Patents

Literature

222results about "Pulsating combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

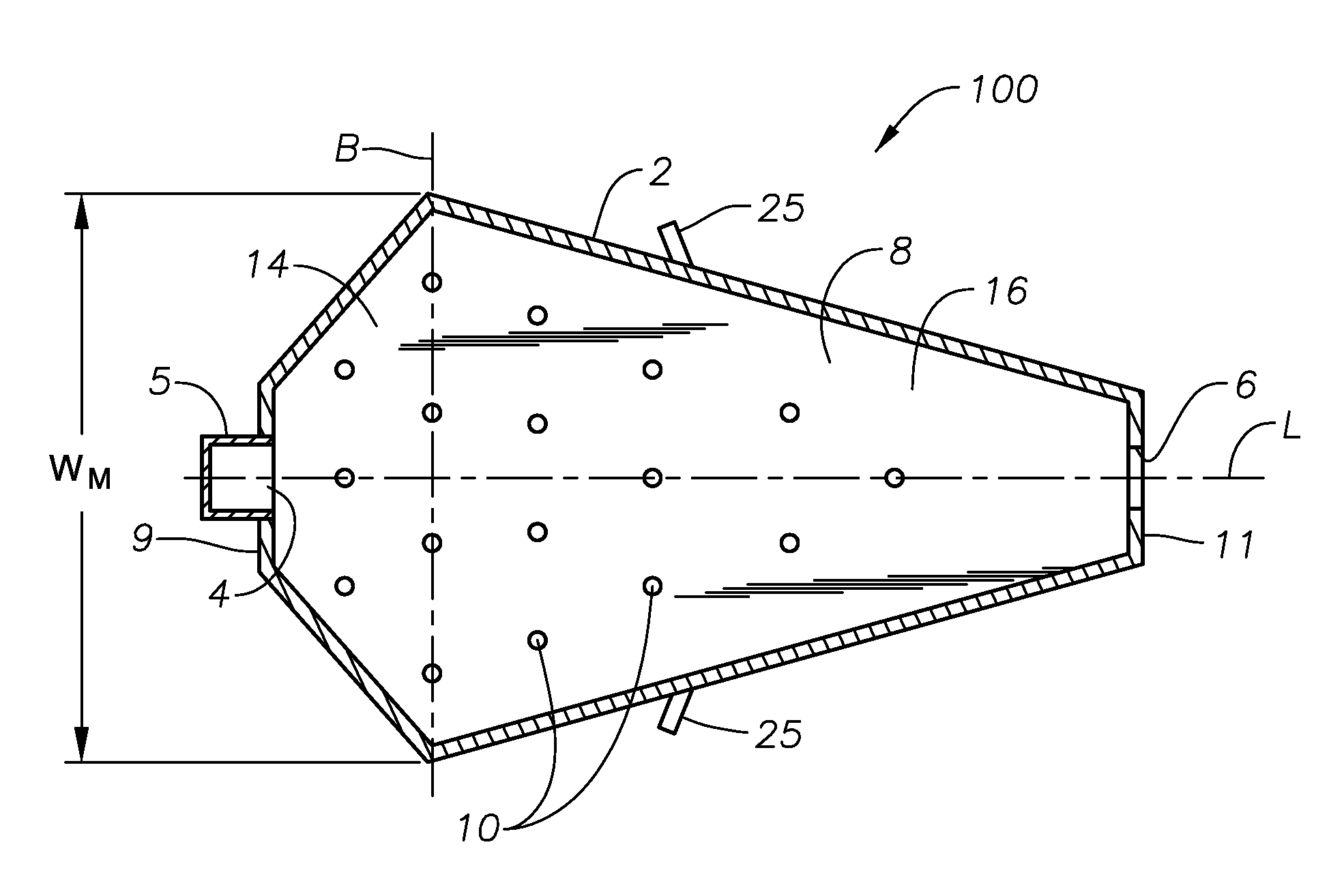

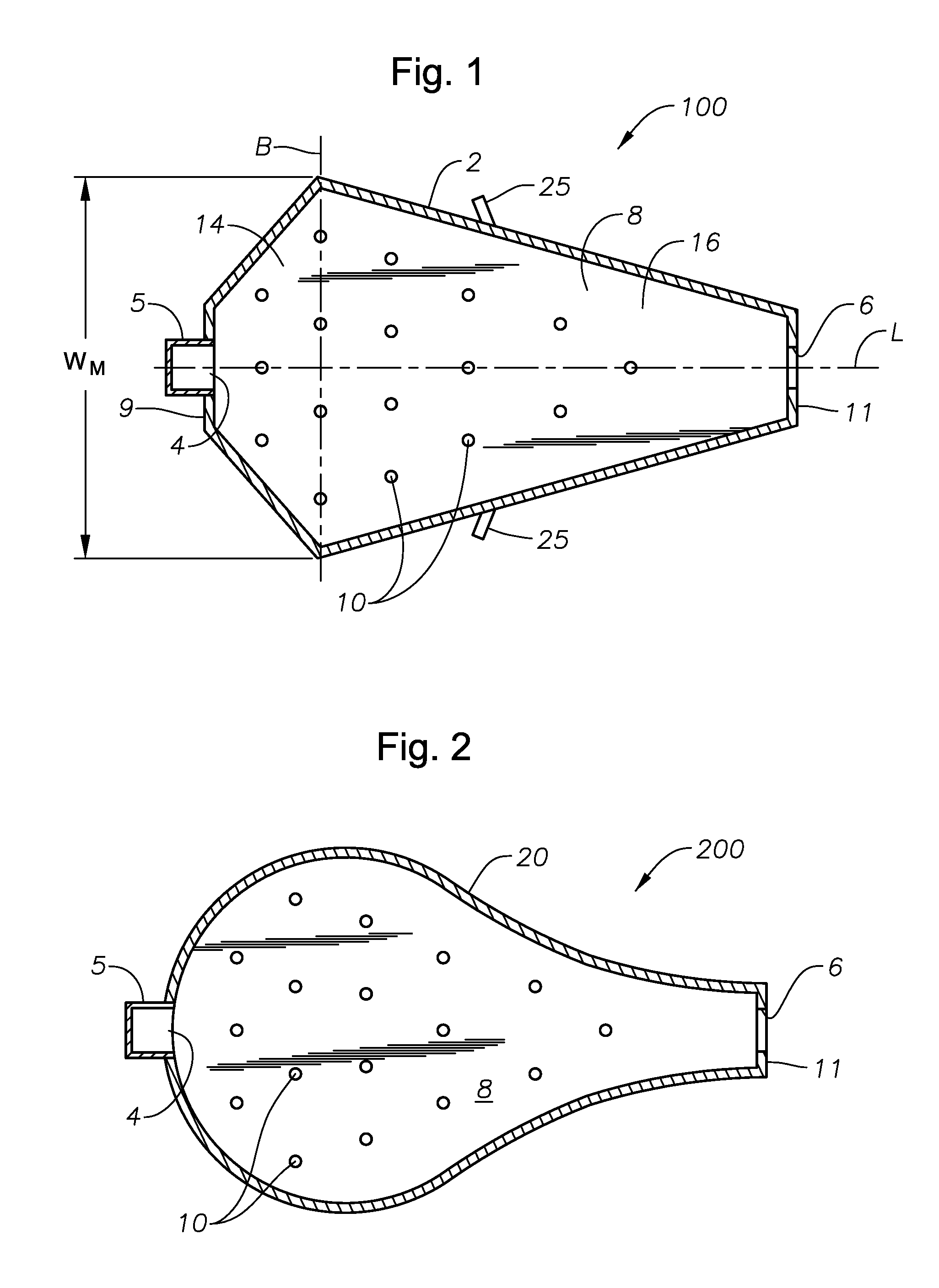

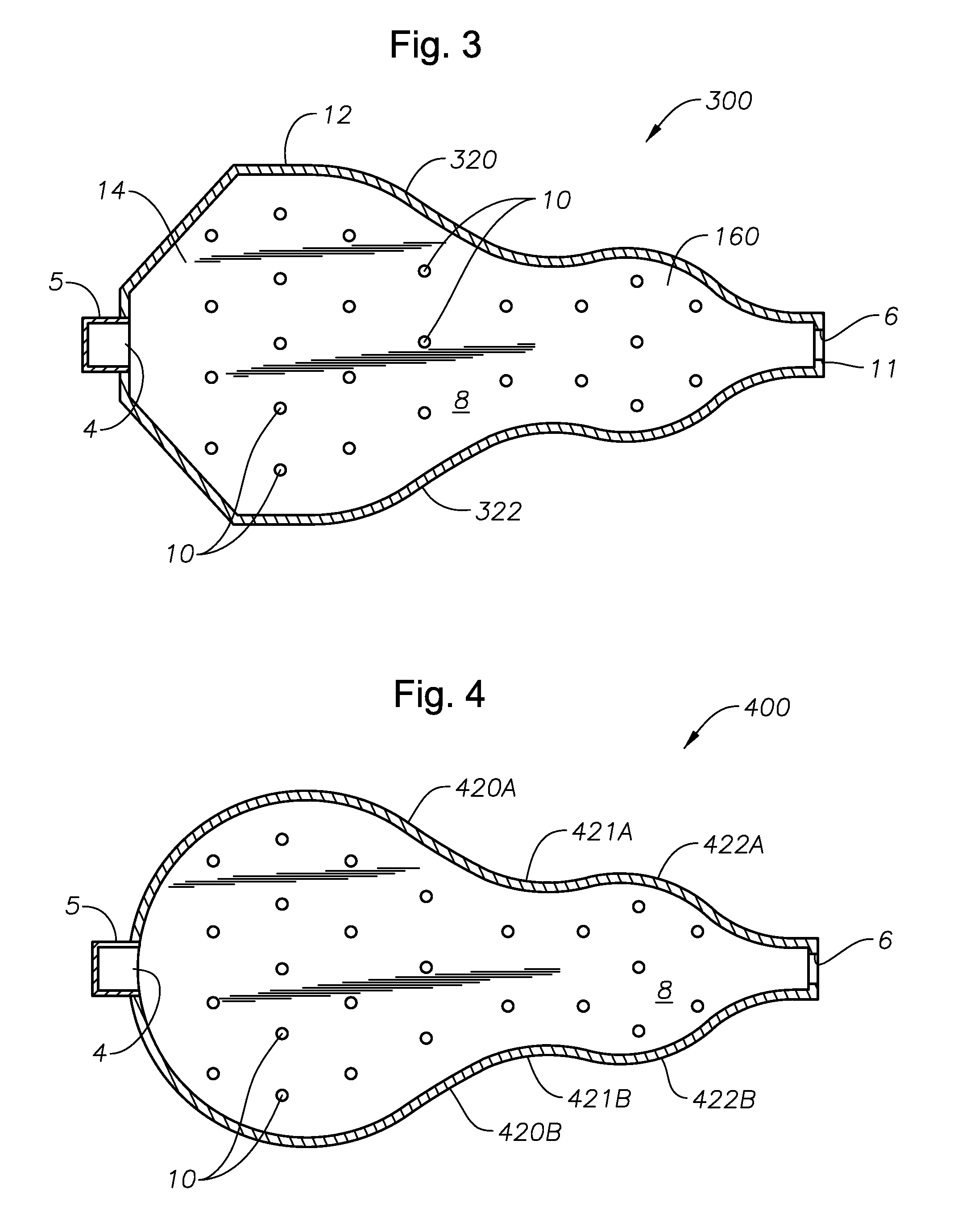

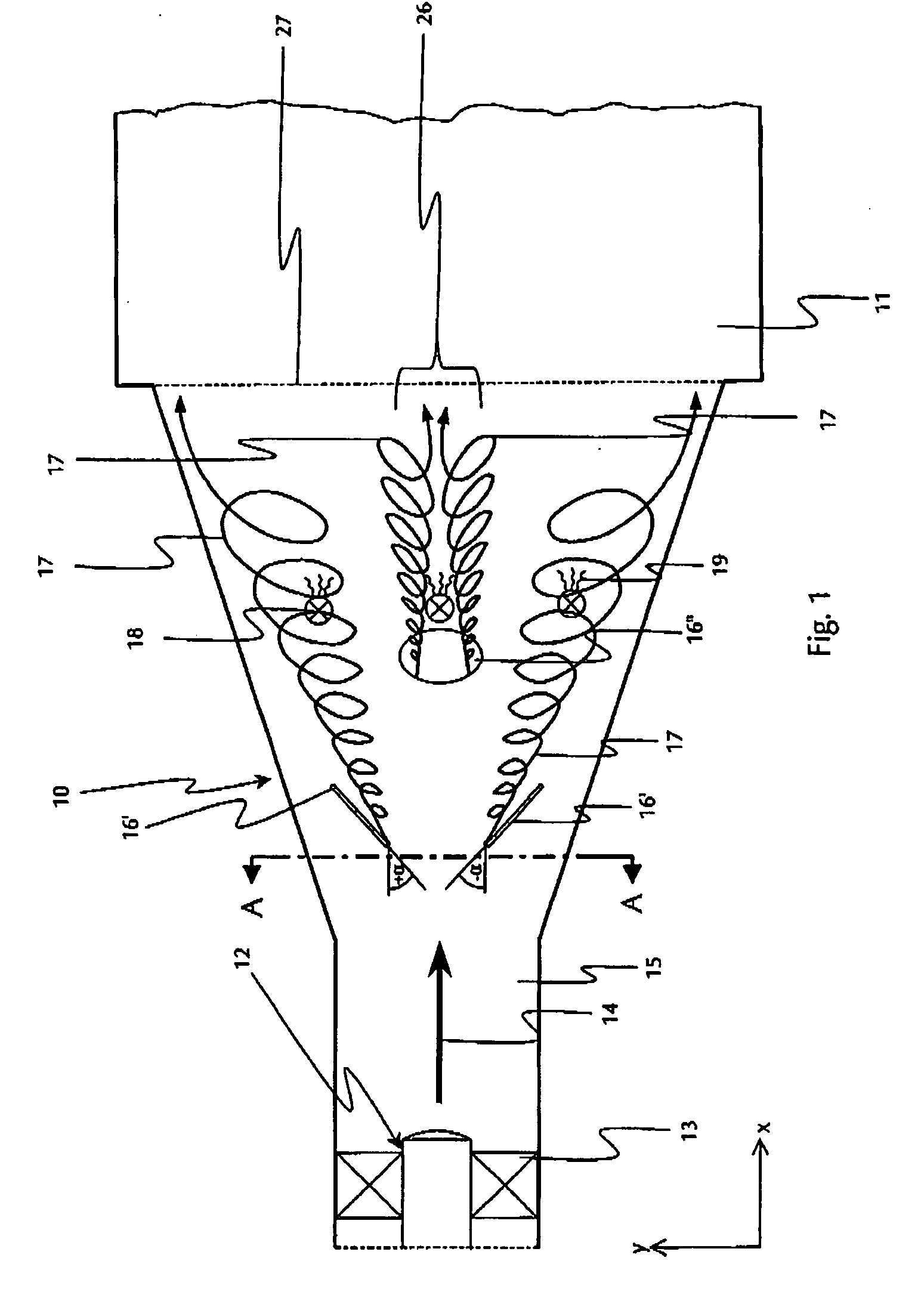

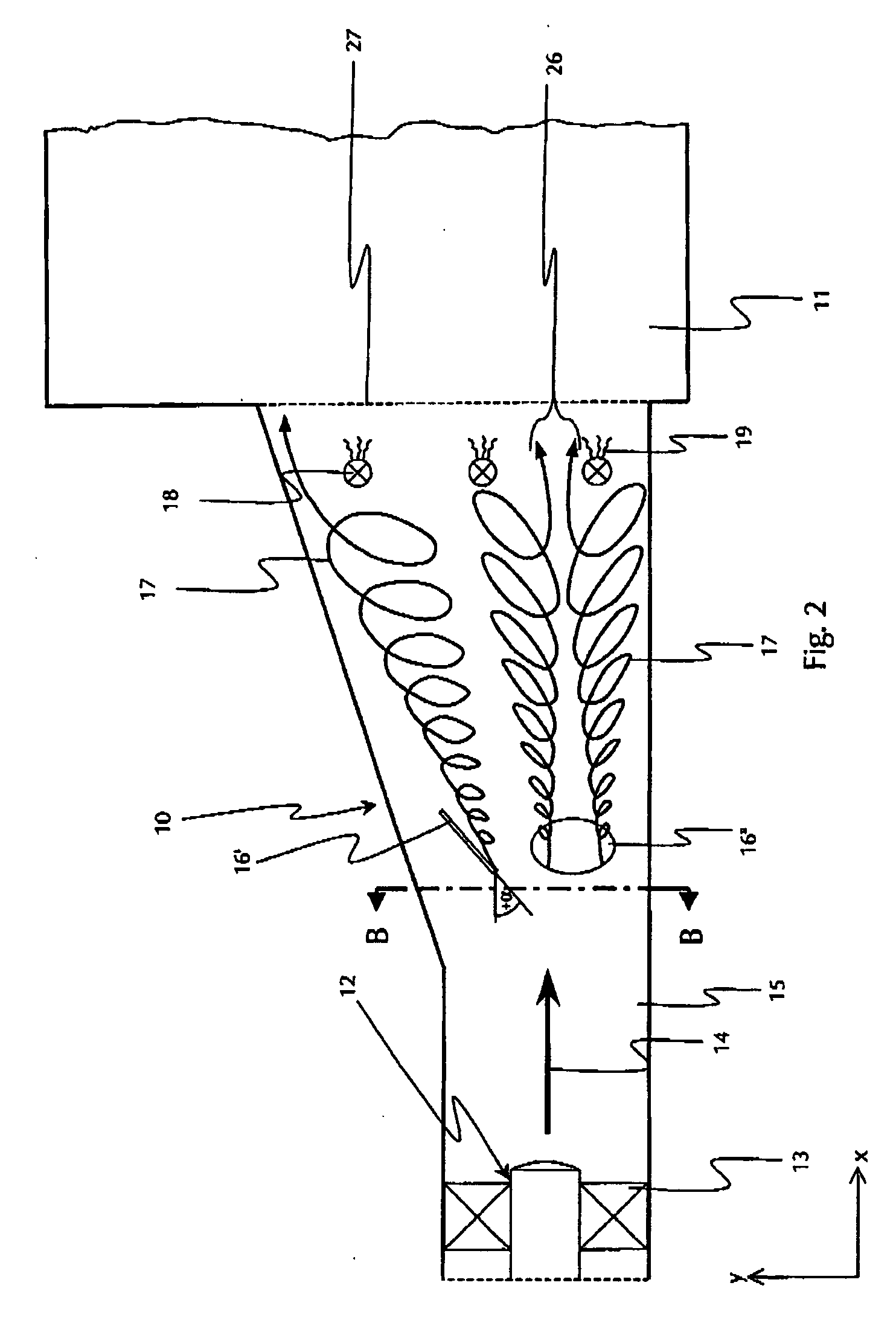

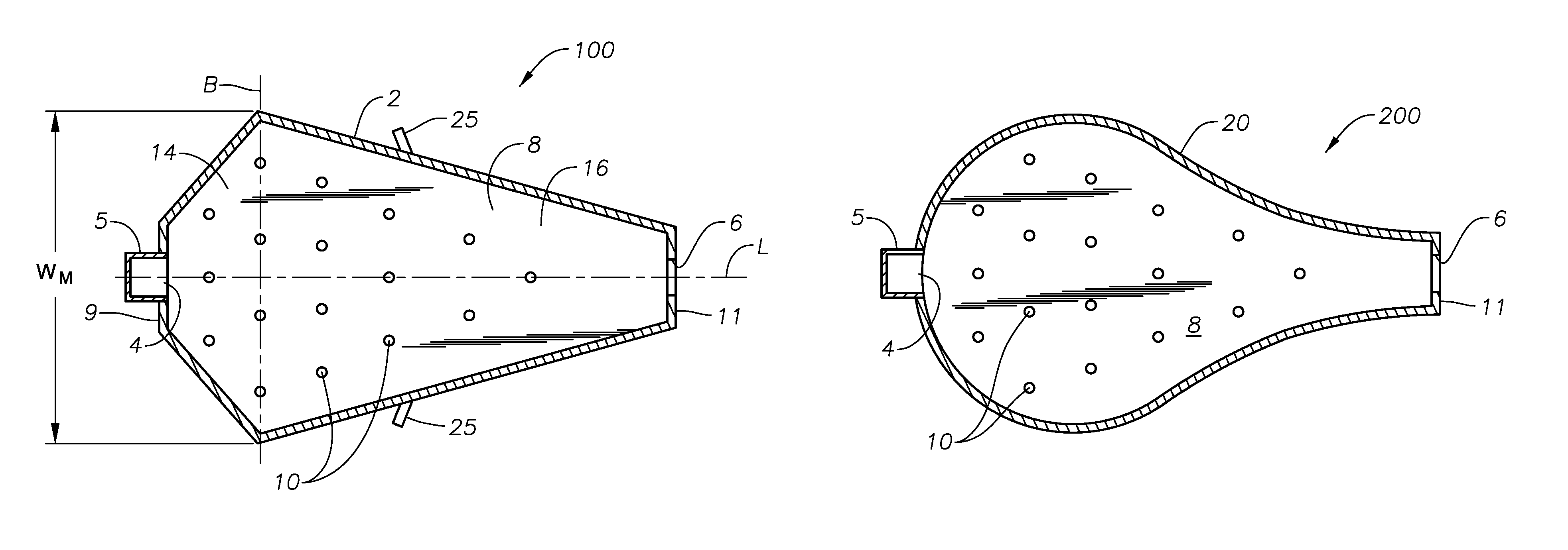

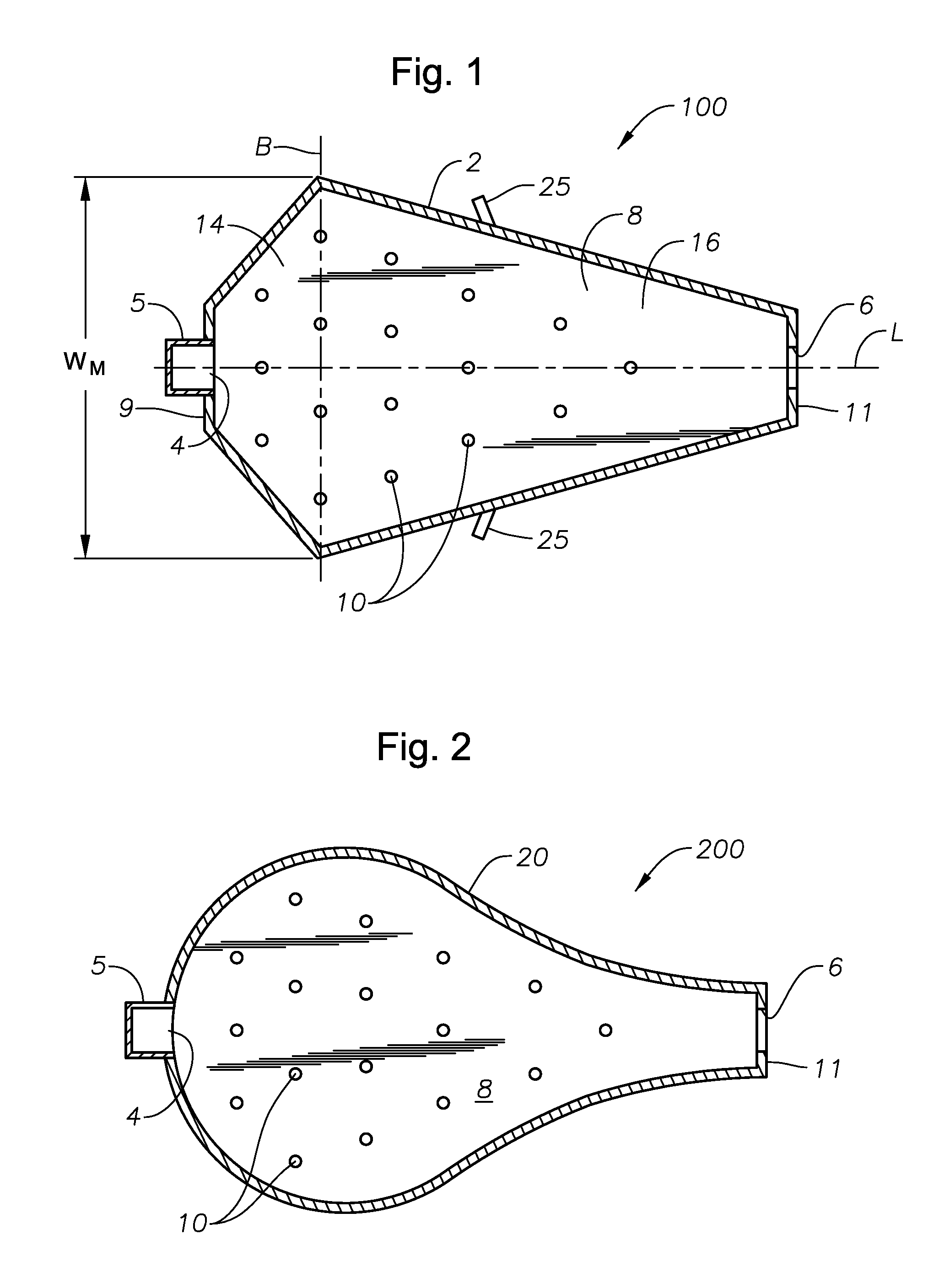

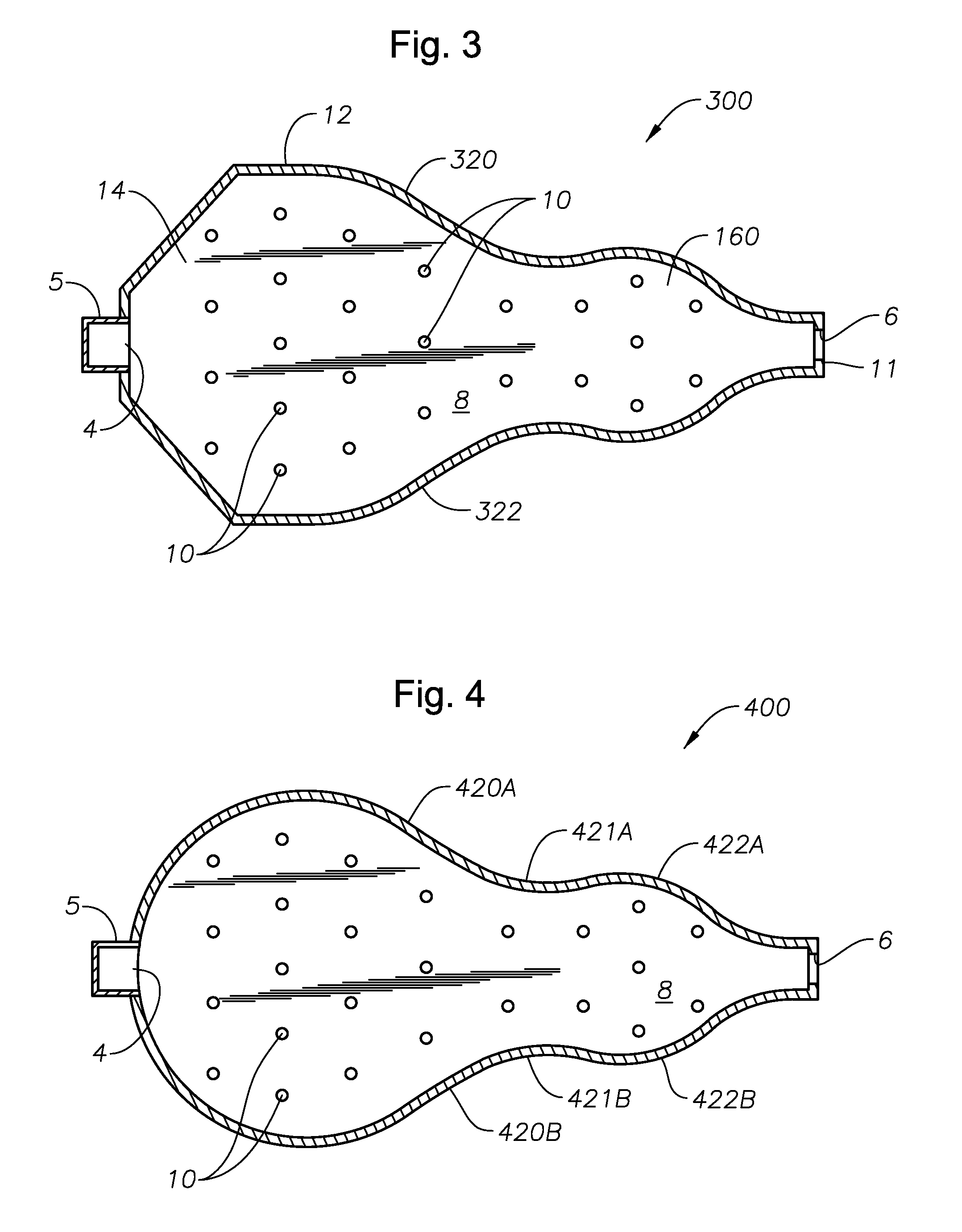

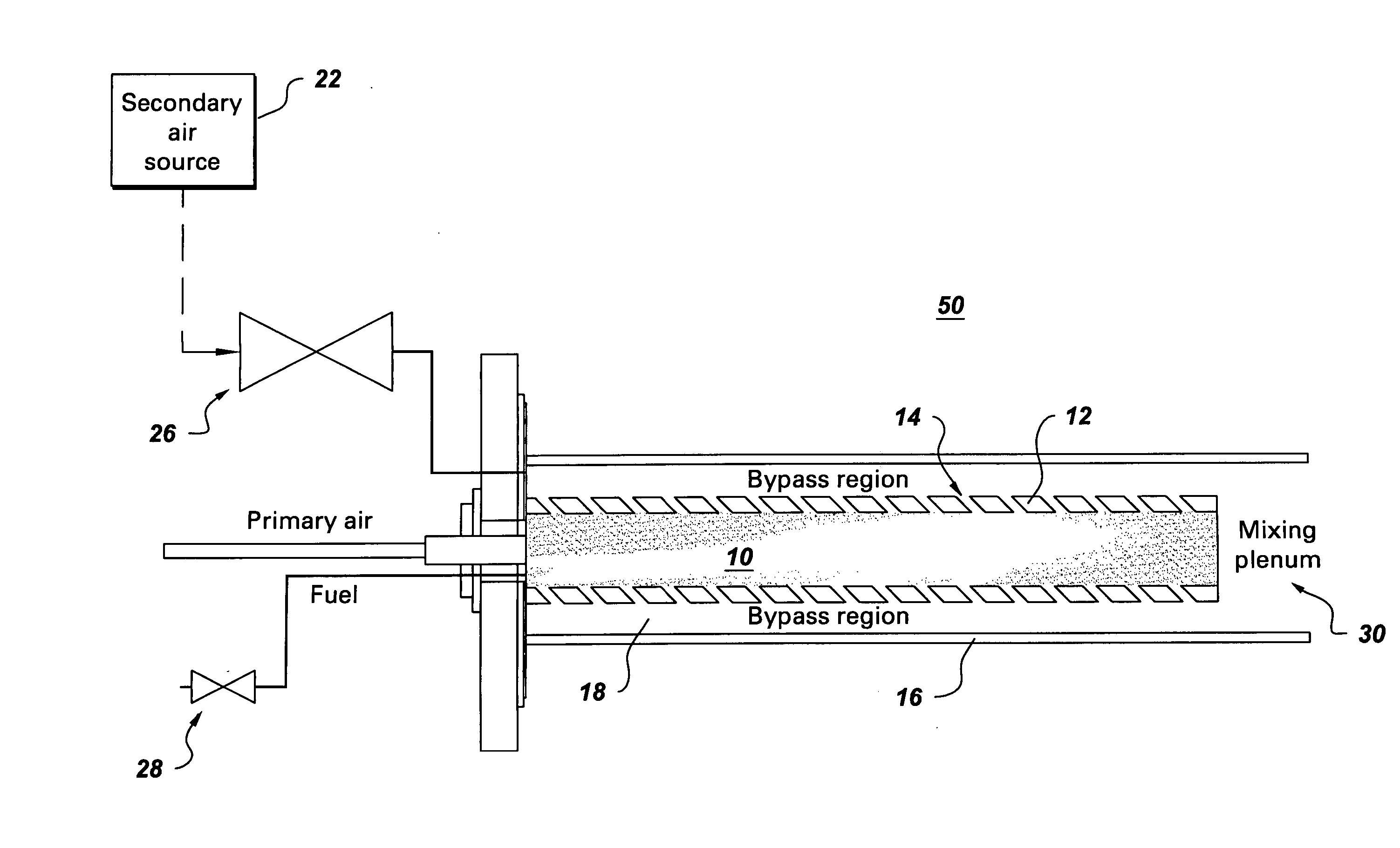

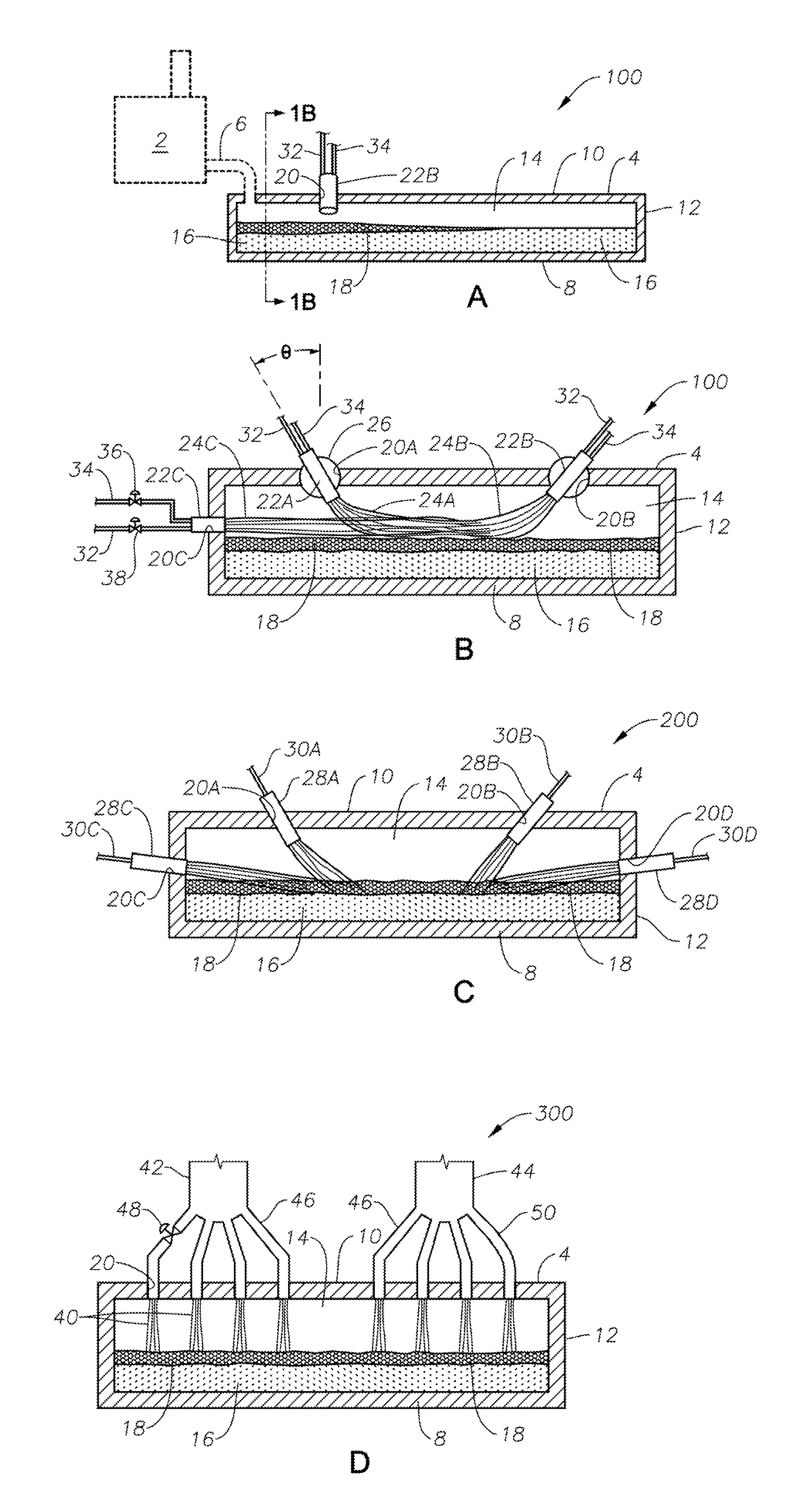

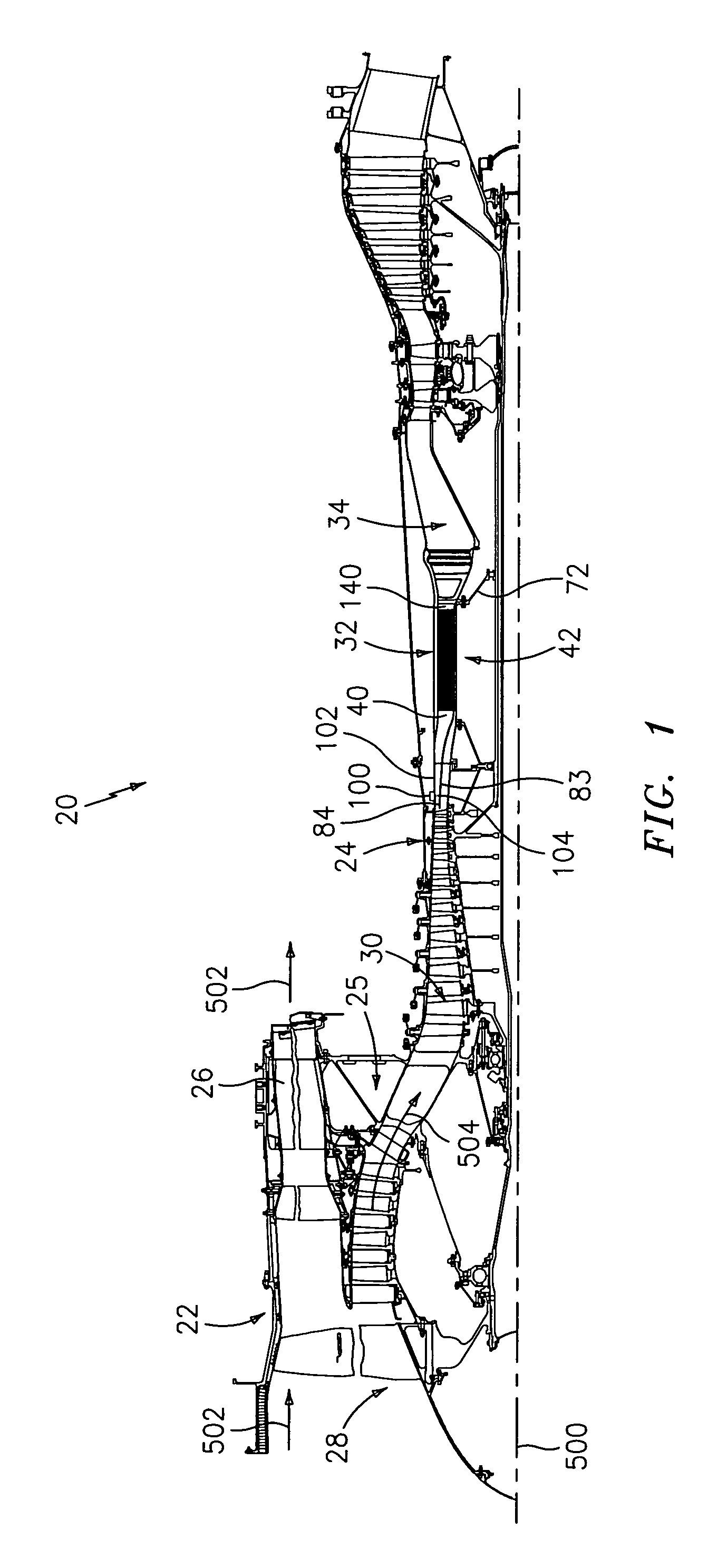

Panel-cooled submerged combustion melter geometry and methods of making molten glass

ActiveUS20110308280A1Reduce dead flow (stagnant) regionSmall sizePulsating combustionTank furnacesCombustorDirect combustion

