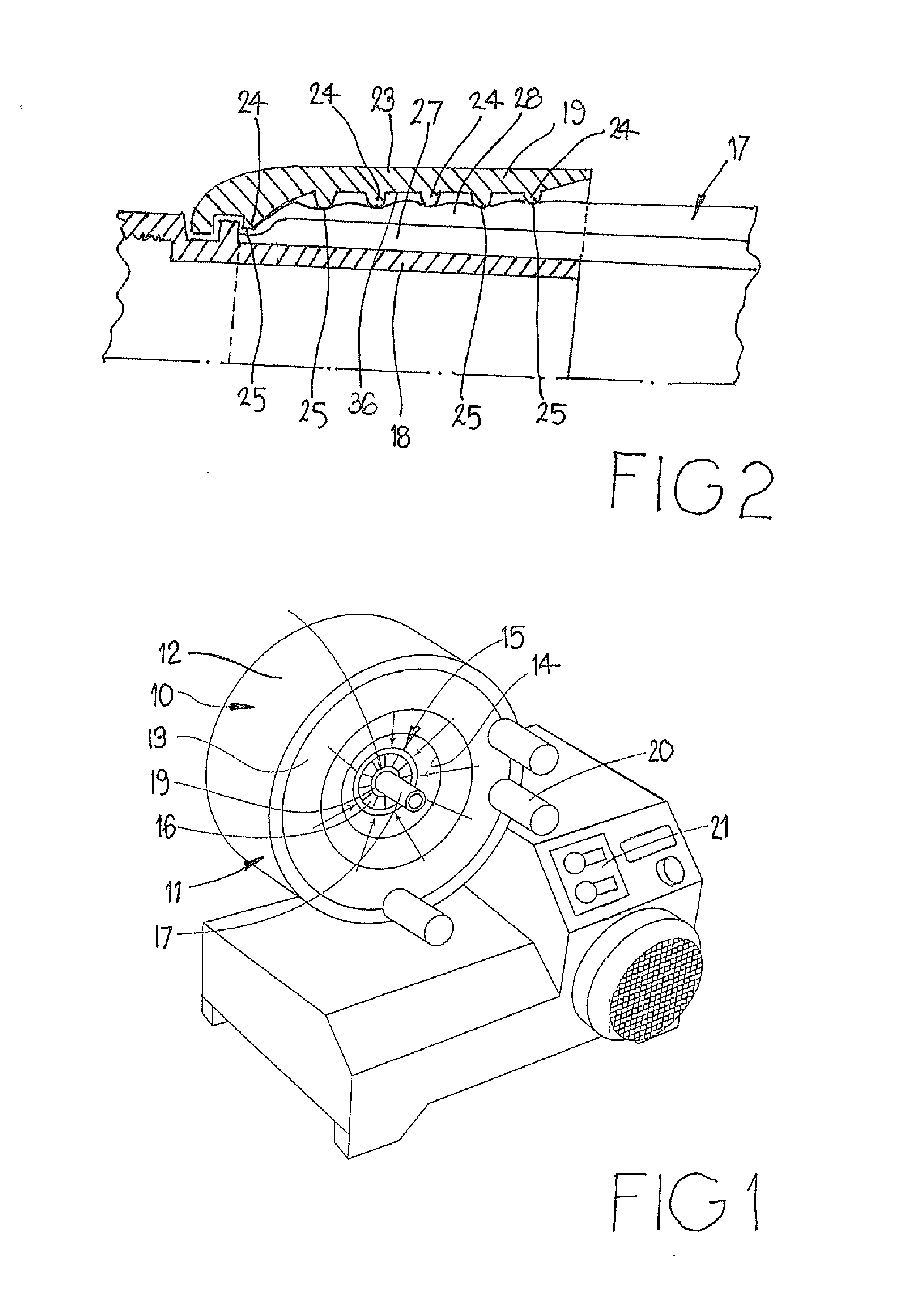

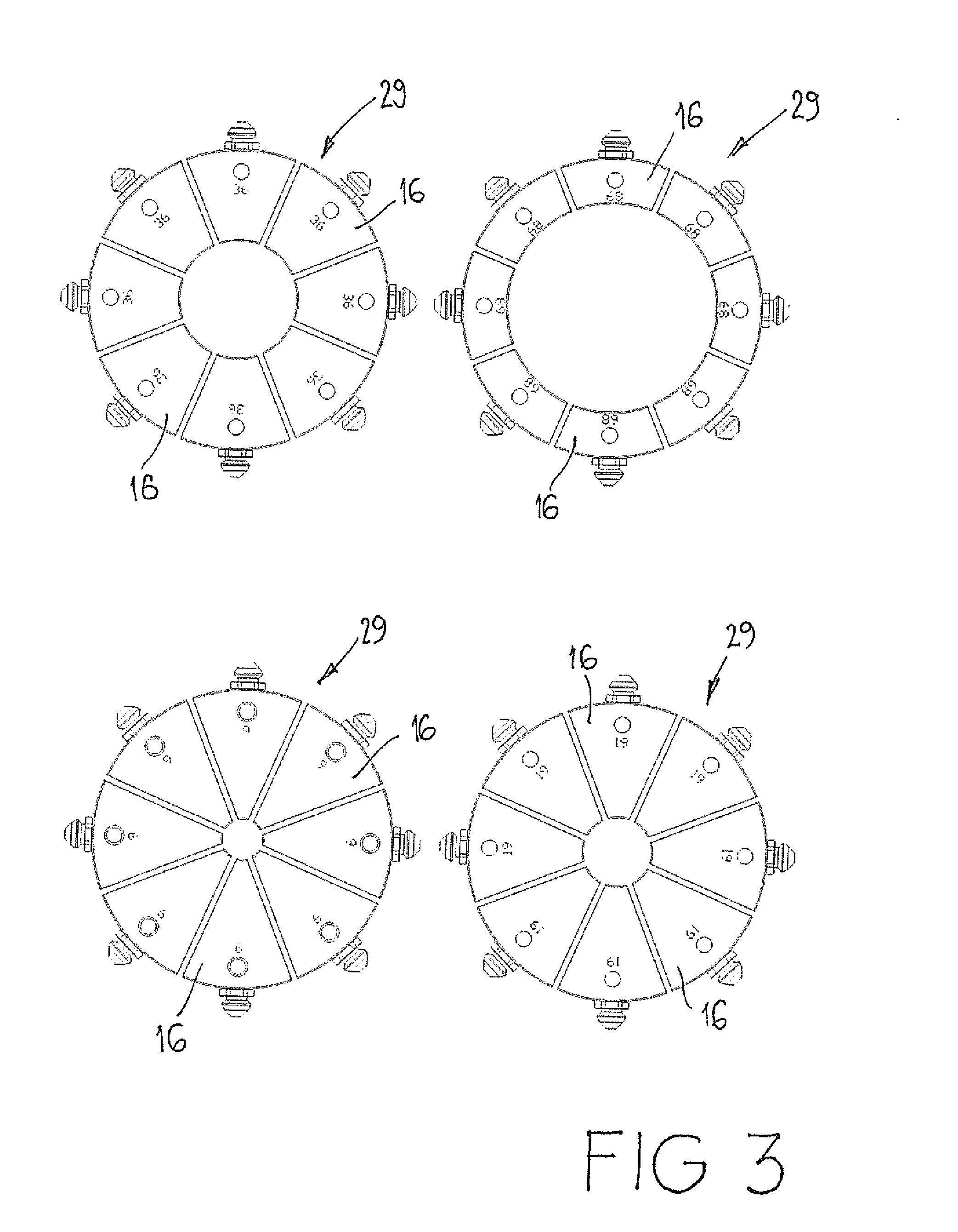

Pinch Decompression in Radial Crimp Press Machines

The specification discloses a crimping process for crimping a metal ferrule (19) onto a hose (17) including the steps of applying a radially inwardly directed crimping force to die elements (16) adapted to engage the ferrule (19) and increasing said crimping force to a first level over a first period of time, at least partially removing the crimping force from said die elements after said first period of time, and reapplying the radially directed crimping force to said die elements (16) and increasing said crimping force to a second level over a second period of time, said second crimping force level being equal to, higher or lower than said first level, and at an end of the crimping process, removing the crimping force fully from the die elements (16).

Owner:BETASWAGE

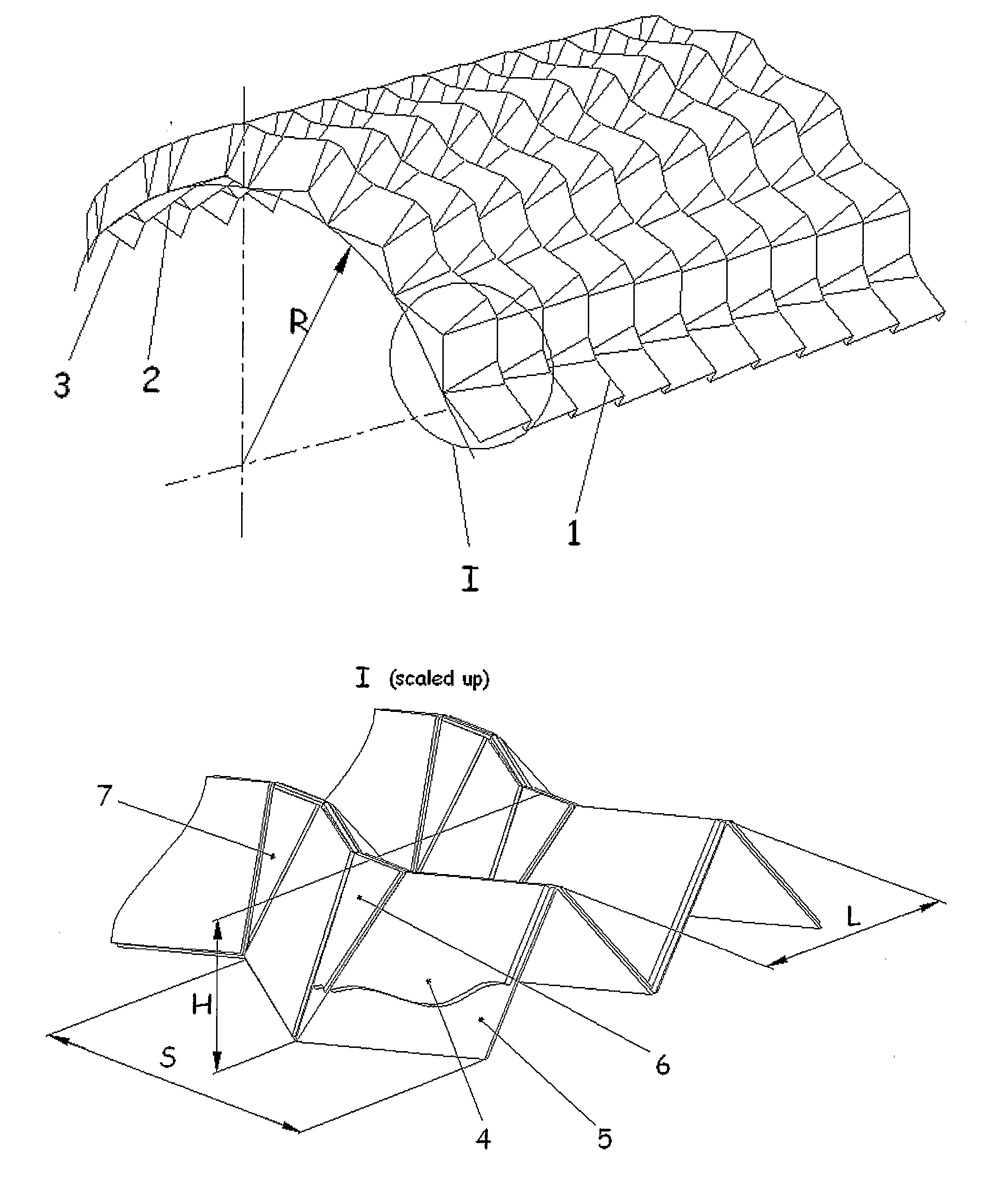

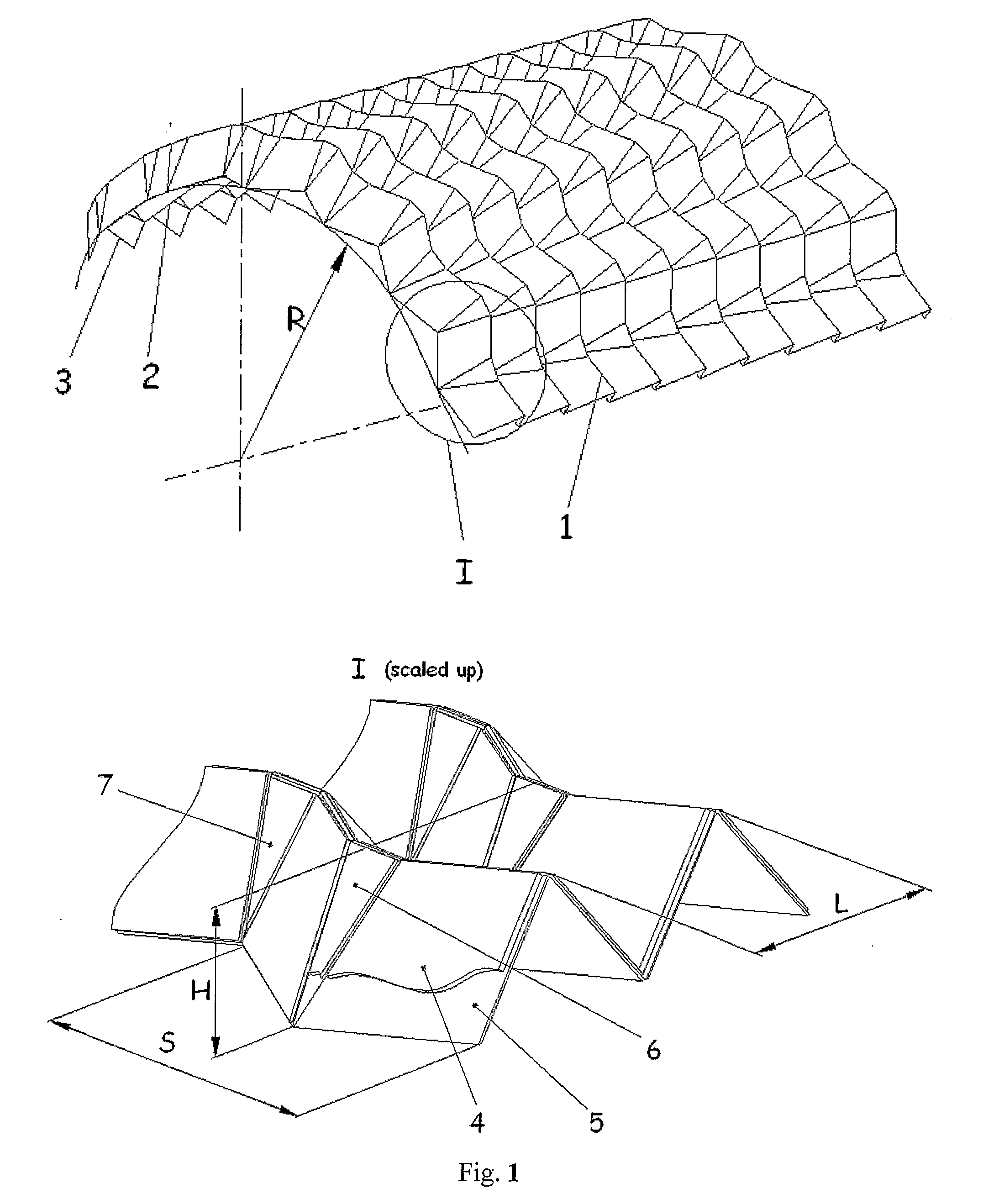

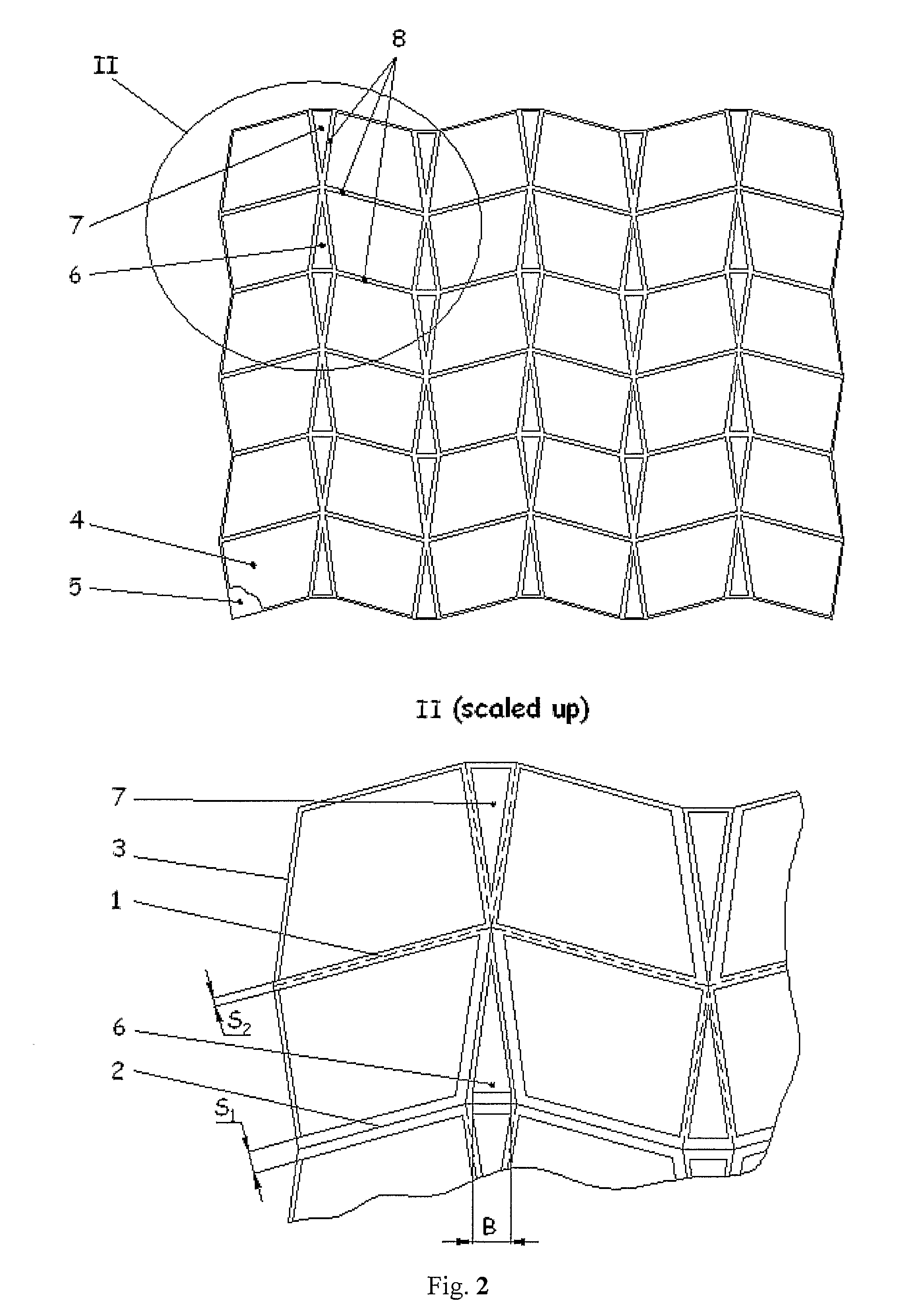

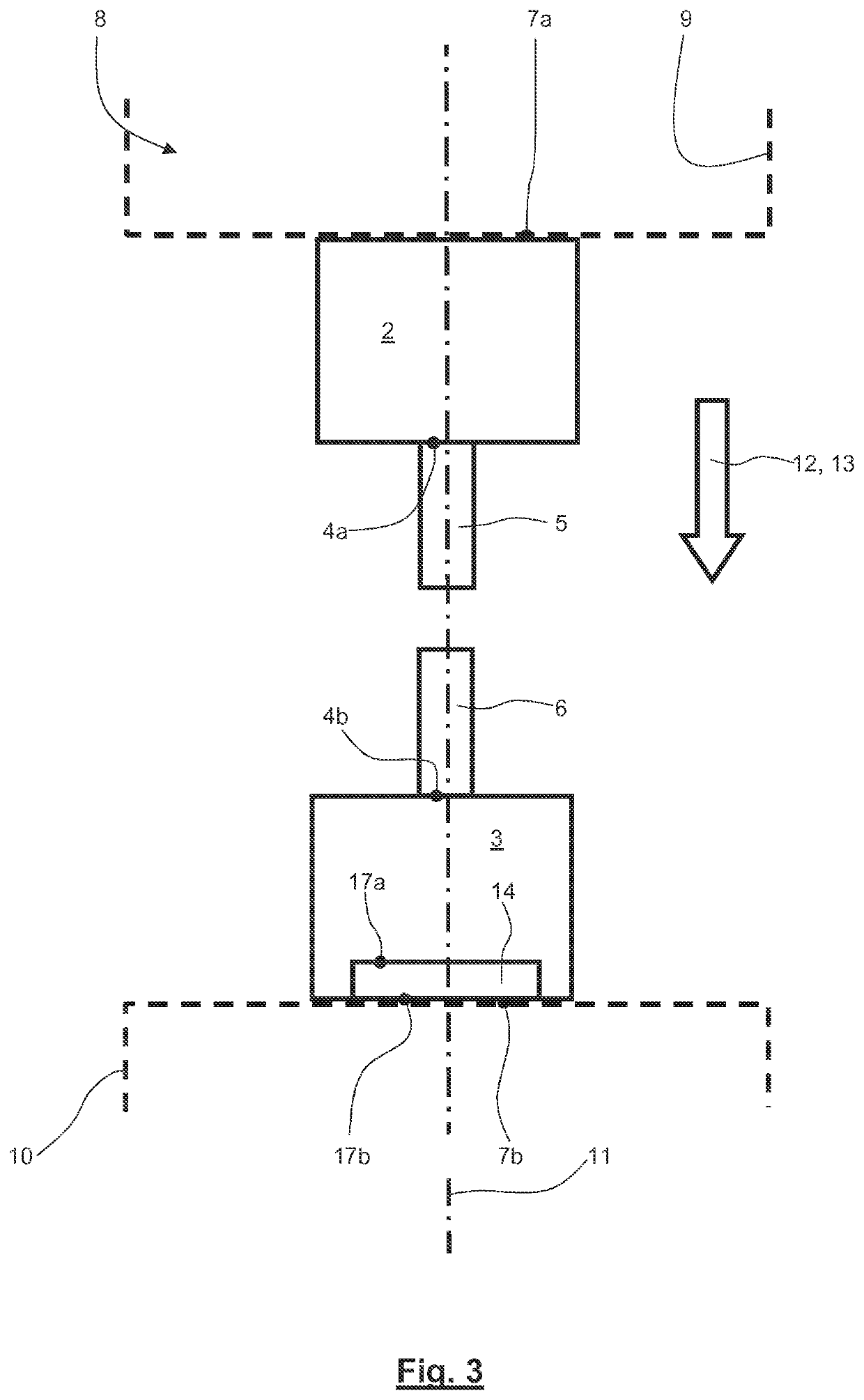

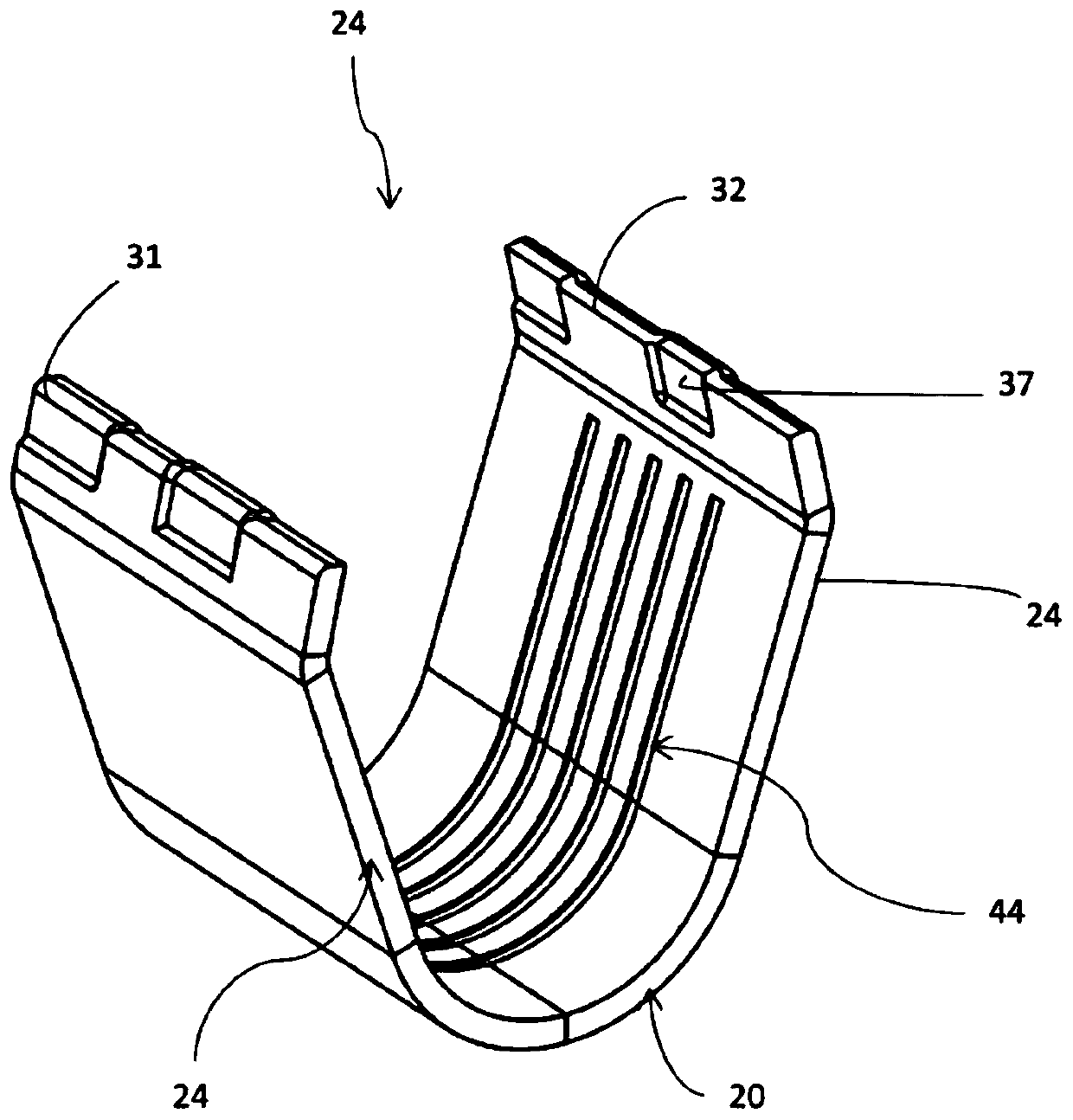

Foldable mandrel for production of a single curvature folded core for a sandwich panel

The invention can be defined in its most general form as a device for sheet material corrugation by means of bending and can be applied in the devices for production of single curvature folded core used in production of aircraft and craft curvilinear panels. The invention has for its object to broaden the technological capabilities. For that the mandrel is made in the form of a set of alternating rows of plane elements (4, 6, 7) made in the form of trapeziums (4) and isosceles triangles (6, 7) fixed on the flexible material of the base (5) forming thus the gap-pivots between the elements. At the same time the bases of the triangular elements (6, 7) face each other in pairs along the bending lines while said bending lines correspond to the protrusions lines of the core folded structure. The base of the triangular elements (6, 7) is the function of the folded core block curvature radius and the geometrical parameters of the zigzag crimp structure. The width of the gap-pivots is taken so that to provide the folding of the mandrel together with the blank forming thus the single curvature zigzag corrugated structure with the lateral direction of crimps.

