Patents

Literature

1015results about "Springs/dampers manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shock absorbing component and construction method

InactiveUS6029962AImprove the immunityGood flexibilitySolesHollow wall articlesEngineeringMechanical engineering

Owner:SKYDEX TECH +2

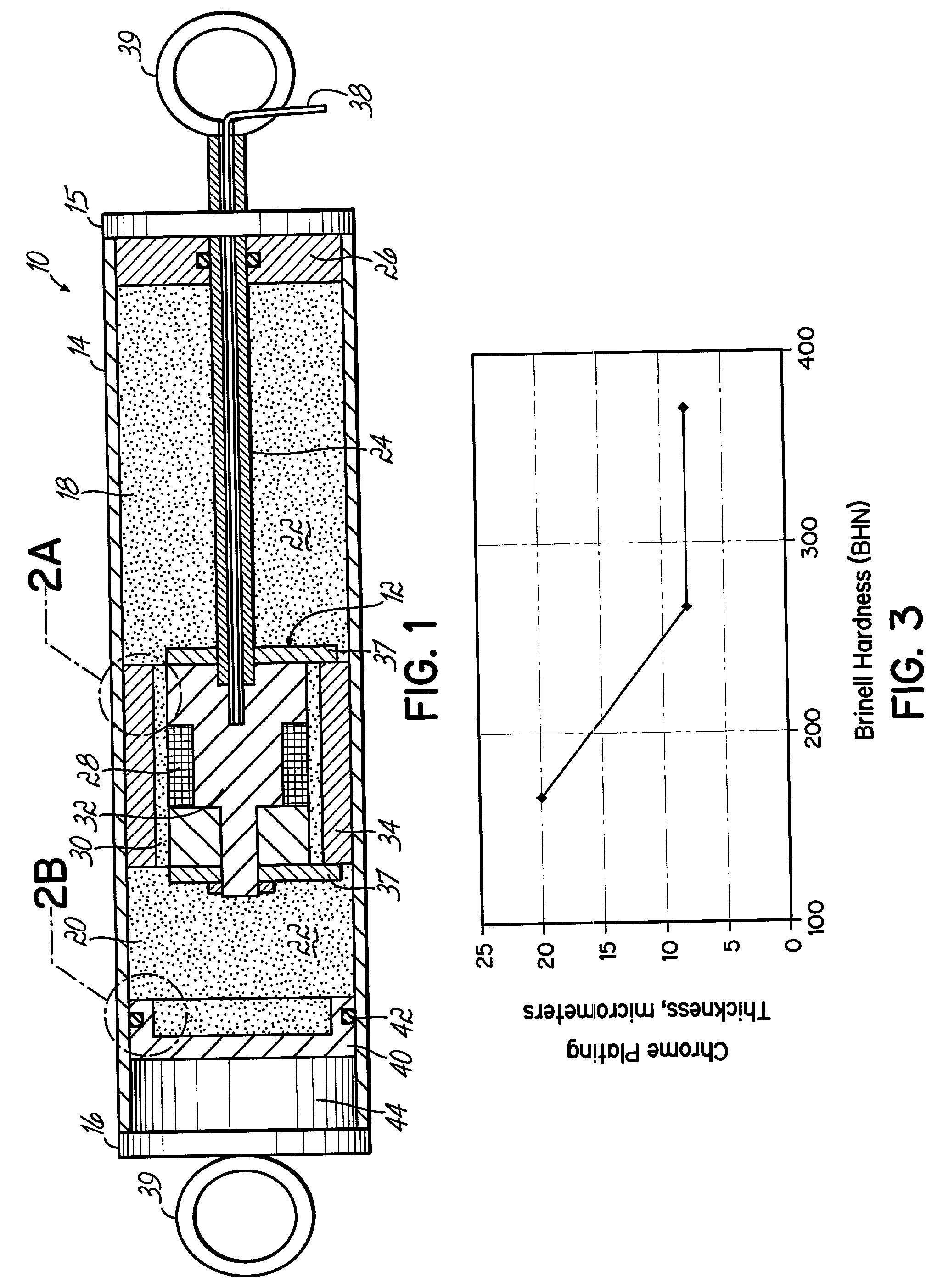

Magnetorheological dampers with improved wear resistance

InactiveUS20020130003A1Improve wear resistanceIncrease effective viscositySpringsNon-rotating vibration suppressionEngineeringHardness

A damper body for a magnetorheological (MR) damper and associated methods of forming the damper body. The damper body is formed of a base material, such as a steel, and is coated with an abrasion-resistant layer comprising chromium. The layer of chromium provides a sliding wear surface for sliding contact with a reciprocating piston. To avoid high-stress abrasive wear over the expected service life of the magnetorheological damper, the layer of chromium has a minimum thickness greater than or equal to a minimum thickness of about 8 .mu.m. In other embodiments, be fore applying the abrasion-resistant layer of chromium, the damper body is coated with a layer of a hard coating material having a hardness greater than the hardness of the base material. The effective hardness of the damper body is a composite of the respective hardnesses of the base material comprising the damper body and the layer of hard coating material. The thickness of abrasion-resistant layer of chromium is chosen in direct relation to the effective hardness.

Owner:BWI CO LTD SA +1

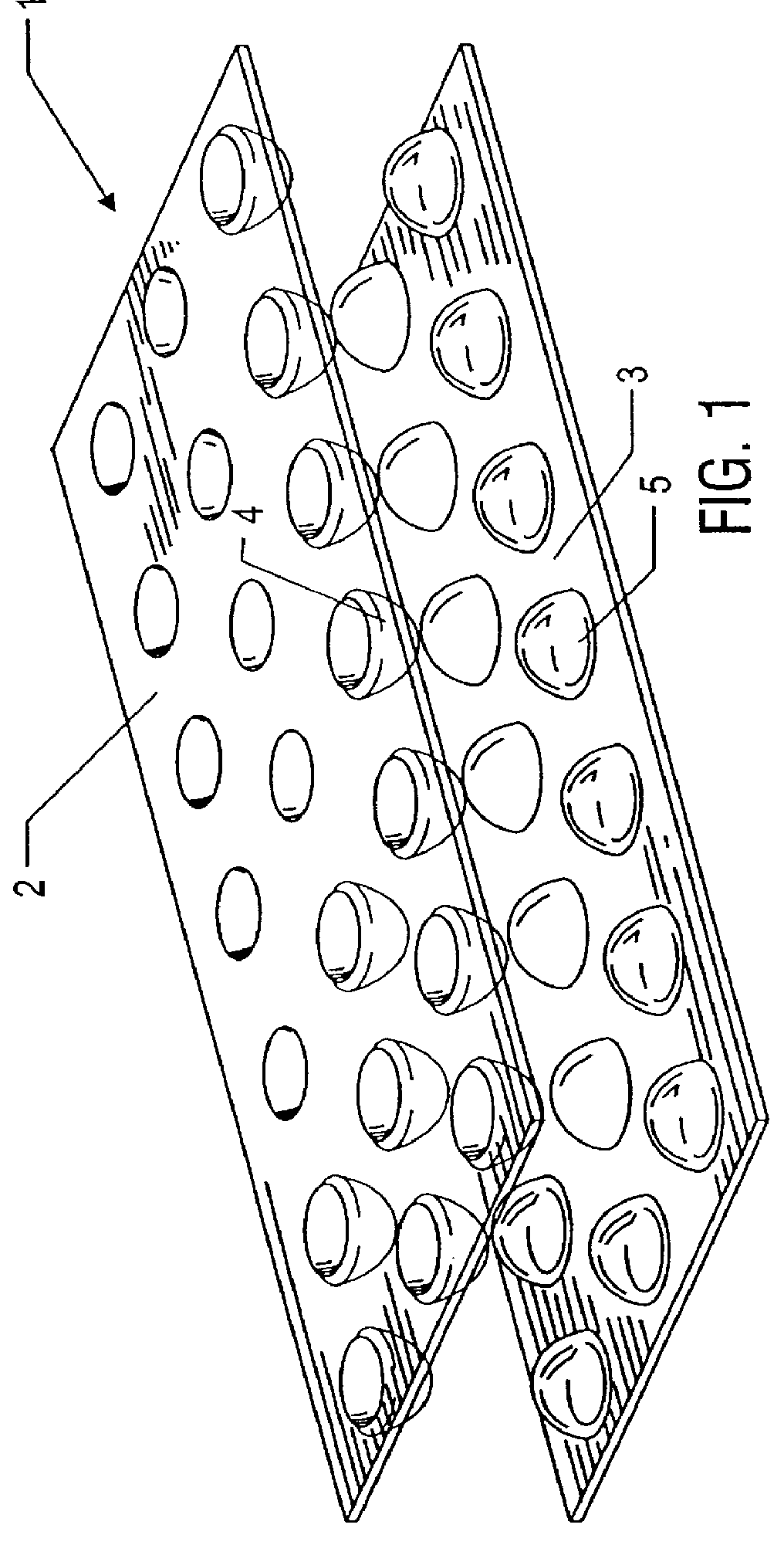

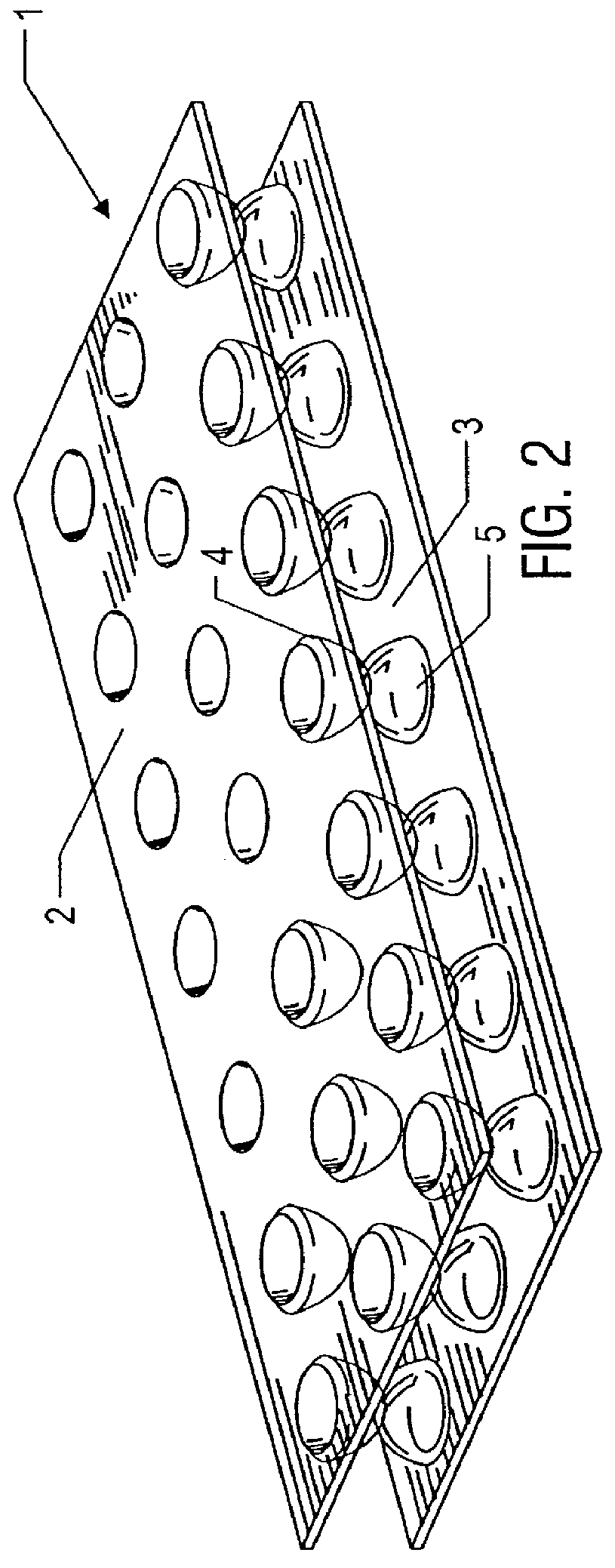

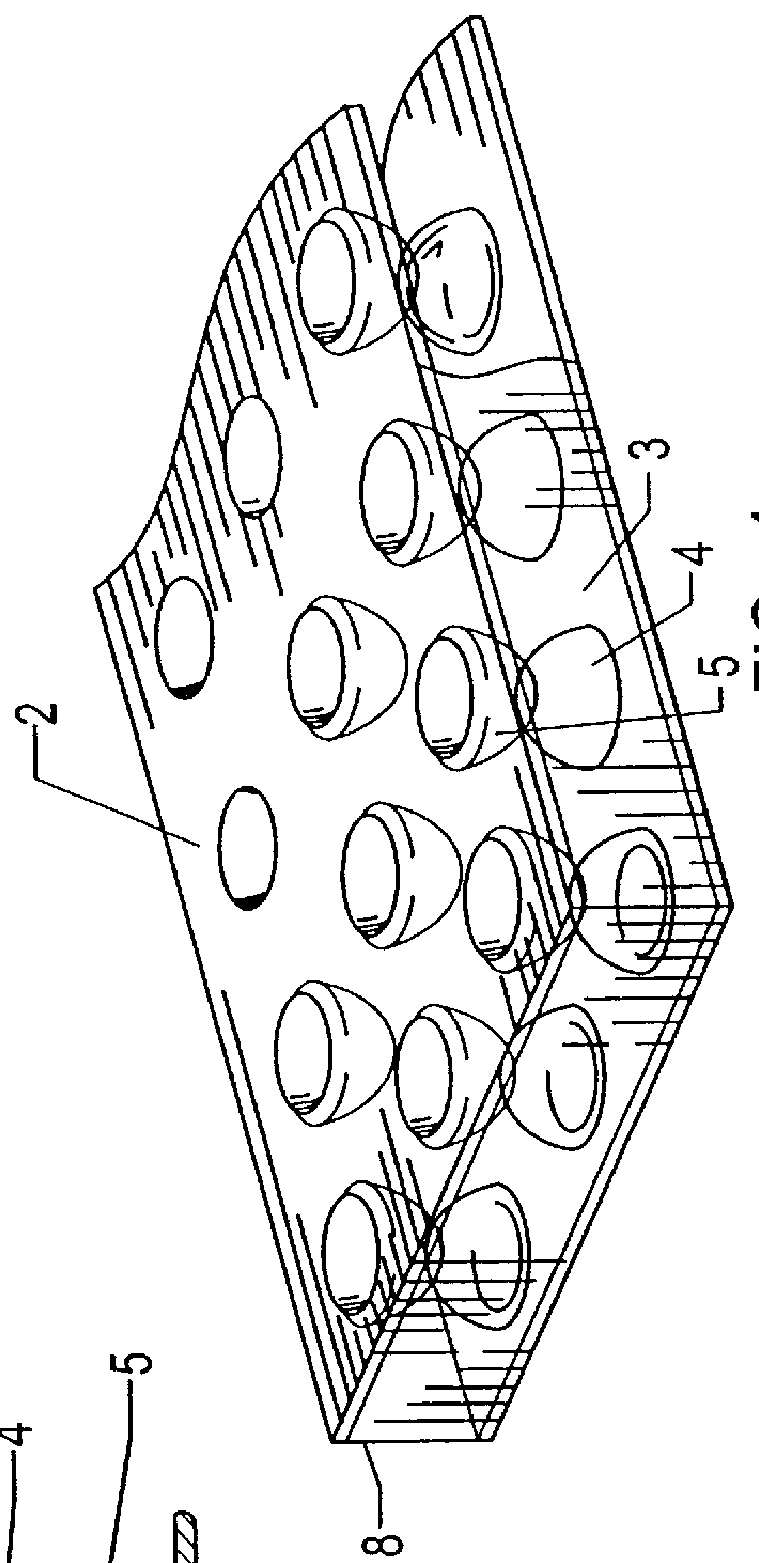

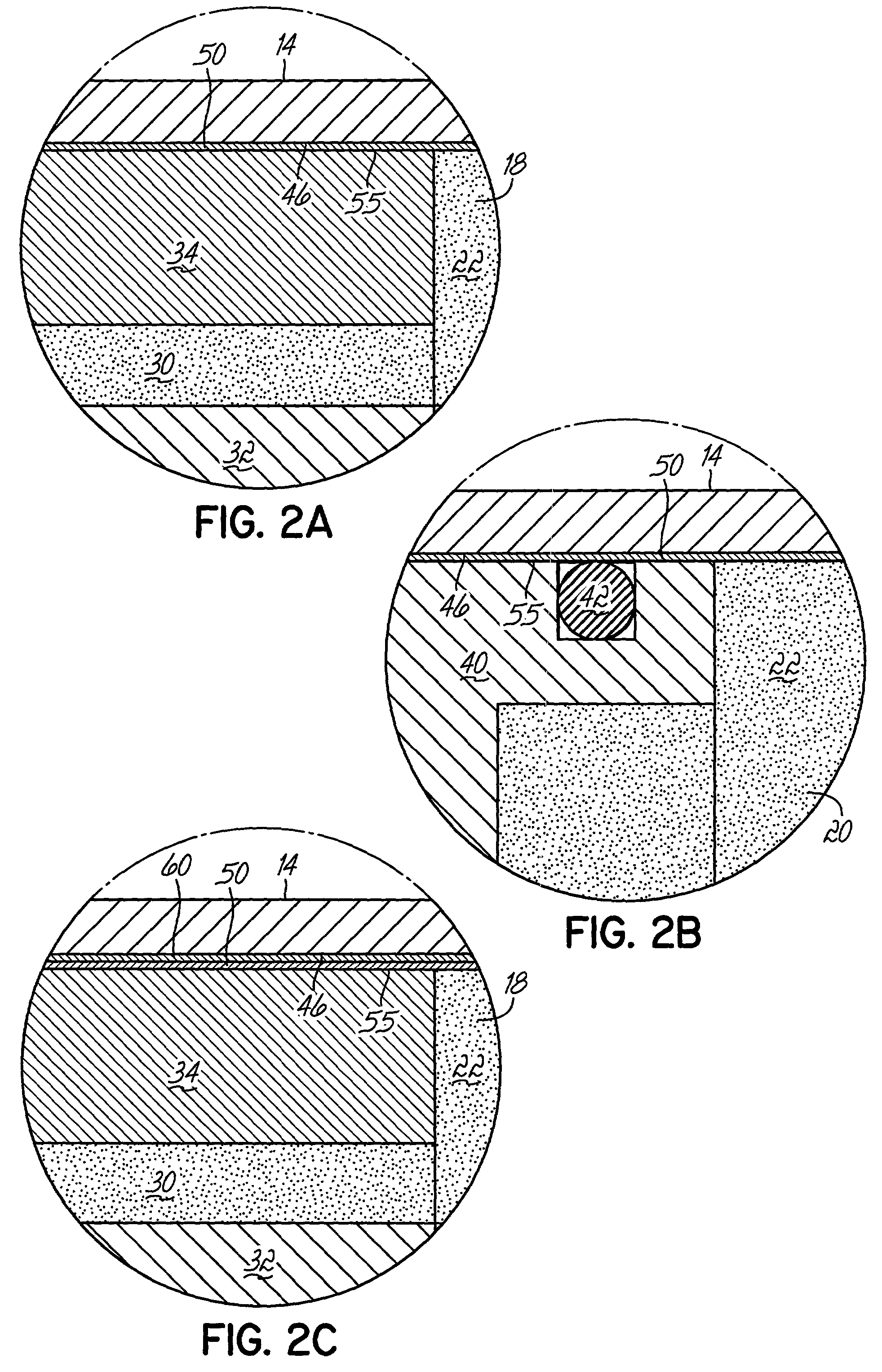

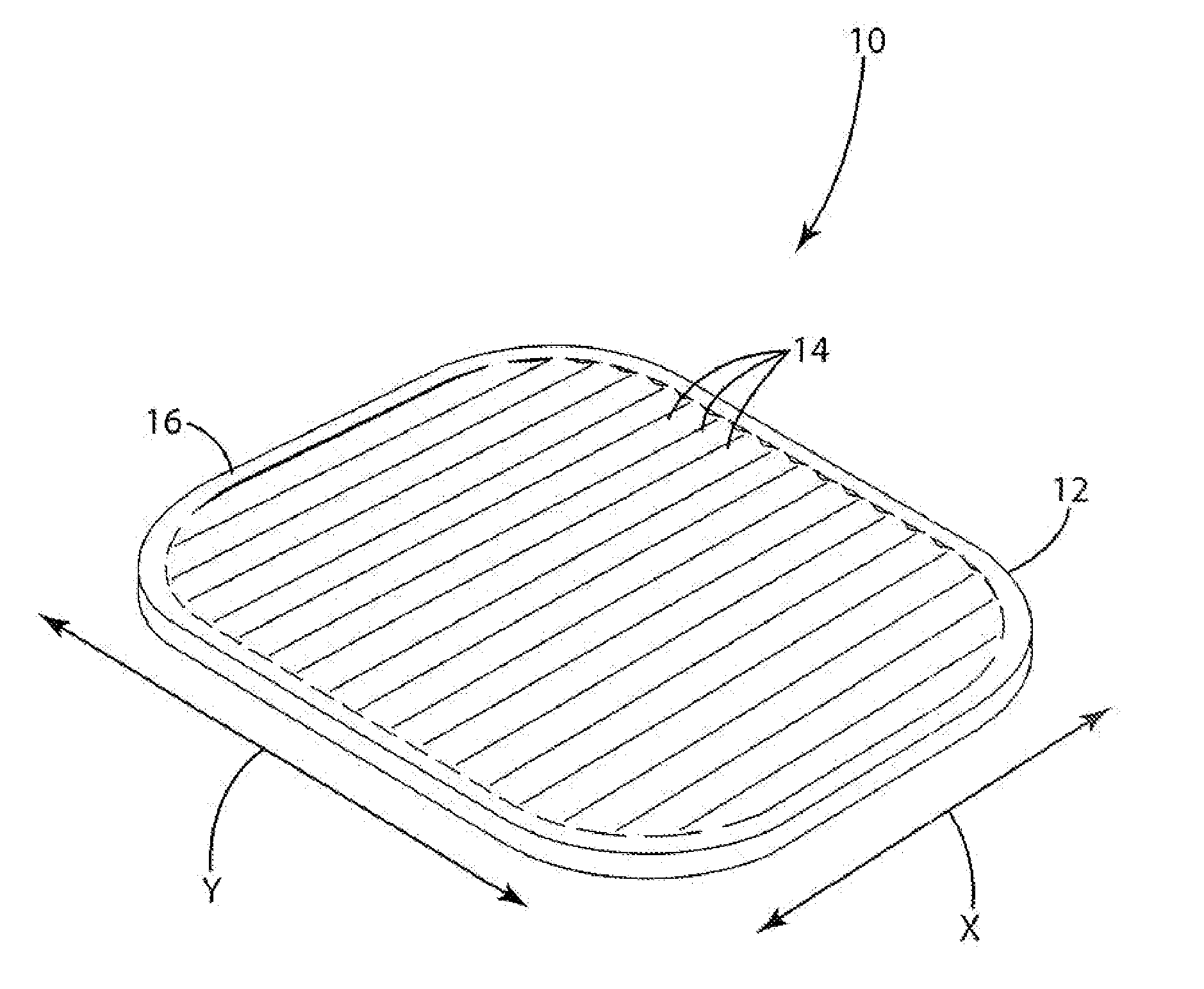

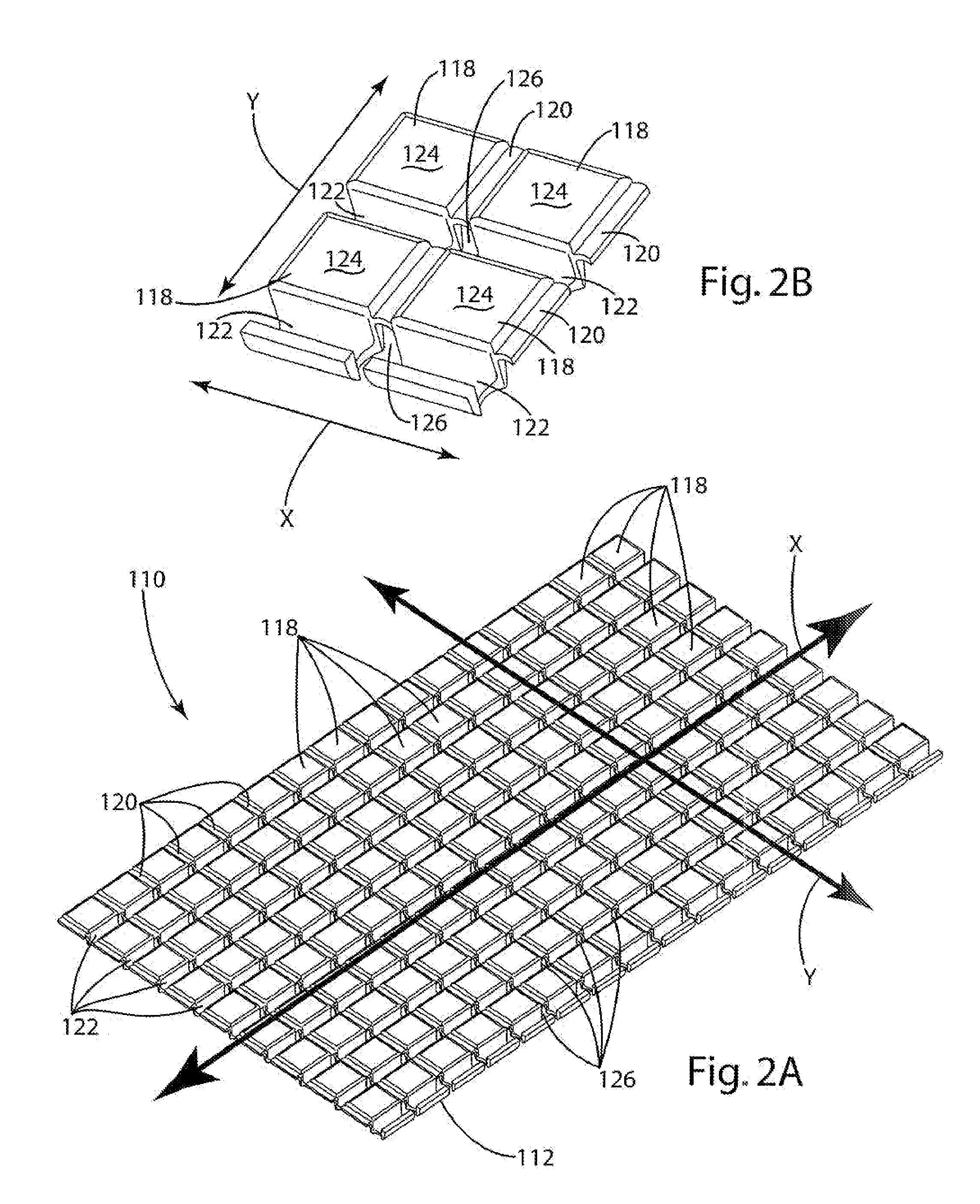

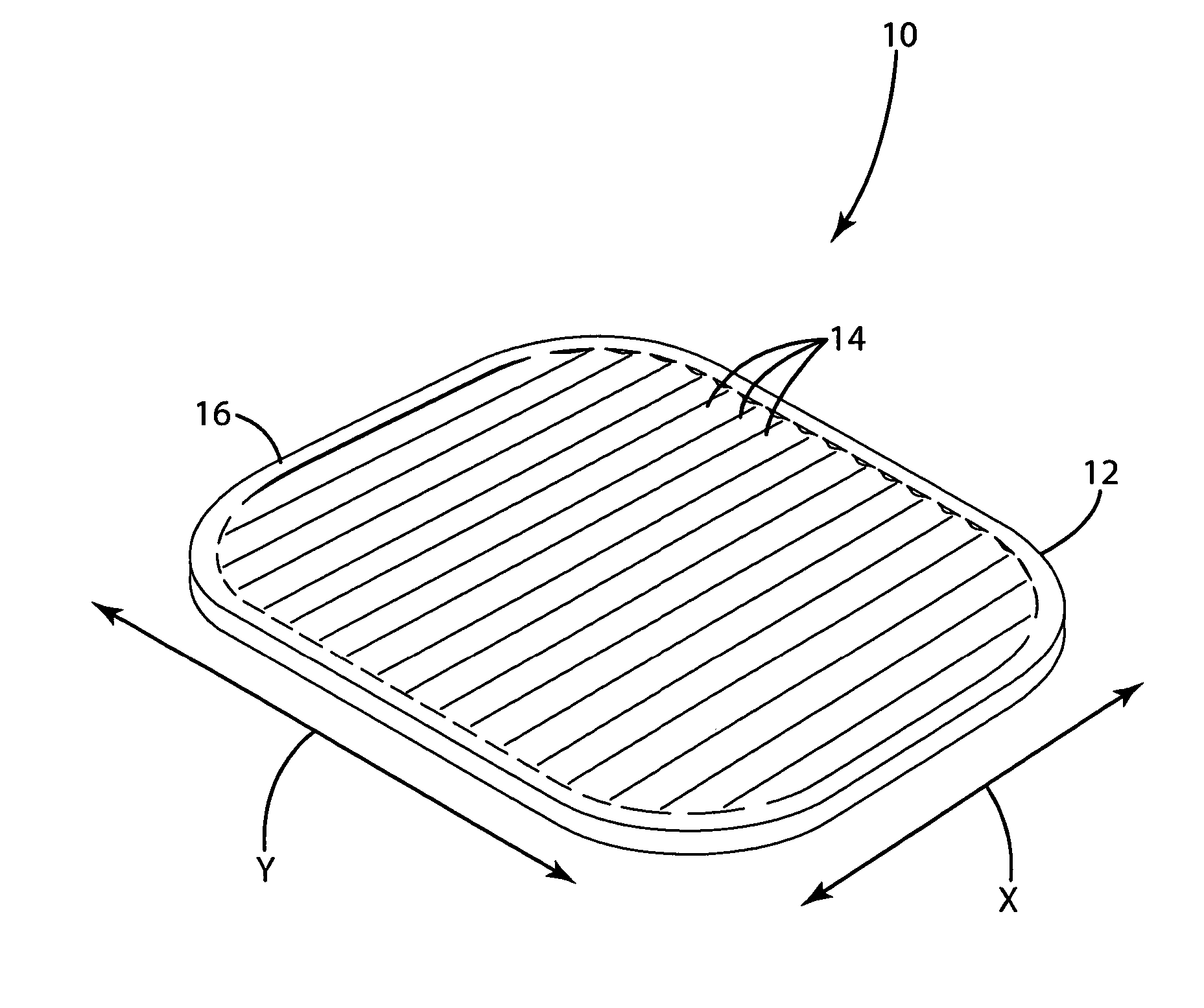

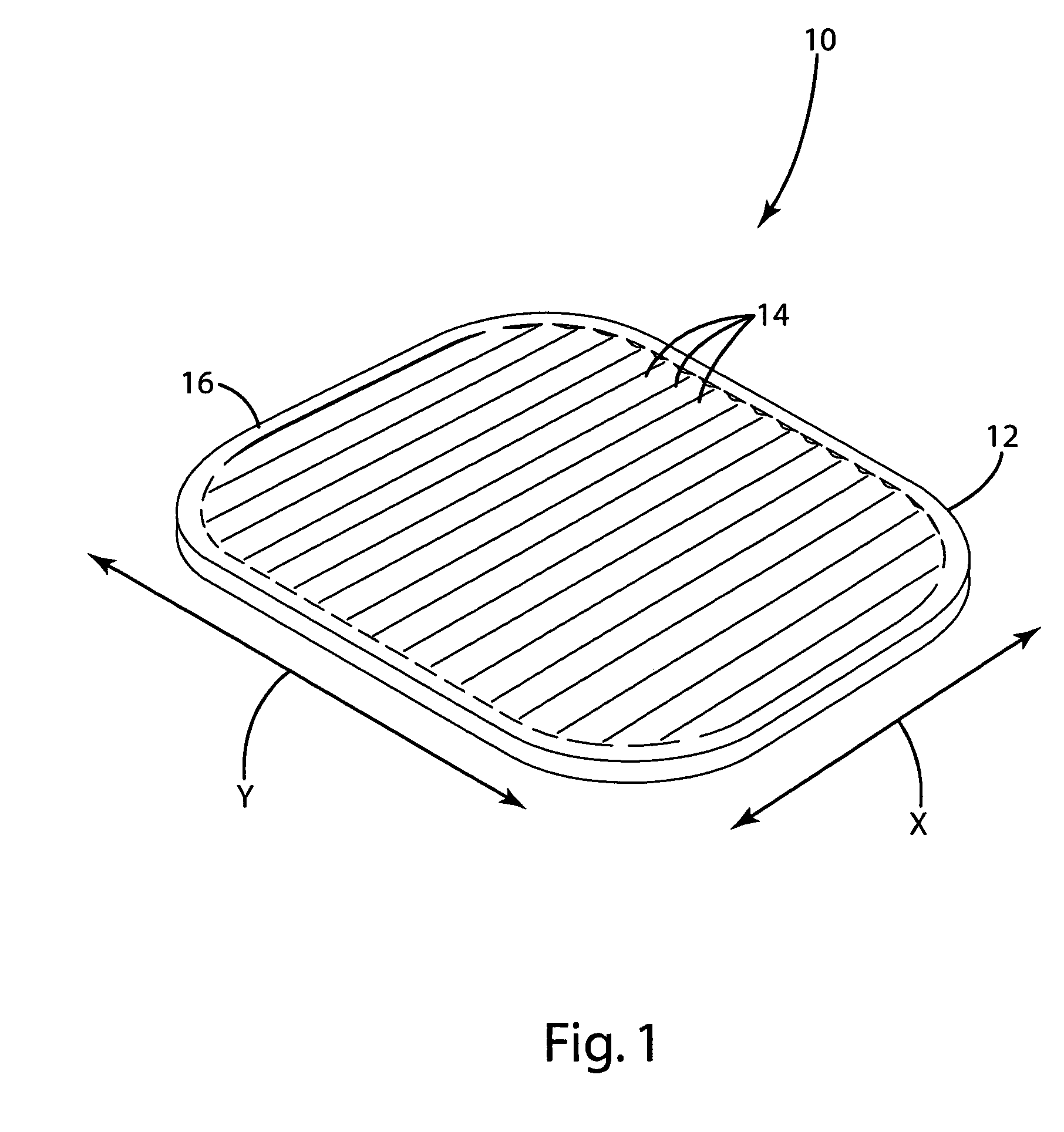

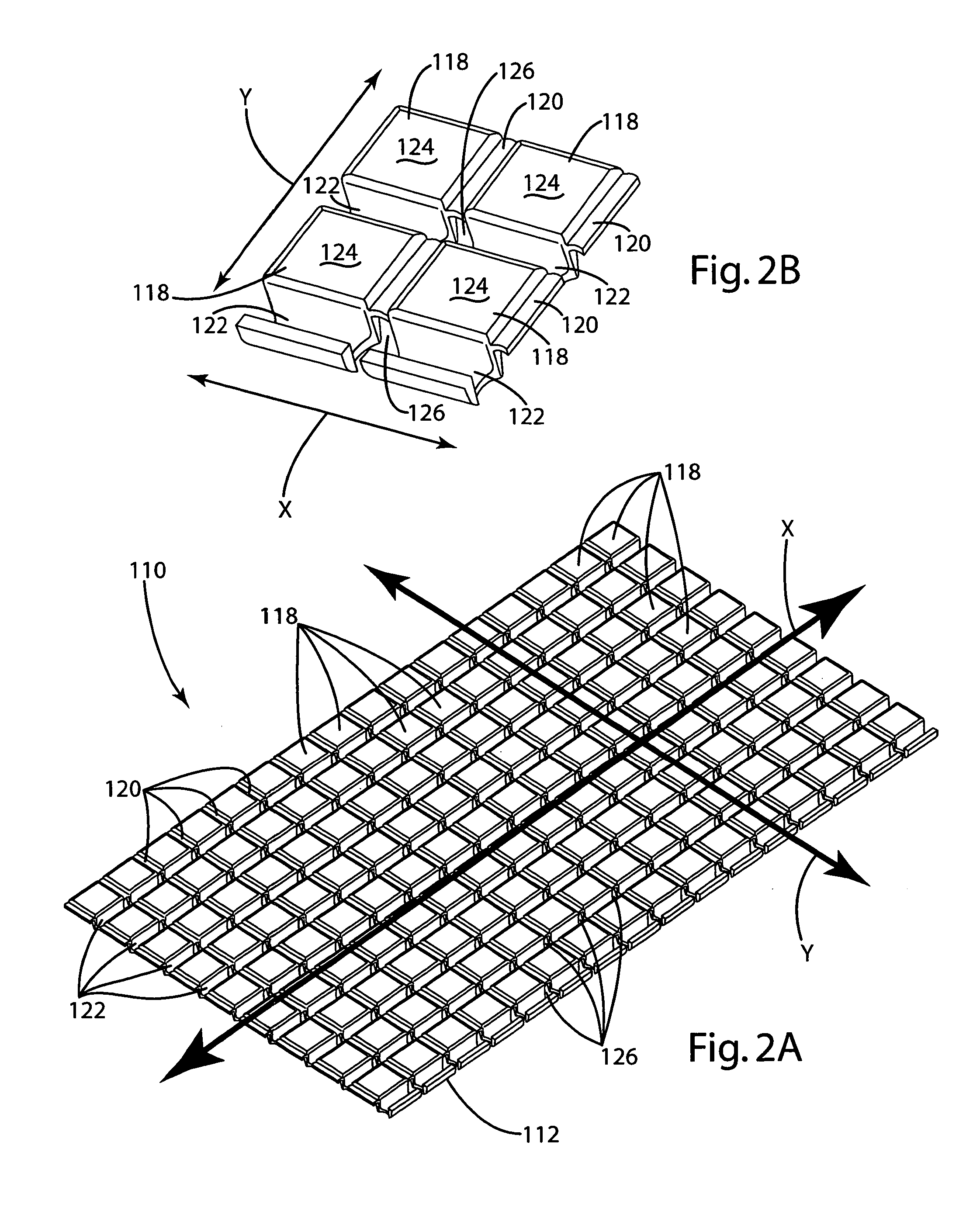

Load bearing surface

An elastomeric load bearing surface with different load support characteristics in different directions. In one embodiment, the surface includes an elastomeric membrane that is oriented in only a single direction, for example, by compression or stretching. In another embodiment, the surface includes mechanical structures, such as connectors and variations in thickness that vary the load support characteristics in different directions. In another embodiment, a surface is both oriented and includes mechanical structures.