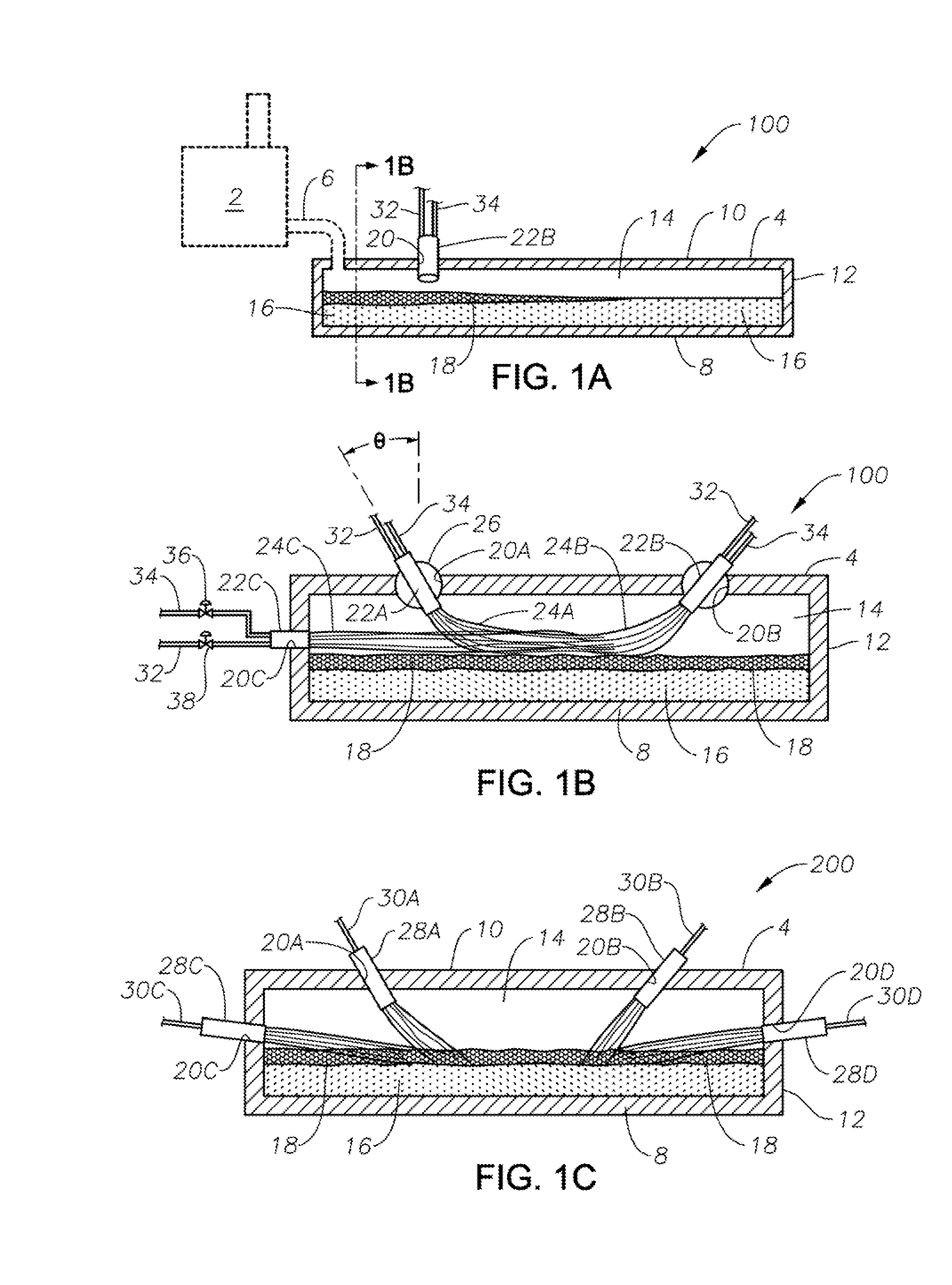

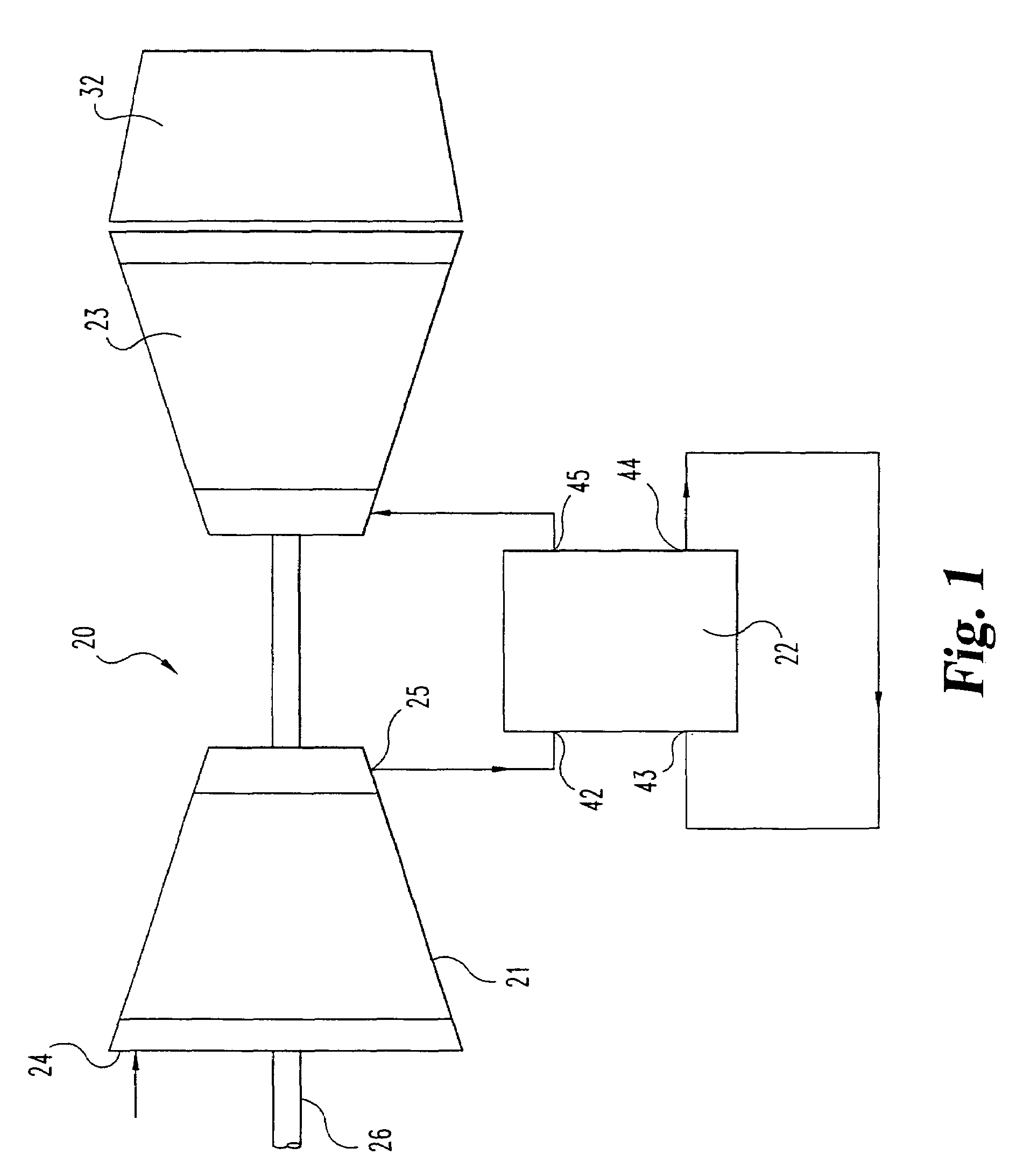

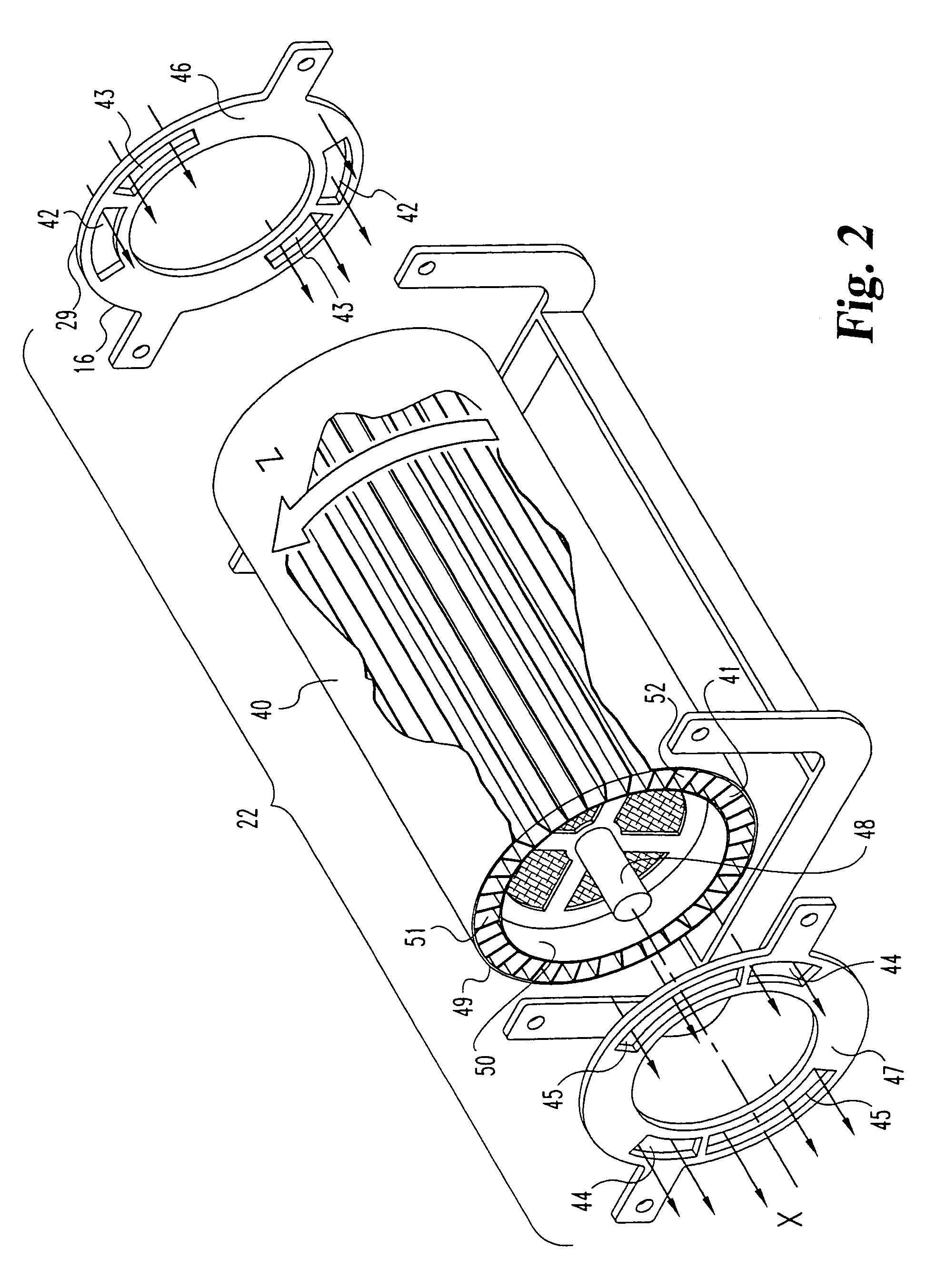

A melter apparatus includes a floor, a ceiling, and a substantially vertical wall connecting the floor and ceiling at a perimeter of the floor and ceiling, a melting zone being defined by the floor, ceiling and wall, the melting zone having a feed inlet and a molten glass outlet positioned at opposing ends of the melting zone. The melting zone includes an expanding zone beginning at the inlet and extending to an intermediate location relative to the opposing ends, and a narrowing zone extending from the intermediate location to the outlet. One or more burners, at least some of which are positioned to direct combustion products into the melting zone under a level of molten glass in the zone, are also provided.

Owner:MANVILLE JOHNS

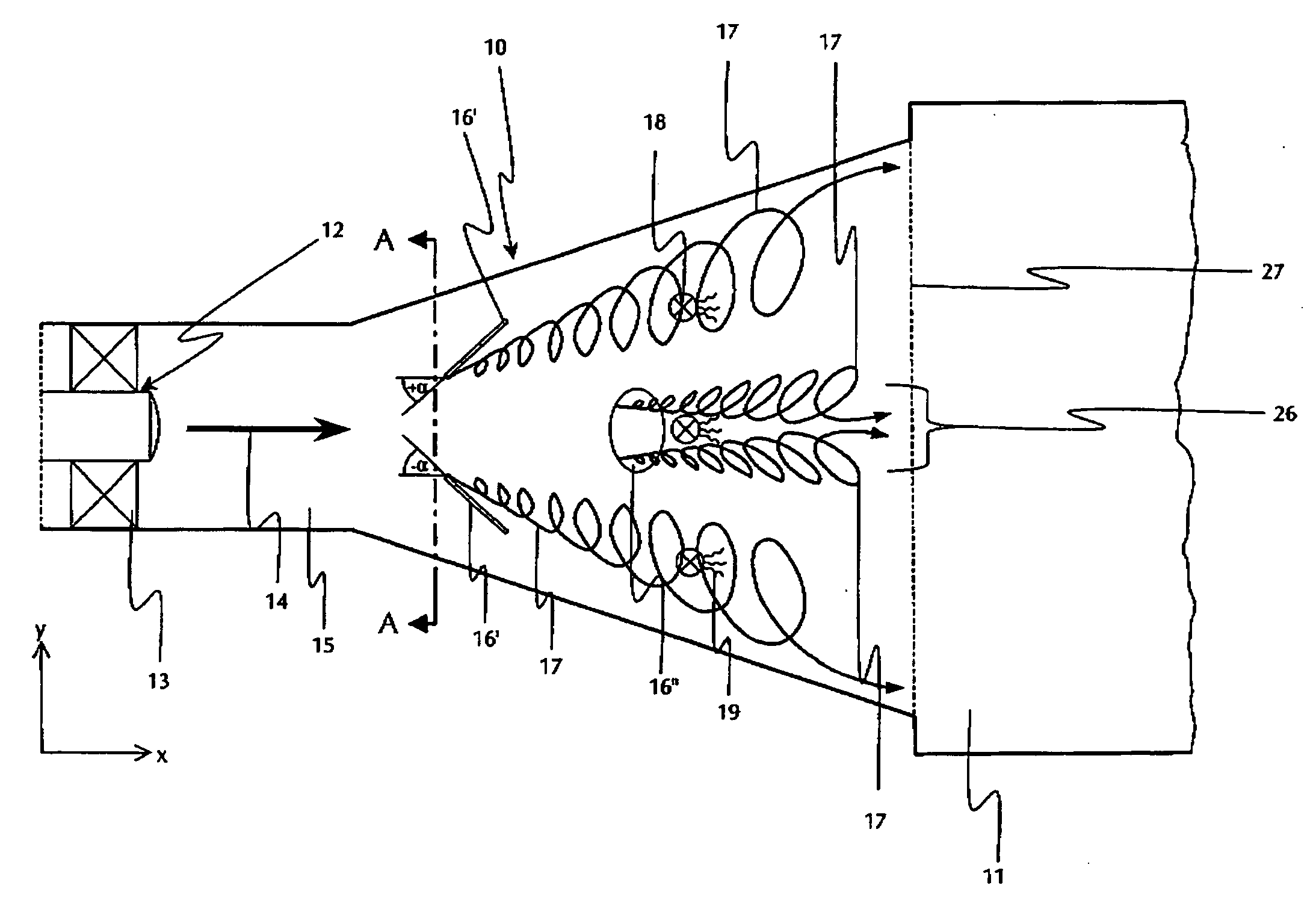

Exhaust gas guide of a gas turbine and method for mixing the exhaust gas of the gas turbine

ActiveUS20070044475A1Efficient powerImprove efficiencyBurnersContinuous combustion chamberLeading edgeCombustor

The present invention relates to an exhaust gas guide of a gas turbine, which is situated between the gas turbine and a downstream waste heat boiler or a downstream gas diverter and which comprises a flow channel which has a cross-section expanding in at least some areas in the main flow direction, having installed surfaces influencing the flow. In order to achieve a more compact implementation of the exhaust gas guide and simultaneously avoid or reduce pressure losses, the installed surfaces are implemented as a swirl device generating a leading edge swirl, which is situated in the diverging area of the flow channel and is implemented to distribute the exhaust gas flow uniformly over the flow cross-sectional area upon entry into the waste heat boiler or the gas diverter. Furthermore, the present invention relates to a method for mixing the exhaust gas of a gas turbine with hot exhaust gas streams generated in an auxiliary firing of at least one burner. This thorough mixing is achieved by generating at least one leading edge swirl system in the flow channel.

Owner:HOWDEN ROTHEMUHLE GMBH

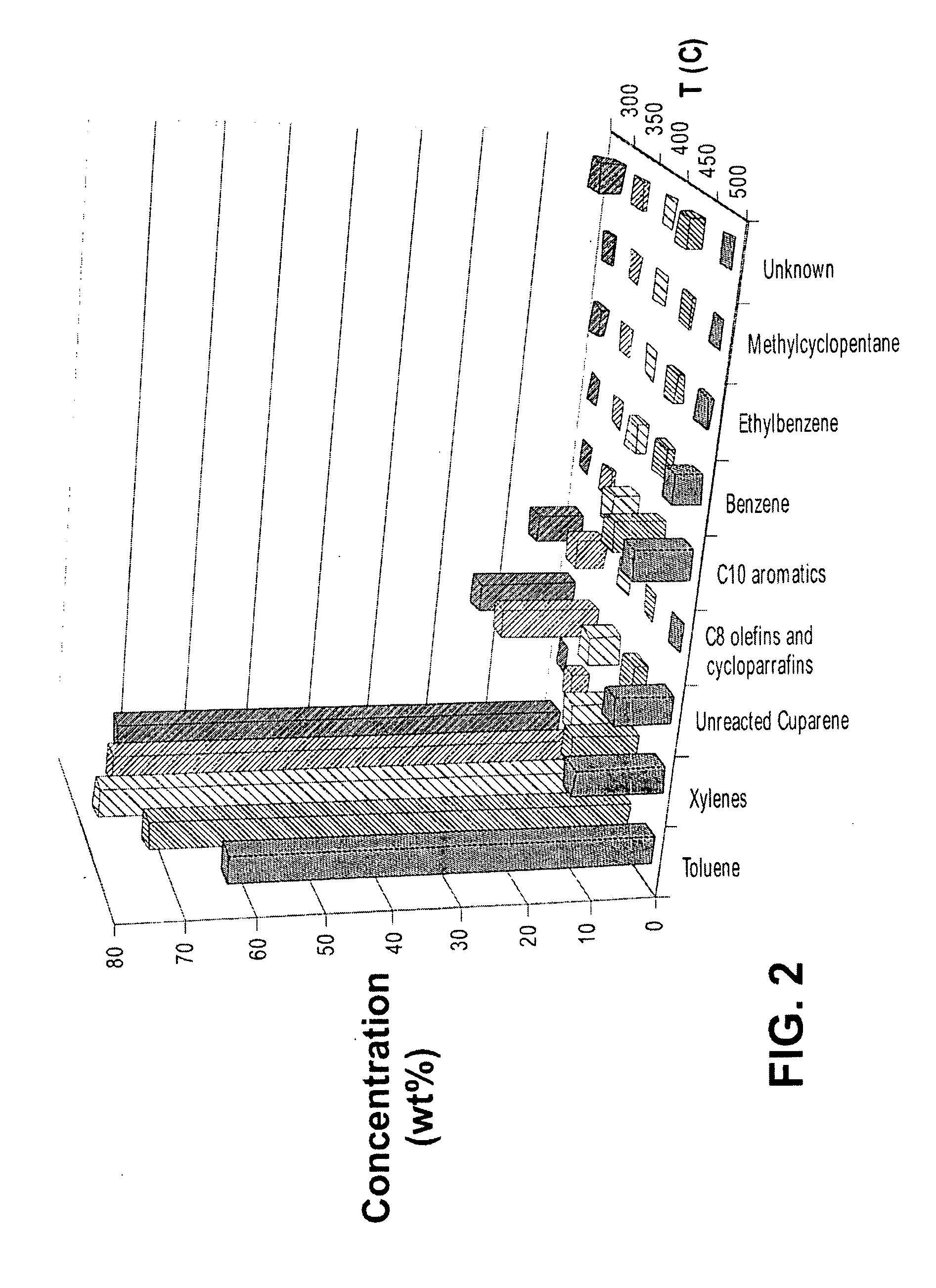

Methods of refining hydrocarbon feedstocks

Processes of converting to feedstocks comprising hydrocarbons to compositions comprising light hydrocarbon products are described herein. Also described are processes and methods of producing and refining compositions comprising terpenes from biomass that can be suitable as a fuel product.

