Patents

Literature

1936results about "Pulverulent fuel combustion burners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

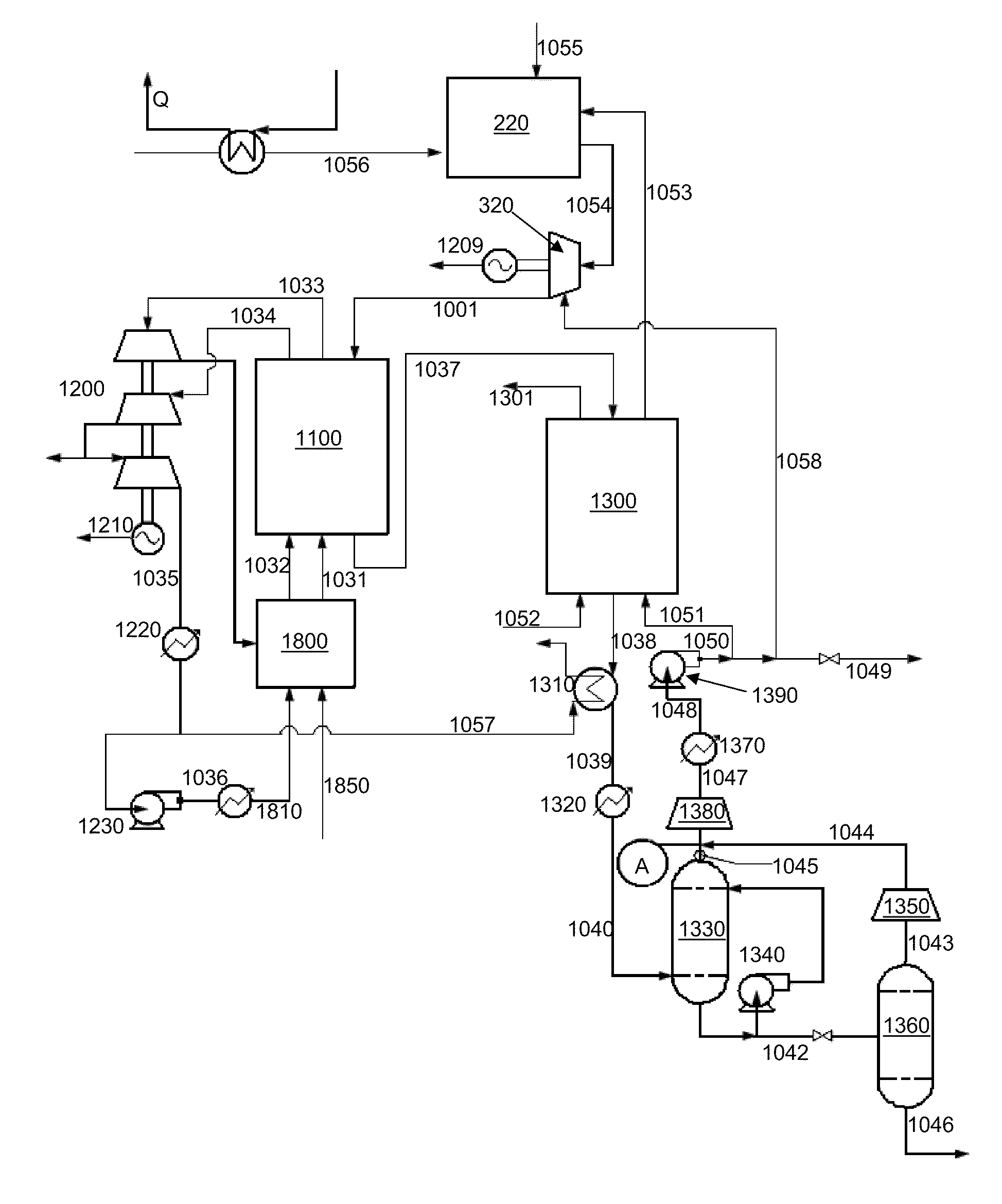

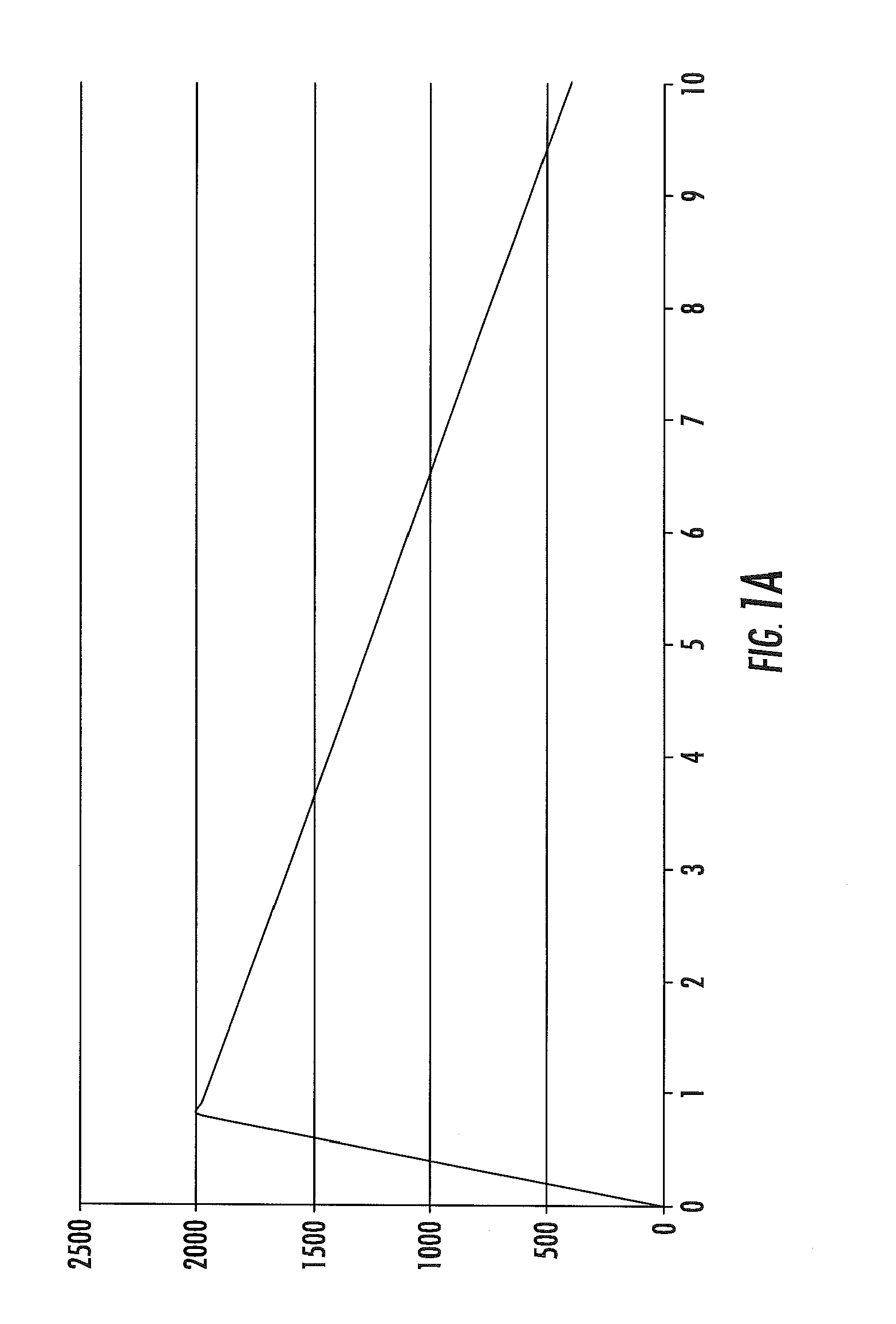

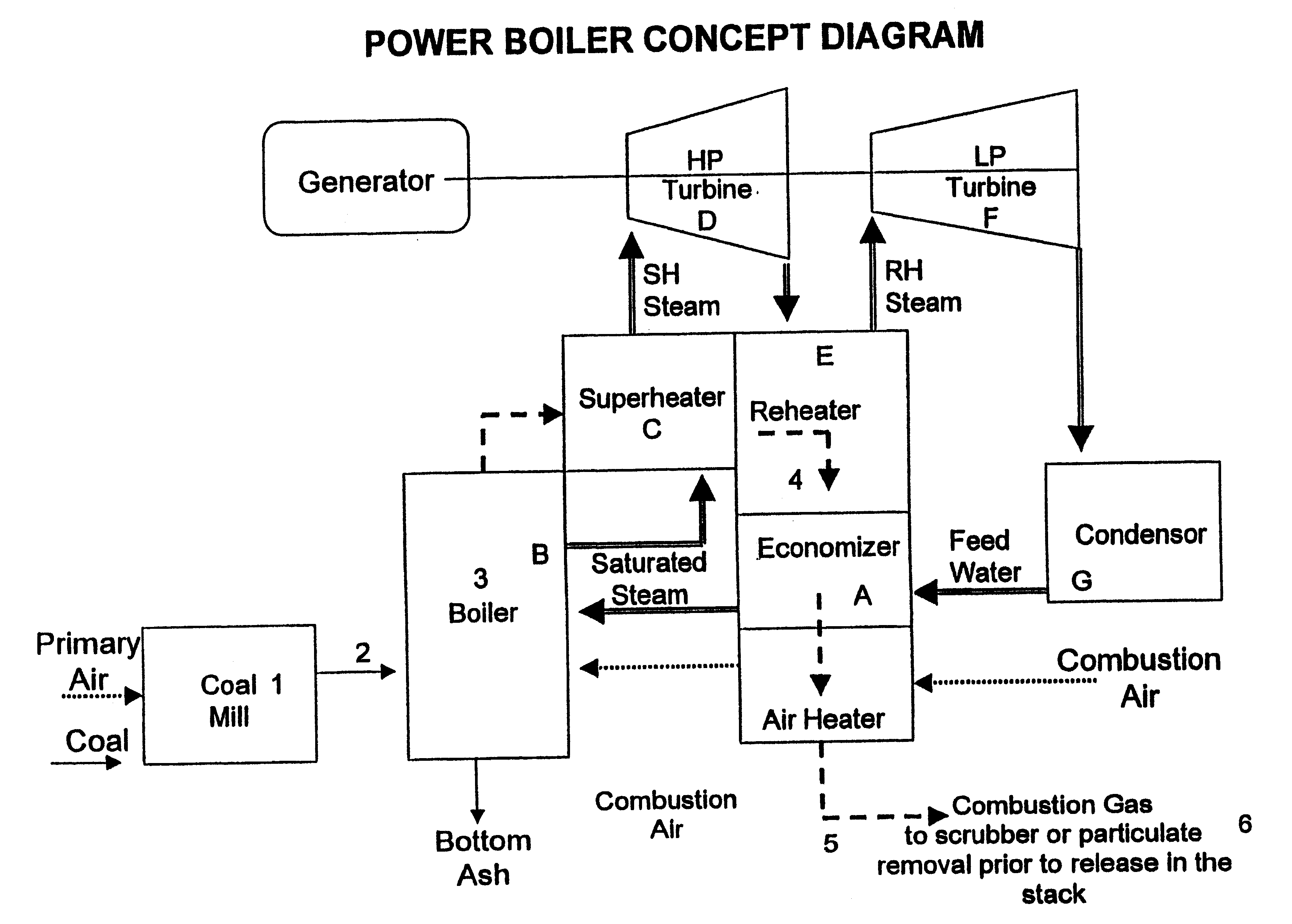

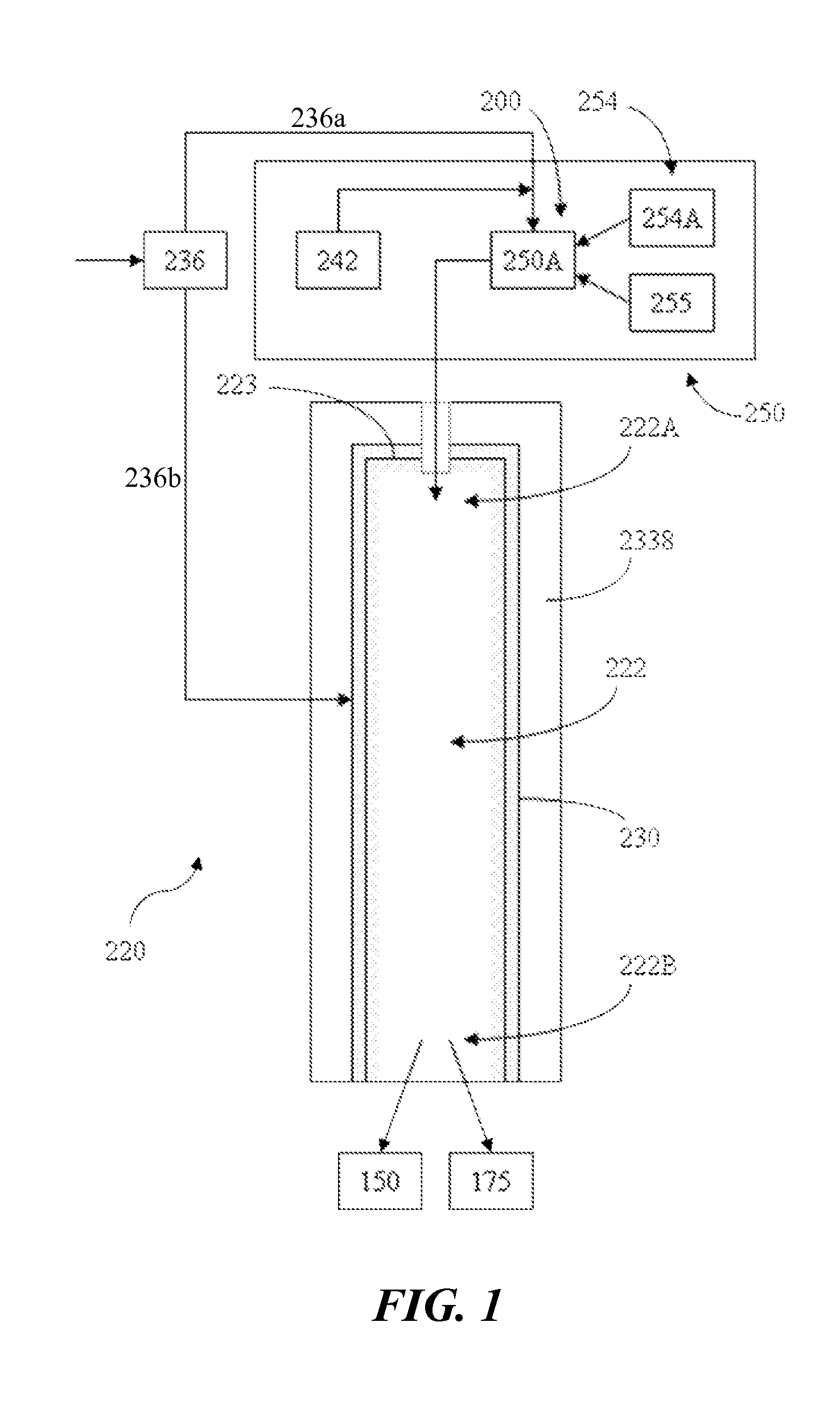

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

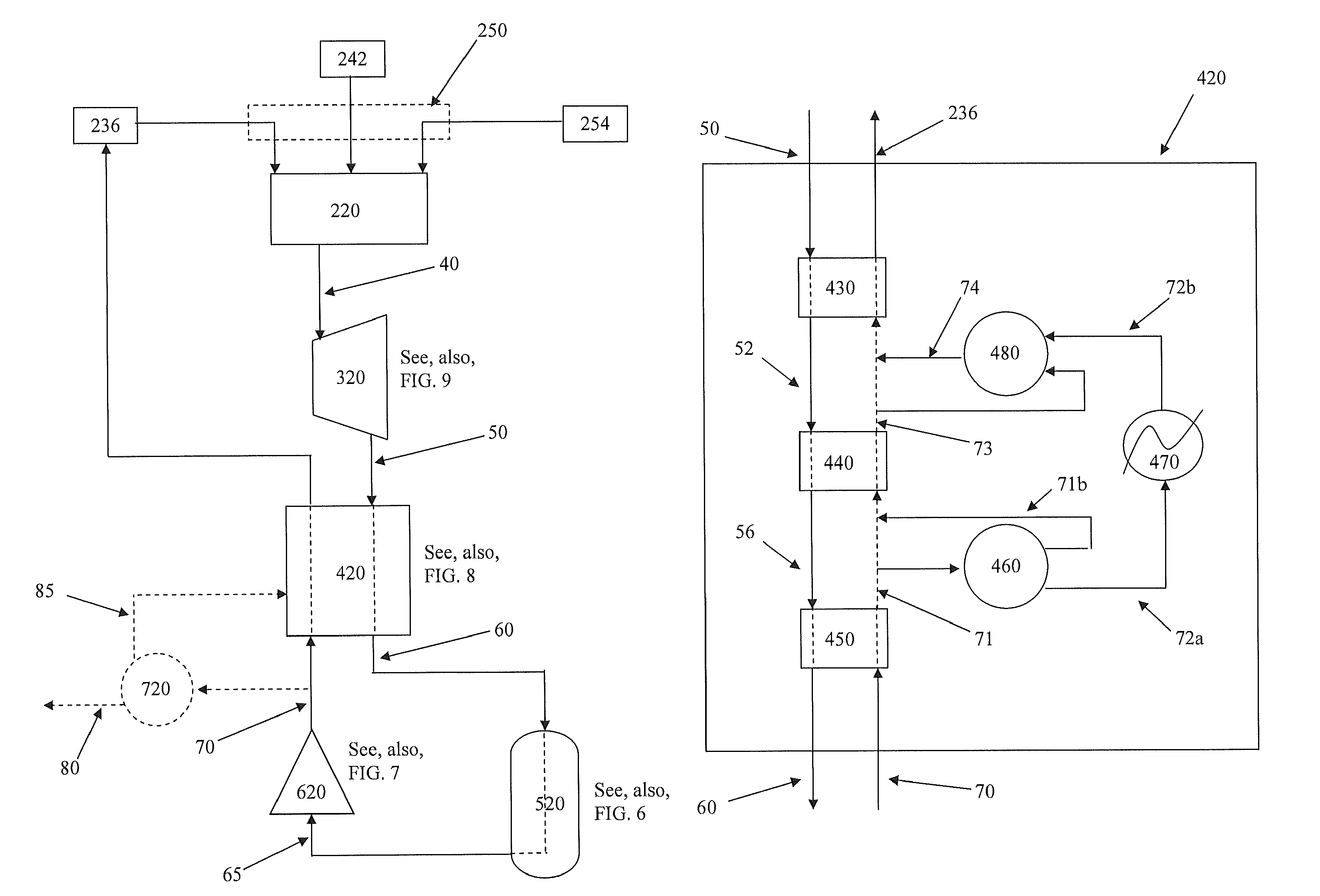

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

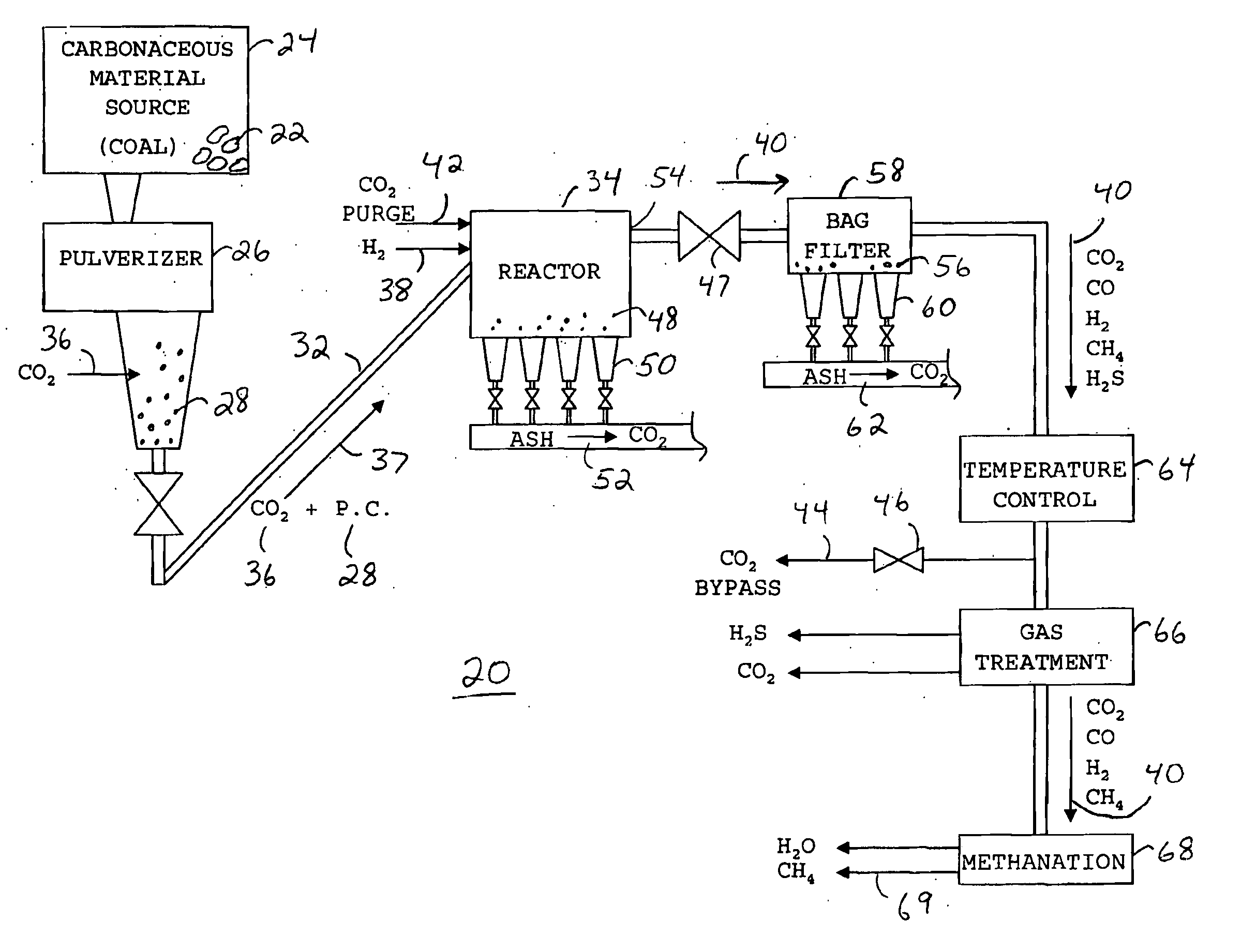

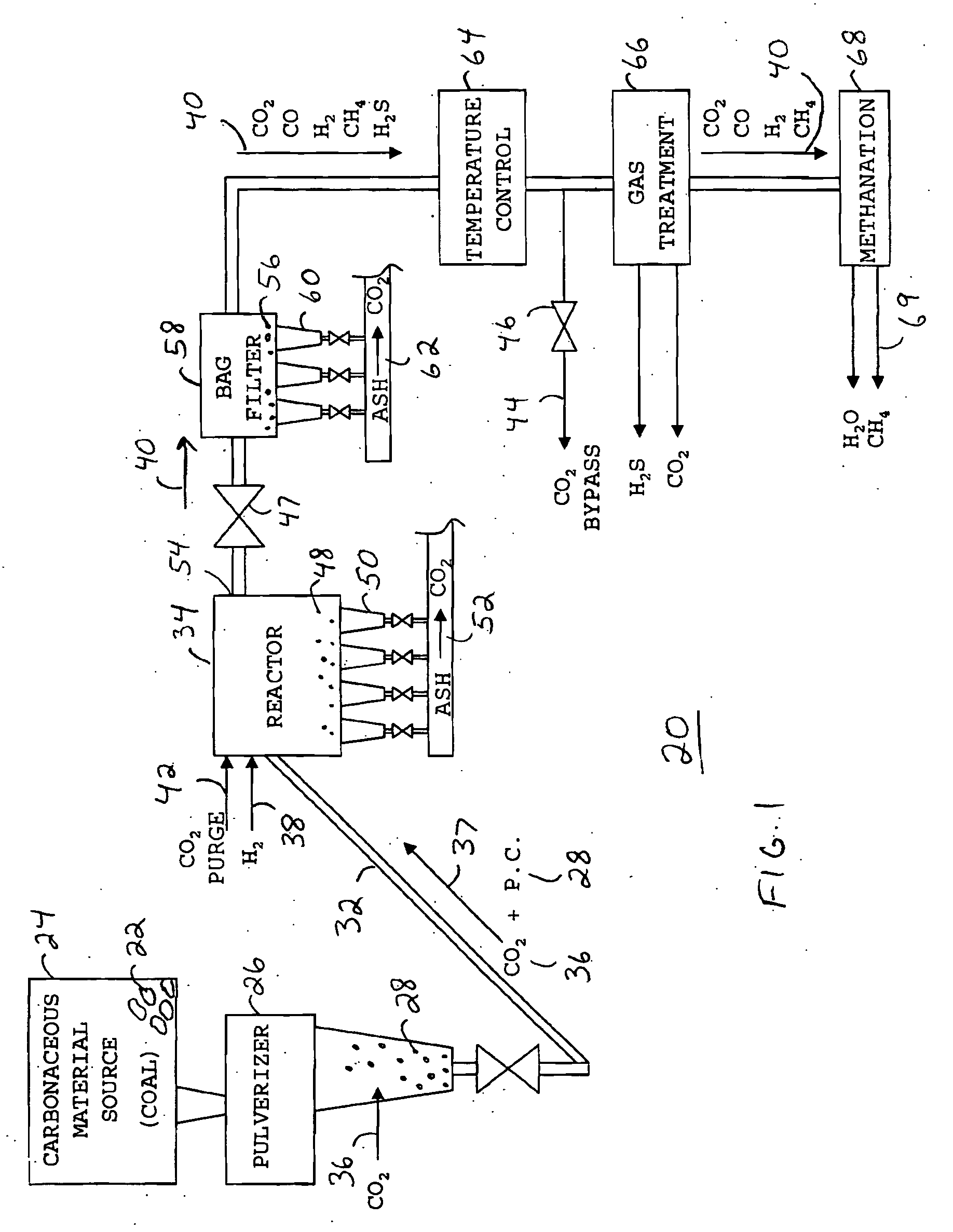

Method and apparatus for producing methane from carbonaceous material

InactiveUS20060265953A1Efficient productionEfficient deliveryHydrogen separationGaseous fuelsHydrogenReaction zone

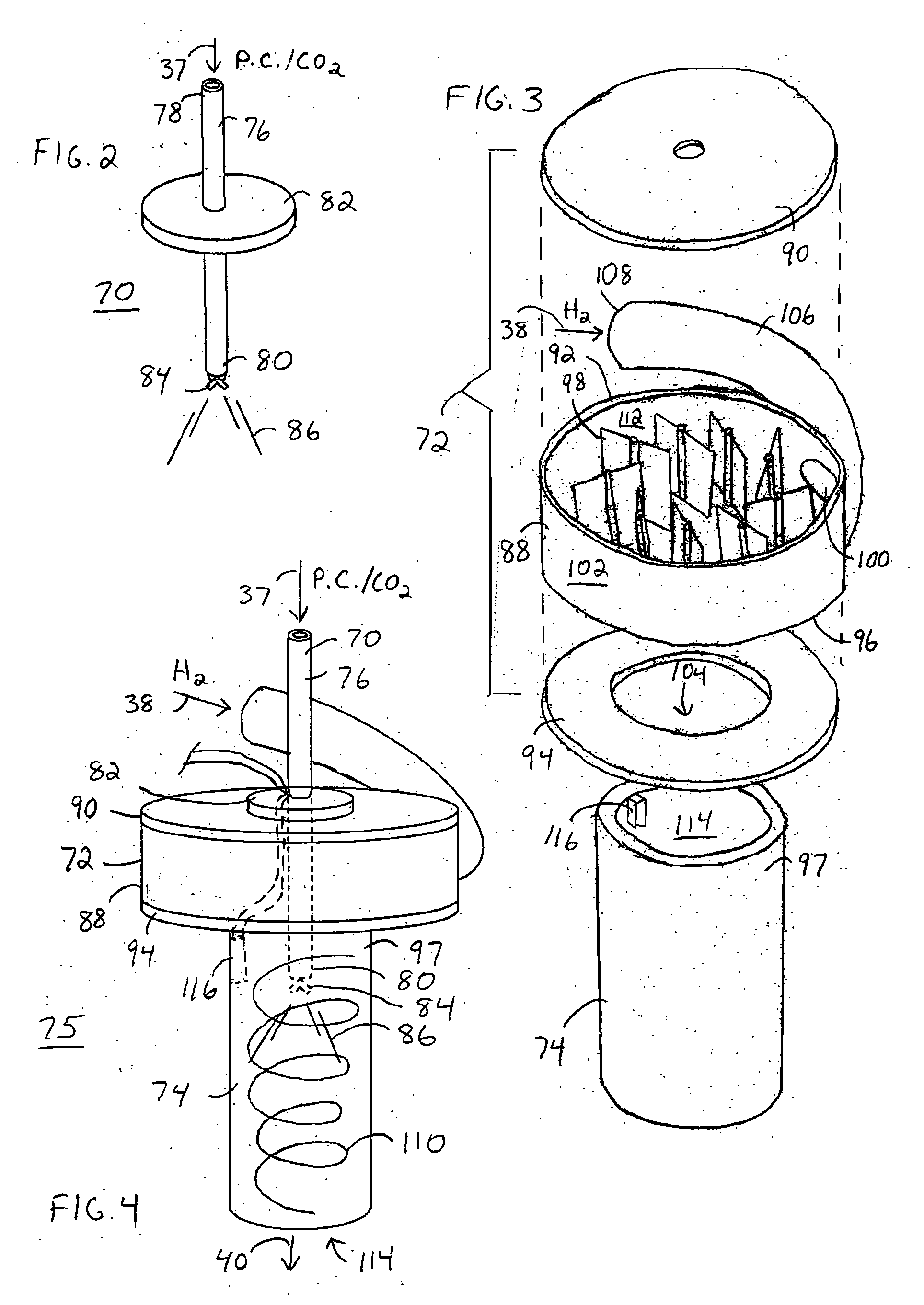

A method for producing methane (69) from a carbonaceous (22) material includes conveying pulverized carbonaceous material (28) entrained in an inert carrier fluid, such as carbon dioxide (36), into a reactor (34). The reactor (34) includes a vortex region (72) for receiving hydrogen gas (38) and imparting a swirling motion to the hydrogen gas (38). The pulverized carbonaceous material (28) is exposed to the swirling stream of hydrogen gas (38) in a first reaction zone (114) within the reactor (34) to form an exit gas (40) that includes methane (69). Remaining unreacted carbonaceous material (28) is further exposed to the hydrogen gas (38) in a second, low velocity, reaction zone (120). The methane rich exit gas (40) is subsequently extracted from the reactor (34) for further processing.

