Patents

Literature

260 results about "Flow splitter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flow splitter, in hydraulic engineering, is any device designed to break up the flow of water or nappe over a dam wall or weir. Flow splitters are used to reduce the likelihood of nappe vibration that might cause the failure of a dam wall by aerating the water flow. They are also used to restrict large flows of stormwater, in situations where a stormwater management device is designed only to treat small storms.

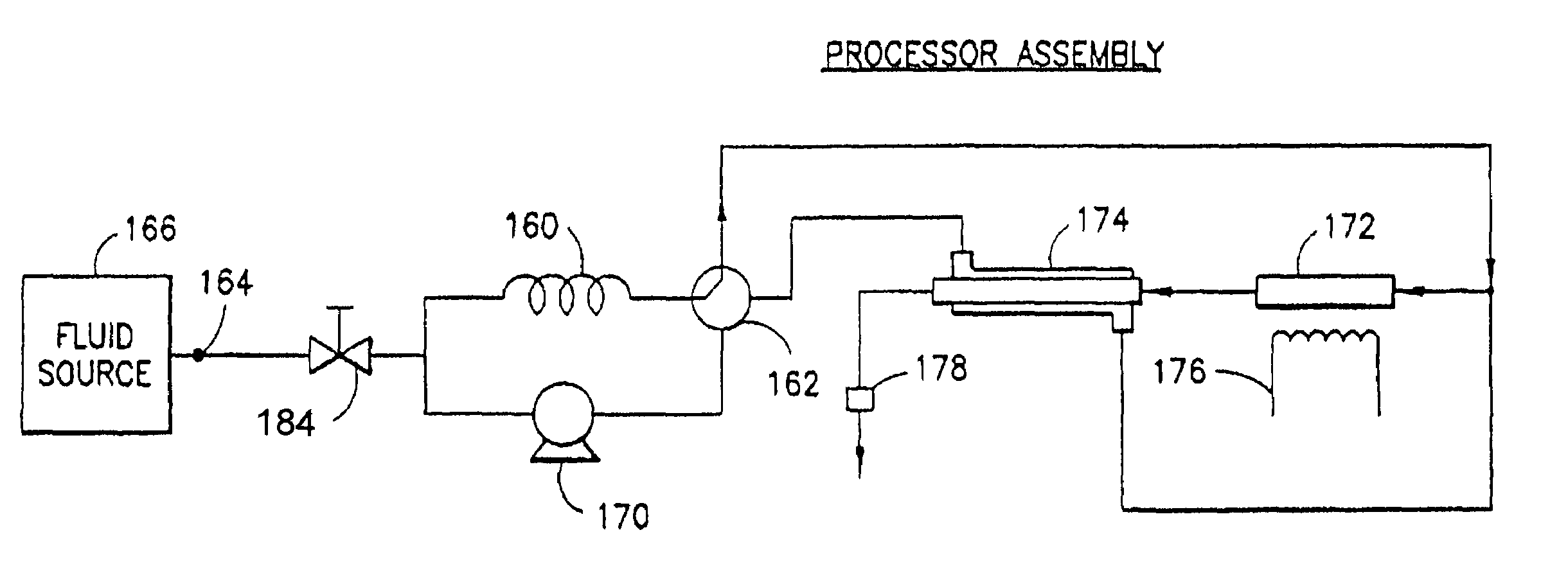

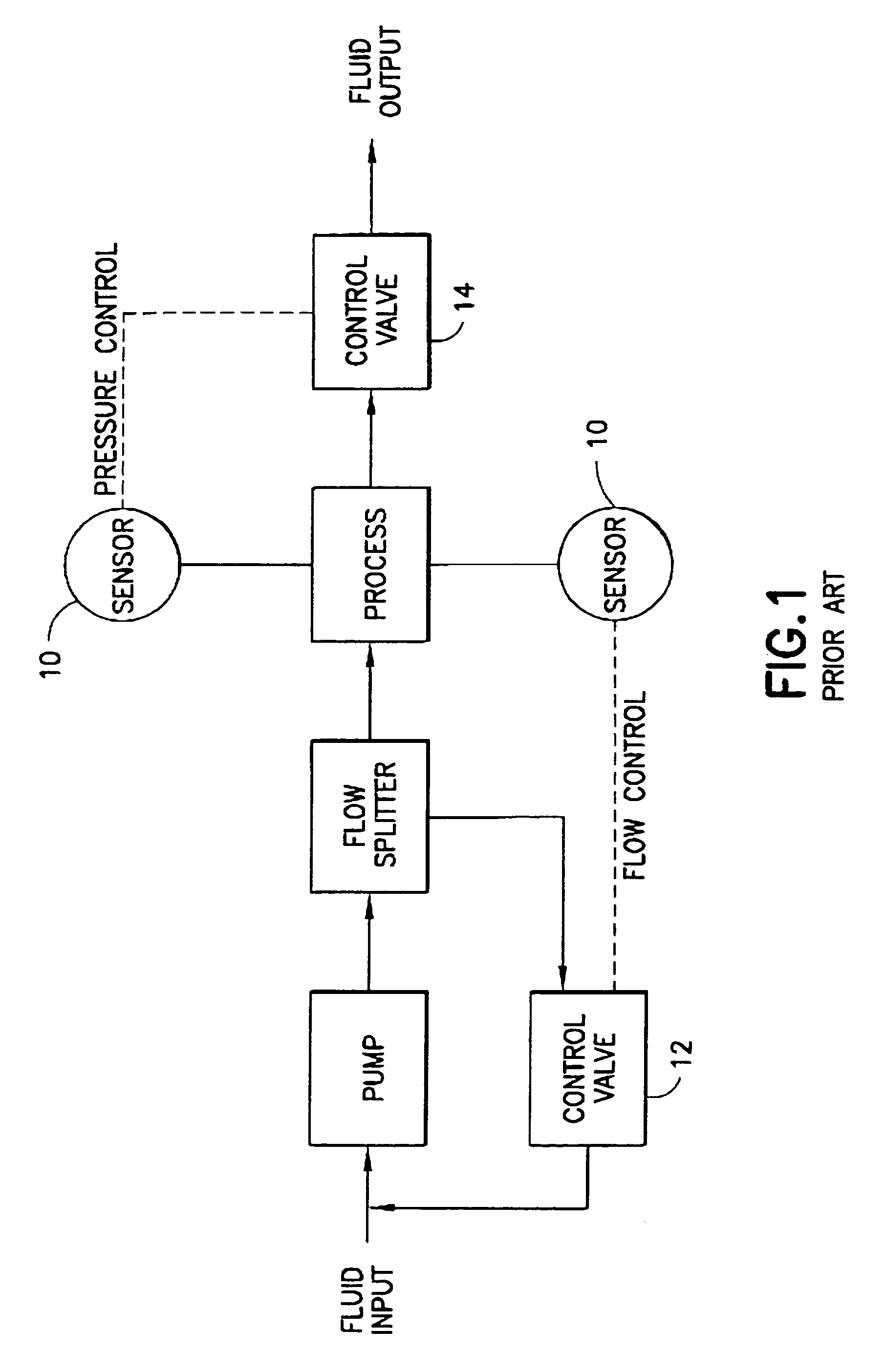

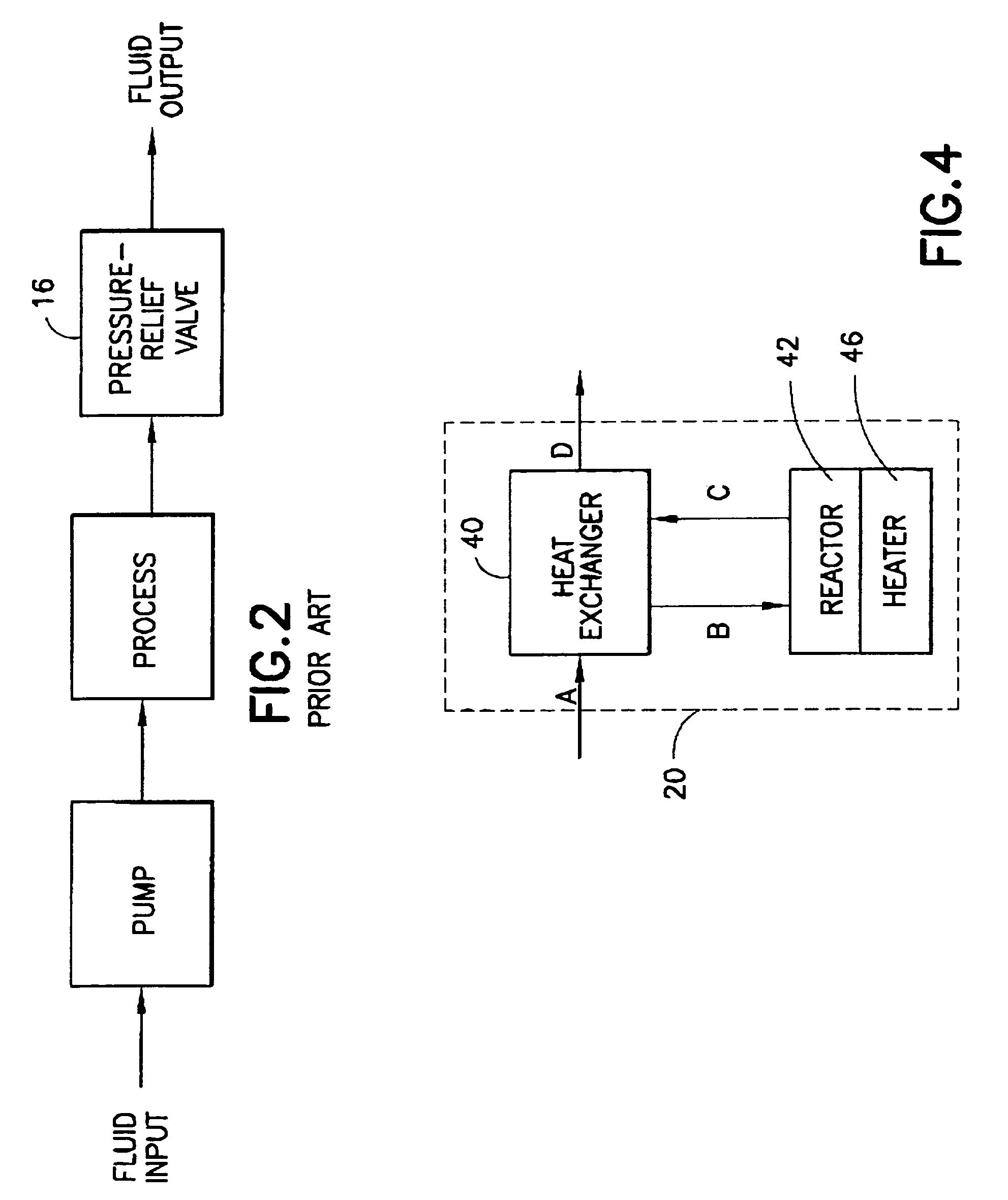

Apparatus and method for continuous depyrogenation and production of sterile water for injection

InactiveUS7122149B2Simple yet dependableReduce contact timeDialysis systemsTreatment involving filtrationDepyrogenationIon exchange

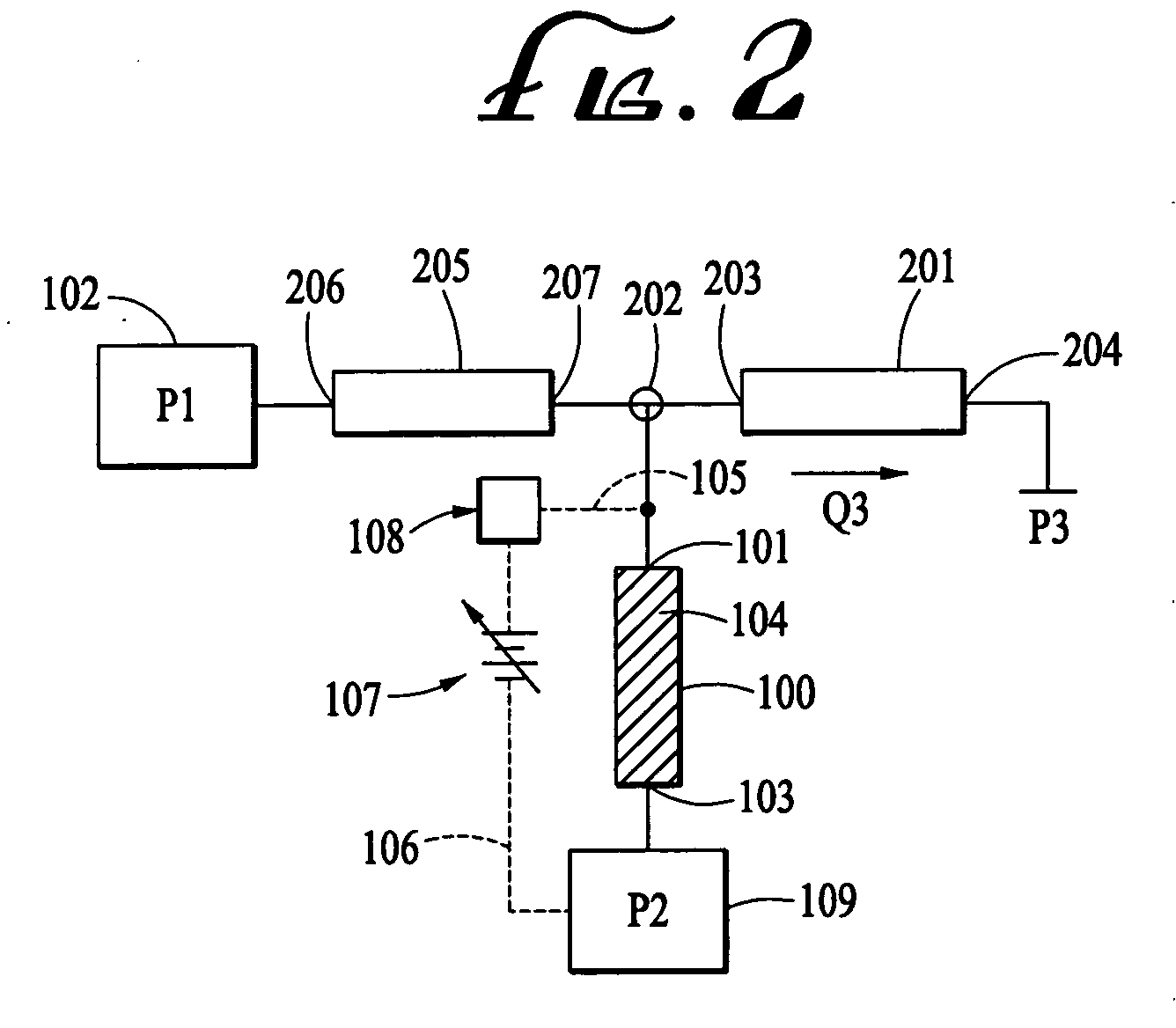

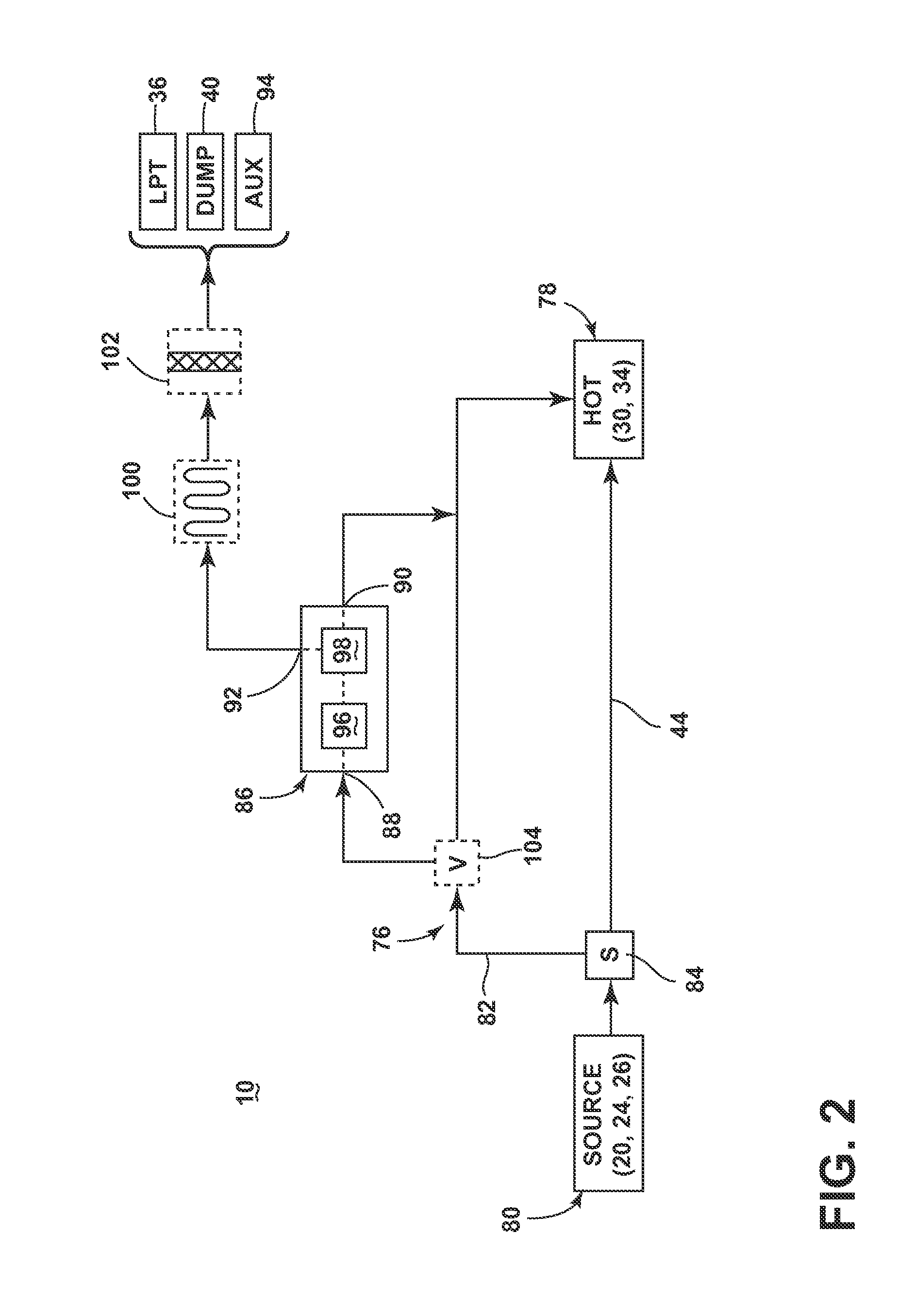

A fluid processor, suitable for the production of sterile water for injection, having a processor assembly and a process control system comprising a pump, a flow splitter, flow restrictors and a pressure relief valve. In a preferred embodiment, the processor assembly comprises a heat exchanger, a reactor and a heater arranged in a nested configuration. The preferred embodiment of the present invention also include a treatment assembly having a combination of filter, reverse osmosis and ion exchange devices and further incorporates an assembly and method allowing for the in situ sanitization of the fluid processor during cold start and shutdown to prevent bacteria growth during storage of the fluid processor. The fluid processor may include an electronic control system comprising a touch screen operator interface, a programmable logic controller and sensors for measuring temperature, pressure, flow rate, conductivity and endotoxin level.