Owner:AIRBUS +1

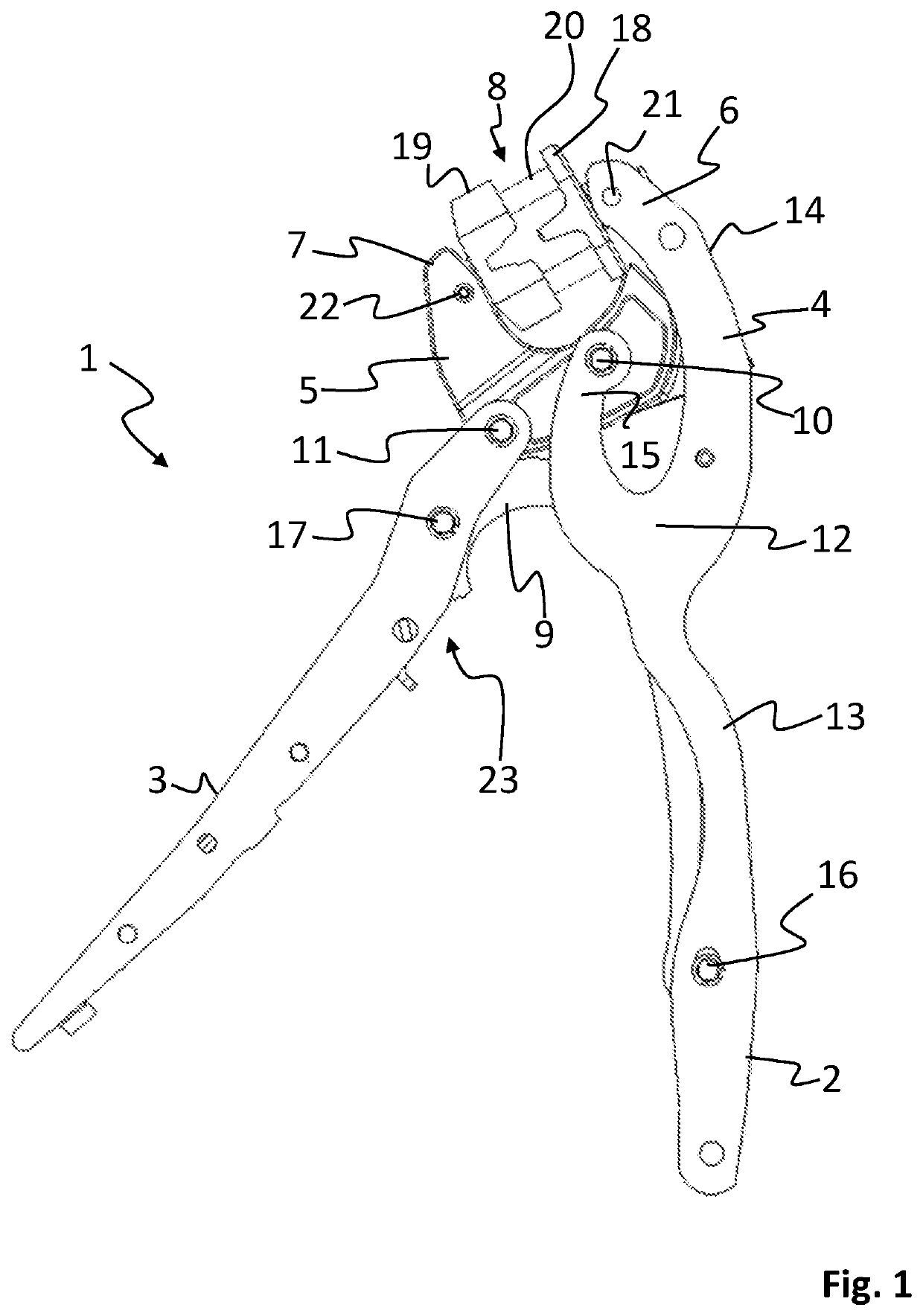

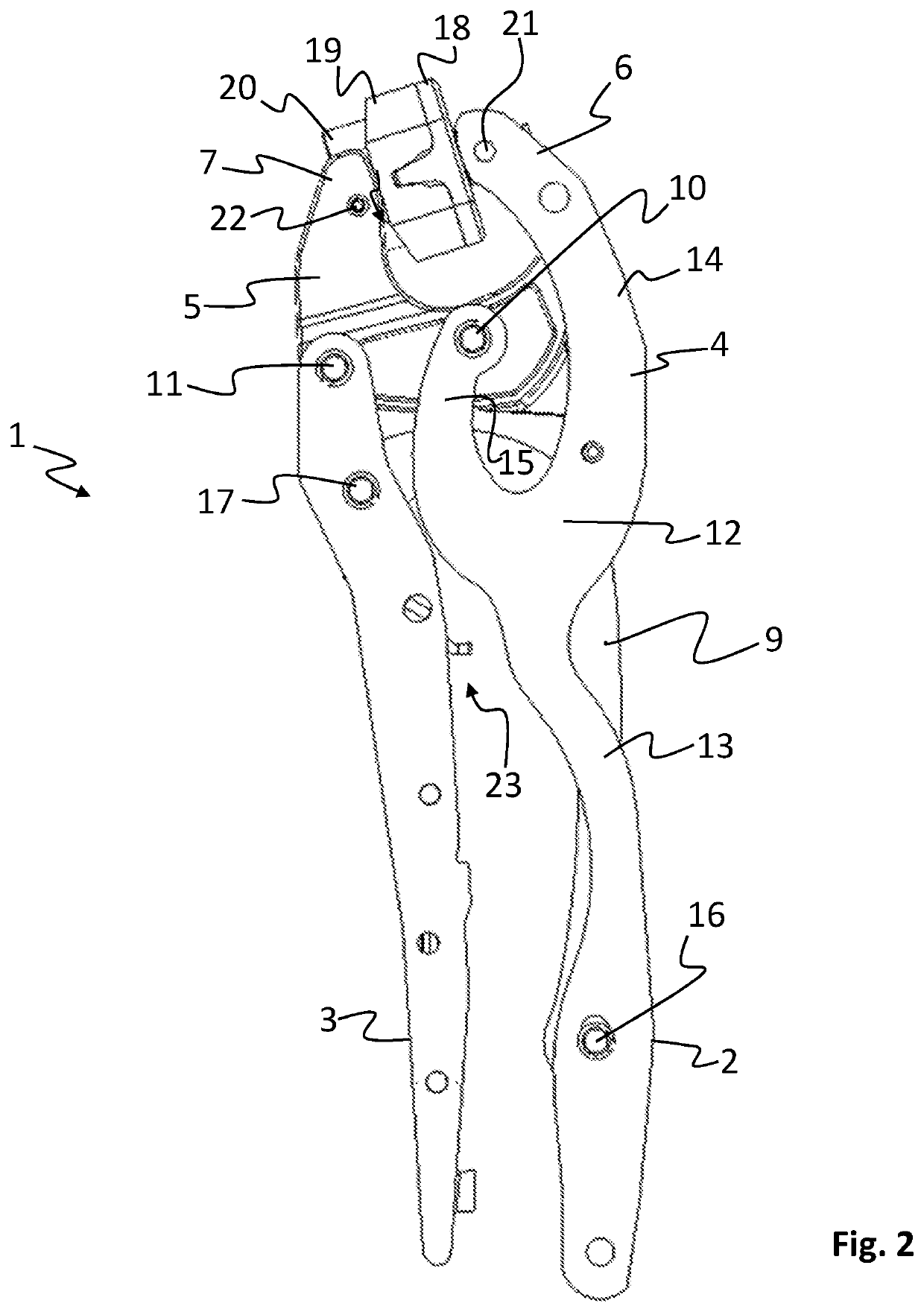

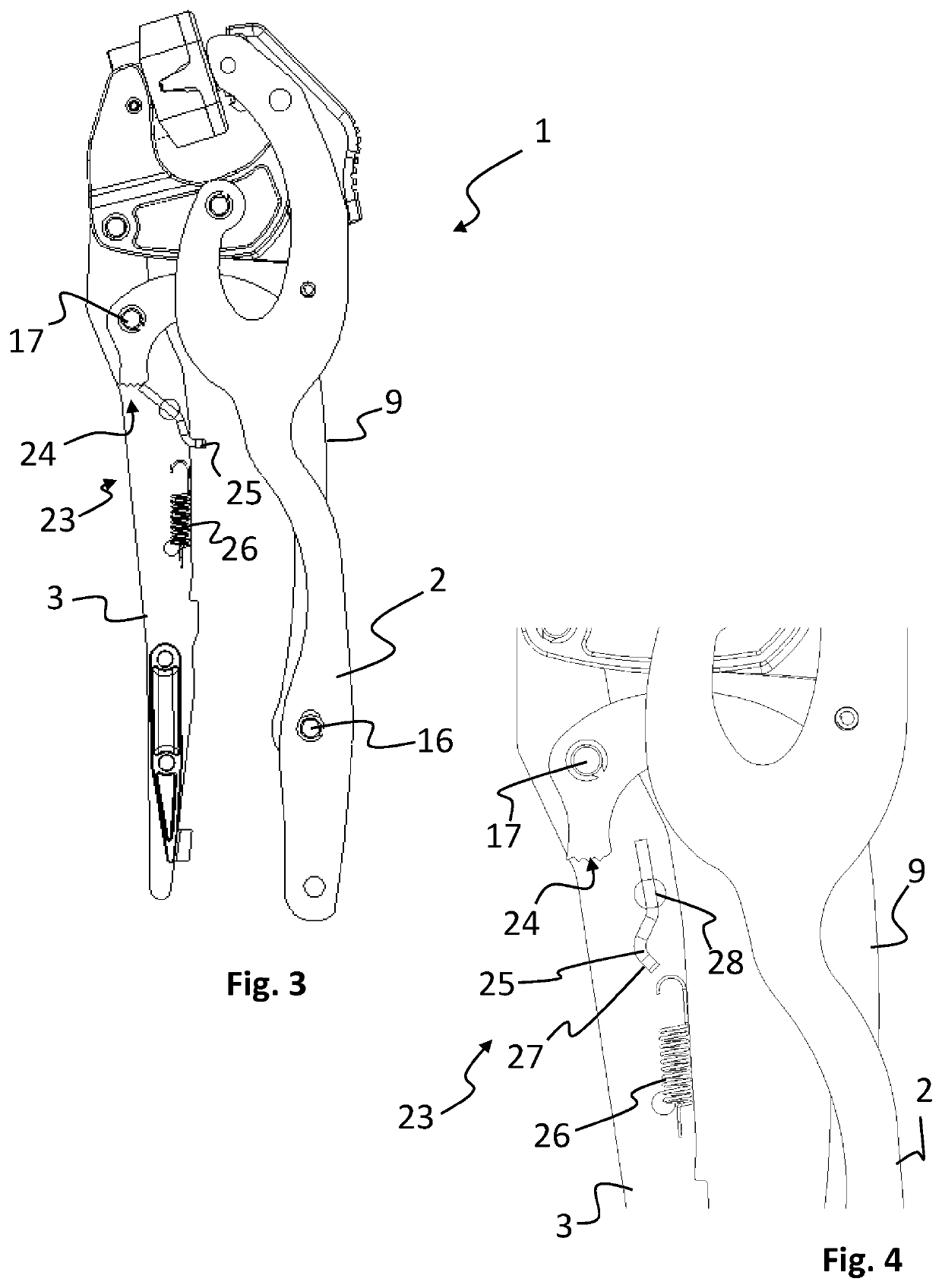

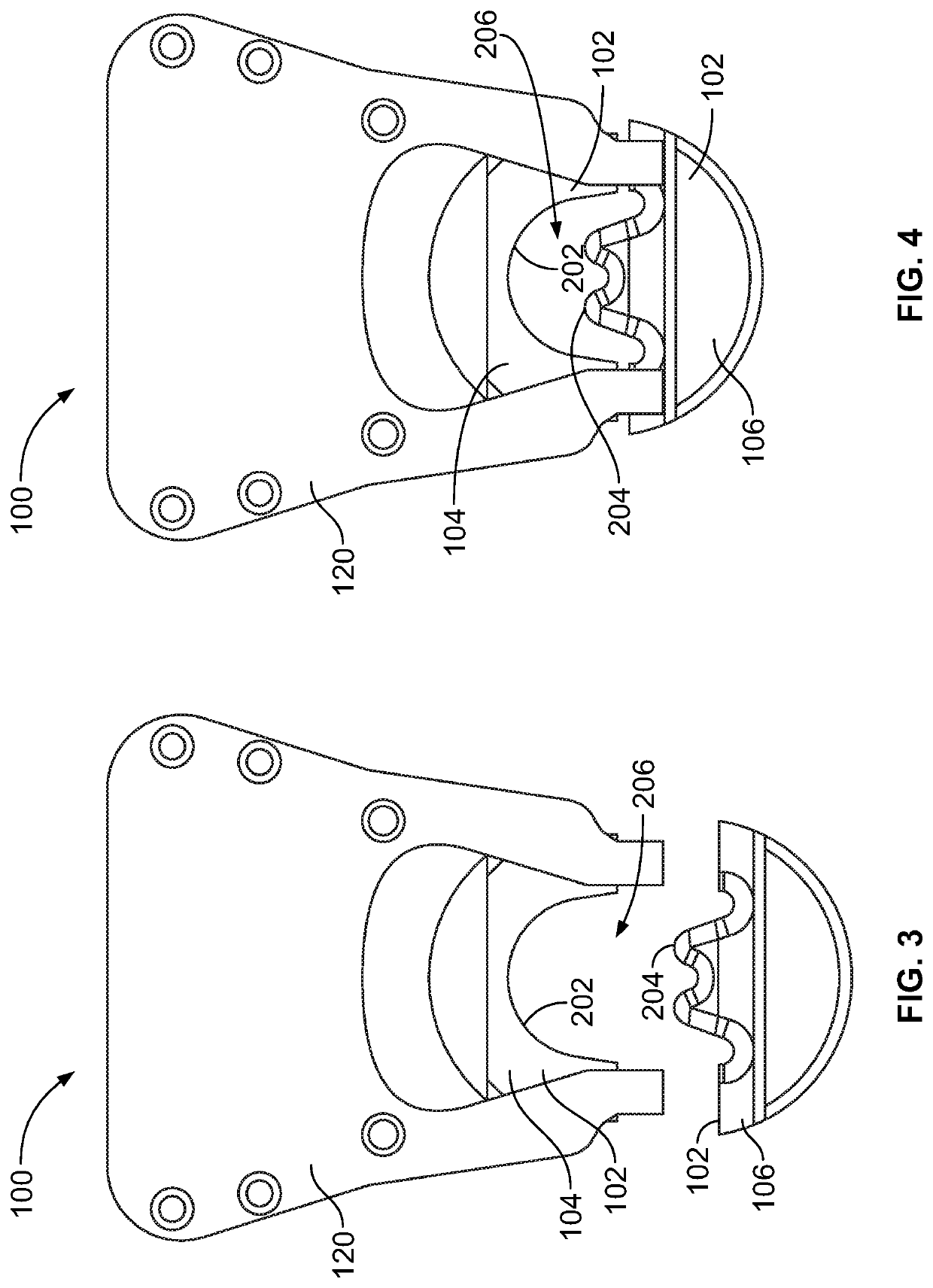

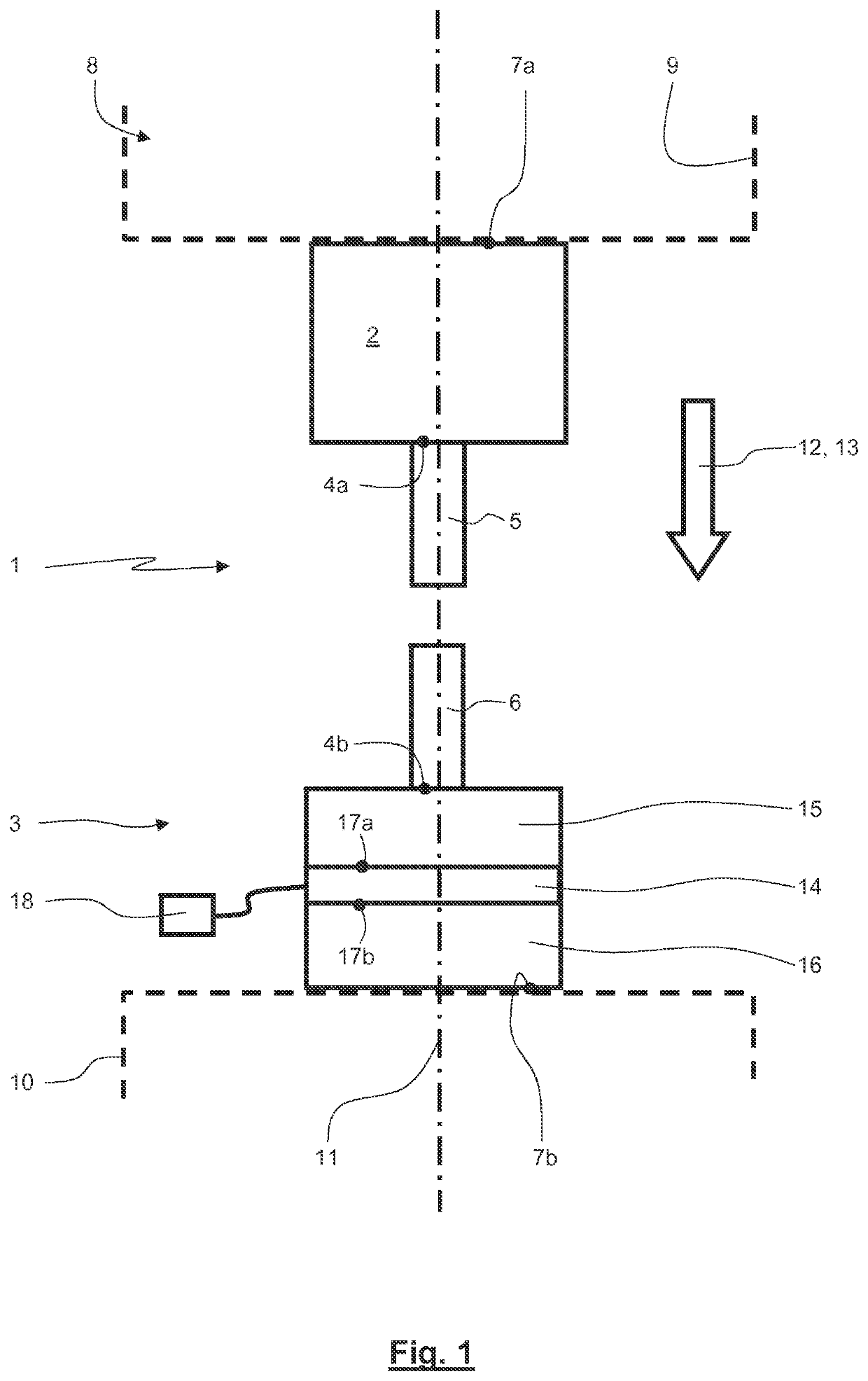

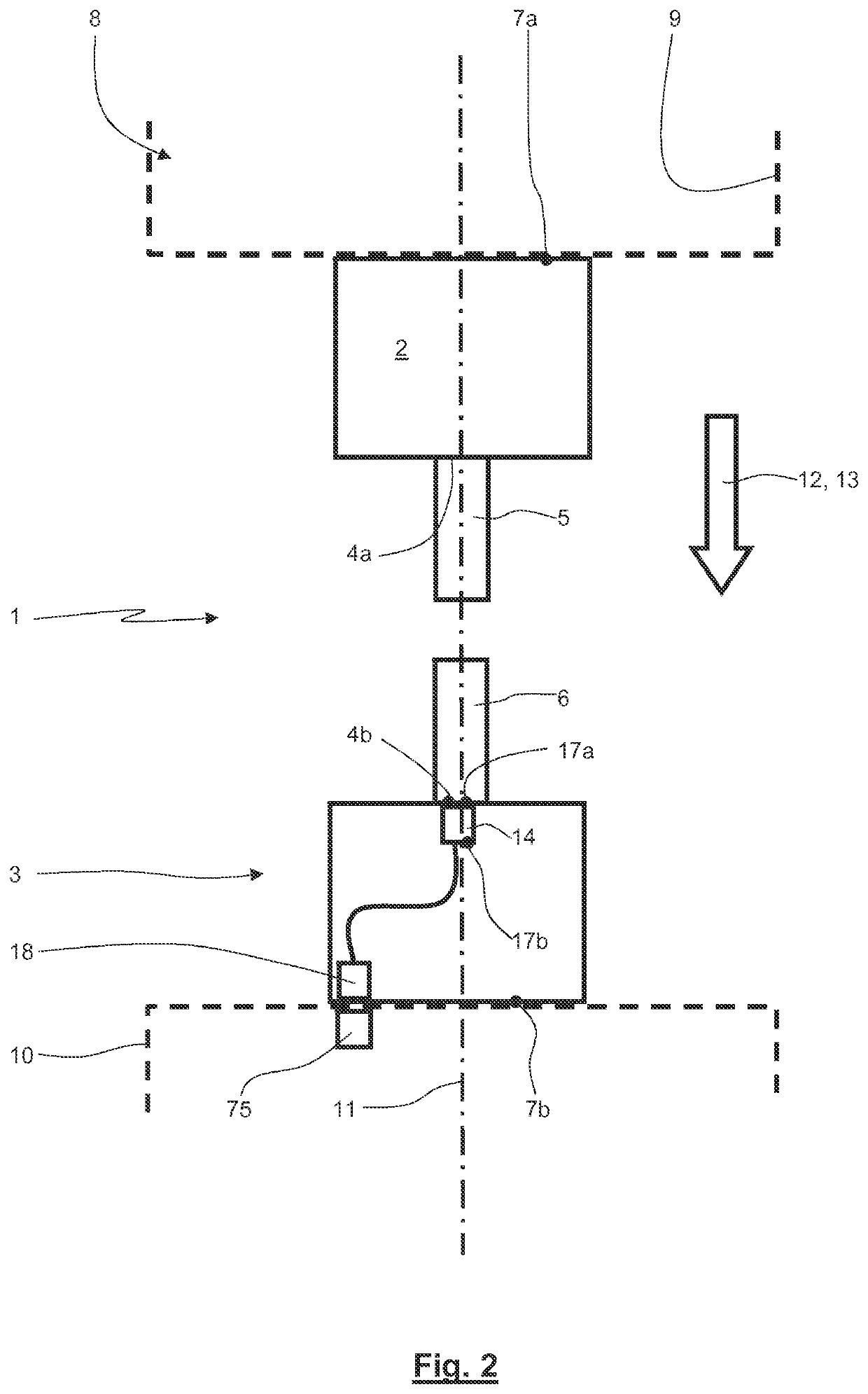

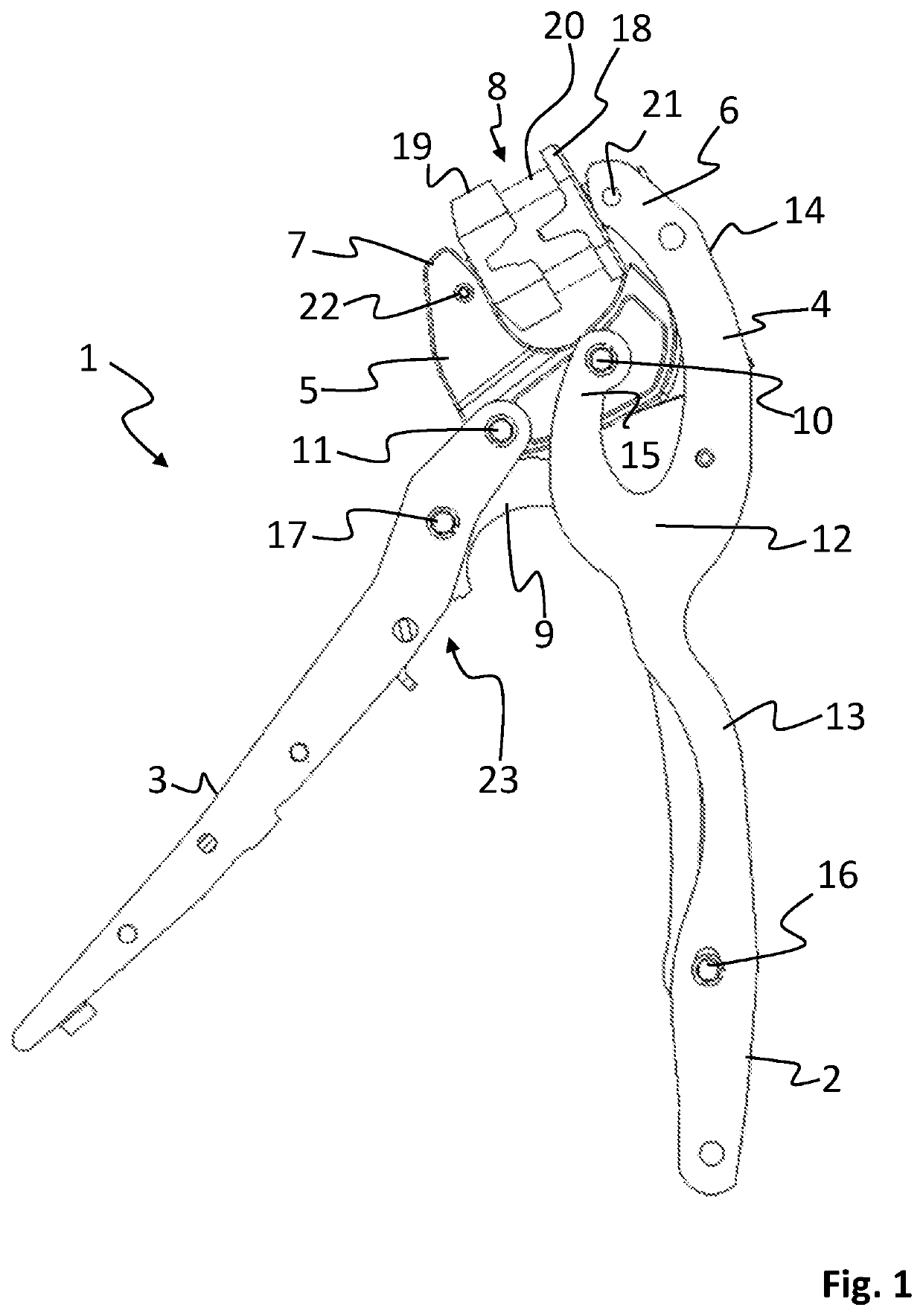

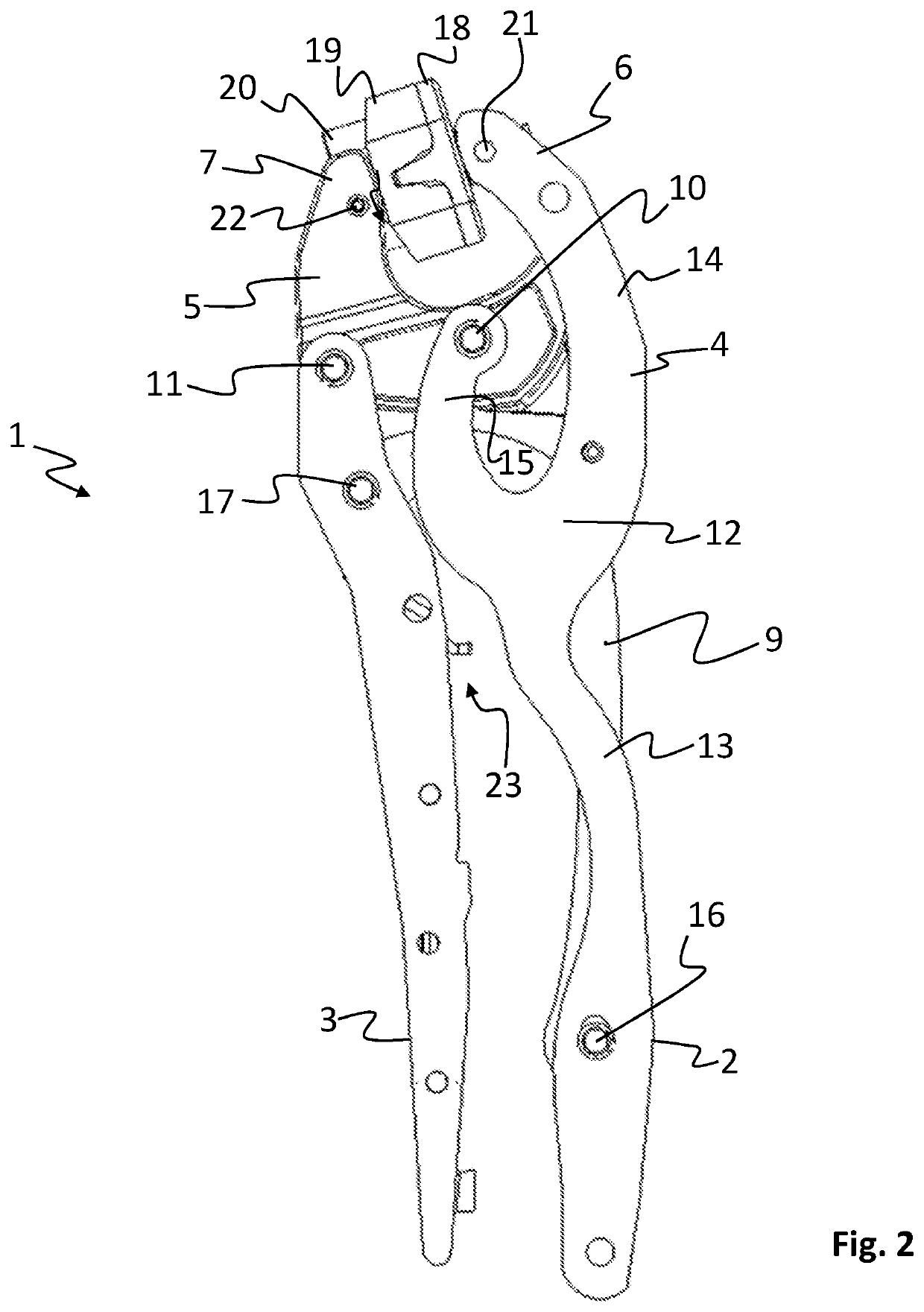

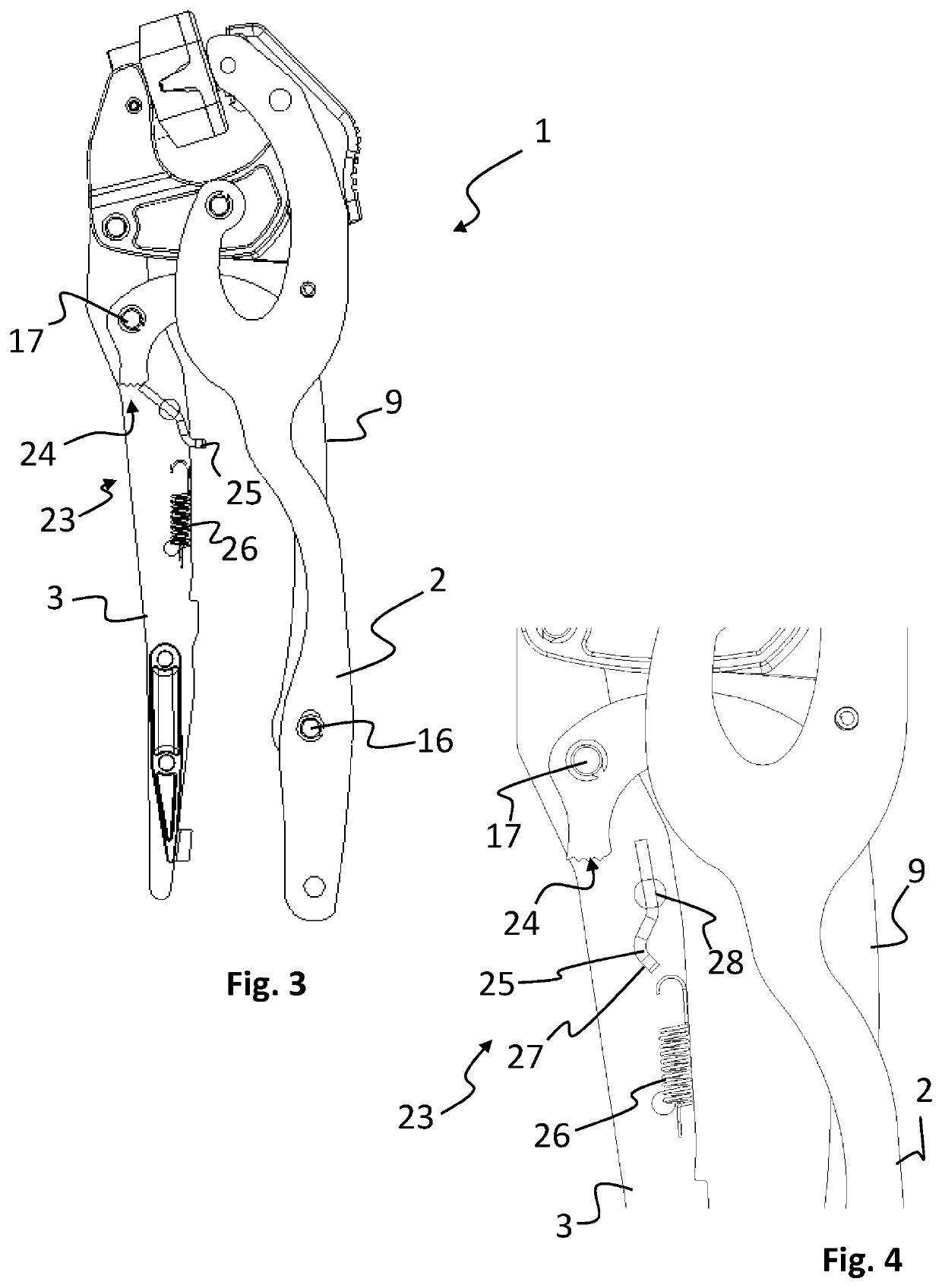

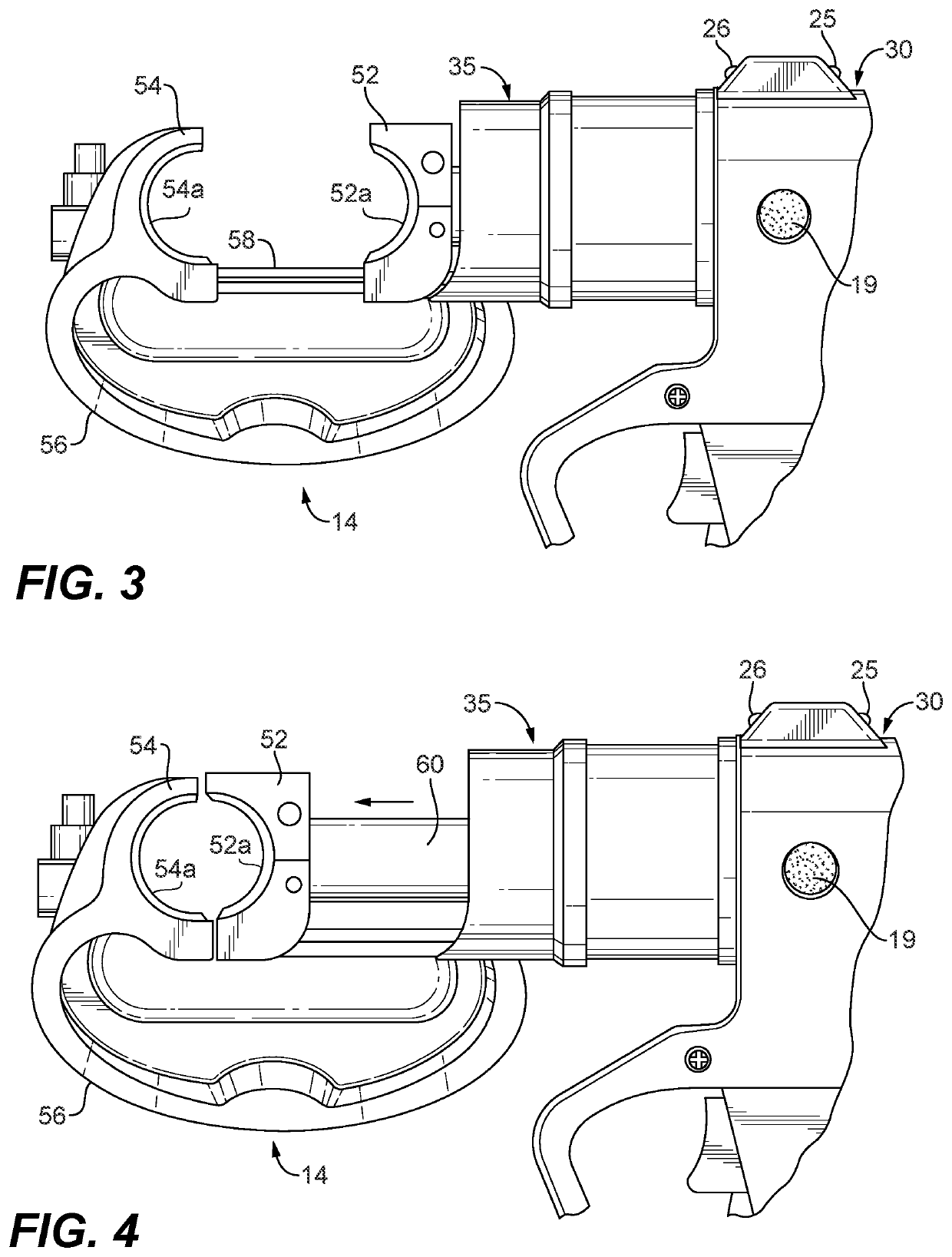

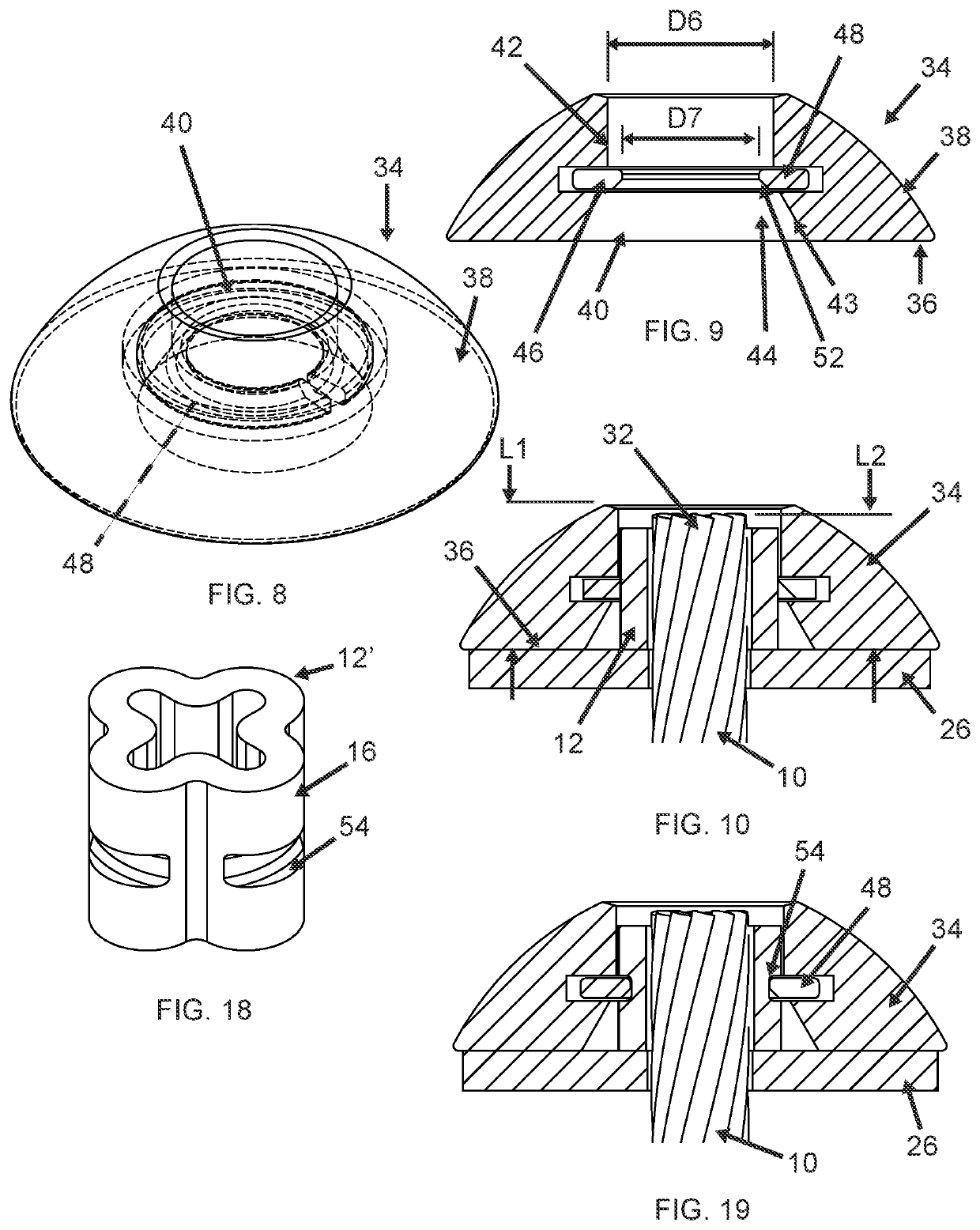

Hand Tool With Self-Resilient Handle

ActiveUS20200223041A1Less complexMore durableLine/current collector detailsPliersStructural engineeringHand tool

A hand tool (1) comprising a first handle (2) and a second handle (3), which are pivotally arranged with respect to each other, a first jaw (4) that is fixed to said first handle (2), the first jaw (4) comprising a first crimp portion (6), and a second jaw (5) comprising a second crimp portion (7), wherein the first and second crimp portions (6,7) are arranged to be moved towards each other by actuation of the first and a second handle (2,3), so as to close a crimp opening (8) formed between said first and second crimp portions (6,7). The second jaw (5) is pivotally arranged with respect to the first handle (2) around a first pivot point (10), and with respect to the second handle (3) around a second pivot point (11) arranged at an upper end of said second handle (3), wherein the first handle (2) comprises a first resilient portion (12) between the first crimp portion (6) and the first pivot point (10), allowing the first crimp portion (6) to flex with respect to the first pivot point (10).