Owner:ARIZONA PUBLIC SERVICE

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

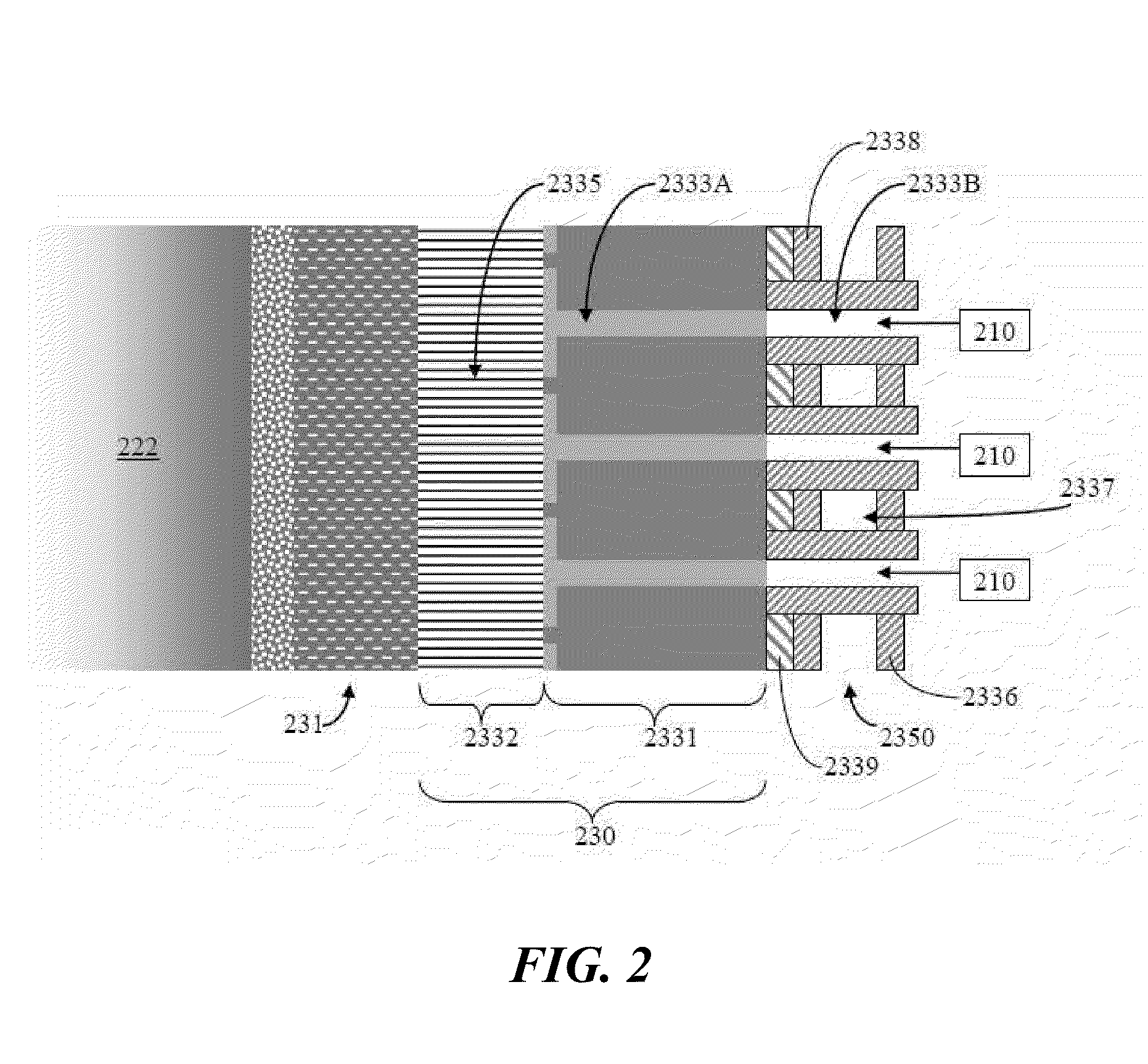

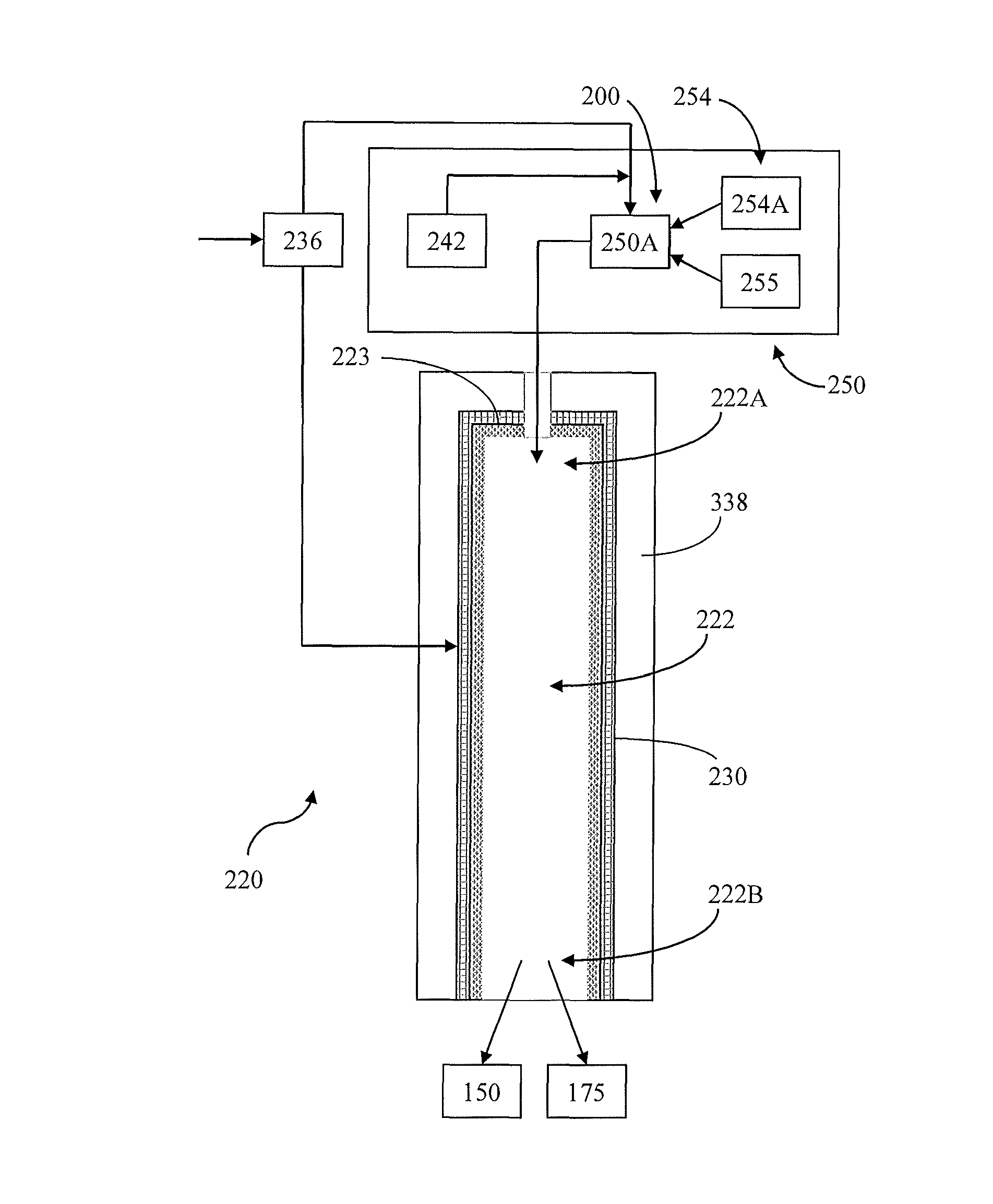

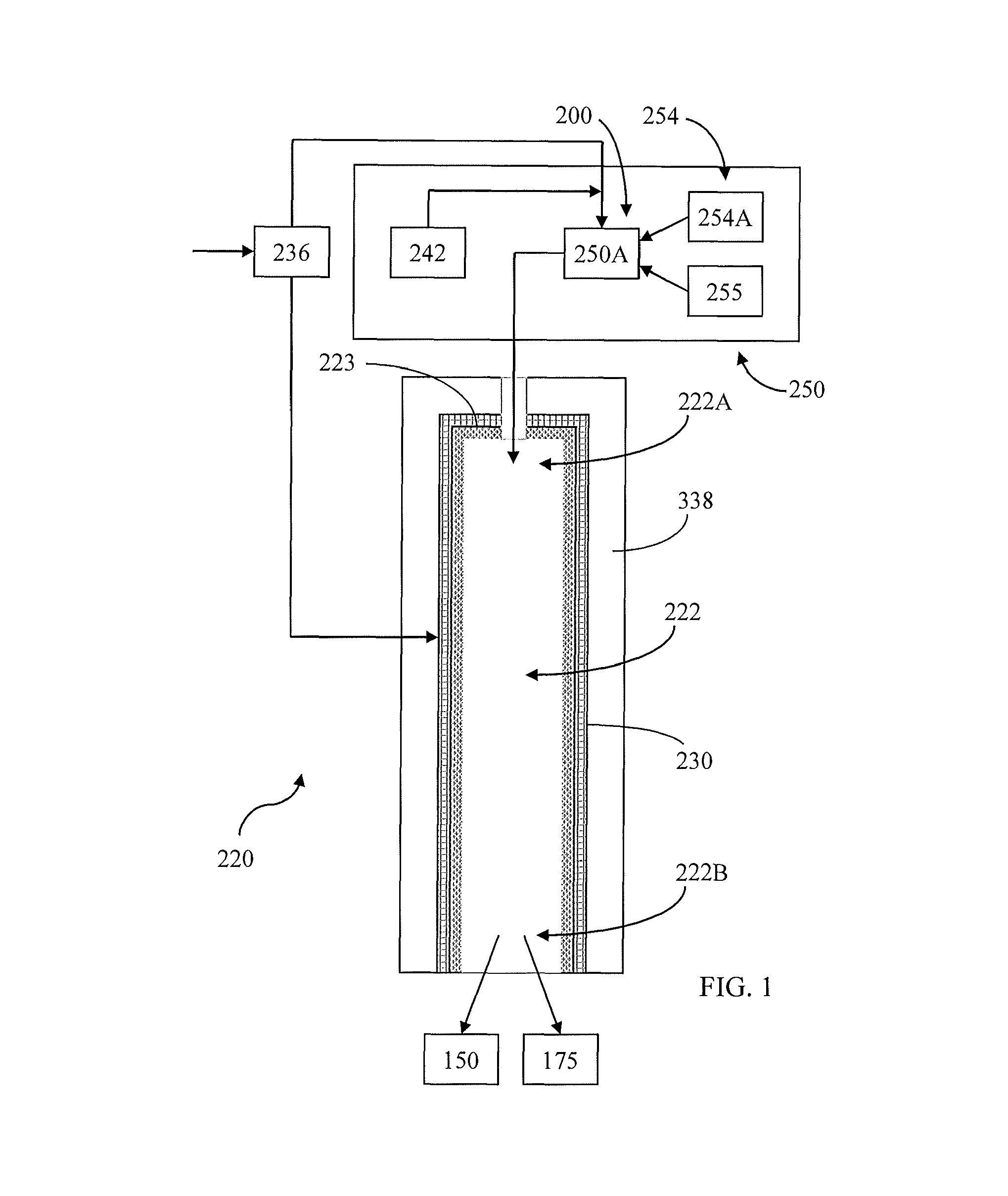

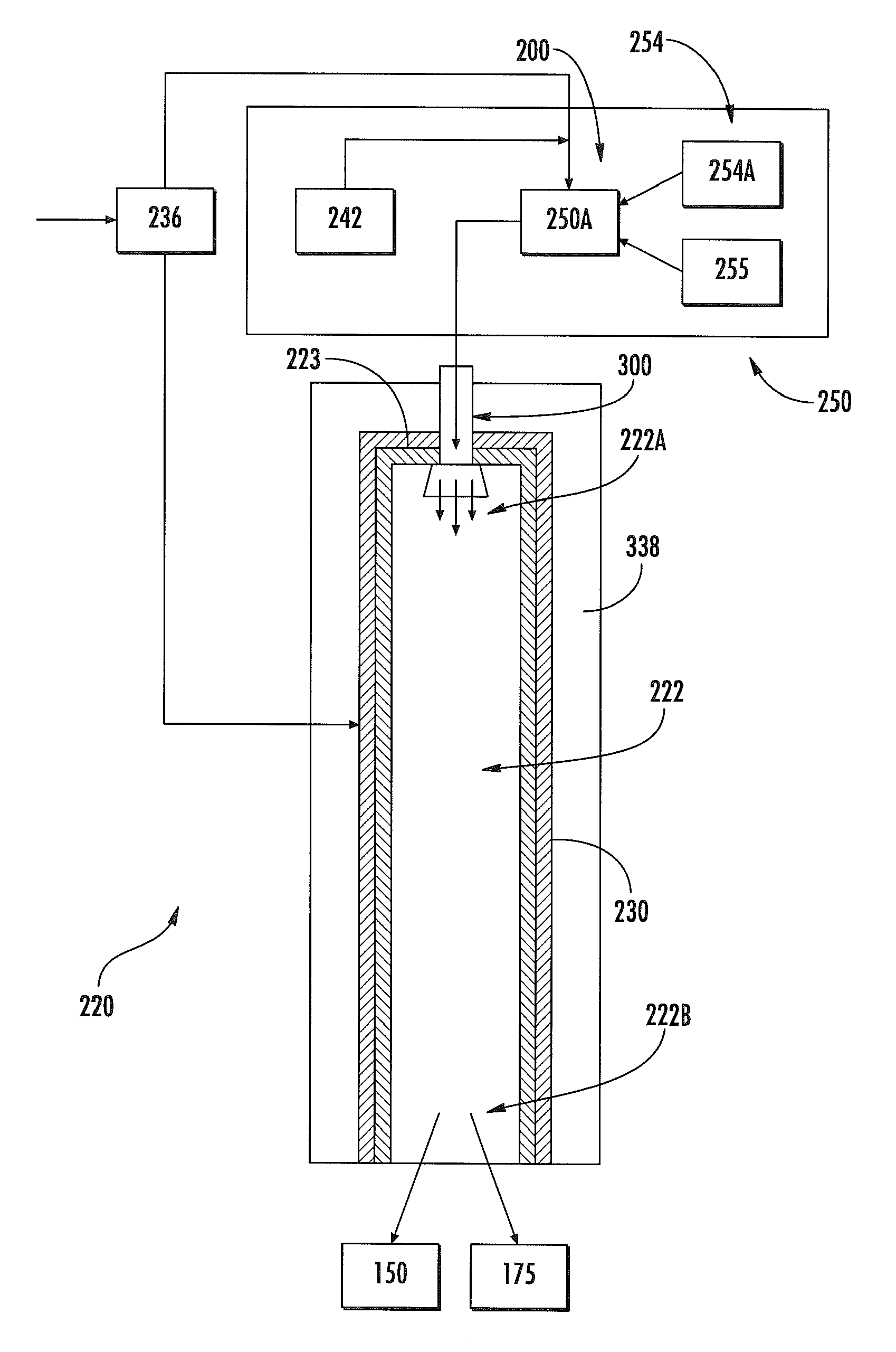

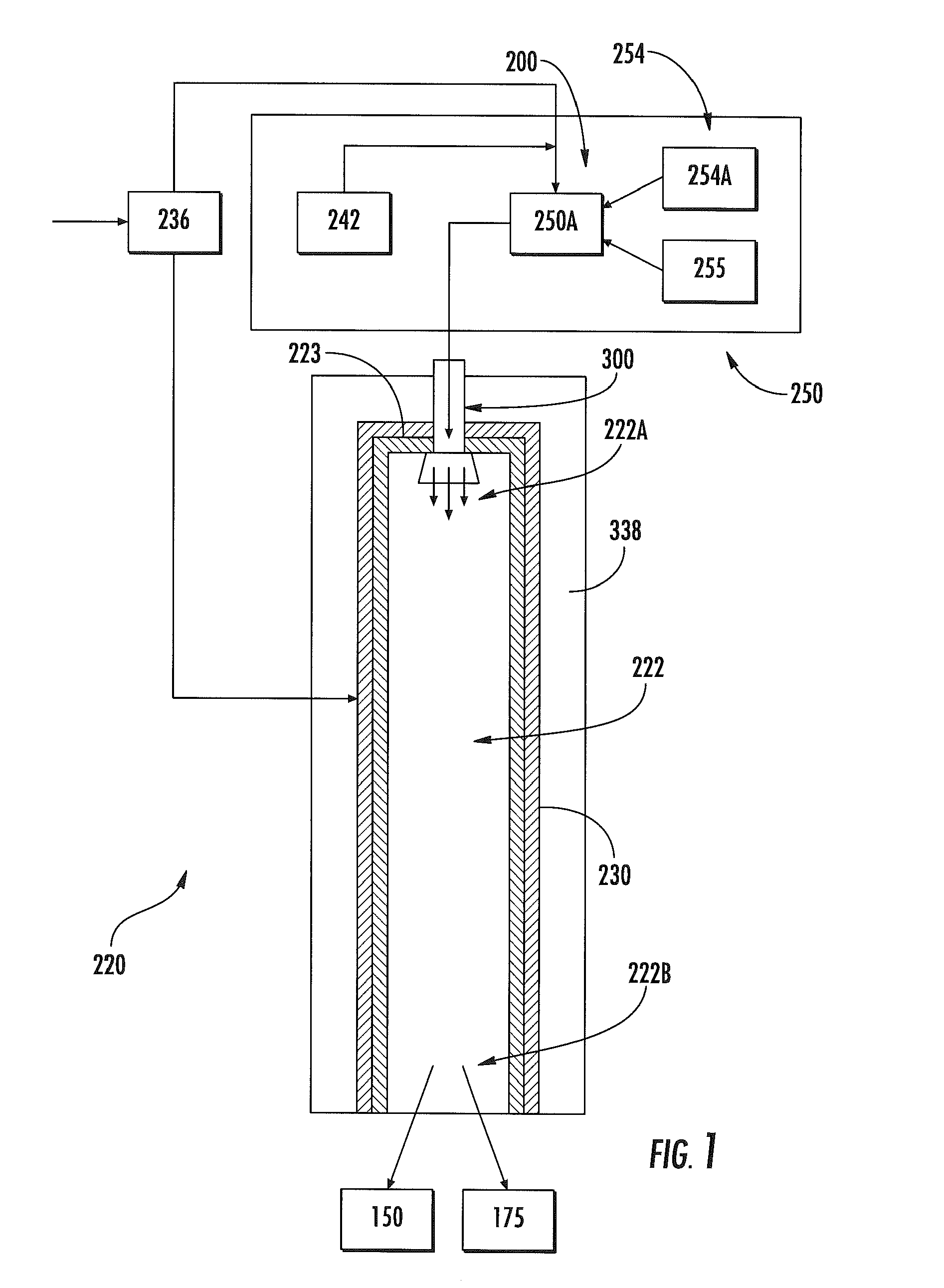

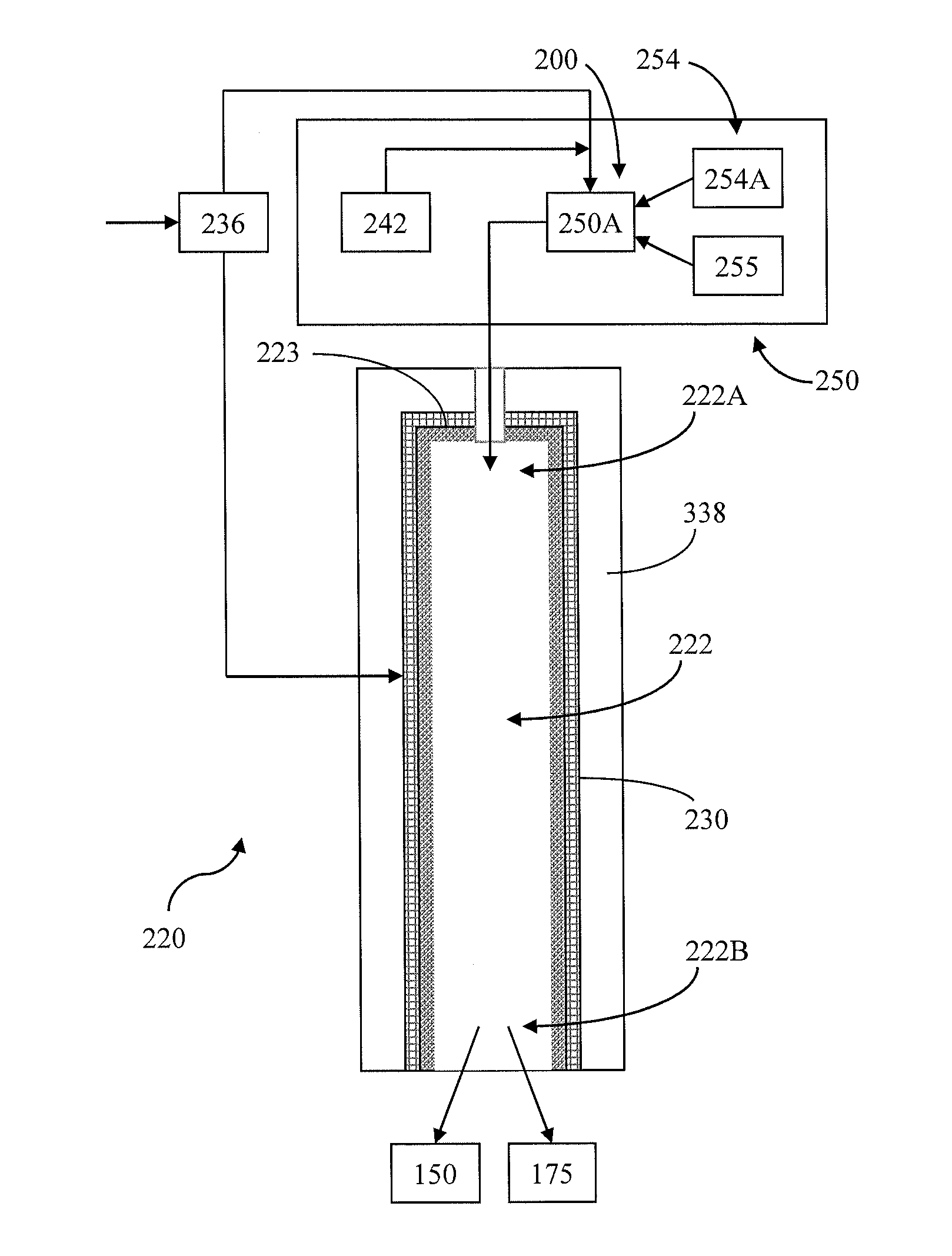

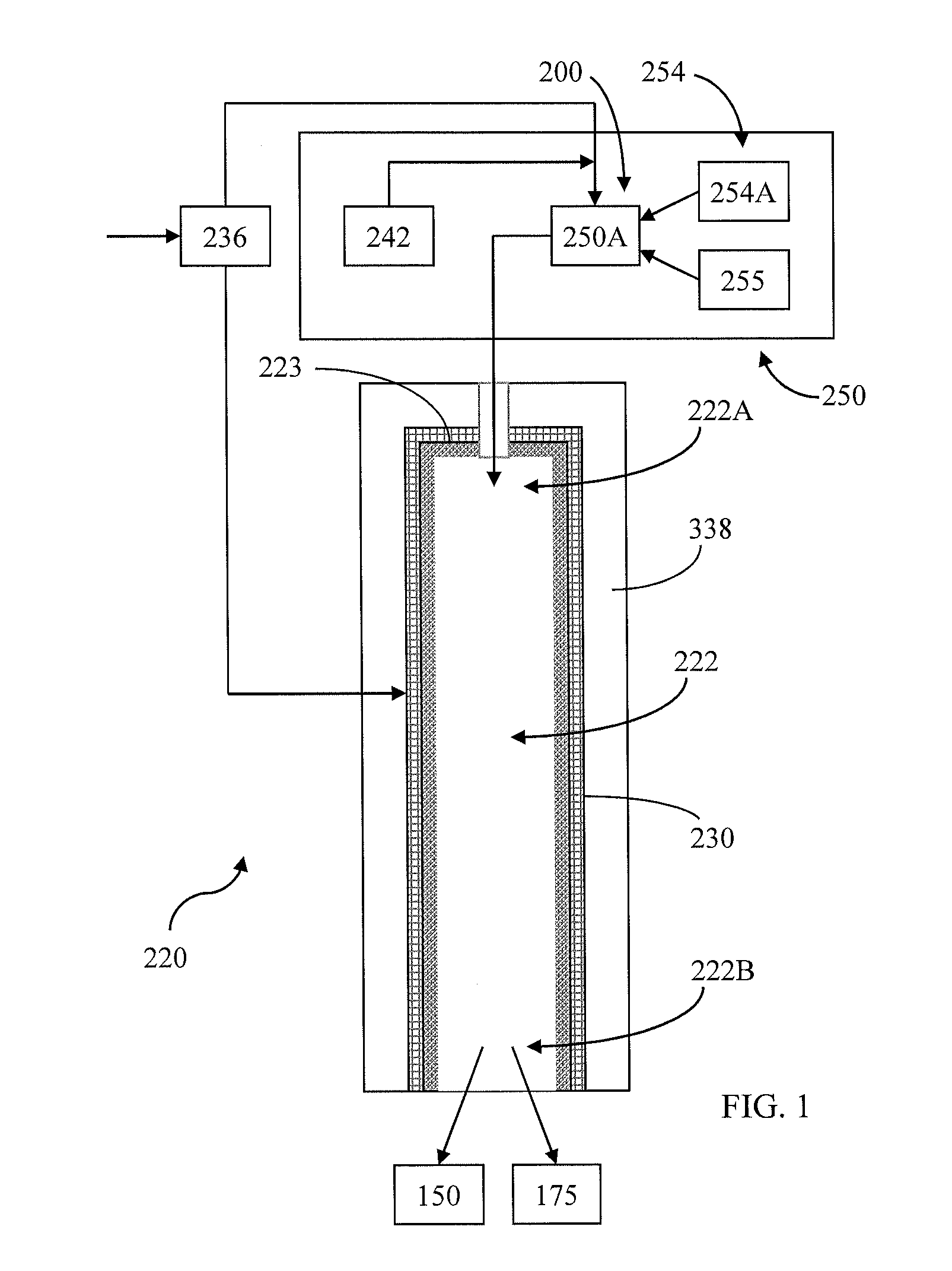

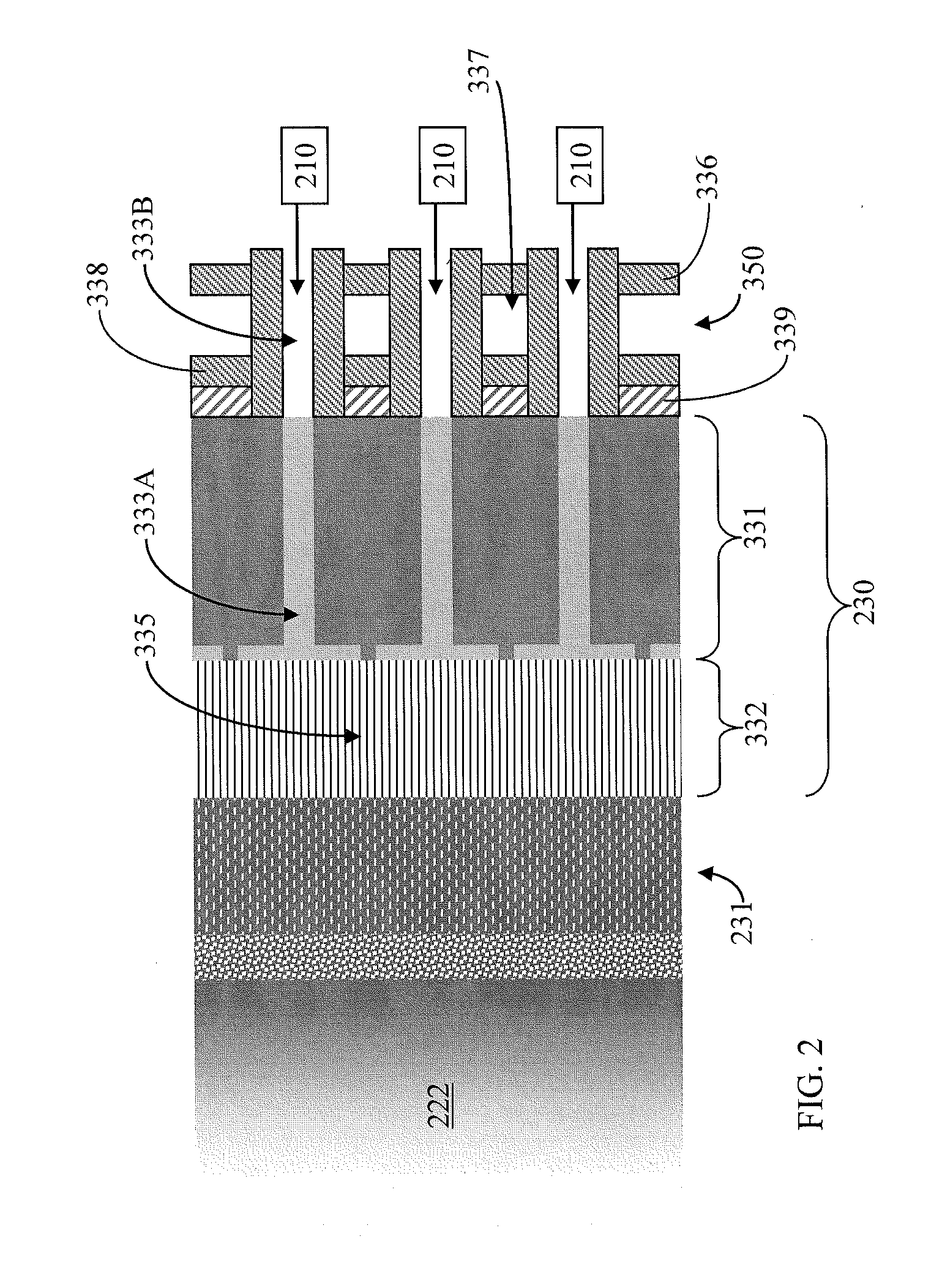

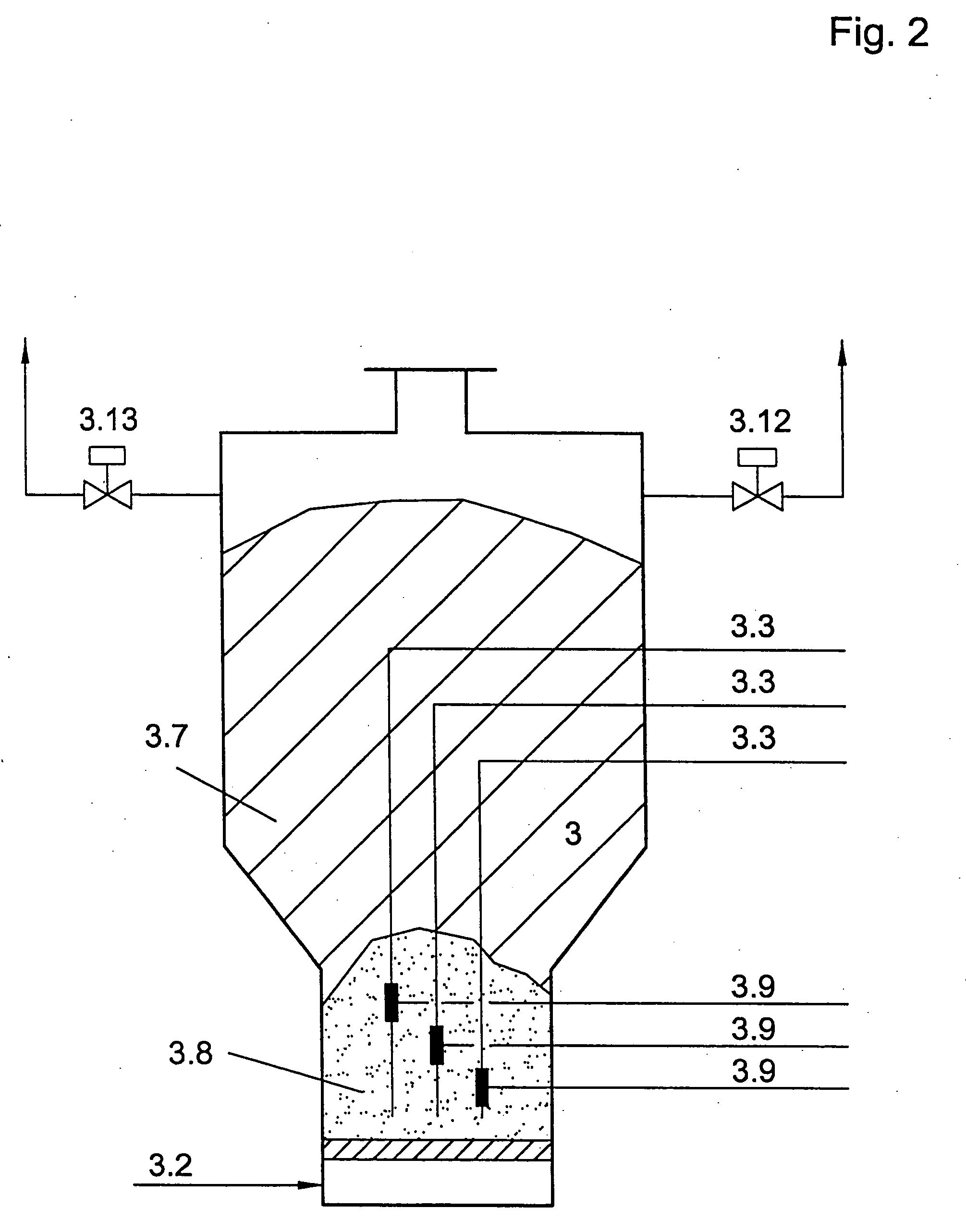

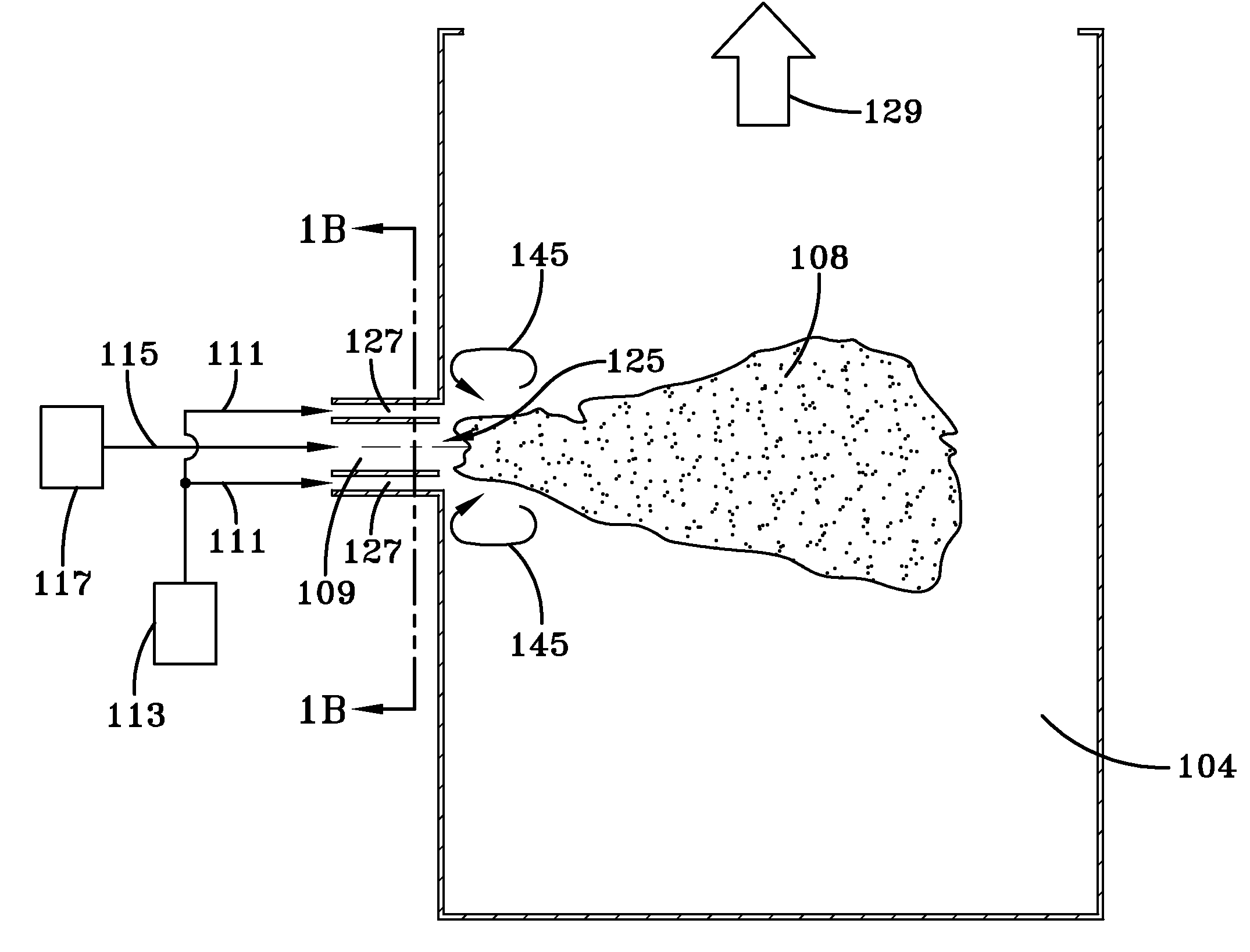

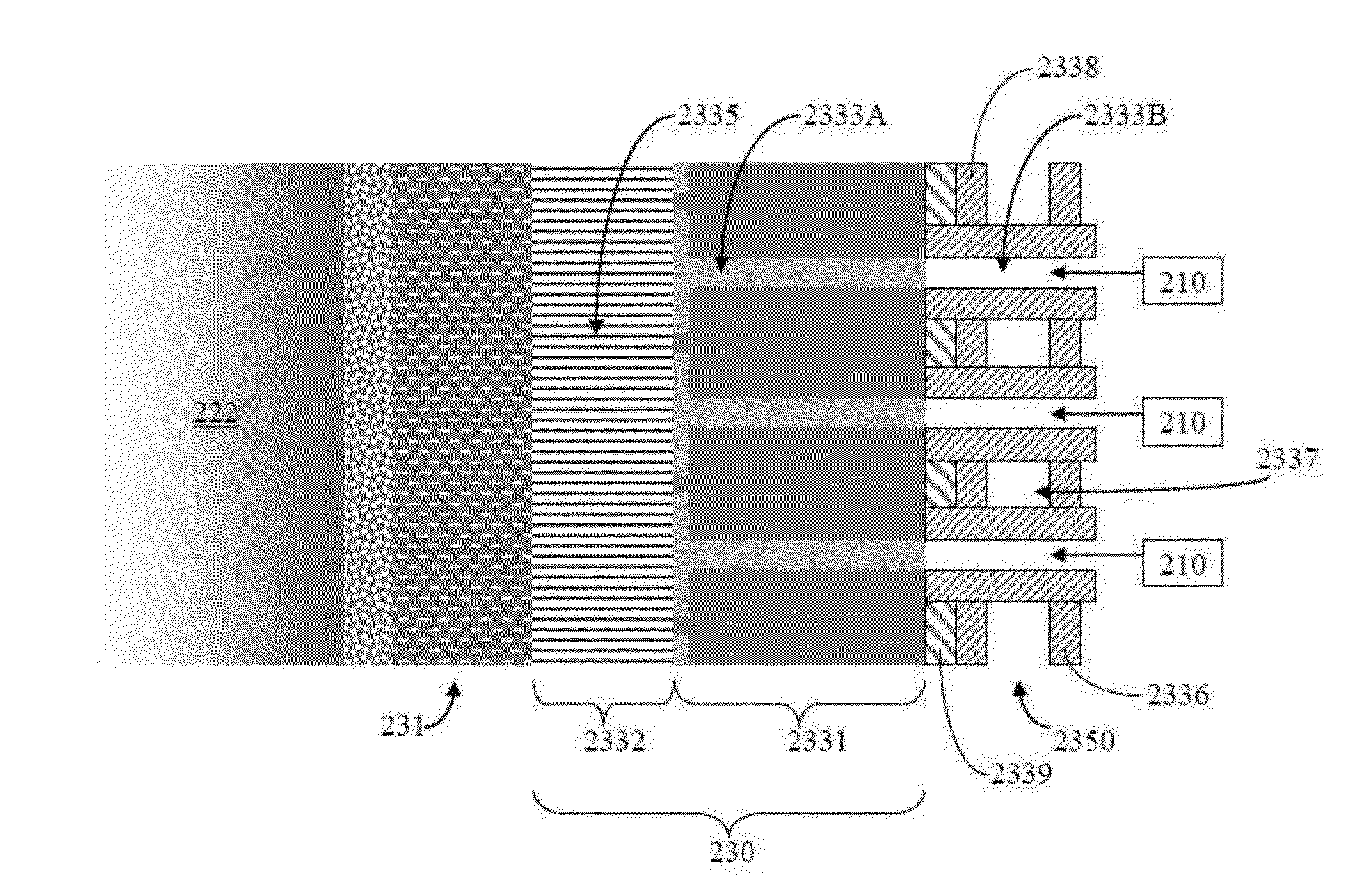

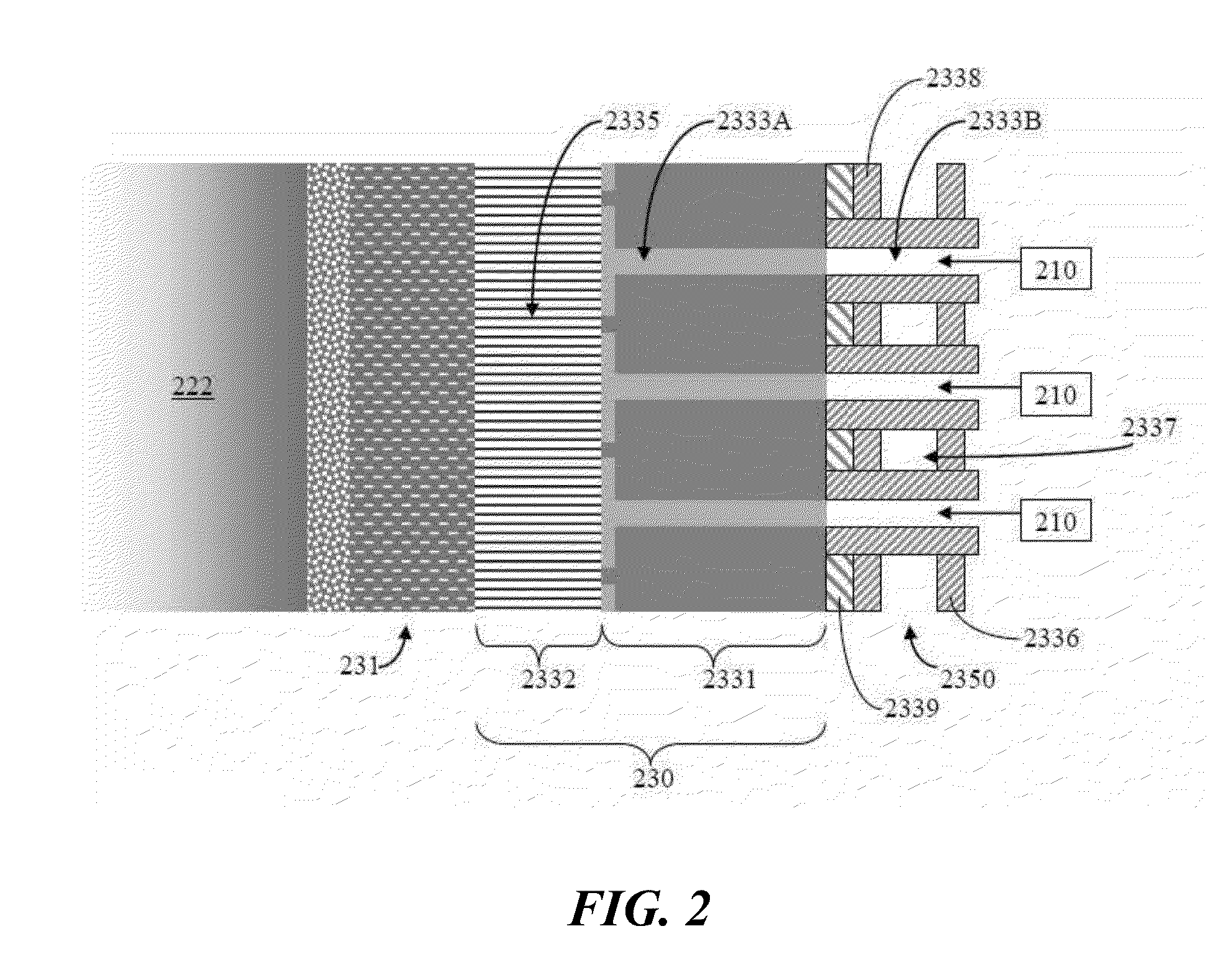

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS9068743B2Reducing and eliminating needEliminate damage to and build-upGas turbine plantsDirect carbon-dioxide mitigationCombustion chamberWorking fluid