Owner:ILLINOIS TOOL WORKS INC

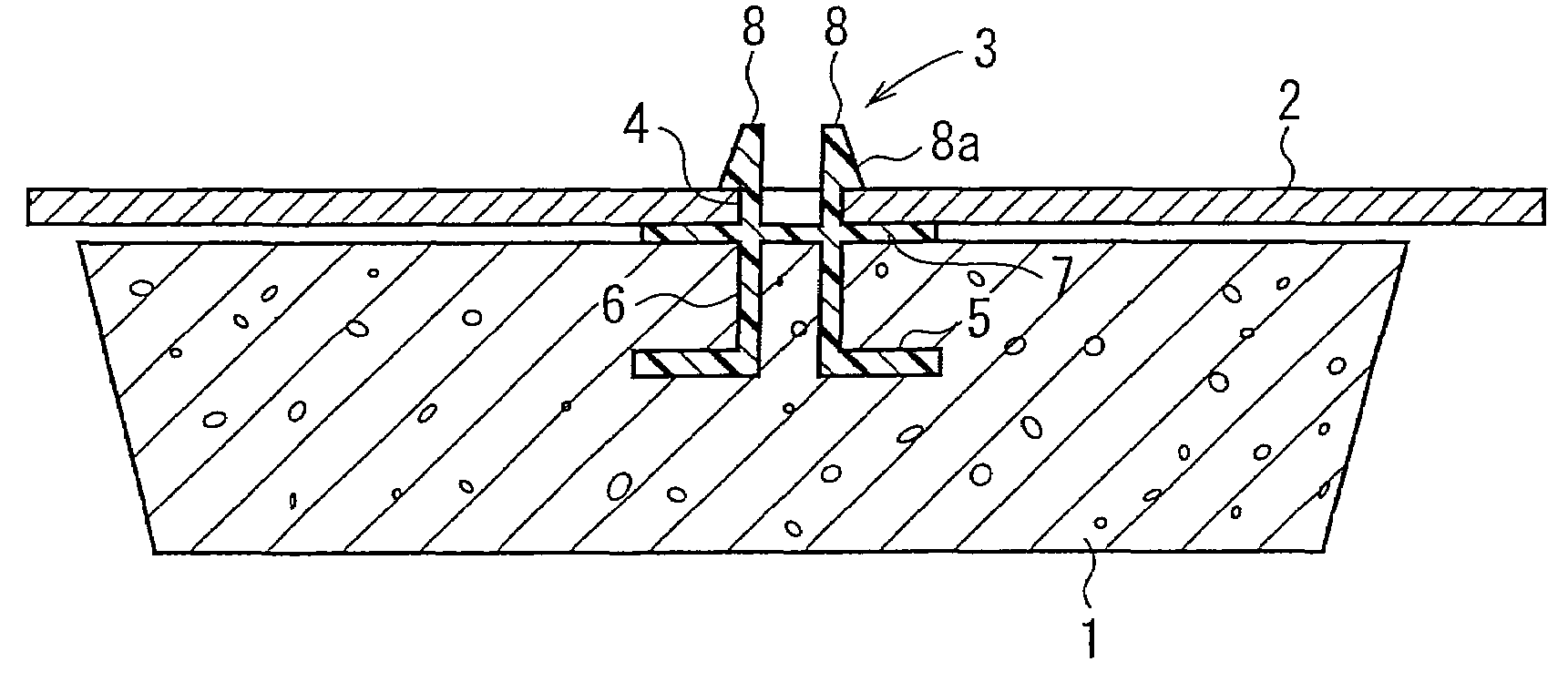

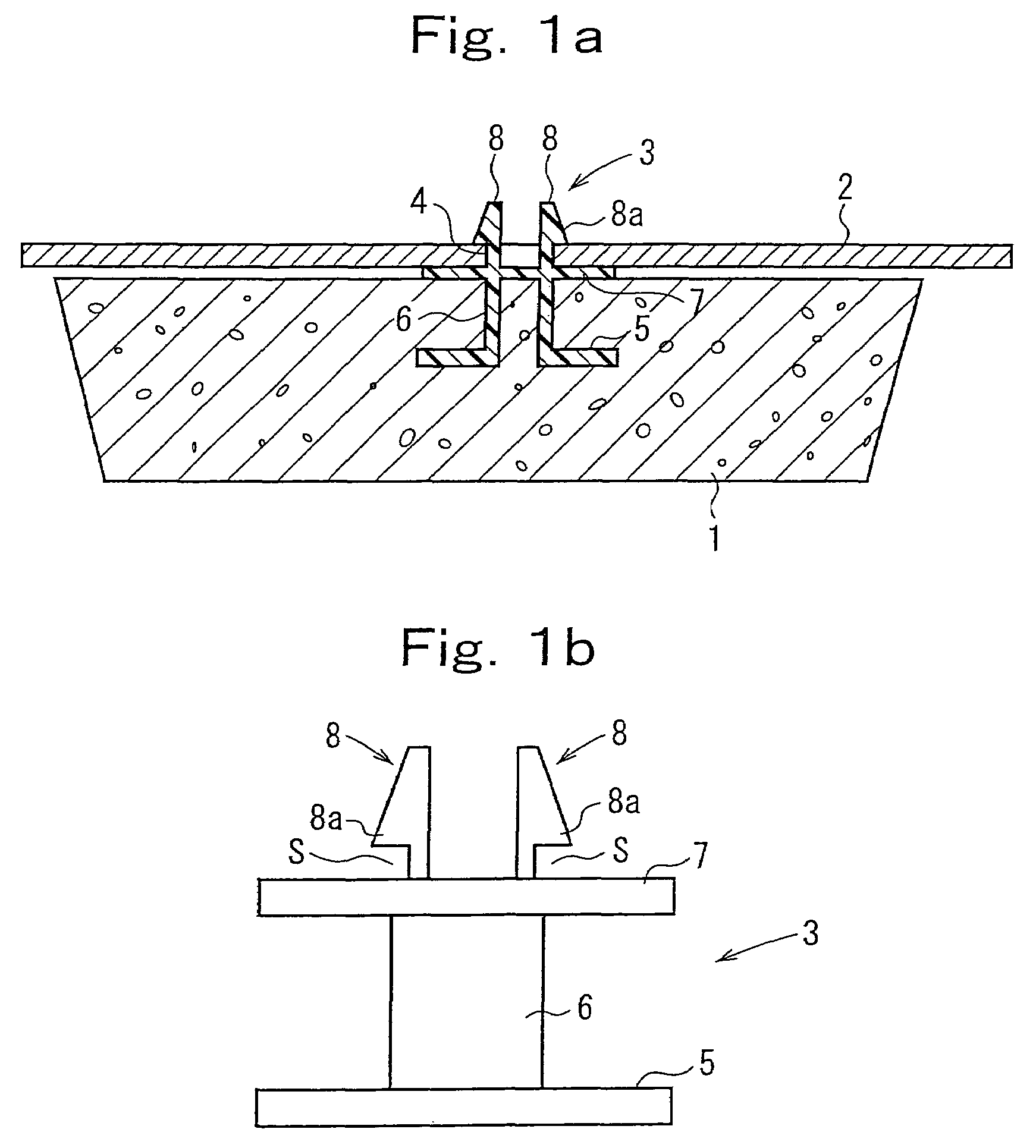

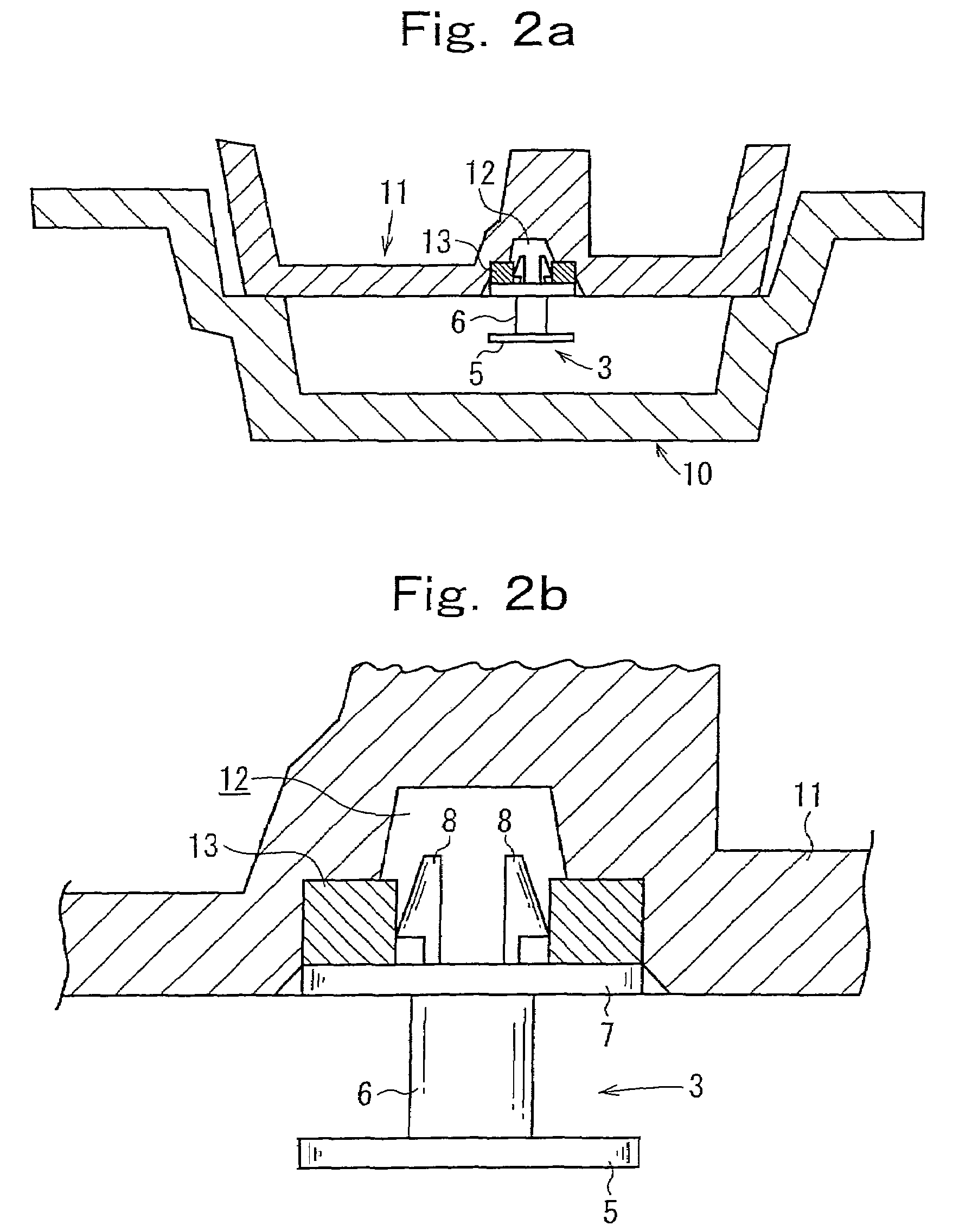

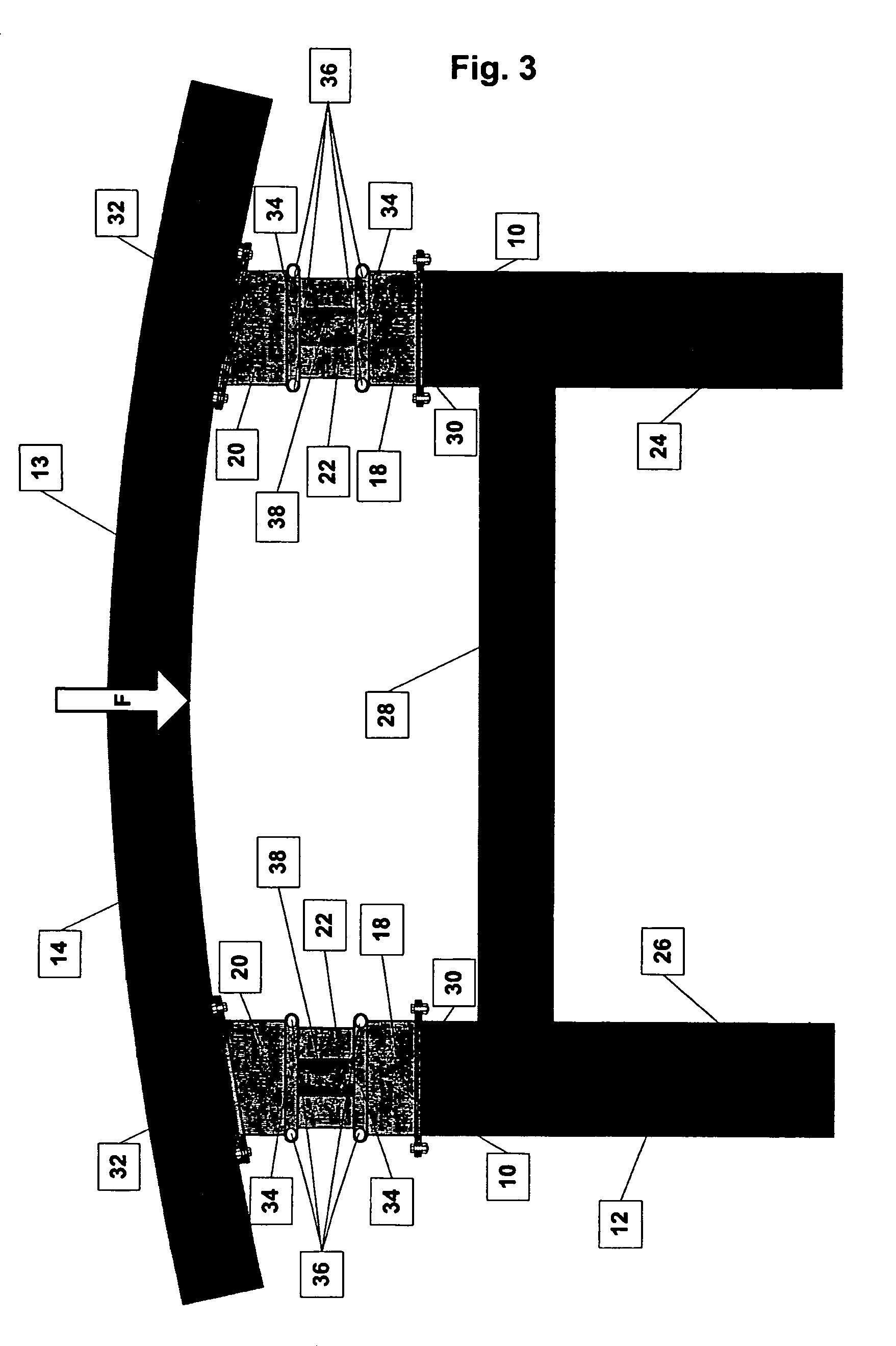

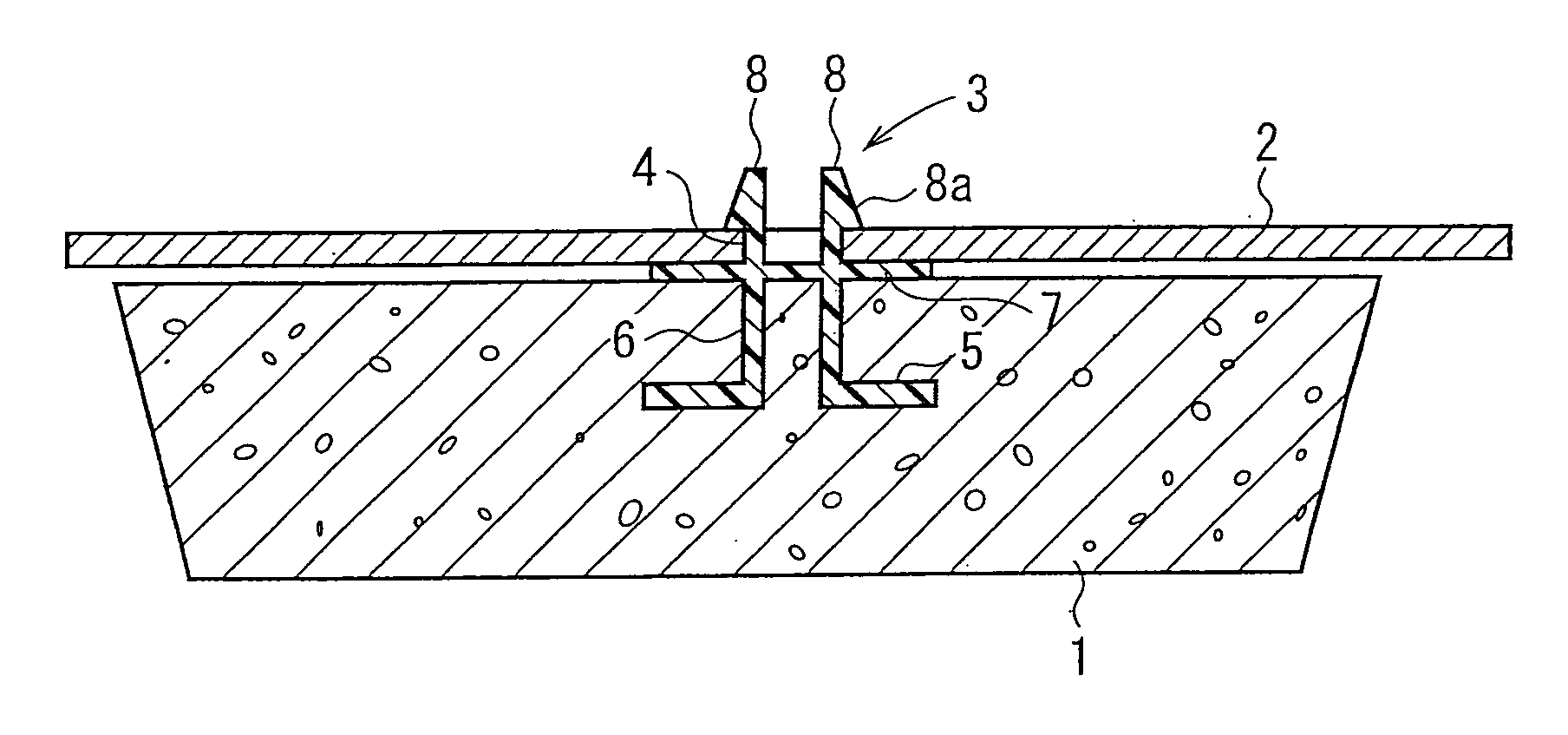

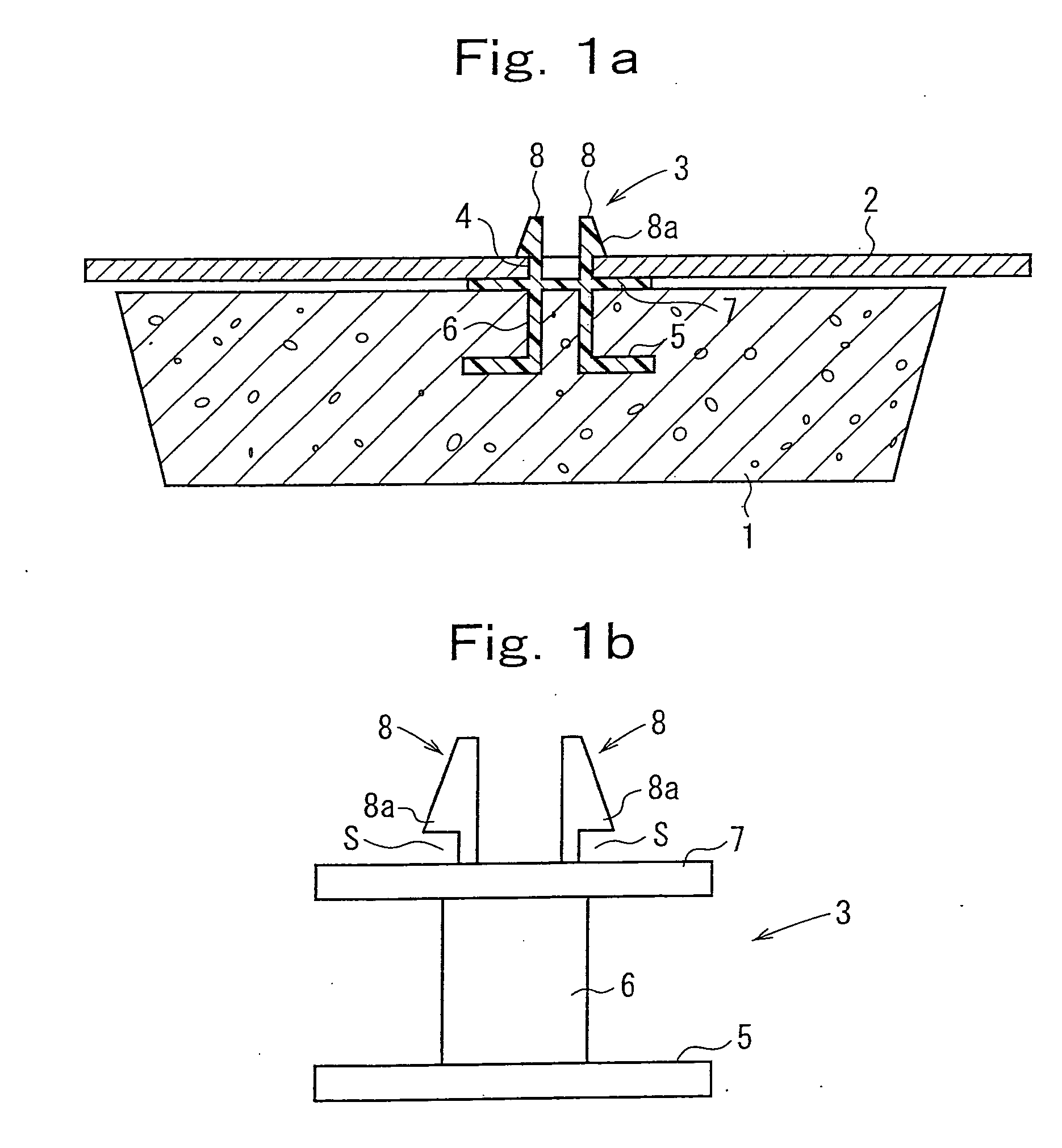

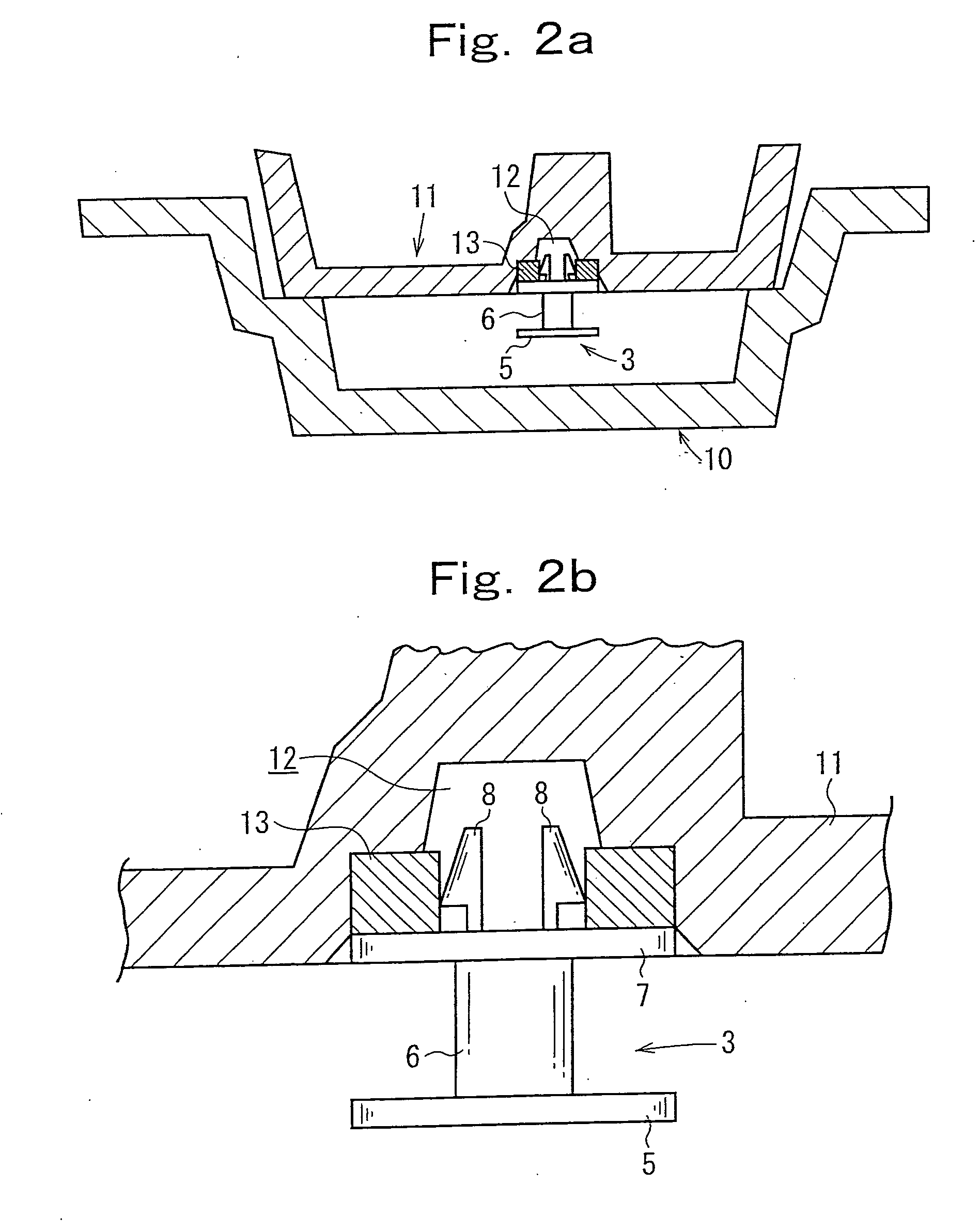

Attachment structure of EA component

InactiveUS7547061B2Workability for attaching the EA componentImprove workabilityVehicle seatsSnap-action fastenersEngineeringSynthetic resin

In an attachment structure of an EA component, the EA component composed of a synthetic resin such as rigid urethane foam is attached to a trim serving as a member, with a first locking part therebetween. The first locking part includes a cylindrical part, an anchor, a flange, and a plurality of projections. The anchor has a flange shape extending from the rear end of the cylindrical part toward the outside. The flange extends from the leading end of the cylindrical part toward the outside. The projections protrude from the leading end of the cylindrical part in the direction parallel to the axis of the cylindrical part. The EA component is attached to the trim by setting the EA component on the trim while the projections are inserted in an opening.

Owner:BRIDGESTONE CORP

Stabilizer bushing

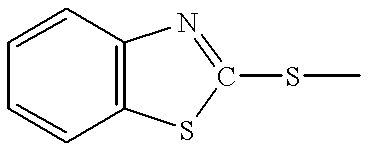

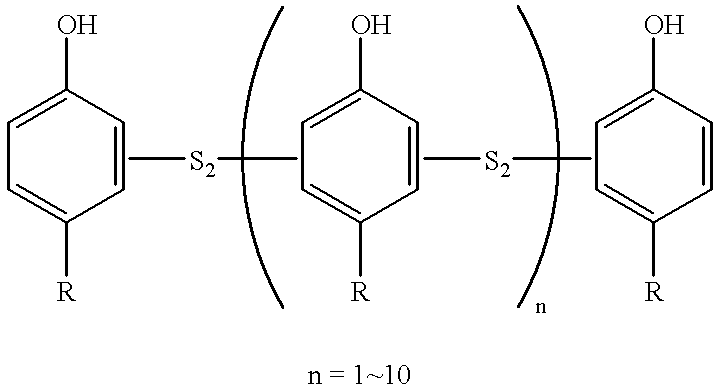

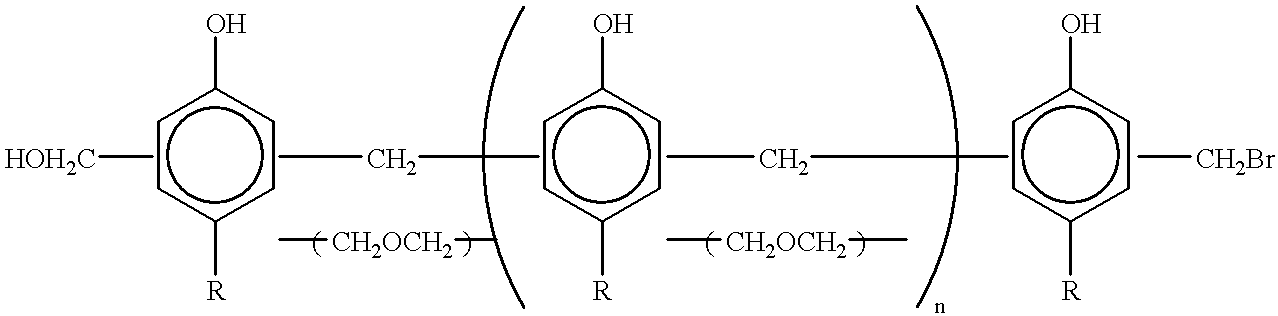

A cylindrical rubber elastic member for having a stabilizer bar inserted therein comprises an inner layer rubber with high sliding properties and an outer layer rubber provided outside of the inner layer rubber. Both the stability in operation and the riding comfort can be improved. Further, the rubber elastic member comprises a sliding surface made of a rubber with high sliding properties at the end face thereof. Frictional resistance can be lowered to prevent abnormal noise. A stabilizer bushing comprising a main body rubber portion of a sulfur-vulcanizable first rubber compound and a sliding rubber portion of a second rubber compound containing a sulfur-vulcanizable lubricant on the inner surface of the main body rubber portion, wherein the first rubber compound exhibits vulcanizability satisfying:and contains a crosslinking tackifier, t90 is a time to 90% vulcanization, t50 is a time to 50% vulcanization, and the vulcanizability is measured by a curastometer in accordance with JIS K 6300.

Owner:TOYO TIRE & RUBBER CO LTD

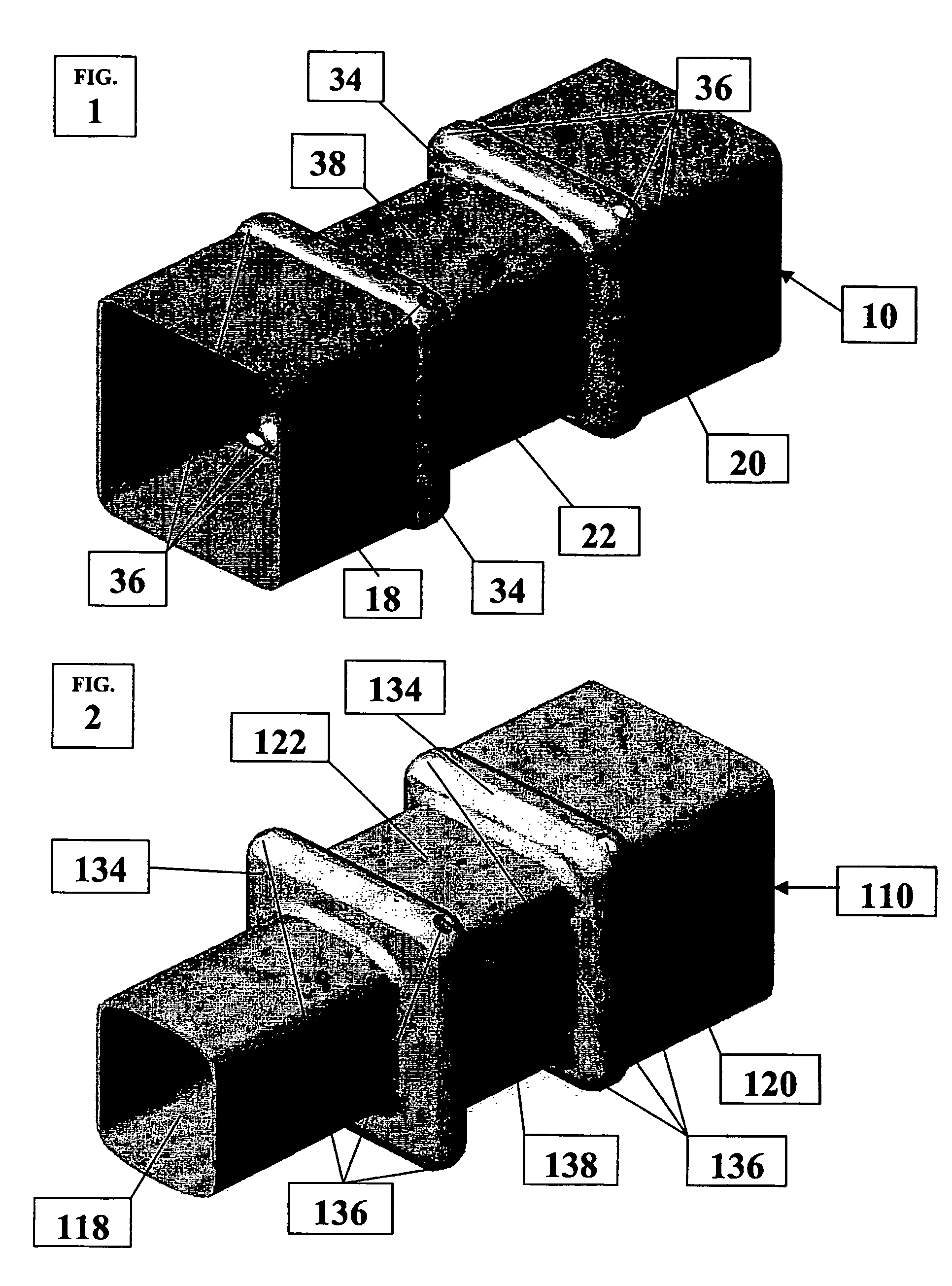

Collision energy-absorbing device

InactiveUS7070217B2Mechanical oscillations controlMicrobiological testing/measurementMobile vehicleVehicle frame

A collision energy-absorbing device includes a body member connected between the frame assembly of a motor vehicle and a bumper beam. The body member collapses as the bumper beam and the frame assembly are moved relatively toward one another during a vehicle collision. The body member has a first telescoping portion and a second telescoping portion that are connected by a connecting portion. The telescoping portions have different cross-sectional dimensions to enable the telescoping portions to move one within the other into collapsing telescoping relation as the body member collapses with the connecting portion being deformed and received between the telescoping portions. One or more protrusions extending from one of the telescoping portions interfere with relative movement of the other of the telescoping portions to retard movement of the telescoping portions into telescoping relation.

Owner:MAGNA INTERNATIONAL INC

Ea member attaching construction

InactiveUS20060125286A1Improve workabilityWorkability for attaching the EA componentVehicle seatsSnap-action fastenersEngineeringSynthetic resin

In an attachment structure of an EA component, the EA component composed of a synthetic resin such as rigid urethane foam is attached to a trim serving as a member, with a first locking part therebetween. The first locking part includes a cylindrical part, an anchor, a flange, and a plurality of projections. The anchor has a flange shape extending from the rear end of the cylindrical part toward the outside. The flange extends from the leading end of the cylindrical part toward the outside. The projections protrude from the leading end of the cylindrical part in the direction parallel to the axis of the cylindrical part. The EA component is attached to the trim by setting the EA component on the trim while the projections are inserted in an opening.