Owner:PRESSMASTER

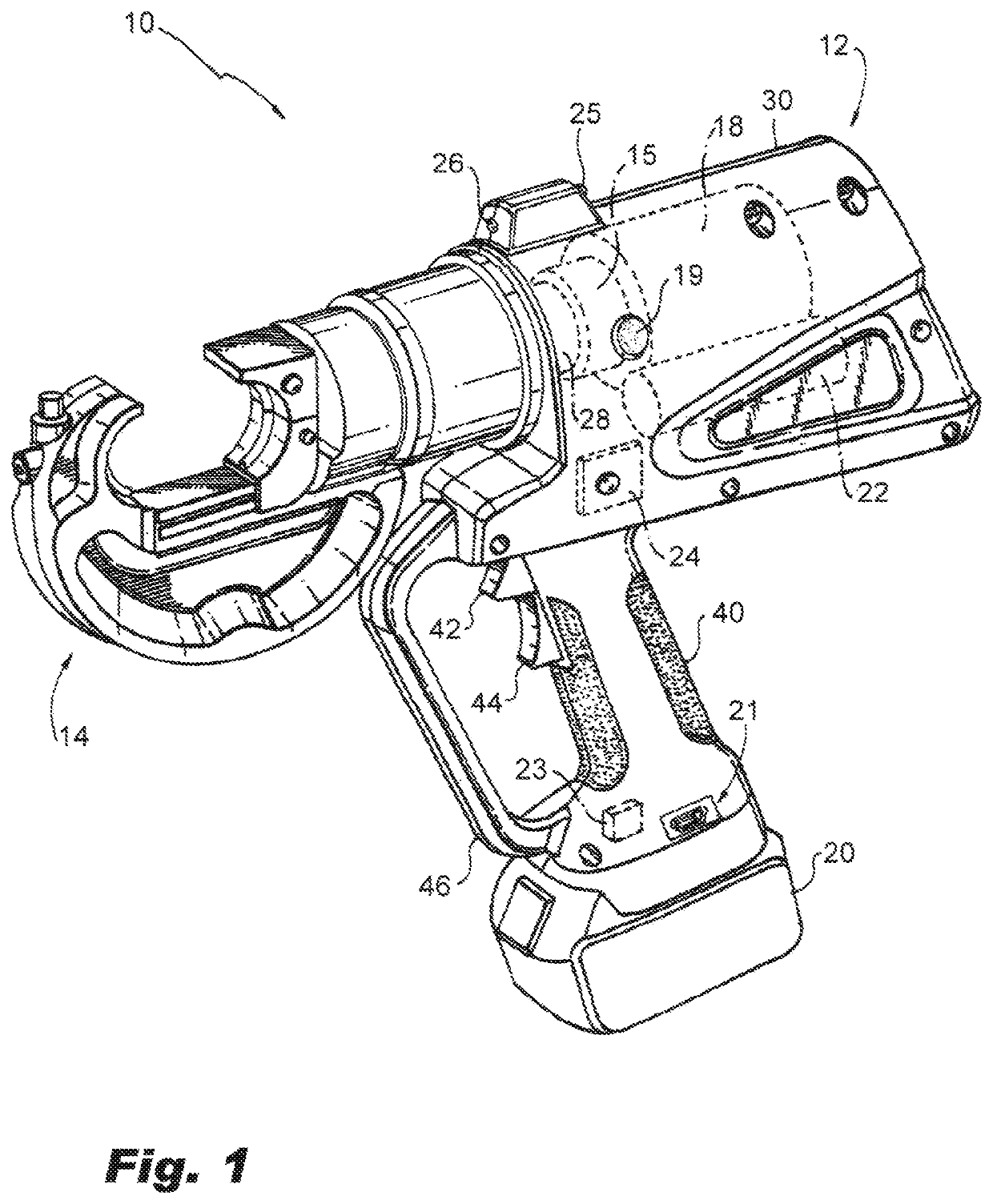

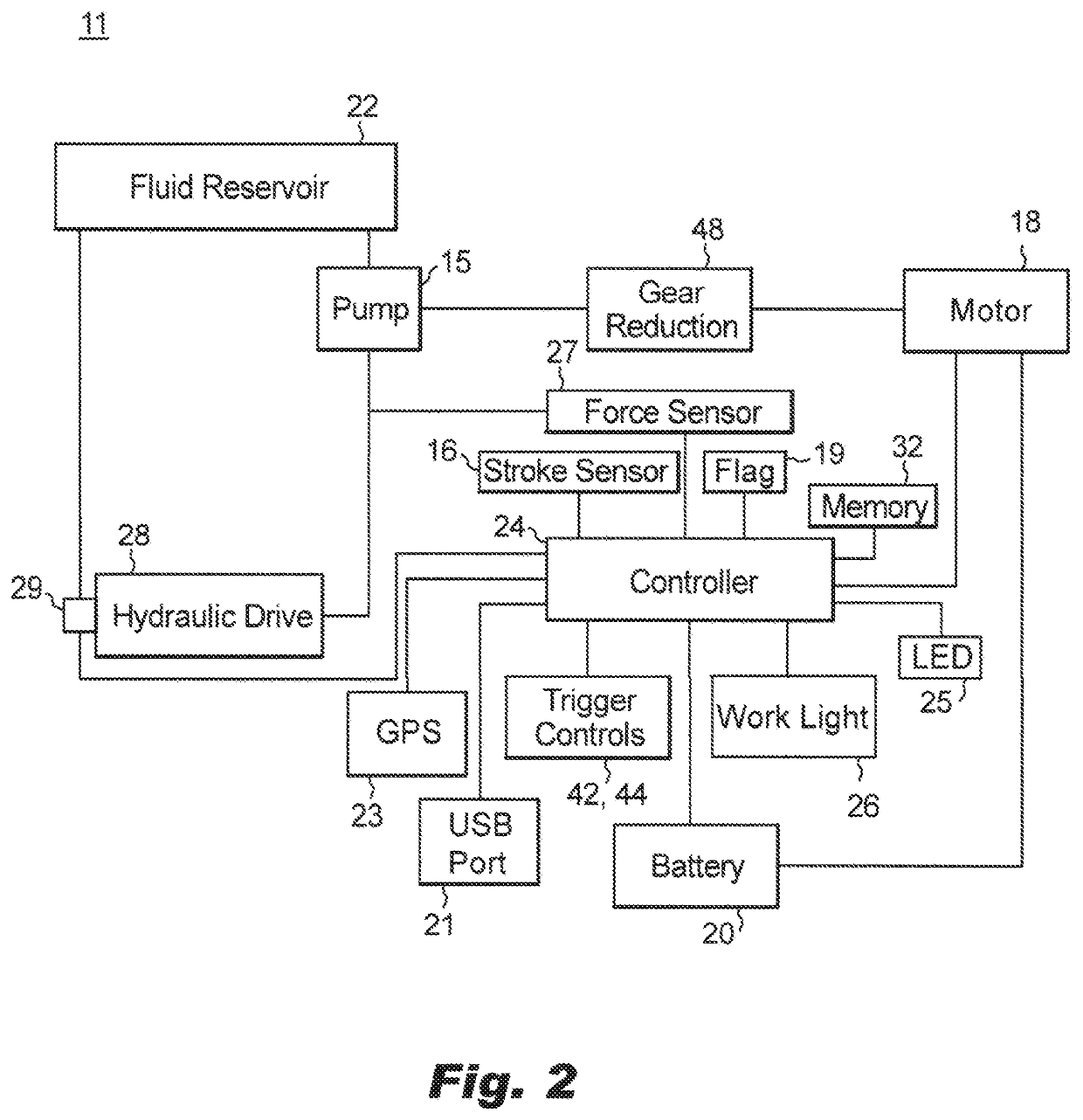

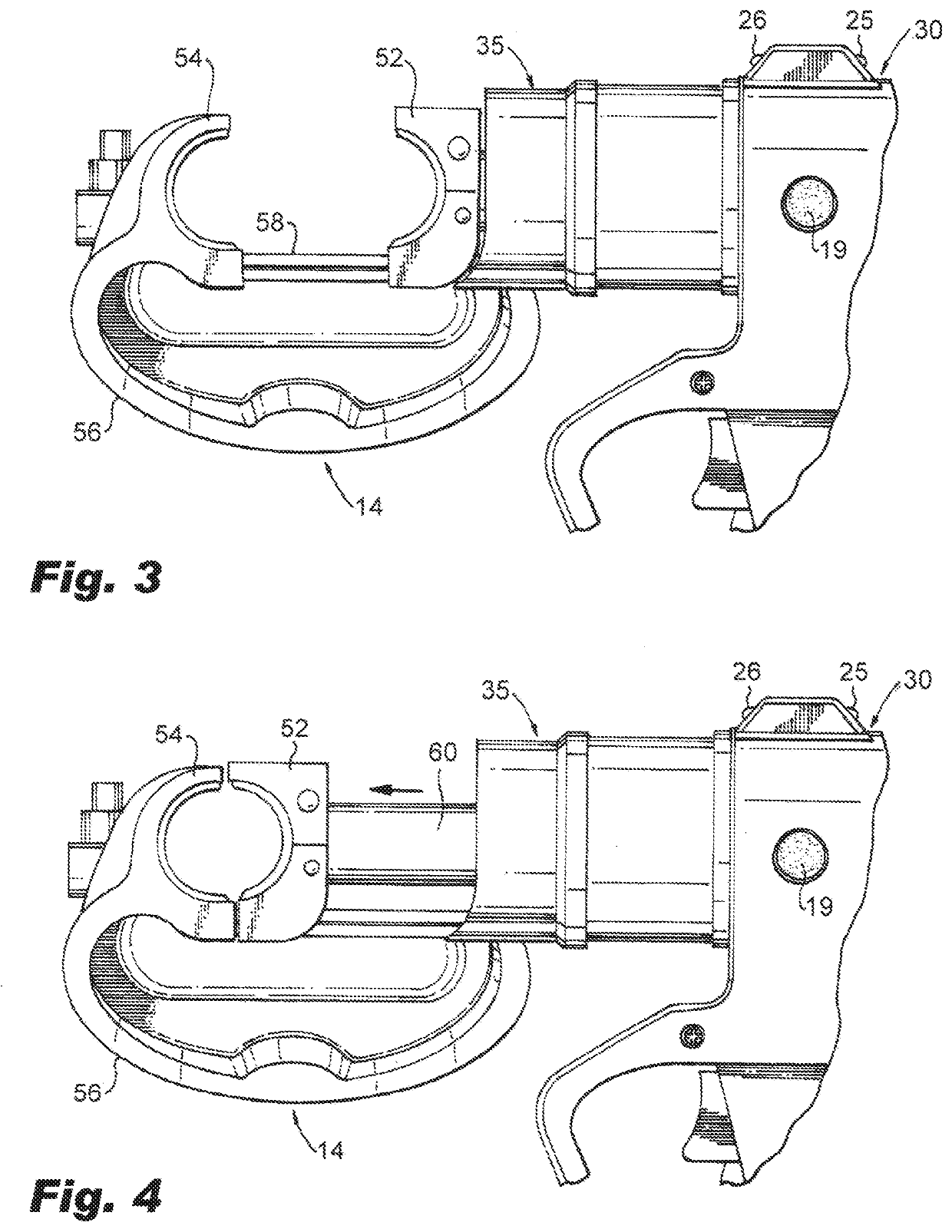

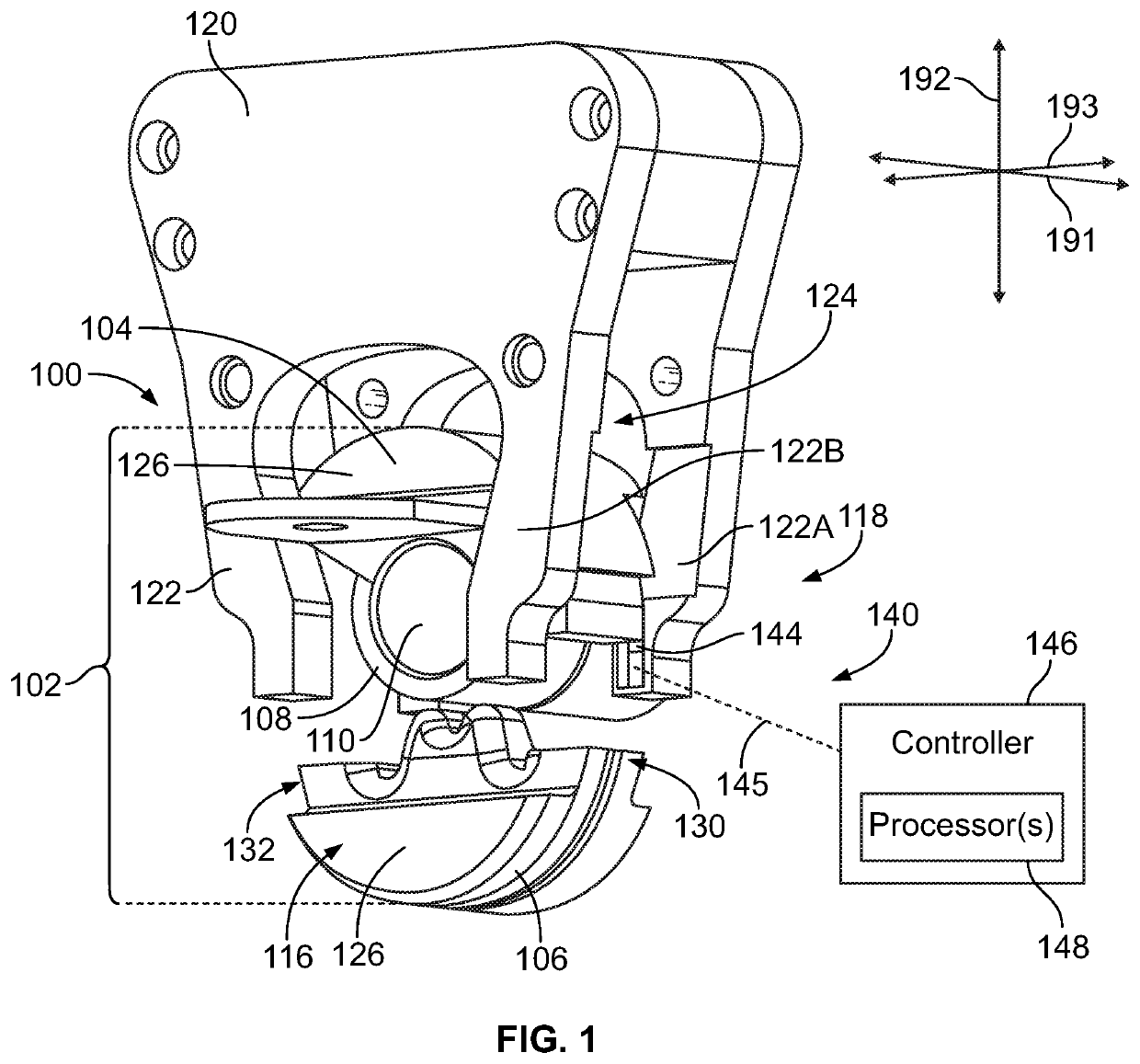

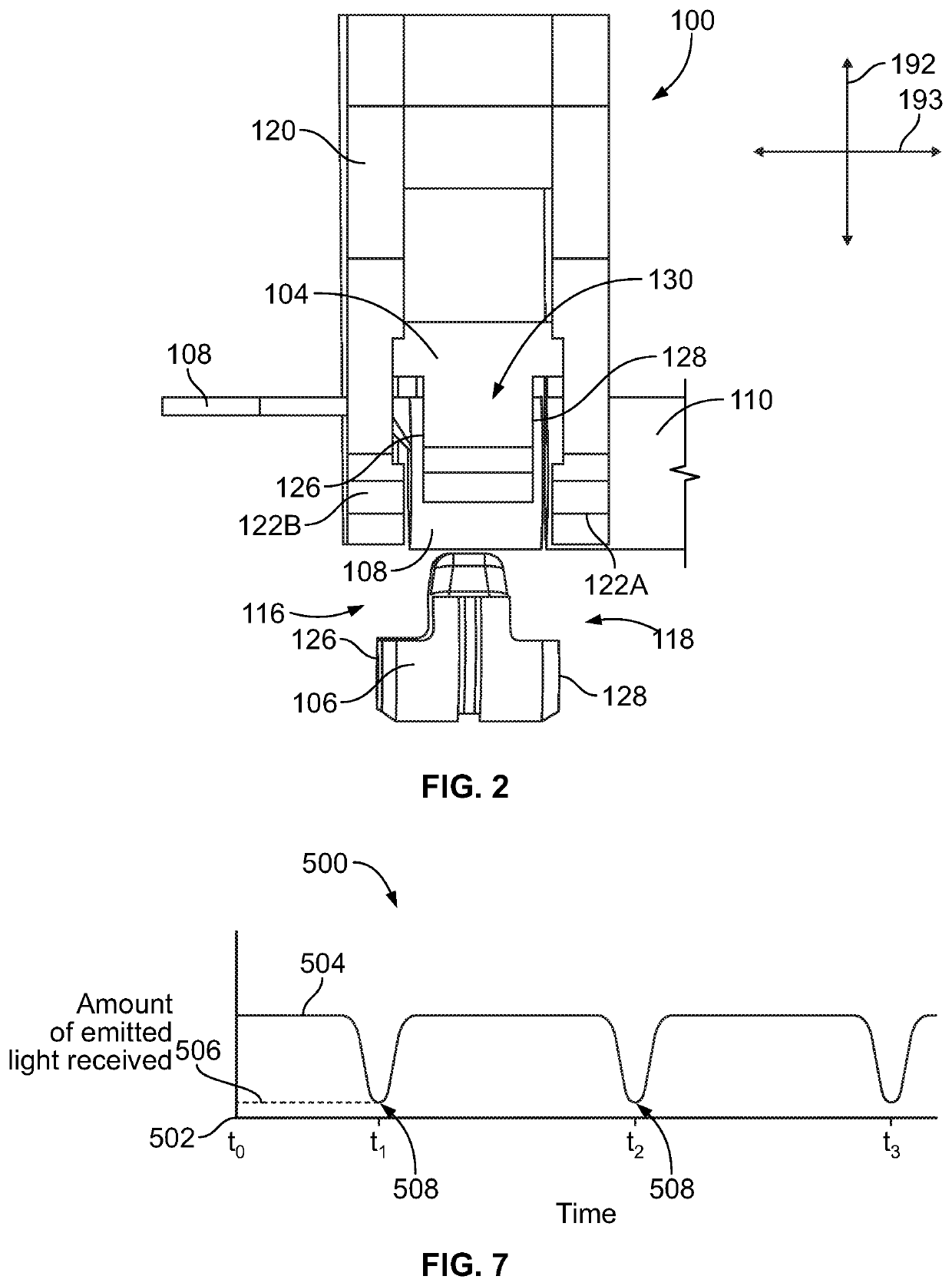

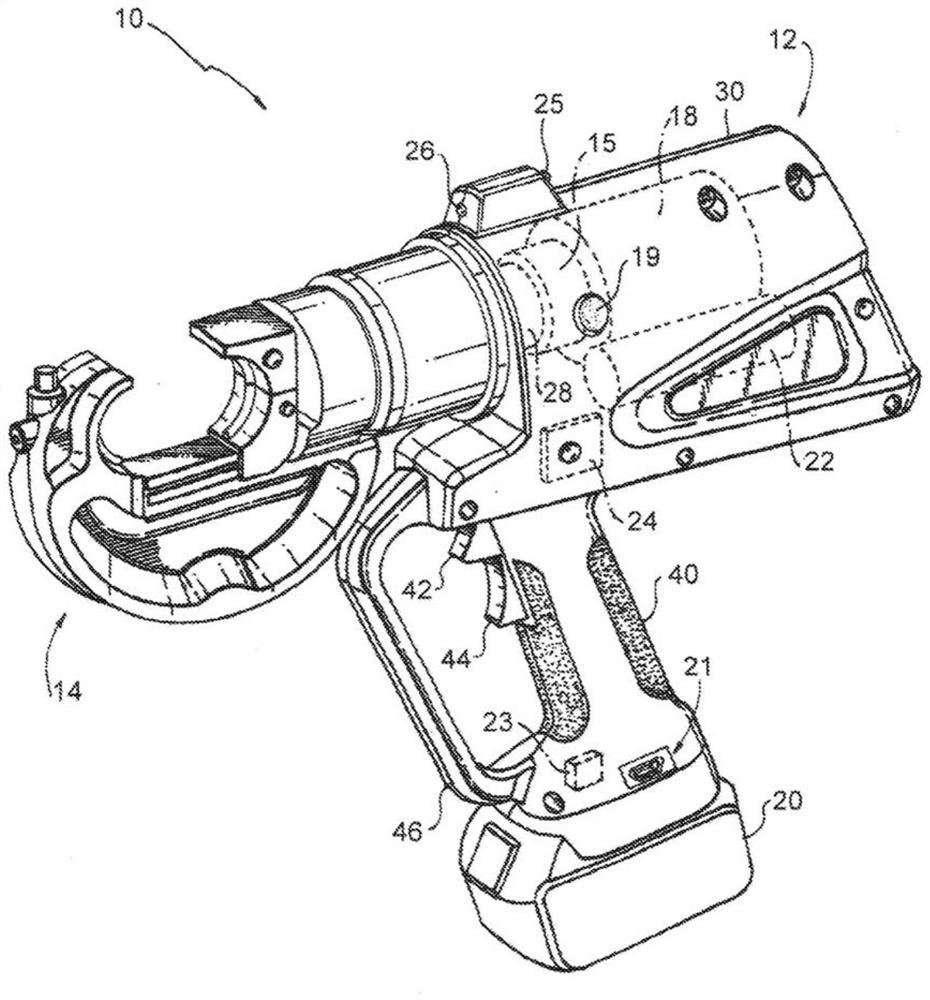

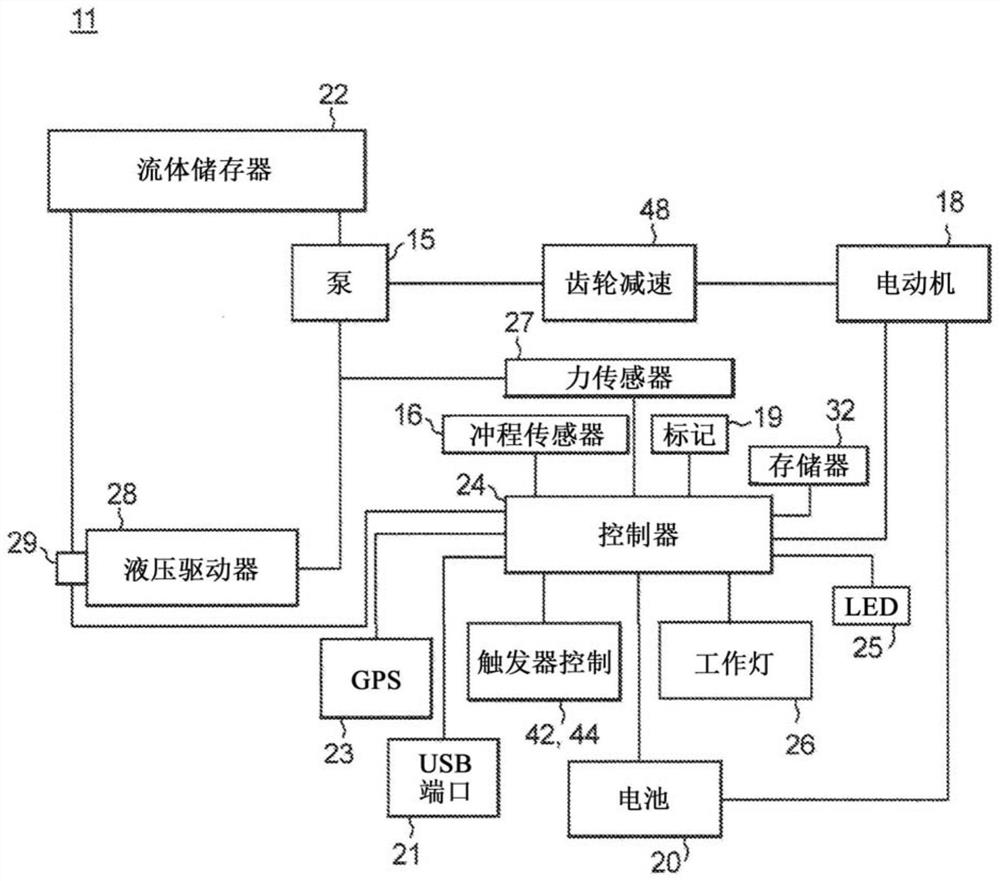

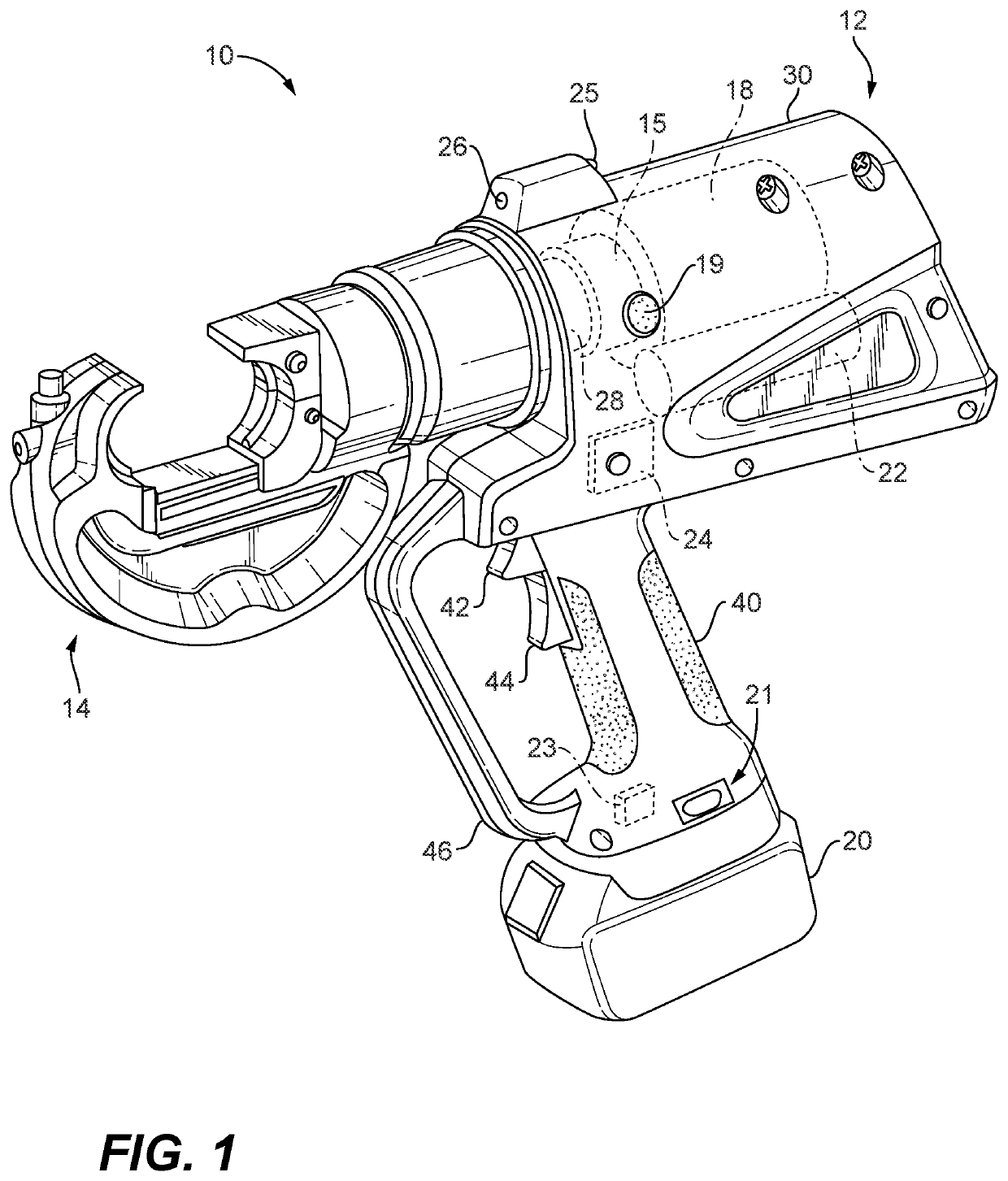

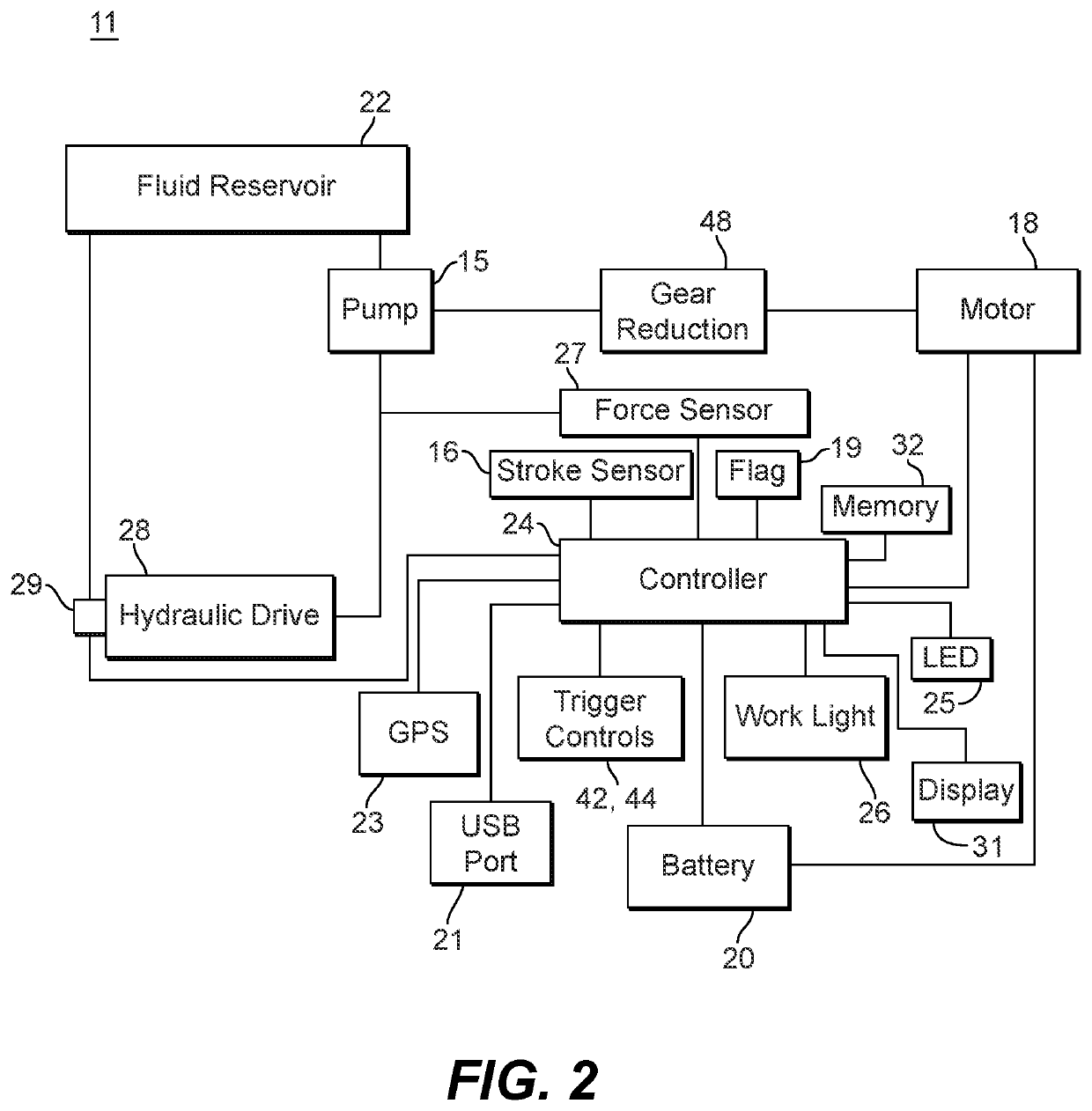

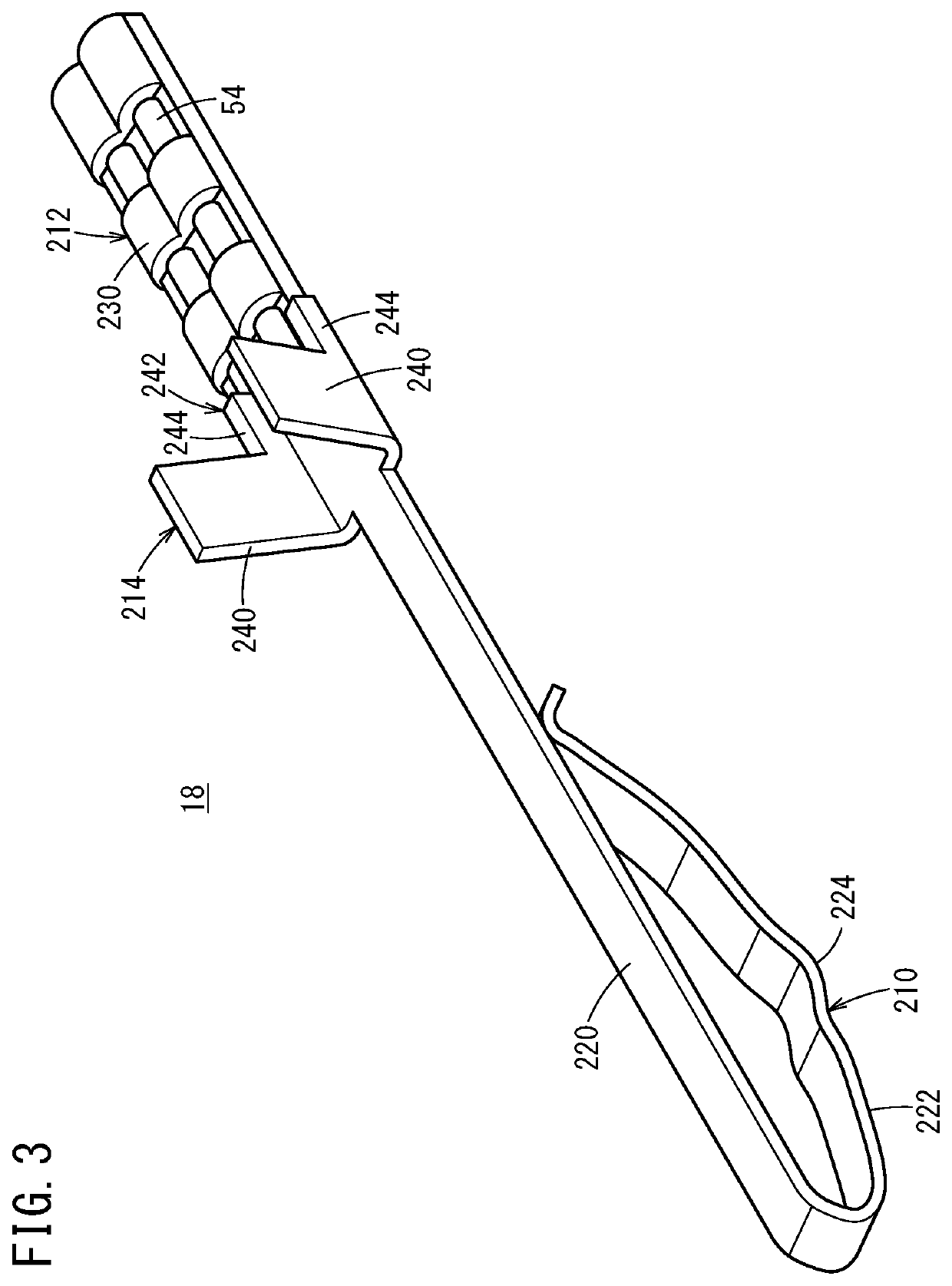

Power tool with crimp localization

ActiveUS20200106230A1Line/current collector detailsMetal-working hand toolsElectrical batteryHand held

Portable, hand-held, battery operated, hydraulic tools are provided with a tool frame, a force sensor, and a location detector. A piston actuated by a hydraulic system within the tool frame applies force to the working head to perform a task, such as to apply a crimp to an electrical connector. The tool determines the maximum force applied to the crimp and records that maximum force along with the geographic location of the tool when the crimp was formed. The maximum force provides an indication of the quality of the crimp and the recorded location allows a potentially defective crimp to be located.

Owner:HUBBELL INC

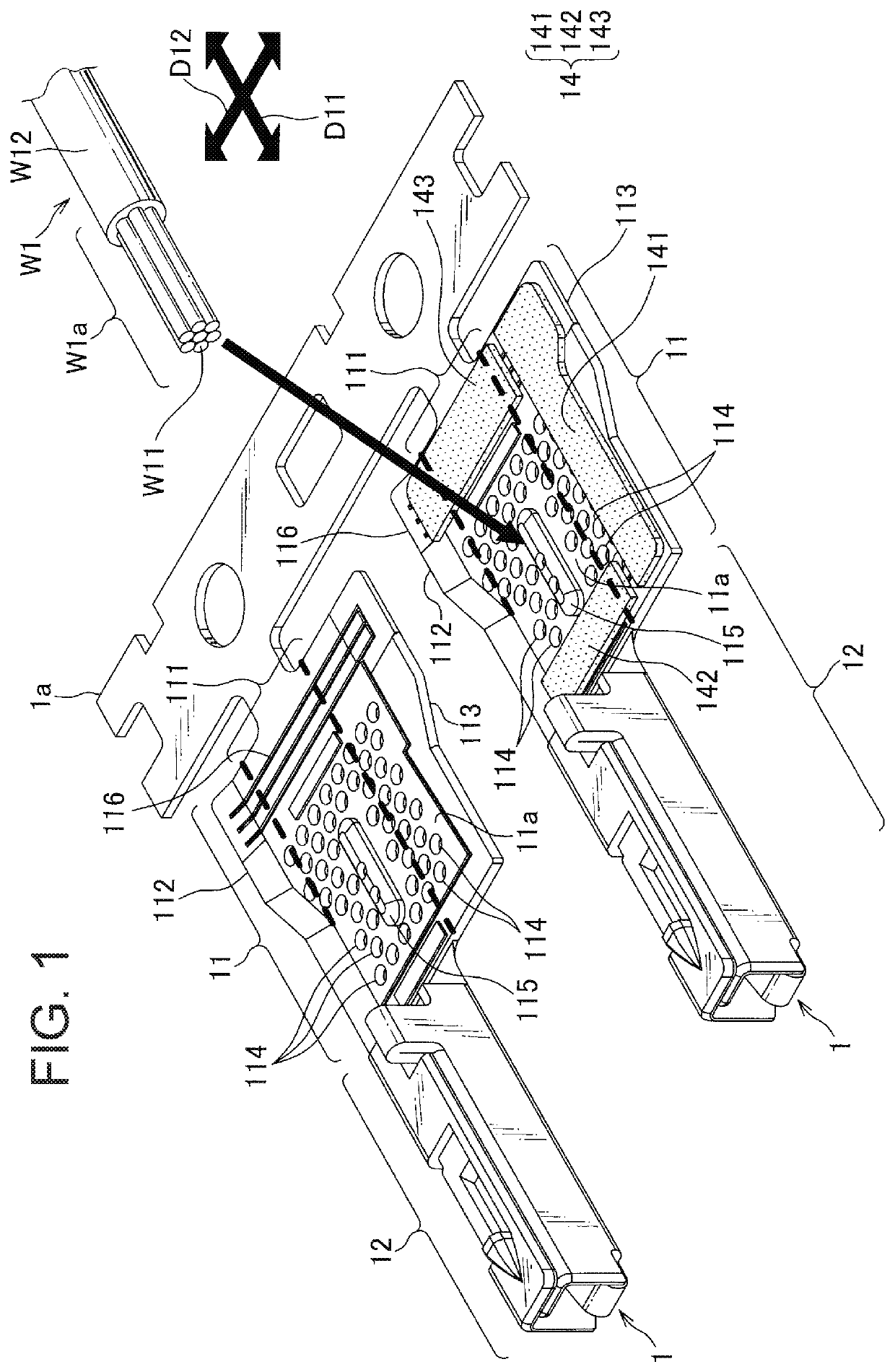

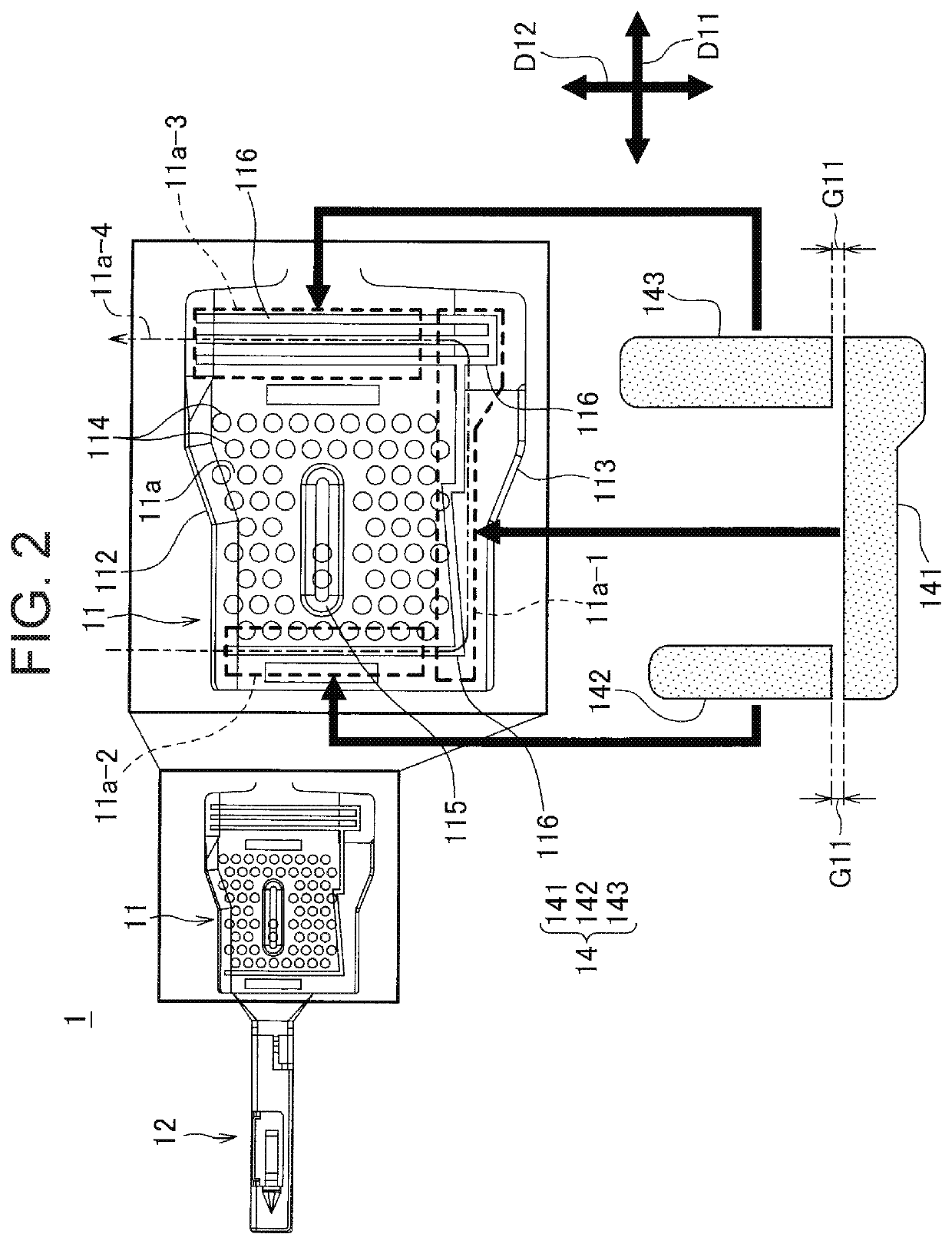

Crimp terminal with seal member

ActiveUS10573978B2Facilitate conductionReduce difficultyCouplings bases/casesConnections effected by permanent deformationEngineeringCrimp