Owner:APPLIED RES ASSOCS INC

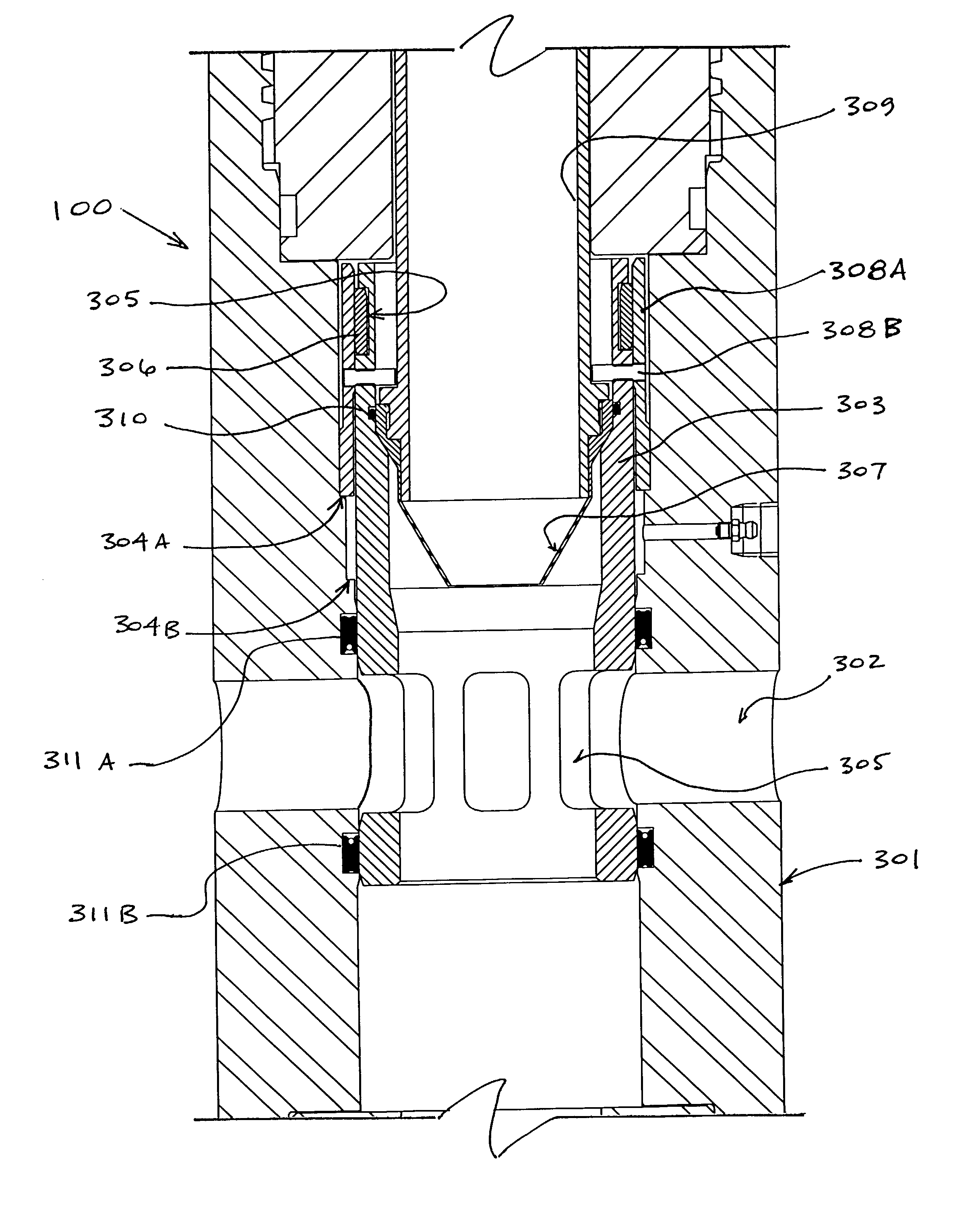

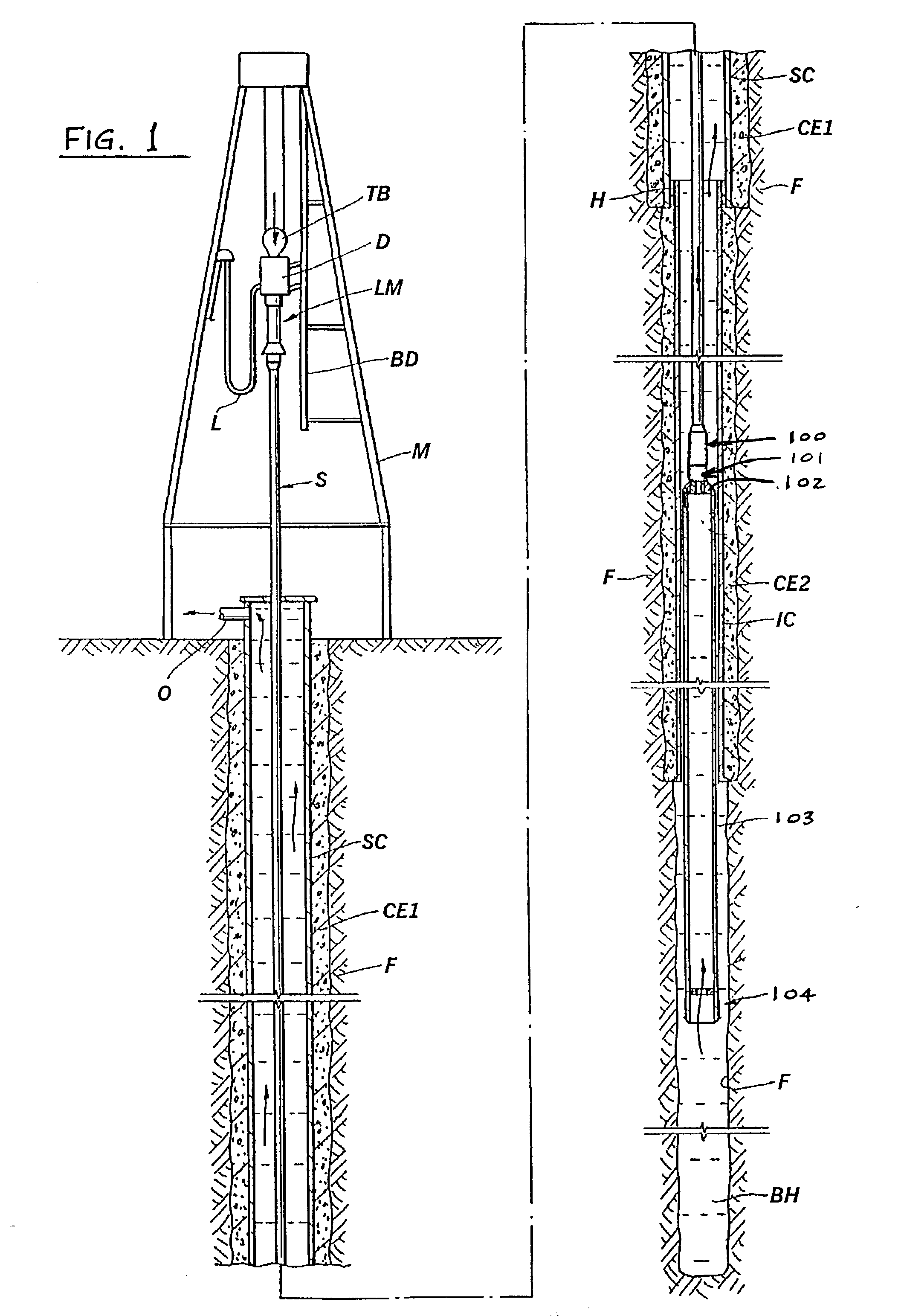

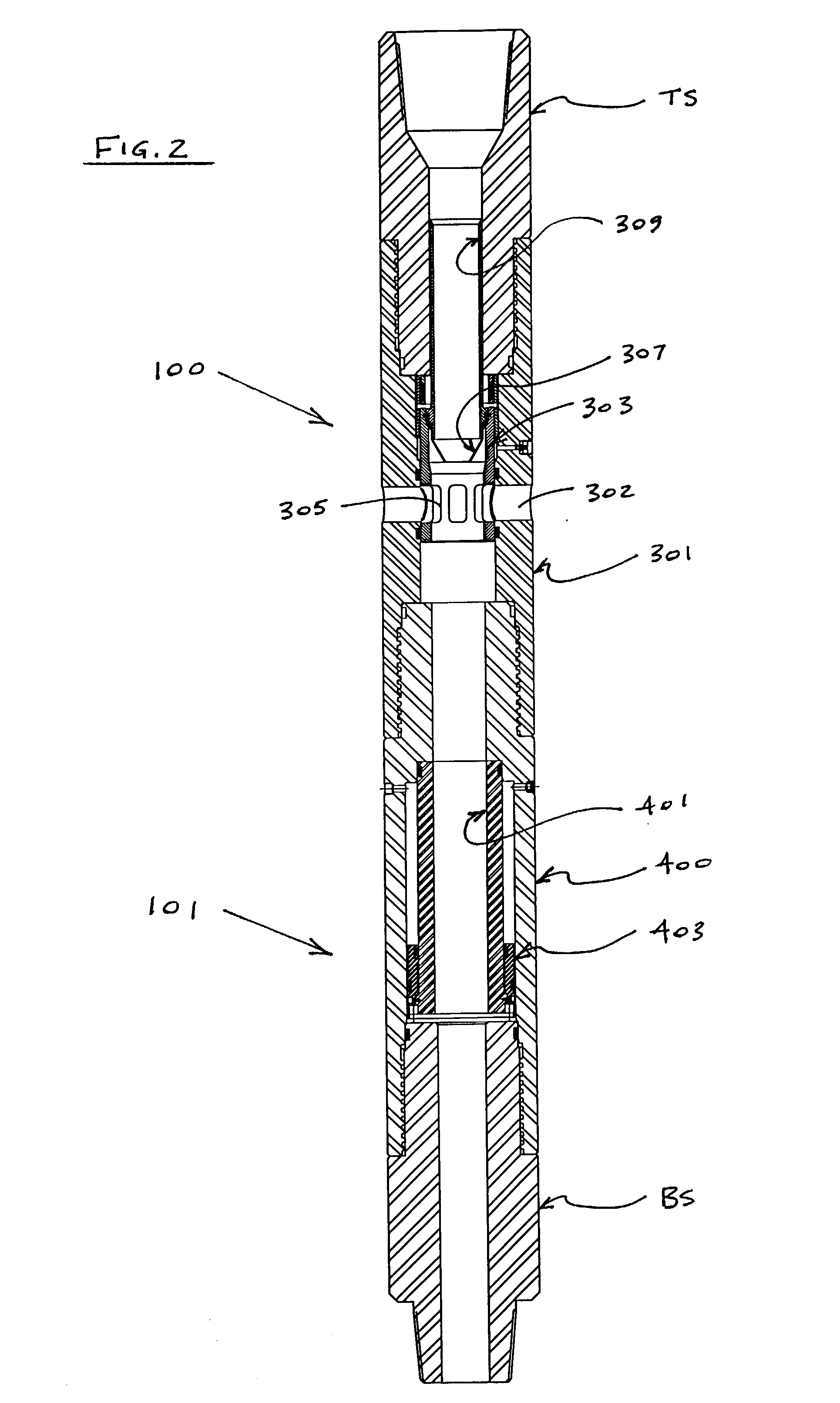

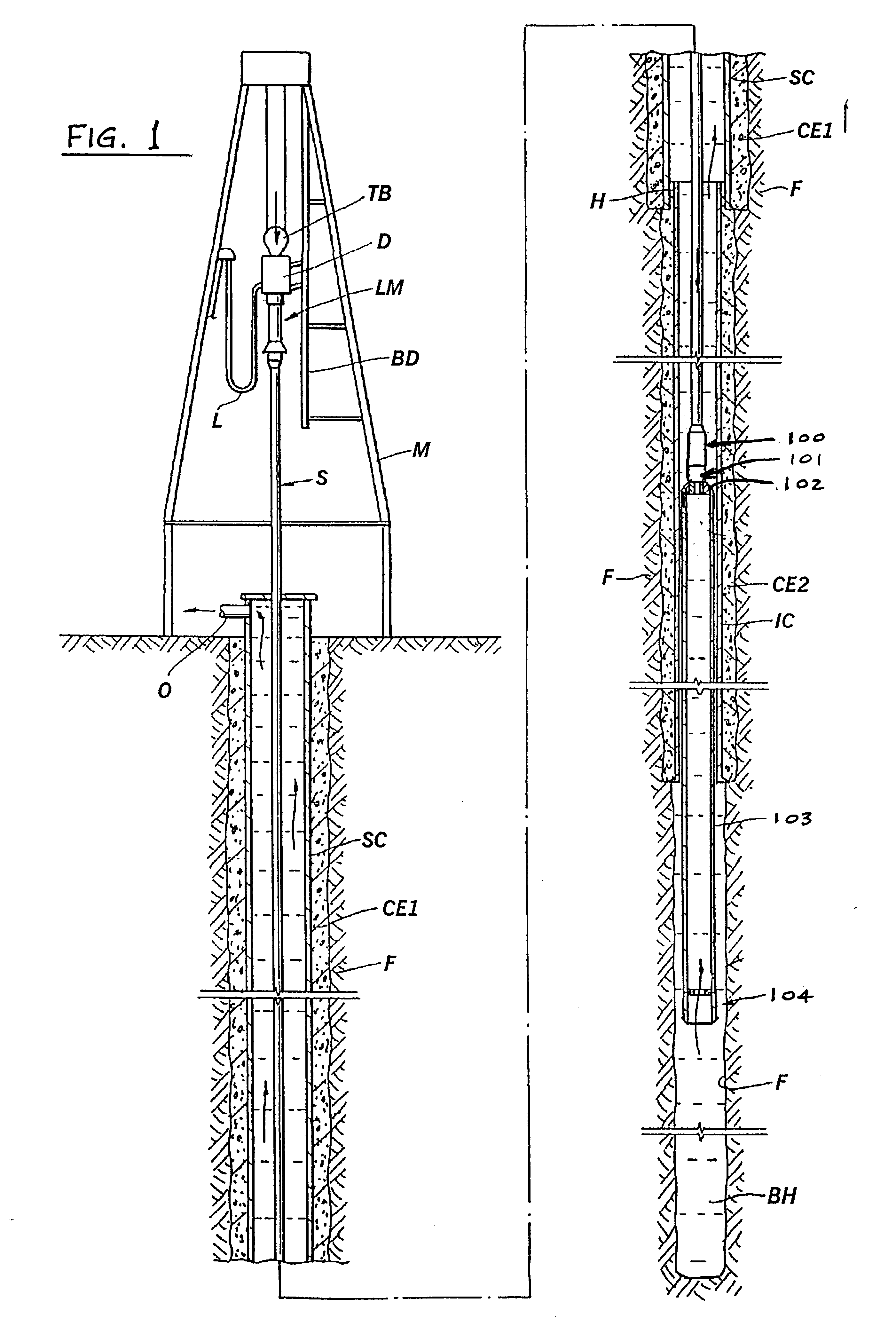

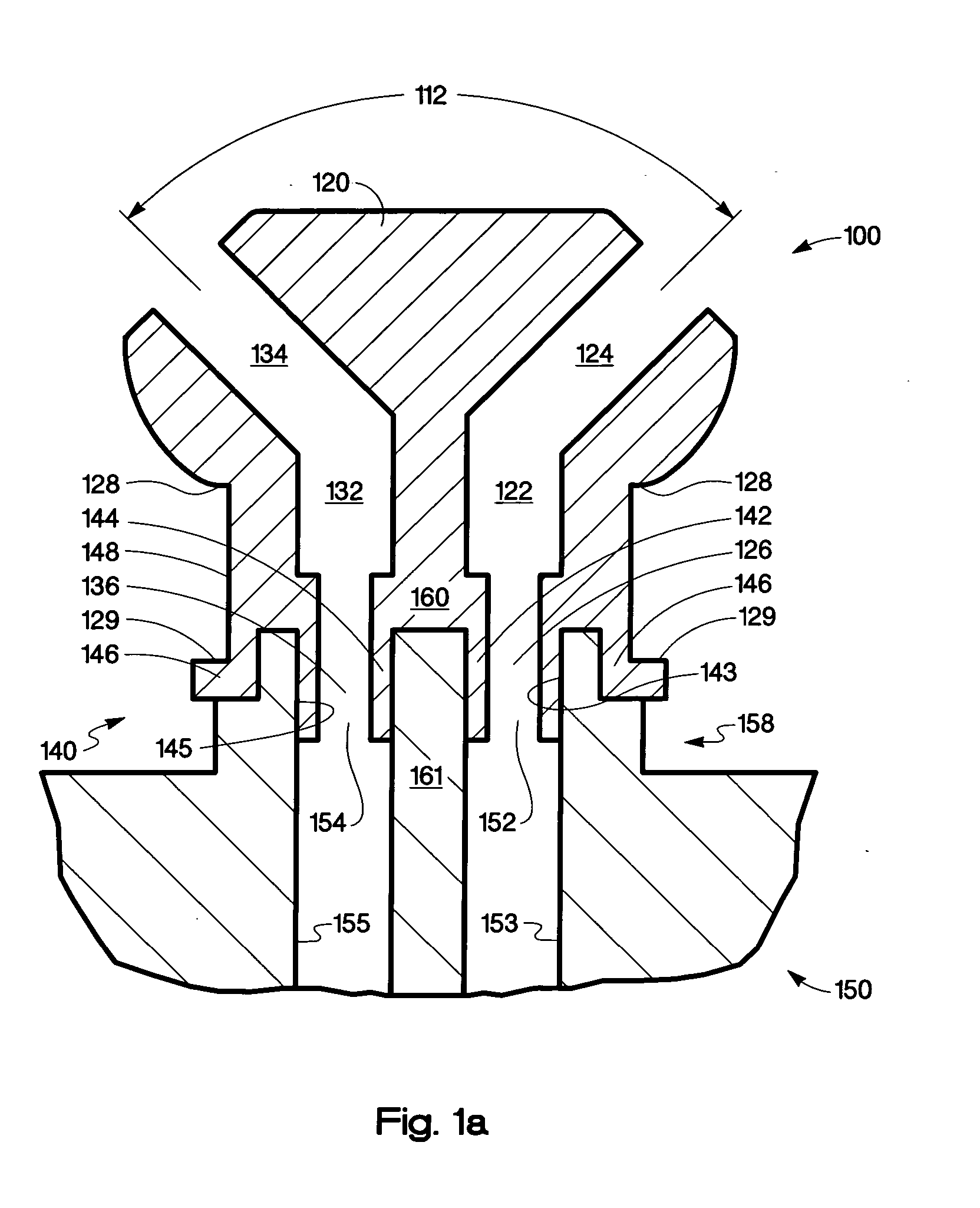

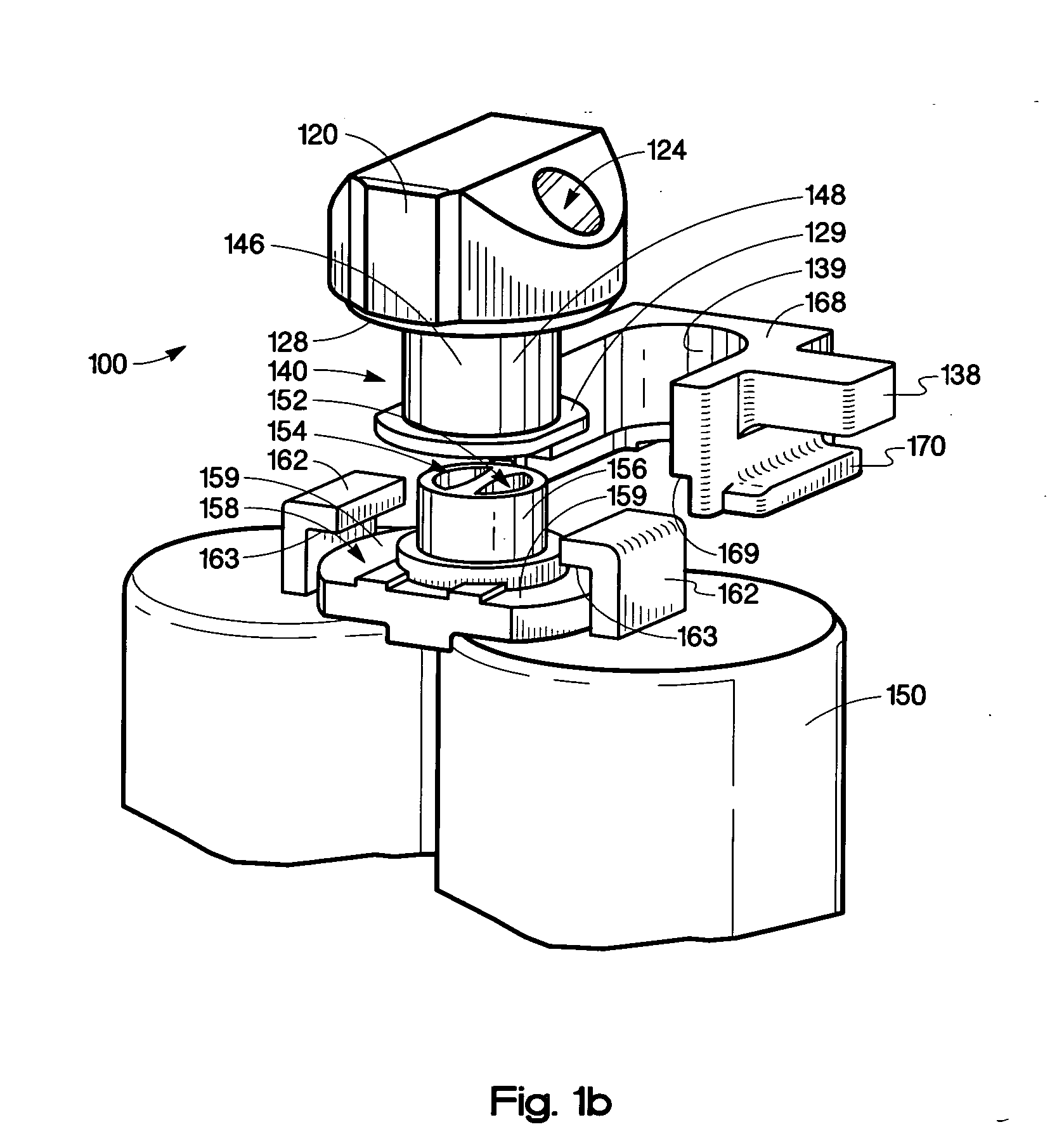

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

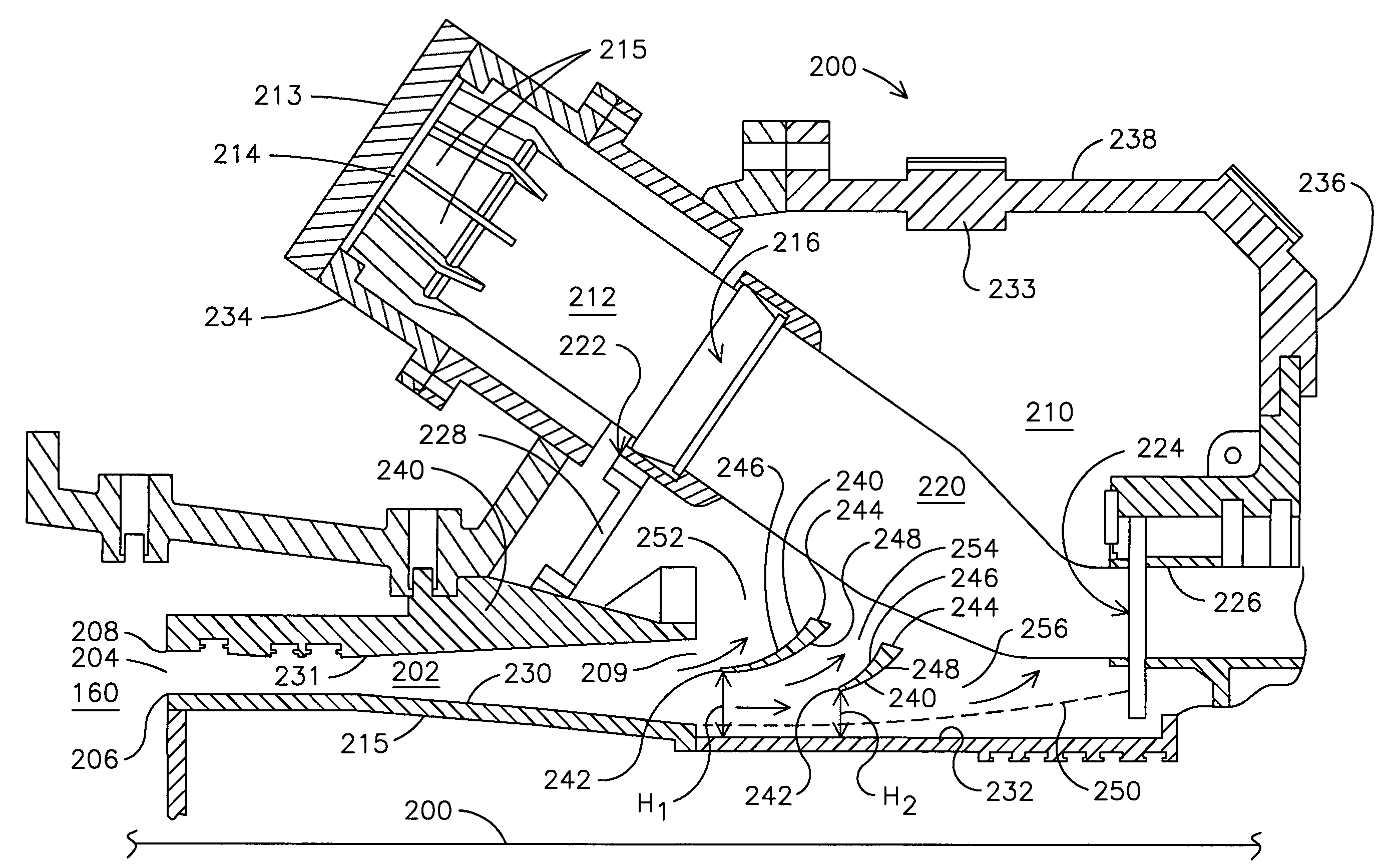

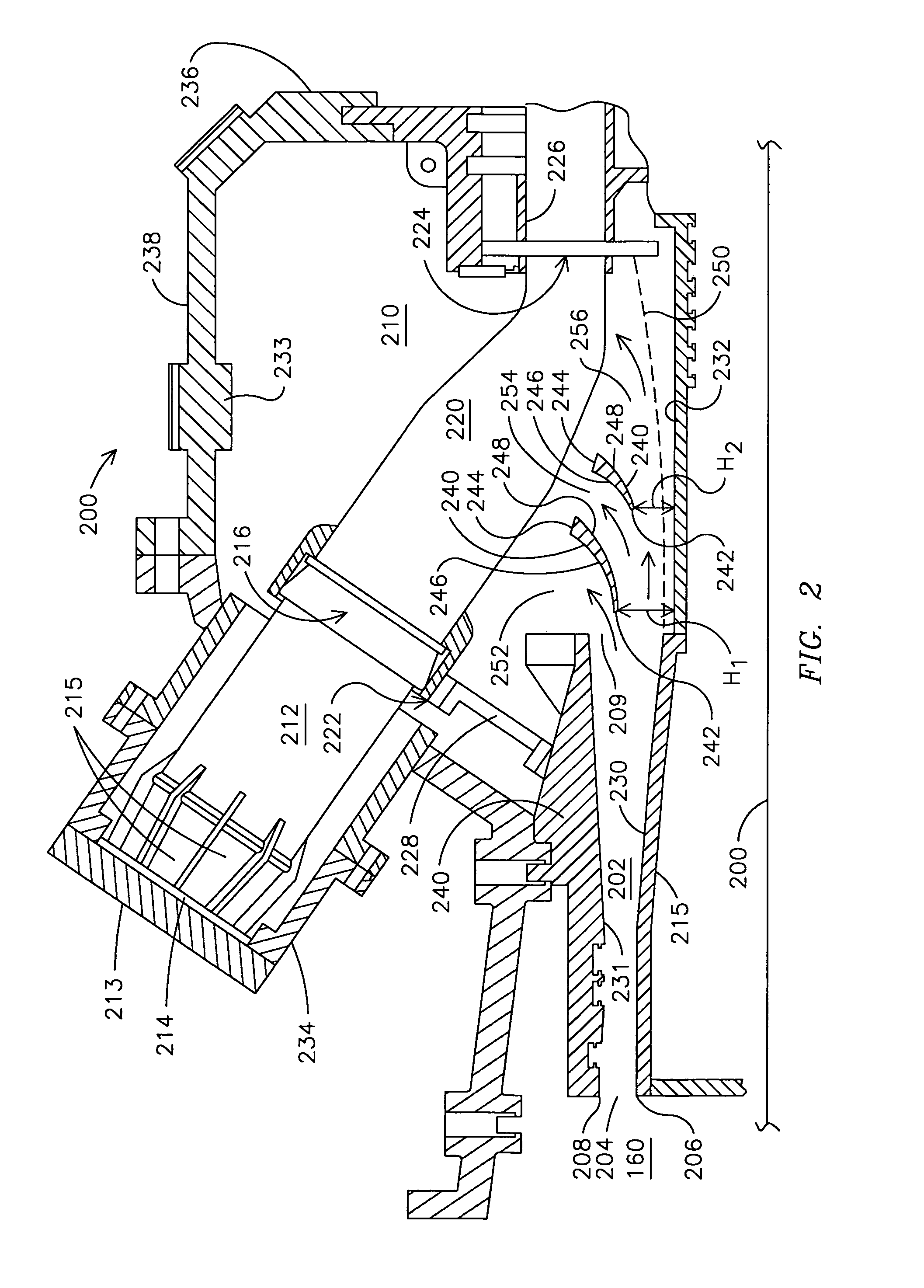

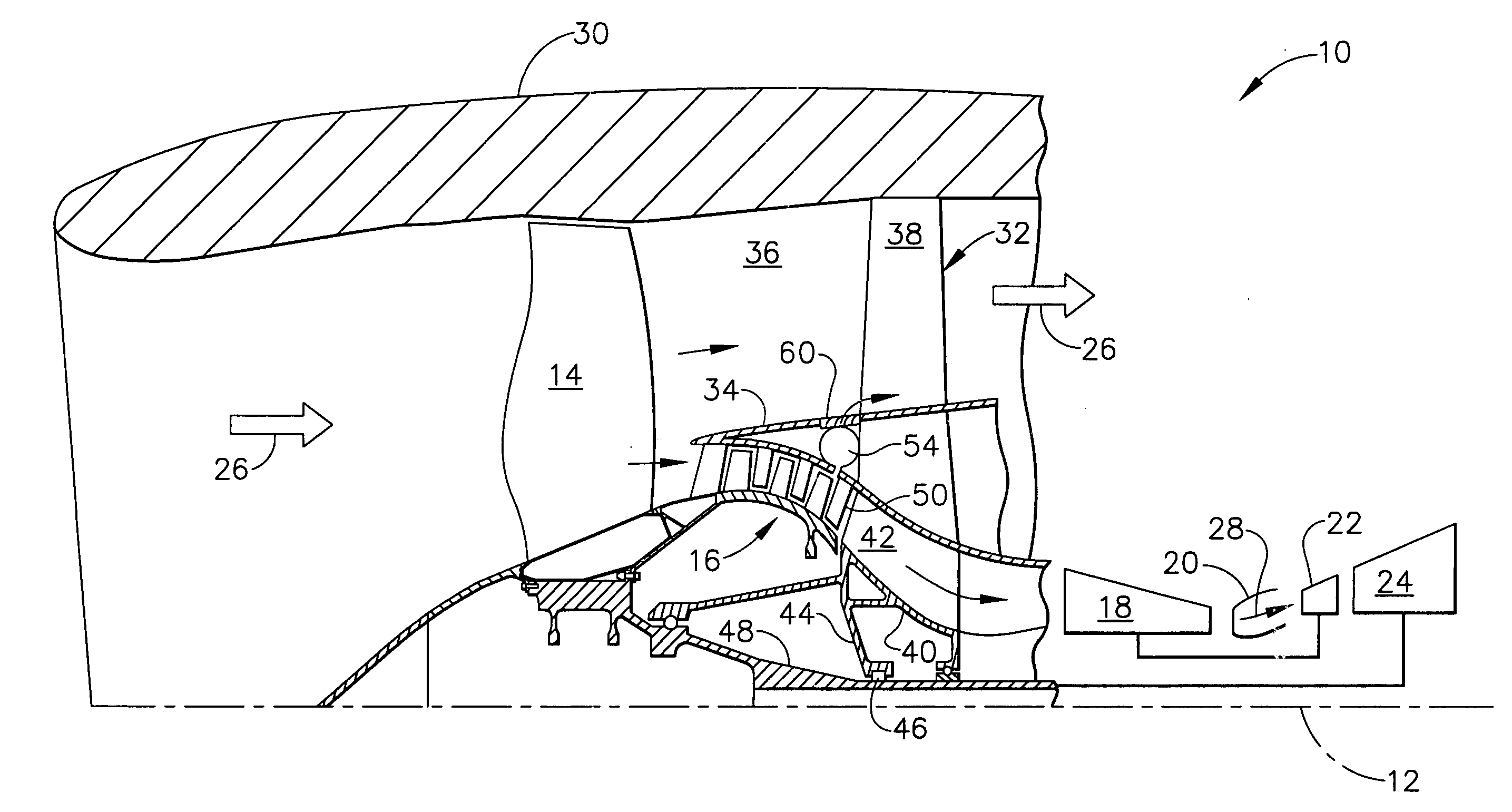

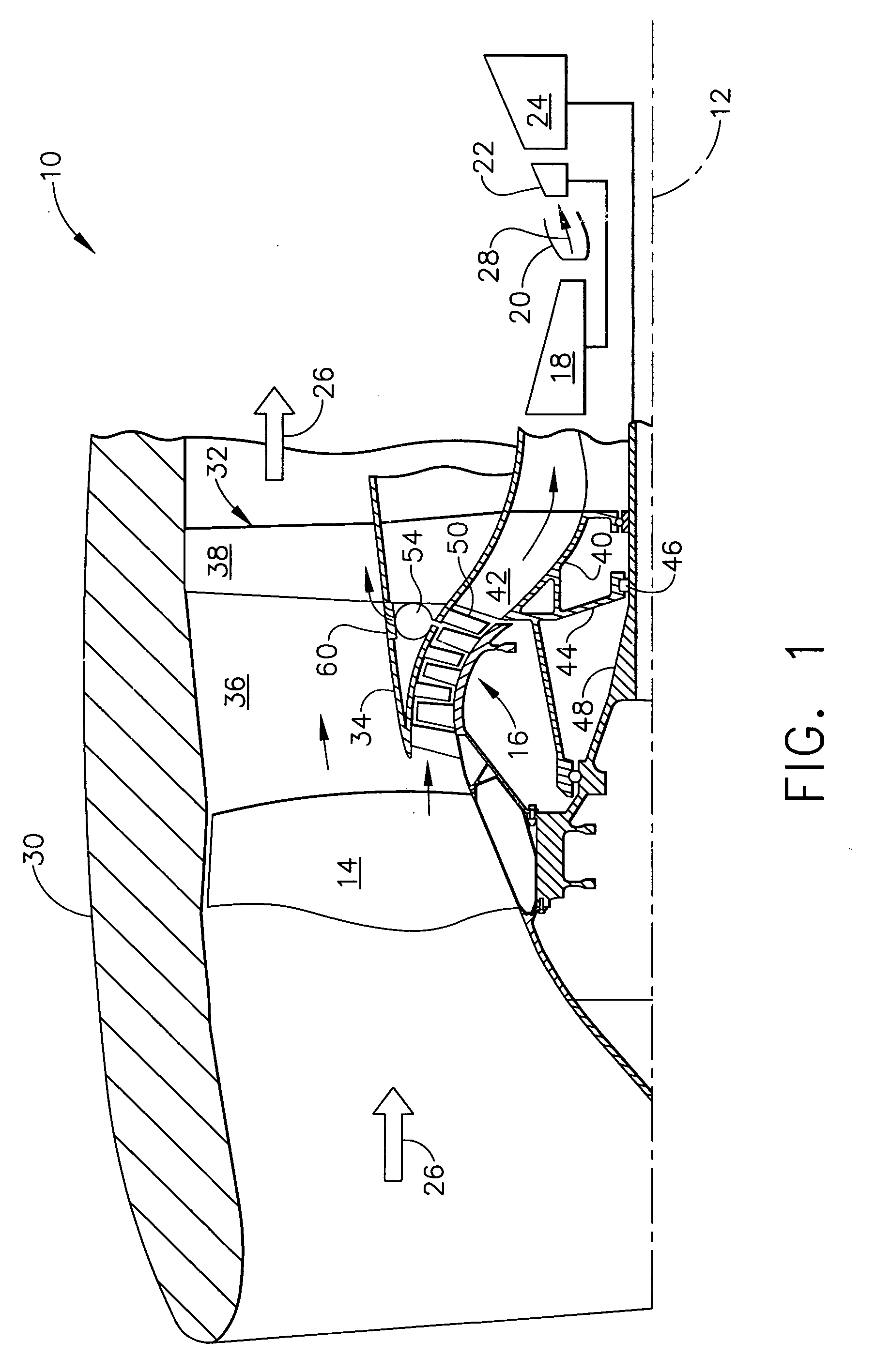

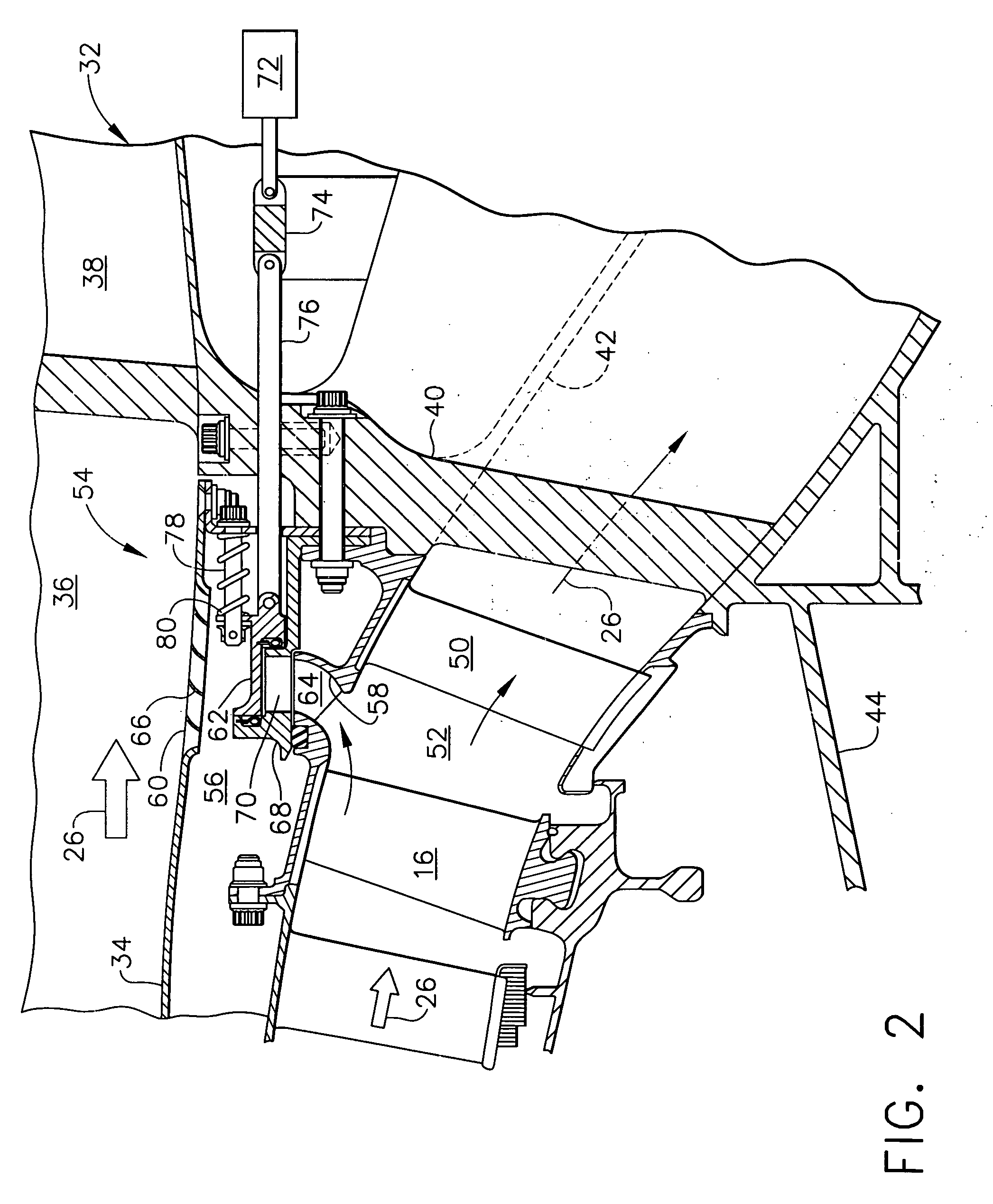

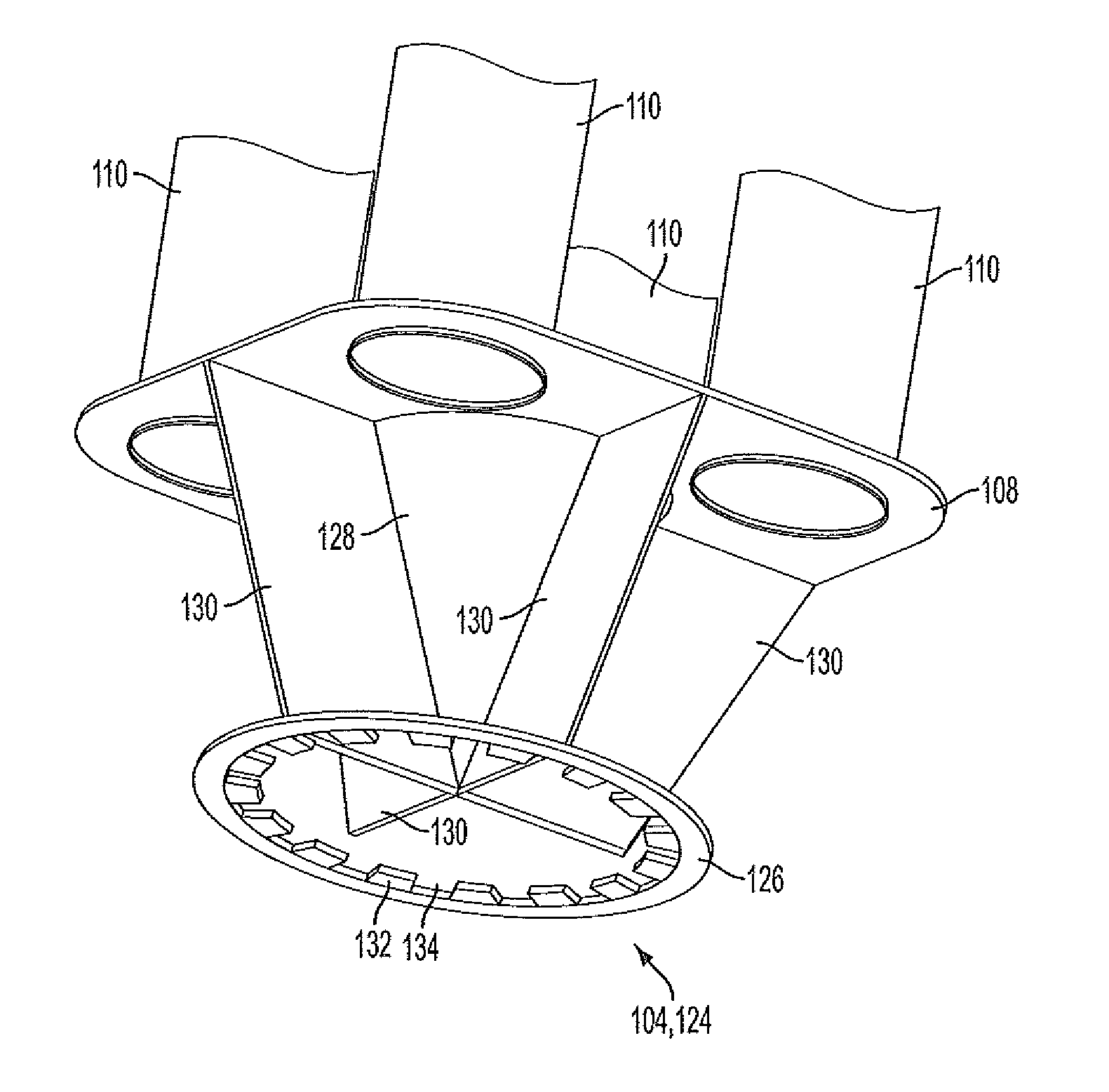

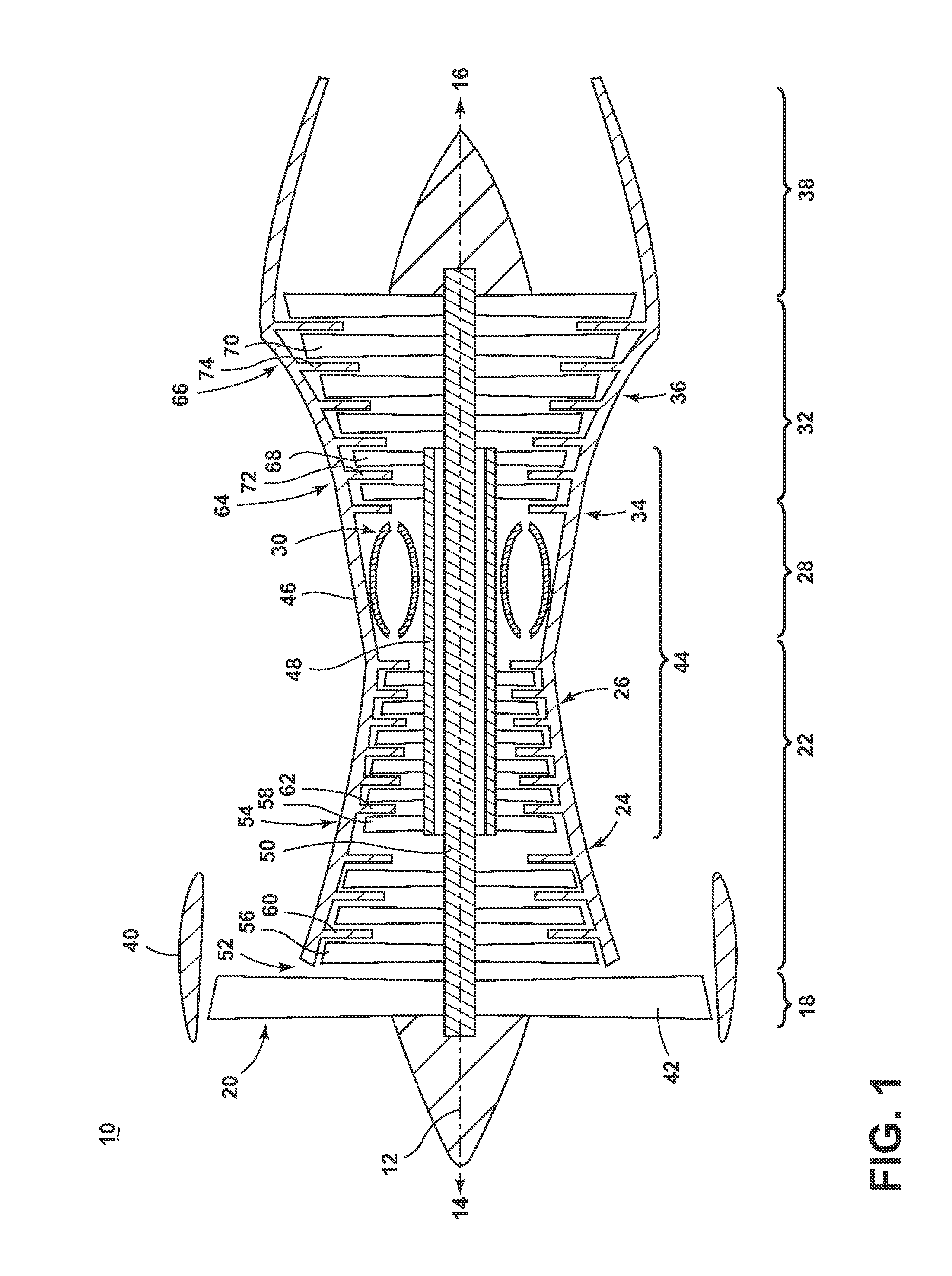

Fluid flow distributor apparatus for gas turbine engine mid-frame section

InactiveUS7600370B2Continuous combustion chamberTurbine/propulsion engine coolingEngineeringDistributor

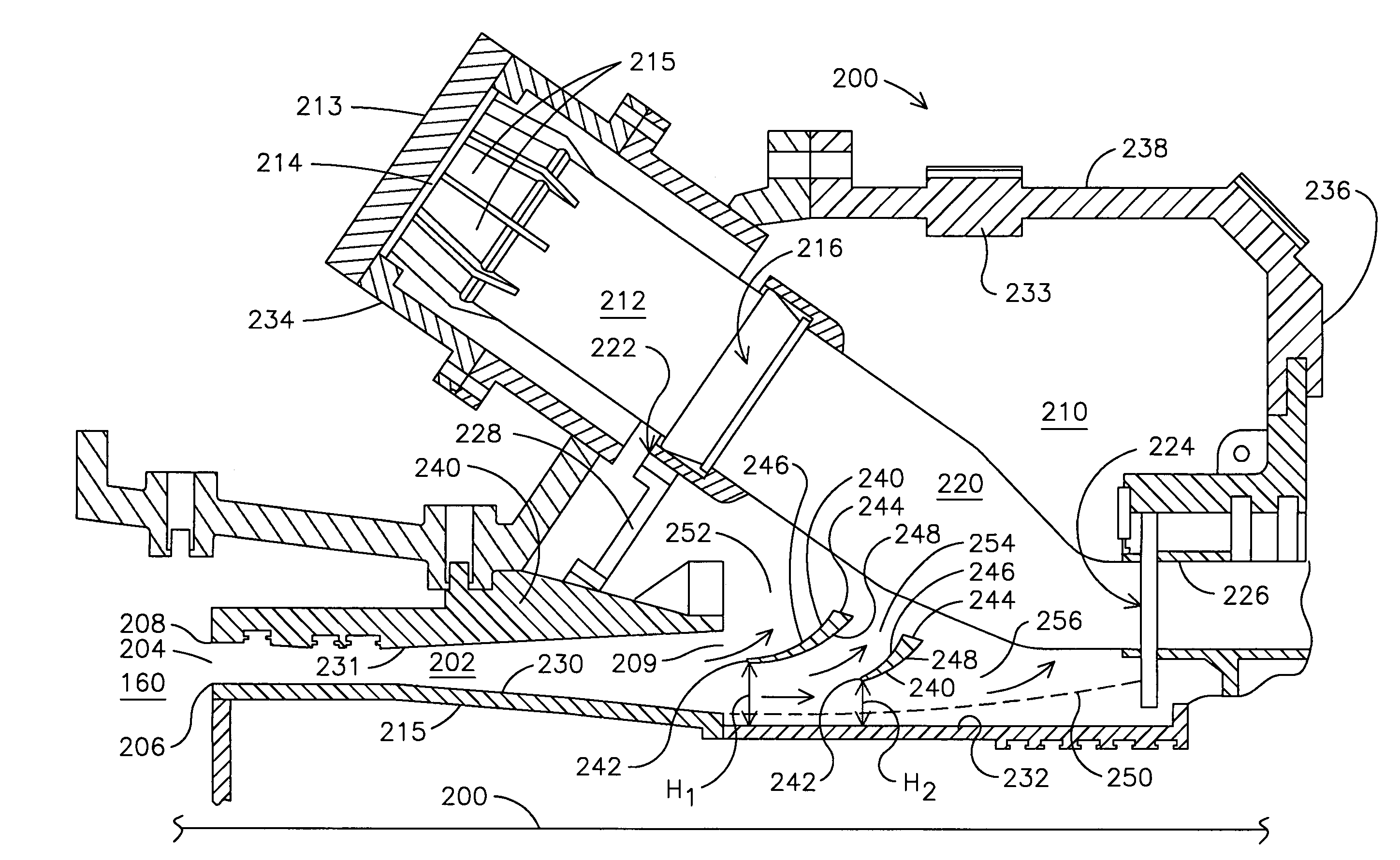

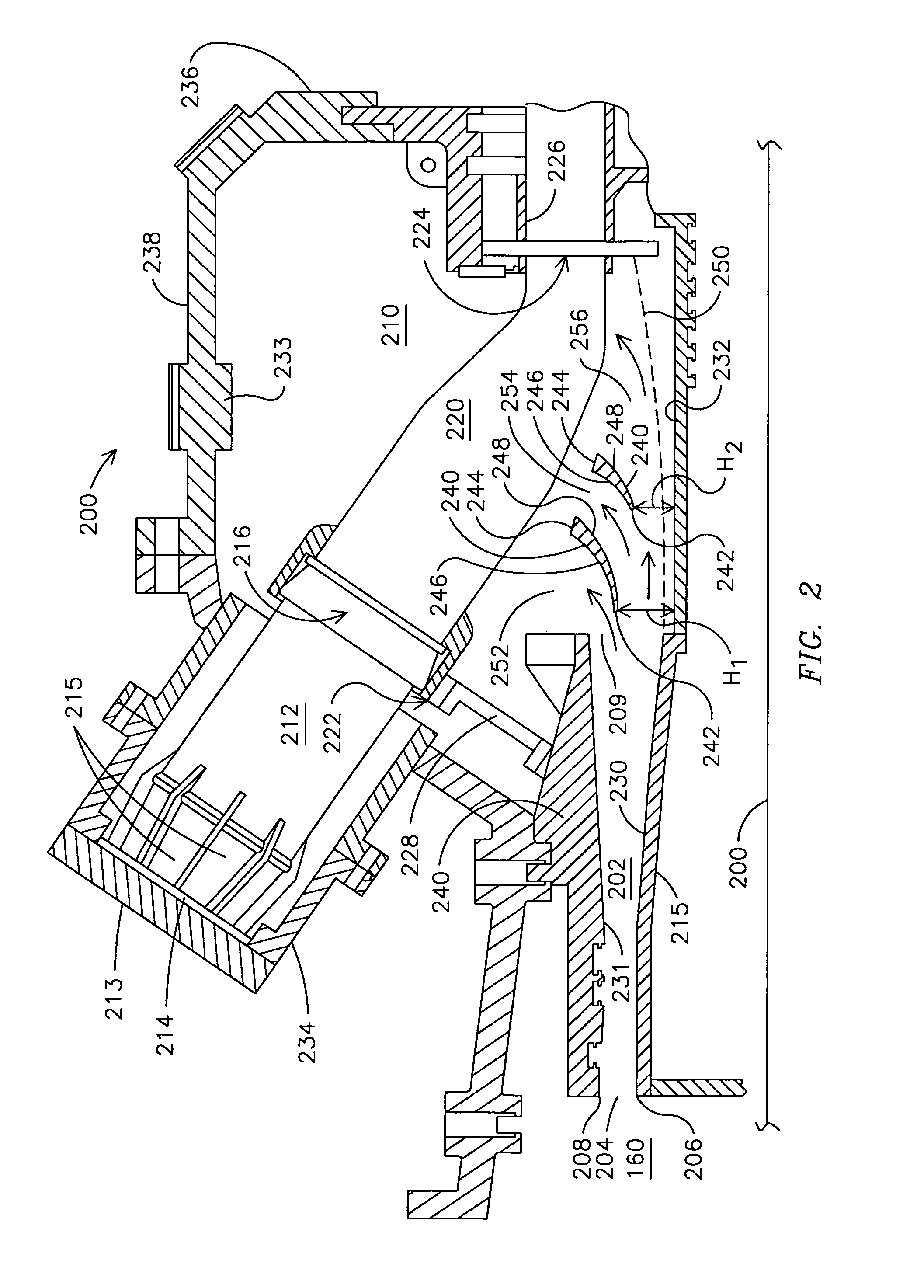

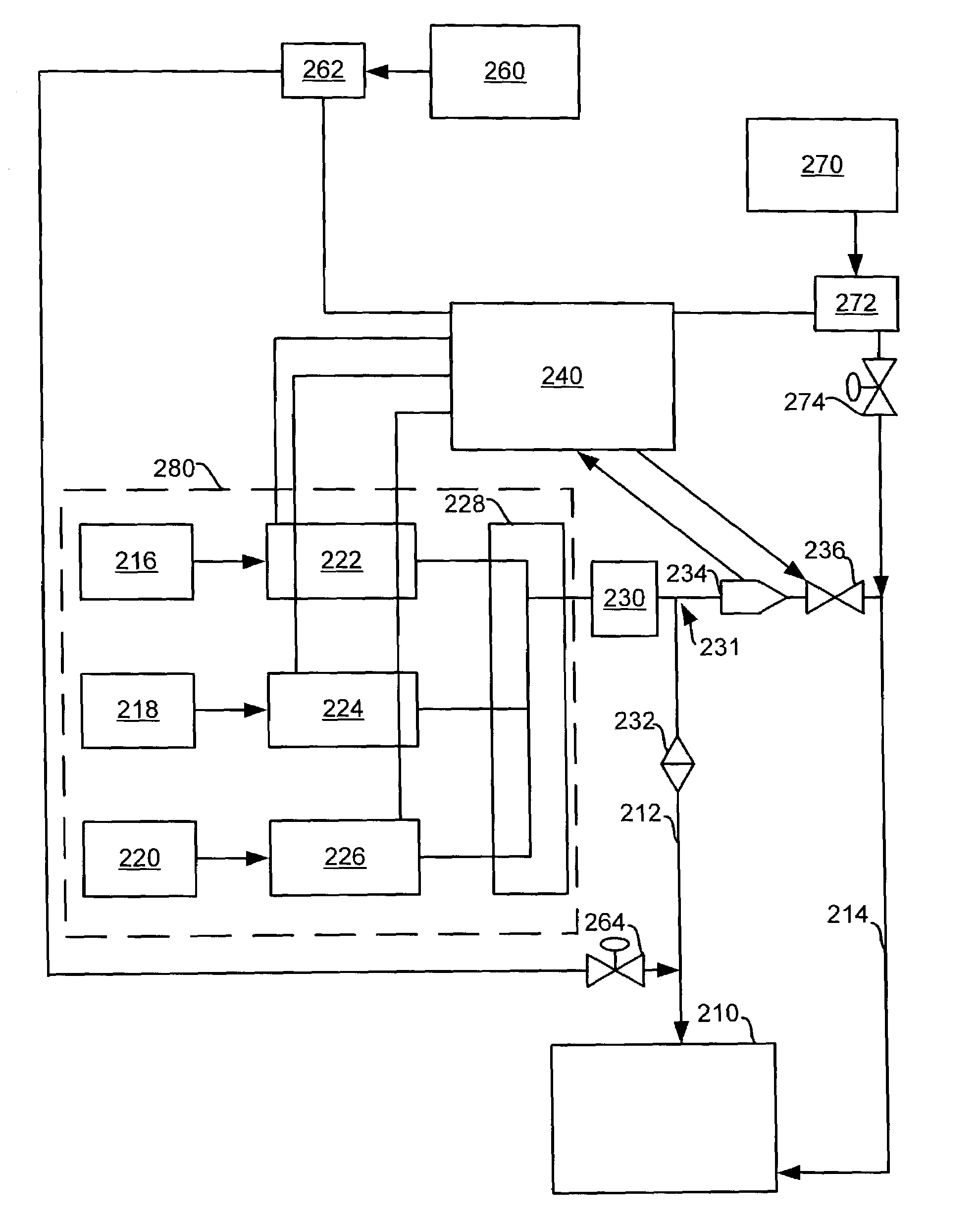

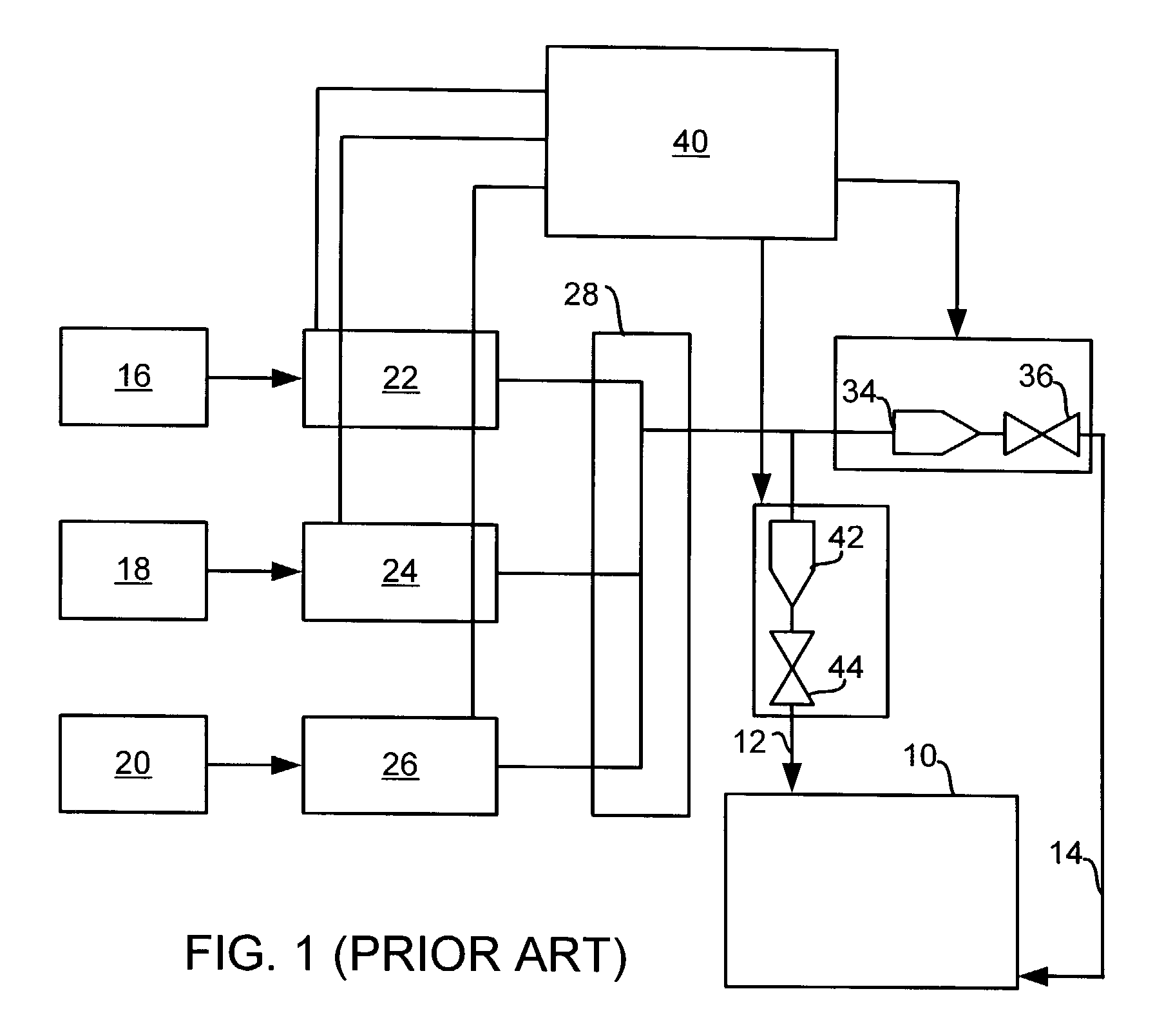

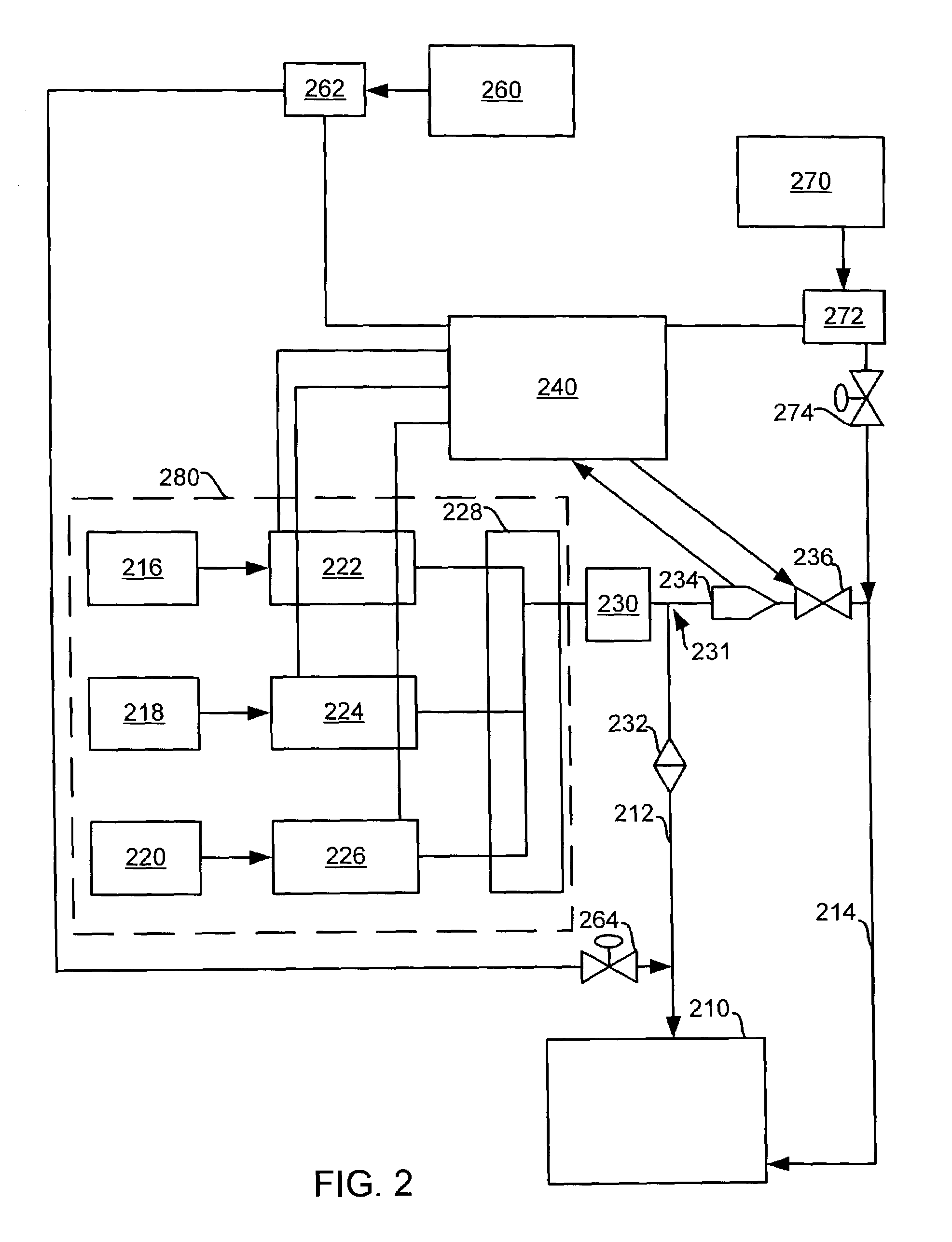

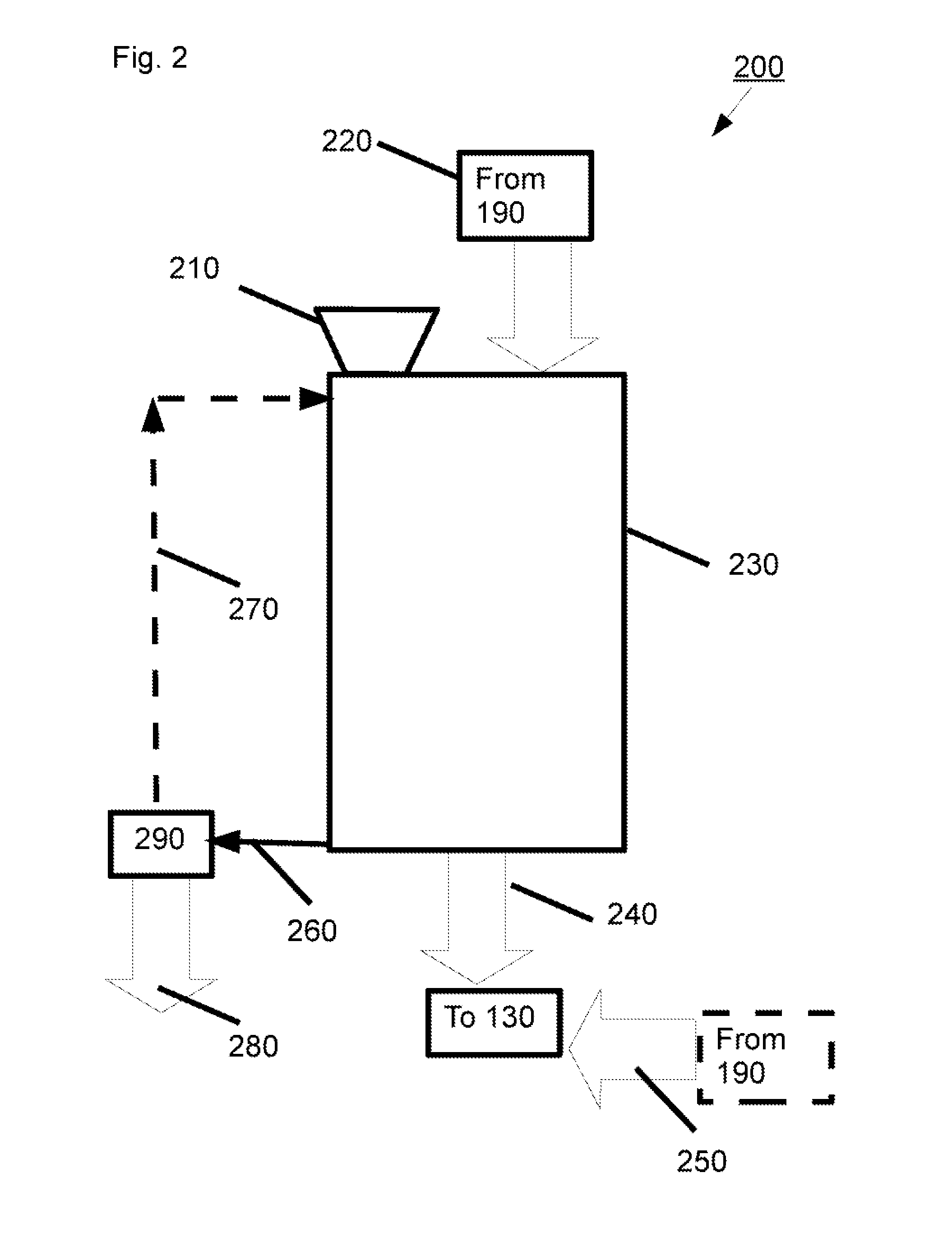

A plenum (210) in a gas turbine engine mid-frame section (200) comprises one or more annular flow splitters (240) spaced from an inboard annular wall (232) that partition air flow flowing from a compressor into two or more portions of flow having different vectors. This provides for an improved balancing between supplying air to compression chamber intakes more directly and to transitions to aid in convective cooling. When an annular diffuser (202) is spaced between the compressor and the plenum (210), the flow splitters (240) may provide an additional diffusion action. When no annular diffuser is so provided, the flow splitters (452, 454, 456) are effective to diffuse the air flow. Embodiments include those in which an annular diffuser (304) is relatively shorter and there is a longer axial expanse in the plenum (320) for flow splitters (350, 352, 354, 356).

