Patents

Literature

6283 results about "Relief valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurised fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the "path of least resistance" as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. The diverted fluid (liquid, gas or liquid–gas mixture) is usually routed through a piping system known as a flare header or relief header to a central, elevated gas flare where it is usually burned and the resulting combustion gases are released to the atmosphere. As the fluid is diverted, the pressure inside the vessel will stop rising. Once it reaches the valve's reseating pressure, the valve will close. The blowdown is usually stated as a percentage of set pressure and refers to how much the pressure needs to drop before the valve reseats. The blowdown can vary from roughly 2–20%, and some valves have adjustable blowdowns.

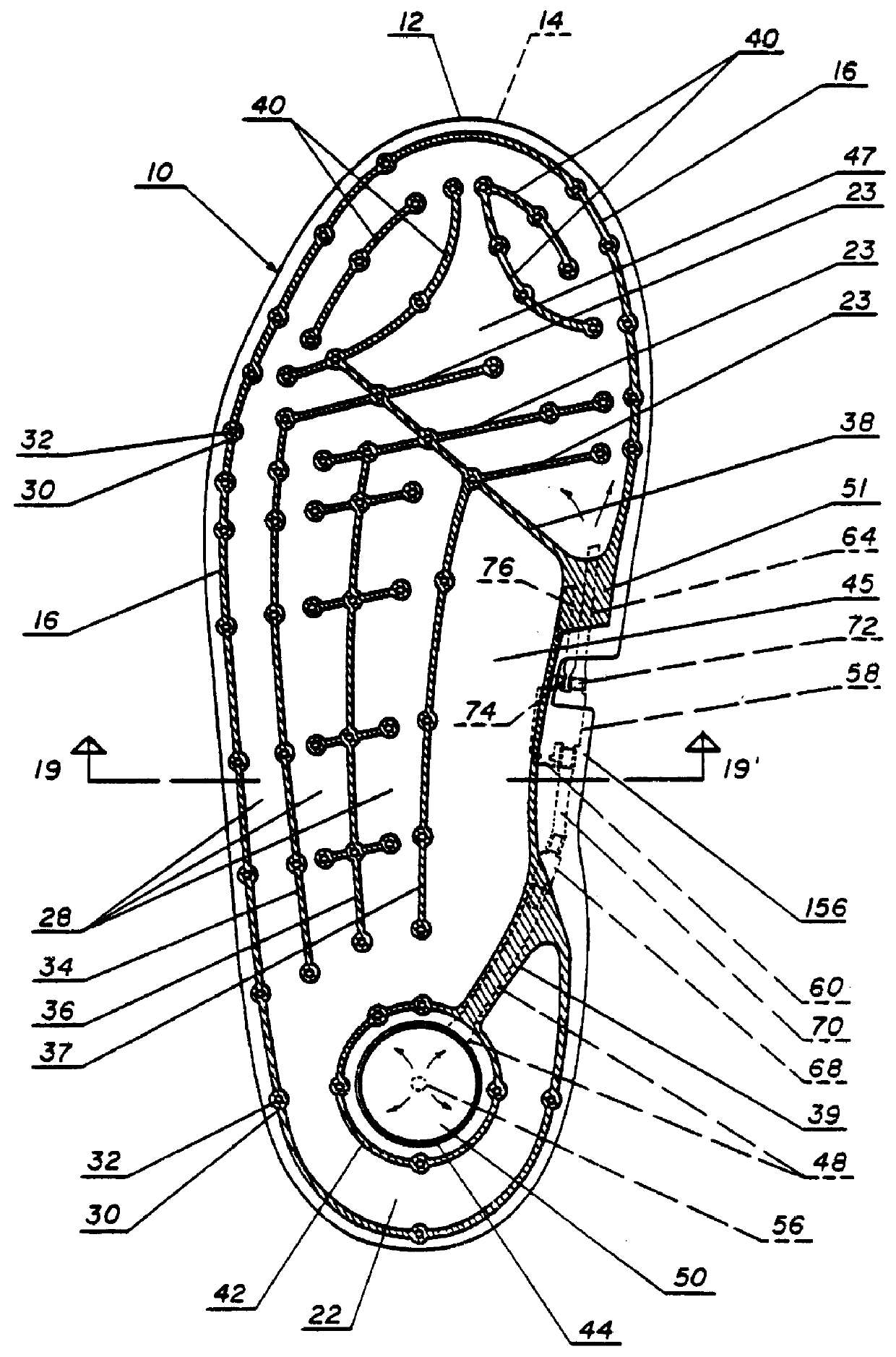

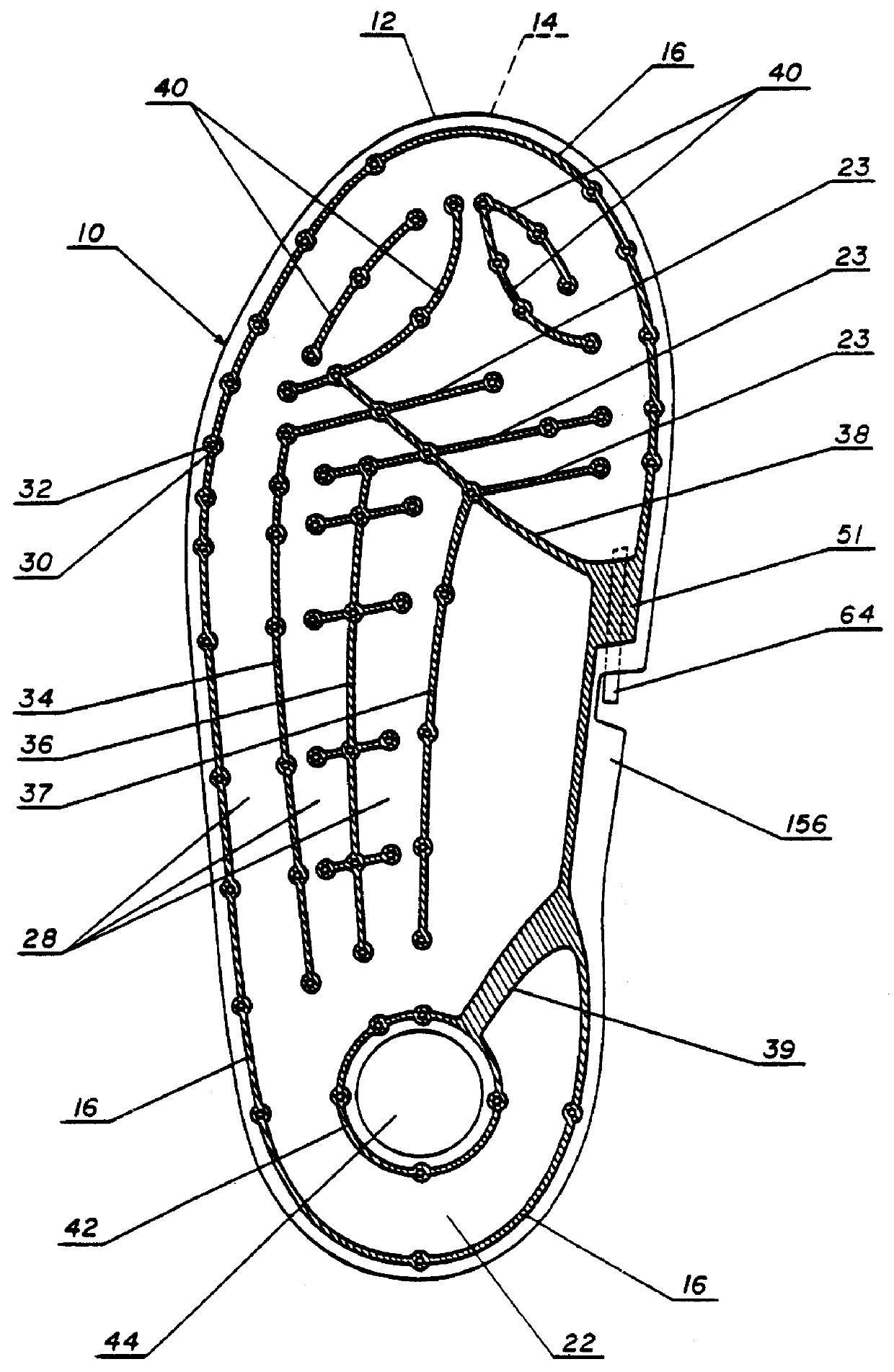

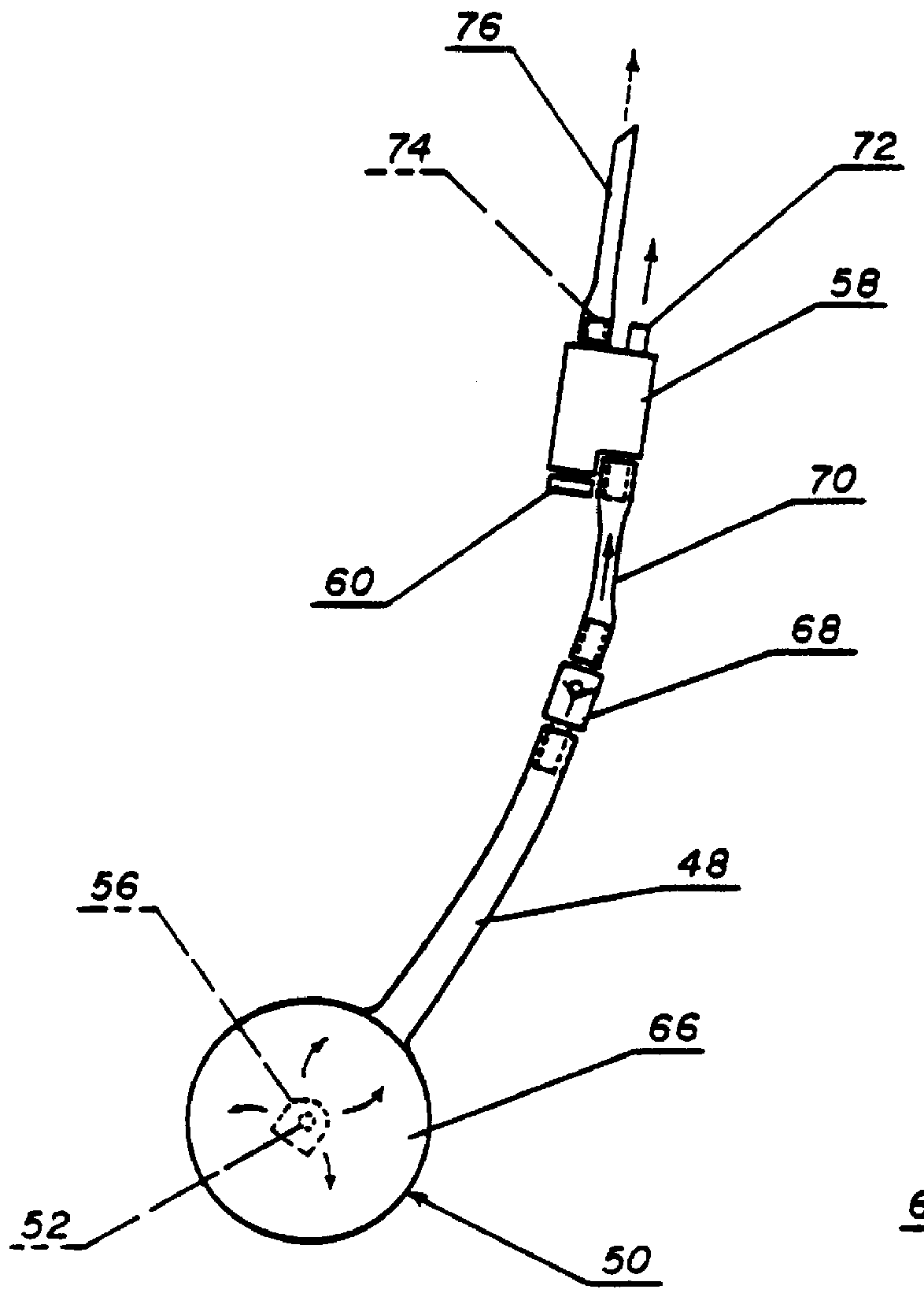

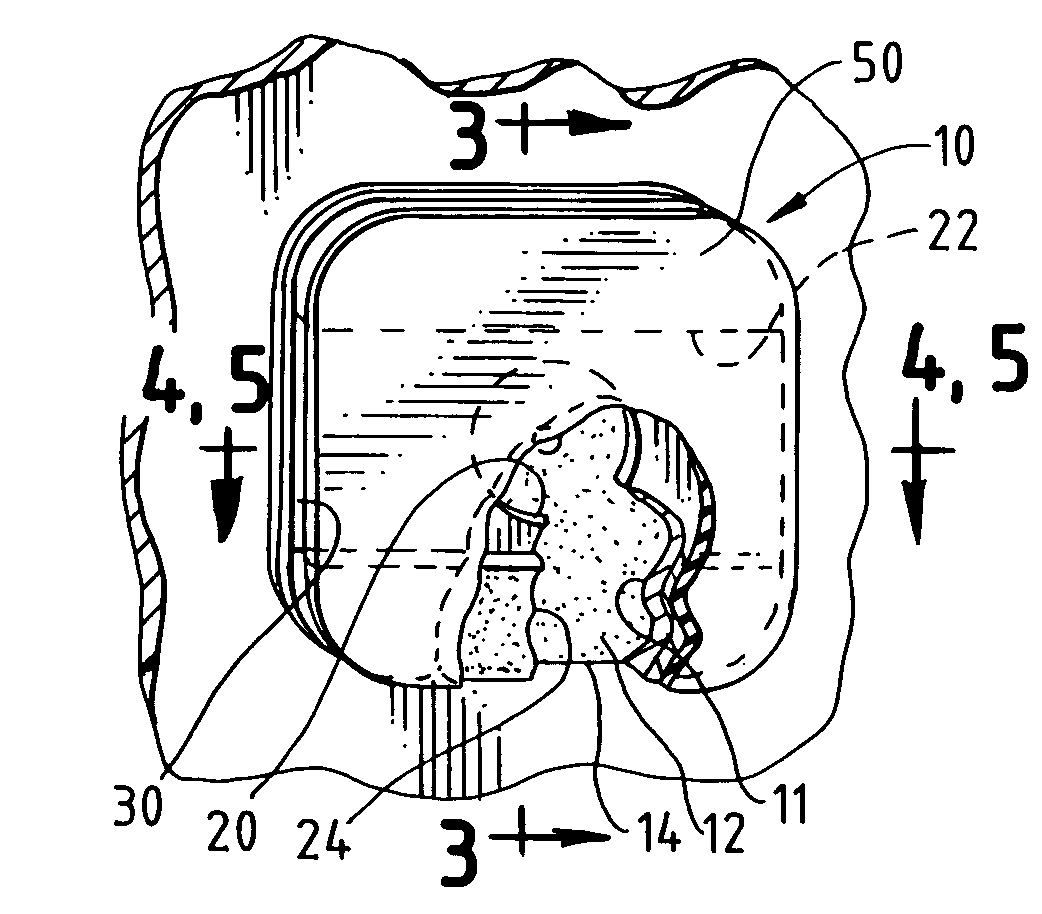

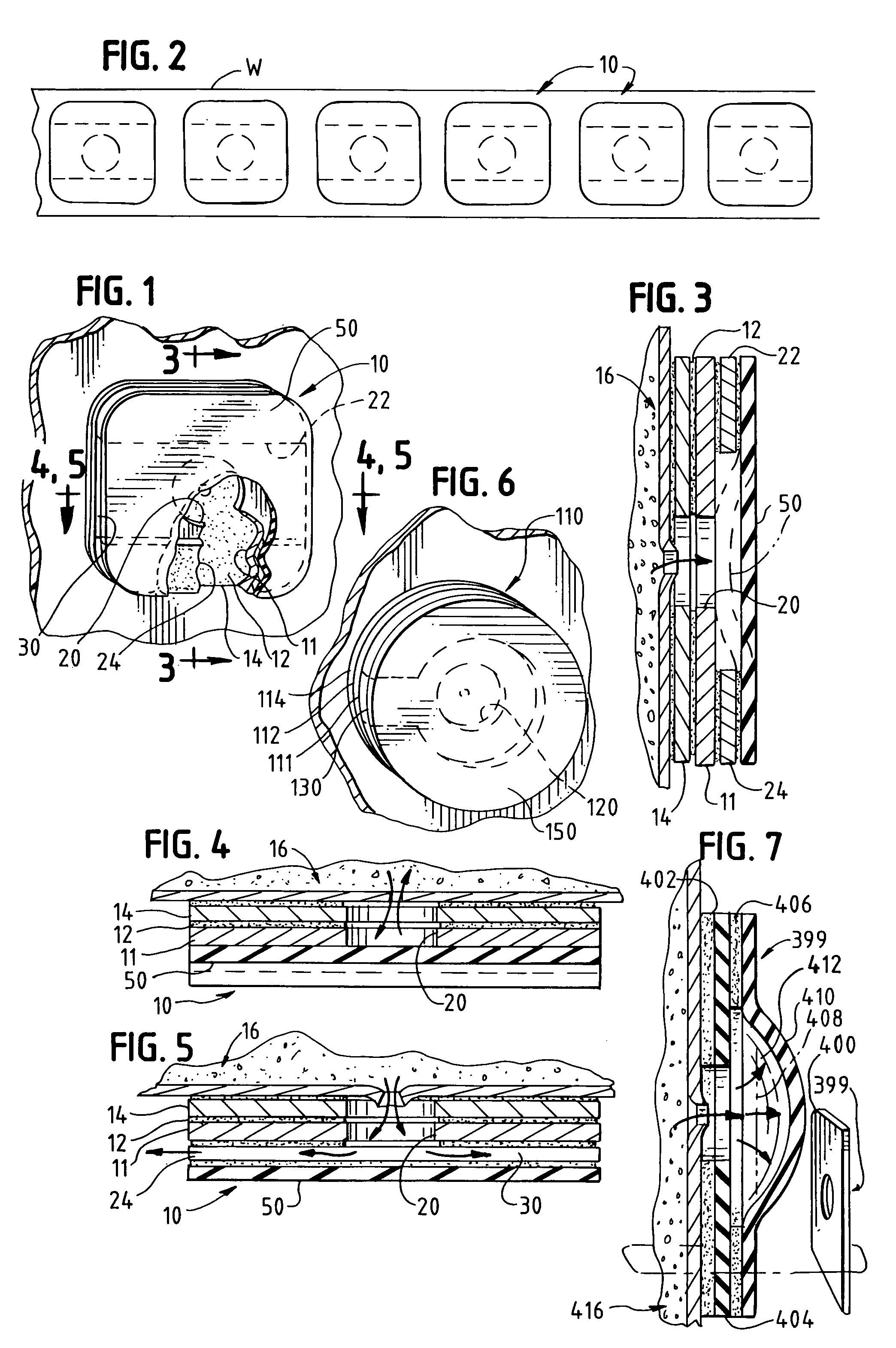

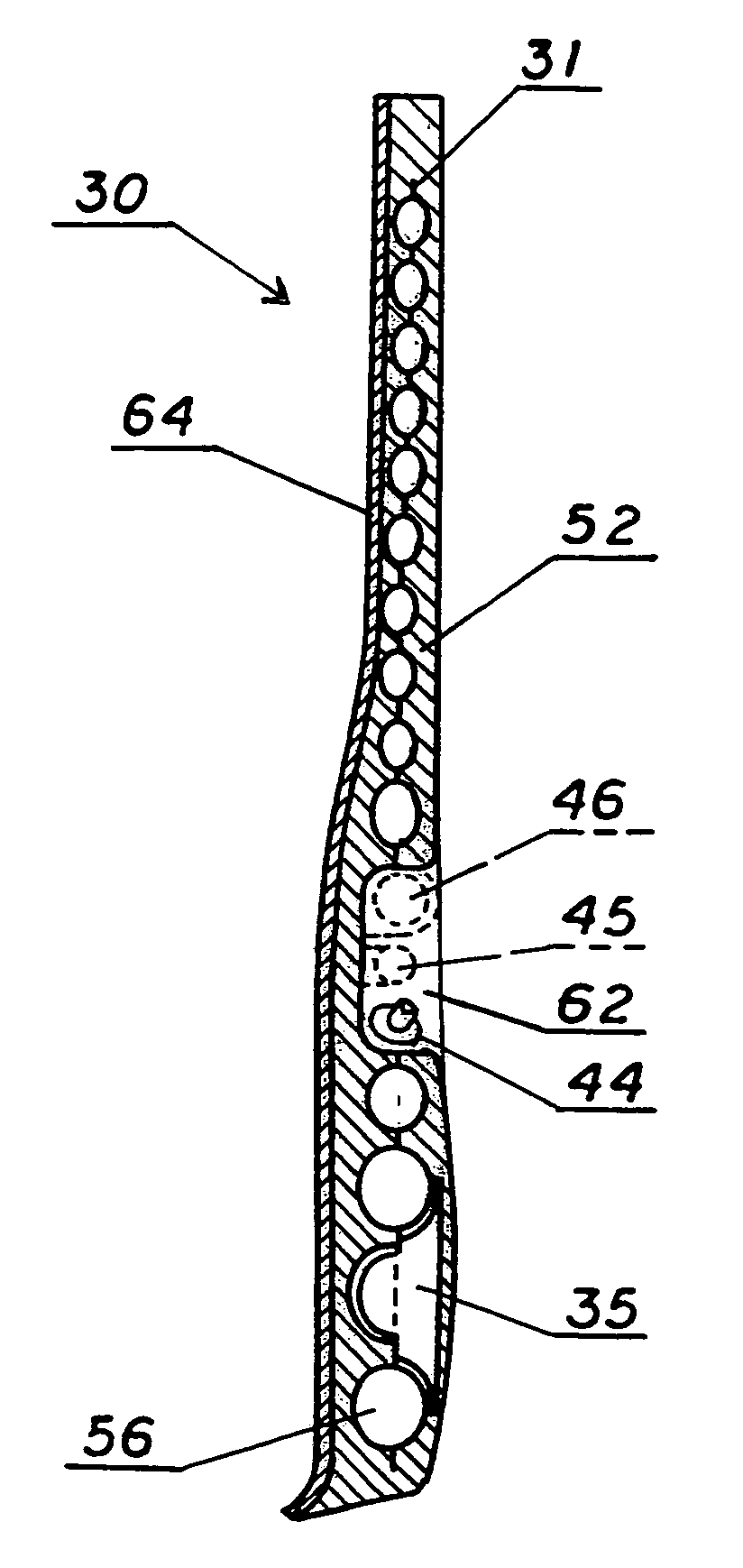

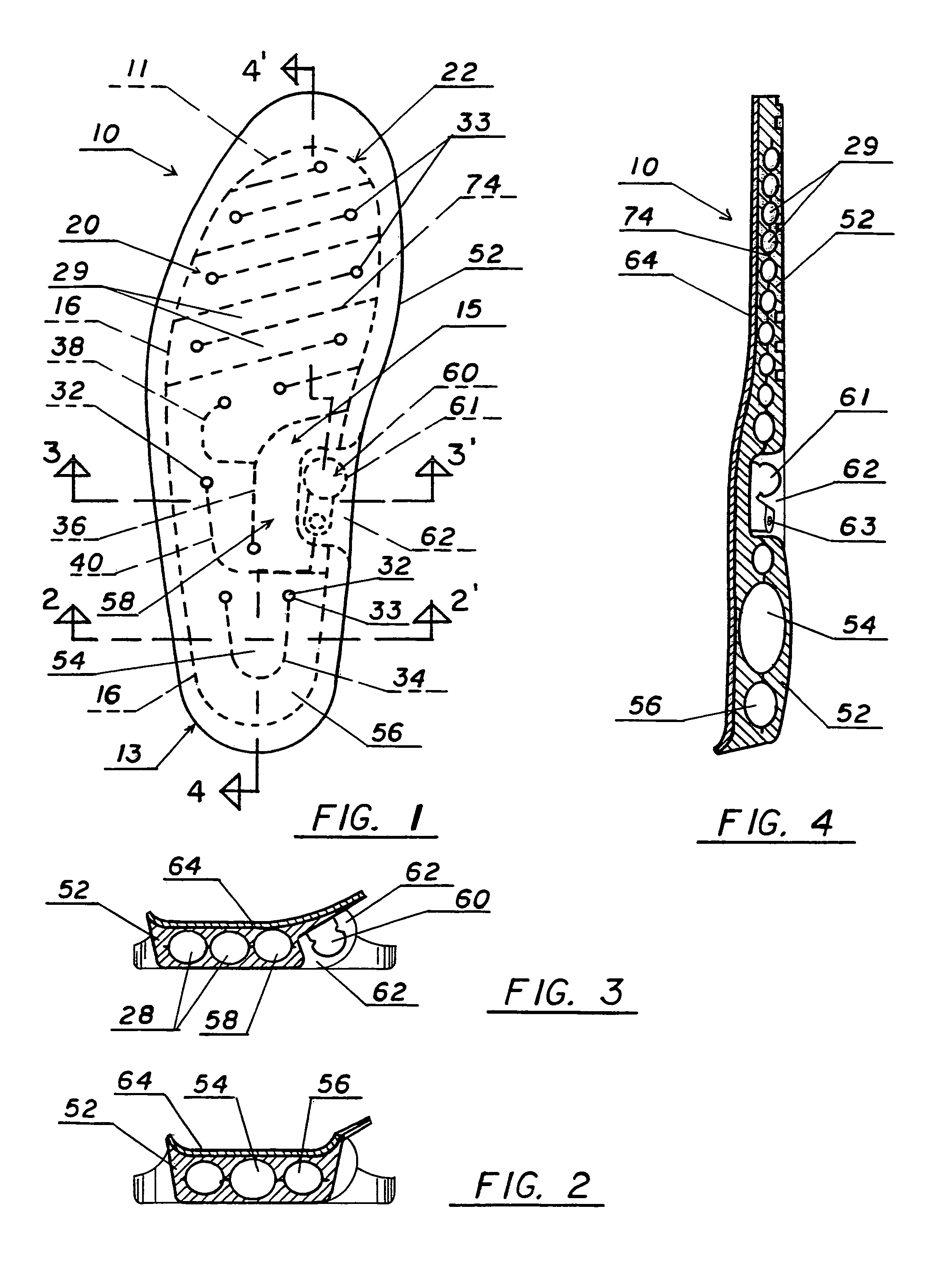

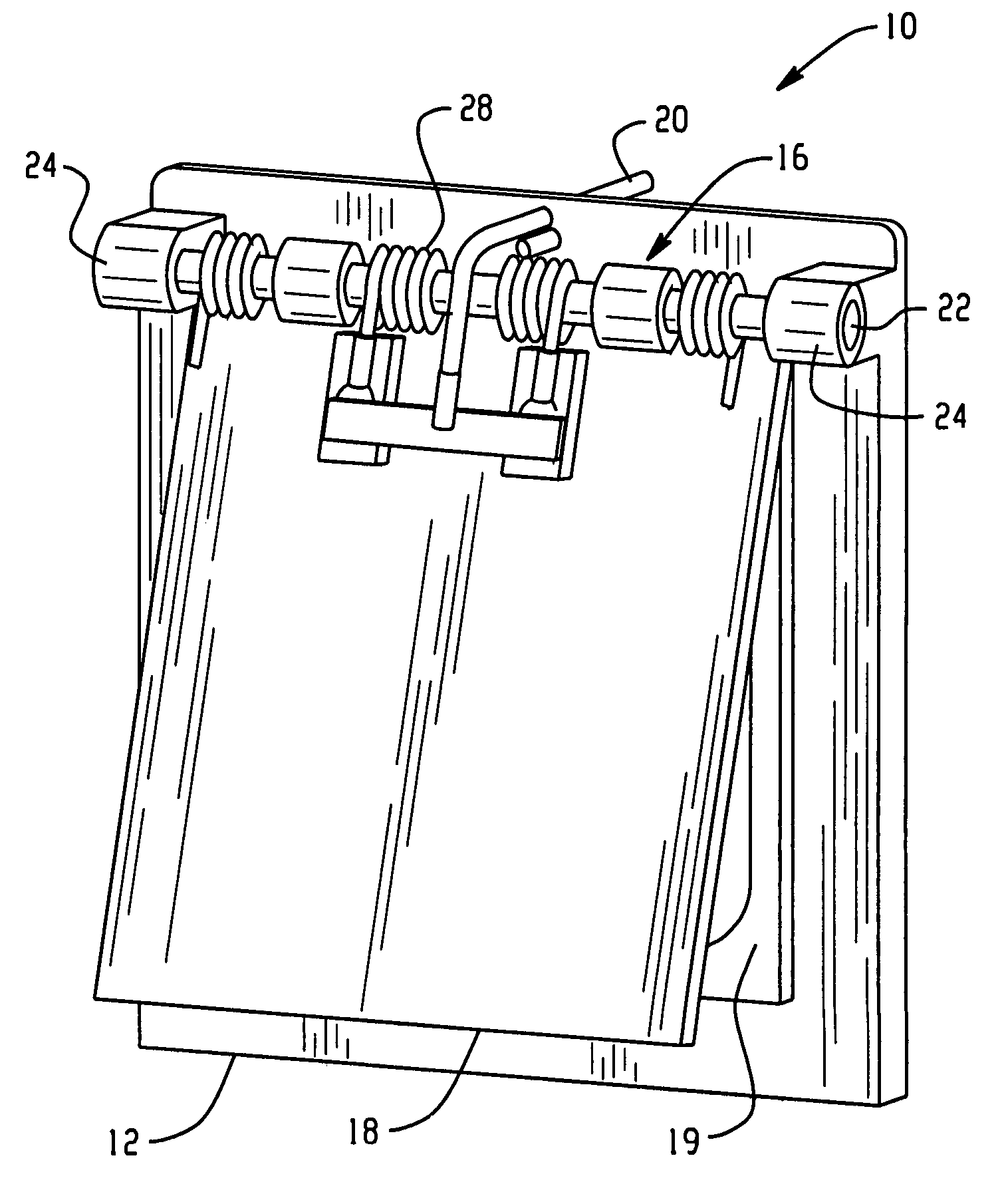

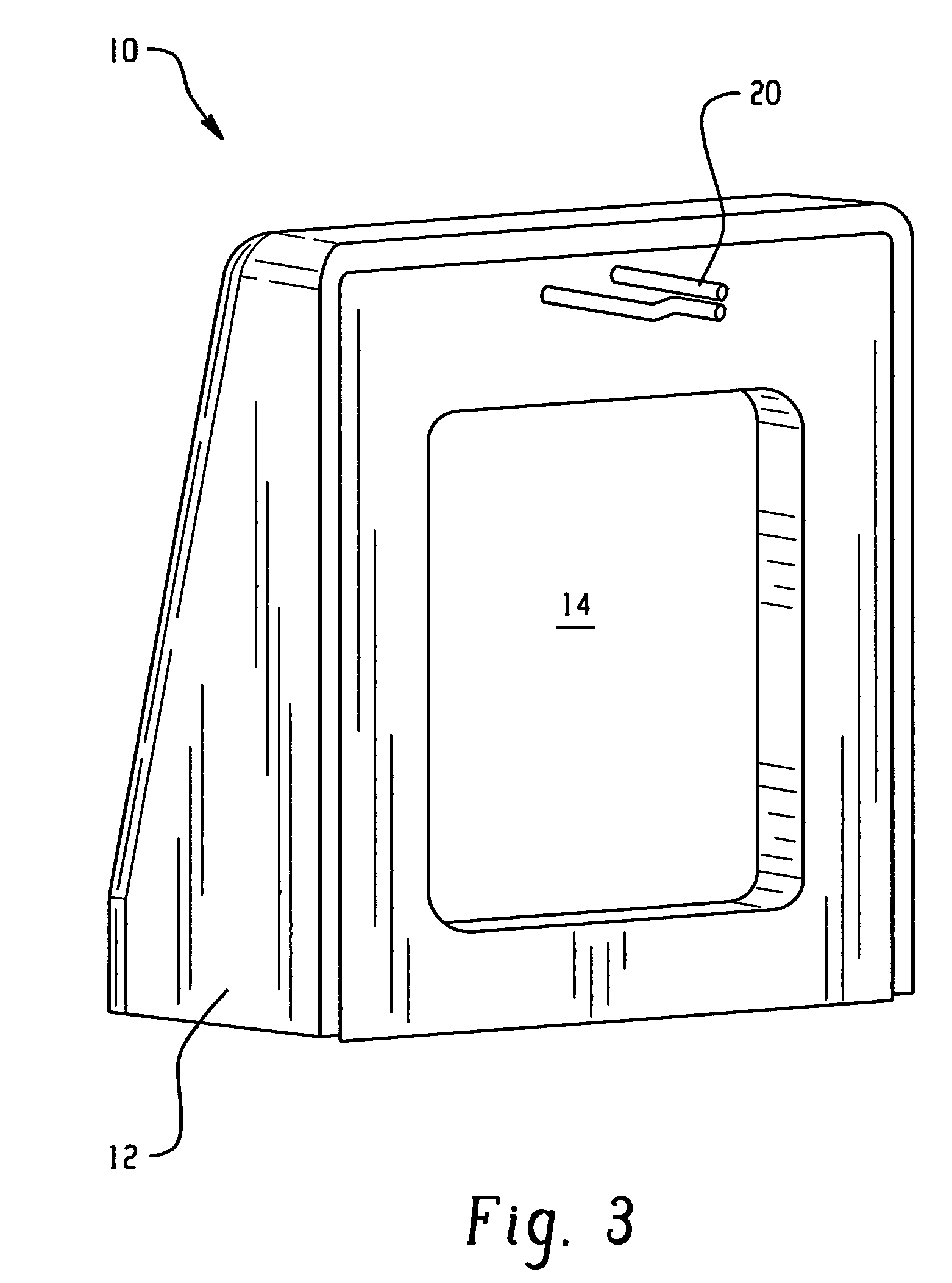

Inflatable sole lining for shoes and boots

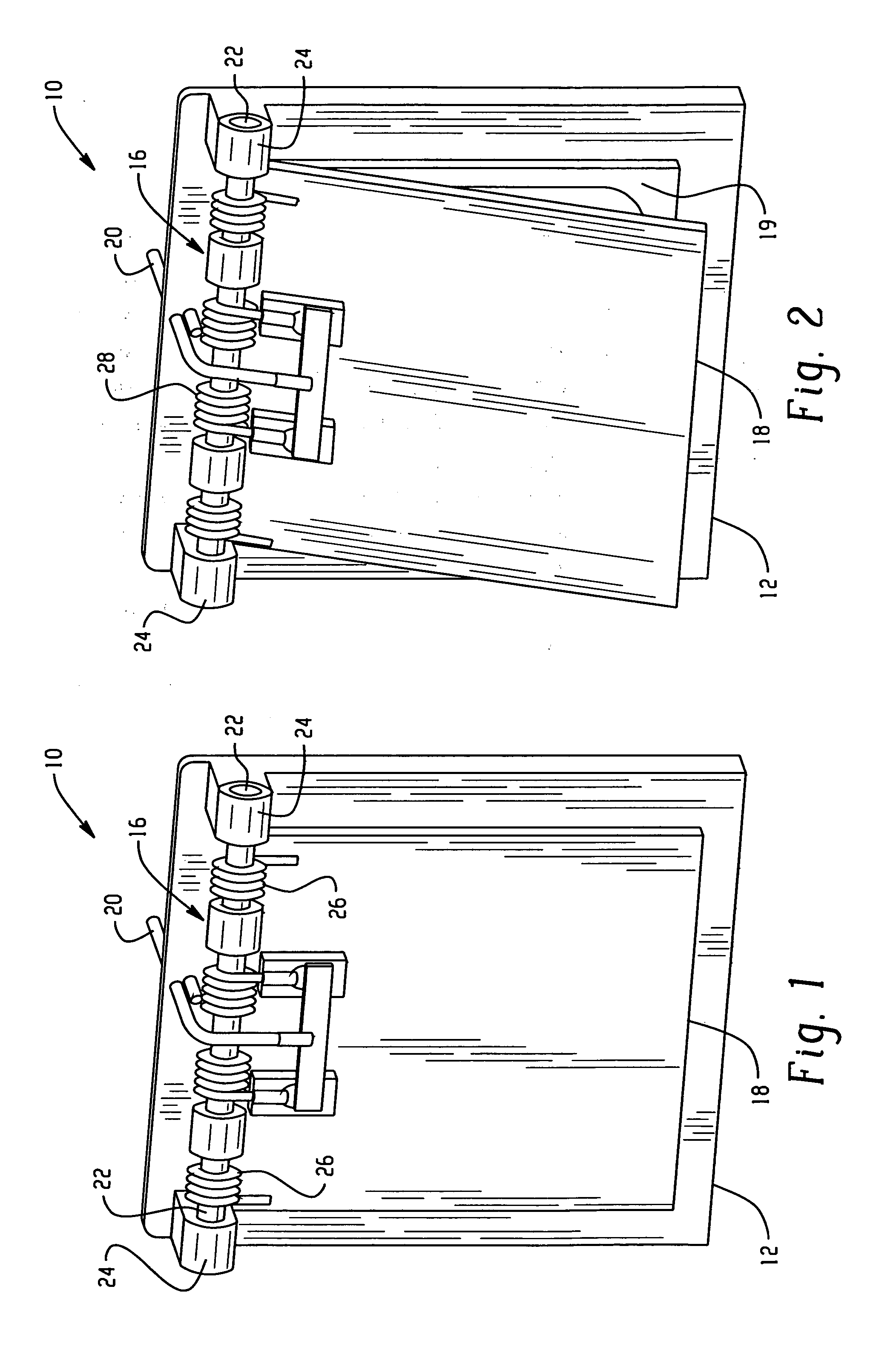

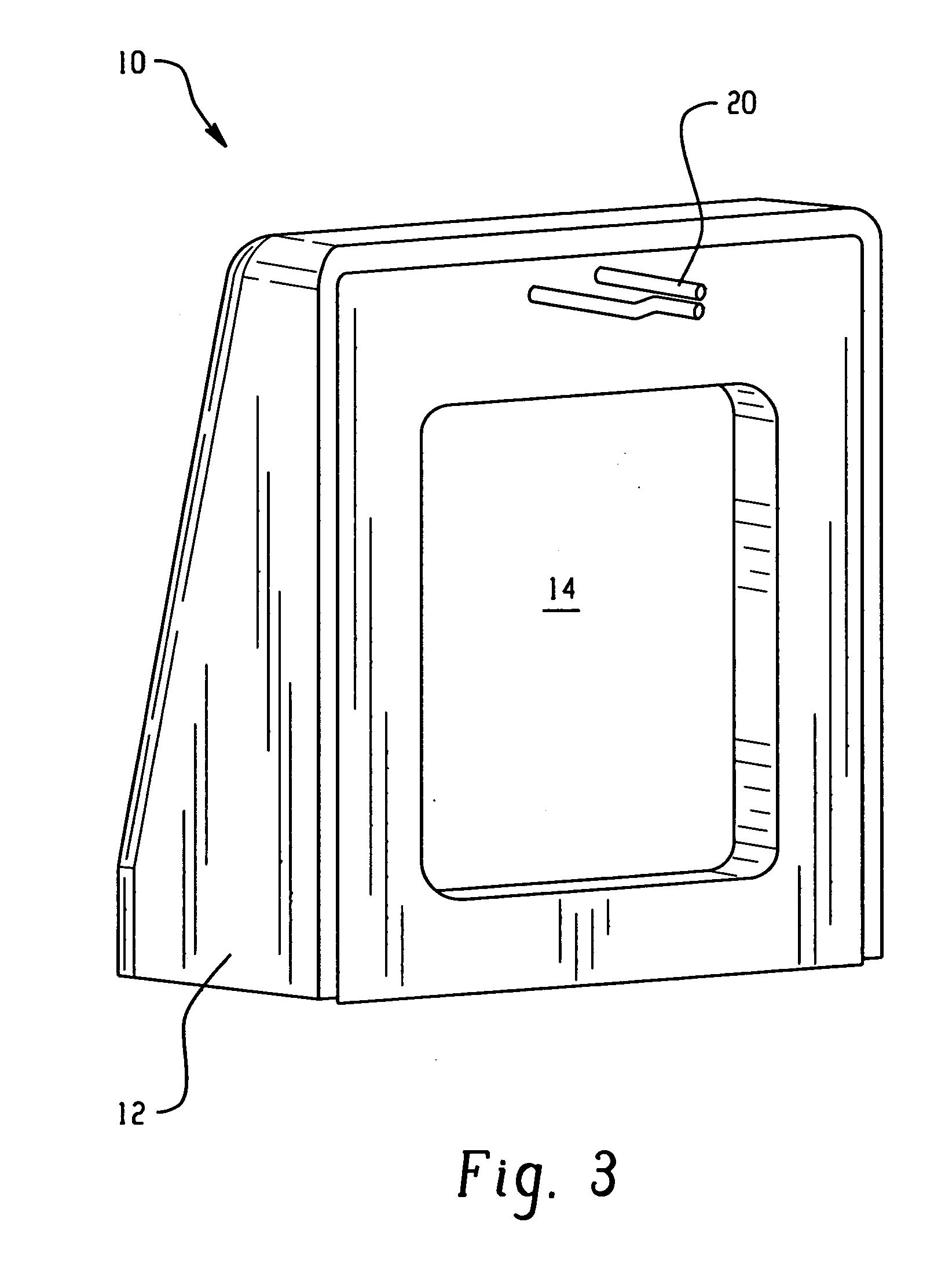

There is disclosed an inflatable lining for selected inner surfaces of footwear, such as a shoe, boot or sandal. The inflatable lining is formed of first and second plastic sheets having the shape and size of the selected inner surfaces, e.g., a sole, or any portion of the upper surfaces of the footwear. The sheets are bonded together in a continuous seam about their peripheral edges thereby forming a sealed interior chamber. A plurality of discontinuous seams are formed between the first and second sheets to create within the sealed interior chamber a plurality of interconnecting tubular passageways, and at least one continuous seam can also be provided that subdivides the interior chamber into two or more subdivided interior chambers. The inflatable liner is provided with an air pump that preferably is a flexible bulb with an inlet valve which discharges into a flexible tube which extends to a pressure control valve and then to the interior chamber of the inflatable inner sole. Preferably the flexible bulb is mounted at the heel of the inner sole. The pressure relief valve is manually adjustable to control the pressure within the inflatable inner sole. Excess air from the pressure control valve can be directed into channels formed on the undersurface of the inner sole where it discharges through sealed apertures in the inner sole thereby providing forced air circulation in the footwear. Alternatively, manually operated air pumps can be provided.