Owner:RENEW BIOPHARMA INC +1

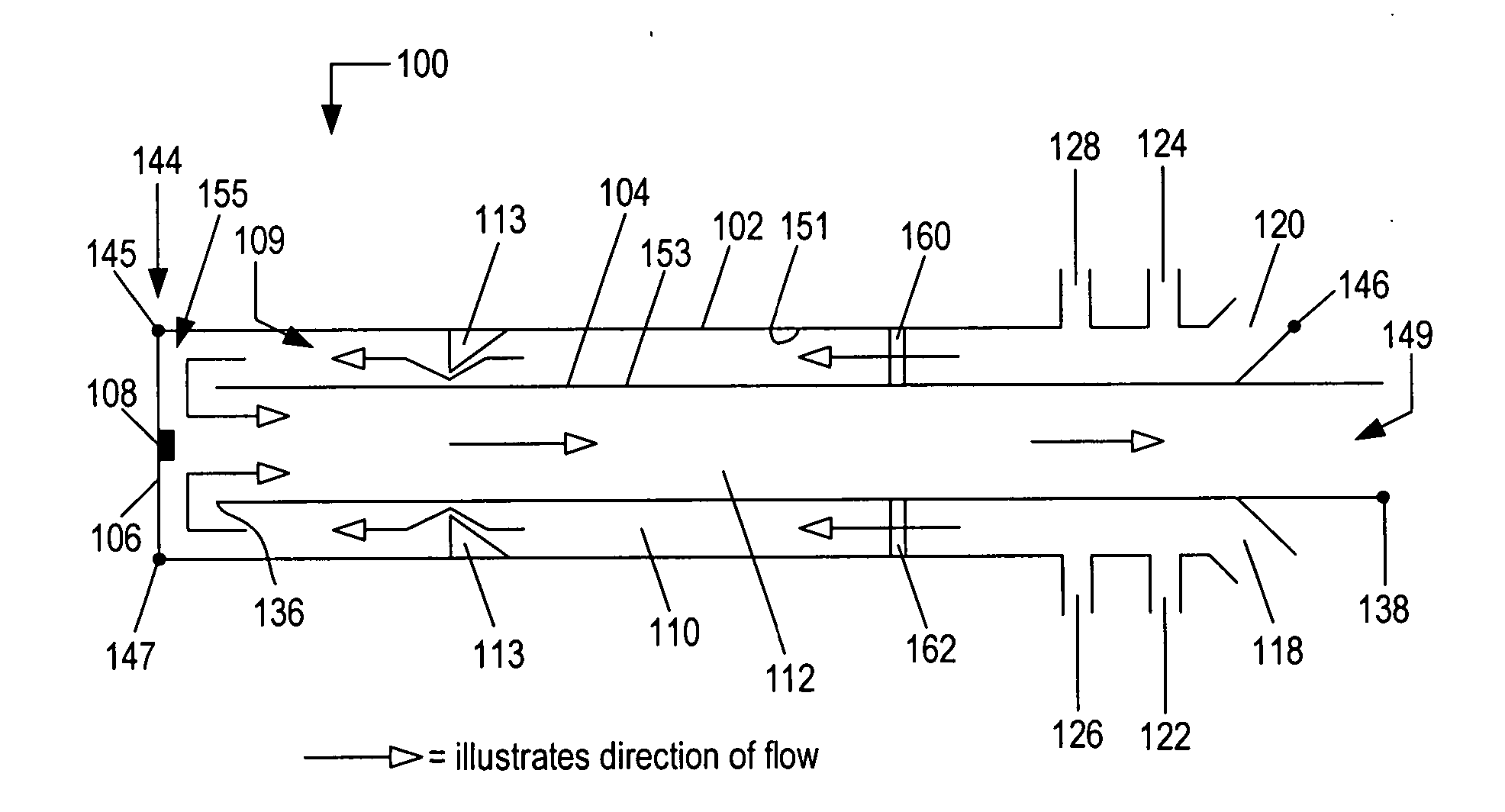

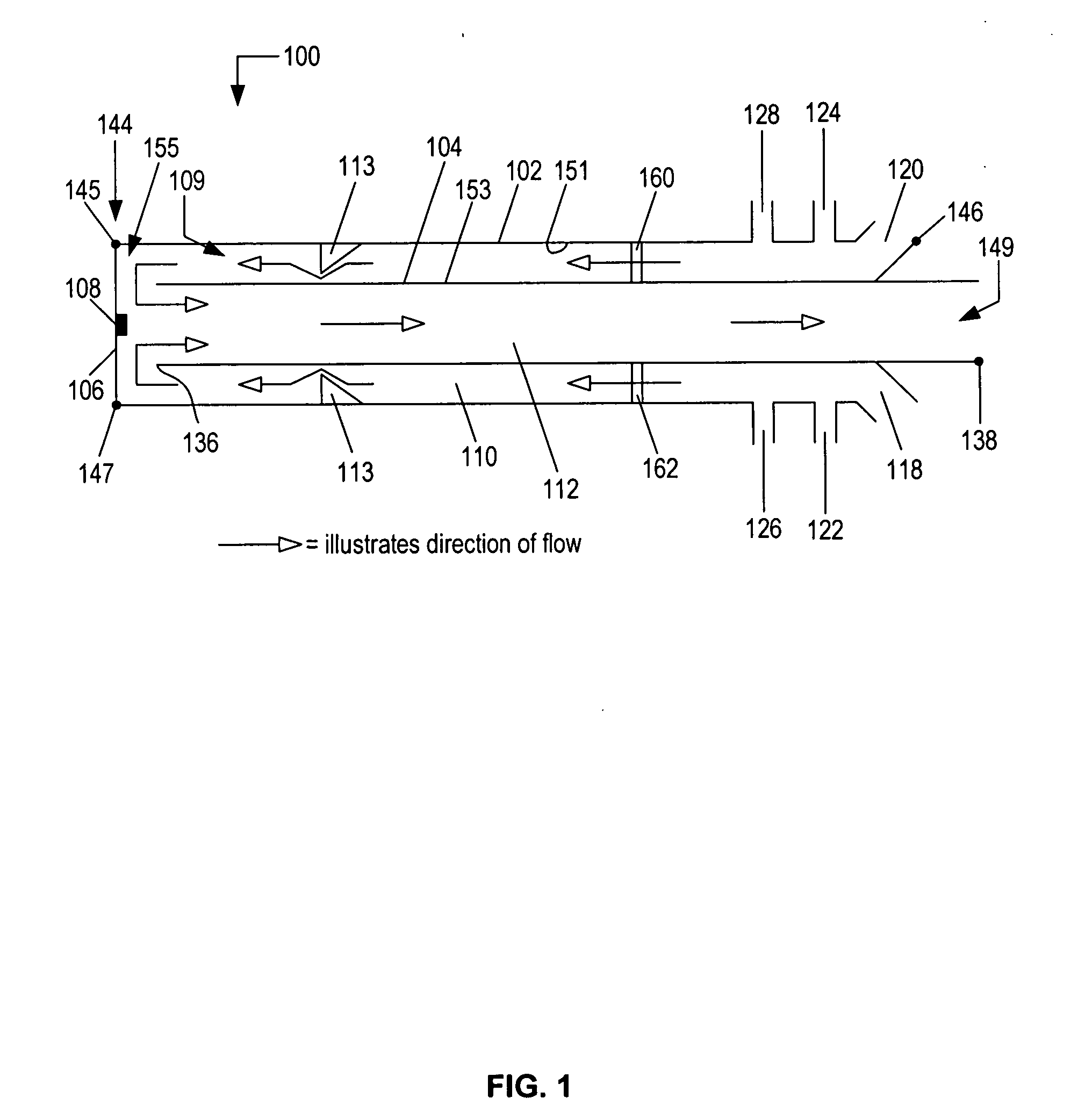

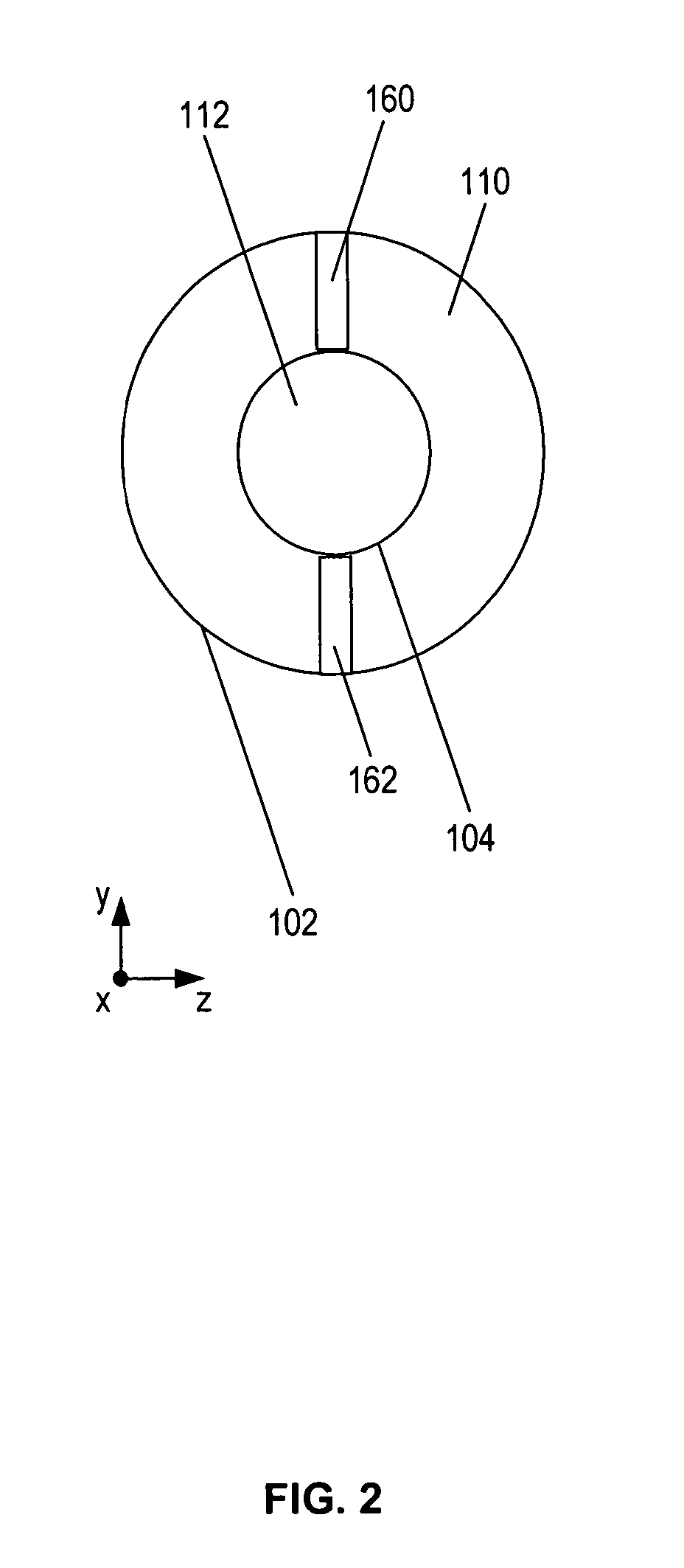

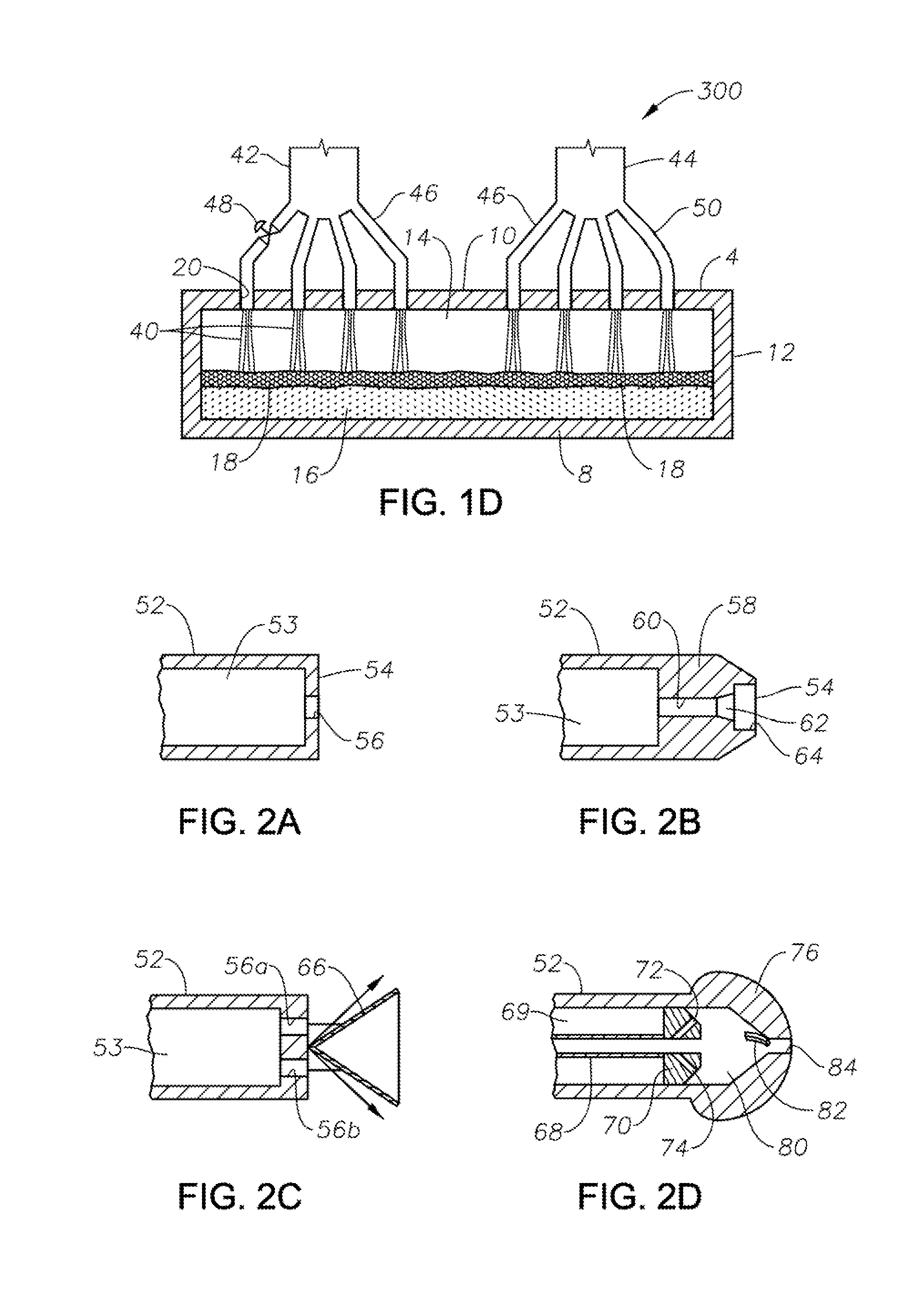

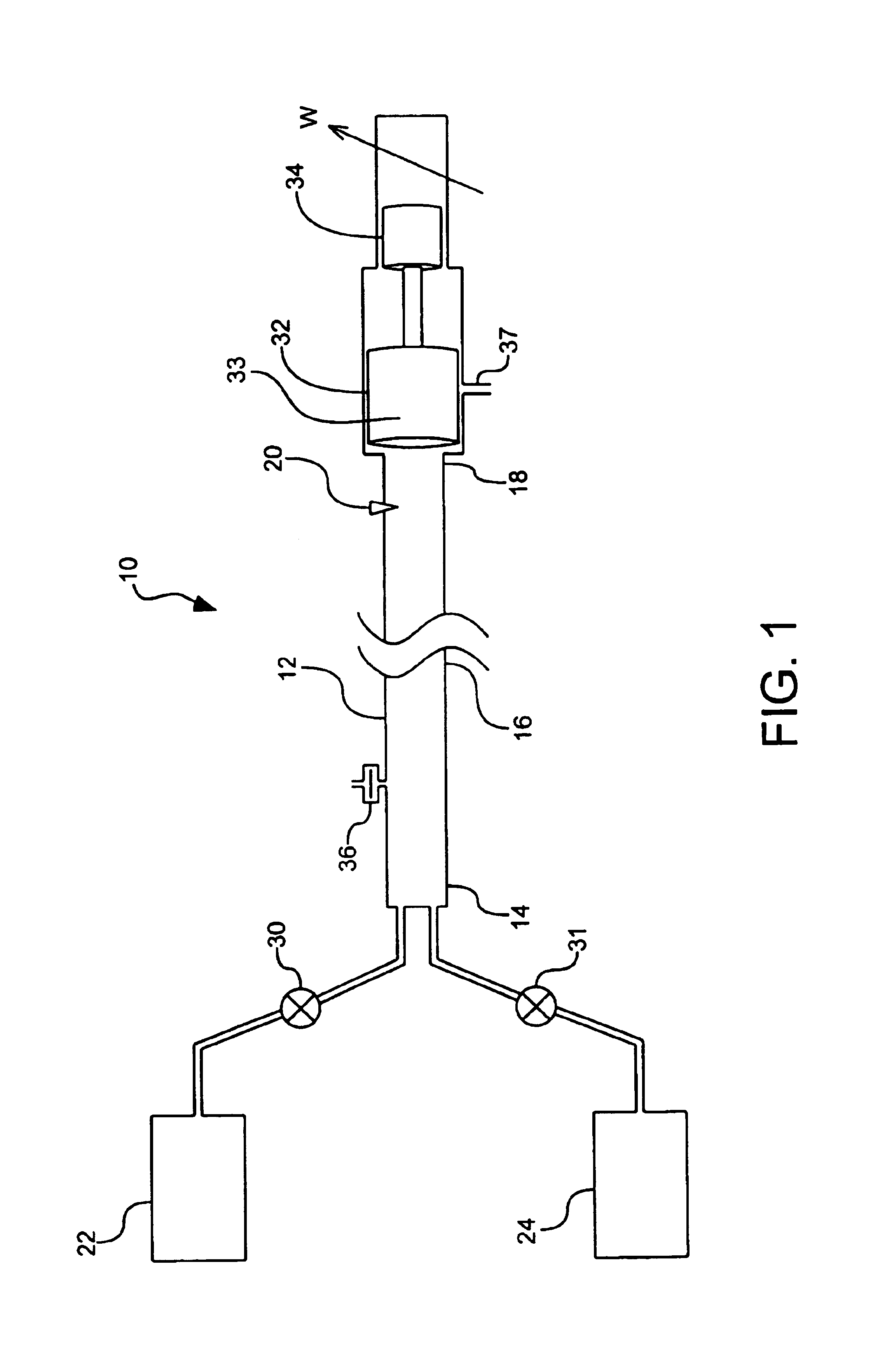

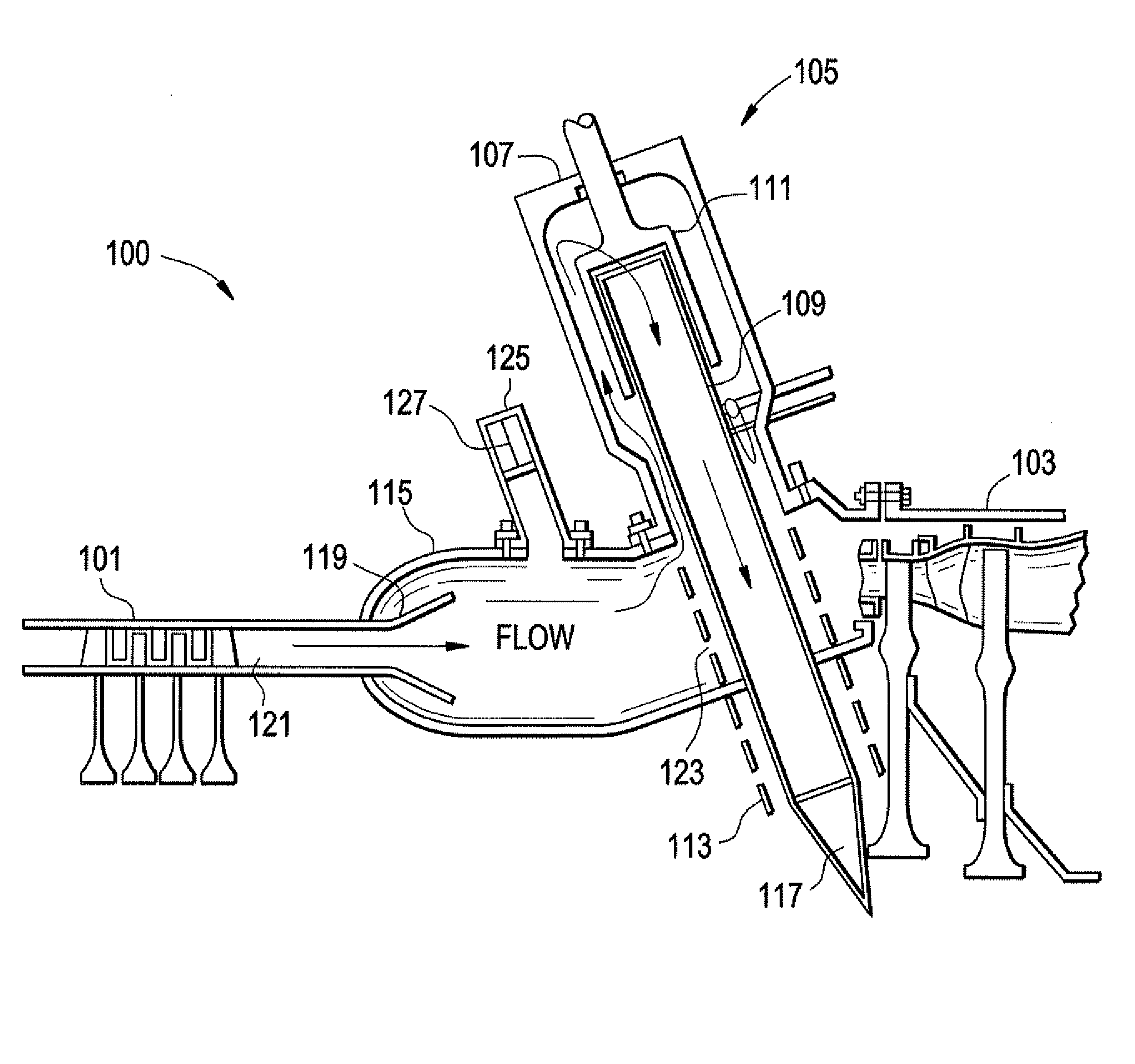

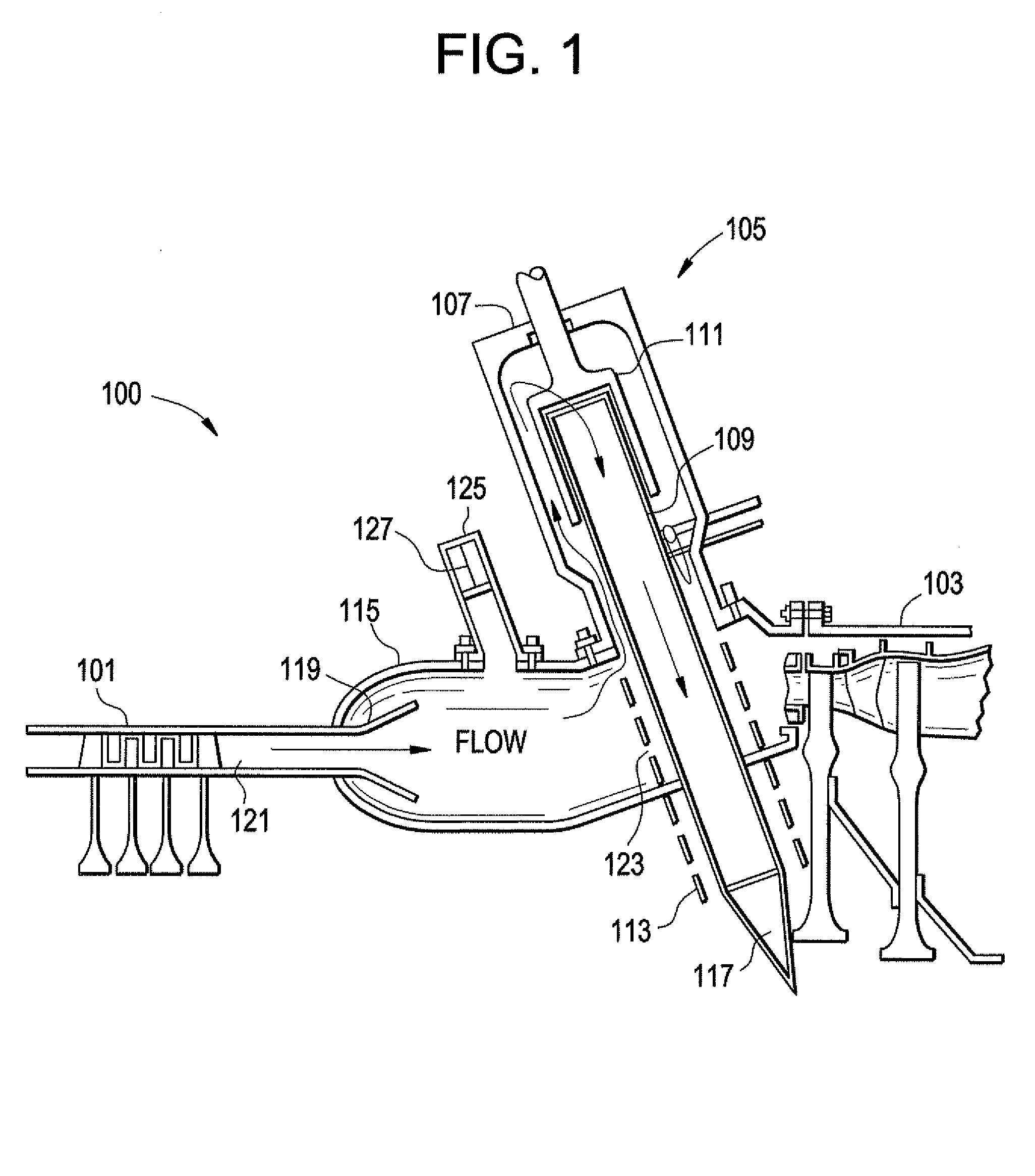

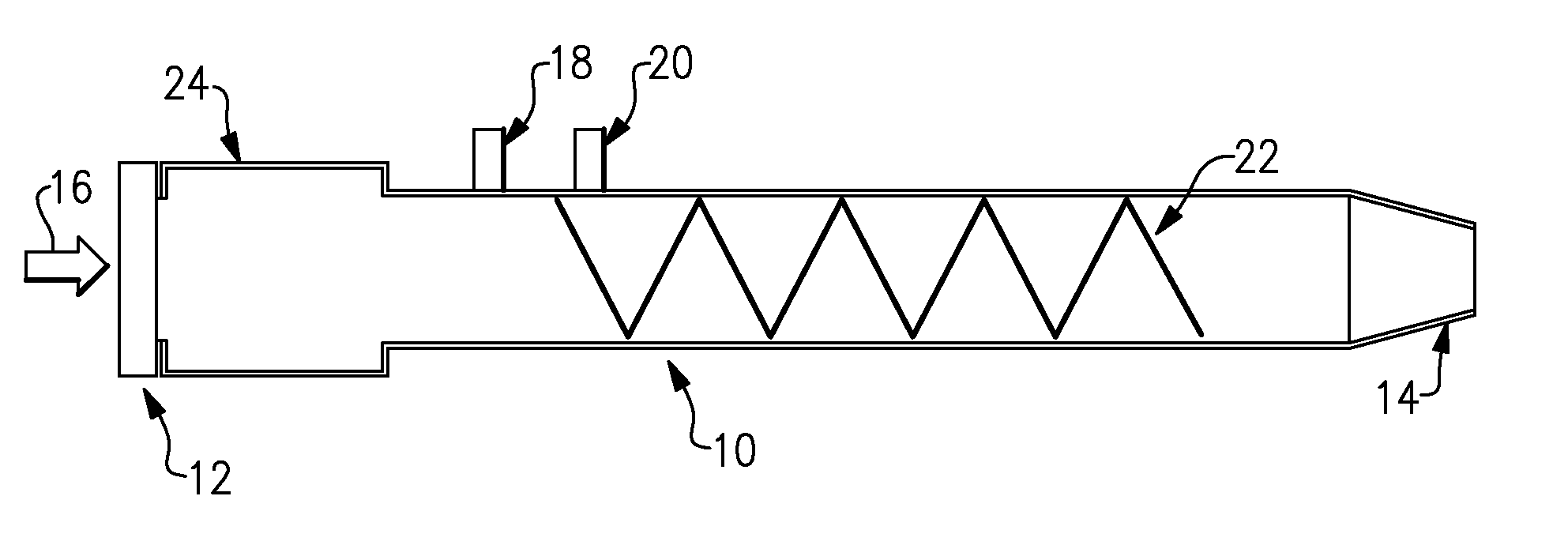

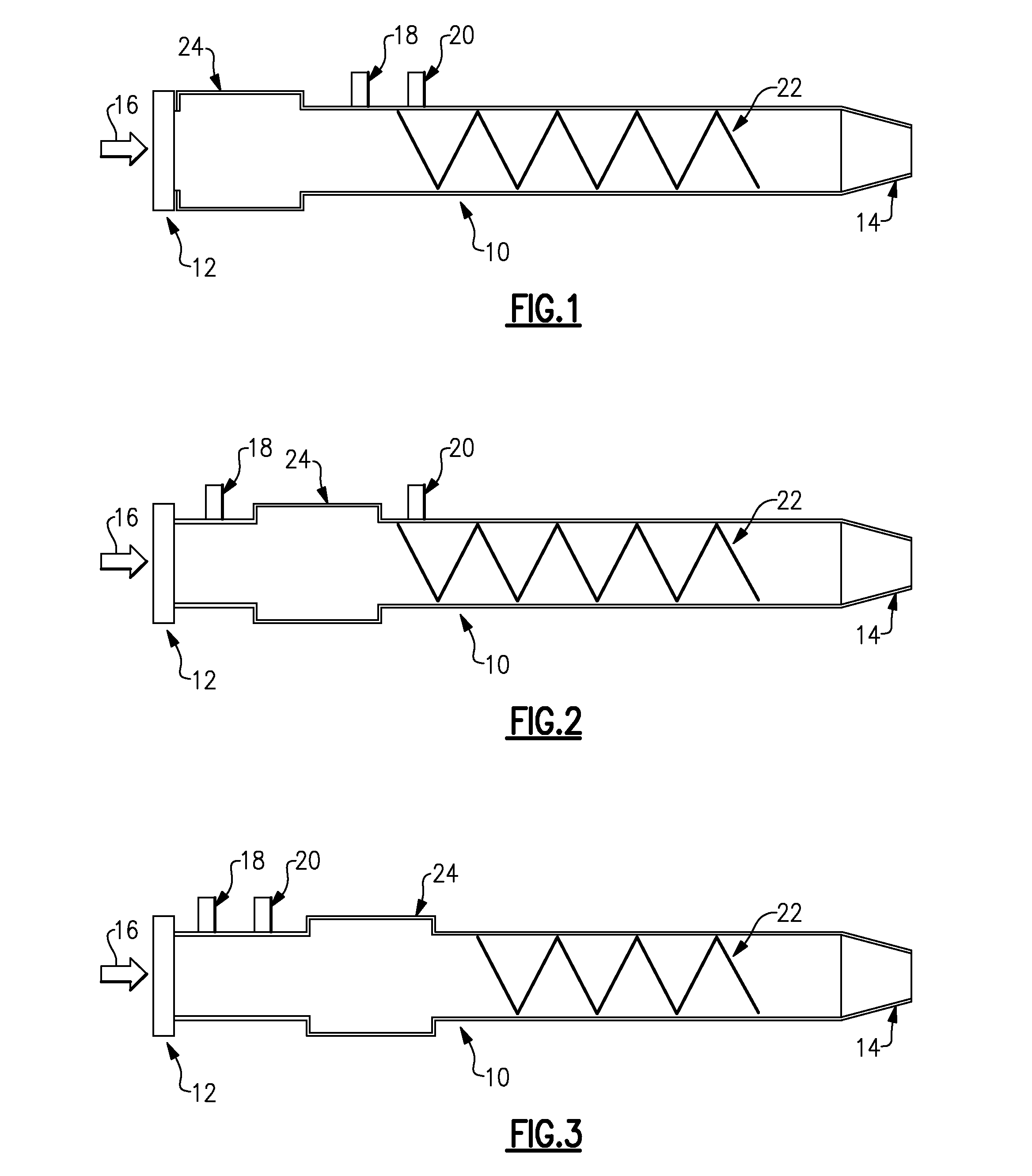

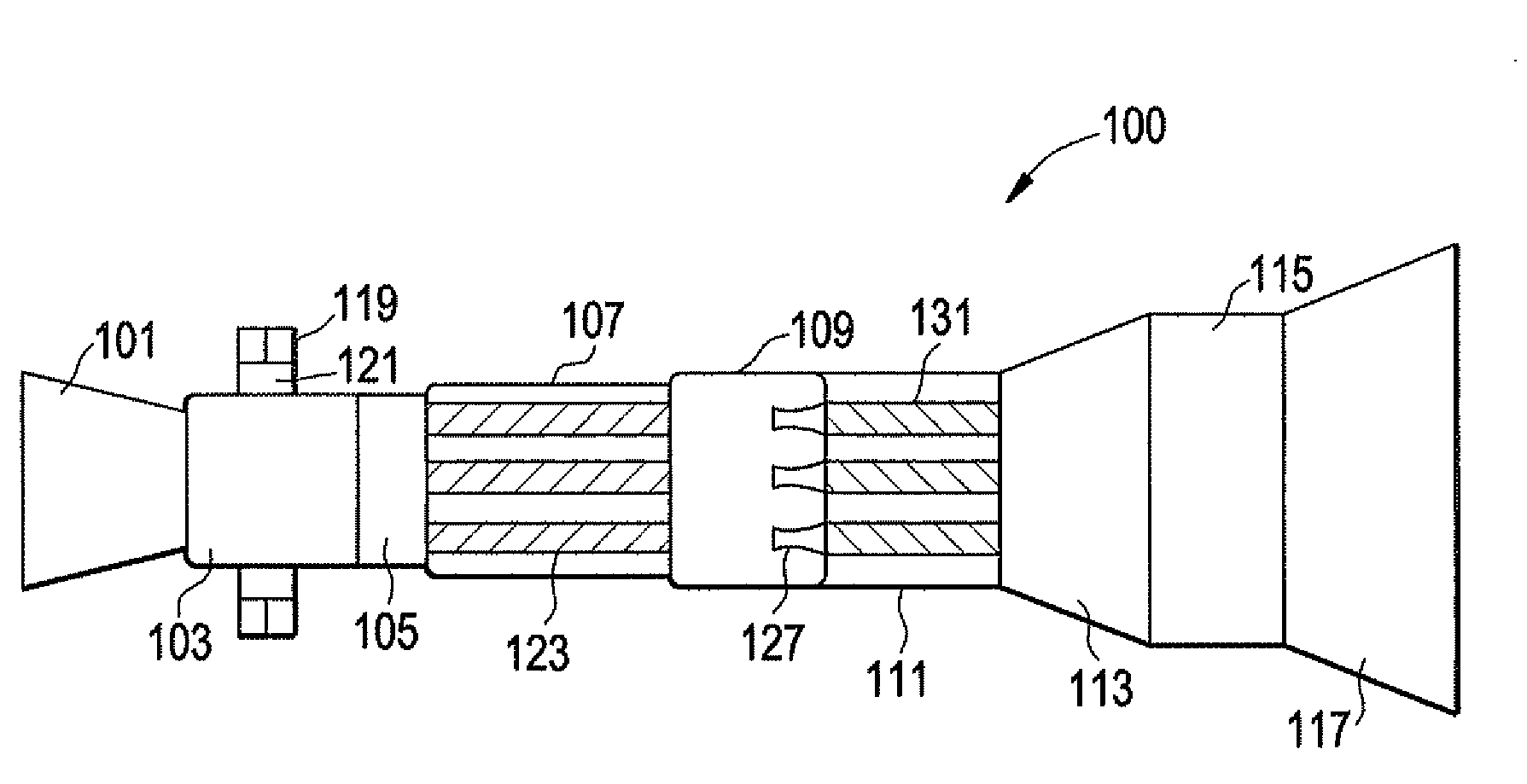

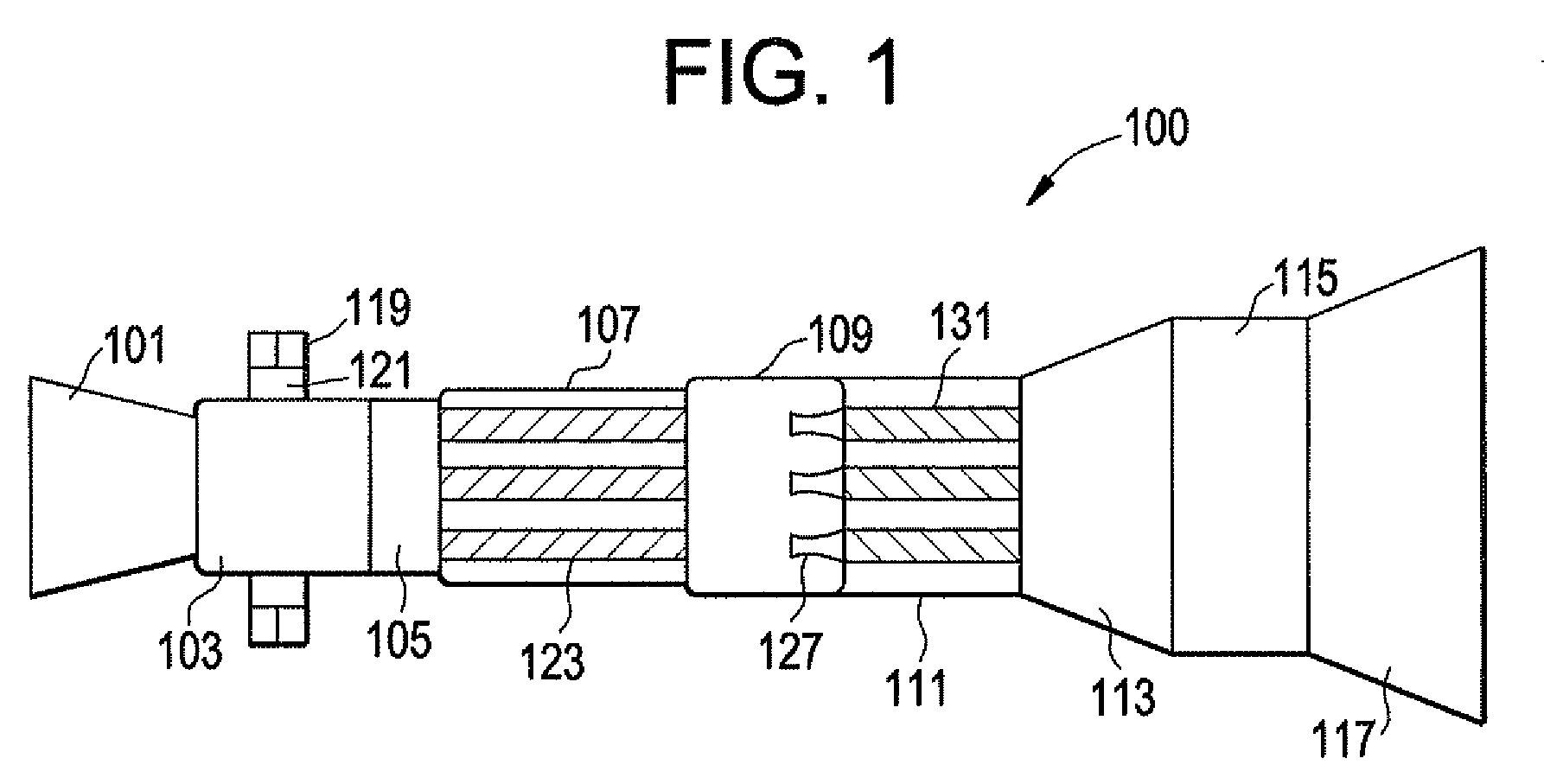

Pulse detonation combustor with folded flow path

A pulsed detonation combustor (PDC) is described. The PDC includes an outer casing defining a first hollow chamber configured to receive a flow and an inner liner. The inner liner includes at least one portion positioned within the first hollow chamber and configured to receive the flow from a plenum formed between the outer casing and inner liner. The PDC further includes a flow turning device with geometric features configured to direct the flow from the plenum to a second hollow chamber defined within the inner liner. The PDC also includes at least one fuel injection port located downstream of an inlet to the outer casing and an ignition device located downstream of the at least one fuel injection port and configured to periodically ignite fuel.

Owner:GENERAL ELECTRIC CO

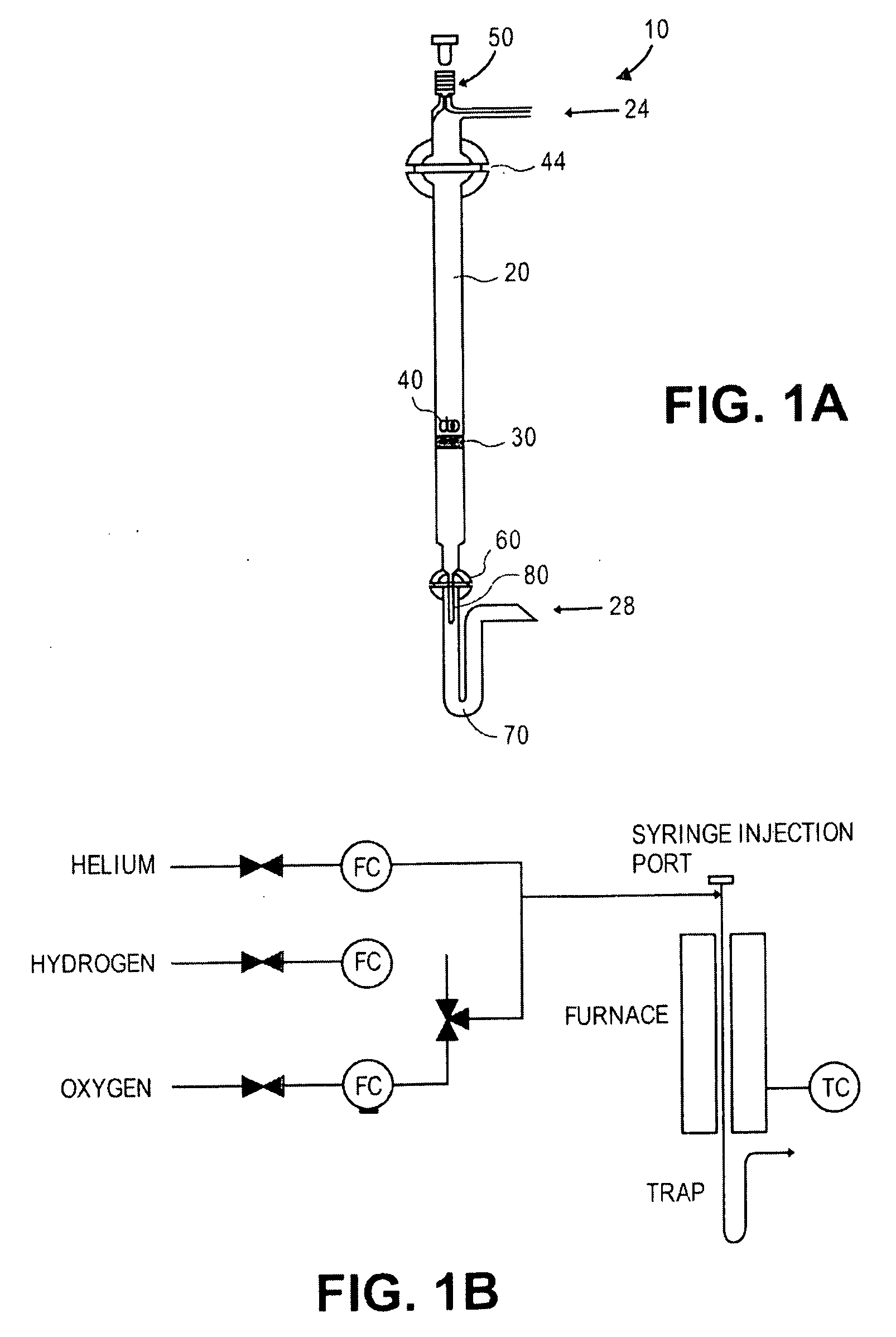

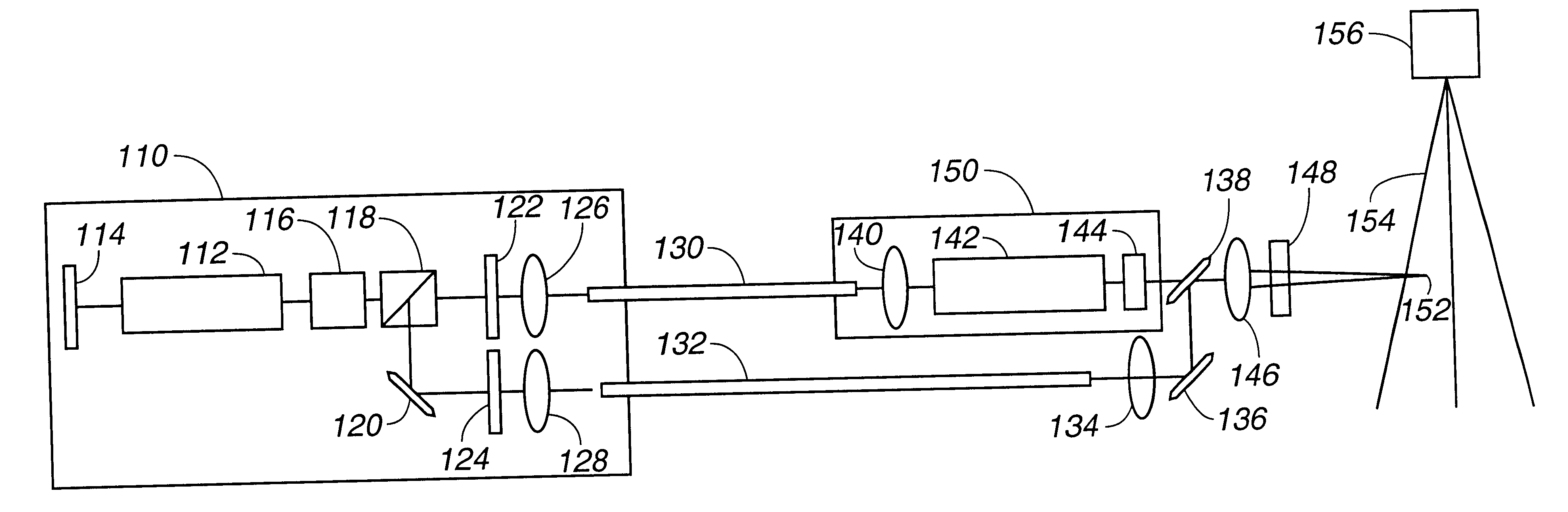

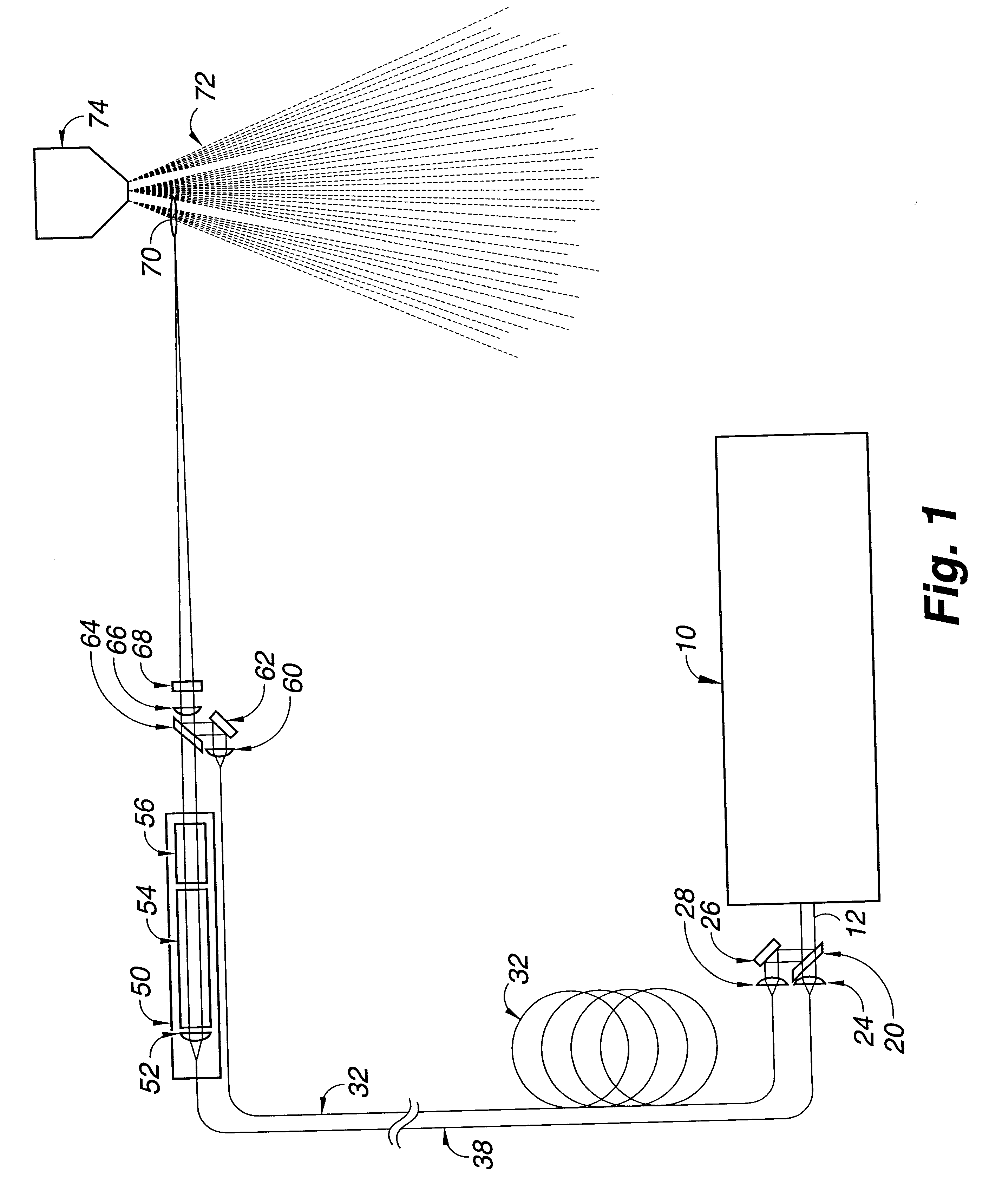

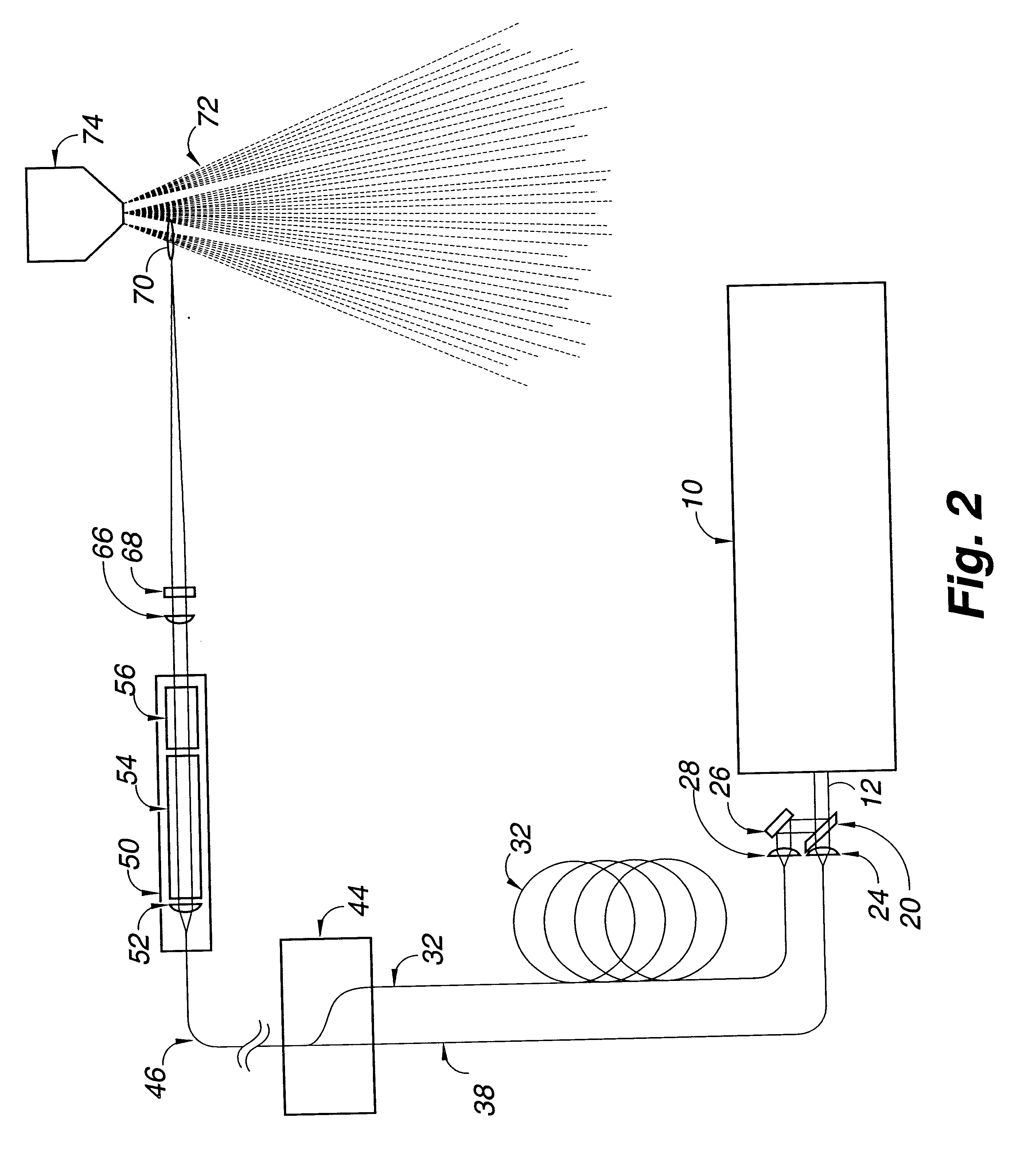

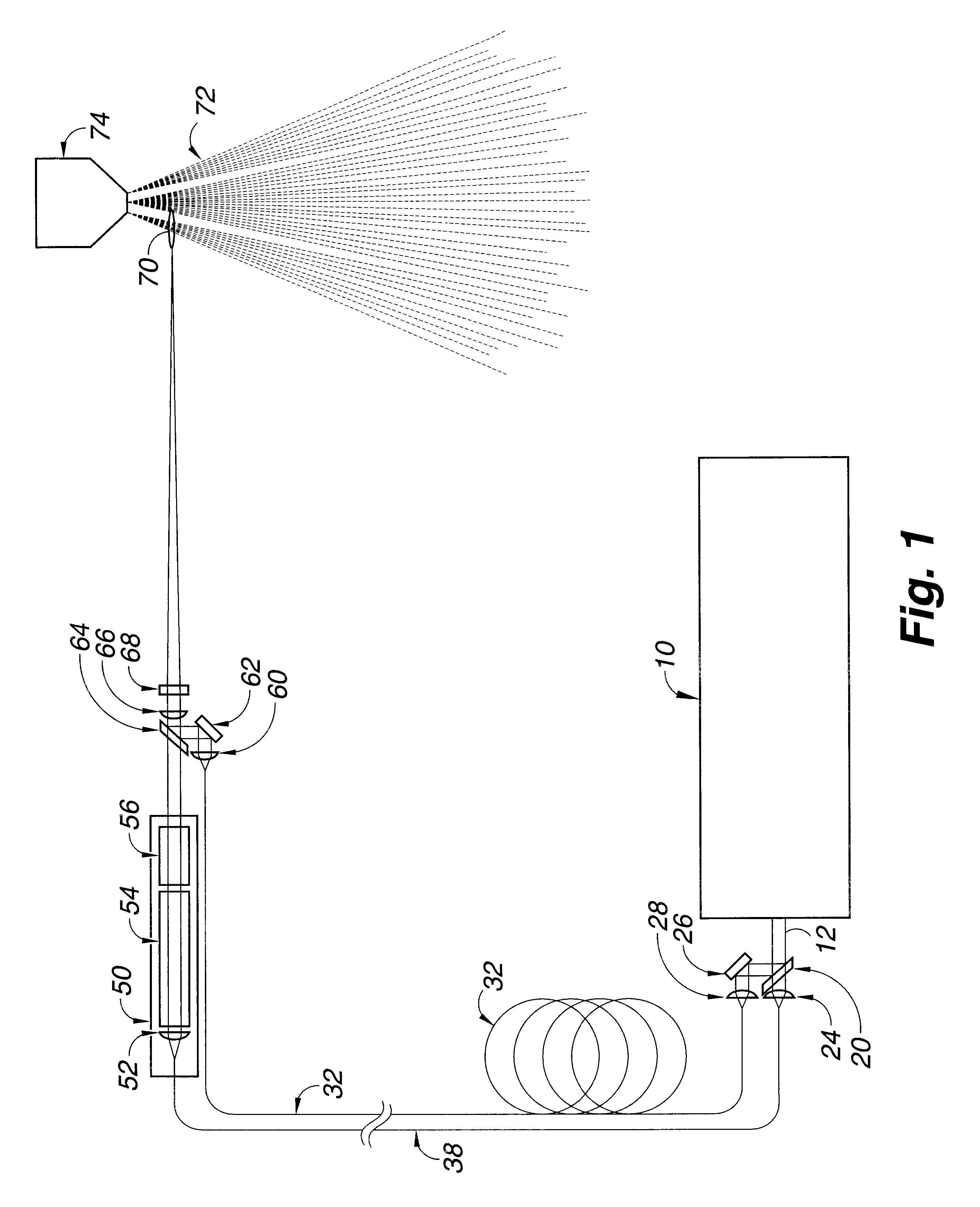

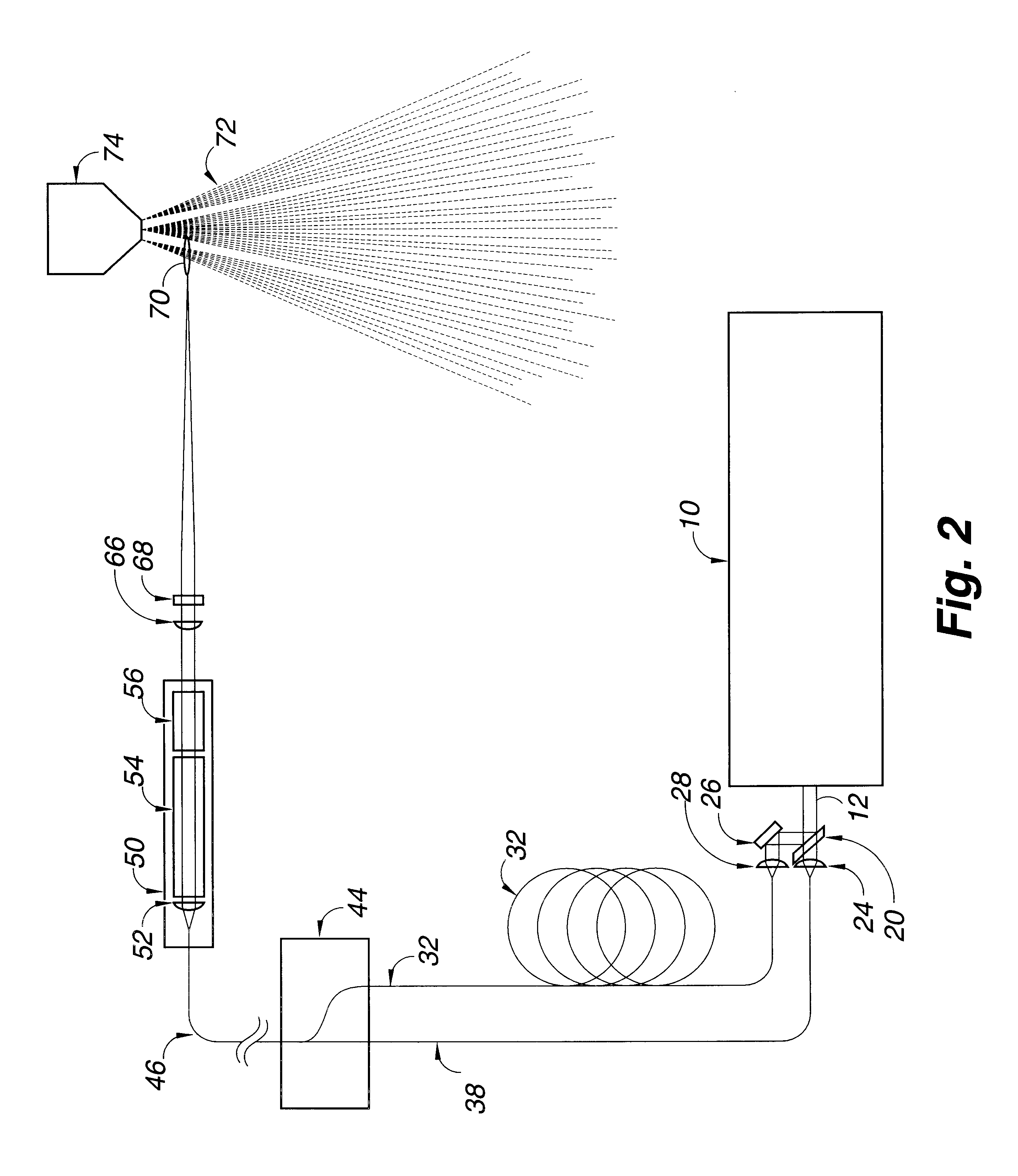

Laser ignition

InactiveUS6676402B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionResonant cavityLight beam

Sequenced pulses of light from an excitation laser with at least two resonator cavities with separate output couplers are directed through a light modulator and a first polarzing analyzer. A portion of the light not rejected by the first polarizing analyzer is transported through a first optical fiber into a first ignitor laser rod in an ignitor laser. Another portion of the light is rejected by the first polarizing analyzer and directed through a halfwave plate into a second polarization analyzer. A first portion of the output of the second polarization analyzer passes through the second polarization analyzer to a second, oscillator, laser rod in the ignitor laser. A second portion of the output of the second polarization analyzer is redirected by the second polarization analyzer to a second optical fiber which delays the beam before the beam is combined with output of the first ignitor laser rod. Output of the second laser rod in the ignitor laser is directed into the first ignitor laser rod which was energized by light passing through the first polarizing analyzer. Combined output of the first ignitor laser rod and output of the second optical fiber is focused into a combustible fuel where the first short duration, high peak power pulse from the ignitor laser ignites the fuel and the second long duration, low peak power pulse directly from the excitation laser sustains the combustion.

Owner:LOS ALAMOS NATIONAL SECURITY

Panel-cooled submerged combustion melter geometry and methods of making molten glass

ActiveUS8769992B2Small sizeAllows more flexibility in the shape of the melterPulsating combustionGlass furnace apparatusThermodynamicsCombustor

A melter apparatus includes a floor, a ceiling, and a substantially vertical wall connecting the floor and ceiling at a perimeter of the floor and ceiling, a melting zone being defined by the floor, ceiling and wall, the melting zone having a feed inlet and a molten glass outlet positioned at opposing ends of the melting zone. The melting zone includes an expanding zone beginning at the inlet and extending to an intermediate location relative to the opposing ends, and a narrowing zone extending from the intermediate location to the outlet. One or more burners, at least some of which are positioned to direct combustion products into the melting zone under a level of molten glass in the zone, are also provided.