Owner:YAZAKI CORP

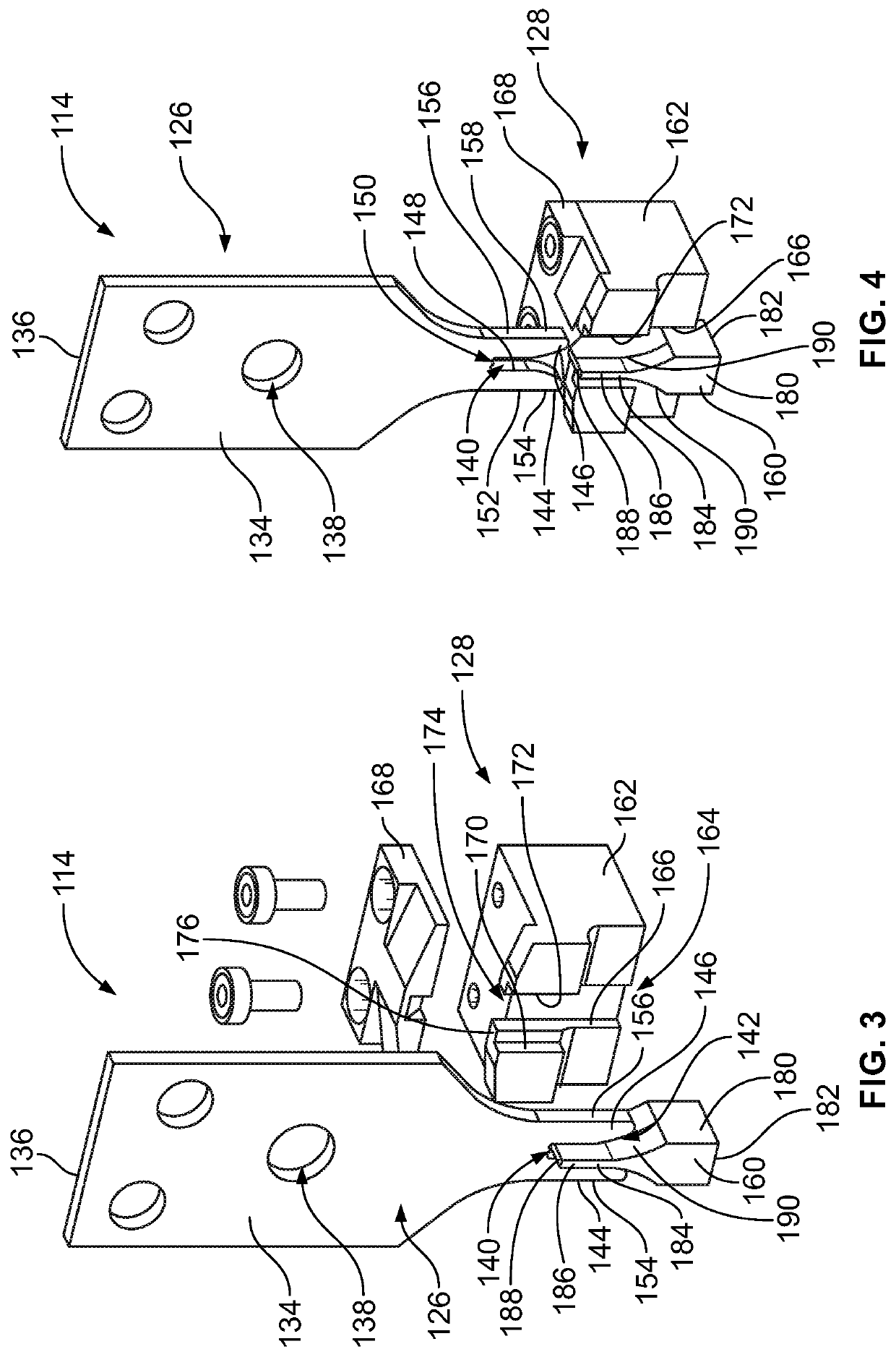

Die clearance monitoring system for a crimping device

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Guide tube retainment feature during crimping of guide tubes

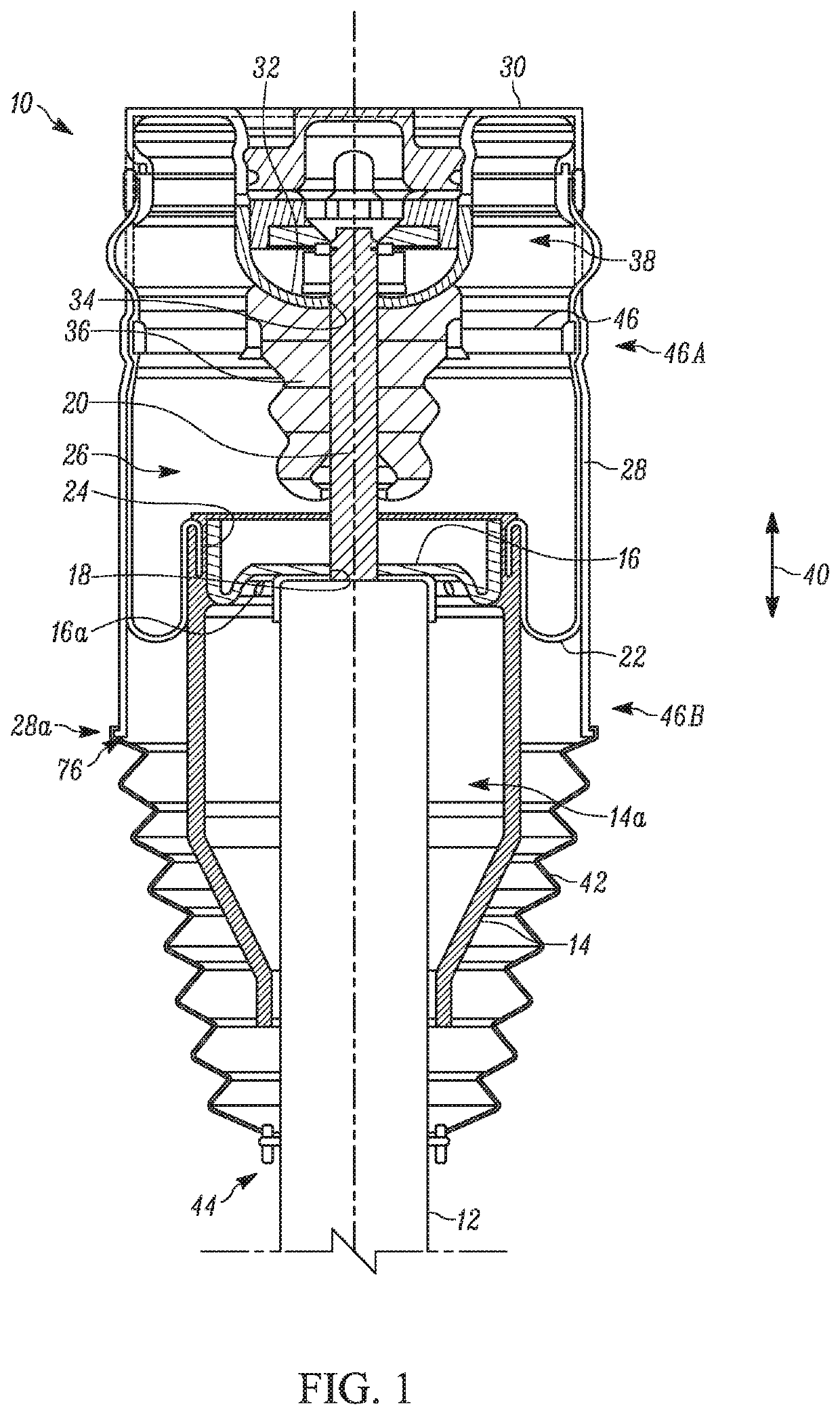

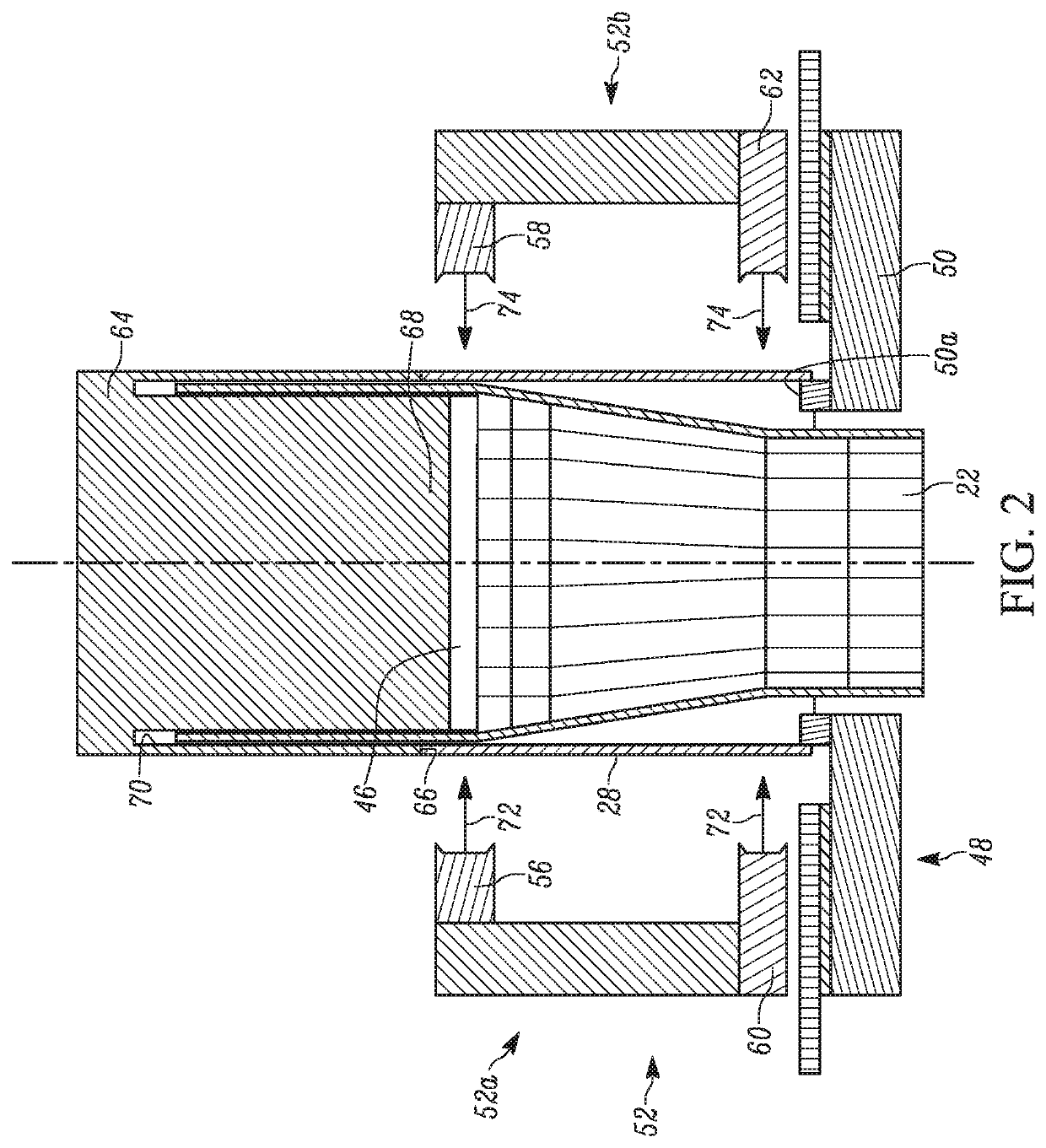

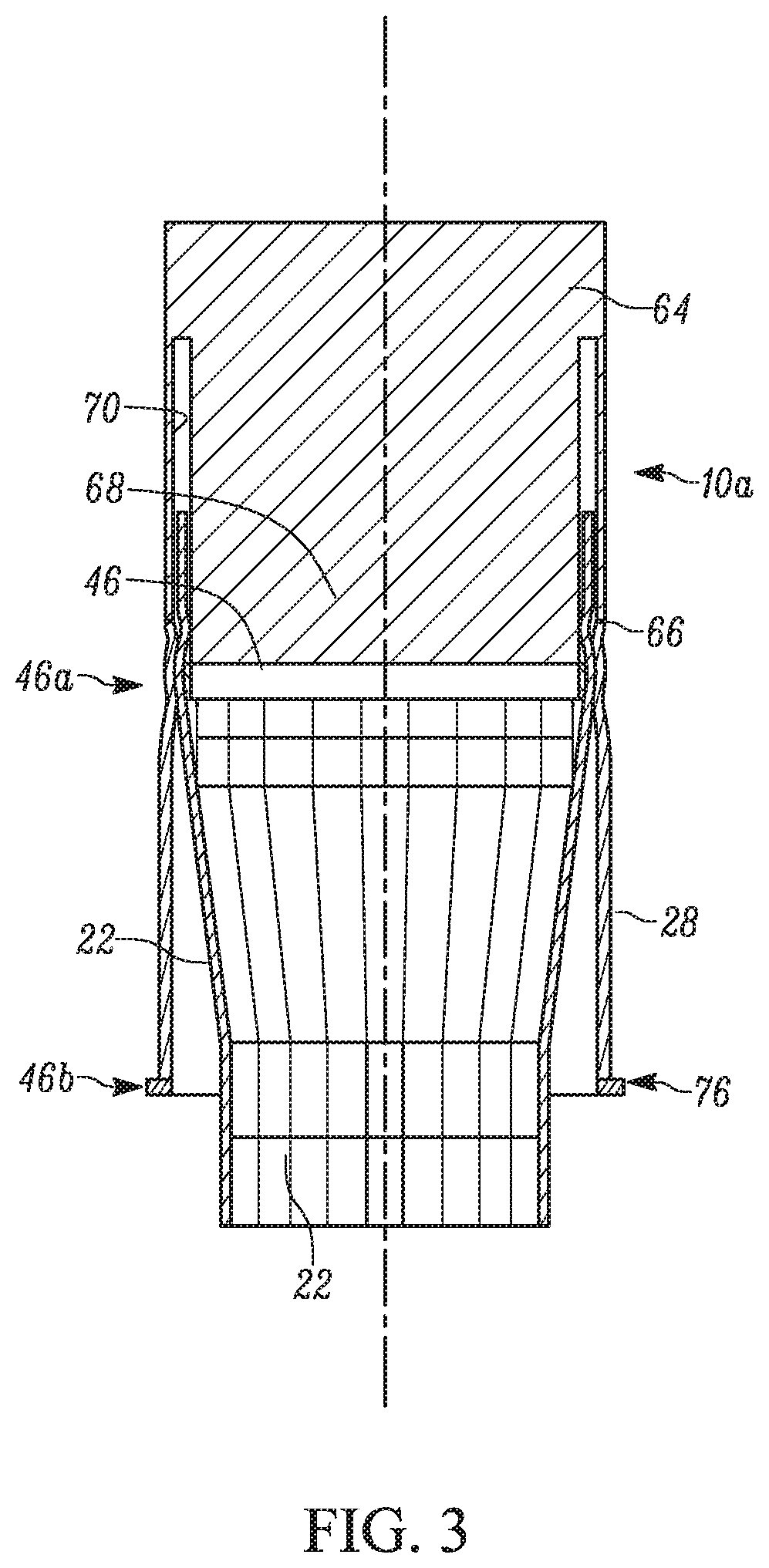

ActiveUS20200180006A1Reduce manufacturing costEliminate needSpringsSprings/dampers manufactureAir springCrimp

A method for making an air spring assembly, including the steps of providing a bellow, a support ring, and a guide tube. The support ring is positioned relative to a bellow adapter such that a portion of the bellow adapter extends through the support ring. The bellow is then positioned such that a portion of the bellow extends over the support ring and a portion of the bellow adapter. The guide tube is then positioned relative to the bellow and the support ring, such that a portion of the bellow extends into the guide tube and the guide tube is supported by the bellow adapter, and a portion of the guide tube is supported by a ridge support fixture. The first clamp and second clamp are then moved towards the guide tube, applying force to the guide tube, simultaneously forming a first crimp and a second crimp.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