Owner:LAKIC NIKOLA

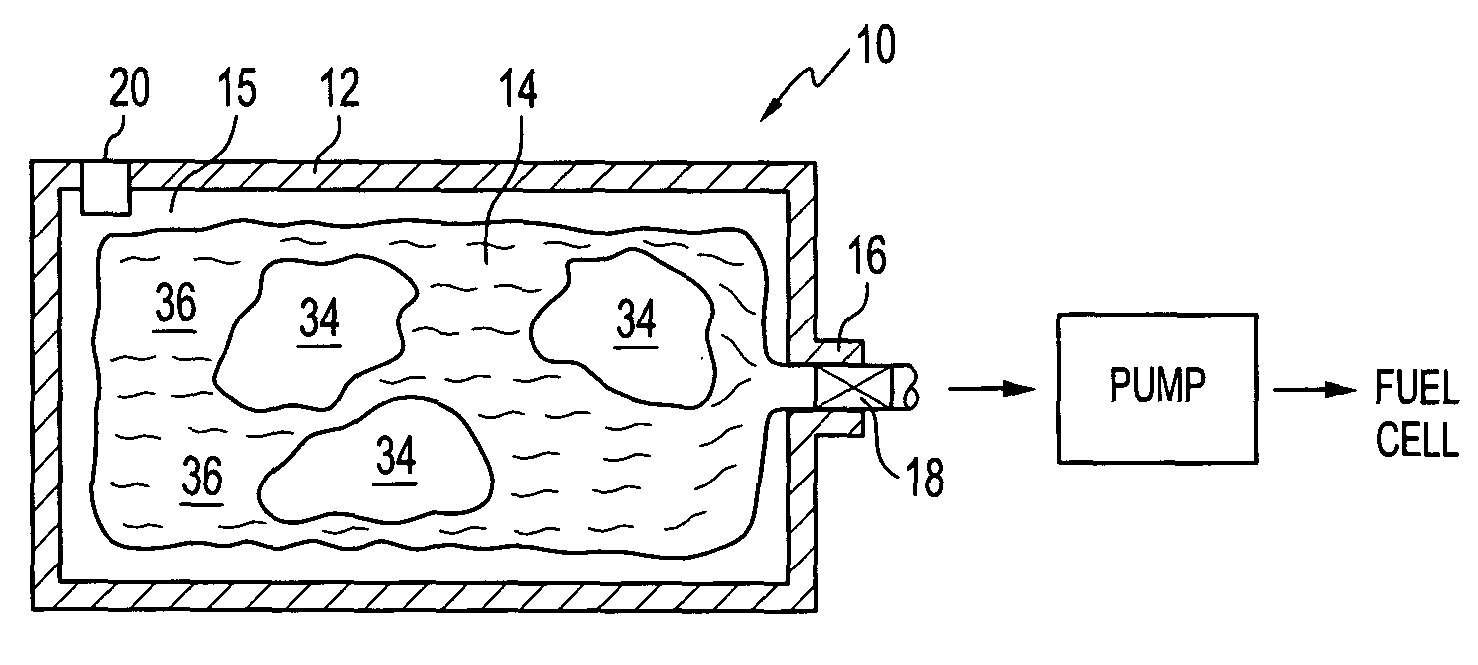

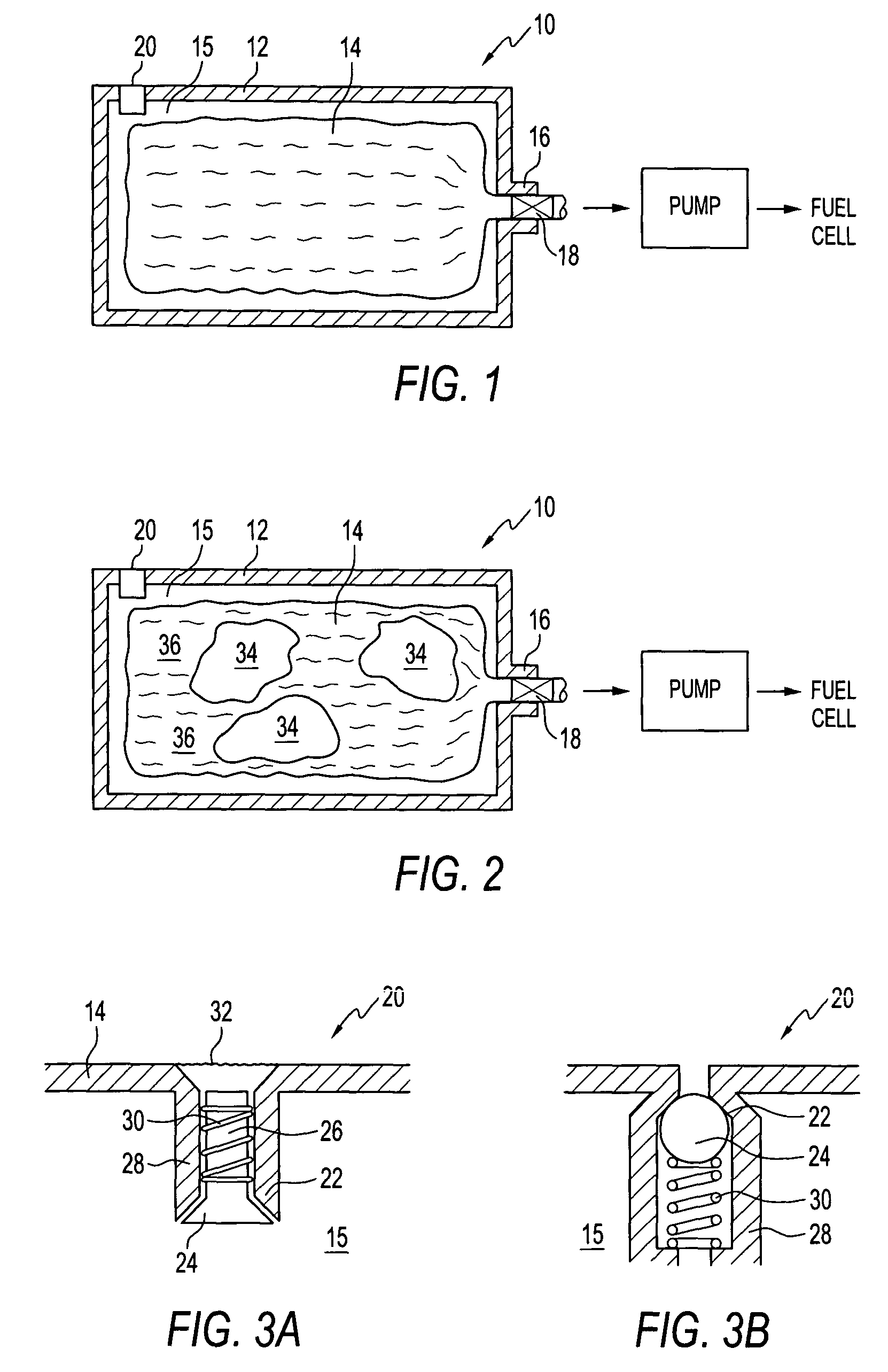

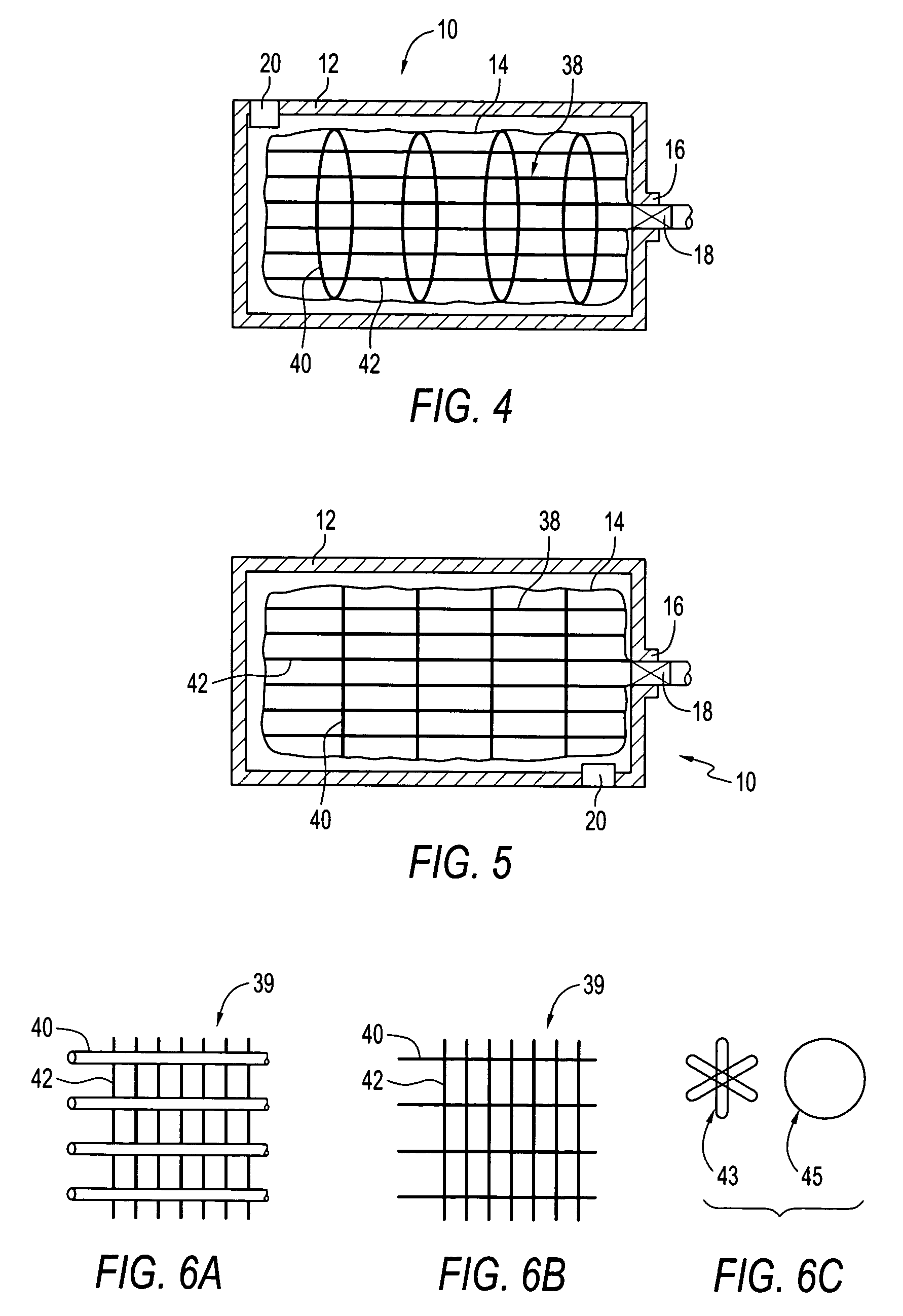

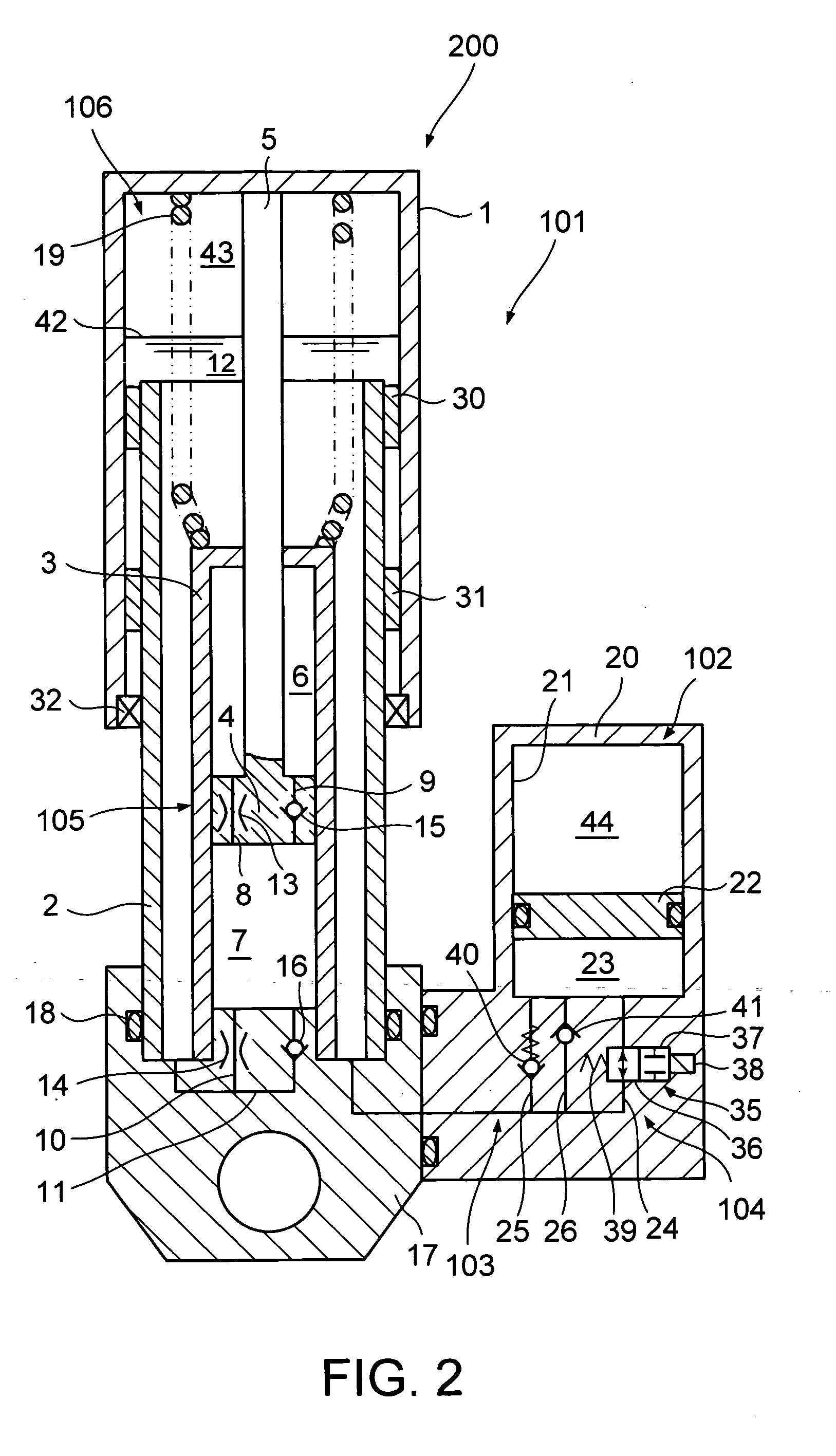

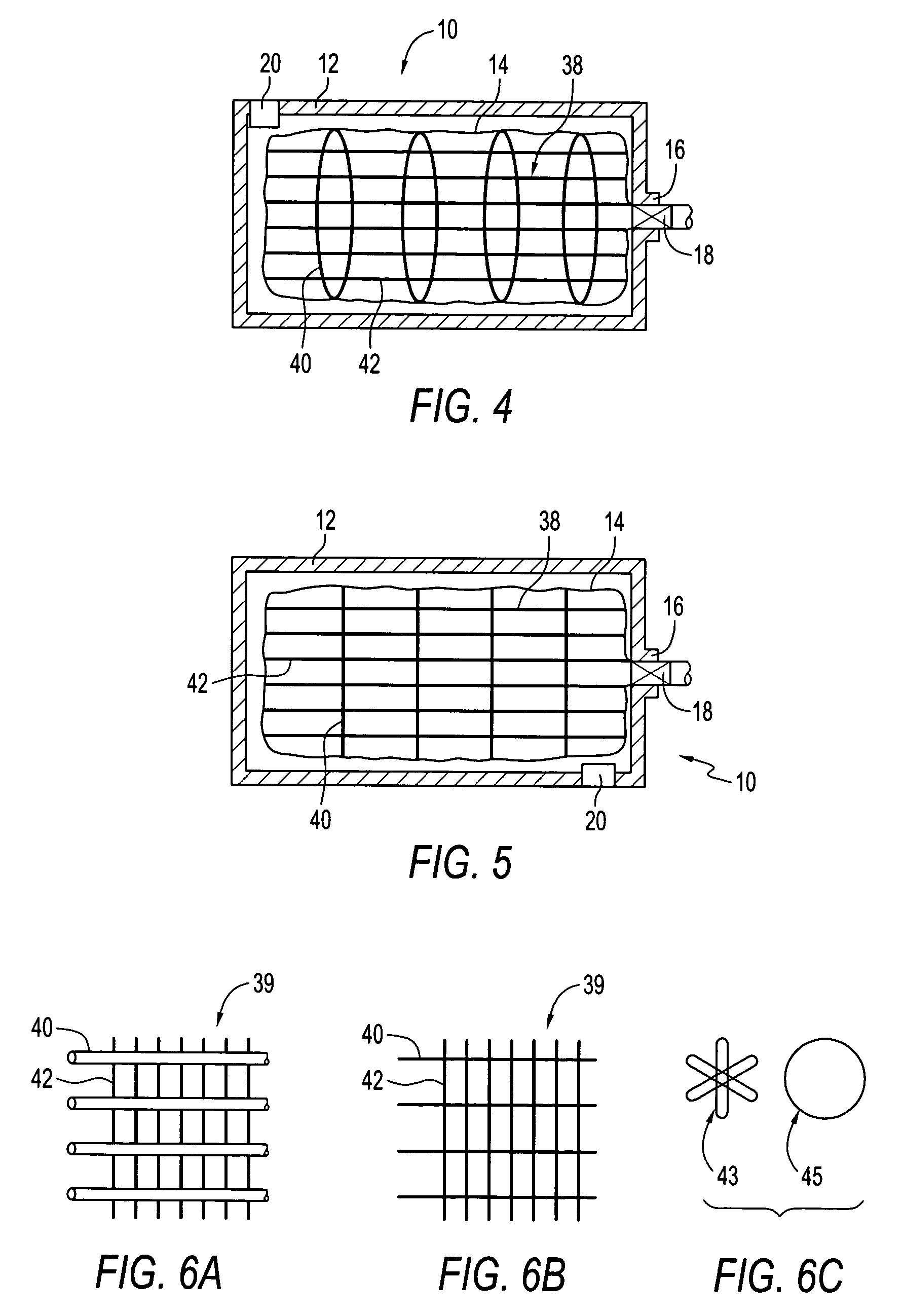

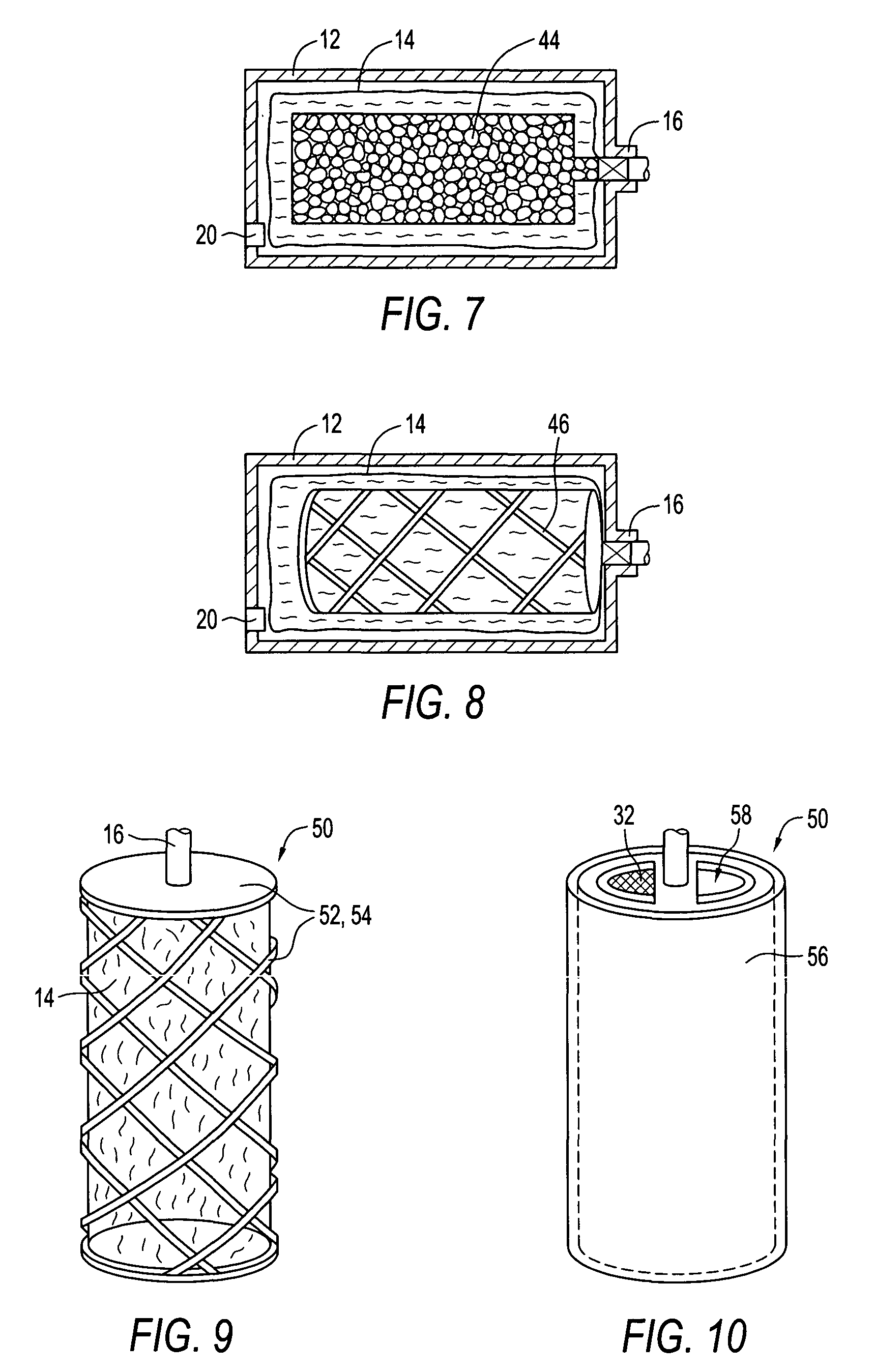

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

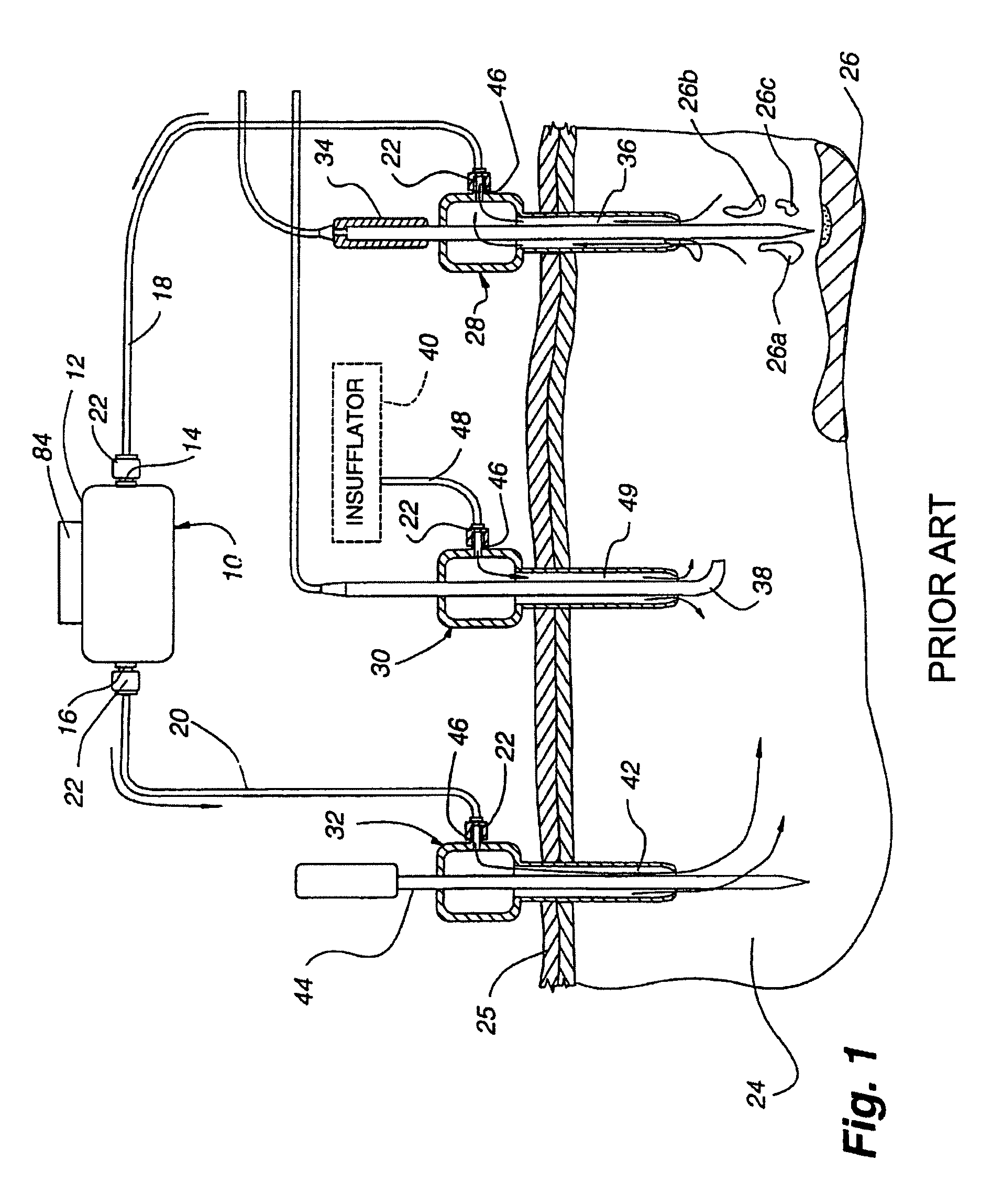

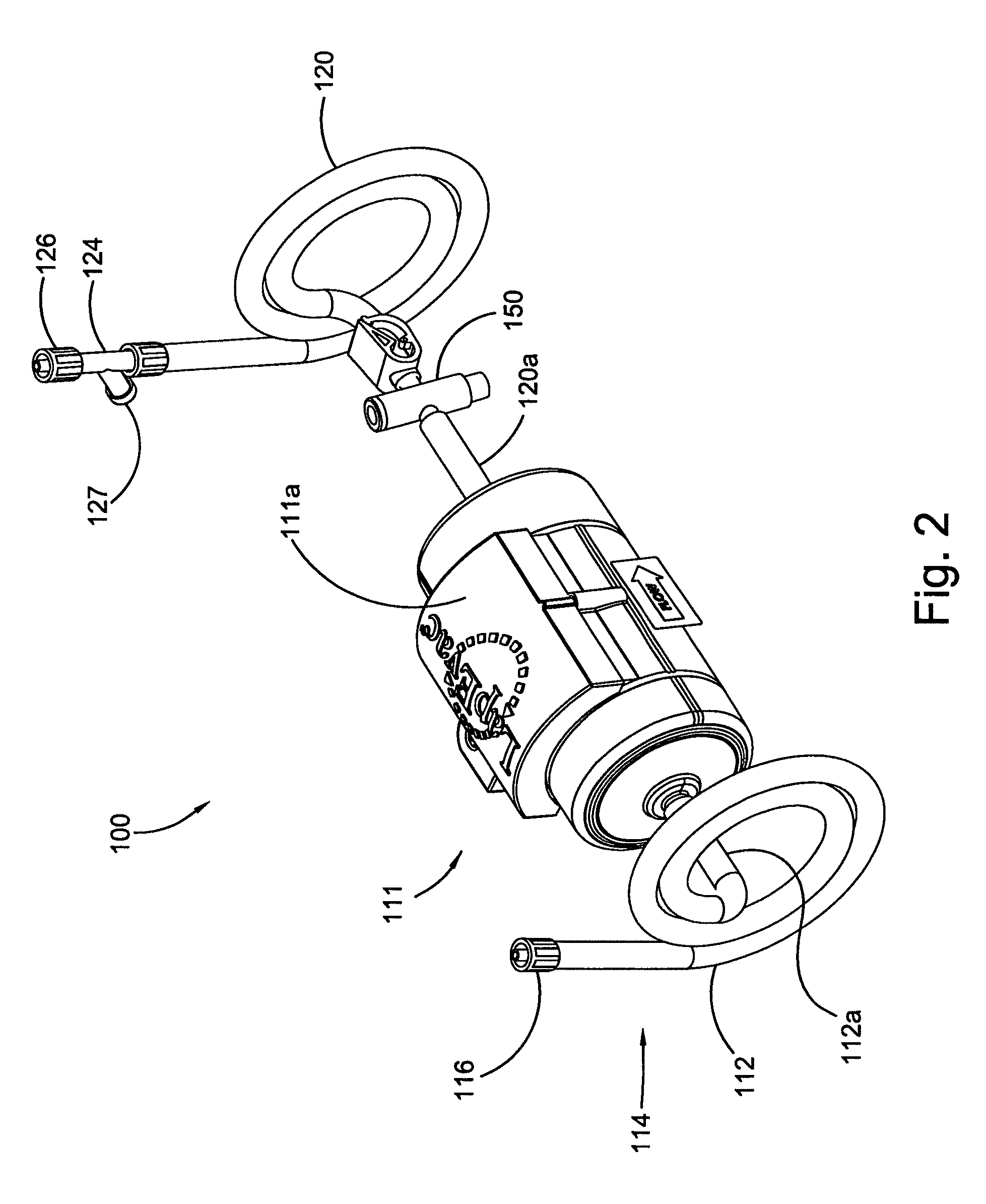

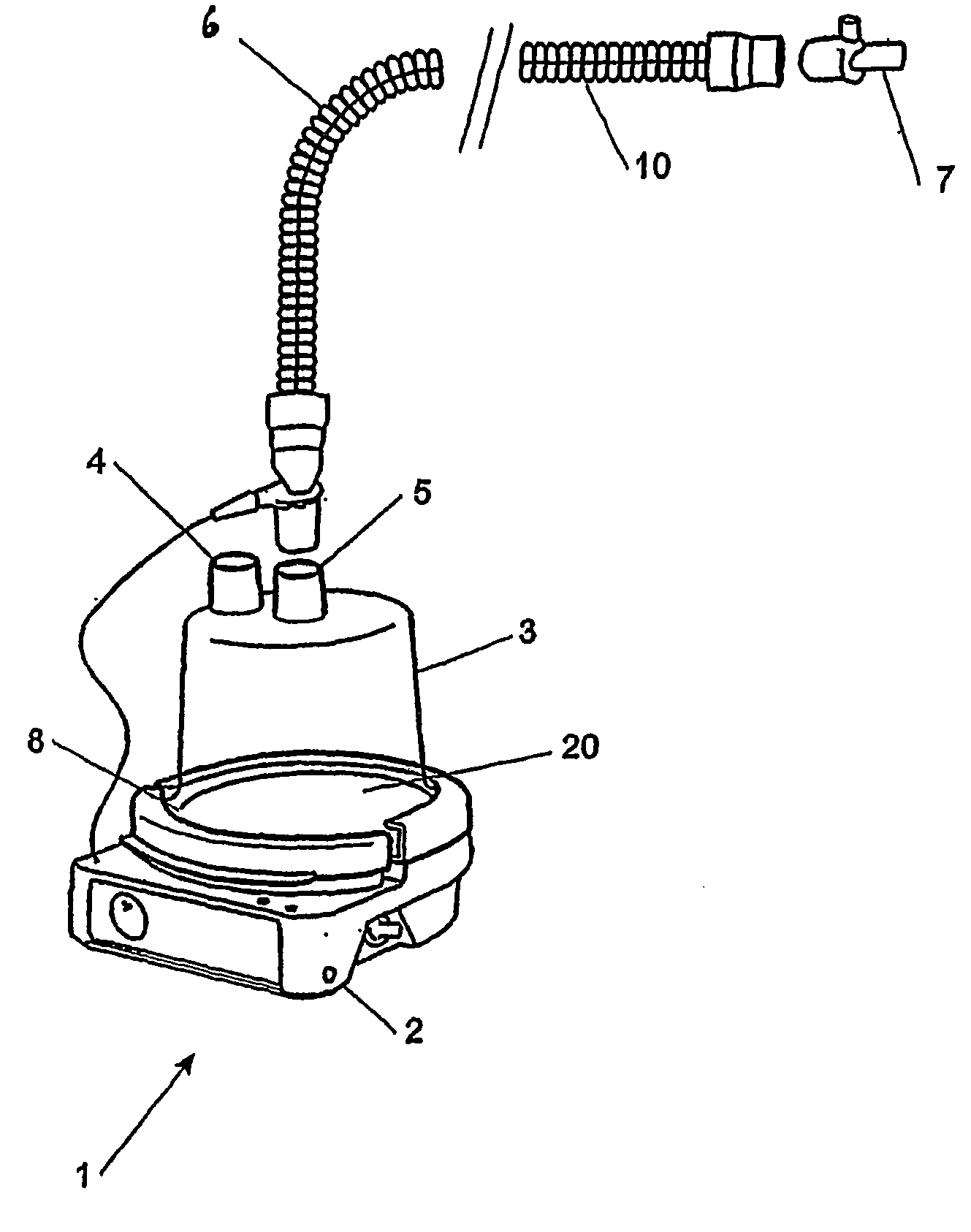

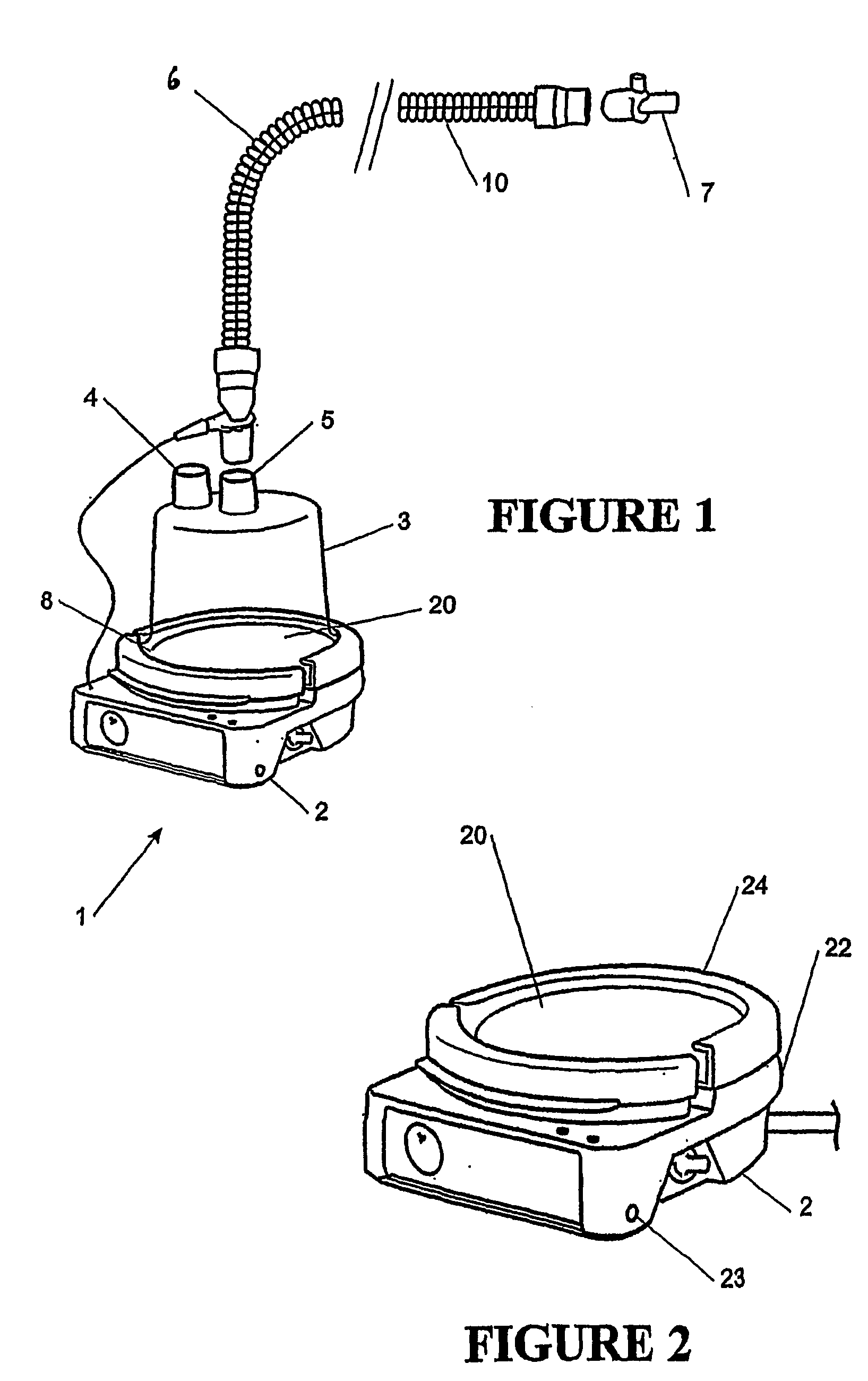

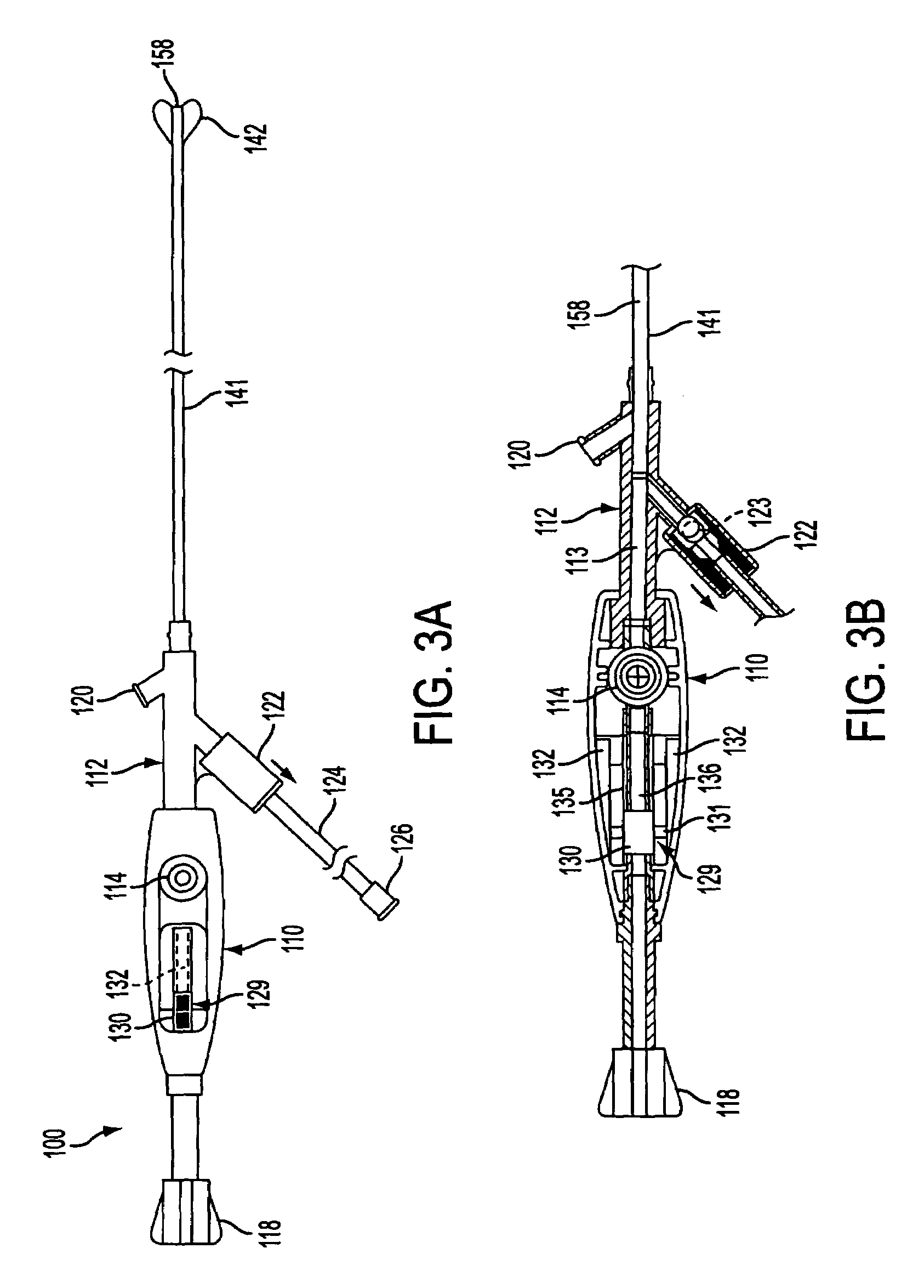

Wick and relief valve for disposable laparoscopic smoke evacuation system

ActiveUS9011366B2Reduce and eliminate blockingReduce eliminate stratificationDispersed particle filtrationMedical devicesPERITONEOSCOPESurgical site

The present invention relates to an improved smoke evacuation device for use in laparoscopic surgeries. One improvement is a hydrophilic wick positioned within the inlet system of the smoke device for absorbing moisture and trapping surgical waste entering the smoke evacuation device. The second improvement is a multi-outlet valve inserted into the outlet system of the smoke evacuation device to enable quick depressurization of the surgical site.