Owner:BRIDGESTONE CORP

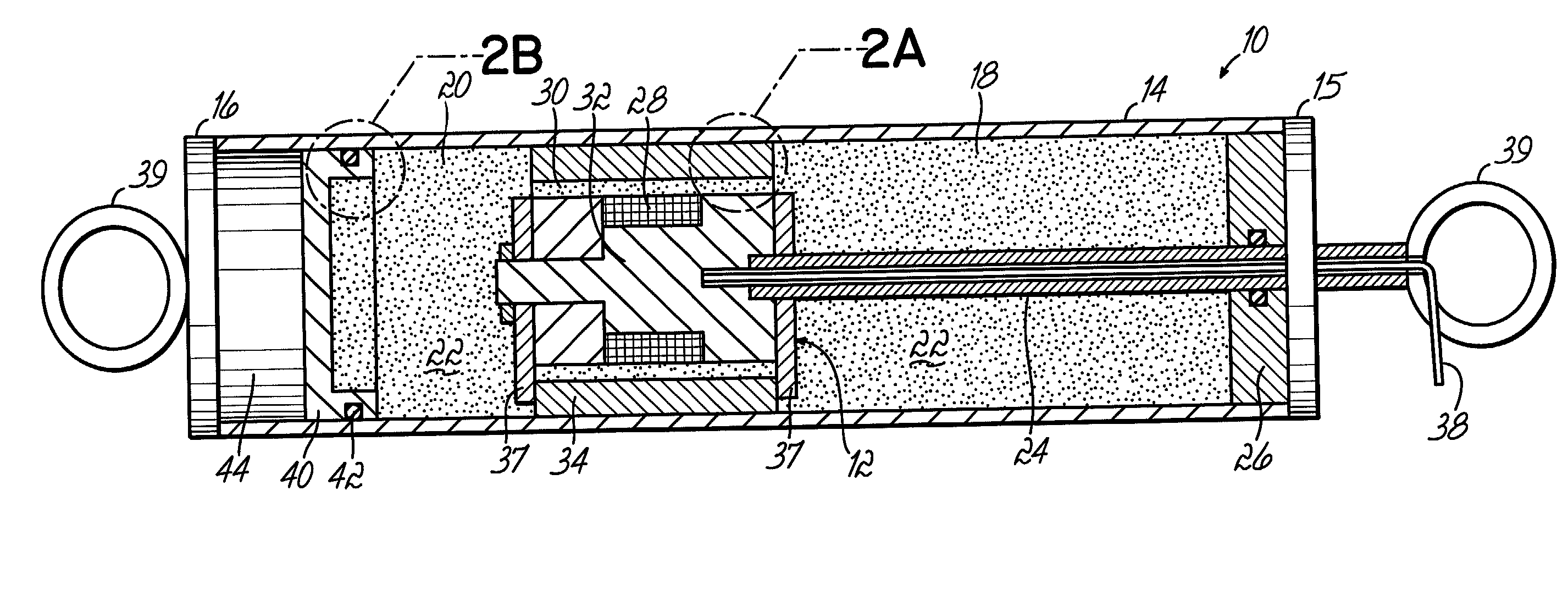

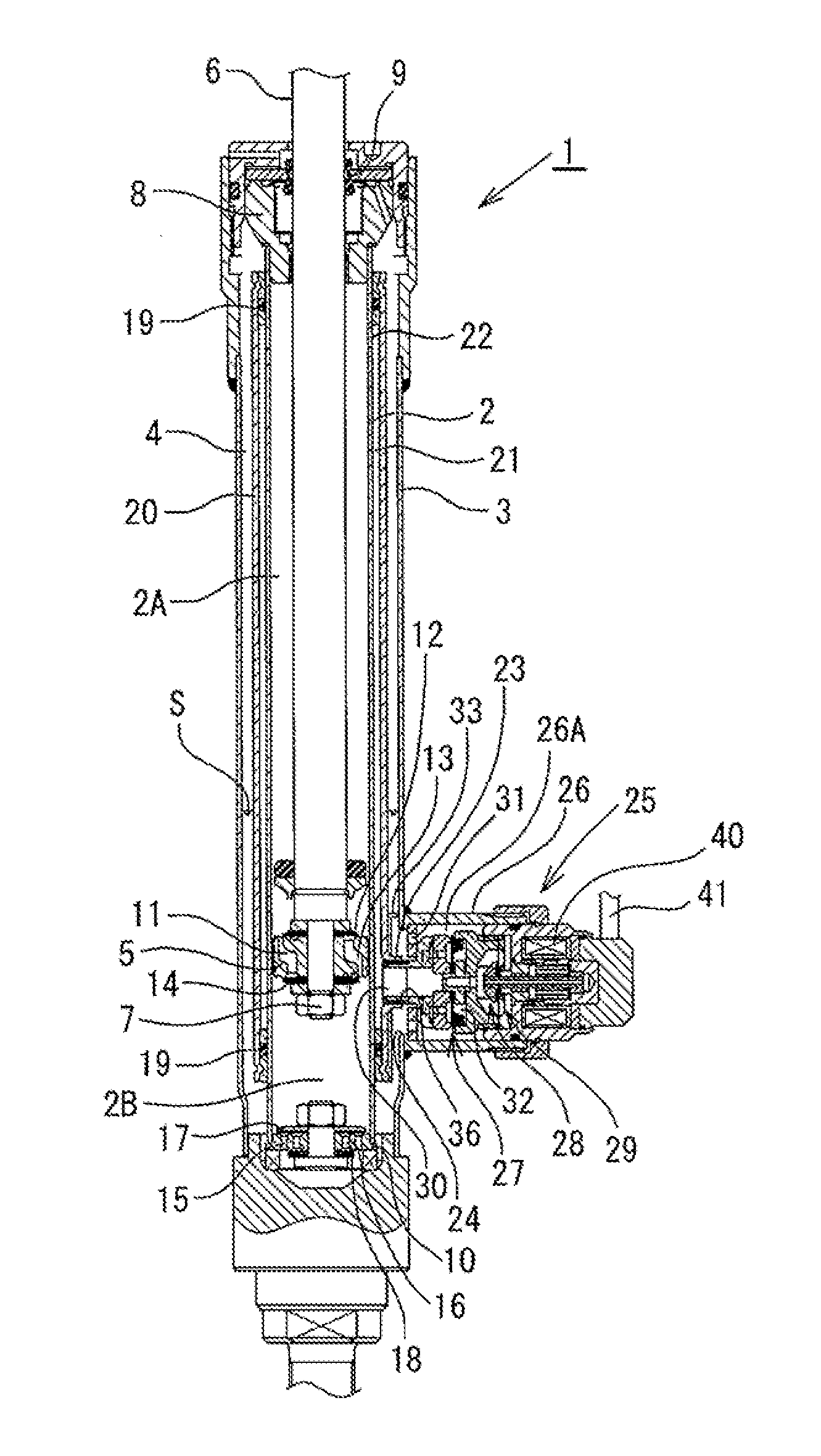

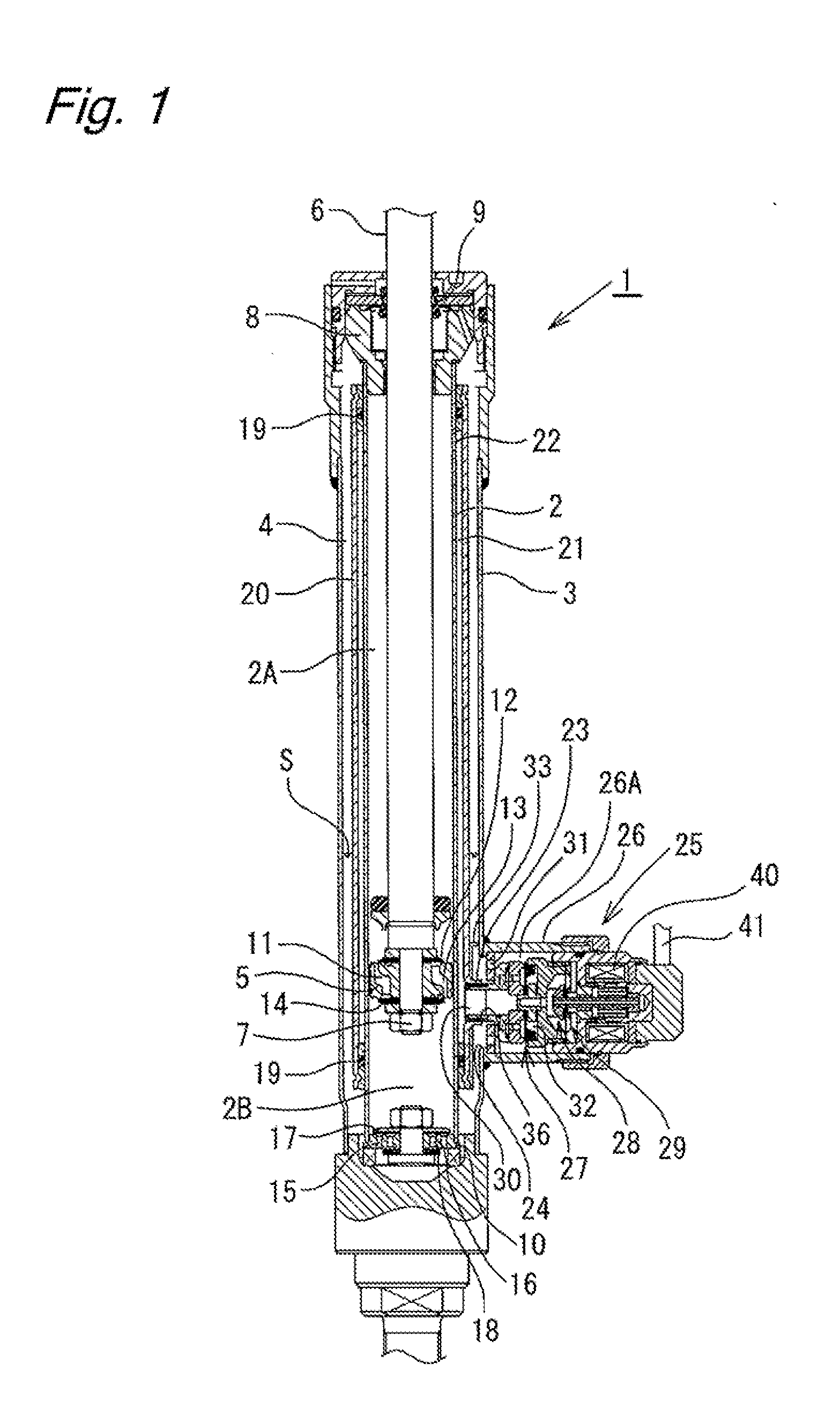

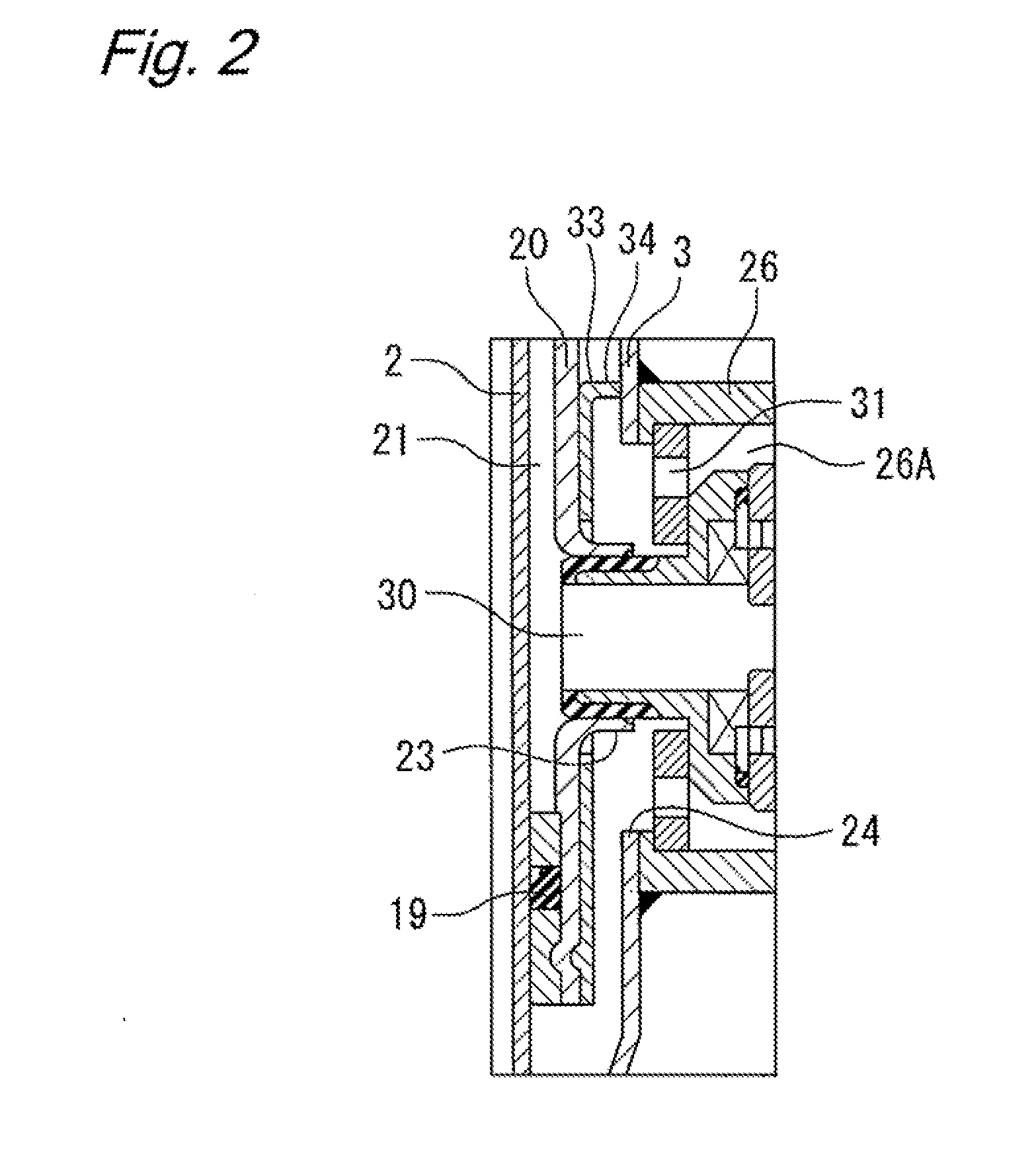

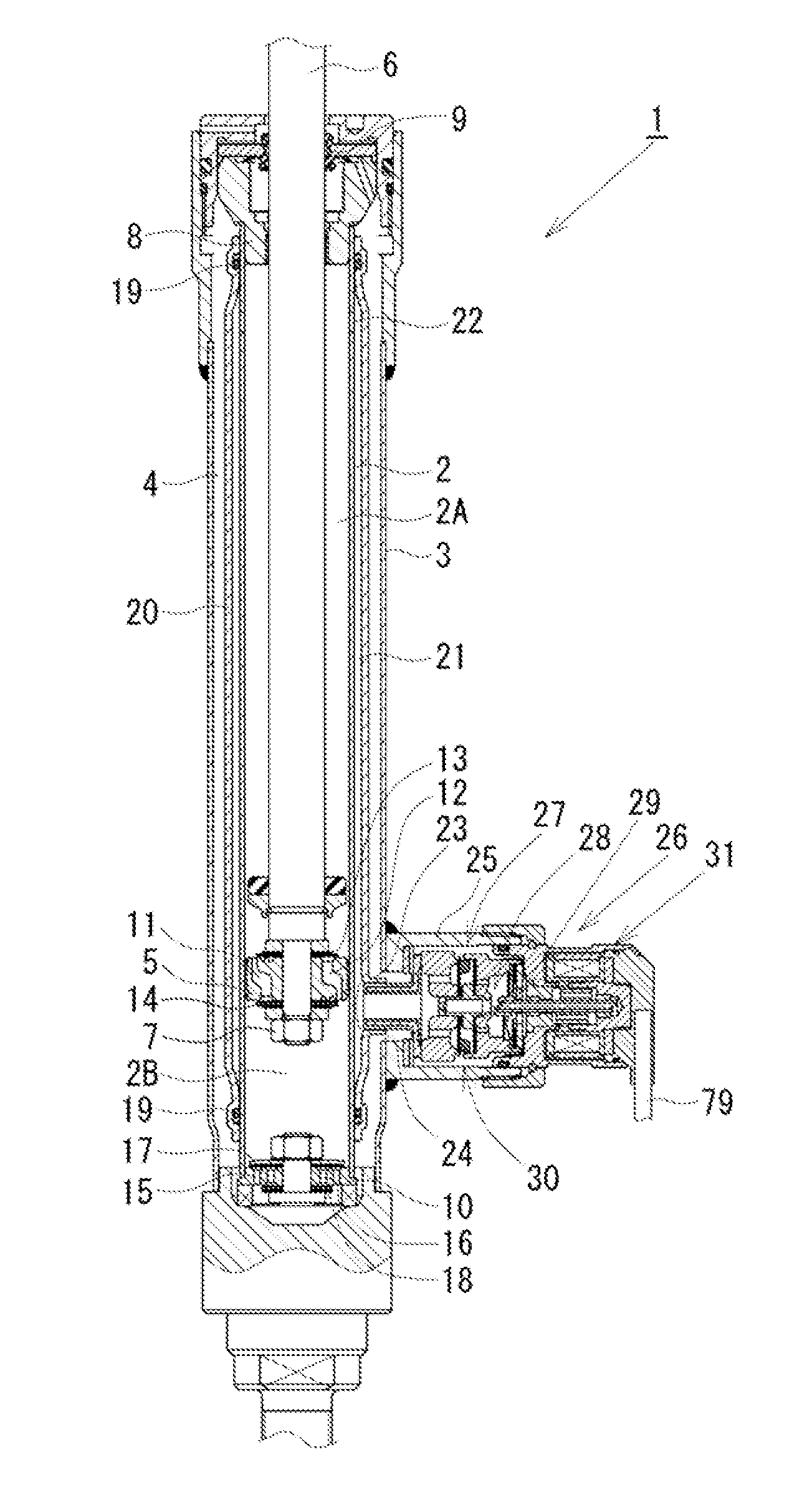

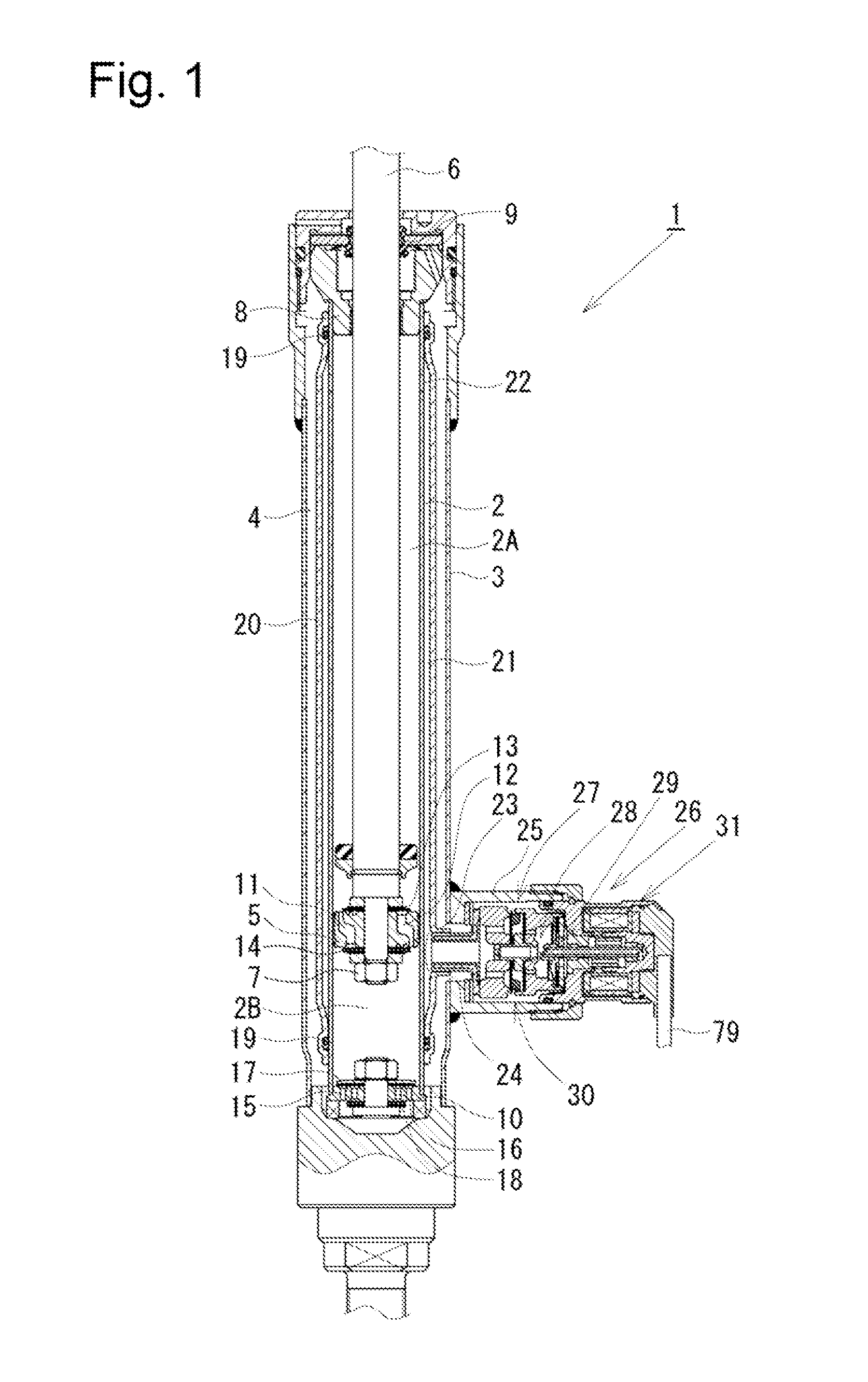

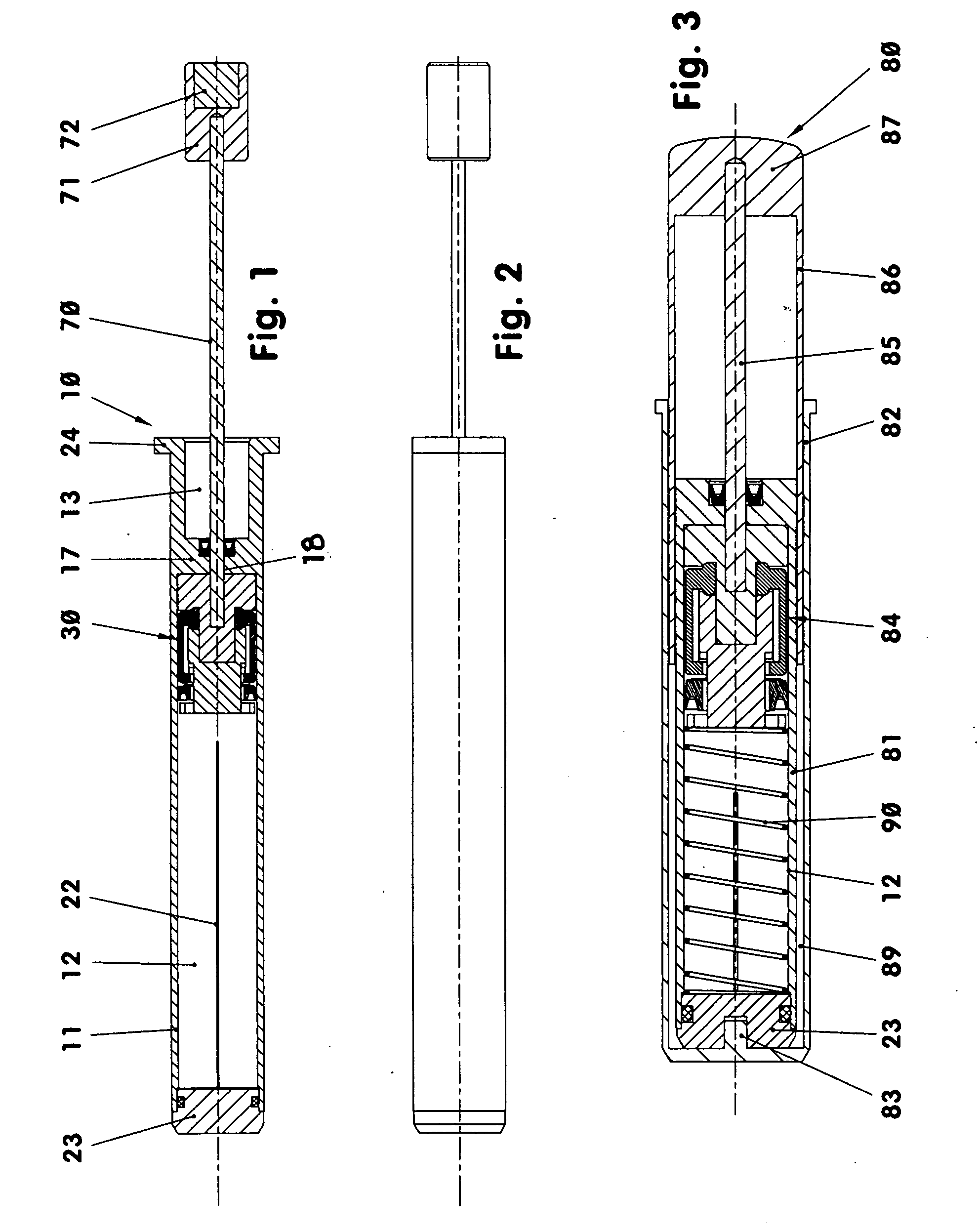

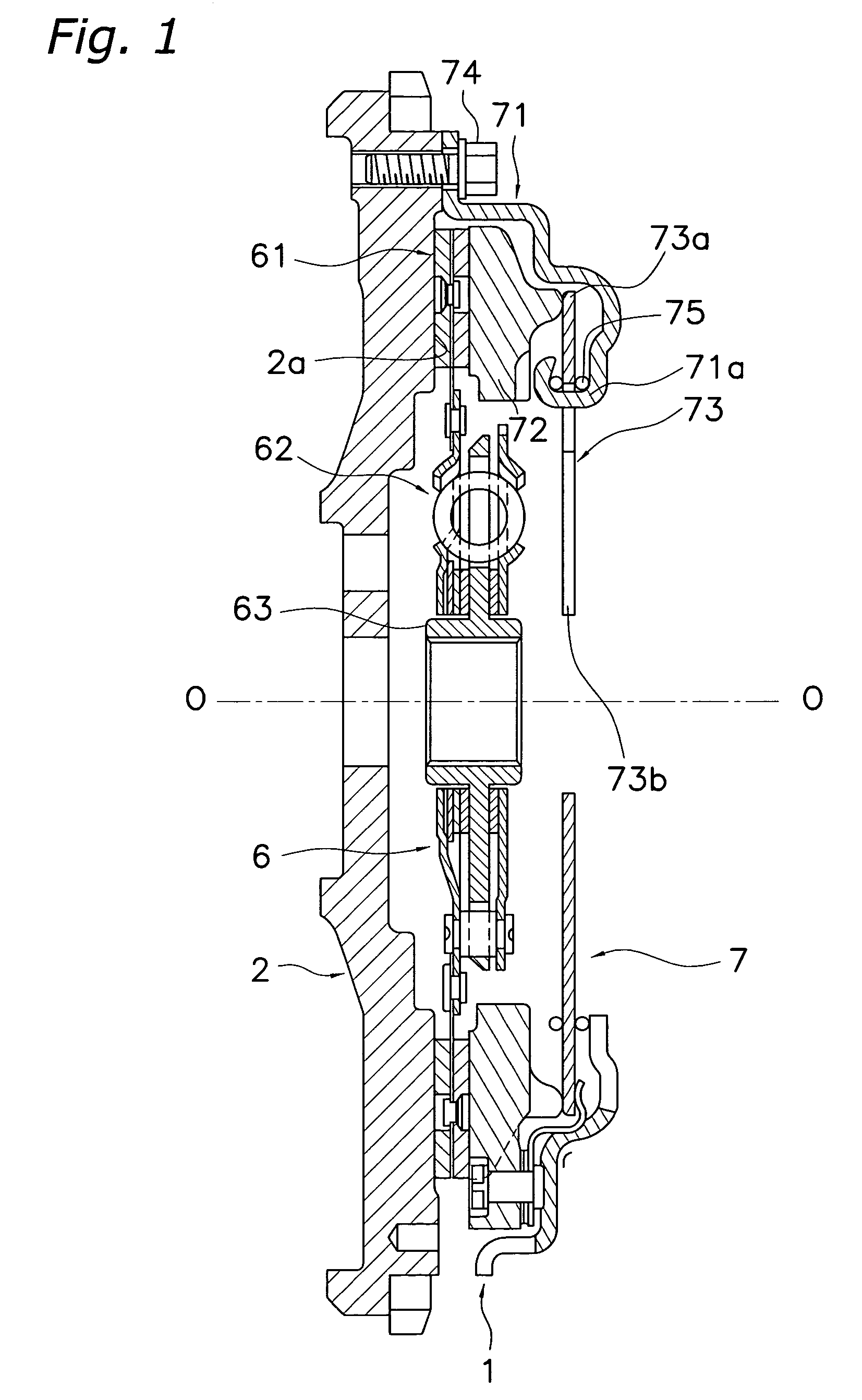

Shock absorber

A flow of hydraulic oil induced by sliding movement of a piston in a cylinder is controlled by a pilot-type main valve and a pilot valve, which is a pressure control valve, to generate a damping force. The pilot valve is adjusted in its valve-opening pressure with the thrust of a solenoid and adjusts the pressure in a back pressure chamber to control the valve-opening pressure of the main valve. A baffle plate is provided in a reservoir to isolate from each other the surface of hydraulic oil in the reservoir and an inlet port through which the hydraulic oil flows into the reservoir from a damping force generating mechanism, thereby suppressing the occurrence of aeration and cavitation. The baffle plate is secured by inserting a connecting port through a positioning opening and holding a separator tube with a pair of arm portions.

Owner:HITACHI ASTEMO LTD

Shock absorber

A shock absorber in which a flow of hydraulic oil caused by sliding movement of a piston in a cylinder is controlled by a pilot type main valve and a pilot valve to generate damping force. The valve-opening operation of the main valve is controlled by adjusting the pressure in a pilot chamber with the pilot valve. A valve block and a solenoid block are connected together into one unit and inserted into a casing before being secured with a nut. At this time, an actuating rod of the solenoid block is engaged with a pilot valve member retained by a pilot spring and a fail-safe spring in a cylindrical portion of a pilot body of the valve block.

Owner:HITACHI ASTEMO LTD

Pneumatic damper for slowing down movable furniture parts

ActiveUS20060118371A1Increase construction spaceGood effectMultiple spring combinationsAutomatic initiationsEngineeringMechanical engineering

In a pneumatic damper for slowing down movable furniture parts, comprising a cylinder and a piston movably disposed in the cylinder so as to form a displacement chamber at one side and a vacuum chamber at the other side of the piston, the piston includes a seal element which, in one end position thereof, is in close contact with the wall of the cylinder whose cross-section increases toward the opposite end of the cylinder so that the sealing effect collapses when the piston approaches its other end position and the piston includes a piston rod, which has a diameter of less than 35% of the piston diameter and sealingly extends through a cylinder end wall.

Owner:ZIMMER GUNTHER +1

Load bearing surface

ActiveUS20050279591A1Reduce manufacturing costAvoid heat retentionStuffed mattressesLayered productsElastomerEngineering

An elastomeric load bearing surface with different load support characteristics in different directions. In one embodiment, the surface includes an elastomeric membrane that is oriented in only a single direction, for example, by compression or stretching. In another embodiment, the surface includes mechanical structures, such as connectors, variations in thickness and apertures, that vary the load support characteristics in different directions. In another aspect, the present invention provides a multilayer load bearing surface in which the layers cooperate to provide a controlled force / deflection profile that is variable in different regions of the surface. In one embodiment, the upper layer includes a plurality of loosely connected nodes and a lower layer having a plurality of resilient elements that separately support each node.

Owner:ILLINOIS TOOL WORKS INC

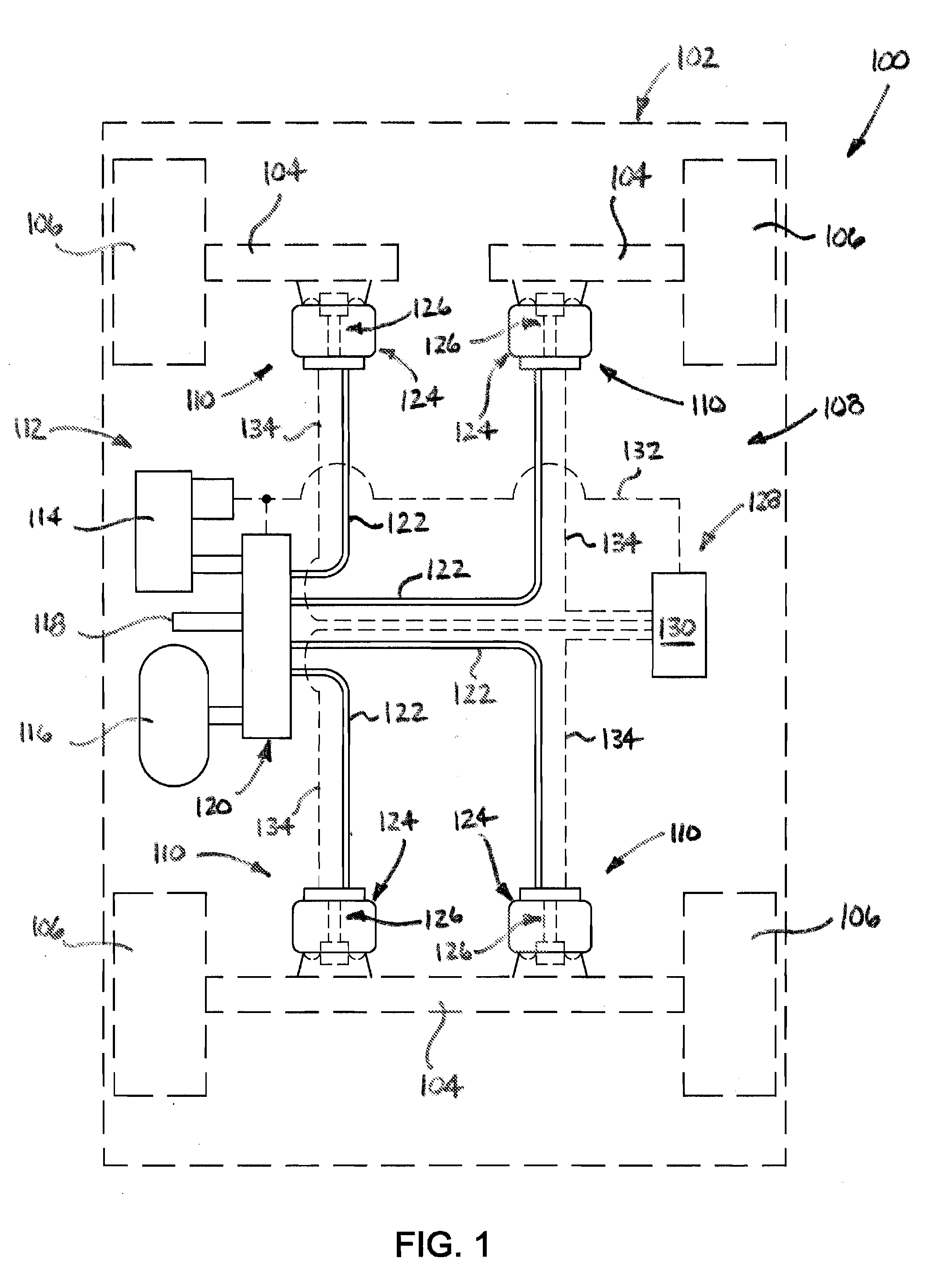

Gas spring and gas damper assembly and method

A gas spring and gas damper assembly (1000) includes a gas spring assembly (1002) and a gas damper assembly (1004). The gas spring assembly (1002) includes a first wall portion (1006), a second wall portion (1008) disposed in spaced relation to the first wall portion (1006), and a flexible wall section (1010) connected therebetween. The gas damper assembly (1004) includes a third wall portion (1094) disposed in longitudinally-spaced relation to the first wall portion (1006), and a second flexible wall section (1104) connected between the second wall portion (1008) and the third wall portion (1094). A fourth wall portion (1070) is disposed between the first (1006) and second (1008) wall sections to define two pressurized gas chambers (1012, 1004). A damper rod (1130) connects at least the first (1006) and third (1094) wall portions. Methods are also included.