Owner:JOHNS MANVILLE CORP

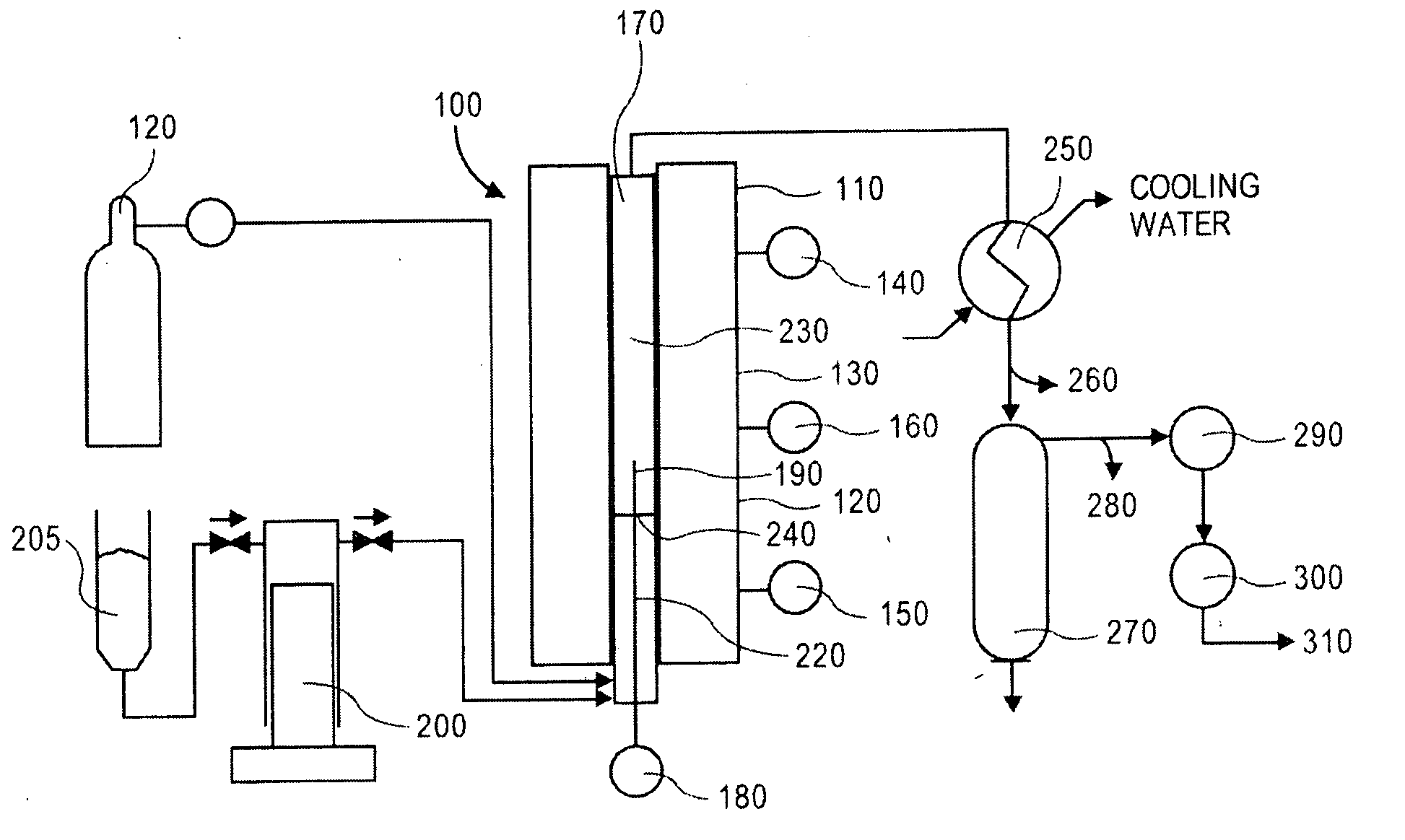

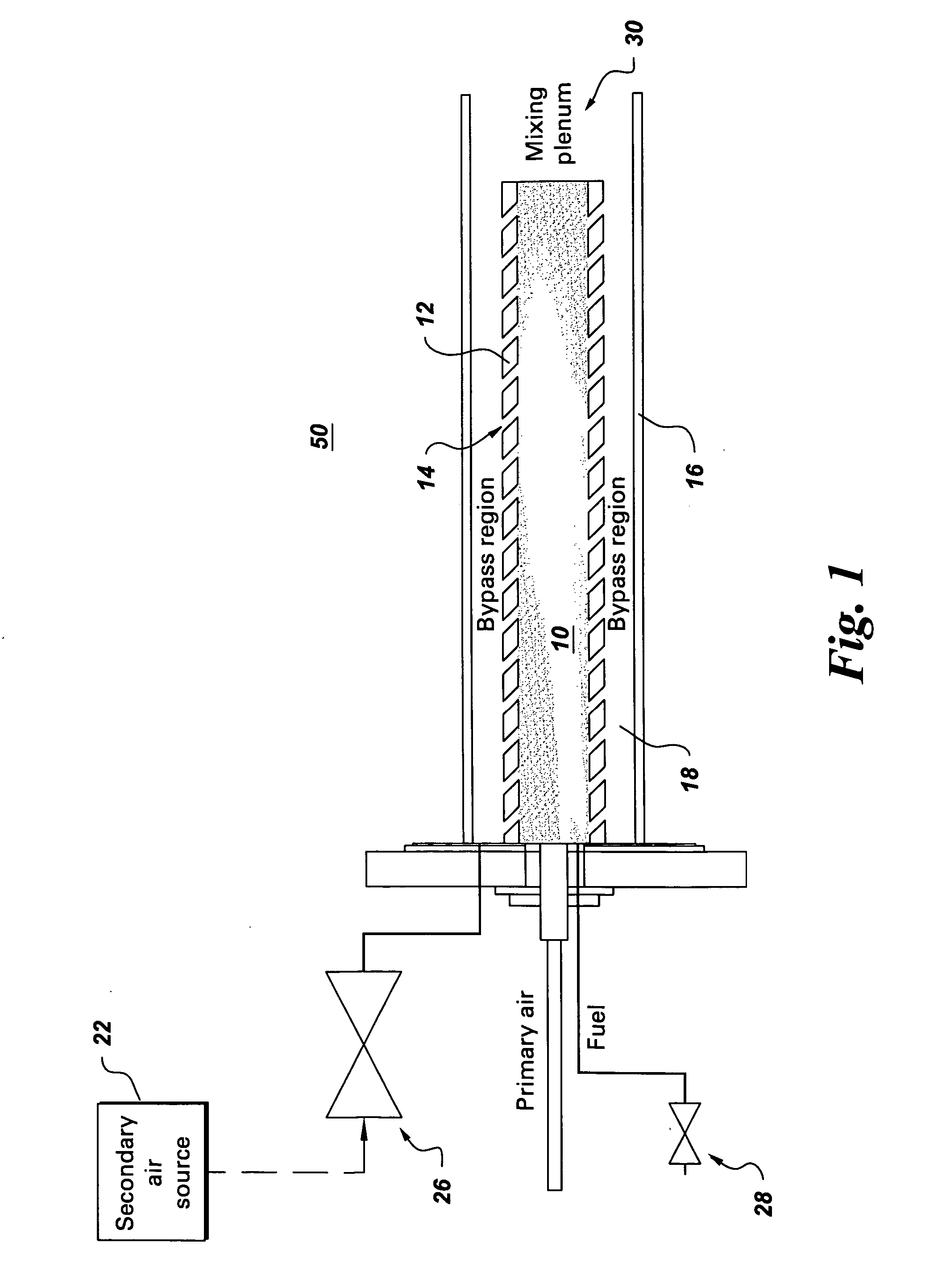

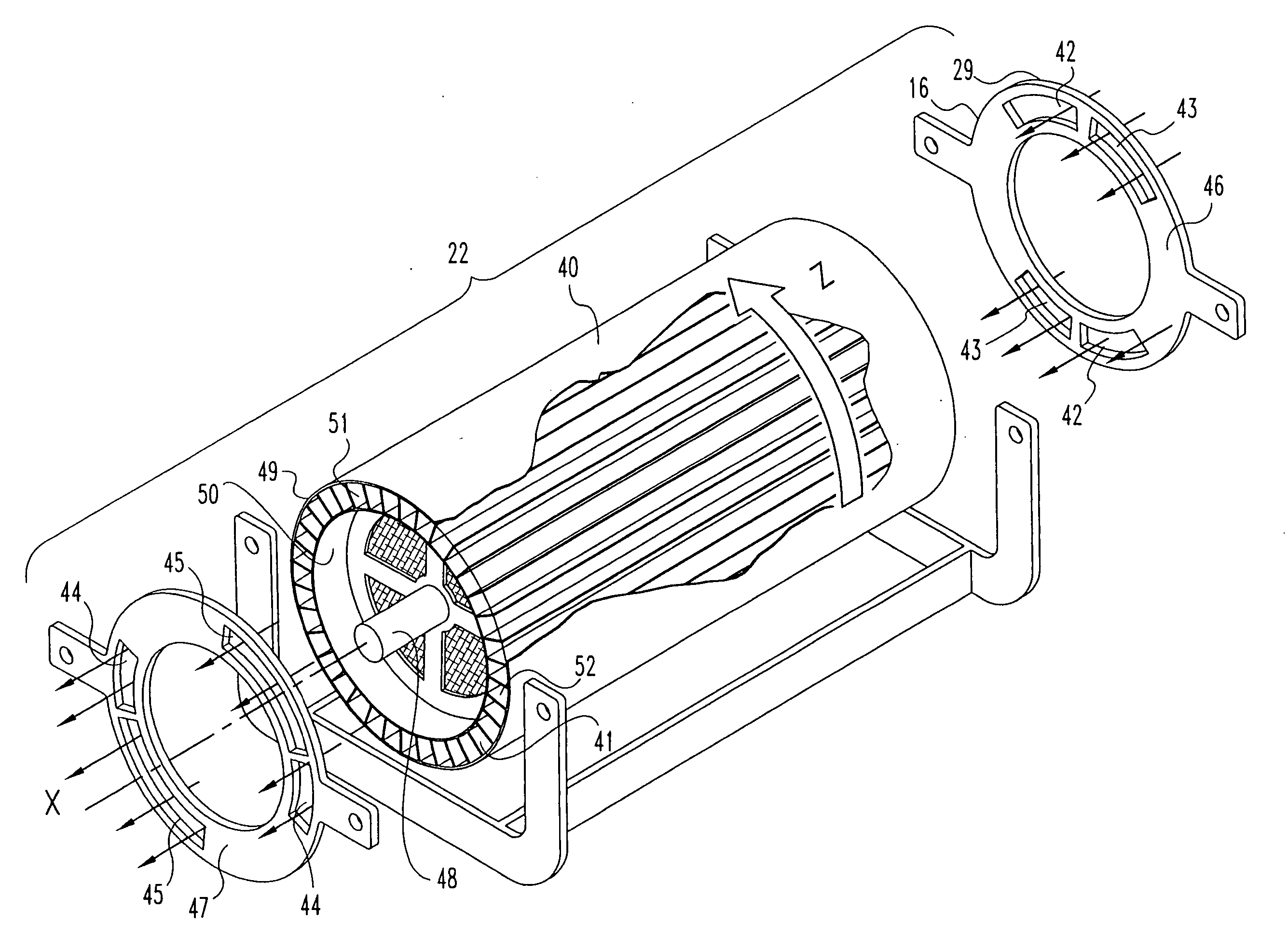

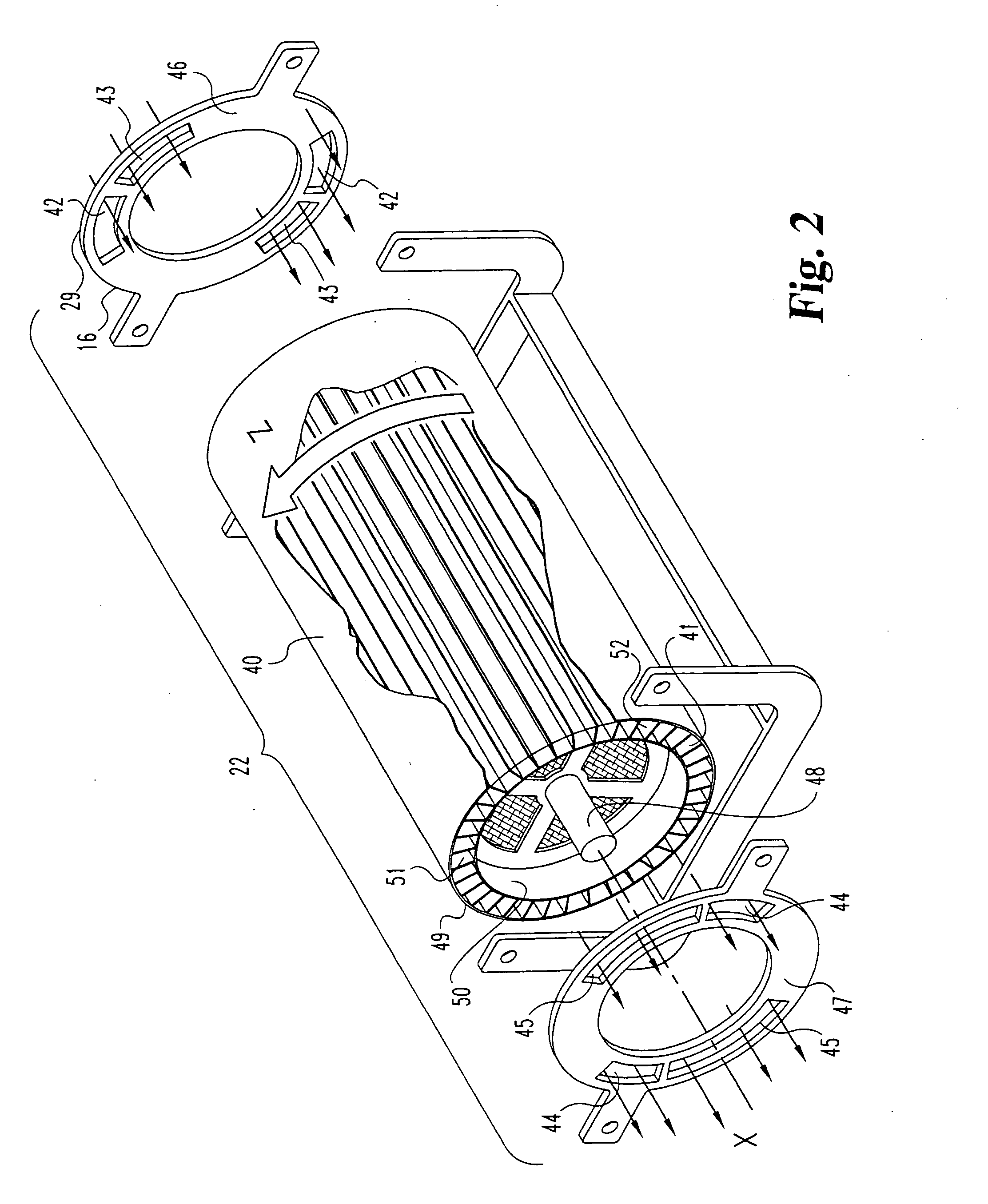

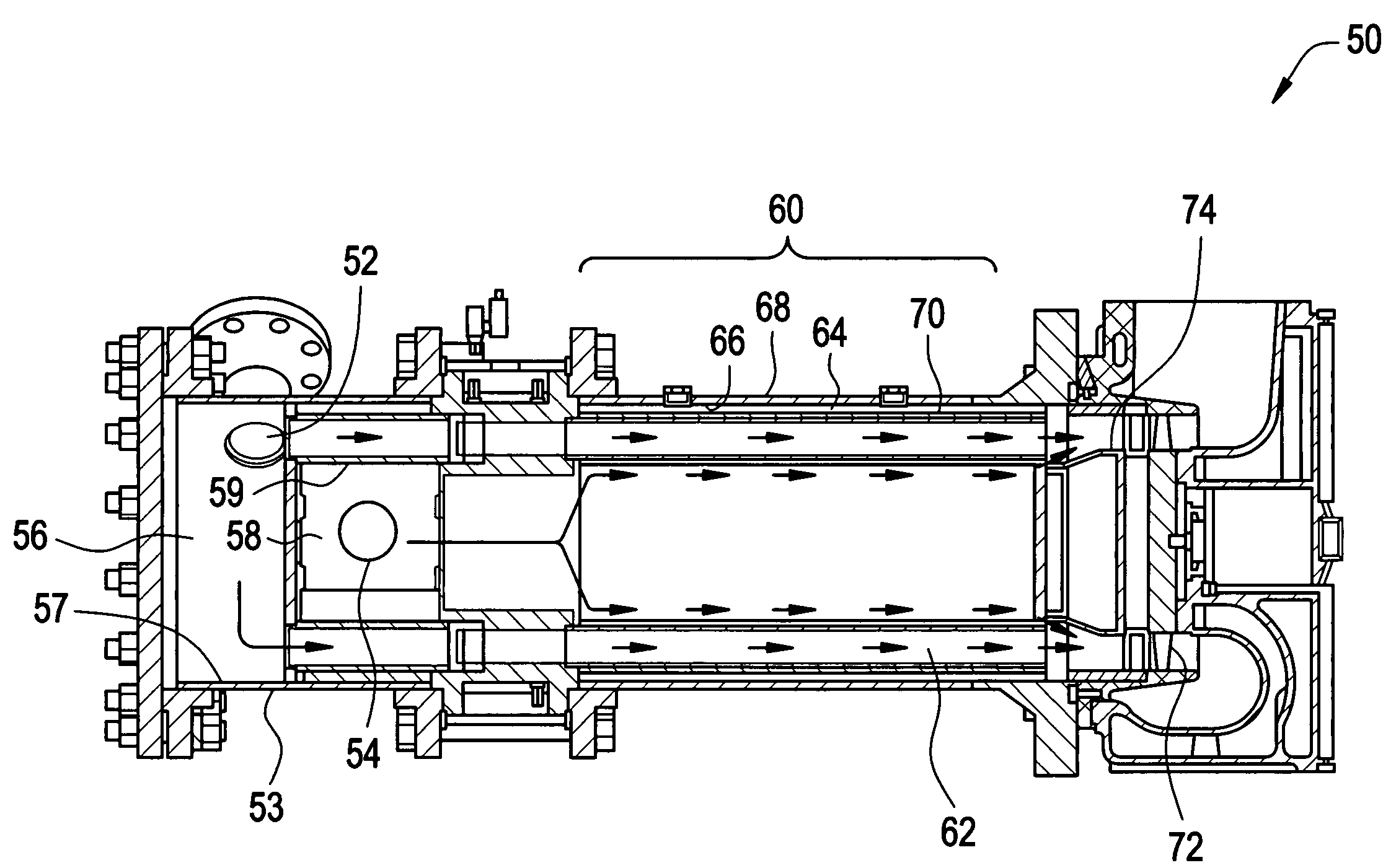

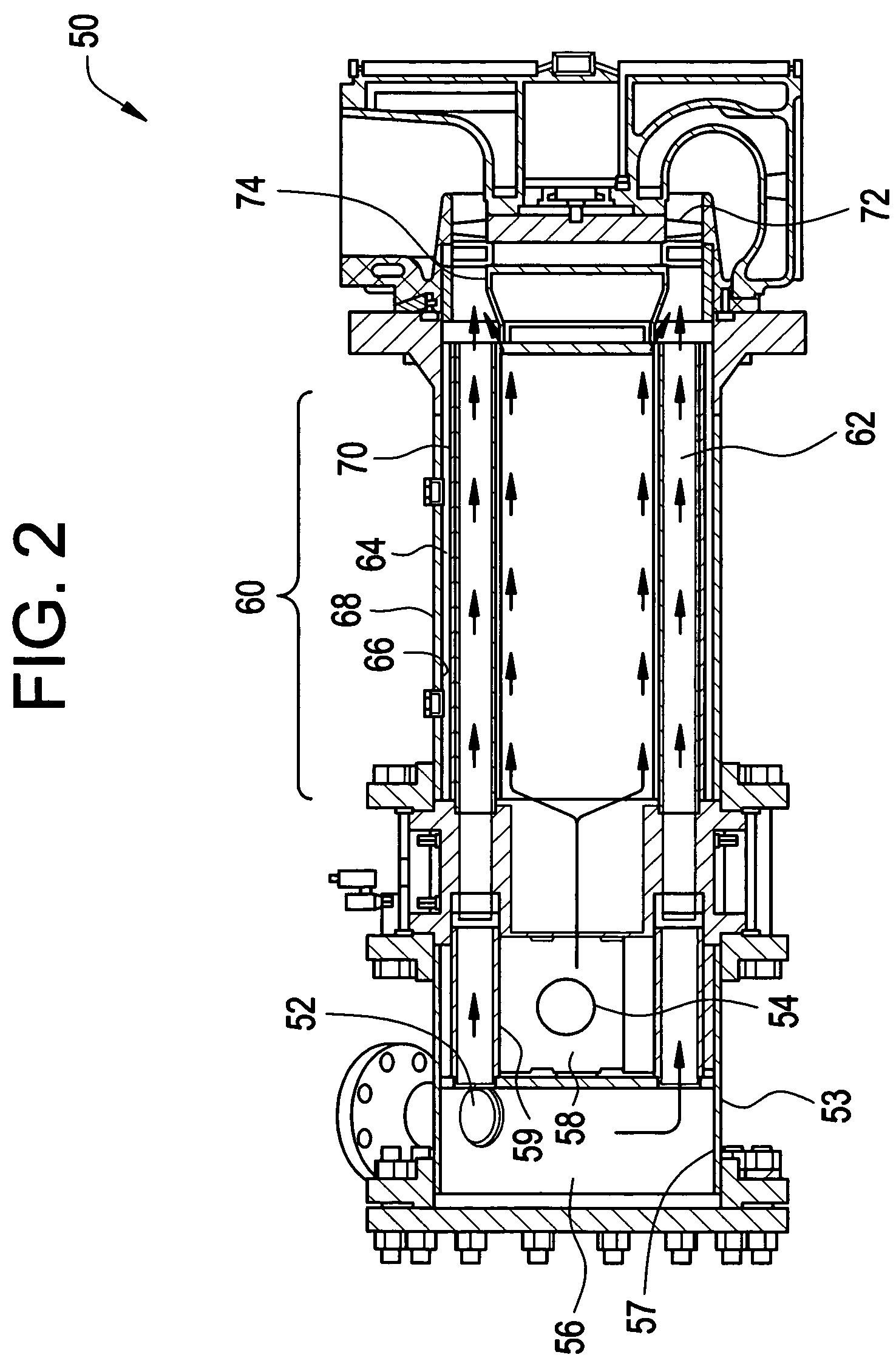

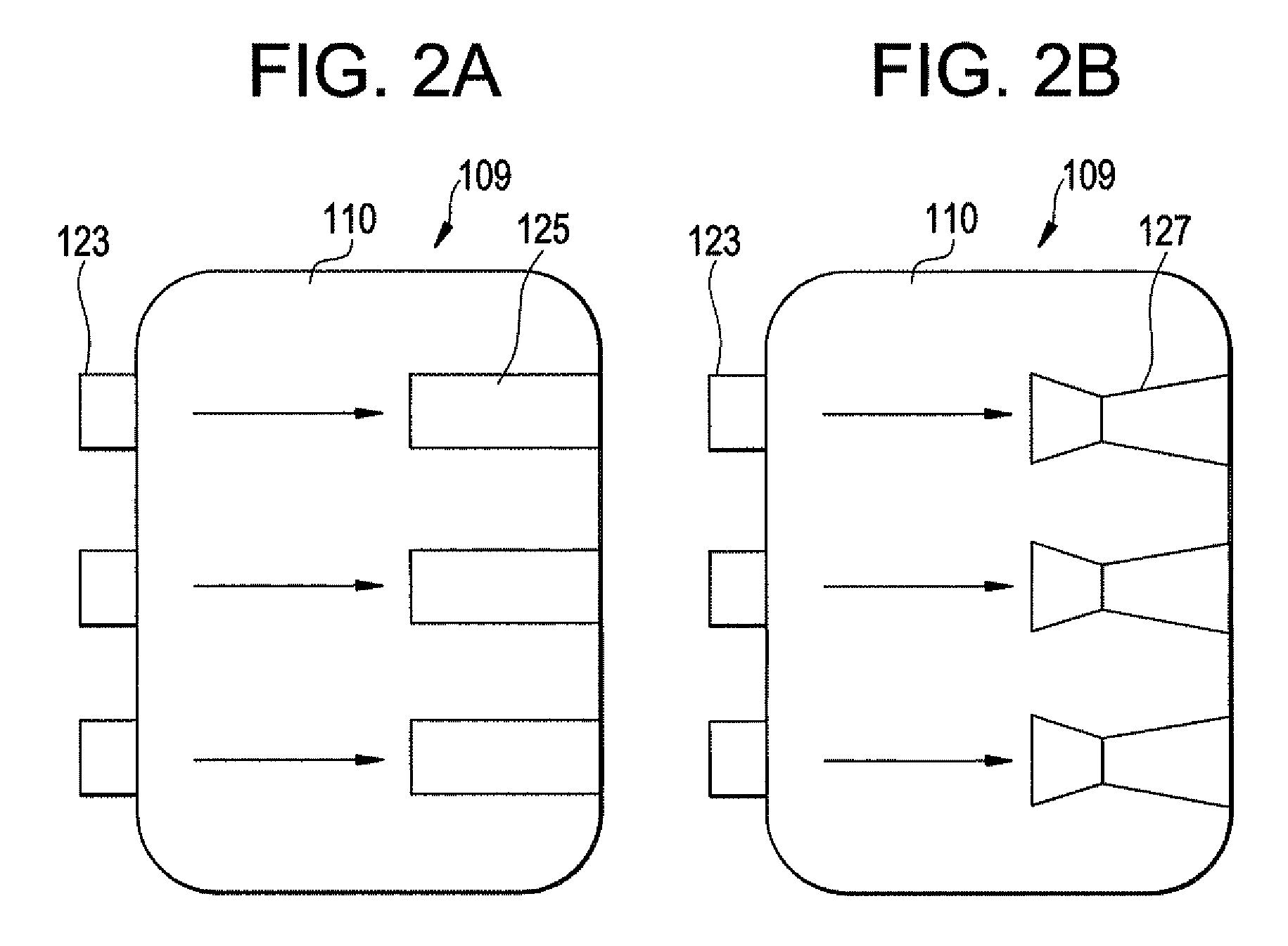

Pulse detonation assembly with cooling enhancements

A pulse detonation (PD) assembly includes at least one PD chamber having a wall, which defines cooling holes arranged along at least a portion of the PD chamber. A manifold extends around the PD chamber. The manifold and PD chamber are separated by a bypass region. A PD assembly with reverse flow cooling includes at least one PD chamber. A sleeve extends around the PD chamber. The sleeve and PD chamber are separated by a reverse flow cooling passage configured to receive a flow of air and to flow the air in a reverse direction to supply the PD chamber. A PD assembly with bypass flow cooling includes at least one PD chamber and a manifold extending around the PD chamber(s), which are separated by a bypass region. The PD assembly further includes a mixing plenum configured to receive and mix the bypass flow from the bypass region and the detonation by-products from the PD chamber(s).

Owner:GENERAL ELECTRIC CO

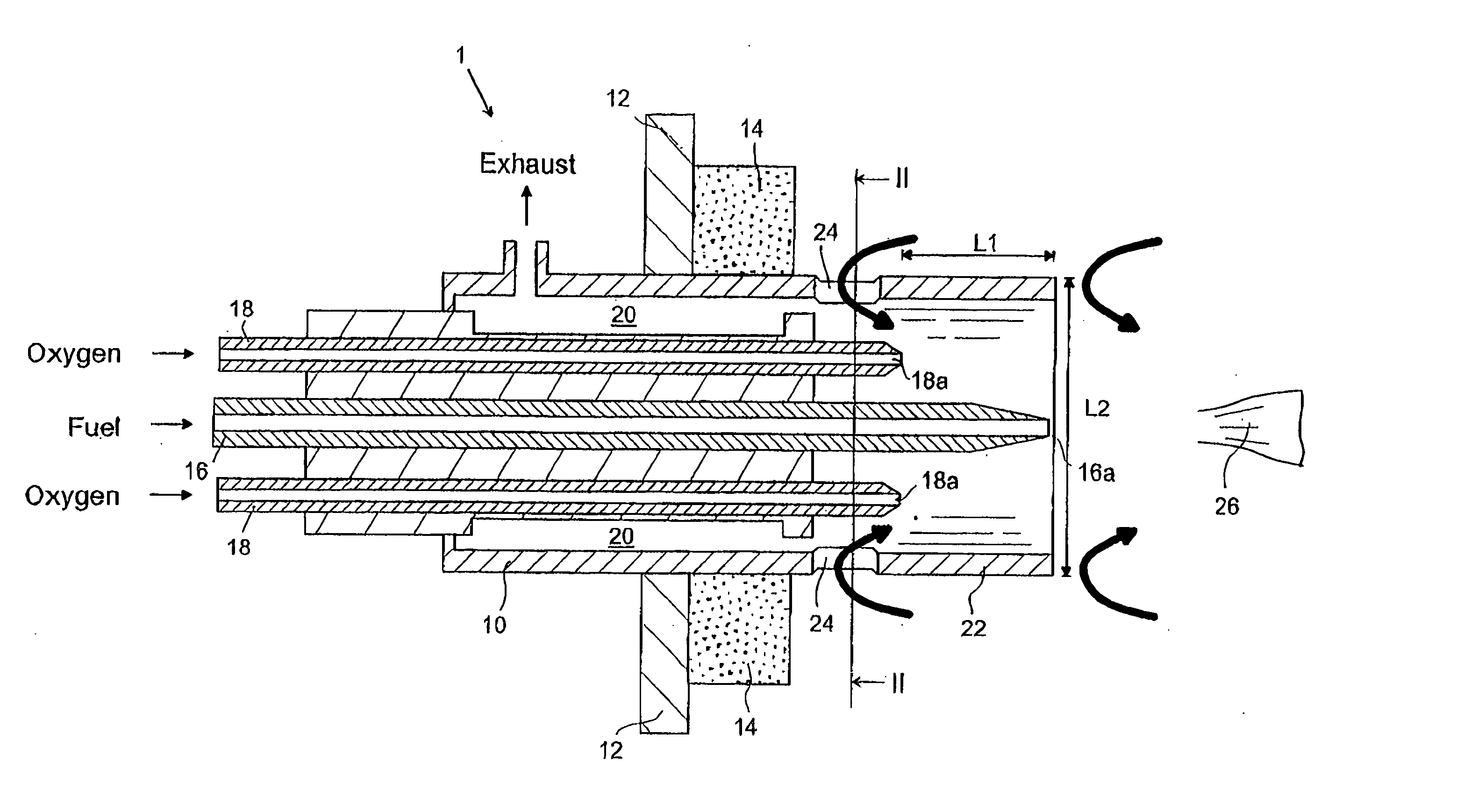

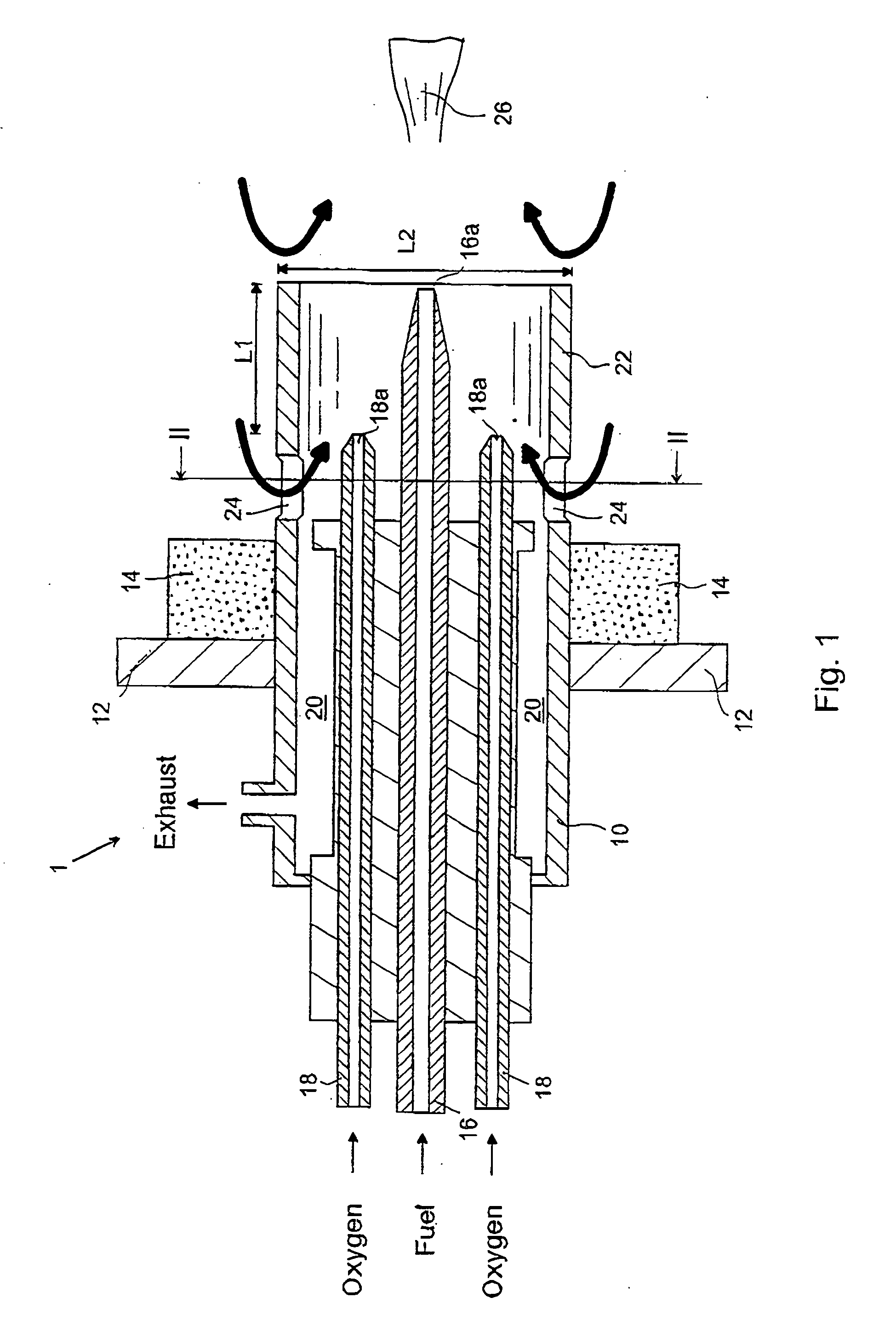

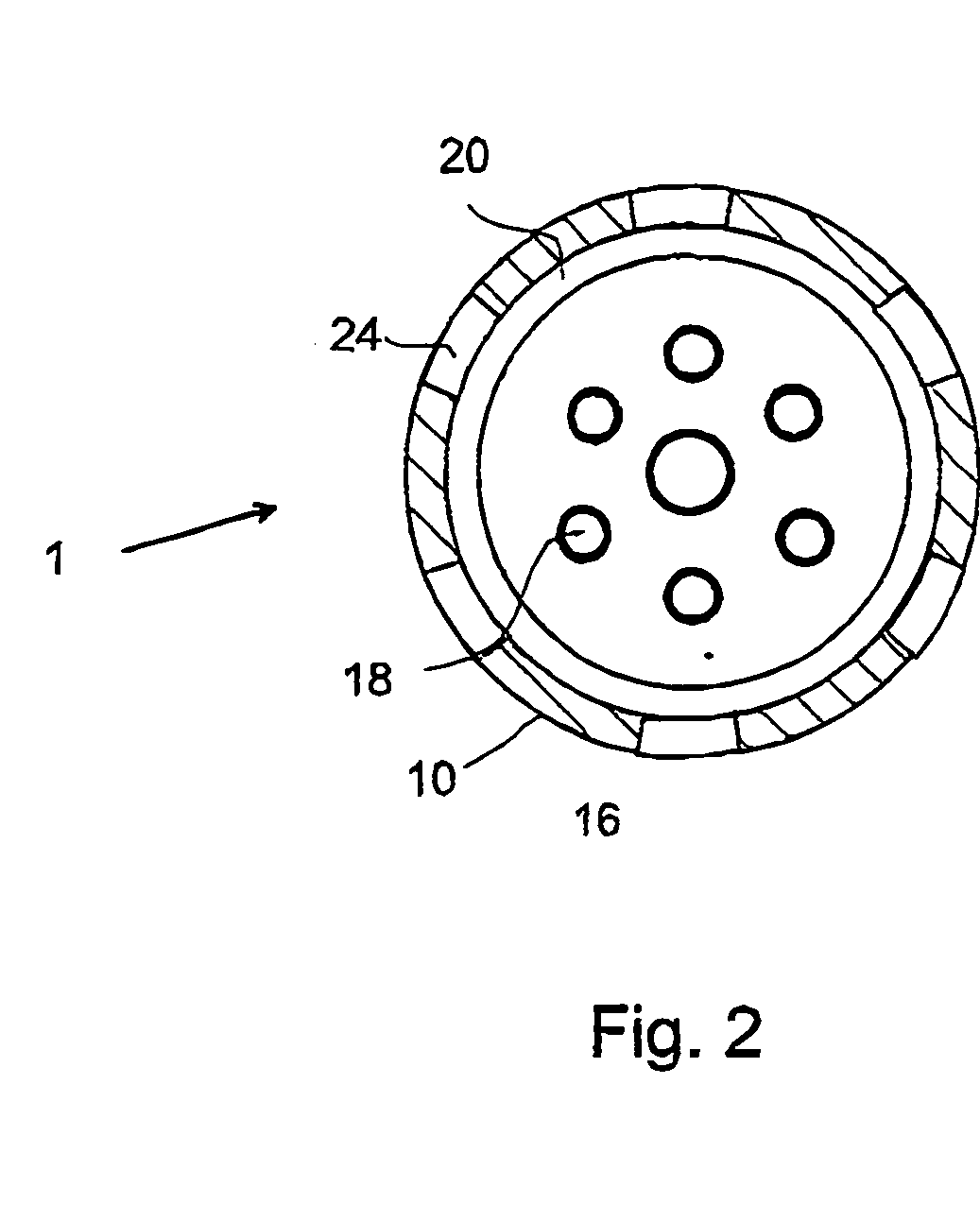

Method and apparatus for heat treatment

InactiveUS20050239005A1High degreeCombustion using gaseous and pulverulent fuelPulsating combustionCombustorCost effectiveness

A method and an apparatus for heat-treatment of materials, preferably metals, are provided. The method comprises the following steps: providing and maintaining a flame by supplying a burner with fuel and gas containing at least 80 percent by volume oxygen; creating an oxygen-hot exhaust mixture by recirculating exhausts from the flame to the gas containing oxygen by means of an ejector effect; mixing the oxygen-exhaust mixture and the fuel; and providing a secondary recirculation by recirculating exhausts from the flame to the oxygen-exhaust-fuel mixture. The method and apparatus allow for extremely low NOx emissions and high efficiency, resulting in an environmentally friendly and at the same time cost effective process.

Owner:LINDE AG

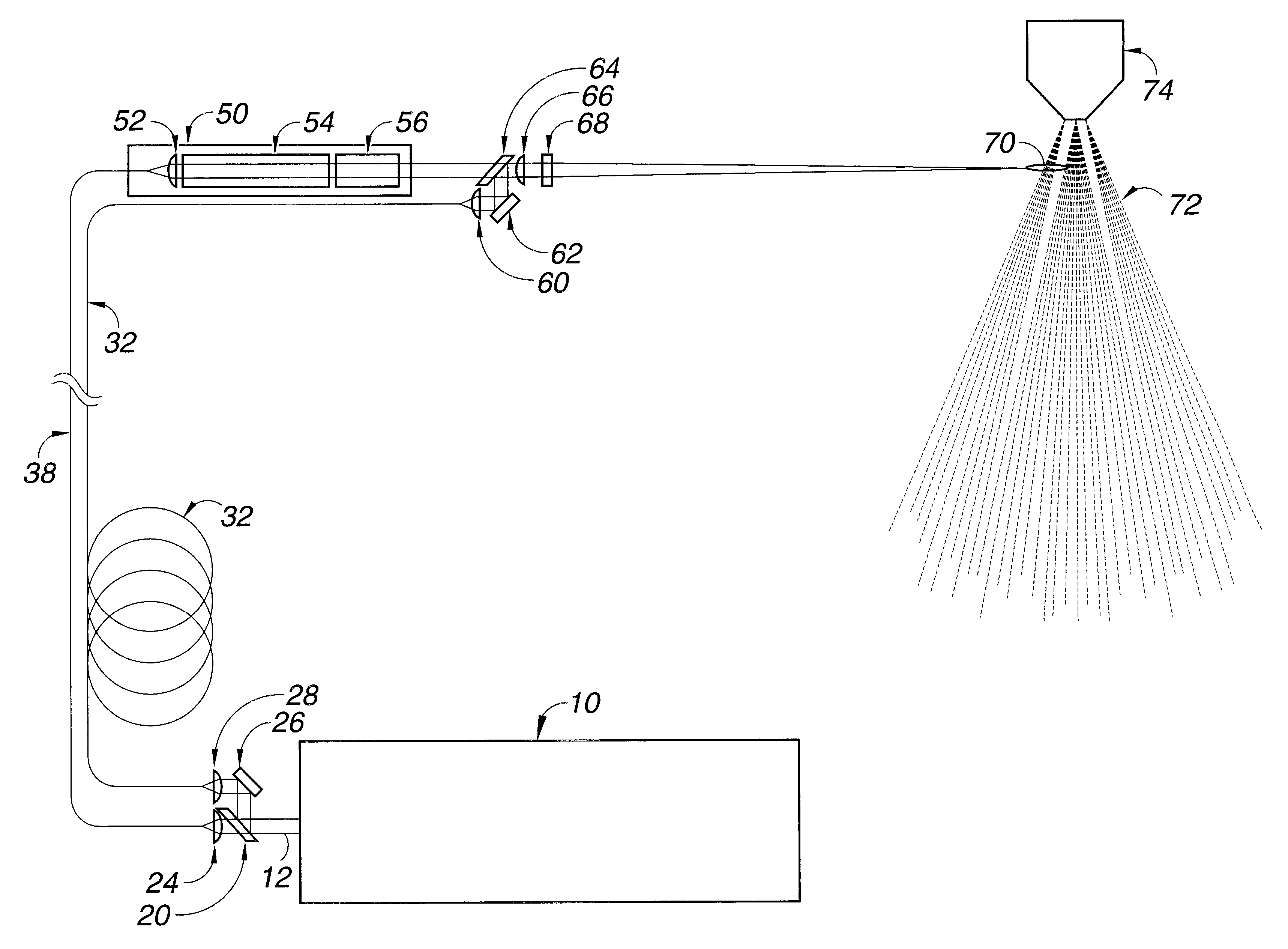

Laser ignition

InactiveUS6382957B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionLight beamEngineering

In the apparatus of the invention, a first excitation laser or other excitation light source is used in tandem with an ignitor laser to provide a compact, durable, engine deployable fuel ignition laser system. Reliable fuel ignition is provided over a wide range of fuel conditions by using a single remote excitation light source for one or more small lasers located proximate to one or more fuel combustion zones.In the embodiment of the invention claimed herein, the beam from the excitation light source is split with a portion of it going to the ignitor laser and a second portion of it being combined with either the first portion after a delay before injection into the ignitor laser.