Owner:BUFFALO FILTER

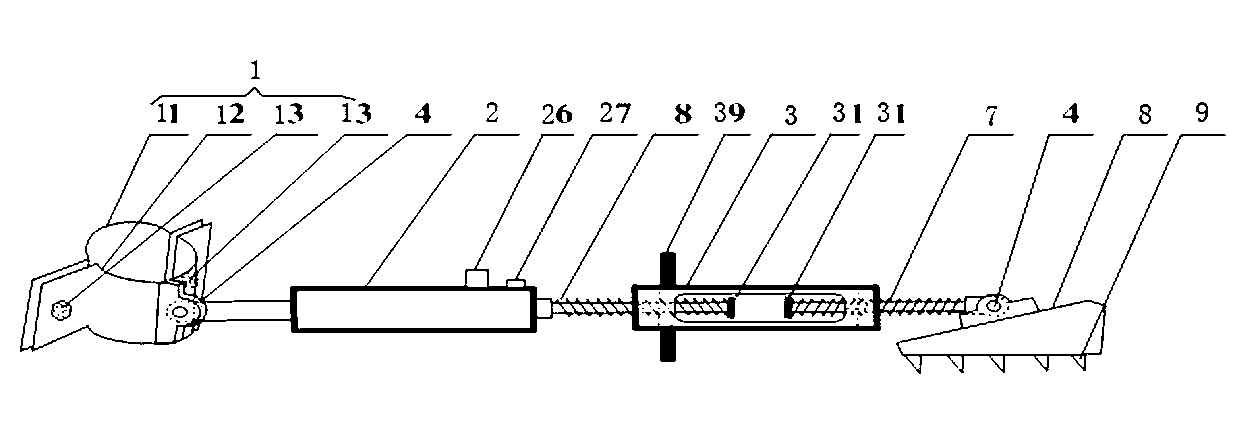

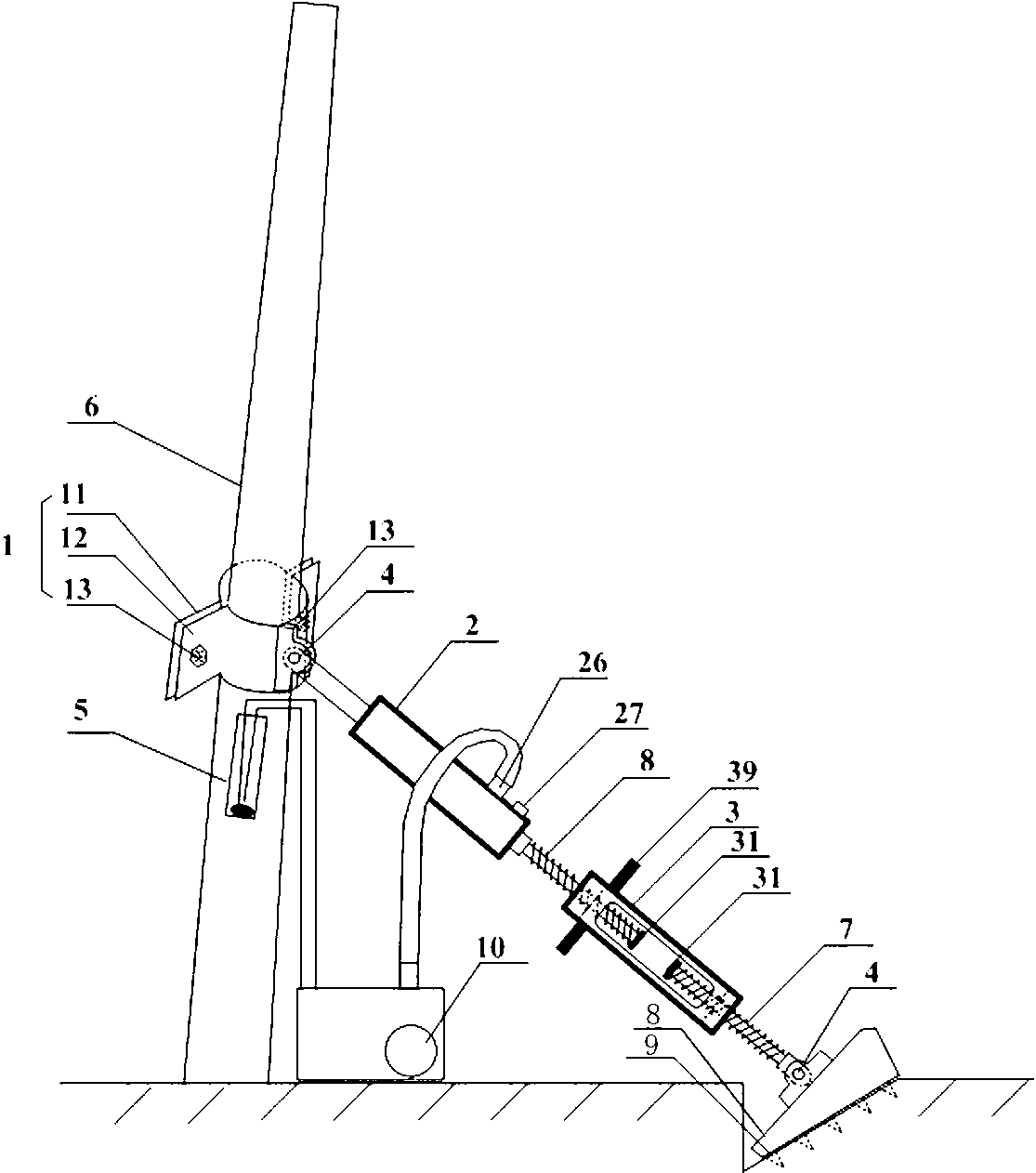

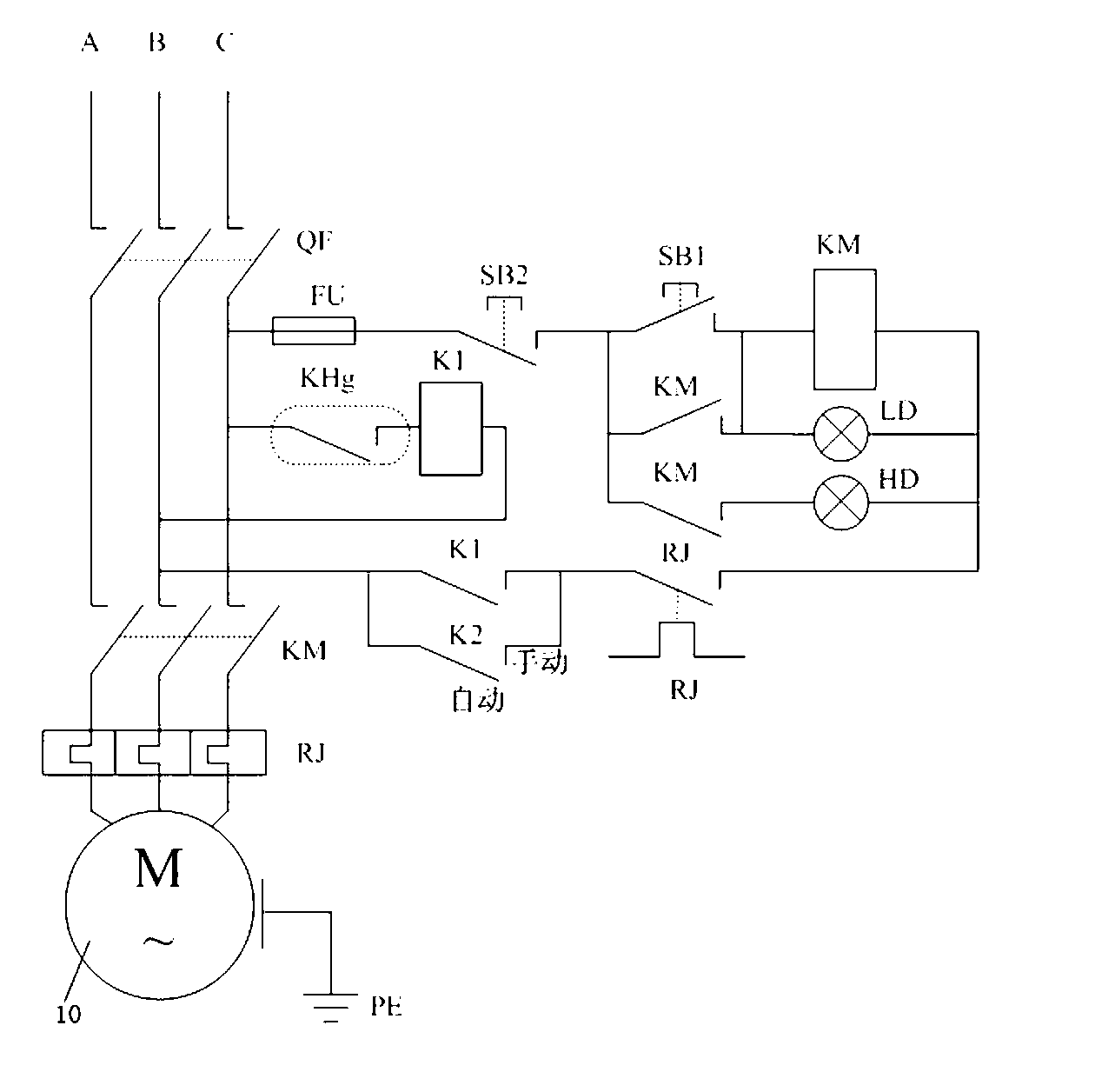

Full-automatic utility pole centralizer

InactiveCN103291117AEnsure power supply reliabilityImprove work efficiencyTowersHydraulic pumpEngineering

The invention relates to a full-automatic utility pole centralizer comprising a hoop, a hydraulic mechanism, a length adjuster, a connecting shaft, a right hand thread screw, a left hand thread screw, a base, a mercury switch and an electric hydraulic pump. The hoop is connected with the hydraulic mechanism through the connecting shaft. The hydraulic mechanism and the right hand thread screw are welded together. The right hand thread screw and the left hand thread screw are screwed in two ends of the length adjuster, respectively. A limit stopper is arranged at the end of each of the screws screwed into the length adjuster. The other end of the left hand thread screw is connected with the base through the connecting shaft. The hydraulic mechanism is provided with a relief valve and a hydraulic joint. The electric hydraulic pump is connected with the hydraulic joint through a high-pressure rubber pipe. The mercury switch is parallelly attached to a utility pole and is connected with the electric hydraulic pump through a circuit. The full-automatic utility pole centralizer has the advantages that when tilting, the utility pole can be automatically centralized with no power outage; power supply reliability is ensured, work efficiency is improved, and risks caused by power outage are reduced.

Owner:STATE GRID CORP OF CHINA +1

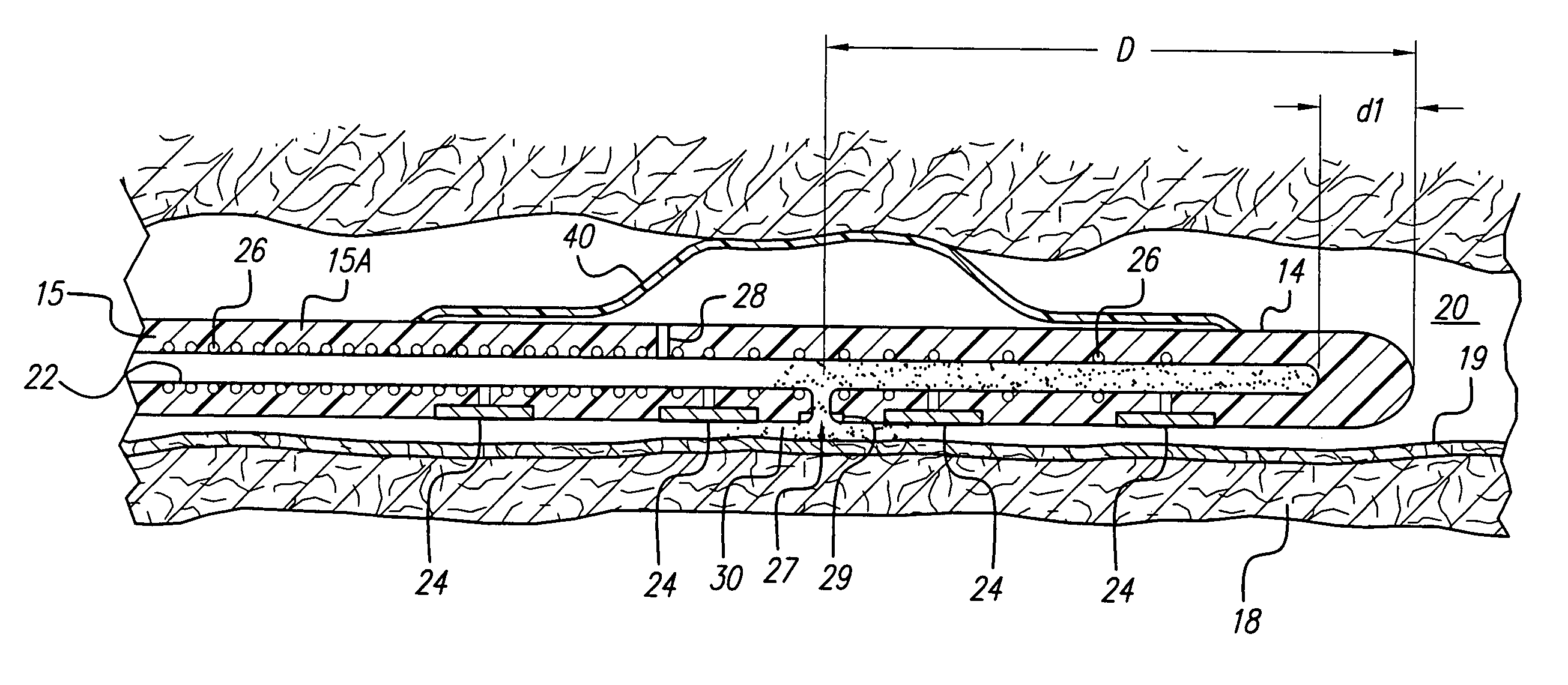

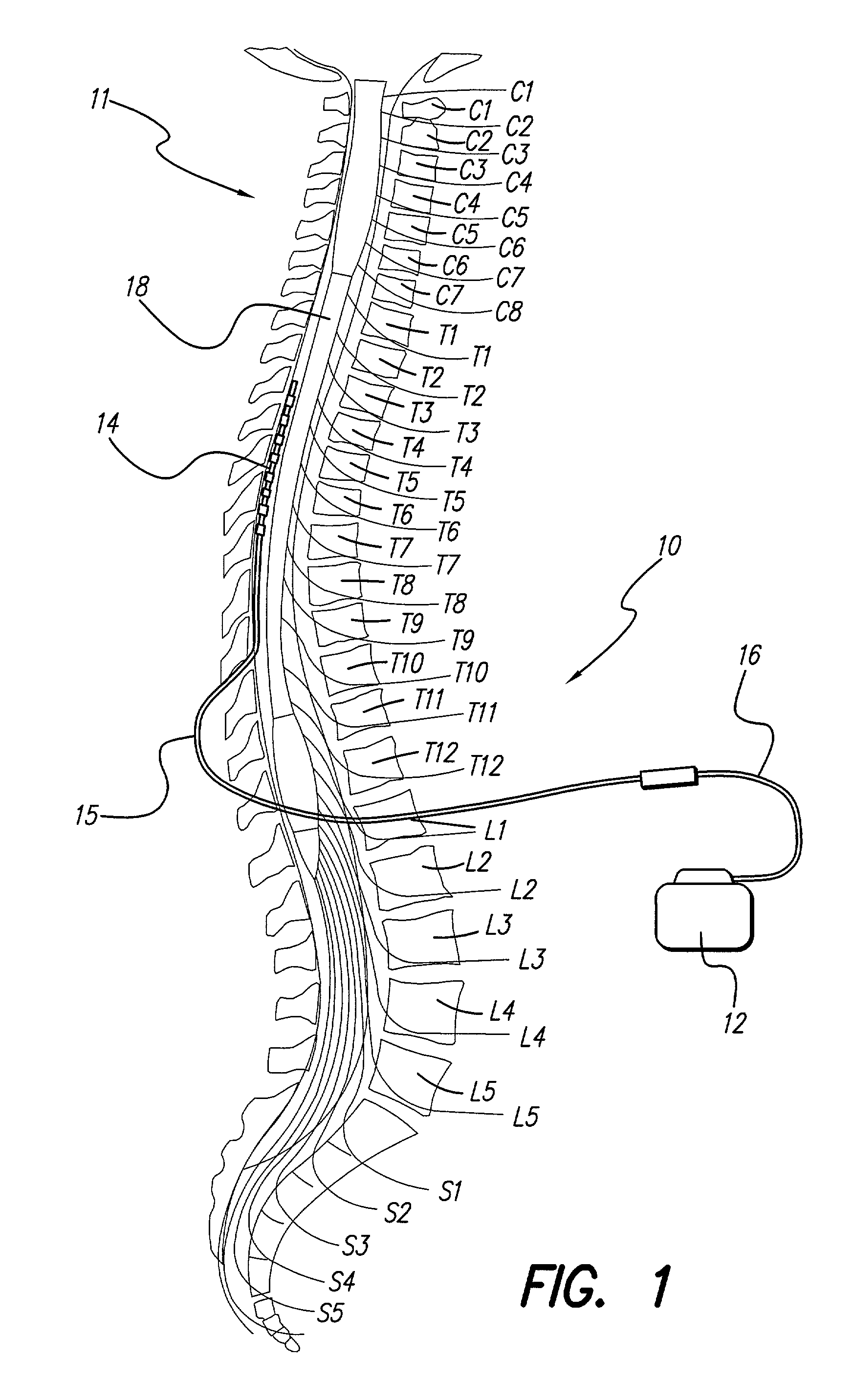

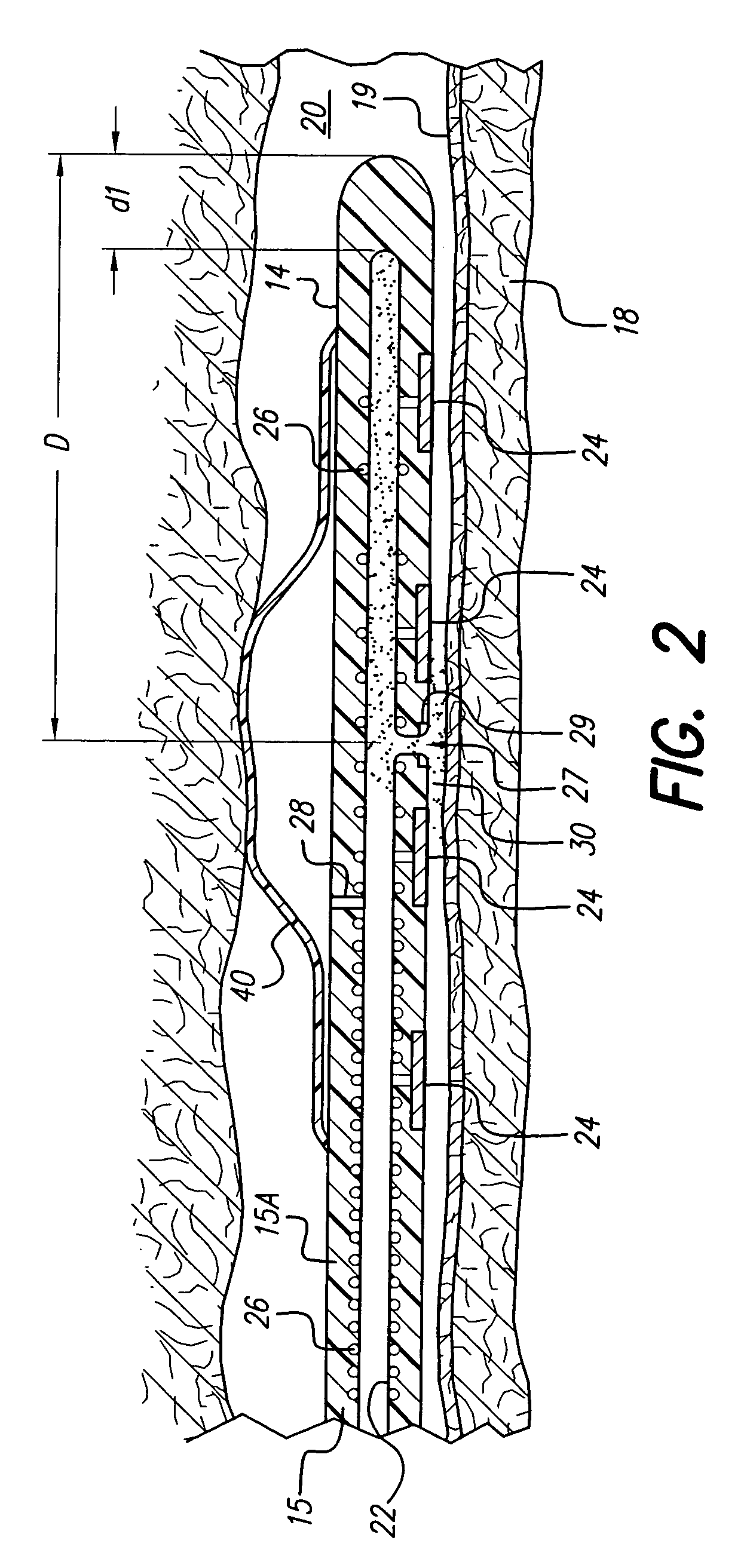

Neural stimulation lead fixation

An implantable lead having at least one electrode contact at or near its distal end prevents undesirable movement of the electrode contact from its initial implant location. One embodiment relates to a spinal cord stimulation (SCS) lead. A balloon may be positioned on the electrode lead array. The balloon is filled with air, liquid or a compliant material. When inflated, the balloon stabilizes the lead with respect to the spinal cord and holds the lead in place. The pressure of the balloon is monitored or otherwise controlled during the filling process in order to determine at what point the filling process should be discontinued. An elastic aspect of the balloon serves as a contained relief valve to limit the pressure the balloon may place on the surrounding tissues when the epidural space is constrained.

Owner:BOSTON SCI NEUROMODULATION CORP

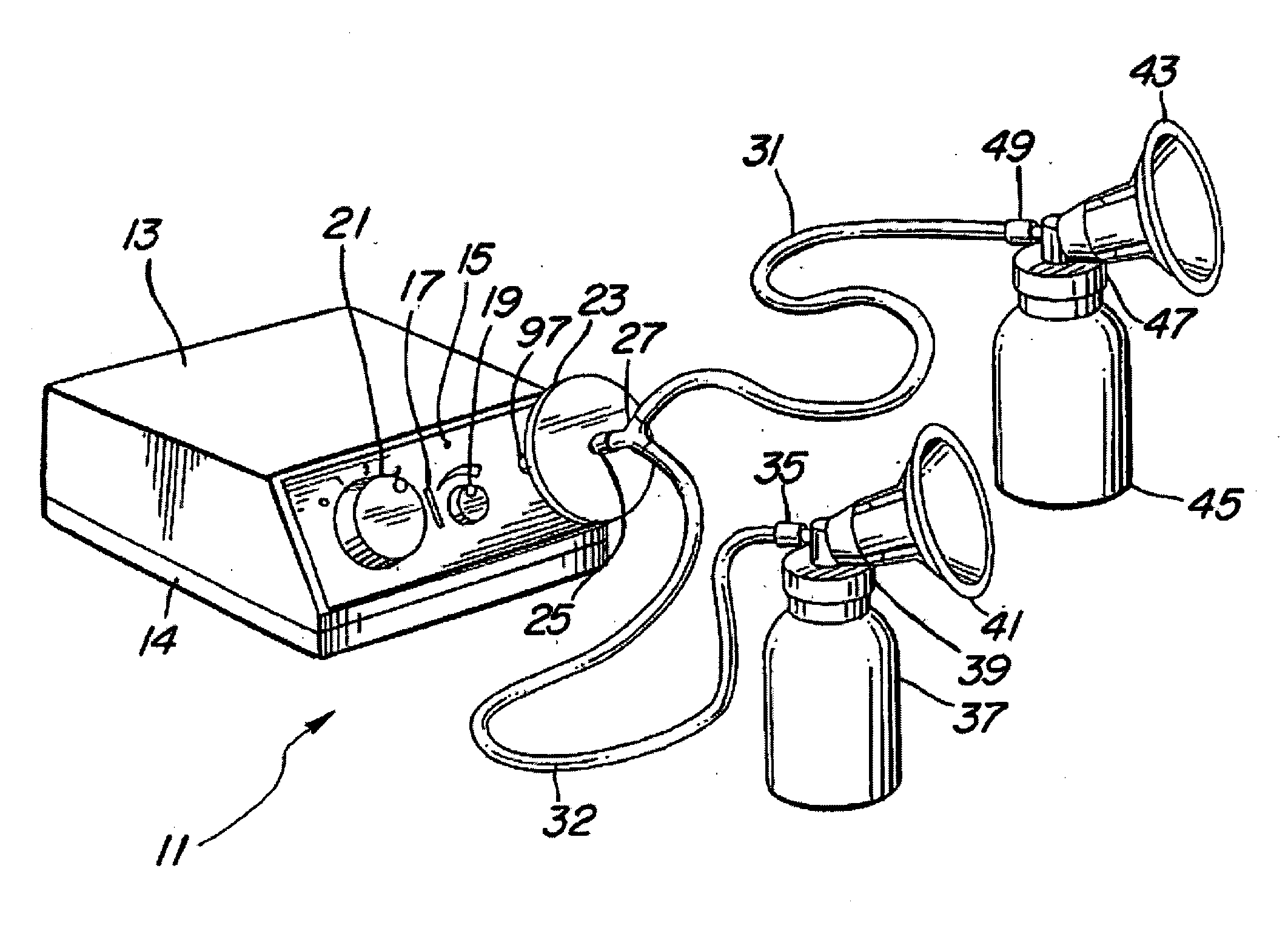

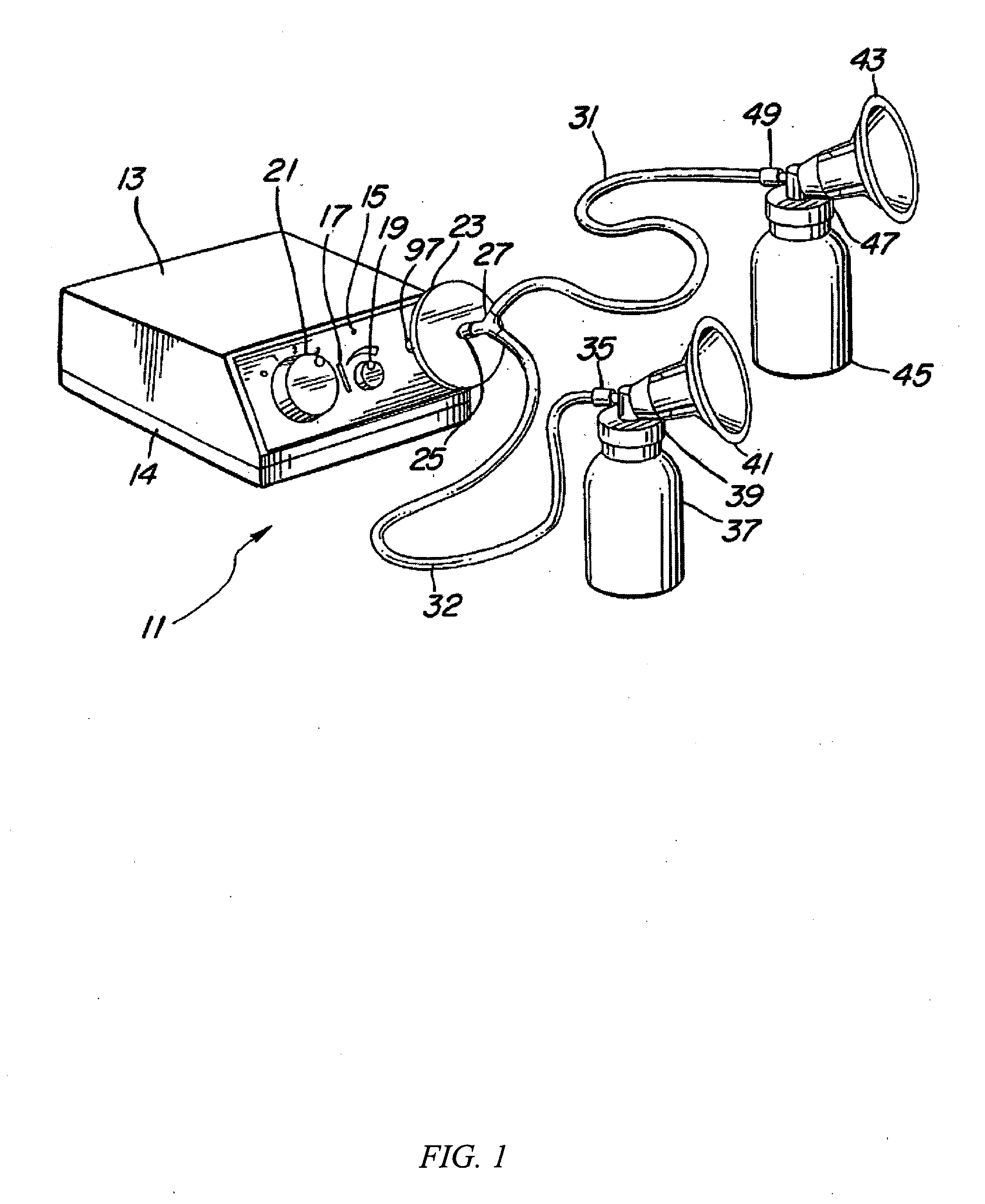

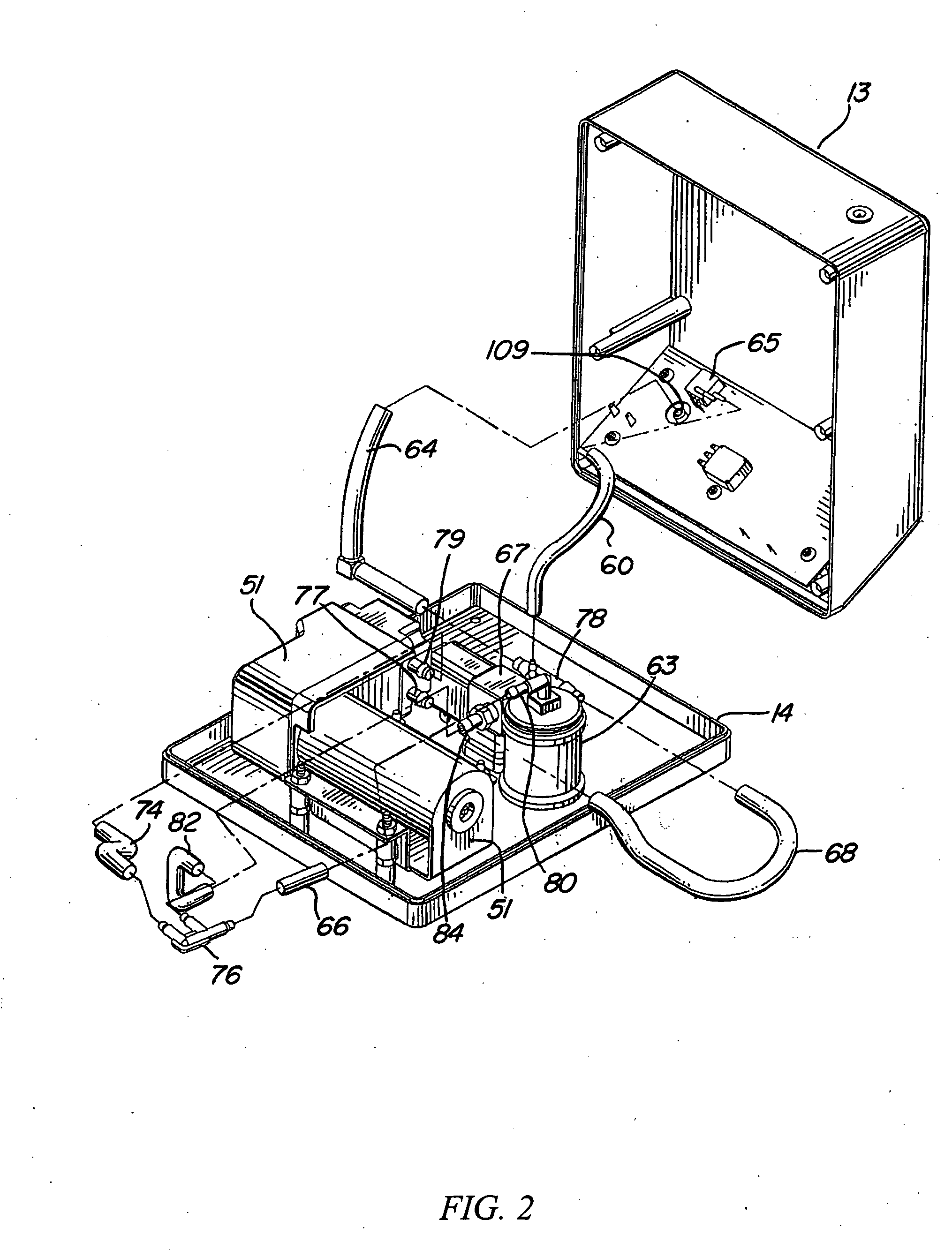

Programmable electric breast pump

A programmable electric breast pump system includes a vacuum pump pneumatically coupled to breast cups and a vacuum relief valve bypassing the vacuum pump. A controller receives command input from a vacuum level selector and a vacuum rate selector, and feedback from a pressure sensor measuring vacuum in the breast cups. In response, the controller cycles the relief valve between minimum and maximum vacuum setpoints to create a periodic vacuum pulse in the breast cups. By adjusting the vacuum min / max levels and vacuum rate, a user may change the strength of the pulse after let-down, or synchronize the frequency of the pulse with the natural refractory time of a lactating breast. Related methods for operating a breast pump mimic the suckling cycle of a nursing infant and may include steps for bypassing a vacuum pump with a vacuum relief valve, selecting a vacuum rate and a vacuum level, driving a vacuum pump at the selected vacuum rate, cycling the relief valve according to the vacuum level, and adjusting the vacuum level until the vacuum pulses in phase with a natural refractory time.

Owner:LIMERICK LTD

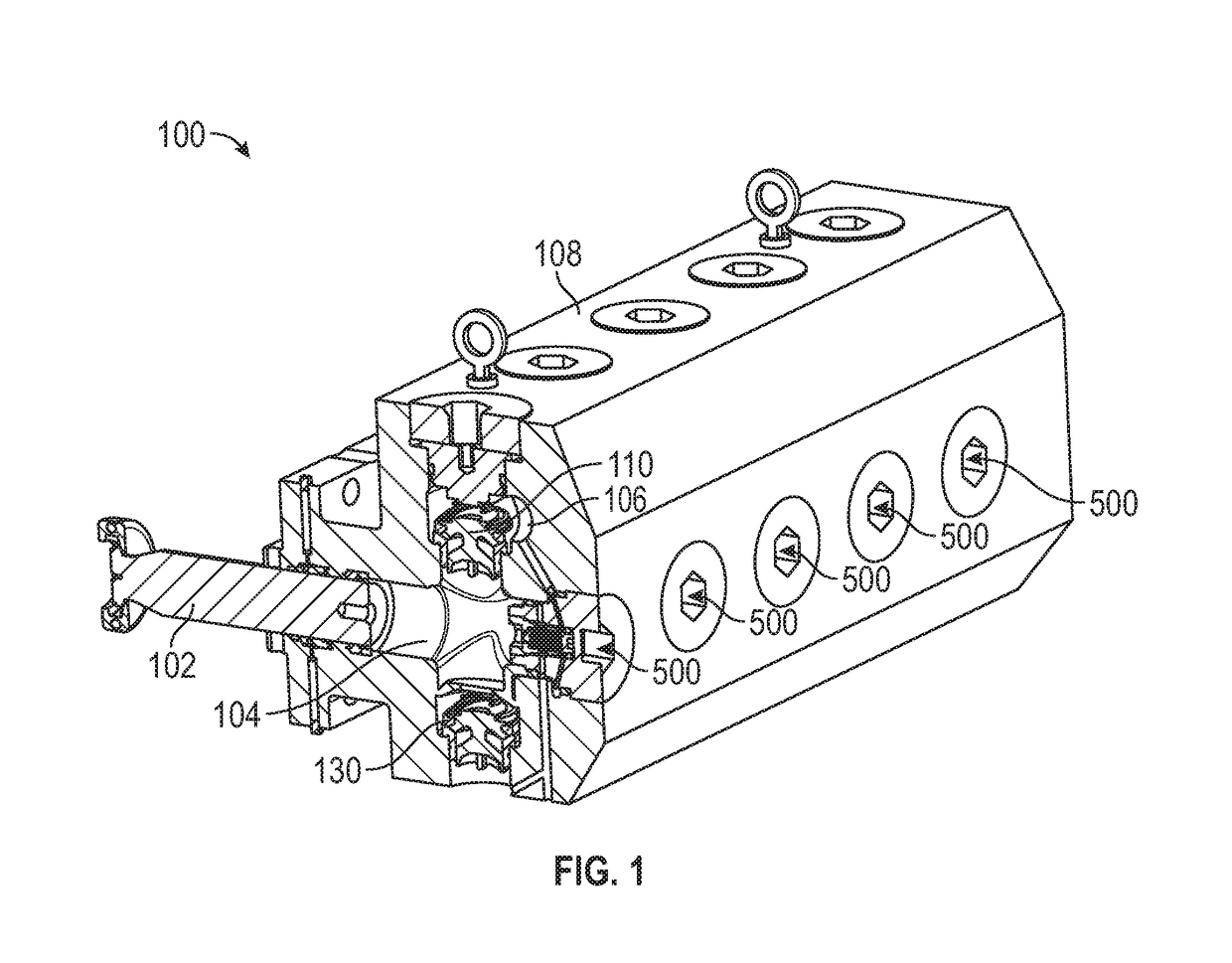

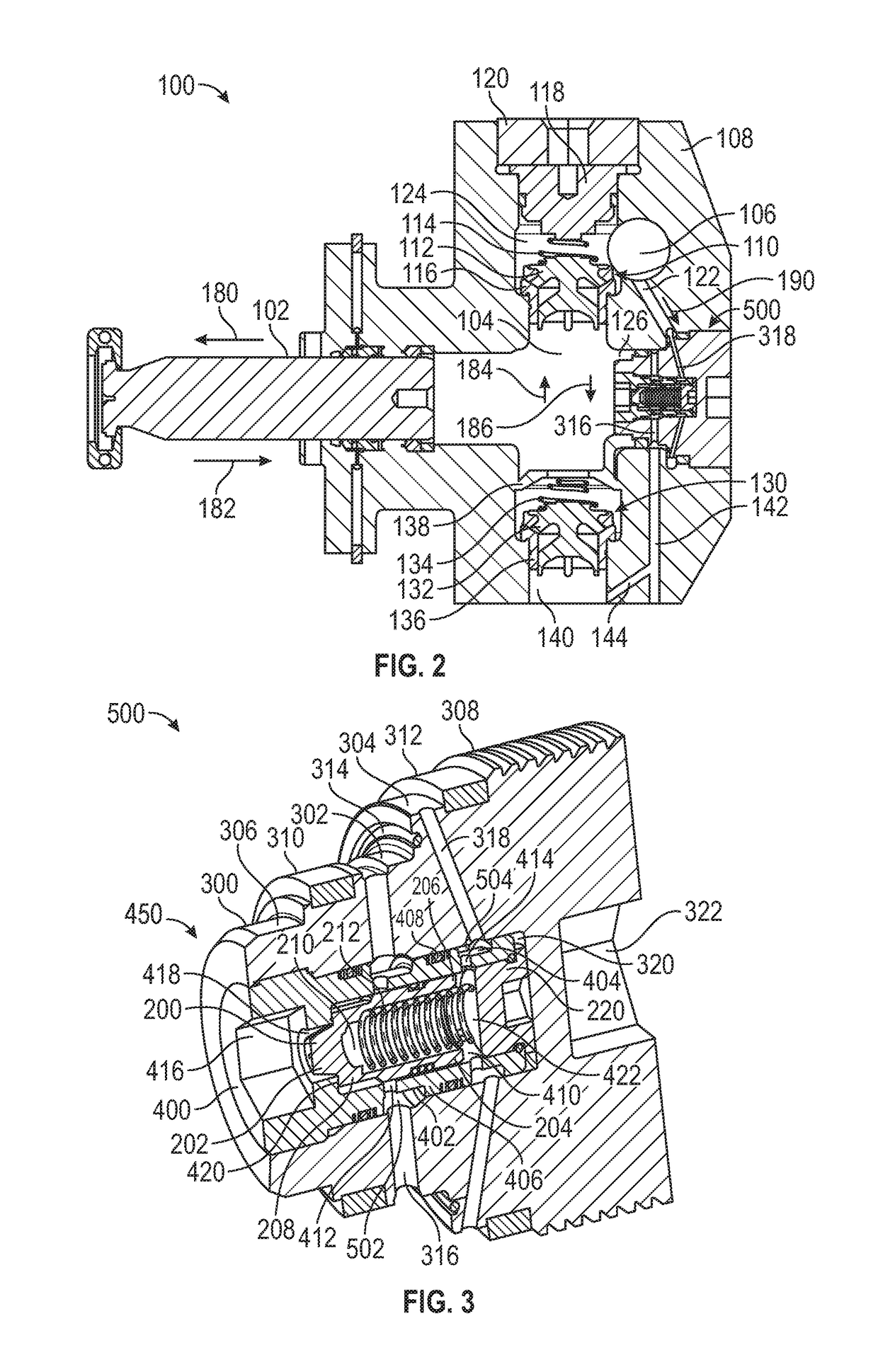

Over pressure relief system for fluid ends

ActiveUS10082137B2Fluid pressure sealed jointsPositive displacement pump componentsInlet pressurePiston

A relief valve assembly includes a housing assembly defining a chamber therein. The relief valve assembly includes a piston. The piston may be at least partially disposed within the chamber. The relief valve assembly includes a pilot inlet. The pilot inlet may be configured to provide a pilot pressure proximate a second end of the chamber. The relief valve assembly includes an overpressure inlet sealed from a first end of the chamber by the piston. The overpressure inlet may be configured to provide an inlet pressure which may actuate the piston when the inlet pressure exceeds the pilot pressure.