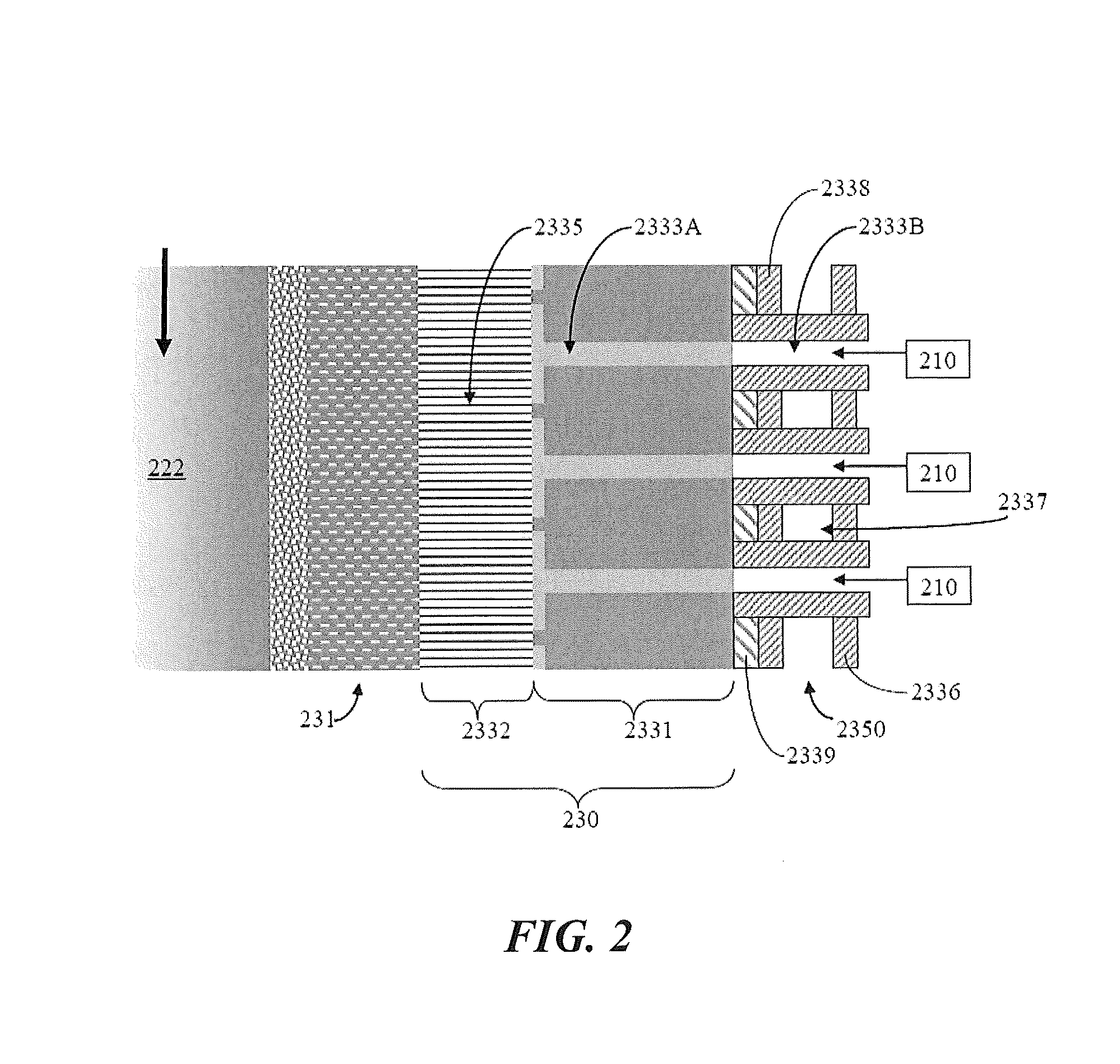

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

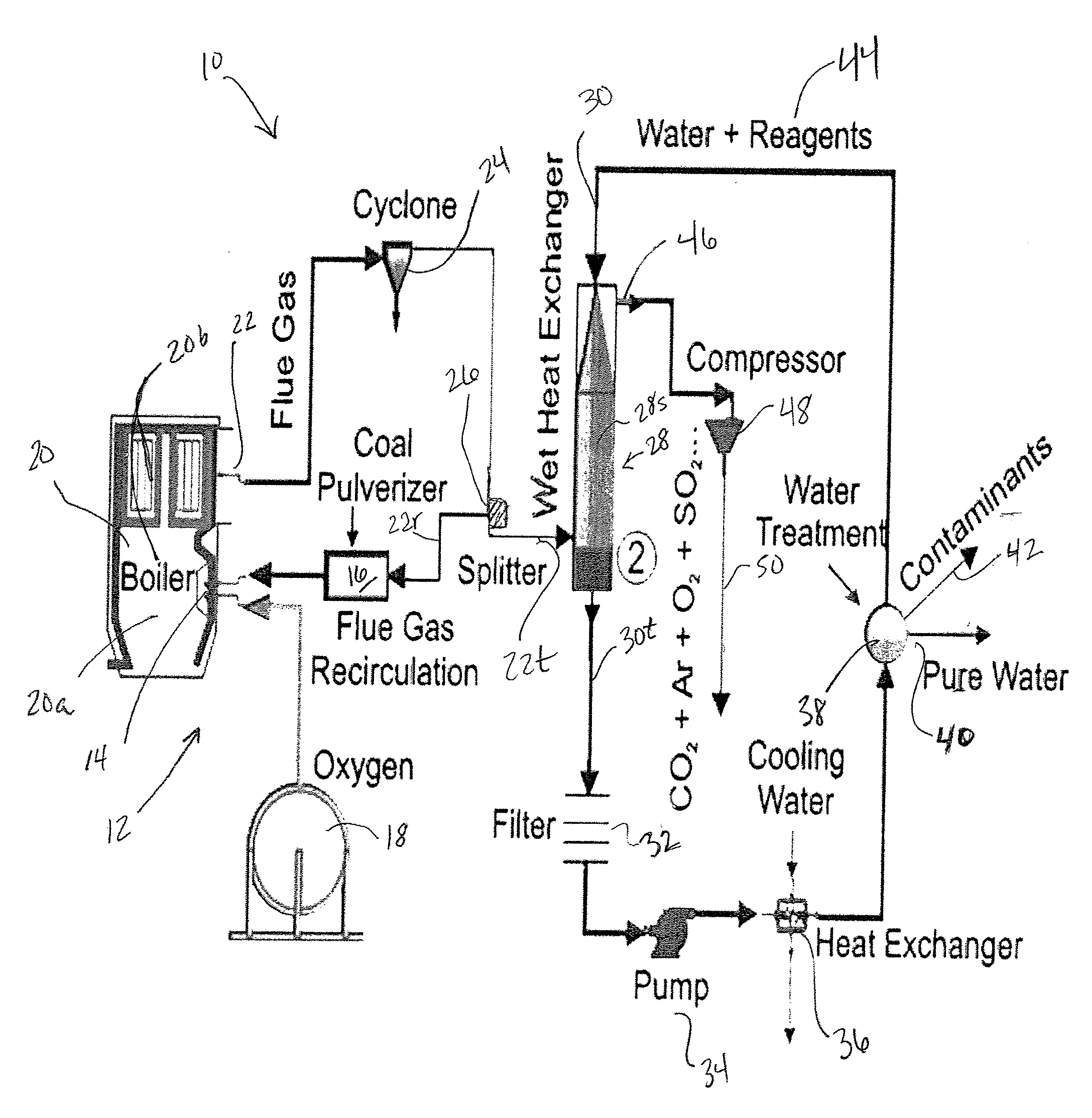

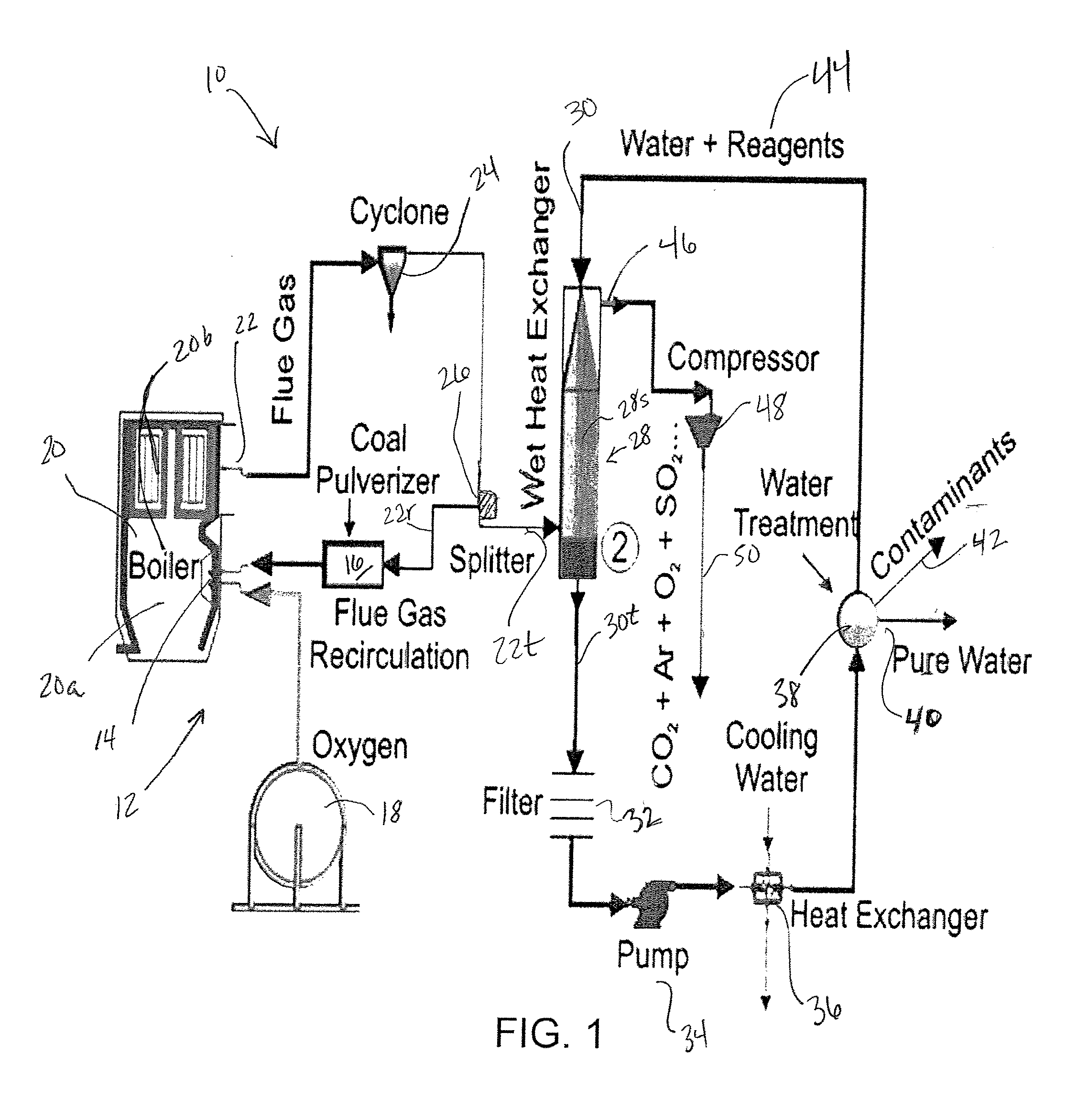

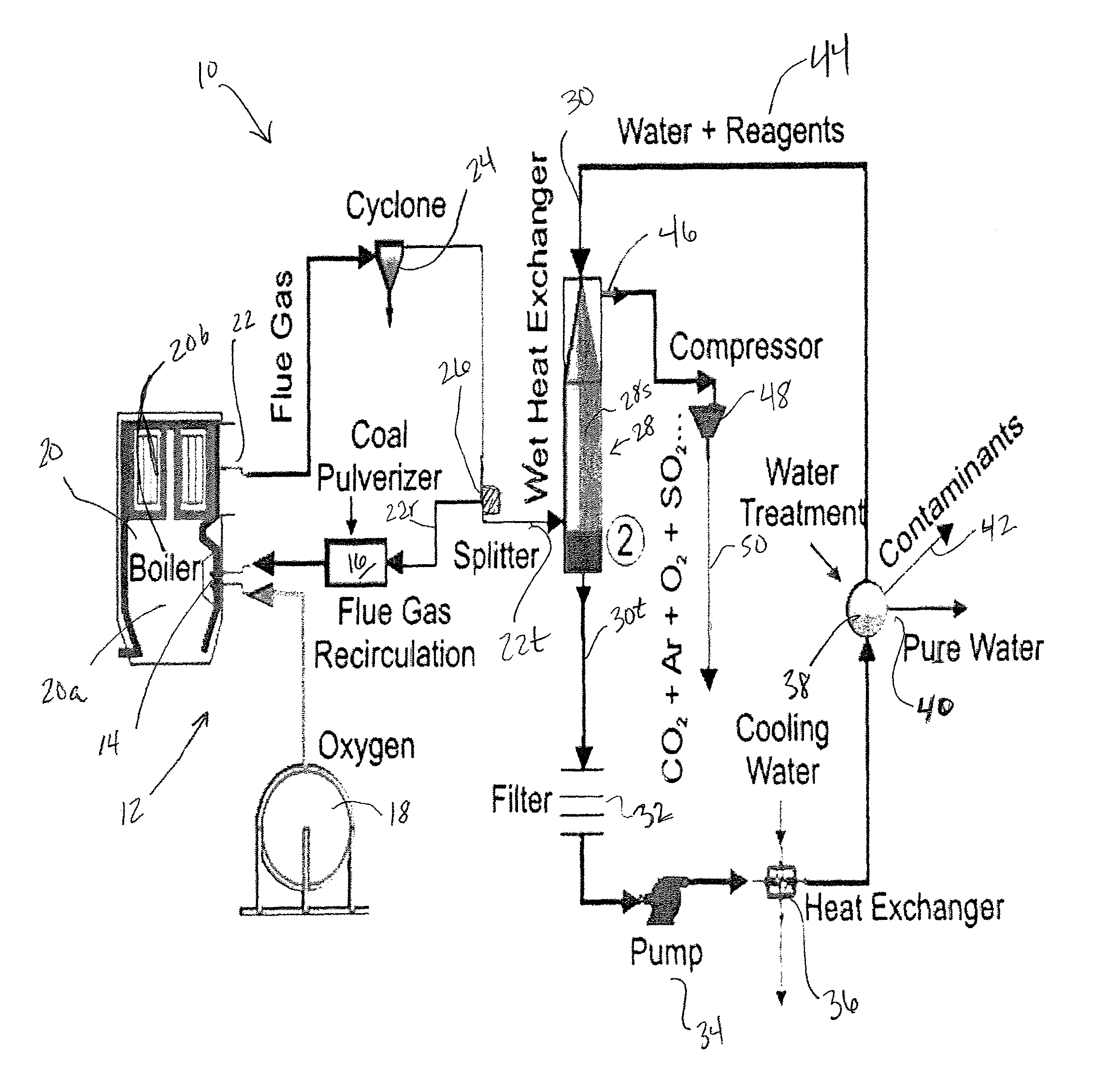

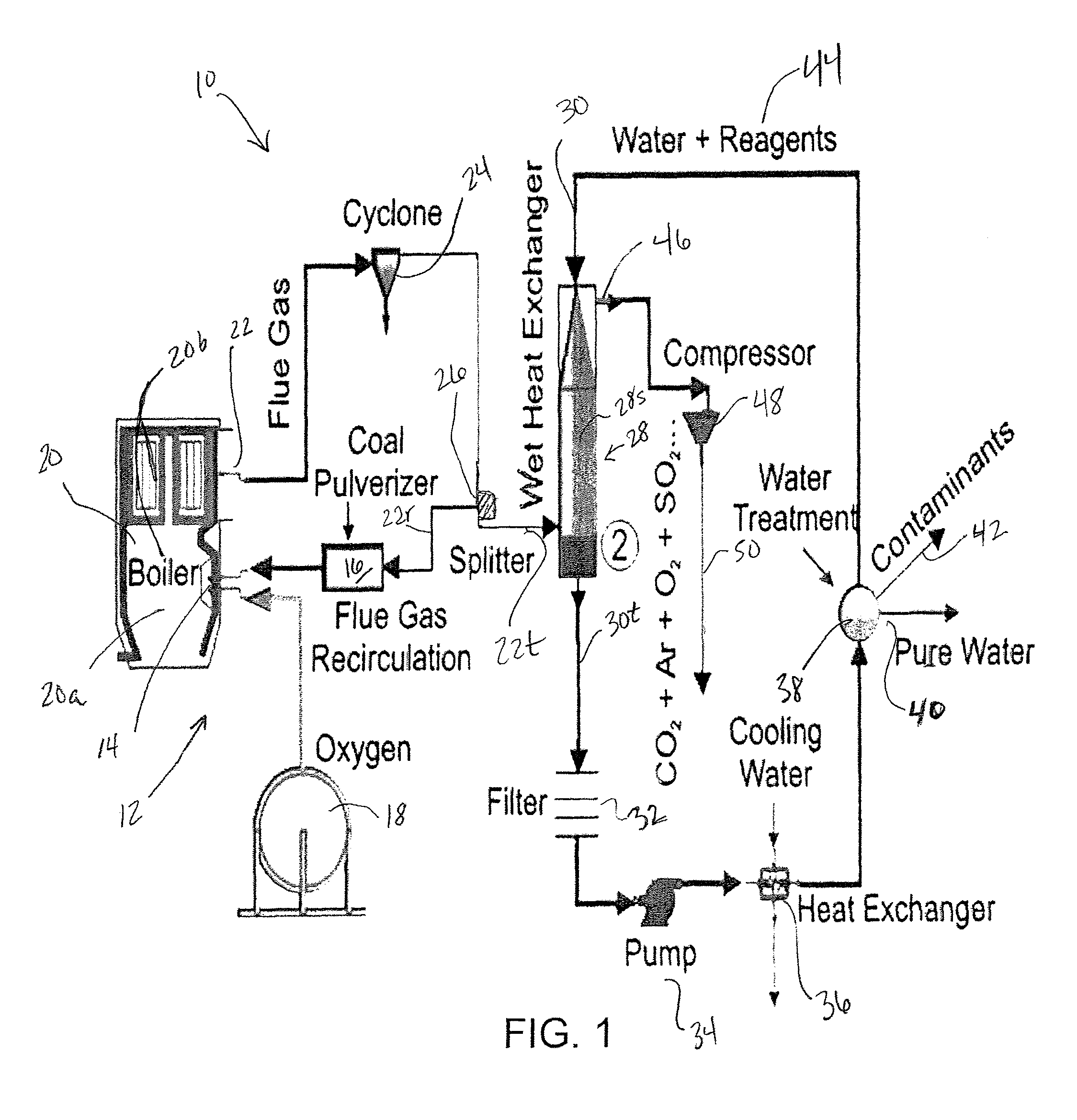

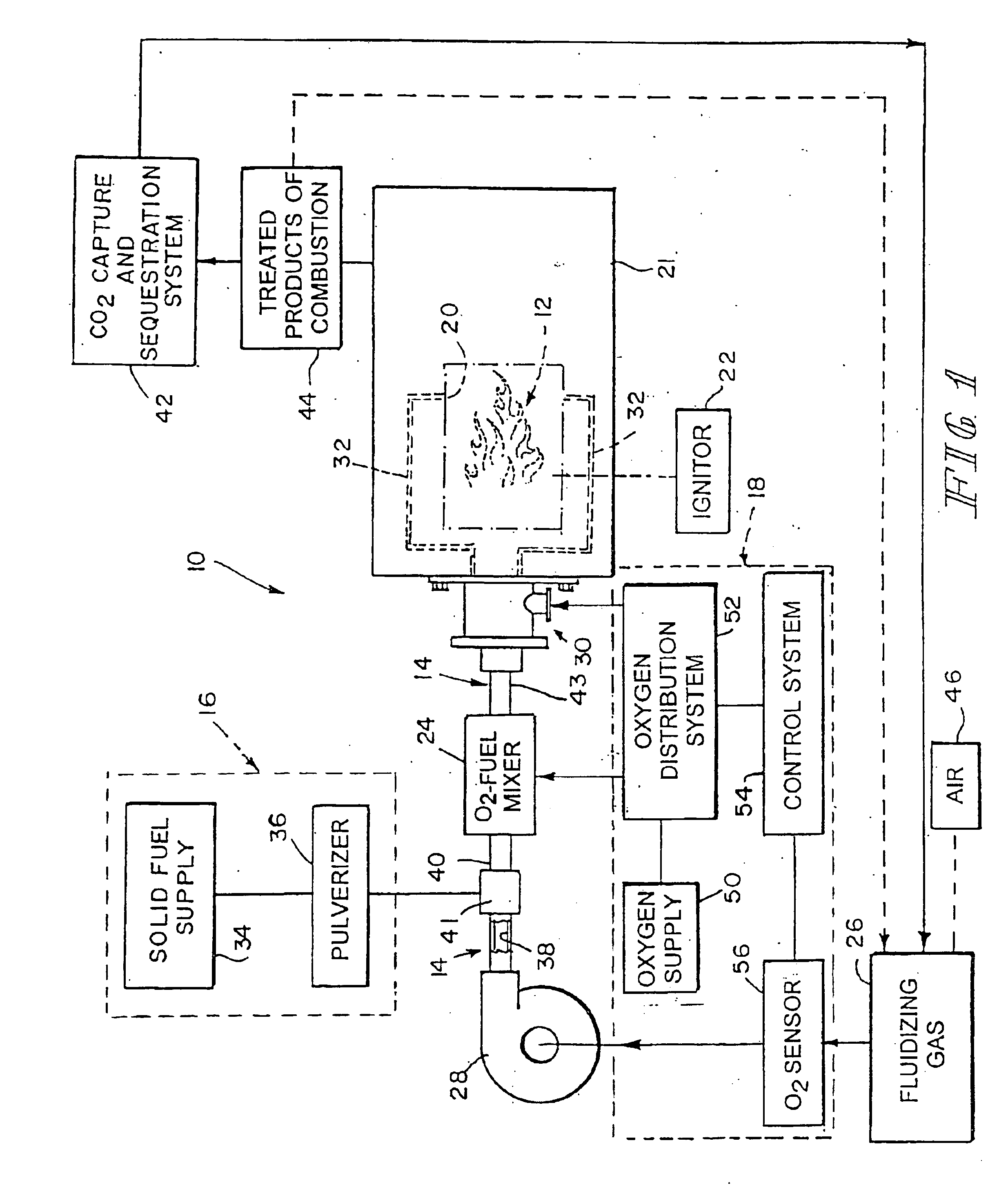

Integrated capture of fossil fuel gas pollutants including co2 with energy recovery

ActiveUS20080016868A1Increase costMaximum recoveryUsing liquid separation agentEmission preventionParticulatesEnergy recovery

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

Integrated capture of fossil fuel gas pollutants including CO2 with energy recovery

ActiveUS8038773B2Maximum recoveryUsing liquid separation agentEmission preventionParticulatesAtmospheric air

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

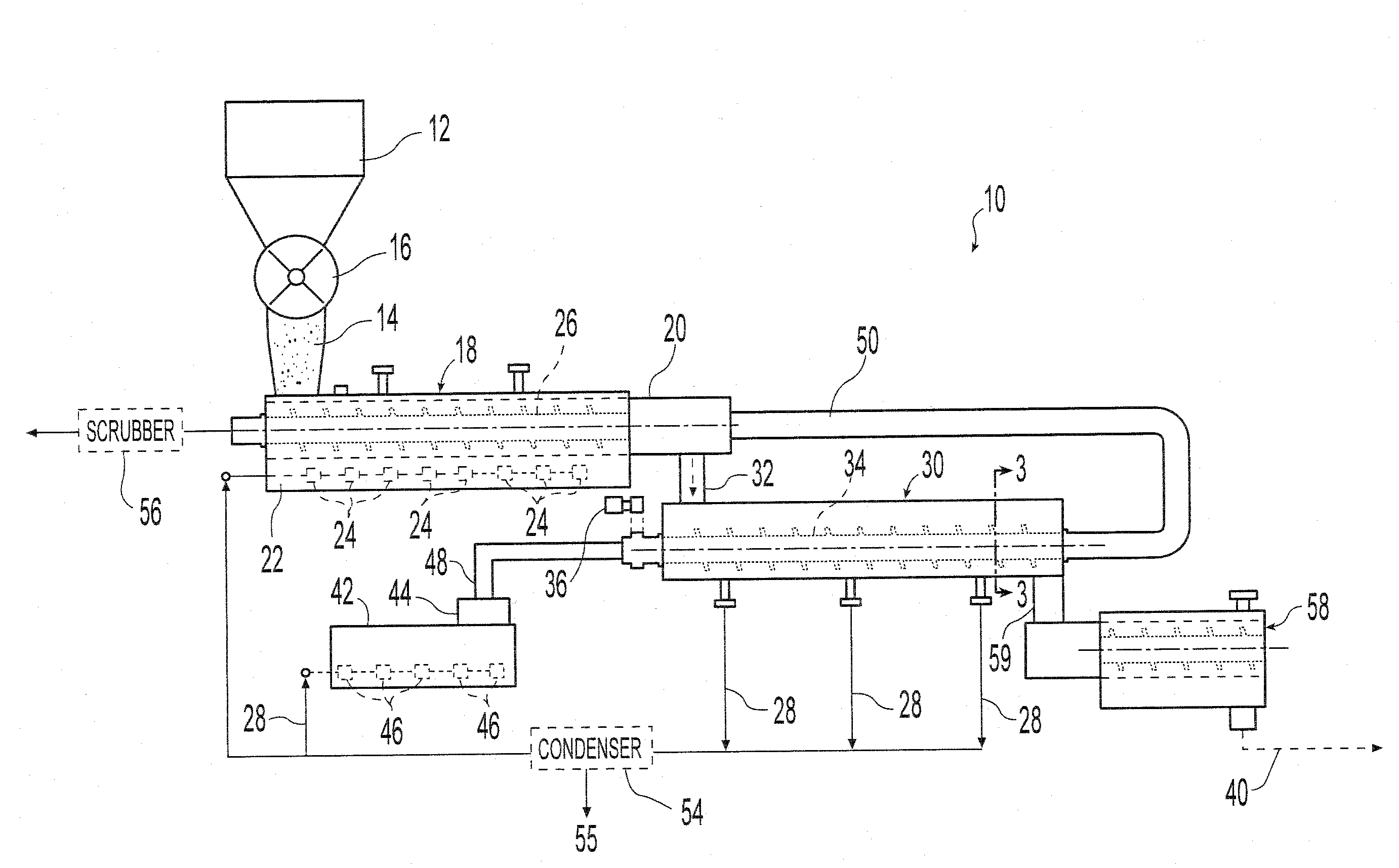

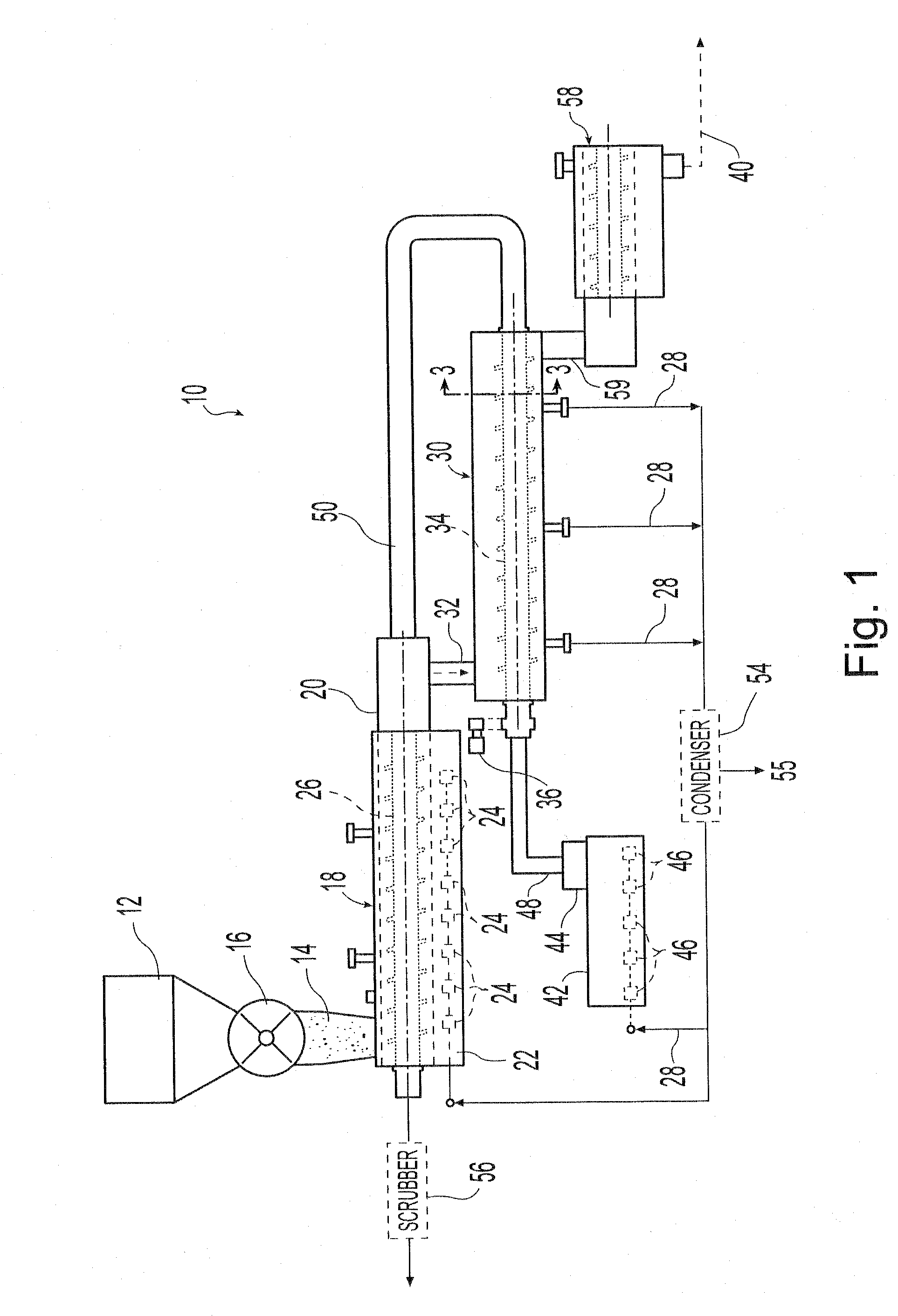

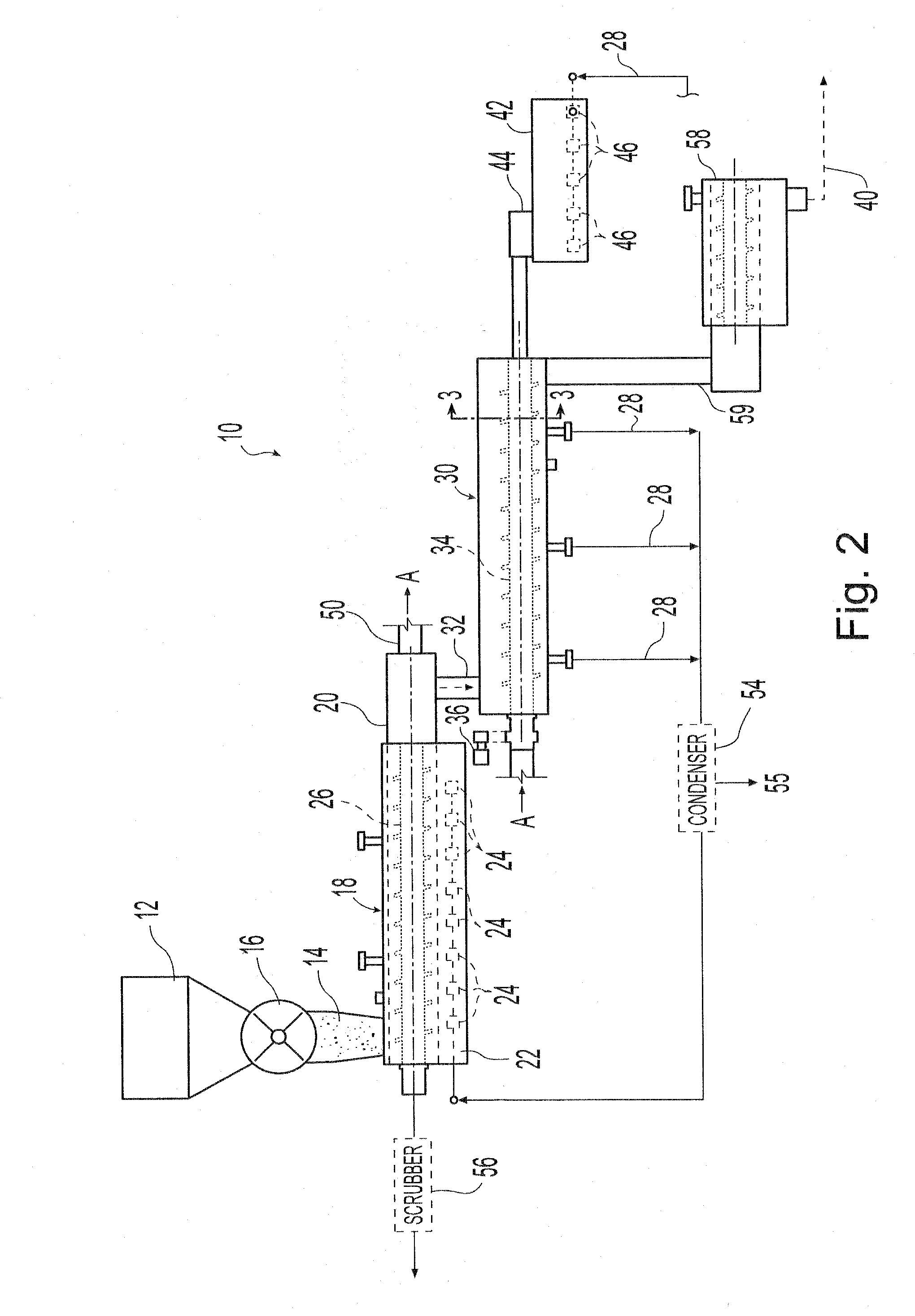

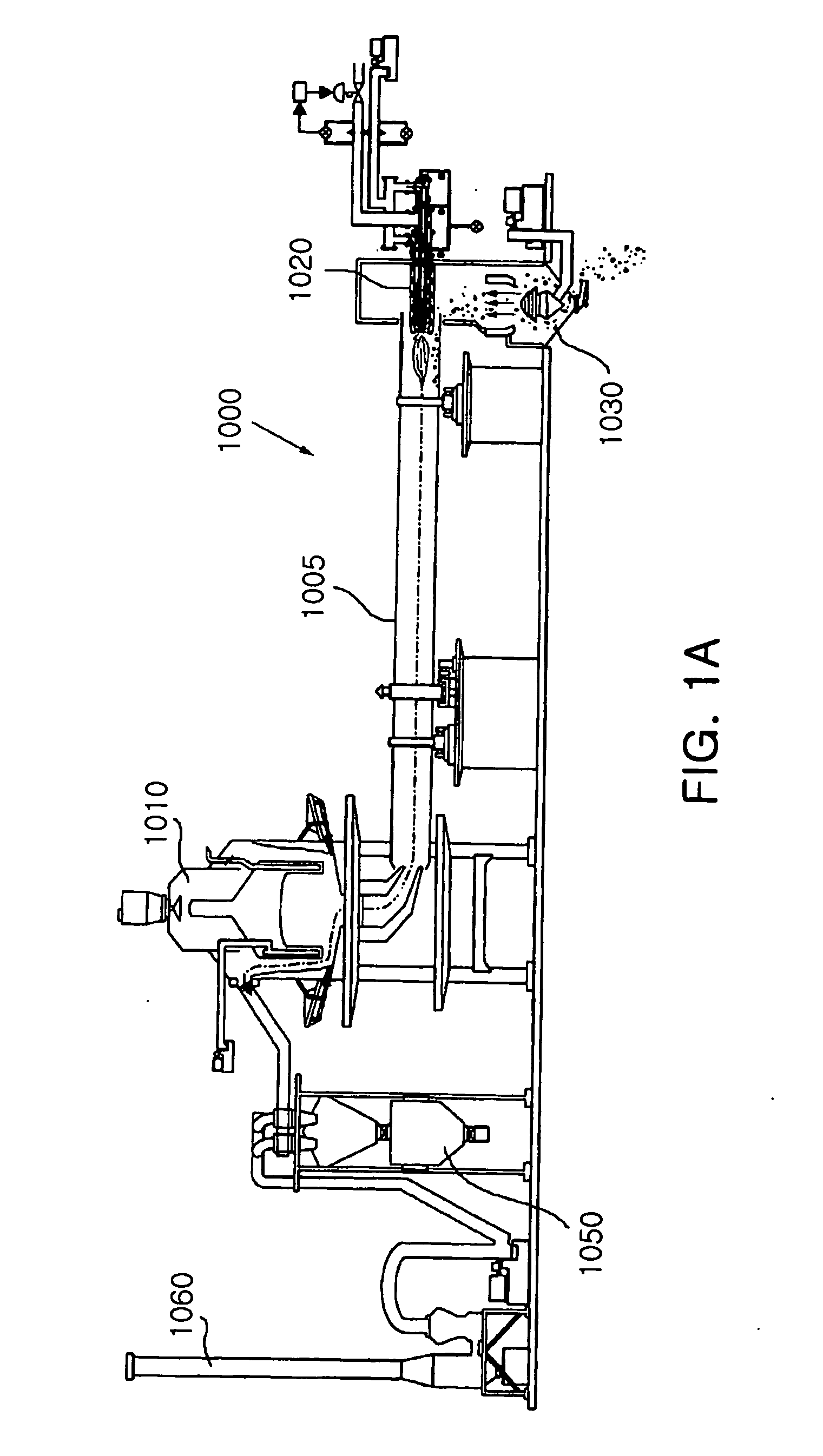

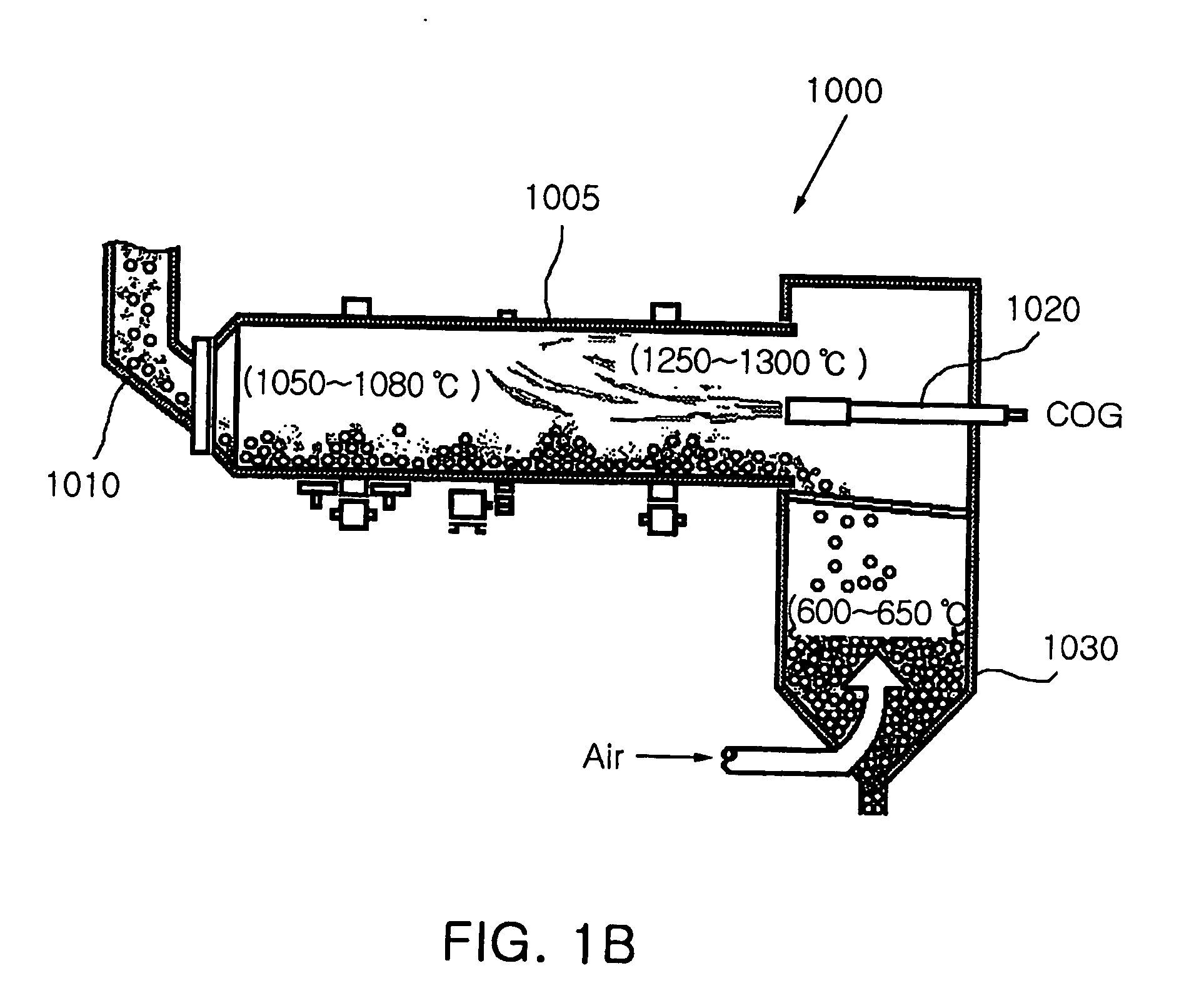

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20080149471A1Weaken energyLower Level RequirementsMechanical conveying coke ovensDirect heating destructive distillationCombustion chamberDrive shaft

A pyrolyzer and method is provided for devolatizing coal and other volatile materials. The pyrolyzer has a pyrolyzer furnace housing having at least two screws laterally positioned adjacent and overlapping rotatably mounted within the furnace for moving volatile material through the pyrolyzer furnace housing. The screws have hollow drive shafts with a diverter inside for converging heated fluid to heat the volatile material moving through the pyrolyzer furnace housing. A combustion chamber combusts fuel to create heated exhaust gas for directing through the hollow drive shafts to heat the volatile material. The pyrolyzer furnace housing may have a double wall with a cavity between, capable of receiving heated fluid for further heating of volatile material moving through the pyrolyzer furnace housing.