Owner:SIEMENS ENERGY INC

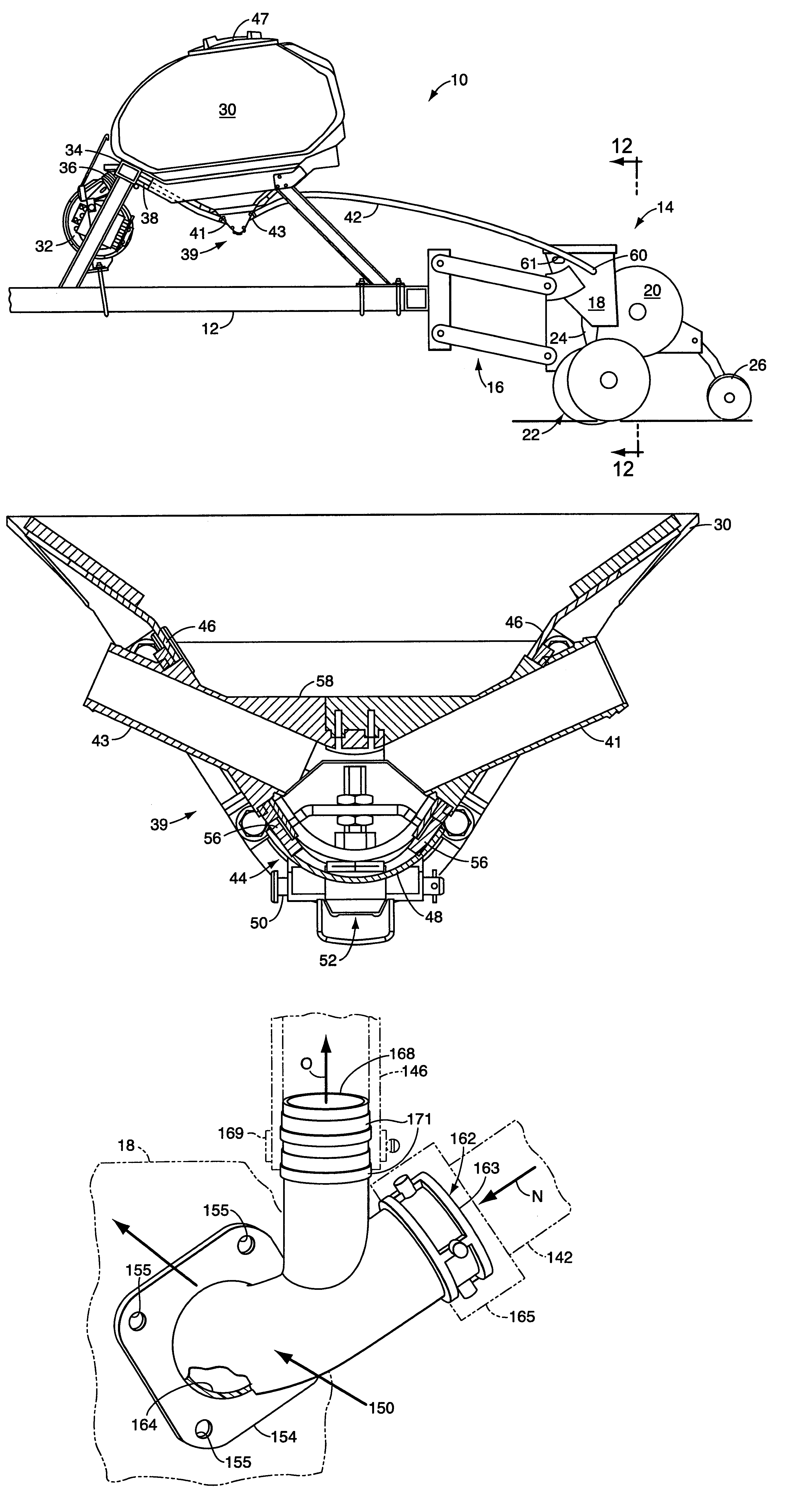

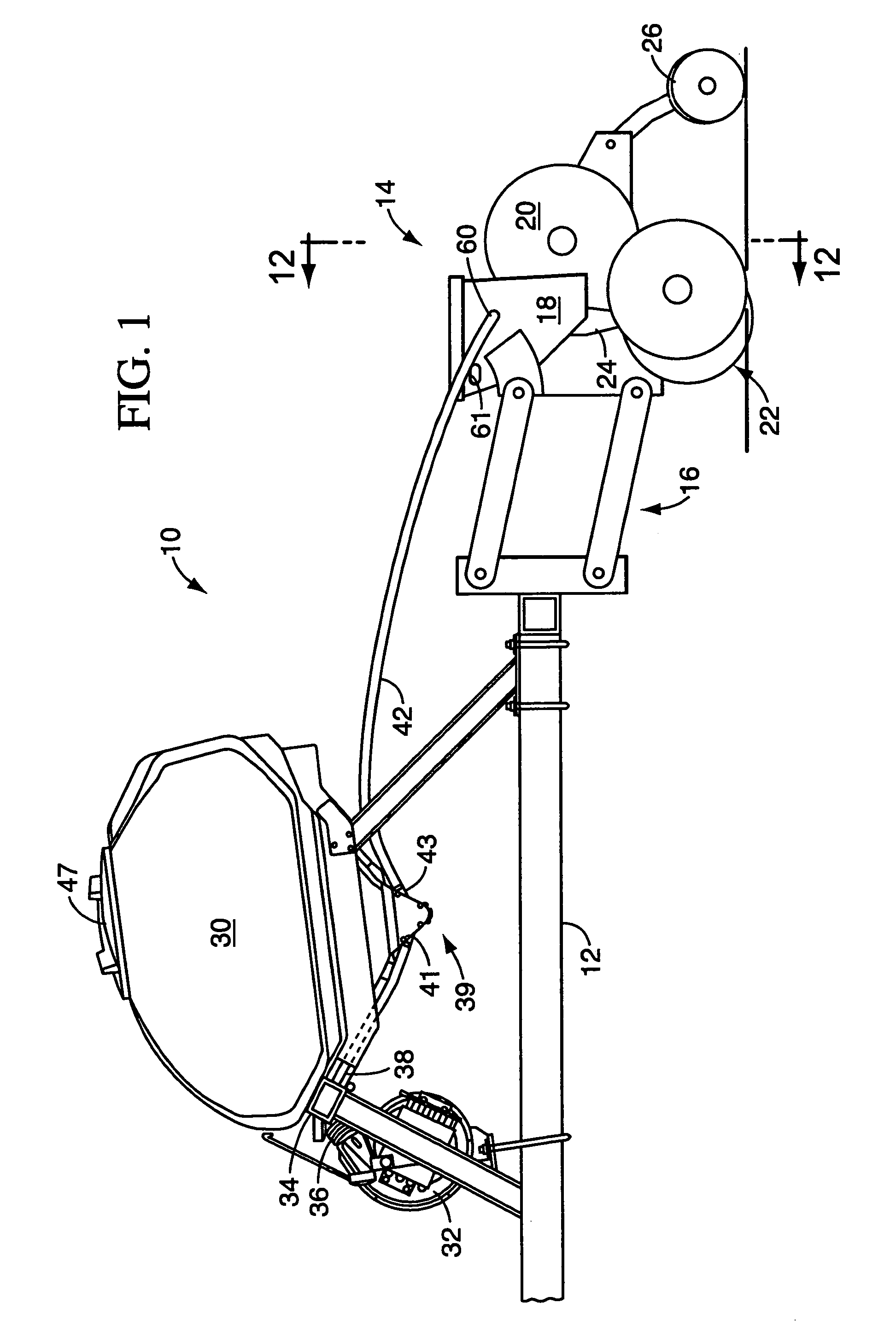

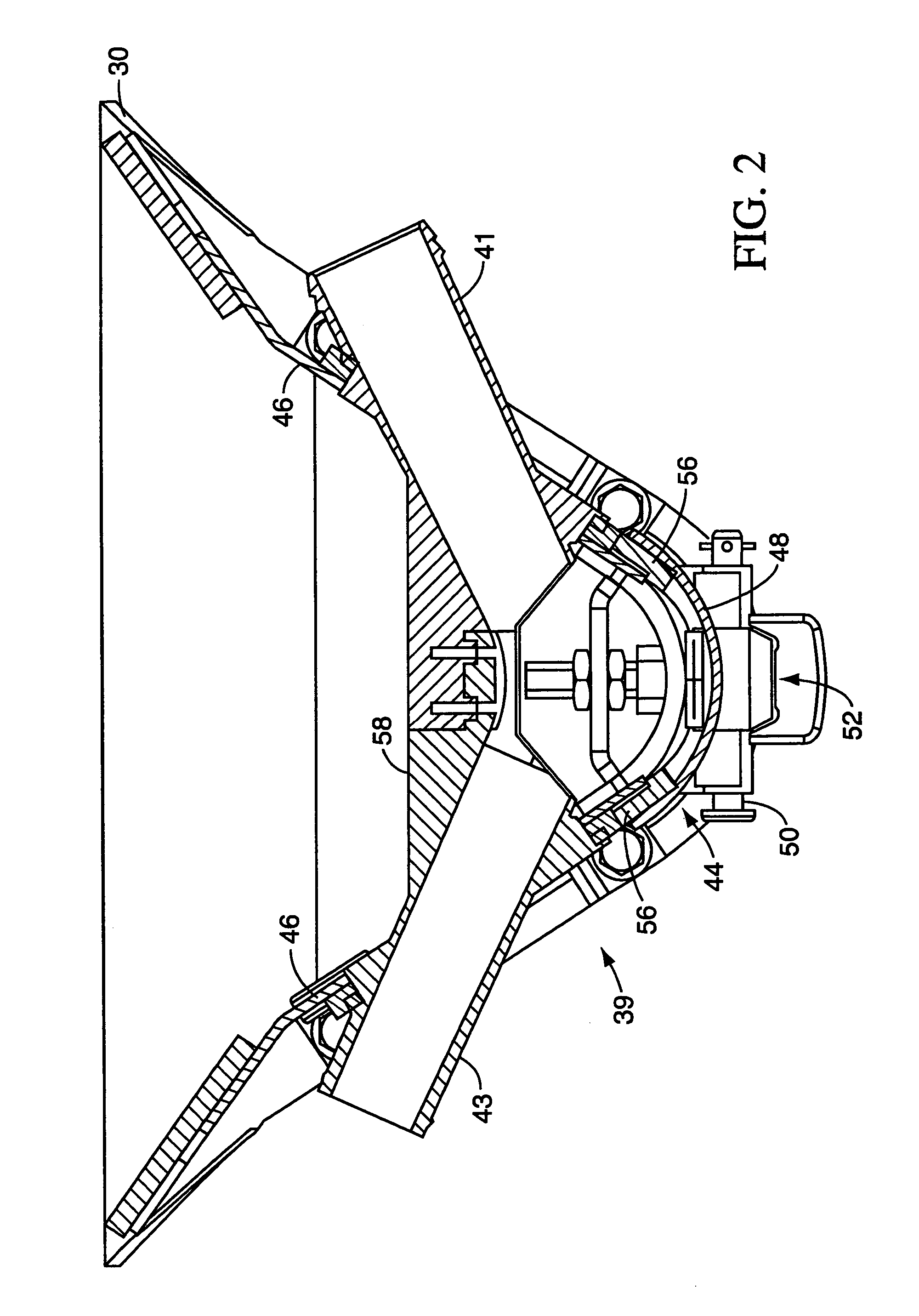

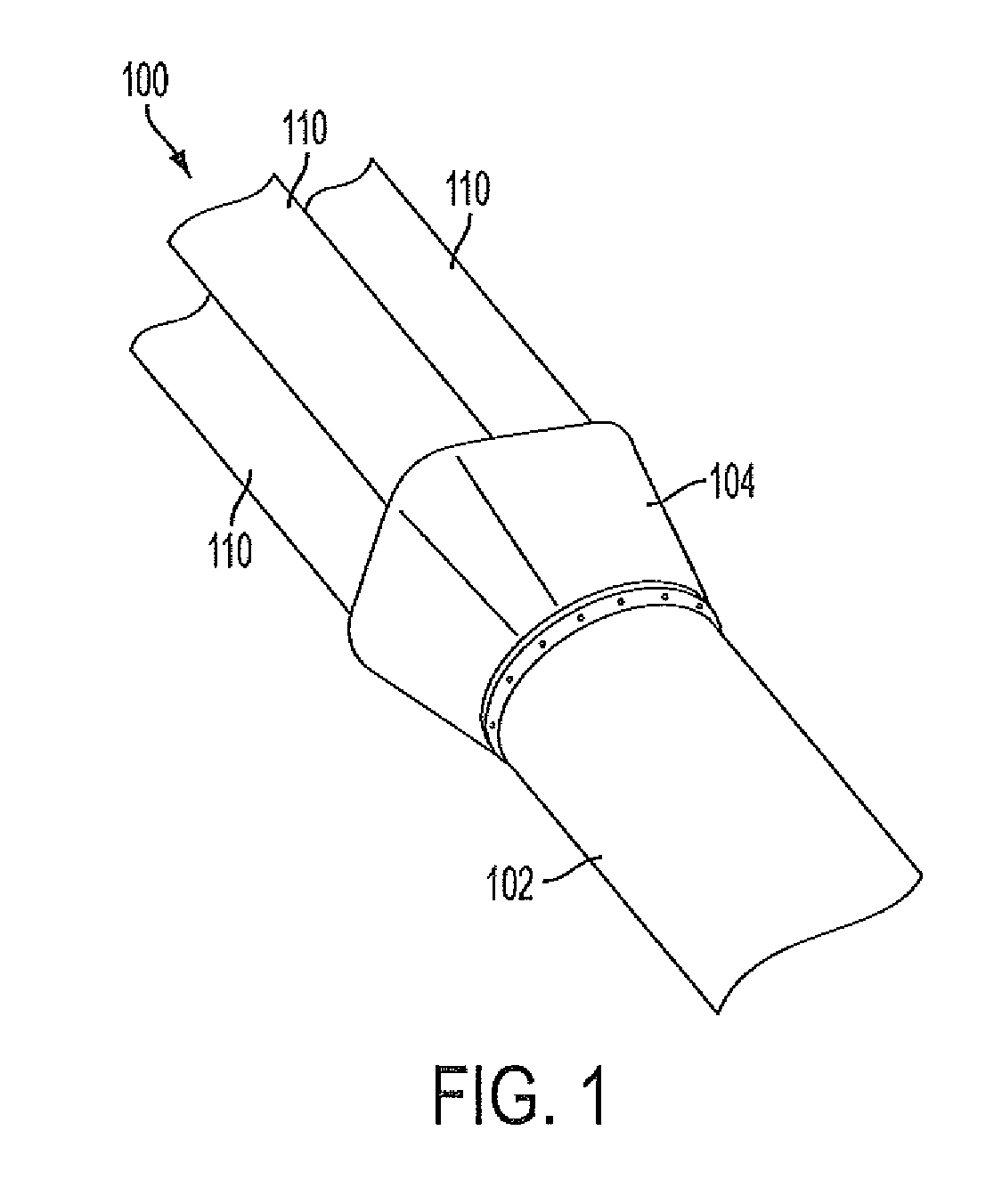

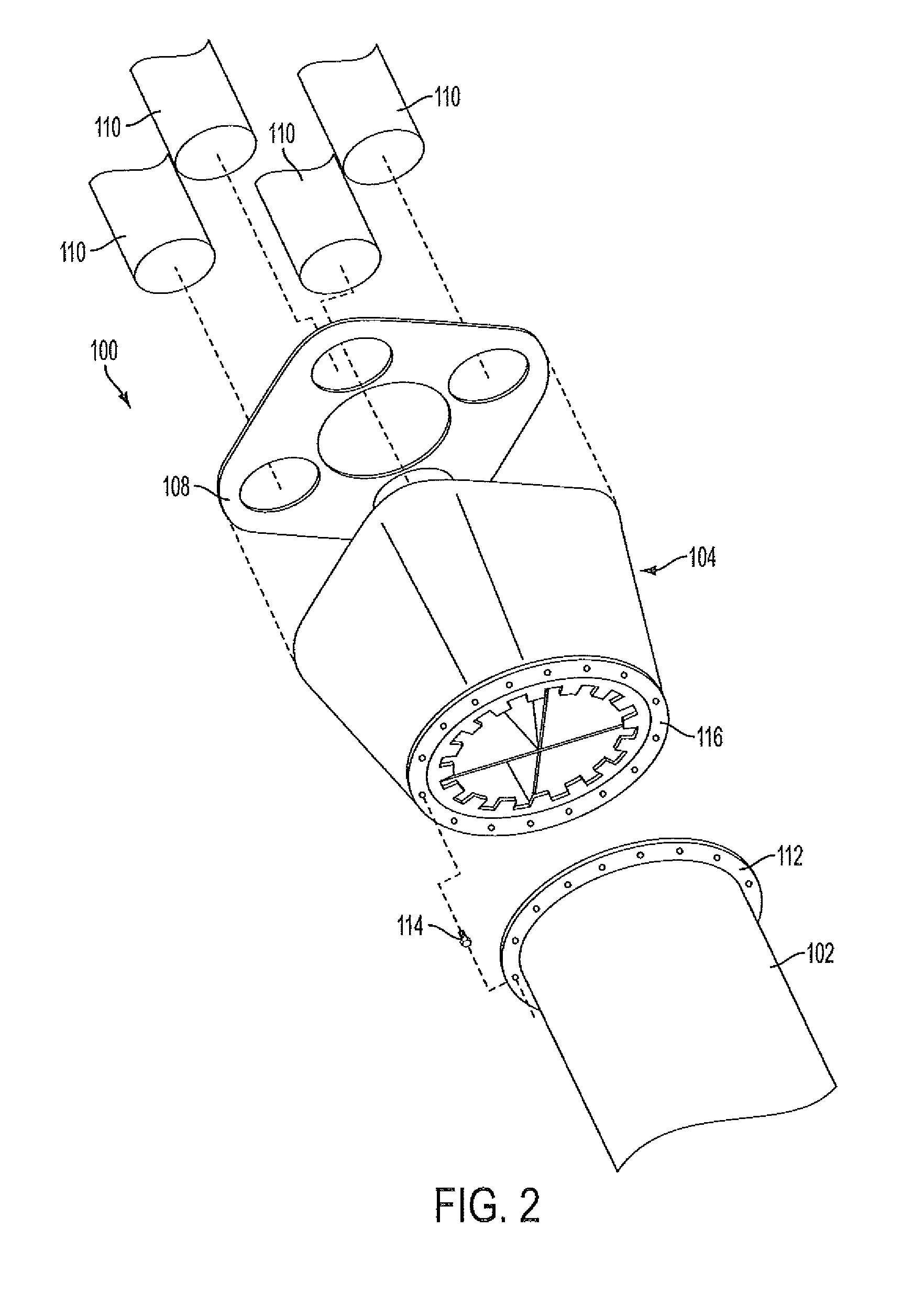

Flow splitter arrangement for series fed product application units

ActiveUS7025010B2Avoid cloggingReduce in quantityPotato plantersFurrow making/coveringVelocity vectorInlet flow

A product-on-demand delivery system applies an agricultural product, such as seed, to a field. The system includes a frame that mounts a main hopper, a splitter fitting, a primary product hose, a secondary product hose, a primary application unit and a secondary application unit. The main hopper has an air nozzle wherein an air stream through the air nozzle entrains product within the air stream and delivers the air / product to the primary outlet hose. The splitter fitting has a splitter inlet flow-connected to the primary product hose and two splitter outlets flow-connected to the application units. The secondary application unit is coupled to the primary product supply hose by the secondary product hose connected at an outlet branch. The outlet branch is connected at an angle such that a product flow velocity vector in the primary product supply hose at the outlet branch is at an obtuse angle to a flow velocity vector of product flowing through the outlet branch. The outlet branch is oriented for a vertical upward flow of air and product.

Owner:DEERE & CO

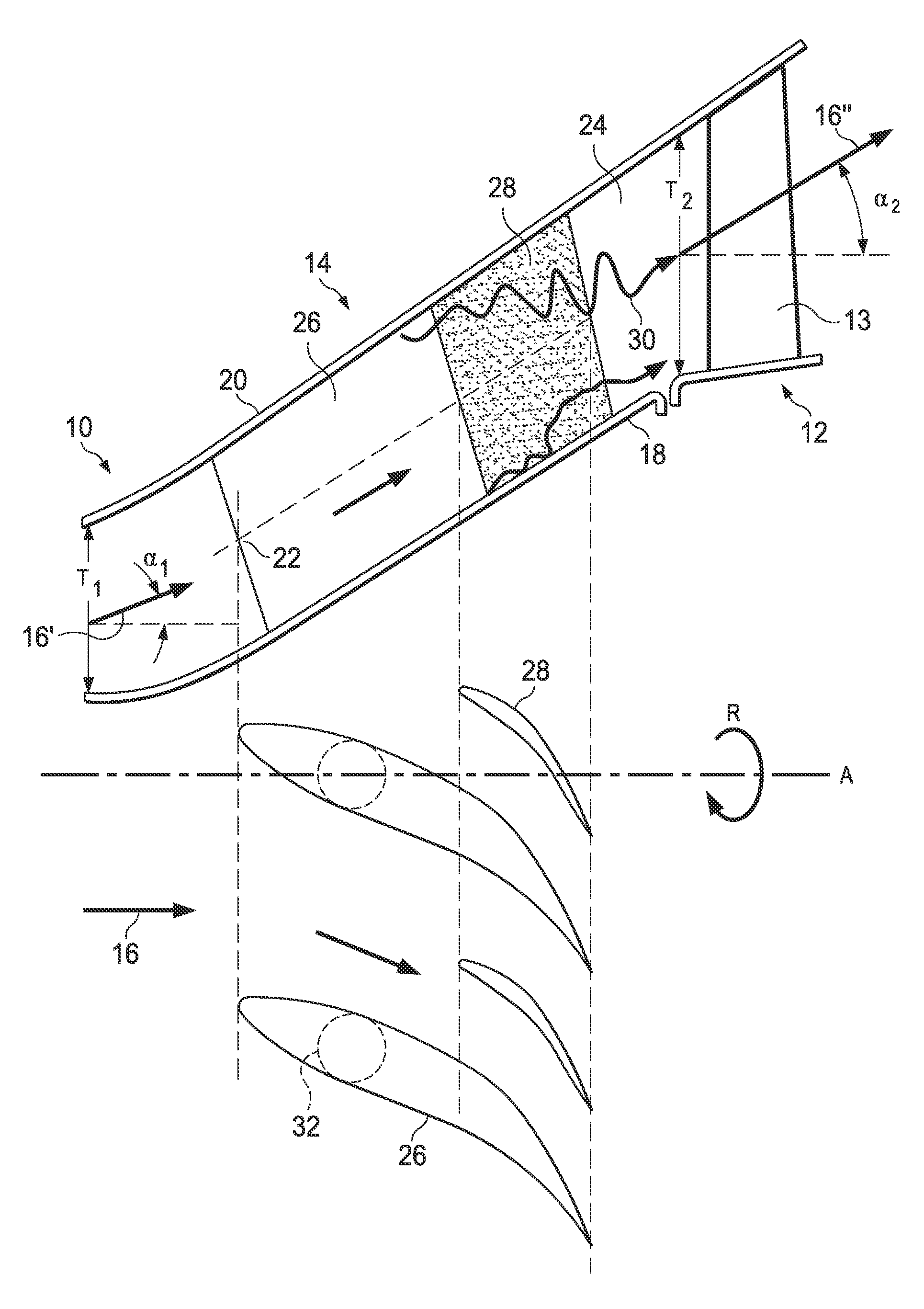

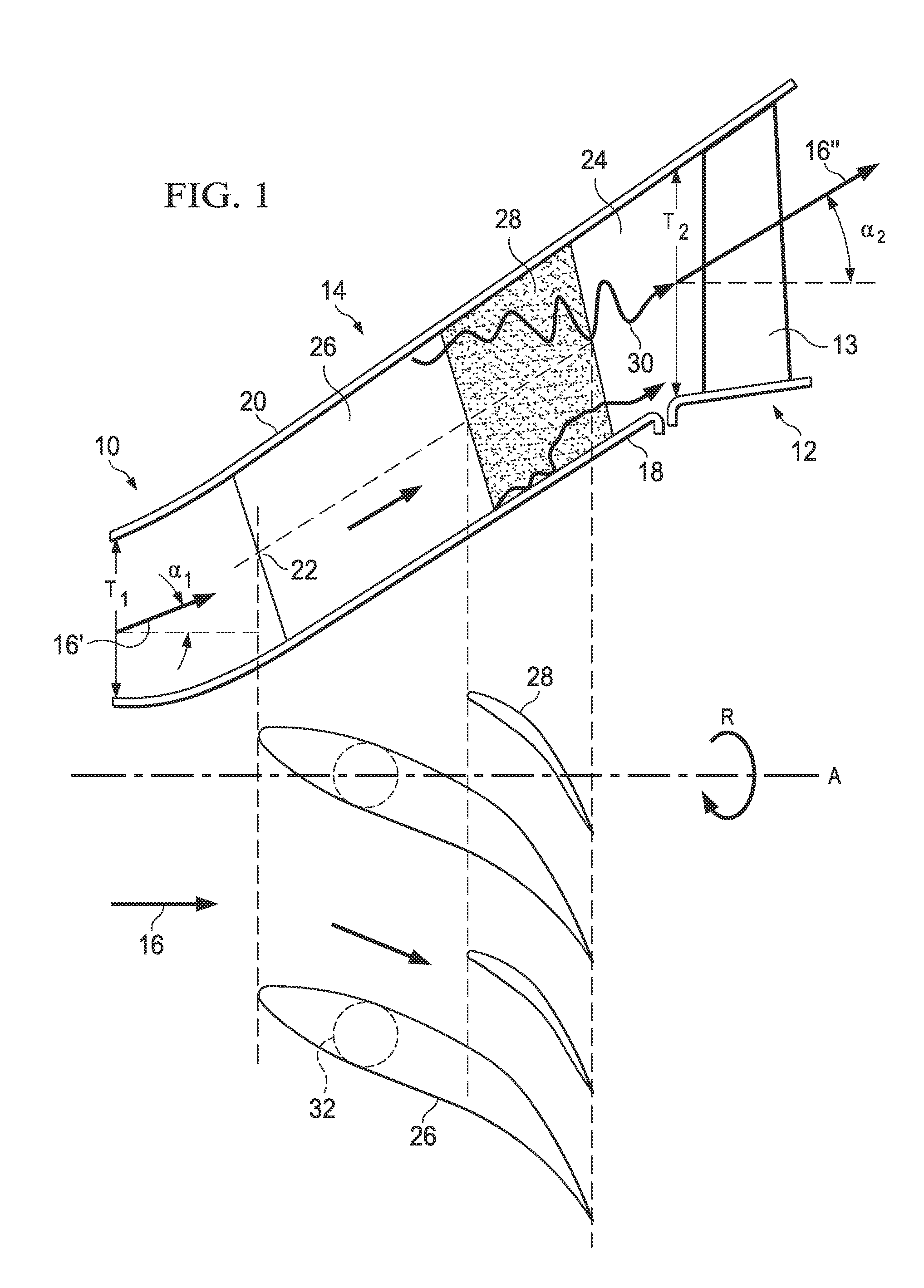

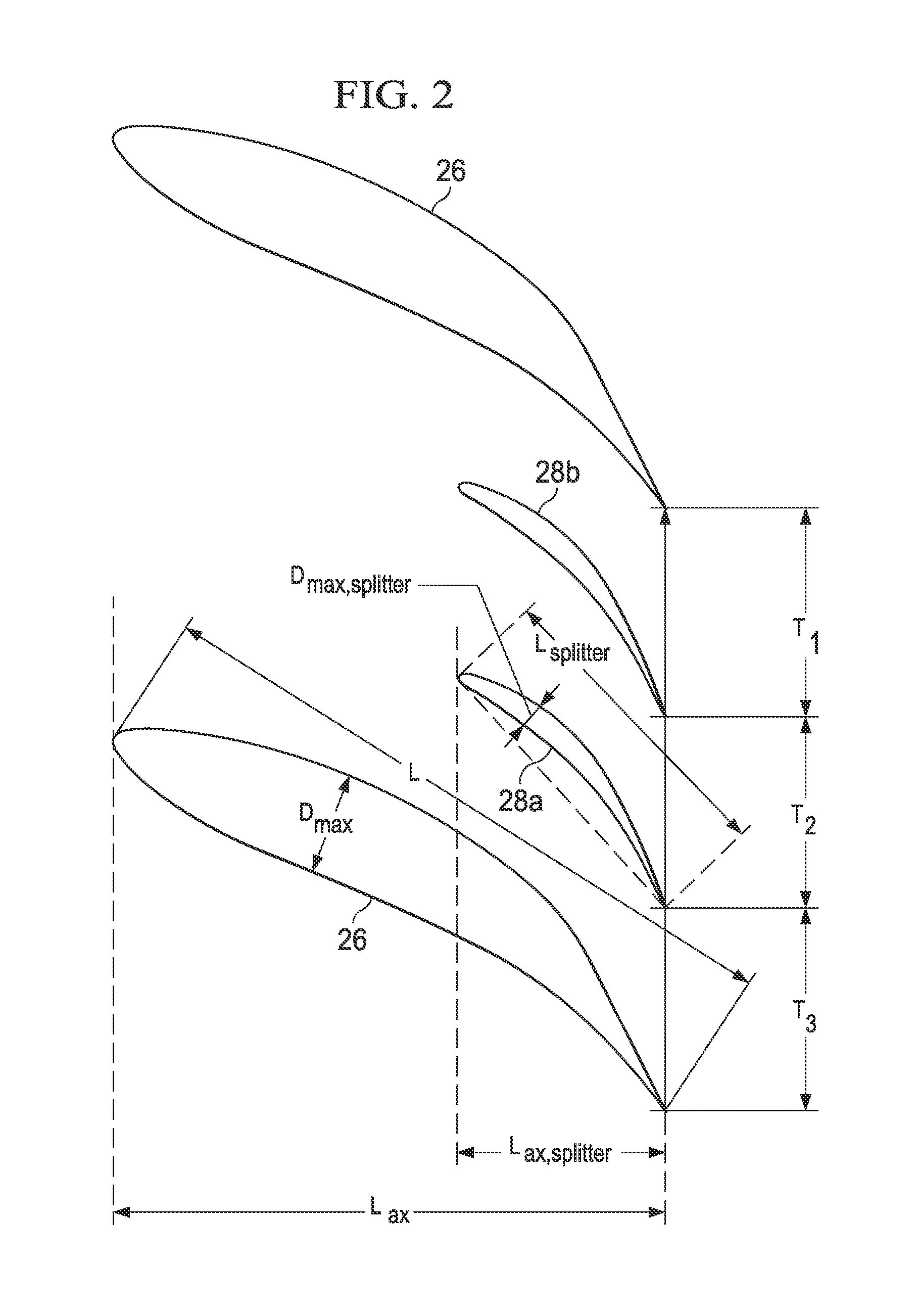

Transition channel of a turbine unit

InactiveUS20130051996A1High trafficIncrease deflectionPump componentsGas turbine plantsTurbineFlow splitter

A transition channel for a turbine unit with at least two components is configured as a flow channel from one component of a first pressure to a component of a second pressure. The transition channel has support ribs, extending between envelope surfaces of the transition channel and having a profile that is configured for the deflecting of a flow from an inlet cross section to an outlet cross section of the transition channel. Flow splitter blades are arranged between the support ribs, having a smaller relative profile thickness than the support ribs and / or a shorter axial design depth or profile chord length than the support ribs. Thanks to the integration of the slim and / or short flow splitter blades (tandem blades), it is possible to largely dissipate parasite secondary flows.