Owner:CATERPILLAR INC

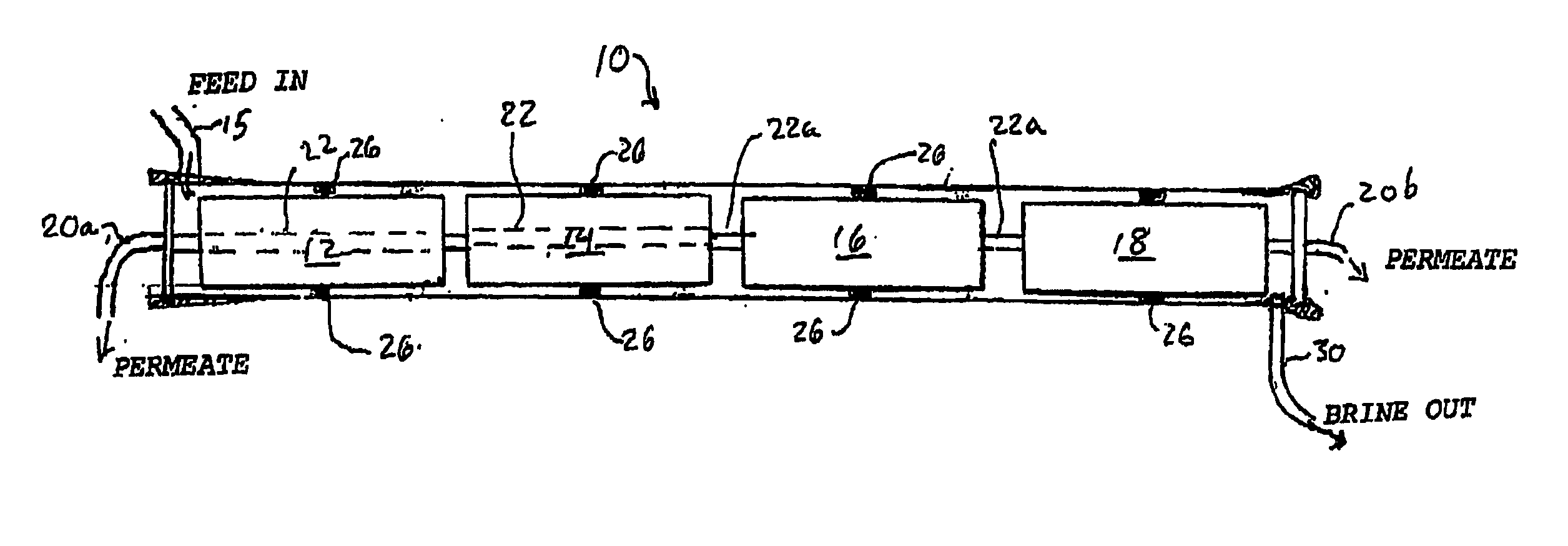

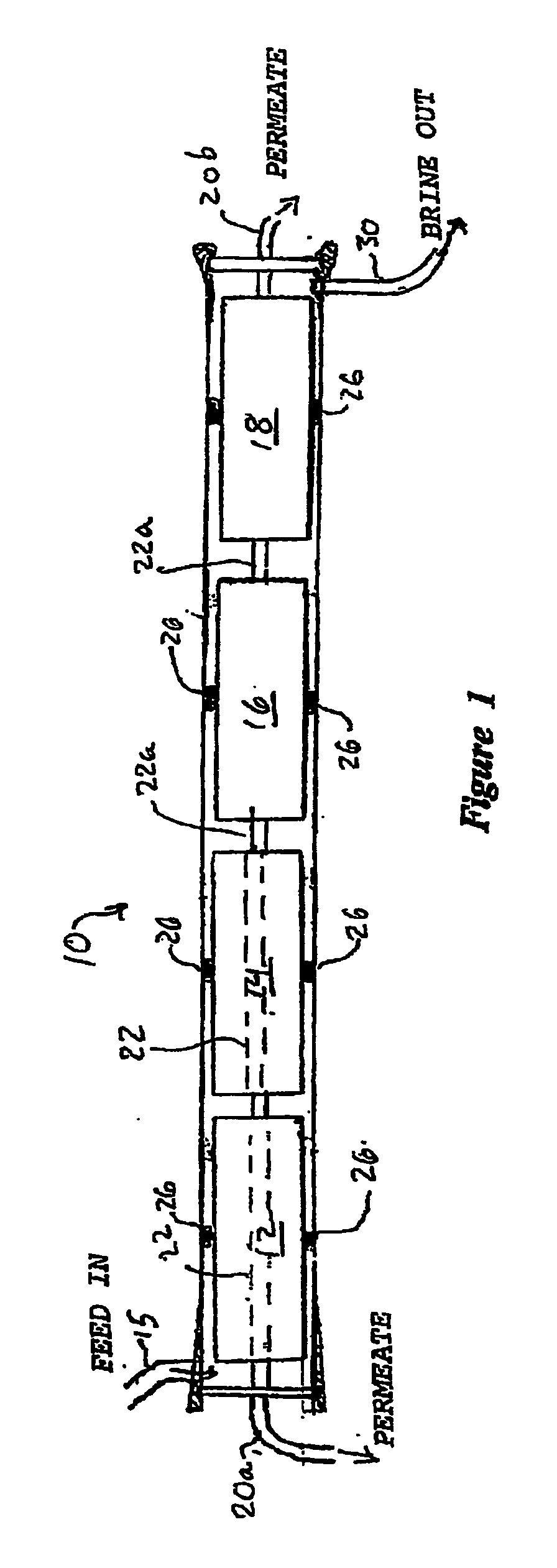

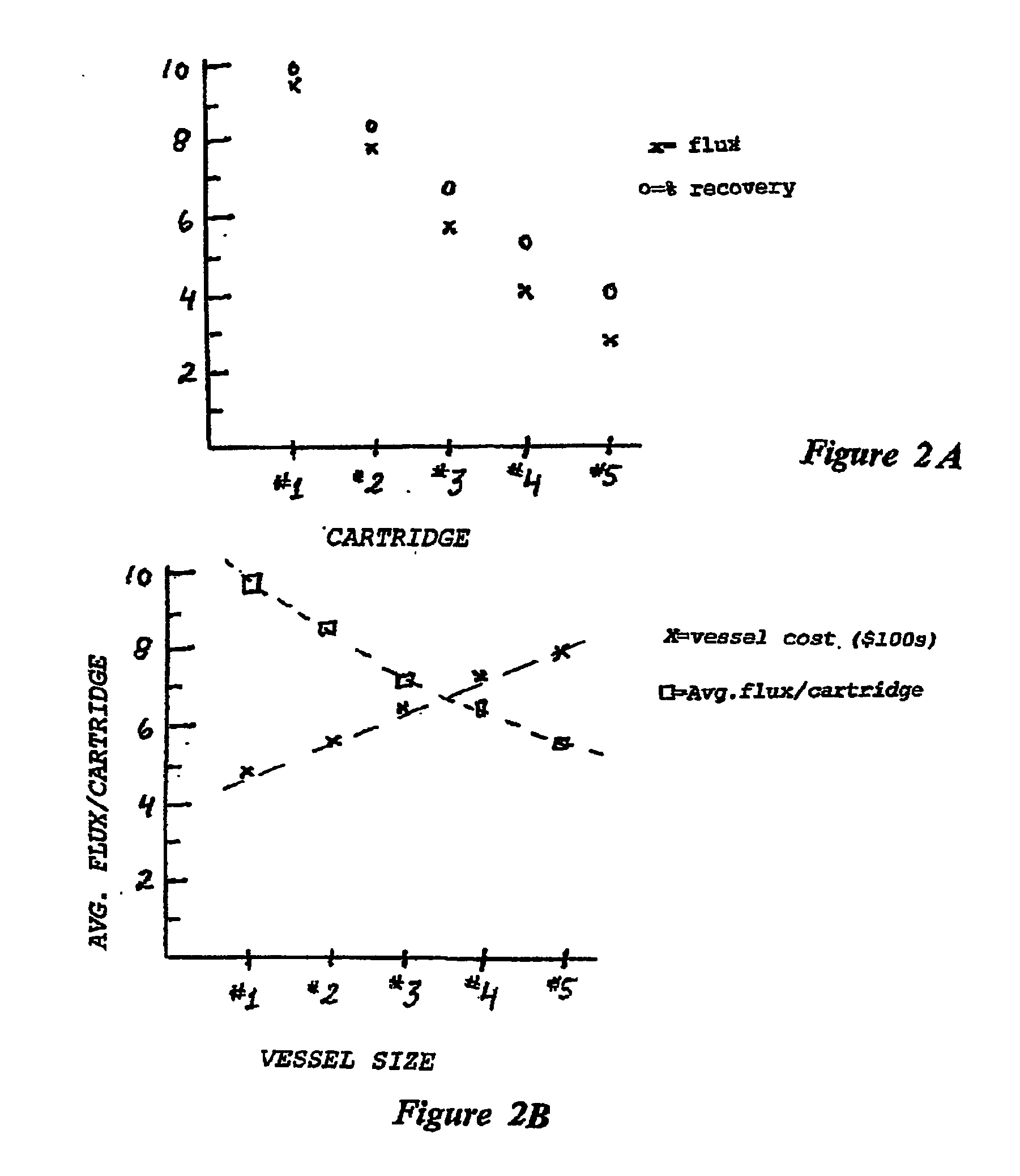

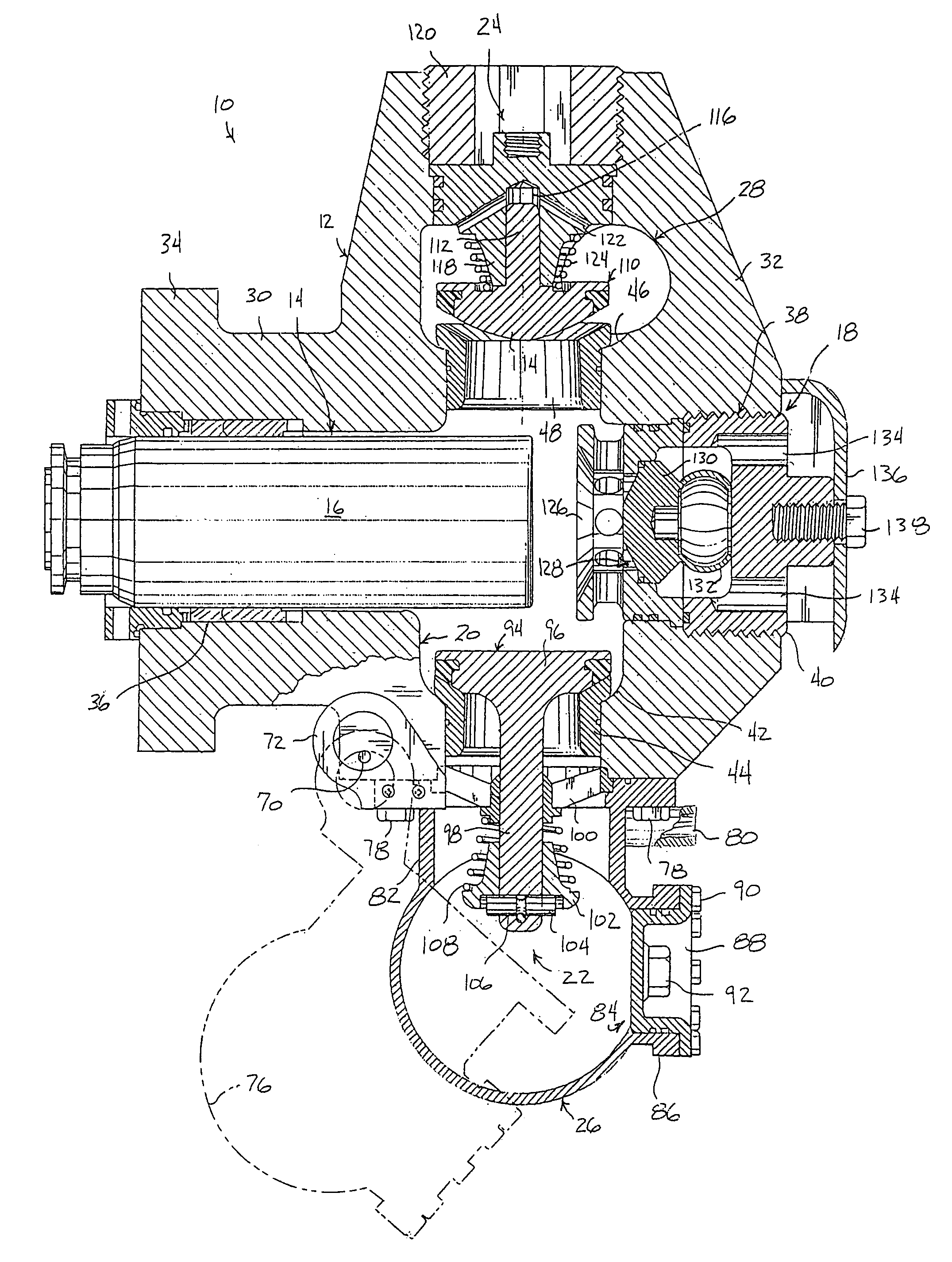

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

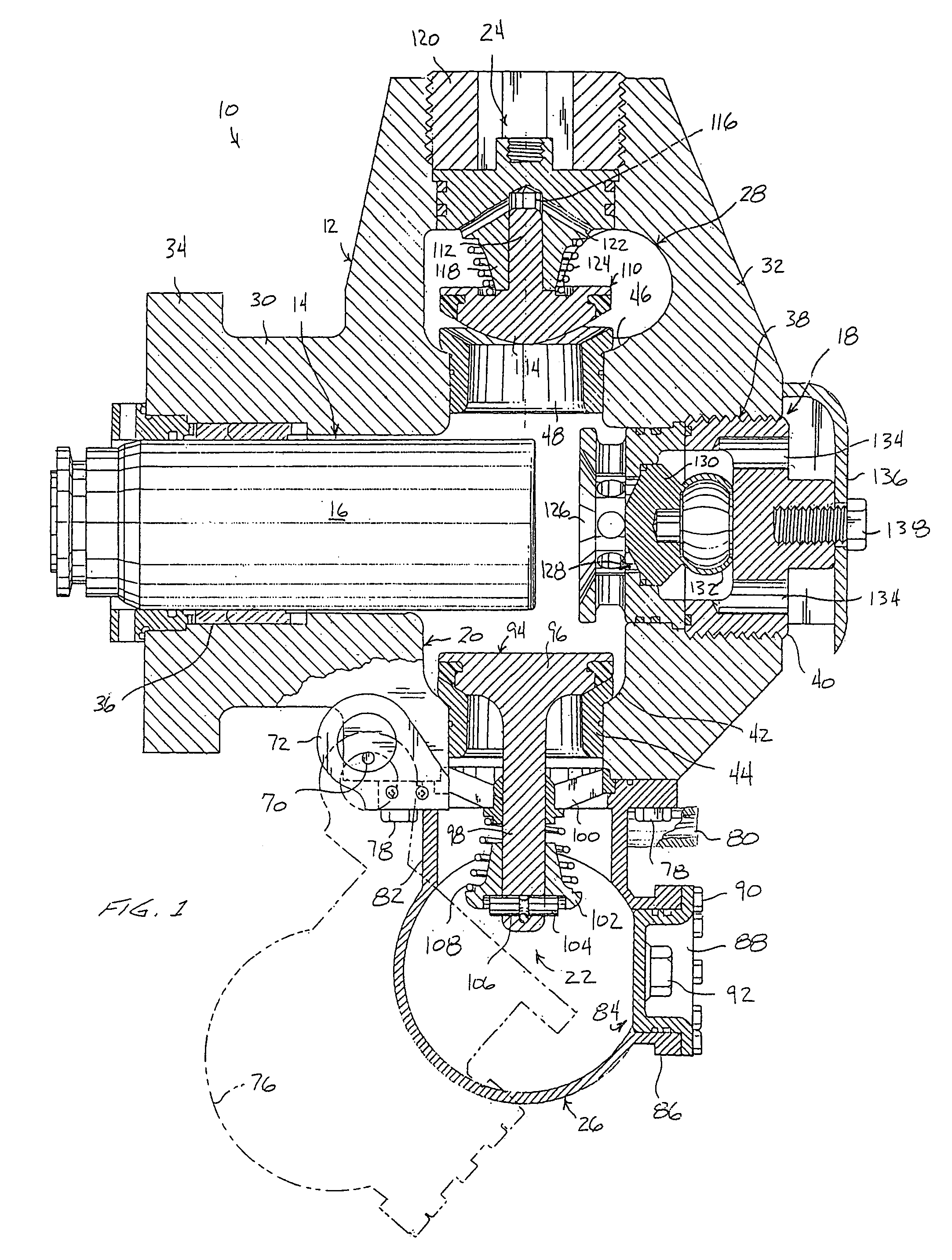

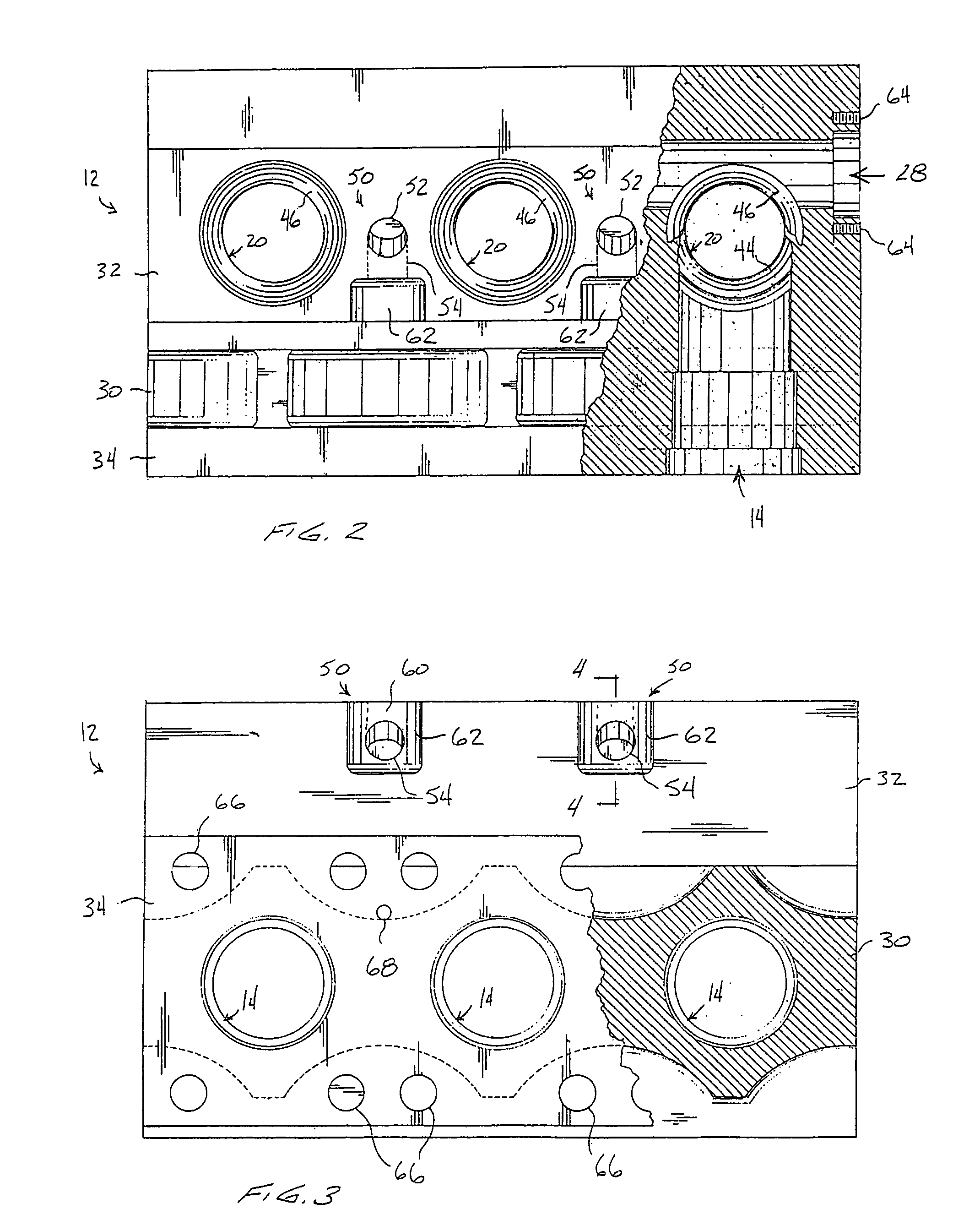

Fluid end

ActiveUS7335002B2High strengthIncreased durabilityPositive displacement pump componentsServomotor componentsEngineeringHigh pressure

A fluid end for a high-pressure pump including a unitary body with a plurality of horizontal passages each for receiving a reciprocating plunger at one of its ends and a pressure relief valve at the other of its ends. The body is provided with a corresponding number of vertical passages each of which intersect one of the horizontal passages and contains a suction valve at its bottom and a discharge valve at its top. A suction manifold is hingedly attached to the bottom of body to provide a flow of fluid into the body via the suction valves. A discharge passage intersects the vertical passages and receives fluid pressurized by the plungers via discharge valves and ports such from the fluid end.

Owner:GD ENERGY PROD LLC

Breathing assistance apparatus

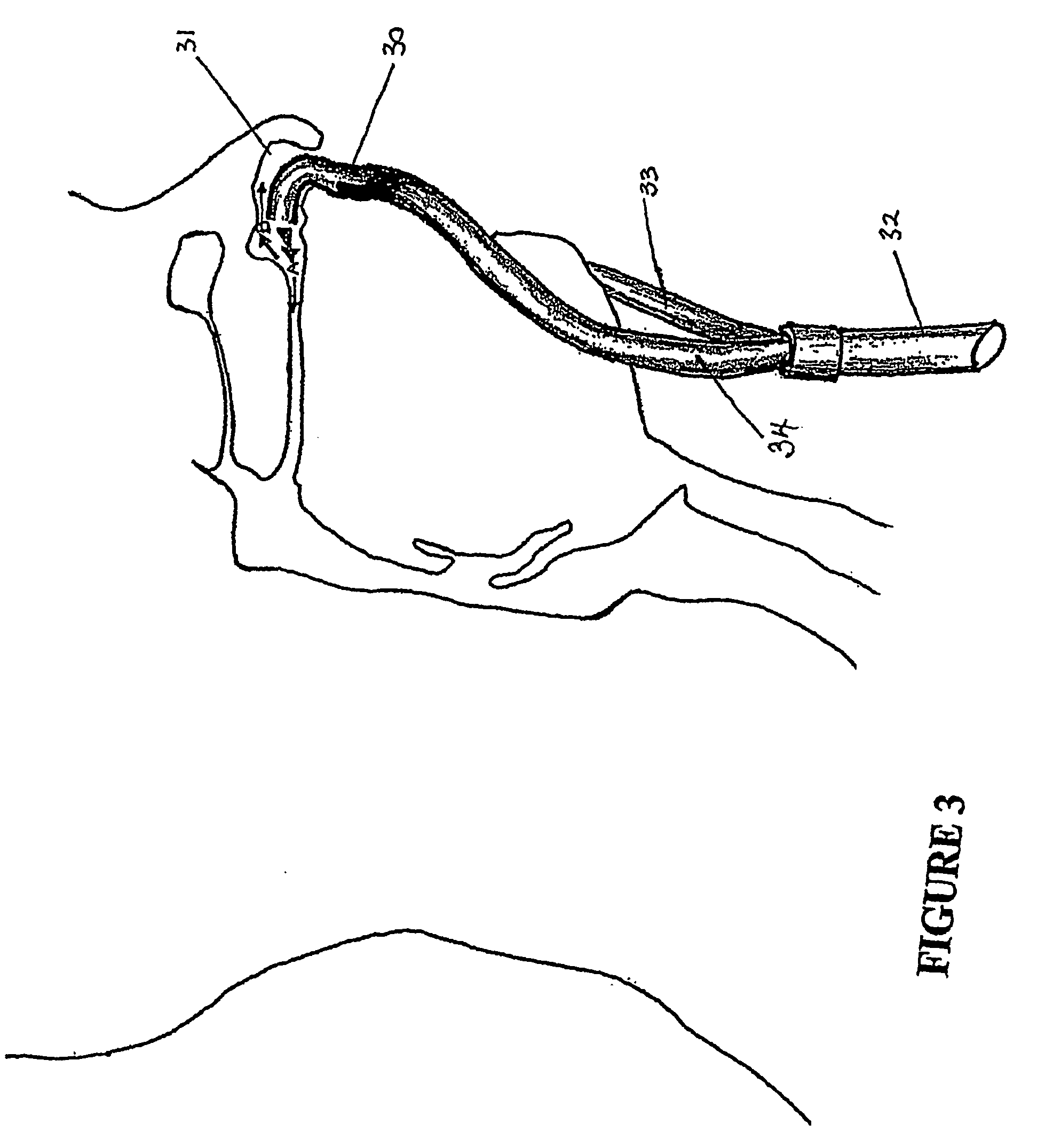

The present invention relates to the delivery of high flow humidified pressurised oxygen and / or air to a patient by way of a wide bore nasal cannula (30). The cannula of the present invention comprises wide bore cannula to minimise the flow resistance and the entry velocity. The nasal cannula includes two nasal prongs (40, 41) fittable into a patient's nostrils. The prongs follow the inner shape of the patient's nostrils such that a more efficient flow of gases into the patient's lungs is achieved as gases flow are directed down the main nasal passage more accurately. The cannula do not seal within the nasal cavities of the patient, and in some embodiments the cannula may be provided with a pressure relief valve to allow gases to be exhausted from the cannula.

Owner:FISHER & PAYKEL HEALTHCARE LTD

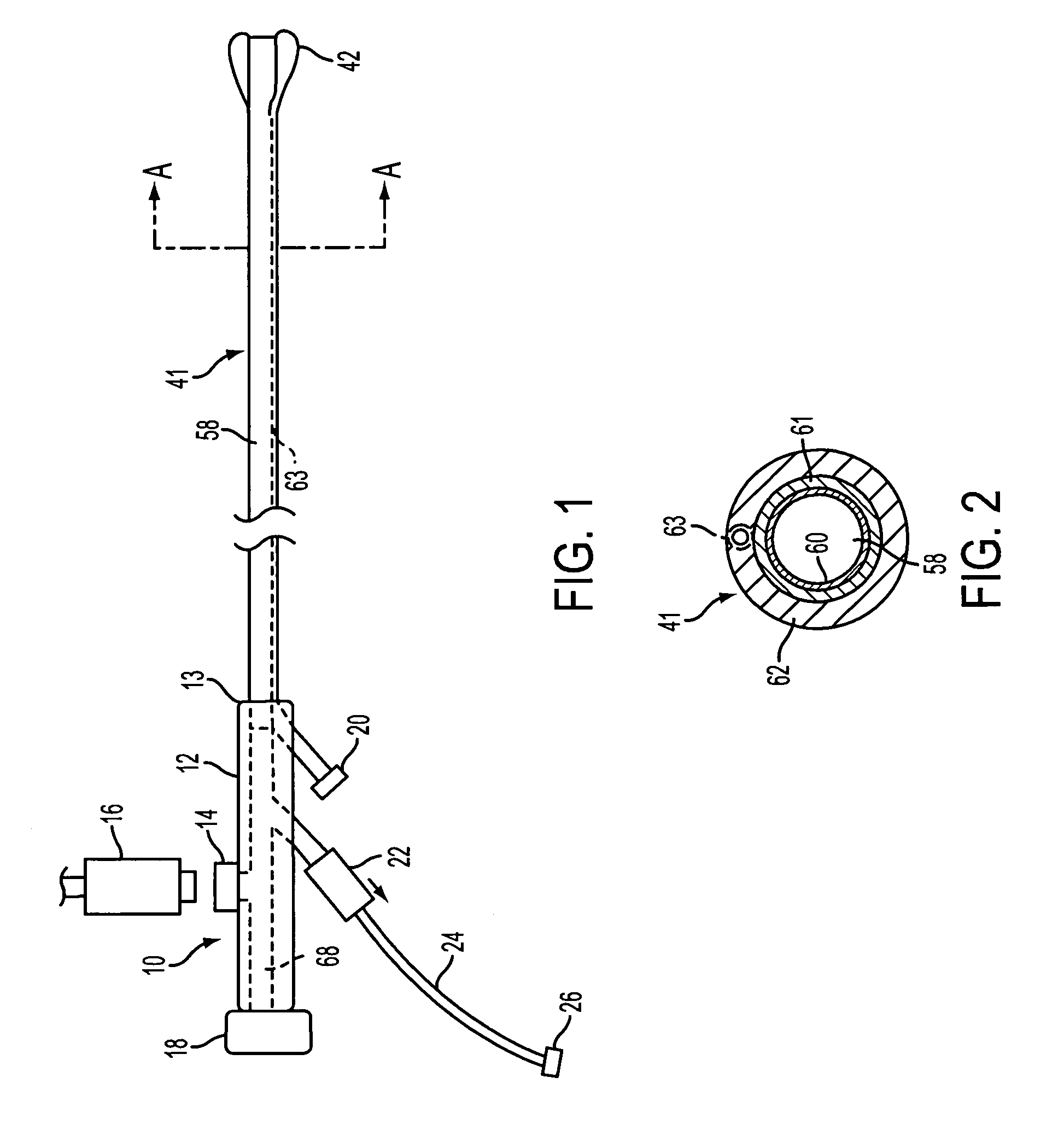

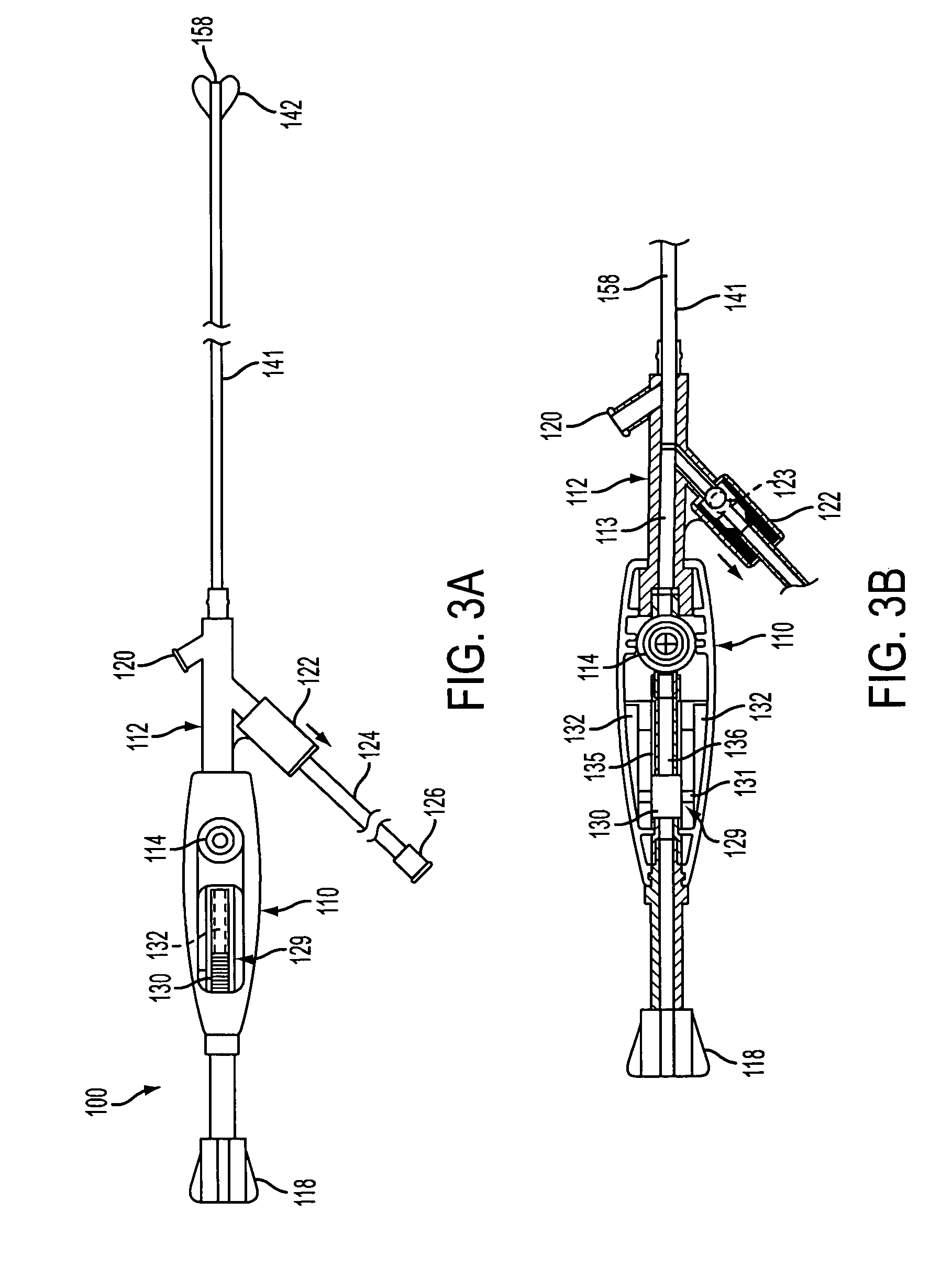

Proximal catheter assembly having a self-limiting aspiration valve

InactiveUS7004931B2Efficient removalIncrease chanceCatheterExcision instrumentsSelf limitingHigh rate

The present invention is directed to a proximal catheter assembly configured to facilitate natural or suction-assisted aspiration through a catheter lumen. The proximal catheter assembly comprises a multi-function valve configured to perform functions associated with conventional check valves and relief valves. The valve is configured to regulate the direction of fluid flow, and further configured to regulate the rate of suction-assisted aspiration provided through the lumen of the catheter. When the rate of suction-assisted aspiration exceeds a predetermined threshold, the valve opens to allow fluid to be drawn from tubing coupled to the proximal catheter assembly, thereby mitigating excessively high rates of aspiration imposed upon the patient's vessel.

Owner:WL GORE & ASSOC INC

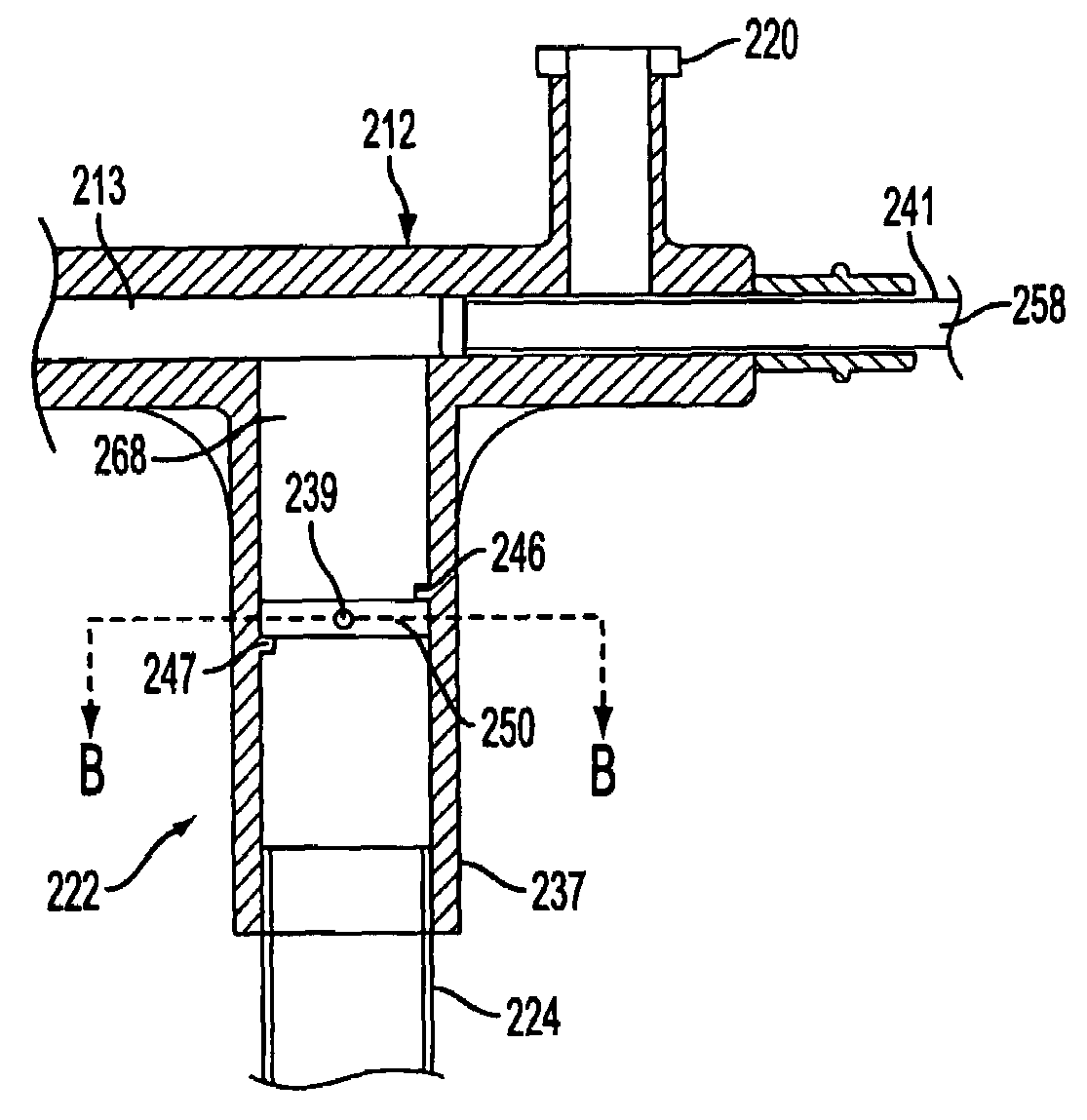

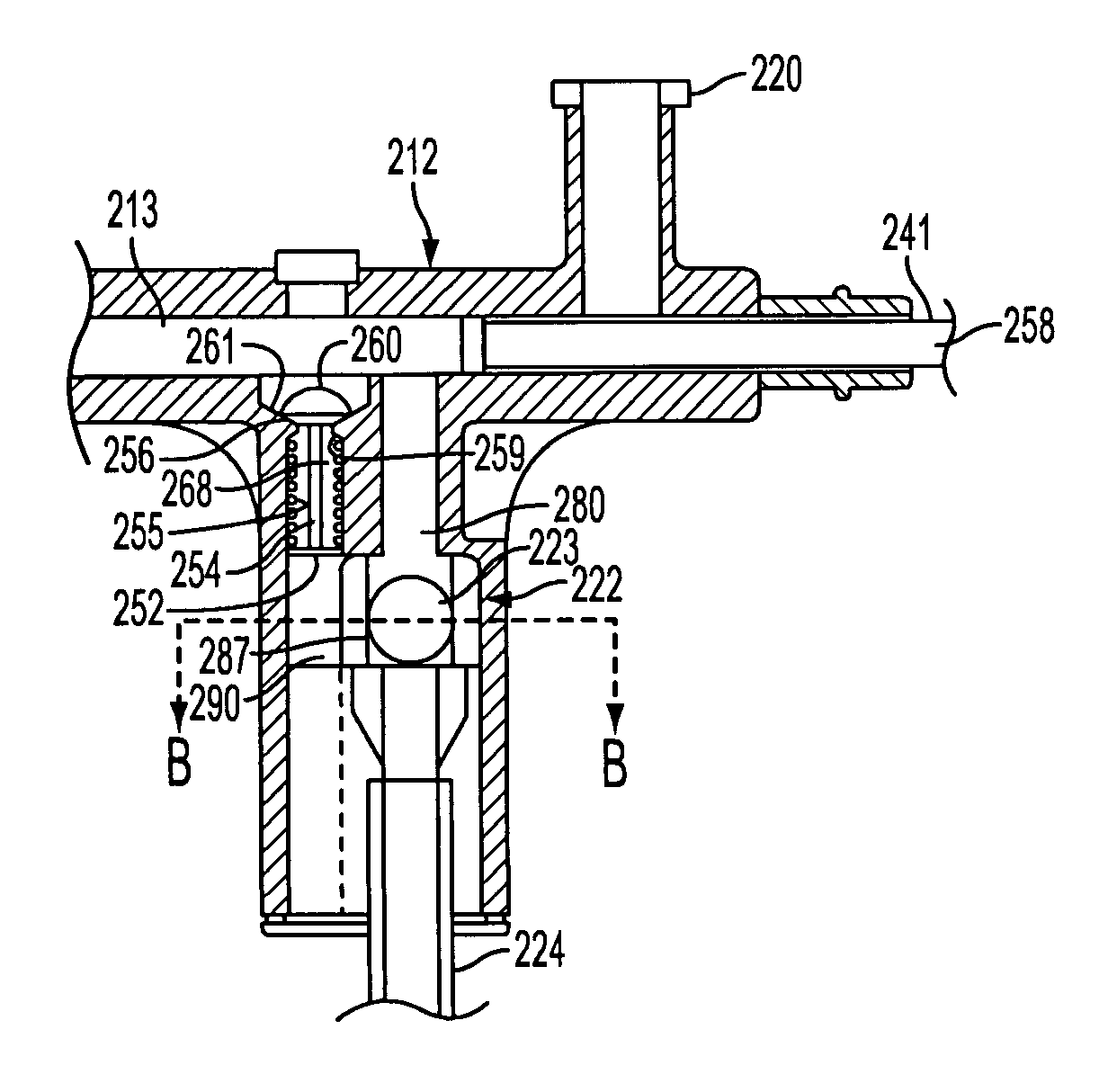

Proximal catheter assembly having a relief valve

The present invention is directed to a proximal catheter assembly that is configured to facilitate natural or suction-assisted aspiration through a catheter lumen. The proximal catheter assembly comprises a relief valve configured to regulate the level of suction-assisted aspiration provided through the working lumen of the catheter. When the level of suction-assisted aspiration exceeds a predetermined threshold, the relief valve opens to allow fluid to be drawn from tubing coupled to the proximal catheter assembly, thereby mitigating the relatively high levels of aspiration imposed upon the working lumen and the patient's vessel.