Owner:FIRESTONE IND PROD COMPANY

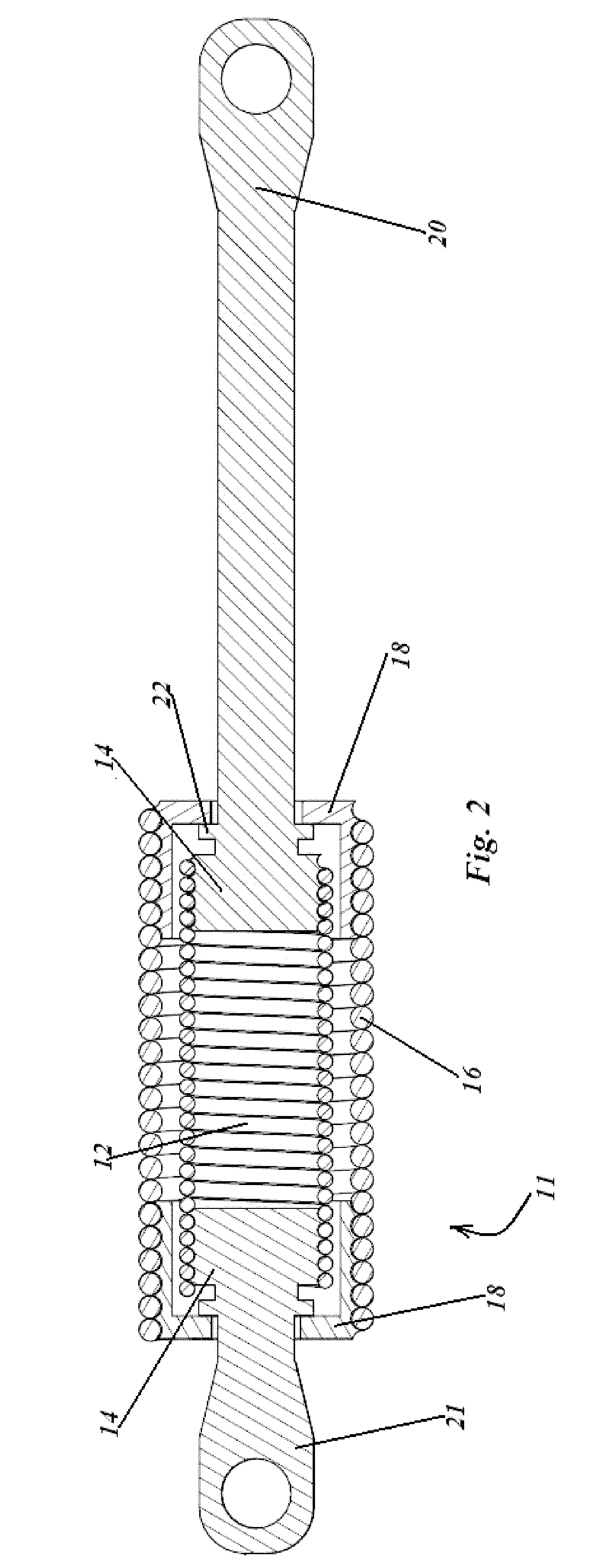

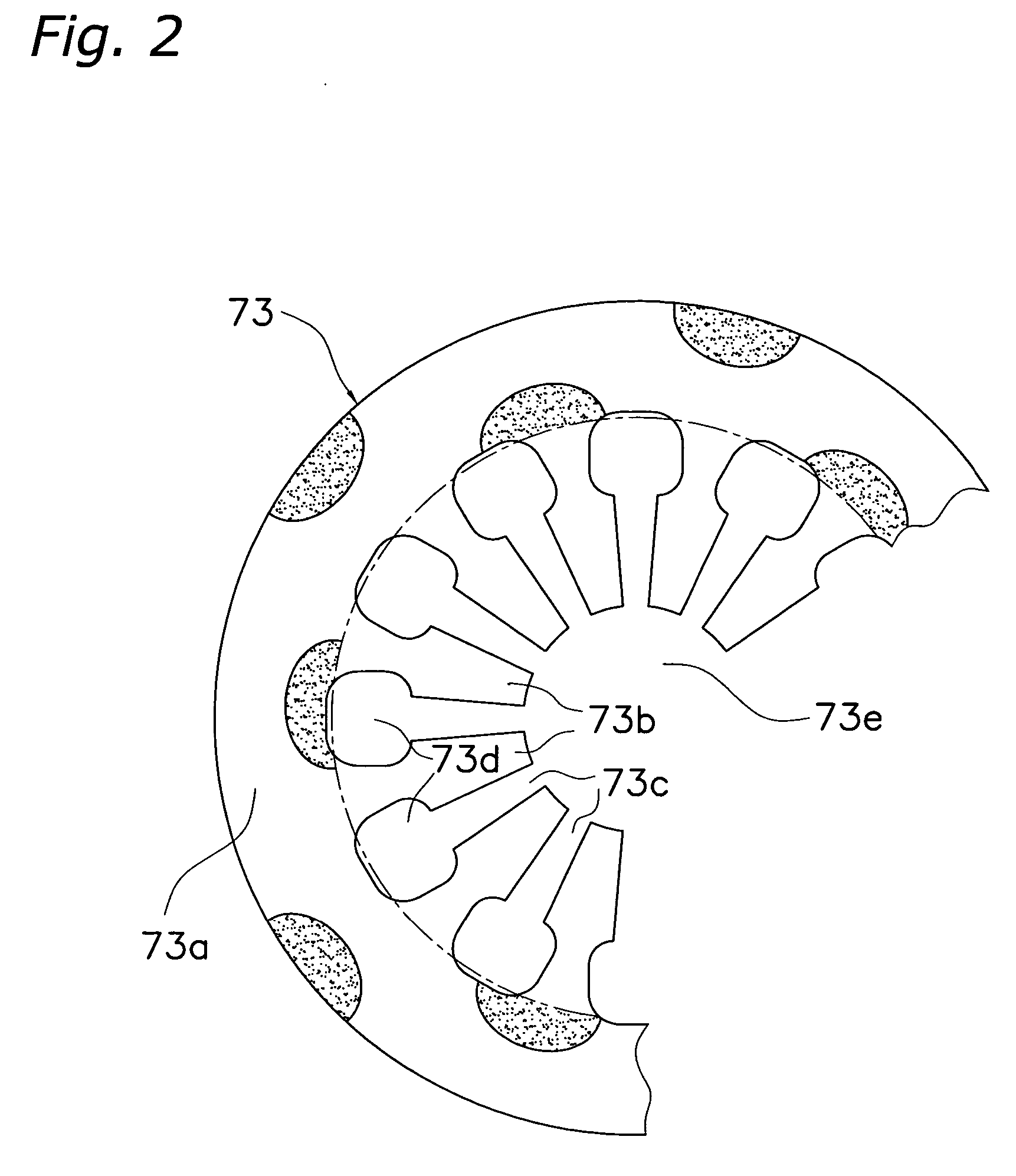

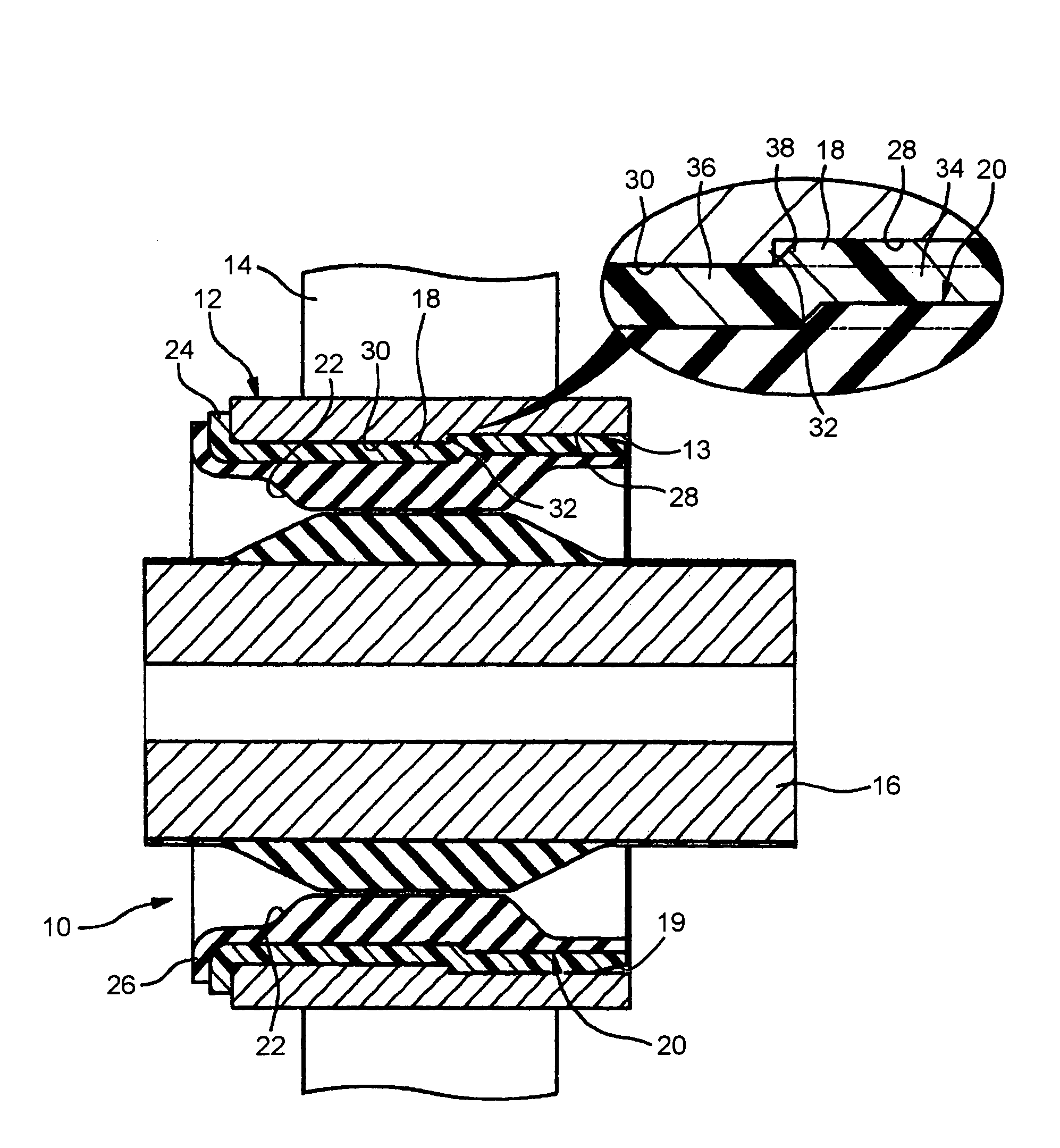

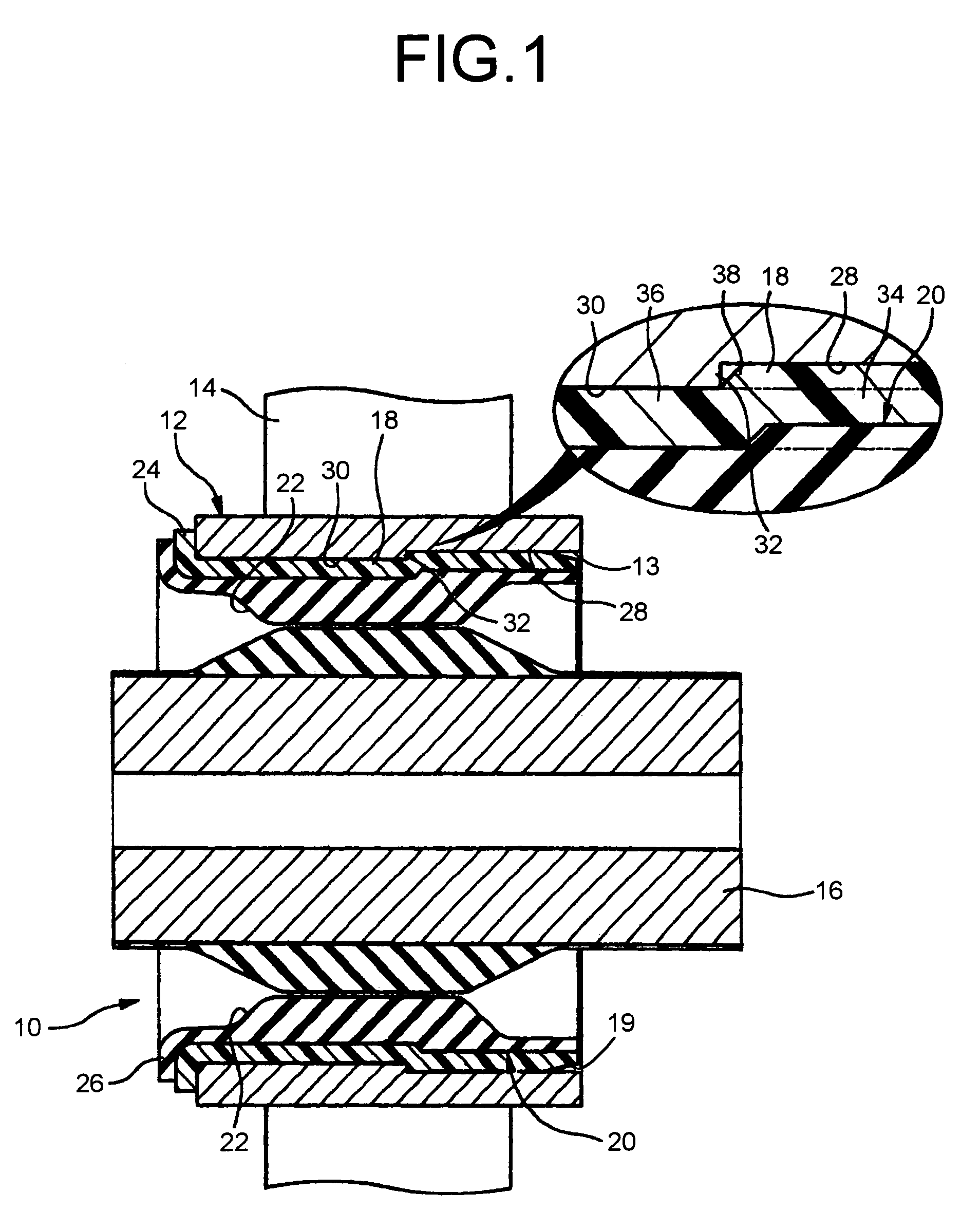

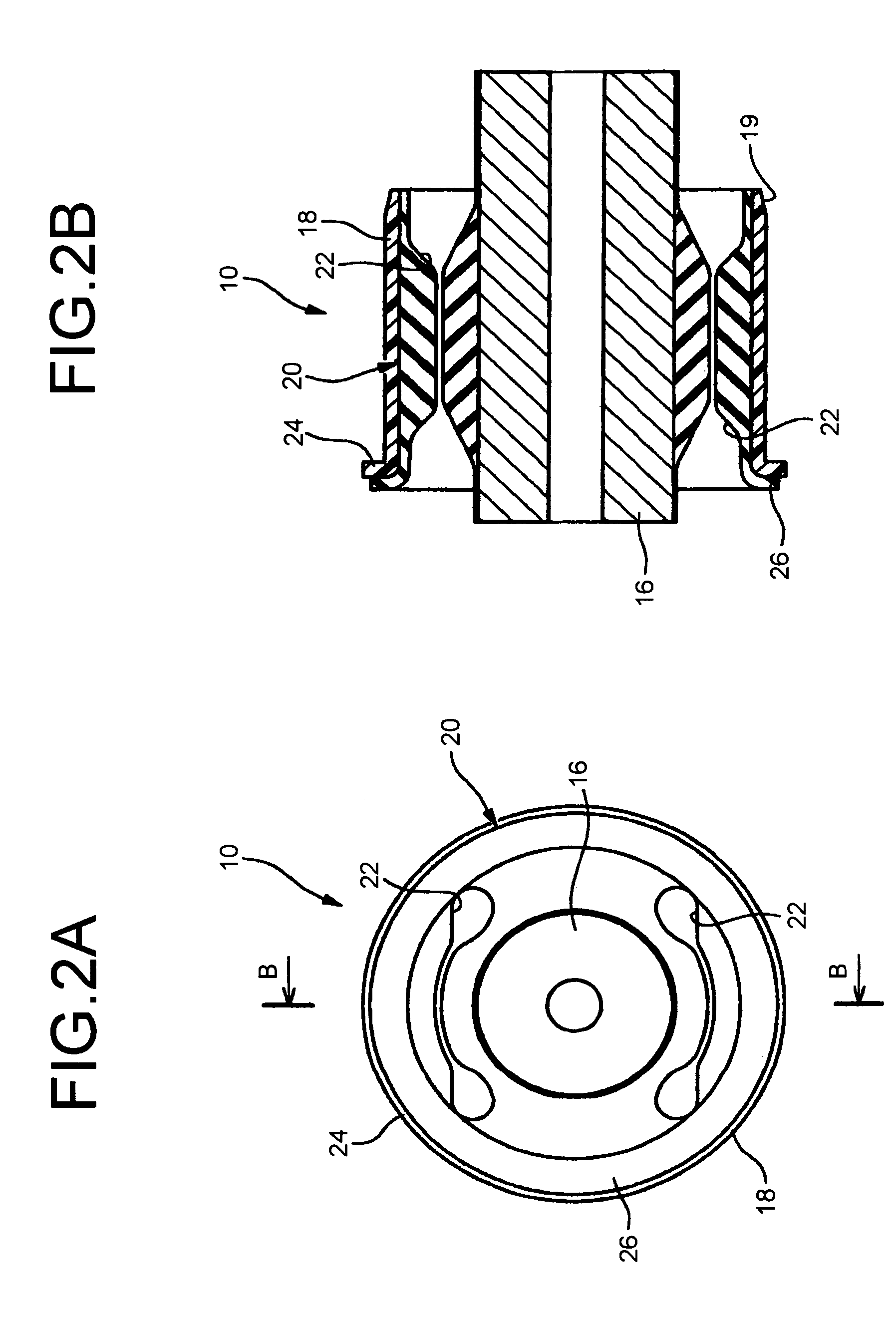

Tubular vibration-damping device used for vibration-damping connecting rod, vibration-damping connecting rod using the same, and method of manufacturing vibration-damping connecting rod

ActiveUS20160053848A1Easy to handleImprove degree of tuning freedomNon-rotating vibration suppressionWire springsElastomerEngineering

Provided are a tubular vibration-damping device for a vibration-damping connecting rod, a vibration-damping connecting rod using the same and a method of manufacturing the vibration-damping connecting rod. The device including an inner shaft member and an outer tubular member being connected by a main rubber elastic body, the inner shaft member having a structure wherein first and second connecting members are inserted into a sleeve member bonded to the main rubber elastic body, the connecting members being axially overlapped with and spaced from each other to provide a rod-end insertion space communicated with outside via rod insertion holes that open through peripheral walls of the sleeve member and the outer tubular member, one end of a rod main body being inserted via the rod insertion holes into the rod-end insertion space and fixed to the first and second connecting members by a fastening member.

Owner:SUMITOMO RIKO CO LTD

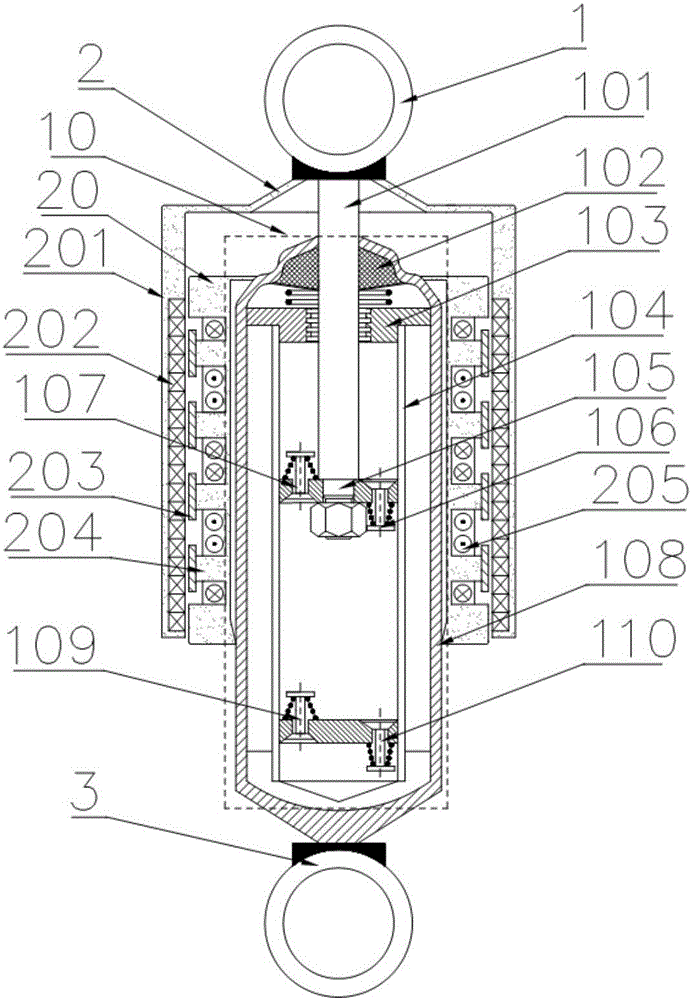

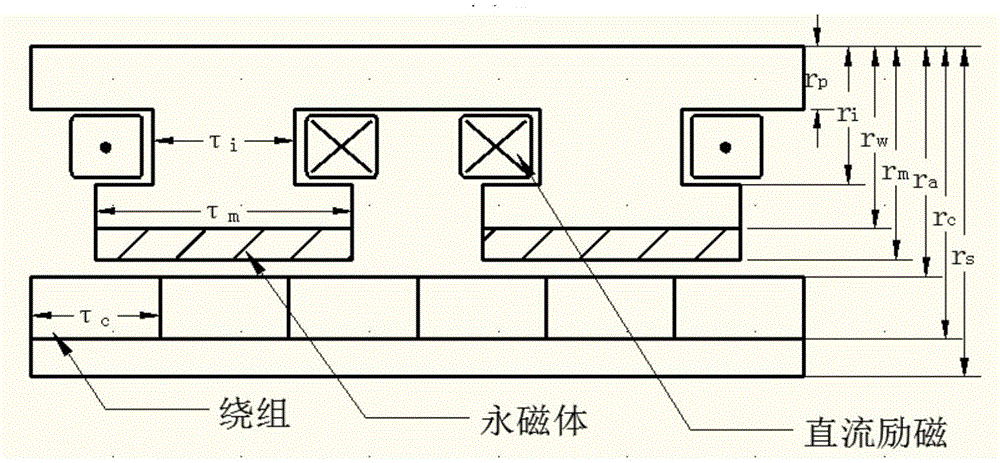

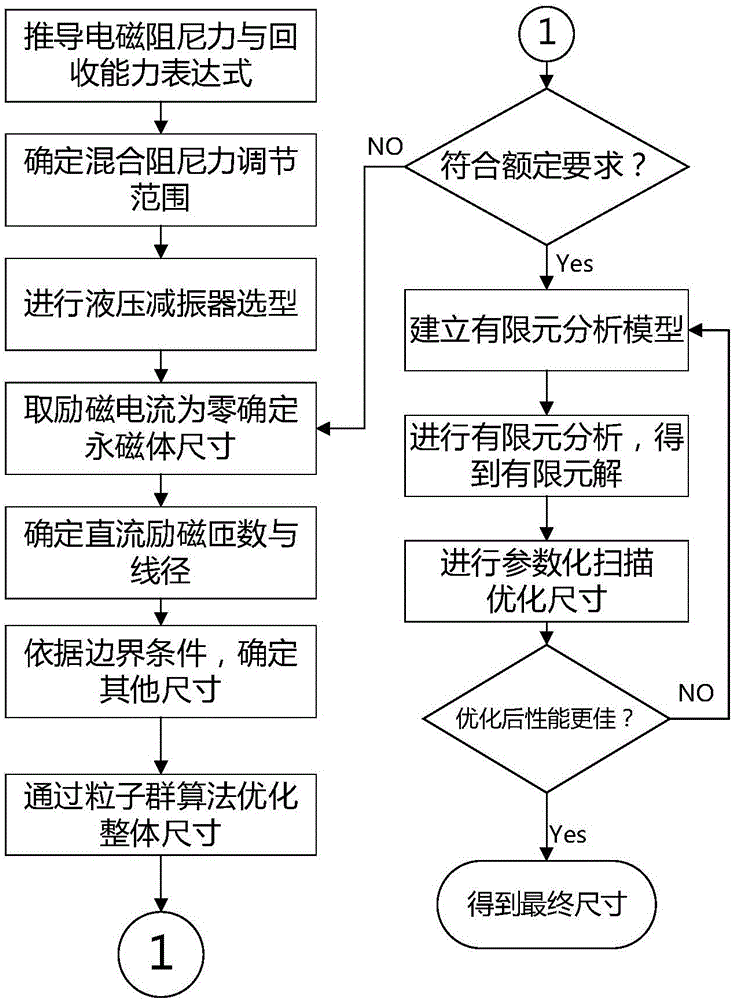

Semi-active energy regenerative suspension shock absorber based on mixed excitation and size determining method of shock absorber

ActiveCN106224425AAdjustable damping forceGood vibration isolationGeometric CADAuxillary drivesViscous dampingSemi active

Owner:JIANGSU UNIV

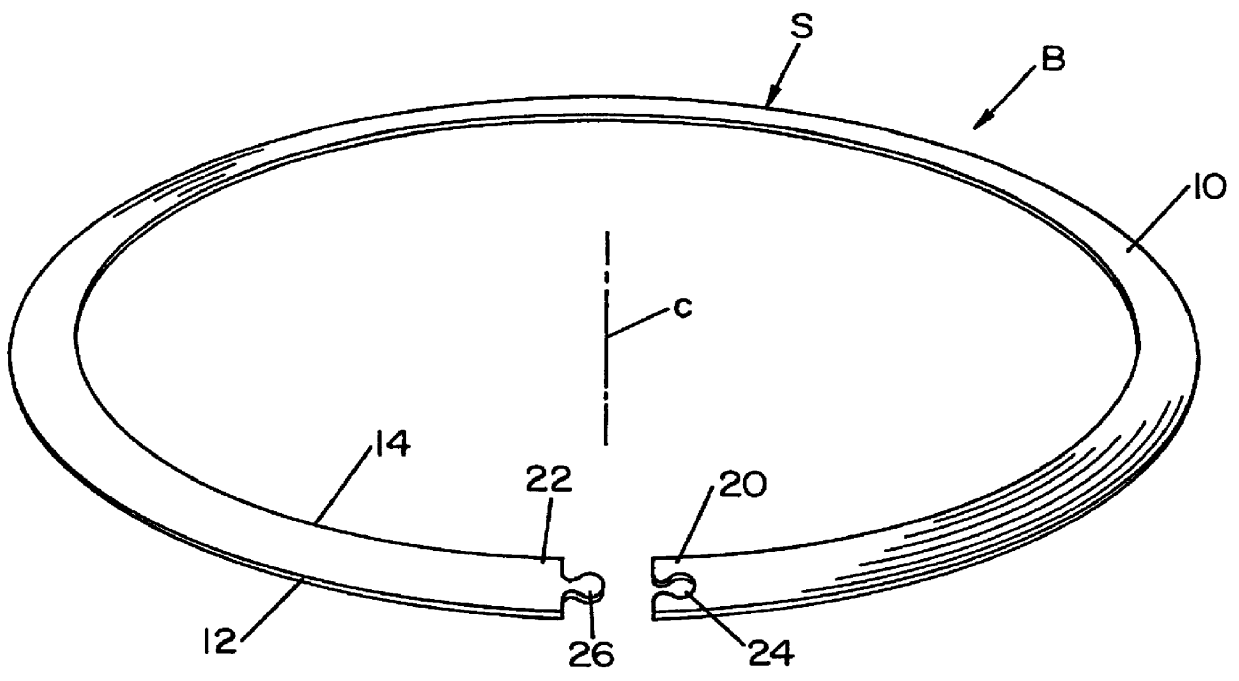

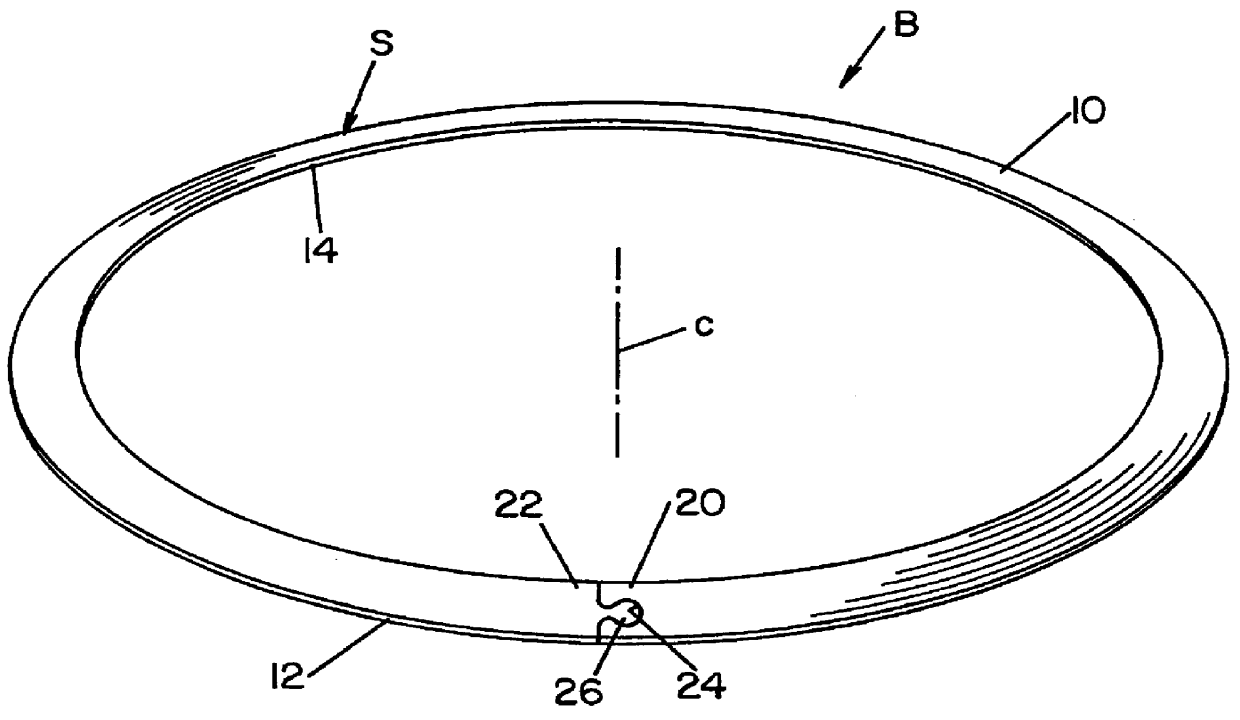

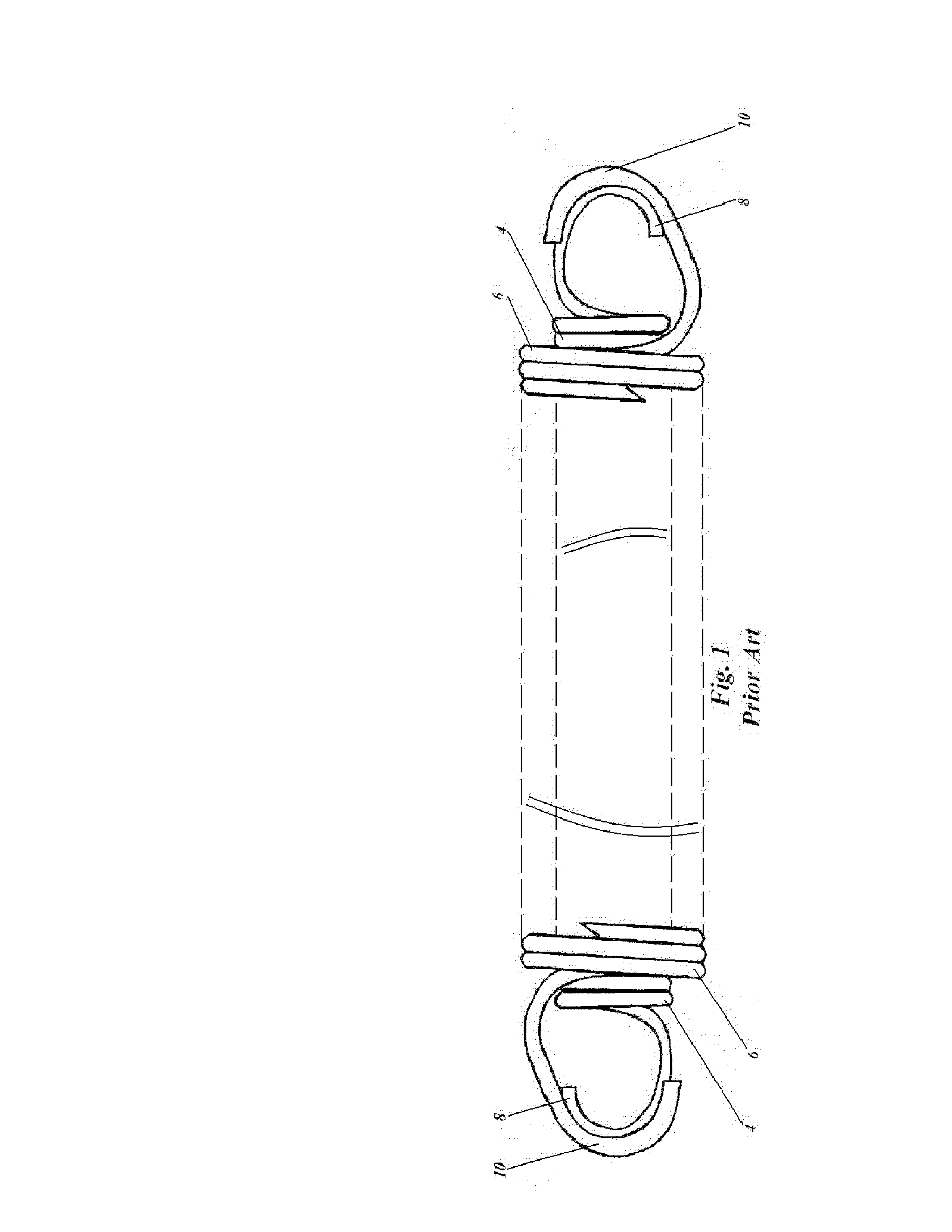

Belleville spring

InactiveUS6102382AReduce scrapEliminate needWashersSprings/dampers manufactureCoil springSpring steel

A Belleville spring comprising a thin strip of hardened spring steel coiled into a circular shaped body with a frusto-conical configuration having an inner diameter and an outer diameter, wherein the strip has two free ends and the coiled spring steel body has the free ends joined together.

Owner:BARNES GROUP

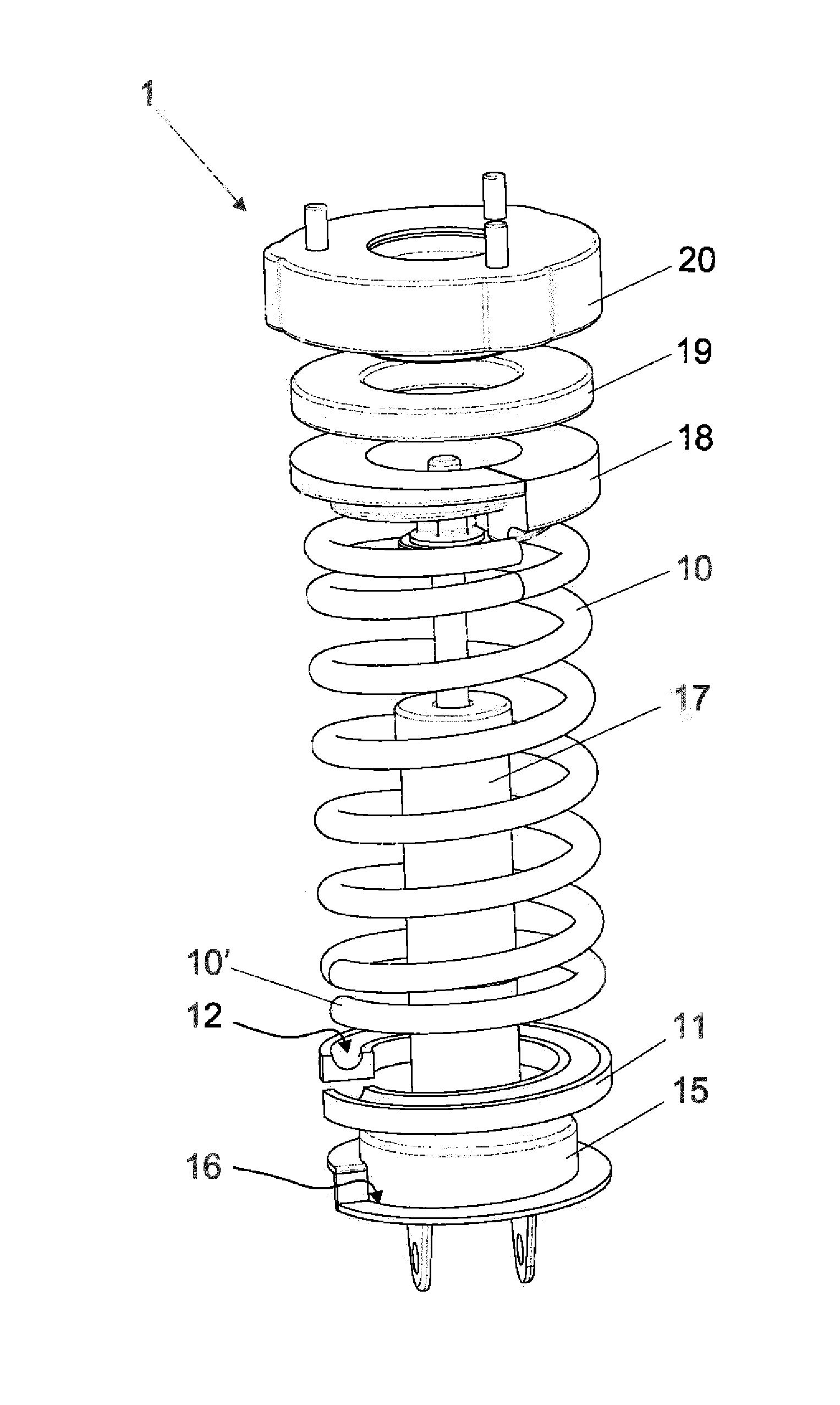

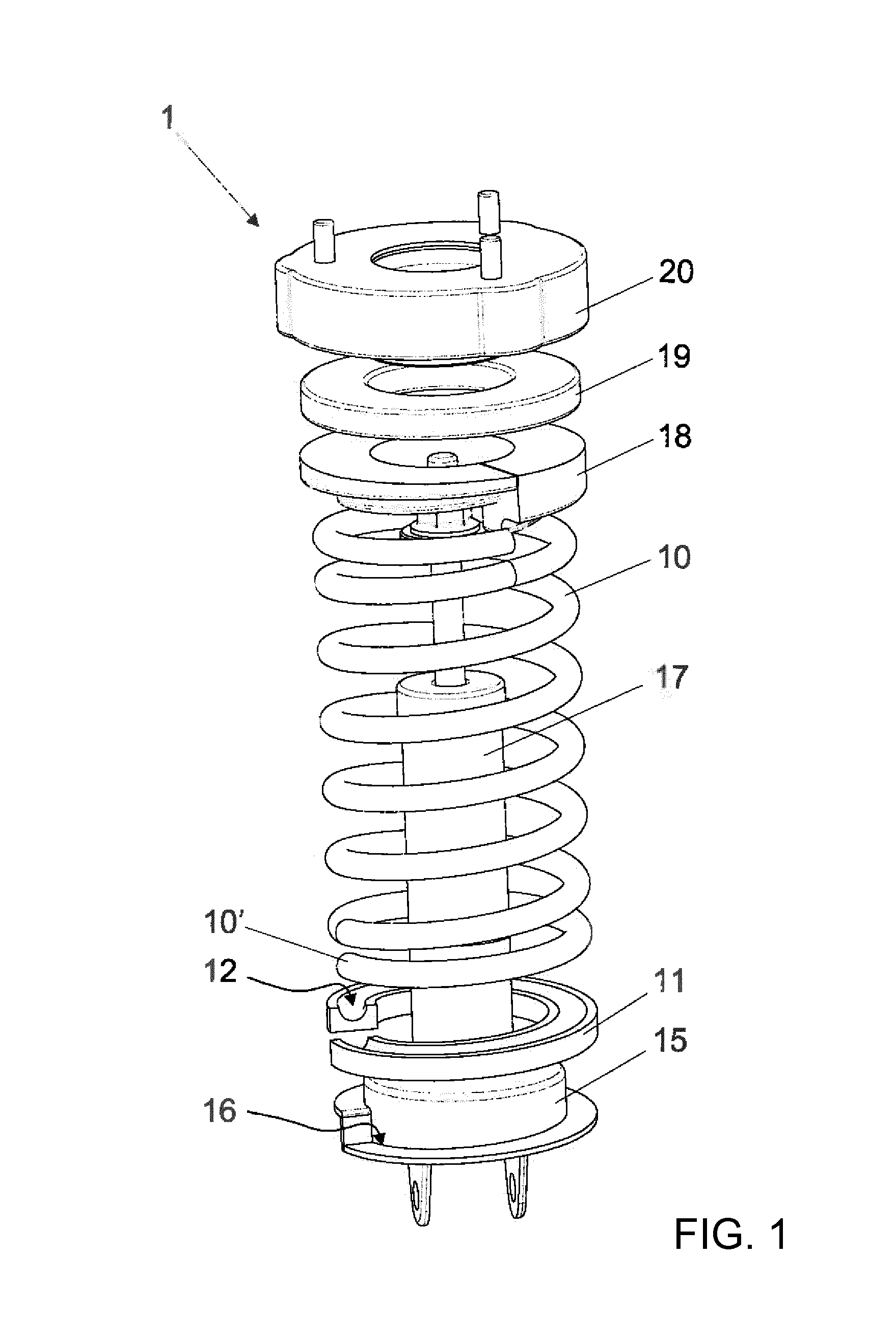

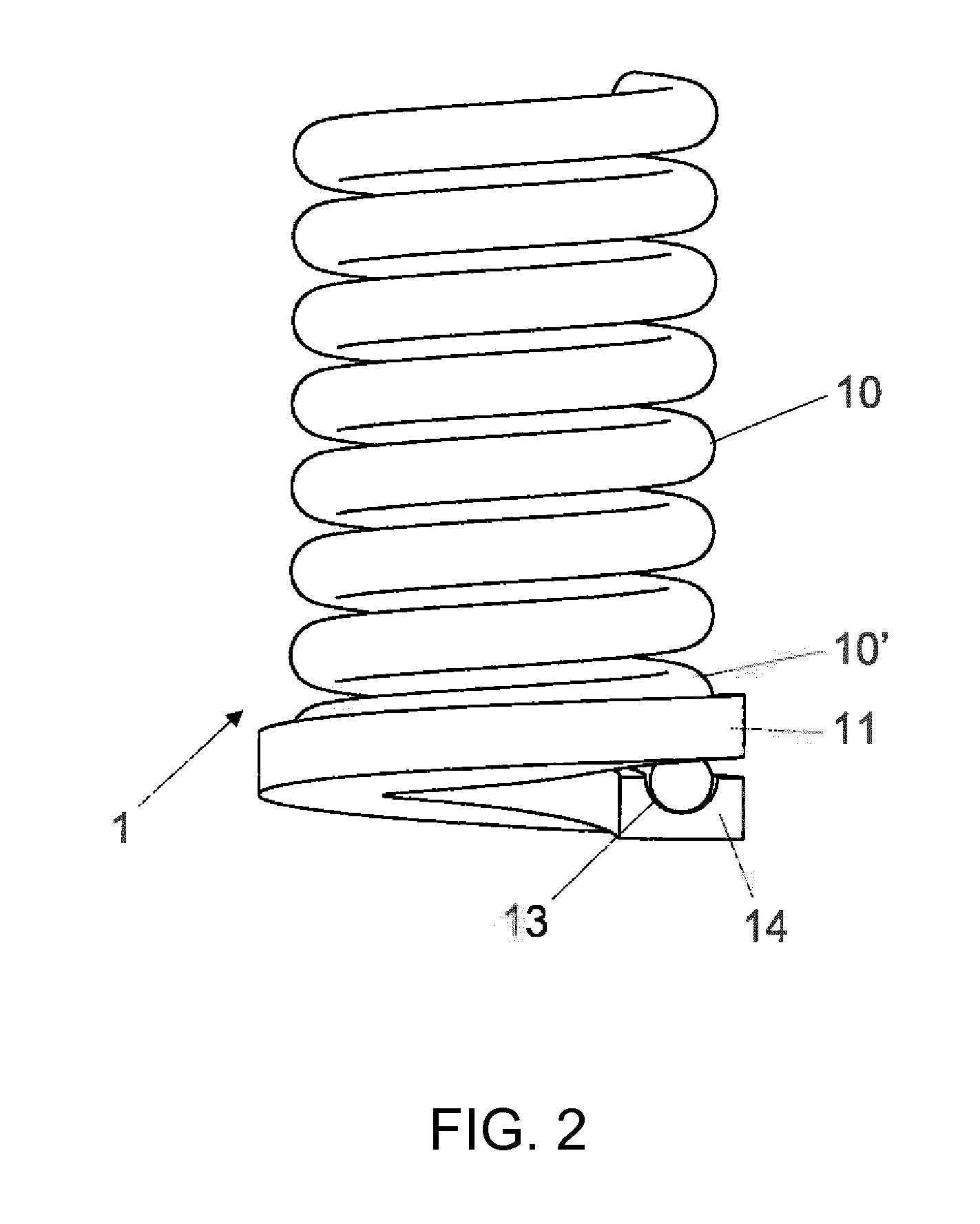

Bearing arrangement for a spring of a vehicle chassis

ActiveUS20140225319A1Easy to incorporateEasy to manufactureLaminationLamination apparatusElastomerAdhesive

A bearing arrangement and a method for forming a bearing arrangement for a spring, in particular for a spring of a vehicle chassis, having at least one spring insert in which at least part of a spring coil of the spring is accommodated. The spring insert is an elastomer and is flexible. The spring insert is configured to be movable with a moving of the spring coil. An adhesive is introduced between the spring and the spring insert, with the result that the connection of the spring insert to the spring has a bonded connection.