Owner:LOS ALAMOS NATIONAL SECURITY

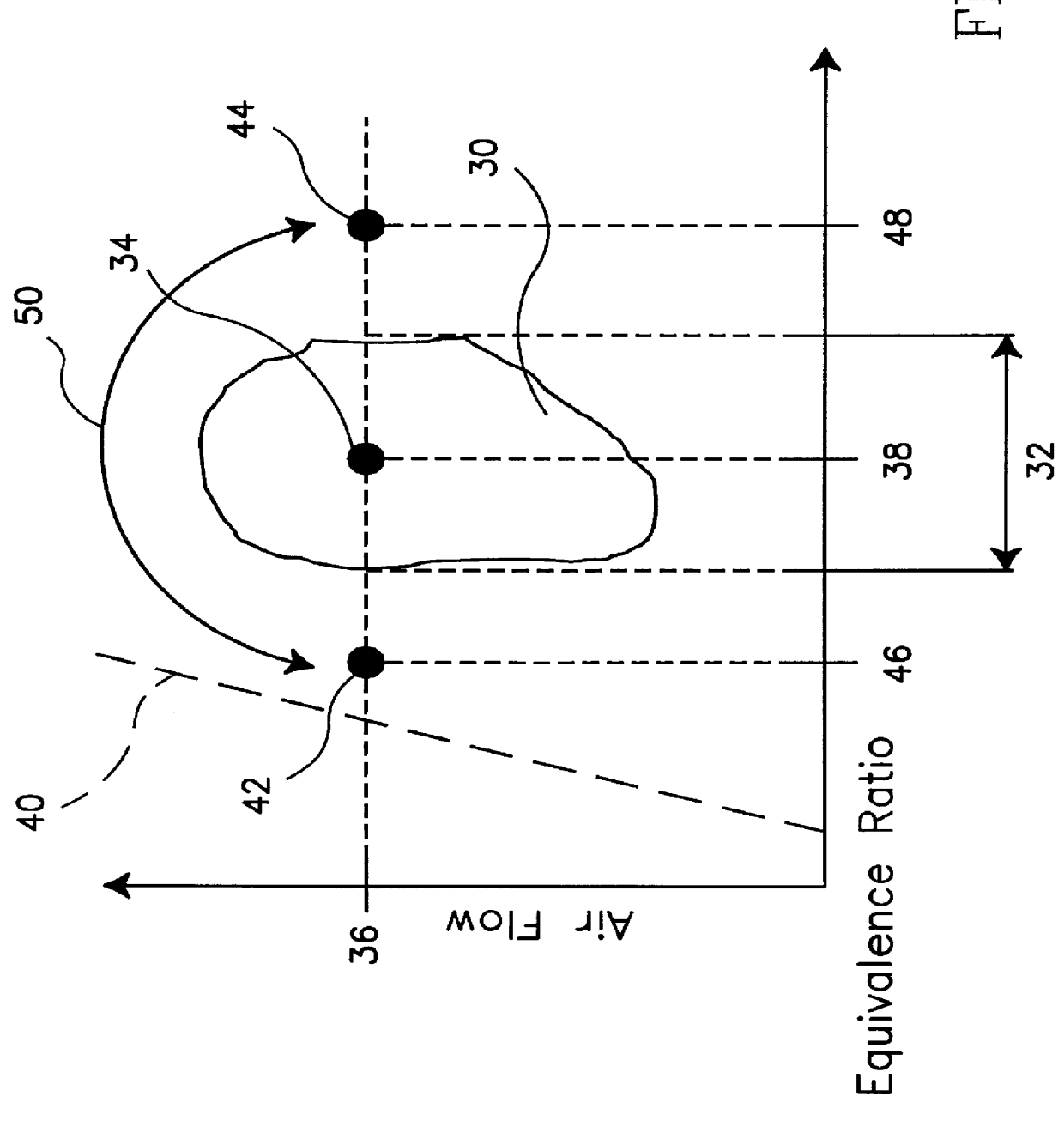

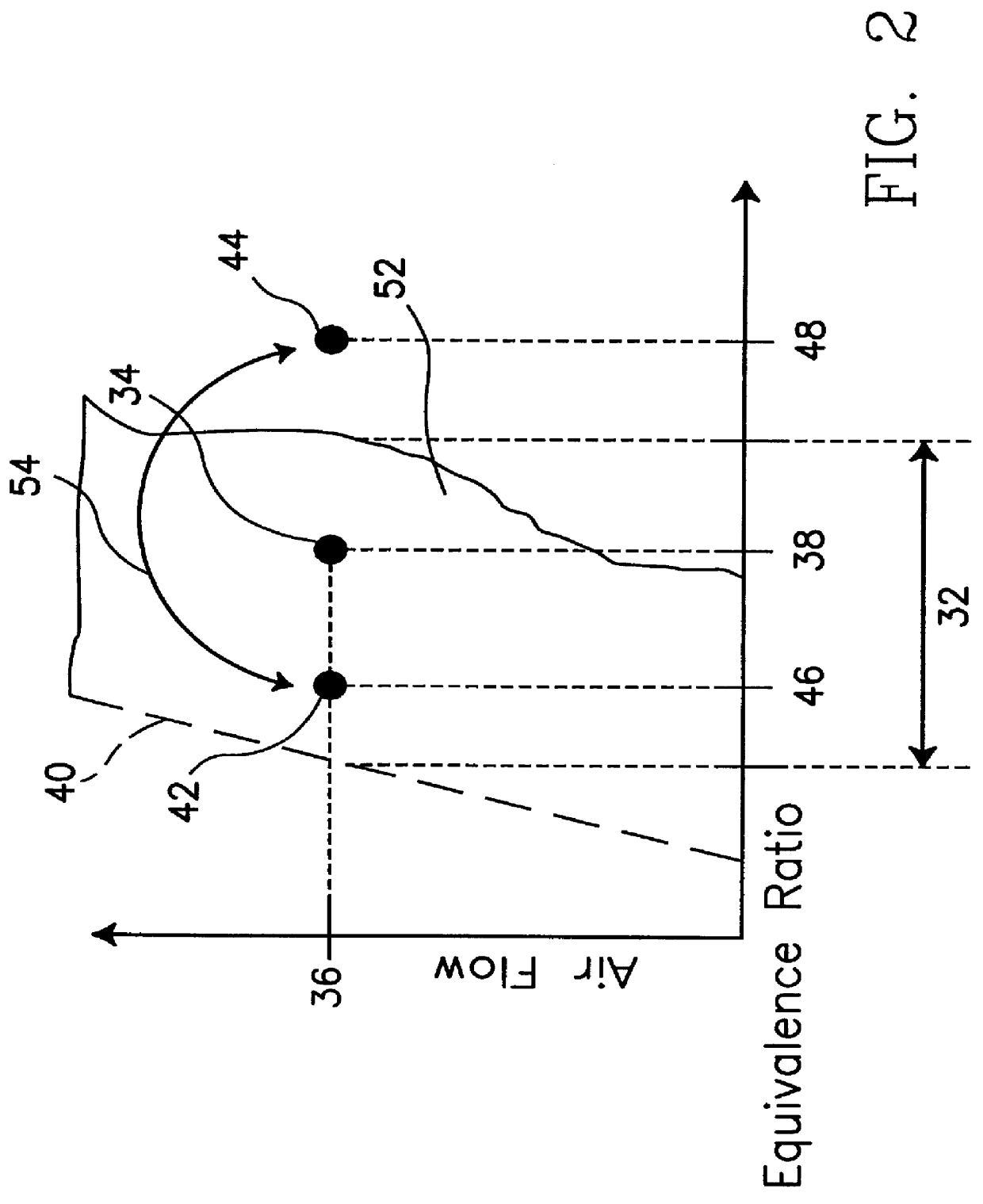

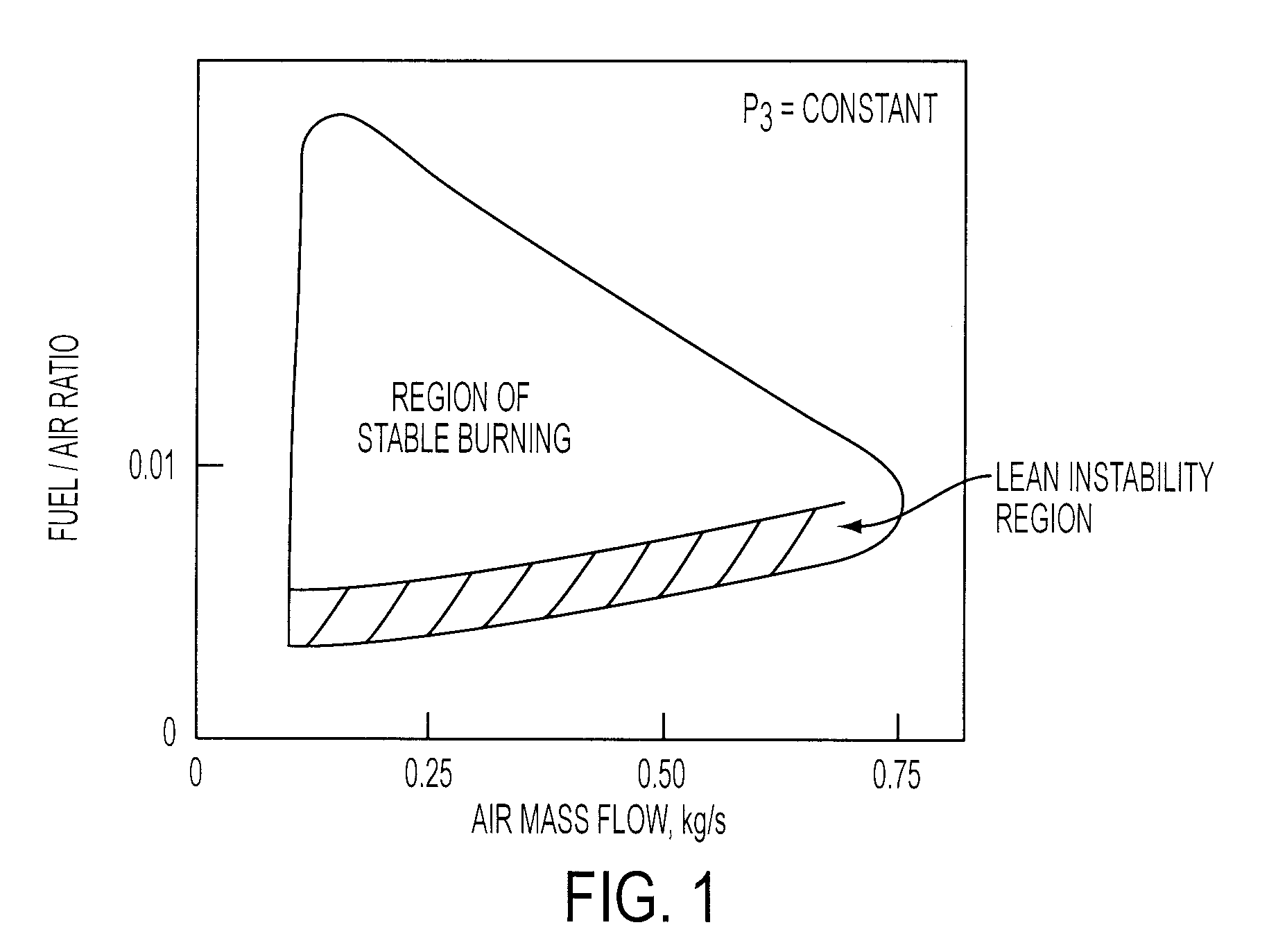

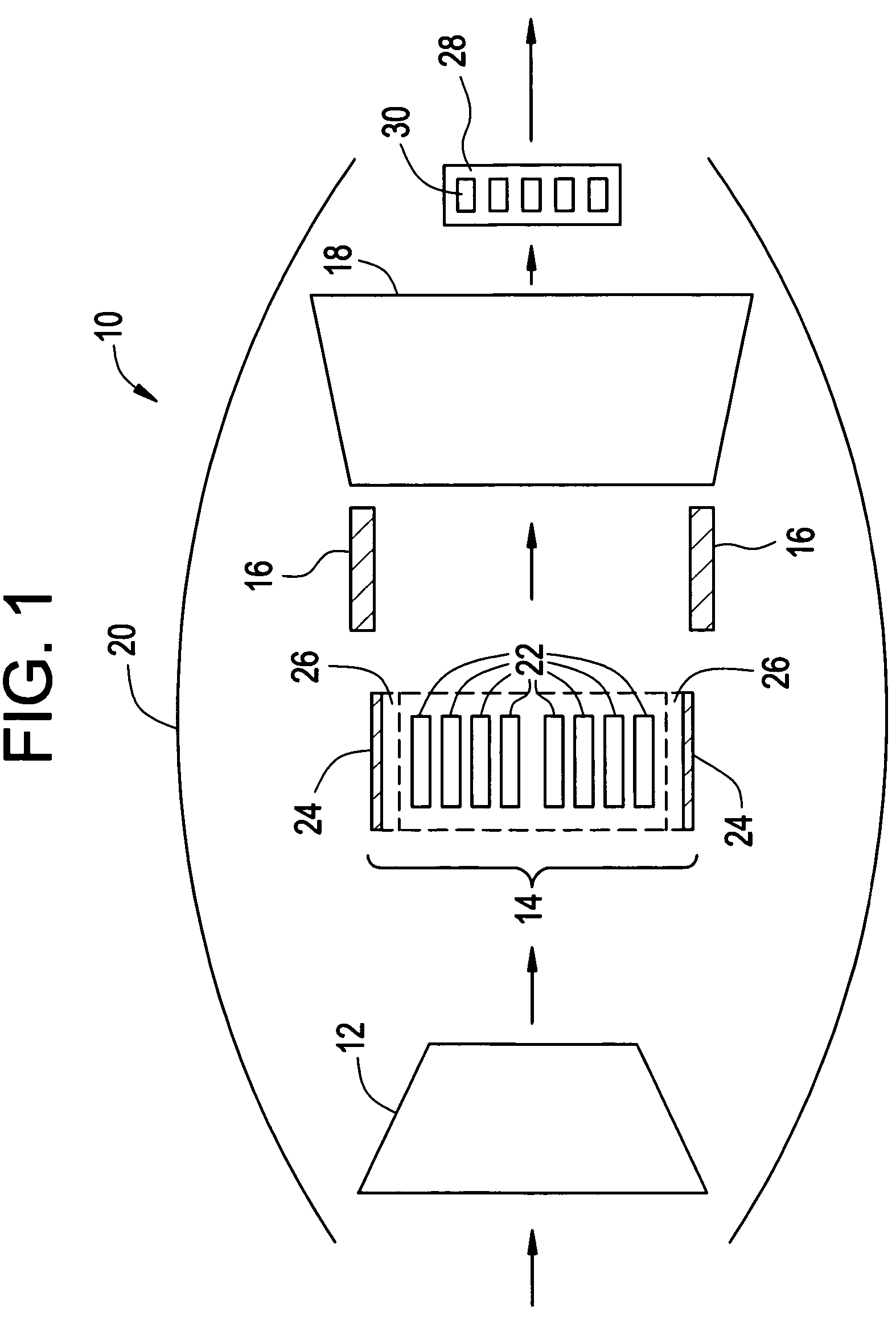

Periodic equivalence ratio modulation method and apparatus for controlling combustion instability

InactiveUS6059560AReduce pollutant emissionsReduce instabilityTurbine/propulsion fuel supply systemsPulsating combustionCombustion instabilityStable state

The periodic equivalence ratio modulation (PERM) method and apparatus significantly reduces and / or eliminates unstable conditions within a combustion chamber. The method involves modulating the equivalence ratio for the combustion device, such that the combustion device periodically operates outside of an identified unstable oscillation region. The equivalence ratio is modulated between preselected reference points, according to the shape of the oscillation region and operating parameters of the system. Preferably, the equivalence ratio is modulated from a first stable condition to a second stable condition, and, alternatively, the equivalence ratio is modulated from a stable condition to an unstable condition. The method is further applicable to multi-nozzle combustor designs, whereby individual nozzles are alternately modulated from stable to unstable conditions. Periodic equivalence ratio modulation (PERM) is accomplished by active control involving periodic, low frequency fuel modulation, whereby low frequency fuel pulses are injected into the main fuel delivery. Importantly, the fuel pulses are injected at a rate so as not to affect the desired time-average equivalence ratio for the combustion device.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

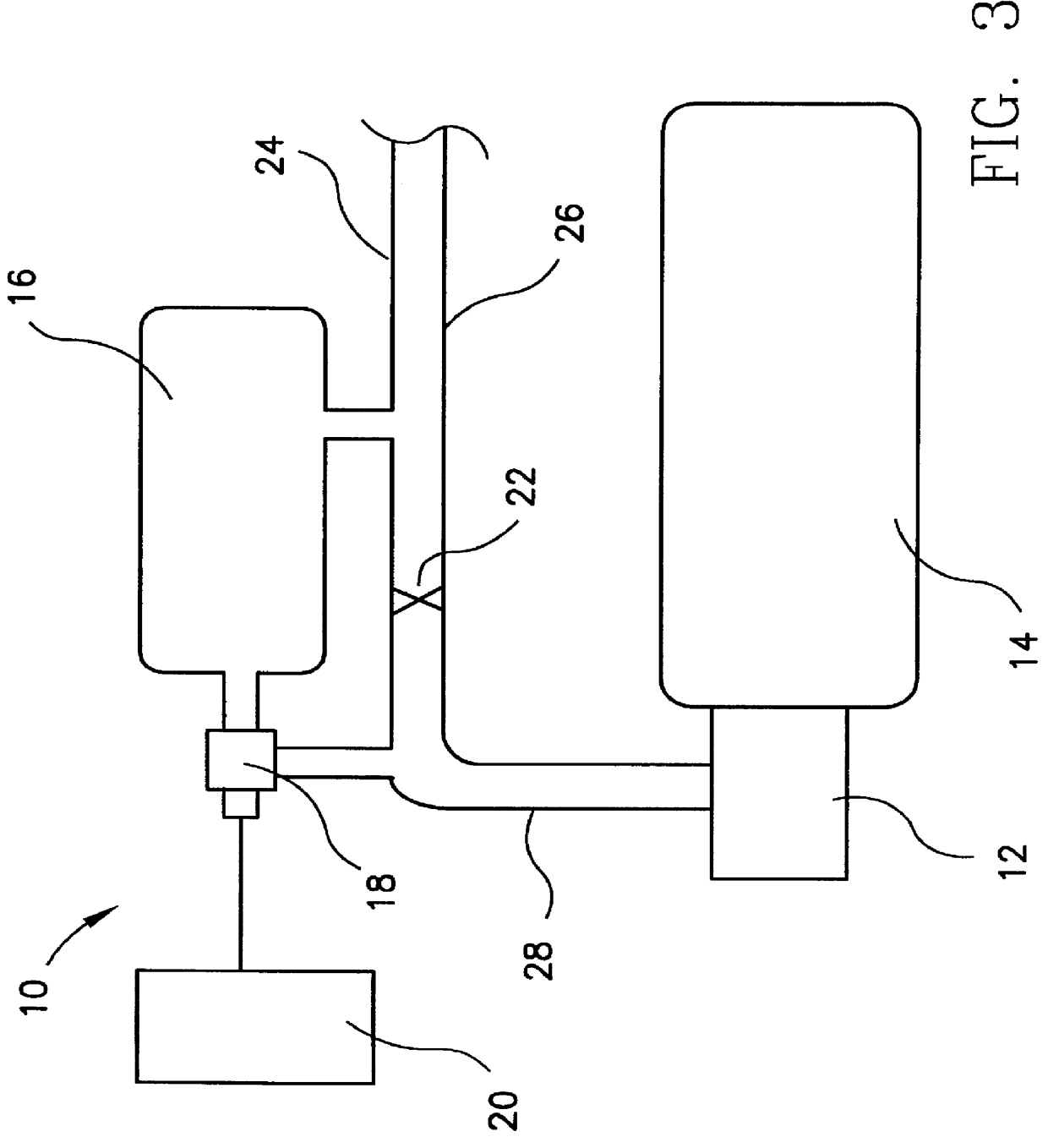

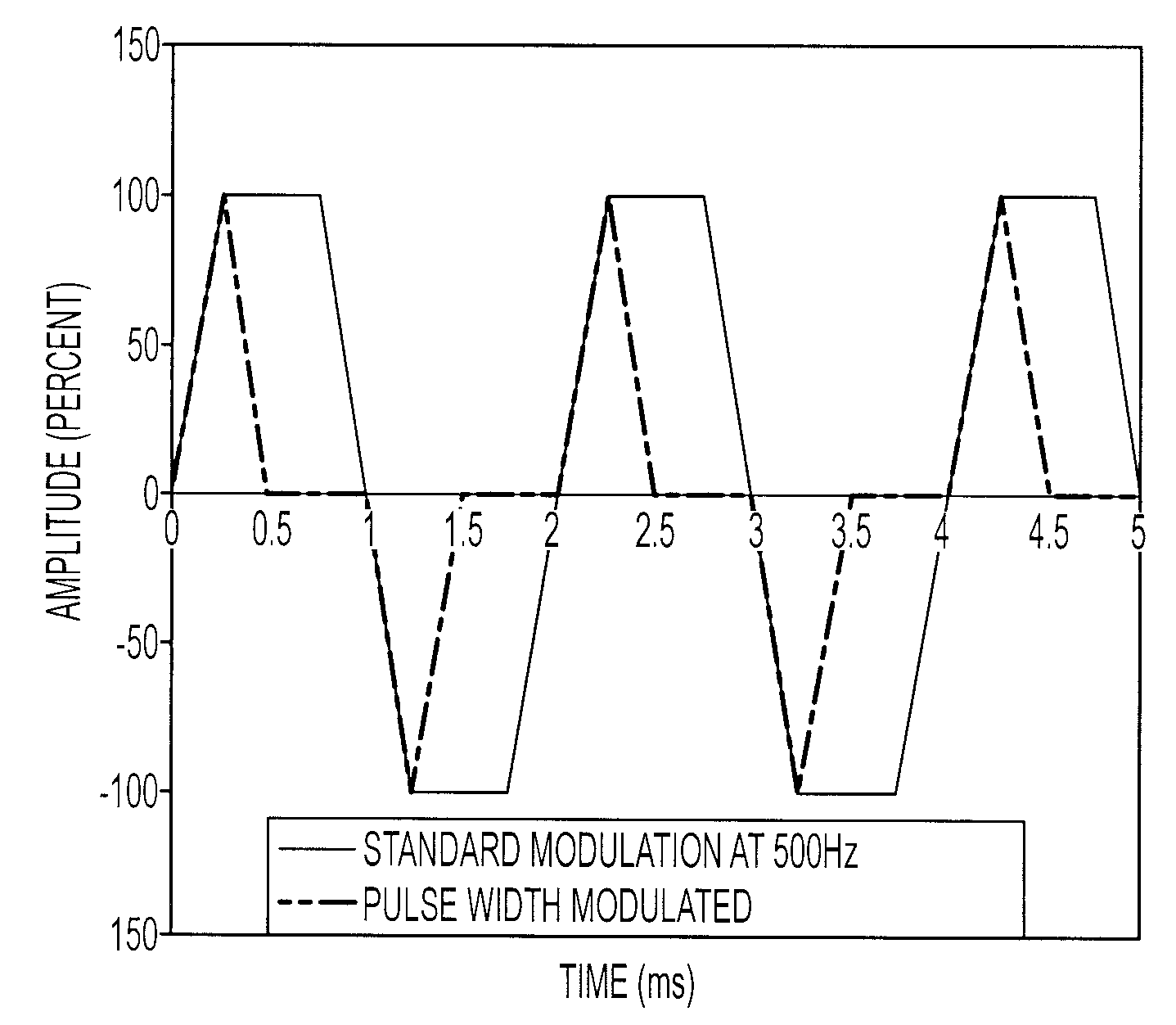

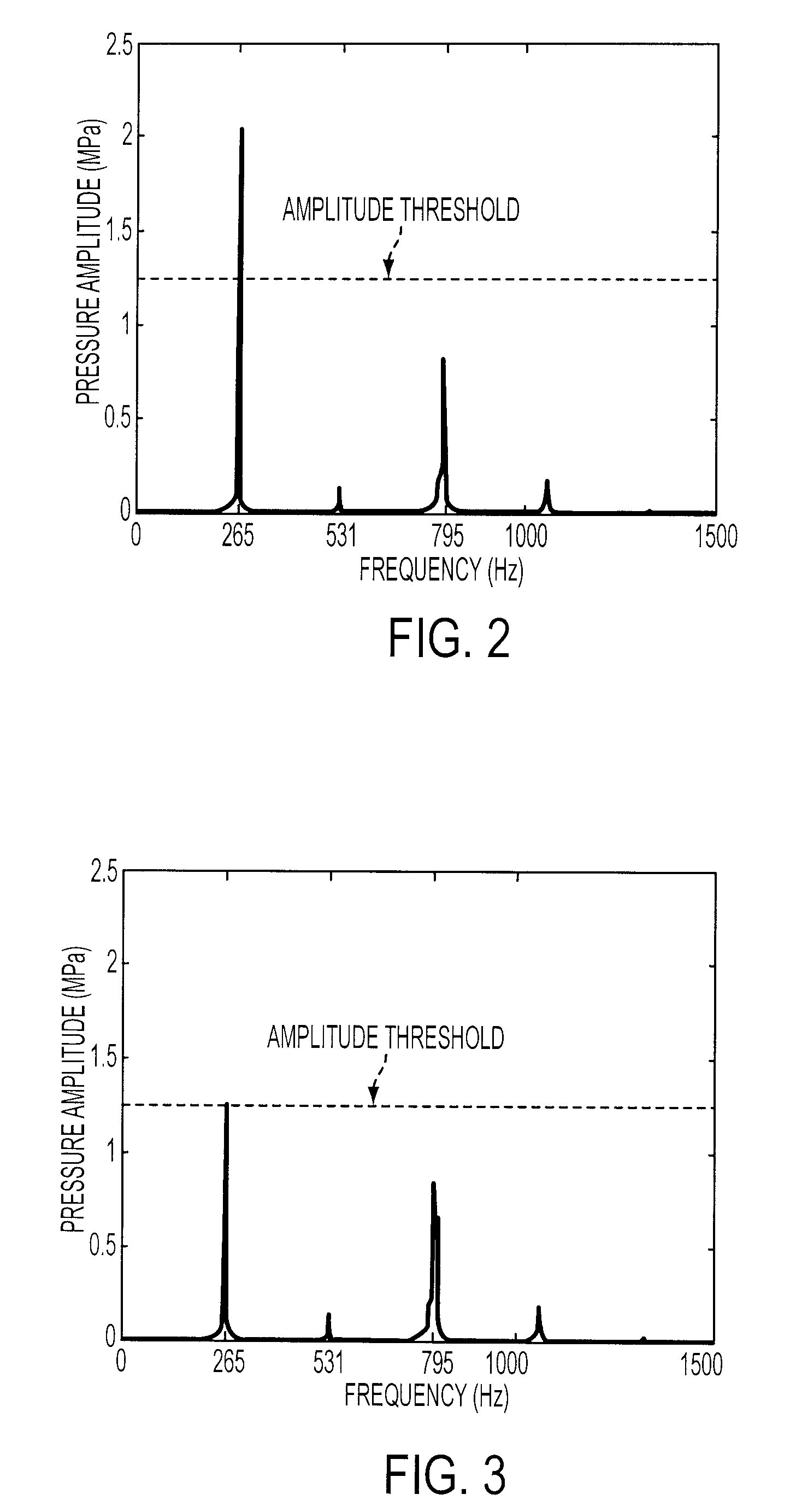

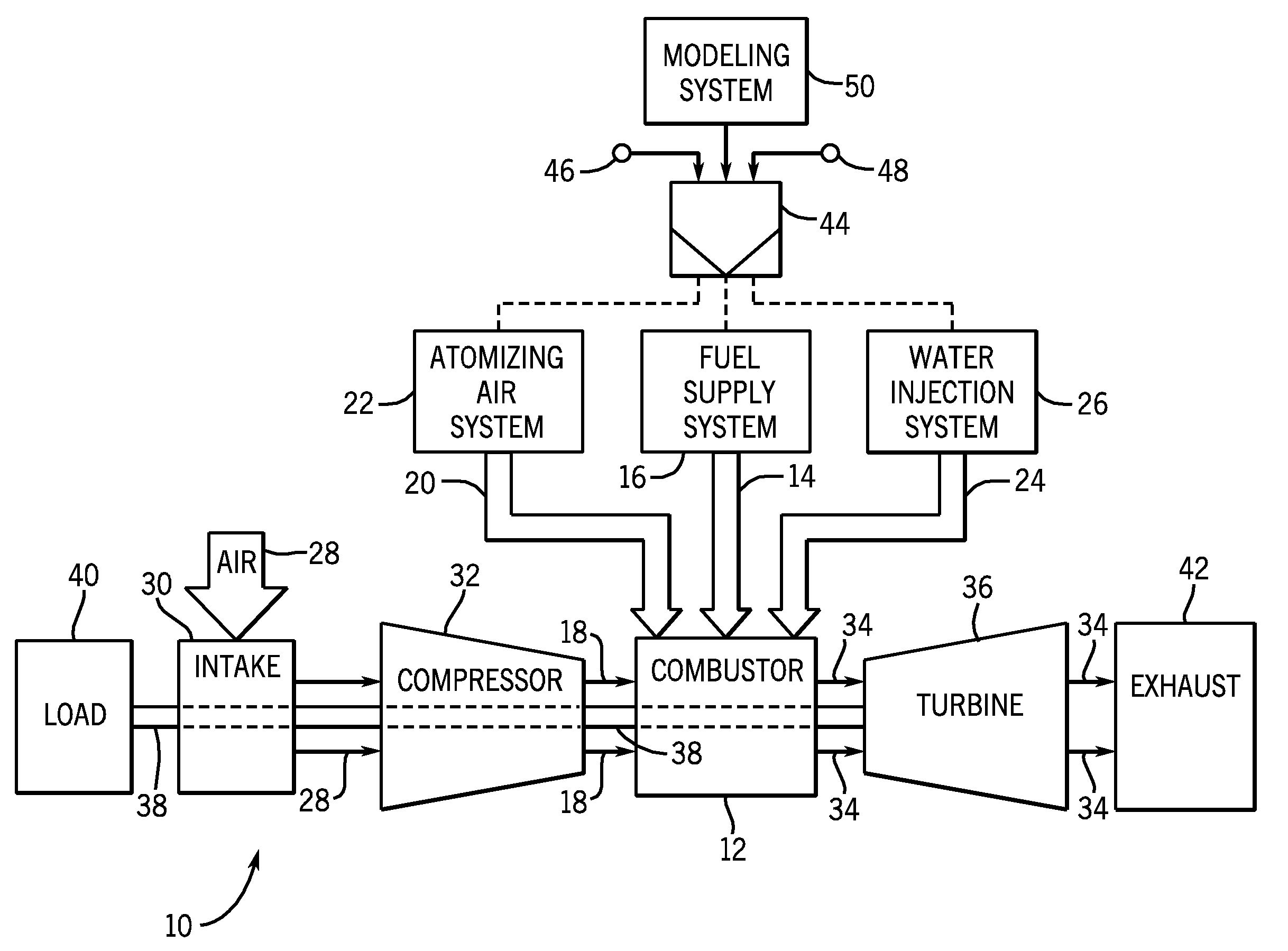

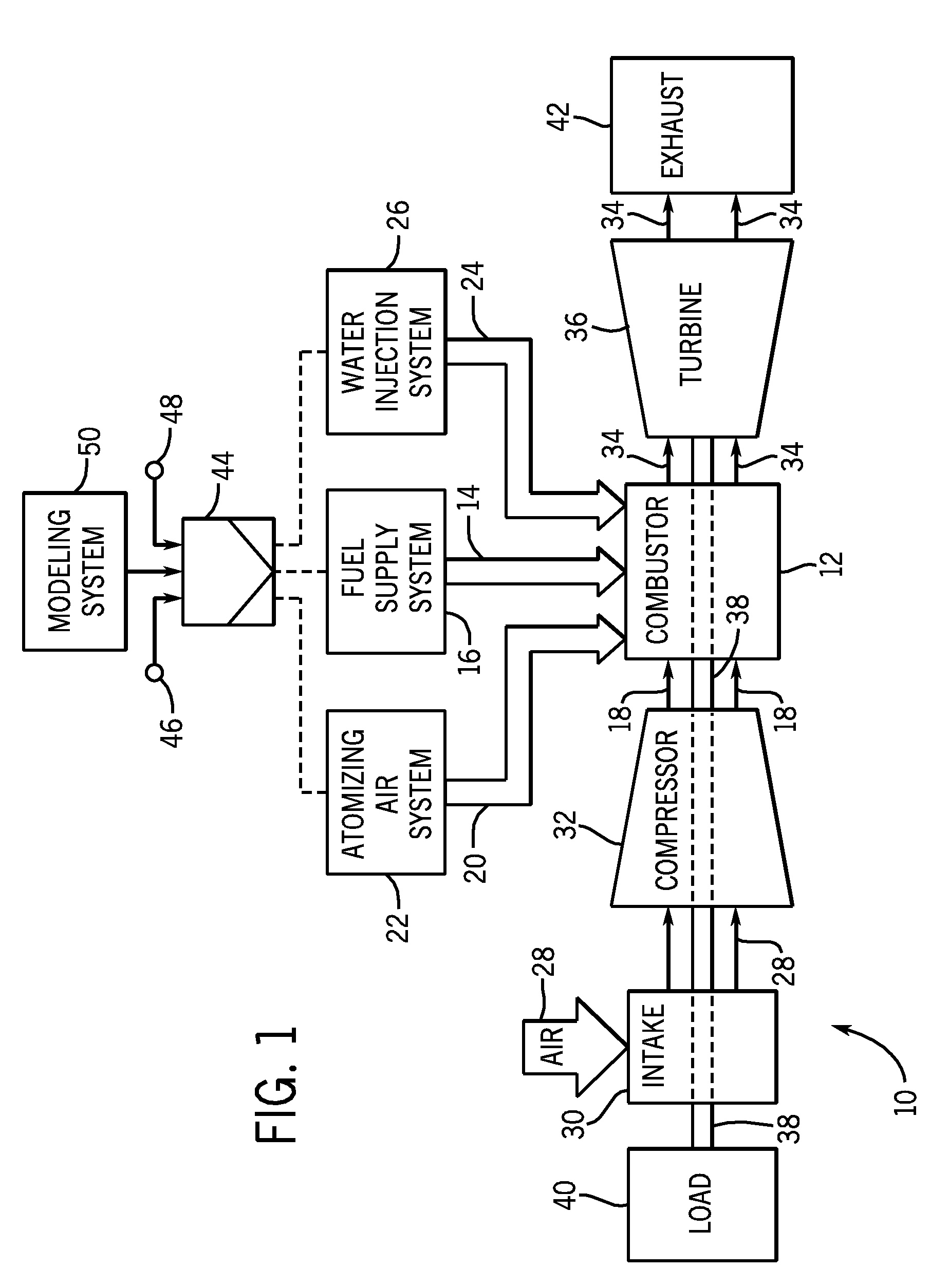

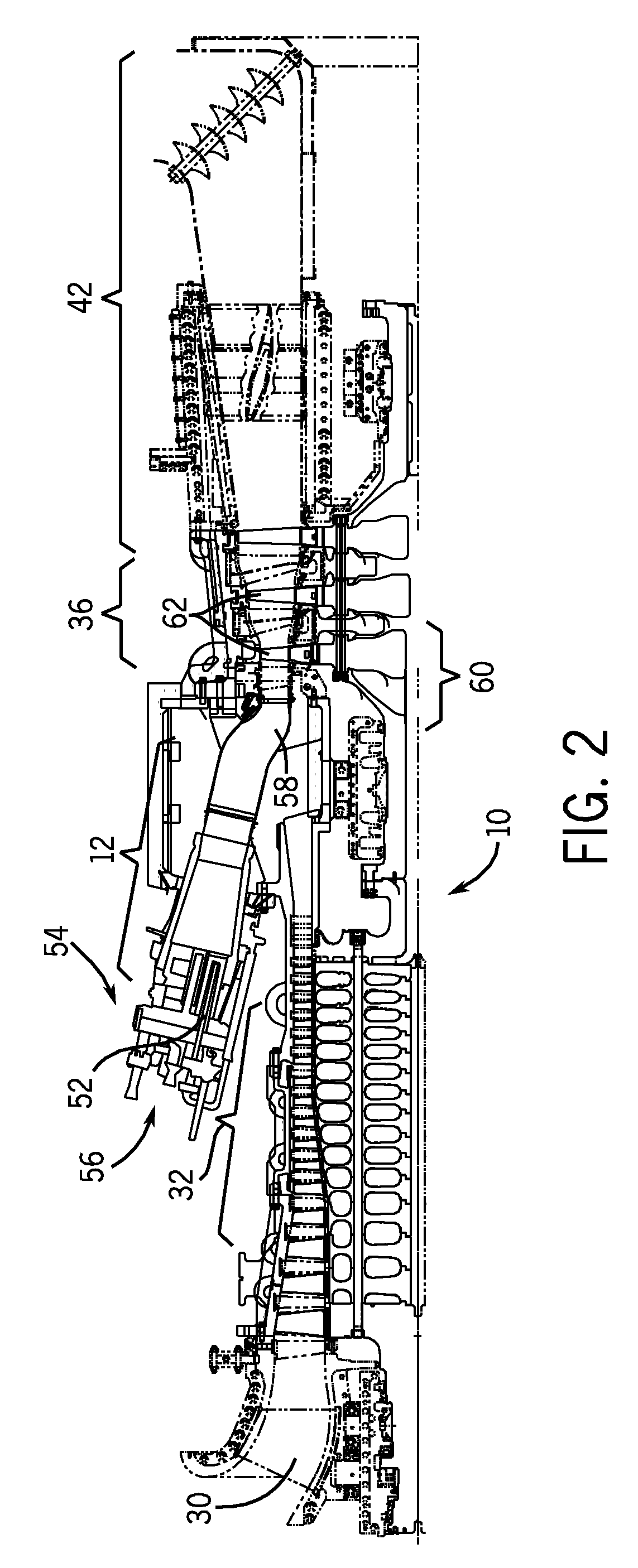

Methods and systems for modulating fuel flow for gas turbine engines

ActiveUS20090204306A1Magnitude is minimisedReduce the amplitudeAnalogue computers for vehiclesContinuous combustion chamberCombustion instabilityCombustion

A method of combustion stability control for a gas turbine engine is provided, and includes the steps of receiving by a stability controller, information regarding environmental and operating conditions, and comparing the environmental and operating conditions to pre-programmed information to determine if a likelihood of combustion instability exists. The method further includes the steps of determining optimal fuel modulation frequency and amplitude for the environmental condition to reduce combustion instability, if a likelihood of combustion instability exists, and actuating at least one fuel modulation valve to, at the optimal fuel modulation frequency and amplitude, reduce combustion instability, if a likelihood of combustion instability exists. Systems for modulating fuel flow are also provided.

Owner:COLLINS ENGINE NOZZLES INC

Methods and systems for inducing combustion dynamics

InactiveUS20100287943A1Increase combustion dynamicReduce combustion dynamicPulsating combustionEngine fuctionsDynamic methodCombustion

Methods and systems are provided for inducing combustion dynamics within turbine engines to remove combustion deposits within the turbine engine during operation of the turbine engine.