Owner:MTU AERO ENGINES GMBH

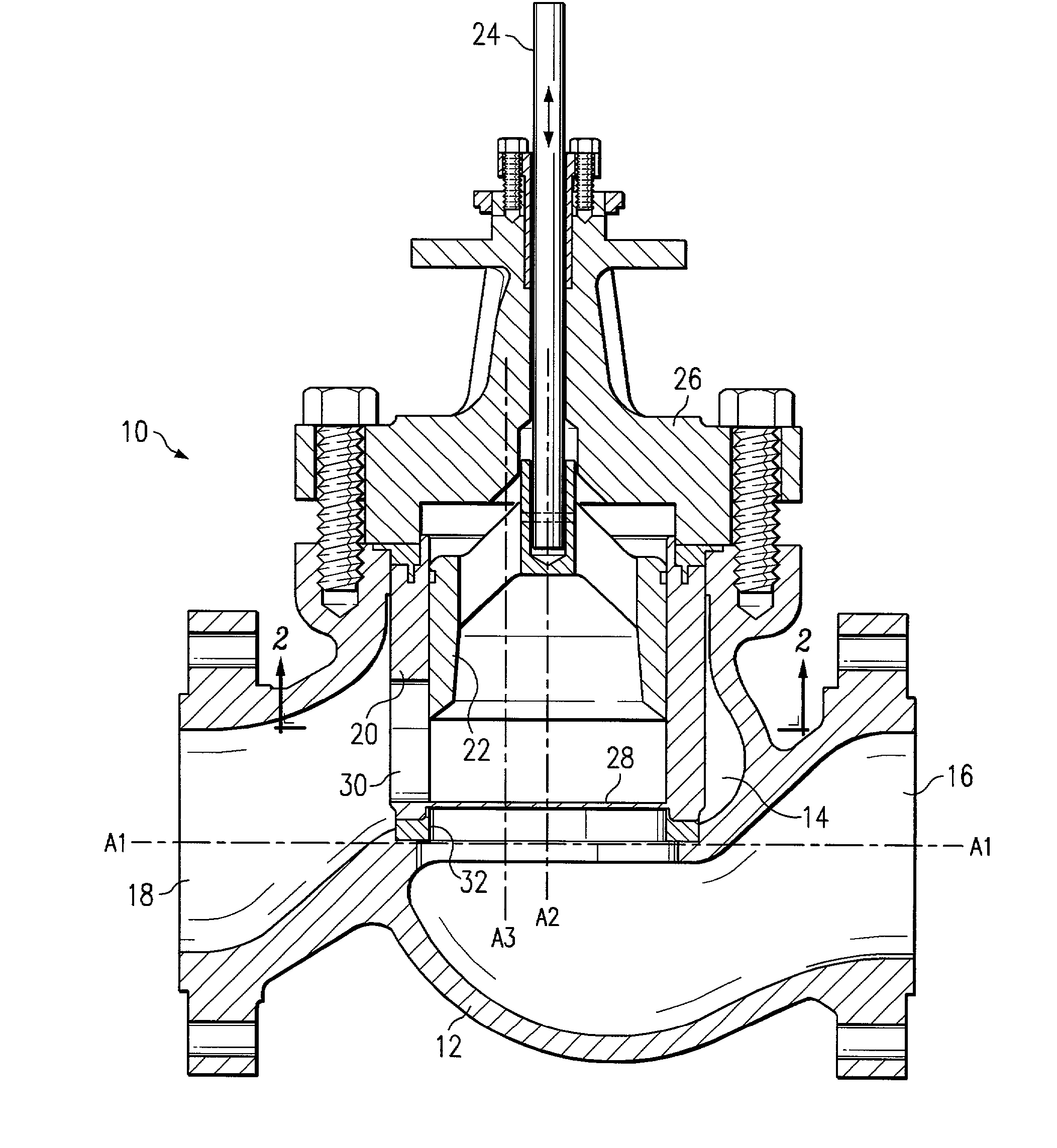

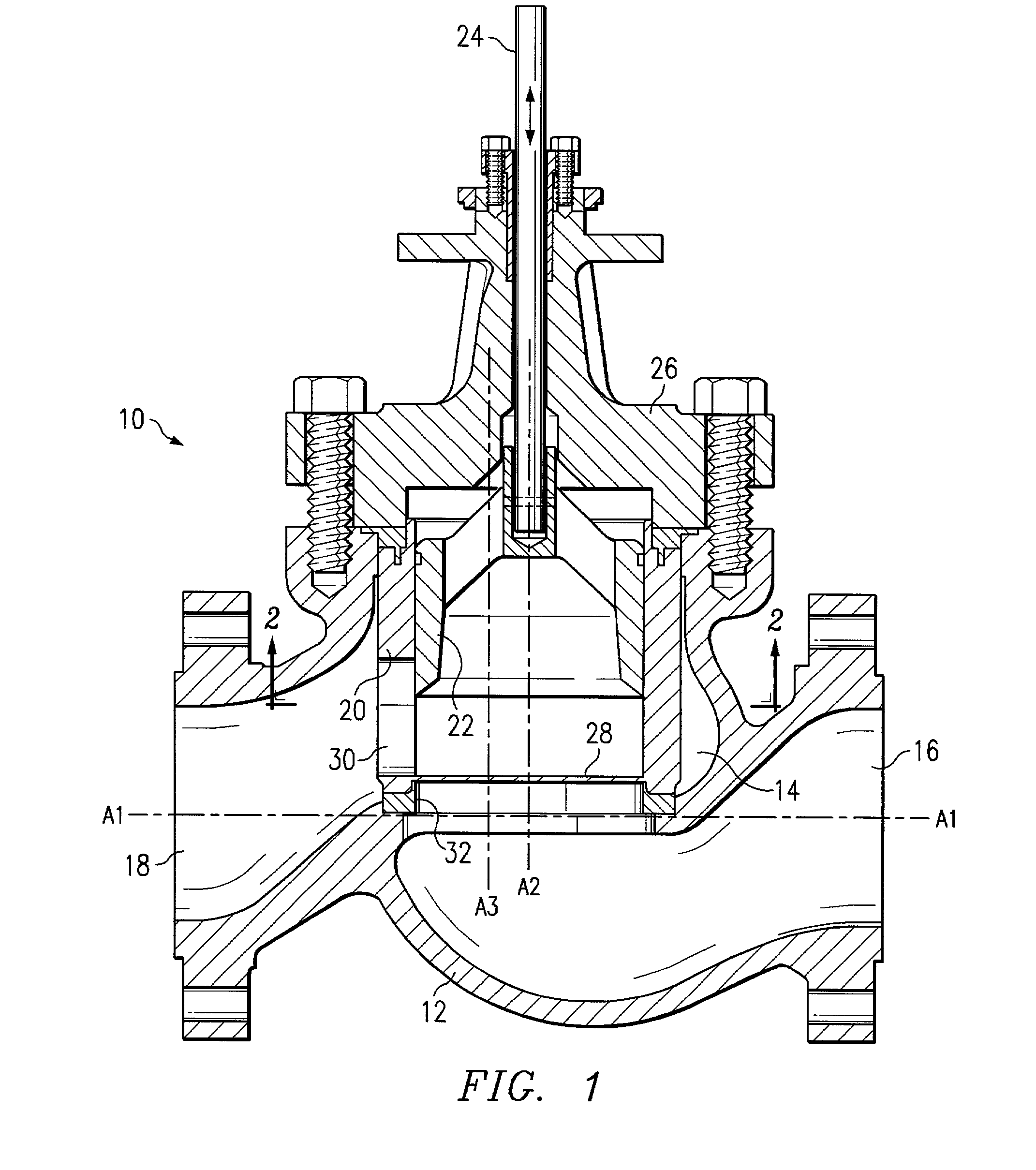

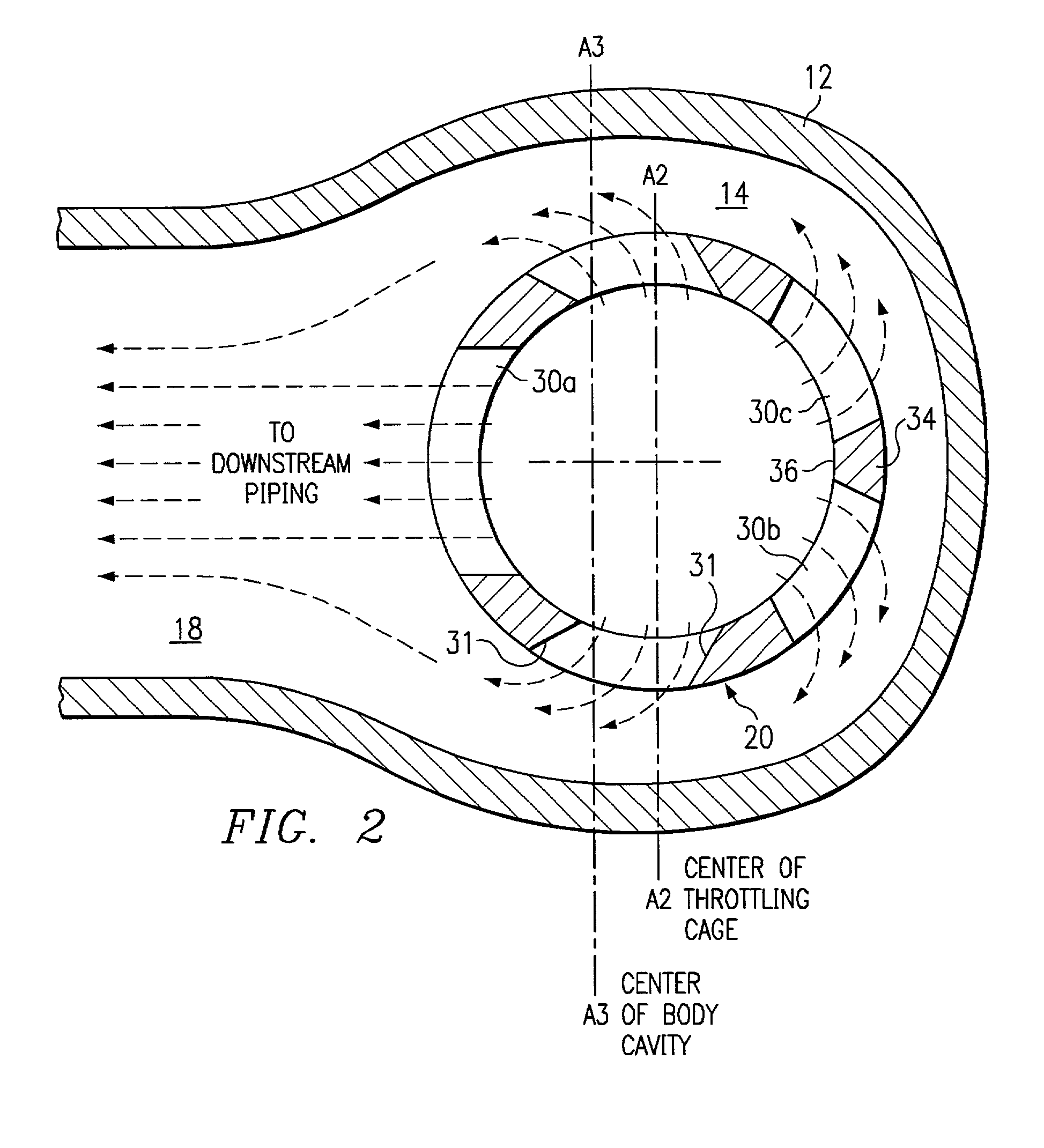

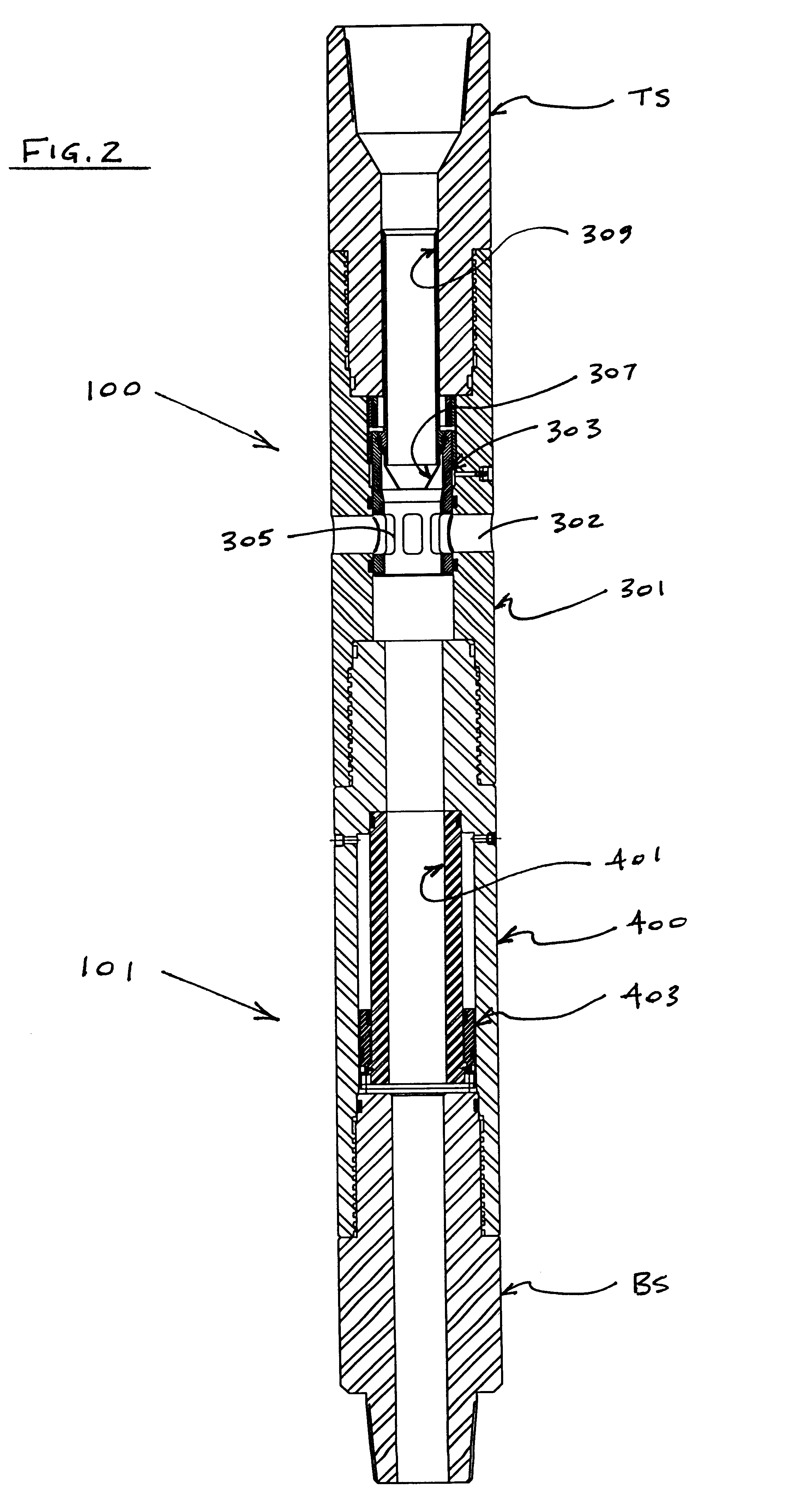

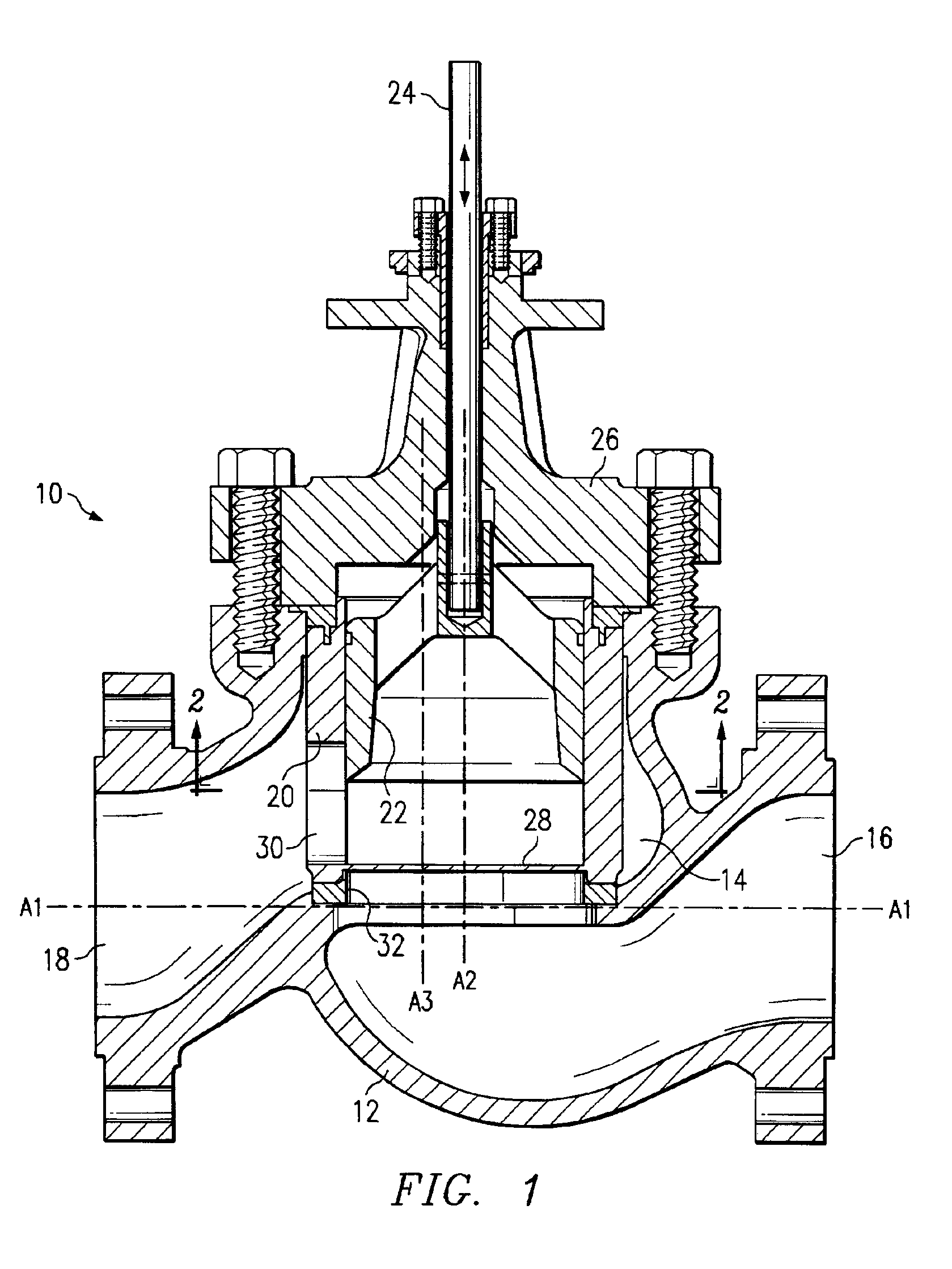

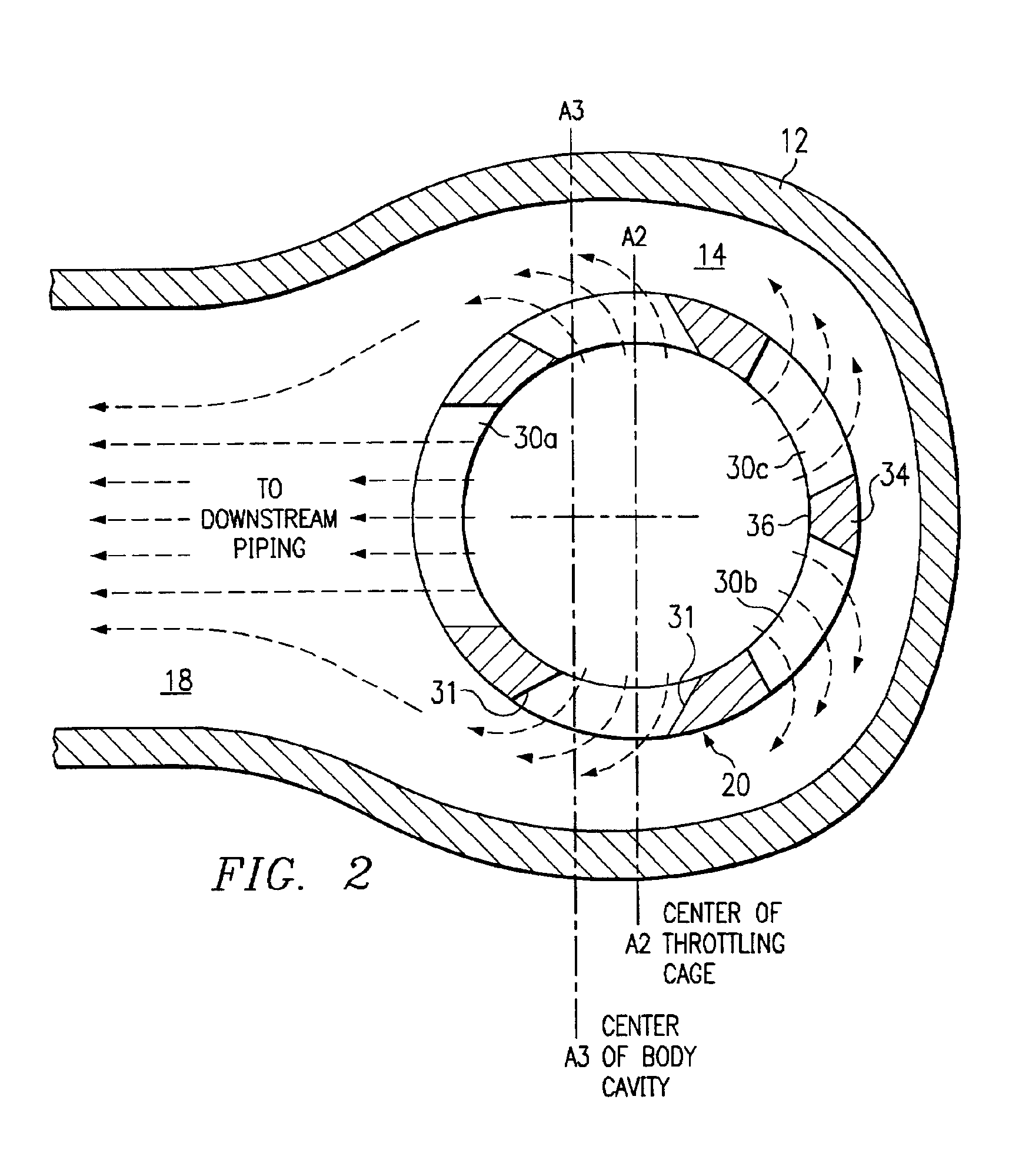

High capacity globe valve

InactiveUS20030159737A1Reduce traffic lossLess-expensive to manufactureMultiple way valvesSlide valveEngineeringStreamflow

A high flow globe valve with a body defining an interior cavity in communication with a first and second fluid passages. A tubular throttling cage is offset in the cavity away from the second fluid passage and has an open end in communication with the first fluid passage. The throttling cage has flow ports angled towards the second fluid passage and the flow port nearest the second fluid passage is oversized. The throttling cage has flow splitter defined by two adjacent flow ports through the cage opposite the second flow passage. A plug is closely received in the throttling cage and moveable to cover the flow ports thereby restricting flow through the throttling cage.

Owner:DRESSER LLC

Electroosmotic flow controller

ActiveUS20070000784A1Rapid and accurate flow controlEasy to makeSludge treatmentVolume/mass flow measurementElectricitySalt bridge

Electroosmotic flow controllers and methods of fluid flow control are described. The invention uses an electroosmotically generated flow component in conjunction with a pressure driven flow component to modulate fluid flow. The devices and methods of the invention may include salt bridges for making electrical connection between a power supply and a channel filled with a porous dielectric material and a fluid. Embodiments including flow controllers and flow splitters are described as is their use in a variety of fluid handling applications.

Owner:SCIEX

Fluid flow distributor apparatus for gas turbine engine mid-frame section

InactiveUS20070271923A1Continuous combustion chamberTurbine/propulsion engine coolingEngineeringDistributor

A plenum (210) in a gas turbine engine mid-frame section (200) comprises one or more annular flow splitters (240) spaced from an inboard annular wall (232) that partition air flow flowing from a compressor into two or more portions of flow having different vectors. This provides for an improved balancing between supplying air to compression chamber intakes more directly and to transitions to aid in convective cooling. When an annular diffuser (202) is spaced between the compressor and the plenum (210), the flow splitters (240) may provide an additional diffusion action. When no annular diffuser is so provided, the flow splitters (452, 454, 456) are effective to diffuse the air flow. Embodiments include those in which an annular diffuser (304) is relatively shorter and there is a longer axial expanse in the plenum (320) for flow splitters (350, 352, 354, 356).

Owner:SIEMENS ENERGY INC

Gas distribution system with tuning gas

InactiveUS7169231B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDistribution systemProcess engineering

An apparatus for providing different gases to different zones of a processing chamber is provided. A gas supply for providing an etching gas flow is provided. A flow splitter in fluid connection with the gas supply for splitting the etching gas flow from the gas supply into a plurality of legs is provided. A tuning gas system in fluid connection to at least one of the legs of the plurality of legs is provided.

Owner:LAM RES CORP

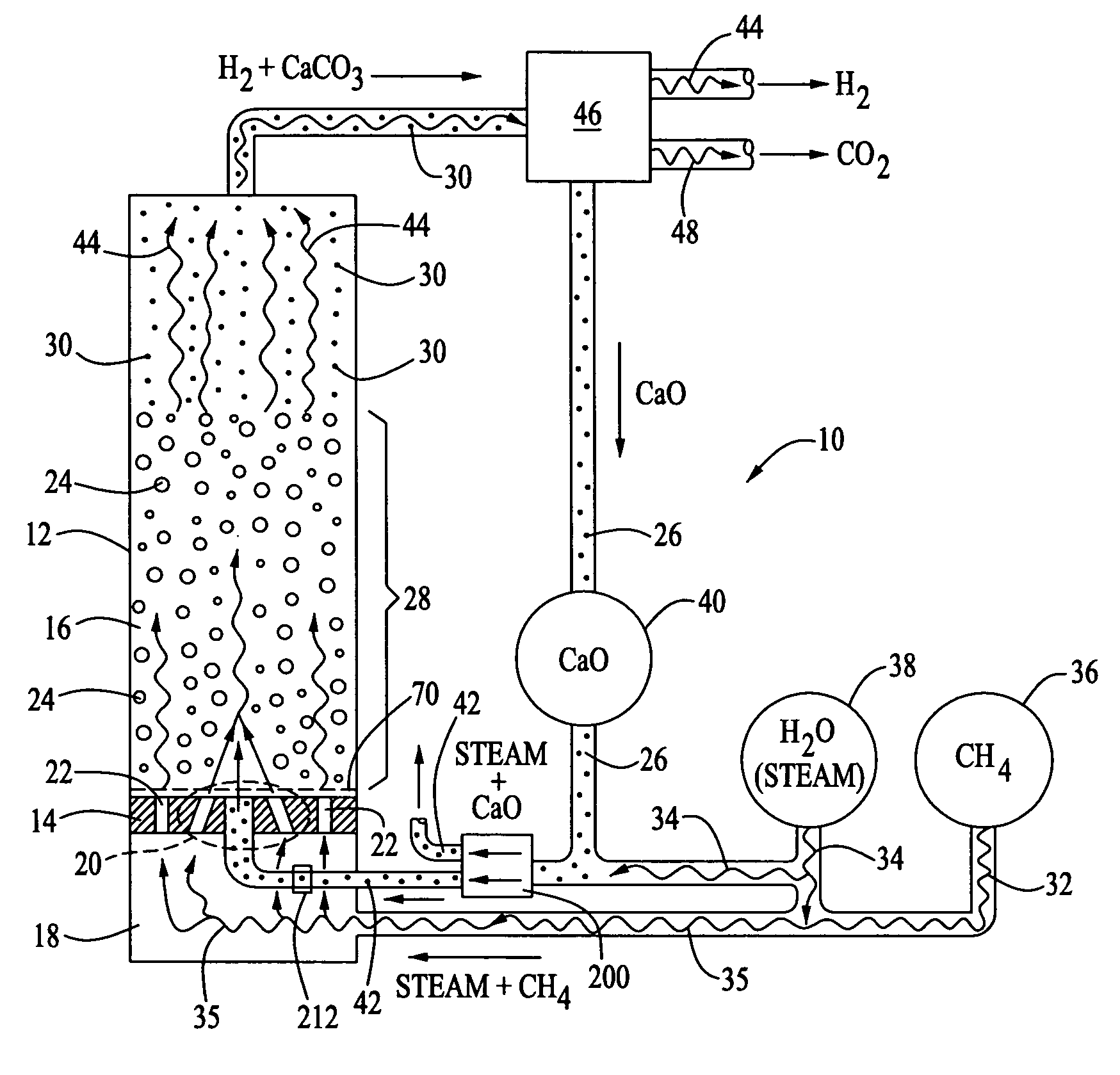

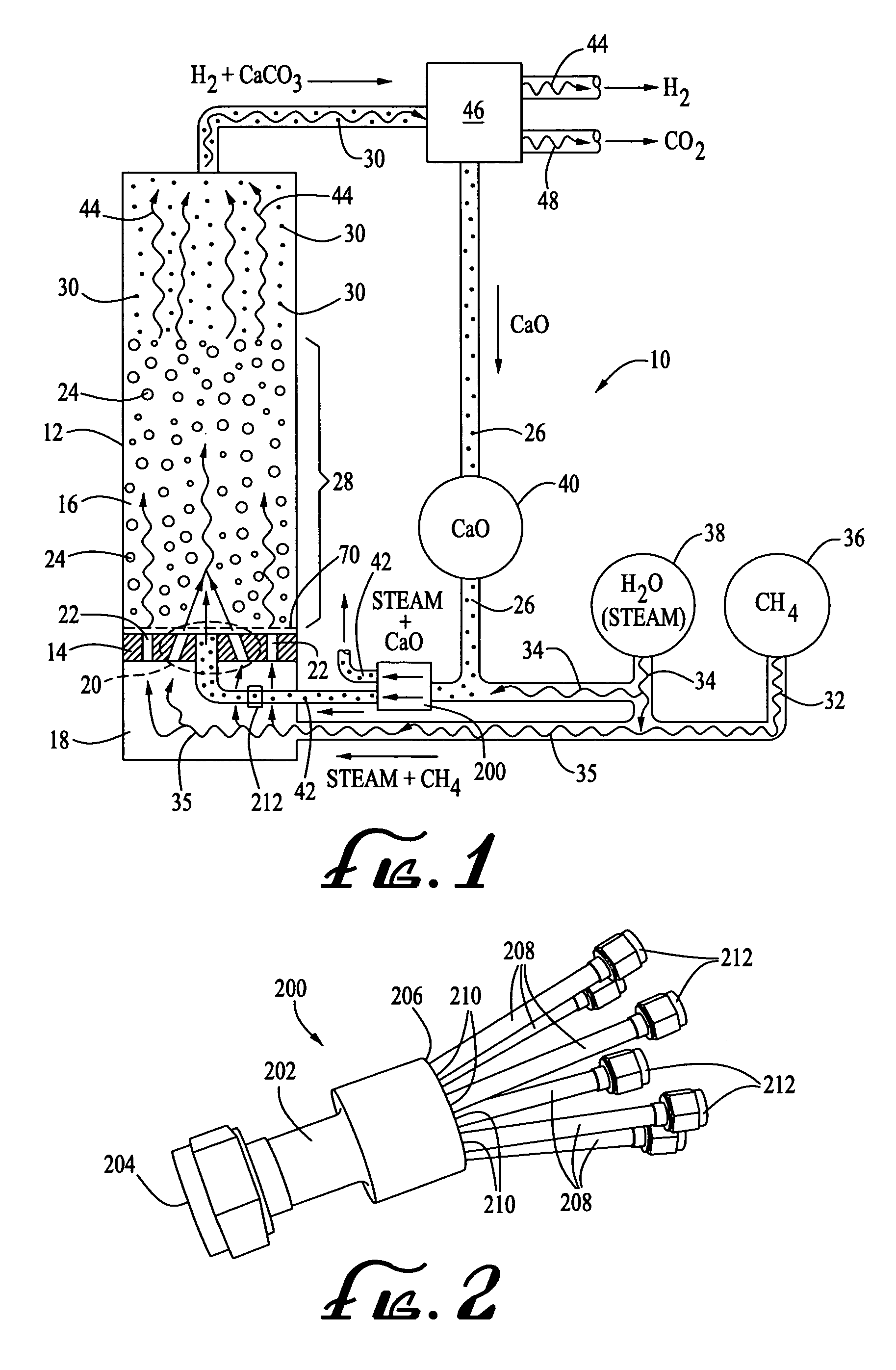

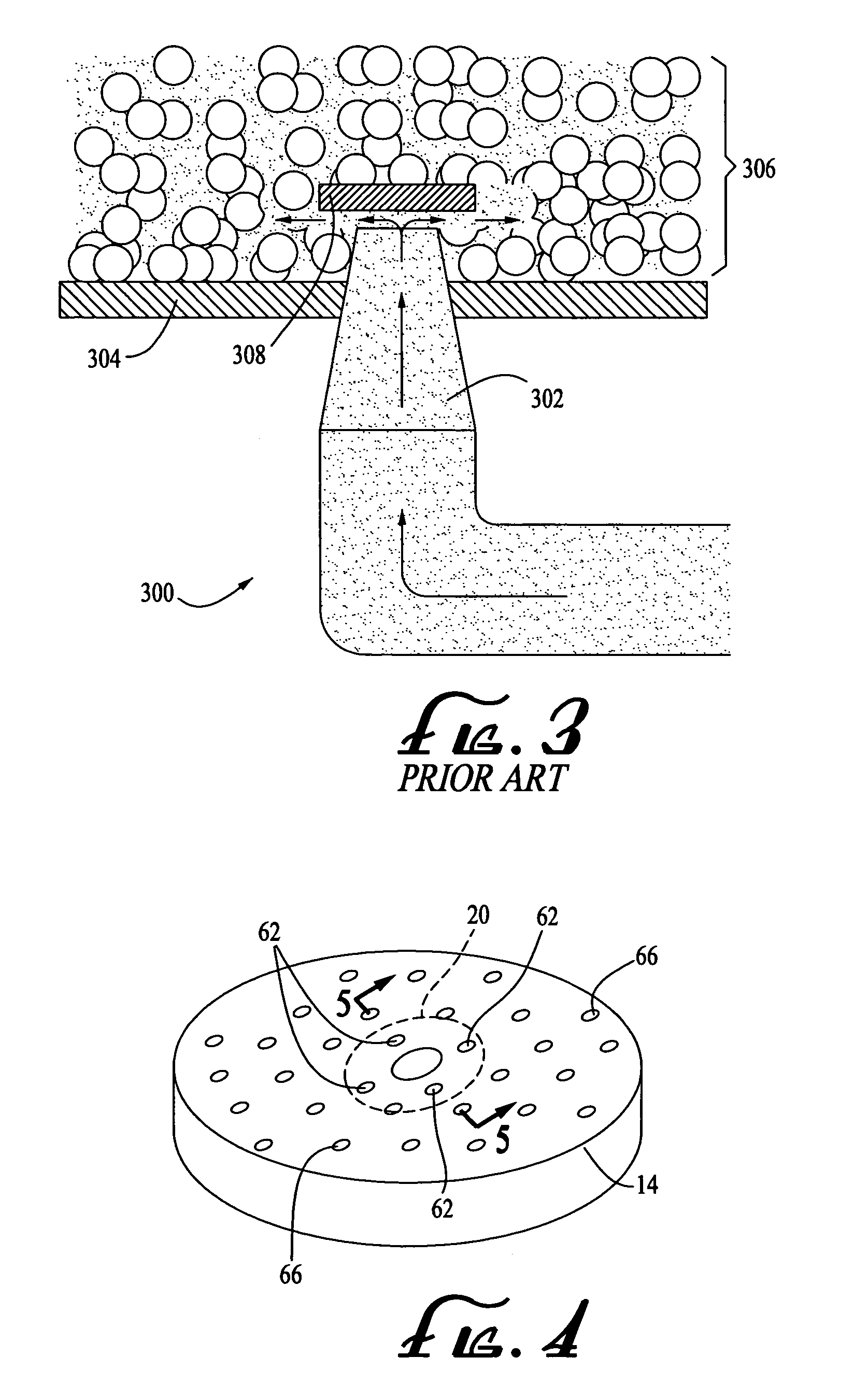

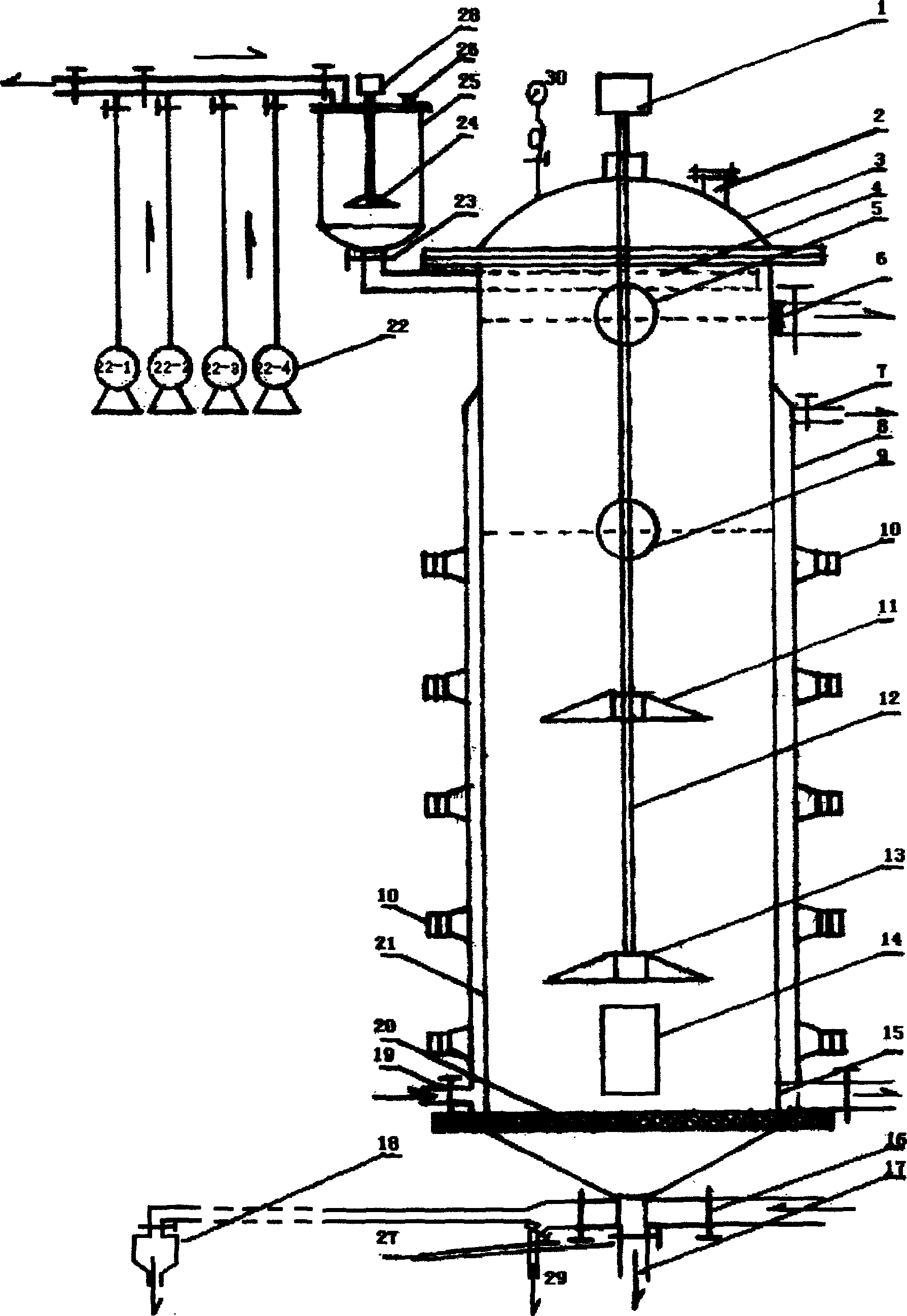

Two phase injector for fluidized bed reactor

A fluidized-bed reactor for producing hydrogen from methane by steam reforming includes a flow splitter that splits a dense-phase flow of a gas having entrained calcium oxide particles into a plurality of equal flow streams. The reactor also incorporates an orifice plate having at least one high-velocity, rocket-style impinging injector for injecting reactants into the reactor bed. The injector includes a central orifice extending perpendicularly through the plate, and one or more adjacent peripheral orifices that extend through the plate at such an angle that respective streams of reactants injected into the reactor bed through the peripheral orifices impinge on a stream of reactants injected vertically into the reactor bed through the central orifice. The injector cooperates with adjacent base-bleed orifices in the plate to provide a uniform distribution and rapid mixing of the calcium oxide particles with a steam / methane gas mixture across the entire bottom of the reactor bed.