Owner:THYSSENKRUPP FEDERN & STABILISATOREN

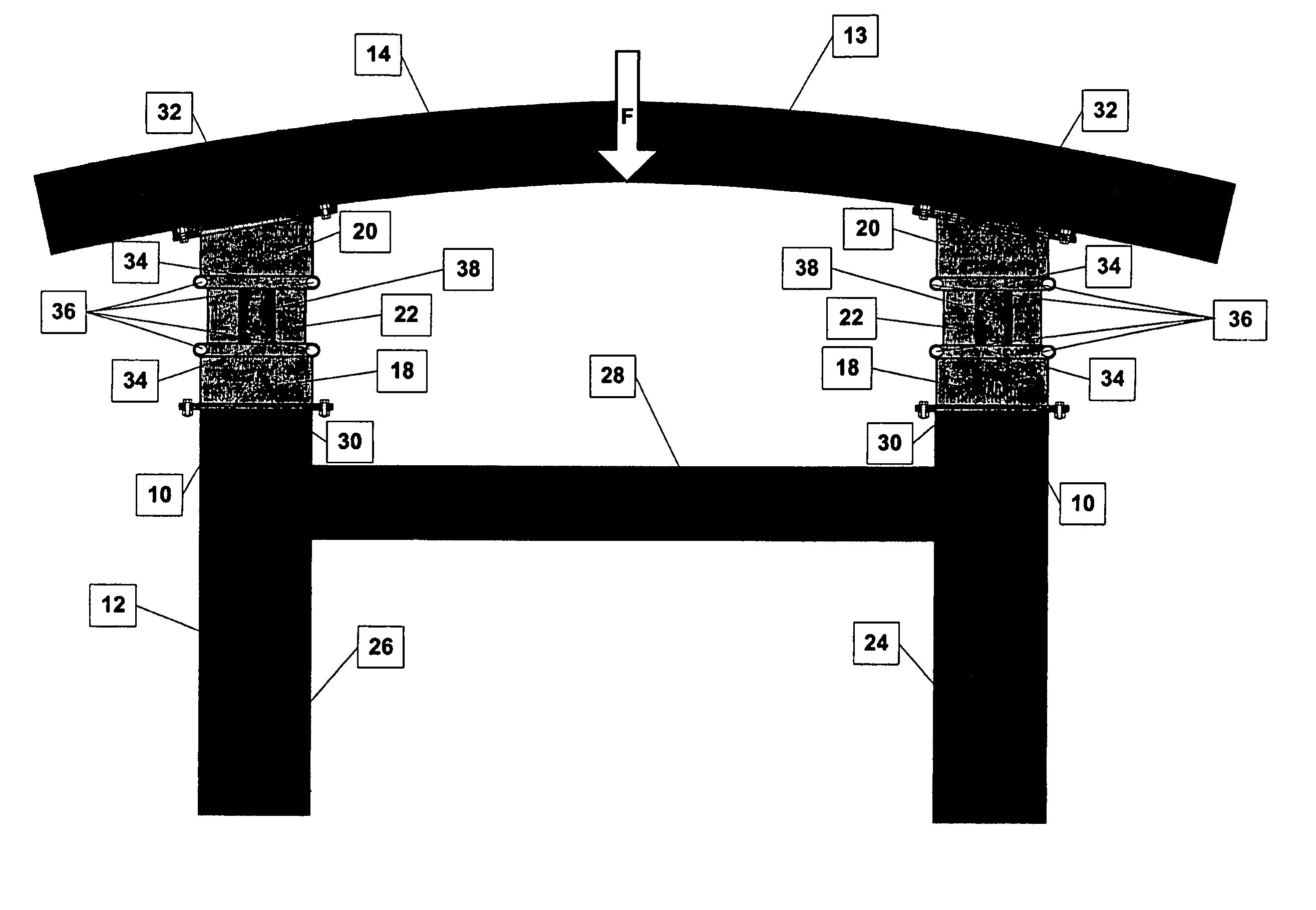

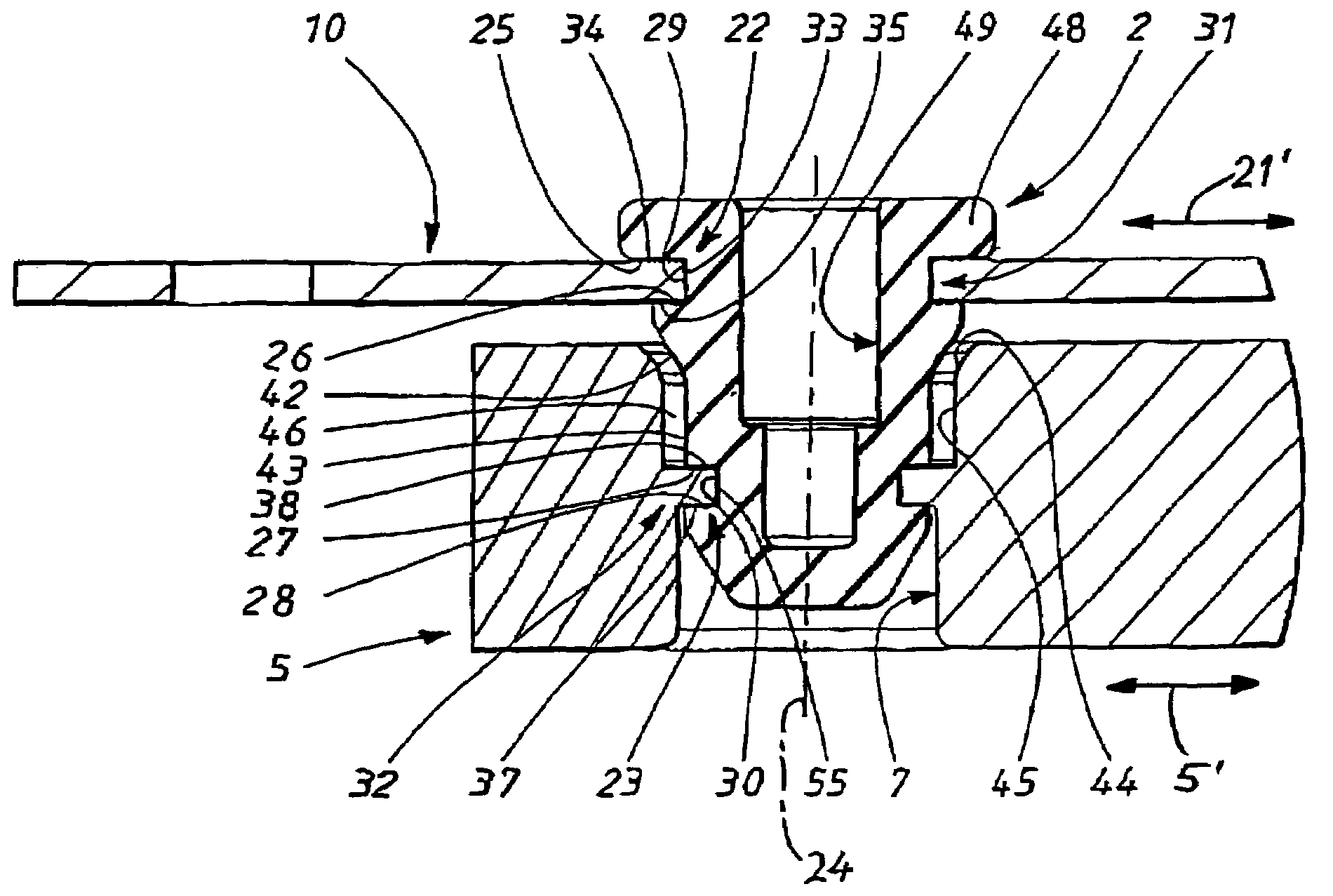

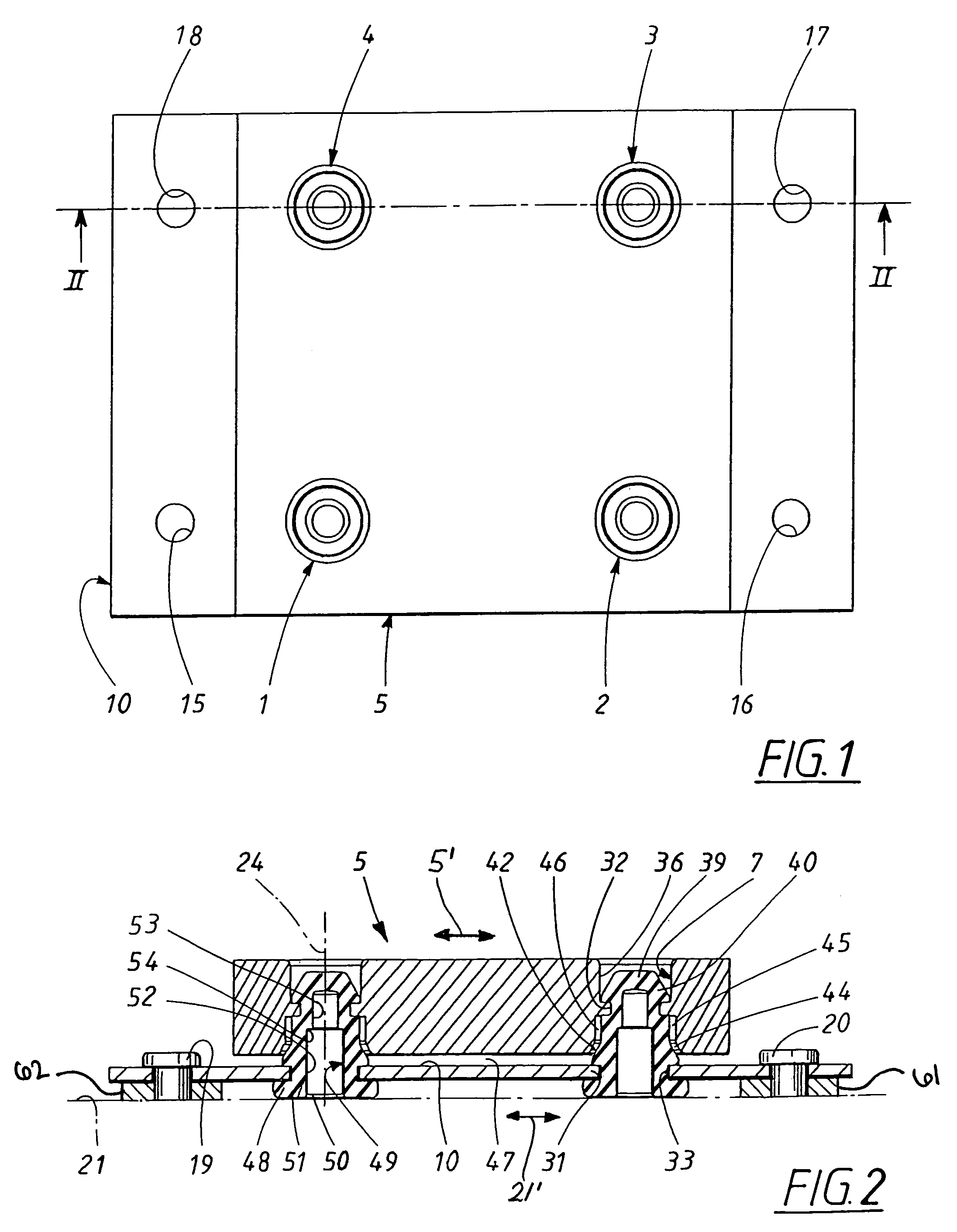

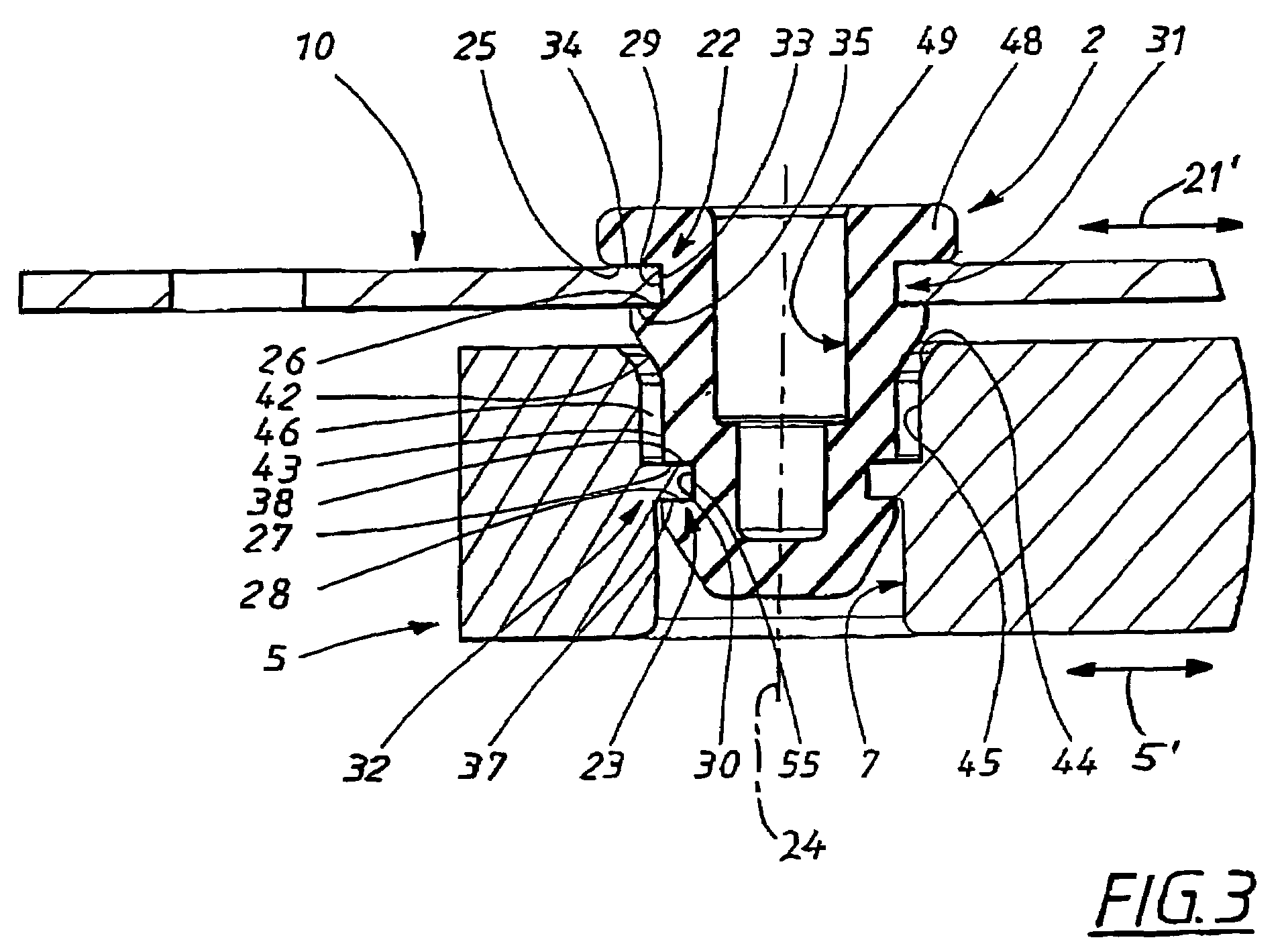

Method for damping vibrations and a method for mounting the device

InactiveUS7246797B2Easy to assembleEasy to producePortable framesNon-rotating vibration suppressionEngineeringResonance damping

Device for damping vibrations of a vibration surface (21) of the frequency tuned resonance damping kind consisting of one or several elastic damping elements (1–4) and a vibration body (5) supported by the damping elements which together are tuned to damp the vibrations of said surface within a selected frequency range. First mutually co-operating form grip organs give a form grip between said damping elements (1–4) and the vibration surface (21) and second mutually co-operating form grip organs give a form grip between the damping elements and the vibration body. The form grip organs in addition have a recess with gripping surfaces (25–30, 33–35) for transferring vibrations.

Owner:TRELLEBORG AUTOMOTIVE FORSHEDA

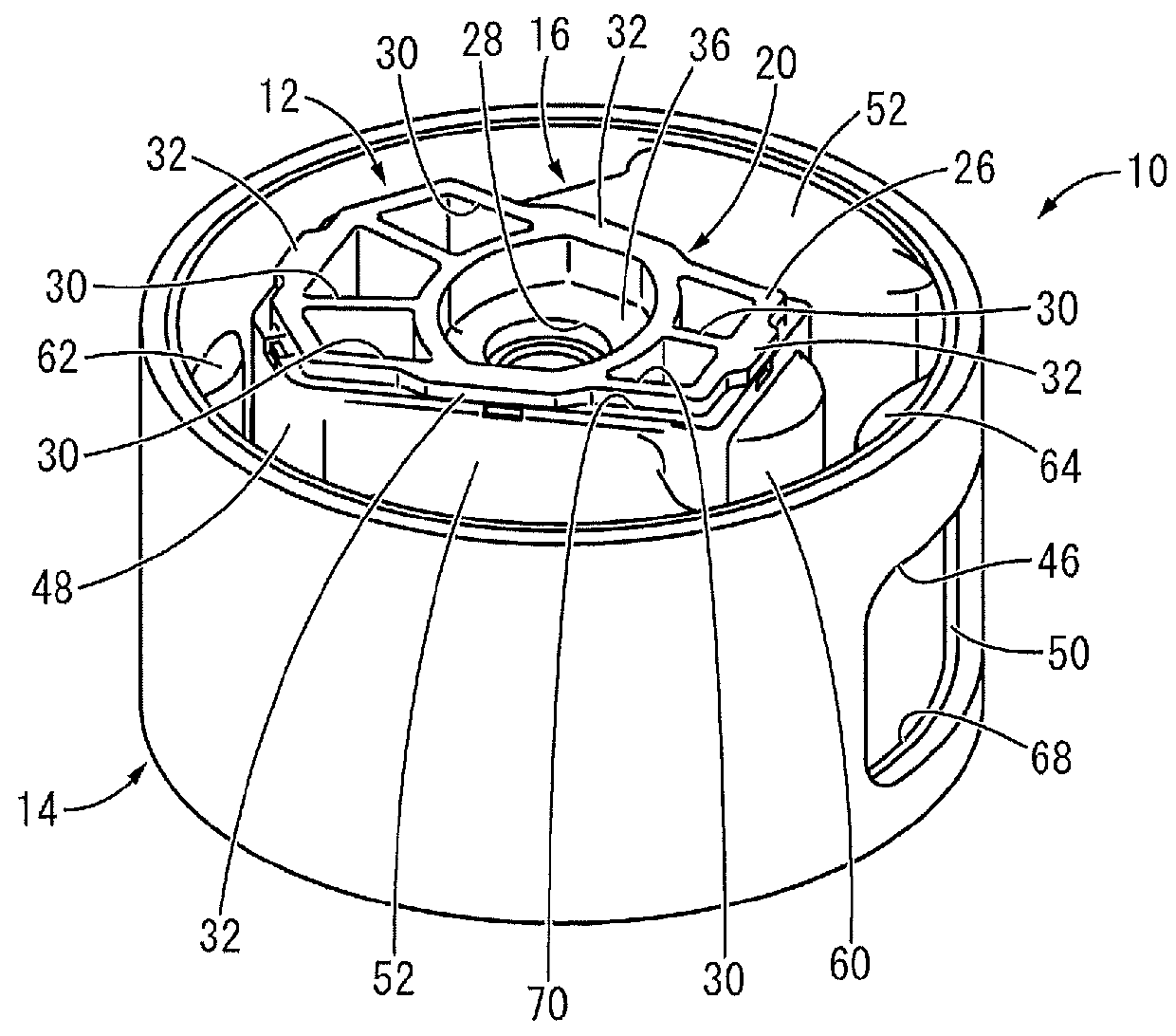

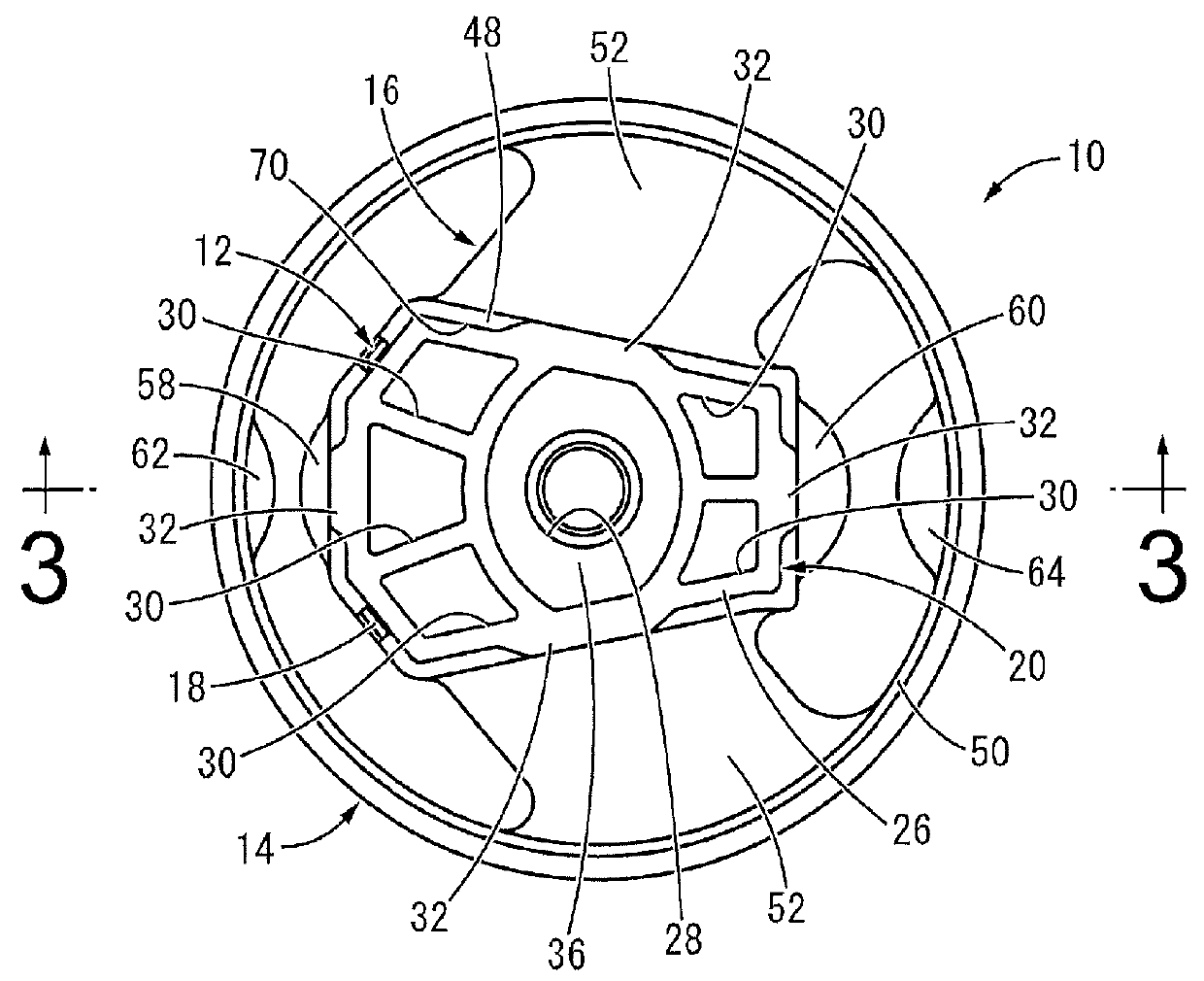

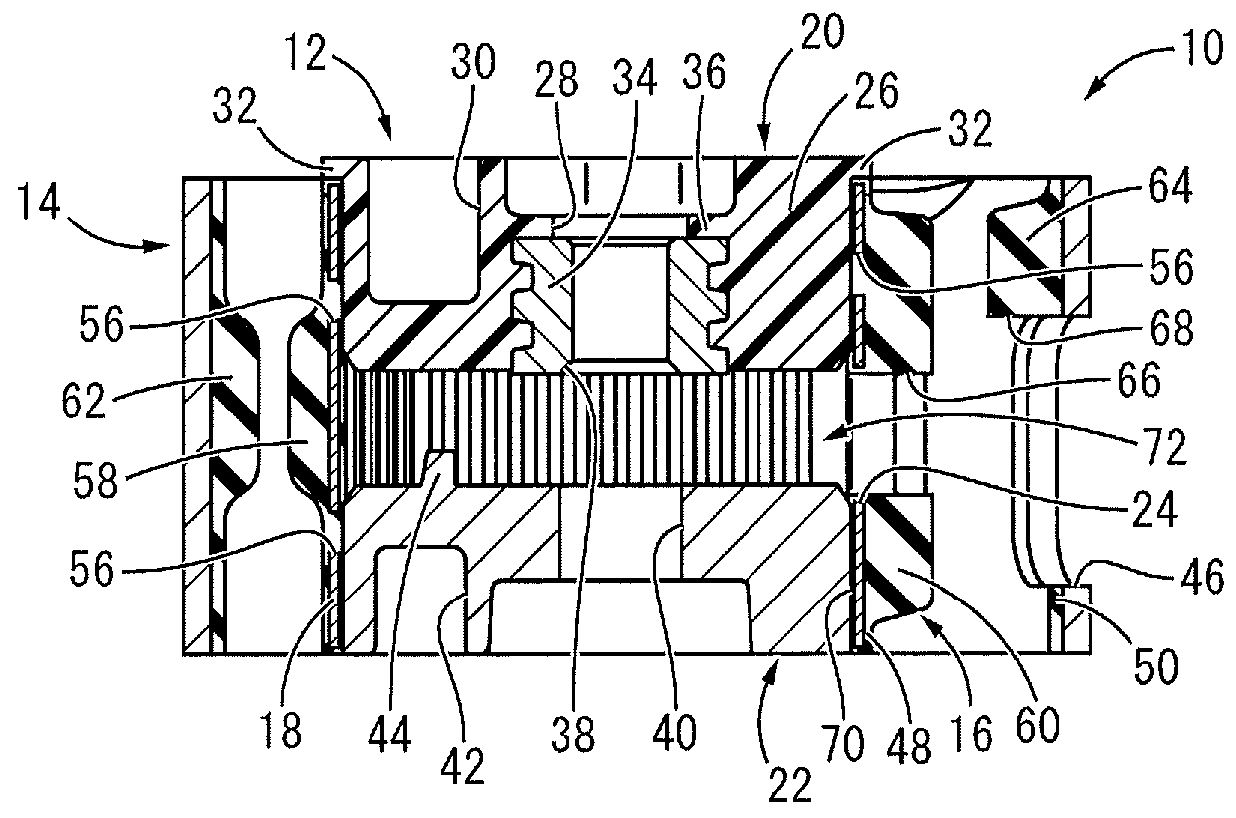

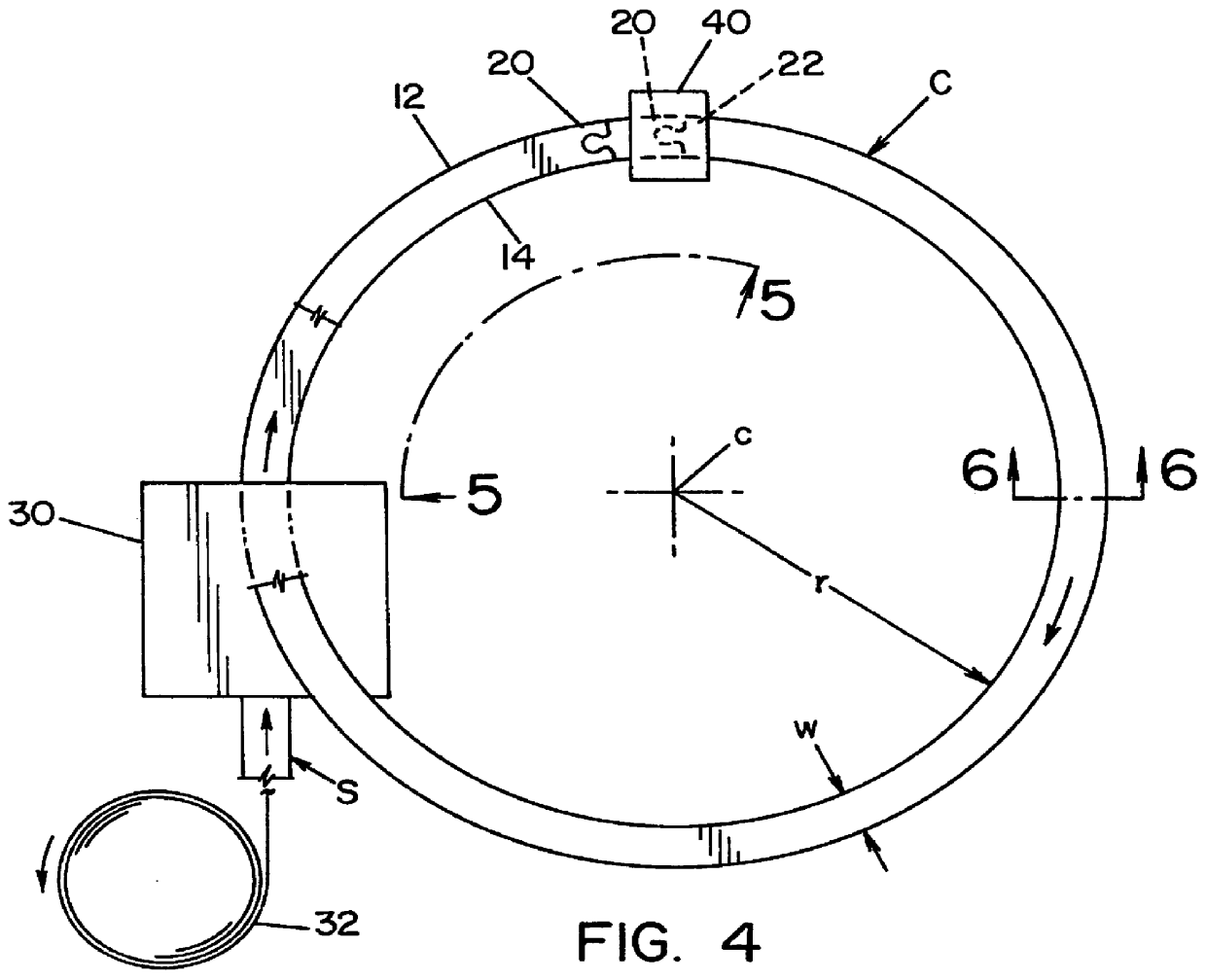

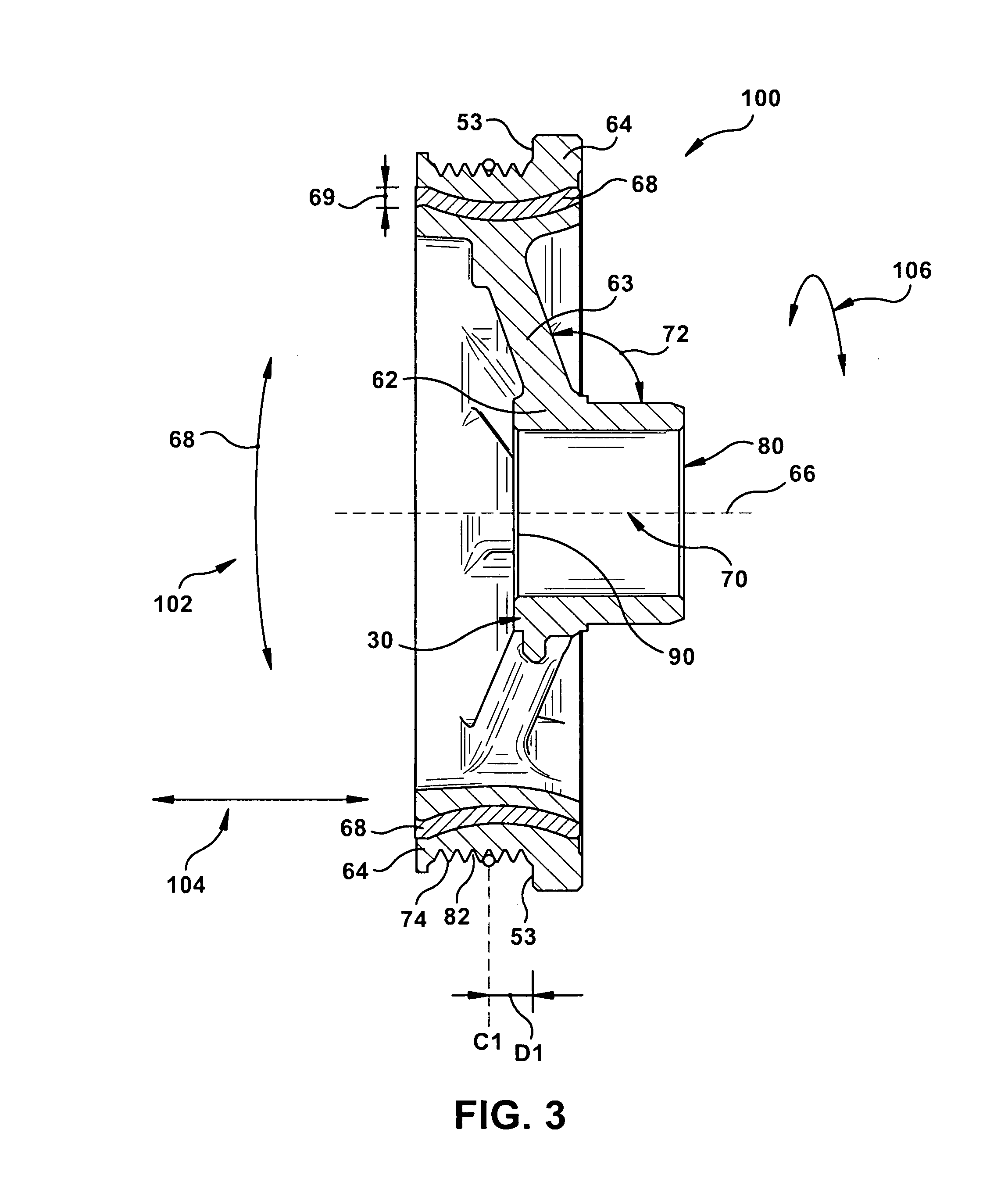

Single mass dual mode crankshaft damper with tuned hub

InactiveUS20090145261A1Cost effectiveReduce torsional vibrationRotating vibration suppressionSpringsElastomerDual mode

A damper for attachment to a crankshaft of an engine is provided. The damper has a hub member, an inertia member spaced radially outward from the hub member and an elastomer positioned between the hub member and the inertia member. The hub member has an opening for attachment to the crankshaft and extends at an angle away from the opening such that the inertia member is offset from the opening of the hub member. The offset inertia member prevents amplification of noise from the crankshaft. The elastomer has a curvature to improve dampening of bending vibrations.