Owner:GENERAL ELECTRIC CO

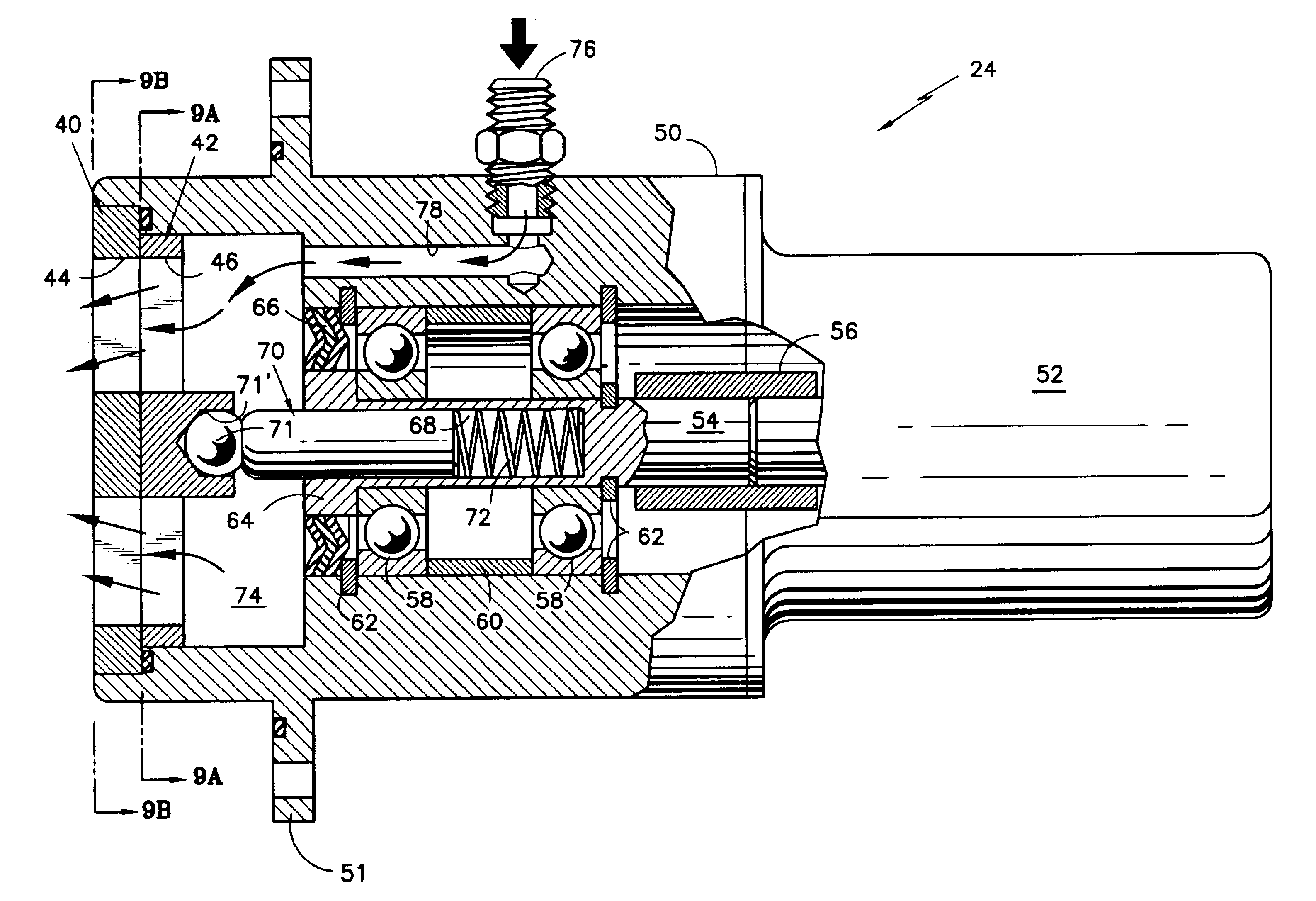

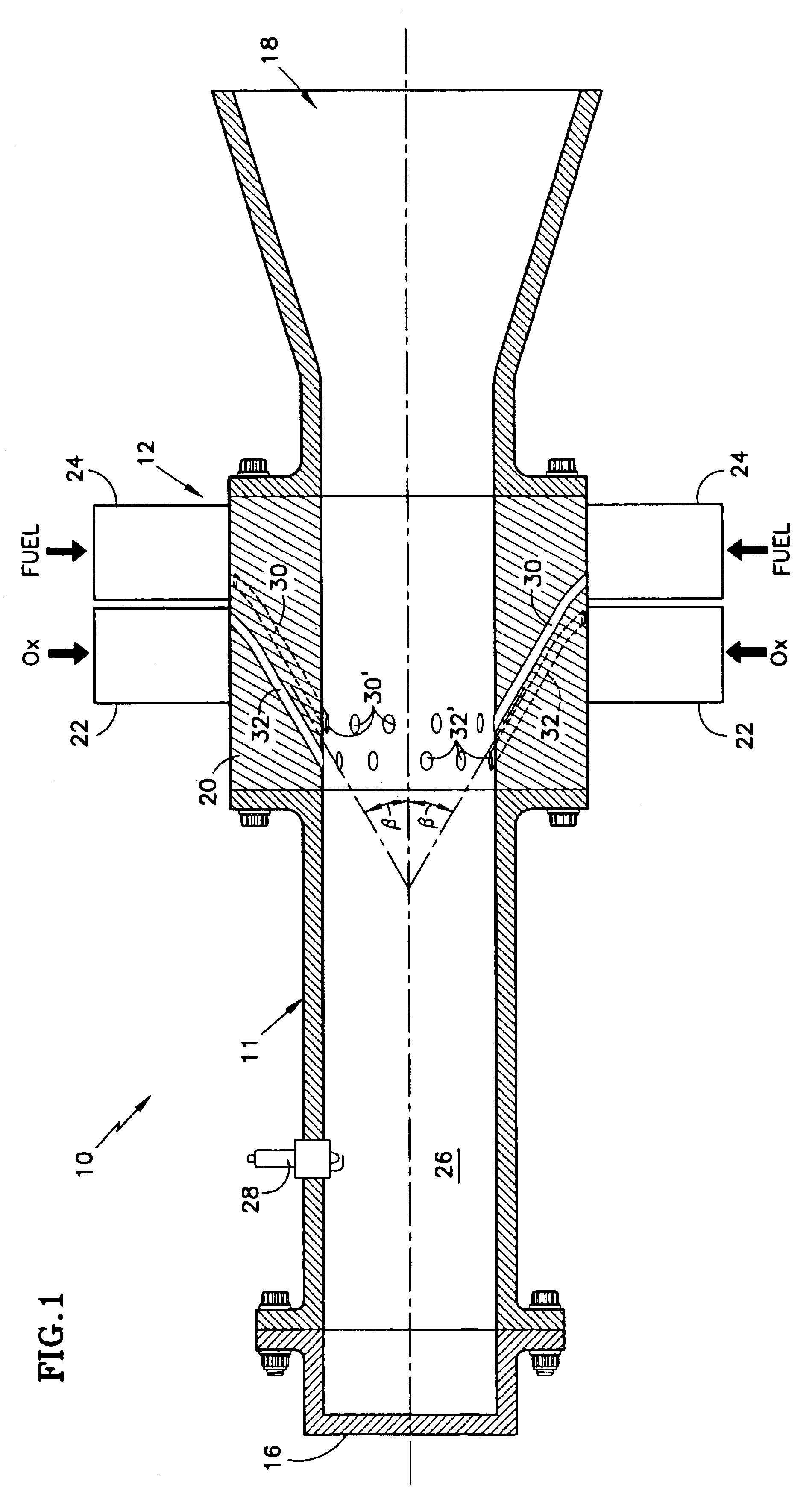

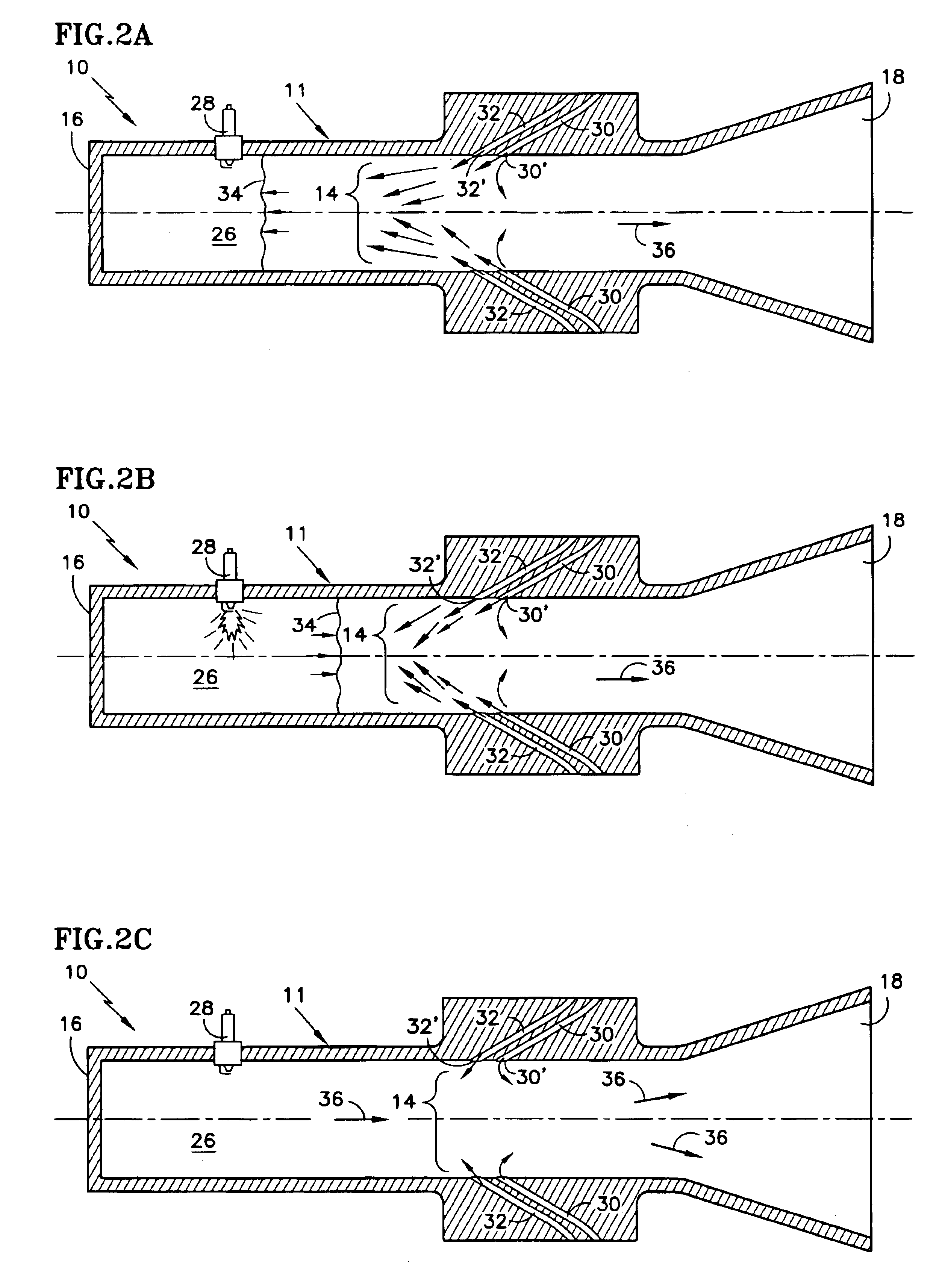

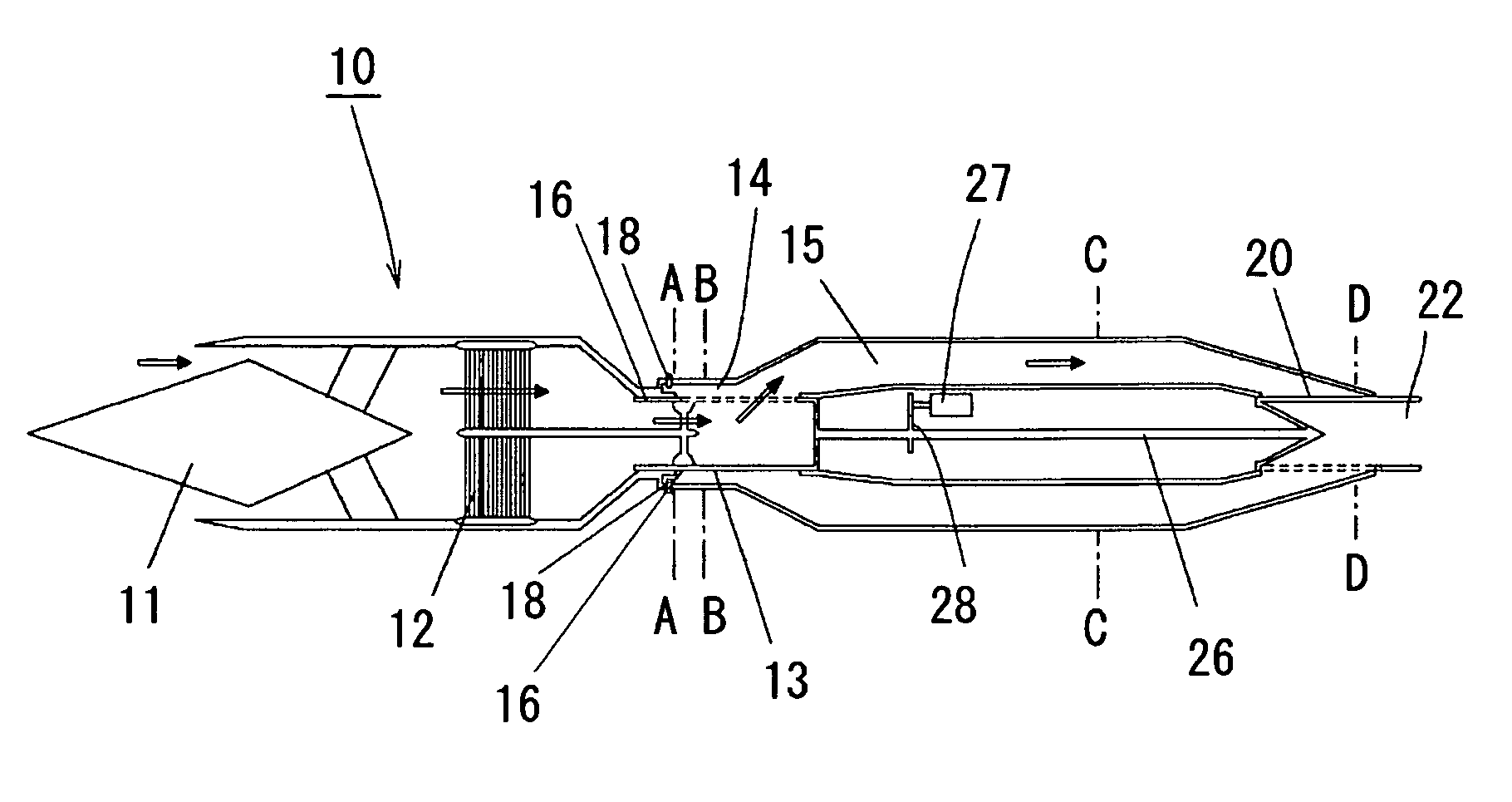

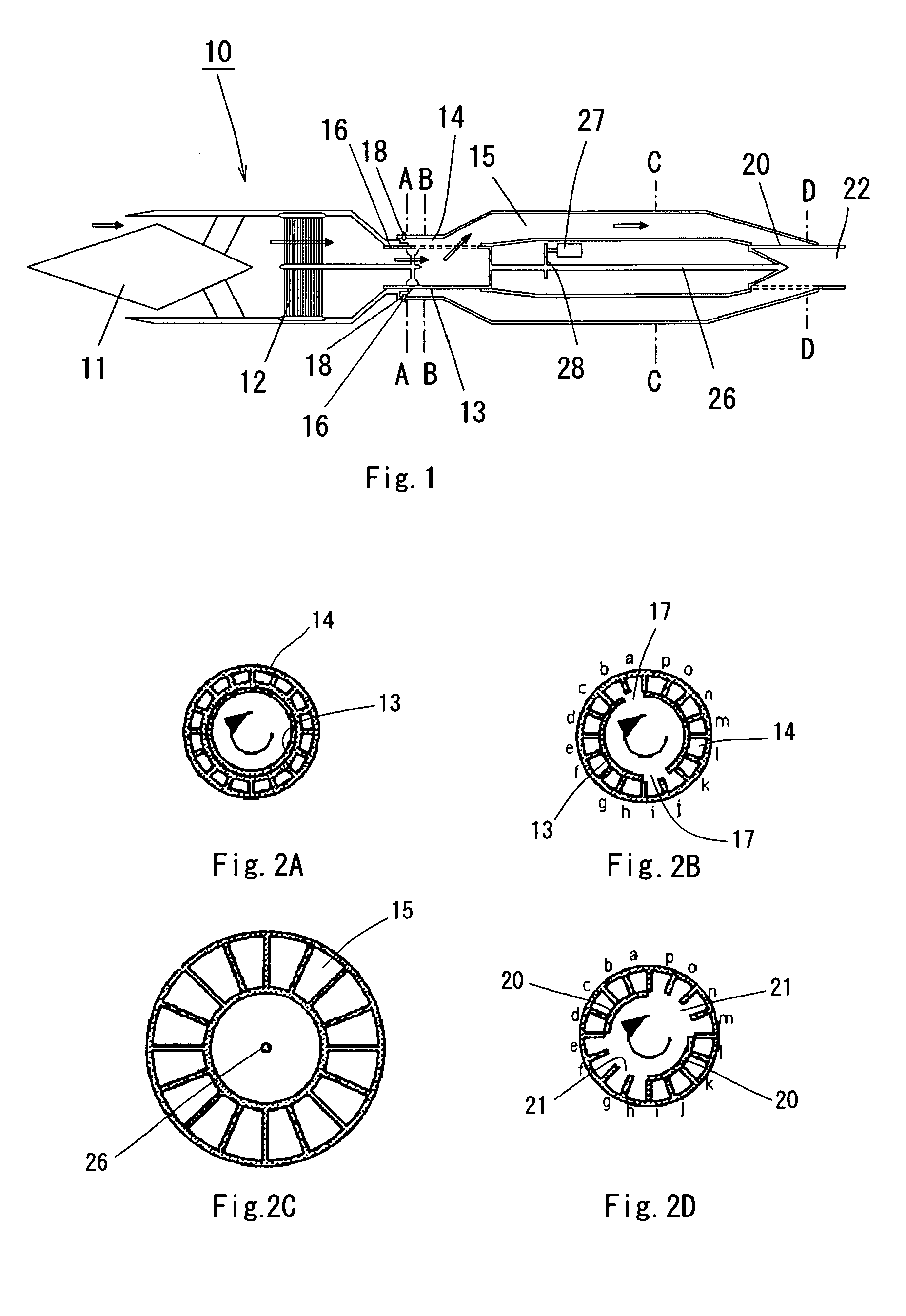

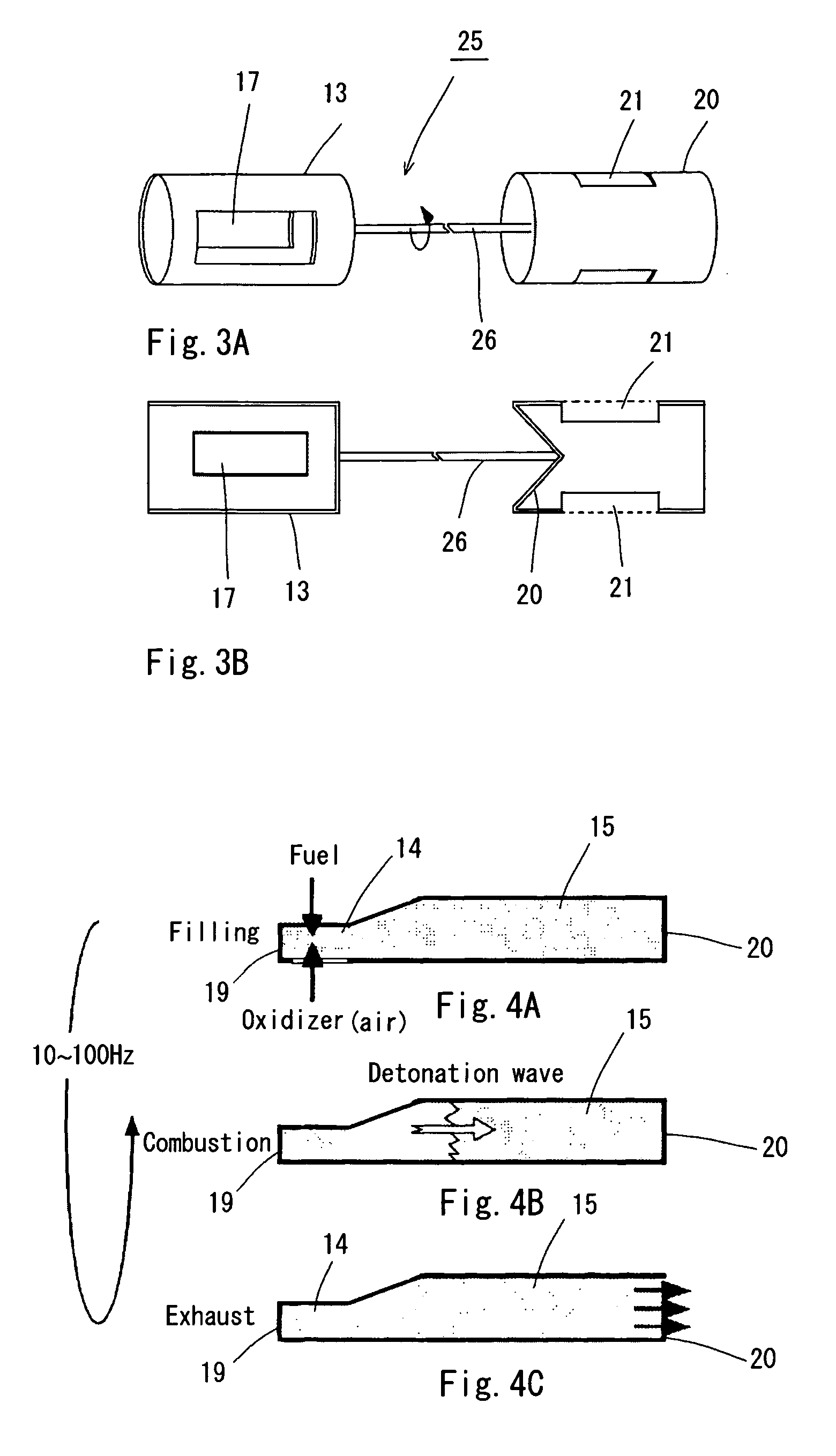

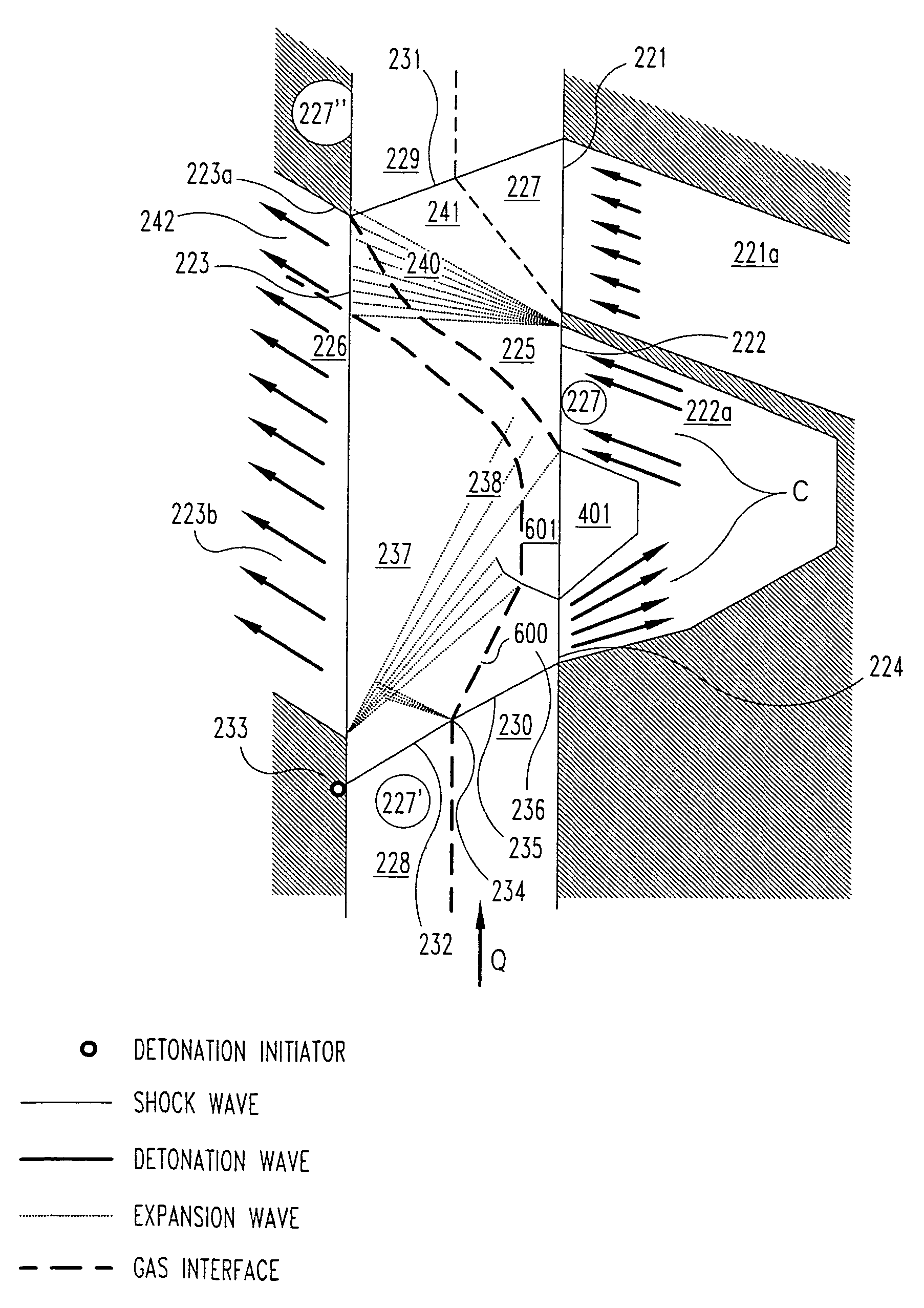

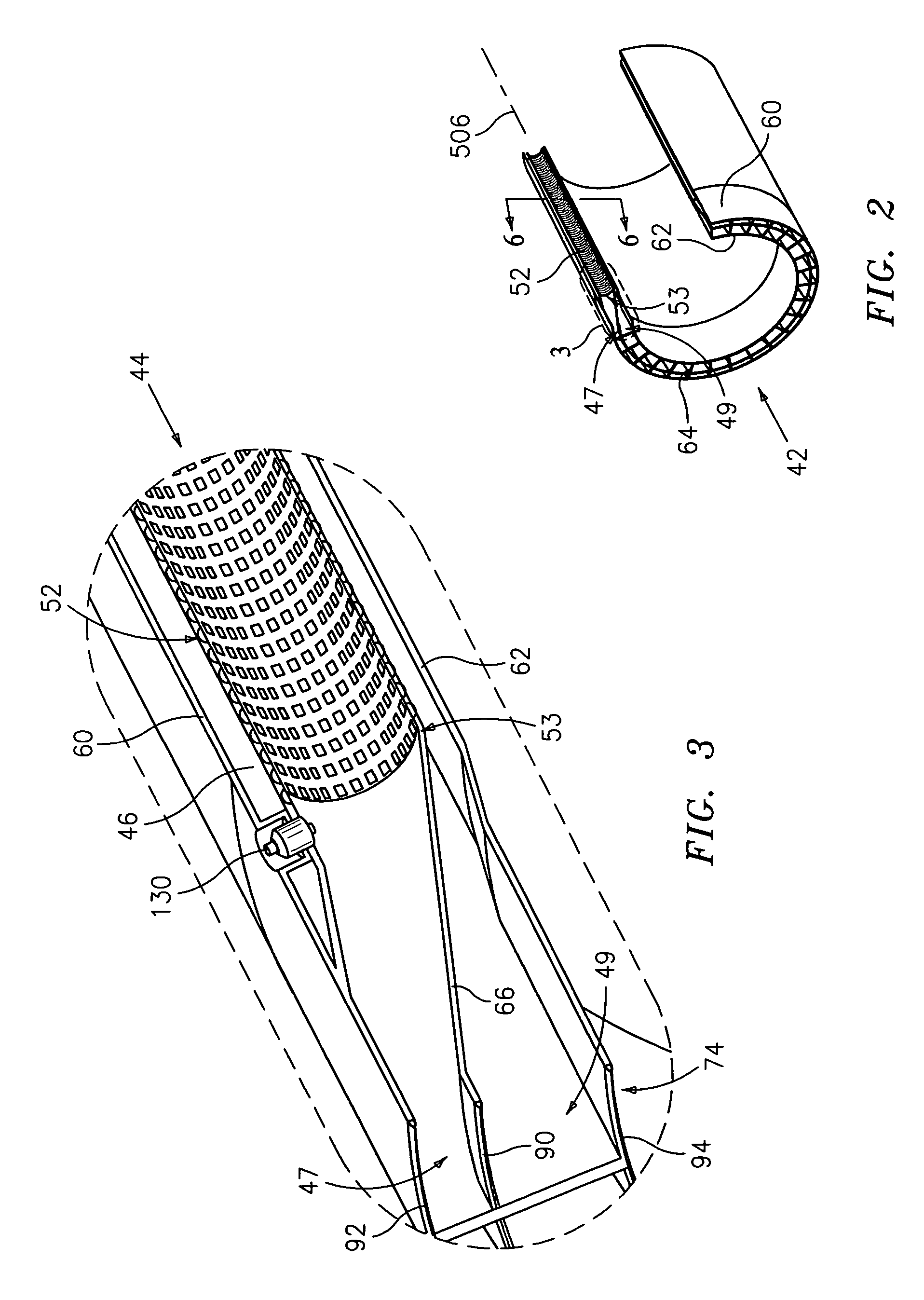

Pulse detonation engine having an aerodynamic valve

InactiveUS6883543B2Increase pressureSave pressurePulsating combustionCosmonautic vehiclesShock wavePropellant

A pulse detonation engine (10) is provided with an aerovalve (14) for controlling the pressure of injected propellants (Ox, Fuel) in an open-ended detonation chamber (26). The propellants are injected at such pressure and velocity, and in a direction generally toward a forward thrust wall end (16) of the detonation chamber (26), an aerovalve (14) is formed which effectively inhibits or prevents egress of the propellant from the detonation chamber (26). A shock wave (34) formed by the injected propellant acts, after reflection by the thrust wall end (16) and in combination with the aerovalve (14), to compress and conserve, or increase, the pressure of the injected propellant. Carefully timed ignition (28) effects a detonation pulse under desired conditions of maintained, or increased, pressure. Termination of the propellant injection serves to “open” the aerovalve (14), and exhaust of the combusted propellants occurs to produce thrust. Alternate embodiments of propellant injection mechanisms (12, 112) provide pulse valves (24, 122, 124) each having a fixed slotted disk (40, 140, 240) and a rotating slotted disk (42, 142, 242) to provide the desired high speed valving of discrete pulses of propellant for injection.

Owner:UNITED TECH CORP

Methods and systems for destabilizing foam in equipment downstream of a submerged combustion melter

Methods and systems for de-stabilizing foam produced in submerged combustion melters. A molten mass of glass and bubbles is flowed into an apparatus downstream of a submerged combustion melter. The downstream apparatus includes a floor, a roof and a wall connecting the floor and roof, but is devoid of submerged combustion burners and other components that would increase turbulence of the molten mass. The molten mass has foam on at least a portion of a top surface of the molten mass. One method includes directly impinging an impinging composition onto at least a portion of the foam in the downstream apparatus. Systems for carrying out the methods are described.

Owner:JOHNS MANVILLE CORP

Pulse detonation assembly and hybrid engine

ActiveUS20060254252A1Reducing undesirable interactionReduce the overall heightPulsating combustionGas turbine plantsDetonationTurbine

A pulse detonation (PD) assembly includes a number of PD chambers adapted to expel respective detonation product streams and a number of barriers disposed between respective pairs of PD chambers. The barriers define, at least in part, a number of sectors that contain at least one PD chamber. A hybrid engine includes a number of PD chambers and barriers. The hybrid engine further includes a turbine assembly having at least one turbine stage, being in flow communication with the PD chambers and being configured to be at least partially driven by the detonation product streams. A segmented hybrid engine includes a number of PD chambers and segments configured to receive and direct the detonation product streams from respective PD chambers. The segmented hybrid engine further includes a turbine assembly configured to be at least partially driven by the detonation product streams.

Owner:GENERAL ELECTRIC CO

Constant volume combustor

InactiveUS20070157625A1Increase pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorMagnetic bearing

A constant volume combustor device includes detonative combustion. In one form the wave rotor of the constant volume combustor is supported by magnetic bearings.

Owner:ROLLS ROYCE NORTH AMERICAN TECH

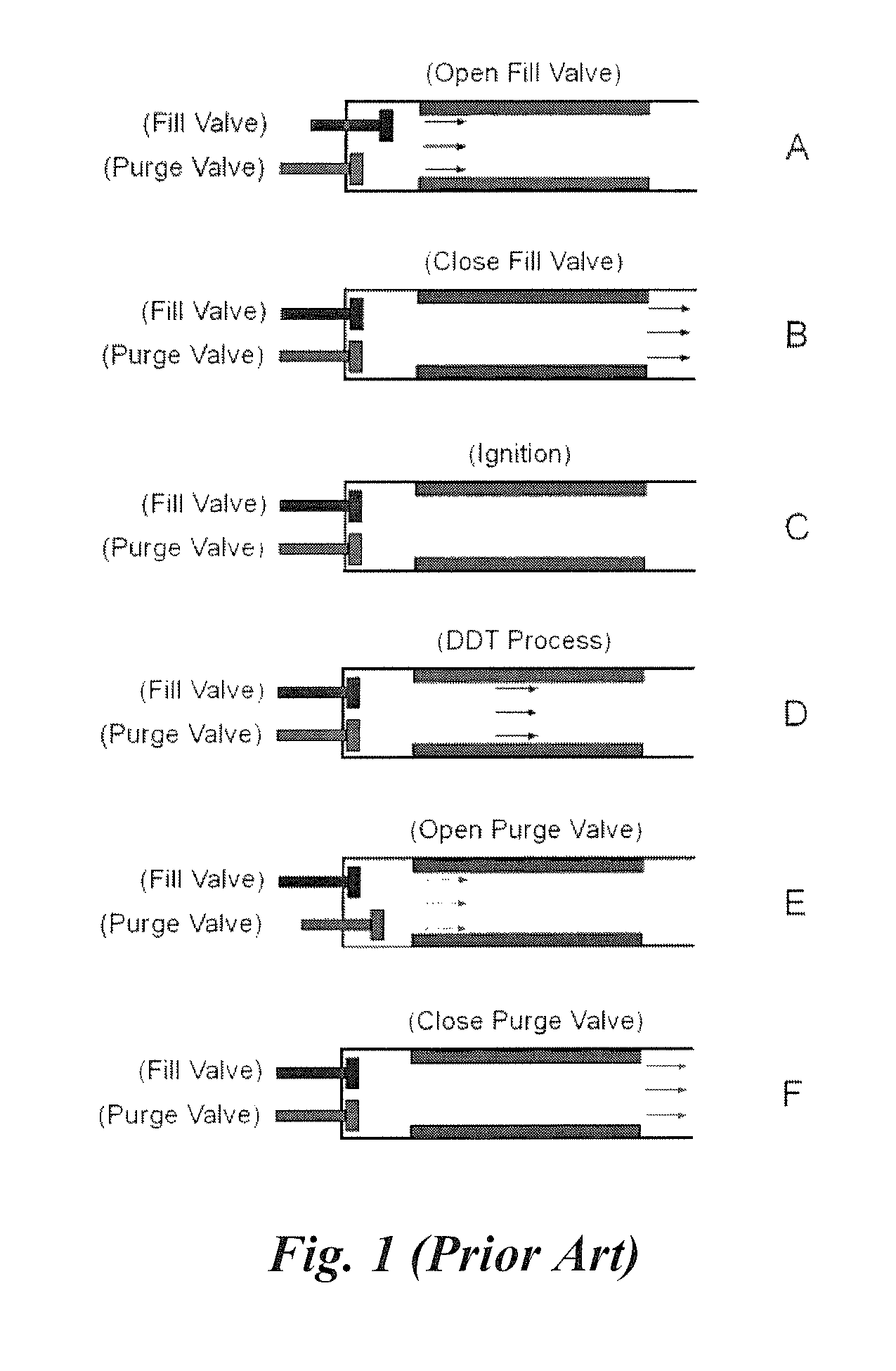

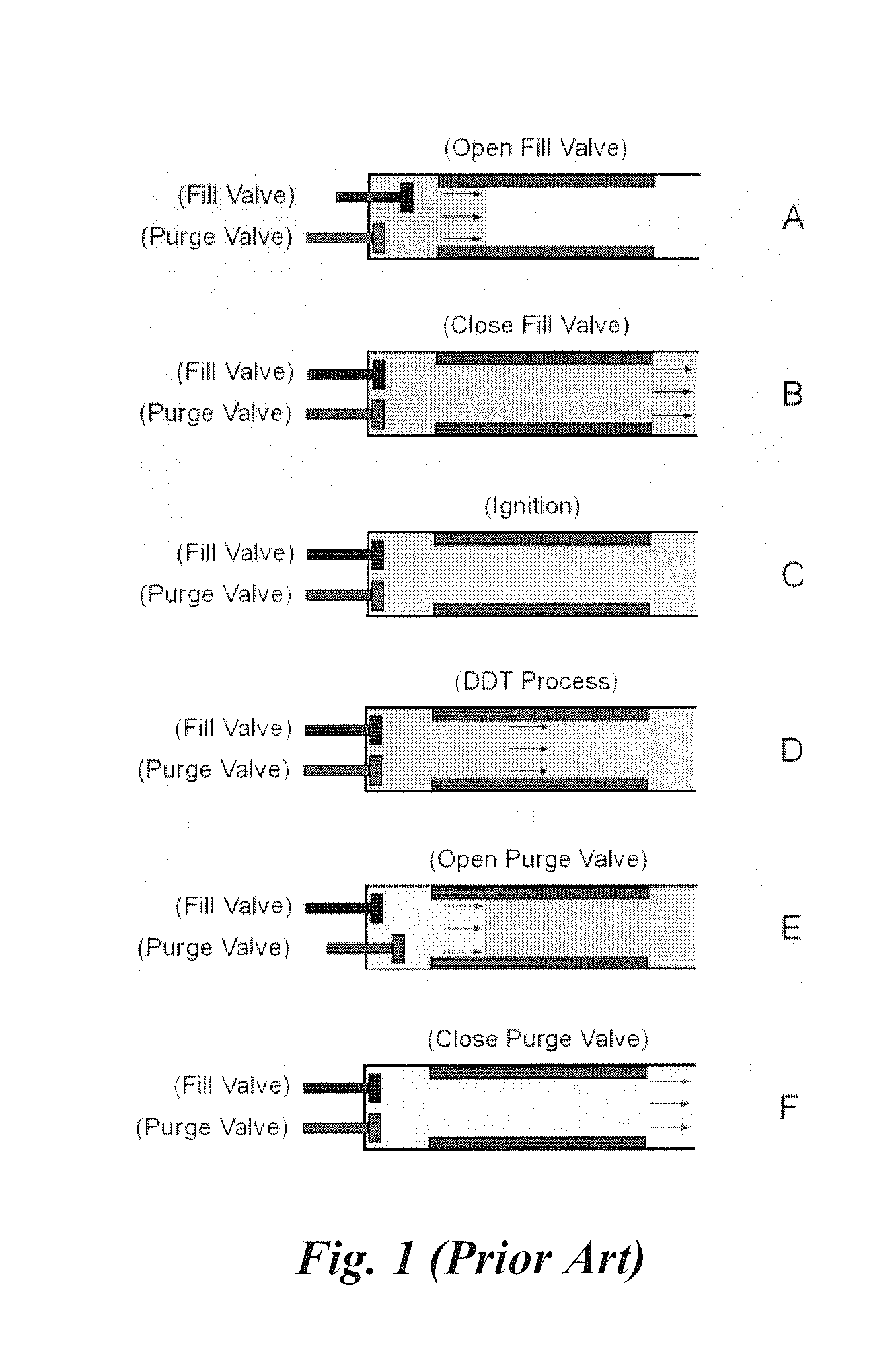

Valveless pulsed detonation combustor

Pulse detonation combustors of valveless construction. One valveless pulse detonation combustor, having a tube with a closed end and an open end, is constructed with a flame accelerator within the tube, adjacent the open end. A valveless, apertured flow restrictor is positioned between the flame accelerator and the closed end of the tube. A sparking device is positioned within the tube, between the flow restrictor and the flame accelerator. Valveless fuel and air ports are positioned between the flow restrictor and the closed end of the tube. Substantially right-angle manifold passageways are in communication with each of the ports.

Owner:PURDUE RES FOUND INC

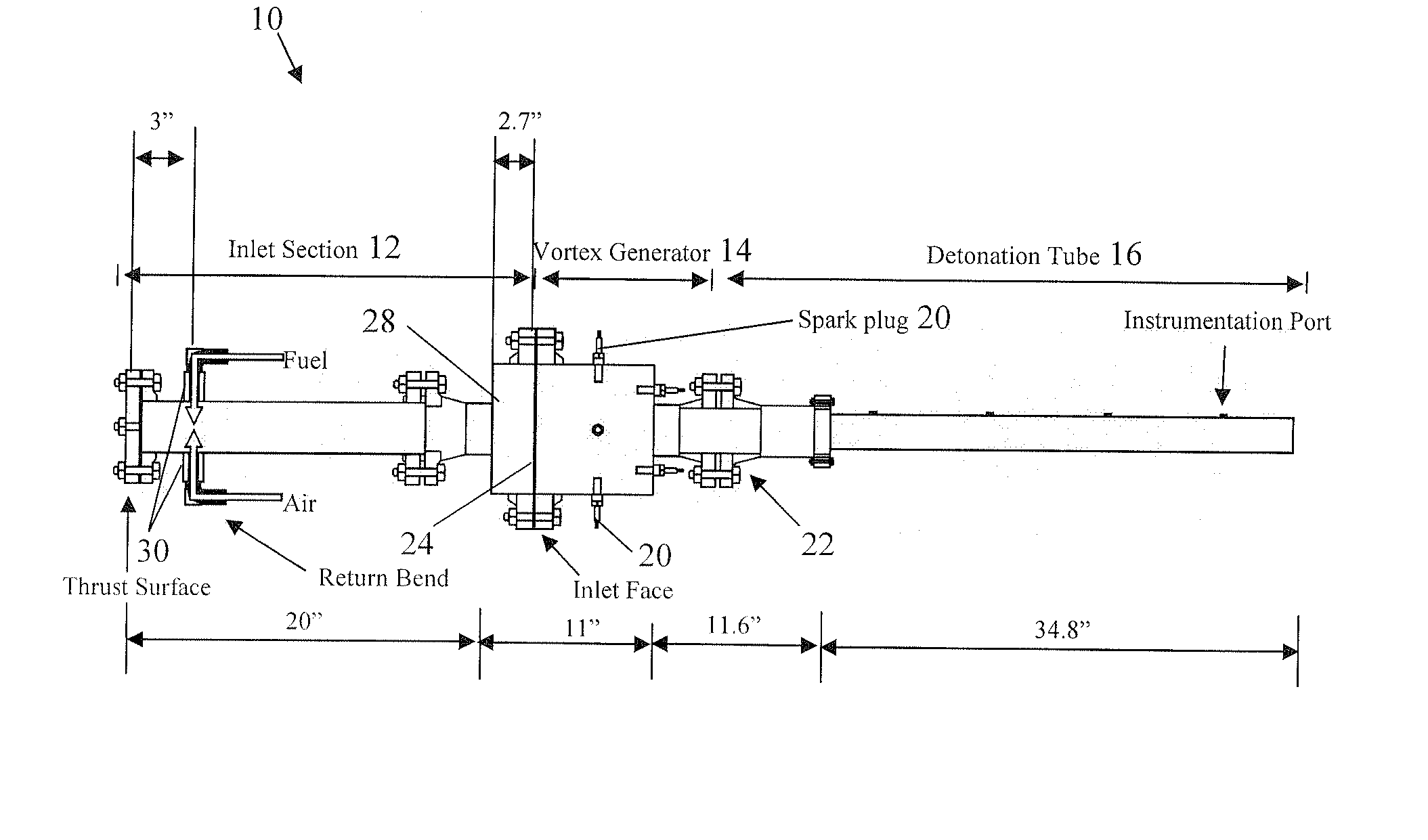

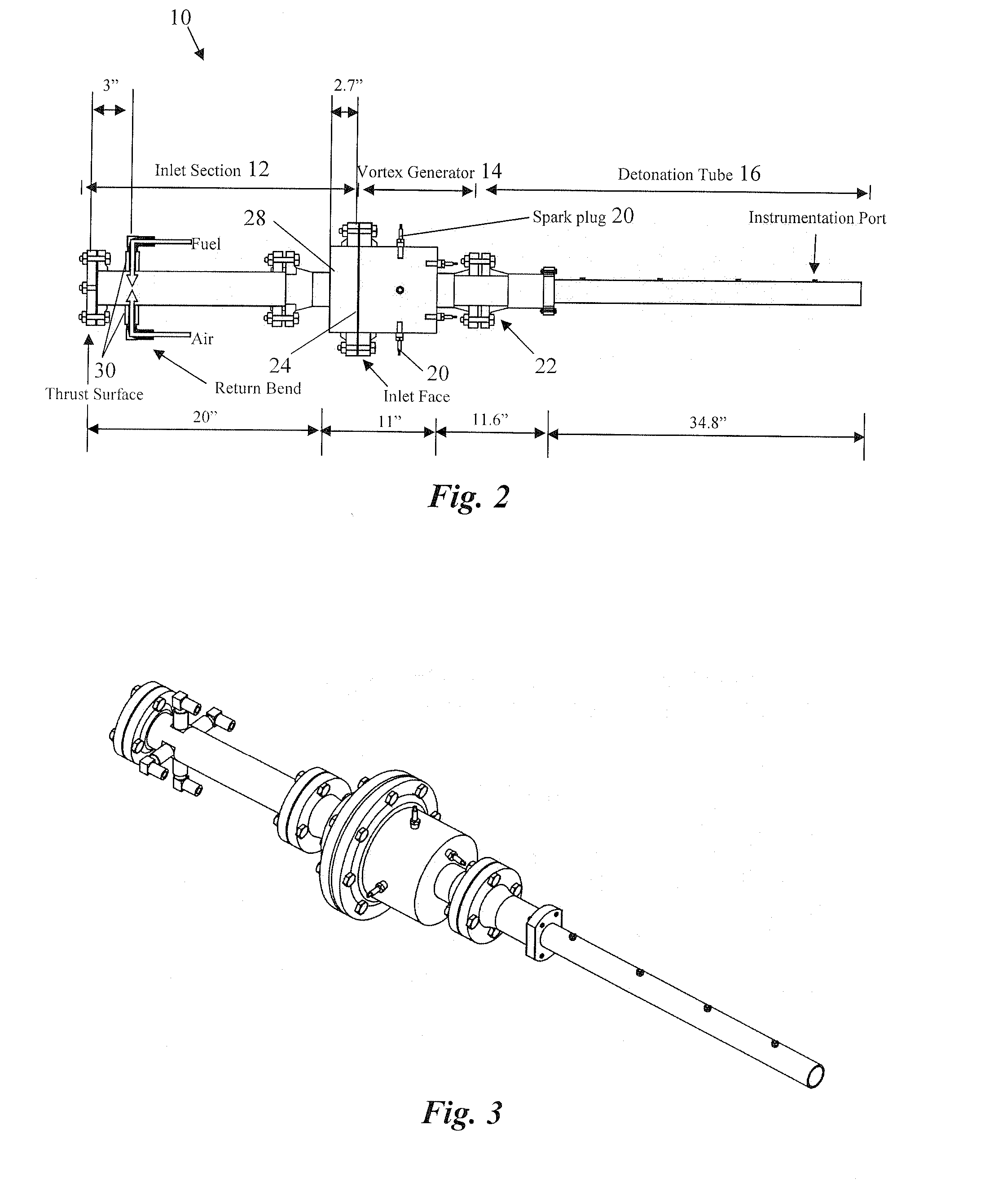

Controllable combustion method and device

InactiveUS6938588B2High bandwidthFast energy extractionPulsating combustionFuel-injection pumpsCombustionEngineering