Owner:THE BOEING CO +2

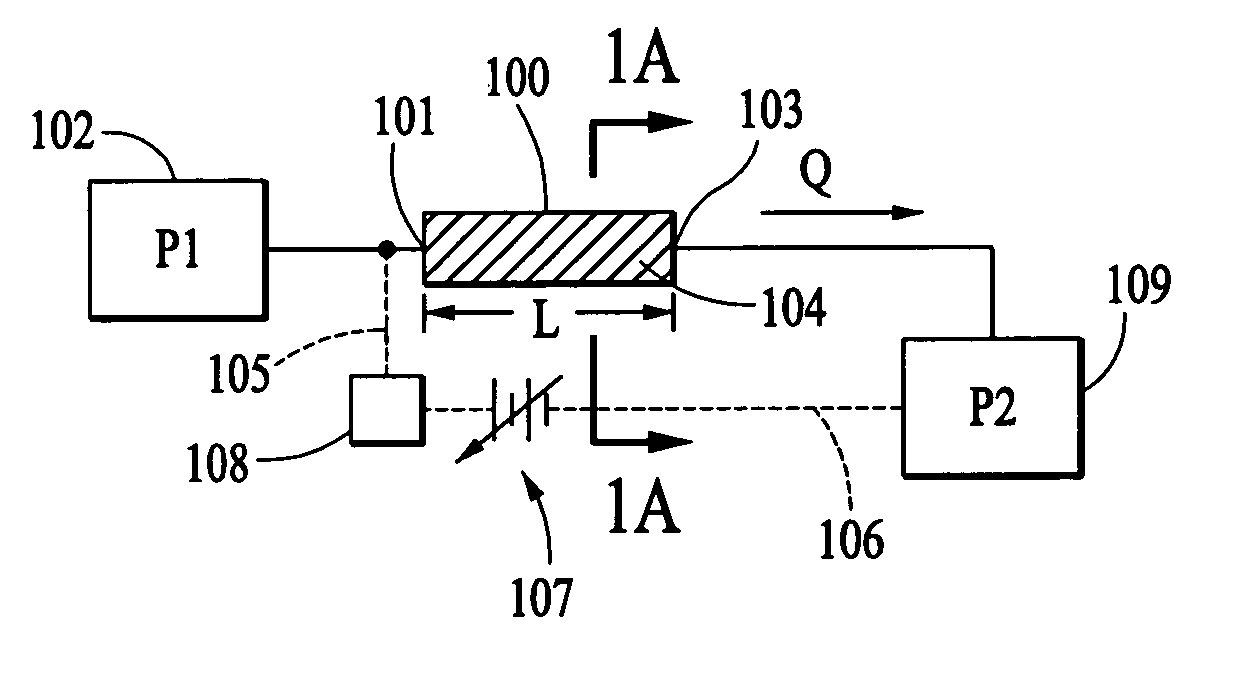

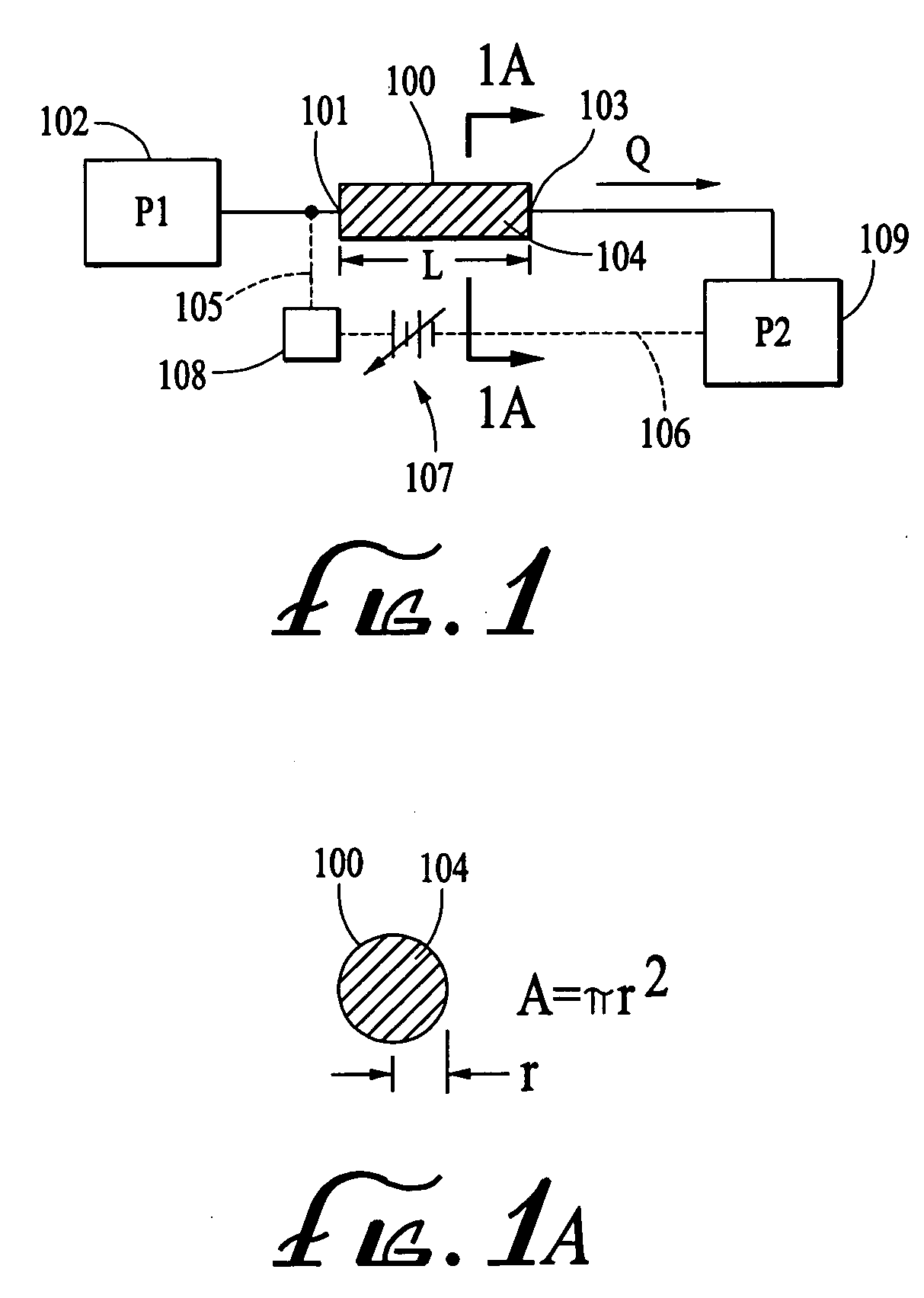

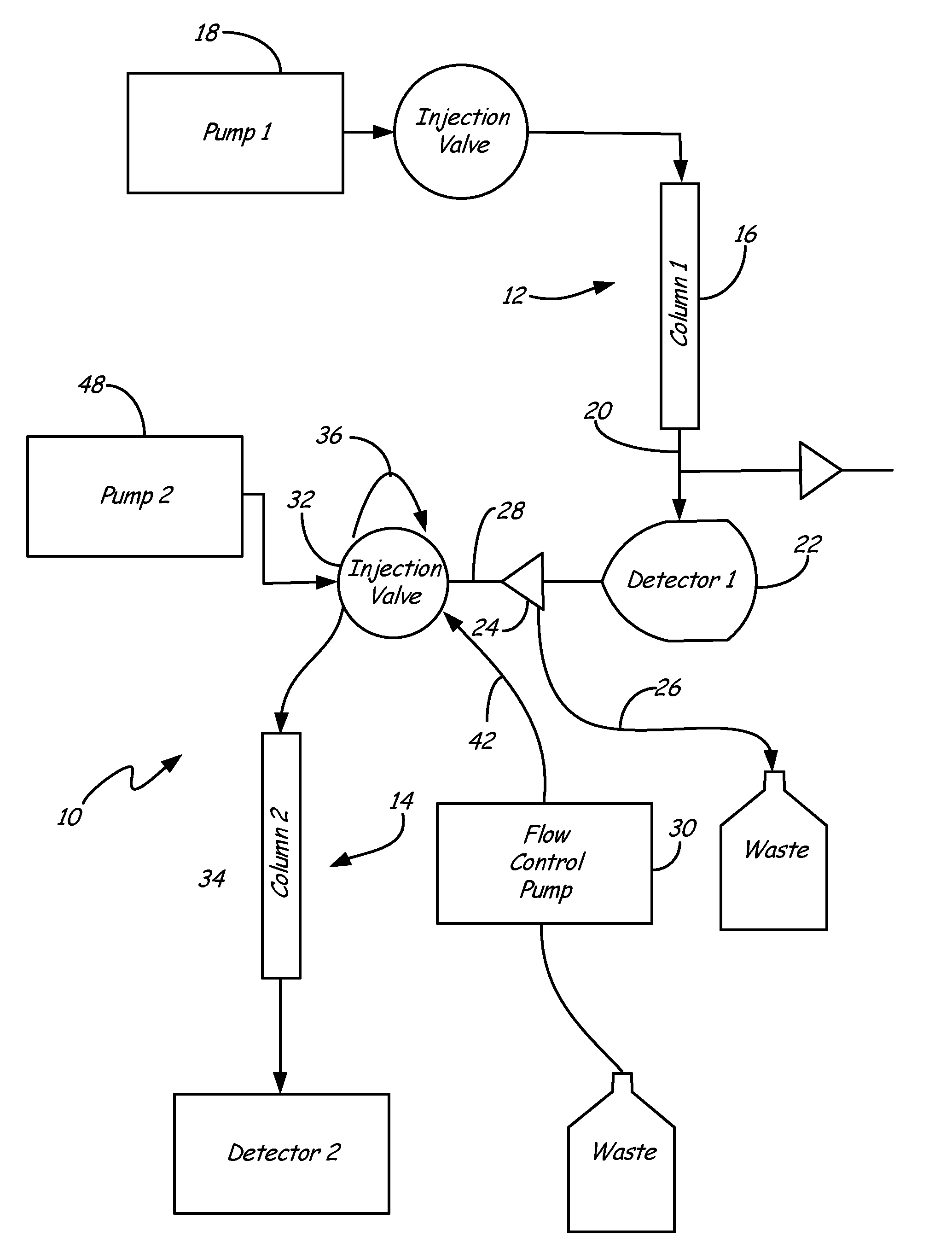

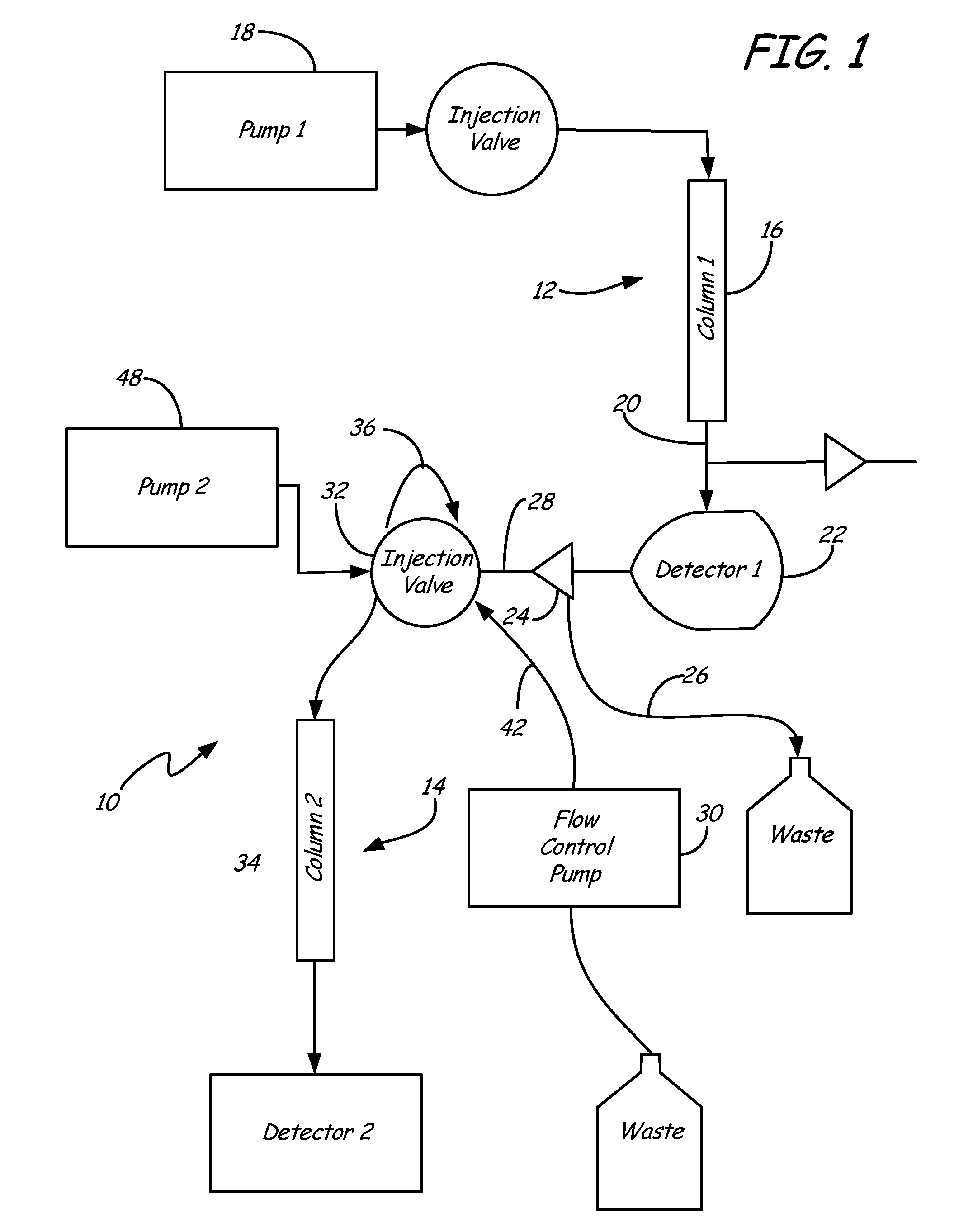

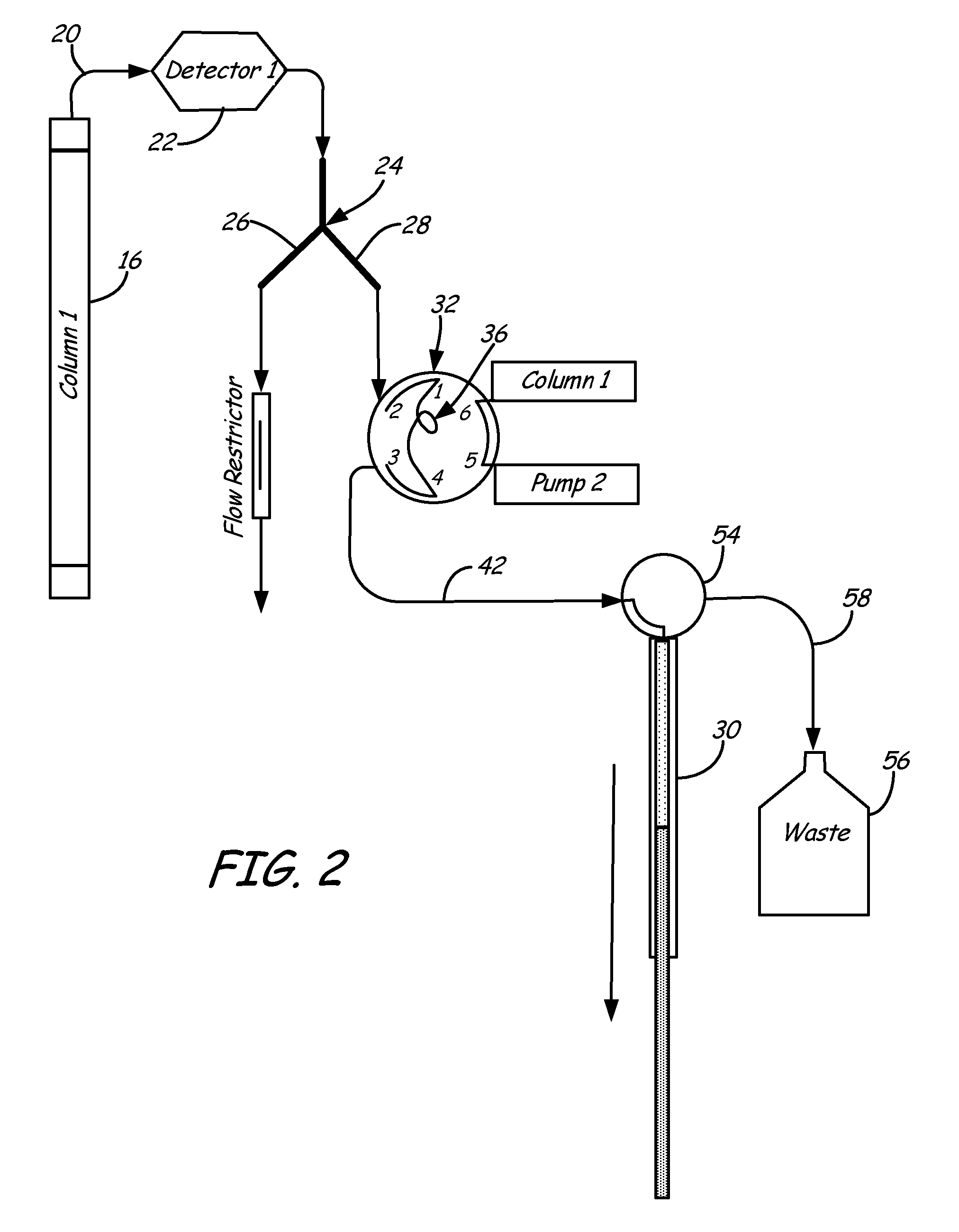

Valve and Splitting System for Multi-Dimensional Liquid Analysis

A multi-dimensional liquid analysis system includes a flow splitter for separating mobile phase outflow from a first dimension liquid analysis system into first and second liquid split outlet flows. Volumetric flow rate control of the split outlet flows is provided by a flow control pump which withdraws one of the split outlet flows from the flow splitter at a controlled withdrawal flow rate to define the other split outlet flow rate as the difference between the outflow rate from the first dimension system and the withdrawal flow rate. In this manner, accurate and consistent flow division can be accomplished, which is particularly useful for multi-dimensional liquid analysis.

Owner:RGT UNIV OF MINNESOTA

Compact booster bleed turbofan

A Turbofan engine includes a fan mounted to a fan frame inside a fan nacelle. A booster compressor is joined to the fan inboard a flow splitter. A booster bleed system is disposed inside the splitter, and includes an inlet at the compressor outlet, and an outlet joined to the bypass duct following the fan

Owner:GENERAL ELECTRIC CO

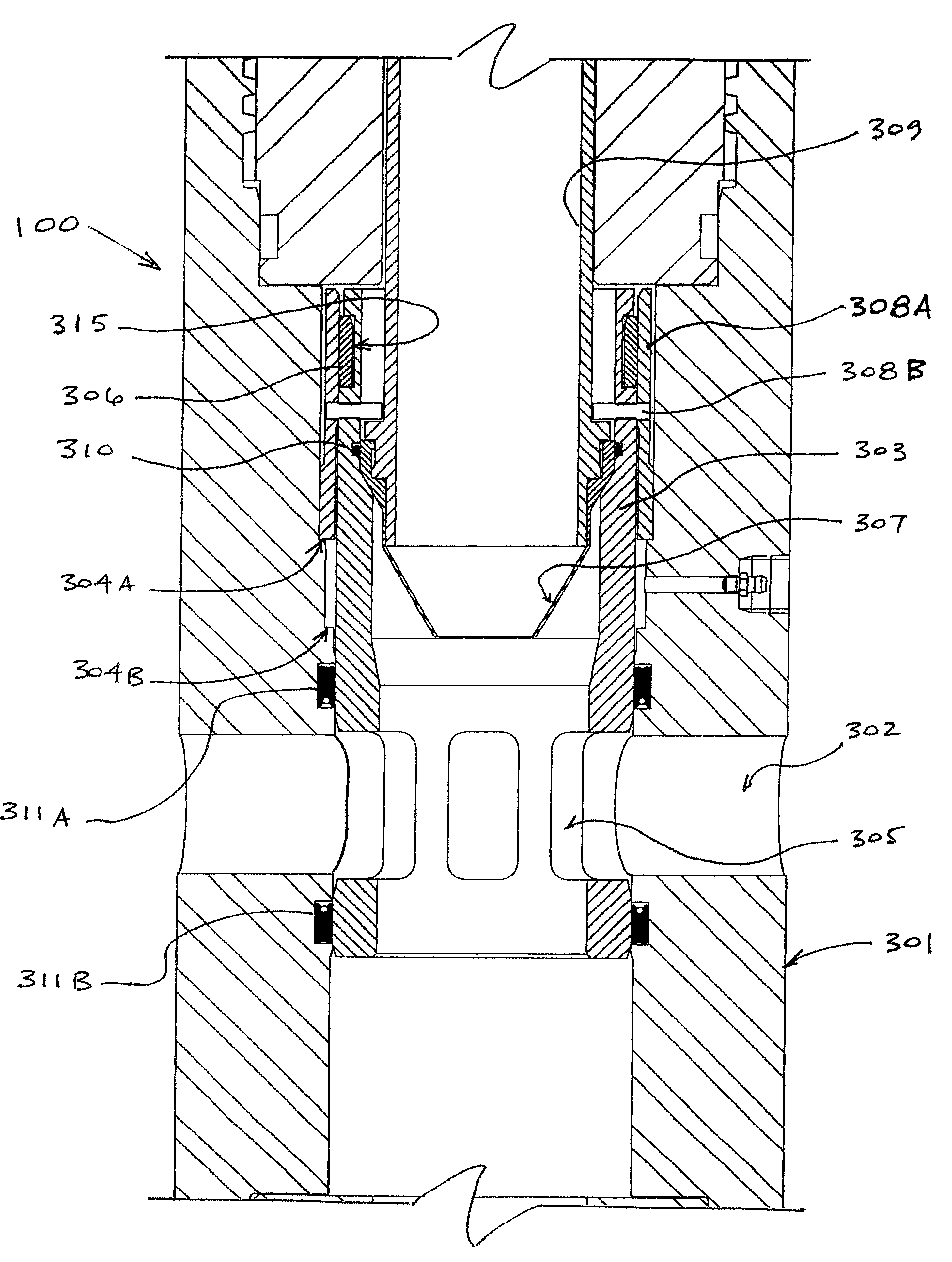

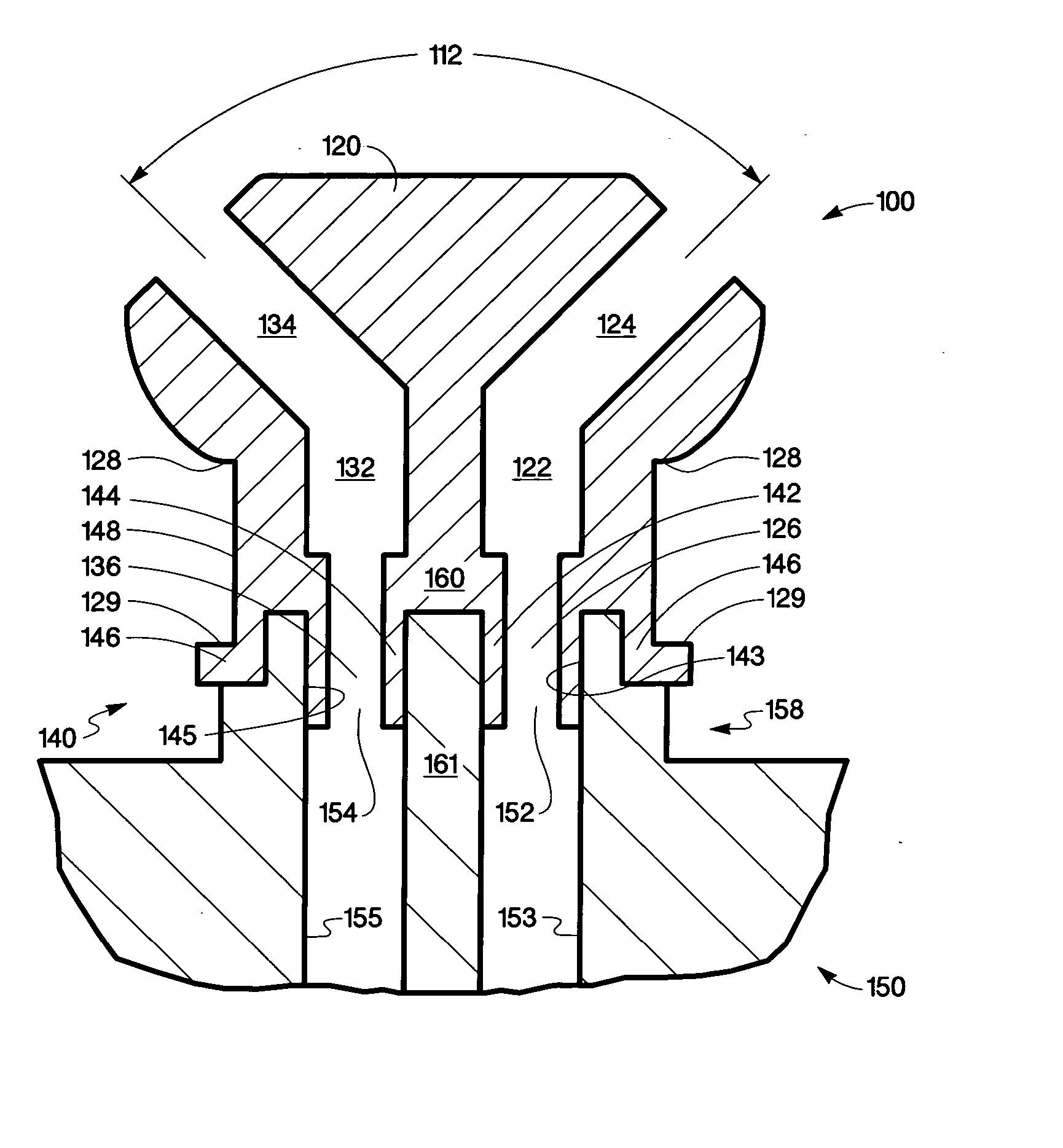

Downhole surge reduction method and apparatus

InactiveUS6769490B2Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

High capacity globe valve

InactiveUS6935371B2Reduce fluid separationReduce traffic lossValve members for absorbing fluid energySlide valveEngineeringStreamflow

A high flow globe valve with a body defining an interior cavity in communication with a first and second fluid passages. A tubular throttling cage is offset in the cavity away from the second fluid passage and has an open end in communication with the first fluid passage. The throttling cage has flow ports angled towards the second fluid passage and the flow port nearest the second fluid passage is oversized. The throttling cage has flow splitter defined by two adjacent flow ports through the cage opposite the second flow passage. A plug is closely received in the throttling cage and moveable to cover the flow ports thereby restricting flow through the throttling cage.

Owner:DRESSER LLC

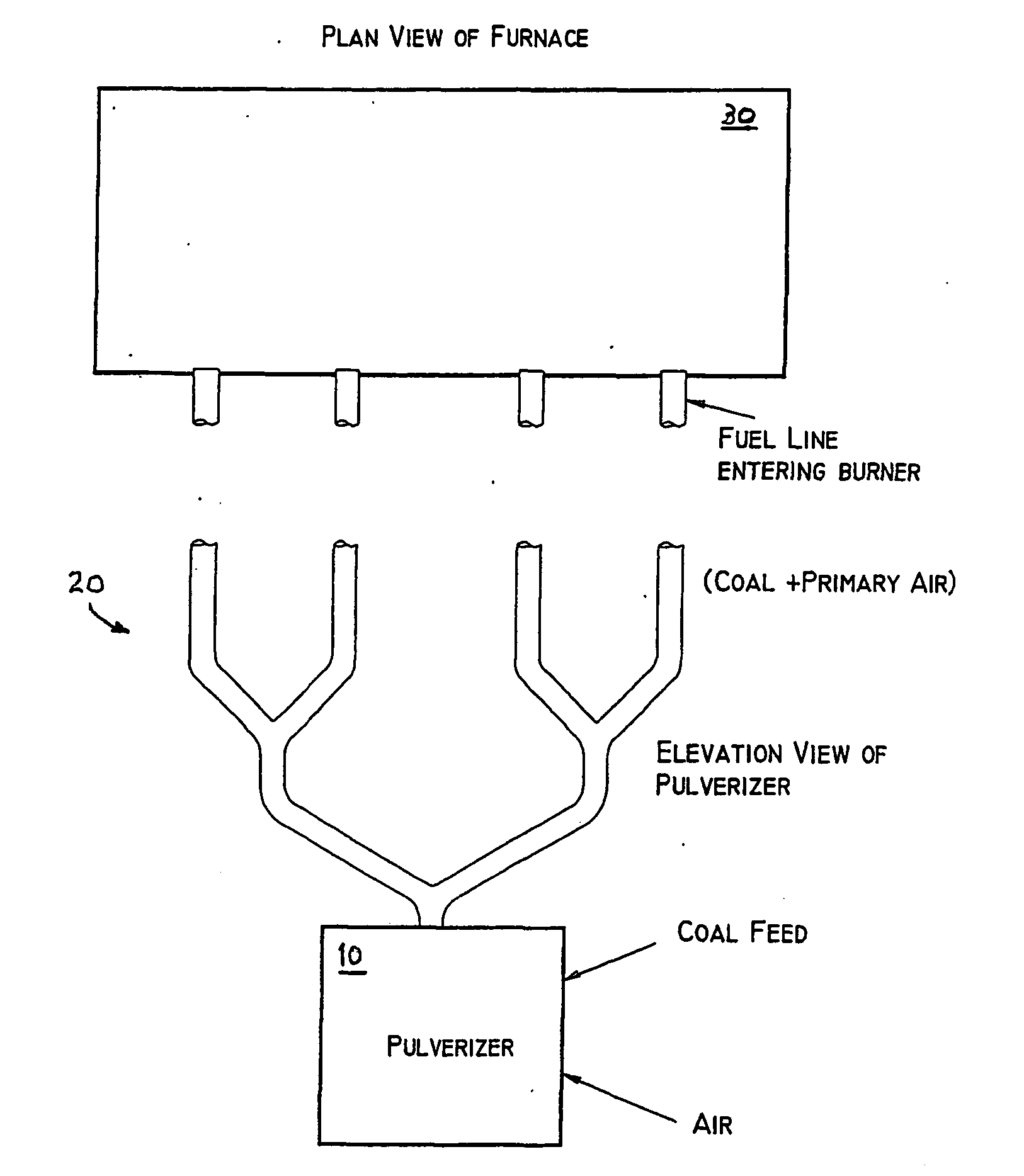

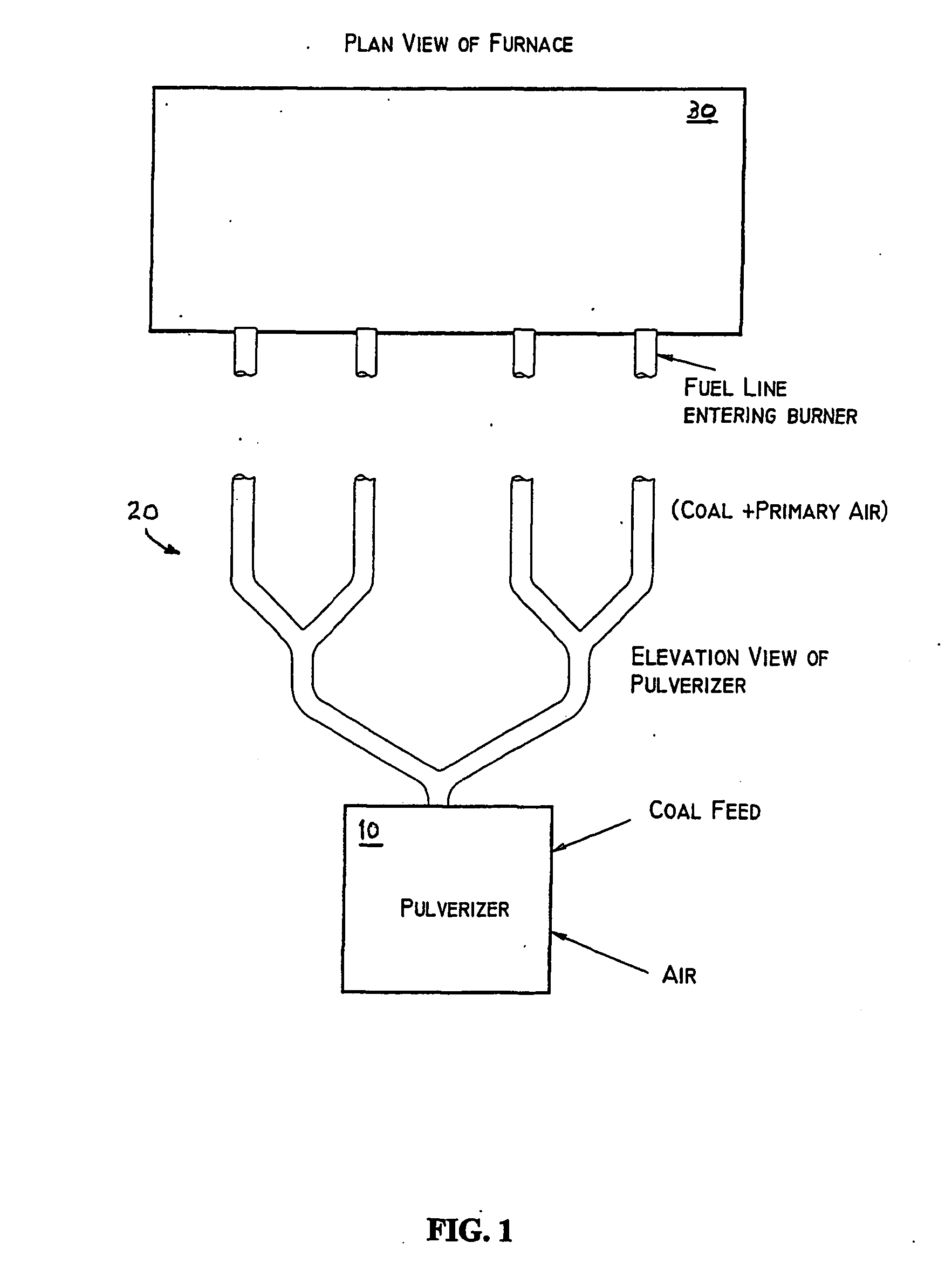

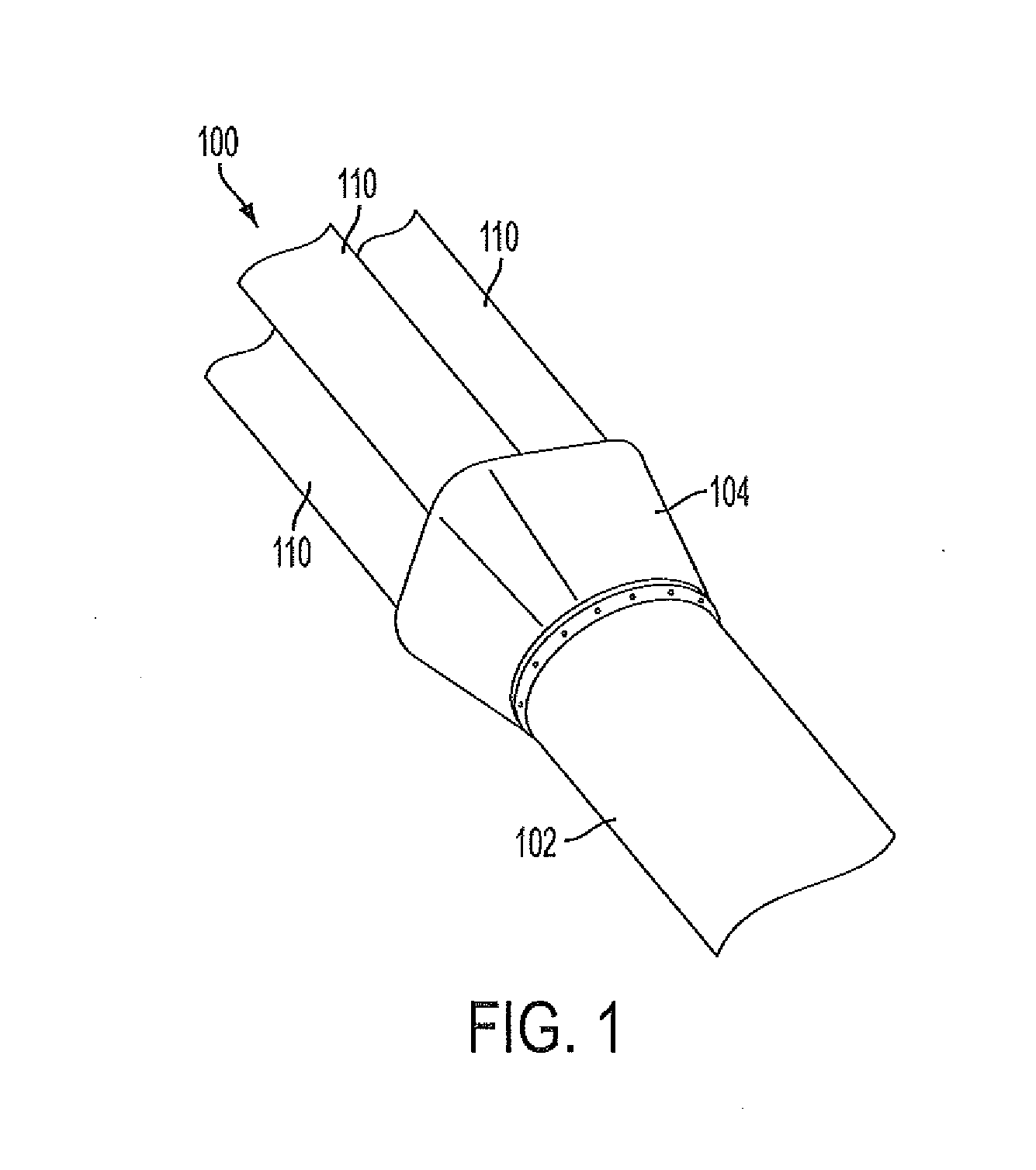

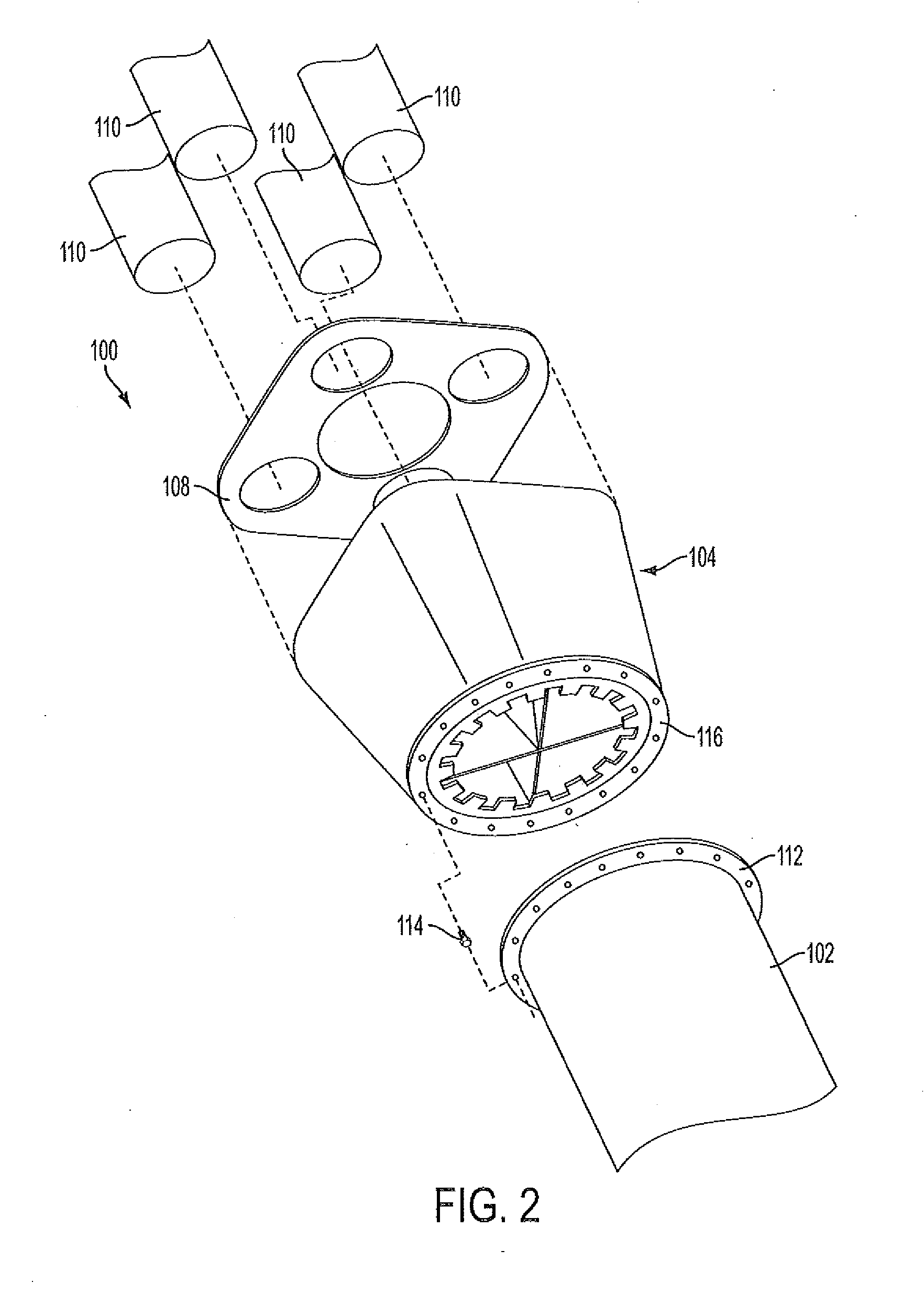

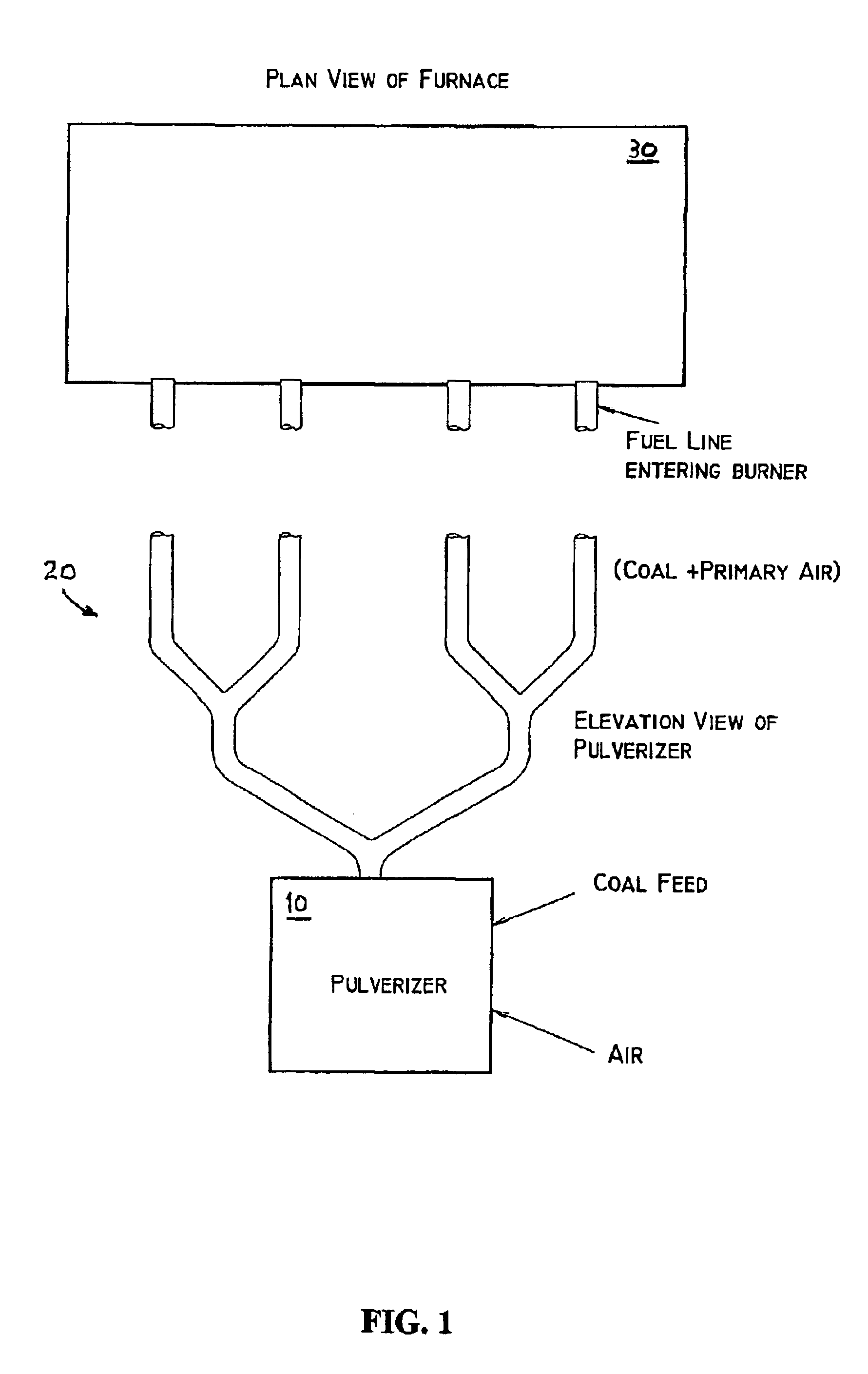

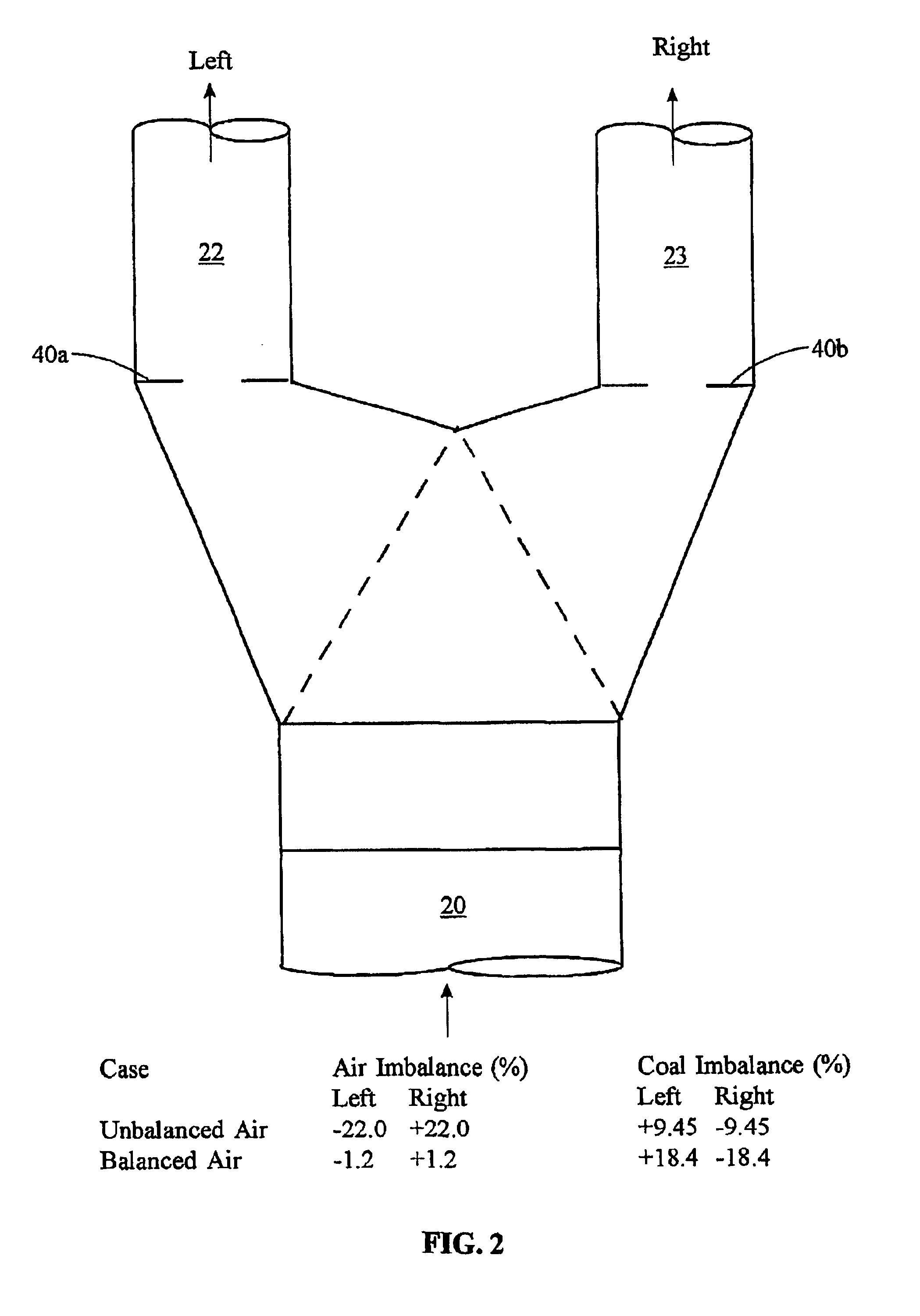

Coal flow balancing devices

InactiveUS20120186501A1Reduce unevennessImprove uniformityFuel feeding arrangementsBulk conveyorsParticle flowSolid particle

A flow splitter distributes solid particles flowing in a fluid, such as coal particles flowing in air, through a piping system. The flow splitter includes a divider housing having an inlet configured to connect to an upstream pipe and having an outlet configured to connect to a plurality of downstream pipes, e.g., by way of a divider head. A divider body is mounted within the divider housing. A plurality of divider vanes is included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow from the outlet to each of the downstream pipes.