Owner:NUCOR CORP

Vortex type gas lamp

A vortex type gas lamp comprising a base and an axially extending-transparent shield. Gas is supplied near the bottom end of the shield. The shield is formed of a plurality (preferably two) axial curved sections which overlap one another at their axial edges to form tangentially directed port. Combustion of the gas with atmospheric oxygen admitted through the ports results in an axial vortex of burning gas useful for illumination, decoration and heat.

Owner:CHESNEY PETER

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

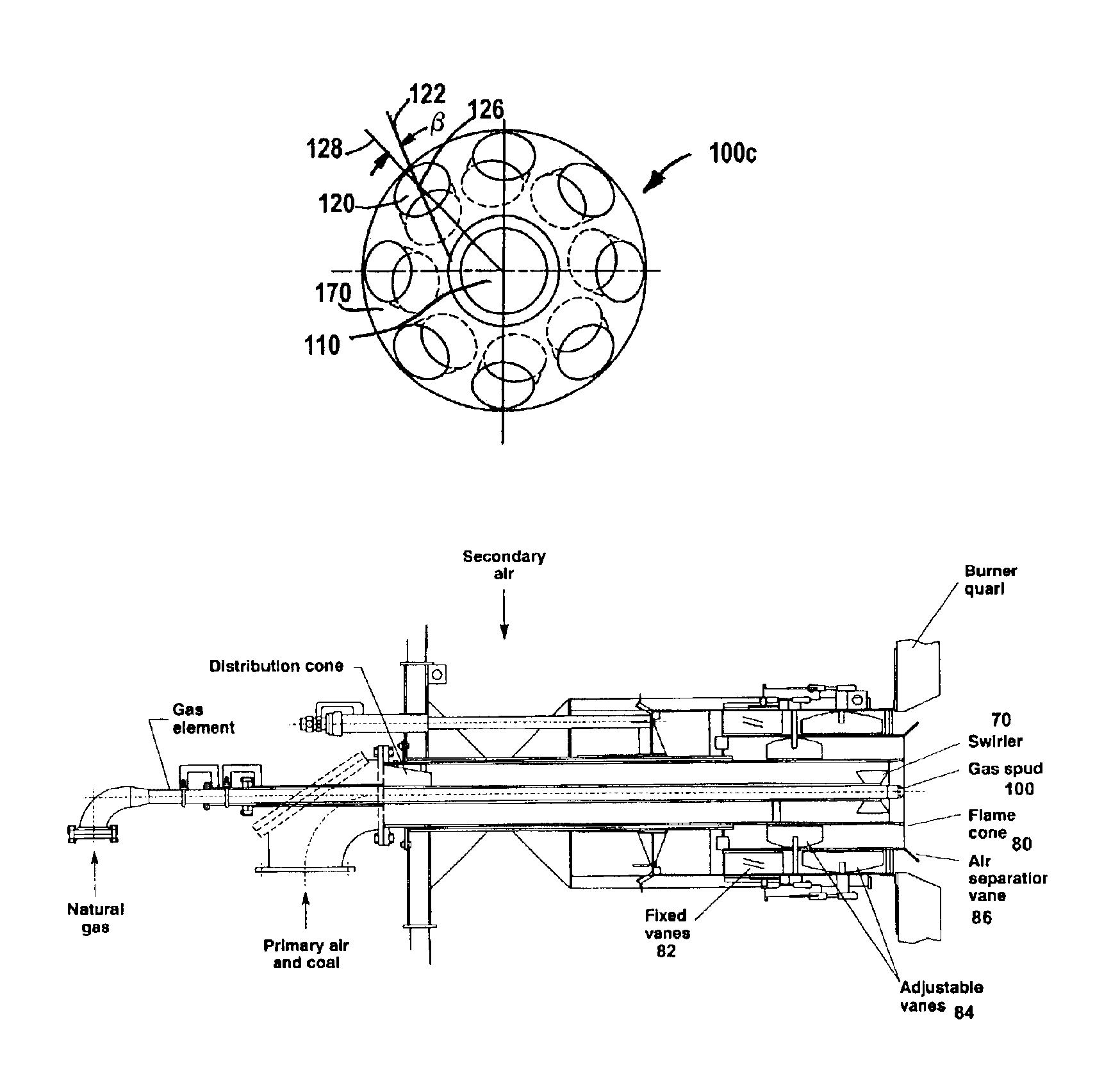

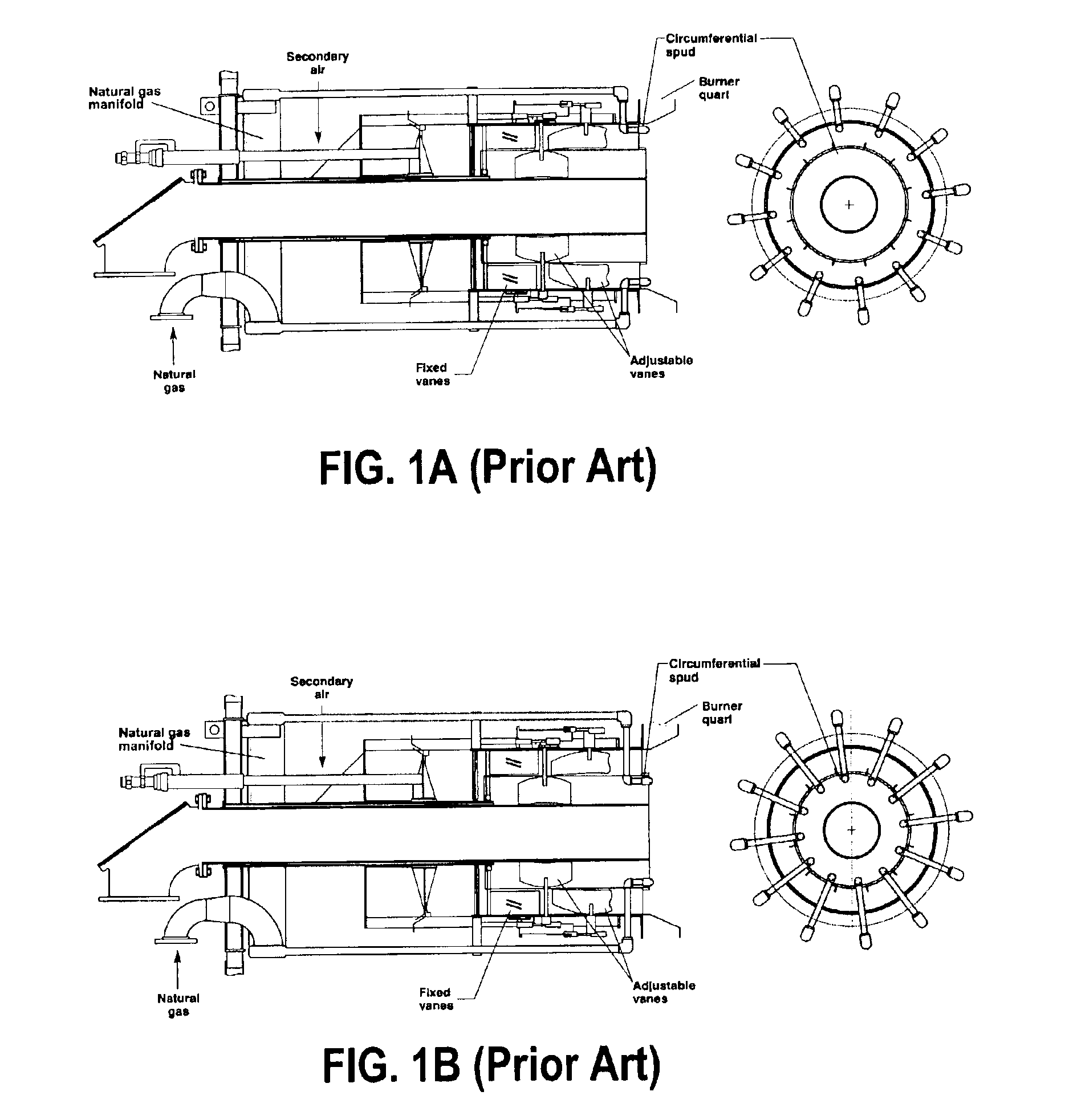

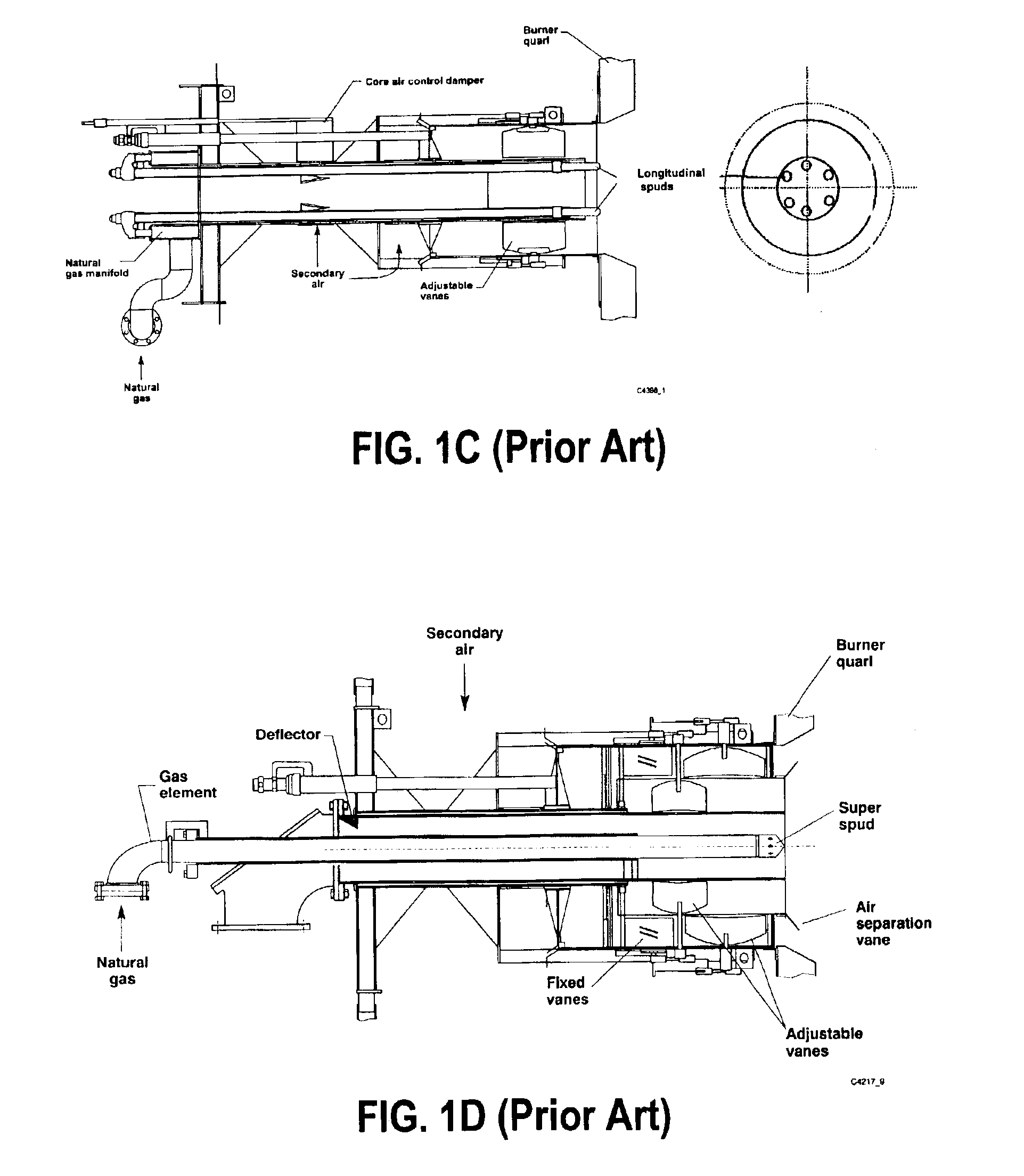

Dual fuel burner for a shortened flame and reduced pollutant emissions

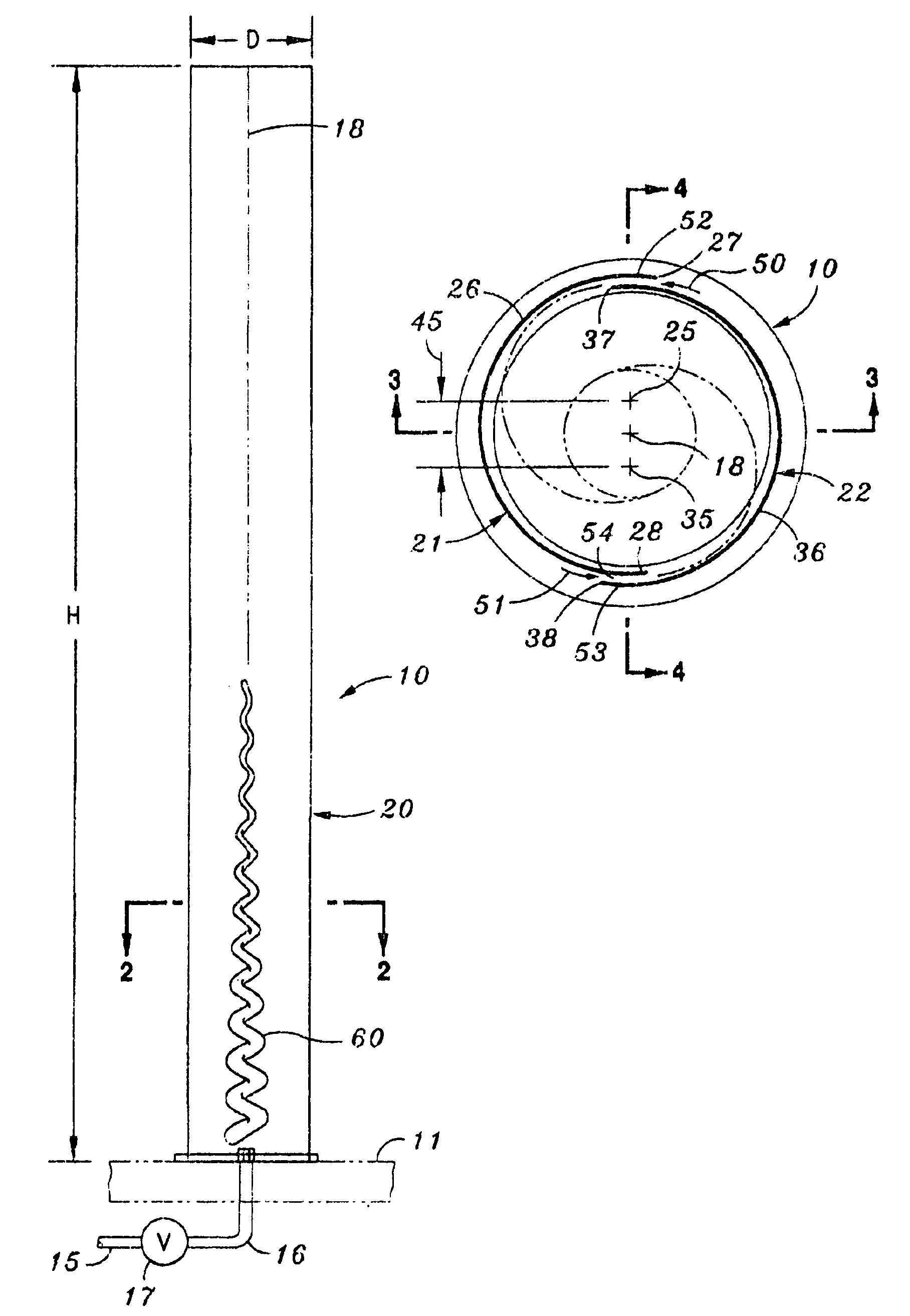

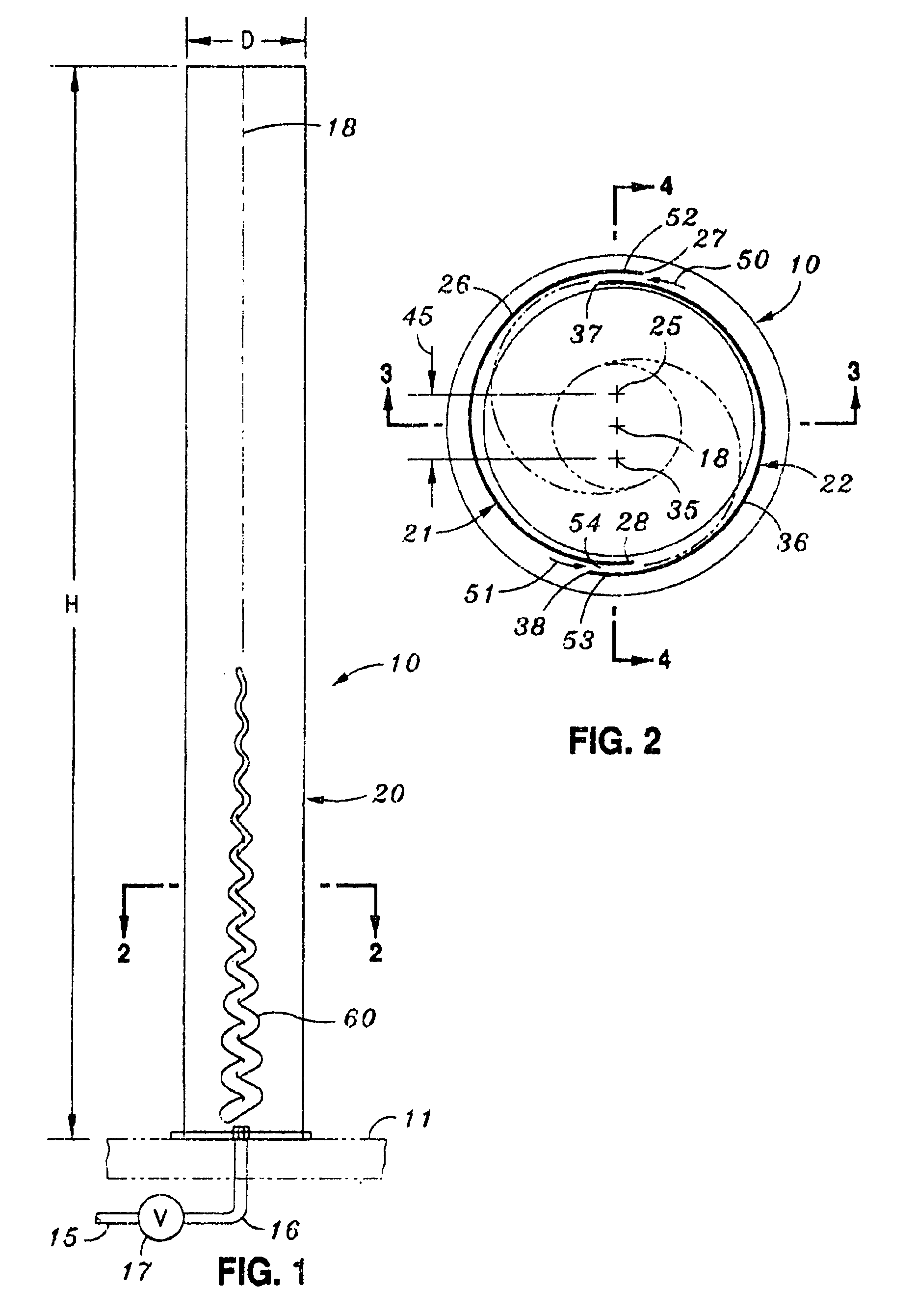

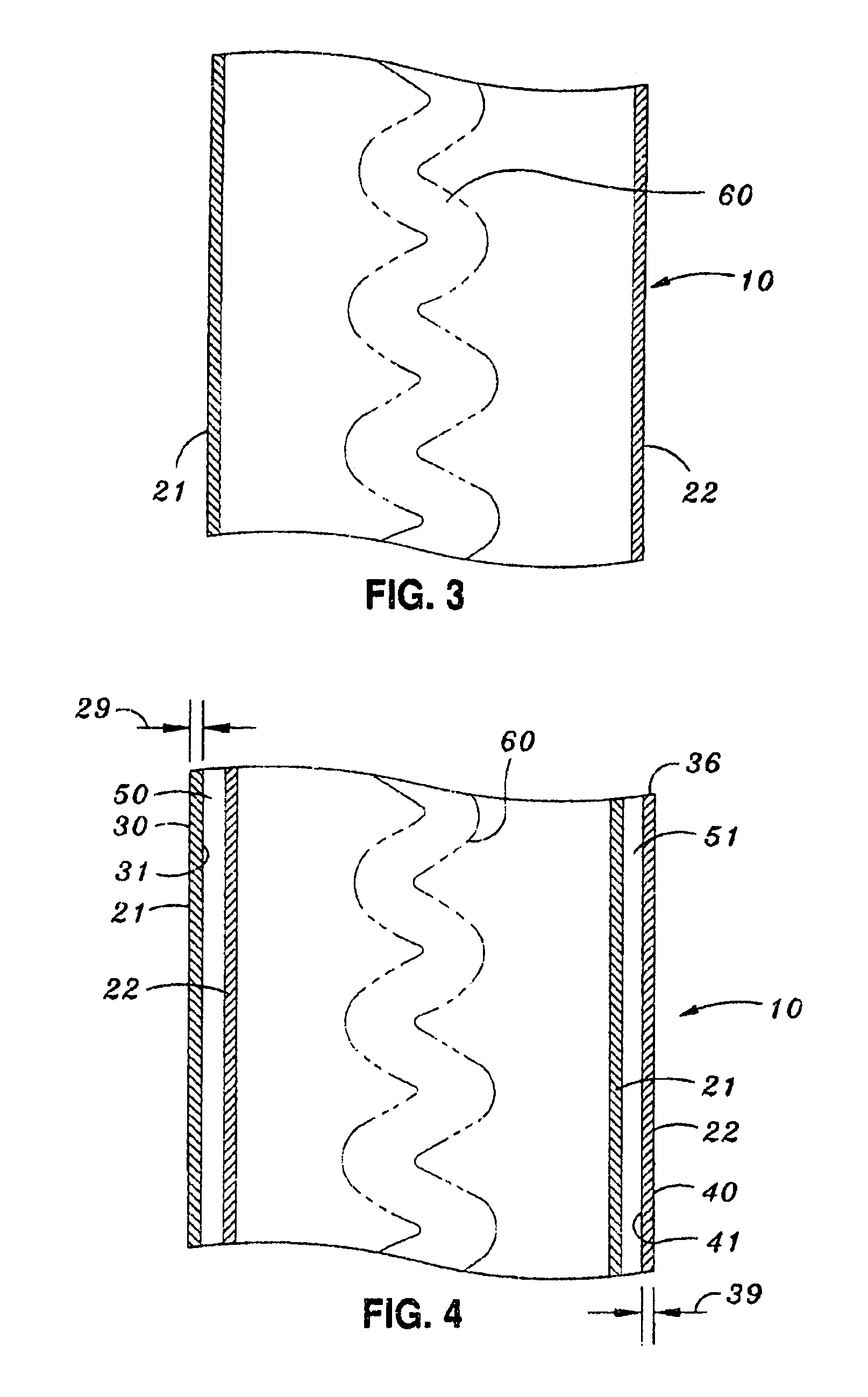

InactiveUS6951454B2Emission reductionShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePollutant emissions

A dual fuel burner including an elongated supply pipe and a gas injector for a boiler furnace having a plurality of peripheral openings around a center opening. The peripheral openings are pitched radially away from the longitudinal axis of the gas injector and also pitched either clockwise or counter-clockwise, to impart a swirling motion to gaseous fuel exiting the injector through the openings. A first sleeve member is concentrically spaced about the supply pipe and the gas injector to form an inner annular passageway for conveying a mixture of primary air and pulverized coal to the furnace combustion zone. A second sleeve member is concentrically spaced about the first sleeve member to form an outer annular passageway for conveying secondary air to the furnace combustion zone, and a plurality of circumferentially spaced vanes mounted within the outer annular passageway for inducing a swirling motion to the secondary air discharging from the outer annular passageway into the furnace combustion zone.