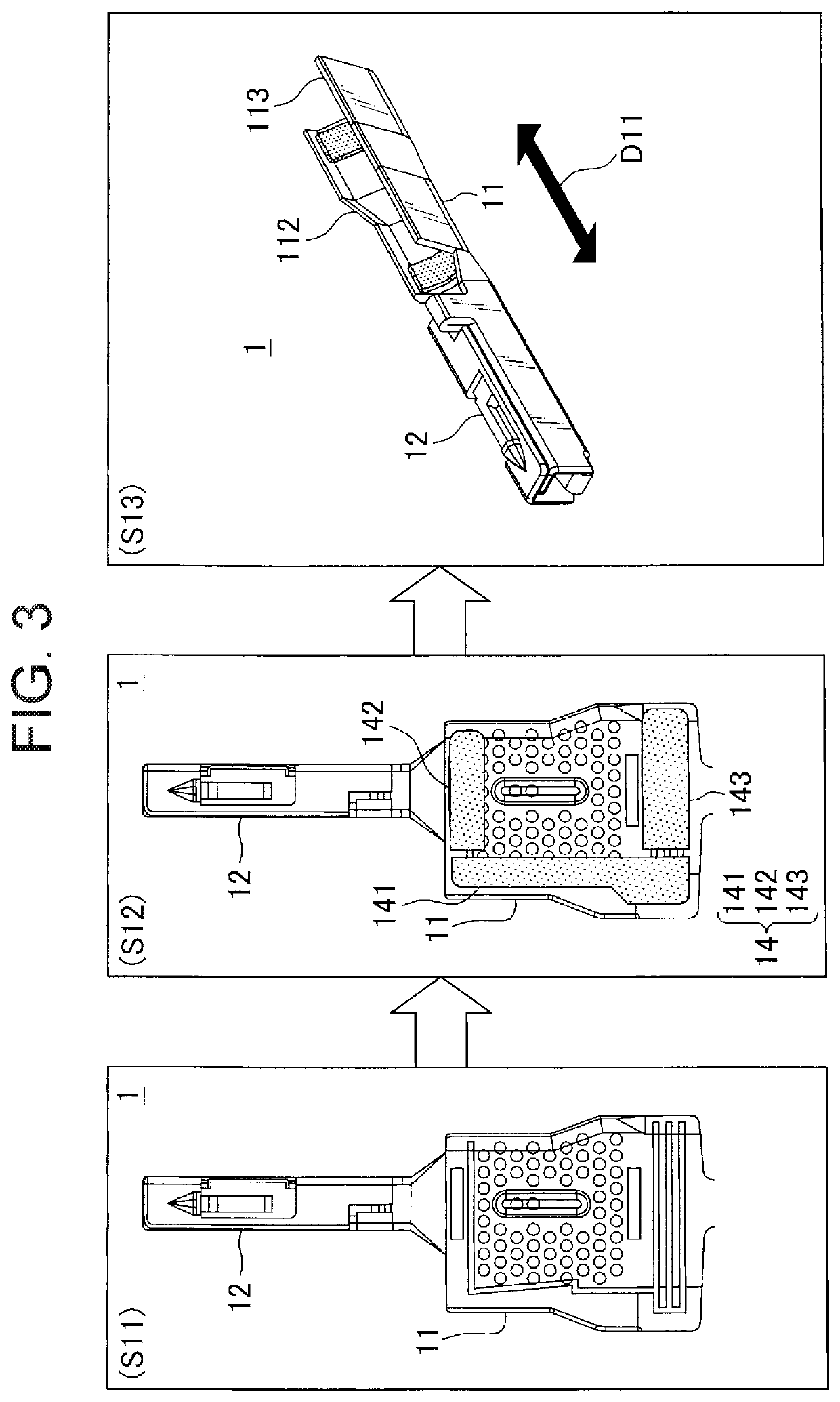

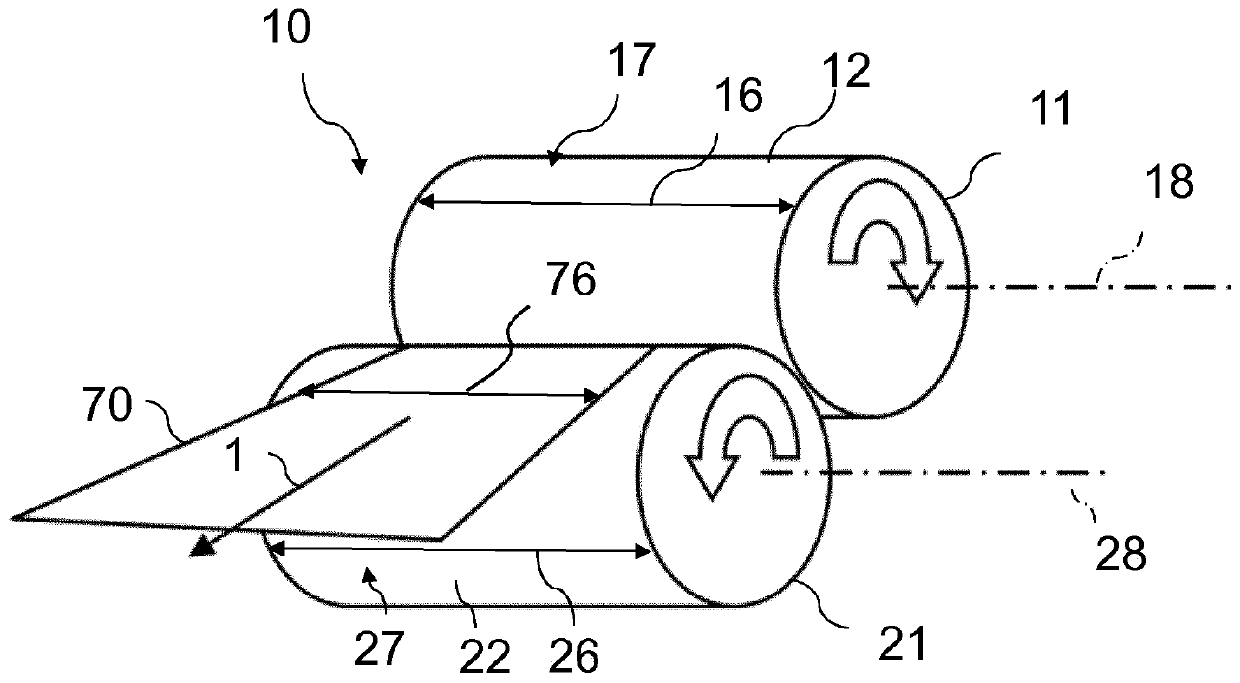

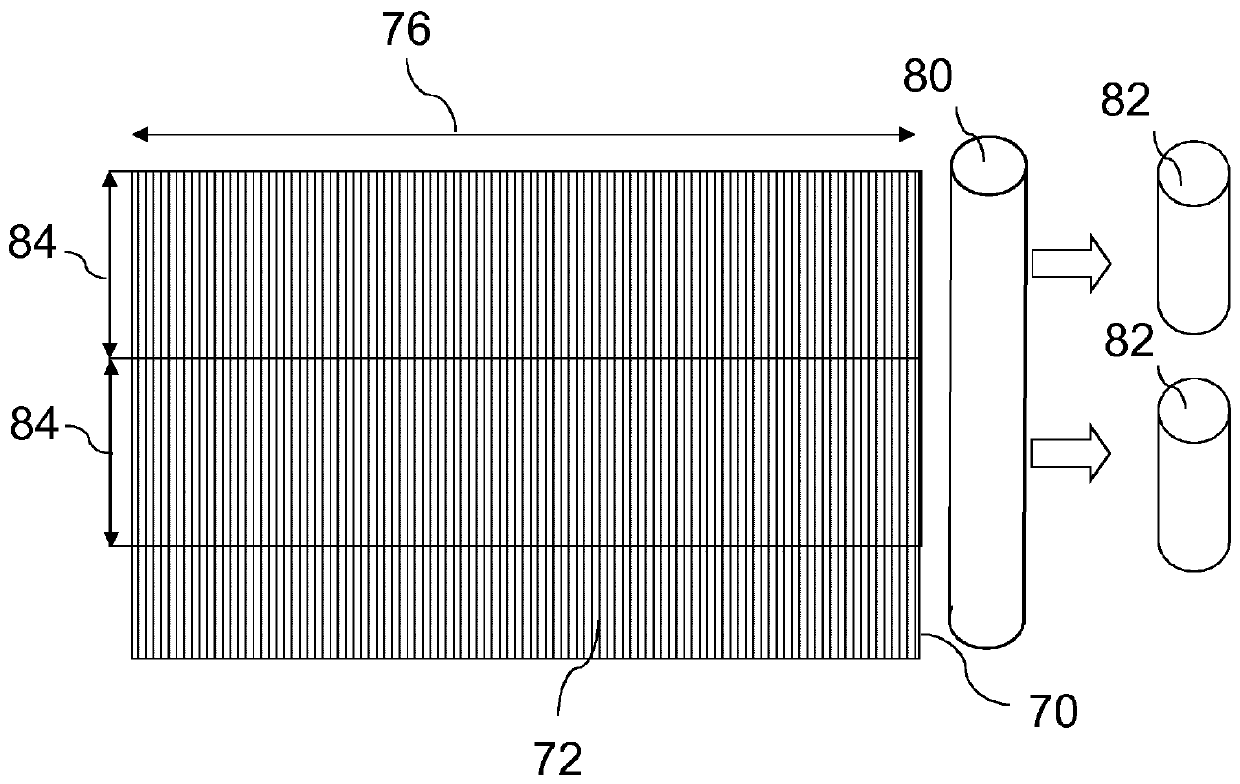

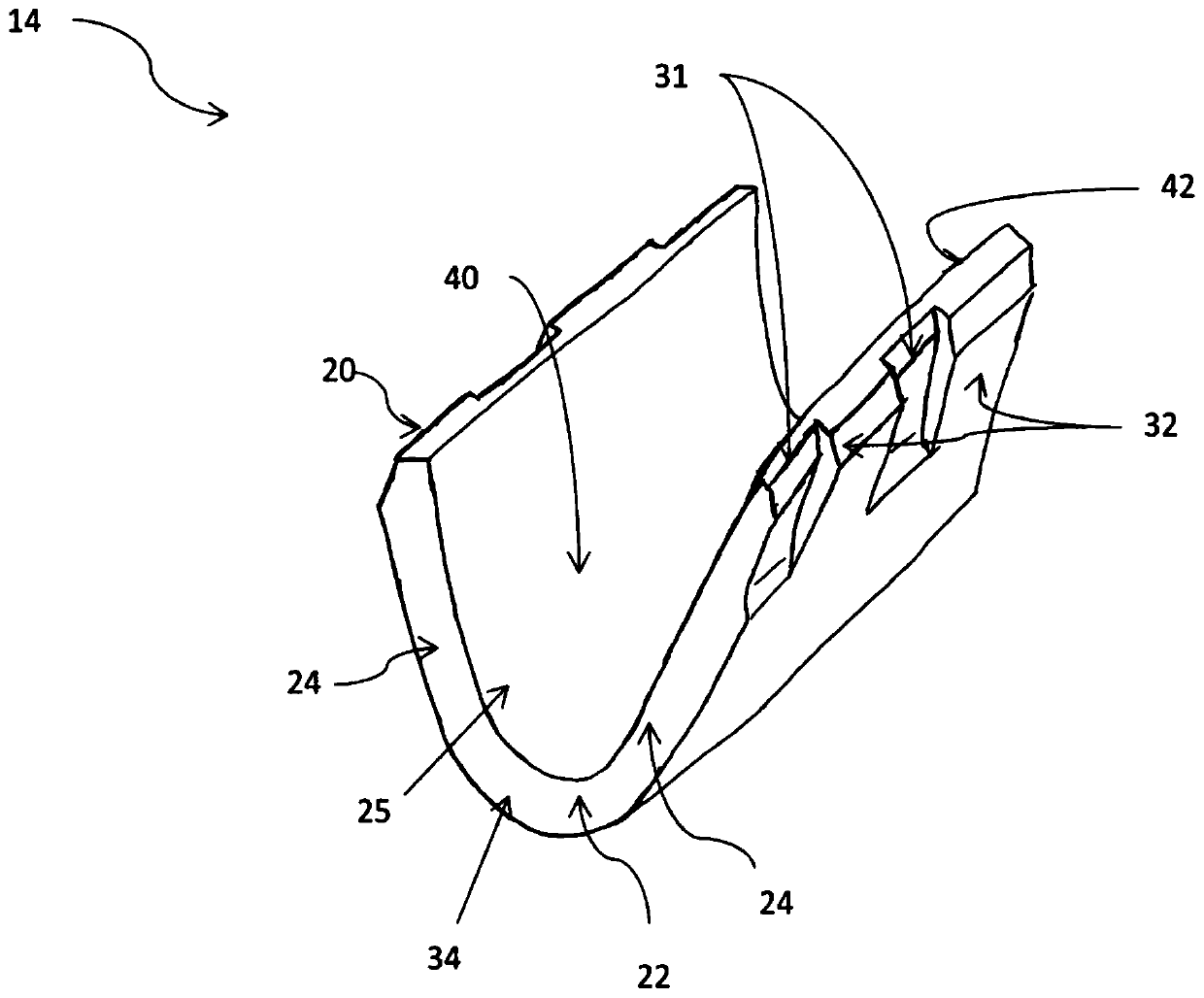

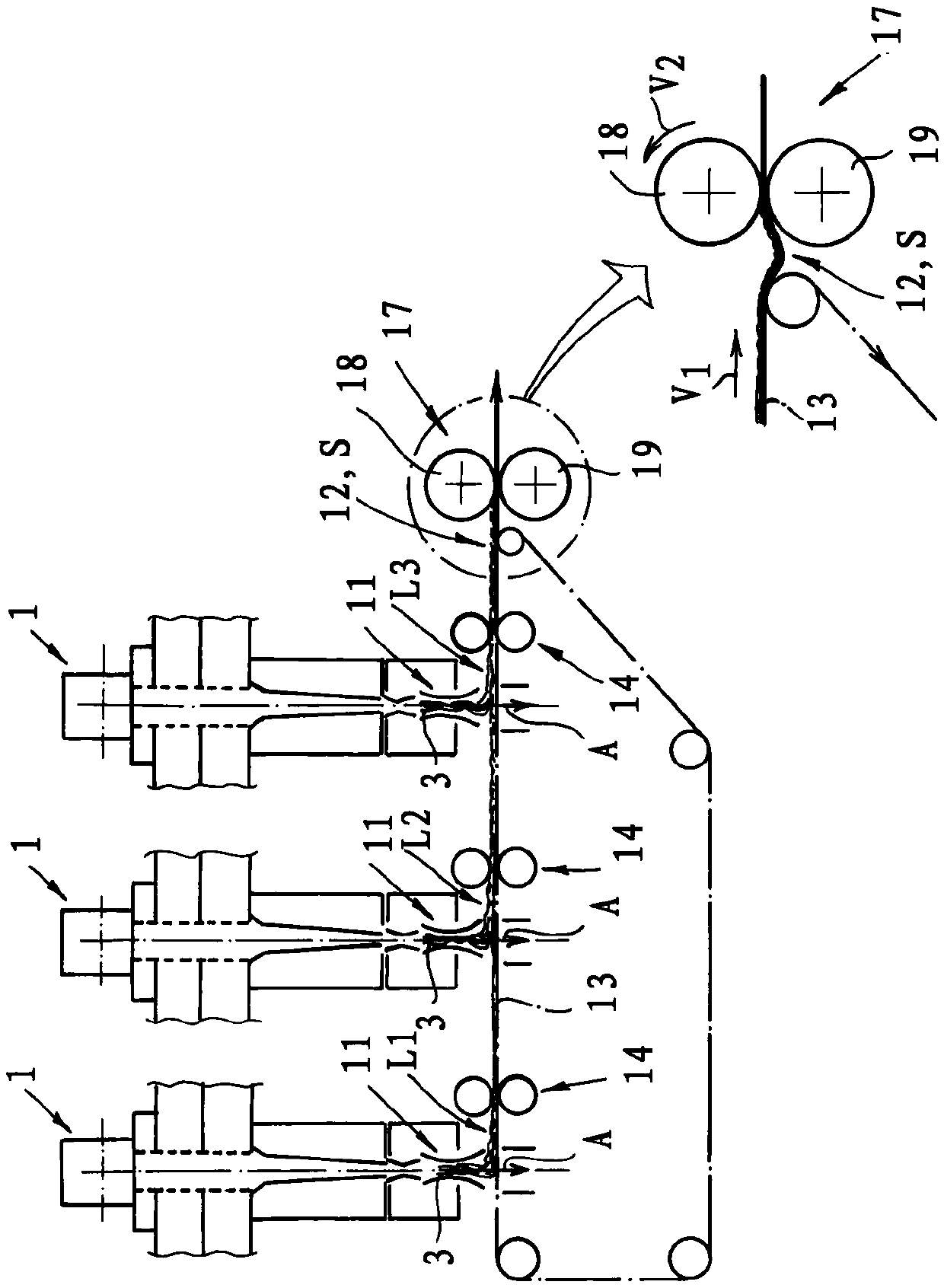

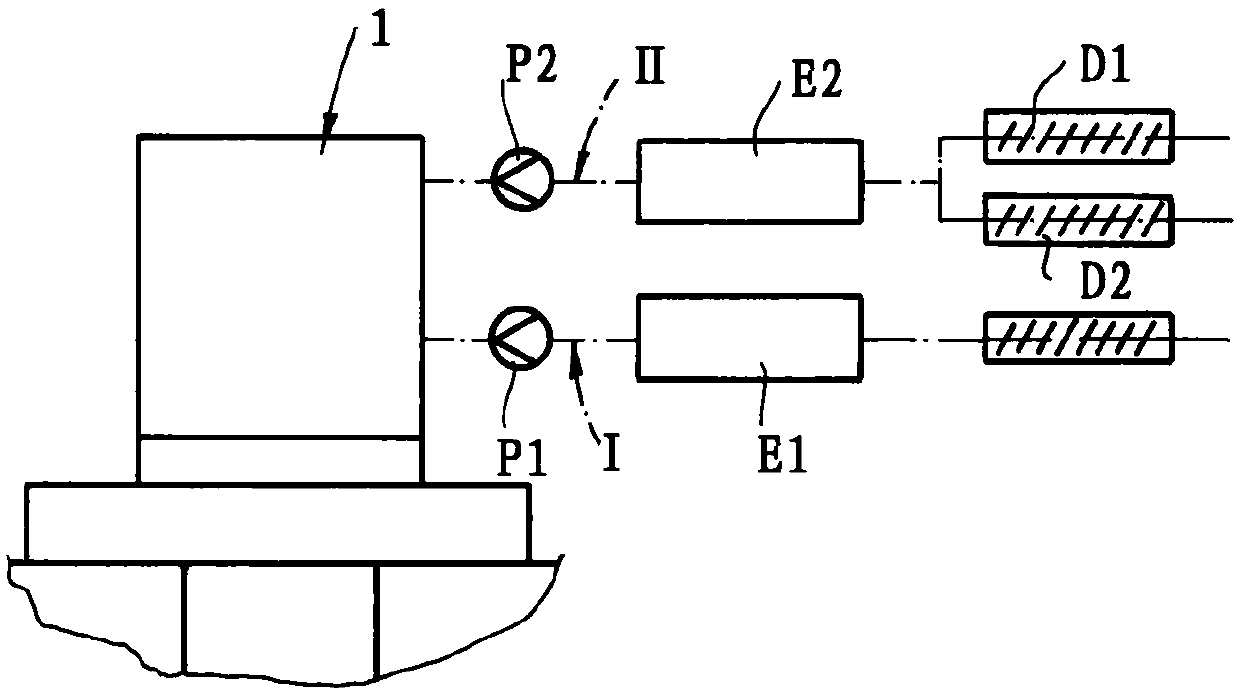

Method for the production of sheet-like tobacco material

The invention relates to an apparatus and a method of manufacturing a crimped sheet (70) of material for an aerosol-generating article. The method comprises the step of feeding a substantially continuous sheet of material to a set of crimping rollers (11, 21) in a transport direction (1), the set of crimping rollers comprising a first roller (11) having a first surface (12) and having a first plurality of ridges (17) across at least a portion of its width and a second roller having a second surface, the second surface (22) being formed at least for a portion thereof in a material having an hardness lower than the hardness of a material forming the first surface. Further, the method comprises crimping the substantially continuous sheet of material to form the crimped sheet by feeding the substantially continuous sheet between the first and second rollers in the transport direction of the sheet such that the corrugations of the first roller apply a plurality crimp corrugations to the substantially continuous sheet.

Owner:PHILIP MORRIS PROD SA

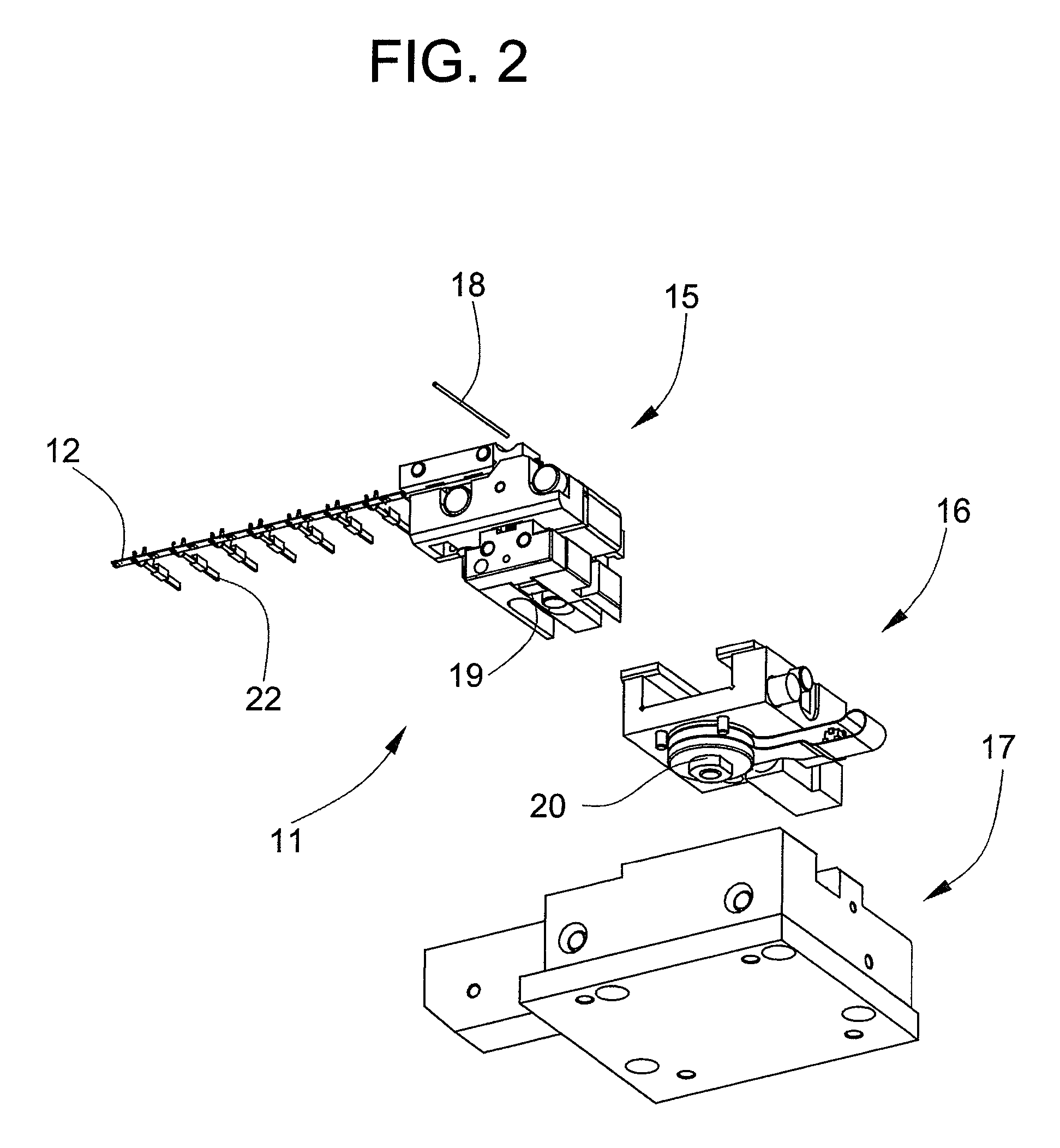

Set of interchangeable crimp units

ActiveUS10862258B2High precisionHigh sensitivityLine/current collector detailsPressesPolymer scienceCrimp

Owner:WEZAG GMBH & CO KG

Laminate and method of making same

ActiveUS10894384B2Satisfactory stabilityGood flexibilityLamination ancillary operationsPersonal carePolymer scienceCrimp

A laminate is made by first non-crimping or low-crimping continuous filaments to form a first spunbond layer and preconsolidating the first spunbond layer with a heated or calendering roller. Then continuous filaments with a greater crimp than the continuous filaments of the first spunbond layer are deposited as a second spunbond layer over the first spunbond layer to create a two-layer structure. Finally, the two-layer structure of the first and second spunbond layers is consolidated such that a total thickness of the laminate is 0.15 to 3 mm, preferably 0.2 mm to 2.5 mm and especially 0.2 mm to 2 mm.

Owner:REIFENHAUSER GMBH & CO MASCHFAB +1

Crimp for connecting wires

PendingCN110034419ALine/current collector detailsConnections effected by permanent deformationEngineeringCrimp

The invention relates to a crimp for connecting wires. The crimp comprises a crimp barrel having a base and a pair of opposing side walls extending from the base. Each of the side walls is adapted tobend around a plurality of wires disposed in the crimp barrel and a pair of ends of the side walls engage with one another along a staggered seam.