Owner:BABCOCK POWER SERVICES

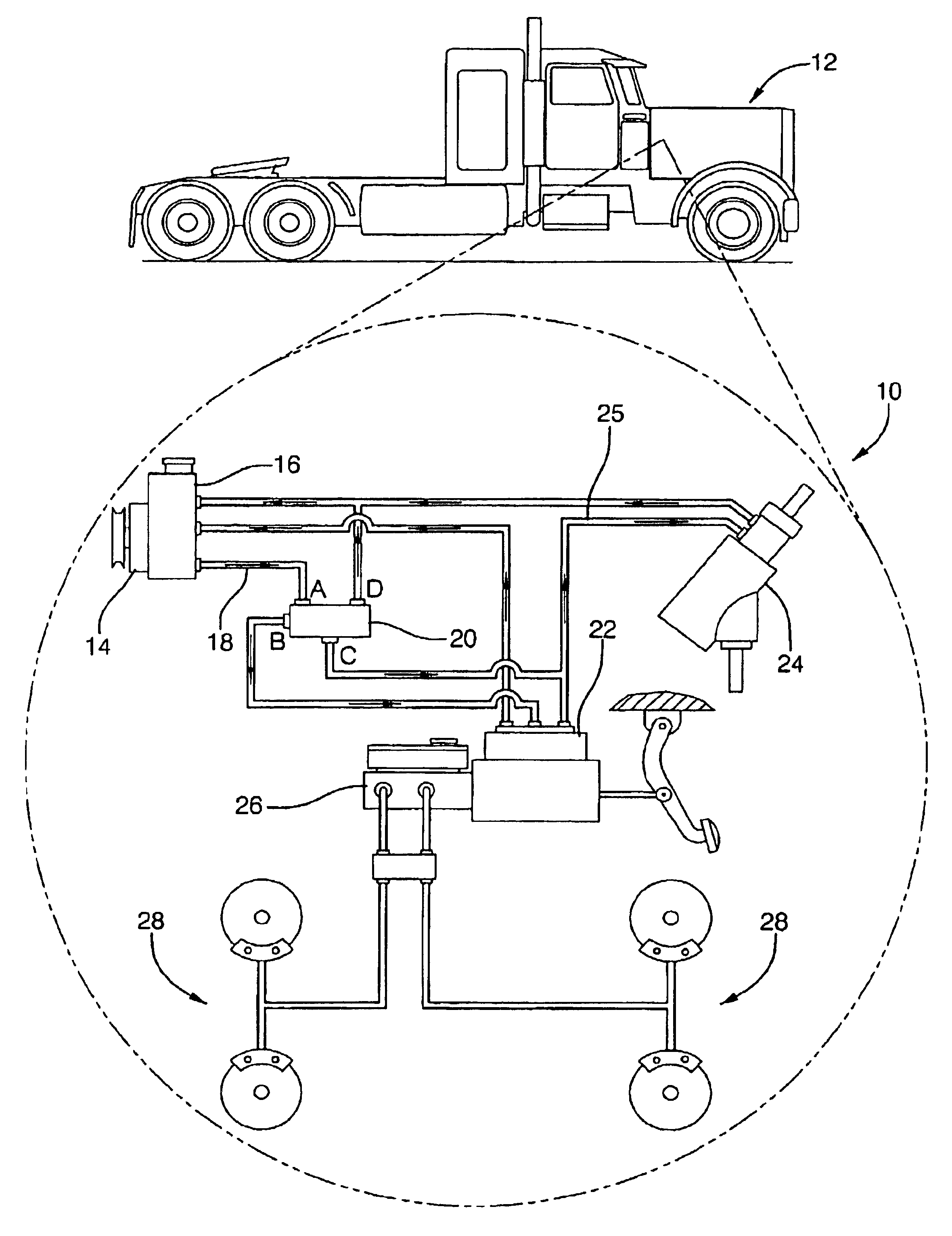

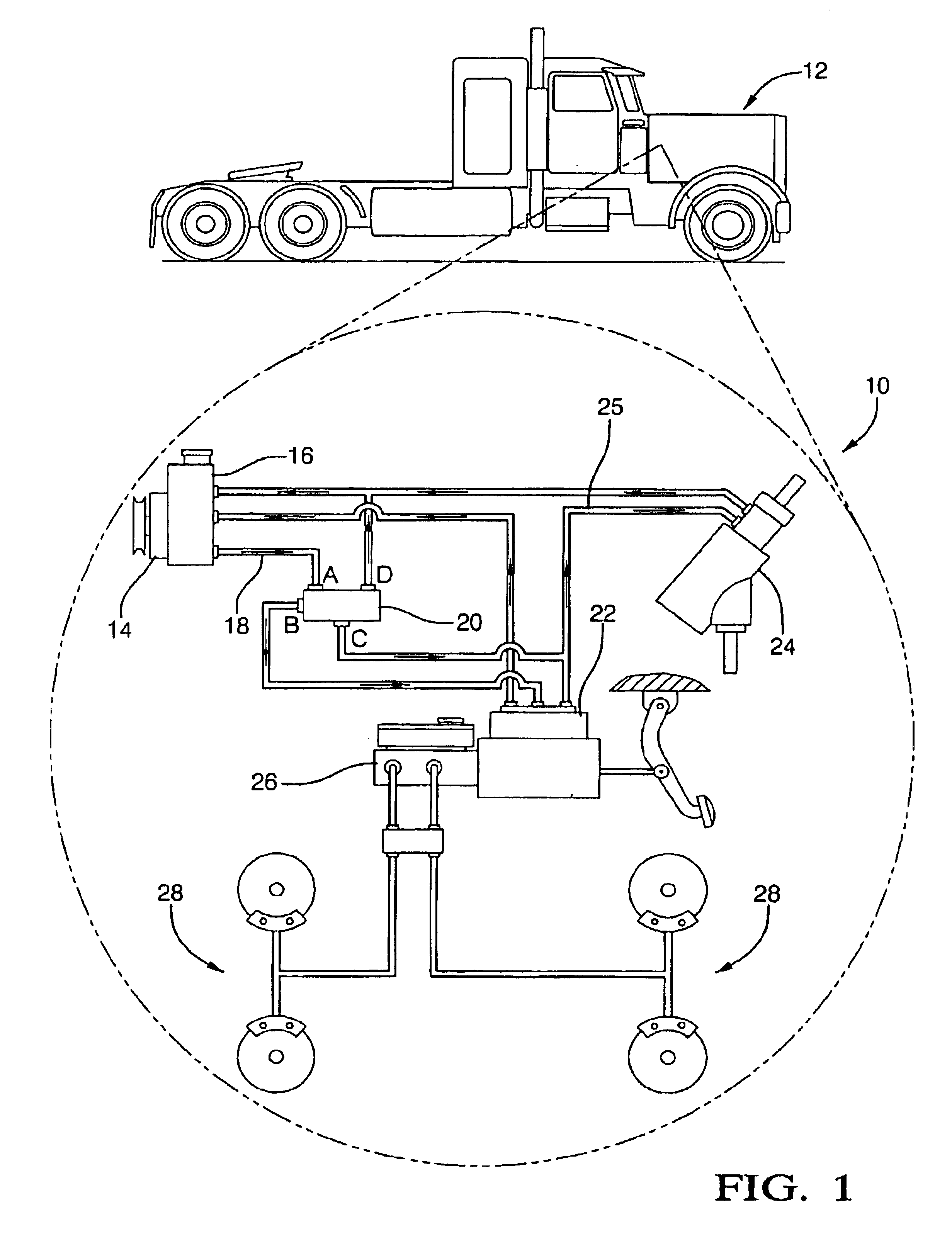

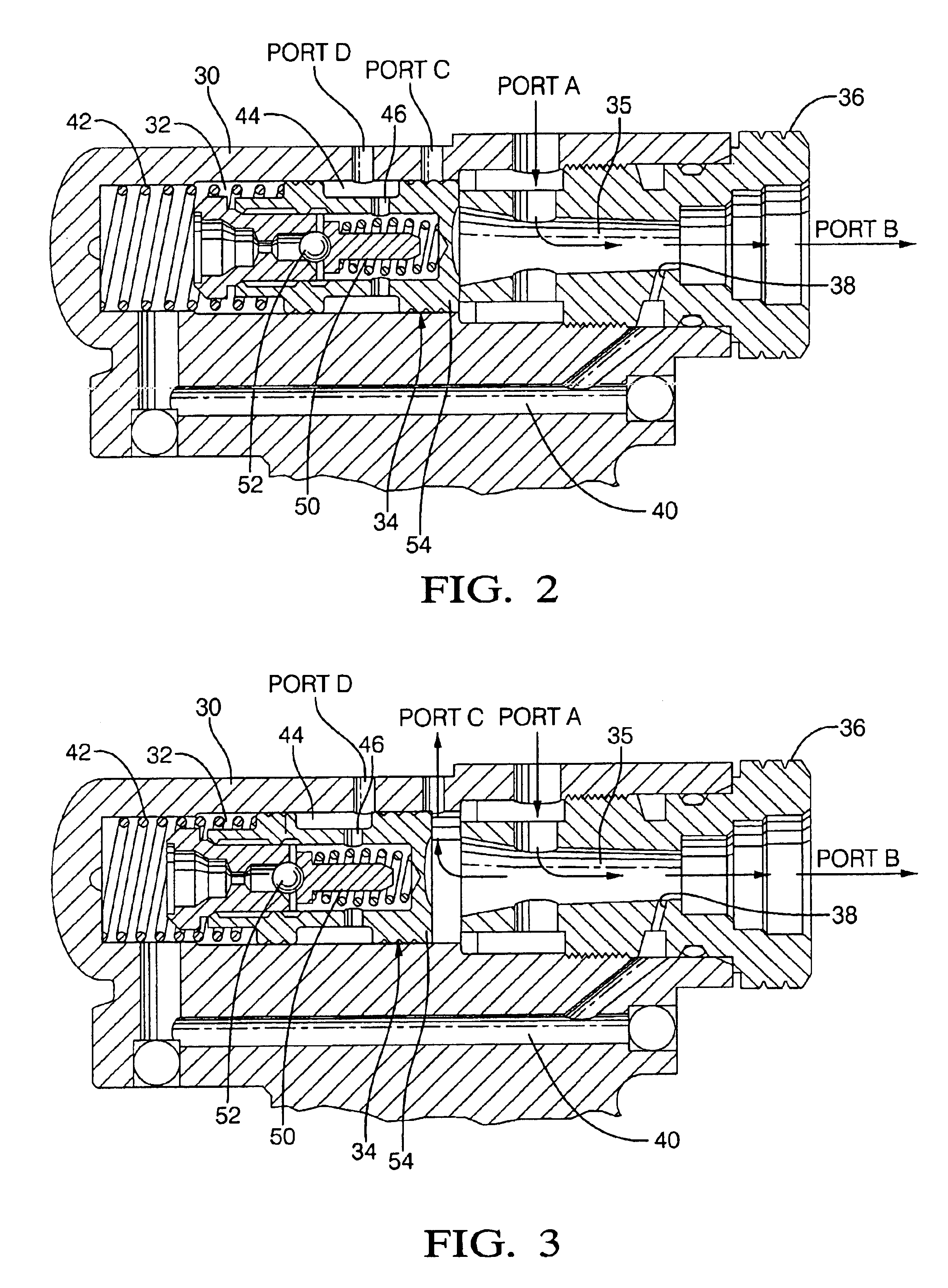

Hydraulic brake and steering assist system

InactiveUS6814413B2Simple designLess componentsBraking action transmissionServomotor componentsHydraulic pumpHeavy load

Owner:STEERING SOLUTIONS IP HLDG +1

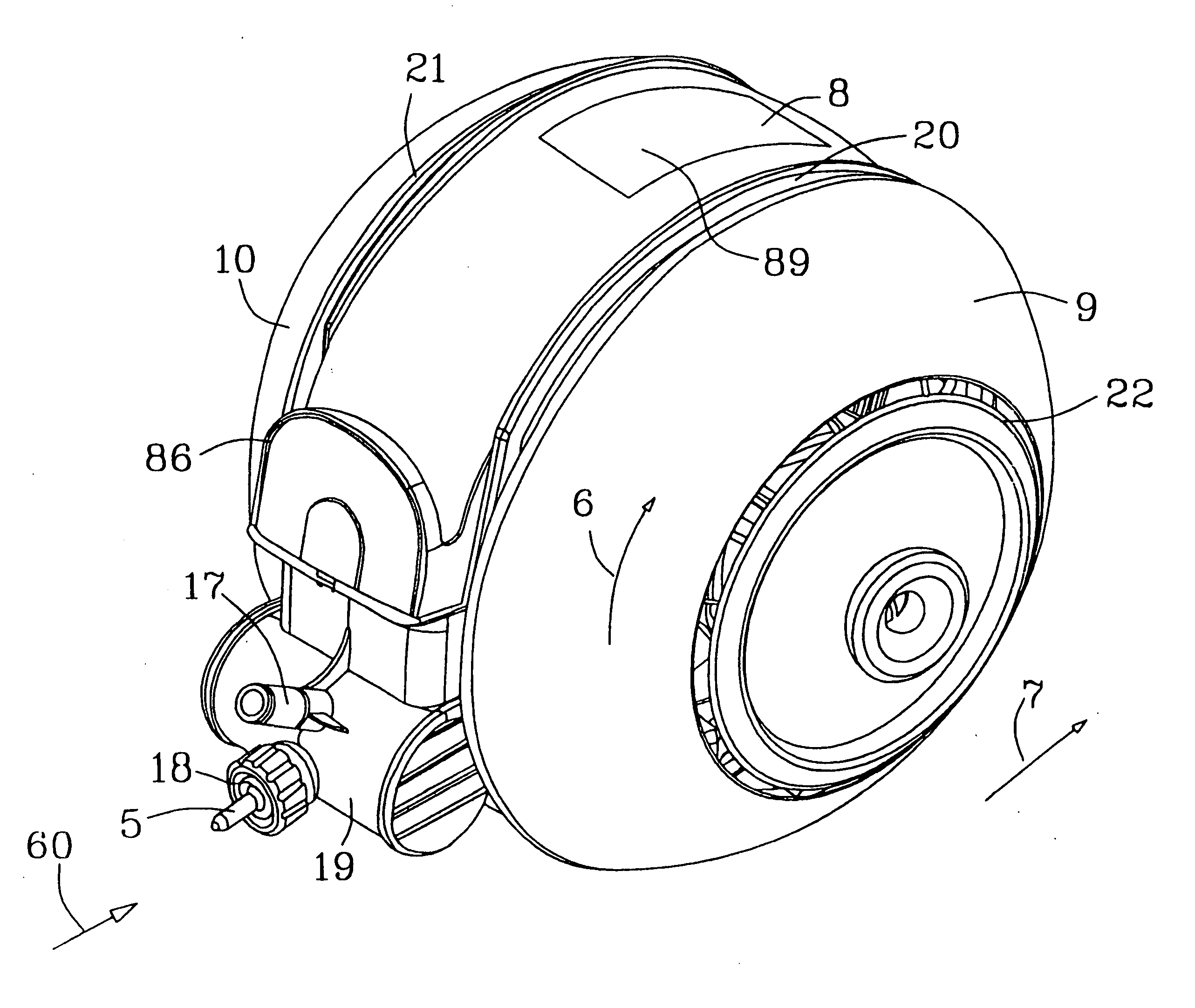

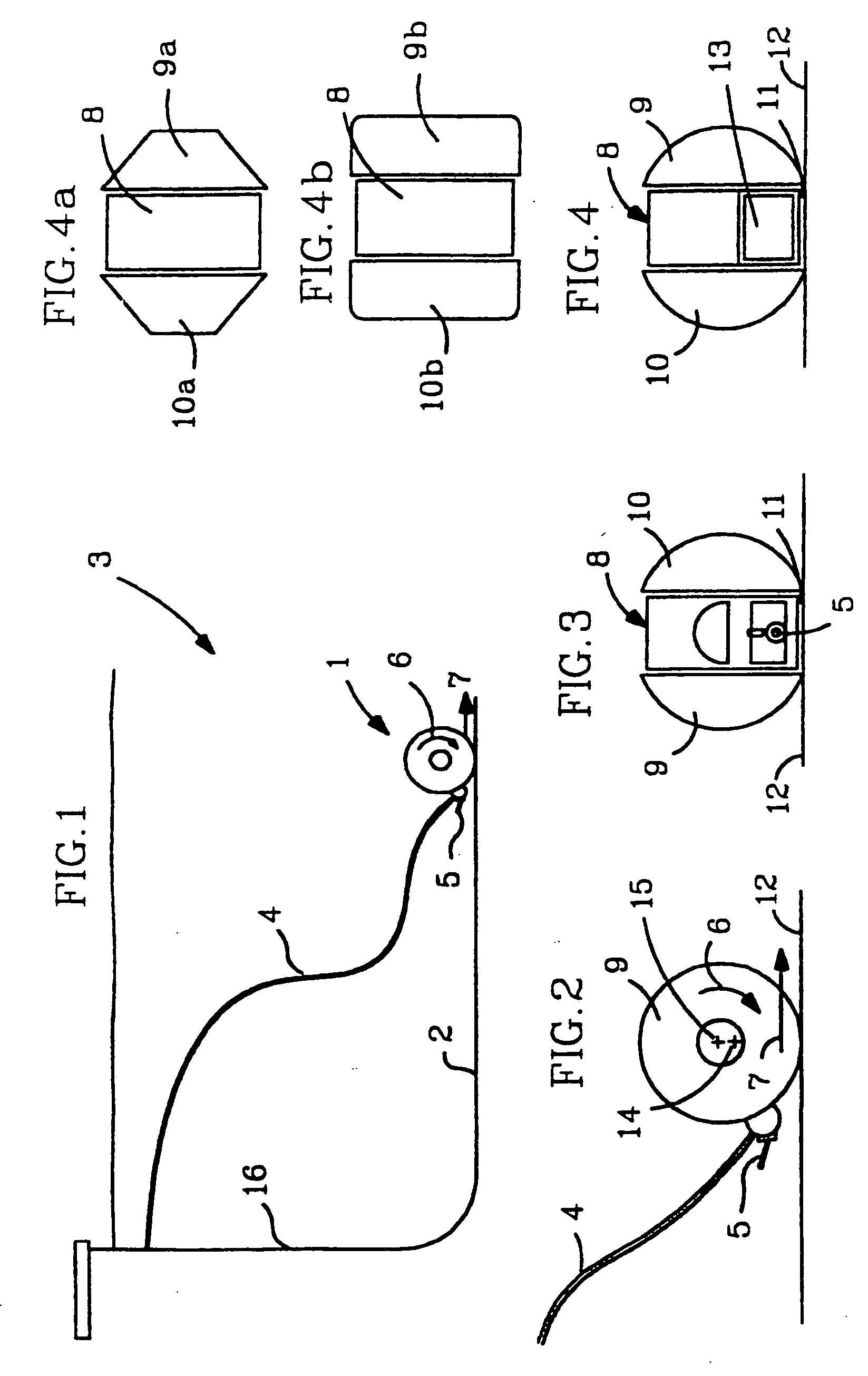

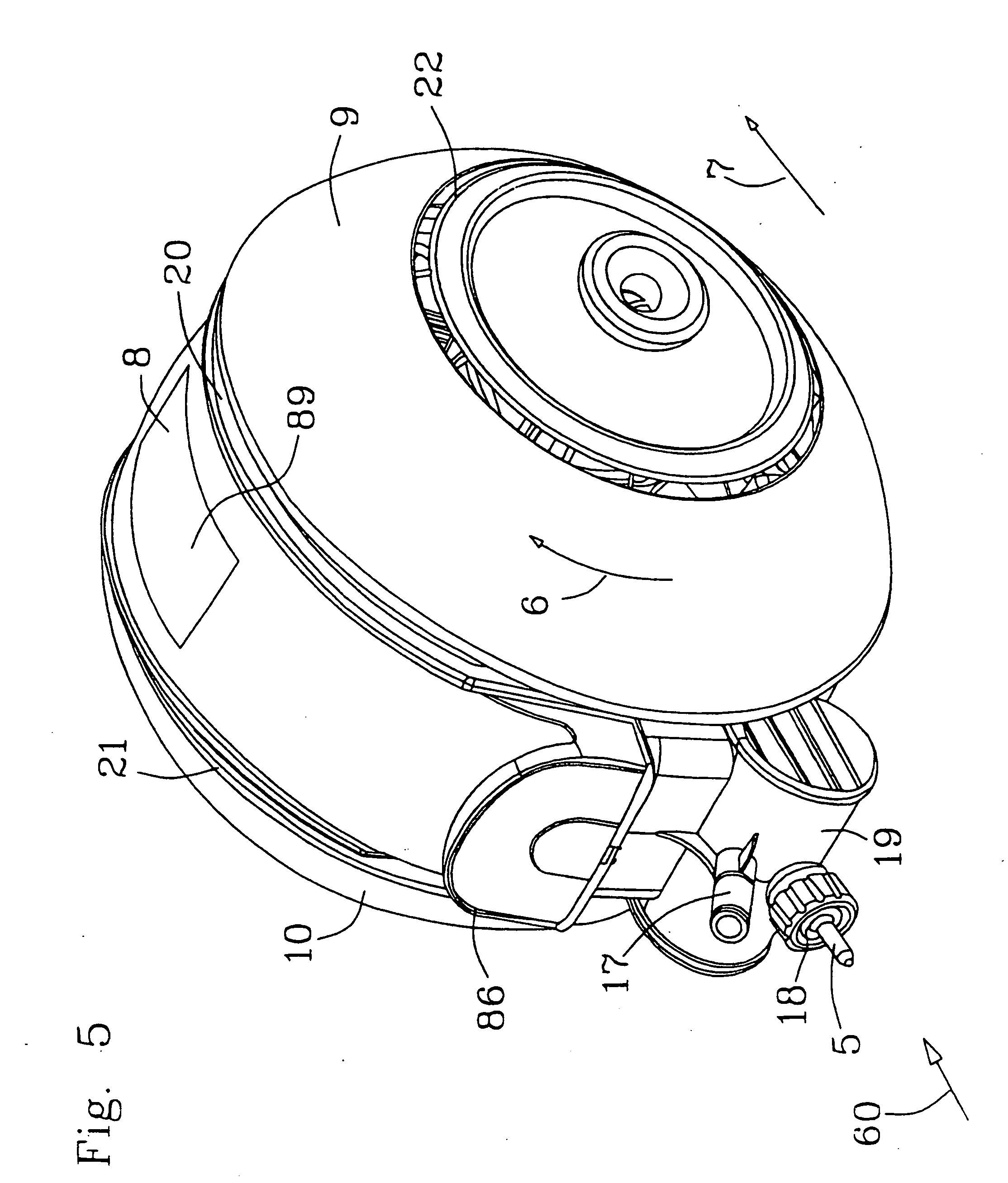

Pool cleaner

InactiveUS20060207041A1Less stable device under waterTolerableGymnasiumSwimming poolsGear wheelWater flow

Owner:ZODIAC POOL CARE +1

Viscoelastic liquid flow splitter and methods

A viscoelastic liquid flow splitter includes a flow splitter body having a first bore including a first bore outlet and a first bore inlet, and a second bore including a second bore outlet and a second bore inlet The bore inlets are substantially parallel to each other and the bore outlets diverge from each other at an angle. The flow splitter also includes a compression fitting having a first and a second tubular portion fluidically coupled to the first and second bore inlets where the tubular portions are configured to fluidically couple to a double barreled viscoelastic liquid dispensing syringe.

Owner:HEWLETT PACKARD DEV CO LP

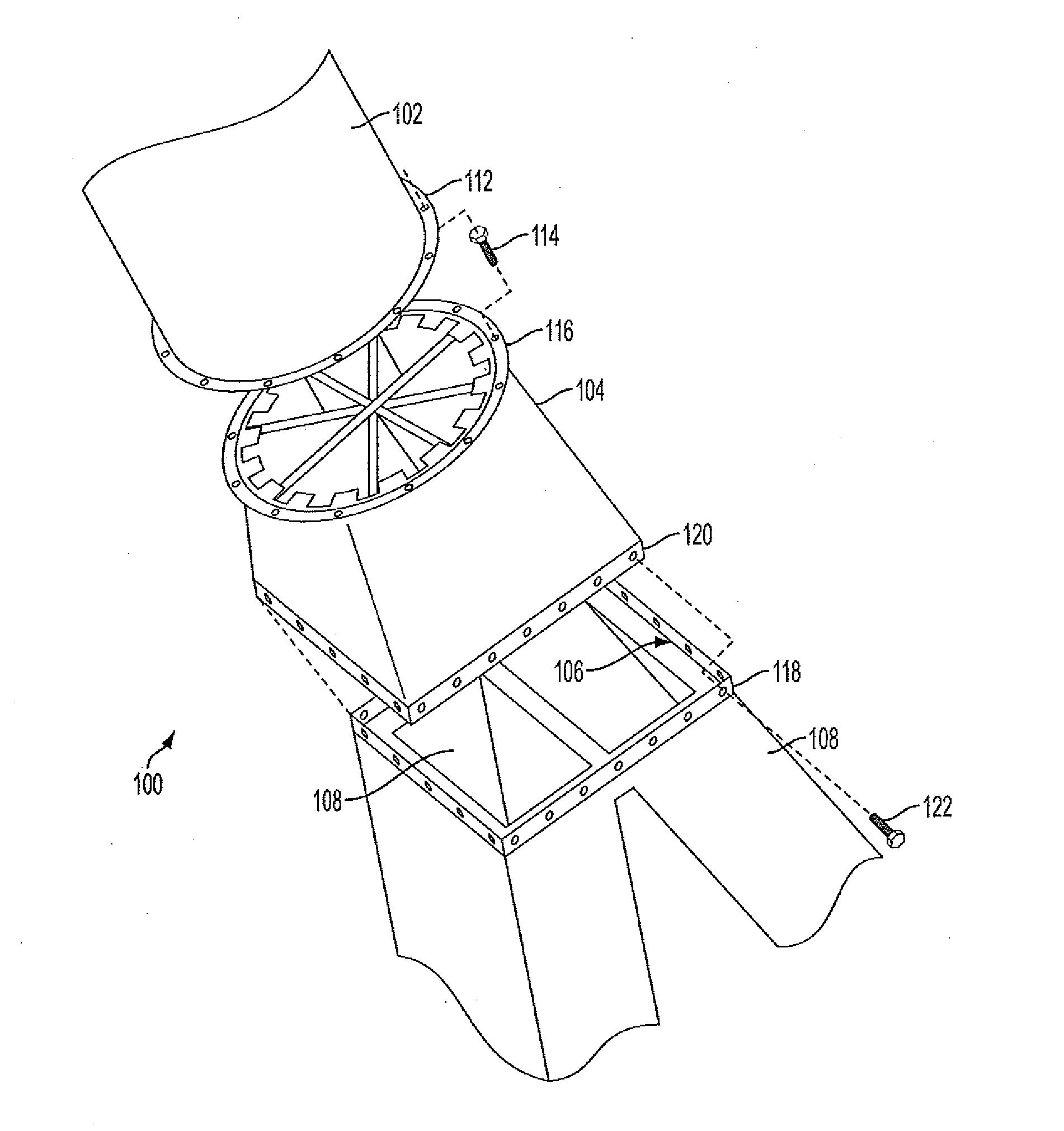

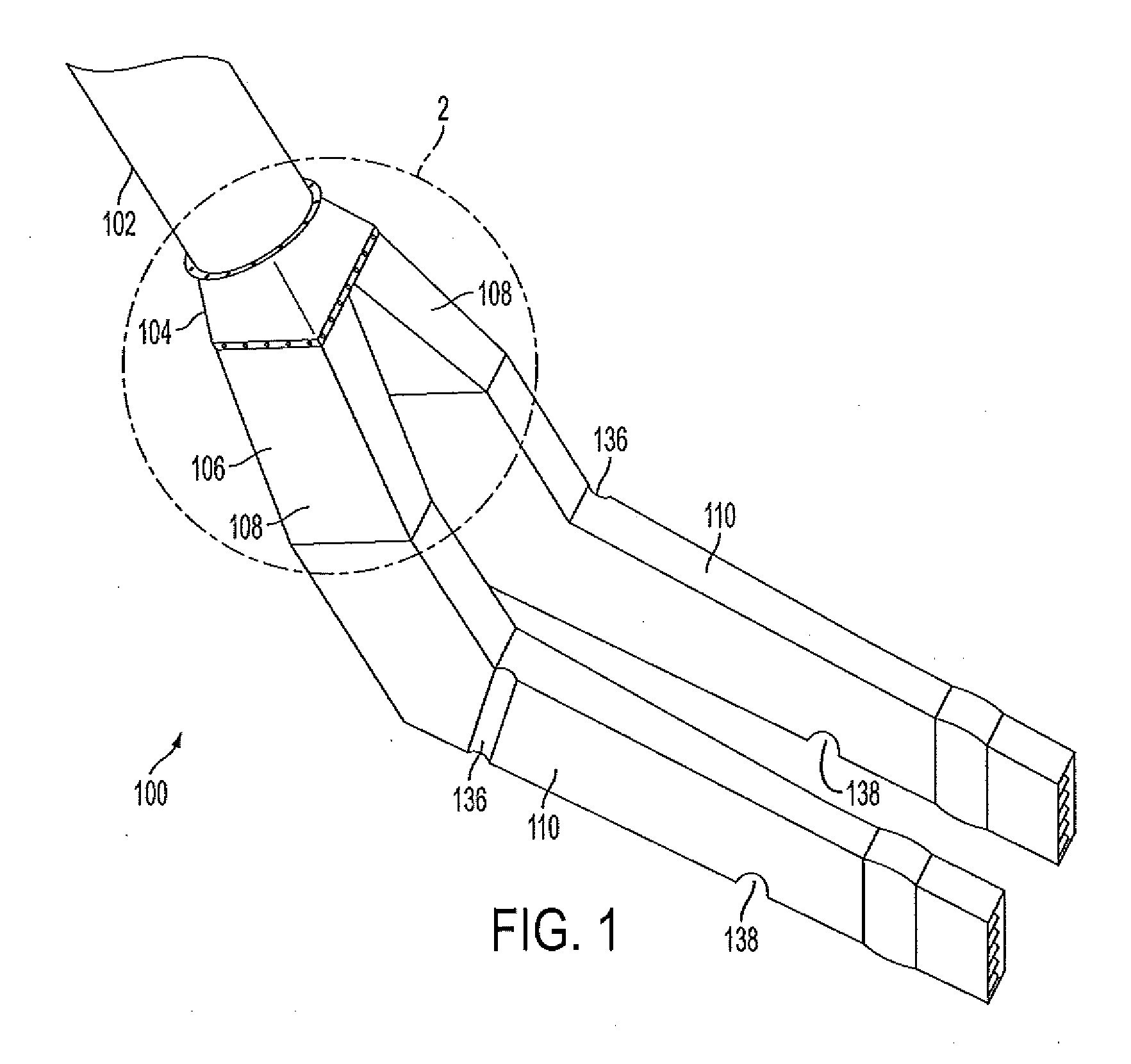

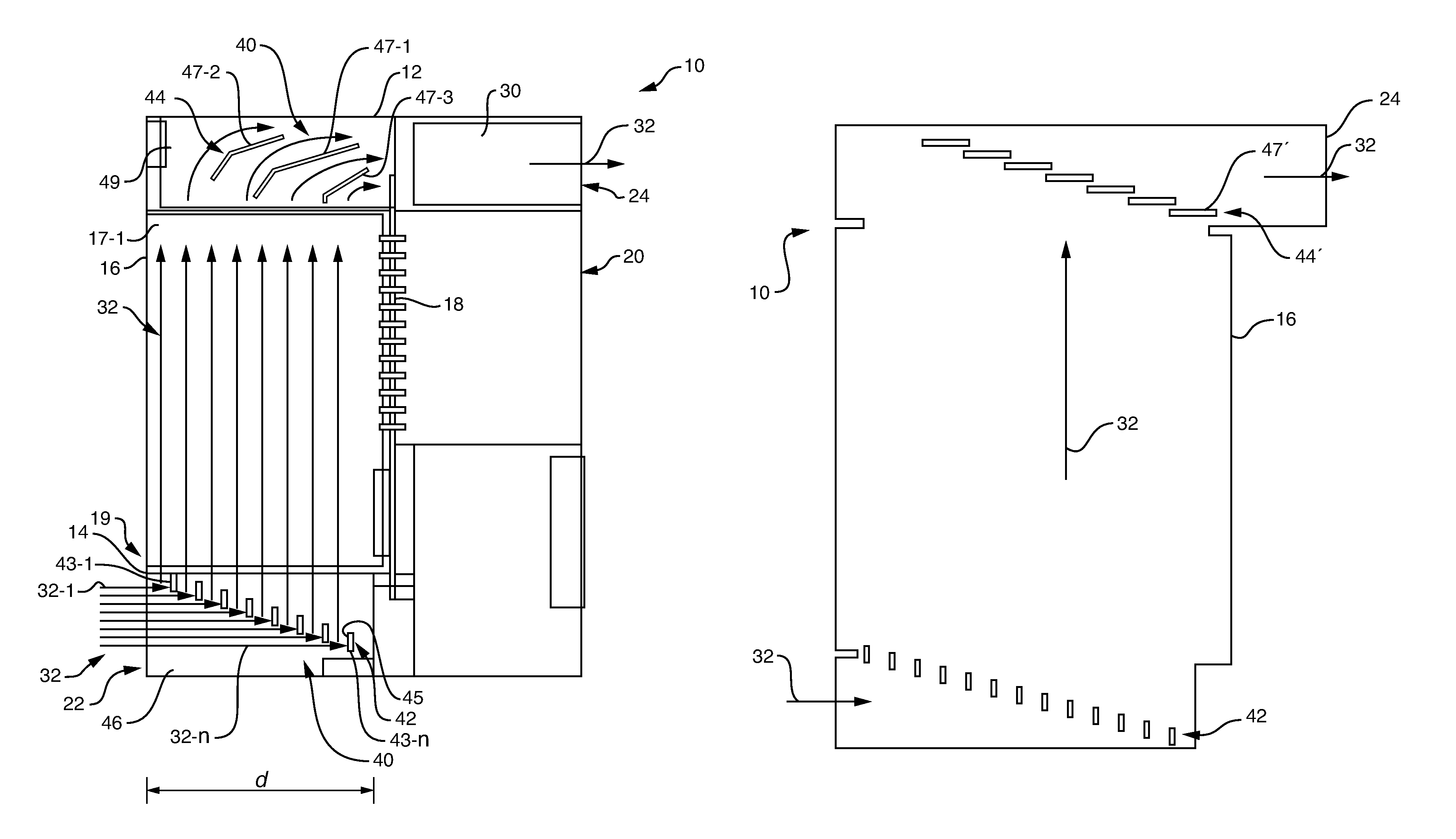

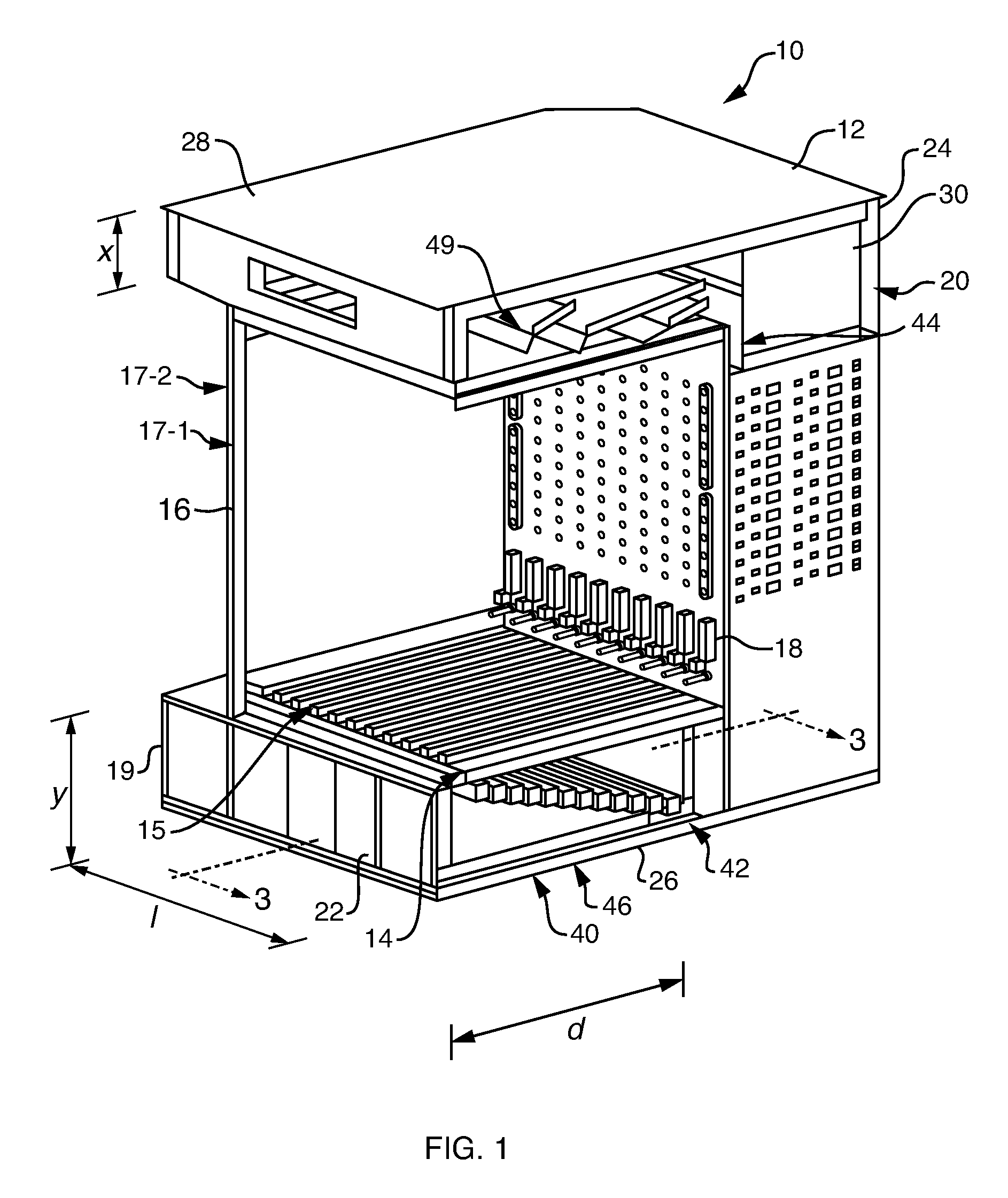

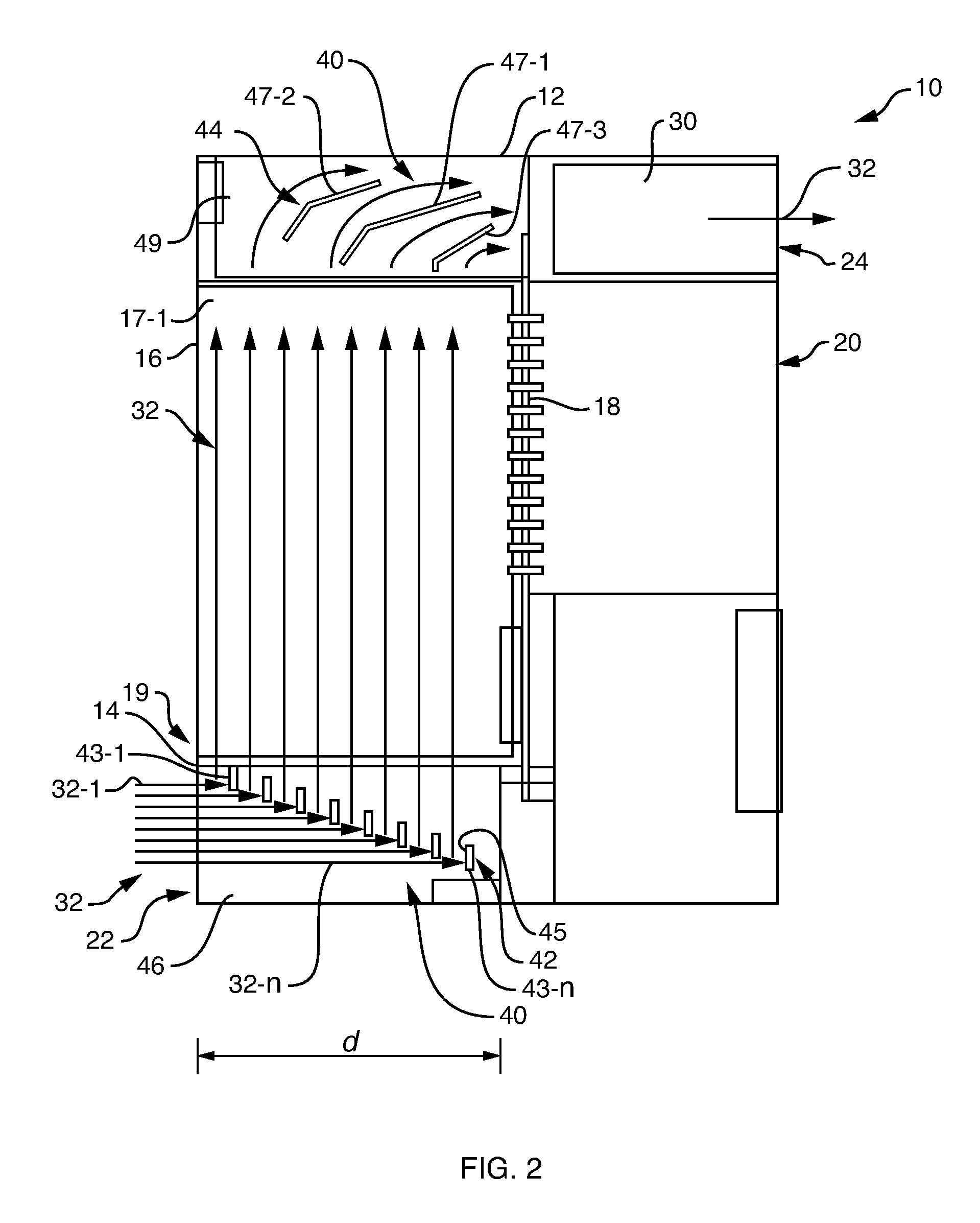

Method and apparatus for providing thermal management in an electronic device

InactiveUS7957133B2Minimize recirculationMaximize coolingShow cabinetsDigital data processing detailsElectronic systemsInlet flow

An electronic system includes a chassis, an air flow distribution assembly having a first set of baffles disposed within an intake volume of the chassis and a second set of baffles disposed in proximity to an air outlet of the chassis. The first set of baffles is configured to turn the flow of an air stream approximately 90 degrees, relative to an inlet flow direction of the air stream, toward circuit boards disposed within the chassis. The second set of baffles is configured as a flow splitter that receives the air stream from the circuit boards and partitions the air stream into separate portions prior to the air stream exiting via the air outlet. The use of both the first and second set of baffles redirects and distributes the air stream, flowing into the air inlet, in a substantially even manner across the circuit board component mounting surfaces of the circuit boards disposed within the system.