Owner:METALDYNE LLC

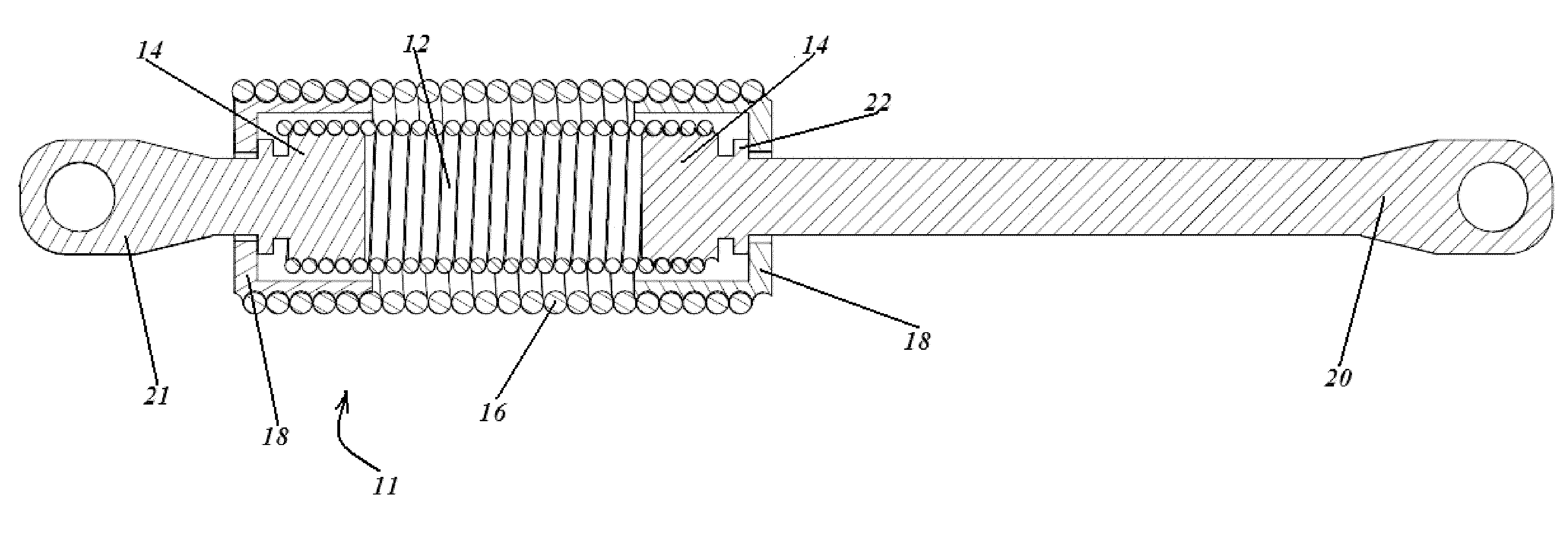

Tension spring mount

ActiveUS20110204550A1Reduce the total massHigh strengthVibration dampersMultiple spring combinationsMechanical engineeringKeyhole

End mounts are used to secure a helical tension spring to end fixtures with various shapes and sizes. These end mounts contain an inner hole to encase the inner spring end mount and secure the end mount making it like a cap. There is also a keyhole created in the top surface that goes through the end mount allowing it to fit over the fixtures but not over the inner end mount, holding it in place. Grooves are machined in a helical pattern on the cylindrical side wall of the end mount. The spring is wound onto the grooves of the end mount.

Owner:RENTON COIL SPRING

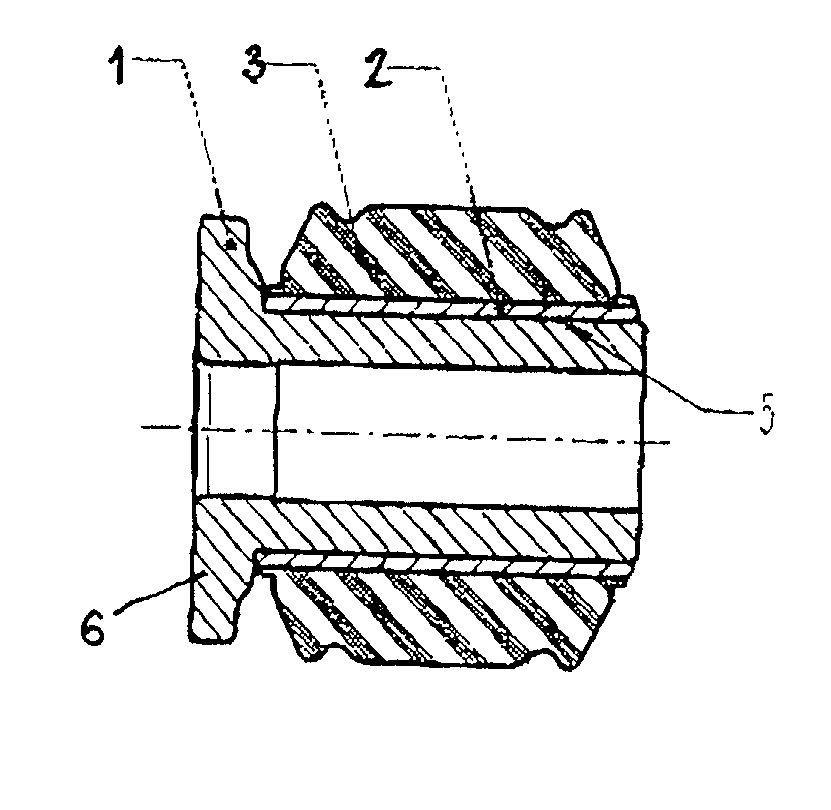

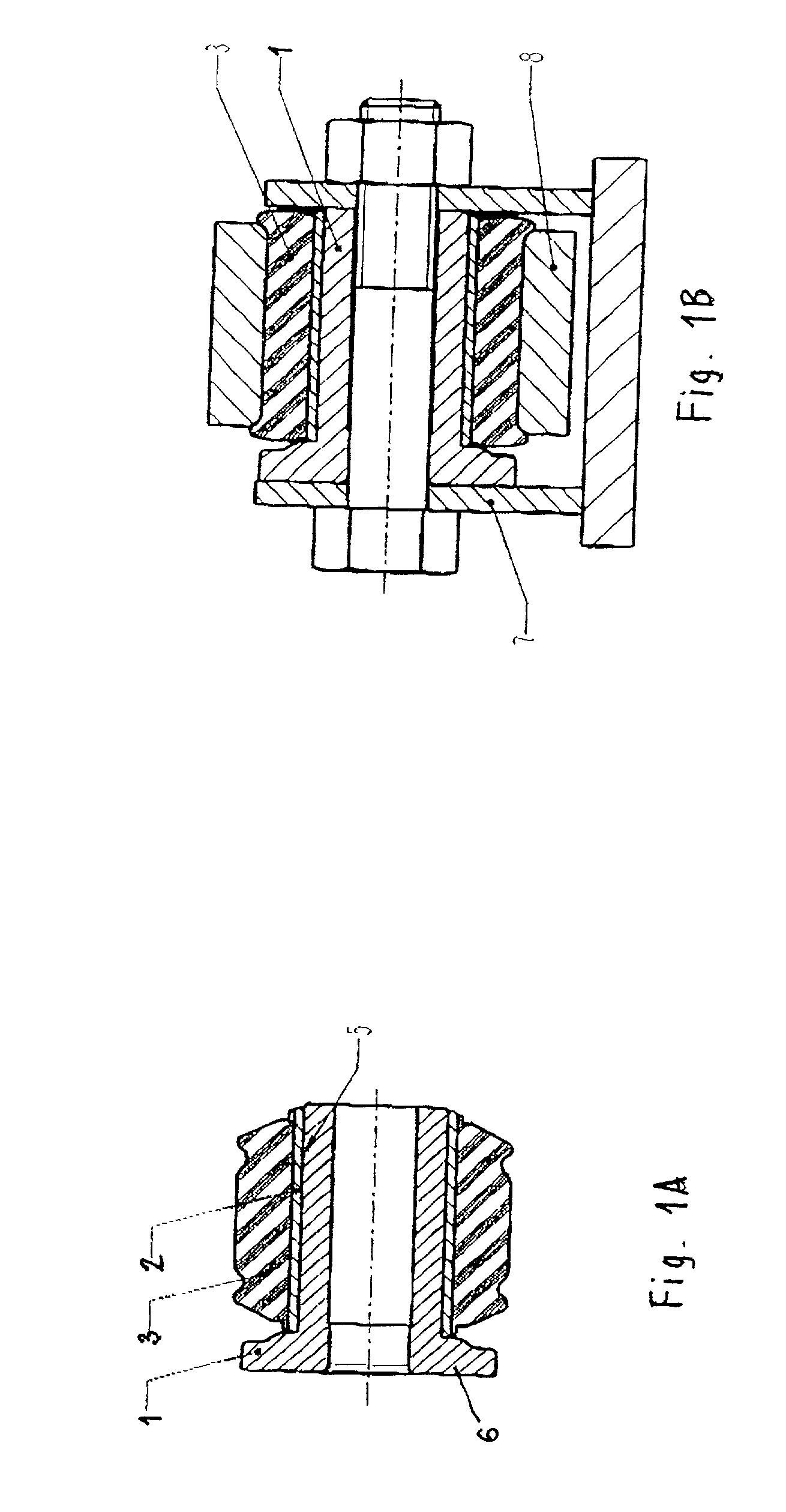

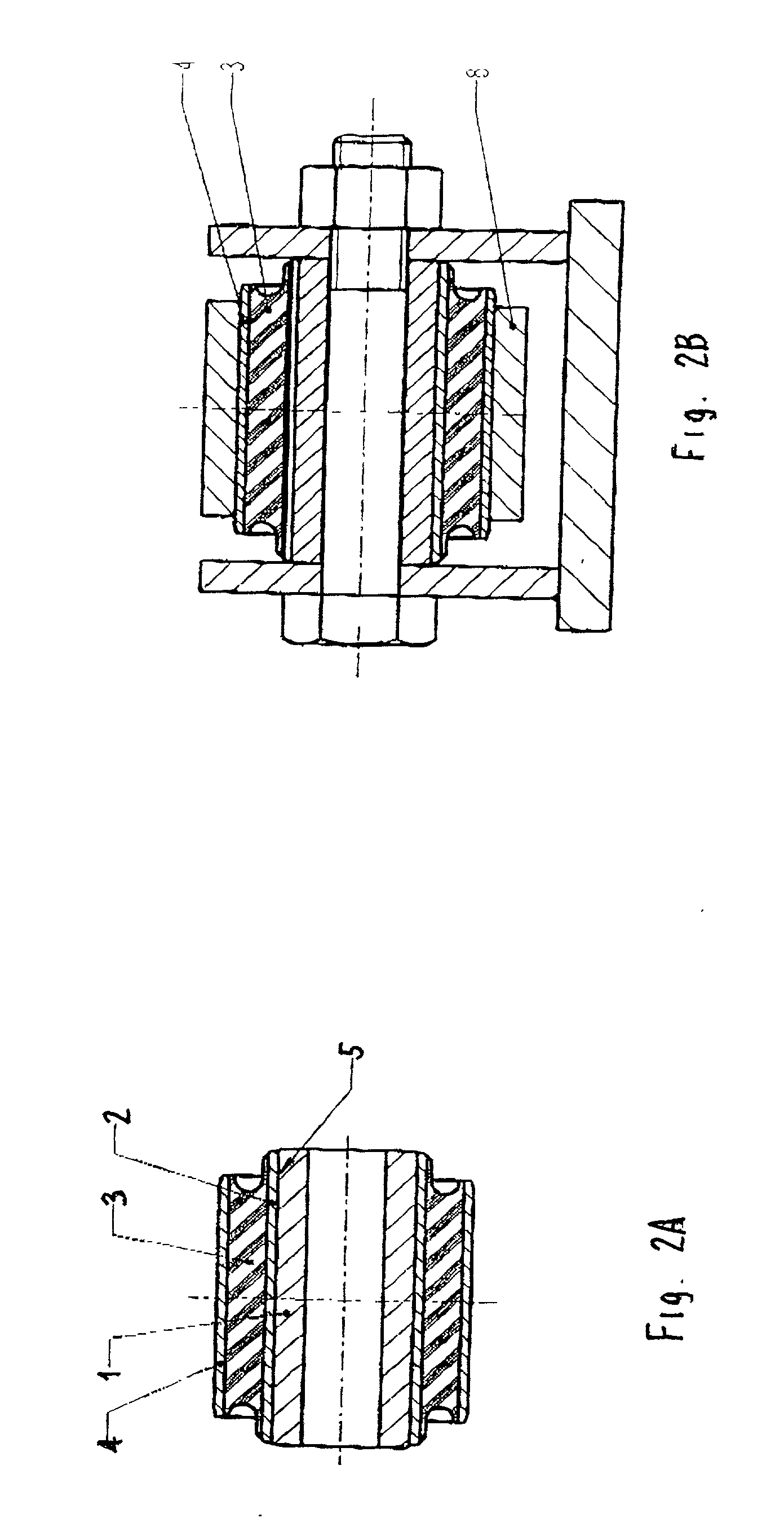

Rubber bearing for chassis parts in motor vehicles

InactiveUS20020141669A1Improves chassis comfortImprove responseSliding contact bearingsSprings/dampers manufactureElastomerMobile vehicle

Rubber bearing for chassis parts in motor vehicles includes an inner tube which can be installed in a first chassis part, a concentrically arranged intermediate part which is slideably rotatable on said inner tube, an elastomeric body which surrounds and tightly adheres to the intermediate part and which can be installed in a second chassis part. The intermediate part which is fixedly connected with the elastomer body is provided with a sliding coat on its inner circumferential surface.

Owner:BOGE ELASMETALL GMBH +1

Method for producing corrosion-resistant surfaces of nitrated or nitrocarburated steel components

ActiveCN101896632AReduce processing timeReduce processing costsSpringsSolid state diffusion coatingMetallurgyNitrogen

The invention relates to a method for producing corrosion-resistant surfaces of nitrated or nitrocarburated steel components, the surfaces having roughness heights (Rz) of Rz >= 1.5 [mu]m. The method comprises the following steps: oxidation of the surfaces of the nitrated or nitrocarburated components in a first oxidation step; carrying out at least a second oxidation of the component surfaces inan immediately subsequent oxidation step; polishing the component surface in a final method step, directly after the final oxidation.

Owner:DURFERRIT GMBH

Method of producing a plate spring

InactiveUS20040016278A1Improve fatigue strengthIncrease freedomBelleville-type springsFriction clutchesFree stateEngineering

A method of producing a plate spring is disclosed which allows one to adjust the load-displacement characteristics thereof to a desired degree. The method includes stamping slits and a small diameter hole from a disk-shaped plate member, and forming the plate spring into a cone shape. Shot-peening is then performed on a resilient portion of the plate spring that retains a flat cone shape in the free state. Furthermore, shot-peening is performed on only a portion of the resilient portion and not on the entire surface of the plate spring.

Owner:EXEDY CORP

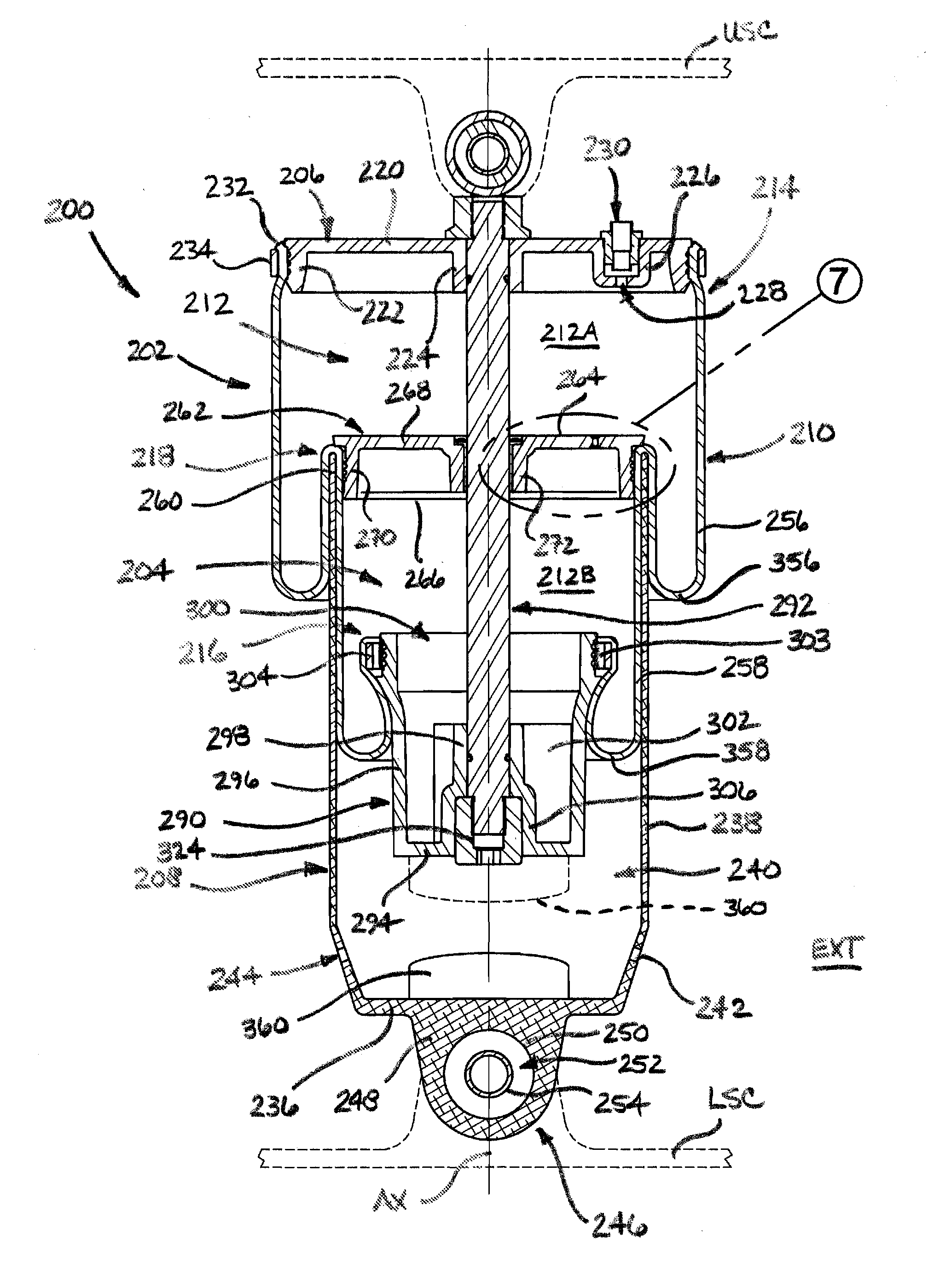

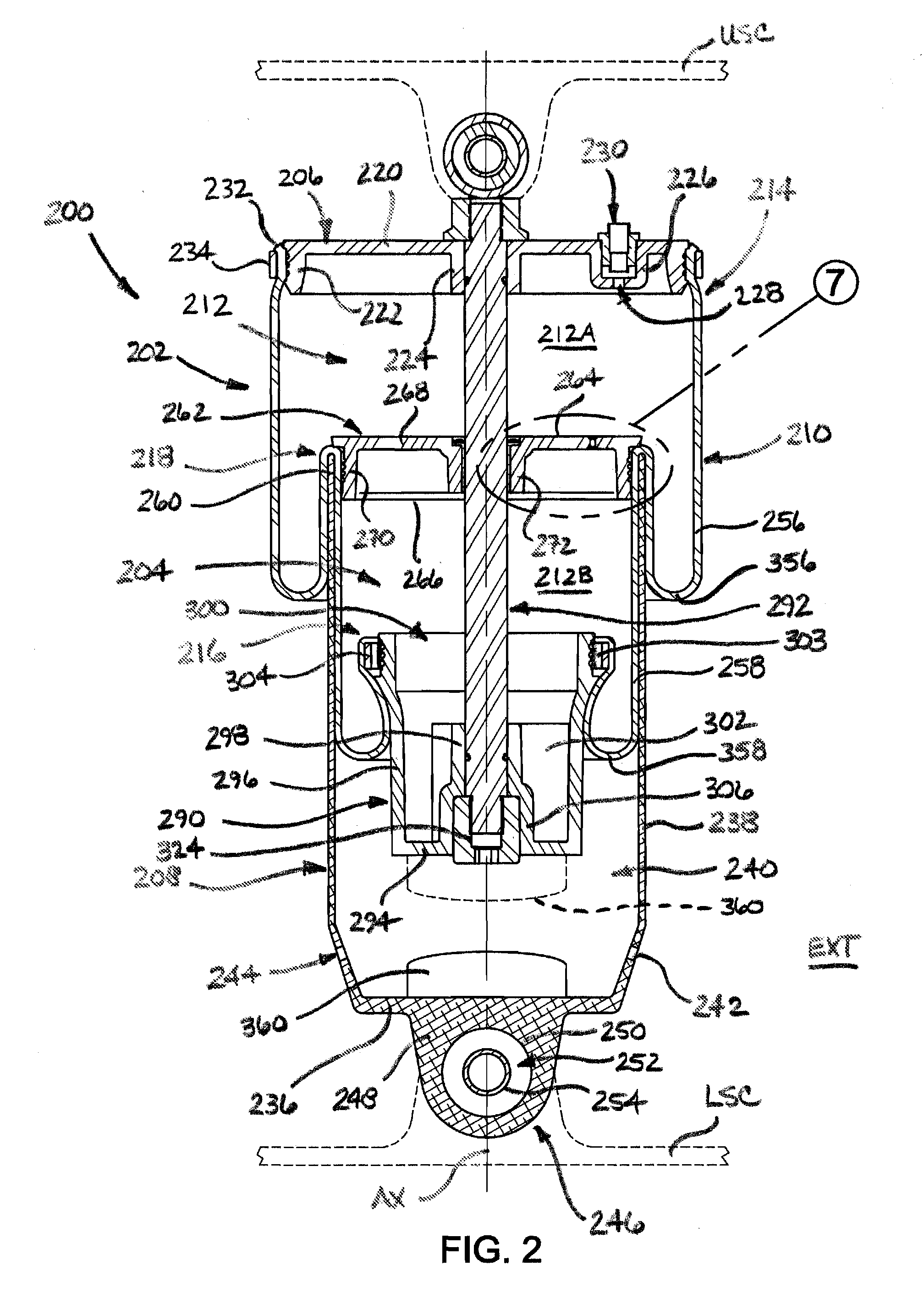

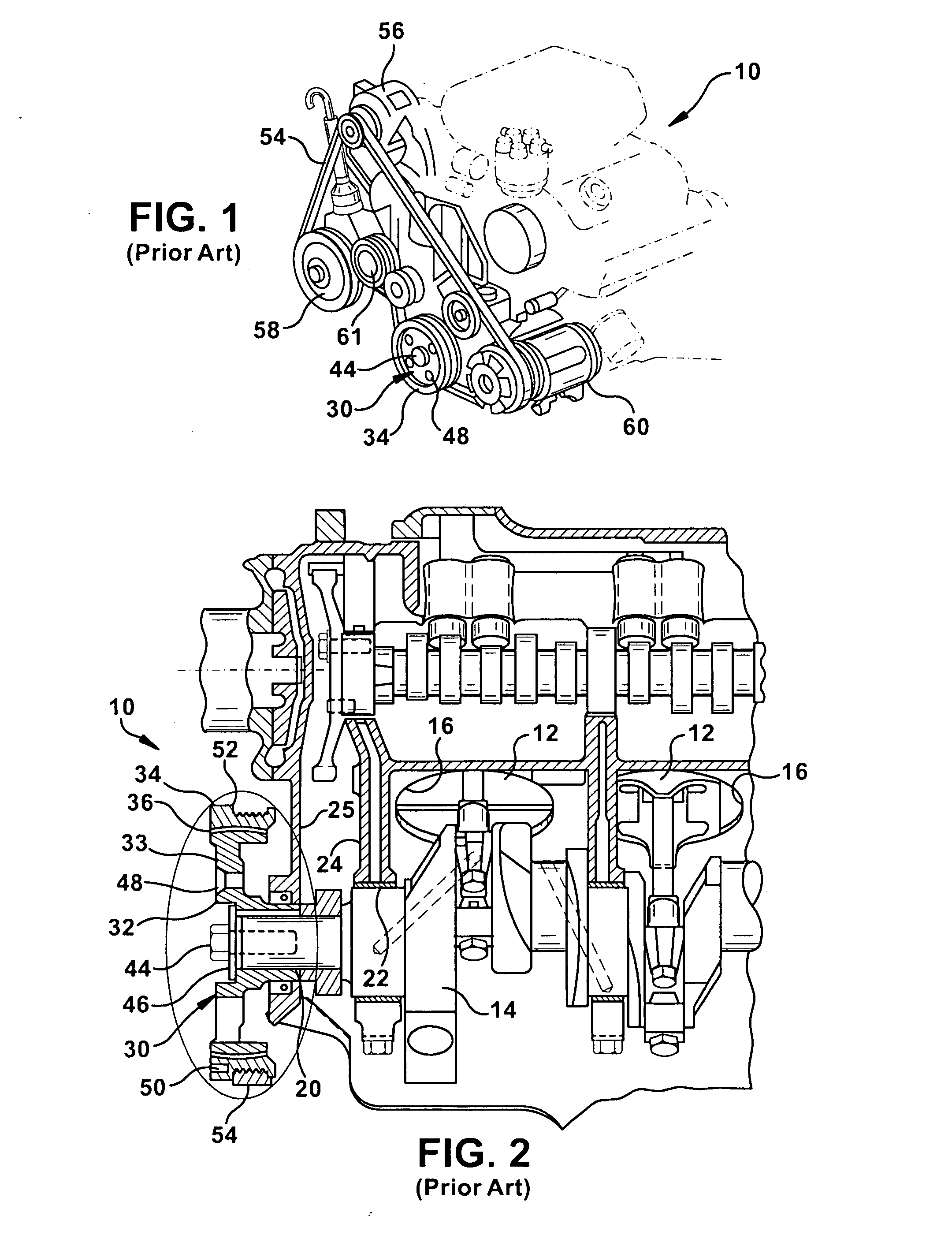

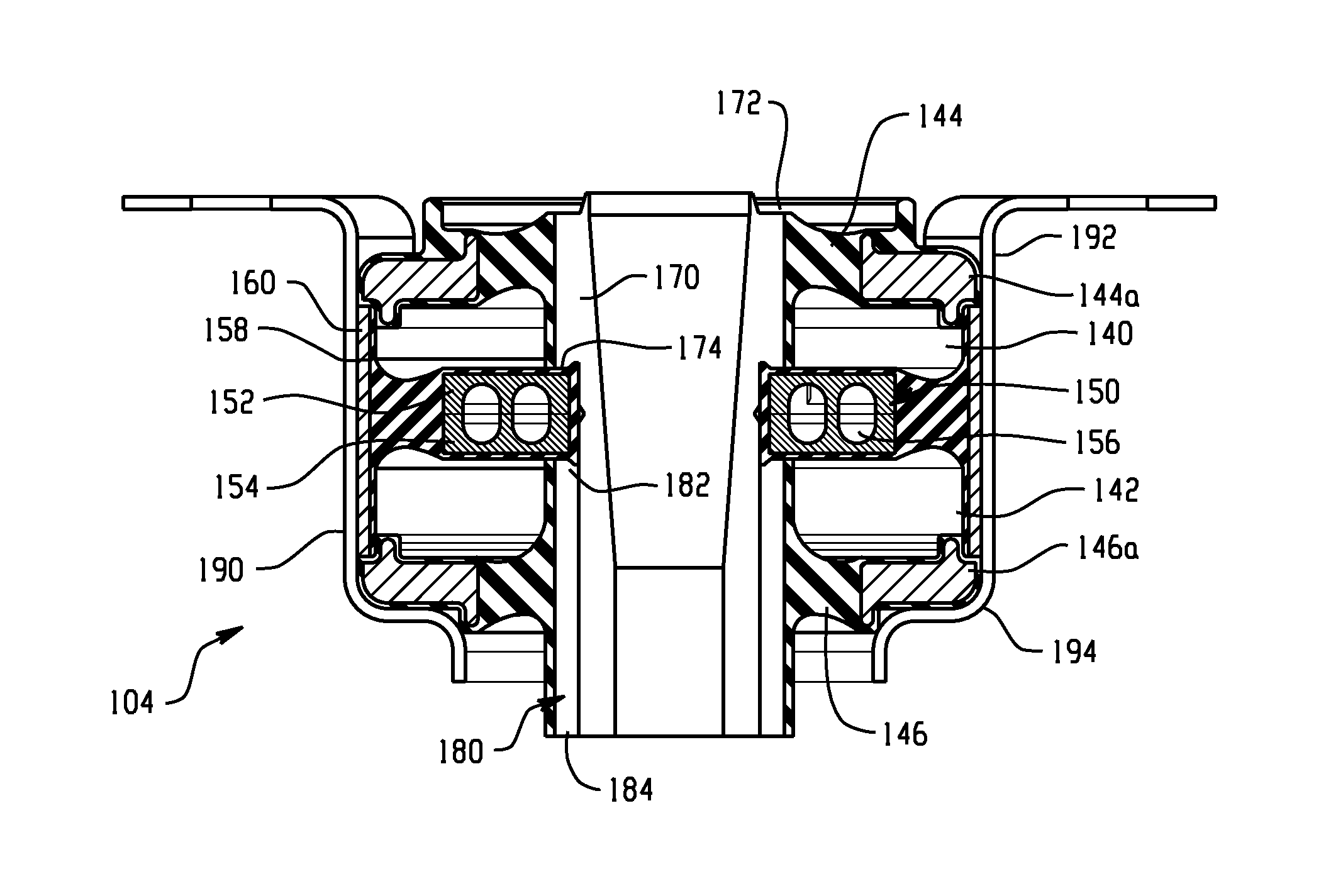

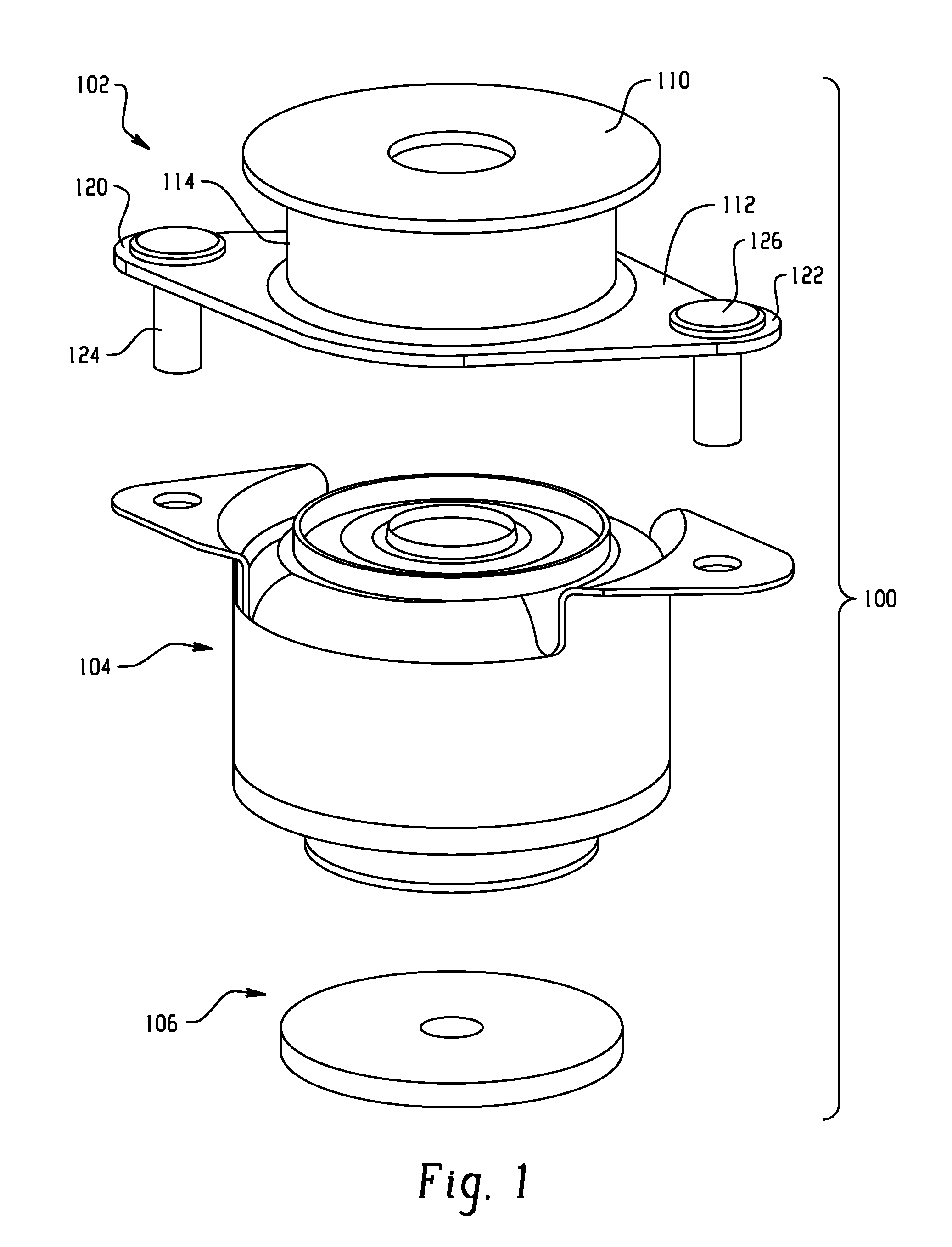

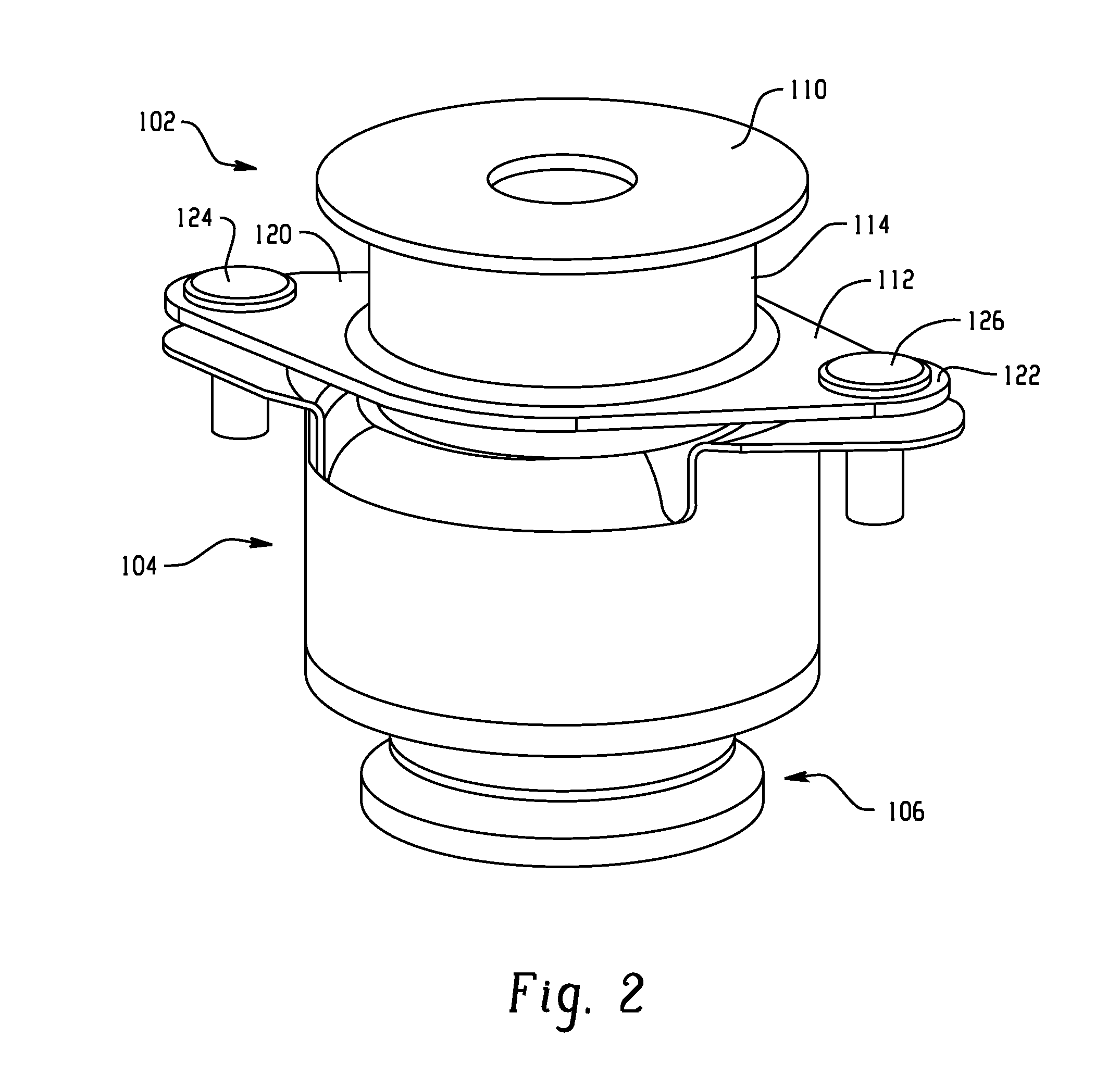

Axially damped hydraulic mount assembly

ActiveUS20160003322A1Function increaseStands/trestlesSpecial foundation layoutEngineeringMechanical engineering

An example mount assembly includes an upper mount and a lower mount. The assembly also includes an inertia track having a central opening defining an axis. The inertia track defines a passage in fluid communication with the first chamber and the second chamber. The inertia track is moveable along the axis.