Owner:WL GORE & ASSOC INC

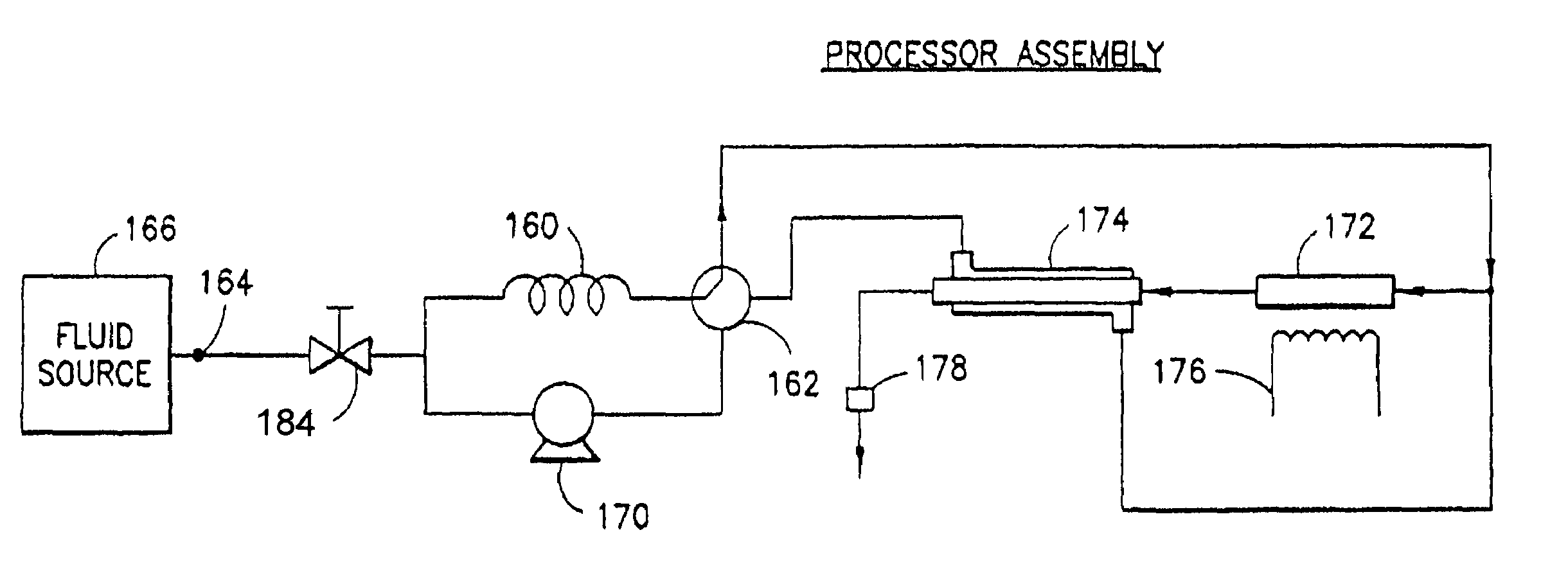

Apparatus and method for continuous depyrogenation and production of sterile water for injection

InactiveUS7122149B2Simple yet dependableReduce contact timeDialysis systemsTreatment involving filtrationDepyrogenationIon exchange

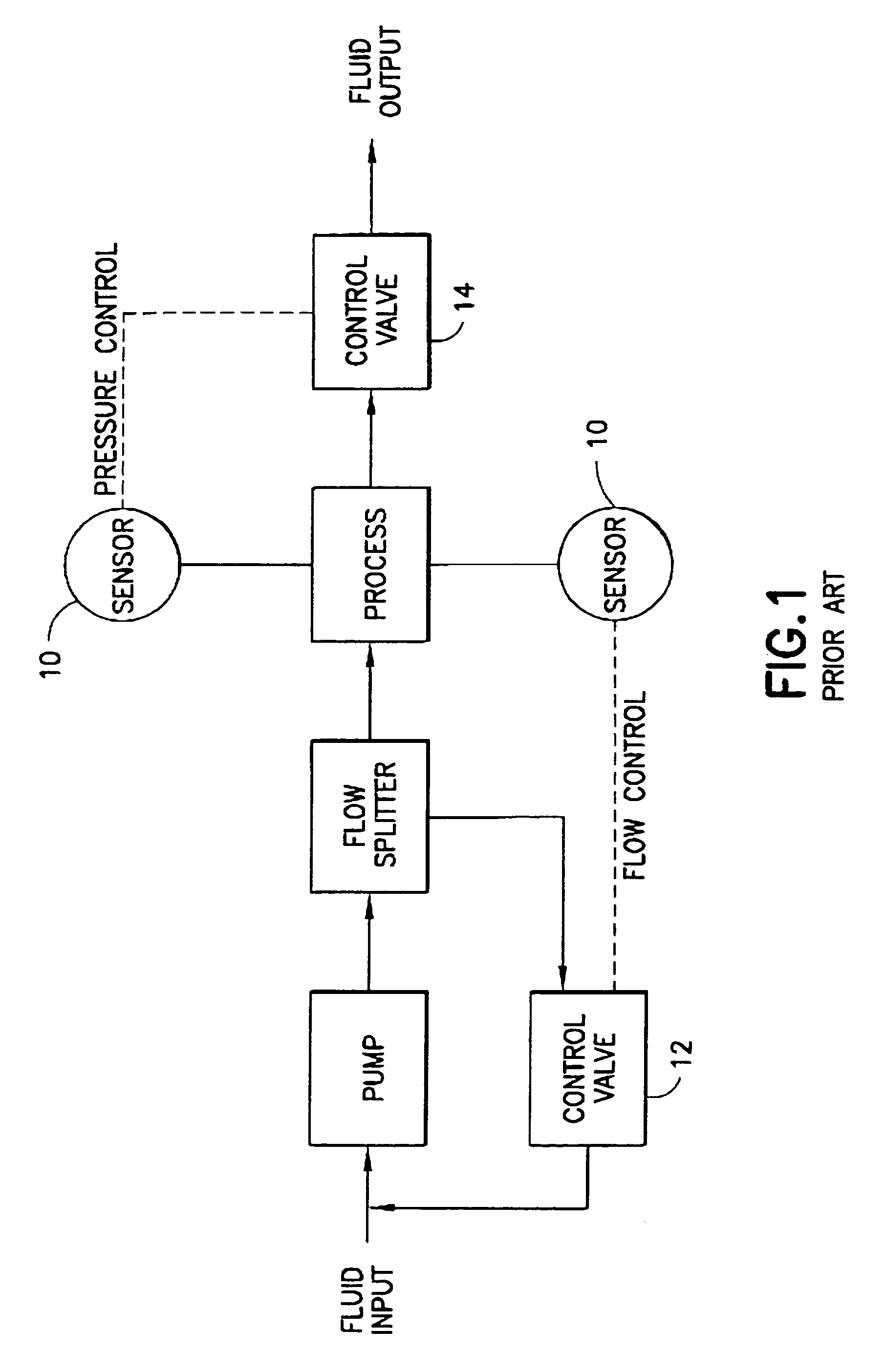

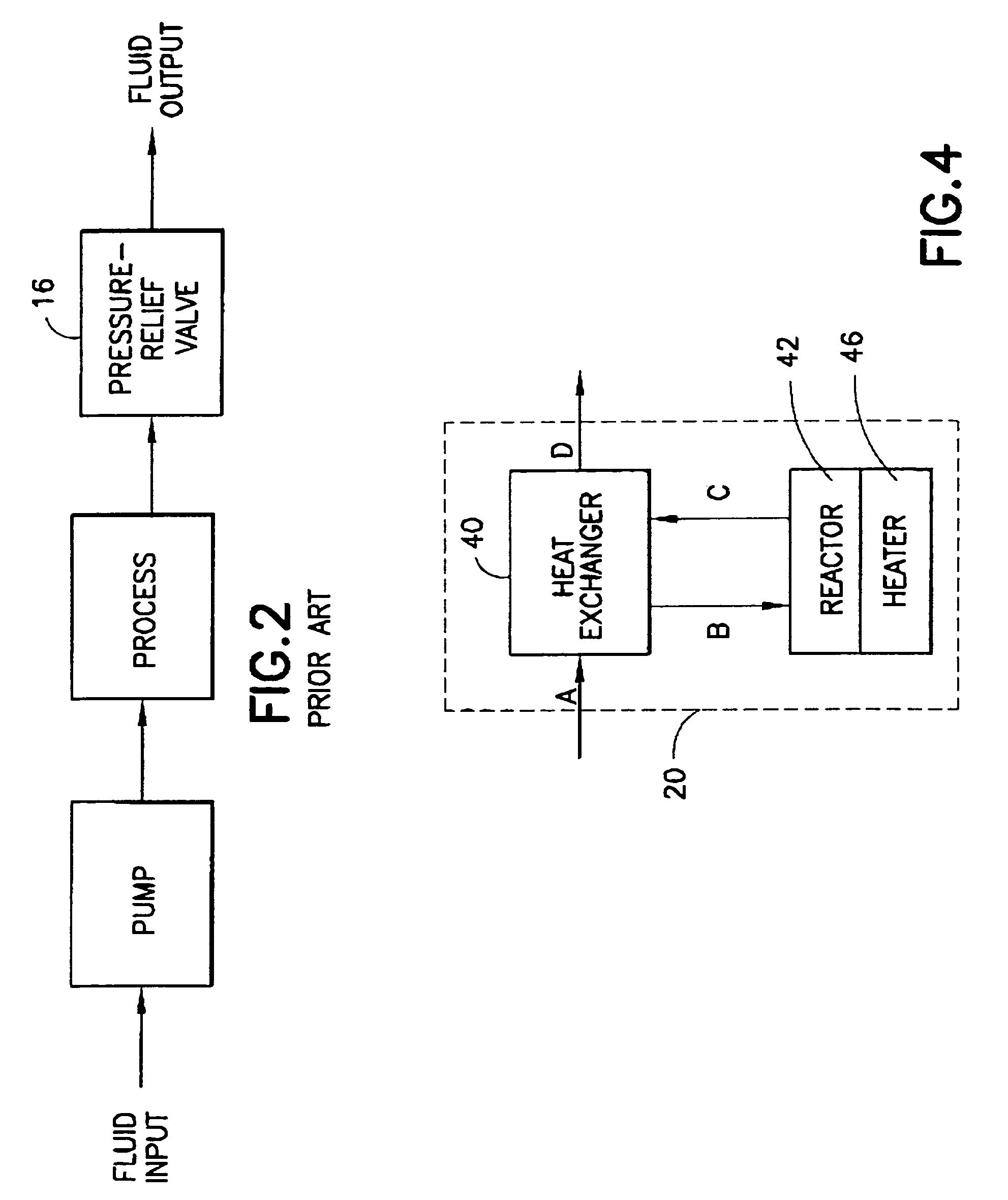

A fluid processor, suitable for the production of sterile water for injection, having a processor assembly and a process control system comprising a pump, a flow splitter, flow restrictors and a pressure relief valve. In a preferred embodiment, the processor assembly comprises a heat exchanger, a reactor and a heater arranged in a nested configuration. The preferred embodiment of the present invention also include a treatment assembly having a combination of filter, reverse osmosis and ion exchange devices and further incorporates an assembly and method allowing for the in situ sanitization of the fluid processor during cold start and shutdown to prevent bacteria growth during storage of the fluid processor. The fluid processor may include an electronic control system comprising a touch screen operator interface, a programmable logic controller and sensors for measuring temperature, pressure, flow rate, conductivity and endotoxin level.

Owner:APPLIED RES ASSOCS INC

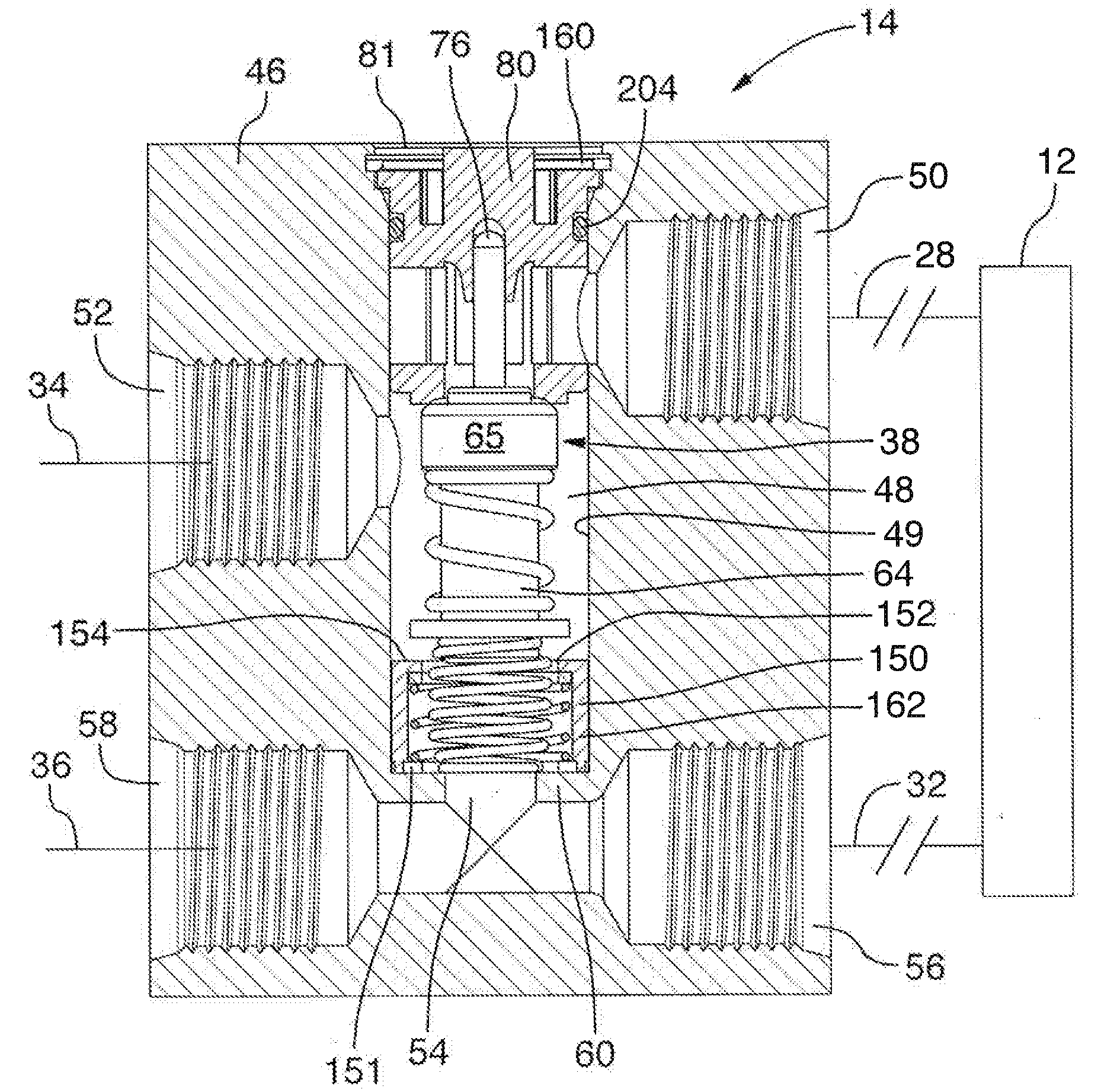

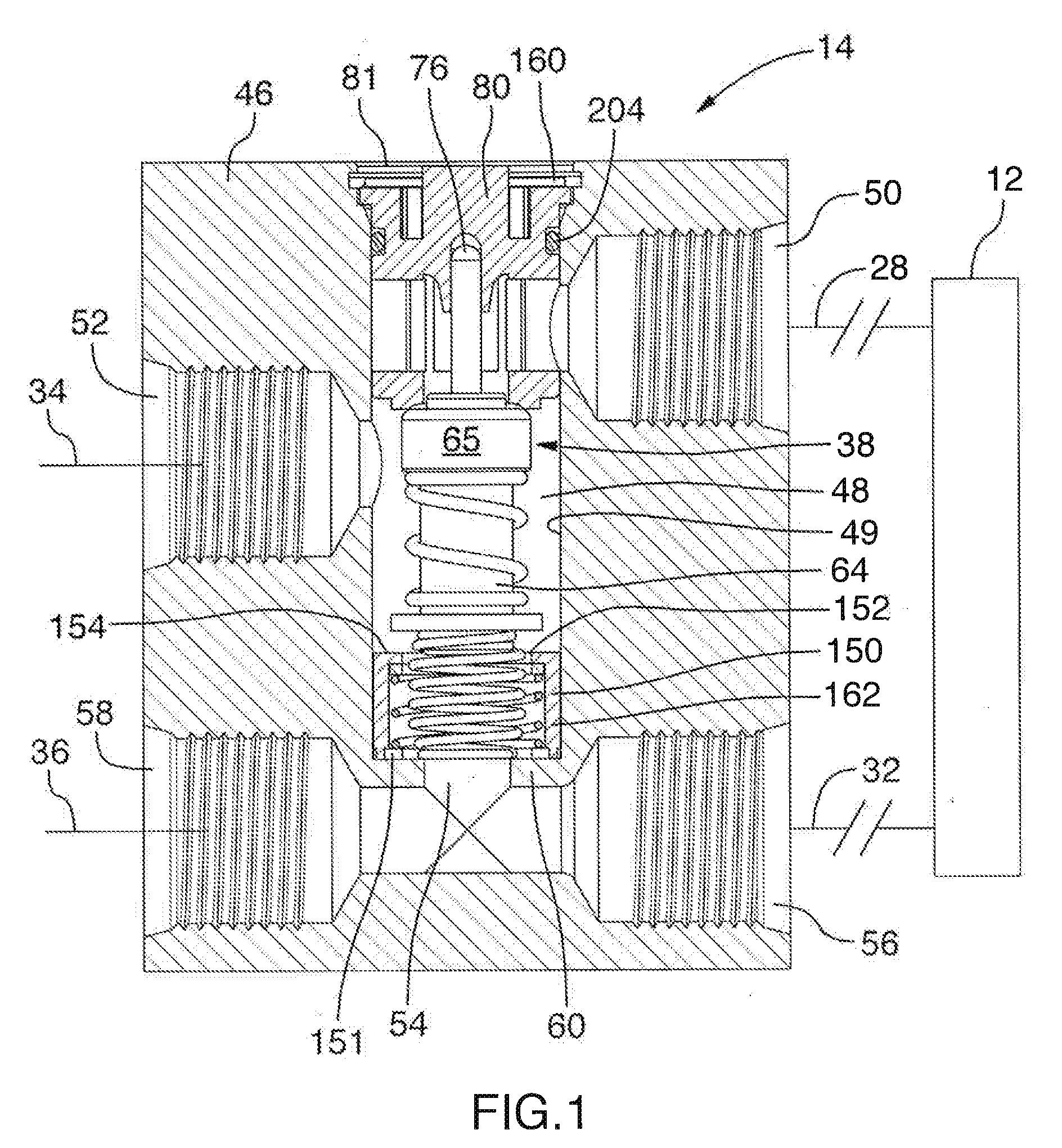

Thermal bypass valve with pressure relief capability

ActiveUS20100126594A1Relieve excessive stressIncrease dependenceTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringActuator

A by-pass valve for a heat exchanger circuit that includes a cooler has a chamber and ports for flow of fluid into and out of this chamber. A thermally sensitive actuator is mounted in the chamber and can extend or retract in dependence on its body temperature as influenced by temperature of the fluid. A by-pass valve seat is arranged in a valve housing along with a by-pass valve member movable by the actuator into or out of engagement with the seat. A relief valve is mounted in the chamber and has a relief valve member movable between closed and open positions in order to close or open pressure relief ports. This relief valve member is biased towards the closed position. Excessive pressure build up in an end section of the chamber causes the relief valve member to move to its open position.

Owner:DANA CANADA CORP

Variable speed hydraulic pump

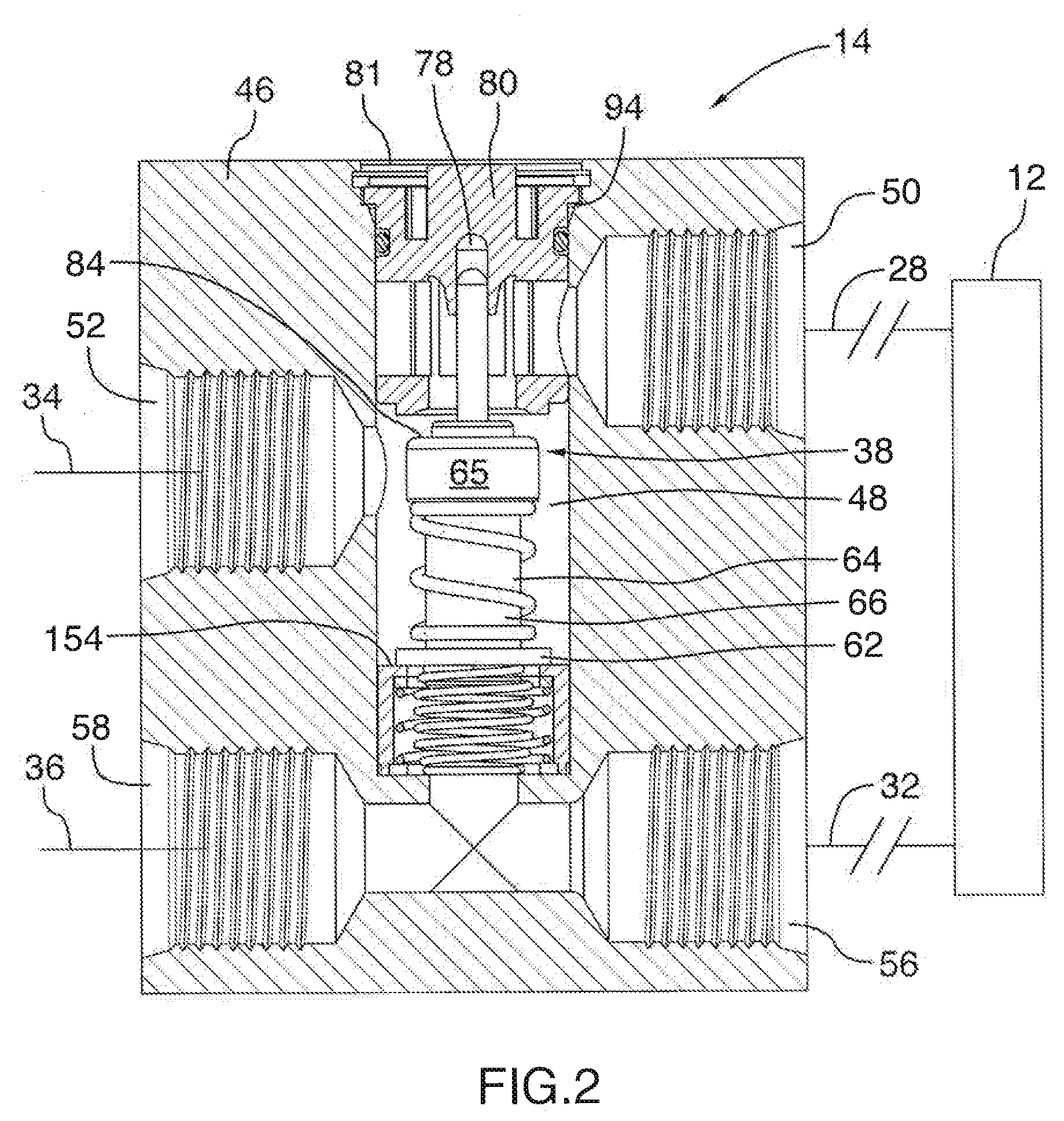

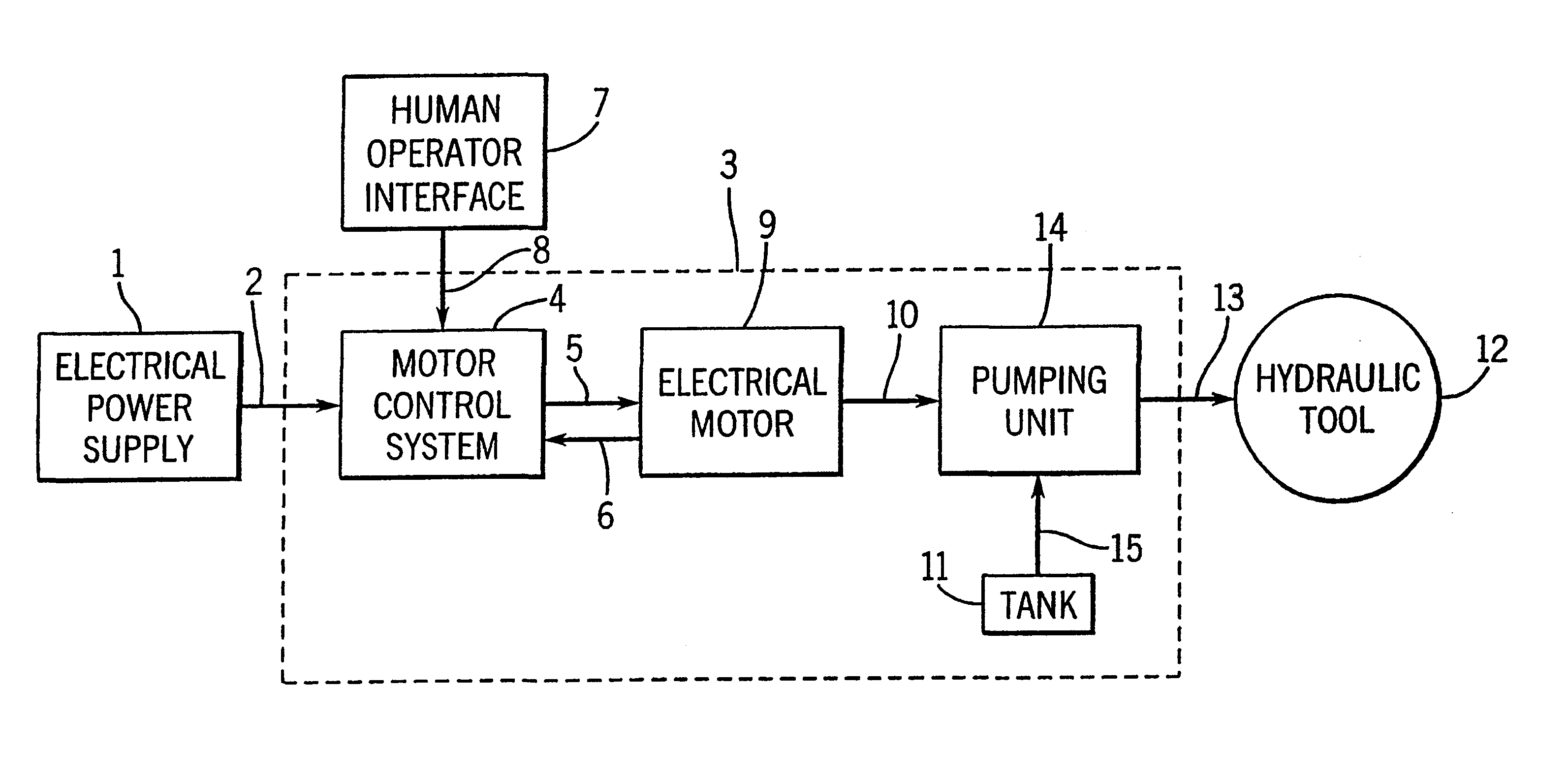

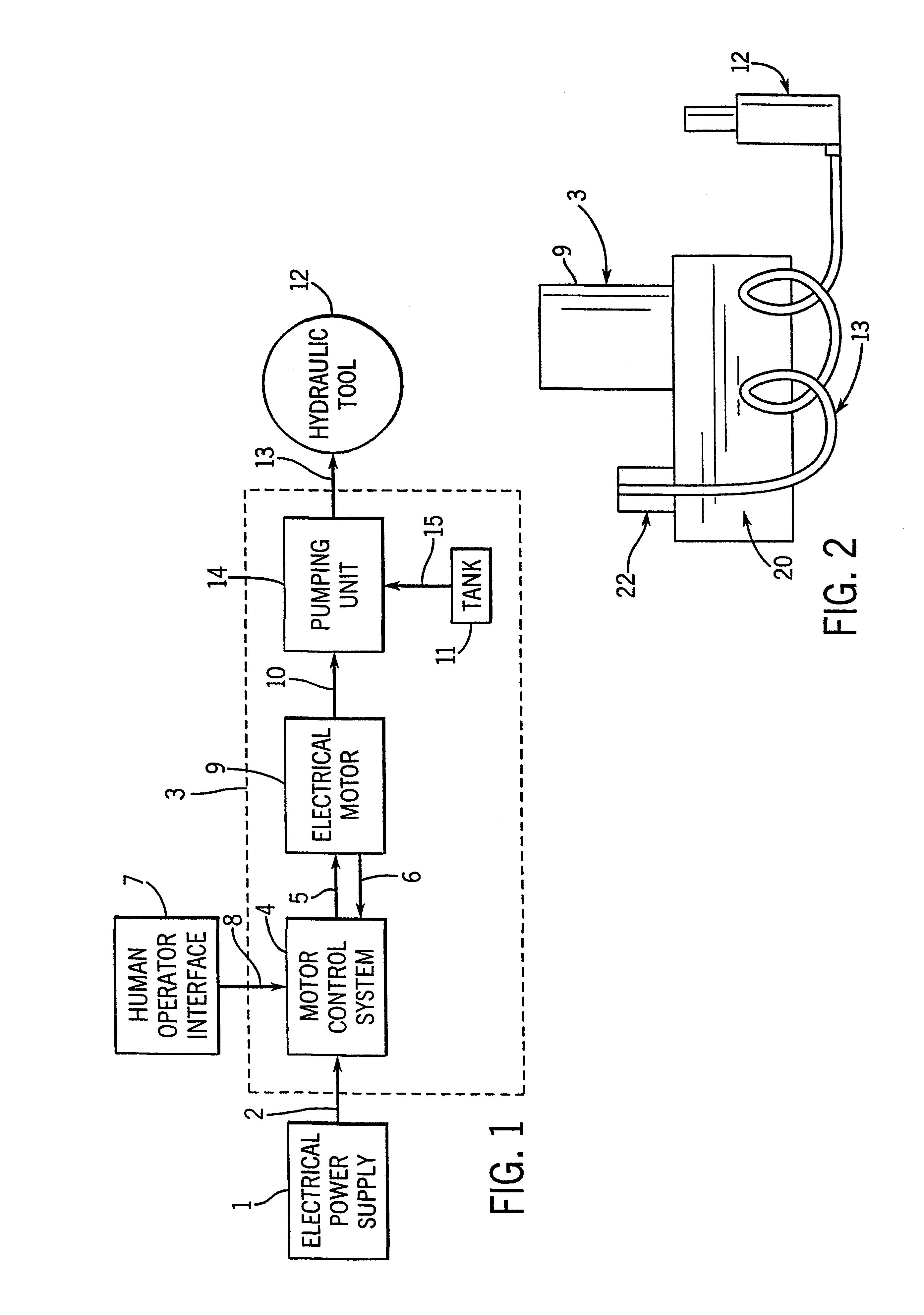

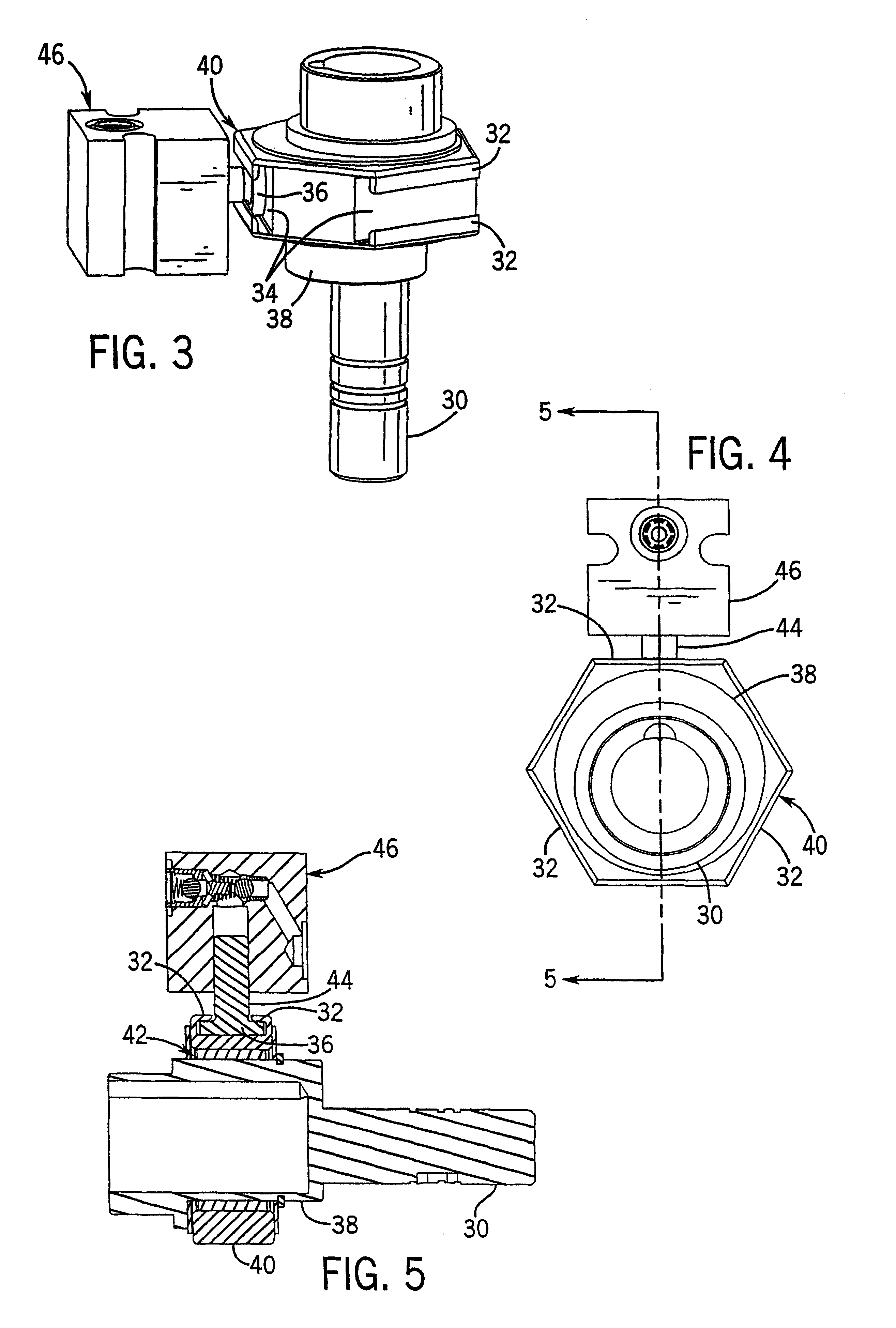

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Active pressure relief valves and methods of use

ActiveUS20050199845A1Efficient changeOperating means/releasing devices for valvesCheck valvesElastomerElectricity

Active pressure relief valves and methods of use for regulating atmospheric conditions within an interior compartment of a vehicle generally include an active material to effect movement of a flap relative to an opening. The active material has the ability to remember its original at least one attribute such as dimension, shape, and / or flexural modulus, which can subsequently be recalled by applying or removing an external stimulus, as will be discussed in detail herein. Suitable active materials include, without limitation, shape memory alloys, ferromagnetic shape memory alloys, shape memory polymers, piezoelectric materials, electroactive polymers, magnetorheological fluids and elastomers, electrorheological fluids, composites of one or more of the foregoing materials with non-active materials, combinations comprising at least one of the foregoing materials, and the like. Depending on the particular active material, the activation signal can take the form of, without limitation, an electric current, a temperature change, a magnetic field, a mechanical loading or stressing, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