Owner:CISCO TECH INC

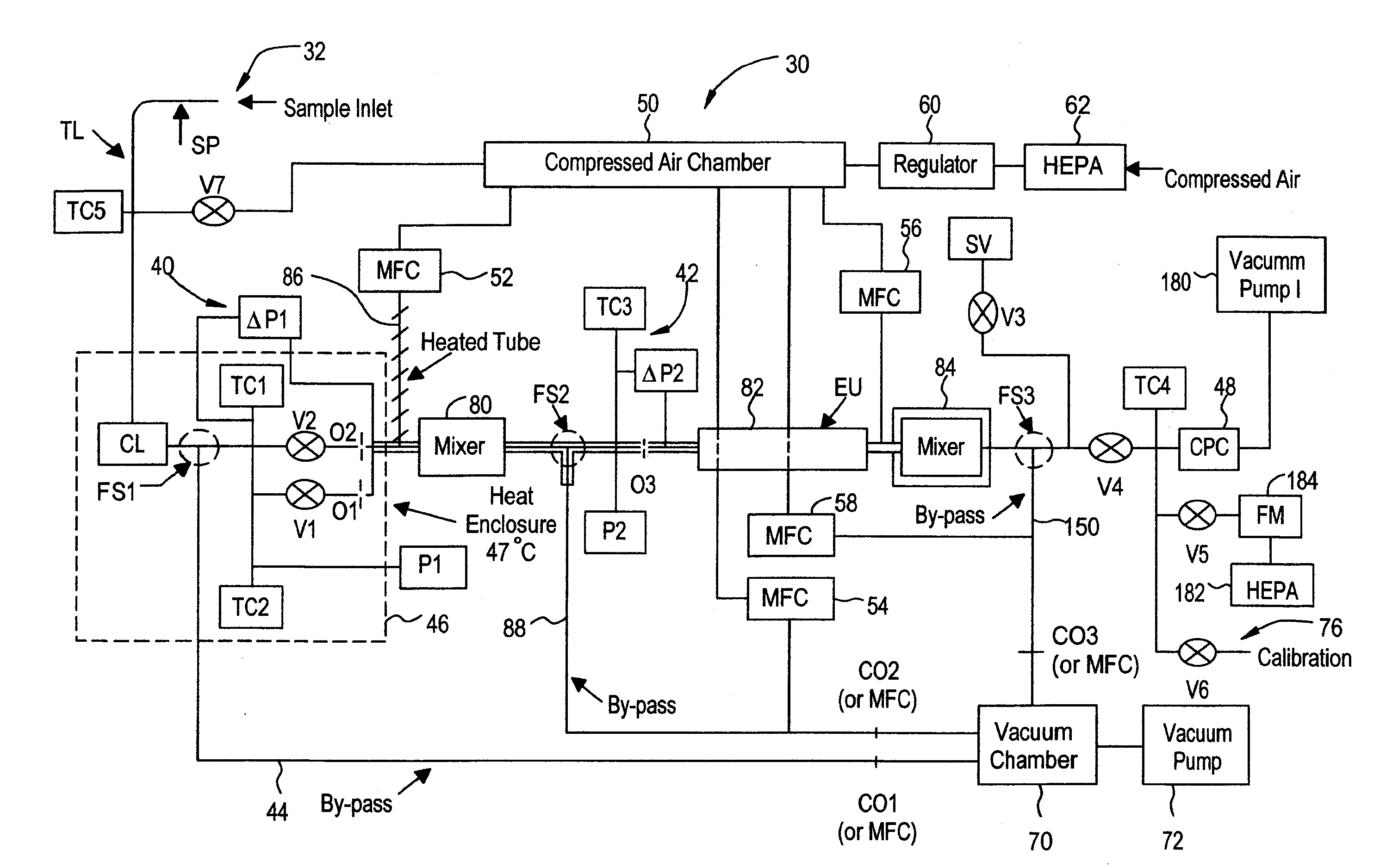

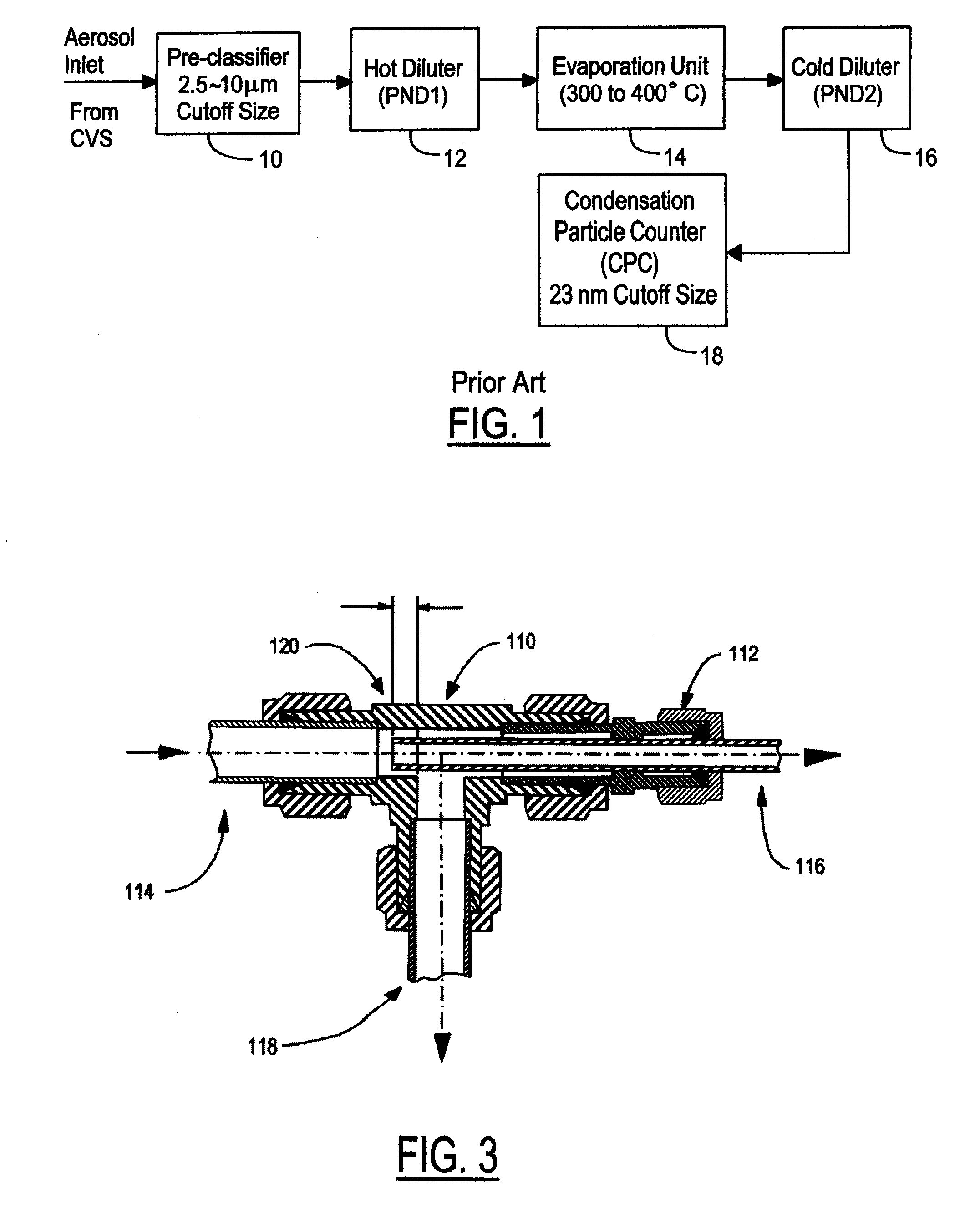

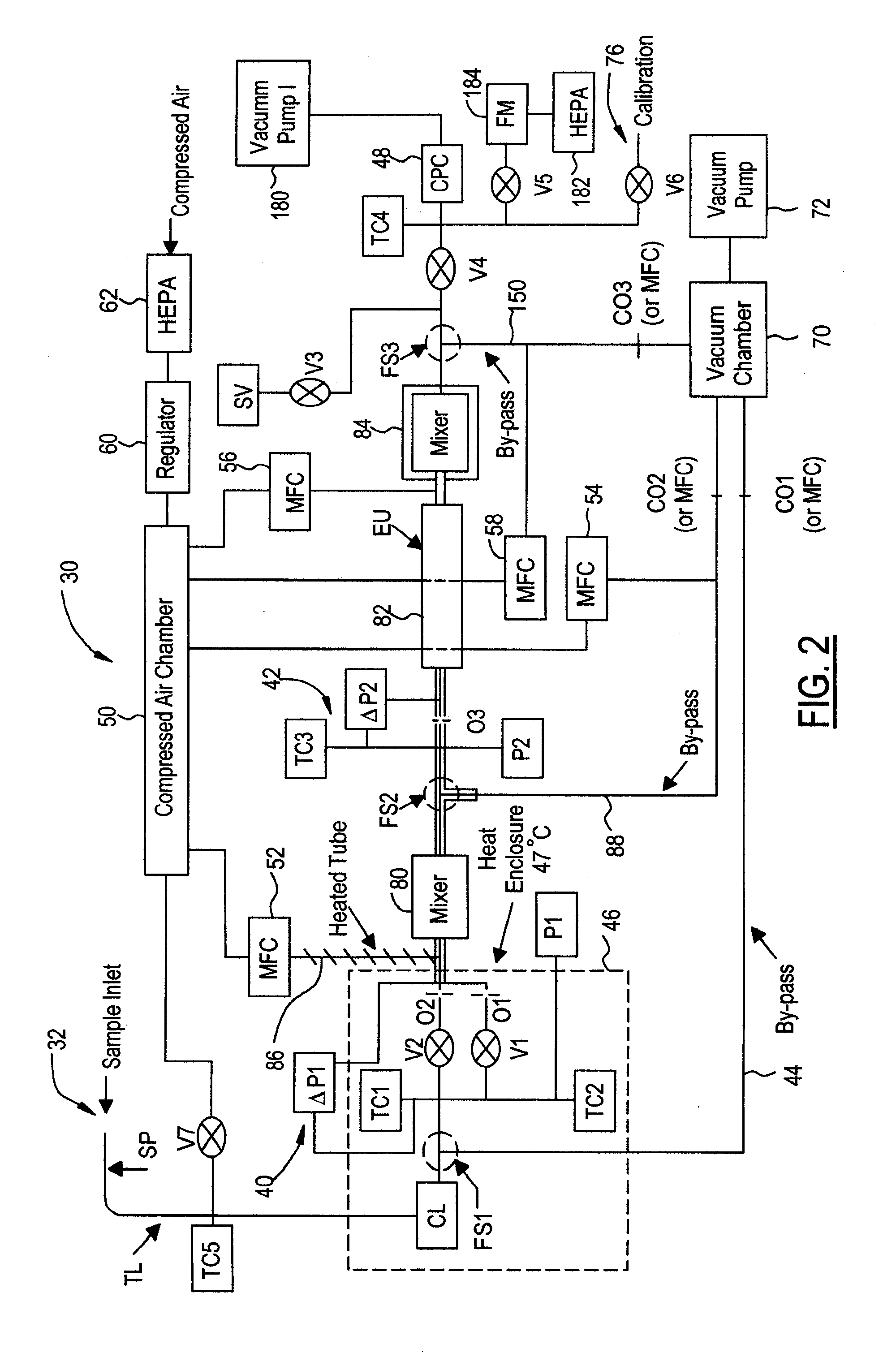

Solid particle counting system with valve to allow reduction of pressure pulse at particle counter when vacuum pump is started

InactiveUS20080148812A1Avoiding work fluid backflowReduce pressure pulseInternal-combustion engine testingElectrical controlWorking fluidEngineering

A solid particle counting system for measuring solid particle number concentrations from engine or vehicle exhausts in real-time includes a diluter arrangement, a particle counter, and a flow splitter. The diluter arrangement mixes the dilution gas with flowing sample gases. The flow splitter receives the output flow from the diluter arrangement, provides a portion of this flow to the particle counter, and provides a by-pass flow that is received by a vacuum pump. A second flow route to the particle counter includes a valve arranged such that opening the valve during the starting of the vacuum pump reduces a pressure pulse at the particle counter caused by the starting of the vacuum pump, thereby avoiding work fluid backflow from the particle counter prior to the vacuum pump stabilizing.

Owner:HORIBA LTD

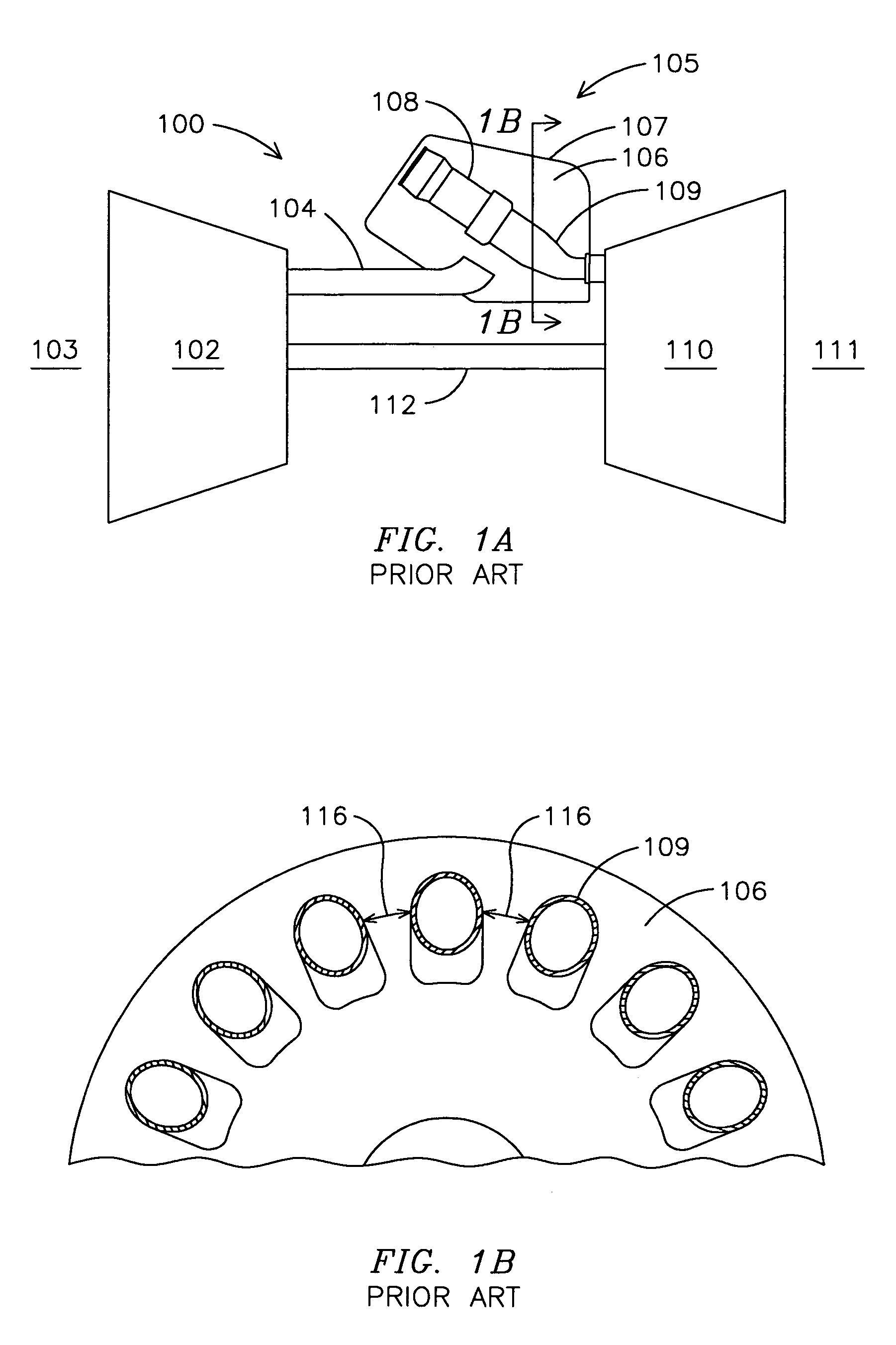

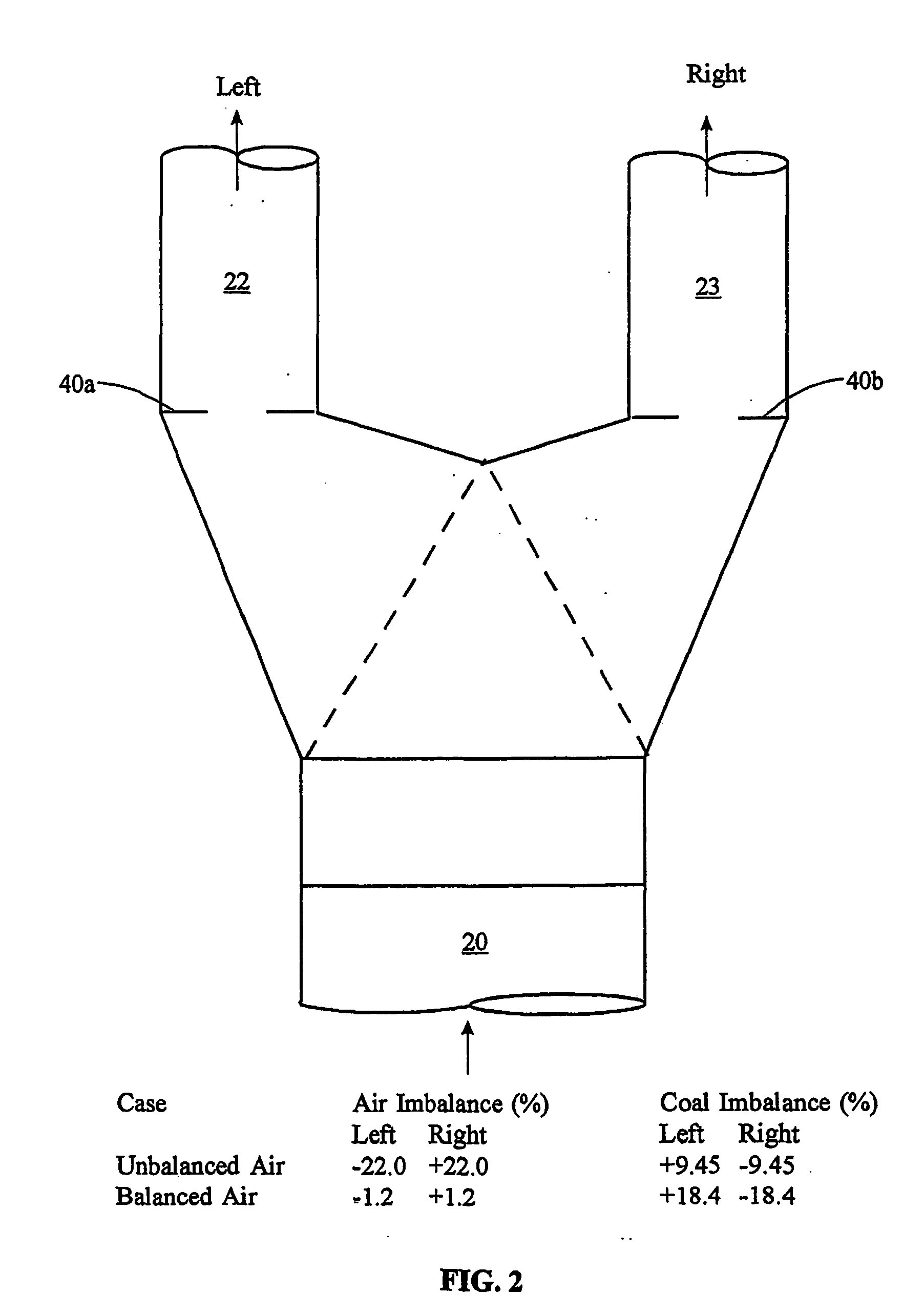

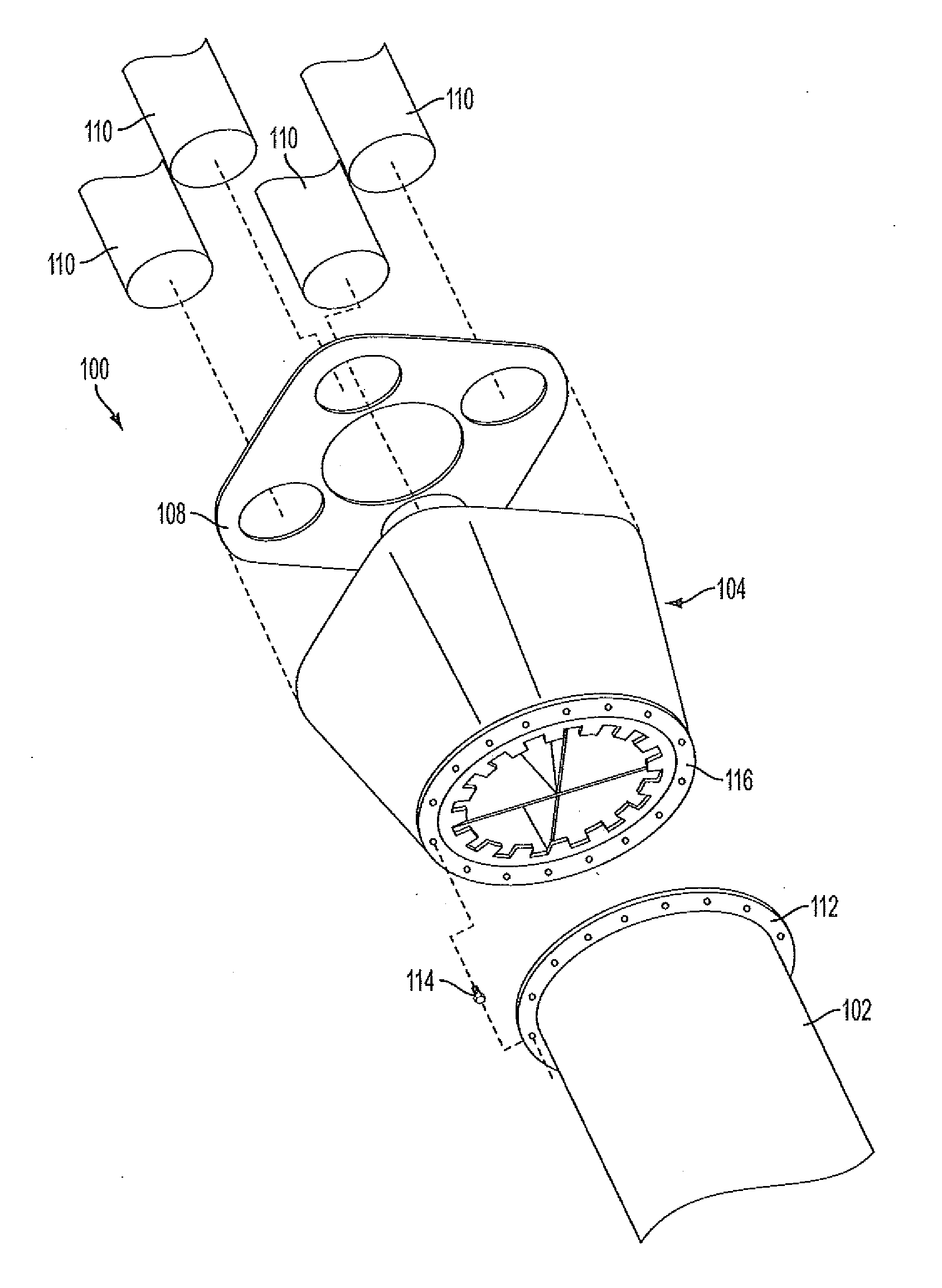

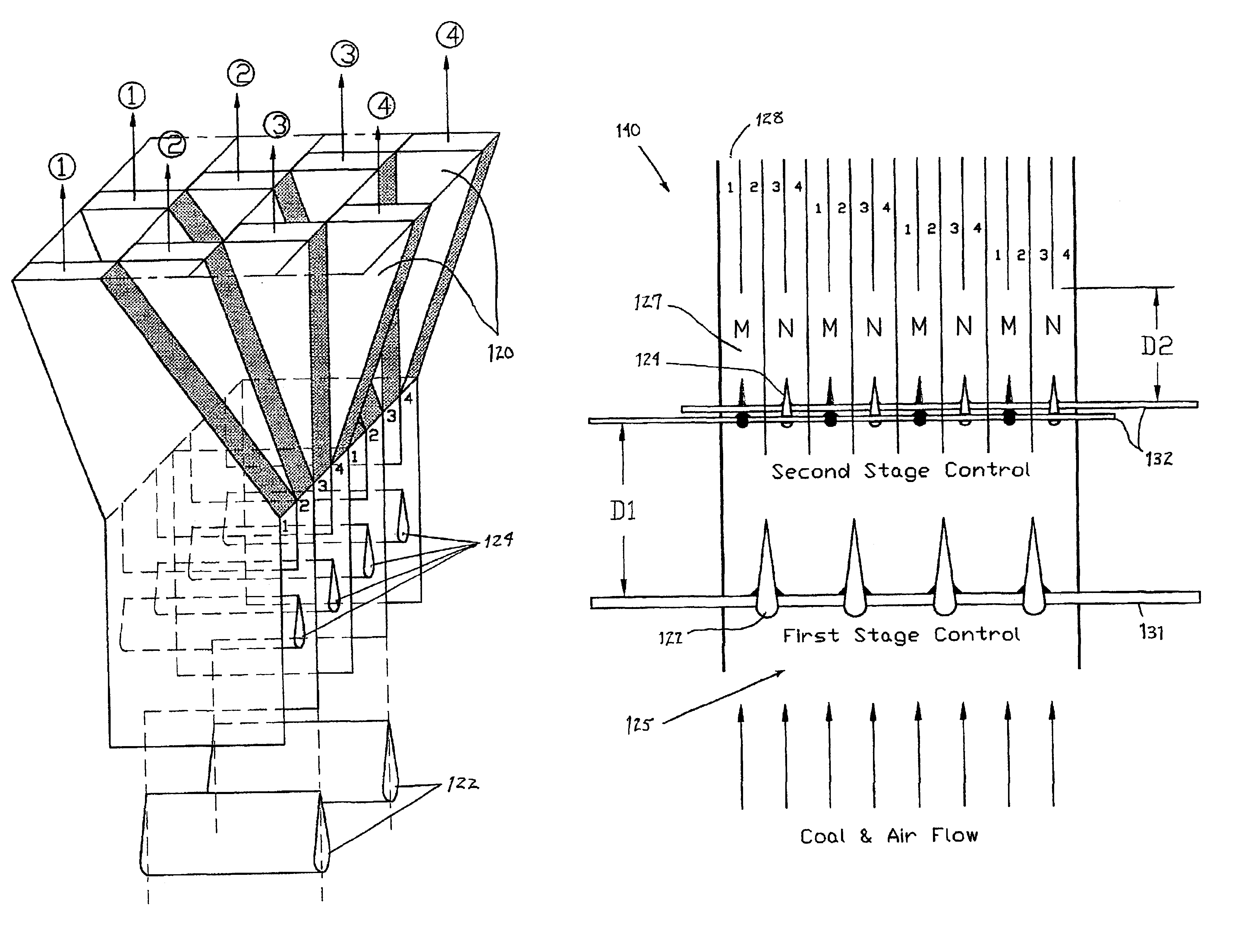

Adjustable air foils for balancing pulverized coal flow at a coal pipe splitter junction

InactiveUS20050042043A1Coal flow imbalanceIncreasing and decreasing flowFuel feeding arrangementsDamper arrangementPollutant emissionsCoal

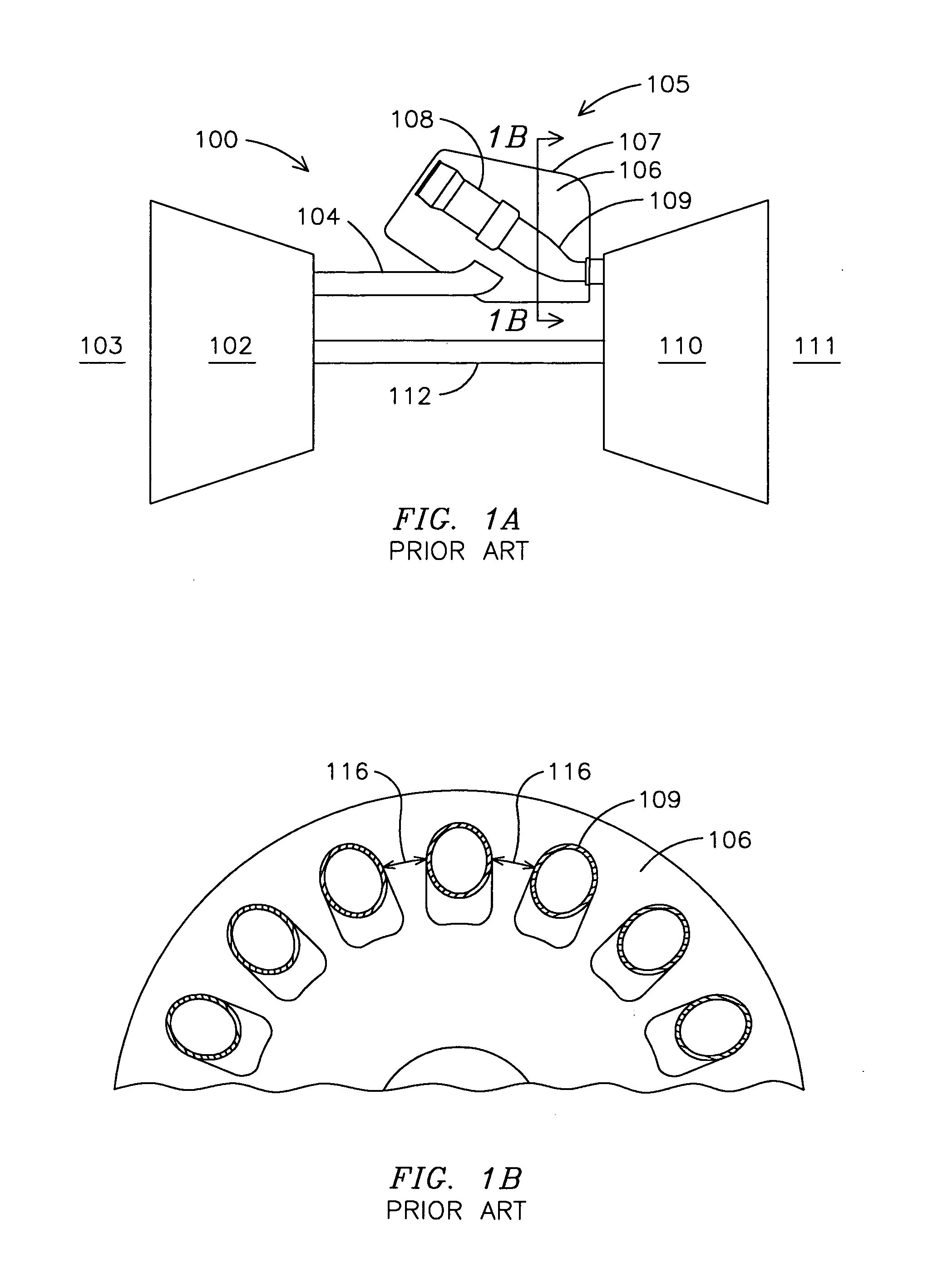

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of wake inducing airfoils (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each wake-inducing airfoil has a cross-section defined by a width W that varies along its length H for creating upstream turbulence, and a particle wake that preferentially diverts the coal flow to one of the outlet pipes at the splitter junction without affecting primary air flow. For example, each wake inducing airfoil may comprise a rounded convex edge leading to straight tapered sides. The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers. In addition, conventional fixed or variable orifices may be used in combination with the wake inducing airfoils for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air, resulting in closely balanced coal flow, reduced pollutant emissions and improved combustion efficiency.

Owner:LEVY EDWARD KENNETH +3

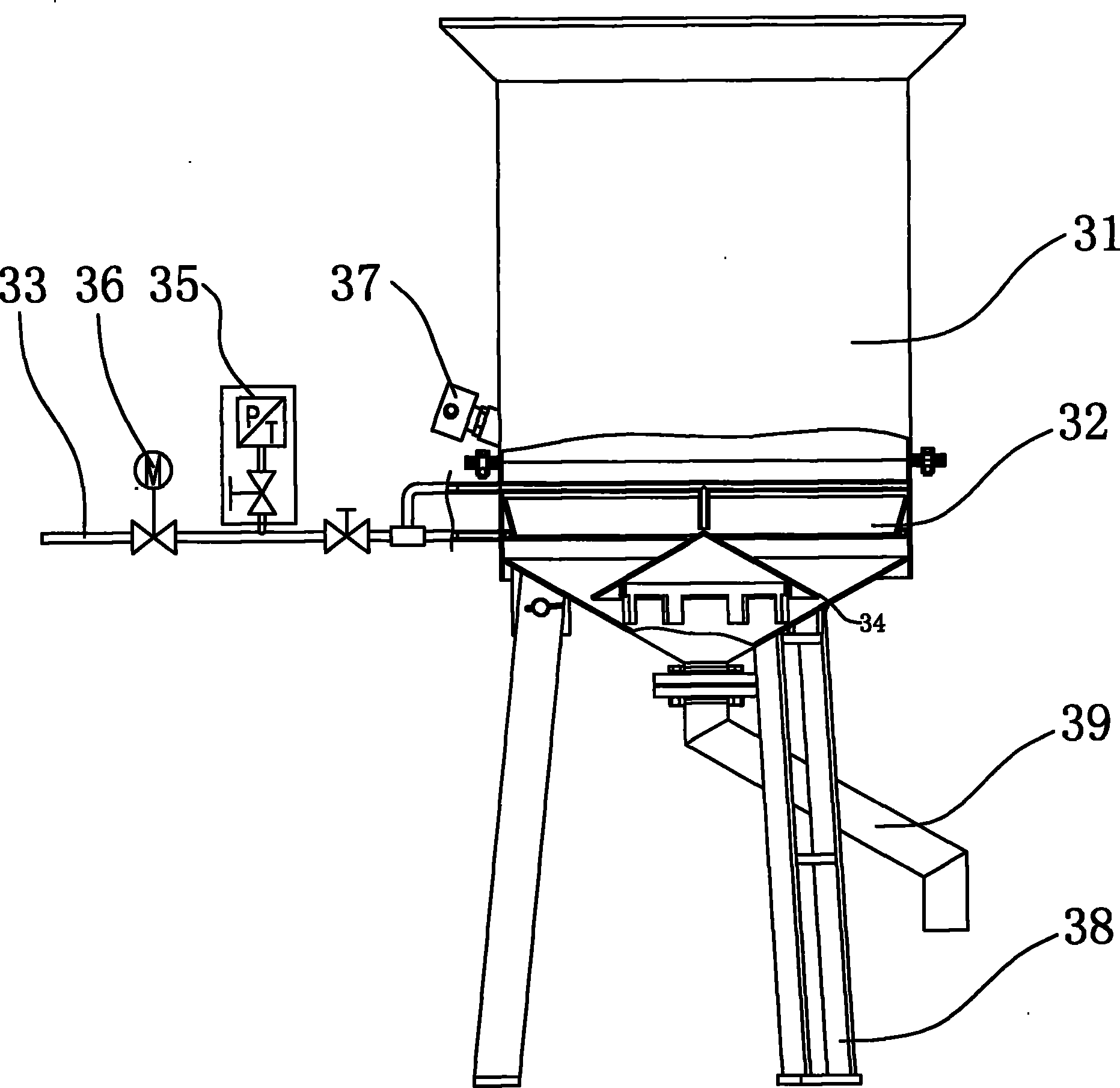

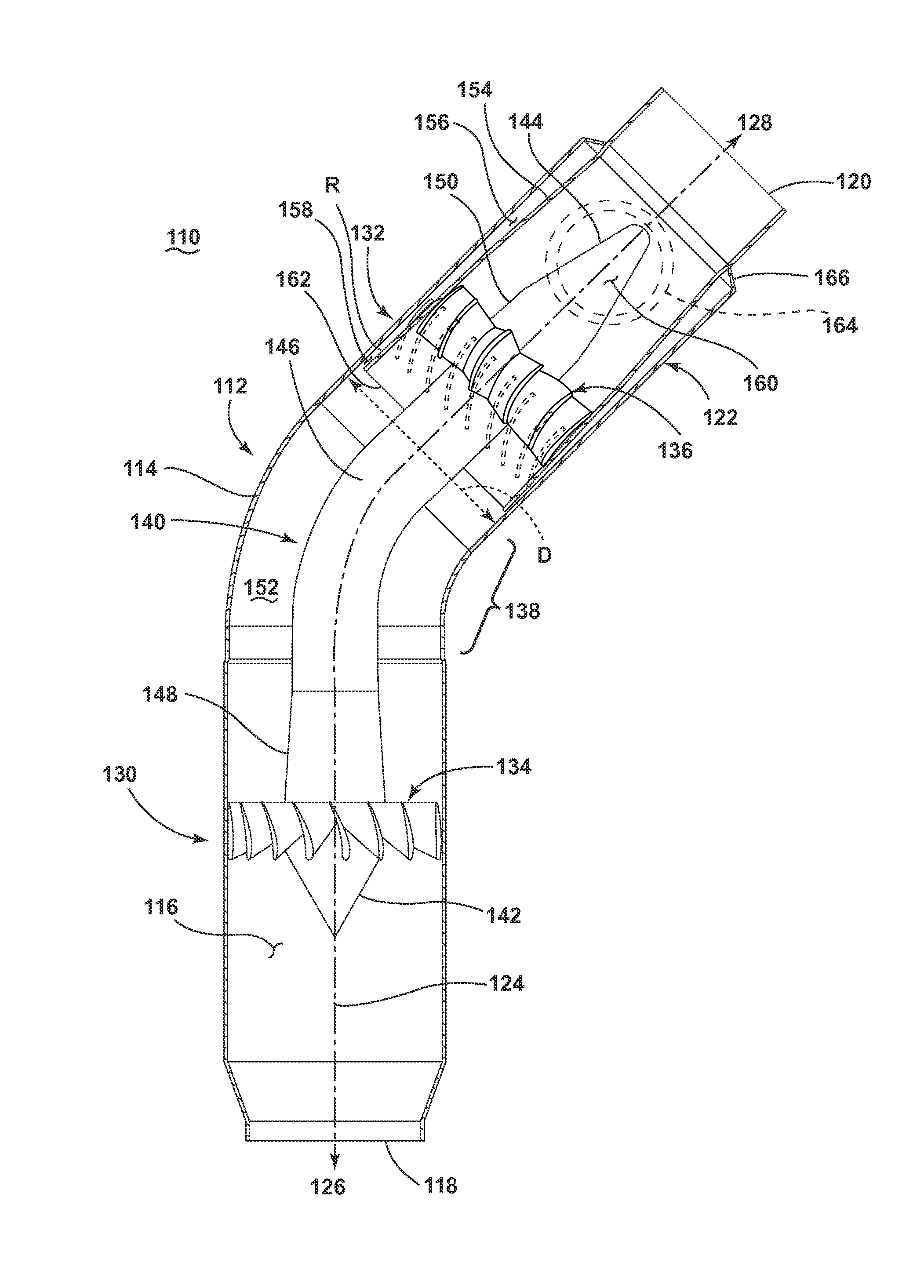

Coal flow splitters and distributor devices

A flow splitter for distributing solid particles flowing in a fluid through a piping system includes a divider housing. The divider housing has an inlet configured to connect to an upstream pipe and has a plurality of outlets, each outlet being configured to connect to a respective downstream pipe. A divider body is mounted within the divider housing. A plurality of divider vanes are included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow to each outlet.

Owner:BABCOCK POWER SERVICES

Adjustable flow control elements for balancing pulverized coal flow at coal pipe splitter junctions

InactiveUS6789488B2Lower Level RequirementsImprove combustion efficiencyFuel feeding arrangementsPulverulent fuel combustion burnersCombined usePollutant emissions

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of flow control elements (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each flow control element preferably comprises a rounded convex edge leading to straight tapered sides (FIG. 9). The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers (FIG. 9). In addition, conventional fixed or variable orifices may be used in combination with the flow control elements for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air. The combination of the riffler assembly and the coal flow control elements (60) results in closely balanced coal flow. Balanced coal flow is imperative to the optimization of the operation of pulverized coal boiler systems (i.e. reduced pollutant emissions, improved combustion efficiency).

Owner:LEVY EDWARD KENNETH +2

Left ofloxacin and Pidotimod compound preparation tech and its appts.

Tea leaves is used as raw material, by using water or solvent, to extract tea-polyphenol, then settle, centrifugal separation, column absorbing, extracting by ethyl acetate, vacuum concentrating, drying to obtain crude tea-polyphenol. Said crude product is then dissolved in water, absorbed by resin column, washed-off by agent gradient adding-in, based-on standard flowing curve to obtain 7 monomer catechins with purity>99%. For this purpose, full automatic absorbing resin column is equiped with metering pump to adjust fed-in of water, solution and solvent, HPLC real-time monitoring and pick-correcting to washing-off liquid is achieved by proportional flow-splitter. Automatic back-wash and resin-exchanging are achieved by being equiped with over-flow hole, resin discharging hole and others.