Owner:CONTITECH USA INC

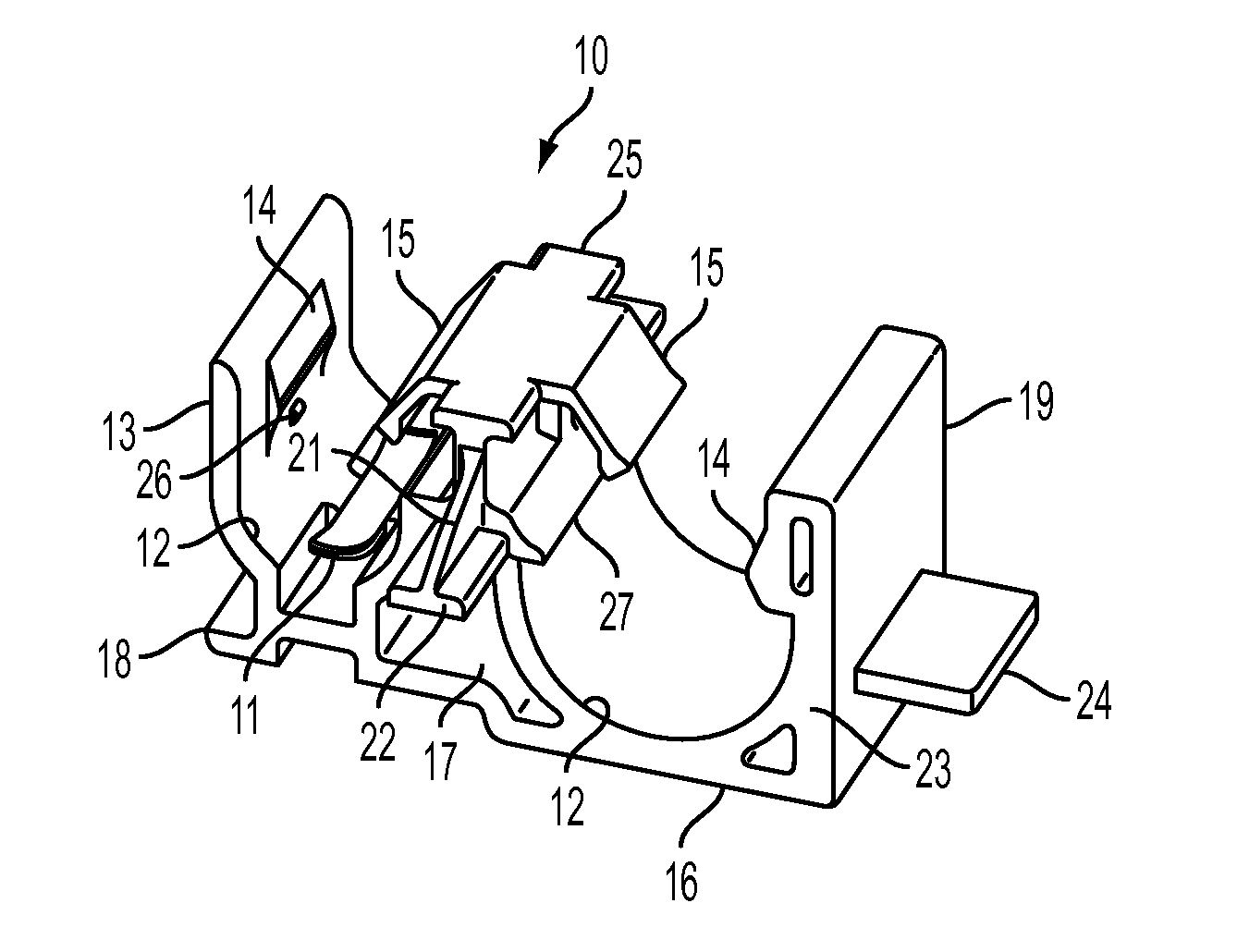

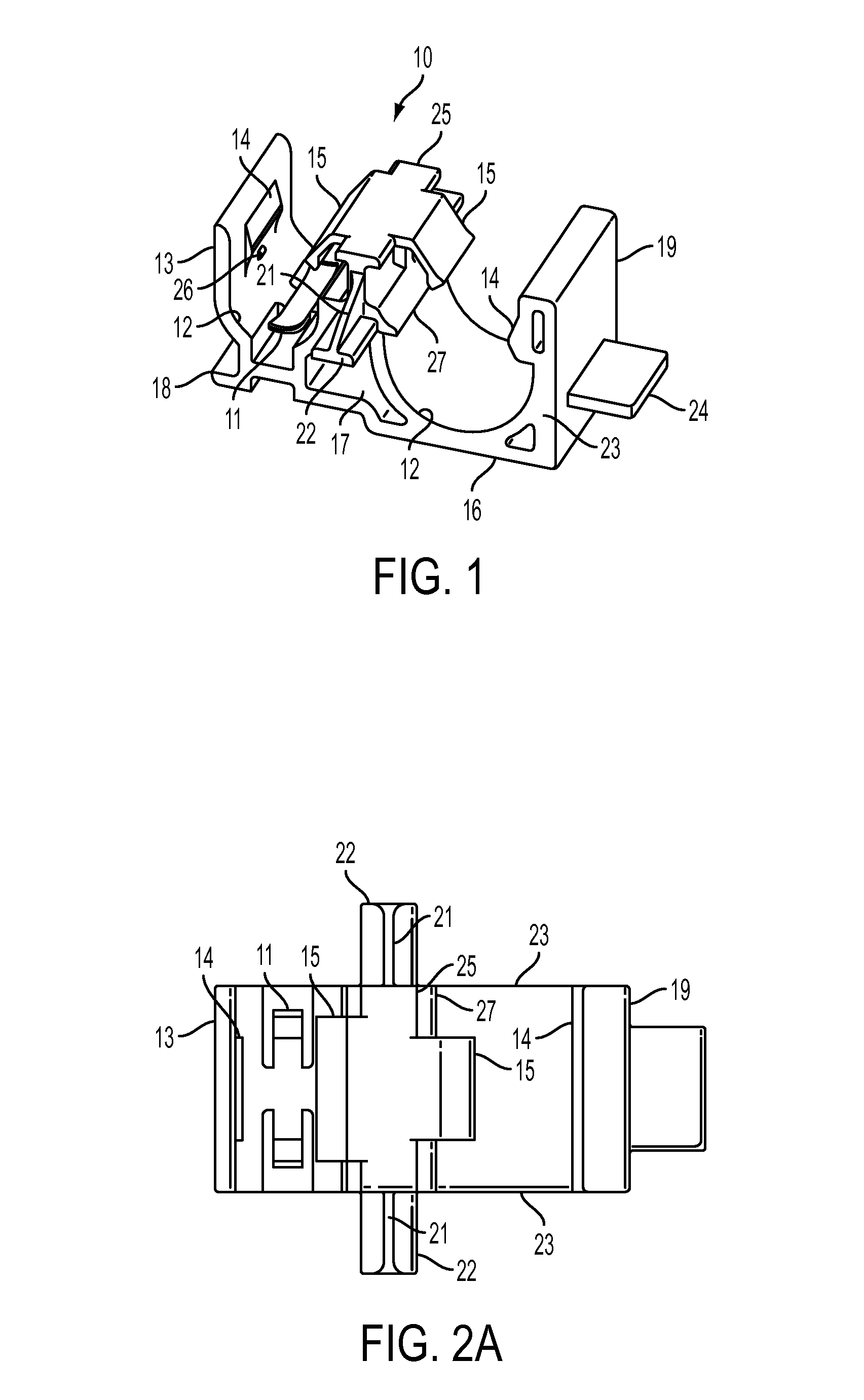

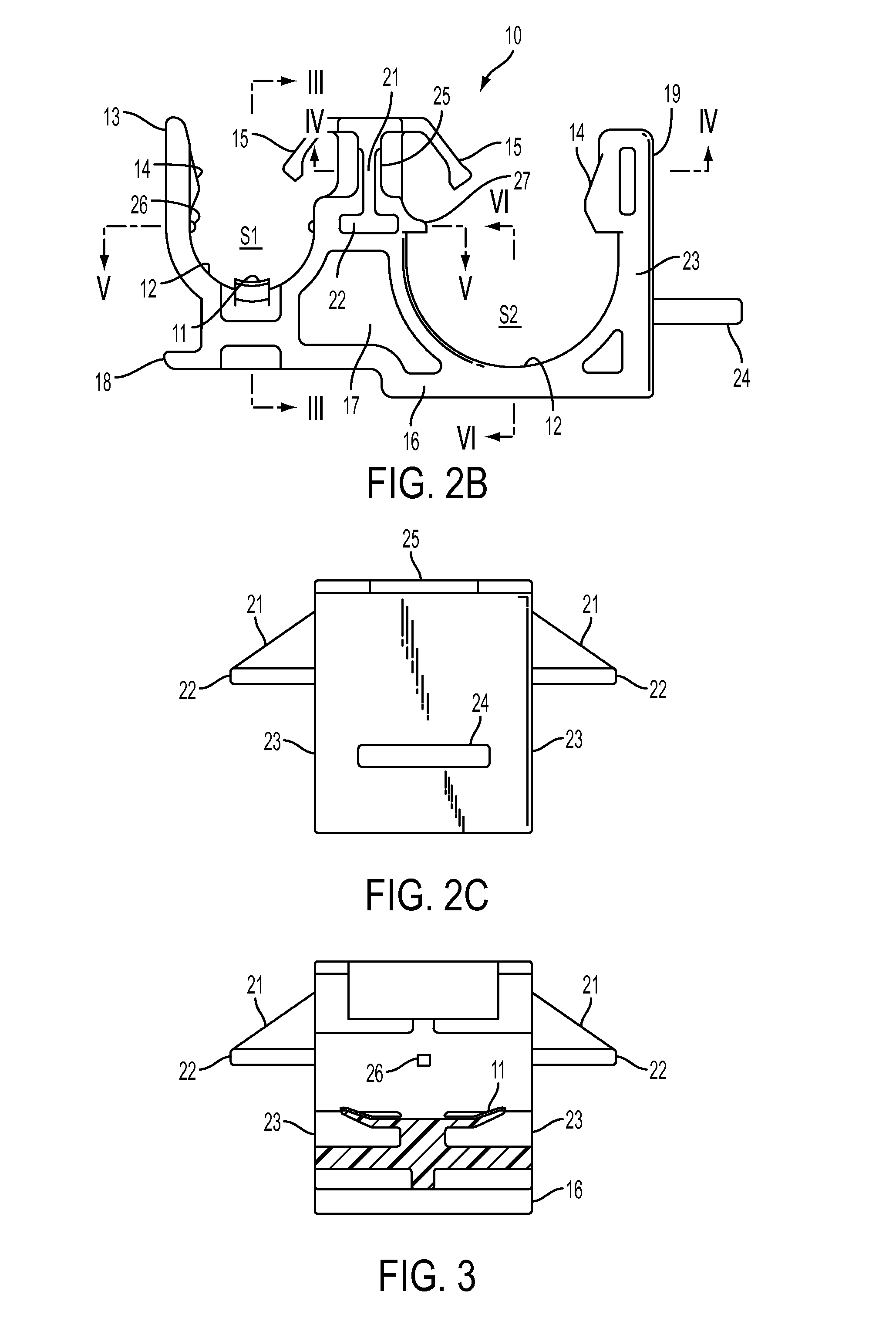

Anti-vibration clamp

ActiveUS20140070070A1Increase anti-vibration functionHigh joining strengthPipe supportsSpringsEngineeringMechanical engineering

An anti-vibration clamp for holding pipes includes a pipe holding component which further includes pipe holders for locking the pipes; a clamp body including a stud locking portion for locking to a stud, and a floating attachment portion for holding the pipe holding component; and an elastic connecting component made of soft resin placed between the pipe holding component and the clamp body so that the pipe holding component and the clamp body do not contact one another directly. The pipe holding component, the elastic connecting component and the clamp body are held so that it is difficult for them to each slip mutually.

Owner:NEWFREY

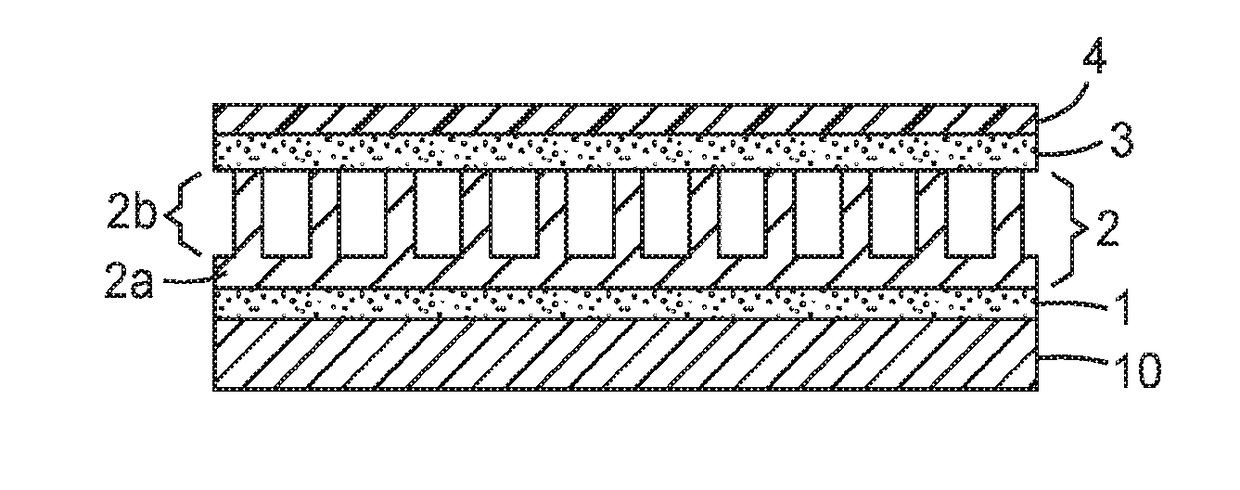

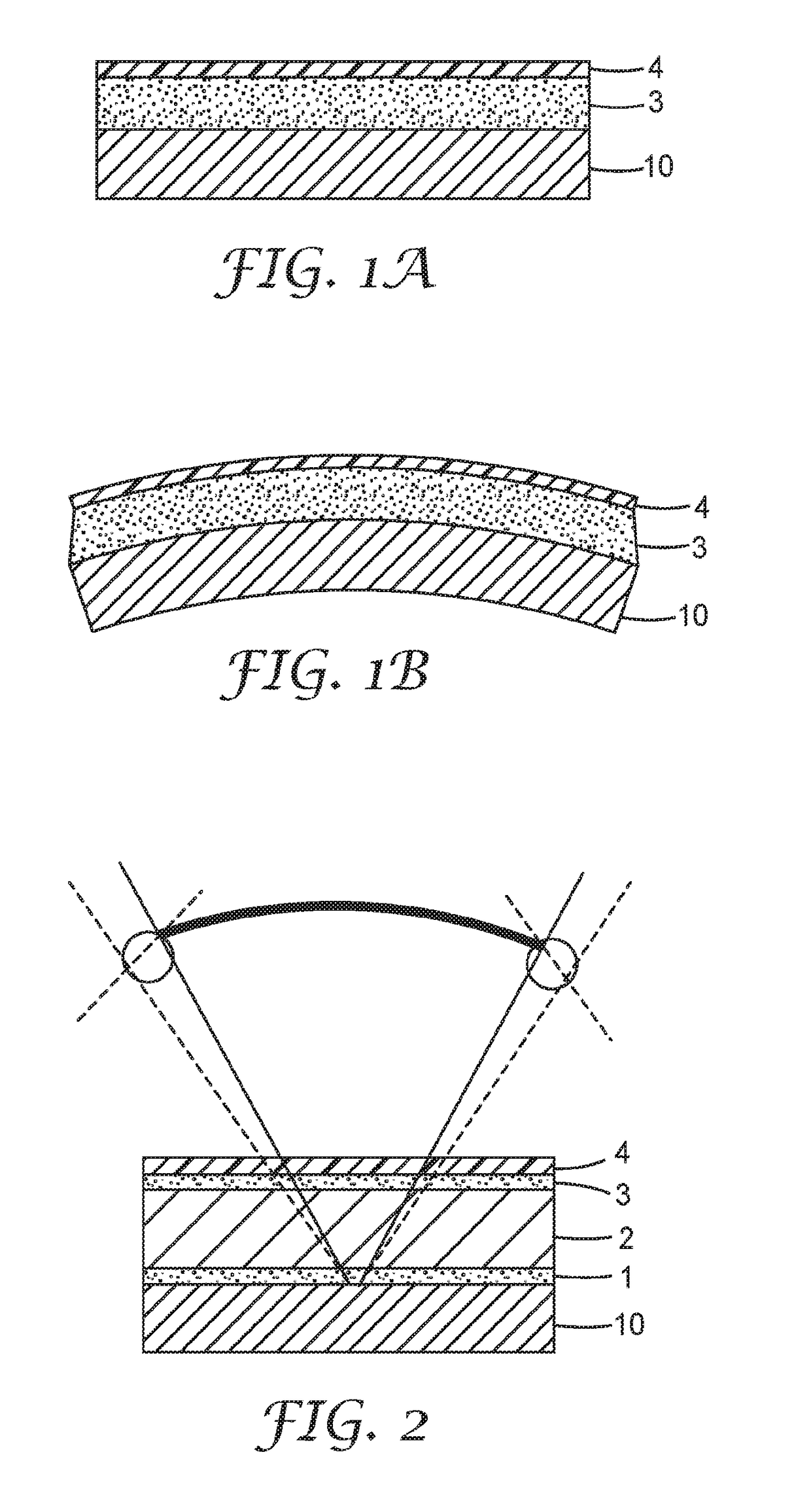

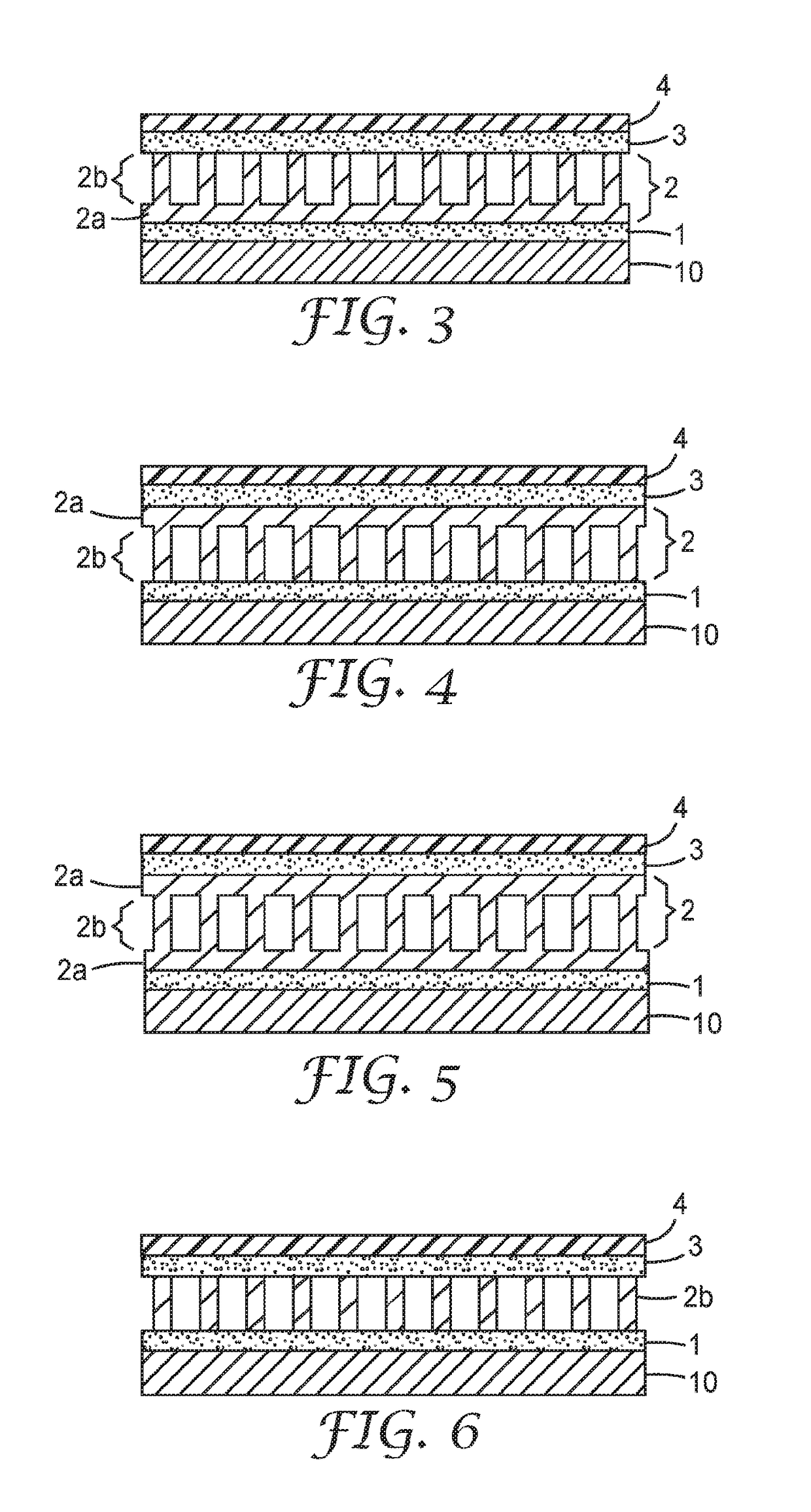

Multilayer damping material

Owner:3M INNOVATIVE PROPERTIES CO

Impact-absorbing members for dynamic impact applications

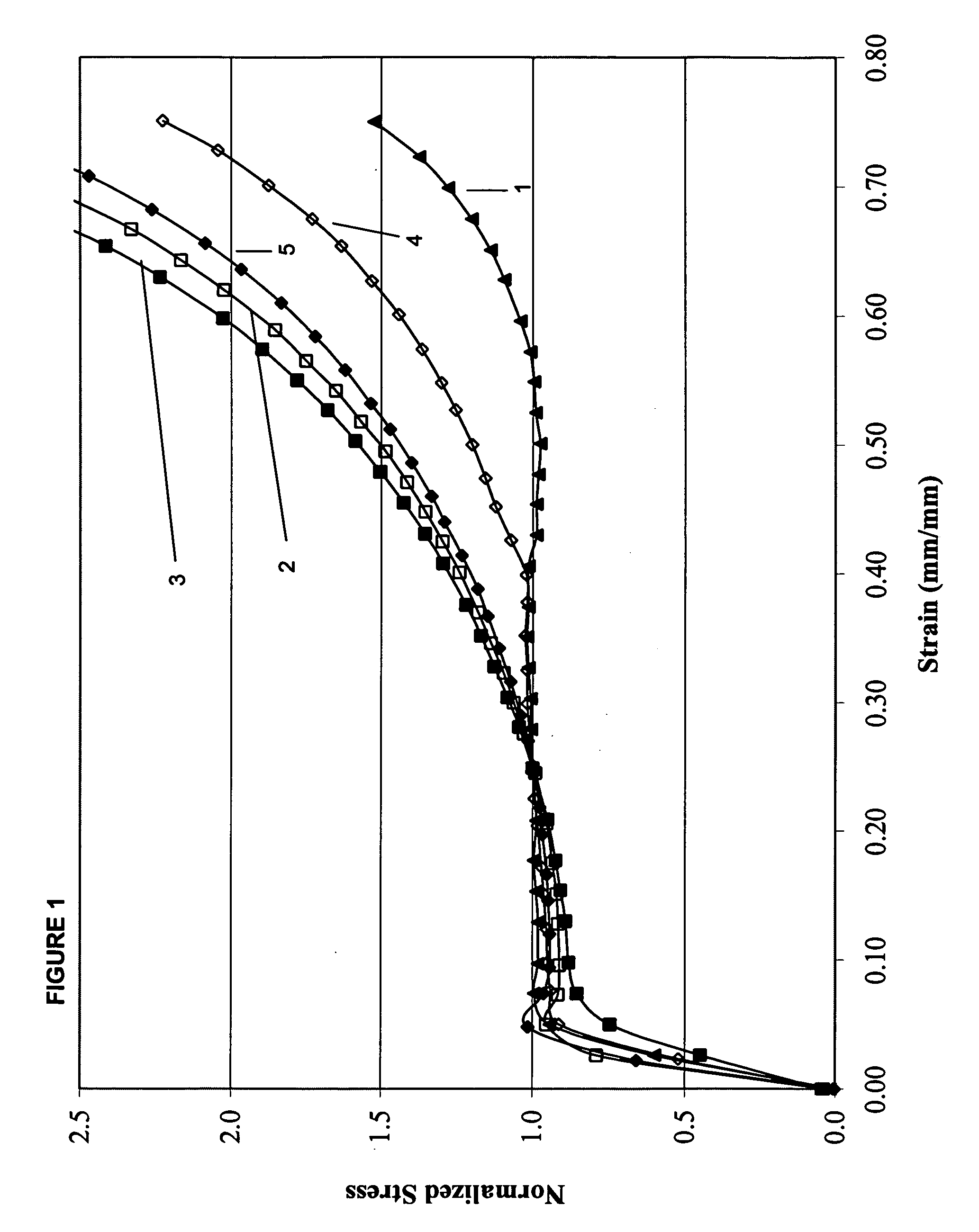

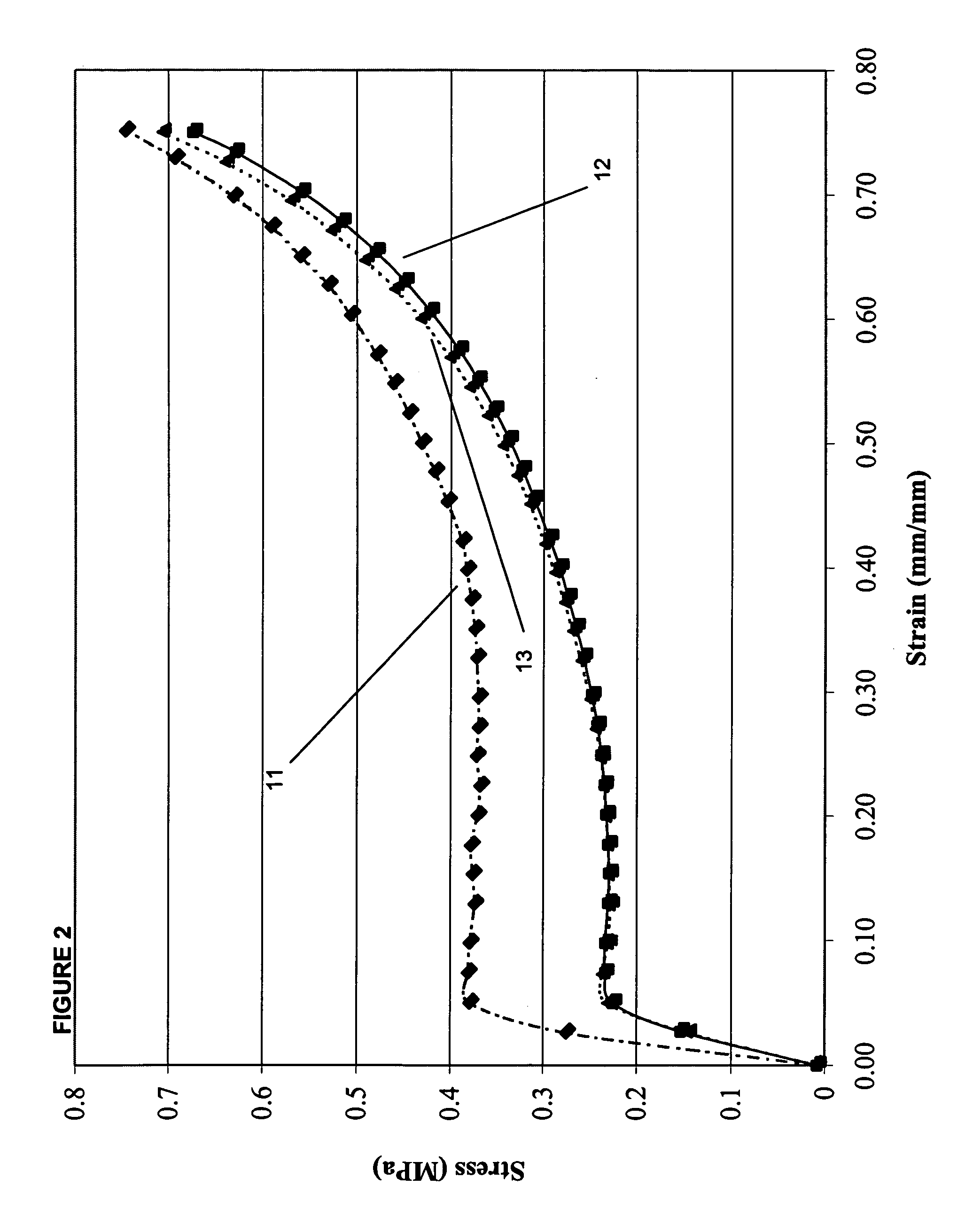

ActiveUS20060148919A1Improve compression efficiencyHigh level of deformationPedestrian/occupant safety arrangementPeptide preparation methodsCountermeasureCompressive strength

Cushions for dynamic impact applications include anisotropic cellular polymers made in an extrusion, expanded bead or reactive foaming process. The anisotropic behavior represented by CE / CT, CV / CT and CH / CT, wherein CE, CV and CH represent the compressive strength of the cellular polymer in each of three orthogonal directions E, V and H, respectively, as measured by compressing a 25-50 mm thick sample of the cellular polymer at a strain rate of 0.08 s−1 to 25% strain, CT represents the sum of CE, CV and CH, and at least one of CE / CT, CV / CT and CH / CT has a value of at least 0.40, up to about 0.80. The cellular polymer also preferably has density of 1.75 to 2.35 pounds / cubic foot and a compressive stress in the direction of maximum compressive strength of 290-600 kPa at 25% strain when used for headliner countermeasure applications. The cushions are useful in automotive applications such as automotive headliners, door panels, knee bolsters, pillars, headrests, seat backs, load floors or instrument panels.

Owner:DOW GLOBAL TECH LLC

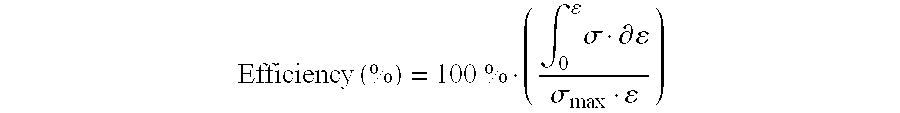

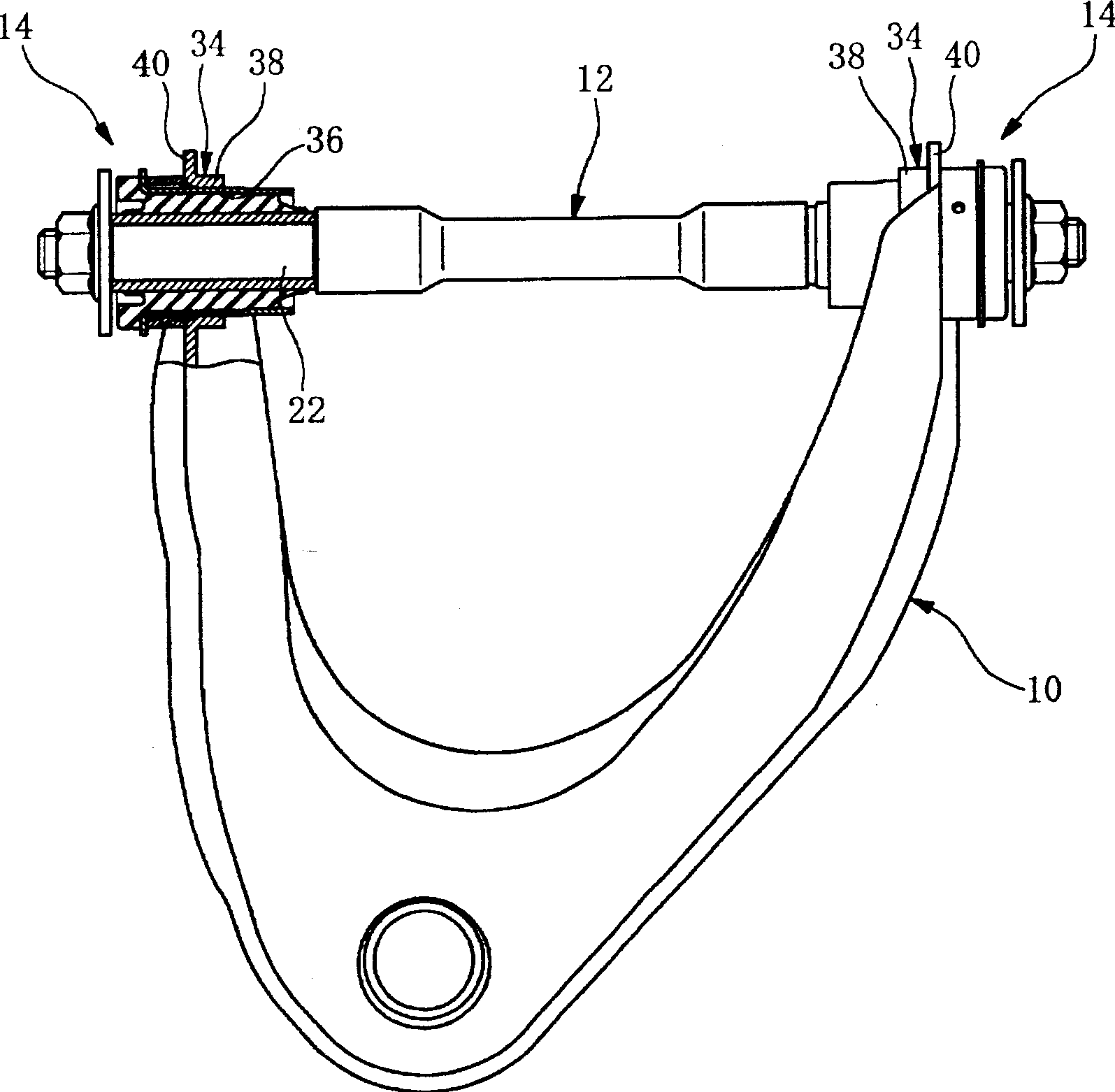

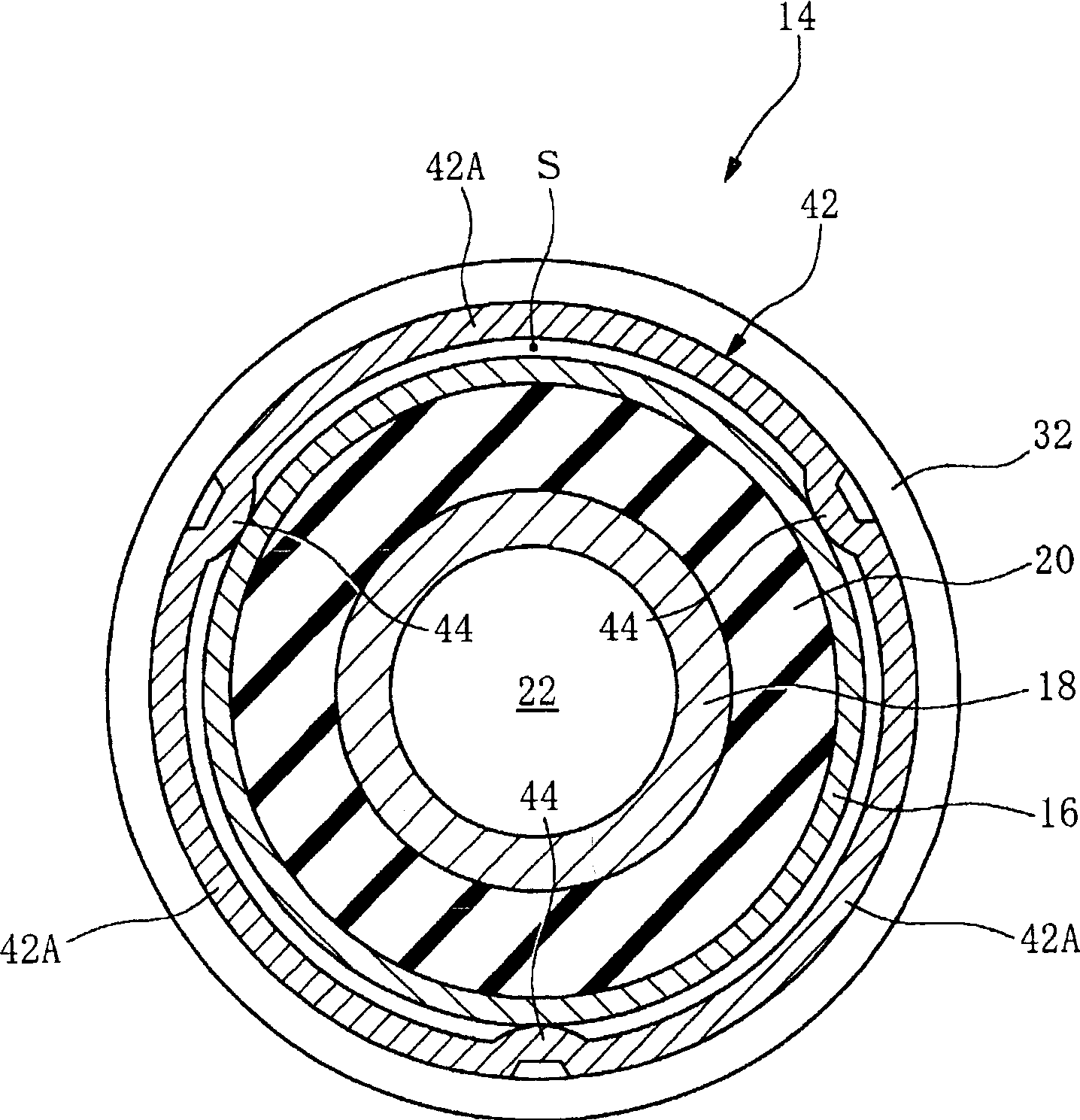

Vibration-damping bushing assembly

InactiveCN1779290ASprings/dampers functional characteristicsSprings/dampers manufactureAxial pressureFlange

The invention discloses an anti-vibration bushing assembly, wherein the anti-vibration bushing (14) is axially press-fitted to a rigid cylindrical retainer ( 34) in order to assemble it together. A rigid spacer band (42) in the form of a ring continuous in the circumferential direction and integrally a belt is mounted on the peripheral surface of the outer cylinder member in a state of external fit with axial pressure. The flange of the outer cylindrical part and the end face of the cylindrical holding part are axially contacted by the spacer ring band, and the spacer ring band partially has at least one protruding protrusion (44) on the inner peripheral surface, so as to Fit and fix to the outer cylinder part. The invention also discloses an anti-vibration bushing and a rigid spacer band for the assembly.