Owner:THE BABCOCK & WILCOX CO

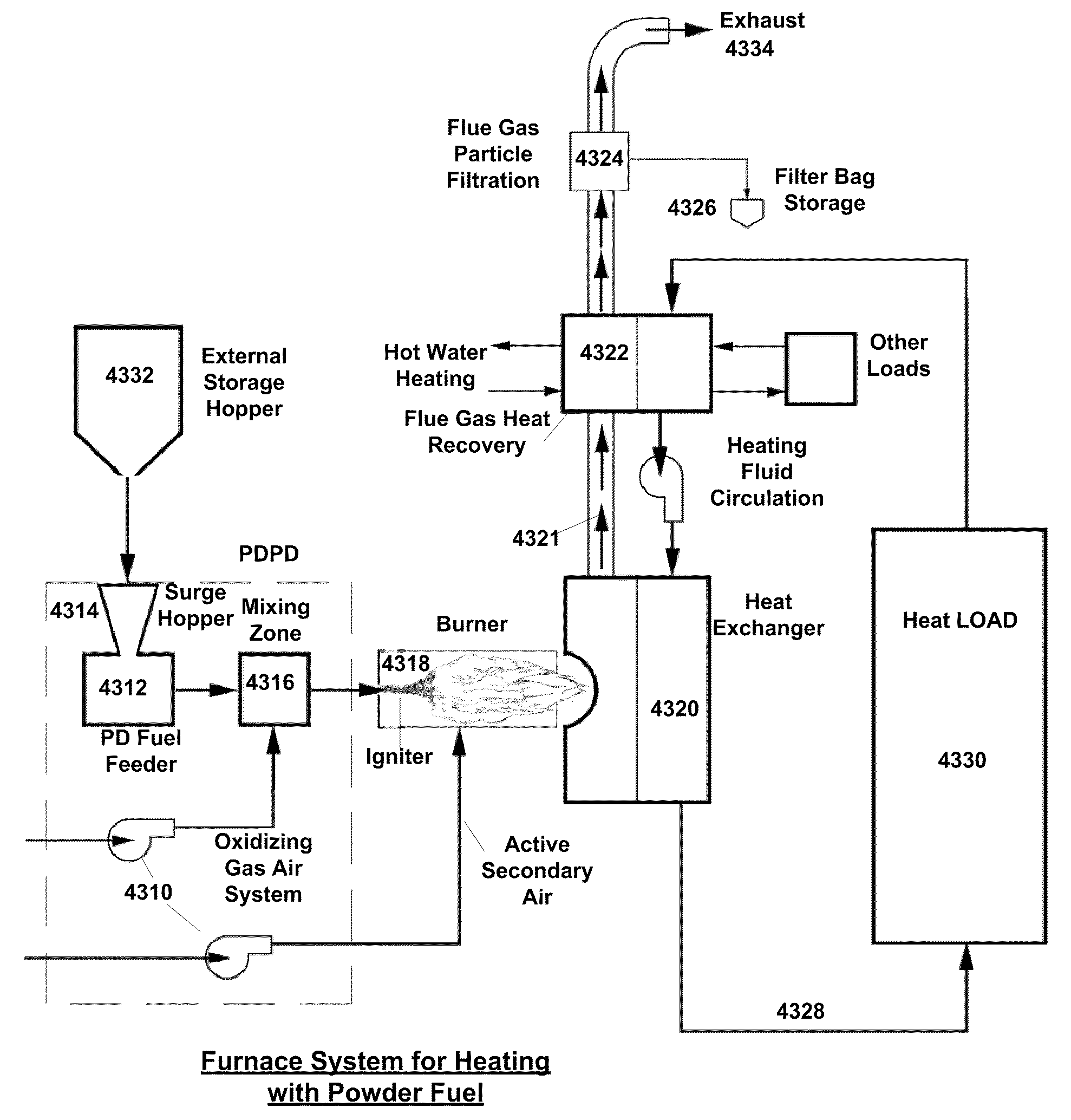

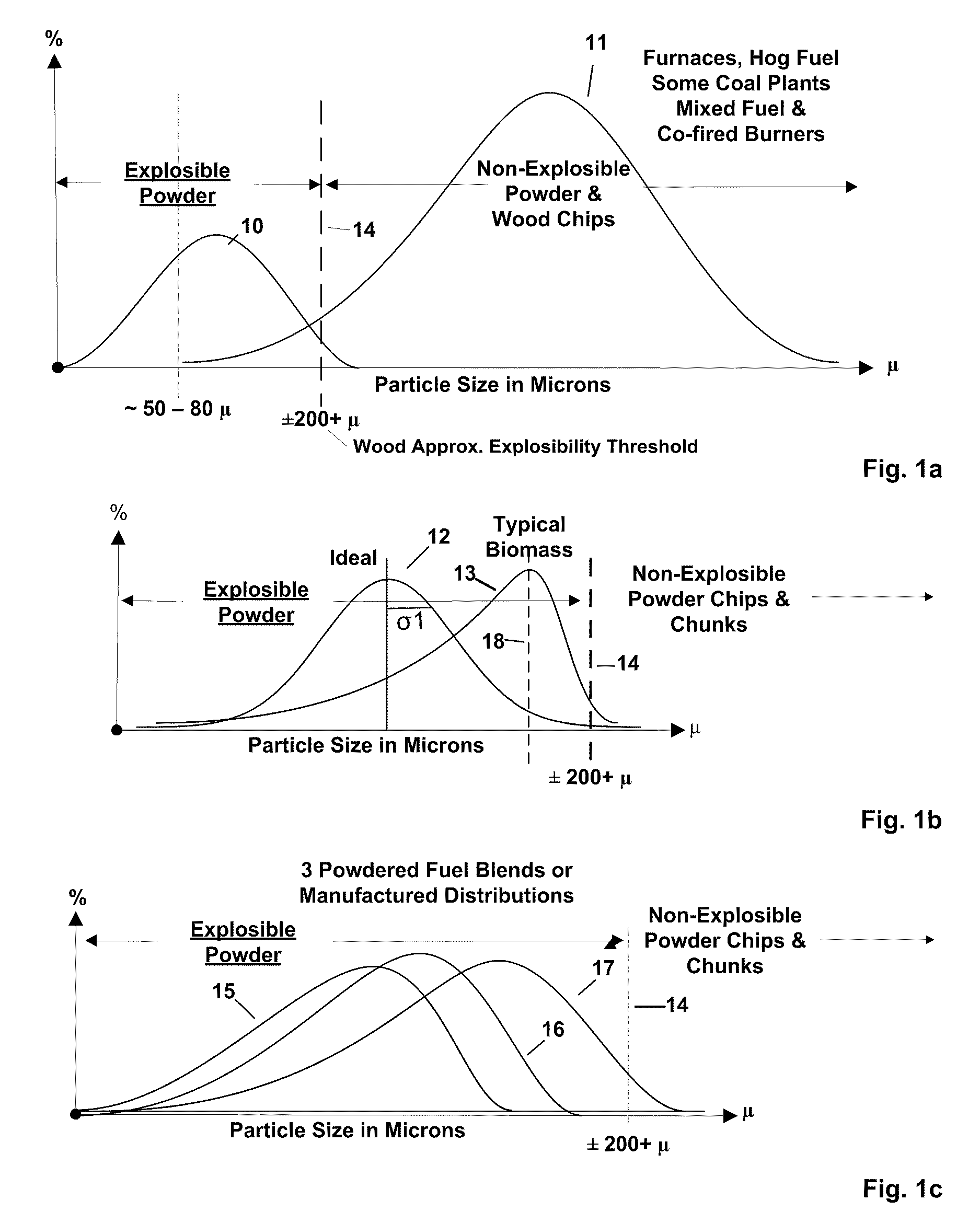

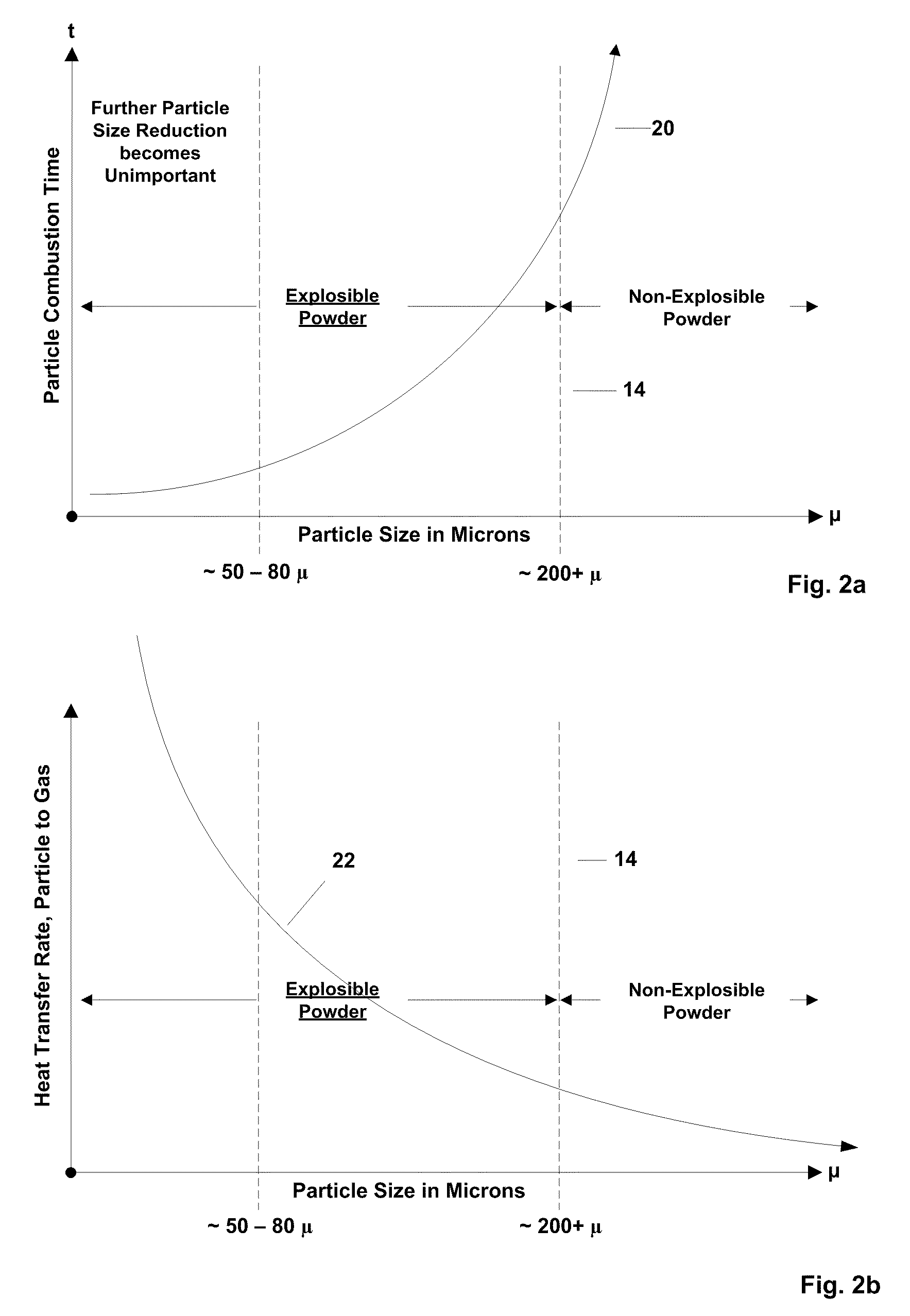

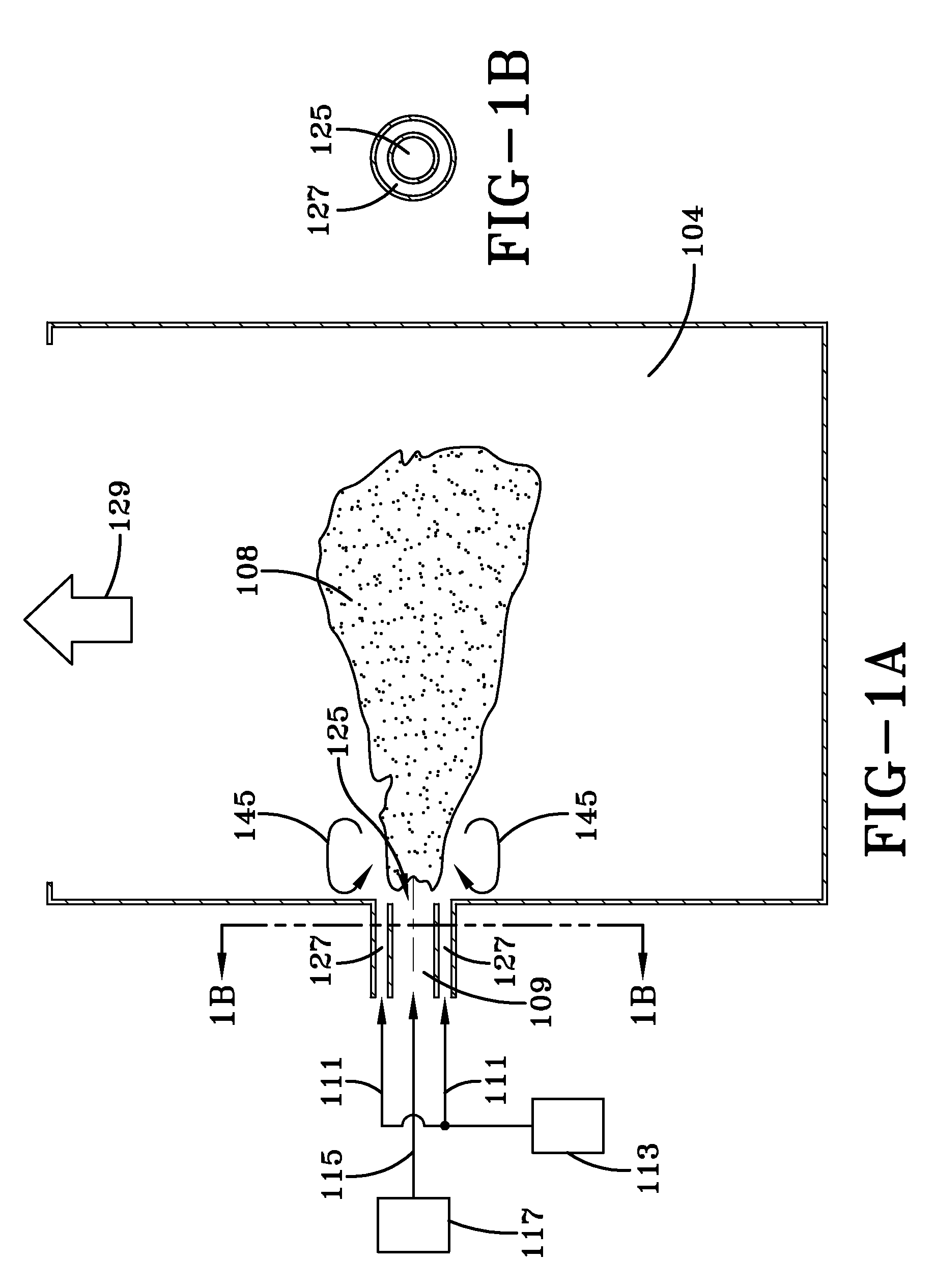

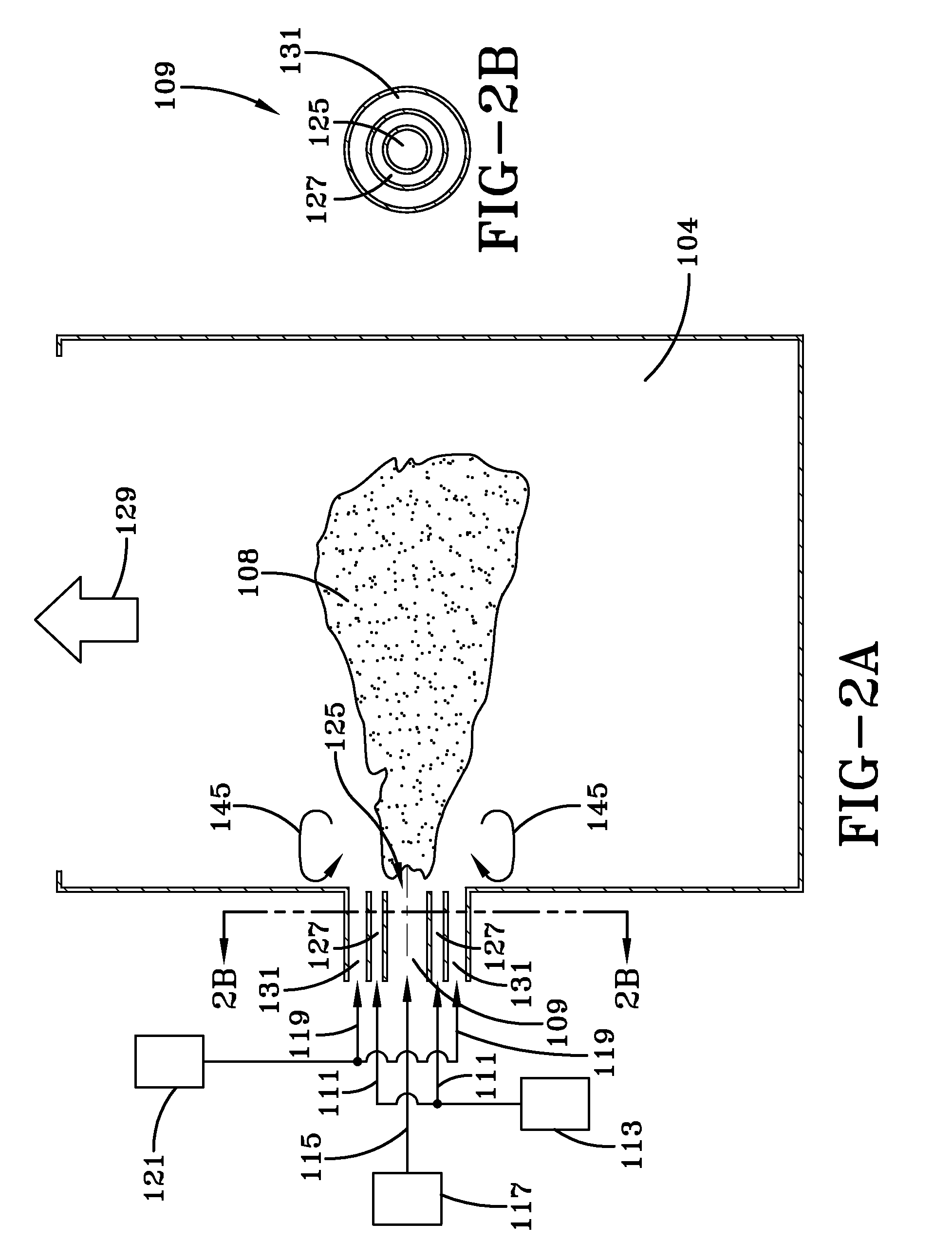

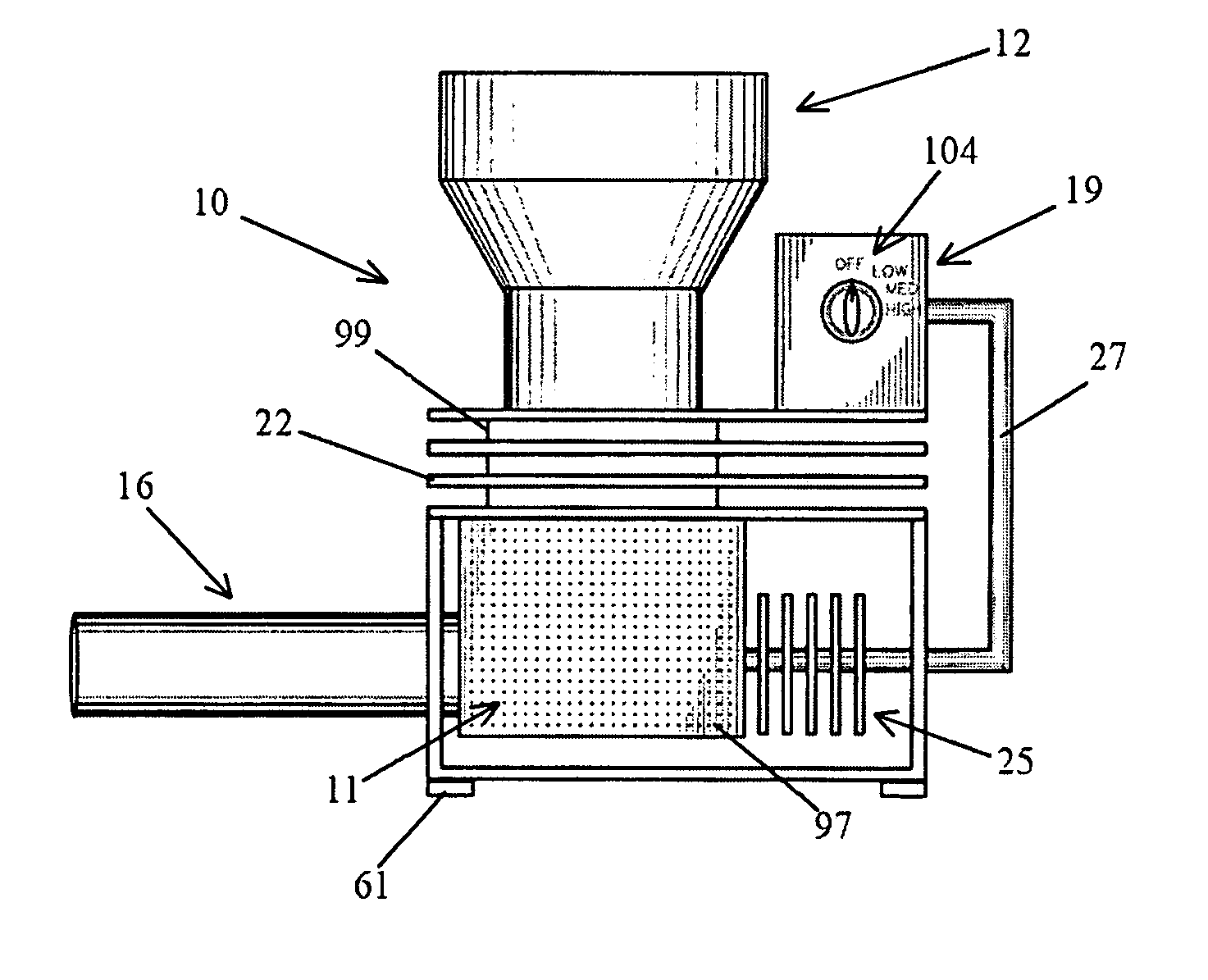

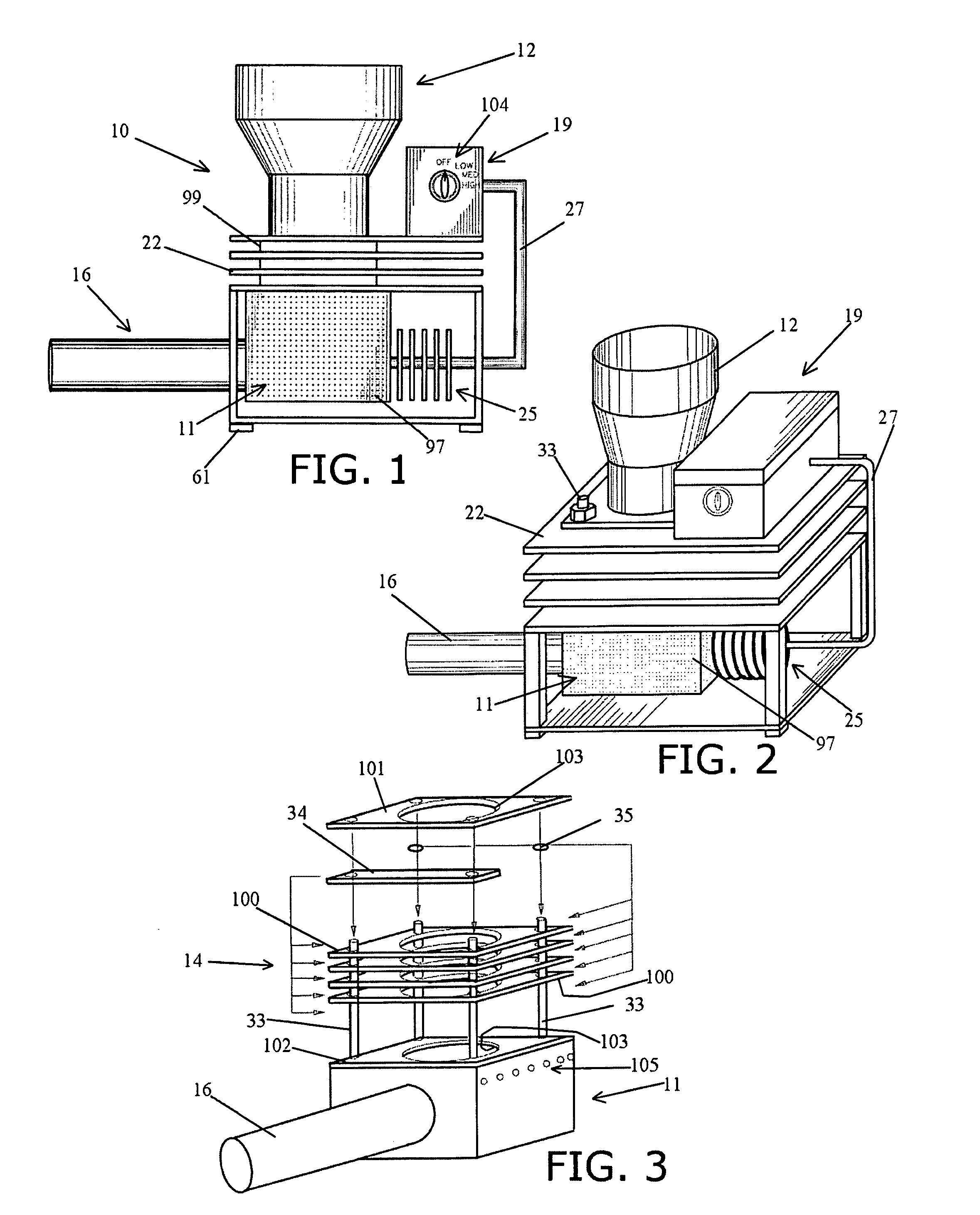

Powdered fuel conversion systems and methods

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

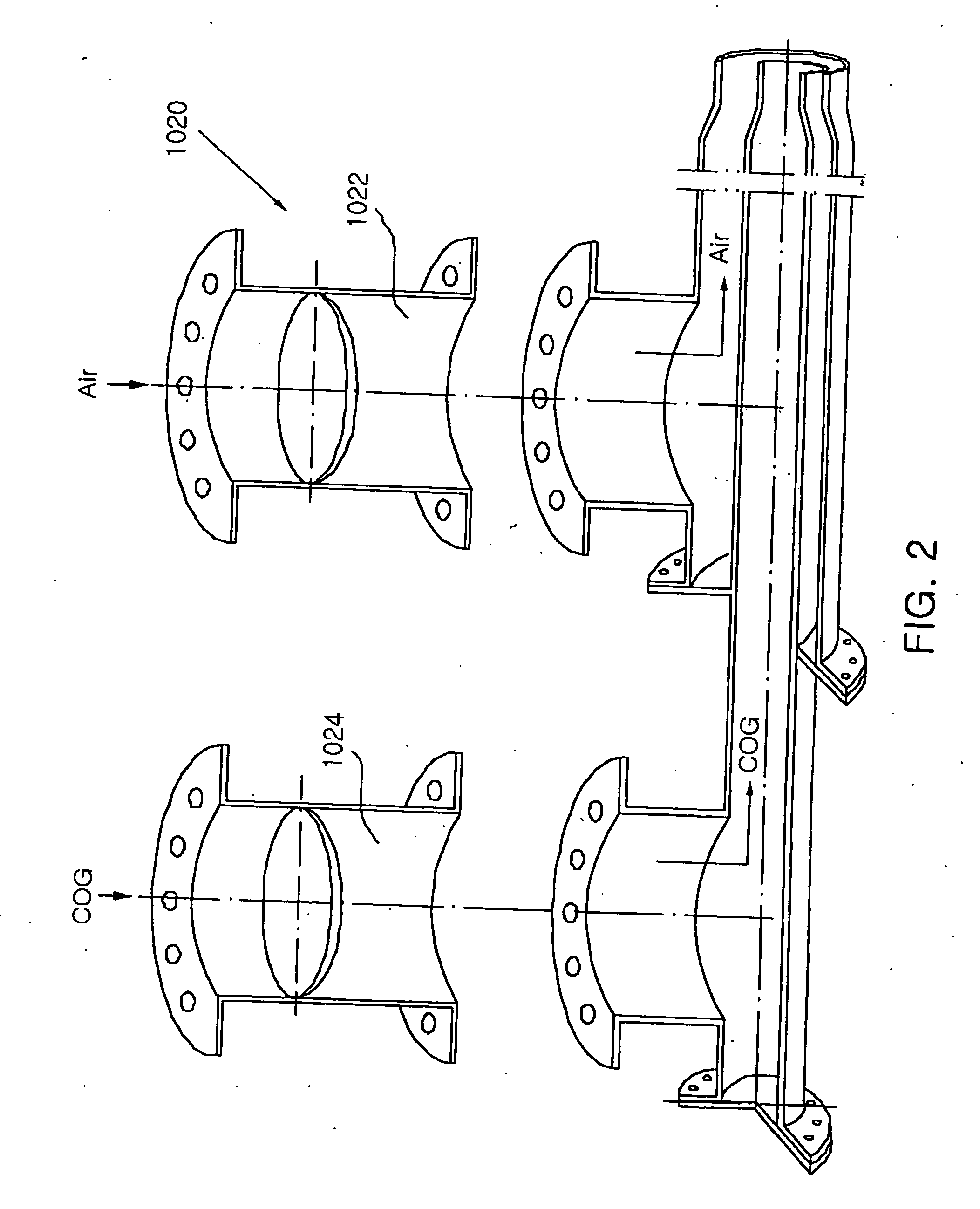

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

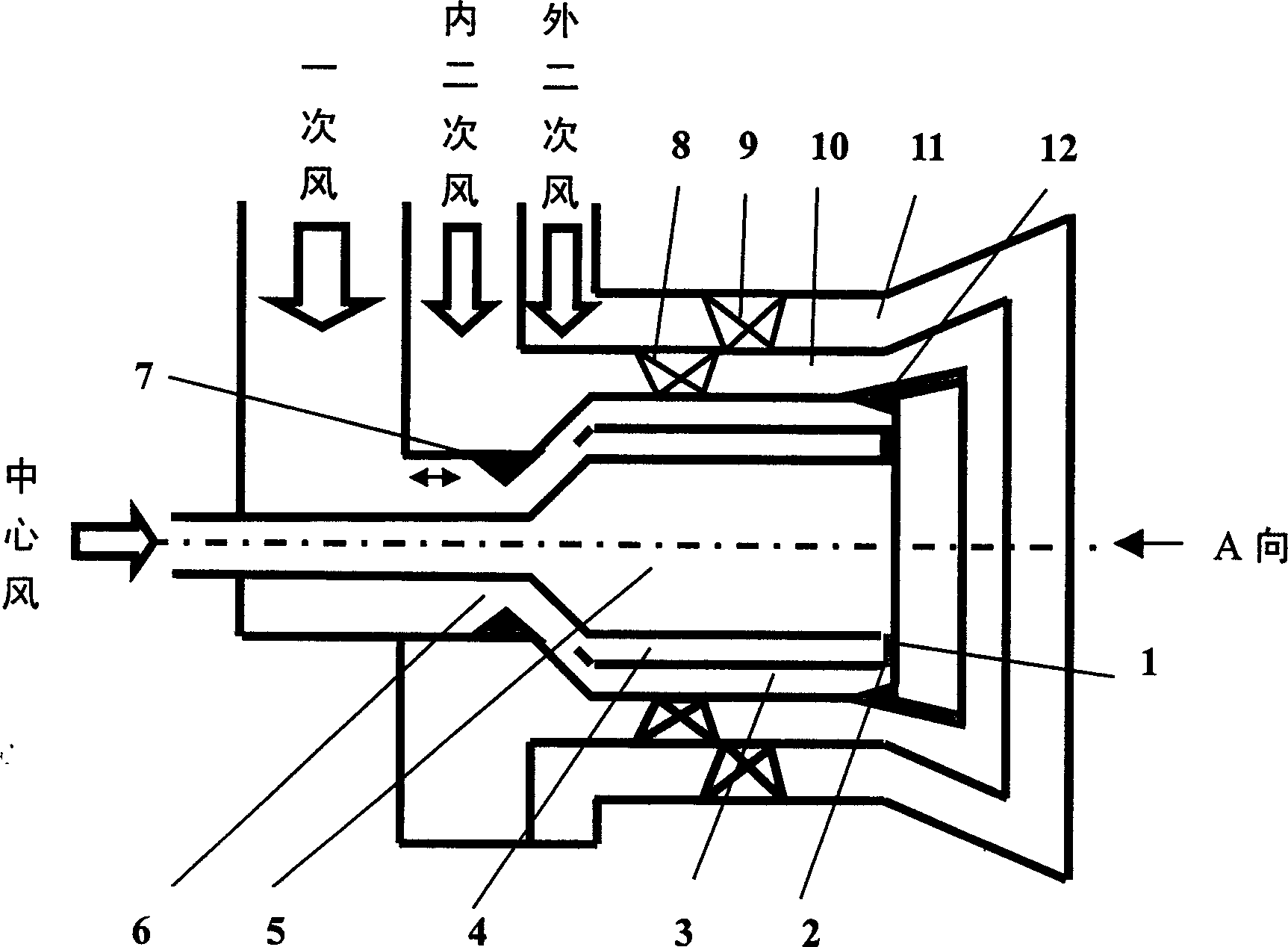

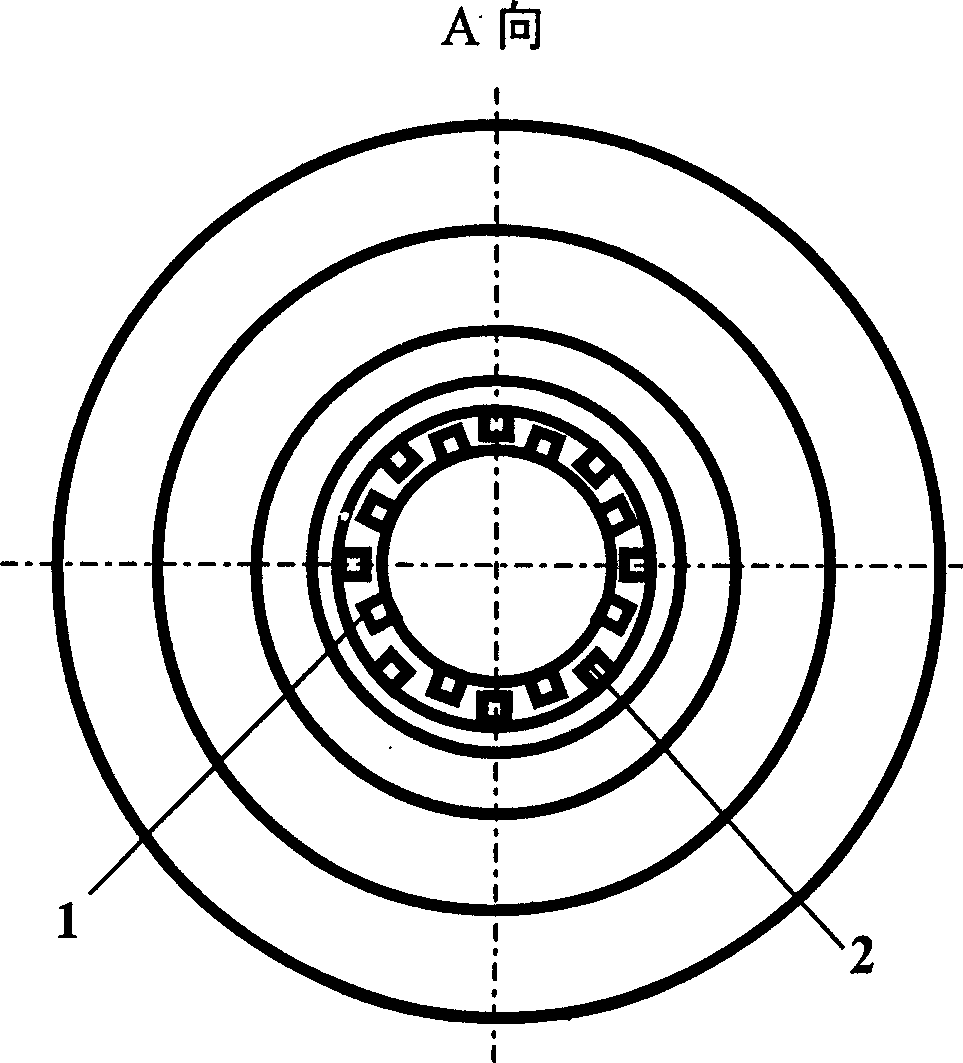

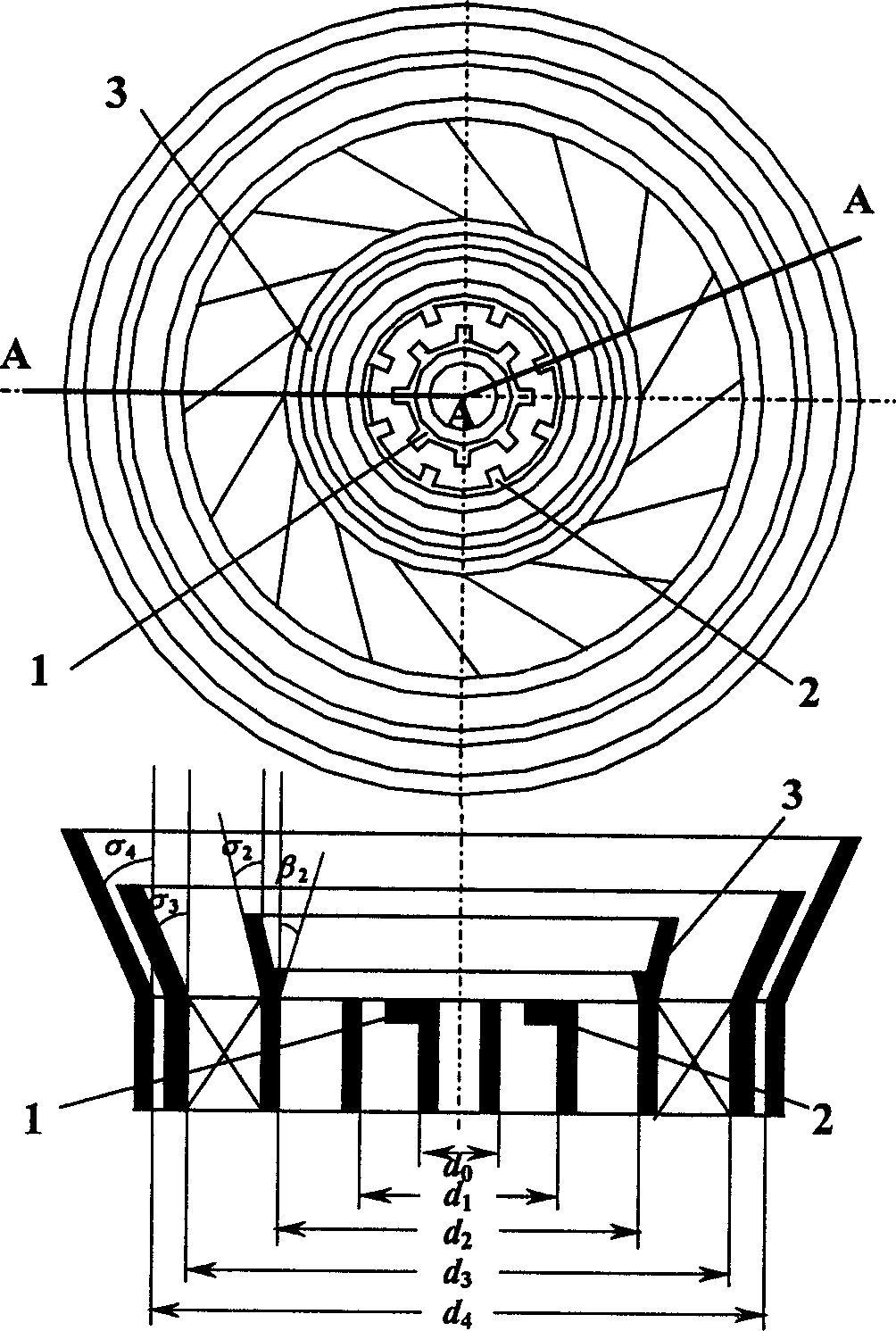

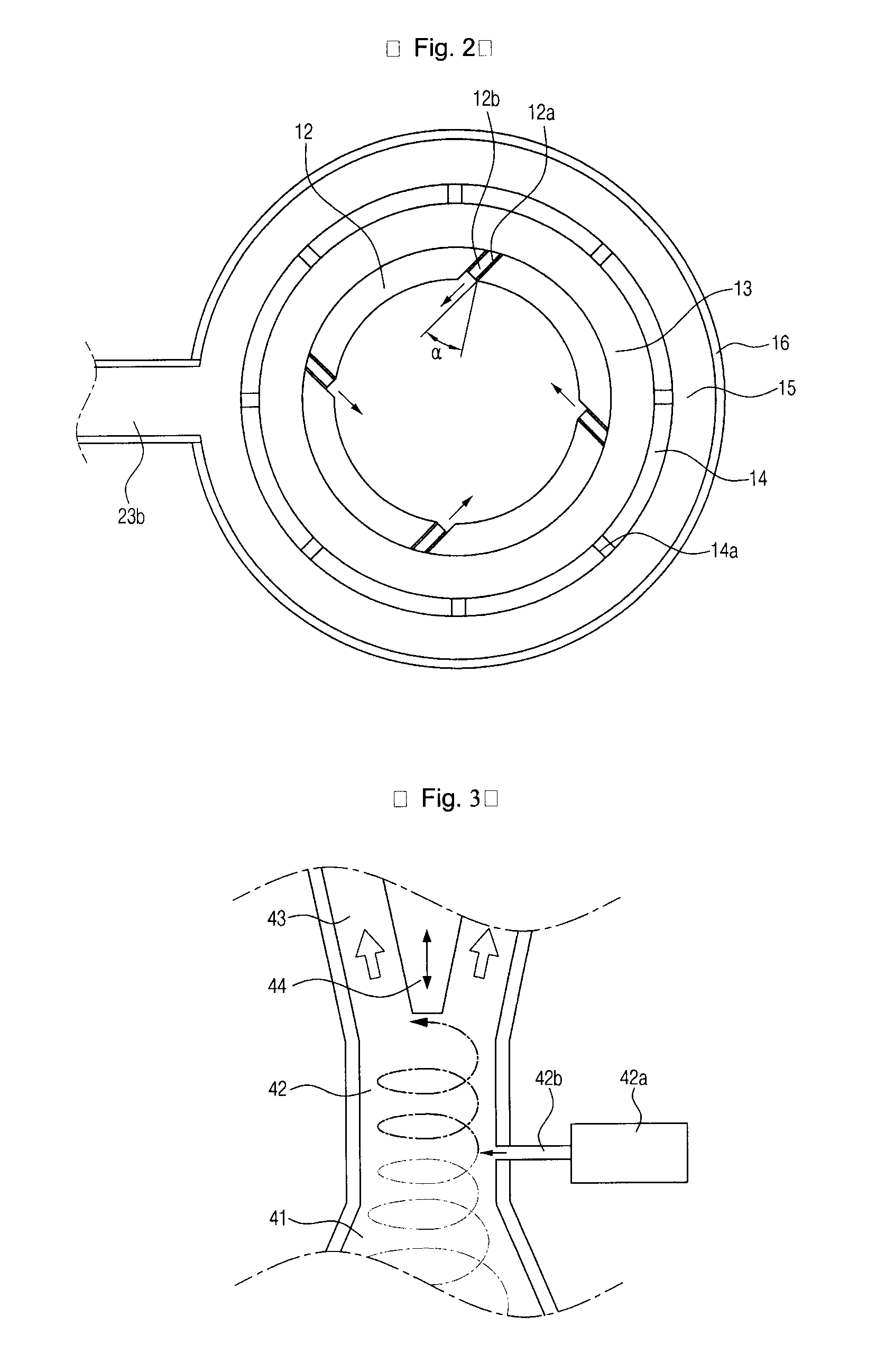

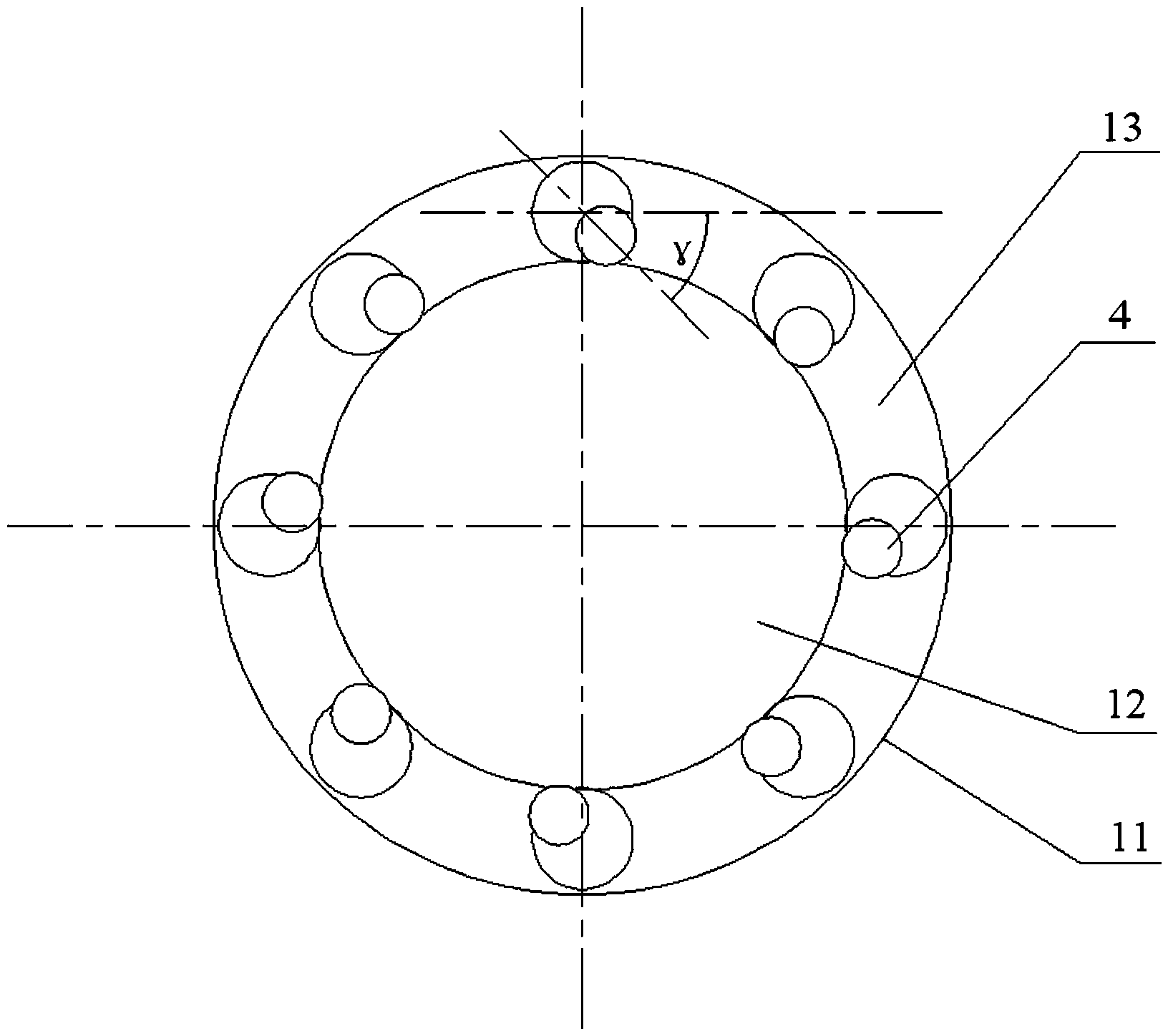

Radial gradient two air-controlled cyclone coal dust combustor

InactiveCN1477330AIncrease concentrationImprove heat transfer performancePulverulent fuel combustion burnersCycloneAir volume

The present invention discloses a radial gradation double air regulation cyclone coal powder burner, including nozzle with burner, internal first air channel, external first air channel, internal second air channel, external second air channel, internal tooth profile combustion-stabilizing ring, external tooth profile combustion-stabilizing ring, double-cone flare, stopper coal powder concentrator and central pipe cyclone coal powder burner. It utilizes two air channels to implement radial gradation combustion.

Owner:XI AN JIAOTONG UNIV

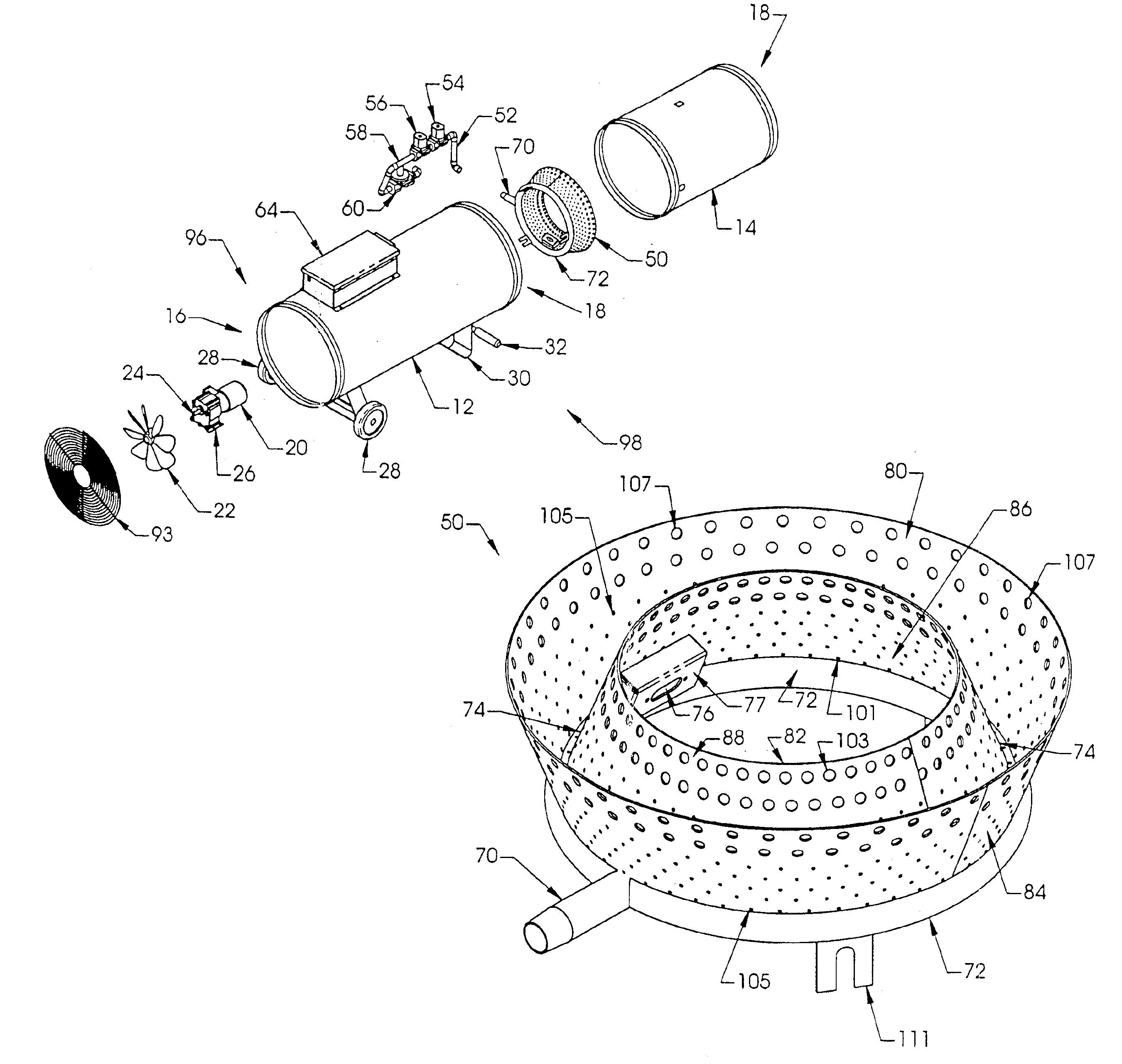

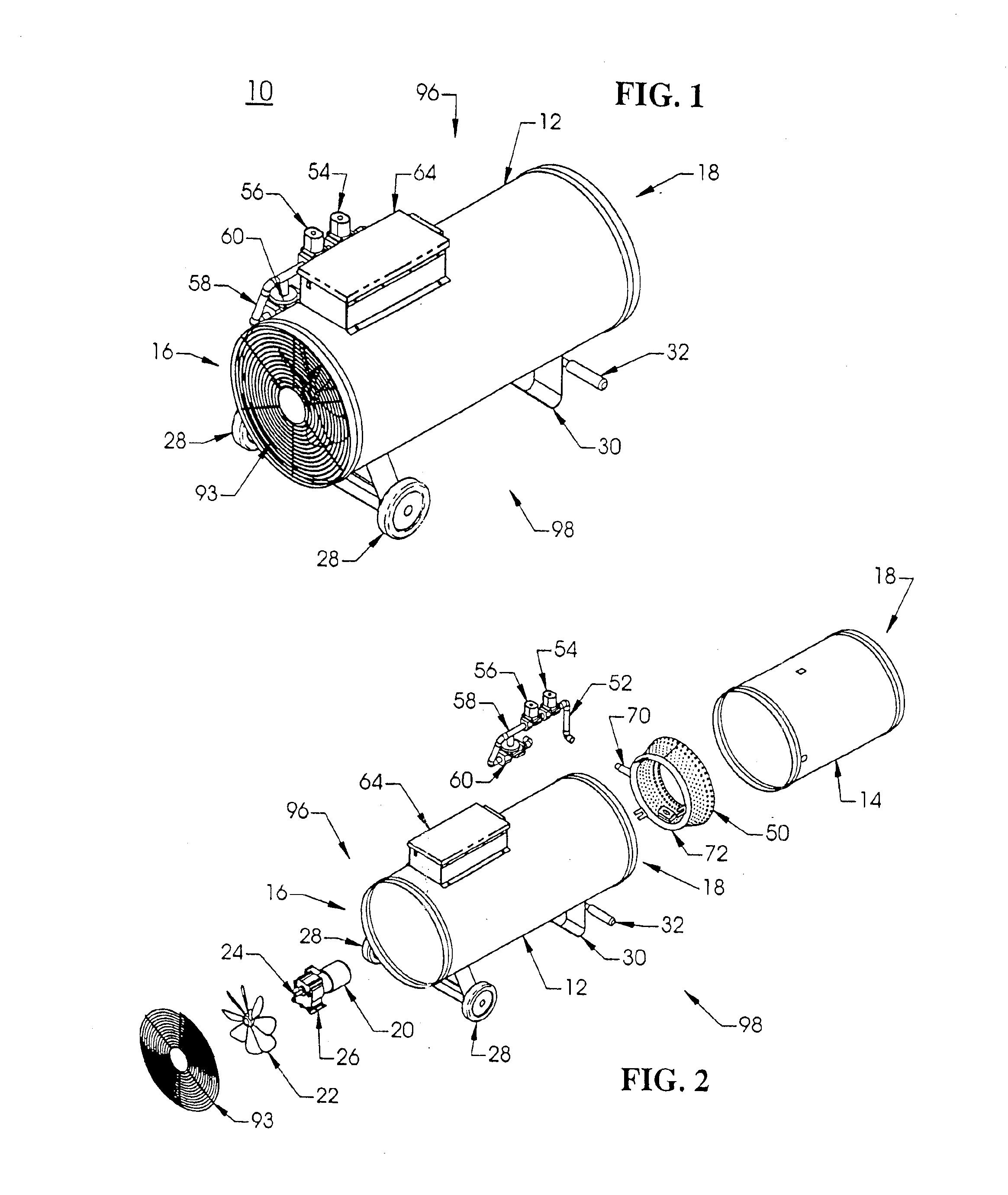

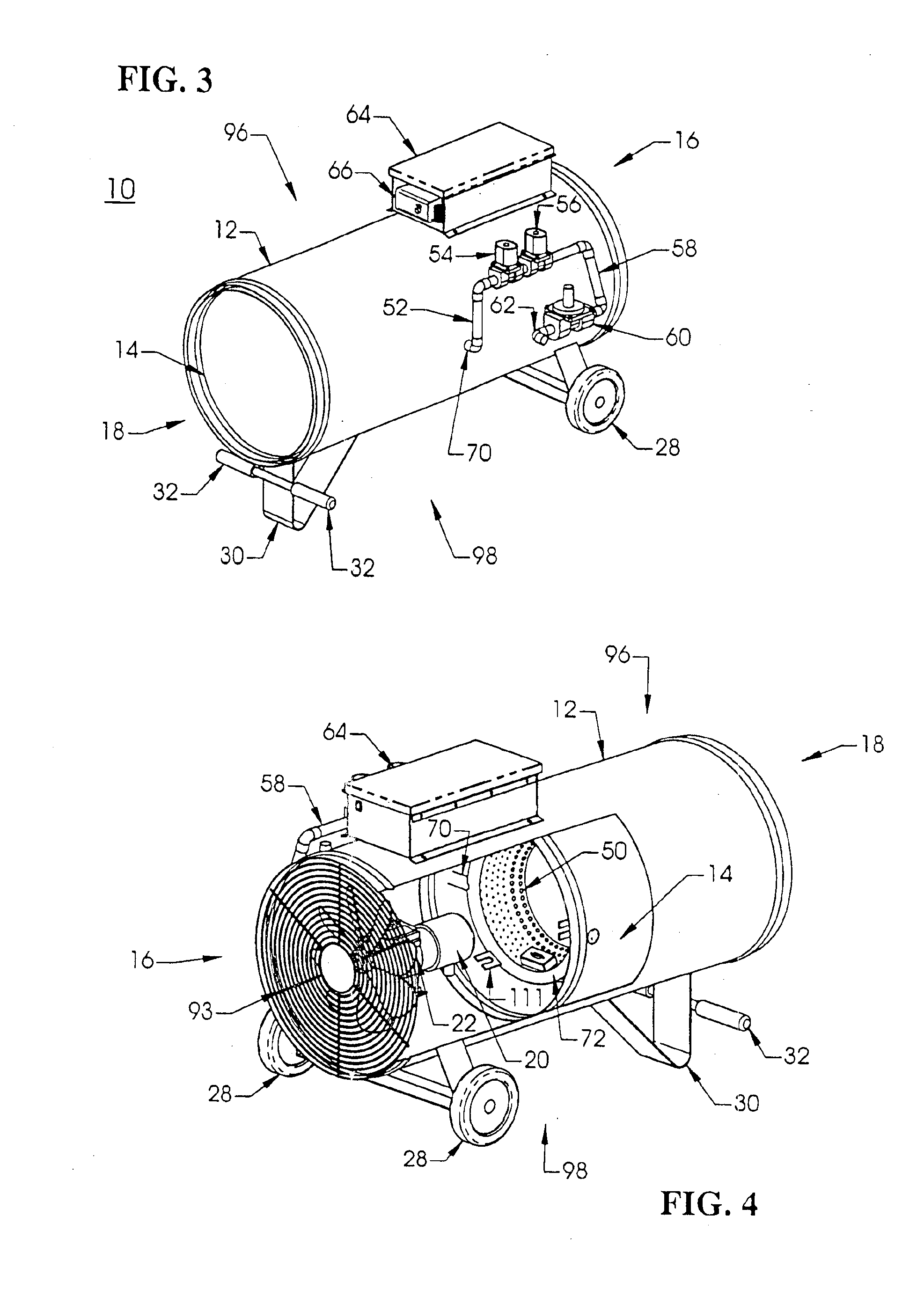

Combustion system for a heater

InactiveUS6880549B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemGas heater

A combustion system for a portable forced air heater having two frusta-conical sections attached to a circular burner tube, wherein each frusta-conical section has pre-determined vent hole patterns that allow the gas heater to have a variable burn rate.