Owner:胡绍海

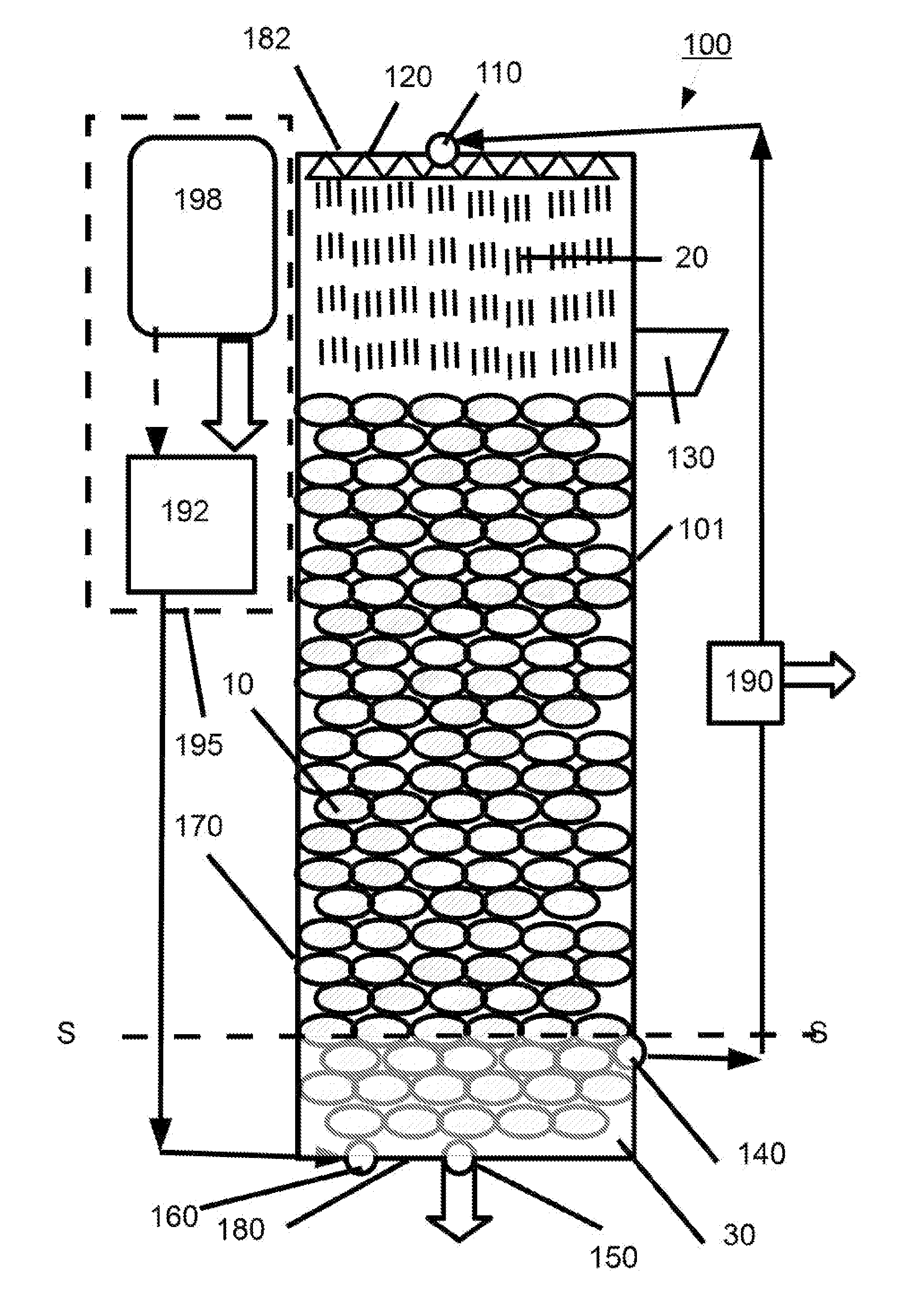

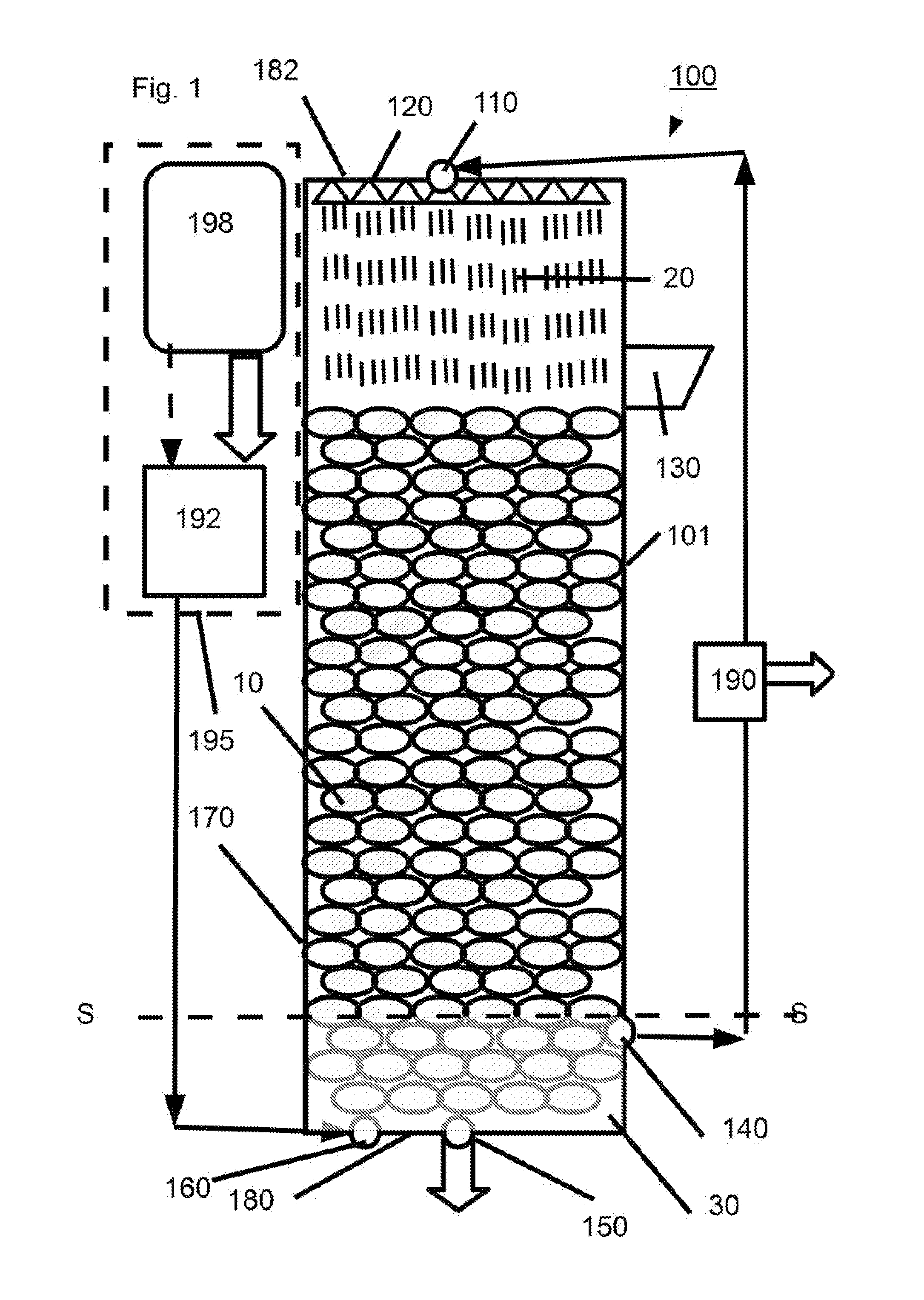

Hydrolysis systems and methods

InactiveUS20120227733A1Residence timeIncrease sugar productionPressurized chemical processChemical/physical/physico-chemical processesHydrolysisFlow splitter

A hydrolysis system comprising: (a) a reactor vessel including a sprinkler at an upper portion thereof and a drain; (b) a pump re-circulating a flow of an acidic reaction liquid from a selected height in said vessel to said sprinkler; (c) an acid supply mechanism delivering a supply of HCl at a concentration≧39% to a lower portion of said reactor vessel; and (d) a flow splitter diverting a portion of the acidic reaction liquid so that a level of liquid in the vessel remains in a predetermined range.

Owner:VIRIDA

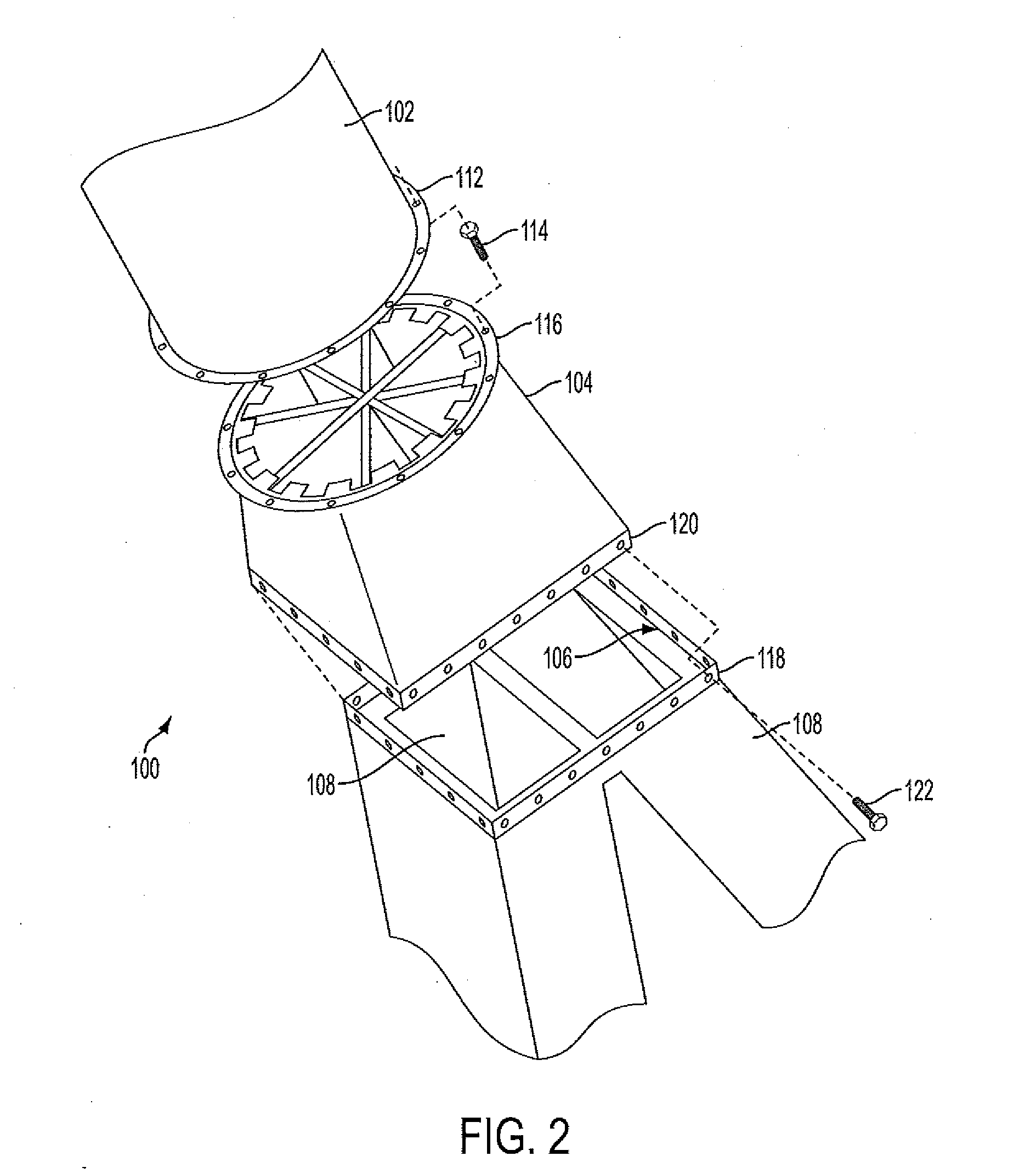

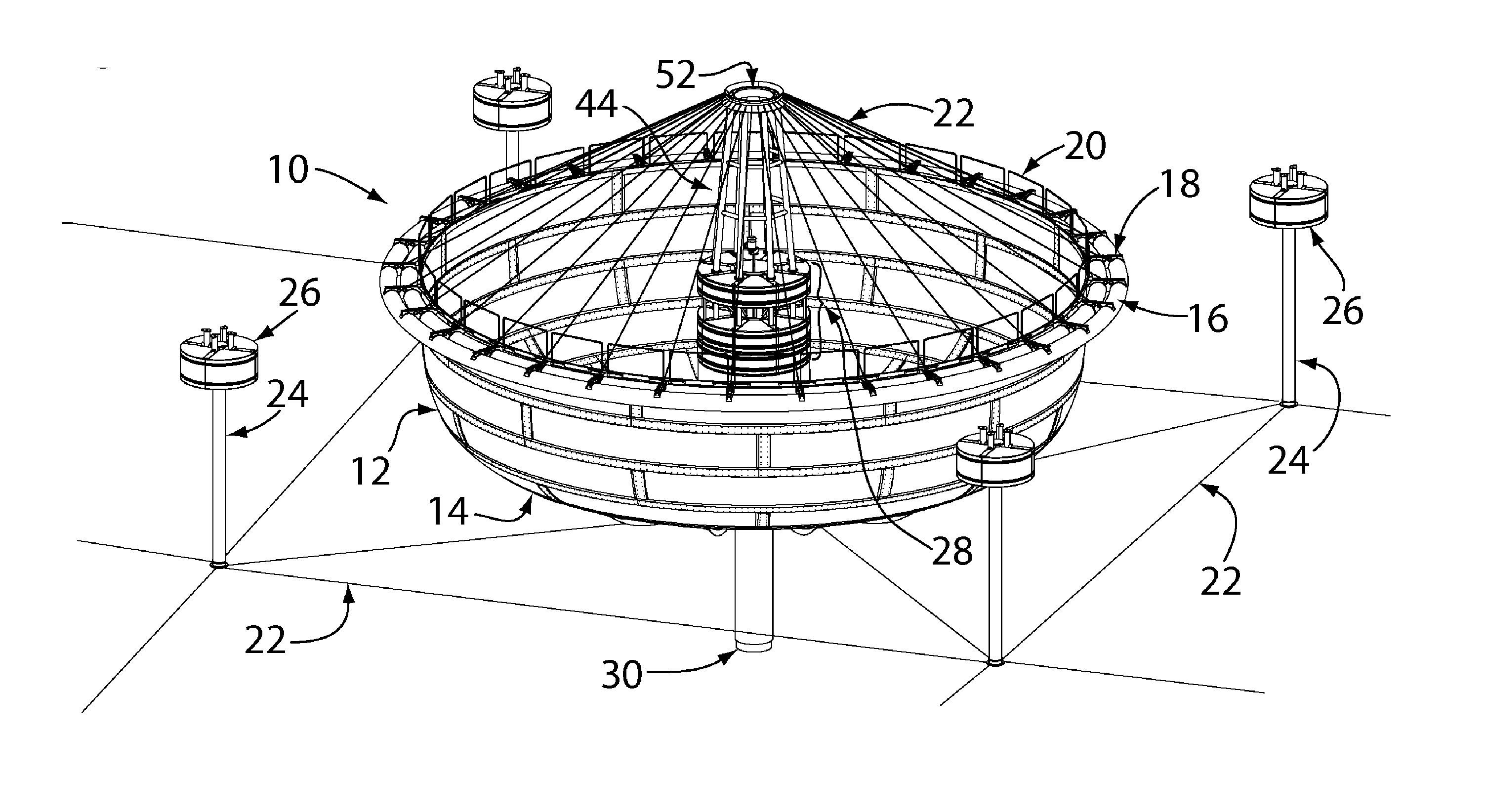

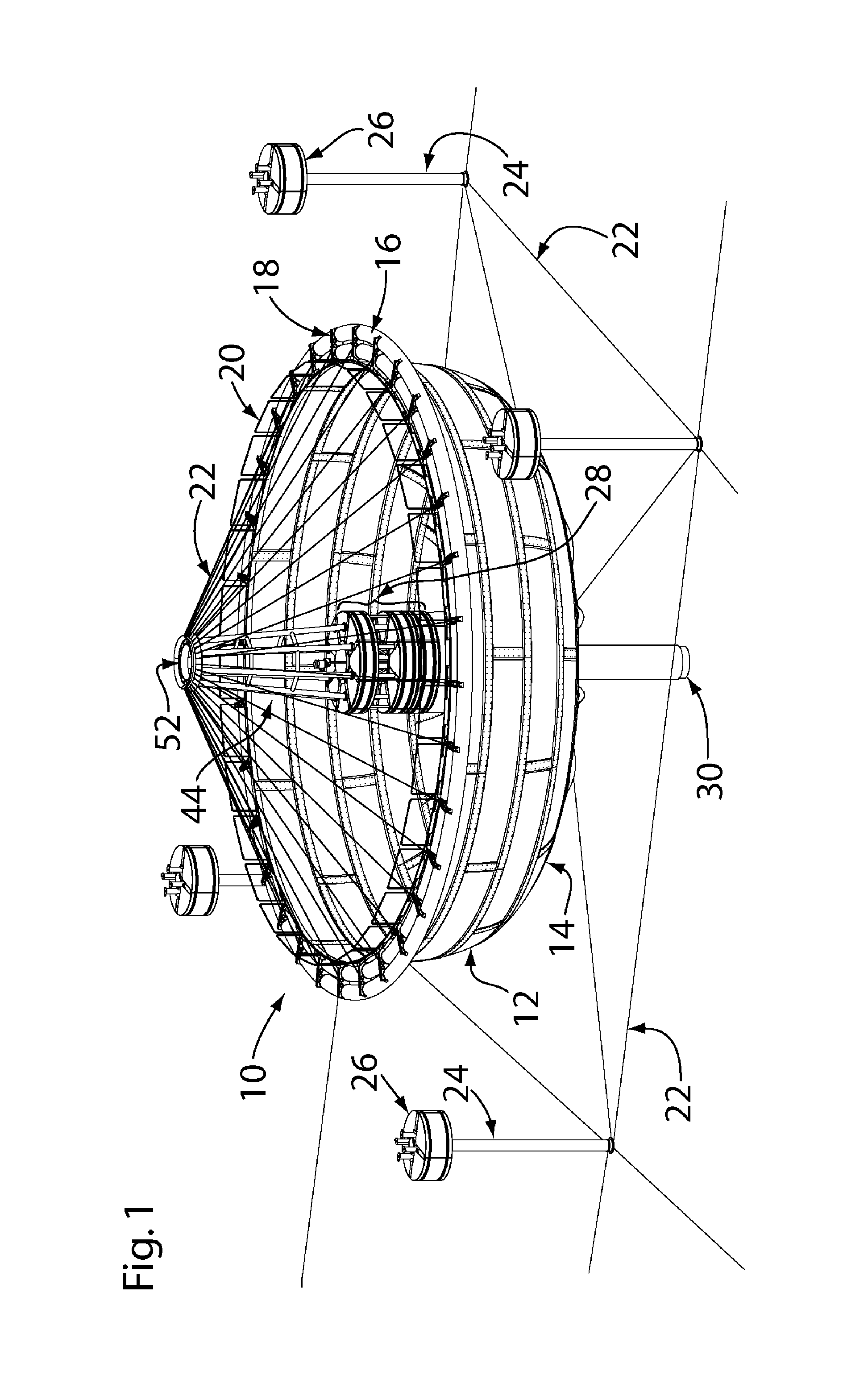

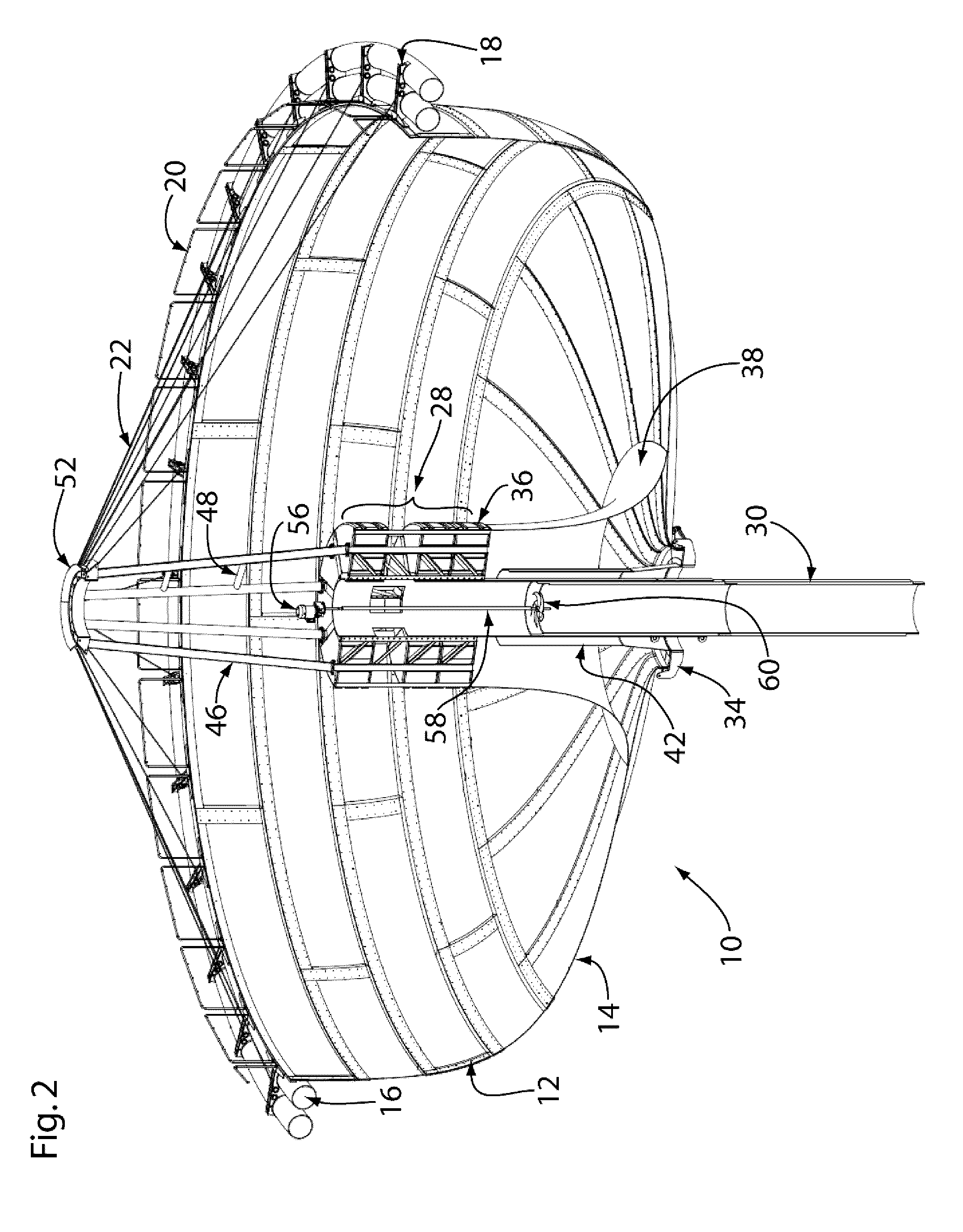

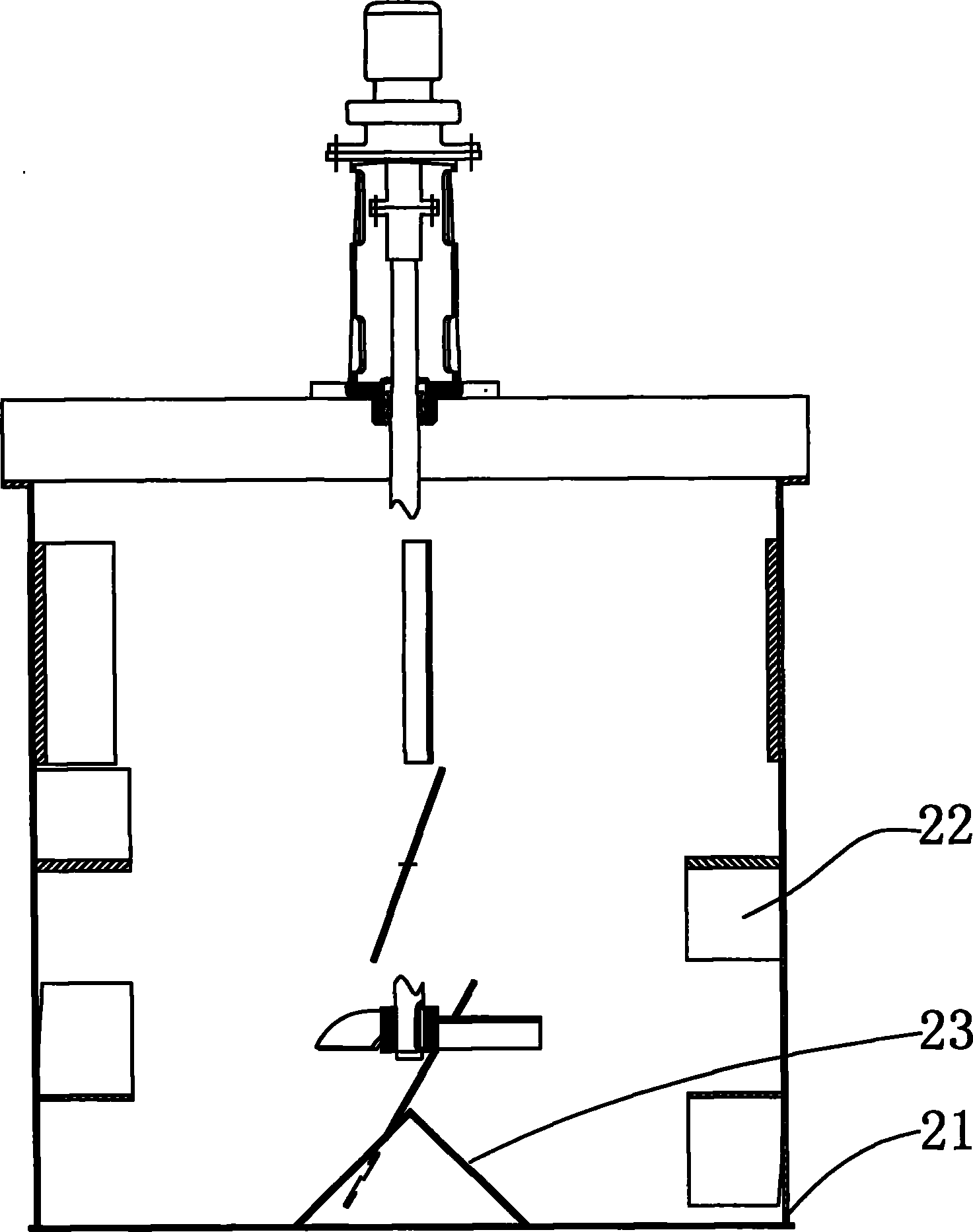

Aquaculture rearing enclosure and circulation induction system

ActiveUS20150150223A1WithstandRobust designClimate change adaptationPisciculture and aquariaPipeflowWater flow

A system for efficiently circulating water in a large volume of rearing space for aquatic organisms, comprising an impervious enclosure for containing the water and aquatic organisms and a pump for pumping water from an intake duct through intake ducting to a flow diverter, which then directs a flow of water radially outward within the enclosure to directly induce a circulation of water within the enclosure. The ‘center drive’ circulation pattern is sufficiently uniform to provide optimum rearing conditions for cultured finfish, while also ensuring that solid wastes are swept toward the central drain, even in a very large tank.

Owner:AGRIMARINE HLDG INC

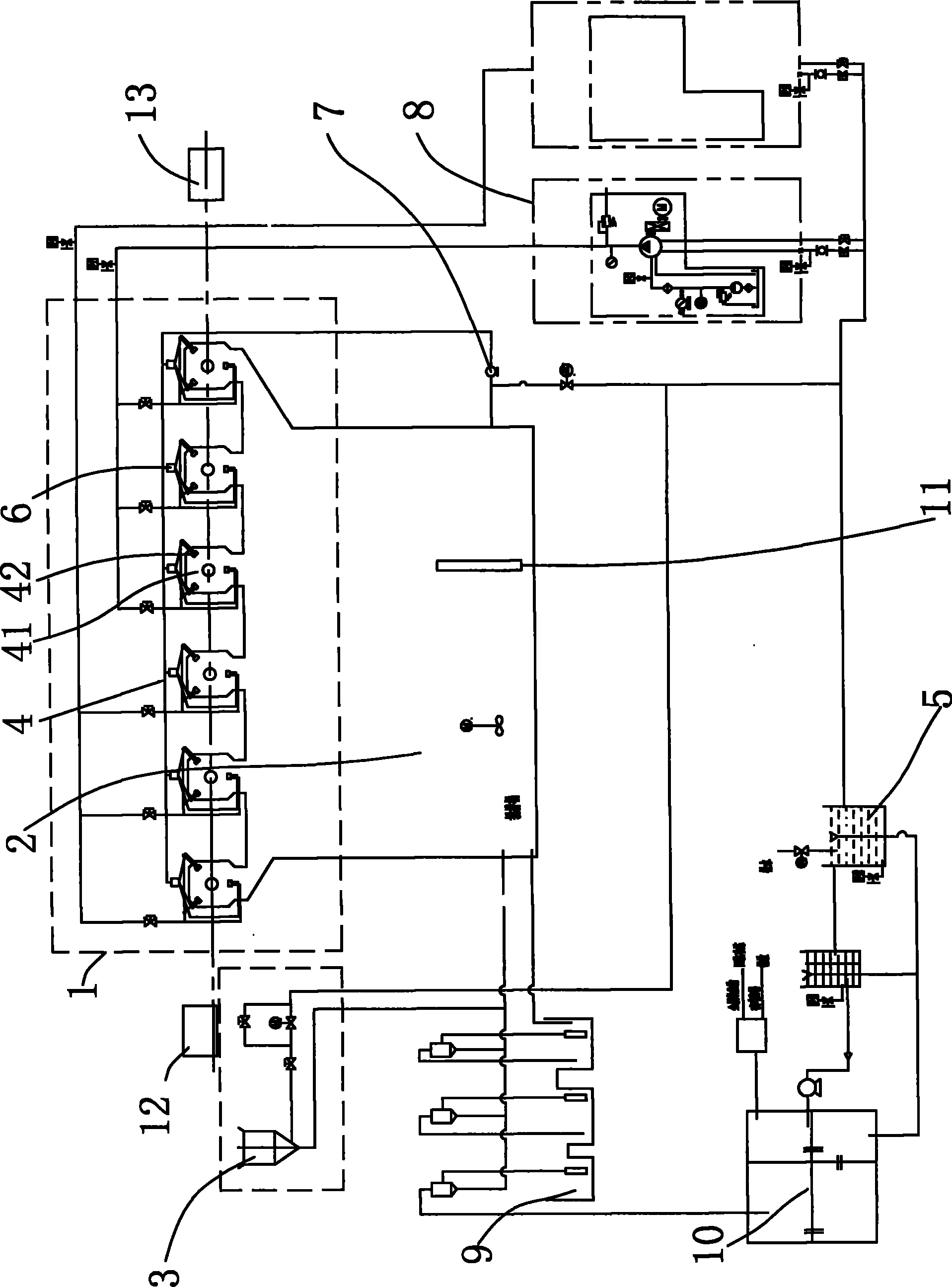

Method and equipment for removing scale on metal wires or metal bars by grinding material water jet

The invention discloses a method for removing scale on metal wires or metal bars by grinding material water jet, which comprises the following steps: 1) preparing a grinding material by mixing sand and water in a preset proportion; 2) pumping the prepared grinding material into a splitter by a mortar pump and then allowing the prepared grinding material to enter a jetting cavity; and simultaneously, pressurizing the water by a high-pressure pump to change the water into high-pressure water and convey the water into the jetting cavity, and impacting the grinding materials by taking the high-pressure water as motive power to remove scale through jetting. Special scale removal equipment provided by the method comprises a mixing tank positioned below a scale removal box, an automatic fluidifying and sanding-up device for sanding up sand to the mixing tank, a jetting device and a water box, and also comprises a sand separator positioned in the scale removal box, a high-pressure pump for generating the high-pressure water and the mortar pump for conveying the grinding materials to the sand separator. The grinding materials are impacted by taking high-pressure water as the motive power to remove the scale on the metal wires or the metal bars, and the method and the equipment have the advantages of improving the working efficiency effectively, relieving the labor strength of workers, along with quick cleaning speed, difficult blocking of sprayers, good scale removal effect, no damage to metal matrixes and no environmental pollution.

Owner:HUNAN NONFERROUS HEAVY MACHINERY

Coal flow splitters and distributor devices

A flow splitter for distributing solid particles flowing in a fluid through a piping system includes a divider housing. The divider housing has an inlet configured to connect to an upstream pipe and has a plurality of outlets, each outlet being configured to connect to a respective downstream pipe. A divider body is mounted within the divider housing. A plurality of divider vanes are included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow to each outlet.

Owner:BABCOCK POWER SERVICES

Inertial separator

An inertial separator for removing particles from a fluid stream includes a body defining a through passage, with at least one separator inlet and at least one separator outlet, a turn provided in the body between the at least one separator inlet and the at least one separator outlet, and a flow splitter having at least one particle outlet fluidly coupled to the outside of the through passage.

Owner:GENERAL ELECTRIC CO

Stormwater Treatment System with Gutter Pan Flow Diverter

ActiveUS20140367328A1Reduce workloadFatty/oily/floating substances removal devicesSewerage structuresProcess regionWater flow

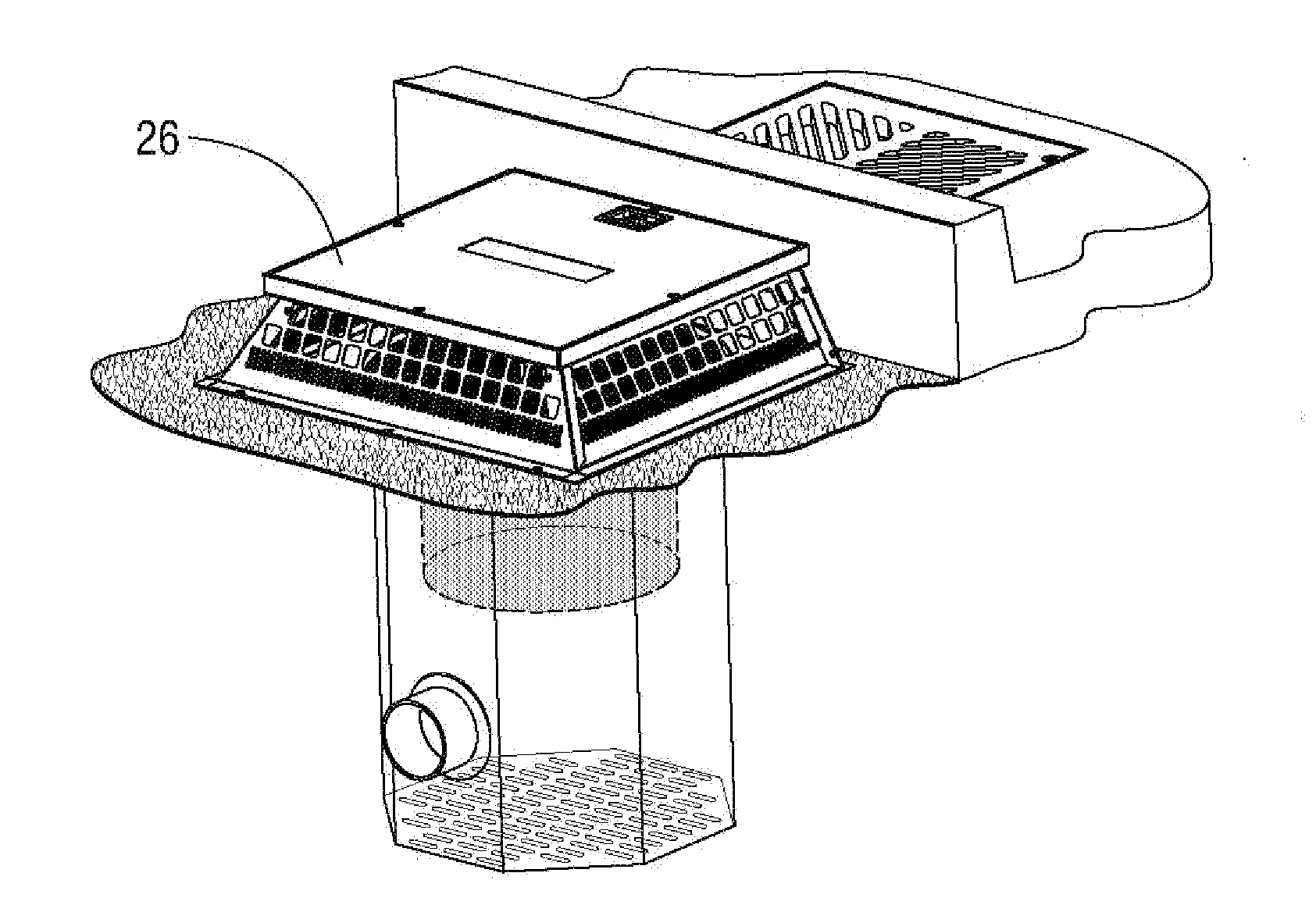

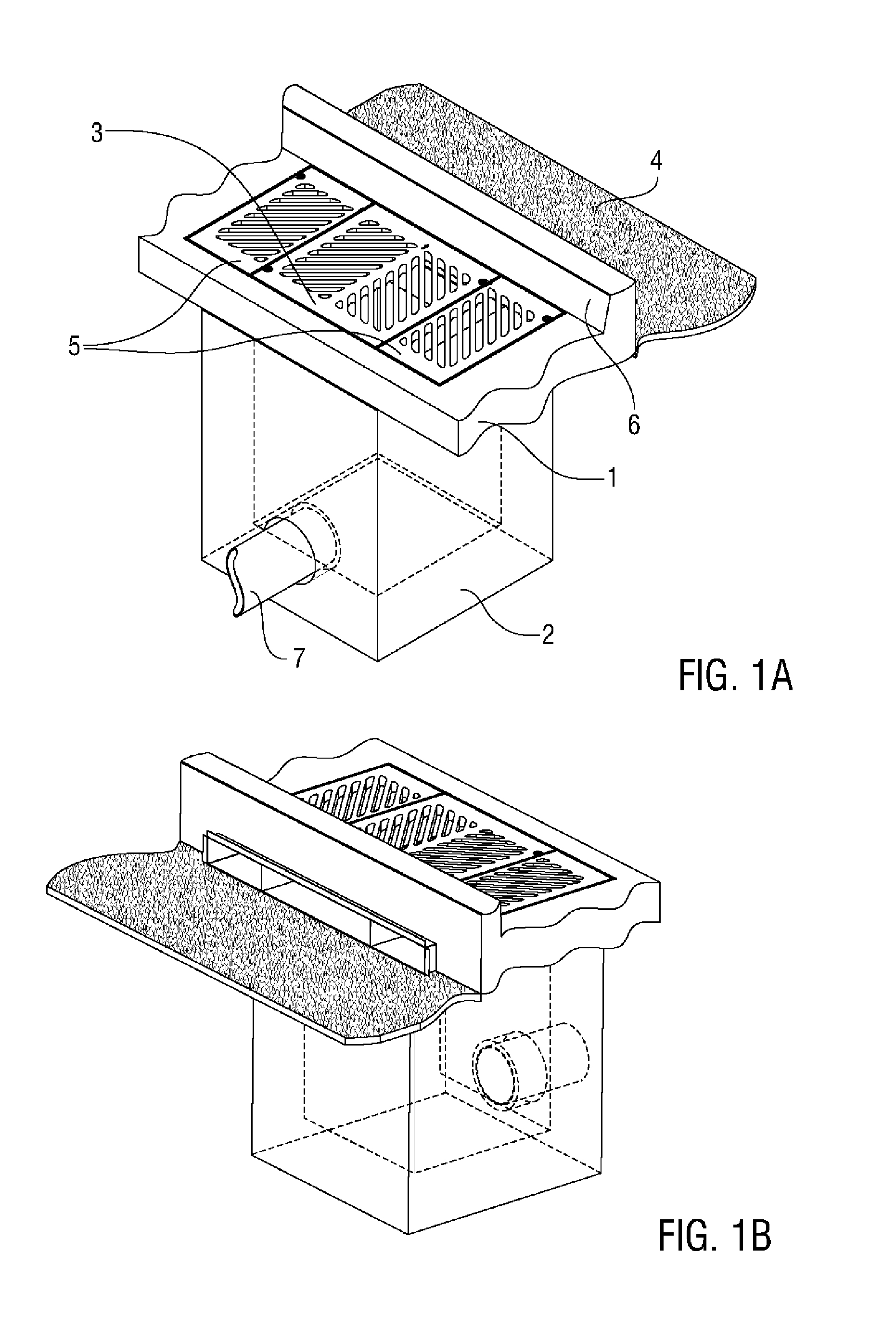

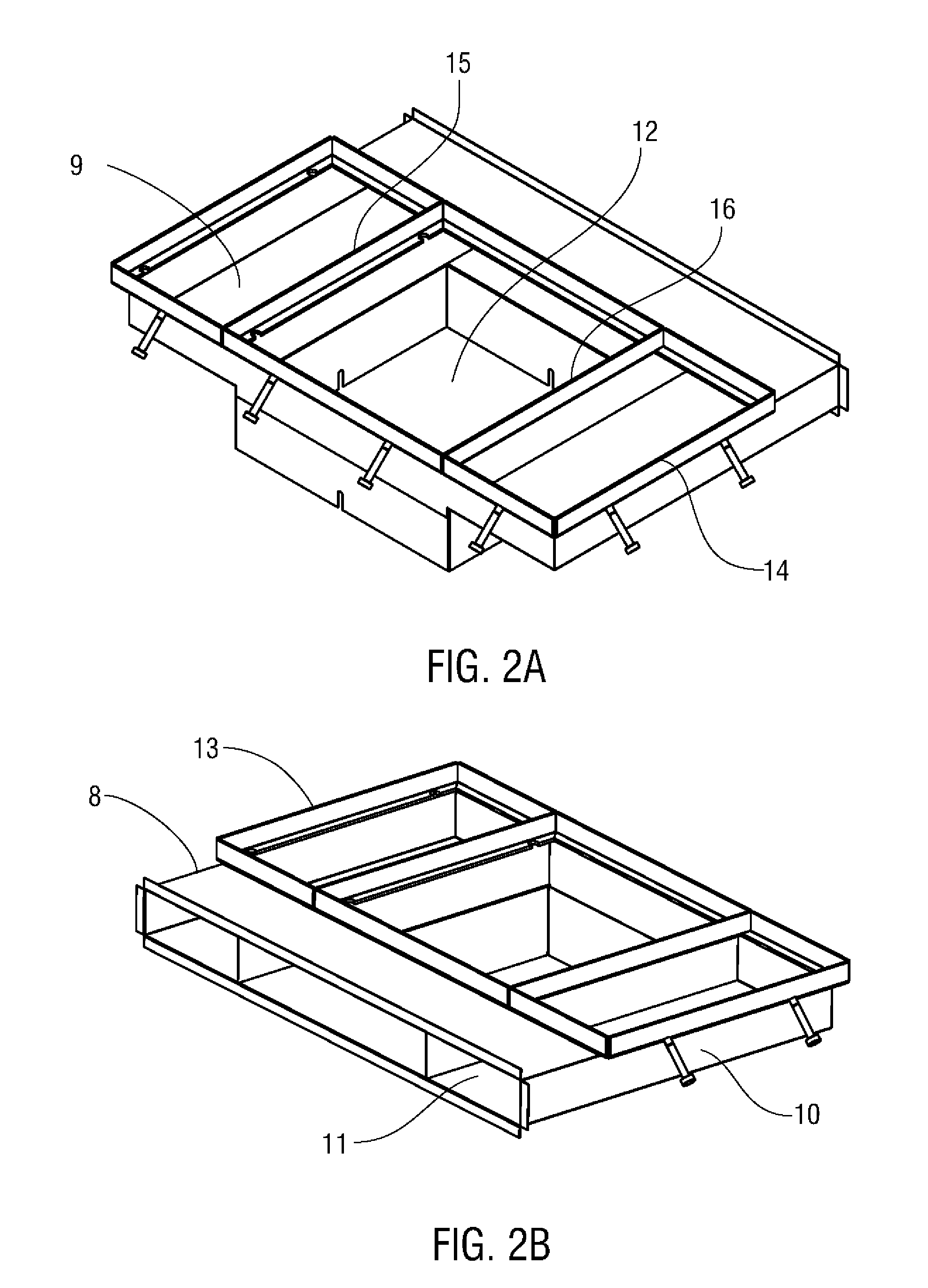

The invention provides structures, methods, and assemblies for processing fluid entering a treatment area. The invention also provides methods, apparatuses, and additional structures that are useful for managing storm water flow and inhibiting the flow of pollutants, debris, and other contaminants into drainage systems. One or more flow diverter pans are installed at one or more inlets of a treatment area, such as a bioretention treatment area or a storm water retention and detention system. The apparatus comprises a structural framework that can include a pan placed adjacent to an inlet of the treatment area, and internal walls extending upward from the floor of the pan and at least partially framing a bypass opening adjacent to the floor. Inlet and outlet openings of the pan define a primary flow route for fluid passing through the pan and to the surface of the treatment area. Inlet and bypass openings of the pan comprise a secondary flow route for fluid passing through the tray.

Owner:OLDCASTLE PRECAST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com