Owner:SUMITOMO RIKO CO LTD

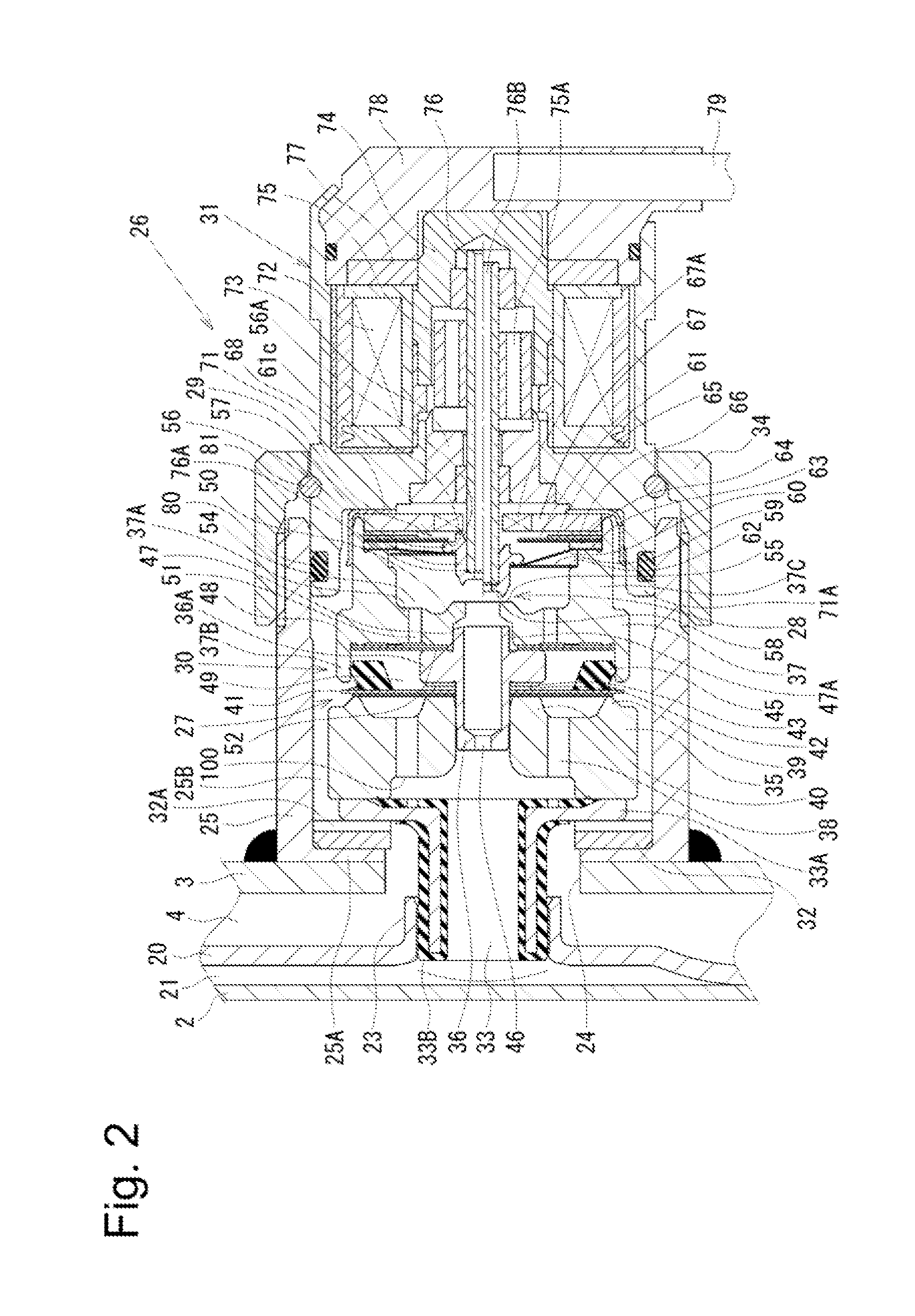

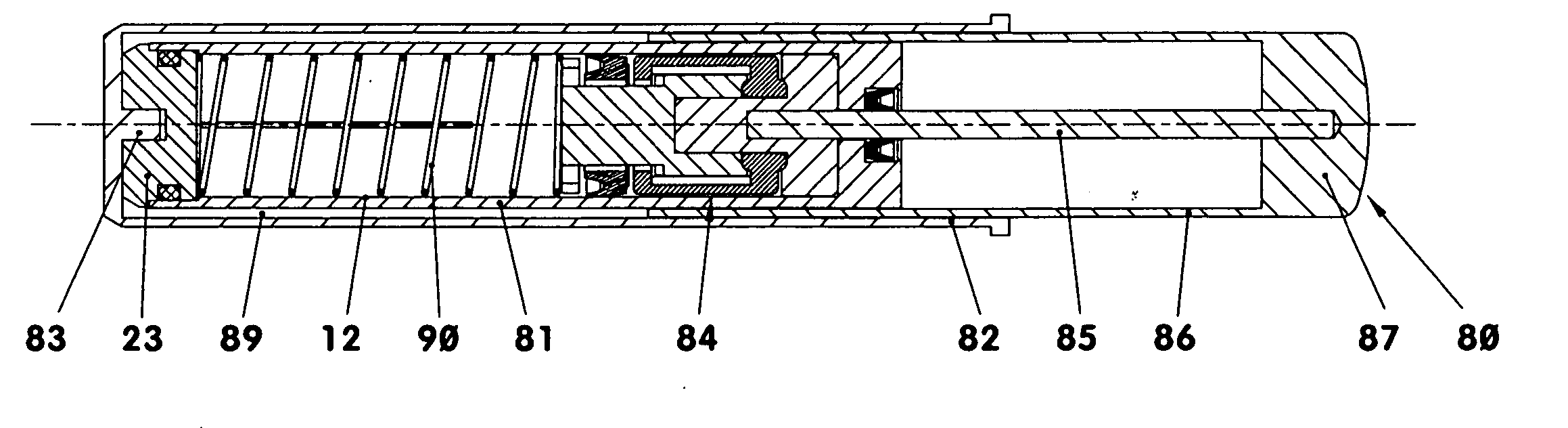

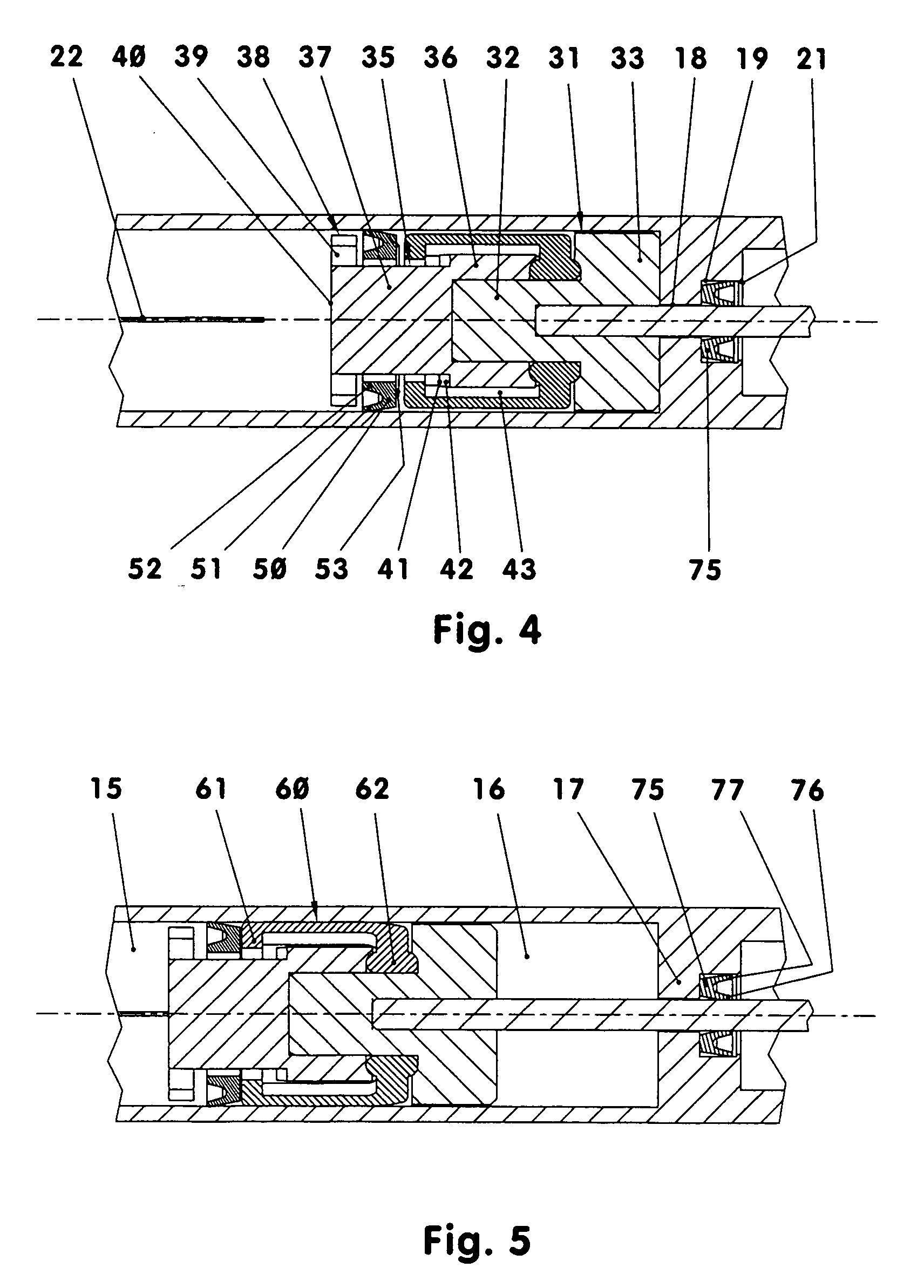

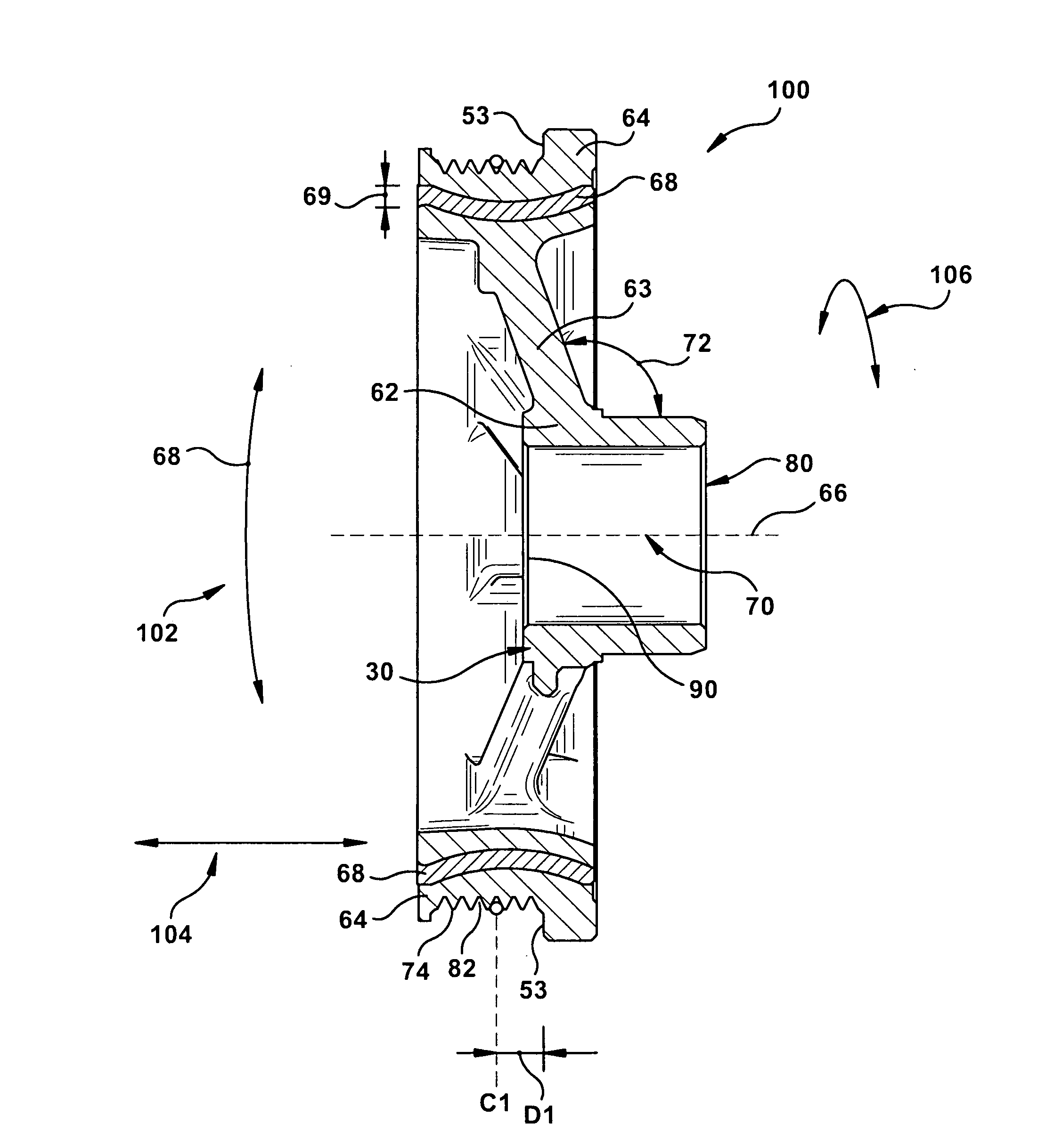

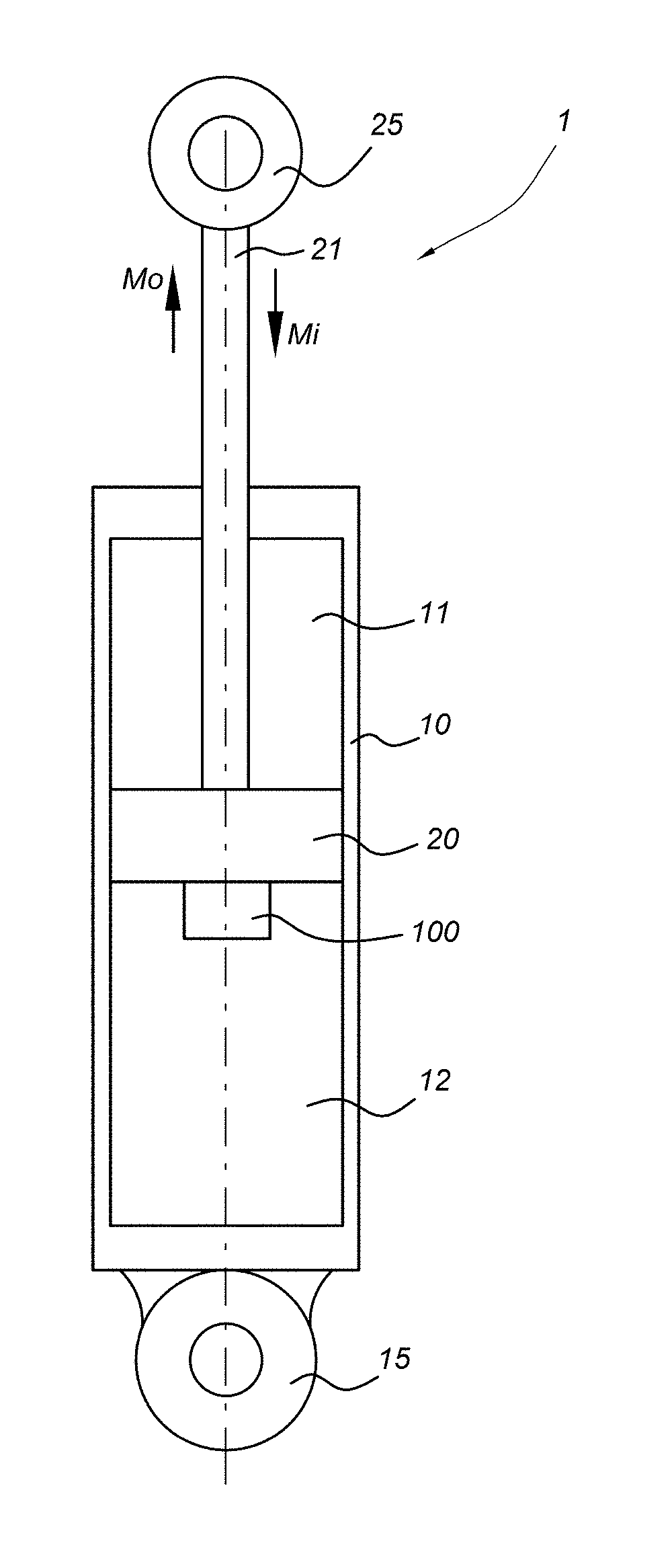

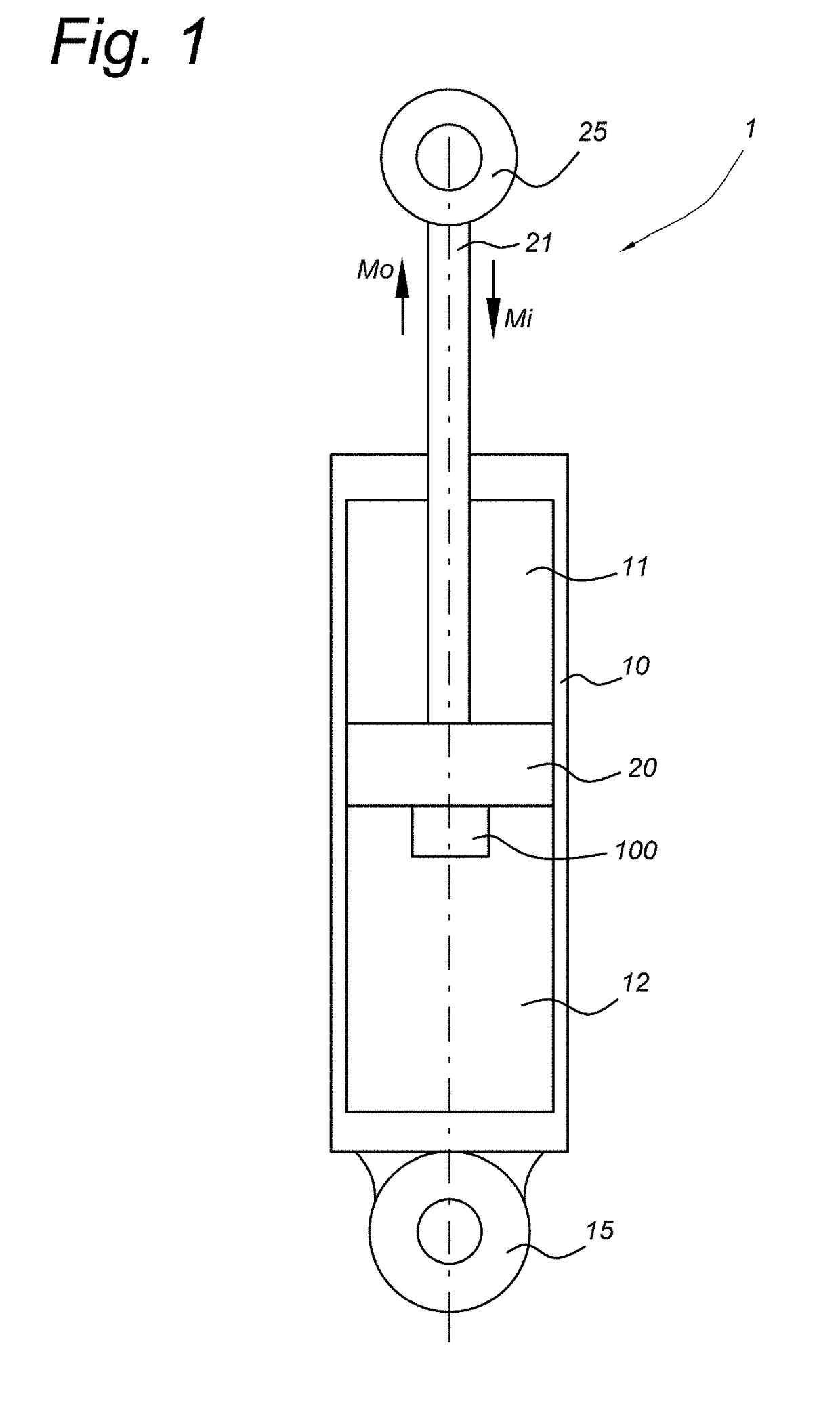

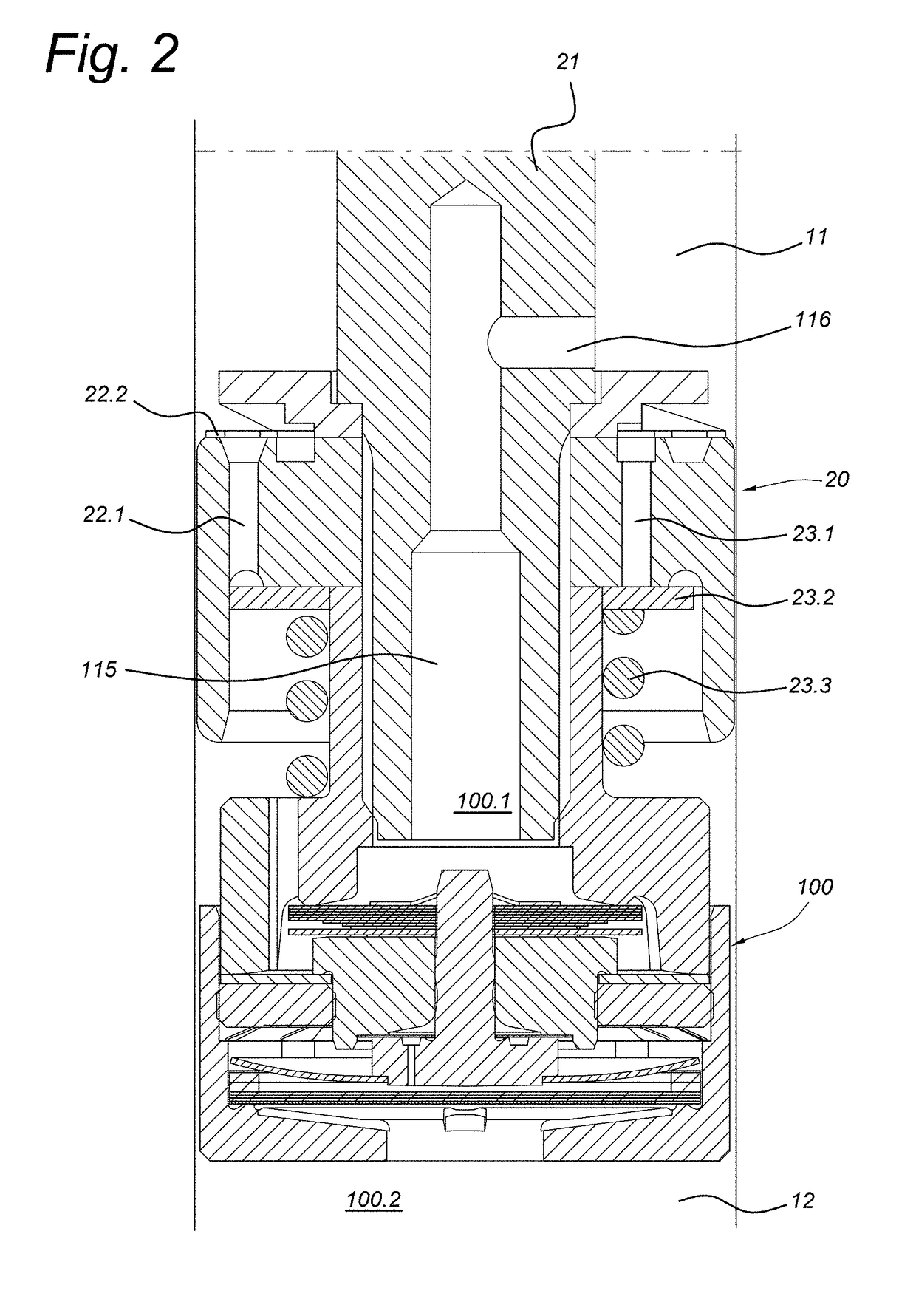

Frequency selective damper valve, and shock absorber comprising such damper valve

ActiveUS20180135720A1Increase forceIncrease volumeSpringsSprings/dampers functional characteristicsControl roomControl valves

A damper valve (100) comprises a controlled flow channel (115) between a valve inlet side (100.1) and a valve outlet side (100.2); a controlled valve (130) provided in the controlled flow channel; a movable valve body (120) acting on the controlled valve so as to change a closing force of the controlled valve; and a control chamber (126). The control chamber comprises a control chamber inlet (125) in fluid connection with the valve inlet side (100.1) upstream of the controlled valve (130); a configuration providing a variable volume of the control chamber, a change in volume of the control chamber acting to cause a movement of the movable valve body (120); and a pressure relief valve (160) to allow a relief fluid flow from the control chamber (126) to the valve inlet side (100.1) bypassing the flow restriction (160.1) of the control chamber inlet (125).

Owner:KONI BV

Cylindrical vibration damping device

ActiveUS7104533B2Increase resistanceImprove stabilityMachine framesSprings/dampers functional characteristicsElastomerEngineering

A cylindrical vibration-damping device includes: a rubber bushing having a rubber elastic body elastically connecting an inner sleeve and a resin outer sleeve; a rigid mounting member having a cylindrical bore into which the rubber bushing is press fit; an engaging stepped face formed on an inner surface of the mounting member; and an engaged stepped face produced on an outer surface of the outer sleeve once the outer sleeve is press fit into the cylindrical bore of the mounting member, by means of elastic deformation of the outer sleeve. The engaged stepped face is opposed to the engaging stepped face in an axial direction of the device, and is brought into engagement with the engaging stepped face so as to exhibit a resistance to dislodging of the rubber bushing from the mounting member in at least one of opposite axial directions. The method of producing the same is also disclosed.

Owner:SUMITOMO RIKO CO LTD

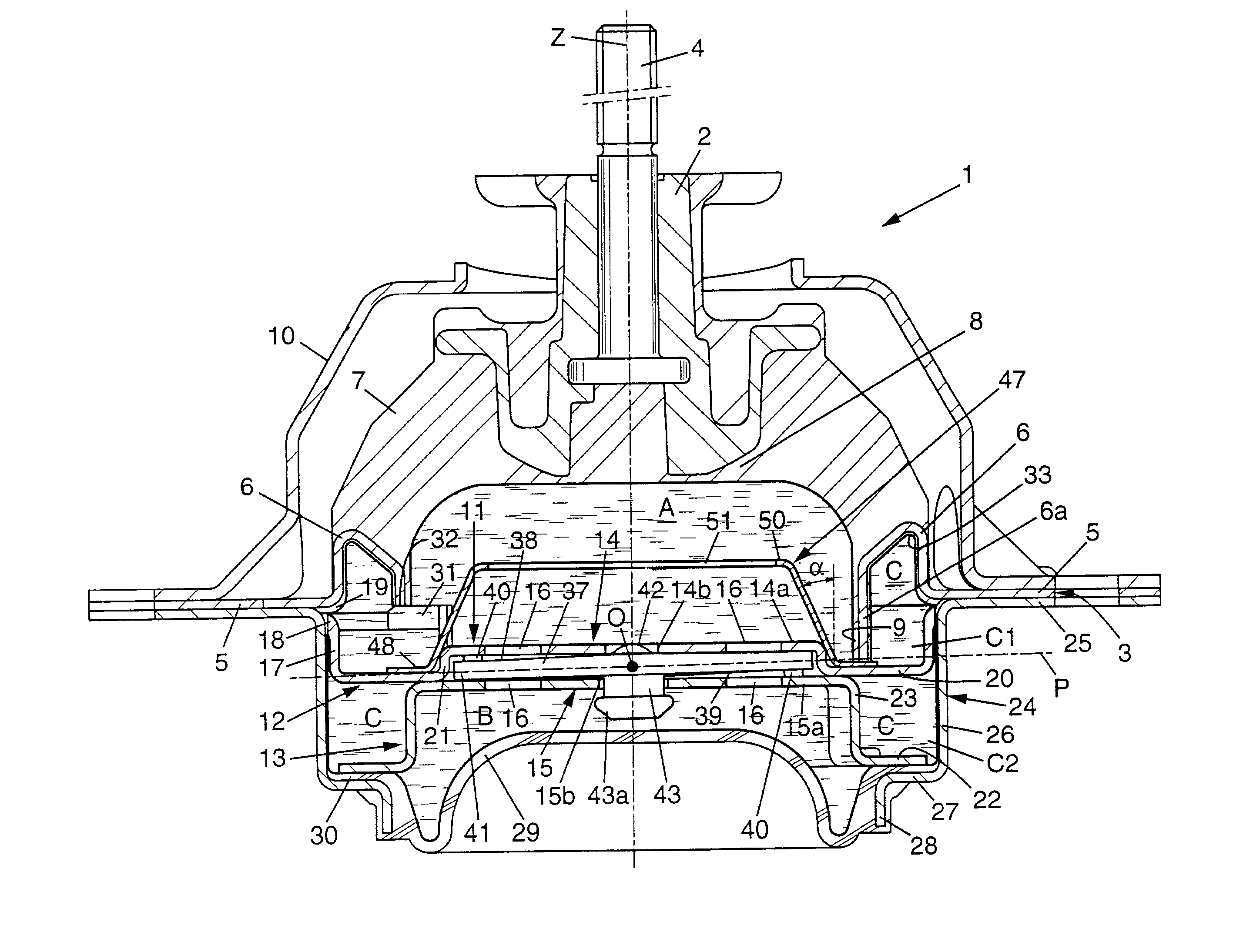

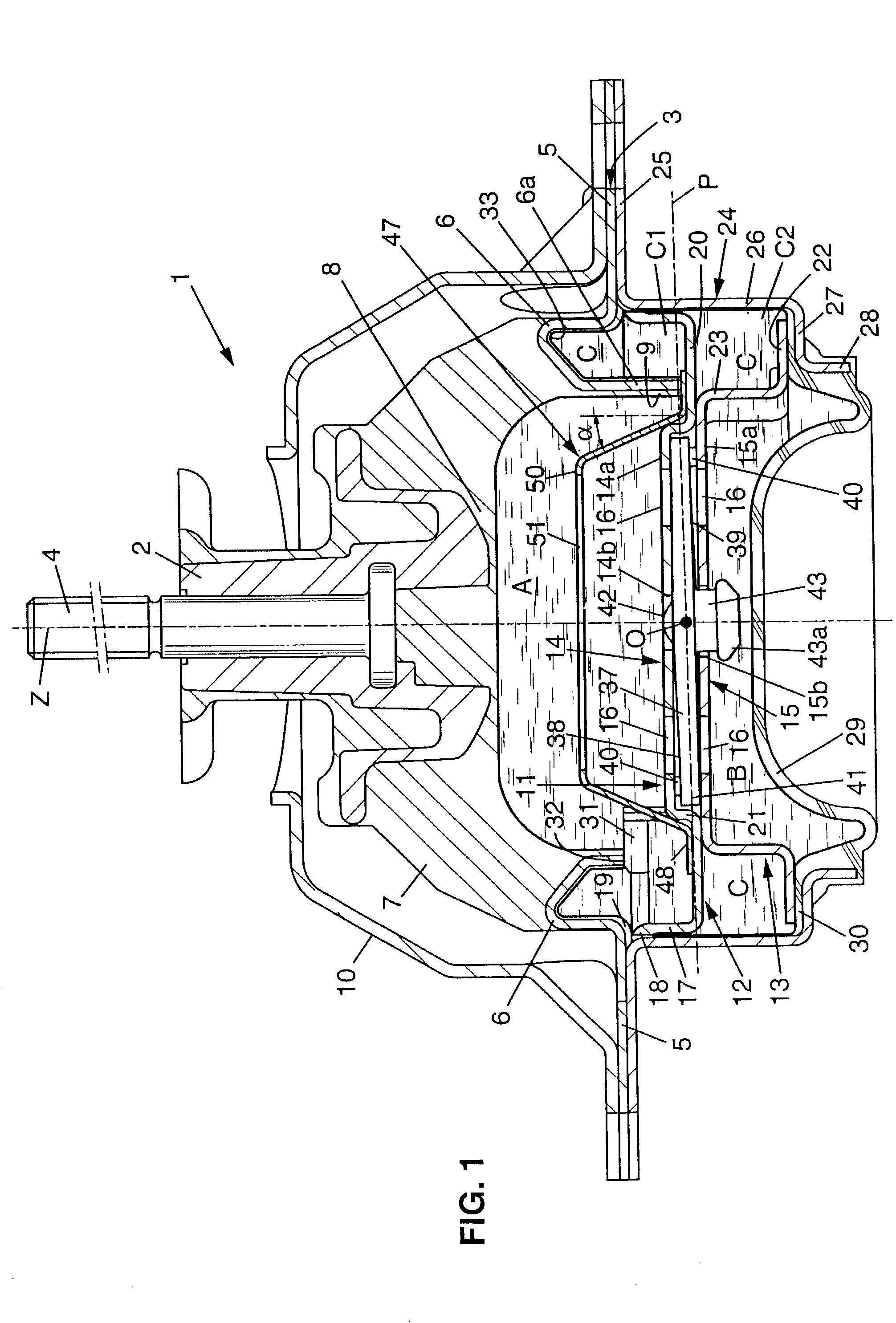

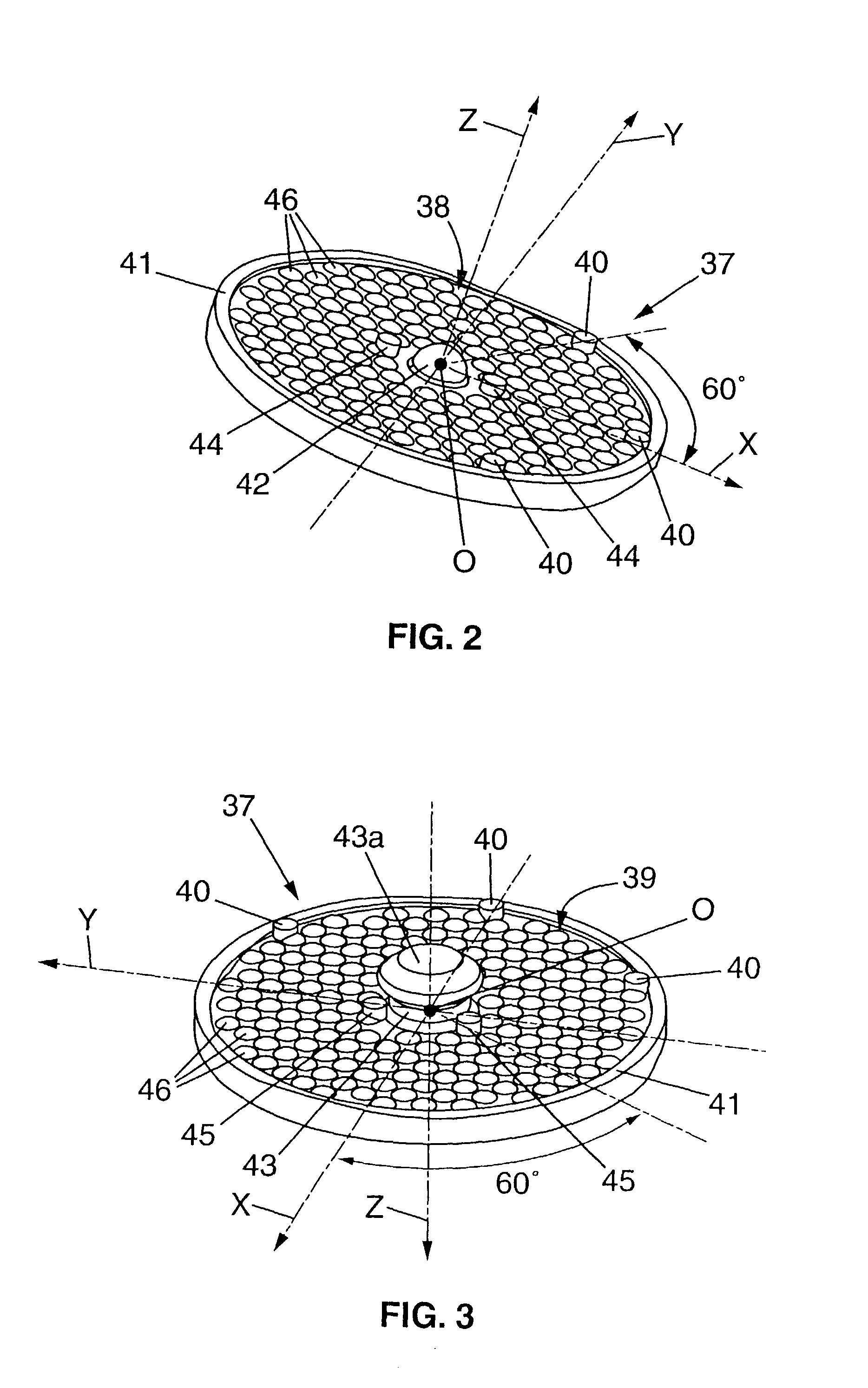

Hydraulic vibration-damping support

InactiveUS20030038414A1Mitigate such drawbackLightweight and inexpensiveMachine framesLiquid springsElastomerMetal forming

A hydraulic vibration-damping support comprising two strength members interconnected by an elastomer body defining in part a working chamber filled with liquid, said working chamber communicating via a constricted passage with a compensation chamber separated from said working chamber by a rigid partition. The constricted passage is made up of two stages defined by two pieces of sheet metal forming the rigid partition.

Owner:HUTCHINSON SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com