Owner:TE CONNECTIVITY INDIA +1

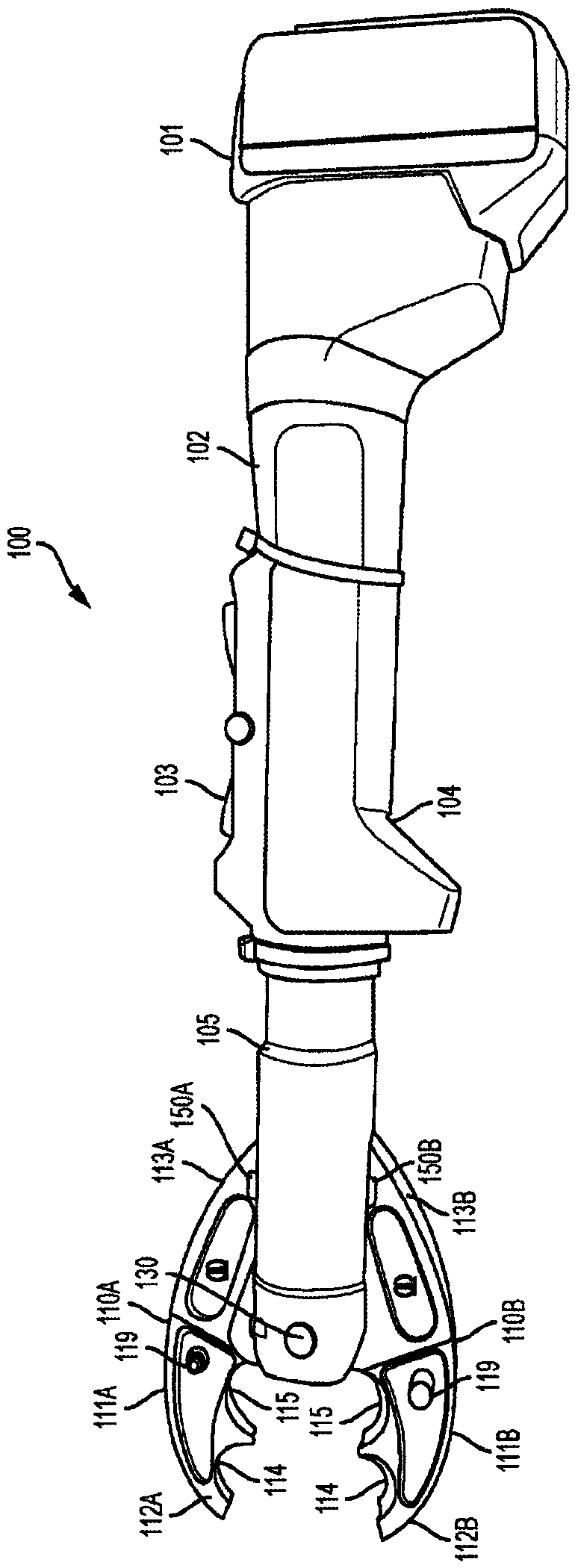

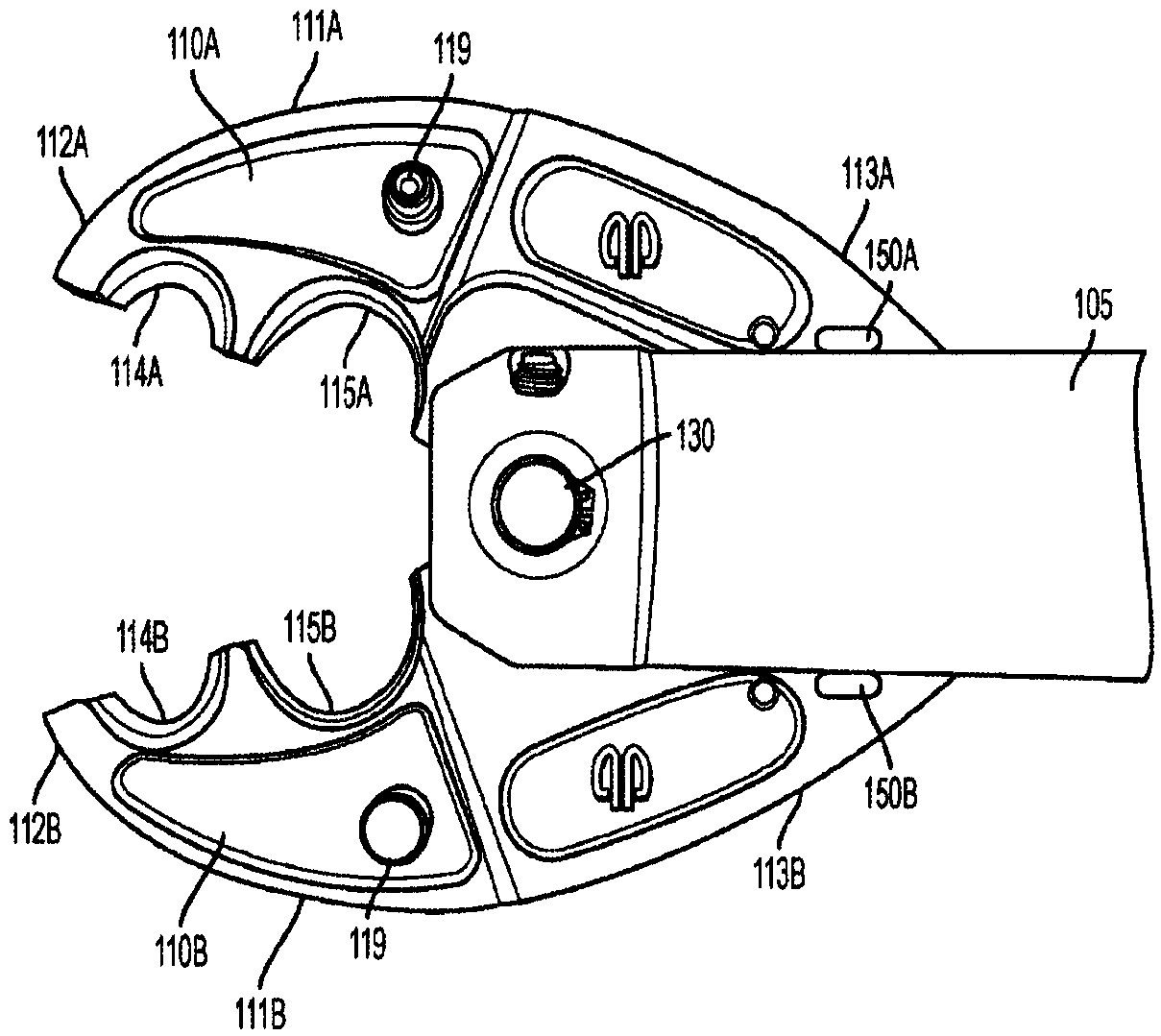

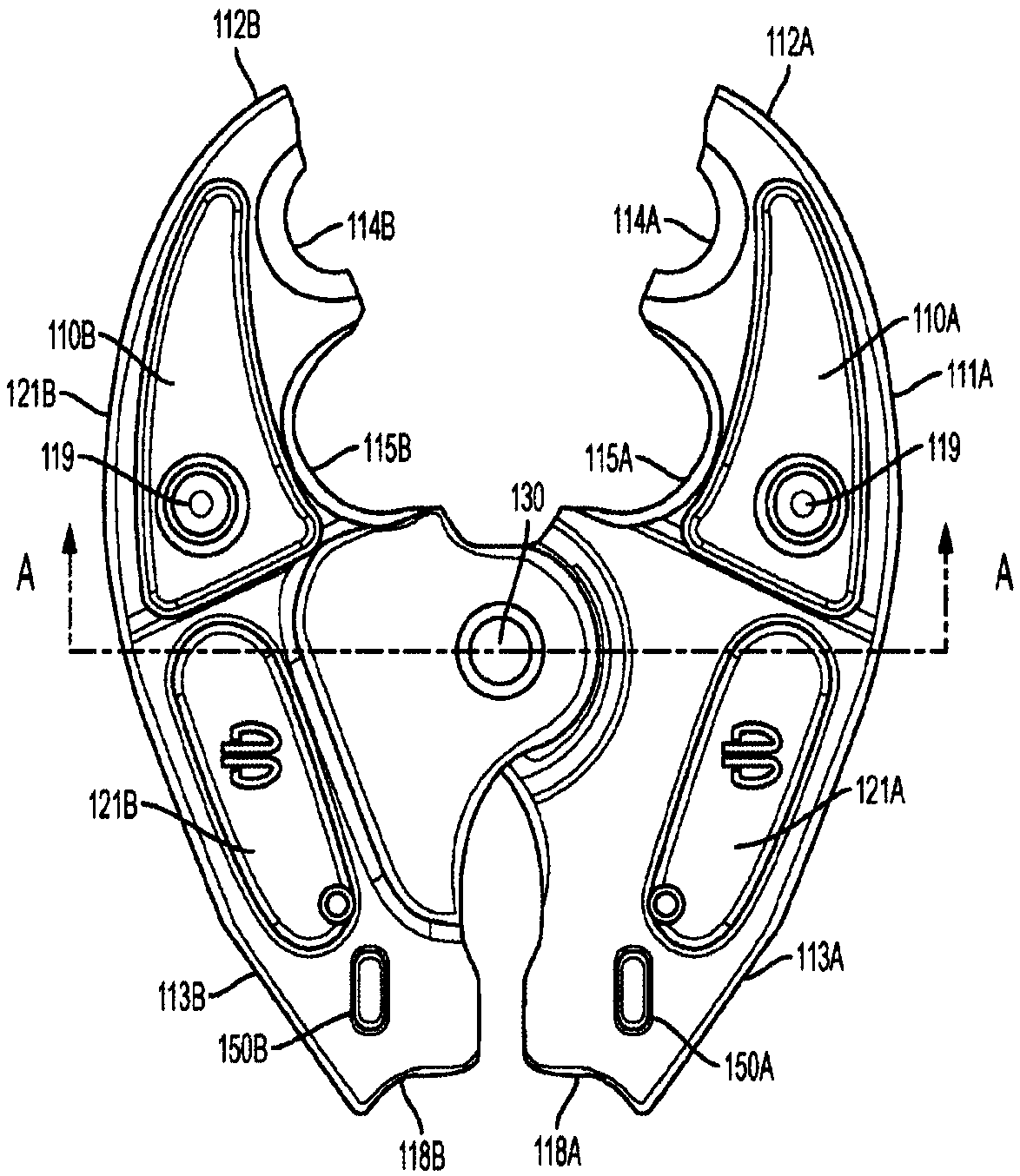

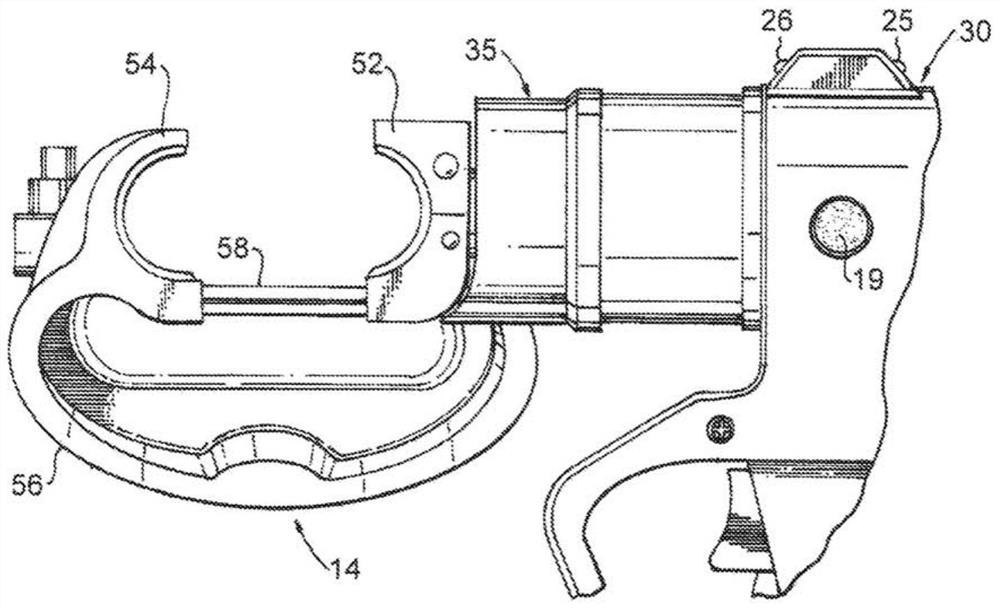

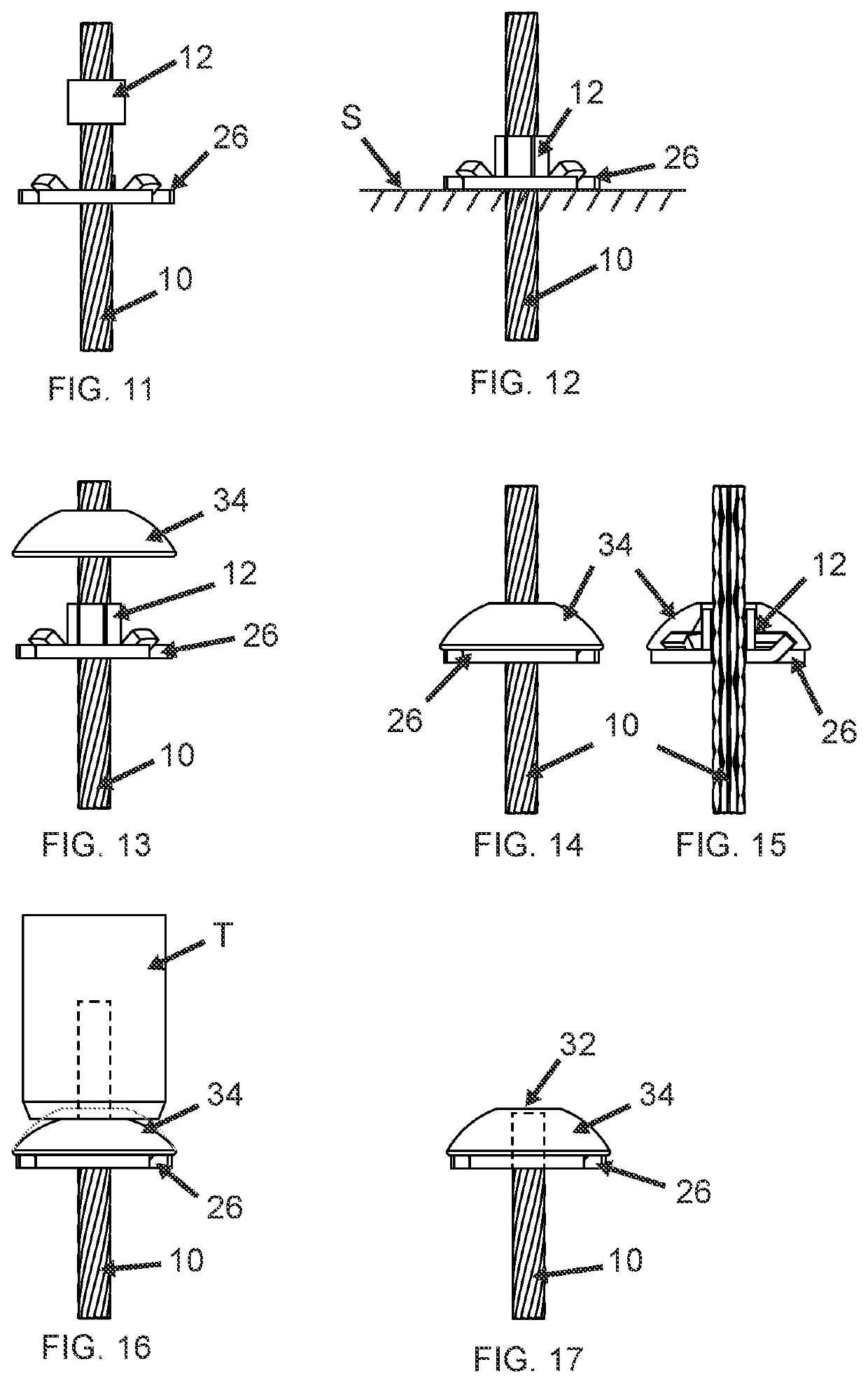

In-line hydraulic crimp tool

ActiveCN109070177AReduce intensityStrength maximizationShaping toolsLine/current collector detailsEngineeringCrimp

A crimp tool having jaw members joined in a tongue-in-groove connection held in place by a locking pin. Each jaw member is tapered and includes weight reducing pockets defined in respective sidewalls.Each jaw member includes a locking tab on an outside edge that mates with a respective locking tab opening in the neck of the tool. When the locking pin is removed, the jaws of the tool separate androtate away from one another until their respective locking tabs engage their respective locking tab opening, thereby holding the opened jaws in the neck of the tool.

Owner:HUBBELL INC

Crimp tooling having guide surfaces

Owner:TE CONNECTIVITY GERMANY GMBH +1

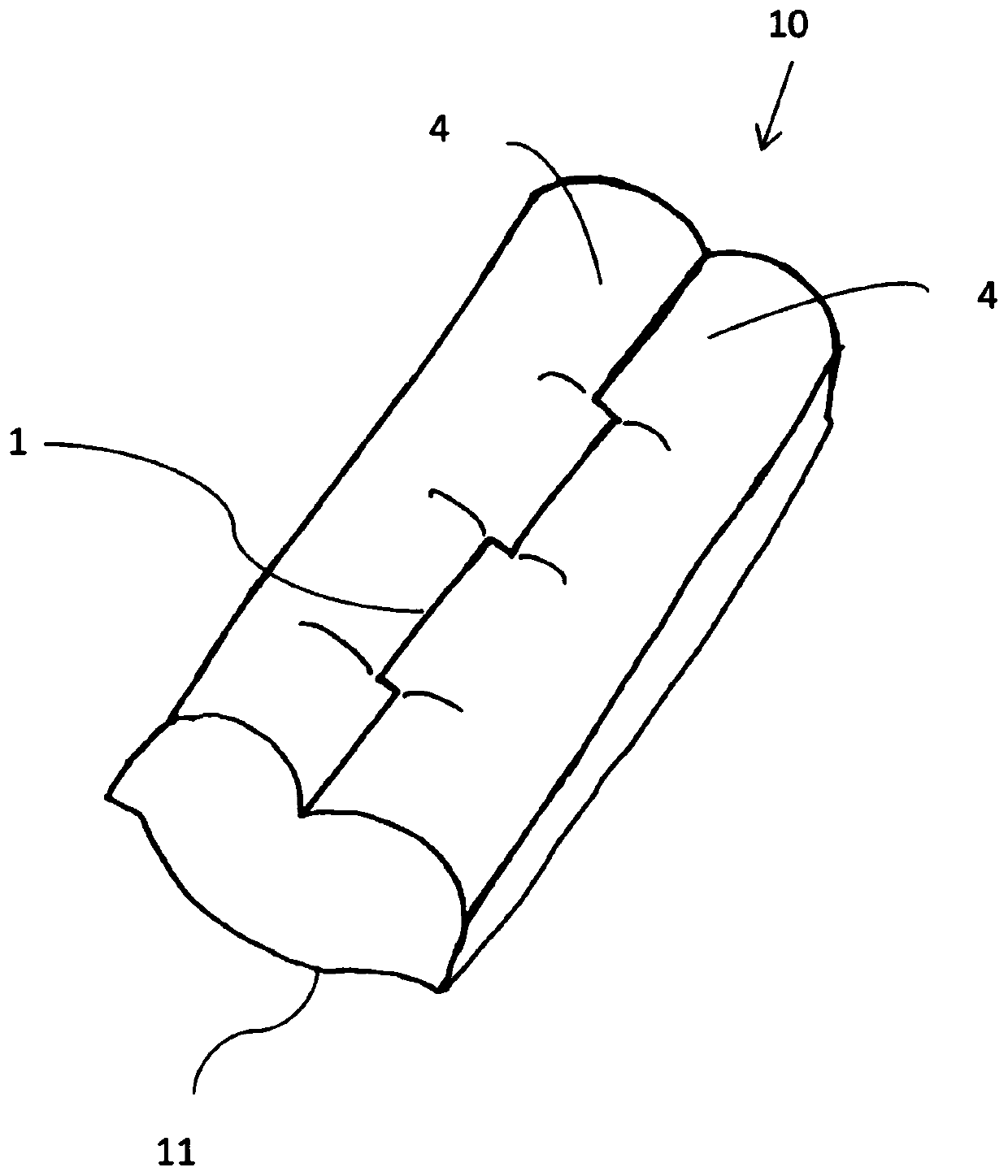

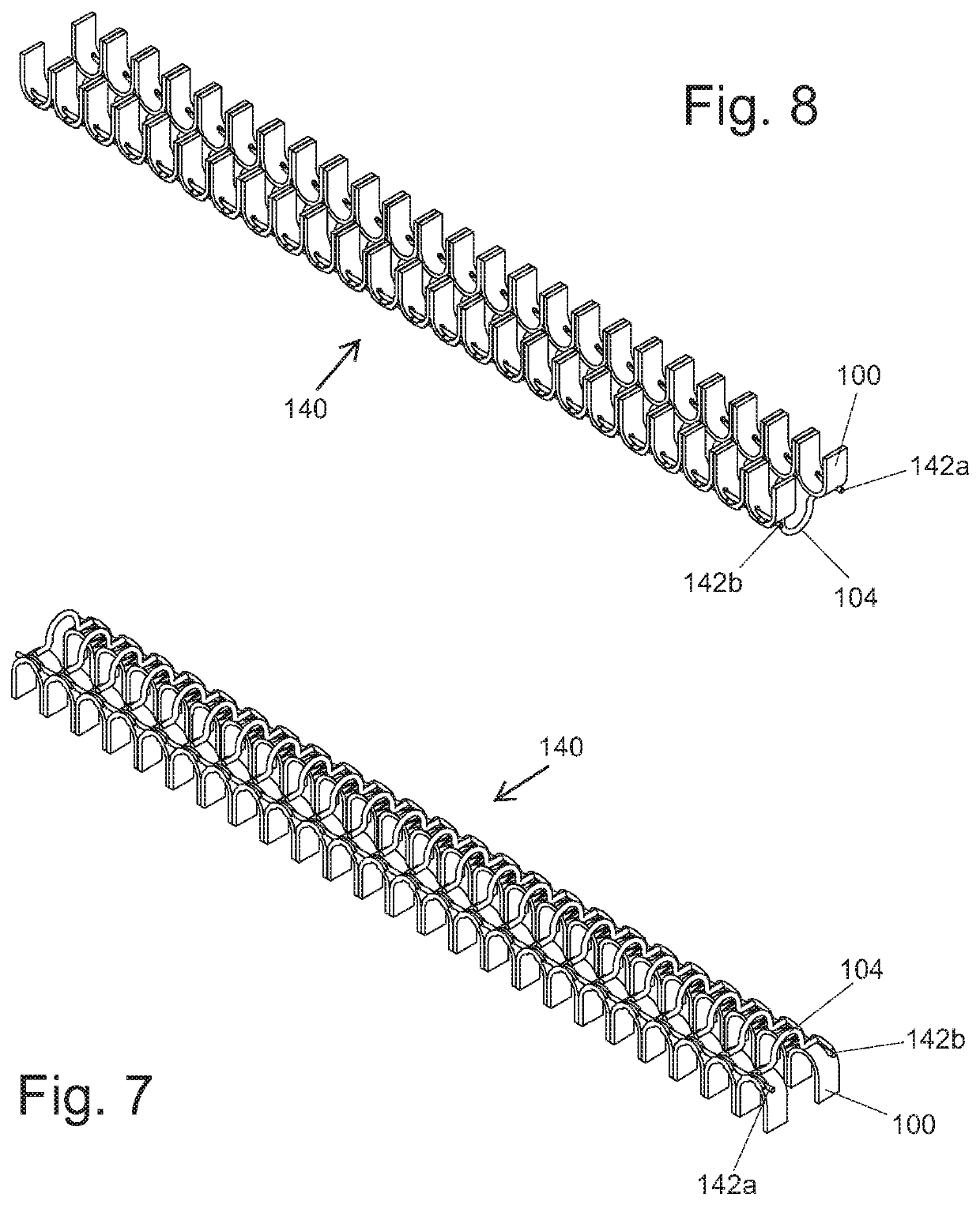

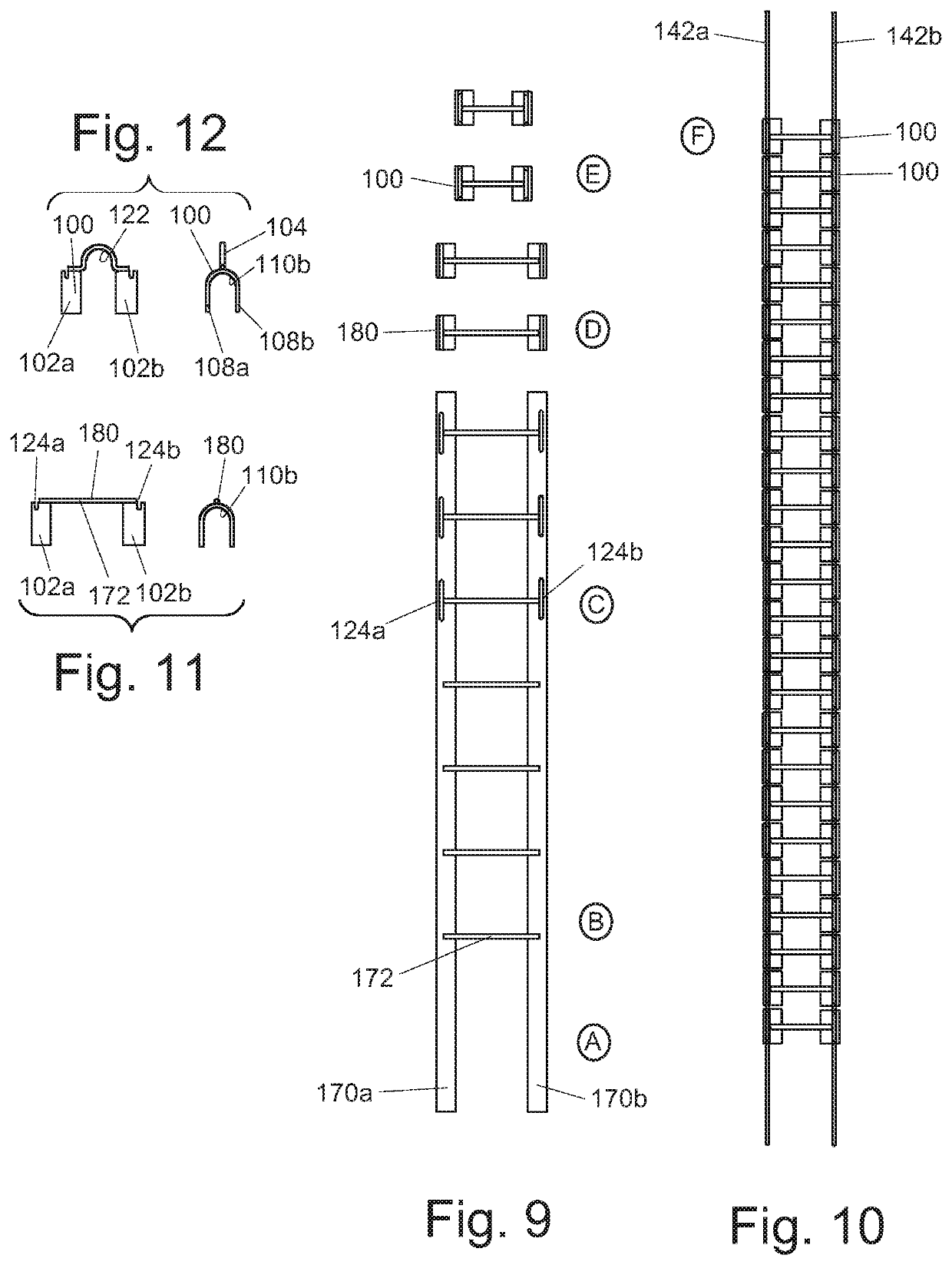

Collated rebar clinch clip

ActiveUS11319707B1Less costlyClosely connectedBuilding reinforcementsBuilding material handlingClassical mechanicsStructural engineering

A collated rebar clinch clip has three components including a pair of spaced U-shaped crimp elements and a U-shaped bridge element connecting the crimp elements. The crimp elements and bridge element are cut from continuous lengths of stock material. A plurality of clinch clips are joined together by a pair of cords to form a collated series of clinch clips that may be arranged in a linear series or spirally wound to form a coil. The tool includes a frame, a die set with a sliding blade and a fixed anvil, an actuator to linearly move the blade relative to the anvil, and a magazine to hold collated clinch clips for sequential delivery between the blade and anvil to tie together a first length of rebar extending through the bridge element and a second orthogonal length of rebar extending through the crimp elements.

Owner:AYRES DON

Crimp contact

PendingCN111817029AVehicle connectorsContact member manufacturingPolymer scienceElectrical conductor

The invention relates to a crimp contact for crimping a conductor having a crimpable crimp flank for enclosing the conductor after crimping, and a receptacle for the conductor, which receptacle extends in a longitudinal direction of the crimp contact up to a receiving end. The crimp flank extends in the longitudinal direction over the receiving end up to a front end, with a front region of the crimp contact being arranged between the receiving end and the front end. The crimp contact has at least one structured region in the front region.

Owner:TE CONNECTIVITY GERMANY GMBH

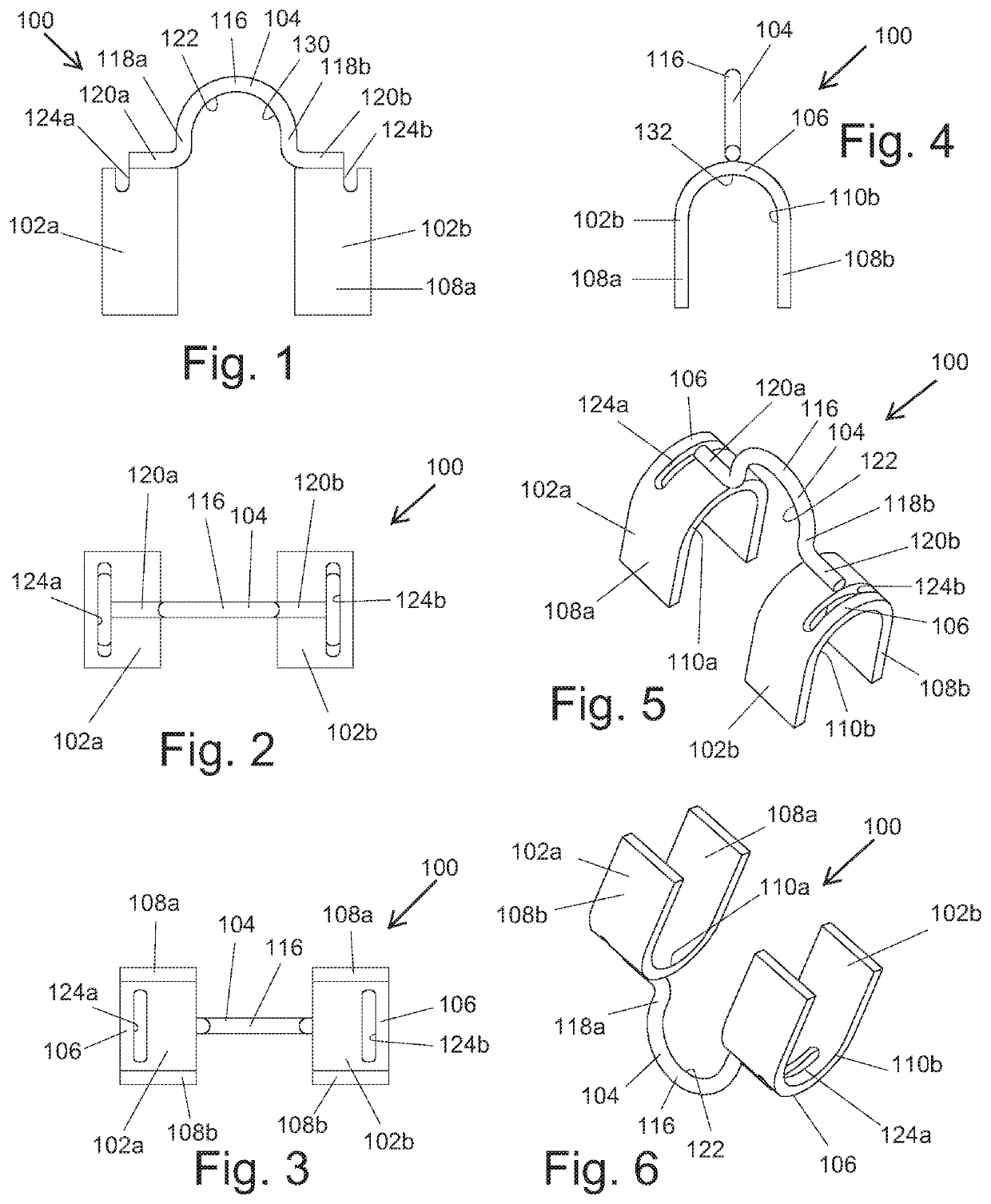

Hand tool with self-resilient handle

ActiveUS11465265B2Less complexMore durableLine/current collector detailsPliersStructural engineeringHand tool

A hand tool (1) comprising a first handle (2) and a second handle (3), which are pivotally arranged with respect to each other, a first jaw (4) that is fixed to said first handle (2), the first jaw (4) comprising a first crimp portion (6), and a second jaw (5) comprising a second crimp portion (7), wherein the first and second crimp portions (6,7) are arranged to be moved towards each other by actuation of the first and a second handle (2,3), so as to close a crimp opening (8) formed between said first and second crimp portions (6,7). The second jaw (5) is pivotally arranged with respect to the first handle (2) around a first pivot point (10), and with respect to the second handle (3) around a second pivot point (11) arranged at an upper end of said second handle (3), wherein the first handle (2) comprises a first resilient portion (12) between the first crimp portion (6) and the first pivot point (10), allowing the first crimp portion (6) to flex with respect to the first pivot point (10).

Owner:PRESSMASTER

Power tool with crimp localization

PendingCN112930630AAutomatic control devicesLine/current collector detailsElectrical batteryHand held

Portable, hand-held, battery operated, hydraulic tools are provided with a tool frame, a force sensor, and a location detector. A piston actuated by a hydraulic system within the tool frame applies force to the working head to perform a task, such as to apply a crimp to an electrical connector. The tool determines the maximum force applied to the crimp and records that maximum force along with the geographic location of the tool when the crimp was formed. The maximum force provides an indication of the quality of the crimp and the recorded location allows a potentially defective crimp to be located.

Owner:HUBBELL INC

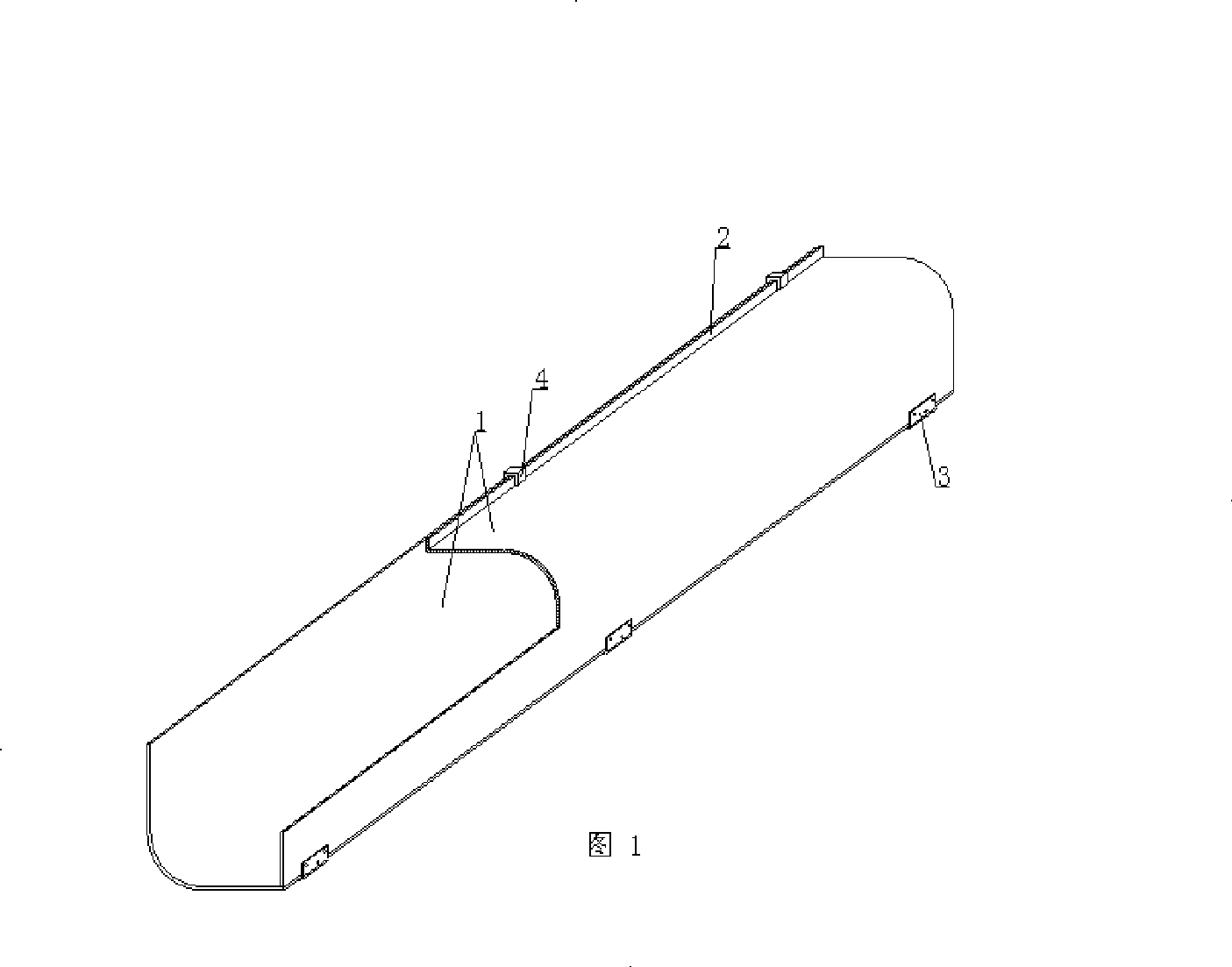

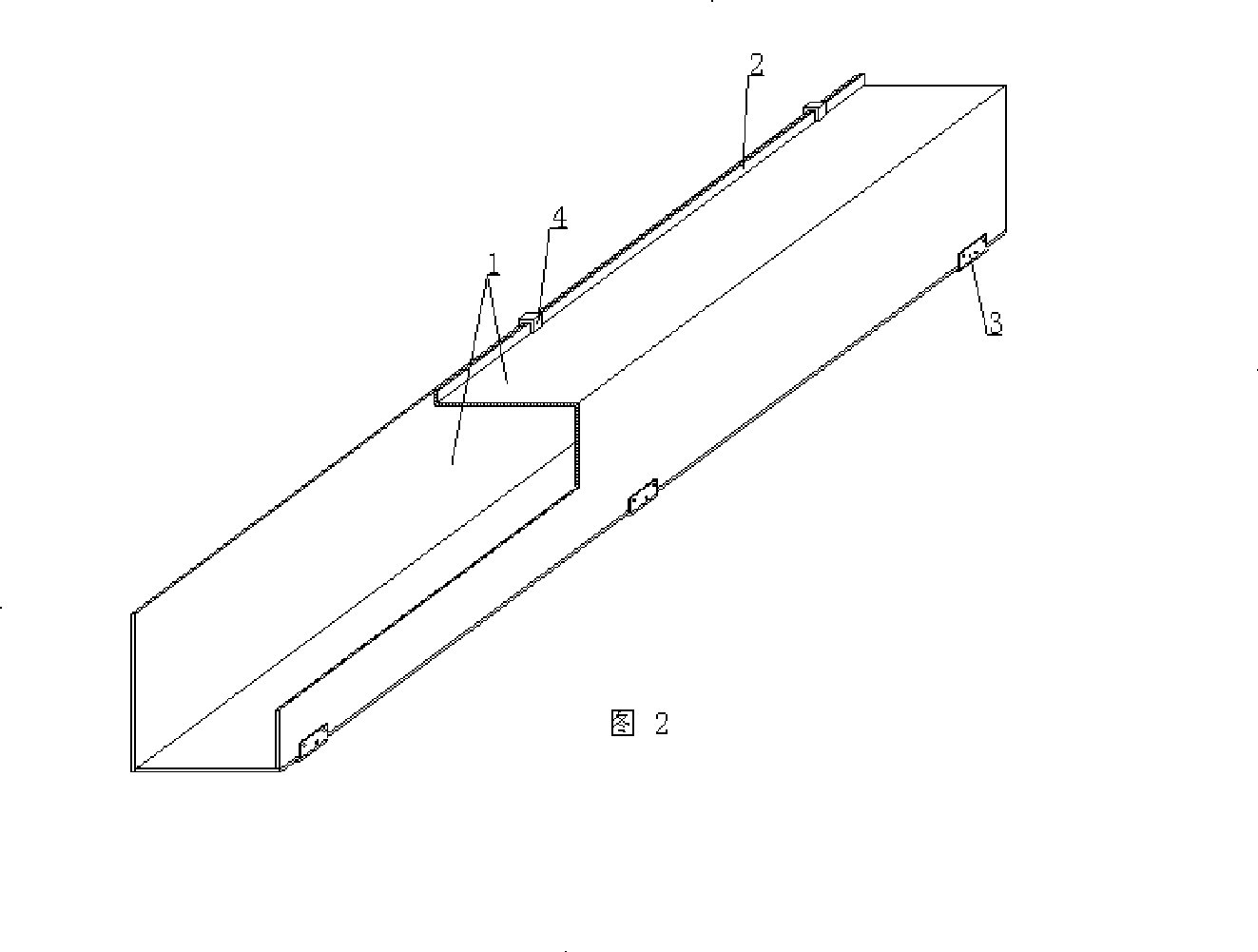

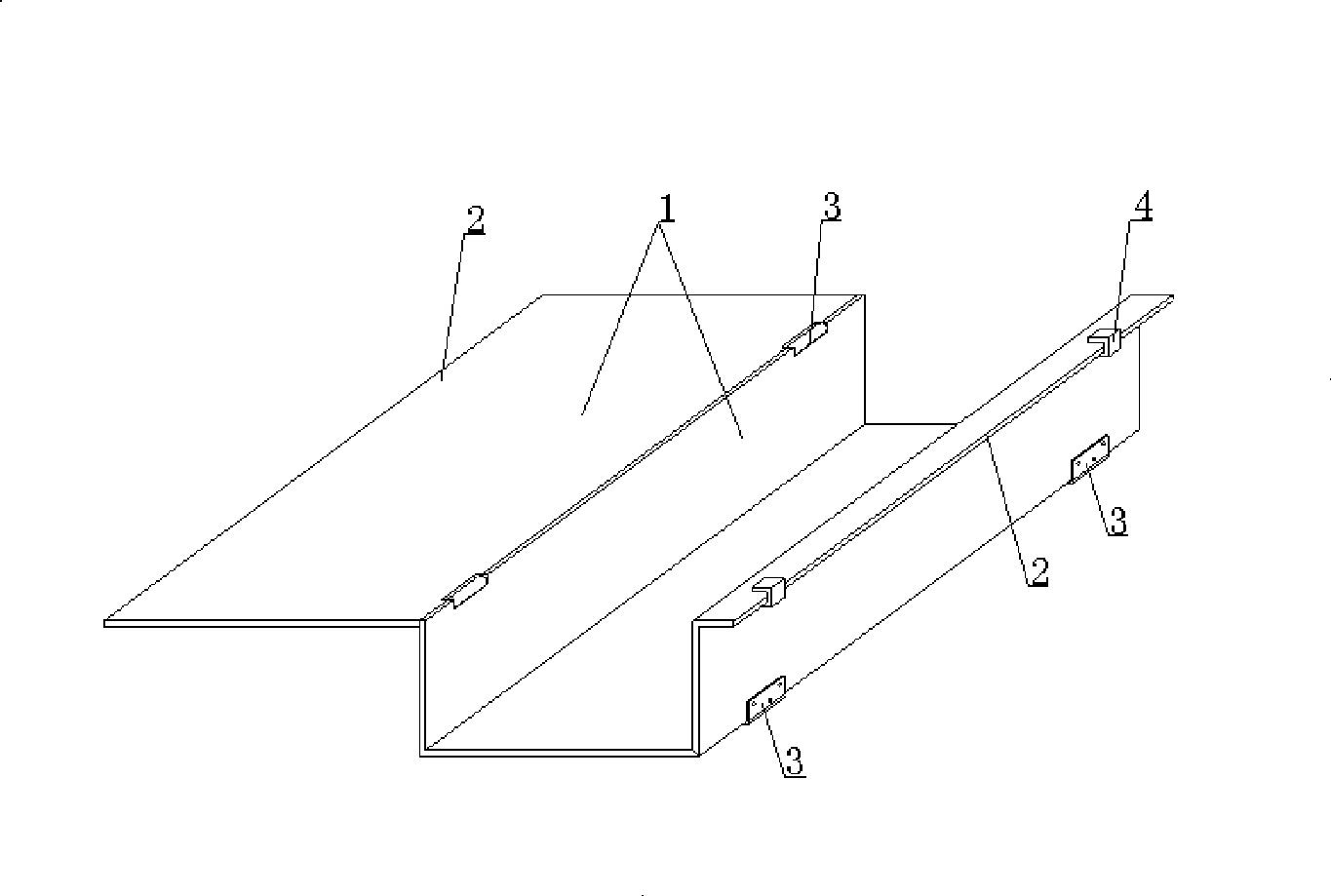

Tubular mould for molding concrete filled hollow thin wall component

InactiveCN101391440AReduce manufacturing costMould separation apparatusMouldsEngineeringUltimate tensile strength