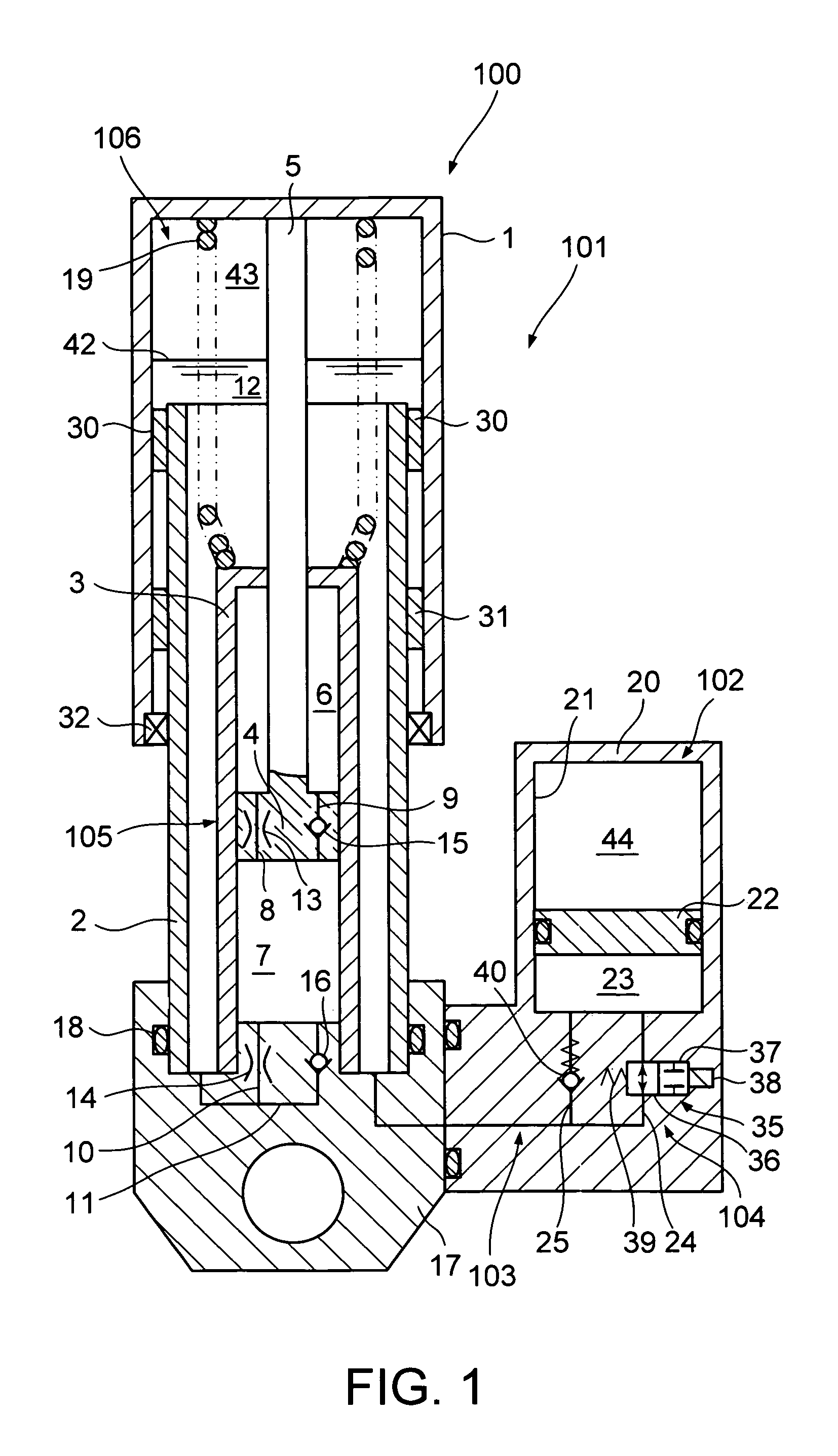

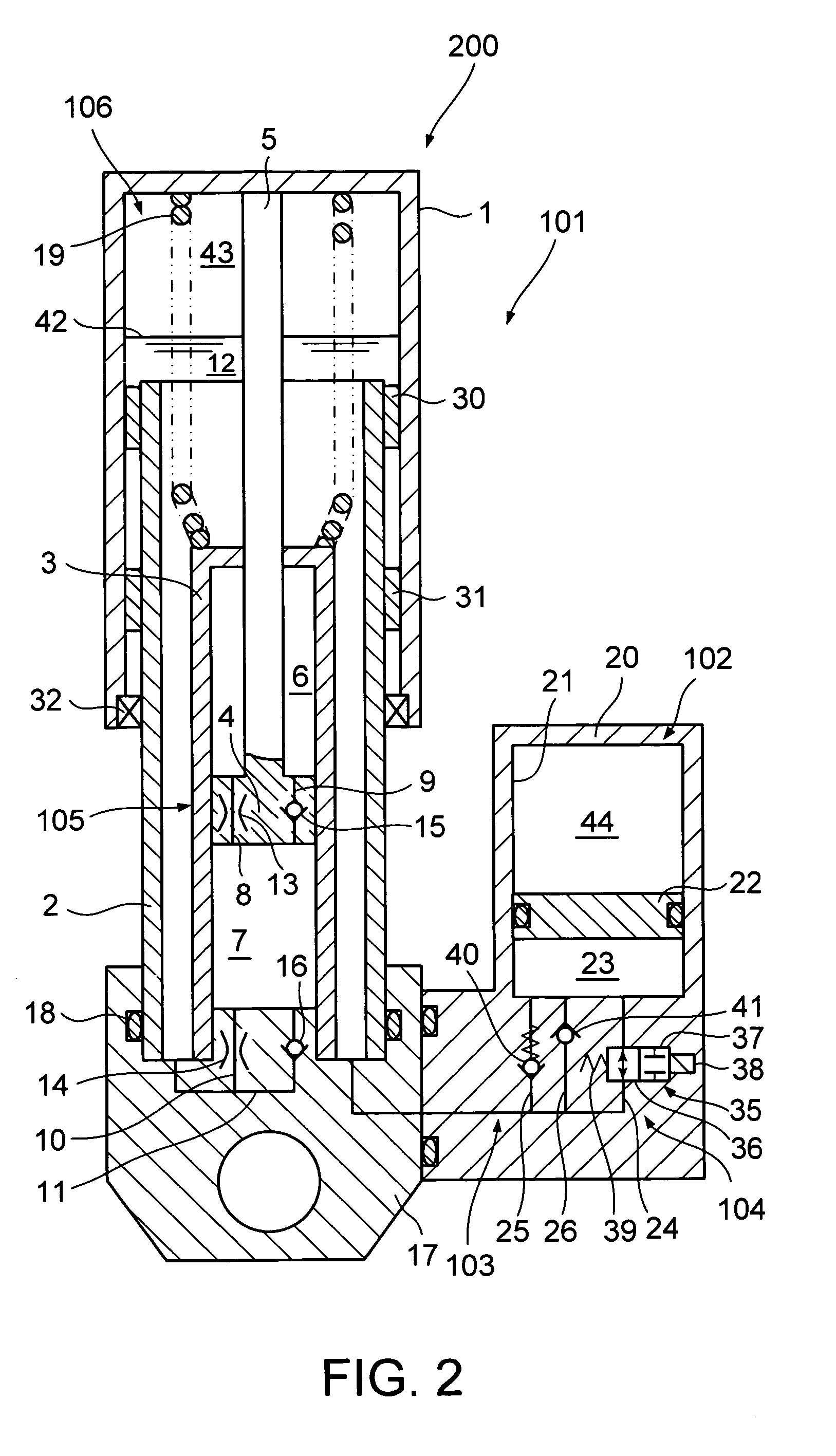

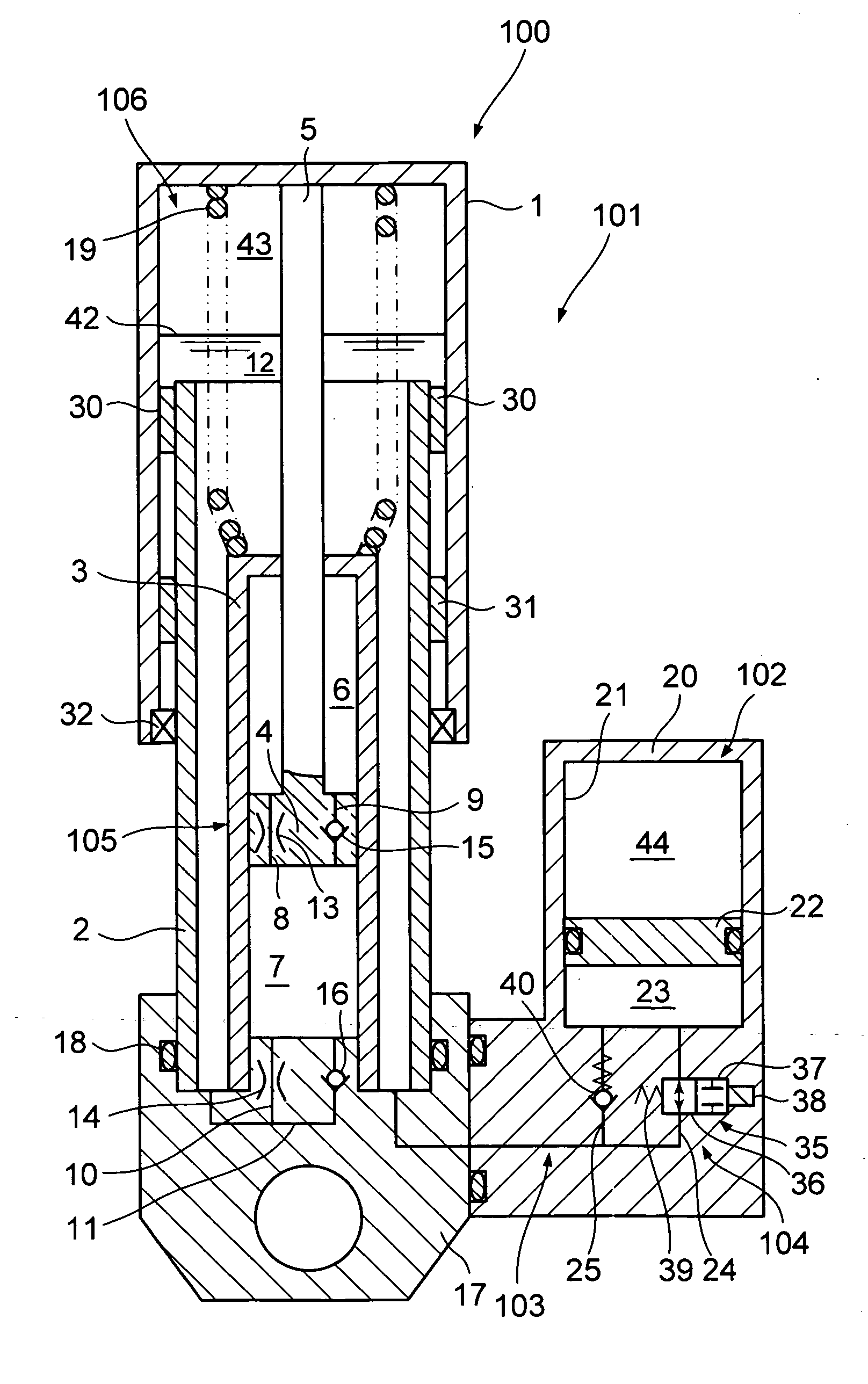

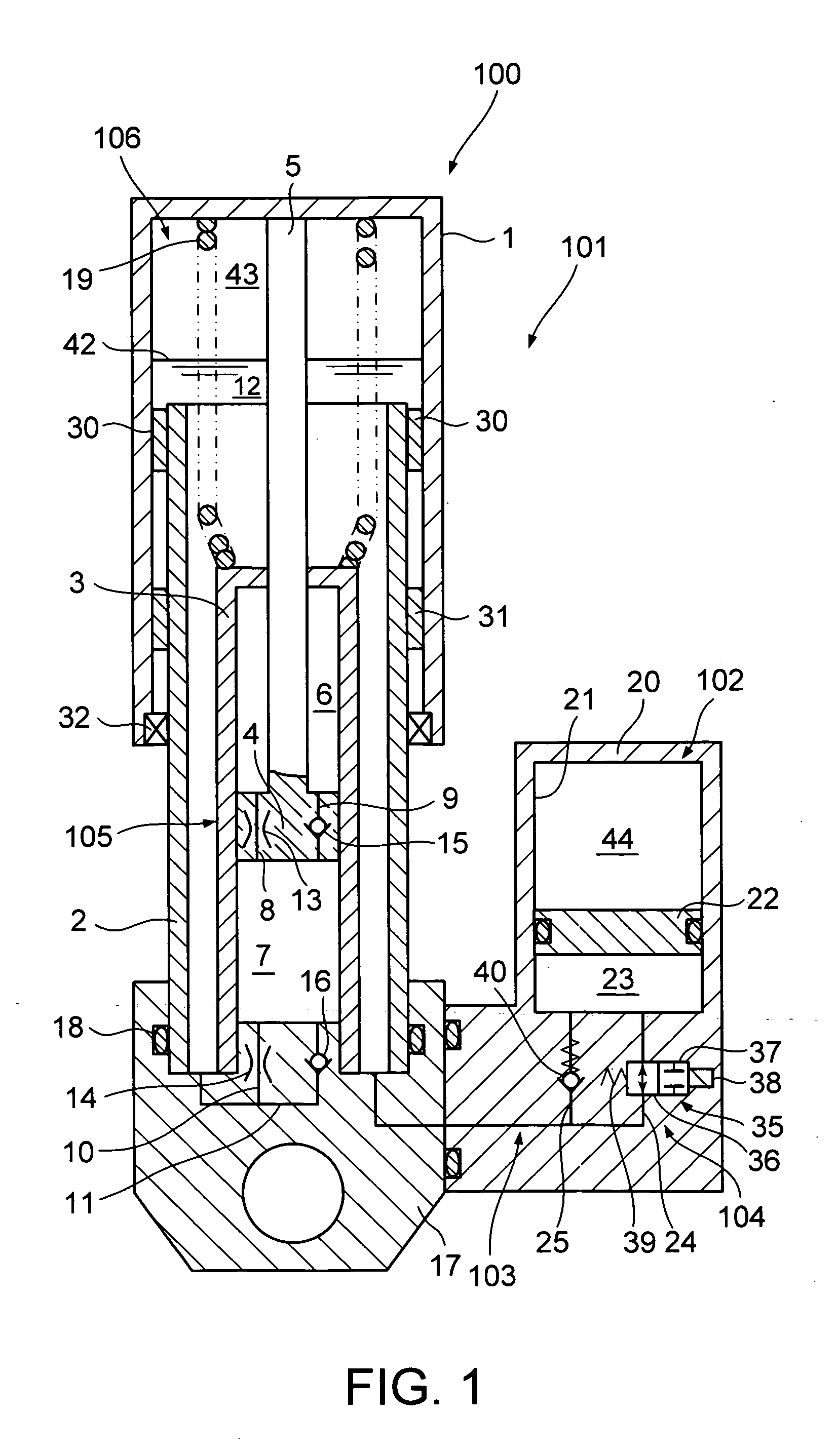

Front fork

ActiveUS7441638B2Stably reducingRide-comfort can be improvedSpringsAxle suspensionsIn vehicleEngineering

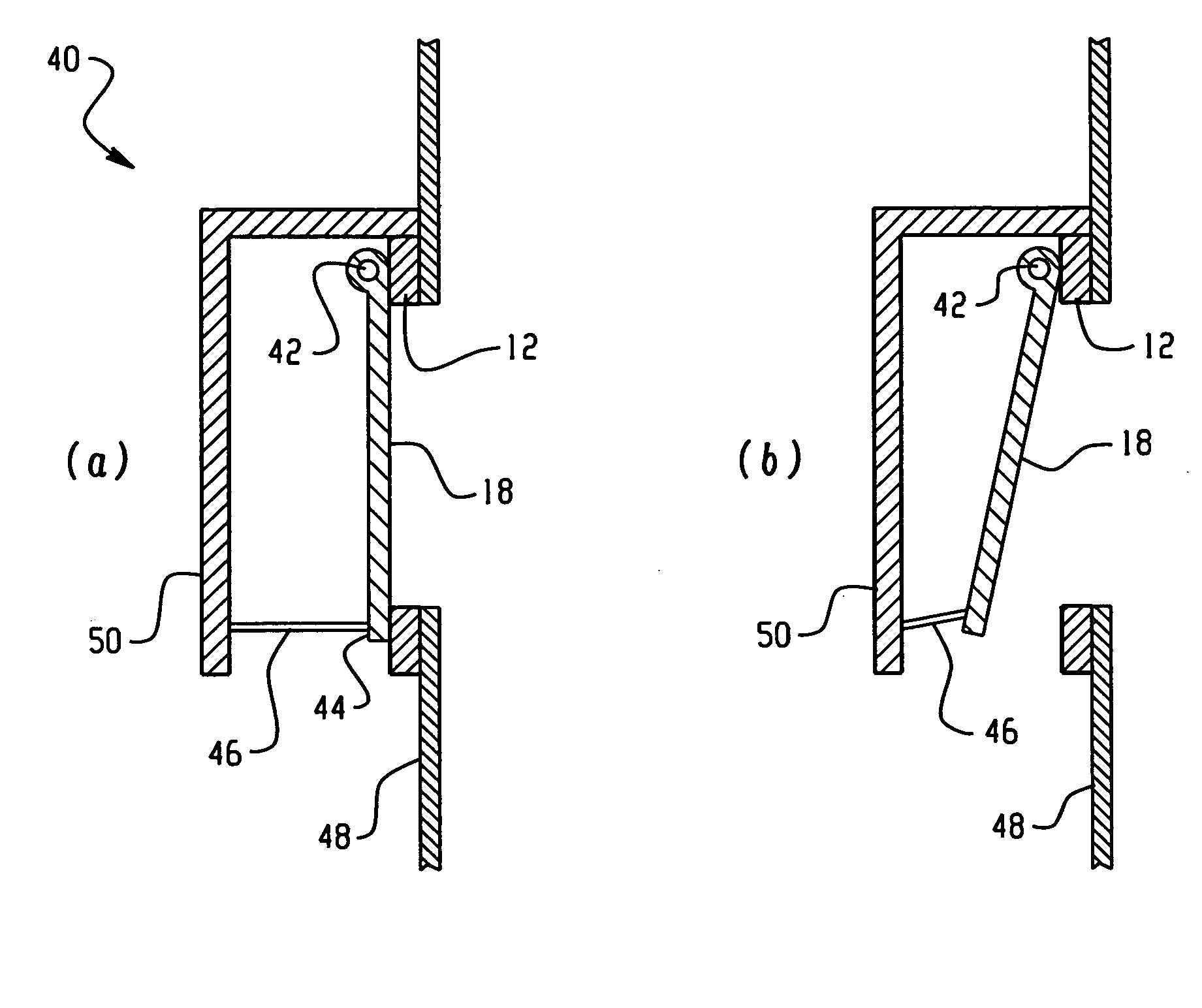

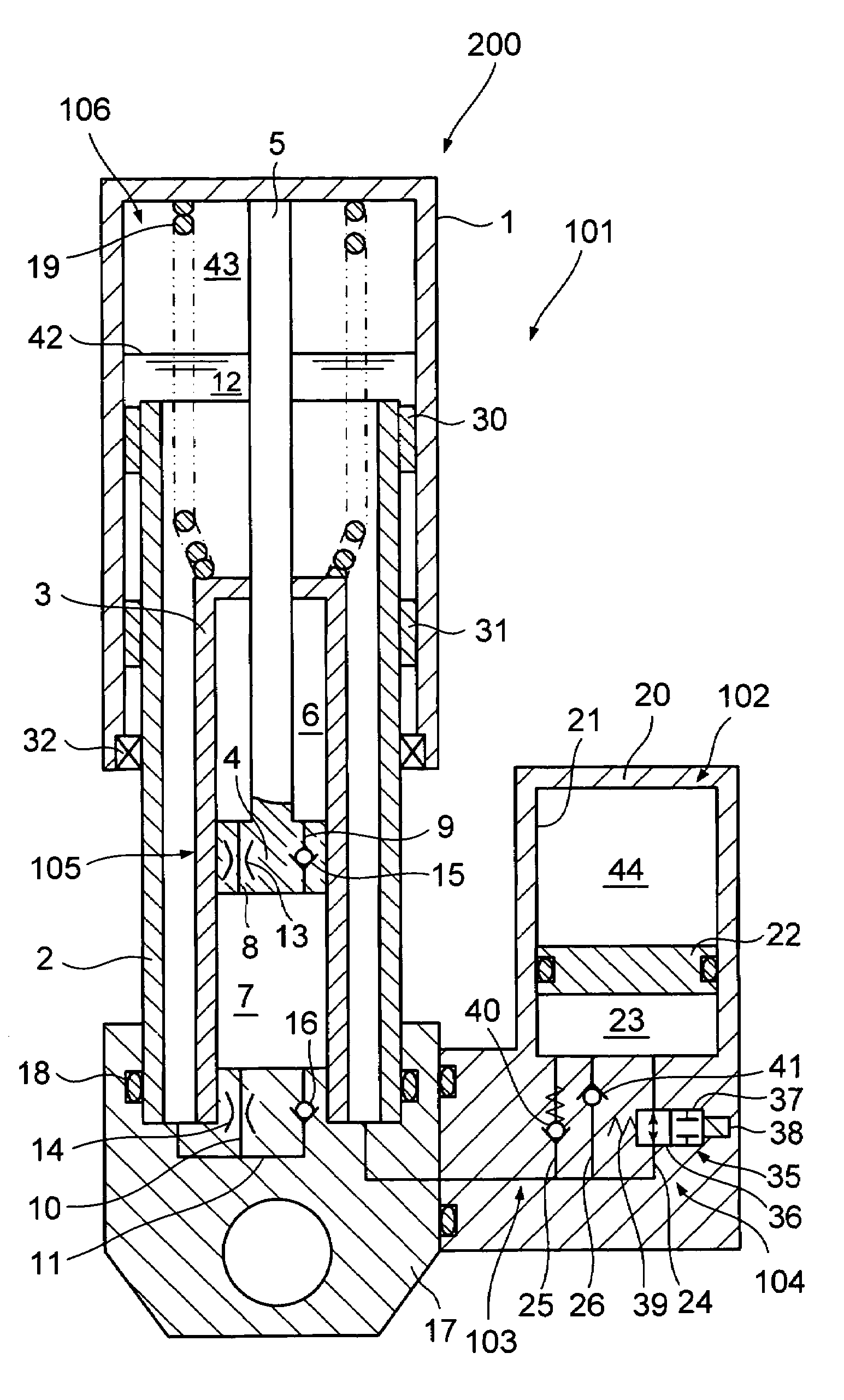

A front fork, which is interposed between a vehicle body and an axle to restrain a change in vehicle attitude, comprises a fork body (101) including a reservoir chamber (106) partially filled with gas and performing an expansion and contraction operation, a reservoir tank (102) partially filled with gas and communicating with the reservoir chamber (106) through a flow path (103) in which hydraulic oil flows, an on-off valve (35) switching between opening and closing of the flow path (103), and a relief valve (40) accepting flow of hydraulic oil from the reservoir chamber (106) toward the reservoir tank (102) when a pressure of the reservoir chamber (106) reaches a predetermined pressure.

Owner:KYB CORP

Pressure relief valve

InactiveUS7178555B2Relieve stressDistortion in appearanceReady-for-oven doughsCheck valvesEngineeringRelief valve

A pressure relief valve that is mountable to protect packaging so as to vent pressurized gases contained within the packaging. The present invention also pertains to a pressure relief valve which includes at least one passageway defined by at least one inner rail and which is in communication with an aperture.

Owner:PULTEK L L C

Ink jet recording apparatus, ink supplying mechanism and ink supplying method

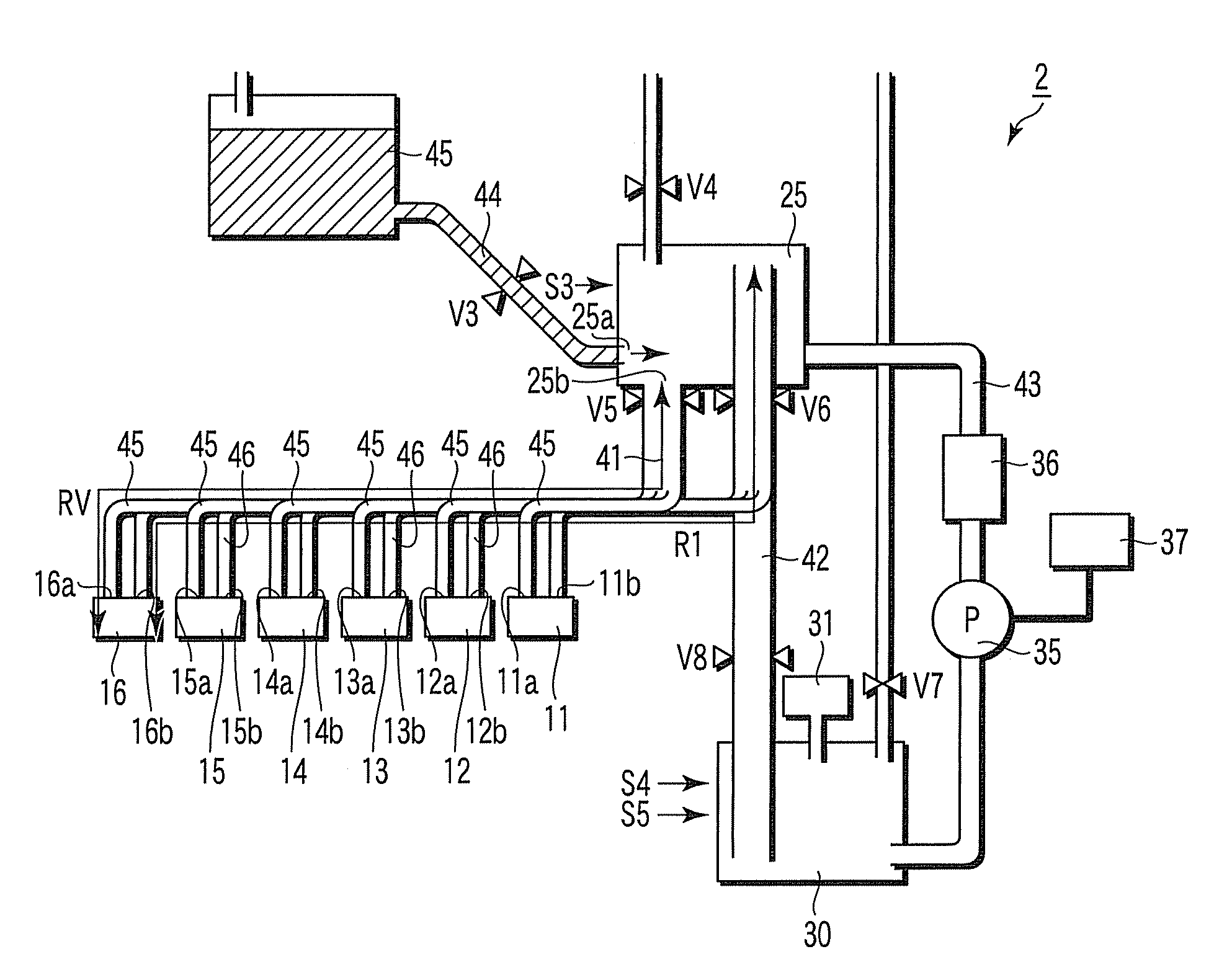

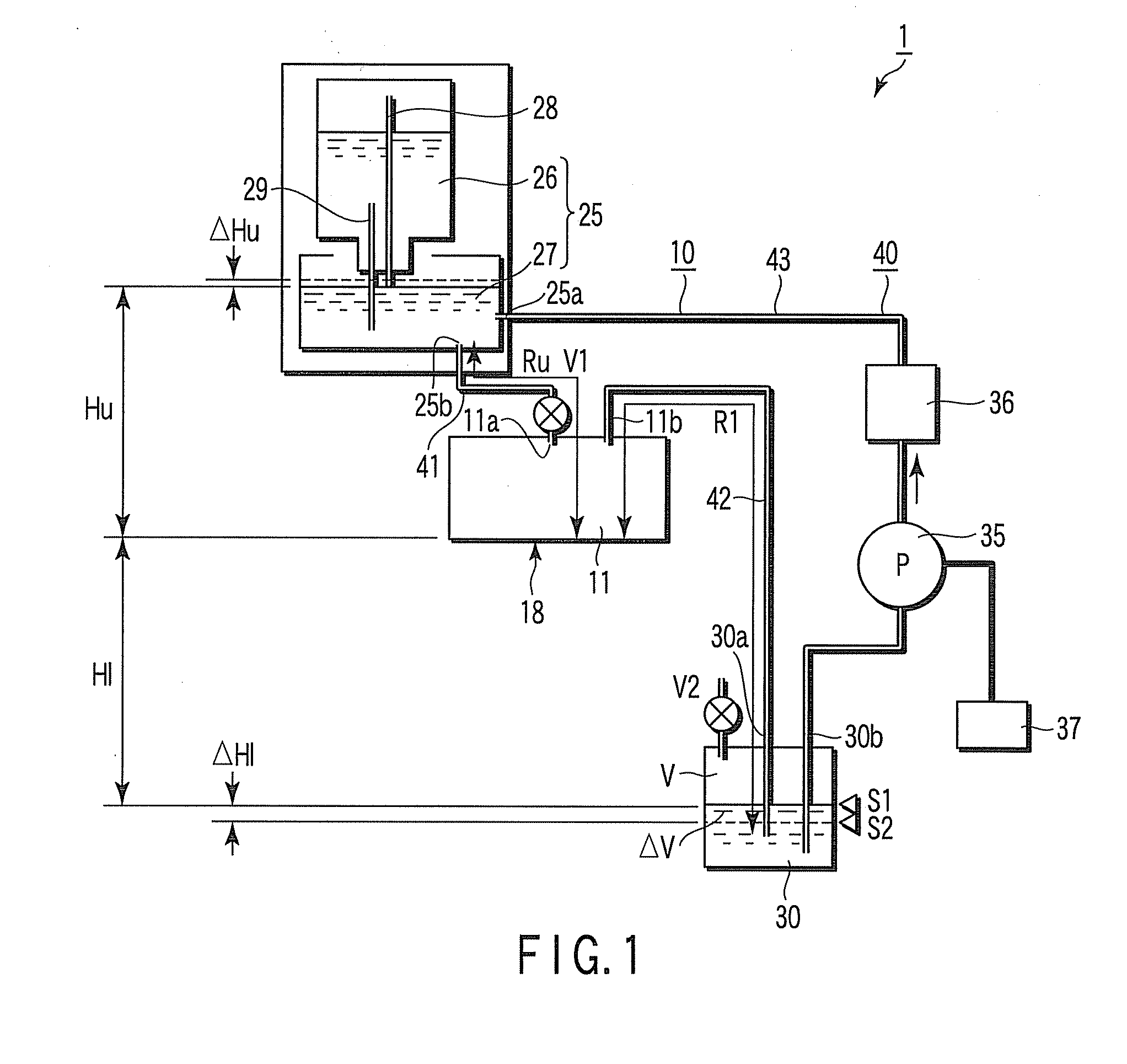

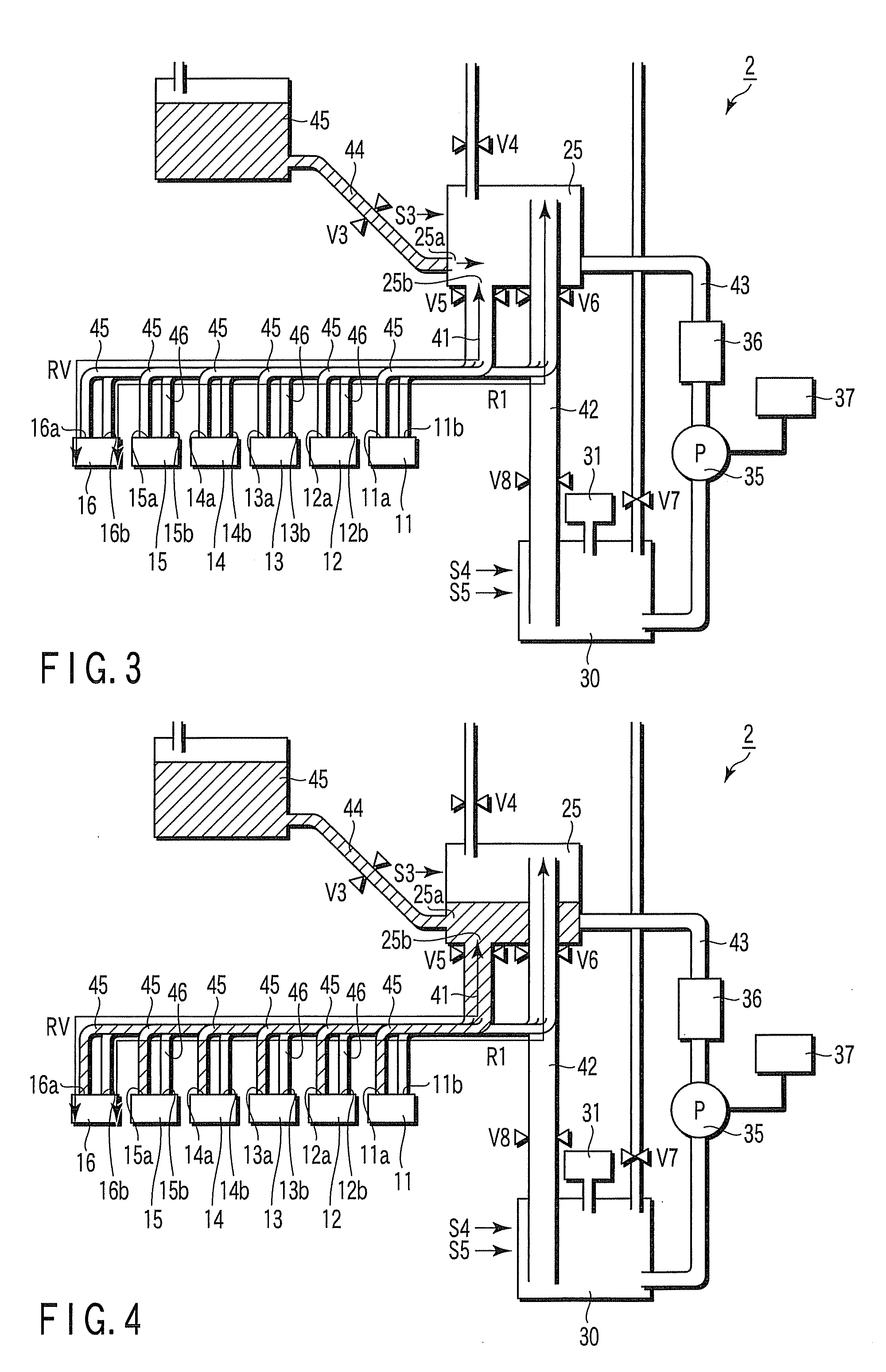

An ink supplying mechanism includes a circulating system that connects an ink jet head having a nozzle, a pressure chamber opposed to the nozzle, and an upstream port and a downstream port that communicate with the pressure chamber, an upstream side tank that communicates with the ink jet head via the upstream port and is capable of storing an ink, a downstream side tank that communicates with the ink jet head via the downstream port and is capable of storing the ink, and a circulating pump that feeds the ink from the downstream side tank back to the upstream side tank. The ink supplying mechanism has a relief valve that is capable of opening and closing at least a liquid surface of the downstream side tank with respect to the atmospheric pressure, closes the relief valve to drive the circulating pump, sets the liquid surface of the downstream side tank to a negative pressure, and feeds the ink from the downstream side tank back to the upstream side tank via a feedback channel to circulate the ink.

Owner:TOSHIBA TEC KK

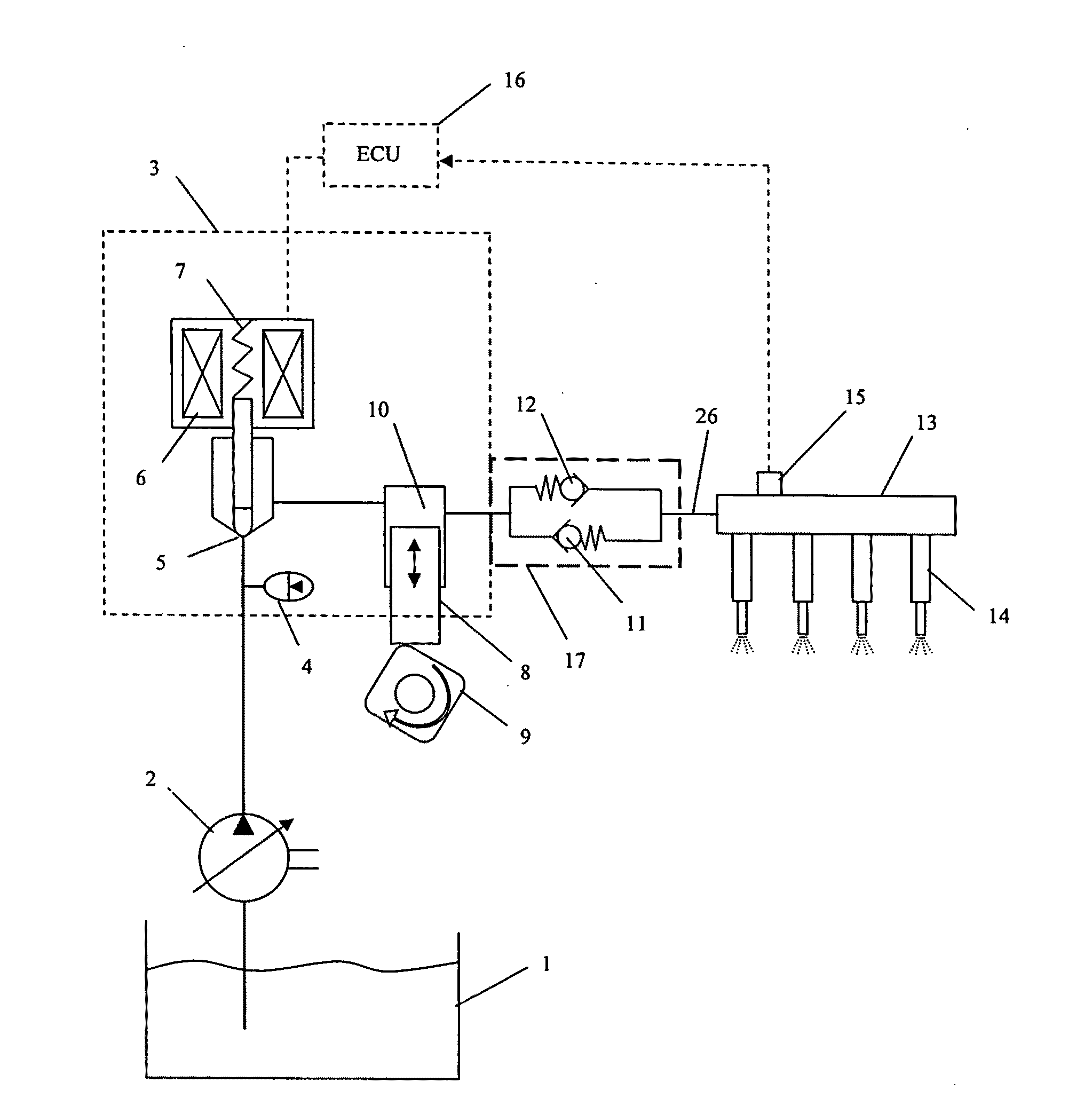

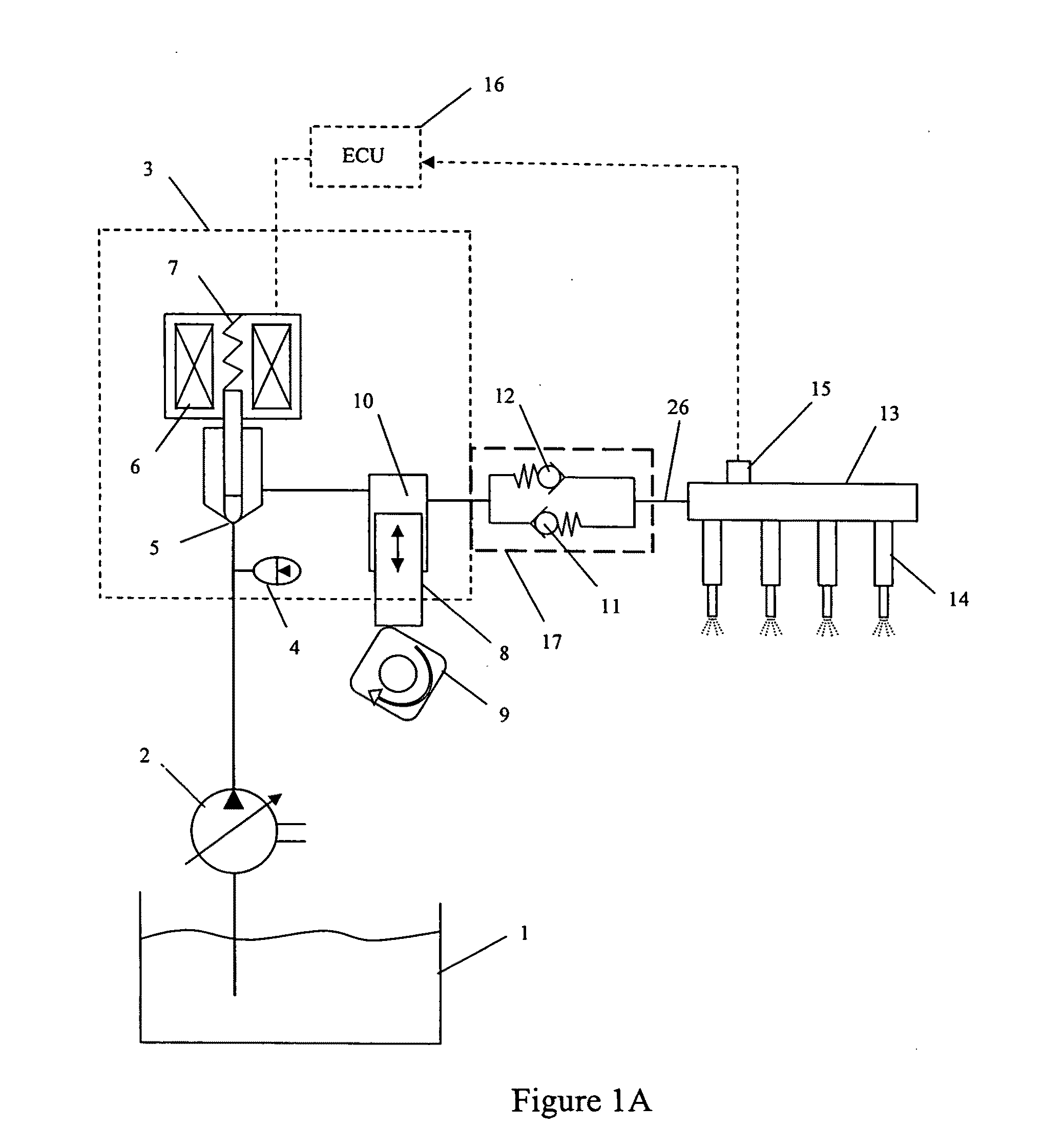

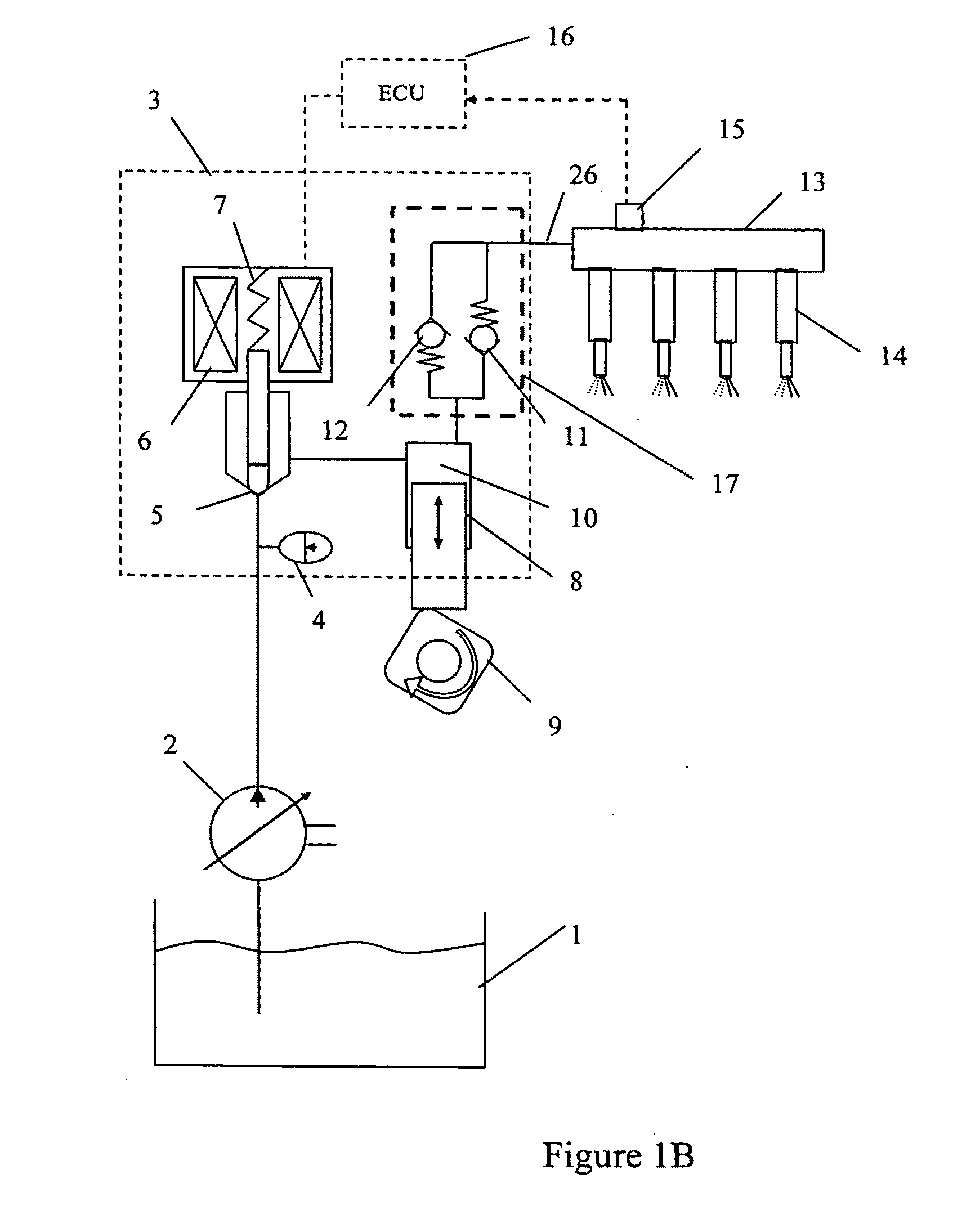

Common rail fuel pump with combined discharge and overpressure relief valves

ActiveUS20110126804A1Reduce system costIncrease flexibilityCheck valvesEqualizing valvesCommon railPump chamber

A high pressure piston fuel pump having a discharge check valve between the pumping chamber and a pressurized fuel reservoir and a pressure relief valve between the fuel reservoir and a passageway in the housing, wherein the discharge check valve and the pressure relief valve are contained within a single fitting assembly affixed at the pump housing. A first end flow passage is in fluid communication with the pumping chamber and provides an inlet to the discharge check valve and an outlet from the pressure relief valve. A second end flow passage is in fluid communication with the fuel reservoir and provides an outlet for the discharge check valve and an inlet for the pressure relief valve. Advantages include the ability to pre-test the outlet check and pressure relief prior to assembly into the pump housing, and improved flexibility of the outlet fitting location.