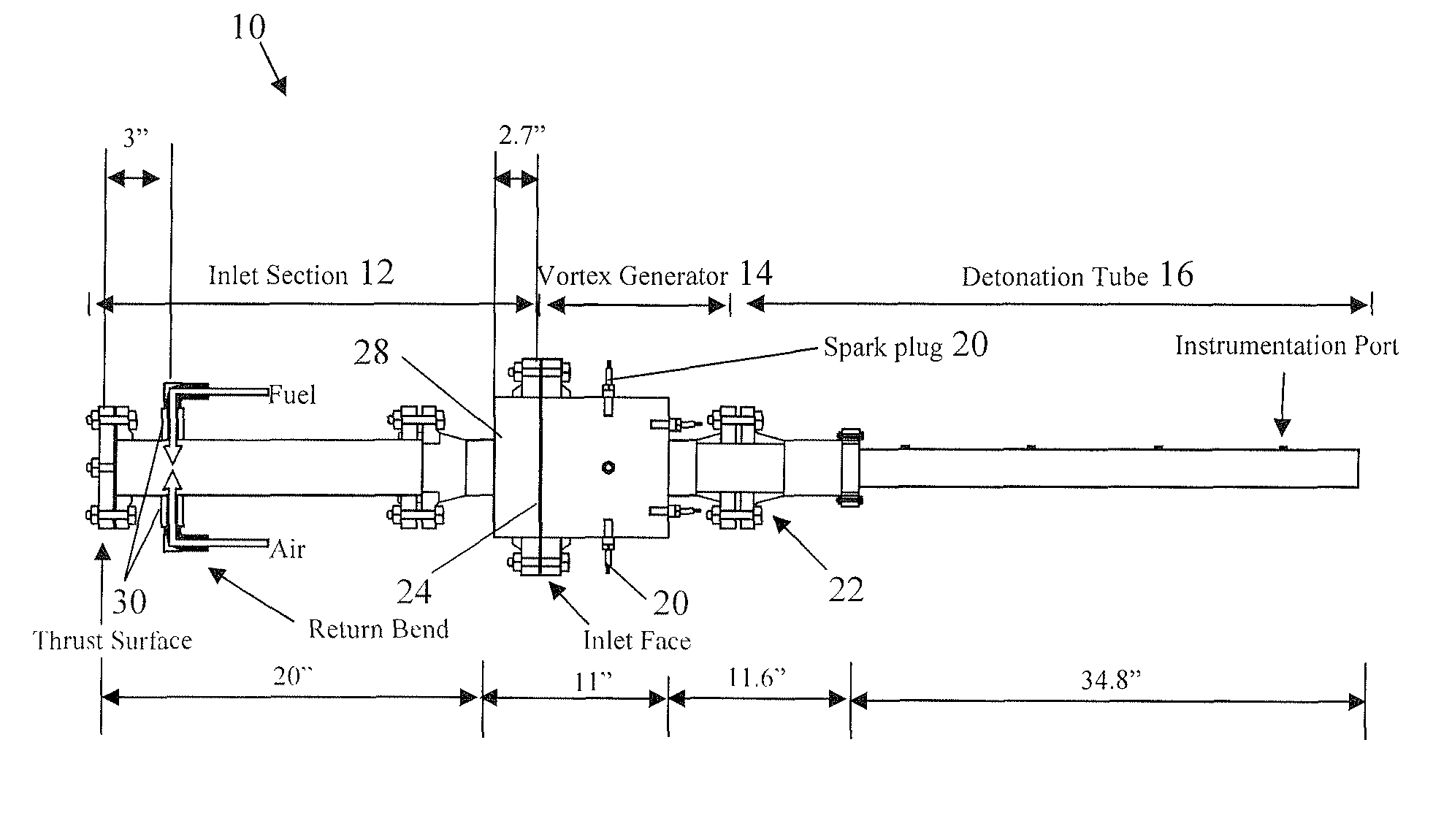

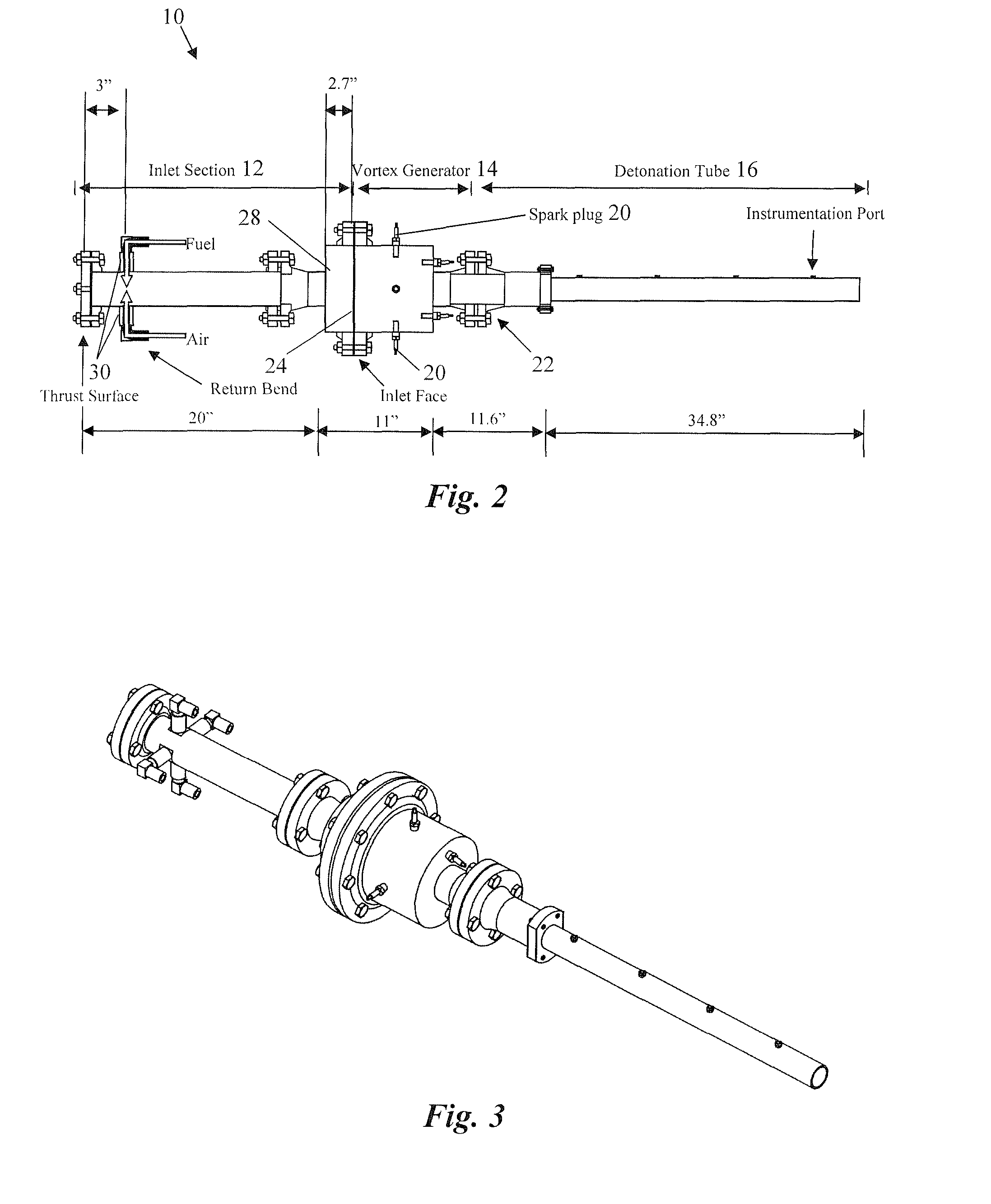

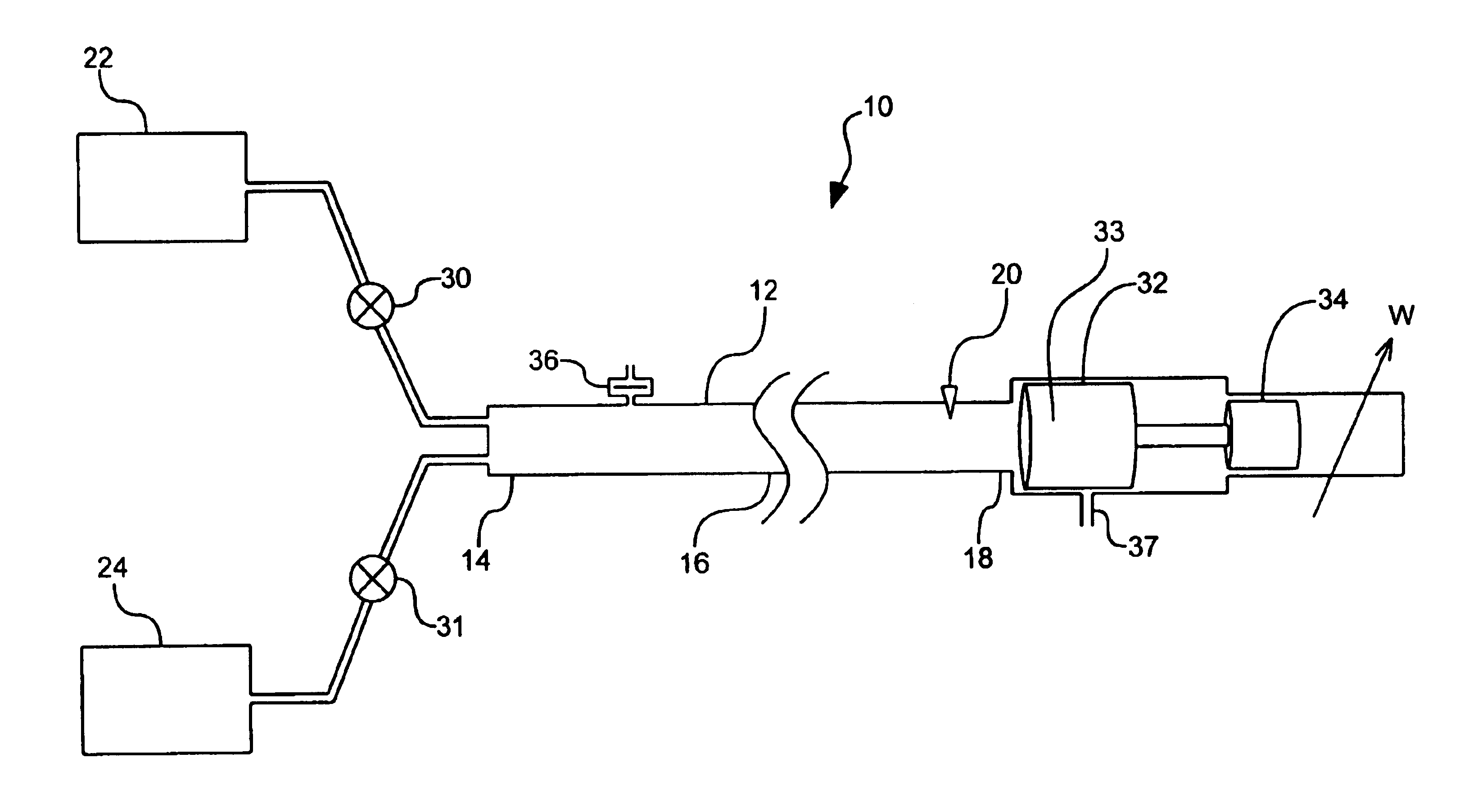

A method and device for controllably combusting combustible material, including a combustion device comprising an elongate combustion tube having an inlet section including an inlet for combustible material, an ignition section, including an igniter displaced along a length of the tube from the inlet section to ignite the combustible material, and at least one energy extraction device operatively coupled to the combustion tube and configured to extract energy from combustion of the combustible mixture.

Owner:SARCOS LC

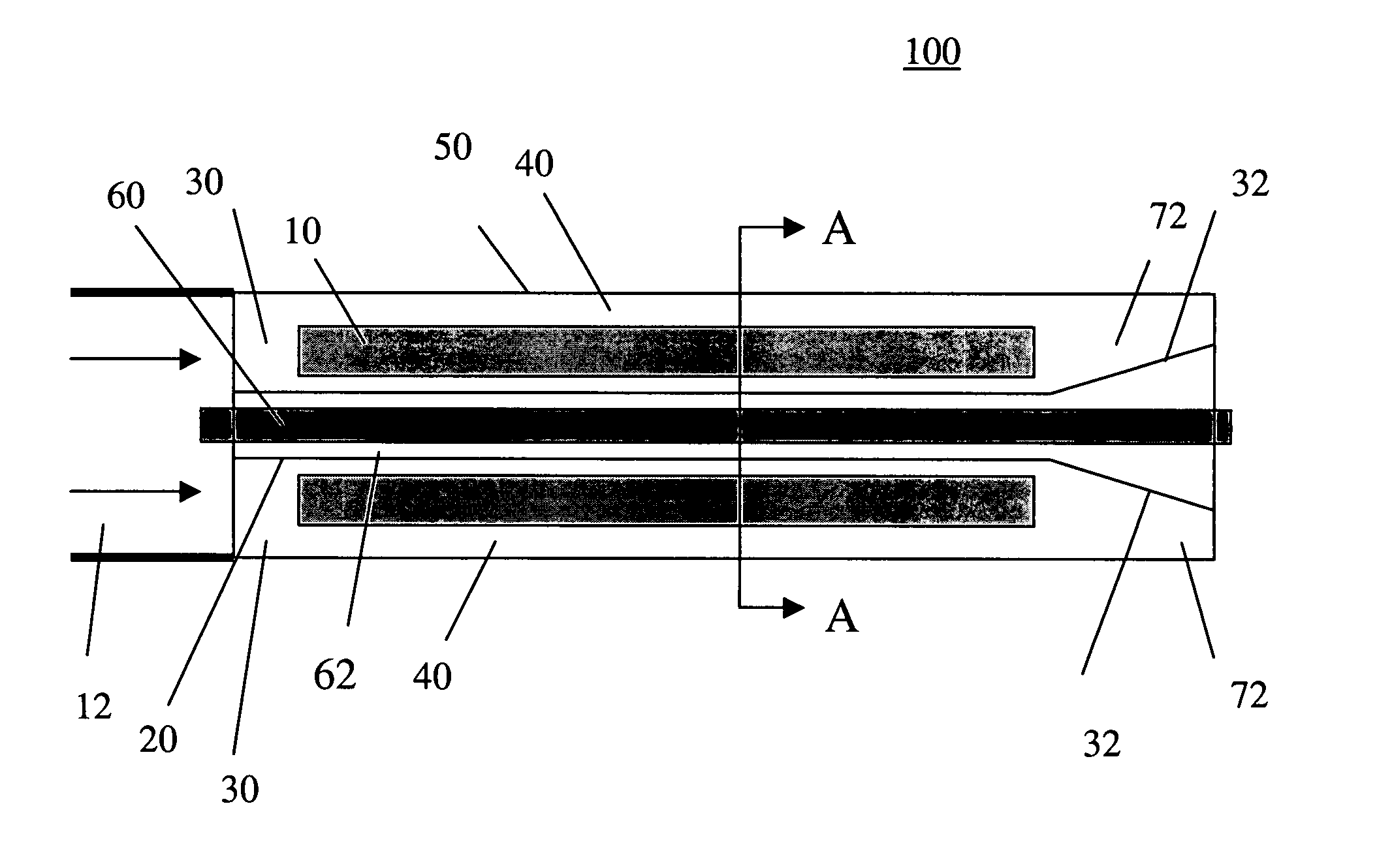

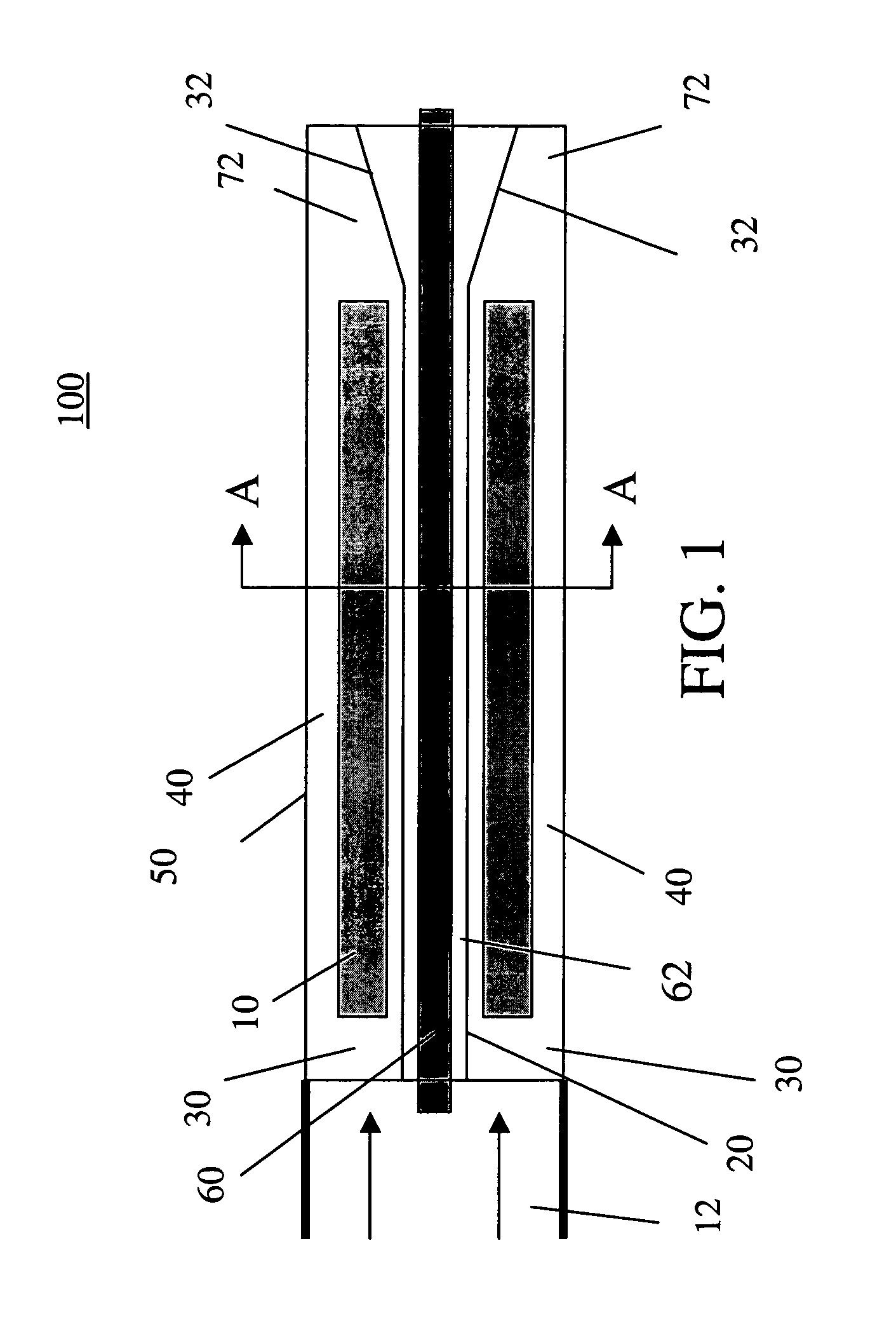

Pulse detonation engines and components thereof

A pulse detonation engine comprises a primary air inlet; a primary air plenum located in fluid communication with the primary air inlet; a secondary air inlet; a secondary air plenum located in fluid communication with the secondary air inlet, wherein the secondary air plenum is substantially isolated from the primary air plenum; a pulse detonation combustor comprising a pulse detonation chamber, wherein the pulse detonation chamber is located downstream of and in fluid communication with the primary air plenum; a coaxial liner surrounding the pulse detonation combustor defining a cooling plenum, wherein the cooling plenum is in fluid communication with the secondary air plenum; an axial turbine assembly located downstream of and in fluid communication with the pulse detonation combustor and the cooling plenum; and a housing encasing the primary air plenum, the secondary air plenum, the pulse detonation combustor, the coaxial liner, and the axial turbine assembly.

Owner:GENERAL ELECTRIC CO

Pulse detonation engine and valve

InactiveUS20050183413A1Accurate timingIncrease air densityPulsating combustionTurbine/propulsion fuel heatingCombustion chamberCombustor

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

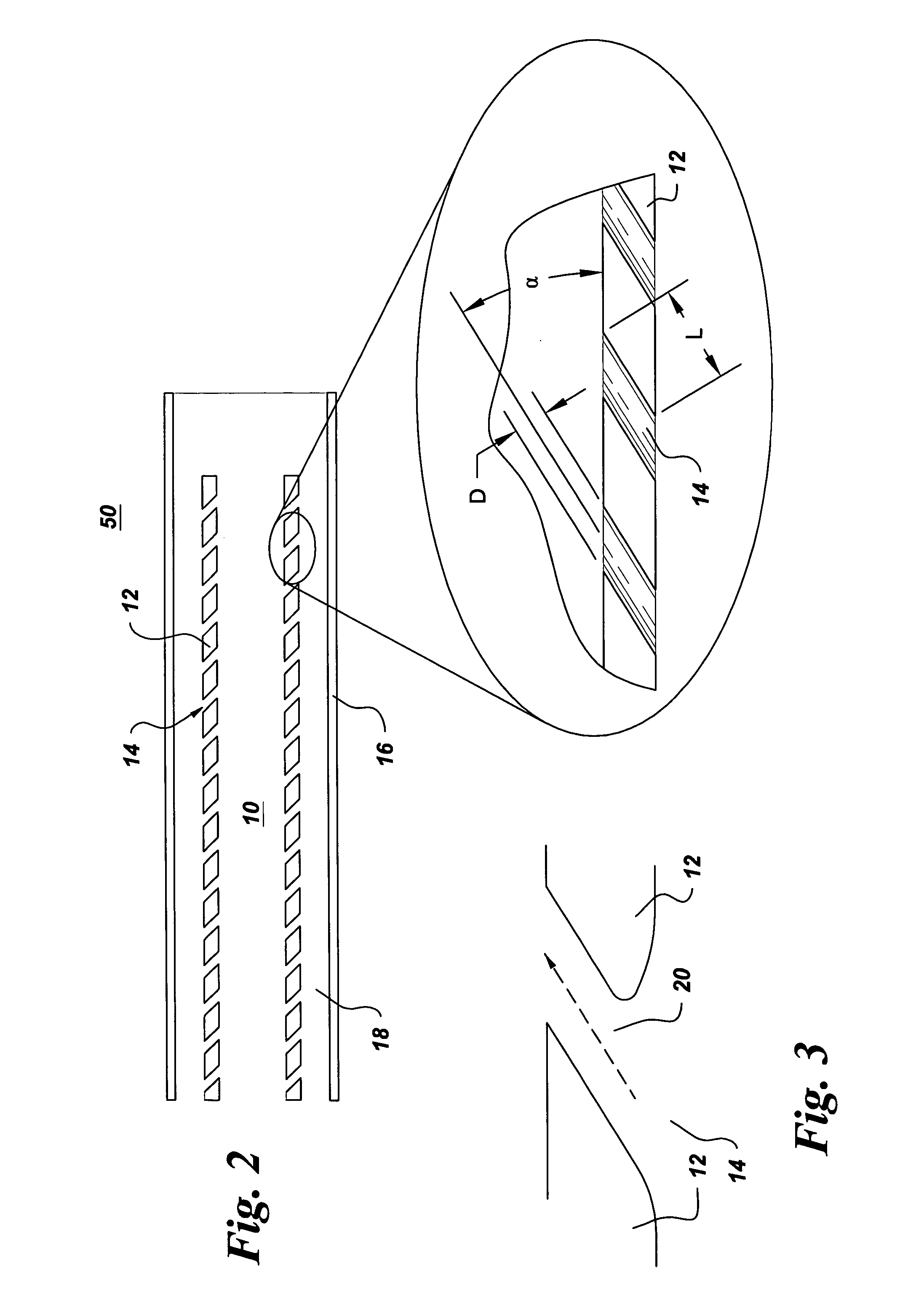

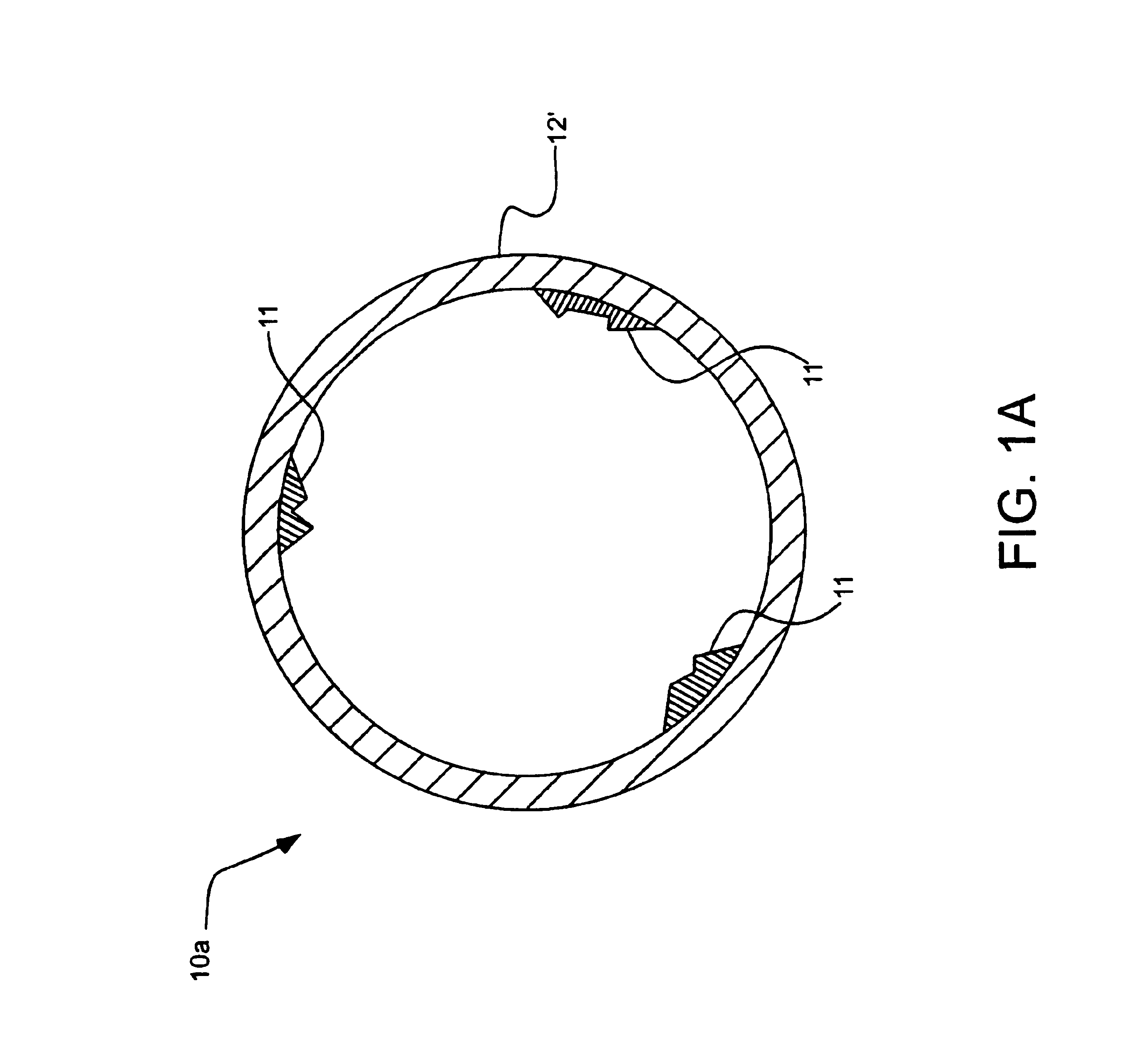

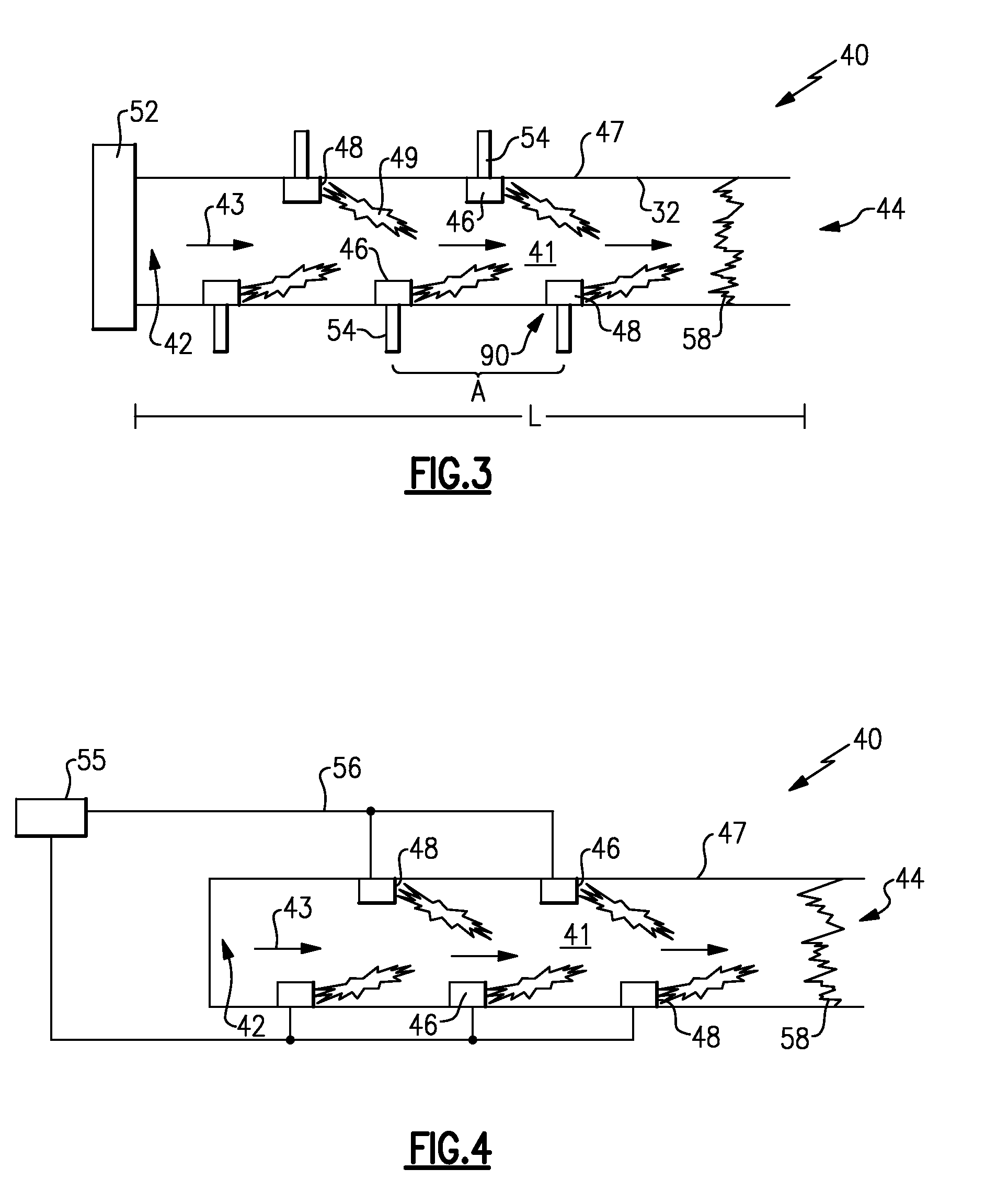

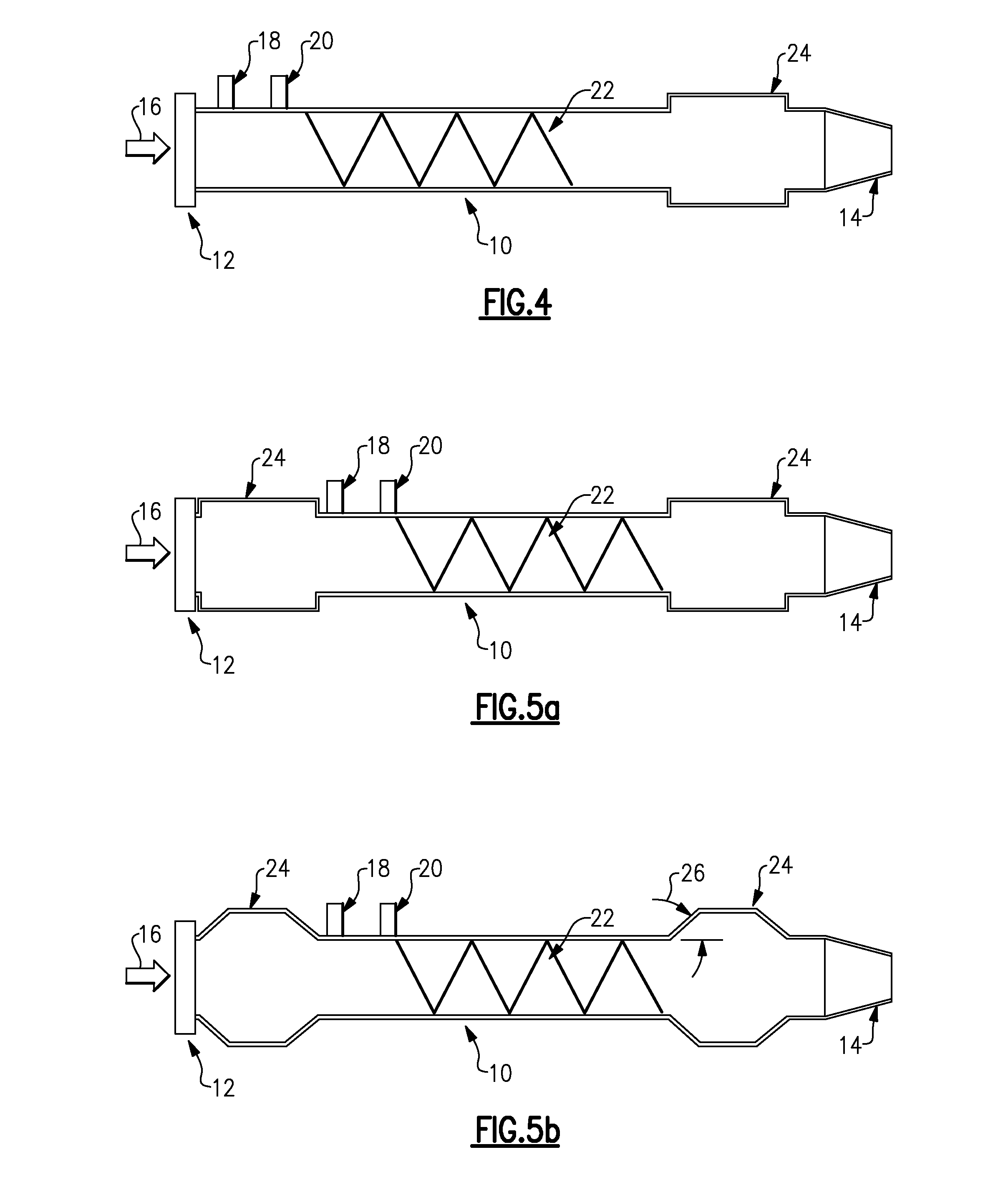

Integrated deflagration-to-detonation obstacles and cooling fluid flow

A detonation chamber and a pulse detonation combustor including a detonation chamber, wherein the detonation chamber includes a plurality of initiation obstacles and at least one injector in fluid flow communication with each of the plurality of initiation obstacles. The plurality of initiation obstacles are disposed on at least a portion of an inner surface of the detonation chamber with each of the plurality of initiation obstacles defining a low pressure region at a trailing edge. The plurality of initiation obstacles are configured to enhance a turbulence of a fluid flow and flame acceleration through the detonation chamber. The at least one injector in provides a cooling fluid flow to each of the plurality of initiation obstacles, wherein the cooling fluid flow is one of a fuel, a combination of fuels, air, or a fuel / air mixture.

Owner:GENERAL ELECTRIC CO

Constant volume combustor having a rotating wave rotor

InactiveUS7621118B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorMagnetic bearing

A constant volume combustor device includes, in one form, a detonative combustion. In one form the wave rotor of the constant volume combustor is supported by magnetic bearings. The constant volume combustor device includes a rotor having a number of fluid passageways that rotate about an axis. End plates having at least one inlet port and at least one outlet port are located on either end of the rotor. Relatively compressed air enters the rotor through the at least one inlet port, is burned with fuel in a pulsed combustion process, and exits at least one exit port. The pulsed combustion process can be a pulsed detonation combustion process or a pulsed deflagration combustion process.

Owner:ROLLS ROYCE NORTH AMERICAN TECH

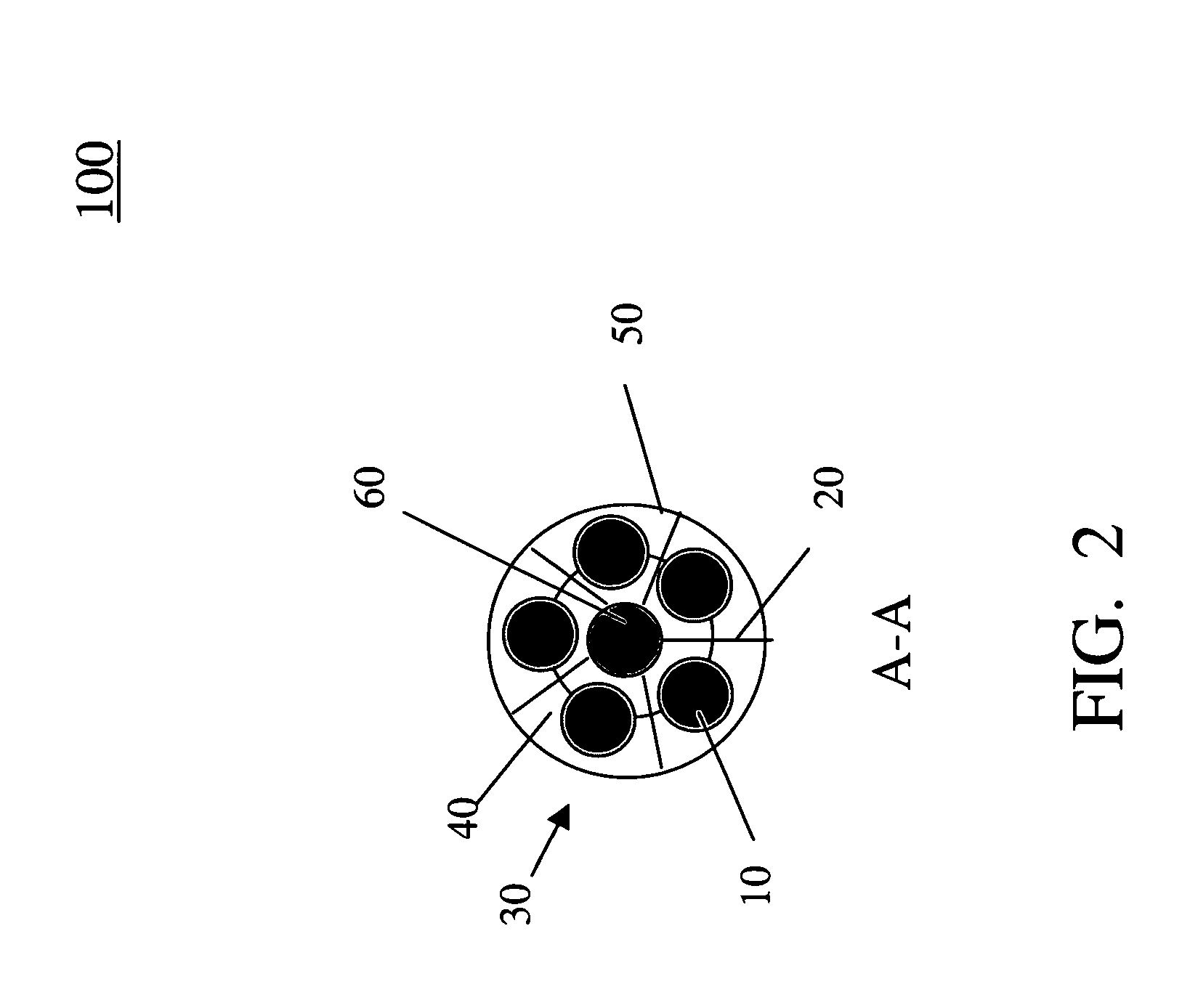

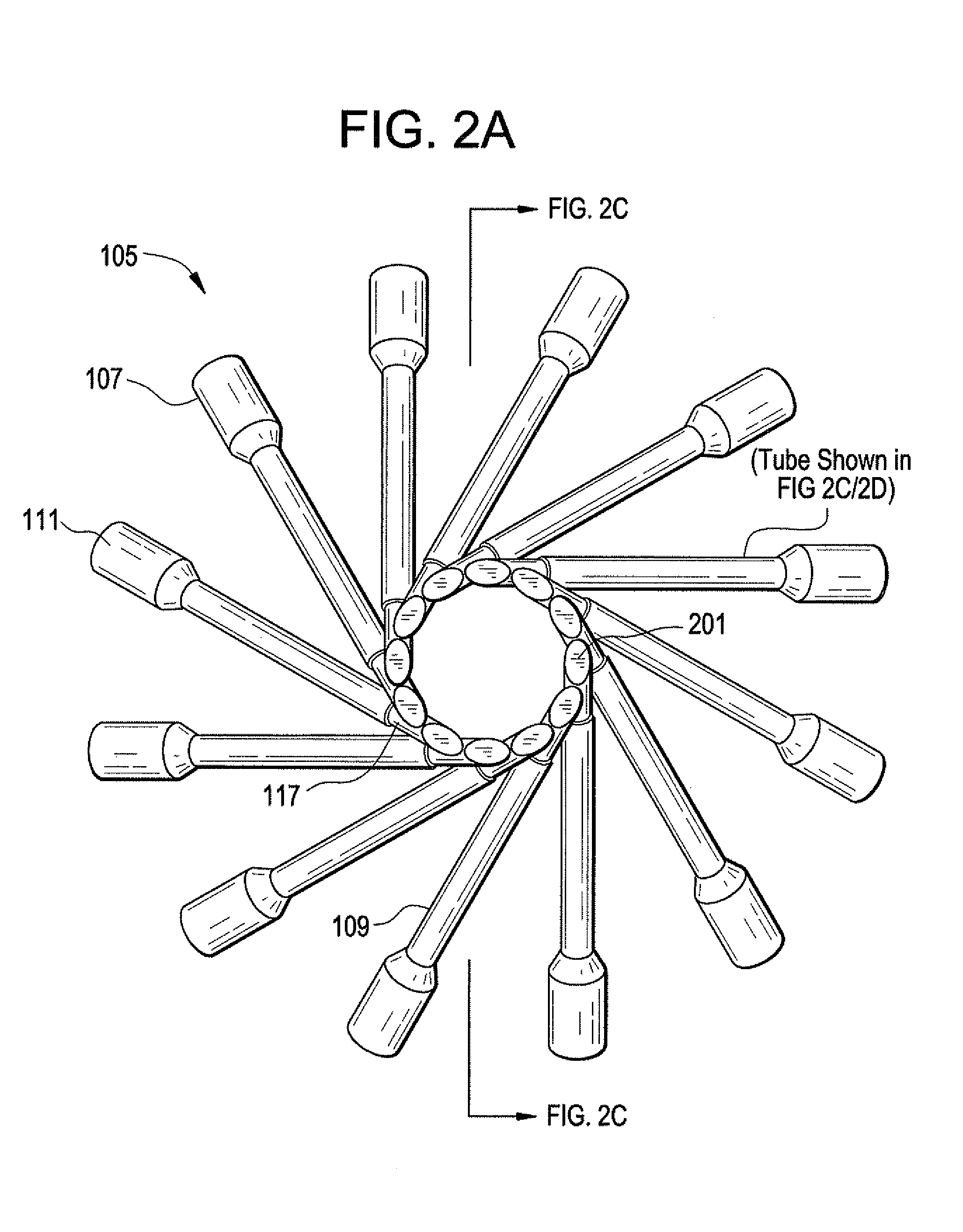

Multi-tube, can-annular pulse detonation combustor based engine with tangentially and longitudinally angled pulse detonation combustors

An engine contains a compressor stage, a pulse detonation combustion stage and a turbine stage. The pulse detonation combustion stage contains at least one pulse detonation combustor which has an inlet portion. The pulse detonation combustor is oriented longitudinally and / or tangentially with respect to a centerline of the engine.

Owner:GENERAL ELECTRIC CO

Valveless pulsed detonation combustor

Pulse detonation combustors of valveless construction. One valveless pulse detonation combustor, having a tube with a closed end and an open end, is constructed with a flame accelerator within the tube, adjacent the open end. A valveless, apertured flow restrictor is positioned between the flame accelerator and the closed end of the tube. A sparking device is positioned within the tube, between the flow restrictor and the flame accelerator. Valveless fuel and air ports are positioned between the flow restrictor and the closed end of the tube. Substantially right-angle manifold passageways are in communication with each of the ports.