Disclosed is a cylinder-shape die for molding a concrete filling hollow thin-walled component, which at least includes two formworks(1), a connector(2), a rotatable part(3) and a fastener(4). The rotatable part(3) is used to connect the formworks(1), the connected formworks(1) can be correspondingly rotated, the connector(2) is arranged on the formworks(1), the formworks(1) are shut by the fastener(4)and are fixed to form the cylinder-shape die; the die is characterized in that at least one formwork(1) is an non-planar crimp-shape or folded plate-shape formwork(1), the non-planar crimp-shape or folded plate-shape formwork(1) are U-shape, the U-shape formwork(1) and the plate shape formwork(1) are shut to form the cylinder-shape die, at least one end of at least one formwork(1) in the formworks(1) is connected with an end formwork(1). Thus, after the fastener is loosened, the demoulding is very convenient. Moreover, the die also has the advantages that the structure is simple, the manufacture is easy, the strength is high, and the cost is low and the like. The die is applicable for producing various opened or closed polyhedron components.

Owner:邱则有

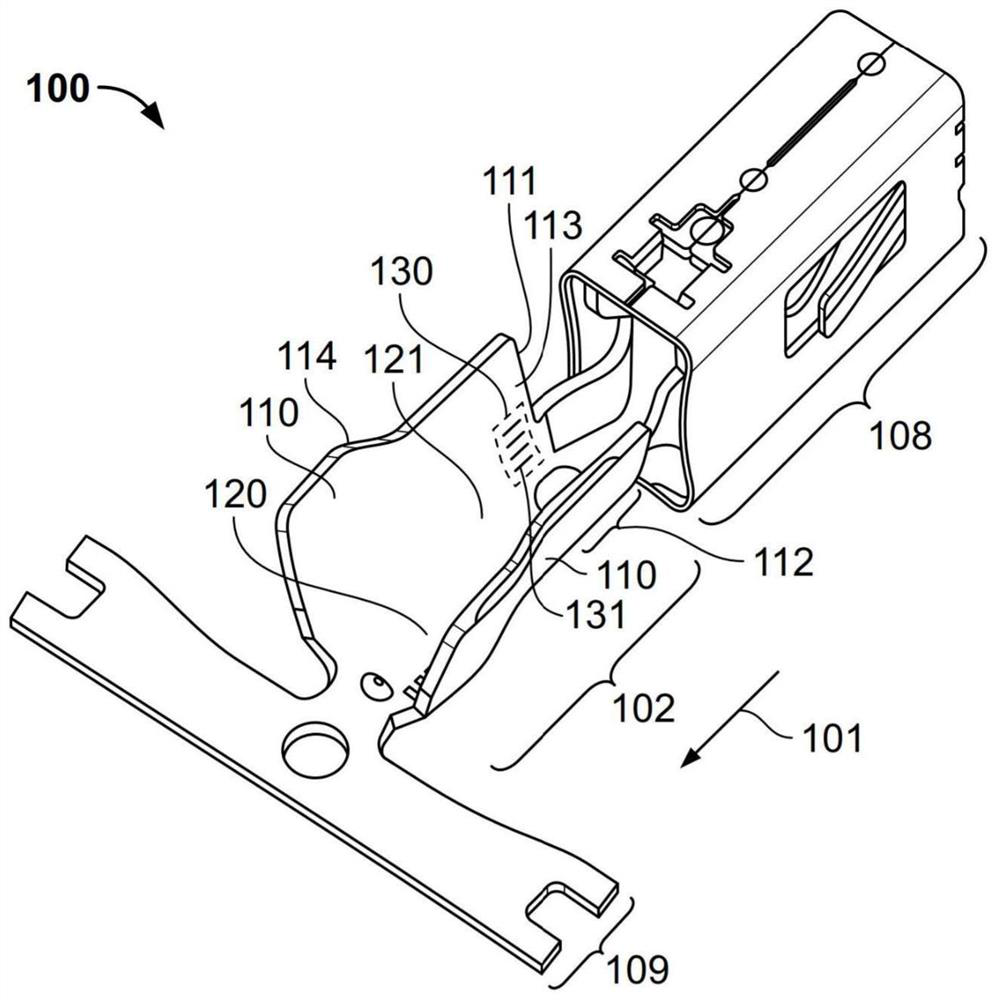

Power tool with crimp image

PendingUS20210397155A1Easy to organizeEasy accessProgramme controlComputer controlWeb serviceElectrical battery

Portable, hand-held, battery operated, hydraulic tools are provided with a tool frame, a force sensor, and a location detector. A piston actuated by a hydraulic system within the tool frame applies force to the working head to perform a task, such as to apply a crimp to an electrical connector. The tool determines the maximum force applied to the crimp and records that maximum force along with the geographic location of the tool when the crimp was formed. The maximum force provides an indication of the quality of the crimp and the recorded location allows a potentially defective crimp to be located. Images of crimps can be uploaded to a web service and linked to cycle information for retrieval and review at a later date.

Owner:HUBBELL INC

Nonwoven fabric laminate and method and device for manufacturing same

ActiveCN110093718ASatisfied with processabilityIncreasing the thicknessPersonal careLaminationPolymer scienceNonwoven fabric

Owner:REIFENHAEUSER GMBH& CO KG MASCHFAB +1

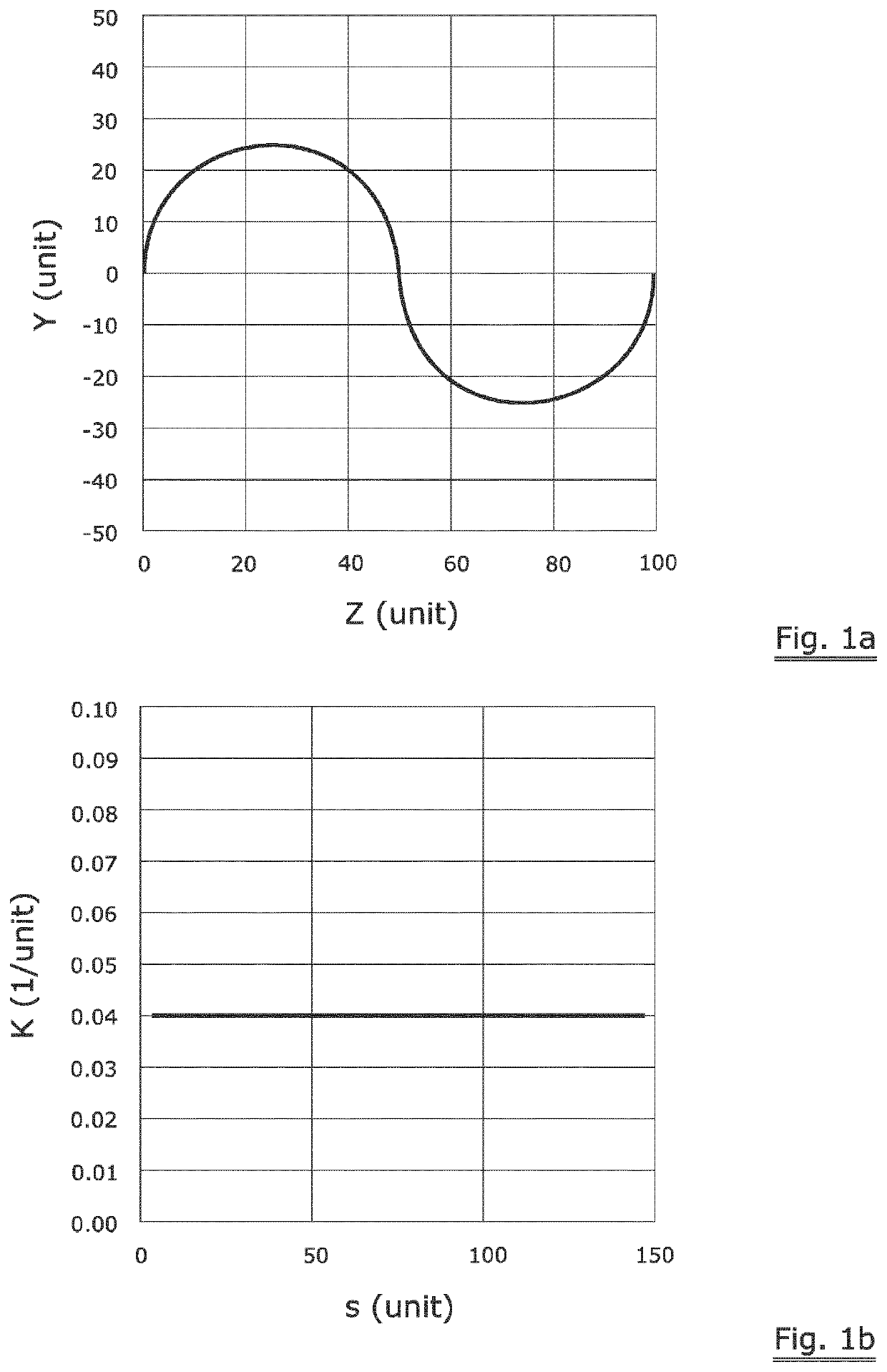

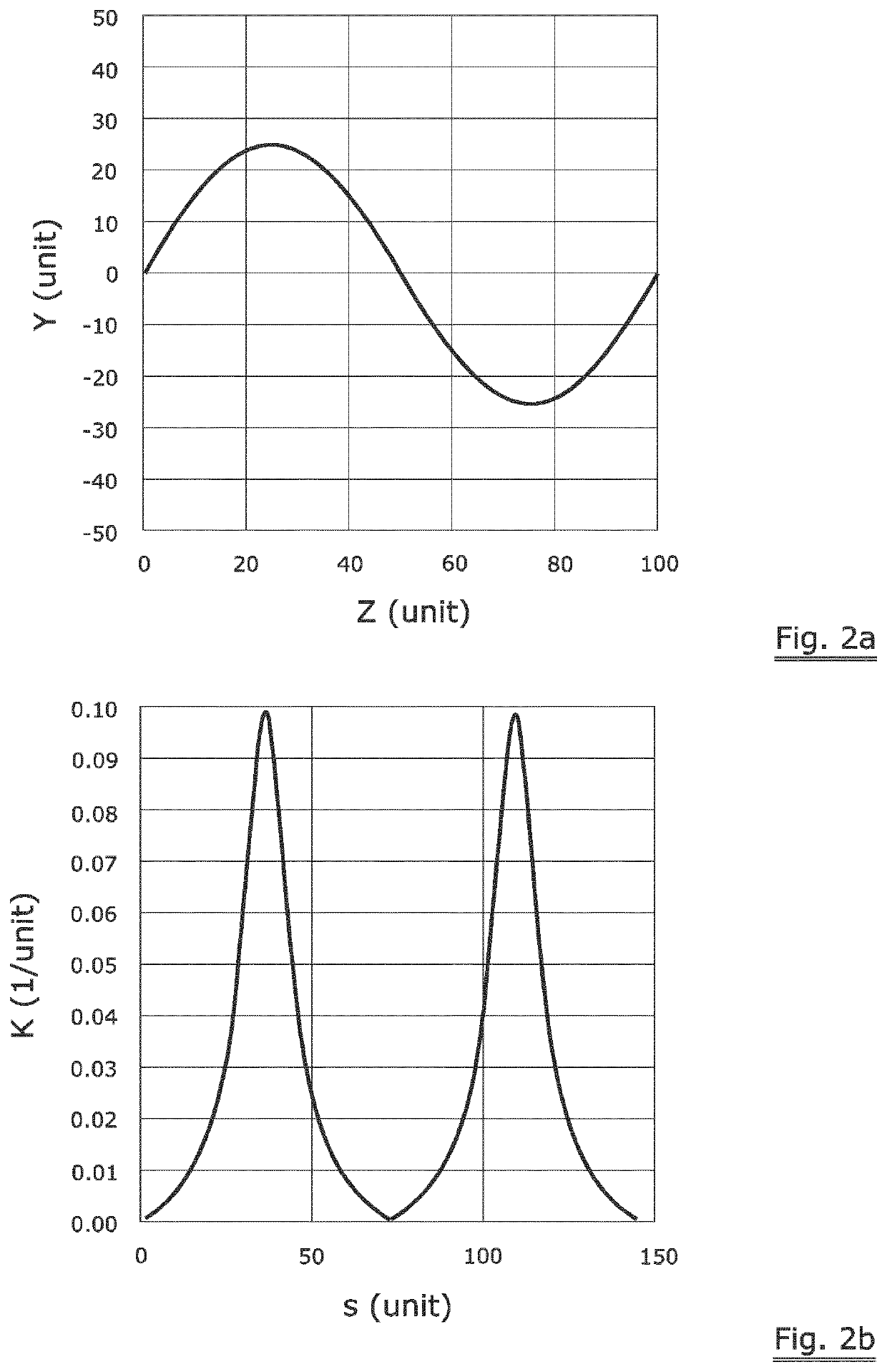

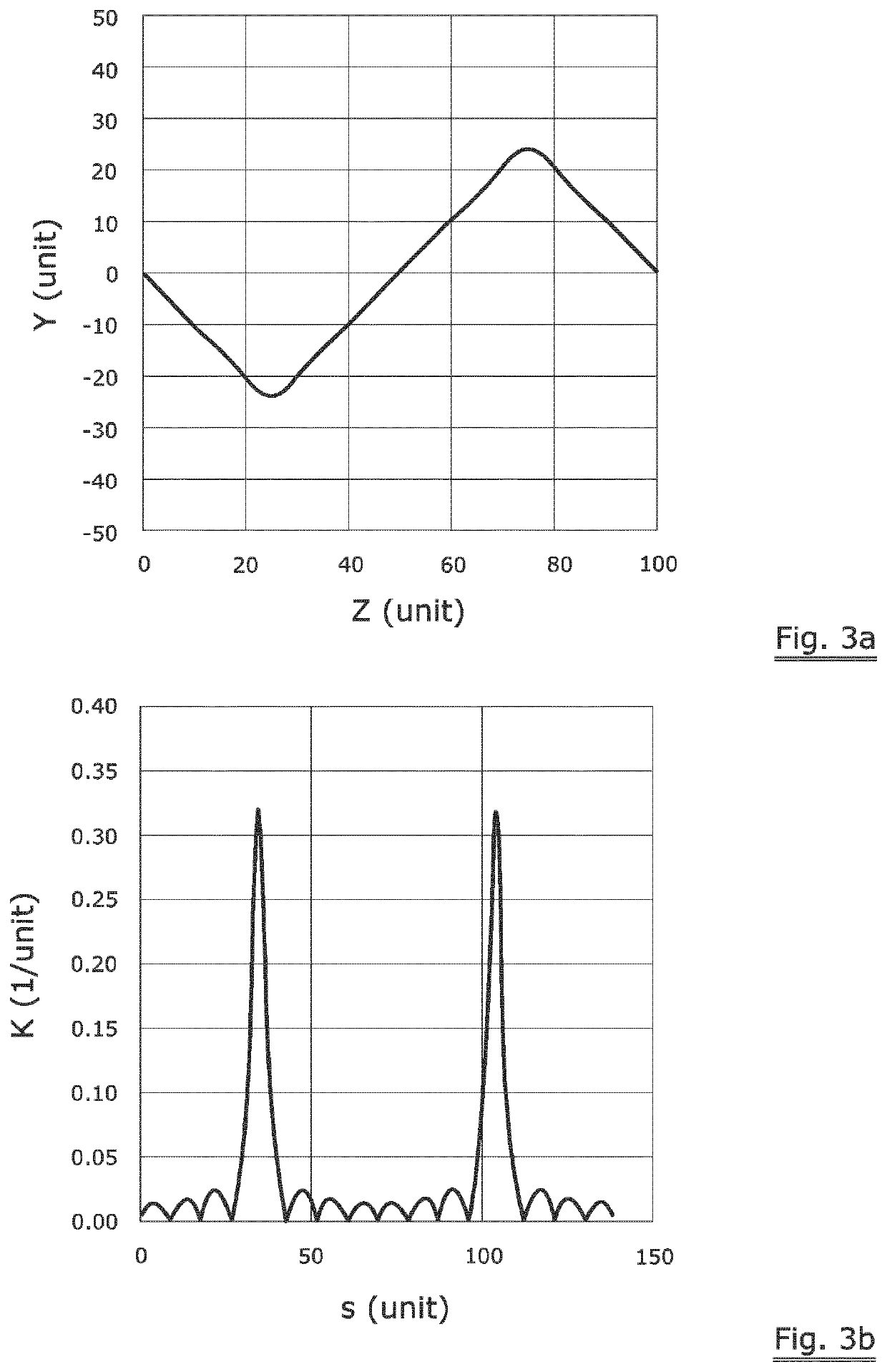

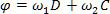

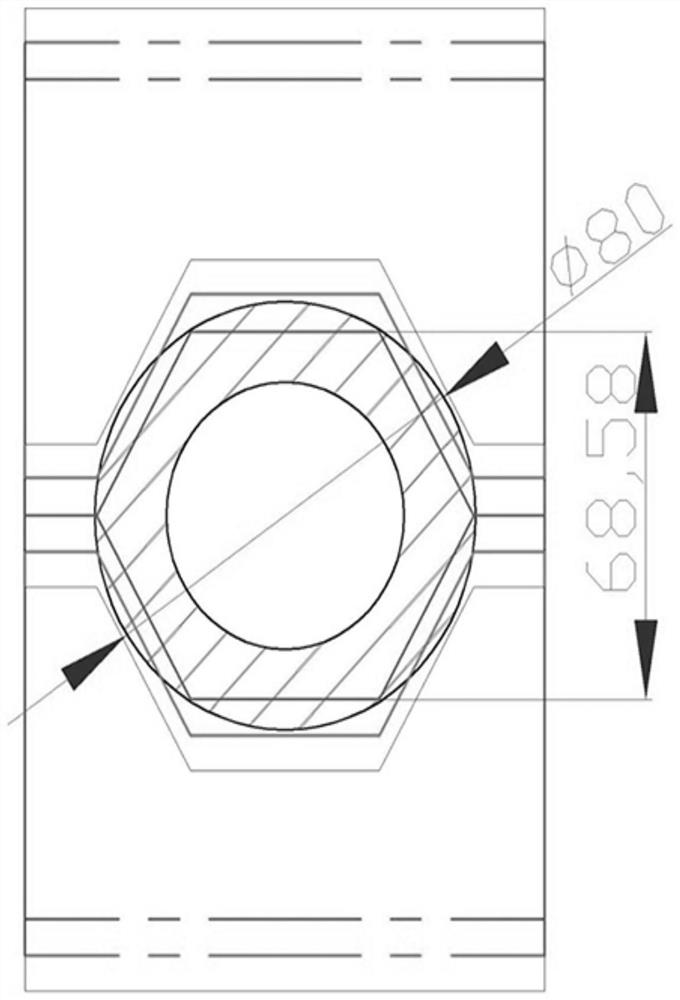

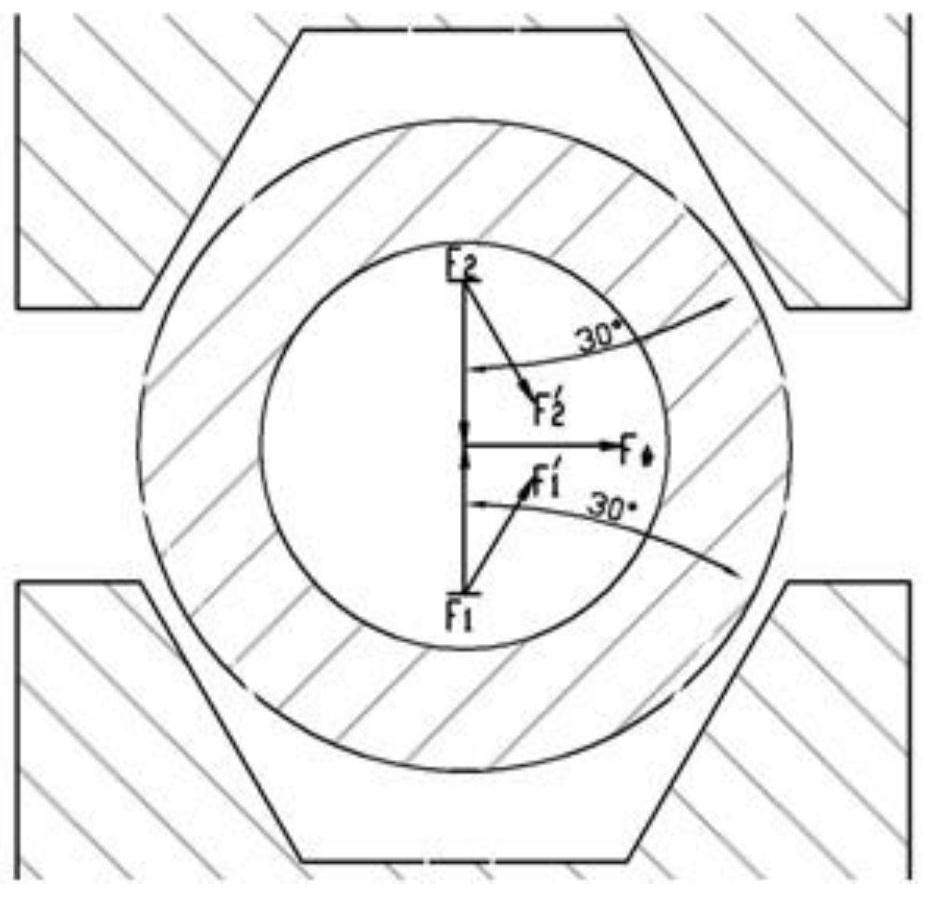

Shaped saw wire with controlled curvature at bends

ActiveUS10835973B2Less prone to preferred orientationIncrease the number ofMetal sawing tool makingMetal sawing toolsClassical mechanicsStructural engineering

A saw wire to cut hard and brittle materials is disclosed that comprises a steel wire that is provided with bends with segments in between. The average degree of bending of the bends is between 0.5% and 5%. Such a saw wire has a higher breaking load compared to saw wires having a conventional, higher average degree of bending. A method to measure the curvature is described as well as a process to make the inventive saw wire. The invention is applicable to any shaped saw wire for example a single crimped saw wire, a saw wire with at least two crimps in different planes, a saw wire with crimps rotating in a plane.

Owner:BEKAERT BINJIANG STEEL CORD CO LTD

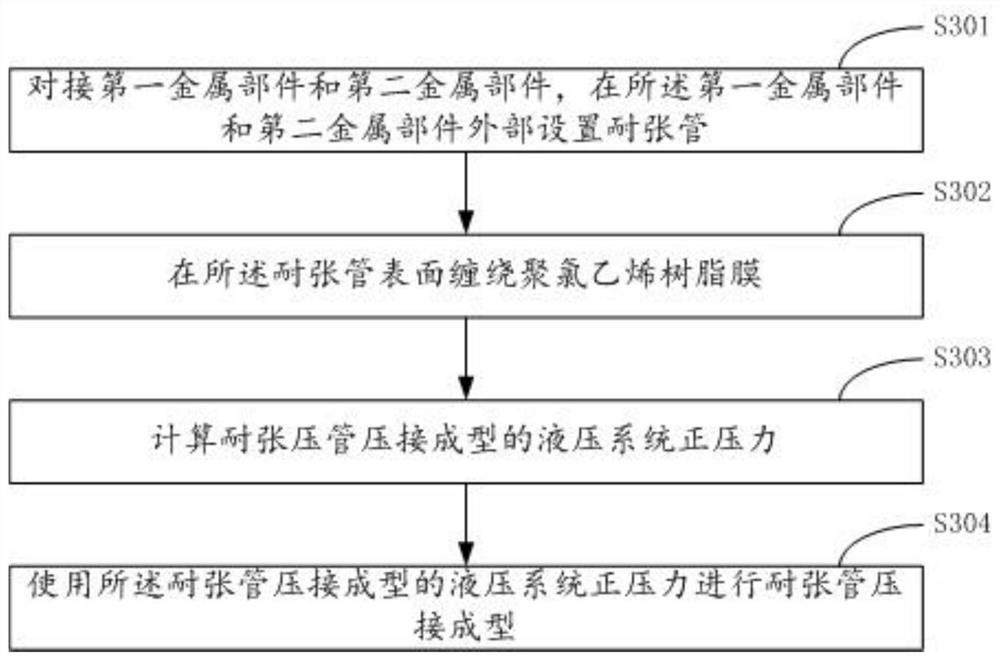

A high-precision stepped crimping hole processing method

ActiveCN112423477BHigh precisionReduce the impact of positioning point deviationNuclear energy generationPrinted element electric connection formationEngineeringCrimp

Owner:AOSHIKANG TECH CO LTD

Metal terminal

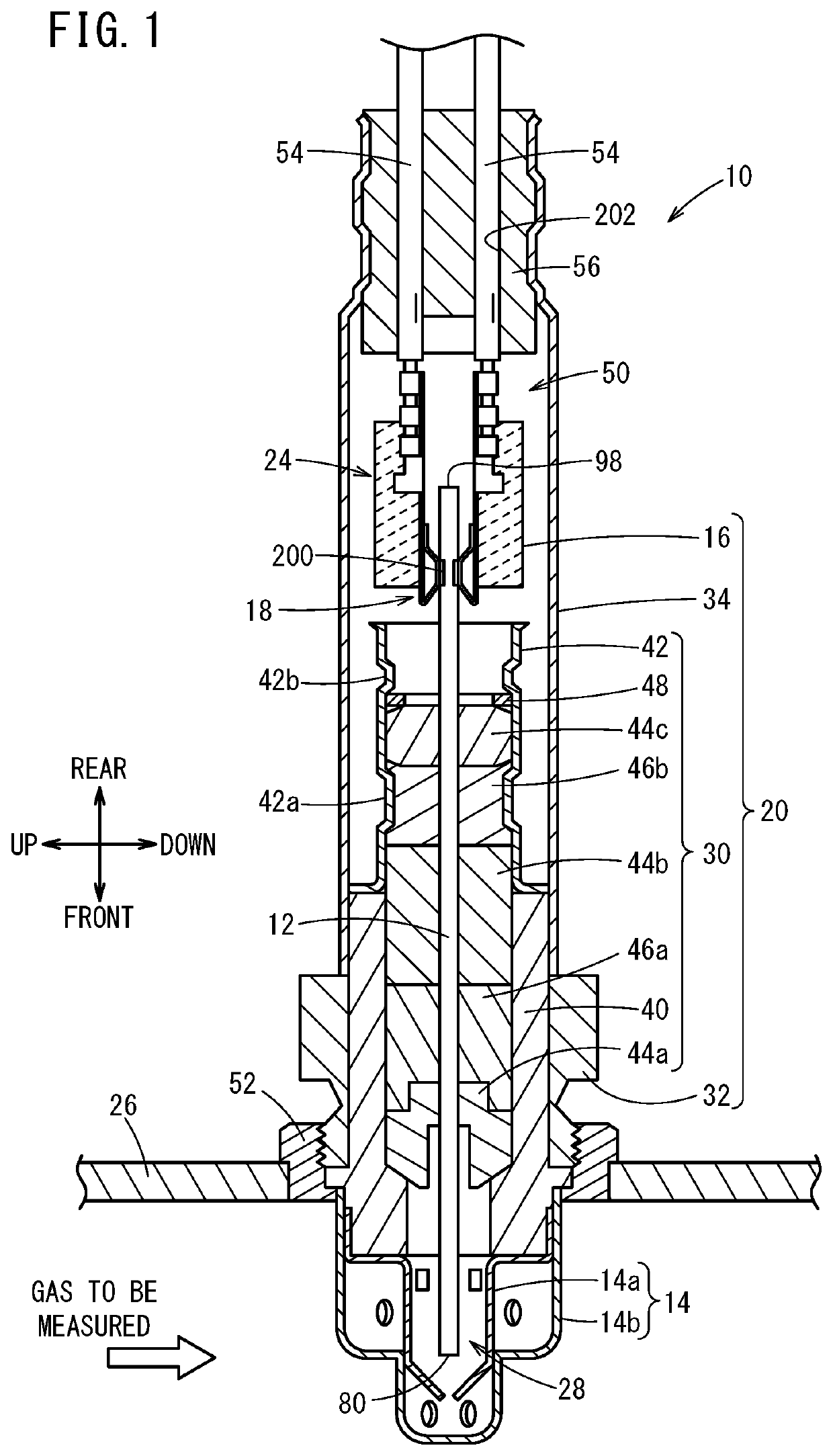

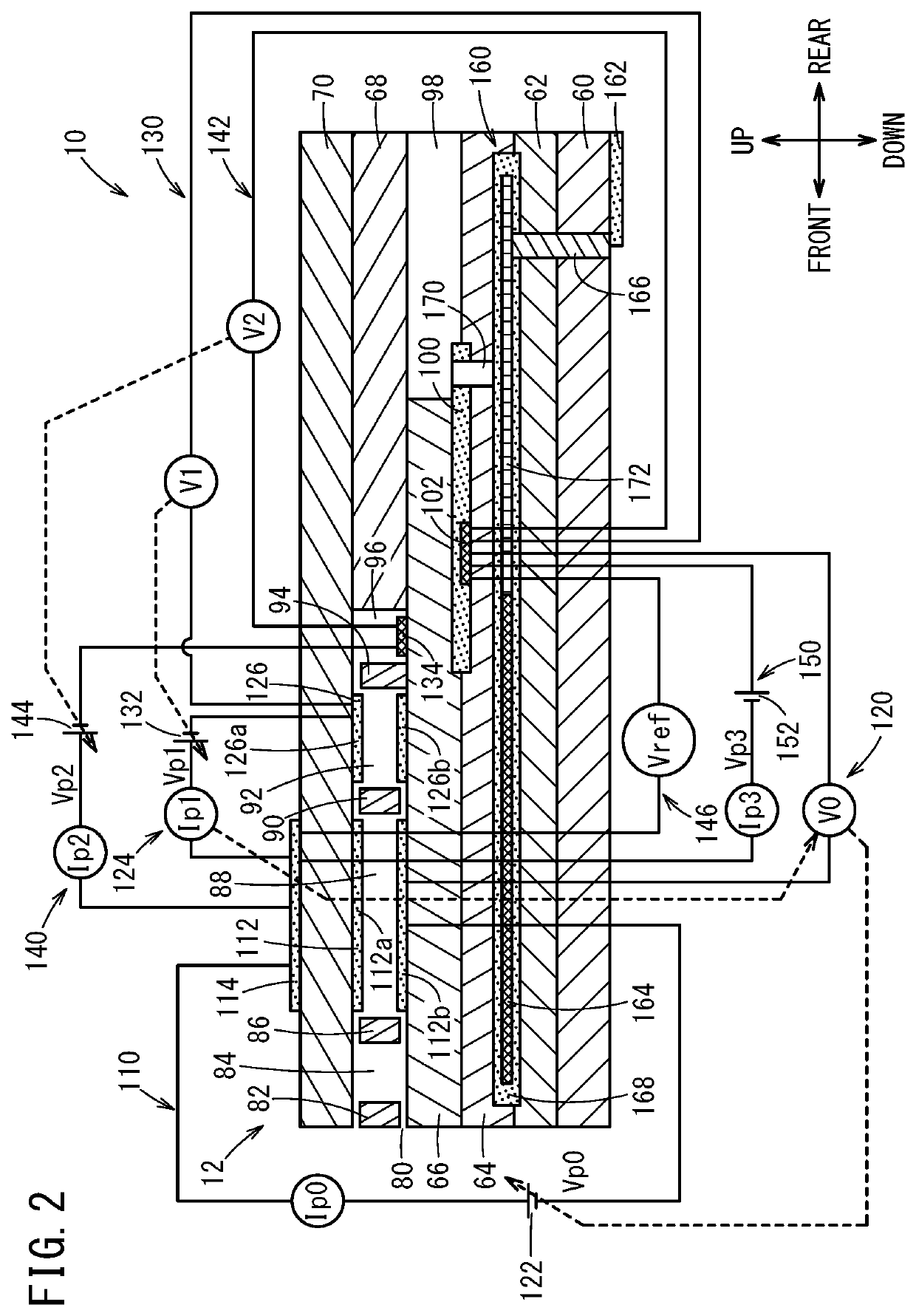

PendingUS20210172902A1Avoid damageMaterial analysis by electric/magnetic meansCoupling contact membersEngineeringCrimp

A metal terminal includes an element contacting portion which is disposed at one end of the metal terminal and is placed in contact with a sensor element, a lead wire retaining member which is disposed at another end of the metal terminal, and crimps and retains lead wires, a positioning member disposed between the one end and the other end and extending in a direction intersecting one direction, the positioning member positioning the metal terminal on a ceramic housing, and a guide member provided integrally with the positioning member at a site between the positioning member and the lead wire retaining member.