Owner:STANDYNE INC

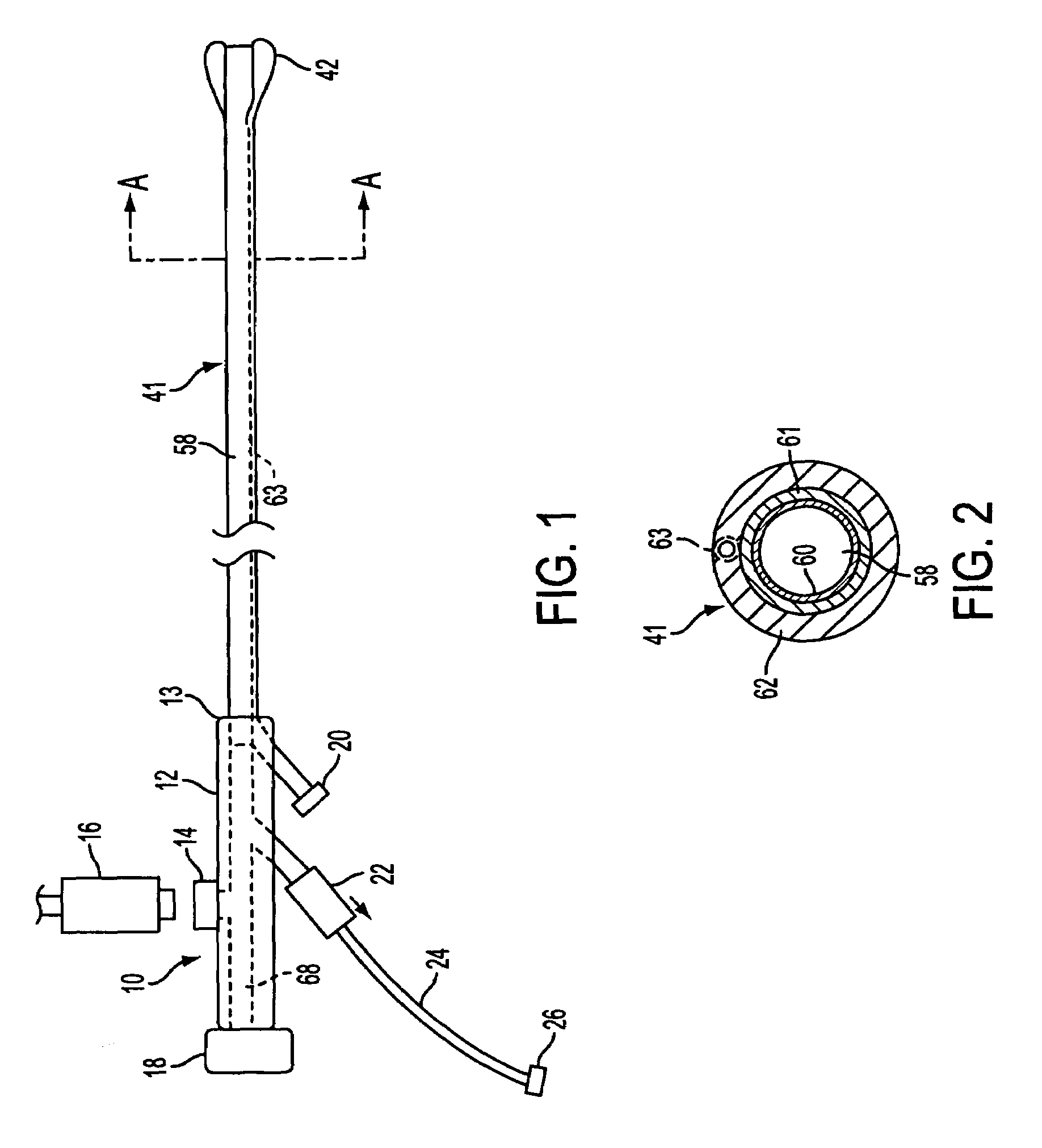

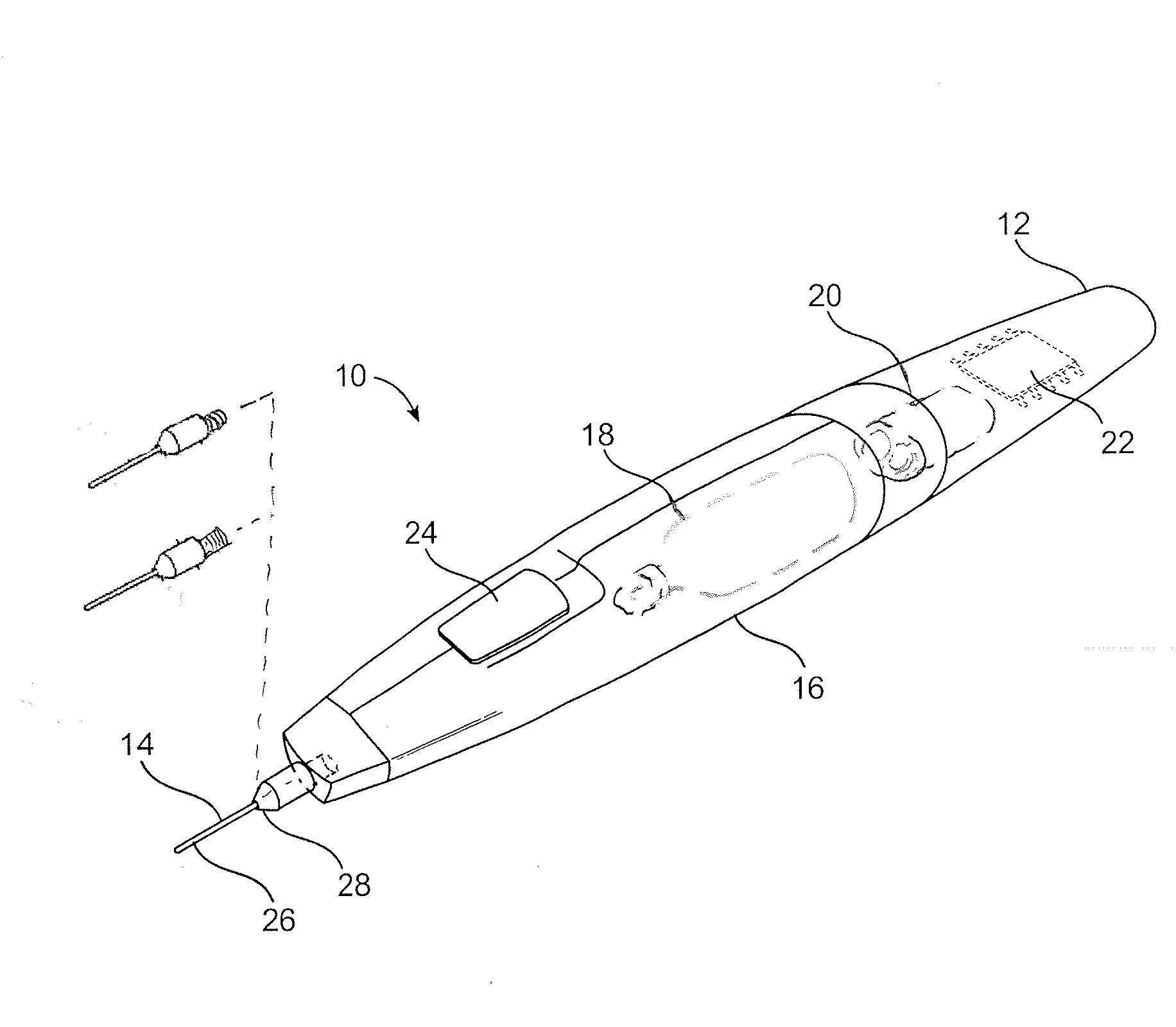

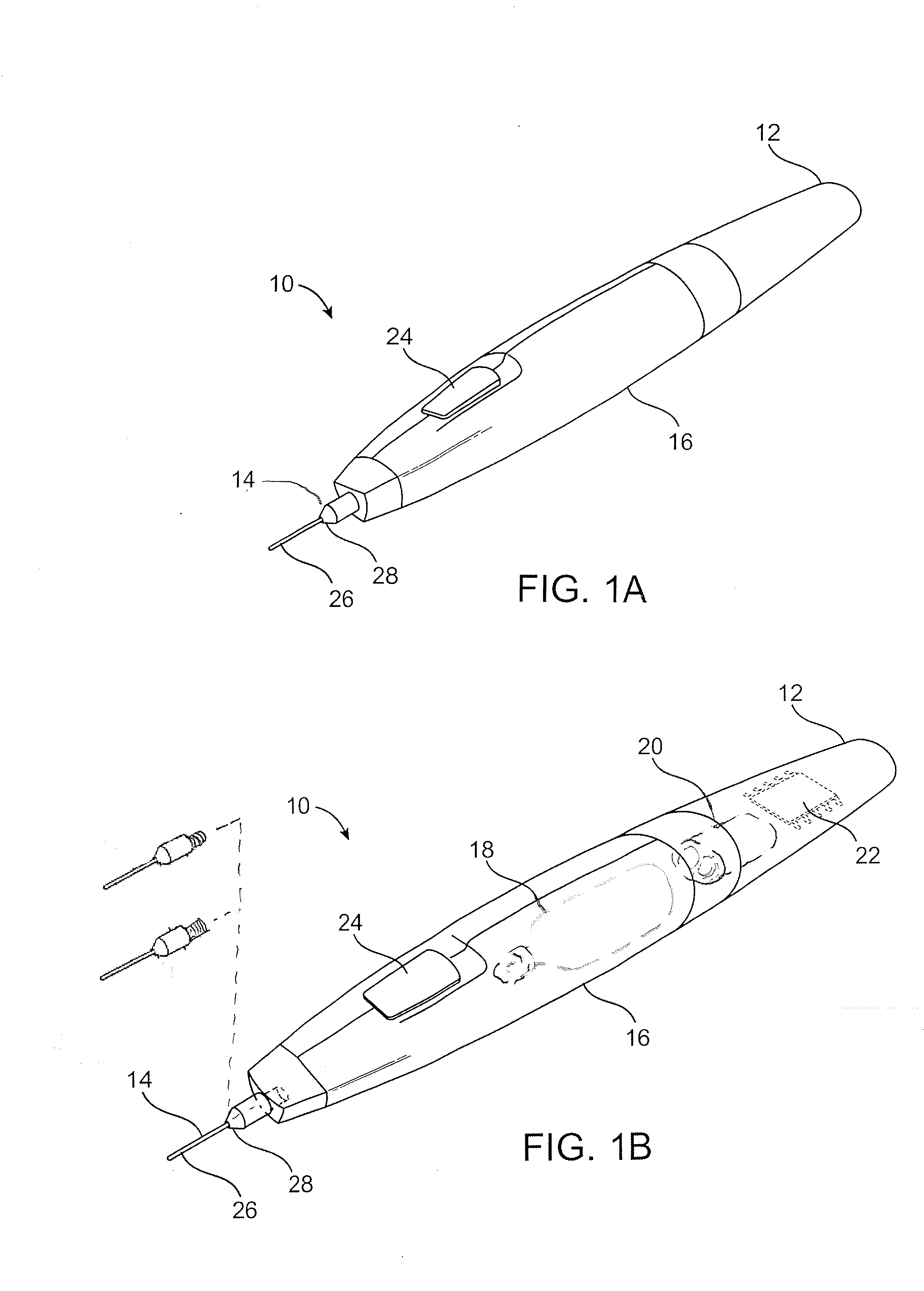

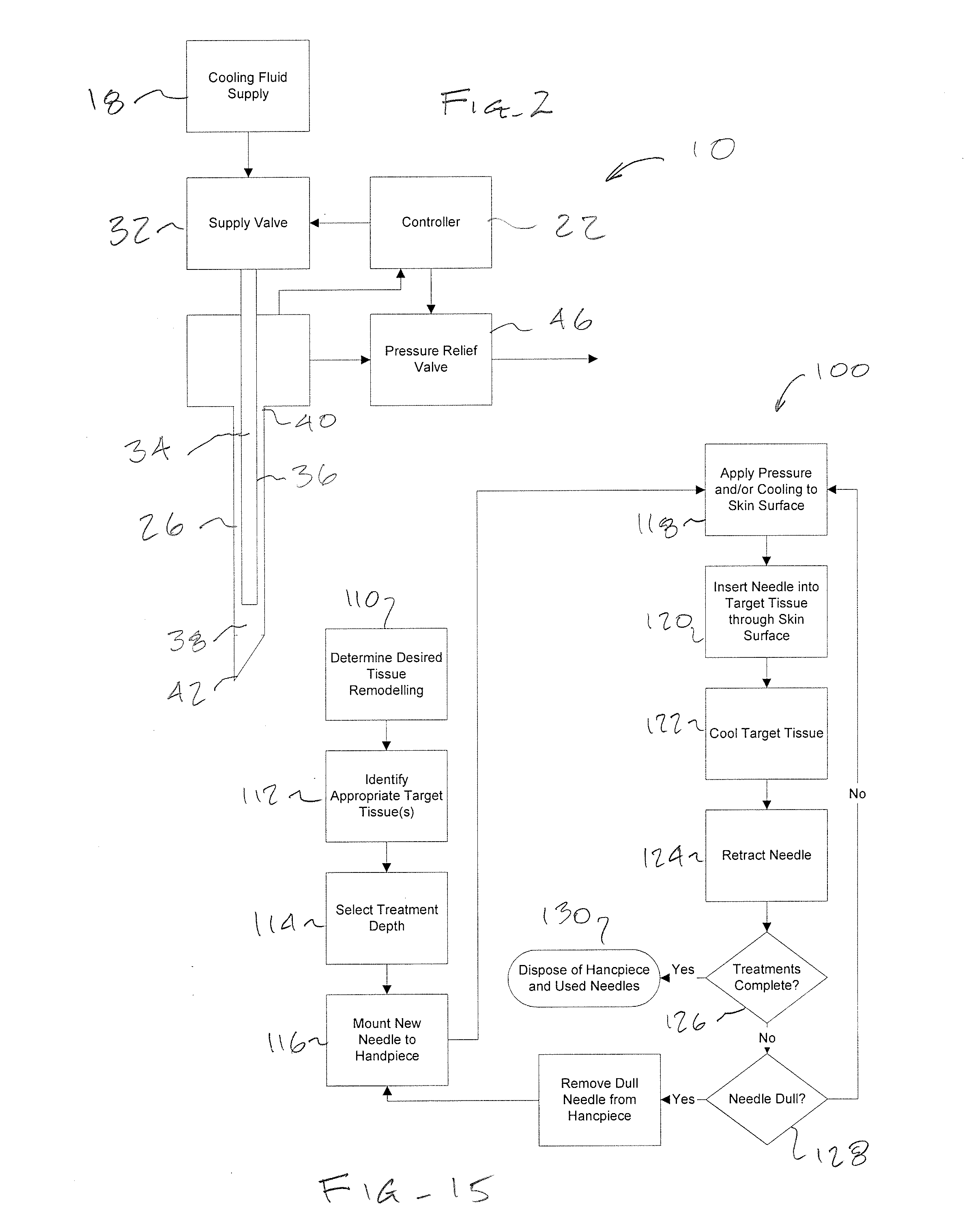

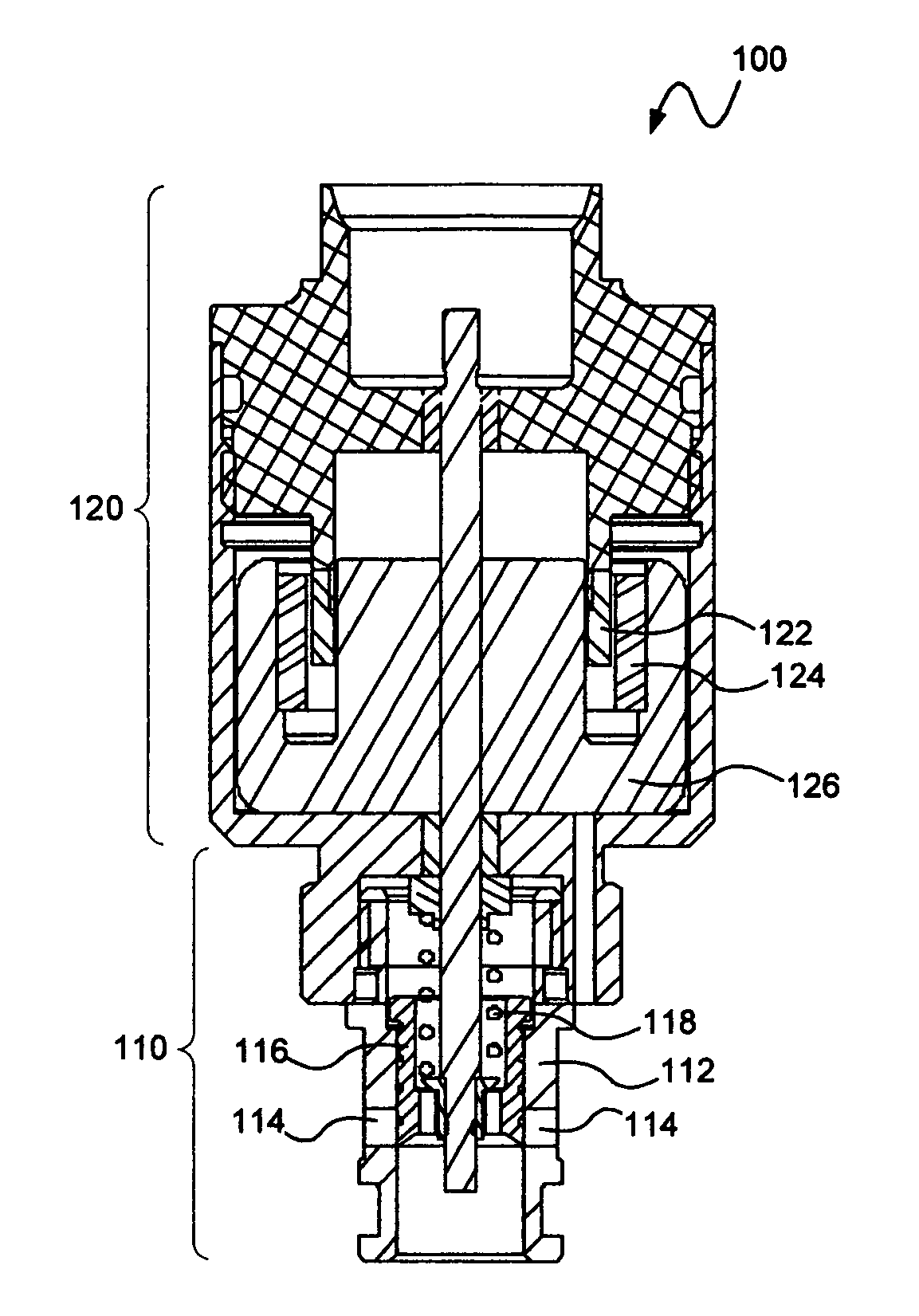

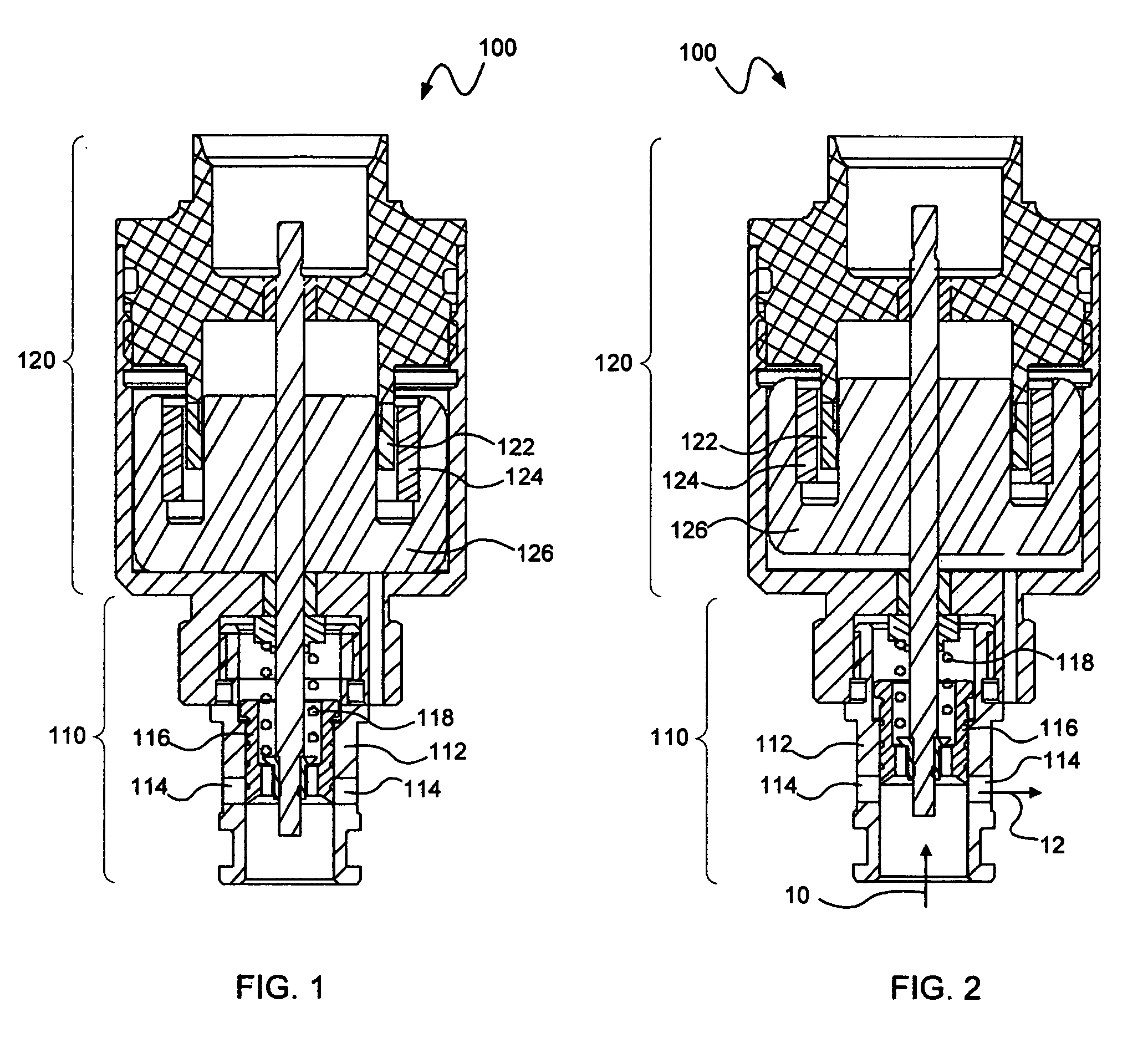

Dermal and Transdermal Cryogenic Microprobe Systems and Methods

ActiveUS20080154254A1Increase temperatureTime control be enhancedSurgical instruments for coolingTime controlMedical device

Medical devices, systems, and methods optionally treat dermatological and / or cosmetic defects, and / or a wide range of additional target tissues. Embodiments apply cooling with at least one small, tissue-penetrating probe, the probe often comprising a needle having a size suitable for inserting through an exposed surface of the skin of a patient without leaving a visible scar. Treatment may be applied along most or all of the insertable length of an elongate needle, optionally by introducing cryogenic cooling fluid into the needle lumen through a small, tightly-toleranced lumen of a fused silica fluid supply tube, with the supply tube lumen often metering the cooling fluid. Treatment temperature and / or time control may be enhanced using a simple pressure relief valve coupled to the needle lumen via a limited total exhaust volume space.

Owner:PACIRA CRYOTECH INC

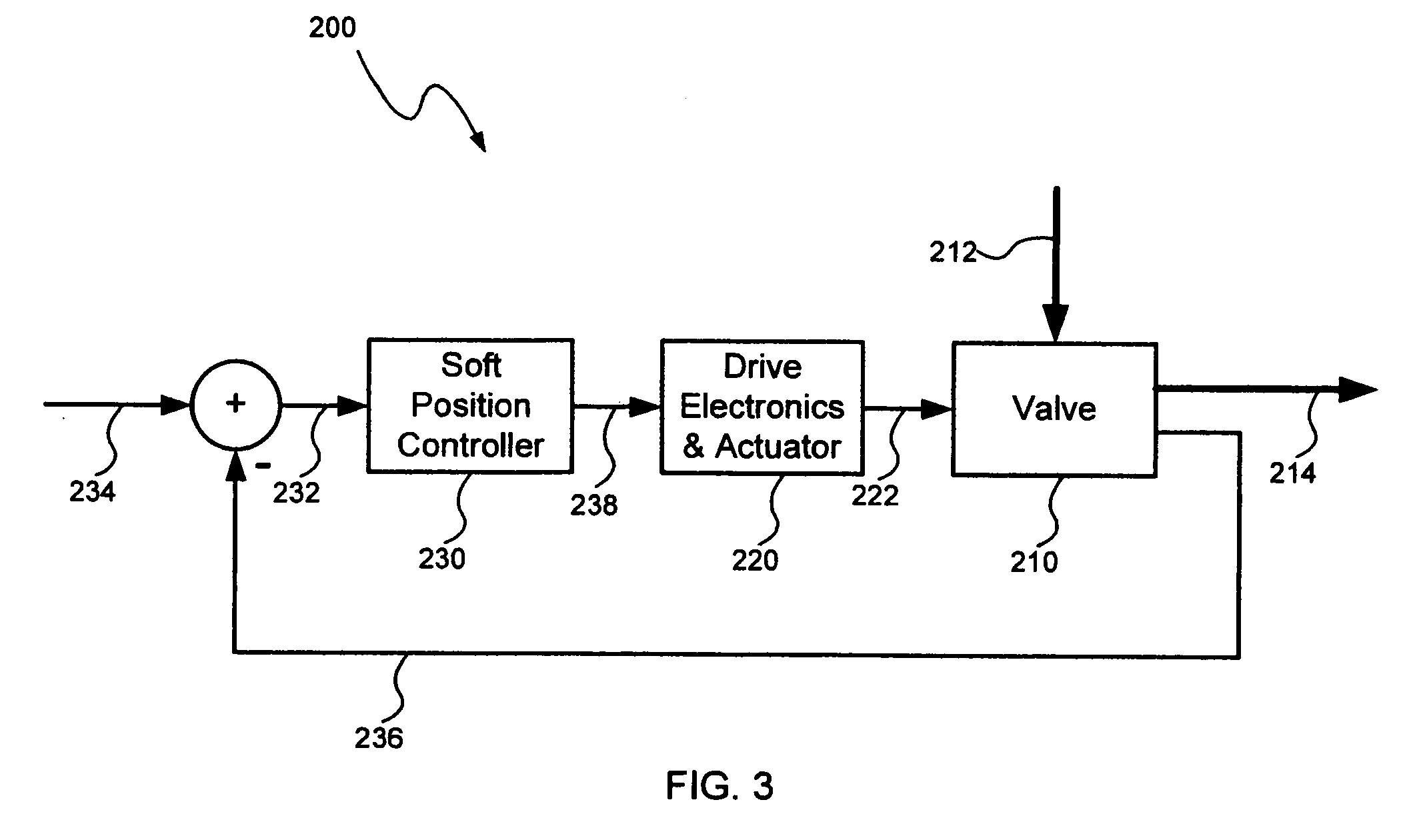

Electrically controlled pressure relief valve and system and method for controlling same

ActiveUS7299112B2Operating means/releasing devices for valvesLevel controlControl systemControl valves

A system and method for controlling an electrically controlled pressure relief valve may use a soft position control loop to control the position of the valve. A pressure relief valve may also include a modified orifice shape to improve stability, to uniformly distribute the effective bandwidth over the valve operating range, and to provide a tunable default mode.

Owner:GENERAL KINETICS ENG CORP

Front fork

ActiveUS20060124414A1Stably reducingRide-comfort can be improvedSpringsAxle suspensionsIn vehicleEngineering

A front fork, which is interposed between a vehicle body and an axle to restrain a change in vehicle attitude, comprises a fork body (101) including a reservoir chamber (106) partially filled with gas and performing an expansion and contraction operation, a reservoir tank (102) partially filled with gas and communicating with the reservoir chamber (106) through a flow path (103) in which hydraulic oil flows, an on-off valve (35) switching between opening and closing of the flow path (103), and a relief valve (40) accepting flow of hydraulic oil from the reservoir chamber (106) toward the reservoir tank (102) when a pressure of the reservoir chamber (106) reaches a predetermined pressure.

Owner:KYB CORP

Fuel cartridge with flexible liner containing insert

Owner:INTELLIGENT ENERGY LTD

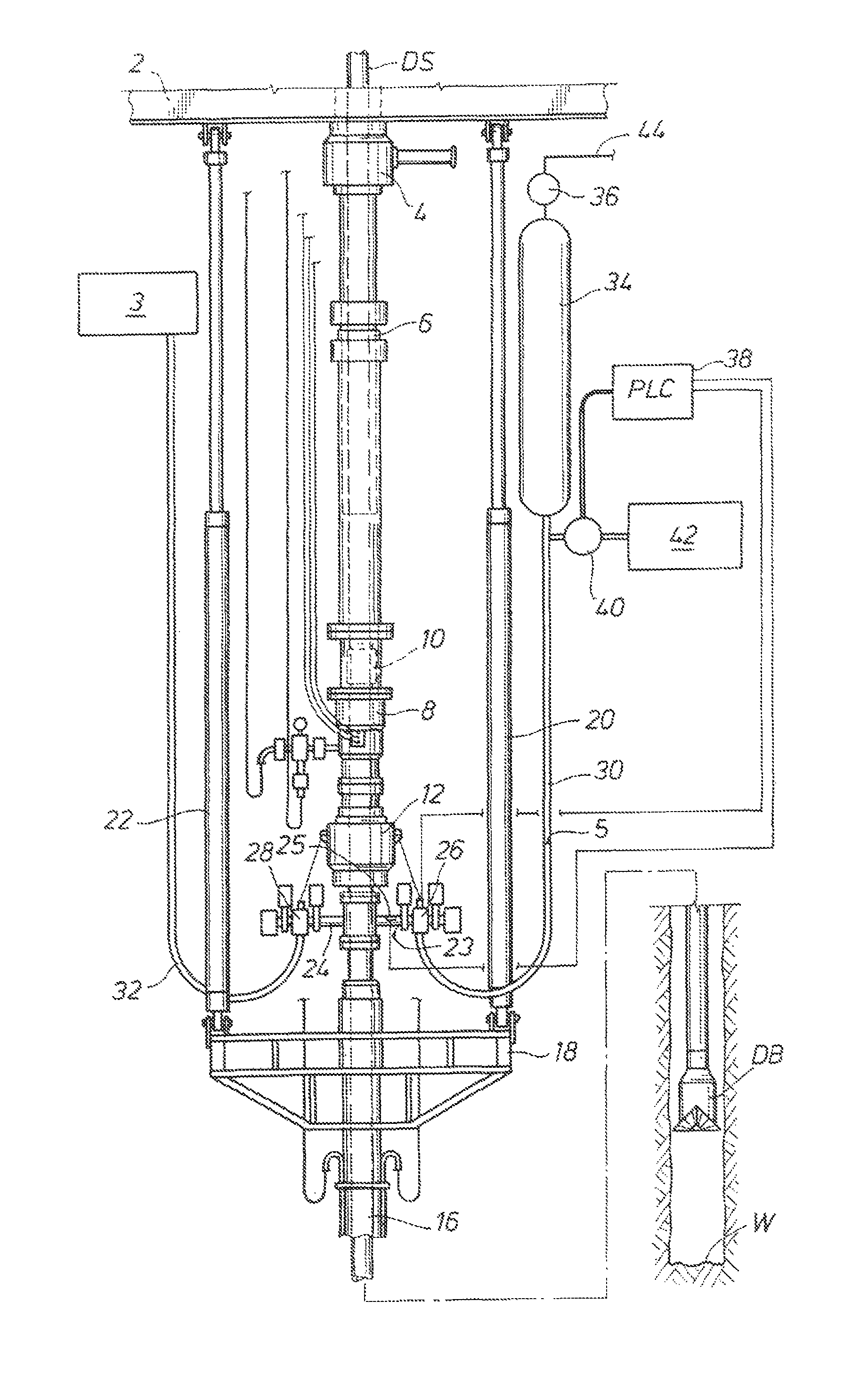

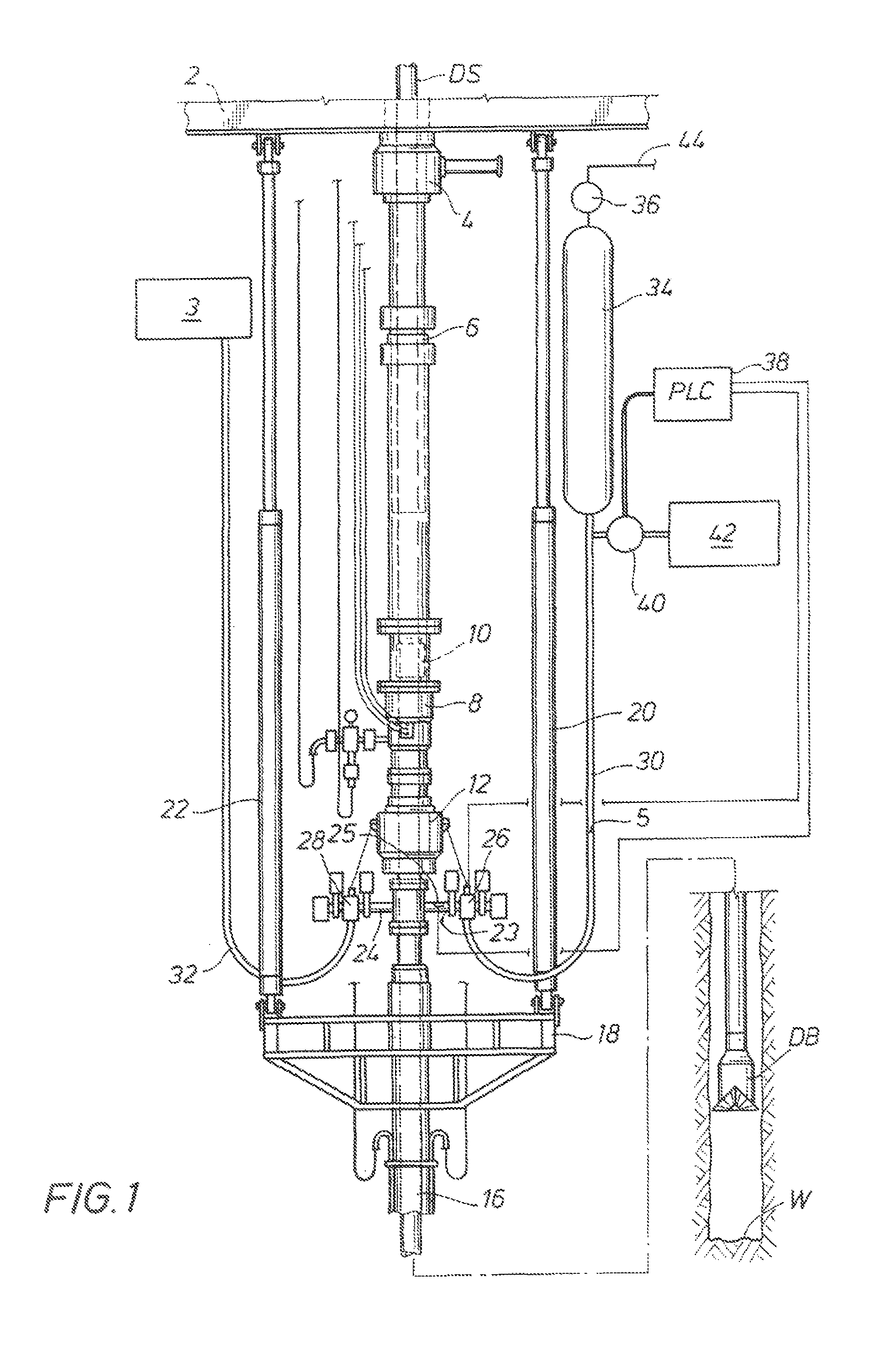

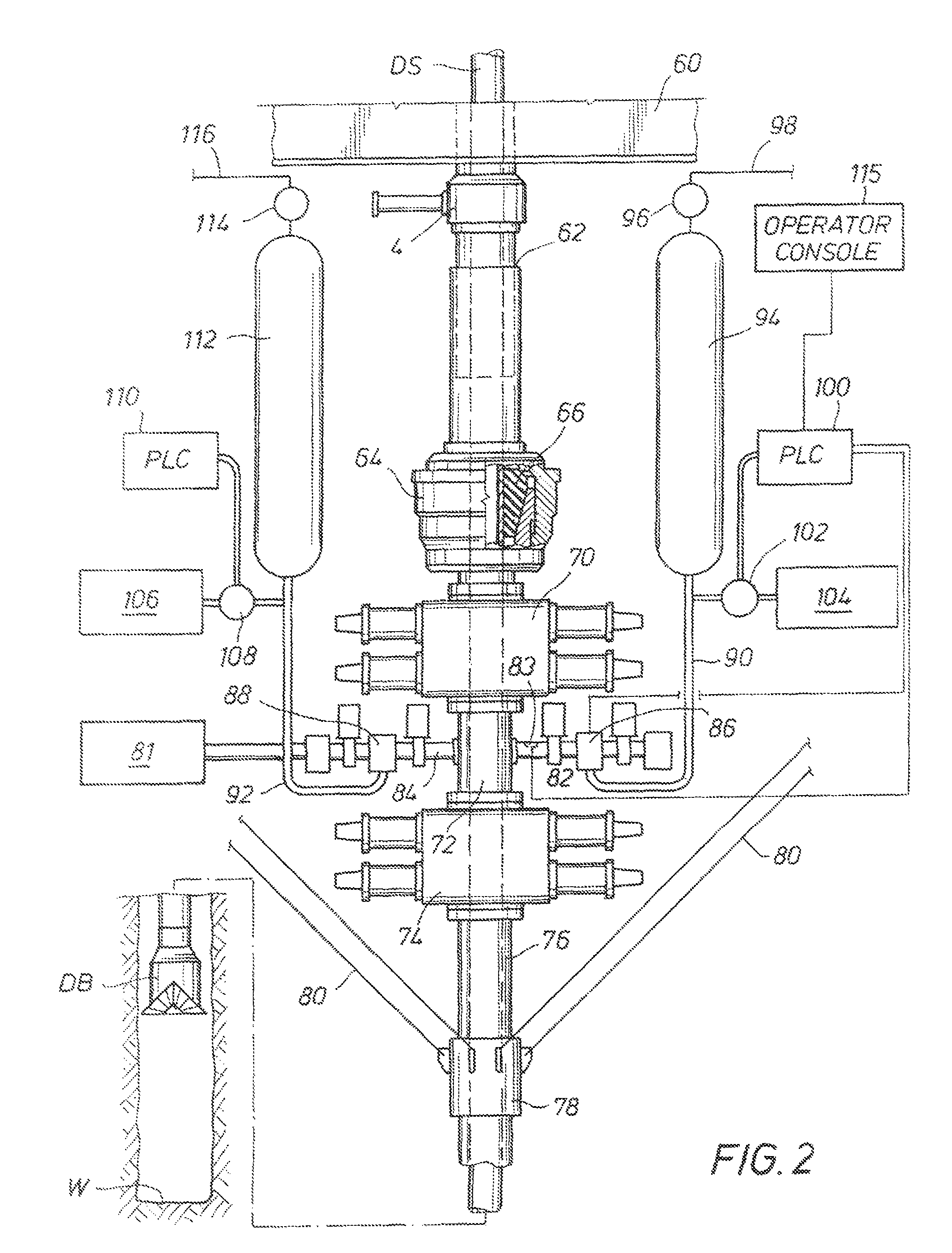

System and method for managing heave pressure from a floating rig

A system compensates for heave induced pressure fluctuations on a floating rig when a drill string or tubular is lifted off bottom and suspended on the rig, such as when tubular connections are made during MPD, tripping, or when a kick is circulated out during conventional drilling. In one embodiment, a liquid and a gas interface moves along a flow line between a riser and a gas accumulator as the tubular moves up and down. In another embodiment, a pressure relief valve or adjustable choke allows the movement of fluid from the riser when the tubular moves down, and a pump with a pressure regulator moves fluid to the riser when the tubular moves up. In other embodiments, a piston connected with the rig or the riser telescoping joint moves in a fluid container thereby communicating fluid either into or out of the riser annulus.