Owner:SUNBELT RENTALS INC

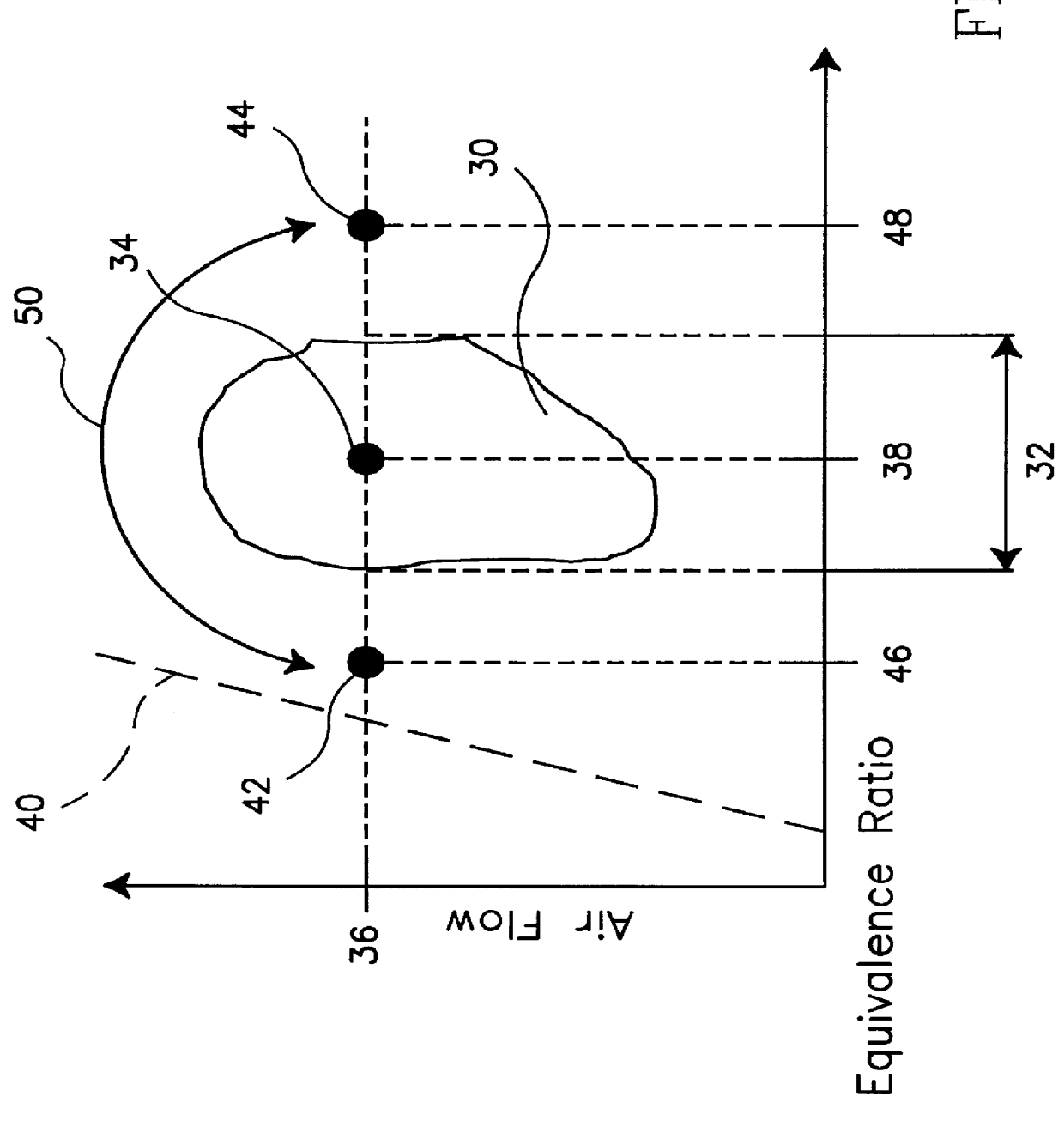

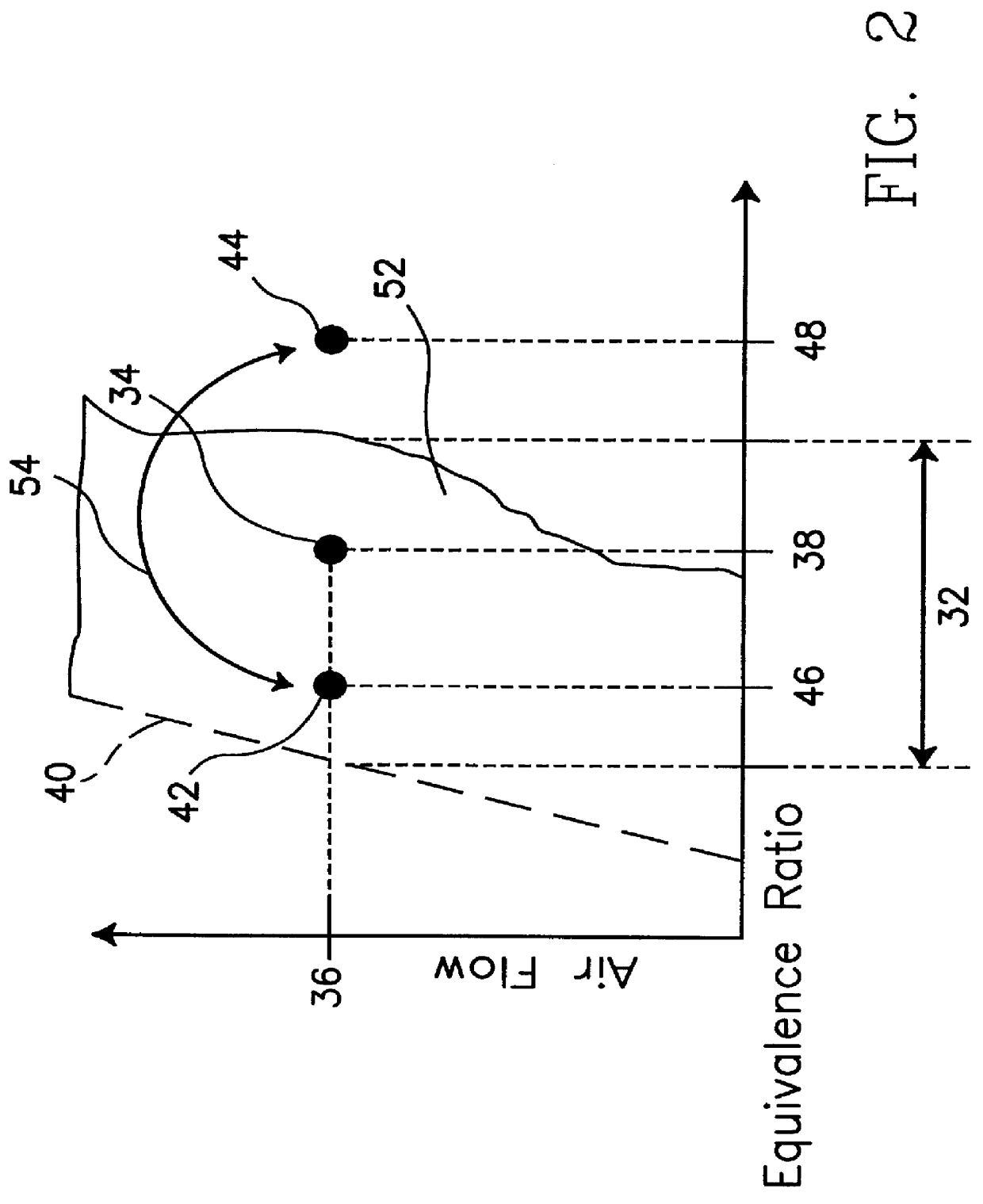

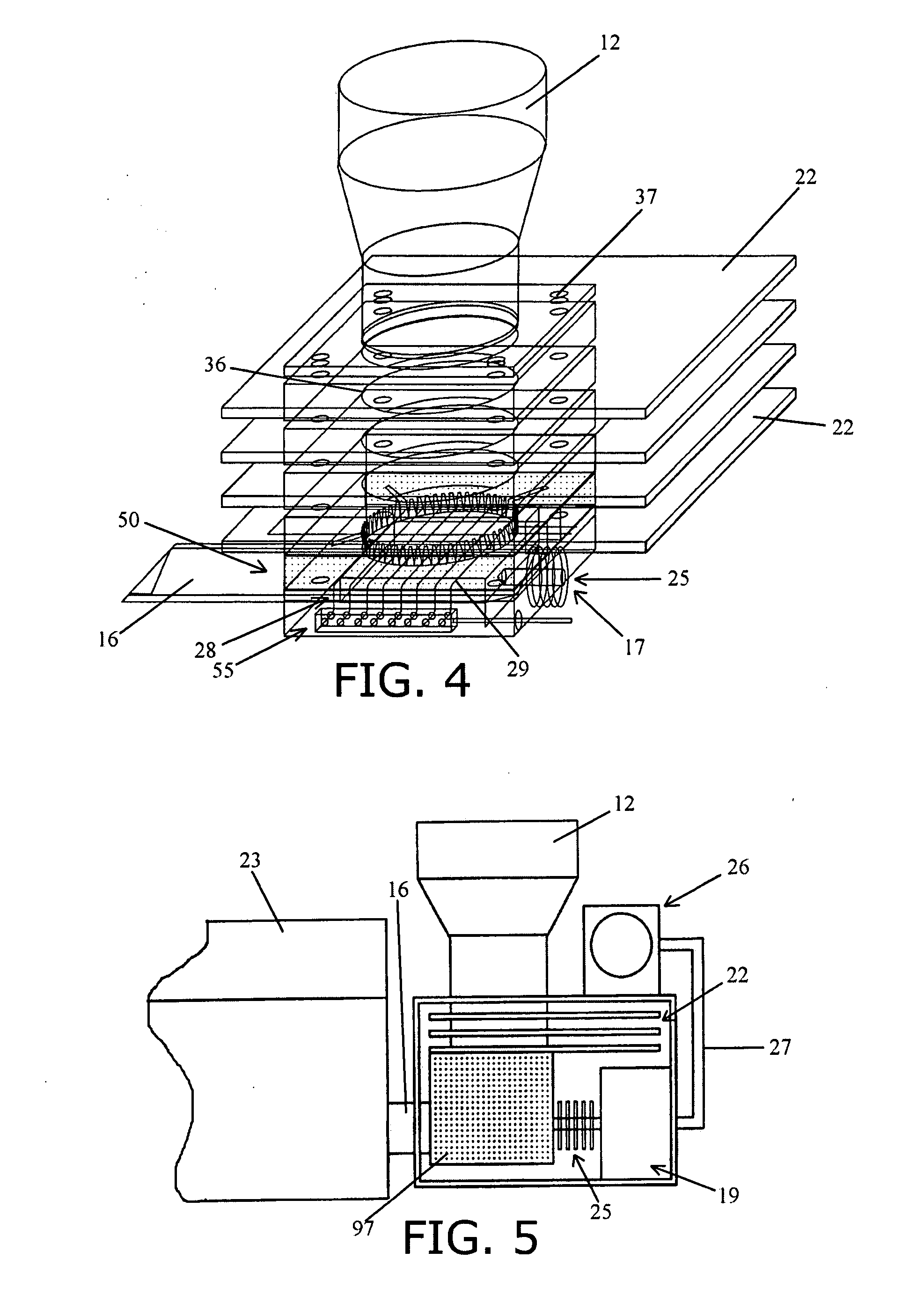

Periodic equivalence ratio modulation method and apparatus for controlling combustion instability

InactiveUS6059560AReduce pollutant emissionsReduce instabilityTurbine/propulsion fuel supply systemsPulsating combustionCombustion instabilityStable state

The periodic equivalence ratio modulation (PERM) method and apparatus significantly reduces and / or eliminates unstable conditions within a combustion chamber. The method involves modulating the equivalence ratio for the combustion device, such that the combustion device periodically operates outside of an identified unstable oscillation region. The equivalence ratio is modulated between preselected reference points, according to the shape of the oscillation region and operating parameters of the system. Preferably, the equivalence ratio is modulated from a first stable condition to a second stable condition, and, alternatively, the equivalence ratio is modulated from a stable condition to an unstable condition. The method is further applicable to multi-nozzle combustor designs, whereby individual nozzles are alternately modulated from stable to unstable conditions. Periodic equivalence ratio modulation (PERM) is accomplished by active control involving periodic, low frequency fuel modulation, whereby low frequency fuel pulses are injected into the main fuel delivery. Importantly, the fuel pulses are injected at a rate so as not to affect the desired time-average equivalence ratio for the combustion device.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

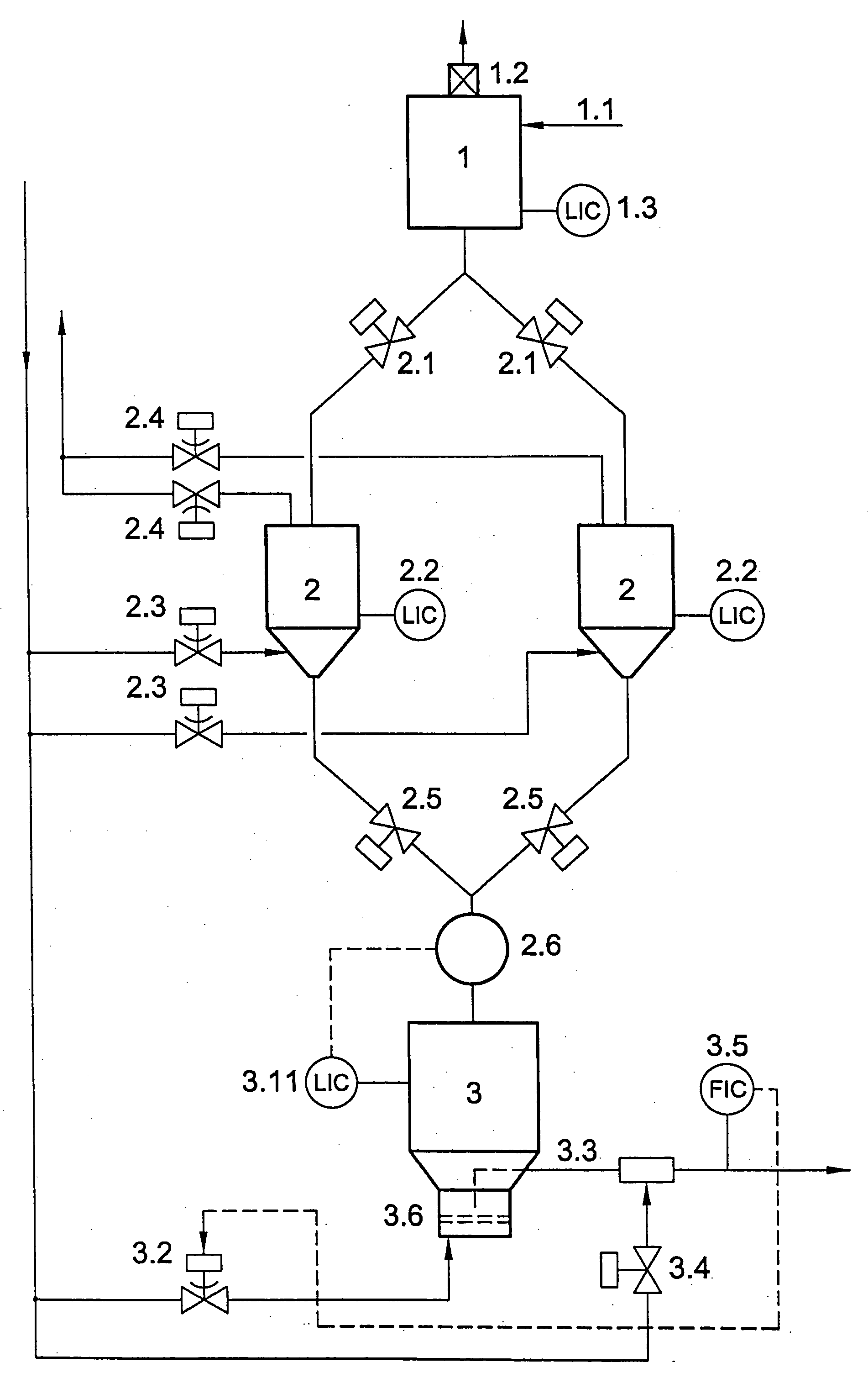

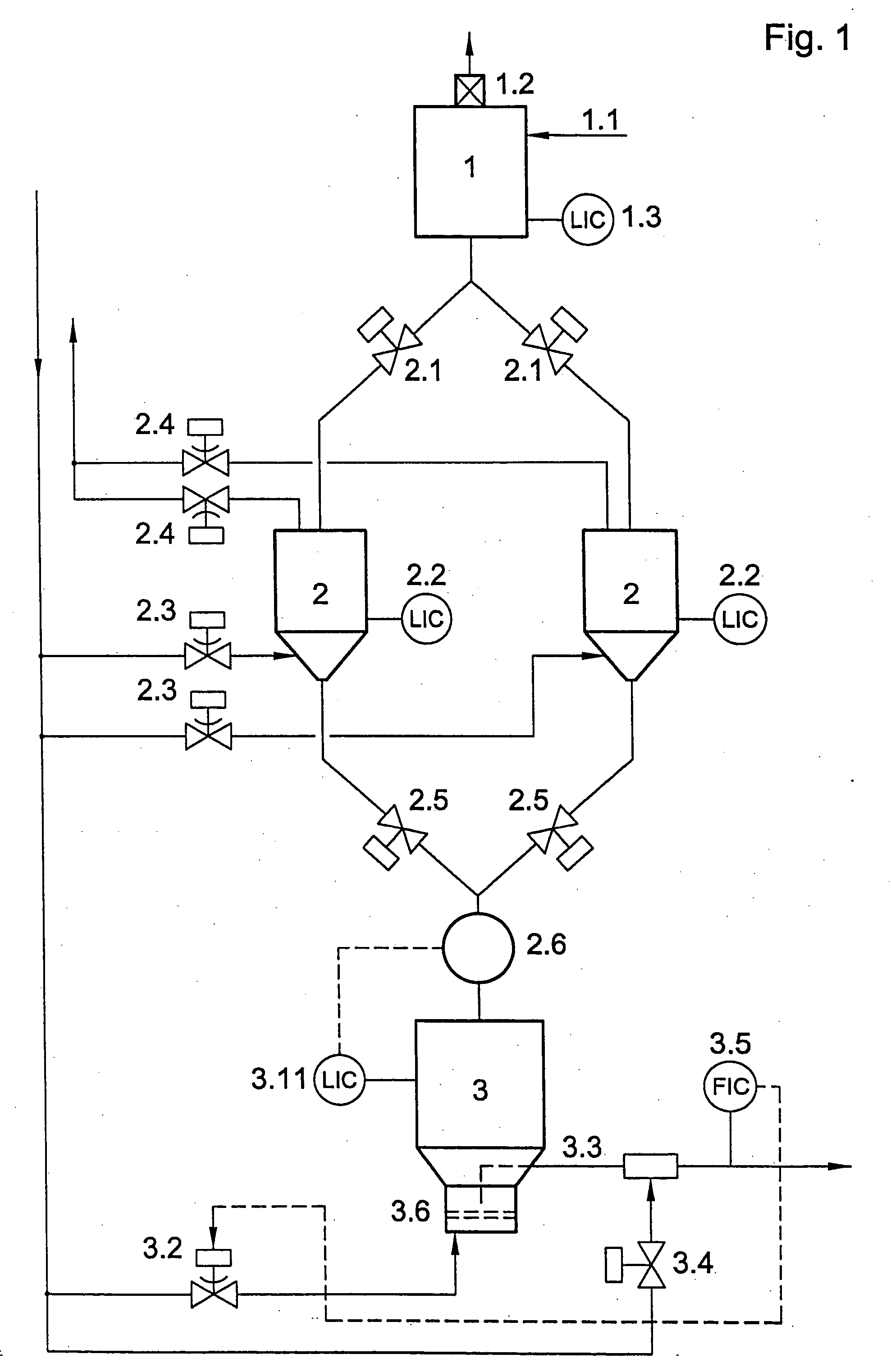

Method and device for the regulated feed of pulverized fuel to an entrained flow gasifier

ActiveUS20070074643A1Constant flowDouble gratePulverulent fuel combustion burnersCombustorFluidized bed

A method and device for metering and feeding pulverized fuels under pressure into gasification reactors, with the pulverized fuel being supplied alternately from an operational bunker through pressurized sluices to a metering tank, in the bottom of which a dense fluidized bed is formed by introducing fluidizing gas through a turbulence plate, with transport pipes immersed in the fluidized bed horizontally or vertically, by which the fluidized fuel is fed continuously through burners to a pressurized gasification reactor. By feeding in auxiliary gas in the immediate vicinity of the transport line inlet into the metering tank or the transport lines, the pressure differential between the metering tank and the gasification reactor is controlled and is utilized as a control parameter for pulverized fuel transport.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

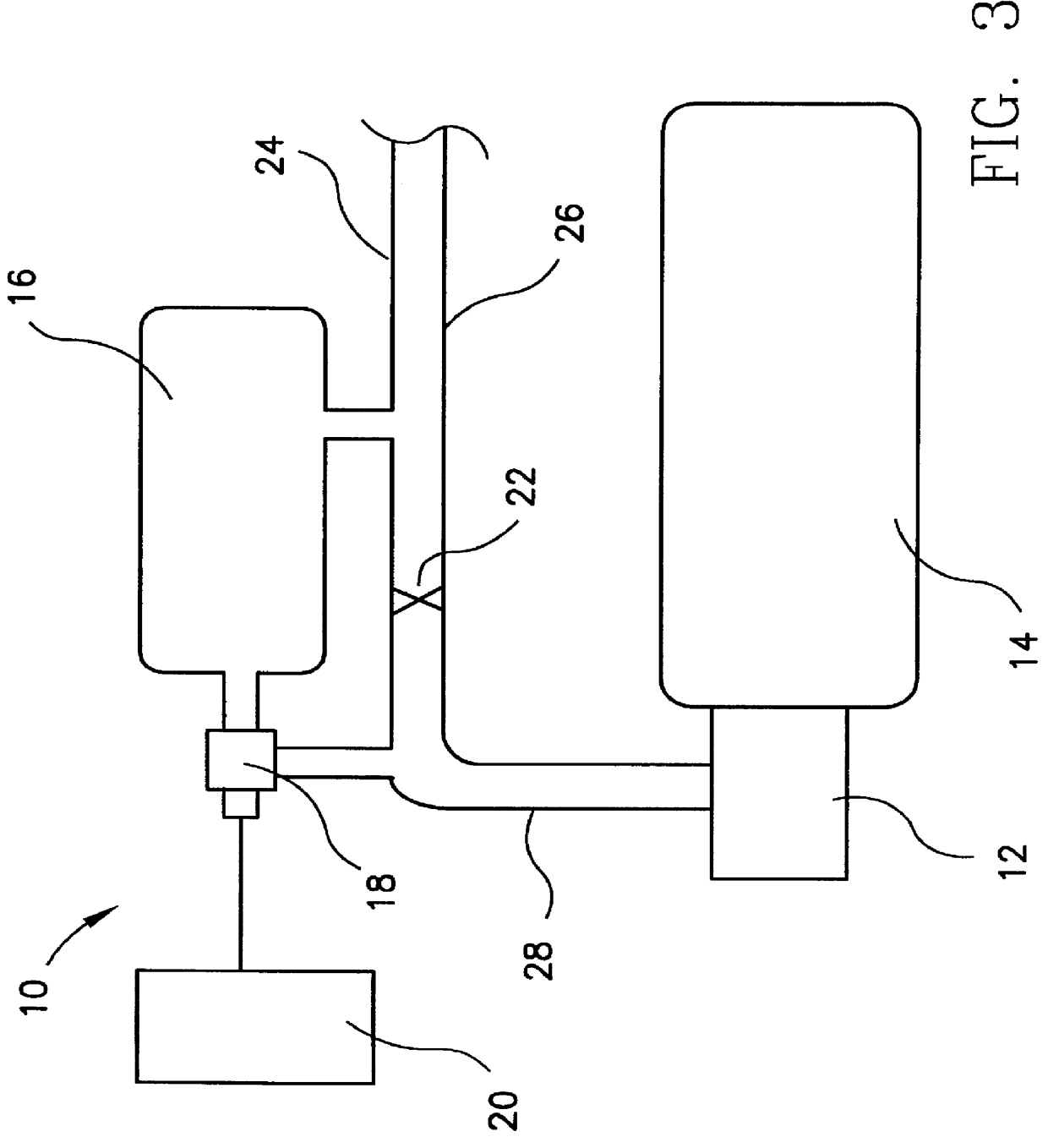

Combustion system with precombustor

InactiveUS20100077944A1Extended stayComplete combustionLiquid carbonaceous fuelsPulverulent fuel combustion burnersCombustion systemSolid fuel

A precombustor having a chamber having a first end and a second end, and an inlet configured to deliver a substantially parallel flow of solid fuel surrounded by oxygen at the first end. The first end further includes a recirculation step and the second end fluidly communicates with a furnace. The inlet and the recirculation step are arranged to form a recirculation zone of at least a portion of the solid fuel and the oxygen. A combustion system and method for operating a combustion system are also disclosed.

Owner:AIR PROD & CHEM INC

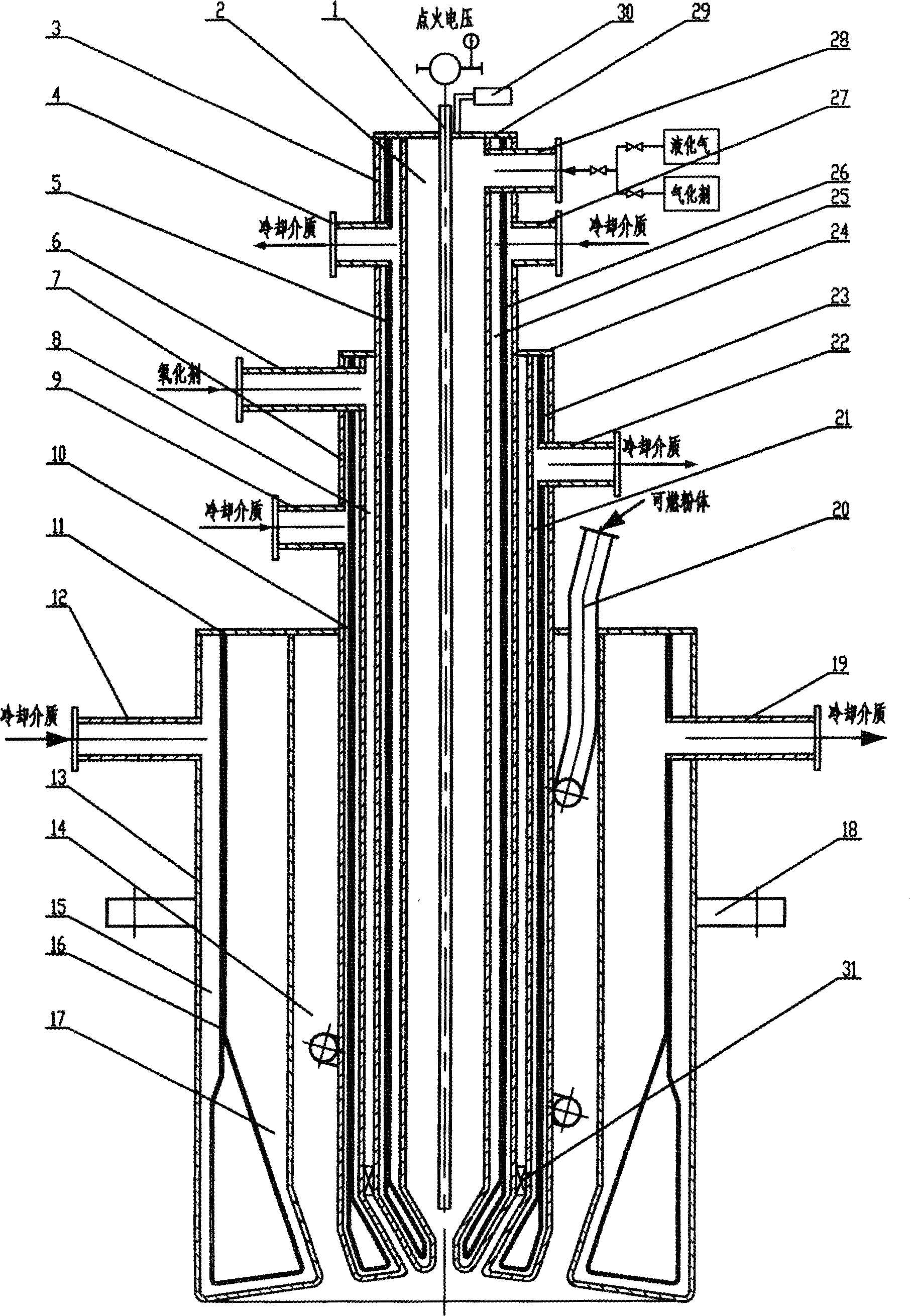

Powder-combustible vortex burner

ActiveCN1710333AAvoid ablationExtended service lifePulverulent fuel combustion burnersFlame detectionCooling channel

A vortex burner of combustible micropowder i.e pulverized coal is prepared by setting primary cooling jacket with an ignition device at the centre of it and a flame detection device at jacket top cover ; arranging primary , secondary and tertiary cooling jackets in sequence coaxially as radial outwards to form primary and secondary air channel and cooling channel , tertiary micropowder channel and tertiary channel ; connecting primary air-channel to fuel gas inlet tube and gasifying agent inlet tube after they are combined for switching over two gases by valve ; setting spiral - flow device at secondary air-channel outlet and jetting out pulverized coal in spiral - flow way at its conveying tube outlet.

Owner:CHANGZHENG ENG

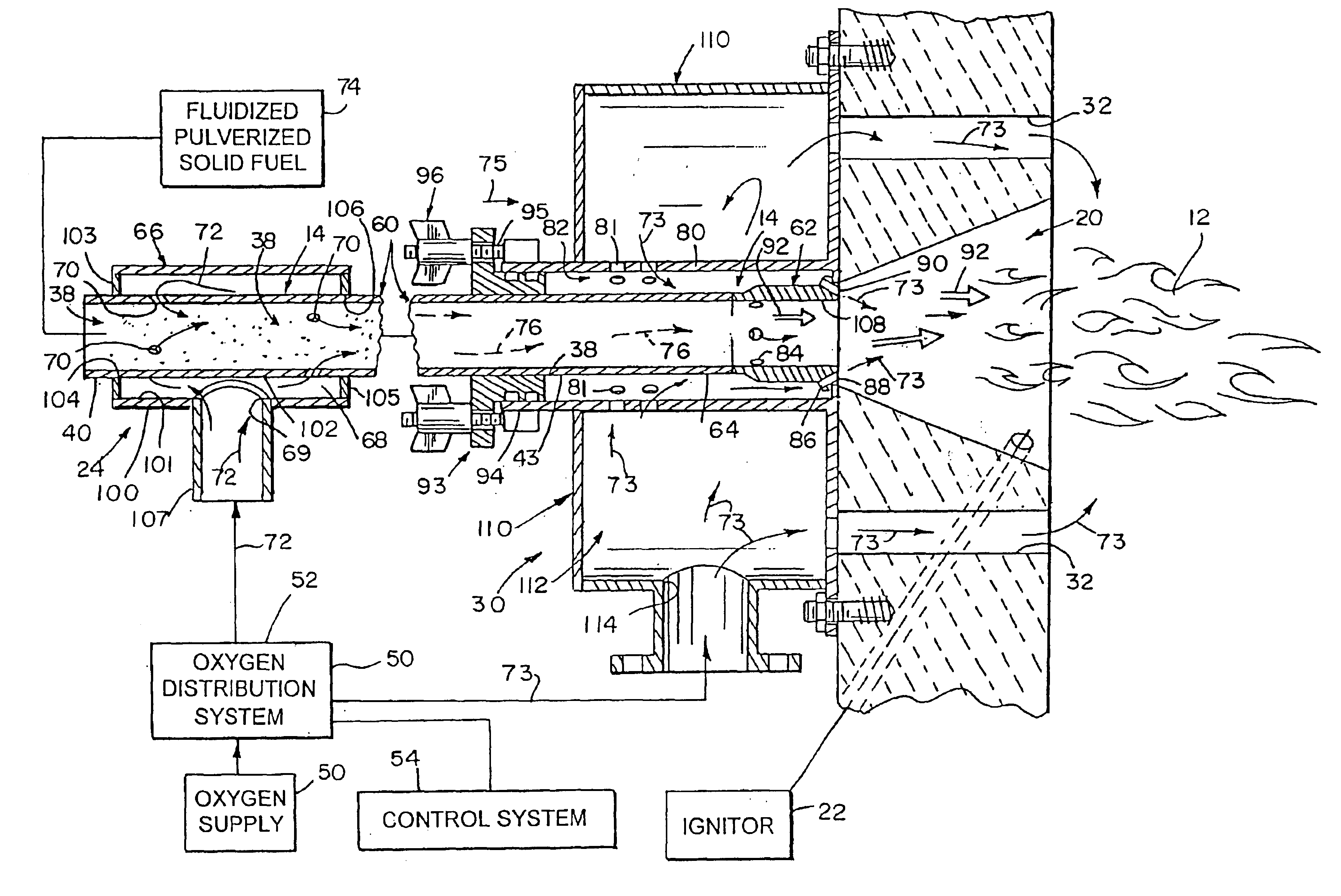

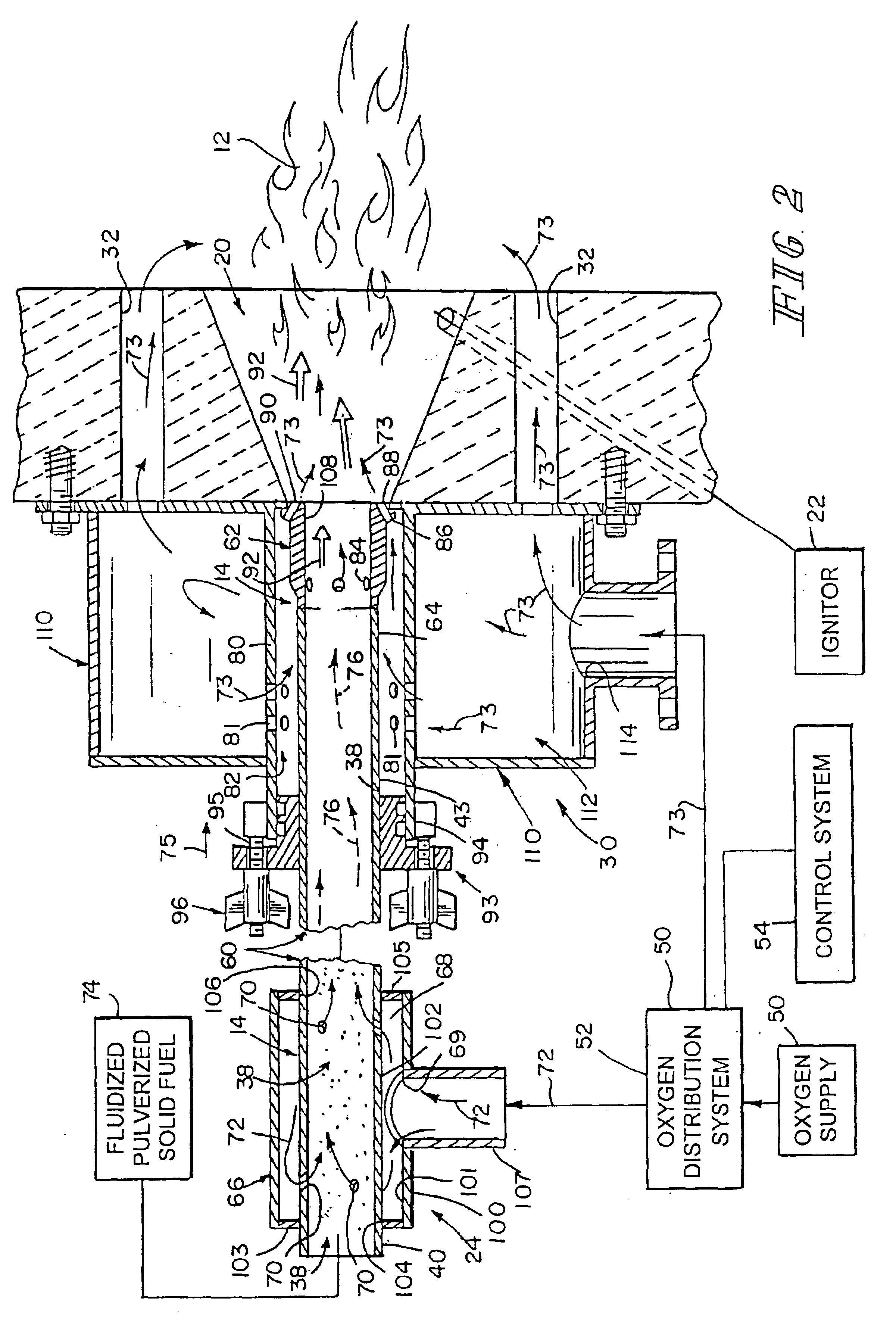

Burner with oxygen and fuel mixing apparatus

InactiveUS6843185B1Reduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSolid fuel

An oxygen-fuel combustion system combines oxygen and fuel to produce a flame. The system distributes oxygen to a stream of fluidized, pulverized, solid fuel at various sites before and after ignition. The system is operable to vary the concentration of oxygen in an oxygen-fuel mixture extant at those sites.