Owner:NGK INSULATORS LTD

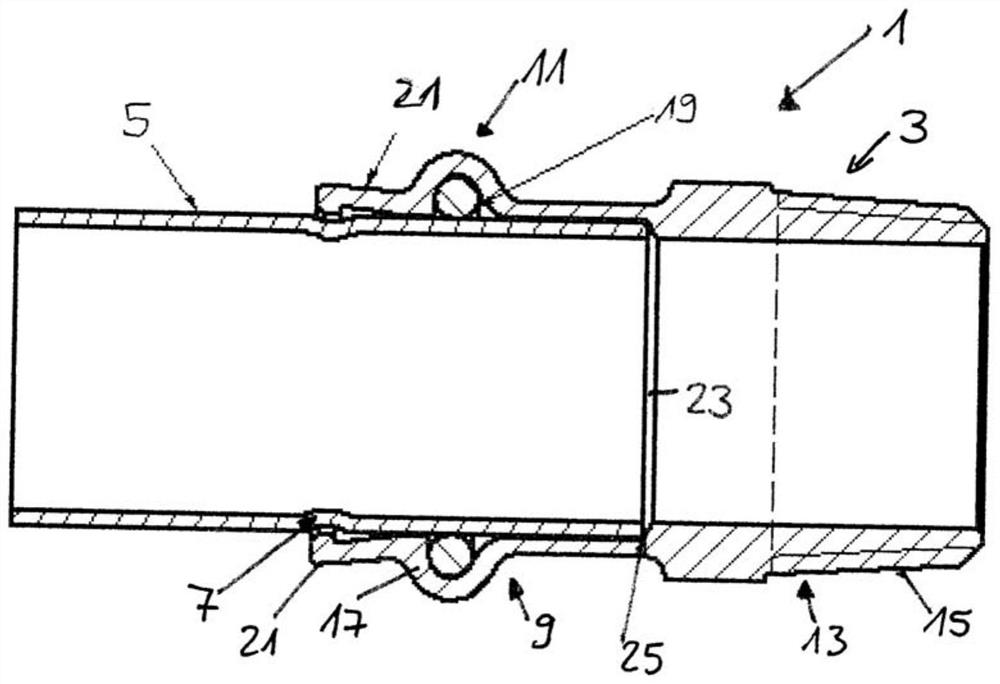

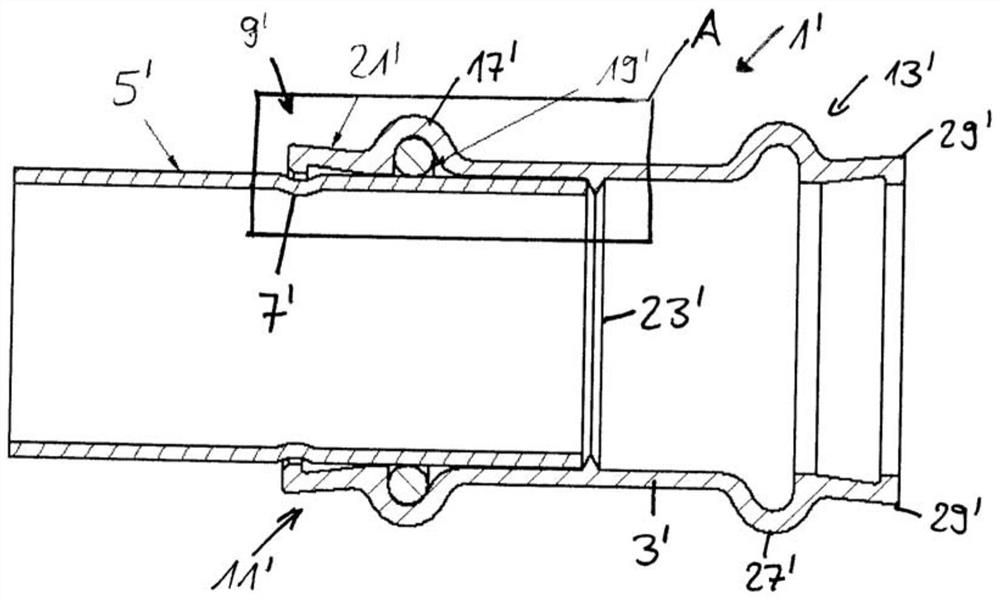

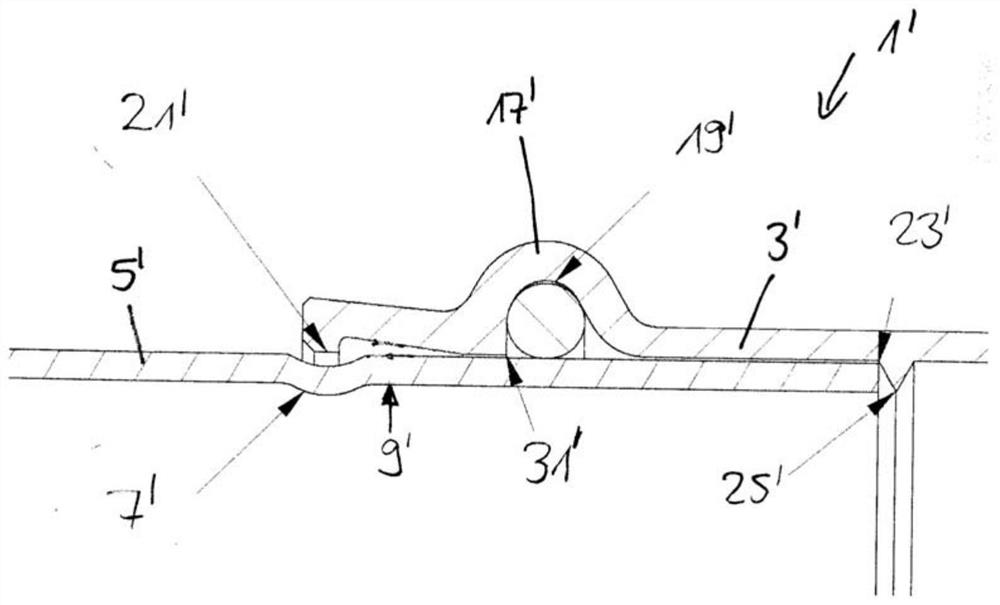

Fitting for connecting to a tubular element and tubing connection

The invention relates to a fitting for connecting to a tubular element and a tubing connection. The invention relates to the fitting for connecting to a tubular element having a first end section comprising at least one first connection element, wherein the diameter of at least a part of the first connection element can be reduced in a radial direction in order to produce a connection, wherein the first connection element comprises at least one first hook element and / or at least one first crimp configured to be connected in force-fit and / or form-fit manner to at least one second crimp and / or at least one second hook element formed on the outer surface of the tubular element, when the diameter of at least a part of the first connection element is reduced, as well as a tubing connection and a method for connecting a fitting to a tubular element.

Owner:CONEX IPR

An Artificial Intelligence-Based Evaluation Method for Hot Rolled Coil Curl

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

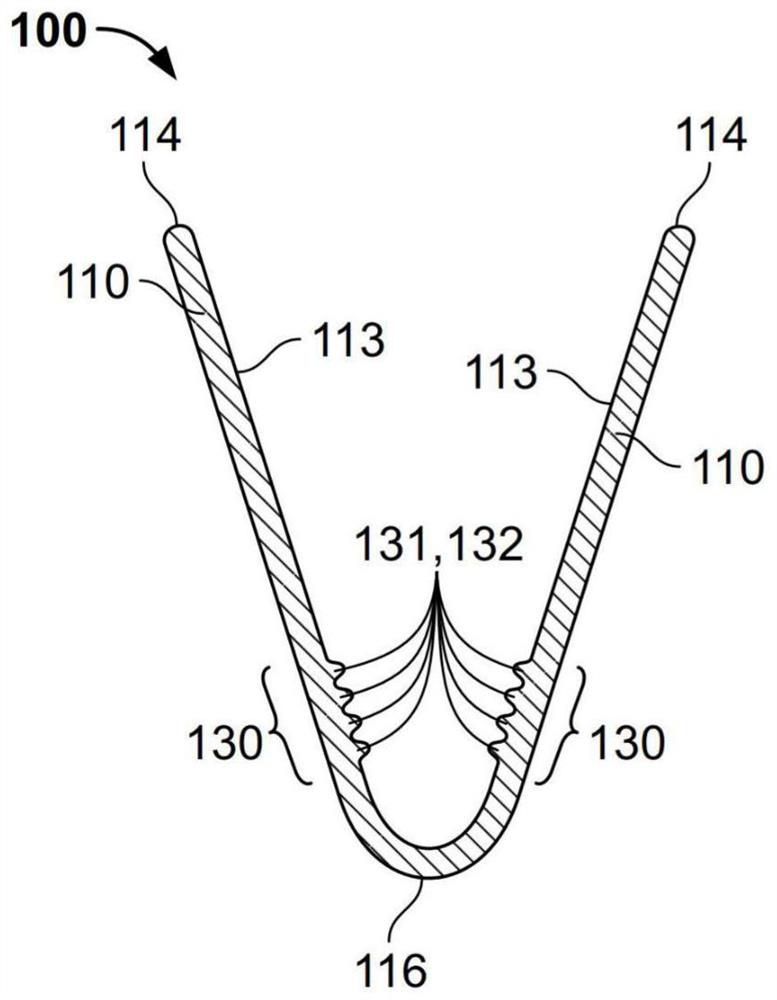

Cable crimp cap apparatus and method

PendingUS20210338300A1Effective coverageSuture equipmentsInternal osteosythesisClassical mechanicsStructural engineering

A crimp cap apparatus includes: a crimp sleeve having a peripheral wall defining an exterior surface and an interior passage sized to receive a tensile member having a predetermined outer diameter, the crimp sleeve being configured such that it can be crimped around the tensile member by an application of mechanical force which reduces its dimensions from a first size to a second, smaller size; and a cap having a bottom surface, a convex top surface, a central bore extending from the bottom surface to the top surface for receiving the crimp sleeve, wherein the cap includes a clamping structure disposed in the central bore and configured to permit elastic deflection in response to being pressed over the crimp sleeve the crimp sleeve and apply a clamping force there-to to secure the cap in place.

Owner:LITTLE ENGINE LLC

A Method for Reducing the Crimping Flash Rate of Conductor Tension Tubes of Overhead Transmission Lines

ActiveCN108879278BEasy to cleanReduce frictionConnection formation by deformationCompression moldingCrimp

A method for reducing the crimping flash ratio of an overhead transmission line conductor comprises butting a first metal part and a second metal part, and arranging a tensile tube outside the first metal part and the second metal part; probing into the material of the tensile pipe and calculating the positive pressure of the hydraulic system of compression molding of a tensile pipe according to the material of the tensile pipe; using the positive pressure of the hydraulic system of tensile pipe crimp forming for tensile pipe crimp forming. In accordance with the invention, a PVC resin film iswound on the surface of the tensile tube, so that the friction force is reduced during crimping molding, as the probability of generating flash is greatly reduced dure crimping, and the PVC resin film is easy to clean, and the positive pressure of hydraulic crimping is calculated by querying the parameters corresponding to the material quality, so that the crimping force is controlled, thereby controlling a large number of flashes caused by the frictional force when crimping, and solving the problems of high flash rate leading to unreliable physical connection in the existing crimping processand more time-consuming problems caused by troublesome subsequent processing steps.

Owner:SHENZHEN POWER SUPPLY BUREAU

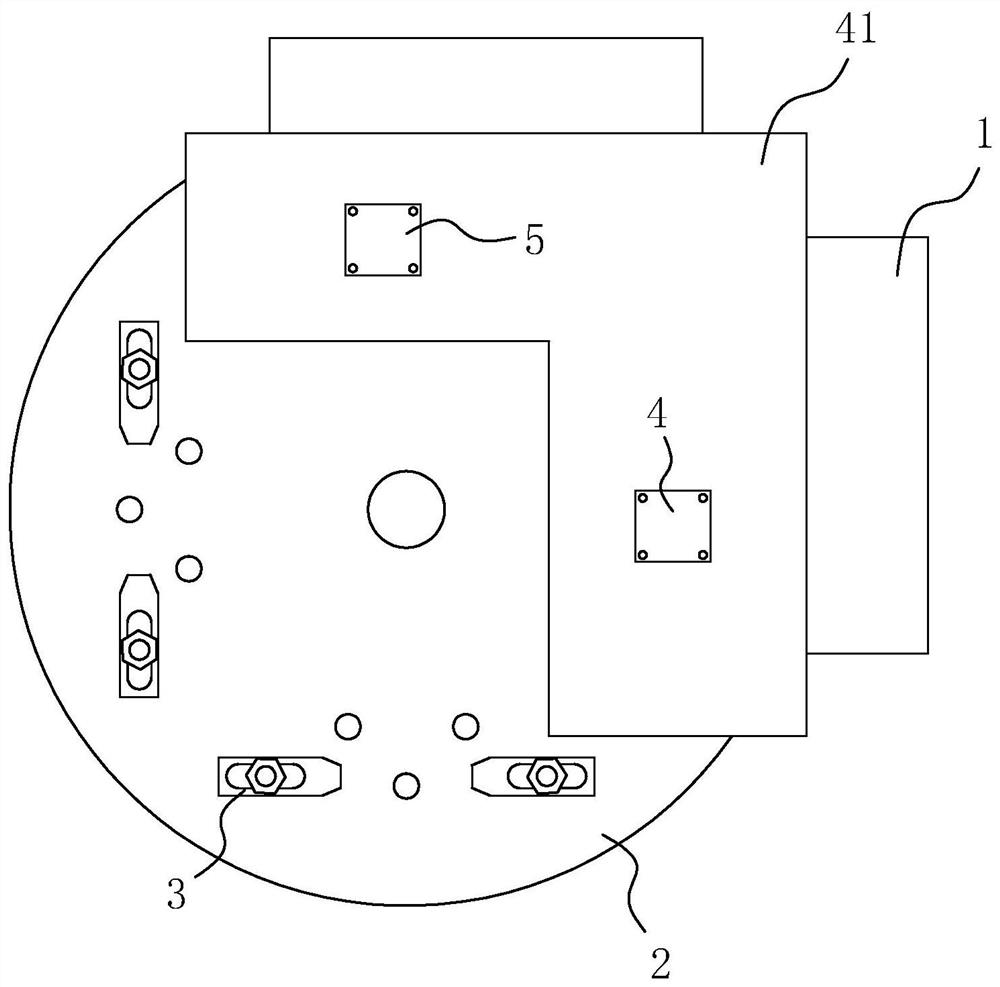

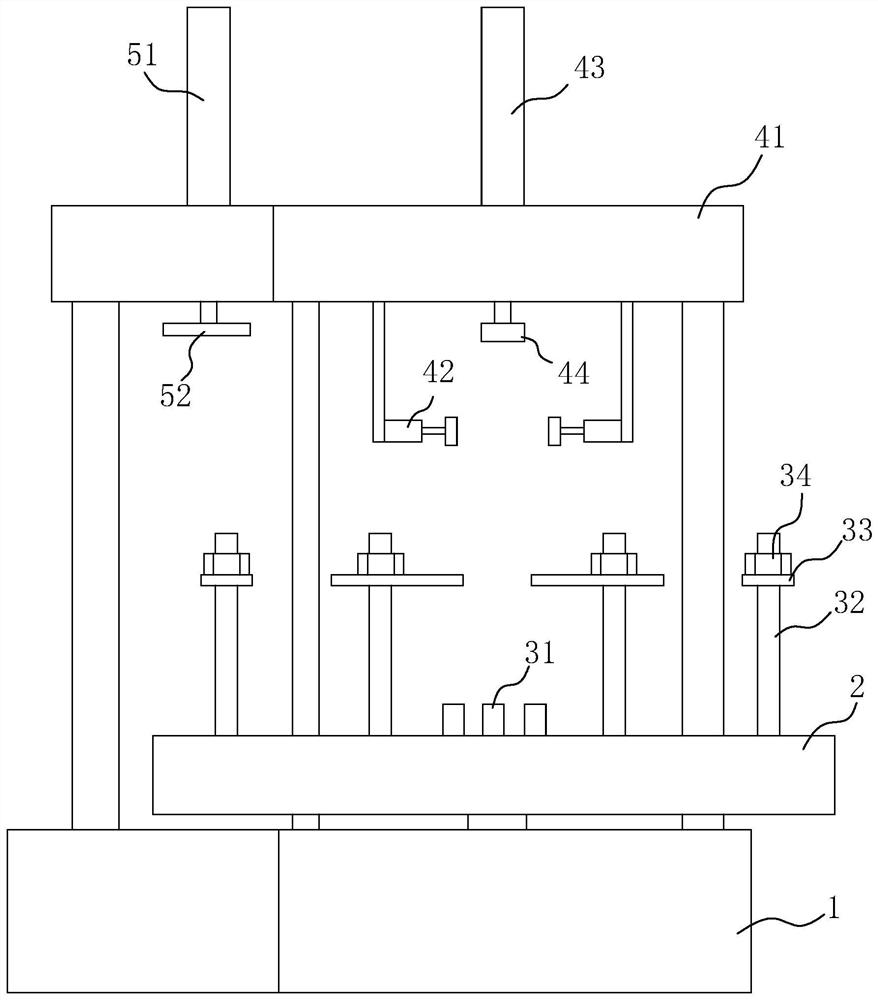

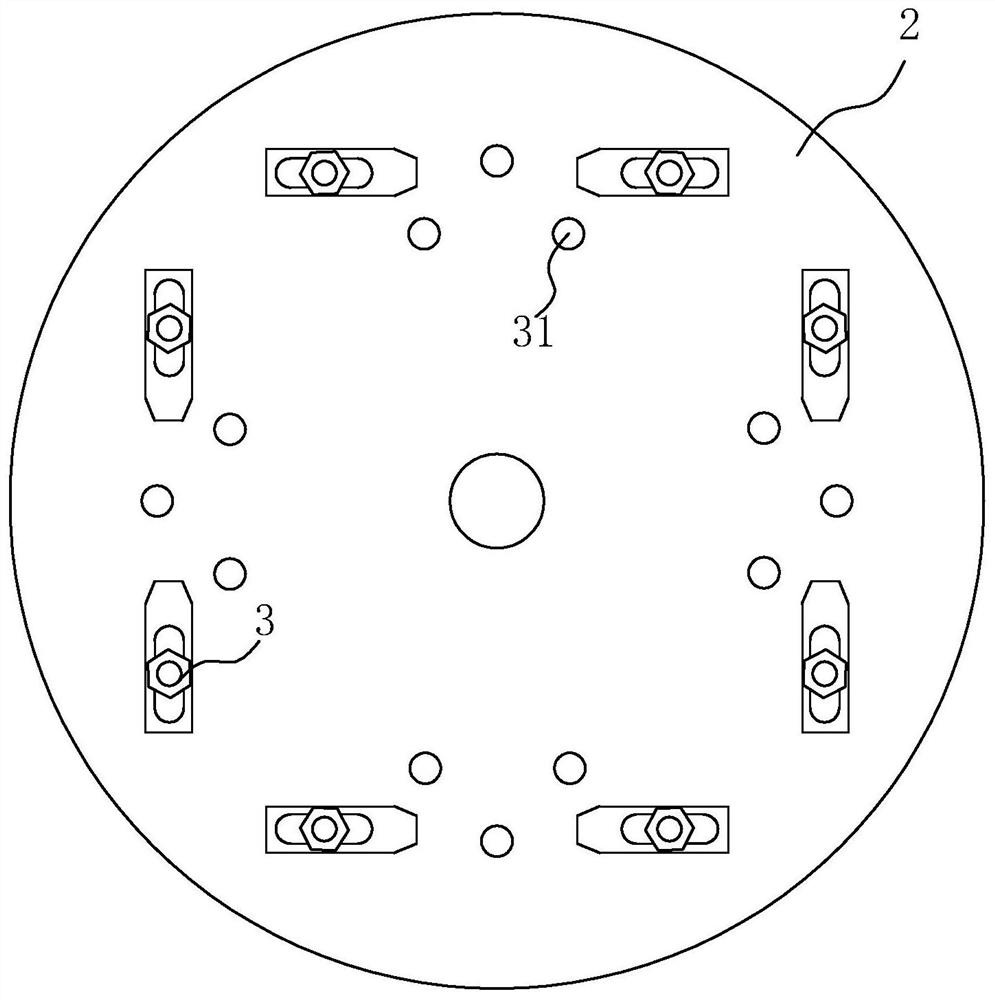

A copper pipe crimping device and crimping process for large-scale products

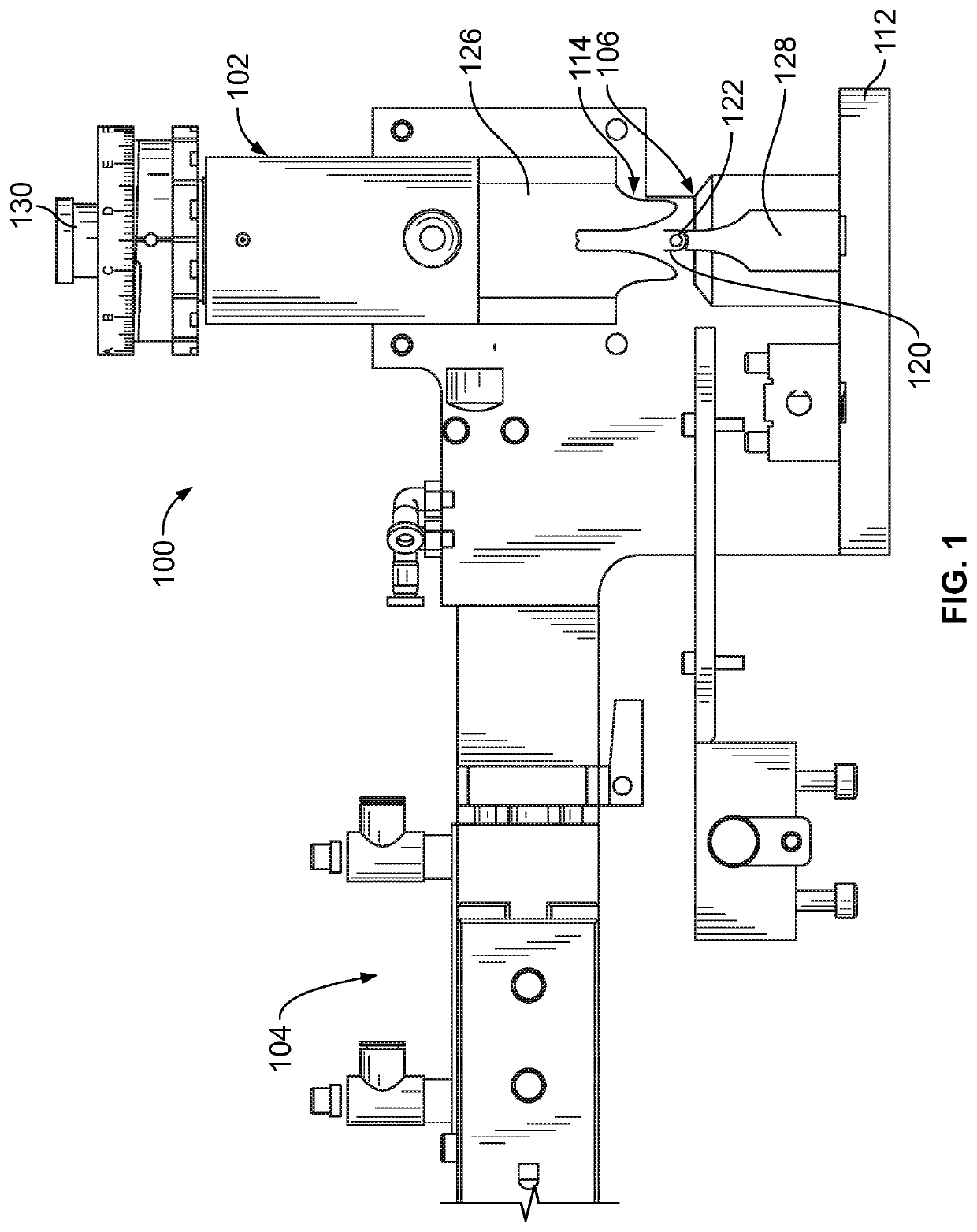

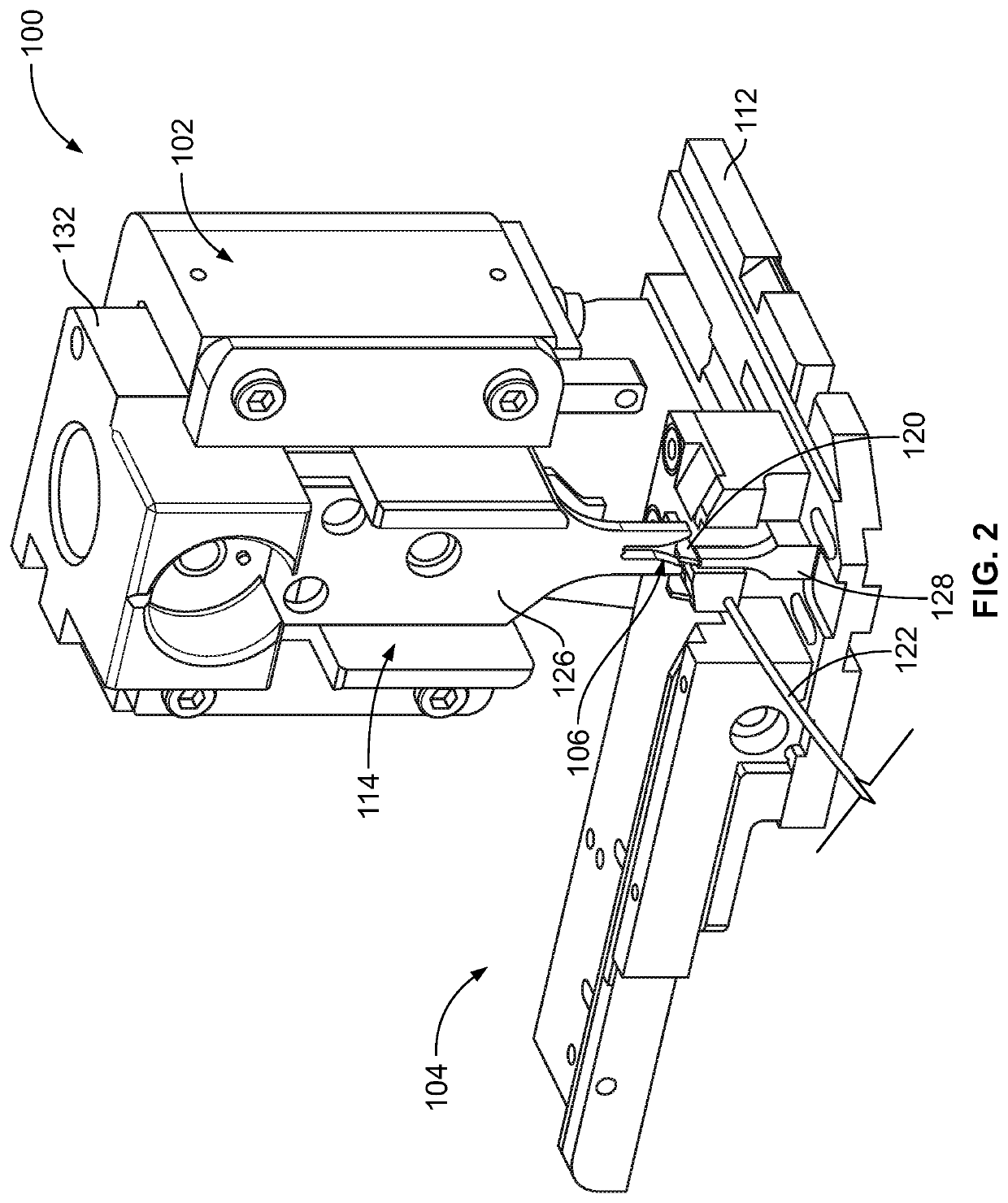

ActiveCN109968002BEasy to assembleHigh precisionMetal working apparatusHydraulic cylinderElectric machinery

The invention relates to a copper tube crimping device and crimping process for large-scale products, wherein the crimping device includes: a machine; a supporting turntable that is rotatably connected to the machine; The driving motor that supports the rotation of the turntable, the support turntable is provided with at least three assembly stations; the pre-installation mechanism carried on the machine table, the pre-installation mechanism includes: a pressing table, a clamping assembly, and a The press table is used to drive the copper tube to press down and pre-press the first hydraulic cylinder fixed on the product to be crimped; and, the press-fit mechanism. Since at least three assembly stations are set up, the product assembly can be carried out at the same time as the press assembly, without the need to disassemble the product after the press assembly is completed and then assemble the product to be crimped, which improves the production efficiency. Two steps of pressing and pressing are used to assemble the copper tube, which makes the copper tube assembly more convenient, has higher precision, and improves the yield.

Owner:SUZHOU JOYO METAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com