Owner:WEATHERFORD TECH HLDG LLC

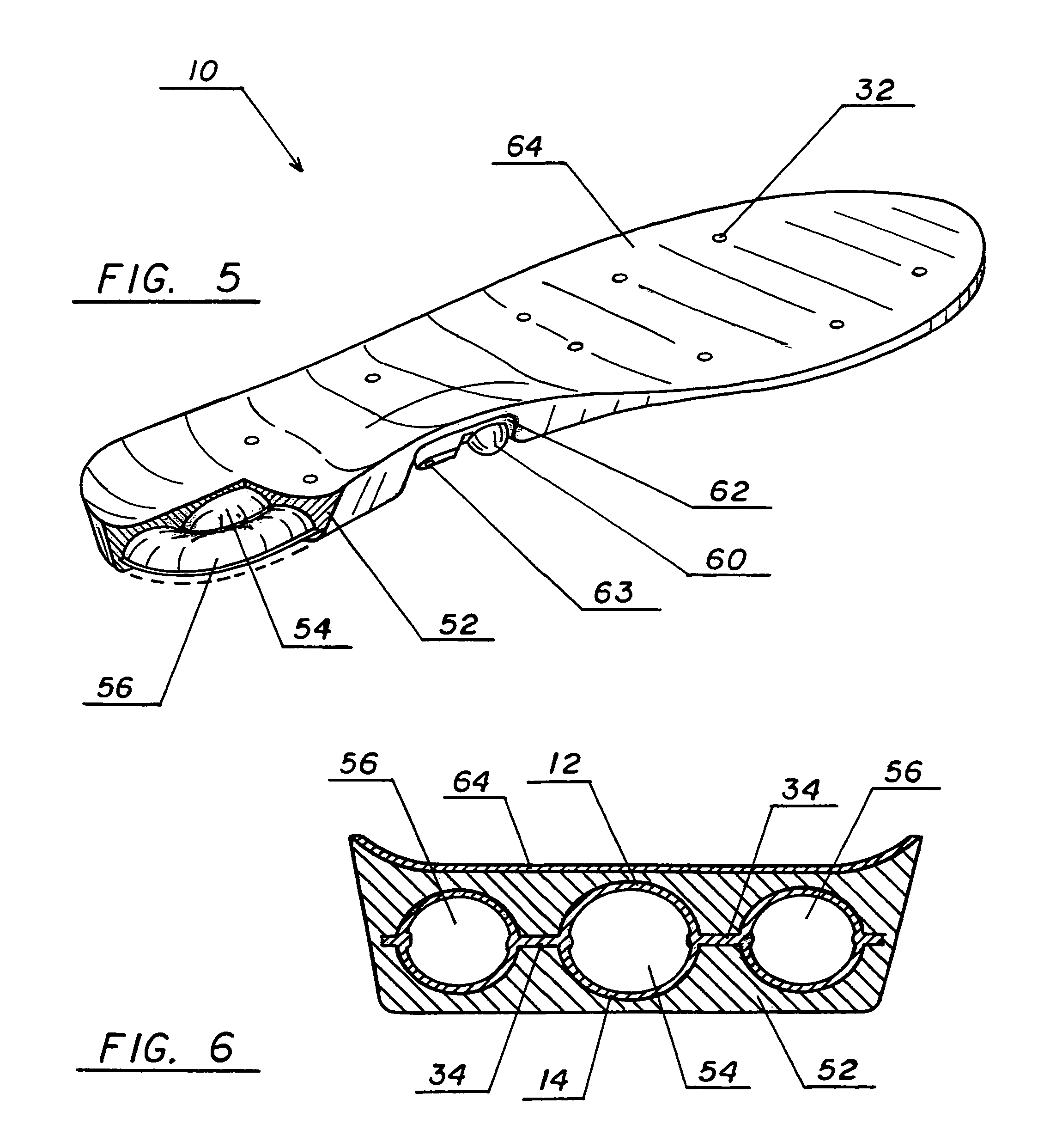

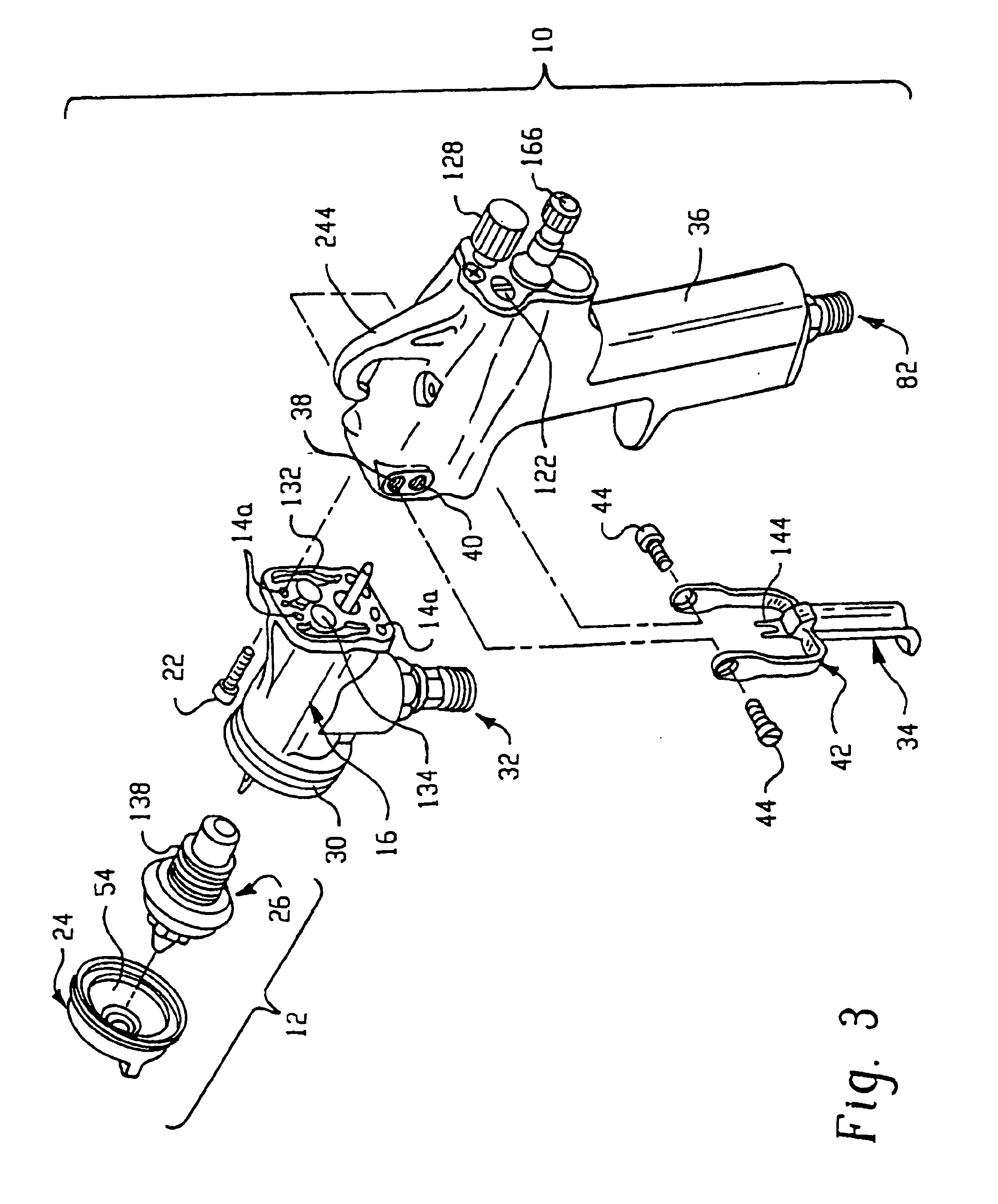

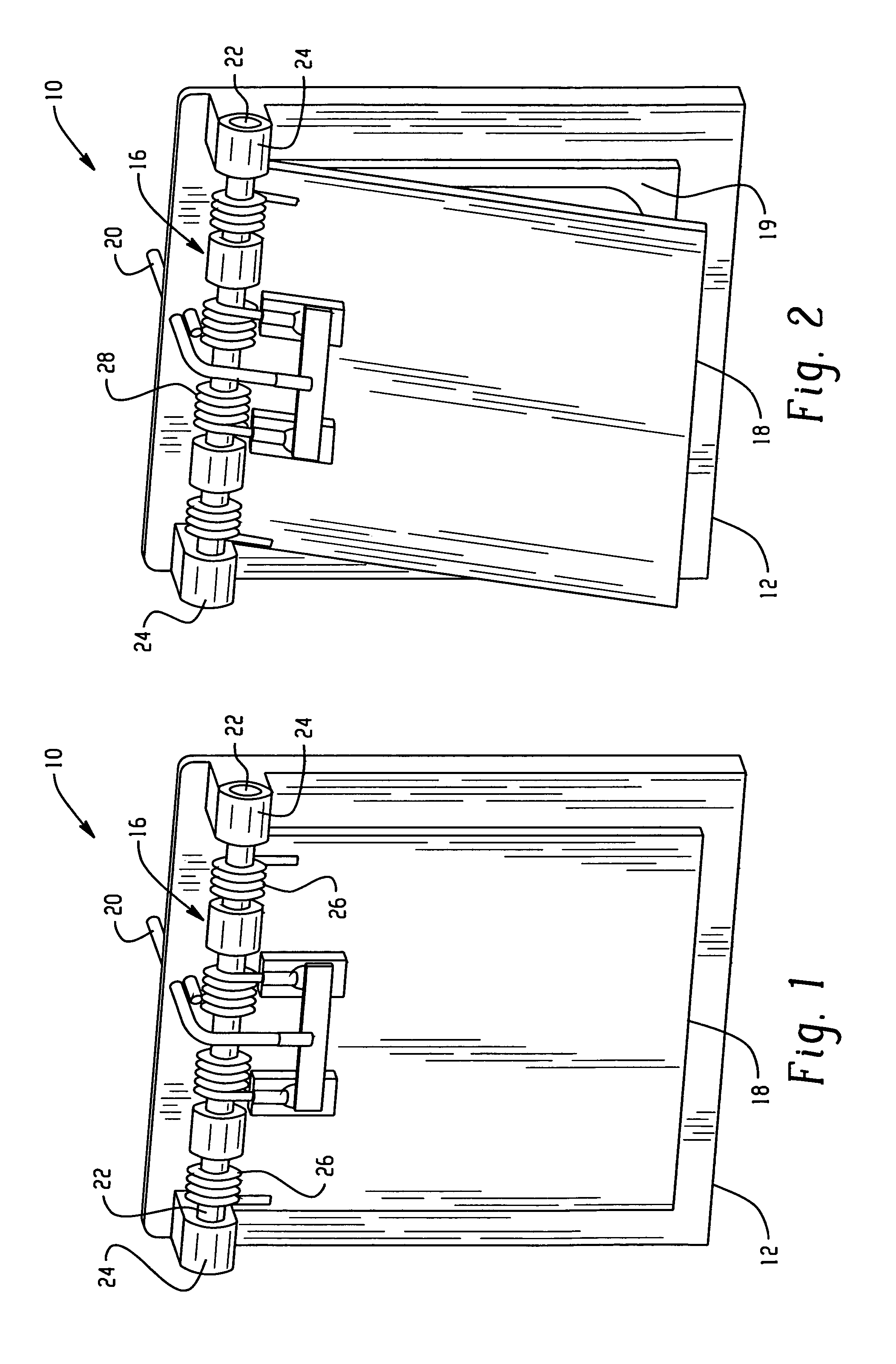

Inflatable lining for footwear with protective and comfortable coatings or surrounds

InactiveUS7017285B2Enhances fit and stability and comfortEasy to manufactureSolesInsolesOn boardEngineering

The invention is an inflatable inner sole for footwear which has a flexible, inflatable enclosure with an inflation system that preferably includes an on-board air pump and a pressure relief valve. In this invention the inner sole has a sheet and / or foam cover or surround on the flexible enclosure for enhanced comfort. Useful sheet covers can be plastic, including rubber, films in solid or foamed state, or fabric which are applied against the upper, wearing surface of the inflatable enclosures. The covers can be bonded only to the edges of the inflatable enclosures to permit relative movement between the covers and enclosures, or can be bonded to the top surface of the enclosures, or formed as surrounds which encapsulate the inflatable enclosures.

Owner:LAKIC NIKOLA

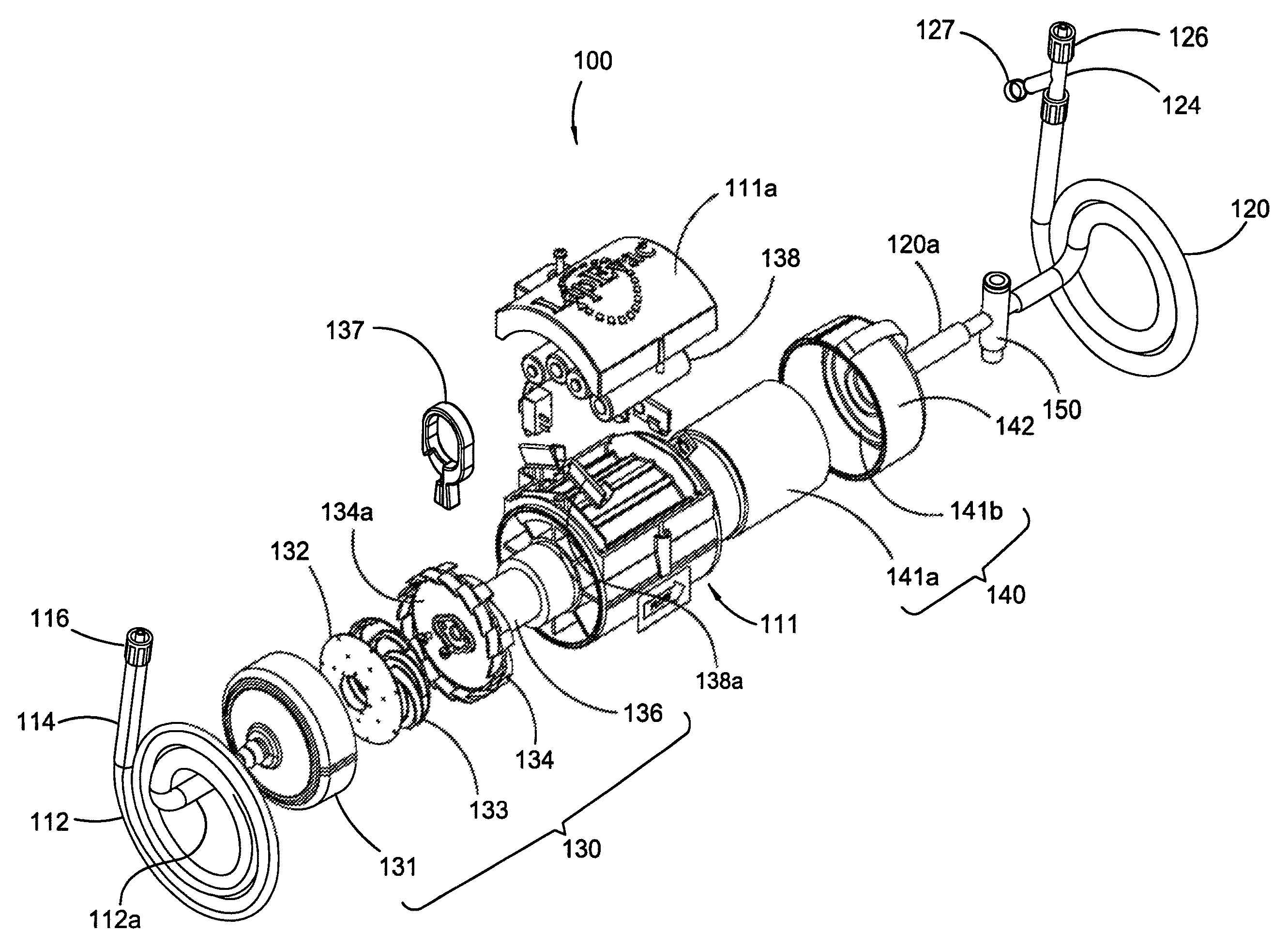

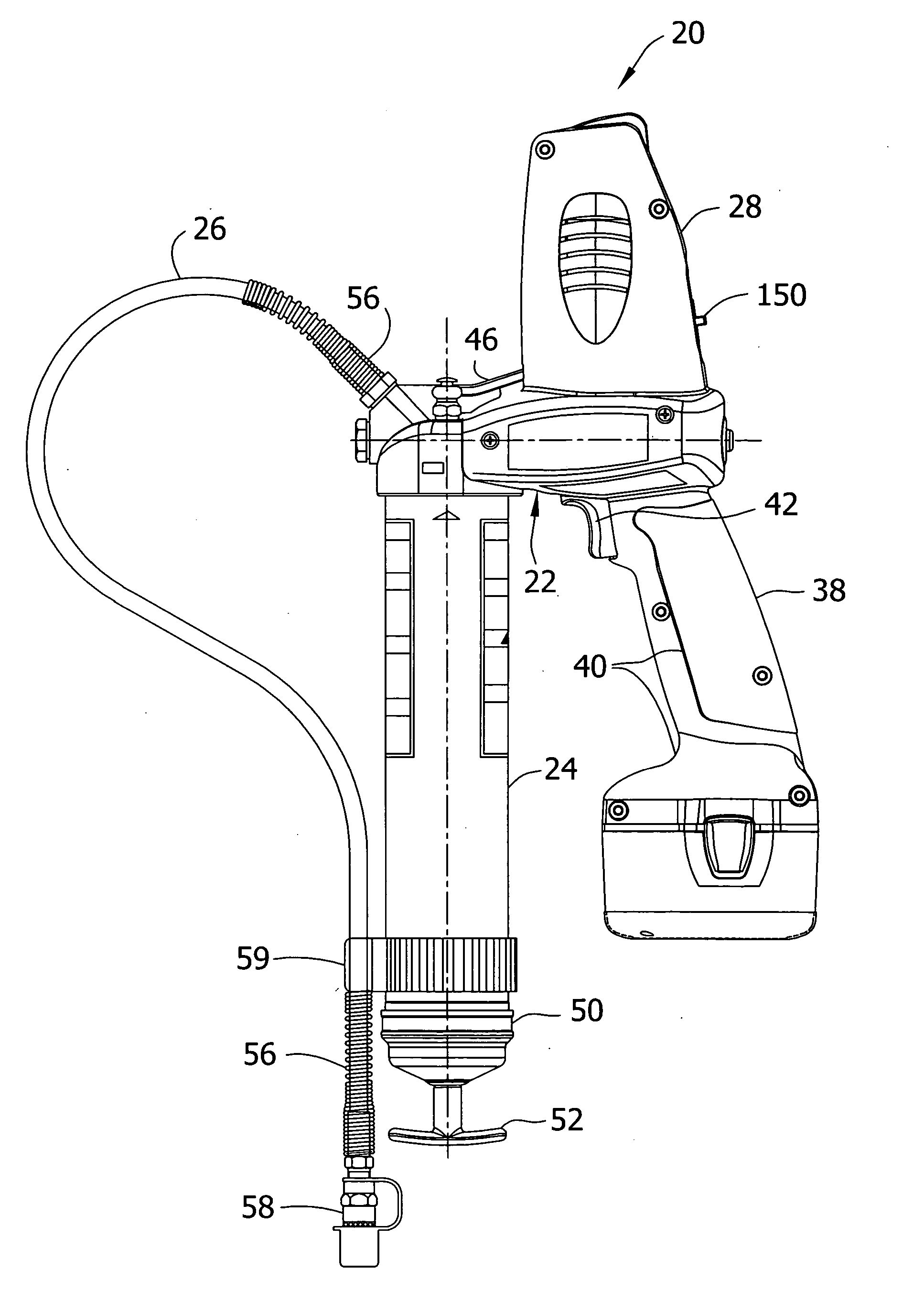

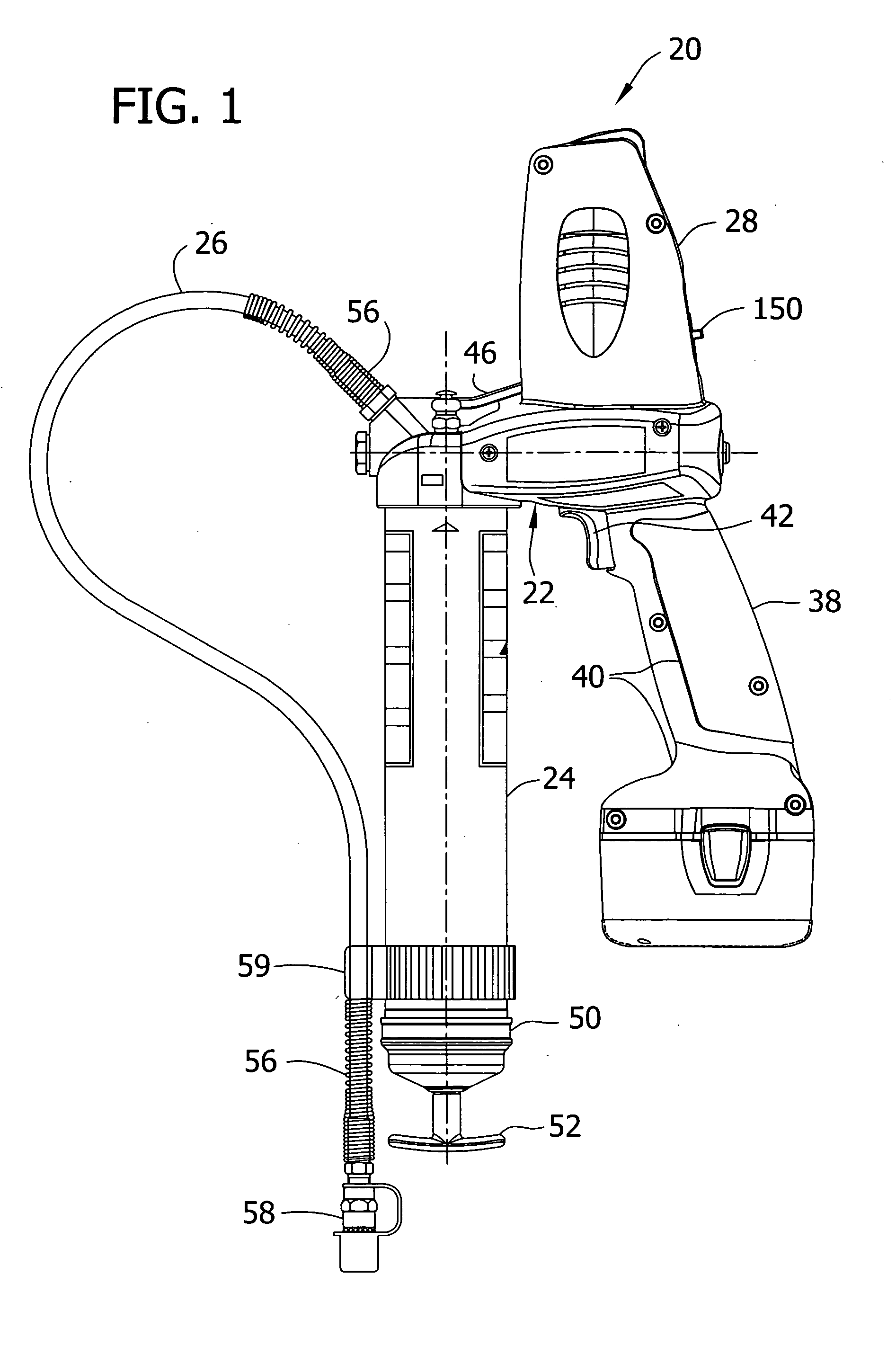

Grease gun

InactiveUS20060108180A1Avoid damageGuaranteed economic efficiencyManual lubricationMachines/enginesElectricityTransmitted power

A device for dispensing a viscous fluid, such as grease gun for dispensing lubricant. The grease gun delivers lubricant with a selectable variation in pressure and / or output. It includes a reservoir, a pump having a reciprocating plunger, an electric motor driving the pump, and a variable speed transmission for transmitting power from the motor to the pump. The transmission has at least two different output speed settings adapted to be selected for reciprocating the plunger at different cyclical frequencies. A cycle indicator provides an indication corresponding to a quantity of lubricant dispensed. Embodiments of the grease gun include a pressure relief valve which inhibits damage due to an over-pressure condition, and a circuit breaker which inhibits damage due to electrical overload.

Owner:LINCOLN INDUSTRIES CORP

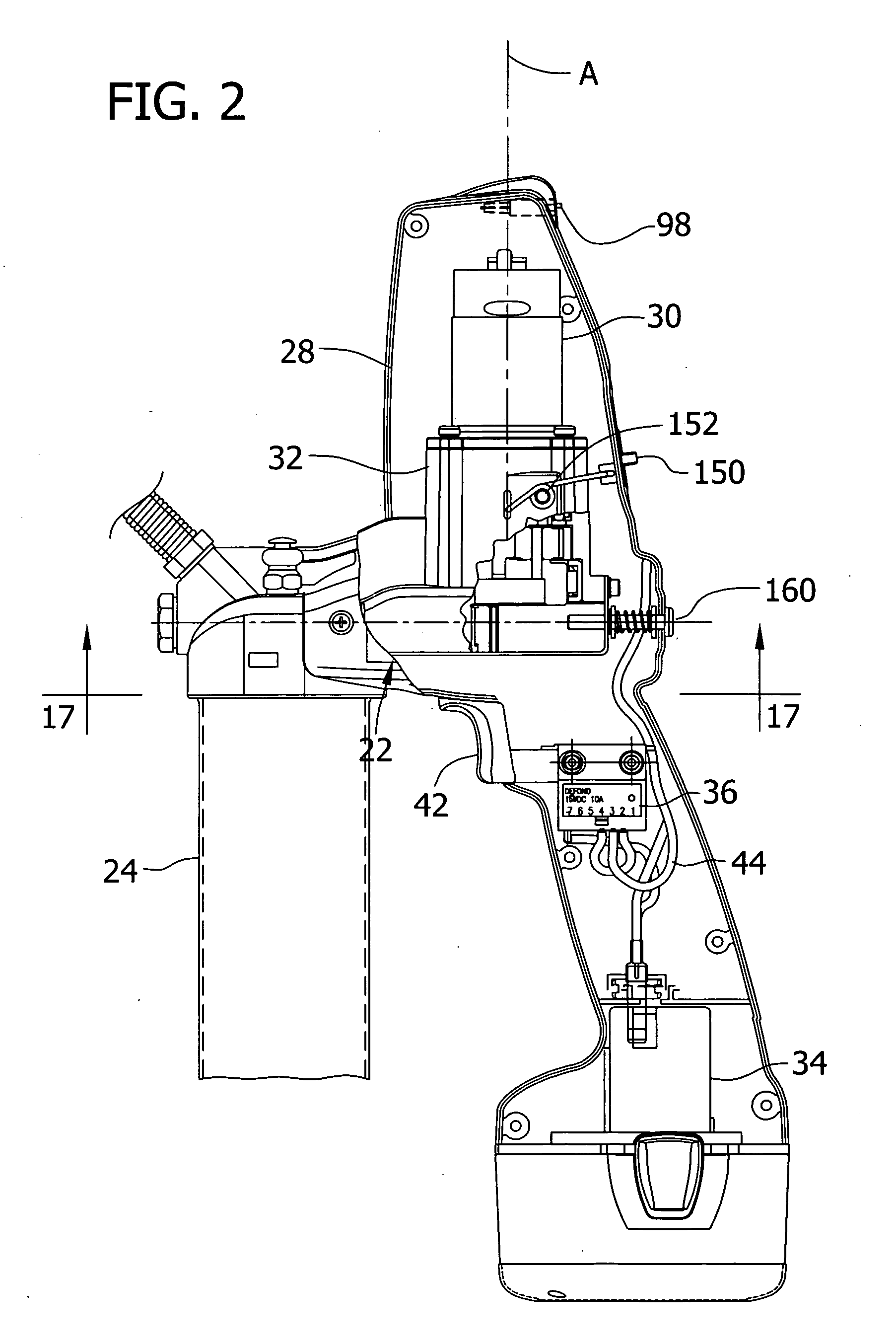

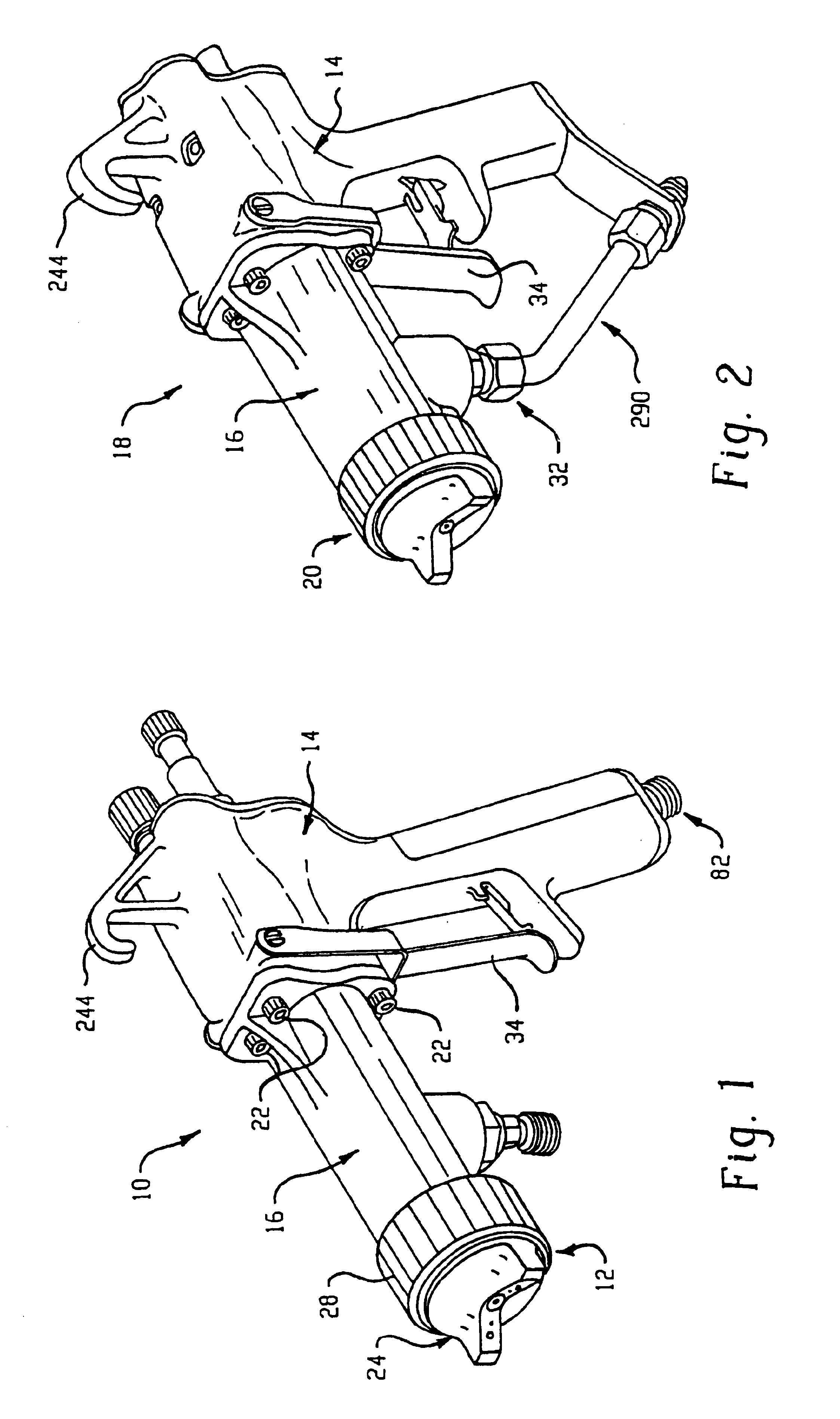

Spray gun having improved fluid tip with conductive path

InactiveUS6877681B2Reduce operator fatigueImprove ease of useBurnersSpraying power supplySpray nozzleEngineering

A modular spray gun that can be configured and built to operate using a selectable spray process. The modular spray gun includes a gun body, an extension and a selectable spray atomizing component. The basic gun body and extension are used to configure a spray gun that can operate as an air spray gun, an airless spray gun, an AAA gun or an HVLP spray gun. The modular extension can be selected to allow circulating or non-circulating operation. The modular extension also permits a variety of spray nozzle assemblies to be mounted thereon depending on the selected spray process to be used with the specific gun. The modular gun body allows selective connection of an atomizing air supply and additional components specific to a particular spray process. An indicator device and / or a relief valve is provided for spray guns using an HVLP spray process to provide an indication that the spray gun is in compliance with the maximum nozzle air pressure limit, usually less than 10 psi. A new air valve seal assembly is also provided. The modular gun design can accommodate electrostatic and non-electrostatic versions.

Owner:NORDSON CORP

Active pressure relief valves and methods of use

Active pressure relief valves and methods of use for regulating atmospheric conditions within an interior compartment of a vehicle generally include an active material to effect movement of a flap relative to an opening. The active material has the ability to remember its original at least one attribute such as dimension, shape, and / or flexural modulus, which can subsequently be recalled by applying or removing an external stimulus, as will be discussed in detail herein. Suitable active materials include, without limitation, shape memory alloys, ferromagnetic shape memory alloys, shape memory polymers, piezoelectric materials, electroactive polymers, magnetorheological fluids and elastomers, electrorheological fluids, composites of one or more of the foregoing materials with non-active materials, combinations comprising at least one of the foregoing materials, and the like. Depending on the particular active material, the activation signal can take the form of, without limitation, an electric current, a temperature change, a magnetic field, a mechanical loading or stressing, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

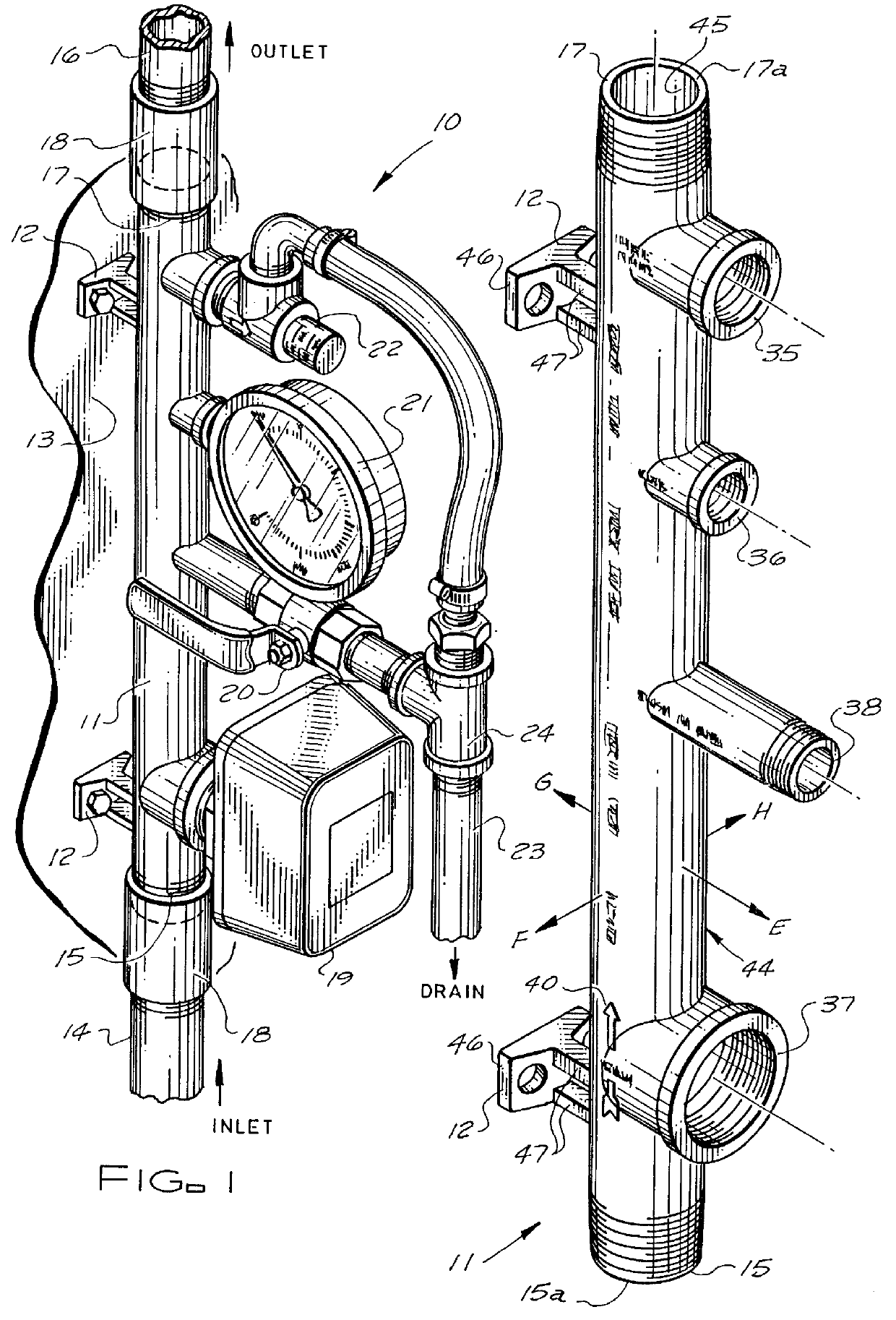

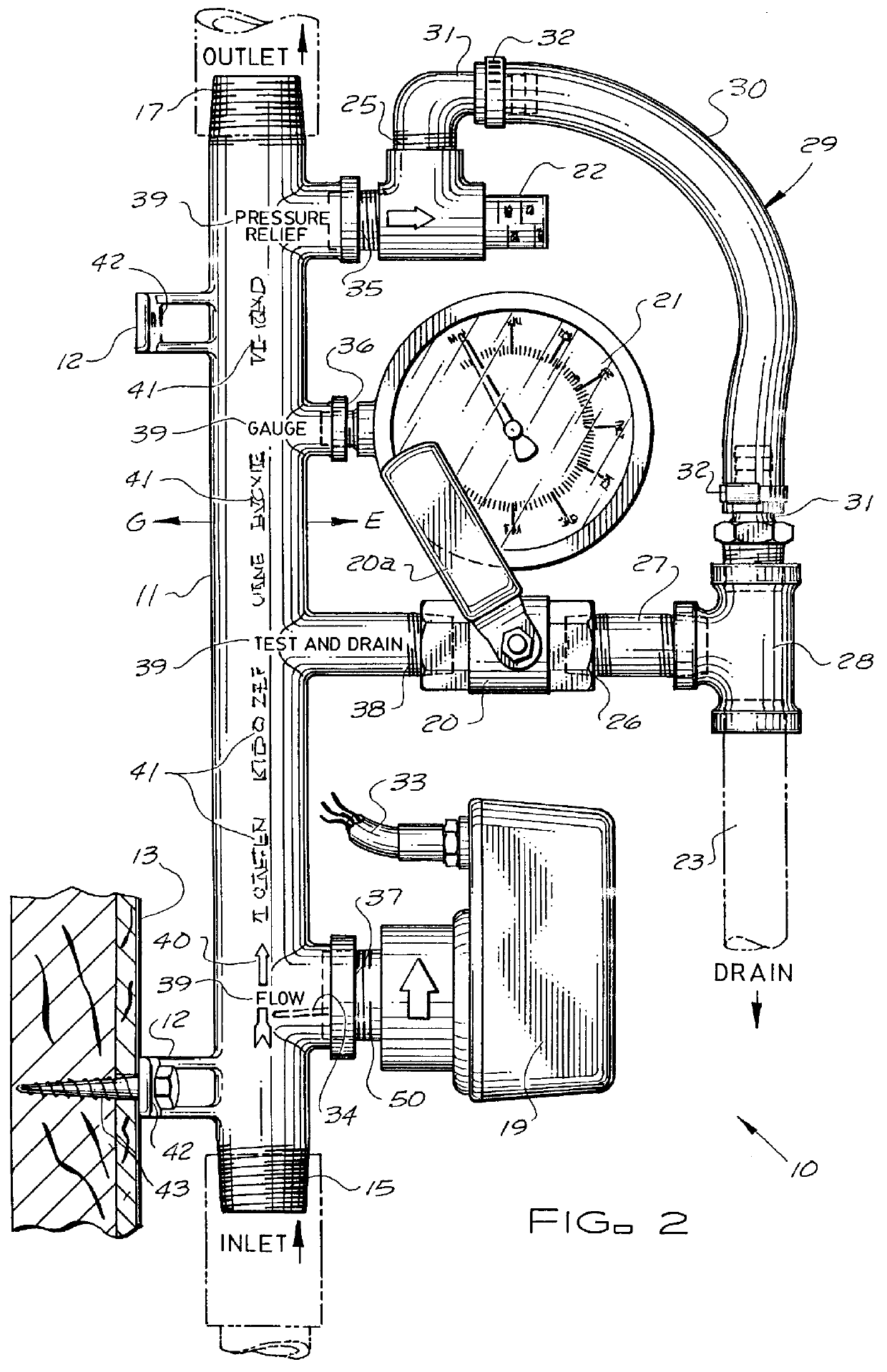

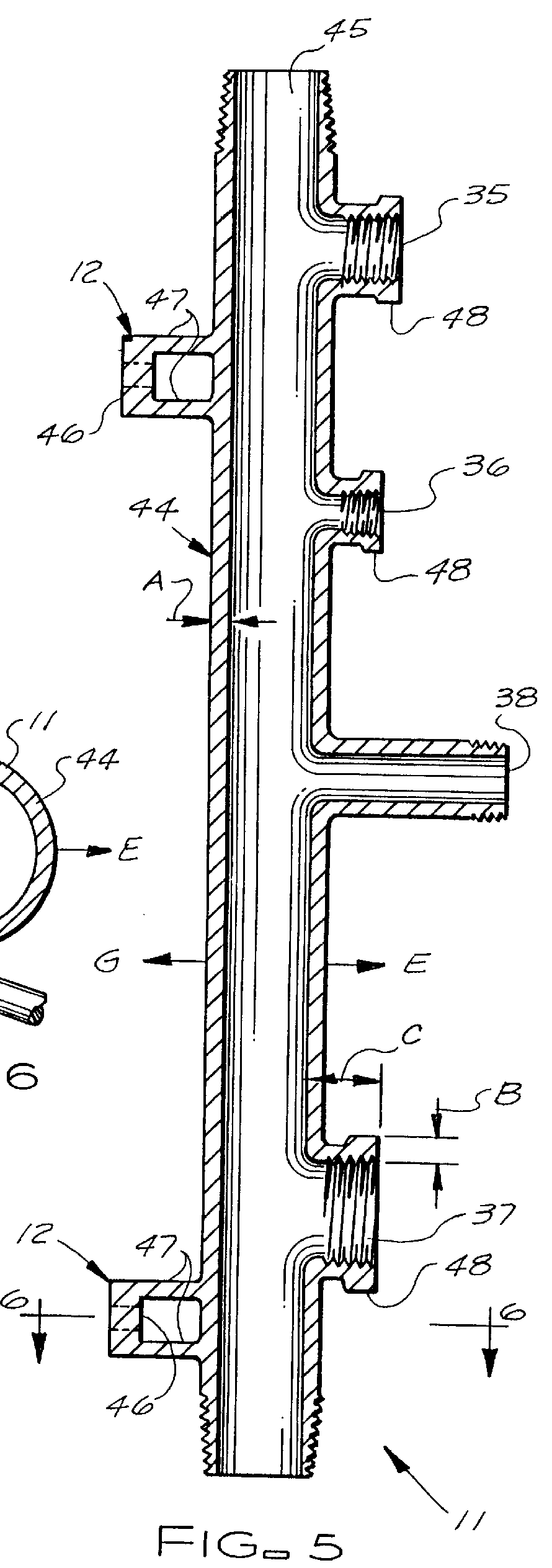

Fire-control sprinkler system riser means

This invention provides a fire-control sprinkler system riser for a residence, including a unitary manifold for porting to system components. The longitudinal manifold has pipe threads on its ends to connect to an inlet water pipe and an outlet sprinkler system; and it has ports all to one side of the manifold for mounting the riser system components in the following order from inlet to outlet: flow switch means; test and drain valve means; pressure gauge means; and relief valve means. On the other side of the manifold are support connections, as for attachment to a beam of the residence. The manifold may be connected facing either way, i.e., left support or right support, and it has indicia on both manifold facing sides for indicating flow direction and port identifications to a user from either side. Dimensions provide high efficiency in use of space, etc.

Owner:NIKON CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com