Owner:PURDUE RES FOUND INC

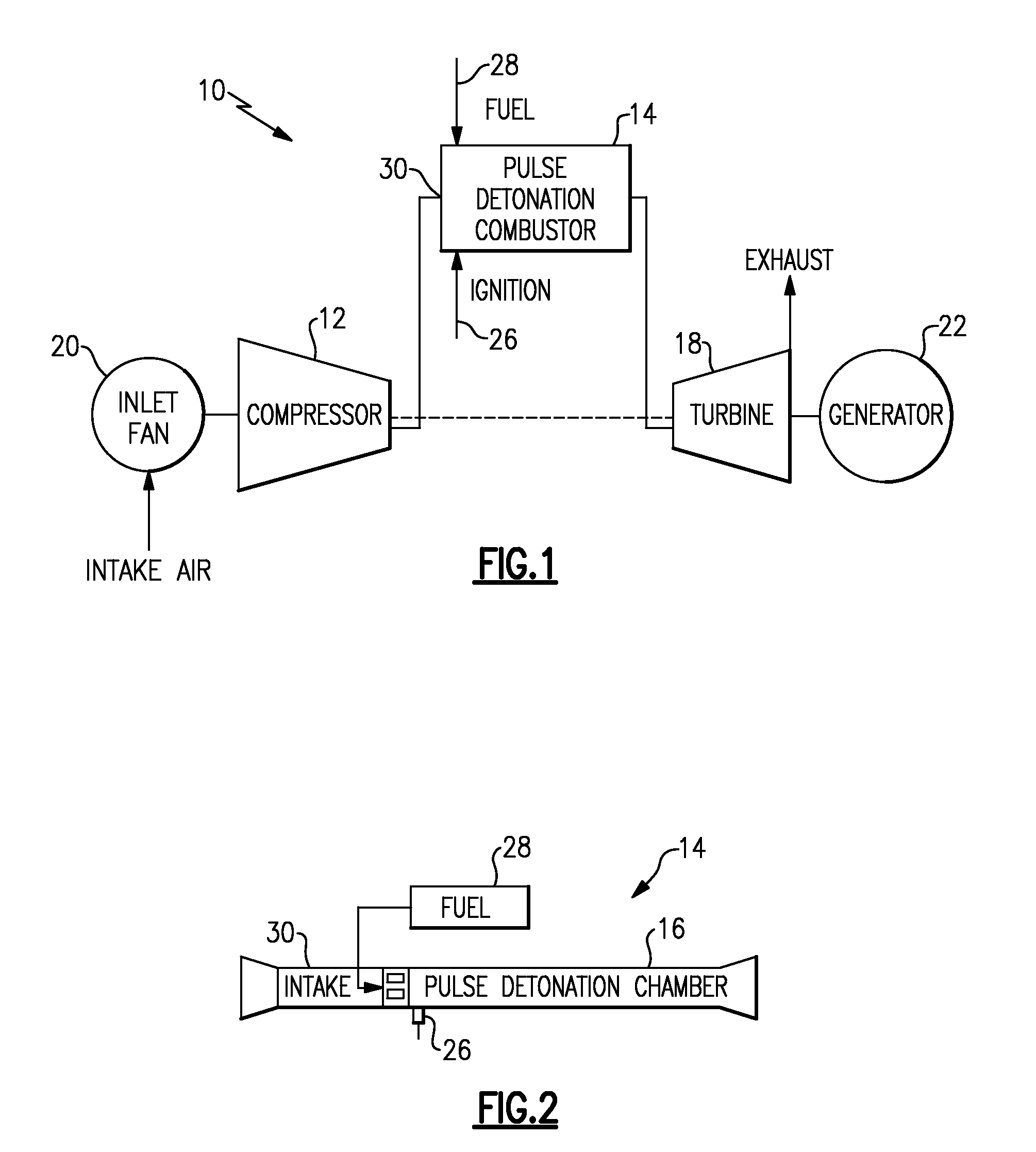

Pulse detonation combustor with plenum

InactiveUS20130042595A1Extended durationExtension of timePulsating combustionIntermittent jet plantsCombustorDetonation

A pulse detonation combustor includes at least one plenum located along the length of the pulse detonation combustor. The plenum can be located: 1) proximate an air valve; 2) between a fuel injection port and an ignition source; 3) downstream of both the fuel injection port and the ignition source; and 4) proximate an exit nozzle of the pulse detonation combustor. In addition, the pulse detonation combustor can have multiple plenums, for example, proximate the air valve and proximate the exit nozzle. The location and dimensions of the plenum can be selectively adjusted to control mechanical loading on the wall, the velocity of fluid flowing within the combustor, and the pressure generated by the pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

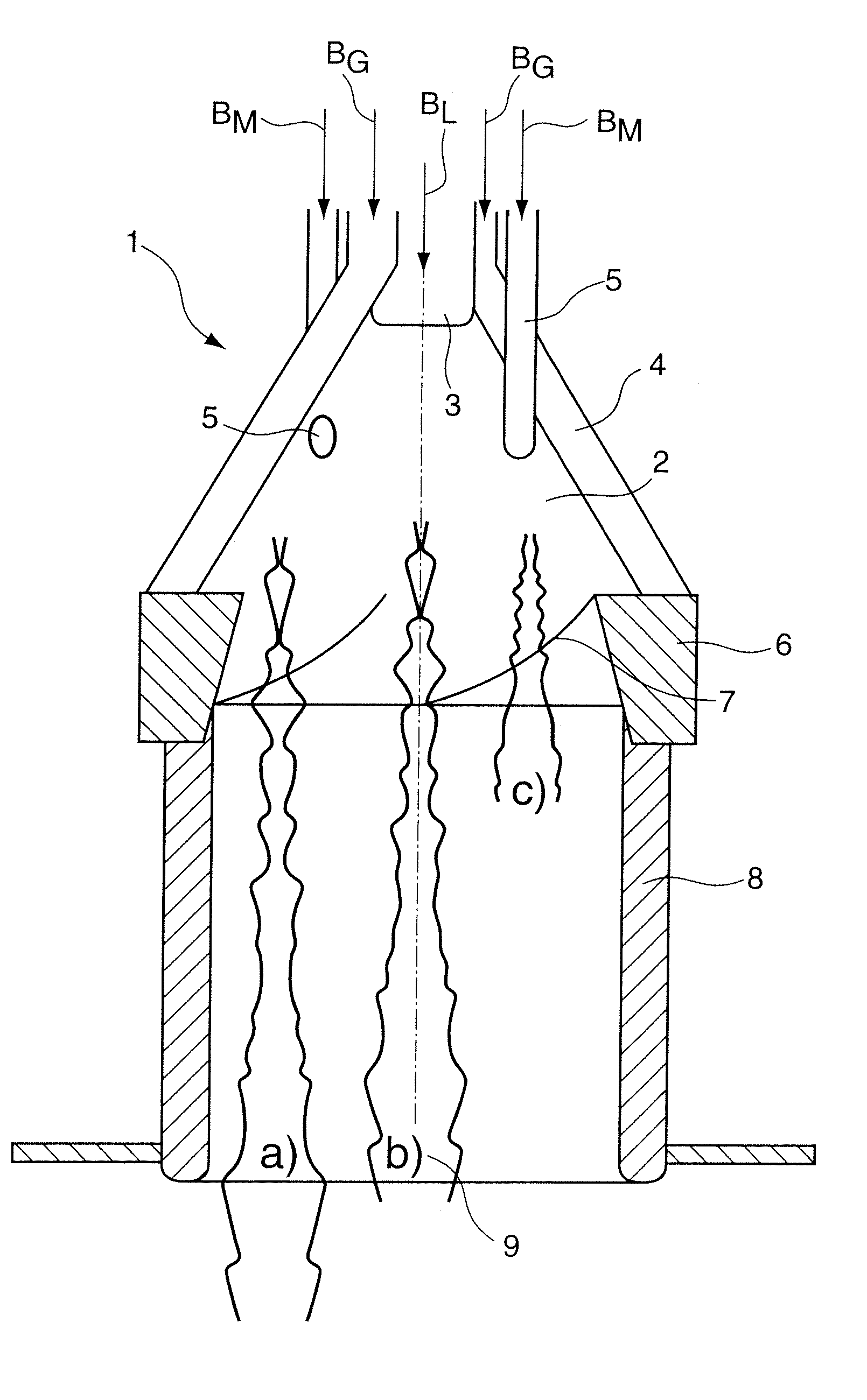

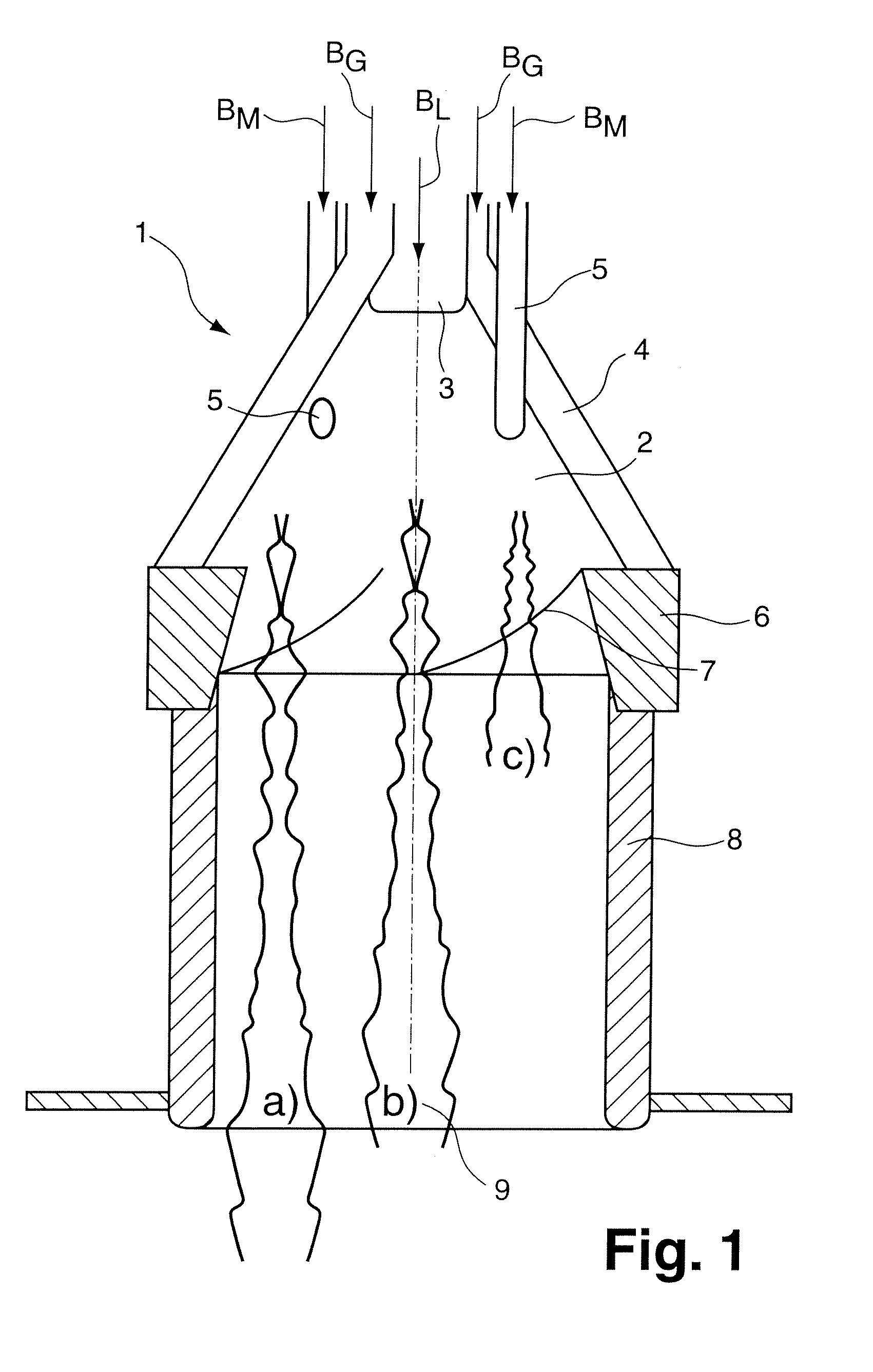

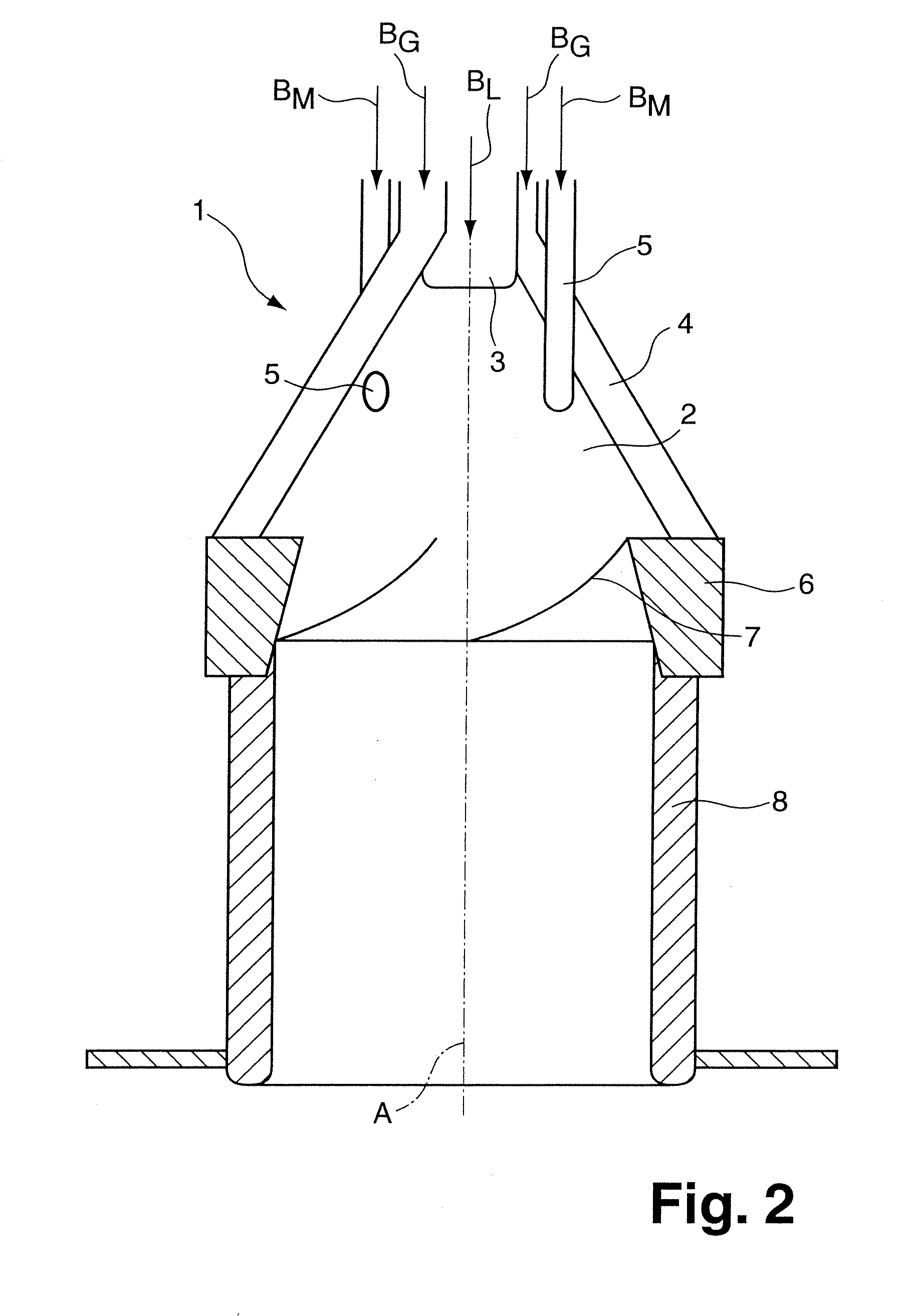

Method and Device for Burning Hydrogen in a Premix Burner

ActiveUS20080280239A1Stable flow conditionWell mixedCombustion using gaseous and pulverulent fuelPulsating combustionCombustorHydrogen

A method and a device for combusting gaseous fuel which contains hydrogen or consists of hydrogen, includes a burner which provides a swirl generator (1) into which liquid fuel is feedable centrally along a burner axis (A), forming a liquid fuel column which is conically formed and which is enveloped by, and mixed through with, a rotating combustion air flow which flows tangentially into the swirl generator (1). The gaseous fuel is fed inside the swirl generator (1) largely axially and / or coaxially to the burner axis (A), forming a fuel flow with a largely spatially defined flow pattern (9) which is maintained inside the burner and bursts open in the region of the burner outlet.

Owner:ANSALDO ENERGIA SWITZERLAND AG

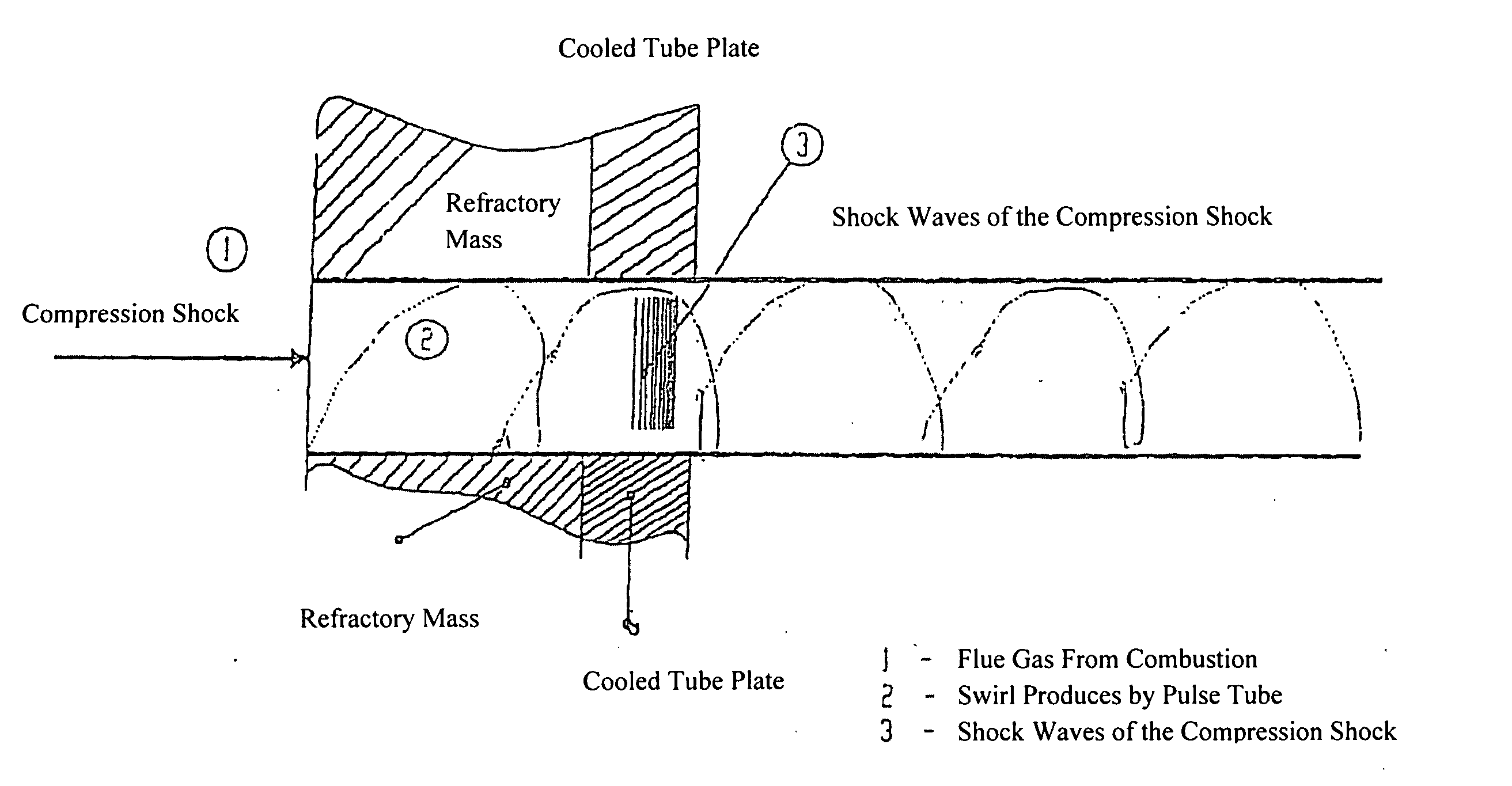

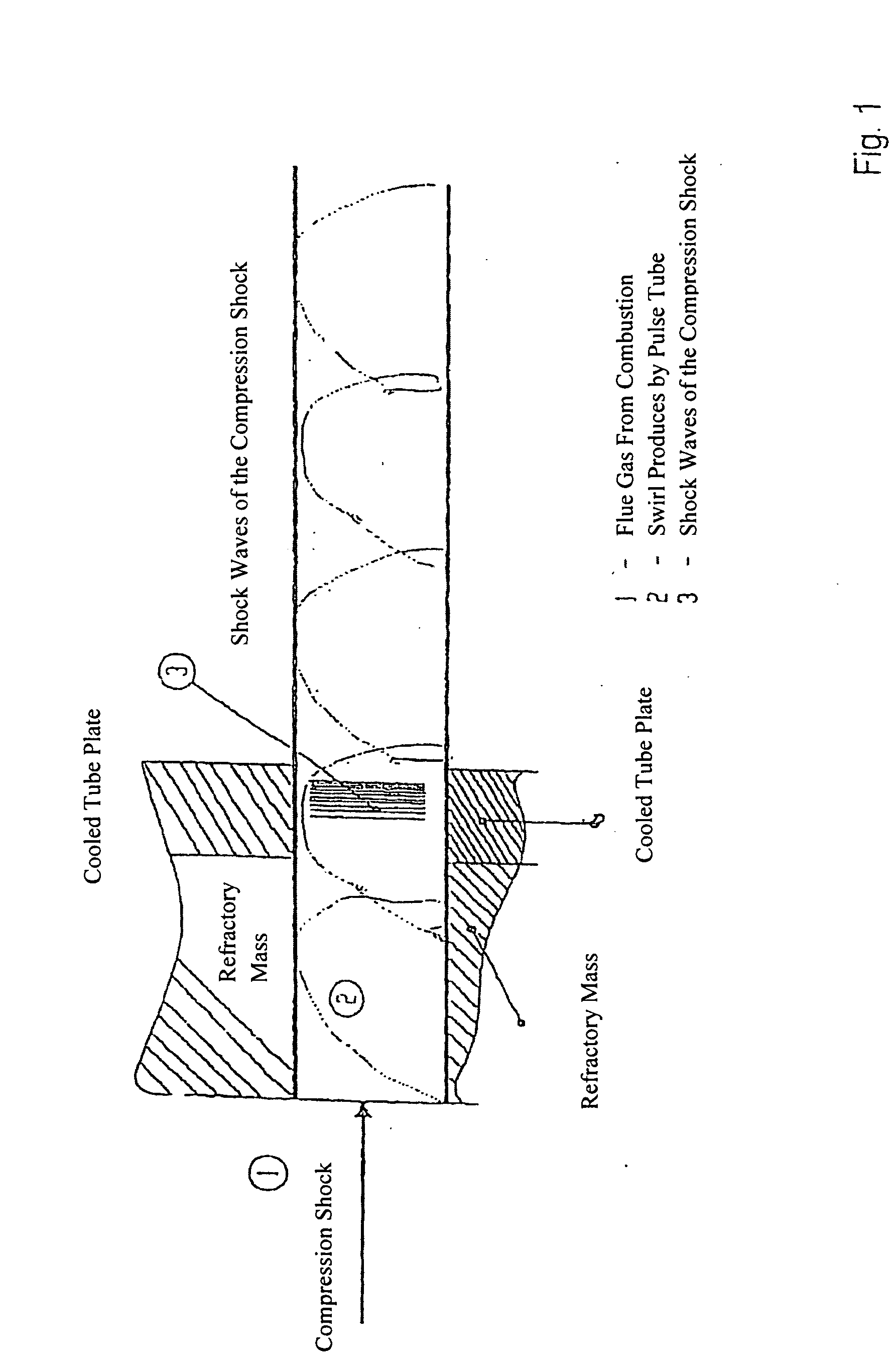

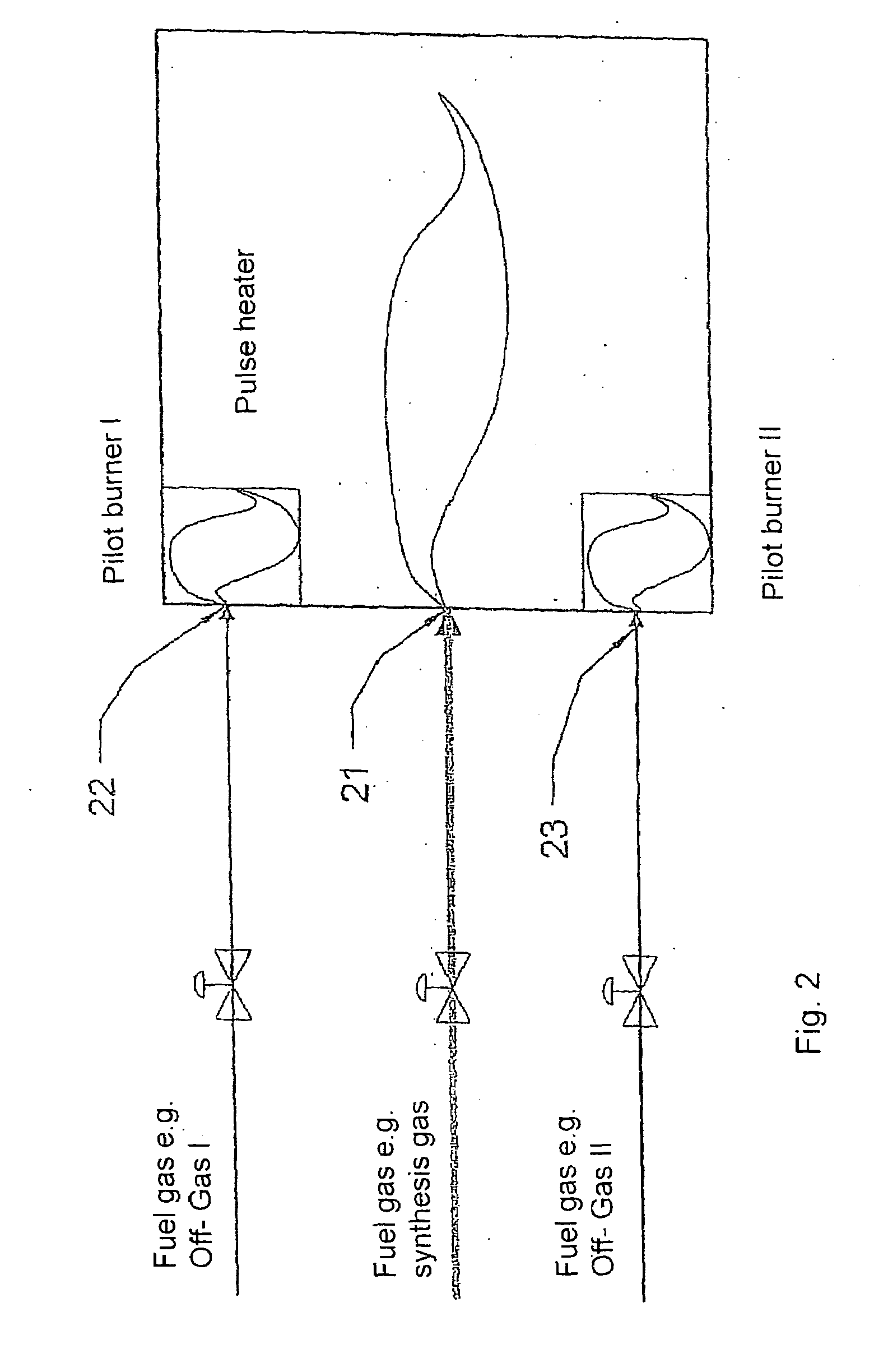

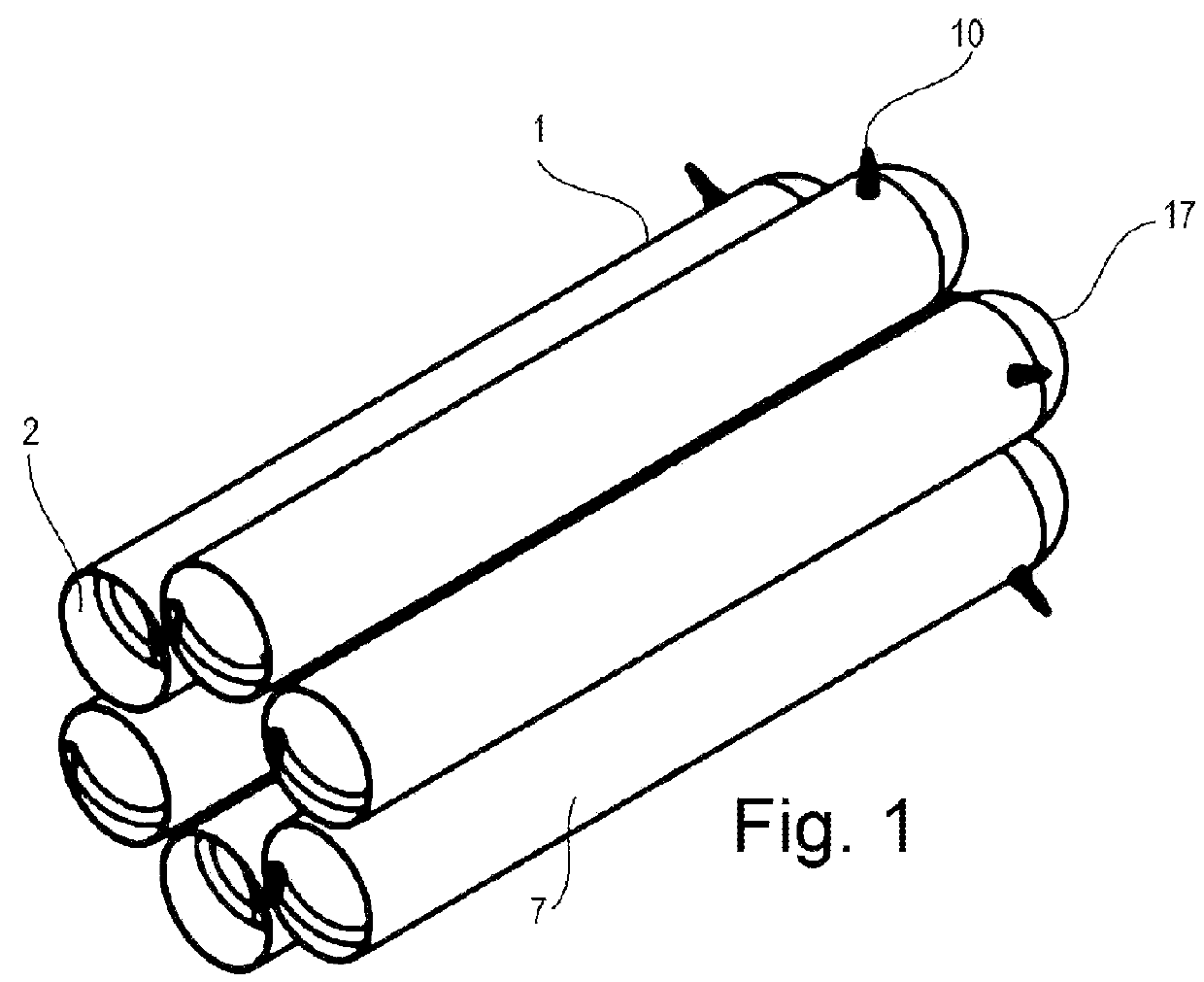

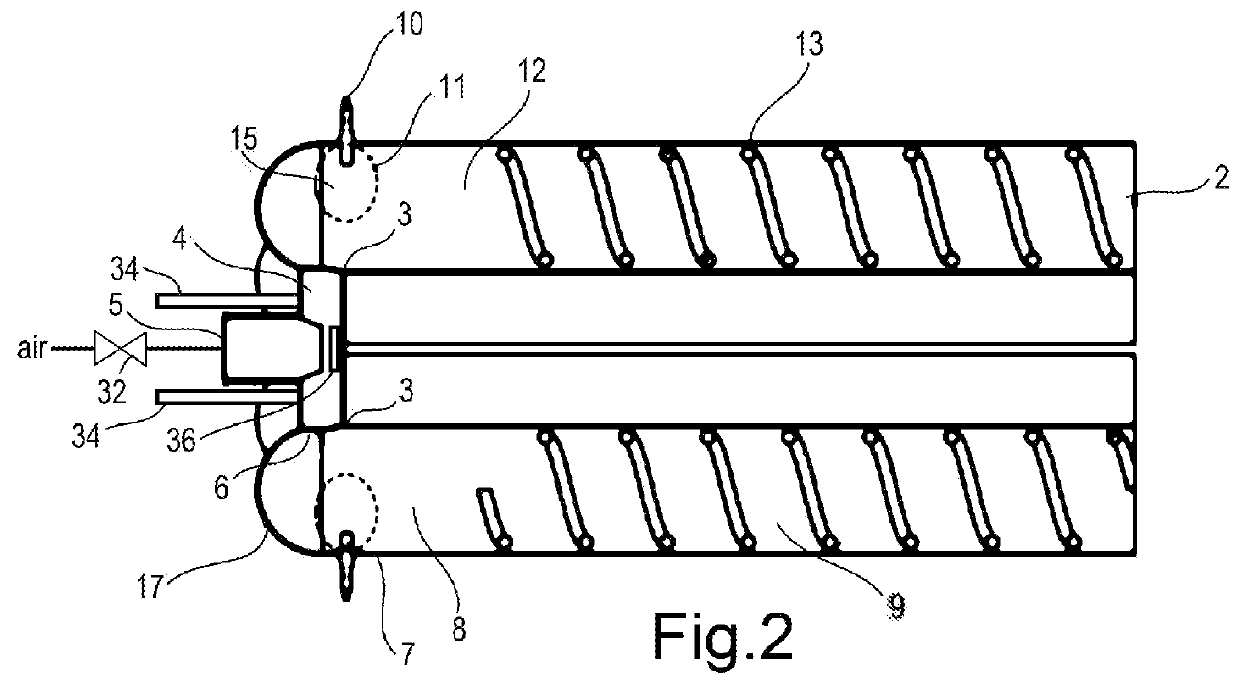

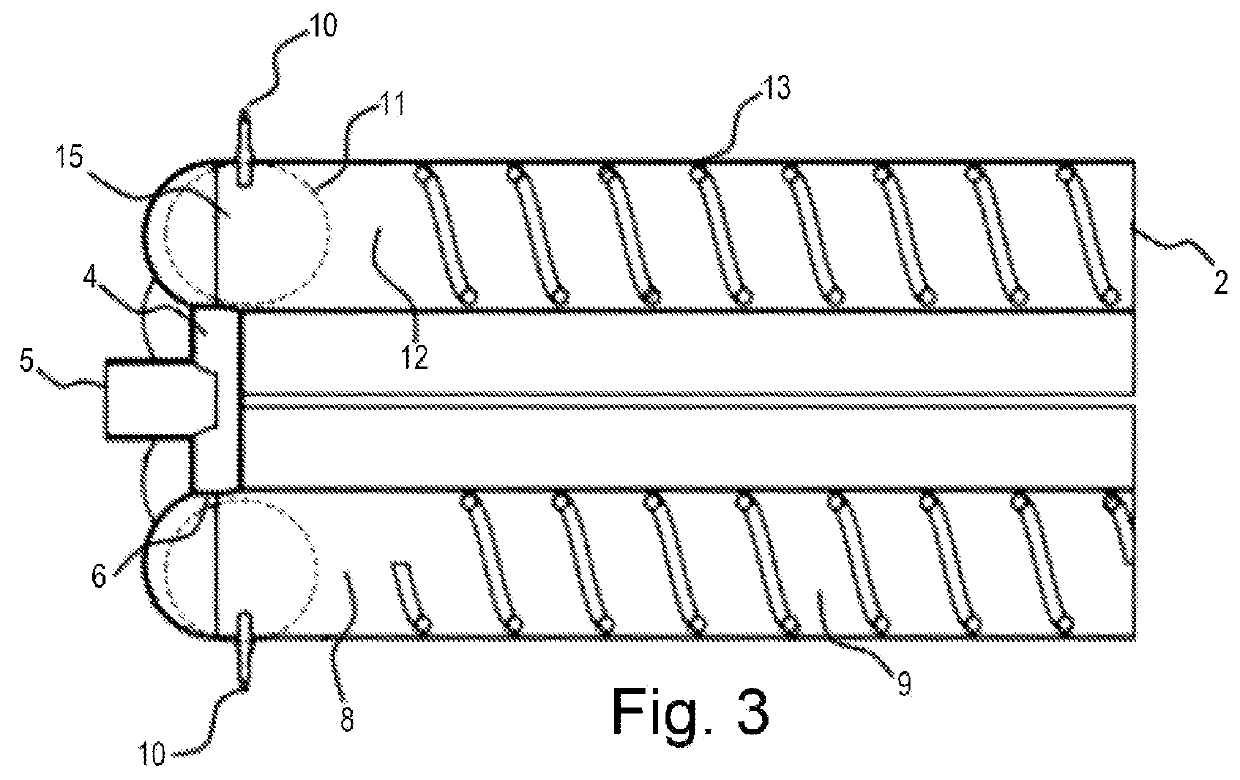

Method and device for achieving better heat transfer when using pulse heaters

InactiveUS20090084036A1Improve heat transfer performanceImprovement and increase in heat transferBurnersHydrogenHeat flowHelmholtz resonator

The invention relates to heat exchanger tubes acting like resonant tubes of a Helmholtz resonator and used as swirl tubes. They are capable of drastically increasing heat transfer in the boundary layers determining the heat flow to be exchanged as a result of their geometrically deformed surfaces.

Owner:SPOT SPIRIT OF TECHNOLOGY AG

Multitube valveless pulse detonation engine

ActiveUS9359973B2Minimizes back pressureReduce impactPulsating combustionGas turbine plantsShock waveEngineering

Disclosed herein is a valveless multitube pulse detonation engine including: a plurality of detonation tubes, wherein each detonation tube comprises an independent discharge outlet, and the plurality of detonation tubes interconnected at a common air / fuel mixture intake port. In the disclosed engine, an air and fuel mixture is detonated in the detonation tubes simultaneously, and the common air / fuel mixture intake port minimizes back-pressure caused by detonating the air / fuel mixture by directing multiple reverse shock waves into one another and effectively using the back-pressures as reacting surfaces for one another and effectively reducing the effect of back flowing shock waves moving towards upstream. The detonation tubes may be non-linear, and may have independent discharges. The independent discharges may be coupled to an adapter nozzle terminating in a combined exhaust outlet.

Owner:EXPONENTIAL TECHNOLOGY

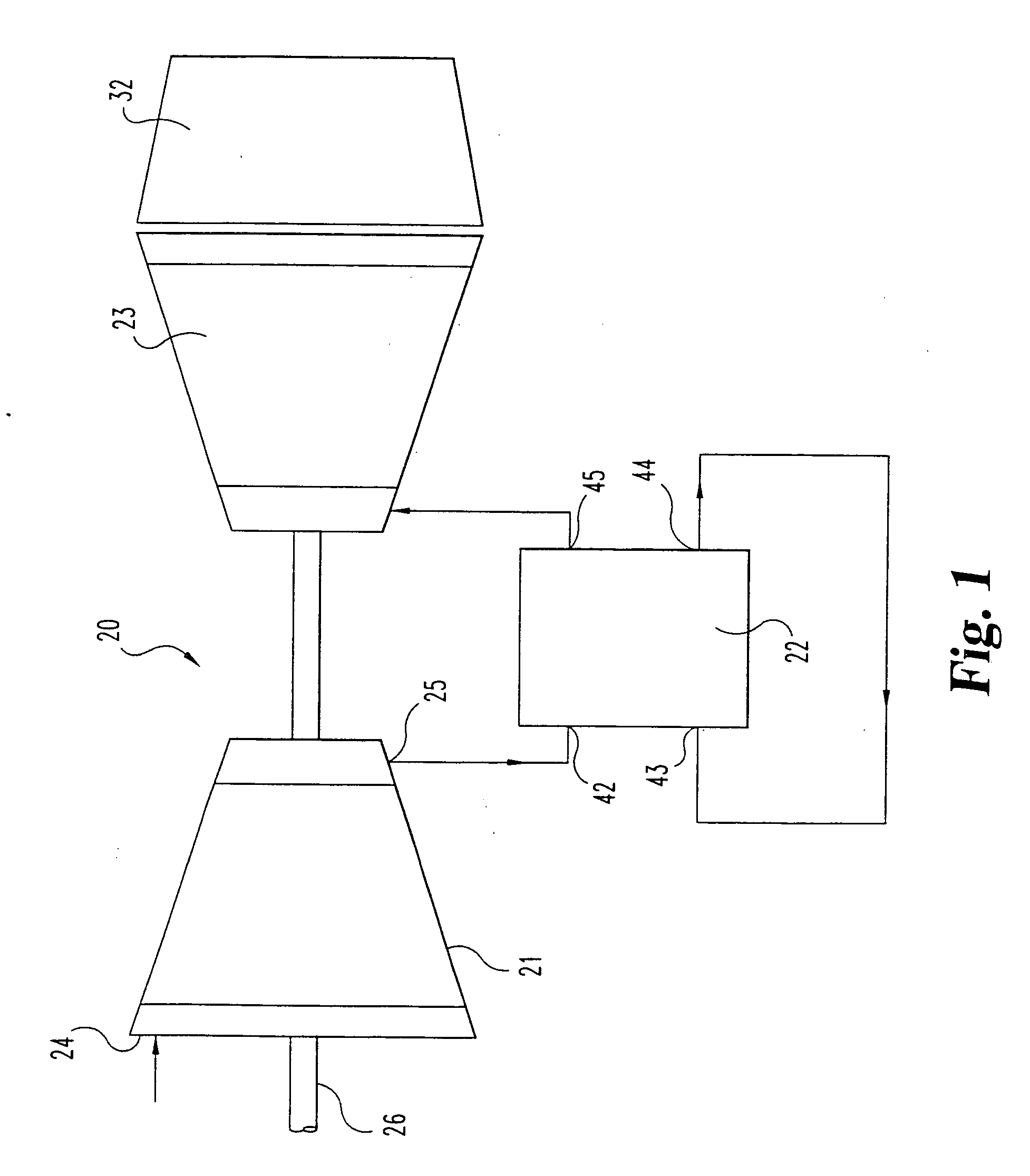

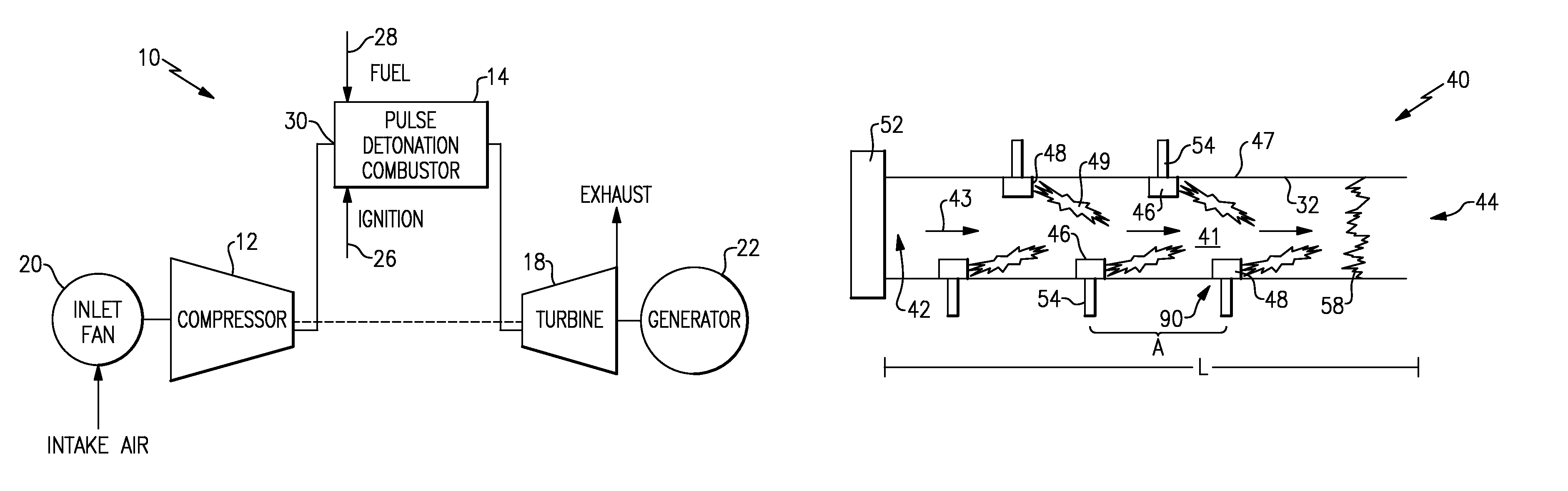

Ground-based simple cycle pulse detonation combustor based hybrid engine for power generation

An engine contains a compressor stage, a compressor plenum, an inlet valving stage, a PDC stage, a PDC exit nozzle stage, a transition stage, a high pressure turbine stage, a turbine plenum, and a low pressure turbine stage. The PDC stage contains at least one pulse detonation combustor and each of the compressor plenum, PDC exit nozzle stage and turbine plenum contain a volume used to reduce and / or widen pressure peaks generated by the operation of the PDC stage.

Owner:GENERAL ELECTRIC CO

Pulsed combustion engine

Owner:RTX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com