Owner:MAXON

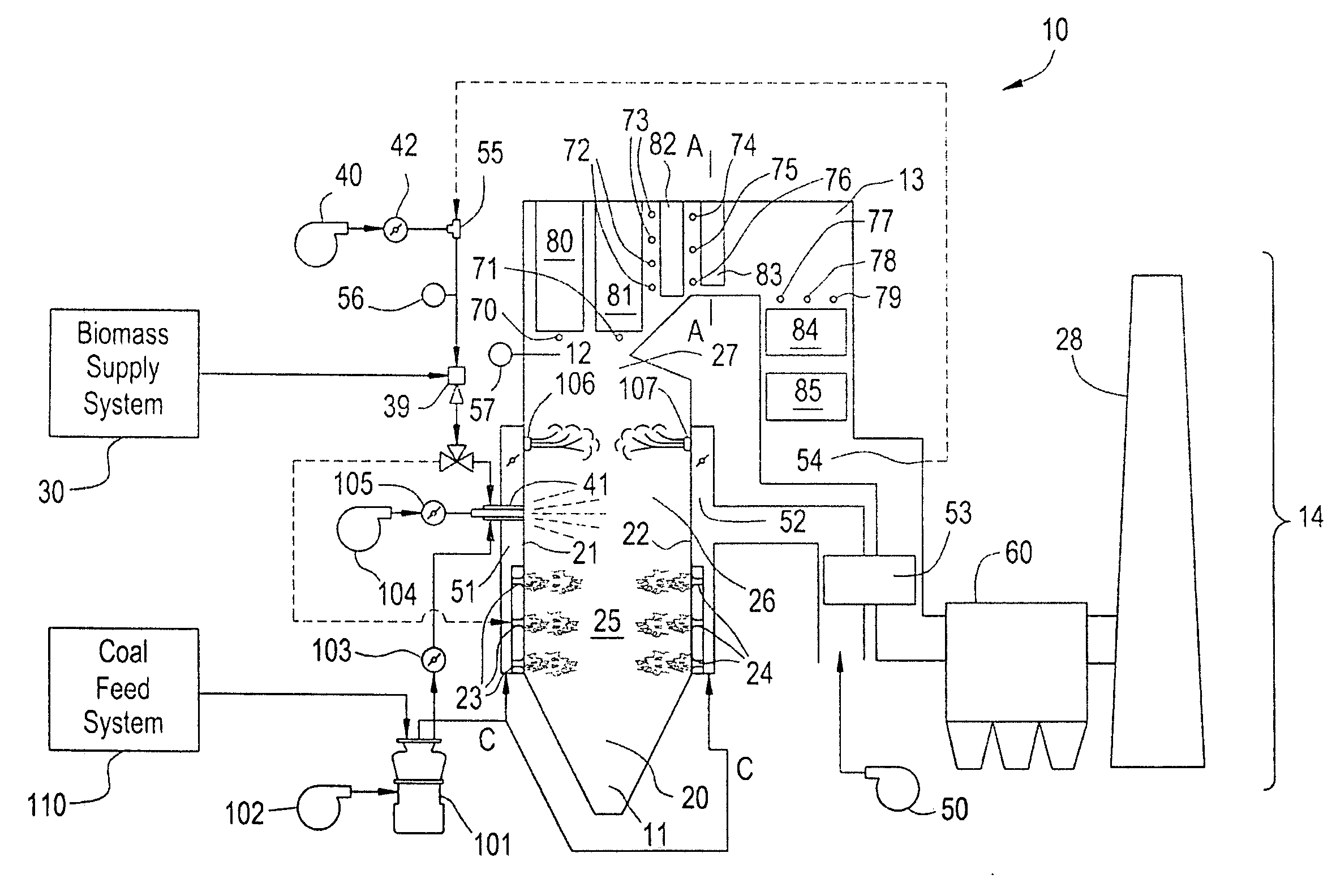

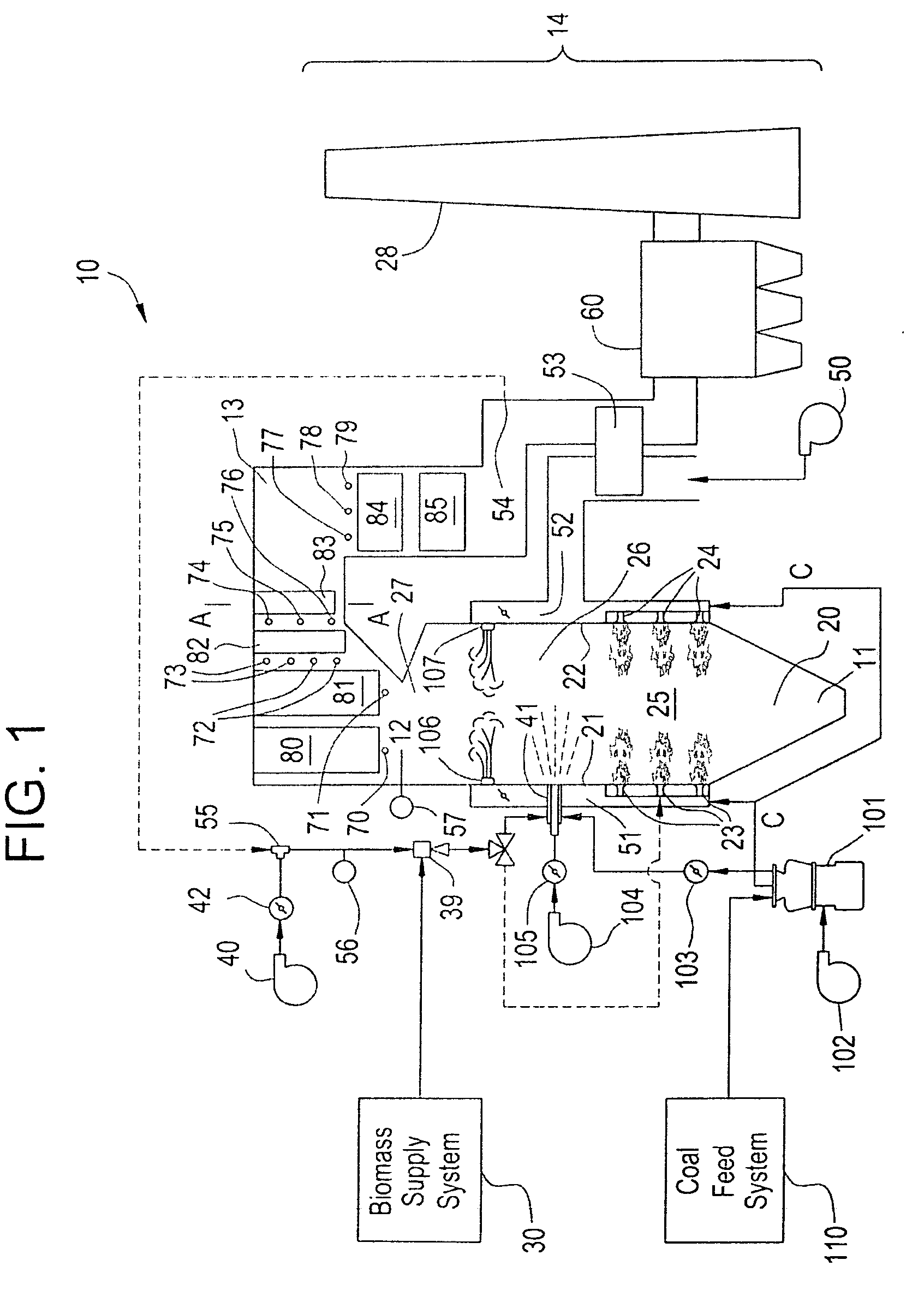

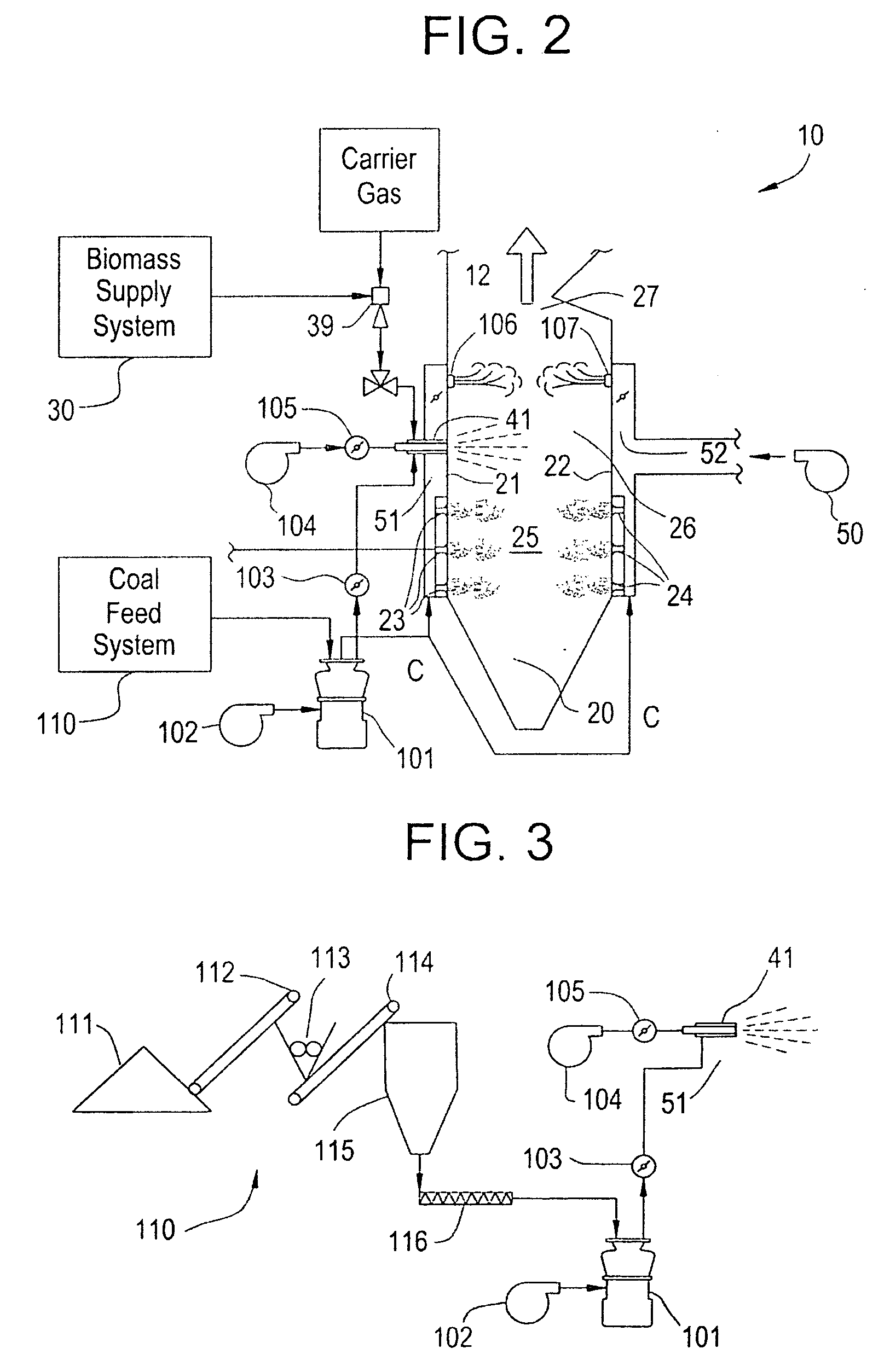

Method and apparatus for operating a fuel flexible furnace to reduce pollutants in emissions

ActiveUS20090078175A1Reduce pollutant emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionAdditive ingredient

A fuel flexible furnace, including a main combustion zone, a reburn zone downstream from the main combustion zone, and a delivery system operably coupled to supplies of biomass and coal and configured to deliver the biomass and the coal as ingredients of first and reburn fuels to the main combustion zone and the reburn zone, with each fuel including flexible quantities of the biomass and / or the coal. The flexible quantities are variable with the furnace in an operating condition.

Owner:GENERAL ELECTRIC CO

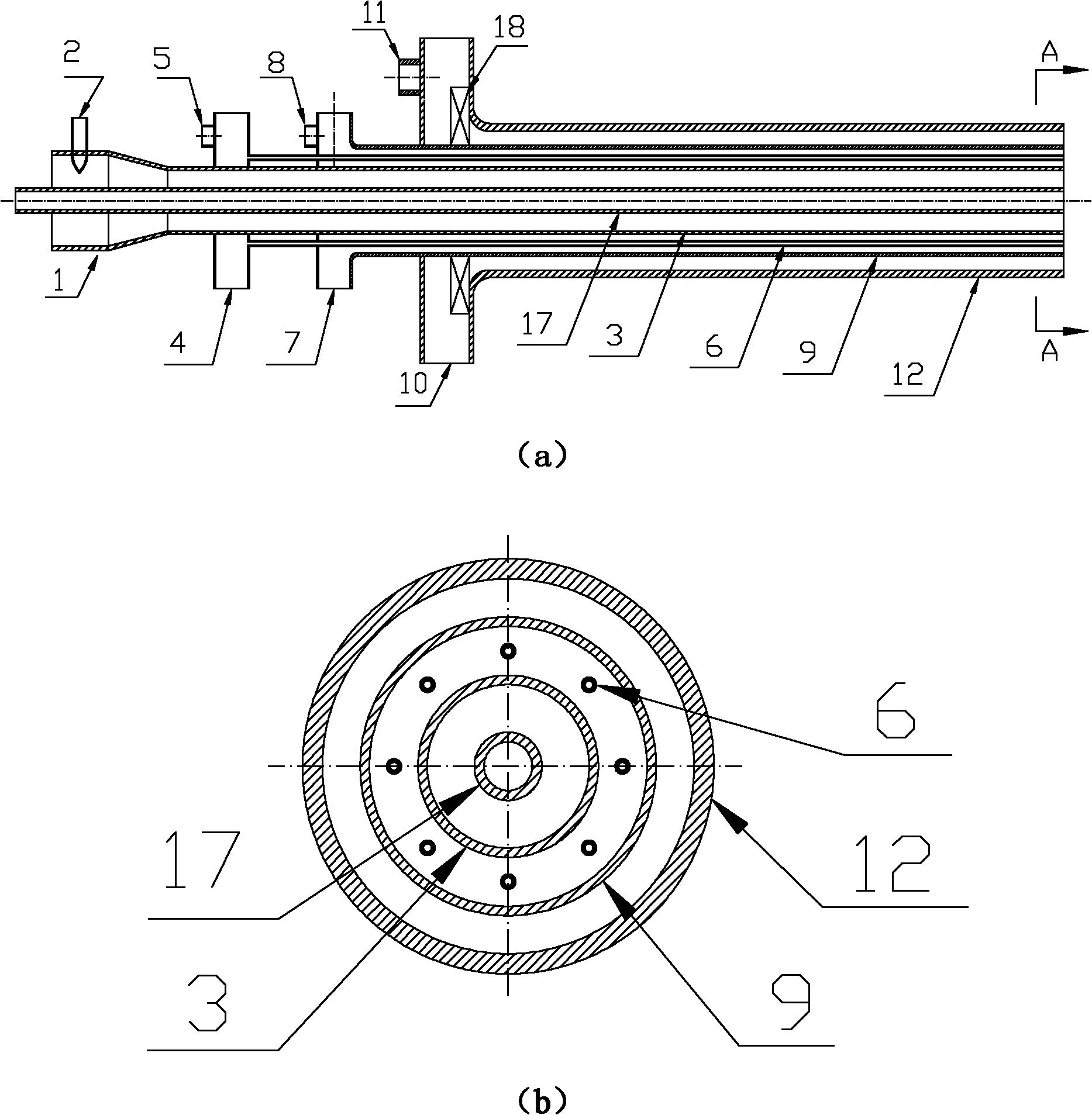

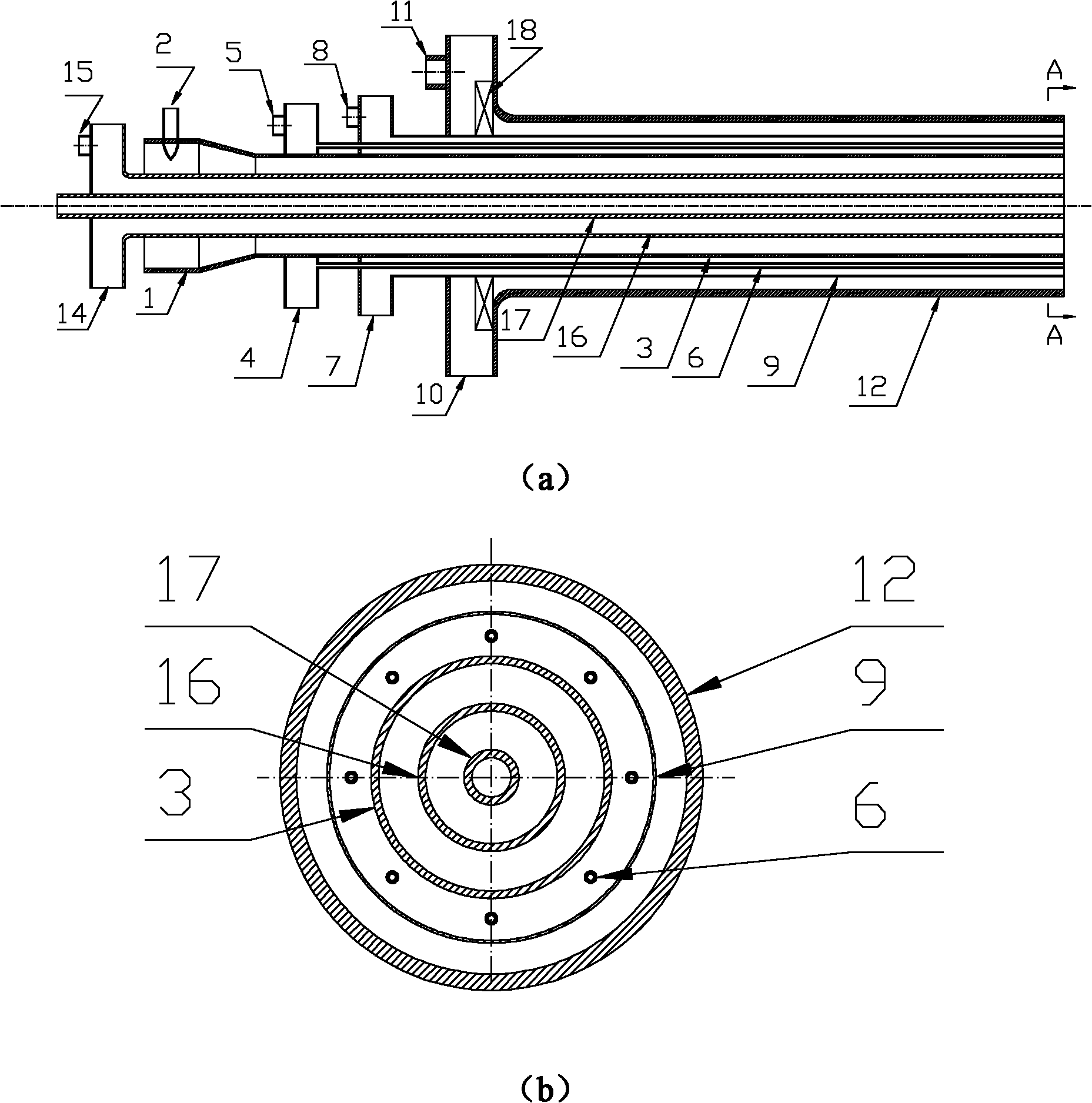

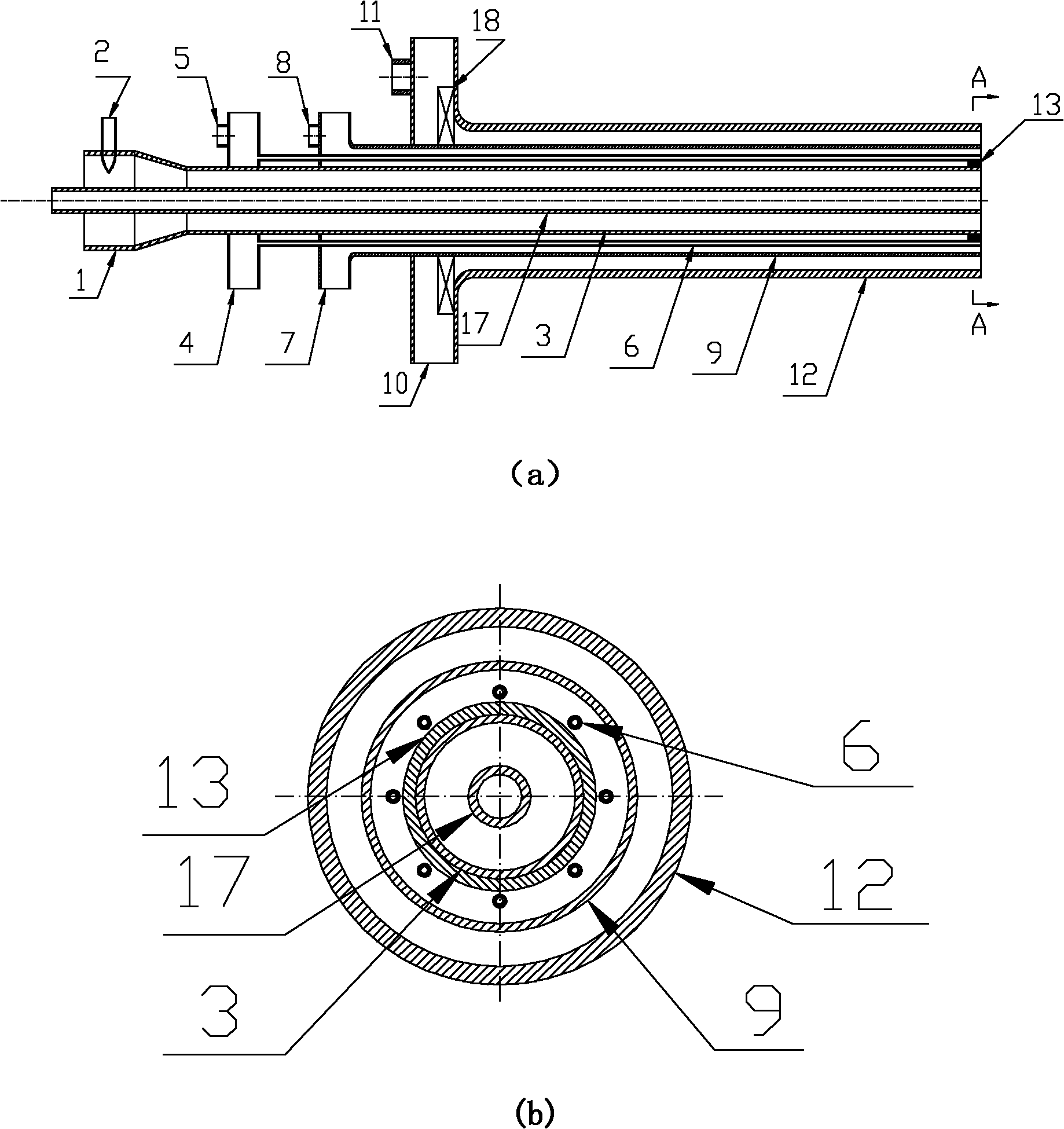

Oxygen-rich combustor

ActiveCN101825278AStable combustionSimple technologyPulverulent fuel combustion burnersDirect carbon-dioxide mitigationCombustorJet flow

The invention discloses an oxygen-rich combustor, which comprises an oil gun barrel, a primary air swirl generator, an inner secondary air generator and an outer secondary air swirl generator arranged coaxially, wherein an oxygen injector is positioned between the primary air swirl generator and the inner secondary air generator and comprises an oxygen chamber, an oxygen inlet pipe and oxygen pipes, the oxygen inlet pipe is positioned at one end of the oxygen chamber, and the oxygen pipes are connected with the other end of the oxygen chamber; and the oxygen pipes are uniformly distributed along the circumference around the axial direction. The air or a circulating flue gas is used as primary air for conveying coal powder; the oxygen injector conveys the air or pure oxygen; the inner secondary air and the outer secondary air mainly are the air or the pure oxygen / the circulating flue gas; the swirling number adjustability of the outer secondary air swirl generator, the action of high-speed oxygen jet flows and the oxygen mixed mode ensure that primary and secondary wind momentums are adjustable, and are favorable for sufficient combustion, low pollutant emission and heat and mass transfer.

Owner:HUAZHONG UNIV OF SCI & TECH

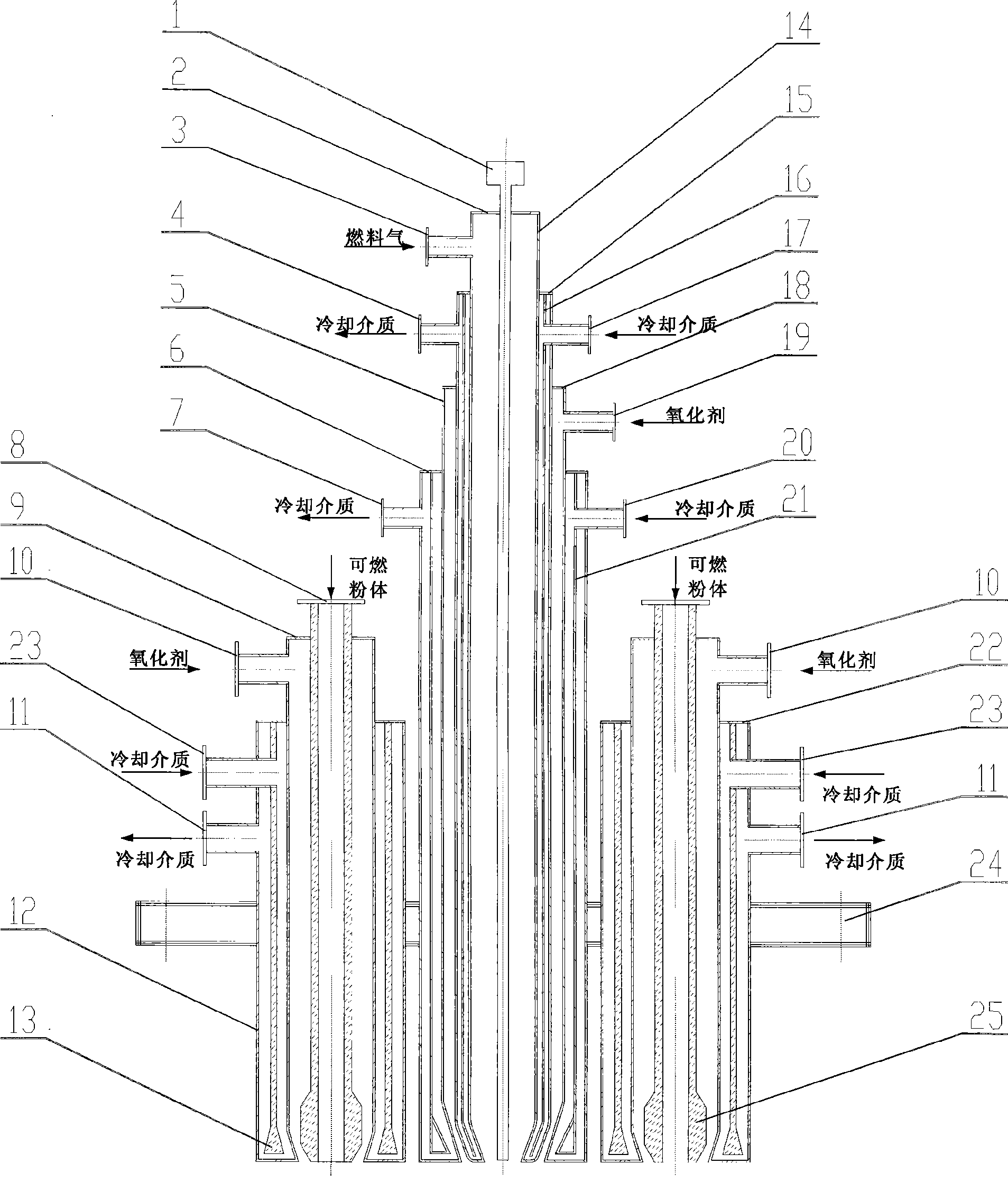

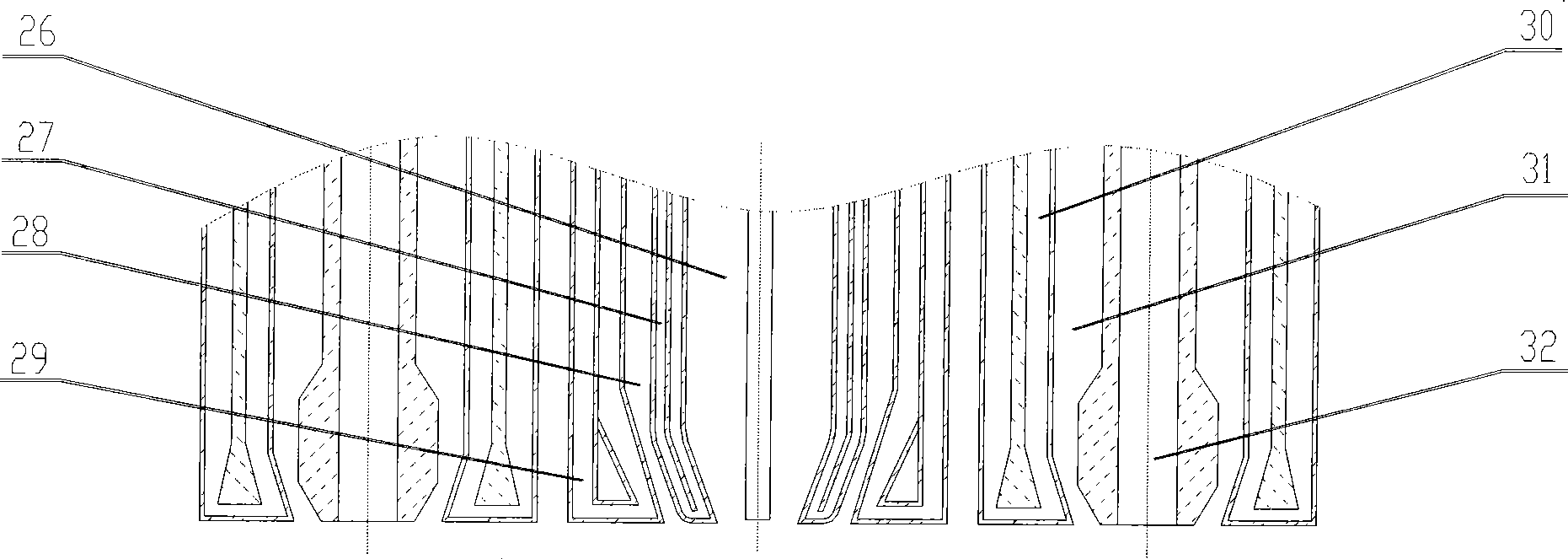

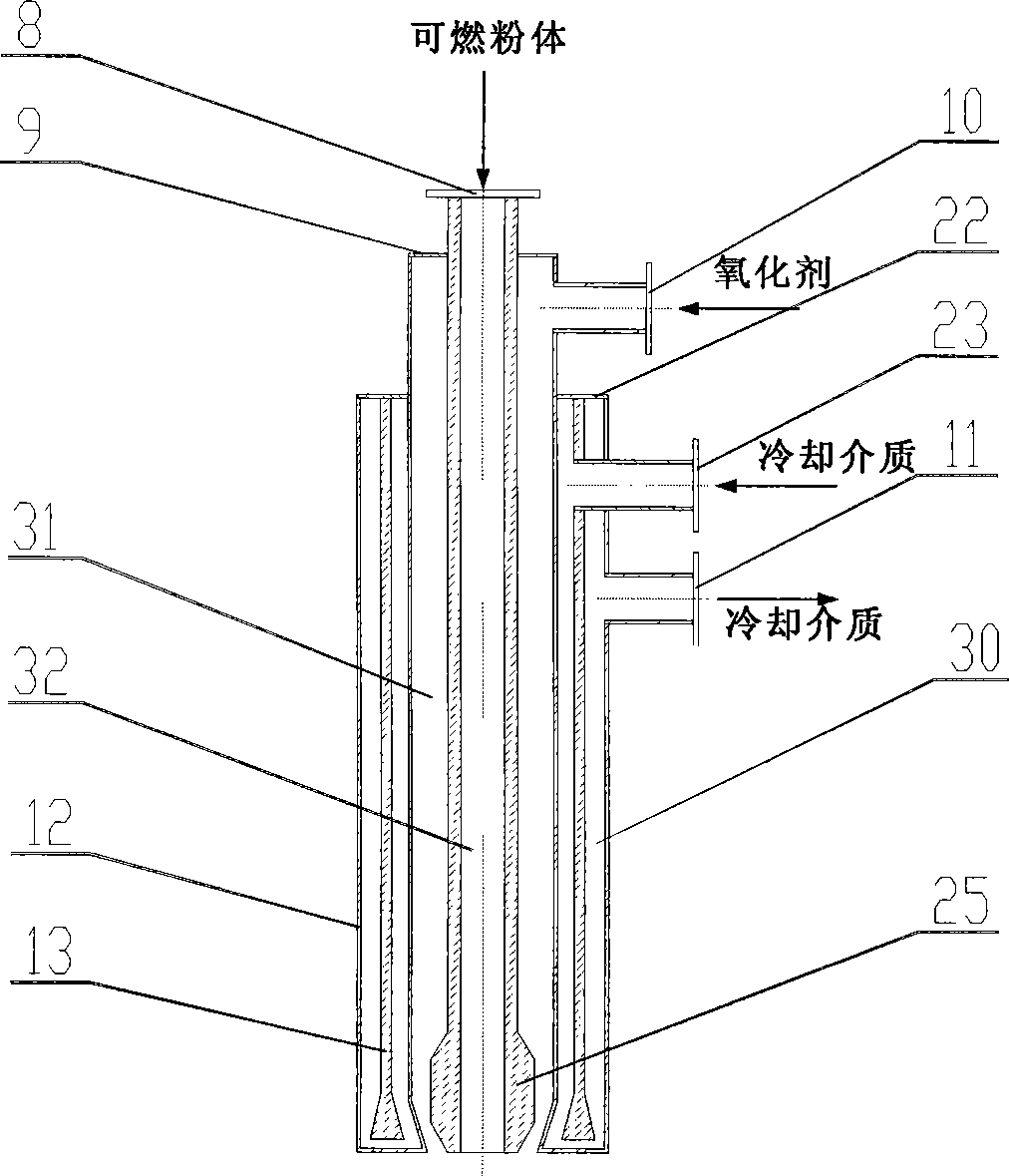

Combined type multi-injector burner

ActiveCN101446413AReduce wearUniform temperature fieldPulverulent fuel combustion burnersMultiple burner assemblyCombustorSingle process

The invention provides a combined type multi-injector burner with a flammable powder body, which comprises an igniter burner positioned at the center of the burner and a plurality of process combustion nozzles which are evenly formed on the periphery of the igniter burner in the circumferential direction, wherein, each process combustion nozzle comprises a coal dust passage positioned at the center of each process combustion nozzle and a first annular oxidizer passage arranged outside the coal dust passage. In the combined type multi-injector burner, a plurality of process combustion nozzles and the igniter burner are assembled together, the structure is compact, and the combustion efficiency as well as the gasification efficiency are increased; the maintenance of each single process combustion nozzle is flexible, and the disassembly and the assembly are convenient; the process combustion nozzles can limberly adjust the load of the burner, mediums in a hearth can be mixed evenly through repeated impacts, the flame fullness degree is good, and a uniform multilayer cooling structure can protect the burner effectively and prolong the service life of the burner.

Owner:CHANGZHENG ENG

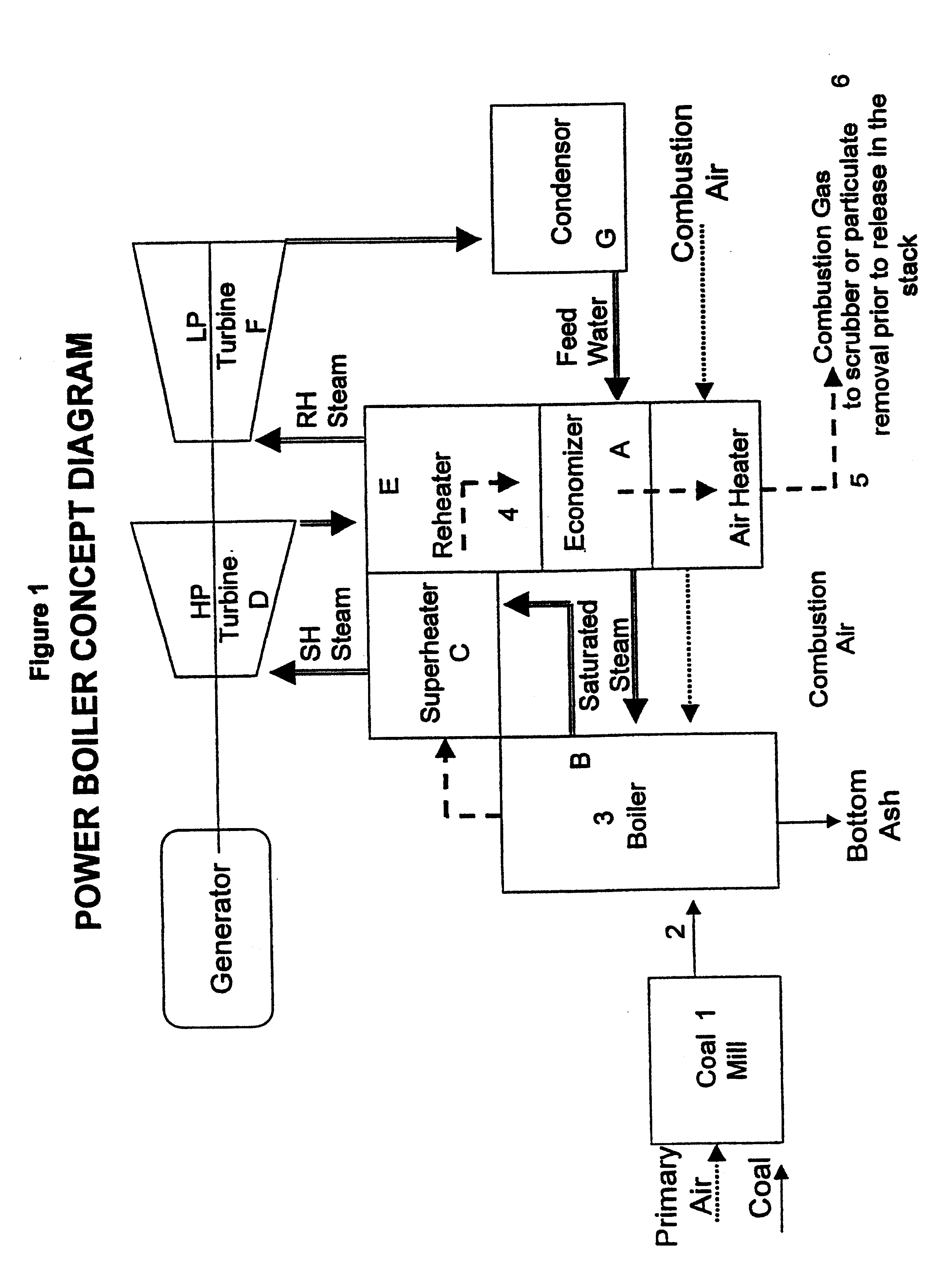

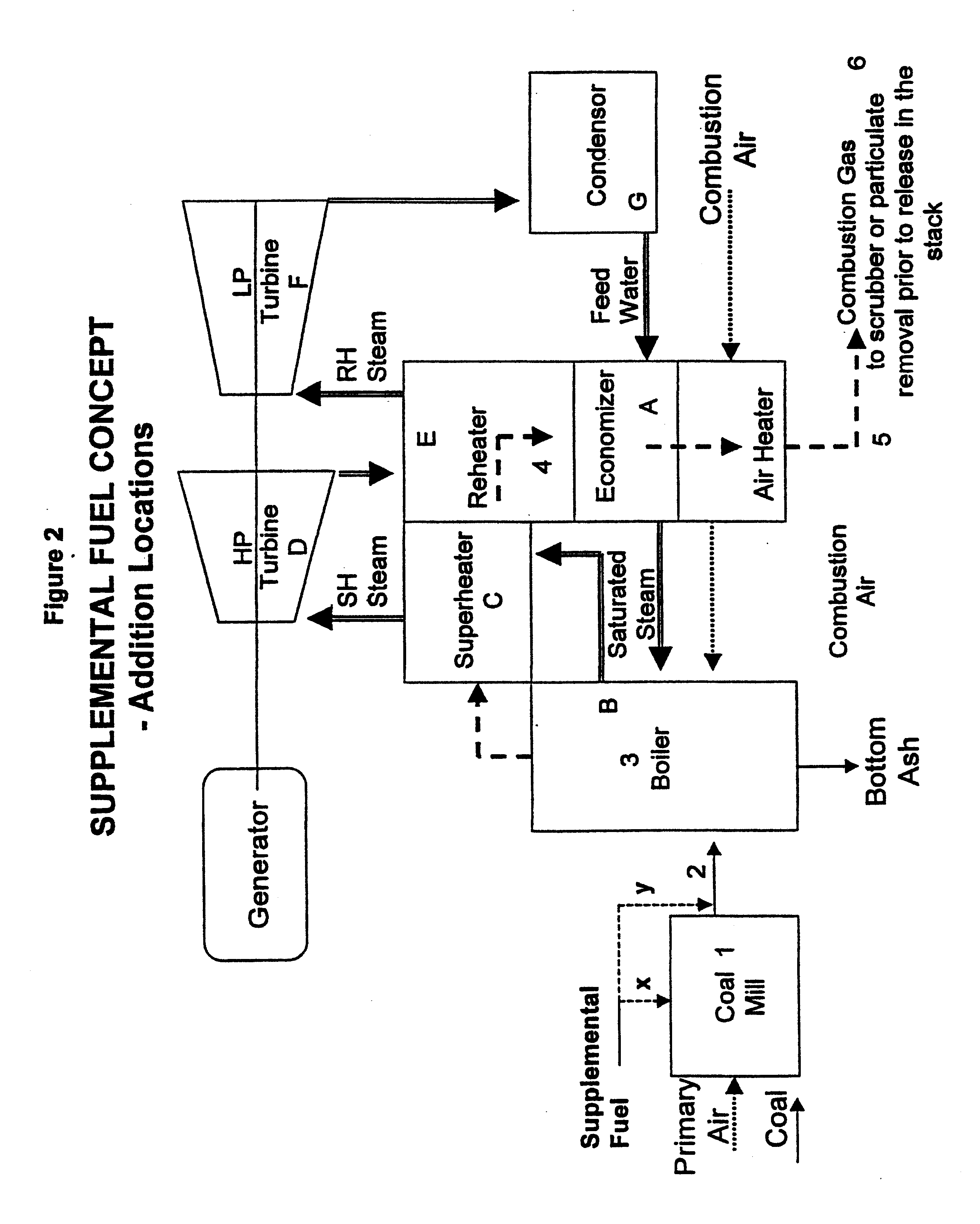

Process to improve boiler operation by supplemental firing with thermally beneficiated low rank coal

InactiveUS6325001B1Improve combustion characteristicsImprove combustion performanceSolid fuel pretreatmentSolid fuelsDevice typeBrown coal

The invention described is a process for improving the performance of a commercial coal or lignite fired boiler system by supplementing its normal coal supply with a controlled quantity of thermally beneficiated low rank coal, (TBLRC). This supplemental TBLRC can be delivered either to the solid fuel mill (pulverizer) or directly to the coal burner feed pipe. Specific benefits are supplied based on knowledge of equipment types that may be employed on a commercial scale to complete the process. The thermally beneficiated low rank coal can be delivered along with regular coal or intermittently with regular coal as the needs require.

Owner:SYNCOAL SOLUTIONS

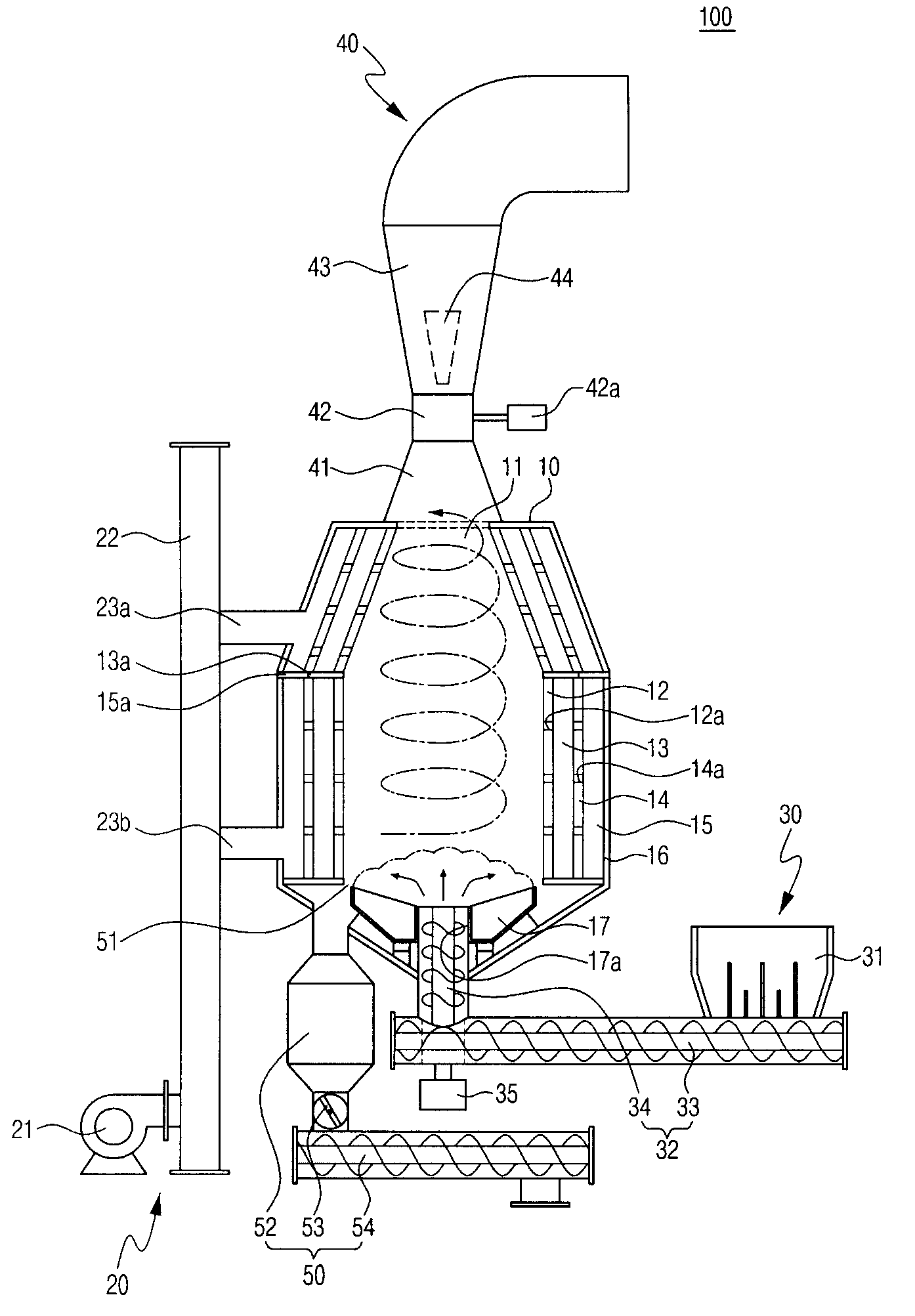

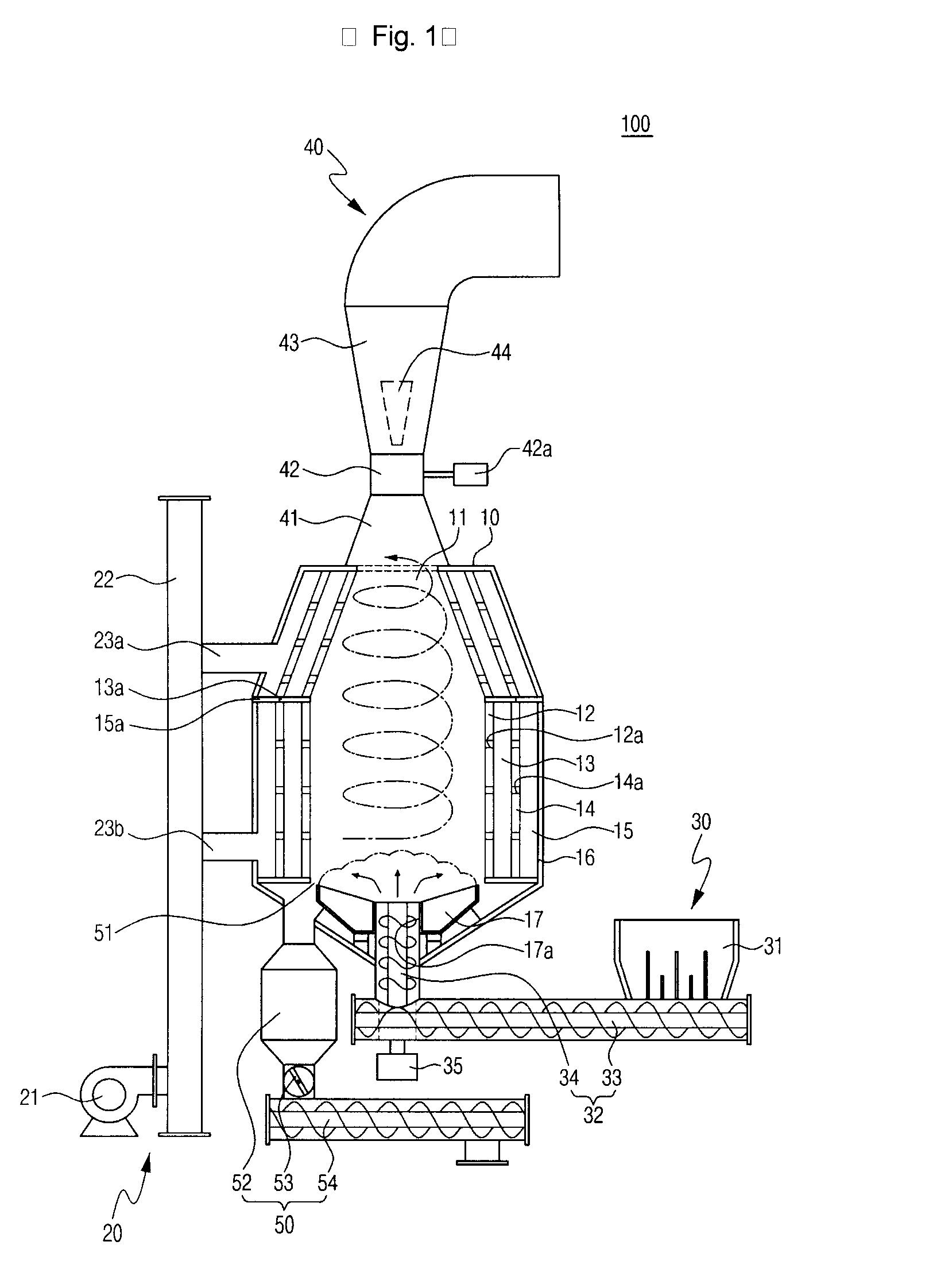

Combustion Apparatus For Recovering Heat

InactiveUS20090126607A1Low costReduce generationPulverulent fuel combustion burnersDamper arrangementCombustion chamberHeat losses

A combustion apparatus for recovering heat according to the present invention comprising a combustion tank for burning fuel contained in the interior by combustion air supplied from the exterior, characterized in that: a combustion chamber surrounded by an inner wall for burning fuel is defined in said combustion tank; a swirl flow supply chamber for supplying a combustion air into said combustion chamber is defined around the outer circumference of the inner wall of said combustion tank; a combustion air supply passage for supplying combustion air from said swirl flow supply chamber into said combustion chamber is defined on the inner wall of said combustion tank; said combustion air supply passage is slanted at a predetermined angle to the vertical direction of the inner face of the inner wall in said combustion tank; and the combustion air generates a swirl flow in the combustion chamber. Furthermore, the combustion apparatus for recovering heat according to the invention characterized in that; an air cooling chamber for supplying combustion air supplied from the exterior into said swirl flow supply chamber is defined around the outer circumference of said swirl flow supply chamber in said combustion tank, and the combustion air supplied from the exterior is supplied through said cooling chamber into the swirl flow supply chamber to decrease a heat loss and to improve a thermal efficiency.

Owner:ENERONE

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20140053529A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

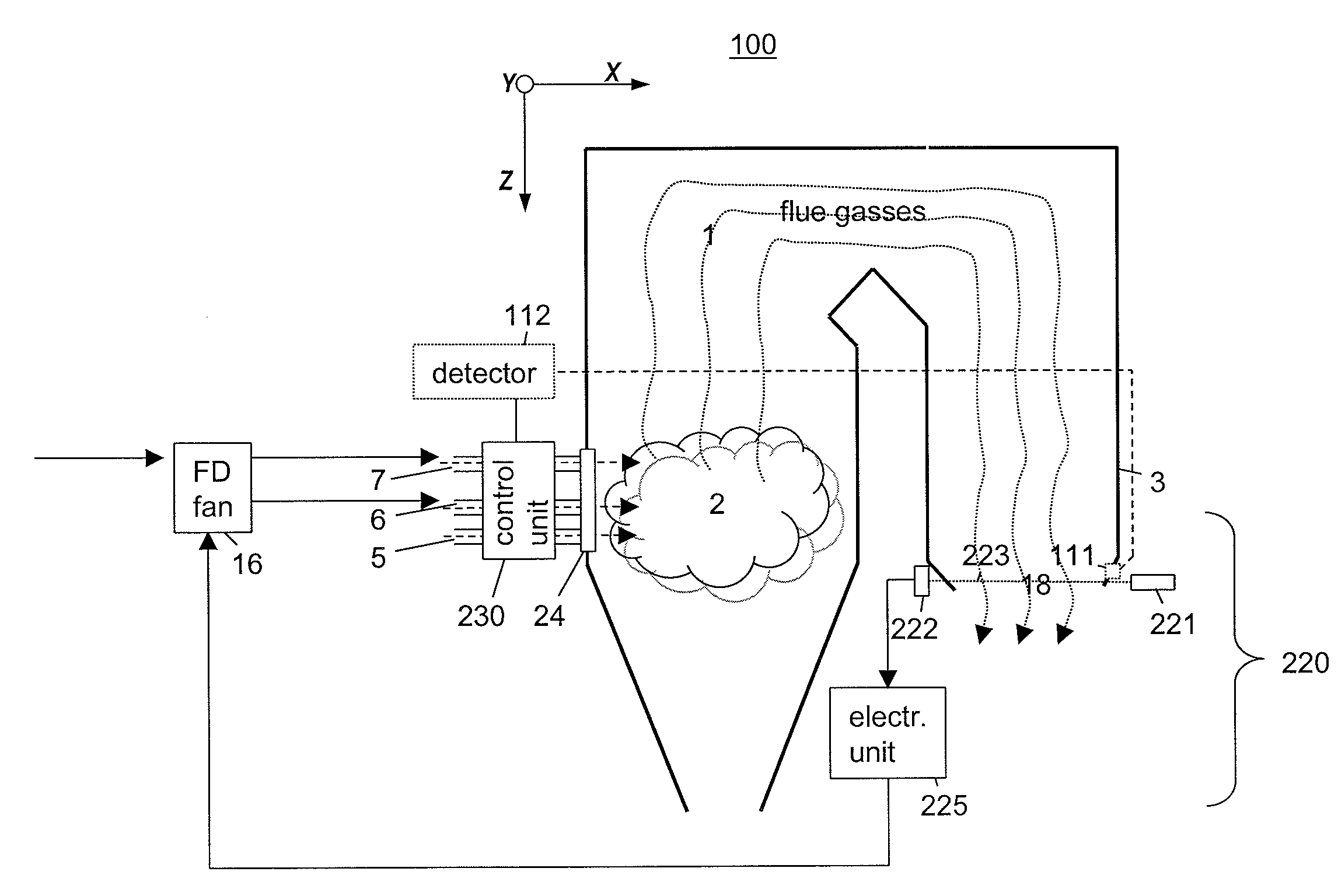

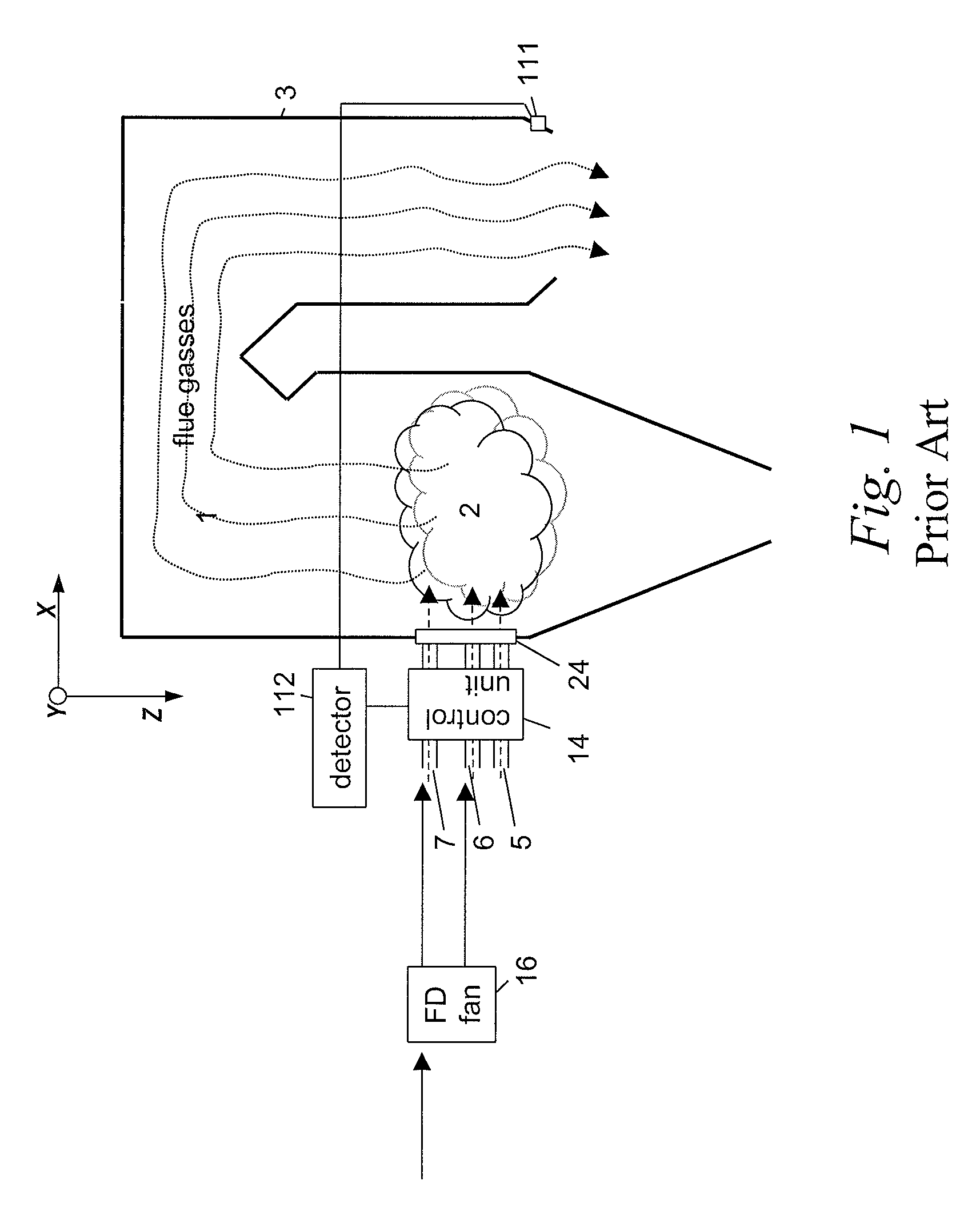

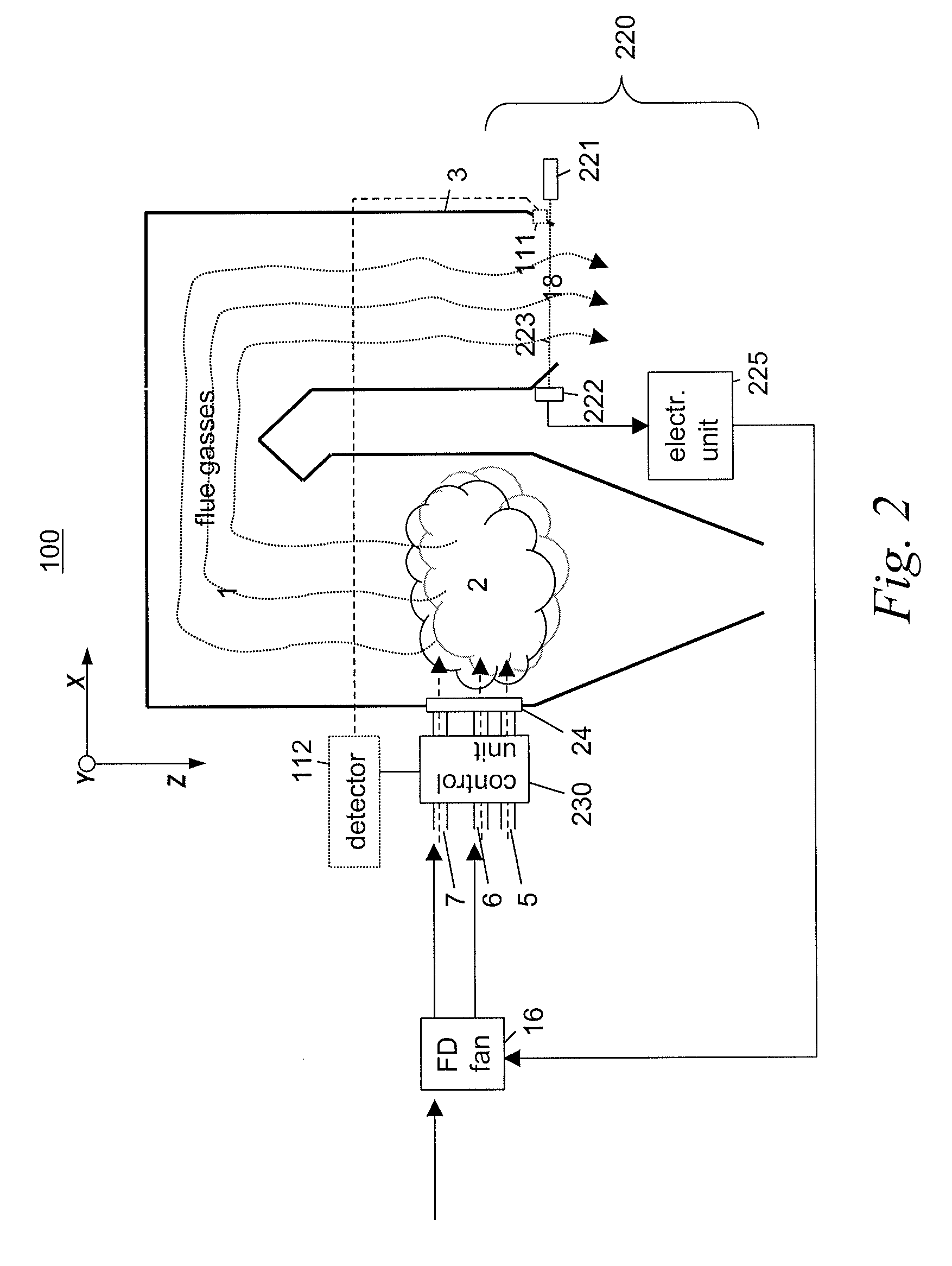

Optical flue gas monitor and control

InactiveUS20110045422A1Minimise concentrationFuel supply regulationEmission preventionCombustorFlue gas

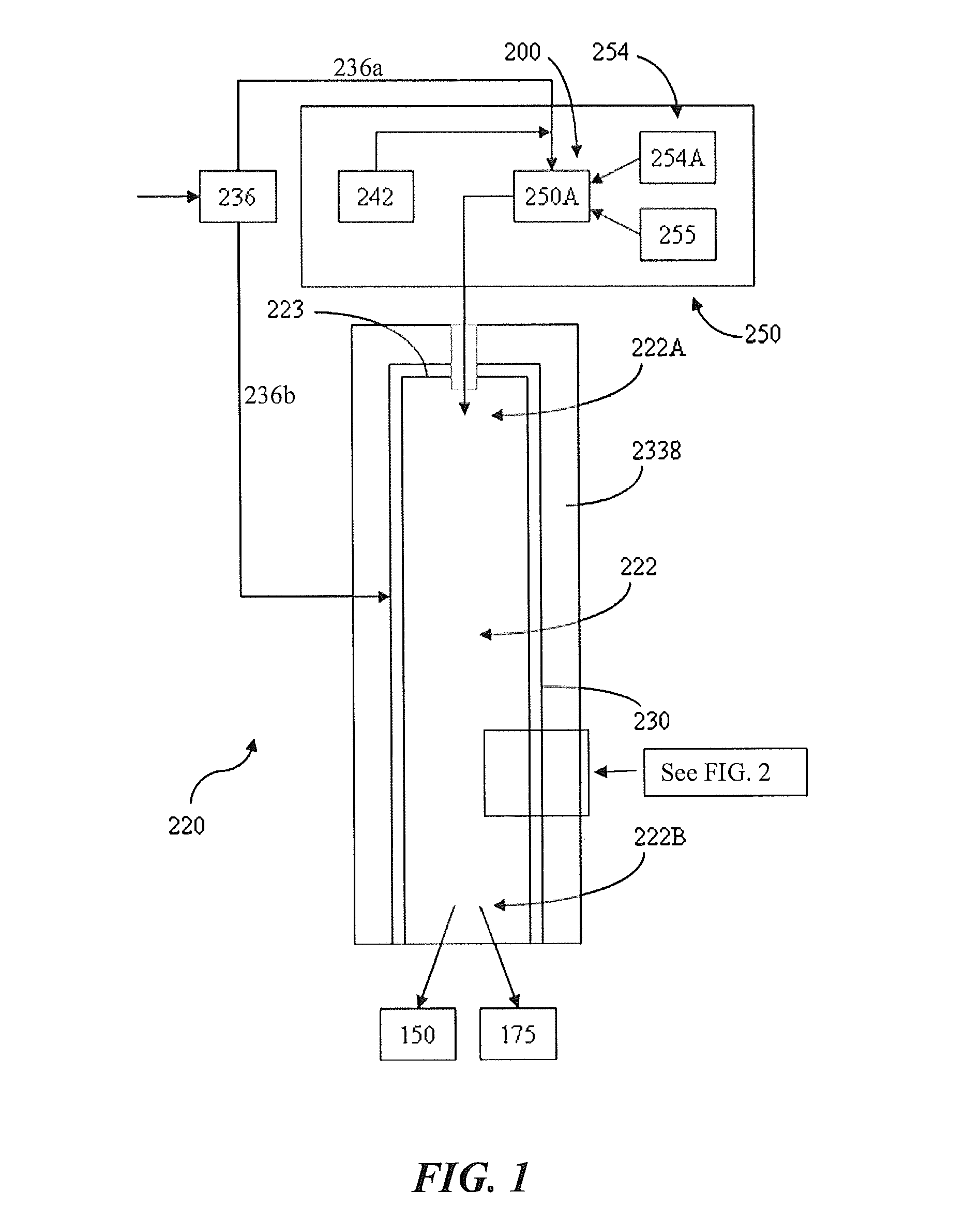

A plurality of optical monitoring systems 220,320 sense the concentration of at least one constituent in flue gasses of a furnace 1 and its emission control devices. The monitoring devices 220,320 includes at least one optical source 221 for providing beams 223 through a sampling zone 18 to create a combined signal indicating the amount of various constituents within the sampling zone 18. The combined signal may be fed forward to emission control devices to prepare them for oncoming emissions. The combined signals may also feed backward to adjust the emission control devices. They may also be provided to a control unit 230 to control stoicheometry of the burners of furnace 1. This results in a more efficient system that reduces the amount of emissions released.

Owner:ALSTOM TECH LTD

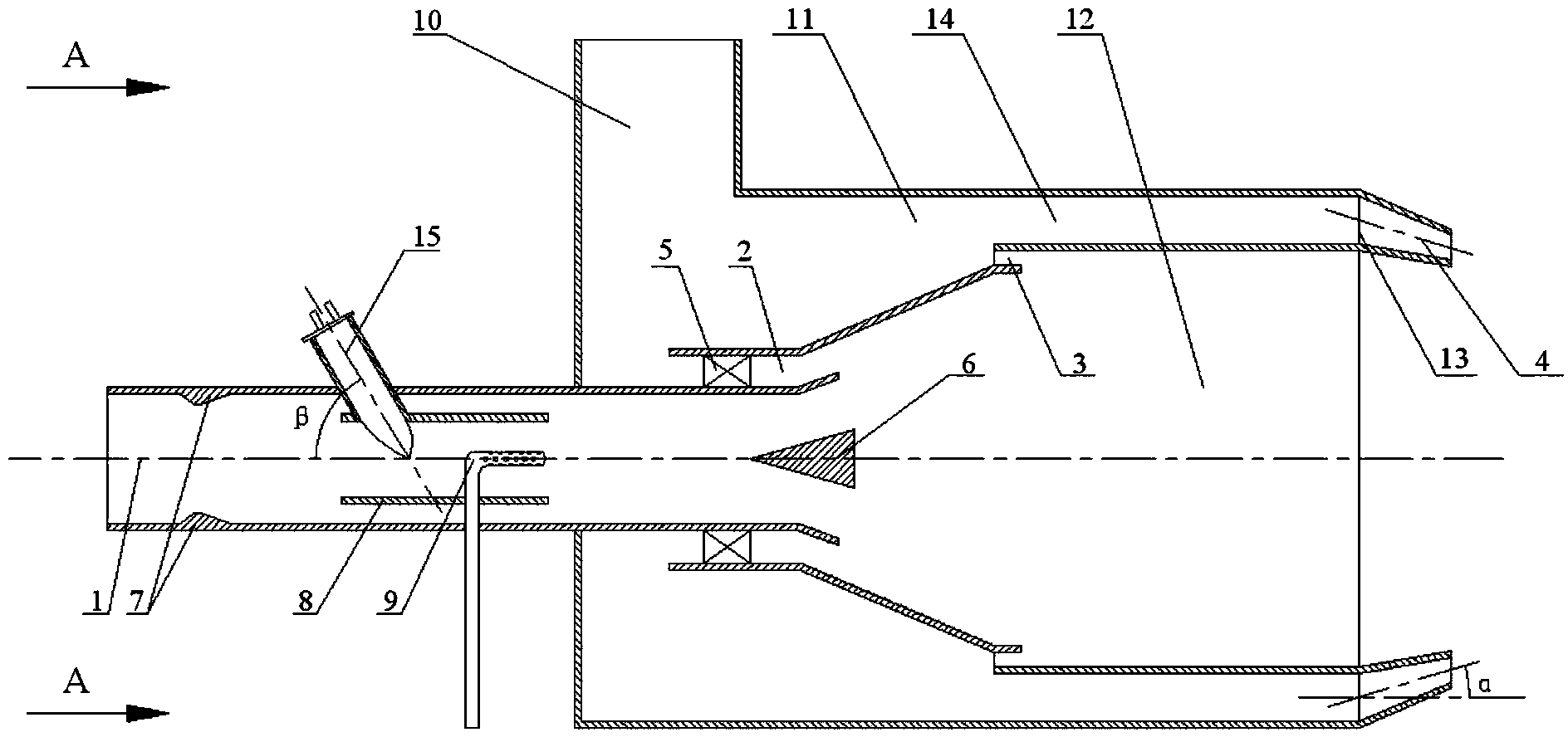

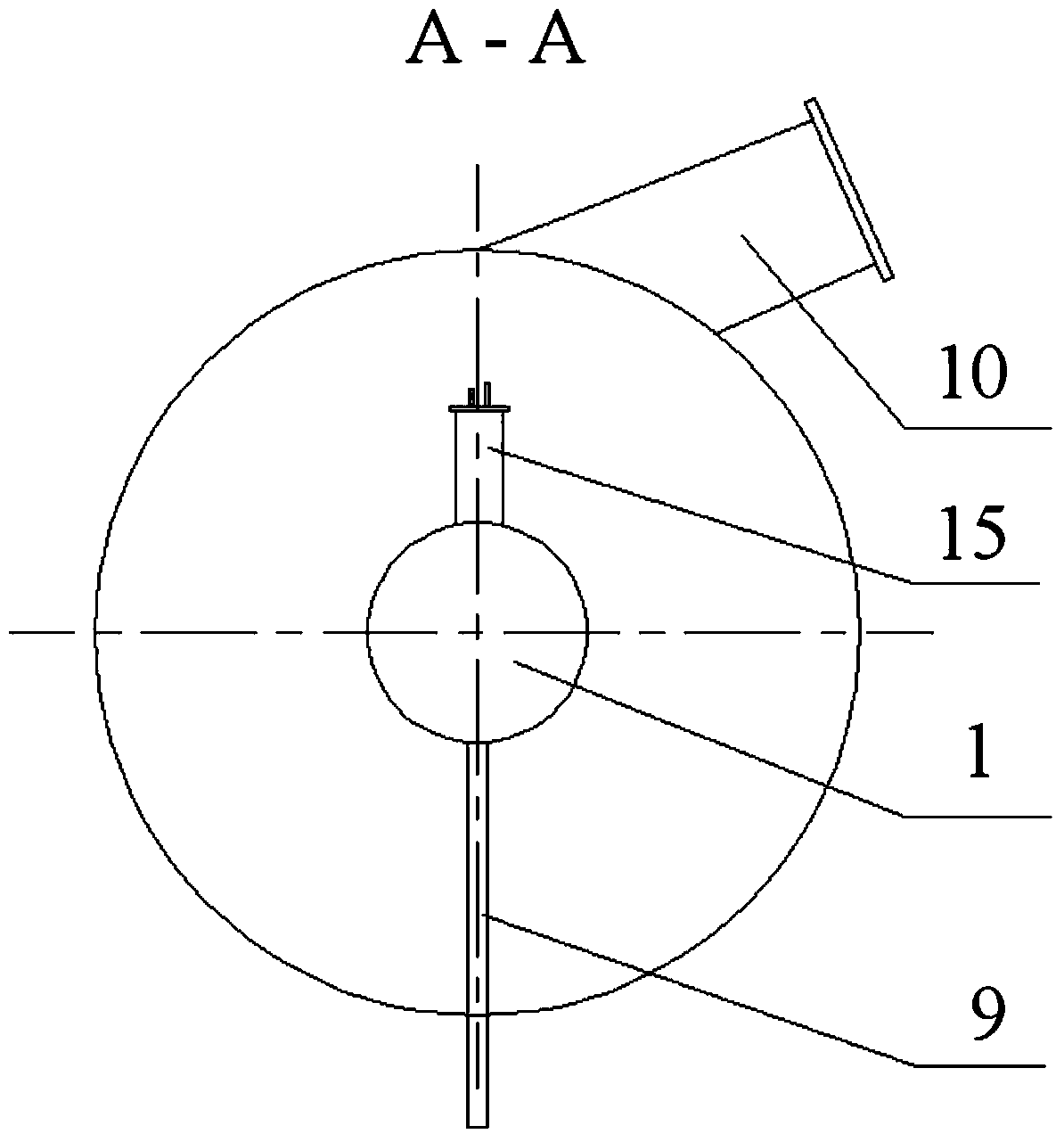

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com